Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5328 results about "Corundum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corundum is a crystalline form of aluminium oxide (Al₂O₃) typically containing traces of iron, titanium, vanadium and chromium. It is a rock-forming mineral. It is also a naturally transparent material, but can have different colors depending on the presence of transition metal impurities in its crystalline structure. Corundum has two primary gem varieties: ruby and sapphire. Rubies are red due to the presence of chromium, and sapphires exhibit a range of colors depending on what transition metal is present. A rare type of sapphire, padparadscha sapphire, is pink-orange.

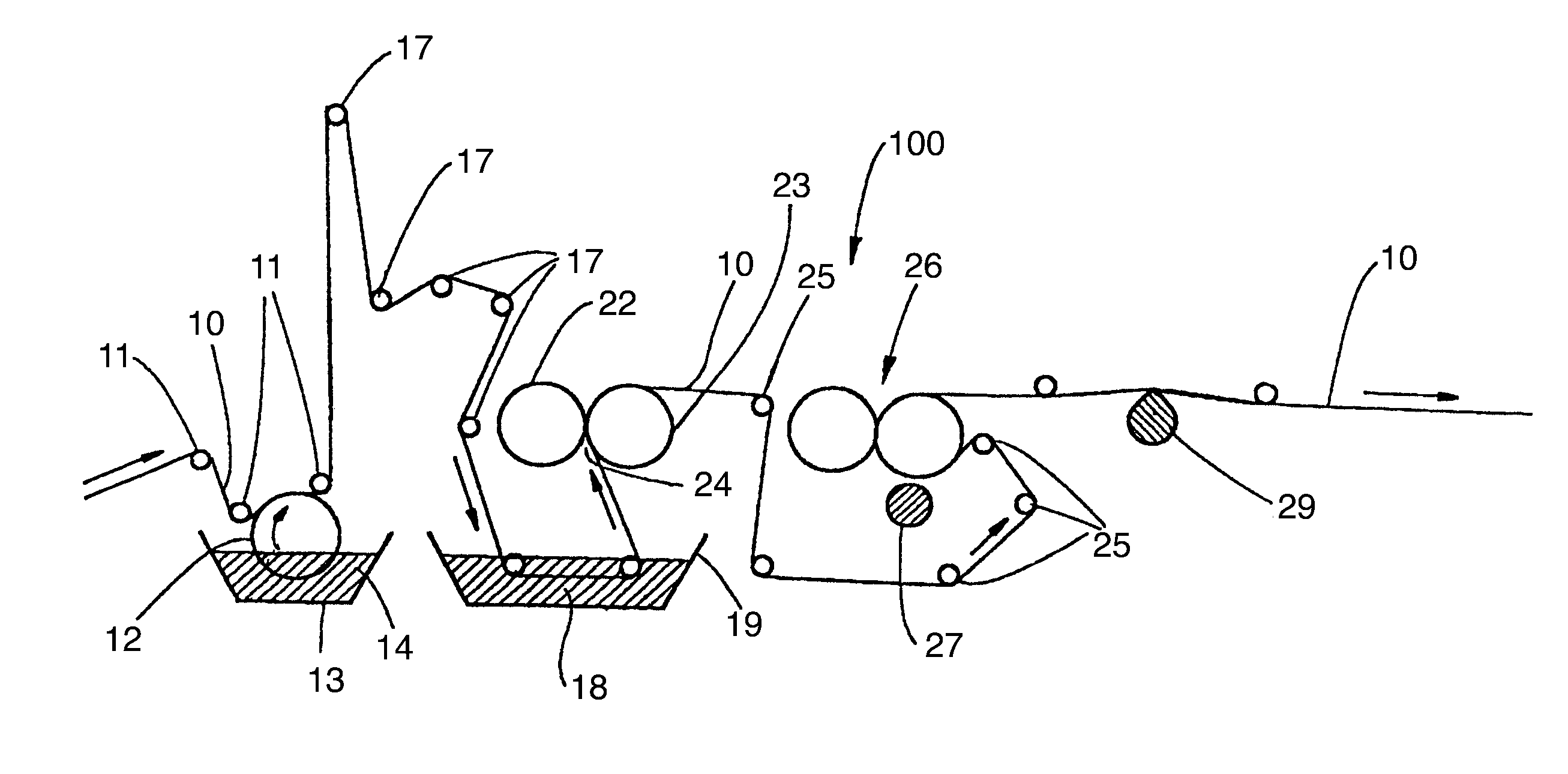

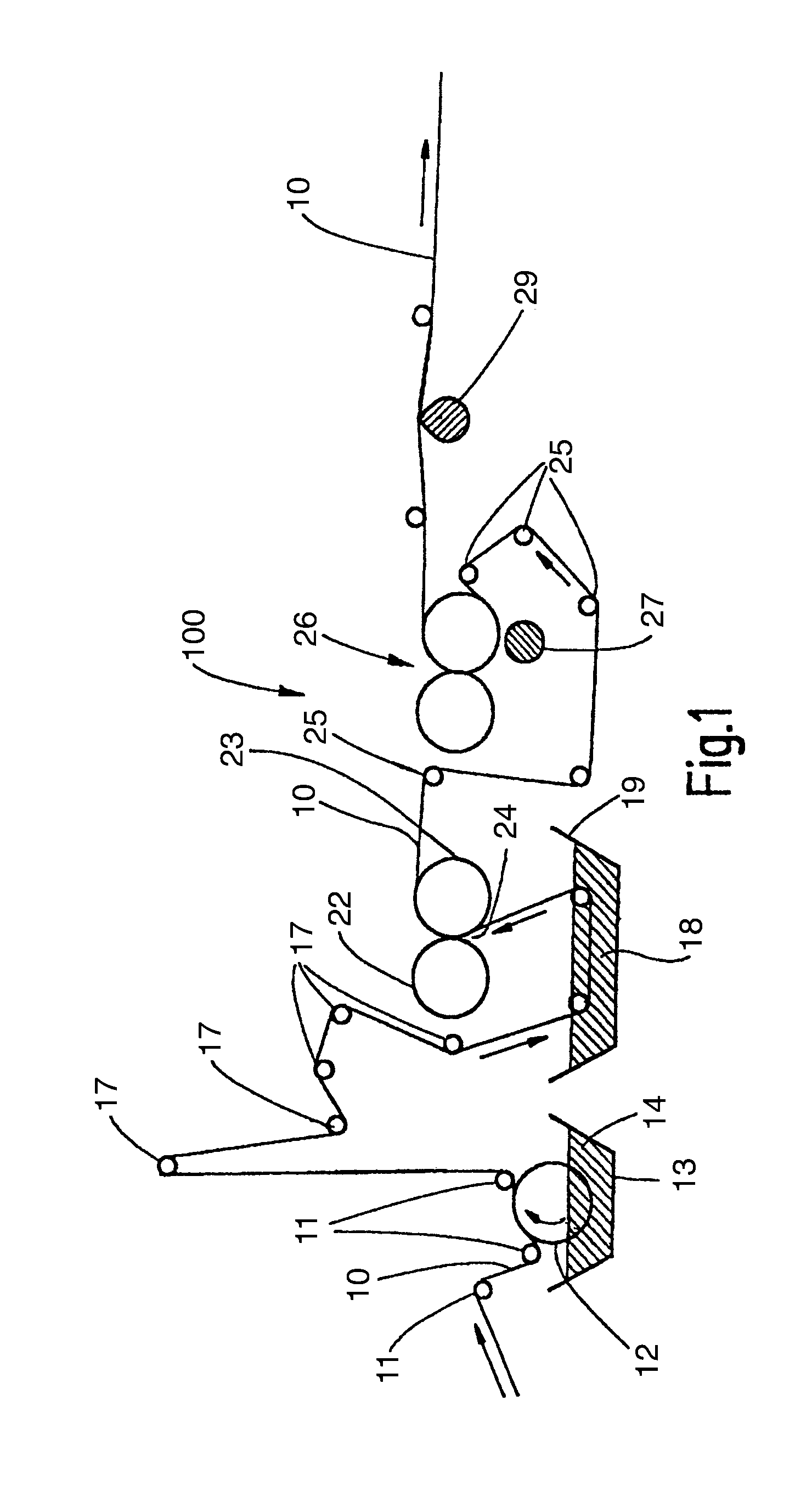

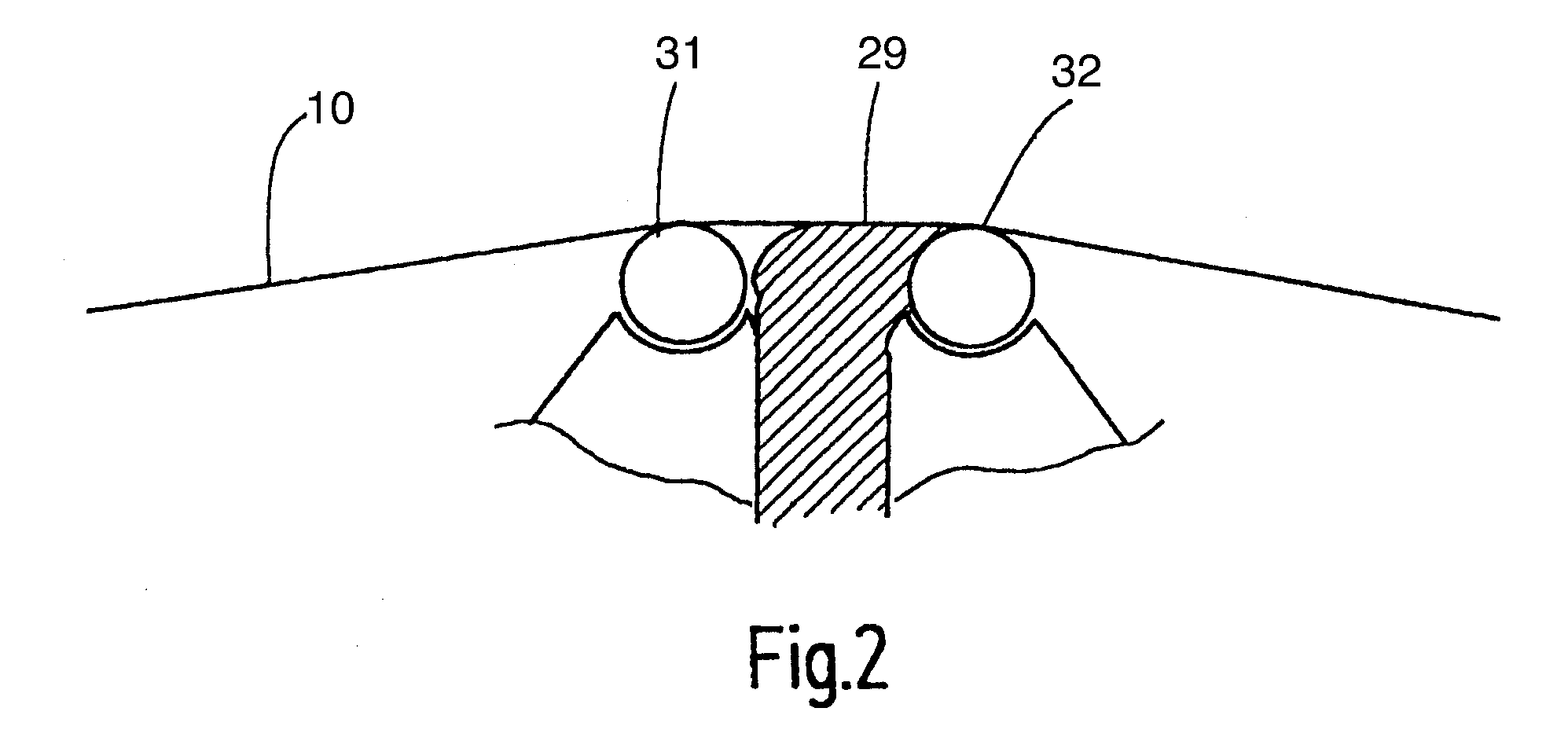

Method for the production of a chafe resistant overlay

InactiveUS20090208646A1Avoid large quantitiesSpecial paperSpecial ornamental structuresBiochemical engineeringCorundum

The invention relates to a method (100) for the production of an overlay, in particular for laminates. For this, firstly an overlay base paper (10) is impregnated in the usual manner and is coated on one side with a resin / coarse corundum application. In order to endow the overlay with additional characteristics, such as for example chafe resistance on the surface, in a further wet-in-wet application step a coating substance (29) is applied on the opposite side and is dosaged by a wiper (31).

Owner:DEKOR KUNSTE

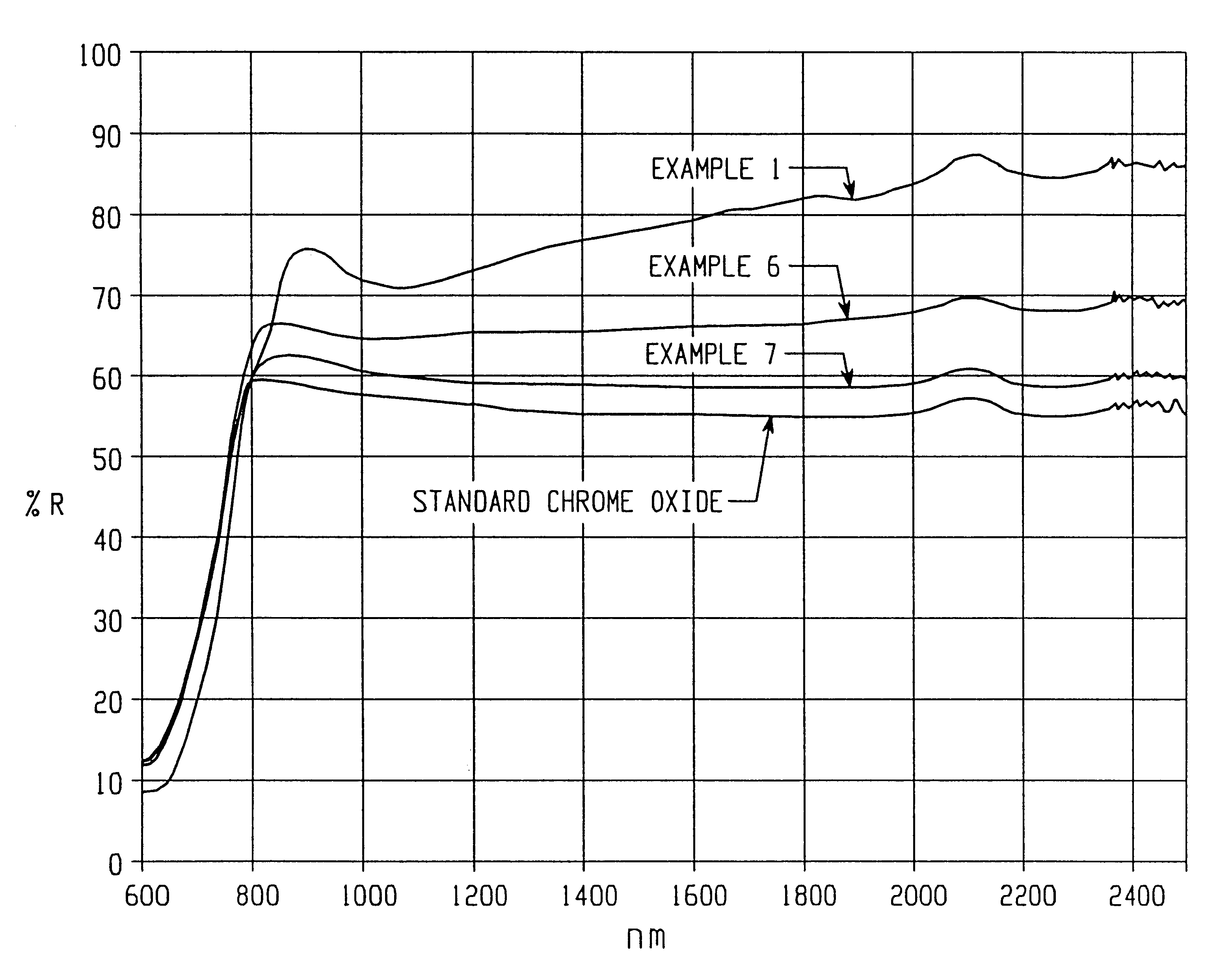

Infrared reflective color pigment

InactiveUS6454848B2Reduce heat buildupReduce energy costsInorganic pigment treatmentCoatingsIndiumCobalt

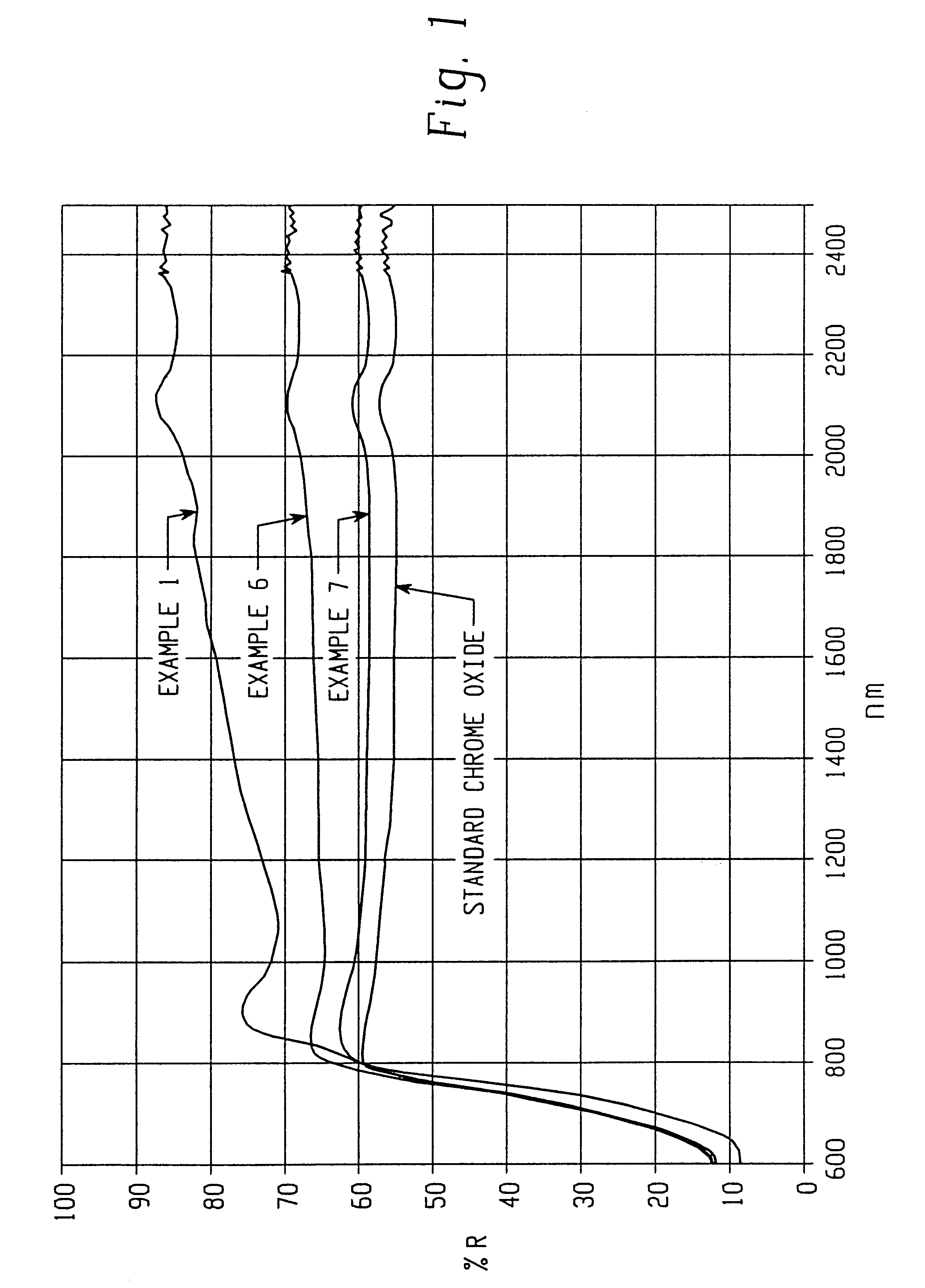

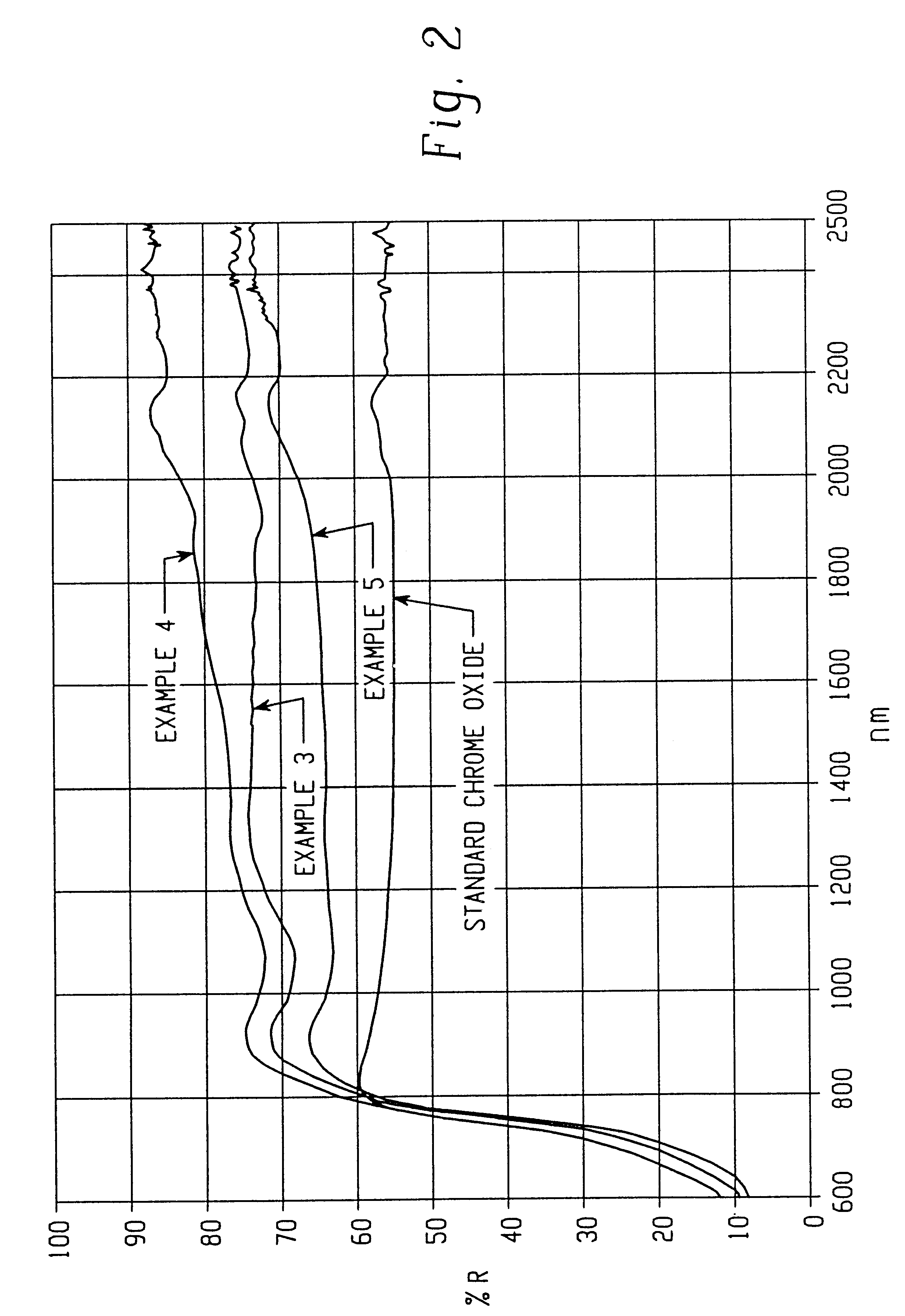

The present invention provides new solid solutions having a corundum-hematite crystalline structure which are useful as inorganic color pigments. Solid solutions according to the present invention include a host component having a corundum-hematite crystalline structure which contains as guest components one or more elements from the group consisting of aluminum, antimony, bismuth, boron, chrome, cobalt, gallium, indium, iron, lanthanum, lithium, magnesium, manganese, molybdenum, neodymium, nickel, niobium, silicon, tin, titanium, vanadium, and zinc. Solid solutions according to the present invention are formed by thoroughly mixing compounds, usually metal oxides or precursors thereof, which contain the host and guest components and then calcining the compounds to form the solid solutions having the corundum-hematite crystalline structure. Some of the new solid solutions according to the present invention exhibit relatively low Y CIE tri-stimulus values and relatively high near infrared reflectance.

Owner:FERRO CORP

Layer system with at least one mixed crystal layer of a multi-oxide

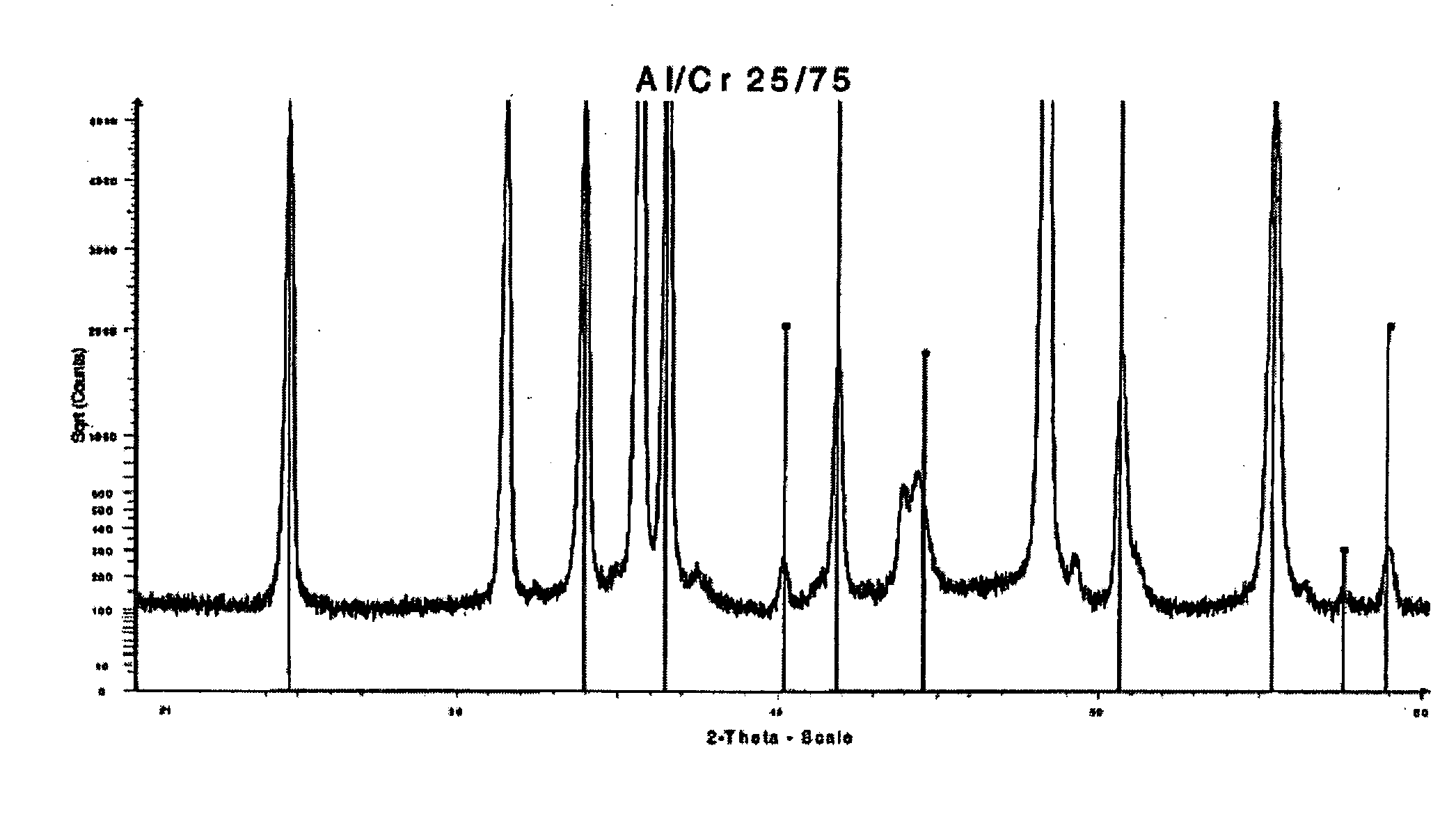

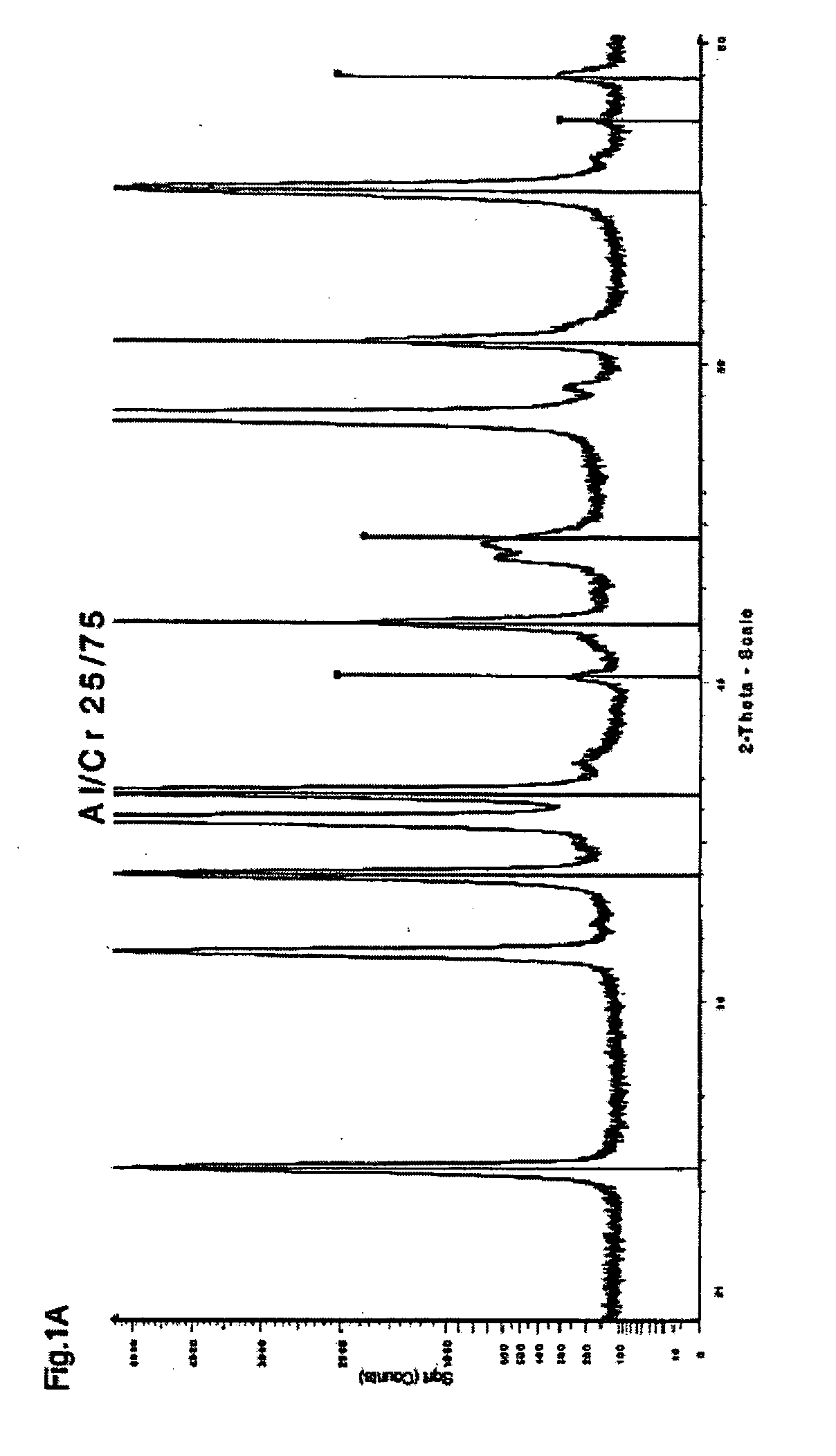

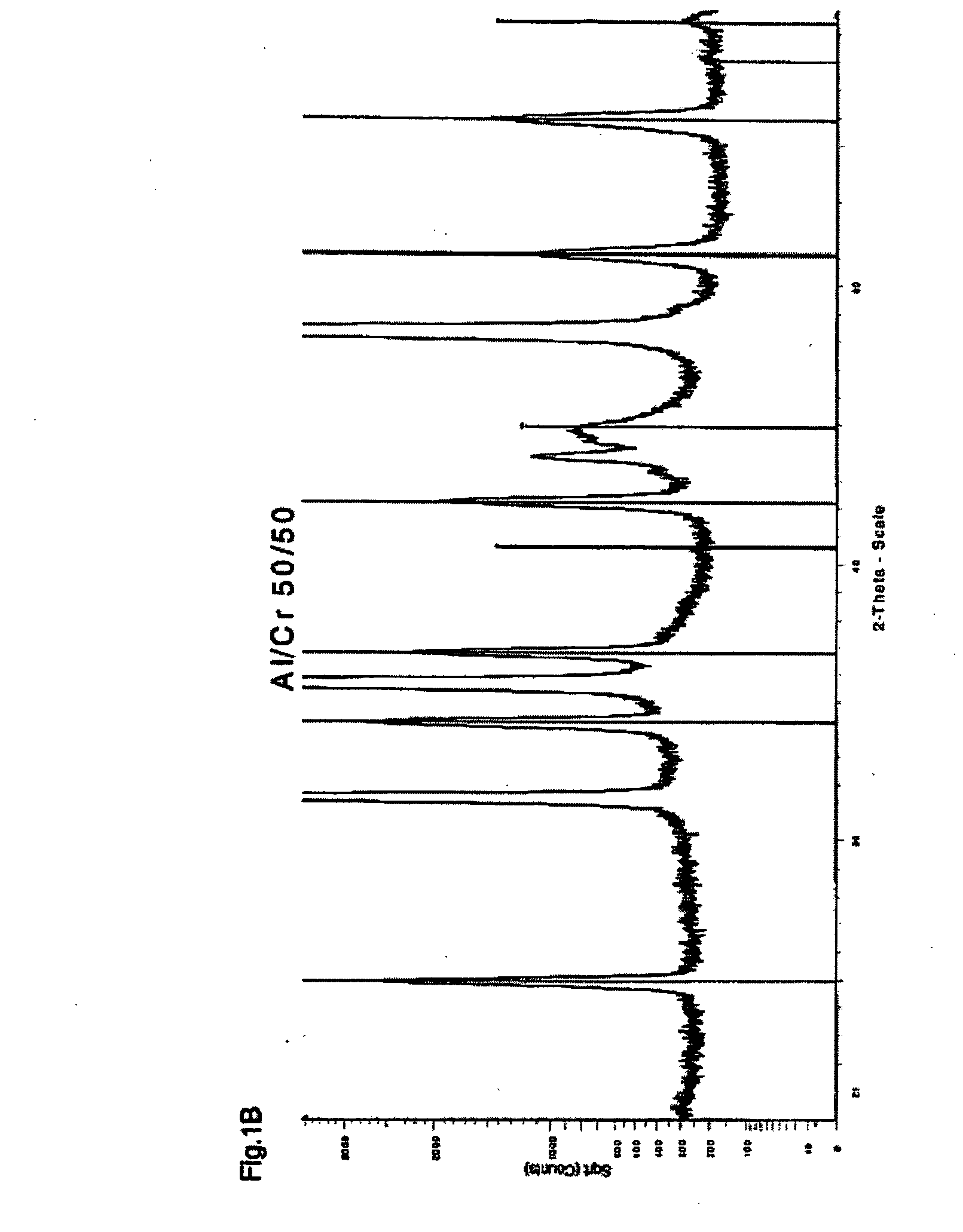

A PVD layer system for the coating of workpieces encompasses at least one mixed-crystal layer of a multi-oxide having the following composition: (Me11-xMe2x)2O3, where Me1 and Me2 each represent at least one of the elements Al, Cr, Fe, Li, Mg, Mn, Nb, Ti, Sb or V. The elements of Me1 and Me2 differ from one another. The crystal lattice of the mixed-crystal layer in the PVD layer system has a corundum structure which in an x-ray diffractometrically analyzed spectrum of the mixed-crystal layer is characterized by at least three of the lines associated with the corundum structure. Also disclosed is a vacuum coating method for producing a mixed-crystal layer of a multi-oxide, as well as correspondingly coated tools and components.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Aluminum and zirconium oxynitride abrasive grains

Corundum-zirconia abrasive grains containing more than 50 wt % of an alumina-zirconia eutectic mixture. The grains contain 0.3 to 3% nitrogen, and more than 75% of the zirconia crystals are cubic in shape. The abrasive grains are of particular use for making grinding wheels, abrasive fabrics and papers, polishing compounds and sprayed abrasives.

Owner:PEM ABRASIFS REFRACTAIRES

Alpha alumina (corundum) whiskers and fibrous-porous ceramics and method of preparing thereof

InactiveUS20120189833A1High mechanical strengthHigh porosityAluminium oxide/hydroxide preparationAluminium hydroxide preparationWhiskersPorous ceramics

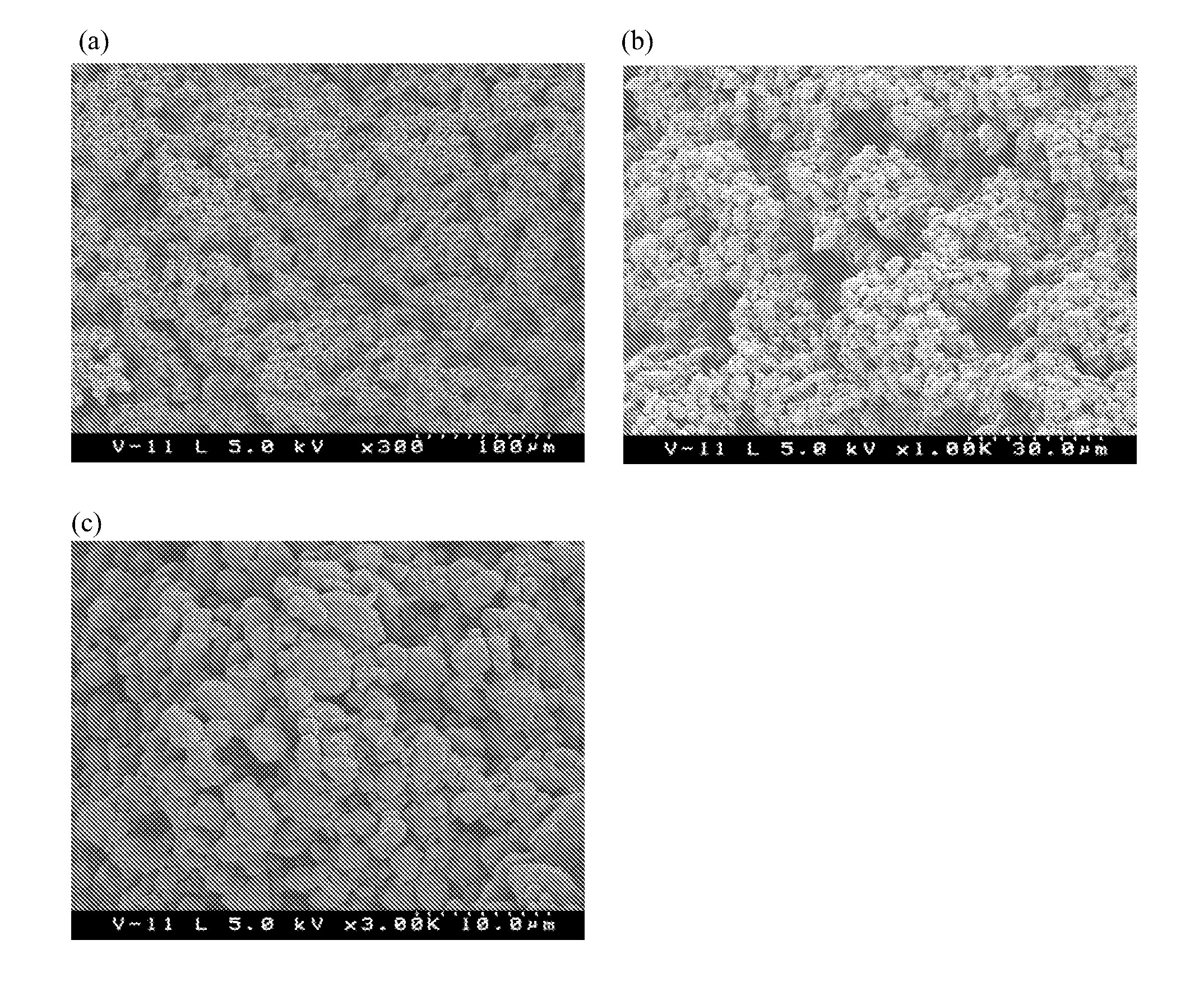

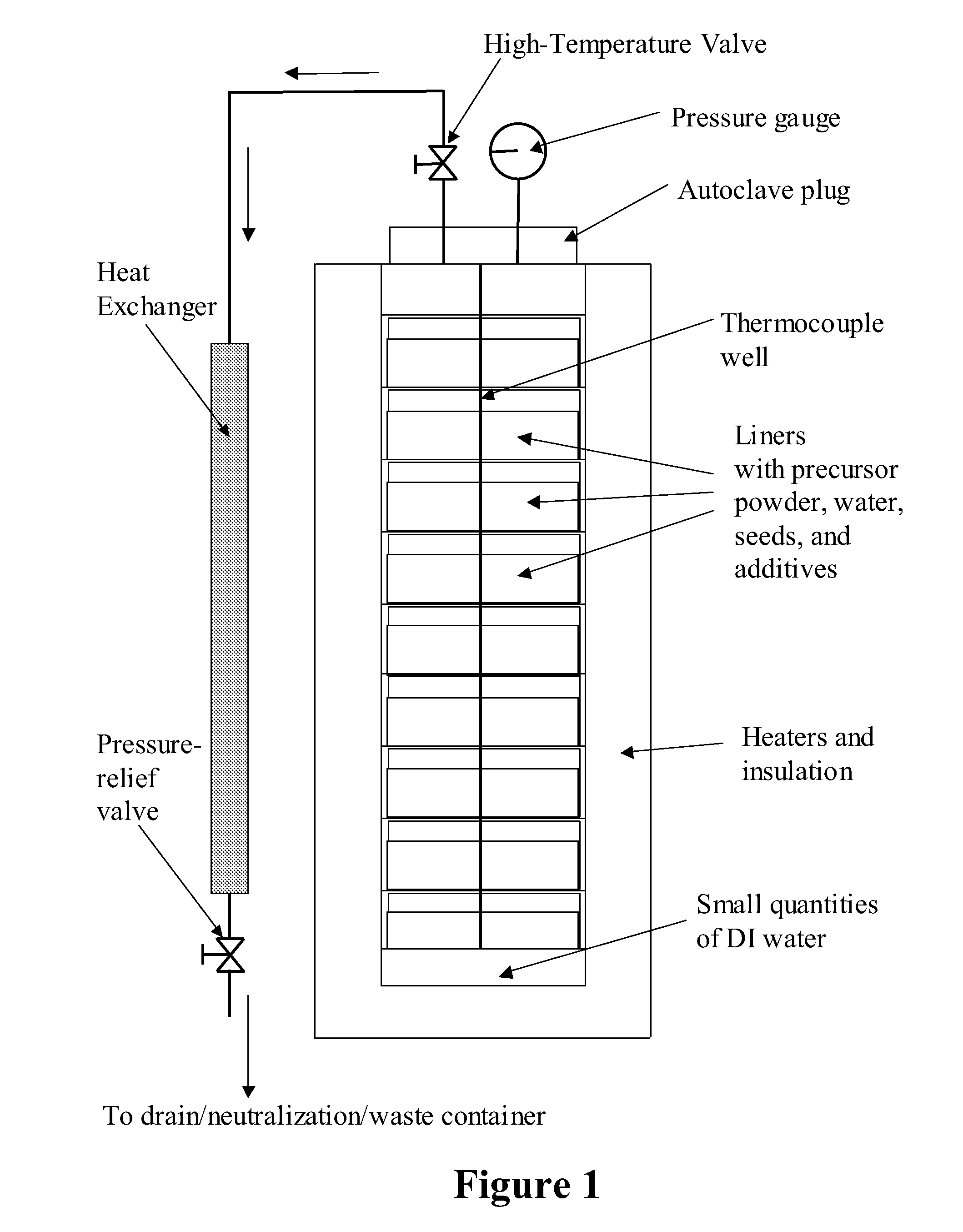

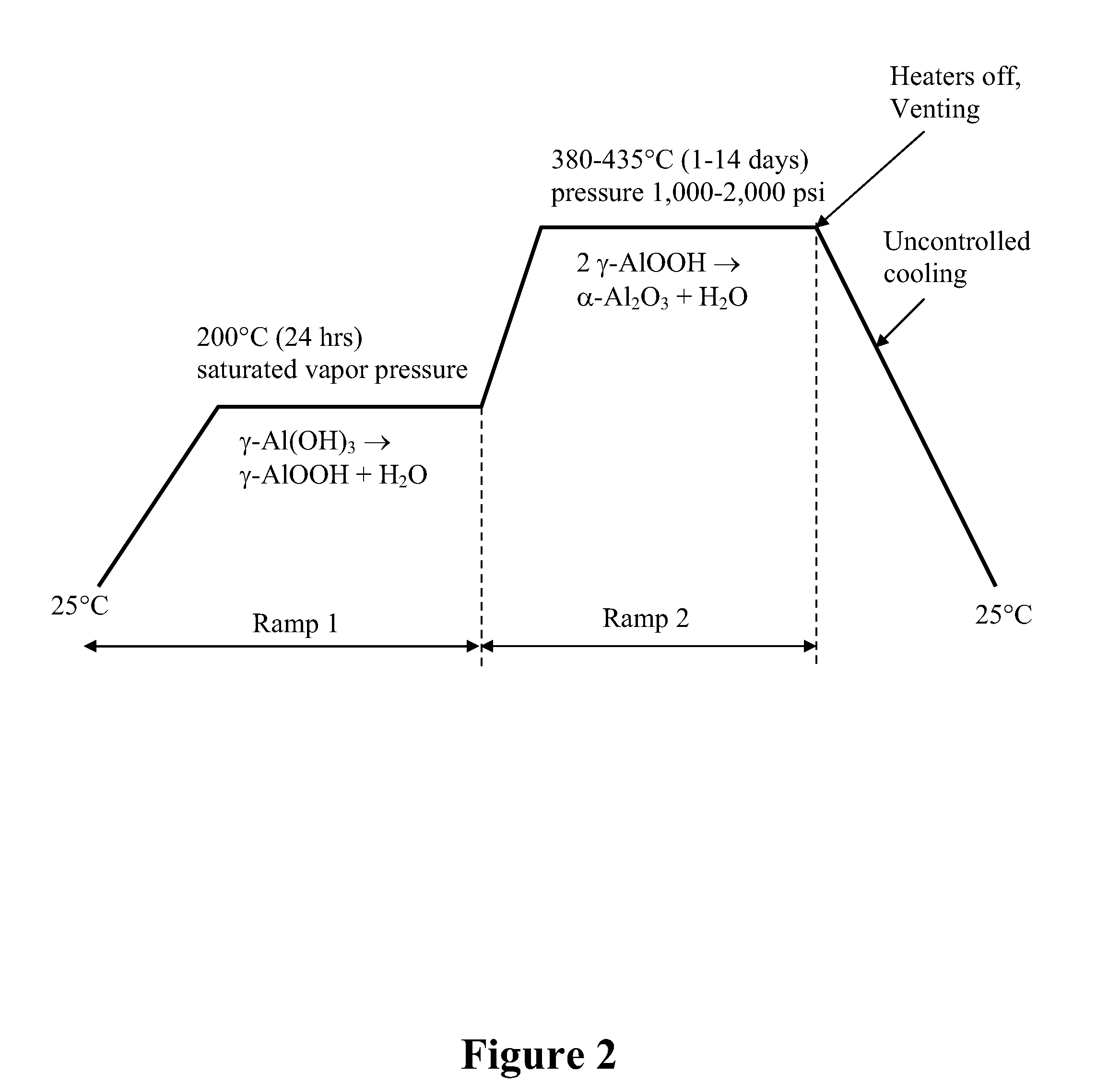

Materials and associated processes for making the materials. For example the material may include alpha alumina crystalline whiskers. The process may include conducting the process as hydrothermal, and producing the whiskers to have a length to diameter aspect ratio of at least two.

Owner:SAWYER TECHN MATERIALS

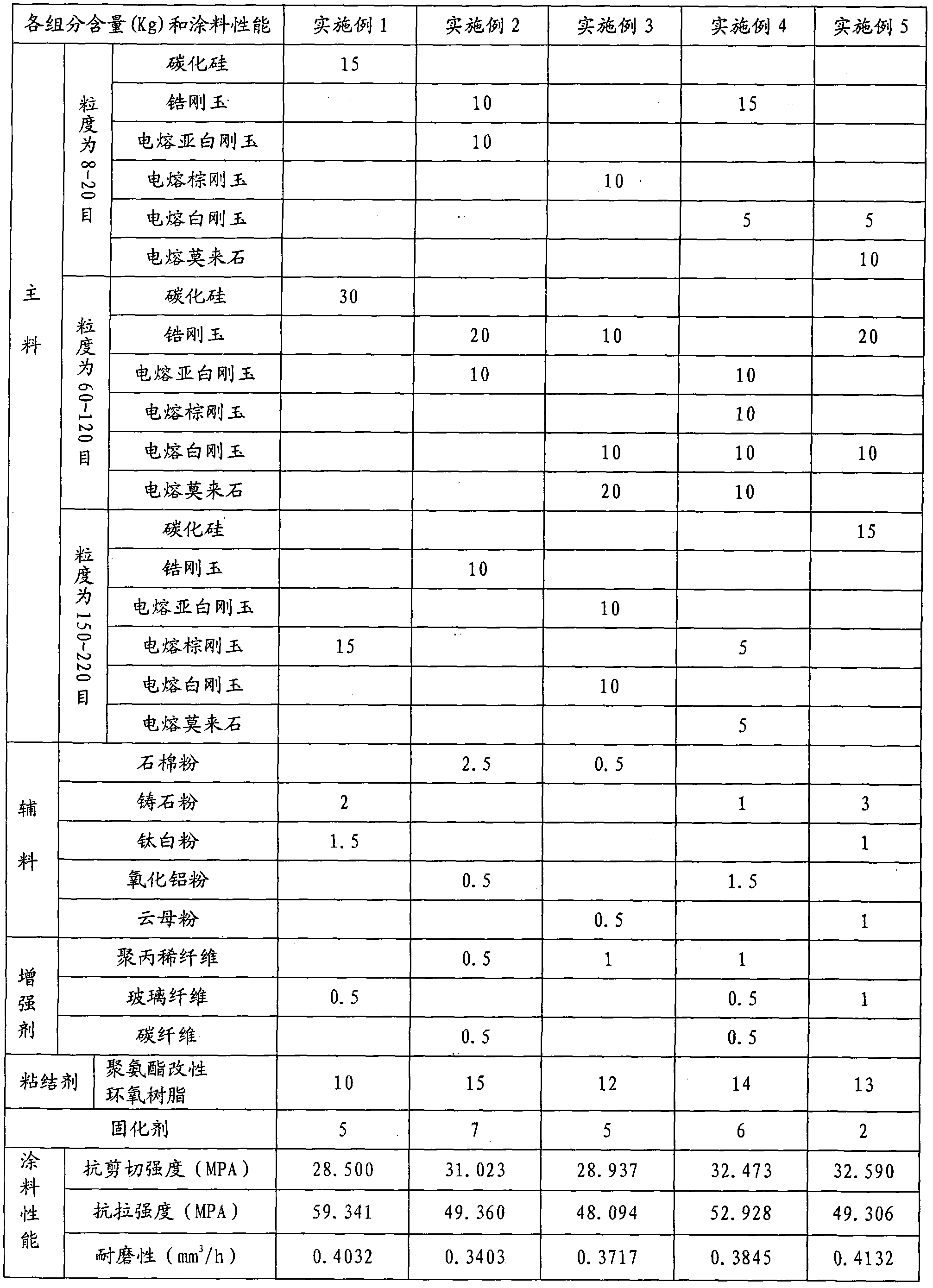

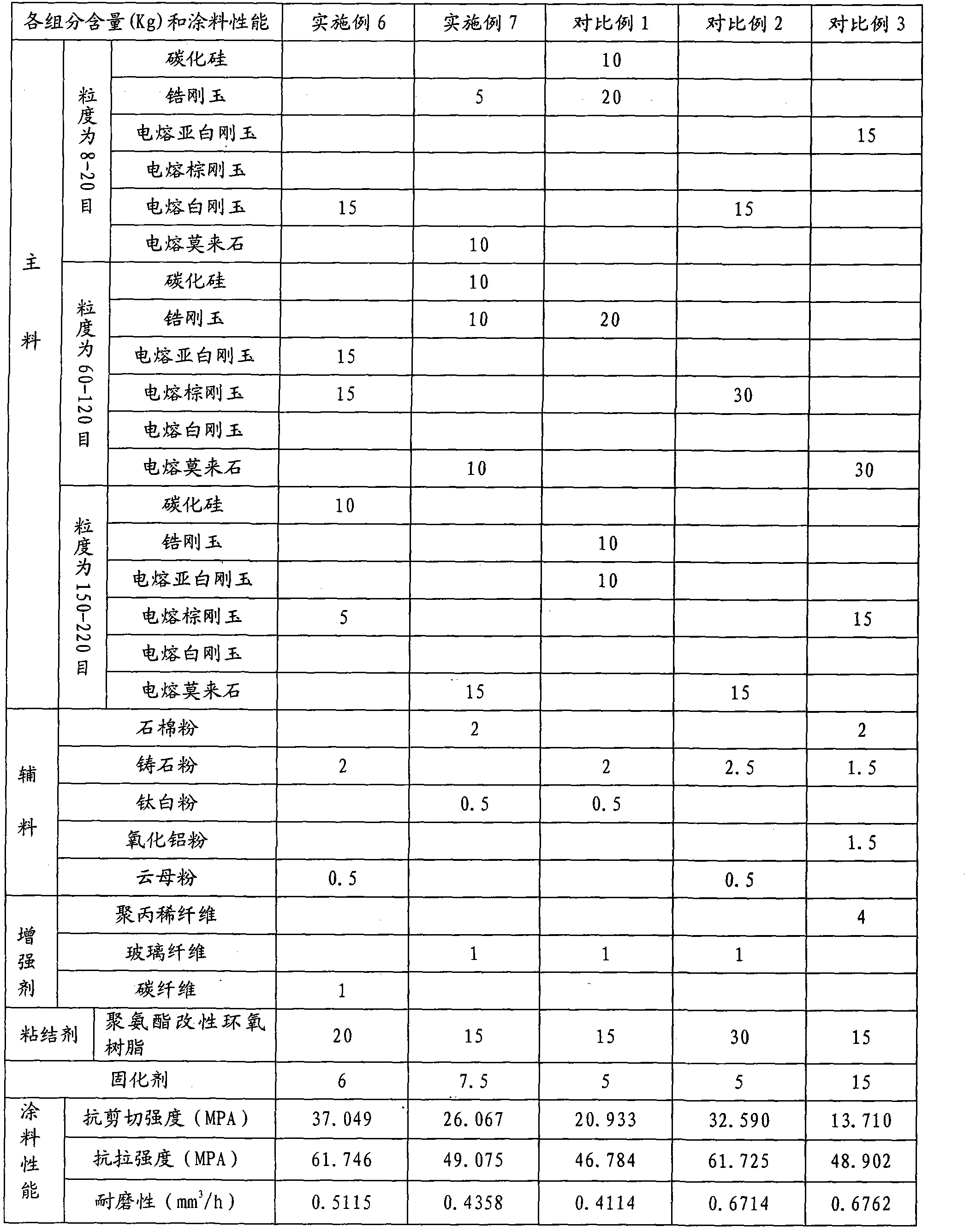

Polymer wear-resistance coating material

ActiveCN102040901AReduce operating costsReduce labor intensityEpoxy resin coatingsEpoxyCarbon fibers

The invention relates to a polymer wear-resistance coating material, which is a coating material consisting of a component A and a component B, wherein the component B is a solidifier, and the weight part of the component B is 2 to 10 percent of that of the component A; the component A consists of 40 to 80 weight parts of a main ingredient which is one or more mixed in random ratio of silicon carbide, fused zirconia alumina, fused sub-white corundum, fused brown aluminium oxide, fused white corundum and fused mullite, 1 to 5 weight parts of an auxiliary material which is one or more mixed in a random ratio of asbestos powder, glass-ceramic powder, titanium white, aluminium oxide powder and mica powder, 0.5 to 2 weight parts of reinforcing agent which is one ore more mixed in a random ratio of polypropylene fibers, glass fibers and carbon fibers, and 10 to 20 weight parts of a bonding agent which is polyurethane modified epoxy resin. The construction and use of the coating material are convenient and quick, the bonding strength of the coating material is high and the use cost of the coating material is low; and the coating material has high wear resistance, corrosion resistance and air corrosion resistance.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

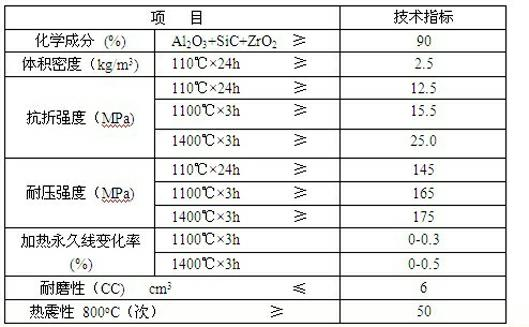

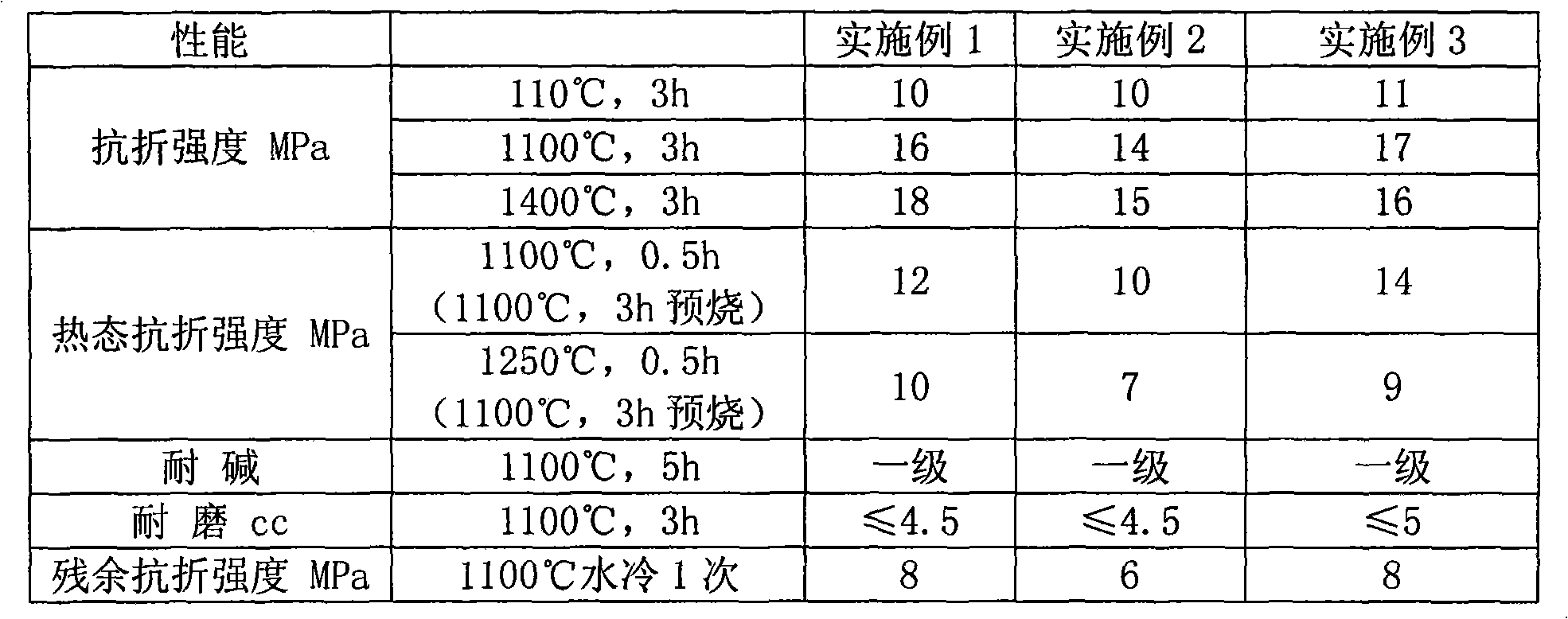

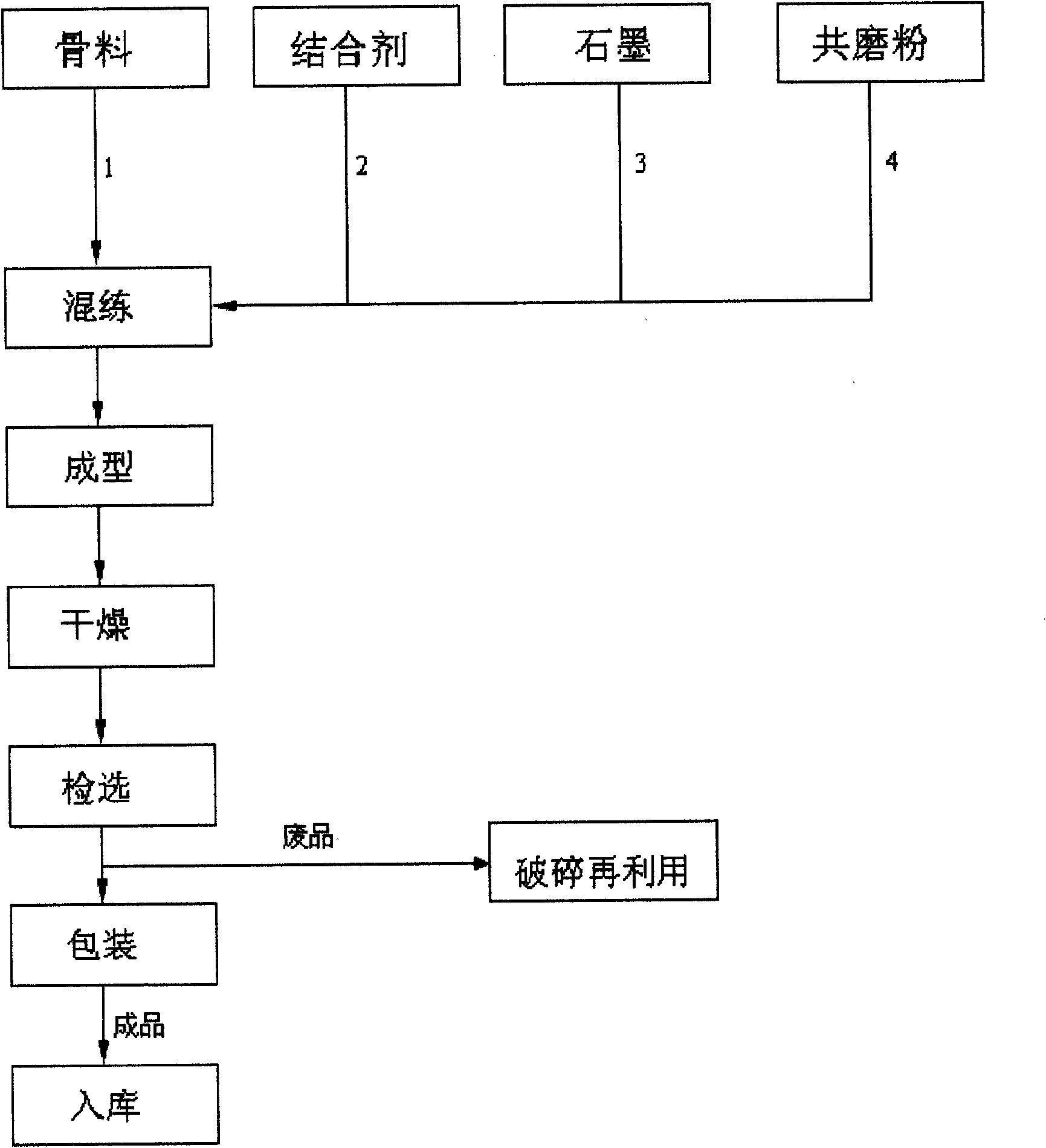

Abrasion-proof fire-resistant moldable refractory

The invention relates to an improvement to abrasion-resistant fireproof plastic, which is characterized in that the invention comprises 60-80wt percent of corundum and / or porzite and / or Al2O3 larger than or equal to 80 percent of bauxite clinker, 5-10wt percent less than or equal to4 micron of alumina micro-powder, 6-15wt percent less than or equal to 0.025mm of chromium corundum fine powder, 2-6wt percent less than or equal to1micron of silicon fine powder, 5-10wt percent of kyanite or andalusite or silimanite, 12-15wt percent of aluminium dihydrogen phosphate or aluminium sulfate wedding agent, and 0.5-3wt percent of calcium aluminate or bauxite cement coagulant. Compared with the prior art, the abrasion-resistant fireproof plastic has the advantages of high compressive strength, good wear-resisting property, high temperature used and strong slag resistance and anti-etching power, thereby greatly prolonging the service life and meeting the use with higher requirements.

Owner:江苏国窑科技有限公司

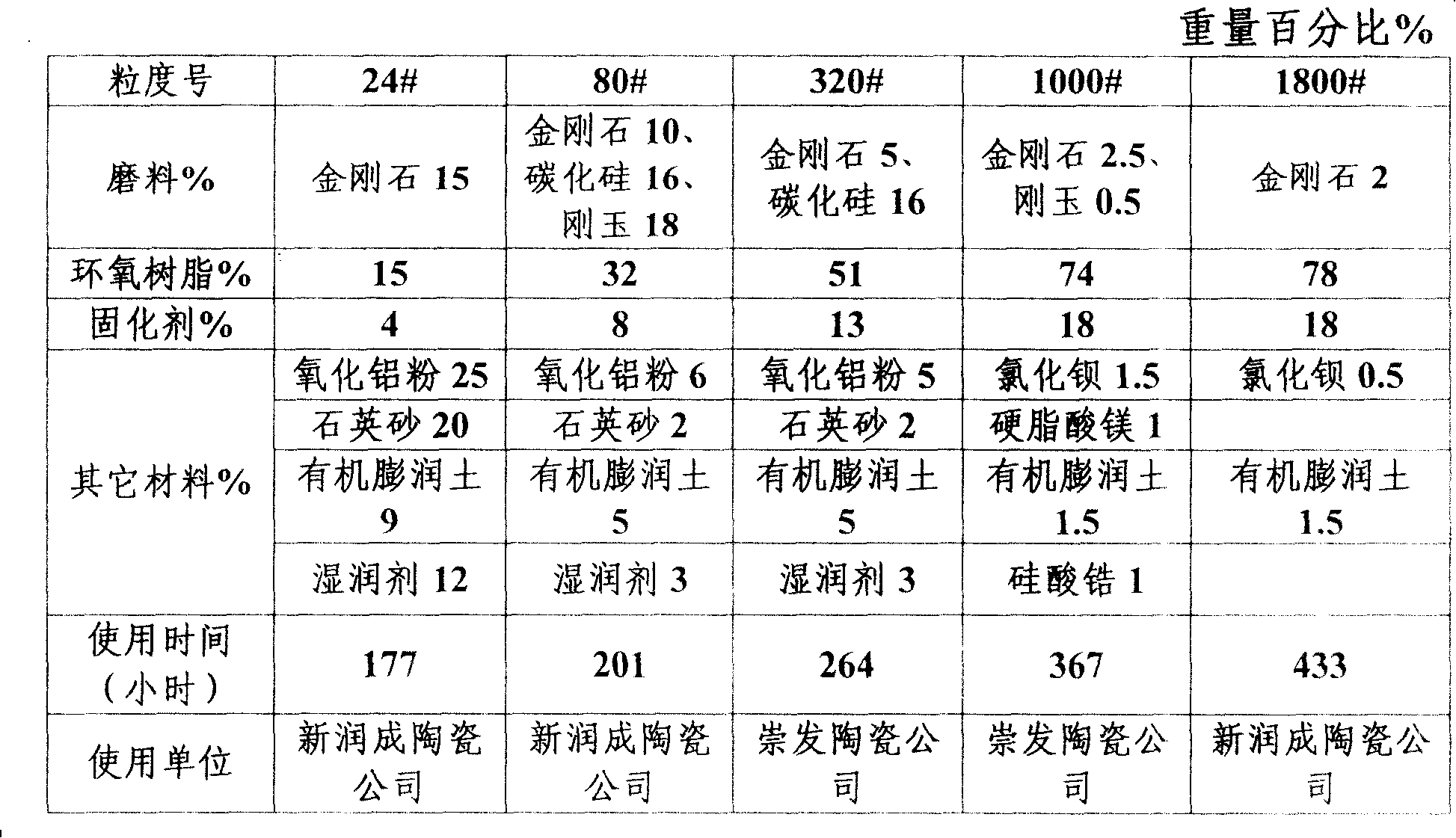

Abrasive tool of epoxy resin combined with compounded abrasive

Disclosed is an abrasive tool made of epoxy resin-bonded compound abrasive material, which comprises epoxy resin, abrasive material and curing agent. The weight percentages are as follow: the epoxy resin is 15 to 78 percent, the abrasive material is 2 to 44 percent and the curing agent is 4 to 18 percent. Wherein, the abrasive material comprises one of diamond, silicon carbide or corundum or the combination of more than one material. The curing agent comprises one of 4.4`-methylenedianil, solid diaminodiphenyl methane or liquid modified diaminodiphenyl methane or the combination of more than one material. The component of the abrasive tool also comprises the other auxiliary material, which comprises one of alumina, barium chloride, sodium chloride, quartz sand, organobentonite, wetting agent, zirconium silicate, calcium carbonate, graphite powder, garnet, magnesium sulfate, phenolic resin, zinc stearate and magnesium stearate, or the combination of more than one material. The product can be made into any shape the same with the present product, which can be applied in various grinding and polishing equipment with wide application scope.

Owner:广东奔朗新材料股份有限公司

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

Special castable for kiln outlet

The invention discloses a special castable for a kiln outlet, which belongs to the field of refractory materials. According to the invention, the special castable comprises the following components in percentage by weight: 8-25% of silicon carbide, 10-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 1-5% of zirconium diboride, 1-5% of silicon nitride,5-15% of alumina micropowder, 3-6% of pure calcium aluminate cement, 0.5-1% of explosion-proof fiber and 0.06-0.2% of sodium tripolyphosphate, which is an additive. By using the special castable for the kiln outlet, disclosed by the invention, the phenomenon of poor wear resistance, block falling and the like in the kiln outlet can be effectively improved; the service life of the cement kiln outlet can be largely prolonged; and the special castable for the kiln outlet, disclosed by the invention, has the advantages of high temperature resistance, heat shock resistance, wear resistance, high strength, irreversible micro expansion and the like.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

High-speed resin heavy-load grinding wheel

InactiveCN102161183AImprove mechanical propertiesImprove automationAbrasion apparatusGrinding devicesFiberZirconia alumina

Owner:江苏华东砂轮有限公司

Wear-resistant transparent glaze and method for preparing glazed tile by utilizing same

The invention provides a wear-resistant transparent glaze and a method for preparing a glazed tile by utilizing the same. According to the components of the wear-resistant transparent glaze, spodumene, frit, potash feldspar, calcinedtalc, barium carbonate and zinc oxide are adopted as a fluxing agent, and the Si / Al ratio is adopted by utilizing wollastonite and kaolin. Meanwhile, the wear-resistant performance of the glaze is improved by adopting white corundum and zirconium oxide as a wear-resistant agent. The weight percentage of zirconia relative to the total weight of the raw materials of the wear-resistant transparent glaze is smaller than or equal to 0.2%. The above wear-resistant transparent glaze is applied onto the surface of a green body, and then the green body is polished after being sintered in a furnace to obtain a glazed tile product. Compared with the prior art, the wear-resistant transparent glaze is excellent in wear resistance, and can be used for preparing ceramic tiles with thin glaze layers. The decorative properties and the anti-pollution characteristics of obtained products are greatly improved. Meanwhile, the manufacturing cost of products is lower.

Owner:FOSHAN DONGPENG CERAMIC +3

Method for producing waterless taphole mix for blast furnace from high-alumina waste refractory materials

The invention discloses a method for producing a waterless taphole mix for a blast furnace from high-alumina waste refractory materials. The produced low-cost waterless taphole mix can satisfy the operating requirements for plugging tapholes of large and medium blast furnaces. The method comprises the selection of raw materials for production, the processing of the raw materials for production, the proportioning of the raw materials for production, and the production process. The waterless taphole mix produced by the method has the characteristics of low cost, good plasticity and sintering property, high middle-and-high-temperature strength, favorable slag and iron erosion resistance and the like, and can completely satisfy the operating requirements of large and medium blast furnaces. Compared with the existing waterless taphole mix, the cost can be reduced by 40-60%; since a great amount of waste refractory materials are used, the emission of the solid waste can be decreased, and a great amount of high-quality refractory materials such as brown corundum, premium / extra grade alumina and the like can be saved; and meanwhile, the energy consumption and the emission of carbon dioxide gas during the smelting of brown corundum and premium / extra grade alumina can be decreased.

Owner:UNIV OF SCI & TECH LIAONING

Special pouring material for coal injection pipe

The invention discloses a special pouring material for a kiln opening and belongs to the field of a refractory material. The special pouring material comprises the following components by weight percent: 10-25% of silicon carbide, 15-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 5-15% of aluminum oxide micro powder, 3-8% of silicon micro powder, 2-5% of pure calcium aluminate cement, and 0.5% and 0.2% of anti-explosion fibers and sodium tripolyphosphate serving as additives. The special pouring material is capable of efficiently improving the wear resistance and avoiding the hot peeling phenomenon of the cement kiln coal injection pipe, has the characteristics of high temperature resistance, heat vibration resistance, wear resistance, high strength, irreversible micro inflation, and the like, and is capable of greatly prolonging the service life of the cement kiln coal injection pipe.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Composite bonding low-temperature constructional castable refractory

The invention relates to a composite bonding low-temperature constructional castable refractory, which can be used for high-temperature kiln engineering. According to the castable refractory, corundum, alumina, mullite and silicon carbide are used as an aggregate, silica sol is used as a bonding agent, aluminate cement is used as a curing agent and a bonding aid, and alumina micro powder, wollastonite, a deflocculant, a retarder, water and the like are added. The composite bonding low-temperature constructional castable refractory has high low-temperature constructional performance, high performance of high-temperature resistance, erosion resistance, thermal shock resistance and high mechanical performance, and meets the requirements of overhauling in winter on the premise that the service life of the castable refractory is not influenced.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Bleed hole stemming and method for producing the same

ActiveCN101219900AGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of producing aluminum oxides and products obtained on the basis thereof

InactiveUS6841497B1Increase contentMaterial nanotechnologyPretreated surfacesNanoparticleCrystal structure

The invention relates to the field of technical ceramics and specifically relates to a method of synthesis for aluminum oxides of different crystalline structure and to the products obtained by the method. The aim of the invention is to provide a method of producing redispersible nanoparticulate corundum and nanoporous Al2O3 sintered products, the method using precursors and being viable on a commercial scale. To this aim, inter alia, a method of producing redispersible nanoparticulate corundum of an average particle size of D50<100 nm is used which method includes the addition of crystal nuclei. According to the method, organic or chlorine-free inorganic precursors are dissolved or processed to a sol and hydrolyzed. The substance is then dried and calcinated at temperatures of between 350 and 650° C. and is then further heated by increasing the temperature to ≦950° C. The aim of the invention is also attained by using a method of producing nanoporous Al2O3 sintered products according to which organic or chlorine-free inorganic precursors are dissolved or processed to a sol and hydrolyzed. The substance is then dried and calcinated at temperatures of between 350 and 750° C.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Preparing method of low-cost oxide ceramic shell for titanium alloy precision casting

A low-cost oxide ceramic mould for the precise casting of Ti-alloy is prepared through preparing paint and wax mould of casting, immersing the wax mould in paint for 10-20 min, leveling the paint, uniformly applying the white electro-corundum powder to the paint layer of wax mould, drying, and high-pressure dewaxing.

Owner:HARBIN INST OF TECH

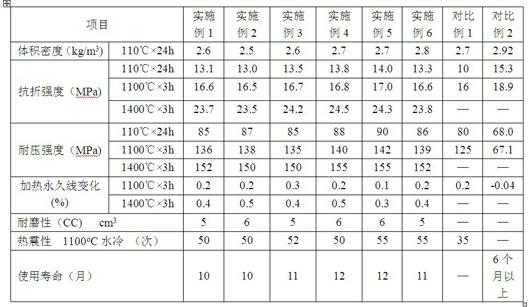

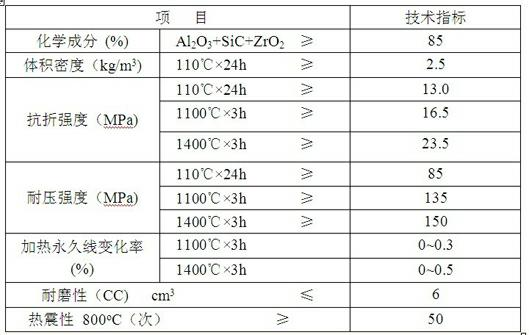

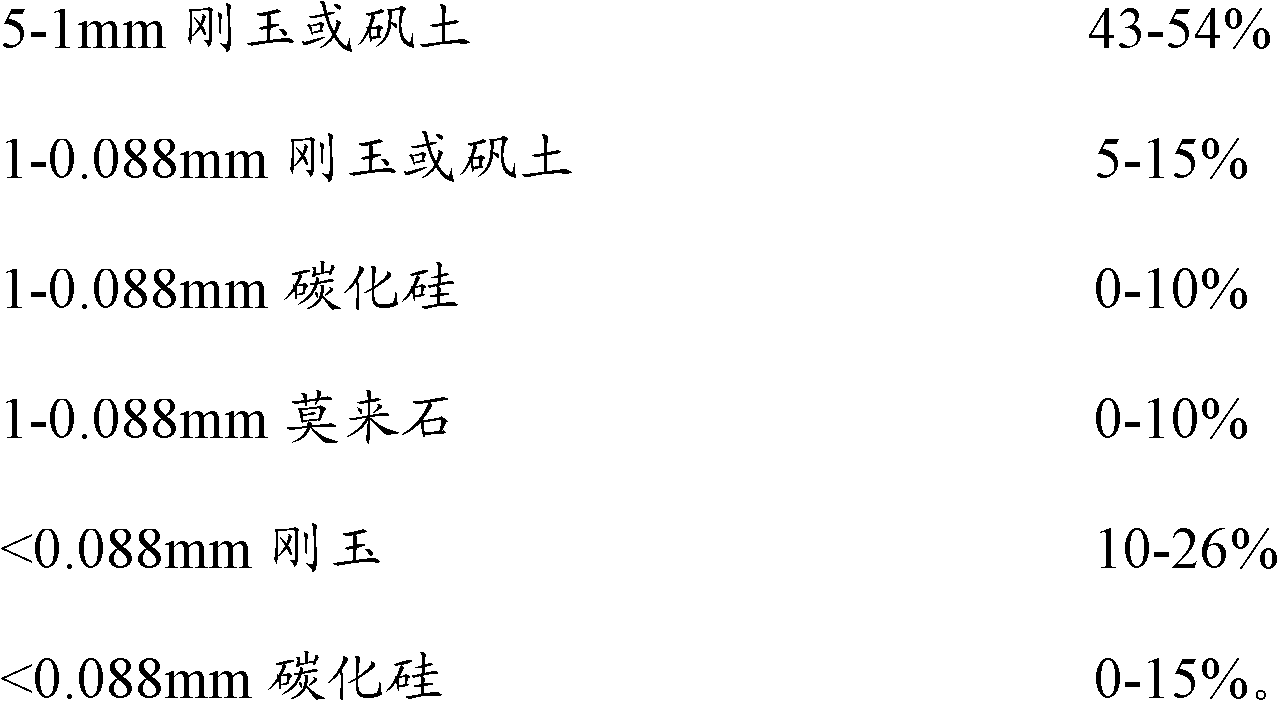

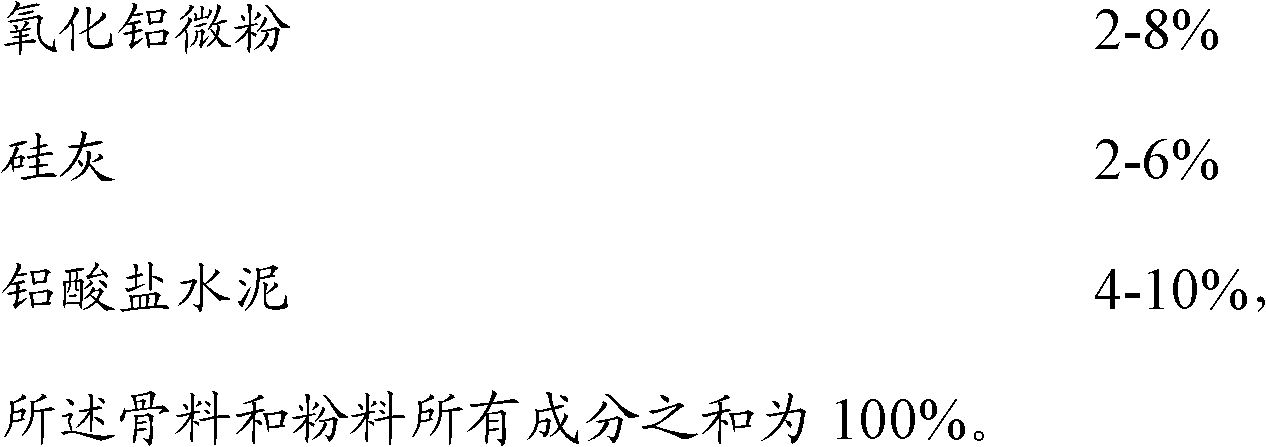

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

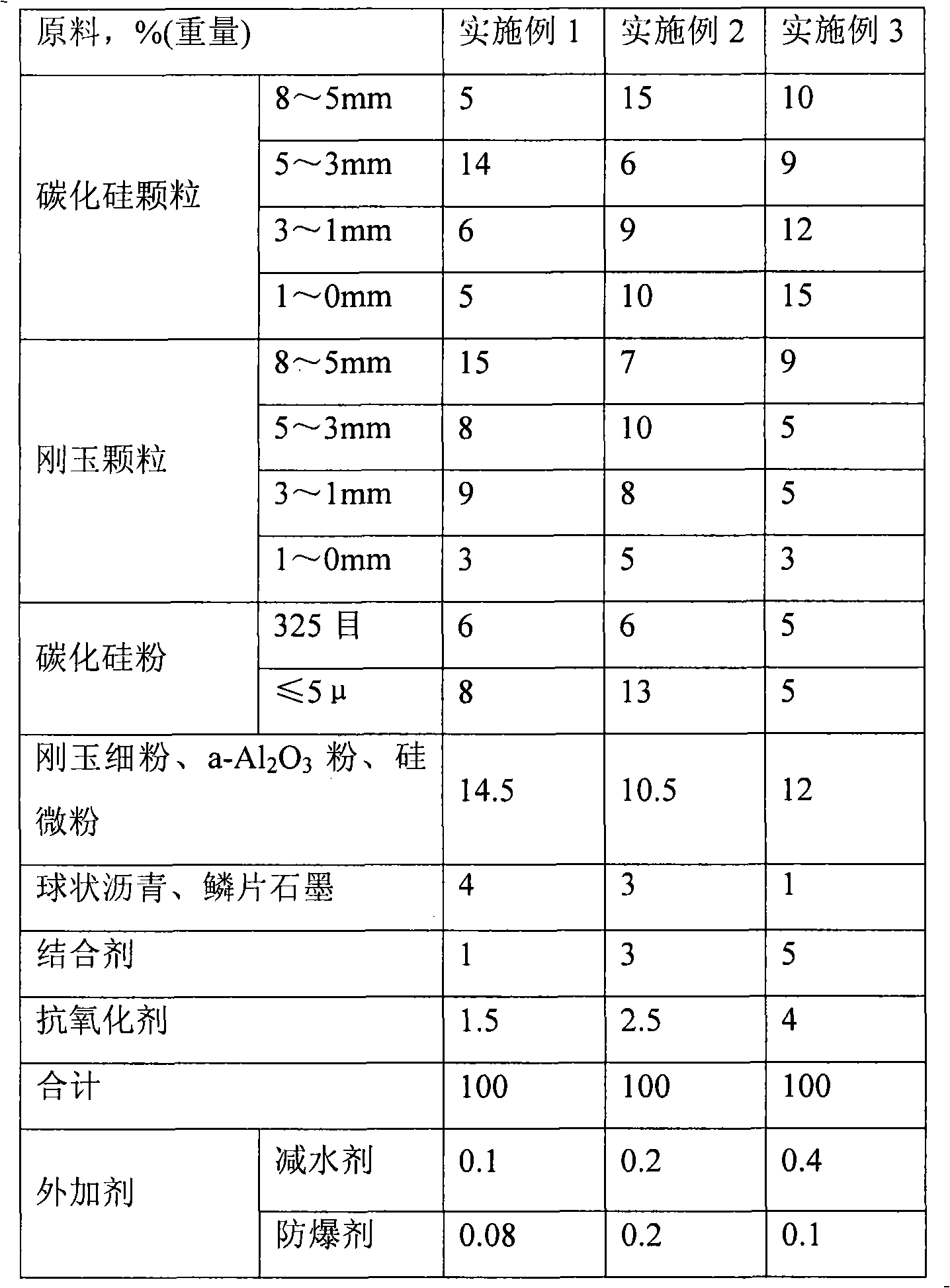

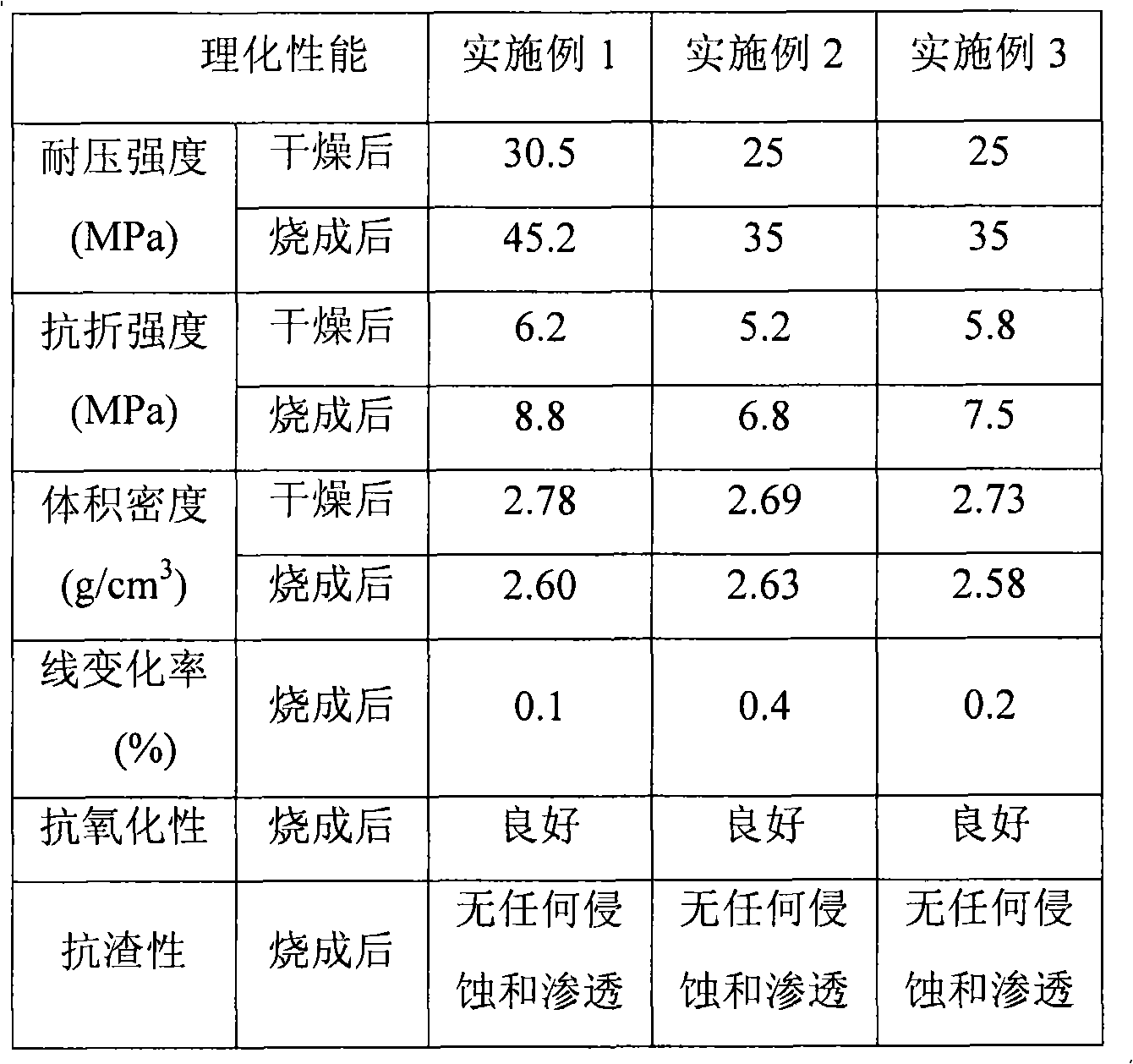

Preparation method of Al2O3-SiC-C castable material for slag line of main trough of blast furnace

The invention relates to an Al2O3-SiC-C castable material for a slag line of a main trough of a large blast furnace and a preparation method thereof. The castable material comprises an aggregate, a matrix, a bonding agent, an antioxidant and an admixture; wherein, the aggregate comprises corundum grains and carborundum grains; the matrix comprises ball pitch, flake graphite, corundum fine powder, a-Al2O3 ultrafine powder, silicon powder and carborundum ultrafine powder; the bonding agent is aluminate cement; the antioxidant is a compound of aluminium powder and silicon powder; the admixture comprises a water reducing agent and a detonation suppressor. The castable material is prepared by the steps of mixing various raw materials evenly, adding water, stirring, casting molding, maintaining and drying. The castable material has strong anti-slag corrosion and anti-scour capabilities, good high temperature resistance, abrasion resistance and thermal shock resistance, slight reheating change and long service life.

Owner:BEIJING TONGDA REFRACTORY TECH CO LTD

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

Roasting sagger for circulating type lithium battery anode material and preparation method thereof

ActiveCN103311498AGood chemical inertnessStrong alkali corrosion resistanceElectrode manufacturing processesCharge supportsMulliteCordierites

The invention discloses and provides a roasting sagger for a circulating type lithium battery anode material, which is simple in manufacturing process and structure, does not easily react with a lithium battery material, can avoid polluting the lithium battery material, does not pollute the environment and can be recycled, and a preparation method thereof. The preparation method of the roasting sagger for the circulating type lithium battery anode material comprises the following steps of: (1) uniformly mixing mullite, cordierite, aluminum oxide, corundum, kaolin, active magnesium oxide, spodumene and a bonding agent; adding the materials into a metal mould according to the weight; and pressing and molding a blank by pressing and molding equipment; (2) uniformly mixing zirconium oxide, the spodumene, cerium oxide, the corundum and the bonding agent; uniformly distributing the materials on the surface of the blank by a material distribution machine or manpower and pressing again by the pressing and molding equipment to obtain a semi-finished sagger product; and (3) drying the sagger semi-finished product and sintering. The roasting sagger disclosed by the invention can be widely applied to the field of the sagger for the lithium battery anode material.

Owner:李艳晖

Composite fire resistant pouring material

The invention relates to an organic-inorganic composite combined advanced monolithic refractory which has the formula of 40 to 56 percent of 5-1mm corundum or bauxite, 12 to 30 percent of 1-0.0088mm corundum or bauxite, 16 to 25 percent of corundum or bauxite with d90 less than 0.088mm, 0 to 5 percent of alpha alumina micropowder, 1 to 8 percent of hydratable alumina, 1 to 6 percent of siliceous dust, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid, 1 to 6 percent of external water and 0 to 3 percent of external heat-resistant steel fiber. Casting materials of the invention have excellent performances of condensation, hardening, demoulding, drying and heating and are suitable for high-temperature furnace projects with changeful field conditions.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Siliceous mullite structure-insulating integrated composite brick and preparation method thereof

The invention discloses a siliceous mullite structure-insulating integrated composite brick and a preparation method thereof. The brick consists of a heavy working layer and a high-strength light insulating layer, wherein the main materials of the heavy working layer are dense bauxite and silicon carbide material, the aggregate of the high-strength light insulating layer is one or the mixture of alumina hollow balls, alumina-magnesia hollow balls, corundum hollow balls, hollow microspheres and light ceramisite, the heavy working layer and the light insulating layer are combined together by adopting vibratory pressing or mechanical pressing, and the length proportion between the heavy working layer and a light insulating layer is 1 to 5:2 to 1. The invention overcomes the defect of the abrasion-resistant siliceous mullite brick for rotary kilns, i.e. high coefficient of heat conductivity, and the defects of the light part of the conventional siliceous mullite composite brick, i.e. low strength and low refractoriness, and the structure-insulating integrated composite brick has the advantages of high abrasion resistance, high refractoriness, high structure strength and high insulating property.

Owner:浙江盛旺耐火材料股份有限公司

Composite bonding wear-resistant castable refractory

The invention relates to a composite bonding wear-resistant castable refractory, which can be used for high-temperature kiln engineering. The amorphous castable refractory which is normal in coagulation, quick in hardening, low in porosity, high in strength and high in abrasive resistance is prepared from silica sol serving as a bonding agent, aluminate cement serving as a curing agent, alumina micro powder and wollastonite which serve as a compact agent, heat resistant steel filters serving as a reinforcing agent and corundum and alumina which serve as an aggregate. The composite bonding wear-resistant castable refractory is suitable for positions such as air pipeline elbows for the cogeneration of cement kilns, cyclone cones and linings for triple air pipe gates which are easy to wear in high-temperature kilns.

Owner:ANHUI RUITAI NEW MATERIALS TECH

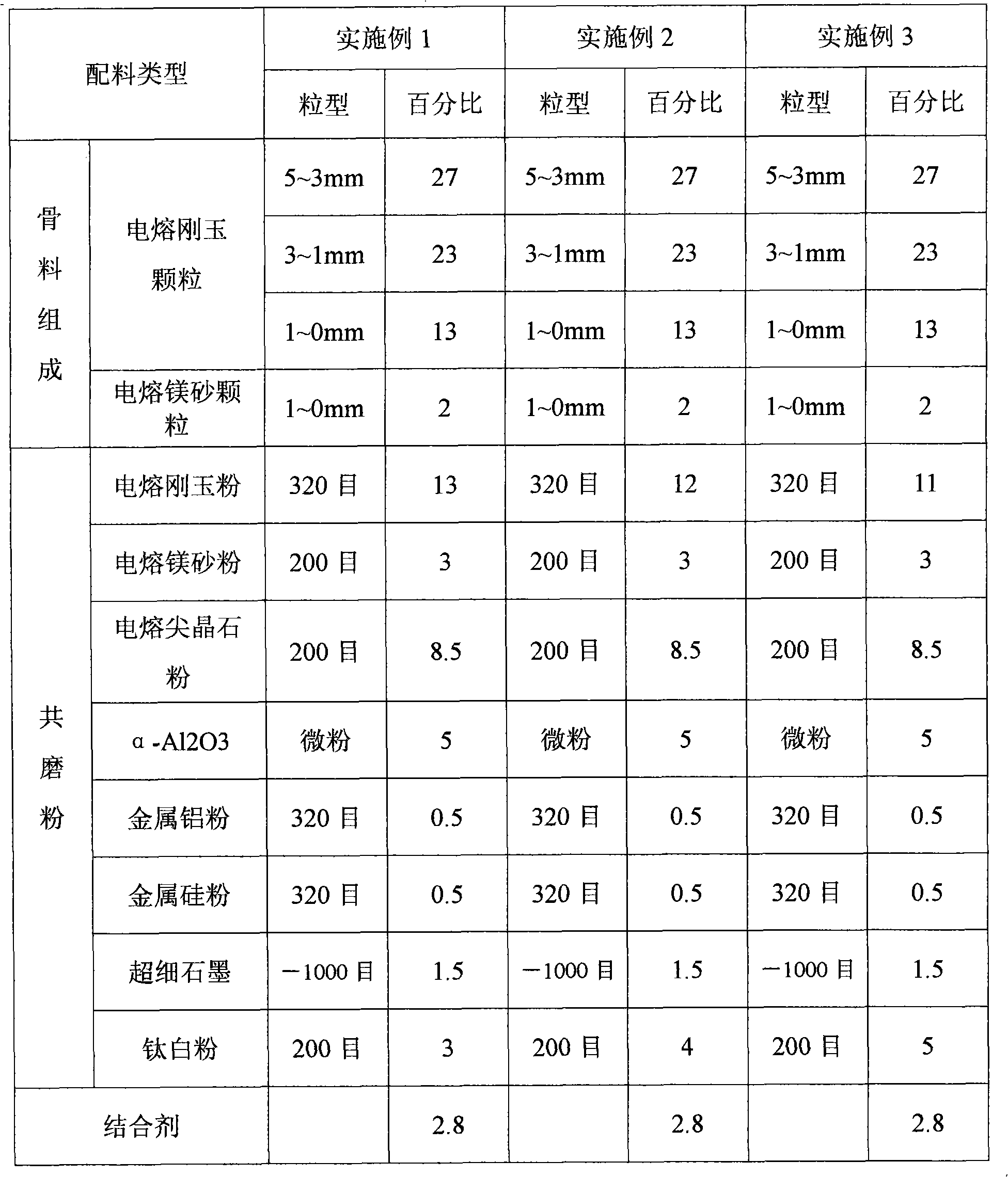

Low-carbon corundum spinelle brick for refined steel ladles and preparation method thereof

The invention relates to a low-carbon corundum spinelle brick for refined steel ladles and a preparation method thereof for overcoming the defect of overhigh carbon content in the prior carbon-contained fireproof material technology. The low-carbon corundum spinelle brick for refined steel ladles comprises the following components in percentage by weight: 60-70 fused corundum particles, 2-6 fused magnesite particles, 10-20 fused corundum fine powder, 2-10 fused magnesite fine powder, 5-15 fused spinelle fine powder, 3-6 alpha-Al2O3 micro powder, 0-2.0 metal aluminum fine powder, 0-2.0 metal silicon fine powder, 2-6 bond, 1-2 superfine graphite and 2-6 titanium white powder. The invention has good thermal stability at high temperature, resists high temperature and the erosion of molten steel and slag and has high mechanical strength, good thermal shock stability and high under-load softening point, thereby being widely applied to various steel ladles, in particular to steel ladles of refined low-carbon steel and ultra-low-carbon steel.

Owner:海城利尔麦格西塔材料有限公司 +2

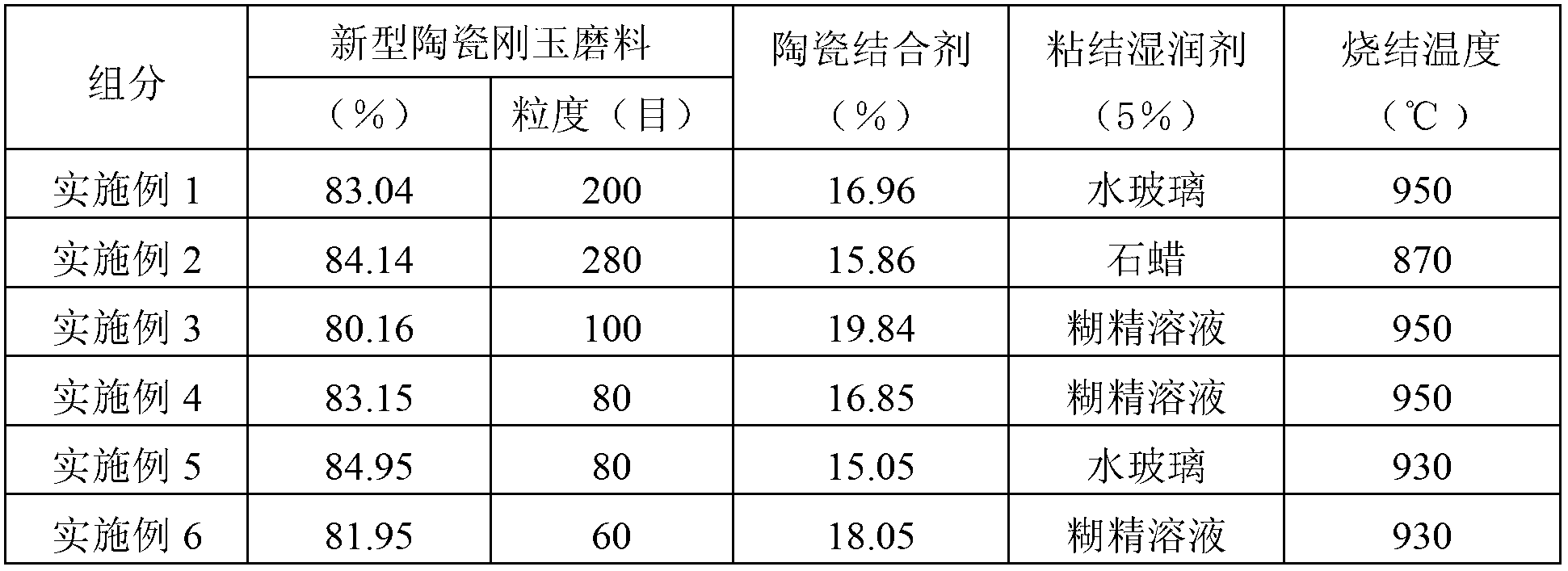

Efficient silicon carbide corundum rare earth ceramic composite grinding wheel and manufacture method thereof

The invention relates to an efficient silicon carbide corundum rare earth ceramic composite grinding wheel which comprises the following raw materials in percentage by weight: 30-75wt percent of silicon carbide abrasive, 25-70wt percent of corundum abrasive, 12-22wt percent of rare earth ceramic and 3.5-8wt percent of normal-temperature binding agent. The composite grinding wheel is manufactured by the steps of calcining, ball-milling, blending, moulding, drying, sintering, and the like. The grinding wheel of the invention has the advantages of high grinding force for grinding a difficult grinding material, sharp grains, high self sharpening, shedding in time of blunt grinding grains and no burning on workpieces. Compared with the traditional single grinding material common ceramic binding agent grinding wheel, the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously improves the grinding efficiency; and compared with a grinding wheel adopting an expensive superhard grinding material (artificial diamond or CBN (Cubic Boron Nitride)), the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously reduces the grinding cost and has wider adaptation and favorable economic and social benefits.

Owner:FUZHOU SHUANGYI GRINDING WHEEL +1

Pouring material for producing high-temperature ceramic abrasion-proof lining body

The invention relates to a castable for preparing a high-temperature ceramic wear-resistant lining, which contains 10-25% of fused mullite with a particle size of 3-5mm, and 20-45% of fused mullite with a particle size of 1-3mm. 3-7% of andalusite with a particle size of 0.1mm-1mm, 8-25% of platy corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum, and pure calcium aluminate with a particle size of <0.074mm 2-10% of cement, 2-6% of silicon micropowder, and 2-10% of alumina micropowder. The castable can be applied to the intersection of blast furnace hot air pipe and air supply branch pipe, etc. where thermal shock stability is high. The lining made of it has good thermal stability, high temperature air erosion resistance, good thermal shock resistance, It has the advantages of long life cycle, simple manufacturing method, short construction period, environmental protection and pollution-free, low cost, and easy industrial production.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

Air brick for magnesia carbon ladle and method for producing the same

The invention discloses an air brick used for a magnesium and carbon ladle, and a producing method thereof, aiming at producing high-quality air bricks used for the ladles. The mass percentage of the chemical compositions of the air brick is: 55 to 99 percent of MgO, 0 to 20 percent of C, 0 to 20 percent of AI2O3, 0 to 5 percent of ZrO2, 0 to 5 percent of AI, 0 to 5 percent of AI-Mg alloy, 0 to 5 percent of CaB6, and 0 to 2 percent of B4; the physical property indexes are: volume density (g / cm<3>): 3.00 to 3.15, apparent porosity (%): 1.5 to 5.0, cold compressive strength (MPa): 40 to 65, and distortion resistance at high temperature (MPa): 14.0 to 25.0. Raw materials adopted by the invention comprise fused magnesite, magnesite clinker, crystalline flake graphite, corundum, zirconia and oxidation inhibitor. The raw materials are added into a pug mill and externally added with a bonding agent for mulling. Mulled pug is added into a mould, and molded by utilizing isopressing equipment or a friction brick press or a hydraulic press. The invention obviously reduces the apparent porosity of the air brick, not only can improve the basic slag corrosion resistant capability of the air brick, but also can reduce the cost of the raw materials by more than two thirds.

Owner:UNIV OF SCI & TECH LIAONING

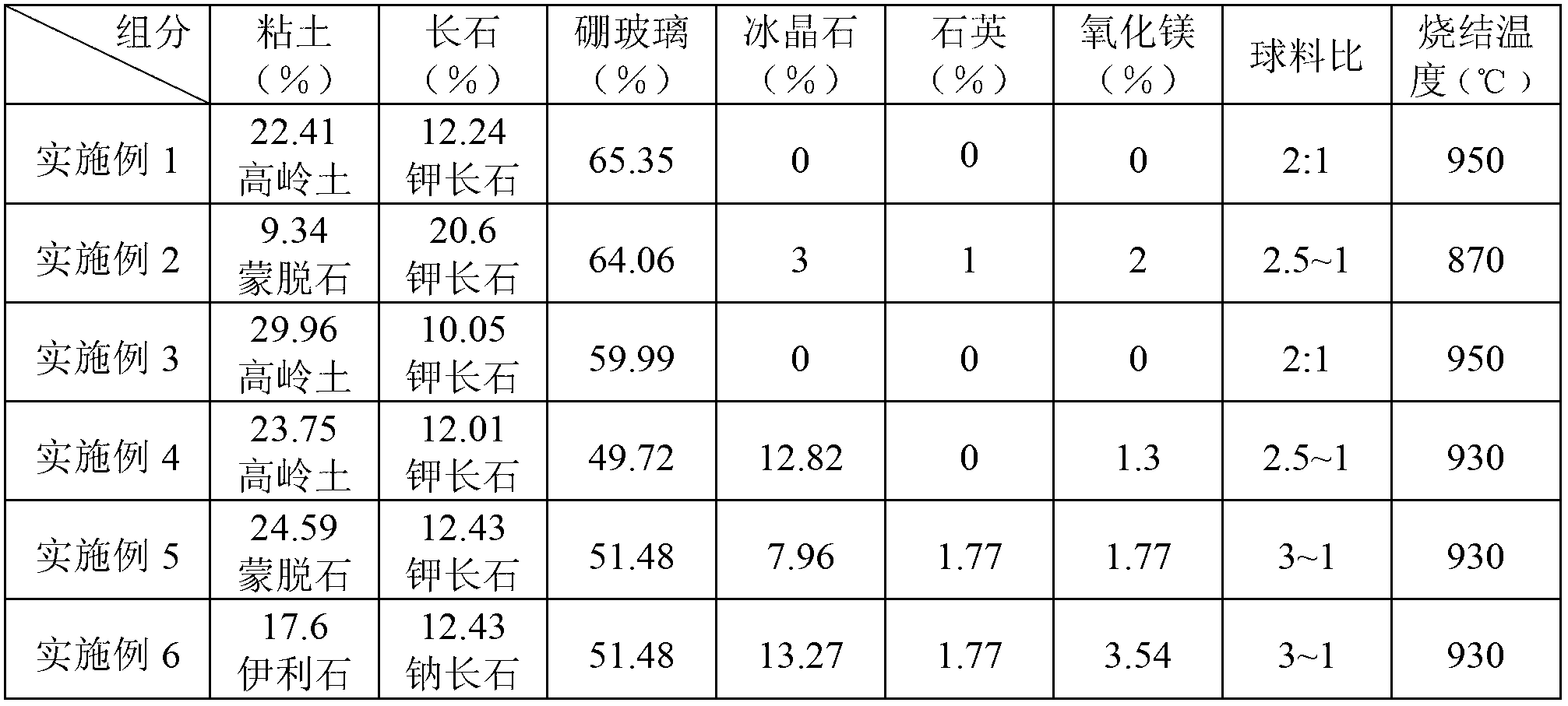

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com