High-efficiency helical water-through jackrod

A drill pipe and screw technology, which is applied in the field of high-efficiency helical water-passing drill pipes, can solve problems such as affecting mine production, clogging the drill pipe with coal dust, and increasing the cost of excavation, so as to reduce hole collapse and sticking, reduce coal dust, and improve The effect of drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

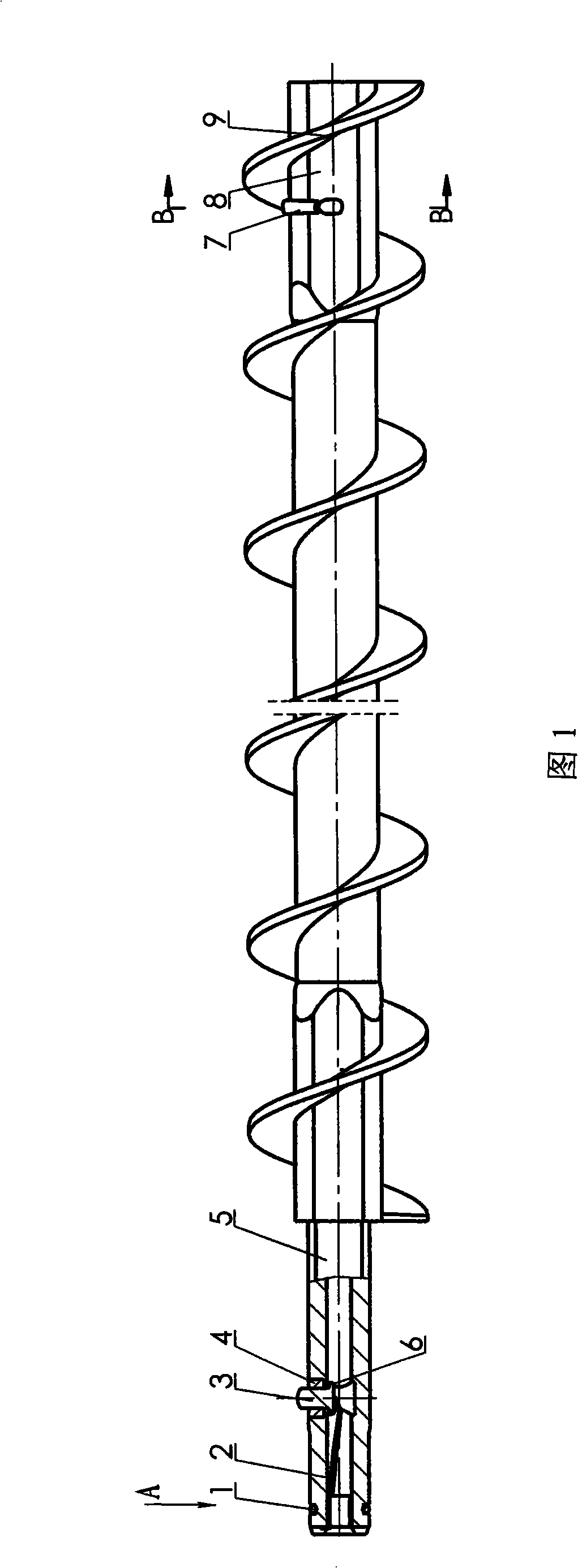

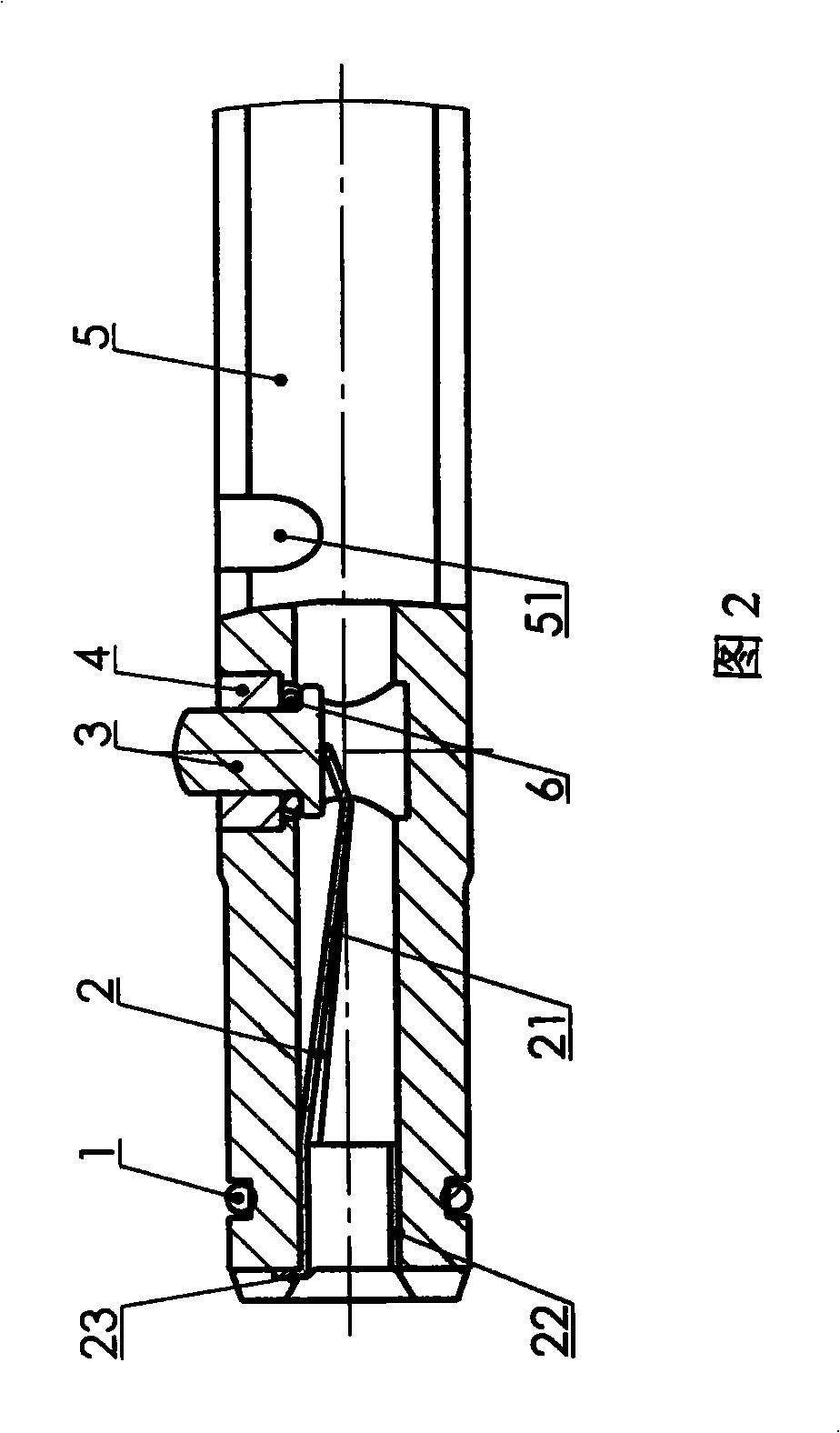

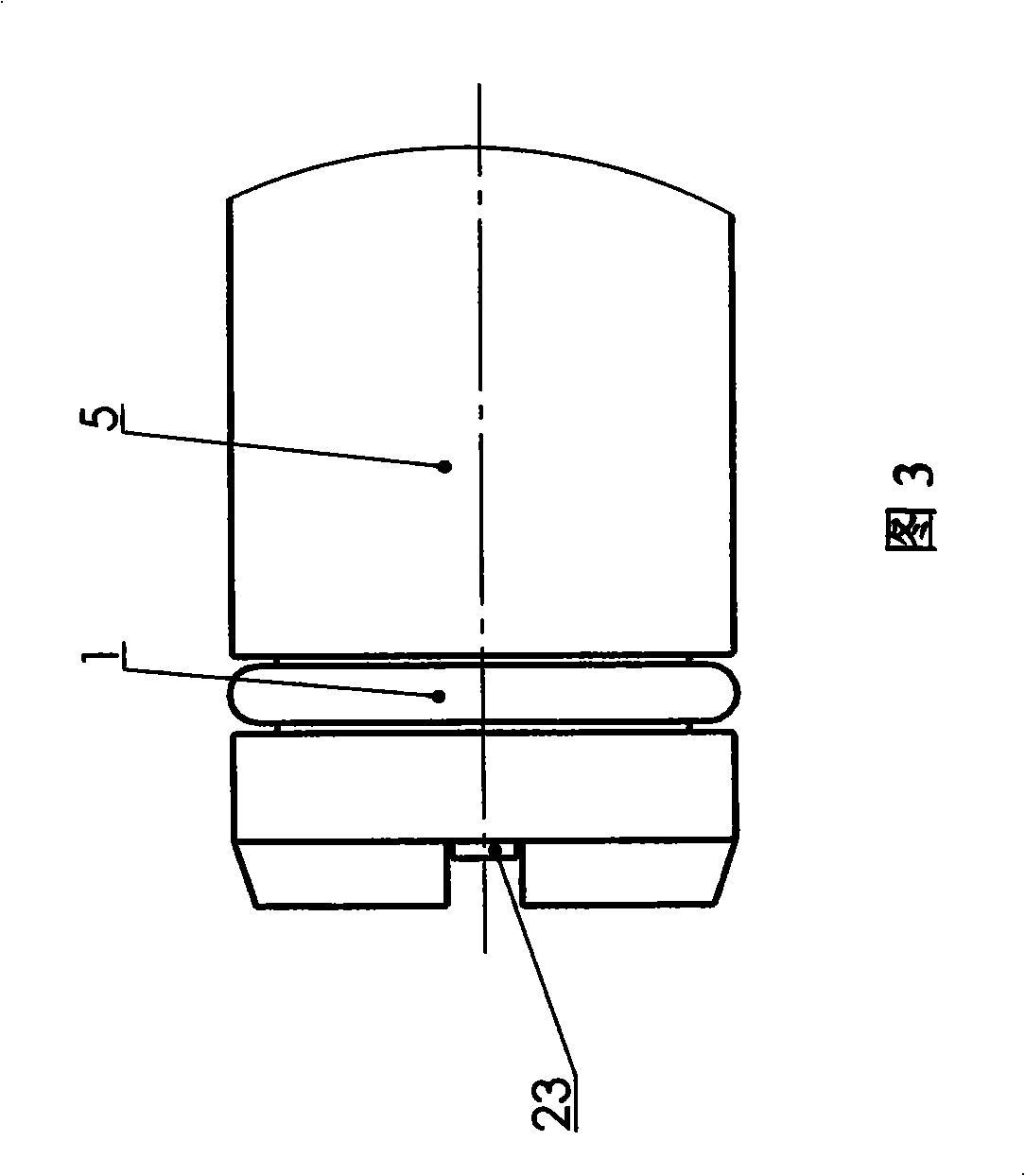

[0015] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, the present invention has several (such as one or two or more) drill pipe units, and each drill pipe unit has drill pipe core 8, is fixed on the drill pipe core The helix 9 on the top, the square rod 5 fixedly connected with the drill pipe core (the square rod inserted into the connection hole in the drill pipe core can be fixedly connected with it by hot pressing), the retaining ring 4 fixed on the square rod, and the retaining ring matched The horizontal pin 3, the spring body 2 which realizes the plug-in positioning of two adjacent drill pipe units to connect the horizontal pin as a limit support. Both the square rod and the drill pipe core have (axial) water ventilation holes, and the water ventilation holes of the two are connected. The drill pipe core 8 is wrapped around the upper spiral body 9 to form a coal channel, which facilitates the export of coal powder during drilling. The cross pin can be a cylindrical shape w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com