Portable automatic saw blade saw

A portable, saw blade technology, used in cutting tools, cutting equipment, gardening, etc., can solve the problems of low manual operation efficiency, high labor intensity, and poor tree climbing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

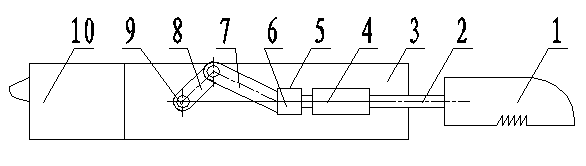

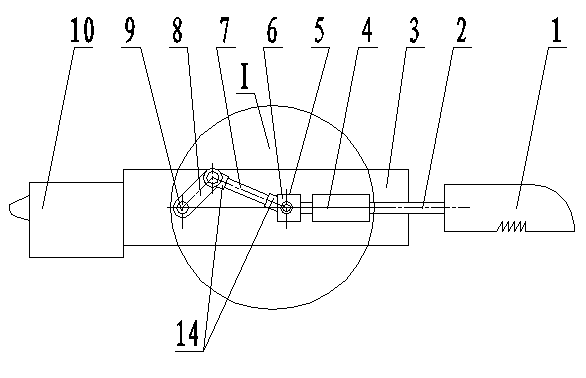

[0018] Embodiment 1: see Figure 1 ~ Figure 2 , the portable automatic saw blade saw includes a saw blade 1, and also includes a base frame 3, the base frame 3 is fixedly connected to the support 13 and the guide block 4, the DC motor 11 is fixed to the support 13, and the DC motor 11 The power shaft 9 is connected with the saw blade 1 through the power transmission device 5 . The power transmission device 5 is a crank slider mechanism, one end of the crank 8 is fixedly connected with the power shaft 9 of the DC motor 11, the other end of the crank 8 is hinged with one end of the connecting rod 7, and the other end of the connecting rod 7 is connected with the slider 6 One end of the slider 6 is hinged, and the other end of the slider 6 is fixedly connected to the optical axis 2. The optical axis 2 is placed inside a sliding fit guide block 4 . The end near the support of the base frame 3 is provided with a connecting pipe 10 which is fixedly connected as a whole and has a w...

Embodiment 2

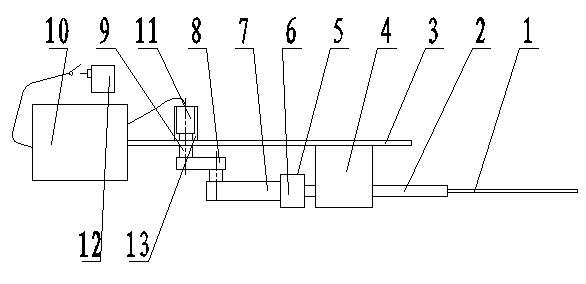

[0020] Example 2: see Figure 3 ~ Figure 6 , the portable automatic blade saw of embodiment 2 is basically the same as embodiment 1, the difference is that: the base frame 3 adopts special-shaped angle iron, the inner side of the wide side of the special-shaped angle iron is fixedly connected with the support 13, and the outer side of the narrow side is fixedly connected with the guide block 4 , the power shaft 9 of the DC motor 11 passes through the narrow side and is positioned at the outside of the narrow side; the crank slider mechanism of the power transmission device 5, the other end of the crank 8 and one end of the connecting rod 7 are hinged through the connecting rod bearing 14, and the connecting rod The pin shaft 15 that the other end of 7 is provided with the notch end of grooved slide block 6 is hinged with connecting rod bearing 14, and pin shaft 15 is connected with the notch end of grooved slide block 6 by bearing 16, and the notch end of grooved slide block 6 ...

Embodiment 3

[0022] Embodiment 3: see Figure 7 , the portable automatic blade saw of embodiment 3 is basically the same as embodiment 2, the difference is that: two extension rods 17 are added, after the two extension rods 17 are fixedly connected, one end is fixedly connected with the connecting pipe 10, and the control cable is passed through the wire The hole is introduced into the connecting pipe 10, and is drawn out from the end of the extension rod 17 to be plugged with the power supply 12.

[0023] The extension rods 17 adopted in the present embodiment 3 are commercially available products of the prior art. The pruning requirement of different height branches, using method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com