Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8913 results about "Abrasive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer materials are known as abrasives.

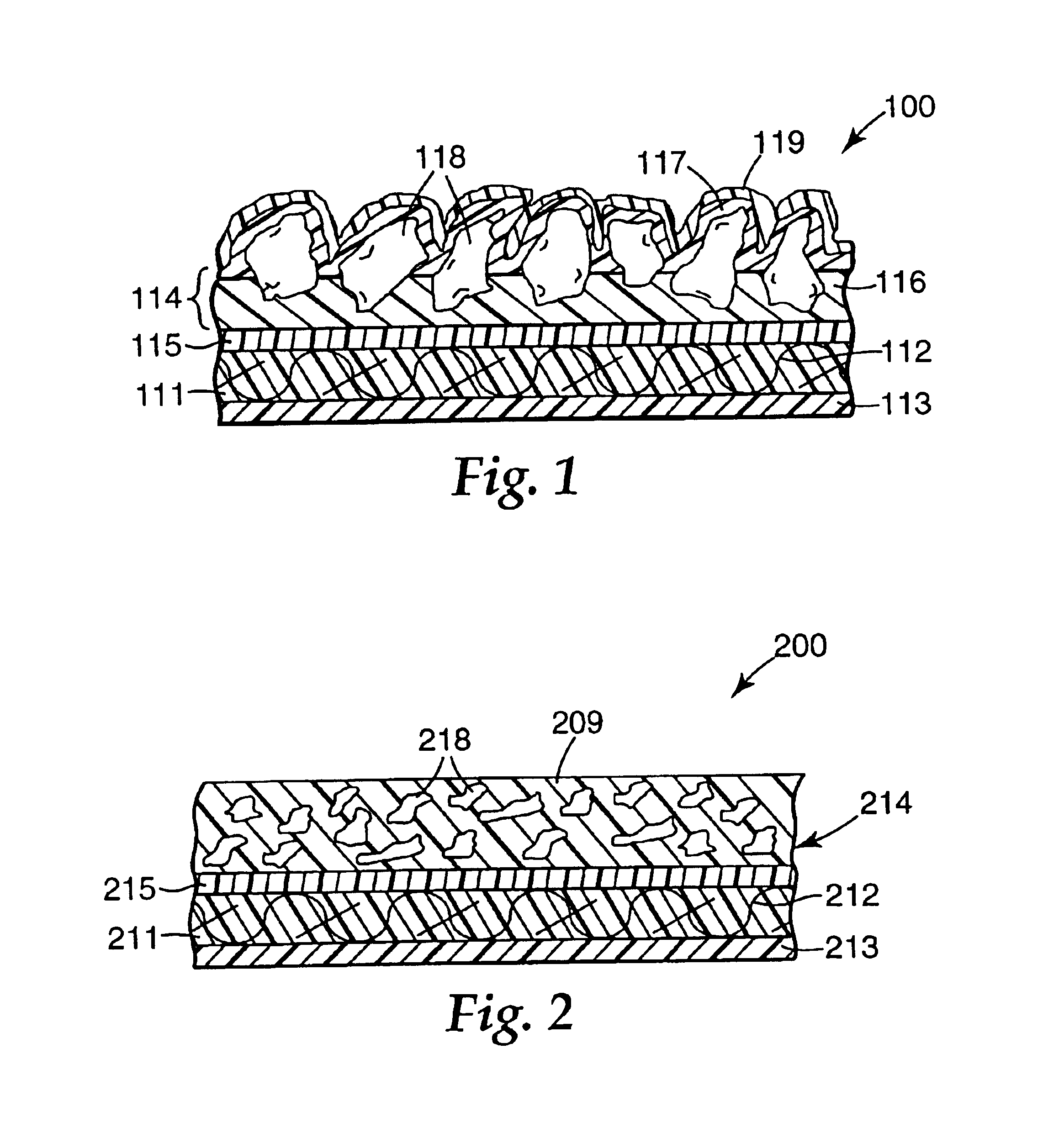

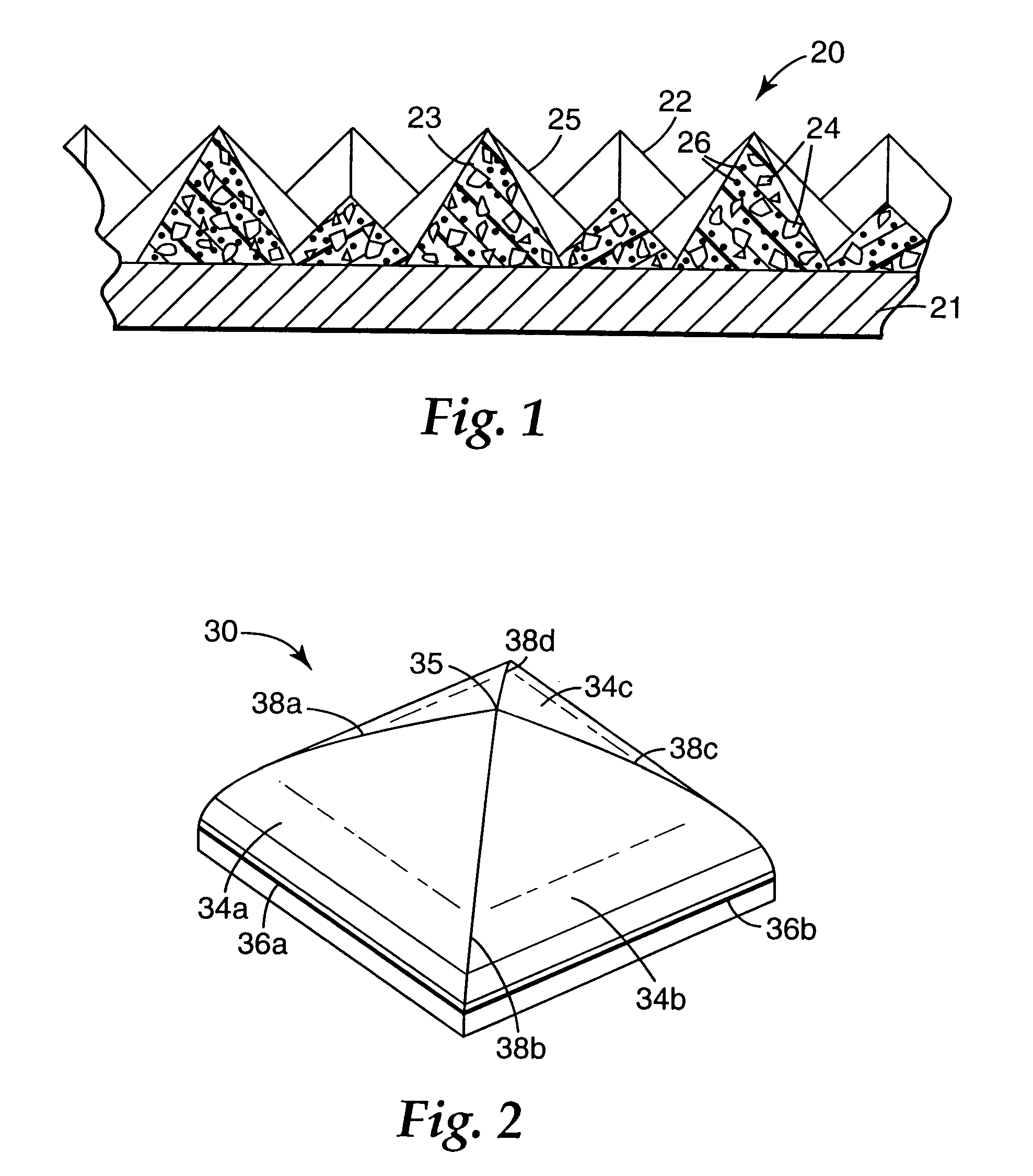

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

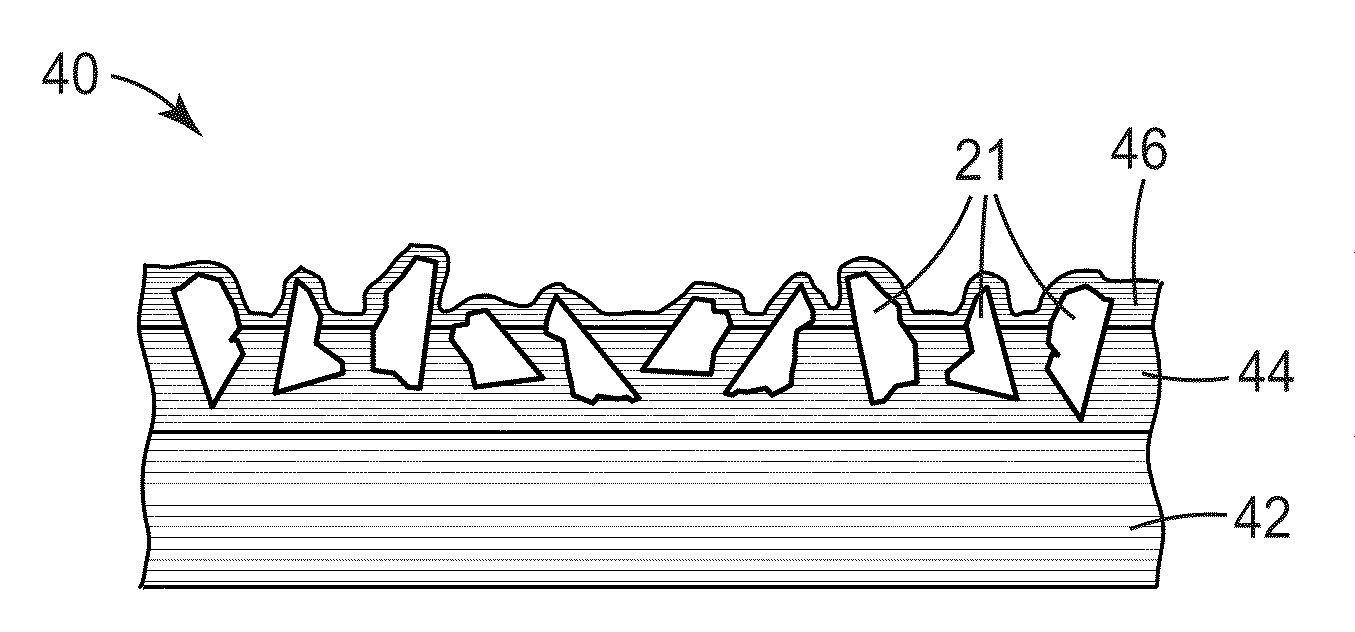

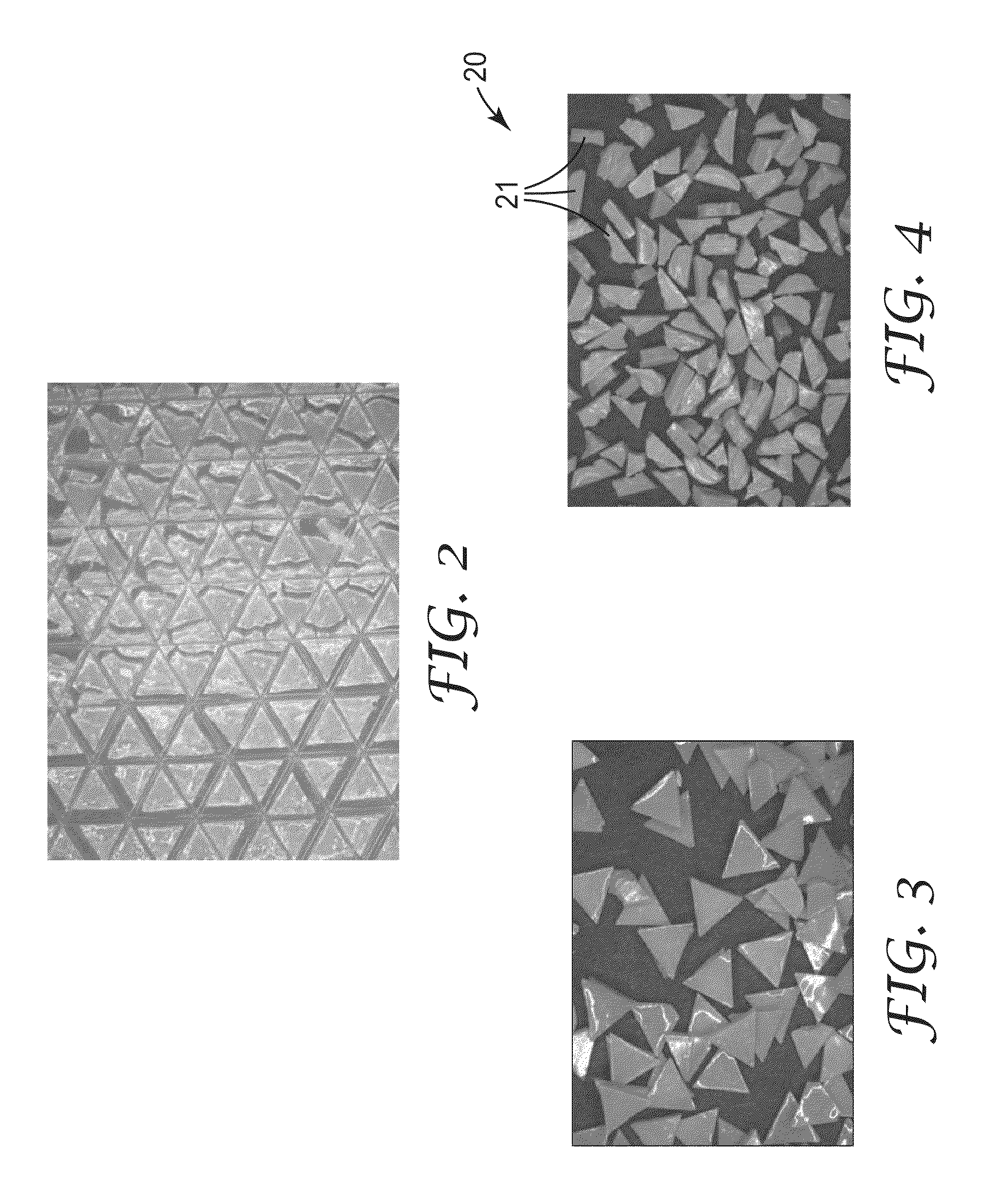

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

Method for providing a grinding surface on glass implements used in personal care

ActiveUS8790749B2Increase variabilityEasy to manufacturePretreated surfacesManicure/pedicurePersonal careFlat glass

Manufacturing method of grinding surface on glass cosmetics, in particular the nail and skin file, from flat glass of FLOAT type, is carried out by marking at least one abrasive surface on one or two sides of a glass pane or intermediate product. This surface is then coated with fusing glue, powdered with clean quartz sand with grain size between 1 and 500 μm using a sieve, and the surplus sand is knocked-down. The intermediate product with fixed sand is inserted into the fusing furnace where it is baked at the temperature of up to 900° C. The abrasive surface may be roughened by sand blasting before the fusing glue application; the intermediate product coated with fusing glue can be decorated with glass fritte.

Owner:HACEK OVER SKUTCHANOVA ZUZANA

Abrasive grain, abrasive articles, and methods of making and using the same

Owner:3M INNOVATIVE PROPERTIES CO

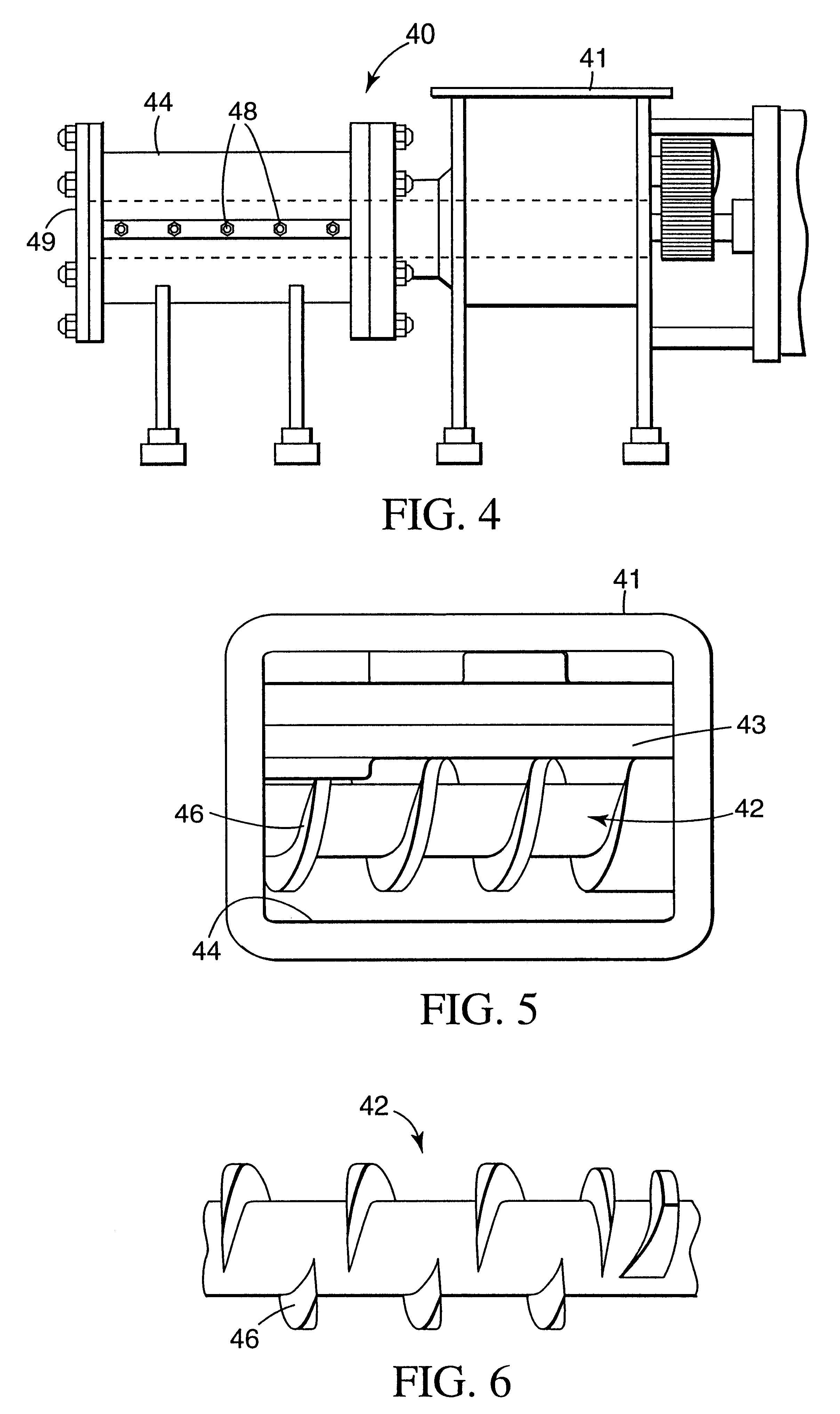

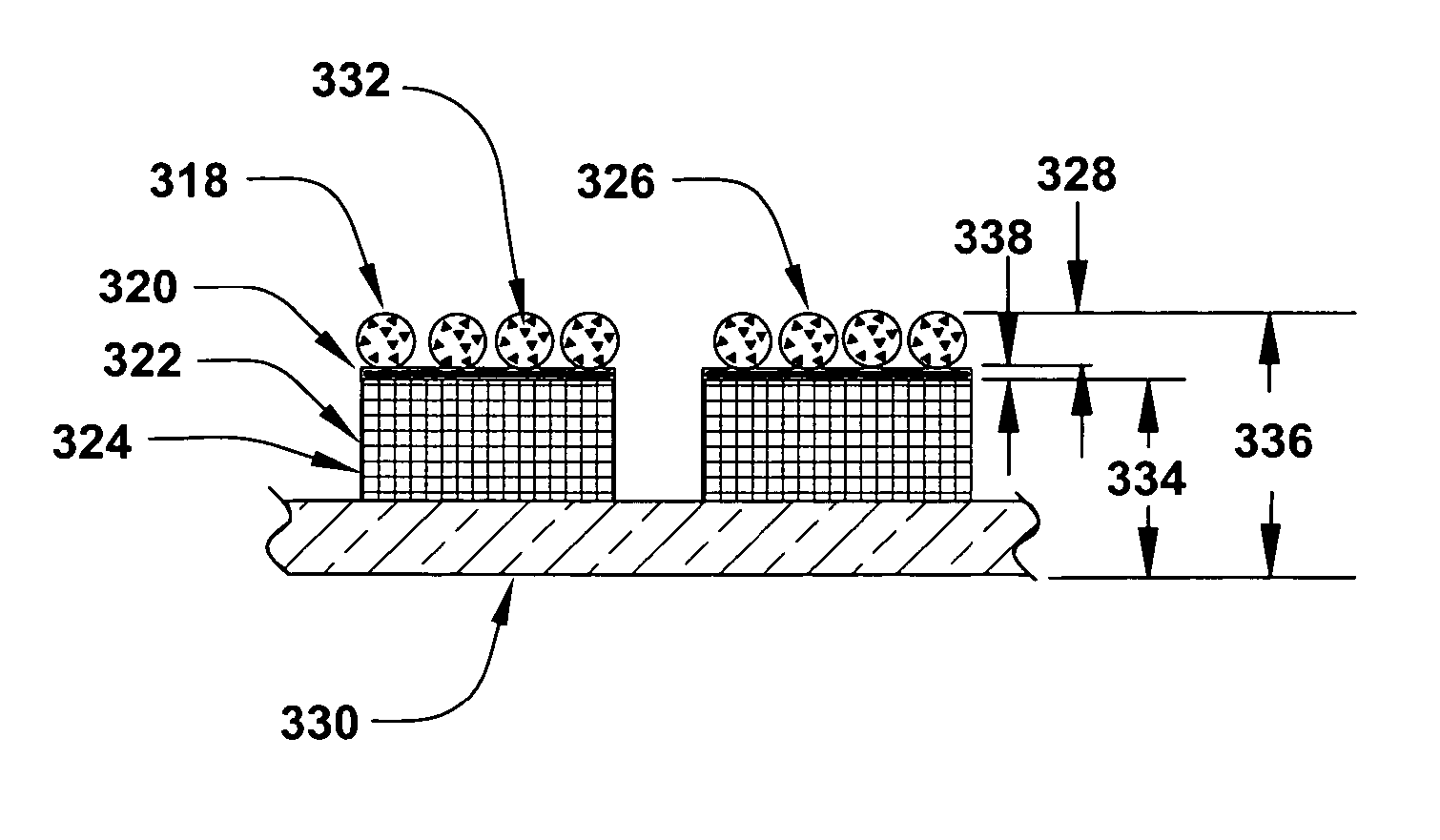

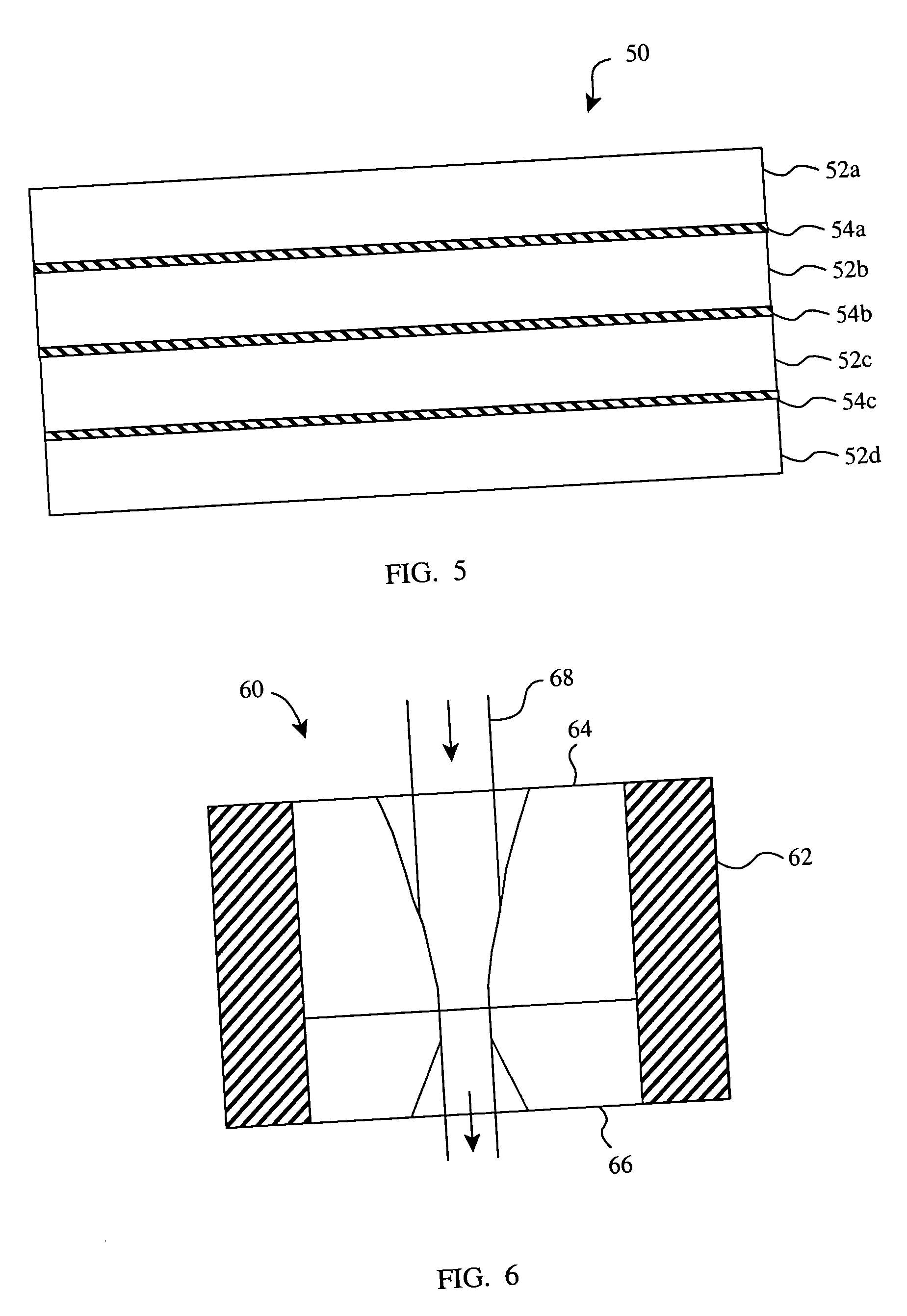

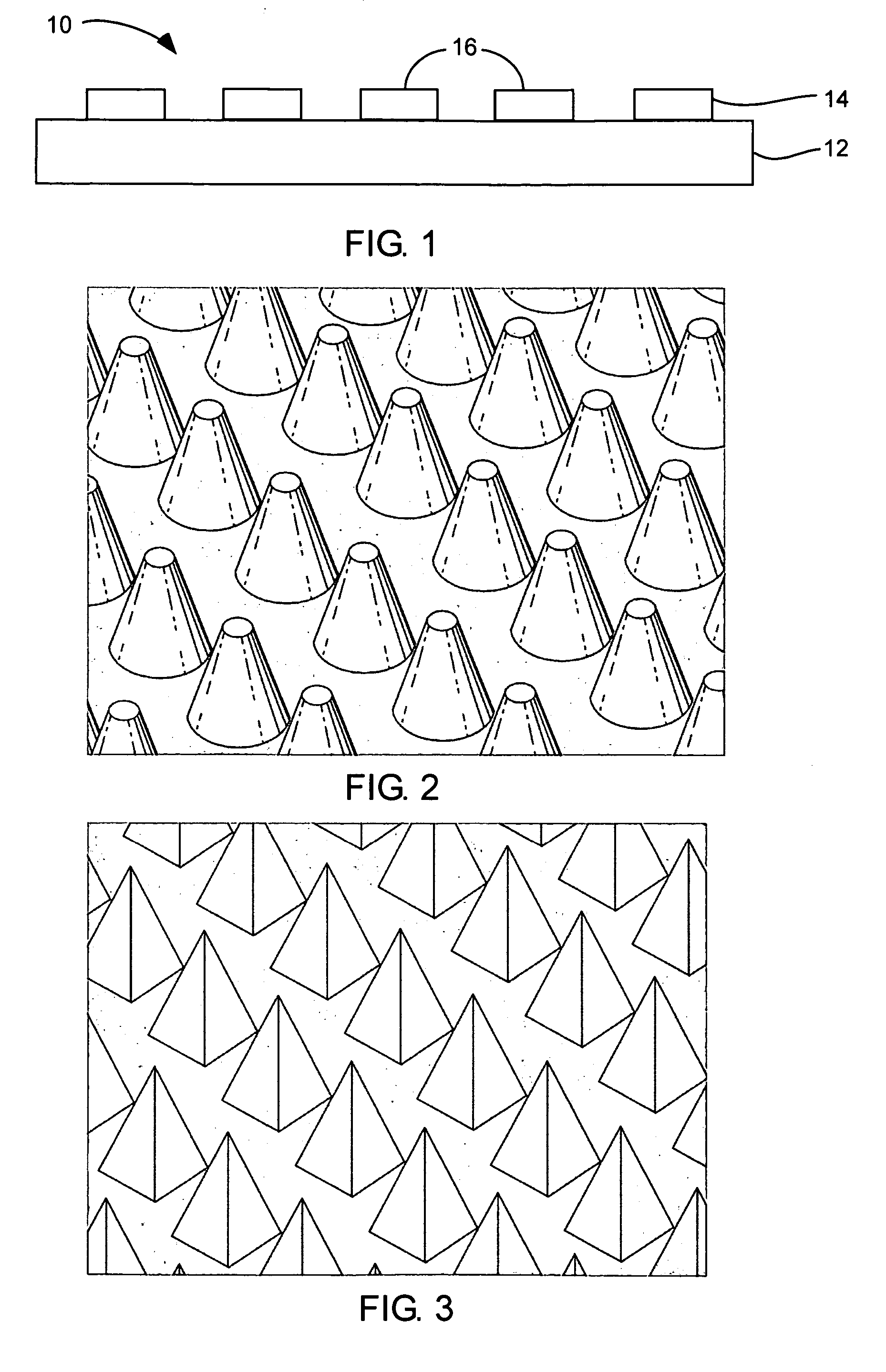

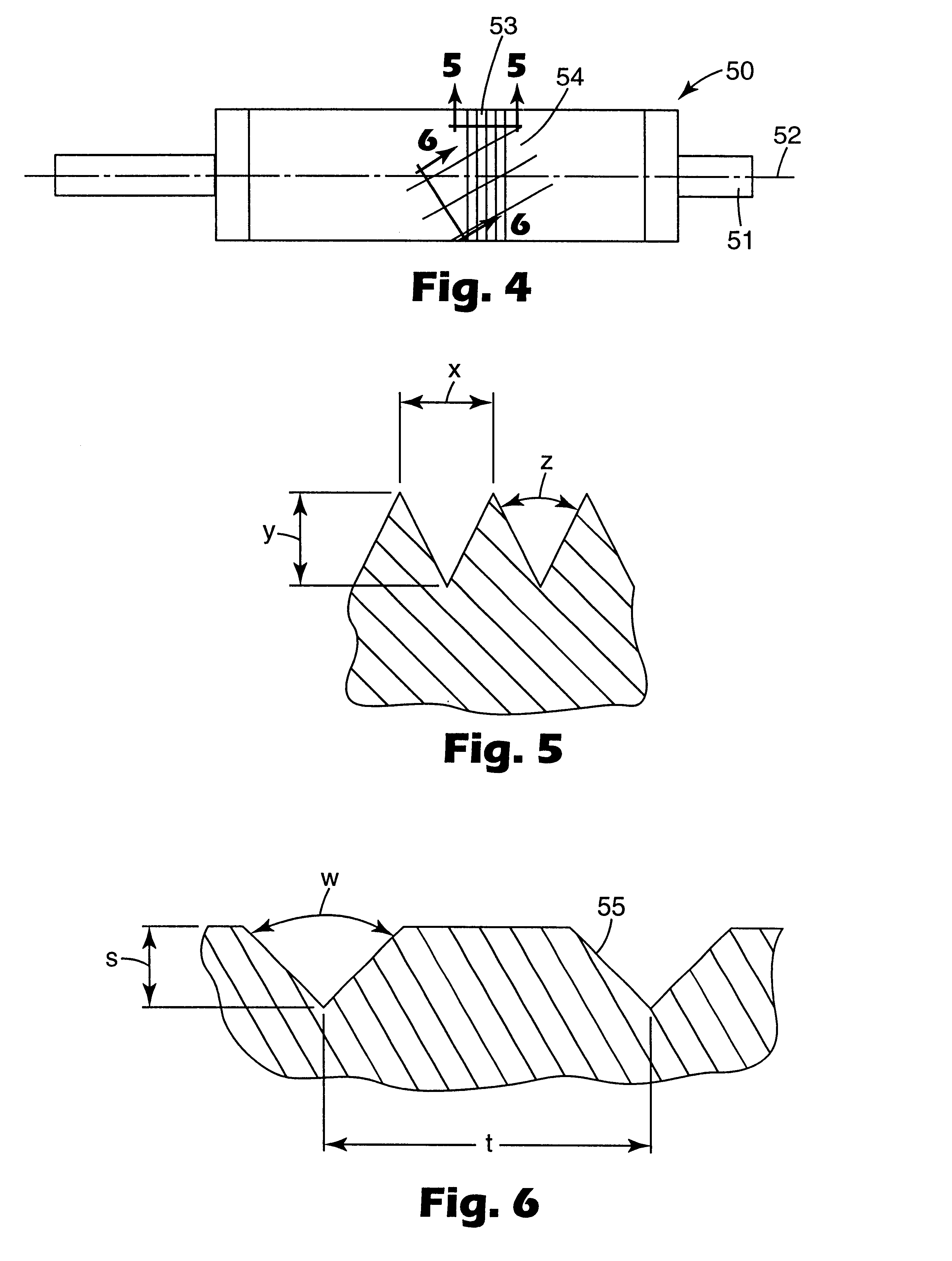

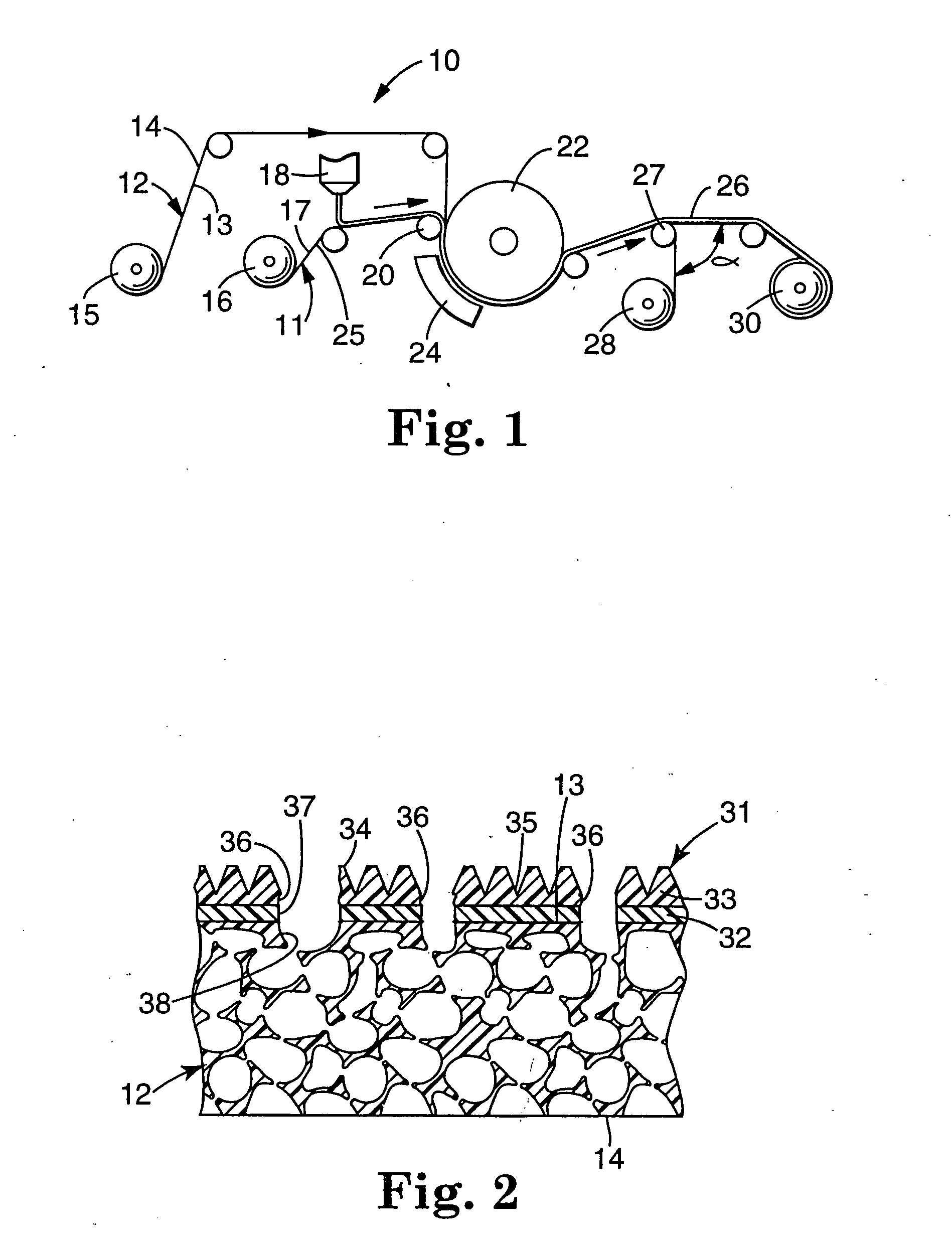

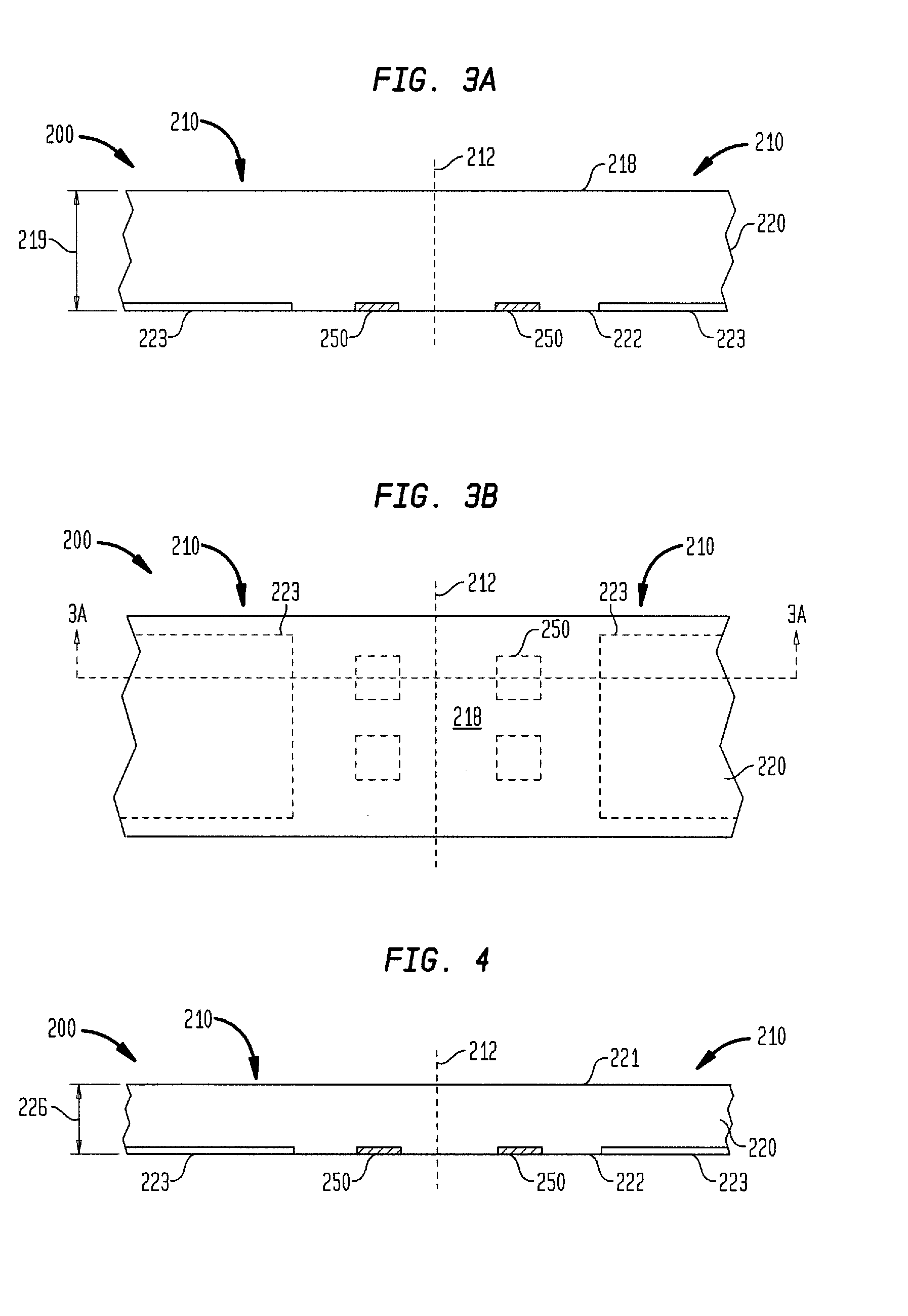

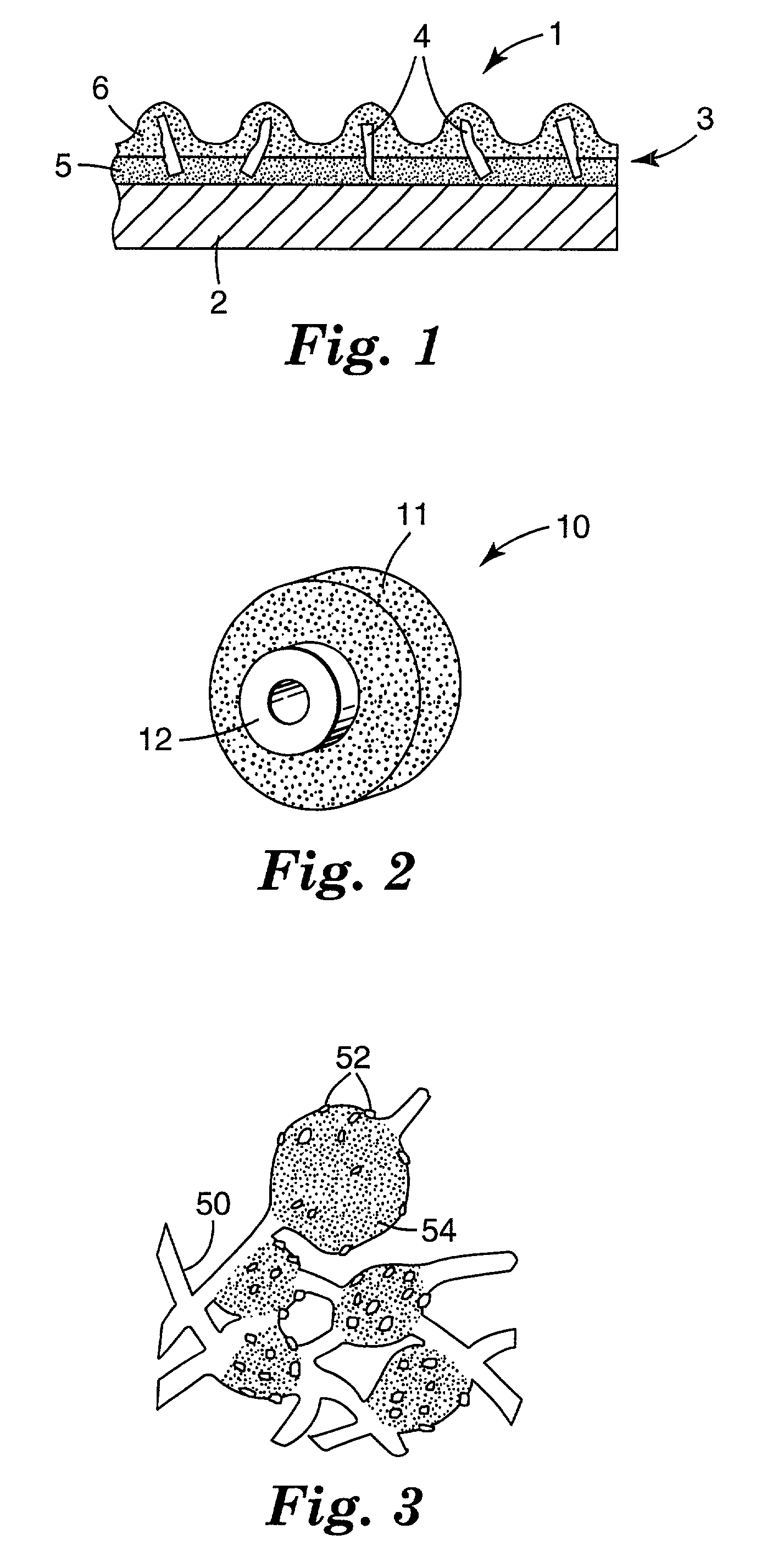

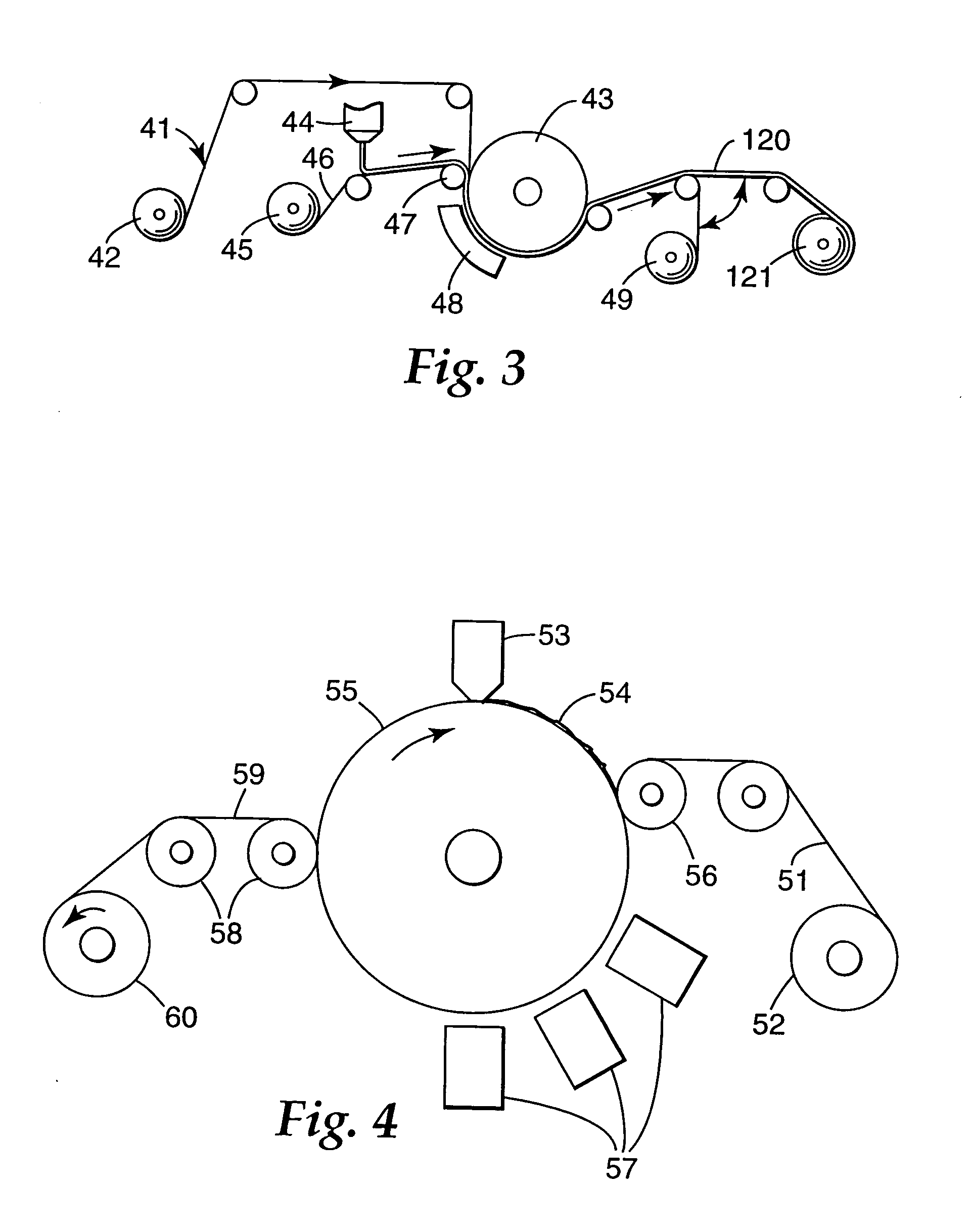

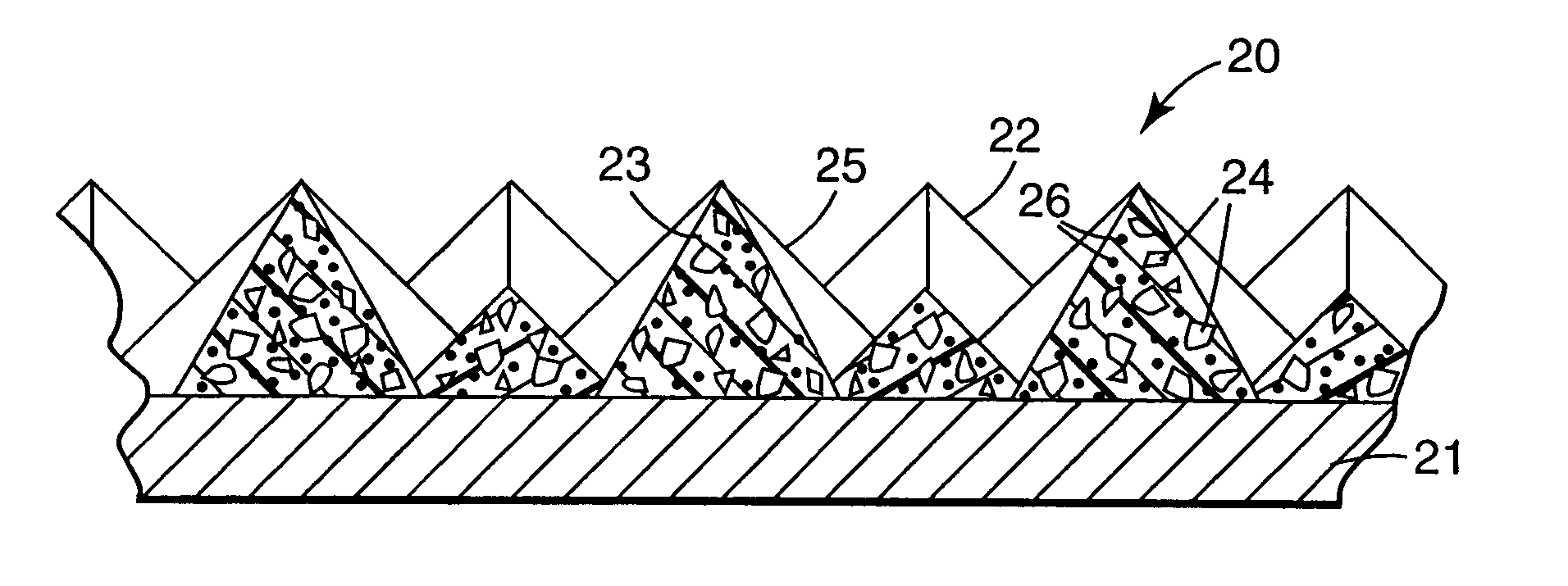

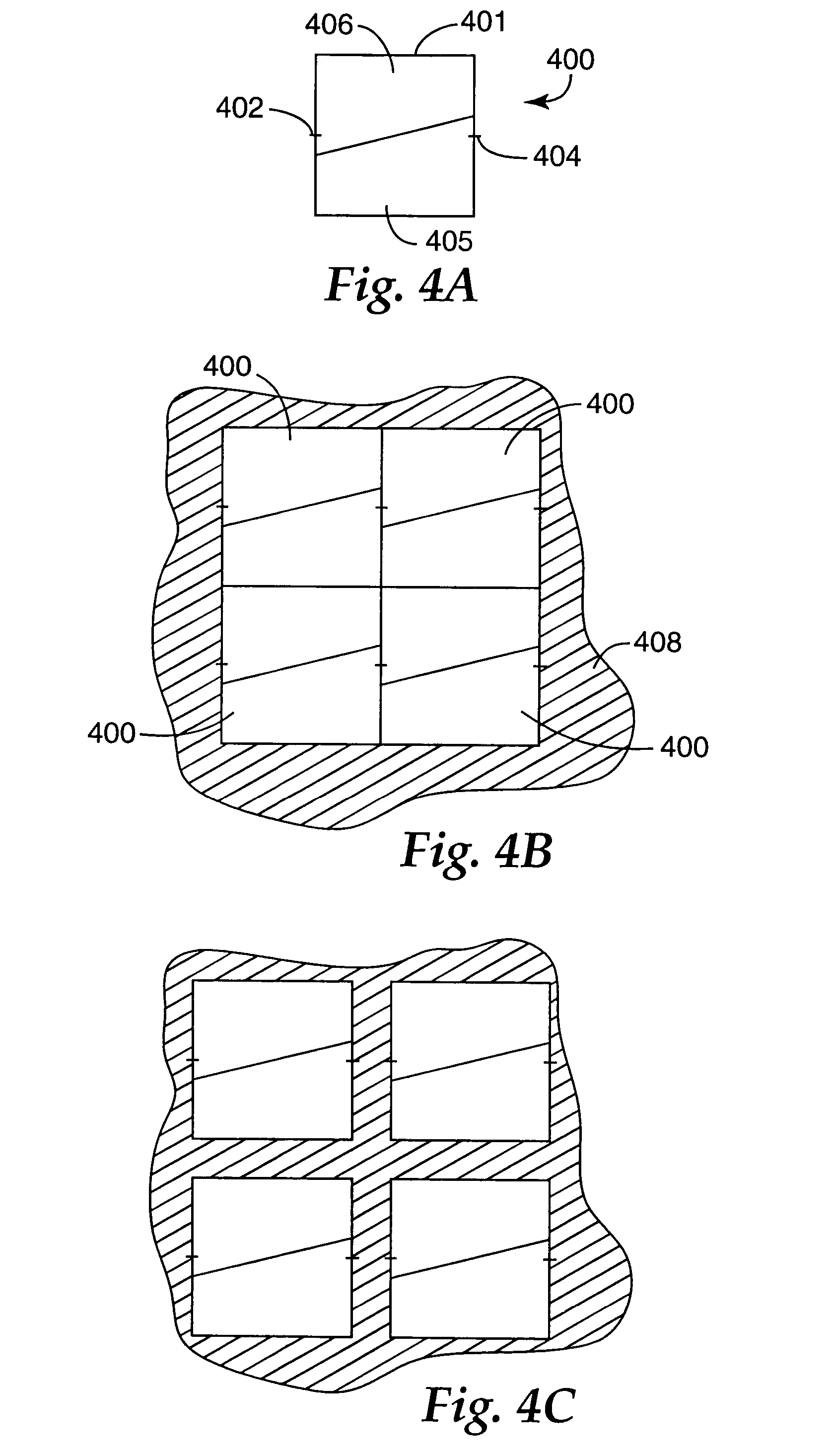

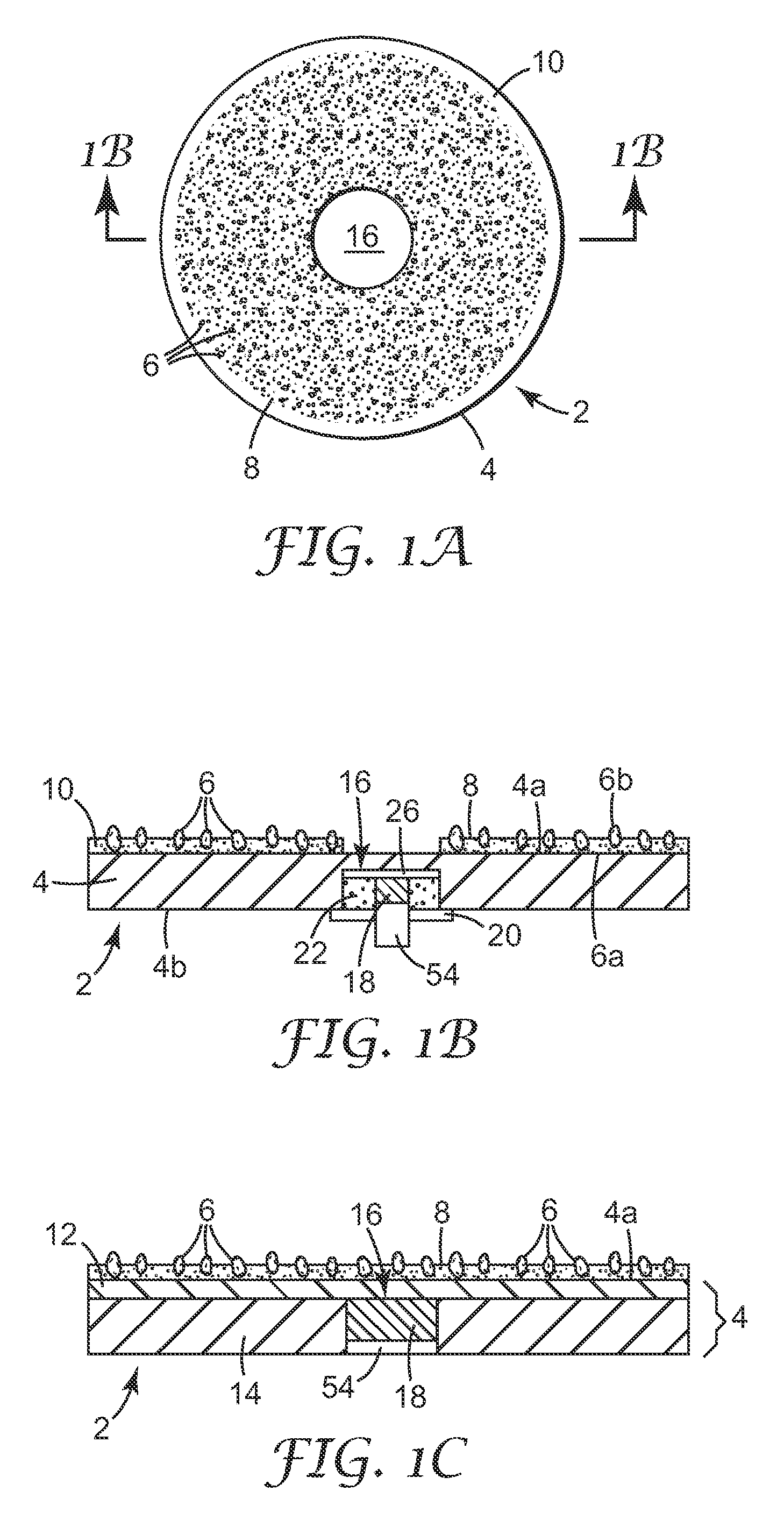

Abrasive bead coated sheet and island articles

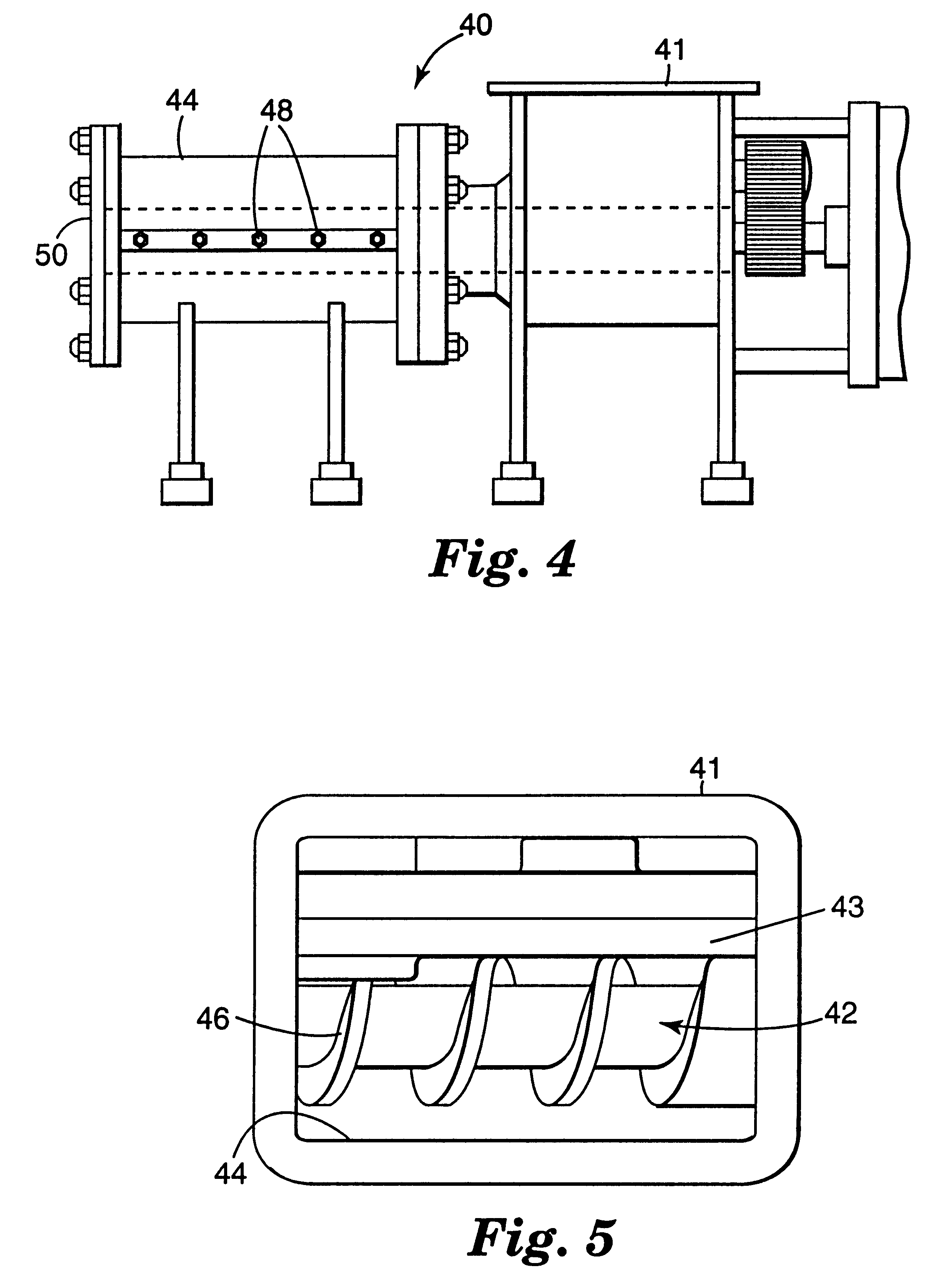

InactiveUS20050118939A1Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedSlurry

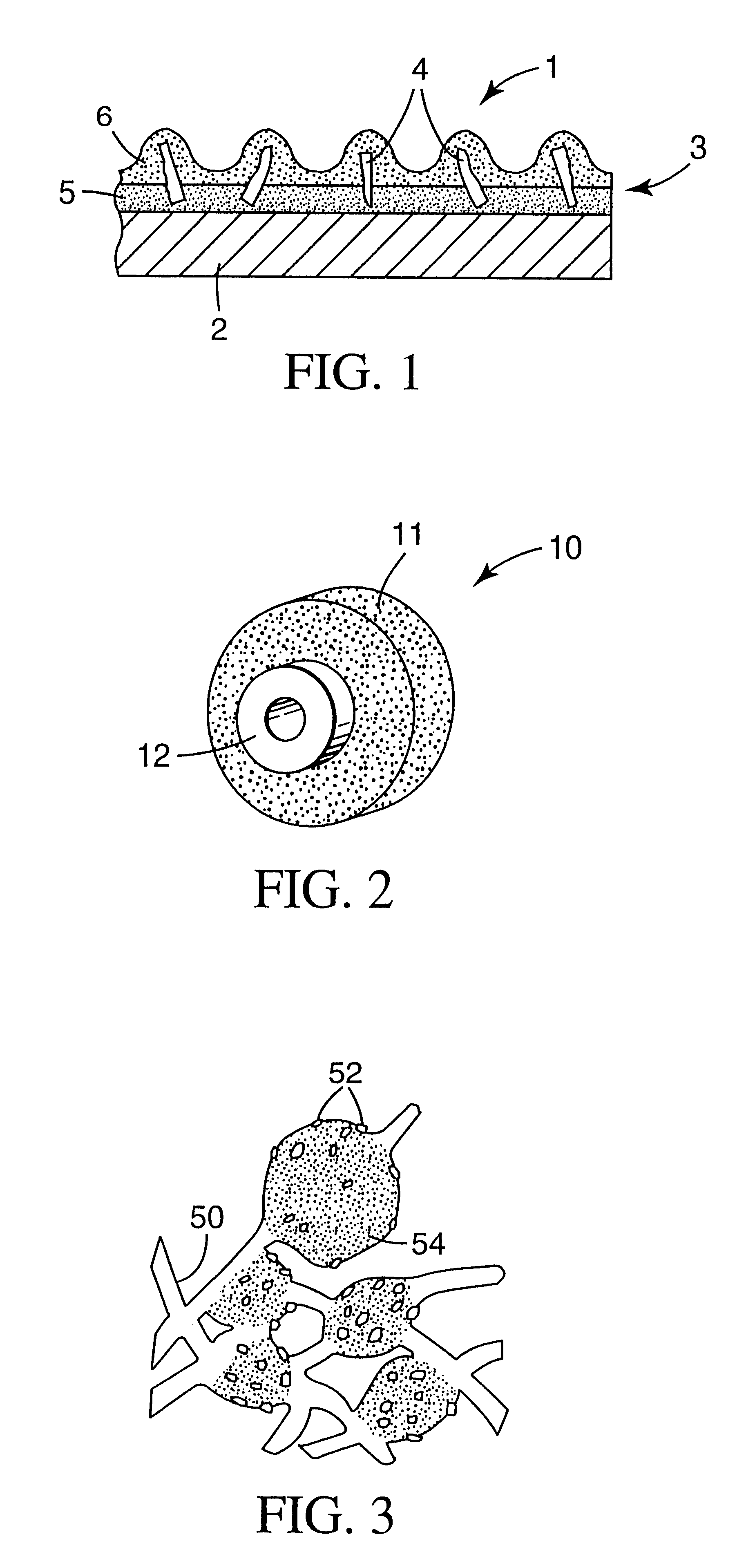

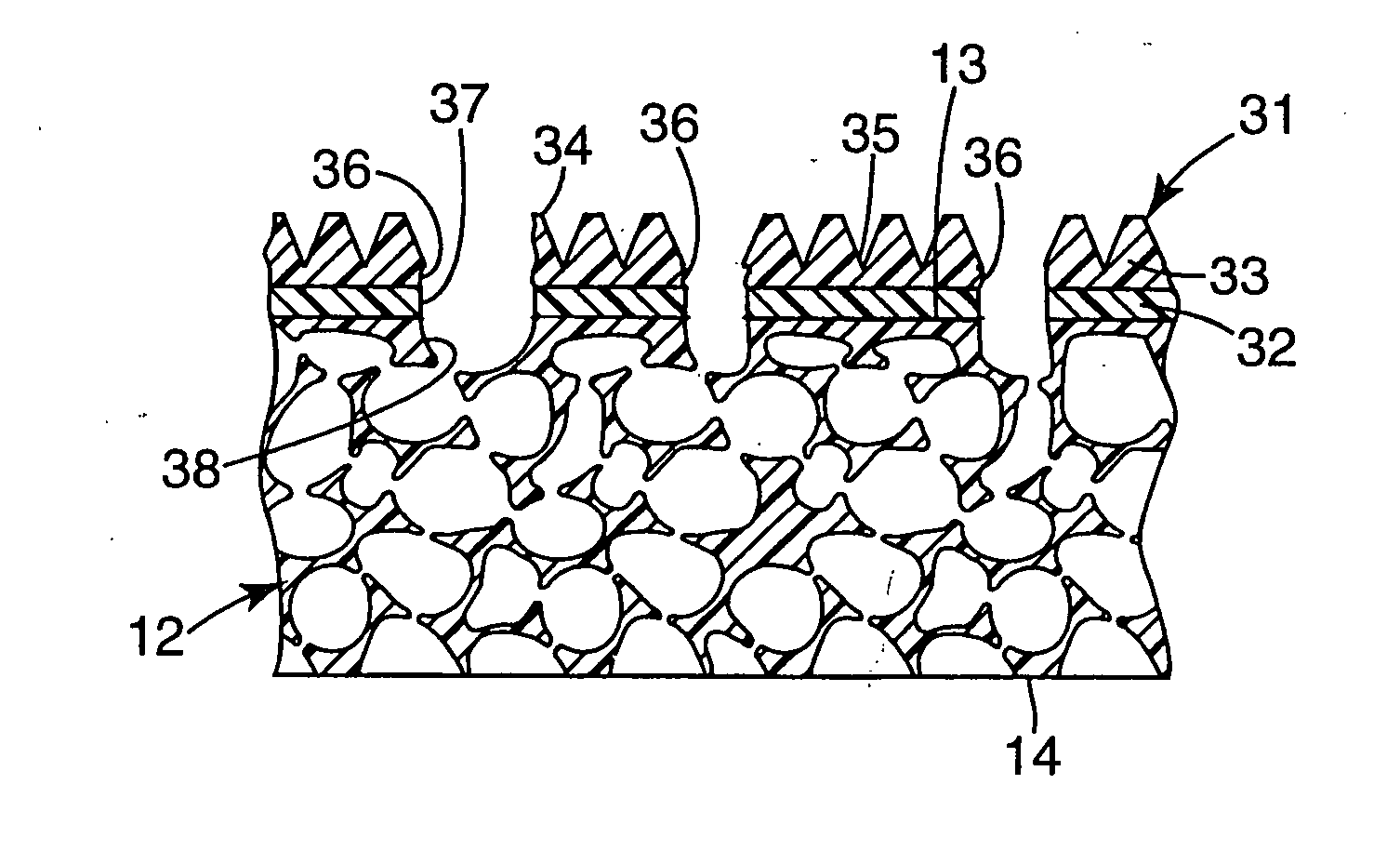

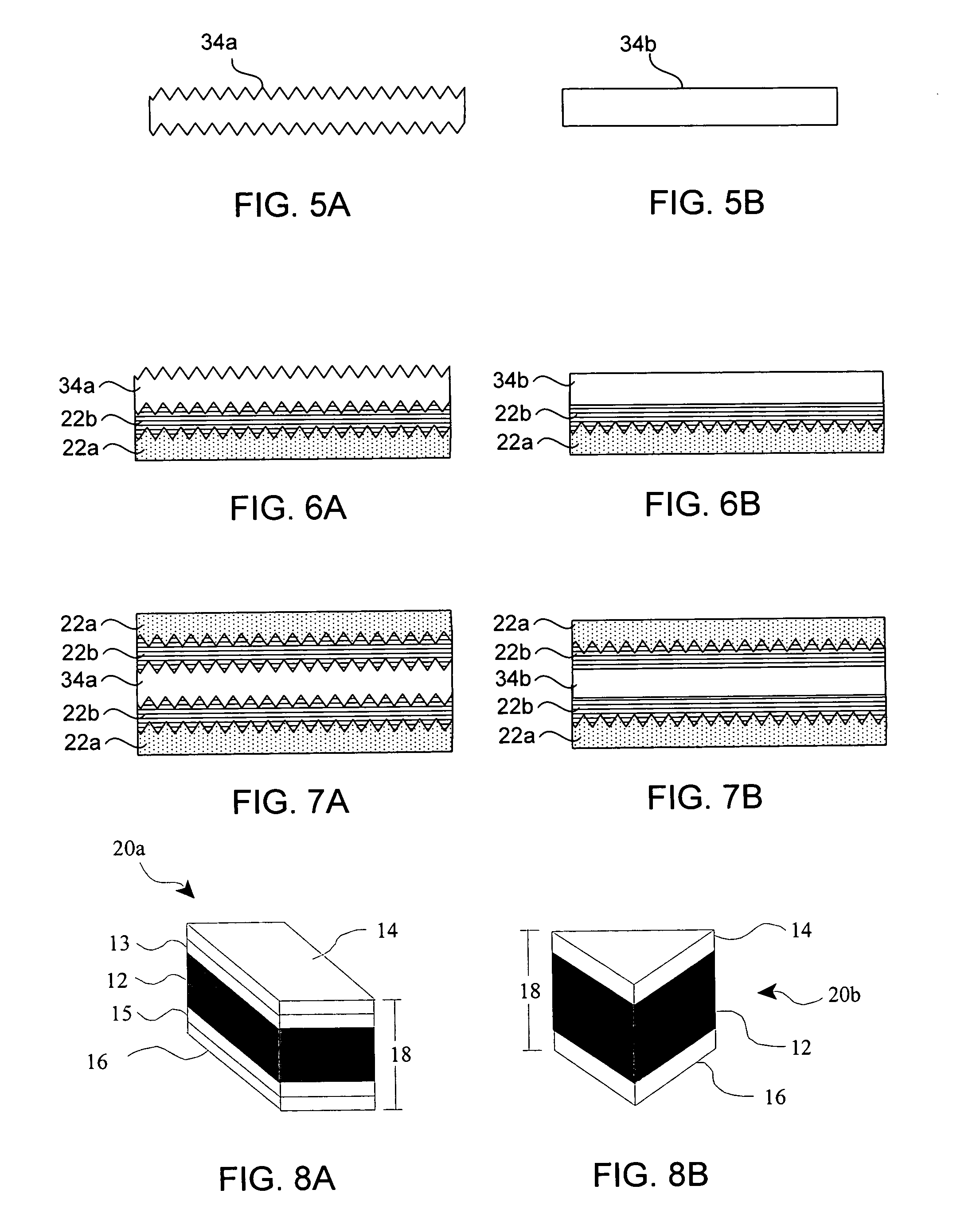

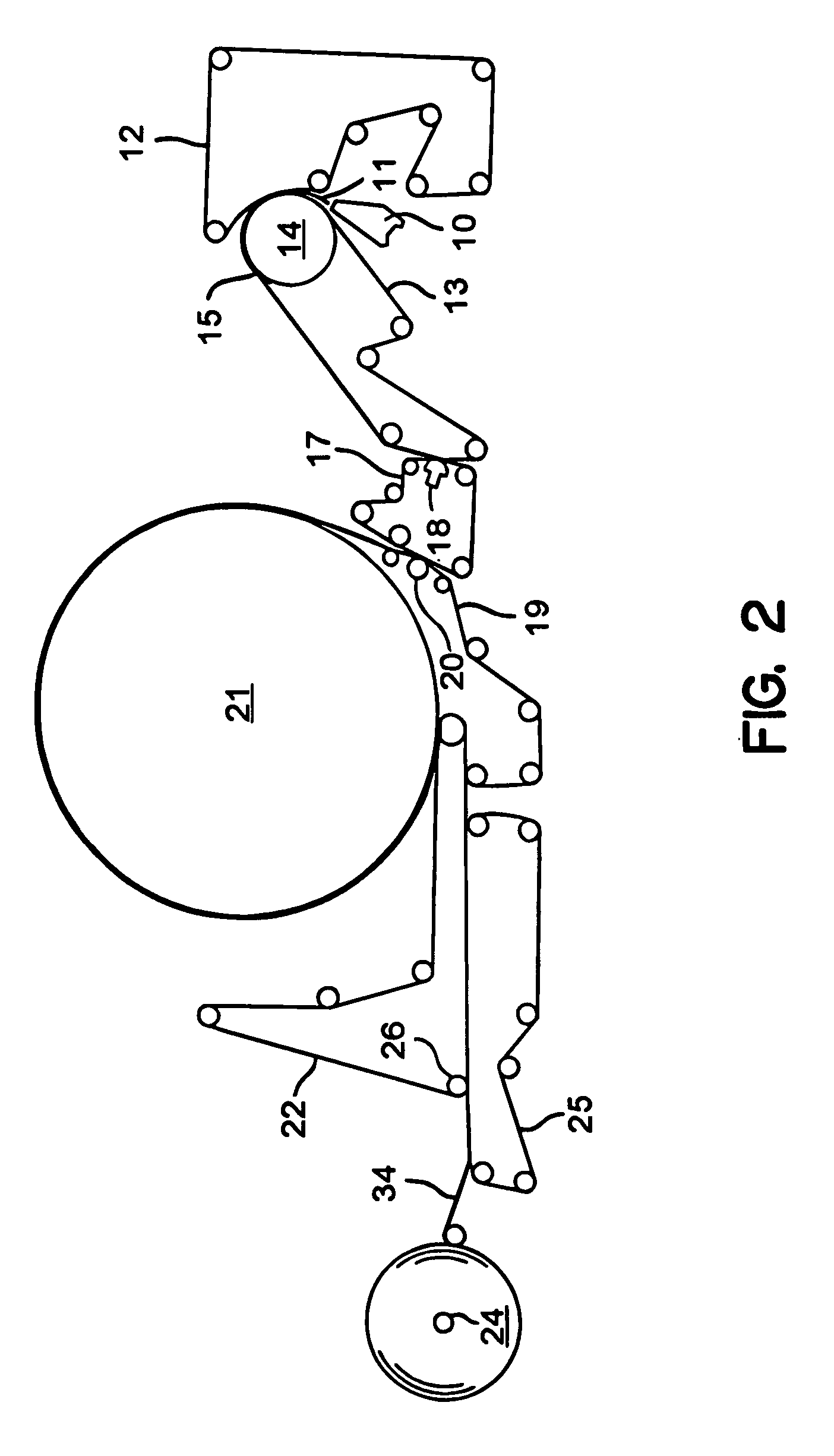

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

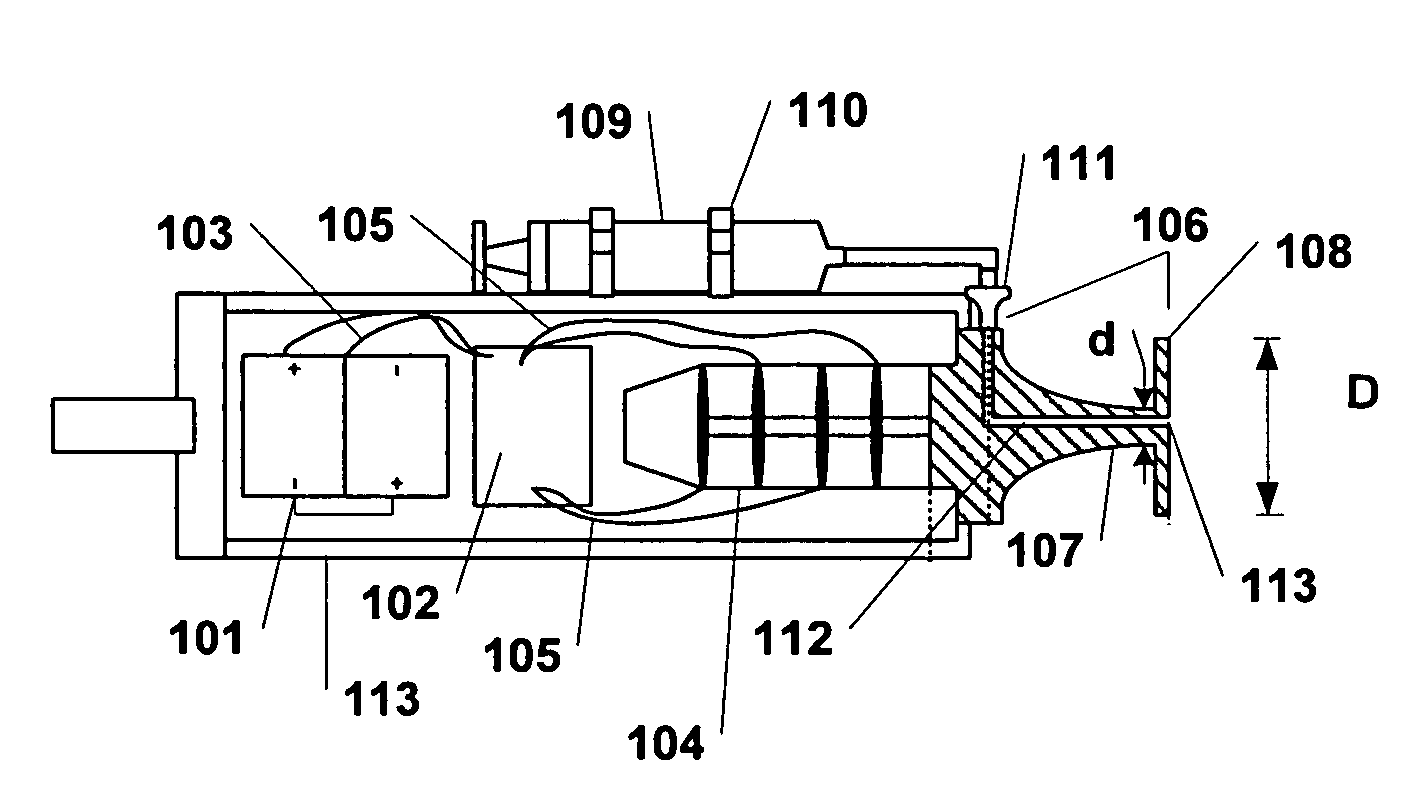

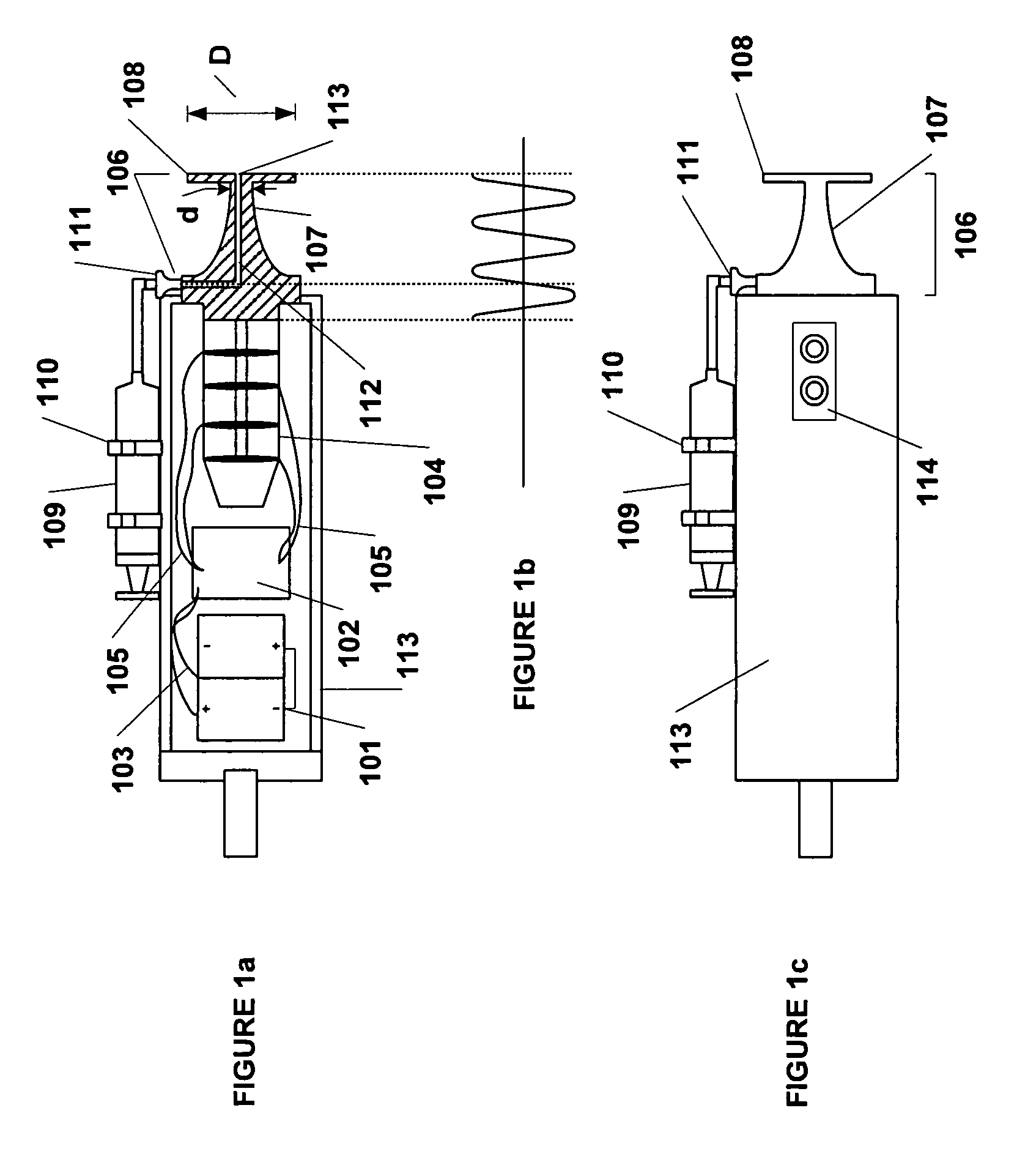

Portable ultrasound device for the treatment of wounds

InactiveUS7878991B2Ultrasonic/sonic/infrasonic diagnosticsUltrasound therapyFocus ultrasoundMedicine

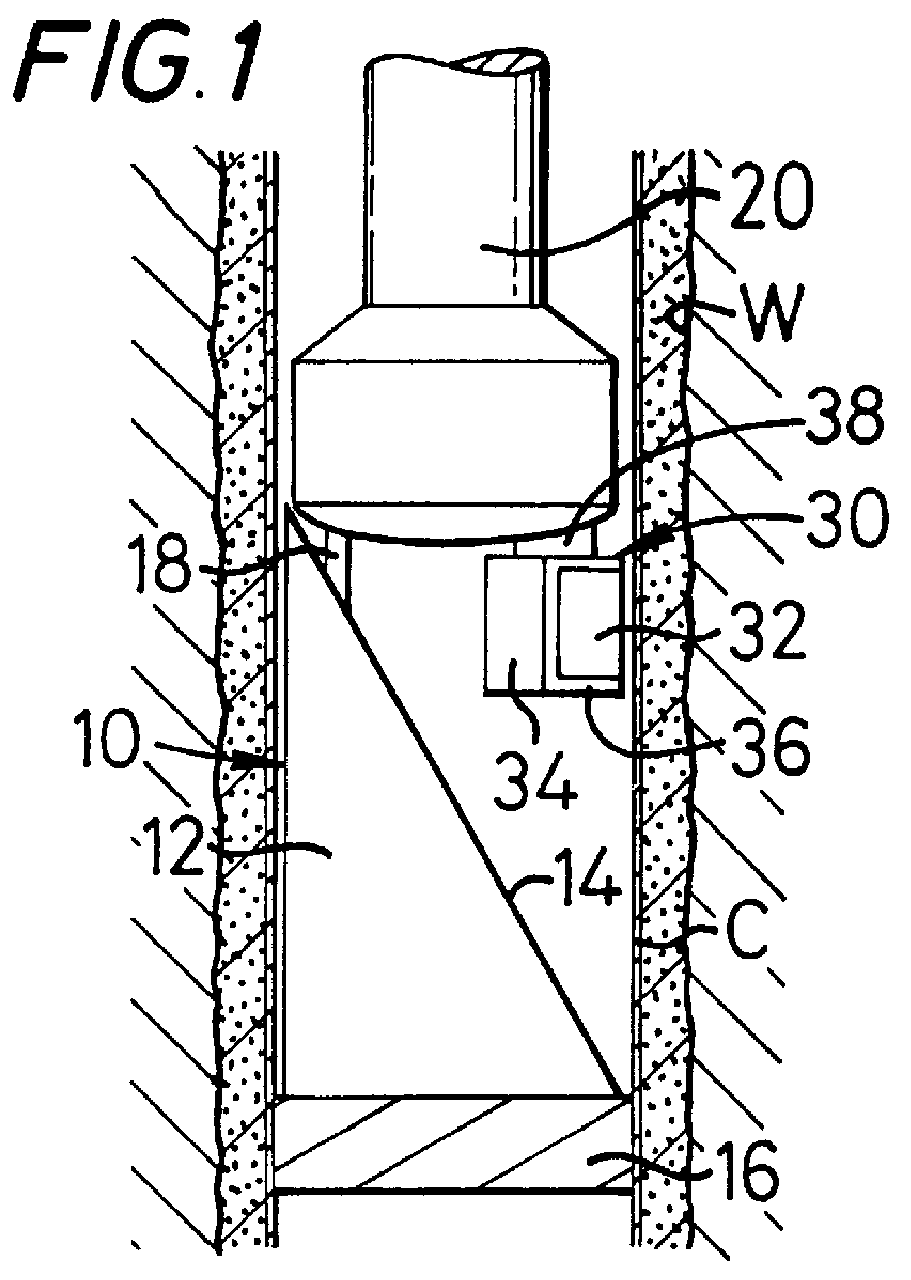

Device and methods for the treatment of wounds using ultrasound energy are disclosed. The portable wound treatment device may deliver ultrasound energy to a wound through direct contact with the ultrasound tip and / or through a liquid coupling medium. Several ultrasound tips specially designed to concentrate and focus ultrasound energy onto a wound are also disclosed. The ultrasound tip may also possess an abrasive peripheral boundary to aid in debriding the wound and / or removing necrotic tissue. The disclosed invention may have multiple beneficial effects in treating a wound such as sterilizing a wound, reducing external bleeding, and / or providing pain relief.

Owner:BACOUSTICS LLC

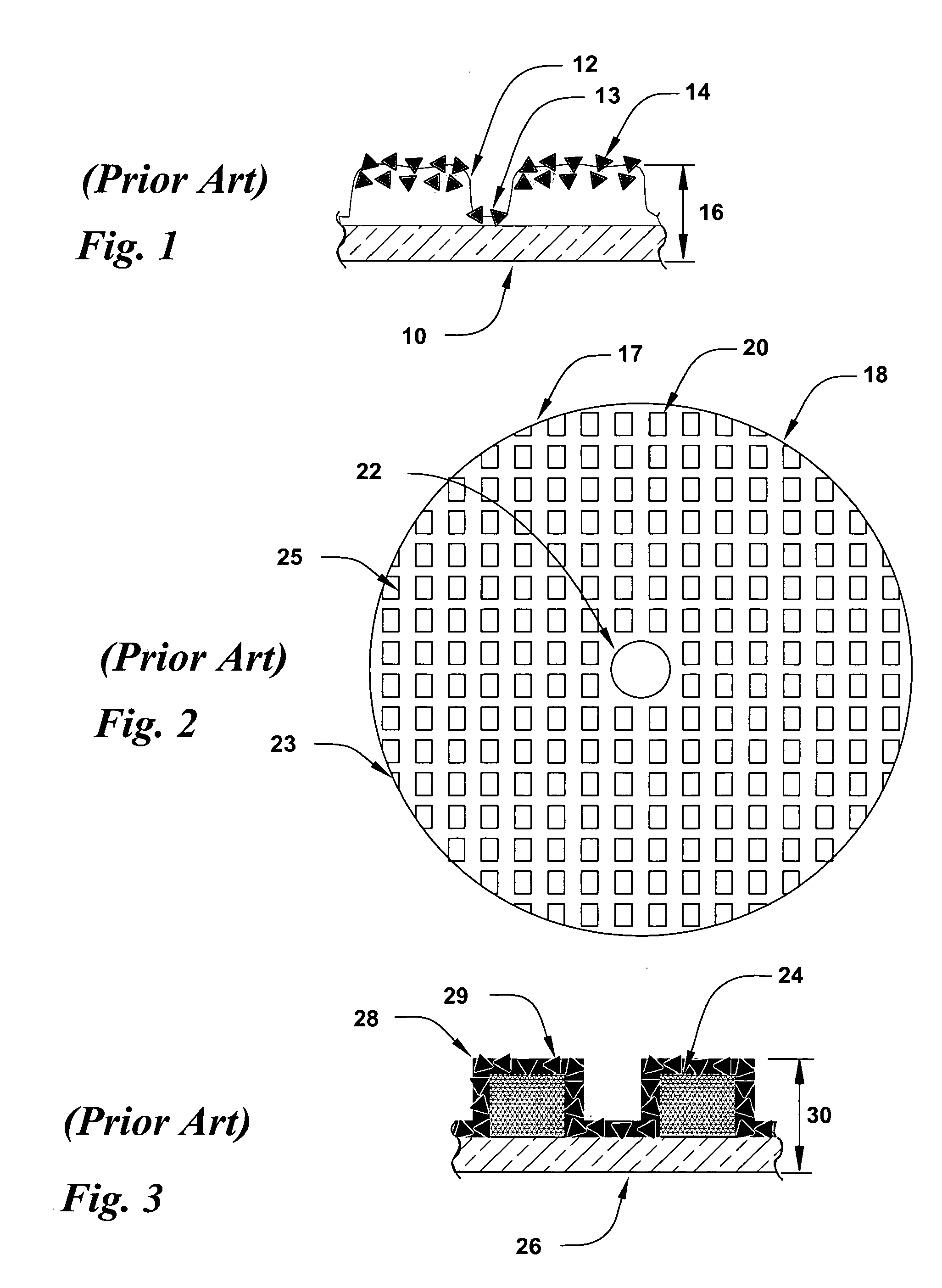

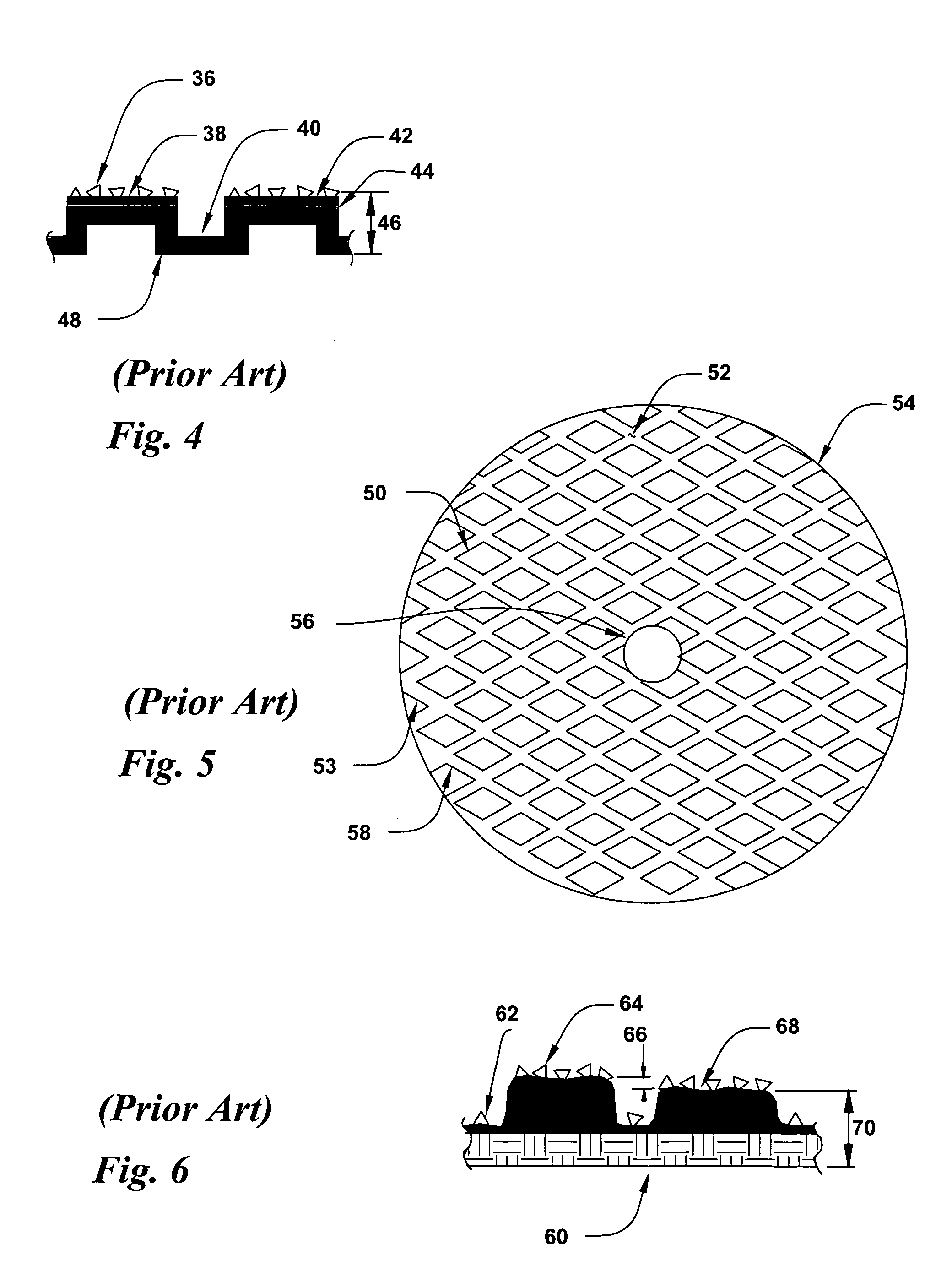

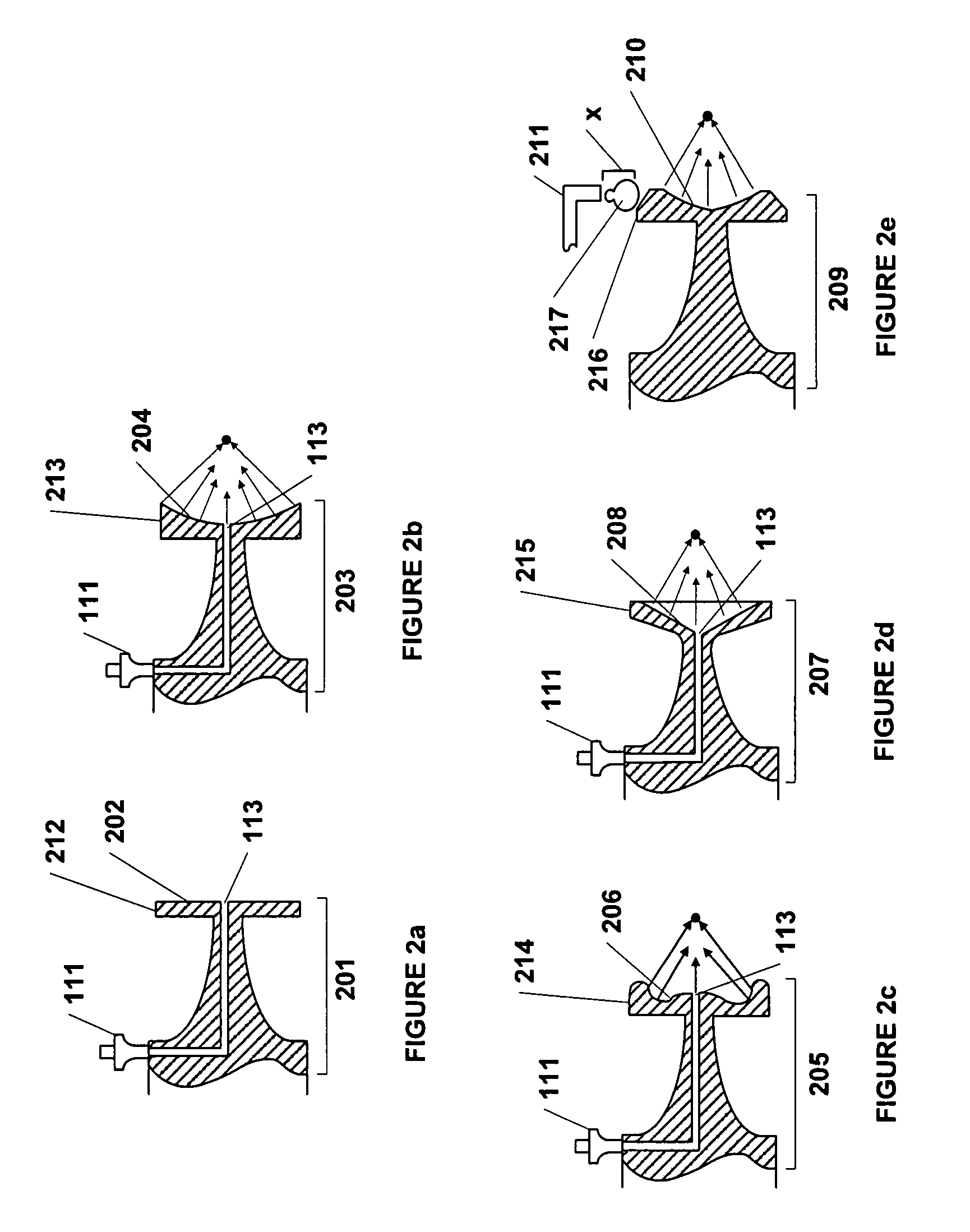

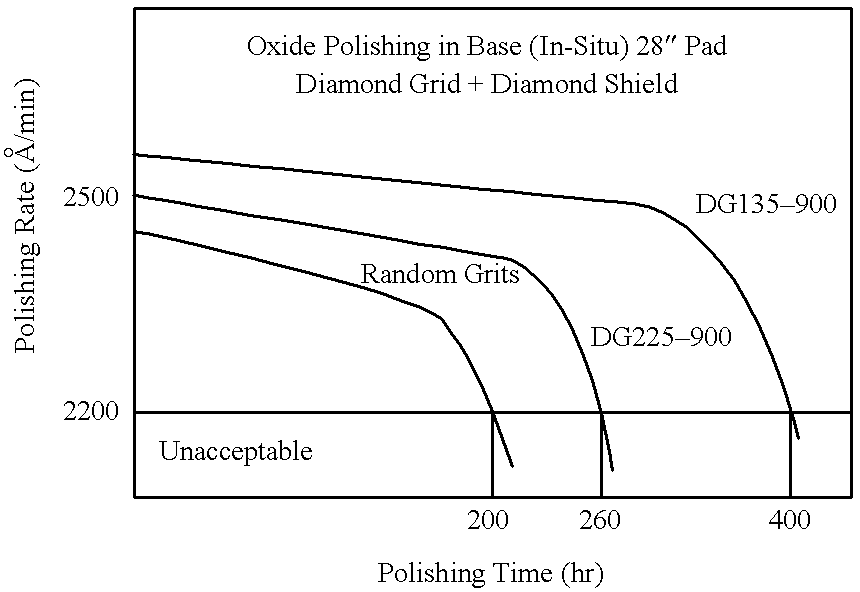

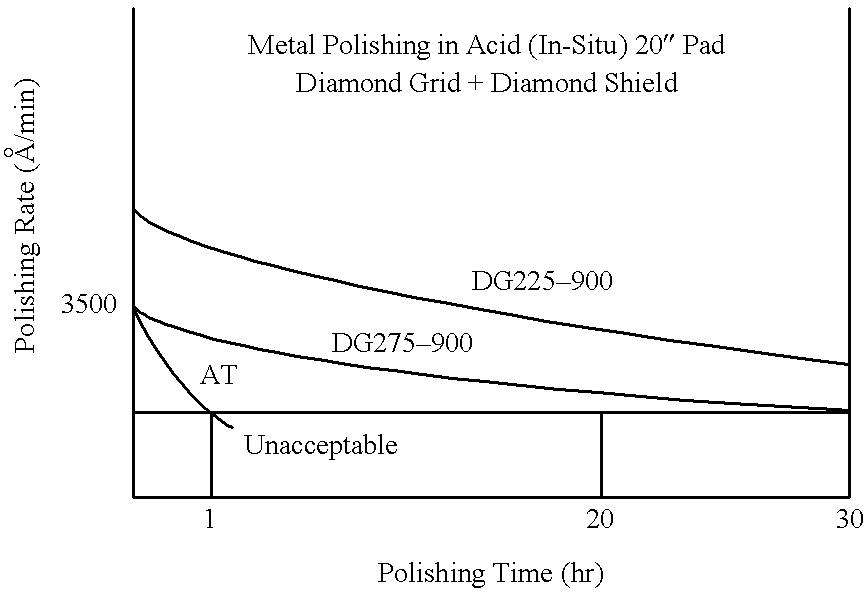

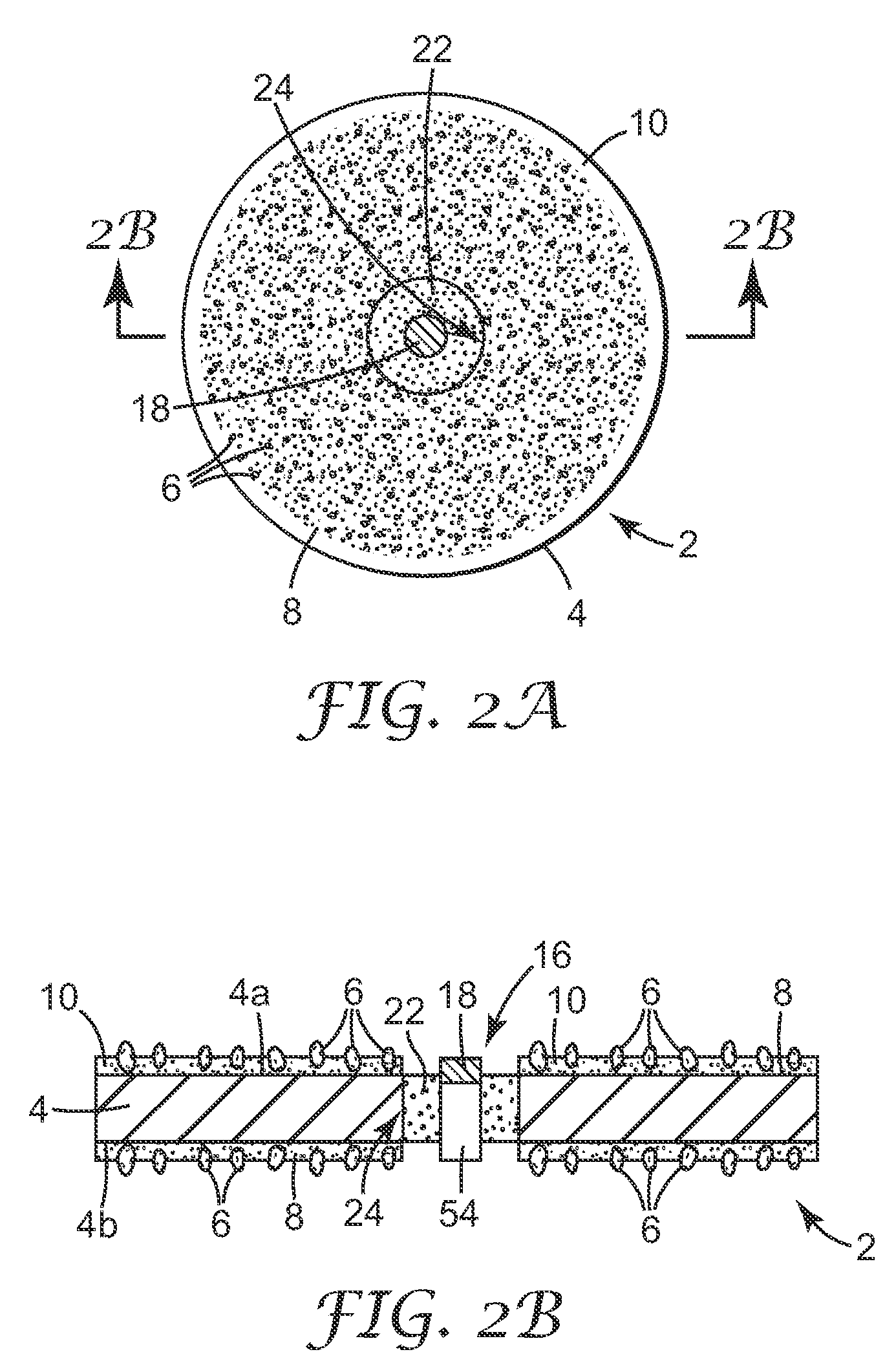

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

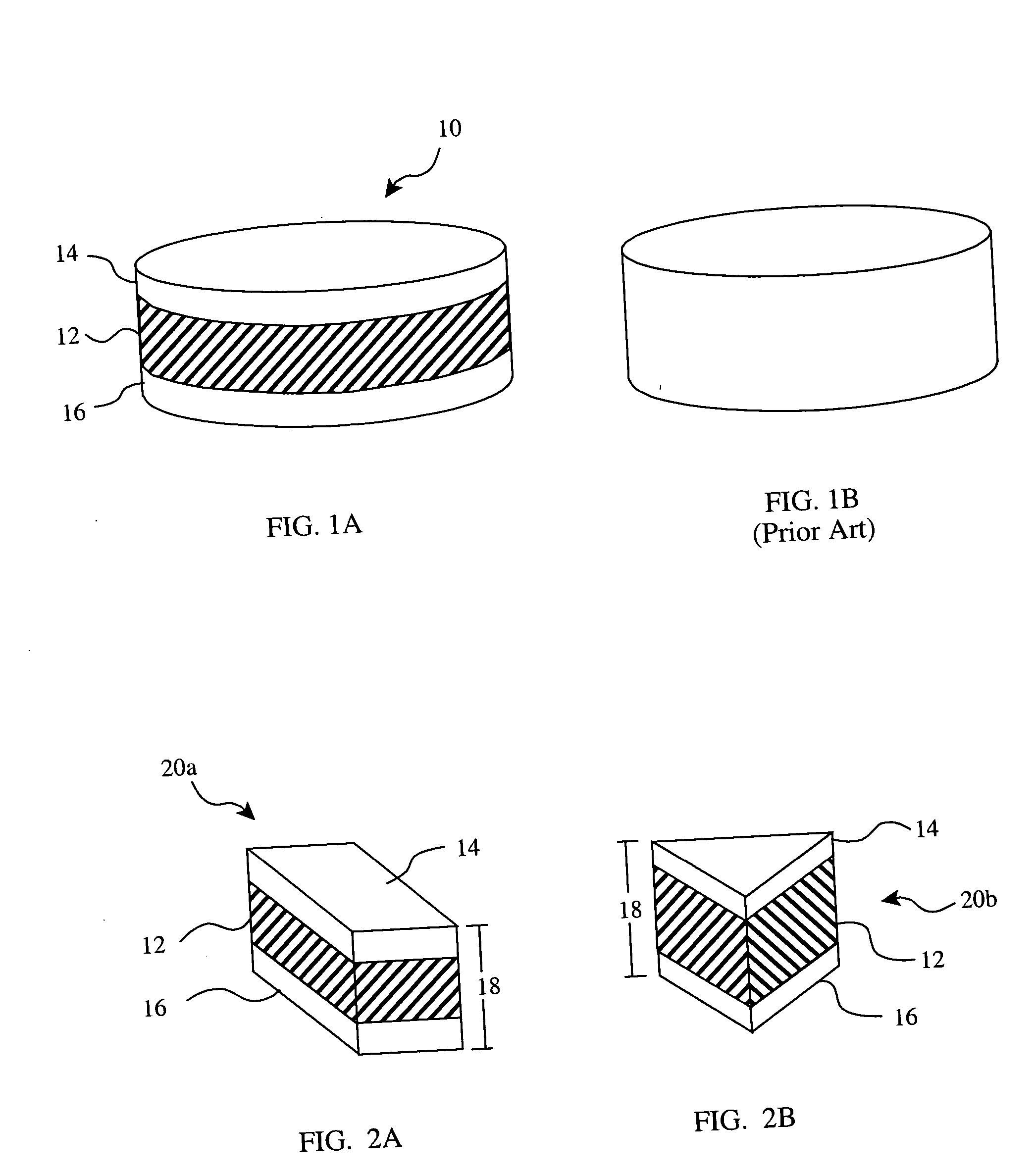

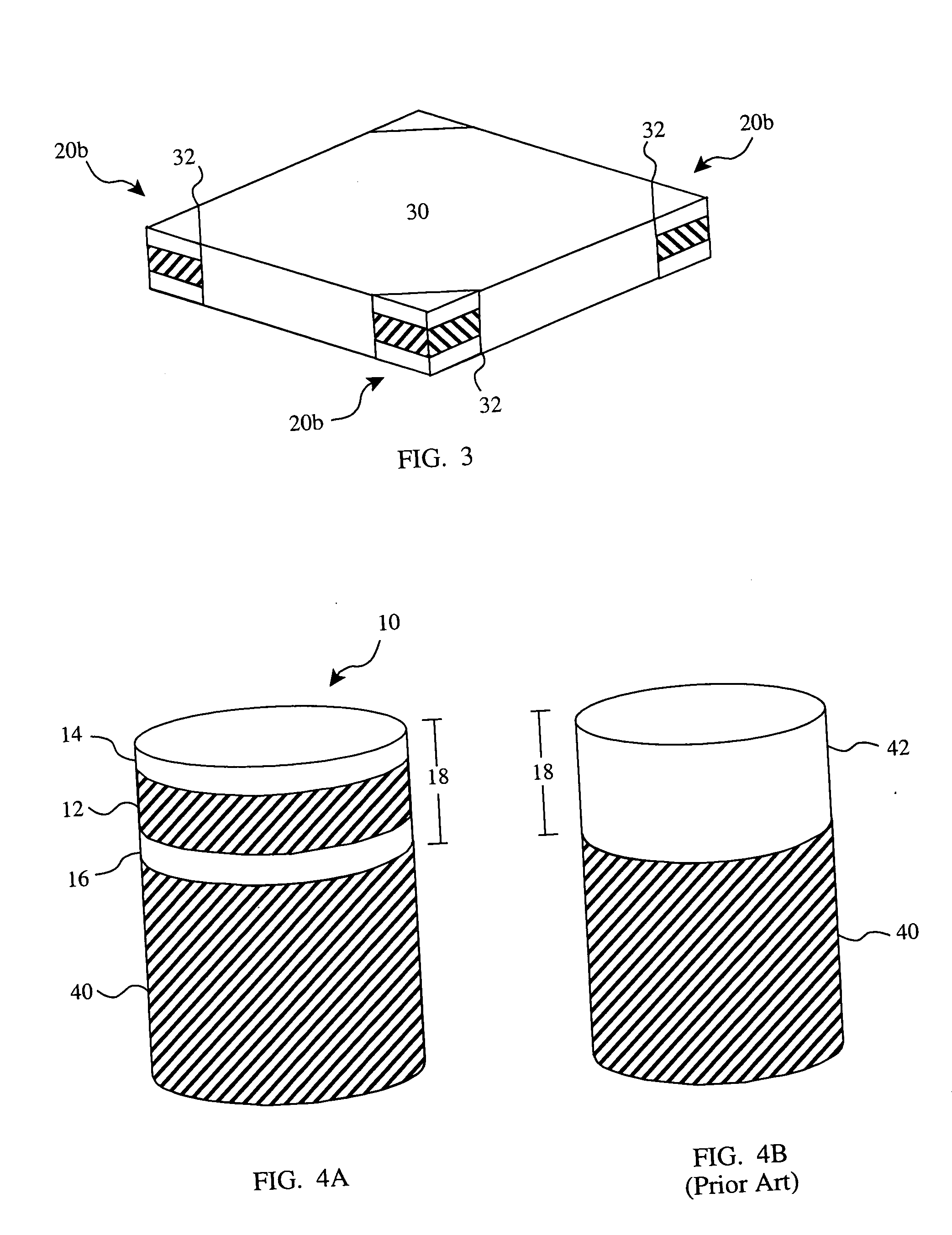

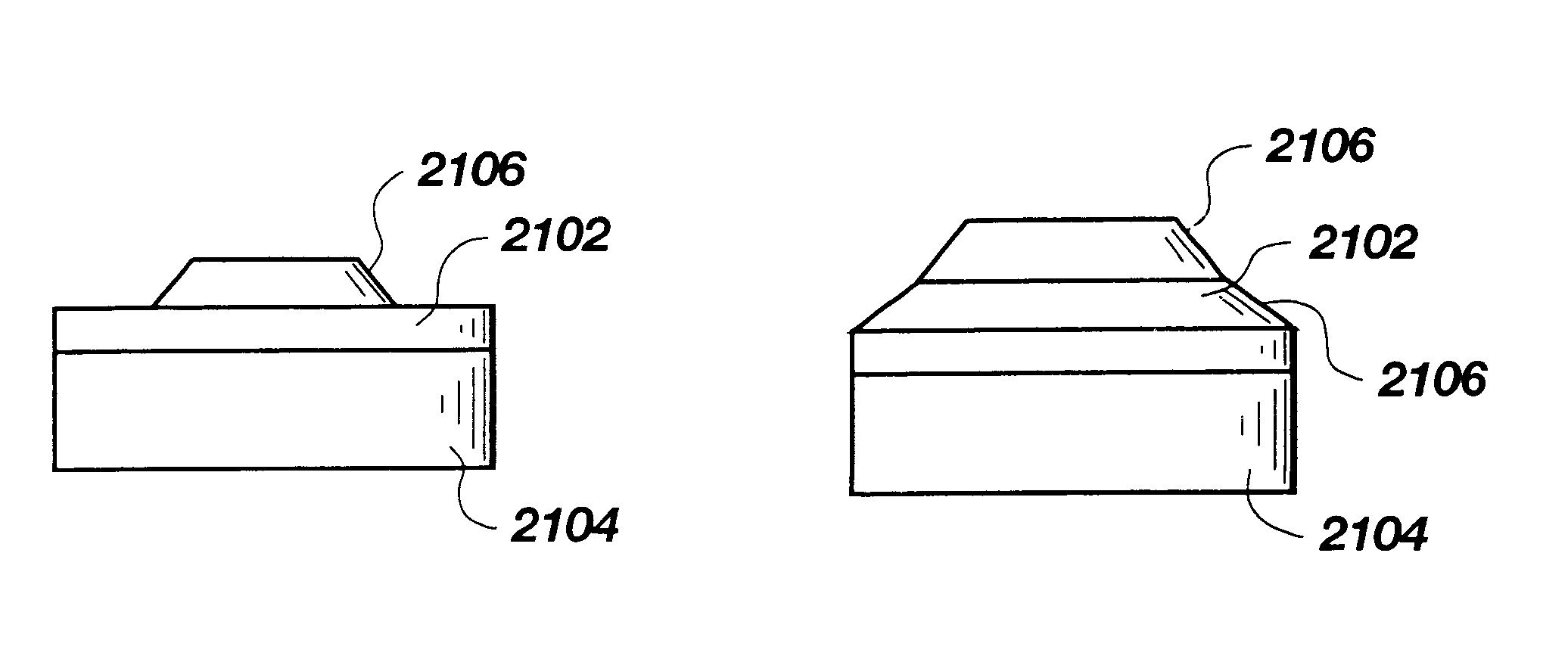

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

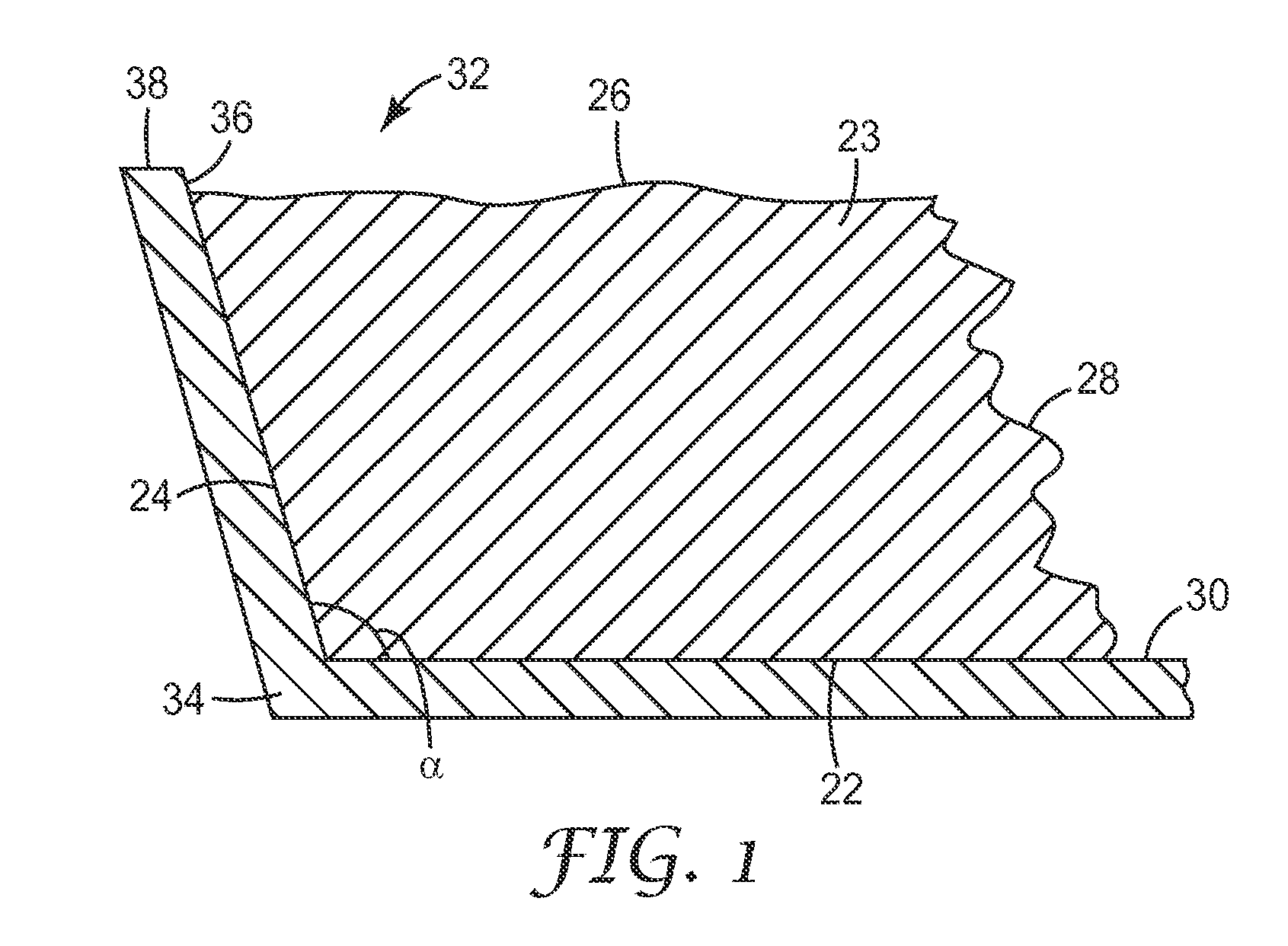

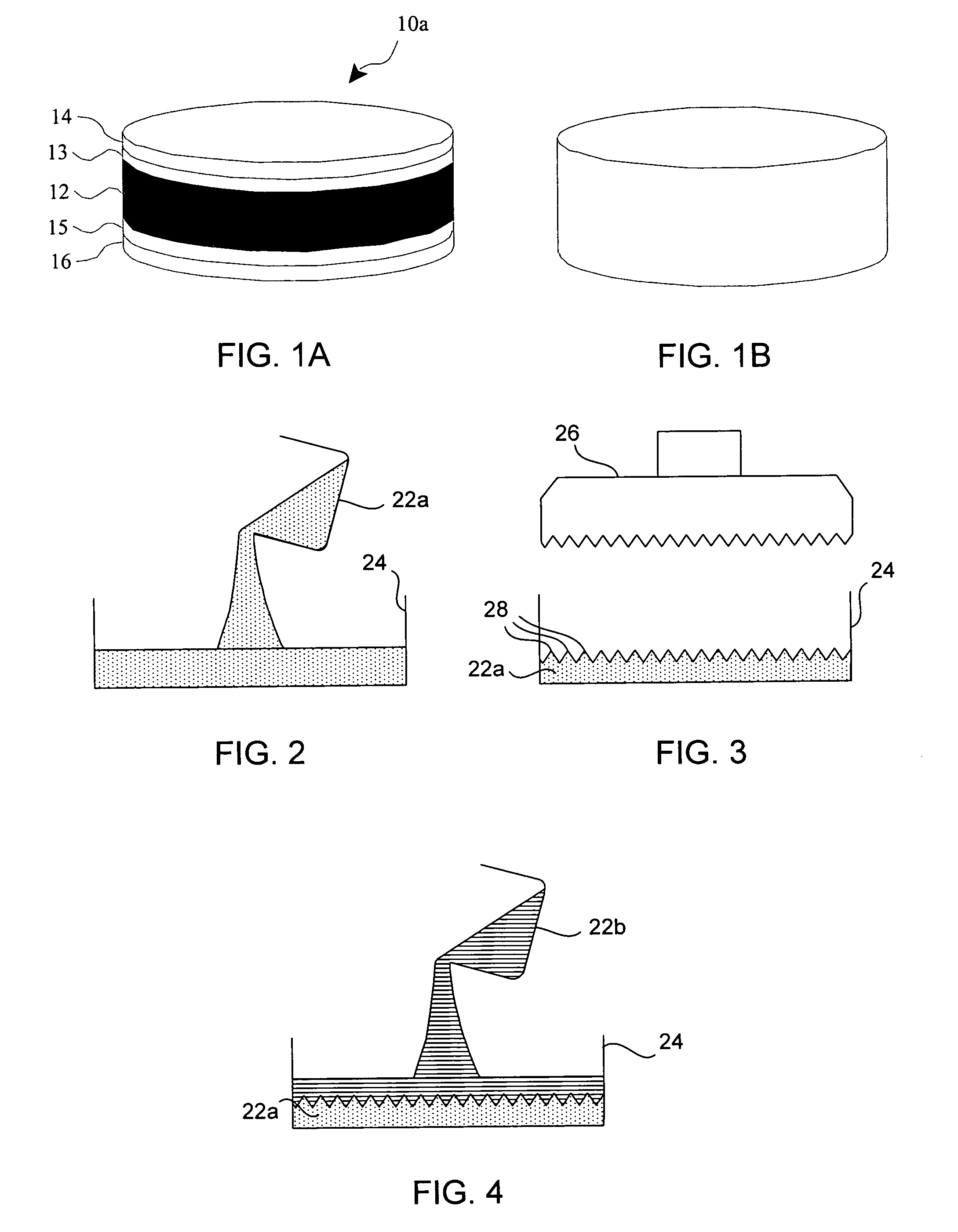

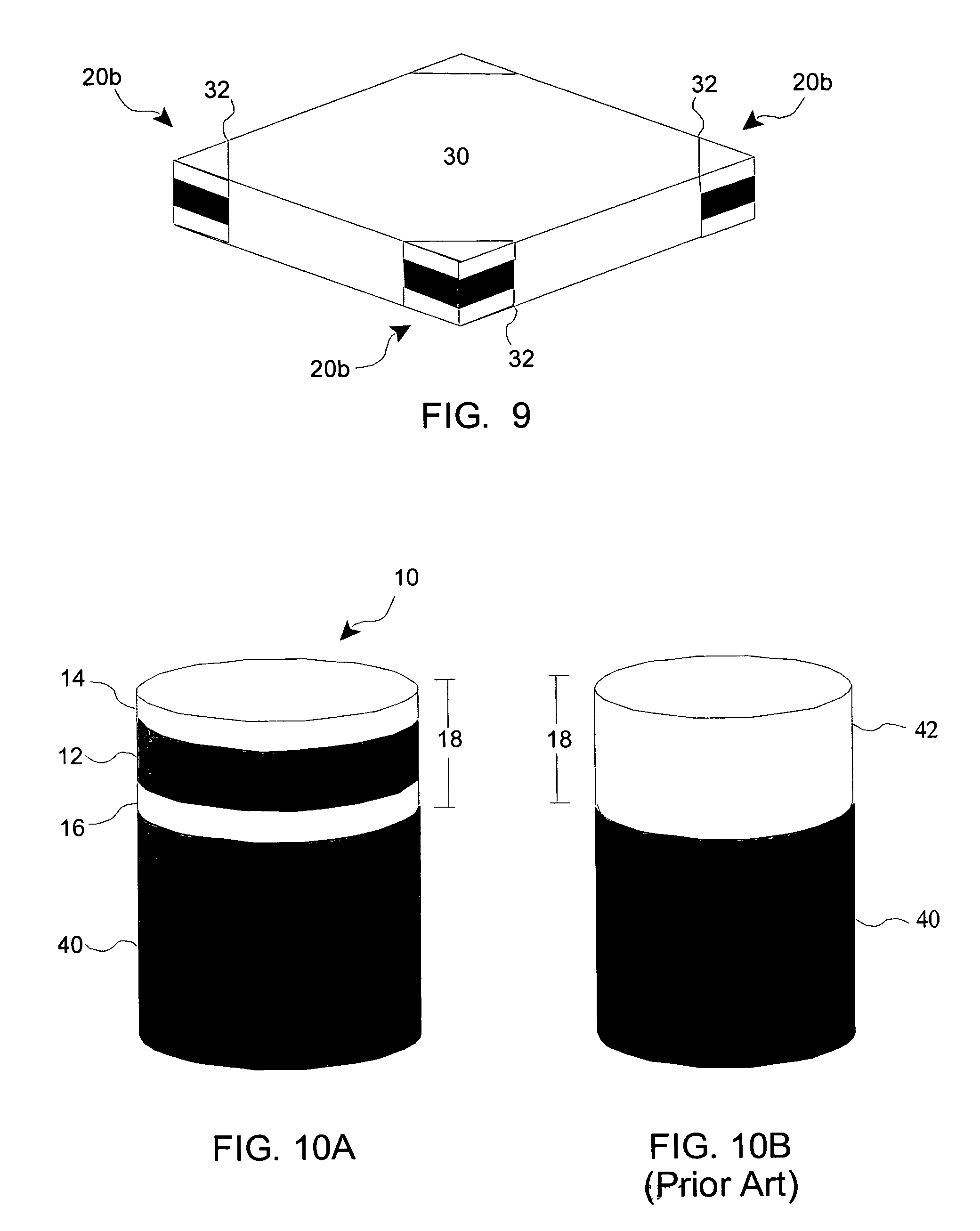

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

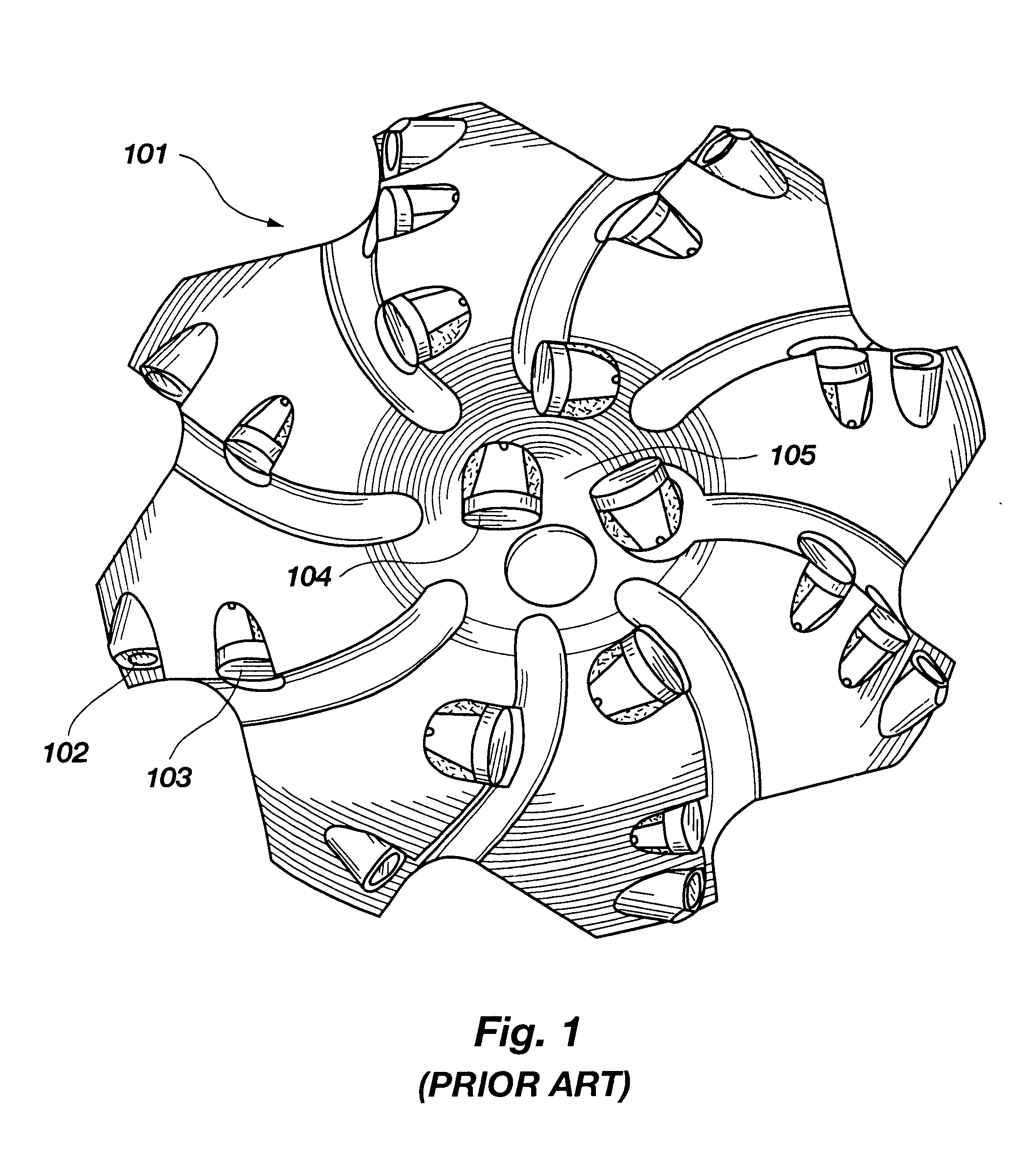

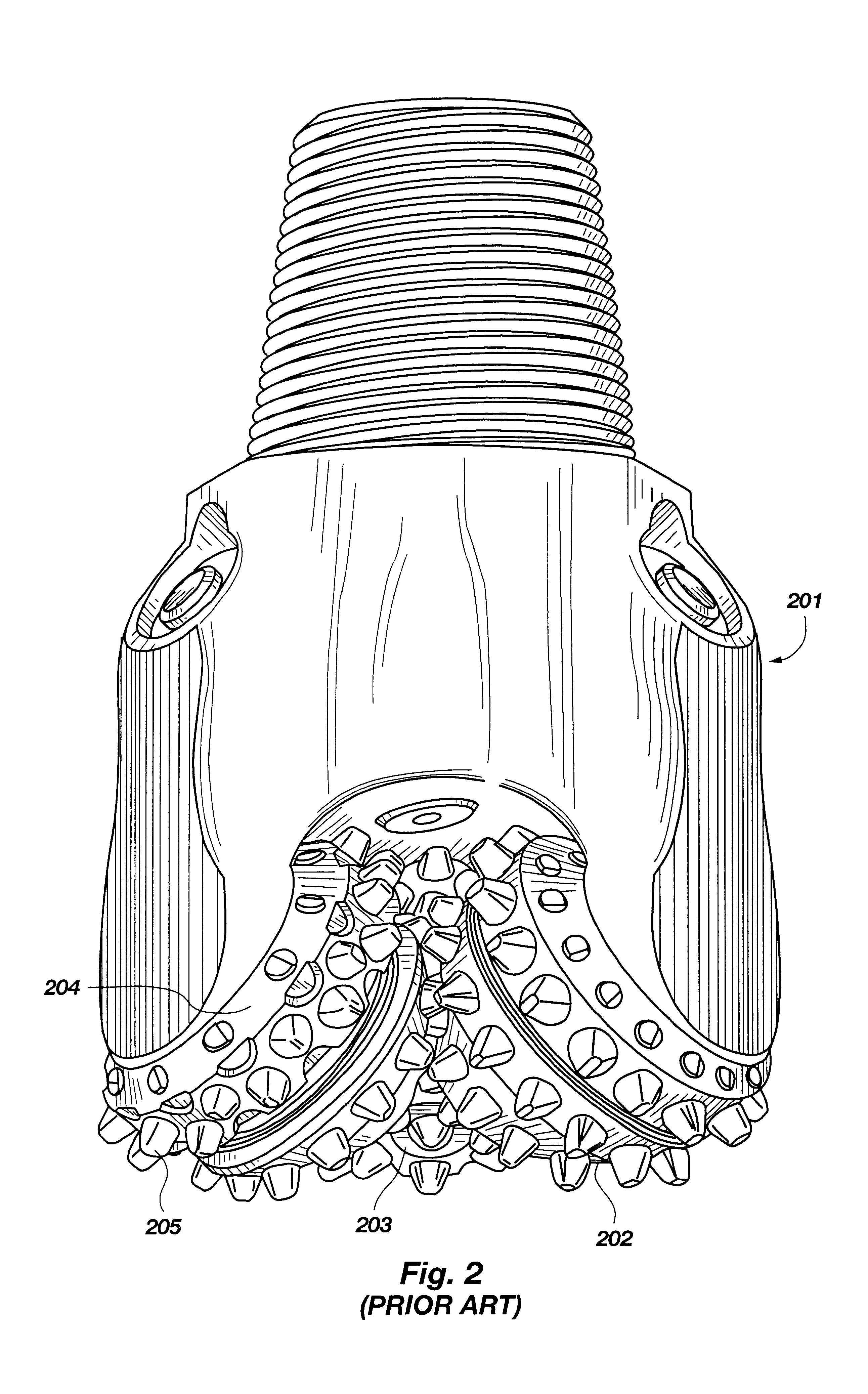

Superabrasive cutting element with enhanced durability and increased wear life and apparatus so equipped

InactiveUS6202770B1Extended service lifeReduced tendency to catastrophically spallDrill bitsConstructionsEngineeringMechanical engineering

A cutting element for use in drilling subterranean formations. The cutting element includes a superabrasive table mounted to a supporting substrate. The superabrasive table includes a two-dimensional cutting face having a cutting edge along at least a portion of its periphery, and a first surface extending forwardly and inwardly from a location radially interior of the cutting edge at a first angle of orientation with respect to the longitudinal axis of the cutting element. The cutting face also includes at least a second surface located between the first surface and the cutting edge and oriented at a different, greater angle to the longitudinal axis than the angle of orientation of the first surface.

Owner:BAKER HUGHES INC

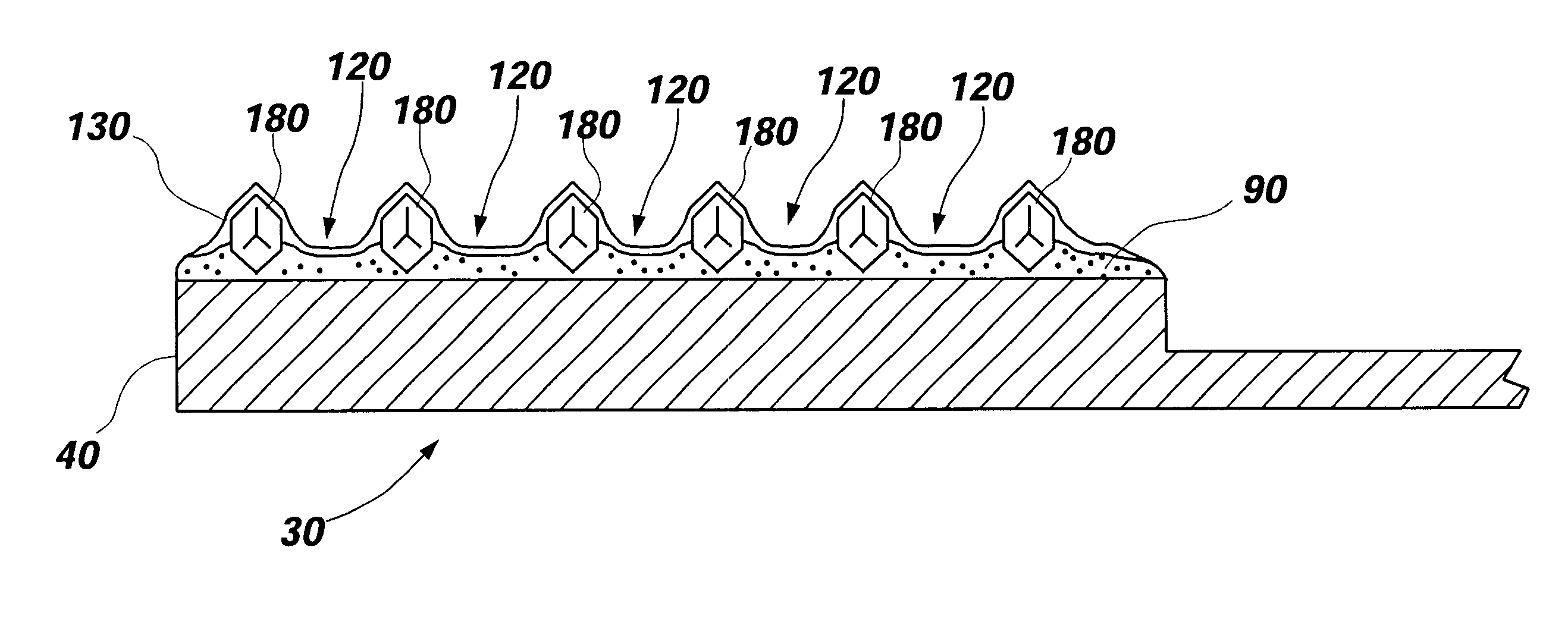

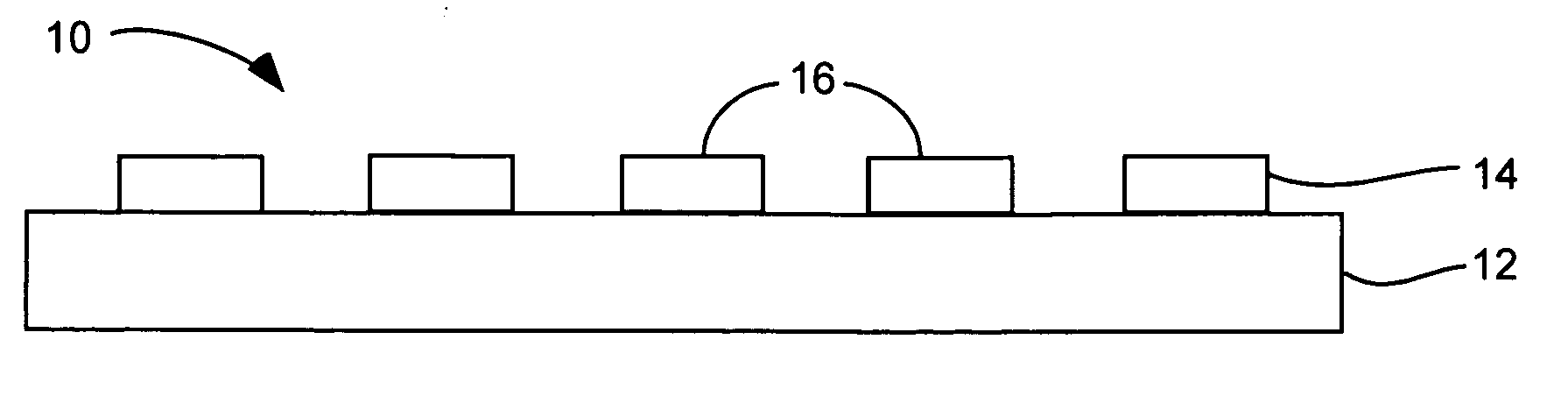

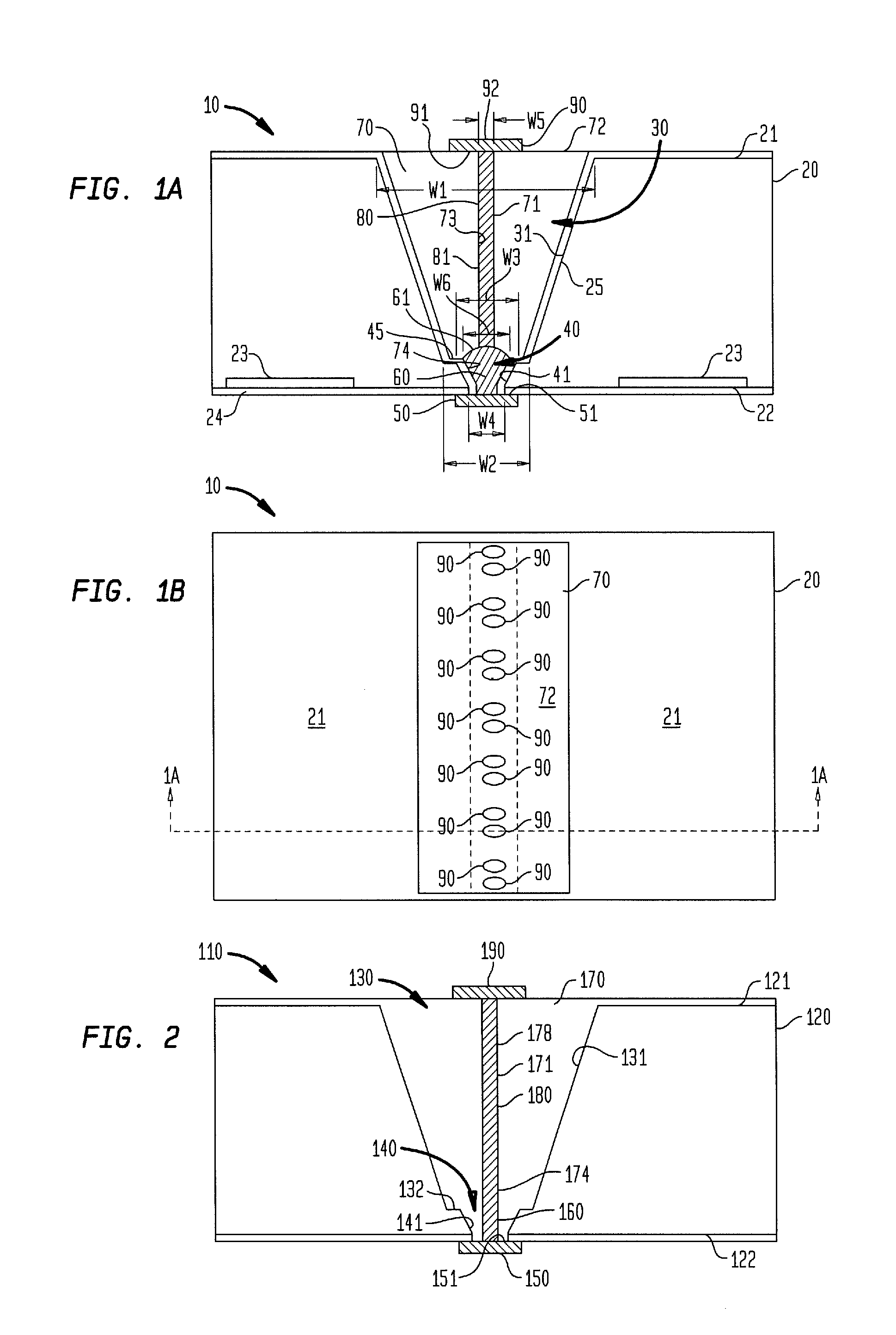

Fixed abrasive tools and associated methods

InactiveUS20050227590A1Easy to remove debrisAdequate material removal rateAbrasion apparatusPlane surface grinding machinesScreen printingMostly True

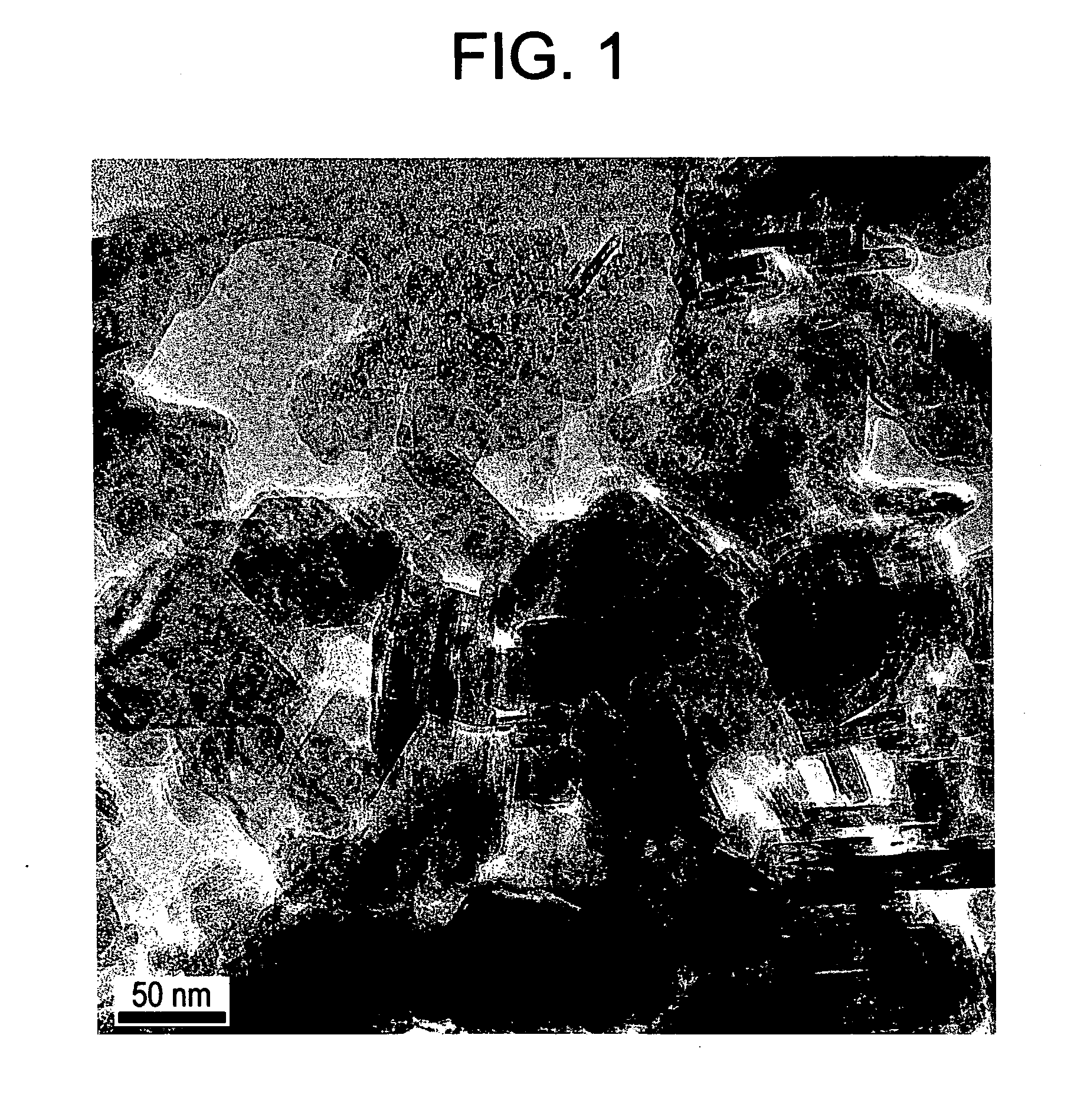

A fixed abrasive tool incorporating nanodiamond particles is described and disclosed. A fixed abrasive tool can include a polishing layer on a substrate. The polishing layer can include an organic matrix with nanodiamond particles therein. The polishing layer can be formed in a wide variety of configurations, depending on the specific polishing application. Most often, the polishing layer can include a plurality of projections which can have a wide variety of configurations in order to achieve a particular polishing performance. Nanodiamond particles used in the present invention can have a particle size from about 1 nm to about 50 nm, and preferably about 2 nm to about 10 nm. Optionally, the nanodiamond particles can include a carbonaceous coating. Such fixed abrasive tools can be formed by screen printing of a slurry of nanodiamond particles and an organic binder to form a predetermined three-dimensional pattern. Other methods can also be used to form the disclosed nanodiamond fixed abrasive tools. These fixed abrasive tools are particularly suitable for polishing expensive workpieces such as silicon wafers, integrated circuitry, gemstones, and hard drive platters.

Owner:SUNG CHIEN MIN

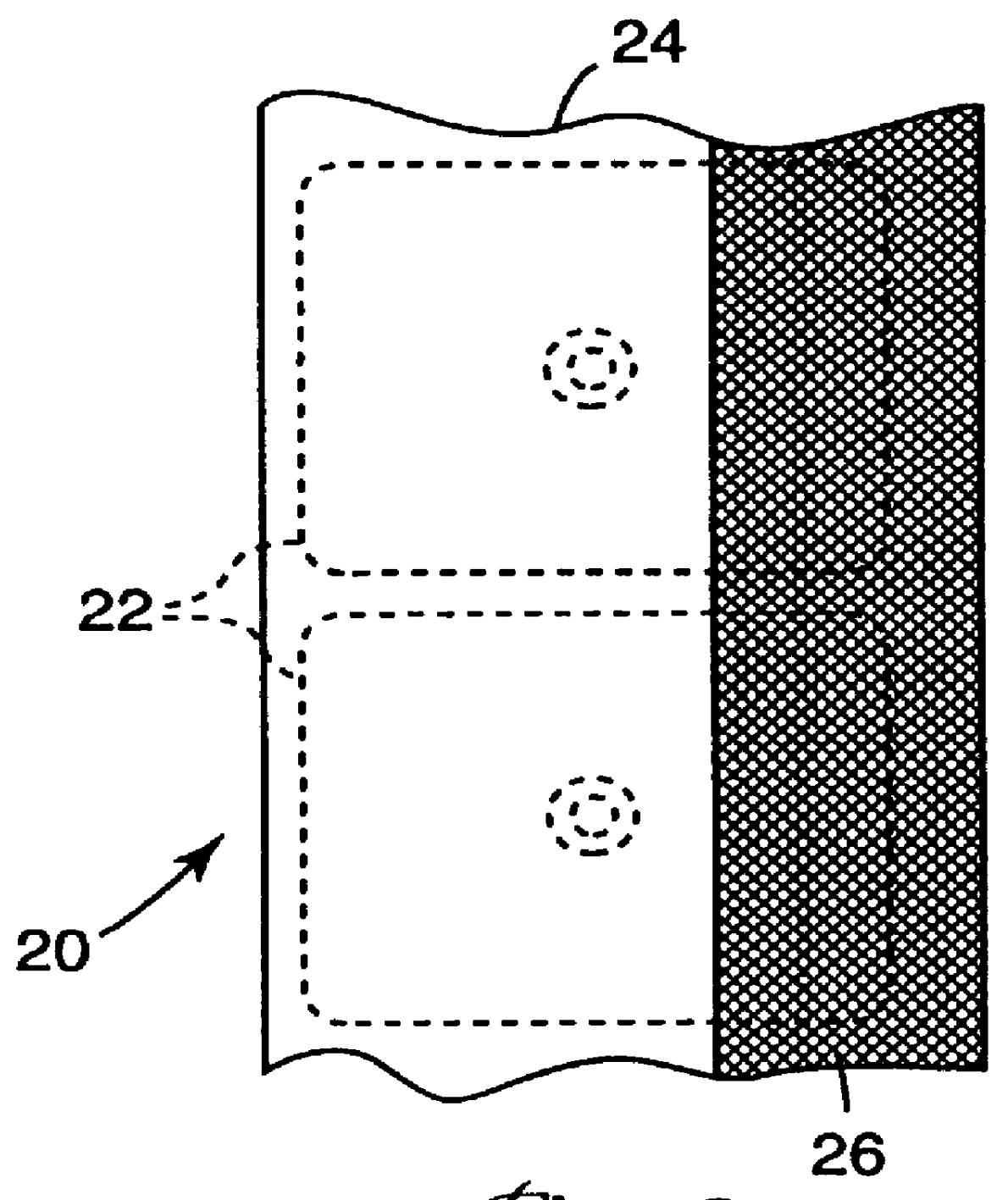

Abrasive product and method of making the same

InactiveUS6613113B2Effectively removing the sanding dust from the abrasive surfaceLess abrasive surfacePigmenting treatmentOther chemical processesElastomerMaterials science

The invention provides a flexible abrasive product comprising a flexible sheet-like substrate comprising a multiplicity of separated resilient bodies connected to each other in a generally planar array in a pattern which provides open spaces between adjacent connected bodies, each body having a first surface and an opposite second surface; and abrasive particles to cause at least the first surface to be an abrasive surface. A method of making the abrasive is provided by providing the substrate and providing abrasive particles to at least the first surface to provide an abrasive surface.

Owner:3M INNOVATIVE PROPERTIES CO

Planarization composition

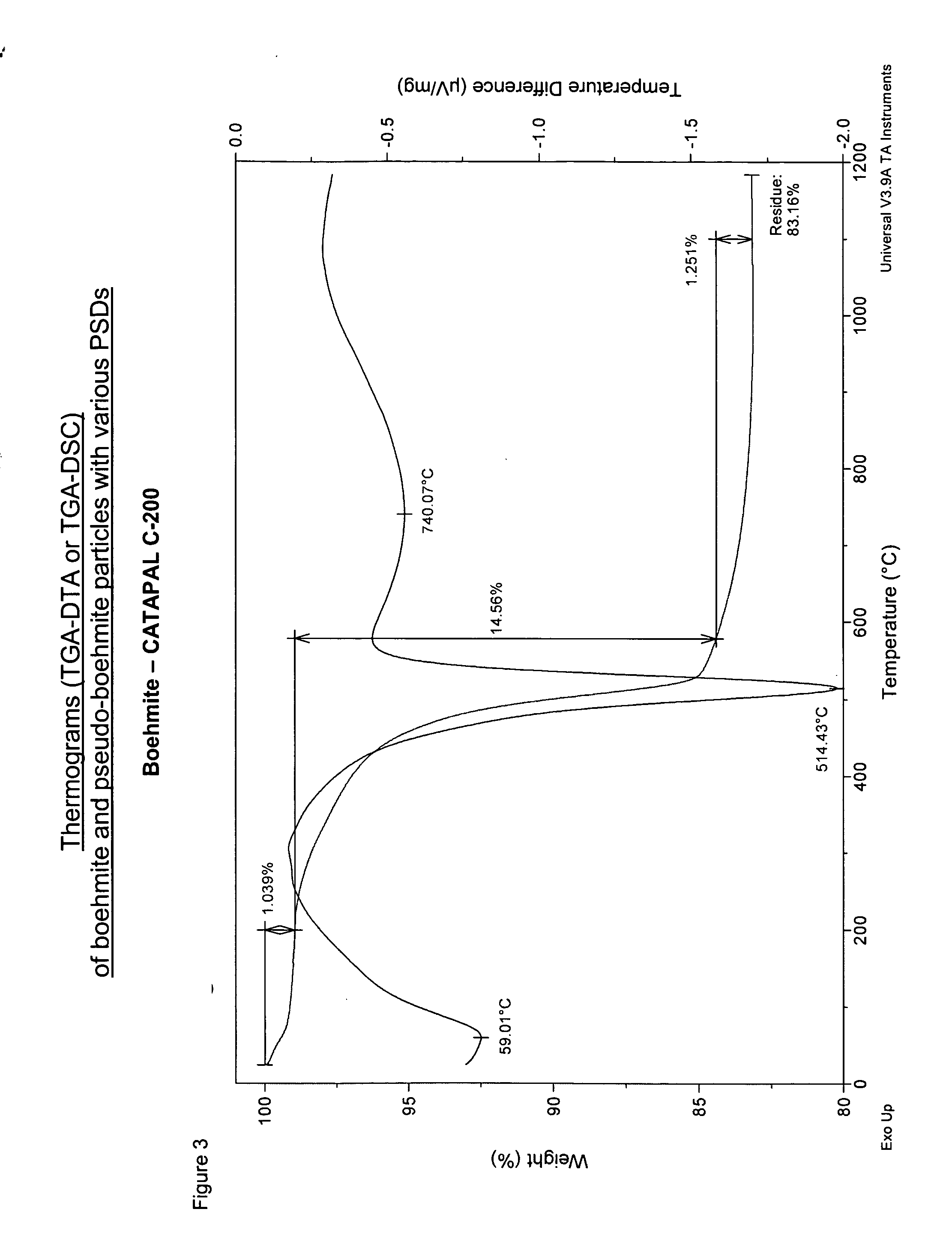

The present invention provides CMP abrasive slurry that is substantially free of aluminum oxide and comprises liquid and solids wherein the solids comprises: (a) in an amount of at least about 90 weight percent based on the solids, at least one non-spherical component having formula Al2O3.xH2O where x ranges from 1 to 3; and (b) up to about one weight percent based on the solids portion of submicron alpha-alumina. The CMP abrasive slurry may be used to polish metallic or dielectric surfaces in computer wafers.

Owner:BASF AG +1

Flexible abrasive product and method of making and using the same

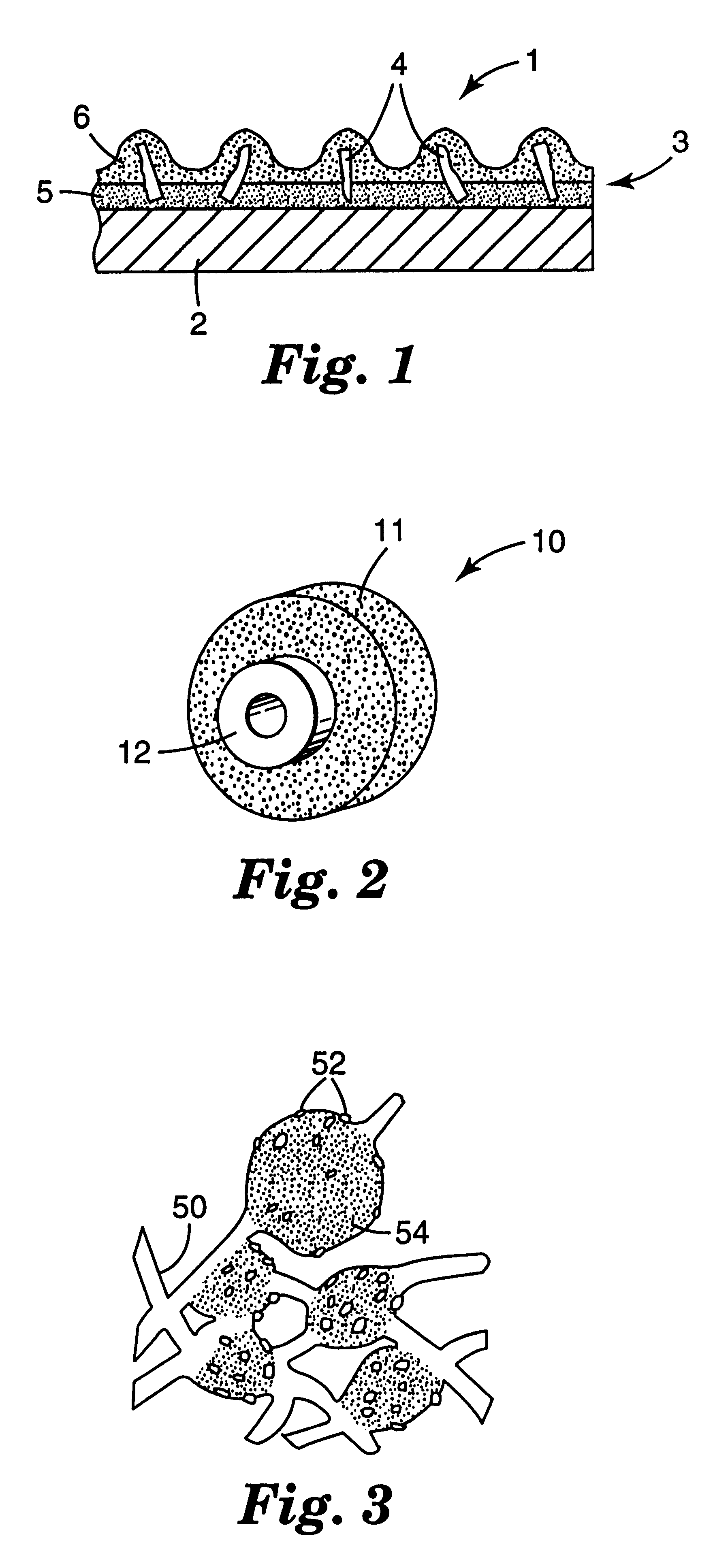

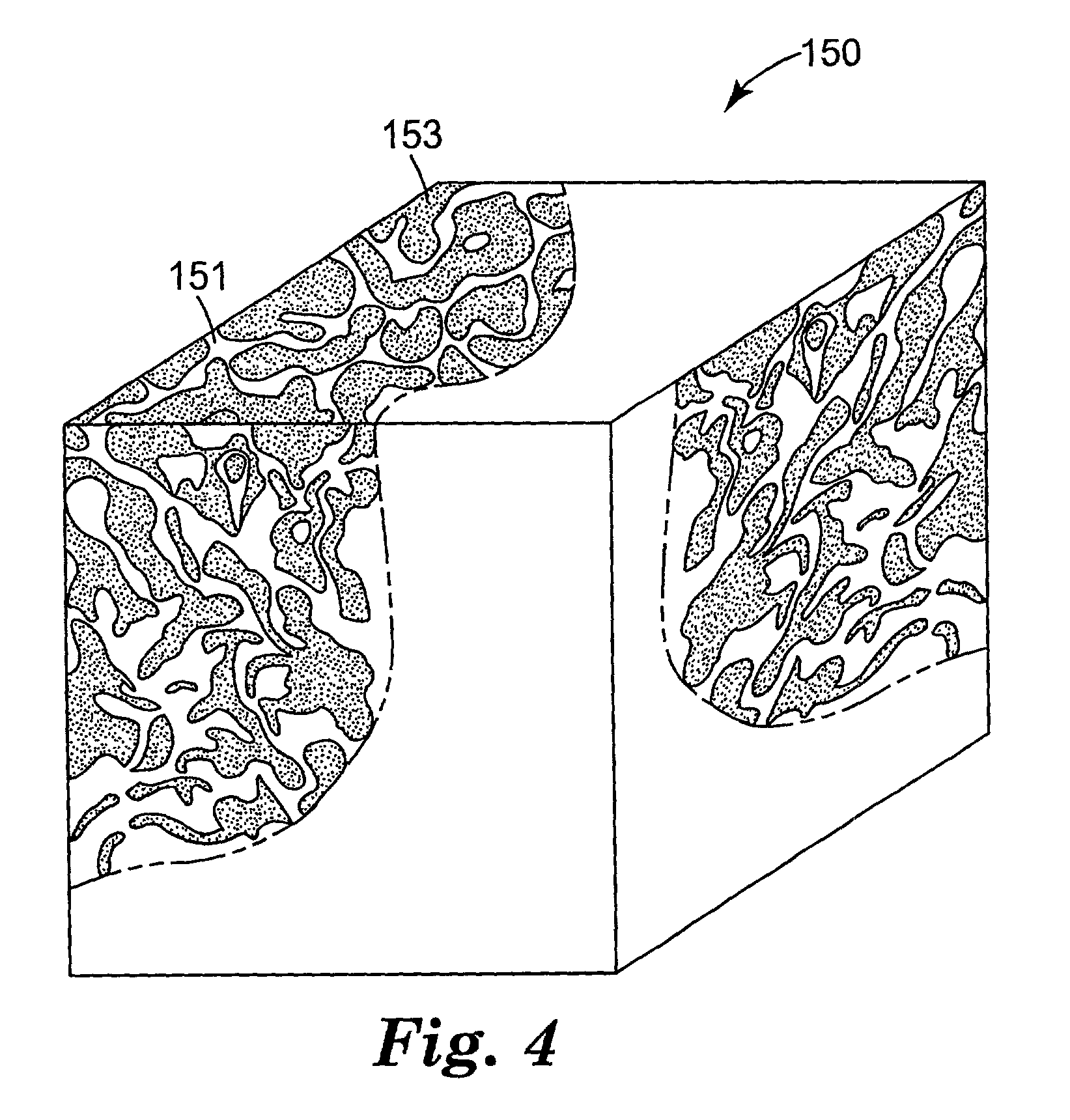

InactiveUS20050020190A1Provide dimensional stabilityFlexible-parts wheelsPlane surface grinding machinesOpen cellCoating

The present invention provides a flexible abrasive product comprised of an open cell foam backing, a foraminous barrier coating and a shaped foraminous abrasive coating. The flexible abrasive article of the invention is made by applying a curable barrier coating over an open cell foam backing, curing the curable barrier coating to provide a foraminous barrier coating having openings therethrough corresponding to openings in the open cell foam, applying a coating composition comprising a curable binder and abrasive particles over the foraminous barrier coating, imparting a textured surface to the coating composition with a production tool which has a textured surface which is the inverse of the textured surface of the abrasive coating and to which production tool textured surface any coating composition coated over an opening of the first major surface may adhere, at least partially curing the binder, and separating the production tool from the textured surface to provide the shaped foraminous abrasive coating.

Owner:3M INNOVATIVE PROPERTIES CO

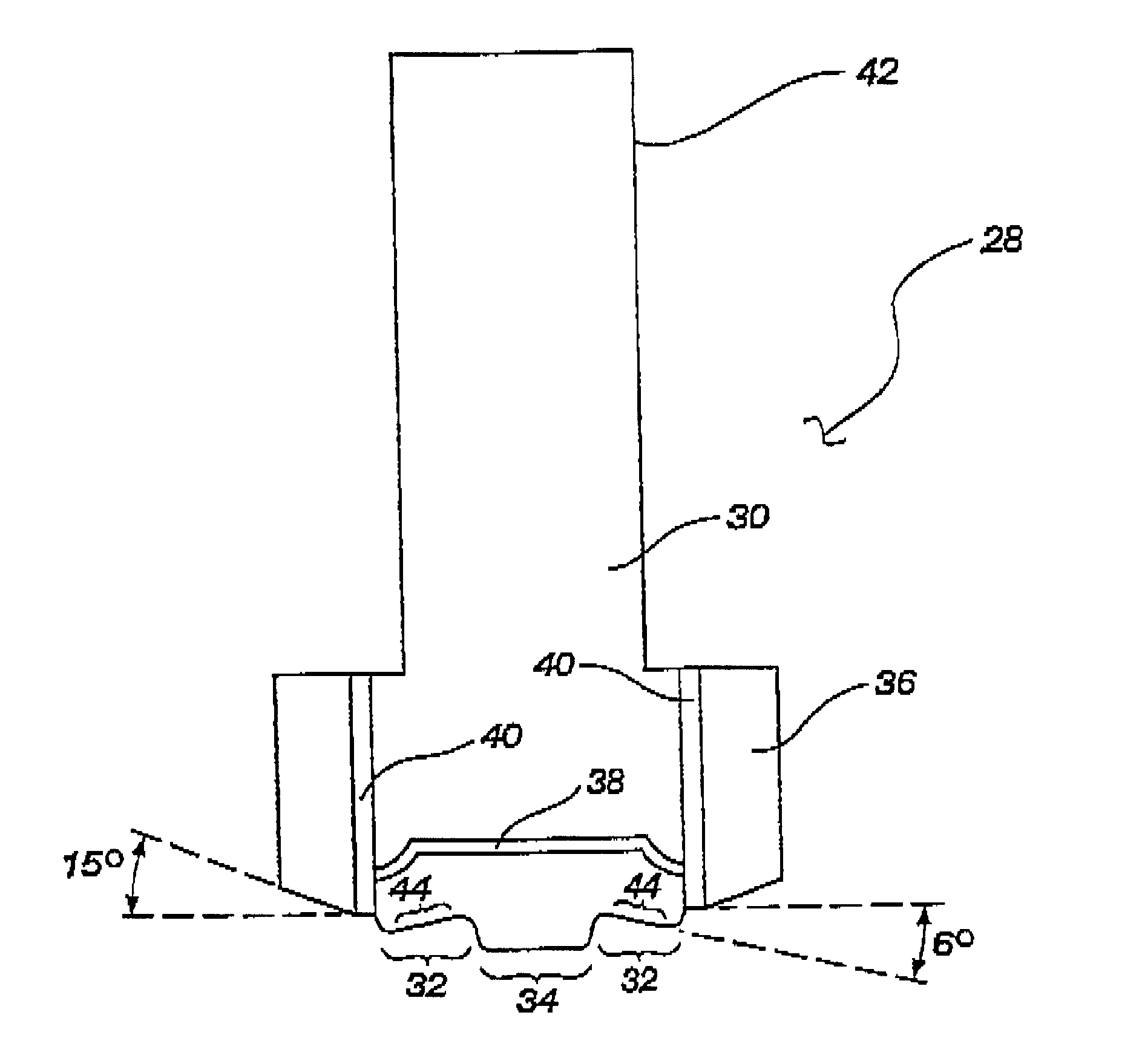

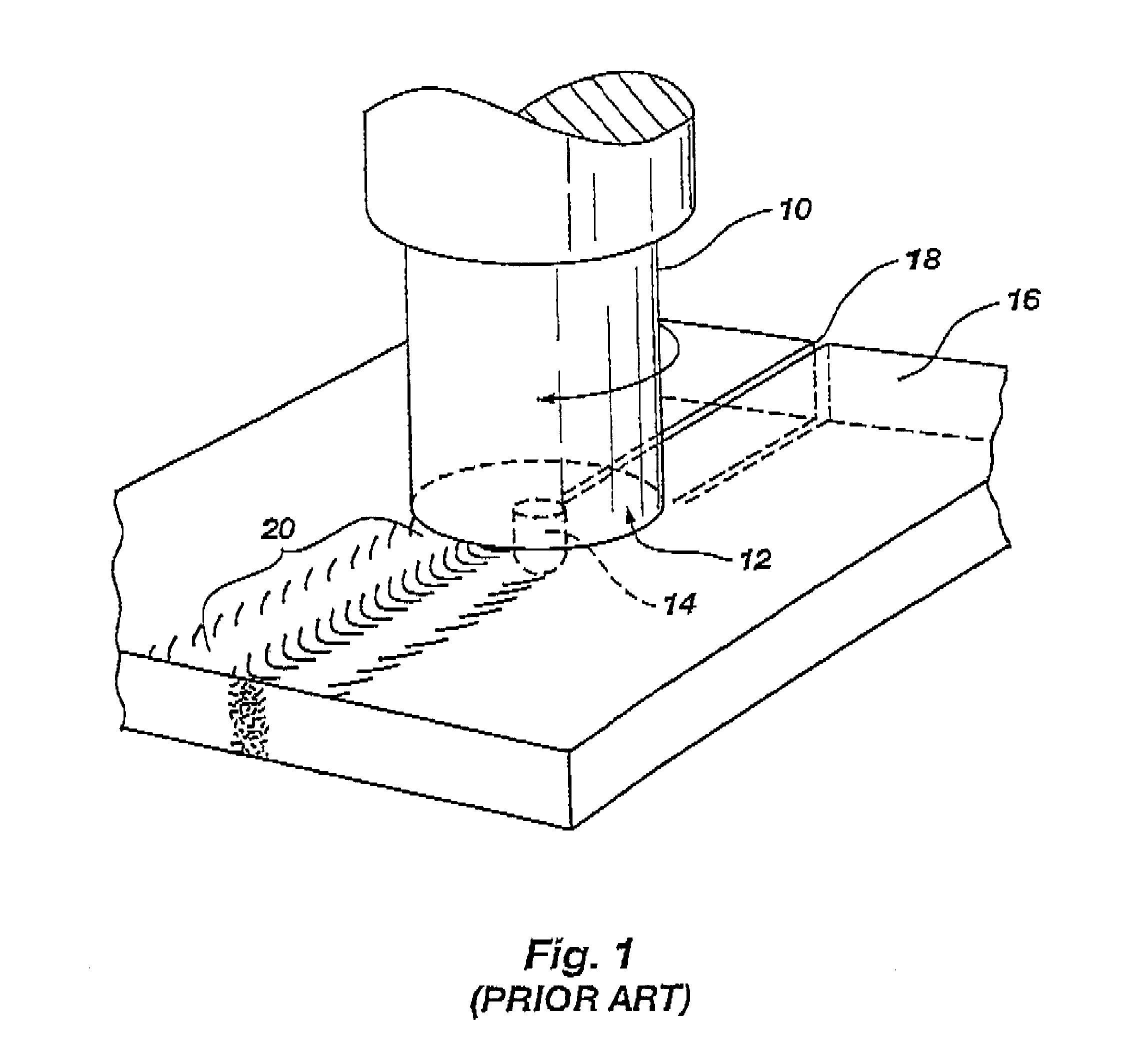

Friction stir welding using a superabrasive tool

InactiveUS6648206B2Improve wear characteristicsReduced tool wearWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowEngineering

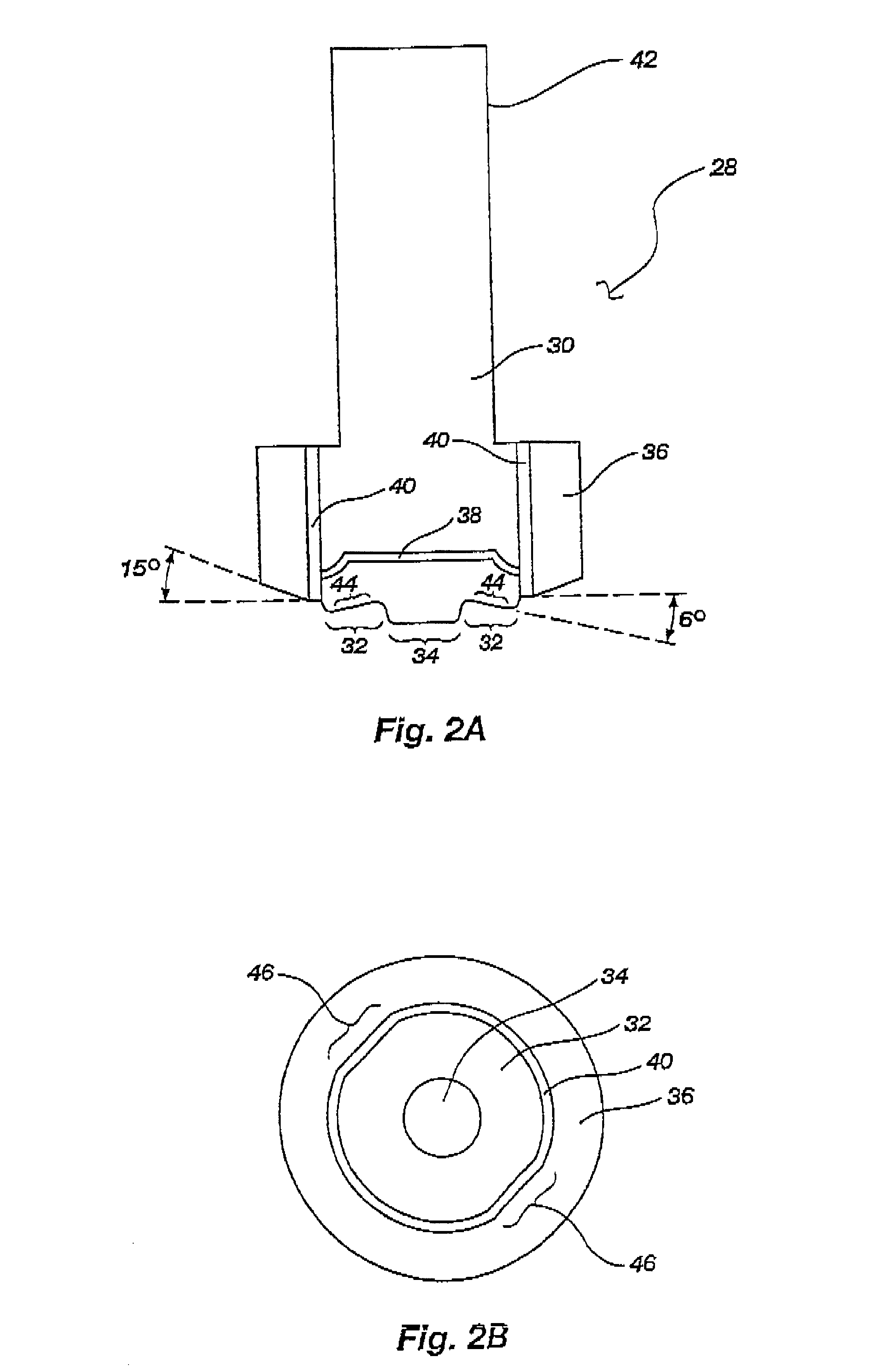

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:BRIGHAM YOUNG UNIV +1

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

Methods of forming semiconductor elements using micro-abrasive particle stream

ActiveUS20120018893A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

A method of fabricating a microelectronic unit includes providing a semiconductor element having a front surface and a rear surface remote from the front surface, forming at least one first opening extending from the rear surface partially through the semiconductor element towards the front surface by directing a jet of fine abrasive particles towards the semiconductor element, and forming at least one conductive contact and at least one conductive interconnect coupled thereto. The semiconductor element can include a plurality of active semiconductor devices therein. The semiconductor element can include a plurality of conductive pads exposed at the front surface. Each conductive interconnect can extend within one or more of the first openings and can be coupled directly or indirectly to at least one of the conductive pads. Each of the conductive contacts can be exposed at the rear surface of the semiconductor element for electrical connection to an external device.

Owner:TESSERA INC

Coated abrasive articles and method of abrading

A curable composition comprises epoxy resin preparable by reaction of epichlorohydrin with at least one of bisphenol A or bisphenol F, polyfunctional (meth)acrylate, dicyandiamide and photoinitiator. The curable composition is useful for preparing treated backings and coated abrasive articles.

Owner:3M INNOVATIVE PROPERTIES CO

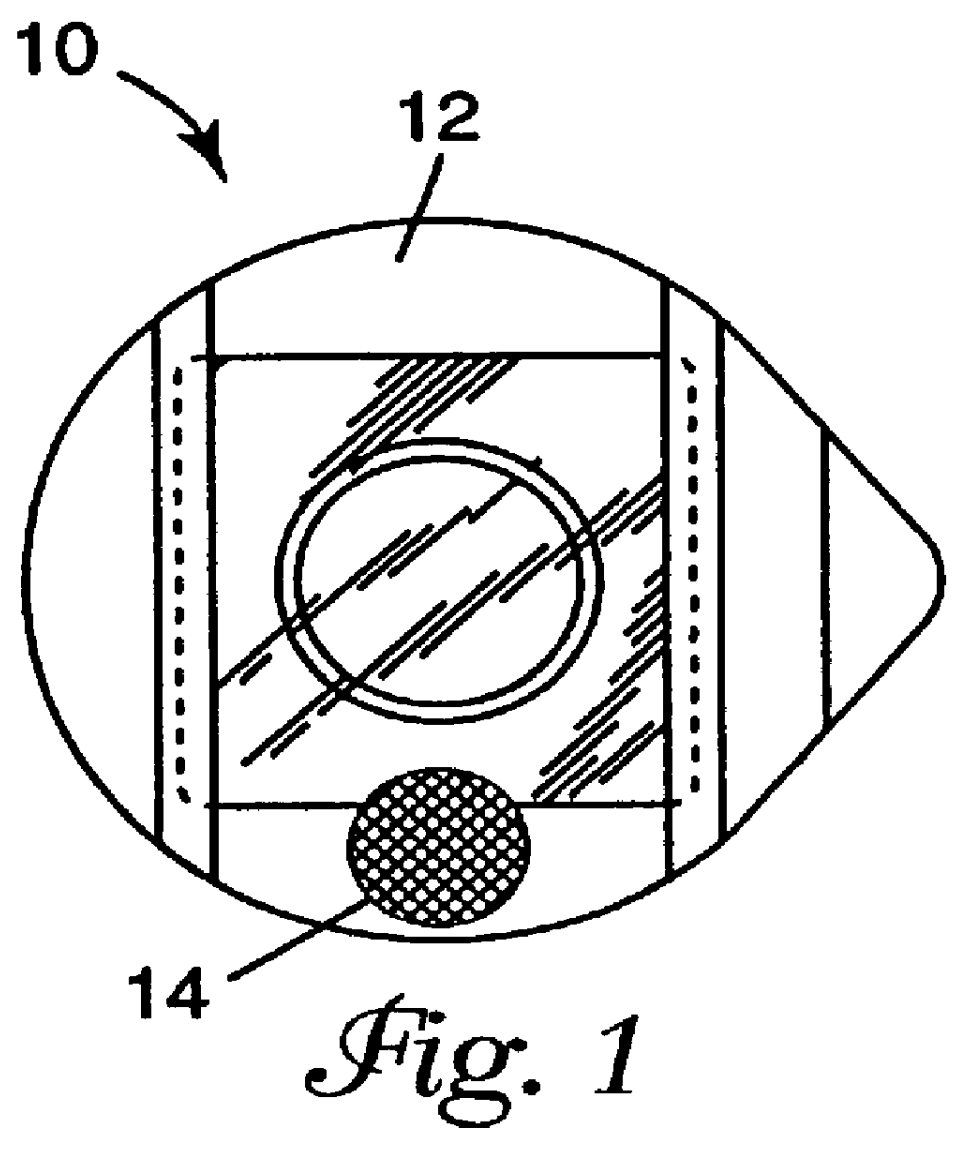

Skin abrader for biomedical electrode

InactiveUS6136008AEfficiently and effectively removesEfficiently and effectively removedElectrocardiographySurgical furnitureStratum corneumBiomedical engineering

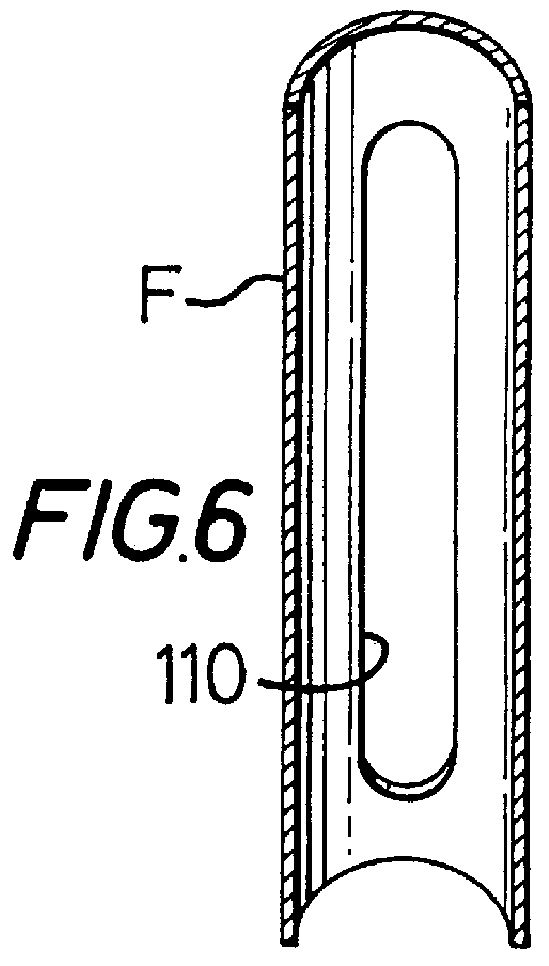

A skin abrader for a biomedical electrode is disclosed wherein the abrader has a geometrically structured surface abrasive selected to provide sufficient abrasive effect to easily remove a portion of the stratum corneum of mammalian skin with minimal skin irritation, in order to reduce skin impedance encountered during diagnosis or monitoring of a mammalian patient.

Owner:BANK ONE N A +1

Method for making abrasive grain using impregnation, and abrasive articles

InactiveUS6206942B1High densityImprove performancePigmenting treatmentOther chemical processesAbrasive

Method for making alpha alumina-based abrasive grain, wherein during an impregnation step of the method, alpha alumina-based ceramic precursor particles conchoidally fracture. The abrasive grain can be incorporated into abrasive products such as coated abrasives, bonded abrasives, and non-woven abrasives.

Owner:3M CO

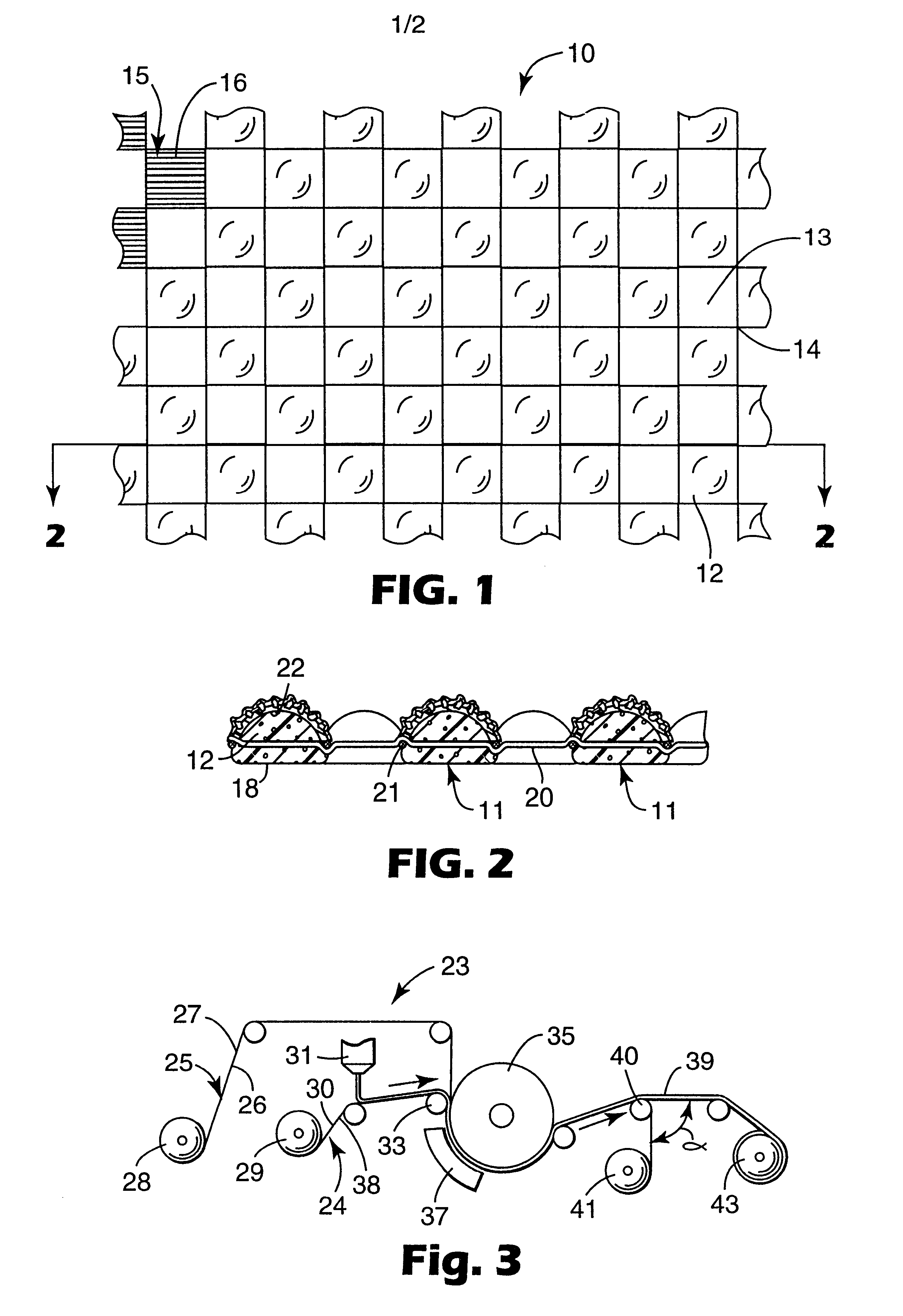

Disposable scrubbing product

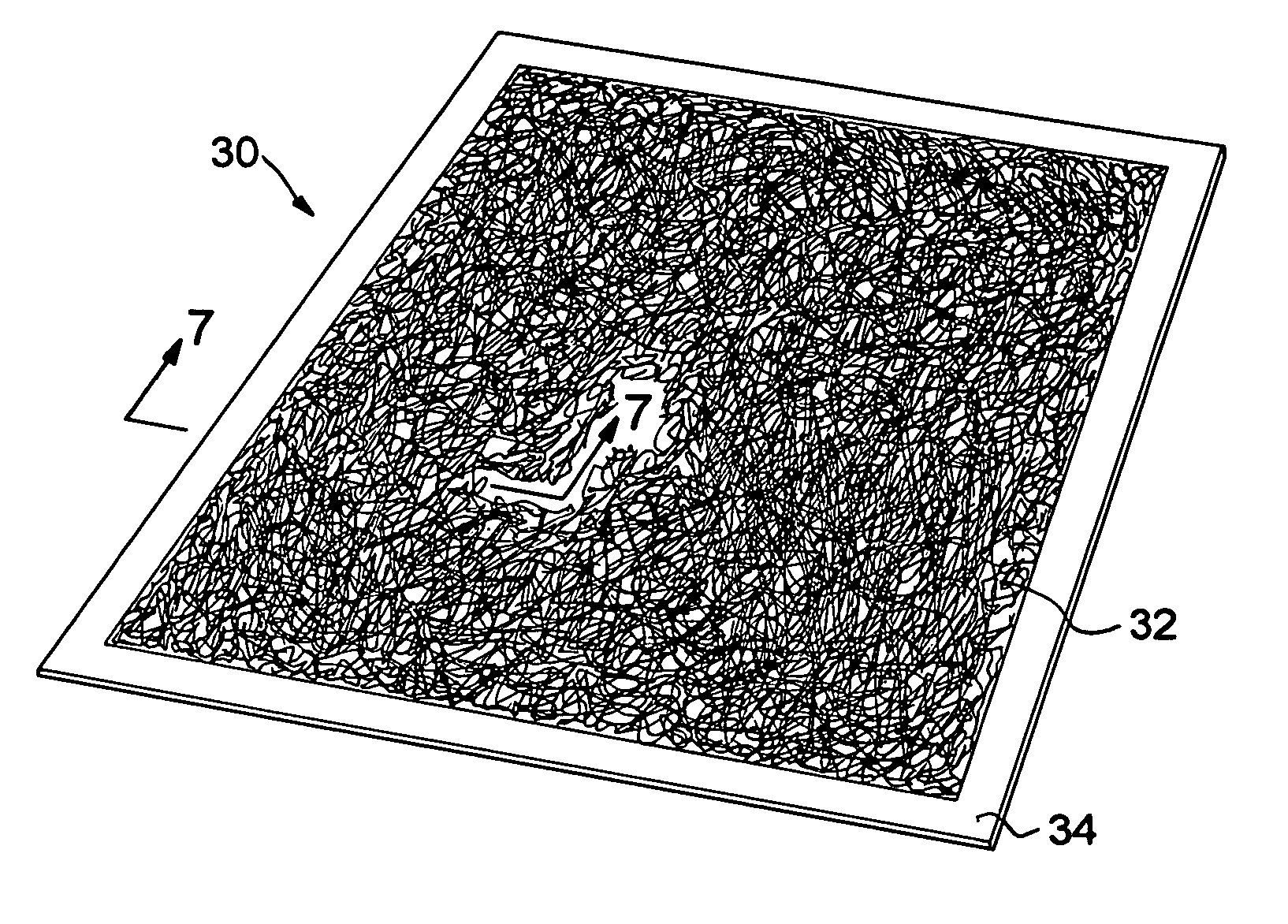

InactiveUS20050130536A1High yieldResists effect of waterPersonal careCarpet cleanersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. In one embodiment, the present invention is directed to a cleaning tool including a handle and a rigid base to which the scrubbing product of the present invention may be attached to form a convenient cleaning tool. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, the abrasive layer comprises multifilamentary aggregate fibers. In one embodiment, the absorbent fibrous layer is an uncreped, through dried paper web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for window formation in wellbore tubulars

InactiveUS6024169APreventing coringEasy millingFluid removalDirectional drillingStream flowEngineering

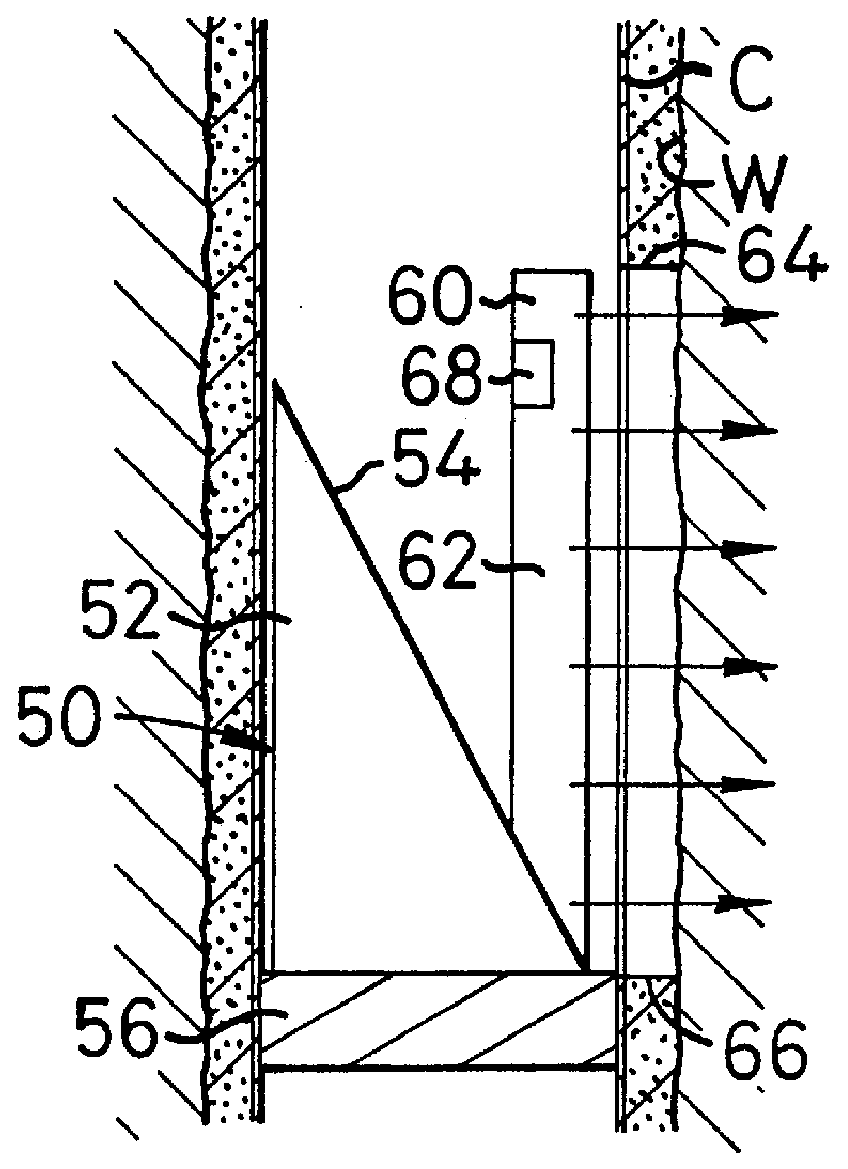

New systems and methods have been invented for explosively forming openings, ledges, windows, holes, and lateral bores through tubulars such as casing, which openings may, in cerain aspects, extend beyond the casing into a formation through which a wellbore extends. In certain aspects openings (e.g. ledges, initial, or completed windows) in wellbore tubulars (e.g. tubing or casing) are made using metal oxidizing systems, water jet systems, or mills with abrasive and / or erosive streams flowing therethrough and / or therefrom.

Owner:WEATHERFORD TECH HLDG LLC

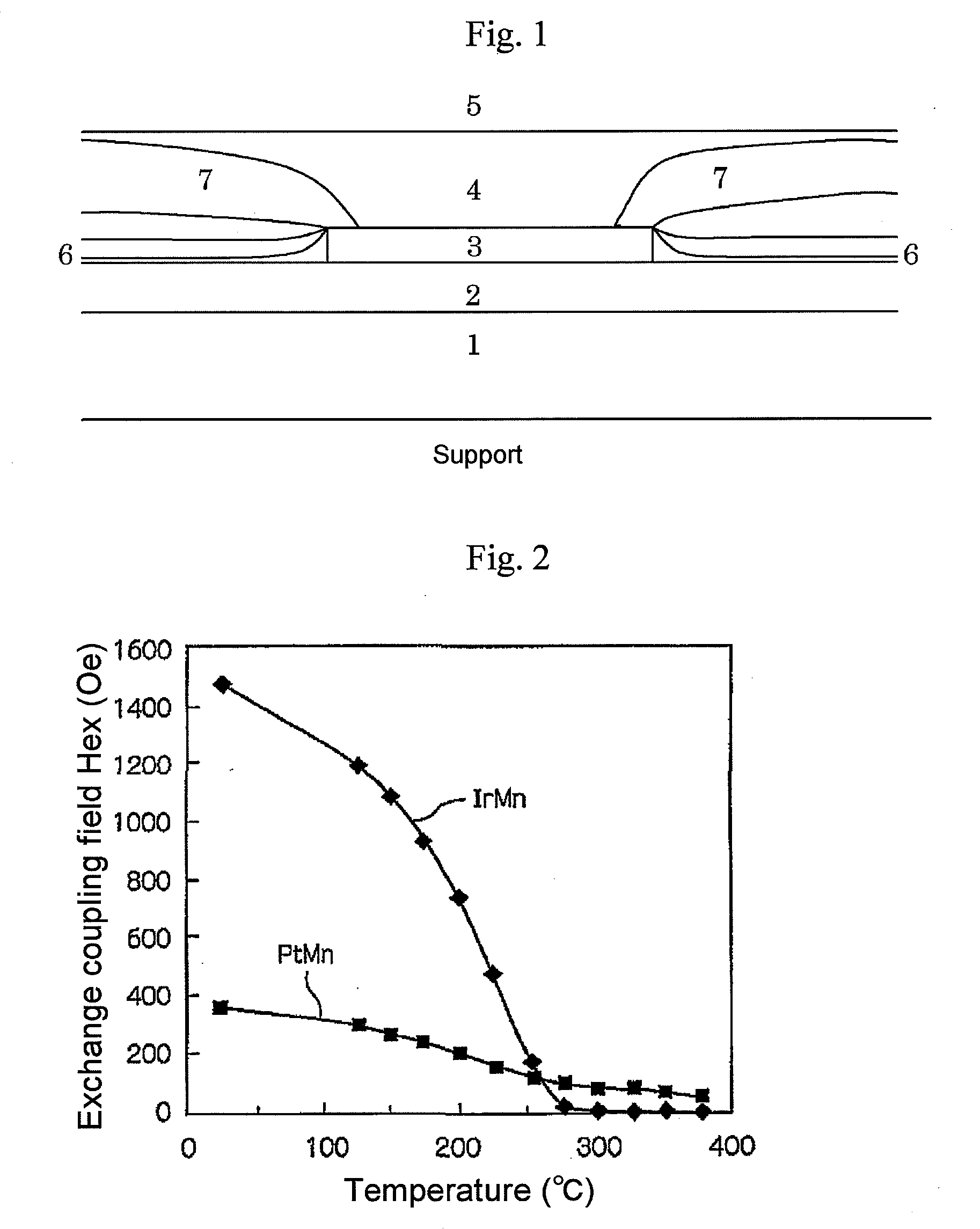

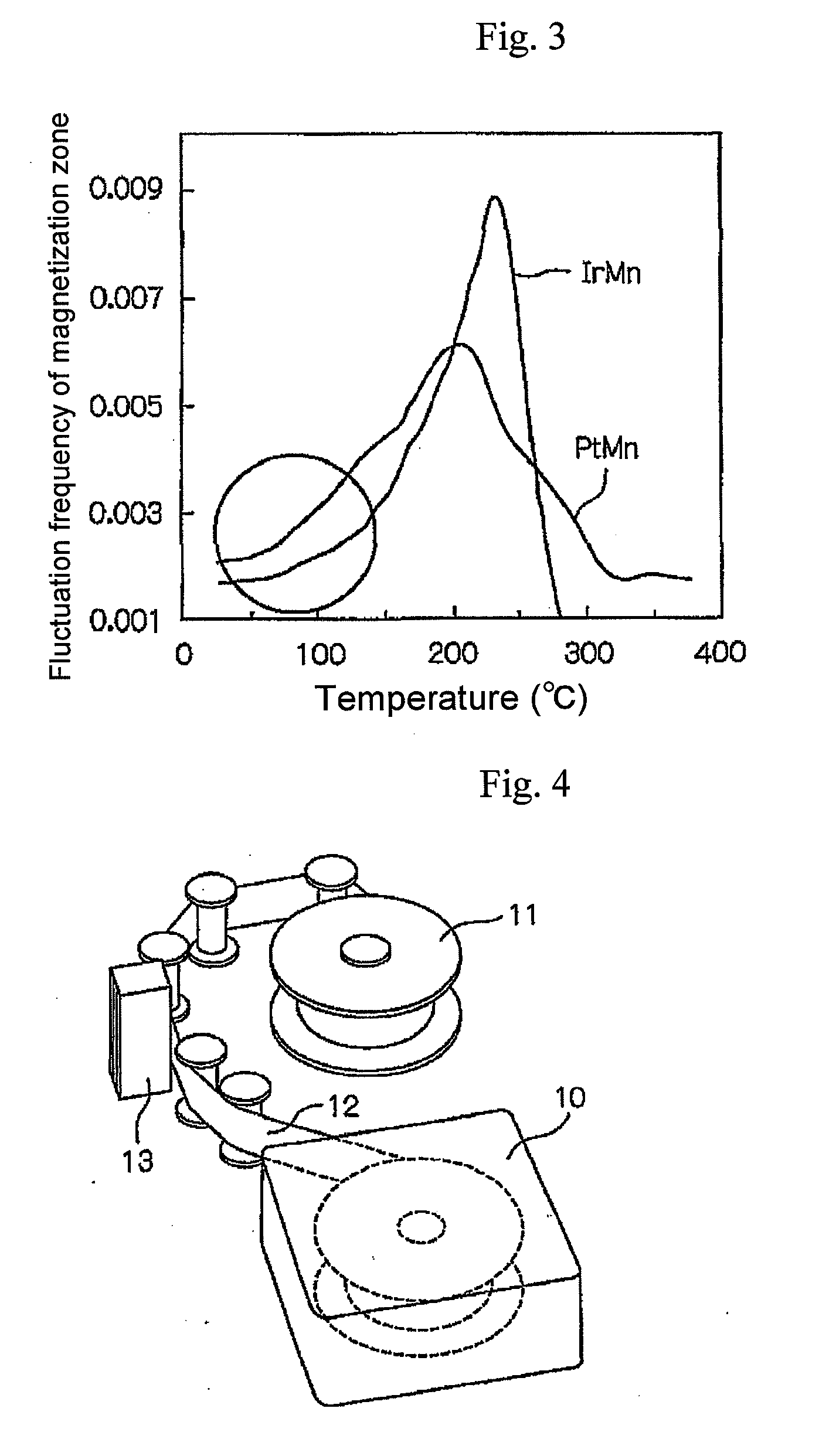

Magnetic signal reproduction system and magnetic signal reproduction method

InactiveUS20090027812A1Stable reproduction propertyDeterioration of reproduction propertyManufacture unitary devices of plural headsRecord information storageIridiumAlloy

The magnetic signal reproduction system comprises a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support and a reproduction head, wherein a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 2500 / 10,000 μm2, a quantity of lubricant on the magnetic layer surface, denoted as a surface lubricant index, ranges from 0.5 to 5.0, a surface abrasive occupancy of the magnetic layer ranges from 2 to 20 percent, the reproduction head is a magnetoresistive magnetic head comprising a spin-valve layer, the spin-valve layer comprises a magnetization free layer, a magnetization pinned layer and an antiferromagnetic layer, and the antiferromagnetic layer is comprised of alloy comprising iridium and manganese, and the reproduction head comes in sliding contact with the magnetic recording medium during signal reproduction.

Owner:FUJIFILM CORP +1

Fused Al2O3-MgO-rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20010027623A1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesRare earthAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

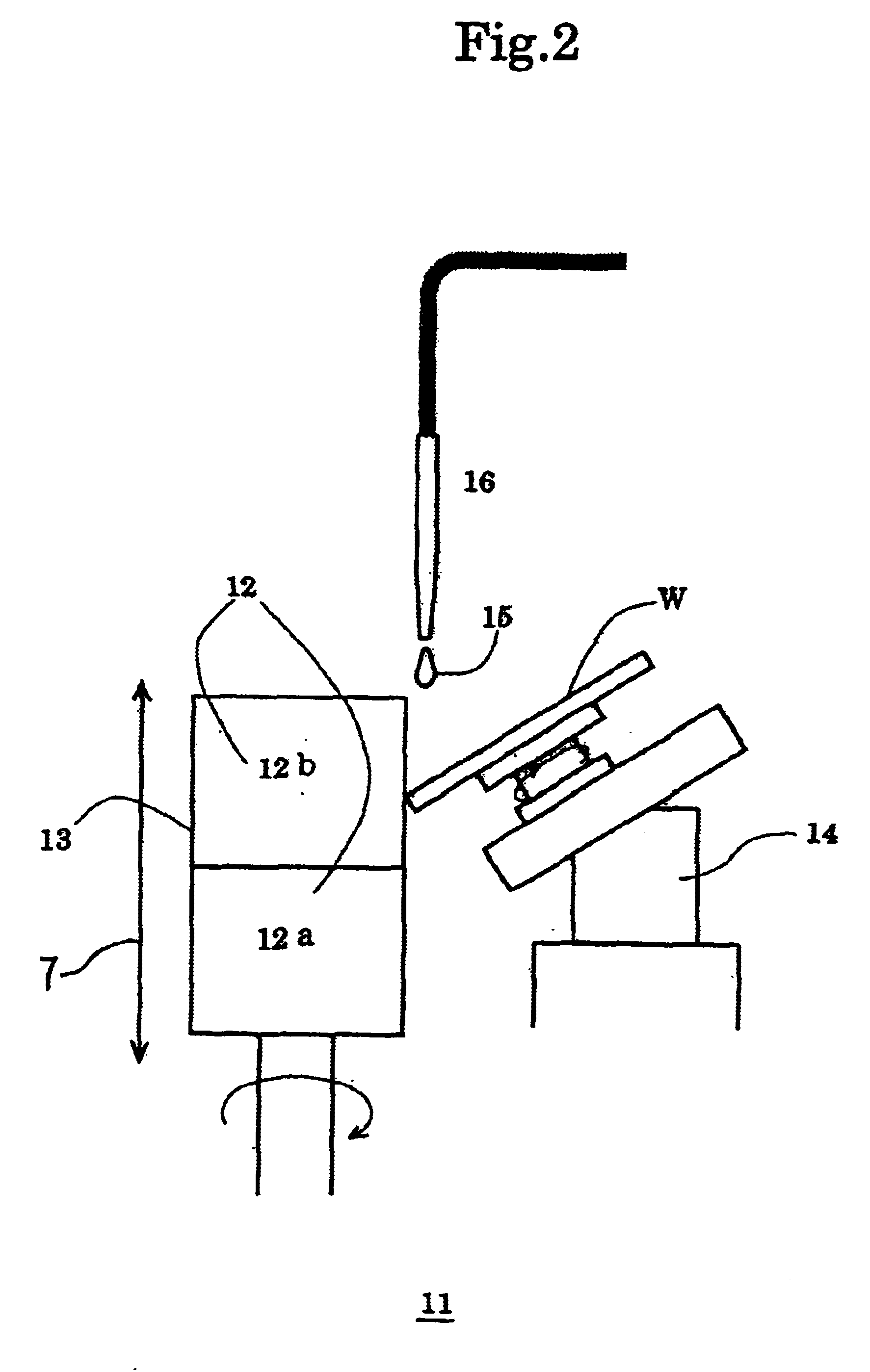

Method for apparatus for polishing outer peripheral chamfered part of wafer

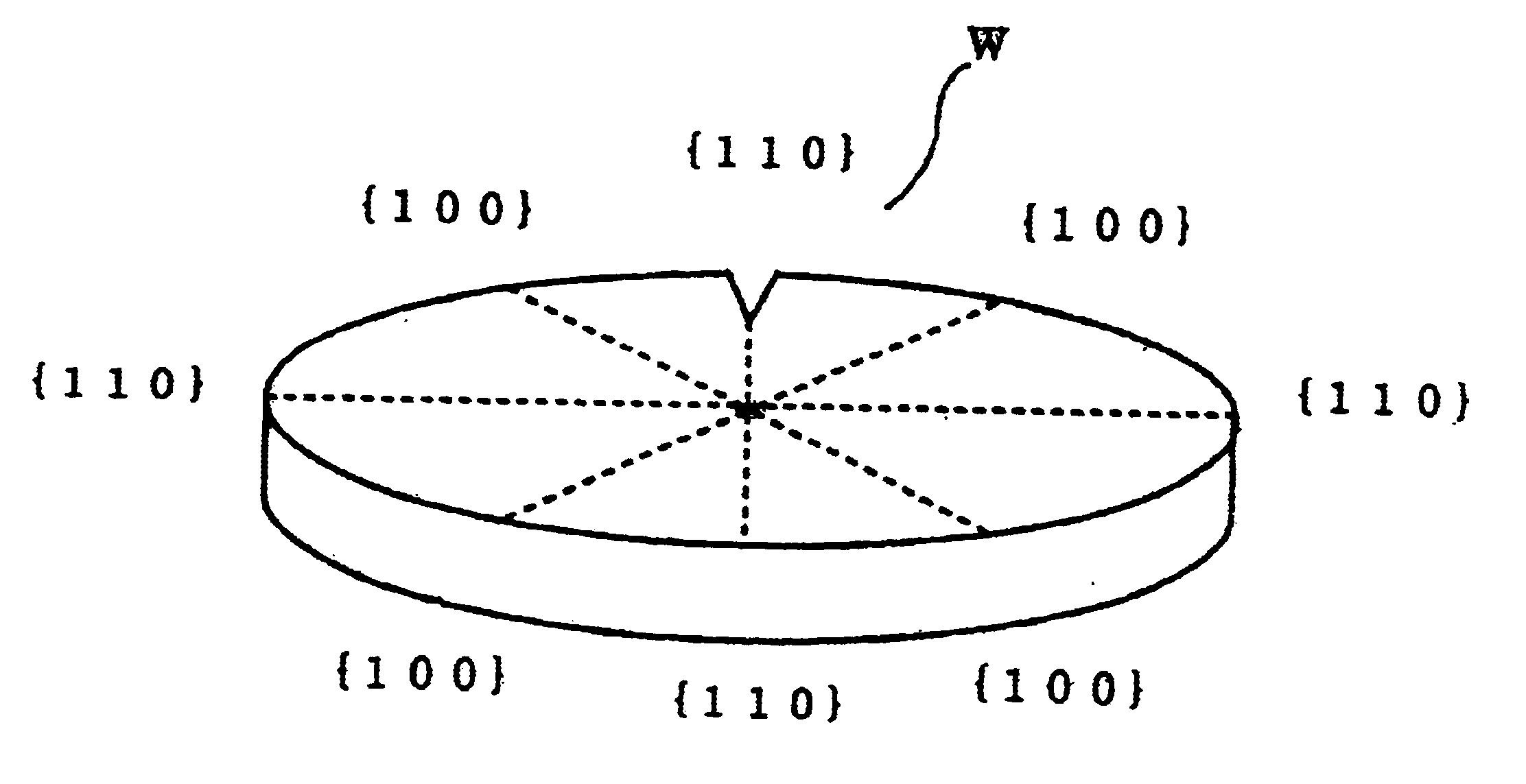

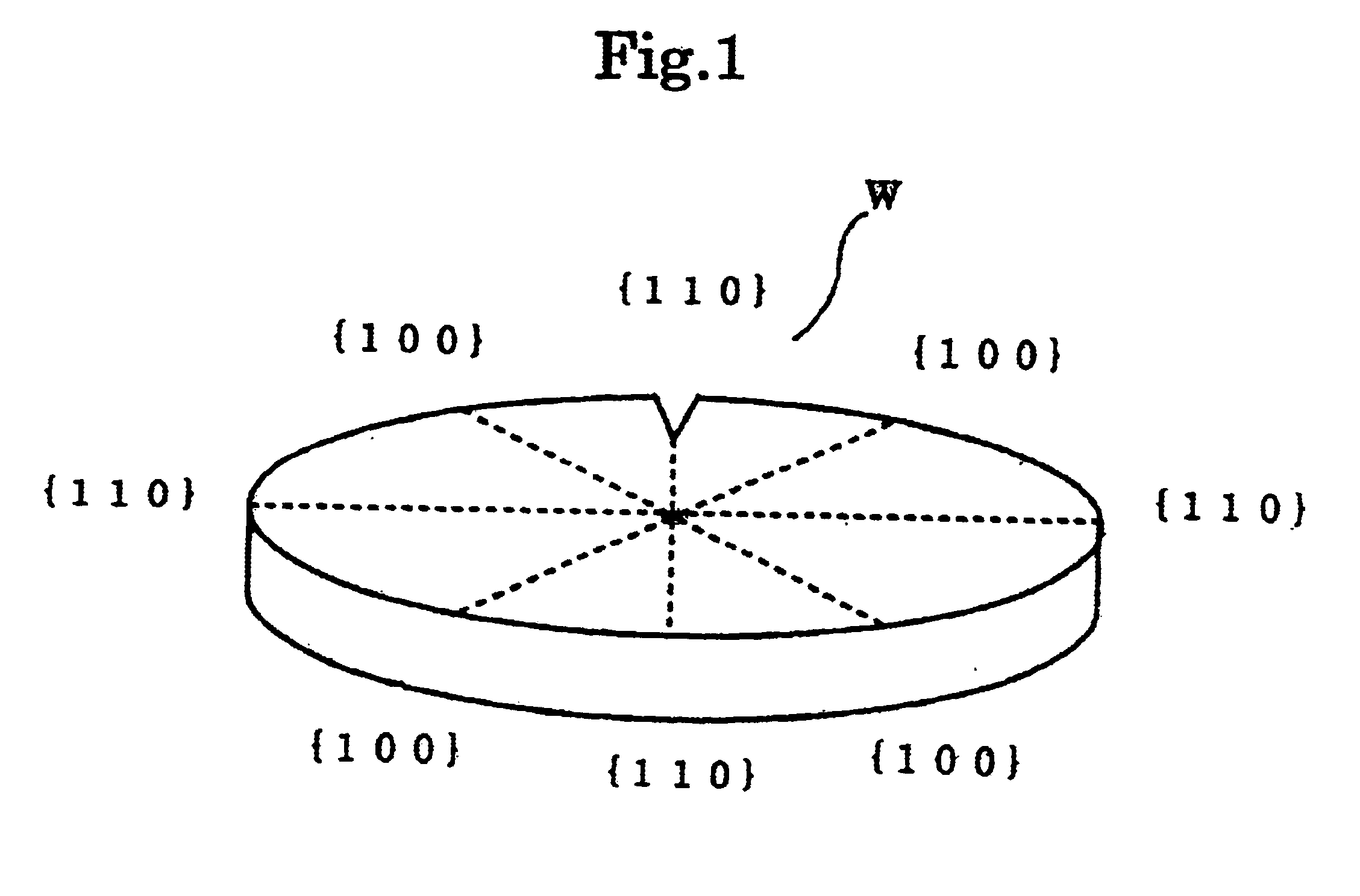

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

Magnetic recording medium

ActiveUS20140272474A1Increased durabilityReduce runningRecord information storageMaterials with non-metallic substancesScanning electron microscopeElectron microscope

An aspect of the present invention relates to a magnetic recording medium, which comprises a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, wherein the ferromagnetic powder is ferromagnetic hexagonal ferrite powder comprising 3 to 12 weight percent of Al, based on Al2O3 conversion, relative to 100 weight percent of a total weight of the powder, the magnetic layer further comprises abrasive, and a maximum plan view surface area of the abrasive as determined for a 4.3 μm×6.3 μm rectangular region of the magnetic layer by a scanning electron microscope is less than 0.06 percent relative to 100 percent of a total surface area of the region.

Owner:FUJIFILM CORP

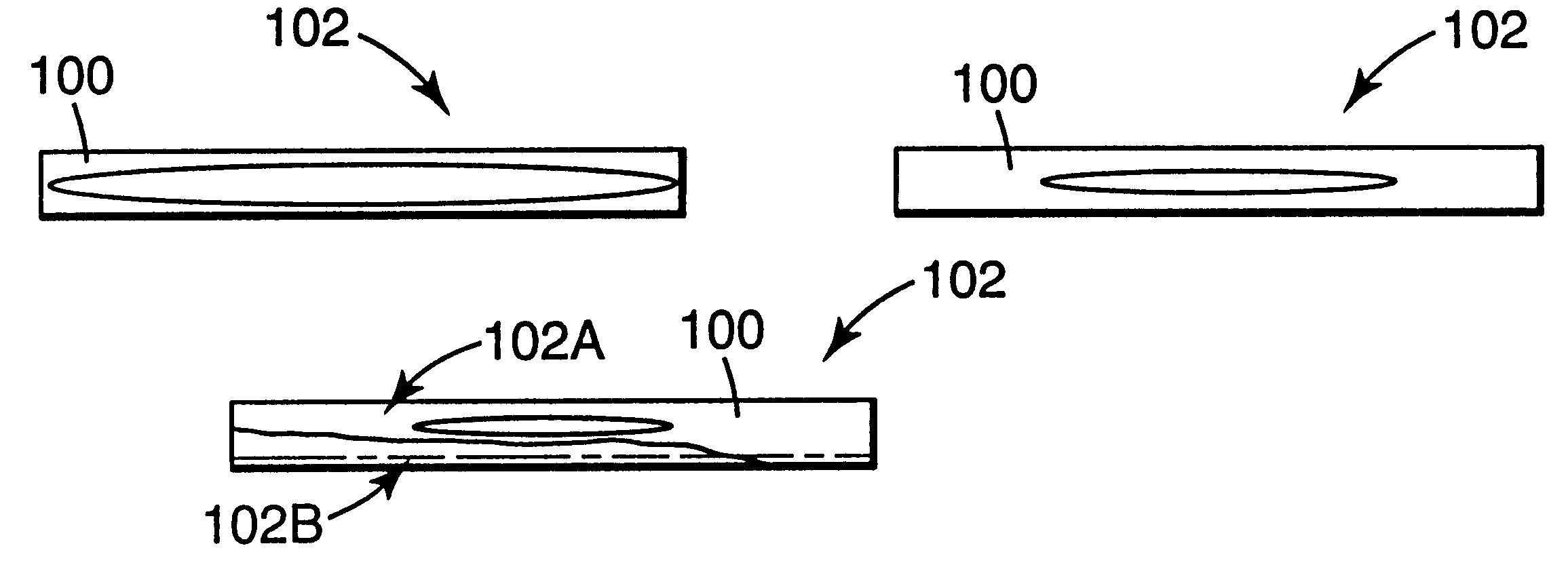

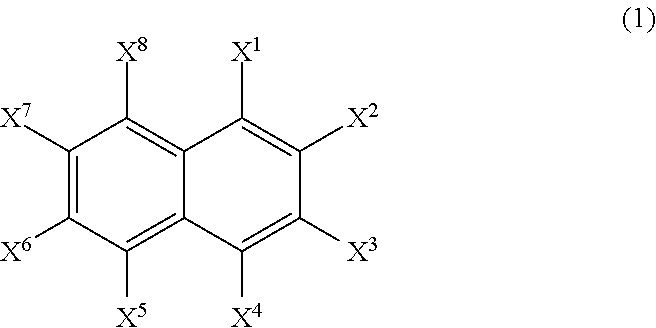

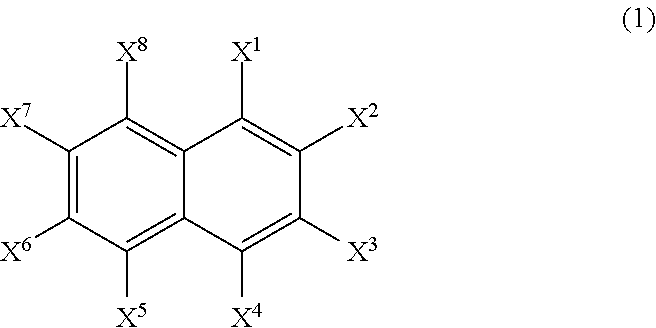

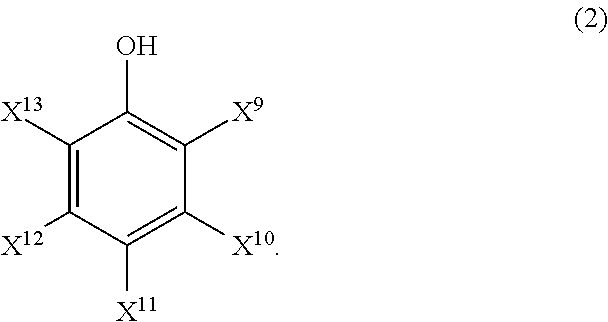

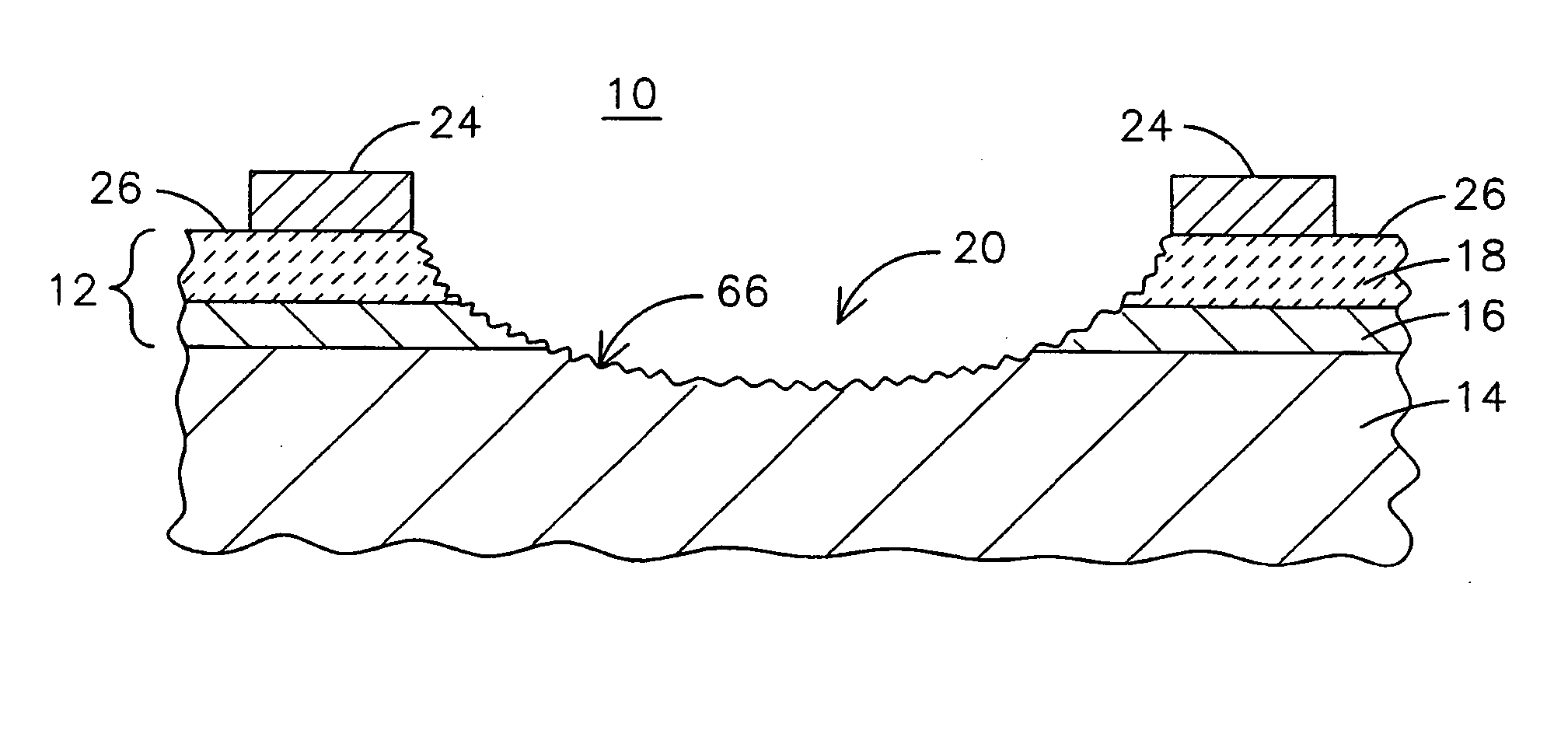

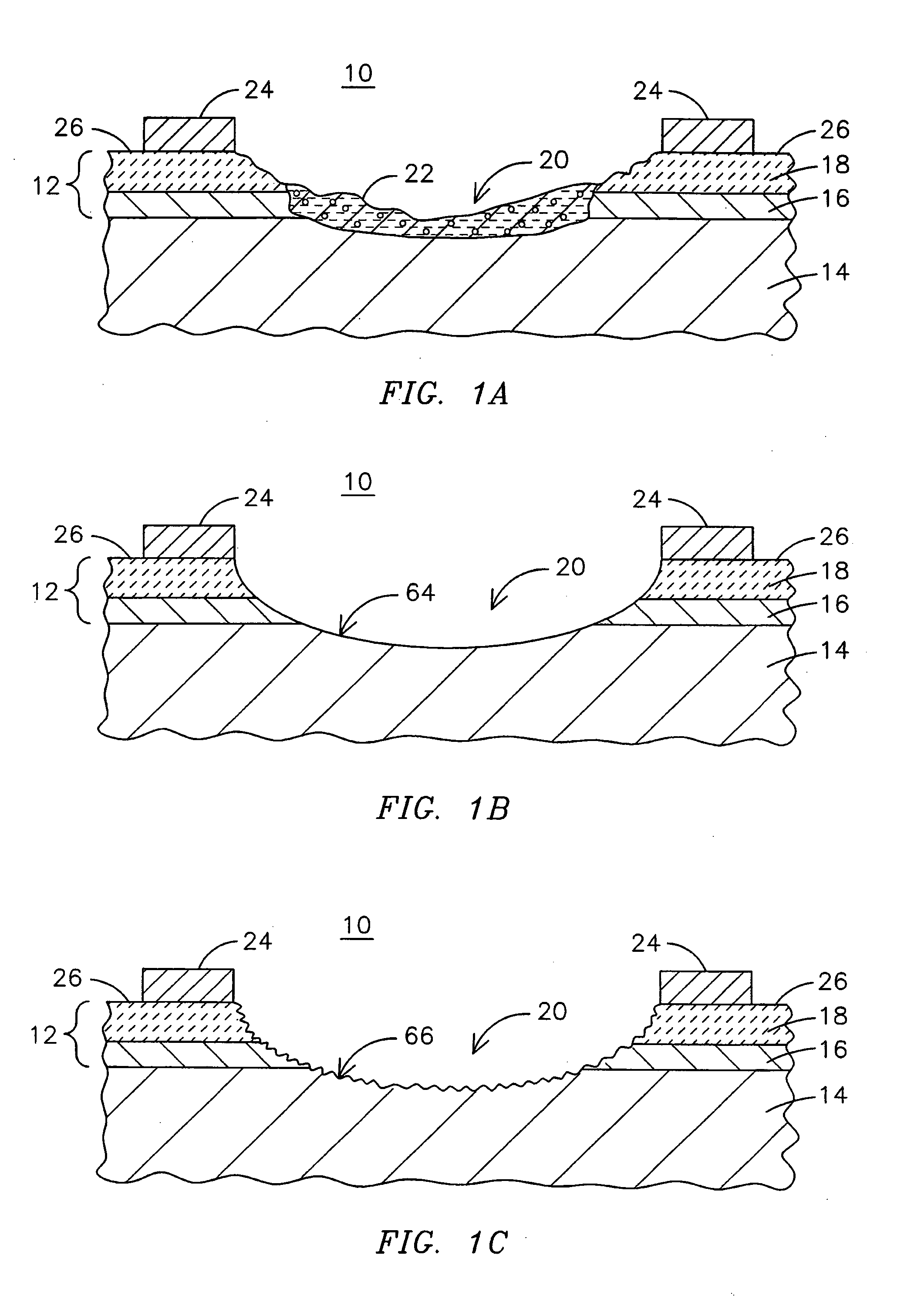

Compositions for abrasive articles

ActiveUS20050060947A1Attenuation consistentImprove cutting lifePigmenting treatmentOther chemical processesSurface finishMicrometer

A structured abrasive article, methods of making an abrasive article, and methods of using an abrasive article. The abrasive composites forming the abrasive article have a height of at least 500 micrometers, and the abrasive particles in the composites have an average particle size of at least 40 micrometers, in some embodiments, at least about 85 micrometers. The large topography composites, together with the large ceramic abrasive particles, provides an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than conventional make / coat abrasive articles with the same size and type of abrasive particles. Additionally, the large topography composites, together with the large ceramic abrasive particles, provide an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than structured abrasive articles having a smaller topography, even with the same abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

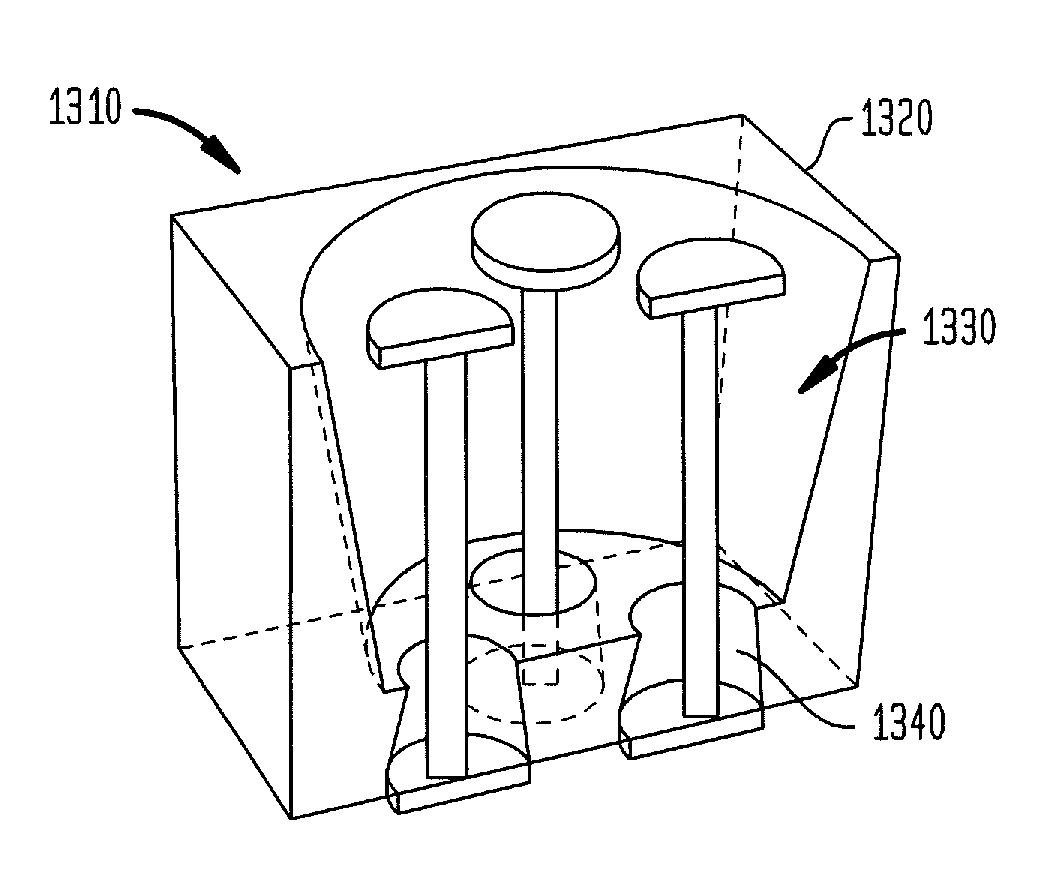

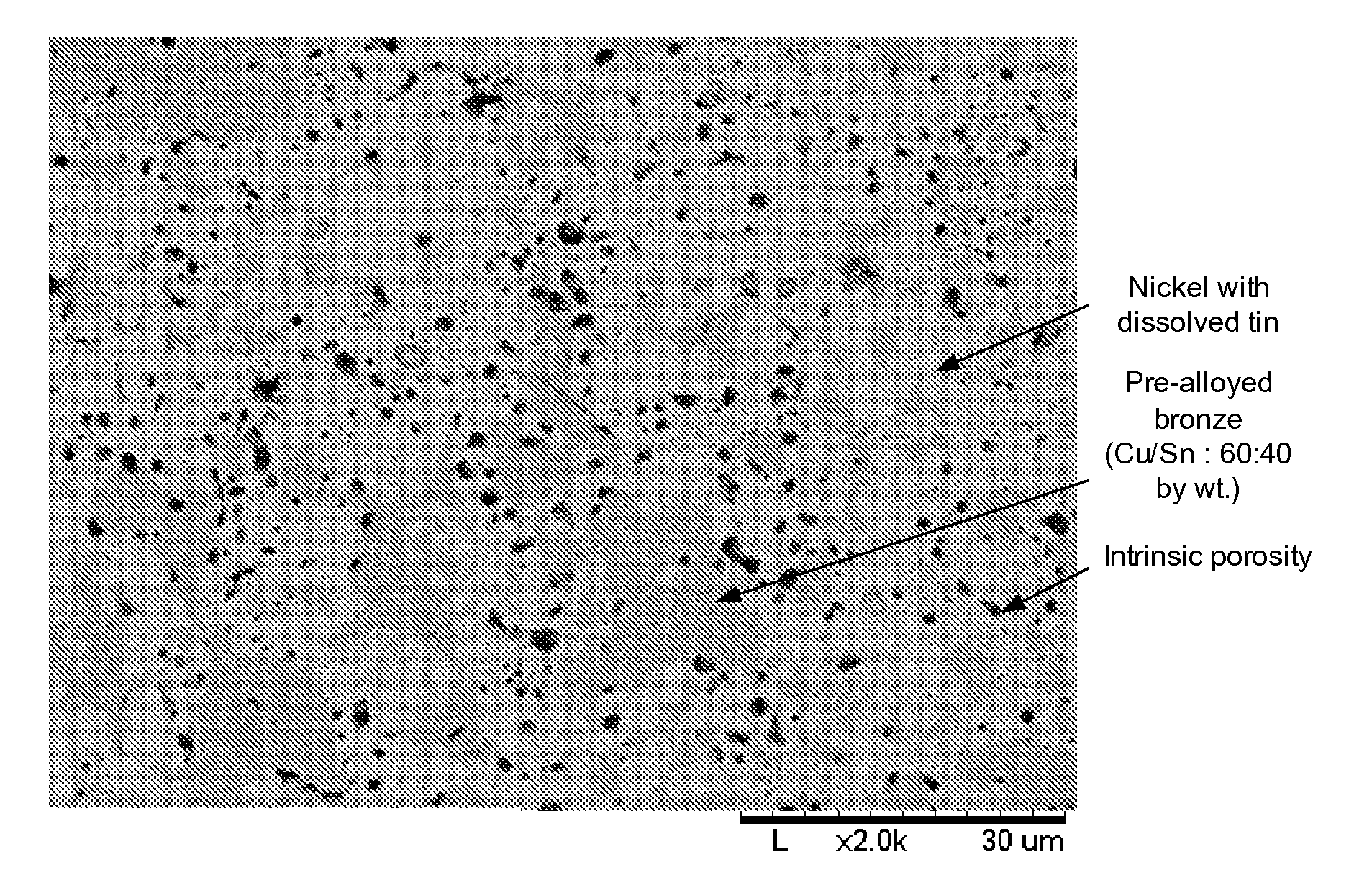

Abrasive Slicing Tool for Electronics Industry

InactiveUS20100000159A1Superior wheel stiffnessProlong lifePigmenting treatmentOther chemical processesPorosityElectronic industry

A bond matrix for metal bonded abrasive tools includes a metal bond system, porosity and an optional filler. Tools according to embodiments of the invention exhibit long tool life, produce an acceptable quality of cut and can have self-dressing properties. The bond matrix can be used, for example, in abrasives tools configured for the electronics industry, such as 1A8 wheels for slicing ball grid arrays (BGAs) and other such slicing operations.

Owner:SAINT GOBAIN ABRASIVES INC +1

Method of doping surfaces

Disclosed herein are methods of treating an article surface. The method comprises removing a metal oxide surface from the metal substrate to expose a metal surface; and delivering particles comprising a dopant from at least one fluid jet to the metal surface to impregnate the surface of the article with the dopant. The method also comprises delivering substantially simultaneously a first set of particles comprising a dopant and a second set of particles comprising an abrasive from at least one fluid jet to a surface of an article to impregnate the surface of the article with the dopant.

Owner:ENBIO

Structured abrasive article

An abrasive article includes an array of protruding abrasive units. Each unit has a base and a distal apex that is off-center from the base when projected on to a plane that is coplanar with the base. The abrasive article includes a backing bonded to an abrasive coating formed to include the aforementioned abrasive units. Methods for making the abrasive article include nipping a production tool, an abrasive slurry, and the backing. A binder within the slurry is cured during fabrication. The abrasive article may be used to abrade a workpiece.

Owner:3M INNOVATIVE PROPERTIES CO

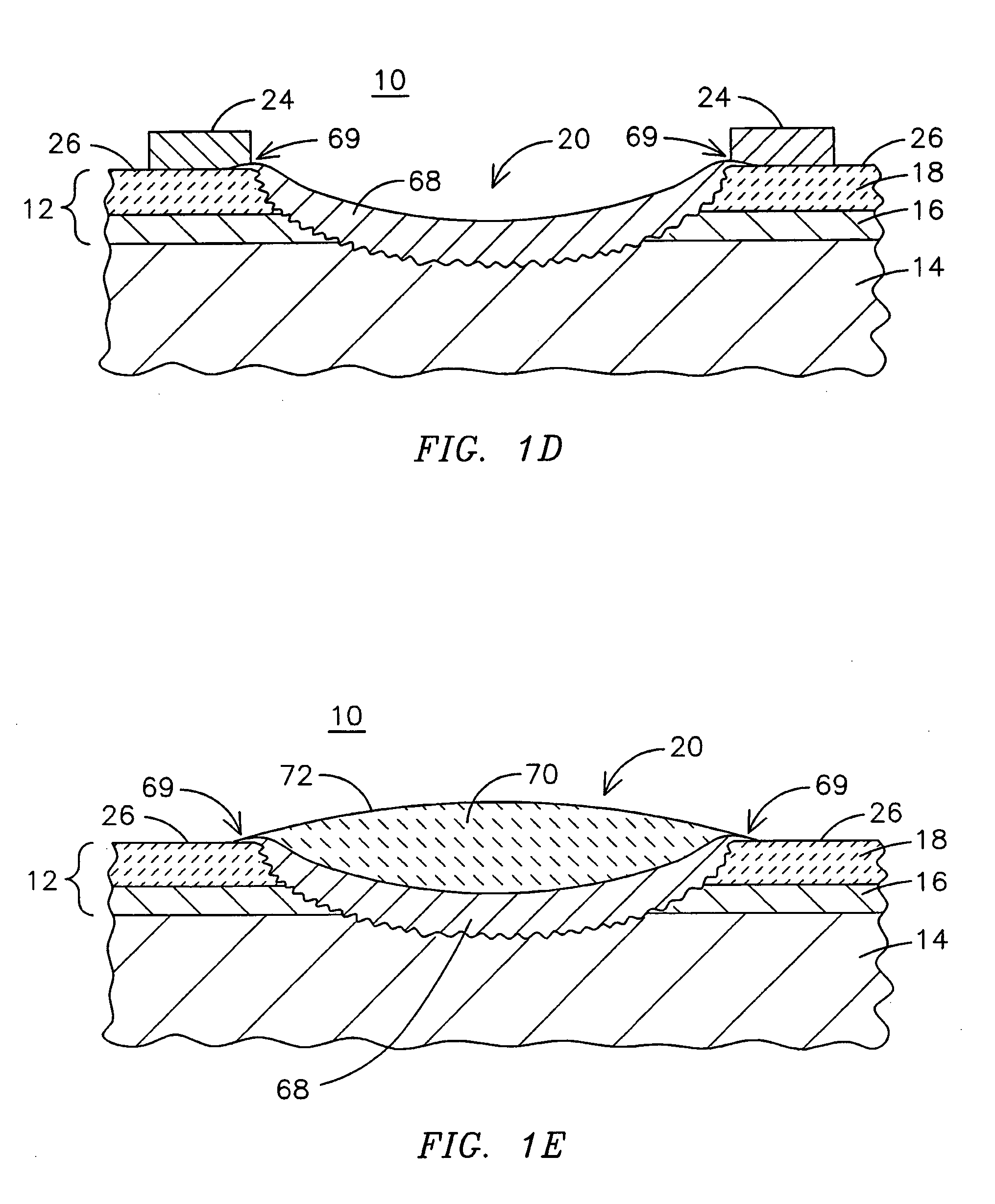

In-frame repair of gas turbine components

A method for in-frame repairing of a thermal barrier coating (12) on a gas turbine component includes cleaning a desired surface portion (10) of the component without removing the component from the gas turbine. The method also includes roughening the surface portion in-frame, applying a bond coat (68) to the surface portion in-frame, and applying a ceramic topcoat (70) to the bond coat, in-frame. A system (28) for cleaning the surface portion in-frame includes an abrasive media (34) having a state change characteristic occurring at a temperature lower than an operating temperature of the gas turbine so that the abrasive media changes from a solid state to another state allowing the media to exit the gas turbine during operation. The system also includes an abrasive media sprayer (36) to direct a spray of the abrasive media at the desired surface portion.

Owner:SIEMENS ENERGY INC

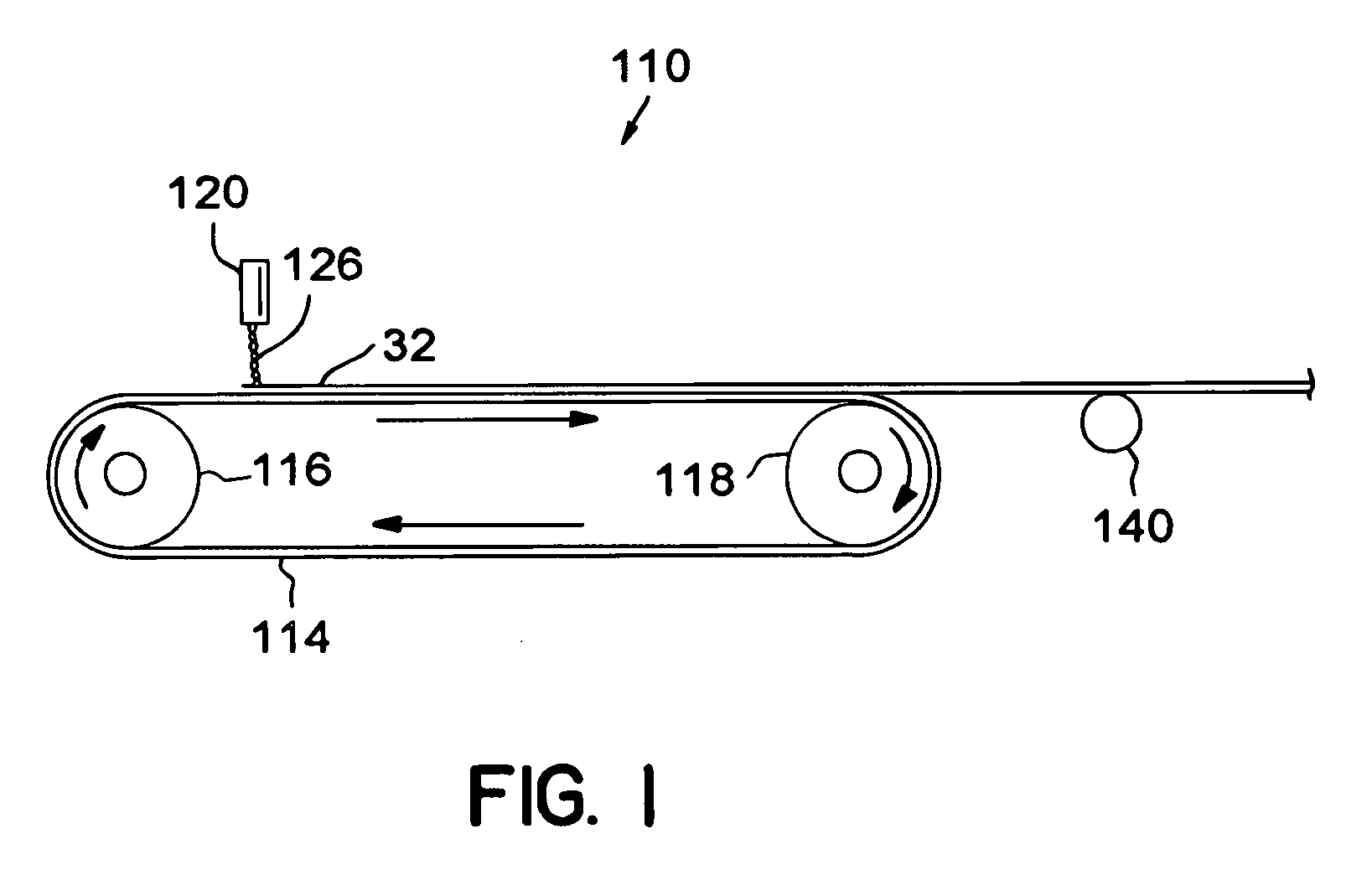

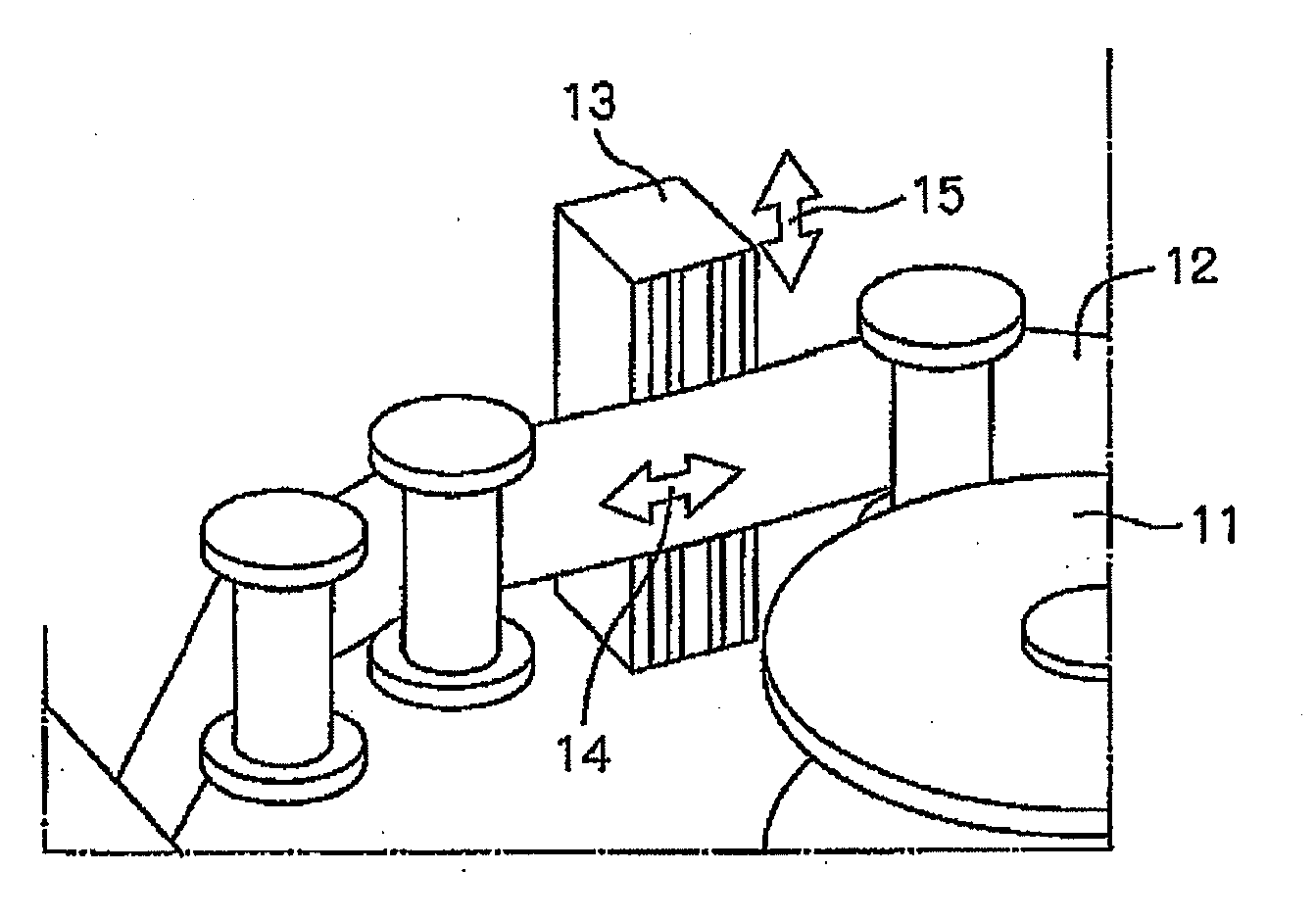

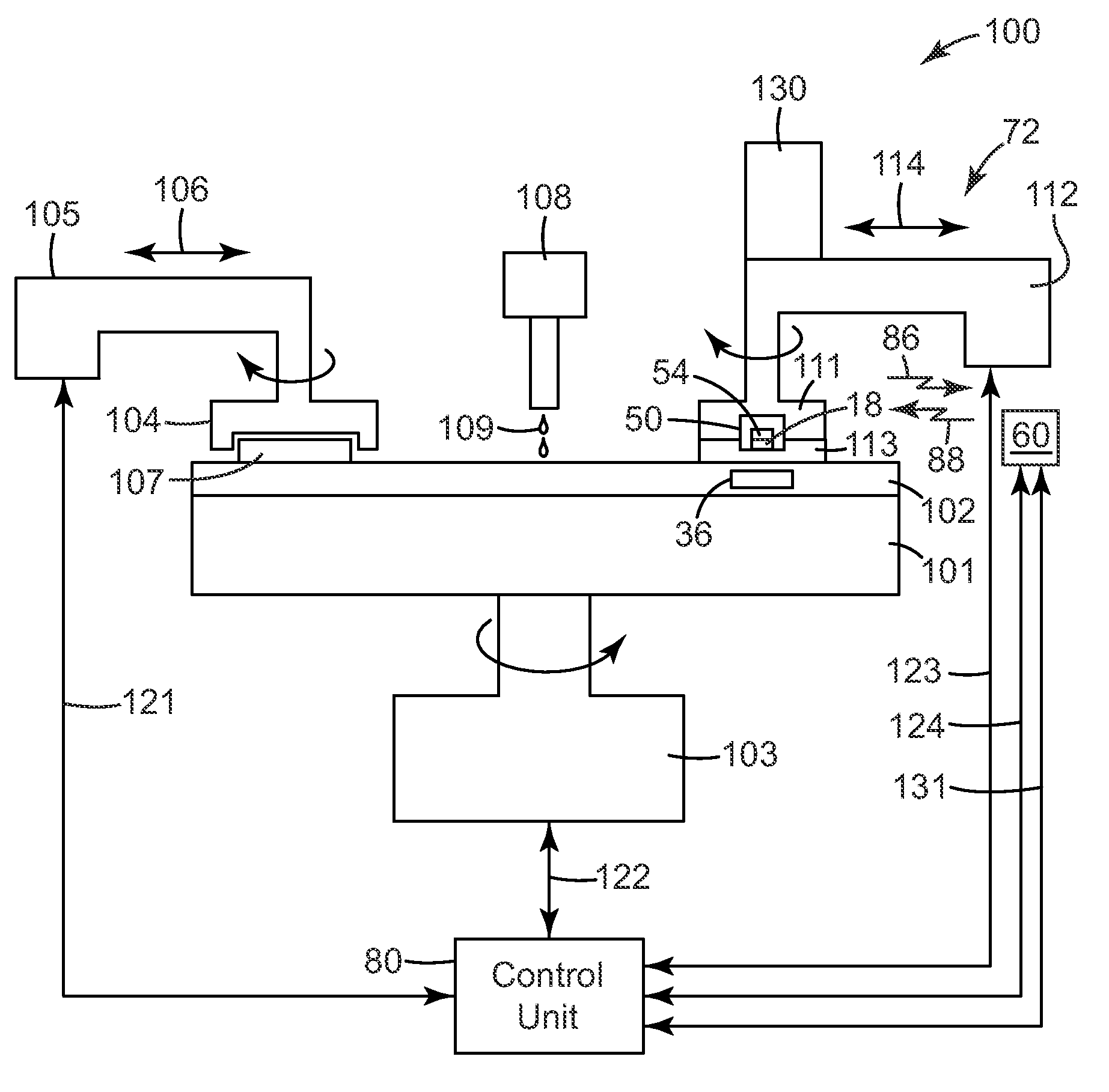

Abrasive Articles, CMP Monitoring System and Method

ActiveUS20080004743A1Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, a means for providing CMP information positioned near the substrate, and a transmitter positioned near the substrate and adapted to transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner having a means for communicating CMP information, a CMP process monitoring system, and a method for conditioning a CMP pad.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com