Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1349 results about "Slider crank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

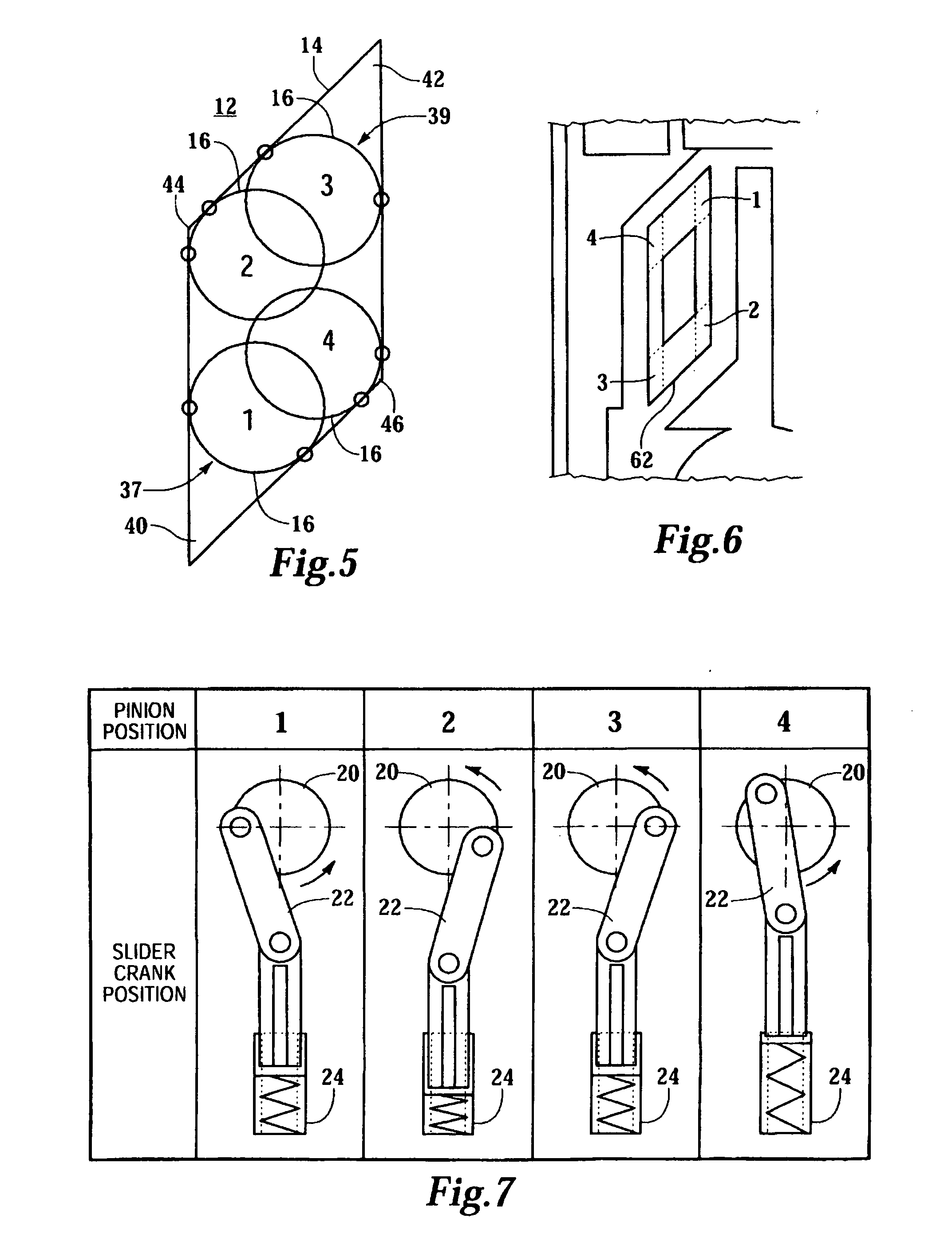

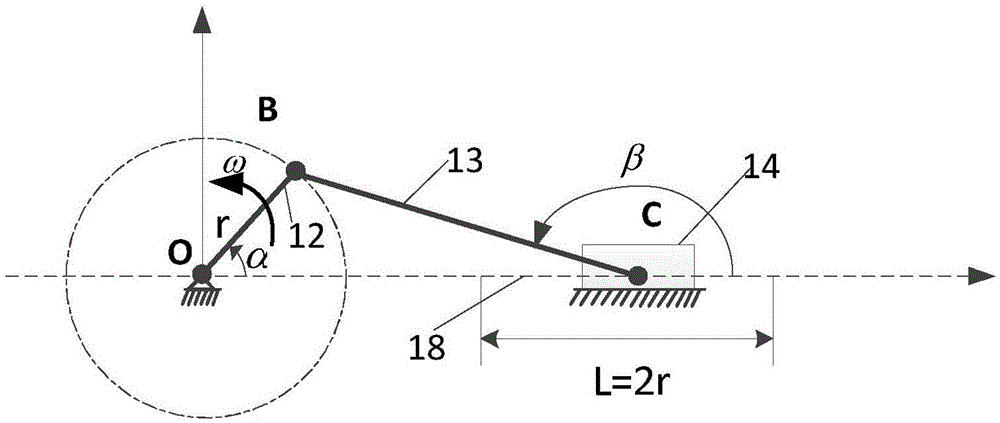

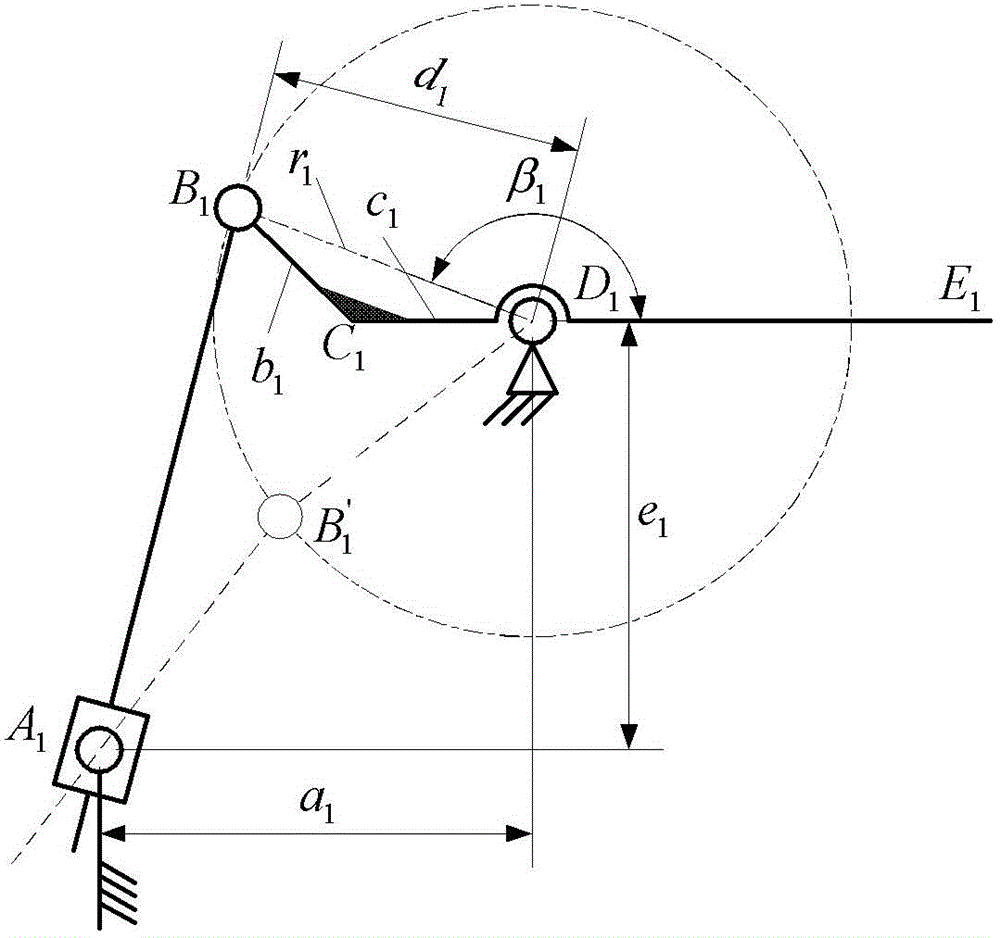

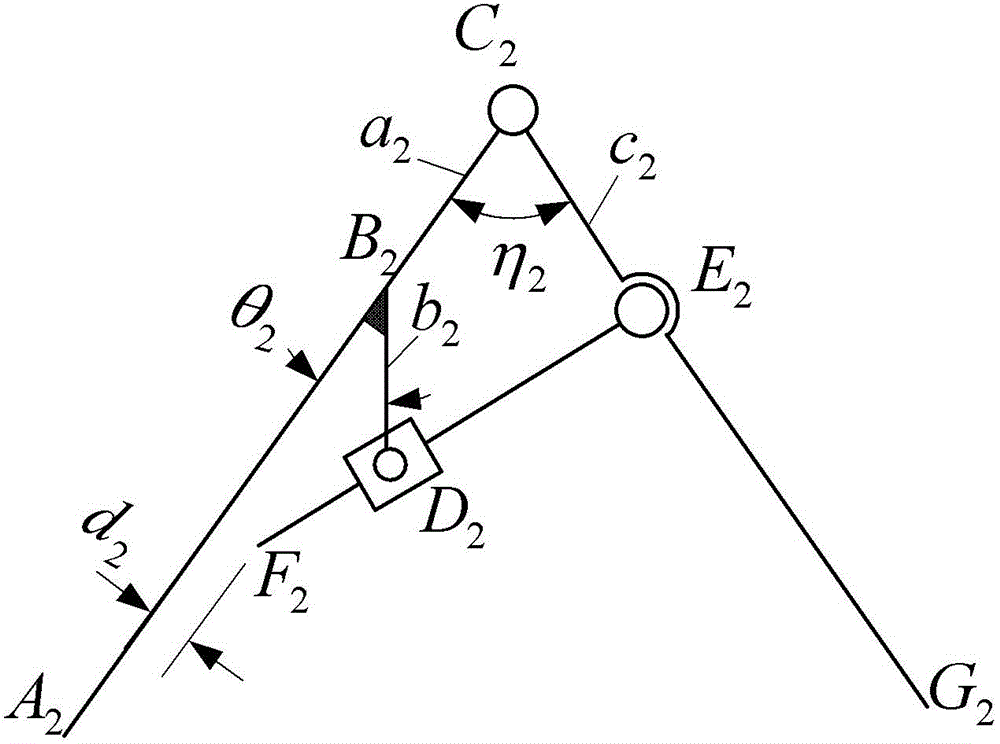

A slider-crank linkage is a four-link mechanism with three revolute joints and one prismatic, or sliding, joint. The rotation of the crank drives the linear movement the slider, or the expansion of gases against a sliding piston in a cylinder can drive the rotation of the crank.

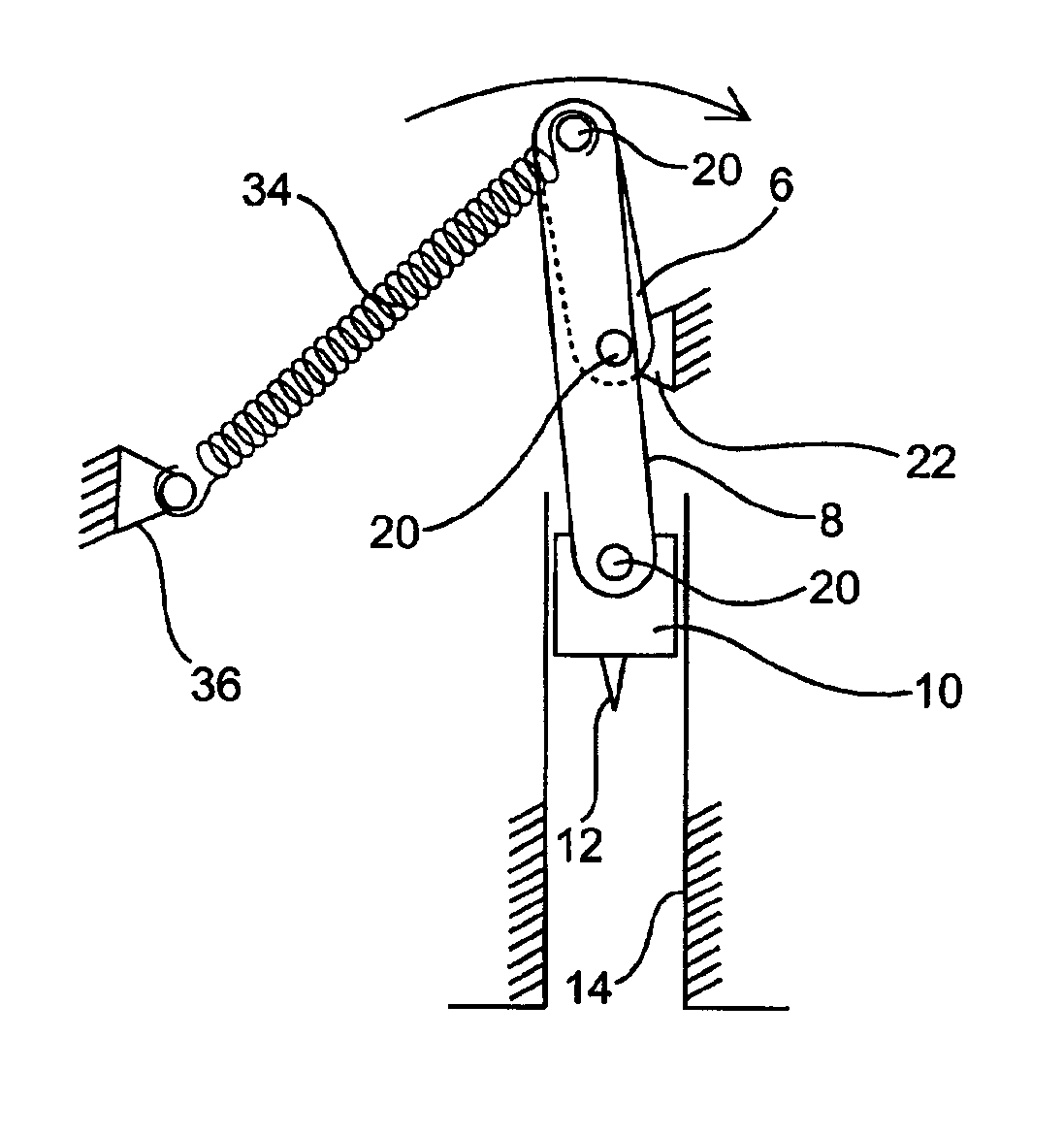

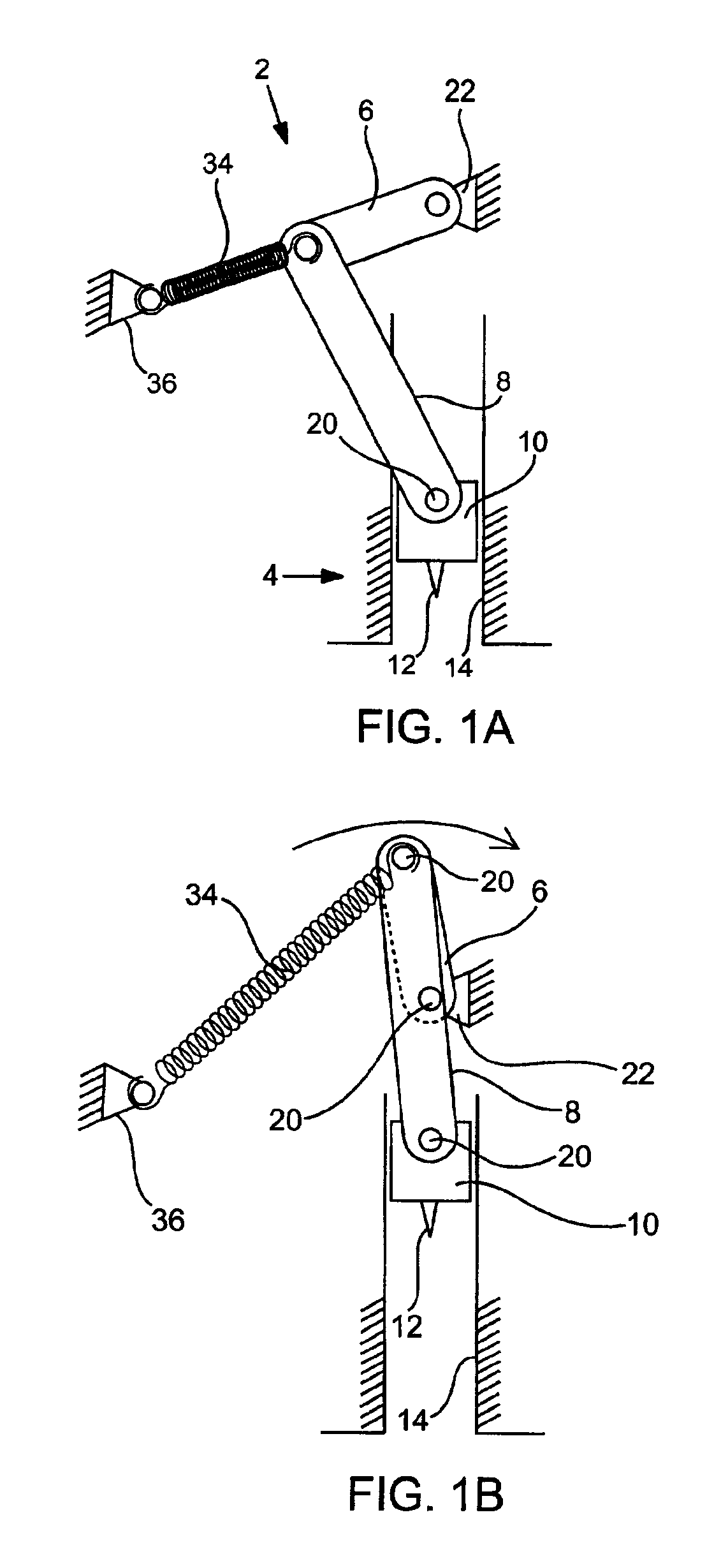

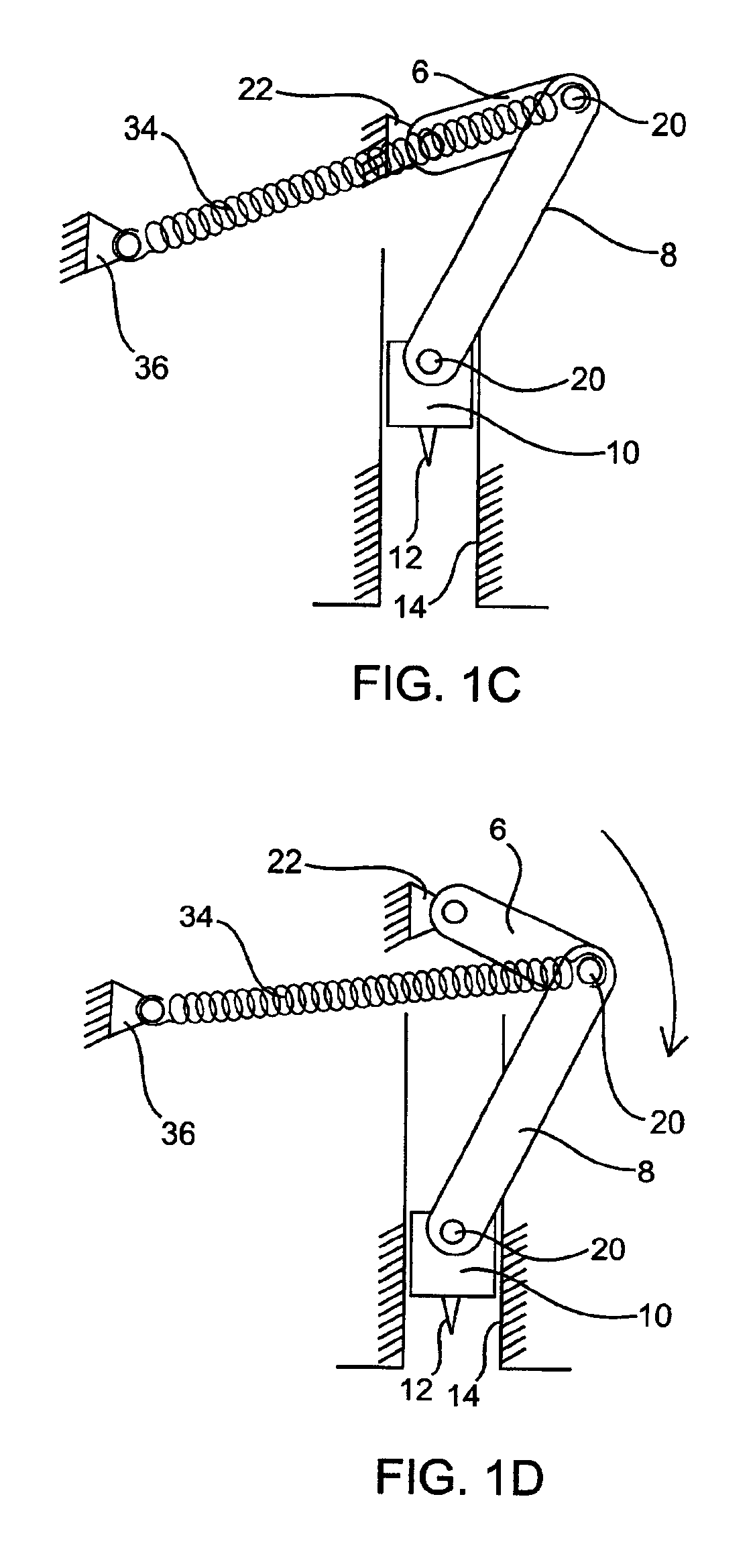

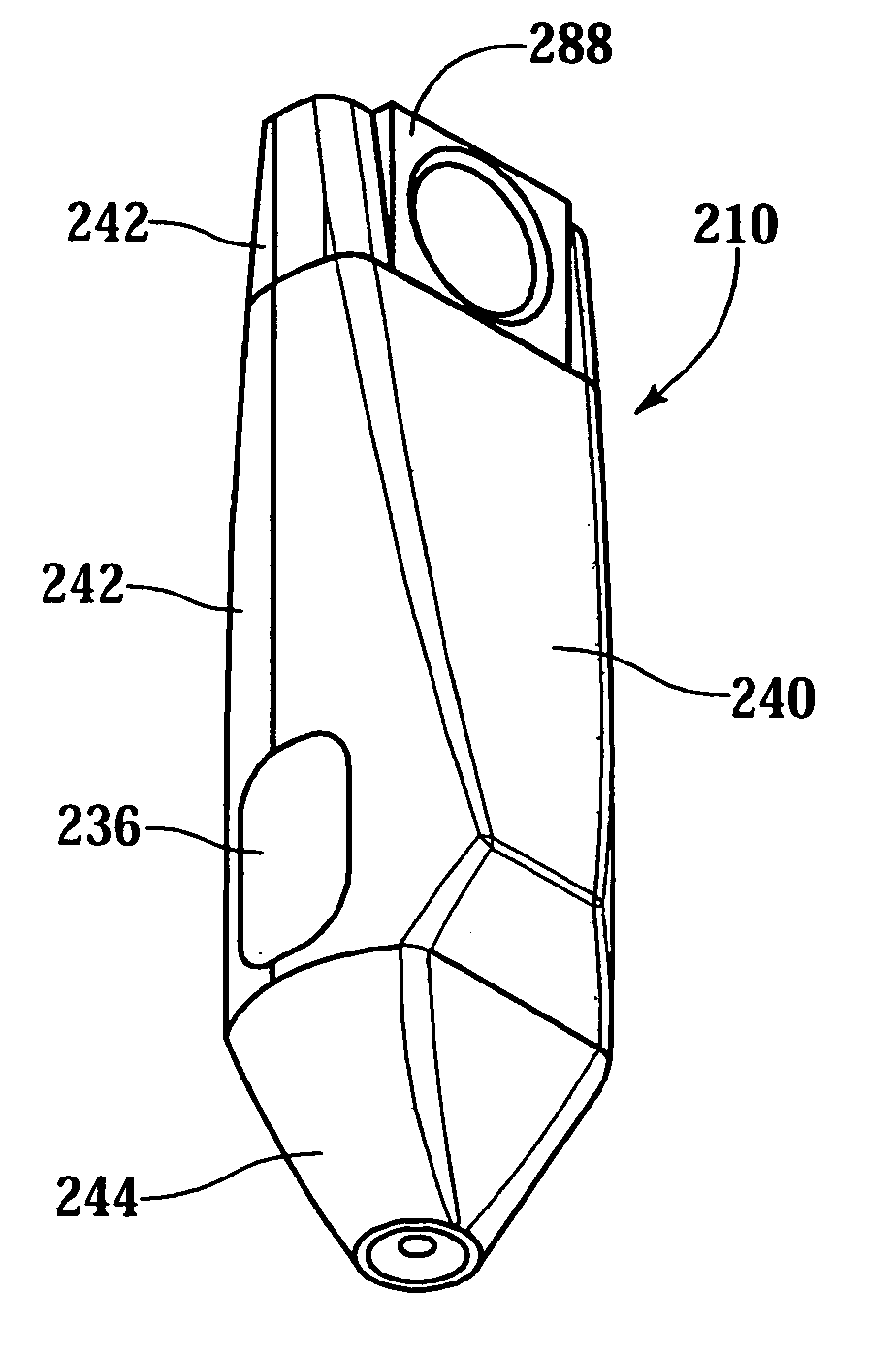

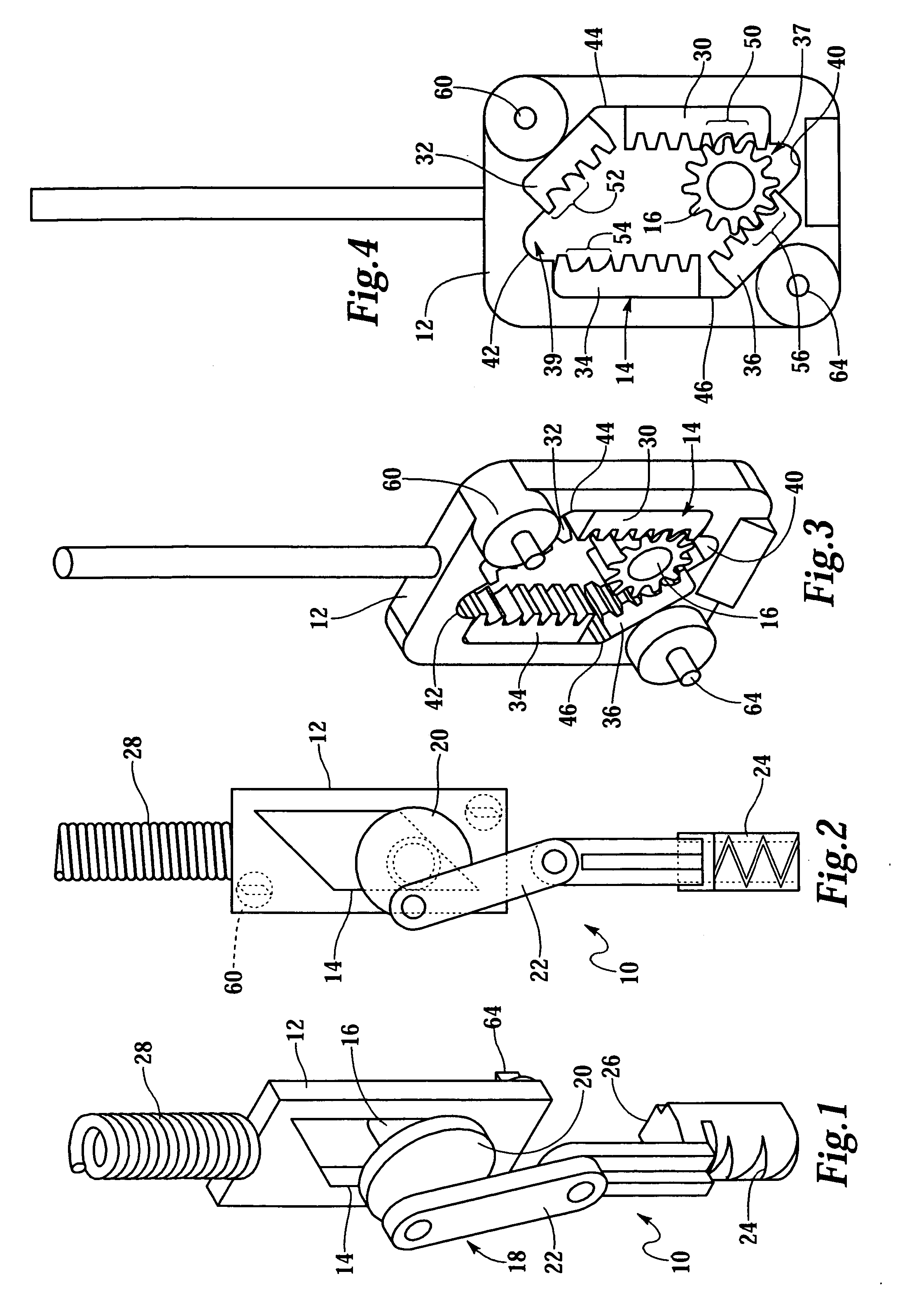

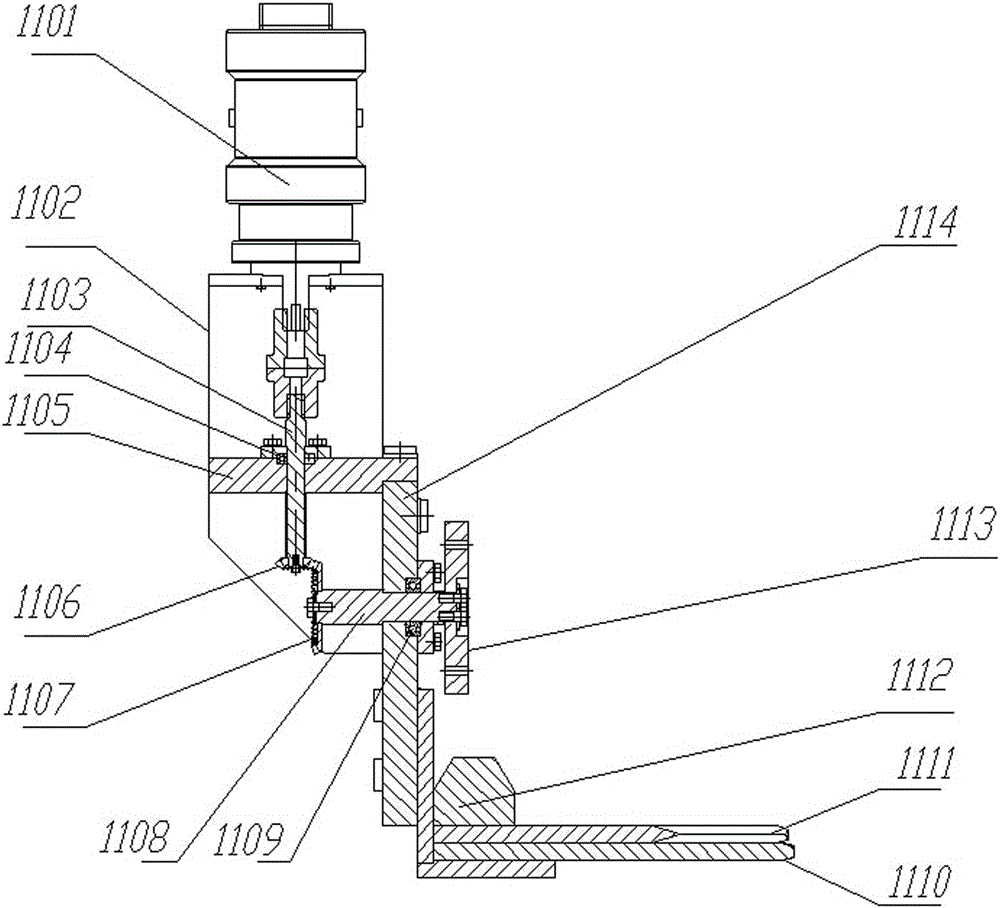

Lancing device with automatic stick and return

A lancing device with automatic stick and lance return features is disclosed. A drive mechanism within the unit comprises a slider-crank linkage combination. It is biased by a spring member to cause automatic firing once a crank member advanced by a user causes movement of an internal linkage member beyond its fully-cocked position. After firing, the lance is withdrawn so as not to pose a threat of secondary injury to the user. In use, the device is substantially silent though its course of operation. Yet, its configuration lends itself to producing a very quick, virtually painless stick with minimal recoil or shock to the device.

Owner:LIFESCAN IP HLDG LLC

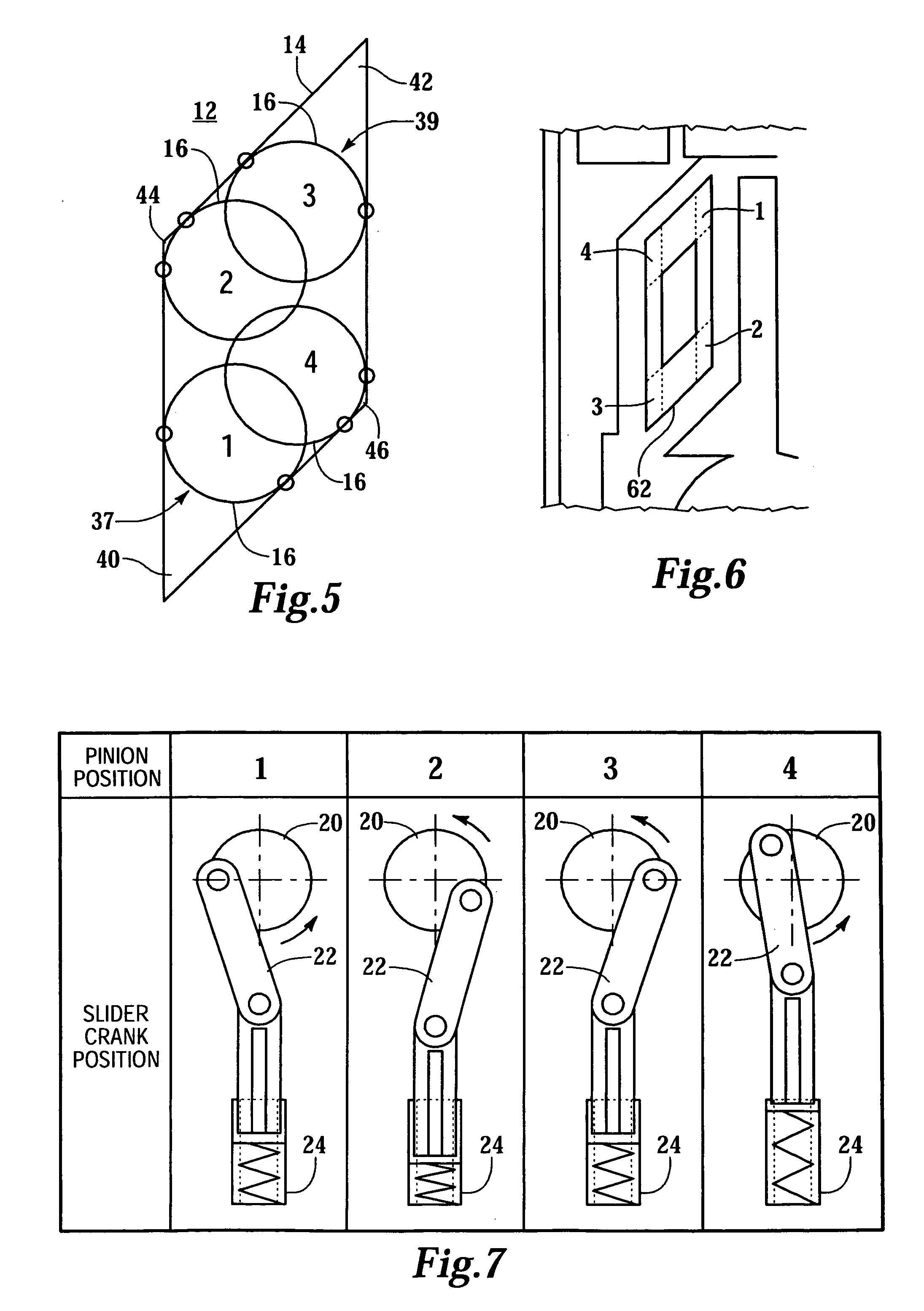

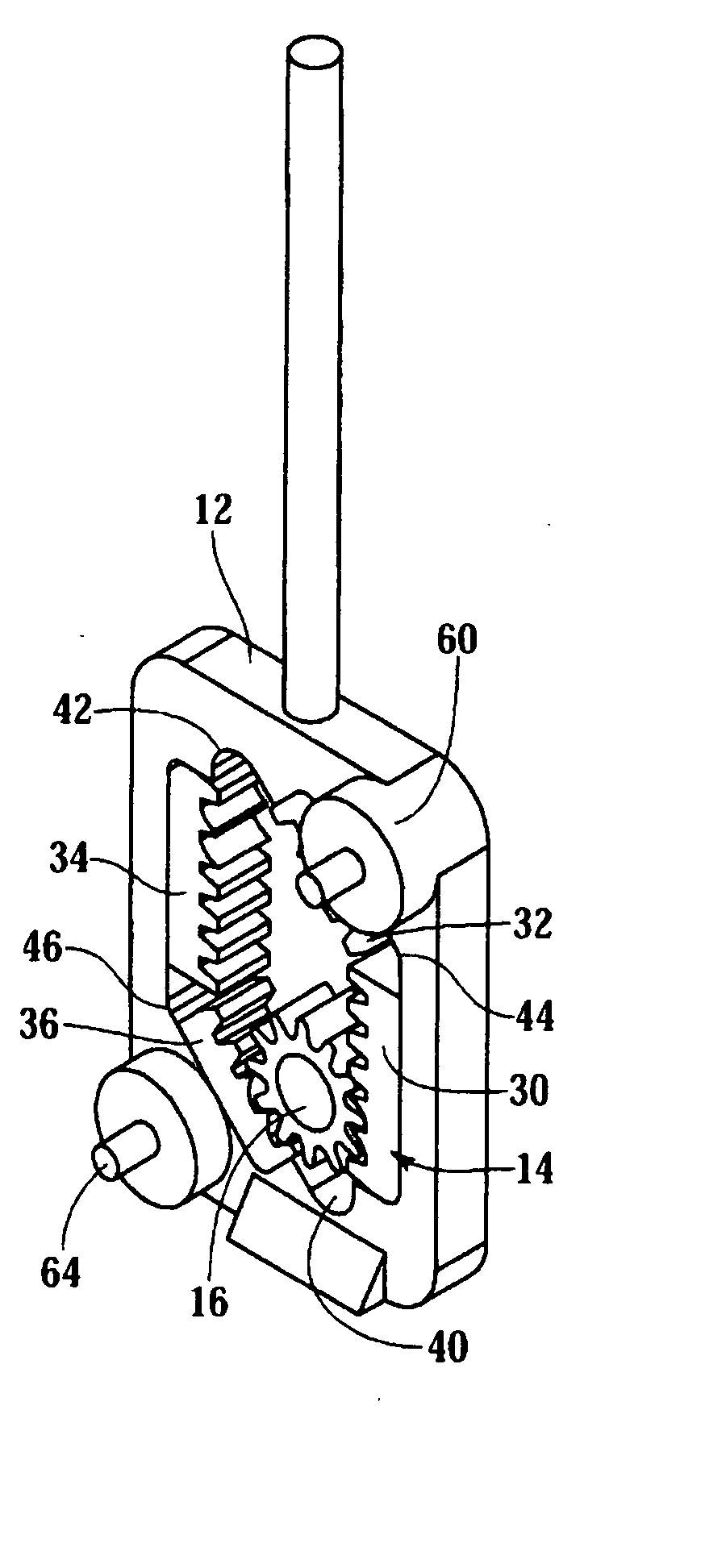

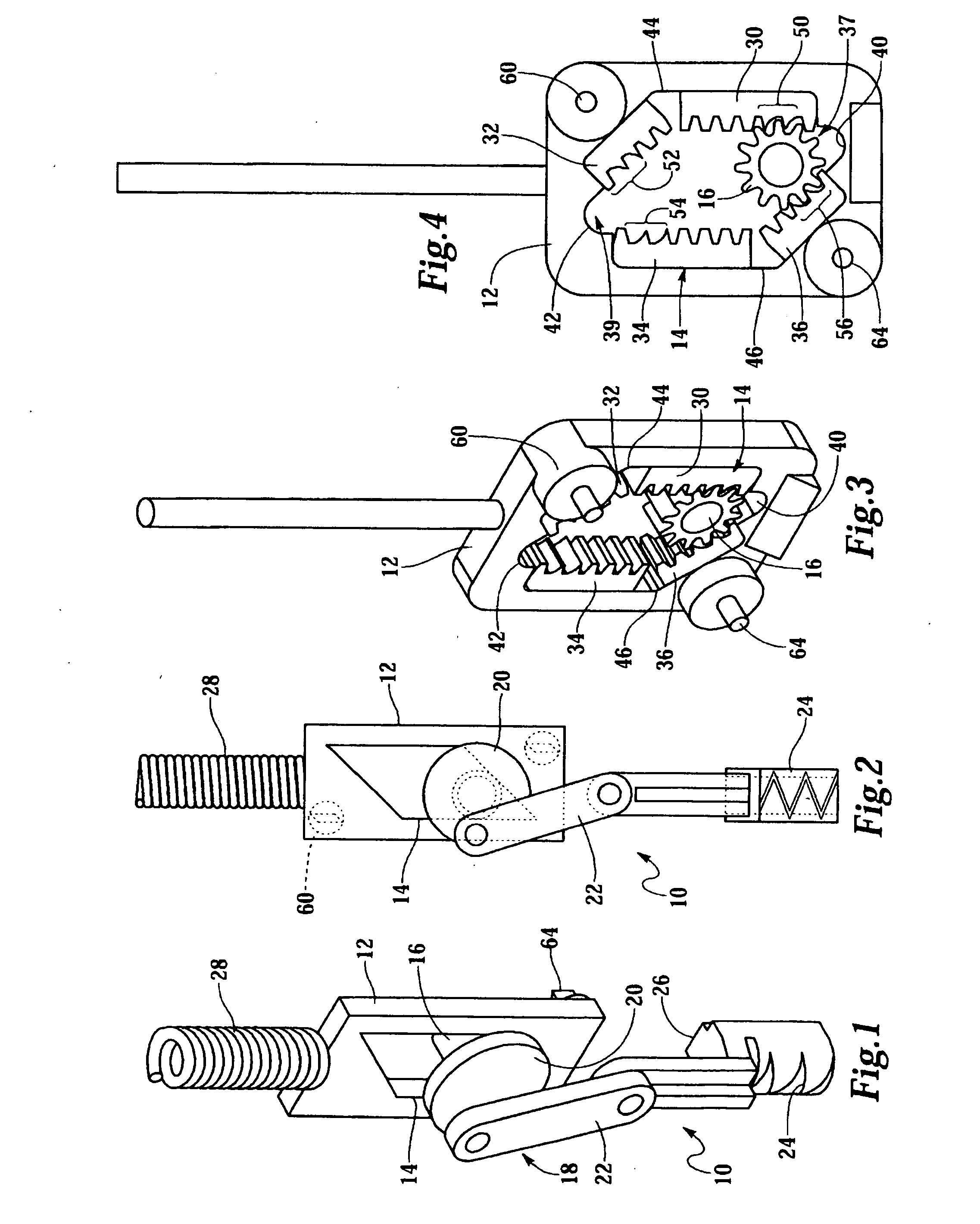

Lancing device

InactiveUS20040127928A1Reduce vibrationEasy to operateSensorsBlood sampling devicesGear wheelEngineering

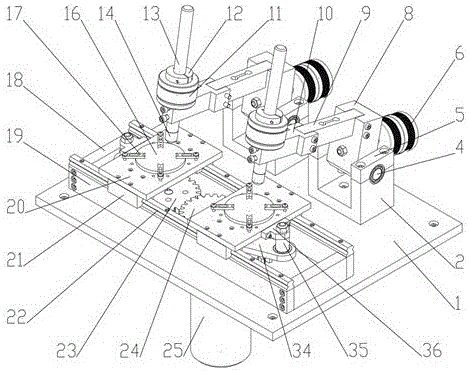

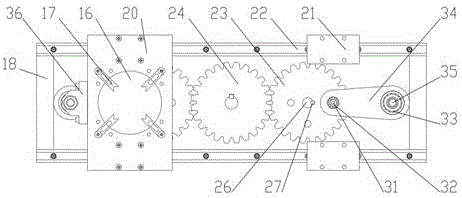

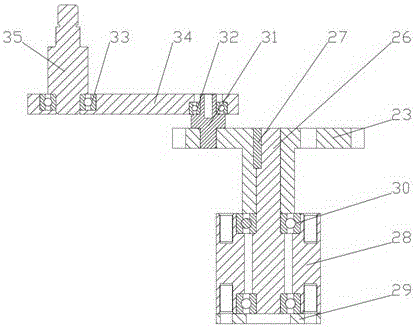

A lancing device comprising a movable parallelogram-shaped rack. The rack rotates a linearly fixed pinion which drives a slider-crank system. The slider-crank system in turn drives a lance holder. The parallelogram-shaped rack defines one or more predetermined paths along which the pinion moves. The lance holder is prevented from being extended beyond a predetermined depth when the pinion reaches a predetermined position along the one or more predetermined paths. The pinion is mechanically stopped from further progress by intersecting two legs of the parallelogram-shaped rack. Teeth of the rack may be modified to reduce the chance the pinion may jam in the rack.

Owner:ASCENSIA DIABETES CARE HLDG AG

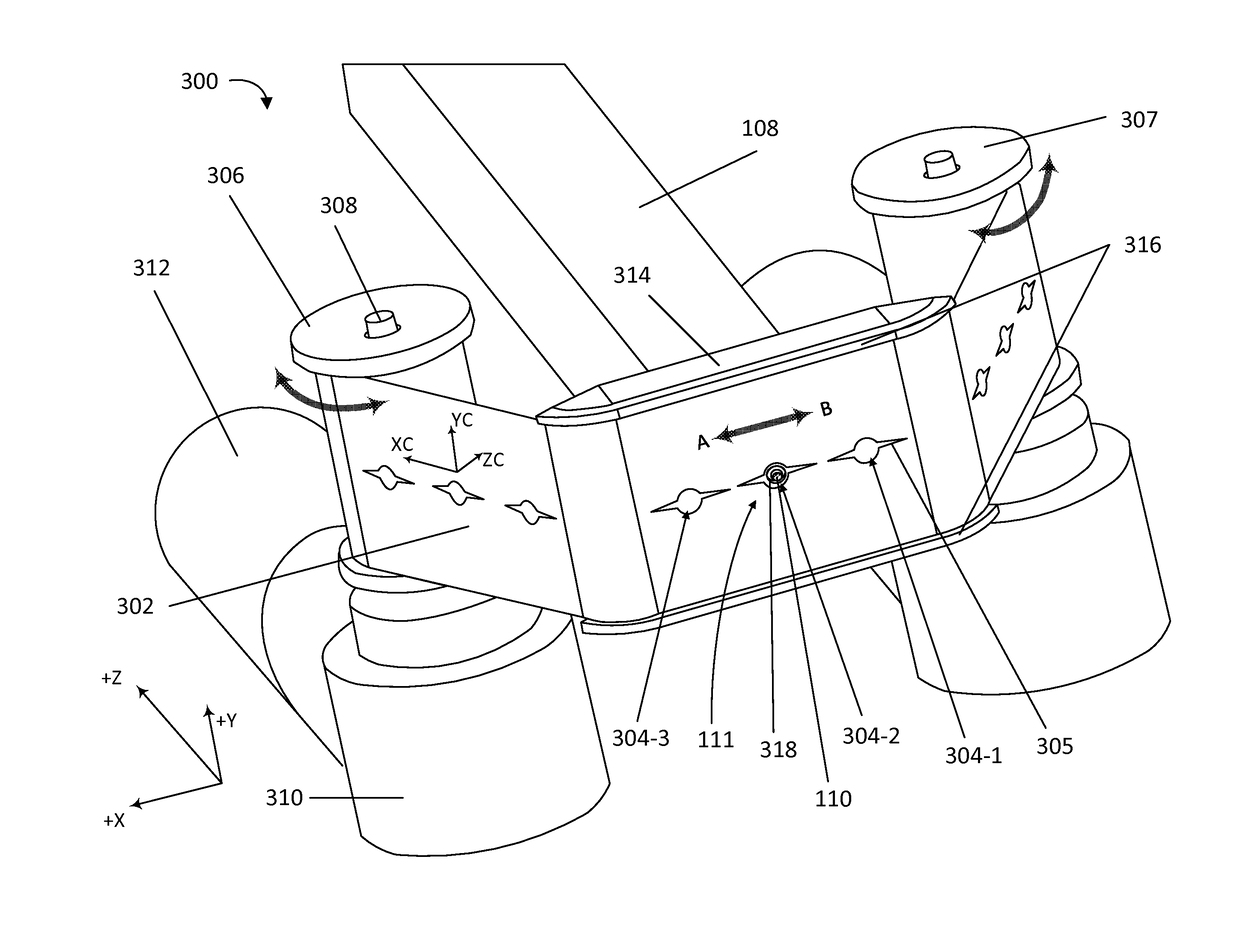

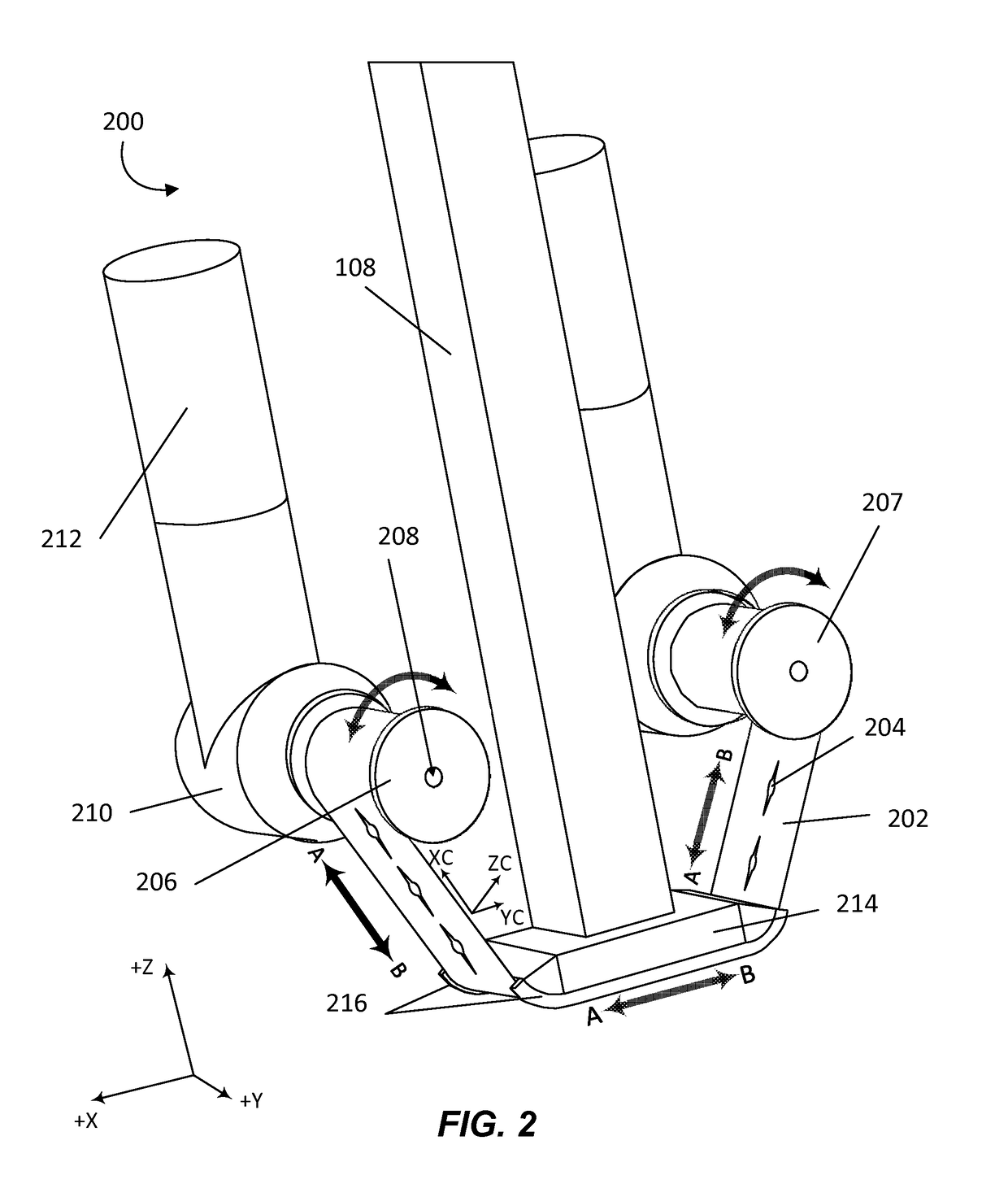

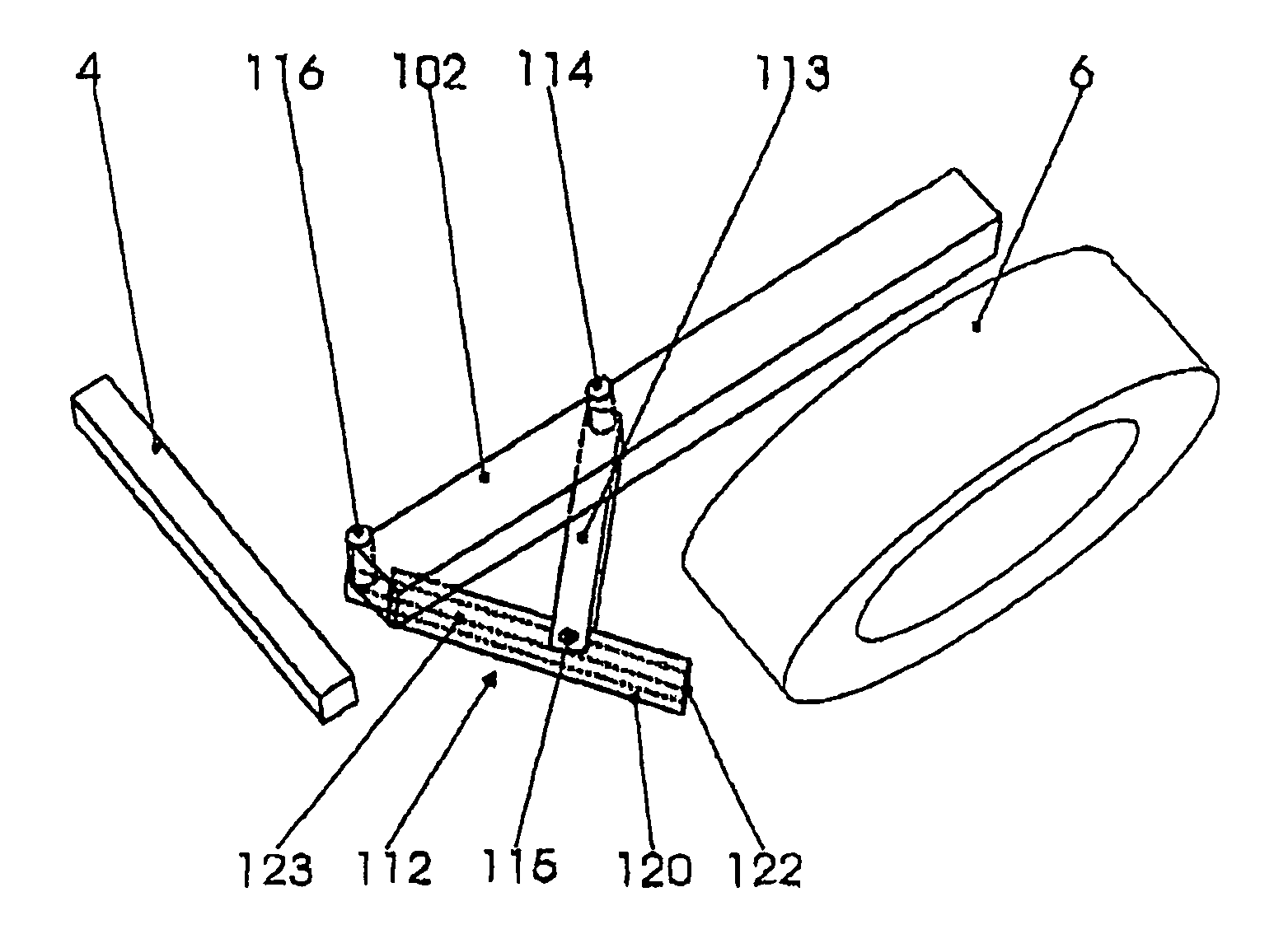

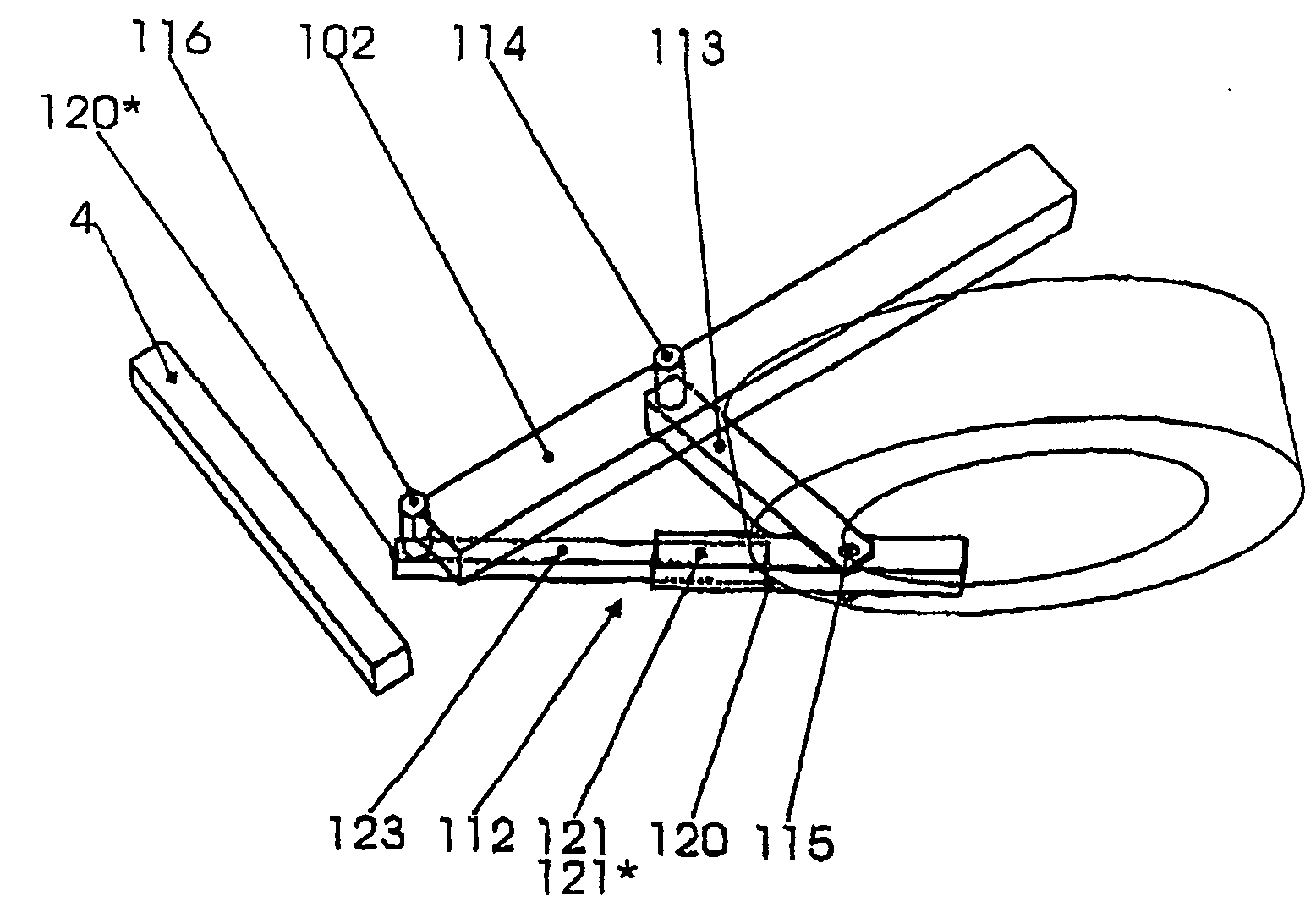

System and method for cutting material in continuous fiber reinforced additive manufacturing

ActiveUS20170144375A1Additive manufacturing with liquids3D object support structuresEngineeringKnife blades

Methods, apparatus, and systems for cutting material used in fused deposition modeling systems are provided, which comprise a ribbon including one or more perforations. Material is passed through at least one perforation and movement of the ribbon cuts the material. A further embodiment comprises a disk including one or more blade structures, each forming at least one cavity. Material is passed through at least one cavity and a rotational movement of the disk cuts the material. A further embodiment comprises a slider-crank mechanism including a slider coupled to a set of parallel rails of a guide shaft. The slider moves along a length of the rails to cut the material. Yet another embodiment comprises one or more rotatable blade structures coupled to at least one rod. The rotation of the blade structures causes the blade structures to intersect and cut extruded material during each rotation.

Owner:THE BOEING CO

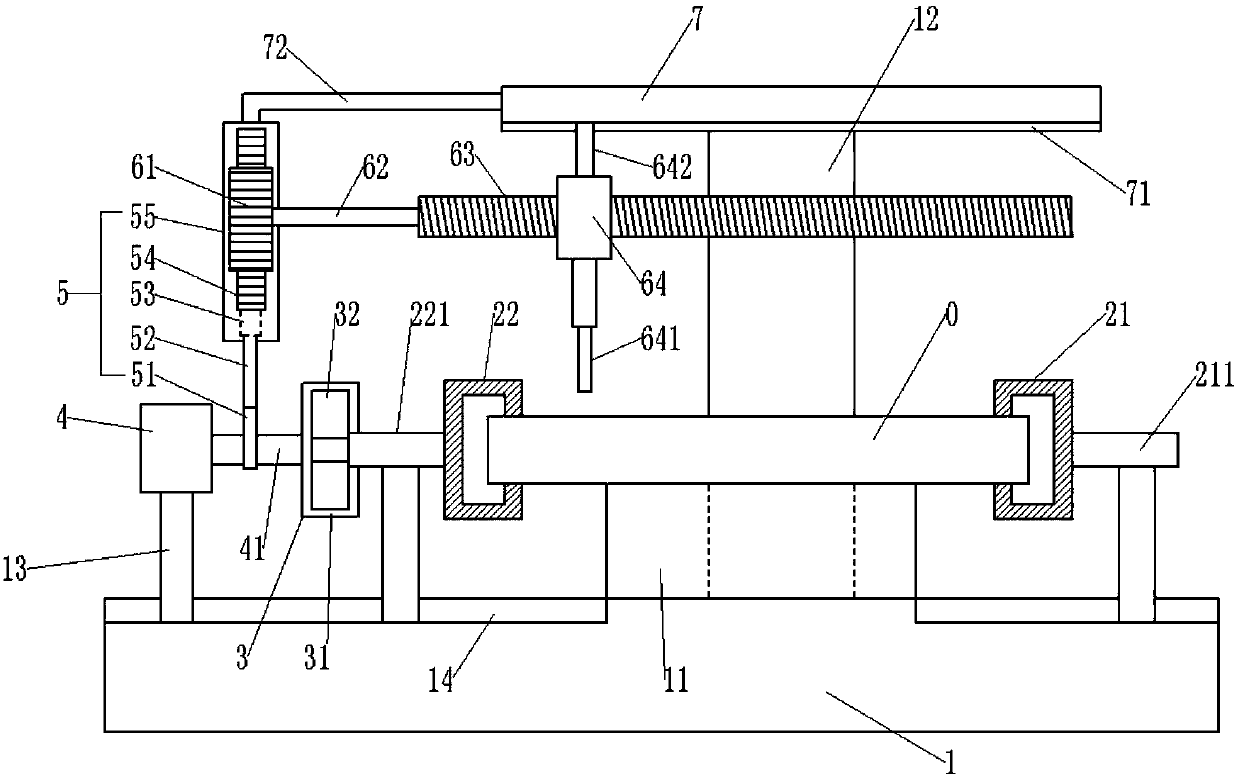

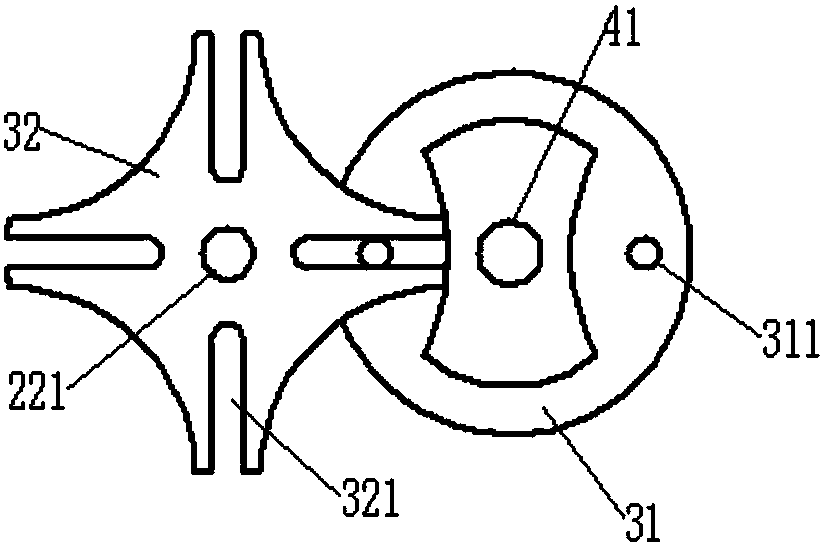

Lancing device

A lancing device comprising a movable parallelogram-shaped rack. The rack rotates a linearly fixed pinion which drives a slider-crank system. The slider-crank system in turn drives a lance holder. The parallelogram-shaped rack defines one or more predetermined paths along which the pinion moves. The lance holder is prevented from being extended beyond a predetermined depth when the pinion reaches a predetermined position along the one or more predetermined paths. The pinion is mechanically stopped from further progress by intersecting two legs of the parallelogram-shaped rack. Teeth of the rack may be modified to reduce the change the pinion may jam in the rack.

Owner:ASCENSIA DIABETES CARE HLDG AG

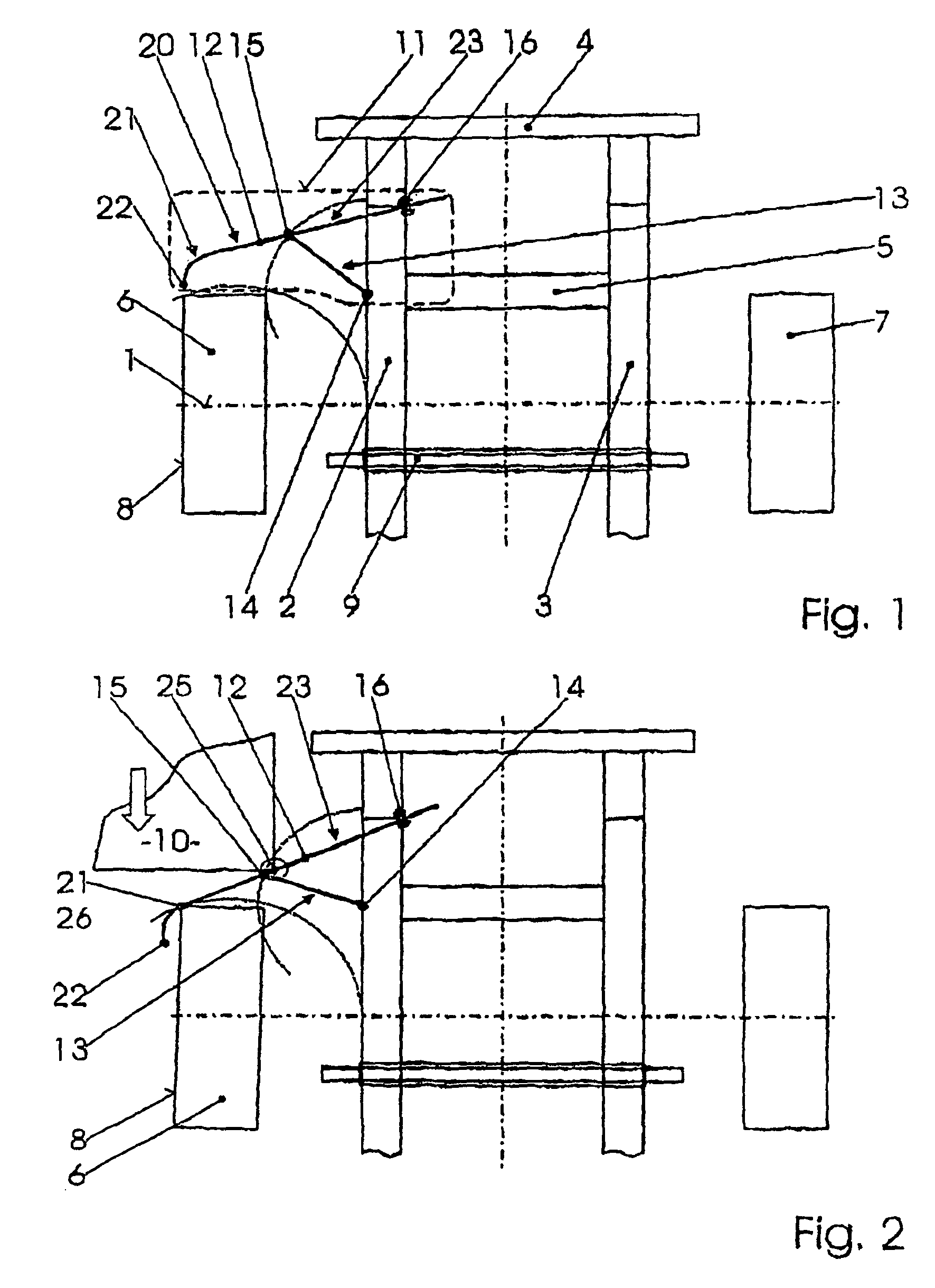

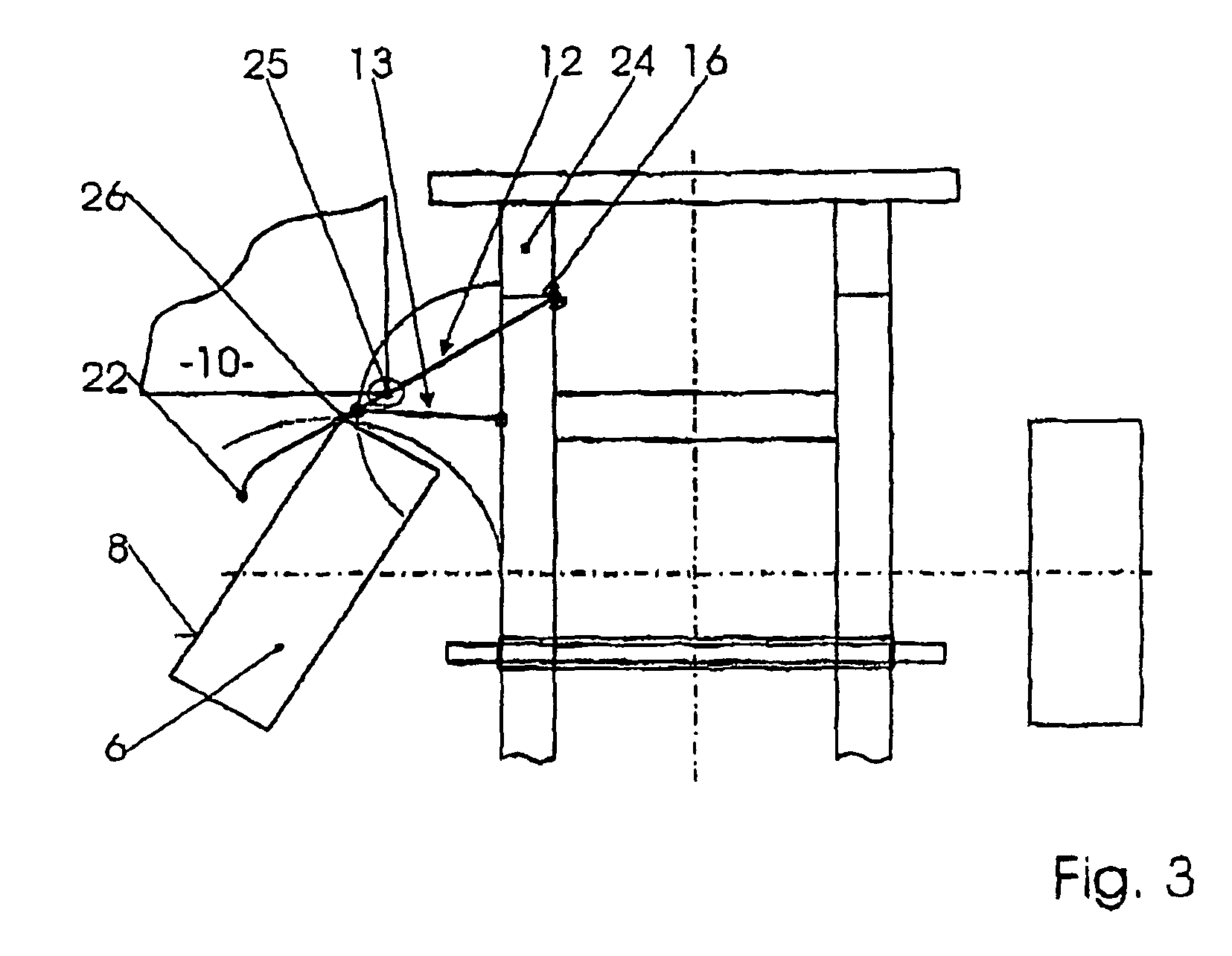

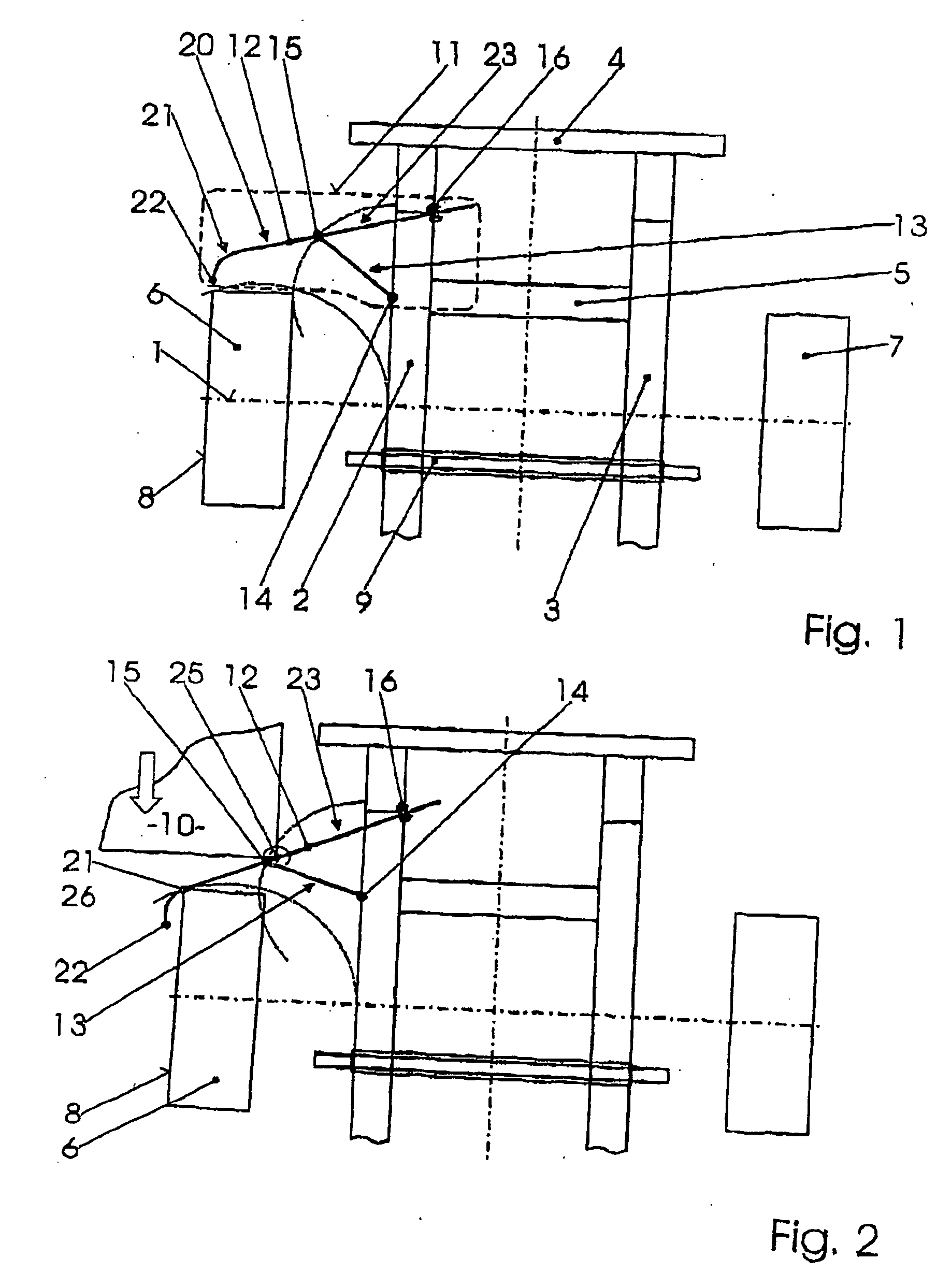

Deflecting device for an offset frontal collision for motor vehicles

InactiveUS7819218B2Effect formPrevent intrusionVehicle seatsPedestrian/occupant safety arrangementMobile vehicleCoupling

In a motor vehicle, a deflecting device (11) for an offset frontal collision for the motor vehicle is arranged in front of a front wheel (6). In order, in the event of a collision, to safely pivot the front wheel inward, the deflecting device (11) forms a kinematic chain, the coupling link of which is a deflector (12) which, under the action of a frontal impact, is pivoted to the rear and is displaced toward the outside of the vehicle. The kinematic chain is a slider crank mechanism comprising a swinging arm (13) which is pivotable about a bearing (14), a further bearing (16), a sliding guide (16) and the coupling link (12) which is connected to the outer end of the swinging arm at a pivot point (15) and is guided in the further bearing (16).

Owner:MAGNA STEYR FAHRZEUGTECHN

Deflecting Device for an Offset Frontal Collision for Motor Vehicles

InactiveUS20080023954A1Increase collision speedMore impact energyVehicle seatsPedestrian/occupant safety arrangementCouplingEngineering

In a motor vehicle, a deflecting device (11) for an offset frontal collision for the motor vehicle is arranged in front of a front wheel (6). In order, in the event of a collision, to safely pivot the front wheel inward, the deflecting device (11) forms a kinematic chain, the coupling link of which is a deflector (12) which, under the action of a frontal impact, is pivoted to the rear and is displaced toward the outside of the vehicle. The kinematic chain is a slider crank mechanism comprising a swinging arm (13) which is pivotable about a bearing (14), a further bearing (16), a sliding guide (16) and the coupling link (12) which is connected to the outer end of the swinging arm at a pivot point (15) and is guided in the further bearing (16).

Owner:MAGNA STEYR FAHRZEUGTECHN

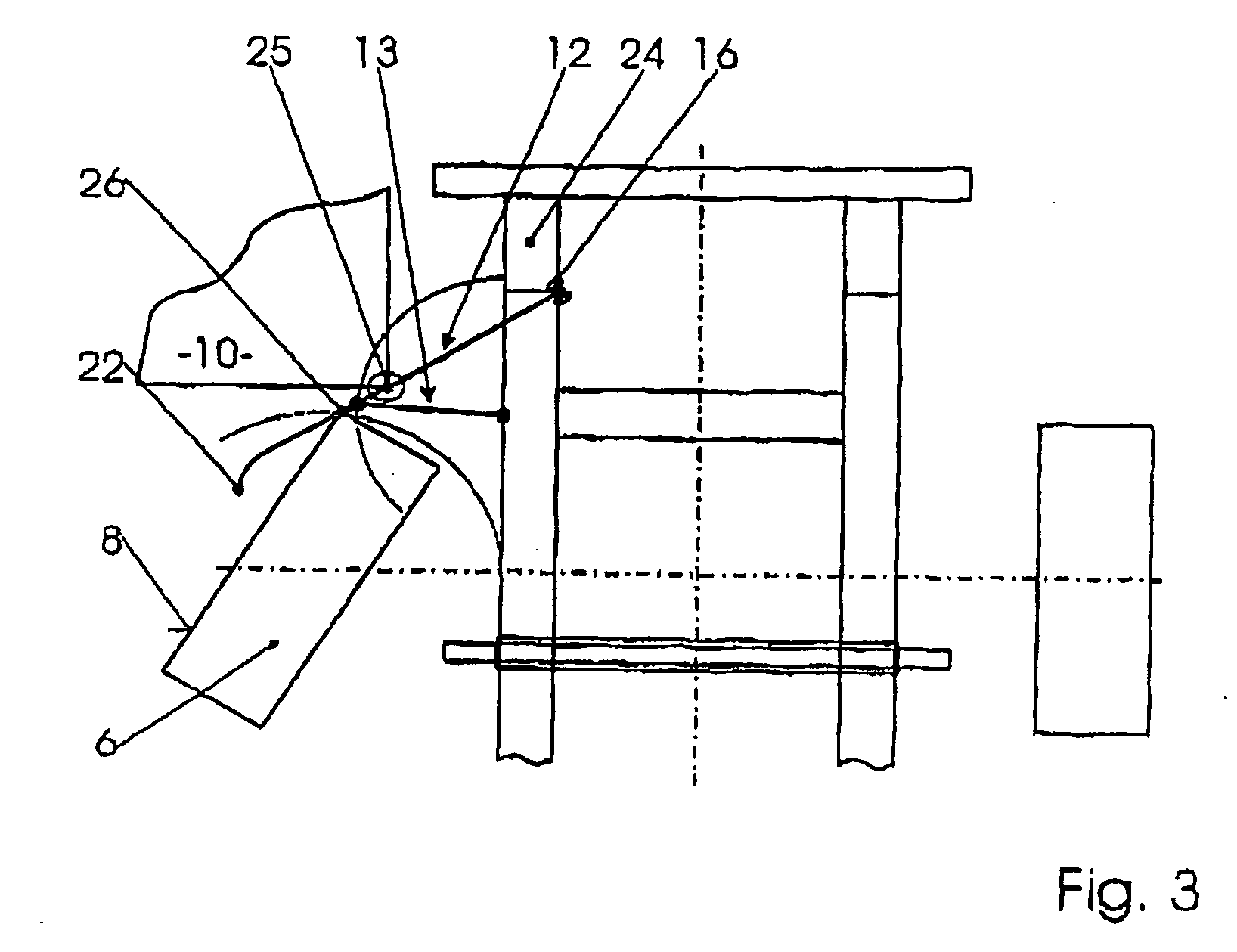

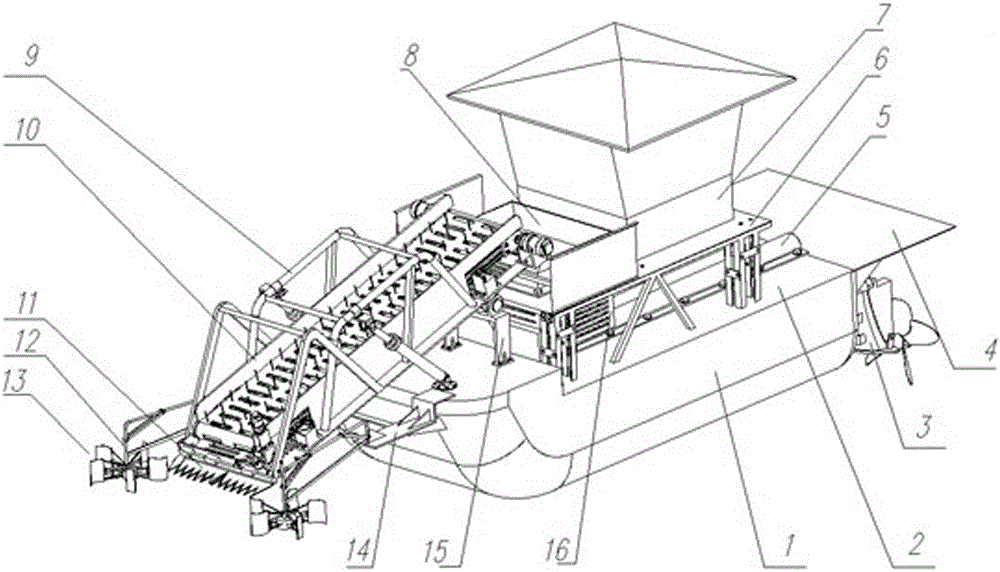

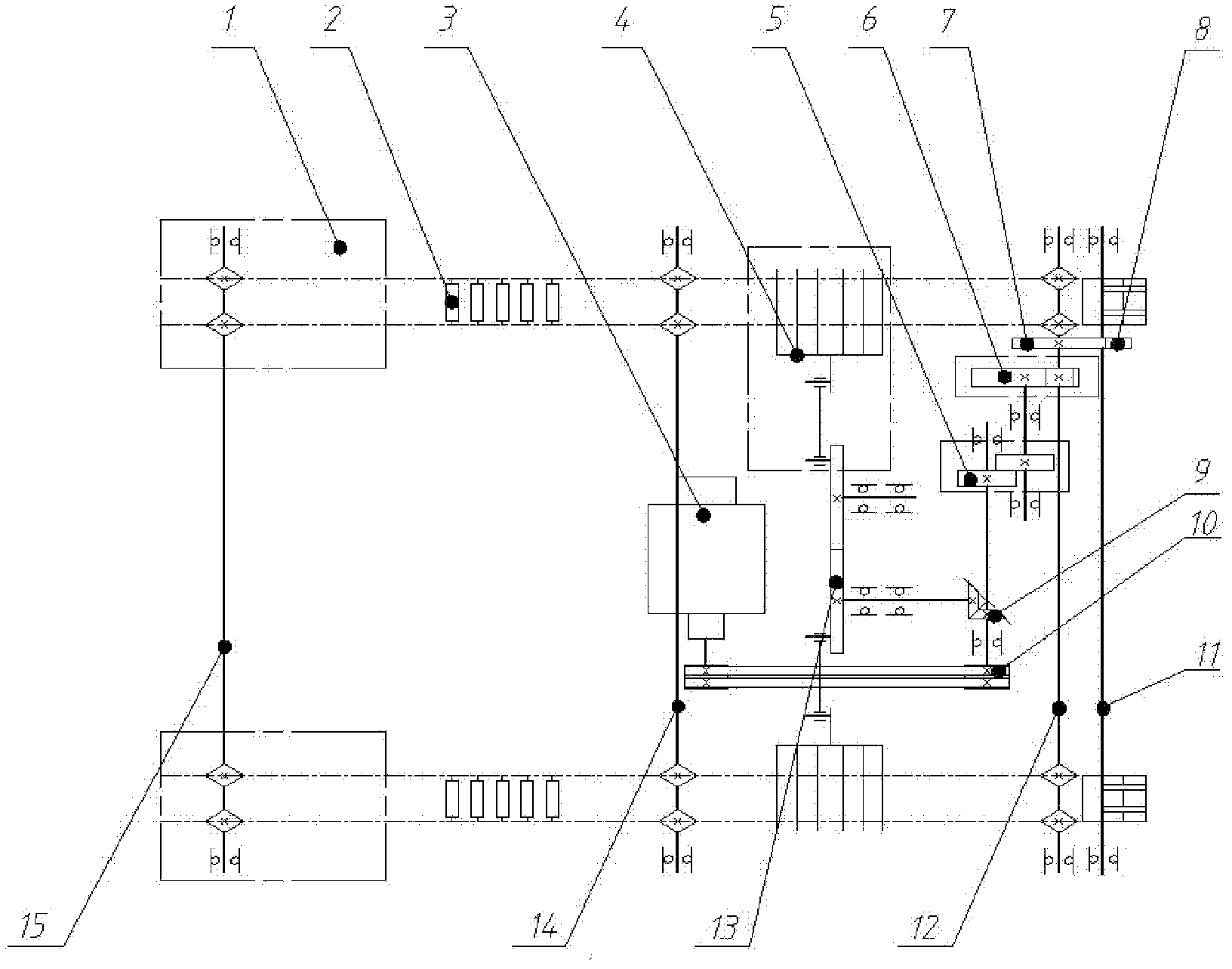

Water plant reaping and harvesting ship

The invention provides a water plant reaping and harvesting ship which comprises a hull, a water plant cutting device, a water plant conveying device, a water plant collecting device, auxiliary collecting devices and a power device. The water plant conveying device is arranged on an installing frame of the bow in an inclined mode, the lowest end of the water plant conveying device is connected with the water plant cutting device, and the water plant collecting device is arranged at one side of the highest end. The water plant cutting device comprises a bevel gear drive mechanism, a slider-crank mechanism and a cutter reciprocating mechanism. The water plant conveying device comprises a chain plate, a chain wheel, a chain, and a water plant leakage preventing mechanism arranged on the chain plate. The water plant collecting device comprises a collecting hopper, a collecting box, a guide rail, and a collecting platform arranged on the stern. The auxiliary collecting devices are profiling variable wing eccentric collecting wheels or collecting plates arranged on the bow. The water plant reaping and harvesting ship integrates water plant cutting, conveying and collecting, all the devices are convenient to combine, and easy to disassemble, replace and maintain, connection in the whole harvesting process is close, the mechanical degree is high, and the reaping efficiency is far higher than that of manual salvage.

Owner:LUOYANG INST OF SCI & TECH

Plastic spraying device

InactiveCN107899799ARealize all-round plastic sprayingSimple structureSpraying apparatusEngineeringAutomation

The invention relates to the technical field of plastic spraying equipment for guardrail production and particularly discloses a plastic spraying device which comprises a motor, a clamping mechanism,a groove wheel mechanism, a slider-crank mechanism, a plastic spraying mechanism and a supporting base. The groove wheel mechanism and the slider-crank mechanism are connected with the motor. The plastic spraying mechanism is located above the clamping mechanism. The supporting base is used for supporting the motor, the clamping mechanism, the slider-crank mechanism and the plastic spraying mechanism. The supporting base is provided with a supporting table used for storing a guardrail. The clamping mechanism comprises two clamps located on the two sides of the supporting table. One clamp is connected with the groove wheel mechanism. The plastic spraying mechanism comprises a lead screw, a nut and a plastic spraying gun. The slider-crank mechanism can drive the plastic spraying gun to movein a reciprocating manner. The groove wheel mechanism can drive the guardrail to rotate intermittently. The plastic spraying device is adopted for carrying out plastic spraying on the guardrail, all-dimensional automatic plastic spraying can be carried out on the guardrail, the automation degree is high, the operation cost is low, and the plastic spraying efficiency is high.

Owner:重庆立帆金属结构有限公司

Diameter-variable wheel for automatically adapting to road surface

InactiveCN101954836AContinuously variable wheel diameterSimple and reliable control processWheelsEngineeringRoad surface

The invention discloses a diameter-variable wheel for automatically adapting to a road surface, which comprises a plurality of outer wheel blades, a plurality of inner wheel blades and a plurality of connecting rod wheel blades; middle parts of the plurality of inner wheel blades are respectively provided with a telescopic strut bar fixed on a circumference of a central wheel hub; end faces on two sides of the central wheel hub are provided with a plurality of crank-slider mechanisms connected with the inner wheel blades, and are provided with a driving device for driving the plurality of crank-slider mechanisms; and one ends of connecting rods of the crank-slider mechanisms are connected with the inner wheel blades through revolute pairs, and the other ends of the connecting rods of the crank-slider mechanisms are connected with cranks through revolute pairs. The diameter-variable wheel solves the contradiction between wheel obstacle-surmounting performance and volume structure restraint, effectively improves the adaptability of the wheel, and solves the problems of the conventional wheels in the environments of underground, planetary surfaces or other comprehensive road surfaces. The wheel controls a servo motor to drive the cranks to rotate a certain angle, and the crank-slider mechanisms parallelly drive the inner wheel blades to radially expand or contract, so that the wheel diameter is continuously variable. The diameter-variable wheel can realize diameter-expanded obstacle surmounting, walking obstacle surmounting, tolerance obstacle surmounting and the like, and the adaptability and the flexibility of the wheel for different road surfaces are enhanced.

Owner:CHINA UNIV OF MINING & TECH

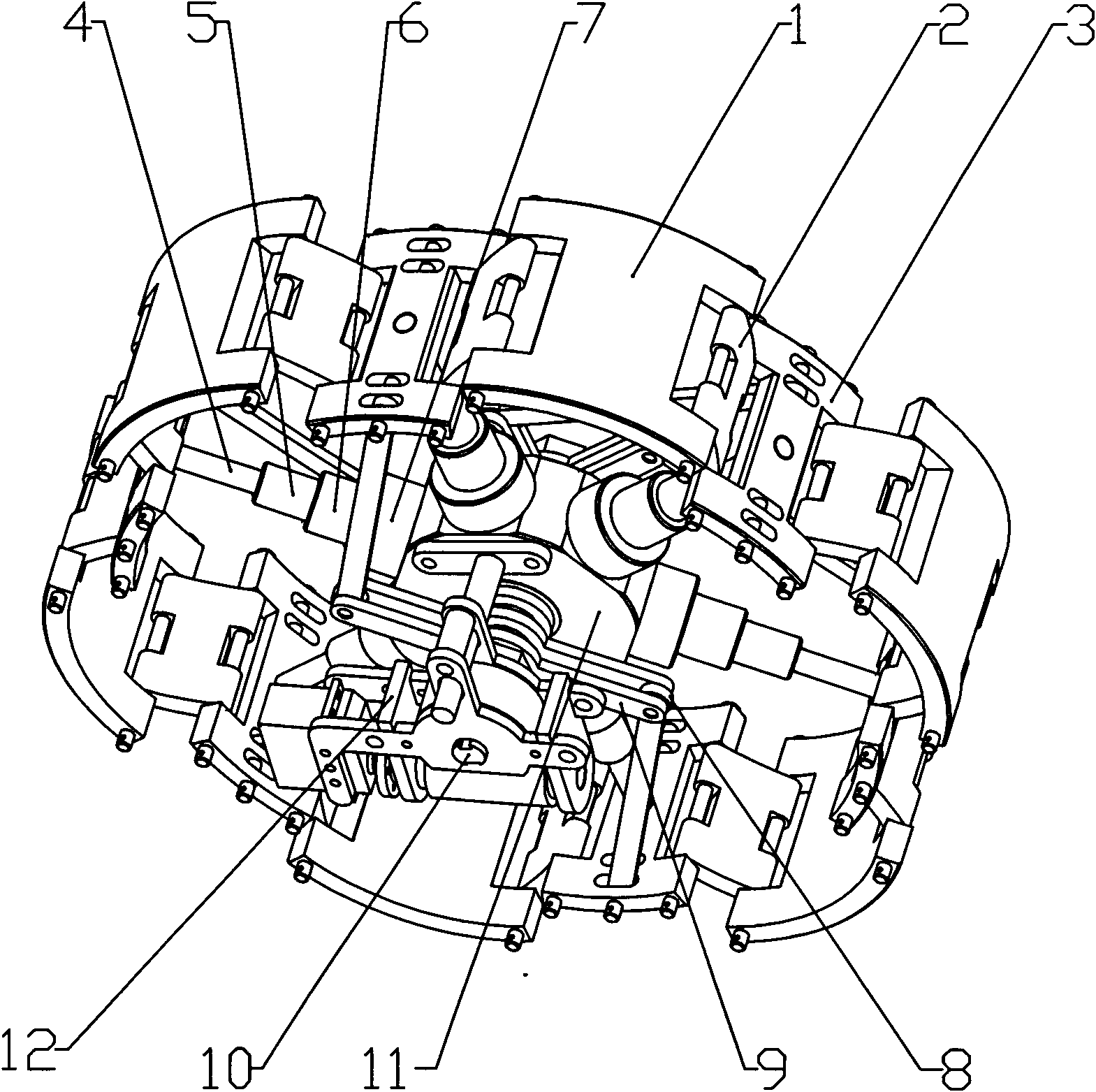

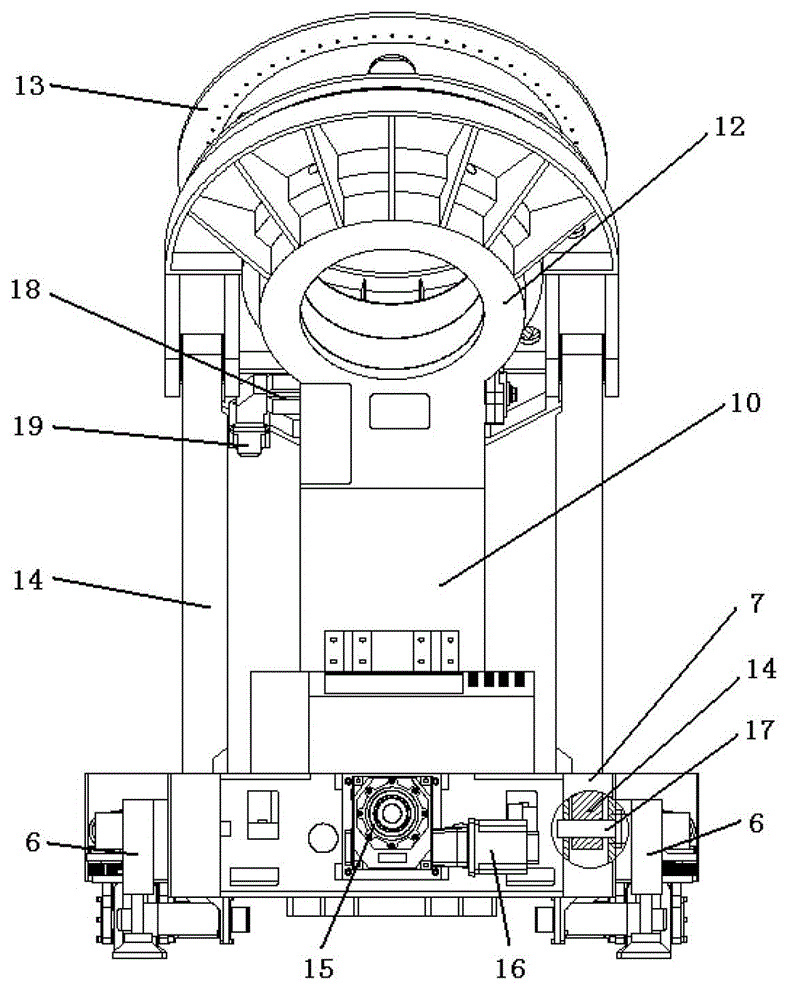

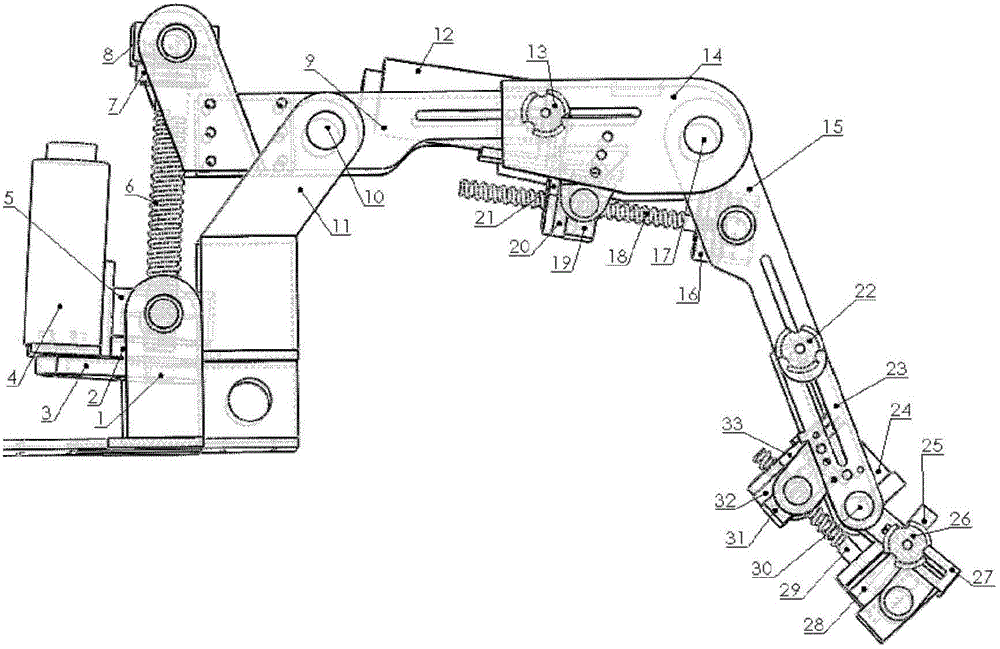

Self-adaptive pneumatic flexible grabbing mechanical gripper based on metamorphic mechanism

Provided is a self-adaptive pneumatic flexible grabbing mechanical gripper based on a metamorphic mechanism. A support is fixedly connected with a base to form a frame-shaped structure, an air cylinder is located in the frame-shaped structure and is fixedly connected with the base, the gripper comprises a slider crank mechanism and the metamorphic mechanism, chunks are fixedly connected with the metamorphic mechanism, a workpiece is a grabbing object, and contact force sensors are arranged on the surfaces, making contact with the workpiece, of the chucks. Connecting rods are connected to an air cylinder piston through revolute pairs A, the connecting rods are movably connected with the metamorphic mechanism, and the slider crank mechanism is formed by the connecting rods, the air cylinder piston and connecting rods 1 in the metamorphic mechanism, the air cylinder piston is the slider of the slider crank mechanism, the connecting rods are movably connected with the air cylinder piston, and a force feedback control system is connected with the contact force sensors and the air cylinder. Compared with the prior art, the self-adaptive pneumatic flexible grabbing mechanical gripper based on the metamorphic mechanism achieves the purposes of being little in drive, simple in control, low in cost and high in reliability, having certain flexibility, and being capable of self-adaptively grabbing objects in complex space geometrical shapes or simulating the movement characteristics of human hands.

Owner:JIANGSU UNIV

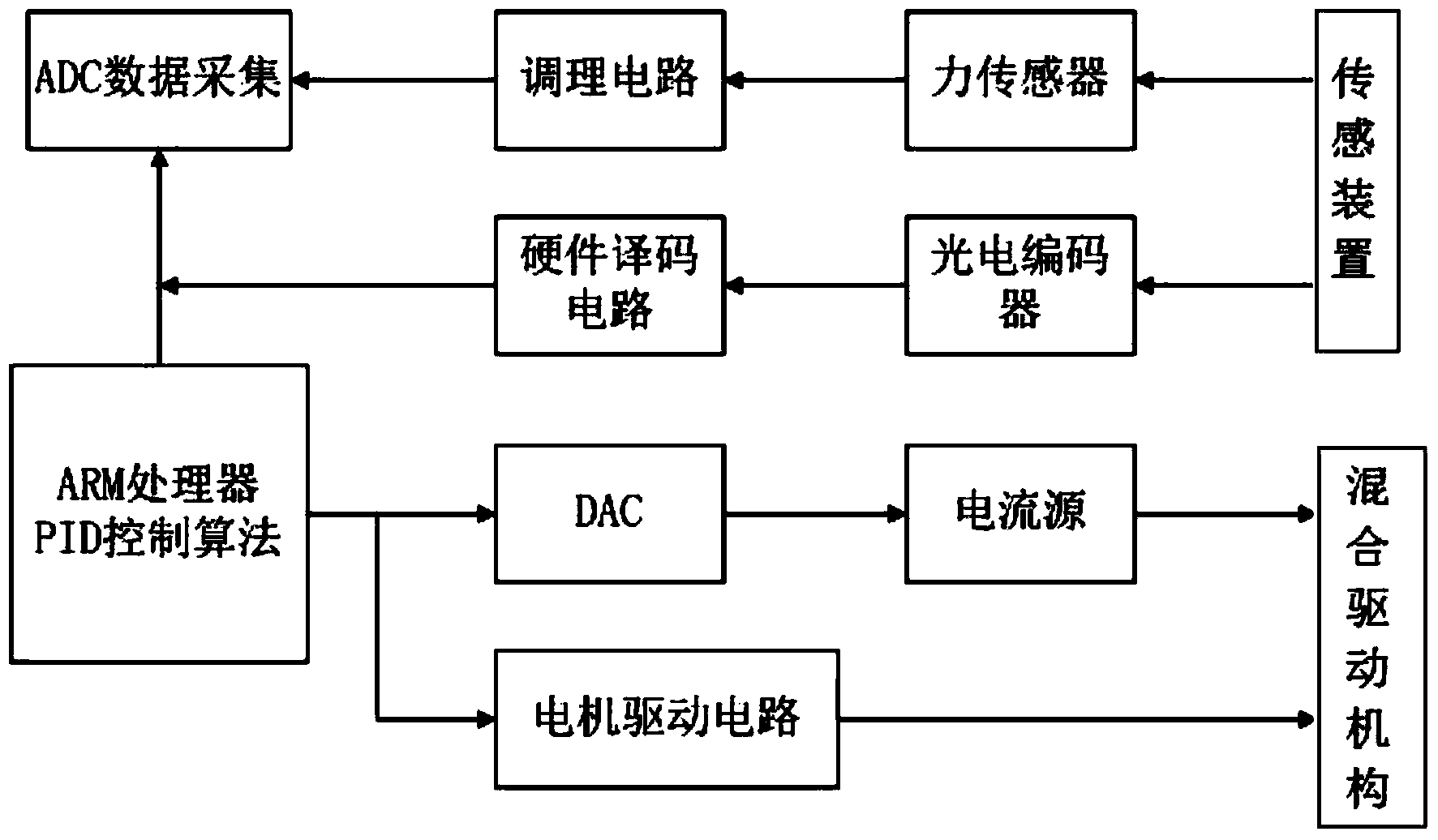

Auxiliary rehabilitation training device for hemiplegic finger of patient

InactiveCN103750980AReduce resistanceMeet the needs of targeted trainingGymnastic exercisingChiropractic devicesControl systemPid control algorithm

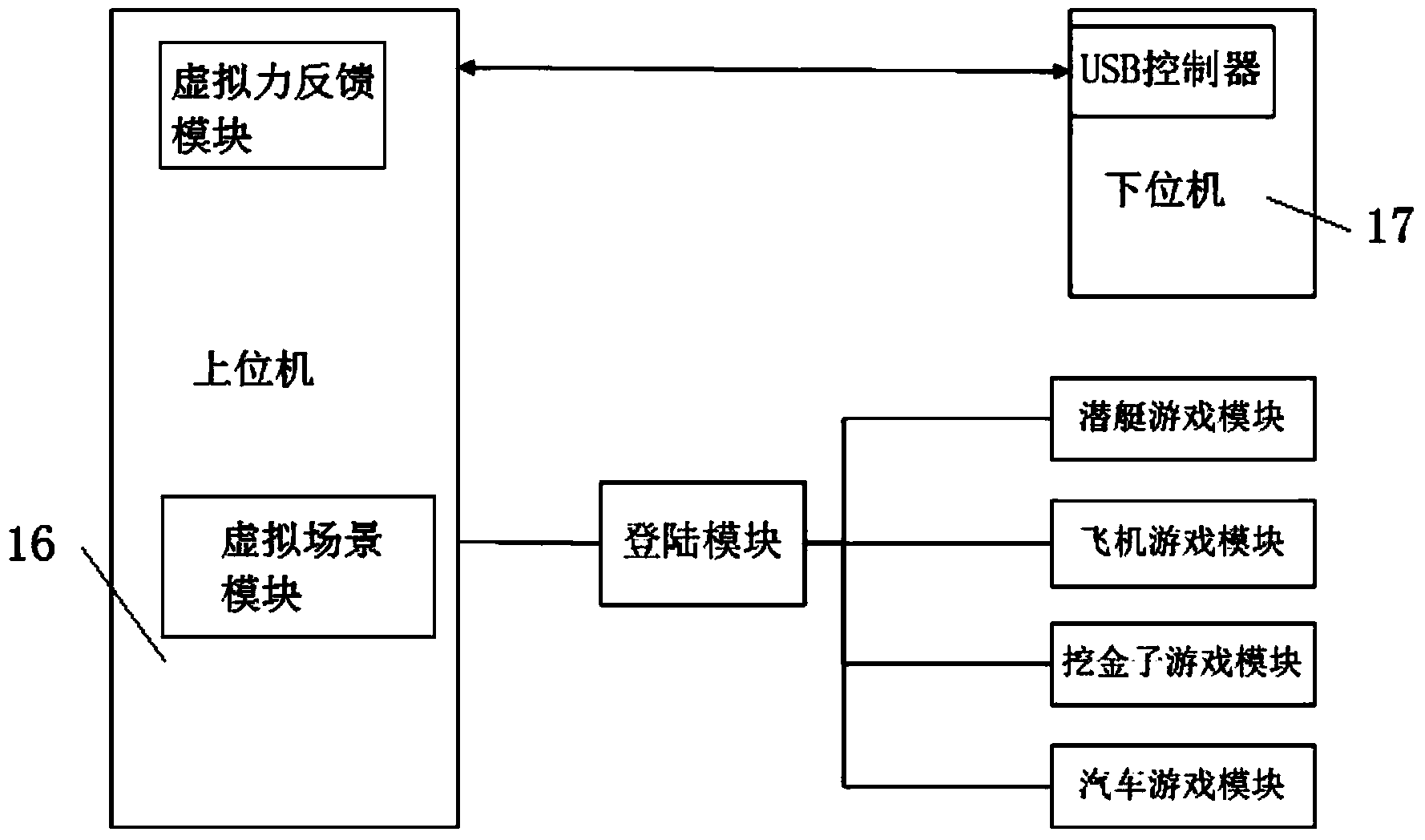

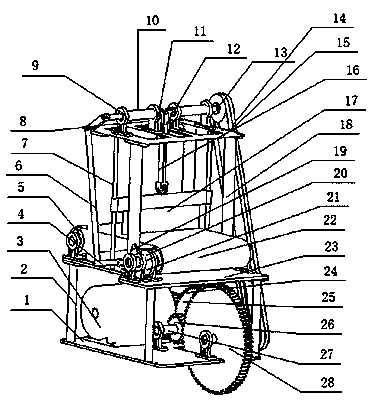

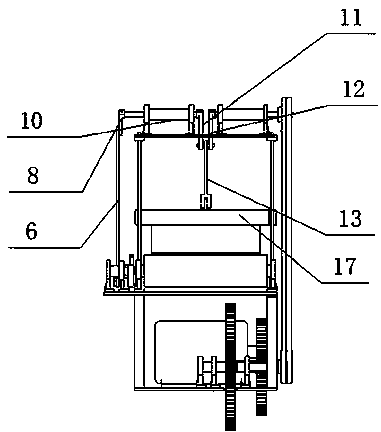

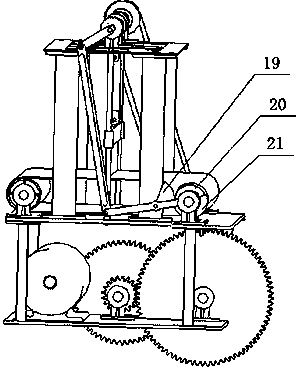

The invention discloses a platform type auxiliary rehabilitation training device for a hemiplegic finger of a patient. The auxiliary rehabilitation training device for the hemiplegic finger of the patient comprises a finger training mechanism, a hybrid driving mechanism, a sensing device and a control system, wherein the hybrid driving mechanism comprises a motor and a magnetorheological fluid damper, the finger training mechanism comprises a slider-crank mechanism and a finger moving device which can rotate freely and slide forwards or backwards under the driving of the slider-crank mechanism, the control system comprises an upper computer and a lower computer, the PID control algorithm is configured in the lower computer, and a virtual scene module and a virtual reality feedback force module are arranged in the upper computer. By the adoption of the auxiliary rehabilitation training device for the hemiplegic finger of the patient, combination of active training and passive training can be achieved for the patient, the mechanical structure, the hybrid driving mechanism, the sensing device and the control system cooperate with one another to achieve man-machine interaction, a training process is controlled strictly, and the interestingness of the training process is improved by the adoption of game images.

Owner:SOUTHEAST UNIV

Automatic feeding pastry slicer

InactiveCN103862499AImprove work efficiencyGuaranteed slicing effectMetal working apparatusBaked article cutting/slicingEngineeringFriction force

Owner:KUNMING UNIV OF SCI & TECH

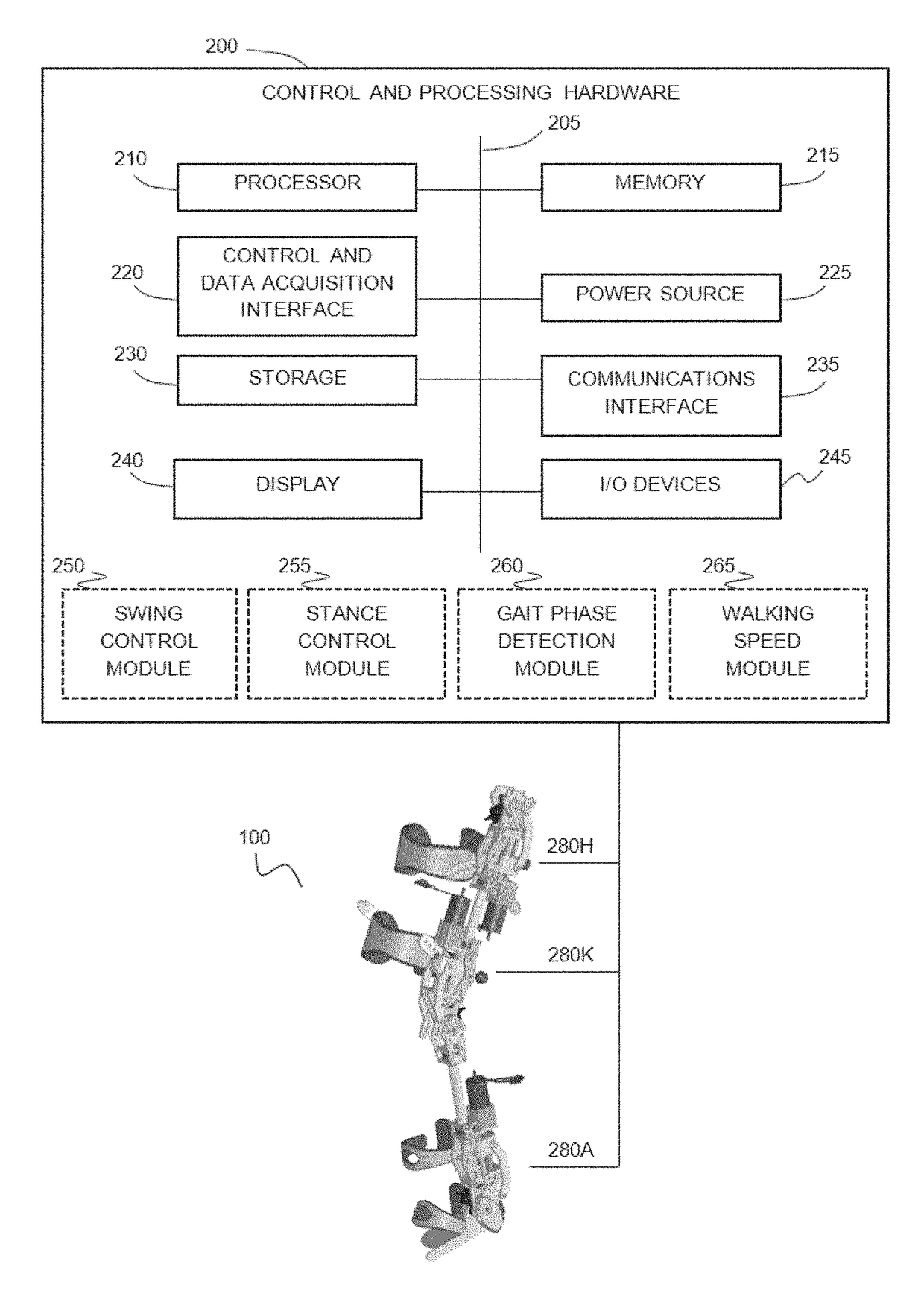

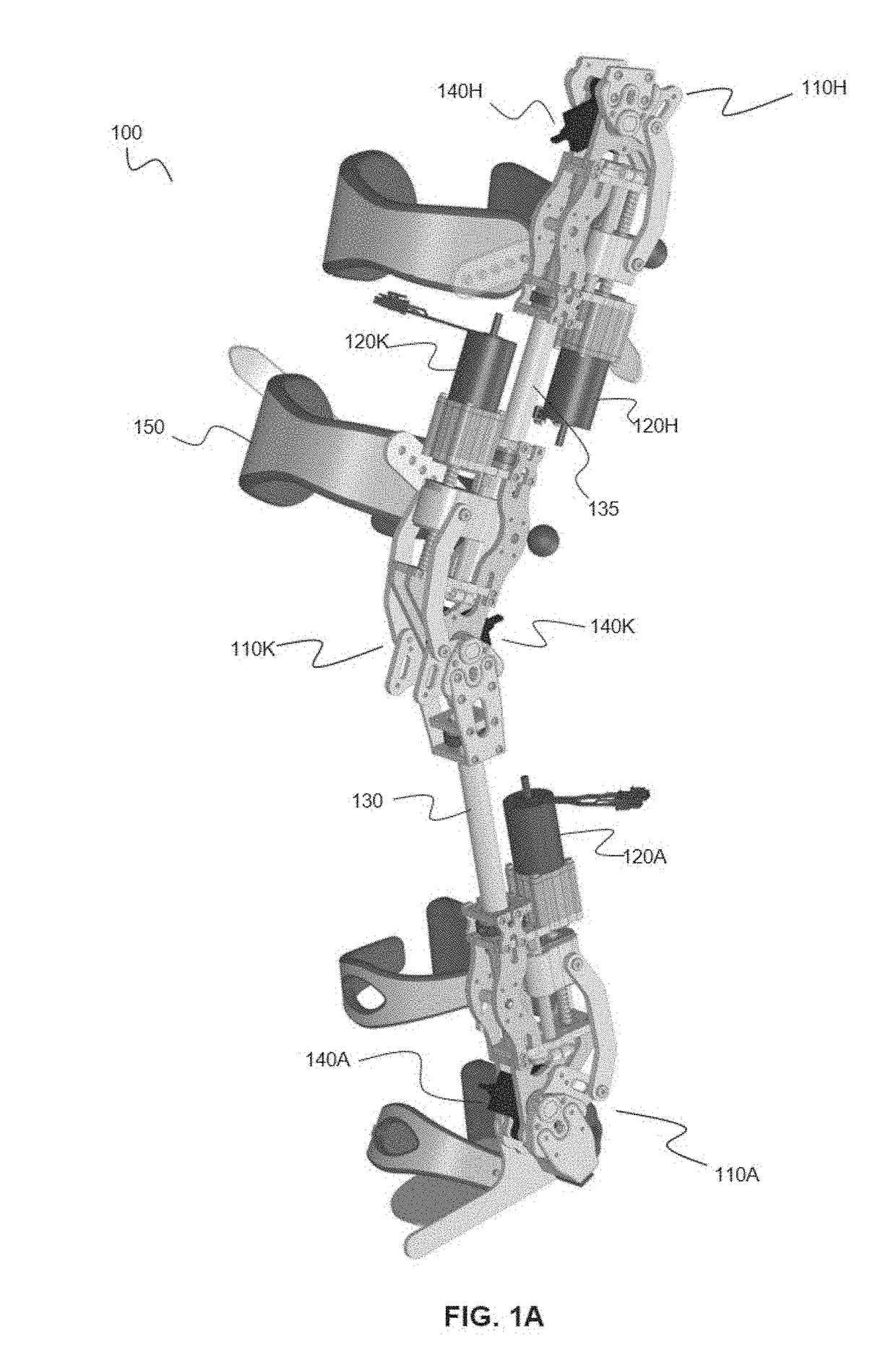

Powered lower limb devices and methods of control thereof

In some aspects, methods are provided for controlling a powered lower limb device. A stance phase control method is disclosed in which the required joint torque is determined based on the difference between two joint angles, such as the knee joint and the ankle joint. A swing control method is also disclosed that employs feedback-based minimum jerk trajectory control. In other embodiments, a joint assembly for use in modular lower limb device is provided. The joint assembly includes a reconfigurable slider-crank mechanism that is configurable to provide a plurality of different ranges of rotational travel, rotational speeds, and torques, for customization according to different anatomical joints. The joint assembly may include a compact coupling device for coupling a ball screw of the slider-crank mechanism to an output shaft of a motor. When employed to form a modular orthosis, the joint assembly may be adapted for self-alignment as its length adjustment method during setup.

Owner:UNIVERSITY OF NEW BRUNSWICK

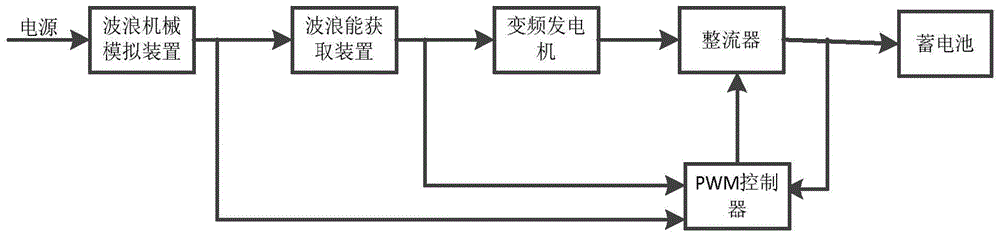

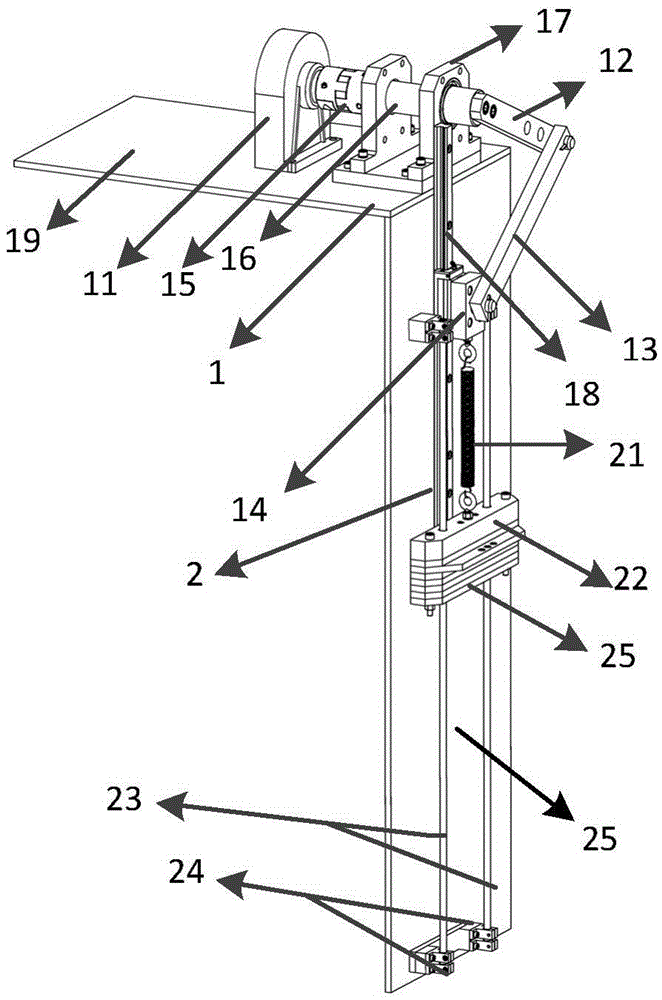

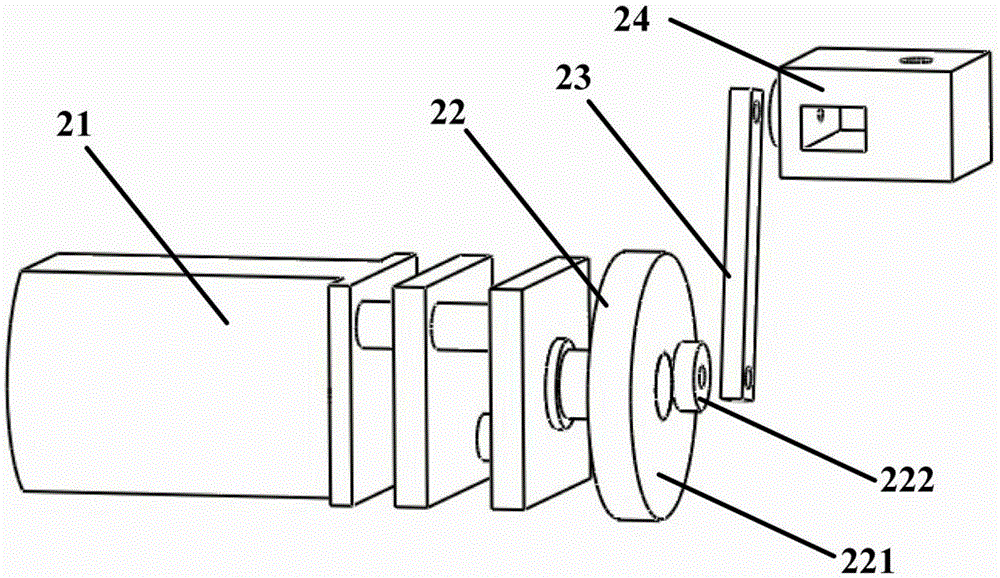

Oscillating float-type wave power generation simulator

InactiveCN105484933ASave spaceSame rotation frequencyMachines/enginesEngine componentsElectricityWave power generation

The invention discloses an oscillating float-type wave power generation simulator which comprises a wave mechanical simulation device and an oscillating float power generation simulation device. The wave mechanical simulation device comprises a power source, a horizontal experiment frame, a variable-frequency motor and a transmission shaft. One end of the transmission shaft is connected with an output shaft of the variable-frequency motor through a coupling and a reduction gearbox. The oscillating float power generation simulation device comprises a vertical experiment frame, a slider-crank mechanism, a wave energy acquisition device and a linear power generation rectifying device. The slider-crank mechanism is connected with the other end of the transmission shaft to be used for converting rotation movement of the transmission shaft to push the wave energy acquisition device to linearly move up and down so as to drive the linear power generation rectifying device to conduct undulation movement in the vertical direction for power generation, rectification and power storage. According to the oscillating float-type wave power generation simulator, the torque of the variable-frequency motor is converted into force of which the magnitude is increased or decreased vertically along with the time in a sine wave change manner, the wave force is simulated, and the simulator is simple in structure, low in cost, small in occupied space, convenient to maintain, economical and reliable.

Owner:SOUTH CHINA UNIV OF TECH

Leg bouncing mechanism for frog-type robot

The invention discloses a leg bouncing mechanism for a frog-type robot. A tension spring is sleeved on a guide rod. The tail end of the spring is connected with a hip joint, and the upper end of the spring is connected with a slider. The guide rod, the slider, an oblique support rod, a thigh and joints form a crank slider structure. The leg part consists of a thigh, a shank, a connecting rod and joints; and the leg structure comprises the combination of two four-rod mechanisms. The stretch and contraction of the leg mechanism can be adjusted by controlling the slide of the slider on the guide rod. The sole of the robot is arc-shaped, and an arch support is arranged on the sole. The mechanical structure of the invention simulates skeletons of a frog, optimizes the leg structure, improves the utilization ratio of energy of power elements, improves the flexibility of the mechanical structure, and improves the jumping ability of the robot.

Owner:BEIJING UNIV OF TECH

Portable automatic saw blade saw

InactiveCN103210795APrevent hanging wearEasy to plug inCuttersCutting implementsStructural engineeringElectric cables

The invention discloses a portable automatic saw blade saw. The portable automatic saw blade saw comprises a saw blade and lengthening rods, and is characterized by also comprising a base frame, wherein the base frame is fixedly connected with a supporting base and a guide block respectively; a direct-current motor is fixedly connected to the supporting base; a power shaft of the direct-current motor is connected with the saw blade through a power transmission device; the power transmission device is a crank slide block mechanism; one end of a crank is fixedly connected with the power shaft of the direct-current motor; the other end of the crank is hinged with one end of a connecting rod; the other end of the connecting rod is hinged with one end of a slide block; the other end of the slide block is fixedly connected with a smooth shaft; and the smooth shaft is arranged in the guide block which is glidingly matched with the smooth shaft. When the portable automatic saw blade saw is used, the number of the lengthening rods is determined according to the trimming requirements on tree branches with different heights, a connecting pipe is fixedly connected with the lengthening rods, a control cable is plugged into a power supply, the saw blade is arranged close to the tree branch to be trimmed, a switch is turned on, the power shaft drives a power transmission device to drive the smooth shaft and the saw blade to reciprocate along the guide block to cut the tree branch, and after trimming is finished, the switch is turned off, the saw blade stops moving. The portable automatic saw blade saw has the advantages of high safety, low labor intensity and high efficiency.

Owner:JILIN SHANGNING TECH

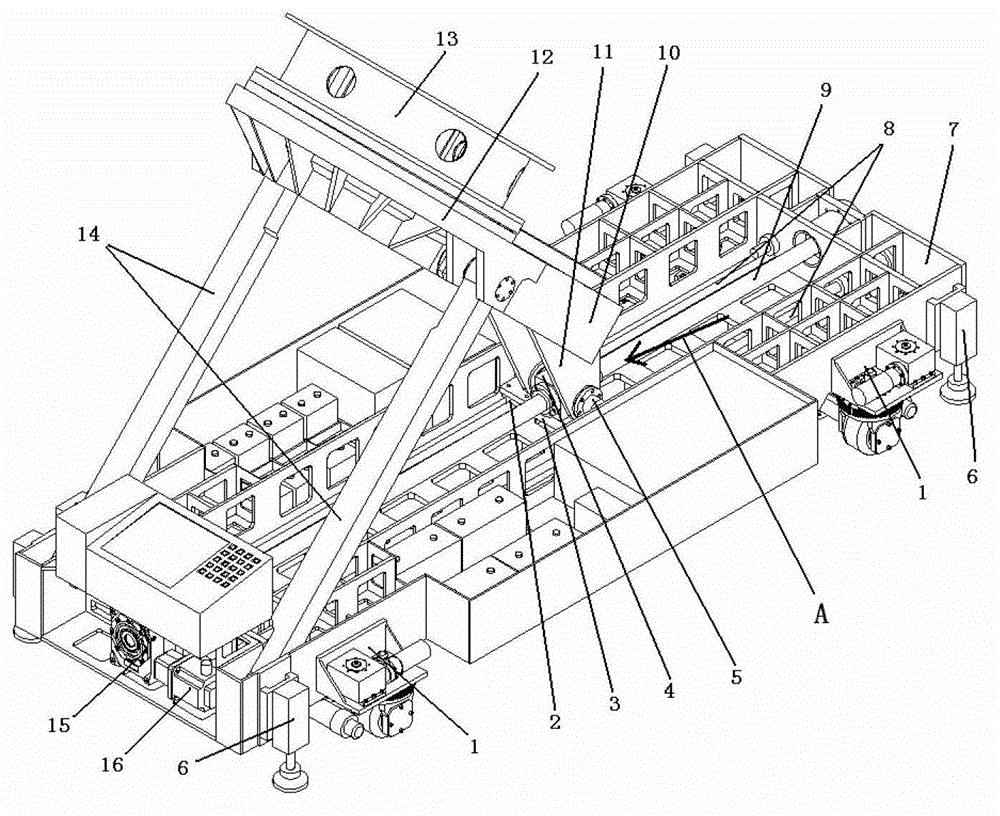

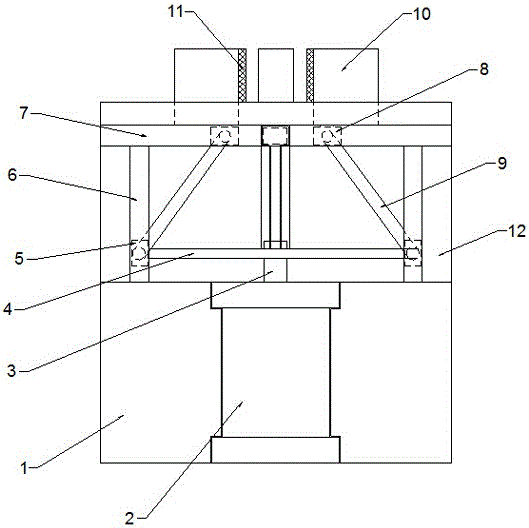

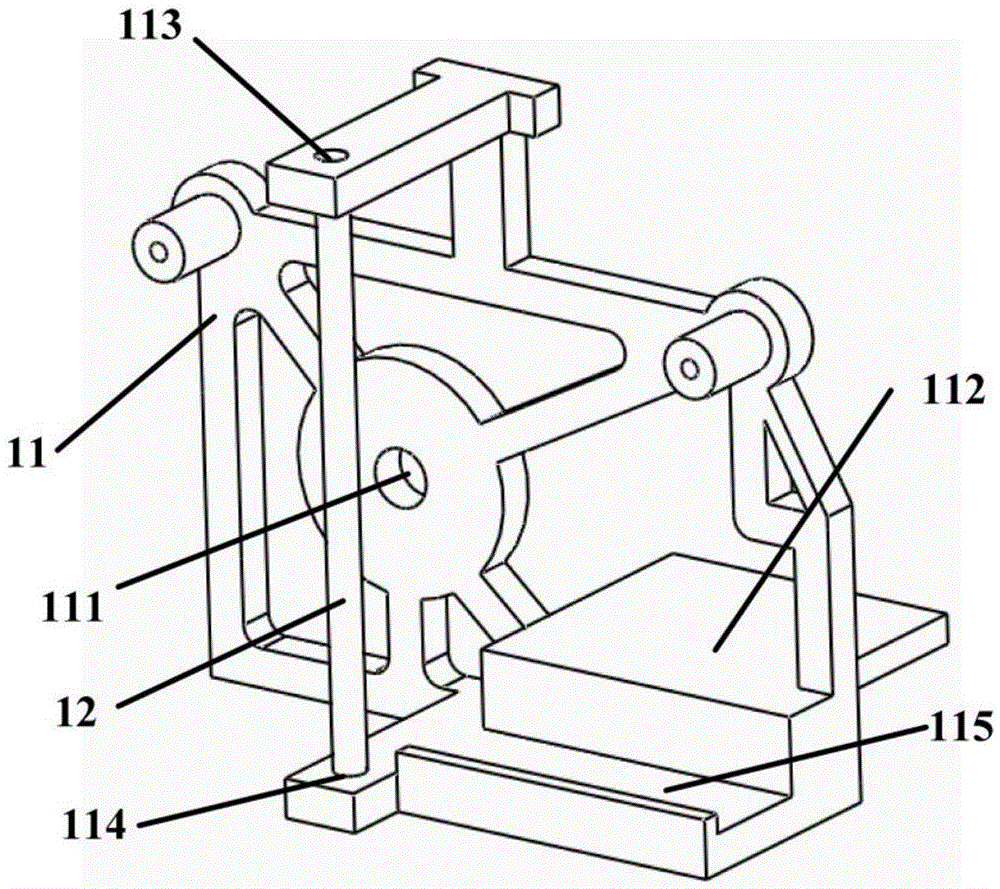

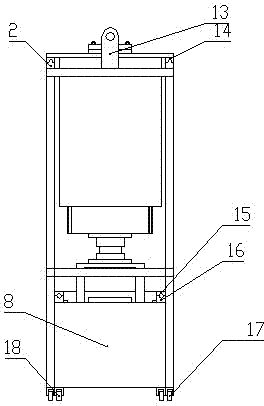

Double-shaft rotating table for adjusting satellite postures

The invention provides a double-shaft rotating table for adjusting satellite postures, which is used for the purposes of satellite assembly, test, experiment and the like. The rotating table comprises a rotating table body and a position pitching system, wherein the table body is provided with a driving wheel group so that the rotating table can flexibly move and is more convenient to use. The weight is lowered due to the adoption of the form of a slider-crank mechanism. A large portion of pressure is bore by guide rails, and the burden of a pitching pivot is lowered. Besides, a lever transmission mode is adopted, the pressure of a pitching motor and a speed reducer is largely reduced, and the bearing capability of the rotating table is improved. As a connecting rod in the slider-crank mechanism is used as the pitching system, the pitching pivot moves along an arc relatively to the table body with the variation of a pitching angle, and the arc takes the length of a crank as a radius. When the pitching angle is 0, the height of the pitching pivot is in a lowest position, so that the height of the whole equipment is lowered, and occupation space is reduced, thus facilitating storage. Transition rings are designed, different types of satellites are fit through the change of the transition rings, universality is improved, and resources are saved.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

Manipulator paw based on stepping motor

The invention relates to the mechanical robot grip. It comprises the motor, connection sleeve, finger bottom plate and grip device, with the motor connected to the finger bottom plate through the linking sleeve barrel, grip hinged to the finger bottom plate, motor connected to the grip through the screw rod. When the progressive motor rotates clockwise viewing from its back, it drives the clockwise rotation of the screw rod through the coupler. Due to the right rotation model of the screw rod mother screw, it can restrain the freedom of the rotation direction, with the mother screw moving downward, driving the downward movement of the grip push plate, driving the open of the fingers, and vice versa. It is simple, low in cost, small in size, and flexible.

Owner:于复生

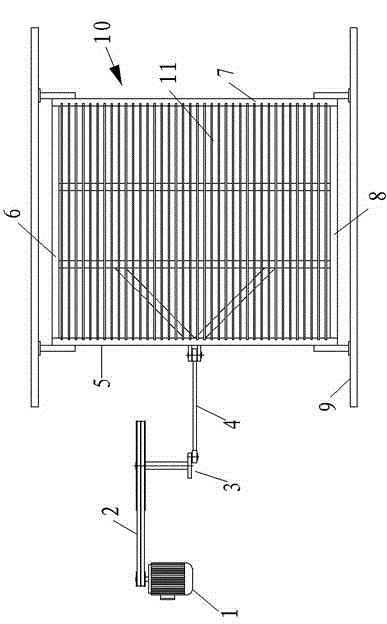

Screening device for brickmaking raw materials

The invention provides a screening device for brickmaking raw materials, which comprises a screen frame for supporting a screen mesh, two parallel slideways extending leftwards and rightwards and a connection rod, the two slideways are respectively used for supporting a front edge and a rear edge of the screen frame in a sliding way, one end of the connection rod is hinged with a left edge or a right edge of the screen frame, the other end of the connection rod is hinged with a crank, the crank, the connection rod, the screen frame and the slideways together form a crank slider mechanism so as to enable the screen mesh to do a reciprocating motion, and the height of the screen mesh is increased or lowered gradually in left and a right directions. Brickmaking raw materials to be screened are conveyed onto the screen mesh, the screen mesh is driven by the crank to do the reciprocating motion in the left and the right directions, the brickmaking materials are screened, a part of qualified raw materials fall down, and the other part of raw materials slide down accompany with an inclination of the screen mesh at the height. The particles of brickmaking raw materials are uniform by screening, so that a normal operation of brickmaking equipment is guaranteed, and working efficiency and product quality are increased.

Owner:张鲁军

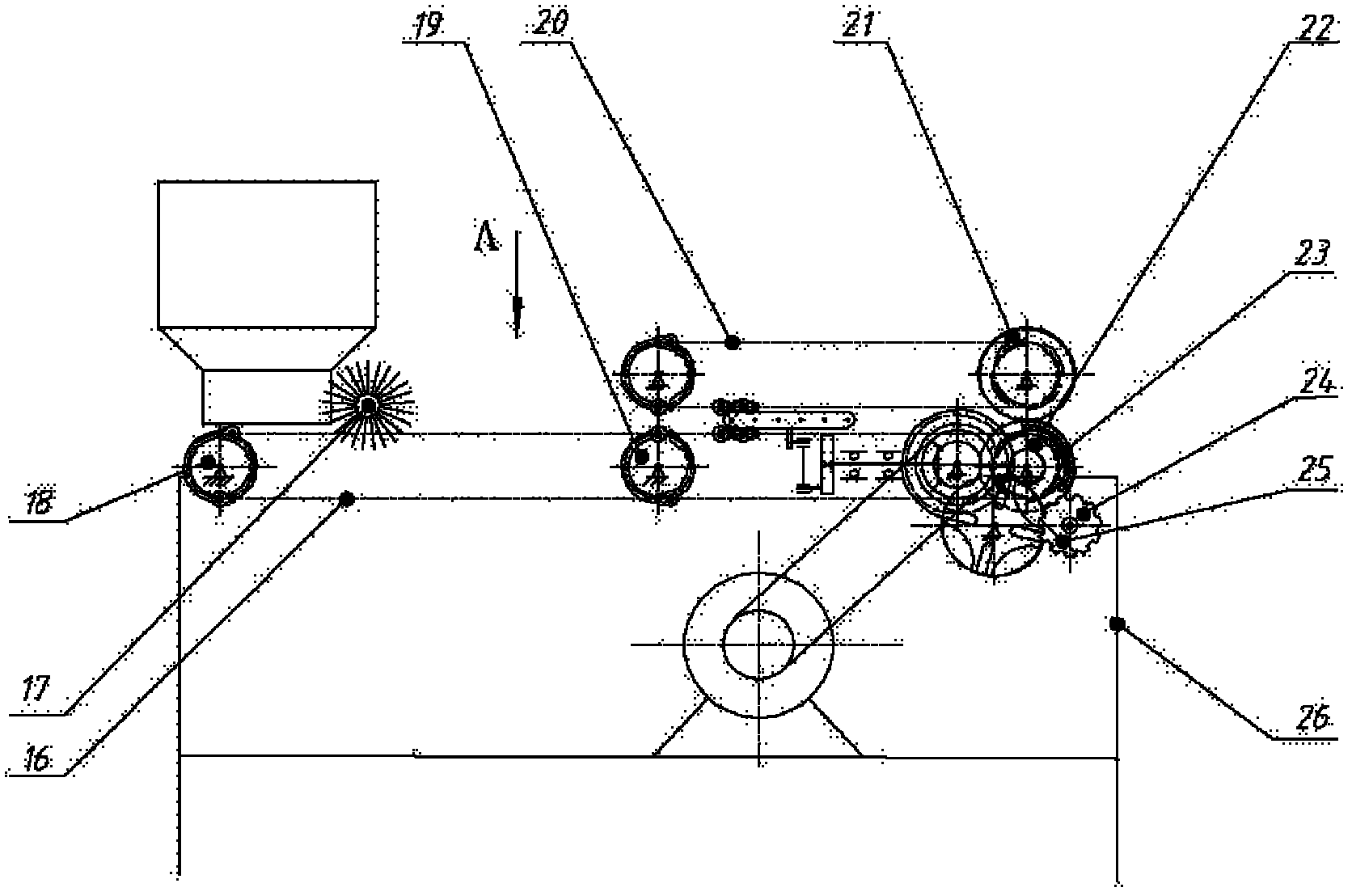

Automatic kernel-removing slicing machine for Chinese dates

ActiveCN102357906AAchieve rotationGood synchronizationFruit stoningMetal working apparatusChain conveyorEngineering

The invention discloses a rolling chain type conveyer, which is used for orientating and transporting Chinese dates, namely horizontally placing the Chinese dates along an axial direction and feeding in a parallel manner. A hairbrush on the upper part of a roller allows only one row of Chinese dates to pass through; a friction plate on the lower part of the roller is used for realizing rotation of the roller; two rows of chains and four rollers are used for positioning and clamping the Chinese dates when the kernels are removed, thereby providing a condition for punch kernel-removing; conveying, kernel-removing and slicing are driven by a same motor; synchronism is excellent; a centric slider crank mechanism is used as a kernel-removing mechanism; and after kernel-removed Chinese dates are moved to the tail end of a conveying chain, the Chinese dates are guided to move to a cutter slot type feeding wheel by an adjustable protecting plate and then are sliced by a blade, thereby forming a plurality of concentric annular slices. The integration of orientating, kernel-removing and slicing is realized.

Owner:启东市天汾电动工具技术创新中心

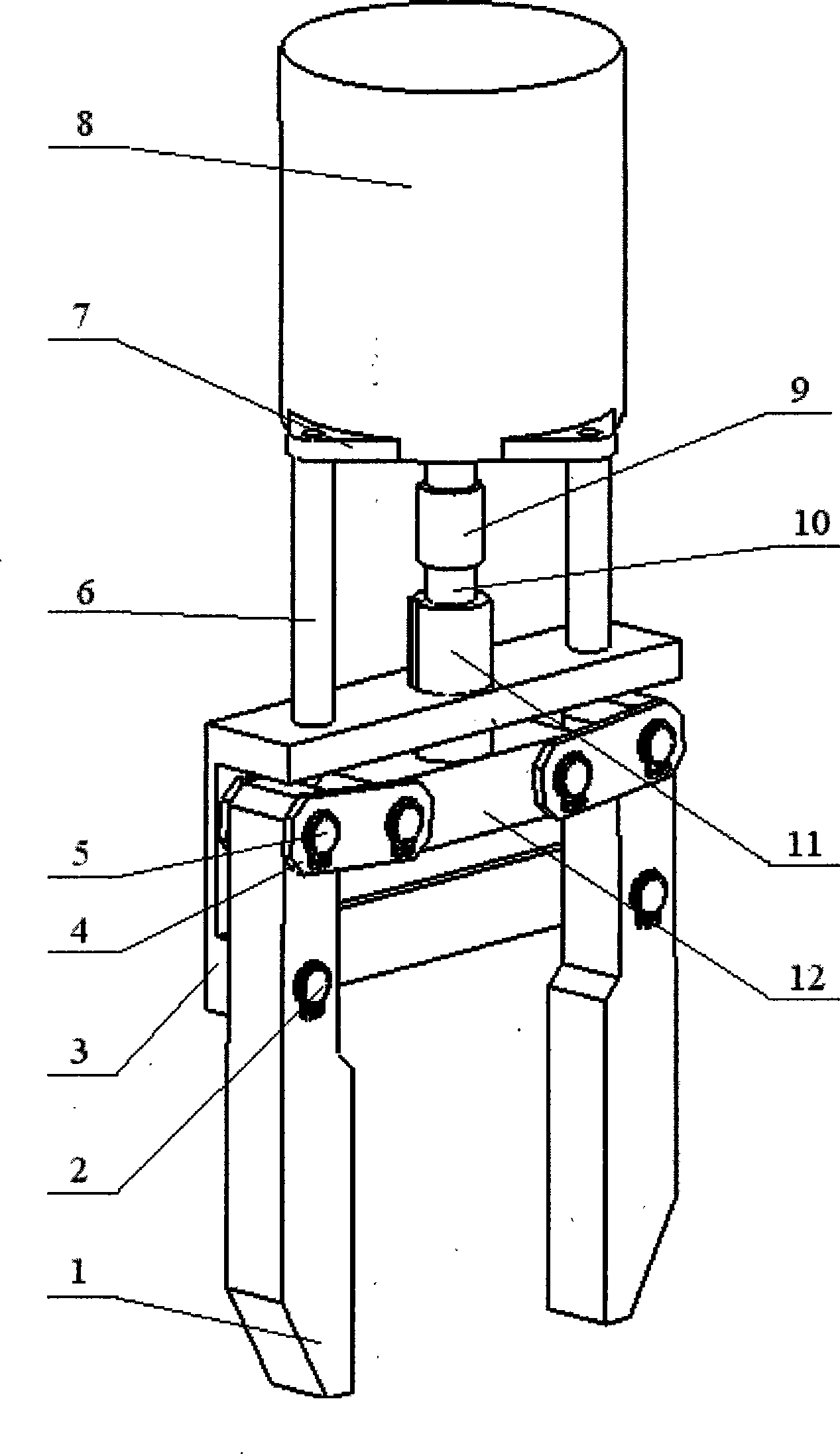

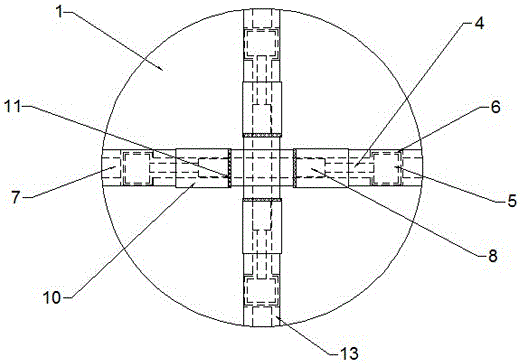

Pneumatic clamping mechanism

InactiveCN105108678ASimple mechanical movementSimple structureWork holdersEngineeringMechanical engineering

The invention relates to a pneumatic clamping mechanism which comprises a chuck body, an air cylinder, a plurality of clamping mechanisms and a guiding mechanism, wherein a cavity for placing the guiding mechanism is formed at one side inside the chuck body; sliding chutes for placing the plurality of clamping mechanisms are formed in the end part of the chuck body; a push rod is connected onto a piston rod of the air cylinder; one sliding block group A is arranged at each of two ends of the push rod; each clamping mechanism comprises a clamping block arranged in the corresponding sliding chute; a sliding block group B is connected to the bottom end of each clamping block; the guiding mechanism comprises guide rails A, guide rails B and a crank; the guide rails A are arranged in the cavity; the sliding block groups A are in inserted fit with the insides of the guide rails A; two ends of the crank are respectively hinged to the sliding block group A and the sliding block group B which are positioned at the lower end of the same sliding chute. The pneumatic clamping mechanism disclosed by the invention has the advantages of consisting of the air cylinder and a crank sliding block mechanism, being simple in mechanical motion and integral structure, and being easy to process; a clamping block is clamped by the motion of pushing the crank sliding block mechanism through the air cylinder; higher precision can be obtained; meanwhile, the pneumatic clamping mechanism is quick in clamping process, so that the working efficiency is improved.

Owner:NANTONG HUAXING OIL EQUIP

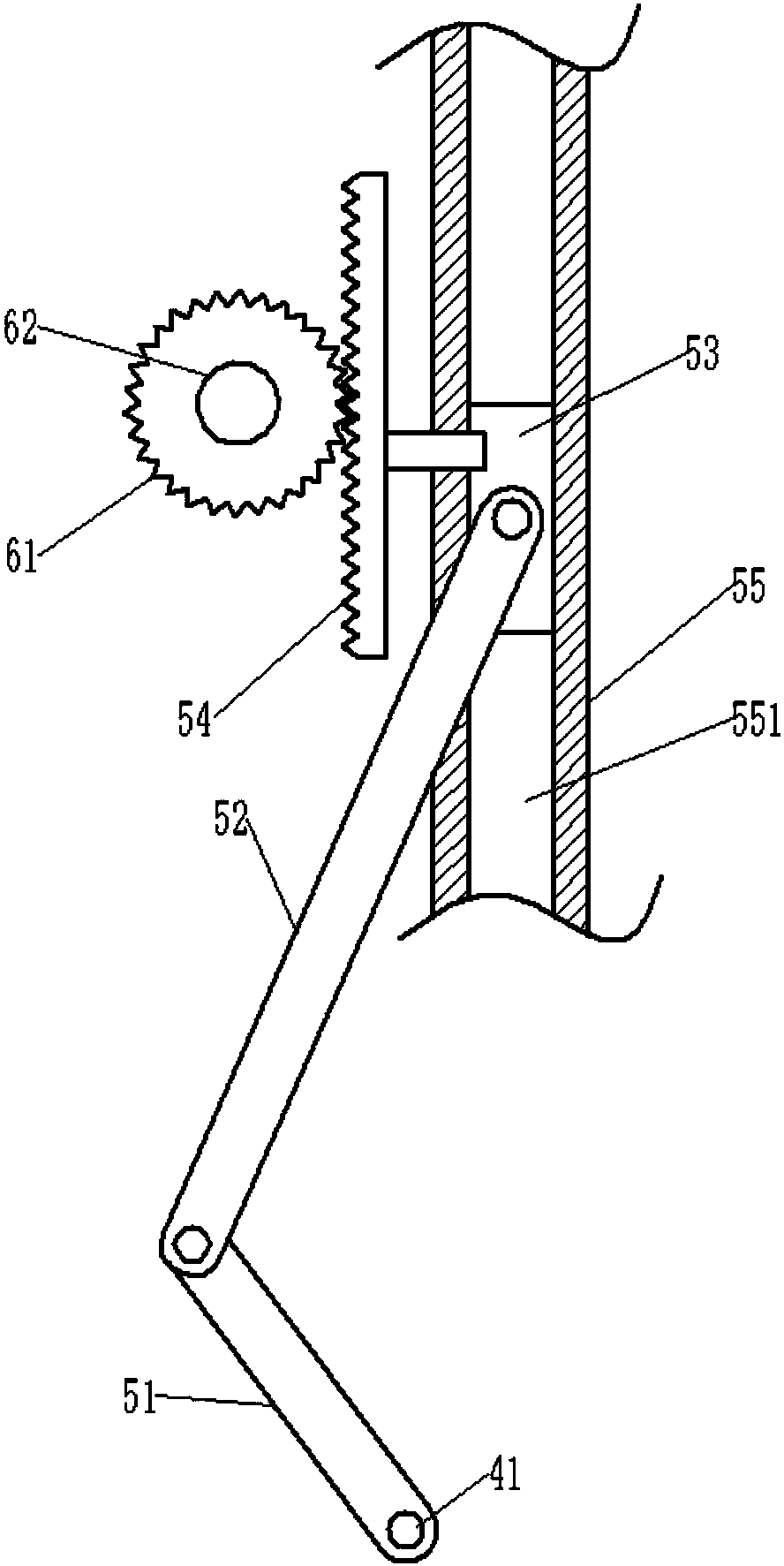

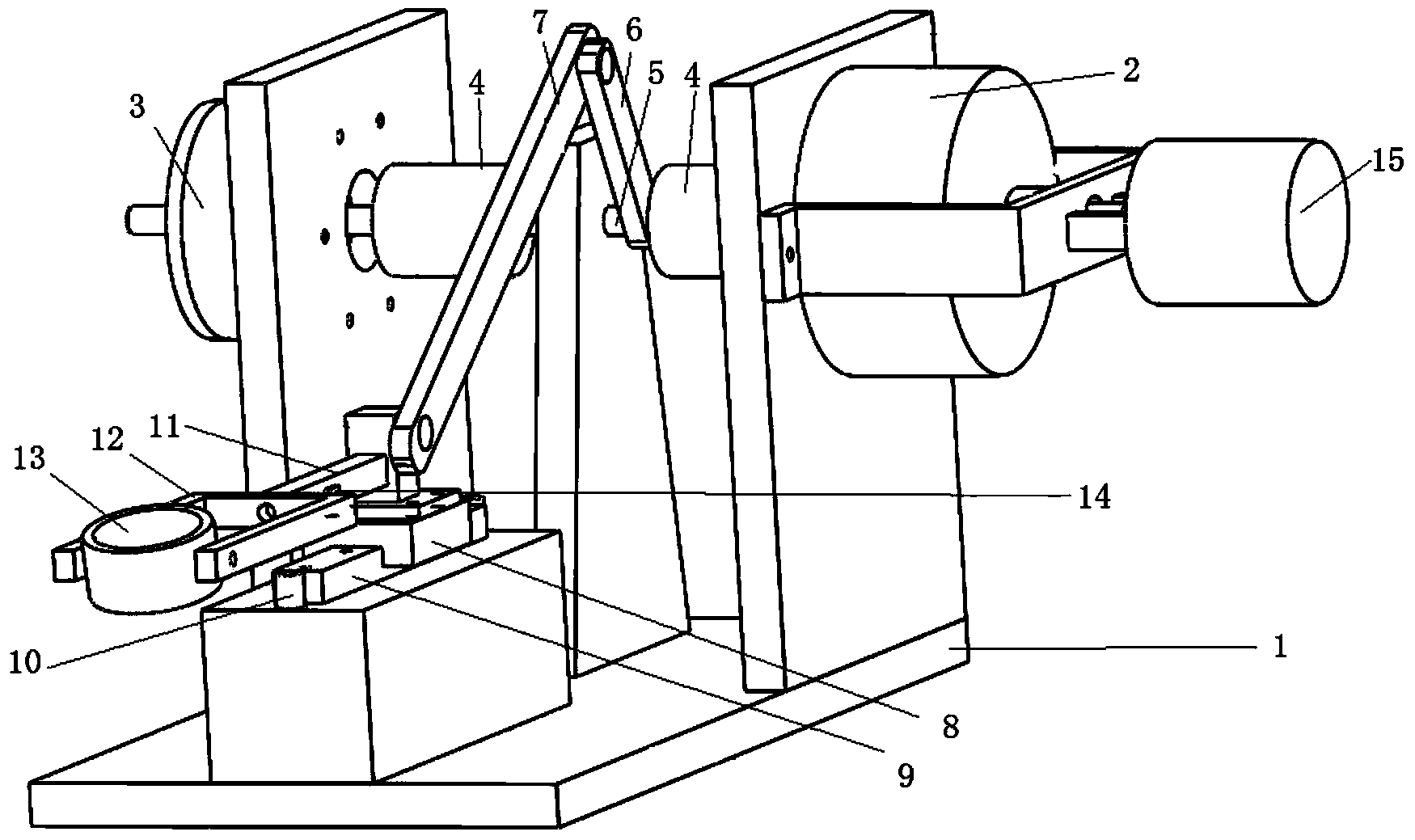

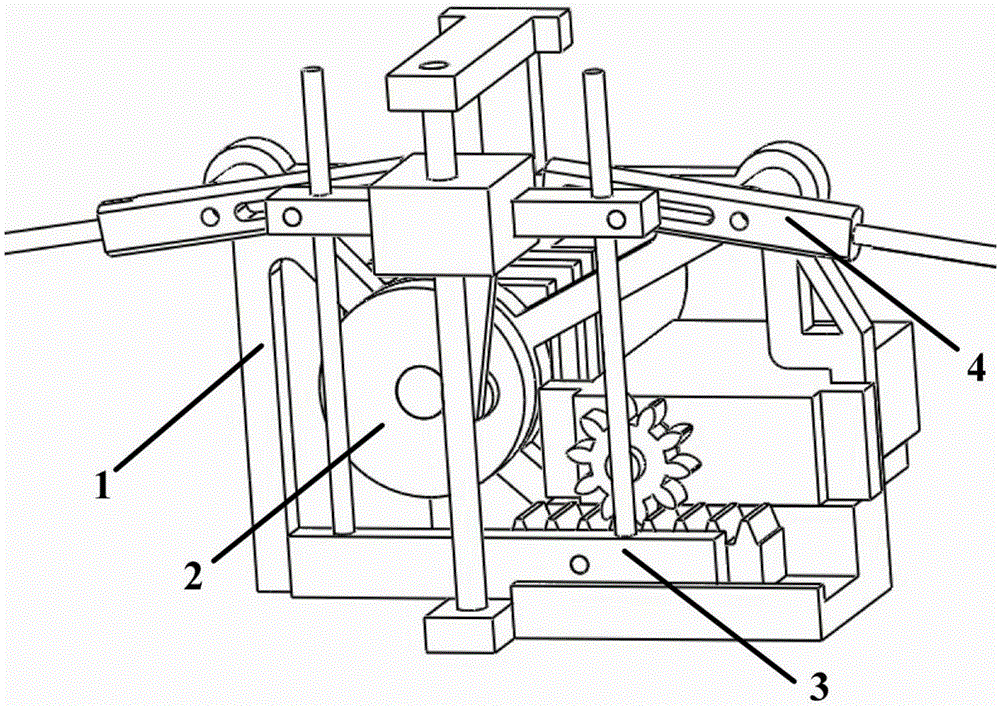

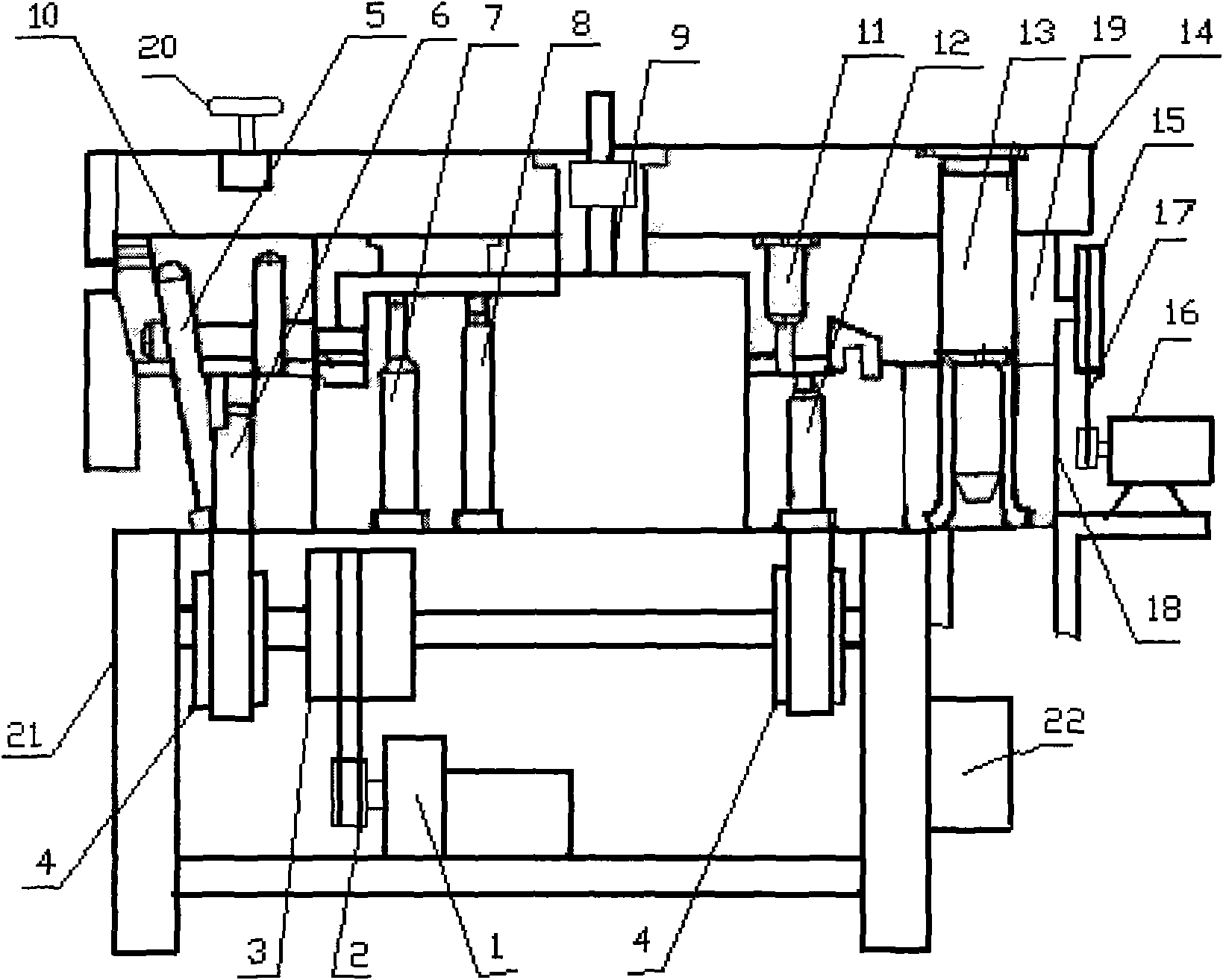

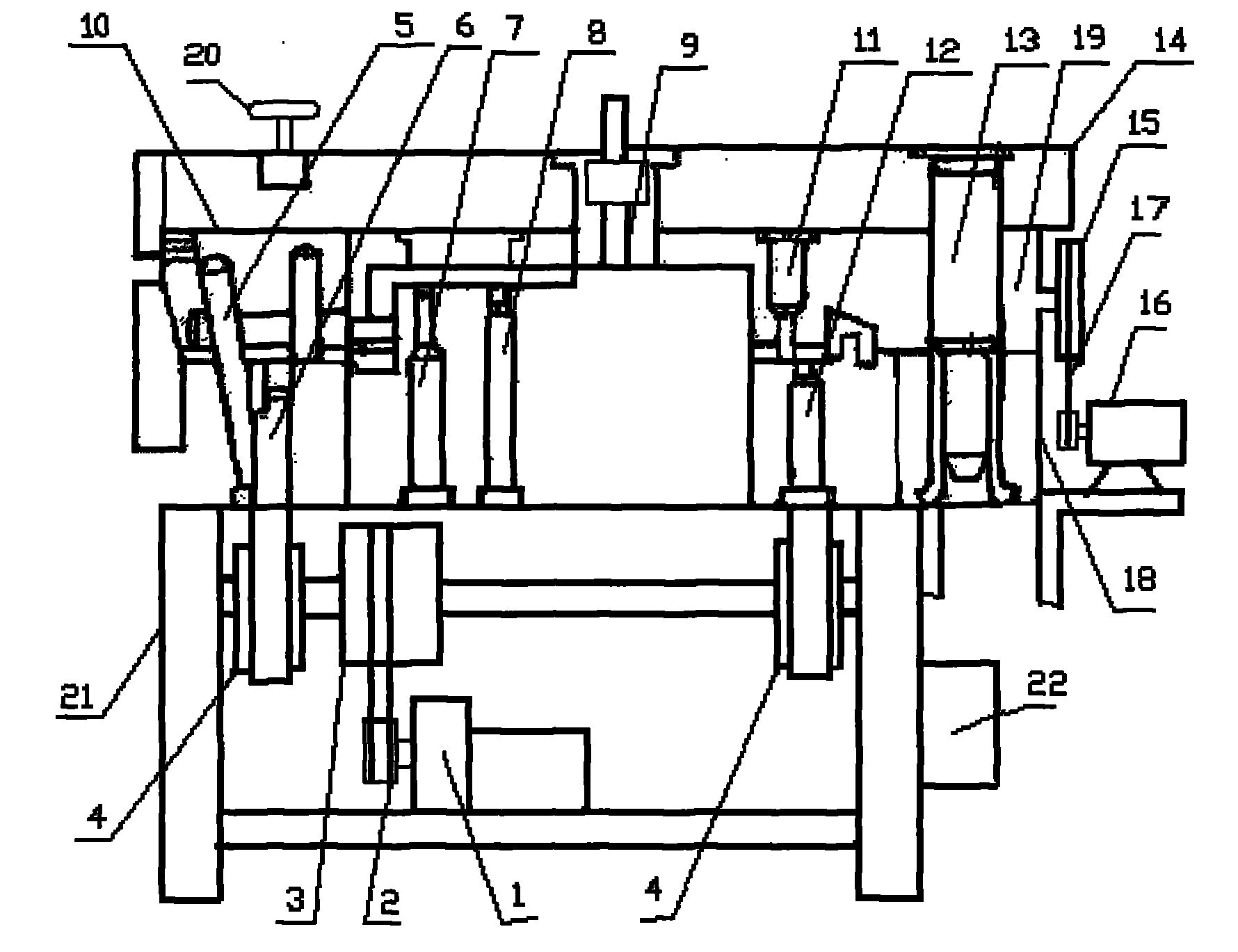

Reciprocating double-station friction-wear tester

ActiveCN106092794ARealize high frequency workZero inertiaUsing mechanical meansInvestigating abrasion/wear resistanceElectric machineReciprocating motion

The invention relates to a reciprocating double-station friction-wear tester which comprises a tester base, a driving system, a loading system, a friction testing system and an abrasion testing system, wherein the driving system is fixed on the base; a driving gear is driven by a speed adjusting motor to rotate, and driven gears are driven by the driving gear to work, so that moving plates can be driven by a slider-crank mechanism to make straight line reciprocation movement. The tester is based on the idea of a symmetric mechanism, two driven gears in opposite rotation directions are adopted to drive the moving plates to make straight line reciprocation movement in opposite directions, and inertia force generated when each moving plate is moved can be just counteracted. The reciprocating double-station friction-wear tester is capable of simulating abrasion and wearing properties of a self-lubricated joint bearing liner in different working environments, is very good in working consistency, and can provide very wide working condition options.

Owner:SHANGHAI UNIV

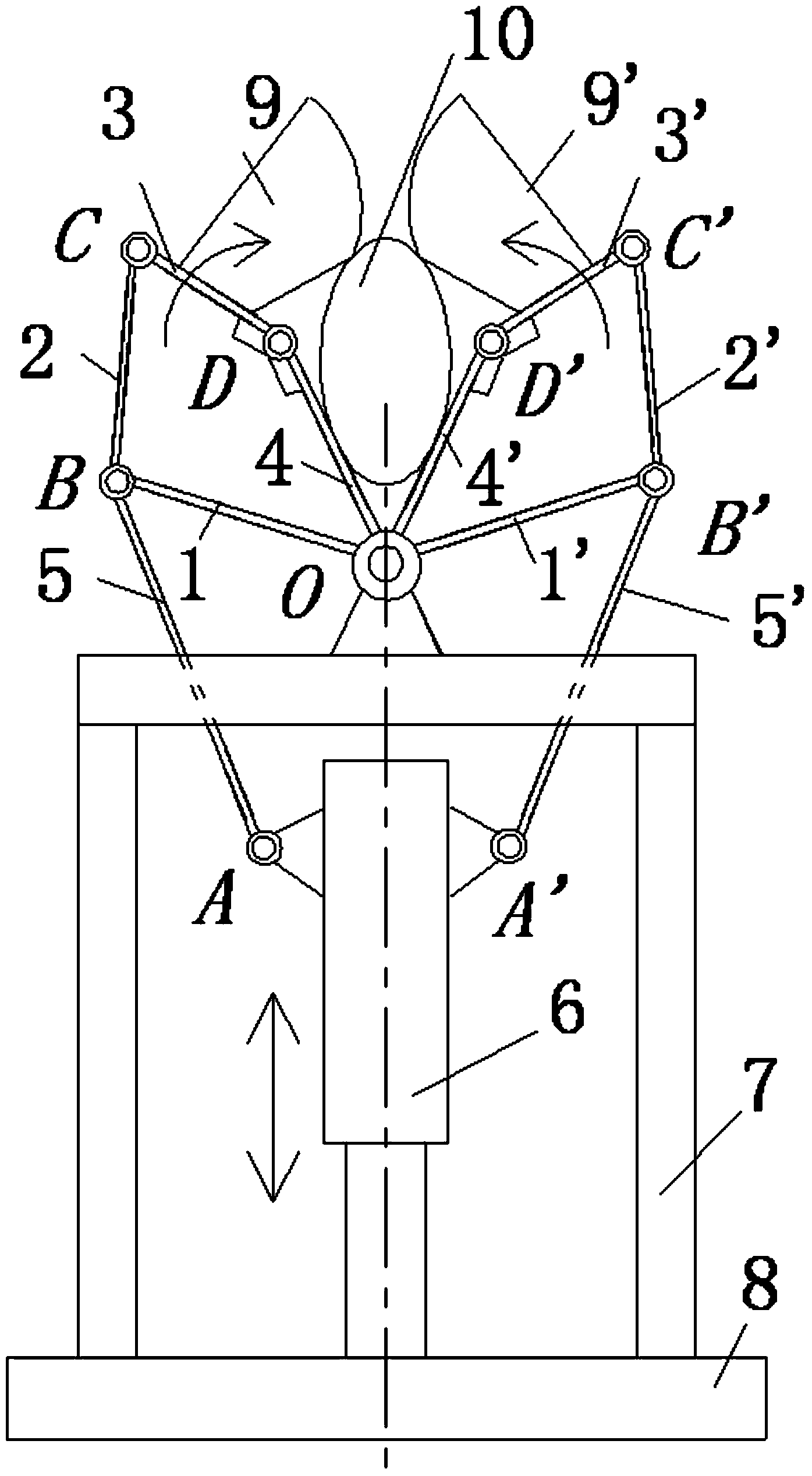

Flapping wing robot capable of automatically adjusting flapping amplitude values of left wing and right wing

The invention discloses a flapping wing robot capable of automatically adjusting the flapping amplitude values of a left wing and a right wing. The flapping wing robot can automatically adjust the flapping amplitude values of the left wing and the right wing while the flapping phase of the left wing and the right wing is not changed. The flapping wing robot comprises a machine frame device, a drive device, an amplitude value adjusting device and swinging devices. Under the effect of a drive motor, the drive device can drive a slider through an off-center slider-crank mechanism to reciprocate vertically along a fixed guide rail, the amplitude value adjusting device is driven to drive the two symmetrically-arranged swinging devices to swing around a fixed point, and the wings flap. The amplitude value adjusting device can move leftwards and rightwards under the effect of a gear and a rack, so that the flapping amplitude values of the wings are changed, and the left wing and the right wing swing at the same phase and different amplitude values. By the adoption of the flapping wing robot, under the condition that the left wing and the right wing flap at the same phase, a rudder drives the amplitude value adjusting device to move to achieve the purpose that the left wing and the right wing flap at the different amplitude values, and the flapping wing robot can be applied to automatic adjustment of the aerial pose of the flapping wing robot.

Owner:BEIHANG UNIV

Novel automatic feed plate cutting mechanism

InactiveCN101856741ASimple structureReduce labor intensityMetal-working feeding devicesShearing machinesMotor driveGear wheel

The invention relates to a novel automatic feed plate cutting mechanism, which consists of a speed reducer, a crank block mechanism, a press-lift roller mechanism, an upper shaft roller, a lower shaft roller, a stepping motor and a programming controller, wherein the speed reducer is connected with the motor and transmits the motion of the motor to a main shaft component through a belt wheel and a large belt wheel of the motor; a pair of eccentric wheels in the crank block mechanism is fixed at both ends of a main shaft; the eccentric wheels drive a top rest through a connecting rod, so that the top rest reciprocates up and down; a pressure feeding mechanism is connected with the top rest, and consists of a pressure plate and a pressure spring; the stepping motor drives the lower shaft roller through a chain wheel, and is controlled by the programming controller; and both ends of the lower shaft roller and the upper shaft roller are engaged by a gear set. In the press-lift roller mechanism, an adjustable slide block is driven by an adjusting screw rod to ascend and descend, so that the upper shaft roller and the lower shaft roller maintain an appropriate gap; and plate materials are pressed and loosened by using the pressure plate, and simultaneously, the plate materials are convenient to feed.

Owner:王玲

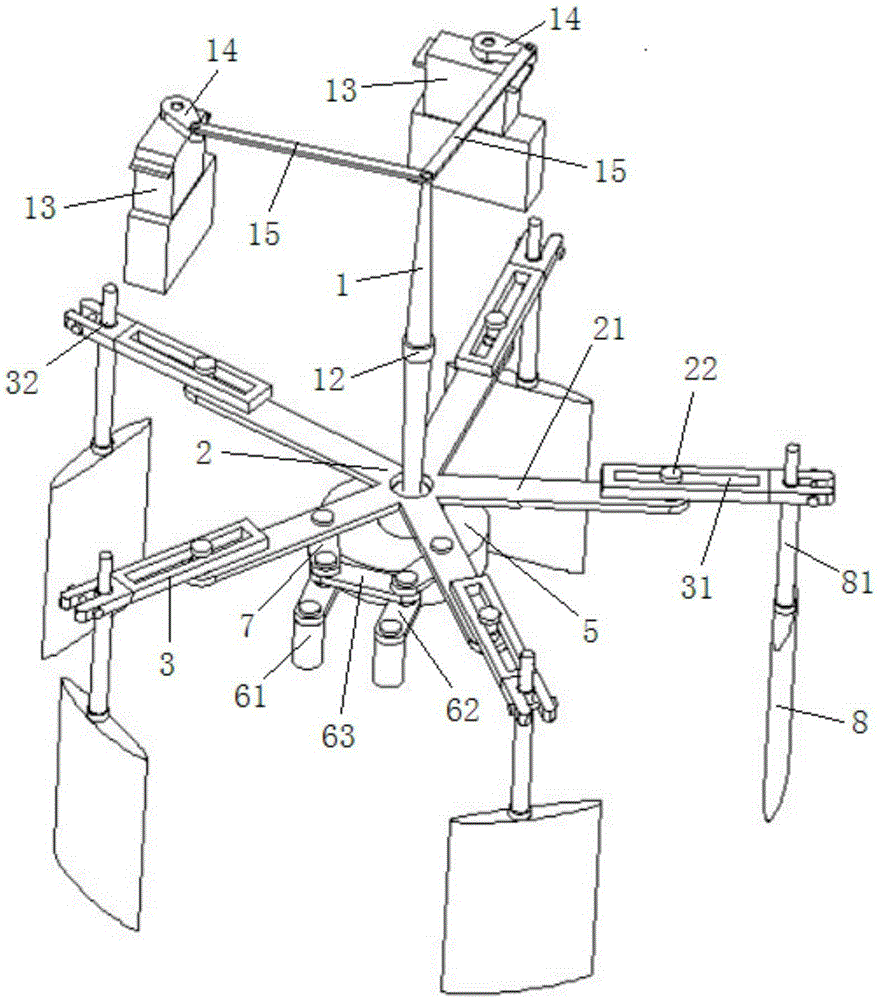

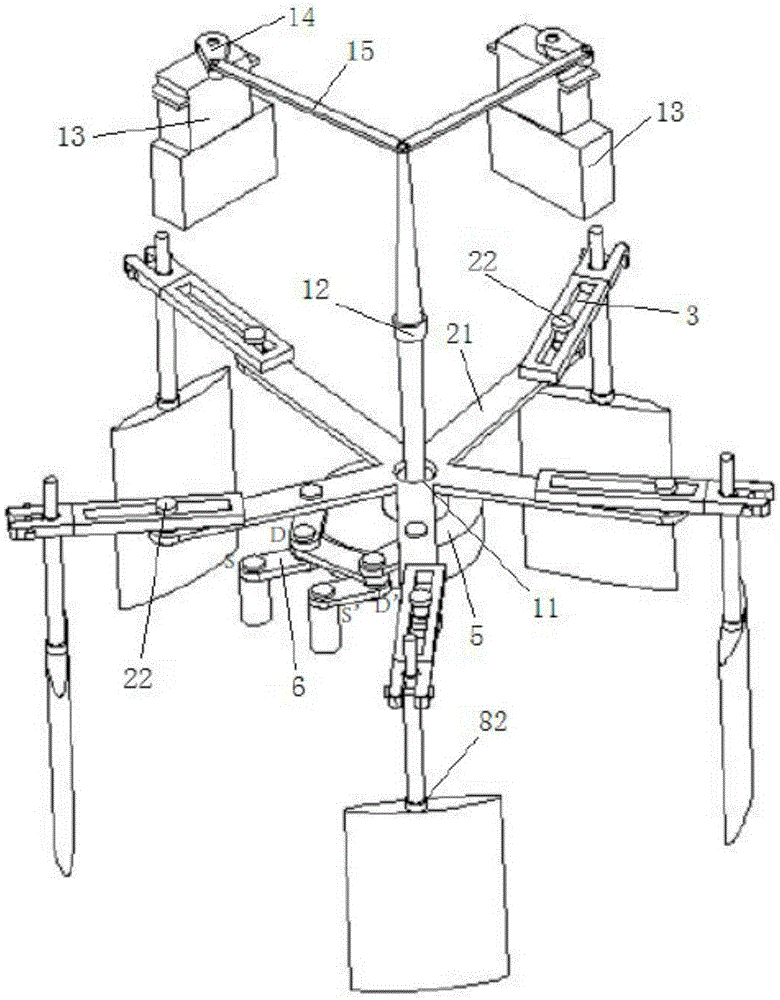

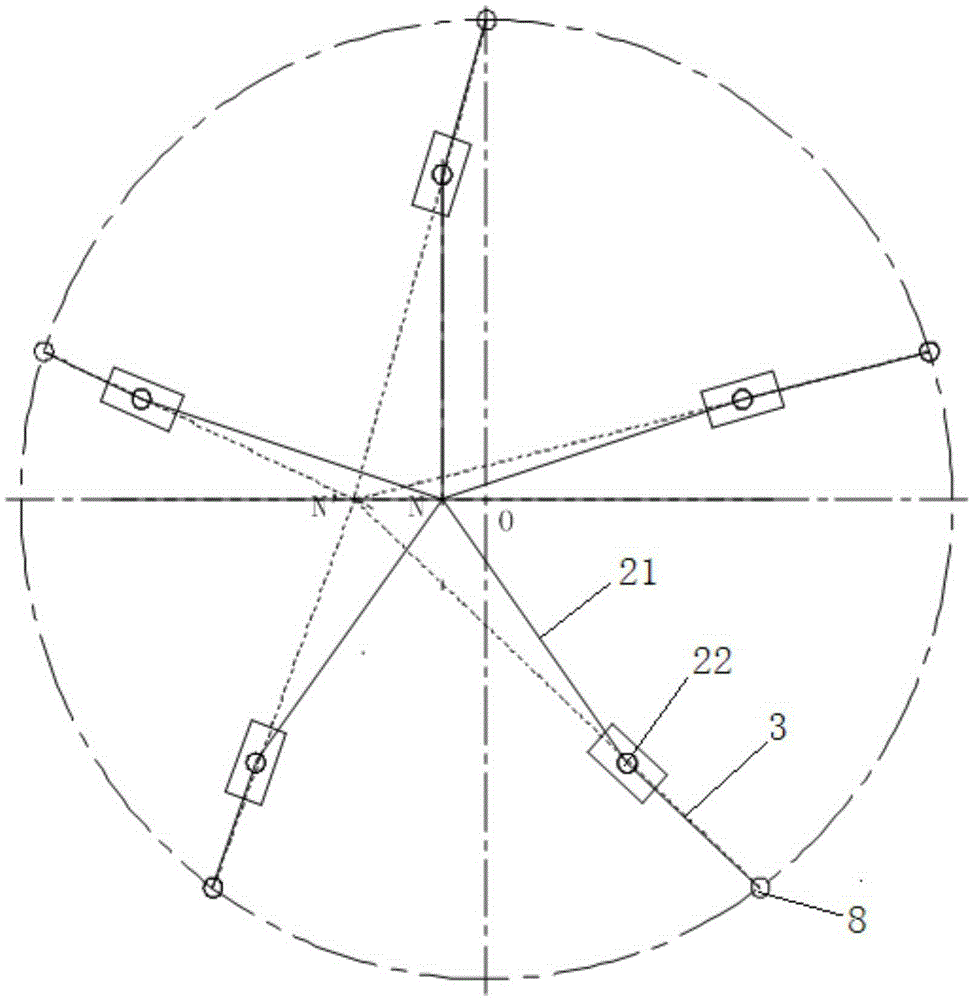

Crank-slider type vane oscillating mechanism and straight-wing propeller comprising same

ActiveCN105383655ACompact and reasonable structureReduce in quantityPropulsive elements of rotary typePropellerEngineering

The invention discloses a crank-slider type vane oscillating mechanism and a straight-wing propeller comprising the same. The crank-slider type vane oscillating mechanism comprises a control rod, a connecting frame, guide rods, a boss, a support frame structure and a connecting rod, wherein the boss and the support frame structure are fixed on a rotary disk, and the connecting rod is connected between the adjacent two frame arms of the connecting frame and the support frame structure; a sliding block sliding along a long groove of each guide rod is arranged at the outer end of each frame arm of the connecting frame, and the outer end of each guide rod is vertically and fixedly connected with the main shaft of a vane; the main shaft of the vane rotationally and vertically penetrates into the rotary disk; under the rotating action of two steering engines, the control rod does a lever motion by taking a second joint bearing in the middle of the control rod as a supporting point, and the lower end of the control rod is mounted in the center of the connecting frame through a first joint bearing and forms a control point N; when the rotary disk drives the vanes to revolute, a crank slider structure drives all the vanes to rotate; the crank slider structure is combined with the guide rods, and therefore the magnification of eccentric distance of the straight-wing propeller is realized.

Owner:ZHEJIANG UNIV

Novel lower limb joint mechanism of reclining-type Lower limb rehabilitation robot

ActiveCN102743838AStable and reliable transmissionHigh precisionGymnastic exercisingThighPhysical medicine and rehabilitation

The invention discloses a novel lower limb joint mechanism of a reclining-type Lower limb rehabilitation robot. The mechanism comprises three joint mechanisms including a hip joint mechanism, a knee joint mechanism and an ankle joint mechanism, and three connection rod mechanisms including a thigh link mechanism, a crus link mechanism and an ankle-high link mechanism. The hip joint mechanism, the knee joint mechanism and the ankle joint mechanism can be conveniently and respectively optimized by adopting different slider-crank mechanisms. Rotary nut-type ball screws are respectively adopted by all the joint mechanisms to form sliding pairs of the slider-crank mechanisms; all the joint mechanisms are respectively provided with a pull pressure sensor which can be used for indirectly measuring the torque of a corresponding joint; each joint is provided with a direct-current motor which can be used for independently driving the corresponding joint mechanism; and the direct-current motors are respectively provided with a position sensor. All the joint mechanisms respectively have a center of rotation, and the thigh link mechanism, the crus link mechanism and the ankle-high link mechanism are adjustable in length, so that the lower limb joint mechanism can be kept highly consistent with lower limbs of a human body.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

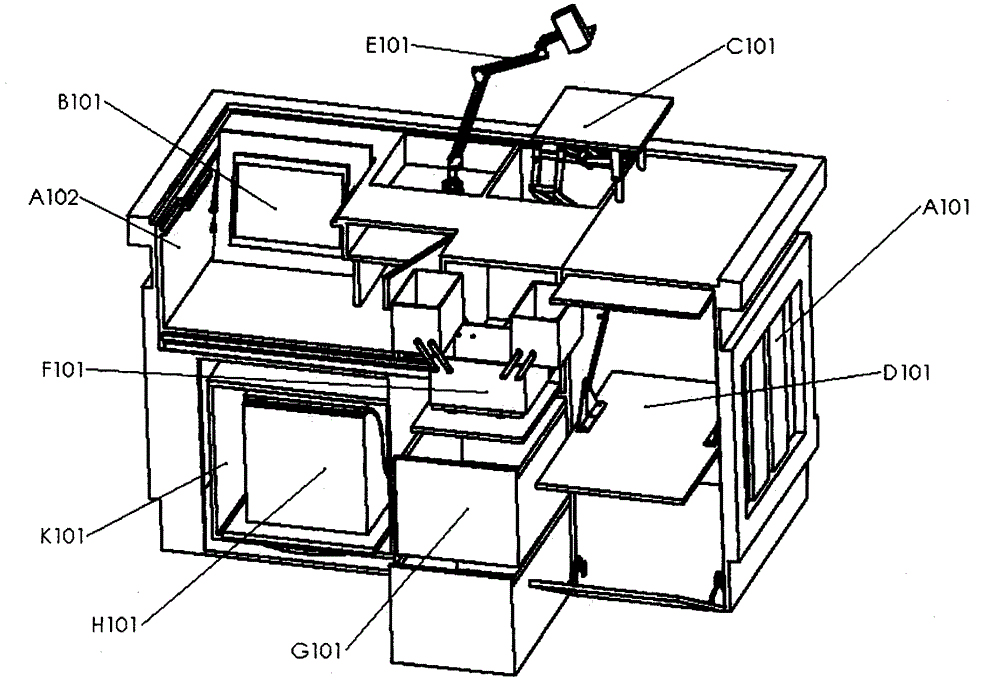

Multifunctional teacher desk

InactiveCN105266422AMeet storageFunction increasePulpitsLecternsProjection systemIndustrial engineering

The invention provides a multifunctional teacher desk comprising nine parts which are an overall frame, an overturn type desk top carrier, a folding teaching aid exhibition stand, a movable material object projection system, a push type model cabinet, a linkage type storage box, an ejection drawer, a lifting stool and a lifting stool holding box. The multifunctional teacher desk is an accommodating supporter of other functional structures. The overturn type desk top carrier can turn part of the desk top to a displayer carrier through double-rocker mechanisms. The folding teaching aid exhibition stand lifts part of the desk top through planar connecting rod mechanism sets to form a model exhibition stand. The ejection drawer can be ejected automatically through rebounding sliding rails. With symmetrical slider-crank mechanisms, the stool top of the lifting stool can ascend and descend and the function conversion of a small stool and a podium is achieved. Through a crank rocker-crank slider combination mechanism, the switching between the rotation of the box body of the holding box and the translation of a box bottom can be achieved. The multifunctional teacher desk has the functions of teaching aid exhibition, material object projection, object storage, etc. and can meet the requirement of different teaching occasions.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

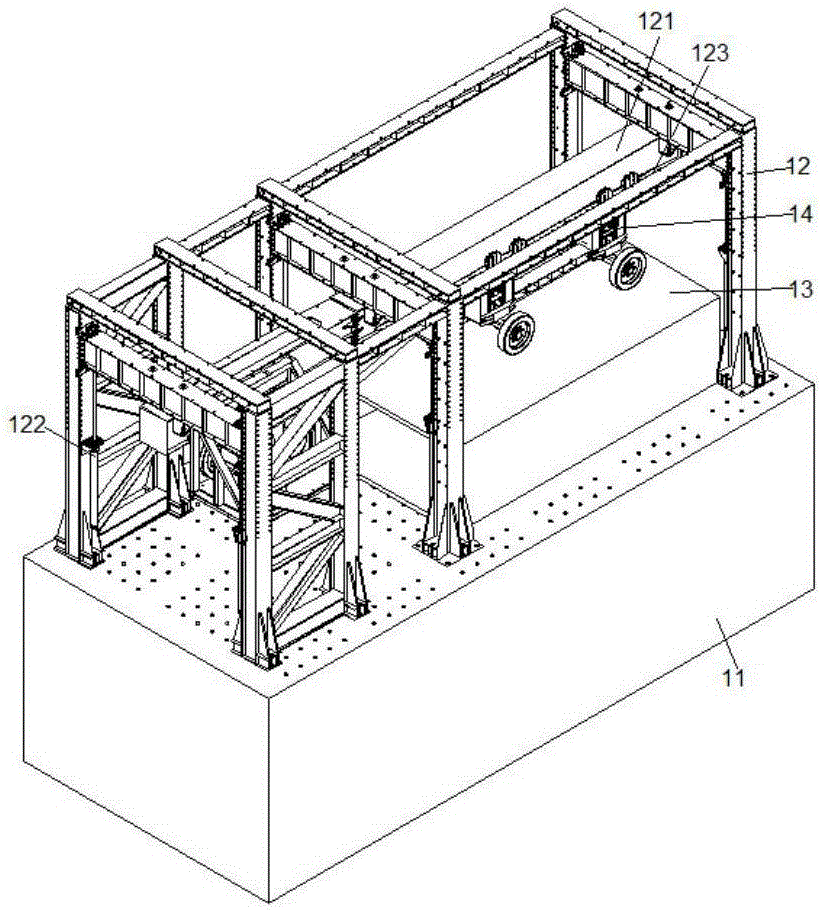

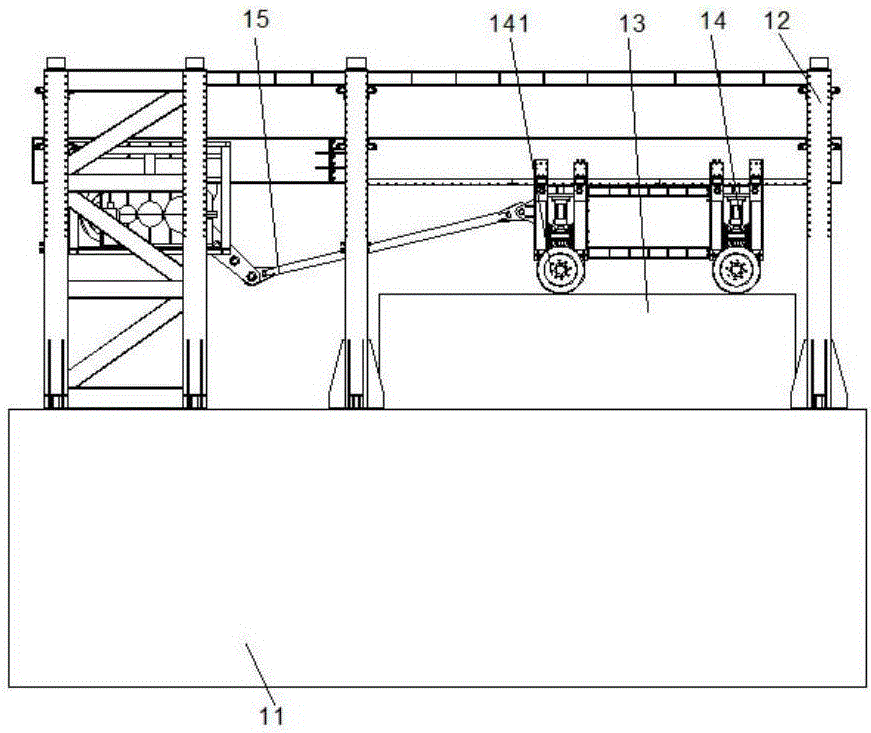

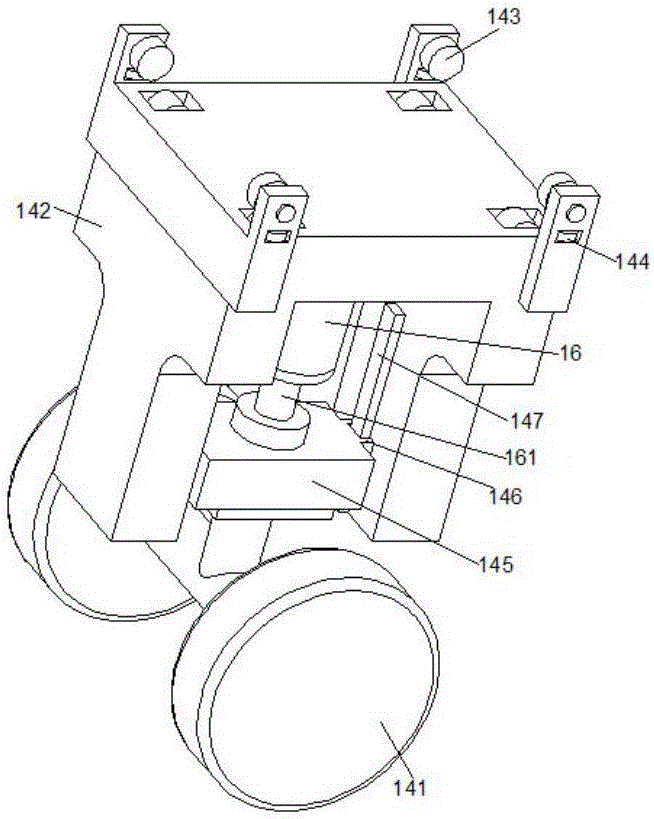

Fatigue test system for bridge and pavement with roller load

PendingCN106525619AEnsure safetyMaterial strength using repeated/pulsating forcesProgramme control in sequence/logic controllersServo actuatorTest sample

The invention discloses a fatigue test system for a bridge and a pavement with roller load. The fatigue test system comprises a counterforce foundation, a combined bearing frame, a tested sample and a loading trolley, wherein the tested sample is fixed on the counterforce foundation; the counterforce foundation and the combined bearing frame are fixed mutually; the loading trolley is arranged on the tested sample; a horizontal cross beam is arranged on the combined bearing frame; the top of the loading trolley is connected onto the horizontal cross beam and the loading trolley can move leftwards and rightwards relative to the horizontal cross beam; a servo motor is further arranged on the horizontal cross beam and drives the loading trolley to move leftwards and rightwards through a slider-crank mechanism; an electro-hydraulic servo actuator on the loading trolley can control rollers of the loading trolley to move vertically. The fatigue test system for the bridge and the pavement with the roller load can perform full-size bridge and pavement fatigue tests and guarantees safety of the bridge and the pavement.

Owner:LIAONING PROVINCIAL TRANSPORTATION PLANNING & DESIGN INST +1

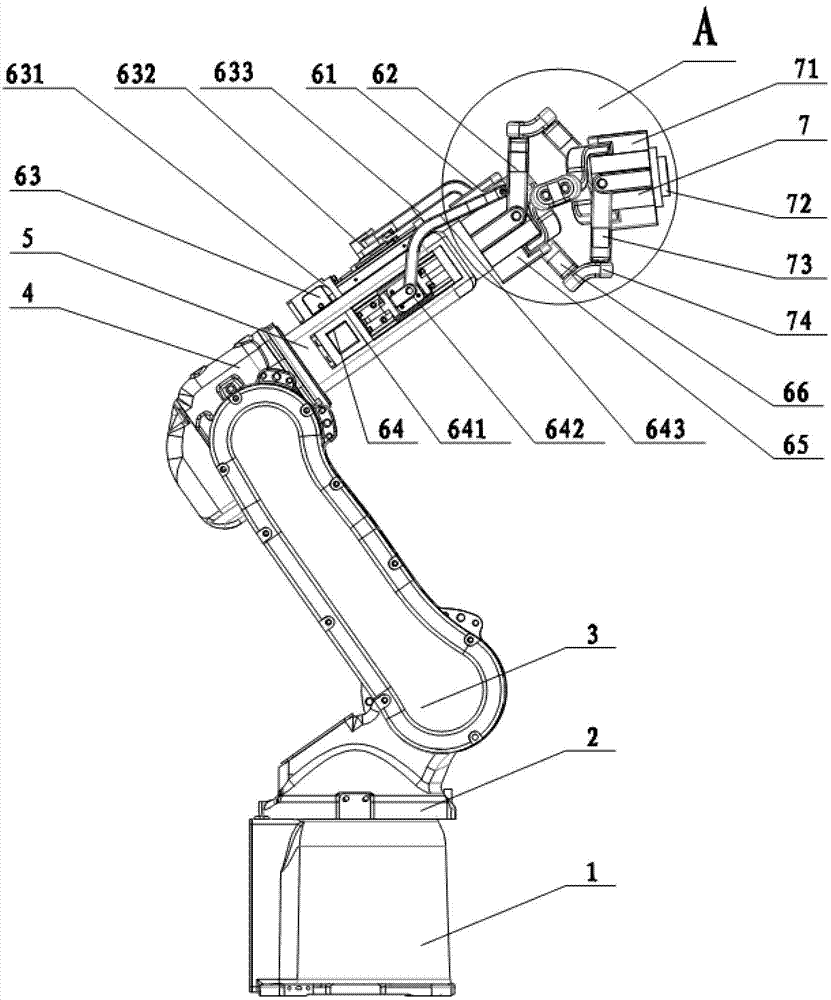

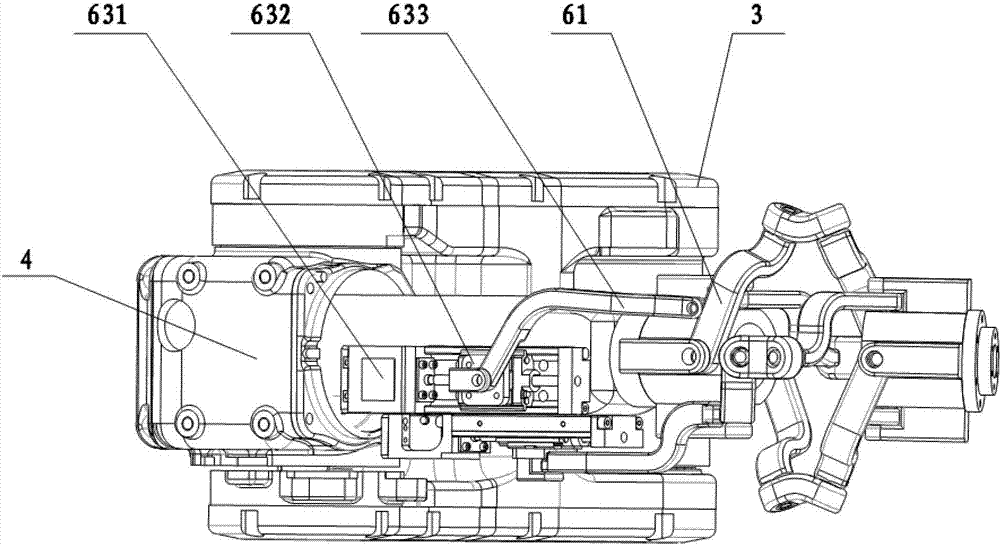

Industrial robot of six-degrees of freedom

InactiveCN102785239ARealize large angle rotationAchieve rotationProgramme-controlled manipulatorLinear motionAngular degrees

The invention provides an industrial robot of six-degrees of freedom. The industrial robot comprises a base, a first component, a second component, a third component, a fourth component, a fifth component and a sixth component, wherein the fifth component and the sixth component are connected with each other through double revolute pairs; the sixth component comprises a lower seat and four third connecting rods; and a first linear module and a second linear module drive a first crank shaft-sliding block structure and a second crank shaft-sliding block structure to conduct linear movement respectively, so as to drive a first connecting rod and a second connecting rod to conduct linear movement respectively, drive a first actuating arm and a second actuating arm to rotate respectively, and drive the fifth component and the sixth component to rotate together. According to the invention, a serial mechanism and a serial mechanism are combined to design the industrial robot with parallel large rotation wrists, so as to realize large angle rotation; and due to the parallel wrists, singular points which are inevitable to a common industrial robot of six-degrees of freedom are avoided. Therefore, the movement of the robot is quicker and smoother, and the robot can be widely applied to industrial operation.

Owner:QKM TECH (DONG GUAN) CO LTD

Soil strength test board for wheel

InactiveCN104122102AIncrease diversityEasy to replaceApparatus for force/torque/work measurementVehicle wheel testingDrive wheelEngineering

The invention relates to a soil strength test board for a wheel. The soil strength test board for the wheel comprises a test board bracket, a wheel and a soil groove body which interacts with the wheel, the soil groove body is arranged at the lower part of the inside of the test board bracket, and the wheel is located at the upper surface of the soil groove body in a rolling press mode; the wheel is connected below a variable load mechanism through a steering mechanism, and the variable load mechanism is connected with a driven wheel drive mechanism through vertical and horizontal moving mechanisms so as to be movably hanged on two upper beams of the test board bracket; the rotating shaft of the wheel is directly connected with an active wheel drive mechanism. The soil strength test board for the wheel can use a counterweight block to change the weight of the soil strength test board for the wheel under an offline state so as to simulate the acting force between the wheel and the ground under different vehicle weights; a slider-crank mechanism changes the distance between two isotropic magnets so as to change the repulsive force there-between to simulate the online real-time vertical load change of the wheel of an air cushion vehicle; the active wheel drive mechanism and the driven wheel drive mechanism simulate the active movement form and driven movement form of the wheel.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com