Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4264 results about "Impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mechanics, an impact is a high force or shock applied over a short time period when two or more bodies collide. Such a force or acceleration usually has a greater effect than a lower force applied over a proportionally longer period. The effect depends critically on the relative velocity of the bodies to one another.

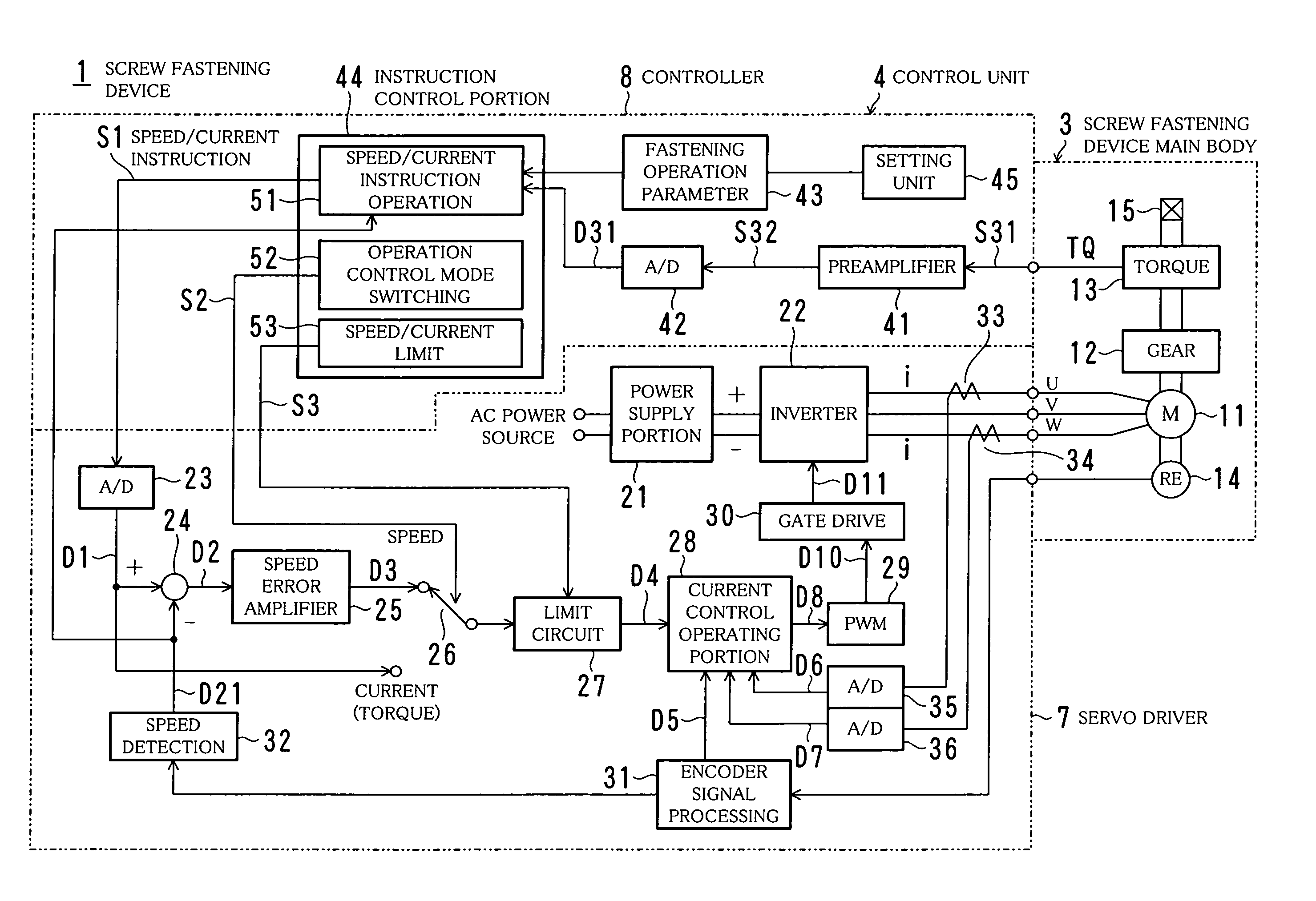

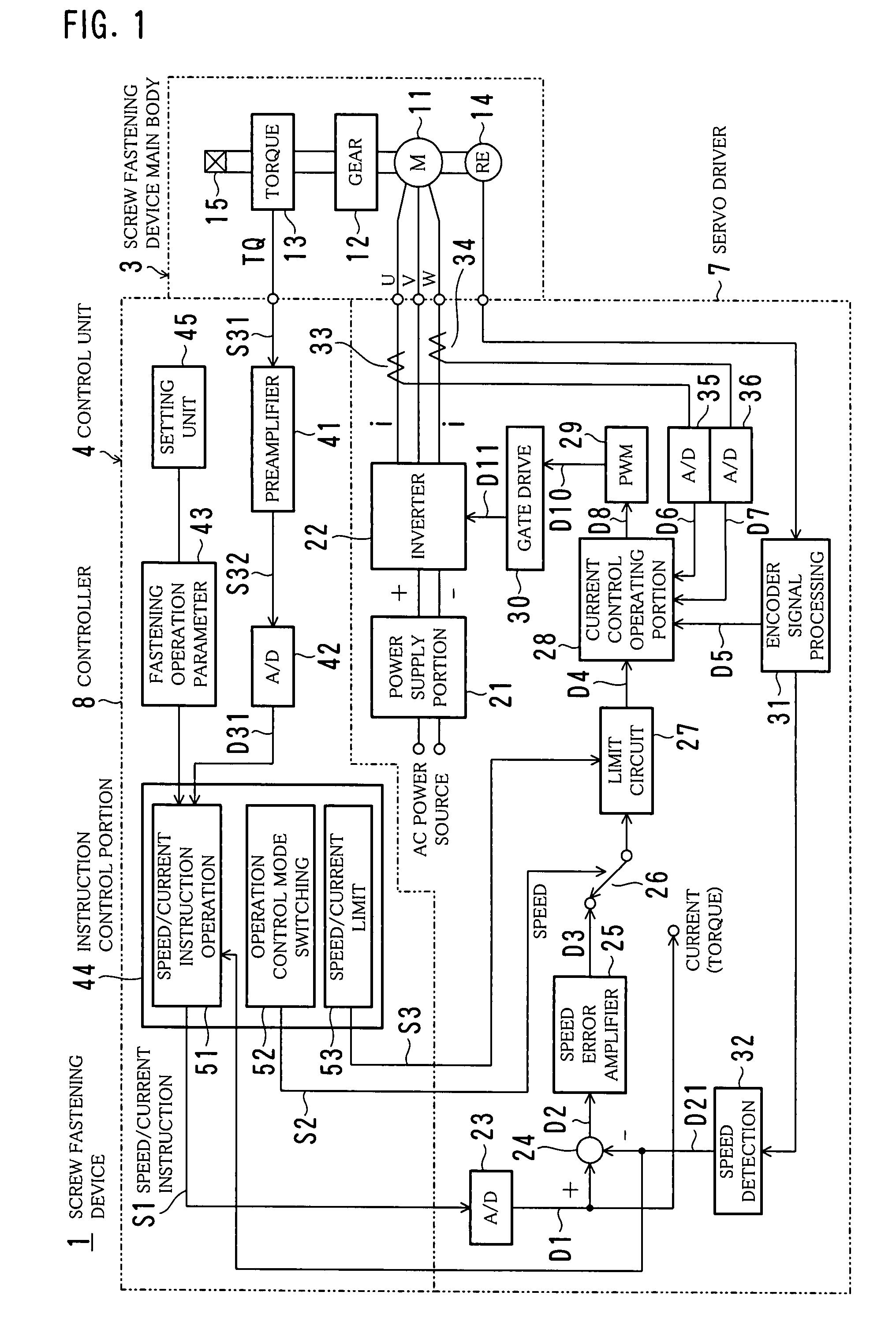

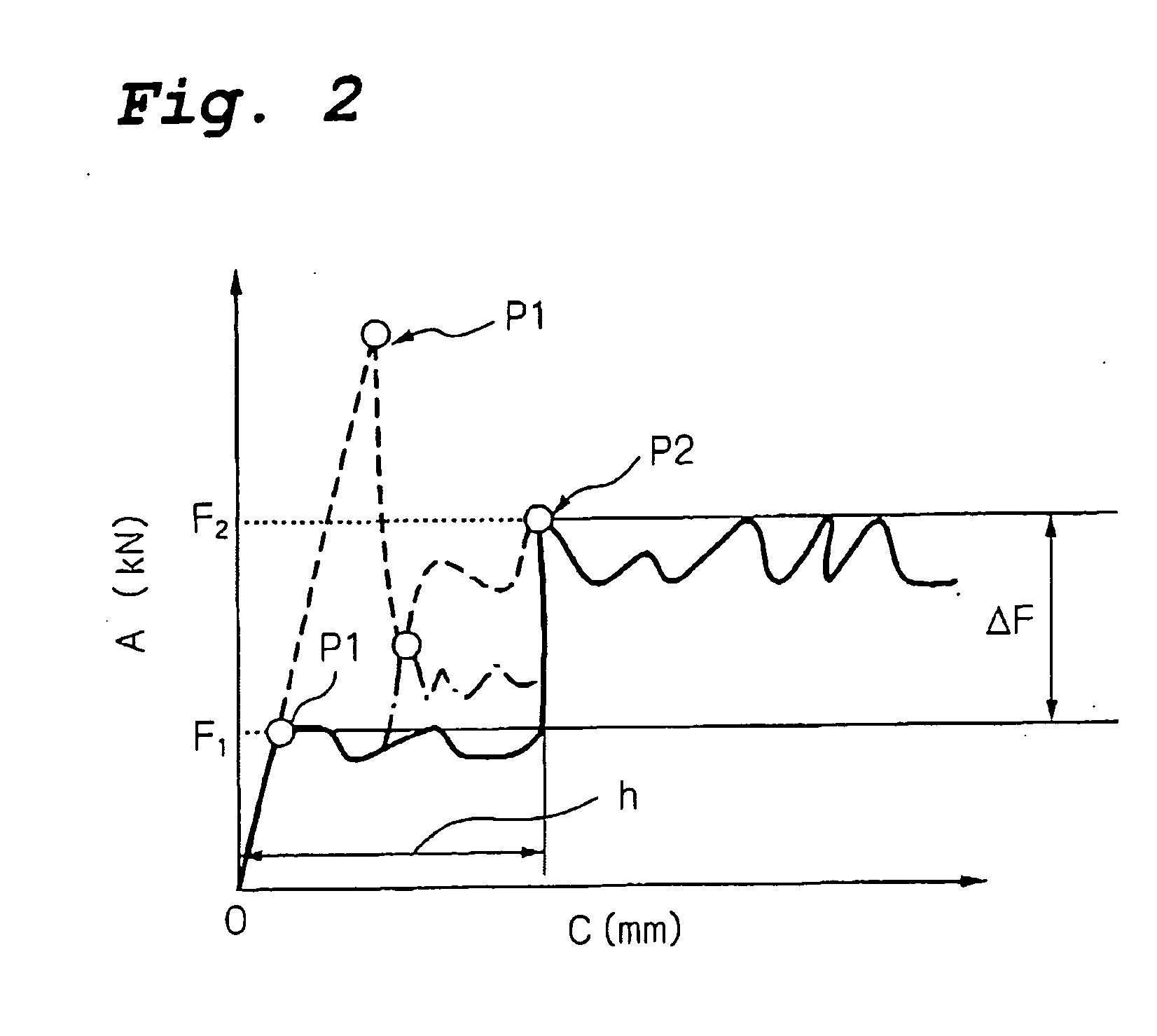

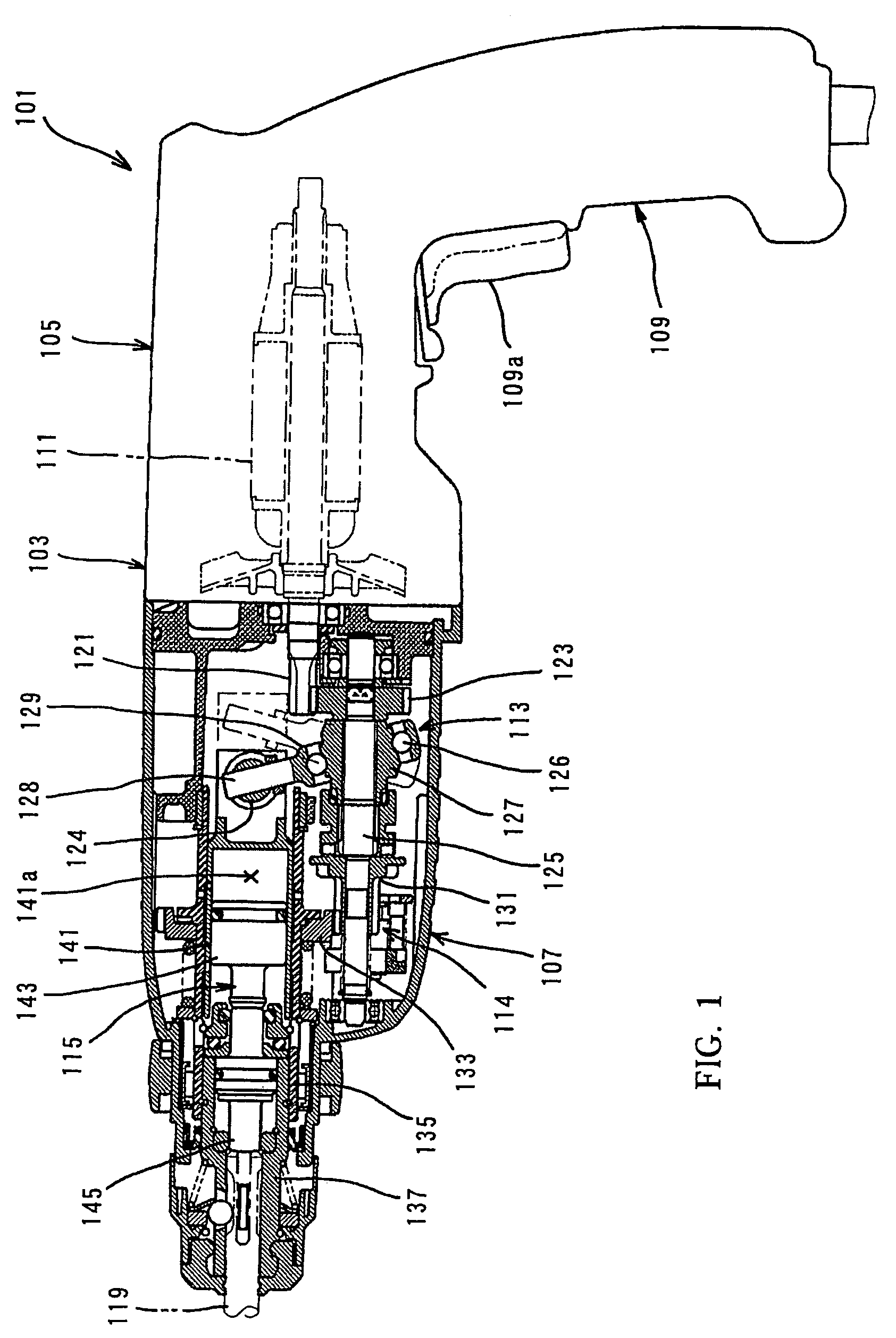

Control method and control unit for impact type screw fastening device

ActiveUS7770658B2Improve accuracyImprove fastening accuracyDrilling rodsConstructionsControl theoryElectrical current

An object is to improve accuracy of tightening torque and to shorten time necessary for fastening a screw in an impact type screw fastening device that uses an electric motor as a rotation driving source. A control method for the impact type screw fastening device that uses an electric motor as a rotation driving source includes the steps of driving the motor to rotate by supplying current to the motor intermittently so that torque exerted on a load by rotation of the motor becomes like pulses on the time axis, and controlling the current of every time of each pulse so that an increment of every time of each pulse of the torque after the torque reaches a target approach torque TQN that is a first set value becomes smaller than that before it reaches the target approach torque TQN.

Owner:ESTIC CORP

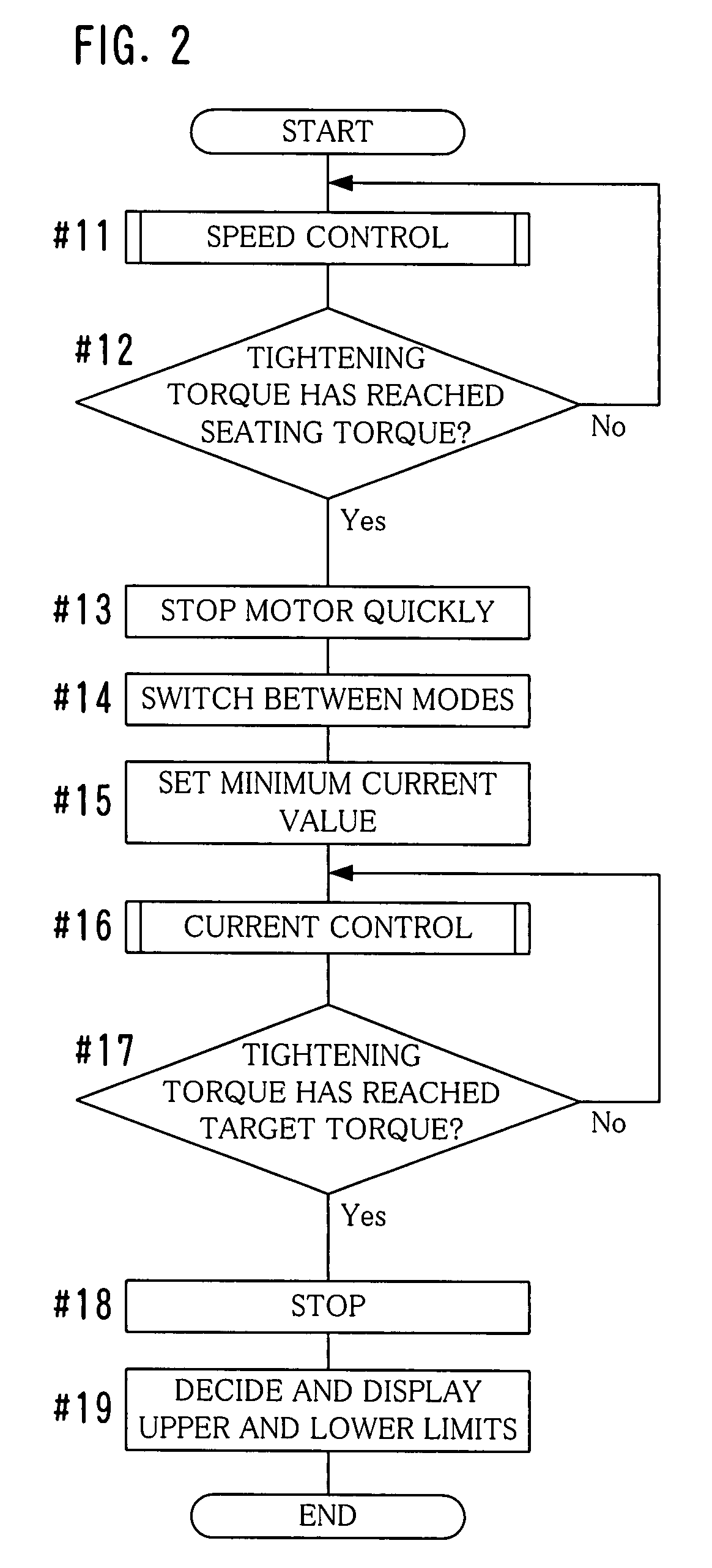

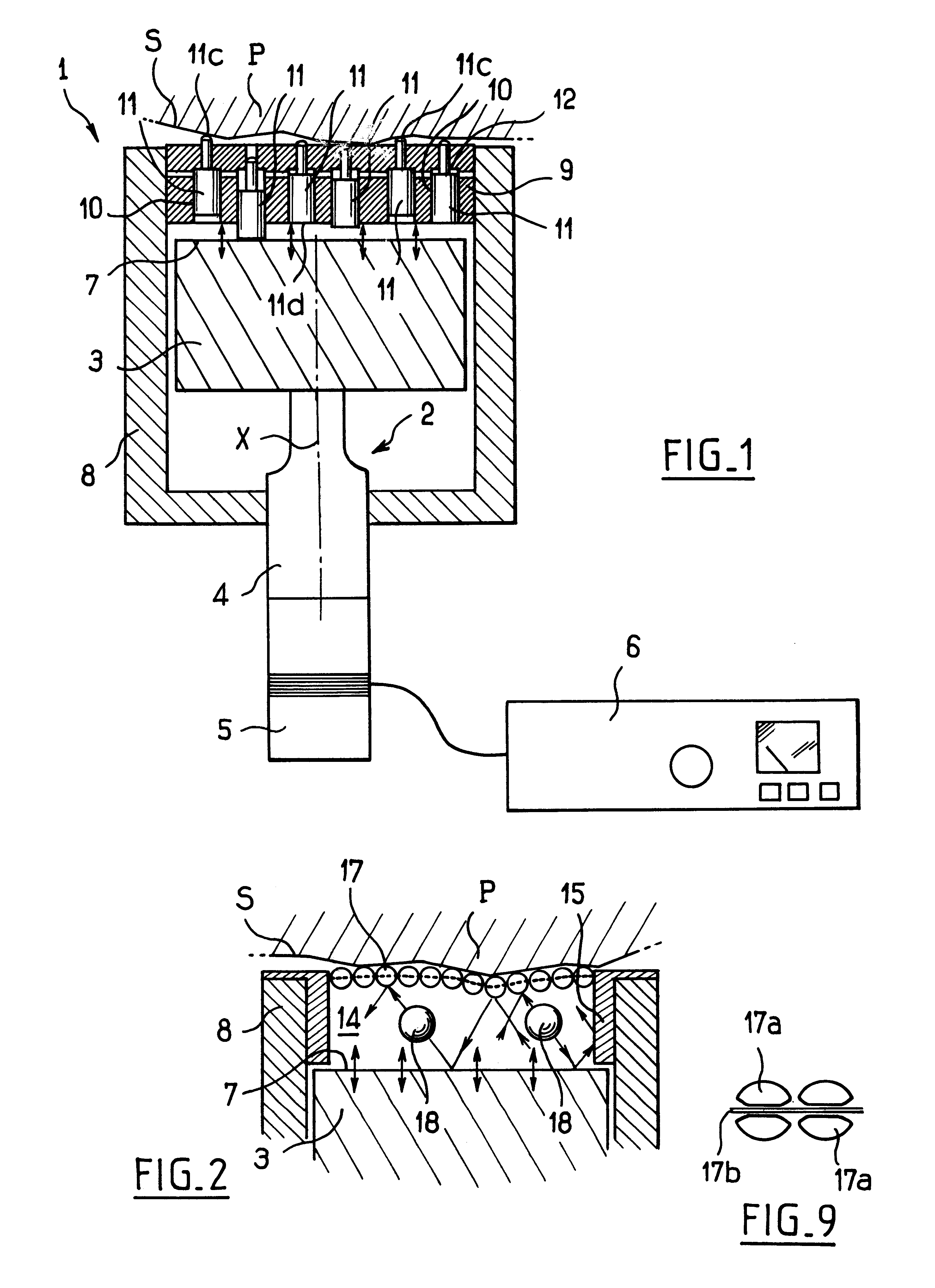

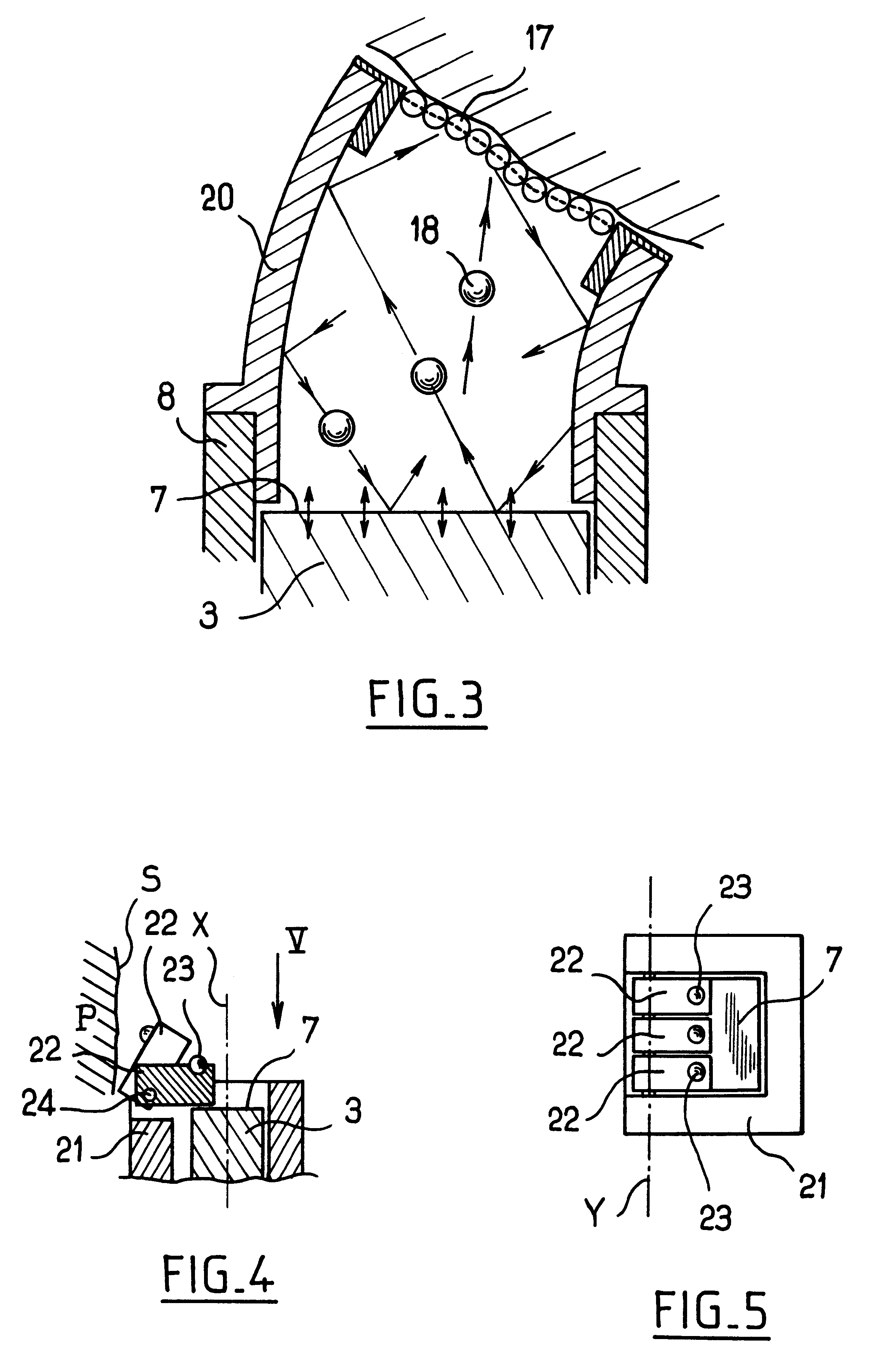

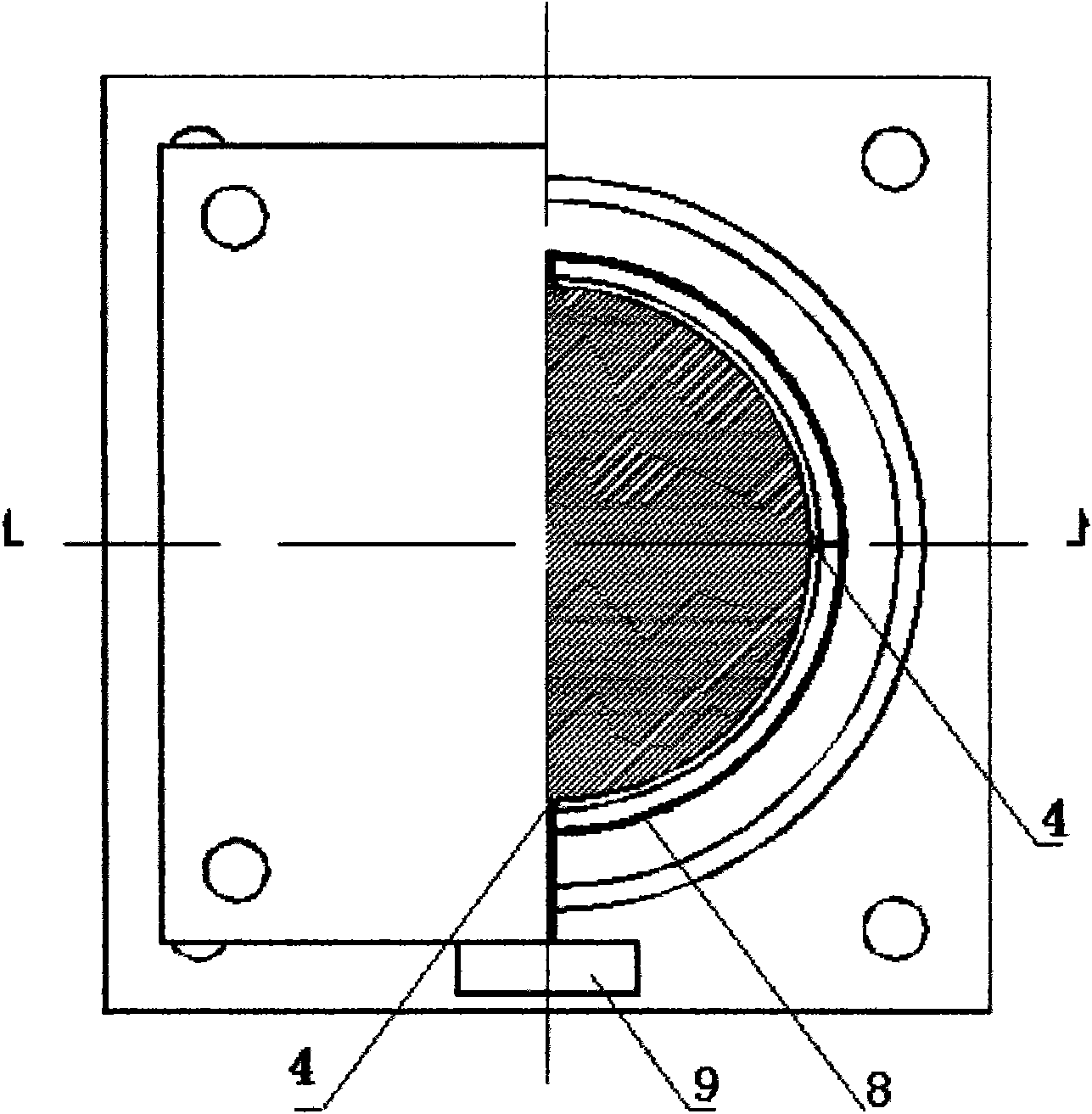

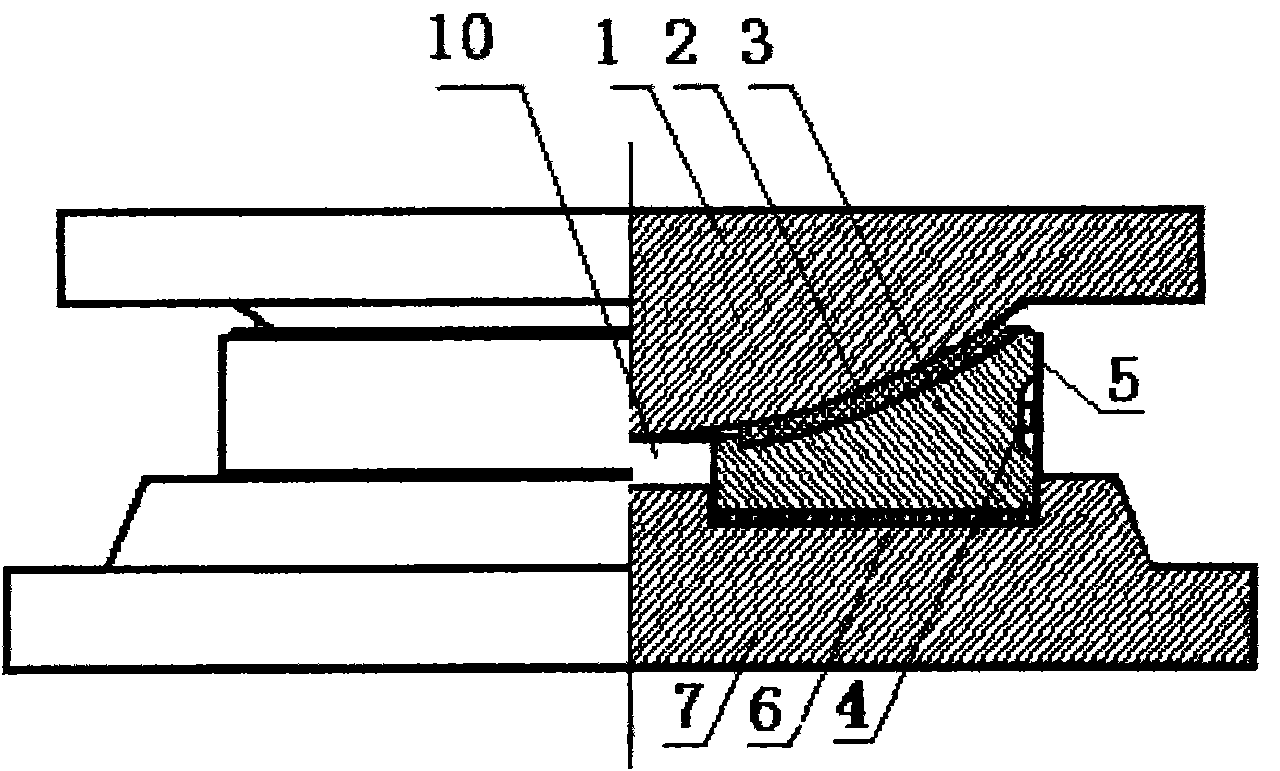

Apparatus for surface treatment by impact

InactiveUS6343495B1Quality improvementSimple treatmentNon-mechanical blast generatorsBurnishing machinesBiomedical engineeringProjectile

The invention relates to apparatus for surface treatment by impact, the apparatus comprising a vibrating surface and at least one projectile suitable for being projected towards the surface to be treated by said vibrating surface. The apparatus includes retaining means for keeping each projectile captive in the apparatus.

Owner:SONATS SOC DES NOUV APPL DES TECHN DE SURFACES

Crash energy absorption member

Owner:NIPPON STEEL CORP +1

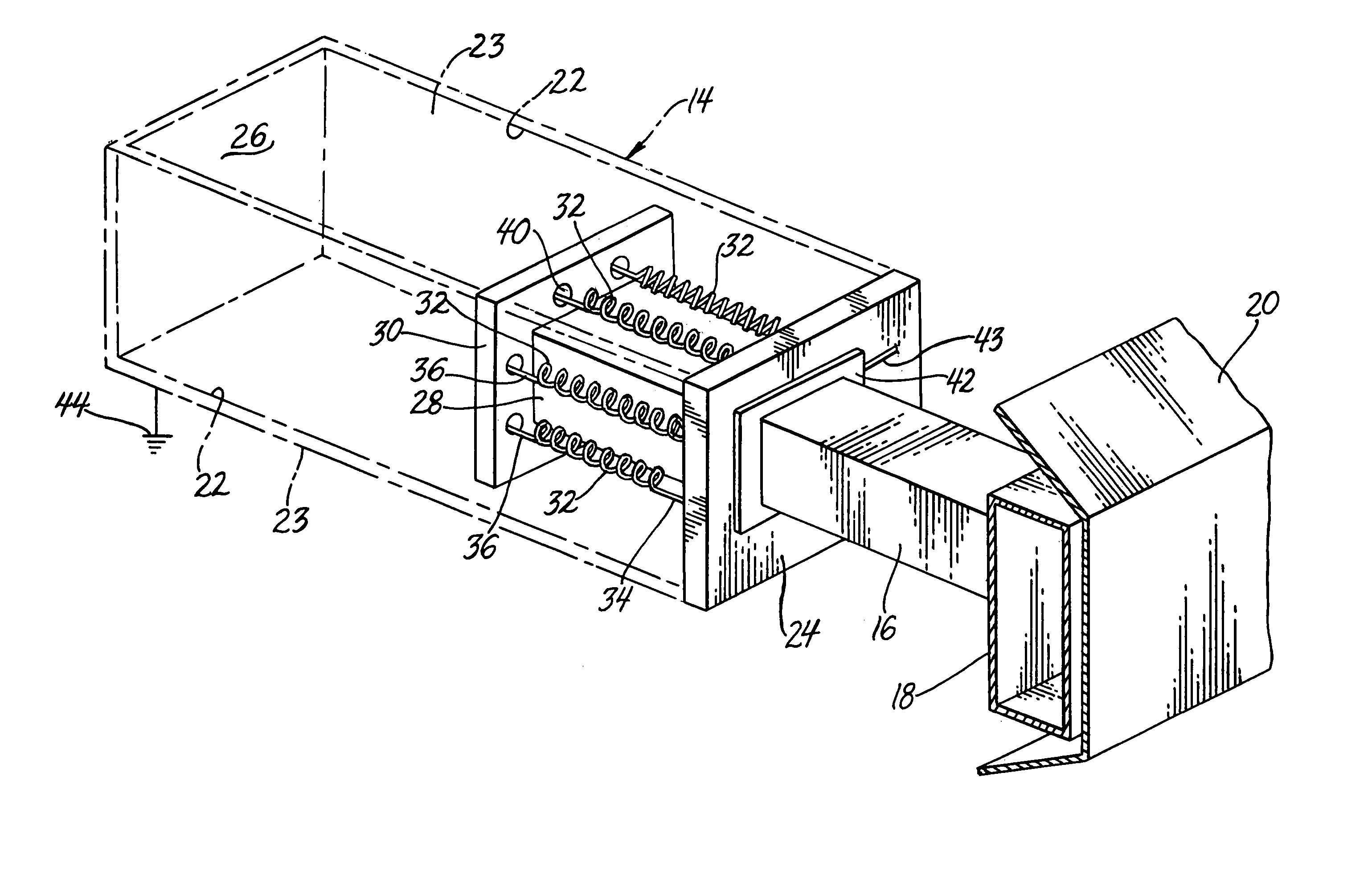

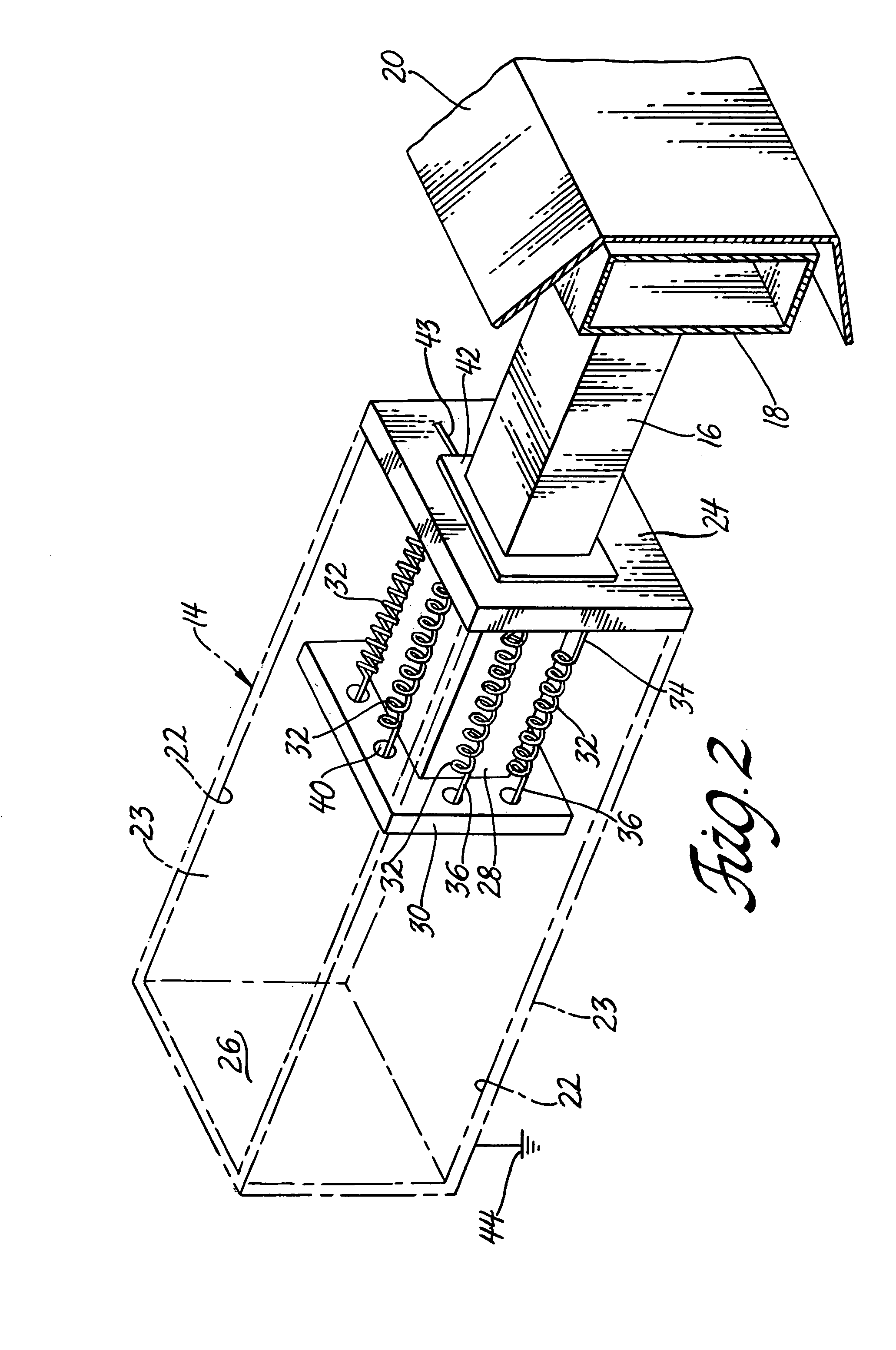

Tunable, healable vehicle impact devices

InactiveUS7029044B2Large energy absorption capacityImprove energy absorptionVehicle seatsPedestrian/occupant safety arrangementLow speedEnergy absorption

Owner:GM GLOBAL TECH OPERATIONS LLC

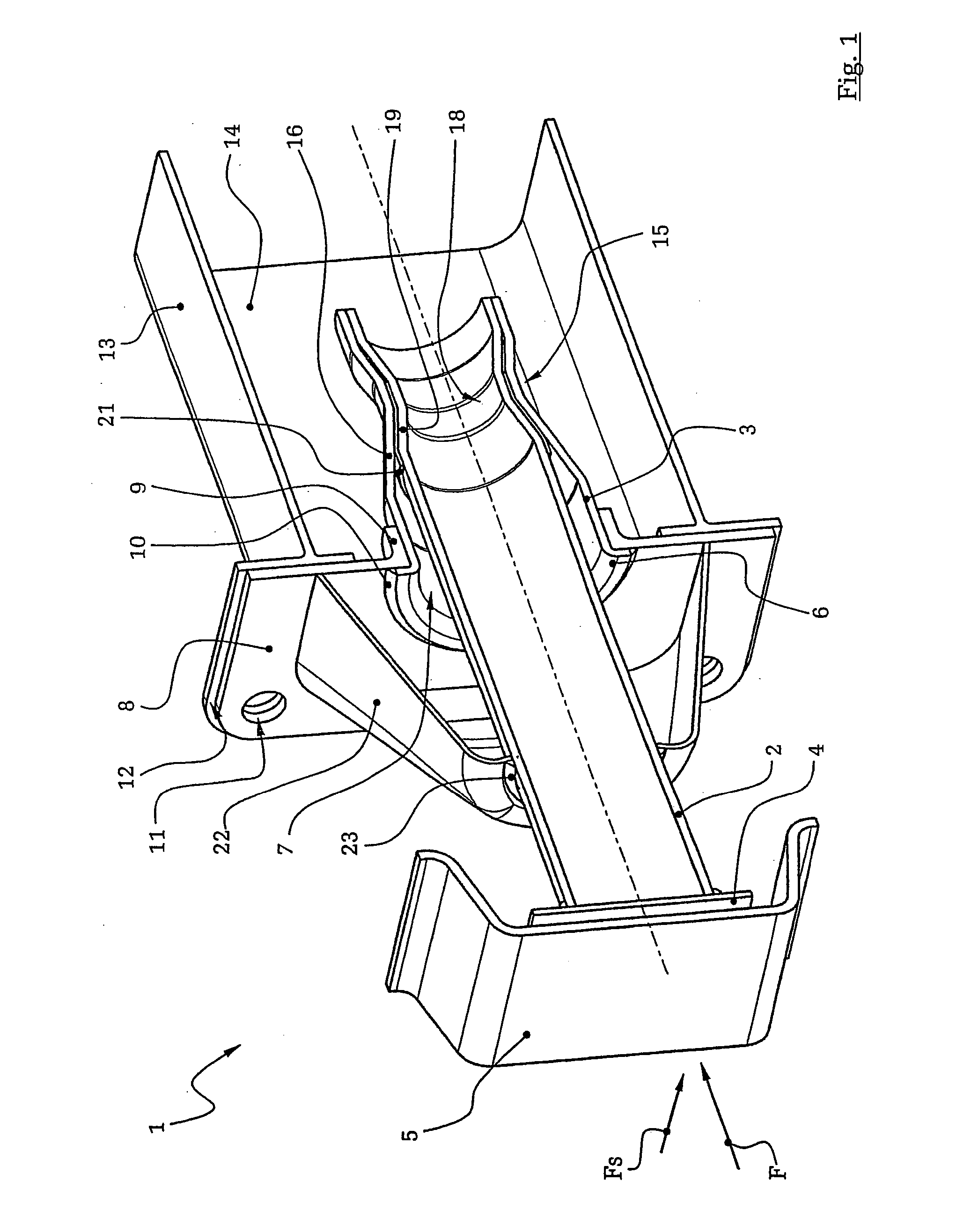

Deflecting Device for an Offset Frontal Collision for Motor Vehicles

InactiveUS20080023954A1Increase collision speedMore impact energyVehicle seatsPedestrian/occupant safety arrangementCouplingEngineering

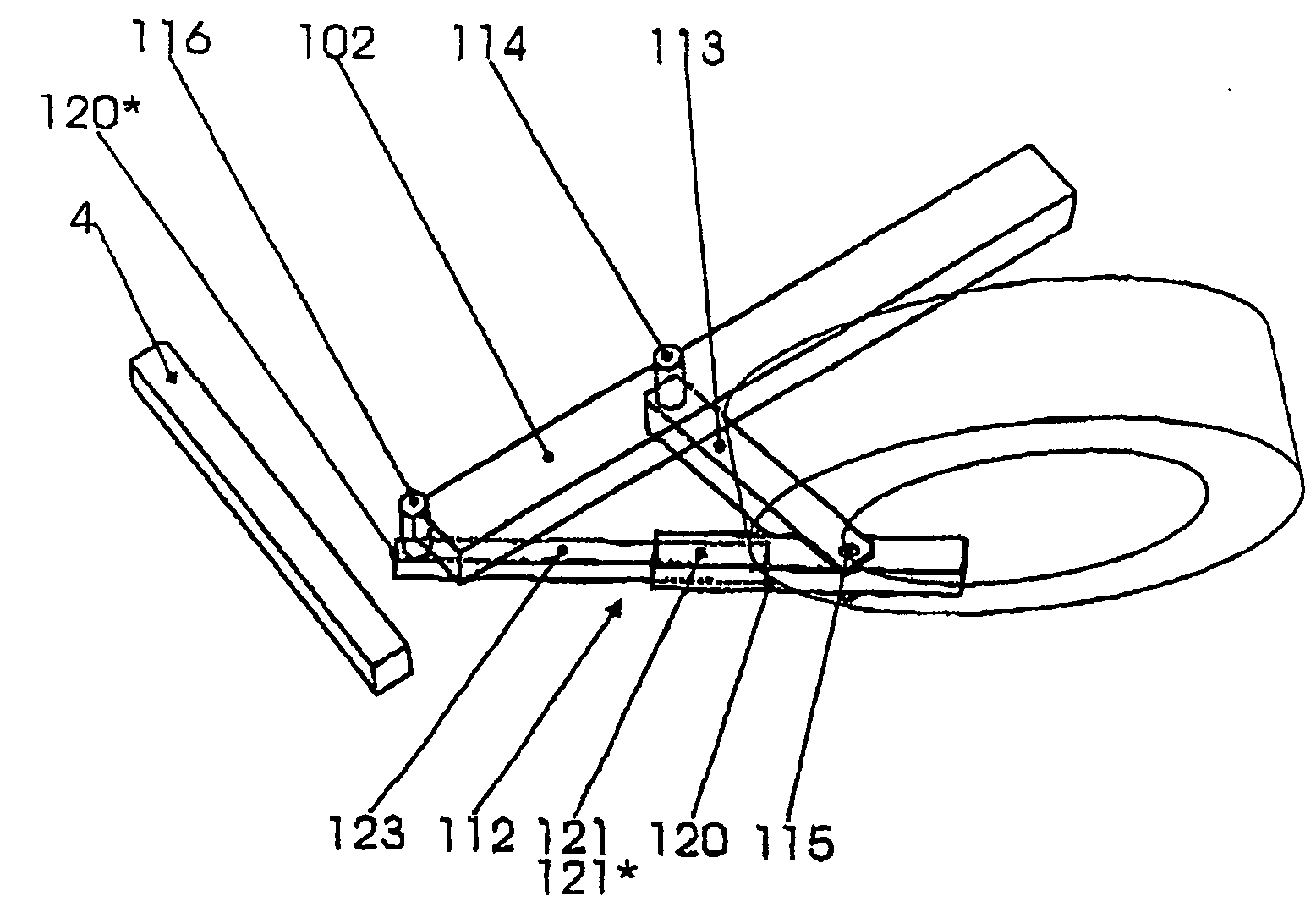

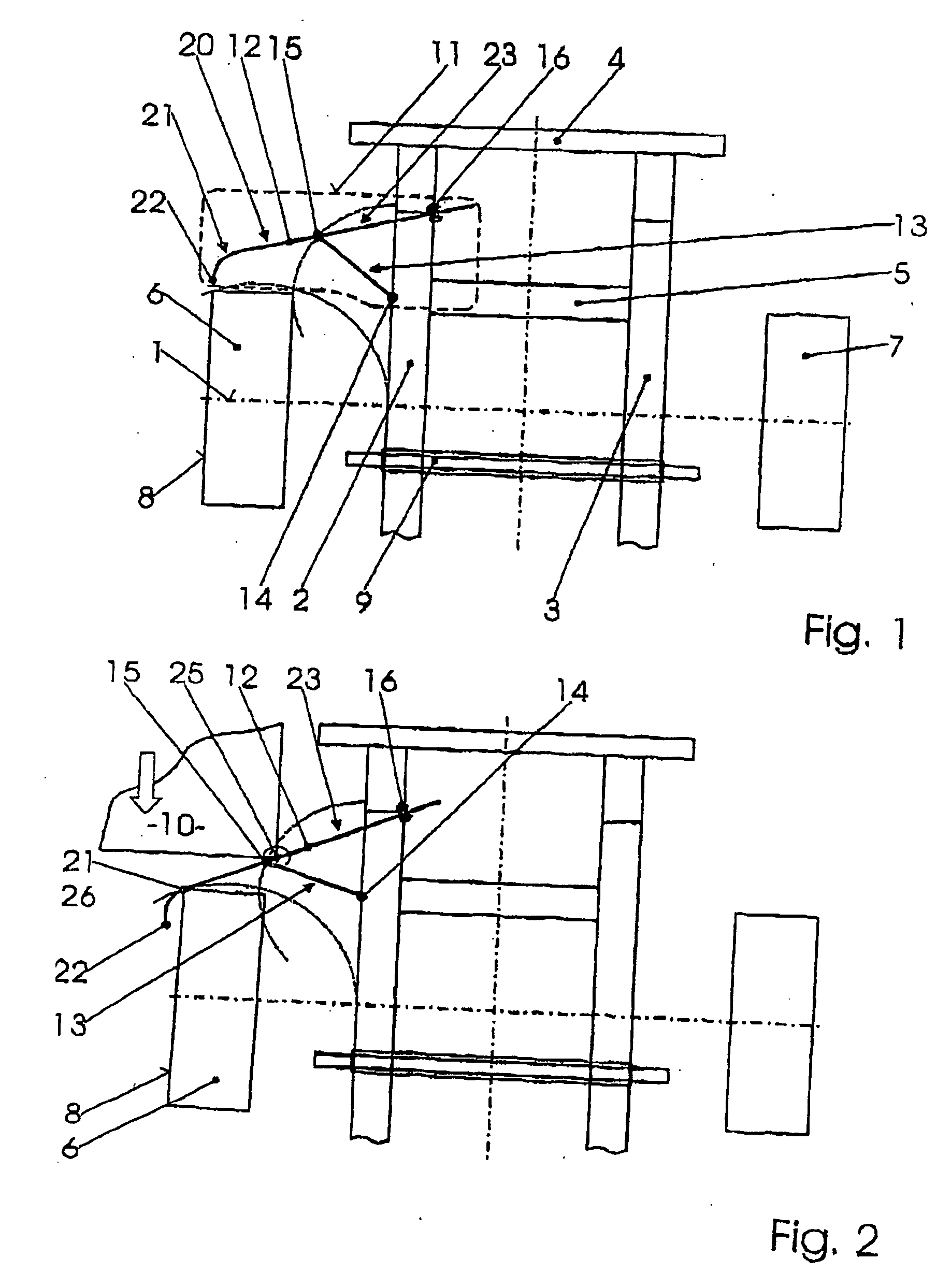

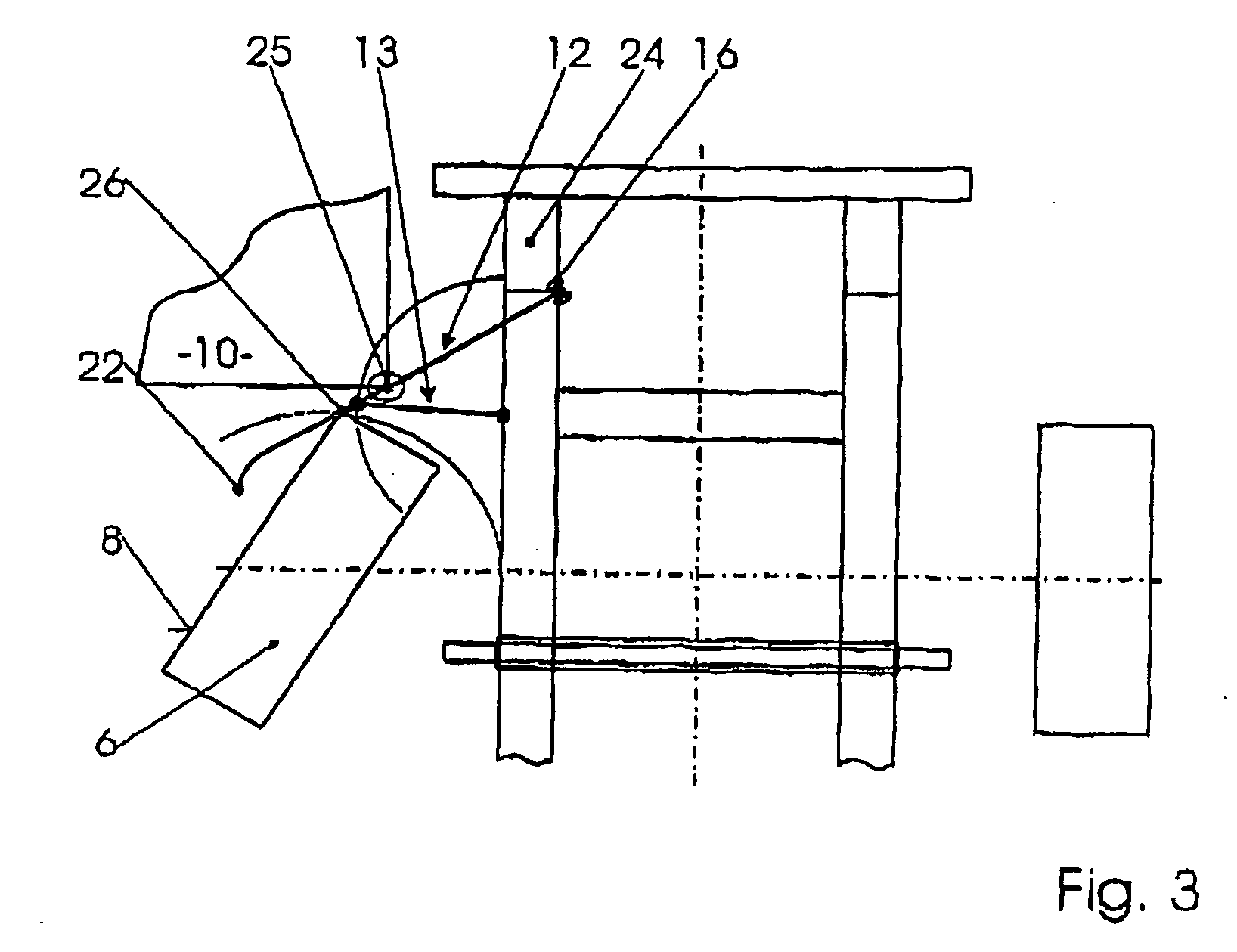

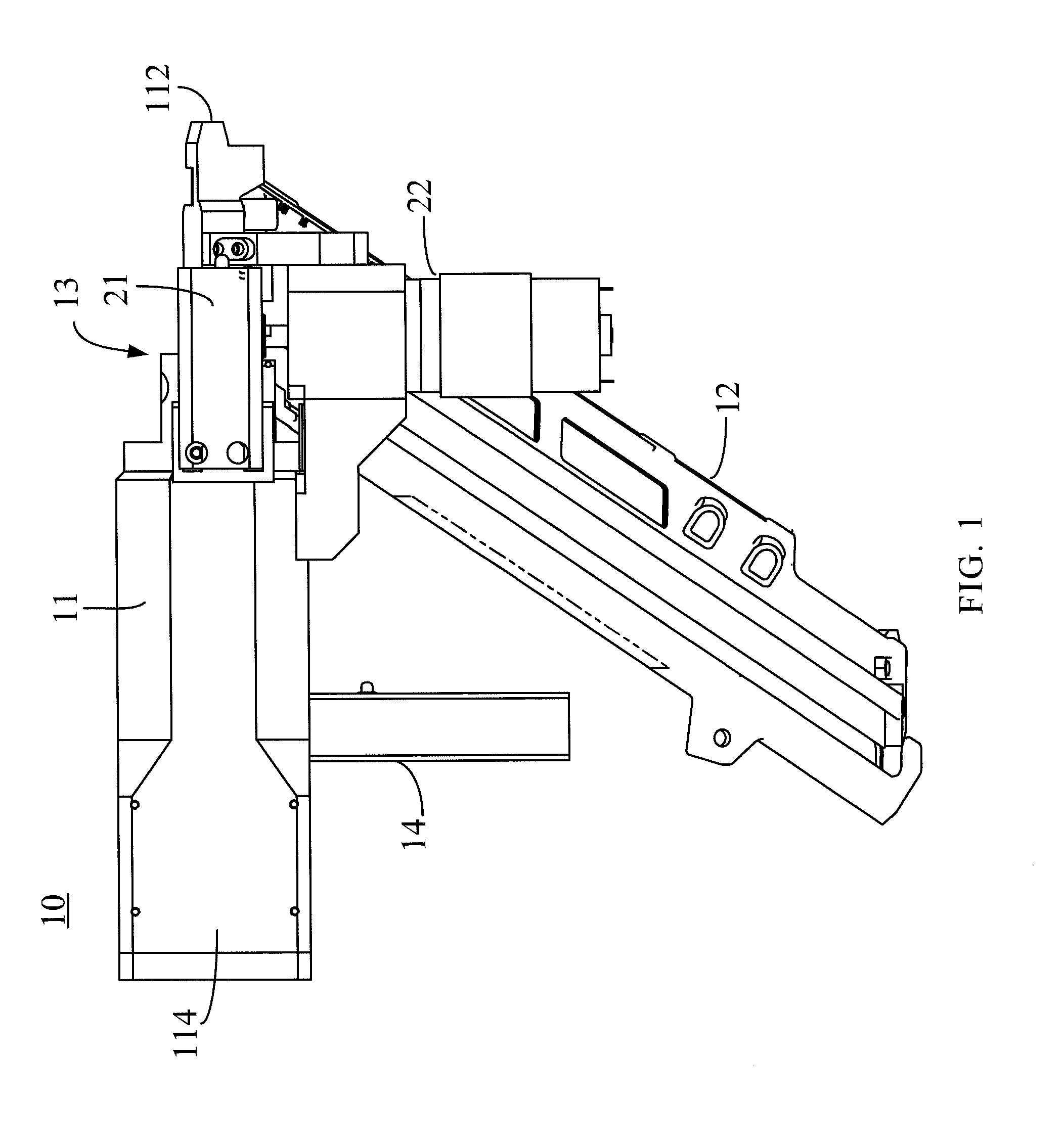

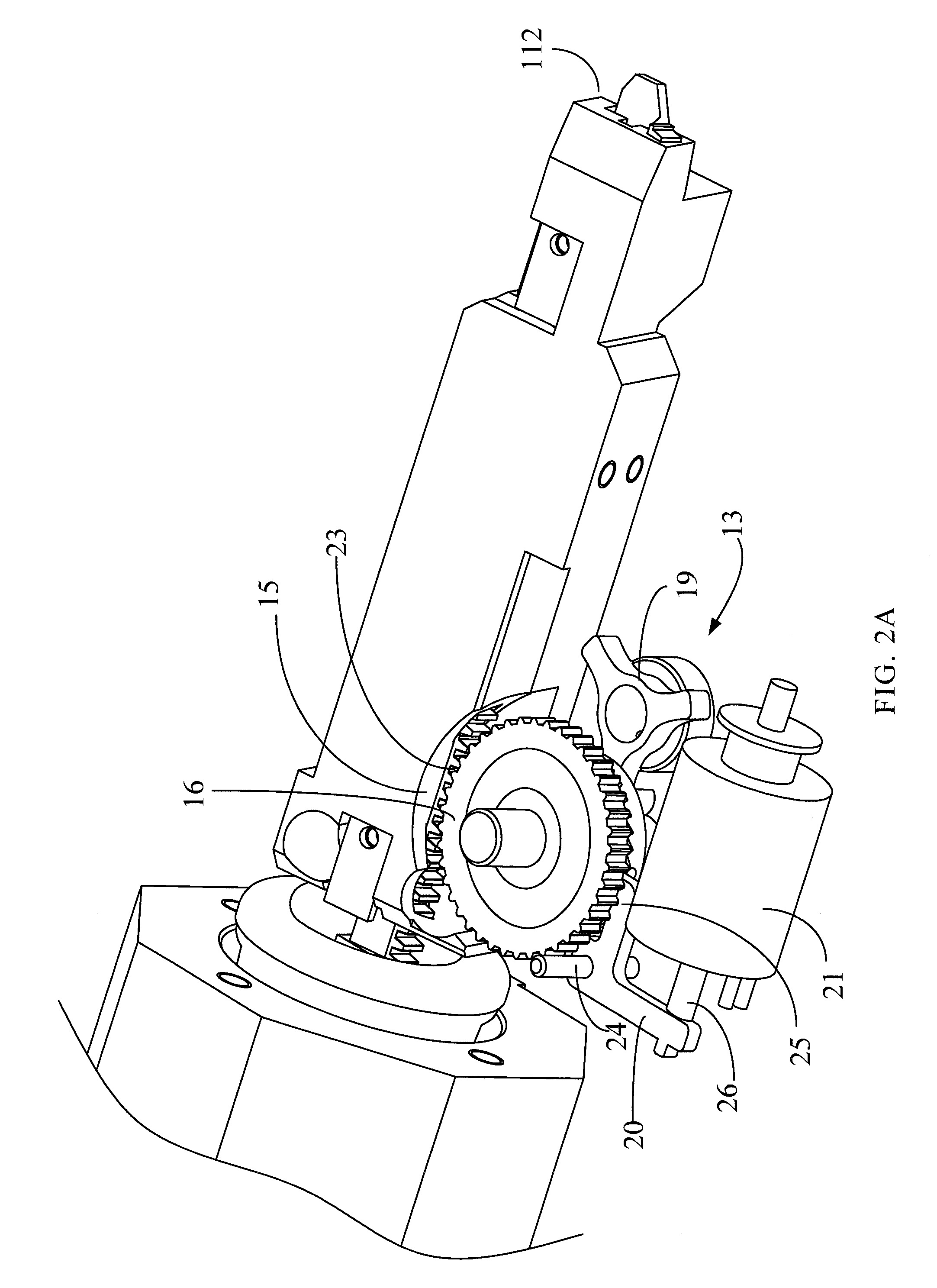

In a motor vehicle, a deflecting device (11) for an offset frontal collision for the motor vehicle is arranged in front of a front wheel (6). In order, in the event of a collision, to safely pivot the front wheel inward, the deflecting device (11) forms a kinematic chain, the coupling link of which is a deflector (12) which, under the action of a frontal impact, is pivoted to the rear and is displaced toward the outside of the vehicle. The kinematic chain is a slider crank mechanism comprising a swinging arm (13) which is pivotable about a bearing (14), a further bearing (16), a sliding guide (16) and the coupling link (12) which is connected to the outer end of the swinging arm at a pivot point (15) and is guided in the further bearing (16).

Owner:MAGNA STEYR FAHRZEUGTECHN

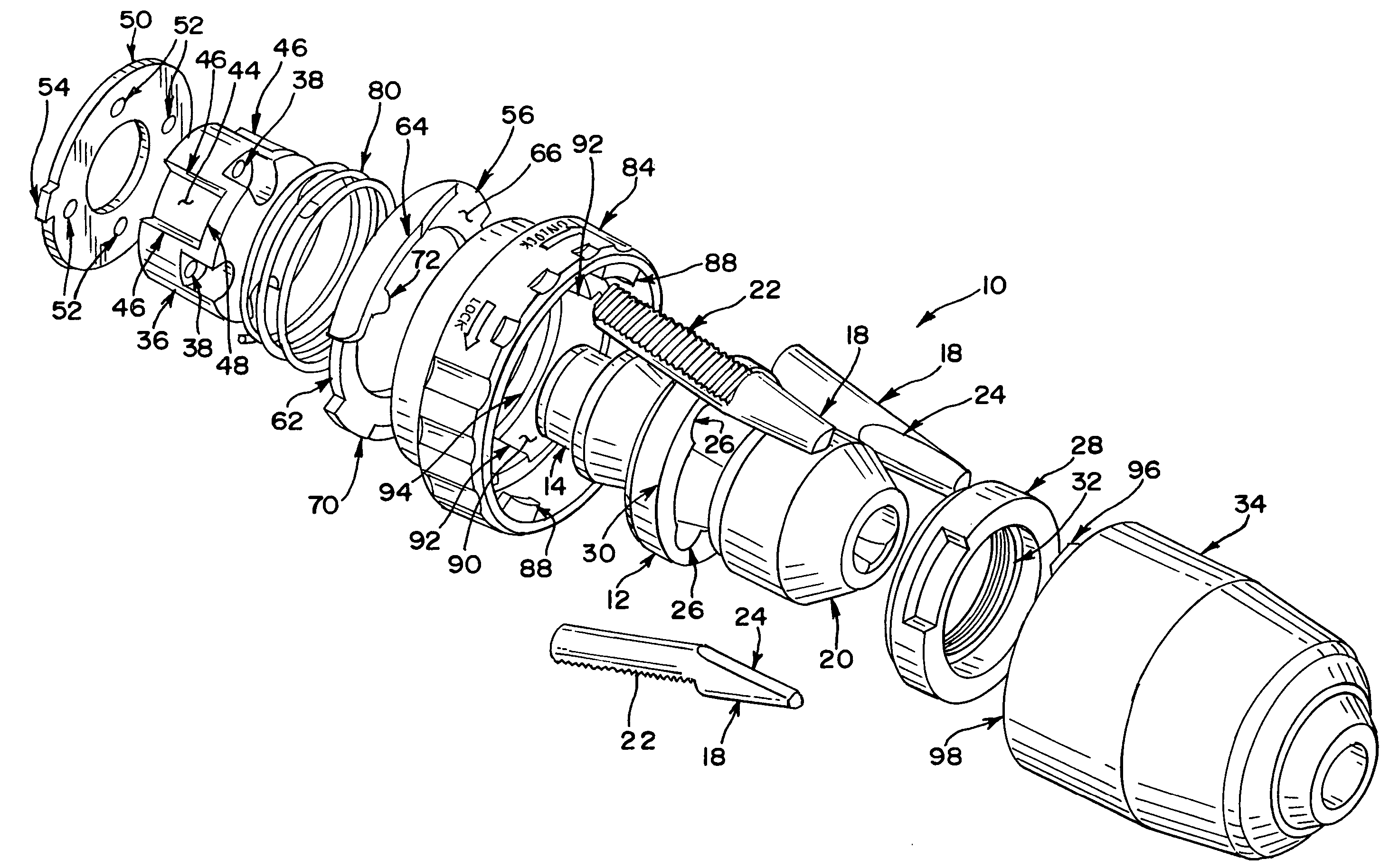

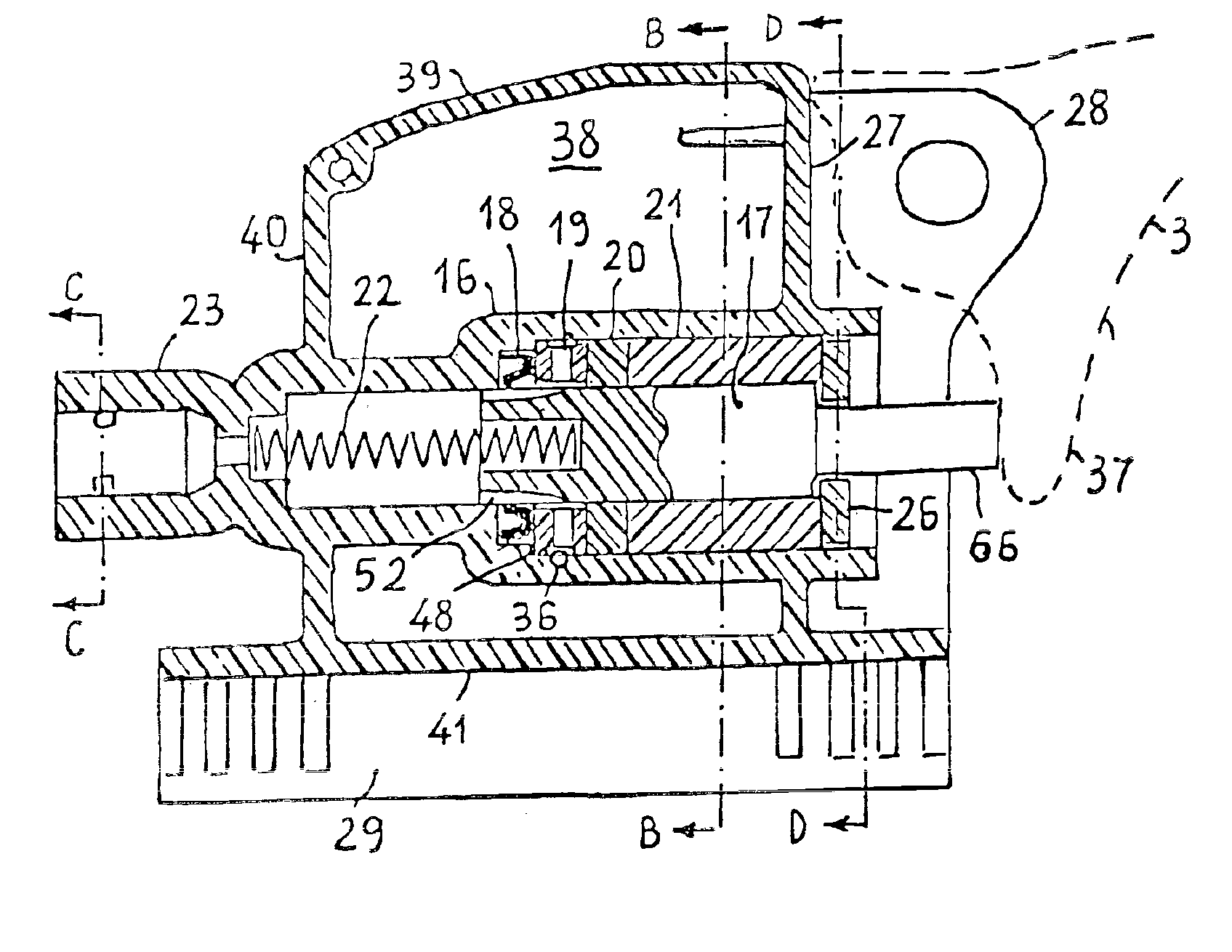

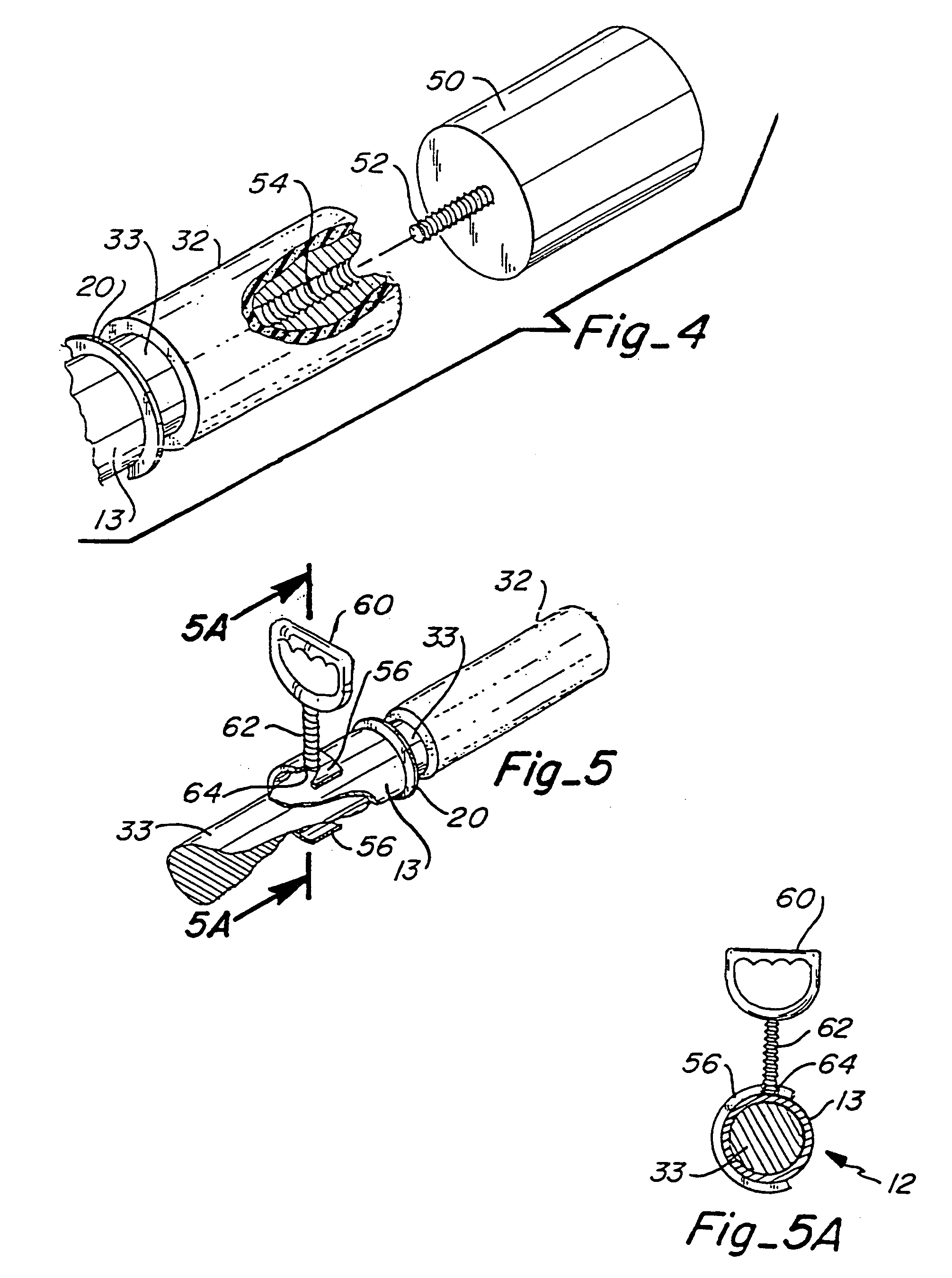

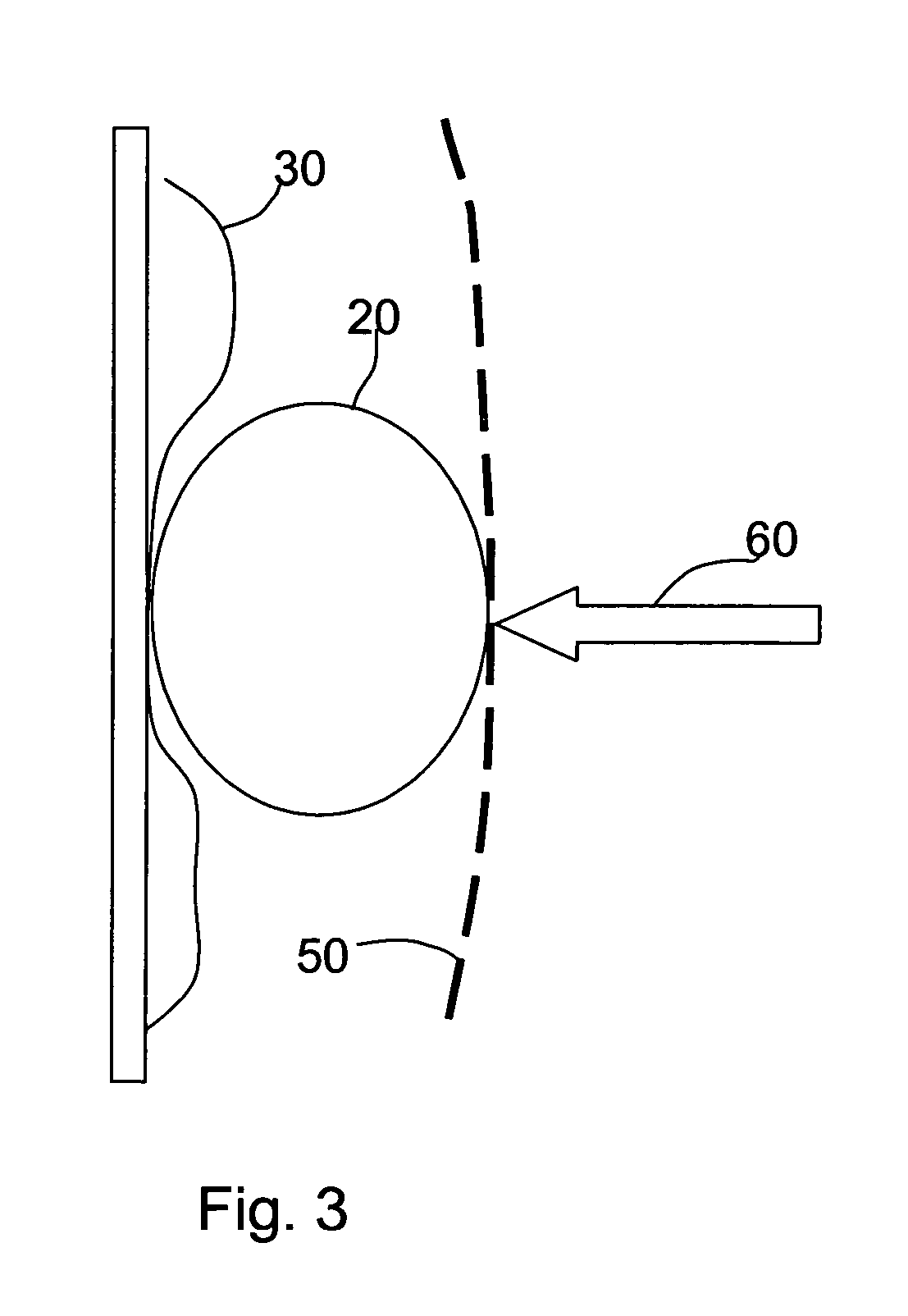

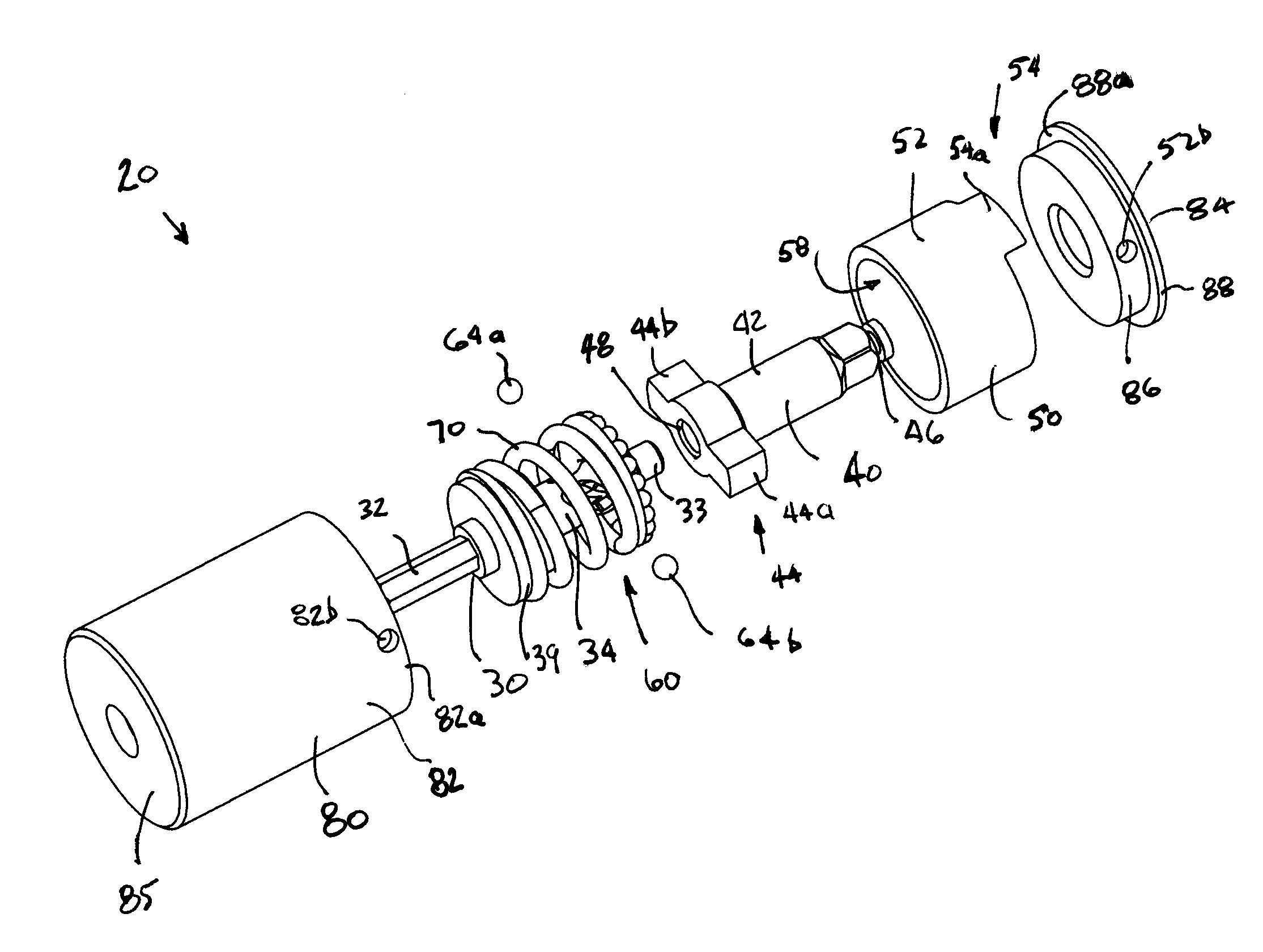

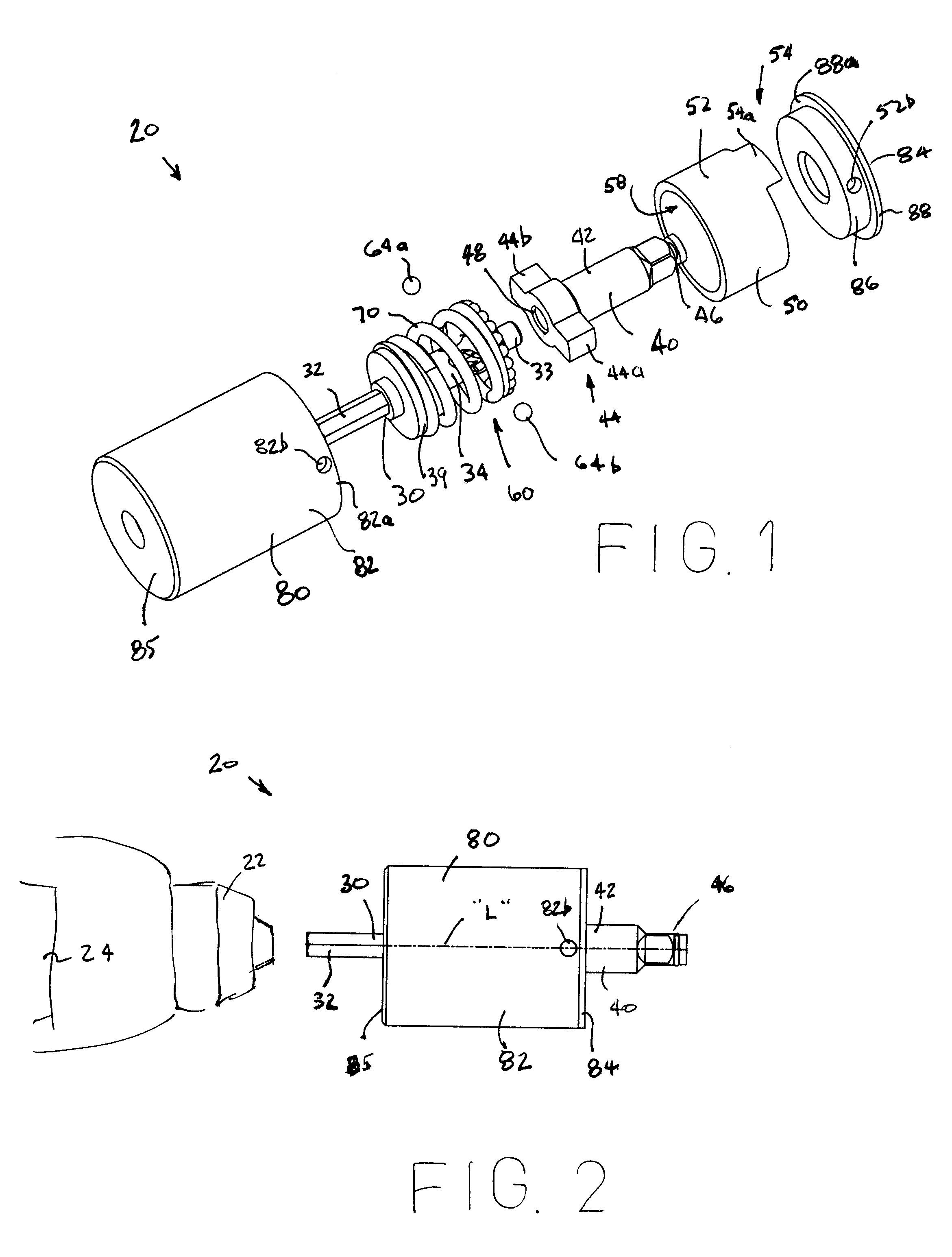

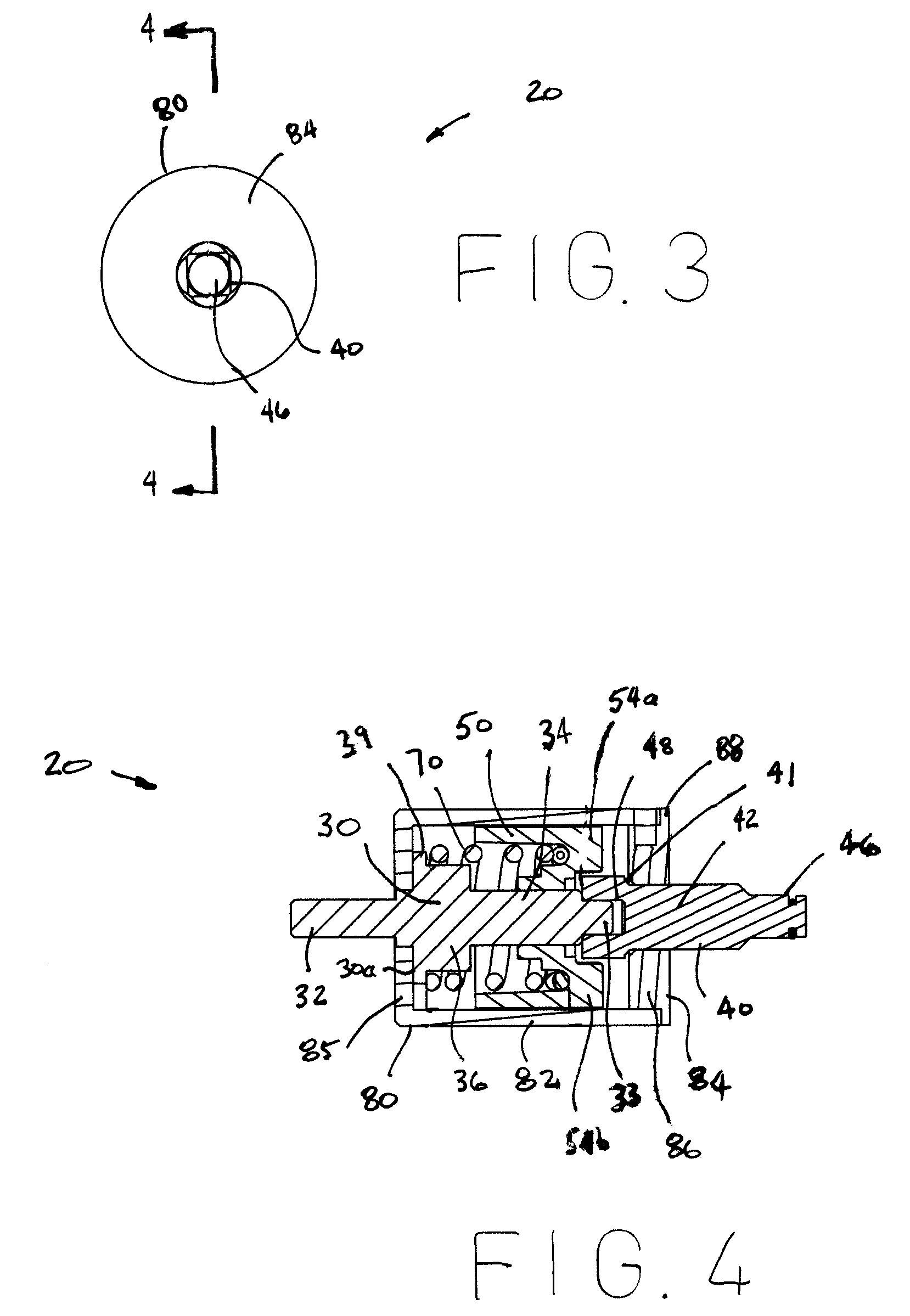

Rotatable chuck

A chuck is provided with a body, a plurality of jaws and an adjustment ring. The adjustment ring is threadably engaged with the jaws. When the adjustment ring is rotated in one direction, the jaws tighten by moving closer to each other. When the adjustment ring is rotated in the opposite direction, the jaws loosen by moving away from each other. An impact member is also provided for engagement with the adjustment ring. When the drive shaft of the power tool is rotated, the adjustment ring impacts against the impact member. As a result, the adjustment ring and the body of the chuck rotate relative to each other causing the jaws of the chuck to loosen or tighten depending on the direction the drive shaft is rotating.

Owner:EASTWAY FAIR

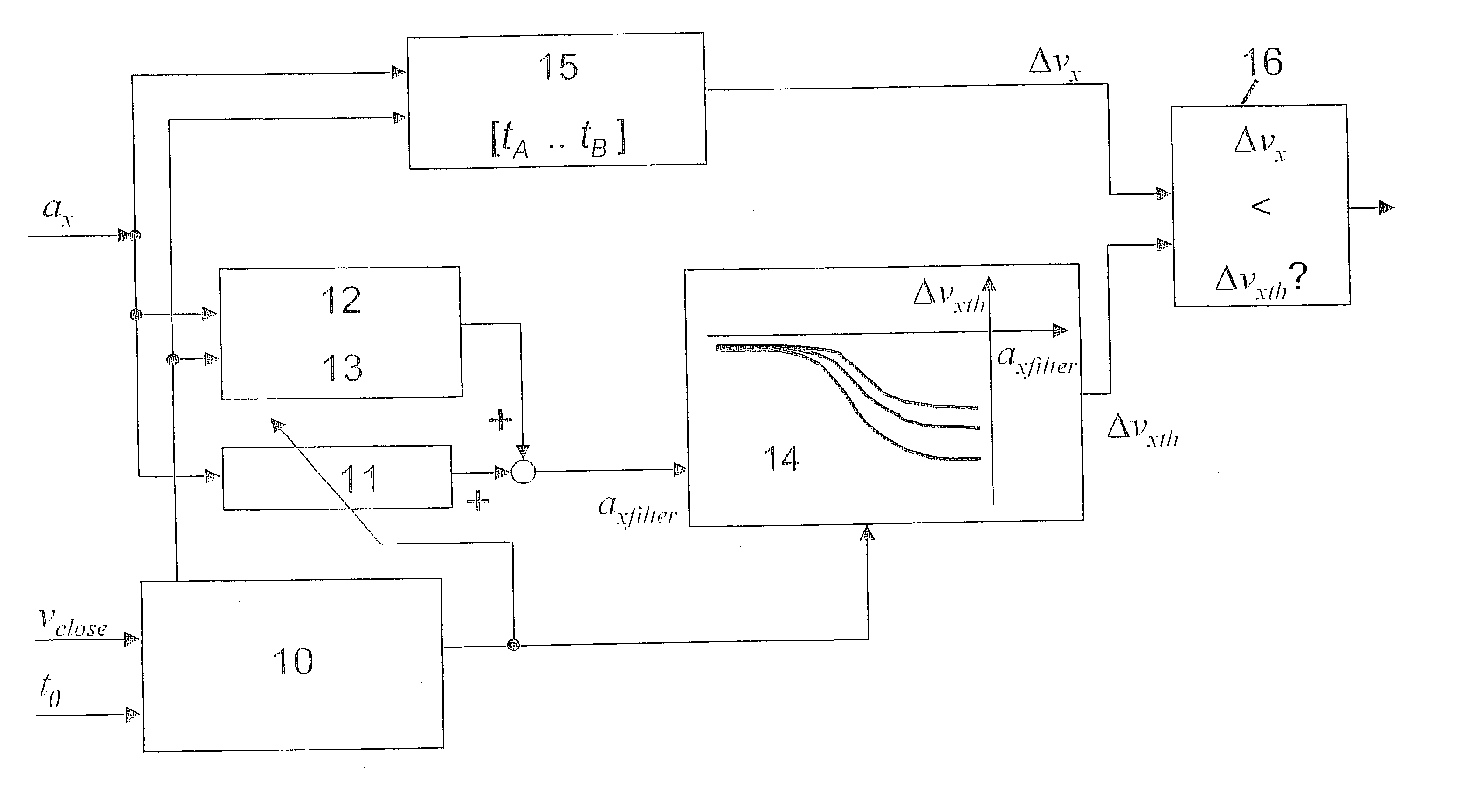

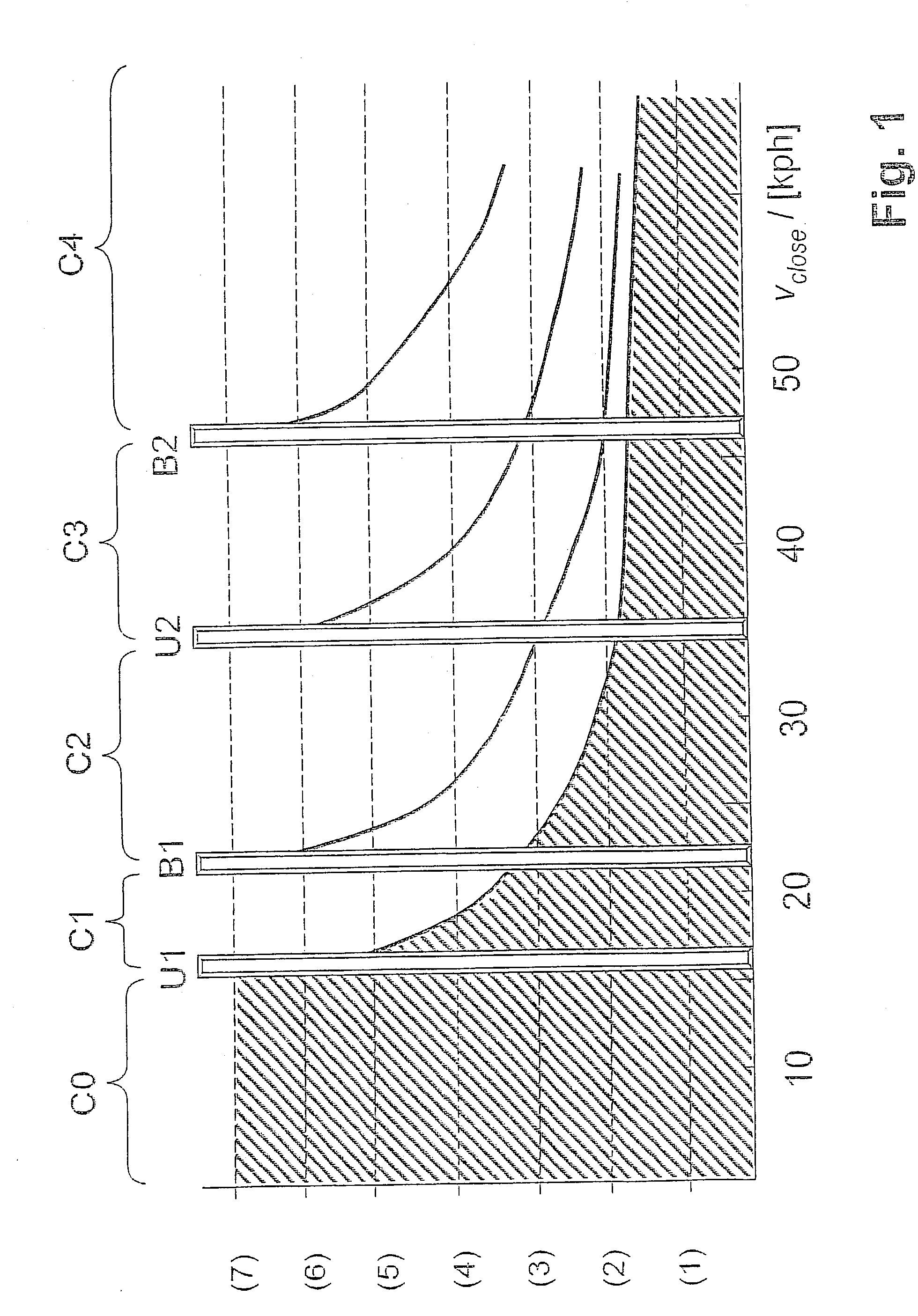

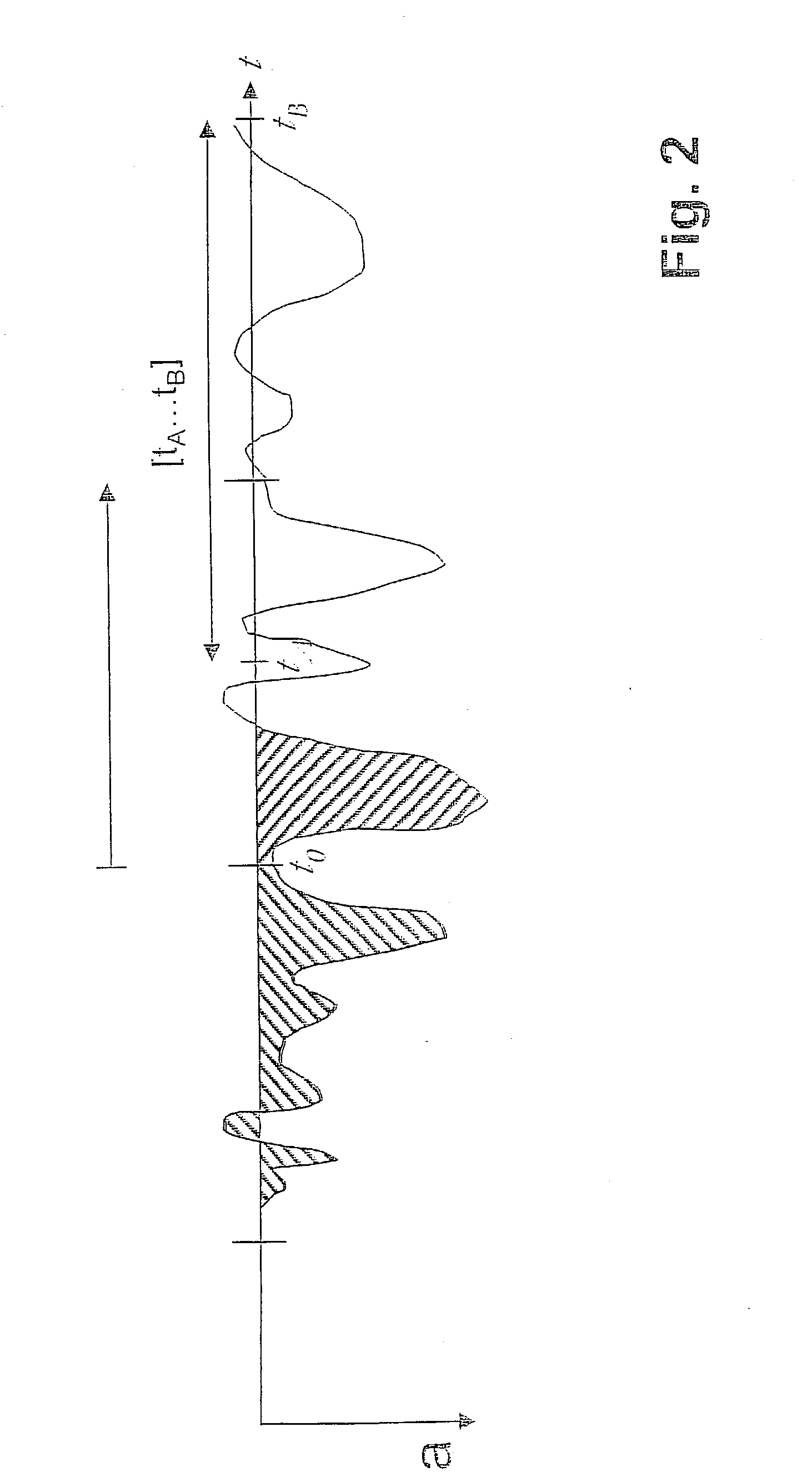

Method for triggering means of restraint in a motor vehicle

A method is described of triggering restraint means in a motor vehicle in the event of an impact and / or a collision with an object, in which the triggering of restraint means, such as airbags and seatbelt tighteners, is better adapted to the concrete impact situation and, in particular, unnecessary triggering of restraint means may be avoided. In the context of this method, the time characteristic of the acceleration is detected in the form of at least one acceleration signal ax. The time characteristic of a velocity DELTAvx is generated from the acceleration signal ax. A threshold value DELTAvxth for the velocity DELTAvx is then determined as a triggering criterion. For this purpose, the impact velocity vclose and the instant of impact t0 are established with the aid of a pre-crash sensor system even before the impact. The impact situation is classified with reference to the impact velocity vclose. With the aid of the classification of the impact situation, a triggering time window [tA . . . tB] is determined, in which the time characteristic of the velocity DELTAvx is generated and, in parallel to this, the threshold value DELTAvxth for the velocity DELTAvx is established from the acceleration signal ax, the classification of the impact situation being taken into consideration.

Owner:ROBERT BOSCH GMBH

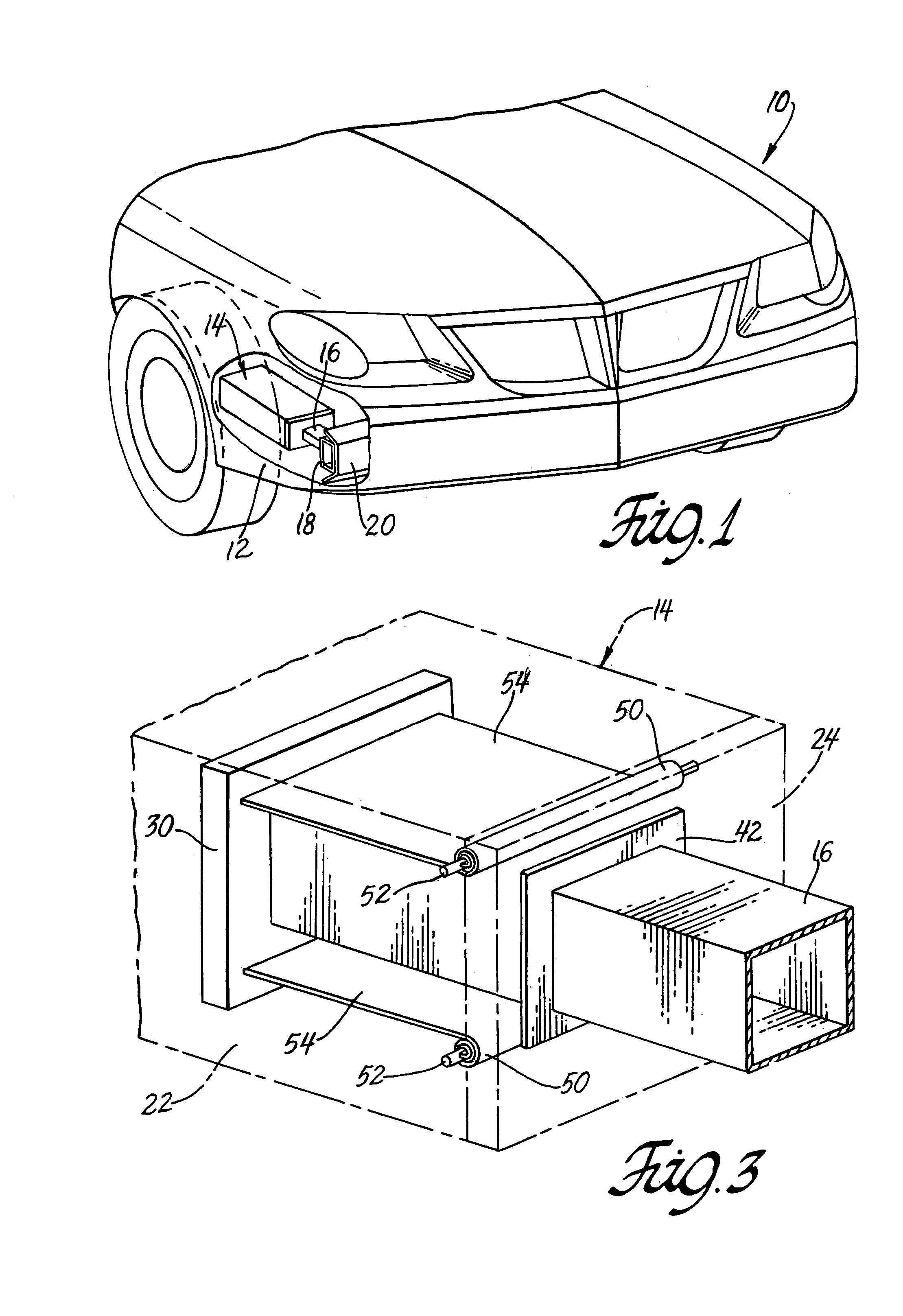

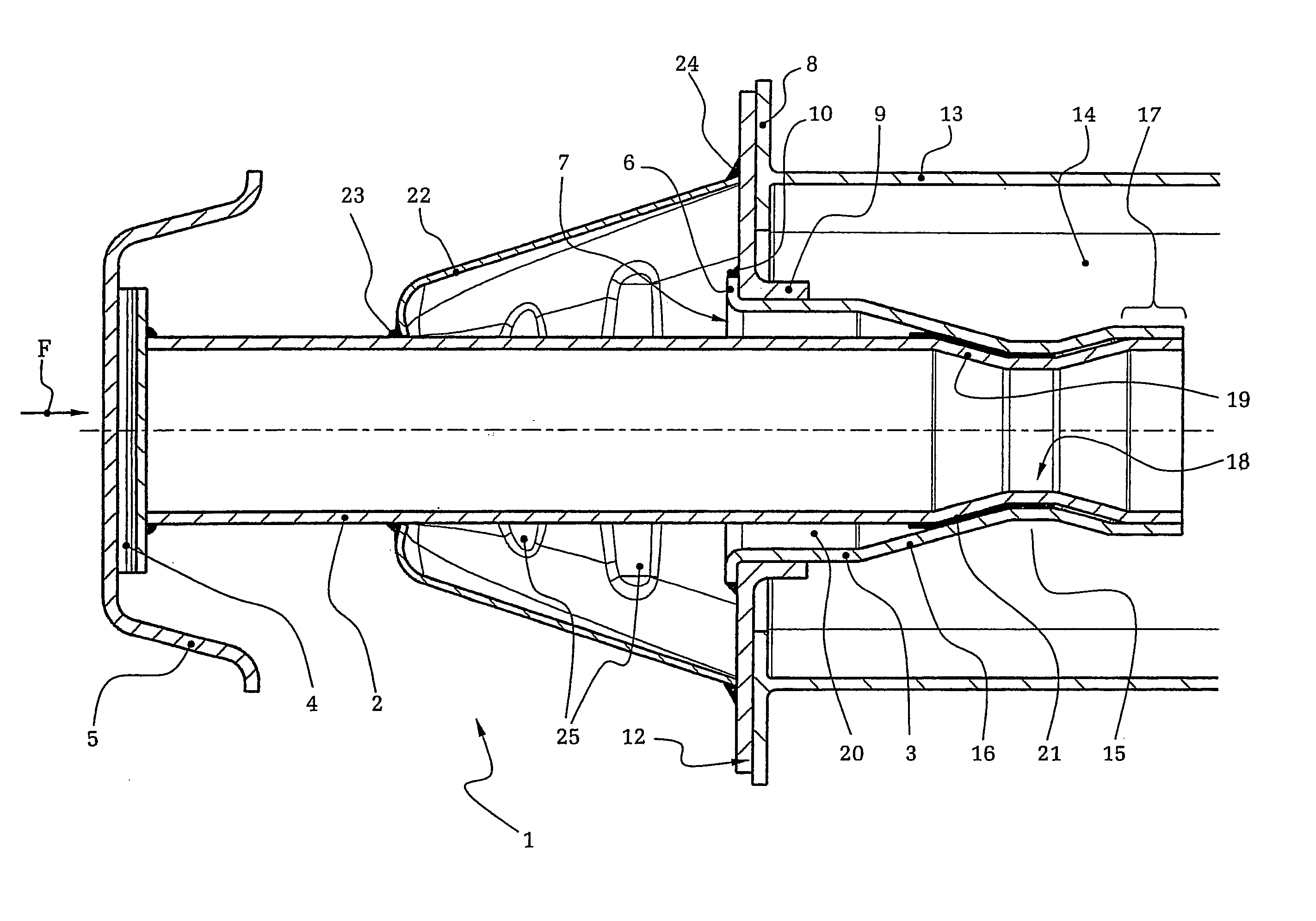

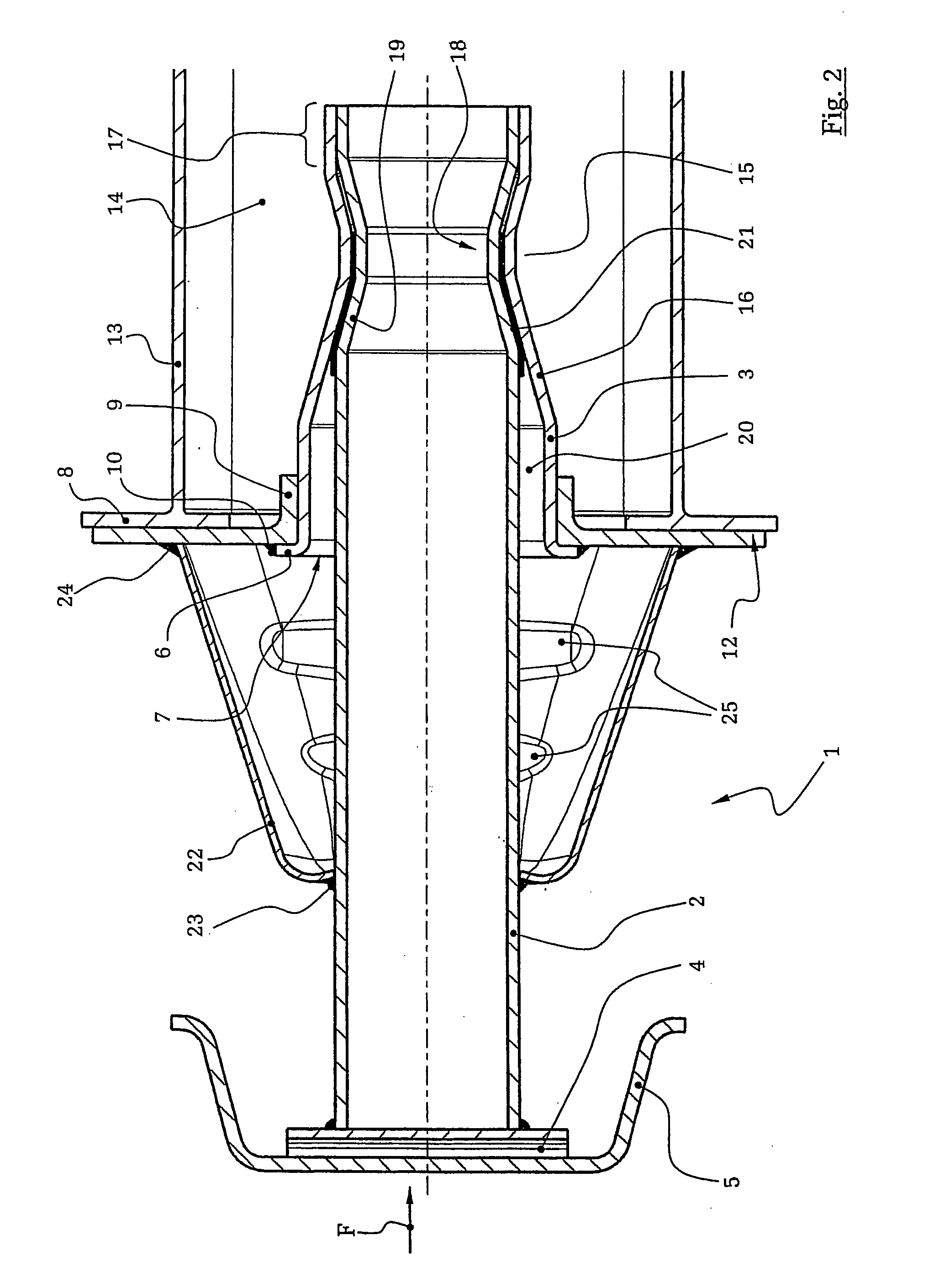

Impact damper assembly for an automobile

InactiveUS20060022473A1Reduce harmImprove vehicle safetyPedestrian/occupant safety arrangementBumpersEngineeringChassis

Impact damper assembly for an automobile, in particular for supporting a bumper 5 on an automobile chassis, with an inner tube 2 movably arranged in an outer tube 3, wherein both tubes 2, 3 have an approximately mutually parallel taper 16, 19, wherein the taper 19 of the inner tube 2 is encompassed by the taper 16 of the outer tube 3, and wherein at least one of the two tubes 2, 3 can be deformed during the movement by the taper 16, 19 of the two tubes. The invention is characterized in that the impact damper assembly includes an additional deformable stiffening element 22.

Owner:ZF FRIEDRICHSHAFEN AG

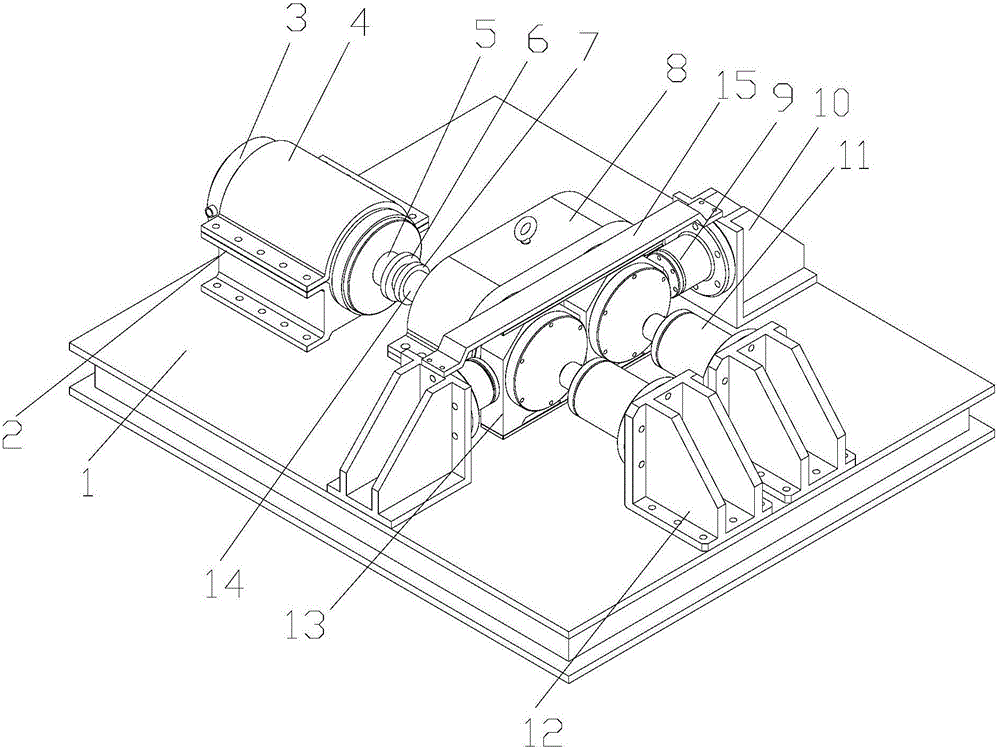

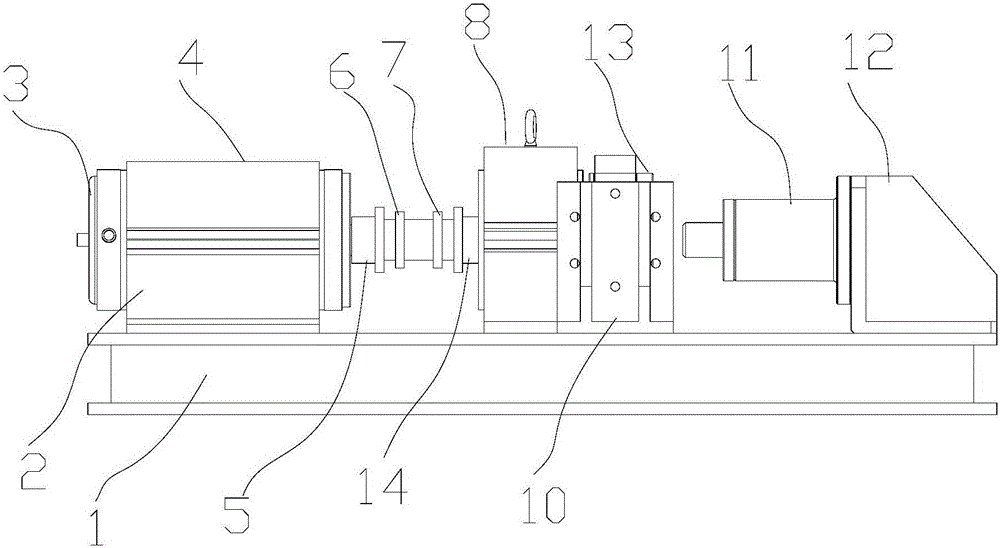

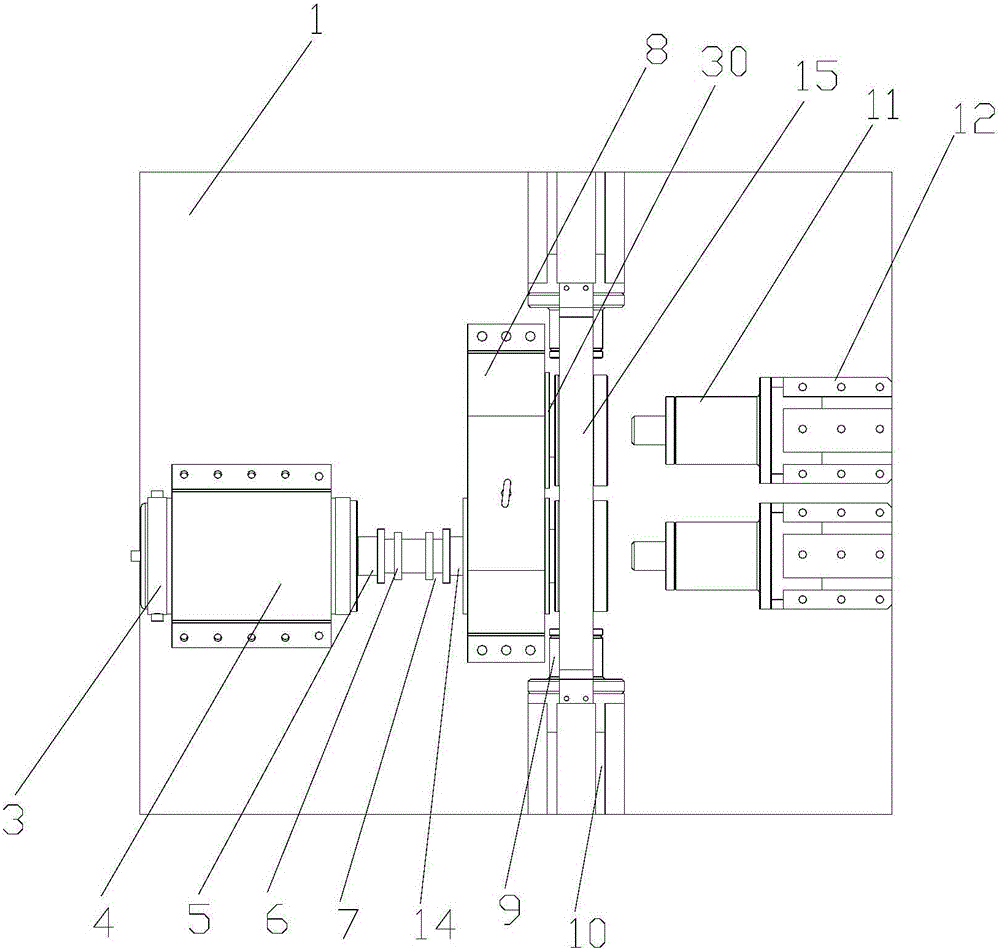

Multifunctional bearing test system

InactiveCN106092576AReal actual service conditionsReliable lifeMachine bearings testingVibration accelerationPilot system

The invention provides a multifunctional bearing test device, which comprises a rotation driving system unit, a loading system unit, a high and low temperature environment box, a lubrication cooling system unit and a measurement control system unit, and is characterized in that the loading system unit can control the loading force and the loading waveform of loading heads on an axial loading unit and a radial loading unit, and the high and low temperature environment box can realistically simulate a real temperature environment of a test. The multifunctional bearing test device can simulate service conditions of a test bearing in a test room, realizes performance testing for the test bearing under conditions of given rotating speed, lubrication, temperature, axial load, radial load and circumferential unbalanced impact load and the like, and analyzes influences imposed on the bearing performance by misalignment, poor lubrication, uneven stress and the like through data such as vibration acceleration, abrasive dust amount and the like acquired in the testing process, thereby being capable of more authentically simulating actual conditions of a rolling bearing when being subjected to the radial load, the axial load and the like, and being more reliable, systematic and scientific in service life and reliability evaluation for the test bearing.

Owner:SUZHOU DONGLING TECH

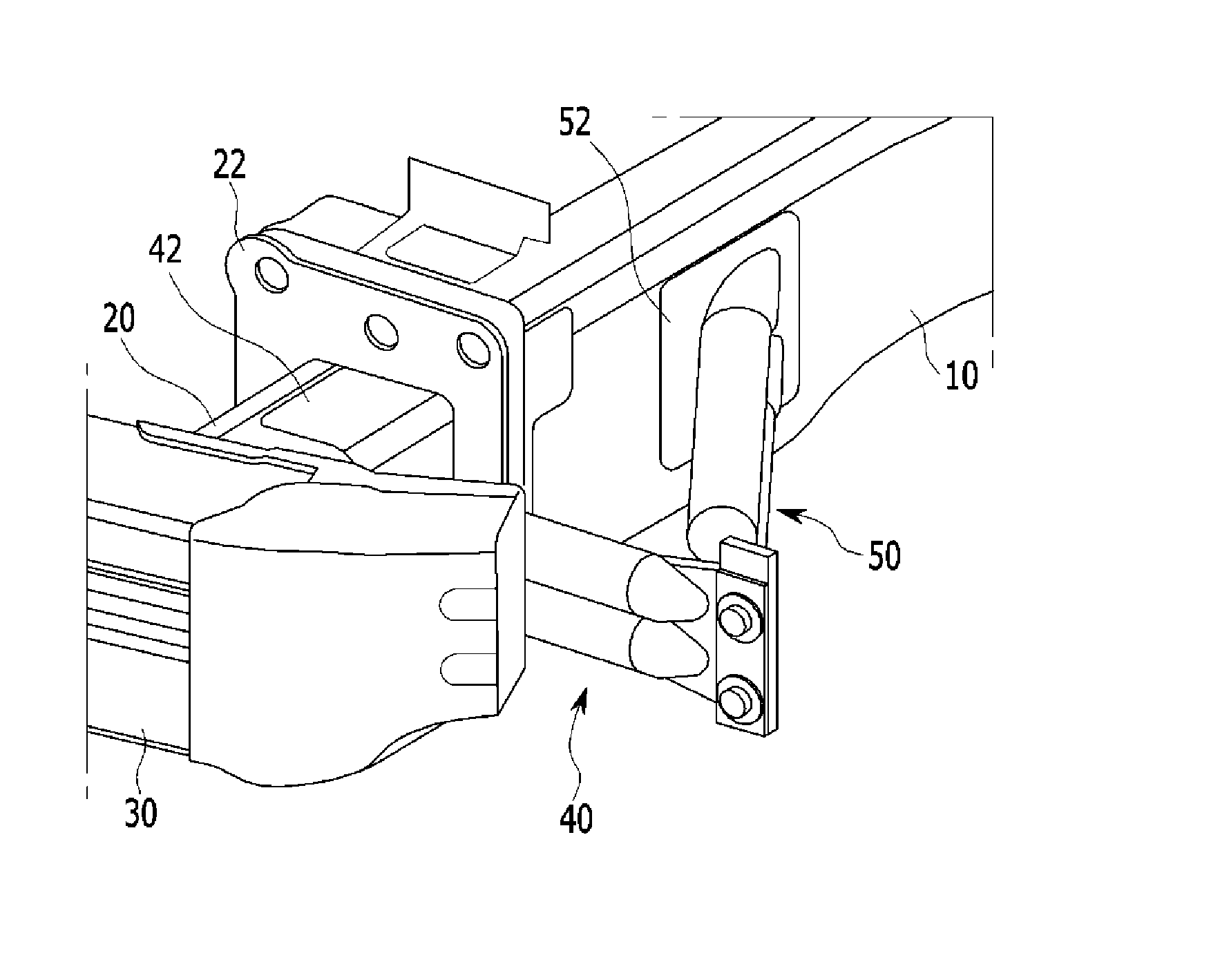

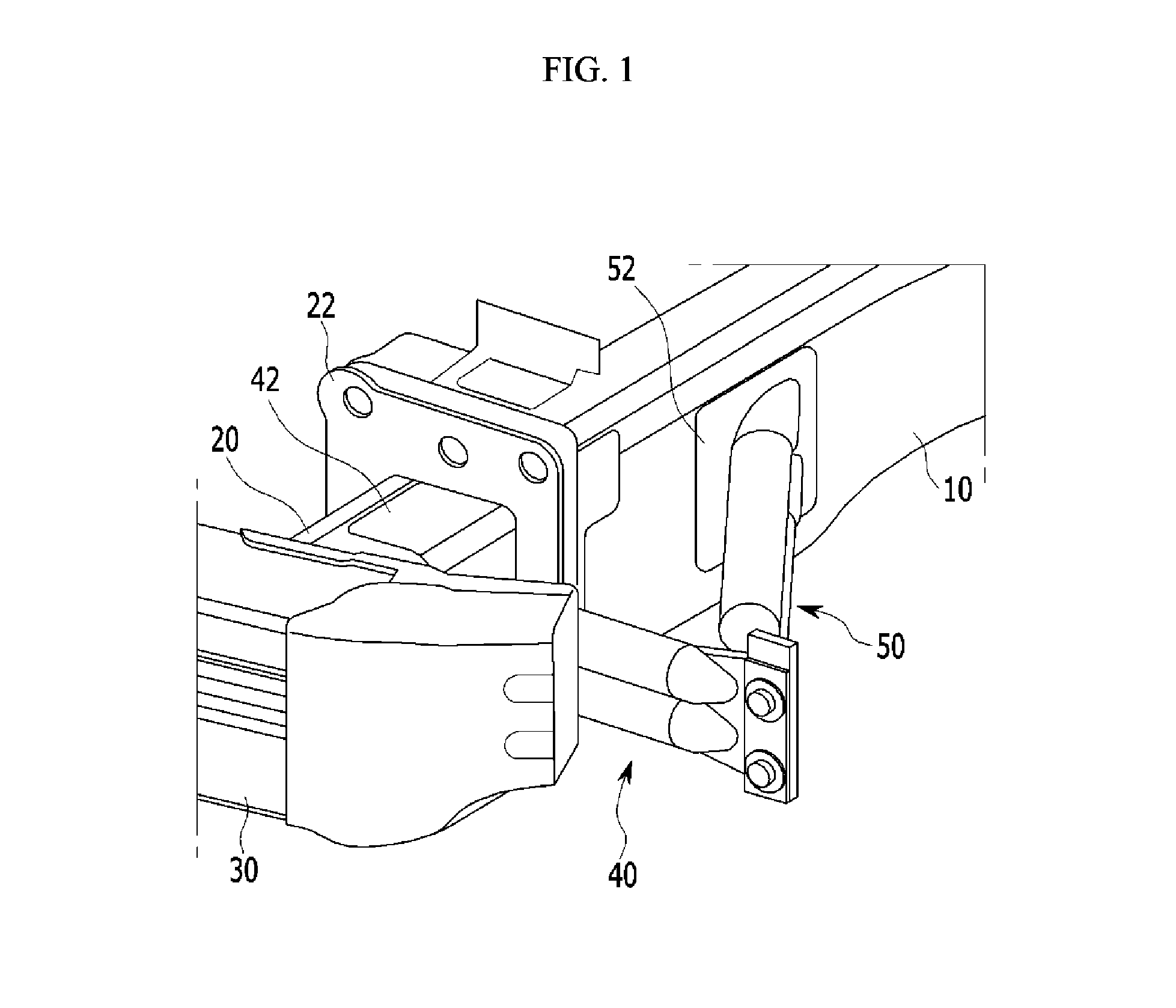

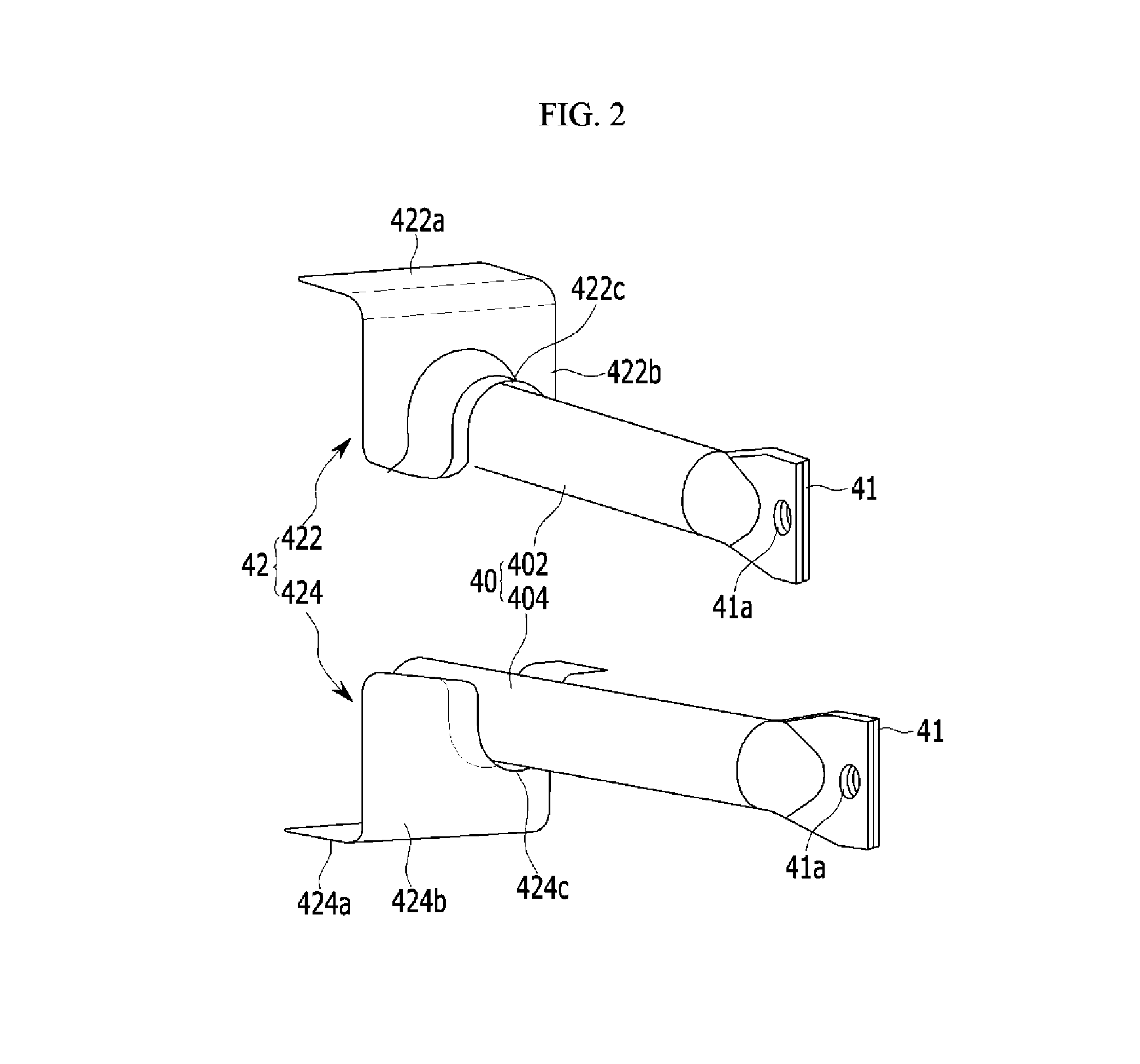

Vehicle body reinforcing structure for coping with small overlap collision

ActiveUS20150336525A1Increase the collision areaIncrease collision widthVehicle seatsUnderstructuresEngineeringMechanical engineering

A vehicle body reinforcing structure for coping with a small overlap collision may include front side members which may be extended in a longitudinal direction of a vehicle and disposed at left and right sides in a width direction of the vehicle, a crash box which is installed to a front end of the front side member in the longitudinal direction of the vehicle and absorbs and reduces impact when receiving the impact to be deformed, a bumper beam which is disposed in front of the crash box in the longitudinal direction of the vehicle, coupled to the crash box, and extended in the width direction of the vehicle, and a reinforcing member which is coupled to both the crash box and the front side member, and protrudes outside of the bumper beam in the width direction of the vehicle to transfer an impact energy to the front side member.

Owner:HYUNDAI MOTOR CO LTD

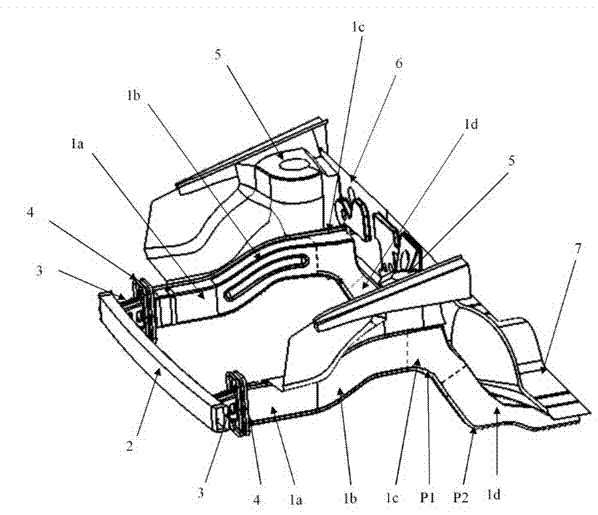

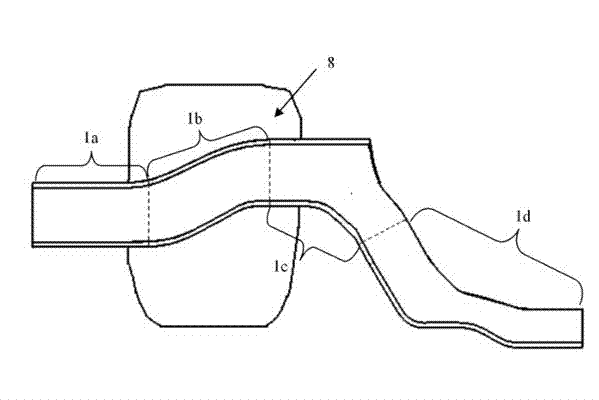

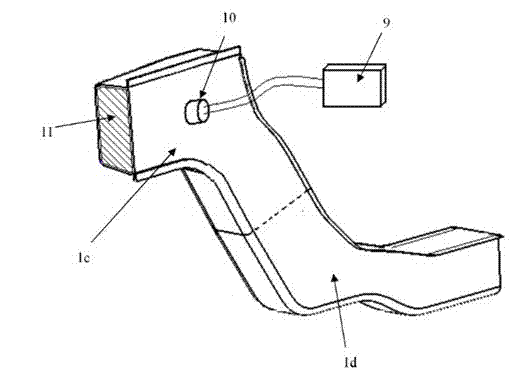

Front longitudinal beam structure for automobiles

Owner:HUNAN UNIV

Handheld power tool and impact block return device thereof

The present invention provides a handheld power tool having an impact block and an impact block return device. The impact block has a plurality of continuous teeth arranged along a lengthwise direction of the impact block. The impact block return device comprises a gearwheel engaged with the teeth of the impact block; a ratchet wheel rotating simultaneously with the gearwheel; and a clamping member operated in a first state and a second state, the clamping member contacting the ratchet wheel in the first state and the clamping member being separated from the ratchet wheel in the second state; wherein the impact block only can do a single-directional movement when the clamping member contacts the ratchet wheel in the first state. The present invention can improve stability of the retraction process of the impact block (e.g., a firing pin).

Owner:BASSO IND CORP

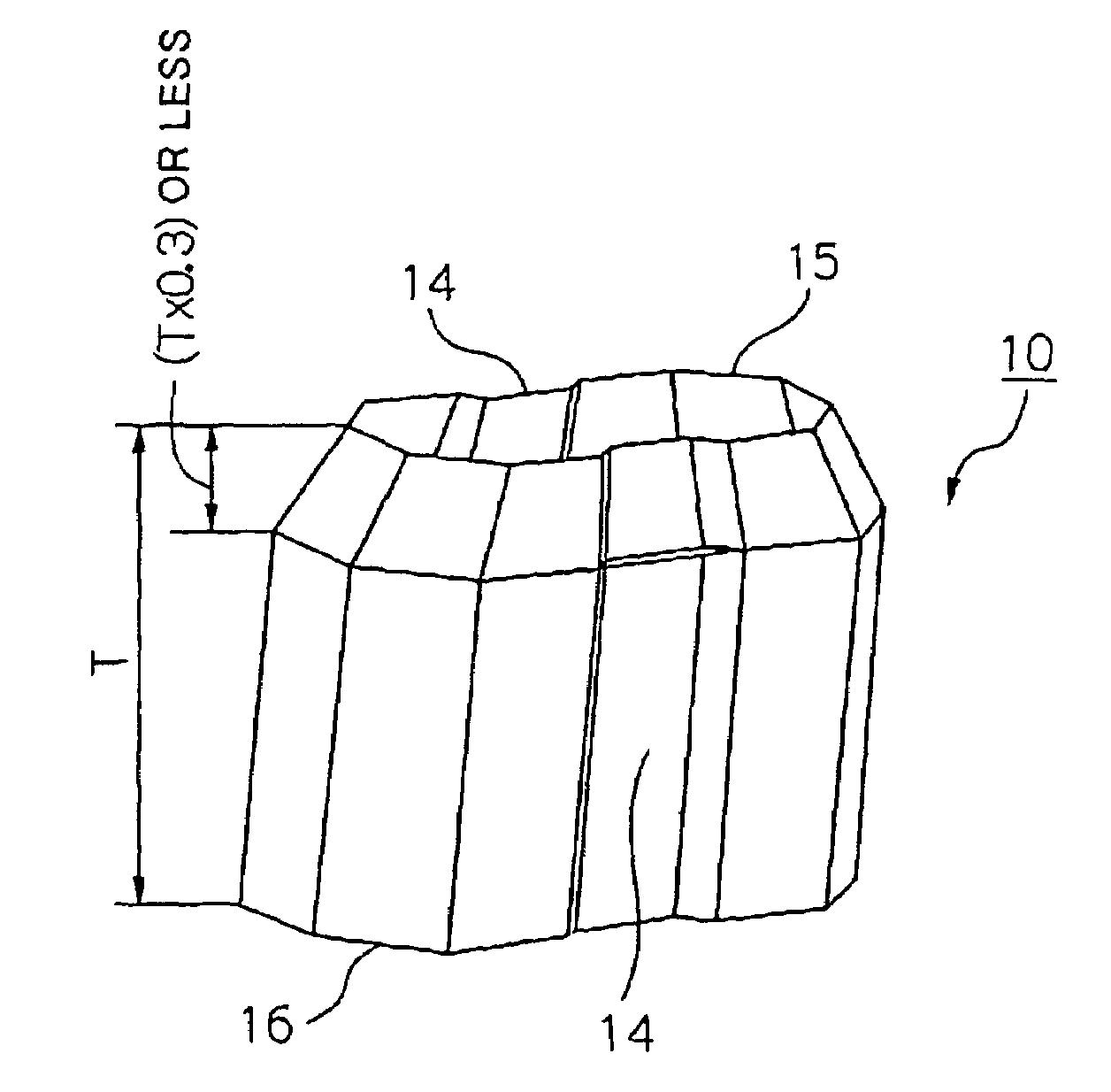

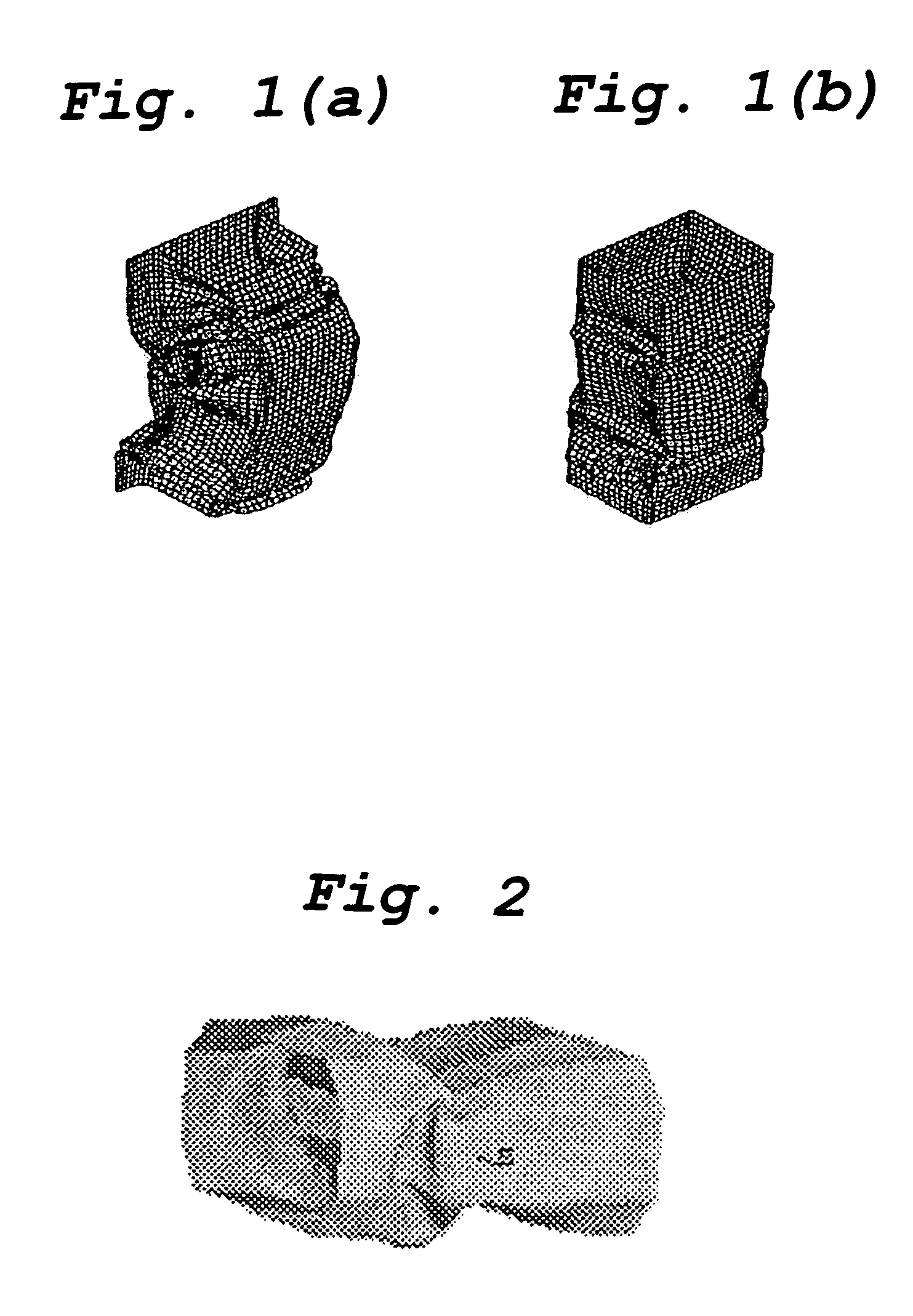

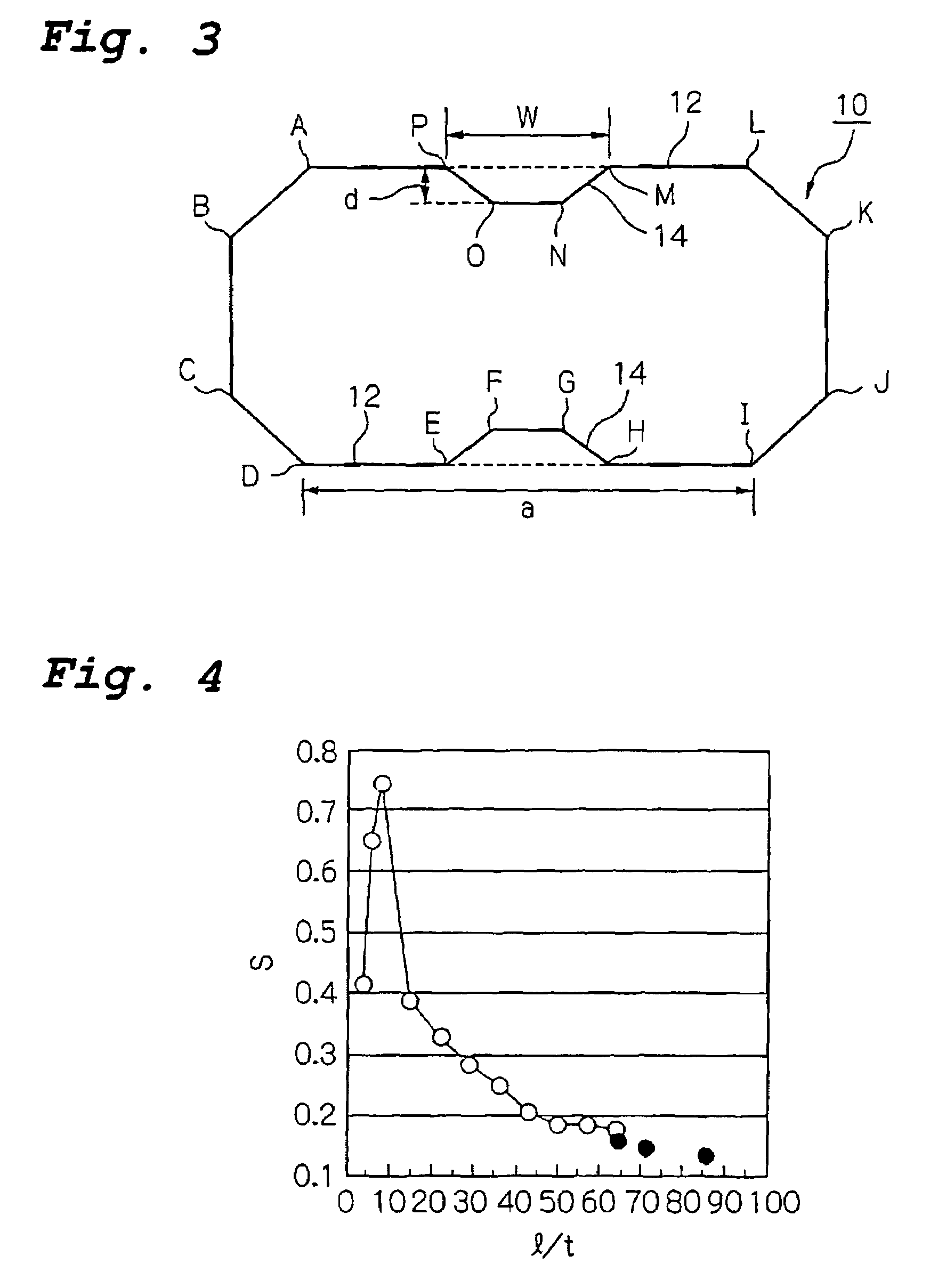

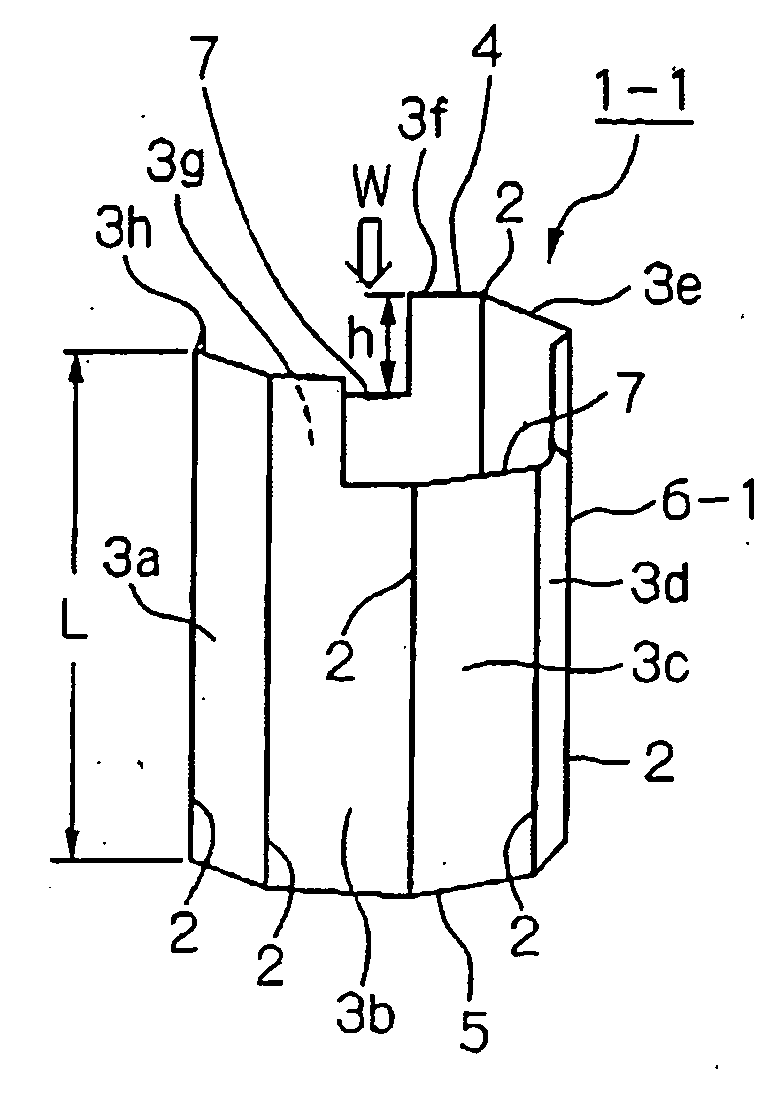

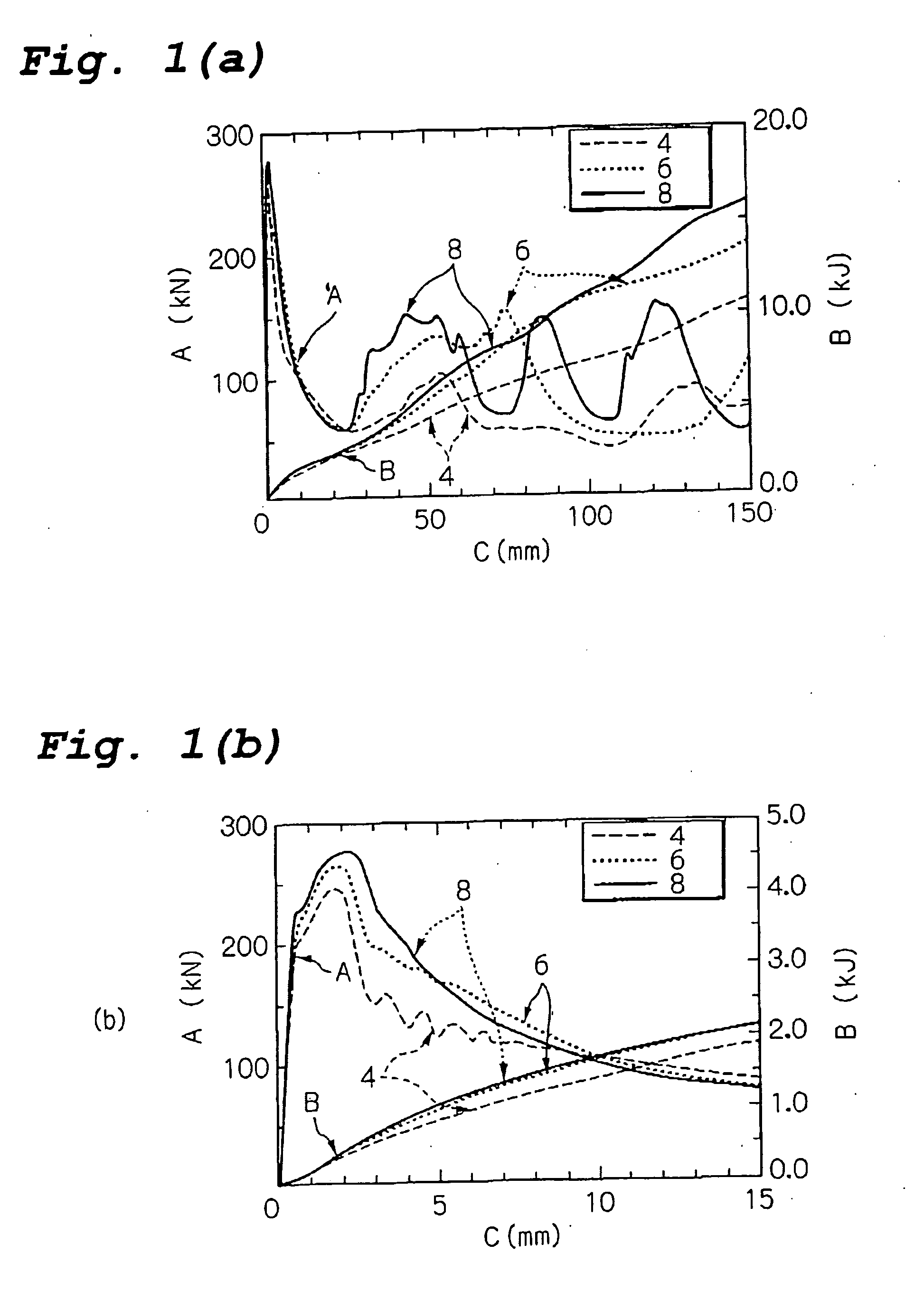

Crash energy absorption member

ActiveUS20060181072A1Easy to getEfficient use ofSteering linkagesUnderstructuresEnergy absorptionEngineering

A crash energy absorption member capable of reducing the initial load without provision of a crushing bead and capable of achieving a sufficient amount of shock absorption with stable buckling behavior. The crash energy absorption member is formed from a tubular body which has a length L and a polygonal transverse cross-sectional shape with 2n corners due to having 2n ridge lines (wherein n is a natural number greater than or equal to 3) and 2n surfaces partitioned by these 2n ridge lines, and which absorbs impact energy by buckling when an impact load is applied to one end in the axial direction towards the other end, characterized in that some of the 2n ridge lines only exist in a region which extends from a position spaced by a distance h in the axial direction from the one end to the other end, and if the number of the remaining ridge lines which have a length L is m, the following equations are satisfied: h≦L×0.30 (1) 4≦m≦2×(n−1) (2).

Owner:NIPPON STEEL CORP +1

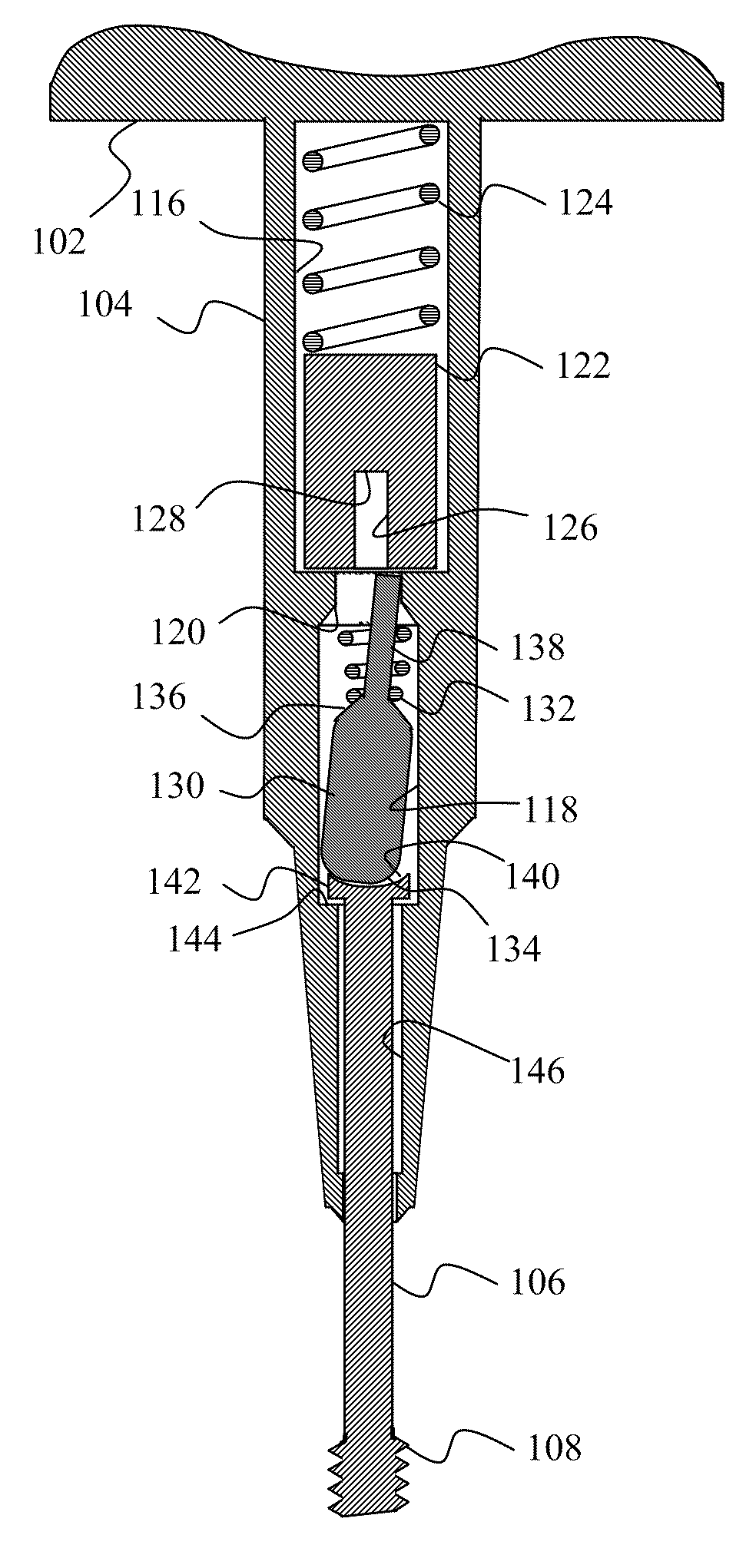

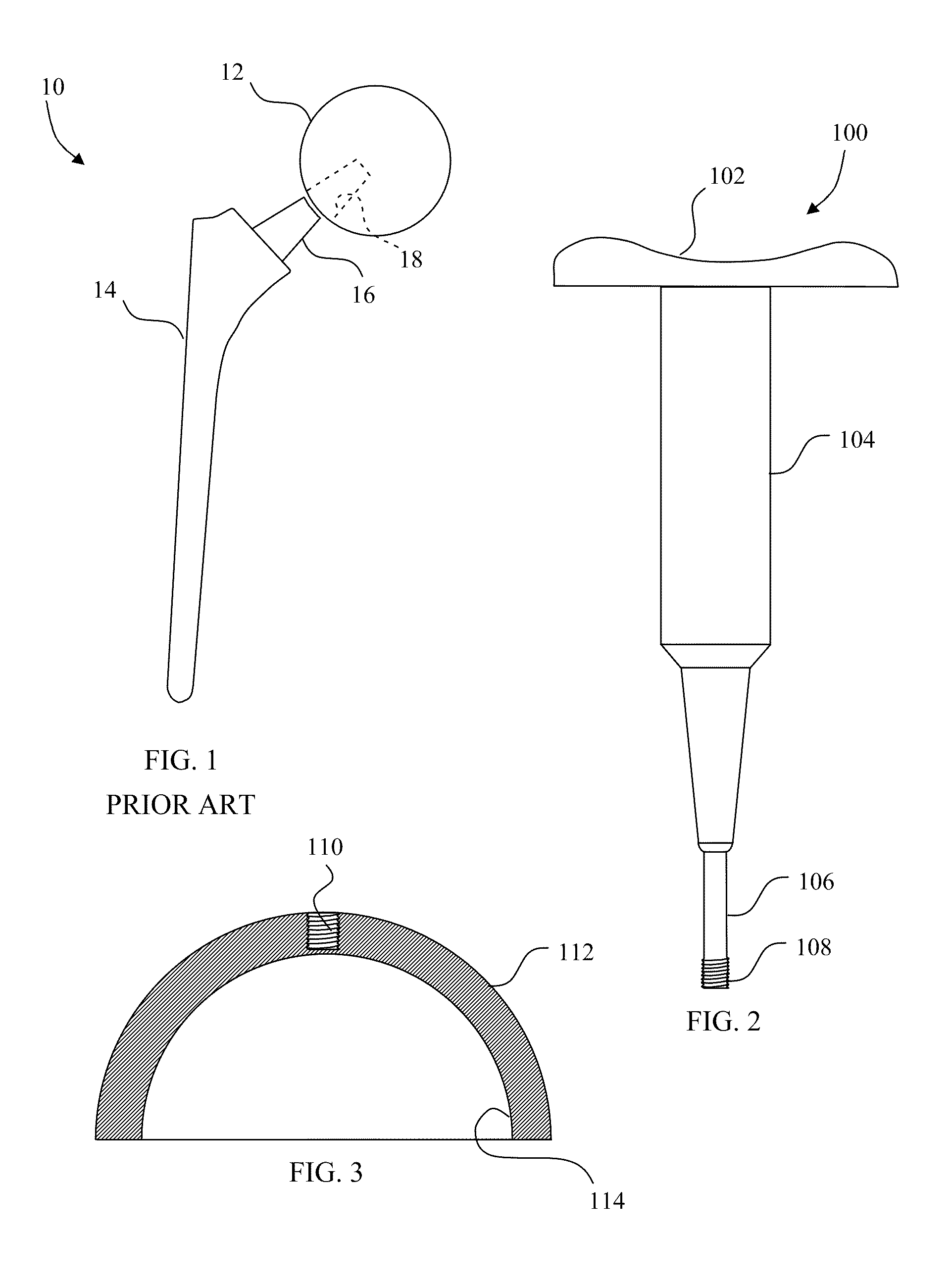

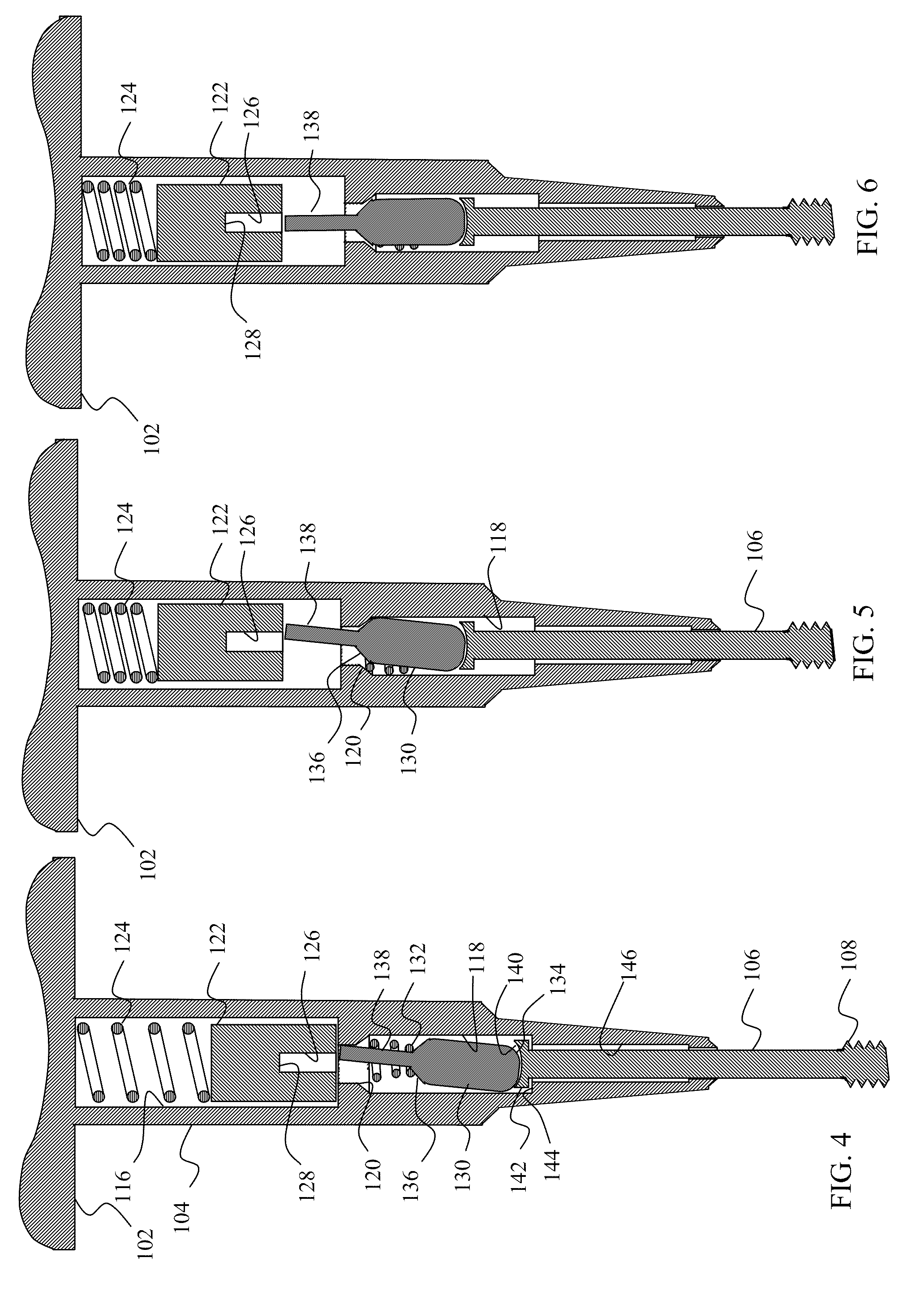

Controlled force impacting device

ActiveUS7708739B2Trend downImplemented relatively simply and inexpensivelyJoint implantsNon-surgical orthopedic devicesStored energyEngineering

An impacting tool includes a trigger mechanism that is activated when a predetermined amount of energy is stored in the impacting tool. When the impacting tool is activated, the stored energy is precipitously discharged through an impact rod which is configured to transfer a controlled force to an orthopaedic component.

Owner:DEPUY PROD INC

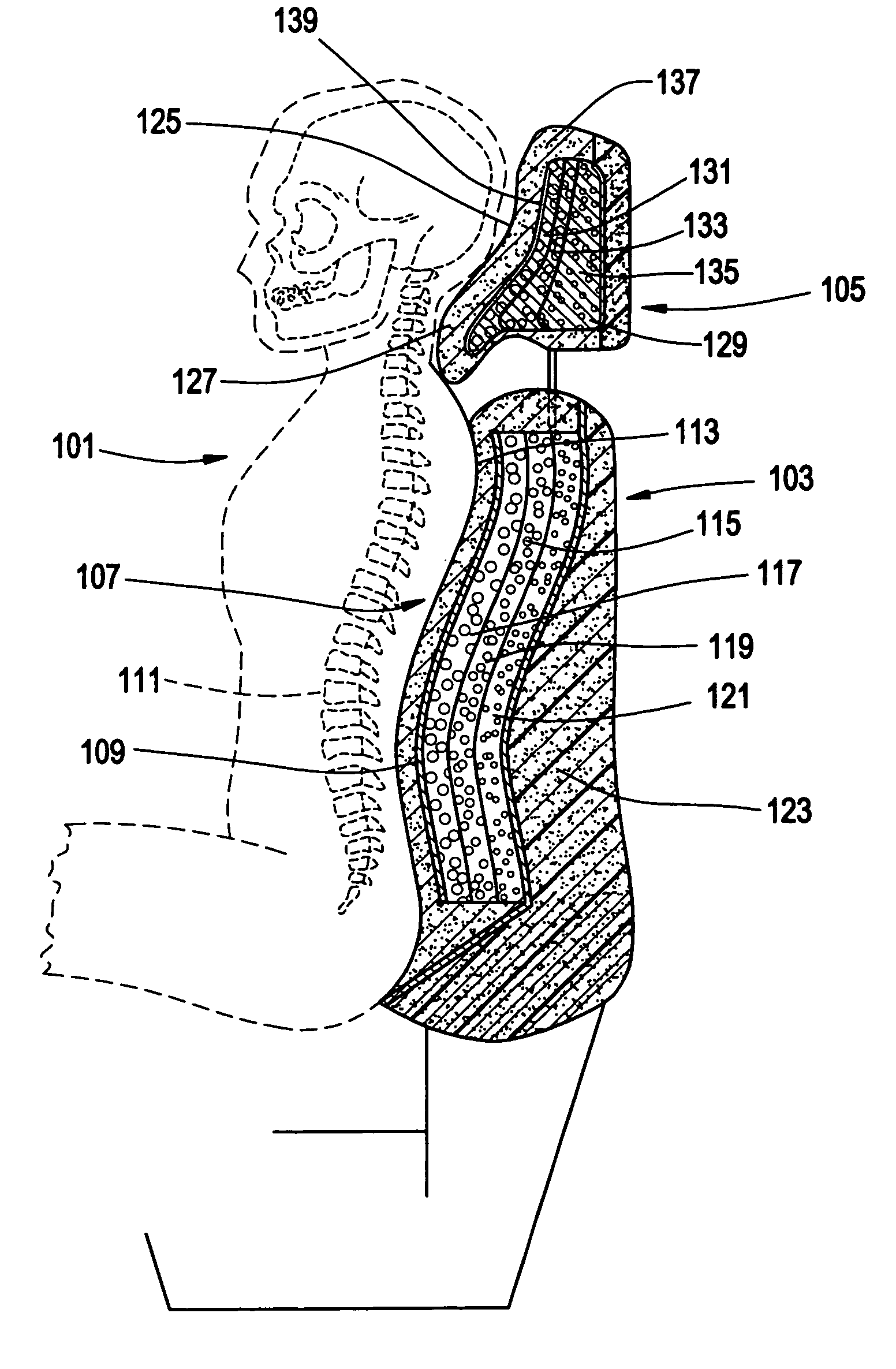

Energy absorbing support for vehicular passengers

InactiveUS7090292B2Vehicle seatsPedestrian/occupant safety arrangementMobile vehicleRear-end collision

Apparatus for preventing or limiting spinal injuries to a passenger seated in a forward facing position in a moving vehicle during vehicular impact or sudden deceleration. The apparatus includes a vehicle-installed supporting seat for the passenger, the seat having a support portion behind the seated passenger which includes a resilient surface in contact with the supported passenger. The resilient portion is supported on an underlying stiff support shell. A controllably deformable energy absorbing crush zone is disposed to the rear of the shell as to be compressed by rearward displacement of the passenger, whereby the support portion acts to decelerate the supported spine of the passenger during a vehicle rear end impact, while the controlled deformation of the crush zone absorbs energy, to prevent or limit spinal injuries to the passenger. The crush zone material is characterized in a rear end collision by exhibiting a total energy absorption of the kinetic energy gained by the impact accelerated passenger of at least 80%; and the coefficient of restitution for the crush zone material being in the range of 0.05 to 0.4.

Owner:DELLANNO RONALD P

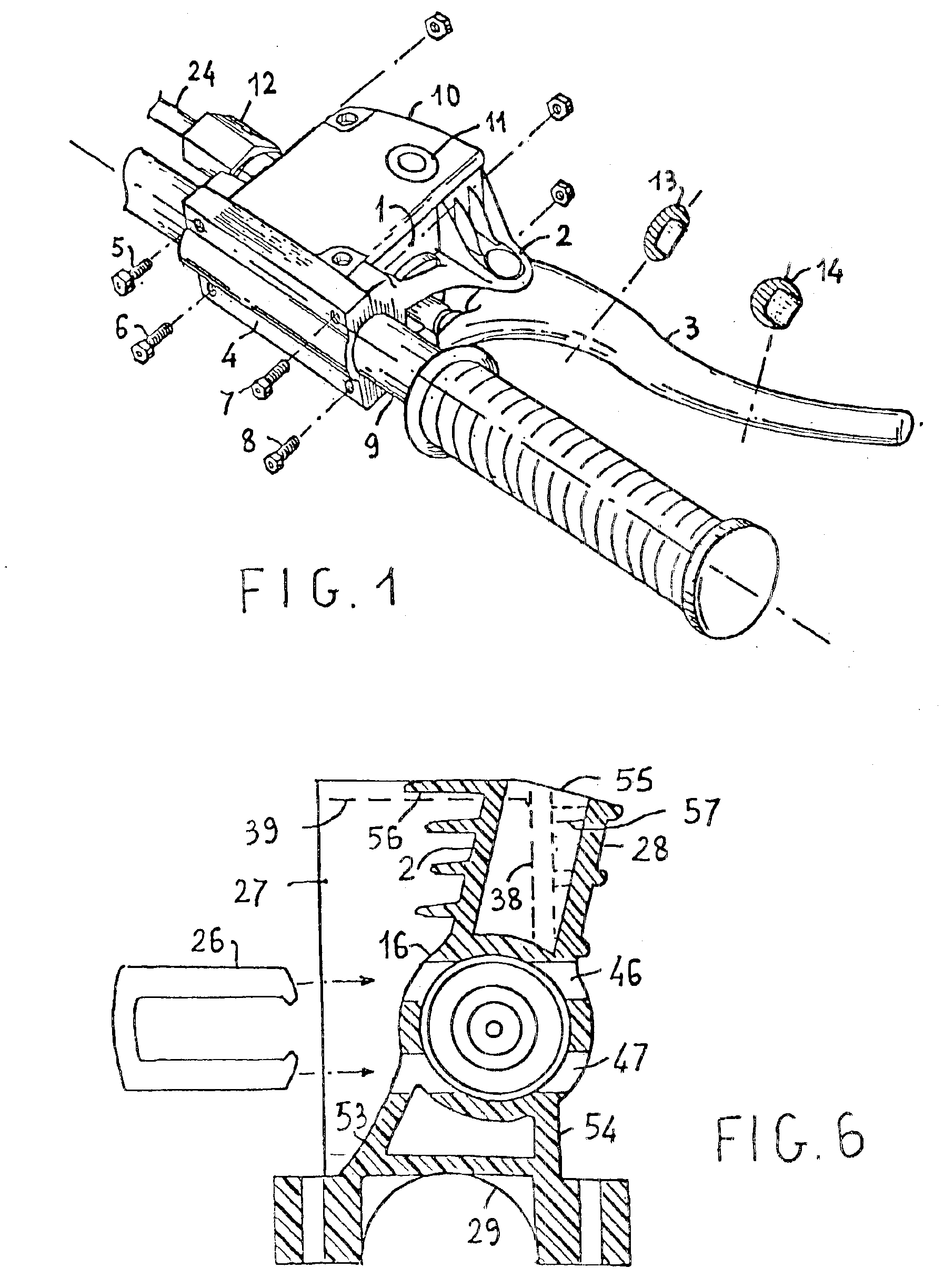

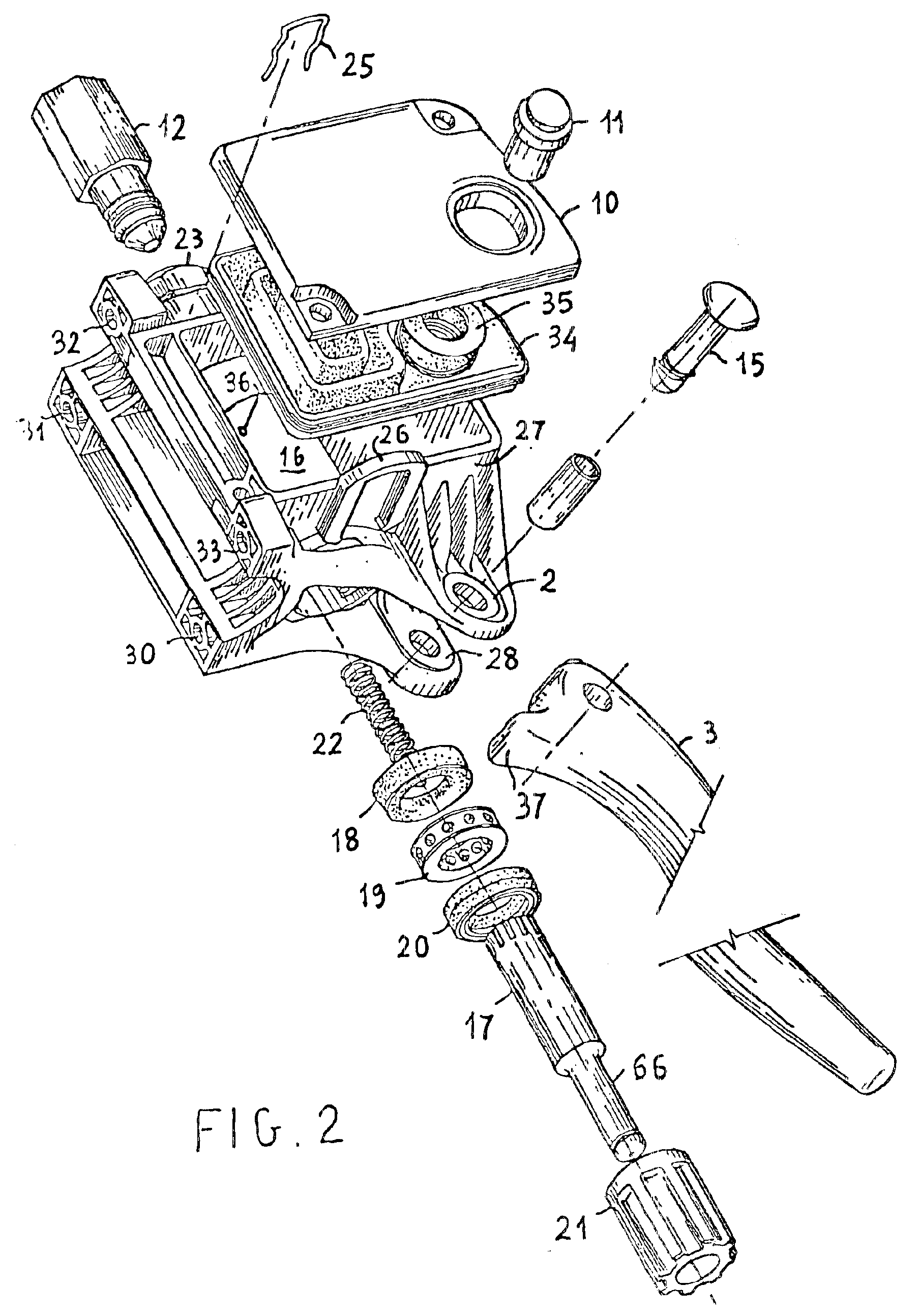

Master cylinder for a brake or clutch of a motorcycle or bike

InactiveUS6871729B2Simple structureRotary clutchesFluid actuated clutchesGlass fiberPlastic materials

A brake / clutch master cylinder for a motorcycle / bicycle or the like, with a body which is produced by moulding of plastics material reinforced by glass fibre without the need for machining operations or metal inserts and which forms, together with the cylindrical shell of the master cylinder, a hydraulic-fluid reservoir, a coupling sleeve for a male quick-fit hydraulic connector, and a seat for fixing to a handlebar, the body having a high degree of structural stiffness with respect to working stresses and adequate resilience for impact stresses imparted to the body by means of the hand operating lever.

Owner:FRENI BREMBO SPA

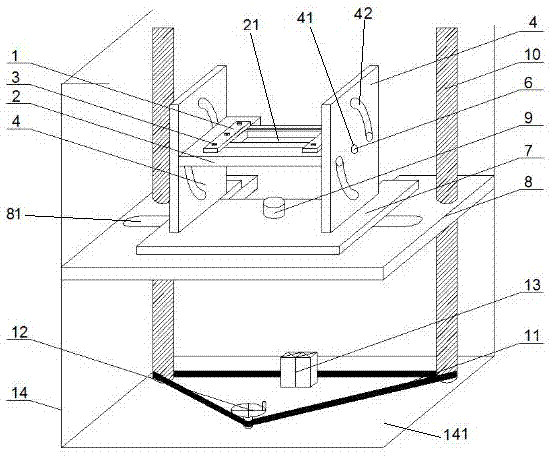

Plate clamper platform for falling weight impact test, and impact speed measurement method

PendingCN106940275ARealize multi-angle impactIncrease flexibilityDevices using optical meansStrength propertiesEngineeringLaser sensor

The invention discloses a plate clamper platform for a falling weight impact test, and an impact speed measurement method. The plate clamper platform comprises a clamper structure, a supporting lifting structure and a laser sensor, wherein the clamper structure comprises a plate clamping device, a multi-angle rotation device and a clamper bottom plate, the multi-angle rotation device comprises wall plates, wall plate bolts and a bottom plate bolt, each wall plate is provided with a central hole and two arc-shaped grooves, the two arc-shaped grooves are symmetrically arranged relative to the central hole, clamping plates can rotate along the arc-shaped grooves after the wall plate bolts are completely loosened, the supporting lifting structure comprises a platform and a lifting driving device, the clamper bottom plate can rotate by adopting the bottom plate bolt as the center and can slidably move along a straight strip hole, and the laser sensor is arranged below the weight tray positioned on the periphery of a hammer head. With the plate clamper platform and the impact speed measurement method of the present invention, the composite material plate specimen can be tightly clamped, the multi-angle impact on the specimen can be achieved, and the speed change during the drop hammer falling and impact process can be real-timely measured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

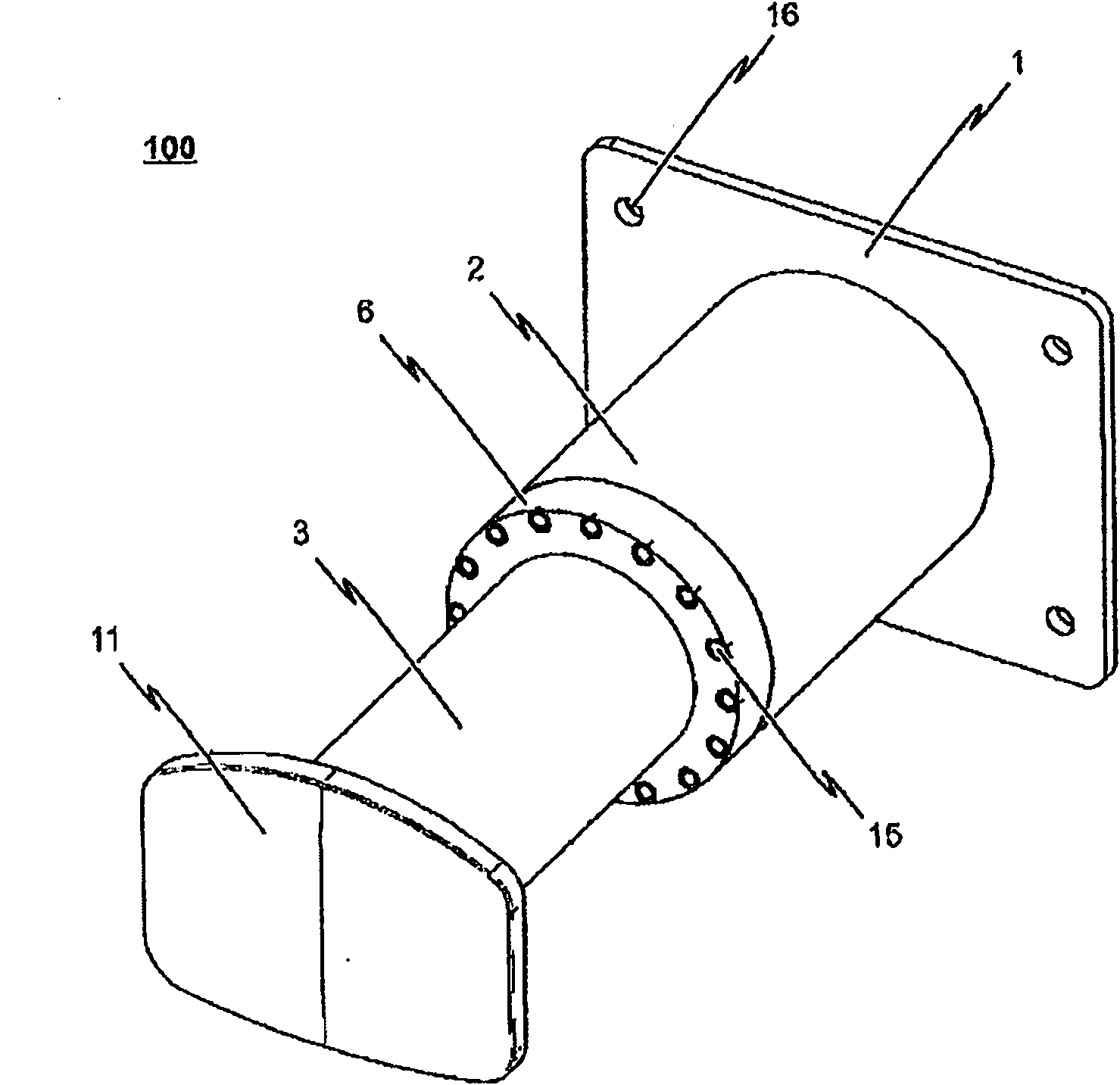

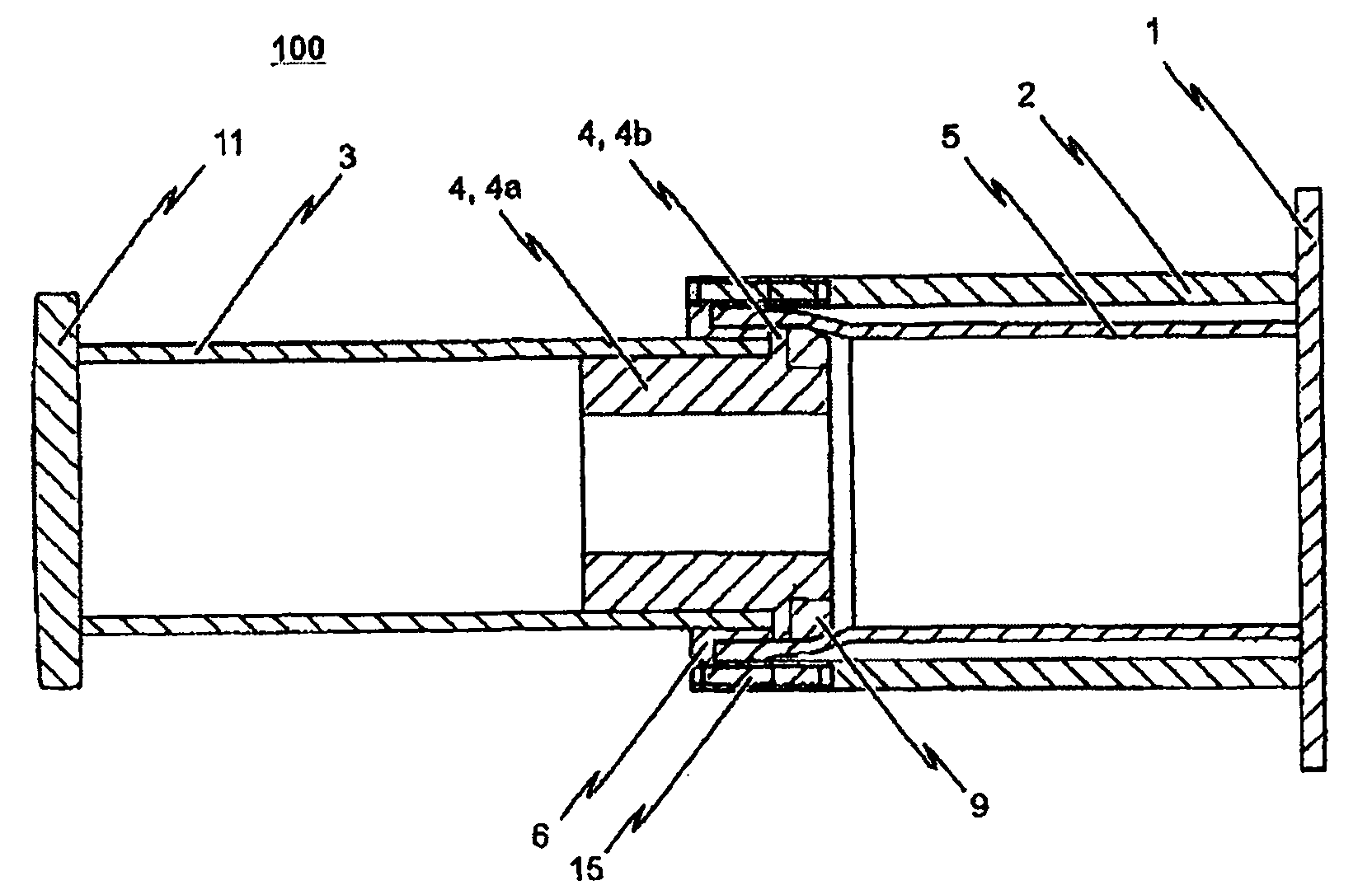

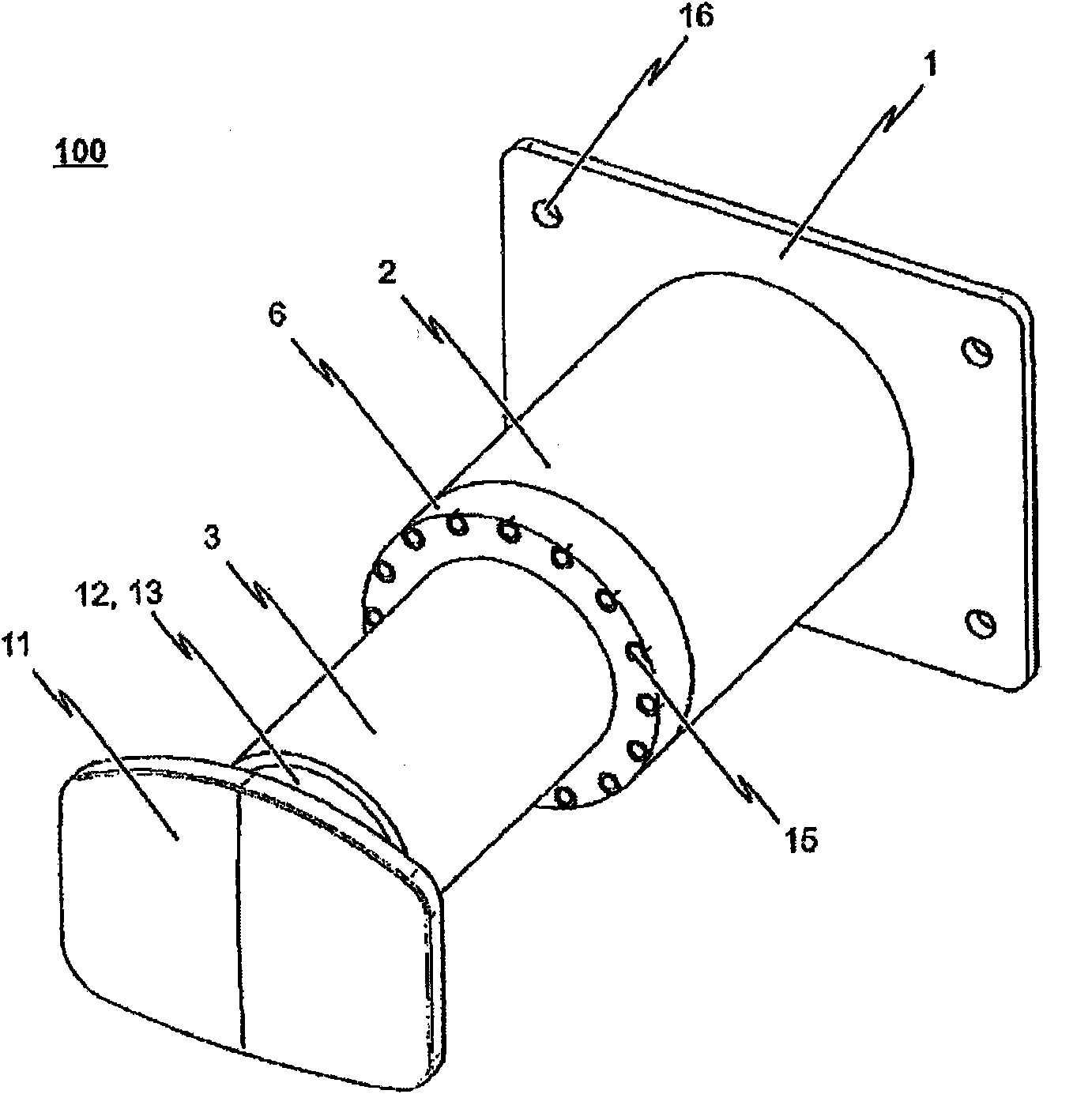

Shock absorber

The invention relates to a shock absorber (100) especially for use as an additional irreversible shock absorbing element in combination with a component for transmitting force. In order to reliably absorb high impact energies, a shock absorber (100) comprises the following elements: a base plate (1); a force transmitting element (3) having a tensioning element (4); an energy absorption element in the form of a deformable tube (5) which is connected to the base plate (1) via a first end section; and a connecting element (6) for detachably connecting the force transmitting element (3) to a second end section of the deformable tube (5), the connecting element (6) pressing against the tensioning element (4) in such a manner that the deformable tube (5) is tensioned between the tensioning element (4) and the base plate (1) without play.

Owner:VOITH PATENT GMBH

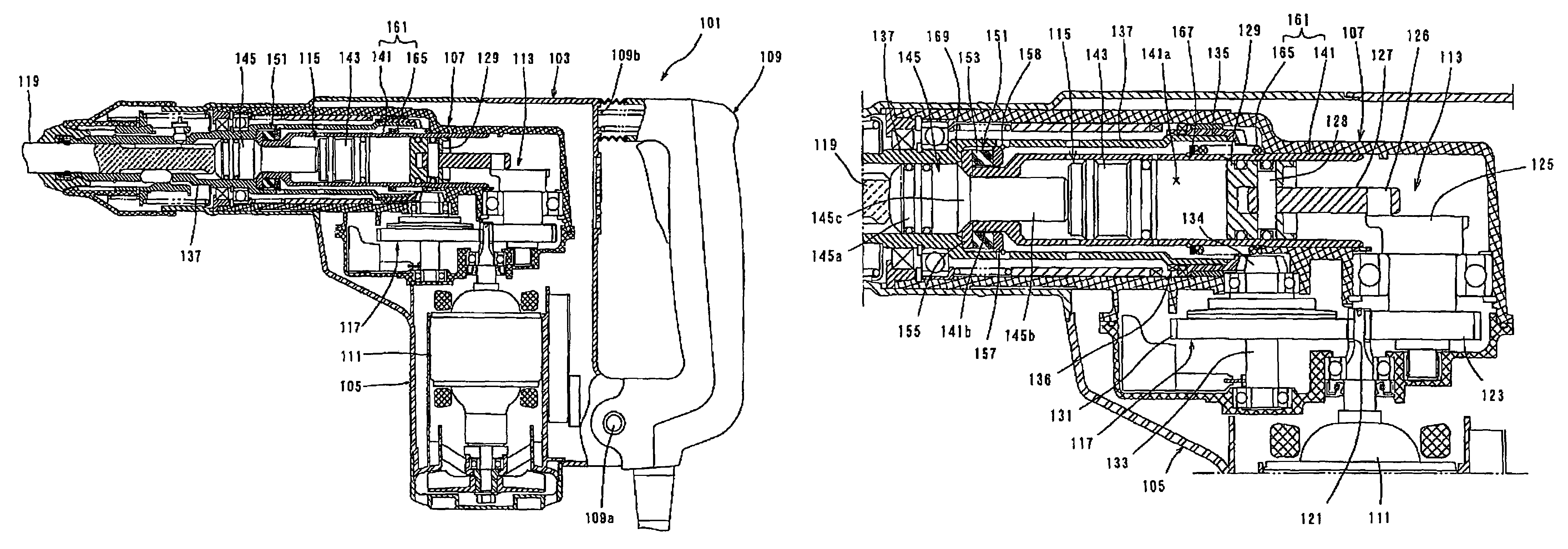

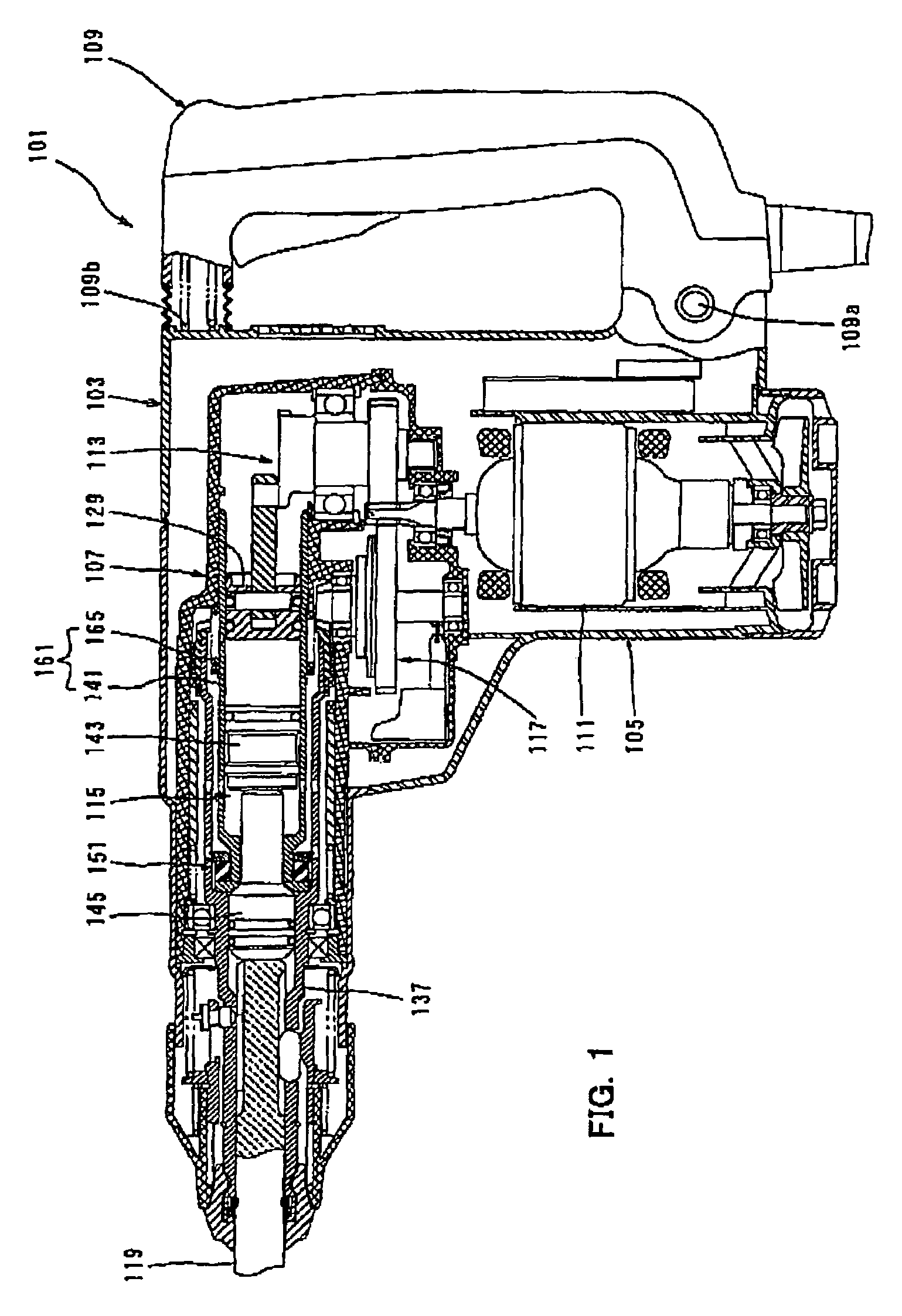

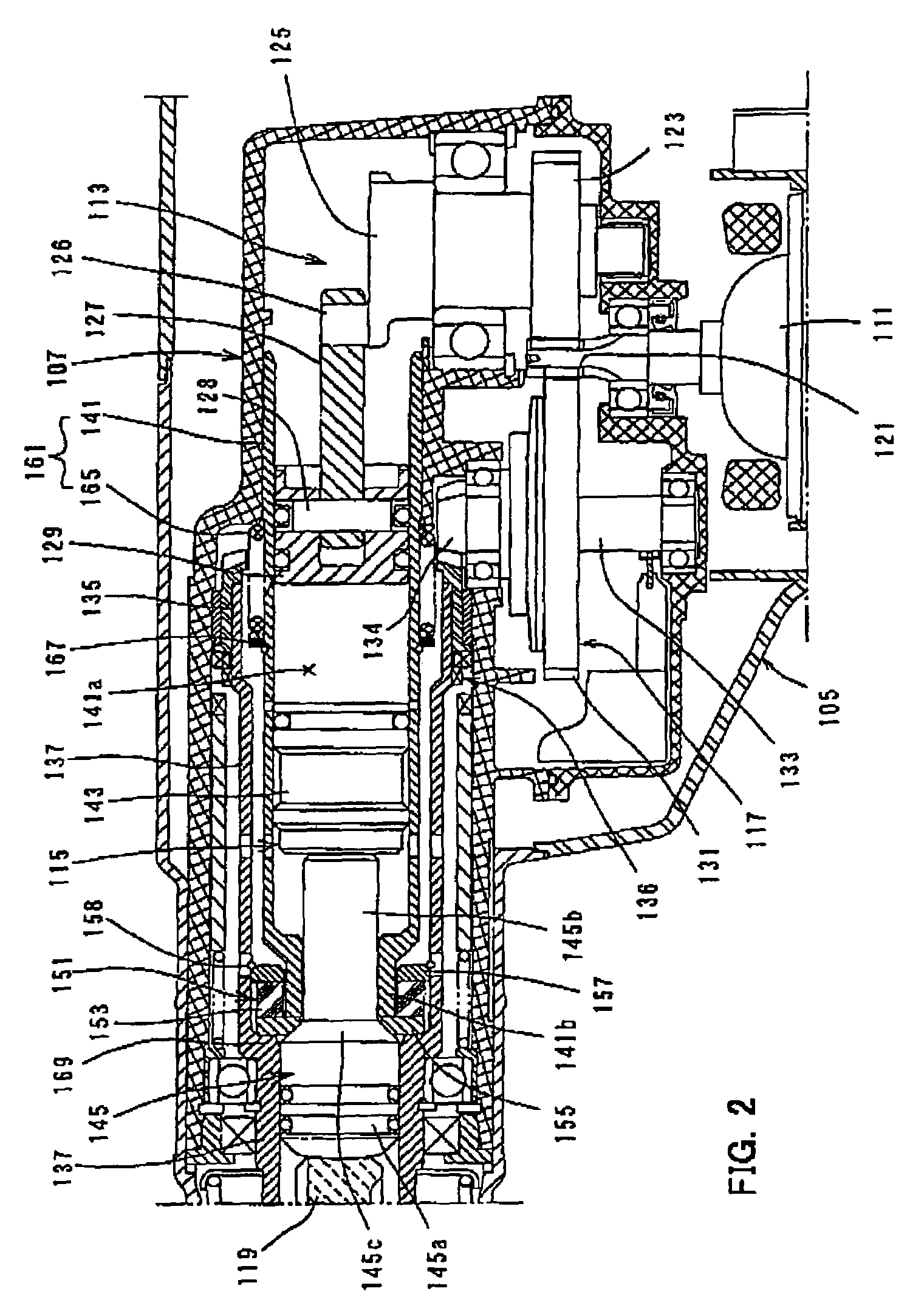

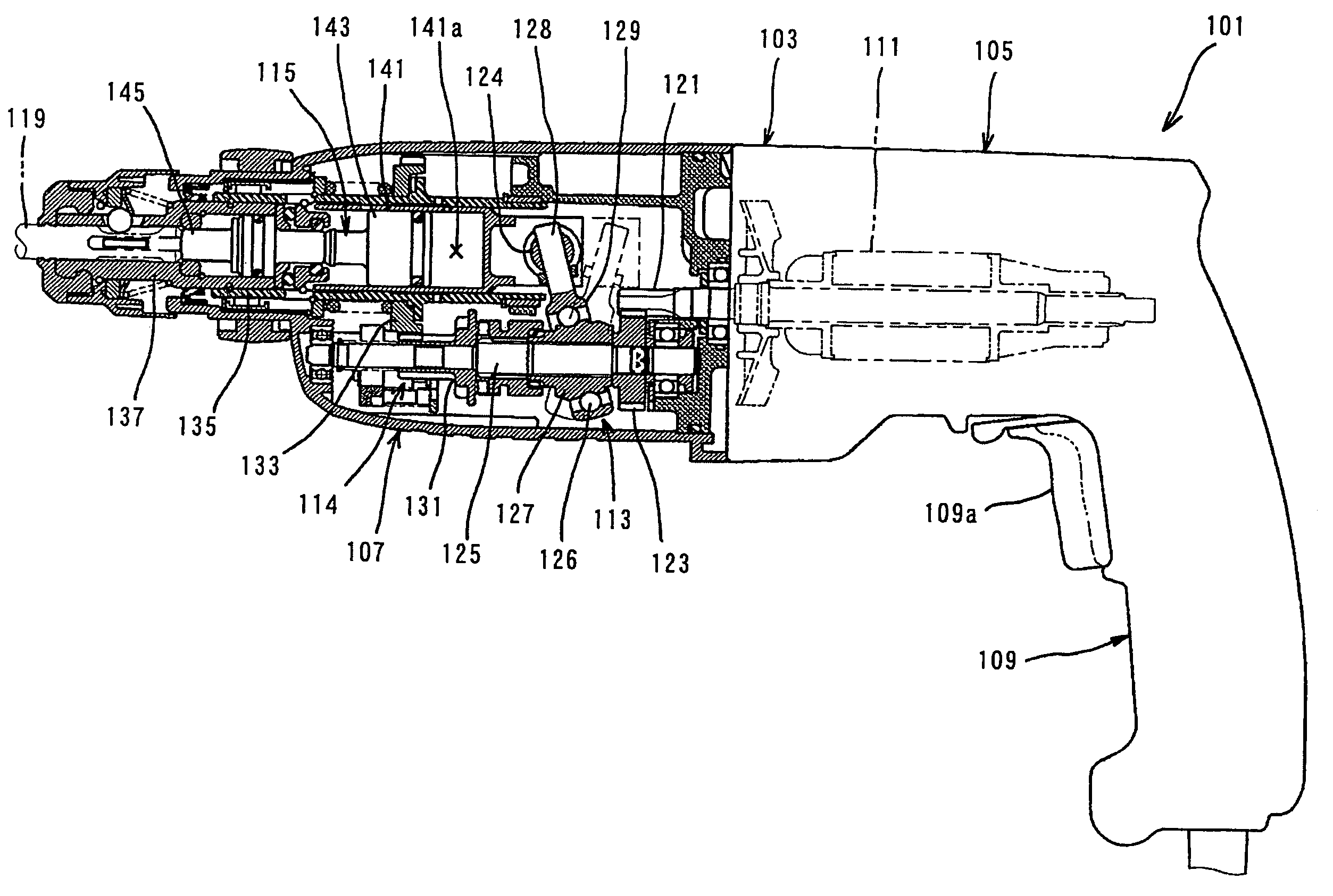

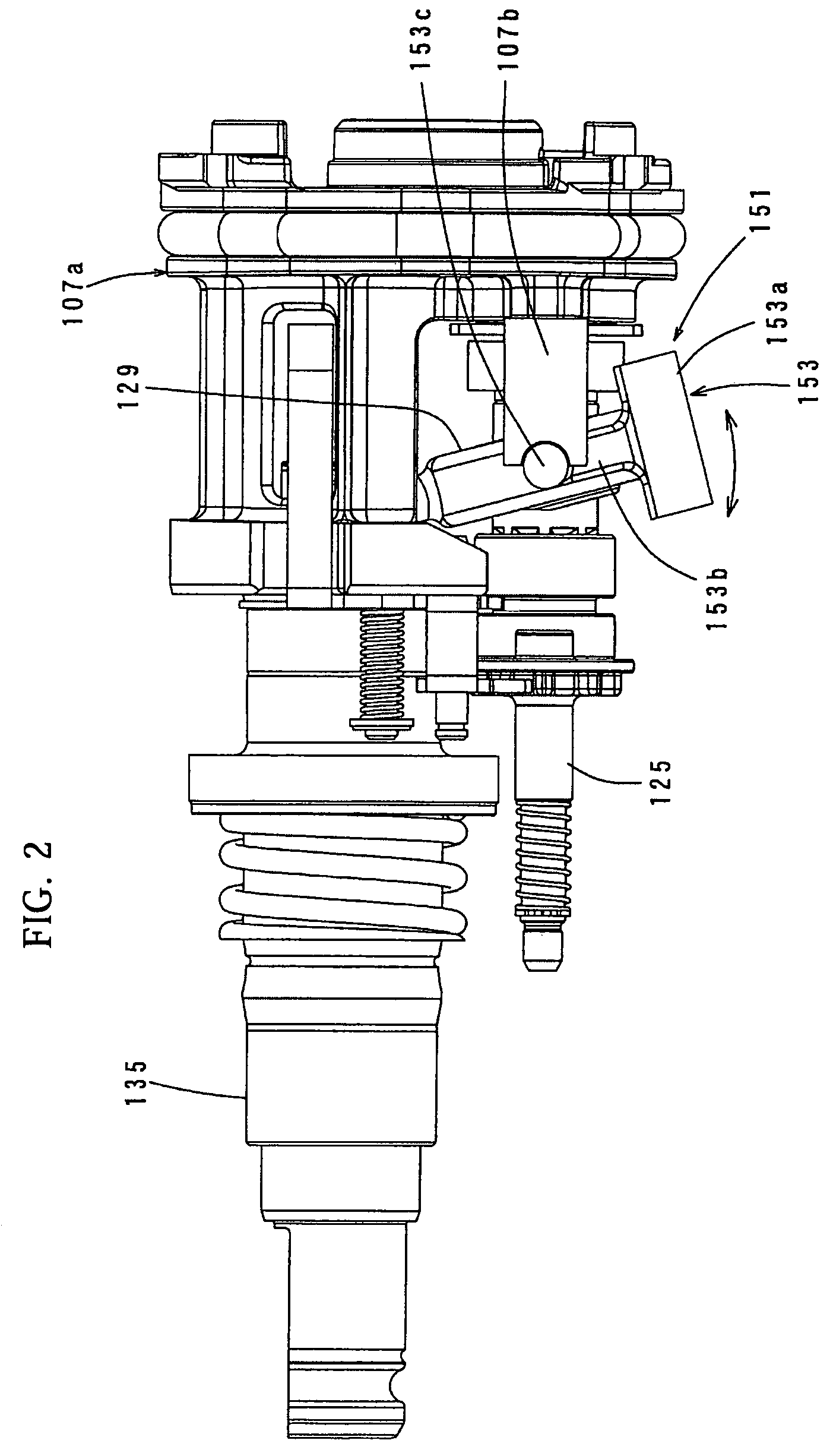

Impact power tool

InactiveUS7523791B2Reduce impactReduce shock vibrationReciprocating drilling machinesConstructionsEngineeringPower tool

An object of the invention is to provide an improved technique for lessening an impact force caused by rebound of a tool bit after its striking movement in an impact power tool. The representative impact power tool comprises a tool body, a hammer actuating member, a tool holder, a driving mechanism, a weight placed in contact with the hammer actuating member to move rearward by a reaction force transmitted from the hammer actuating member when the hammer actuating member performs a hammering operation on the workpiece and an elastic element elastically deformed when the weight moves rearward in the tool body to push the elastic element such that the elastic element absorbs the reaction force transmitted to the weight. The weight is defined one or both of the cylinder and the tool holder.

Owner:MAKITA CORP

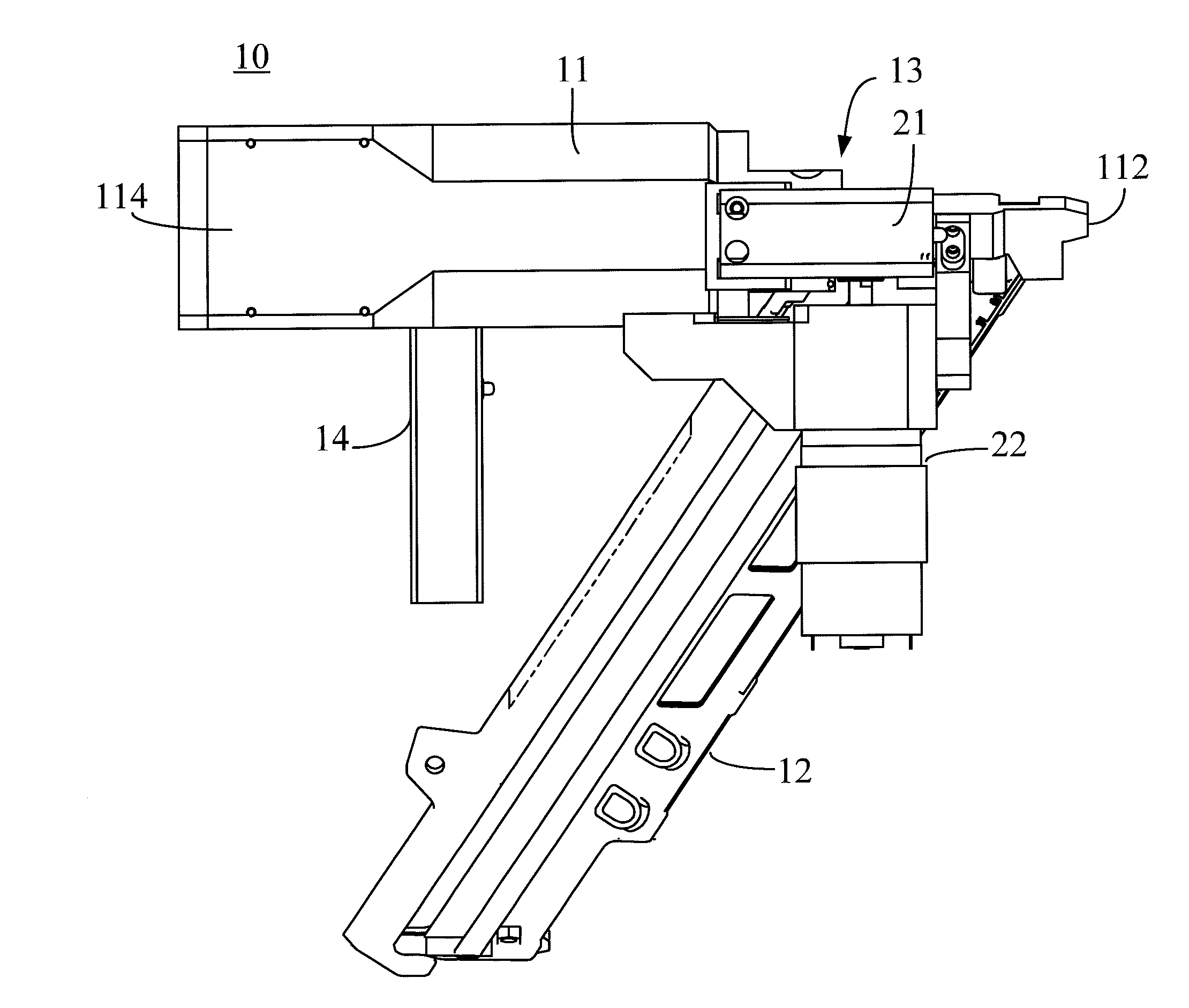

Power impact tool

ActiveUS7588097B2Improve vibration damping effectDrilling rodsReciprocating drilling machinesRotational axisEngineering

It is an object of the invention to provide a technique for further improving the vibration reducing performance in a power impact tool that linearly drives a tool bit by using a swinging mechanism. According to the invention, a representative power impact tool is provided with a motor, a rotating shaft, a swinging member, a tool driving mechanism and a counter weight. The swinging member is supported by the rotating shaft to swing in the axial direction of the rotating shaft by rotation of the rotating shaft. The counter weight is disposed in a region higher than a lower end region of the swinging member in the vertical direction to intersect with the axis of the rotating shaft, and a lower end of the counter weight is connected to the lower end region of the swinging member. The counter weight extends upward from the connection between the counter weight and the swinging member and has a pivot point in the extending end portion, and when the swinging member swings, the counter weight is driven by the swinging member to rotate in the axial direction of the tool bit, thereby reducing vibration caused in the axial direction of the tool bit.

Owner:MAKITA CORP

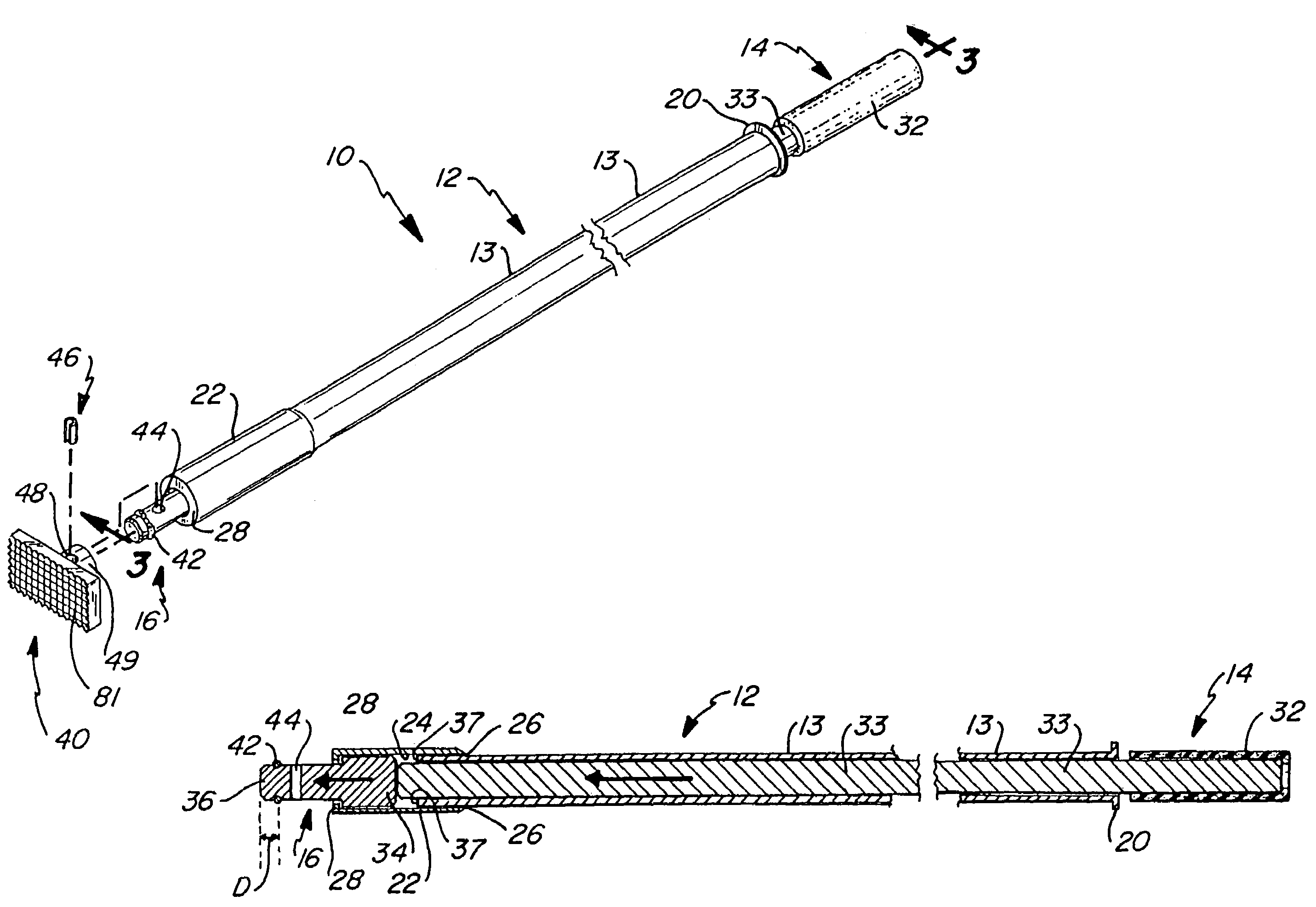

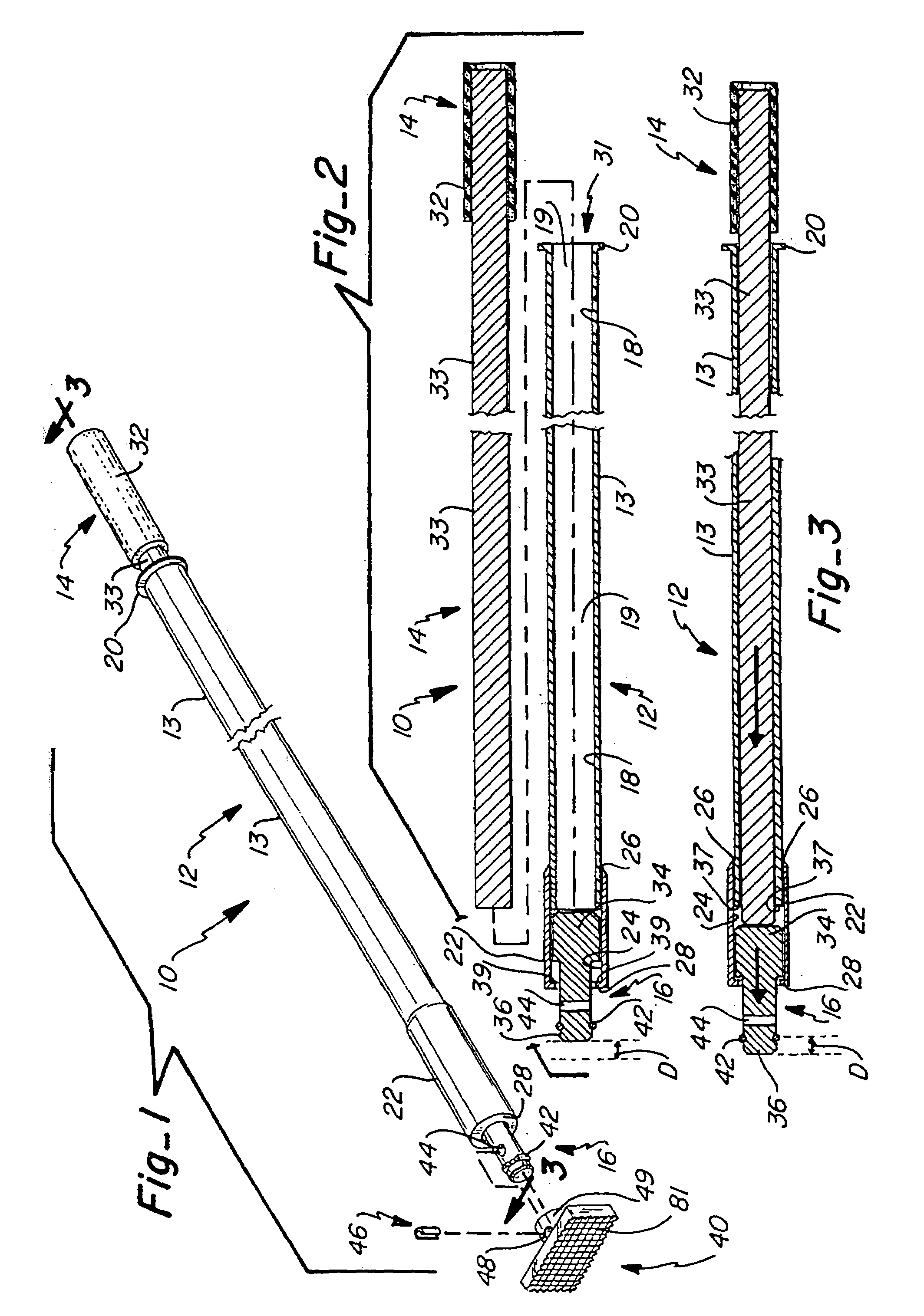

Device and method for transferring force to a targeted objected

InactiveUS7191685B2Increase or decreaseReduce shockConstructionsReciprocating drilling machinesHead movementsMechanical engineering

A slide hammer includes three major components, namely, a guide sleeve, a plunger and an impact head. The plunger is inserted within the guide sleeve. The impact head is secured within the distal end of the guide sleeve, and has a portion which protrudes from the guide sleeve distal end. The impact head is able to freely slide within a segmented portion of the guide sleeve distal end, or the impact head movement may be controlled by a spring. The plunger is slid within the guide sleeve at a selected velocity in order to contact the portion of the impact head slidably secured within the guide sleeve. The force of the plunger striking the impact head is transmitted through the impact head to a targeted object in contact with the protruding portion of the impact head. The impact head may be fitted with various types of tips. Each of the tips has particular advantages in applying force to a targeted object.

Owner:SLIDE SLEDGE

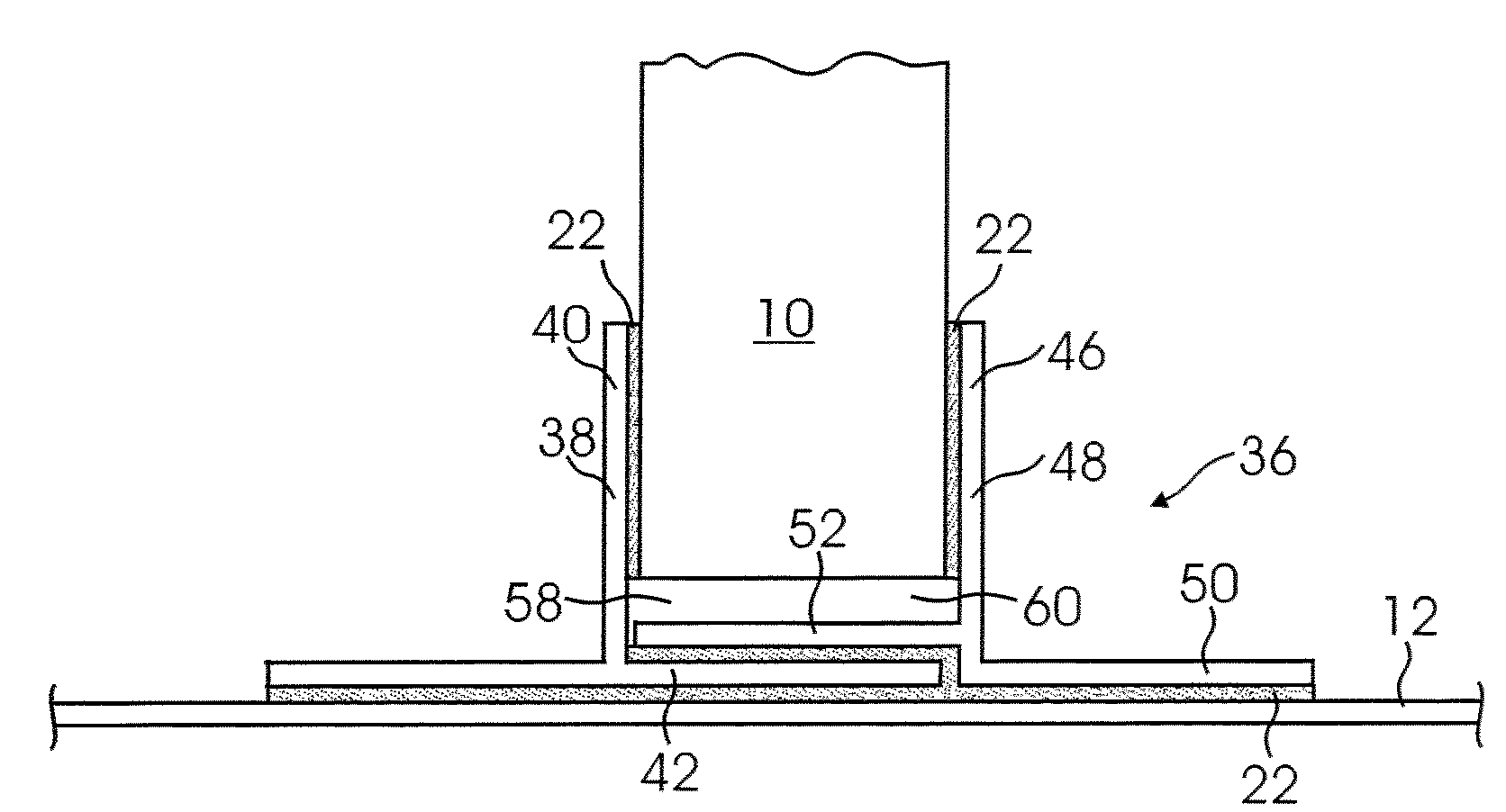

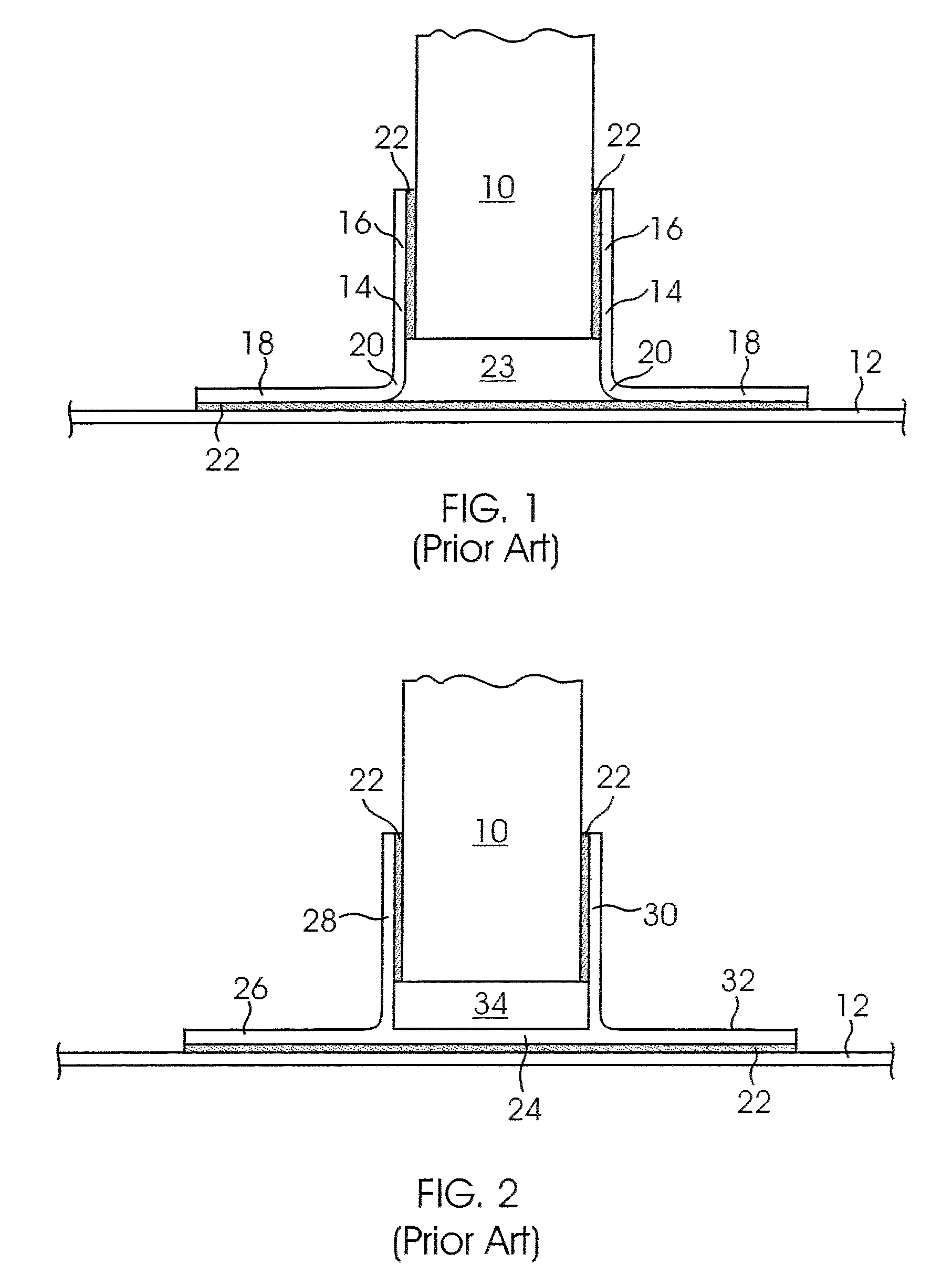

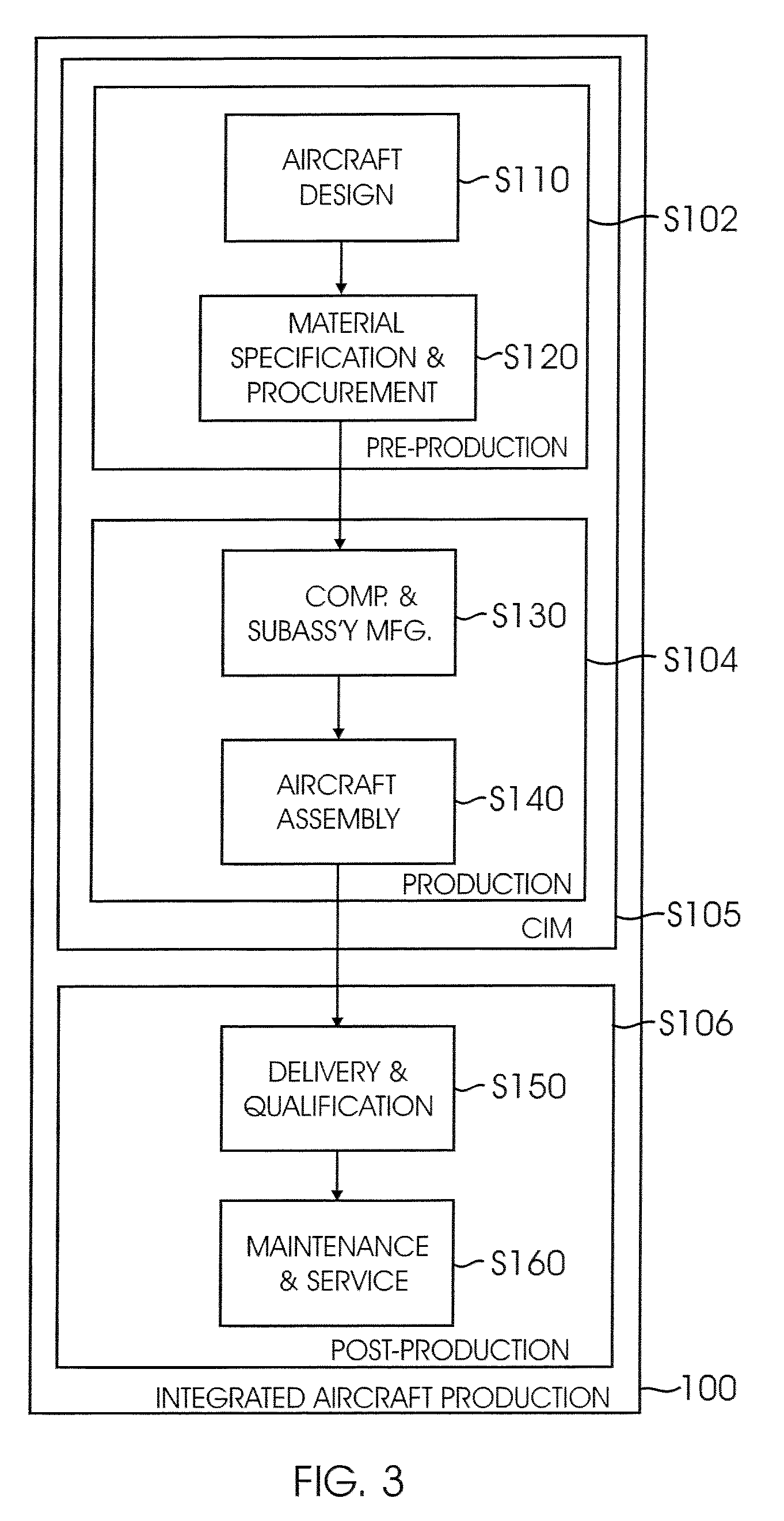

Apparatus and methods for securing a first structural member and a second structural member to one another

ActiveUS20080295334A1Improve the immunityAllowance for thickness variationFuselage framesFuselage bulkheadsVariable thicknessAdhesive

Apparatus and methods for securing a first structural member and a second structural member to one another. In one embodiment a two-piece fitting is provided. The fitting includes a variable gap between attachment surfaces, enabling the fitting to accommodate structural members of variable thickness. The fitting also includes overlapping sections that provide increased resistance to pull-off loads and impact loads. The configuration of the fitting advantageously simplifies the assembly process and preserves the integrity of the adhesive to form a strong joint.

Owner:THE BOEING CO

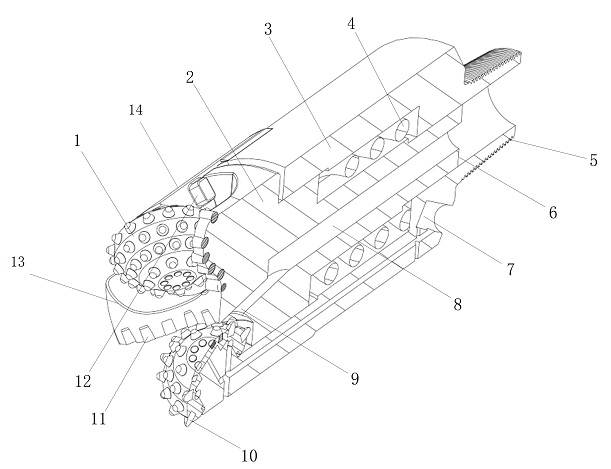

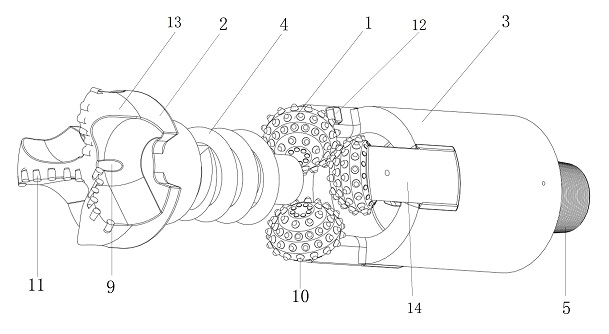

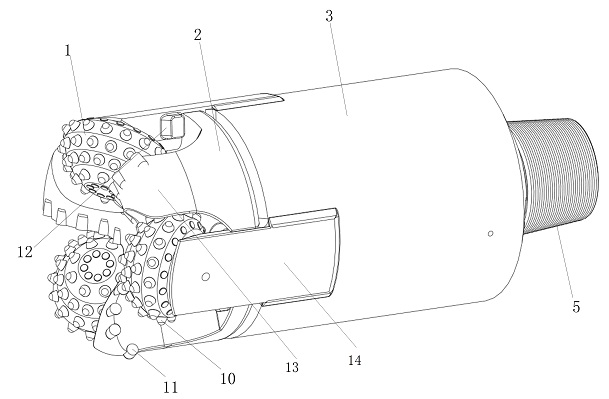

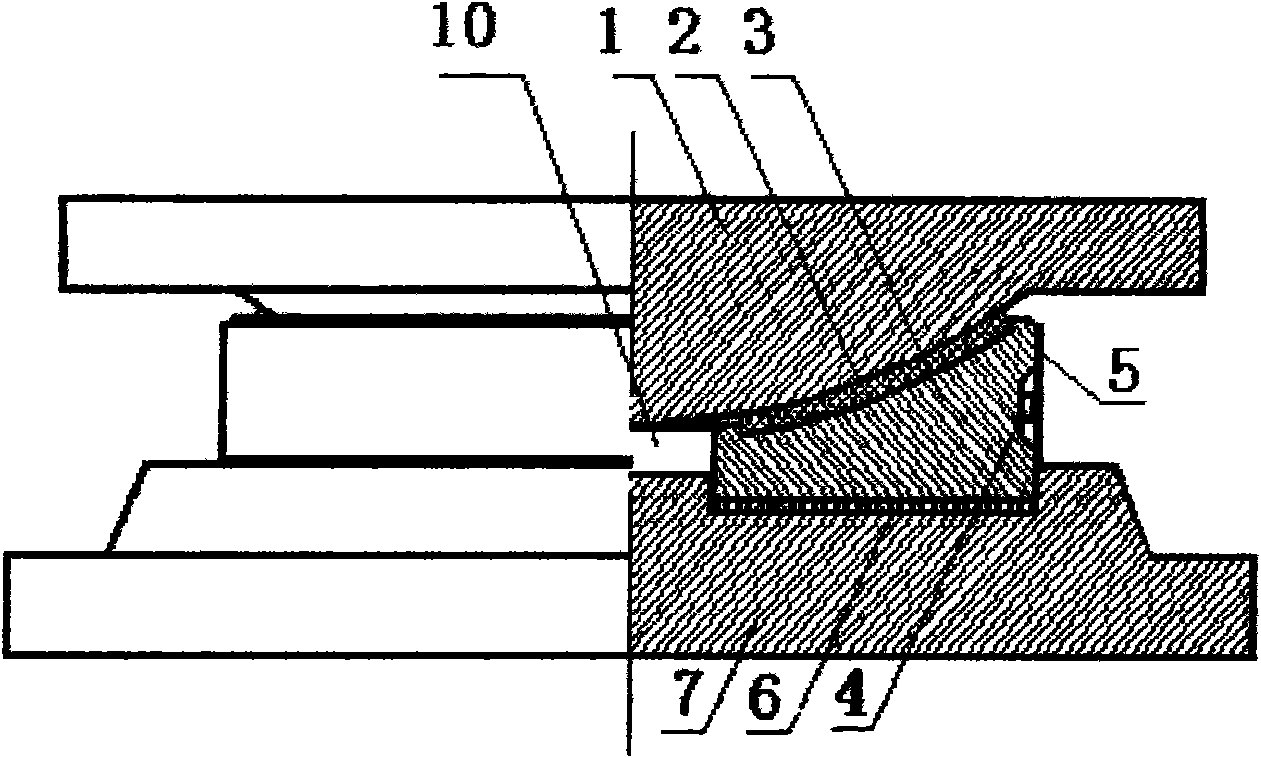

Self-adapting hybrid bit

InactiveCN102561953AOptimize the distribution of rock breaking volumeOptimize allocationDrill bitsAxial forcePetroleum oil

The invention discloses a hybrid bit for petroleum gas exploitation and other exploration drilling applications, wherein cones and blades are simultaneously arranged on a bit main body and are uniformly distributed in a staggering manner, and the cones are arranged on a tooth palm of the bit main body; the hybrid bit further comprises a movable blade body movably arranged in the bit main body and only capable of telescopically moving within a limited range along an axial direction, an elastic element for providing axial force for the movable blade body is also arranged between the movable blade body and the bit main body, the blades are arranged at the front end of the movable blade body, and a compression face for bearing mud pressure is arranged at the tail end of the movable blade body. The self-adapting hybrid bit disclosed by the invention is capable of controlling the relative positions of the cones and the blades in a self-adapting manner according to stress, thereby optimizing the rock breaking quantity distribution of the cones and the blades and guaranteeing a faster rock breaking speed, and the applicability is more extensive. Besides, by the self-adapting design, the rigid impact of common bits and rock stratum is optimized to flexible impact, so that the bit is greatly protected.

Owner:SOUTHWEST PETROLEUM UNIV

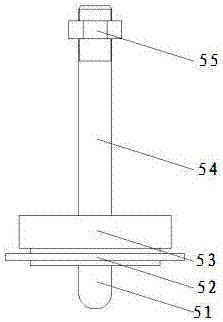

Vertical intelligent force measurement support

ActiveCN102032959AJudging the working statusSimple structureMeasurement apparatus componentsForce measurementPull forceEngineering

The invention relates to a vertical intelligent force measurement support which comprises an upper pendulum, a lower pendulum and a base, wherein the lower surface of the upper pendulum is a convex spherical surface, the upper surface of the lower pendulum is a concave spherical surface, the upper pendulum is in spherical contact with the lower pendulum, the lower pendulum is arranged on the base, is provided with at least one resistance strain element on the peripheral cylindrical surface thereof and generates the circumferential horizontal pulling force under the action of the upper pendulum spherical normal compressive strain, the circumferential horizontal pulling force enables the resistance strain element on the peripheral cylindrical surface of the lower pendulum to vary, and the variable quantity reduces the size of load acting on the intelligent force measurement support after collection, analysis and treatment of a data collection module. The vertical intelligent force measurement support can be used as a support of a bridge, a building or other engineering structures, is used for testing and monitoring various loads including vertical loads such as static load, dynamic load, impact load and the like for a long term, in particular to monitoring the reaction force of a high-speed railway bridge support, and has important practical significance on ensuring the safety of high-speed railway operation.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

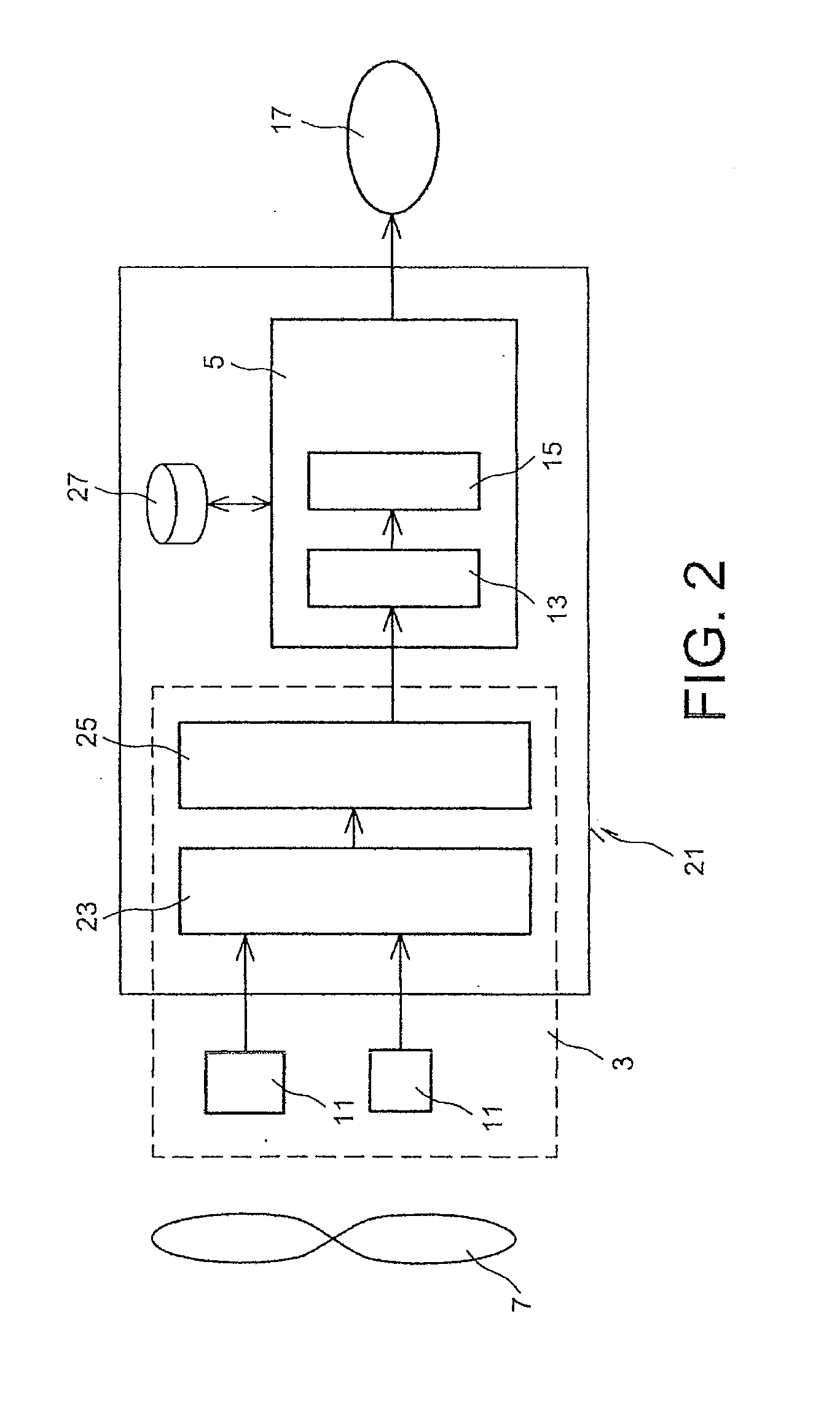

System for detecting an impact on an aircraft engine impeller wheel

ActiveUS20130197747A1Minimal calculation timeAccurate representationVibration measurement in solidsVehicle testingImpellerEngineering

The invention relates to a method and a system for detecting an impact on an impeller wheel (7) of an aircraft engine, characterised in that it comprises:acquisition means (13) for acquiring a revolutions per minute of said engine and a series of deflection signals representative of the deflections on the blades of said impeller wheel at said revolutions per minute, andcorrelation means (15) for constructing signals for detecting impact on said impeller wheel by correlating each of the deflection signals with a predetermined signature of a shock on a blade at said revolutions per minute.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

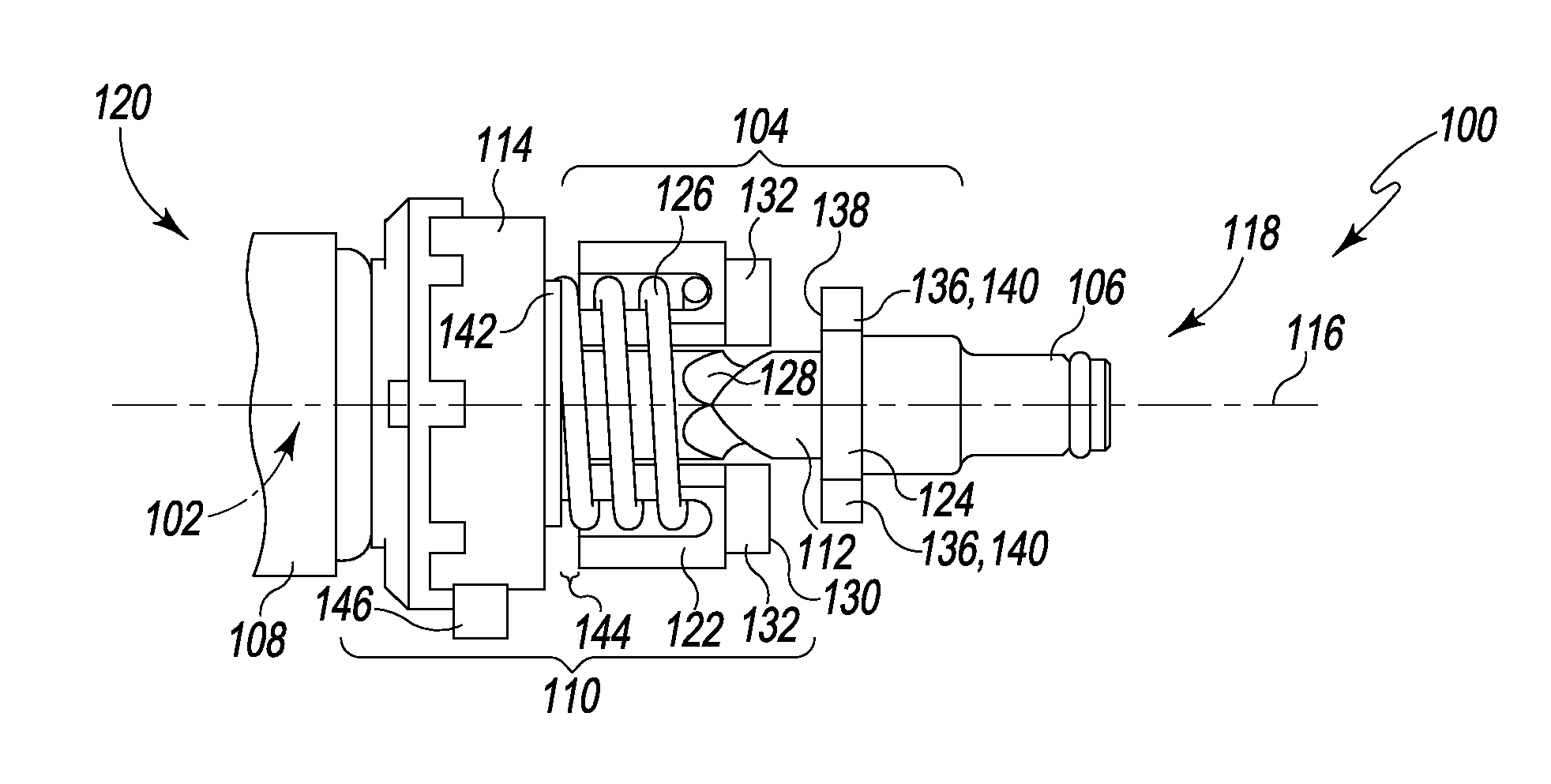

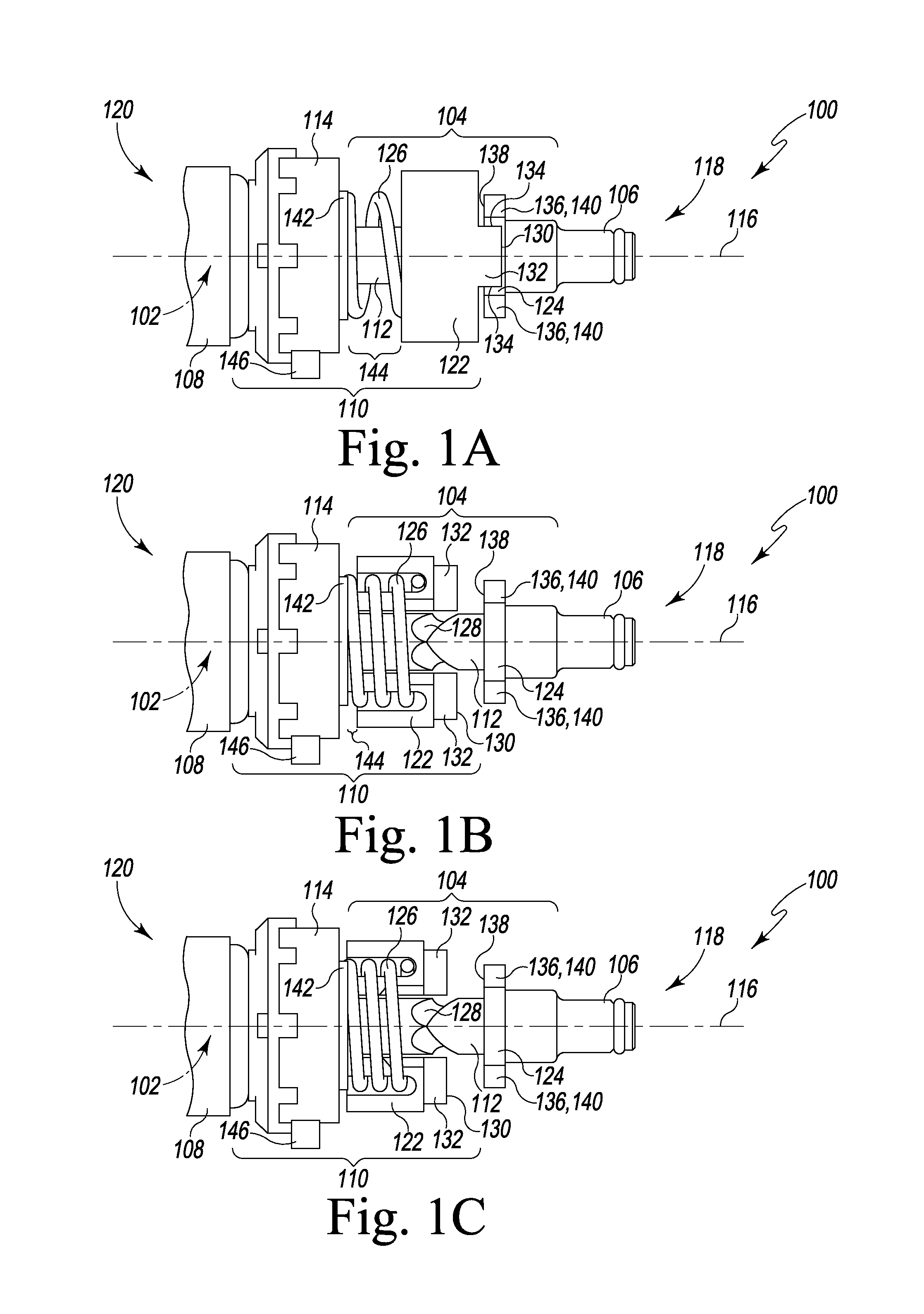

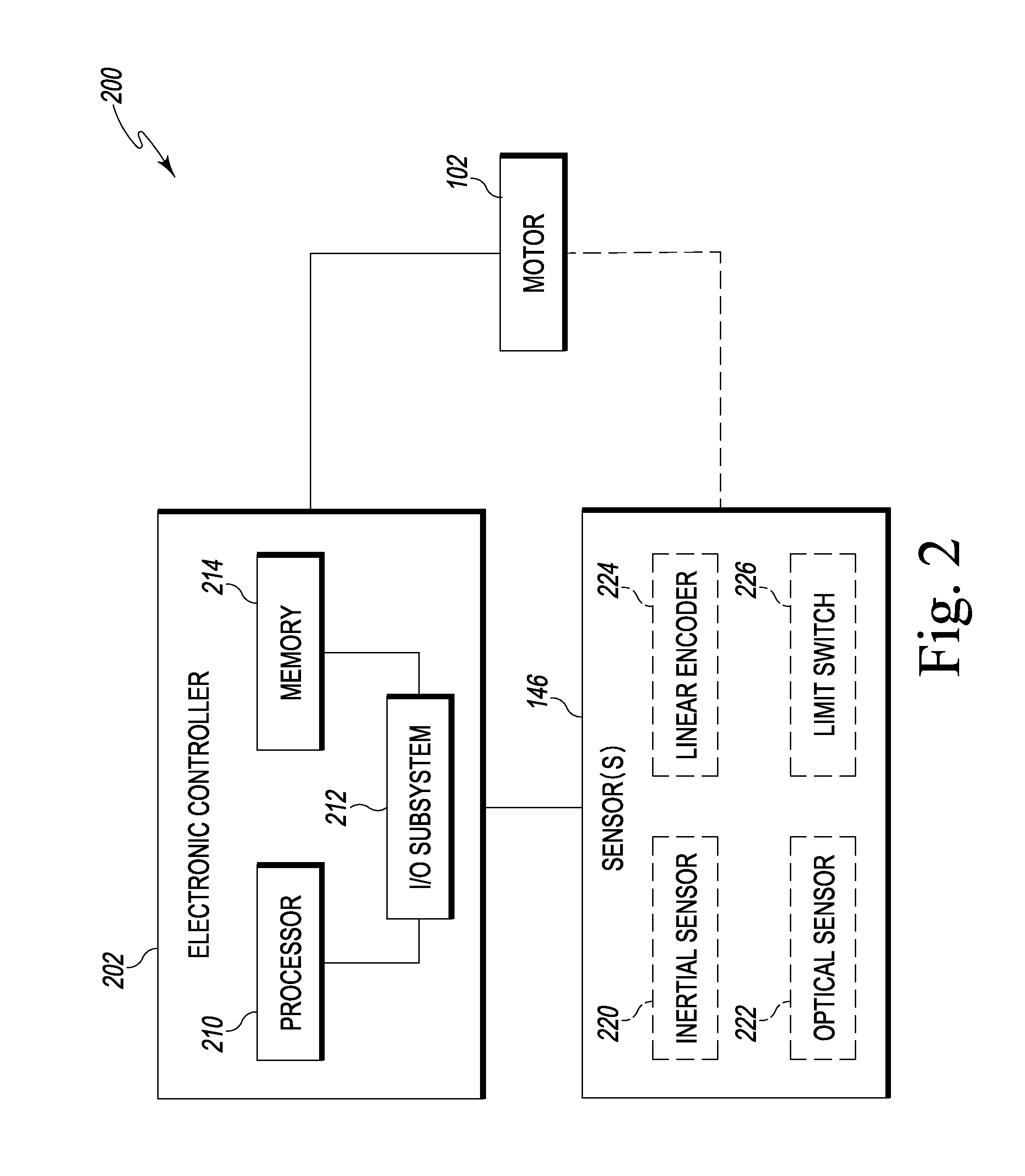

Impact Tools

ActiveUS20150165604A1Reduce speedDerricks/mastsPortable percussive toolsElectronic controllerRotation velocity

In at least one illustrative embodiment, an impact tool may comprise an impact mechanism including a hammer and an anvil. The hammer may be configured to rotate about an axis and to translate along the axis to impact the anvil to cause rotation of the anvil about the axis. The impact tool may further comprise a motor, a drive train, an inertial sensor, and an electronic controller. The drive train may be configured to transfer rotation from the motor to the hammer of the impact mechanism. The inertial sensor may be configured to sense an acceleration of the drive train along the axis. Further, the electronic controller may be operably coupled to the motor and to the inertial sensor and configured to decrease a rotational speed of the motor in response to determining that the acceleration of the drive train has exceeded a threshold acceleration.

Owner:INGERSOLL RAND IND U S INC

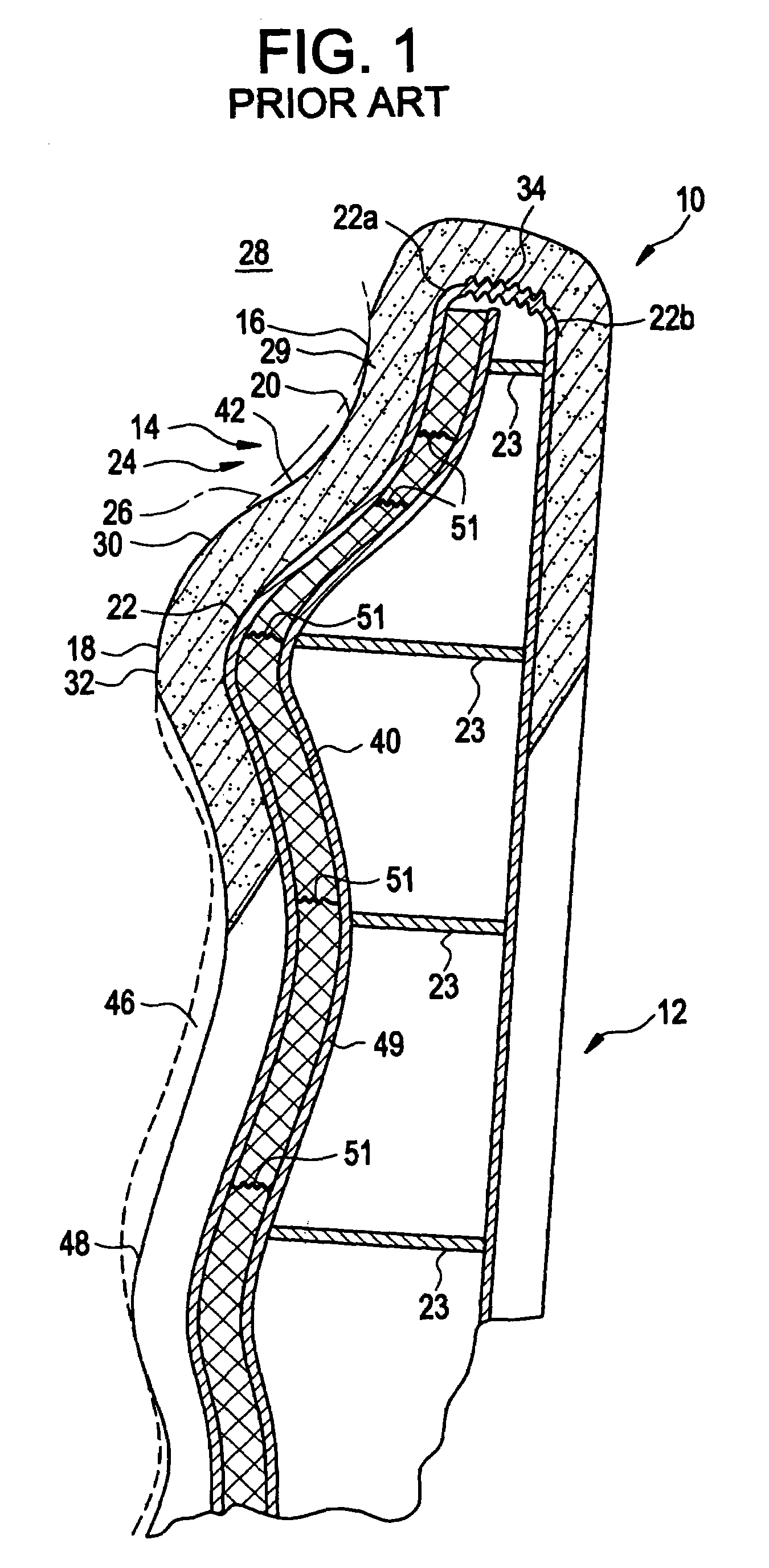

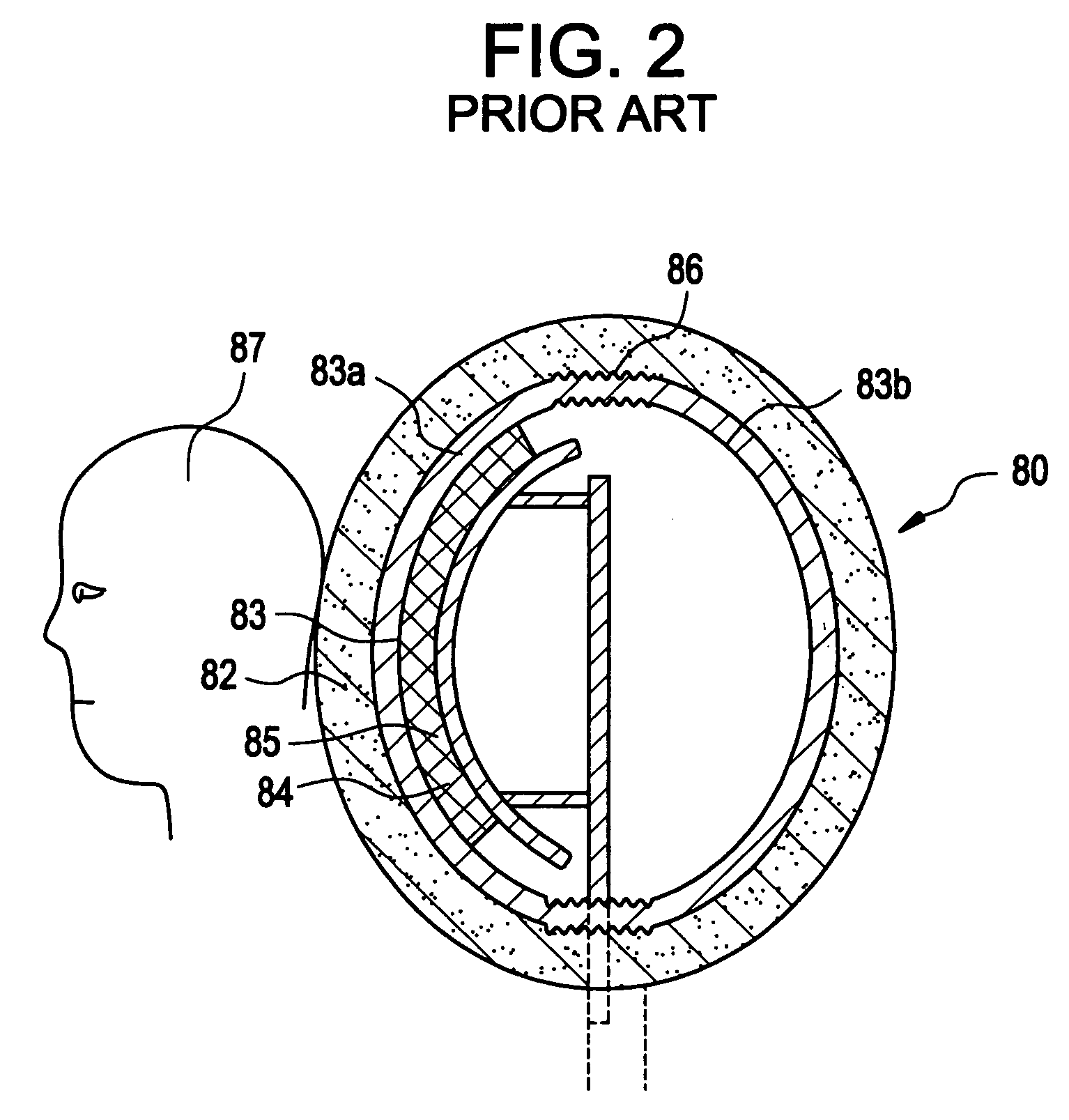

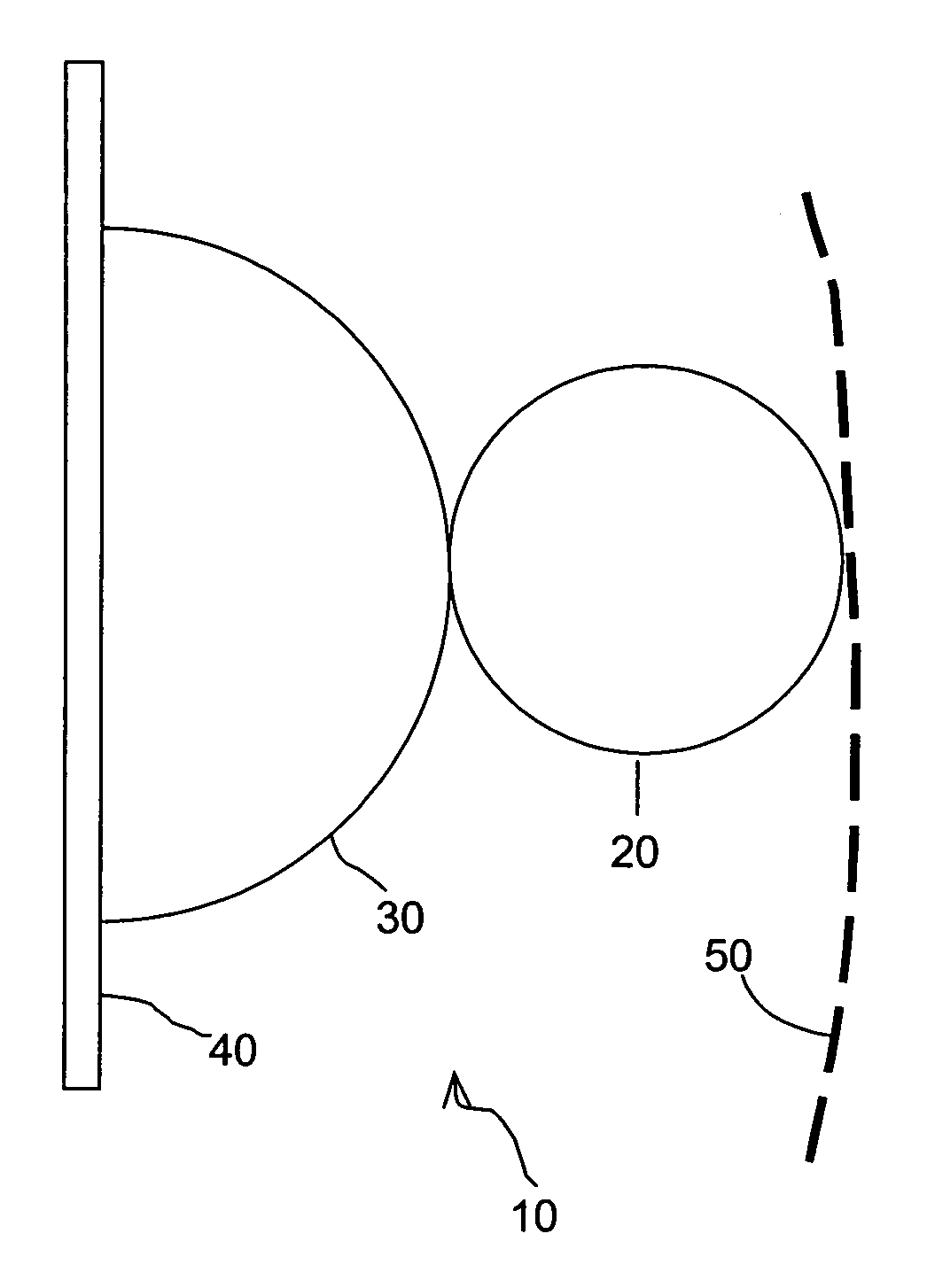

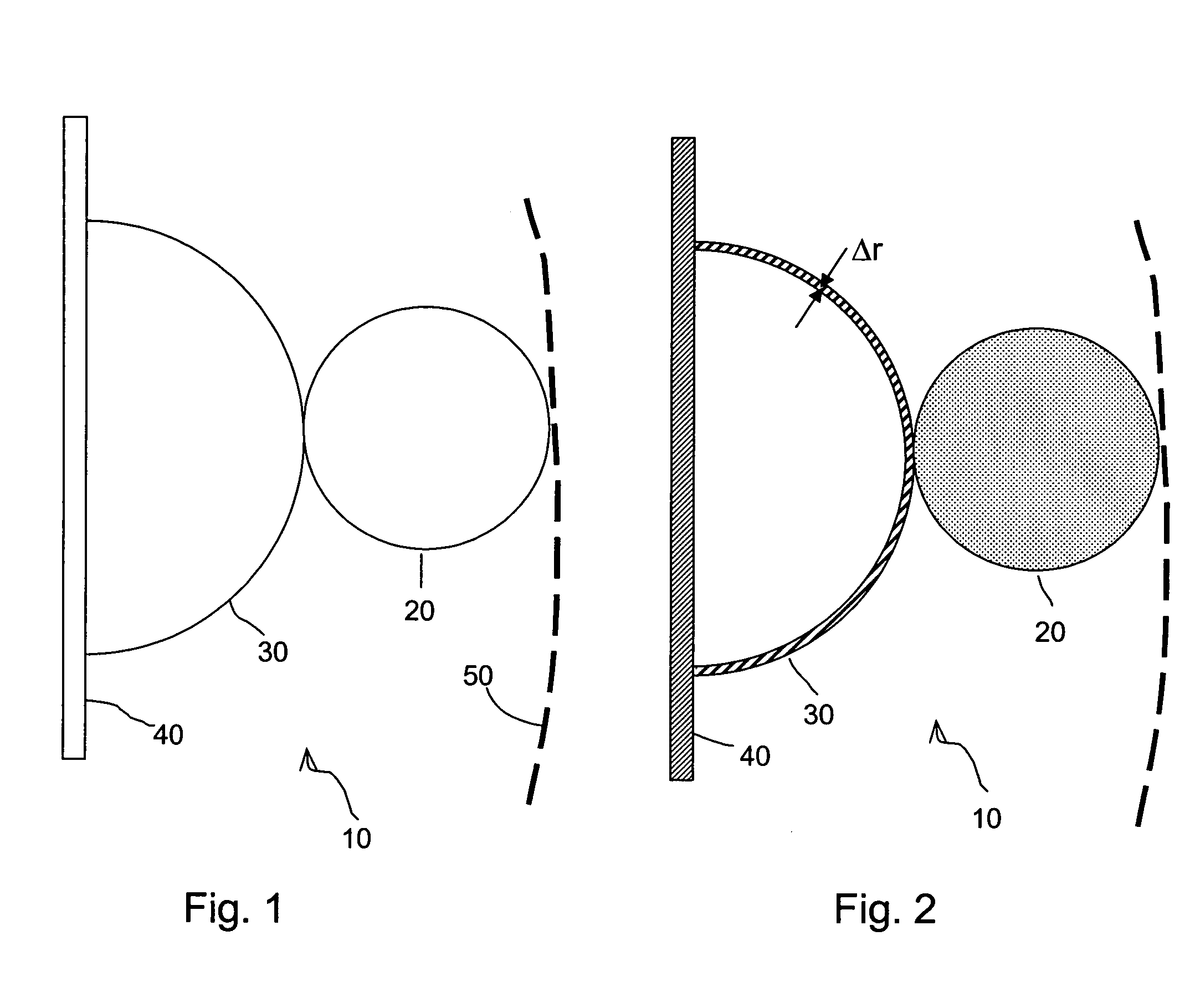

Resilient and deformable member for absorbing kinetic energy

The present invention generally relates to devices and methods for absorbing kinetic energy. In particular, the present device is well suited for use in an automobile door, where it can be positioned for the purpose of absorbing the energy of a side-impact collision. In one embodiment, the device includes a first mass, a shell, and a plate, with the shell being disposed between the mass and plate. Both the first mass and shell are preferably constructed from deformable materials, allowing them to absorb energy during an impact. By absorbing the energy through deformation, the present device reduces the amount of energy that is transmitted through the door and thus reduces the amount of energy that may be transmitted to the occupants of the vehicle.

Owner:PEDRO FROMMER M D P A

Impact mechanism

An impact mechanism comprises a drive motor engaging member and a tool bit retaining member rotatably inter-connected therewith. The tool bit retaining member has a main body portion, an anvil portion securely attached thereto for co-rotation therewith, and a tool bit retaining portion securely attached thereto for co-rotation with the main body portion. A hammer member is mounted on the drive engaging member for movement between an anvil contact position wherein force is transmitted from the hammer member to the anvil portion, and a release position whereat the hammer member is temporarily removed from the anvil portion. A spring biases the hammer member to the anvil contact position. In use, the hammer member to move from its anvil contact position towards its release position, wherein the hammer member is propelled by the spring and the rotation of the drive engaging member to impact on the anvil portion.

Owner:GRAND

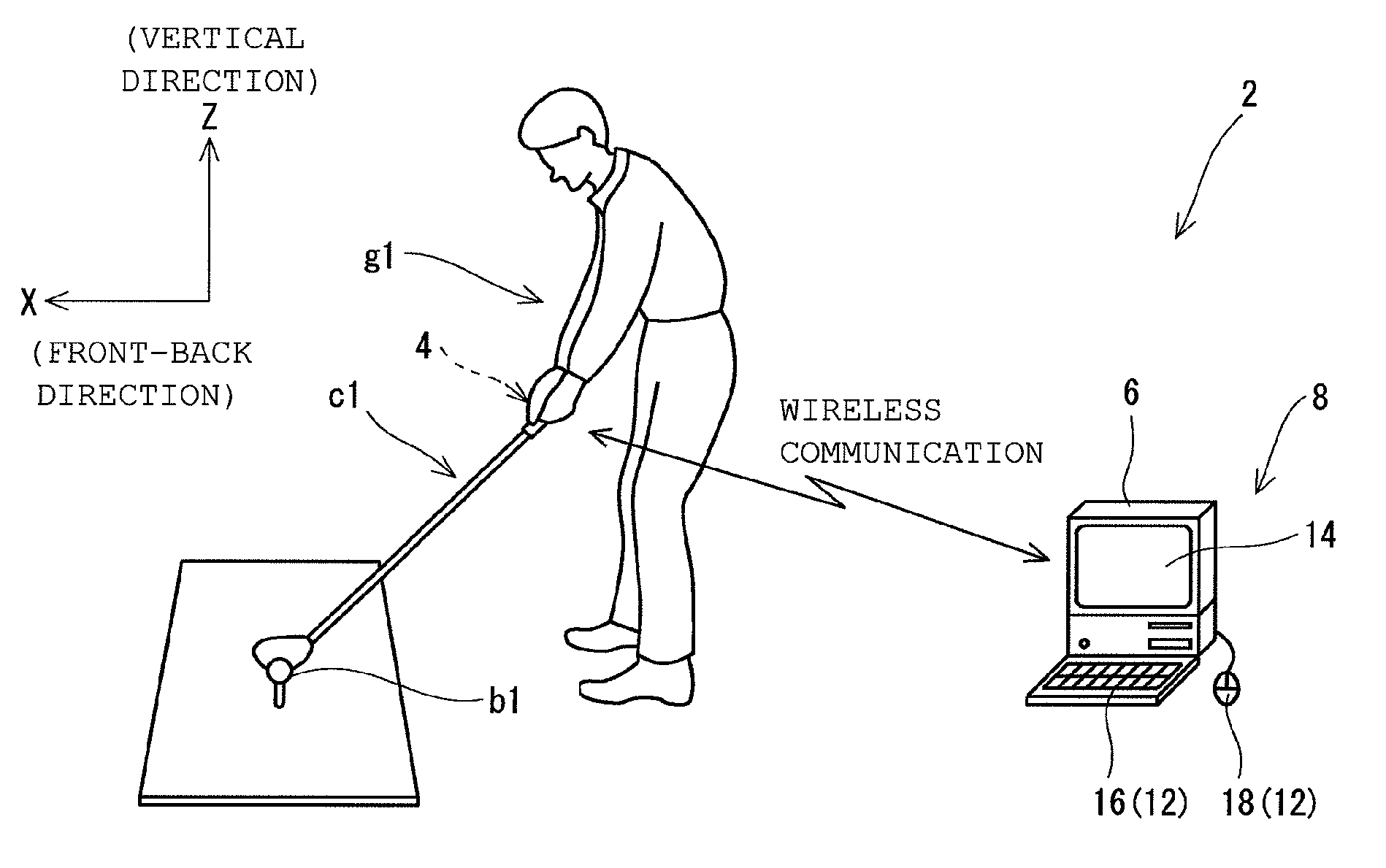

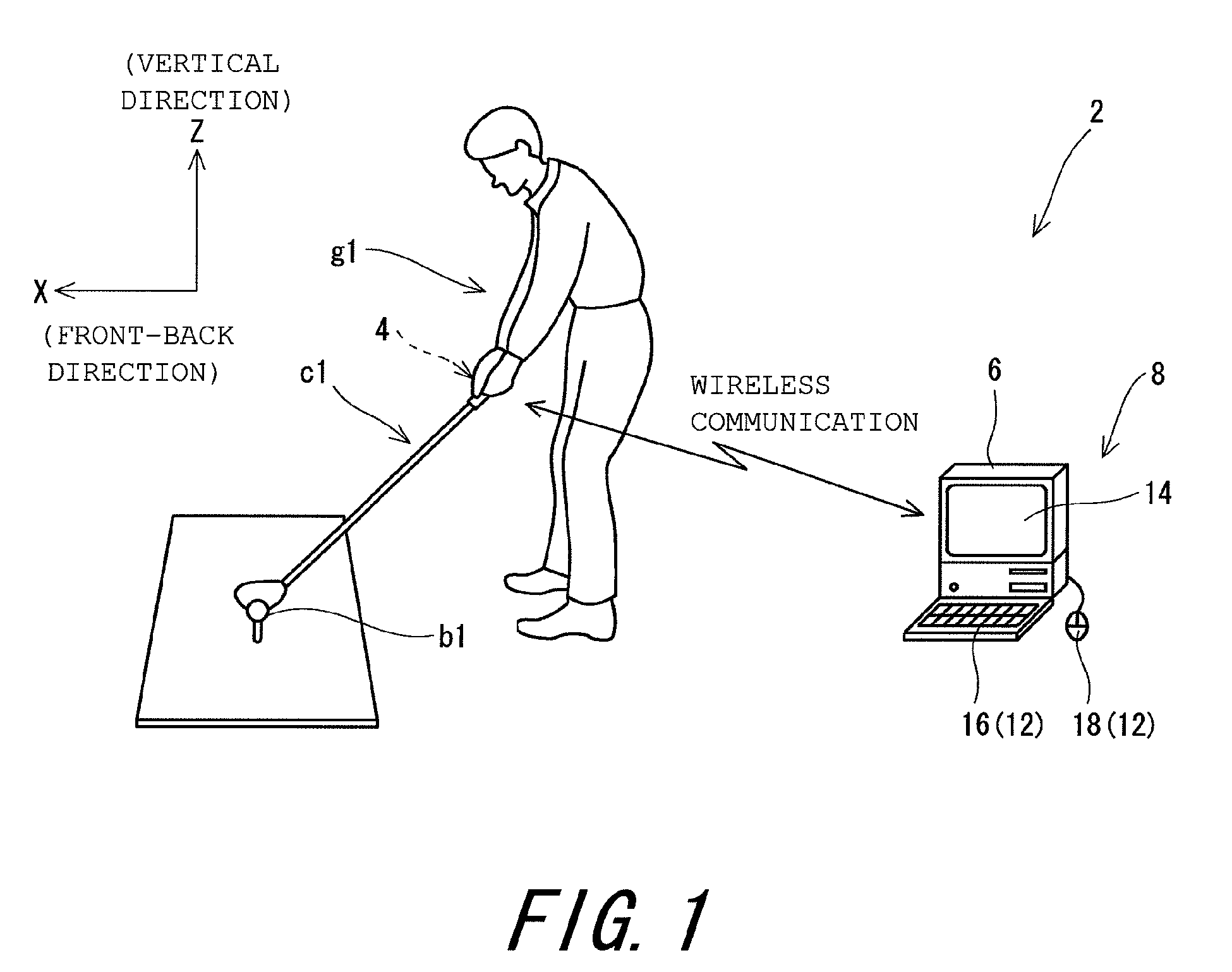

Swing analysis method

ActiveUS8657707B2Simple equipmentInput/output for user-computer interactionGymnastic exercisingAngular velocityGolf Ball

An analysis method includes the steps of: measuring a swing of a golf club to which a sensor capable of measuring accelerations in directions of three axes and angular velocities or angles about the three axes is attached; obtaining an index for classifying the swing based on a measuring result of the sensor; and classifying the swing based on the index. The index includes the item (a) or (b): (a) a grip angular velocity at least at one time during a downswing; and (b) a grip velocity at least at one time during the downswing. Preferably, times of an address, a top, and an impact are determined in the analysis method.

Owner:SUMITOMO RUBBER IND LTD

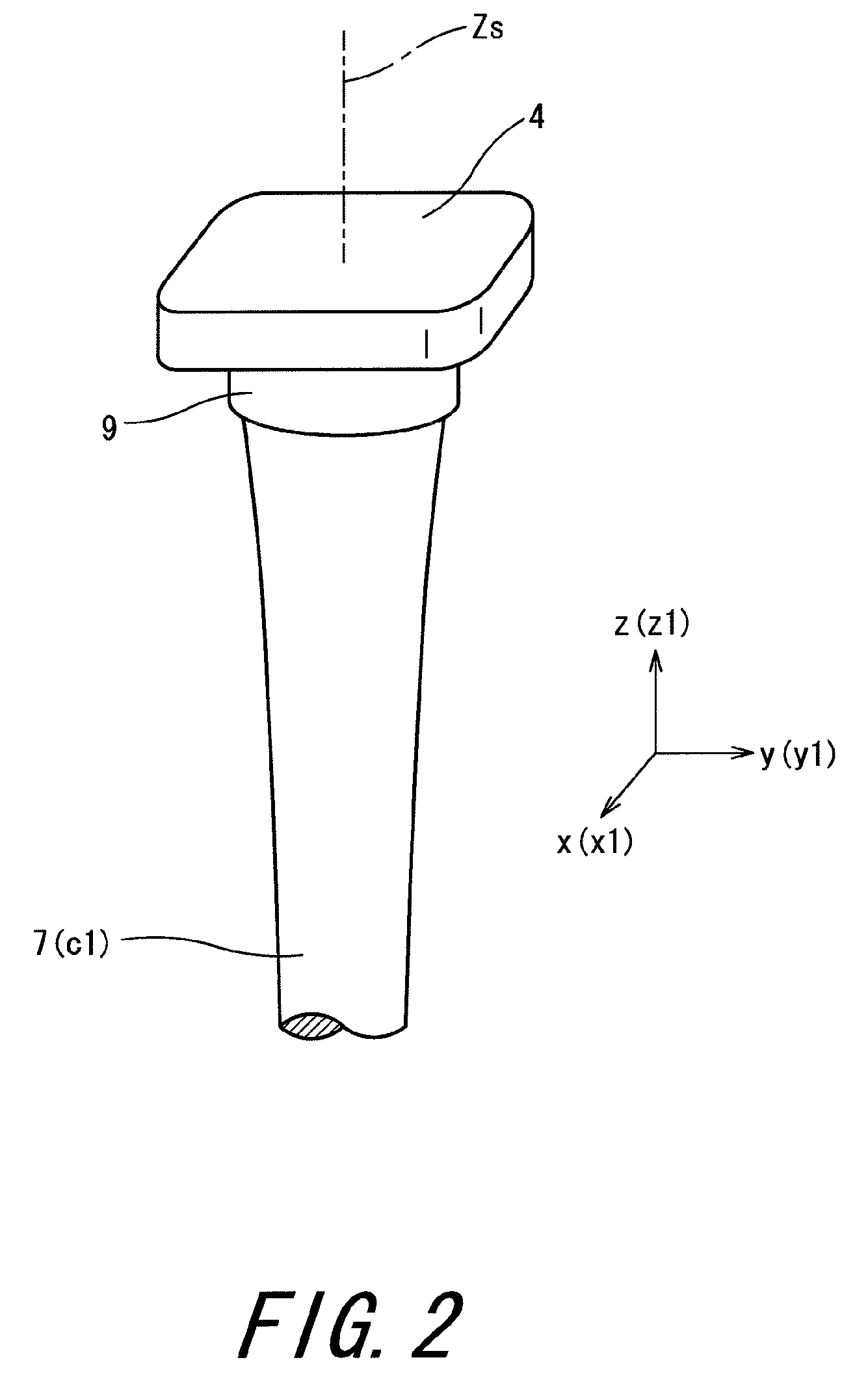

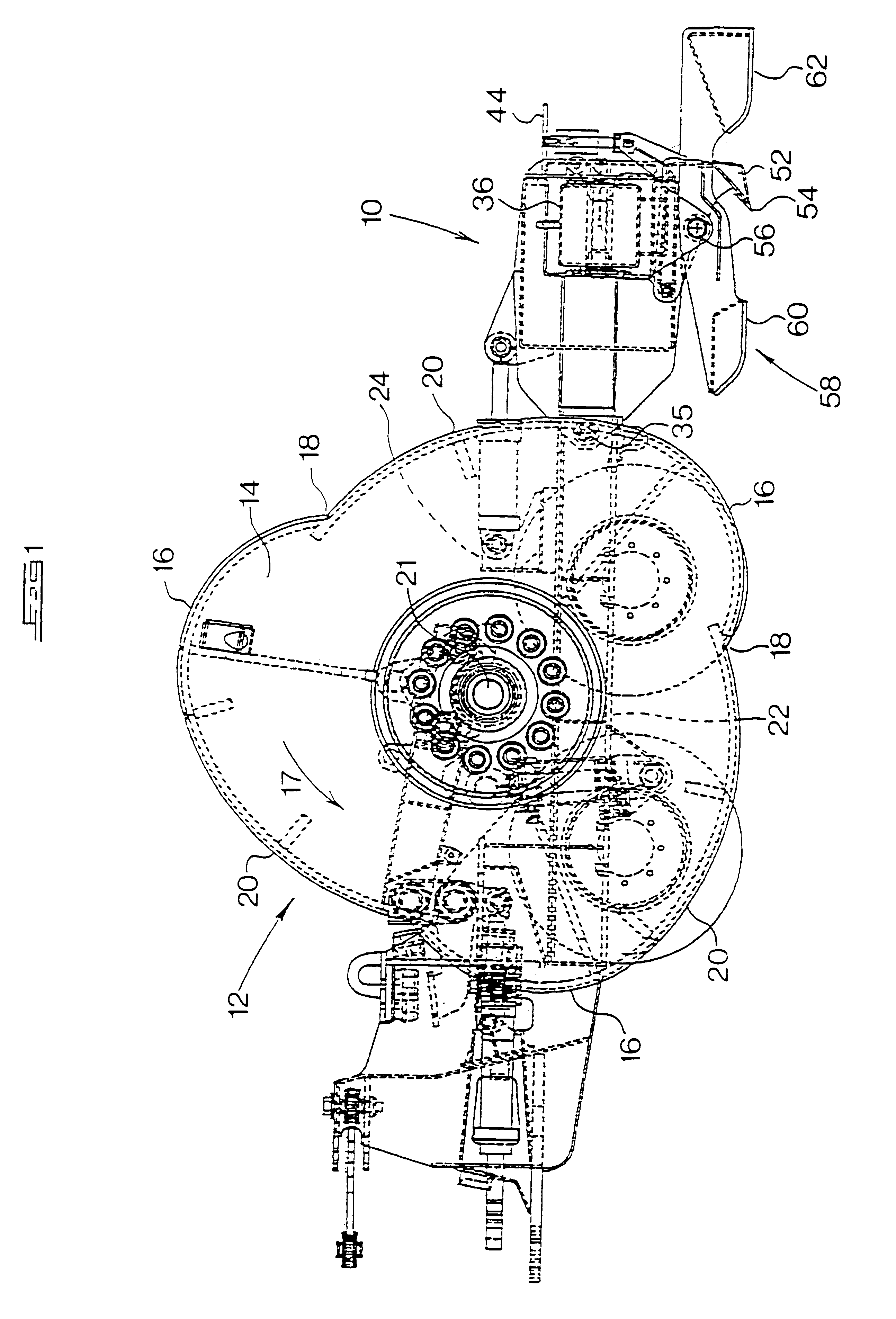

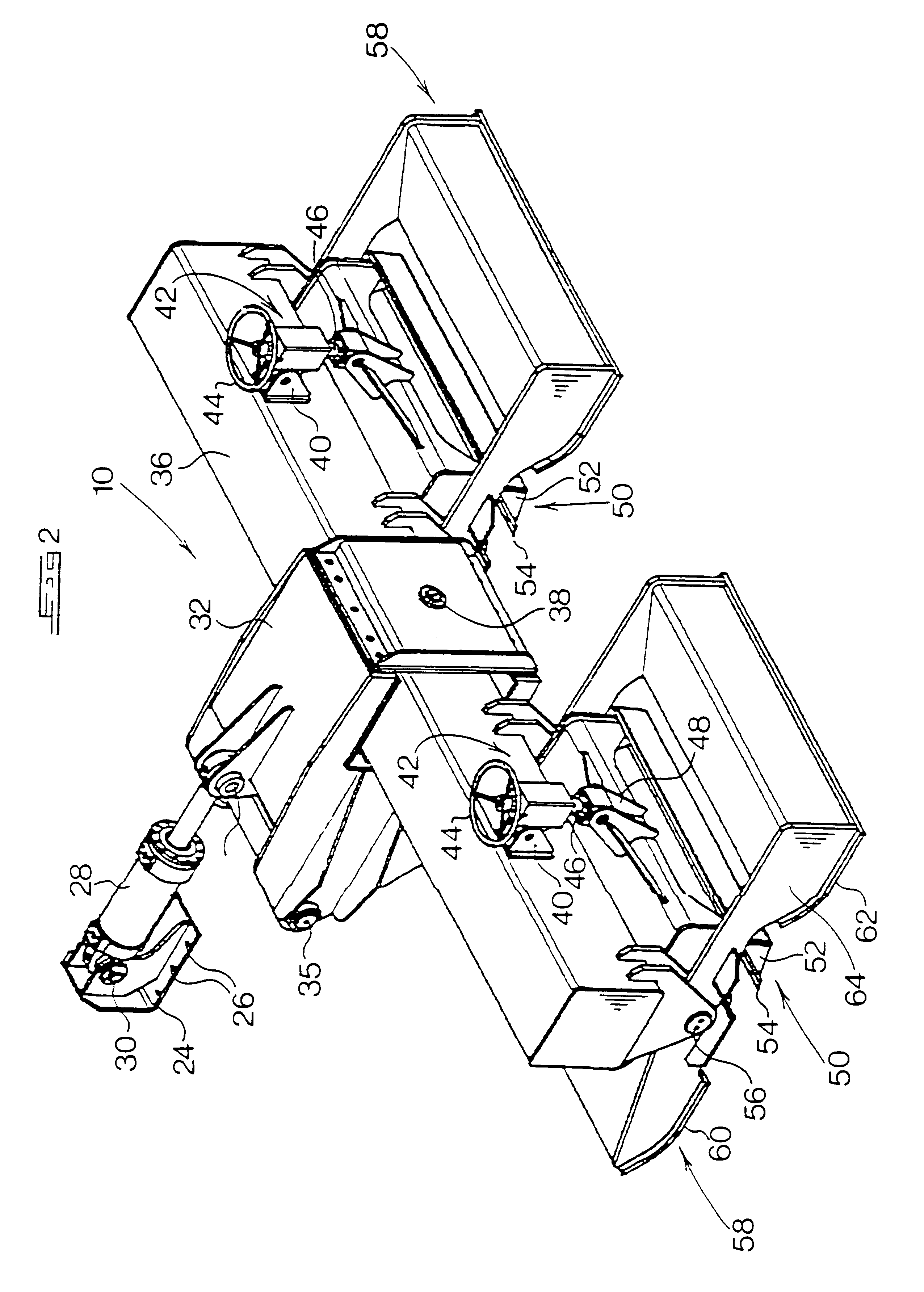

Soil levelling device

The invention concerns a levelling device (10) for an impact roller of the type having at least one out-of-round compactor mass which, when caused to traverse a soil surface, applies periodic compacting blows to that surface. The levelling device of the invention is coupled to the impact roller so as to trail behind the impact roller. It includes a support frame (36) and, for each compactor mass of the impact roller, a ground-engaging levelling blade (52) fast with the support frame. The levelling blade is arranged to cut soil which has been traversed by the compactor mass and thereby to perform a soil levelling action. A ground-engaging shoe (58), one for each levelling blade, is connected to the support frame for pivotal movement about an axis transverse to the direction of movement of the impact roller The shoe serves to control the depth of cut achieved by the levelling blade.

Owner:COMPACTION TECH SOIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com