Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1266 results about "Coal dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal dust is a fine powdered form of coal, which is created by the crushing, grinding, or pulverizing of coal. Because of the brittle nature of coal, coal dust can be created during mining, transportation, or by mechanically handling coal. It is a form of fugitive dust.

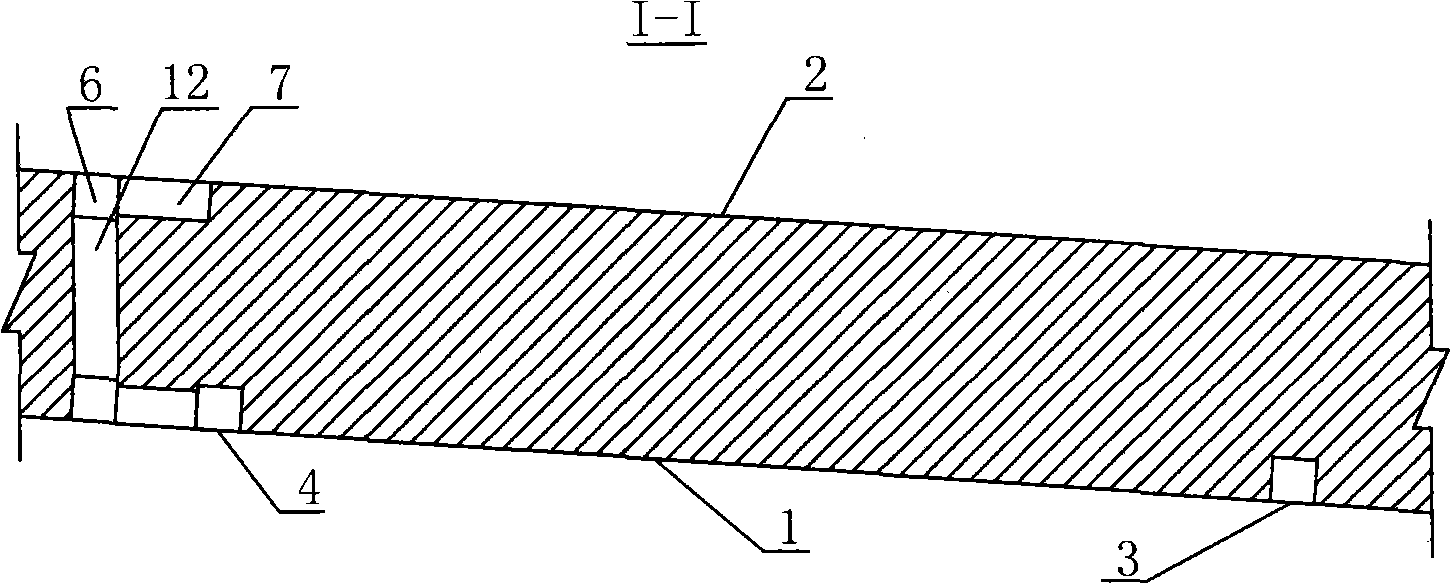

Coking coal dust shaping technique

A process method of coking coal dust forming chiefly aims at settling the problem about a second dust emission in the course of transportation. First, the large quantity of small smut produced by a fluidized bed can be collected by a dust precipitator, be conveyed to a smut collecting storehouse, and constantly transmitted into a high pressure molding machine by an incessant closed conveyer. The feeding mouth of the high pressure molding machine is provided with a repressing screw to ensure the smut entering a high pressure rolling pair to be with certain pressure. Then the smut can be extruded into effigurate briquette, which at last is conveyed into a production coal conveying system after the molding. The process can prevent the production coal from producing the second dust emission during the transportation, thus reducing the engineering investment and environmental pollution with the advantages of less floor space and increasing the coke yield produced by coke oven.

Owner:SHANDONG IRON & STEEL CO LTD

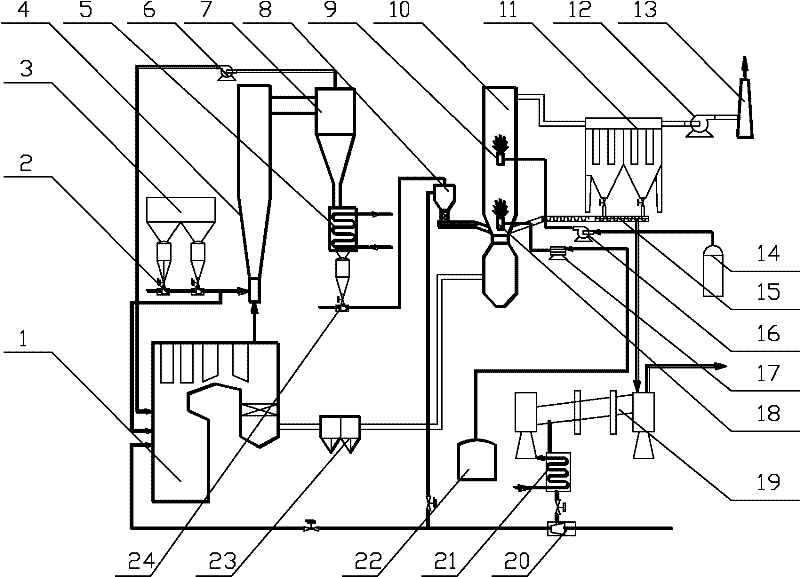

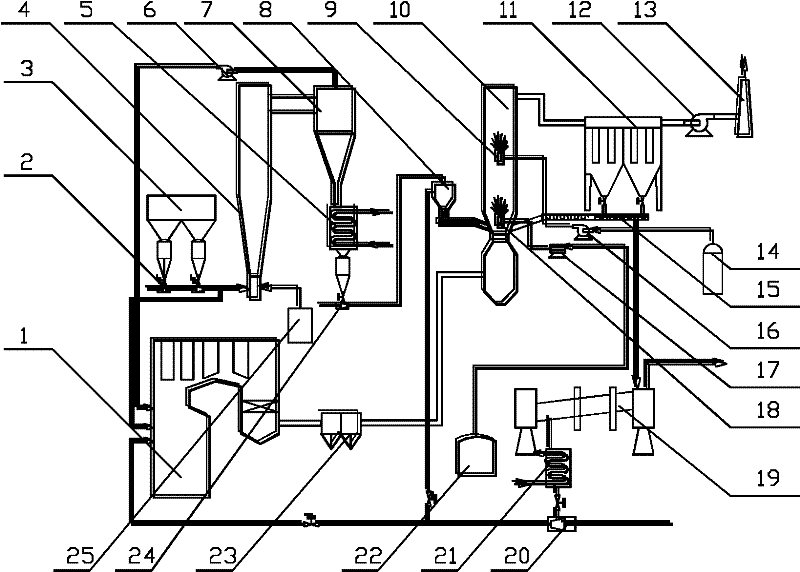

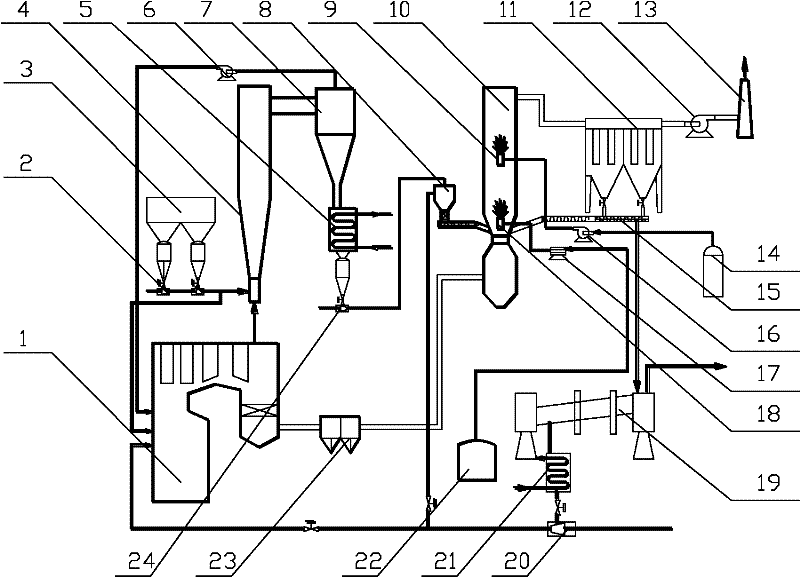

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

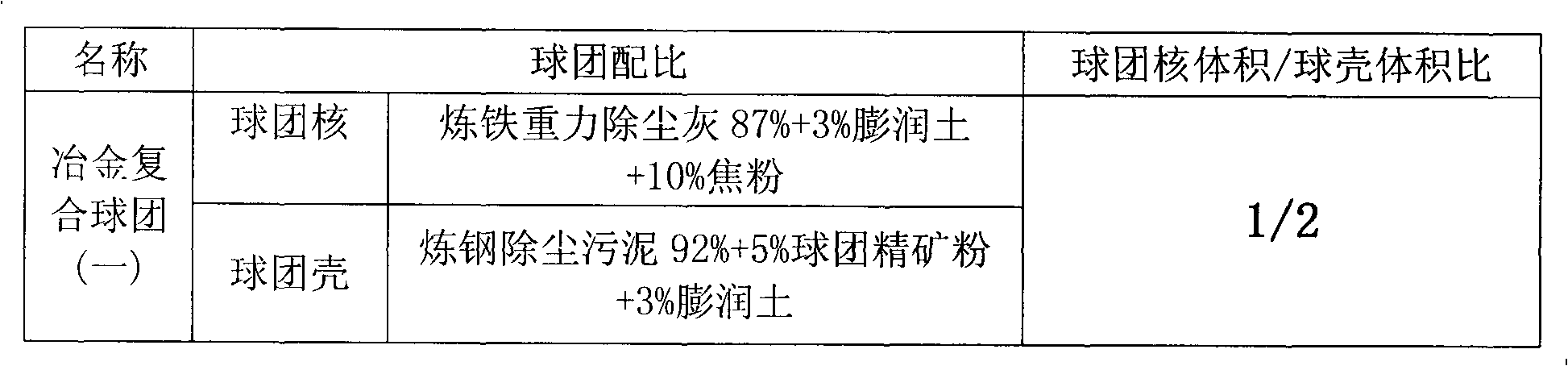

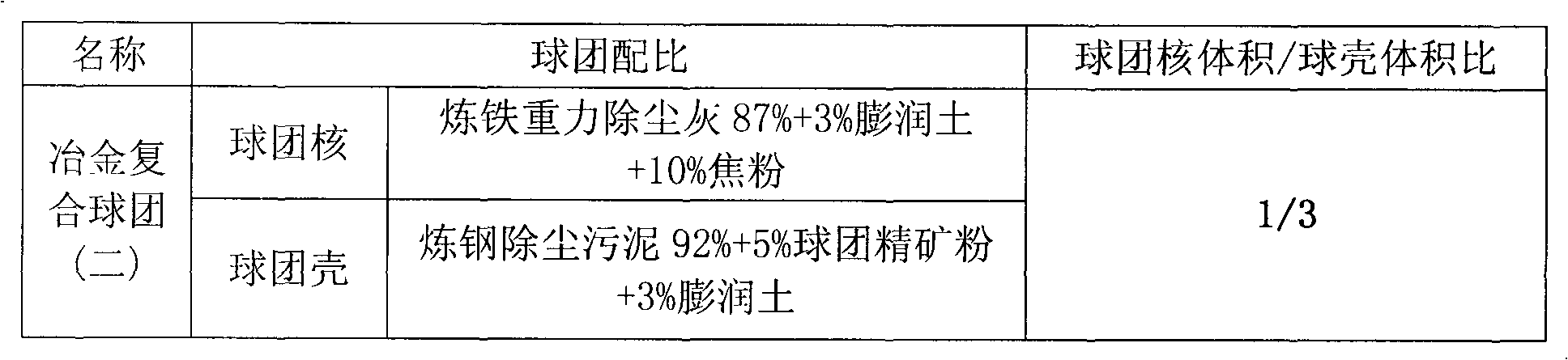

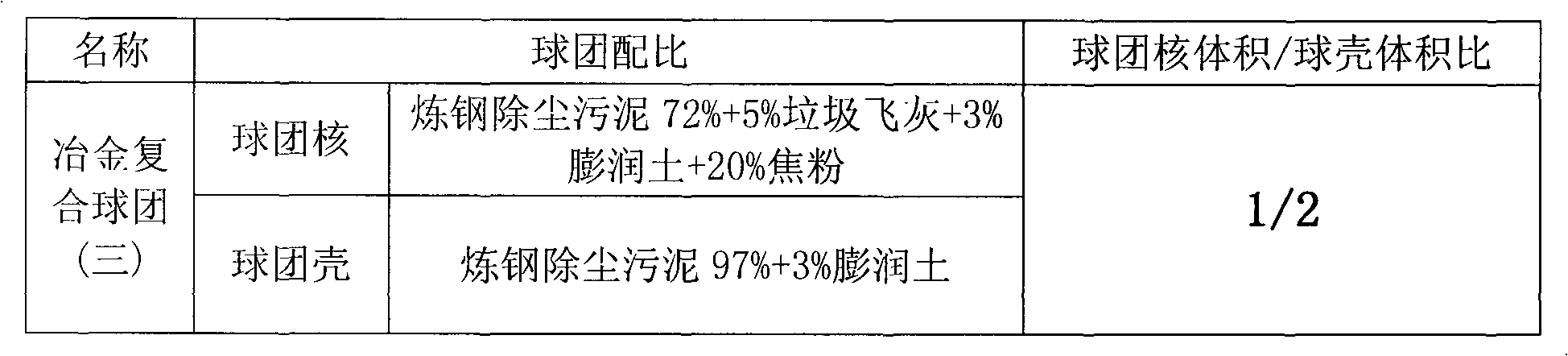

Metallurgical composite pelletizing prepared through twice pelletizing method, as well as preparation method and application thereof

ActiveCN101613800AImprove iron gradeIncrease valueBlast furnace detailsManufacturing convertersSocial benefitsAdhesive

The invention provides a metallurgical composite pelletizing prepared through a twice pelletizing method, as well as a preparation method and an application thereof. The pelletizing is provided with a pelletizing shell formed by a central pelletizing core and a pellet material coating the outside of the pelletizing core. The internal pelletizing core of the formed pelletizing is in a reducing atmosphere, the outside of the formed pelletizing is in an oxidizing atmosphere, and the metallurgical composite pelletizing undergoing twice pelletizing satisfies the metallurgical requirements. The pelletizing core takes an iron-containing material and reducing coal dust or coke powder as raw materials in which adhesive and waste fly dust are added, and is obtained by means of disk pelletization or pressure pelletization. The pelletizing shell takes the iron-containing material and the pelletizing core as raw materials in which the adhesive is added, and is obtained by means of disk pelletization and taking the pelletizing core as the center of the sphere. Various metallurgical performance indexes of the composite pelletizing are highly better than normal pellets. The composite pelletizing not only realizes the harmlessness and the recycling of the waste fly ash, but also can greatly improve the technical and economic indexes of iron making blast furnaces. In addition, the composite pelletizing not only achieves such social benefits as energy conservation, emission reduction, environment protection and environment pollution treatment, but also can create considerable economic benefits.

Owner:CHONGQING ANGRUIYUE SCI & TECH

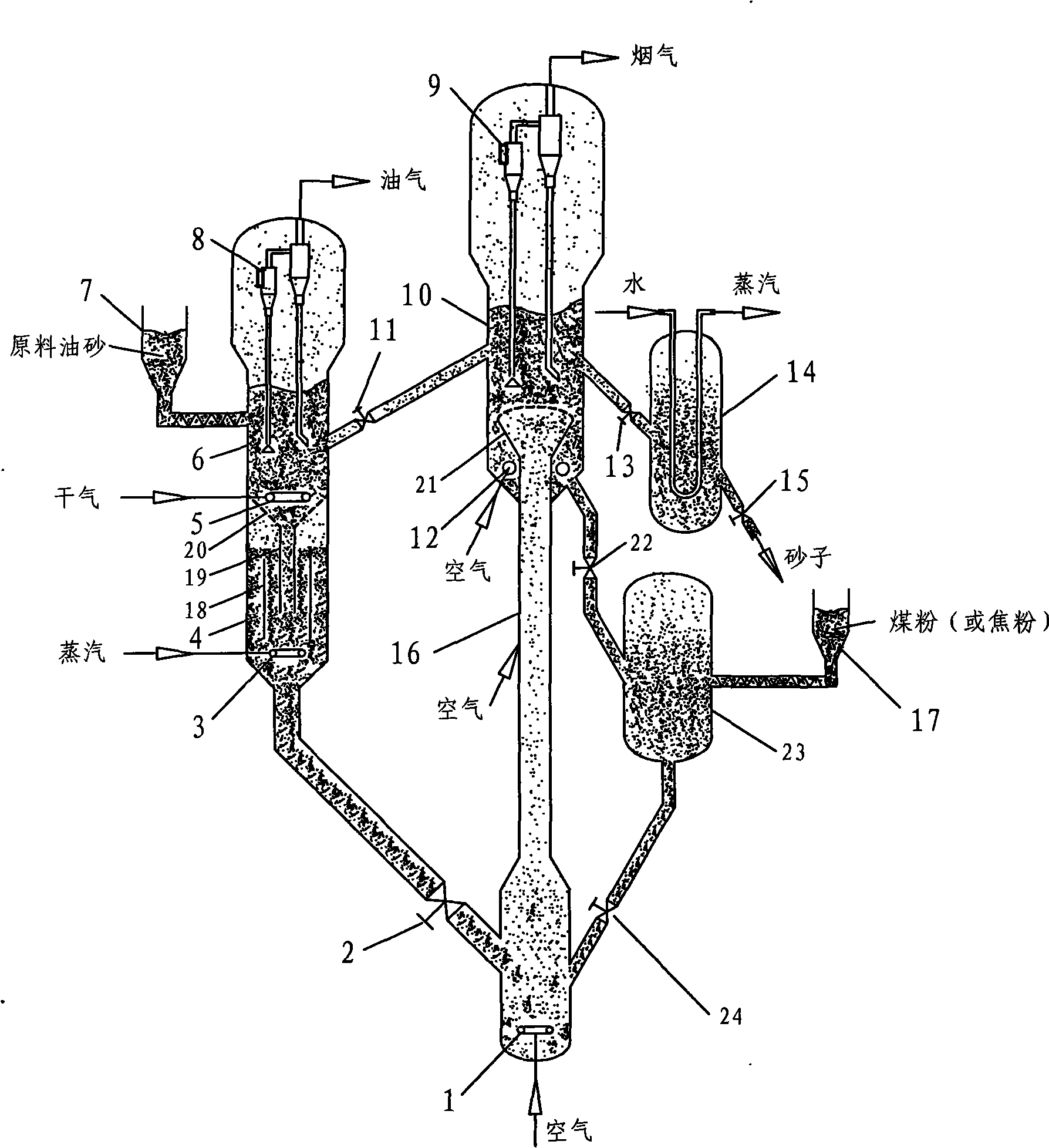

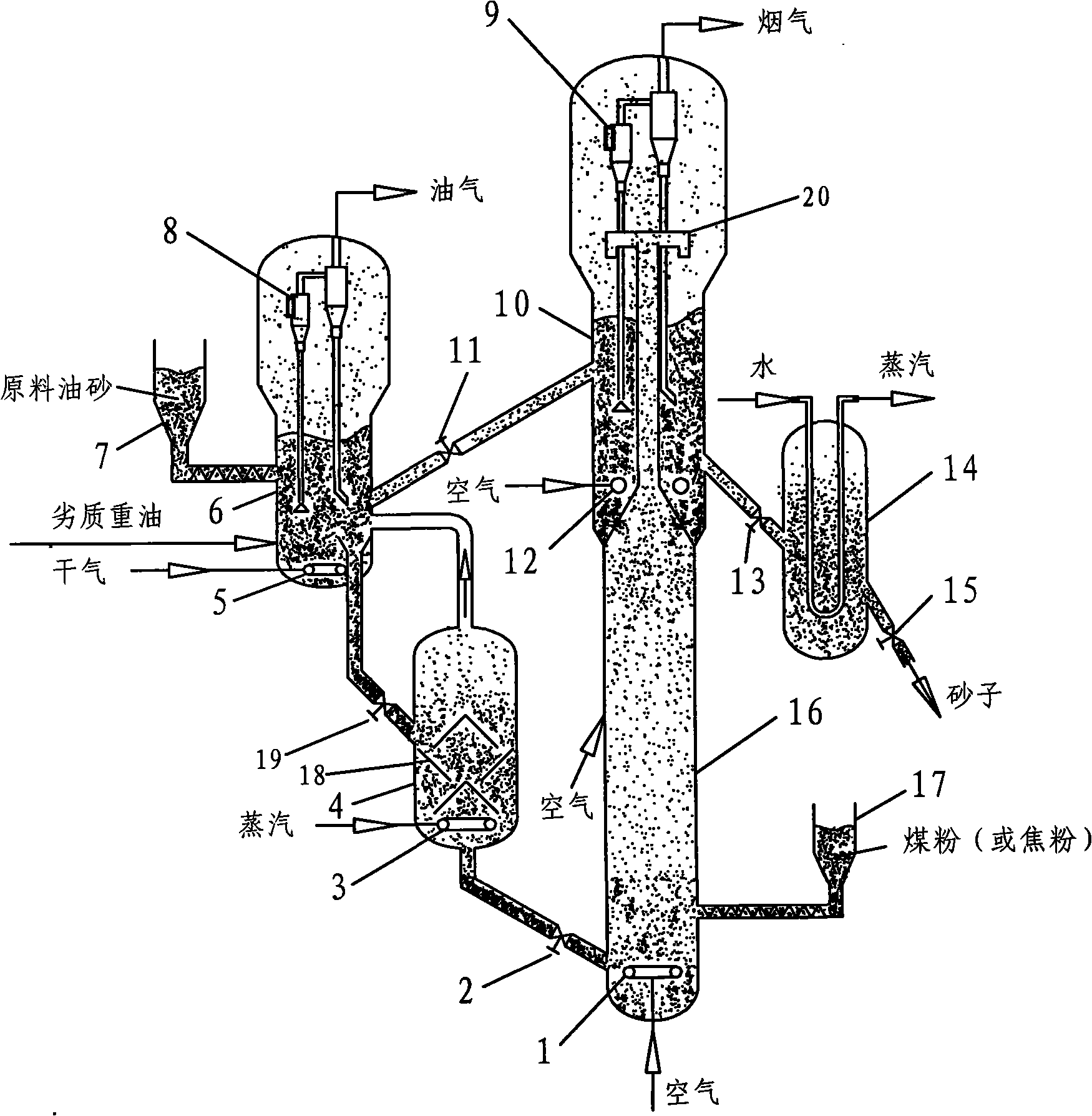

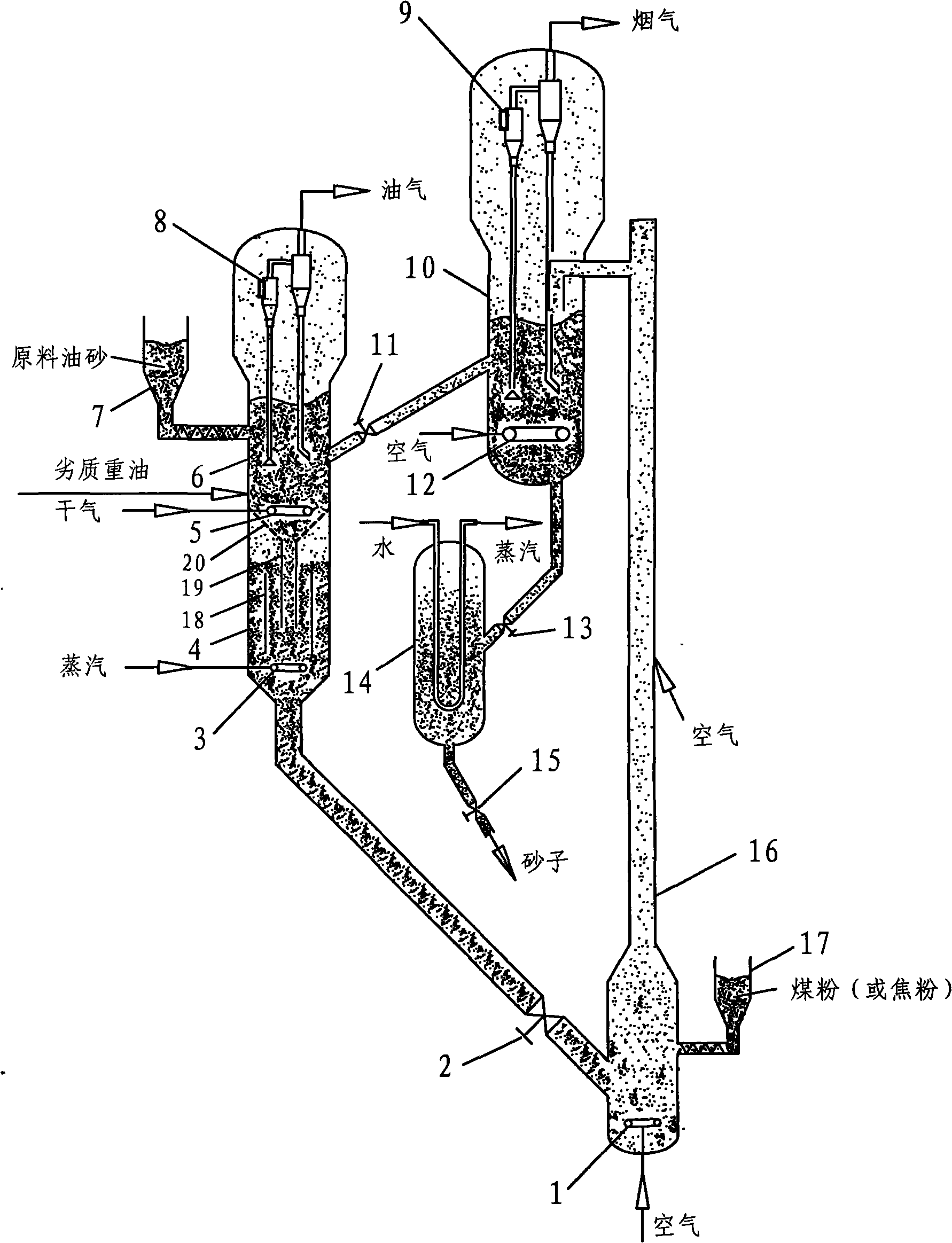

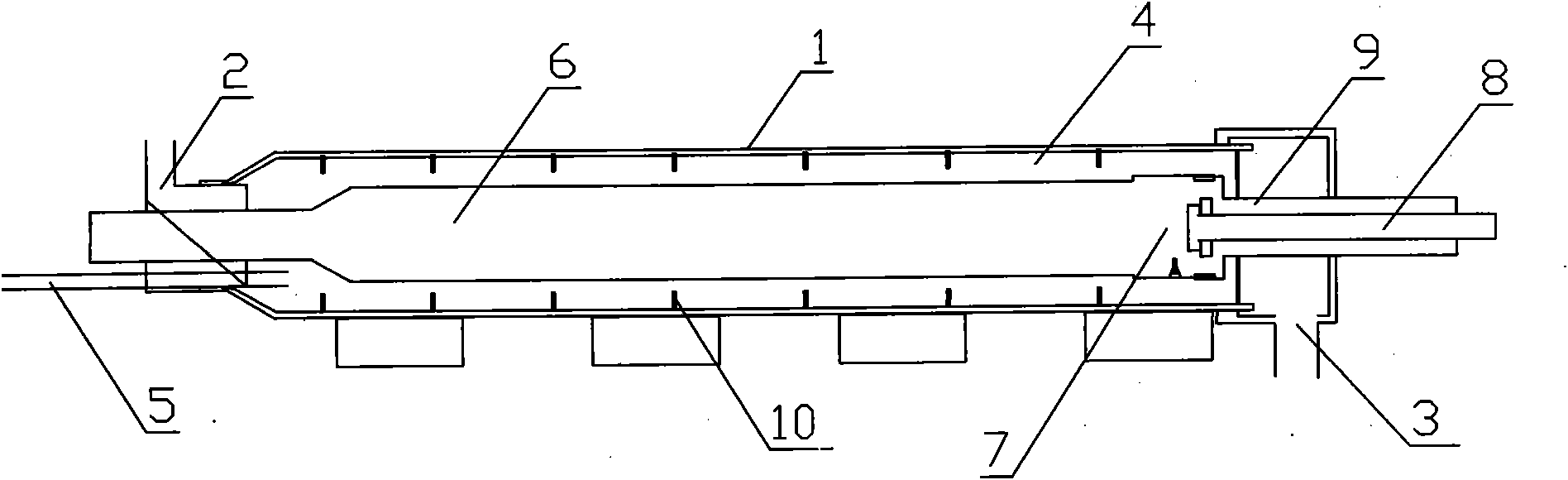

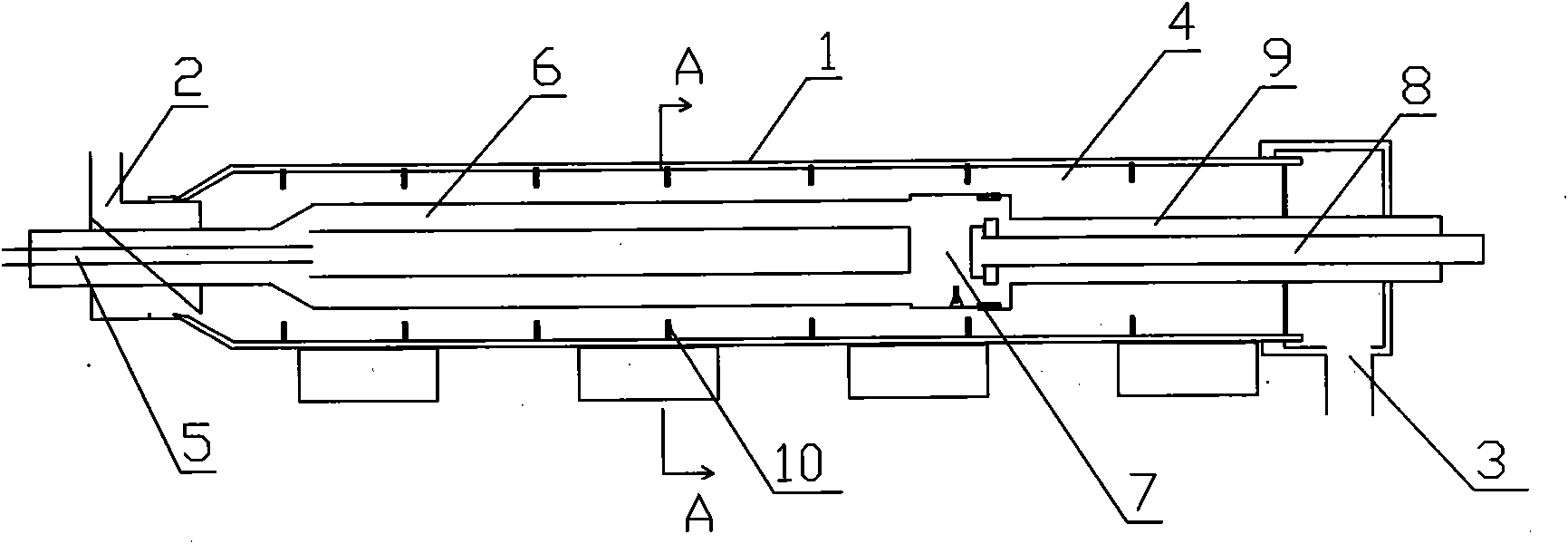

Method for directly fluid coking oil sand and apparatus

ActiveCN101358136ANo pollution in the processContinuous processingLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The present invention provides a method and a device which are used for the direct coking of oil sand on a fluidized bed. The method is as follows: after being mixed with and exchanging heat with the high-temperature sand from a dense-phase coking-burning reactor, the oil sand material in a coking reactor undergoes coking reaction; the dedusted oil gas enters into a fractionation and absorption stabilization system; after being stripped by a stripper, tar sand is led into a dilute-phase coking-burning riser to be burnt in the dilute-phase coking-burning riser and the dense-phase coking-burning reactor above the dilute-phase coking-burning riser; and one flow of the burnt hot sand serving as a heat carrier is led into the coking reactor, and the other flow is led into an external heat collector for heat exchange. If the coke yield is low and the coke-burning heat is insufficient, burning oil, coal dust or coke powder can be added into the coking-burning riser in order to maintain the heat balance of the system. The device at least comprises a material feeder, the coking reactor, the stripper, the dilute-phase coking-burning riser, the dense-phase coking-burning reactor, the external heat collector and a cyclone separator. The device, which is characterized by strong continuous operability and high flexibility, can directly process unconventional petroleum resources such as oil sand and oil shales and does not pollute the environment, and the comprehensive energy utilization rate of the system is high.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

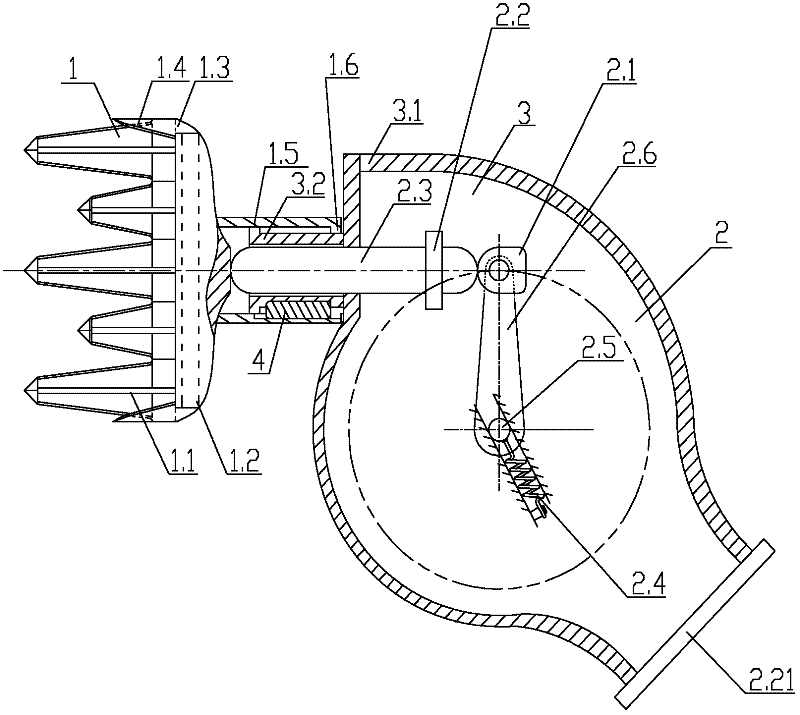

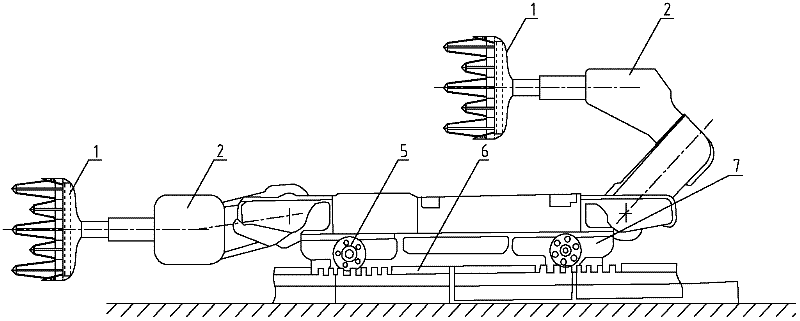

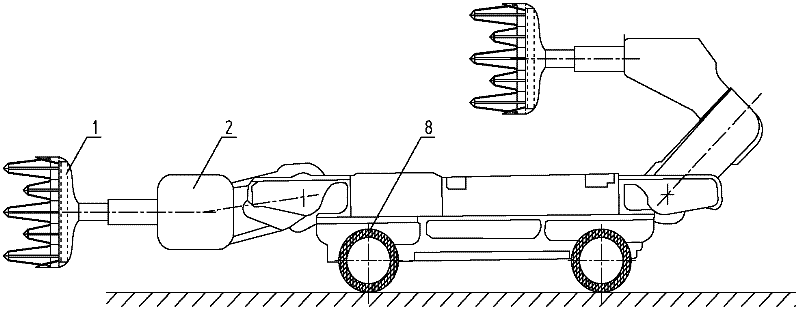

High-efficiency blocking coal shovel

The invention relates to coal mining equipment and specially, relates to a high-efficiency blocking coal shovel. The high-efficiency blocking coal shovel comprises a shovel body. The shovel body comprises a frame. The high-efficiency blocking coal shovel also comprises an impulsion shovel mechanism. The impulsion shovel mechanism comprises a shovel head and an impulsion device. The shovel head comprises shovel teeth and a fixing part. The shovel teeth are installed on the fixing part. A rear part of the fixing part is provided with an impulsion stroke guiding mechanism. The impulsion stroke guiding mechanism is sildingly connected to a guiding sleeve. The guiding sleeve is arranged on the impulsion device and / or the frame. The impulsion device impacts the impulsion stroke guiding mechanism. Only through one impulsion process, the shovel head can complete both coal falling and surface cleaning. The impulsion shovel mechanism is arranged on the shovel body. The shovel body drives the whole high-efficiency blocking coal shovel to walk. Coal mined by the high-efficiency blocking coal shovel is not broken fully. The high-efficiency blocking coal shovel has a high blocking rate and low power consumption, produces a small quantity of coal dust, provides a good work environment, realizes continuous coal mining, synchronously completes both coal falling and surface cleaning, and saves a mass of energy.

Owner:刘素华

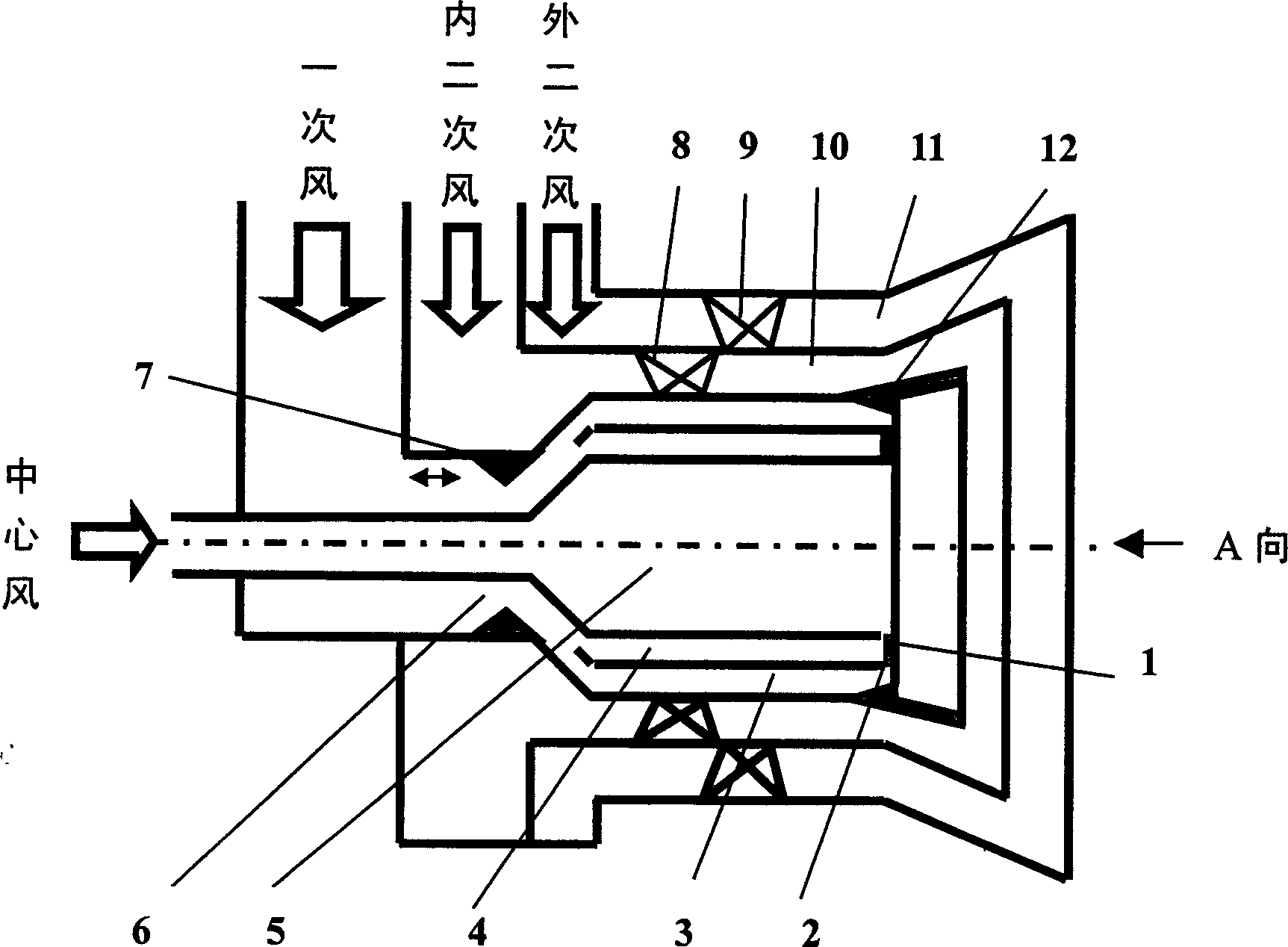

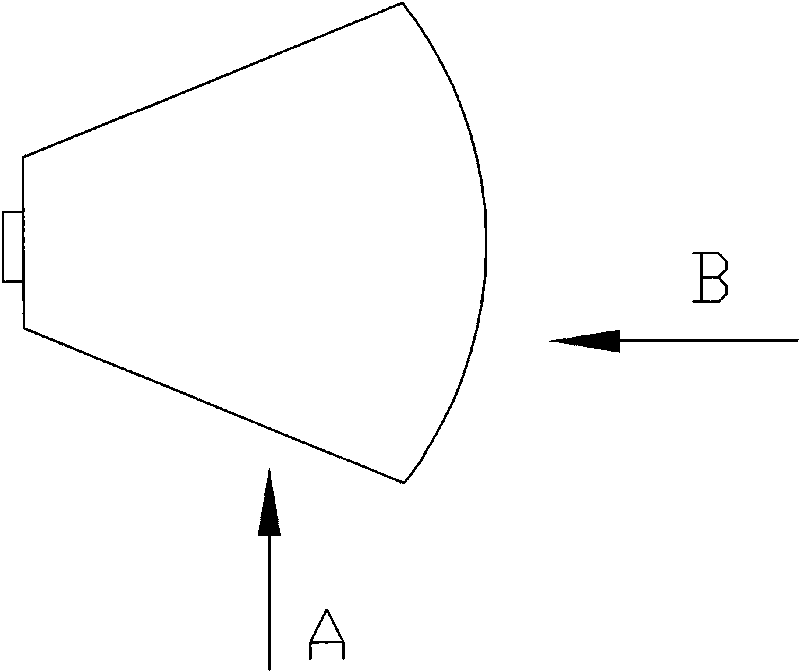

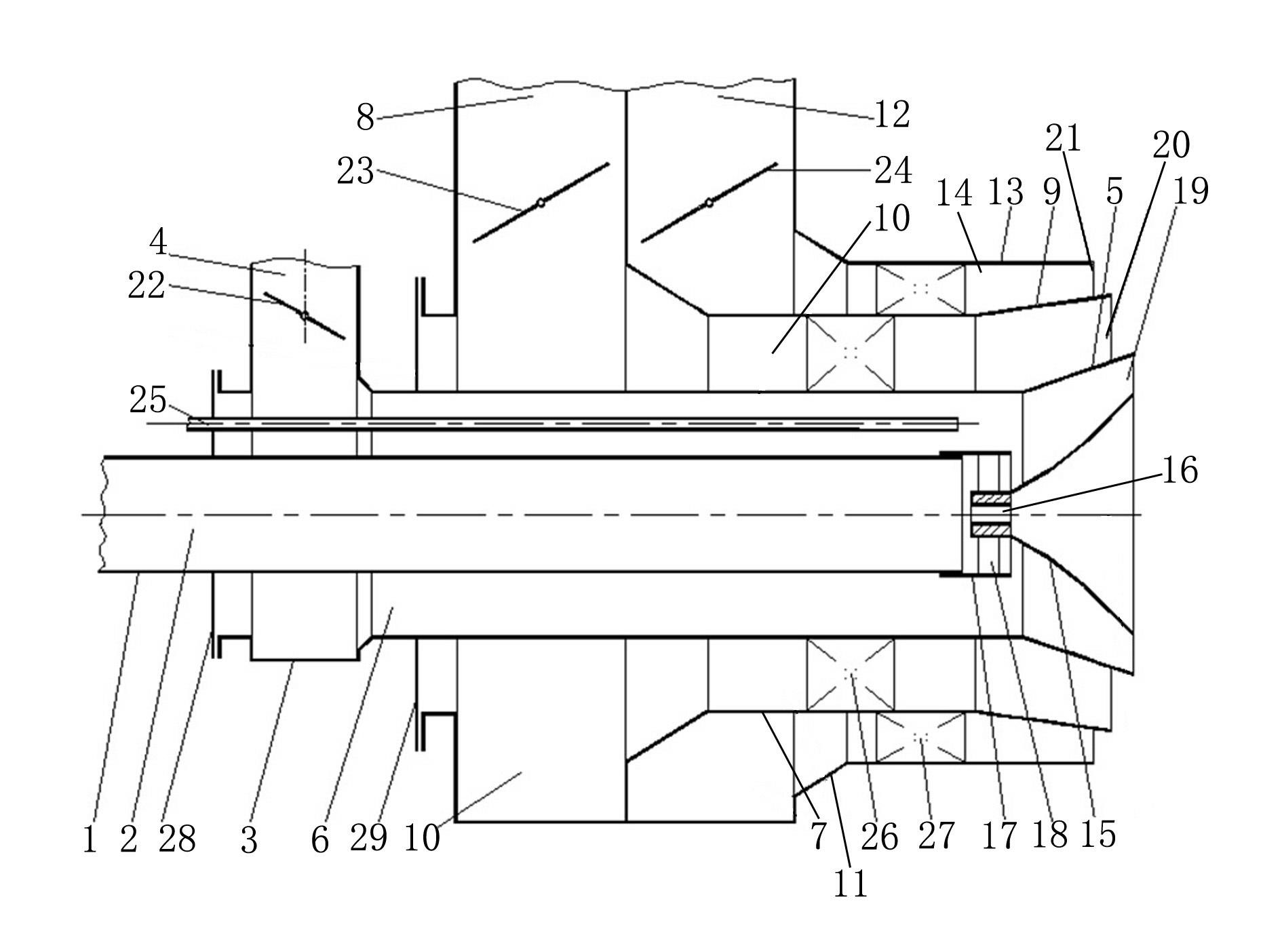

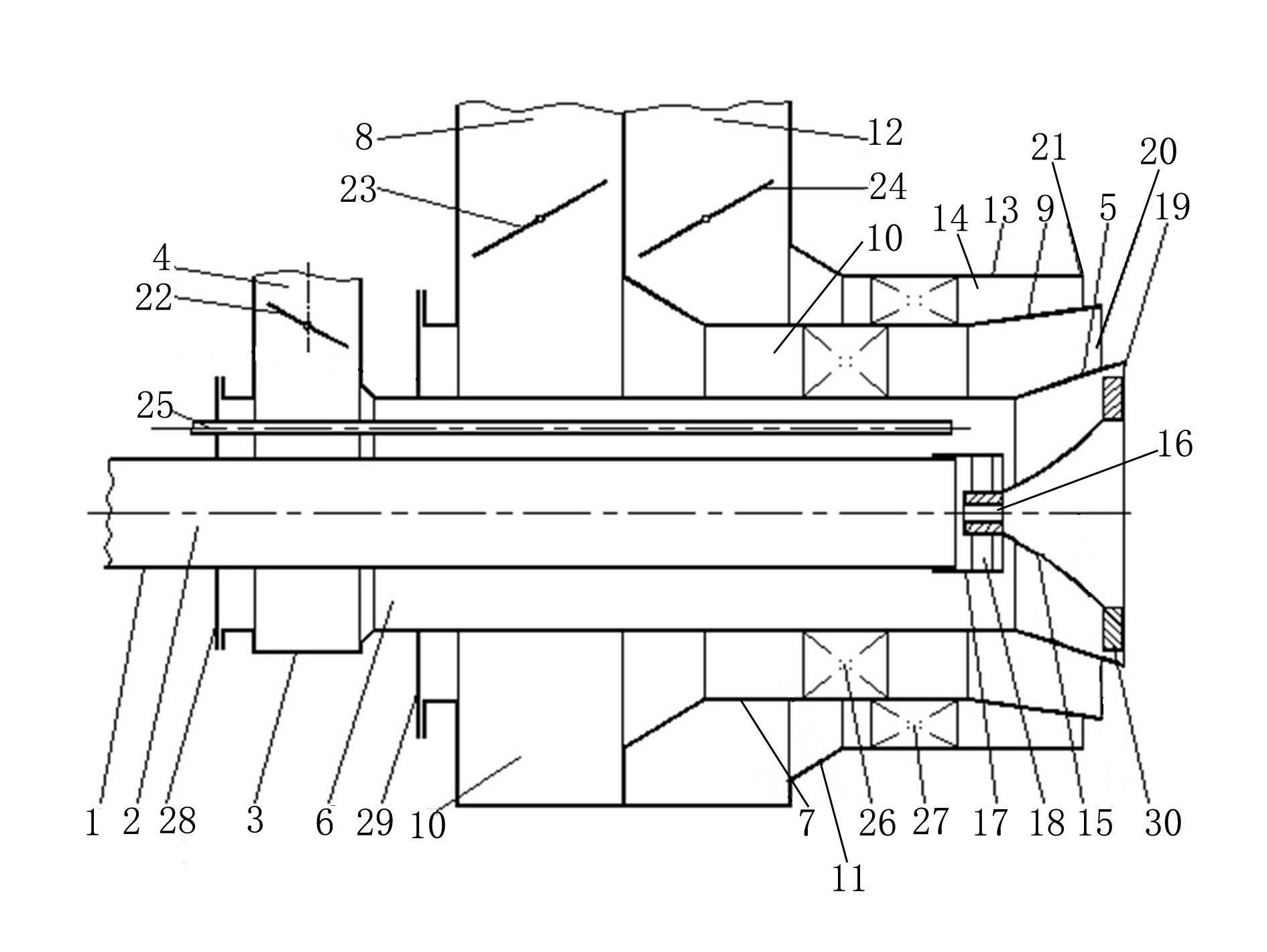

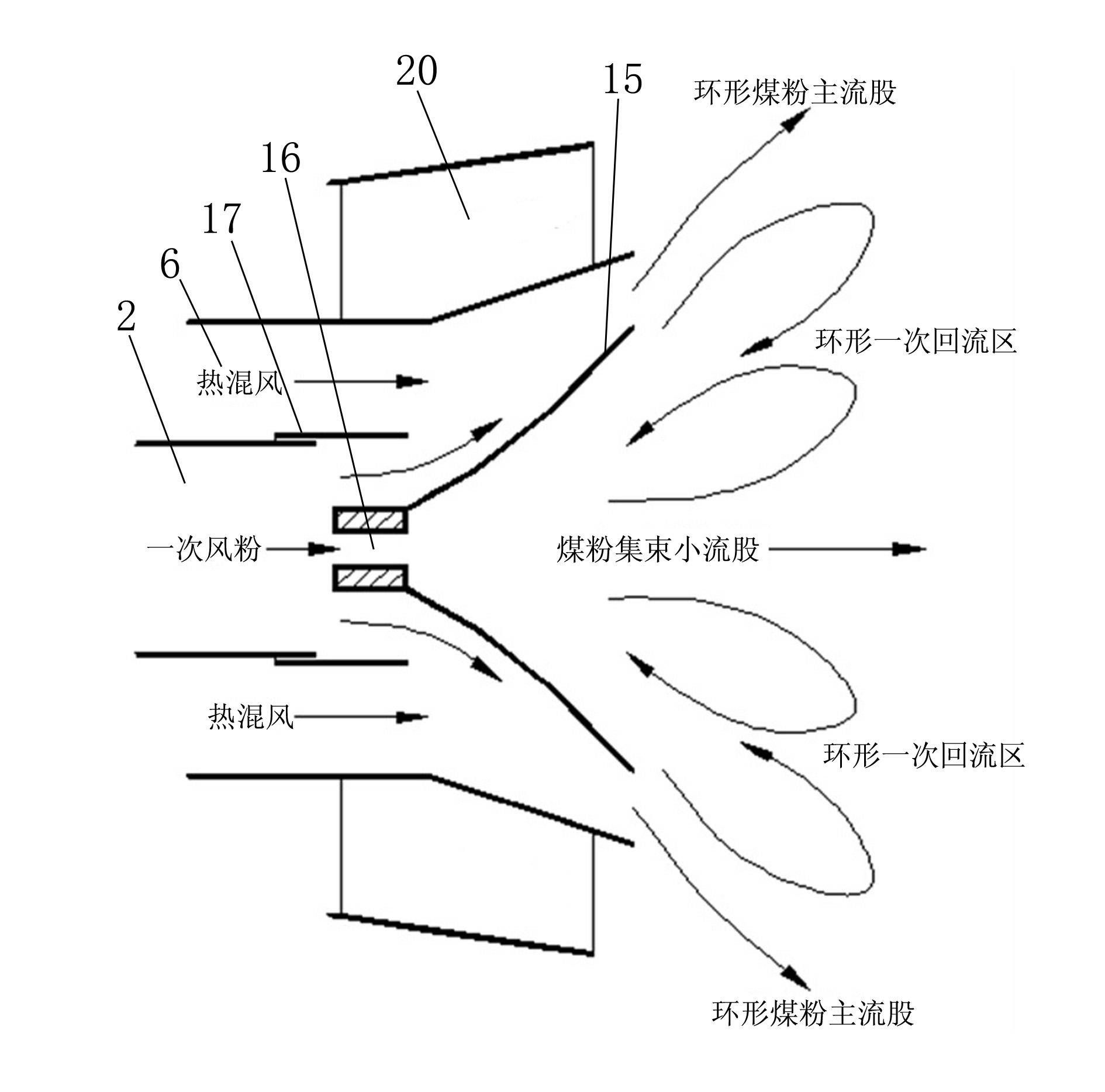

Radial gradient two air-controlled cyclone coal dust combustor

InactiveCN1477330AIncrease concentrationImprove heat transfer performancePulverulent fuel combustion burnersCycloneAir volume

The present invention discloses a radial gradation double air regulation cyclone coal powder burner, including nozzle with burner, internal first air channel, external first air channel, internal second air channel, external second air channel, internal tooth profile combustion-stabilizing ring, external tooth profile combustion-stabilizing ring, double-cone flare, stopper coal powder concentrator and central pipe cyclone coal powder burner. It utilizes two air channels to implement radial gradation combustion.

Owner:XI AN JIAOTONG UNIV

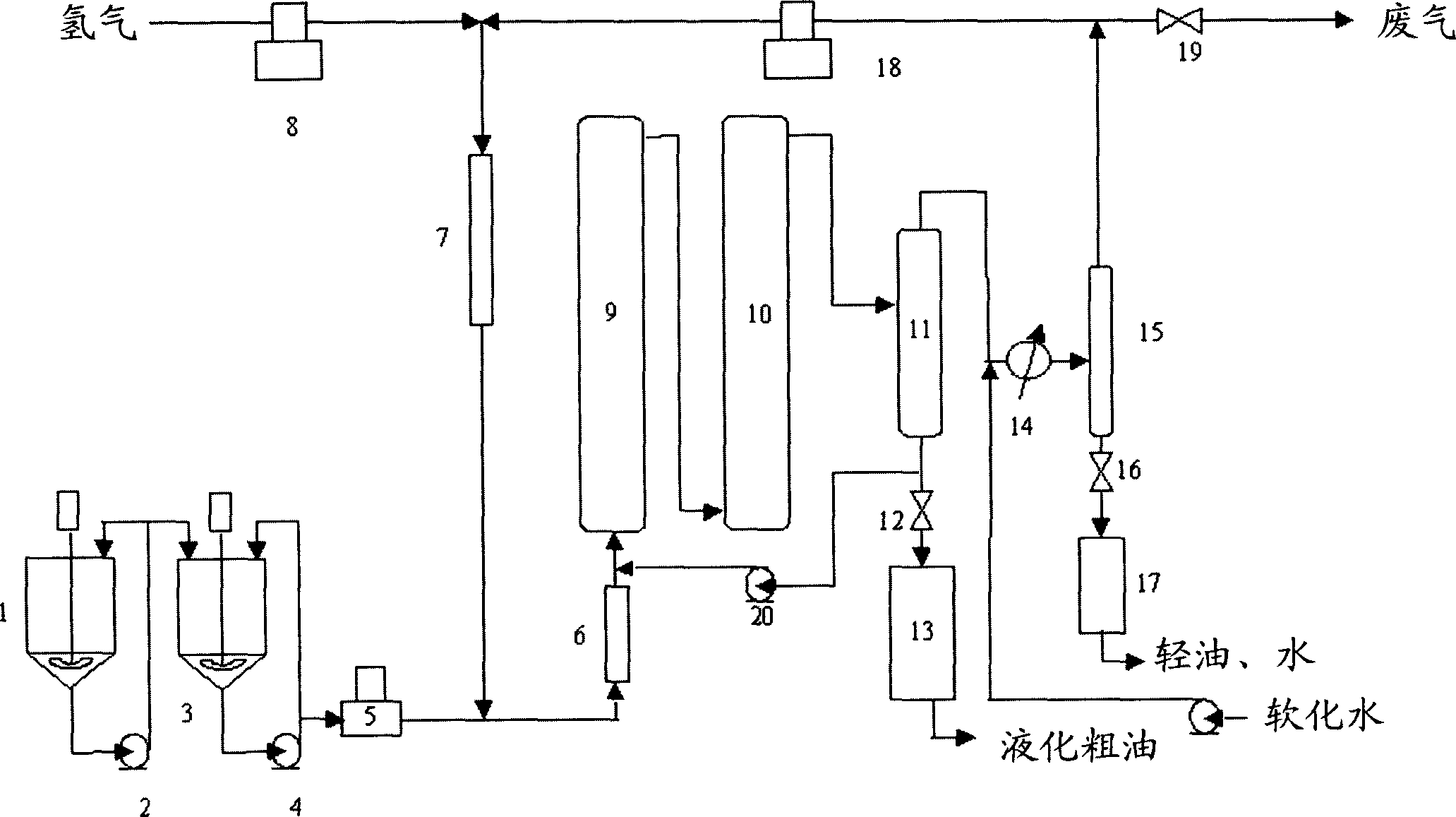

Method of directly liquifying coal

ActiveCN1869159AHigh yieldAvoid secondary decompositionLiquid hydrocarbon mixture productionCoal dustPre treatment

The invention relates to a coal direct liquefaction method. It includes the following steps: mixing coal slurry which is made up of coal dust, hydrogenation cycle solvent, and iron catalyst with freshness or cycle hydrogen; reacting by the first and second reactor; sending the product from the second reactor to high temperature separator to separate; the weight flow ratio of the recycle and freshness materials is 2-20. The method can reduce hydrogen consumption and gas yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

Railway coal transportation dust-depressor and manufacturing method thereof

ActiveCN101348706AAvoid dustEasy to manufacture and implementOther chemical processesLoading/unloadingPolymer scienceCoal dust

The invention discloses a coal railway transportation dust depressor, which is invented for solving the problems of high cost, poor depression effect and so on in the prior art. The raw materials by weight percent for preparing effective compositions in the coal railway transportation dust depressor are: 2 to 7 percent of synthesized water-soluble polymer, 0.1 to 5 percent of modified cellulose water-soluble polymer, 85 to 95 percent of water and 0 to 2 percent of bluestone, wherein the synthesized water-soluble polymer is prepared by complexing at least two water-soluble polymers. The coal railway transportation dust depressor consists of more than two synthesized water-soluble polymers and a small amount of auxiliary agent, and has the advantages of high viscosity and low cost. When used, the coal railway transportation dust depressor is uniformly sprayed on particles on the surface of a coal bed to form a curing layer with certain strength, thereby the coal-dust particles of various grain sizes are bonded together and have certain toughness, and the aim of preventing flying dust on the surface of the coal bed is achieved.

Owner:随州市荷叶精细化工有限公司 +2

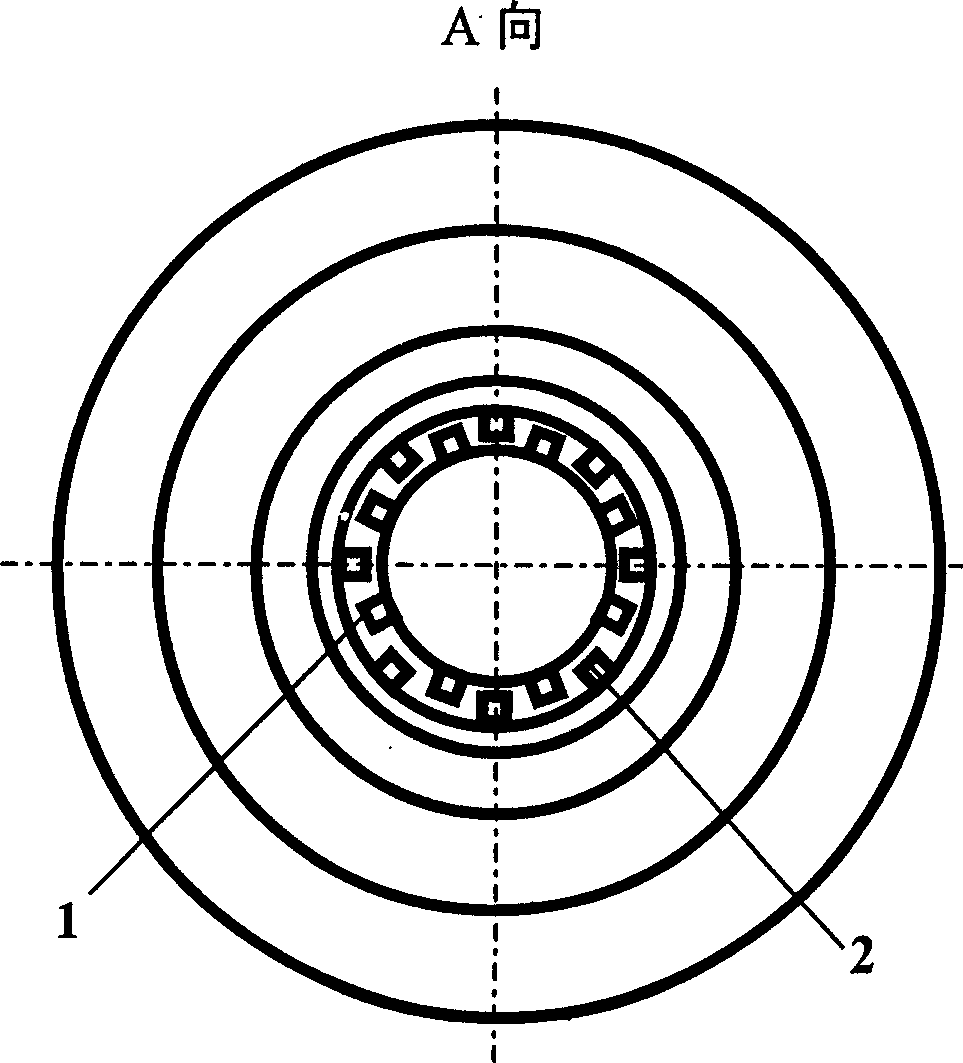

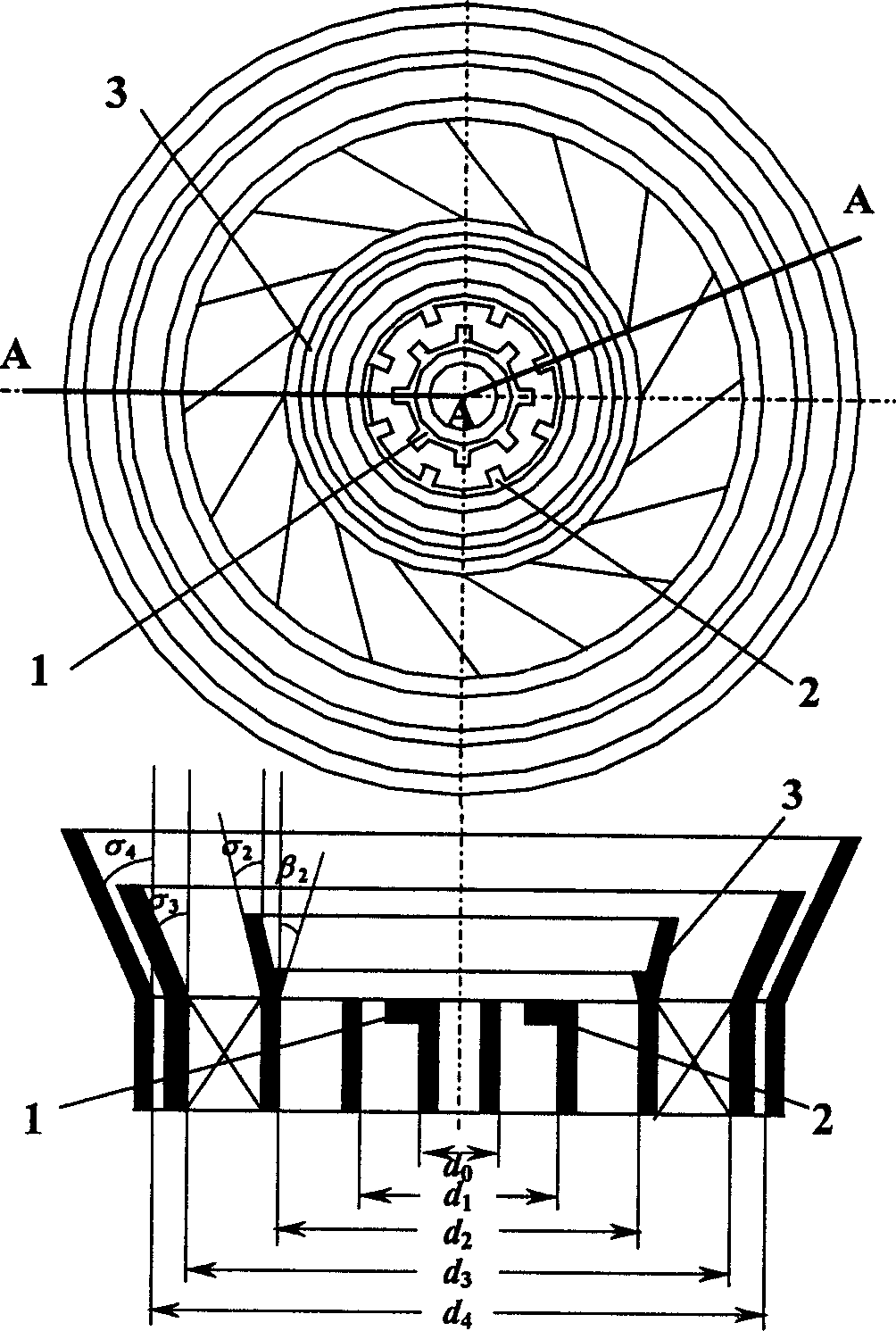

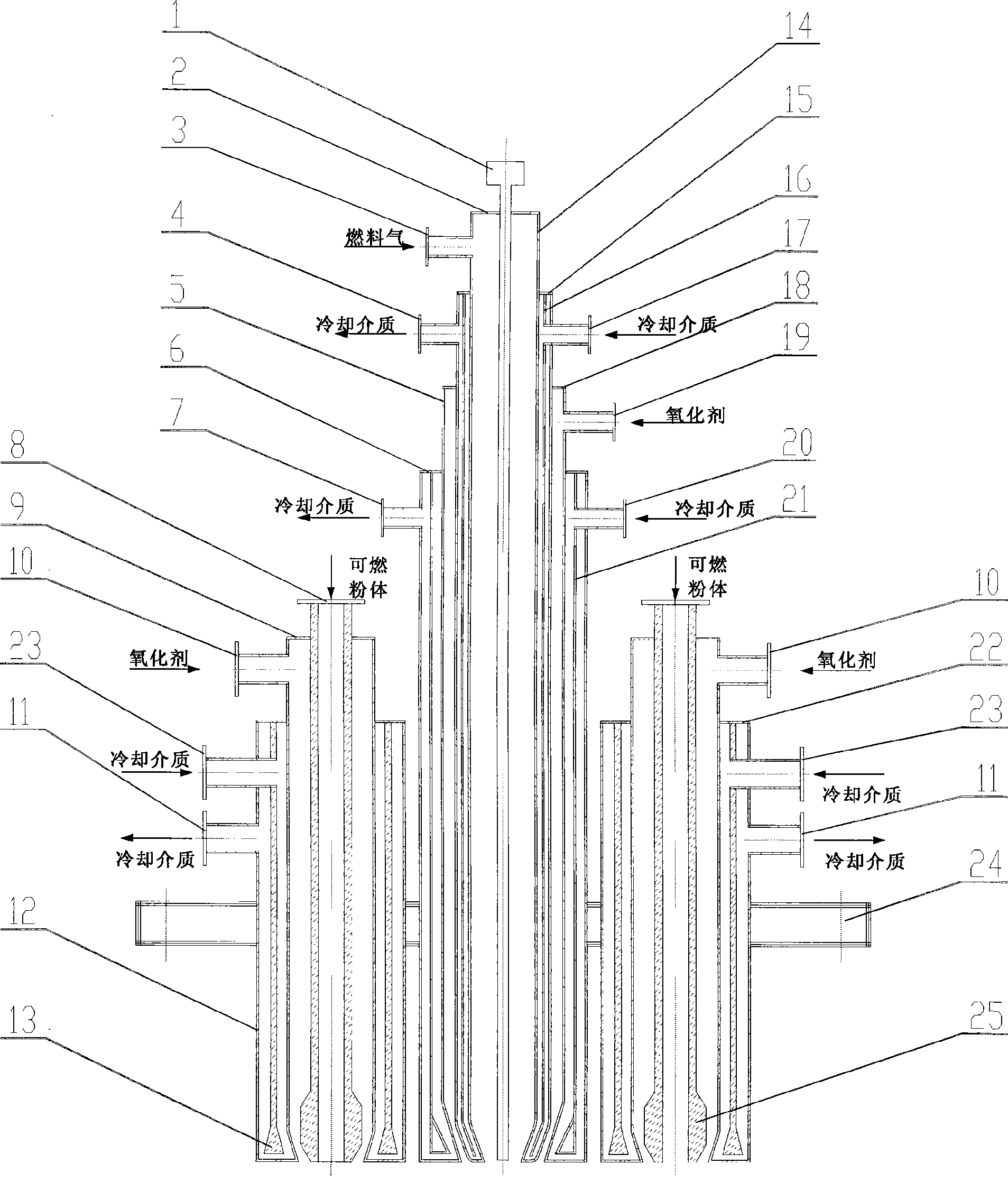

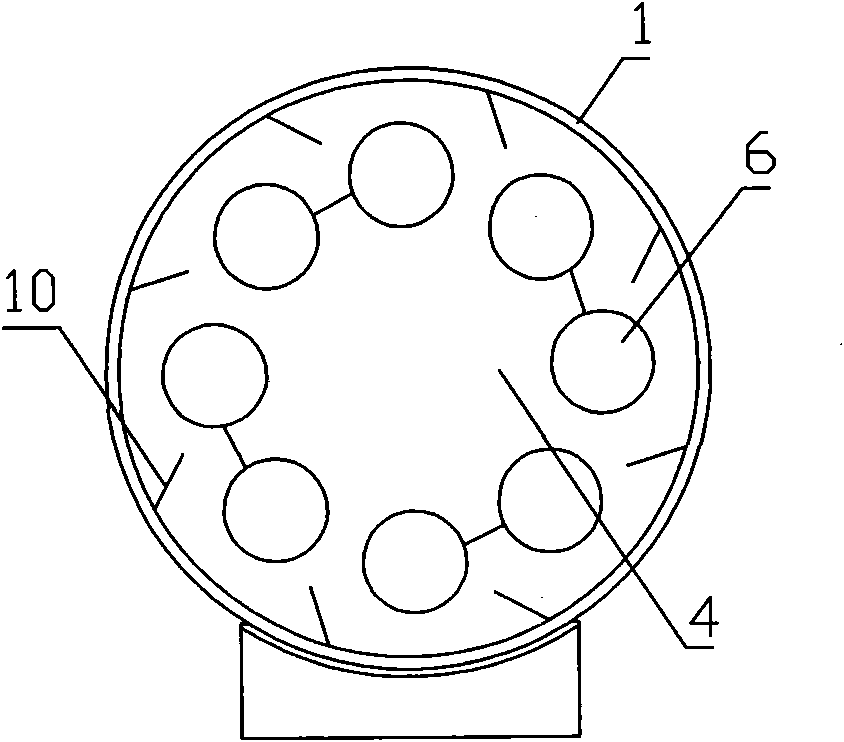

Combined type multi-injector burner

ActiveCN101446413AReduce wearUniform temperature fieldPulverulent fuel combustion burnersMultiple burner assemblyCombustorSingle process

The invention provides a combined type multi-injector burner with a flammable powder body, which comprises an igniter burner positioned at the center of the burner and a plurality of process combustion nozzles which are evenly formed on the periphery of the igniter burner in the circumferential direction, wherein, each process combustion nozzle comprises a coal dust passage positioned at the center of each process combustion nozzle and a first annular oxidizer passage arranged outside the coal dust passage. In the combined type multi-injector burner, a plurality of process combustion nozzles and the igniter burner are assembled together, the structure is compact, and the combustion efficiency as well as the gasification efficiency are increased; the maintenance of each single process combustion nozzle is flexible, and the disassembly and the assembly are convenient; the process combustion nozzles can limberly adjust the load of the burner, mediums in a hearth can be mixed evenly through repeated impacts, the flame fullness degree is good, and a uniform multilayer cooling structure can protect the burner effectively and prolong the service life of the burner.

Owner:CHANGZHENG ENG

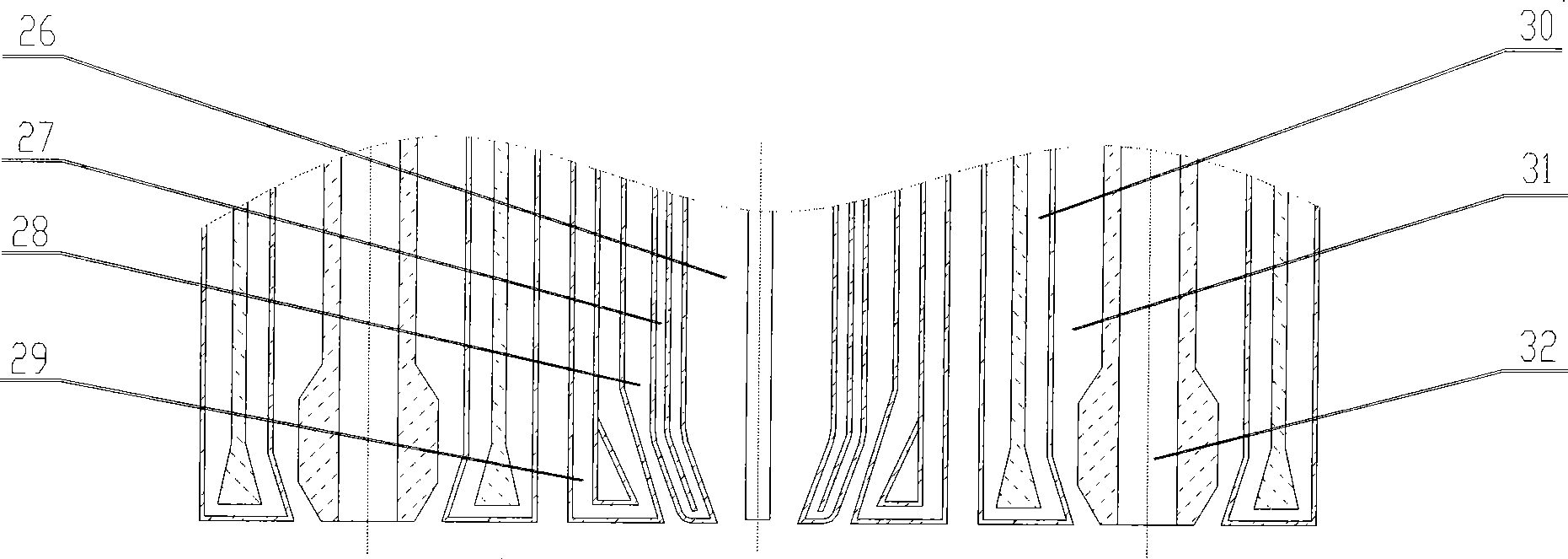

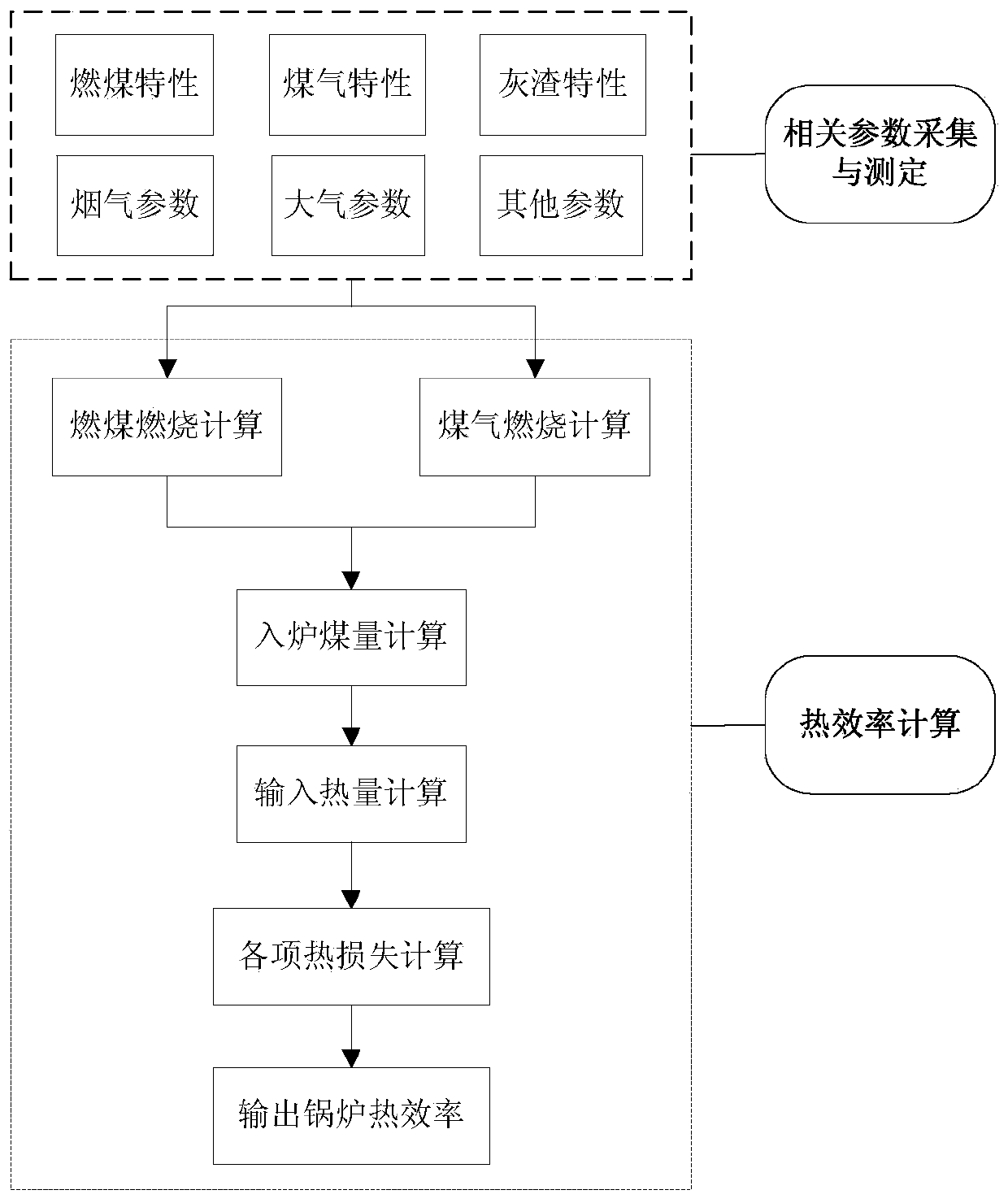

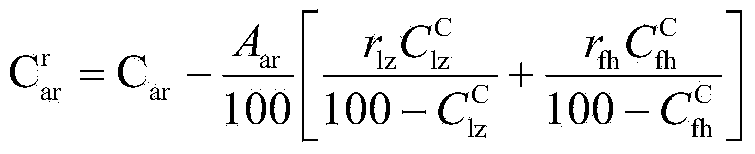

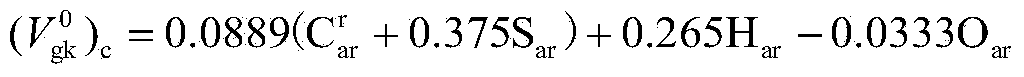

Method for calculating thermal efficiency of coal dust and blast furnace gas co-combustion boiler

ActiveCN104008297ACalculations went wellAvoid errorsCombustion using gaseous and pulverulent fuelSpecial data processing applicationsCombustionCoal dust

The invention discloses a method for calculating thermal efficiency of a coal dust and blast furnace gas co-combustion boiler. The method is designed against the problem that in configuration in the prior art, boilers of storage type coal pulverizing systems cannot accurately obtain the boiler inlet coal quantity under the corresponding working conditions when the thermal efficiency of the boilers is calculated. The method for calculating the thermal efficiency comprises the steps of collection and measurement of relevant parameters, fire coal combustion calculation, gas combustion calculation, boiler inlet quantity calculation, boiler inlet coal quantity calculation, input heat calculation, calculation of various heat losses and thermal efficiency calculation of the boiler. According to the method, the thermal efficiency calculation of the boiler is performed by accurately calculating the boiler inlet coal quantity, main adverse factors influencing the boiler thermal efficiency are found out by analyzing boiler thermal efficiency calculation results, guidance is provided for modification and optimized running of the boiler, and the goal of energy saving and consumption reduction is achieved.

Owner:HUATIAN ENG & TECH CORP MCC

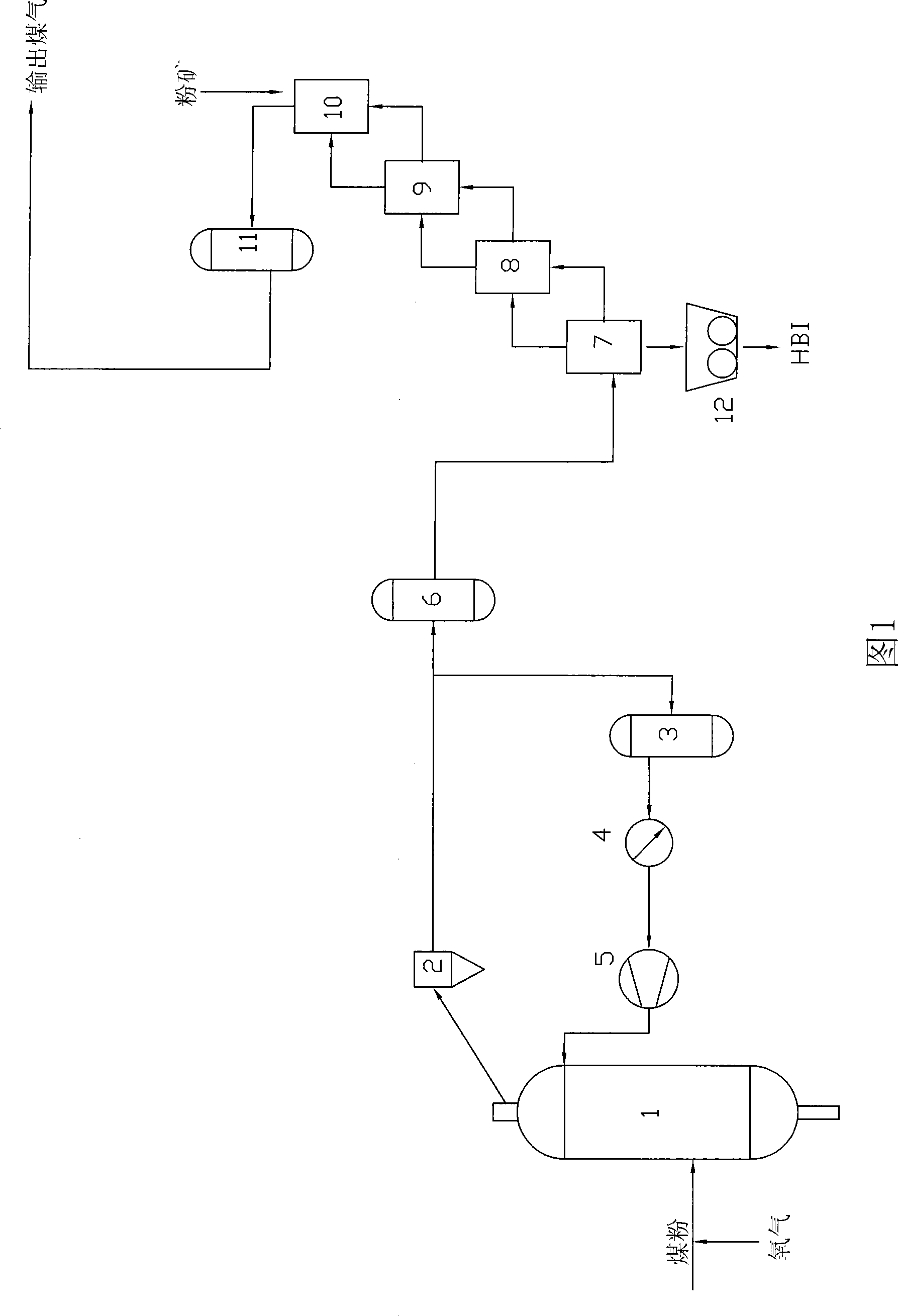

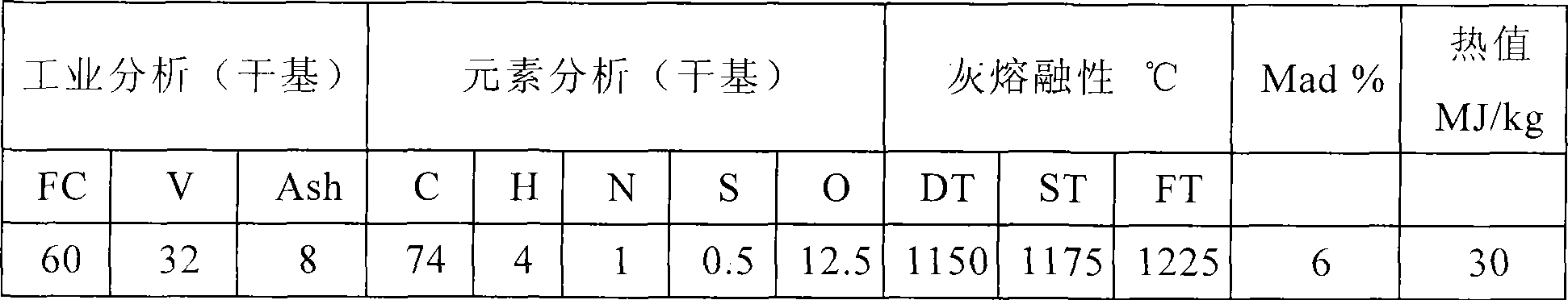

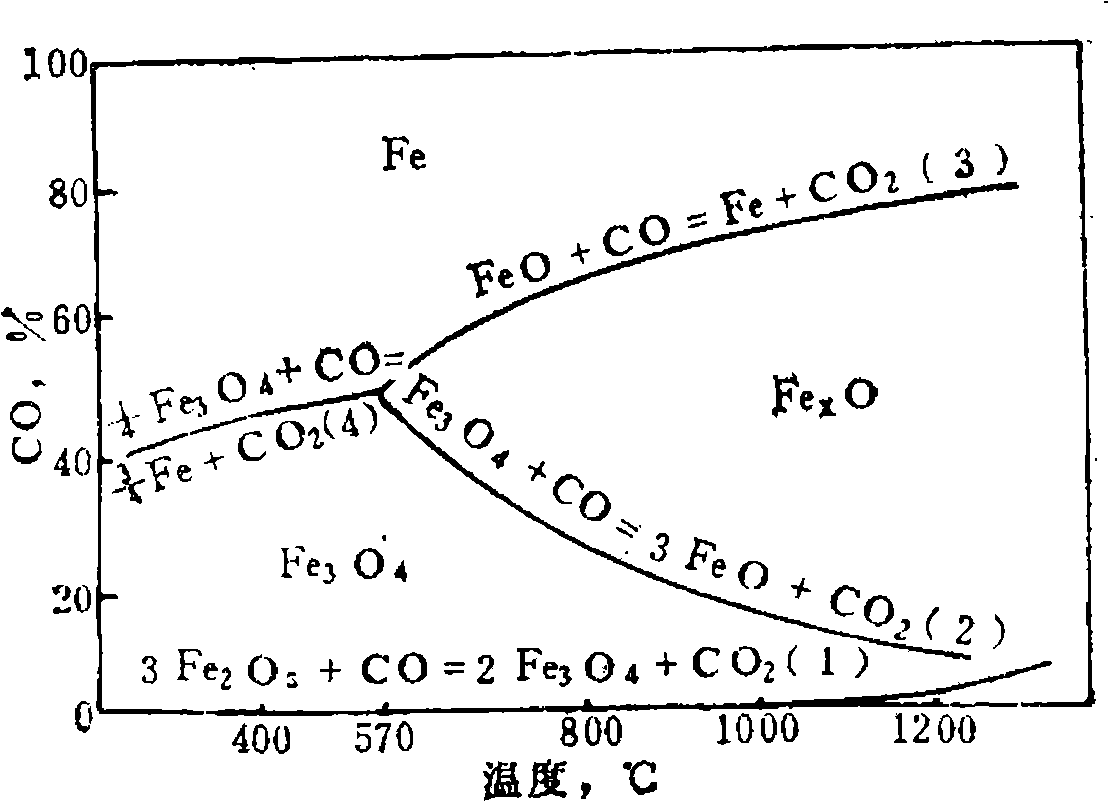

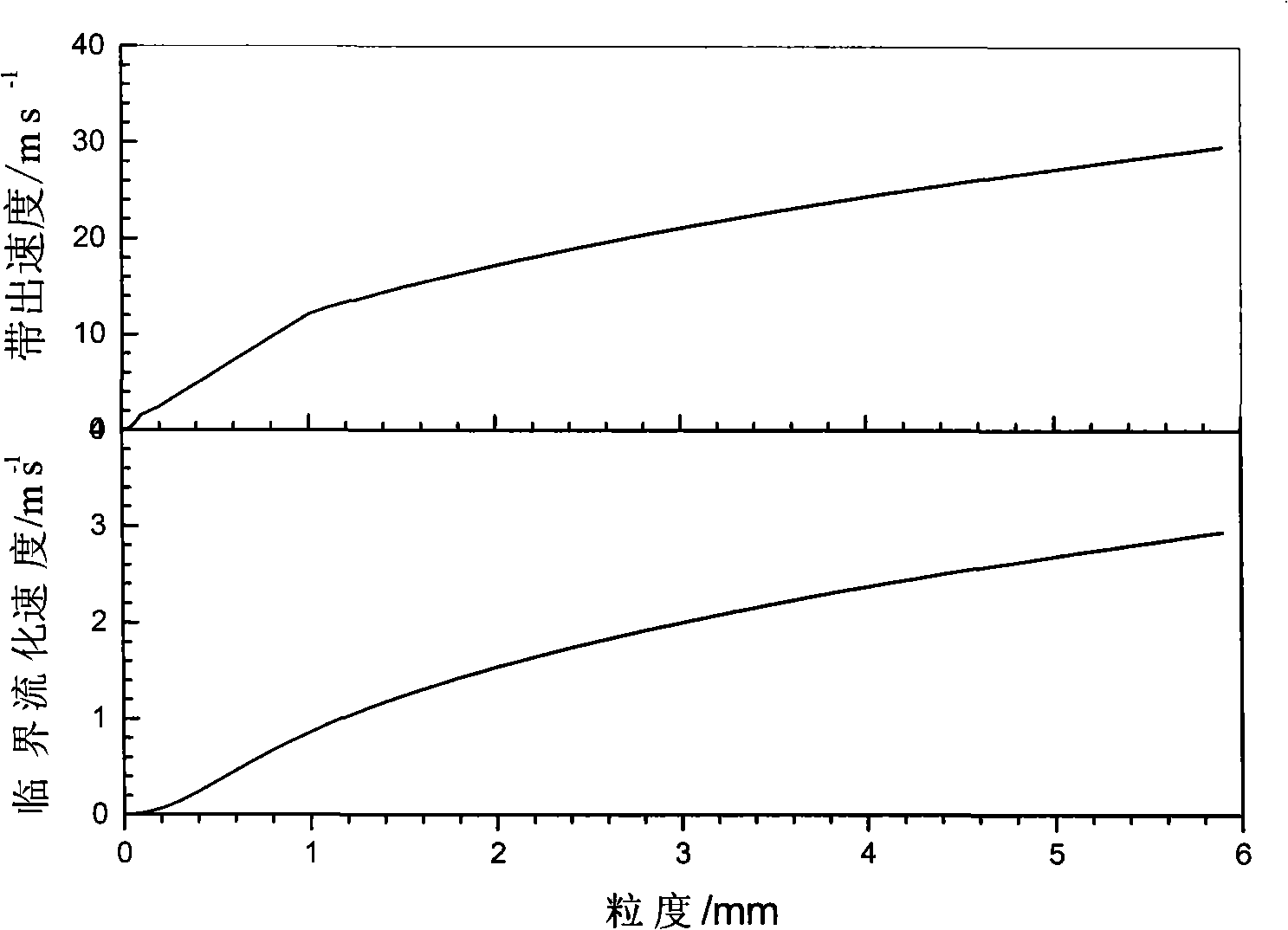

Method for producing spongy iron by direct reduction of dry coal powder gasification and hot coal gas fine ore fluidized bed

InactiveCN101397597AOvercoming gasification link limitationsGas emission reductionIron powderFluidized bed

The invention discloses a method for reducing and producing sponge iron directly by a dry coal dust gasified hot coal gas fineore fluidized bed, which comprises the following steps of: a) grinding and drying the feed coal; b) spraying the dry coal dust and pure oxygen into a pressured gasification furnace; c) chilling the hot coal gas at the top of a gasification furnace to be 900 DEG C to 950 DEG C by the cooled coal gas of 30 DEG C to 80 DEG C, then removing dust, and after washing and cooling part of the coal gas to be 30 DEG C to 80 DEG C, which then returns to the top of the gasification furnace, chilling the high-temperature coal gas; d) desulfurizing the remaining coal gas which is taken as reducing gas for entering a fluidized bed reactor; and e) introducing the hot coal gas into the last level of the multilevel fluidized bed; and then the coal gas flows in the opposite direction of the iron-containing powder lot; the coal gas flows through all levels of the fluidized bed in the reverse direction and the iron-containing powder lot flows through all levels of the fluidized bed in the forward direction, and then the iron-containing powder lot and the reduced gas countercurrent contact with each other, therefore, the sponge iron is obtained by progressive reduction and carburization. The reduced gas is produced by adopting the technology of gas generation; the energy utilization rate is improved by using the sensible heat of the hot coal gas to provide the energy which is necessary in the hematite reduction; and the generated sponge iron can be used for the electrosmelting of steel directly.

Owner:BAOSHAN IRON & STEEL CO LTD

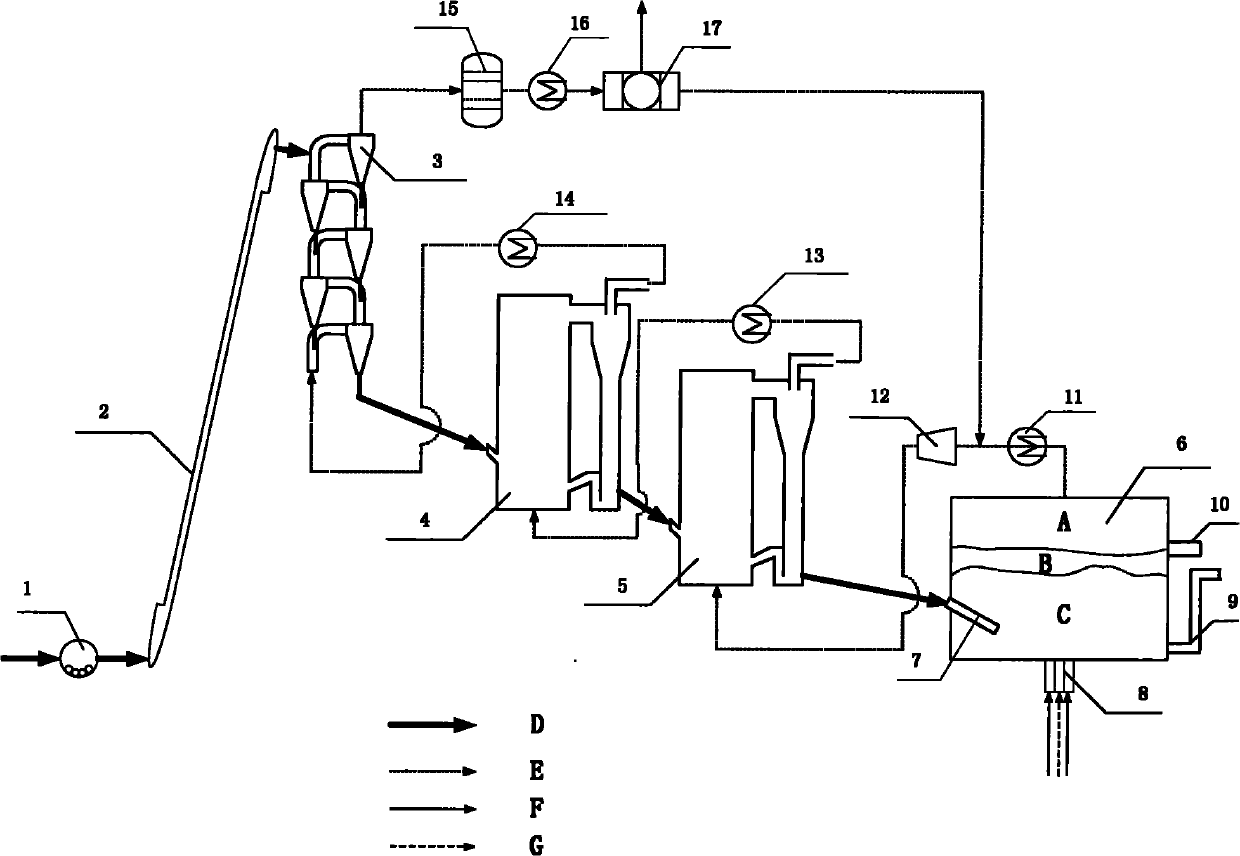

Direct steelmaking process by using fine ores, coal and oxygen

The invention discloses a direct steelmaking process by using fine ores, coal and oxygen. Coal dust and oxygen are blown into a high-temperature melt to produce reducing gas; by utilizing the advantages of gas phase suspension preheating of fine iron ore and high speed and high efficiency of gas phase reduction, the fine iron ore is preheated and reduced respectively in a cyclonic preheater and a recirculating fluidized bed; and the obtained pre-reduced fine iron ore with the metallization rate of over 90 percent is blown into the high-temperature melt to form molten steel. Due to the reduction at lower temperature, the generated pre-reduced fine iron ore achieves less carburization, and less decarbonization is achieved when the finished product molten steel is obtained. The direct steelmaking process simplifies the steelmaking production flow essentially. The direct steelmaking process has the advantages of high productivity, low energy consumption for each ton of steel, equipment and capital investment conservation, full simplification of physical distribution, no temperature loss in the molten iron transporting process, and easy implementation of production continuity and automatic control.

Owner:LAIWU IRON & STEEL GRP

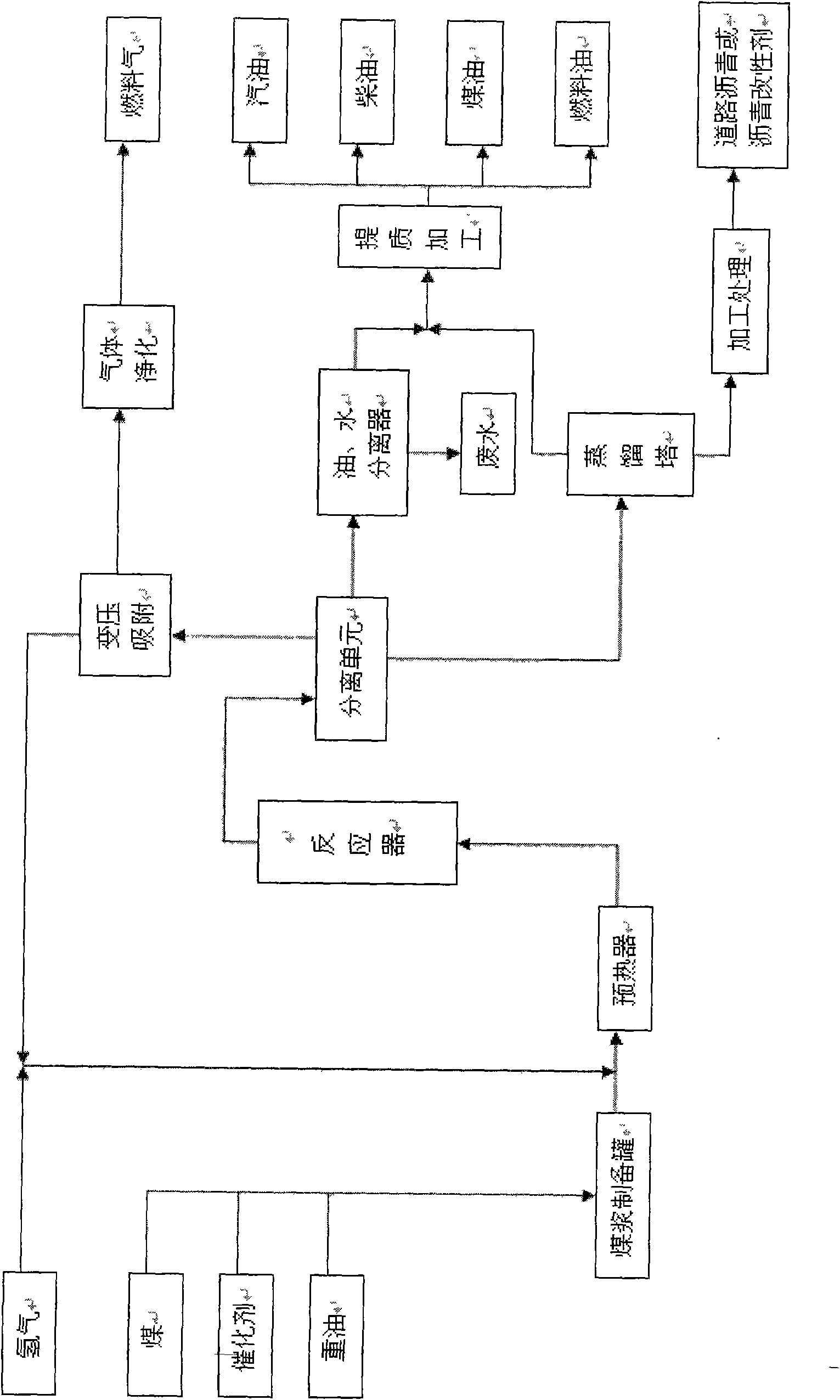

Method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil

InactiveCN101649220AReduce investmentLow costHydrocarbon distillationGaseous fuelsKeroseneDistillation

The invention relates to a method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil. The method comprises the following steps: mixing coal dust, catalyst and heavy oil to prepare pulp; preheating and entering a reactor to carry out reaction; separating reaction products to separate gaseous substance, light oil, water and heavy mixture; extracting hydrogen from the separated gaseous substance through pressure swing adsorption; returning the purified hydrogen to the reactor to be used circularly, and using the remaining gas as fuel after purification; carrying out oil-water separation on the separated light oil and water to obtain the light oil and the water; leading the heavy mixture into a distilling tower to obtain coarse oil and tower bottom product through distillation separation; mixing the coarse oil and the light oil to obtain liquid fuels of gasoline, kerosene, diesel fuel, fuel oil, and the like through upgrading process; and processing the tower bottom product to get the asphalt paving materials. The invention has the advantage that under the moderate process condition, the liquid fuel and asphalt paving materials canbe produced simultaneously.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Coal dust depressor and preparation method thereof

InactiveCN101747866AEasy to operateSimple production methodOther chemical processesSulfonateCoal dust

The invention discloses a coal dust depressor and a preparation method thereof. The coal dust depressor of the invention is composed of 20-30% of sodium lignin sulfonate, 12-18% of crylic acid, 0.4-0.6% of hydrogen peroxide, 5% of calcium chloride, 0.5% of sodium tetraborate, 3% of methyl sodium silicate and 43-59% of water. The coal dust depressor of the invention has simple operation and simple and convenient production and preparation method, does not need special equipment for preparation and production, does not has toxicity, does not have corrosivity to equipment, has lower production cost, is convenient to operate and apply and conforms to environment protection requirements, and dust depression effect, especially water prevention effect is superior to that of the prior art.

Owner:NORTHWEST RES INST CO LTD OF C R E C

Coal dust suppression agent and method of preparing the same

InactiveCN101508884ALow costEasy to operateOther chemical processesLoading/unloadingCarboxymethyl celluloseSocial benefits

The invention relates to a coal dust suppression agent and a preparation method thereof. The coal dust suppression agent comprises 0.5-1.5wt% of sodium carboxymethyl cellulose, 0.5-1.5wt% of sodium carboxy nethyl, 0.1-0.3wt% of glycerol and 96.7-98.9wt% of water. The coal dust suppression agent can be mixed at normal temperature without needing any other warming-up devices; after being mixed at the normal temperature, the coal dust suppression agent is sprayed or coated on the coal of carriage, so that a solidifying layer is formed on the coal, and dust pollution along the line and dust loss of the coal when in the railway transport can be avoided. Furthermore, the coal dust suppression agent does not cause environmental pollution, and has great economic benefit for railway transport and coal customer as well as social benefit for environmental protection. The method of the invention is simple in operation, low in cost and good in dust suppression effect.

Owner:BEIJING UNIV OF CHEM TECH

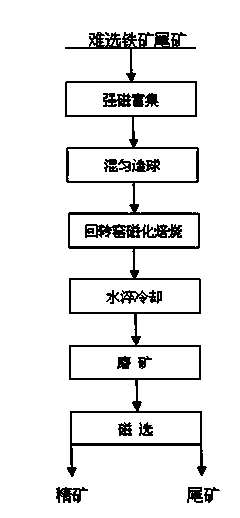

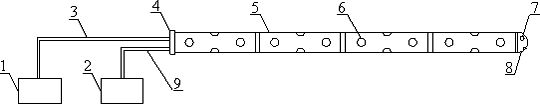

Difficult-separation iron ore tailing pelletizing rotary kiln magnetic roasting treatment technology

The invention provides a difficult-separation iron ore tailing pelletizing rotary kiln magnetic roasting treatment technology. The technology mainly comprises the following technological steps: 1, carrying out magnetic separation enrichment of iron ore tailing by a strongly-magnetic magnet separator having a field intensity of 0.6-1.2T; 2, uniformly mixing an obtained enriched tailing with coal dust and a binder according to a ratio of 100:0.5-2:1-3, drying, carrying out damp milling treatment, and pelletizing; 3, drying pellets obtained in step 2; 4, carrying out the magnetic roasting of dried pellets by adopting a rotary kiln; 5, cooling the magnetically-roasted pellets in a water quenching mode; 6, milling the cooled pellets; and 7, carrying out magnetic separation of ground ore powder to obtain iron ore concentrate. The technology allows the iron ore concentrate having a TF2 grade of about 56% can be obtained, increases the metal recovery rate to above 75% from original 65-70%, improves the resource utilization rate and reduces the environmental pollution.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Feeding method and device for hole protecting pipe for soft coal seam gas extraction hole

The invention relates to a feeding method for a hole protecting pipe for a soft coal seam gas extraction hole. The feeding method is characterized in that an epoxy resin adhesive is used for filling sieve pores of the hole protecting pipe before the hole protecting pipe is fed into a drill hole, air with a certain pressure is pressed into the hole protecting pipe in the process of feeding the hole protecting pipe into the drill hole, the air flows into the drill hole through a vent hole arranged at the top end of the hole protecting pipe, and high-speed air currents discharge coal dusts from an orifice along the hole protecting pipe and a gap of the wall of the drill hole. After the hole protecting pipe is fed into the bottom of the hole, an epoxy resin adhesive dissolving agent is injected into inner holes of the hole protecting pipe for dissolving the expoxy resin adhesive in the sieve pores so as to extract the gas. The feeding method is convenient in operation, can overcome the problem that the hole protecting pipe is difficult to feed into the drill hole due to the residual coal dusts in the gas extraction hole and local hole collapse, and has the advantages of long feeding distance of the hole protecting pipe, thereby ensuring the higher concentration and high flow of the soft coal seam gas extraction. The feeding method is particularly suitable for soft coals and very soft coal seams in which hole collapse easily occurs.

Owner:CHINA UNIV OF MINING & TECH

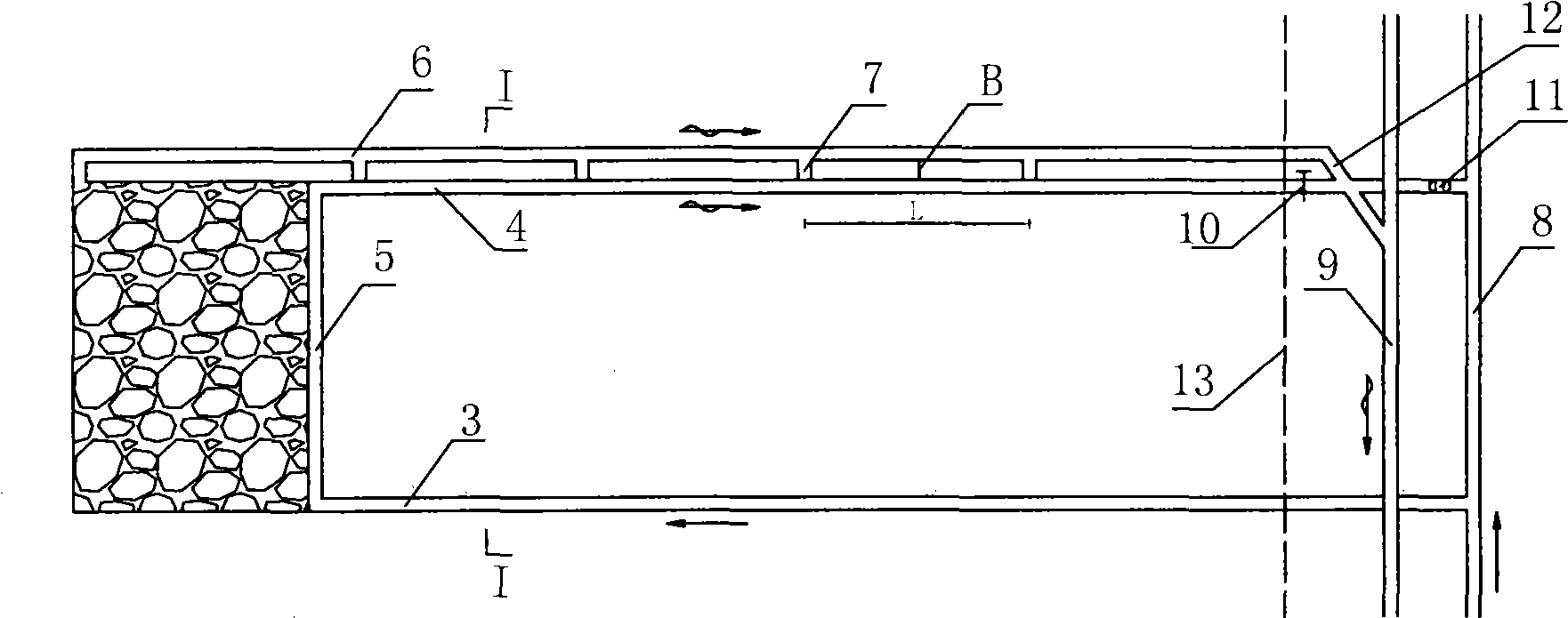

U+I type ventilating system for top-coal caving face

InactiveCN101498225AEfficient dischargeEliminate buildupUnderground miningSurface miningSpelunkingCoal dust

The invention provides a U+I type ventilation system for a work surface of top coal caving, which is an improvement of the arrangement of the U type, the U+L type and the E type or B type laneways and the ventilation systems in the prior art. An air intake way and an air return way of the work surface of top coal caving are arranged along a bottom board of a coal bed, and a regulation air door is arranged on the part of the air return way close to a big air return lane to control the reasonable ventilating parameter of the U+I type ventilating system. The invention is mainly characterized in that air exhausting lanes of top boards are arranged in parallel along the air return way with the parallel outward-staggered distance of 0 m to 5 m from the air return way to form the U+I type ventilating system of a one-intake and two-return mode. The invention fundamentally solves the problem of the accumulation of gas and coal dust on the upper section, the upper spatial angle and the gob area of the work surface of top coal caving, in particular the problem of the accumulation of the gas and the coal dust of the upper space of the upper gob area, provides a safe and high-effect ventilating system, and creates an excellent mechanical environment for realizing the exploitation of the top coal caving of small coal pillars and increasing the recovery rate of coal.

Owner:TAIYUAN UNIV OF TECH

Coal decomposing equipment

InactiveCN101985558AEfficient decompositionIncrease profitMechanical conveying coke ovensCombustible gas coke oven heatingDecompositionTar

The invention discloses coal decomposing equipment, comprising a sealed kiln body with a feeding hole and a discharge hole, wherein the kiln body is provided with a flame gas pipe heating mechanism; coal propelling and decomposing channels are formed between the flame gas pipe heating mechanism and the inner wall of the kiln body; and a coal decomposed gas collecting pipe communicated with the coal propelling and decomposing channels is arranged on the kiln body. As the equipment conducts and radiates vast heat generated by the flame gas pipe heating mechanism on the coal dust in the coal propelling and decomposing channels, the coal dust fully absorbs the heat and is heated and decomposed into gases, tar gases and coal with higher heat value in the coal propelling and decomposing channels, the gases and tar gases are connected with a gas dedusting and liquefying mechanism outside the rotary kiln by the coal decomposed gas collecting pipe, and the gases and tar gases obtained through decomposition are collected, dedusted, separated and liquefied under pressure.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

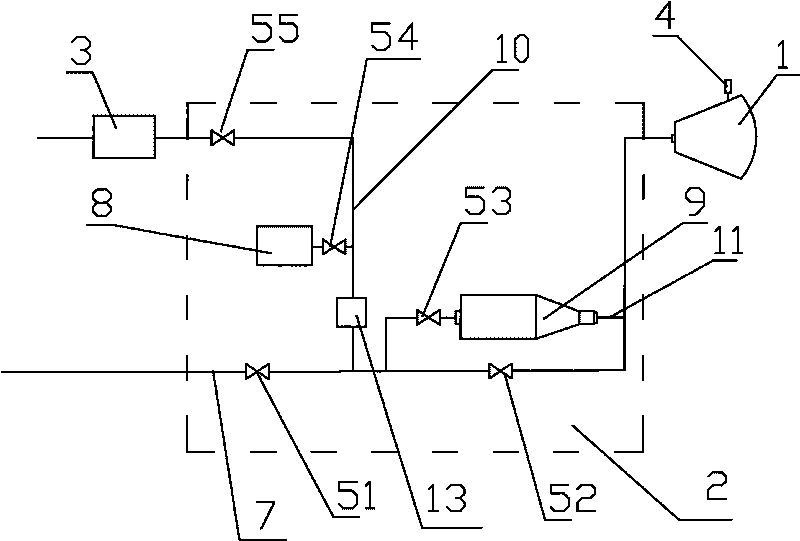

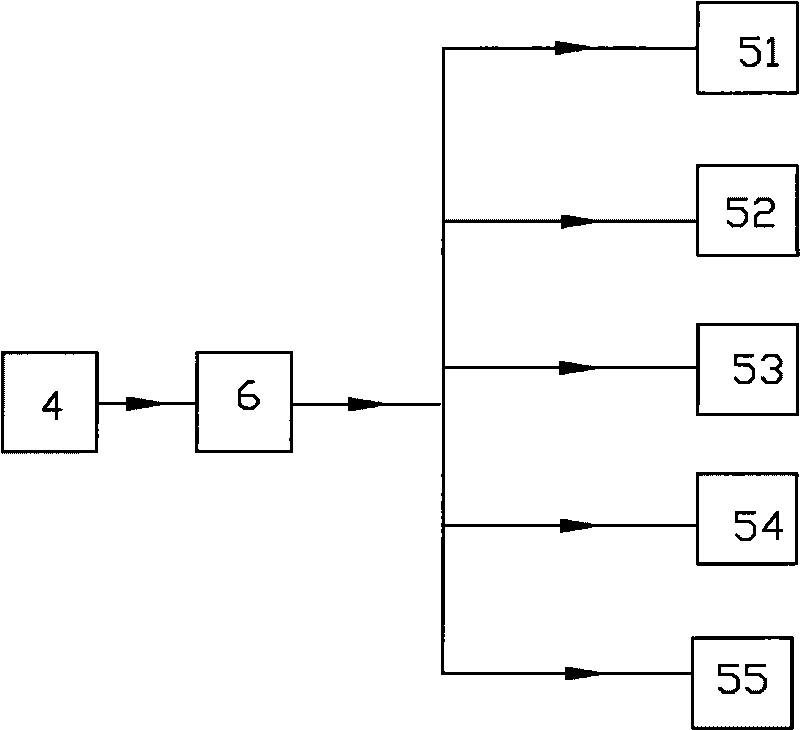

Automatic dedusting system for coal mines

InactiveCN101696636AReduce labor intensityImprove dust removal efficiencyDust removalFire preventionAir compressionAutomatic control

The invention discloses an automatic dedusting system for coal mines, which comprises a nozzle, a dedusting medium supply system, an air compressing device, an explosion-proof coal dust concentration sensor, an explosion-proof electromagnetic control valve and an explosion-proof PLC control system, wherein the explosion-proof coal dust concentration sensor fixedly connected with the nozzle senses the coal dust concentration on the nozzle; the explosion-proof PLC control system analyzes a coal dust concentration signal transmitted by the explosion-proof coal dust concentration sensor and sends a dedusting medium ejecting instruction; and the dedusting medium ejecting instruction is performed by the explosion-proof electromagnetic control valve. The automatic dedusting system for coal mines can realize automatic control on dedusting operation, realize the matching of the ejection quantity of the dedusting medium and the coal dust concentration in real time, improve the dedusting efficiency, reduce medium consumption, save cost and energy source, simplify operation process and reduce labor intensity of workers.

Owner:内蒙古满世煤炭集团罐子沟煤炭有限责任公司

Sand burning preventing coal dust free green sand for casting and preparation method thereof

ActiveCN101733361AReuseRaw sand consumption is lessFoundry mouldsFoundry coresProduction rateCoal dust

The invention relates to a sand burning preventing coal dust free green sand for casting and preparation method thereof. The green sand contains 50-90% of naturally clay-bonded sand, 2-40% of sand burning preventing assistant and 2.5-20% of water by weight percent; the preparation method includes that the naturally clay-bonded sand and the sand burning preventing assistant are mixed in a sand mixing machine and the water is added for mixing to uniform. The green sand of the invention contains no coal dust and can be recycled; the casting mould made by the green sand of the invention is utilized to produce castings, crude sand consumption is low, the surface of casting is not burning-on, surface quality is high, no coal dust is required to add, recycling of moulding sand is good, environmental protection is less, and high temperature mould dismantling improves productivity.

Owner:DONGHUA UNIV

Sewage sludge biomass coal liquid and producing process

The invention relates to sludge biomass coal slurry and a manufacturing process thereof. The invention is characterized in that the manufacturing process comprises the following steps: (1) 10-50 parts of sludge and 0.01-5 parts of sludge modifier are mixed by part by weight to form modified sludge after full reaction; (2) the modified sludge obtained in the step (1) and 40-70 parts of coal dust, 1-50 parts of water, 1-60 parts of fuel oil and 0.01-2 parts of dispersant are mixed by part by weight and ground fully, so that the average grain diameter of solid particles in the mixture is less than 300 micron, thus obtaining the sludge biomass coal slurry. Compared with the prior art, the invention has the advantages of fully utilizing useful ingredients in the sludge and being environmentally friendly and energy-saving.

Owner:吴荣标

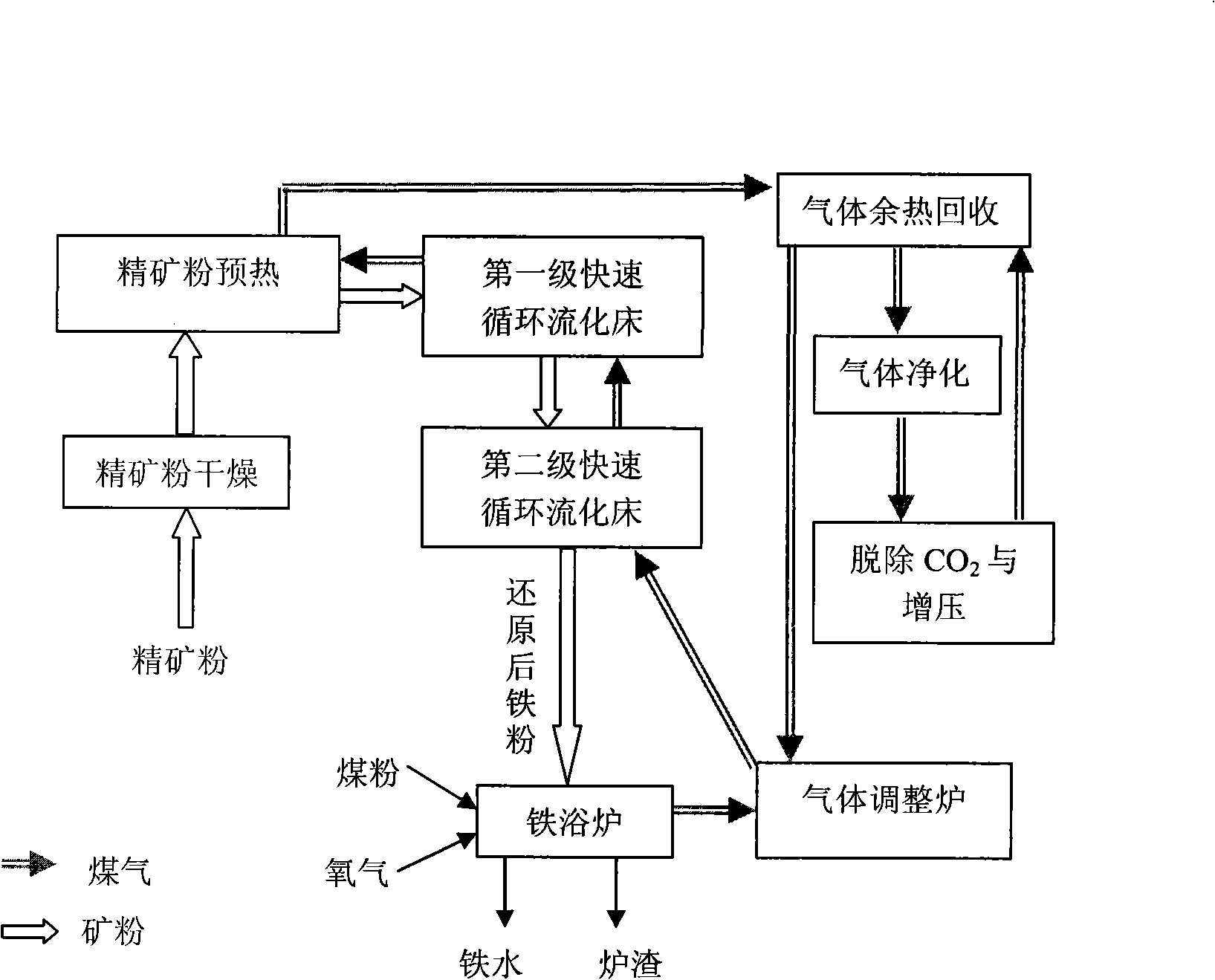

Fusion reduction iron-smelting method for directly using concentrate powder

ActiveCN101260448AHigh calorific valueImprove utilization factorProcess efficiency improvementGas emission reductionProduction lineSteelmaking

The invention belongs to the steelmaking field, and in particular relates to a smelting reduction steelmaking method of using concentrate powder directly. The production line is as follows: the concentrate powder is dried firstly and is pre-heated by the tail gas generated by a secondary rapid circulating fluid bed, the pre-heated concentrate powder enters the rapid circulating fluid bed to be pre-reduced, the metallization rate of the pre-heated iron powder is up to 55 to 80 percent; the pre-reduced iron powder and the coal dust as well as the oxygen are injected into an iron bath furnace to reduce and melt the mineral powder, and the molten iron and slag as well as coal gas are obtained. Compared with the prior art, the smelting reduction steelmaking technique has the advantages of high efficiency, low energy consumption, low pollution and easy implementation.

Owner:CENT IRON & STEEL RES INST +1

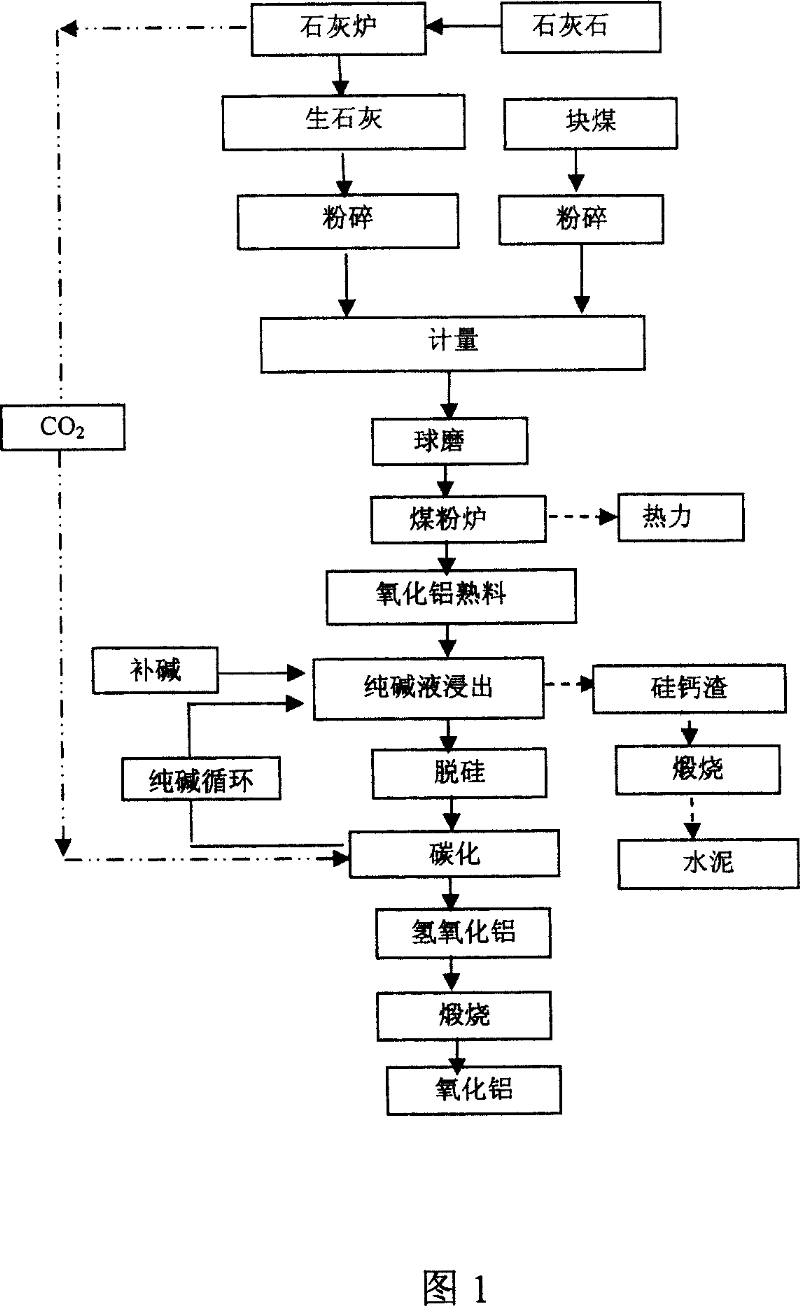

Method for extracting aluminium oxide from coal ash and producing cement by using waste slag

InactiveCN101041449AOvercoming qualityOvercome the problem that it is not easy to obtain high-grade cementAluminium oxide/hydroxide preparationCement productionSlagCoal dust

The invention discloses a method of extracting aluminum oxide from coal ash and preparing cement with waste slag, which comprises the following steps: adopting ''one stove two usage'' craft through coal dust stove of heat power plant; cooling and producing aluminum oxide clinker at the same time; abstracting aluminum oxide to get aluminum oxide product; using waste slag to prepare cement. This invention possesses characterize of reducing the energy consumption of aluminum oxide and cost of production.

Owner:CHANGAN UNIV

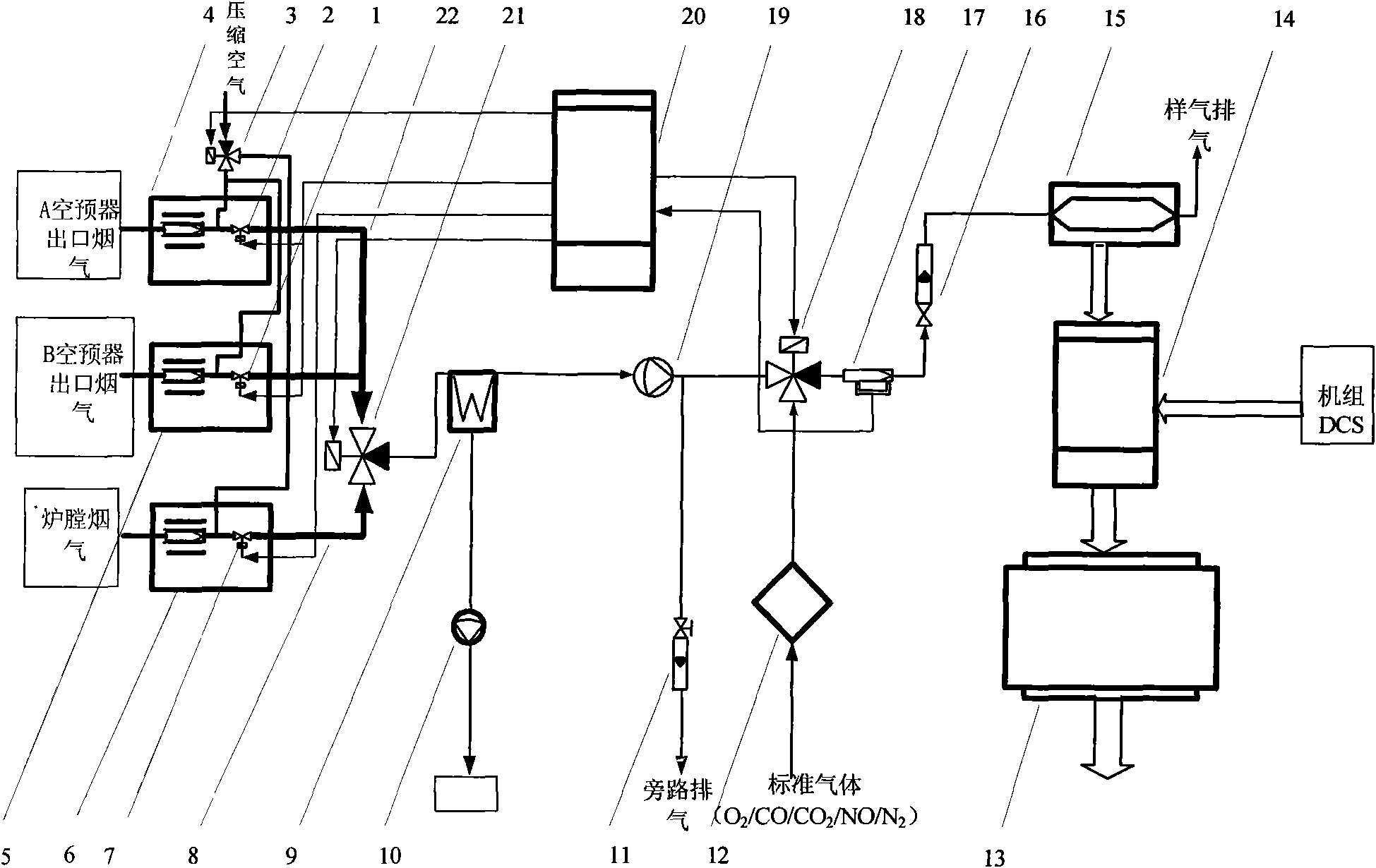

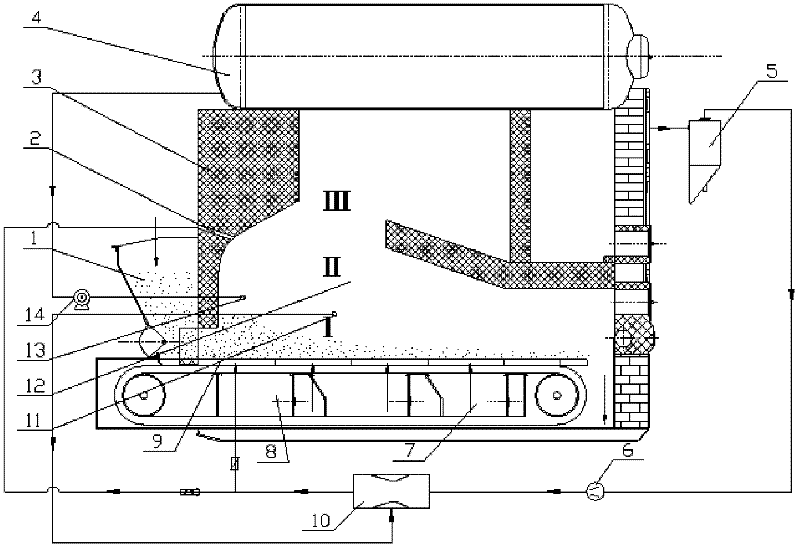

Stratified combustion on-line optimization control system of boiler coal dust and optimization method thereof

ActiveCN101619859AGood running safetyReduce emission concentrationWithdrawing sample devicesIndirect carbon-dioxide mitigationAir preheaterCoal dust

The invention discloses a stratified combustion on-line optimization control system of boiler coal dust, comprising a gas sampling system and a data processing system, wherein the gas sampling system comprises a fume sampling probe and a fume component continuous monitoring system. The invention is characterized in that the fume sampling probe comprises a first fume sampling probe arranged at an opening of an A air preheater, a second fume sampling probe arranged at an opening of a B air preheater and a third fume sampling probe arranged in a boiler chamber; the data processing system comprises an industrial computer connected with the fume component continuous monitoring system and provided with a stratified combustion on-line optimization computation module; and DCS data of the industrial computer and a generator set are connected by a data collector. The invention utilizes a support vector machine theory by the method and the method to establish an on-line optimization model to carry out automatic training and optimization so as to obtain combustion optimization condition parameters to guide operation, thereby keeping high operation safety of the boiler, improving operation economical efficiency and reducing the emission concentration and totals of pollutants.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

Efficient coal dust combustor for reducing smoke NOx content

InactiveCN102679338ASolve the problem that it is not suitable for small and medium pulverized coal boilersPulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to coal dust combustion technology and particularly relates to an efficient coal dust combustor for reducing smoke NOx content. The invention solves the problem that the existing grading air supply coal dust combustor cannot be applied to small and medium coal dust boilers. The efficient coal dust combustor comprises a primary air pipe, wherein an inner cavity of the primary air pipe forms a primary air channel; the outer side of the primary air pipe is coaxially sleeved with an air mixing sleeve; the inlet end of the air mixing sleeve is communicated with an air mixing inlet pipe; the air outlet end of the air mixing sleeve is provided with an air mixing expansion section; the inner wall of the air mixing sleeve and the outer wall of the primary air pipe jointly encircle an annular air mixing channel; the outer side of the air mixing sleeve is coaxially sleeved with an inner secondary air sleeve; and the inlet end of the inner secondary air inlet is communicated with an inner secondary air inlet pipe. Based on a brand-new structure, the efficient coal dust combustor disclosed by the invention effectively solves the problem that the existing grading air supply coal dust combustor cannot be applied to the small and medium coal dust boilers; in addition, the efficient coal dust combustor can be applied to the small and medium coal dust boilers.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

Coal mine gas explosion burst treatment method and its matched gas dissolving and elimineting agent

InactiveCN1624298AAvoid Explosion Prominent AccidentsGuarantee the safety of lifeDust removalFire preventionCoal dustCoal mine methane

This invention relates to a method and a gas dissolvant for the frequent gas explosions in coal mine. Its procedures are as following: the gas dissolvent and water are poured in turn into the coal seams containing gas. The gas dissolvent is a kind of water solution made up of acetum and yeast which selective weight ratio is 1000:5-15. The acetum is preferred to be replaced by vinegar of the same acetum. After the vinegar is added into the yeast, their dehydro-ratio is 2-8 times as heavy as the vinegar. The advantages are safety efficient, more feasible and harmless to human body.

Owner:洛阳保矿安矿山设备有限公司

Coal dust combustion improver for cement kiln

The invention discloses coal dust combustion improver for cement kilns, which comprises the following components by weight percentage: 50-80% of manganese ore, 10-40% of chemical activator, 5%-15% of clinker sintering agent, and less than 2% of moisture content. The coal dust combustion improver for cement kilns of the invention has the effects of promoting concentrated combustion of coal powder and improving the strength of clinks, and the combustion-supporting mechanism of the coal dust combustion improver is as follows: by combustion-supporting components, the fire point of coal powder is decreased, the melting point of coal powder ash is increased, and combustion atmosphere is regulated at high temperature, thereby achieving the purpose of utilizing fault coal fully in the process of cement burning and the purposes of promoting the sintering reaction of clinkers and improving the strength of clinkers by adding combustion improver components of cement clinkers.

Owner:洛阳大泽节能环保科技有限公司

Low emission high efficiency grate-firing combustion device and method

InactiveCN102506418AImprove combustion efficiencyReduce conversionSolid fuel combustionNon-combustible gases/liquids supplyCombustorCombustion chamber

The invention relates to a low emission high efficiency grate-firing combustion device and a method. The method is characterized in that coal dust and a sulfur-fixing agent are fully mixed so as to enter into a grate-fired furnace through a hopper, a gas recirculation and spray water combined technology is utilized to rapidly pyrolyze coal dust so as to generate reducing gas, recirculation fume is utilized to carry the reducing gas and part of fine granule semicoke to enter into a recrudescence region in the furnace, and the combustion flow of the furnace is strengthened; and the purpose of reduction NOx is achieved, the no-burnout grains are continually combusted above a combustor, staged combustion of a fuel in the furnace is realized in a hearth, and meanwhile, and the combustion efficiency of the grate-fired furnace is also improved. According to the invention, the grate-fired furnace is introduced through a fuel staged combustion technology, on the one hand, the NOx and SOx discharge of the grate-fired furnace is reduced through combustion adjustment, namely, the NOx deprivation rate is 35%-55%, the SOx deprivation rate is more than 80%, thereby protecting an atmospheric environment; on the other hand, the combustion efficiency of the grate-fired furnace is improved by 1%-2%.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com