Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Low chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

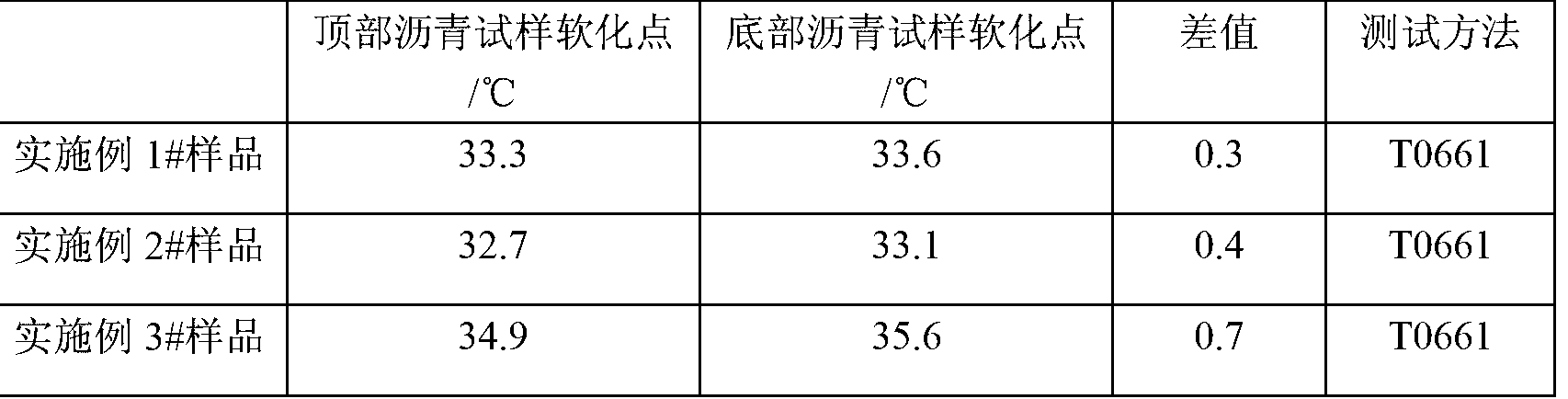

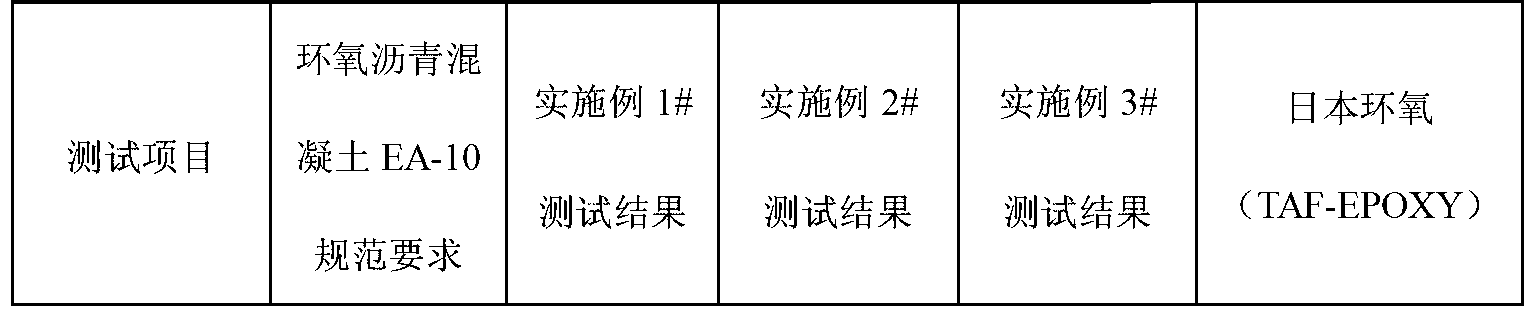

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

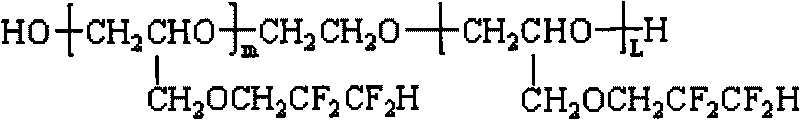

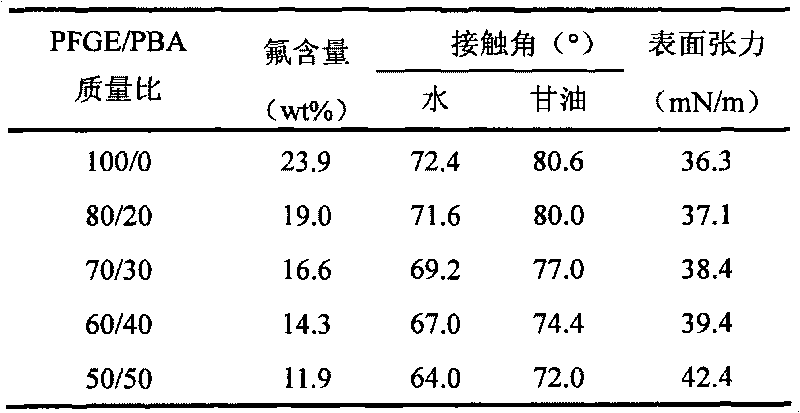

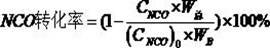

Method for preparing high-toughness thermoplastic fluorine-containing polyurethane elastomer

ActiveCN101717485AKeep the elastomer perfectly linearLower surface energyPolyurethane elastomerThermoplastic

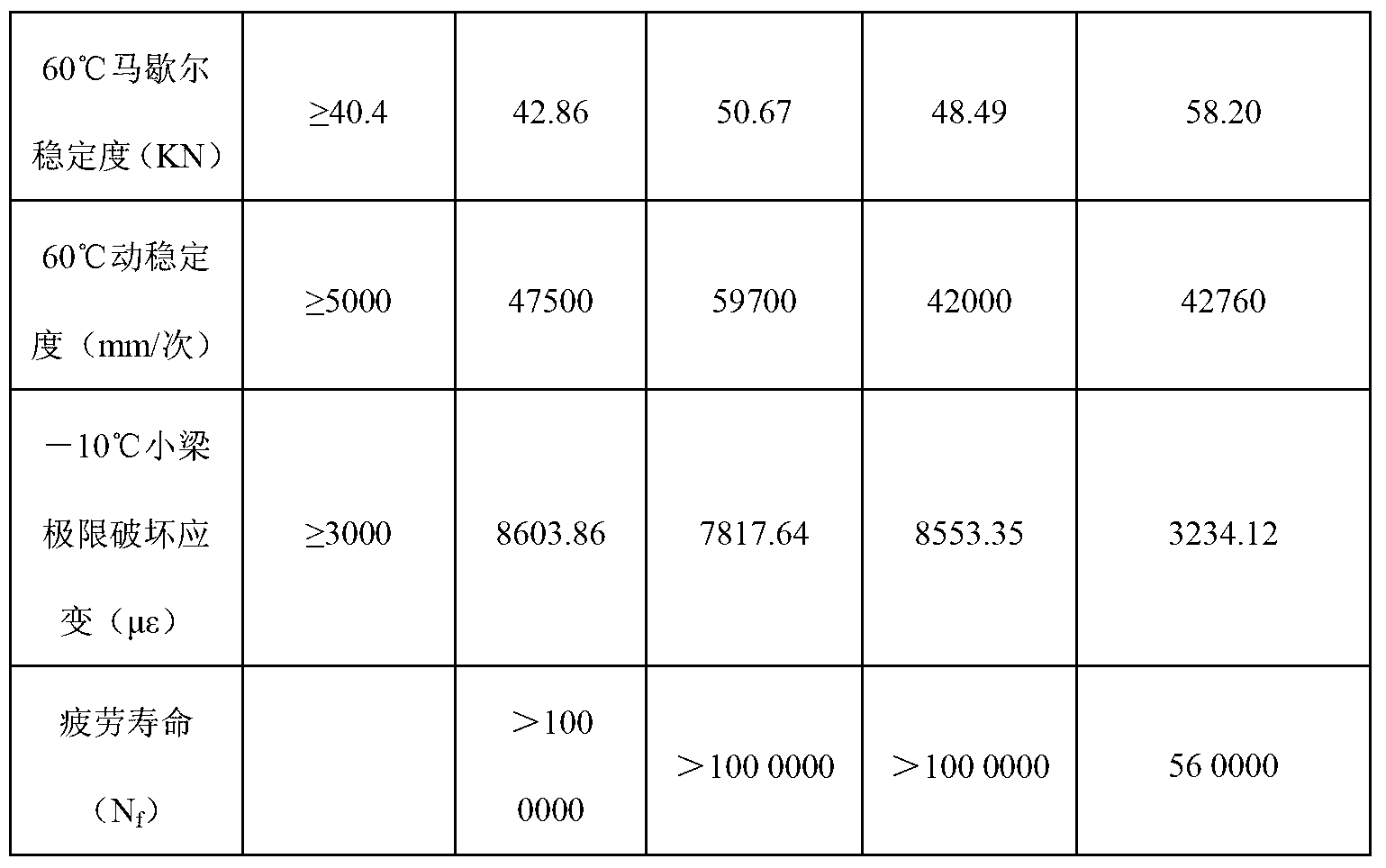

The invention discloses a method for preparing a high-toughness thermoplastic fluorine-containing polyurethane elastomer, which is characterized in that a bulk polymerization two-step method is adopted to synthesize the fluorine-containing polyurethane elastomer, the isocyanate index is 0.98, and the hard segment content is between 20 and 40 weight percent. The method comprises the following steps of: weighing 6 to 40 parts of non-fluorine macromolecular polylol and / or 30 to 80 parts of fluorine-containing polyether diol in a reactor, performing vacuum dehydration on the mixture for 2h at thetemperature of 120 DEG C, cooling the mixture to be between 70 and 100 DEG C, adding 16 to 33 parts of polyisocyanate into the mixture, stirring the mixture to react for 3h, heating the mixture to bebetween 120 and 140 DEG C, adding 0.1 to 15 parts of low molecular (fluorine-containing) diol chain extender into the mixture, uniformly stirring the mixture, then dumping the mixture into a preheated container, and performing vacuum baking for 20 hours at the temperature of between 120 and 140 DEG C to obtain the high-toughness thermoplastic fluorine-containing polyurethane elastomer.

Owner:SICHUAN UNIV

Preparation method of ultraviolet-curable water-borne fluorinated paint with low surface energy

InactiveCN102659995ALower surface energyLow water and oil repellencyPolyurea/polyurethane coatingsAcid valueBottle

The invention discloses a preparation method of ultraviolet-curable water-borne fluorinated paint with low surface energy. The preparation method comprises the following steps: (1), adding a (methyl) acrylate monomer, a monohydroxy (methyl) acrylate monomer, a fluorinated acrylate monomer and part of an initiator into a three-opening bottle, reacting for 3-5 hours at a temperature of 70-90 DEG C, supplementing the initiator, and further reacting for 1.5-3 hours; (2), adding polyisocyanate into another three-opening bottle, and reacting for 4-5 hours at a temperature of 30-50 DEG C; (3), dripping a reaction product in the step (2) into a reaction product in the step (1), and reacting for 10-12 hours; and (4), testing a reaction product in the step (3), determining the acid value, adding a salt-forming agent and deionized water in a certain ratio, shearing and removing the solvent. The ultraviolet-curable water-borne fluorinated paint combines performances of polyurethane and acrylate paint, is free of solvent emission, meets environment-friendly requirements, and is simple and feasible to spray and short in film-forming and curing time.

Owner:NANCHANG HANGKONG UNIVERSITY

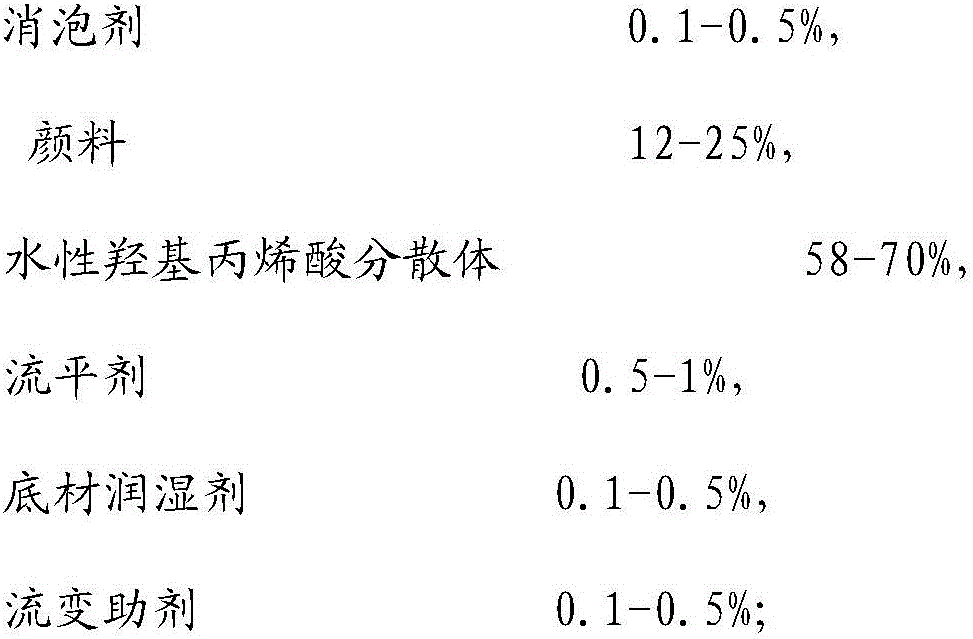

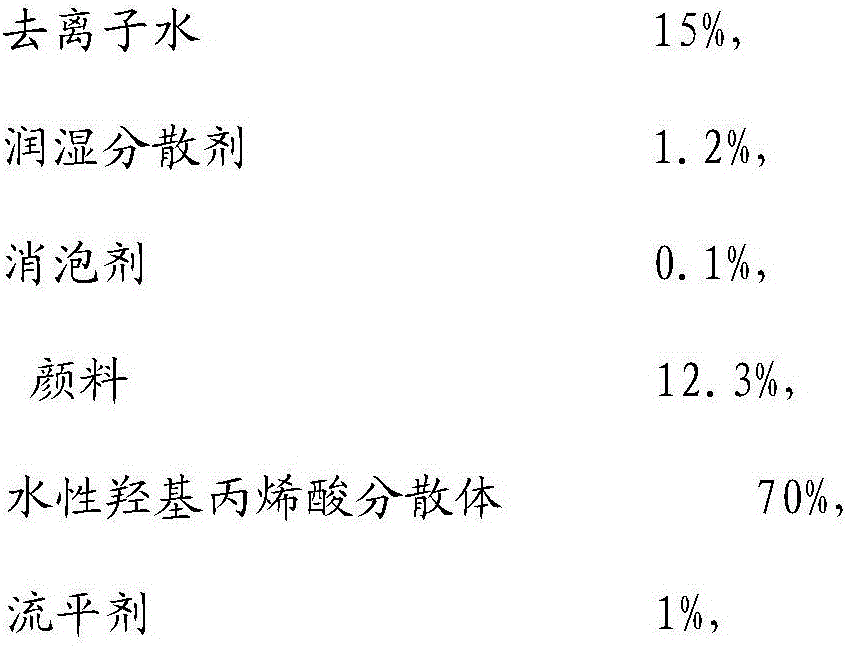

Water-based double-component polyurethane finish paint and preparation method thereof

InactiveCN106800874ALow viscosityLow VOC contentPolyurea/polyurethane coatingsWater basedDefoaming Agents

The invention discloses a water-based double-component polyurethane finish paint and a preparation method thereof. The water-based double-component polyurethane finish paint is composed of a component A and a component B. The component A is composed of the following ingredients in percentage by weight: 10-15% of deionized water, 0.5-1.2% of wetting and dispersing agent, 0.1-0.5% of defoaming agent, 12-25% of pigment, 58-70% of water-based hydroxyacrylic acid dispersion, 0.5-1% of leveling agent, 0.1-0.5% of substrate wetting agent and 0.1-0.5% of rheologic assistant. The component B is an isocyanate curing agent. The water-based double-component polyurethane finish paint has the advantages of low VOC (volatile organic compound) content, high bubble-free film thickness and favorable chemical resistance. The paint film has high crosslinking density, and can not easily peel.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

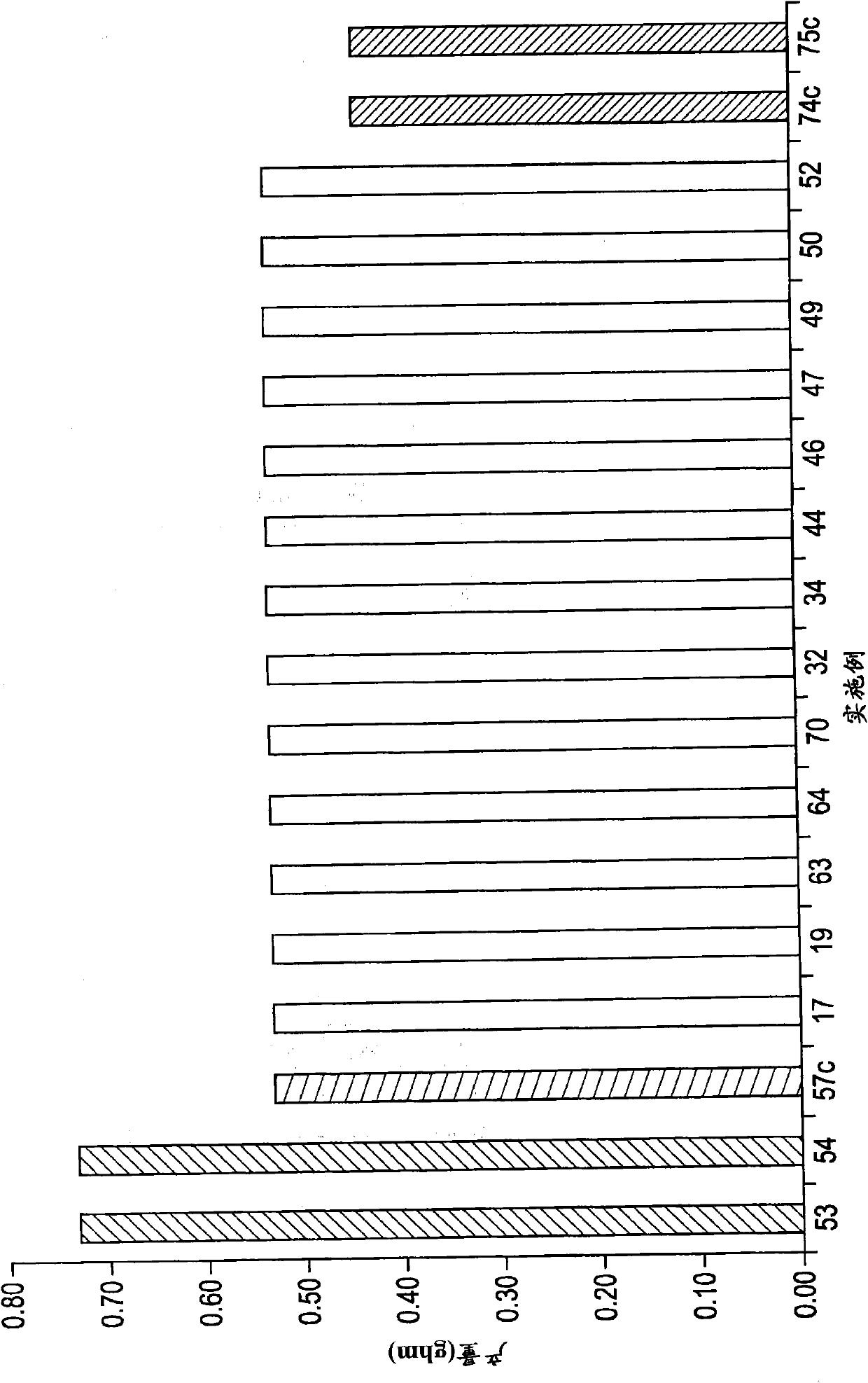

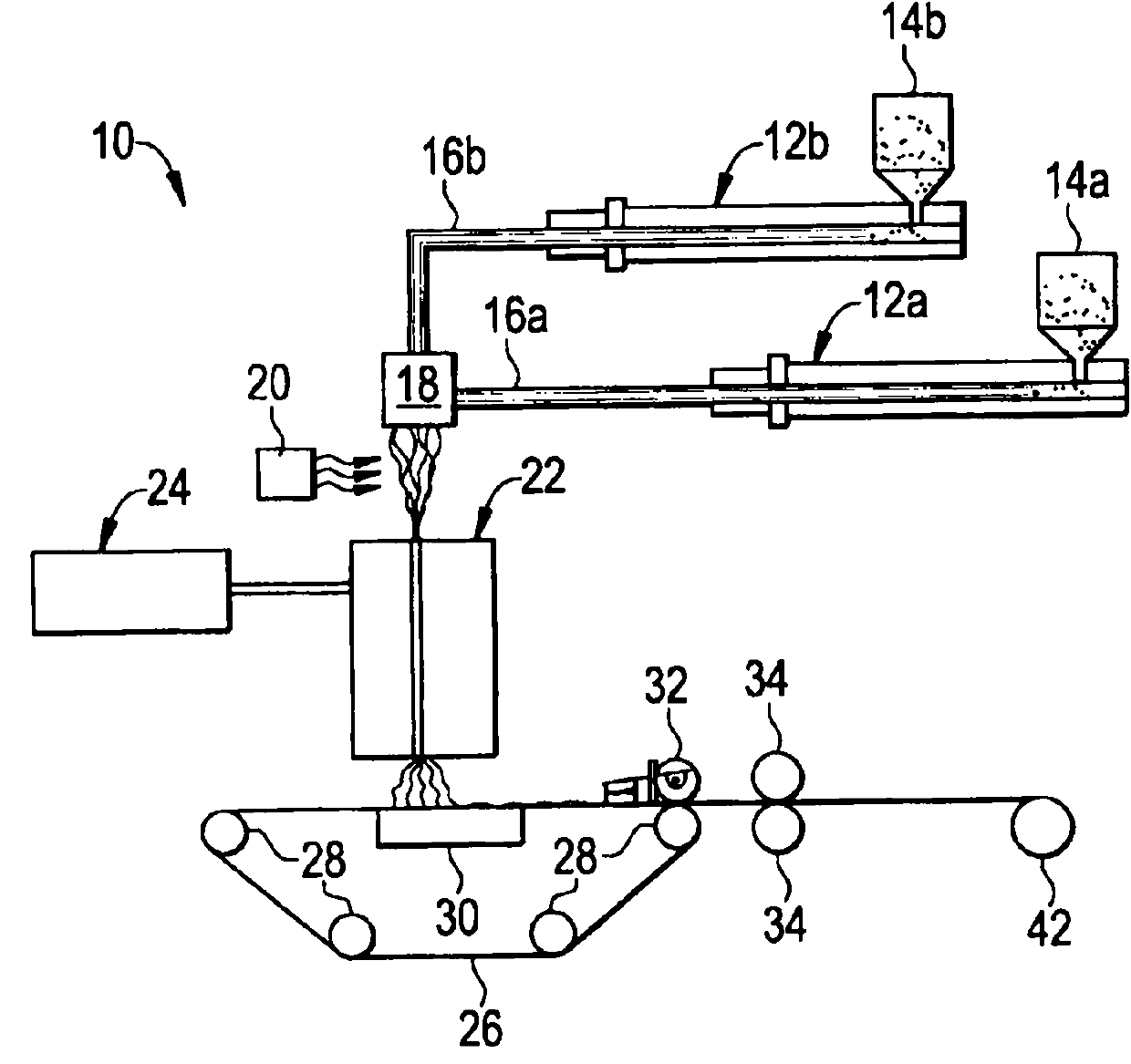

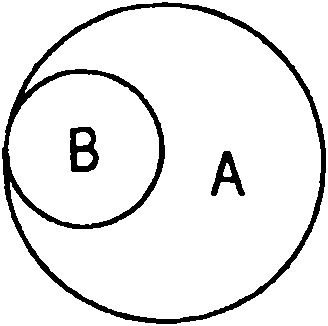

Fibers and fabrics made from ethylene/ alpha-olefin interpolymers

InactiveCN102016149AImprove wear resistanceReduce coefficient of frictionLayered productsFilament/thread formingFiberPolymer science

A bicomponent fiber is obtainable from or comprises an ethylene / alpha-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re >1481-1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics, such as spunbond, melt blown and spun-laced fabrics or webs can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

Photosensitive modified polyimide resin composition and use thereof

InactiveUS20120097435A1Good storage stabilityImprove adhesionPhotosensitive materialsRadiation applicationsPhotosensitizerHeat resistance

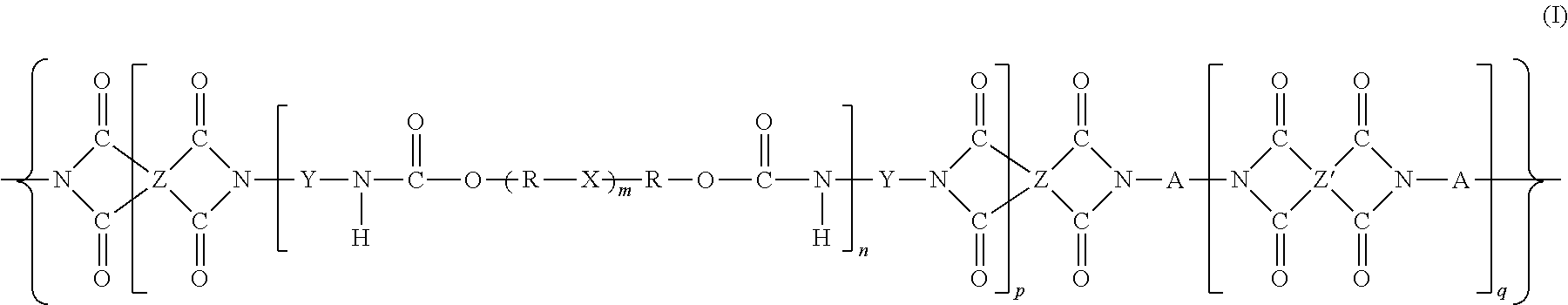

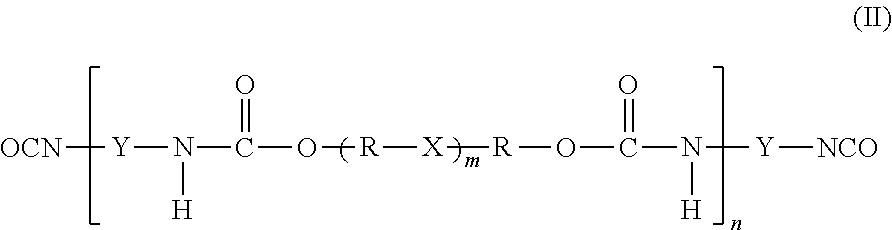

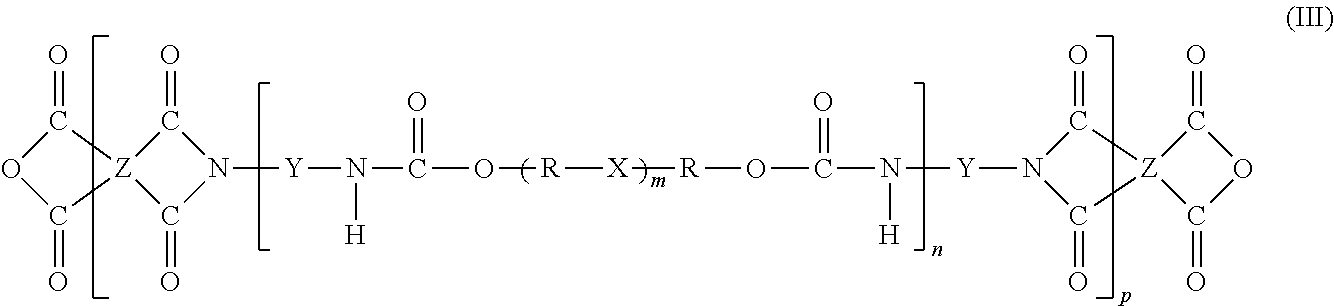

Disclosed are: a photosensitive modified polyimide resin composition having photo-fabrication property, which is excellent in the electric properties and adhesion as well as in the heat resistance, flexibility, bending property, low warping, chemical resistance and storage stability; a resin film formed from the composition; and a printed circuit board, flexible printed circuit board (FPC) and the like which comprises the film as an insulating protective film and / or interlayer insulation film. The photosensitive modified polyimide resin composition comprises a modified polyimide of a specific structure having a flexible structure such as polycarbonate; a photosensitizer; a curing agent; and a solvent.

Owner:PI R & D

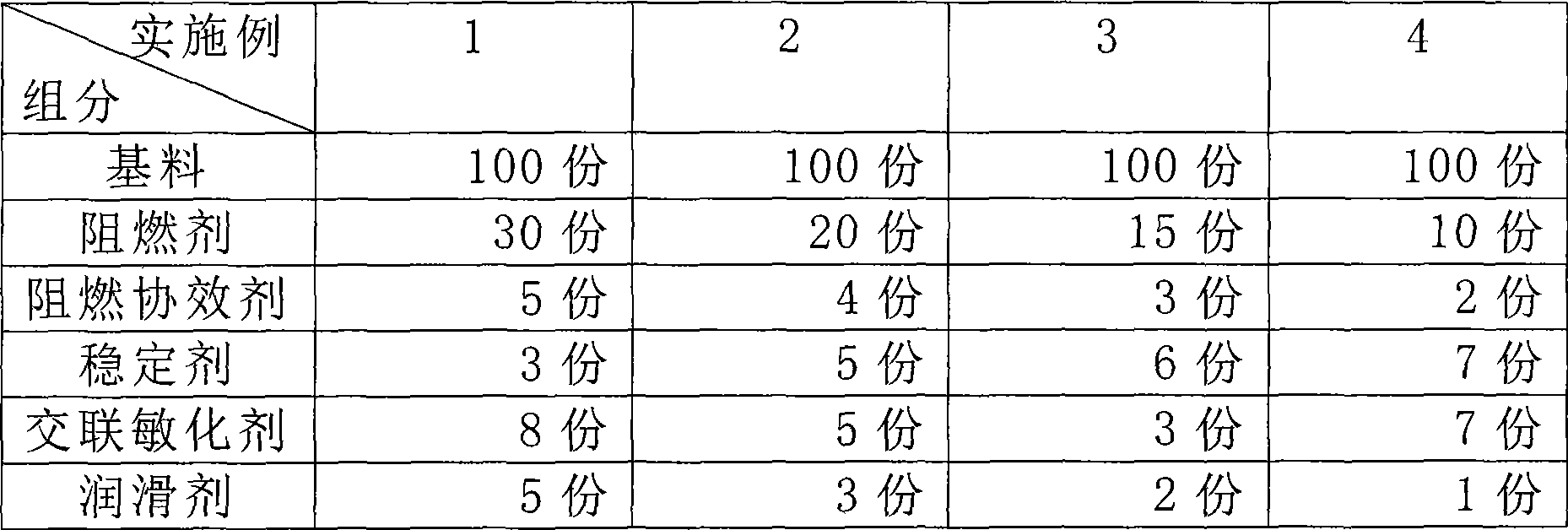

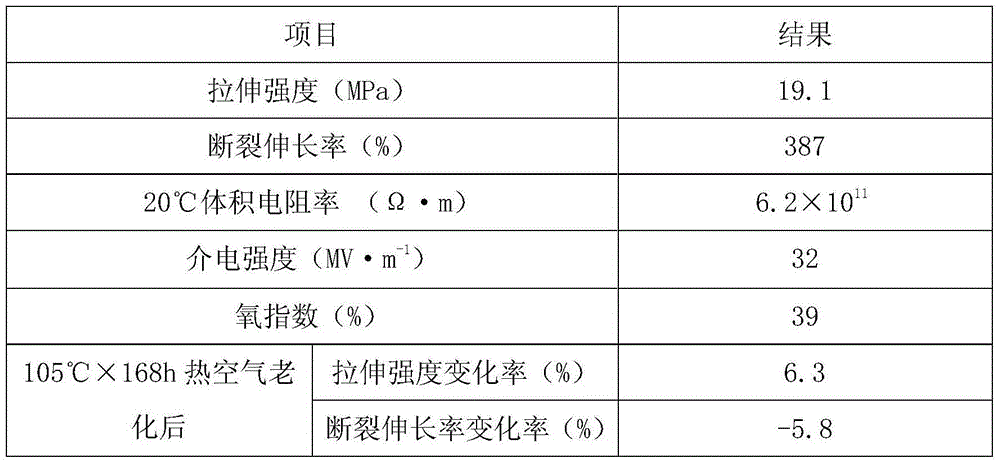

Halogen-free flame retardant insulation material for photovoltaic cable

ActiveCN101456987AImprove aging resistanceGood weather resistancePlastic/resin/waxes insulatorsWeather resistanceEngineering

The invention provides a halogen-free flame retardant insulation material used for a photovoltaic cable, which belongs to a novel cable material technical field and solves the problems exiting in the present halogen-free flame retardant insulation material used for the photovoltaic cable, that is, poor mechanical properties of tensile strength, elongation break and the like, poor heat aging property, shorter service life, and the like. The halogen-free flame retardant insulation material used for the photovoltaic cable comprises the following components according to a weight ratio: a 100 proportion of base material, 8-35 proportion of flame retardant, 2-8 proportion of stabilizer, and 1-10 proportion of crosslinking sensitizer. The halogen-free flame retardant insulation material used for the photovoltaic cable has the advantages of low production cost, good mechanical properties as heat aging property, tensile strength, elongation break and the like, long service life, low temperature tolerance, ozone resistance, weather resistance, direct current voltage resistance, and dynamic penetration resistance, etc.

Owner:临海市亚东特种电缆料厂

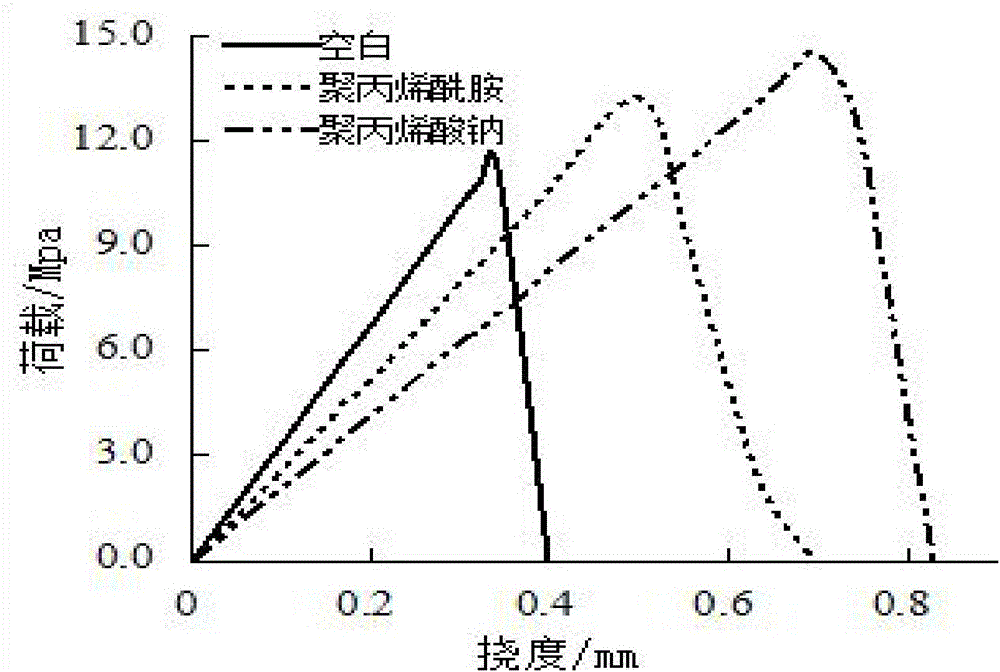

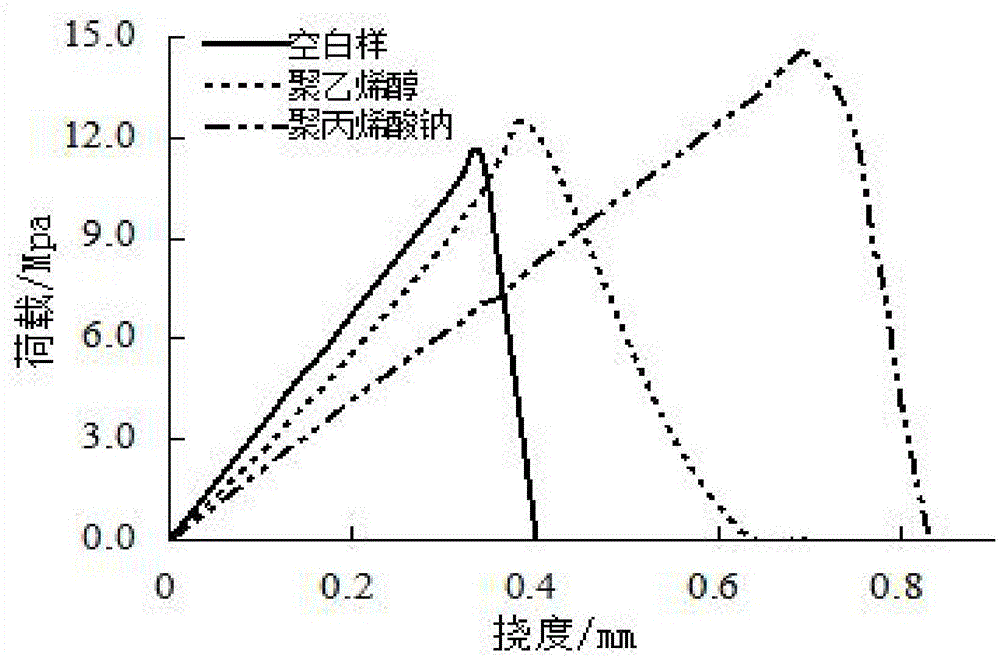

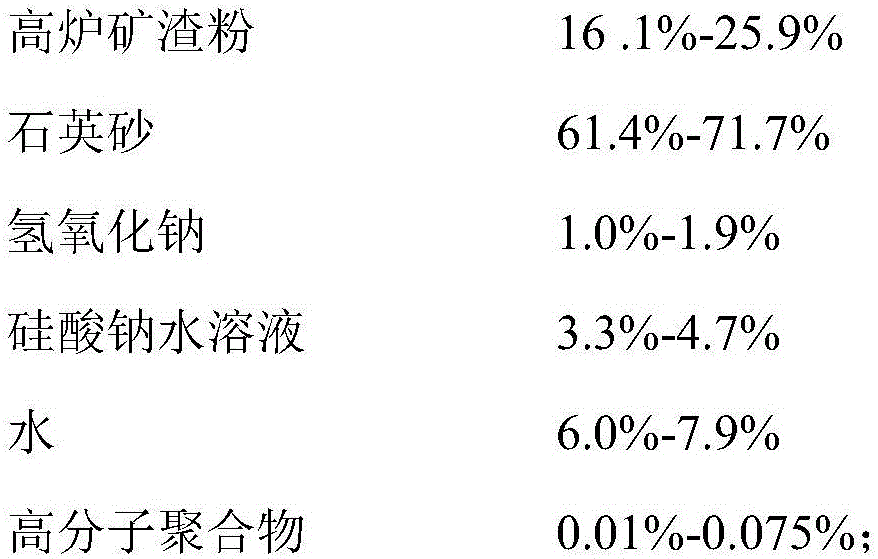

Polymer modification blast-furnace slag powder material

InactiveCN105800969AHigh ultimate flexural strengthImprove flexural toughnessCement productionSodium polyacrylateSodium silicate

The invention discloses a polymer modification blast-furnace slag powder material.The material is prepared from, by weight, 16.1-25.9% of blast furnace slag powder, 61.4-71.7% of silica sand, 1.0-1.9% of sodium hydroxide, 3.3-4.7% of a sodium silicate water solution, 6.0-7.9% of water and 0.01-0.75% of high-molecular polymer.The high-molecular polymer is sodium polyacrylate or polyacrylamide or polyvinyl alcohol.The polymer modification blast-furnace slag powder material has the high ultimate bending strength, high bending toughness and low elastic modulus, the deformation performance can be remarkably improved, the defects that the breaking strength is low and the brittleness is large are overcome, and meanwhile the polymer modification blast-furnace slag powder material has the advantages of resisting high temperature, resisting chemical corrosion, being good in anti-permeability, low in shrinkage rate and the like.

Owner:WUHAN UNIV OF TECH

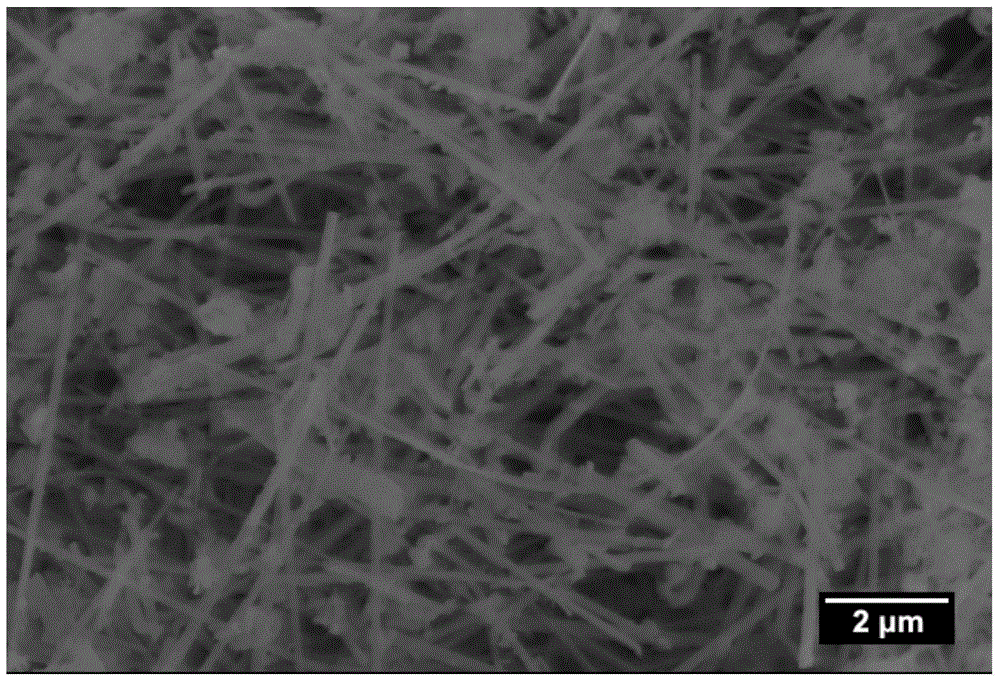

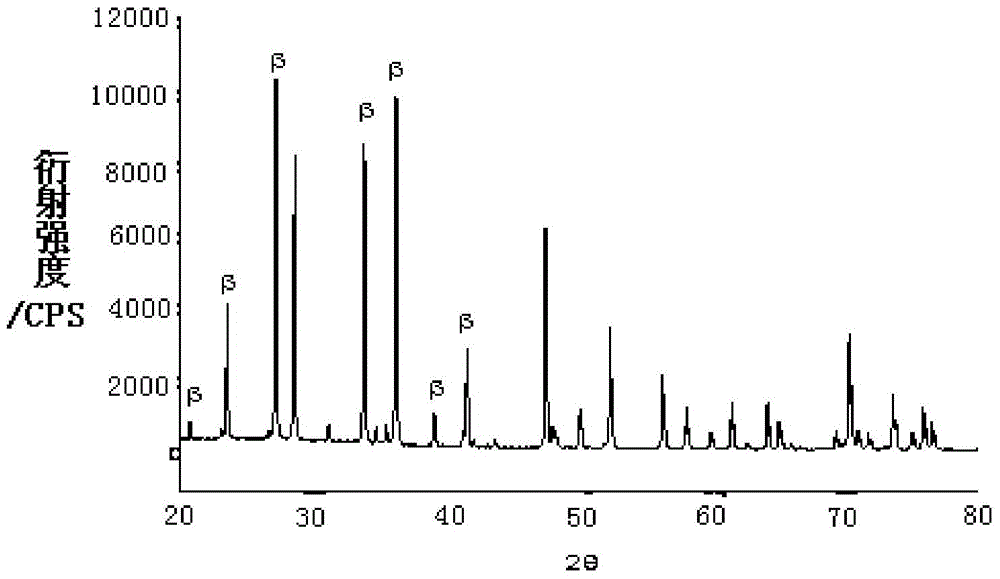

Preparation method of silicon nitride honeycomb ceramics

The invention discloses a preparation method of silicon nitride honeycomb ceramics. The preparation method comprises the following steps: 1) preparing silicon nitride honeycomb blank bodies with parallel pore passages; 2) dumping or degreasing the silicon nitride honeycomb blank bodies; and 3) calcining the silicon nitride honeycomb blank bodies to obtain the silicon nitride honeycomb ceramics with pore passage inner wall extending whisker structures. The ceramic matrix part particles prepared by the method are tightly bonded and whiskers grow on the honeycomb pore inner walls. The honeycomb ceramics have the excellent properties such as high strength, low density, high temperature resistance, chemical corrosion resistance and the like and are suitable for filtration and purification of various fluids. According to the used honeycomb ceramics, filtered matters are easily obtained by adopting various methods and the honeycomb ceramics can be reused. The preparation method is simple in process, is low in equipment requirements, is convenient in operation control, has high production efficiency and is suitable for large-scale industrial production.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

High-temperature thin film sensor with self-healing composite protective layer and preparation method thereof

InactiveCN107201502AImprove antioxidant capacityExtended service lifeEngine testingVacuum evaporation coatingSelf-healingMultilayer membrane

The invention belongs to the technical field of a sensor, and provides a high-temperature thin film sensor with a self-healing composite protective layer and a preparation method thereof, and aims to realize miniaturization and thin-film application of the sensor. The thin film sensor is composed of a substrate, a thin film sensor sensitive functional layer and the self-healing composite protective layer, which are arranged from bottom to top in order, wherein the structure of the self-healing composite protective layer comprises YSiO / HfSiBCN periodic multilayer membrane structures from bottom to top in order, and the lowest layer and the topmost layer of the protective layer are both YSiO low-oxygen diffusion coefficient layers. The high-temperature thin film sensor adopts the self-healing composite protective layer with the self-healing composite protective layer, the YSiO low-oxygen diffusion coefficient layers and HfSiBCN self-healing layers are alternately deposited to form an anti-oxidative protection system with layers of protection, and therefore the thin film sensor can work for a long time under the condition of high temperature of 600-1500DEG C and has the advantages of high temperature resistance, corrosion resistance, oxidation resistance, fast response, etc.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

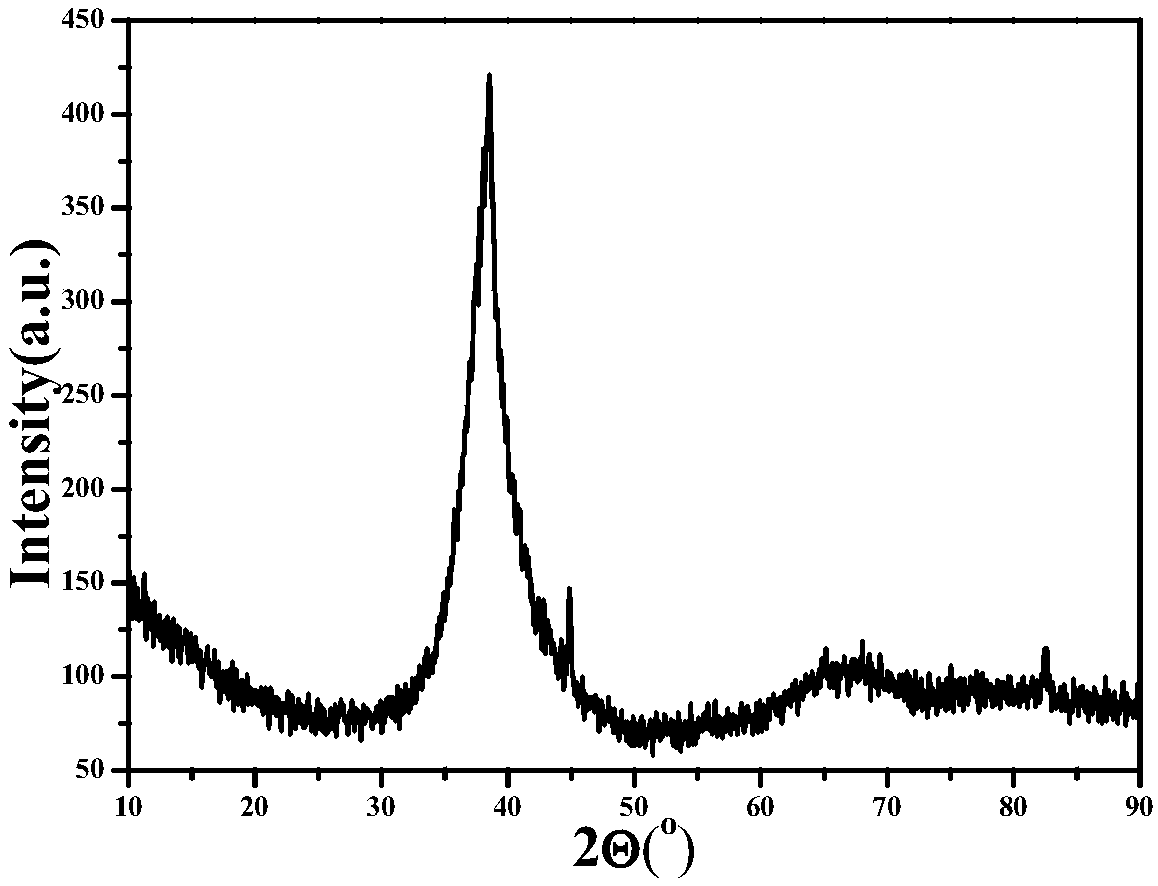

Preparation method of Ta-based high-temperature protection coating with self-healing function

ActiveCN108342705AExtended service lifeHigh bonding strengthVacuum evaporation coatingSputtering coatingSelf-healingComposite film

The invention discloses a preparation method of a Ta-based high-temperature protection coating with a self-healing function. The preparation method of the Ta-based high-temperature protection coatingwith the self-healing function comprises the steps of adopting a 99.99-percent high-pure Ta circular block material as a magnetron sputtering target material, adopting a direct-current magnetron sputtering method, pre-sputtering on a clean stainless steel substrate, preparing a layer of completely covered Ta thin film, and obtaining a Ta middle layer with an alpha phase; and selecting the 99.99-percent high-pure Ta circular block material and a high-pure Ag target material as sputtering raw materials, adopting two direct-current magnetron sputtering power supplies for independently regulatingthe two target materials, and preparing a Ta-Ag self-healing high-temperature protection layer on the Ta middle layer with the alpha phase. According to the preparation method of the Ta-based high-temperature protection coating with the self-healing function provided by the invention, the structure regulation of the self-healing layer can be realized; in a Ta-Ag composite thin film structure, Ag is dissolved into a crystal lattice of the metal Ta so as to form a super-solid solution; during the generation of high-temperature cracks, vacancies and microcracks can be filled to the vacancies through the formation of the precipitated-phase Ag so as to achieve healing; and generated tantalum oxide can form a protection layer on the surface of the thin film, so that the further oxidization is prevented.

Owner:NANJING UNIV OF SCI & TECH

Dicyclohexylmethylmethane-4,4'-diisocyanate prepolymer used for paint curing agent and preparation method thereof

ActiveCN101514269AOvercome yellowingAvoid Toxic HazardsCoatingsOrganometallic catalysisOrganic solvent

The invention discloses dicyclohexylmethylmethane-4,4'-diisocyanate prepolymer used for paint curing agent and preparation method thereof, the prepolymer is mainly prepared from (A) 20-50 mass parts of dicyclohexylmethylmethane-4,4'-diisocyanate; (B) 5-60 mass parts of polyalcohol composition; (C) 30-300 mass parts of organic solvent with boiling point less than 200 DEG C; and selective (D) 0.01-1 mass part of organic metal catalyst; and the prepolymer is used for curing agent for alkyd resin paint and has better weathering resistance, yellowing resistance, chemicals resistance and water resistance.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

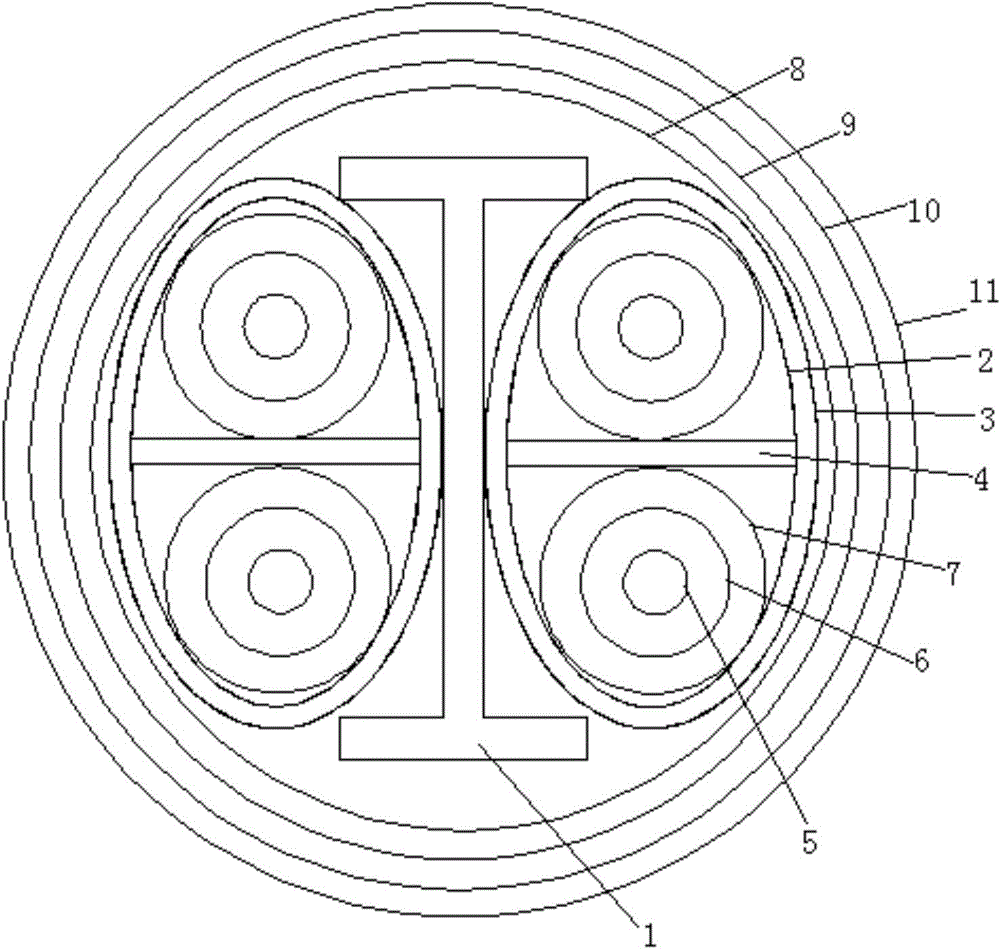

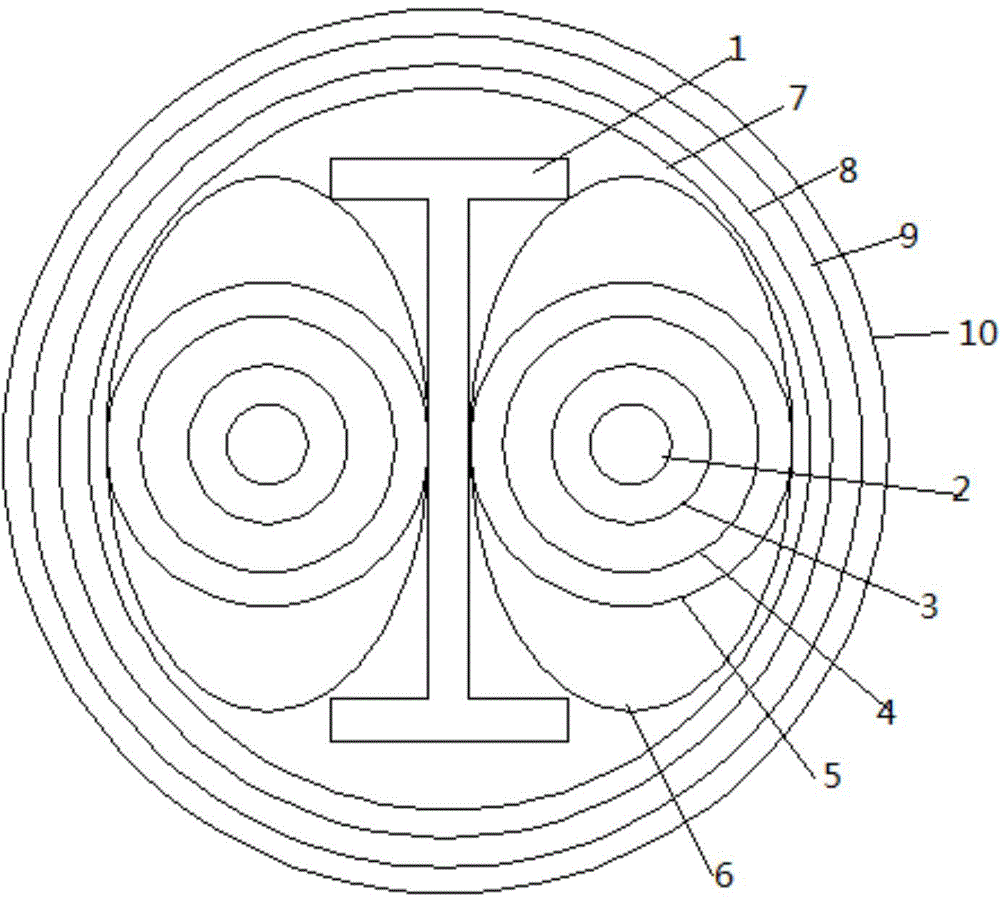

Aerospace tensile power cable

ActiveCN104021871AImprove radiation resistanceGood anti-aging performancePower cables with screens/conductive layersInsulated cablesFiberYarn

The invention discloses an aerospace tensile power cable which comprises a cable core. The cable core comprises an I-shaped nylon framework. Wire cores are placed on the left side and the right side of the I-shaped nylon framework respectively. Each wire core comprises an oval nylon framework coated with waterproof glue. Elastic cushion plates are placed inside the oval nylon frameworks. Conductors are placed on the two sides of each elastic cushion plate respectively. Each conductor is sequentially coated with an aluminum magnesium alloy wire braided shielding layer and an inflaming retarding silica gel inner sheath. The cable core is sequentially coated with a steel wire braided tensile cylinder, a carbon fiber yarn braided layer, an aluminum foil taped covering and an outer sheath. The aerospace tensile power cable is excellent in electrical characteristic, mechanical characteristic and high and low temperature characteristic, low in friction performance, resistant to chemical and weather and incapable of combustion.

Owner:ANHUI AICS SCI & TECH GROUP

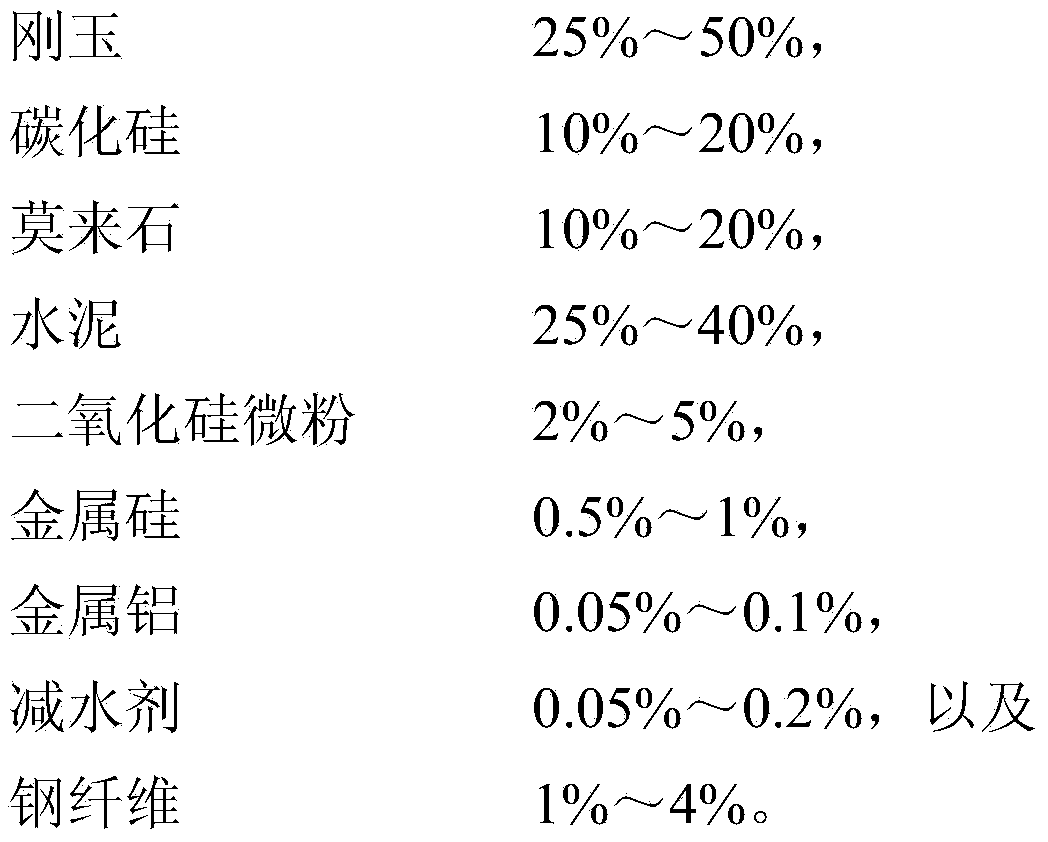

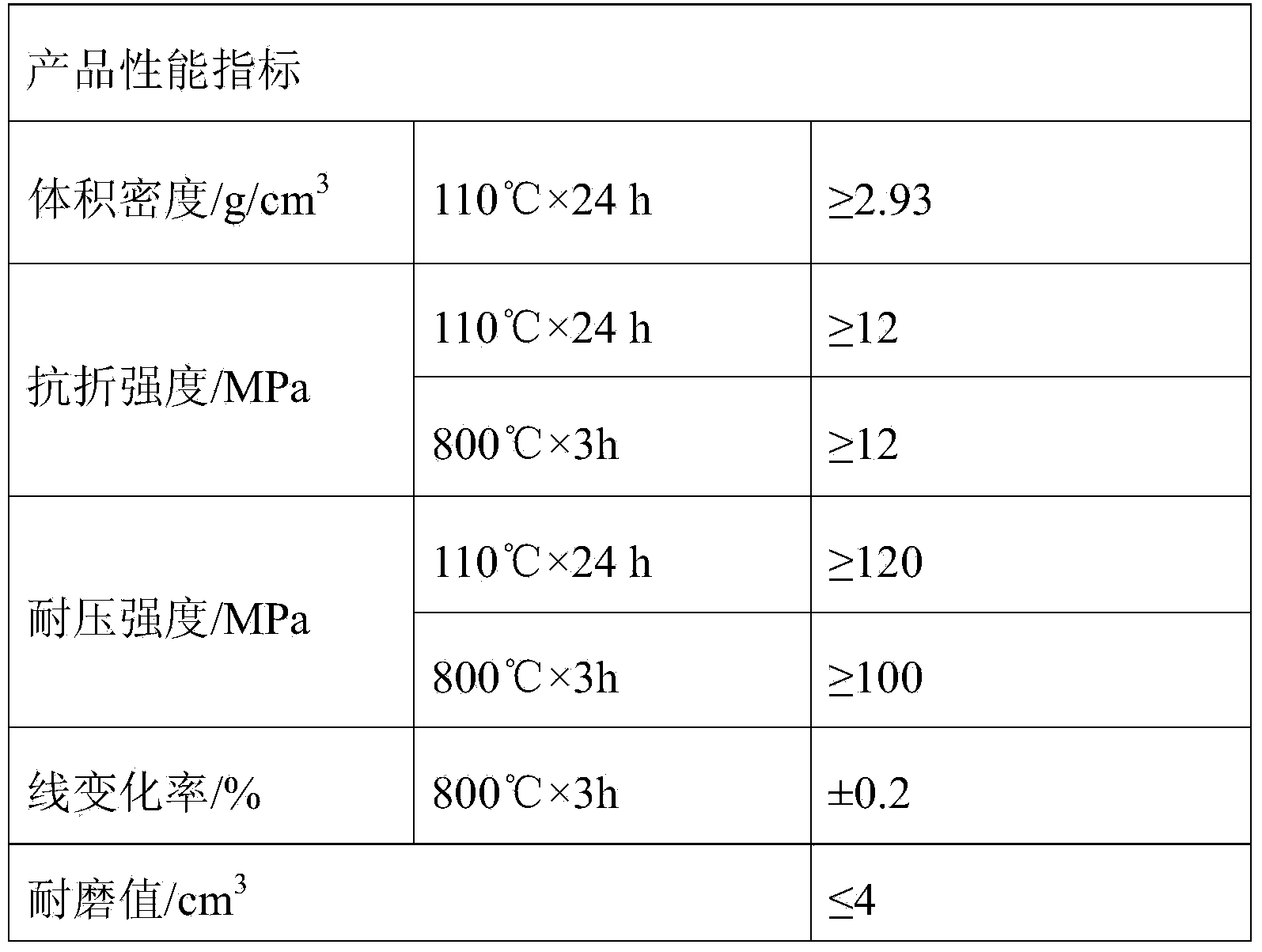

High-strength wear-resistant material for blast-furnace water slag flushing channel and preparation method of high-strength wear-resistant material

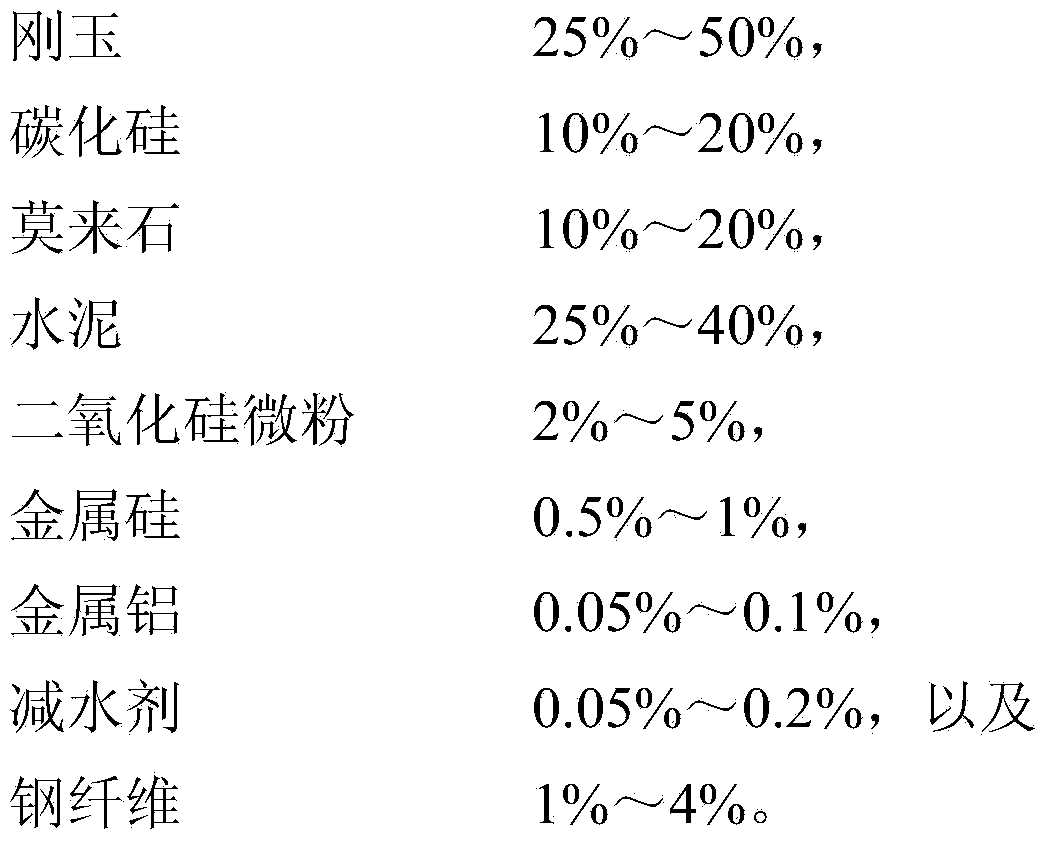

The invention provides a high-strength wear-resistant material for a blast-furnace water slag flushing channel and a preparation method of the high-strength wear-resistant material. The high-strength wear-resistant material for the blast-furnace water slag flushing channel comprises the following raw materials in percentage by weight: 25%-50% of corundum, 10%-20% of silicon carbide, 10%-20% of mullite, 25%-40% o cement, 2%-5% of silica micro-powder, 0.5%-1% of metallic silicon, 0.05%-0.1% of metallic aluminium, 0.05%-0.2% of a water reducing agent and 1%-4% of steel fiber. The high-strength wear-resistant material for the blast-furnace water slag flushing channel provided by the invention is high in applicable temperature, good in thermal shock resistance, good in abrasive resistance and long in service life.

Owner:CHINA JINGYE ENG +2

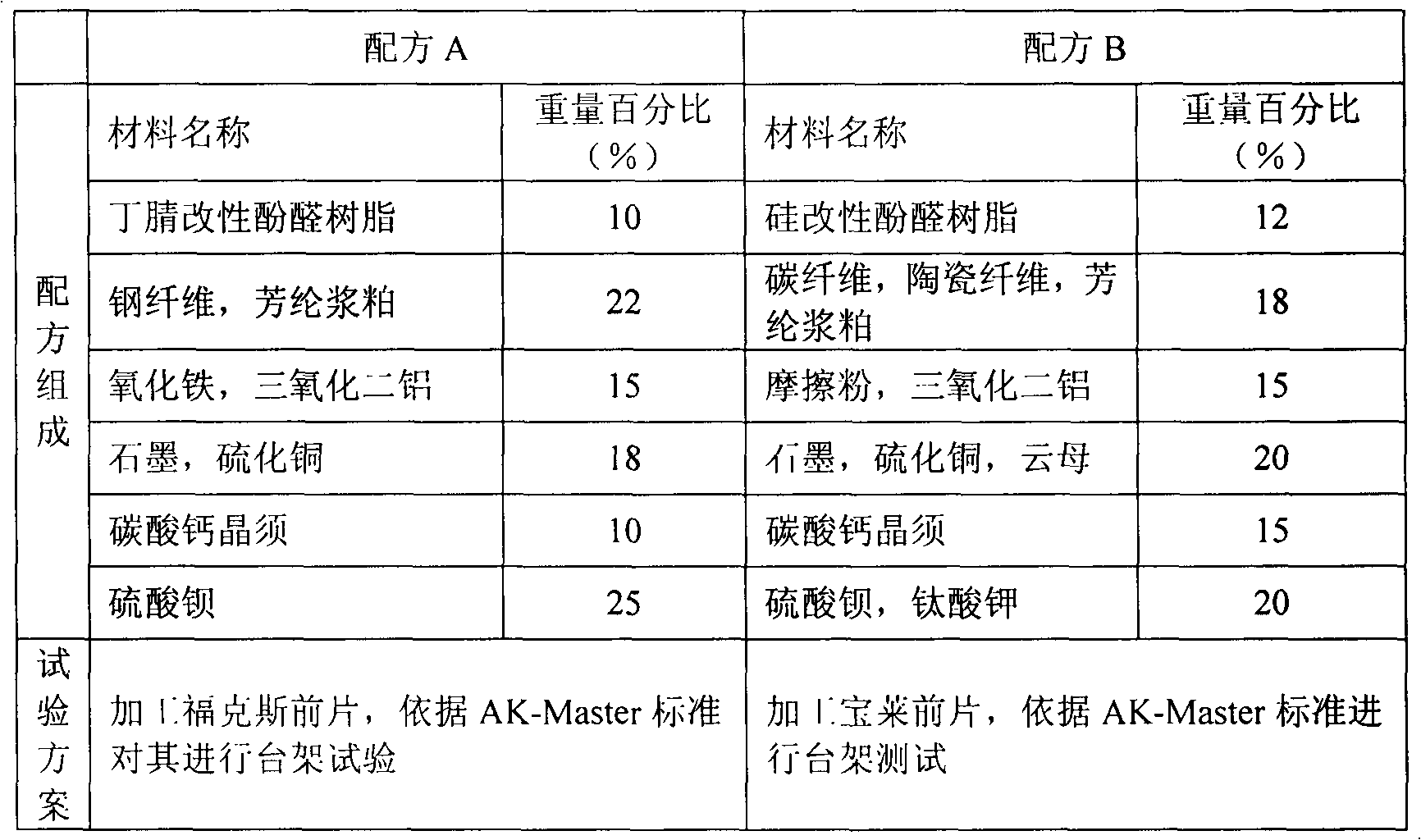

Carbon-ceramic based brake pad

InactiveCN102562890AHigh melting pointExcellent high temperature mechanical propertiesFriction liningCarbon fibersAdhesive

The invention relates to preparation of brake pads in the field of the automobile industry, in particular to a carbon-ceramic based brake pad, which is higher in strength and more stable in performance. In weight percent, the brake pad comprises 5-15% of adhesives, 20-30% of reinforcing materials, 20-30% of frictional property conditioning agents and 30-50% of packing in formula, wherein the adhesives include phenolic resin, silicone modified phenolic resin and butyronitrile modified phenolic resin, the reinforcing materials include carbon fibers, ceramic fibers and aramid pulp, the frictional property conditioning agents include grinding agents and lubricating agents, the grinding agents include aluminum oxide, ferric oxide, magnesium oxide and frictional powder, the lubricating agents include graphite, sulfide and mica, and the packing comprises barium sulfate, potassium titanate and magnesium oxide. The carbon-ceramic based brake pad has negative temperature coefficient, stable chemical performance and resistance to strong acid and strong alkali, and is nonhazardous and extremely high in mechanical performance.

Owner:东营宝丰汽车配件有限公司

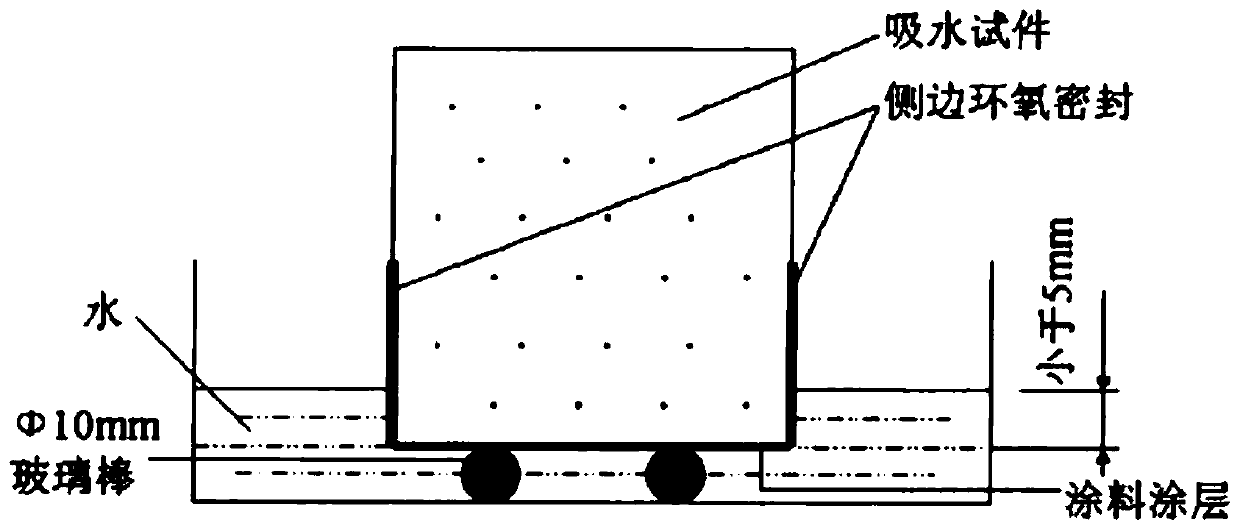

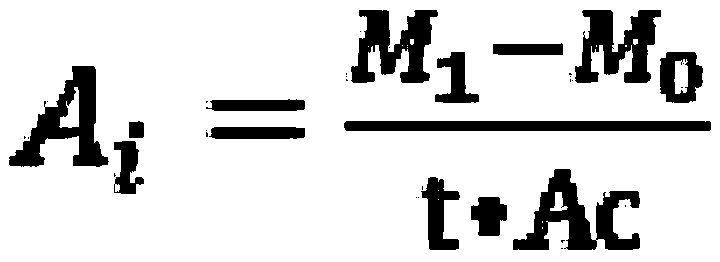

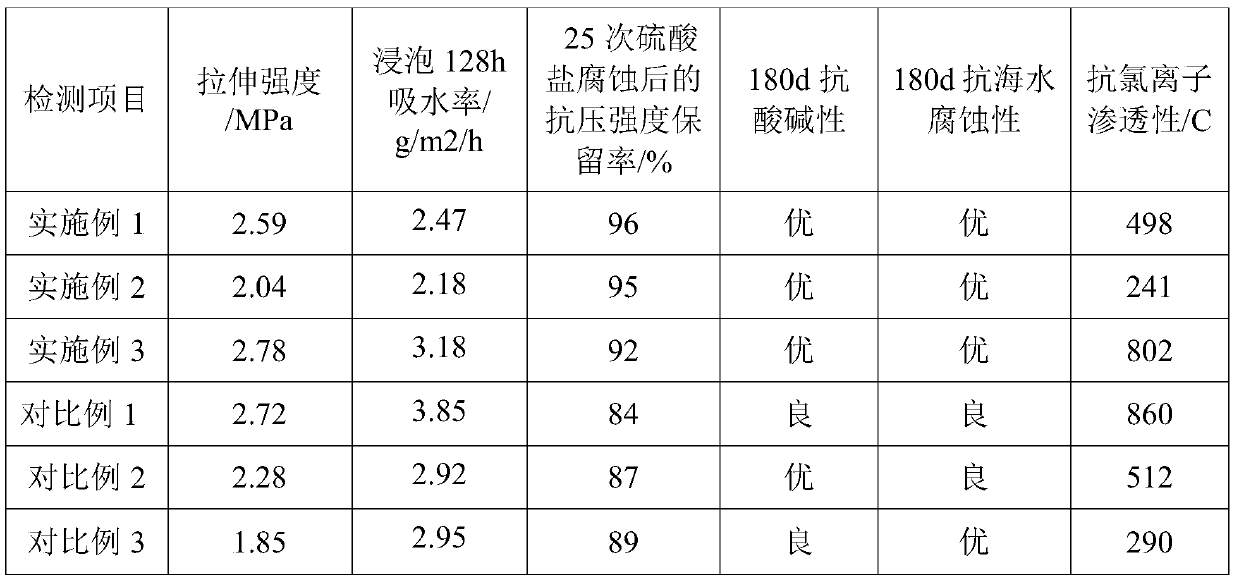

Polymer cement waterproof coating with high corrosion resistance and preparation method thereof

InactiveCN111087868AIncreased durabilityImprove corrosion resistanceConjugated diene hydrocarbon coatingsChloropene polymer coatingsIon permeabilityPolymer emulsion

The invention discloses a polymer cement waterproof coating with high corrosion resistance and a preparation method thereof. The high-corrosion-resistance polymer cement waterproof coating comprises the following raw materials: cement, quartz sand, a coupling agent, a defoaming agent, a water reducing agent, a dispersing agent, a pigment and a polymer emulsion. The polymer cement waterproof coating prepared by the invention is excellent in acid and alkali resistance, sulfate resistance and seawater corrosion resistance and high in bonding strength with a concrete base material, and still has high bonding strength after being corroded by acid, alkali and salt; the polymer cement waterproof coating prepared by the invention has excellent chloride ion permeability resistance, high density andlow water absorption rate; the polymer cement waterproof coating prepared by the invention can be constructed by using a blade coating, picture brushing or roll coating method, is easy to operate andpopularize, can be directly constructed on a humid basal plane, and is relatively low in cost.

Owner:WUHAN POLYTECHNIC UNIVERSITY

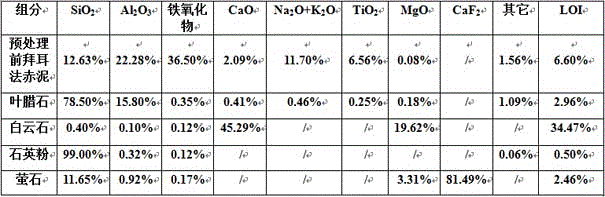

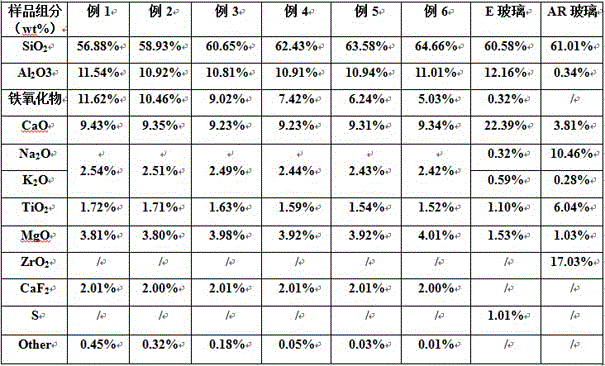

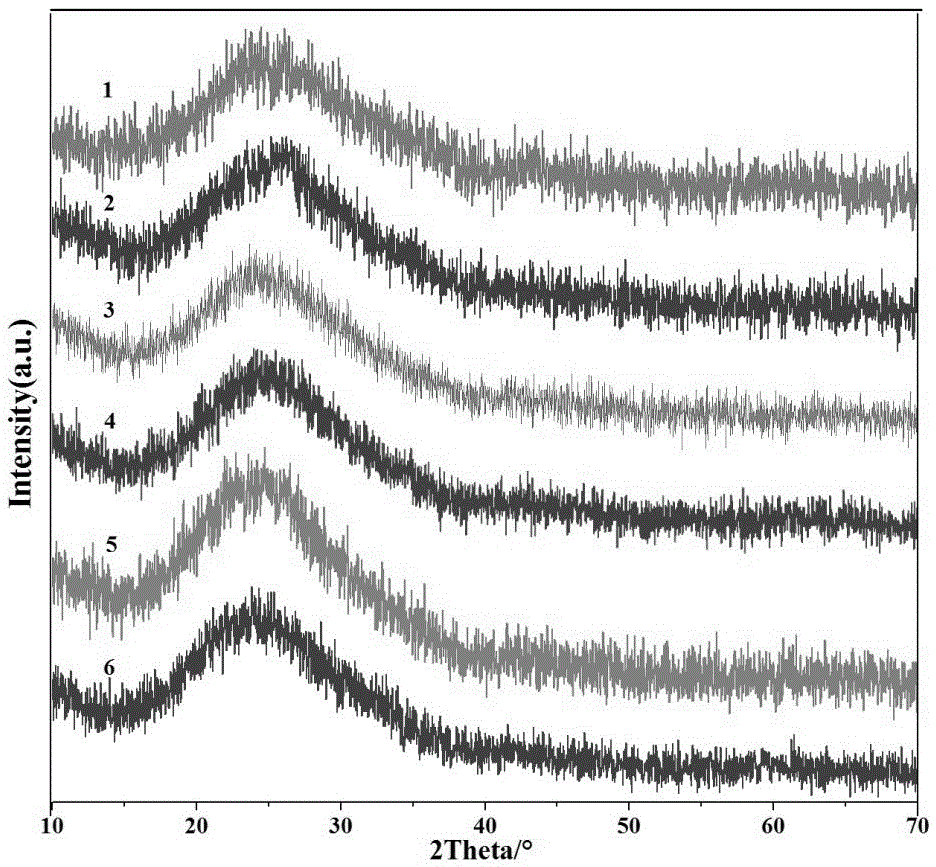

High-performance aluminosilicate glass primarily made from red mud and preparation method of high-performance aluminosilicate glass

The invention discloses a high-performance aluminosilicate glass primarily made from red mud and a preparation method of the high-performance aluminosilicate glass and belongs to the crossing field of waste disposal and inorganic metal materials. Red mud, namely the waste from industrial production of Al2O3, causes water pollution, soil alkalinization and high land occupation and the like. Since red mud is added into industrial raw materials, red mud is utilized effectively, harms to production and life are reduced; and further, on the basis of advantages of content such as Fe2O3, Na2O, K2O and the like of the red mud, performance of aluminosilicate glass can be improved, and particularly, chemical stability of the aluminosilicate glass is much superior to that of conventional E-glass, AR-glass and the like. The aluminosilicate glass is prepared from, by weight, 14.2-27.4% of Bayer-process red mud, 11.9-17.5% of dolomite, 26.3-47.6% of pyrophyllite, 23.8-26.3% of quartz powder and 2-2.5% of fluorite. As all of raw materials of the aluminosilicate glass, except for the red mud, are of industrial grade, the aluminosilicate glass can be applied to industrial production well.

Owner:UNIV OF JINAN

Aerospace cable

InactiveCN103985451AGood oil resistanceImprove heat resistanceInsulated cablesInsulated conductorsElectrical conductorCopper wire

The invention discloses an aerospace cable. The aerospace cable comprises a cable core, wherein the cable core comprises an I-shaped nylon framework, wire cores are placed on the left side and right side of the I-shaped nylon framework respectively, each wire core comprises a conductor, each conductor is covered with a foamed plastic insulating layer, a copper wire winding layer and an aluminum strip linkage armor layer in sequence, each conductor is also sleeved with an oval nylon framework, and the cable core is covered with a tensile belt, a plastic film, a zinc-coated steel wire braided shielding layer and an outer sheath in sequence. According to the aerospace cable, due to the fact that each conductor is sleeved with the corresponding oval nylon framework and the cable core is covered with the tensile belt, the plastic film and the zinc-coated steel wire braided shielding layer, the electrical characteristic, the mechanical characteristic, the high-temperature characteristic, the low-temperature characteristic, the low-friction characteristic, the chemical resistance, the weather resistance and the flame resistance are excellent.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

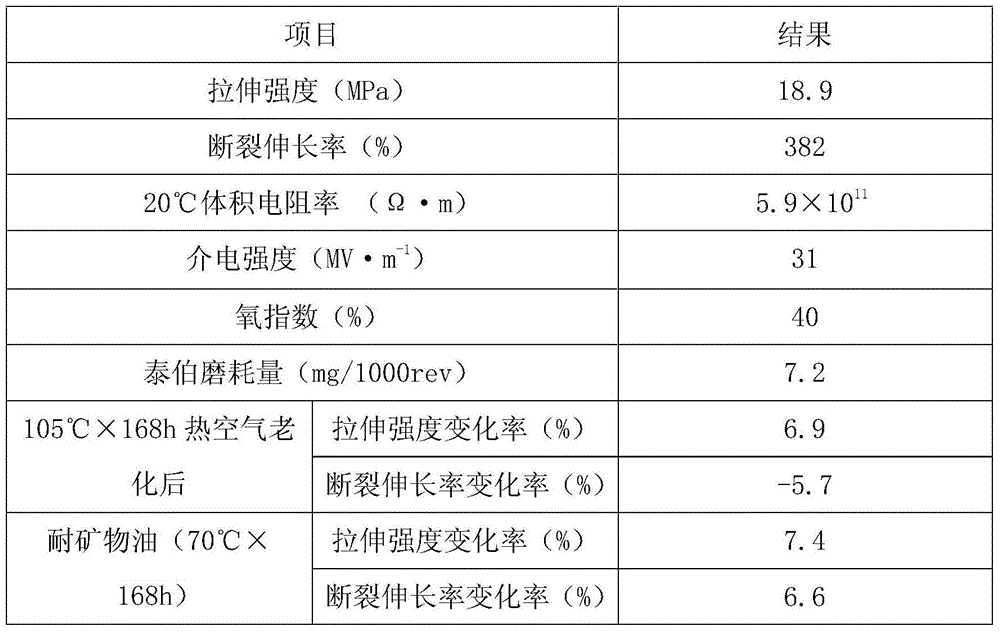

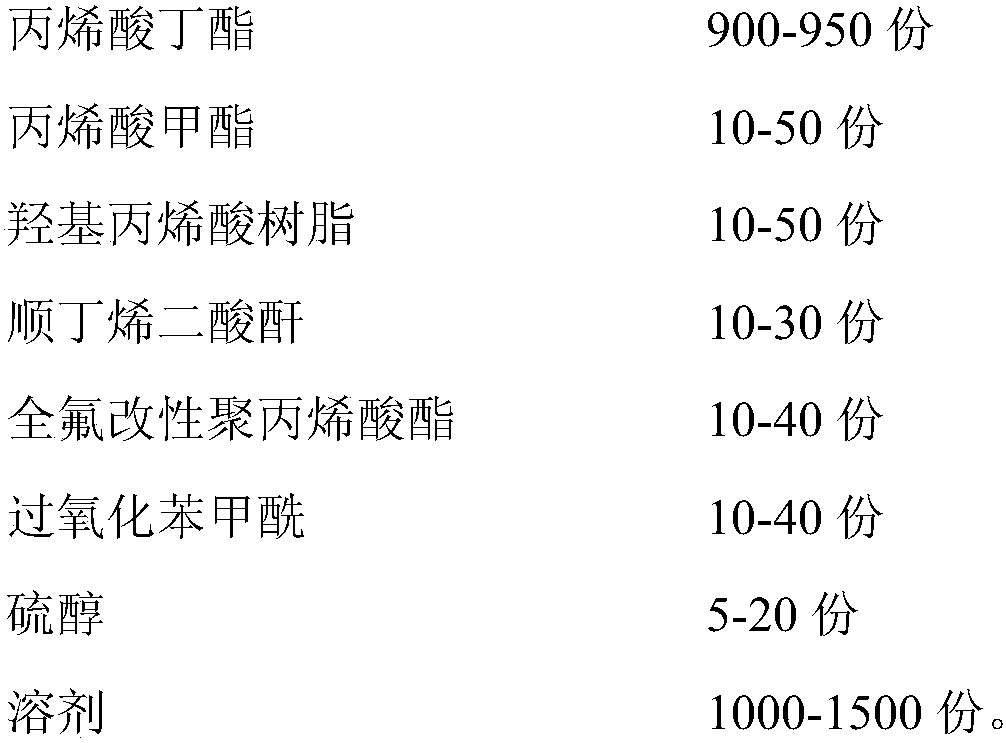

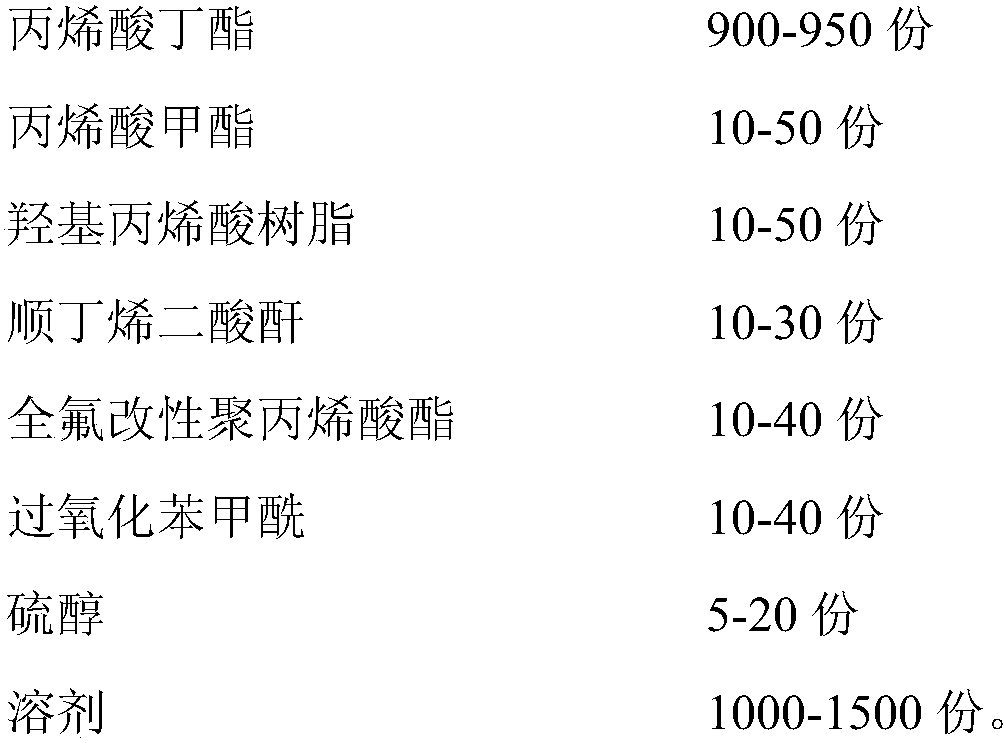

Leveling agent for powdered coating and preparation method of leveling agent

InactiveCN107793822AImprove thermal stabilityGood chemical stabilityAnti-corrosive paintsPowdery paintsChemical synthesisBond energy

The invention belongs to the technical field of chemical synthesis, and particularly relates to a leveling agent for powdered coating and a preparation method of the leveling agent. The leveling agentfor powdered coating is prepared from the following raw materials: butyl acrylate, methyl acrylate, hydroxy acrylic resin, maleic anhydride, perfluoro modified polyacrylate, benzoyl peroxide, mercaptan and a solvent. By the adding of the perfluoro modified polyacrylate into the acrylates leveling agent, as a fluorine carbon bond is small in bond length, high in bond energy and low in fluorine atom polarizability, introduction of a fluorine-containing polymer improves the heat stability, the chemical stability, the glossiness, the low surface energy, the chemical corrosion resistance and the like of the leveling agent, which are higher than the properties of the same type of acrylate products.

Owner:SHANDONG RUIFENG CHEM

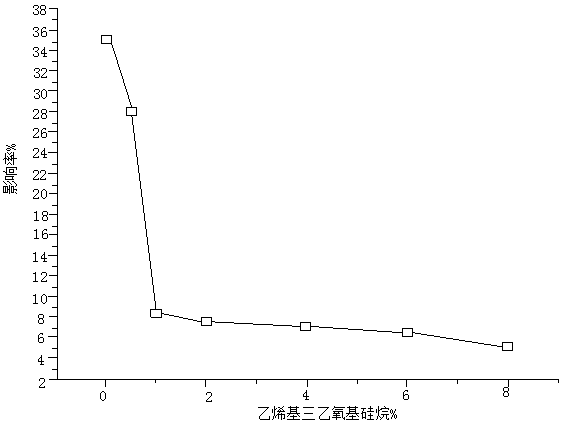

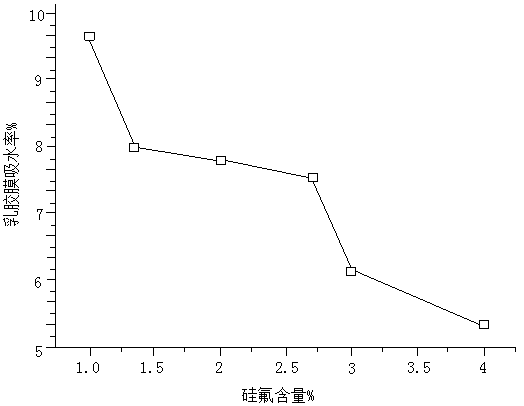

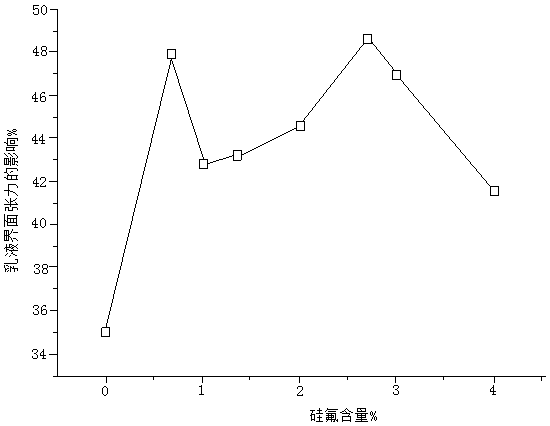

Silicon-fluorine modified styrene-acrylic emulsion and preparation method thereof

The invention relates to a silicon-fluorine modified styrene-acrylic emulsion and a preparation process thereof. The silicon-fluorine modified styrene-acrylic emulsion comprises the following raw materials: butyl acrylate, styrene, acrylic acid, nonylphenol polyoxyethylene ether, lauryl sodium sulfate, vinyltriethoxysilane, ammonium persulfate, sodium bicarbonate, tetrahydrofuran, methacrylic acid, acrylamide, N-hydroxymethyl acrylamide, hydroquinone, a fluorine-containing monomer, ammonia water and a proper amount of deionized water. The preparation process comprises a pre-emulsification method, a semi-continuous monomer dropwise adding method and an organosilicon monomer post-adding method. According to the invention, the comprehensive performance of the emulsion is studied by a polymerization process, a polymerization temperature, the addition amounts and addition modes of organic silicon and organic fluorine, and the dosage and proportion of an emulsifier; the styrene-acrylic emulsion has the advantages of both organic silicon and organic fluorine, so that the performance of the emulsion is better improved on the basis of effectively reducing the cost of the emulsion, the emulsion with higher market competitiveness is obtained, and the blank of domestic and overseas markets is filled.

Owner:SHENZHEN TAIQIANG CHEM

Epoxy-group-containing copolymer, epoxy (methyl) acrylate copolymer using same, and processes for producing copolymers

InactiveCN102112505AImprove insulation performanceLow dielectric propertiesPlastic/resin/waxes insulatorsEpoxyRepeat unit

Disclosed are a novel epoxy-group-containing copolymer and a process for producing the copolymer. Also disclosed are an epoxy (methyl) acrylate copolymer produced by using an epoxy-group-containing copolymer as a raw material and a process for producing the copolymer. The epoxy-group-containing copolymer comprises a specific epoxy-group-containing repeating unit and an olefin-type repeating unit. The copolymer can be reacted with (methyl) acrylic acid, thereby producing the novel epoxy (methyl) acrylate copolymer.

Owner:SHOWA DENKO KK

Improving method for rigid chain liquid crystal polymer and flexible chain nylon compatibility

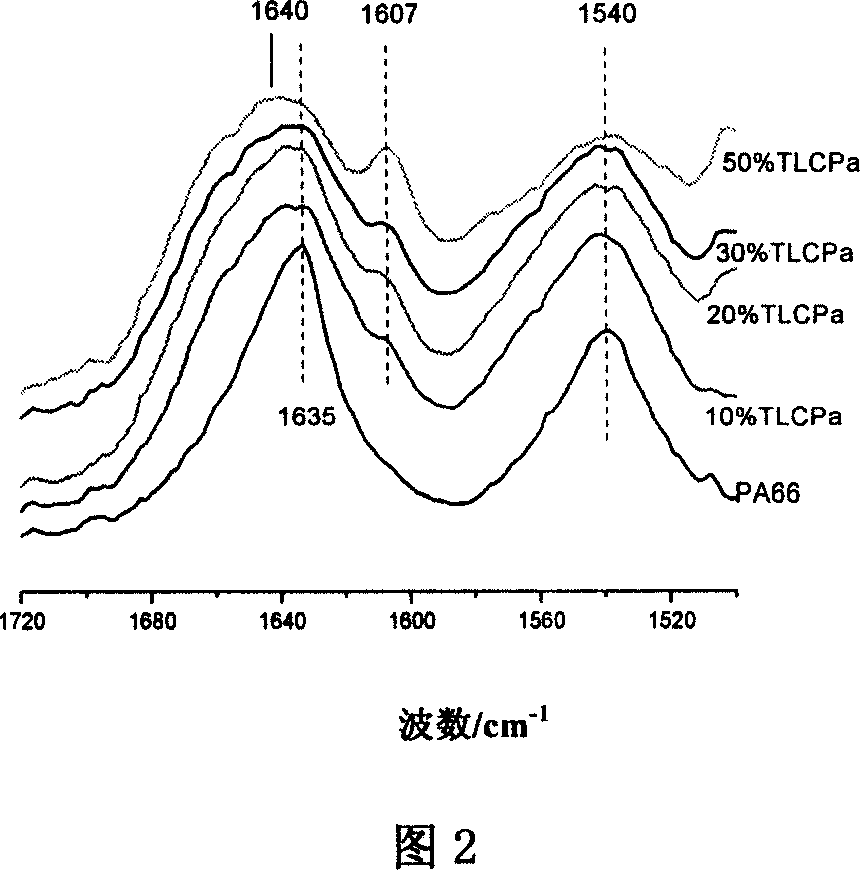

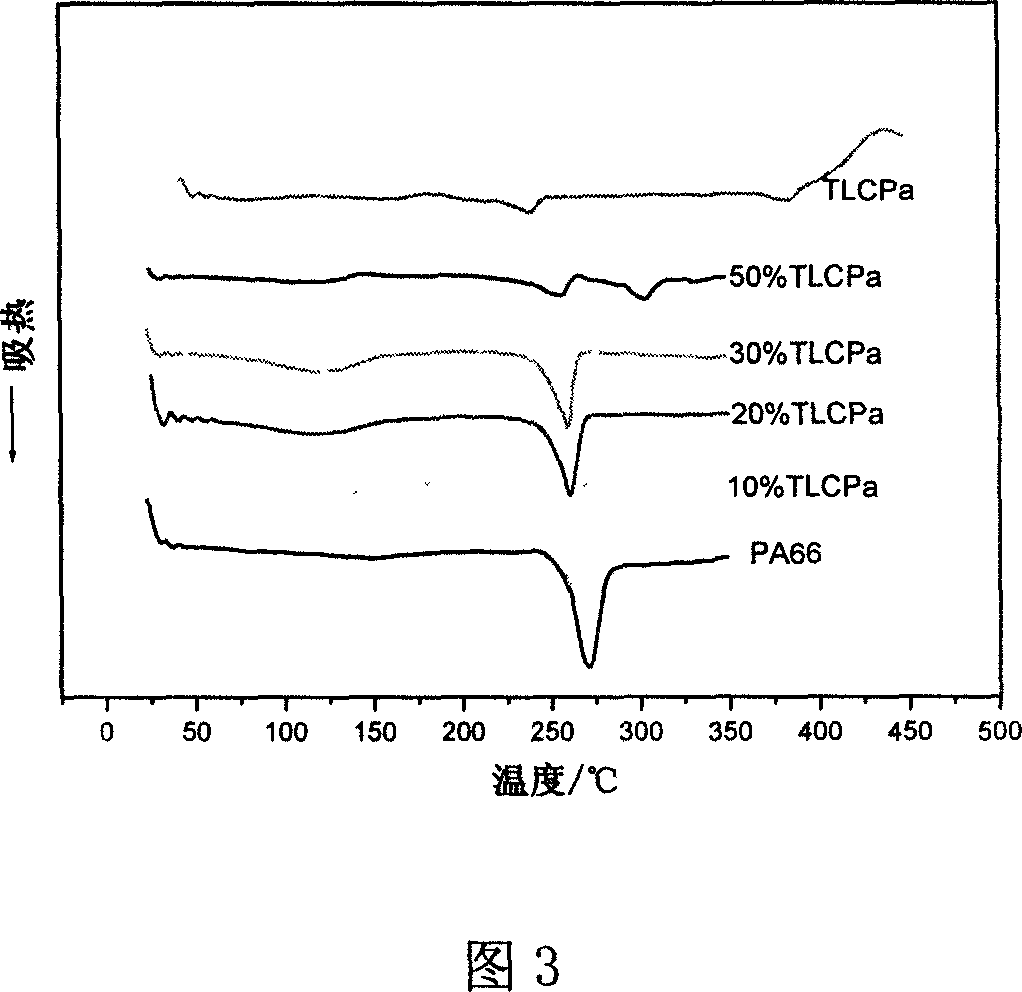

InactiveCN1944532AExpand application spaceImprove mechanical propertiesLiquid crystal compositionsHydrogenPolymer science

The method of improving the compatibility between liquid crystal polymer with rigid chain and nylon with flexible chain is suitable for the compatibility modification of nylon. The method includes the first synthesizing polyamide of smelting point of 223-284deg.c as the liquid crystal polymer with o-tolidine, PEG2 and PEG3 monomers; pre-mixing the polyamide and nylon with fitting smelting point in the weight ratio of 5 to 95-50 to 50; and smelting the mixture in an extruder to obtain the well compatible liquid crystal polyamide reinforced nylon material. The present invention utilizes intermolecular hydrogen bonding in improving the compatibility between liquid crystal polymer and nylon, and simplifies the triphase reinforcing system into a biphase one.

Owner:BEIJING UNIV OF TECH

Sterile vacuum packing technique for infant clothing

The invention discloses a sterile vacuum packing technique for infant clothing. The technique comprises the following steps that (1) the infant clothing is washed with water; (2) the infant clothing washed with the water is subjected to spin-drying and drying; (3) the dried infant clothing is subjected to ozone sterilization; (4) the sterilized infant clothing is subjected to high temperature disinfection, and the temperature of high temperature disinfection is 110 DEG C; and (5) the disinfected infant clothing is subjected to vacuumizing packing. According to the sterile vacuum packing technique for the infant clothing, the contents of impurities, bacteria and the like in the infant clothing can be effectively reduced, so that the wearing health of the infant clothing is improved.

Owner:于基保

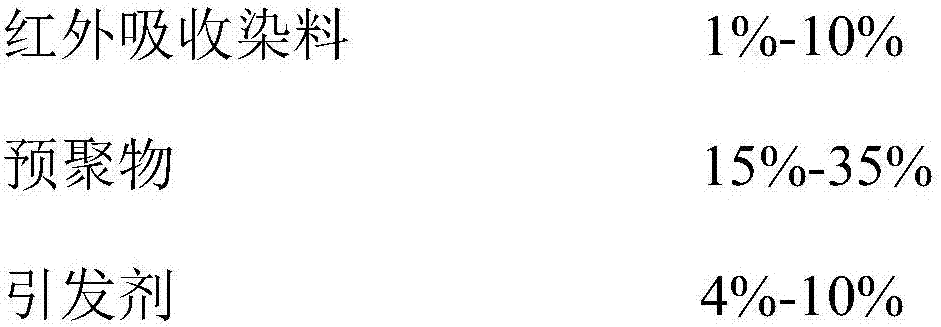

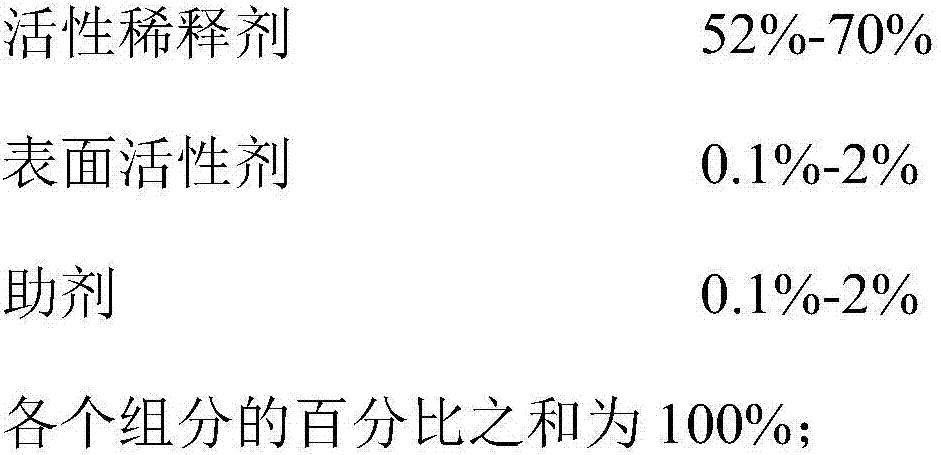

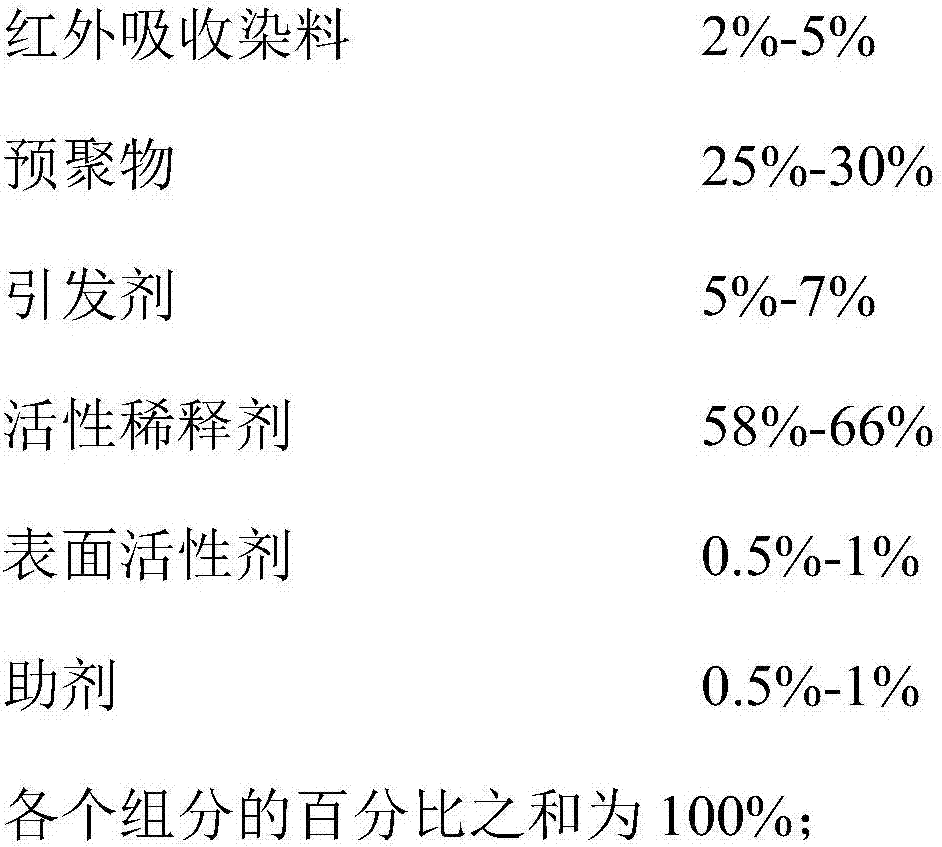

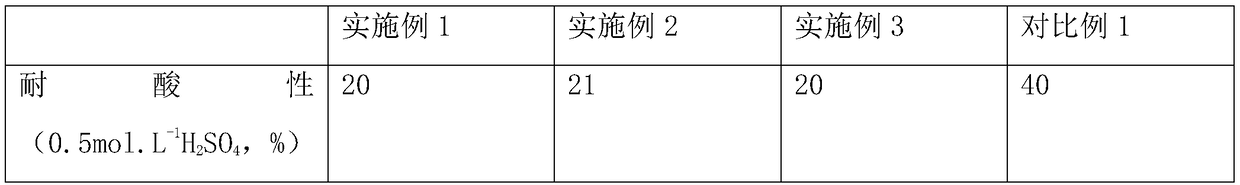

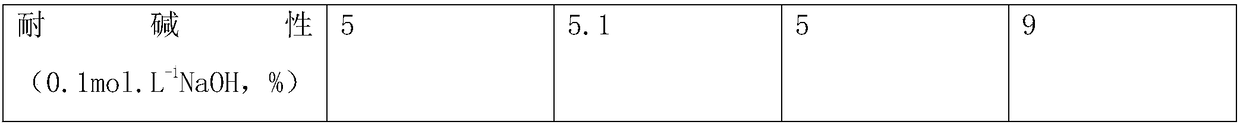

Light-colored infrared absorbing UV-LED ink-jet ink and preparation method thereof

The invention discloses light-colored infrared absorbing UV-LED ink-jet ink and a preparation method thereof. The light-colored infrared absorbing UV-LED ink-jet ink is composed of the following ingredients (by weight): 1-10% of an infrared absorbing dye, 15-35% of a prepolymer, 4-10% of an initiator, 52-70% of a reactive diluent, 0.1-2% of a surfactant and 0.1-2% of an auxiliary agent. The ink-jet ink can be used in industrial production. For one pass ink-jet printing, printing speed is 80 m / min-100 m / min. Smooth printing is guaranteed. The ink-jet ink has characteristics of no misting, rapid solidification, low energy, good light resistance and the like.

Owner:CHINA BANKNOTE INK +1

Ultraviolet (UV) coating capable of forming porcelain lines automatically and production method thereof

The invention discloses an ultraviolet (UV) coating capable of forming porcelain lines automatically and a production method thereof. The UV coating capable of forming porcelain lines automatically is characterized in that the UV coating capable of forming porcelain lines automatically is white and turbid liquid, has specific gravity (25 DEG C) of 0.95 to 1.0 and viscosity (second 25 + / - 1 DEG C)of 12.5 to 13.5 seconds, and comprises 31 to 35% of a solid component. The UV coating capable of forming porcelain lines automatically has excellent wear resistance and scratch resistance thus havinggood conditions for preservation, has high hardness and high toughness thus having excellent buckling performances, has good chemical resistance, has low shrinkage thus being deformed difficultly, and allows gloss adjustment on a surface to realize highlight or delustring. A system of the UV coating capable of forming porcelain lines is a UV system, provides multiple color collocation, and allowscolor adjustment on a line part and the UV coating capable of forming porcelain lines so that diversification of color selectivity is realized.

Owner:JIANGSU ZHONGYING PAINT

Polyketone fiber paper, polyketone fiber paper core material for printed wiring board and printed wiring board

InactiveCN101107397AHigh strengthHigh elastic rateSynthetic cellulose/non-cellulose material pulp/paperMonocomponent synthetic polymer artificial filamentEpoxyVoid ratio

An aliphatic polyketone fiber paper comprising aliphatic polyketone fibers and a polyketone fiber paper core material for a printed wiring board are provided. The polyketone fiber paper and the core material have high strength and modulus of elasticity; excellent dimensional stability, chemical resistance, heat resistance, adhesiveness and electrical insulation; and low dielectricity and water absorbance, and are thin, porous, and uniform. A printed wiring board prepared from the core material having a low dielectric constant, dimensional stability, electrical insulation, and properties of being uniformly bored by laser punching is also provided. The aliphatic polyketone fiber paper and the core material for a printed wiring board comprises 1 to 100% by mass of aliphatic polyketone fibers which comprise the repeating unit of the below-mentioned formula (1), the fibers having an average fiber length of 0.5 to 10 mm, an average fiber diameter of 0.1 to 20 [mu]m, a thickness of 5 to 200 [mu]m, a void ratio of 30 to 90%, and a strength per unit mass of 100 MN / kg or more. Also provided is a single layer or multilayer printed wiring board which comprises a core material impregnated or coated with a polymer resin, a low dielectric polymer resin, or a polyphenylene ether-based epoxy resin. -CH 2 -CH 2 -CO- (1).

Owner:ASAHI KASEI E-MATERIALS CORPORATION

Nylon 11/polylactic acid biological base high molecular alloy and preparation method and application thereof

The invention discloses a nylon 11 / polylactic acid biological base high molecular alloy, which comprises the following substances in parts by weight: 30-70 parts of nylon 11, 30-70 parts of polylacticacid, 1-8 parts of a compatilizer and 0.1-0.6 part of a stabilizer. A preparation method of the nylon 11 / polylactic acid biological base high molecular alloy comprises the following steps: vacuum-drying a PA11 matrix resin, a PLA resin, the compatilizer and the heat stabilizer; uniformly mixing the materials through a high speed mixer; then extruding the mixture through a twin-screw extruder, anduniformly granulating the mixture; and finally, drying the mixture in a vacuum oven to remove water. The primary raw material of the nylon 11 / polylactic acid biological base high molecular alloy is the biological base material, so that the demand on a petroleum-based high molecular material is lowered. The nylon 11 / polylactic acid biological base high molecular alloy material has great tensile strength, high modulus, high impact performance, good heat stability and low price, and the production process technology thereof has low demand on equipment, and the alloy is suitable for industrial production on a large scale.

Owner:ZHONGBEI UNIV

Glass fiber and processing technology thereof

The invention discloses a glass fiber which comprises the following raw materials in parts by weight: 30-50 parts of SiO2, 6-10 parts of Al2O3, 1-4 parts of CaF2, 10-14 parts of ZrO2, 11-16 parts of Ln2O3, 4-6 parts of TiO2, 60-70 parts of H2O and 50-70 parts of H3BO3. The glass fiber is mainly prepared by the following steps: mixing the raw materials, melting, drawing, pickling and performing heat setting treatment. The glass fiber disclosed in the invention has the beneficial effects that (1) the glass fiber disclosed in the invention is excellent in acid resistance, low in molding temperature and low in cost, and the production efficiency is improved; (2) the glass fiber disclosed in the invention is excellent in high temperature resistance, can be applicable to a temperature of 1000 DEG C or less for a long time, and has excellent ablation property, excellent high temperature resistance and chemical resistance; (3) the processing technology of the glass fiber is low in cost, simpleto operate and suitable for more small and medium-sized enterprises.

Owner:旌德县源远新材料有限公司

Preparation method of ultraviolet light-cured coating for seamless steel pipe

ActiveCN101845271BGood weather resistanceGood wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPliabilityPhotoinitiator

The invention discloses a preparation method of an ultraviolet light-cured coating for a seamless steel pipe, which comprises the following steps: adding isocyanate and a catalyst to a reaction vessel, stirring, adding hydroxyethyl acrylate to react for a certain time to obtain an acrylic polyurethane oligomer; adding isocyanate and a catalyst to a reaction vessel, stirring, adding hydroxyethyl acrylate to react and controlling the temperature, adding polyhydric alcohol to react for a certain time to obtain a polyhydric alcohol modified acrylic polyurethane oligomer; mixing the two oligomers obtained, adding bisphenol A epoxy acrylate and organosilane modified polyurethane acrylate, stirring to react, adding activated monomer, photoinitiator and 0.05-5wt% of thermal stabilizer, and mixingto obtain the ultraviolet light-cured coating for the seamless steel pipe. The coating is used for spraying the seamless steel pipe, and is superior to the traditional ultraviolet light cured coatingin the aspects of rigidity, adhesion, shock resistance, wear resistance, and surface smoothness, flexibility and gloss of film coating.

Owner:杭州华仙涂料有限公司

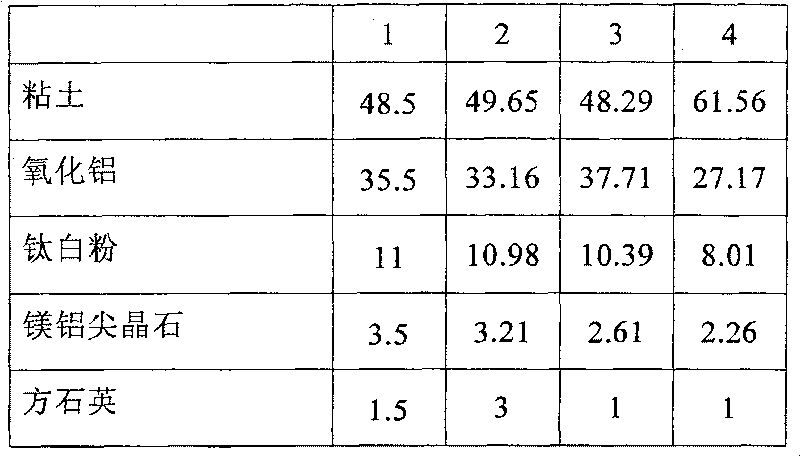

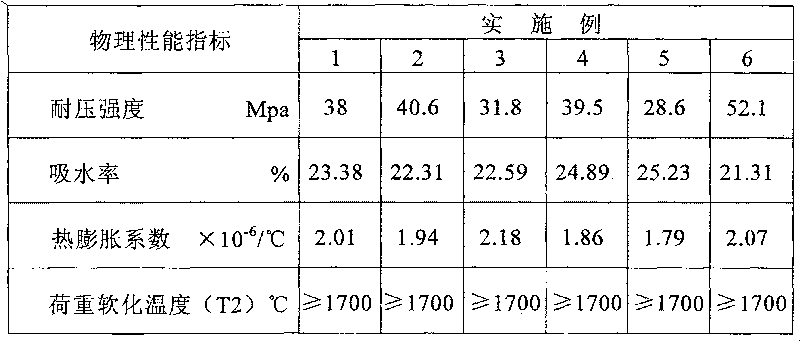

Aluminum titanate-mullite cellular ceramic and its production

An aluminum titanate-mullite cellular ceramic and its production are disclosed. The process is carried out by putting into clay alumina, titanium oxide, ashlar and magnesite-alumina spinel, mixing, wet grinding in ball grinder into powder below 500 meshes, filter pressing, vacuum mud refining to make mud blocks, adding into plastic adhesive with methyl-cellulose and polyvinyl alcohol, extruding, forming, drying and firing at 1450-1600 degree to obtain final product. It's stable, has high melt point, low heat expansion coefficient, excellent chemical-corrosive and thermal shock resistances. Itcan be used in high-temperature heat-storage burning system in industrial furnace, petroleum catalytic cracking and tailed-gas catalytic purifying of automobile industries.

Owner:安徽宁国市先浩高温材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com