Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10867 results about "Iron powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron powder has several uses; for example production of magnetic alloys and certain types of steels. Iron powder is formed as a whole from several other iron particles. The particle sizes vary anywhere from 20-200 μm. The iron properties differ depending on the production method and history of a specific iron powder. There are three types of iron powder classifications: reduced iron powder, atomized powder, and electrolyte iron powder. Each type is used in various applications depending on their properties. There is very little difference in the visual appearances of reduced iron powder and atomized iron powder.

Oxygen scavenging films

InactiveUS20100255231A1Metal-working apparatusGlass/slag layered productsParticulatesAlkaline earth metal

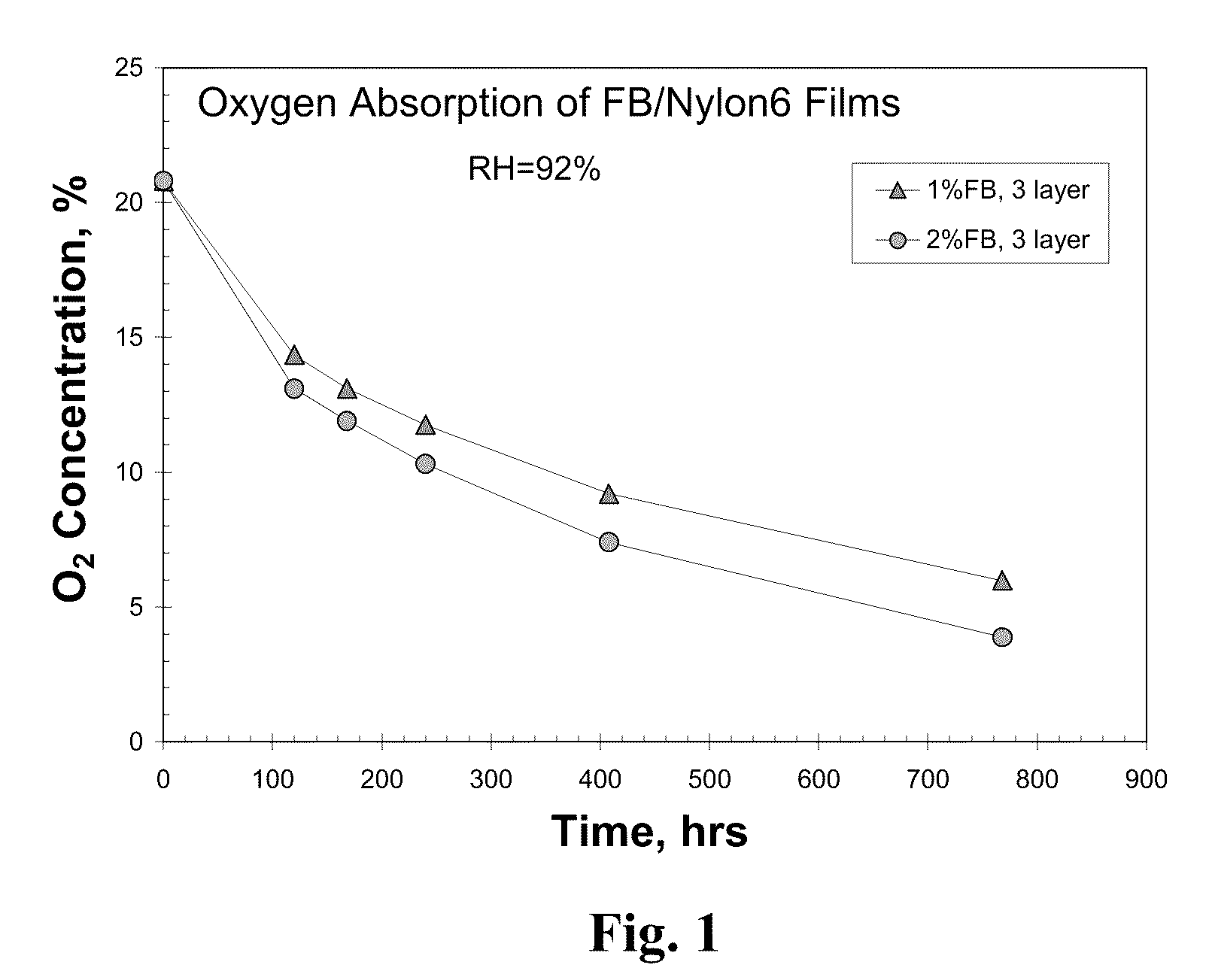

A well dispersed oxygen scavenging particulate compounded in a polymer matrix. The oxygen scavenging formulation consists of iron powder with a mean particle sizes within 1-25 um and pre-coated with at least one or more activating and acidifying powdered compounds, usually in the form of solid organic and inorganic salts of alkaline and alkaline earth metals such as sodium chloride and sodium bisulfate. The pre-coated iron particulate is dispersed into a polymer resin by using a conventional melt processing method such as twin-screw extrusion. The oxygen scavenging compound is mixed with polymer pellets in the solid state prior to melting. The polymer resin pellets and the coated iron powder are preferably treated with a surfactant in the dry state to help dispersing the iron / salt powder with the resin pellets. The melt extruded compounds are pelletized and kept in the dry state to prevent premature activation.

Owner:MULTISORB TECH INC

Method for preparing lithiumion cell positive material Iron-lithium phosphate

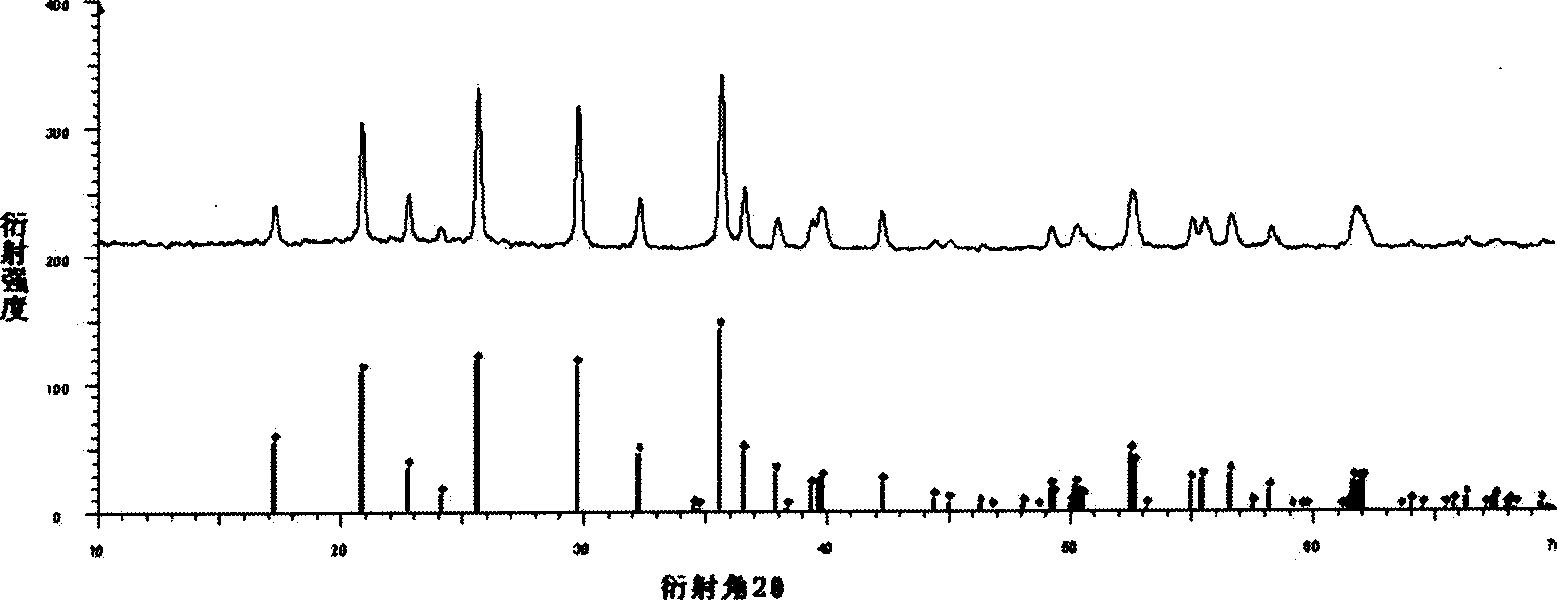

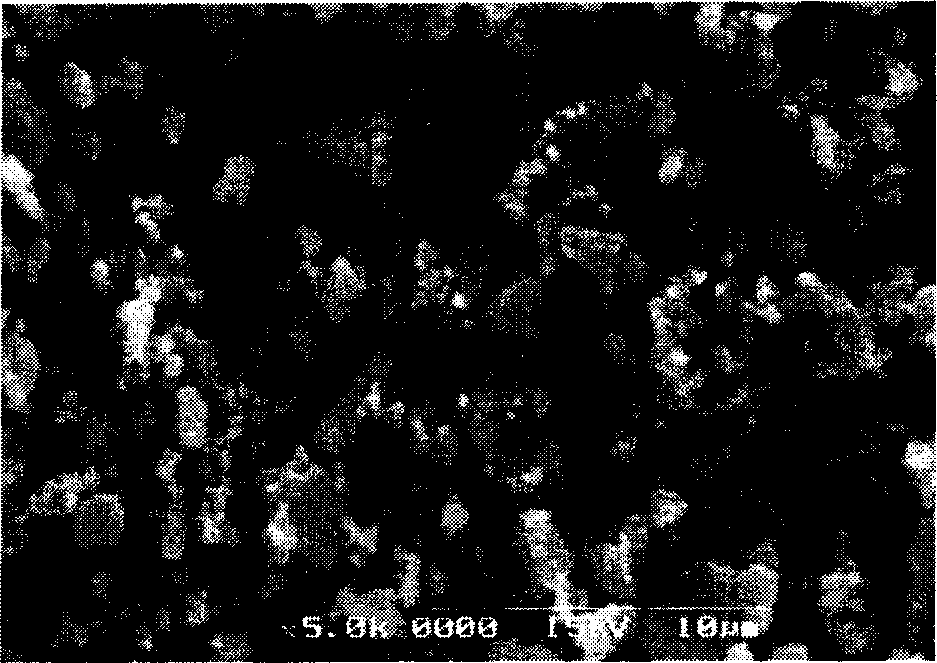

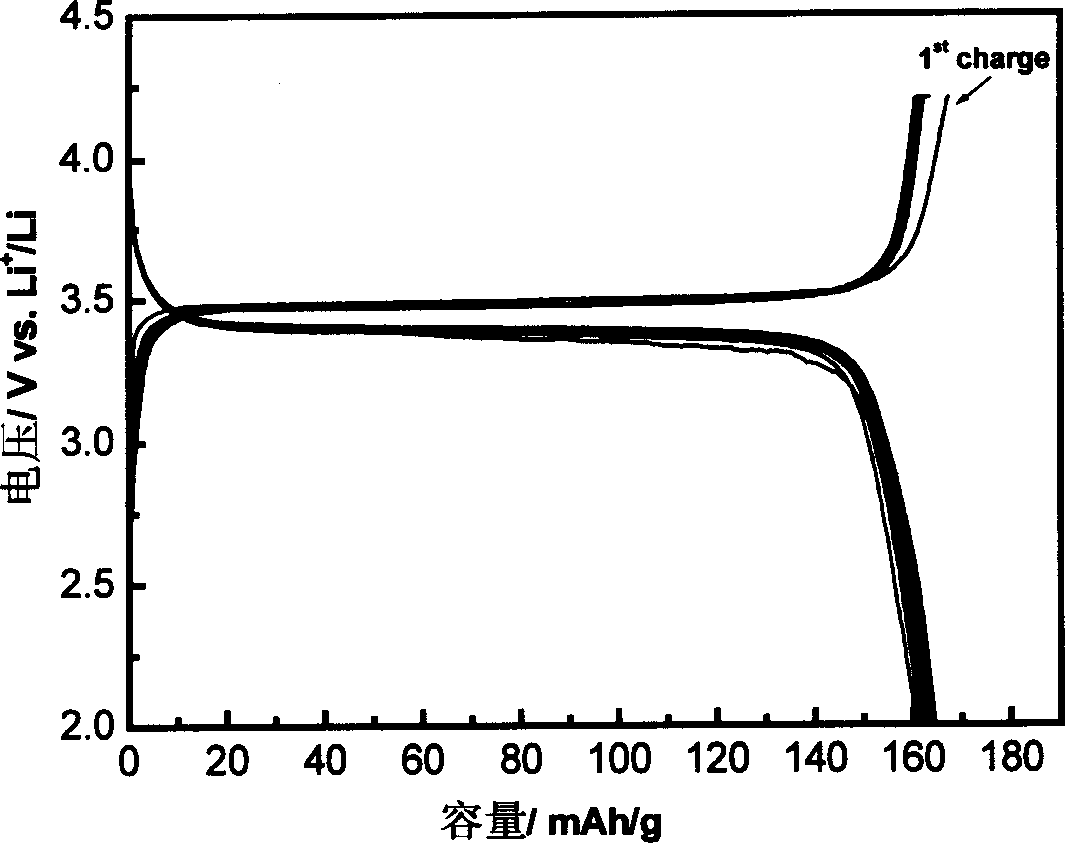

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

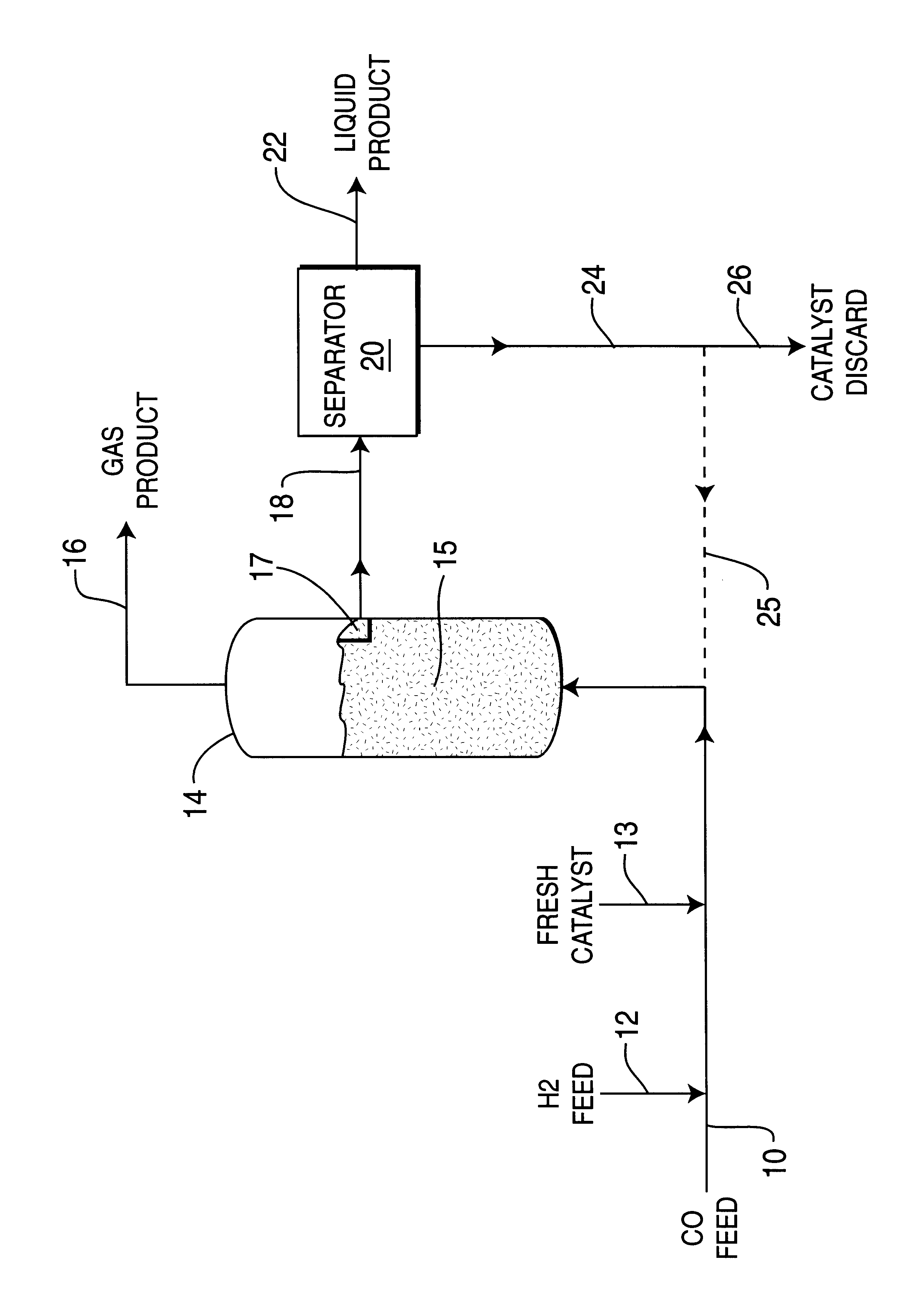

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

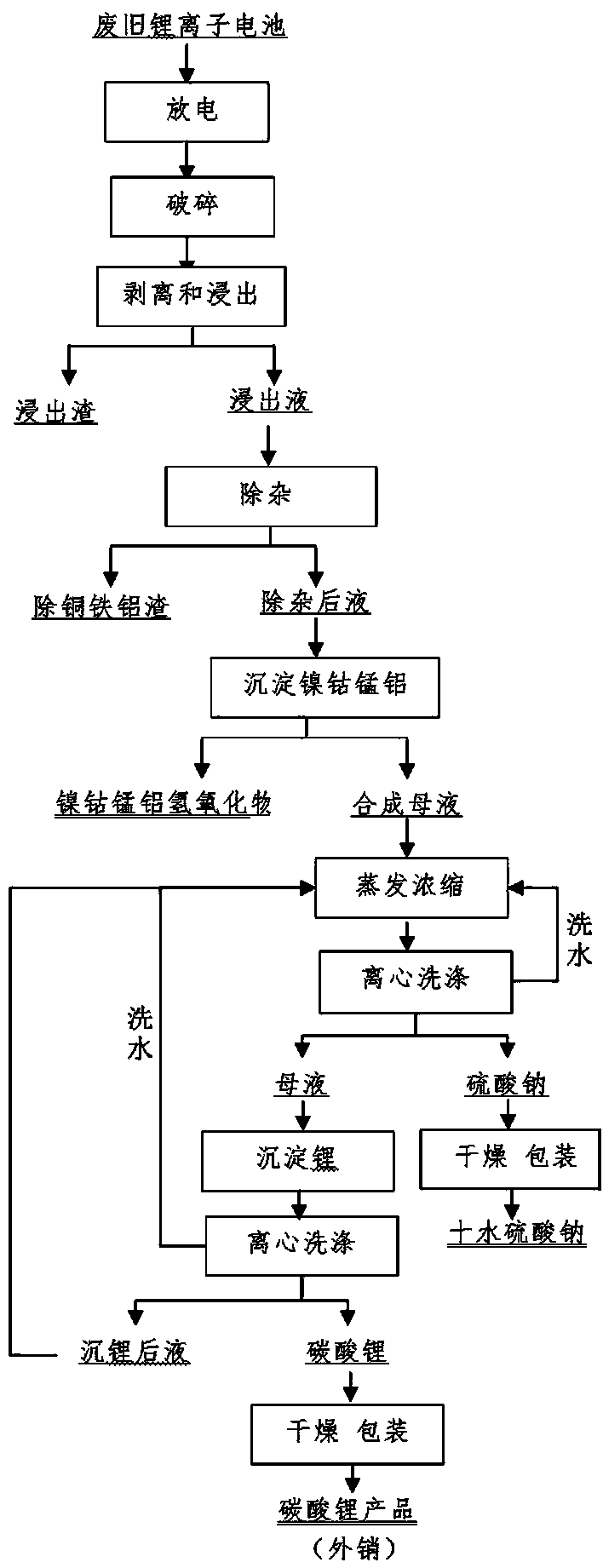

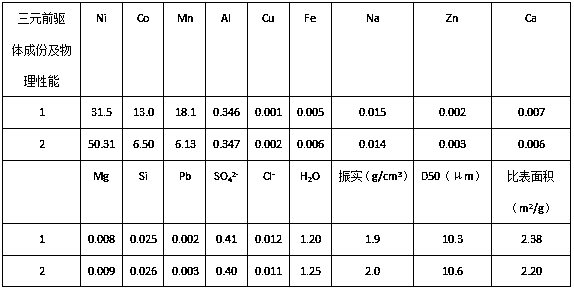

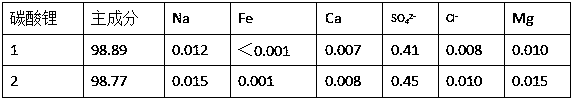

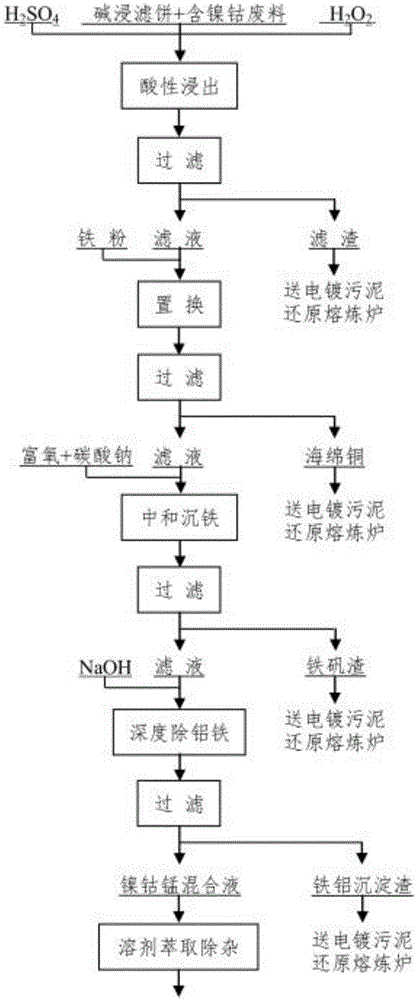

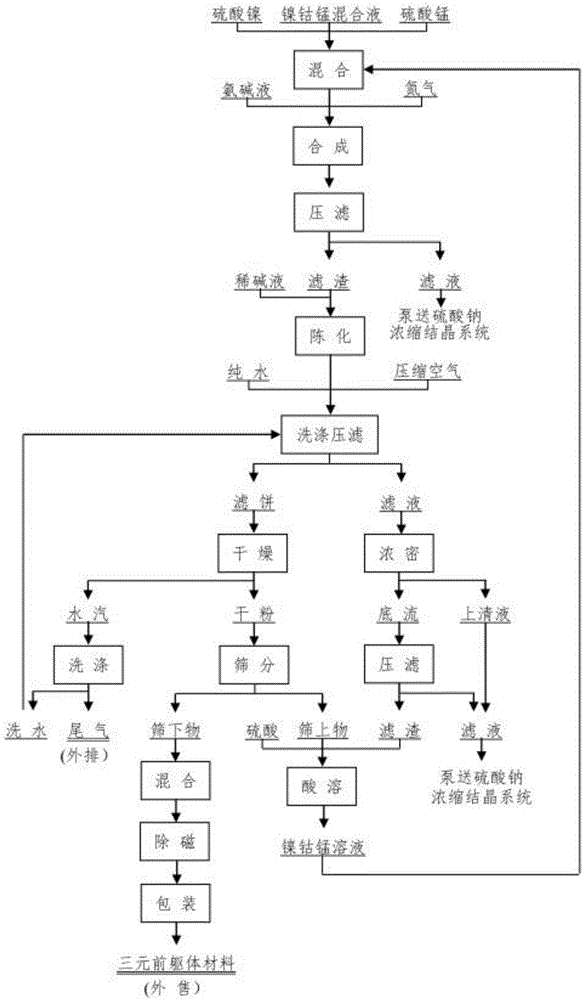

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

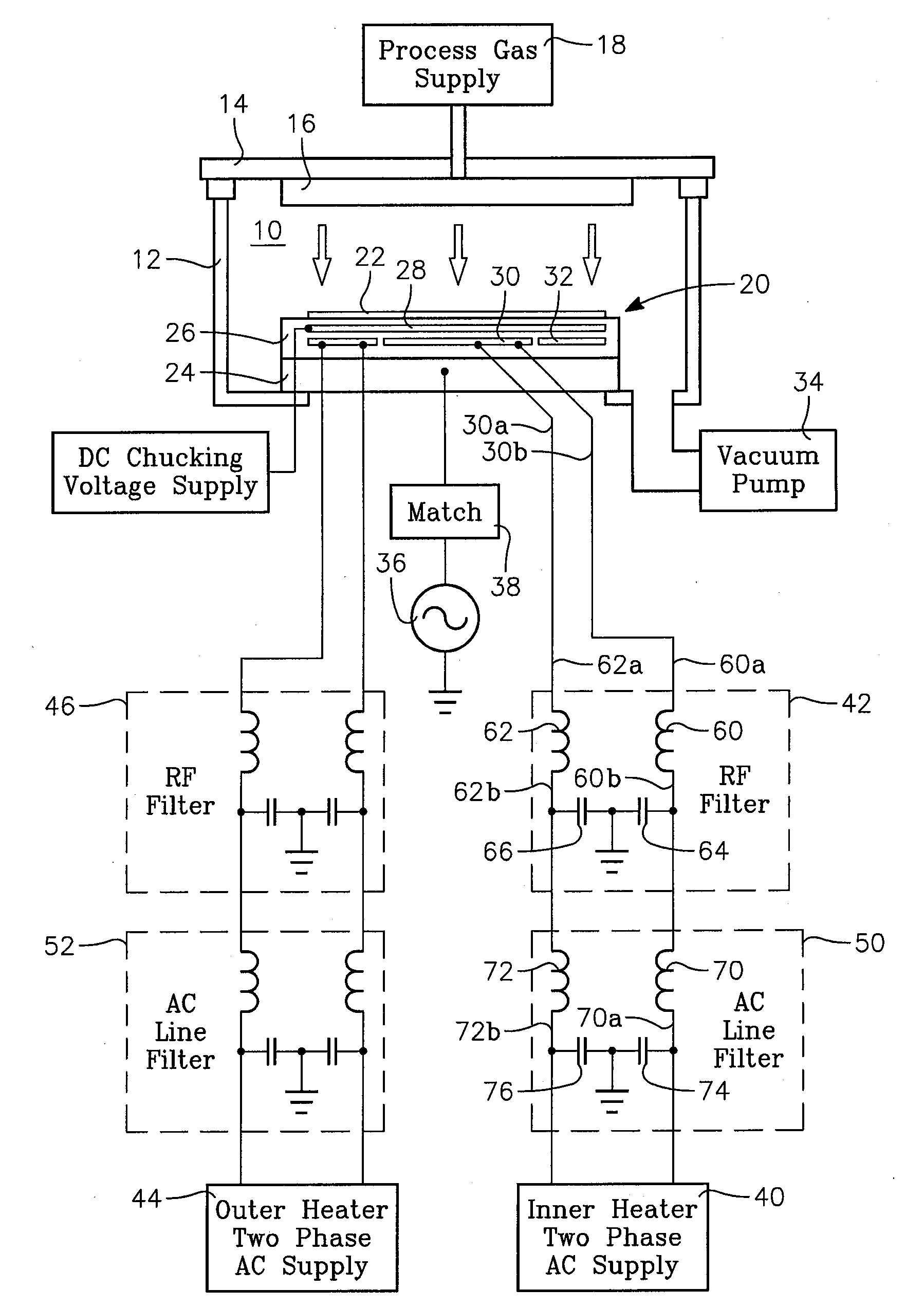

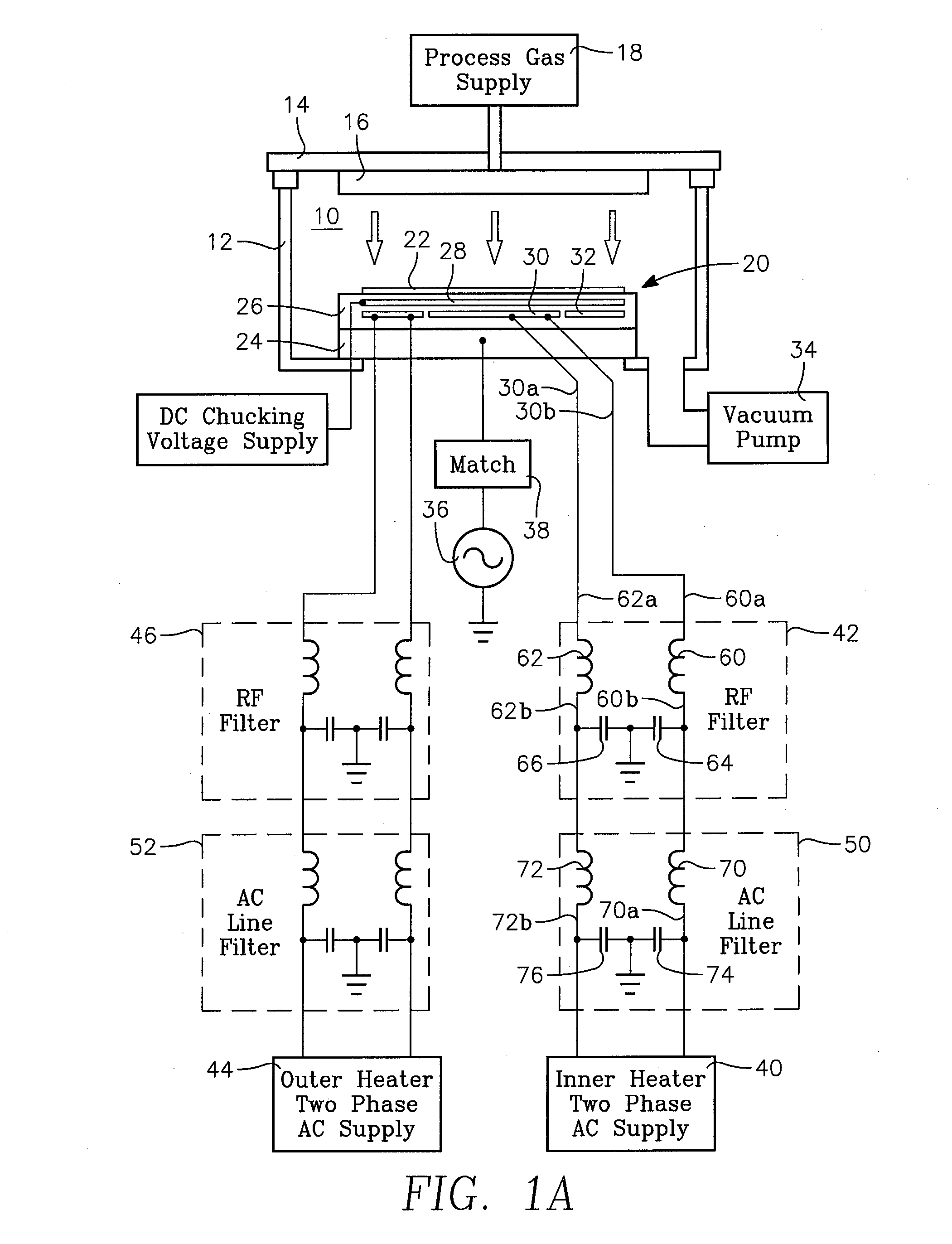

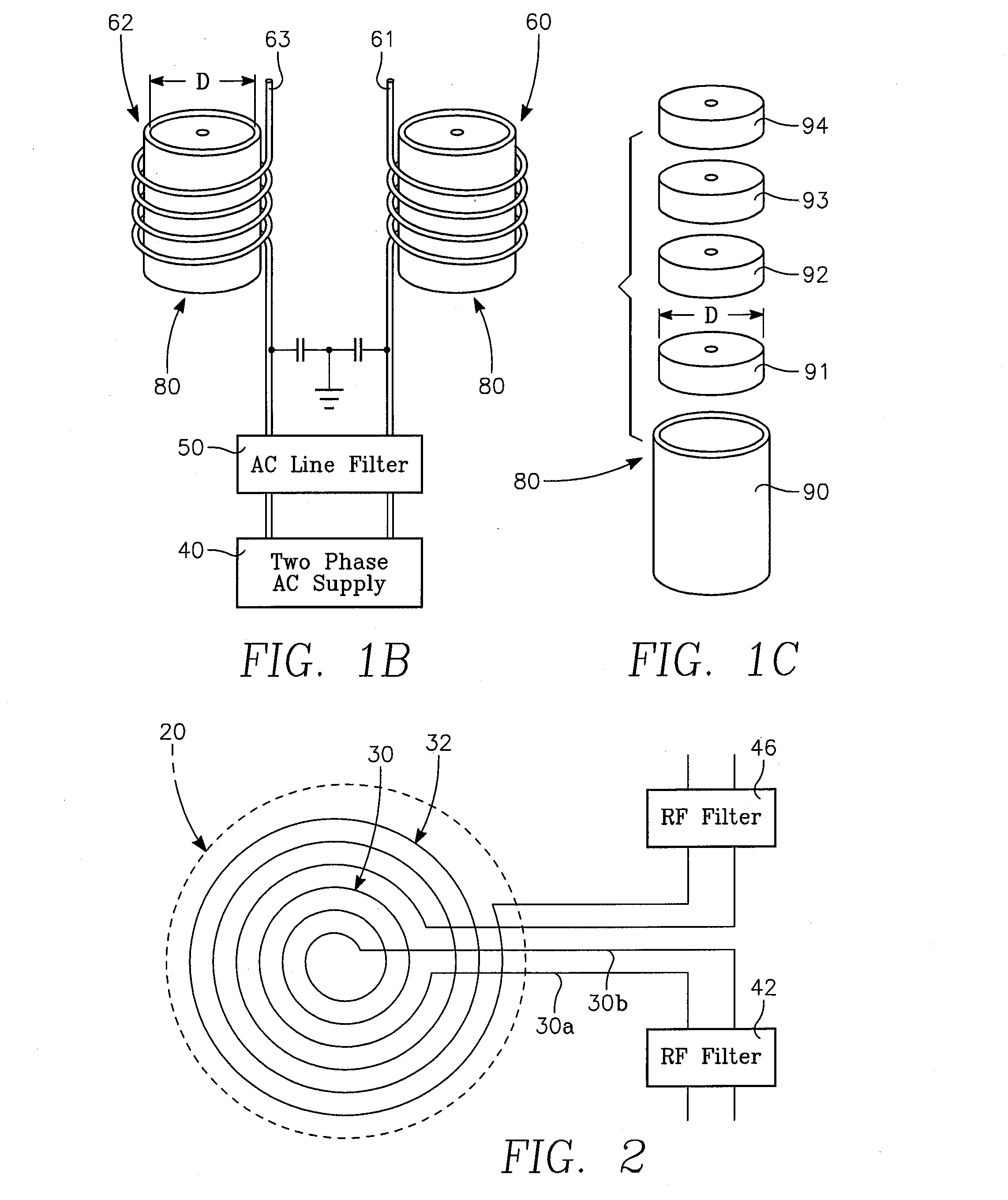

High ac current high RF power ac-RF decoupling filter for plasma reactor heated electrostatic chuck

ActiveUS20070284344A1Multiple-port networksElectric discharge tubesInductor windingsElectrical conductor

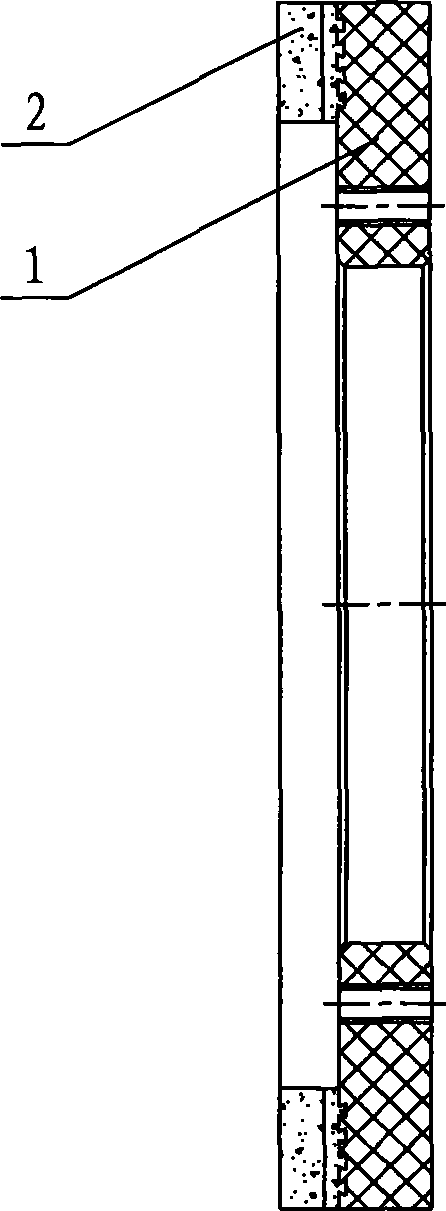

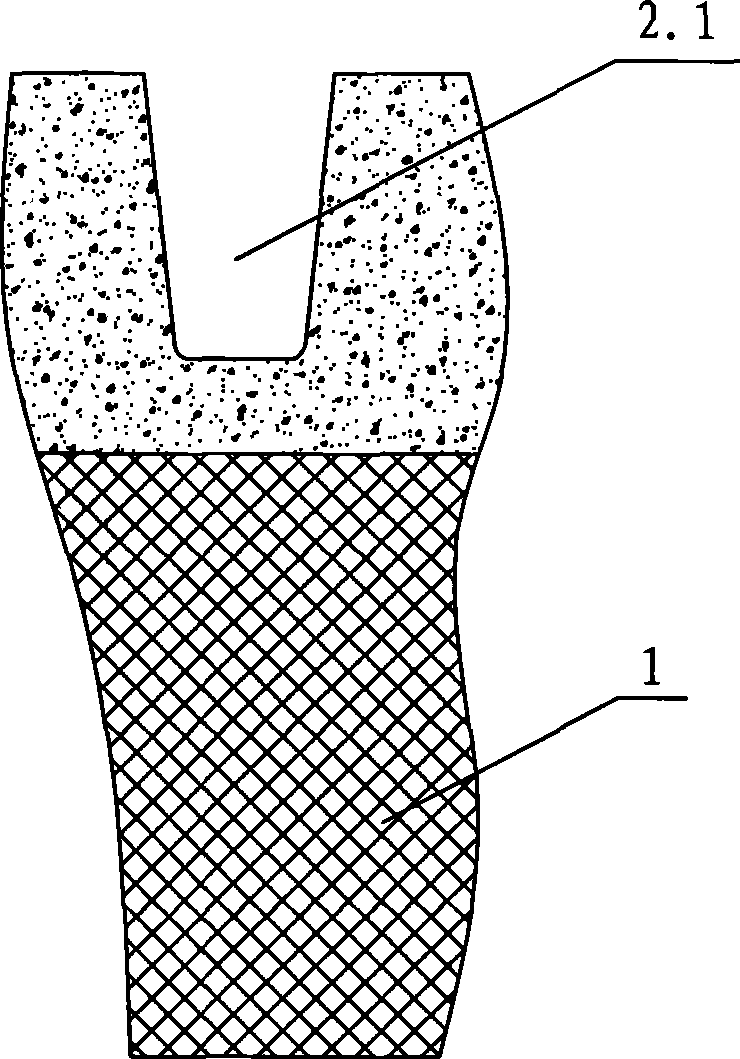

An RF blocking filter isolates a two-phase AC power supply from at least 2 kV p-p of power of an HF frequency that is reactively coupled to a resistive heating element, while conducting several kW of 60 Hz AC power from the two-phase AC power supply to the resistive heating element without overheating, the two-phase AC power supply having a pair of terminals and the resistive heating element having a pair of terminals. The filter includes a pair of cylindrical non-conductive envelopes each having an interior diameter between about one and two inches and respective pluralities of fused iron powder toroids of magnetic permeability on the order of about 10 stacked coaxially within respective ones of the pair of cylindrical envelopes, the exterior diameter of the toroids being about the same as the interior diameter of each of the envelopes. A pair of wire conductors of diameter between 3 mm and 3.5 mm are helically wound around corresponding ones of the pair of envelopes to form respective inductor windings in the range of about 16 to 24 turns for each the envelope, each of the conductors having an input end and an output end. The input end of each one of the conductors is coupled to a corresponding one of the pair of terminals of the two-phase AC power supply, and the output end of each one of the conductors is coupled to a corresponding one of the pair of terminals of the resistive heating element.

Owner:APPLIED MATERIALS INC

Resin anchoring agent diamond grinding wheel and production method thereof

ActiveCN101386154AIncreased durabilityImprove adhesionAbrasion apparatusGrinding devicesBoron carbideZirconia alumina

The invention relates to a resin bonding agent diamond grinding wheel and a manufacturing method thereof, and the grinding wheel comprises a grinding medium layer and a base body, wherein, the grinding medium layer is arranged on the base body and comprises diamond grinding medium, resin bonding agent, filling reinforcement which is a copper cladded iron powder and auxiliary abrasives which can be one or the combination of carborundum, boron carbide, white alundum, single alundum and fused zirconia alumina. The grinding medium layer comprises 5-15% of diamond grinding medium, 10-25% of auxiliary abrasive, 25-50% of thermosetting polyimide resin, 3-10% of copper cladded iron powder, 15-40% of silicon carbide powder and 0-8% of filling of metallic oxide in terms of volume percent. The diamond grinding wheel is characterized by low production cost, strong adhesive force, good sharpness and self-sharpness, long service life and good abrasion cutting effect.

Owner:广东奔朗新材料股份有限公司

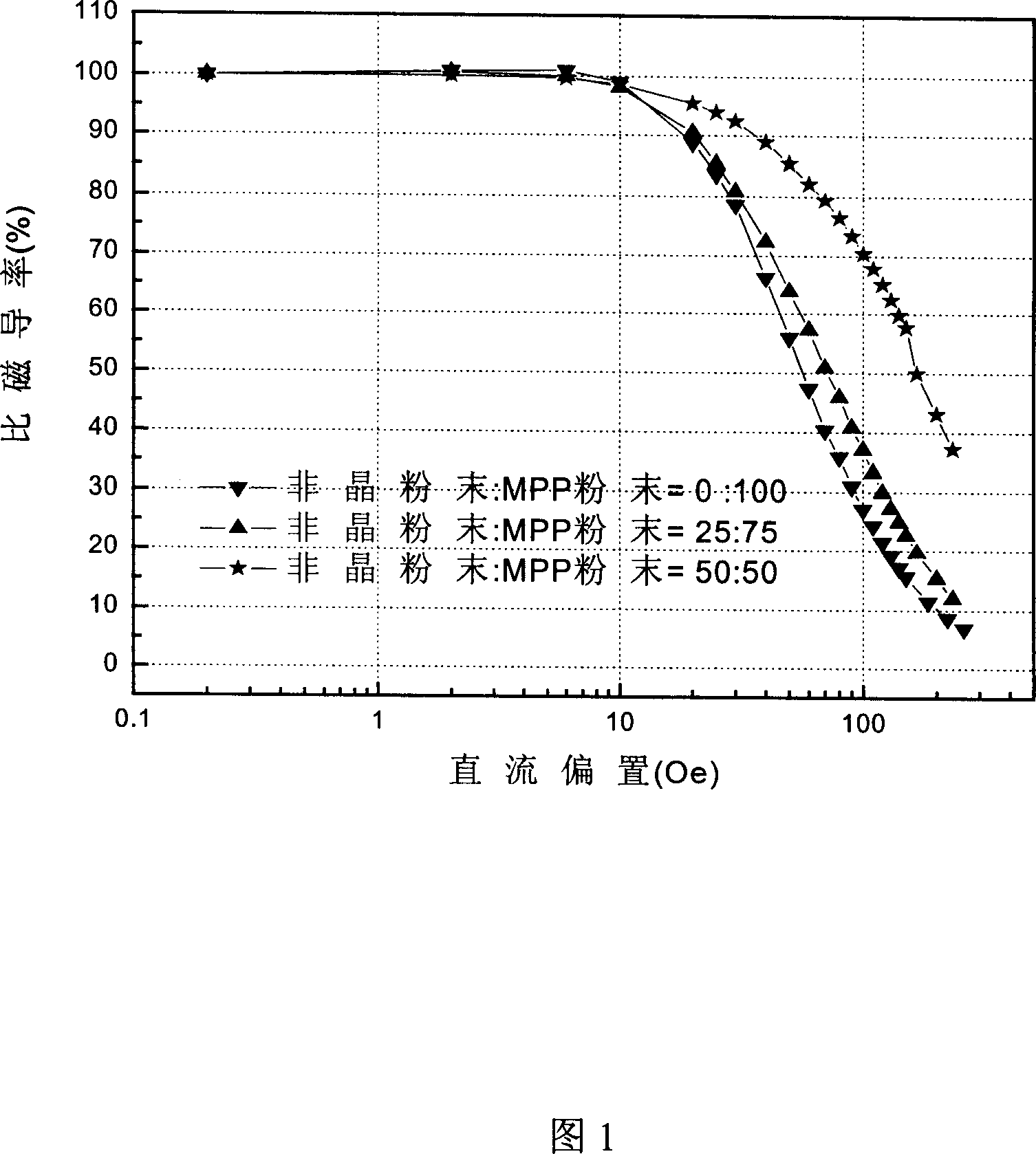

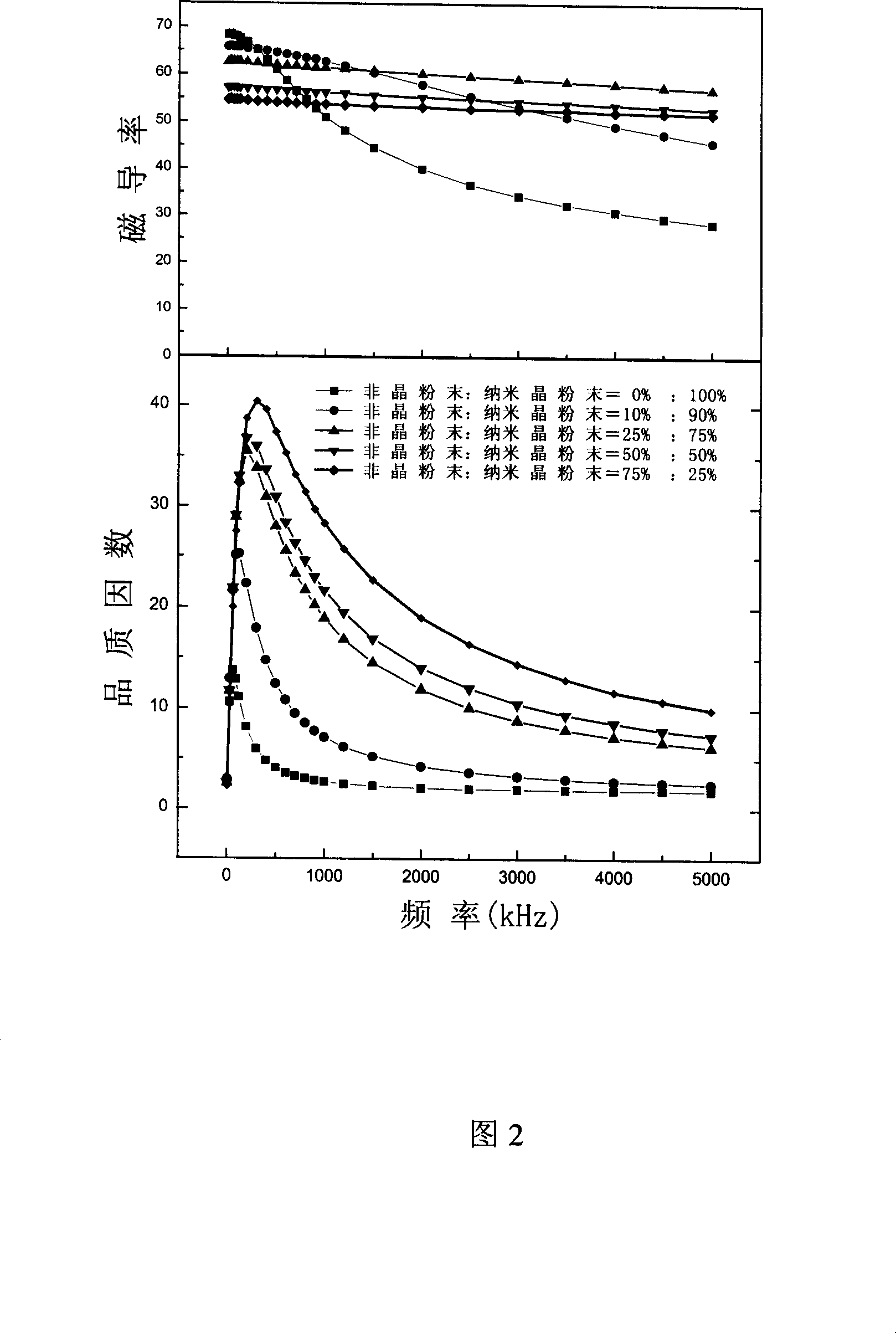

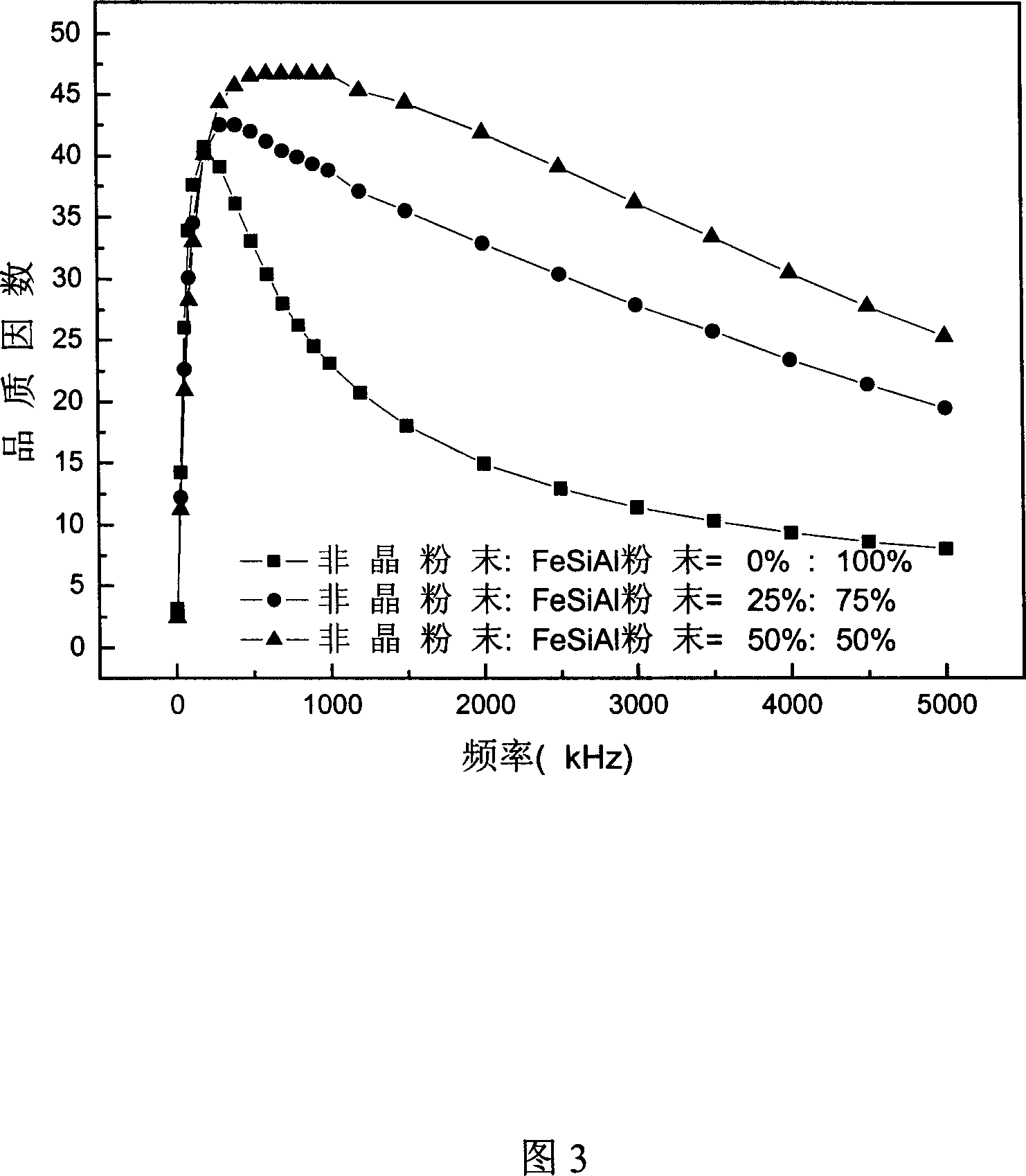

Composite powder, magnetic powder core for magnetic powder and preparation method thereof

InactiveCN101118797AExcellent soft magnetic propertiesIncrease the amount of participationInorganic material magnetismInductances/transformers/magnets manufactureAl powderIron powder

The present invention provides a magnetic powder core, composite powder used for the magnetic powder core, and a production method for the both. The composite powder is blended and formed by powder A and powder B, the content of which comprises 50-96wt percent of the powder A and 4-50wt percent of the powder B; wherein, the powder A is one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-base amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder; the powder B has different demand characteristics compared with the powder A and is selected from at least one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-based amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder. The powder B can be Fe-based soft magnetic amorphous powder as the insulating agent, which can reduce the wastage of magnetic powder core and make up for the declining magnetic conductivity of magnetic powder core caused by the traditional insulating agent. The excellent of soft magnetic properties of the insulating agent is utilized to improve frequency features of the magnetic powder core.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

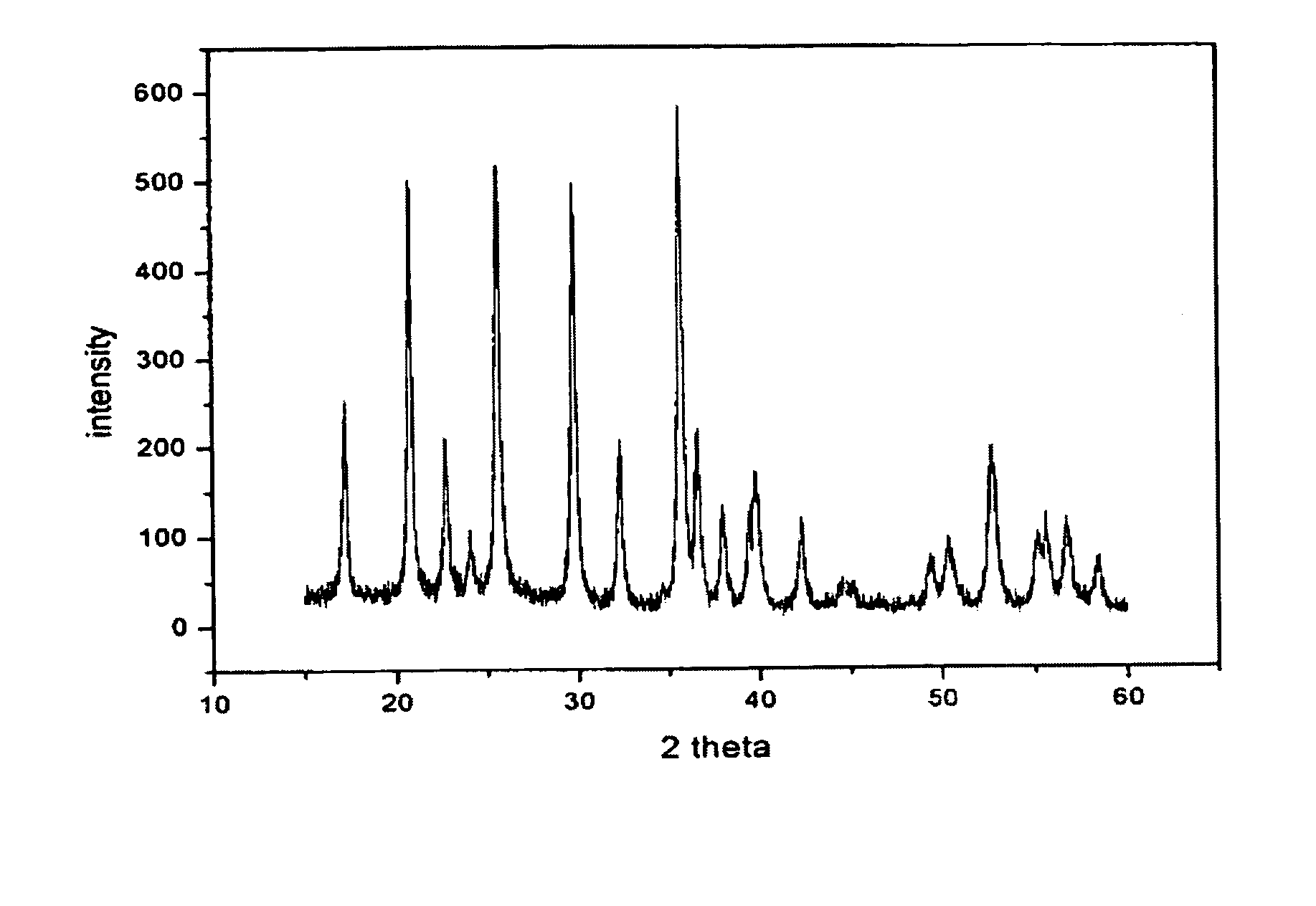

Preparation of olivine Li Fe PO4 cathode materials for lithium batteries via a solution method

InactiveUS20060263286A1Low costImprove conductivityPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesIron powderPhosphate

A preparation method of olivine Li1+xFe1+yPO4 is disclosed, wherein −0.2≦x≦0.2 and −0.2≦y≦0.2, which includes the following steps: (A) adding iron powder, lithium salt, and phosphate into an acid solution to form a mixture, wherein the molar ratio of Li+:Fe2+:PO43− is 1+x:1+y:y; (B) stirring the mixture; (C) drying the mixture to obtain solid precursor powder; and (D) heating the precursor solid powder at a temperature over 500° C. to form olivine structured powders.

Owner:TATUNG COMPANY

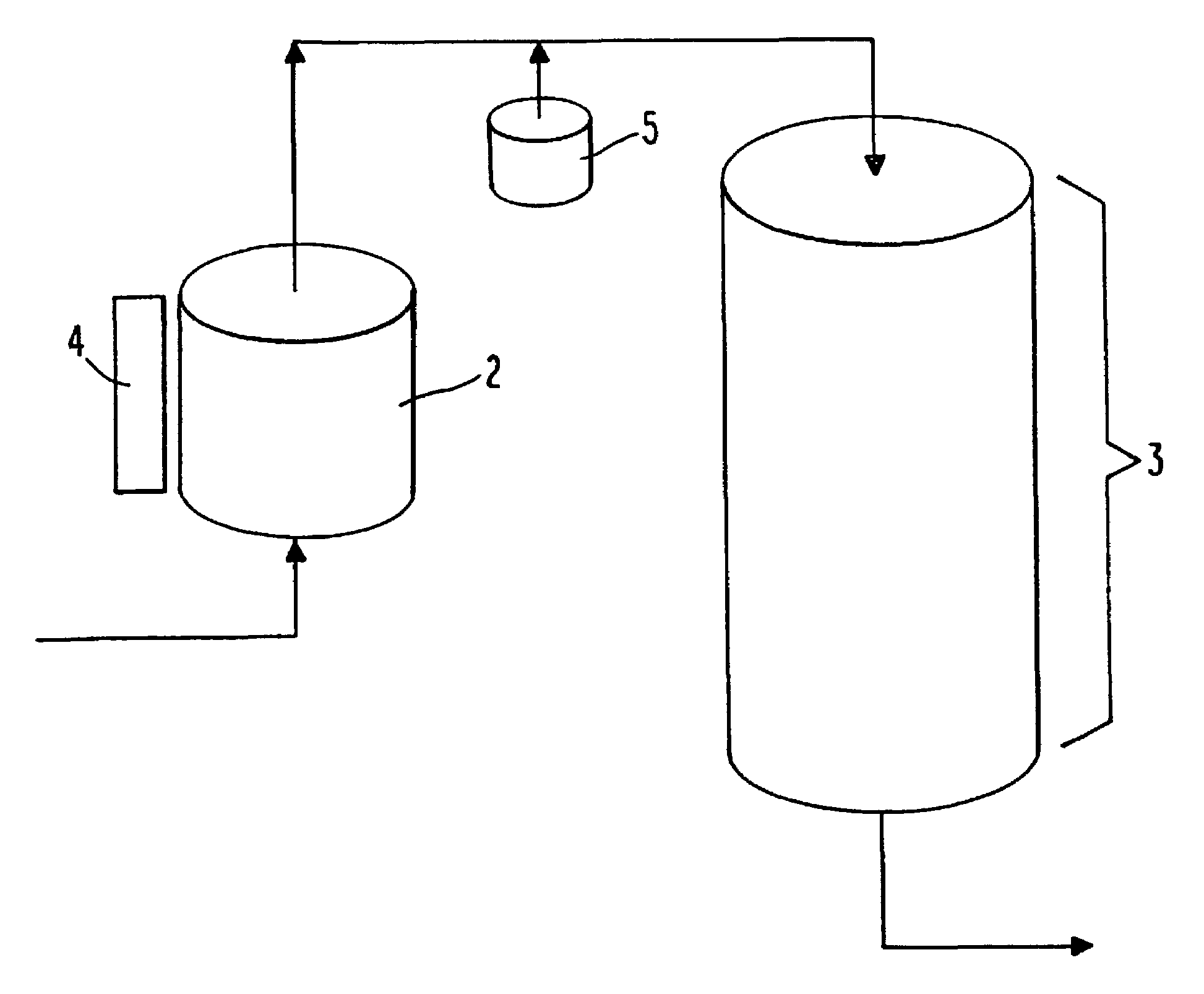

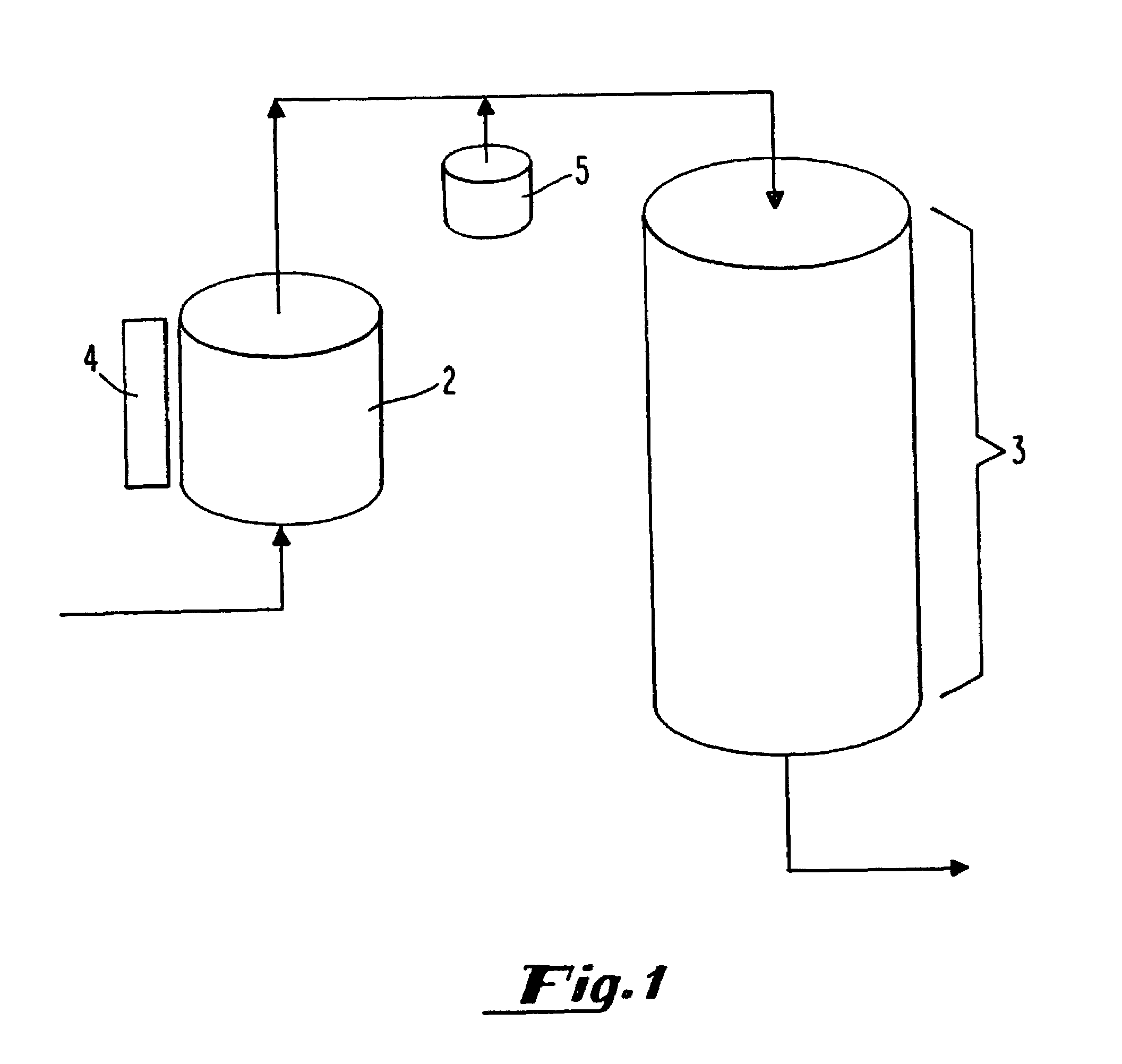

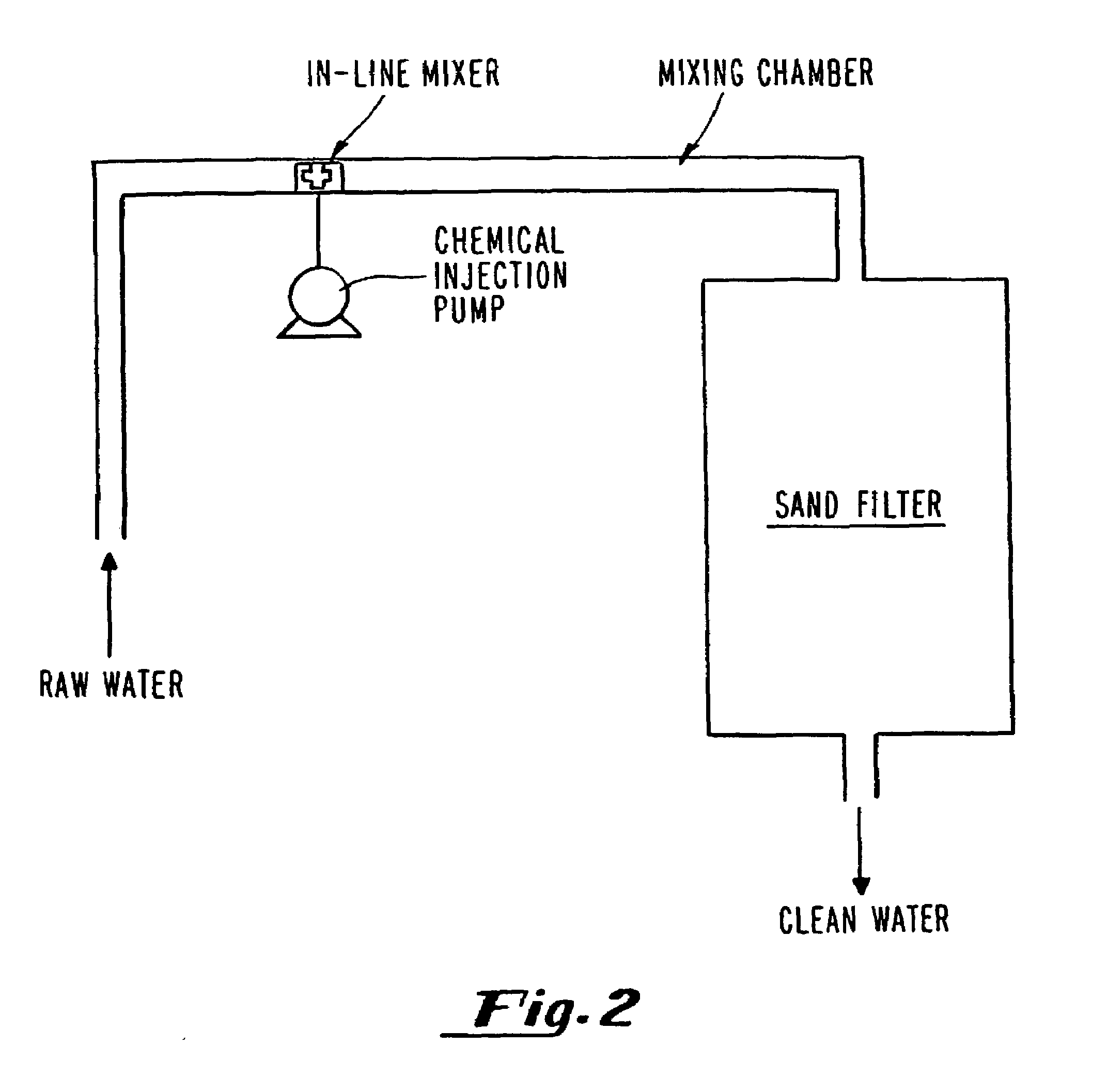

Iron powder and sand filtration process for treatment of water contaminated with heavy metals and organic compounds

InactiveUS6942807B1Improve efficiencyGood removal effectSolid sorbent liquid separationSedimentation separationIron powderFiltration

A water filtration device (3) and method which removes heavy metals and organic compounds from raw water is provided.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

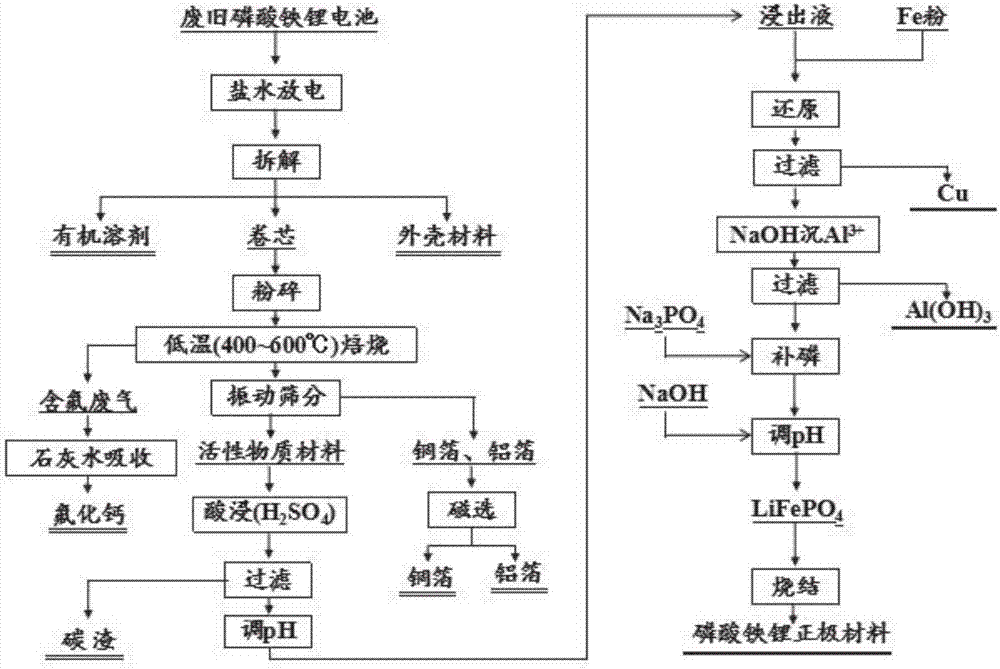

Method for regenerating positive active material from waste lithium iron phosphate batteries

ActiveCN106910889ARealize combination generationQuality assuranceCell electrodesWaste accumulators reclaimingFiltrationCopper foil

The invention discloses a method for regenerating a positive active material from waste lithium iron phosphate batteries. The method comprises the steps as follows: 1) waste lithium iron phosphate batteries are discharged in saline water, and organic solvents, roll cores and casing materials are disassembled; 2) the roll cores are subjected to crushing, calcination and other steps, and active materials, copper foil and aluminum foil are separated through vibrating screening. Fluorine-containing waste gas is absorbed with lime water, the copper foil and the aluminum foil are separated with a magnetic separation method, the active materials are leached out with sulfuric acid, and a leachate and carbon residues are obtained through separation; 3) Cu<2+> in the leachate is reduced to elementary copper by adding iron powder, meanwhile, Fe<3+> is reduced to Fe<2+>, copper and excessive iron residues are filtered out, aluminum is removed through precipitation with an alkaline liquid, the filtrate is supplemented with a phosphorus source after filtration, the pH value is adjusted by adding the alkaline liquid, coarse lithium iron phosphate precipitates are produced, and finally, battery-grade lithium iron phosphate is obtained through sintering. Comprehensive utilization of the waste lithium iron phosphate batteries and regeneration of the active materials are realized with a simple, practical, economical and feasible method, no secondary pollution is produced, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

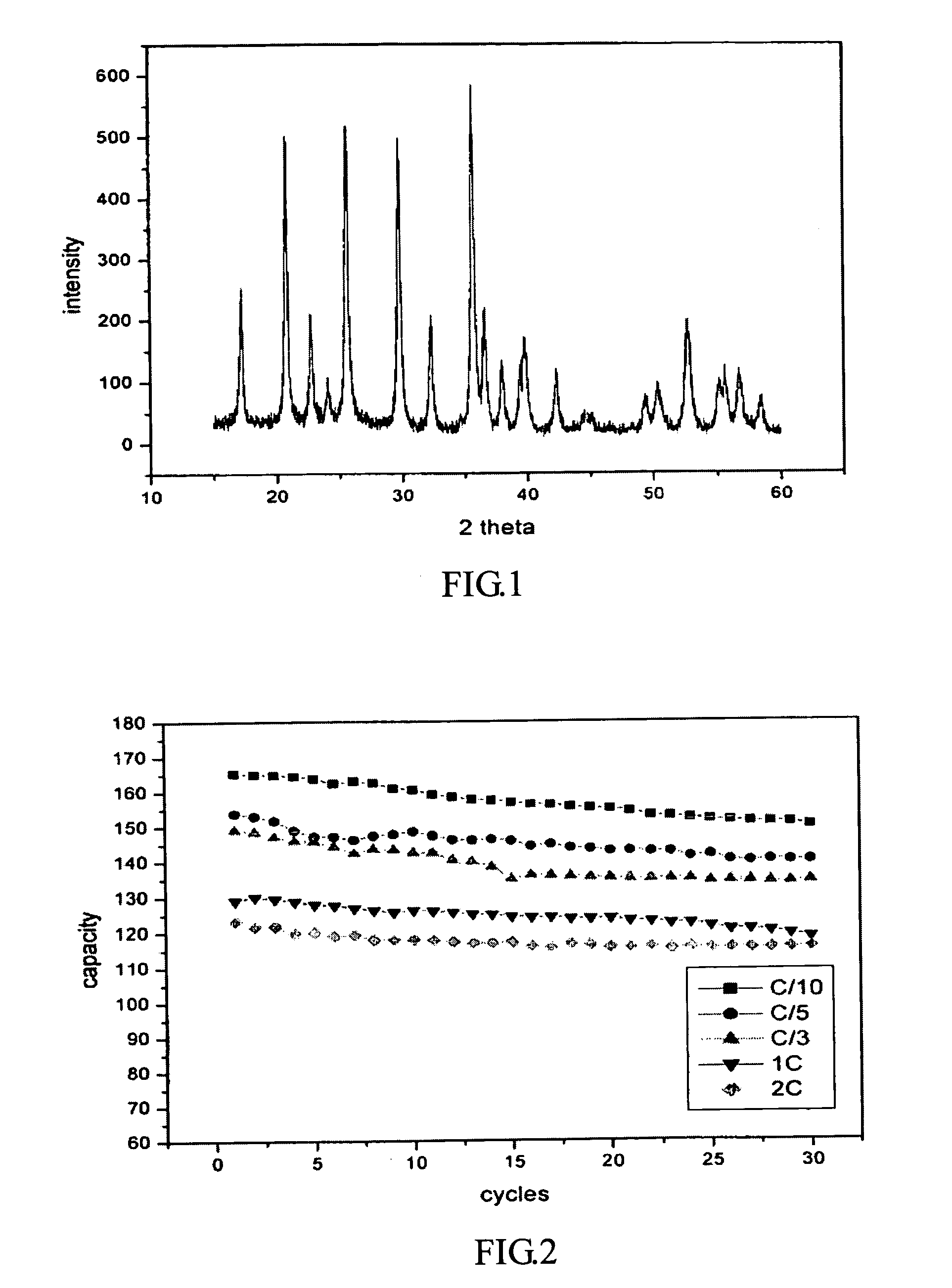

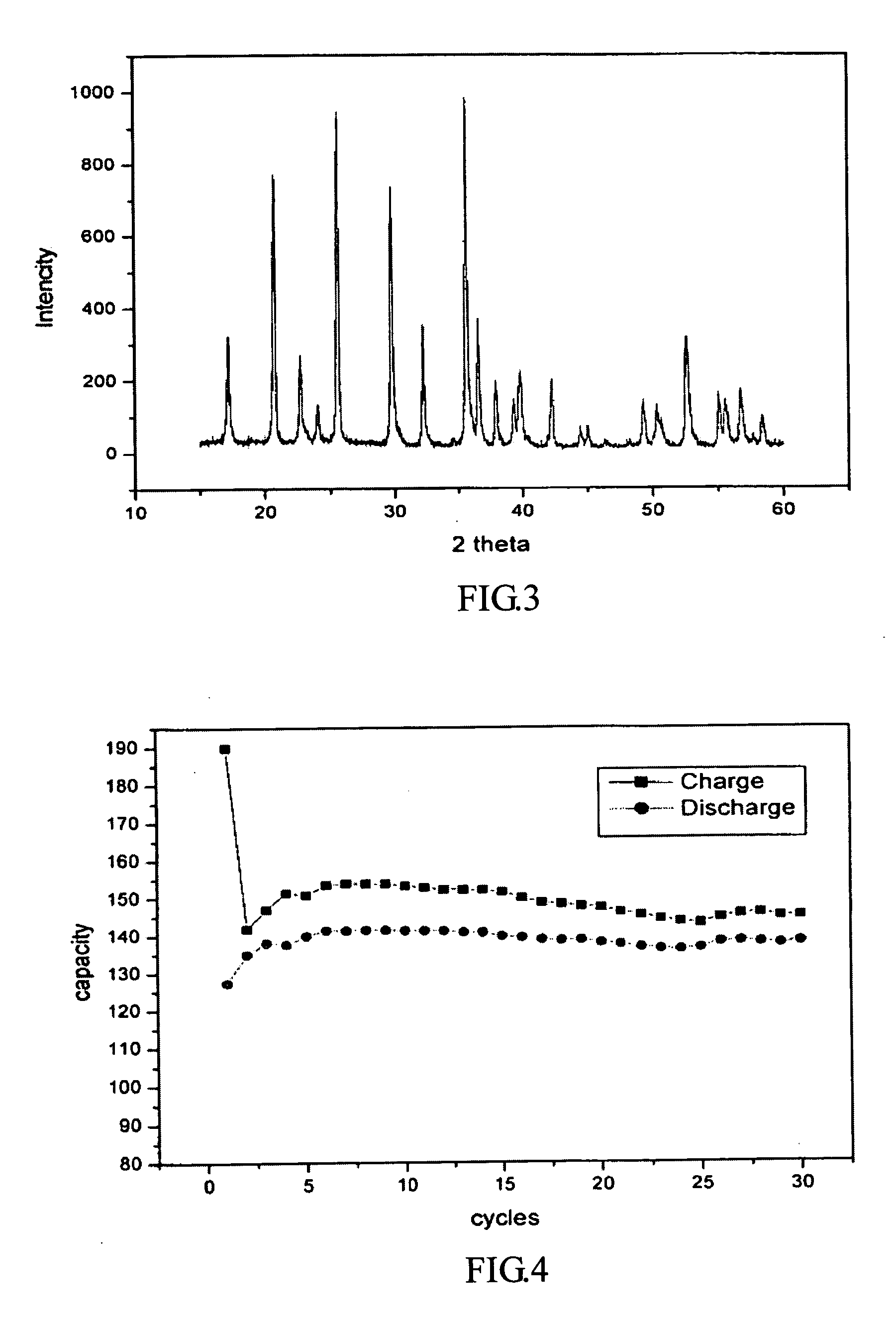

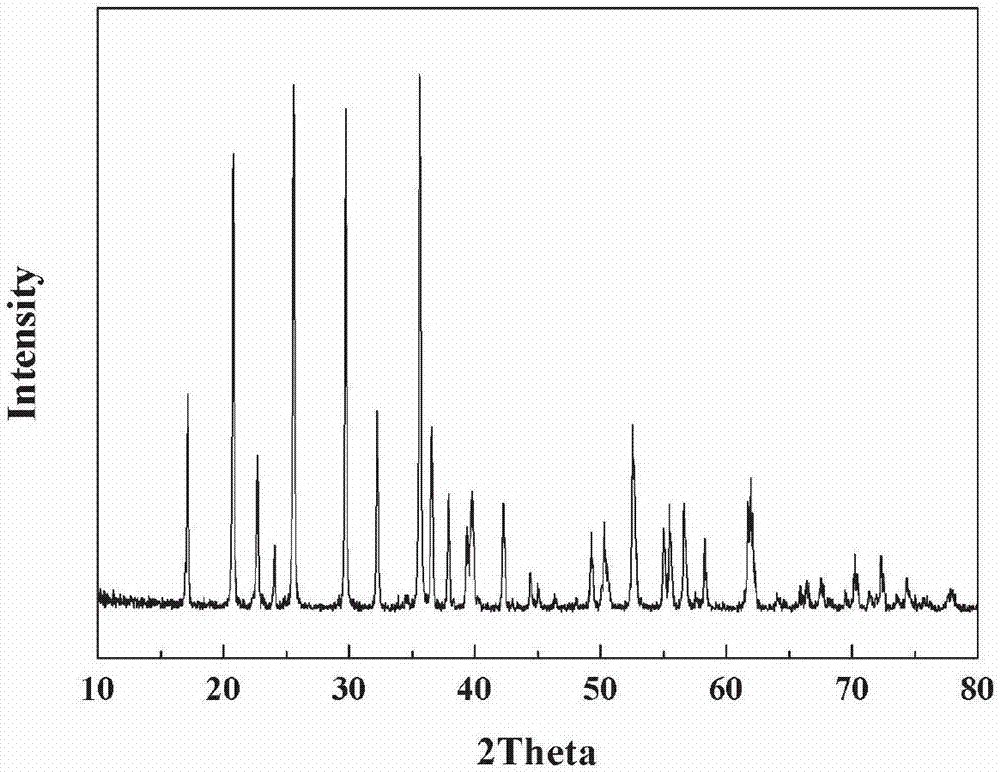

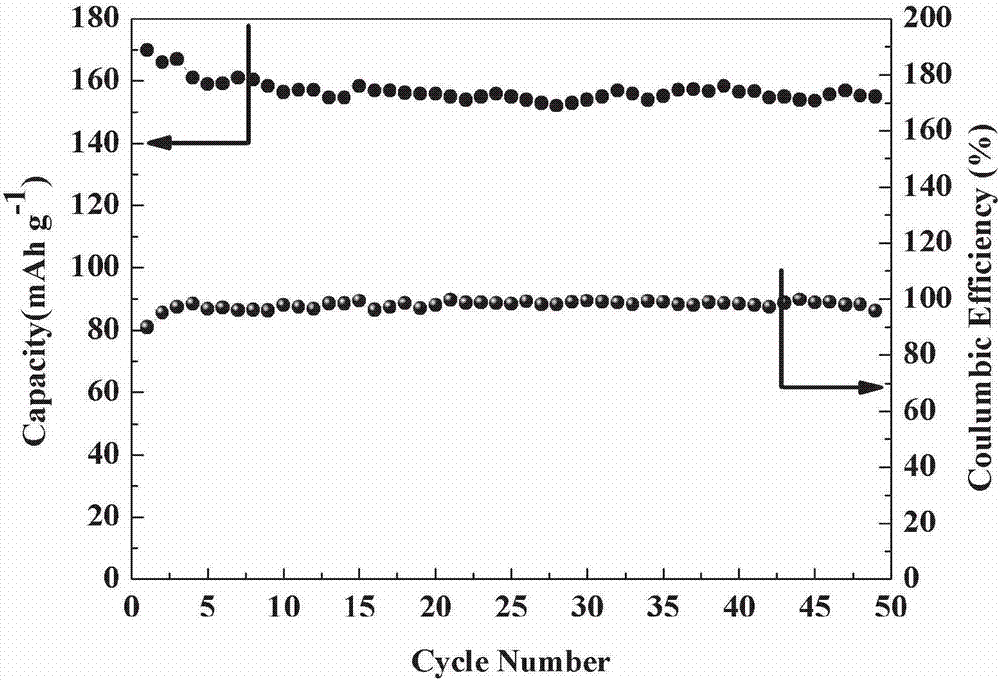

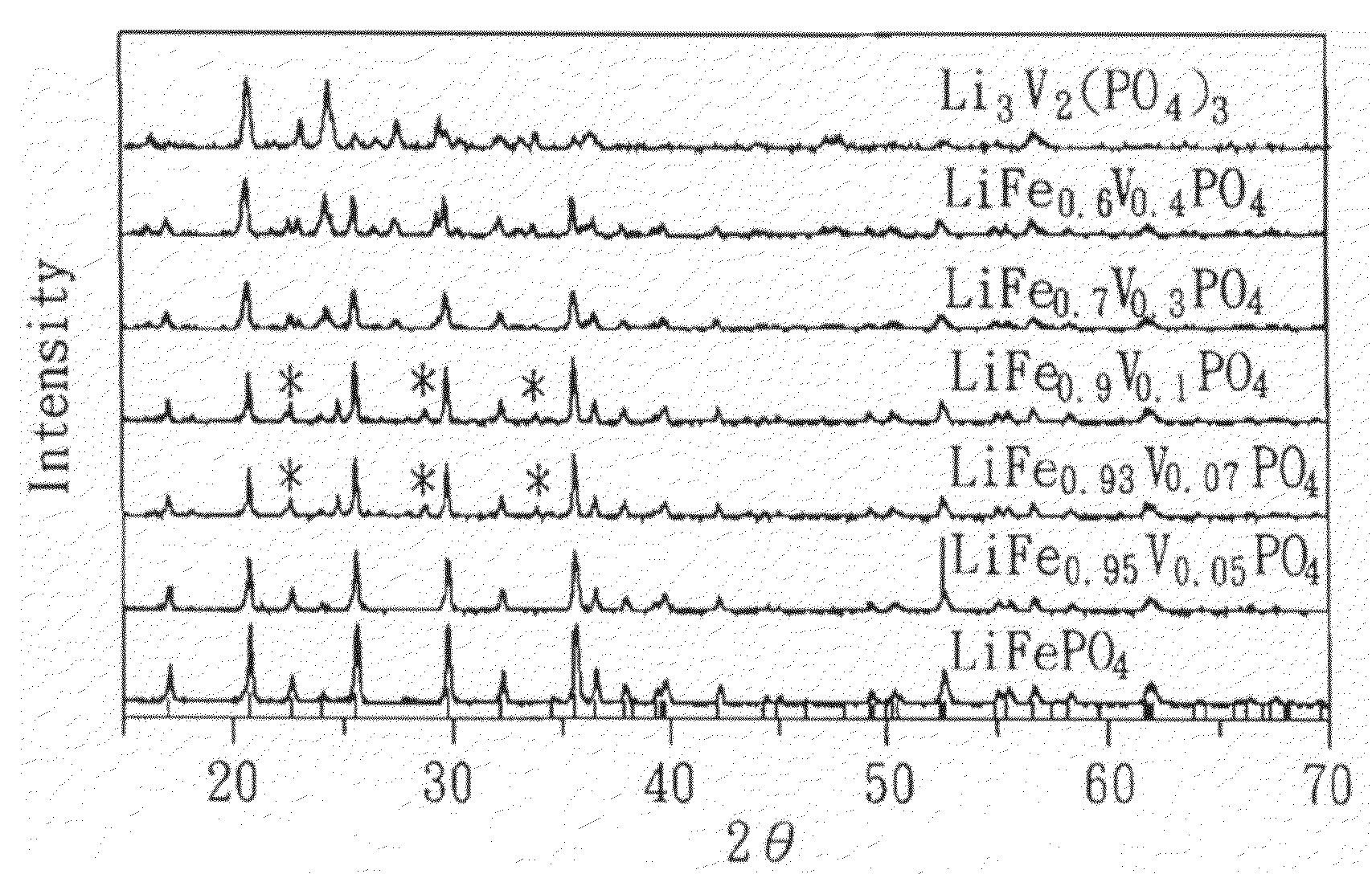

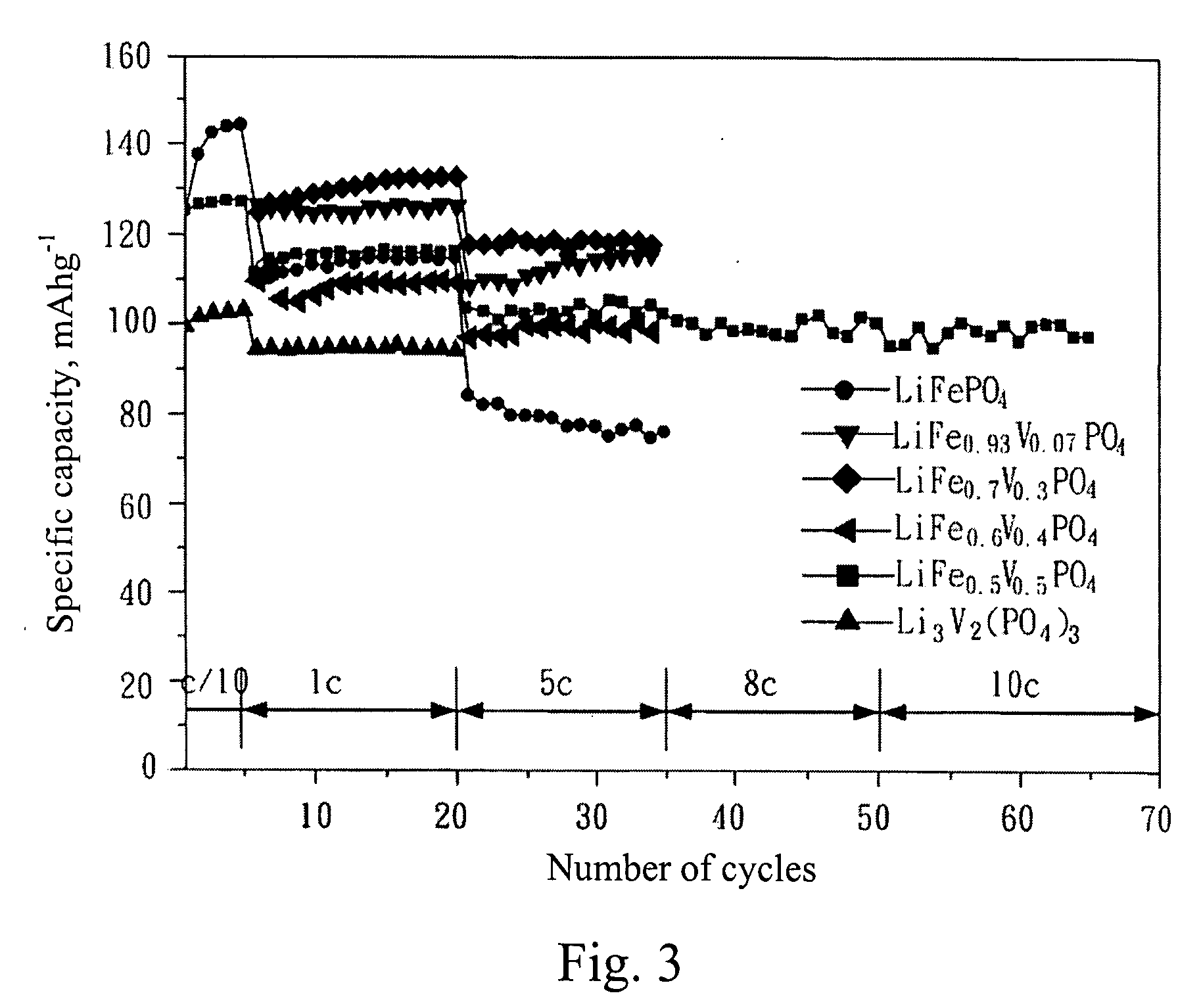

Preparation and application of LiFePO4/Li3V2 (PO4)3 composite cathode materials for lithium ion batteries

InactiveUS20080008938A1Improve conductivityCathode material of highElectrode manufacturing processesDuplicating/marking methodsComposite cathodeIron powder

A method of preparing LiFePO4 / Li3V2(PO4)3 composite cathode materials and their applications as cathode materials for lithium ion batteries are disclosed. The preparation method includes the following steps: (A) providing a mixture of iron powder, lithium salt, vanadium salt, and a phosphate salt whereafter these compounds are dissolved into a mixed acid solution; (B) drying the solution in order to obtain precursor powders; and (C) heating the precursor powders at a temperature ranging between 400 and 1000° C. to form LiFe1-y′Vy′PO4 / Li3V2-y″Fey″(PO4)3 composite powders. Alternatively, prepare the composite cathode by preparing olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y′Fey″(PO4)3 powders as in previous procedures followed by mixing adequately. The low cost of iron powder thus facilitates to prepared composite cathode materials exhibiting higher electrical conductivity and superior cycling performance at high C rates than those of olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y″Fey″(PO4)3. The invention will help the development of the lithium ion batteries and related industries.

Owner:TATUNG COMPANY

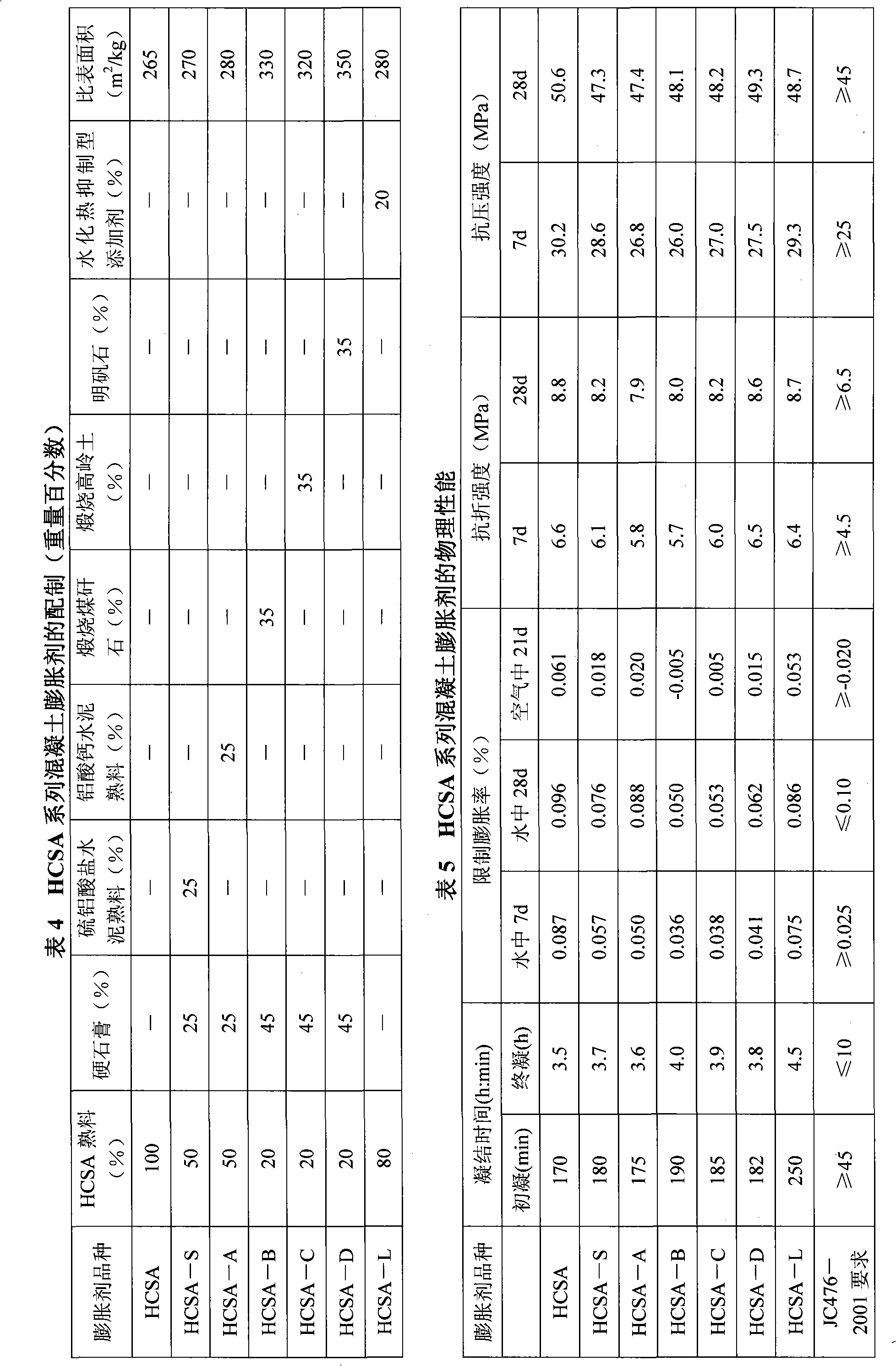

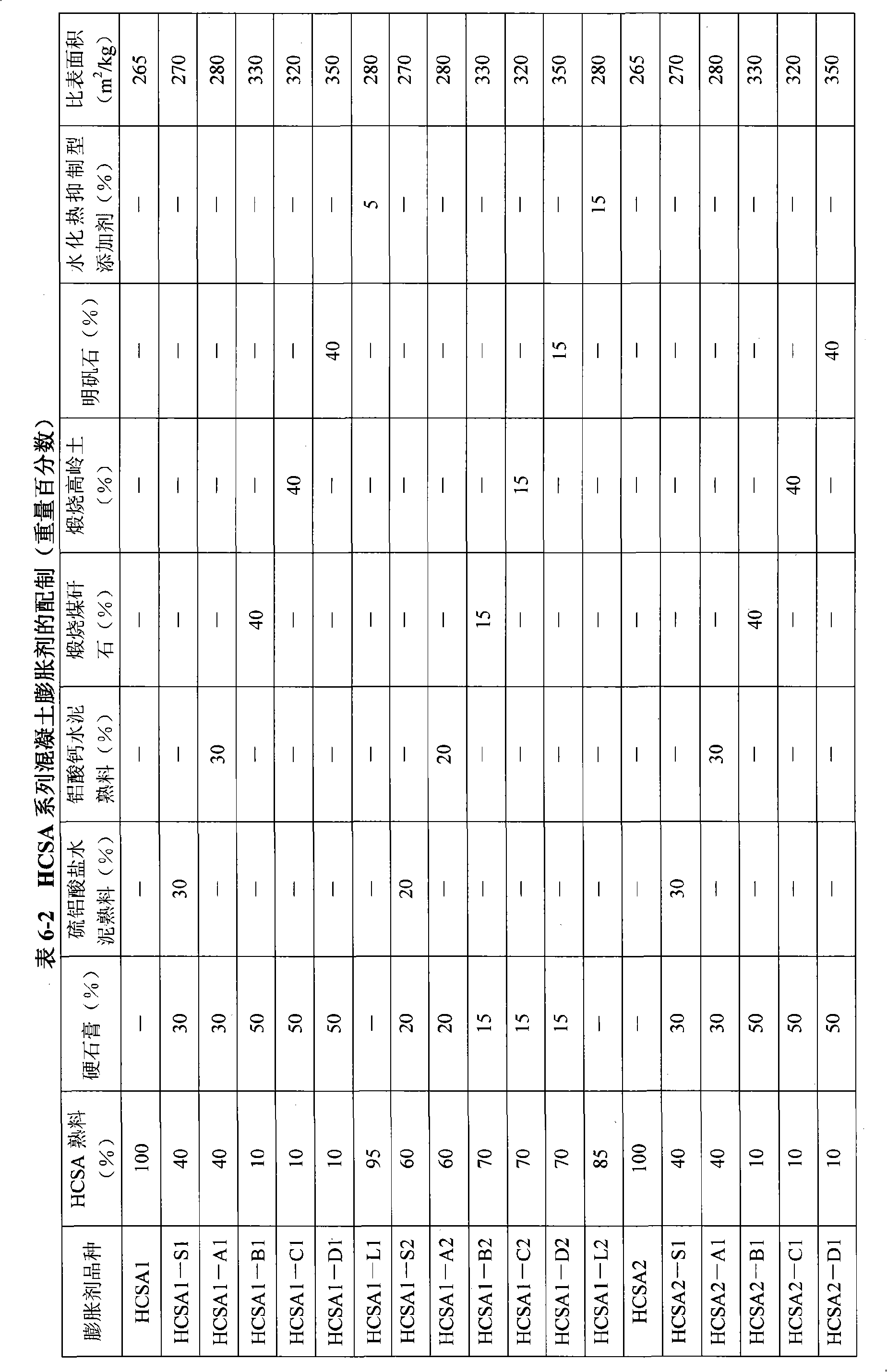

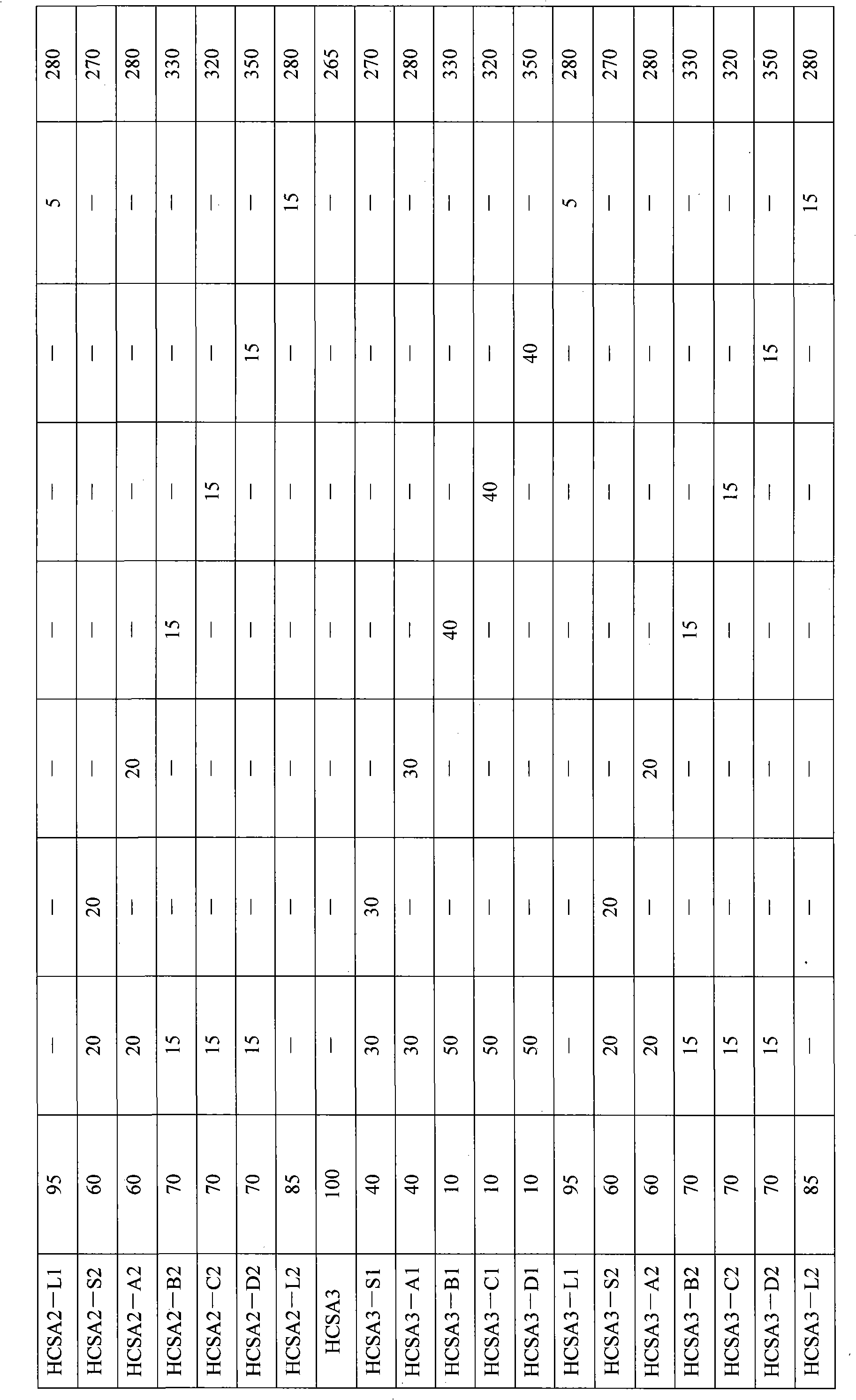

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

Lightweight ceramic tile and production method

The invention discloses a light-weight ceramic brick, which is a light-weight ceramic brick fired at high temperature and has a honeycomb-like internal structure of closed pores. The invention also discloses a preparation method of the above-mentioned lightweight ceramic tiles, which is formed by dry pressing after wet ball milling, sieving, iron removal, spraying drying tower and powder spraying on the vitrified brick polishing waste produced in large quantities in the ceramic industry at present. Method forming, or kneading using wet extrusion molding, and then firing products in continuous or batch kilns. Manufacture a kind of lighter quality ceramic tiles, aiming at the insufficient use of waste materials in the past, more effectively utilize industrial waste residues in large quantities, and because of its light structure, it can be used in the decoration of high-rise building walls, It has good properties such as light weight, high strength, heat preservation, and sound absorption, and it can significantly reduce the weight of the wall structure. At the same time, it also has the characteristics of easy transportation, easy construction, and fast speed. It has great advantages in saving energy and reducing the weight of buildings. The outstanding advantage is that it is an environment-friendly building ceramic decoration material.

Owner:FOSHAN OCEANO CERAMICS

Multi-component oxidation micro-electrolytic filler and preparation method thereof

ActiveCN102276021AIncrease contact areaAvoid separationWater/sewage treatment by sorptionActivated carbonIron powder

The invention belongs to the technical field of environmental engineering wastewater treatment, and particularly relates to multi-component oxidized micro-electrolysis filler and a preparation method thereof. The multi-component oxidized micro-electrolysis filler is mainly prepared from the following components in percentage by mass: 50-60% of iron, 20-30% of activated carbon, 12-15% of adhesive and 3-5% of catalyst through mixing, wherein iron is iron scrap or iron powder with particle size not more than 80 mesh; and activated carbon is in a powder and has particle size not more than 100 mesh. The preparation method of the multi-component oxidized micro-electrolysis filler comprises uniformly mixing iron, activated carbon, the adhesive and the catalyst according to the ratio, adding water, stirring and aging, then carrying out extrusion molding to obtain molded filler, demolding to obtain a filler blank, after naturally drying, drying, sintering in the absence of air, and cooling thefiller blank to obtain the multi-component oxidized electrolysis filler. According to the invention, the hardening, dead pool, stoppage and other practical problems existing in the use of the traditional micro-electrolysis fillers are solved.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

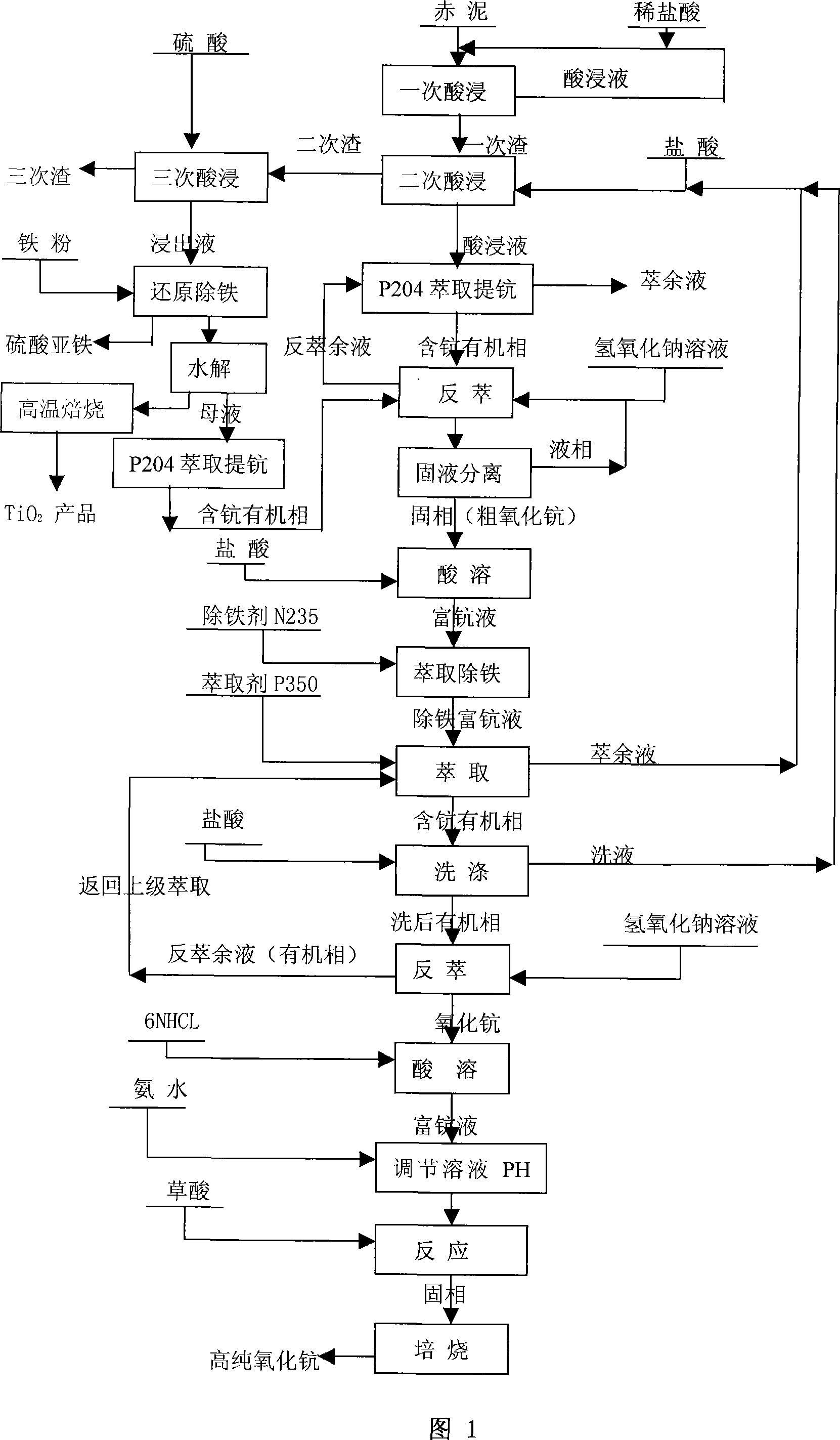

Method for extracting metal scandium and titanium from red mud

ActiveCN101182601AReduce processing costsEfficient use ofProcess efficiency improvementRed mudHydrolysate

The invention relates to a method for extracting metal scandium and titanium from red mud; the method is used for extracting scandium and titanium from the red mud; the method takes the red mud which is produced through the sinter process of the high-grade ore two portion of clinker in alumina plant as the raw material; the hydrochloric acid with a concentration of 2 percent to 6 percent is used for leaching the calcium and sodium from the red mud to increase the content of the scandium and titanium in the red mud; and then the hydrochloric acid with a concentration of 16 percent to 22 percent is used for a second acid dipping of the red mud and the product of scandium oxide is obtained after the leaching liquid passes the processes of extraction, reverse extraction and baking; the hydrochloric acid with a concentration of 80 percent to 90 percent is used for a third acid dipping of the red mud after the second one and the leaching liquid is added with iron powder for reduction and then the temperature is reduced to crystallize and separate out iron in the pattern of FeSO<4>.7H<2>O; the acid liquid which contains titanium after the iron is removed is added with alkali and heated for hydrolysis; the product of titanium oxide is obtained after the hydrolysate is baked. The method is simple and easy to be carried out and most metal elements in the red mud can be recovered and the cost for processing the red mud is low, all of which are beneficial to the comprehensive utilization of the red mud.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

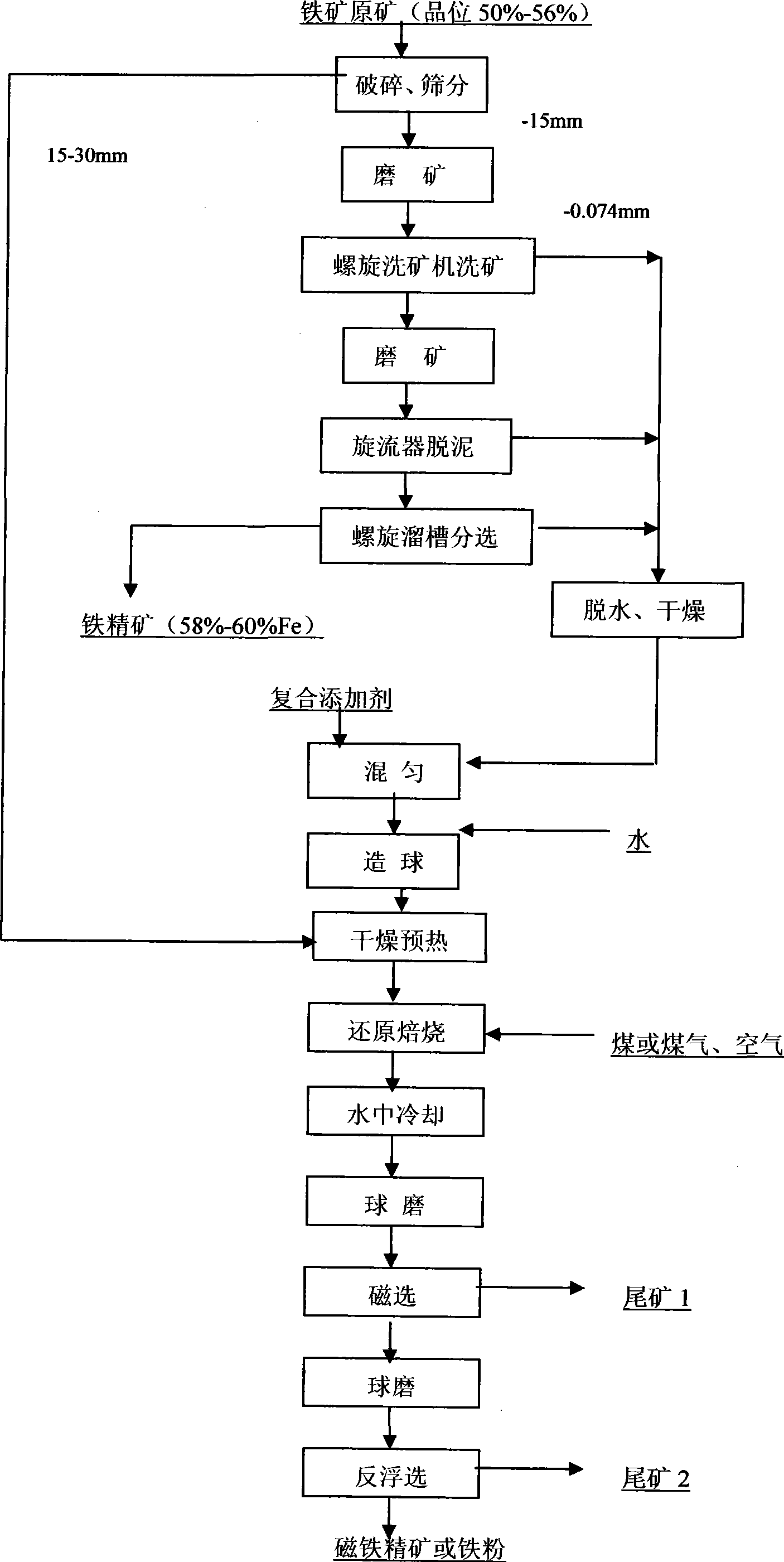

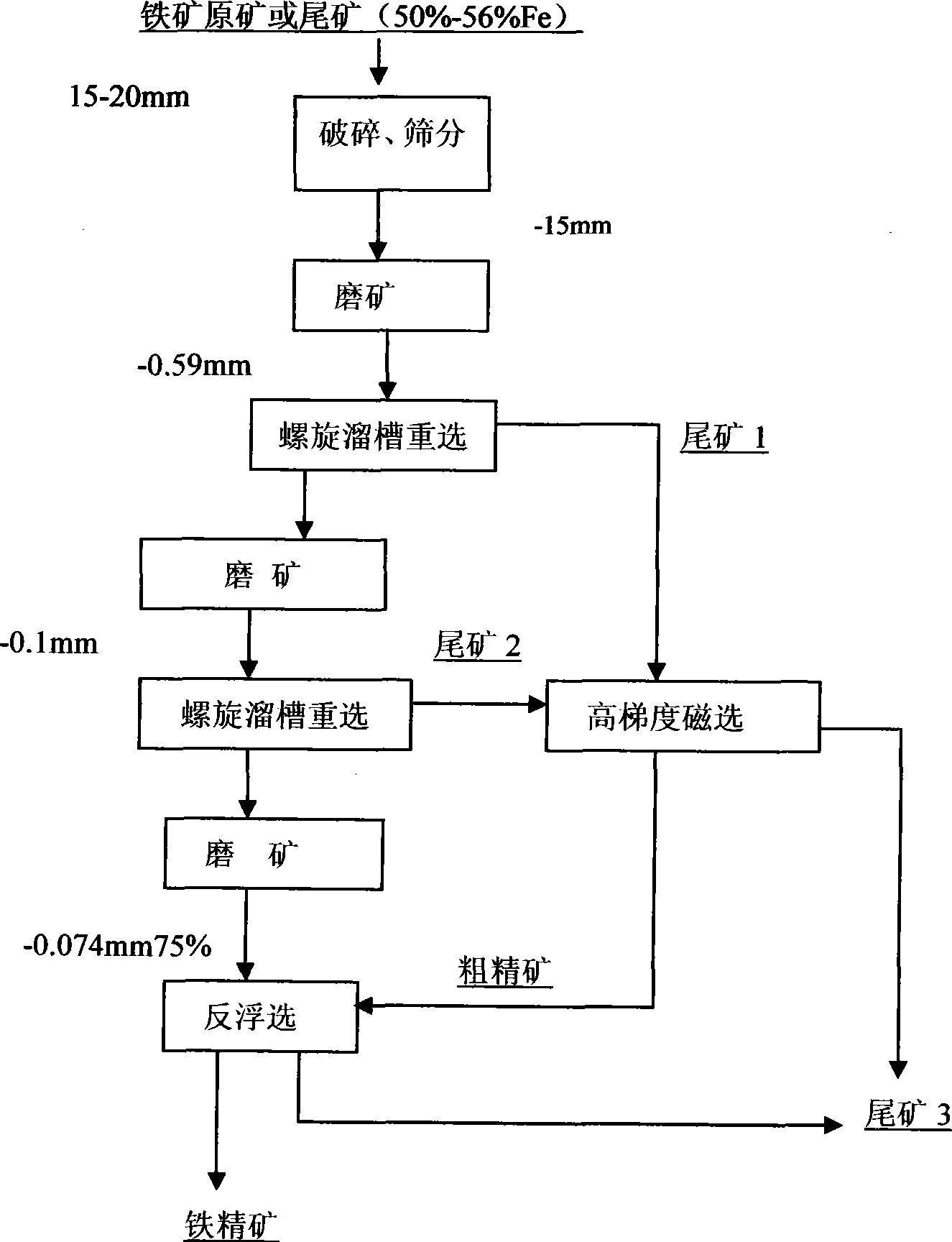

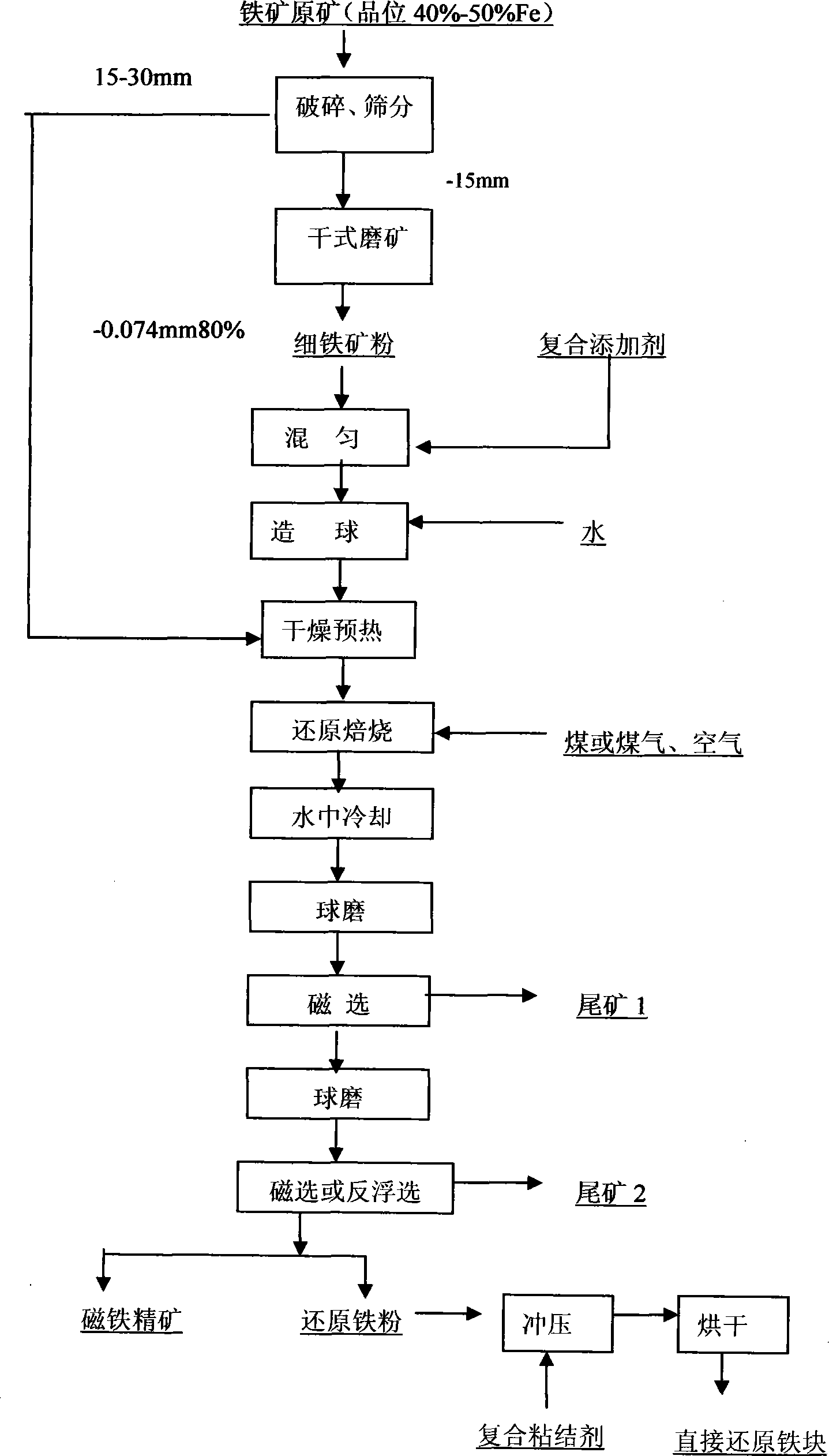

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

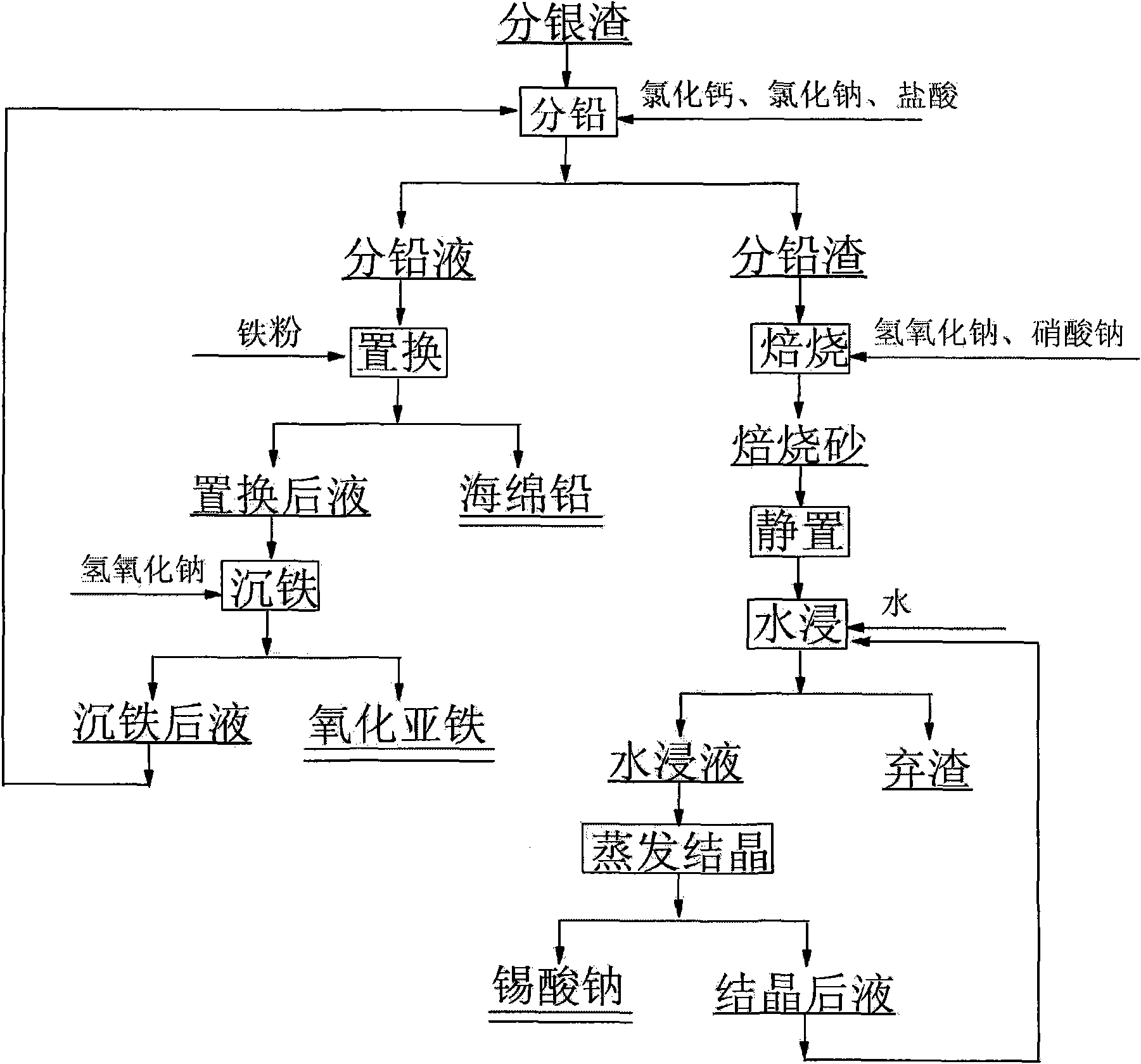

Method for recycling lead-tin in silver separating residue of copper anode slime of circuit board

ActiveCN101555550AReduce generationEmission reductionProcess efficiency improvementIron powderWastewater

The invention discloses a method for recycling lead-tin in silver separating residue of copper anode slime of a circuit board and relates to a method for recycling silver separating residue of copper anode slime of the circuit board by a wetting method. The method comprises the following steps of: stirring silver separating residue, water, hydrochloric acid, calcium chloride and sodium chloride for 0.5 to 2.0h under proper temperature according to requirements, filtering and obtaining lead separating liquid and lead separating residue; carrying out displacement to the lead separating liquid by using excess iron powder, filtering and obtaining spongy lead and displaced liquid; using sodium hydroxide to adjust pH value of the displaced liquid till the precipitate is not generated; and returning lead separating procedure after the iron is precipitated. The lead separating residue, the sodium hydroxide and sodium nitrate are mixed evenly to carry out roasting with the temperature of 350 to 500 DEG C, and then are added with water and filtered, thus obtaining the sodium stannate. Compared with the prior art, due to the adoption of a full-wetting process, the method reduces a large amount of waste gas and dusts in the process of pyrometallurgical treatment; the liquid after the iron is precipitated contains the main compositions of hydrochloric acid and sodium chloride; and the method can return acid pickling procedure, reduce discharge of waste water and lower cost, and is characterized by simple technique, no pollution and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

Copper-free ceramic friction material with little falling ash and preparation method thereof

InactiveCN101823856AAvoid secondary pollutionMeet the requirements of environmental protectionBraking membersFriction liningAdhesiveAramid

The invention discloses a copper-free ceramic friction material with little falling ash and a preparation method thereof. The copper-free ceramic friction material with little falling ash is prepared by mixing, shaping and thermally processing the following raw materials in percentage by weight: 5 to 14 percent of adhesive, 20 to 45 percent of reinforcing material, 10 to 40 percent of ceramic material, 10 to 18 percent of lubricant and the balance of filler, wherein nitrile rubber modified phenolic resin and nitrile rubber powder are used as the adhesive; the reinforcing material is one or a mixture of more of aramid fiber, carbon fiber, steel fiber, foam iron powder and aluminum oxide fiber; the ceramic material is one or a combination of more of molybdenum disulfide, magnesium oxide andferrous disulphide; the lubricant is the mixture of graphite and mica; and the filler is the mixture of composite filler, barite, friction powder and aluminum powder. The material has high friction performance, low brake noise and high heat fading resistance, and particularly shows high performance in aspects of wear resistance, long life and great reduction in the falling ash of a wheel hub; therefore, the material can meet both the requirement of a modern automobile braking system on operating conditions and the requirement on economy and environment friendliness when an automobile is used.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

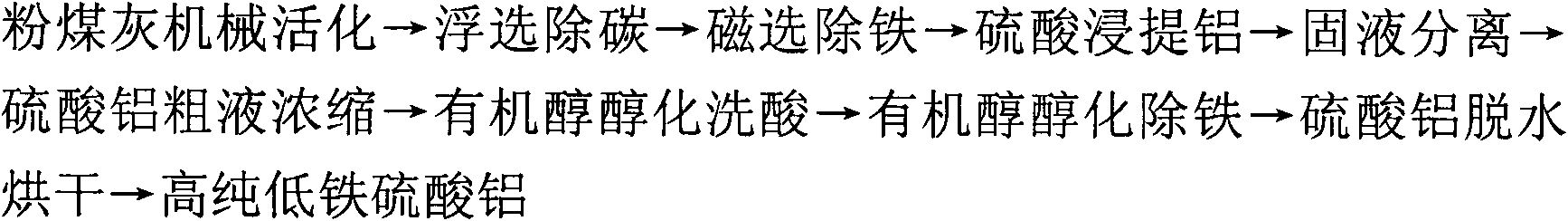

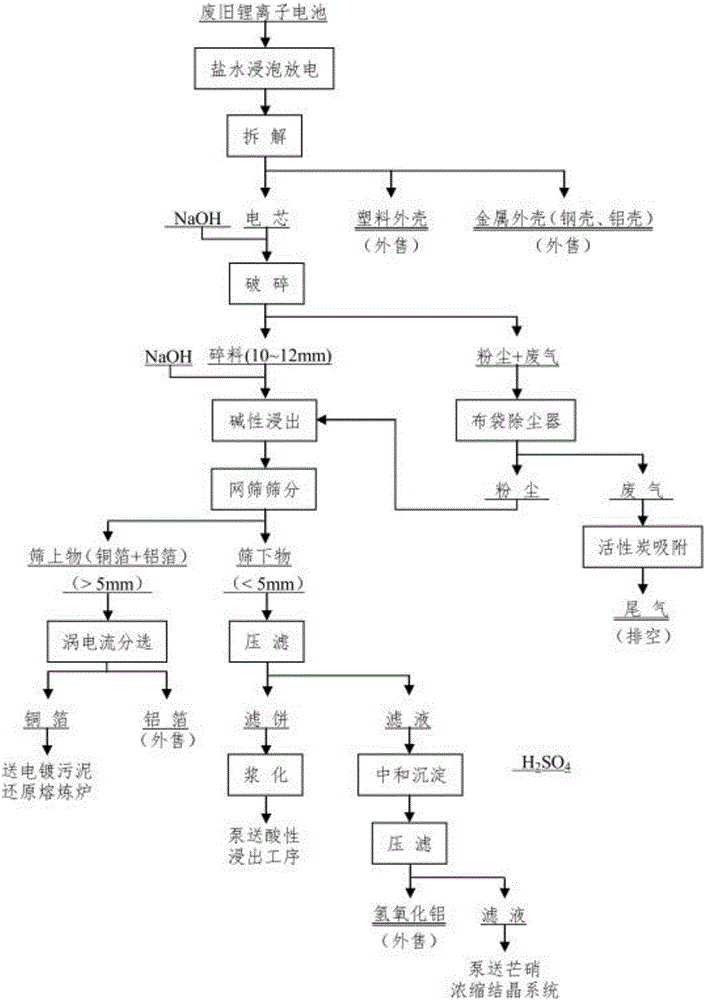

Technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing coal ash

InactiveCN102101689AEasy industrial iron removalLow costPigmenting treatmentSolid waste disposalBiological activationCoal

The invention discloses a technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing the coal ash, comprising the following steps of: carrying out mechanical activation, flotation decarburization, magnetic separation for deferrization, aluminum extraction with sulfuric acid, solid-liquid separation, concentration of aluminum sulfate crude liquor, organic alcohol alcoholization for acid rinse, organic alcohol alcoholization for deferrization and aluminum sulfate dewatering and drying on the coal ash to obtain the high-purity low-iron aluminum sulfate with low Fe content. The invention solves the problems on impurity removal and purification of the aluminum sulfate in the recycling process of the coal ash, simplifies the process flow, reduces the energy consumption, solves the technical problem of overlarge accumulation of secondary residue quantity, achieves high extraction ratio of aluminum contained in the coal ash, and realizes the recycling of organic alcohol and sulfuric acid and the comprehensive utilization of side products including unburnt black, magnetic iron powder, iron-containing aluminum sulfate crystals, high-silicon-dust active mineral blending materials or novel silicon-magnesium cement, and the like. The technological method has the advantages of simple process, short flow, easiness for control of a production process, high aluminum extraction ratio, low impurity content of products and stable quality.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

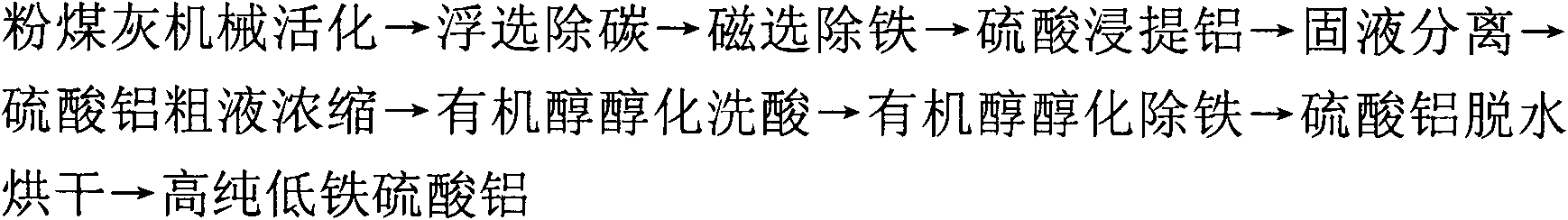

Comprehensive recycling method of lithium ion battery anode material

ActiveCN107267759AReduce sorting costsImprove recycling economicsWaste accumulators reclaimingProcess efficiency improvementSlagElectrical battery

The invention provides a comprehensive recycling method of a lithium ion battery anode material. The method comprises the steps that the anode material of lithium iron phosphate and the anode material of a ternary battery are subjected to high-temperature pretreatment; a product is added into water for pulping processing; concentrated sulfuric acid and hydrogen peroxide are added, and filtering is performed to remove undissolved substances; iron powder is added, filtering is performed to remove copper elements, and heating is performed to generate iron aluminum vanadium slag; a calcium chloride solution is added, and filtering is performed to remove phosphate radicals; series-connection countercurrent extraction is performed through an extraction agent P204 to remove Fe and Ca impurities, and series-connection countercurrent extraction is performed through an extraction agent P507 to separate Ni, Co, Mn elements from Li elements; the organic phase is subjected to reverse extraction with sulfuric acid, a Ni, Ca and Mn solution is obtained, and recycling of nickel, cobalt and manganese is achieved; and the water phase is concentrated, and then a saturated sodium carbonate solution is added to generate lithium carbonate precipitation. By means of the comprehensive recycling method, the anode material of a lithium iron phosphate battery and the anode material of the ternary battery are recycled simultaneously, the battery separation cost is lowered, and the economic benefits of lithium battery recycling are increased.

Owner:南京国轩新能源有限公司

Natural hair dyeing agent prepared by plant pigment catechu and hair dyeing method thereof

The present invention relates to a hair-dying agent, in particular, it relates to a natural hair-dying agent prepared by adopting plant colour matter catechu and its hair-dying method. Said hair-dying agent includes agent A and agent B. The agent A includes (by wt%) 3-10% of plant colour matter catechu, 10-50% of organic solvent and the rest is water; and the agent B includes (by wt%) 1-5% of ferrous salt mordant, 0.2-1.0% of reduced iron powder, 1-10% of surfactant, 1-5% of thickening agent, proper quantity of acidifying agent, 0.1-0.3% of natural essence and the rest is water. The catechu is a traditional Chinese medicinal material, and has the functions of clearing away heat, astringing dampness, resisting bacteria and inhibiting bacteria.

Owner:JIANGNAN UNIV

High hardness ferritic stainless steel wearable surfacing flux-cored wire

InactiveCN101224527AOvercome the disadvantage of poor wear resistanceHigh hardnessWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention provides a high hardness ferrite stainless steel wearable flux-cored wire, which takes a low carbon steel H08A cold rolling thin steel strip as an external wrapper; furthermore, the wrapper is internally provided with a powder core which is composed of graphite, metal and alloy powder; the weight percentages of all ingredients of the powder core are 50-75% of high carbon ferrochrome, 10-16% of ferrovanadium, 6-10% of ferrotitanium, 2-10% of tungsten carbide, 2-3% of nickel powder, 1.5-2.5% of silver graphite, 1-3.5% of boron carbide, 1-2% of aluminium magnesium powder, 0-10% of metallic chromium, and the residual quantity of reduced iron powder; the filling proportion of the powder core is 46-50%; the invention adopts the technical proposal that high-content ferrovanadium and adequate alloy powders such as tungsten carbide and boron carbide, etc. are added into the flux-cored wire, changes the microstructure of the existing ferrite stainless steel flux-cored wire surfacing alloy, overcomes the shortages of poor wearability and ductility, and can be applied to submerged arc bead weld manufacture or repair of the parts which has high requirement of abrasion and the corrosion resistance of the wearable grain.

Owner:XIANGTAN UNIV

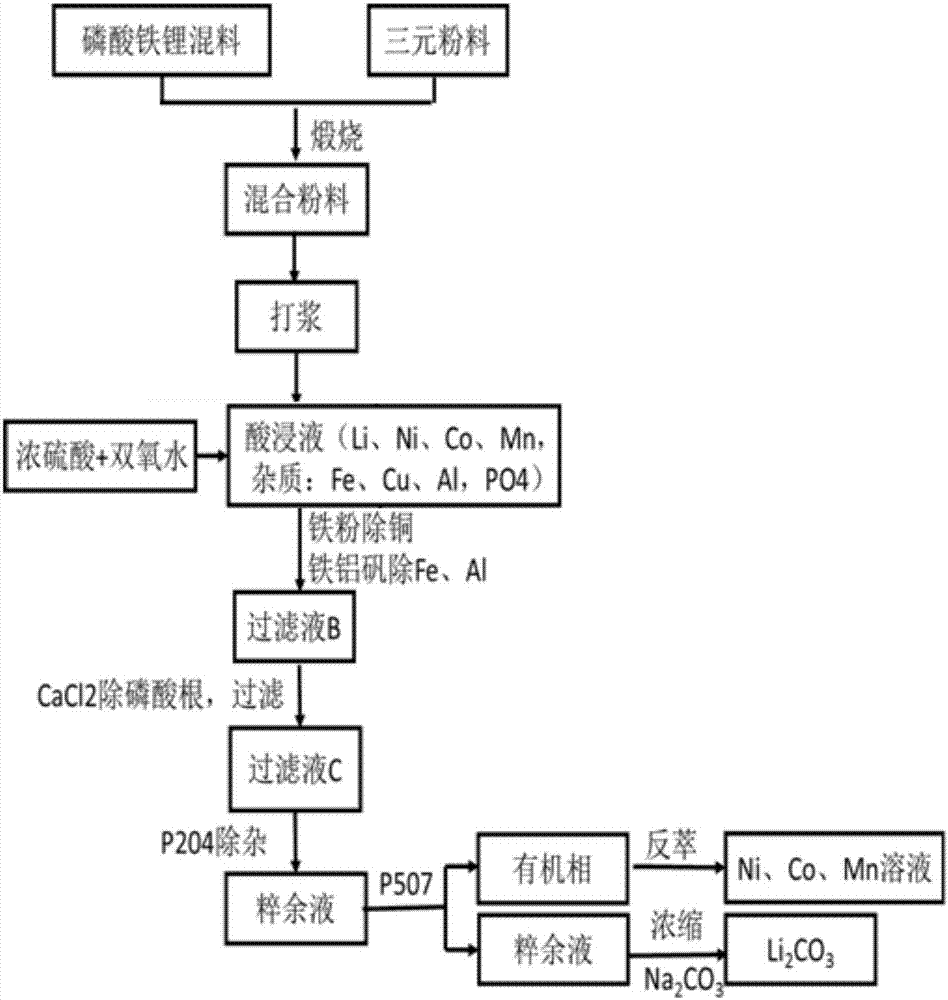

Environmentally-friendly and highly-efficient recovery and separation technology of lithium ion batteries in waste mobile phones

ActiveCN106558739ACause secondary pollutionAchieve recyclingWaste accumulators reclaimingBattery recyclingSeparation technologyLithium-ion battery

The invention discloses an environmentally-friendly and highly-efficient recovery and separation technology of lithium ion batteries in waste mobile phones. The technology mainly comprises brine discharge, disassembling and crushing, alkaline leaching, acidic leaching, iron powder displacement copper precipitation, purification and impurity removal, and precursor synthesis. The technology has the characteristics of advanced process, low cost, high efficiency, substantial economic and social benefits, no discharge of three wastes, no secondary pollution to environment, and realization of cycling of mobile phone resources, so the earth is well protected.

Owner:安徽得盈再生资源回收有限公司

Stable magnetic rheological liquid and its preparation method

InactiveCN1414075AImproving magnetorheological propertiesImprove wear resistanceAdditivesSuspended particlesIron powder

A high-stability magnetic rheopectic liquid is prepared from the magnetic suspended phase including reduced and phosphonated carbonyl iron powder, liquir carrier, nano-class inorganic bentonite or silica oxide-type thixotropic agent and surfactant through cleaning the surface of suspended particles, activating and synthesizing the magnetic rheopectic liquid. Its advantages are high stability without deposition, better antiwear nature, zero field viscosity and ideal rheopectic characteristics.

Owner:CHONGQING MATERIALS RES INST

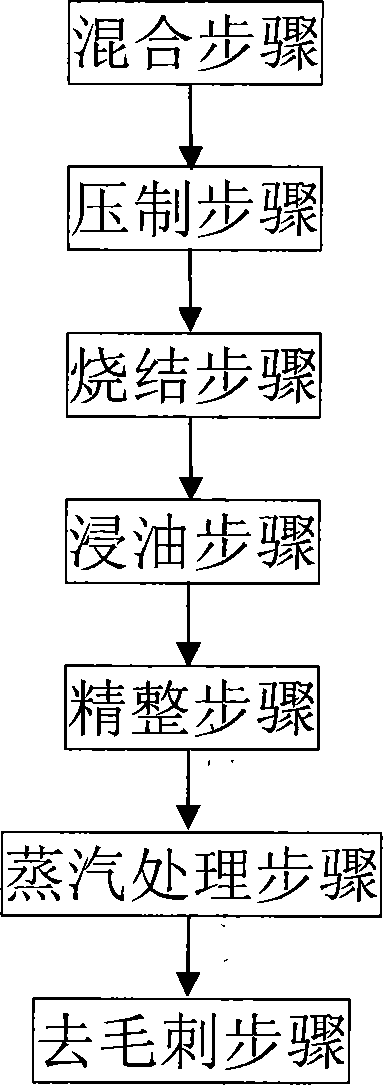

Powder metallurgy prescription and technique

The invention discloses a metallurgic powder formulation and a process thereof. The metallurgic powder comprises graphite powder 0.05% to 5%, zinc stearate 0.08% to 7%, copper powder 0.1% to 10%, and iron powder in balance. The process comprises the following steps of: mixing, pressing, sintering, soaking in oil, finishing, treating by steaming, and deburring. Compared with prior art, the metallurgic powder has low cost and reliable product performance by adopting the formulation: graphite powder 0.05% to 5%, zinc stearate 0.08% to 7%, copper powder 0.1% to 10%, and iron powder in balance. Moreover, the process is properly optimized and simplified, and the steam treatment step can form a dense protection film on the product surface to improve the rustproof performance.

Owner:ZHEJIANG ZHONGPING POWDER METALLURGY

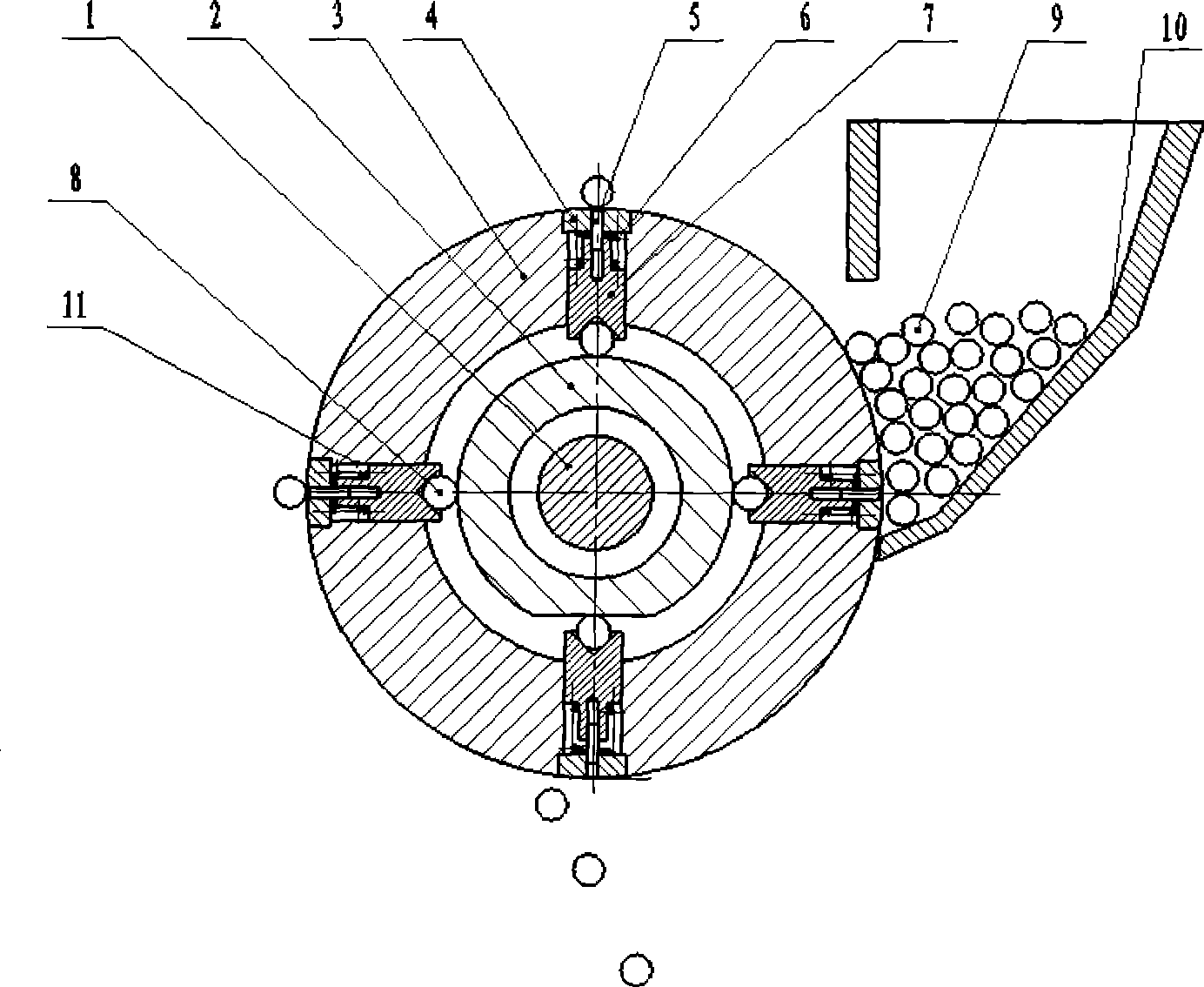

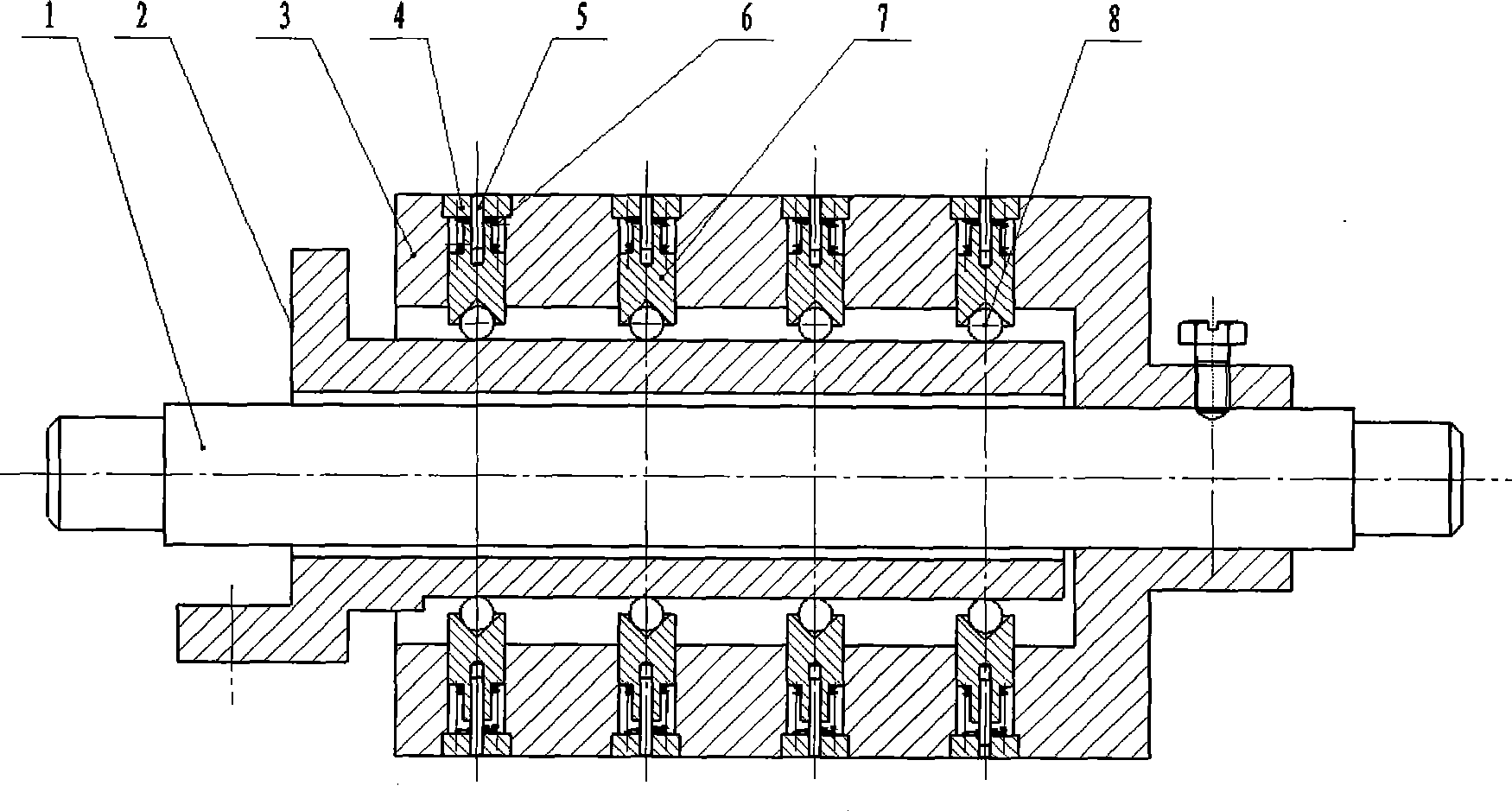

Permanent-magnet magnetic-attraction precision seeding device

InactiveCN101530030ASolve fever problemSmall structure sizeSeed depositing seeder partsSingle grain seedersIron powderSemi open

The invention belongs to agricultural seeding machinery, and in particular relates to a permanent-magnet magnetic-attraction precision seeding device. A semi-open type seed box is arranged on the side of a roller; the roller is fixedly connected with a transmission shaft and follows the transmission shaft to rotate in the single direction; the upper edge of the wall of the roller is uniformly provided with a plurality of through holes in the circumferential direction; a permanent-magnet magnetic attraction head, a magnetic-attraction-head jacket, a magnetic-attraction-head cover plate and a pressure spring are arranged in each through hole; one end of the permanent-magnet magnetic attraction head is arranged in the magnetic-attraction-head jacket, and the other end of the permanent-magnet magnetic attraction head passes through a center hole of the magnetic-attraction-head cover plate but does not exceed the upper surface of the magnetic-attraction-head cover plate; the pressure spring is positioned between the magnetic-attraction-head jacket and the cover plate; a cylindrical cam is hollowly sleeved on the transmission shaft and is fixed; the outline of the cylindrical cam consists of a circular arc surface and a platform surface; and the platform surface is partially arranged on the lower part of the cam. The seeding device has the advantages of improving the magnetic attractive force of the magnetic attraction head, reducing the content of iron powder needed by magnetic-powder coatings of seeds, reducing the structure size of seeding elements and conveniently realizing the automatic seed-taking function and automatic seeding function of the magnetic attraction head.

Owner:JIANGSU UNIV

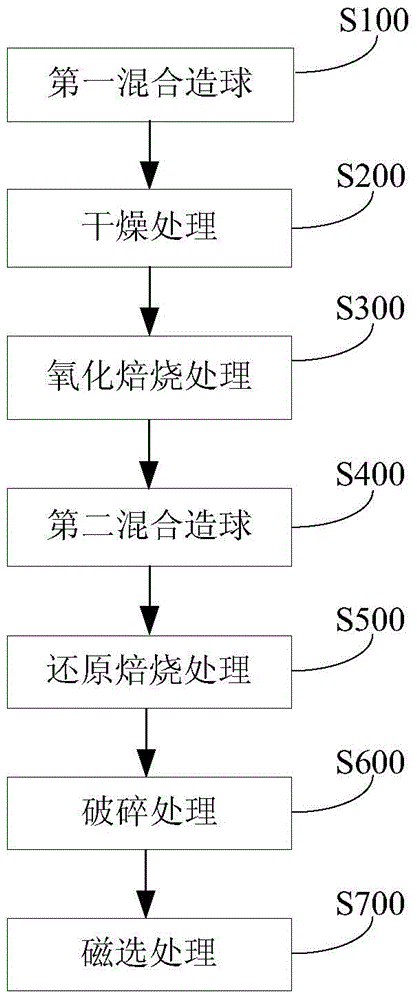

Method for separating valuable metals from copper slag

InactiveCN104404260AReduce consumptionAchieve recyclingProcess efficiency improvementFayaliteAdhesive

The invention discloses a method for separating valuable metals from copper slag. The method comprises the steps: (1) performing primary mixing palletizing on the copper slag and an adhesive to obtain copper slag pellets; (2) performing drying treatment on the copper slag pellets; (3) performing oxidation roasting treatment on the dried copper slag pellets so as to convert fayalite in the copper slag into ferric oxide; (4) performing secondary mixing palletizing on the copper slag pellets subjected to oxidization roasting and a mixture containing a reducing agent, an additive and an adhesive to obtain a pellet material; (5) performing reducing roasting on the pellet material so as to obtain reduced pellets and smoke containing zinc oxide and lead oxide; (6) smashing the reduced pellets to obtain a mixture containing metal iron powder and tailings; (7) performing magnetic separation on the mixture containing the metal iron powder and the tailings to respectively obtain the metal iron powder and the tailings. According to the method disclosed by the invention, iron, zinc and lead can be effectively separated from the copper slag, and the grade of obtained metal iron is higher.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

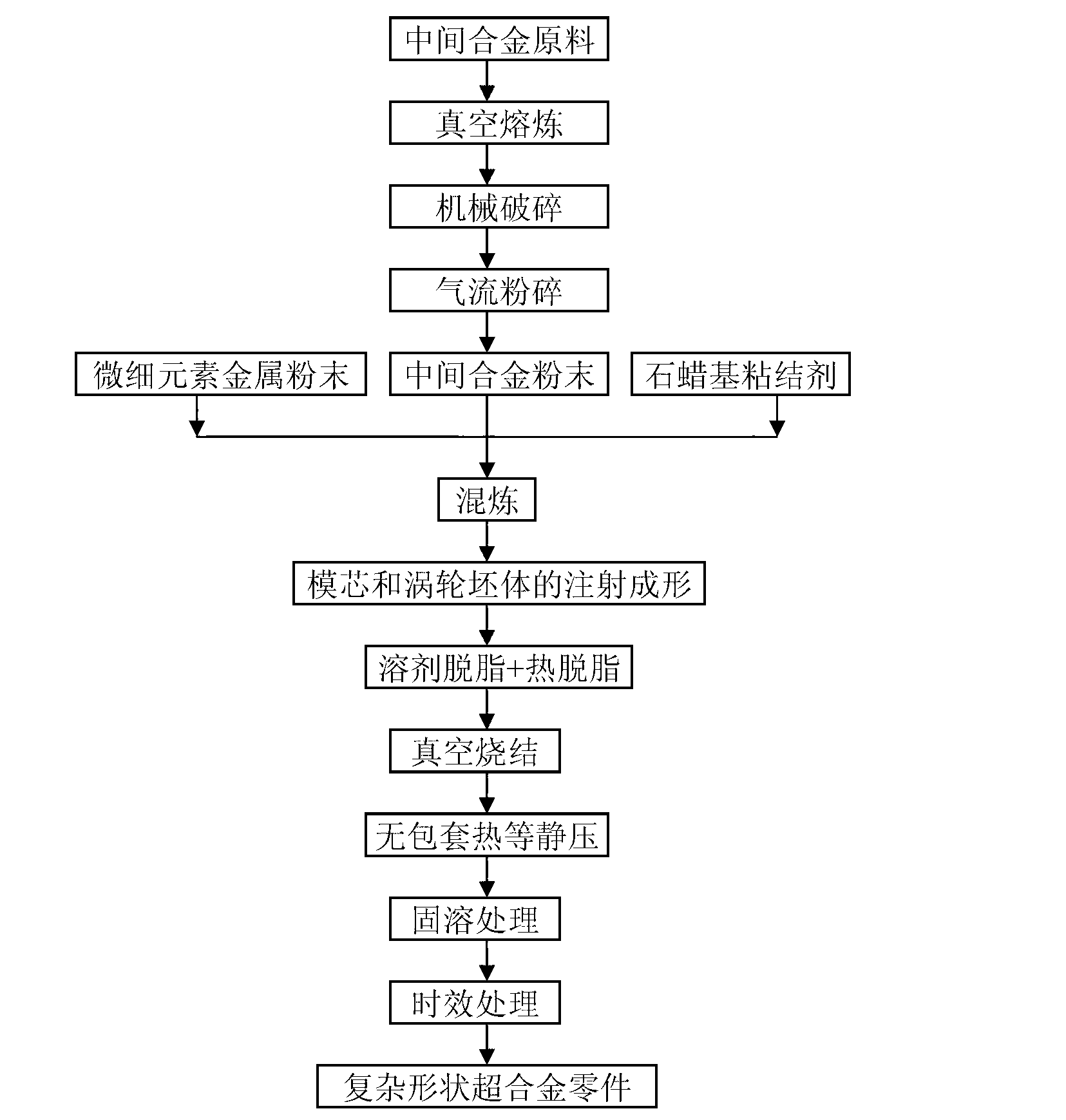

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

Electric welding rod for hand welding X80 grade steel oil, gas transmission pipe

ActiveCN101362257AHas tensile strengthHas a shock valueWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention relates to an electric welding rod used for manual welding. The electric welding rod comprises core welding-wires containing the following chemical compositions (wt%): 0.020-0.100 of C, 0.350-0.550 of Mn, 0.015-0.030 of Si, 0.005-0.015 of P, 0.002-0.005 of S, 0.01-0.20 of Cr, 0.01-0.30 of Ni, 0.01-0.20 of Cu, 98.675-99.47 of Fe, and the residue of impurity; the electrode coating comprises the following compositions: 28-38 of marble powder, 16-28 of fluorite powder, 2-8 of feldspar powder, 2-7 of white titanium pigment, 4-8 of electrolytic manganese, 3-7 of ferrosilicon powder, 6-9 of ferrotitanium powder, 0.5-2 of ferromolybdenum powder, 3-8 of nickel powder, 10-25 of iron power and 5-8 of other elements. The chemical compositions, the performance and the structure of the welding seam of a grade X80 steel pipe welded by using the electric welding rod are closer to the pipe body, and without heat treatment, the welding seam can meet the requirements on technical indicators such as high strength, high toughness, low hardness and the like of the grade X80 steel pipe used for oil and natural gas transferring; the electric welding rod overcomes the defaults in the prior art that the welding seam is required to be heat-treated after welding, the quality is poor, and engineering accidents are easy to happen when in use and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com