Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8813 results about "A diamond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

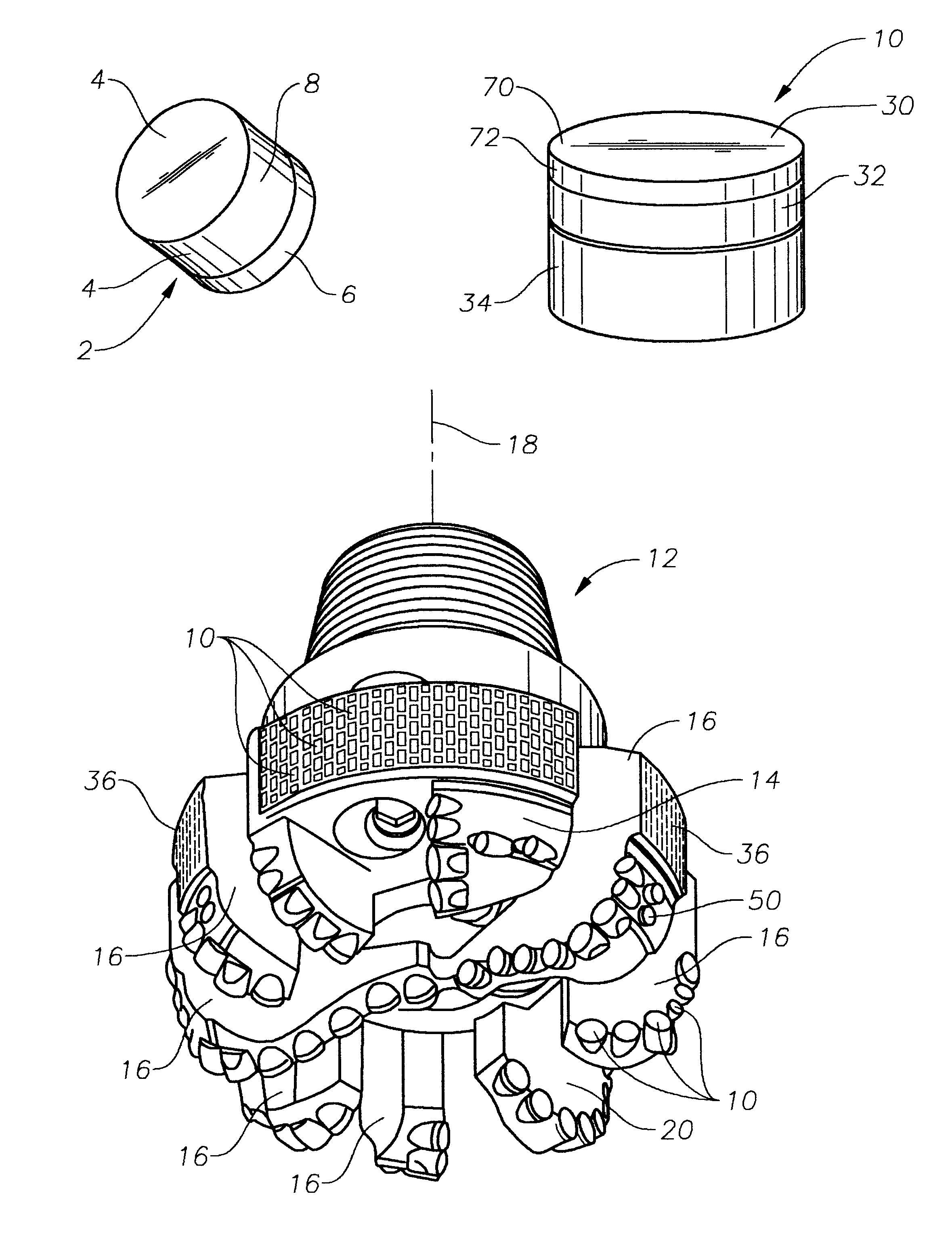

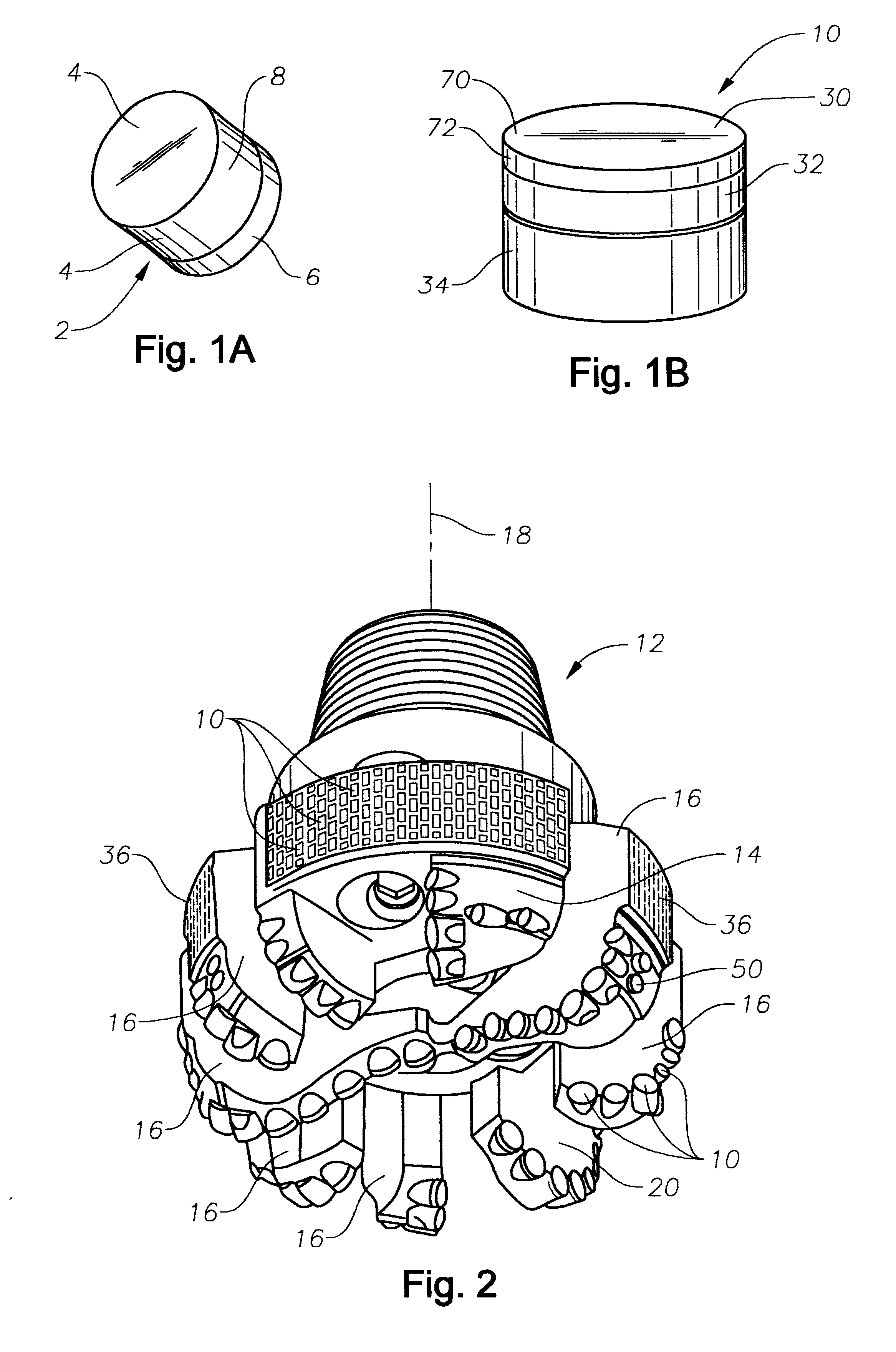

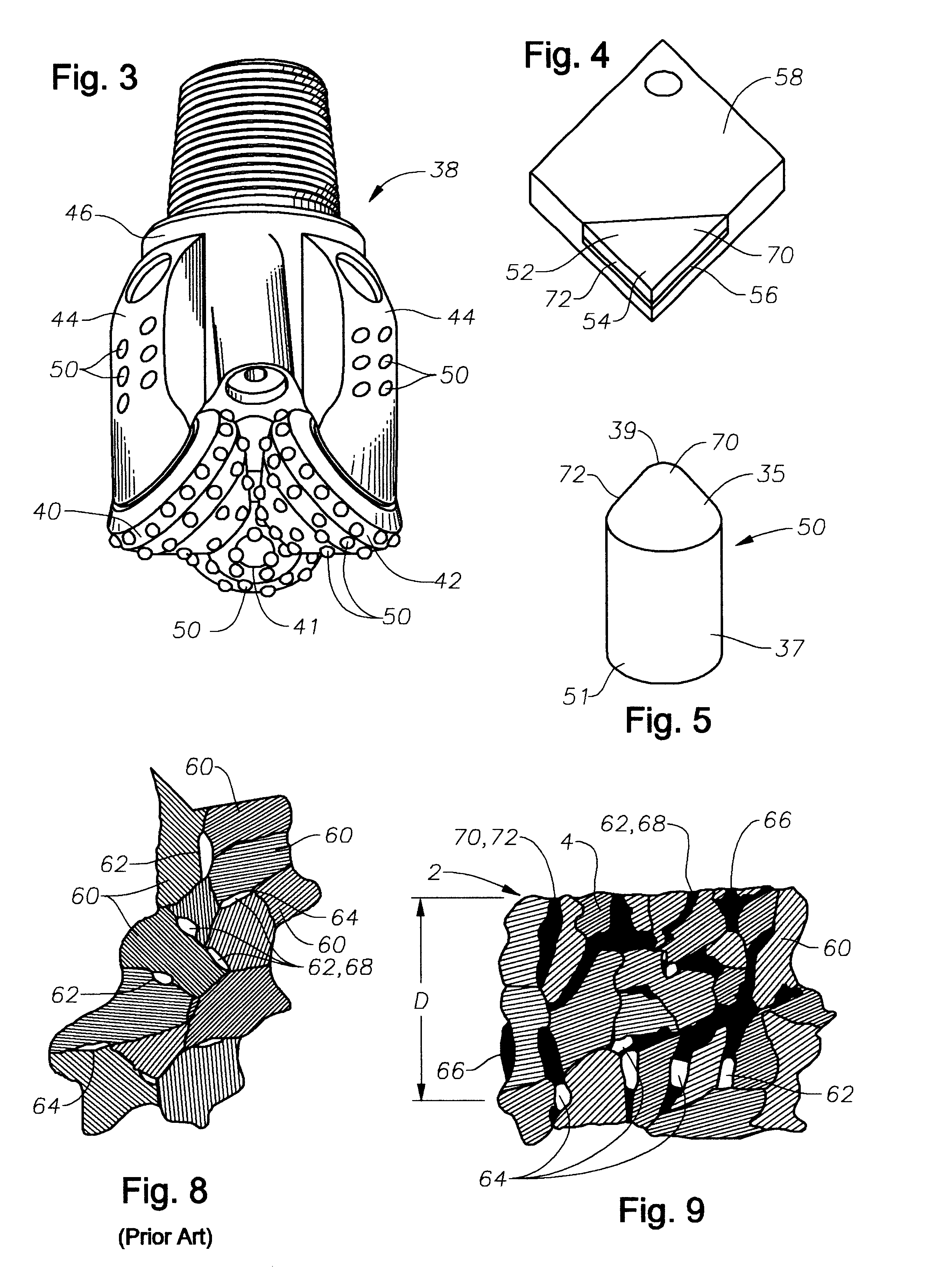

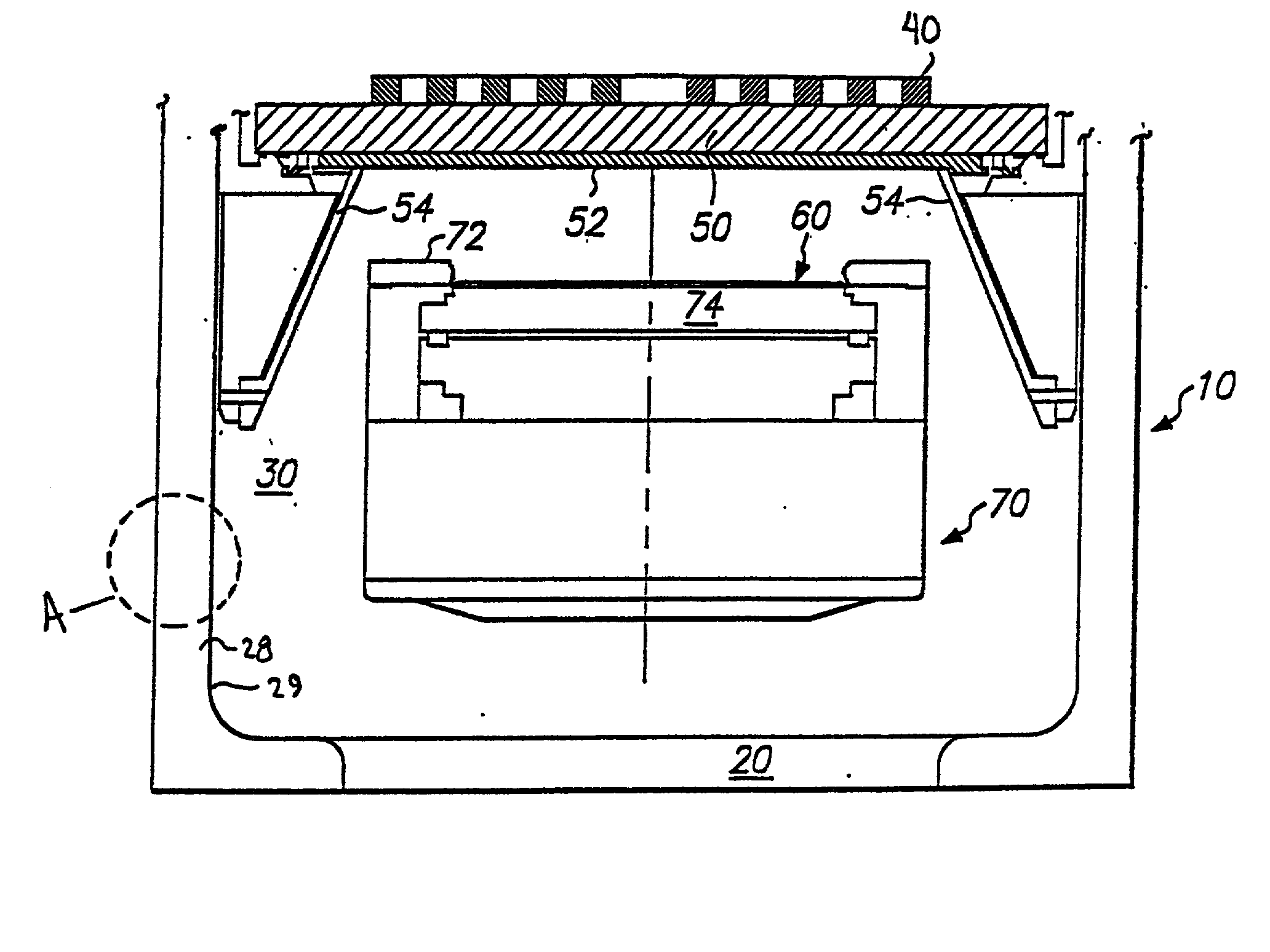

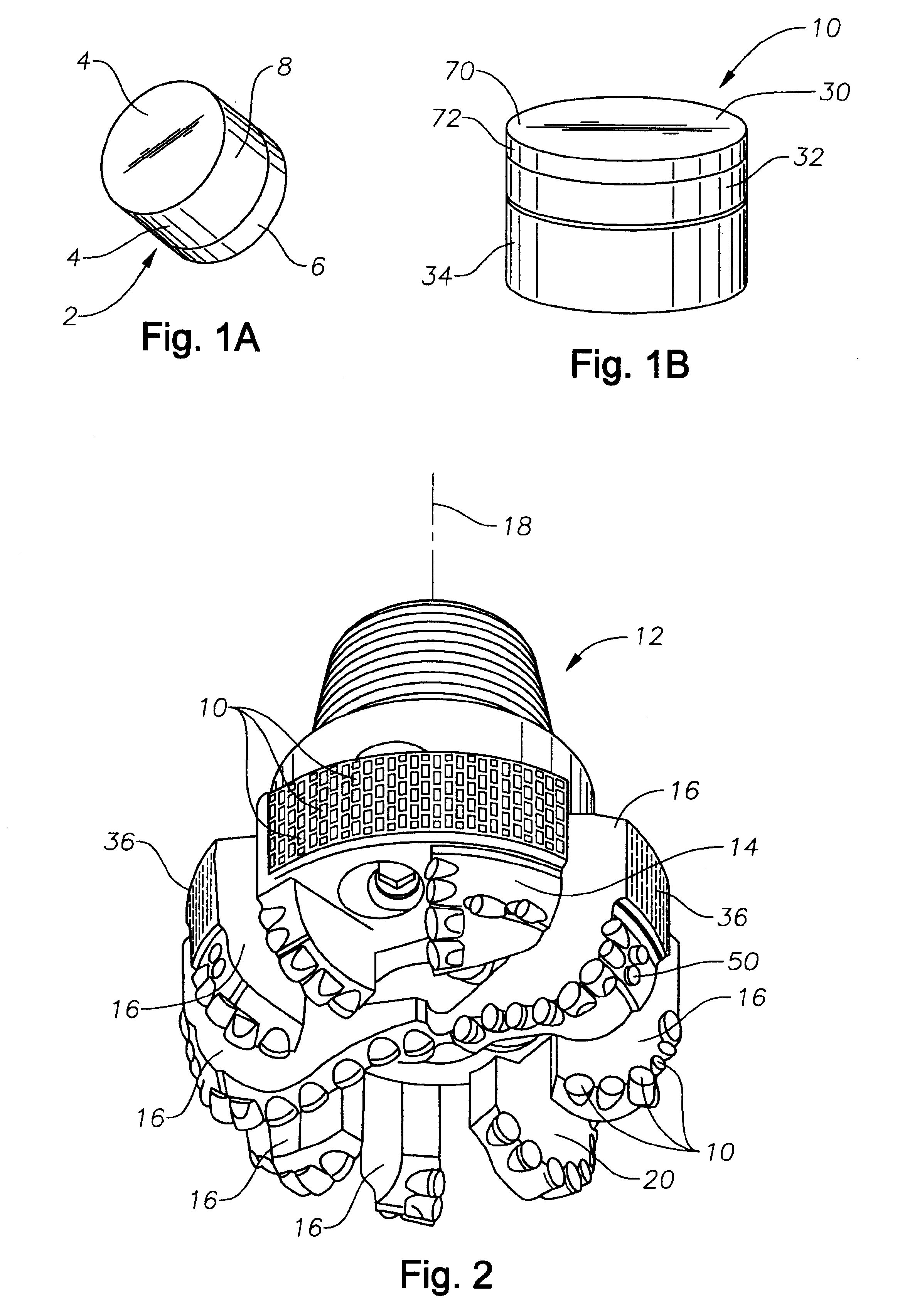

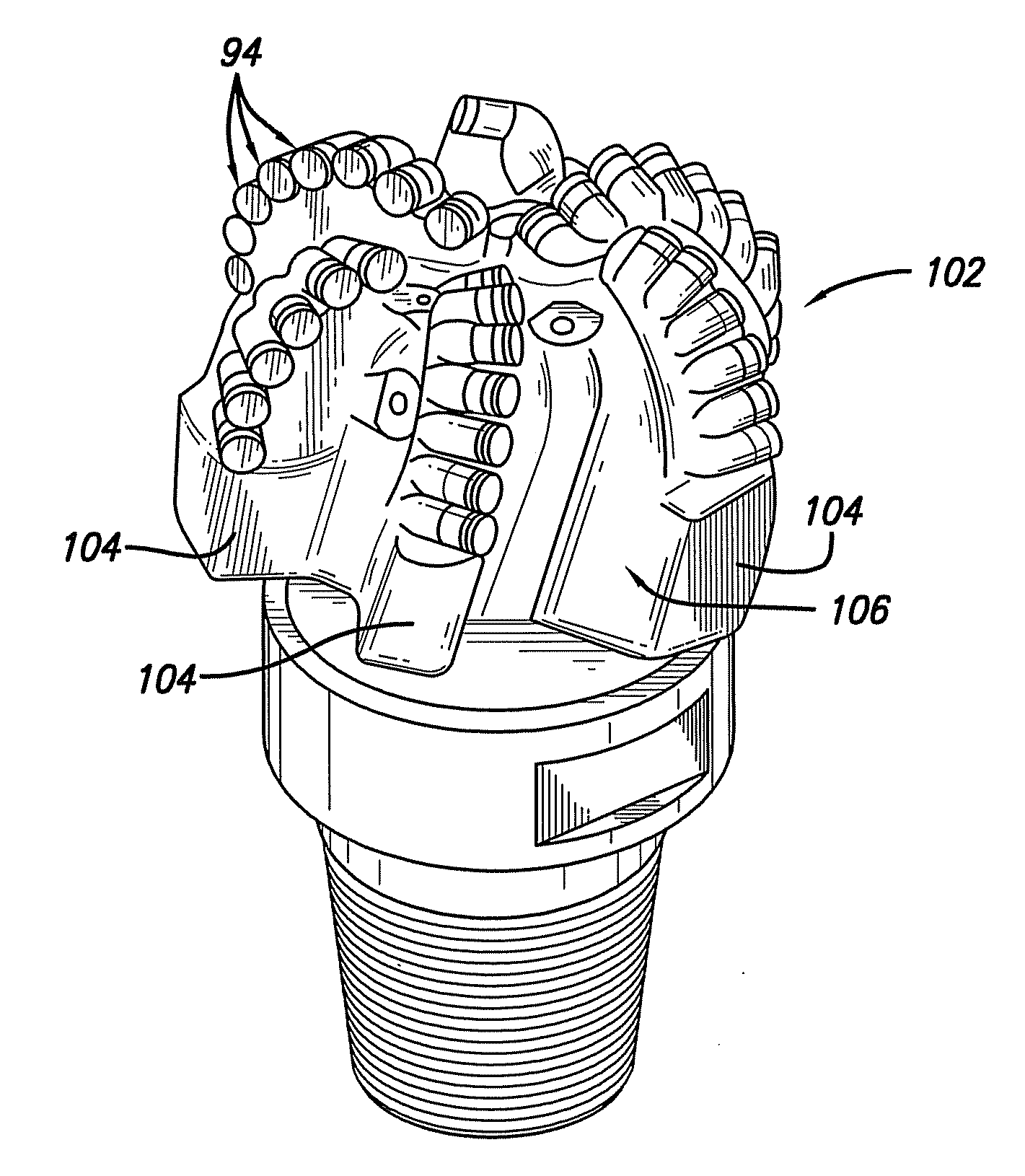

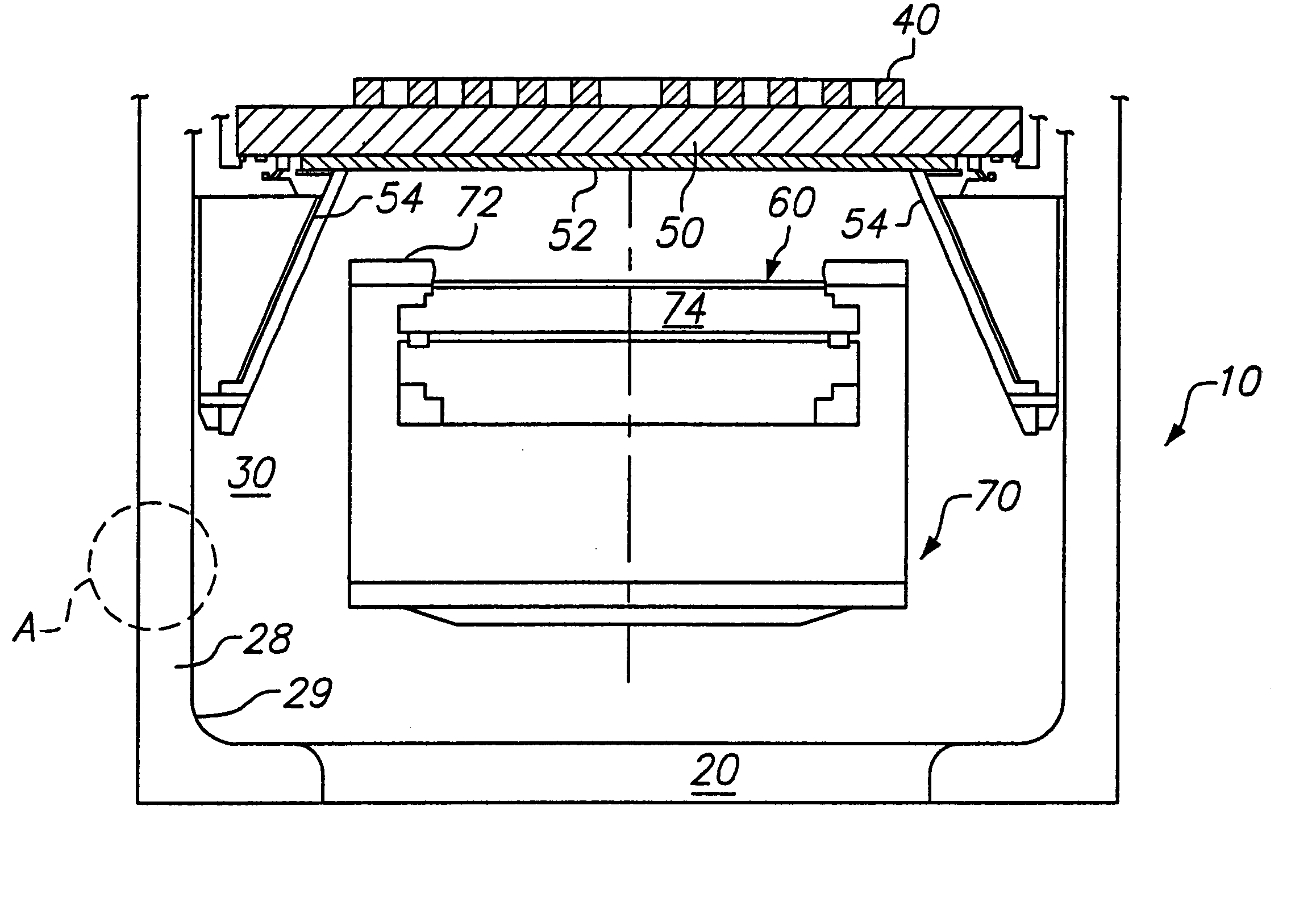

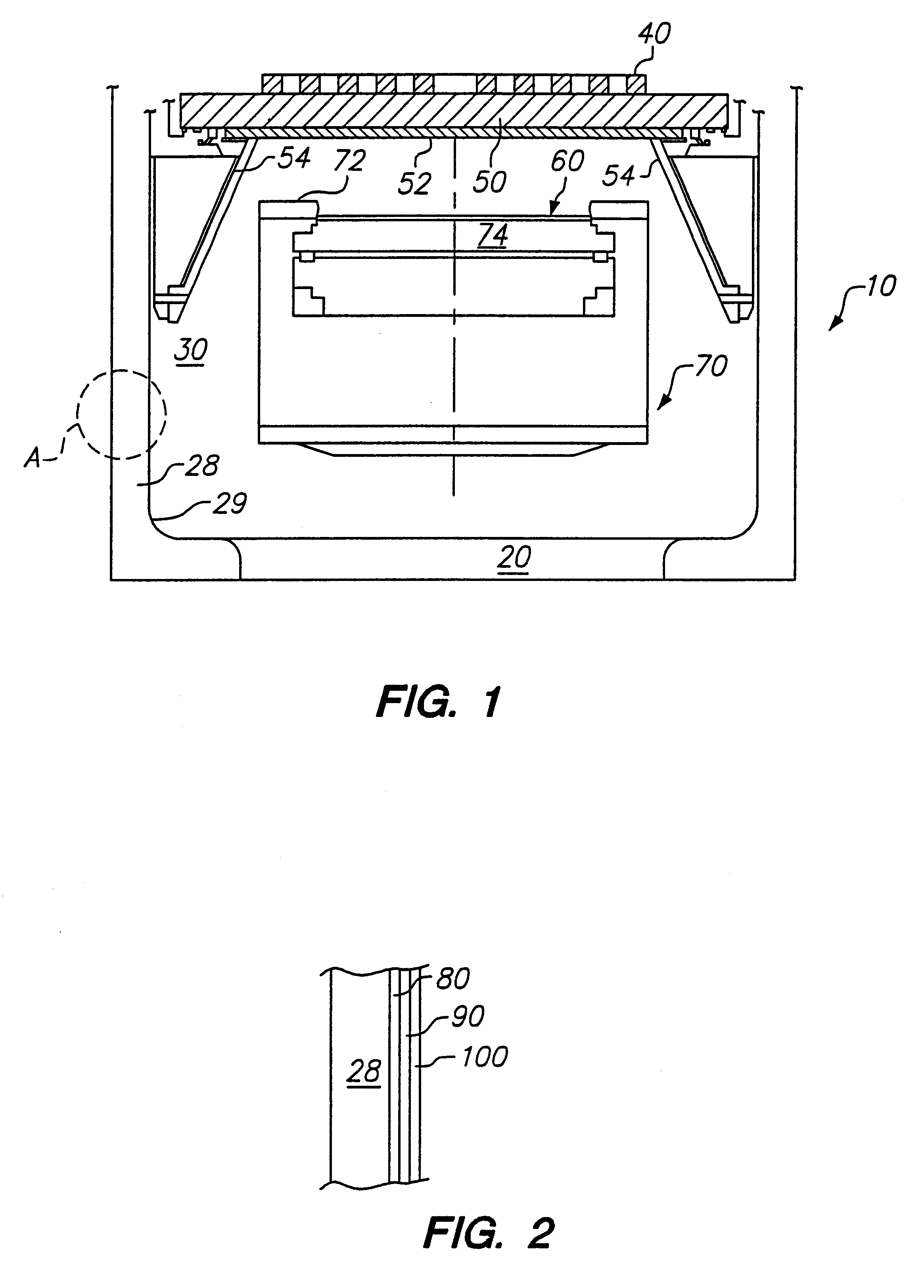

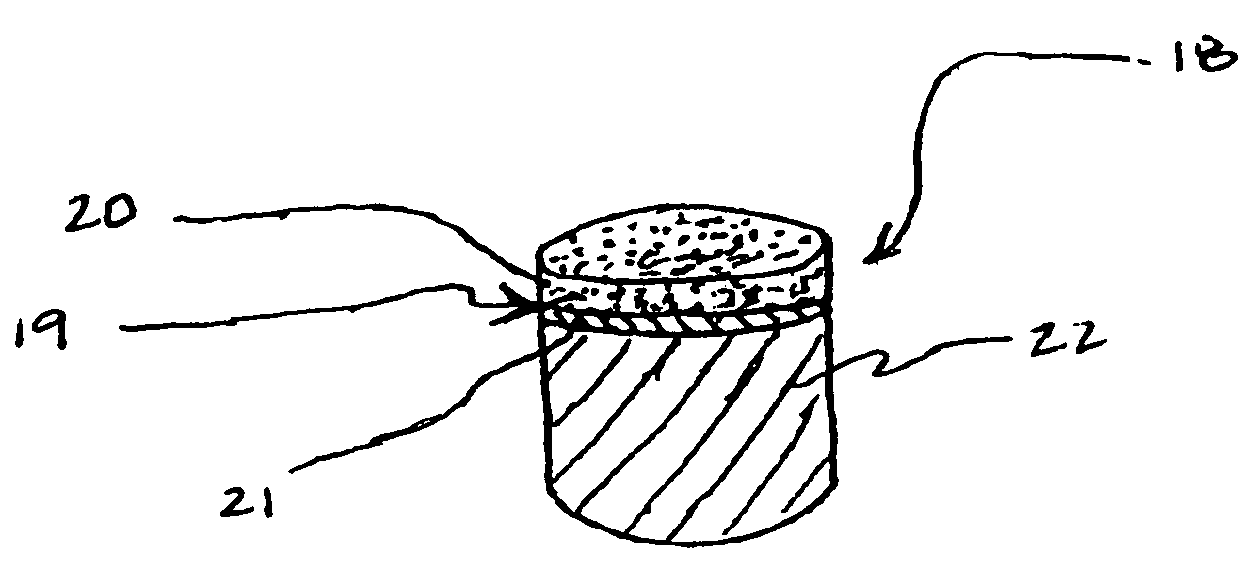

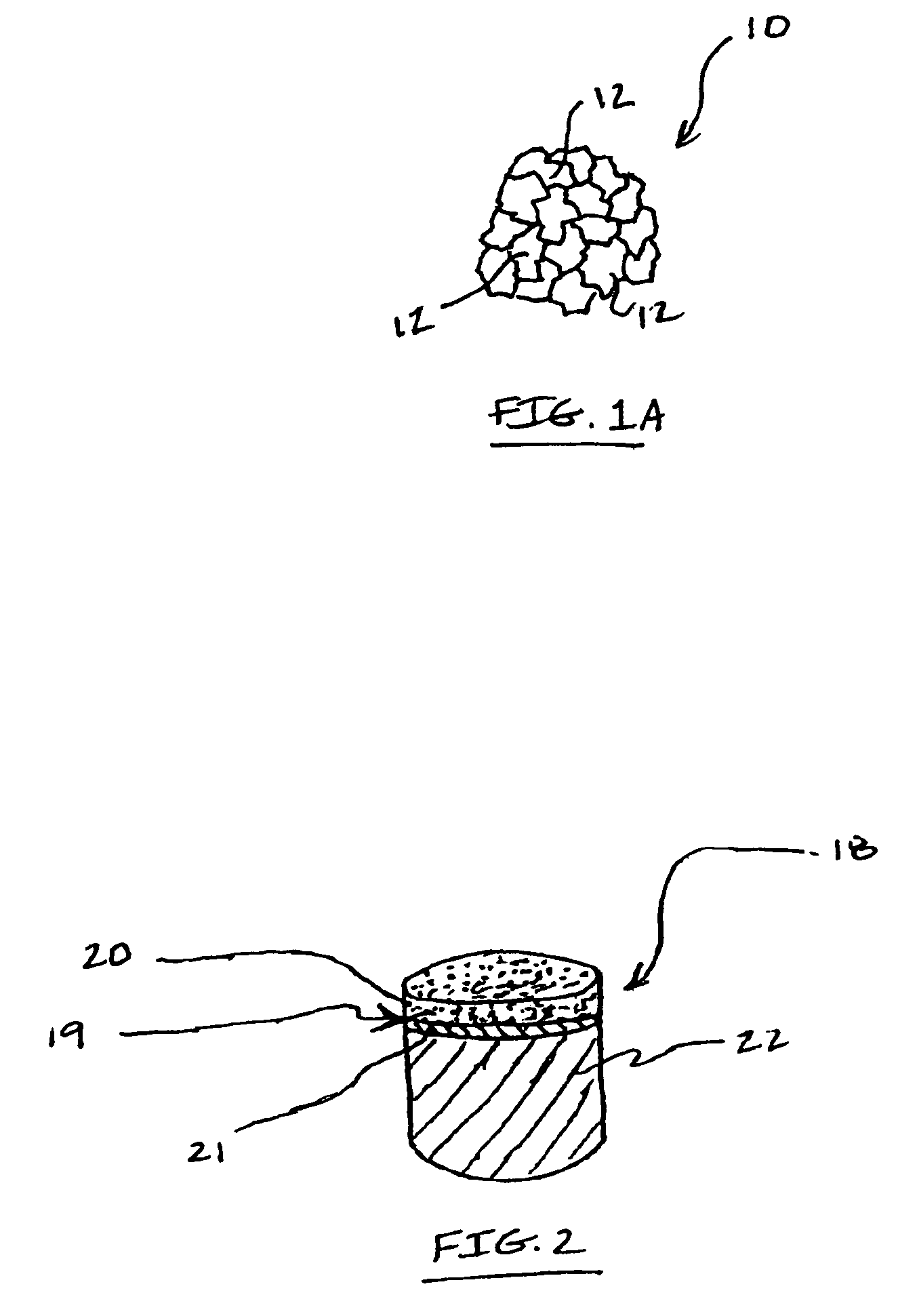

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

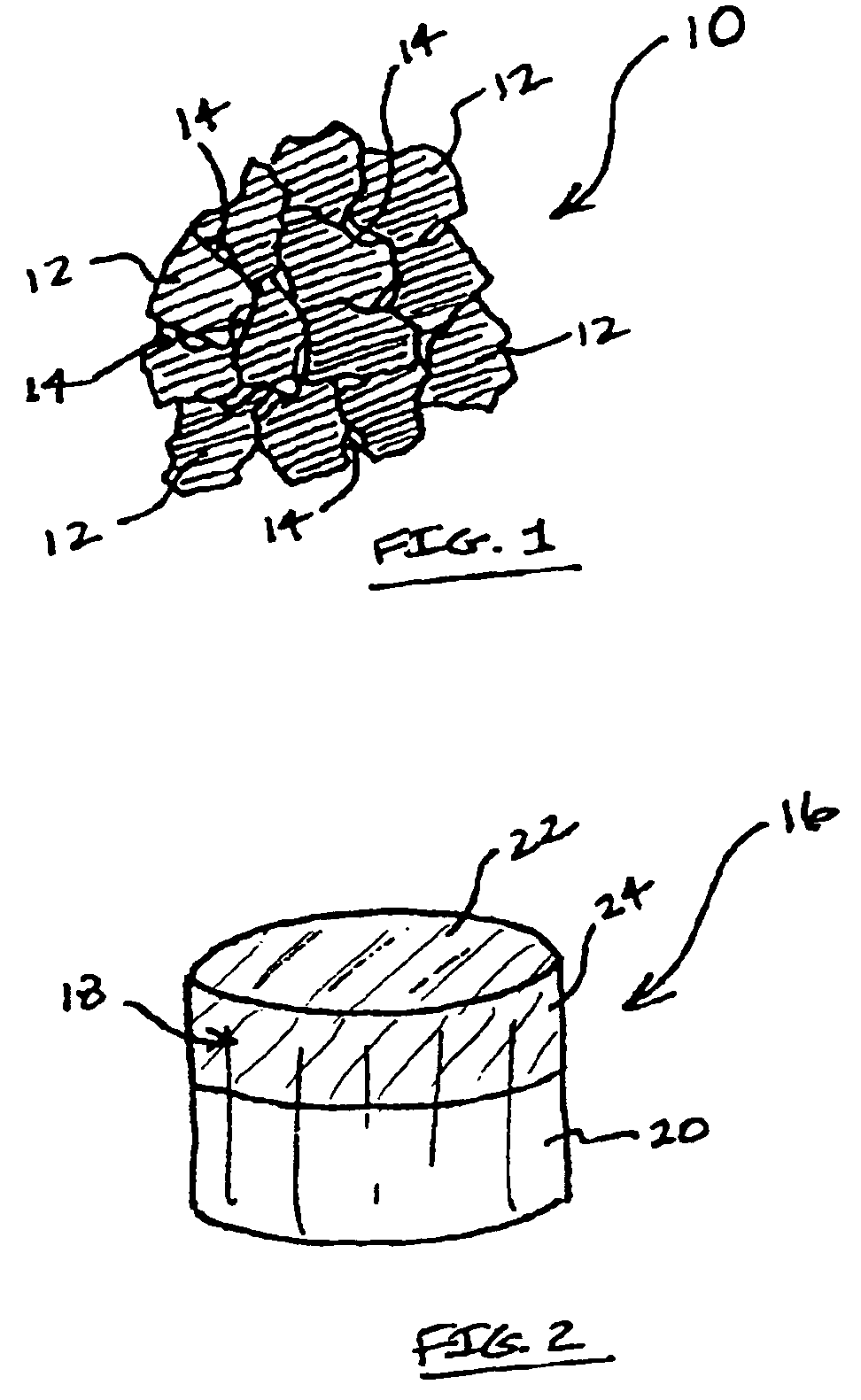

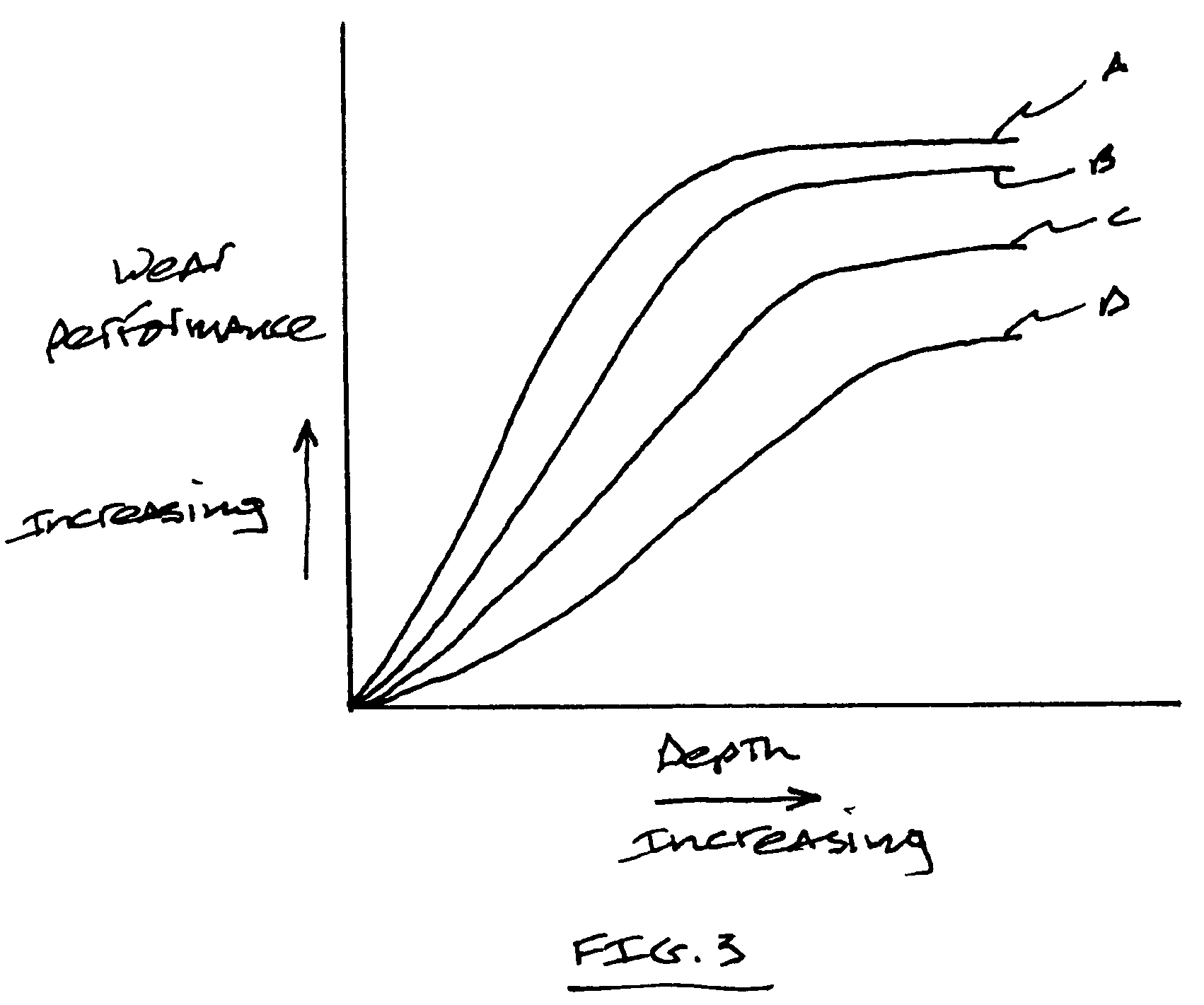

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

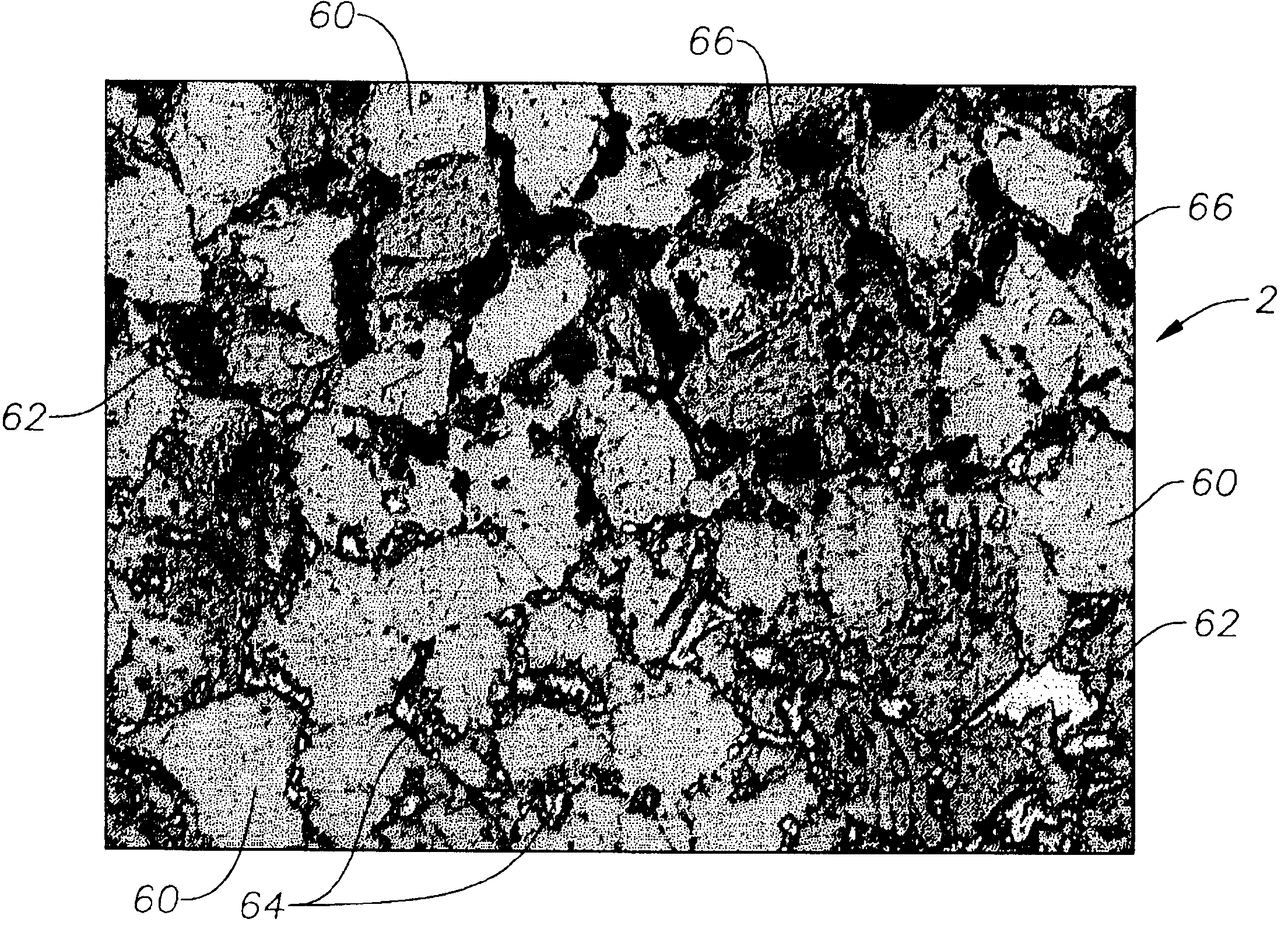

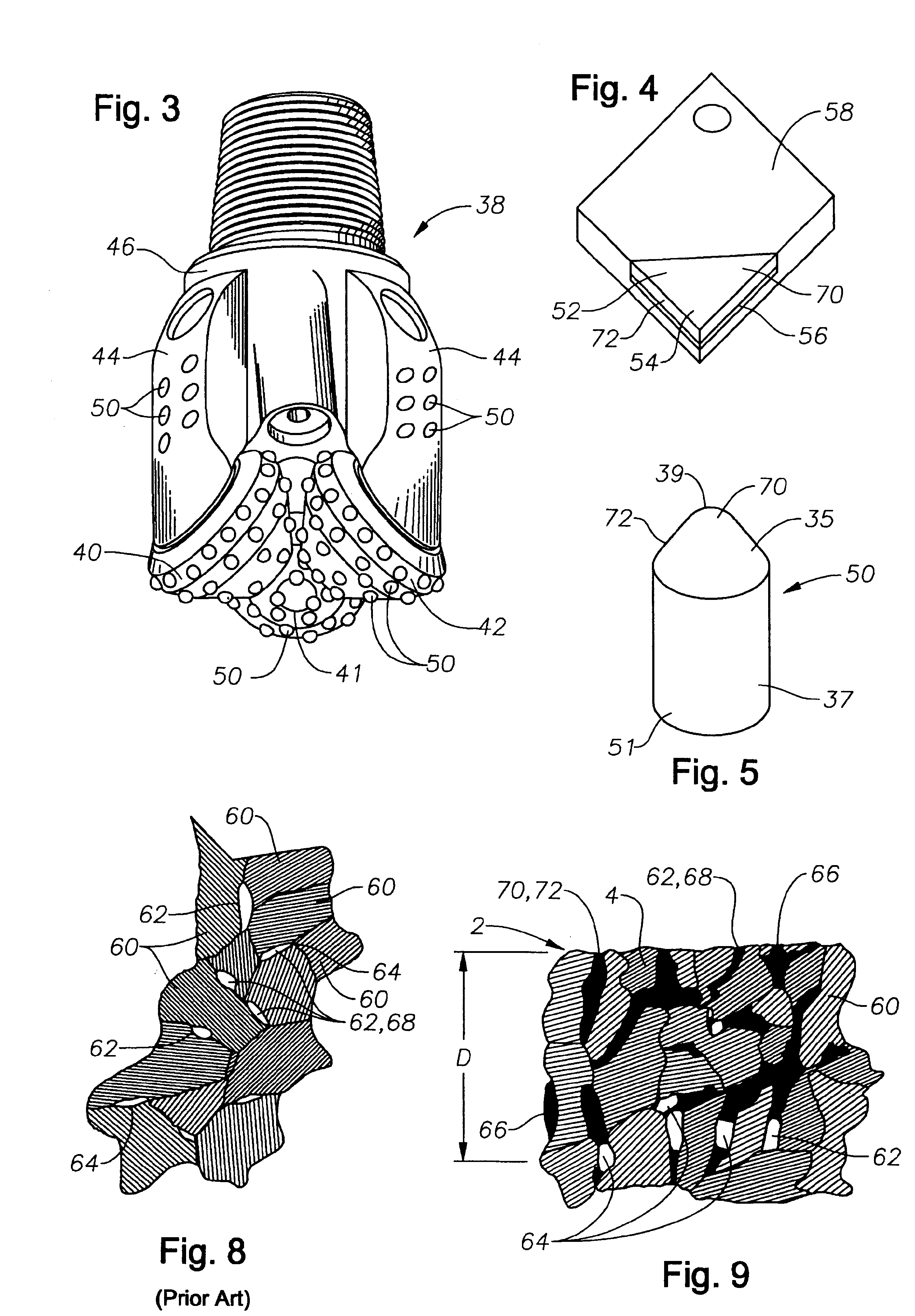

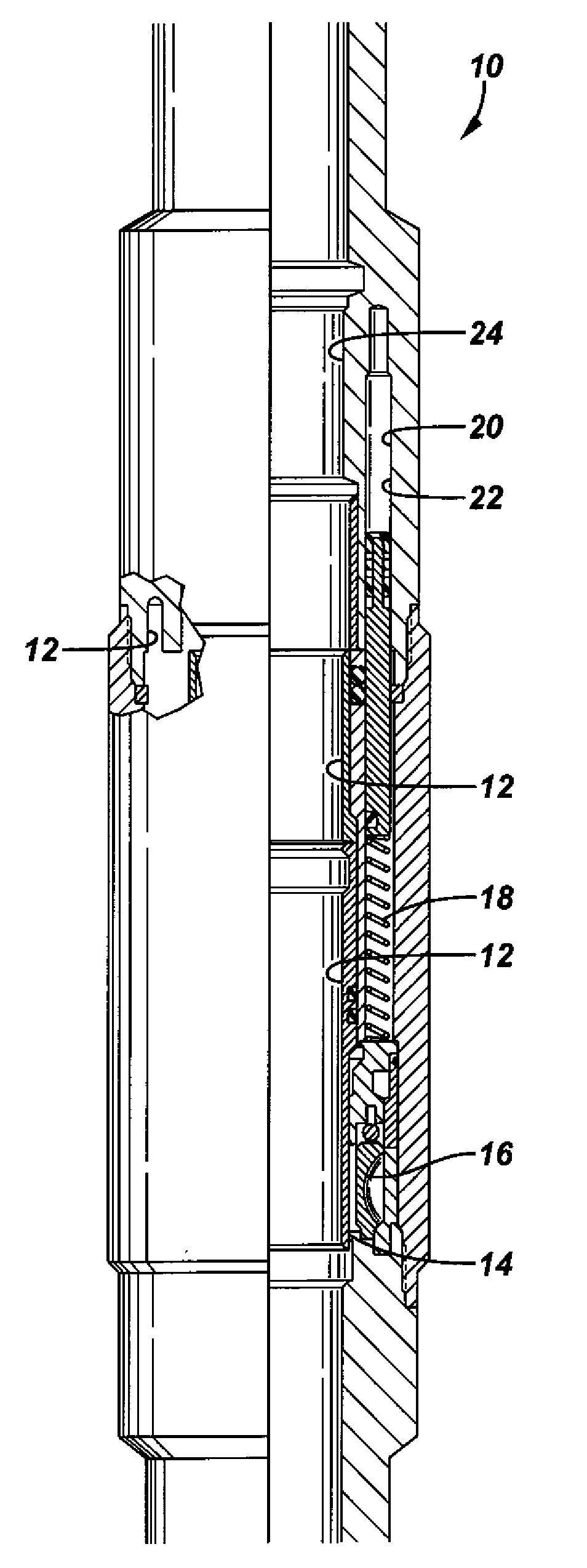

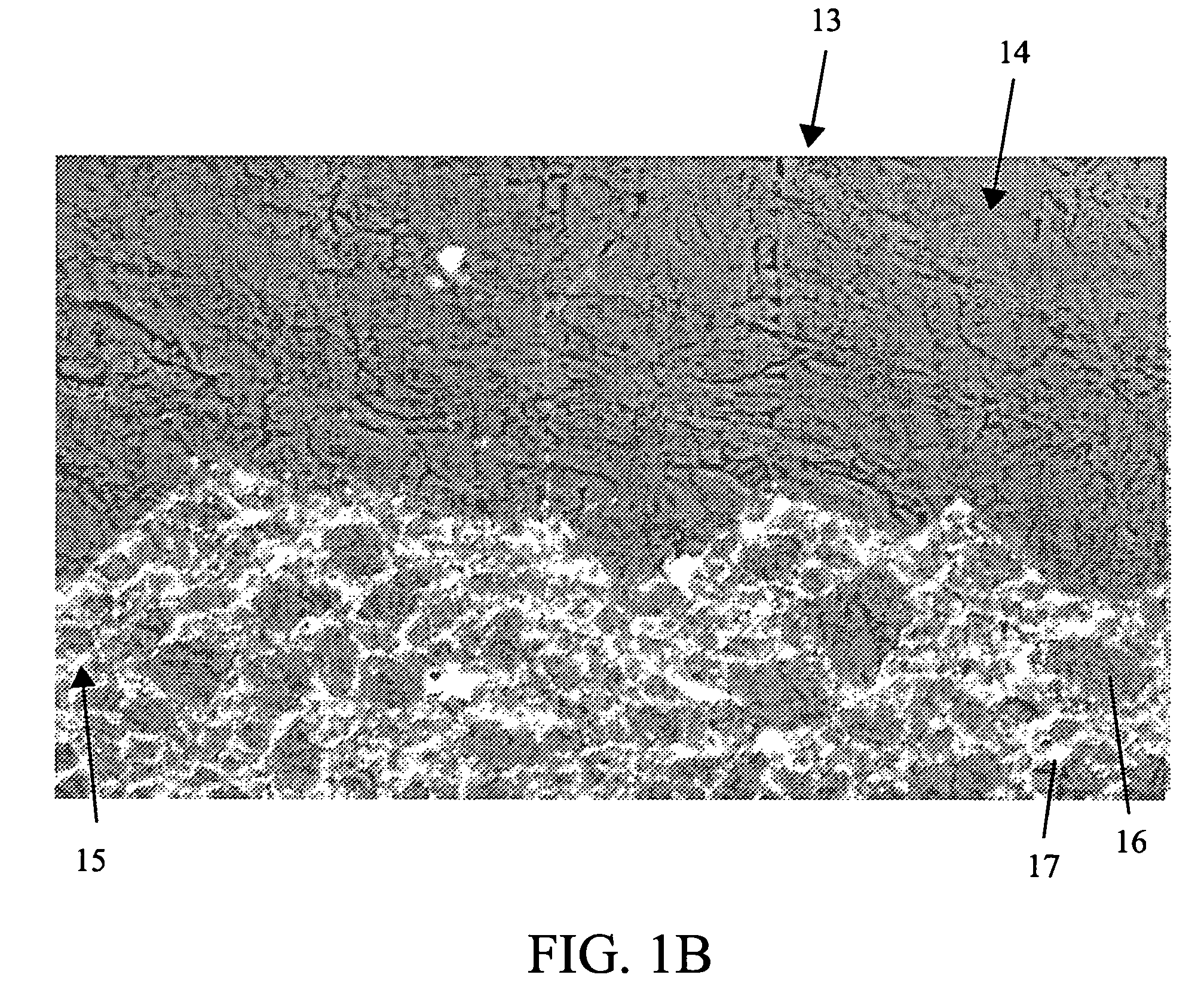

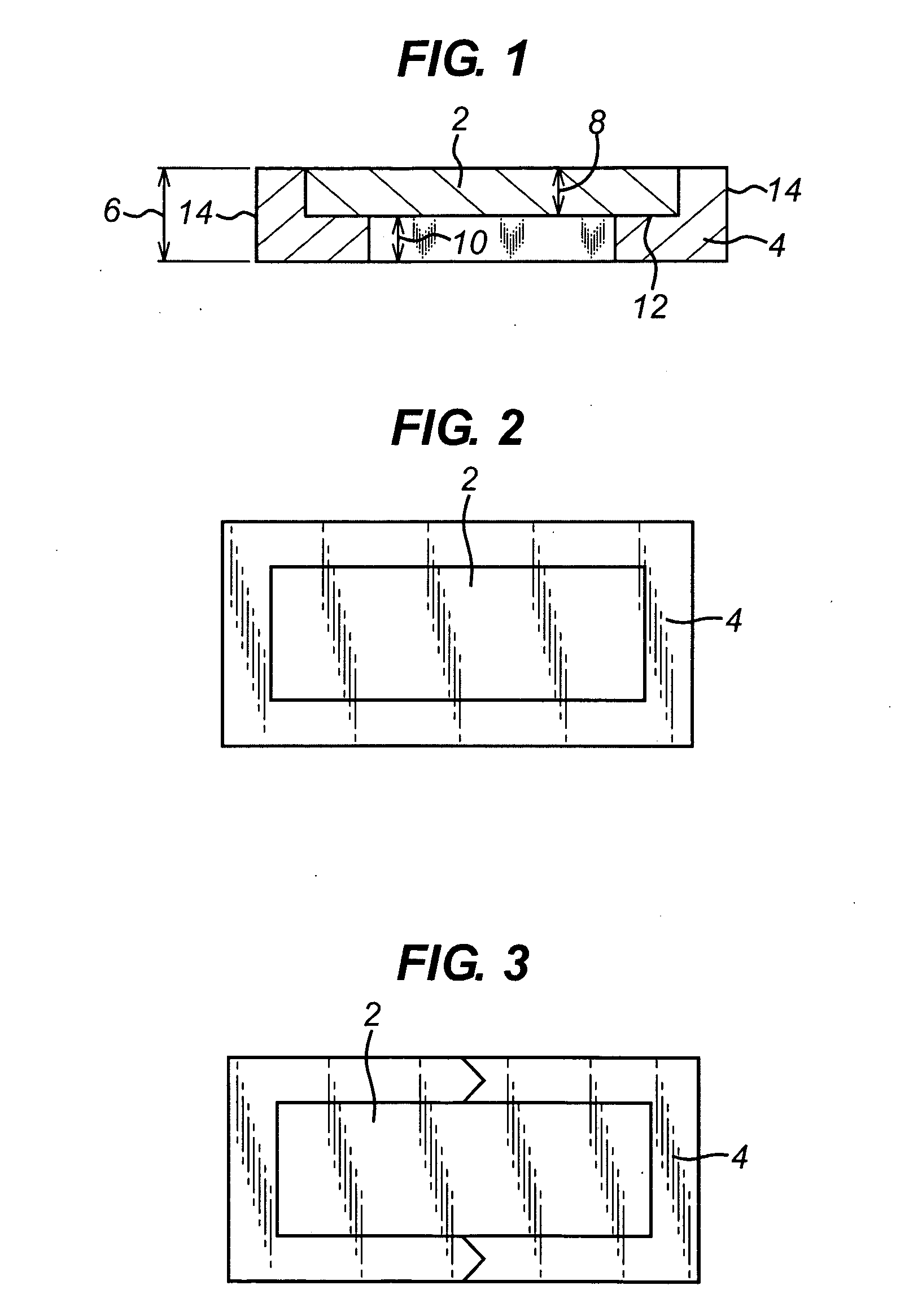

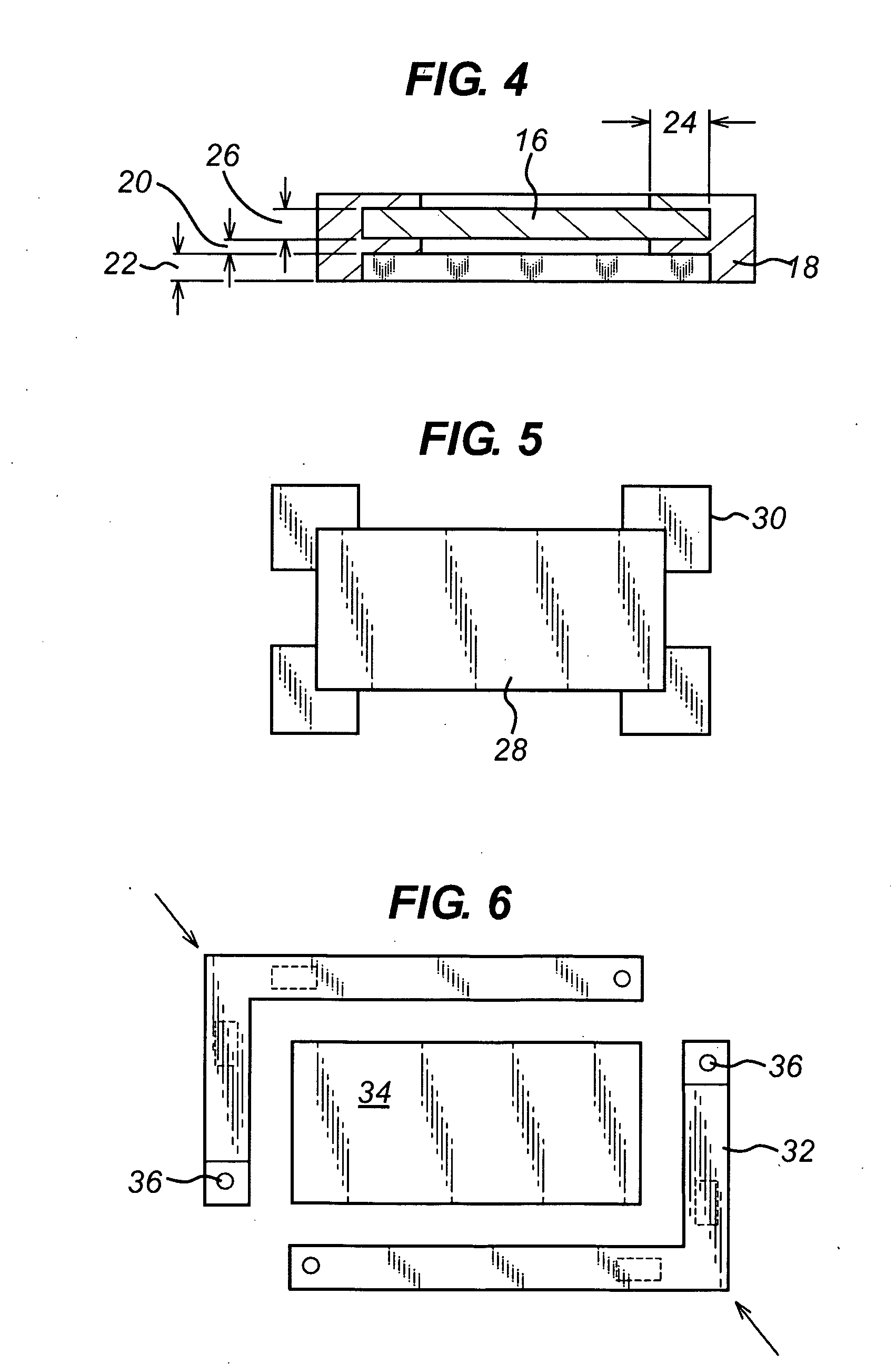

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

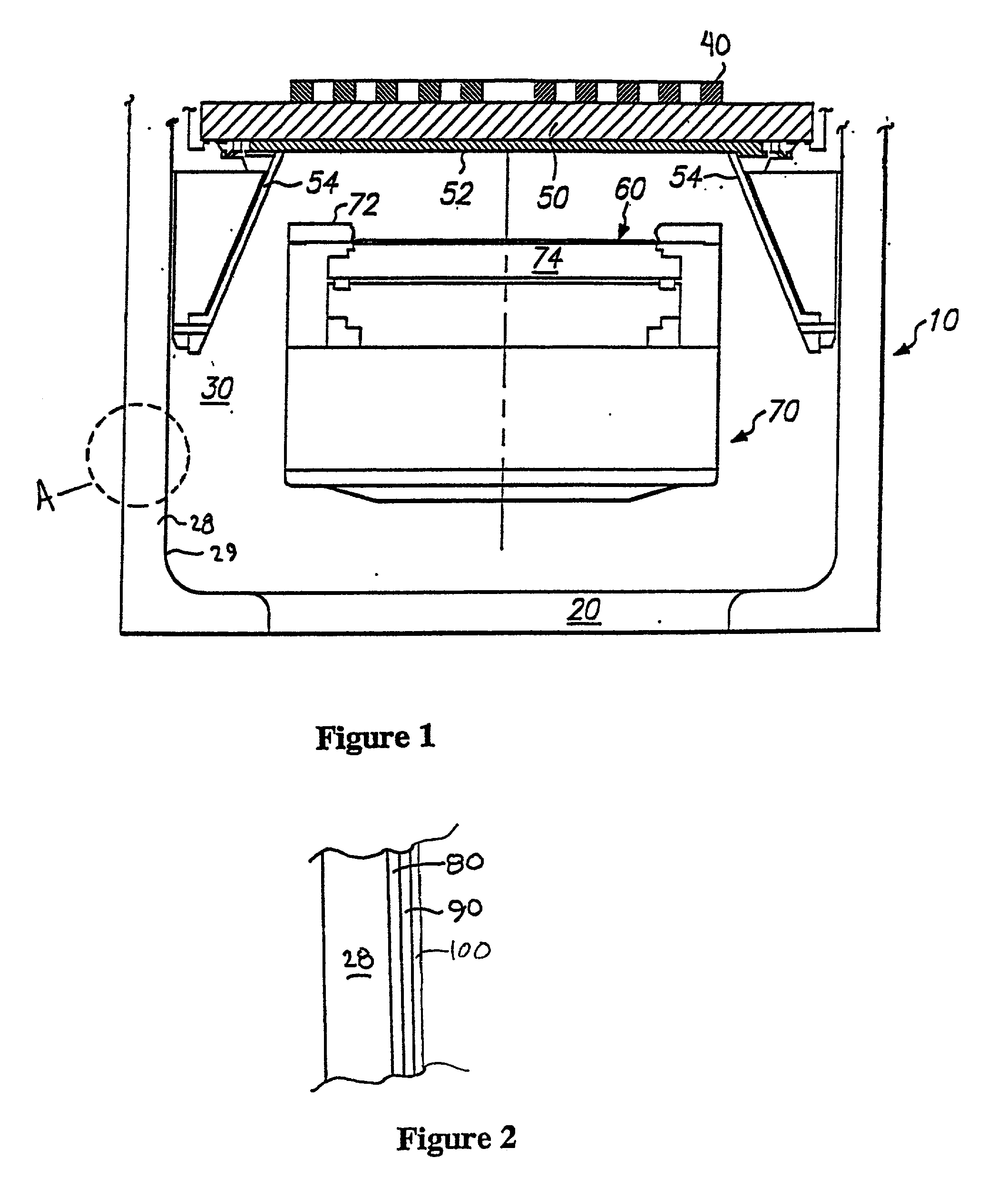

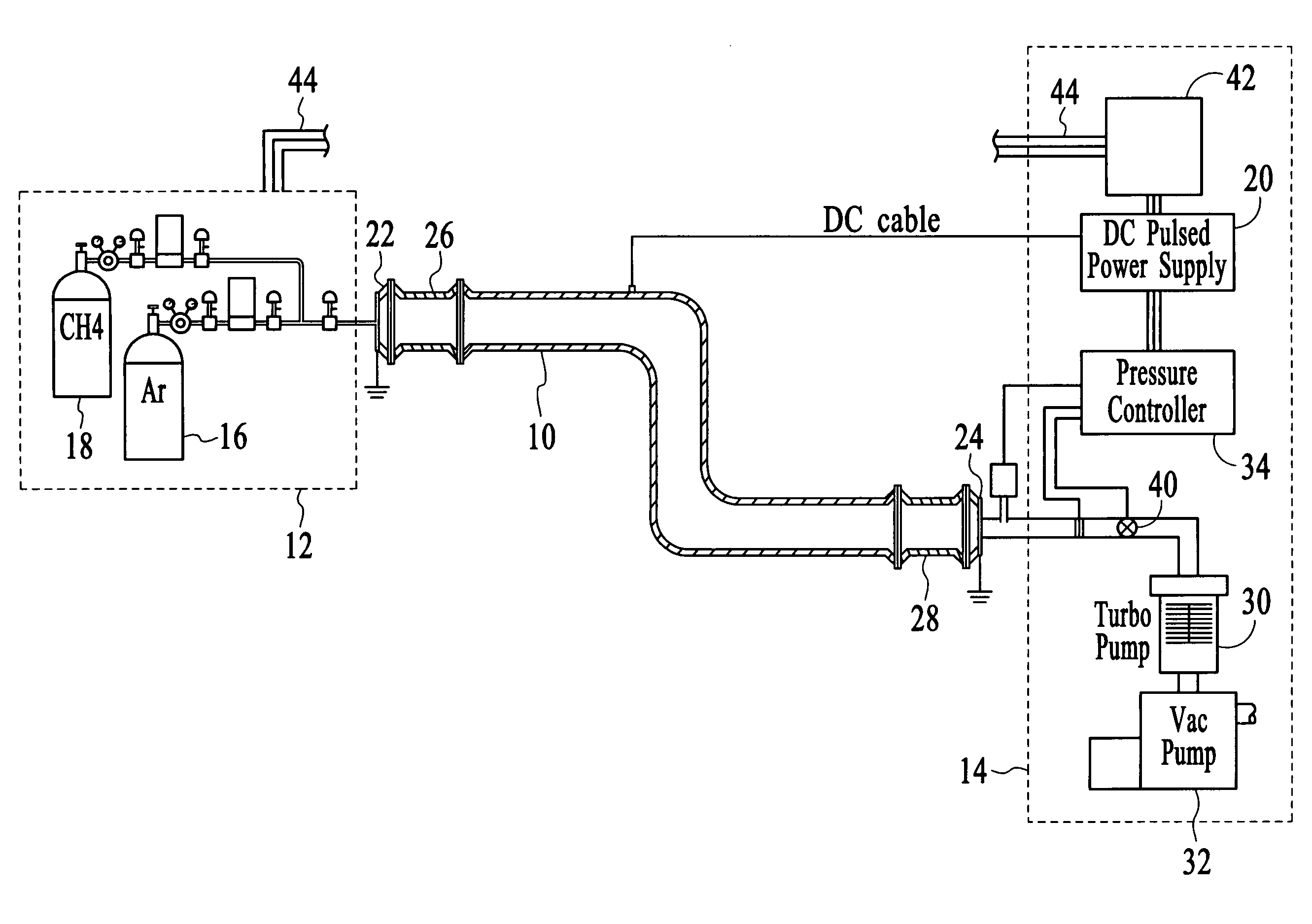

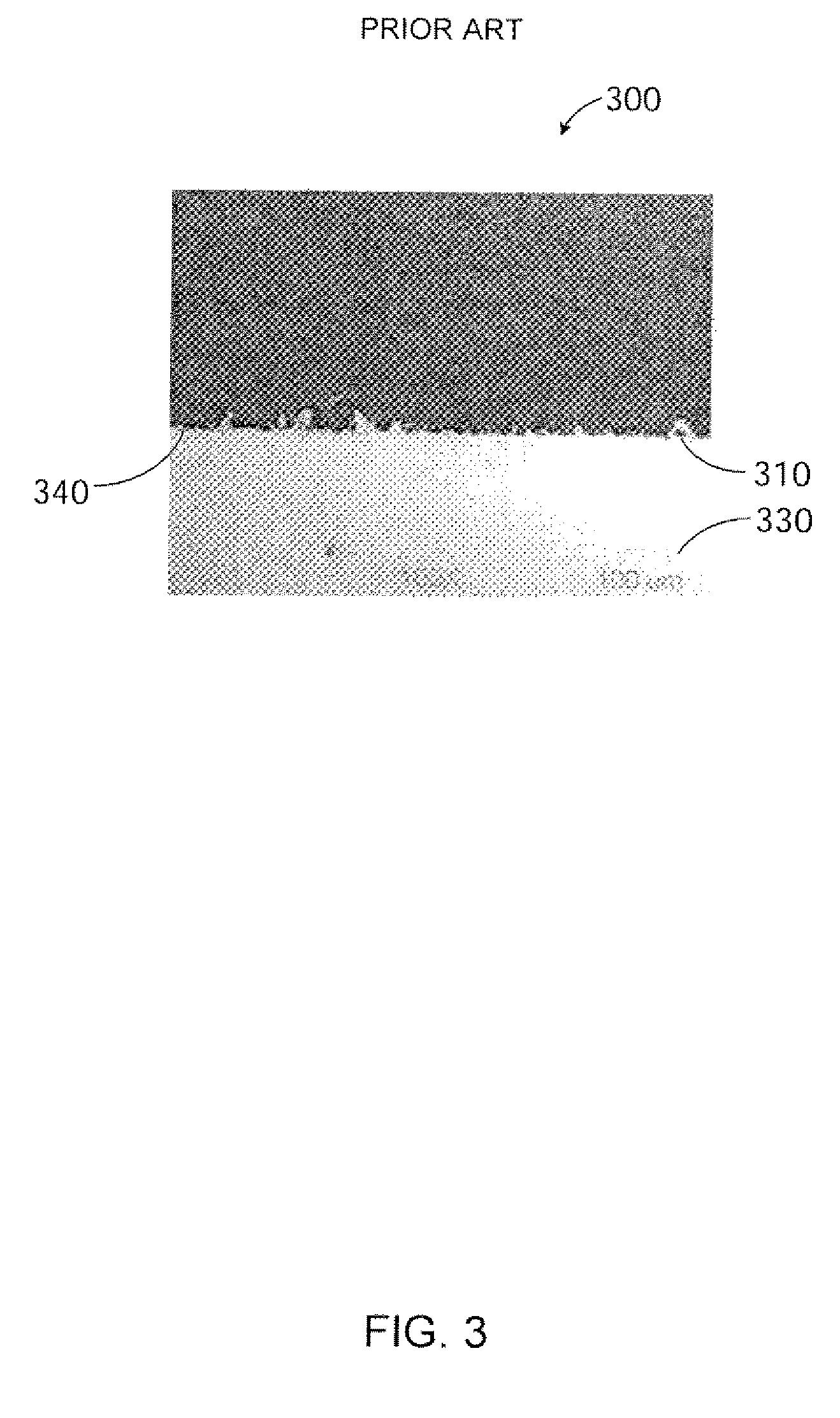

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS20020086501A1High purityIncrease resistanceFrom solid stateVacuum evaporation coatingMetallurgySemiconductor

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

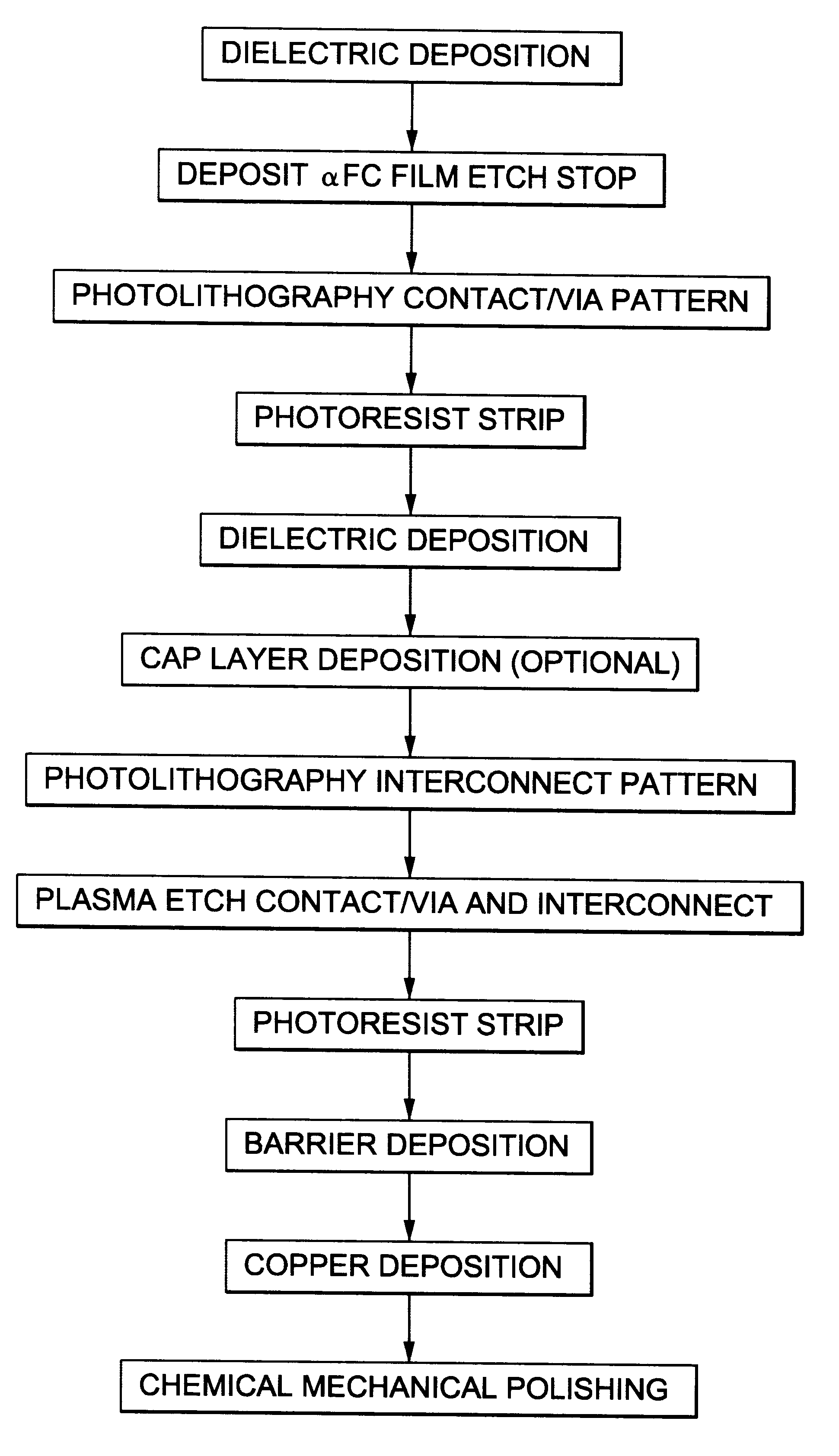

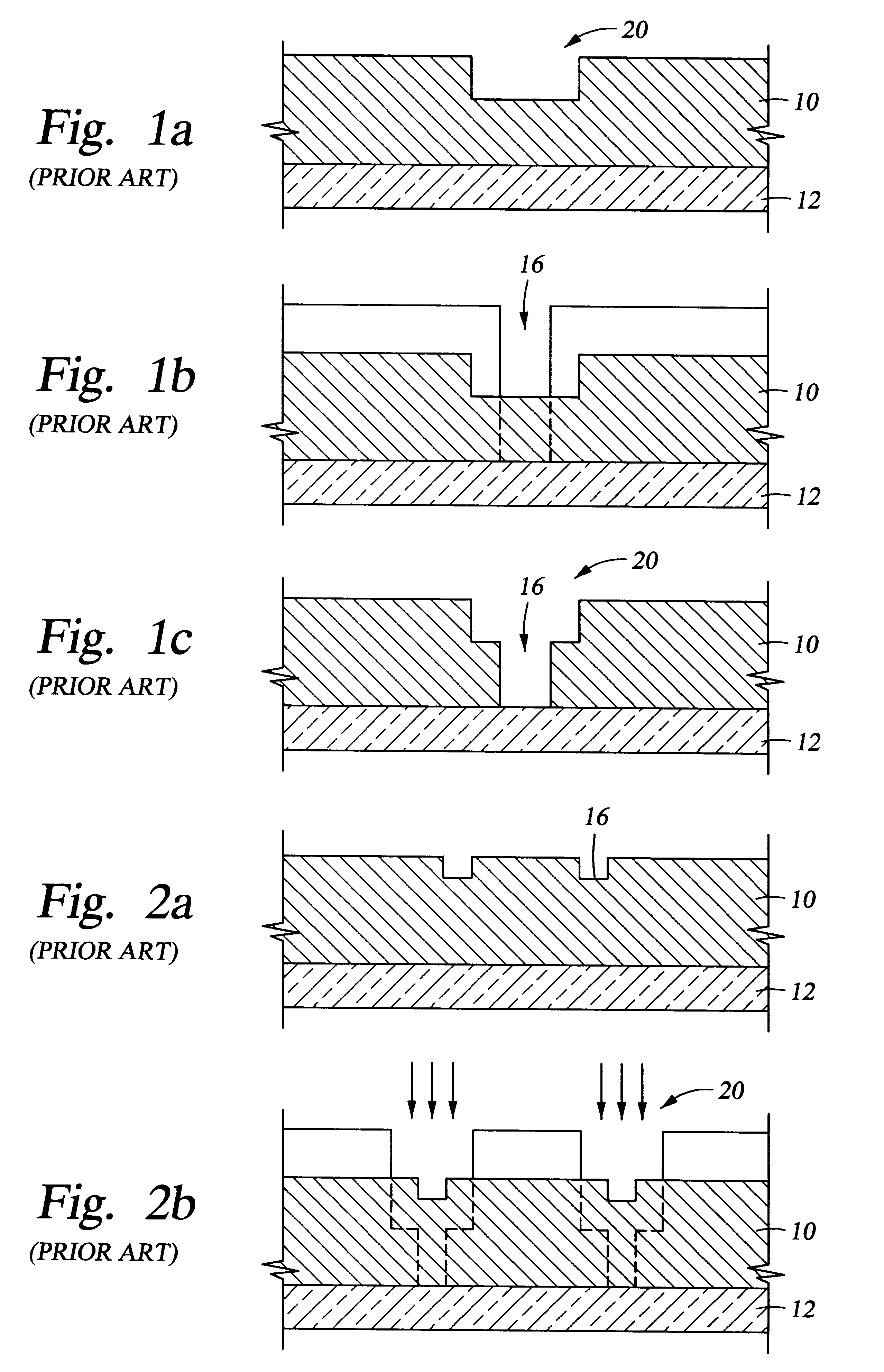

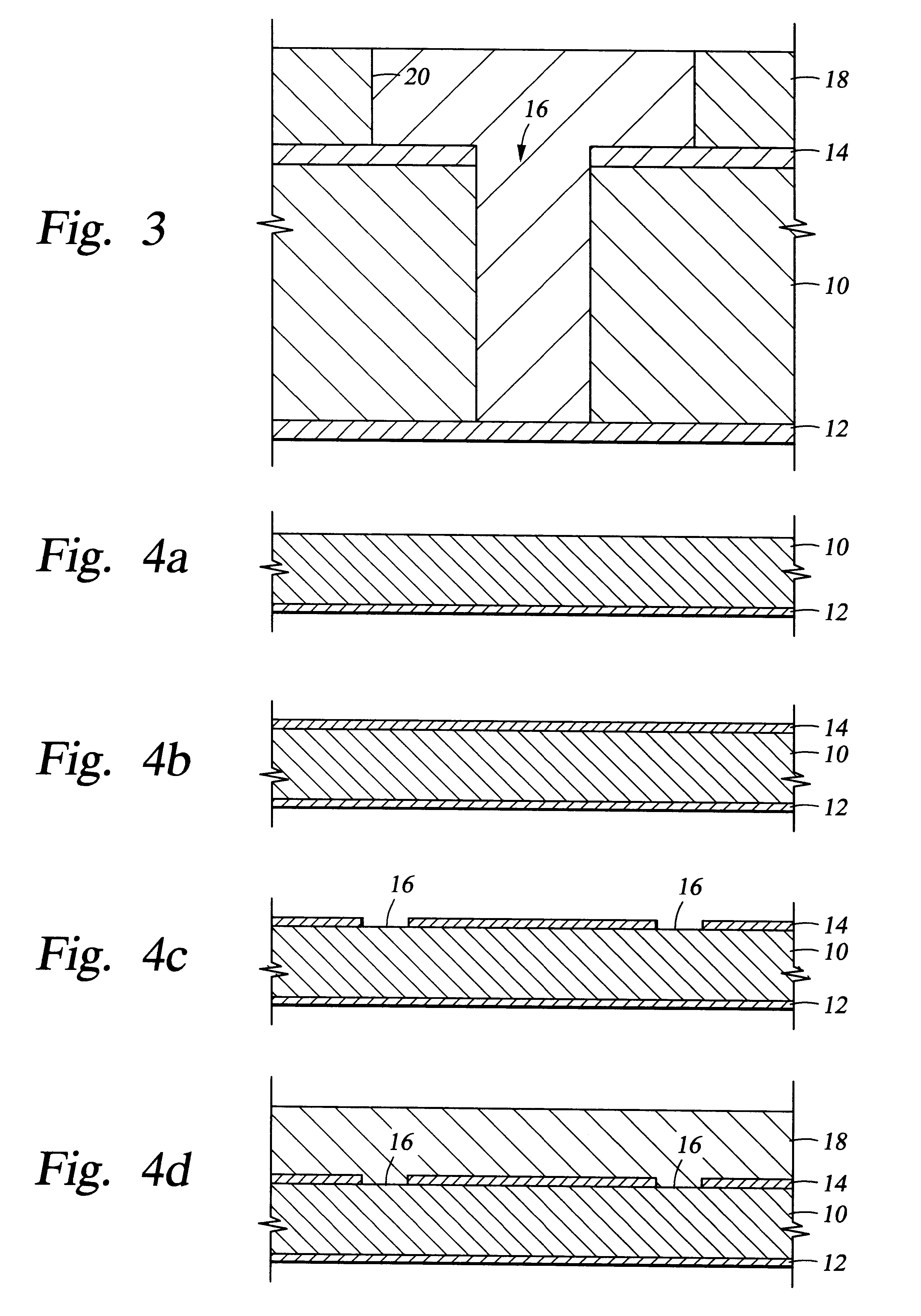

An etch stop layer for dual damascene process

The present invention provides a carbon based etch stop, such as a diamond like amorphous carbon, having a low dielectric constant and a method of forming a dual damascene structure. The low k etch stop is preferably deposited between two dielectric layers and patterned to define the underlying interlevel contacts / vias. The second or upper dielectric layer is formed over the etch stop and patterned to define the intralevel interconnects. The entire dual damascene structure is then etched in a single selective etch process which first etches the patterned interconnects, then etches the contact / vias past the patterned etch stop. The etch stop has a low dielectric constant relative to a conventional SiN etch stop, which minimizes the capacitive coupling between adjacent interconnect lines. The dual damascene structure is then filled with a suitable conductive material such as aluminum or copper and planarized using chemical mechanical polishing.

Owner:APPLIED MATERIALS INC

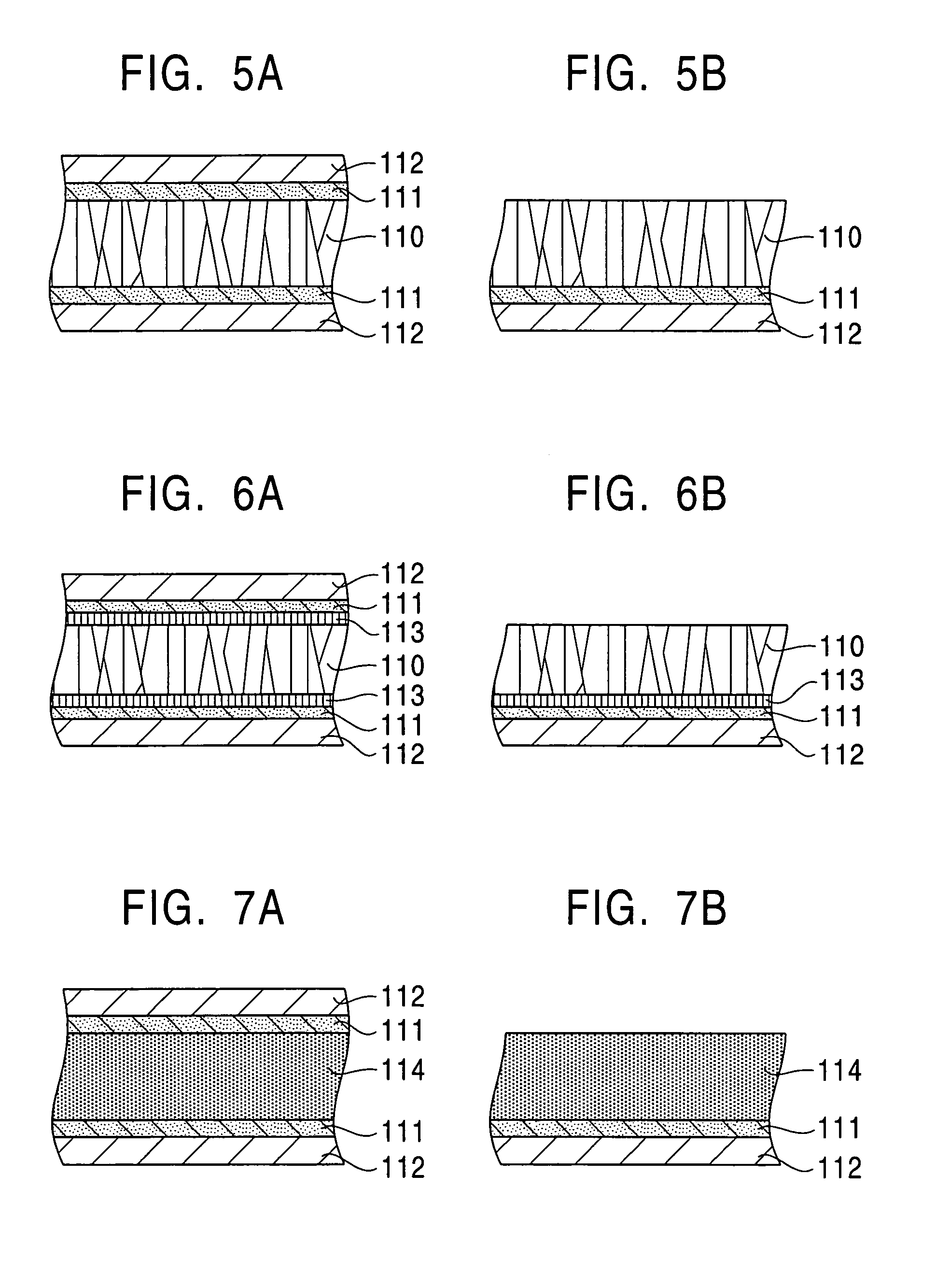

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

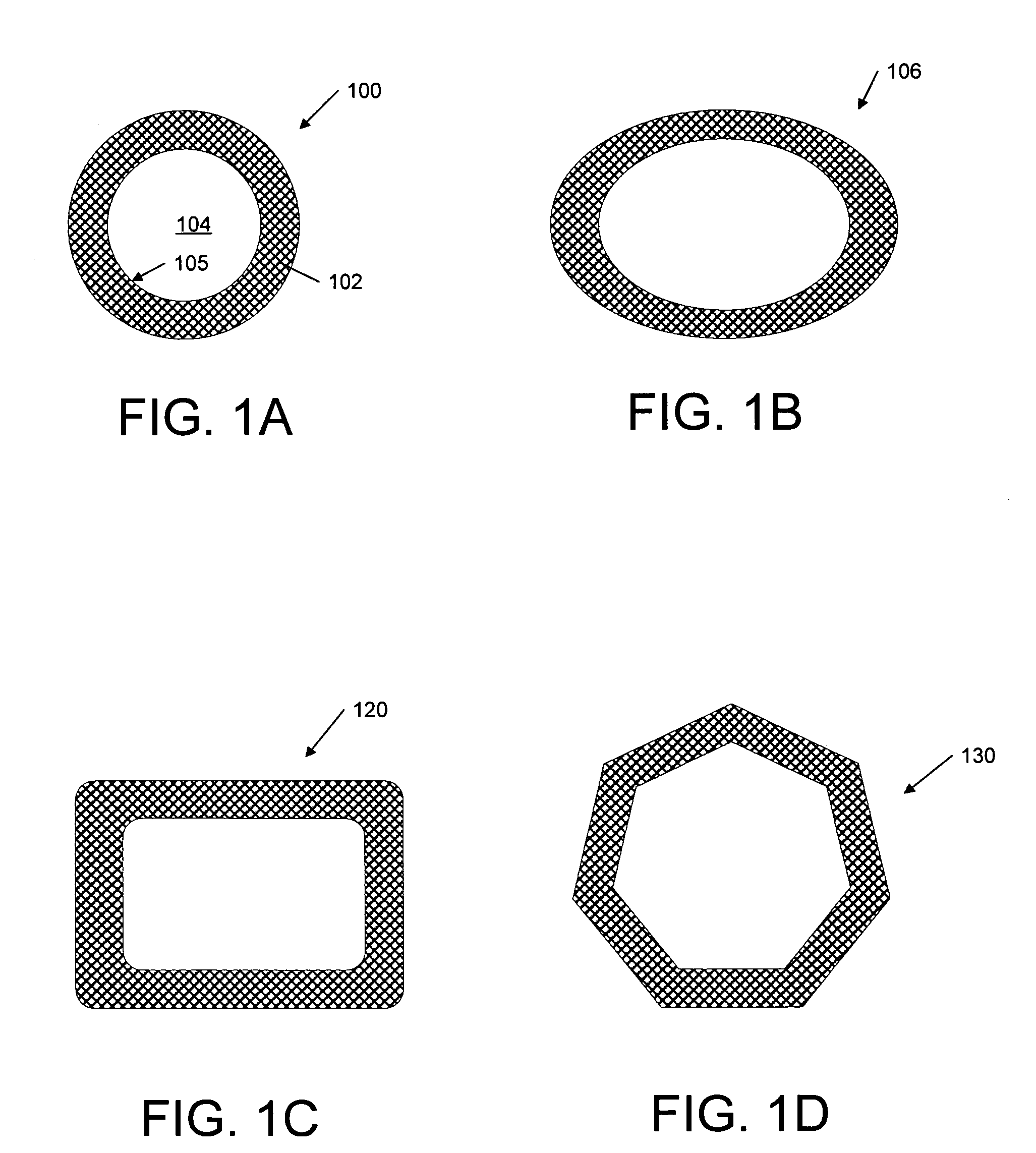

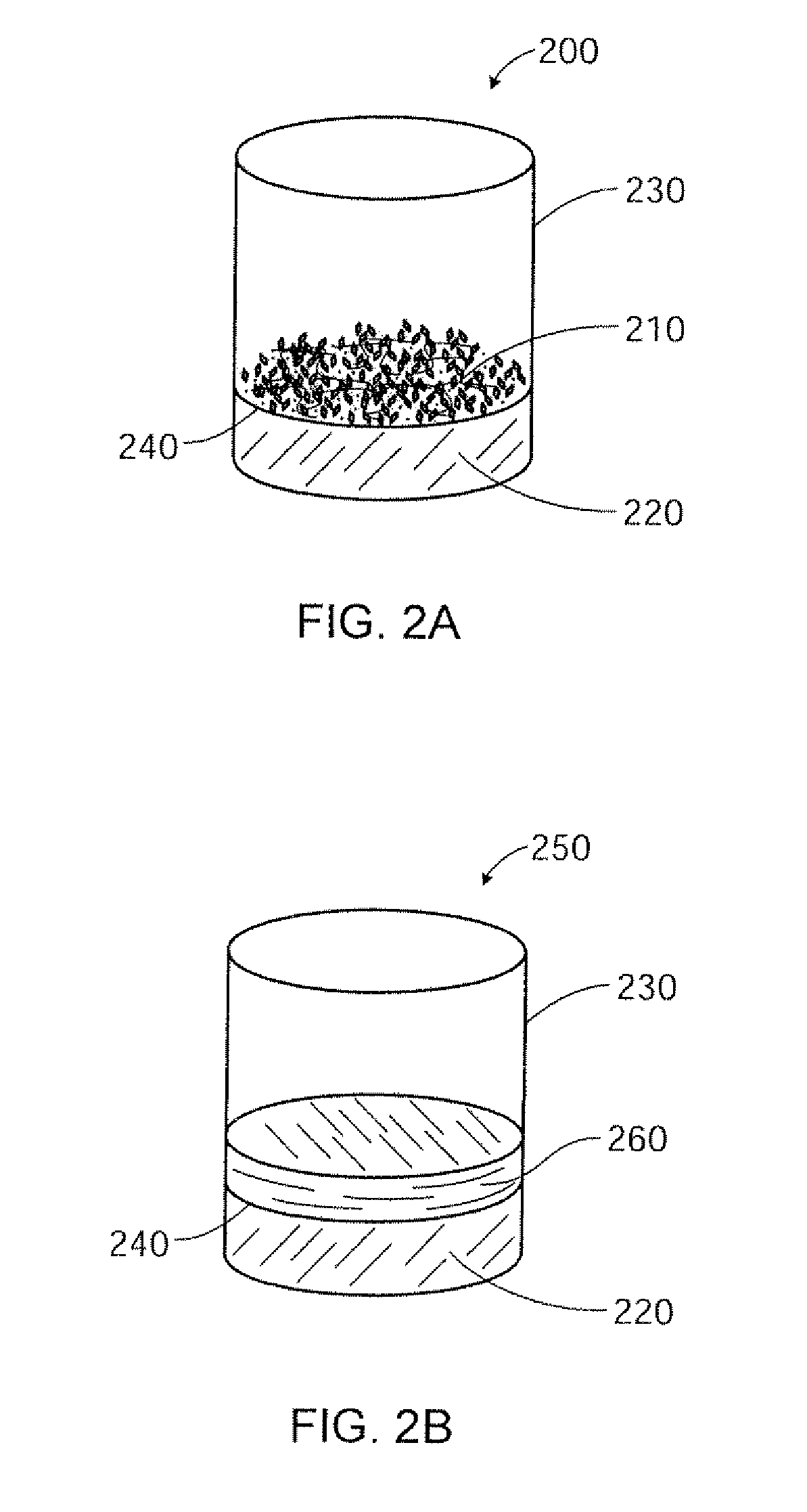

Diamond capsules and methods of manufacture

InactiveUS20100297391A1Reduce temperature differenceImprove conductivityLayered productsShaftsNanocrystalAccess port

Capsules and similar objects are made from materials having diamond (sp3) lattice structures, including diamond materials in synthetic crystalline, polycrystalline (ordered or disordered), nanocrystalline and amorphous forms. The capsules generally include a hollow shell made of a diamond material that defines an interior region that may be empty or that may contain a fluid or solid material. Some of the capsules include access ports that can be used to fill the capsule with a fluid. Capsules and similar structures can be manufactured by growing diamond on suitably shaped substrates. In some of these methods, diamond shell sections are grown on substrates, then joined together. In other methods, a nearly complete diamond shell is grown around a form substrate, and the substrate can be removed through a relatively small opening in the shell.

Owner:SUNSHELL

Method of polishing CVD diamond films by oxygen plasma

InactiveUS6013191APolycrystalline material growthAfter-treatment detailsFluorinated gasesOxygen plasma

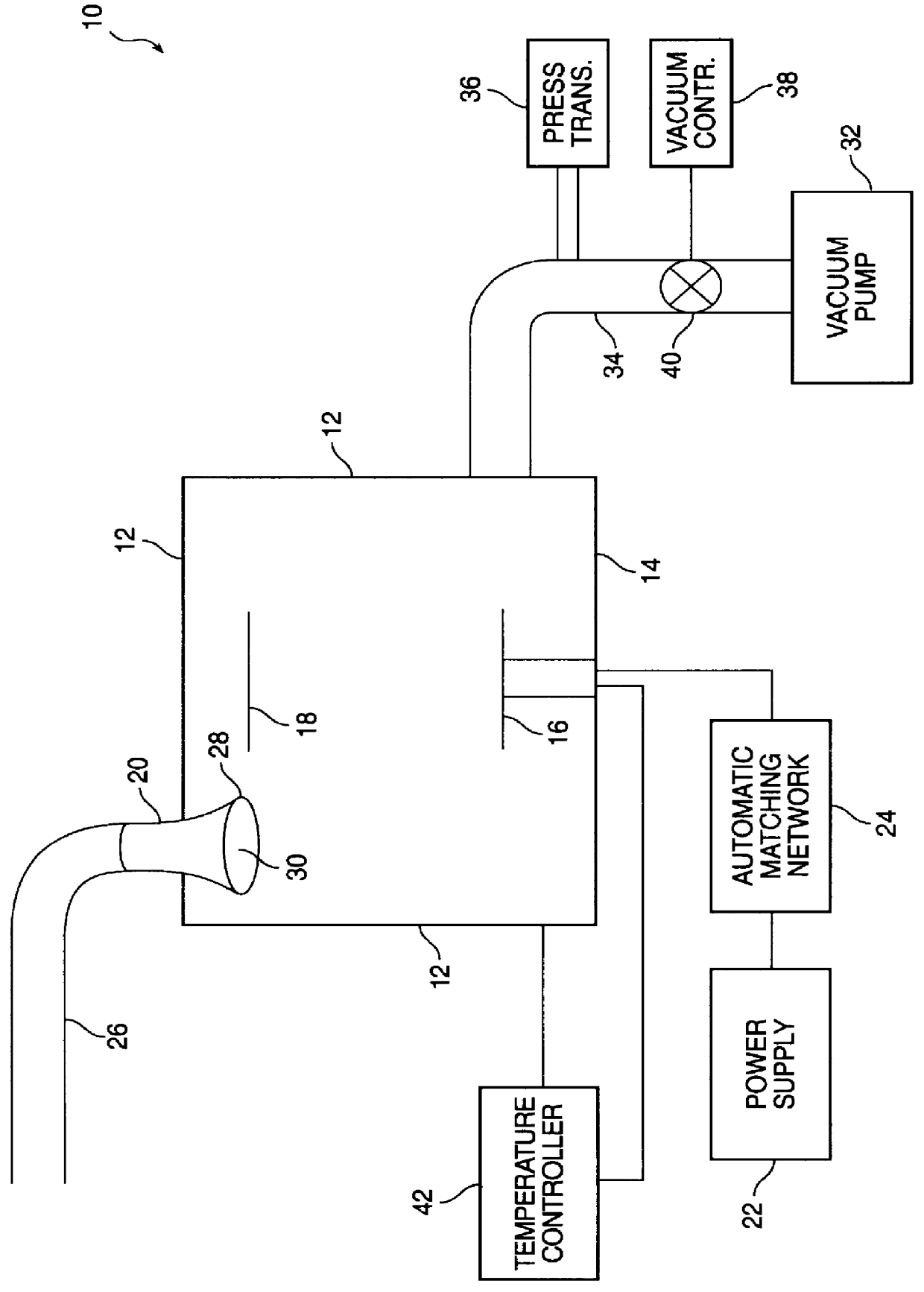

A method for polishing the surface of a diamond film with a low power density plasma in a reactor which comprises disposing O2 gas and a fluorinated gas such as SF6, NF3, and C2F6 in the reactor, providing power to the reactor so that the power density in the reactor is between about 1.0 watts / cm2 and about 1.1 watts / cm2 for a first duration, and maintaining temperature in the reactor at between about 200 DEG to about 400 DEG . The method may alternatively comprise disposing a sputter gas such as Ar,O2 or N2 in the reactor, providing power to the reactor so that the power density in the reactor is between about 3.0 watts / cm2 and about 7.5 watts / cm2 for a first duration, and performing a sputter etch, disposing O2 gas and a fluorinated gas such as SF6, NF3, and C2F6 in the reactor, and providing power to the reactor so that the power density in the reactor is between about 1.5 watts / cm2 and about 3.0 watts / cm2 for a second duration.

Owner:ADVANCED REFRACTORY TECH INC

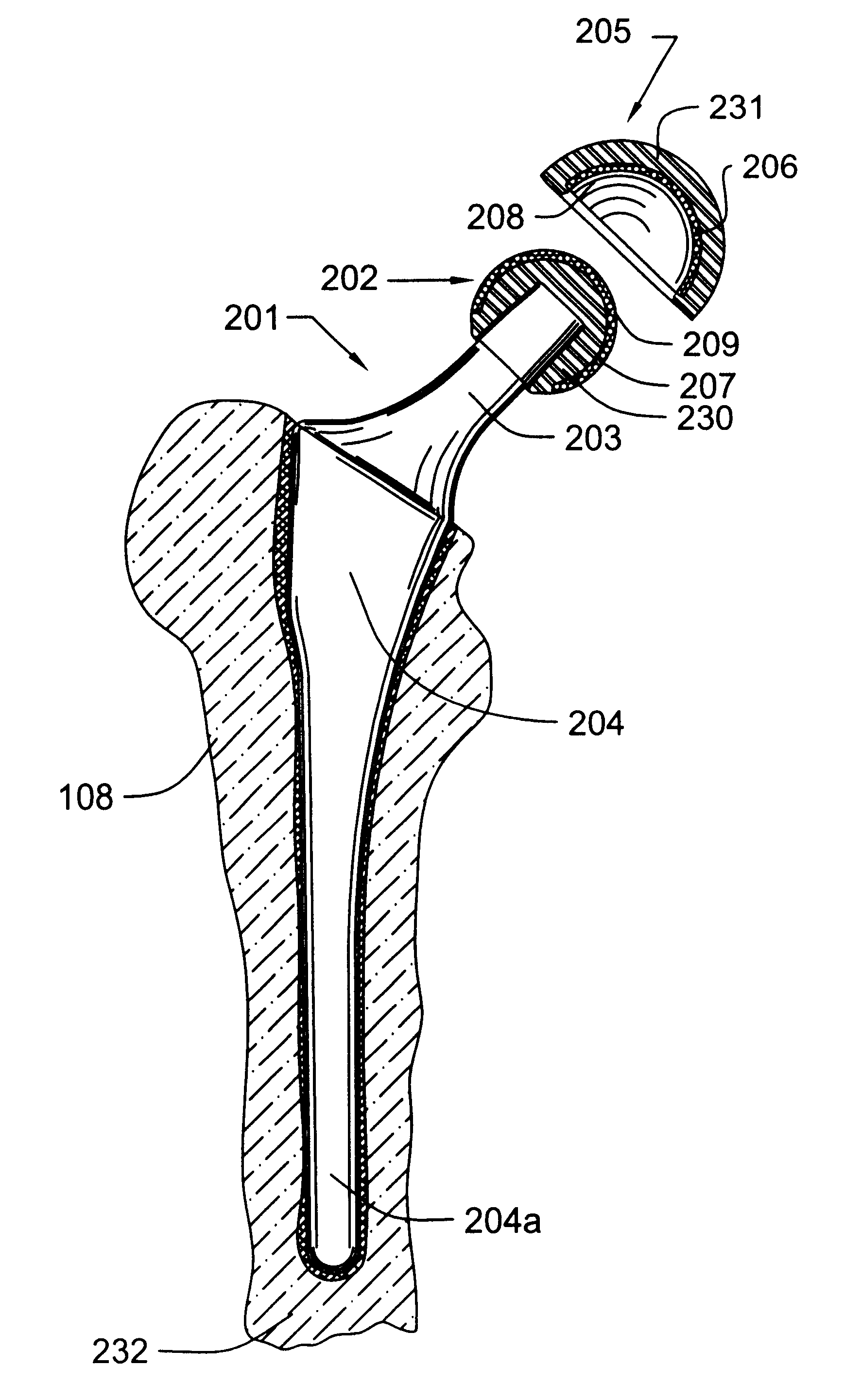

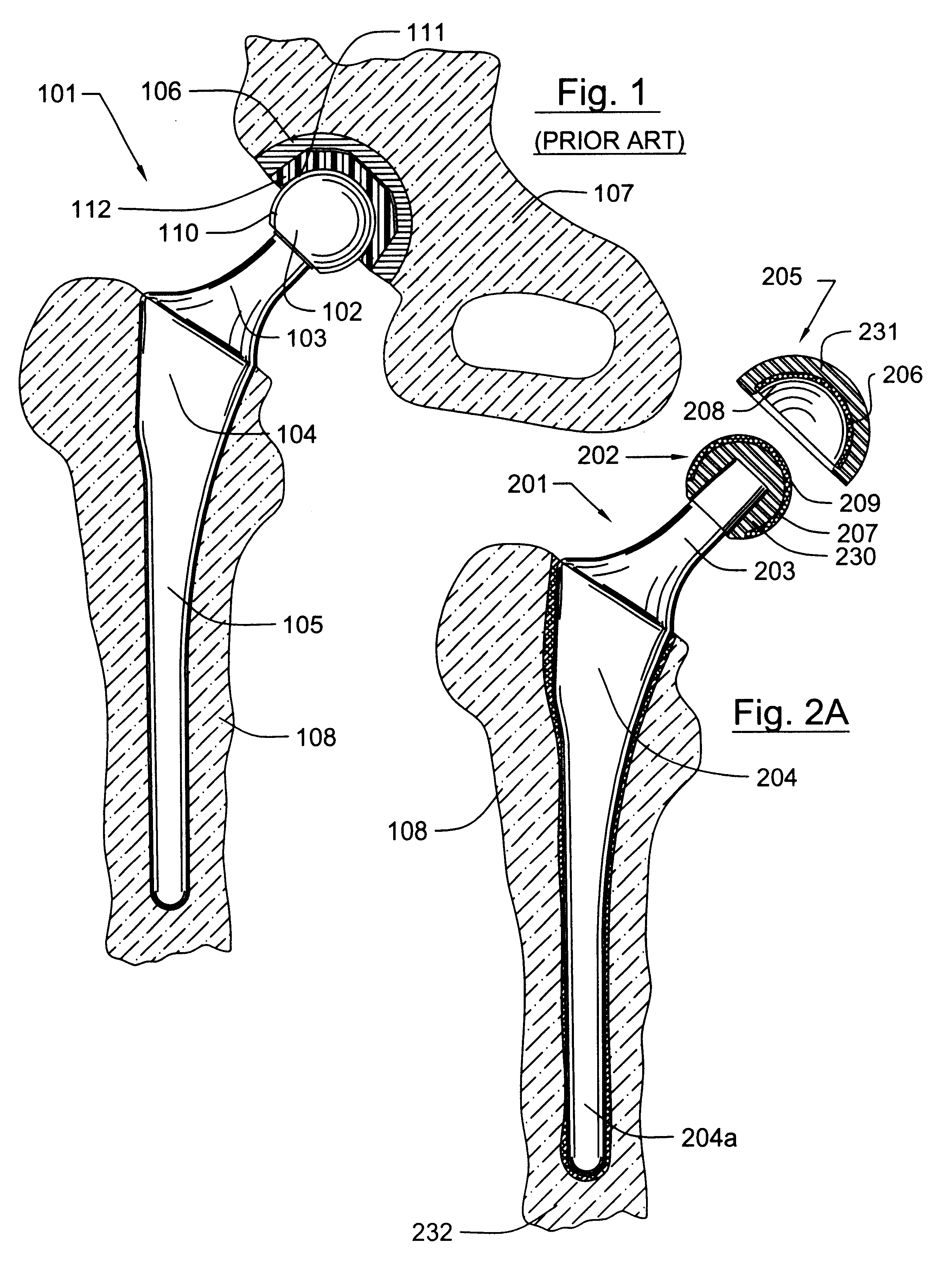

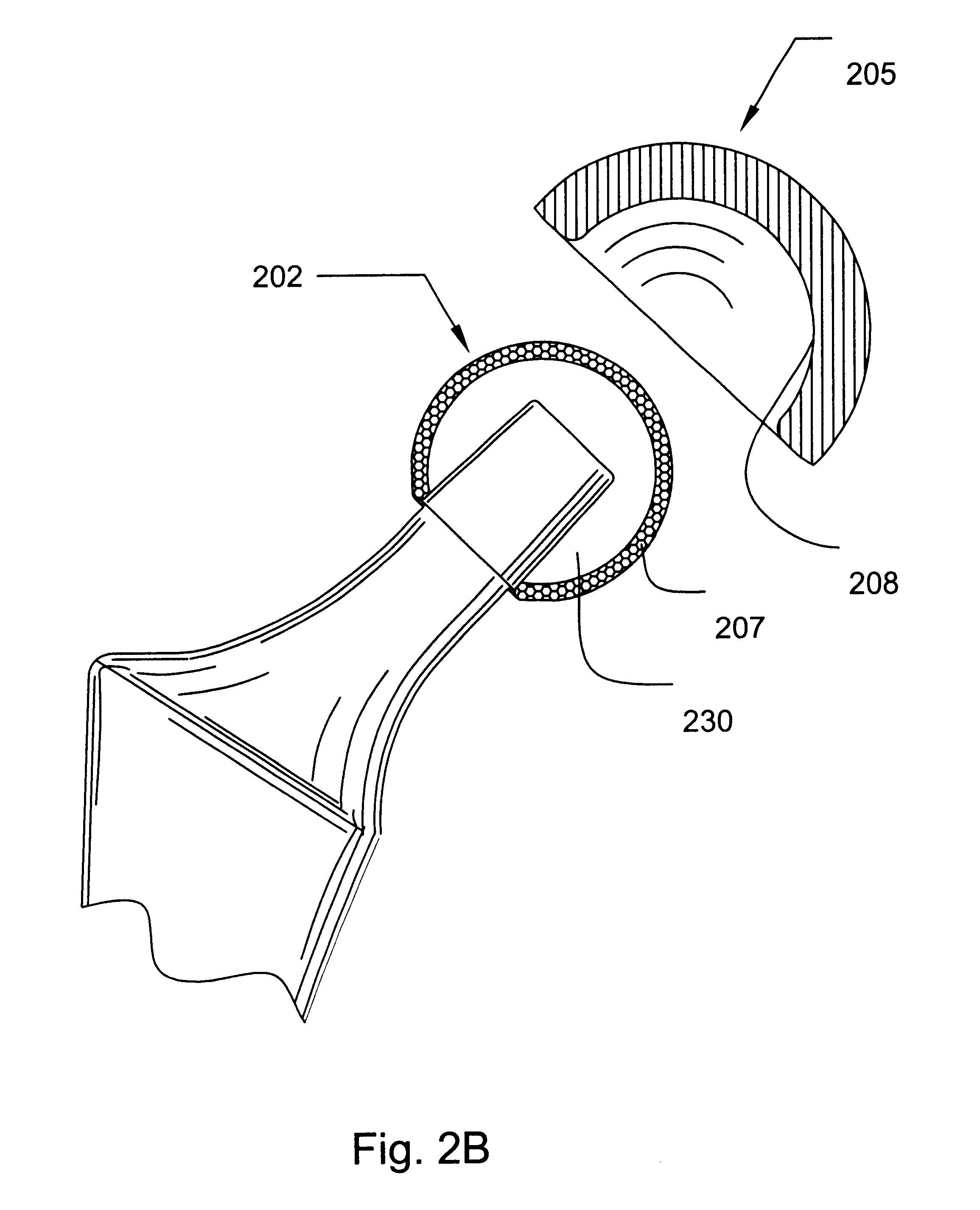

Diamond-surfaced cup for use in a prosthetic joint

InactiveUS6488715B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesSacroiliac joint

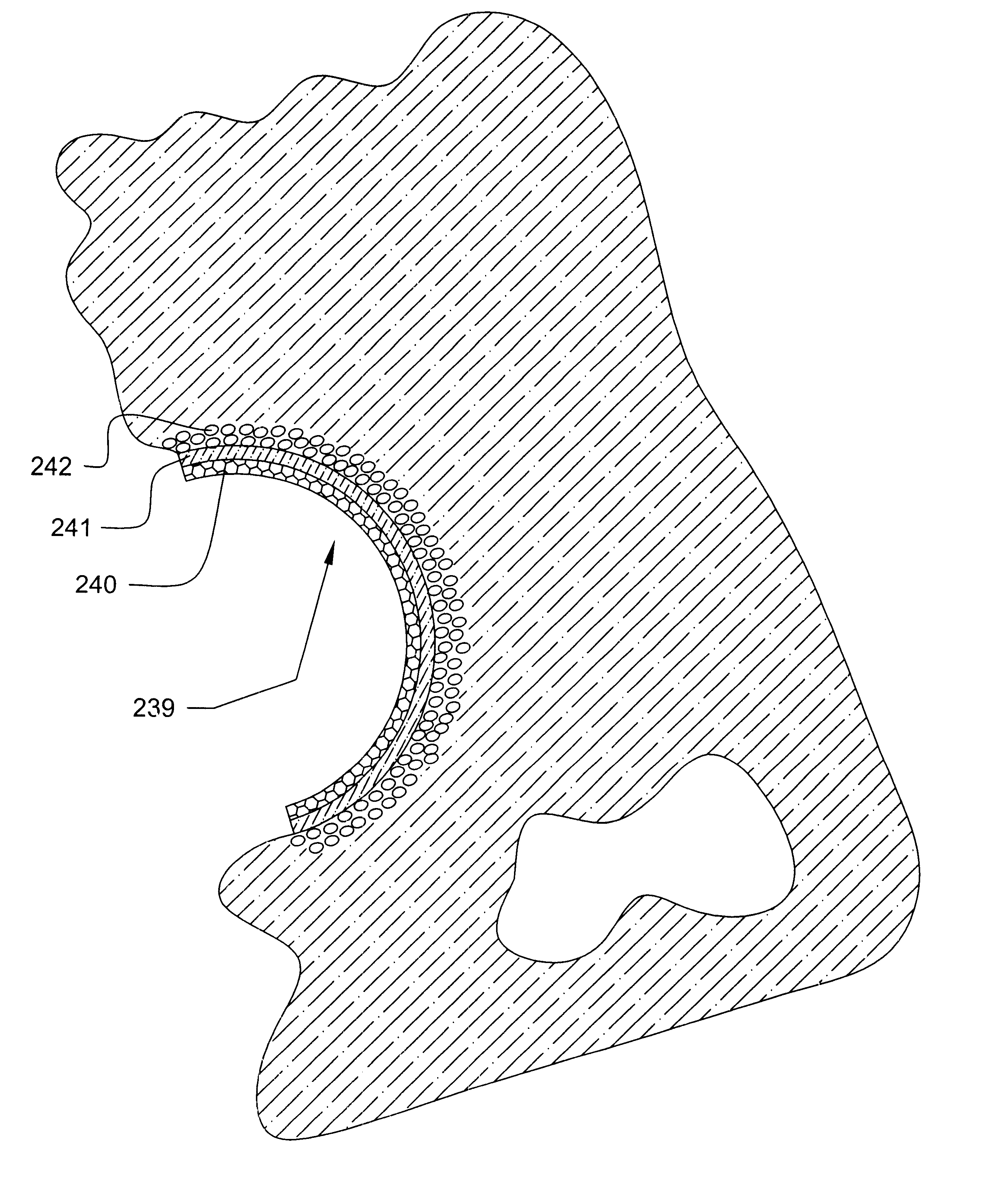

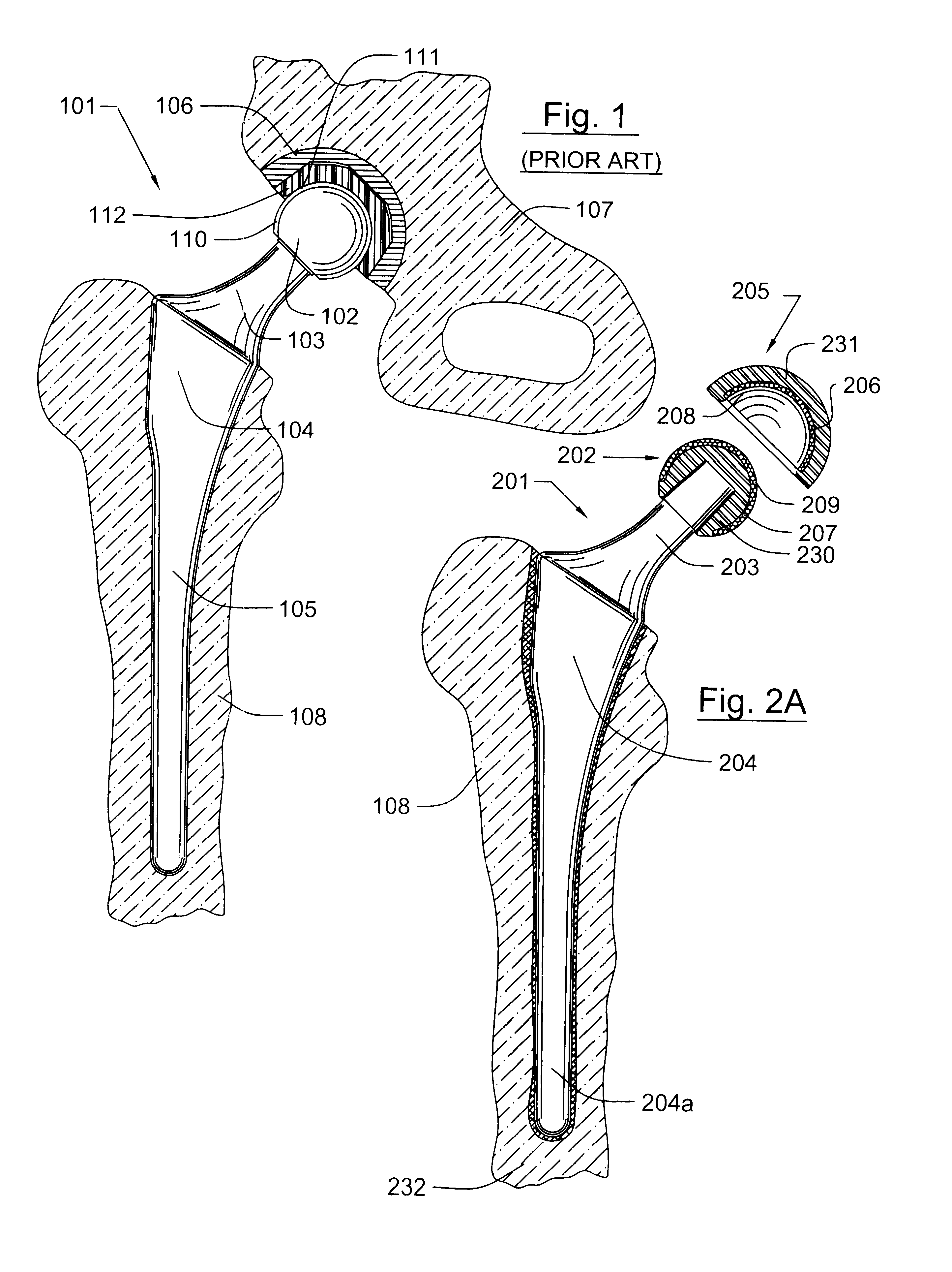

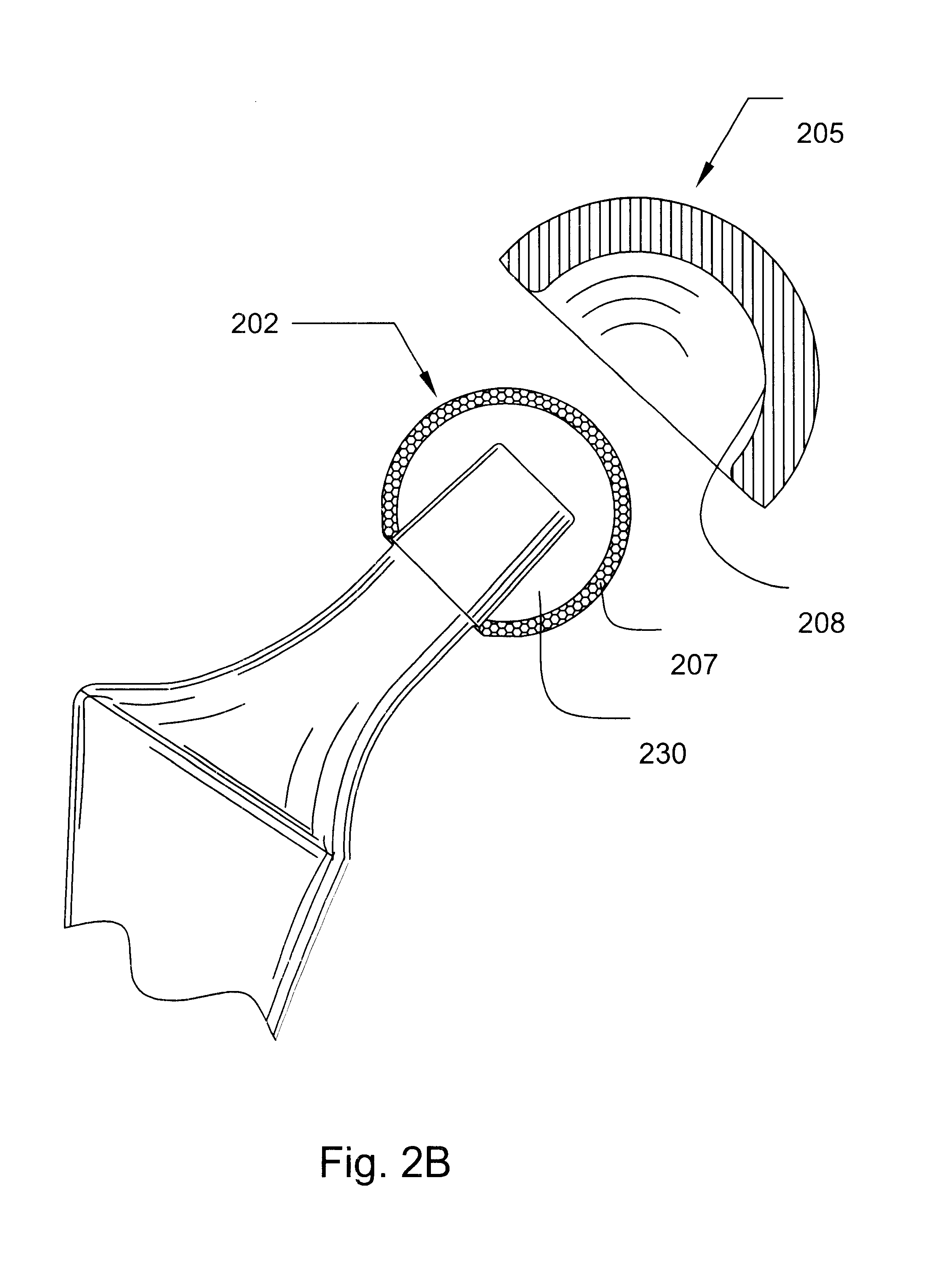

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a diamond-surfaced cup for use in a prosthetic joint.

Owner:DIAMICRON

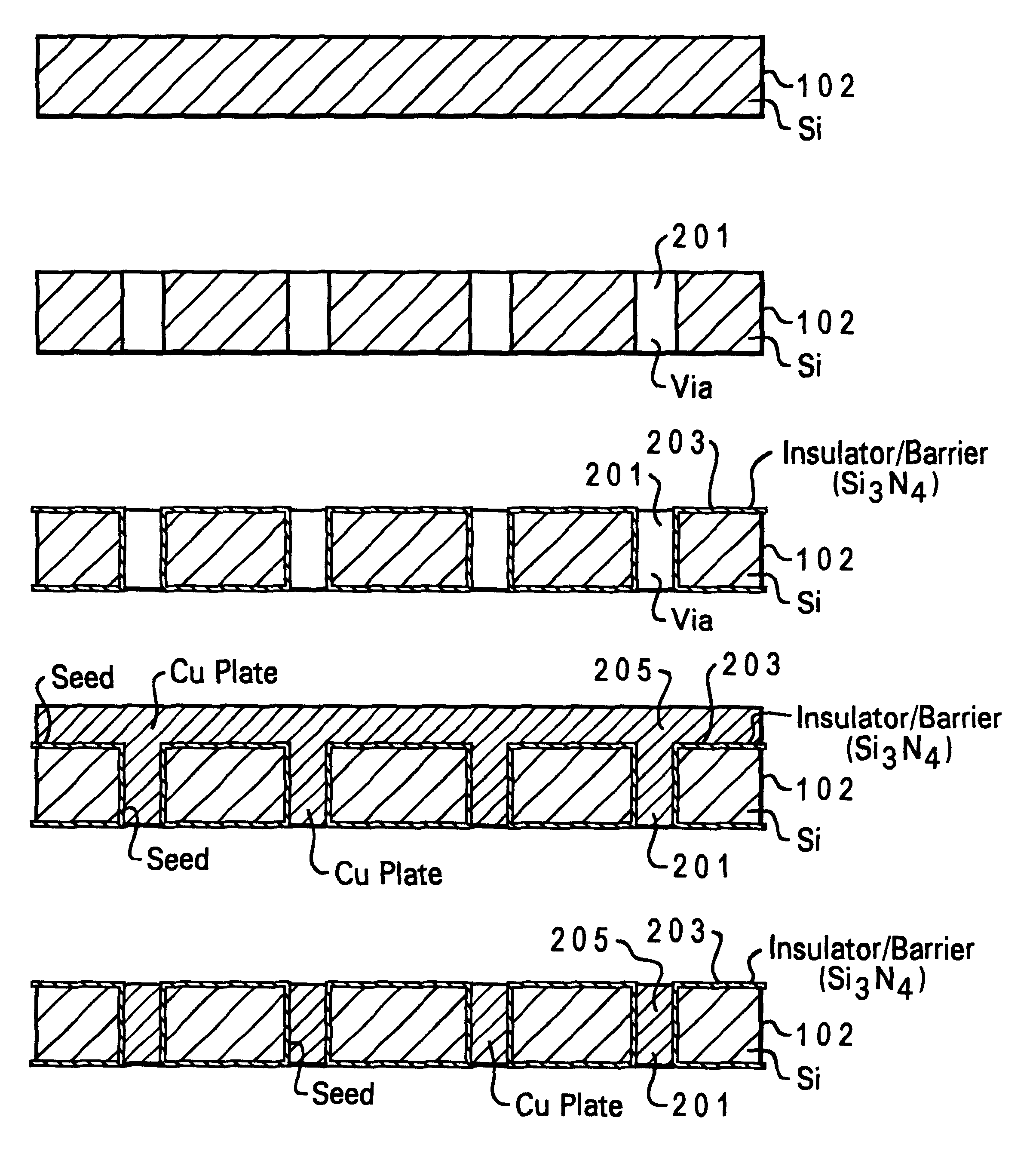

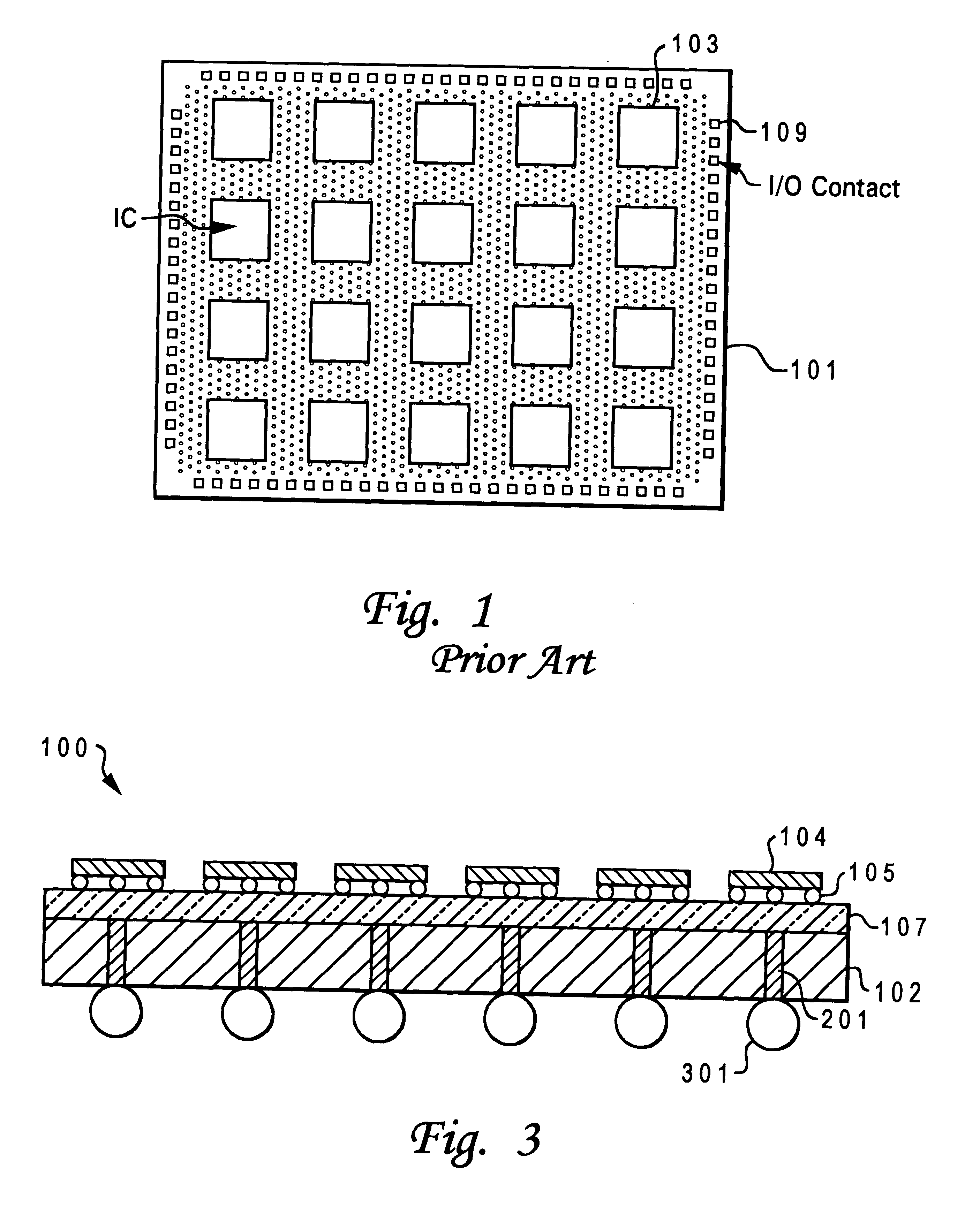

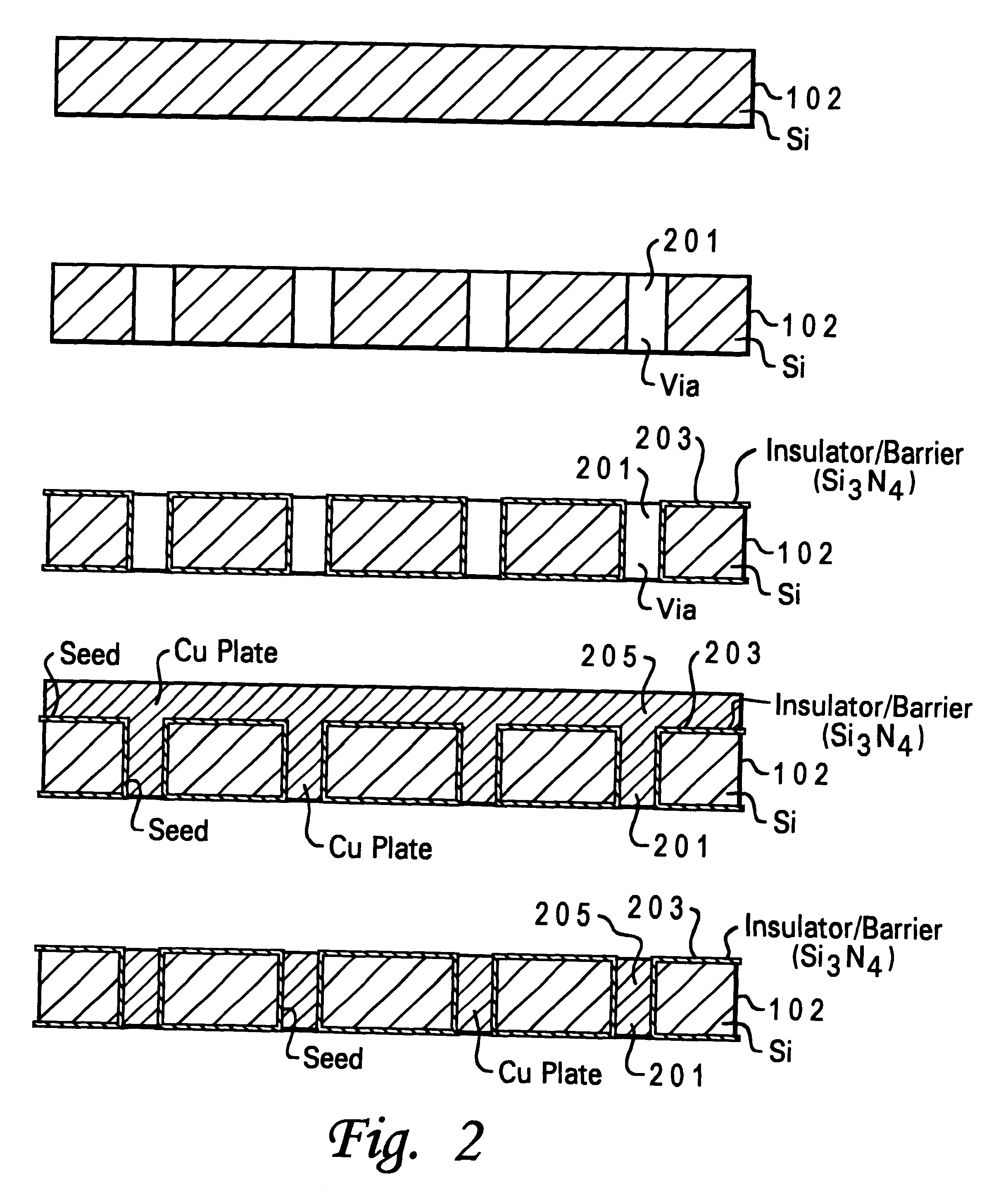

Method for integrated circuit power and electrical connections via through-wafer interconnects

InactiveUS6221769B1Solid-state devicesSemiconductor/solid-state device manufacturingHigh rateElectrical connection

A method for providing a through wafer connection to an integrated circuit silicon package. A hole is first created in the silicon package with an inner surface area extending from the bottom surface of the silicon package to the top surface of the silicon package. The hole is created by one of two methods. The first involves mechanical drilling with a diamond bit rotated at a high rate of speed. The second involves ultrasonically milling utilizing a slurry and steel fingers. The inner surface area of the hole is covered with an insulating material to insulate the conductive material which is later deposited and to serve as a diffusion barrier, then a seed material is placed in the hole. Finally, the hole is filled with a conductive material which is utilized to provide large power inputs or signaling connections to the integrated circuit chips.

Owner:IBM CORP

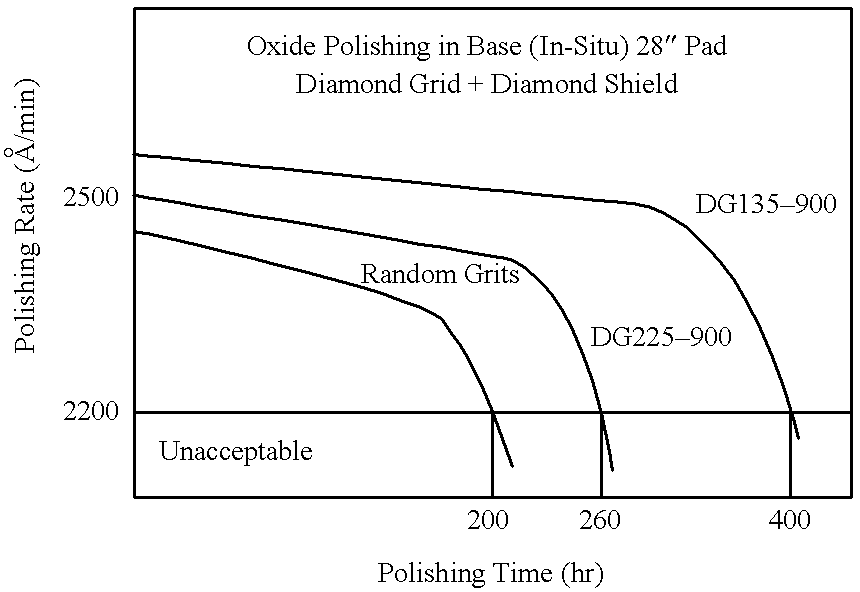

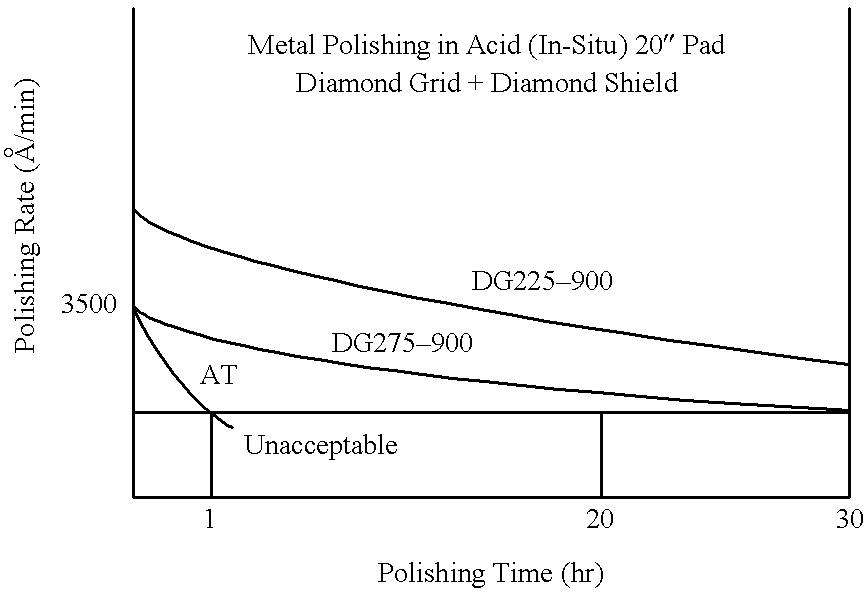

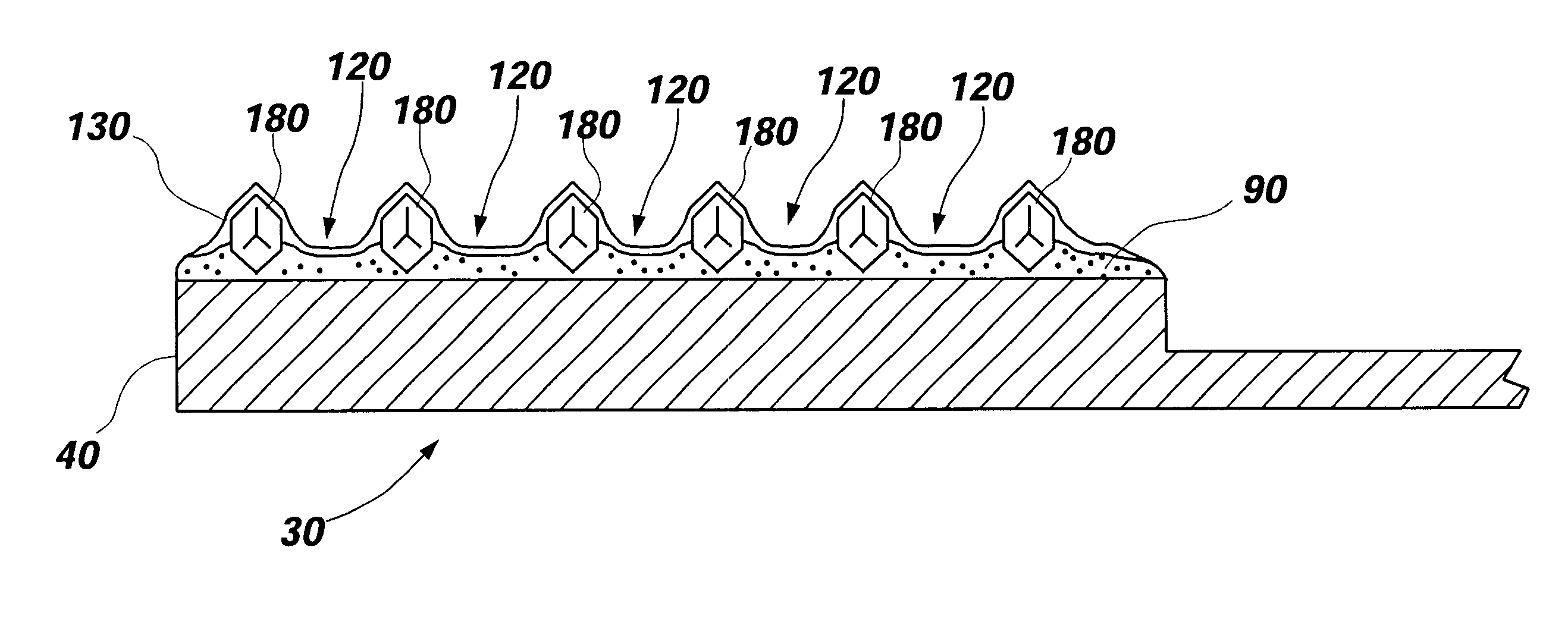

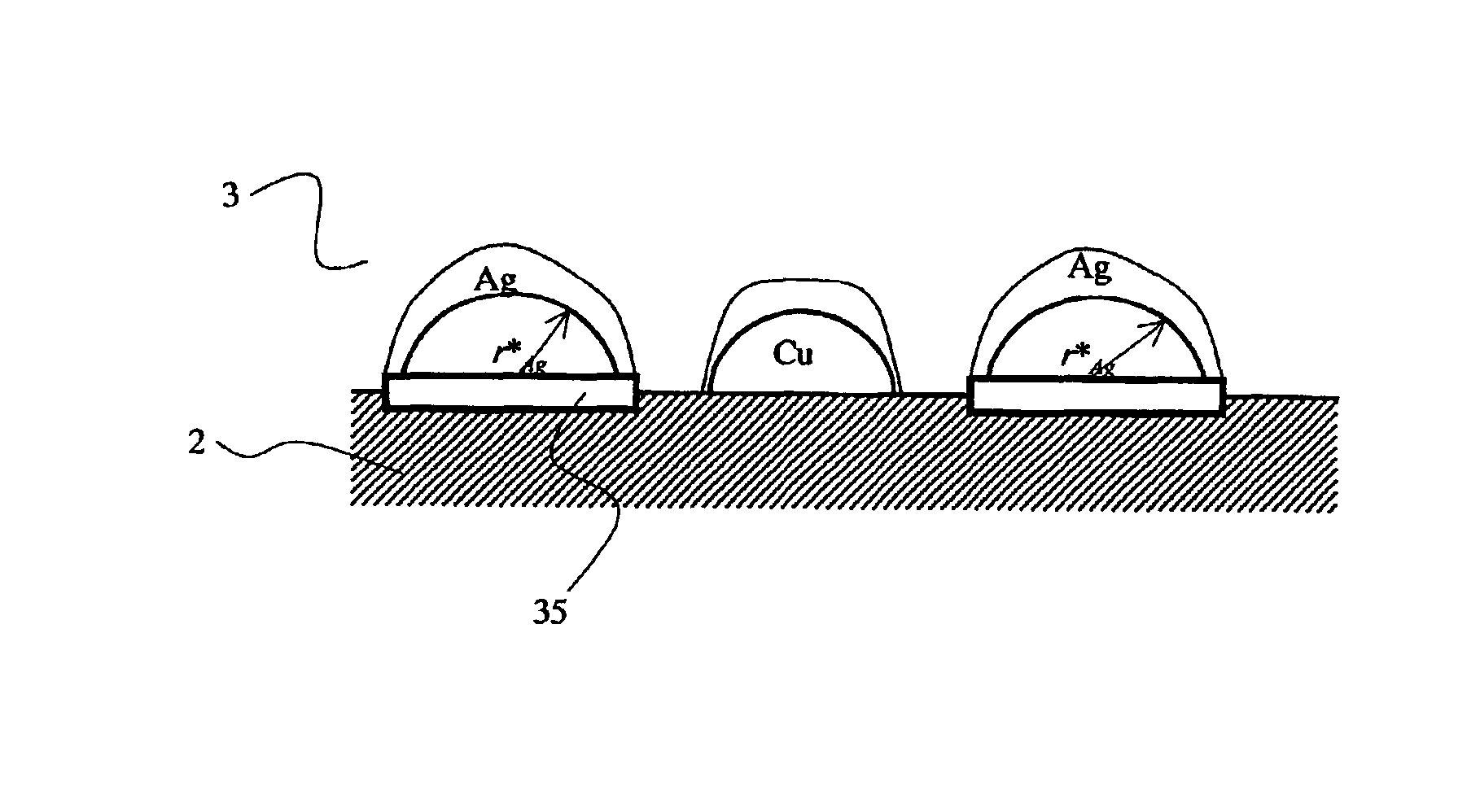

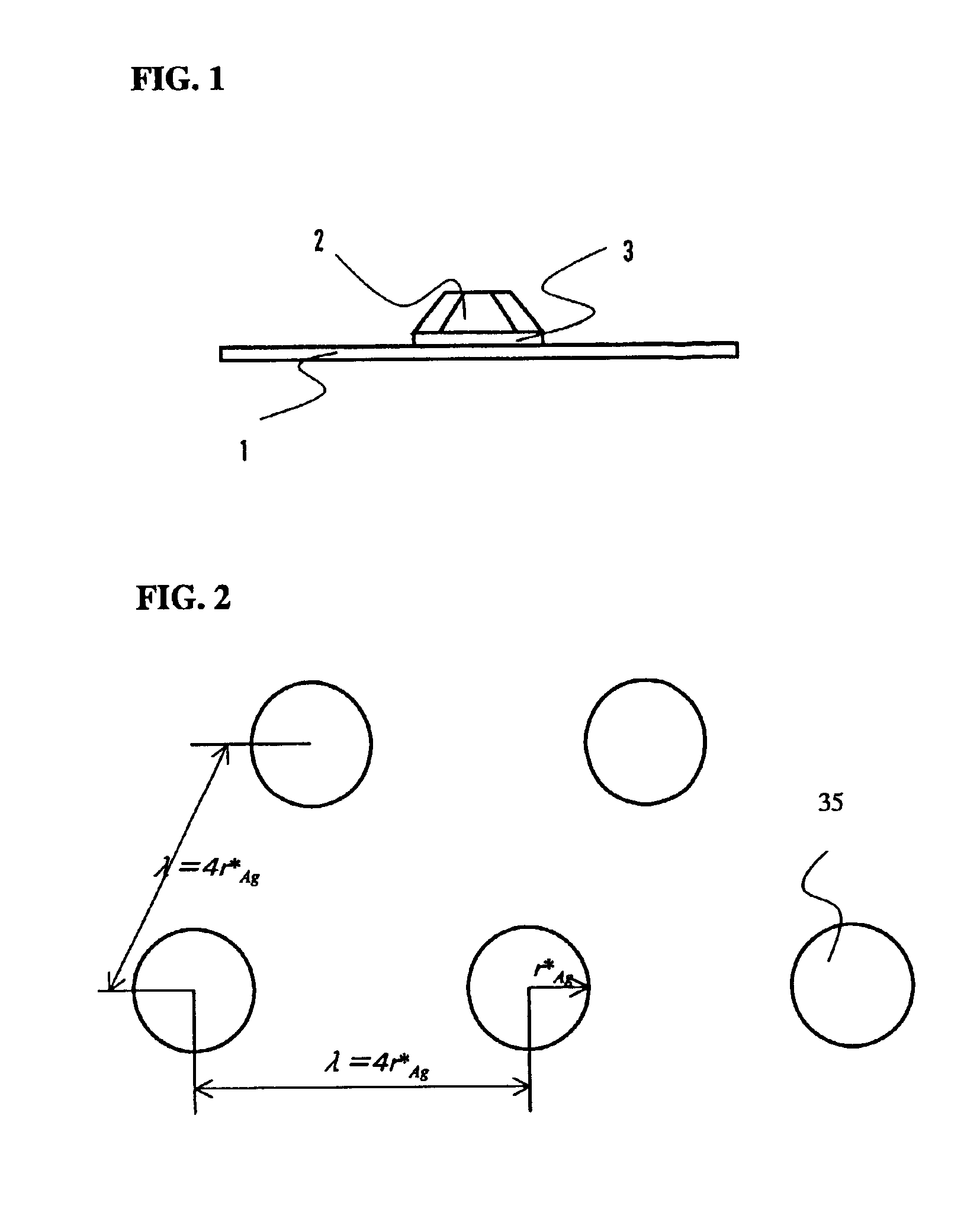

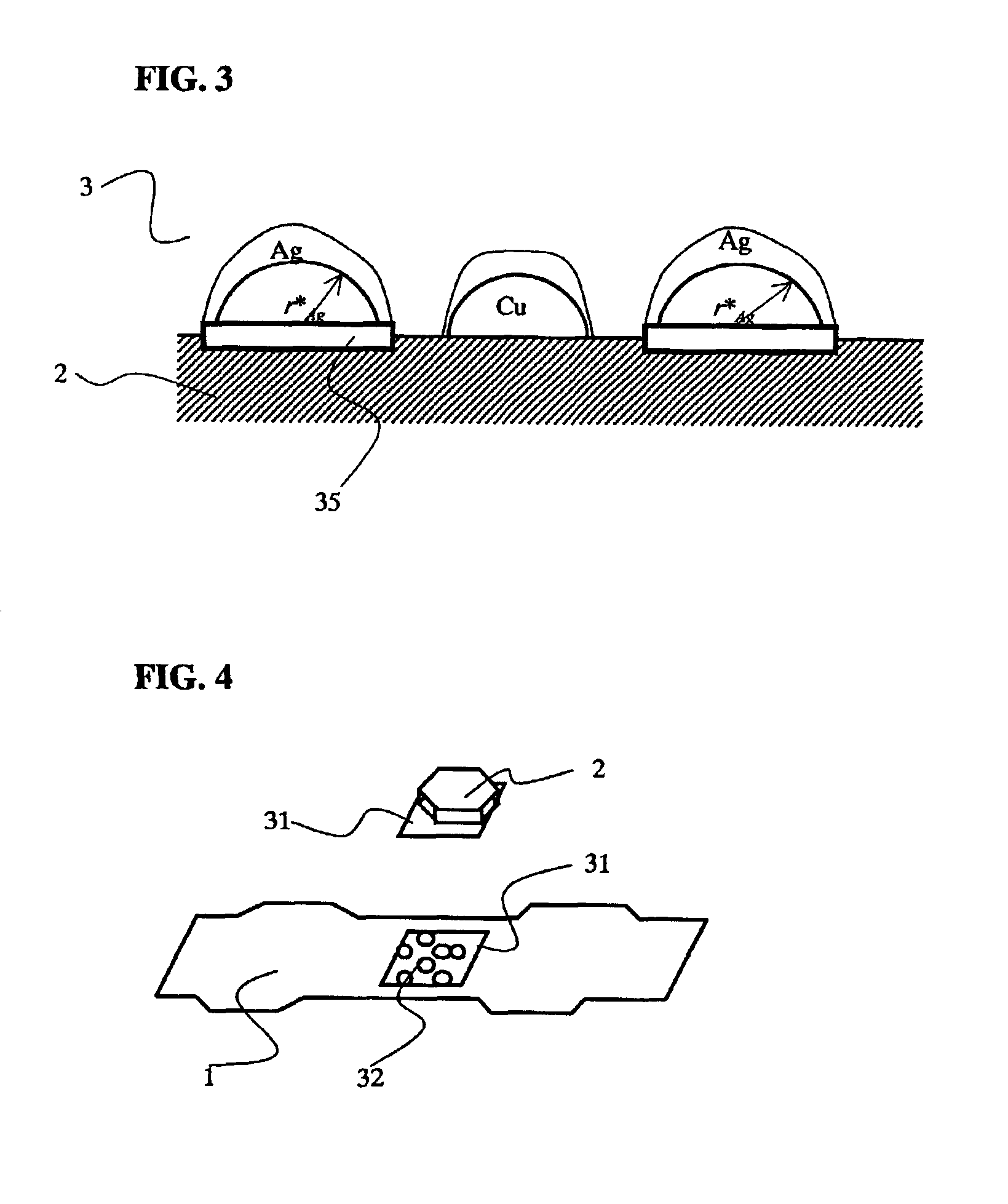

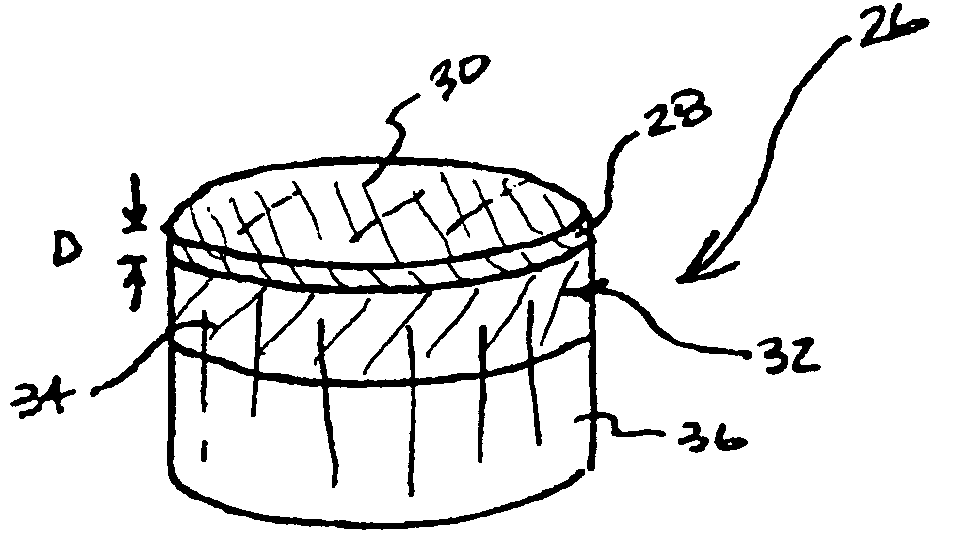

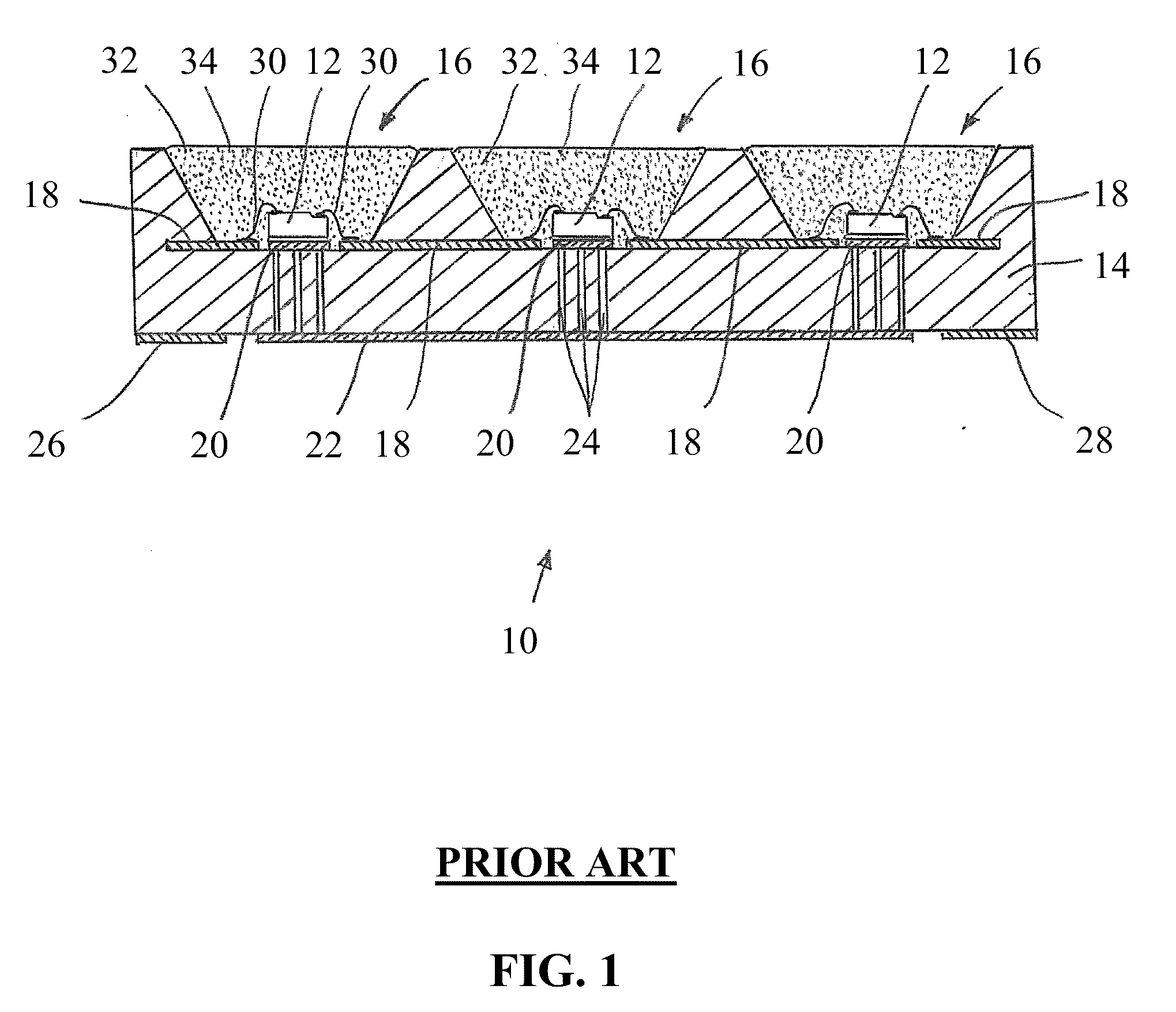

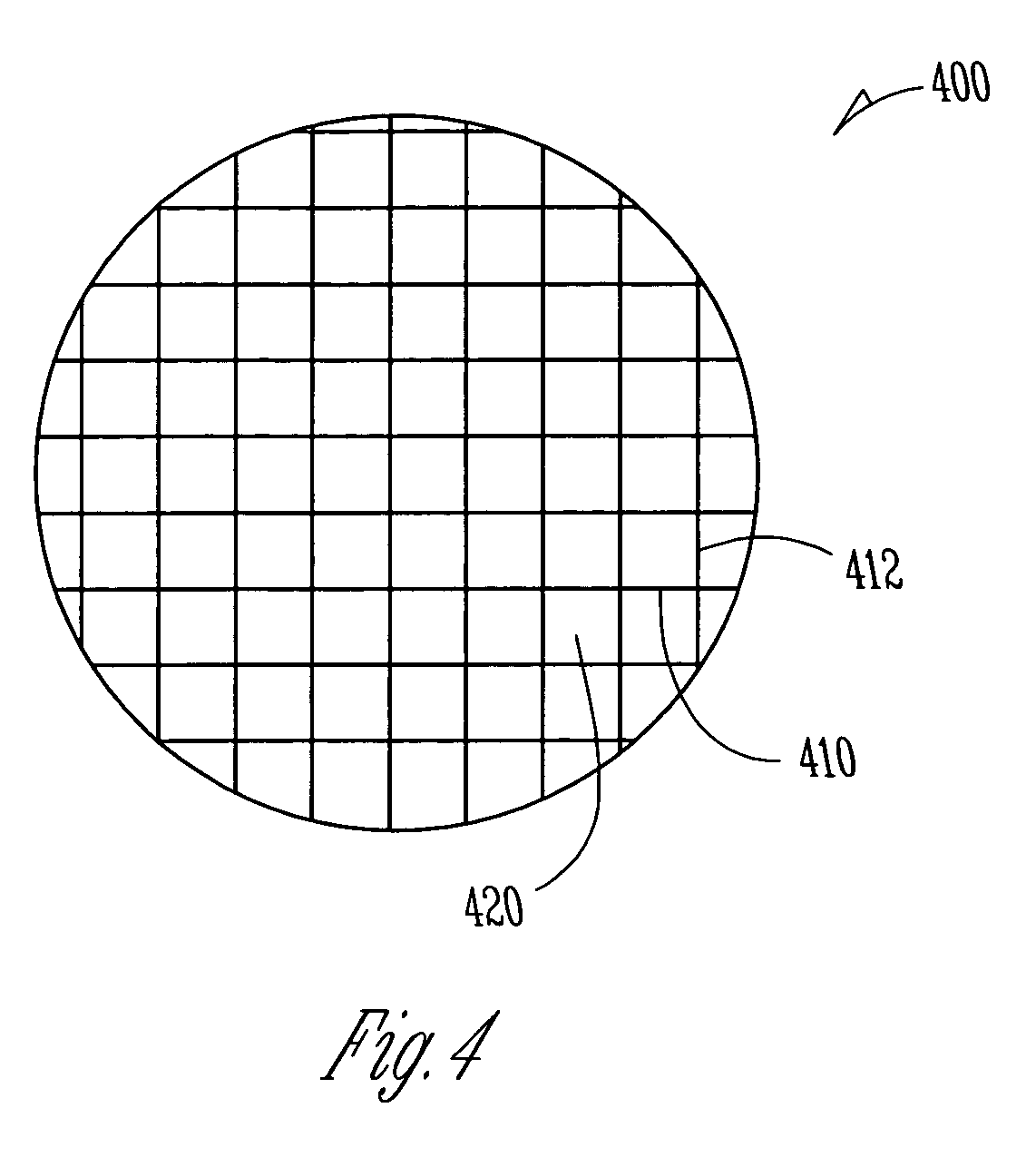

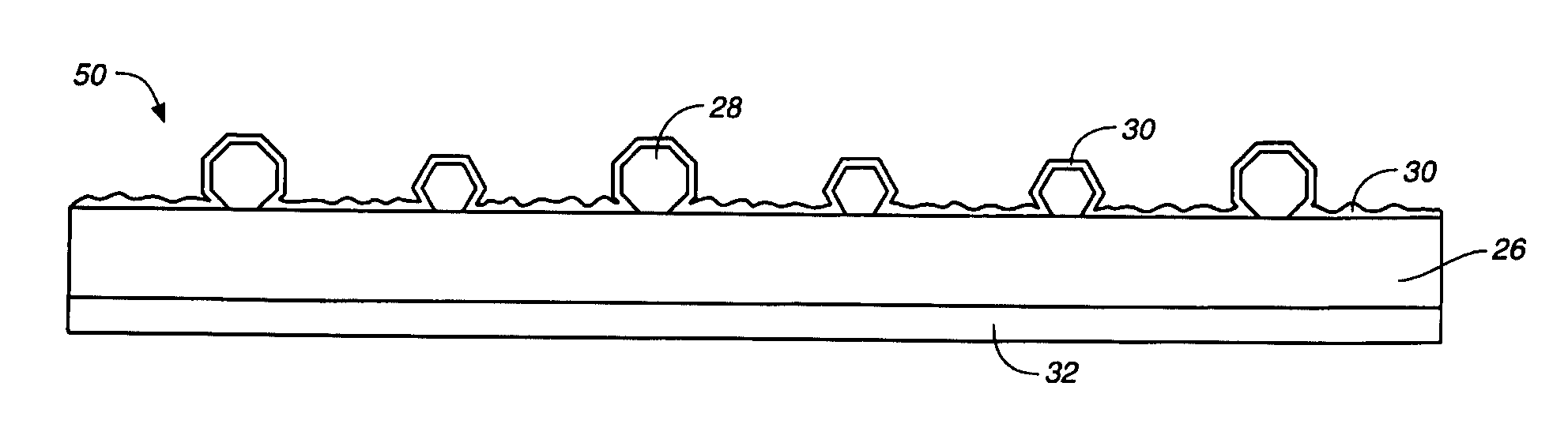

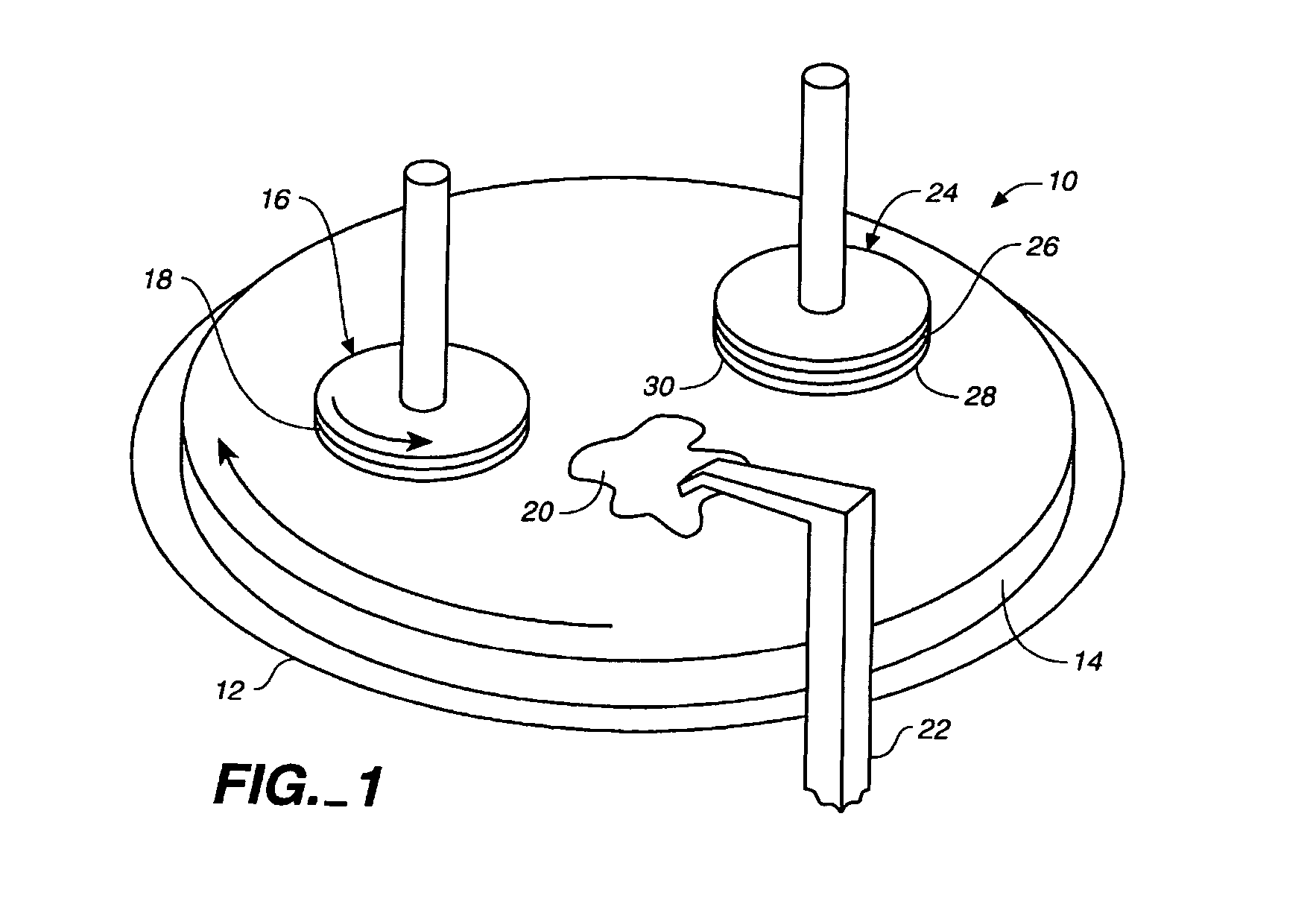

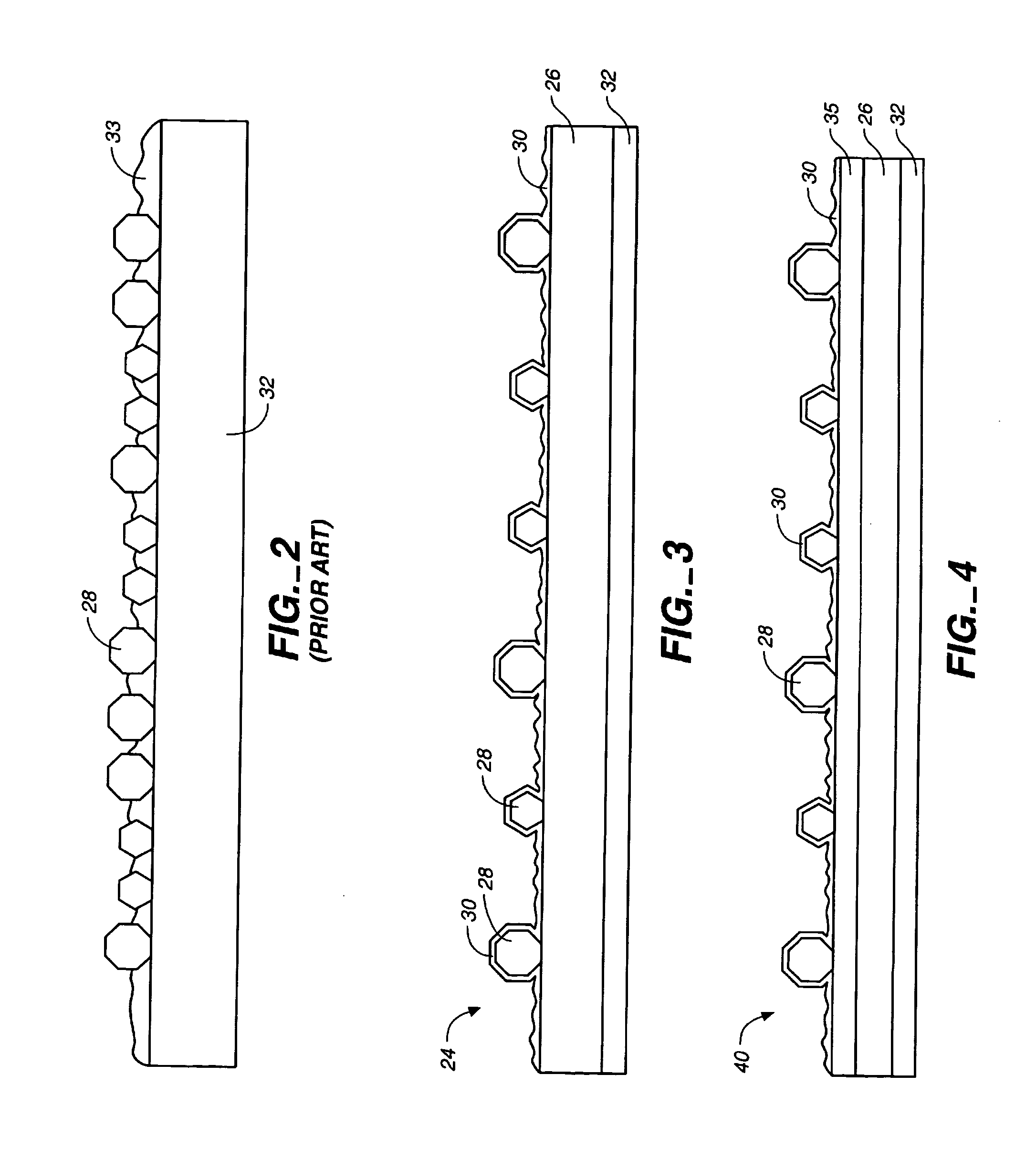

Diamond grid CMP pad dresser

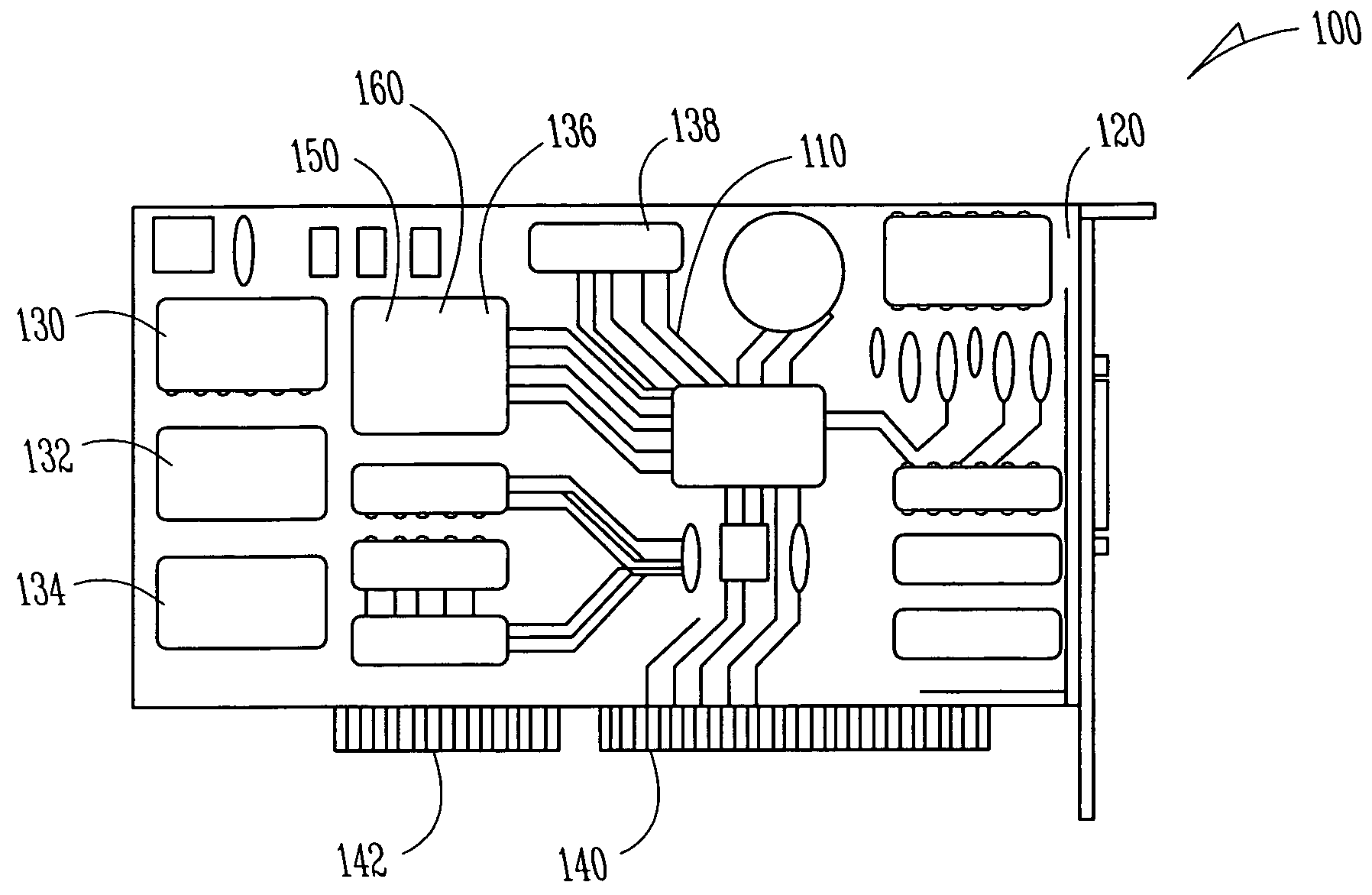

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

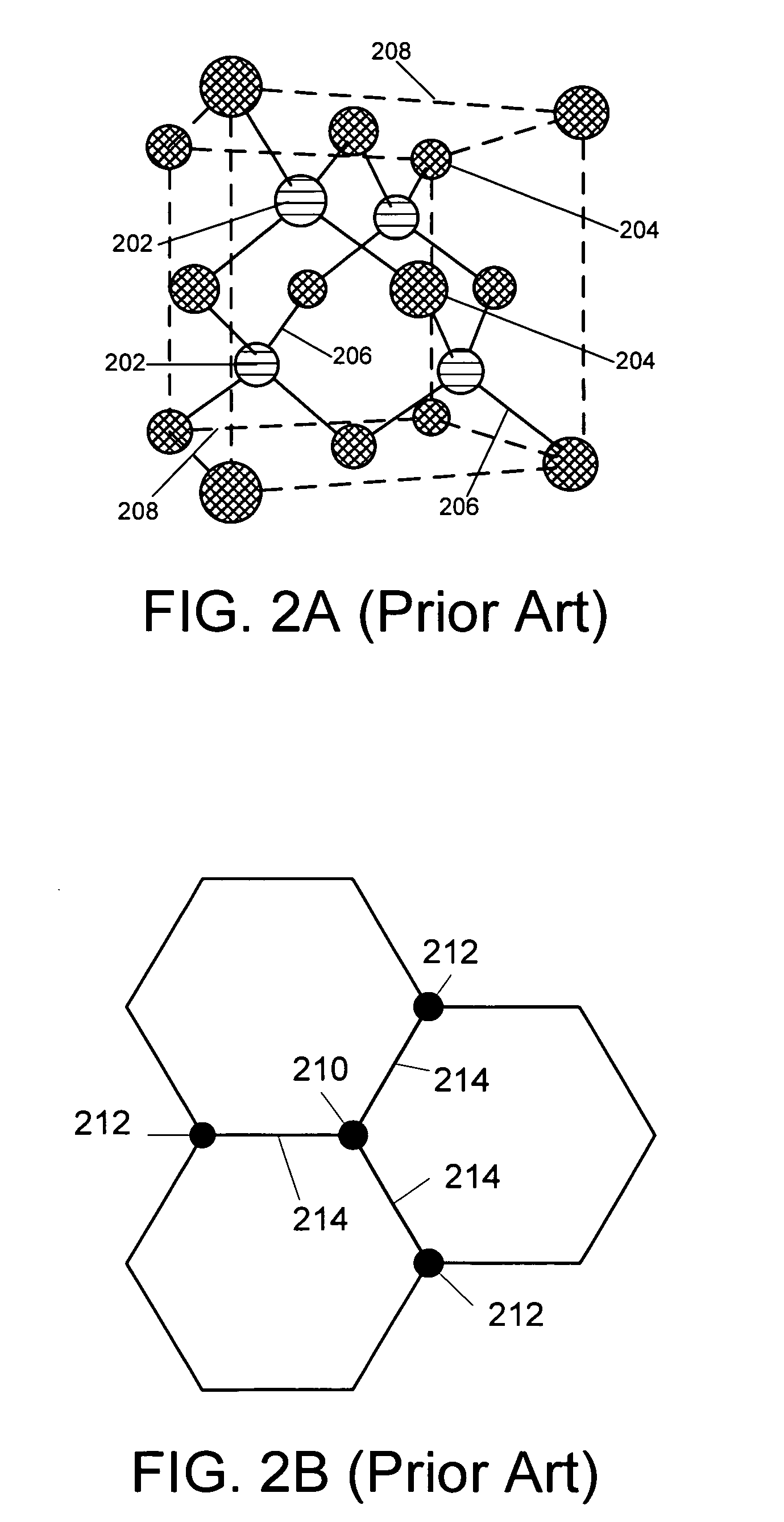

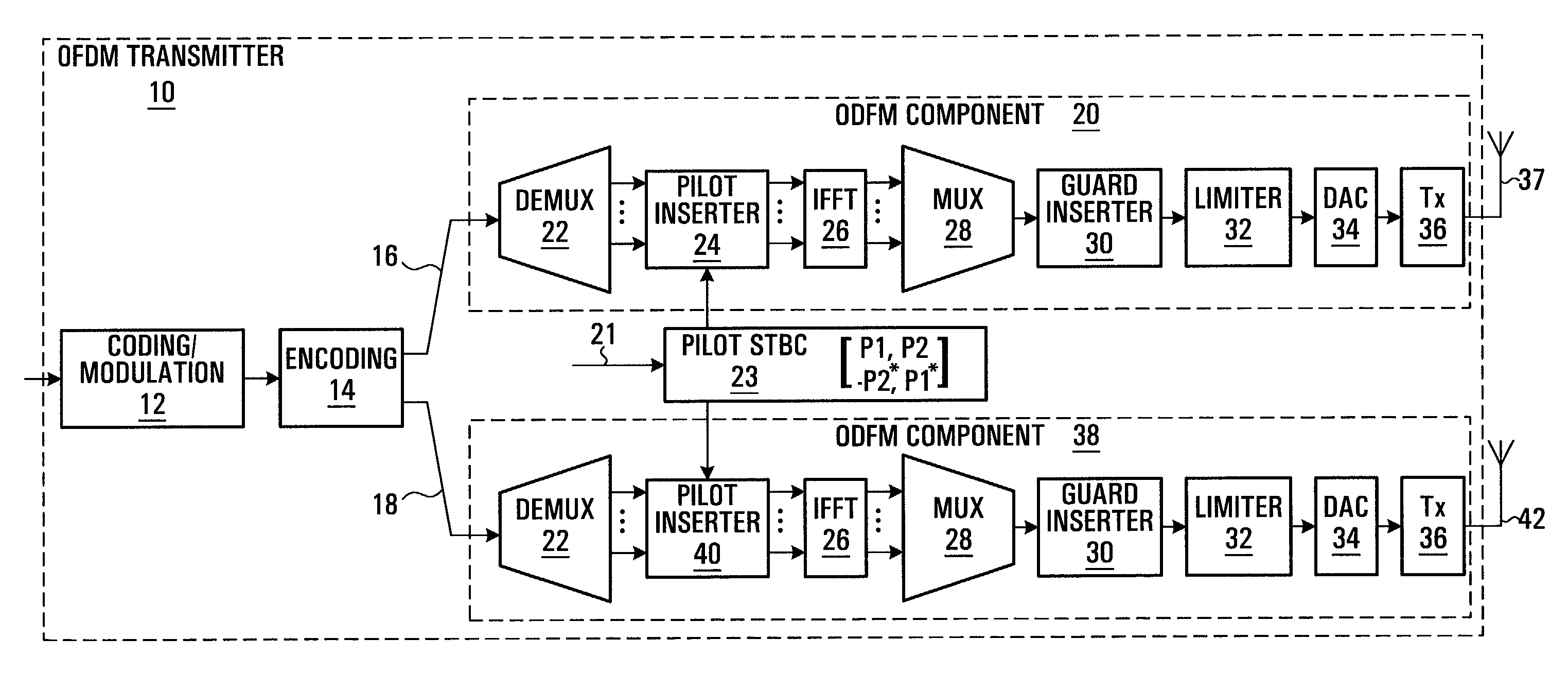

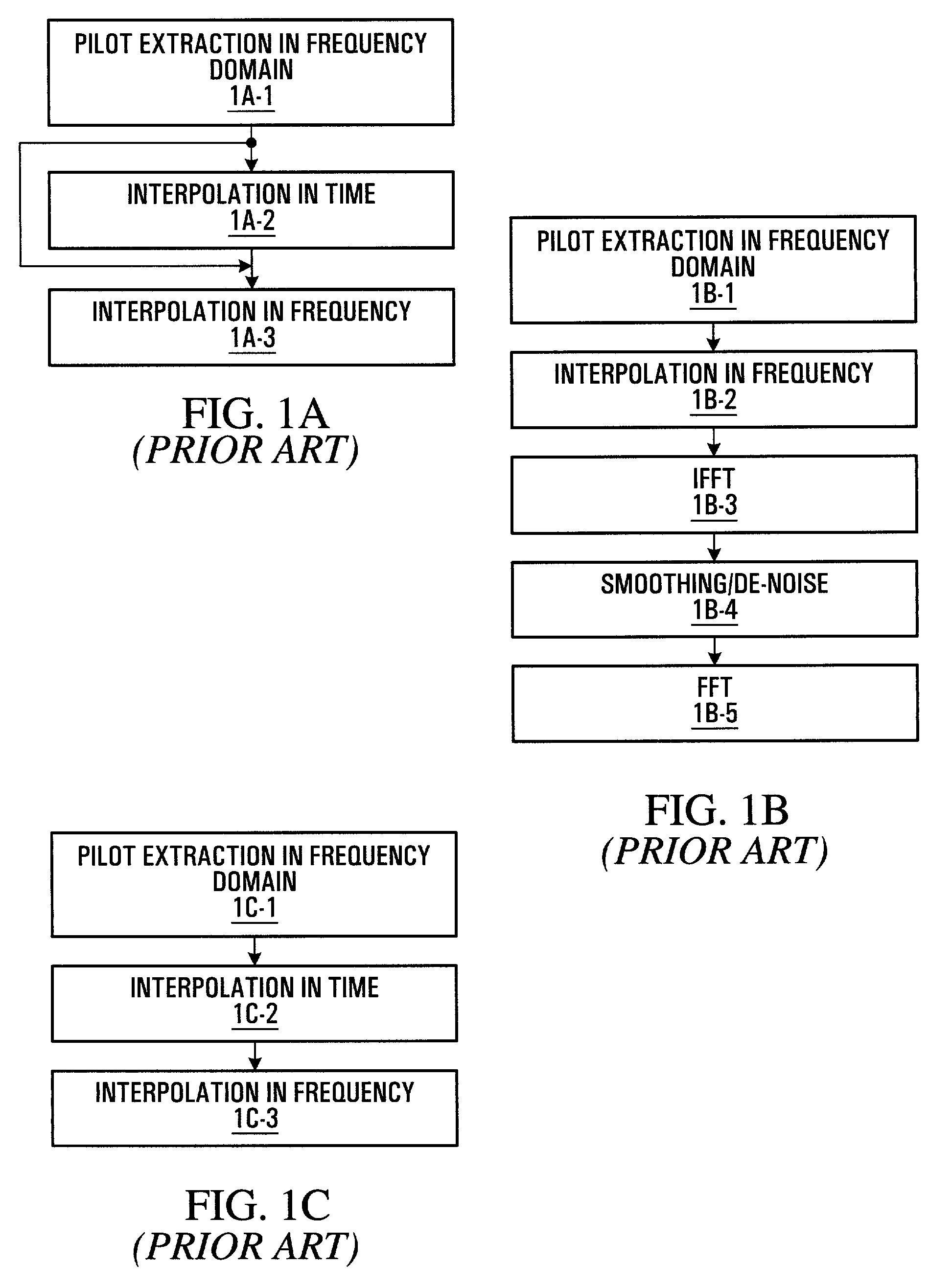

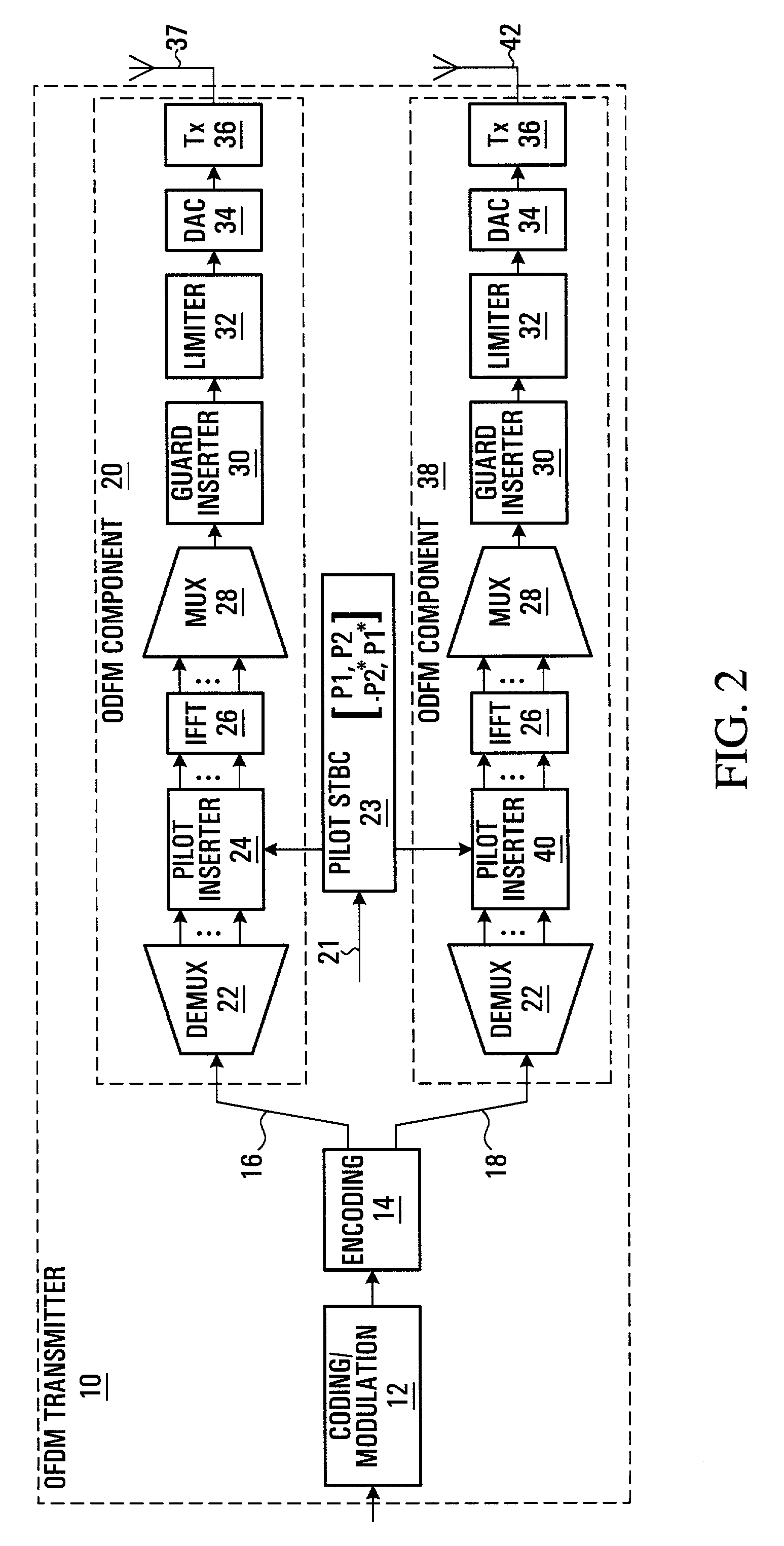

Scattered pilot pattern and channel estimation method for MIMO-OFDM systems

ActiveUS7248559B2Reduced scattered pilot overheadLess computationally complexPower managementSpatial transmit diversityTime domainCommunications system

A method and apparatus are provided for reducing the number of pilot symbols within a MIMO-OFDM communication system, and for improving channel estimation within such a system. For each transmitting antenna in an OFDM transmitter, pilot symbols are encoded so as to be unique to the transmitting antenna. The encoded pilot symbols are then inserted into an OFDM frame to form a diamond lattice, the diamond lattices for the different transmitting antennae using the same frequencies but being offset from each other by a single symbol in the time domain. At the OFDM receiver, a channel response is estimated for a symbol central to each diamond of the diamond lattice using a two-dimensional interpolation. The estimated channel responses are smoothed in the frequency domain. The channel responses of remaining symbols are then estimated by interpolation in the frequency domain.

Owner:MALIKIE INNOVATIONS LTD

Polycrystalline diamond constructions having improved thermal stability

ActiveUS20080223623A1Good adhesionImprove thermal stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Owner:SMITH INT INC

Brazing-filler material and method for brazing diamond

InactiveUS6889890B2Beautiful sceneryStable joint strengthLayered productsOther manufacturing equipments/toolsFilling materialsCopper

When a diamond is brazed to a metal substrate, while obtaining a stable joining strength, a joined interface of the diamond is not eroded to provide a good joint with a beautiful view. A brazing-filler material containing at least one selected from a group consisting of gold and silver, and copper as principal components, and further containing 0.001 to 5 mass % of vanadium is used. Preferably, a vanadium content is not more than 2.0 mass %, and more preferably not more than 0.5 mass %. Using this brazing-filler material, unidirectional solidification is performed from a side of diamond to form vanadium carbide in a joined interface in a shape of islands, and thereby an interface having a beautiful view with stable joining strength can be obtained. In addition, strong joining is possible also by a usual solidification method.

Owner:HOHOEMI BRAINS INC

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

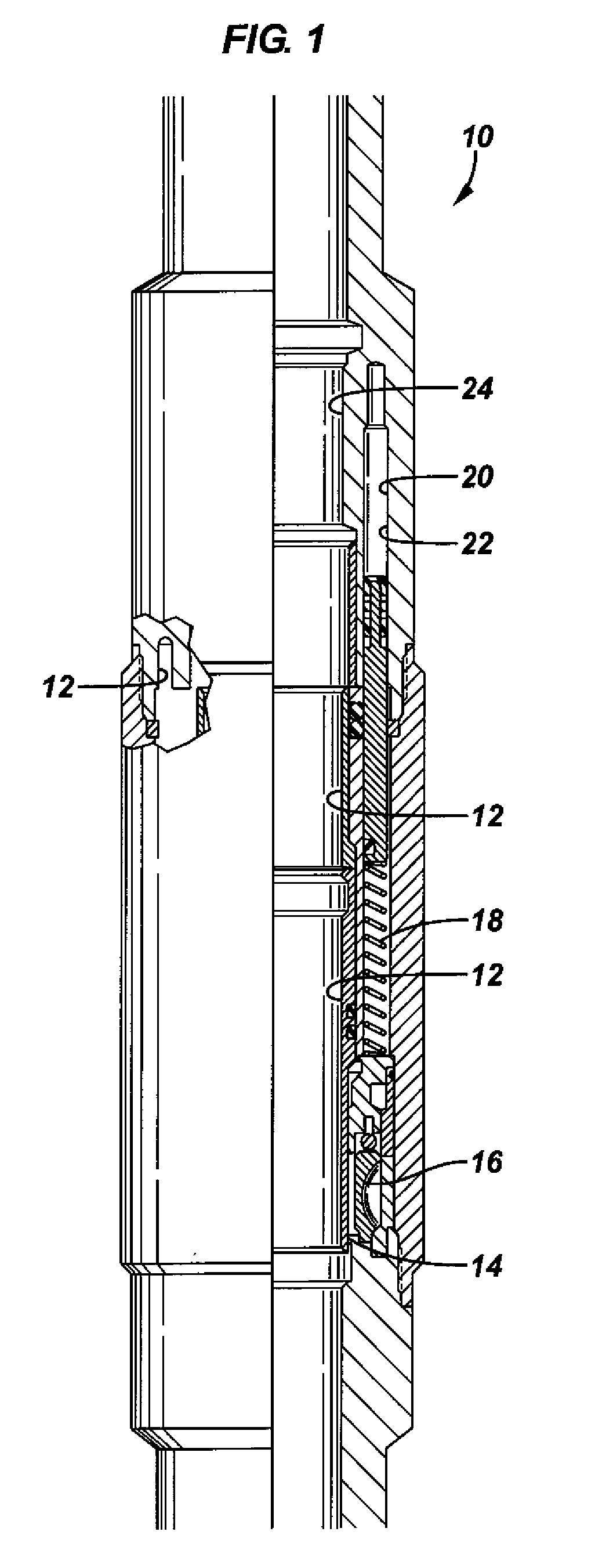

Downhole oilfield apparatus comprising a diamond-like carbon coating and methods of use

Downhole apparatus and methods of using the apparatus are described, the apparatus comprising at least one metallic component having a DLC coating thereon, the coating present at least on one or more internal passageways of the base metal or alloy to be exposed to downhole environments. Methods of using an apparatus in downhole oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

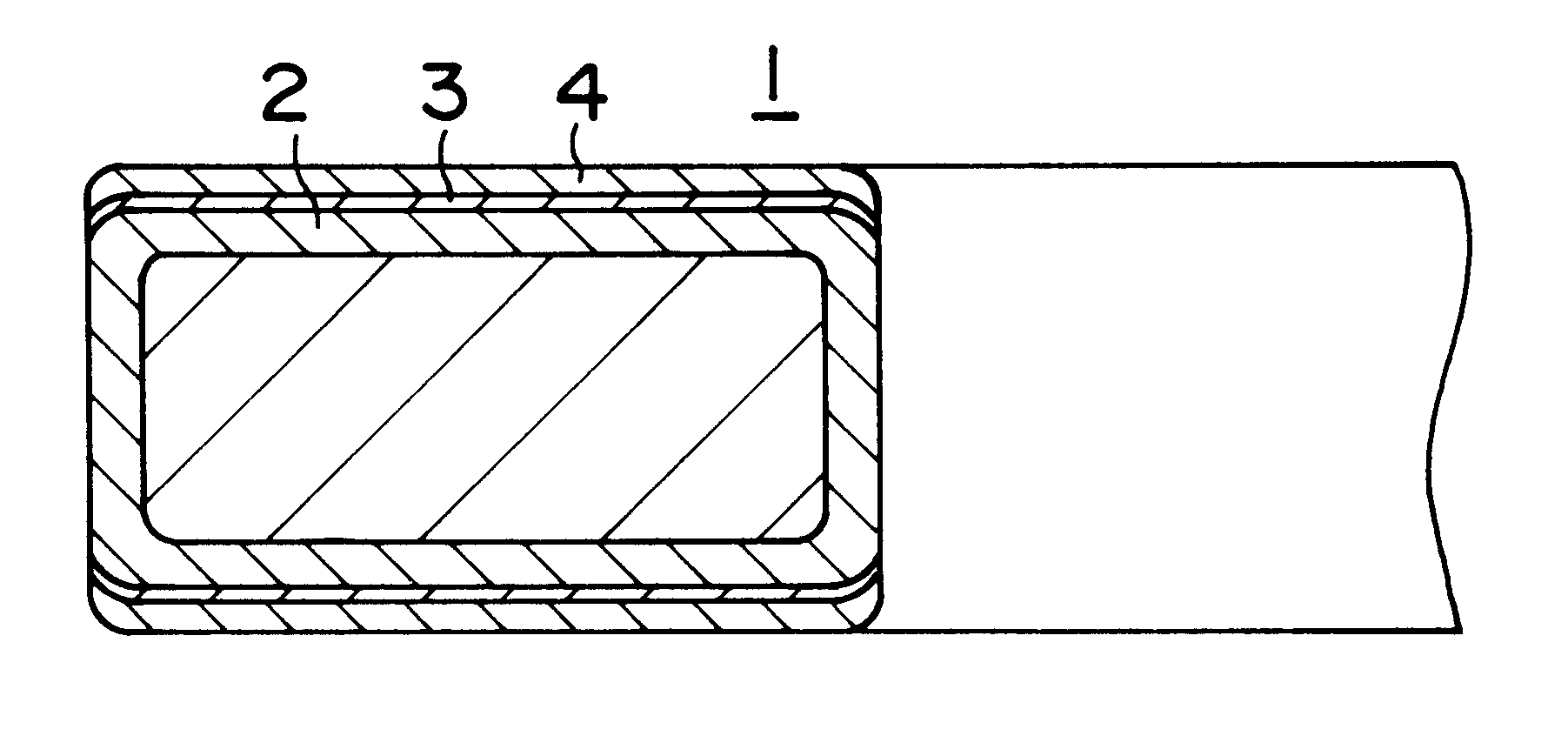

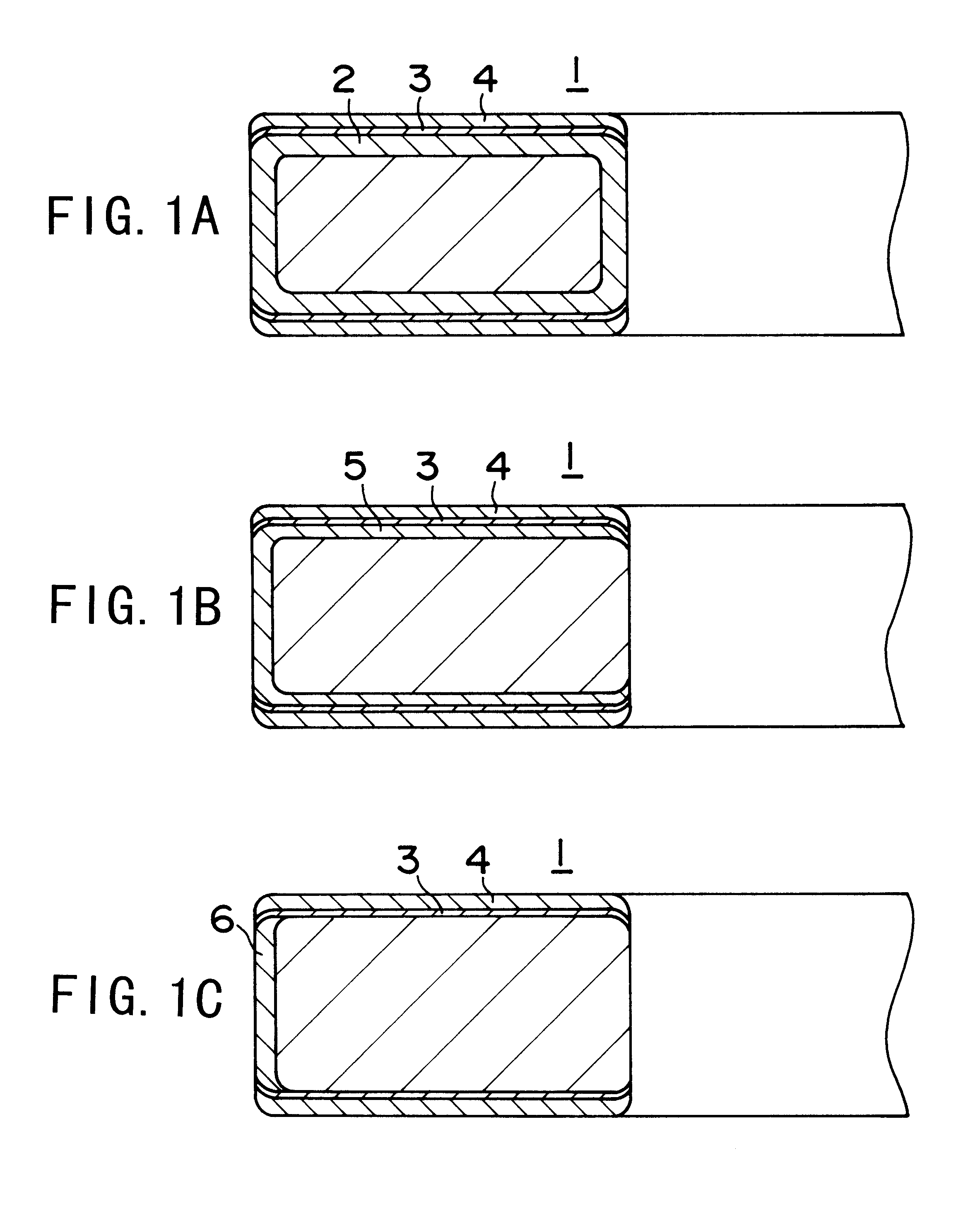

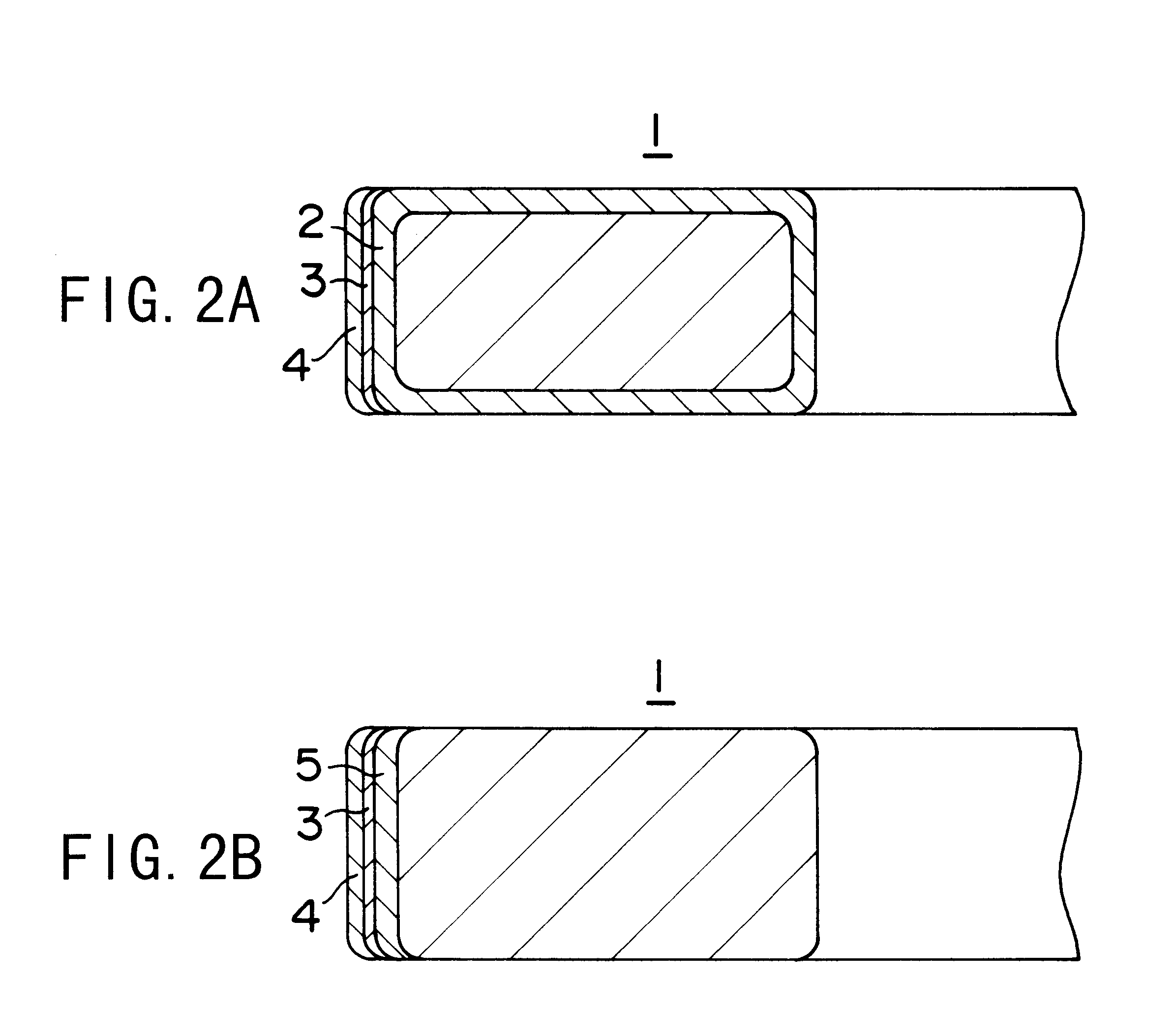

Piston ring

InactiveUS6325385B1Good sliding propertiesRelieve pressurePiston ringsBraking action transmissionCarbon filmDiamond-like carbon

Owner:TEIKOKU PISTON RING CO LTD

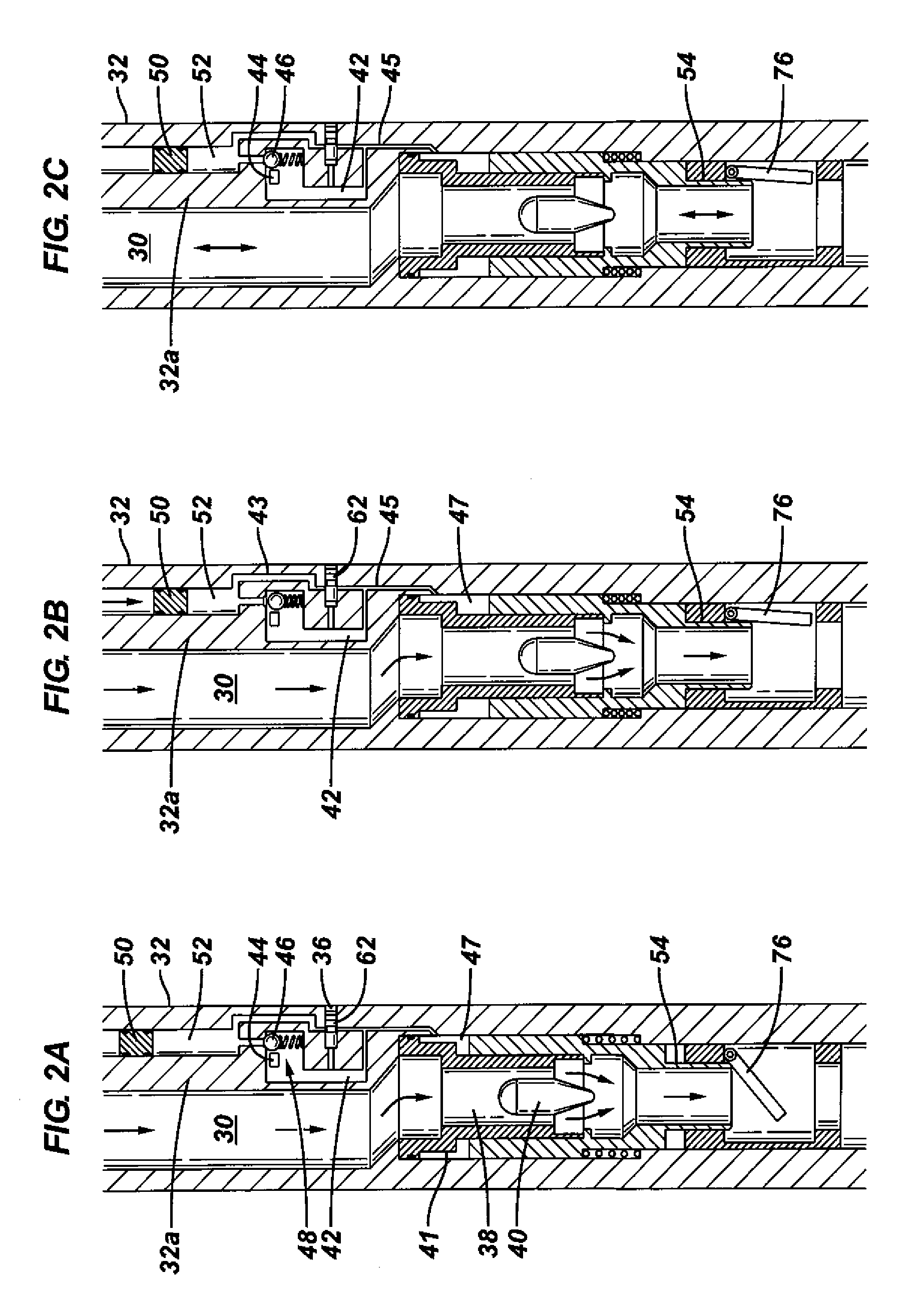

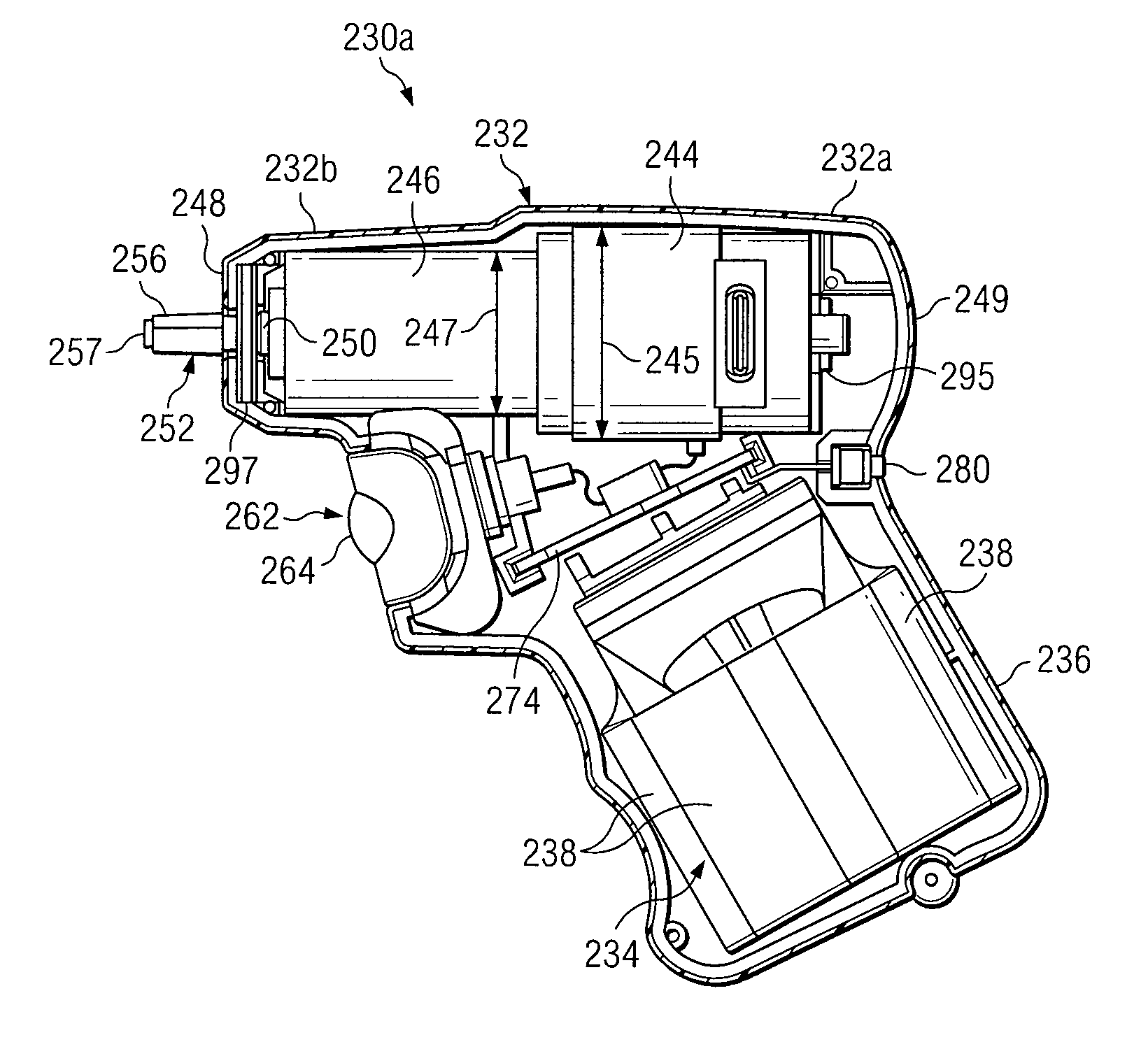

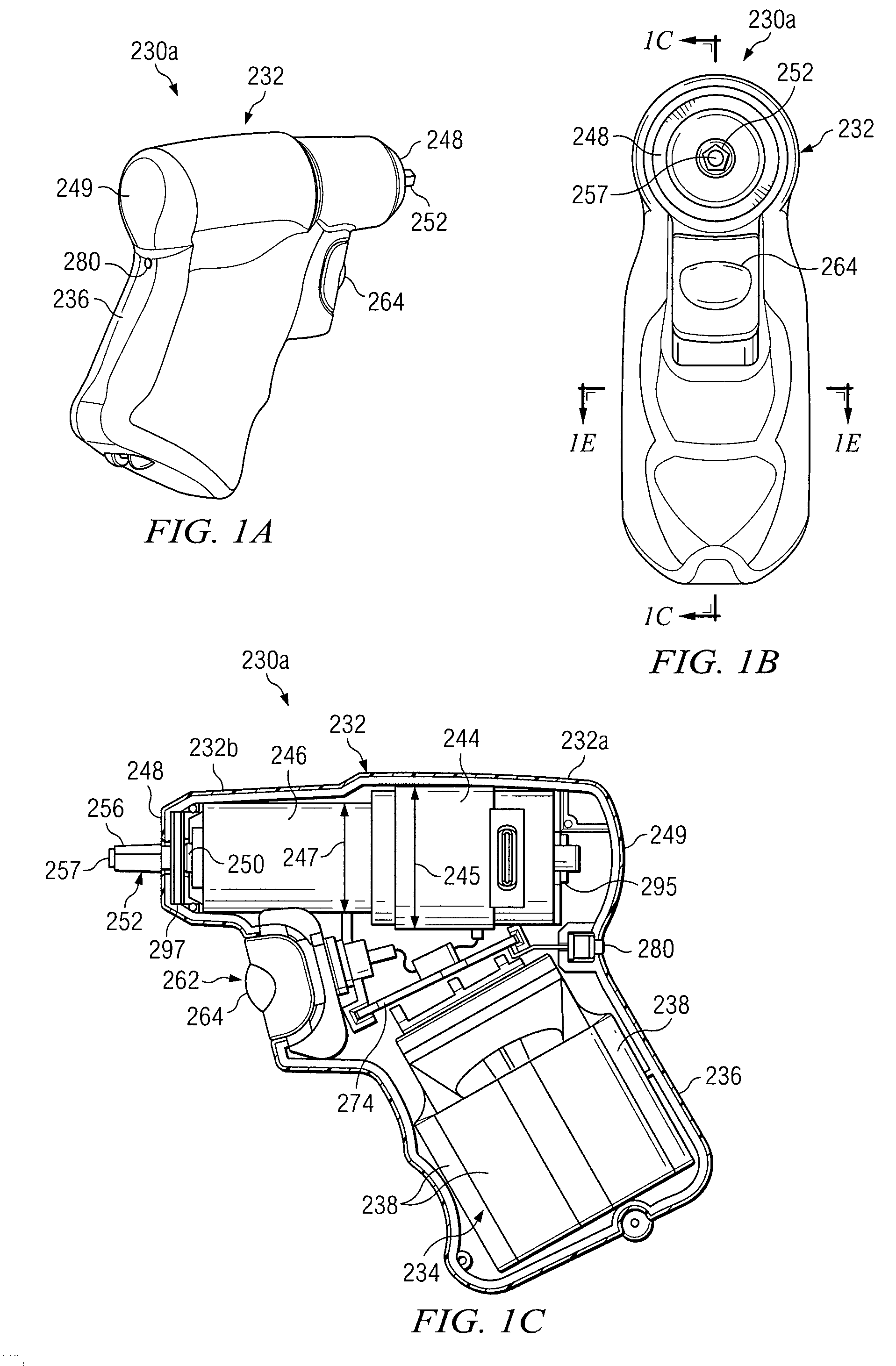

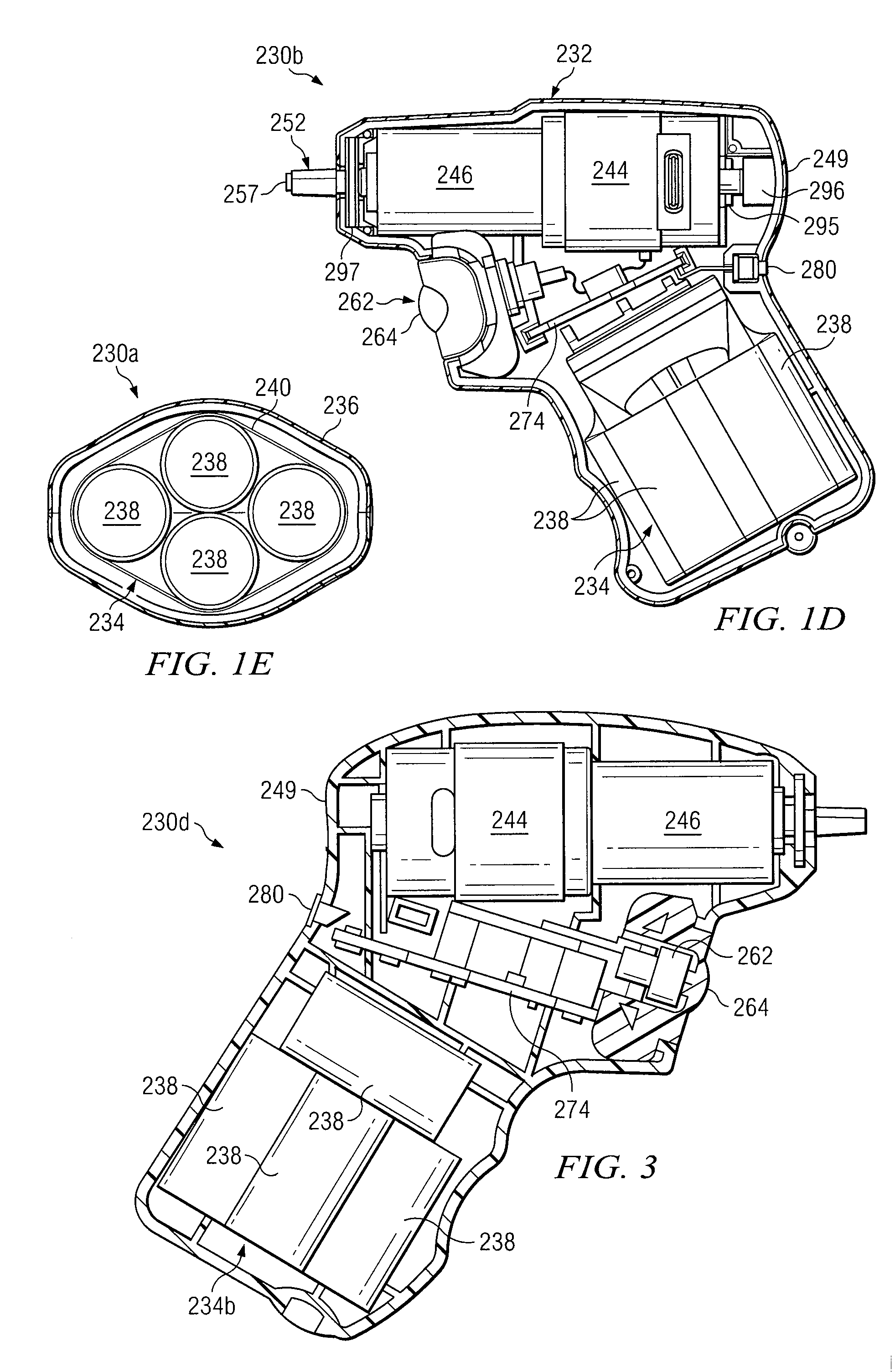

Powered Driver

ActiveUS20080221580A1Reduce speedReduce chanceSafety arrangementSurgical needlesGear wheelEngineering

An apparatus and methods are provided to penetrate a bone and associated bone marrow using a powered driver having a gear assembly and a motor. The powered driver may include an indicator operable to show status of a power supply associated with the powered driver. The power supply may include a battery power pack having a diamond shaped cross section. The powered driver may have a handle with a corresponding cross section.

Owner:TELEFLEX LIFE SCI LTD

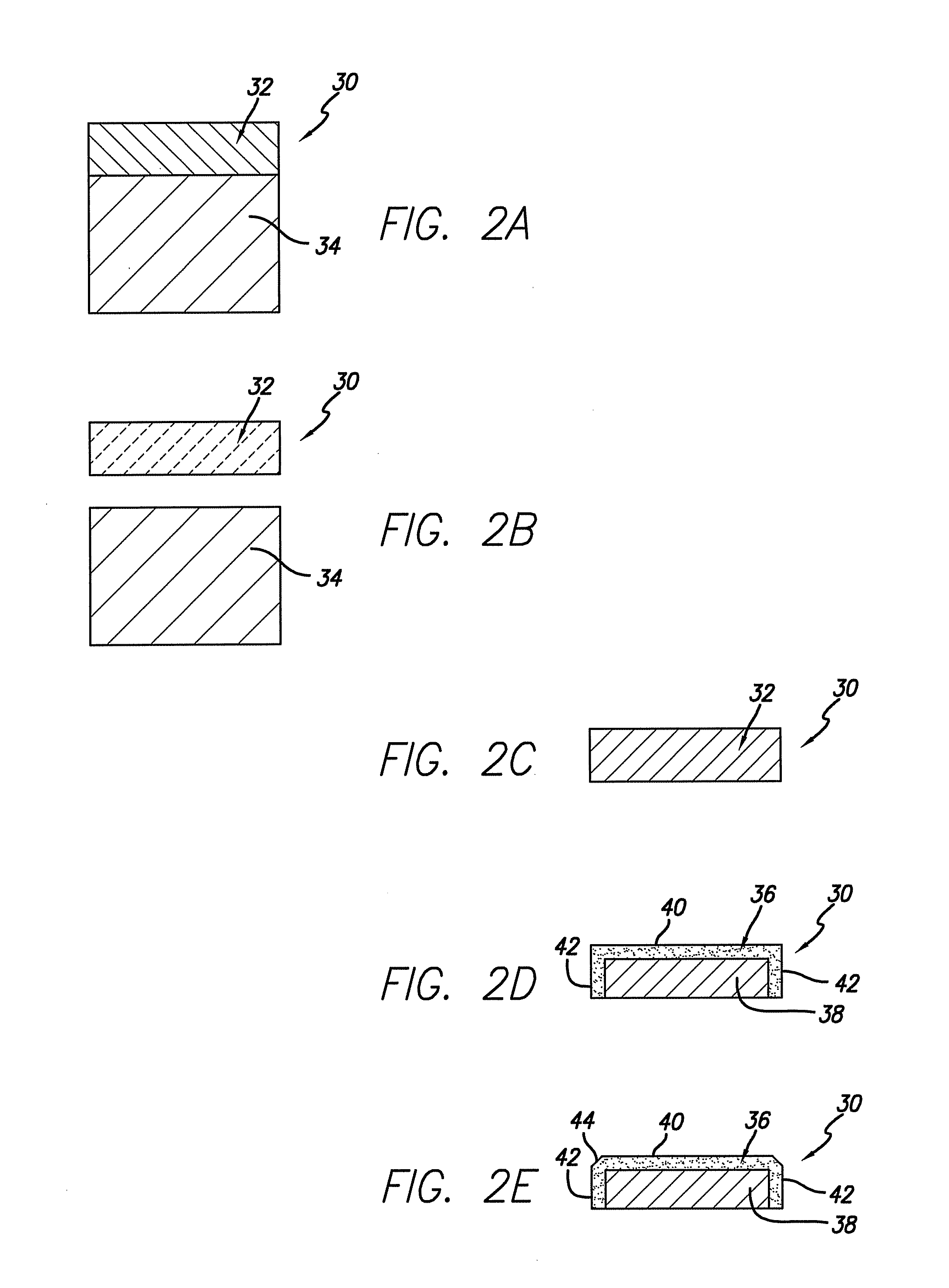

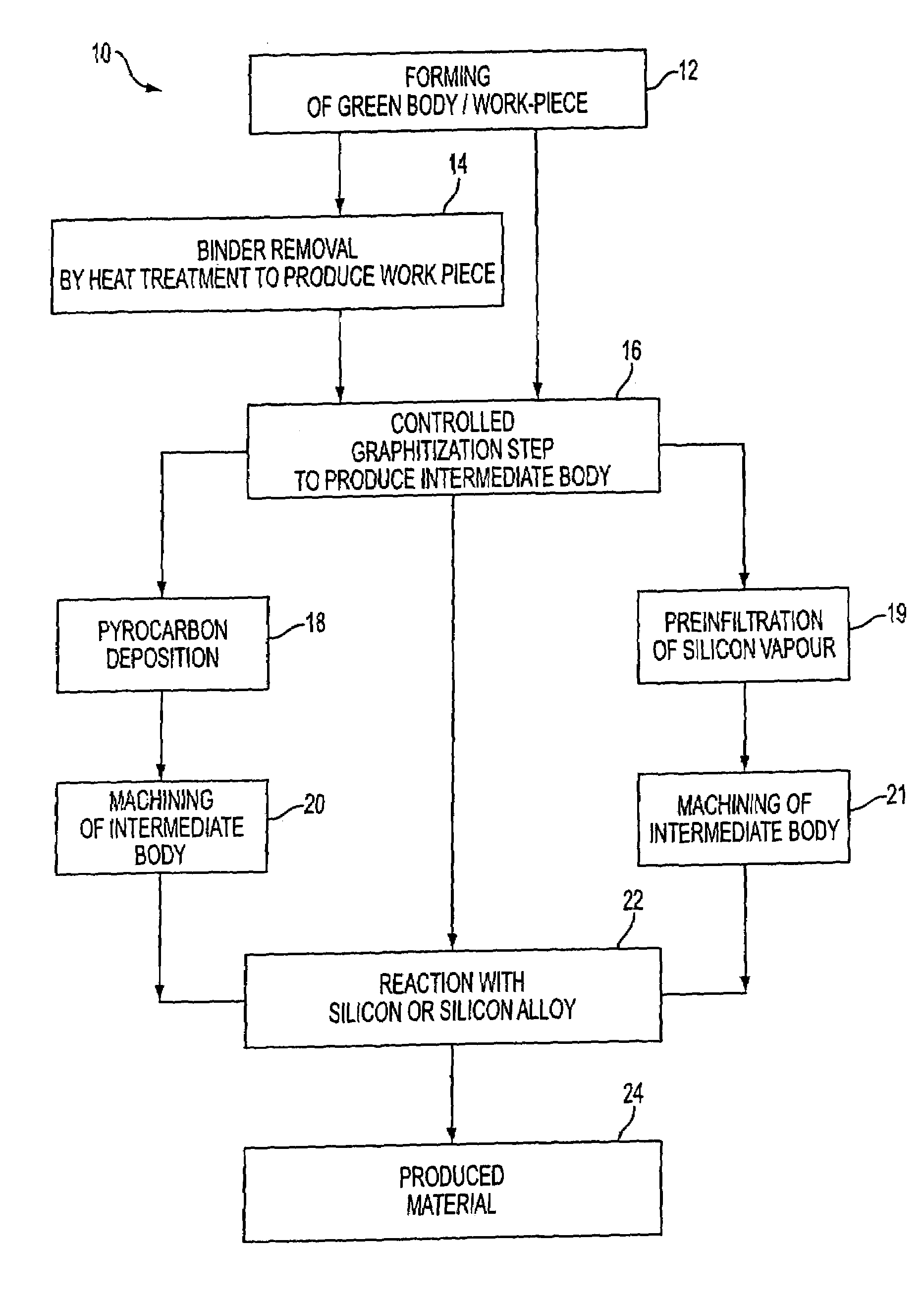

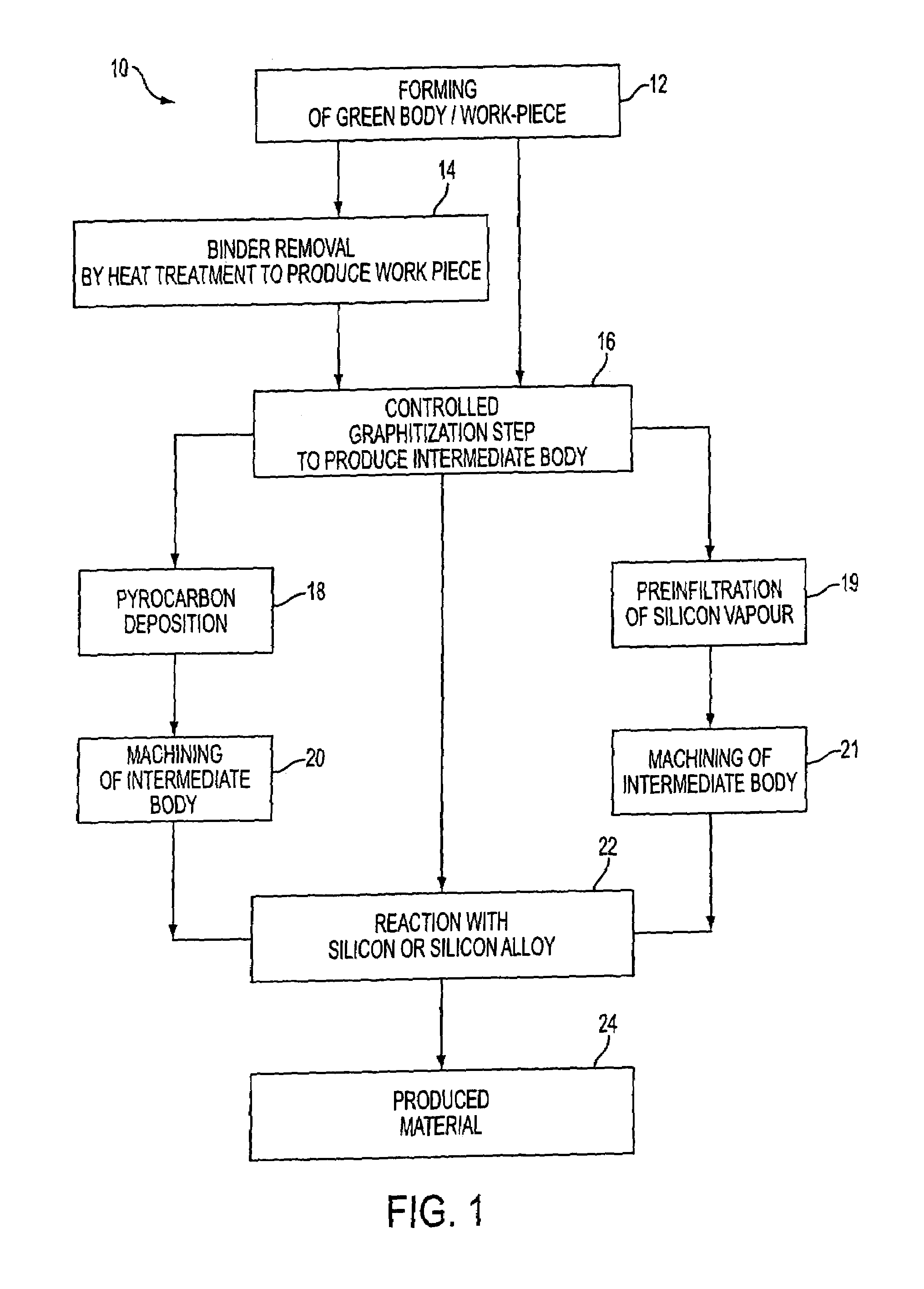

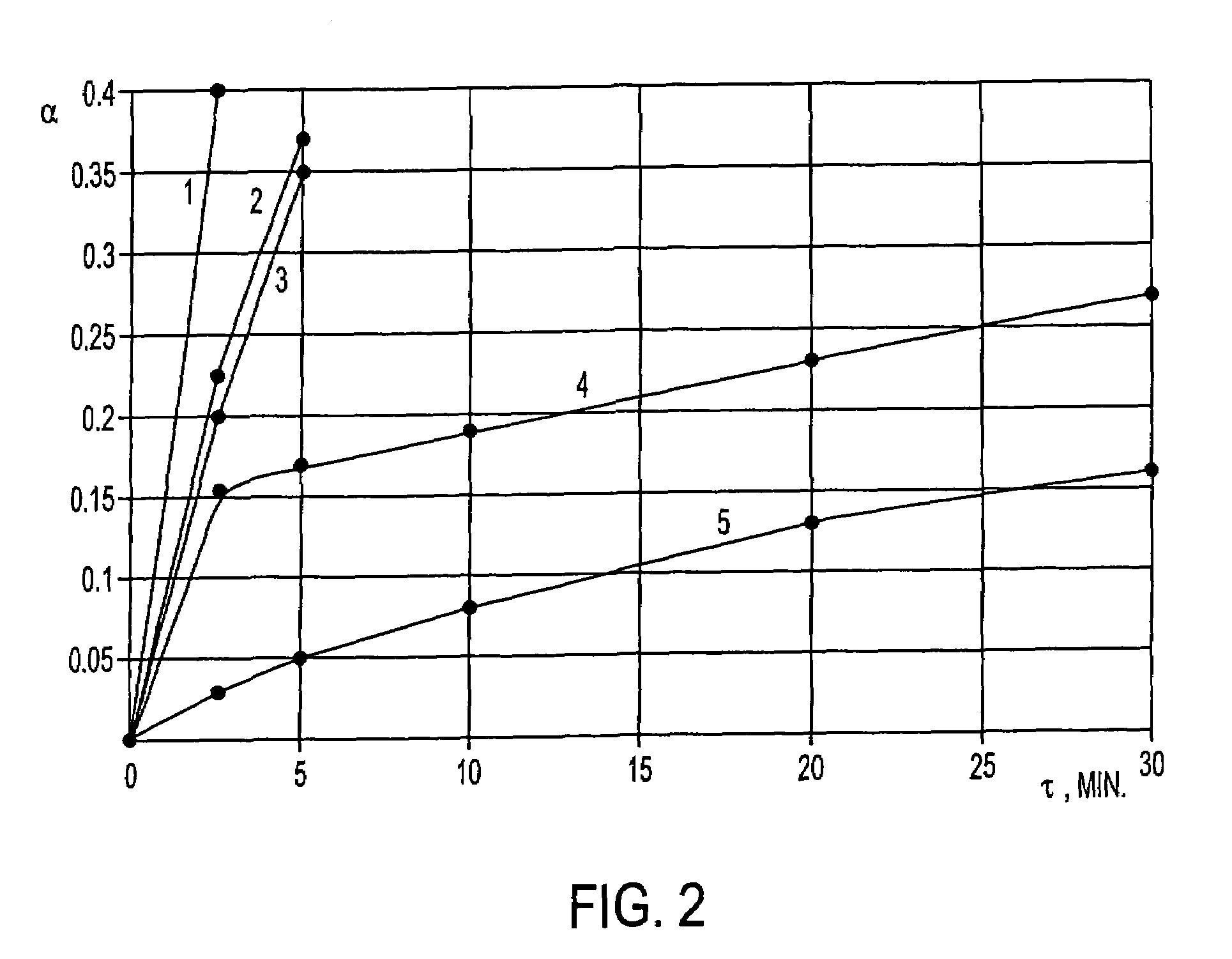

Method of manufacturing a diamond composite and a composite produced by same

InactiveUS7008672B2Simple production equipmentComplex shapeOther chemical processesNatural mineral layered productsHeating timeSilicon alloy

Owner:SKELETON TECH

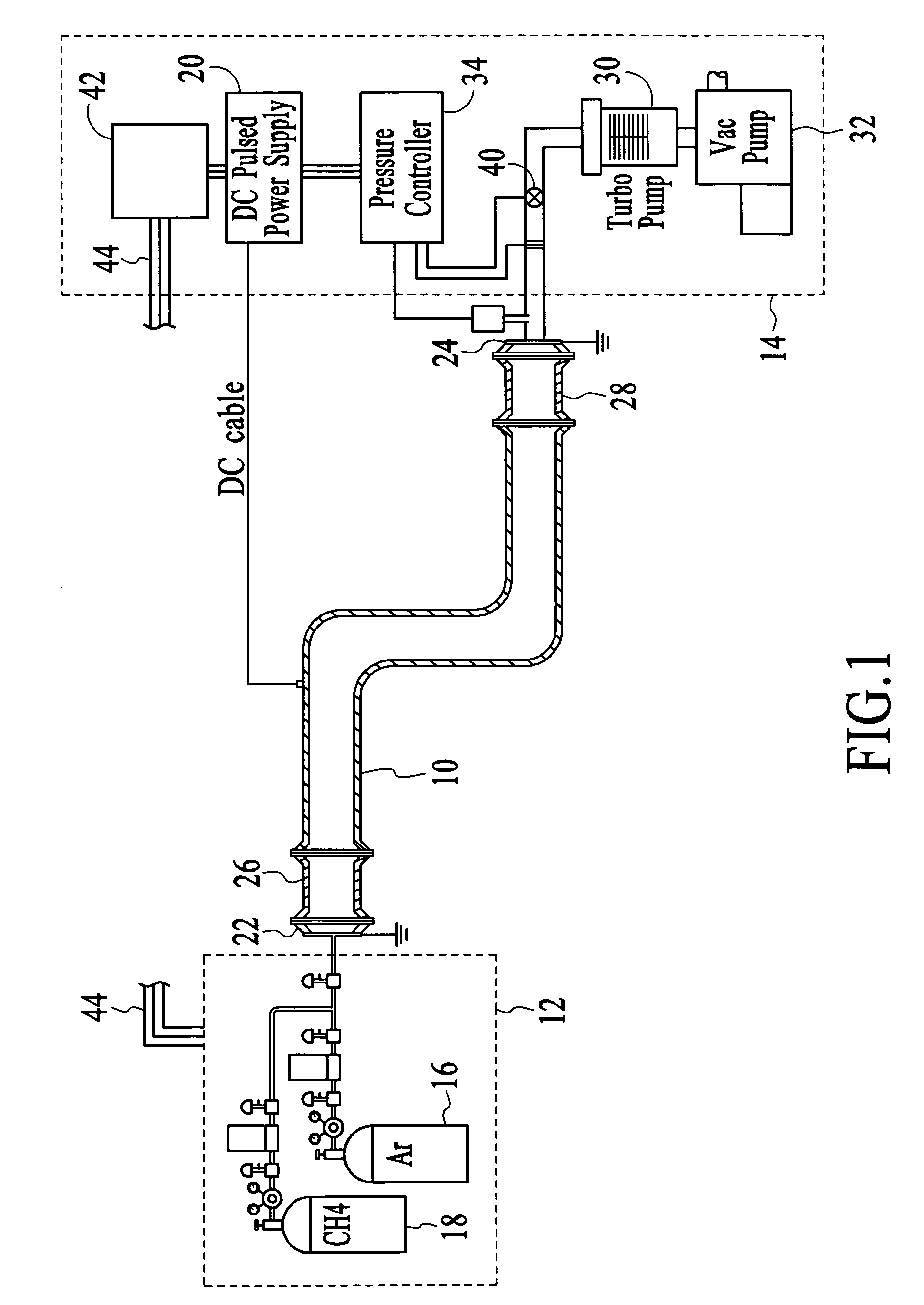

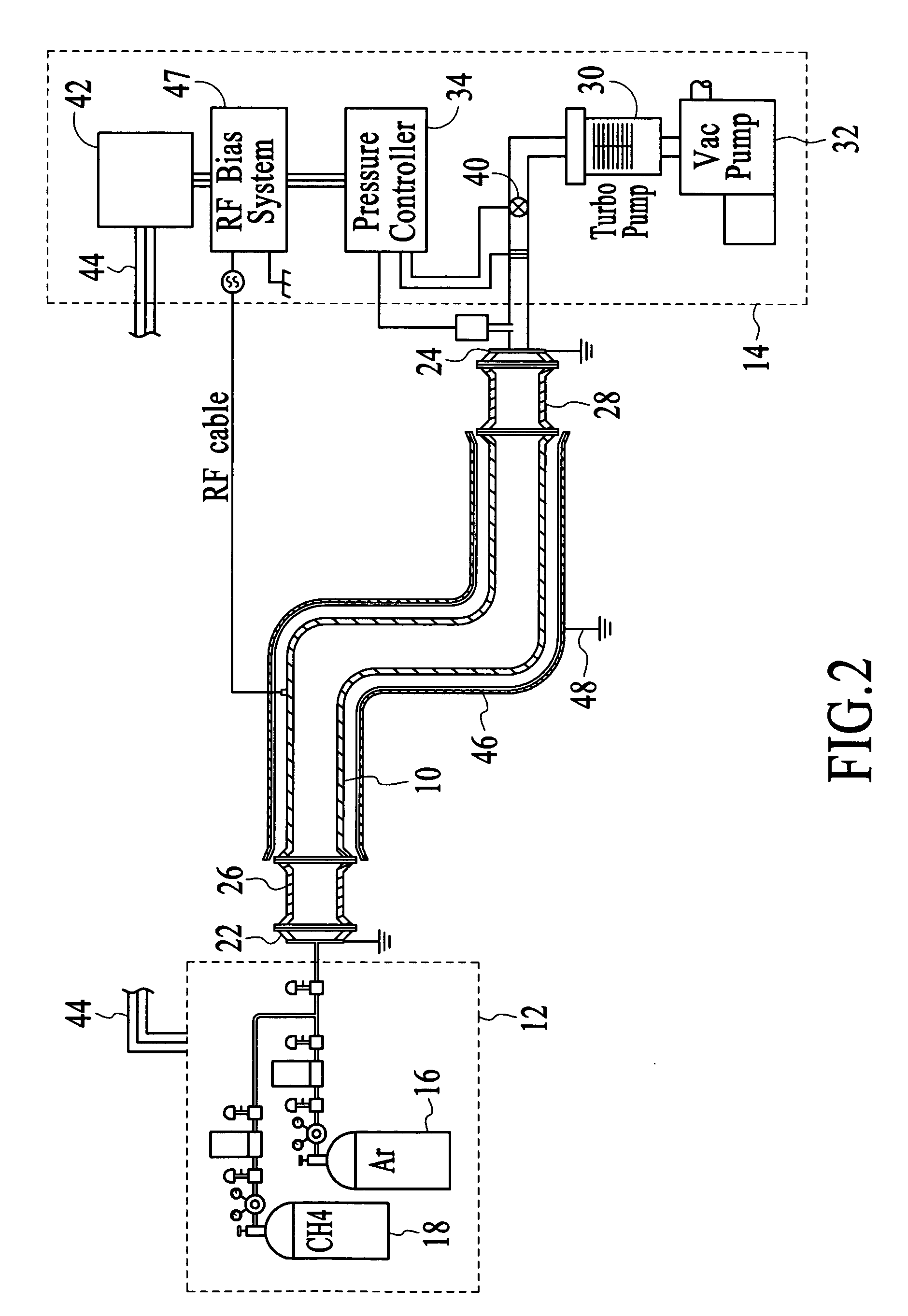

Diamond coatings on reactor wall and method of manufacturing thereof

InactiveUS6537429B2High purityIncrease resistanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingSemiconductorPlasma chamber

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a diamond containing surface and process for manufacture thereof.

Owner:LAM RES CORP

Polycrystalline diamond composite constructions comprising thermally stable diamond volume

ActiveUS7462003B2Improve thermal stabilityConstructionsRecord information storageComposite constructionDiamond crystal

PCD composite constructions comprise a diamond body bonded to a substrate. The diamond body comprises a thermally stable diamond bonded region that is made up of a single phase of diamond crystals bonded together. The diamond body includes a PCD region bonded to the thermally stable region and that comprises bonded together diamond crystals and interstitial regions interposed between the diamond crystals. The PCD composite is prepared by combining a first volume of PCD with a second volume of diamond crystal-containing material consisting essentially of a single phase of bonded together diamond crystals. A substrate is positioned adjacent to or joined to the first volume. The first and second volumes are subjected to high pressure / high temperature process conditions, during process the first and second volumes form a diamond bonded body that is attached to the substrate, and the second volume forms the thermally stable diamond bonded region.

Owner:SMITH INT INC

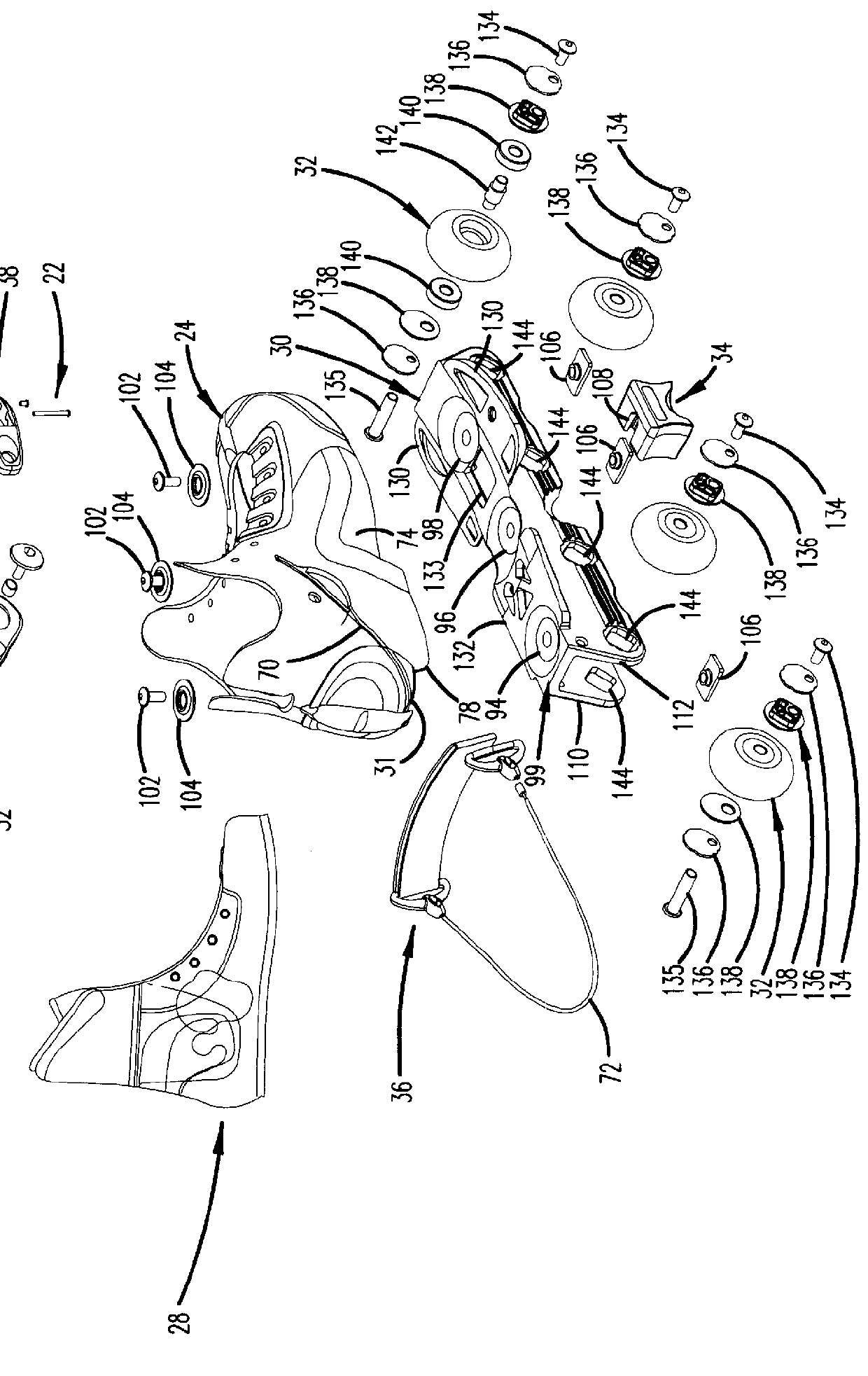

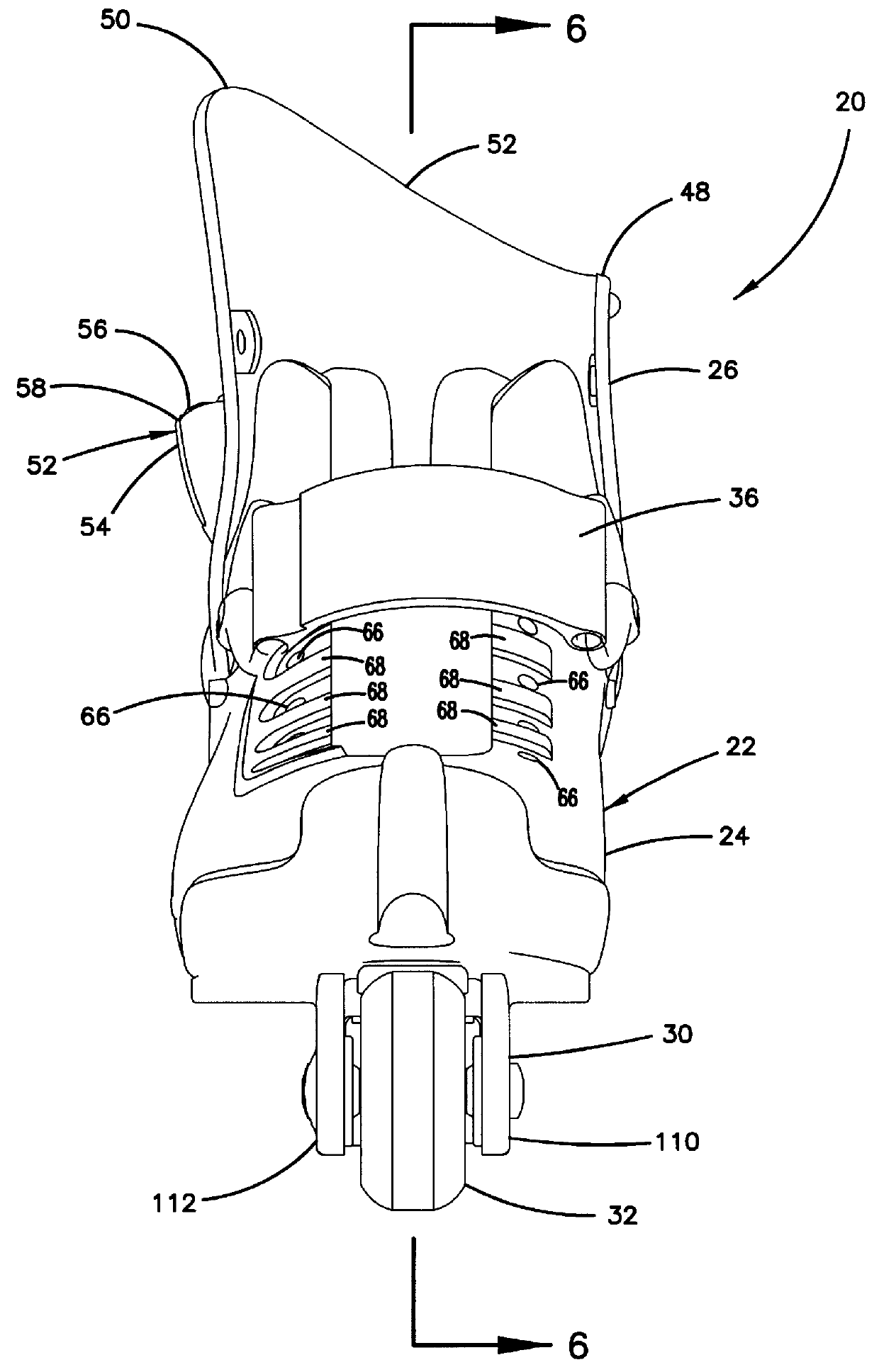

Eccentric spacer for an in-line skate

A diamond-shaped eccentric spacer suitable for use with an in-line roller skate. The spacer defines an eccentric first axle opening sized and shaped for receiving an in-line skate axle. The diamond-shaped spacer also includes a first corner positioned opposite from a second corner, and a third corner positioned opposite from a fourth corner. The eccentric first axle opening is aligned along a diagonal line that extends generally between the first and second corners.

Owner:BENETTON SPORTSYST USA

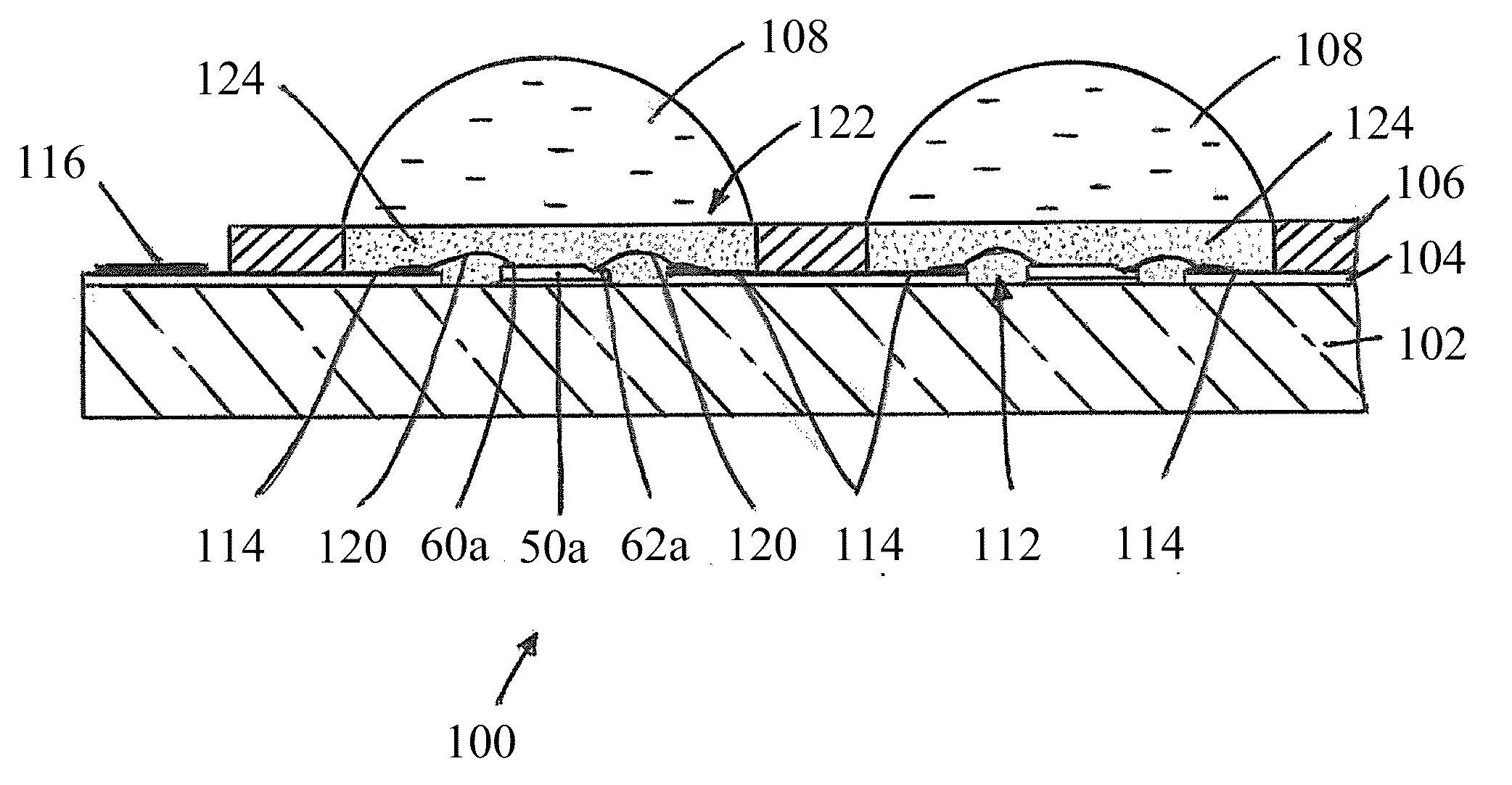

Light emitting device

ActiveUS20100295070A1Thermal resistance minimizationImprove cooling effectPrinted circuit aspectsSolid-state devicesCarbon filmDiamond-like carbon

A light emitting device comprises a plurality of LED chips (“lateral” or “vertical” conducting) operable to generate light of a first wavelength range and a package for housing the chips. The package comprises: a thermally conducting substrate (copper) on which the LED chips are mounted and a cover having a plurality of through-holes in which each hole corresponds to a respective one of the LED chips. The holes are configured such that when the cover is mounted to the substrate each hole in conjunction with the substrate defines a recess in which a respective chip is housed. Each recess is at least partially filled with a mixture of at least one phosphor material and a transparent material. In a device with “lateral” conducting LED chips a PCB is mounted on the substrate and includes a plurality of through-holes which are configured such that each chip is directly mounted to the substrate. For a device with “vertical” conducting LED chips the LED chips are mounted on a diamond like carbon film.

Owner:EPISTAR CORP

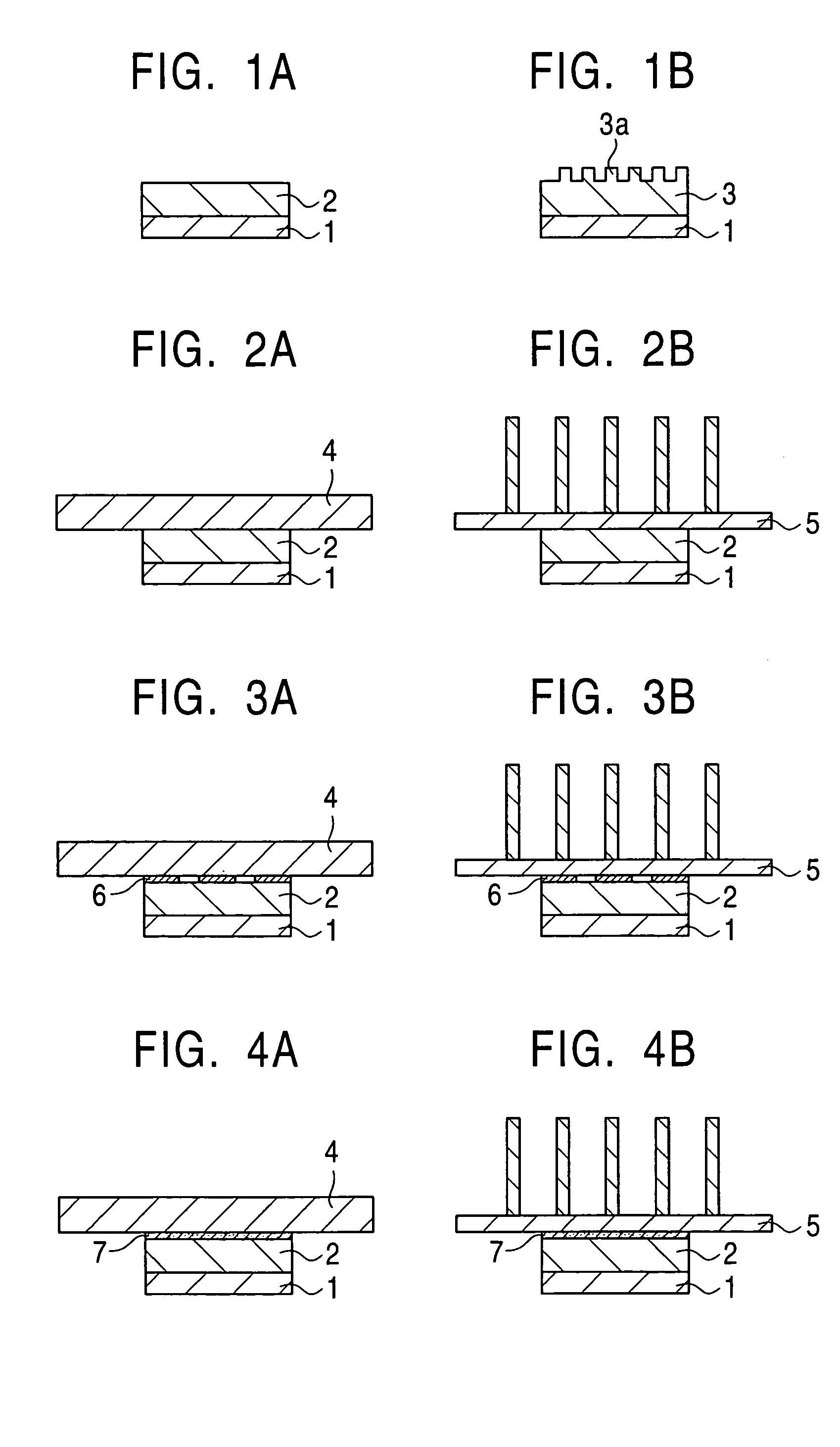

Methods for manufacturing a diamond prosthetic joint component

InactiveUS6596225B1Improve wear resistanceReduce coefficient of frictionCoatingsProsthesisArticular surfacesProsthetic joint component

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including methods for manufacturing a diamond prosthetic joint component.

Owner:DIAMICRON

Method and system for coating internal surfaces of prefabricated process piping in the field

ActiveUS7300684B2Improve adhesionIncreases magnitudeLiquid surface applicatorsVacuum evaporation coatingHydrocarbon mixturesDiamond-like carbon

The coating of internal surfaces of a workpiece is achieved by connecting a bias voltage such that the workpiece functions as a cathode and by connecting an anode at each opening of the workpiece. A source gas is introduced at an entrance opening, while a vacuum source is connected at an exit opening. Pressure within the workpiece is monitored and the resulting pressure information is used for maintaining a condition that exhibits the hollow cathode effect. Optionally, a pre-cleaning may be provided by introducing a hydrocarbon mixture and applying a negative bias to the workpiece, so as to sputter contaminants from the workpiece using argon gas. Argon gas may also be introduced during the coating processing to re-sputter the coating, thereby improving uniformity along the length of the workpiece. The coating may be a diamond-like carbon material having properties which are determined by controlling ion bombardment energy.

Owner:AGM CONTAINER CONTROLS

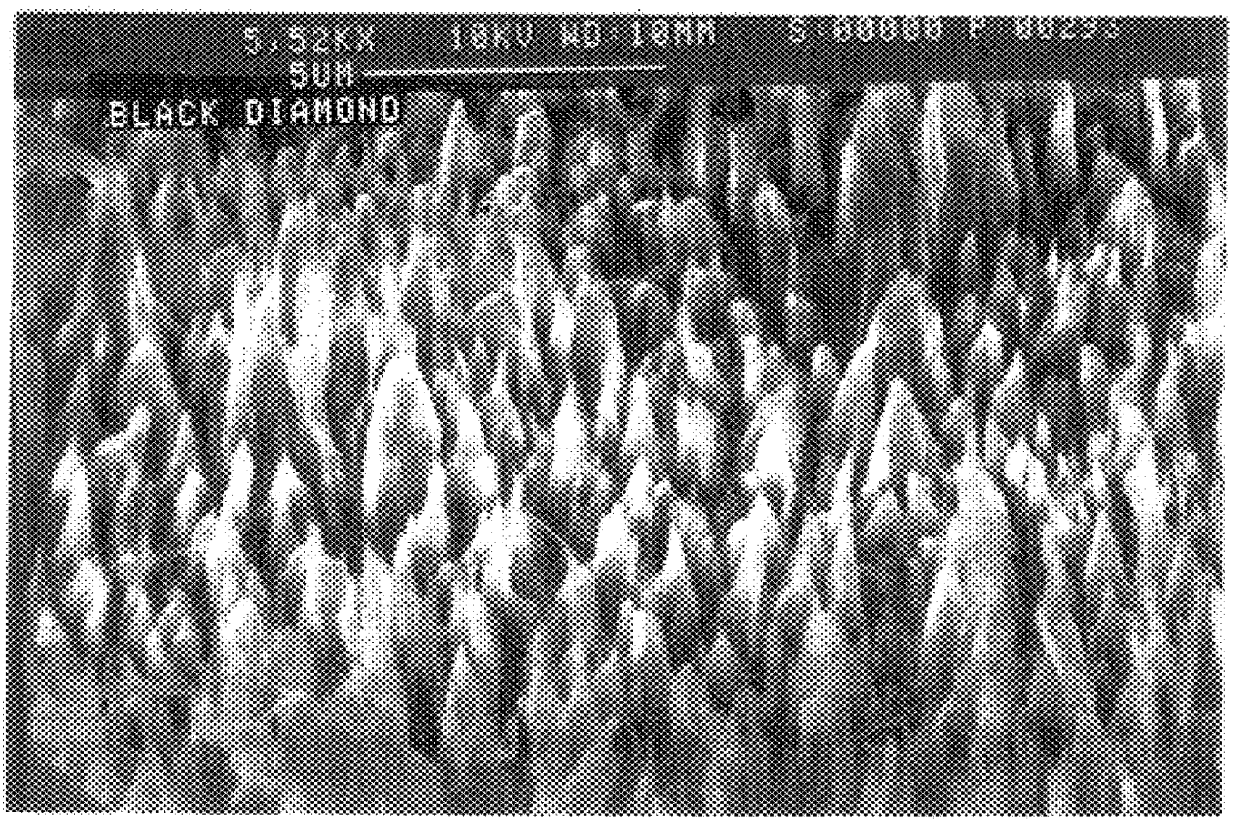

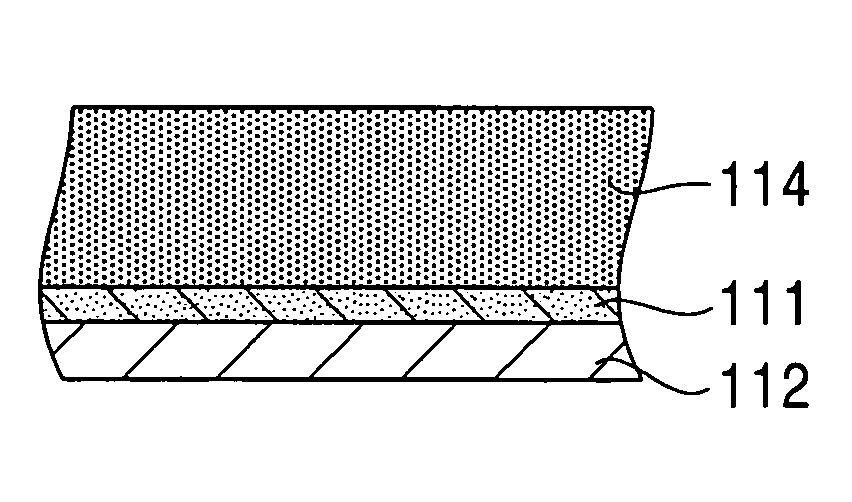

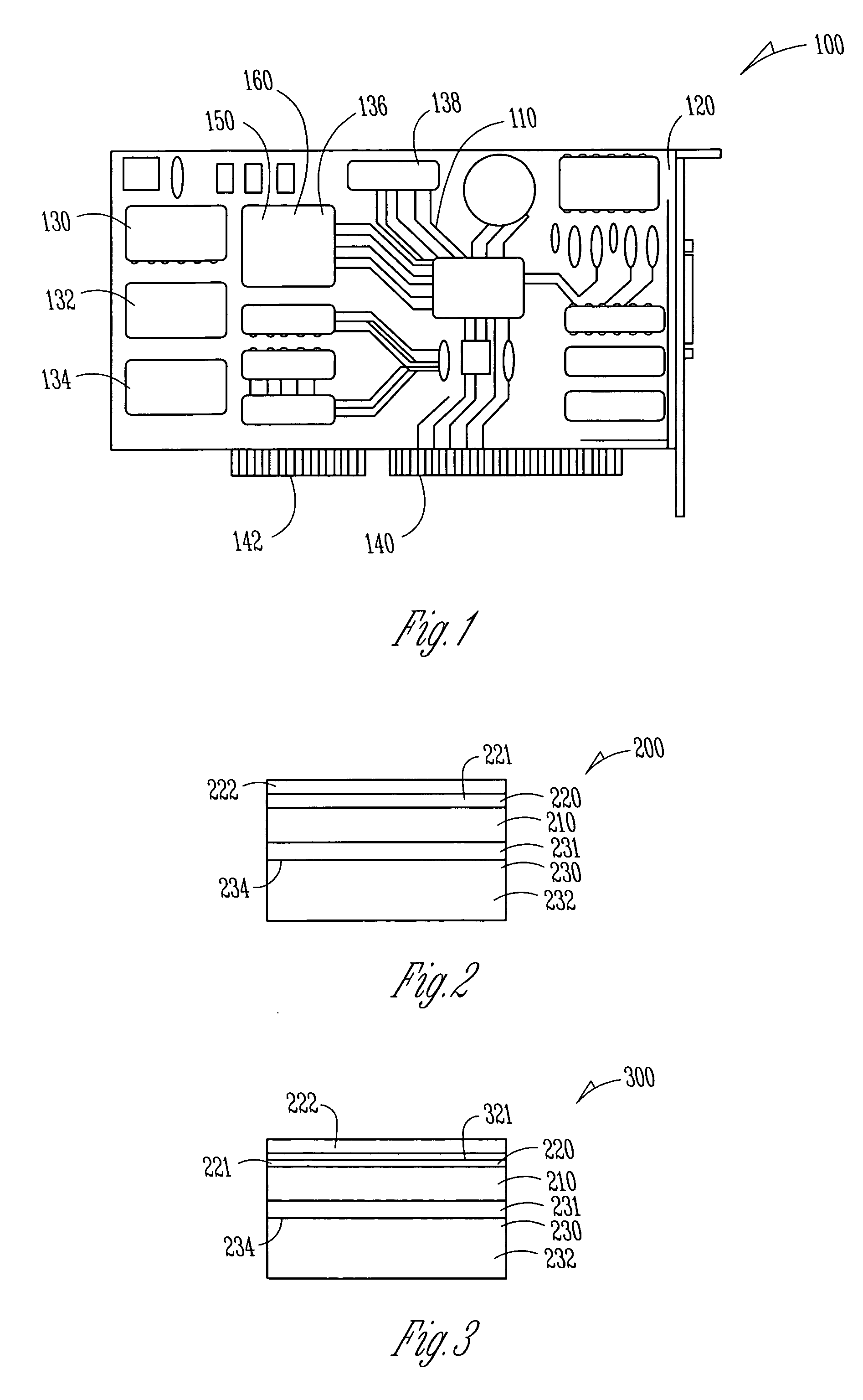

Heat spreader and semiconductor device and package using the same

InactiveUS7067903B2Improve thermal conductivityLarge thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPolymer adhesiveCeramic

A semiconductor device and package has a heat spreader directly disposed on the reverse surface of the semiconductor device. This heat spreader includes a diamond layer or a layer containing diamond and ceramics such as silicon carbide and aluminum nitride. The heat spreader is directly formed on a substrate for the semiconductor device. In particular, the heat spreader is composed of a diamond layer and one or two metal or ceramic members, which are bonded to the diamond layer with one or two polymer adhesive layers. This diamond layer has a fiber structure across the thickness or a microcrystalline structure. Cilia are formed on a surface of the diamond layer facing the one or two metal or ceramic members.

Owner:KOBE STEEL LTD

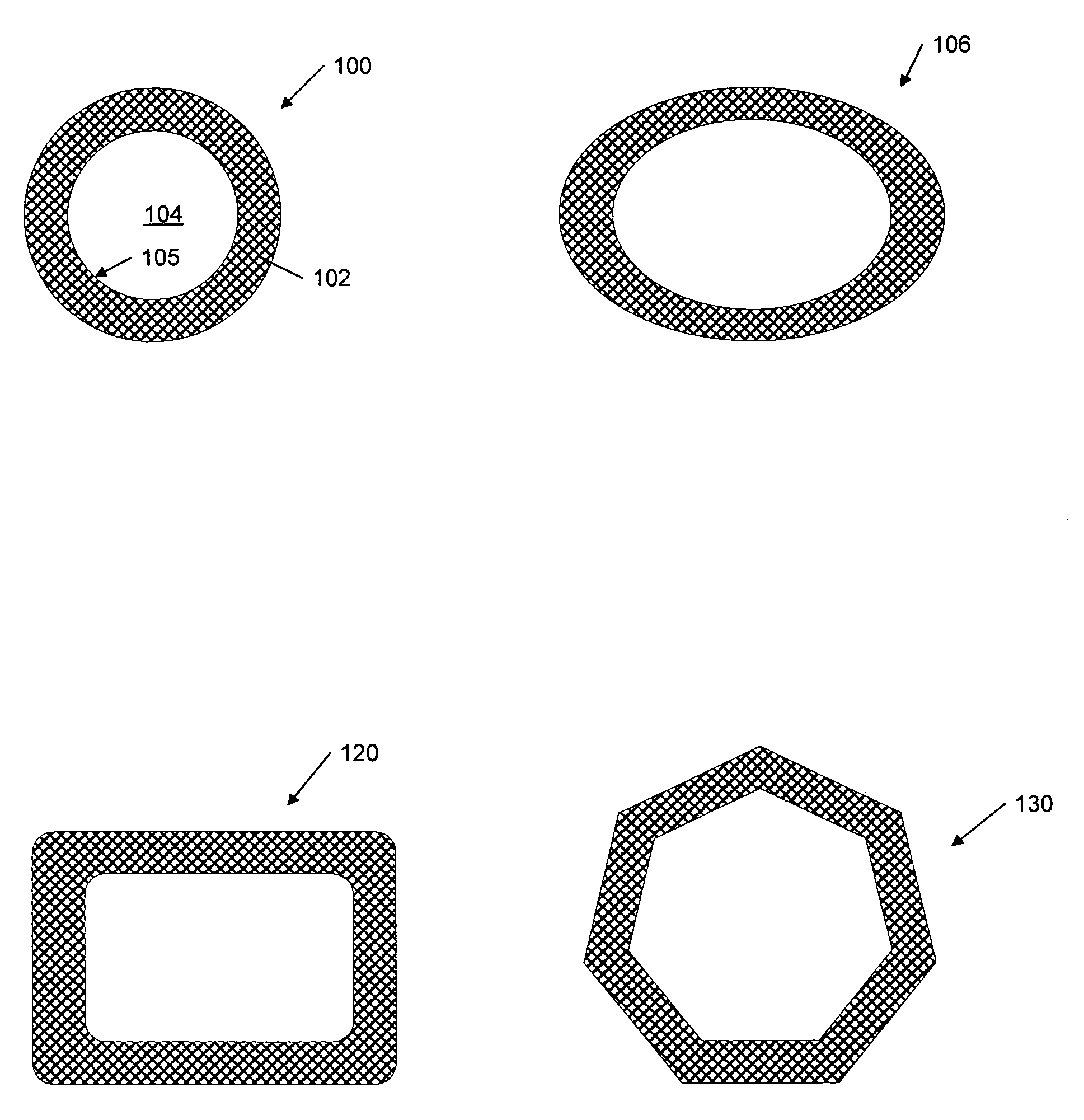

Transcatheter valve with paravalvular leak sealing ring

A prosthetic heart valve includes a collapsible and expandable stent extending from an inflow end to an outflow end and a plurality of prosthetic valve leaflets coupled to the stent. The prosthetic heart valve may also include a sealing ring coupled to the inflow end of the stent, the sealing ring comprising a tube extending circumferentially around the inflow end of the stent. The tube may be formed from a wire coiled into a repeating shape, such as a rectangle or a diamond, so that the tube is collapsible. A covering may at least partially surround the tube. The sealing ring may include a first filler positioned within the tube and / or a second filler positioned between the tube and the covering.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

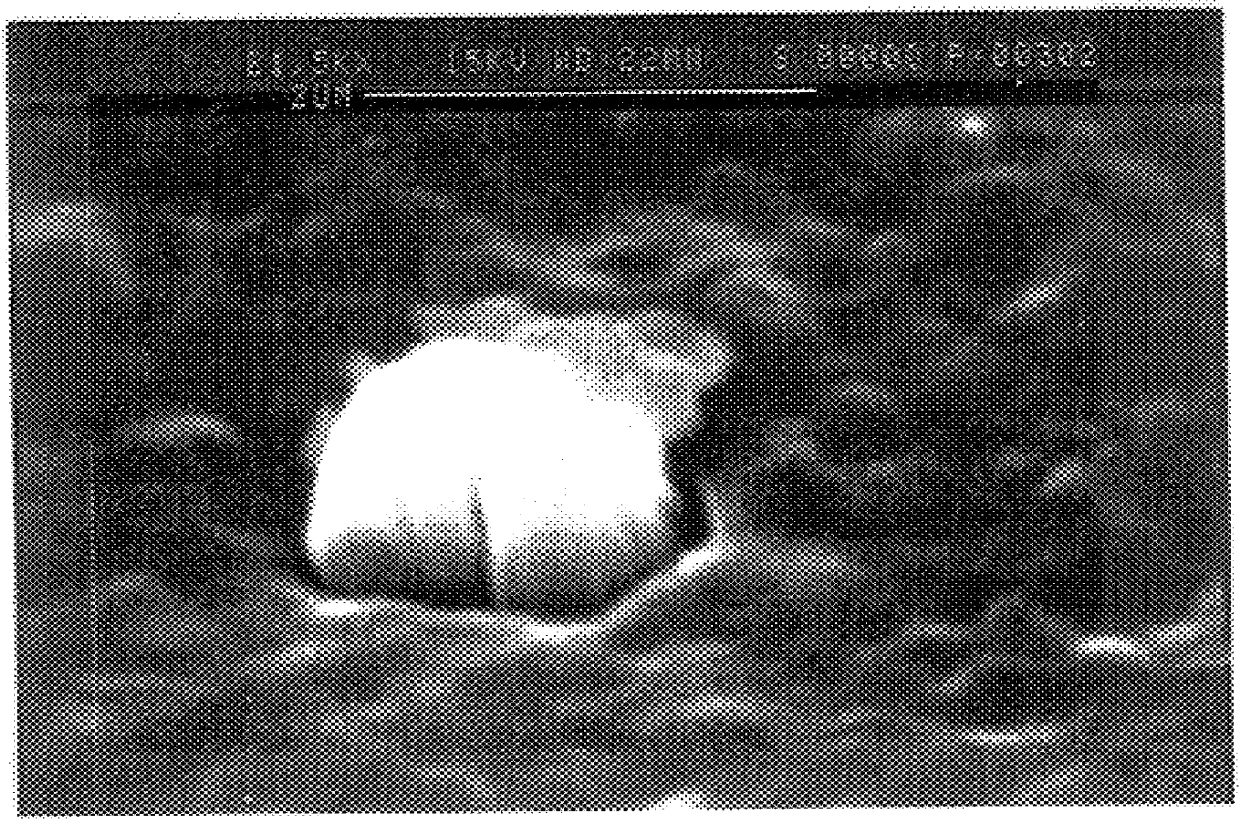

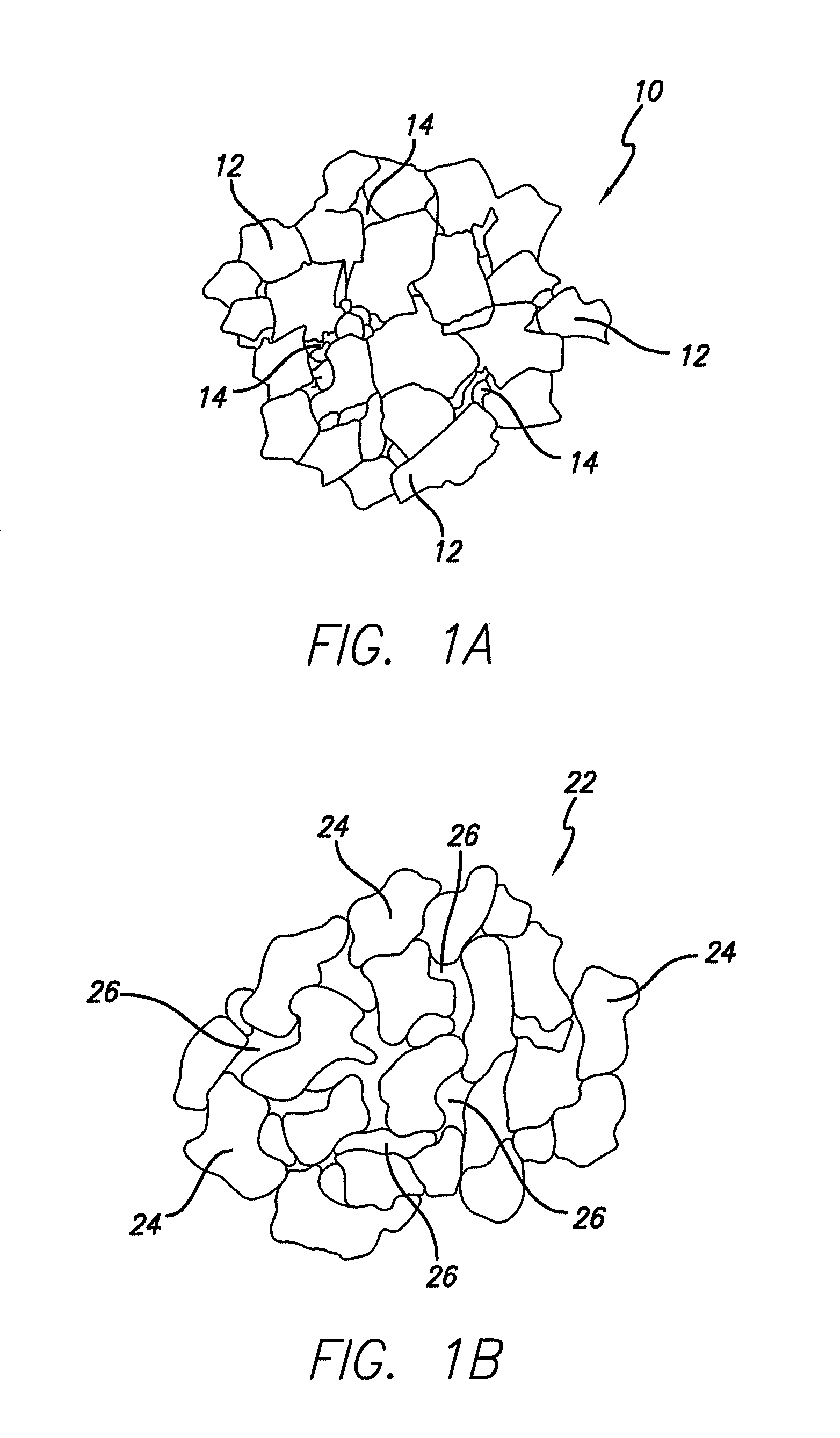

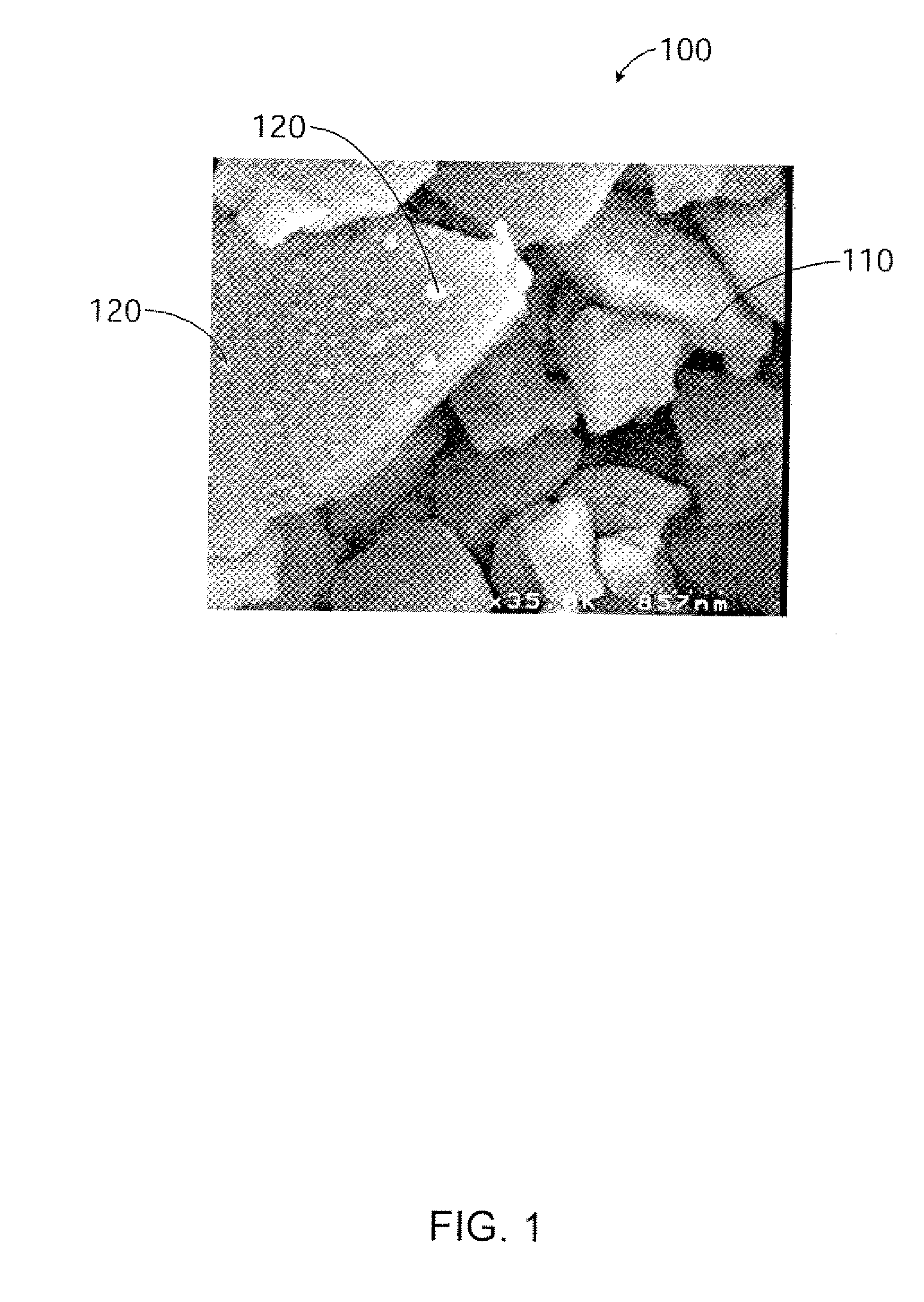

Sintered polycrystalline diamond material with extremely fine microstructures

InactiveUS20070056778A1Uniform particle sizePressurized chemical processDrill bitsPolycrystalline diamondHigh pressure

A sintered polycrystalline diamond material (PCD) of extremely fine grain size is manufactured by sintering a diamond powder with pre-blended catalyst metal under high pressure / high temperature (HP / HT) processing. The PCD material has an average sintered diamond grain structure of less than 1.0 μm.

Owner:DIAMOND INNOVATIONS INC

Heat spreader

InactiveUS20100149756A1Wave amplification devicesSemiconductor/solid-state device detailsEngineeringElectronic packaging

The present invention relates to a package comprising a plate formed from a diamond-composite material and a frame and its use as a lid or cavity lid in electronic packaging applications.

Owner:ROWCLIFFE DAVID +1

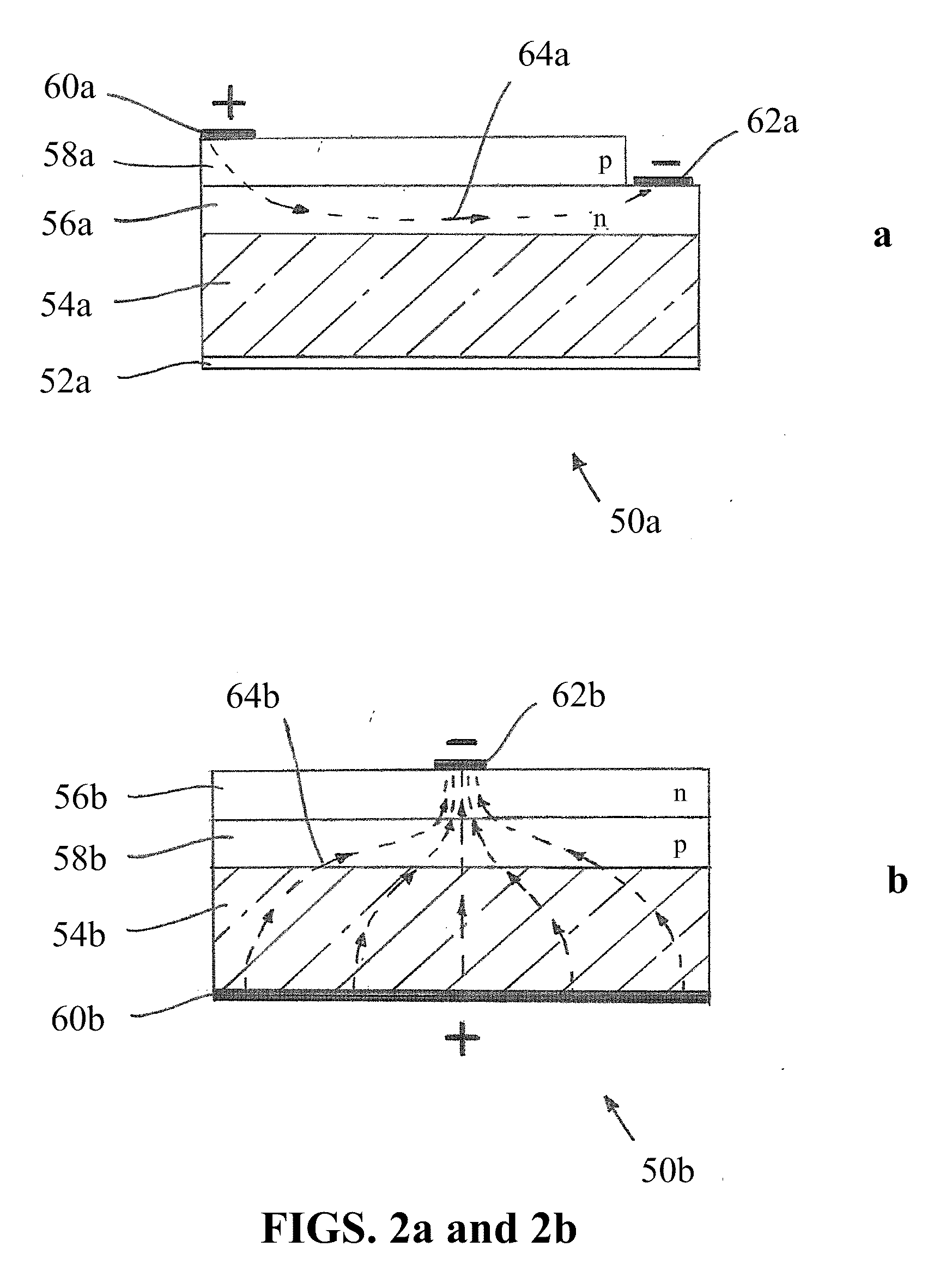

Silicon on diamond wafers and devices

A heat dissipation device includes a first silicon layer, a second silicon layer, and a diamond layer sandwiched between the first silicon layer and the second silicon layer. A method for forming an electronic device includes sandwiching a layer of diamond between a first layer of silicon and a second layer of silicon, and forming an electrical device on one of the first layer of silicon or the second layer of silicon. The method further includes forming an epitaxial layer on one of the first layer of silicon and the second layer of silicon. An electrical device is formed in the epitaxial layer.

Owner:INTEL CORP

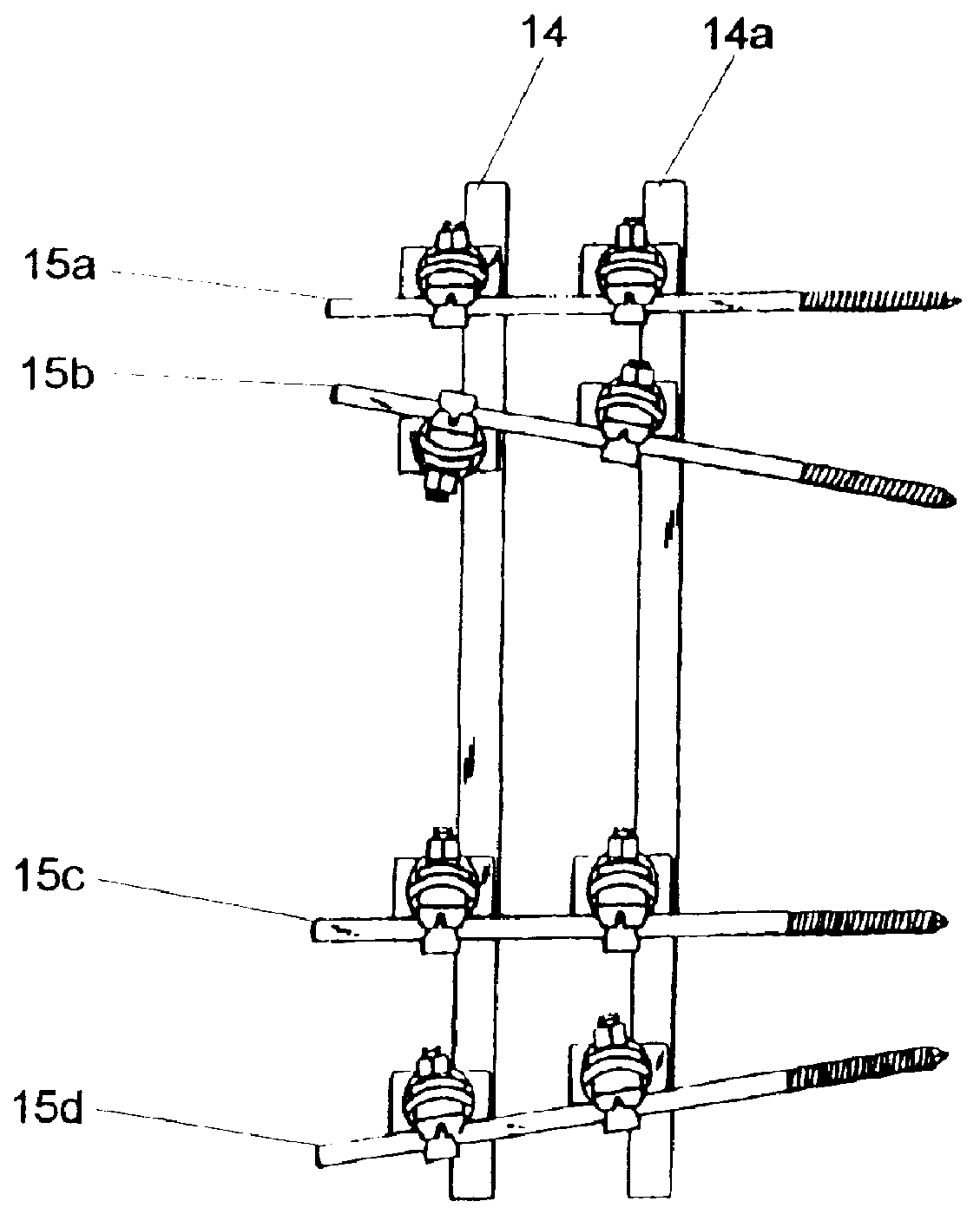

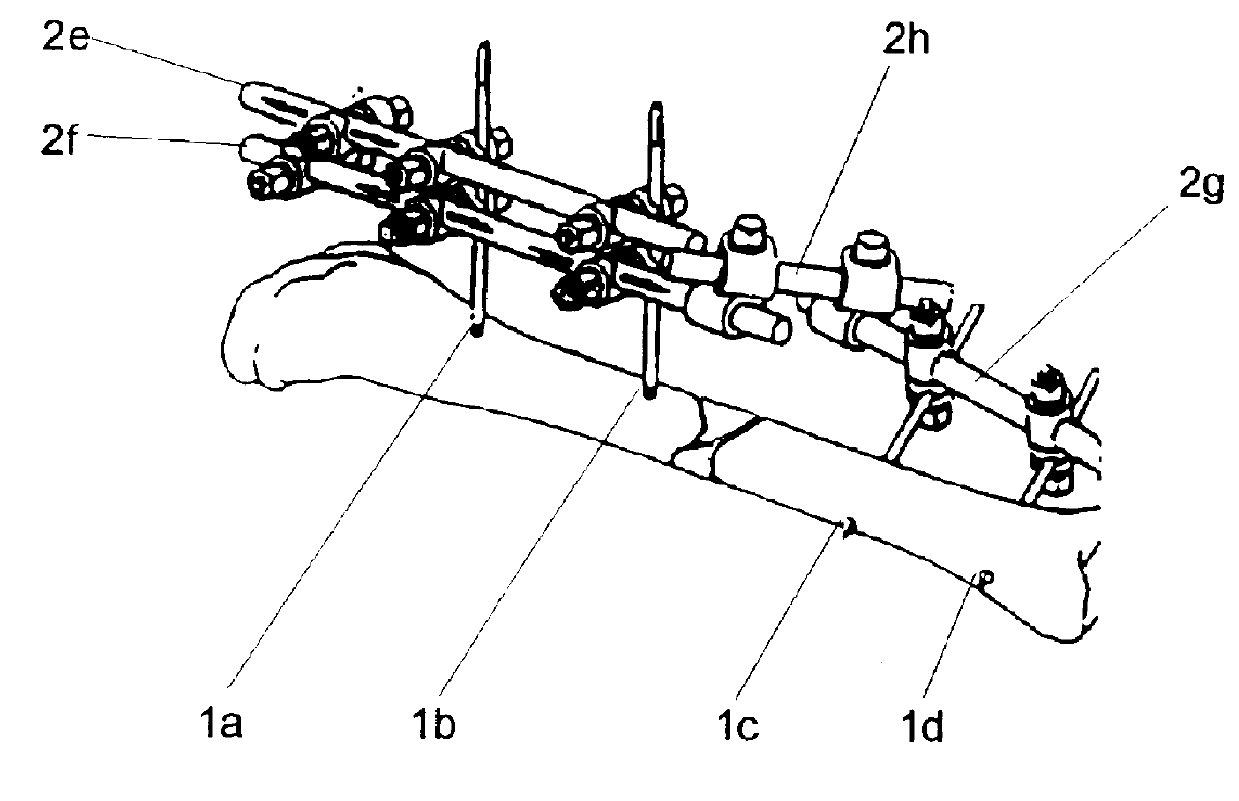

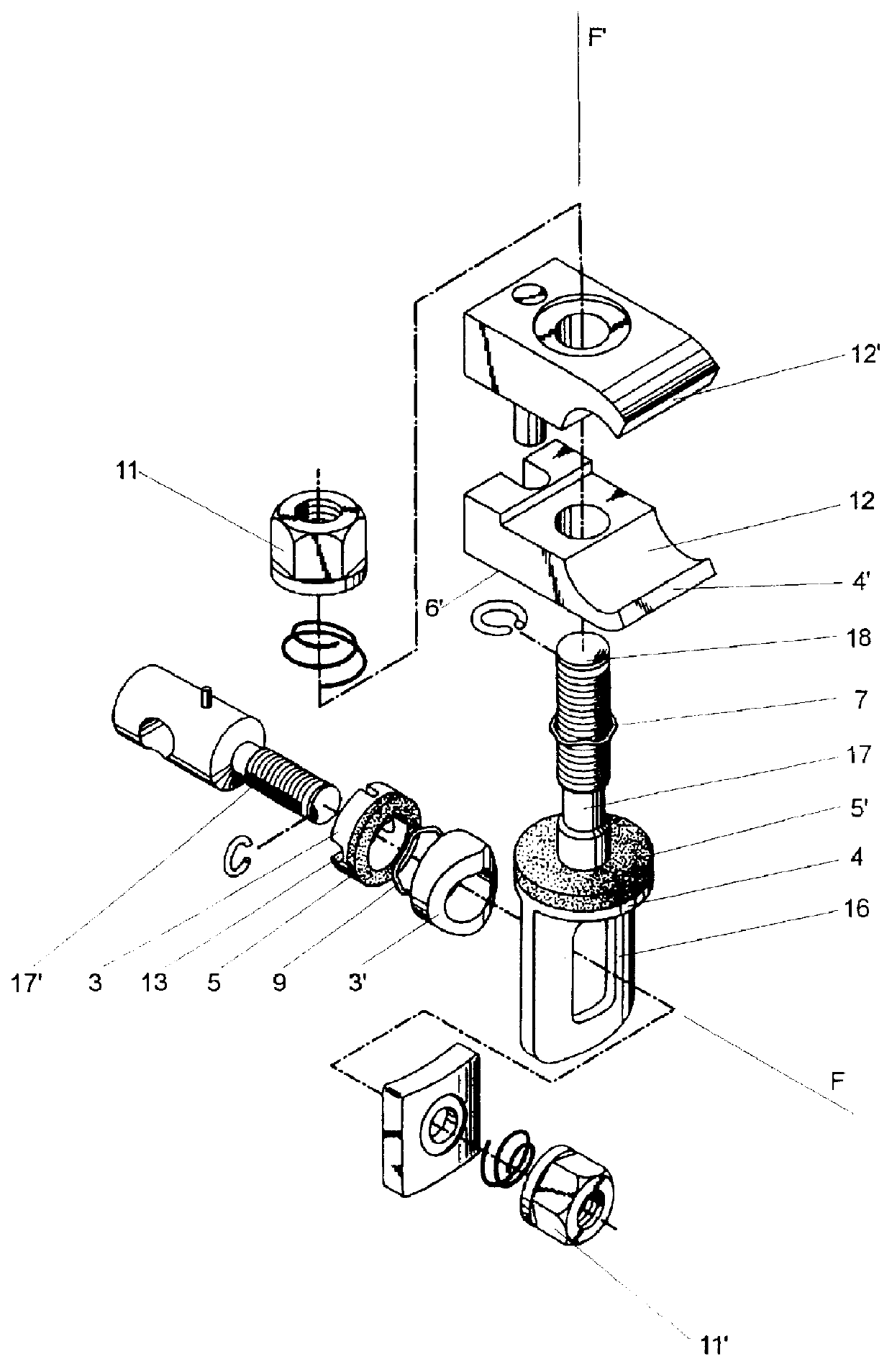

Clamping connection for medical equipment and apparatus

InactiveUS6022348AMinimal motionEasy to disassembleSuture equipmentsLigamentsExternal fixatorCoupling

The invention relates to a coupling of two sides of a synergetically cooperating fixation system in medical equipment and apparatus, illustrated by way of example of an external fixator with rod-like guide elements, wherein a point-precise and internally tension-free clamping connection is formed by in each case two planar parallel disposed faces. The complementary, uncoated coupling surface is shape-matchingly impressed "de novo" and "uniquely" during each coupling closure by a static press-on force based on a diamond, plastic grain layer of a chaotic profile solidly attached to one of the faces, such that a clamping connection with the multilatent force-form match closure is furnished.

Owner:SPITZER DANIEL

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050025973A1Improve adhesionLow costPigmenting treatmentEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same, which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Chemical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:MORGAN ADVANCED CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com