Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11926 results about "Copper foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

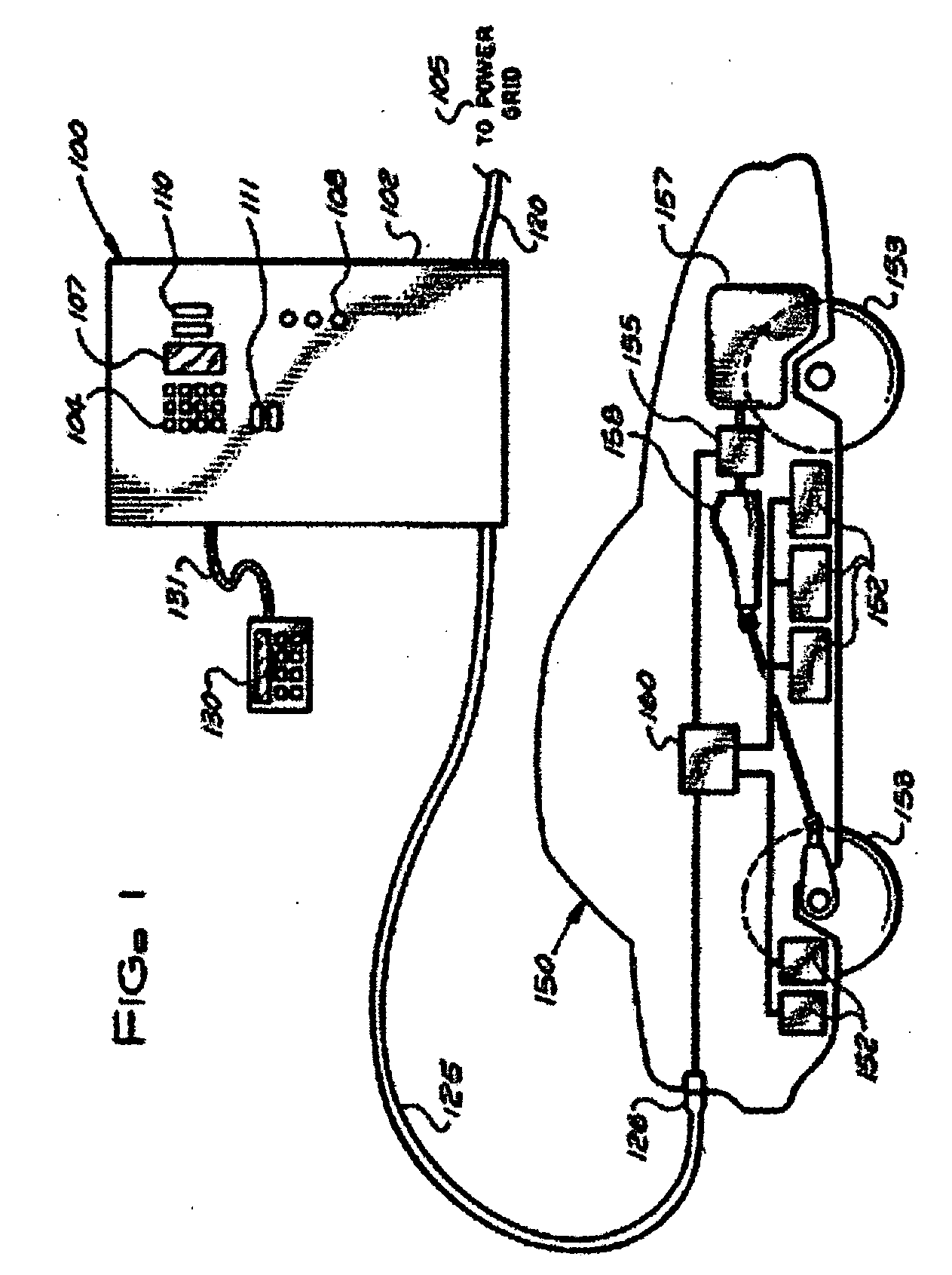

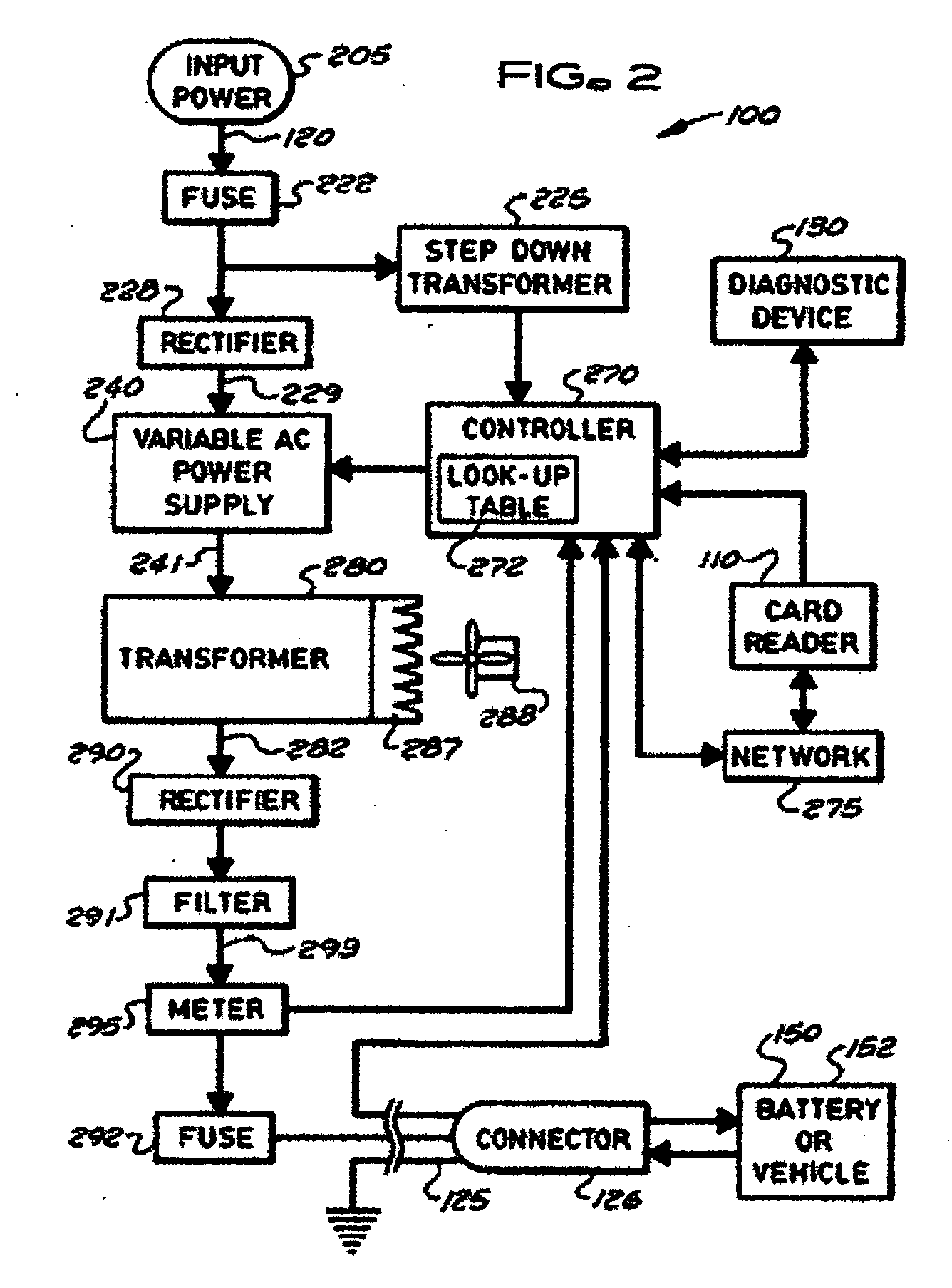

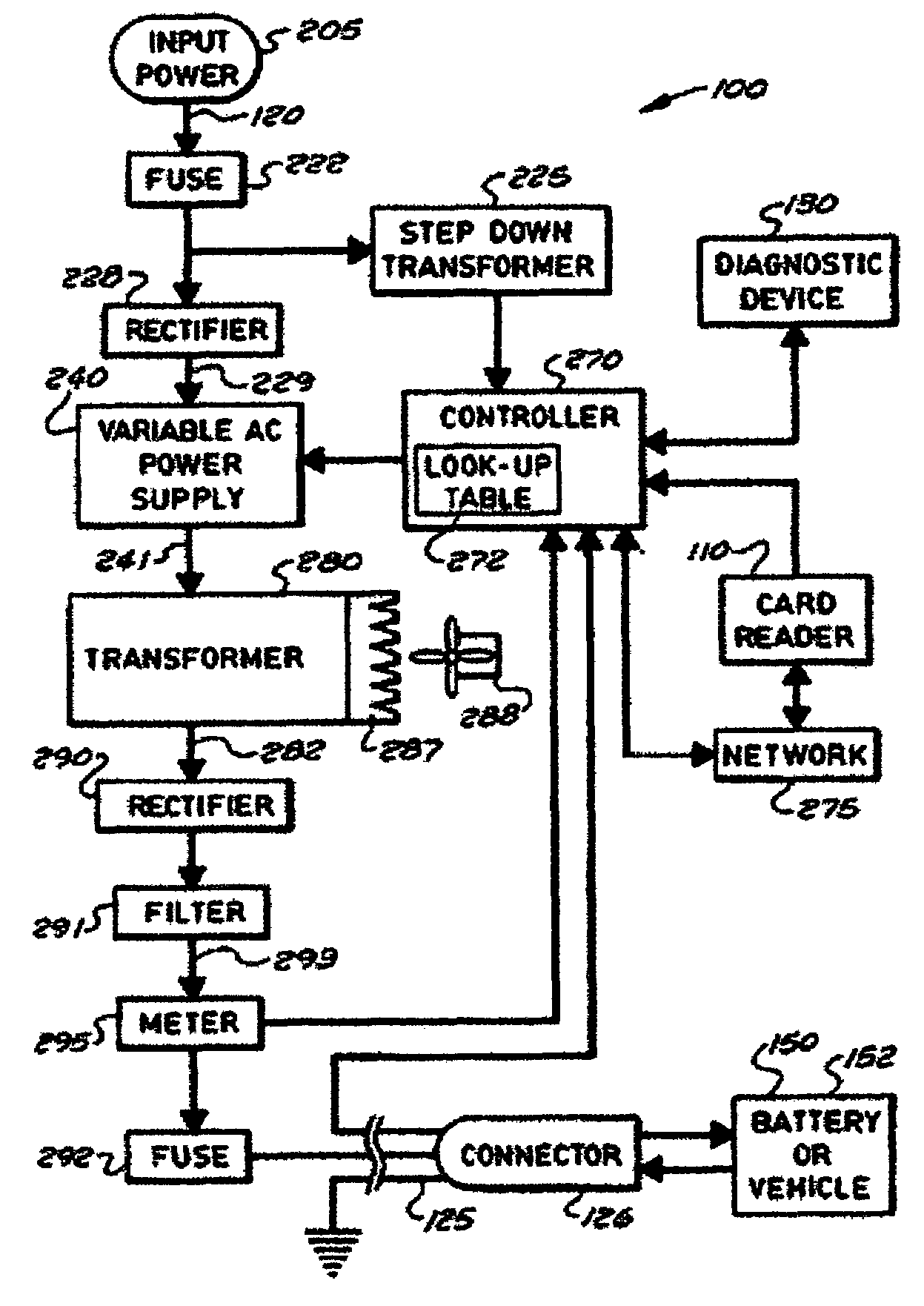

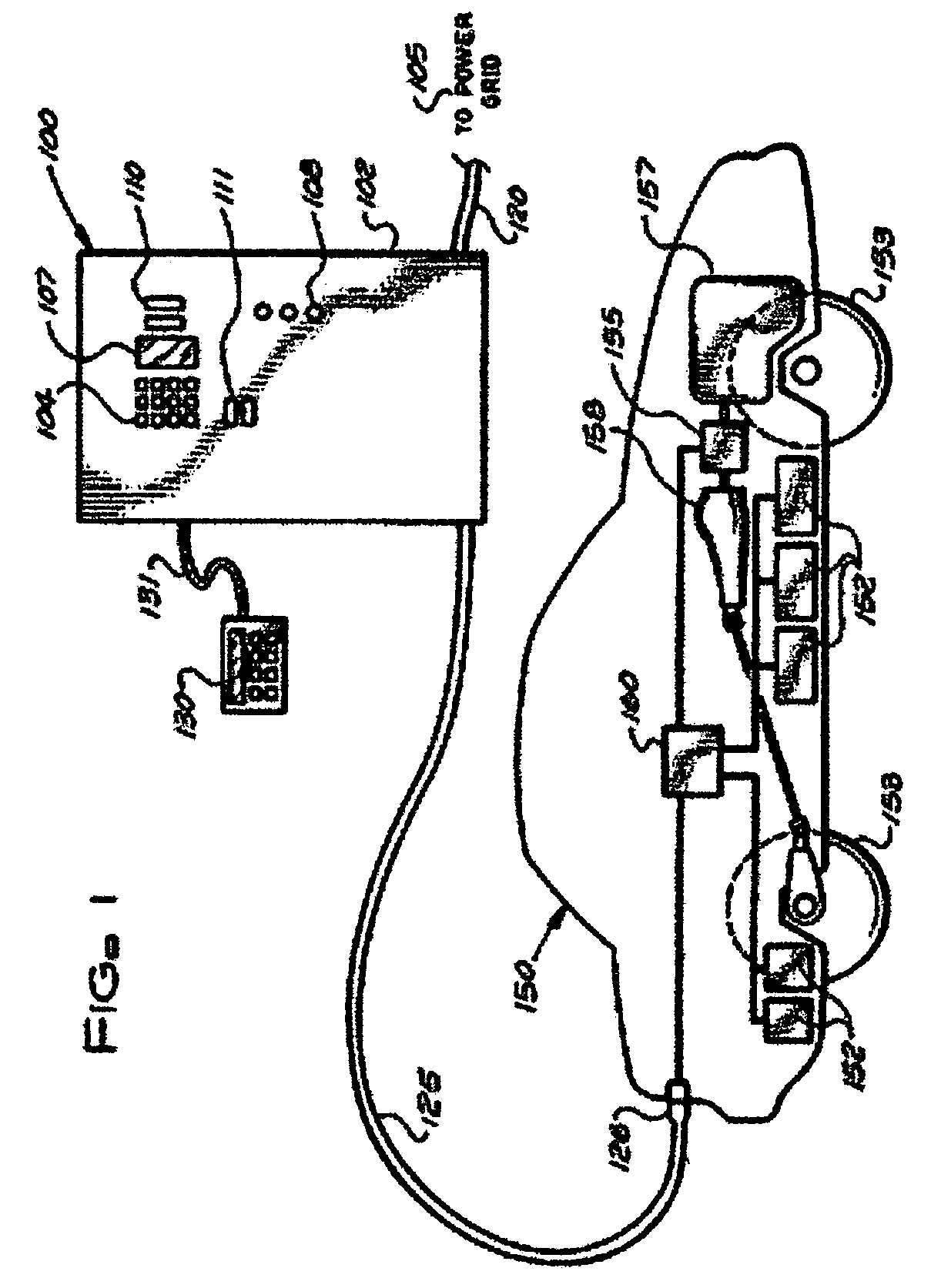

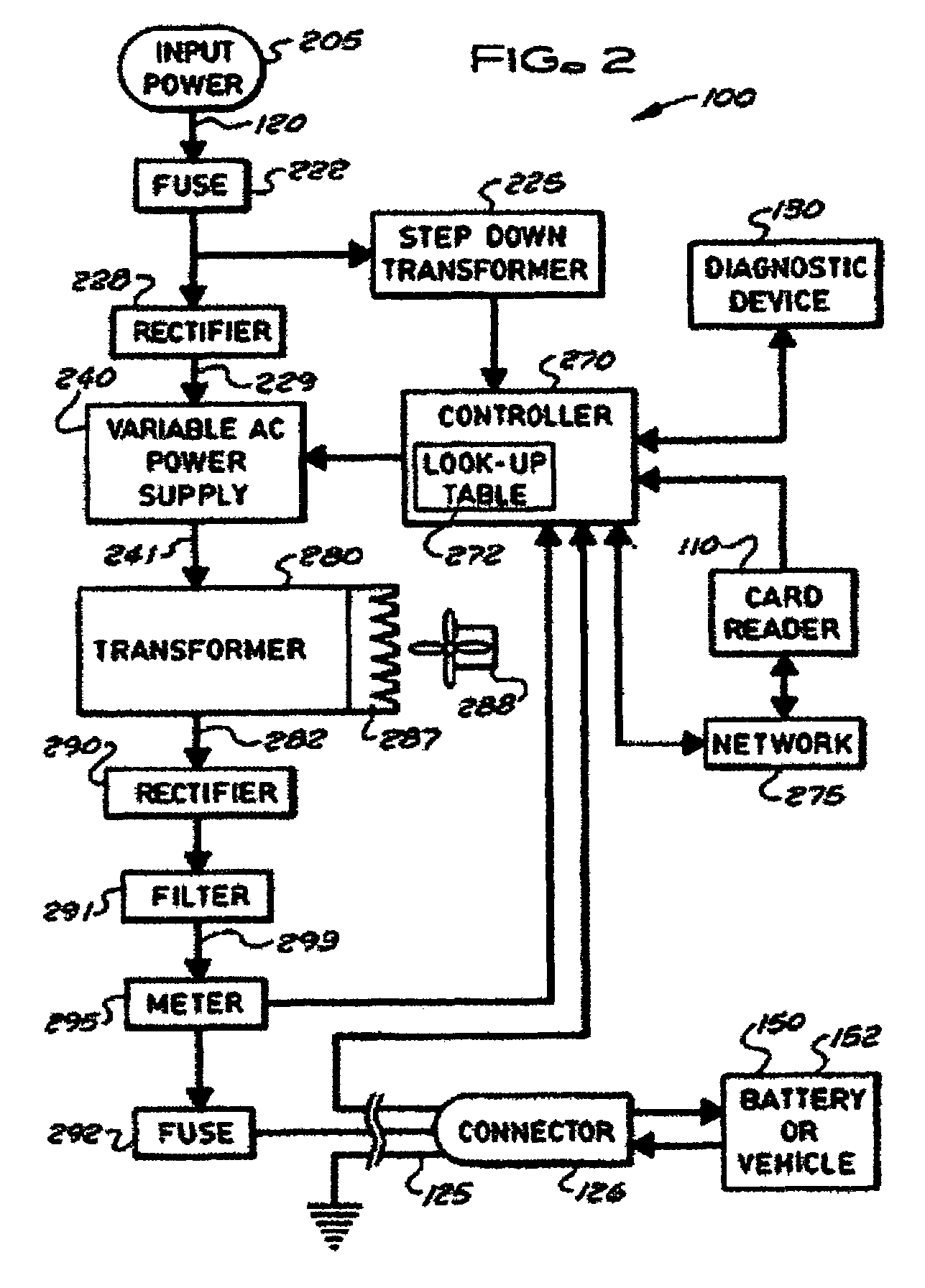

Battery charger and method of charging a battery

InactiveUS6963186B2Quickly and conveniently chargeSmall sizeCircuit monitoring/indicationSecondary cells charging/dischargingOn boardCopper foil

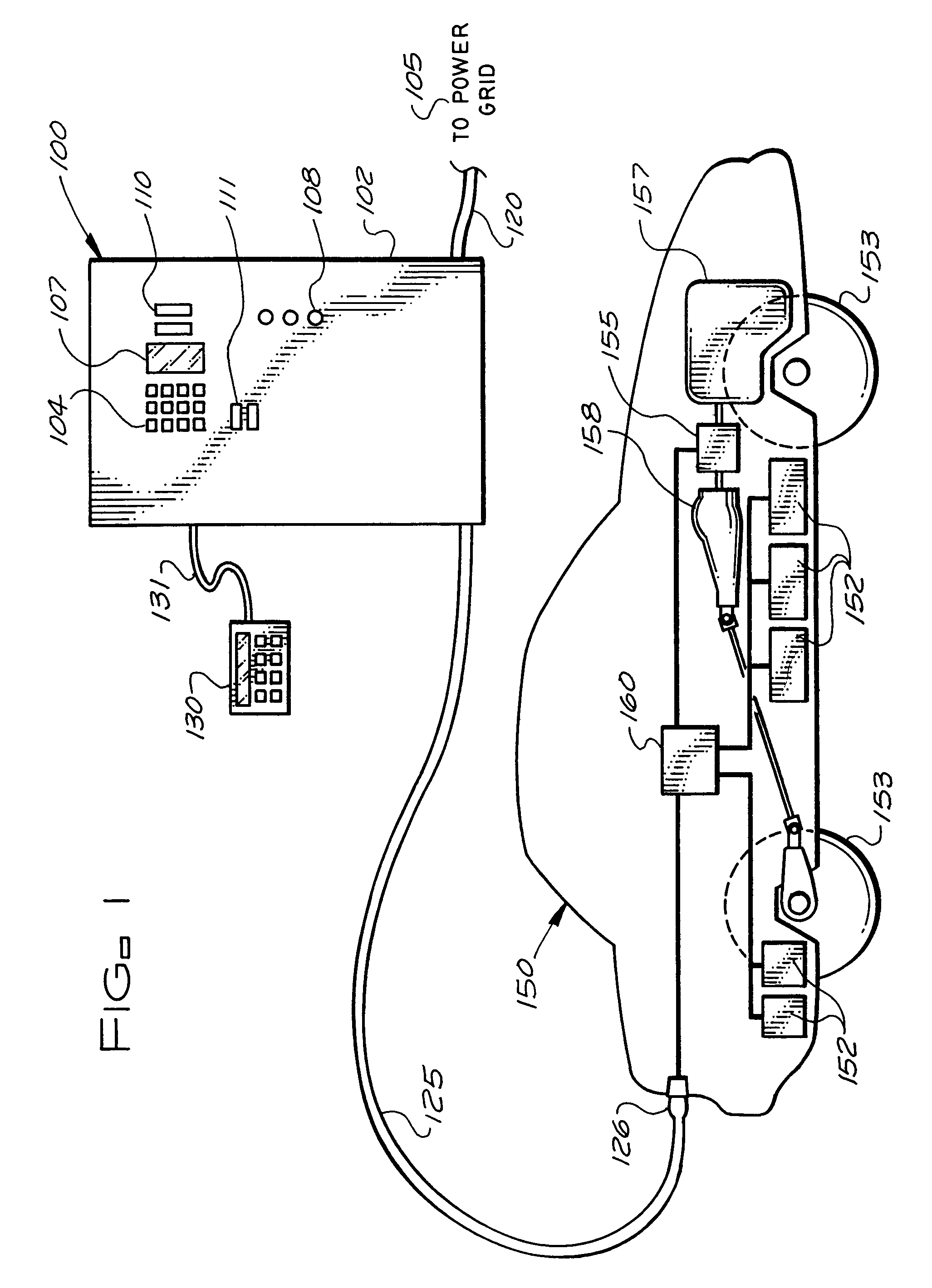

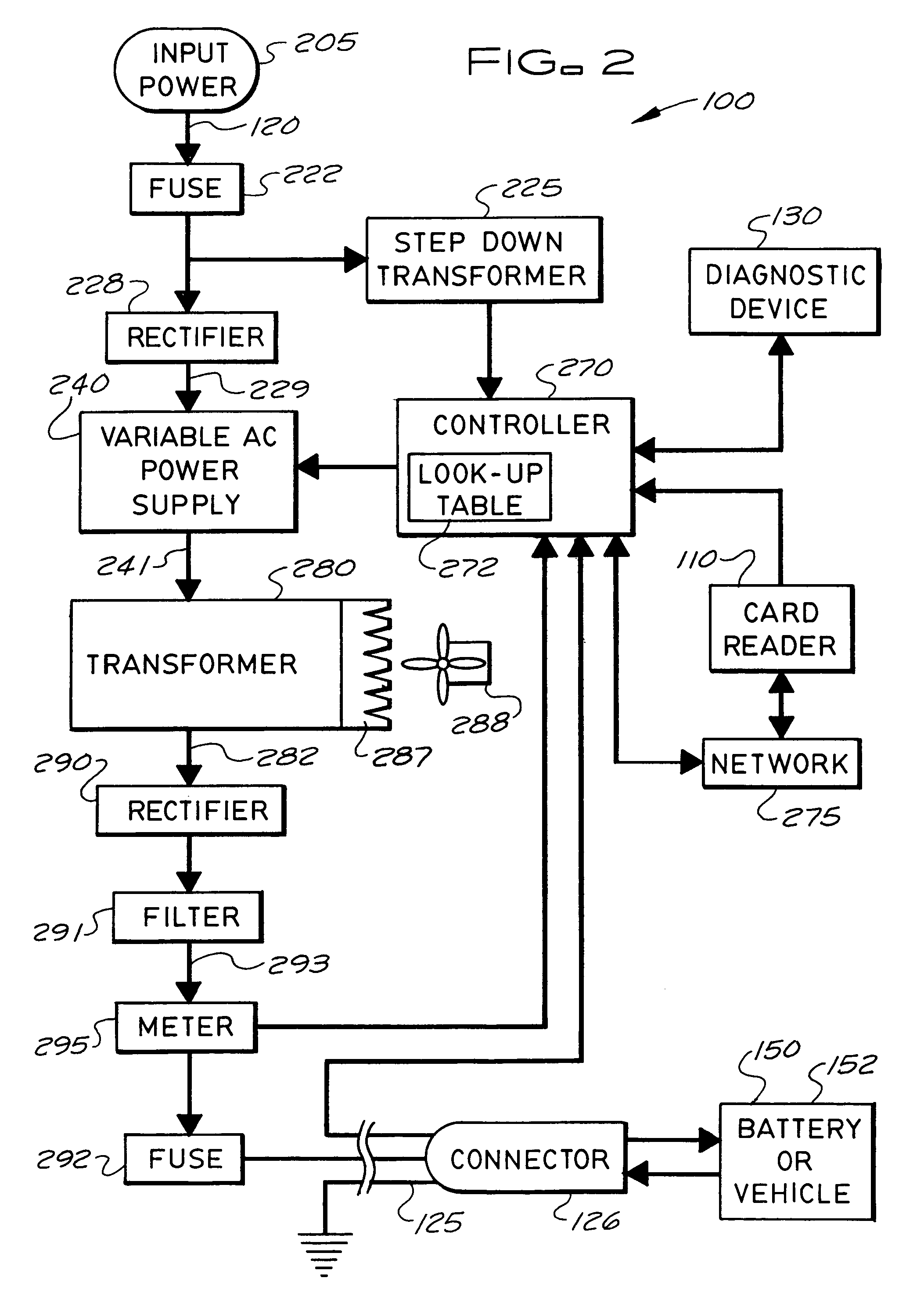

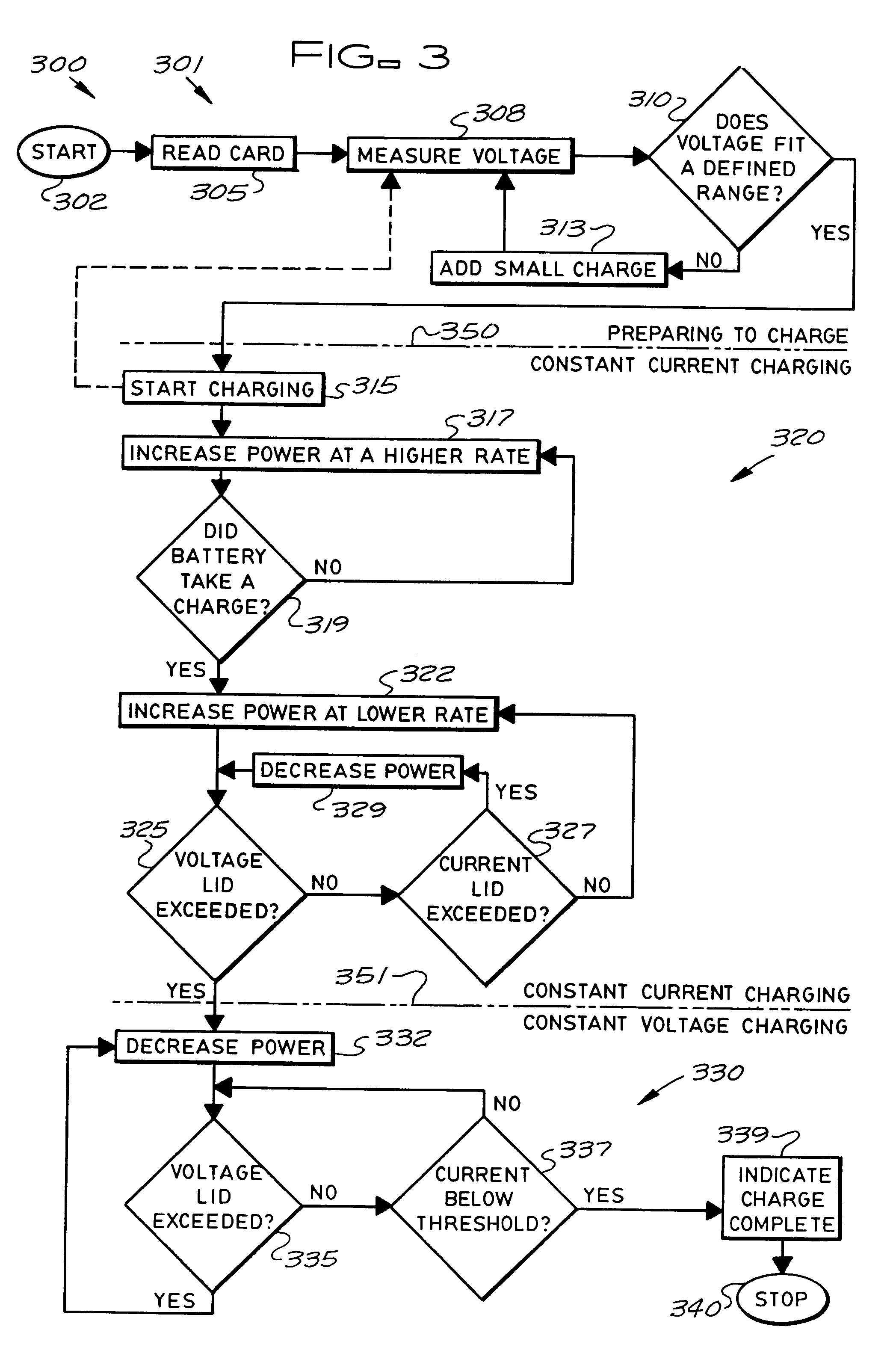

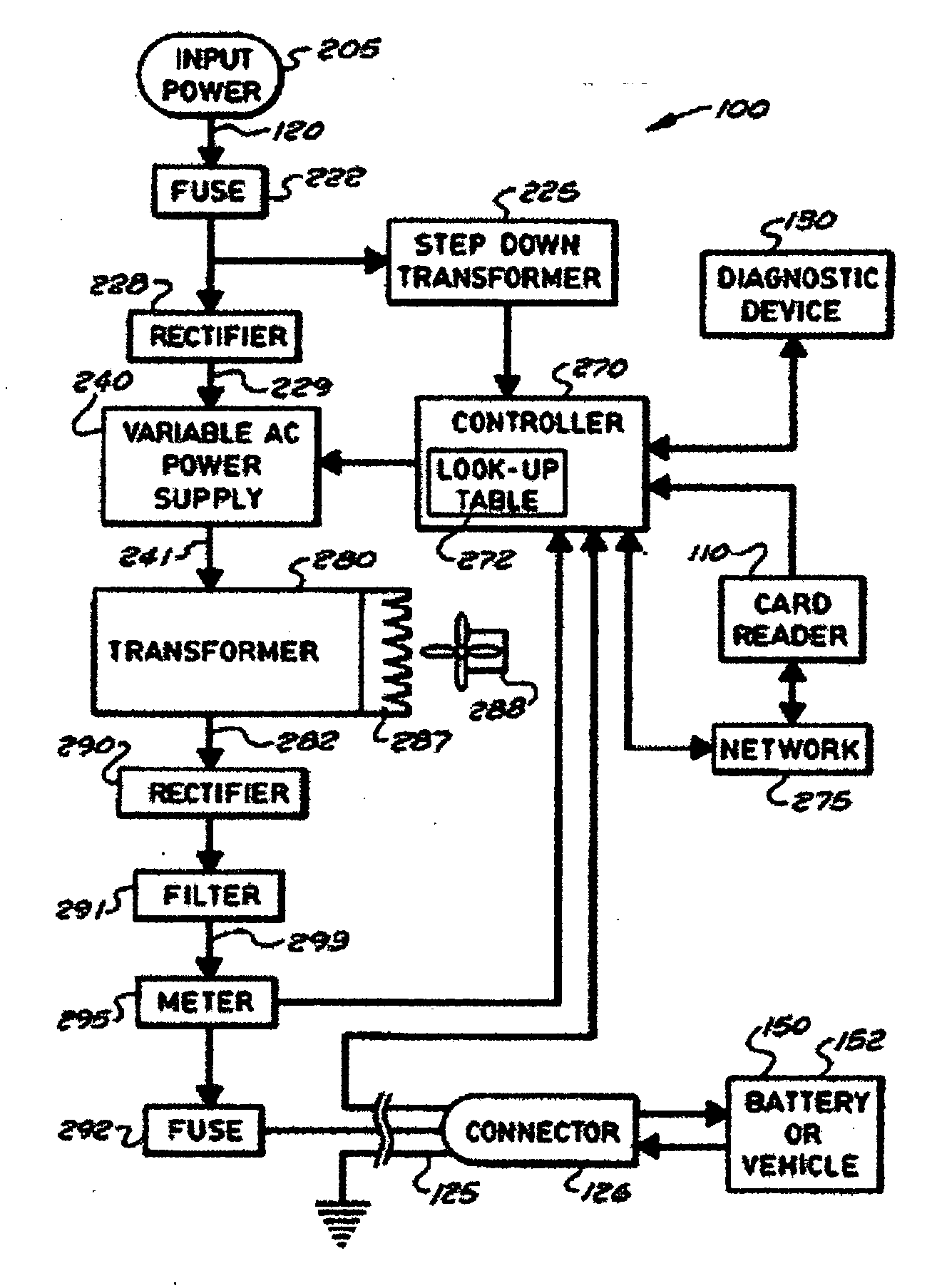

Stationary and on-board battery chargers, methods of charging batteries, electric-vehicle chargers, and vehicles with chargers, including electric vehicles and hybrid electric vehicles. Chargers may automatically charge at the correct battery voltage for various types of batteries. Chargers have variable AC power supplies controlled by digital controllers, isolation transformers, and rectifiers. Transformers may be foil-type, and may have copper foil. Power supplies may be variable-frequency generators and the controllers may control the frequency. Electric vehicle chargers may have card readers, and vehicles may have batteries and a charger. Methods of charging include identifying the battery type and gradually increasing the charging at different rates of increase while monitoring charging voltage, charging current, or both, until a current lid is reached. Charging may occur at constant current and then at constant voltage.

Owner:ARIZONA PUBLIC SERVICE

Battery charger and method of charging a battery

InactiveUS20060028178A1Quickly and conveniently chargeSmall sizeBatteries circuit arrangementsPropulsion by batteries/cellsOn boardCopper foil

Stationary and on-board battery chargers, methods of charging batteries, electric-vehicle chargers, and vehicles with chargers, including electric vehicles and hybrid electric vehicles. Chargers may automatically charge at the correct battery voltage for various types of batteries. Chargers have variable AC power supplies controlled by digital controllers, isolation transformers, and rectifiers. Transformers may be foil-type, and may have copper foil. Power supplies may be variable-frequency generators and the controllers may control the frequency. Use of the variable frequency generator supply facilitates reduced component size and weight and better battery charging performance. Electric vehicle chargers may have card readers, and vehicles may have batteries and a charger. Methods of charging include identifying the battery type and gradually increasing the charging at different rates of increase while monitoring charging voltage, charging current, or both, until a current lid is reached. Charging may occur at constant current and then at constant voltage.

Owner:ARIZONA PUBLIC SERVICE

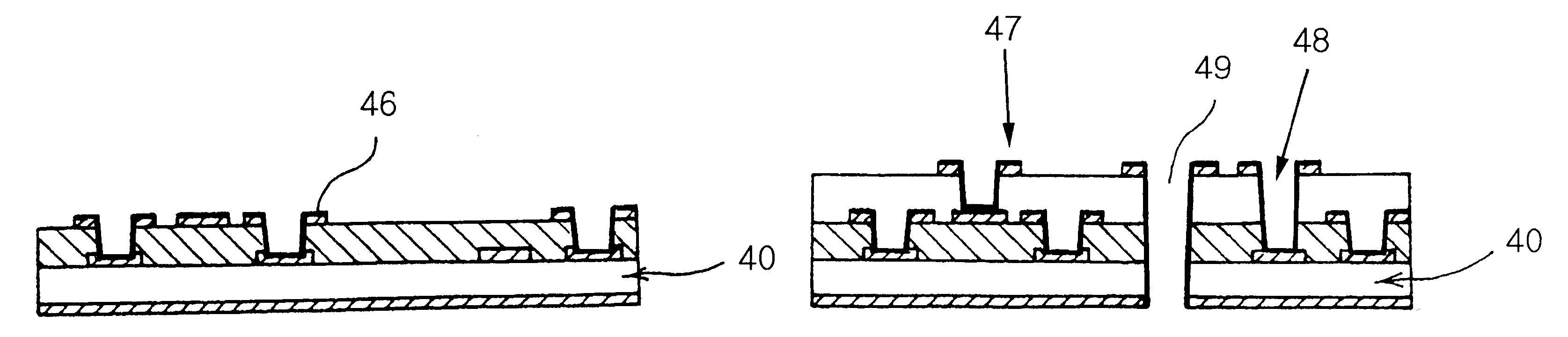

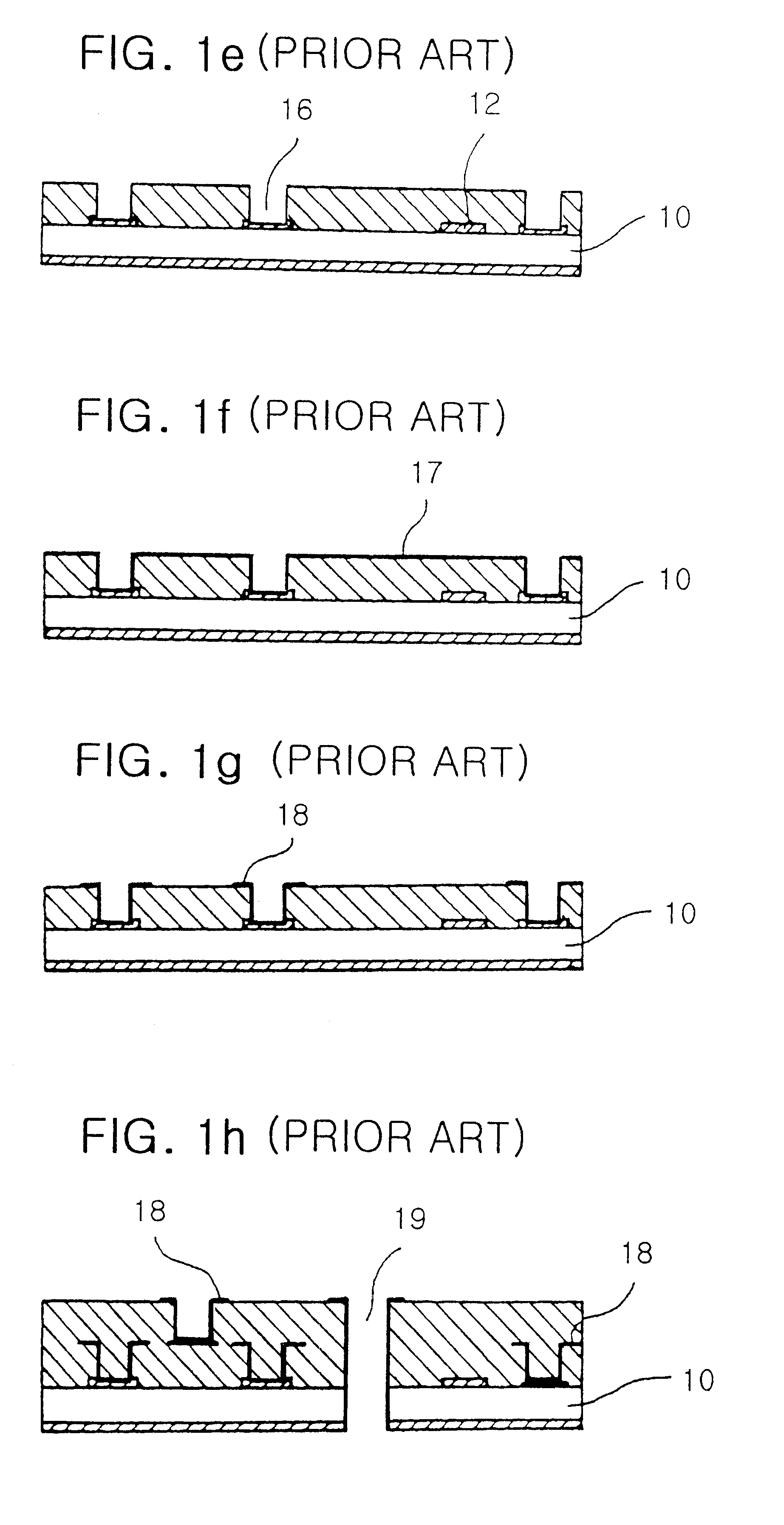

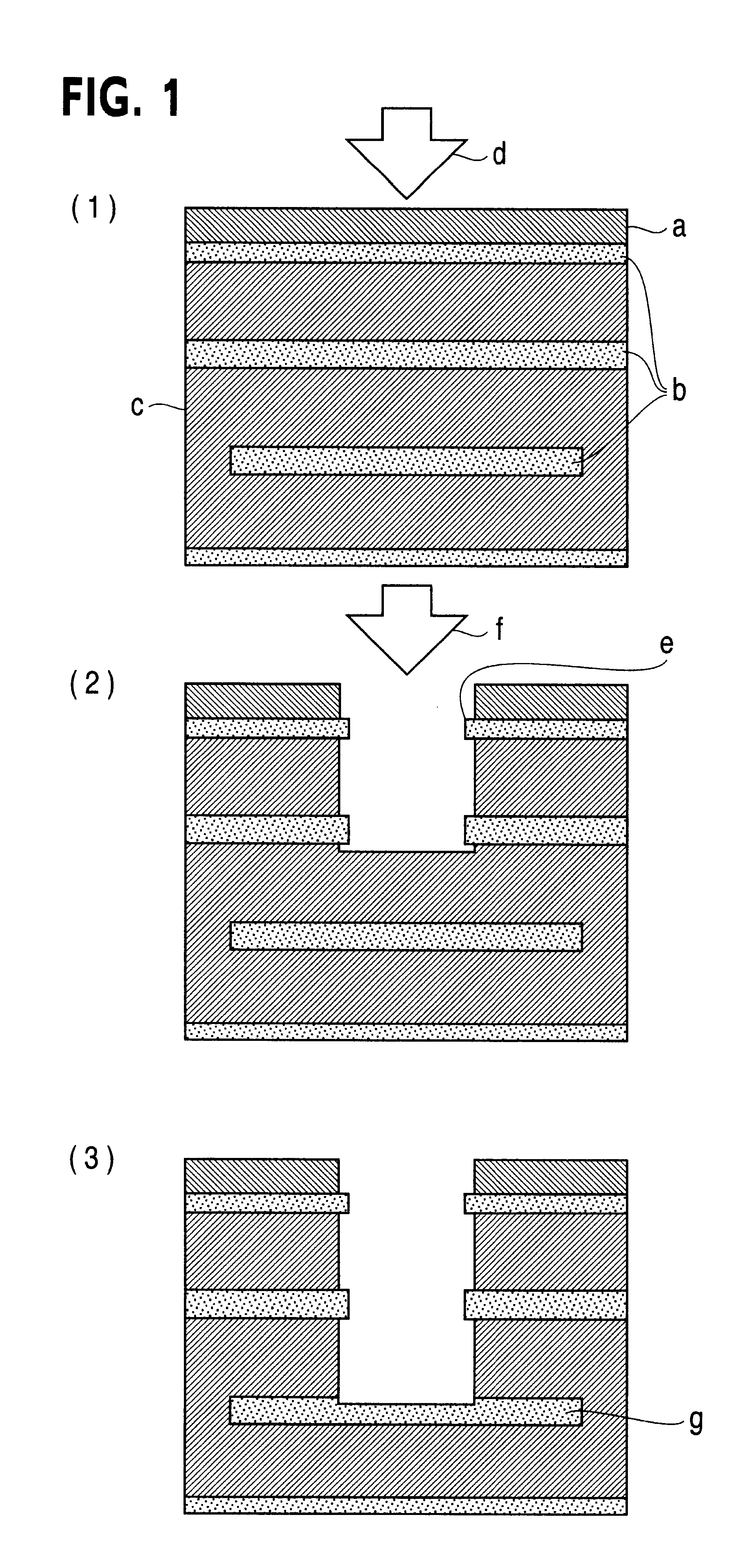

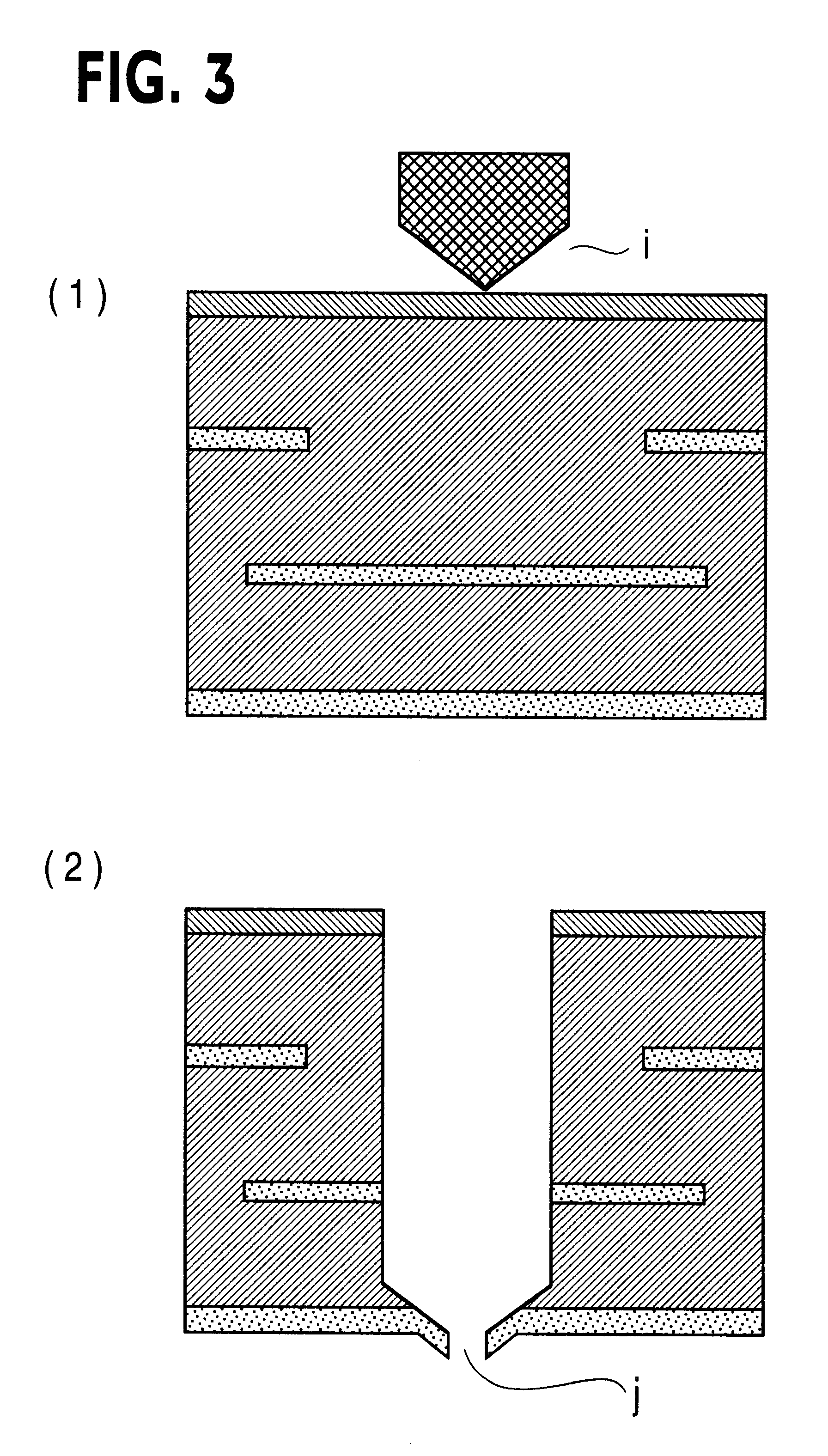

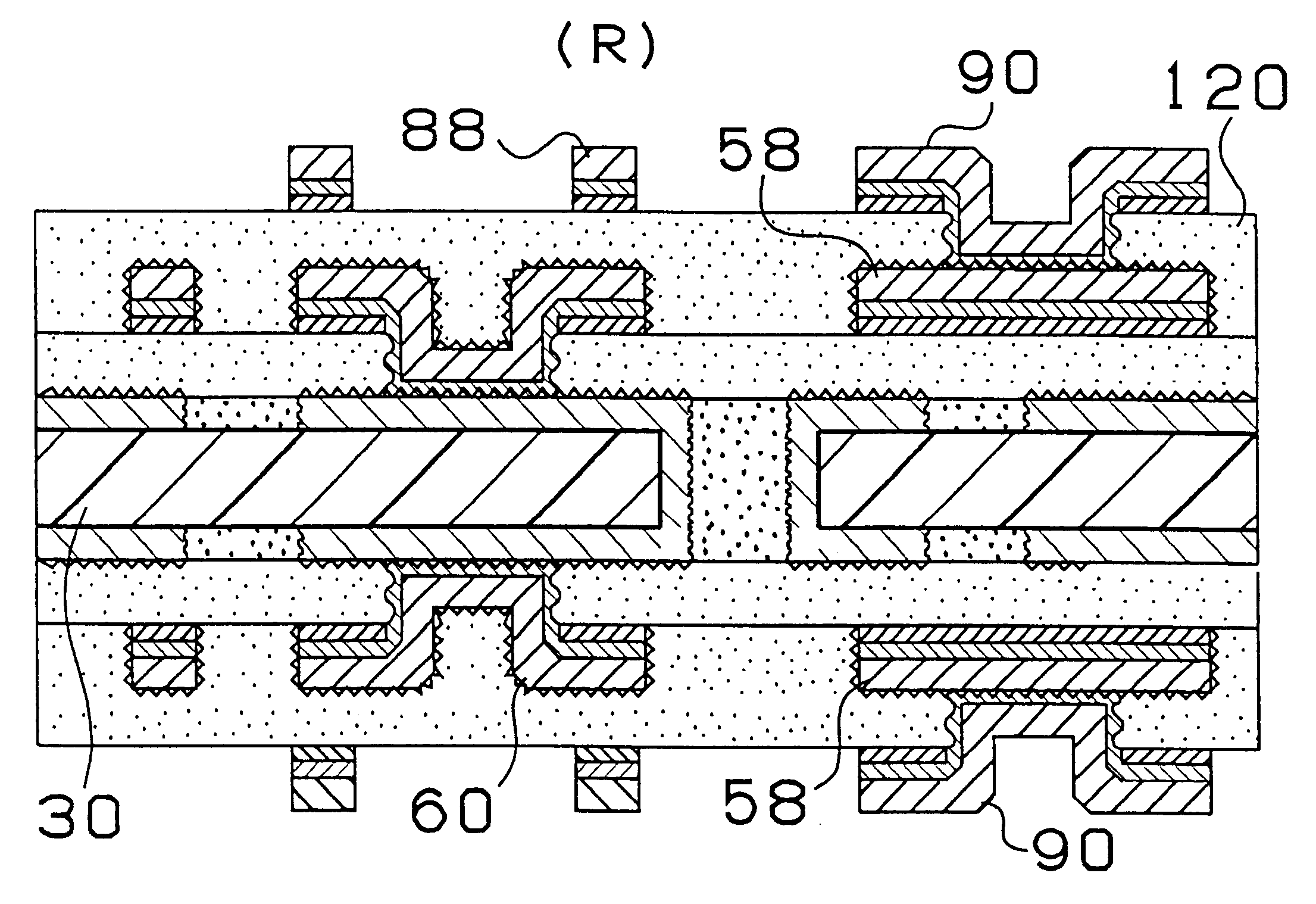

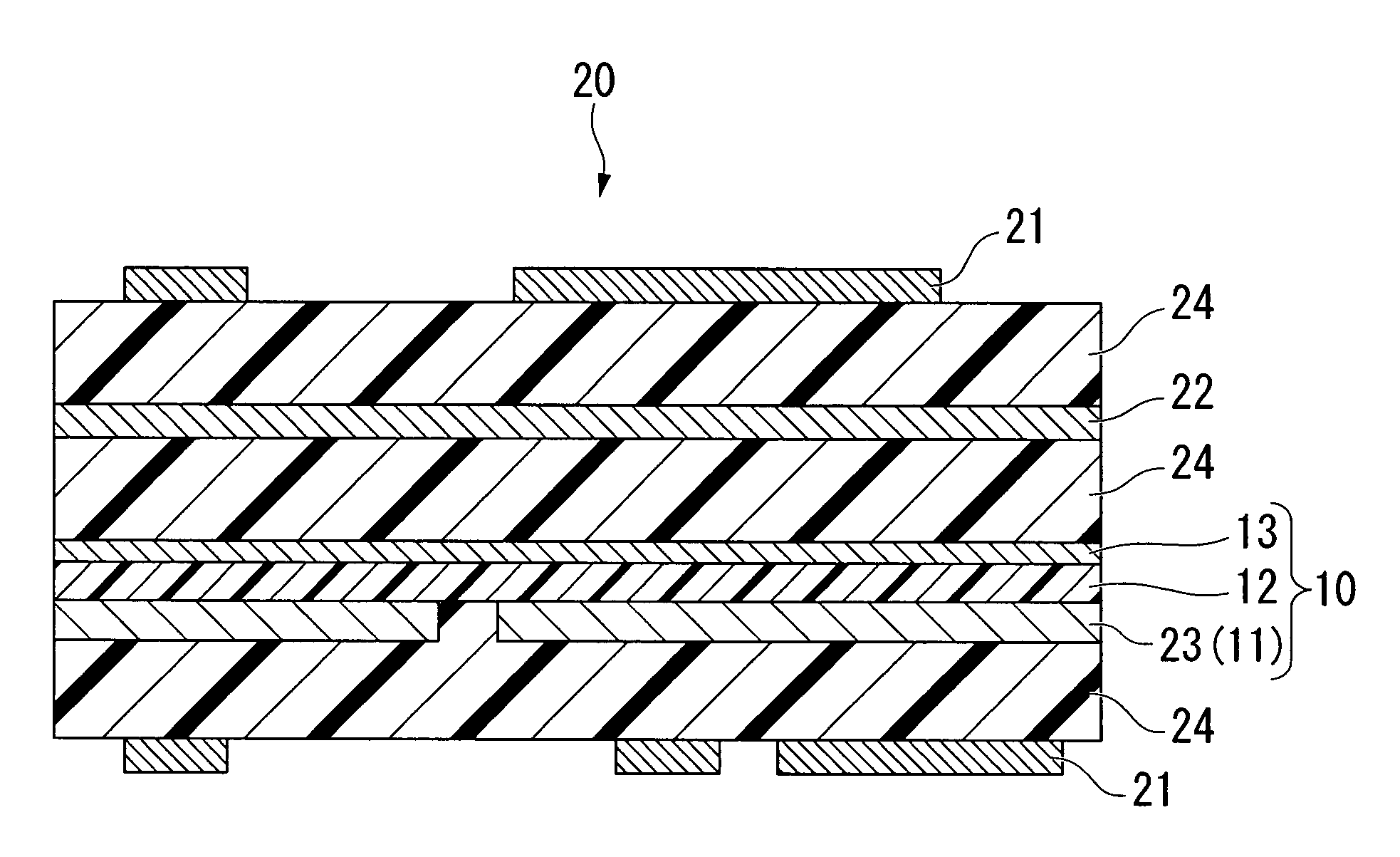

Method for manufacturing build-up multi-layer printed circuit board by using yag laser

A method for manufacturing a build-up multi-layer printed circuit board is disclosed in which a YAG laser is used upon the formation of a via hole in the multi-layer printed circuit board, such that it can have the following advantages: the manufacturing process would become simple; the component packaging density and freedom for the design of the board would be improved; and a high speed of signal process would be ensured. The method for manufacturing a build-up multi-layer printed circuit board includes the steps of: forming a first printed circuit pattern on a copper clad laminate (CCL) by applying a general photo-etching process, the CCL having a copper foil on the one face thereof; stacking a resin-coated (on one face) copper foil (RCC) on the CCL with the first printed circuit pattern formed thereon, and heating and pressing this structure; irradiating a YAG laser to the board with said RCC stacked so as to form a via hole at a predetermined position by removing said RCC; carrying out an electroless and electro copper plating on the board with the via hole formed therein to form a plated layer; and forming a second printed circuit pattern on said plated layer to electrically connect the layers on which the first and second printed circuit patterns are formed.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

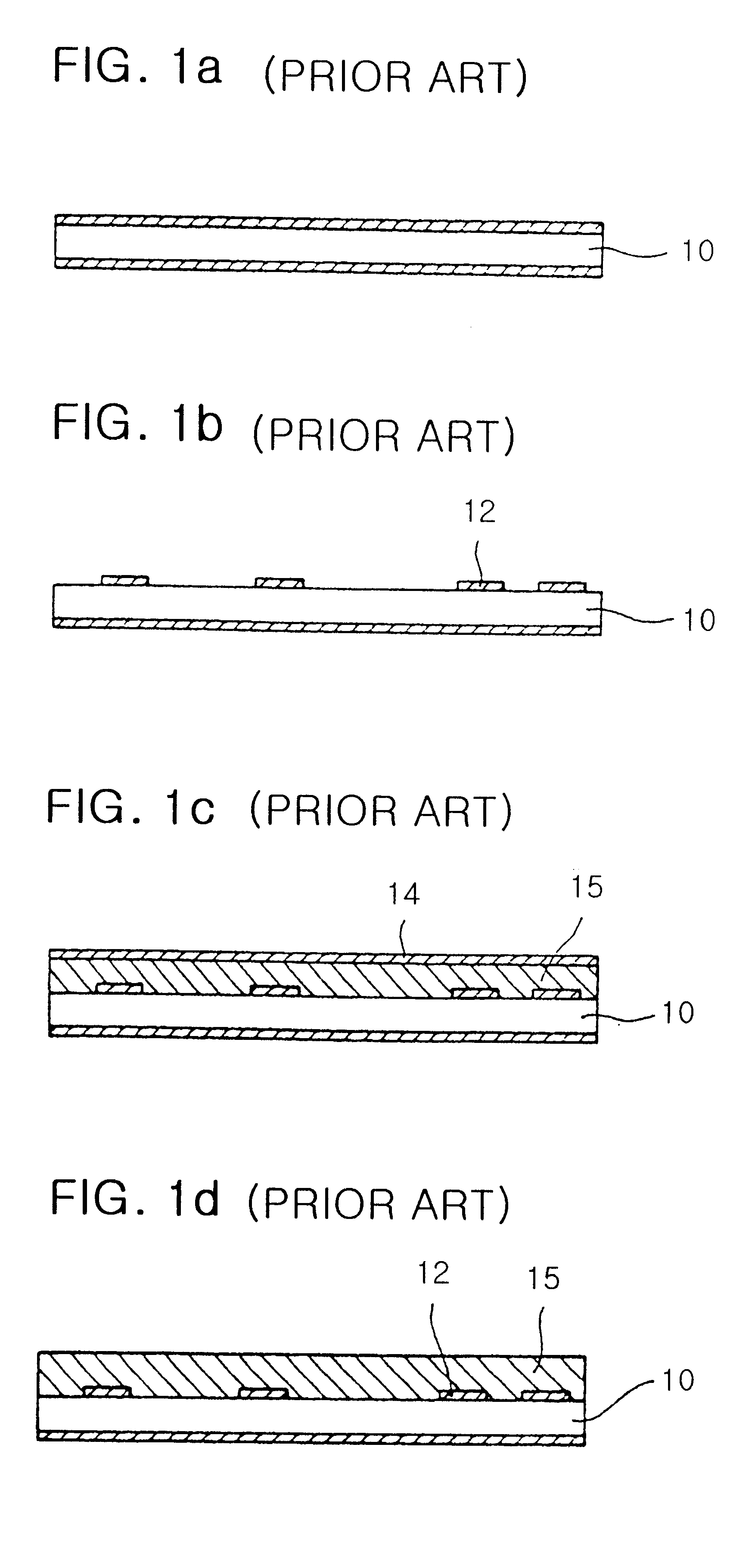

Printed wiring board having highly reliably via hole and process for forming via hole

InactiveUS6280641B1Improve reliabilityImprove productivityLight absorption dielectricsDecorative surface effectsBond energyConductive coating

Disclosed are a printed wiring board having micro-via holes highly reliable for conduction and a method of making the micro-via hole by providing a coating or sheet of an organic substance containing 3 to 97% by volume of at least one selected from a metal compound powder, a carbon powder or a metal powder having a melting point of at least 900° C. and a bond energy of at least 300 kJ / mol on a copper foil as an outermost layer of a copper-clad laminate having at least two copper layers, or providing a coating or sheet of the same after oxidizing a copper foil as an outermost layer, irradiating the coating or sheet with a carbon dioxide gas laser at an output of 20 to 60 mJ / pulse, thereby removing a micro-via-hole-forming portion of at least the copper foil as the outermost layer, then irradiating micro-via-hole-forming portions of the remaining layers with a carbon dioxide gas laser at an output of 5 to 35 mJ / pulse to make a micro-via hole which does not penetrate through the copper foil in a bottom of the micro-via hole, and electrically connecting the copper foil as the outermost layer and the copper foil in the bottom of the micro-via hole with a metal plating or an electrically conductive coating composition.

Owner:MITSUBISHI GAS CHEM CO INC

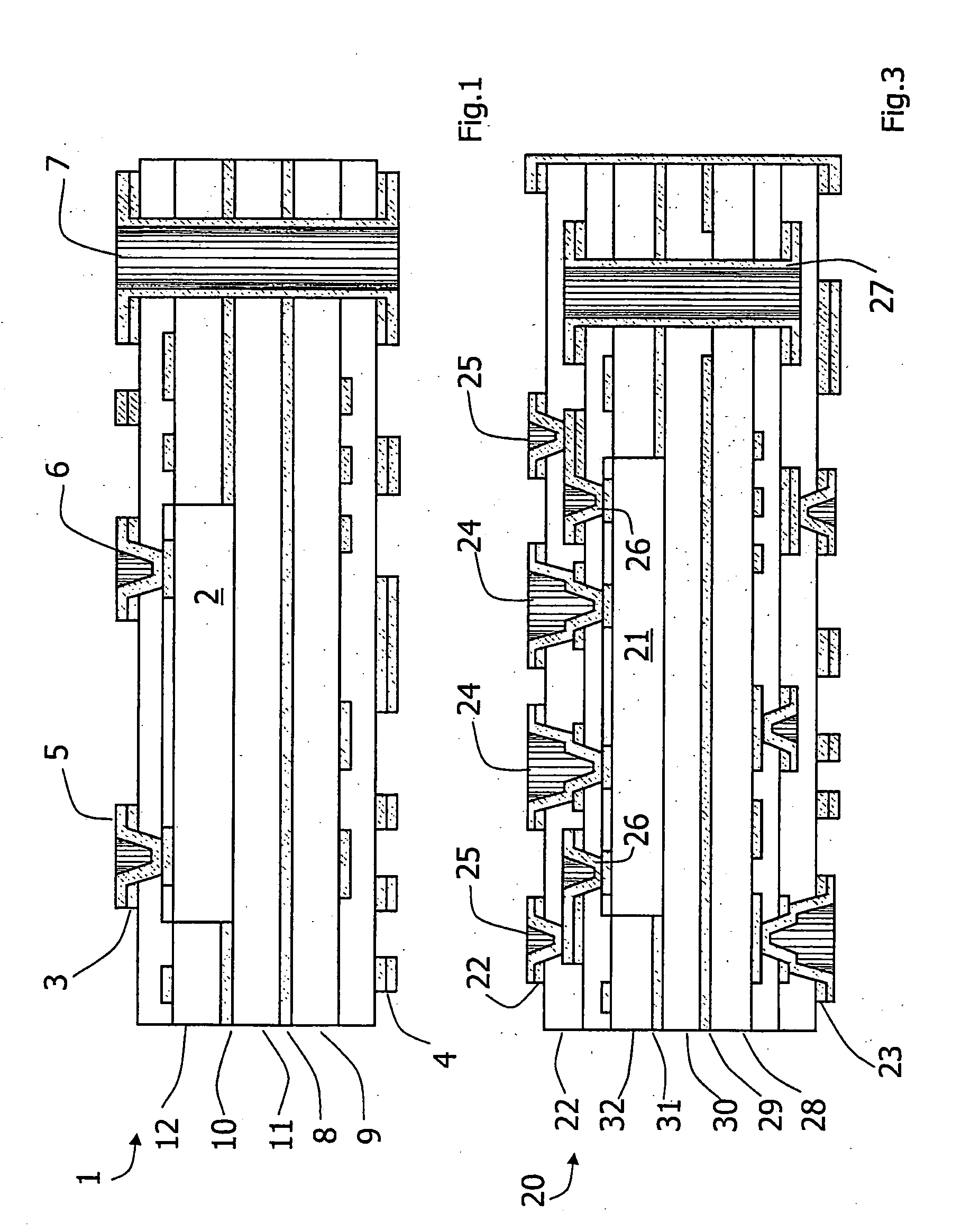

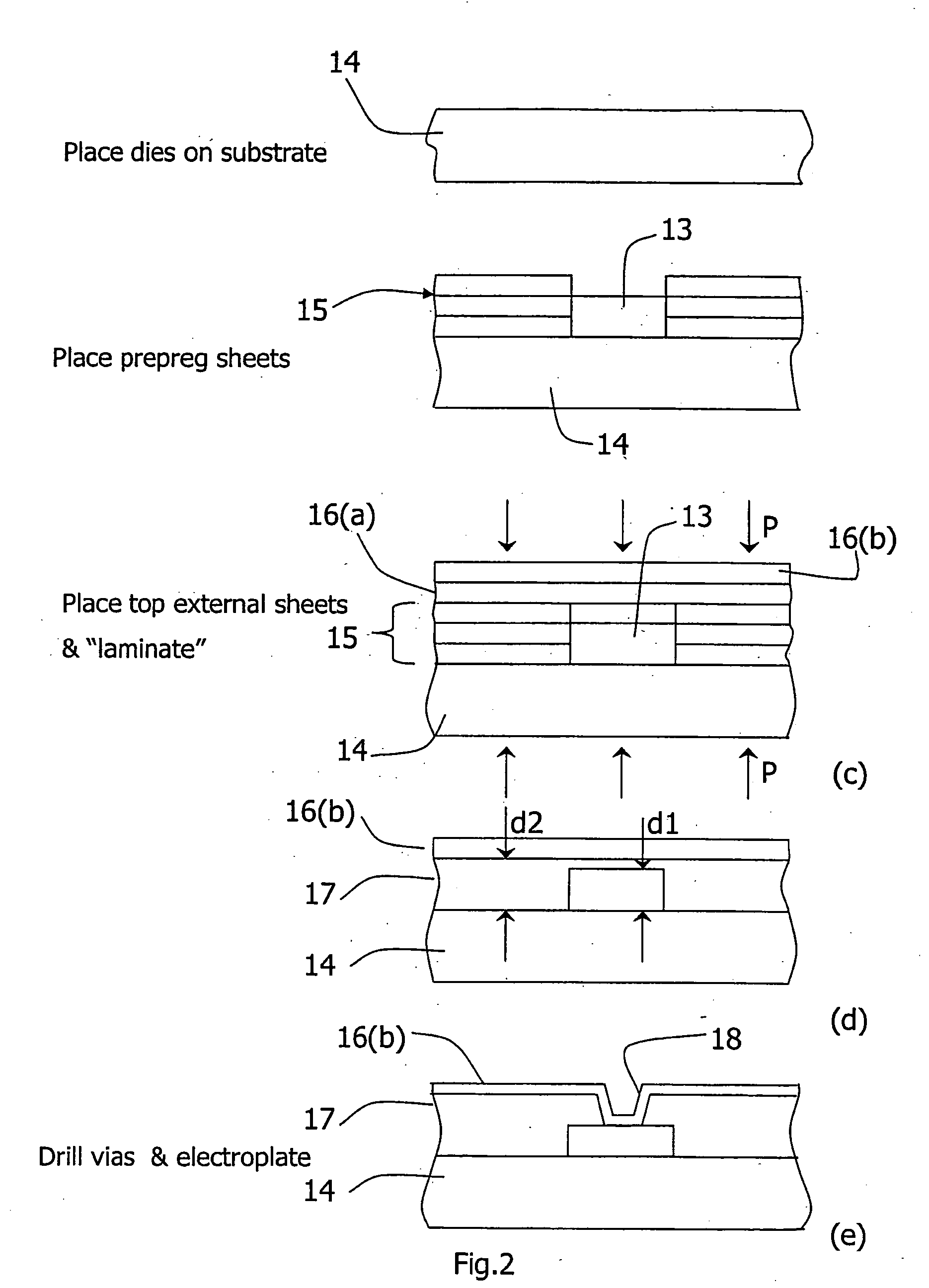

Electronics circuit manufacture

InactiveUS20050112798A1Line/current collector detailsSemiconductor/solid-state device testing/measurementRAIDElectrical connection

A circuit with embedding components (13) is produced by placing the components (13) on a substrate (14) and applying sheets (15) of prepreg. The prepreg sheets (15) have apertures to accommodate the -components, the number of sheets and arrangement of apertures being chosen to accommodate a variety of component X, Y and Z dimensions. A top layer with Cu foil (16(b)) is applied. The assembly is pressed in an operation analogous to conventional multilayer board lamination pressing. This causes all of the prepreg resin to flow to completely embed the components without raids or damage. Electrical connections are made by drilling and plating vias.

Owner:BJORBELL STEN

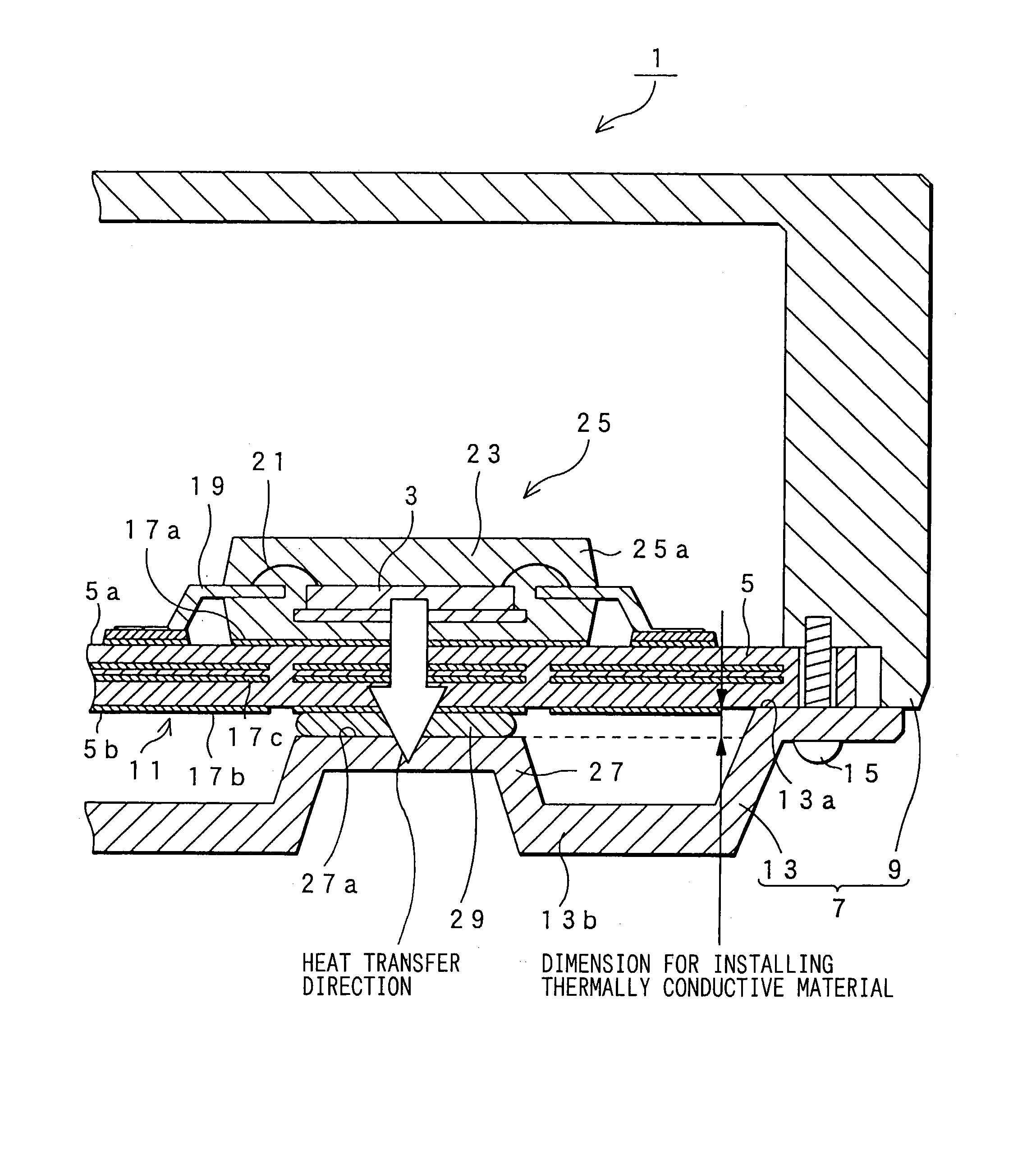

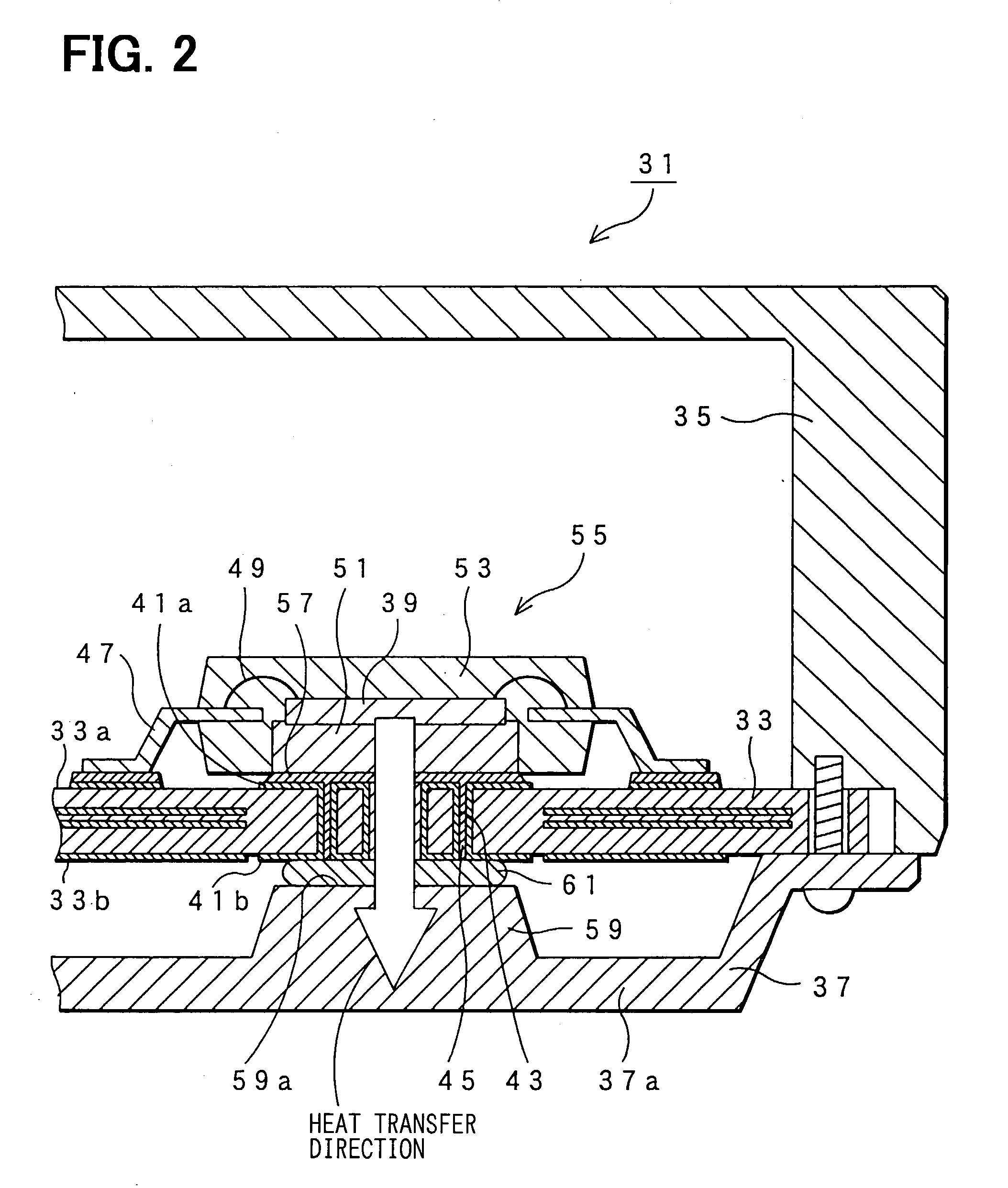

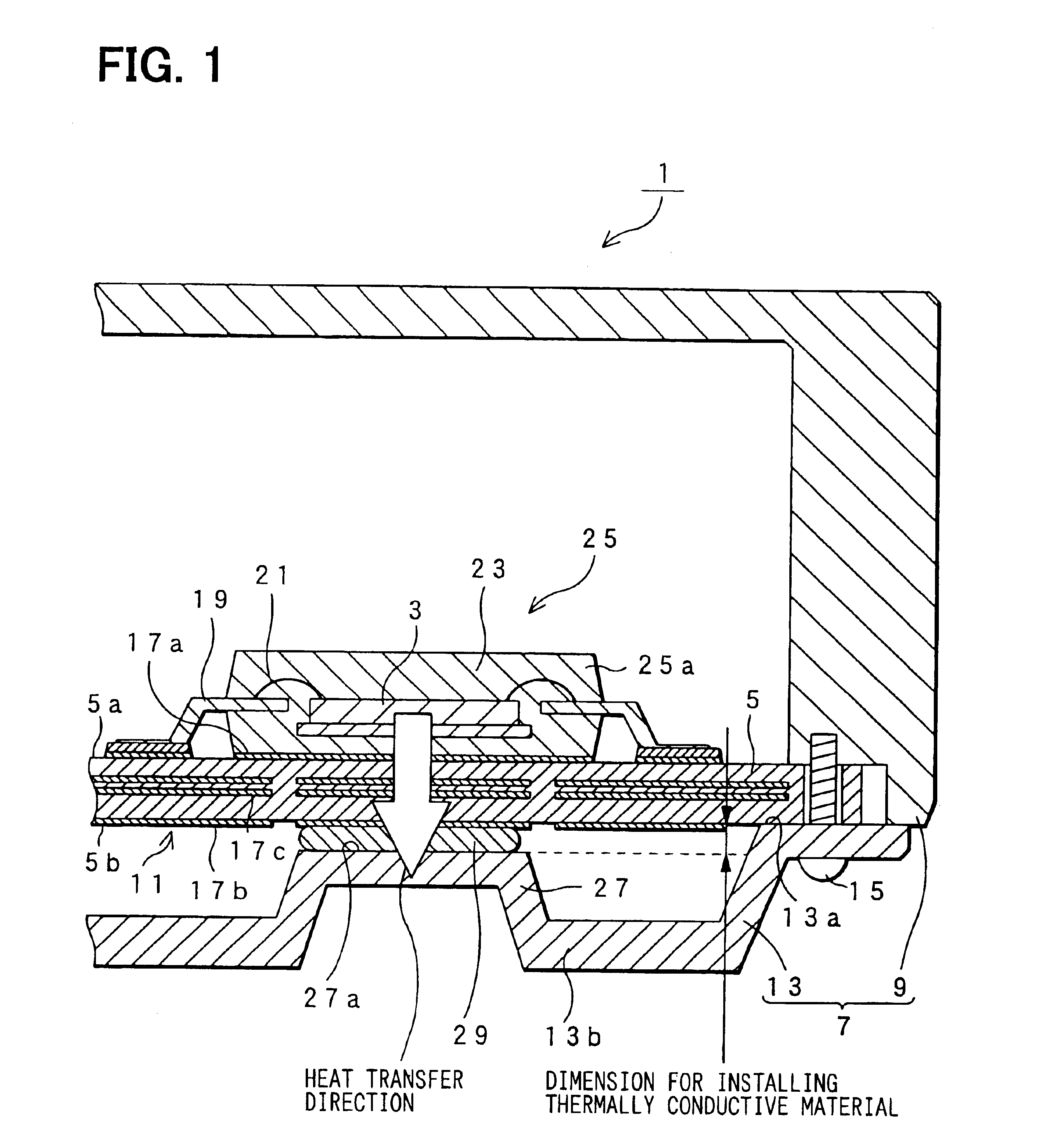

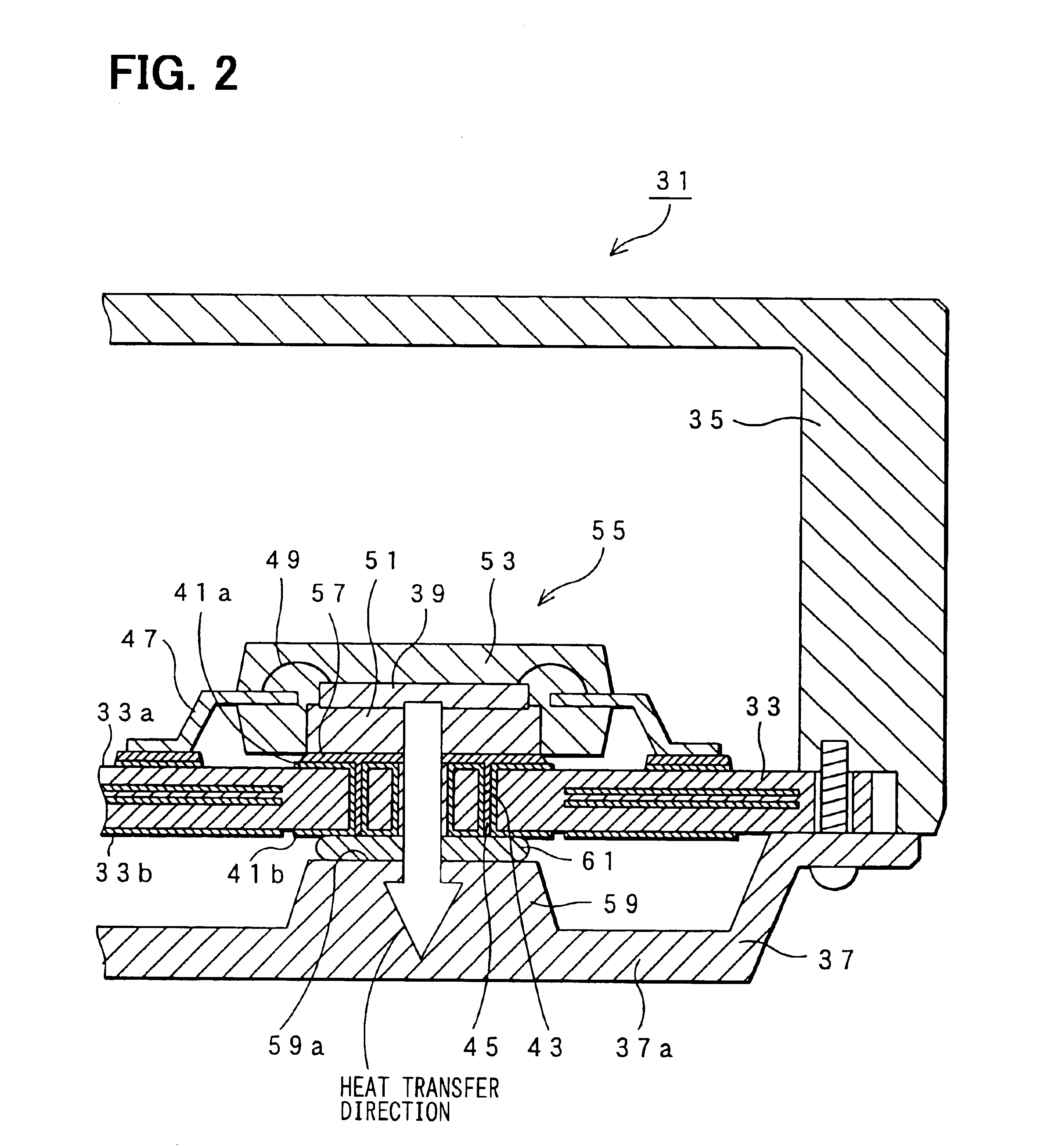

Electronic control unit

InactiveUS20030184969A1Semiconductor/solid-state device detailsPrinted circuit aspectsSemi solidConductive materials

An electronic control device having a high heat dissipating ability includes a printed board secured to an enclosure and interposed between a case and a cover with screws passing through the printed board. Thermally conductive thin film layers made of copper foil are formed in parallel on a mount face and an opposite mount face of the printed board and inside the printed board so as to be thermally separated from each other. A protrusion is provided on the cover and protrudes beyond a bottom part of the cover toward the position where an electronic component is mounted. A flexible, semi-solid thermally conductive material is placed between an end face of the protrusion and the opposite mount face of the printed board corresponding to the position where the electronic component is mounted to be in contact with the end face and the opposite mount face.

Owner:DENSO CORP

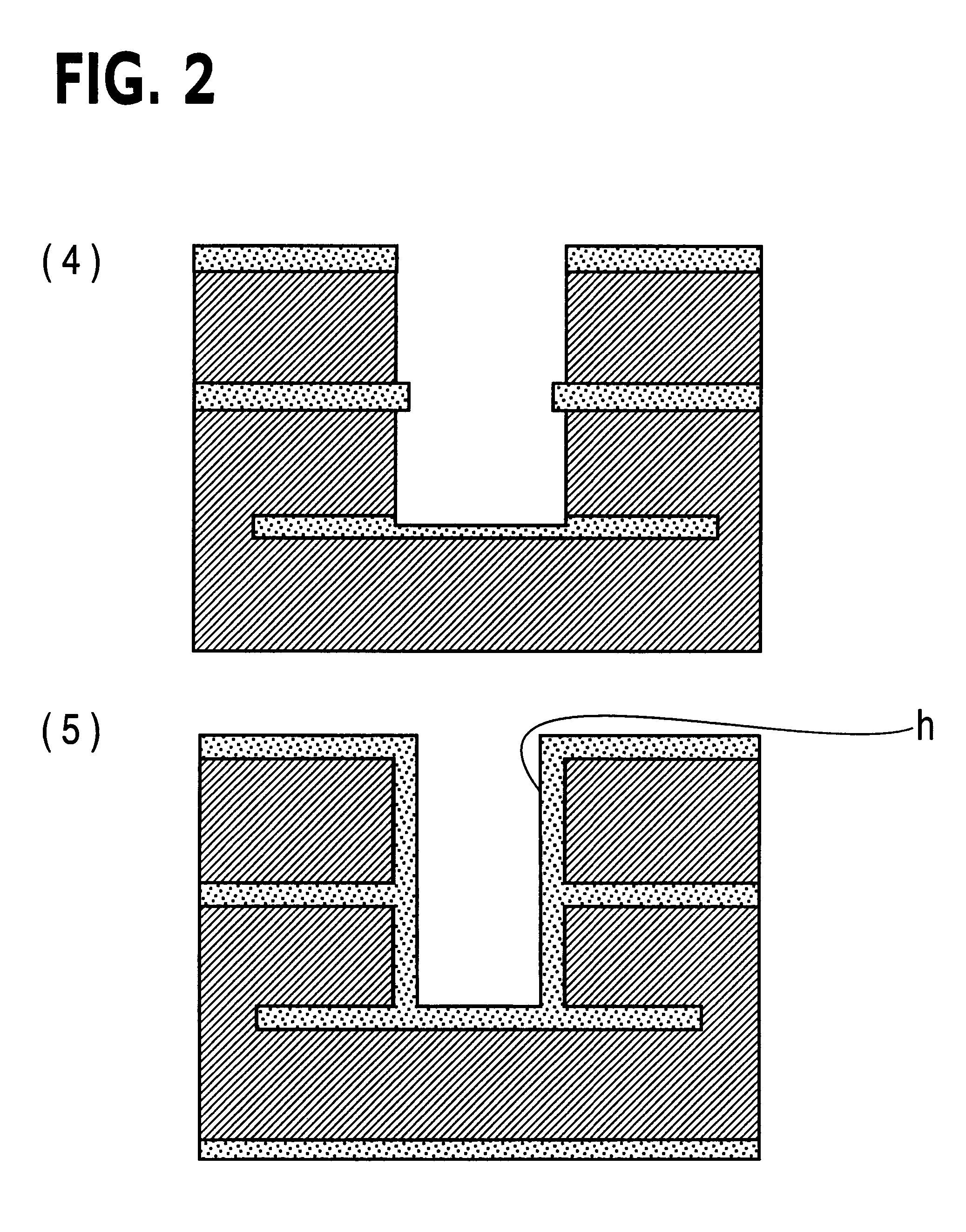

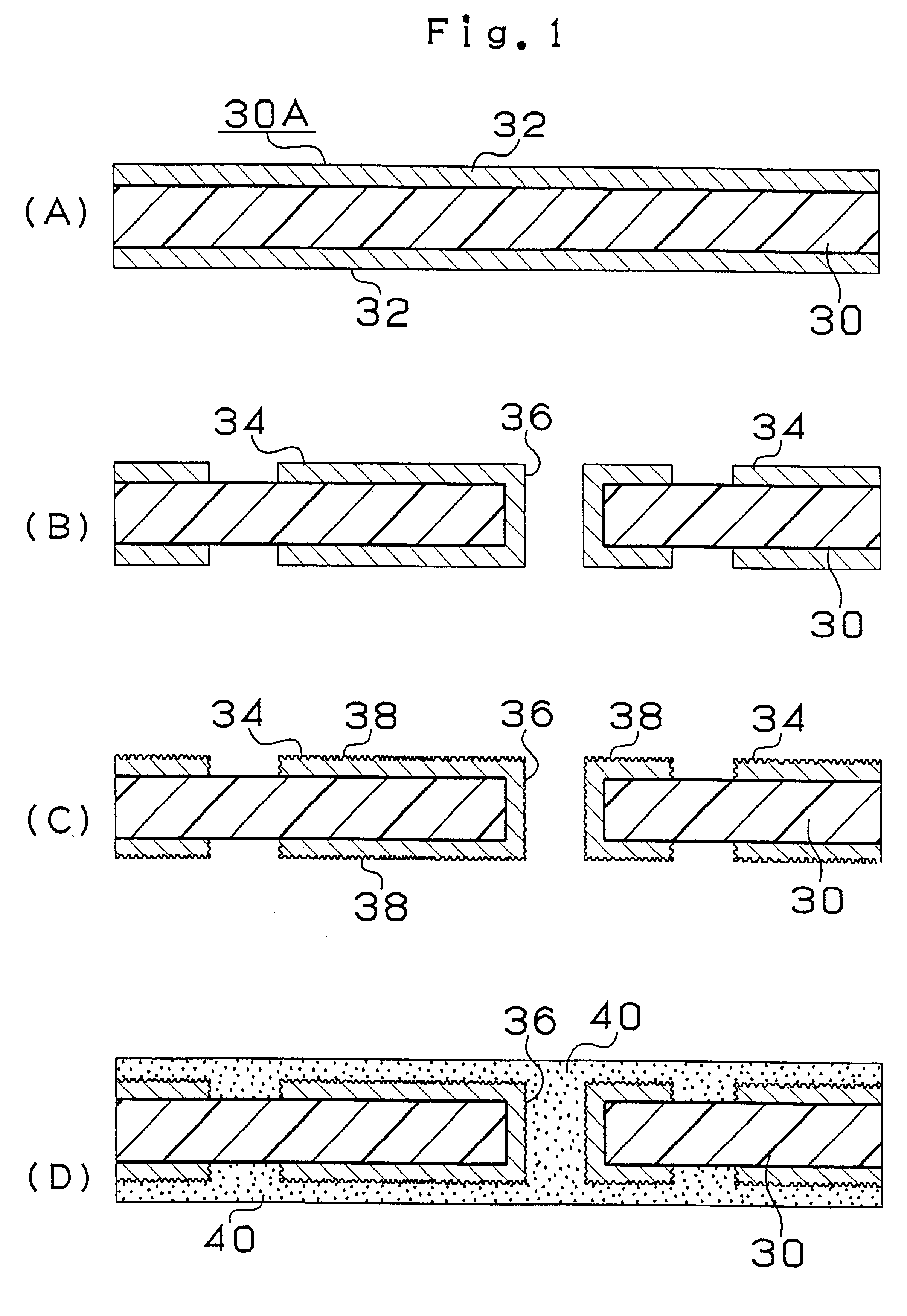

Manufacturing method of a multilayered printed circuit board having an opening made by a laser, and using electroless and electrolytic plating

InactiveUS6591495B2Satisfactory productivityAvoid separationSolid-state devicesInsulating layers/substrates workingCopper foilPulse shaping

An opening is formed in resin by a laser beam so that a via hole is formed. Copper foil, the thickness of which is reduced to 3 mum by etching to lower the thermal conductivity, is used as a conformal mask. Therefore, an opening is formed in the resin and the number of irradiation of pulse-shape laser beam is reduced. Thus, occurence of undercut of the resin, which forms an interlayer insulating resin layer, can be prevented and the reliability of the connection of the via holes can be improved.

Owner:IBIDEN CO LTD

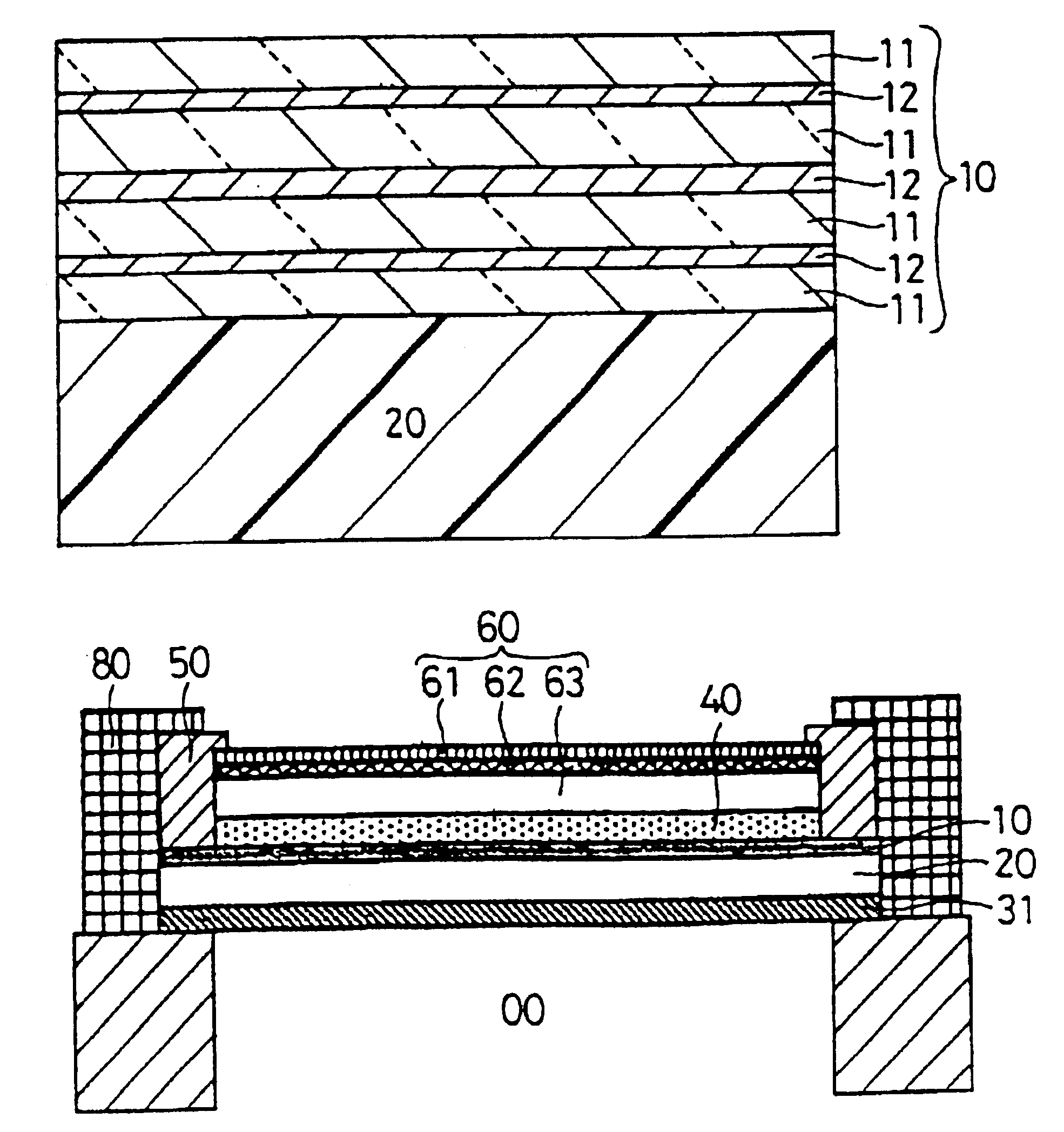

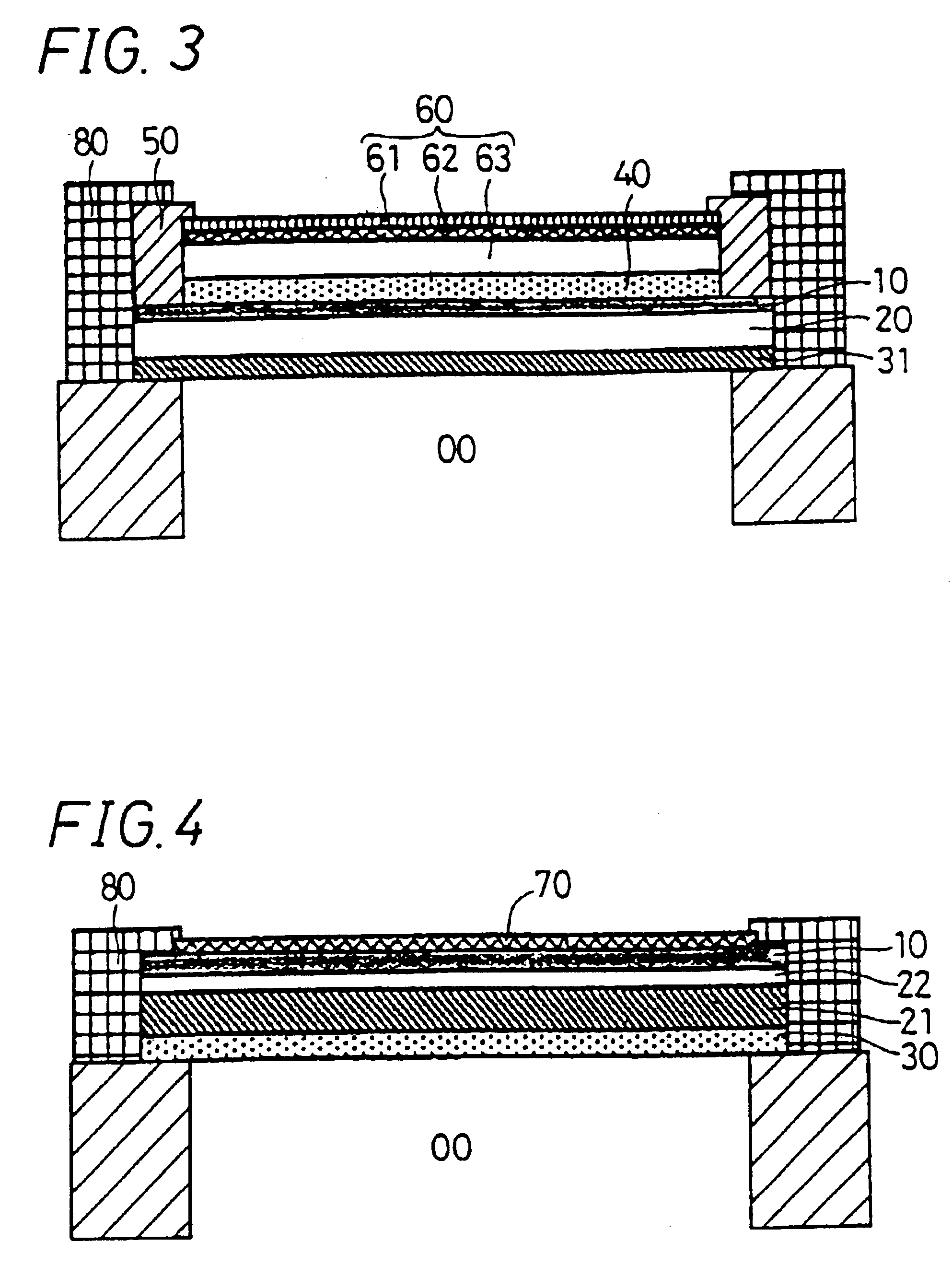

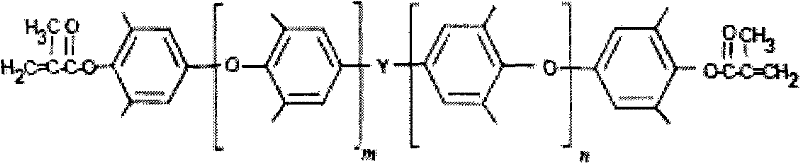

Filter for displaying, display unit and production method therefor

InactiveUS20030156080A1High color purityGood colorMagnetic/electric field screeningStatic indicating devicesDisplay deviceCopper foil

The display filter is constituted by laminating a transparent adhesive layer (C) 31 containing dye, a polymer film (B) 20, a transparent electrically conductive layer (D) 10, a transparent adhesive layer (E) 40, and a functional transparent layer (A) 60 having an anti-reflection property, a hard coat property, a gas barrier property, an antistatic property and an anti-fouling property sequentially in this order, adhered on a display area 00; on this occasion, the transparent electrically conductive layer (D) 10 is grounded to a ground terminal of the display via an electrode 50 and an electrically conductive copper foil adhesive tape 80.

Owner:MITSUI CHEM INC

Battery charger and method of charging a battery

InactiveUS7411371B2Quickly and conveniently chargeReduced size and massBatteries circuit arrangementsPropulsion by batteries/cellsOn boardCopper foil

Stationary and on-board battery chargers, methods of charging batteries, electric-vehicle chargers, and vehicles with chargers, including electric vehicles and hybrid electric vehicles. Chargers may automatically charge at the correct battery voltage for various types of batteries. Chargers have variable AC power supplies controlled by digital controllers, isolation transformers, and rectifiers. Transformers may be foil-type, and may have copper foil. Power supplies may be variable-frequency generators and the controllers may control the frequency. Use of the variable frequency generator supply facilitates reduced component size and weight and better battery charging performance. Electric vehicle chargers may have card readers, and vehicles may have batteries and a charger. Methods of charging include identifying the battery type and gradually increasing the charging at different rates of increase while monitoring charging voltage, charging current, or both, until a current lid is reached. Charging may occur at constant current and then at constant voltage.

Owner:ARIZONA PUBLIC SERVICE

Display filter, display apparatus, and method for production of the same

InactiveUS6965191B2Cathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersDisplay deviceEngineering

The display filter is constituted by laminating a transparent adhesive layer (C) 31 containing dye, a polymer film (B) 20, a transparent electrically conductive layer (D) 10, a transparent adhesive layer (E) 40, and a functional transparent layer (A) 60 having an anti-reflection property, a hard coat property, a gas barrier property, an antistatic property and an anti-fouling property sequentially in this order, adhered on a display area 00; on this occasion, the transparent electrically conductive layer (D) 10 is grounded to a ground terminal of the display via an electrode 50 and an electrically conductive copper foil adhesive tape 80.

Owner:MITSUI CHEM INC

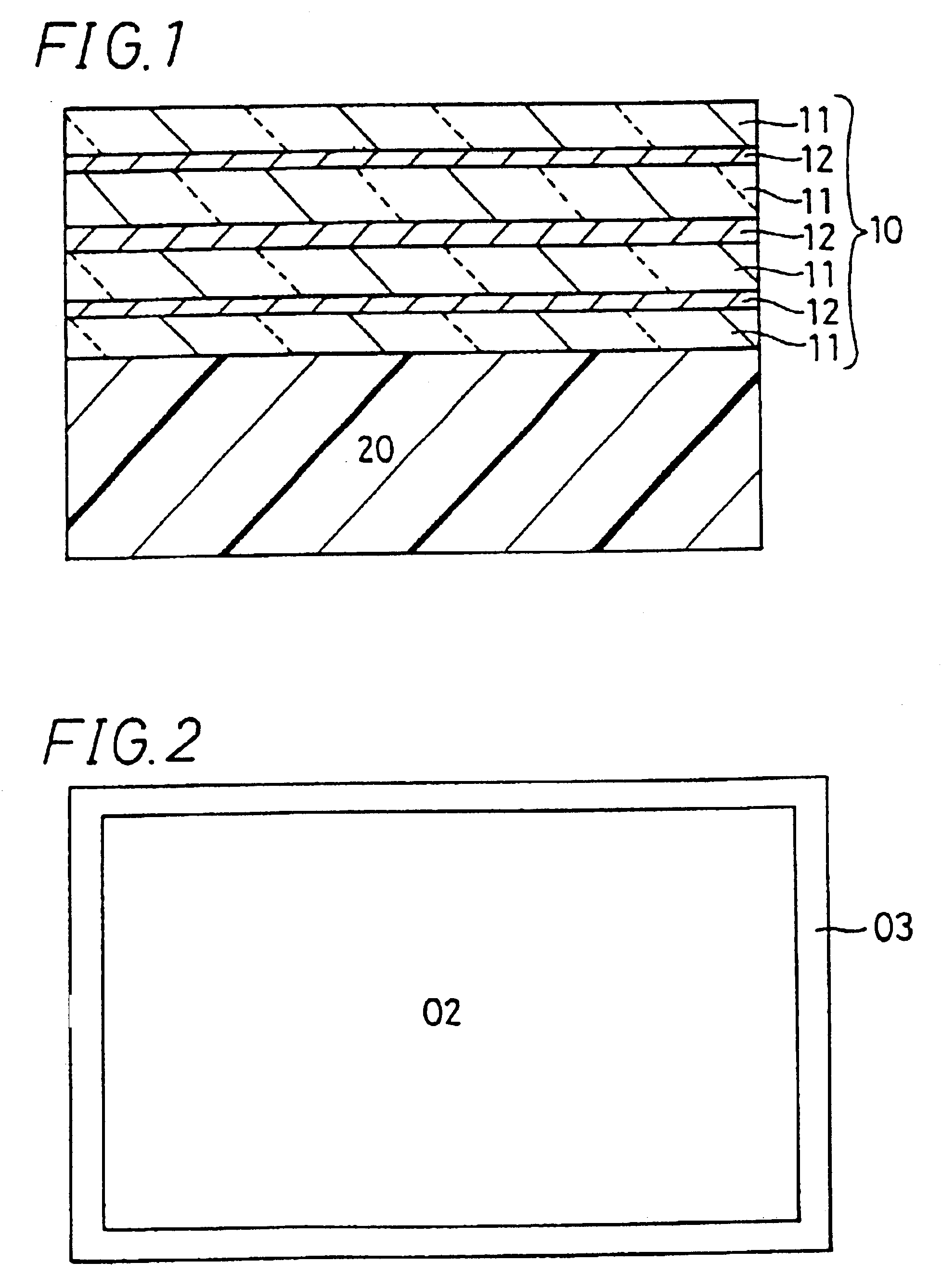

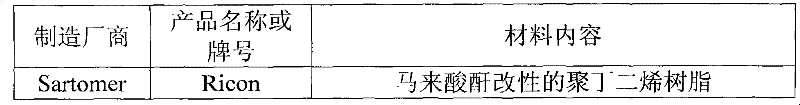

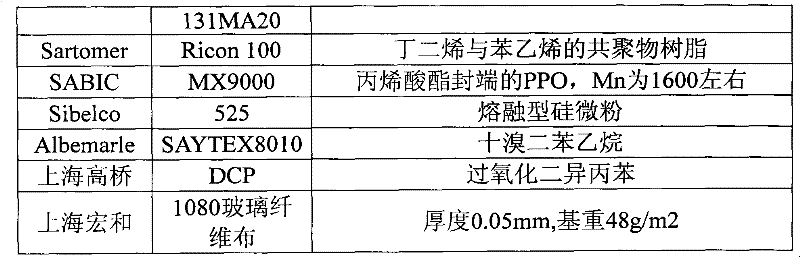

Composite material, high-frequency circuit substrate therefrom and manufacture method thereof

ActiveCN102161823AHigh peel strengthImprove the sticky problemPrinted circuit manufactureCircuit susbtrate materialsDouble bondCopper foil

The invention relates to a composite material, a high-frequency circuit substrate therefrom and a manufacture method thereof. The composite material comprises thermoset mixture, glass fiber cloth, power filler, a fire retardant and a curing initiator, wherein the thermoset mixture comprises more than one kind of vinyl liquid resin and polyphenyl ether resin; the molecular weight of the vinyl liquid resin is below 10000, and the vinyl liquid resin is provided with a polar functional group; the molecular weight of the polyphenyl ether resin is less than 5000, and the molecular tail end of the polyphenyl ether resin is provided with unsaturated double bonds. The high-frequency circuit substrate manufactured with the composite material comprises multiple layers of semi-solidified sheets and copper foils, wherein the semi-solidified sheets are mutually overlaid, and the copper foils are respectively pressed on two sides. The composite material disclosed by the invention causes the semi-solidified sheets to be easily manufactured and have high adhesive bonding force with the copper foils. The high-frequency circuit substrate manufactured by the material has the advantages of low dielectric constant, low dielectric loss angle tangent, good heat resistance and simple technical operation. Thus, the composite material disclosed by the invention is suitable for manufacturing the circuit substrate of the high-frequency electronic equipment.

Owner:GUANGDONG SHENGYI SCI TECH

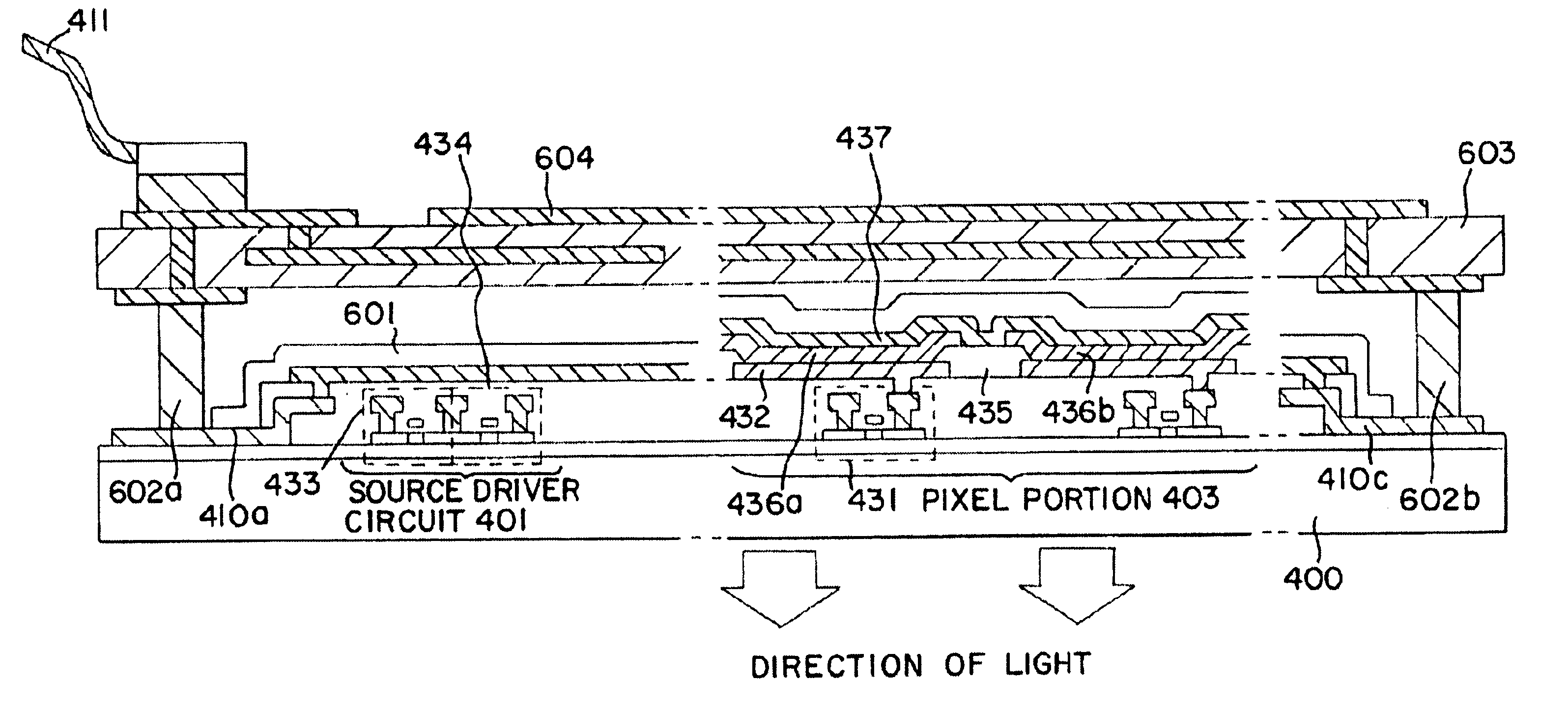

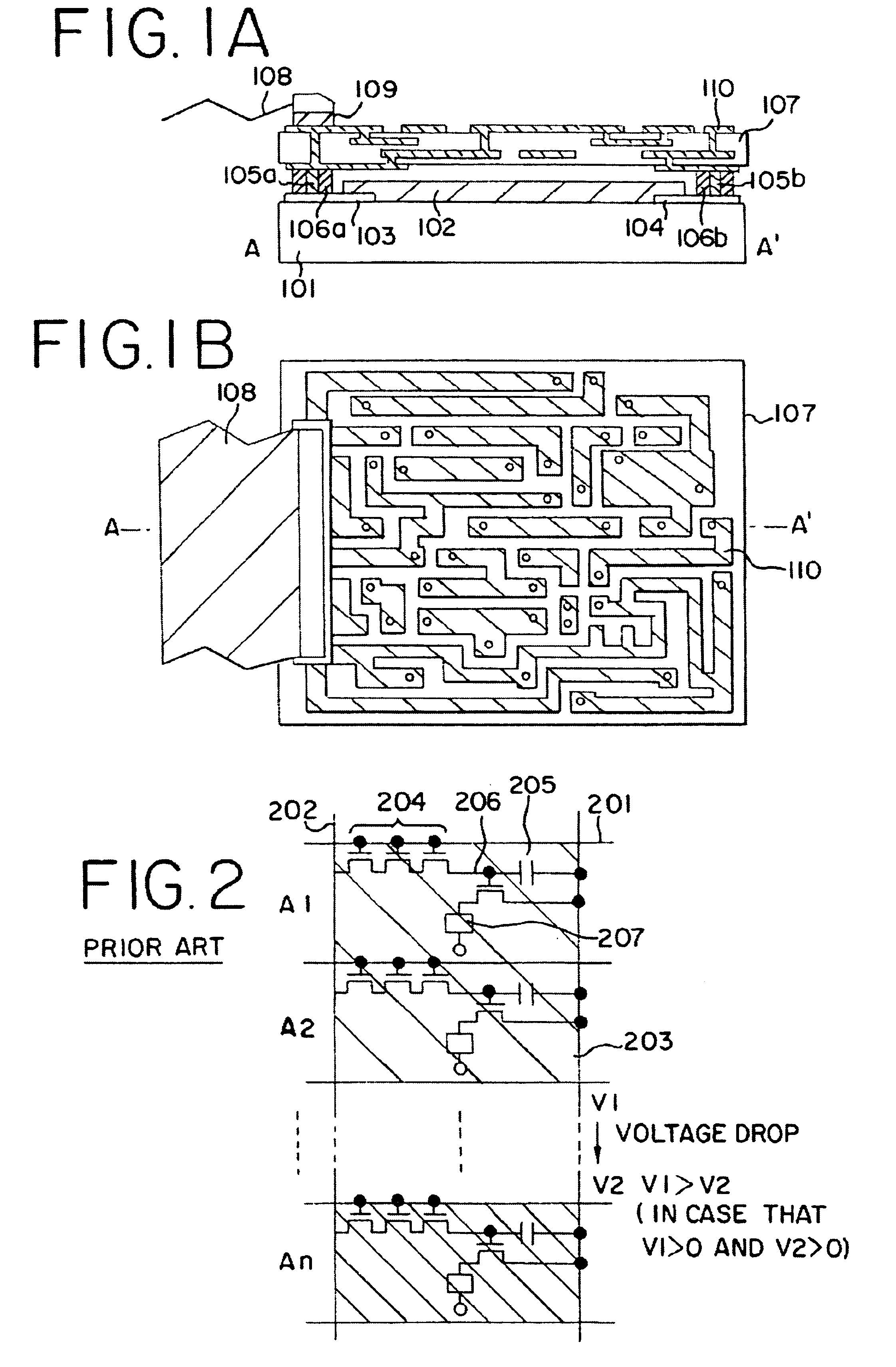

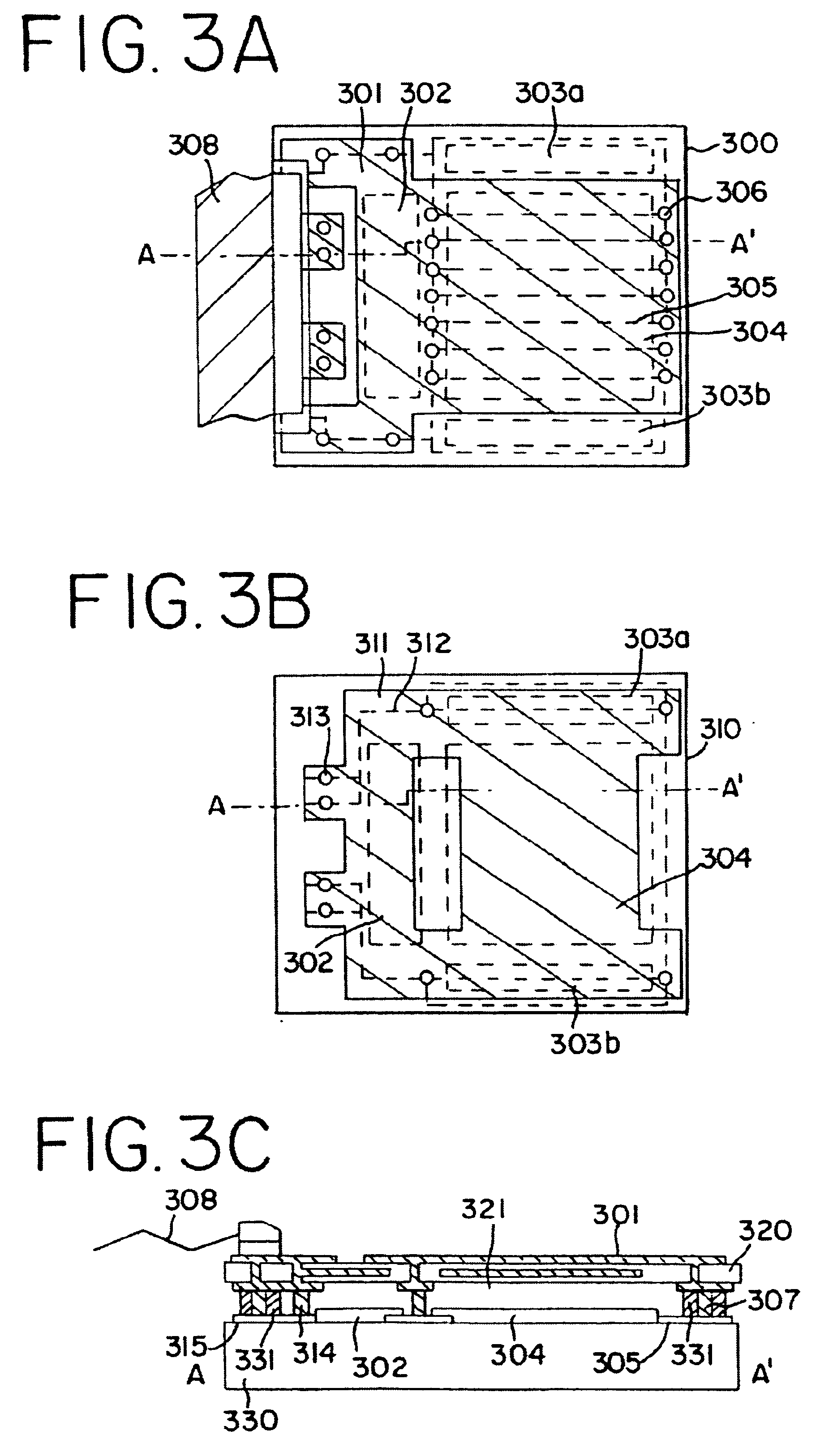

Light-emitting device

InactiveUS6894431B2High speedSuppress delay of wiringTelevision system detailsStatic indicating devicesDriver circuitElectricity

A light-emitting device having the quality of an image high in homogeneity is provided. A printed wiring board (second substrate) (107) is provided facing a substrate (first substrate) (101) that has a luminous element (102) formed thereon. A PWB side wiring (second group of wirings) (110) on the printed wiring board (107) is electrically connected to element side wirings (first group of wirings) (103, 104) by anisotropic conductive films (105a, 105b). At this point, because a low resistant copper foil is used to form the PWB side wiring (110), a voltage drop of the element side wirings (103, 104) and a delay of a signal can be reduced. Accordingly, the homogeneity of the quality of an image is improved, and the operating speed of a driver circuit portion is enhanced.

Owner:SEMICON ENERGY LAB CO LTD

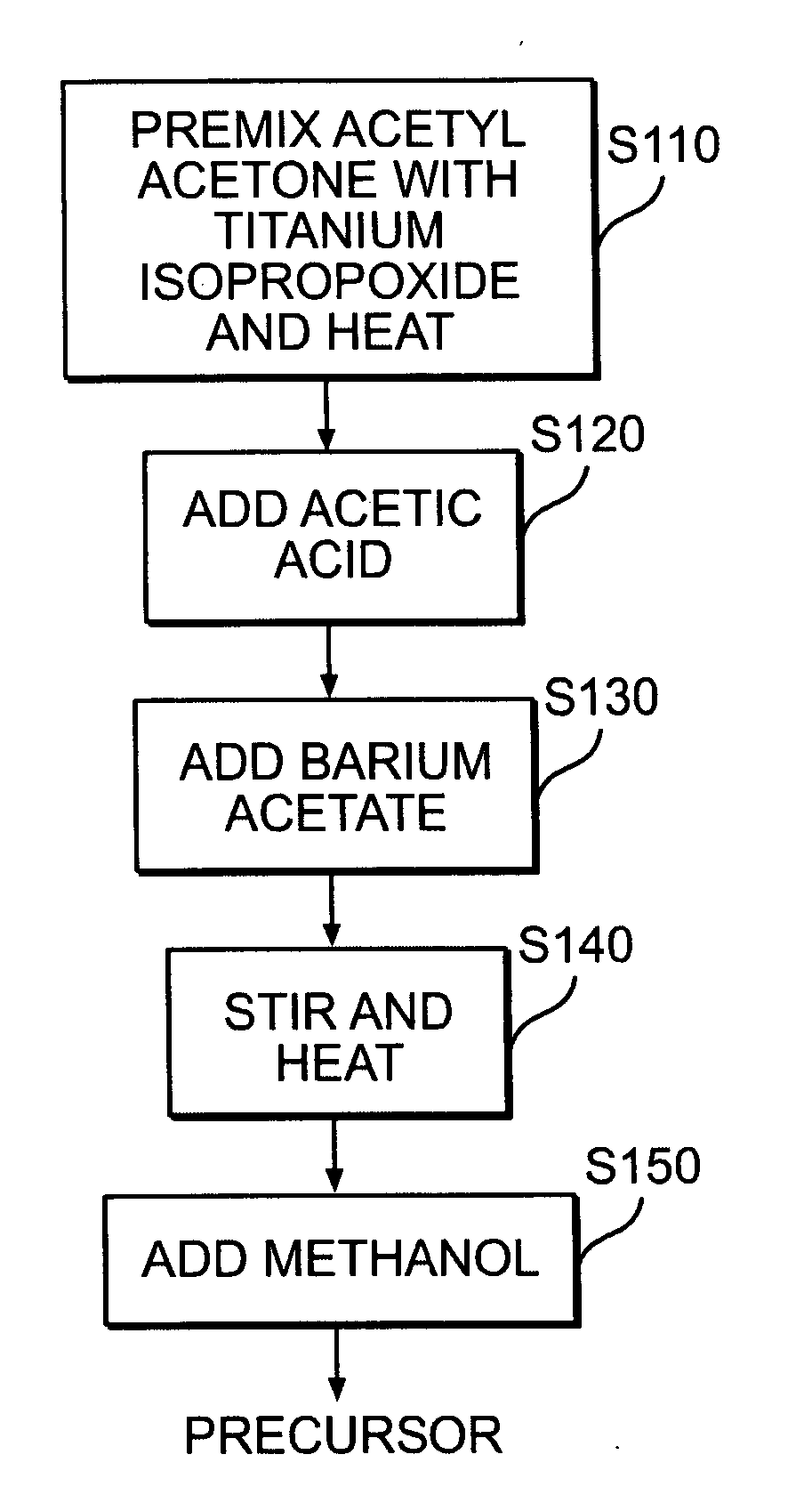

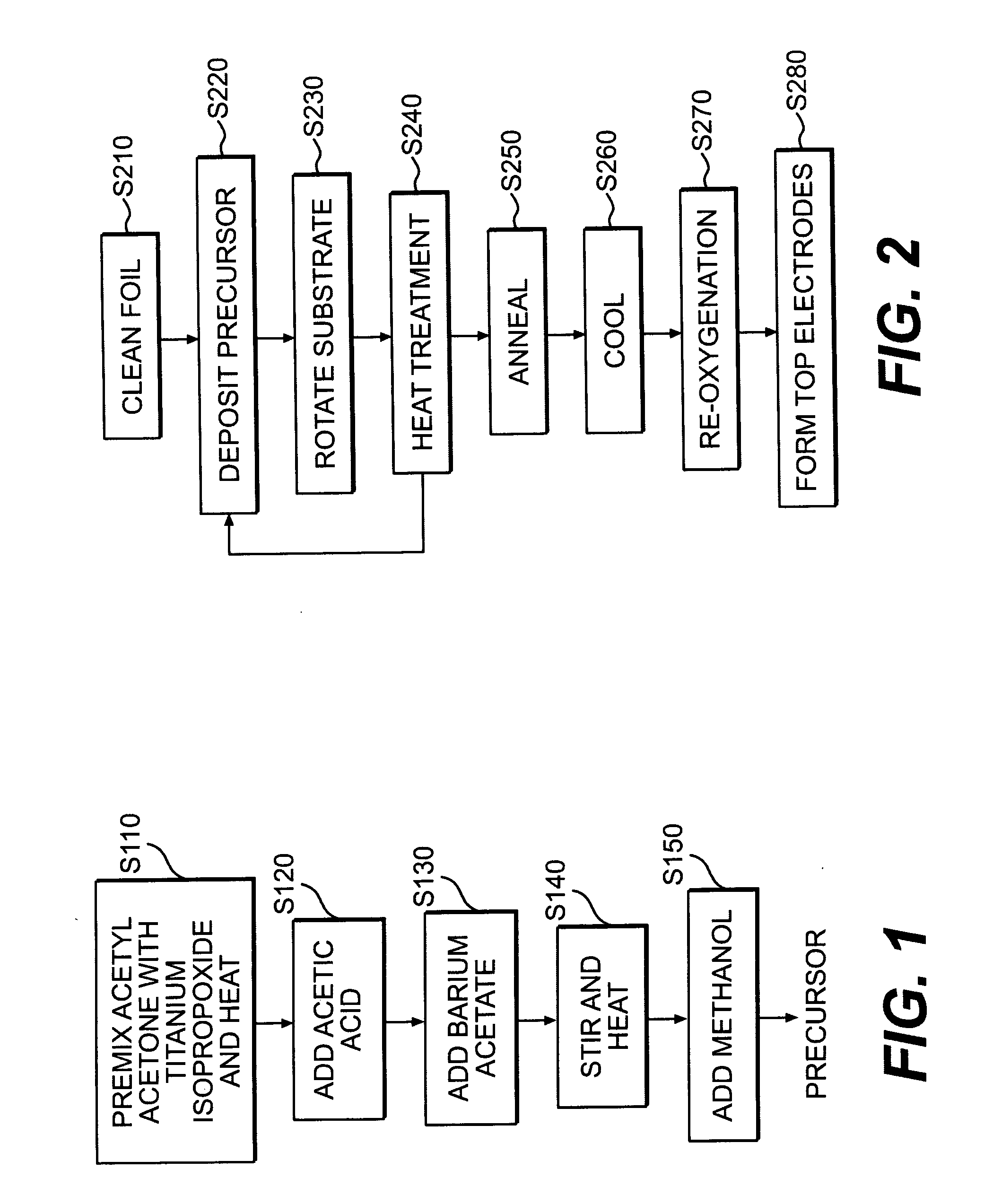

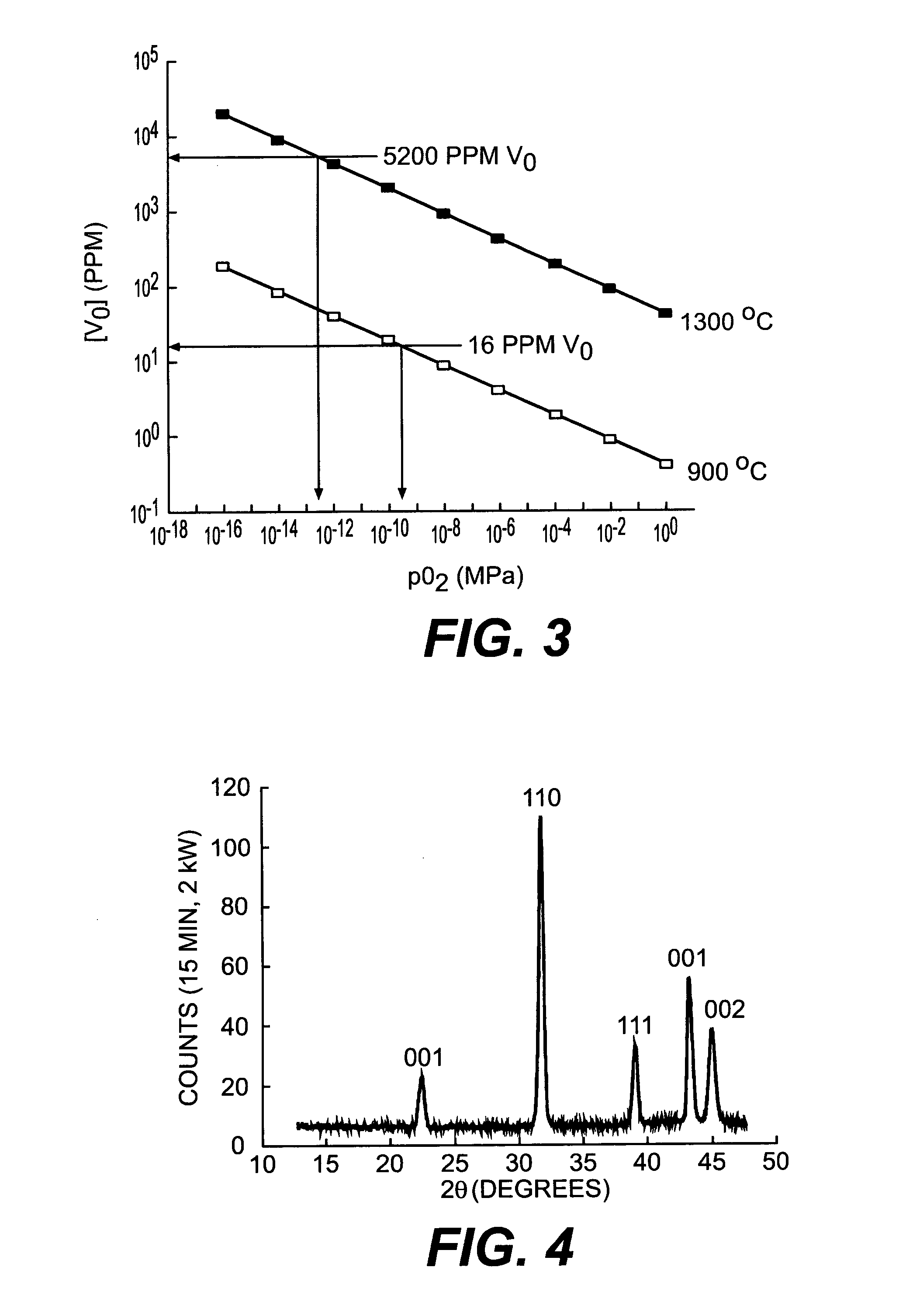

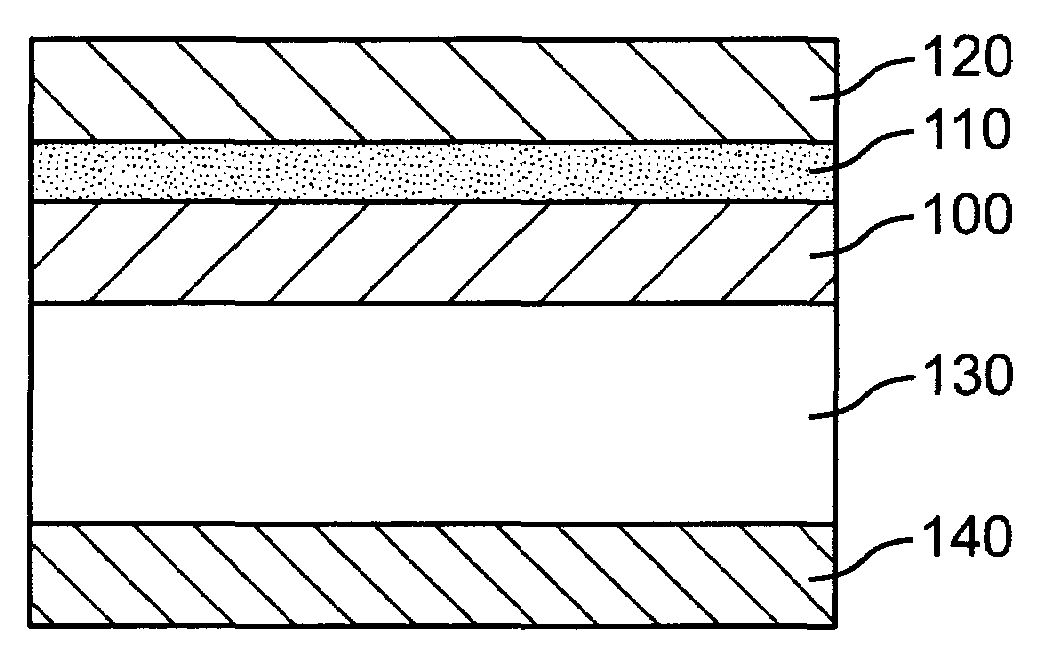

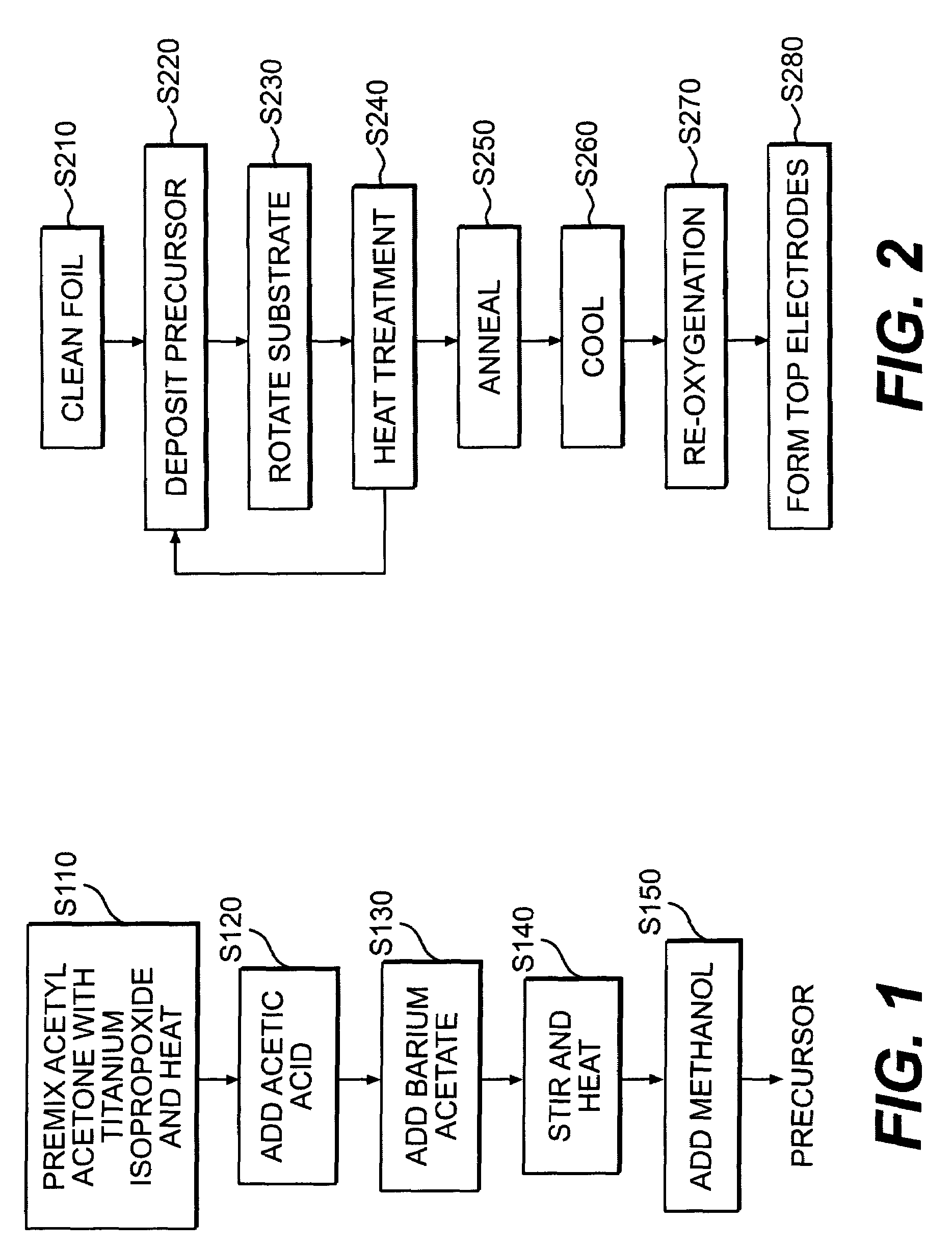

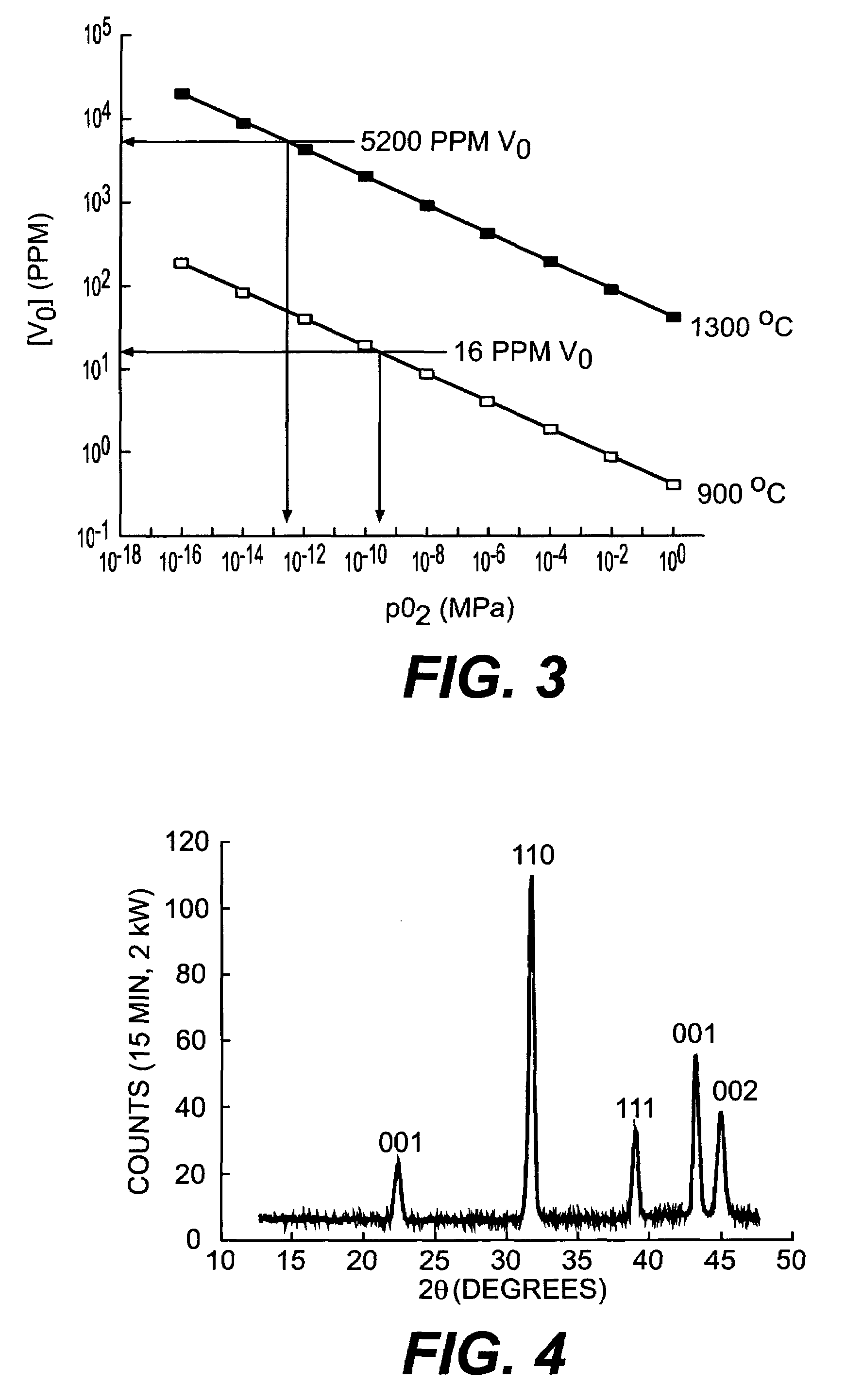

Thin film dielectrics for capacitors and methods of making thereof

ActiveUS20050011857A1Increase capacitance densityLow loss tangentFixed capacitor dielectricPrinted circuit aspectsCopper foilHigh dielectric permittivity

Dielectrics are formed having high dielectric constants, low loss tangents, and other desirable electrical and physical properties. The dielectrics are annealed at temperatures allowing the use of copper foil substrates, and at low oxygen partial pressures.

Owner:NYTELL SOFTWARE LLC

Thin film dielectrics for capacitors and methods of making thereof

ActiveUS7029971B2Increase capacitance densityLow loss tangentFixed capacitor dielectricPrinted circuit aspectsDielectricCopper foil

Dielectrics are formed having high dielectric constants, low loss tangents, and other desirable electrical and physical properties. The dielectrics are annealed at temperatures allowing the use of copper foil substrates, and at low oxygen partial pressures.

Owner:NYTELL SOFTWARE LLC

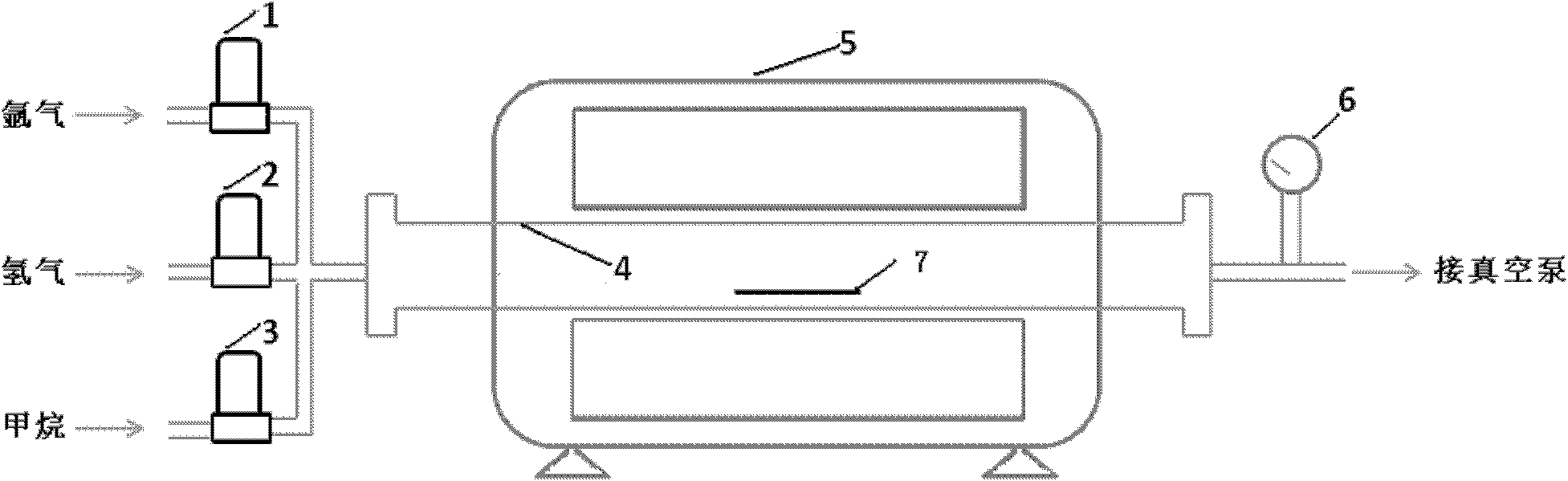

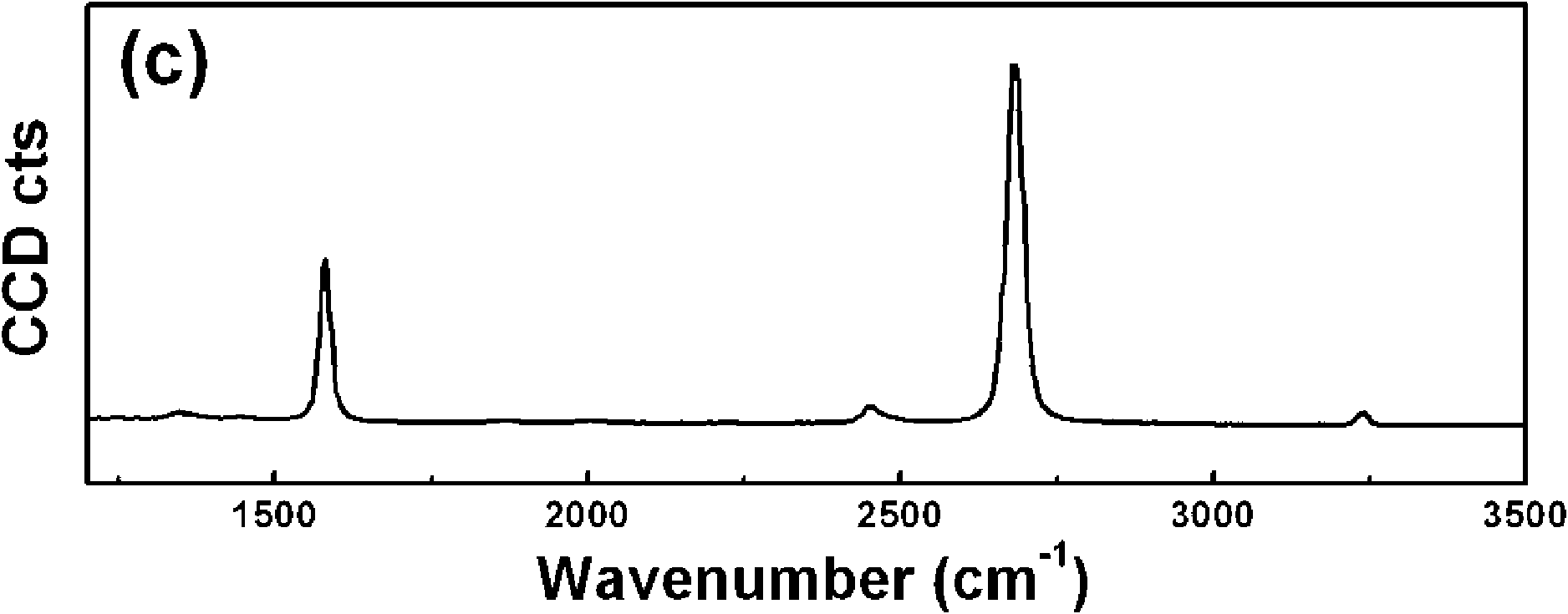

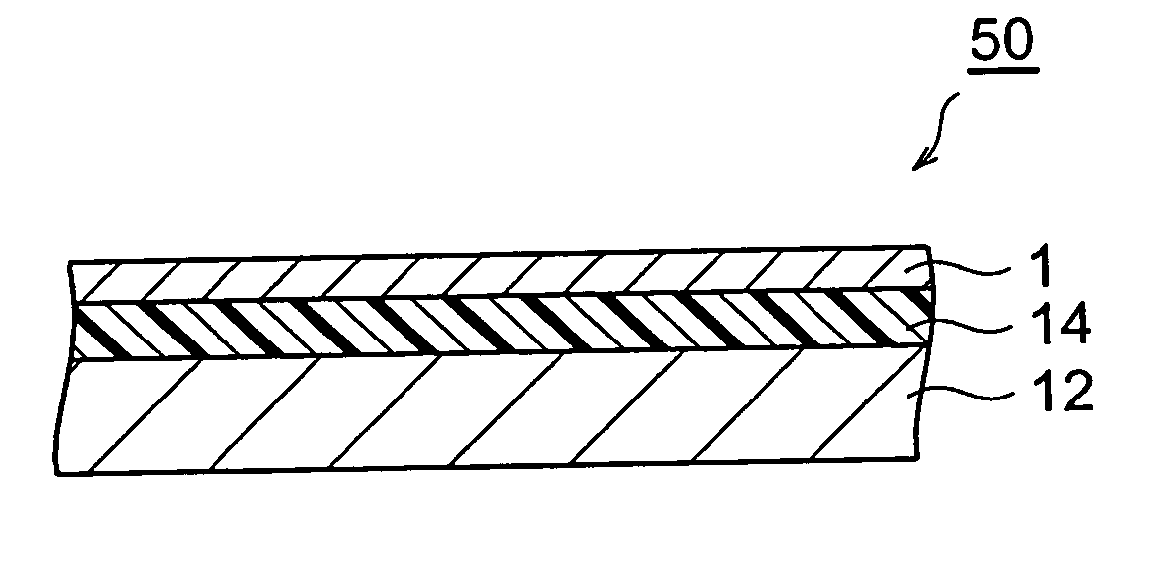

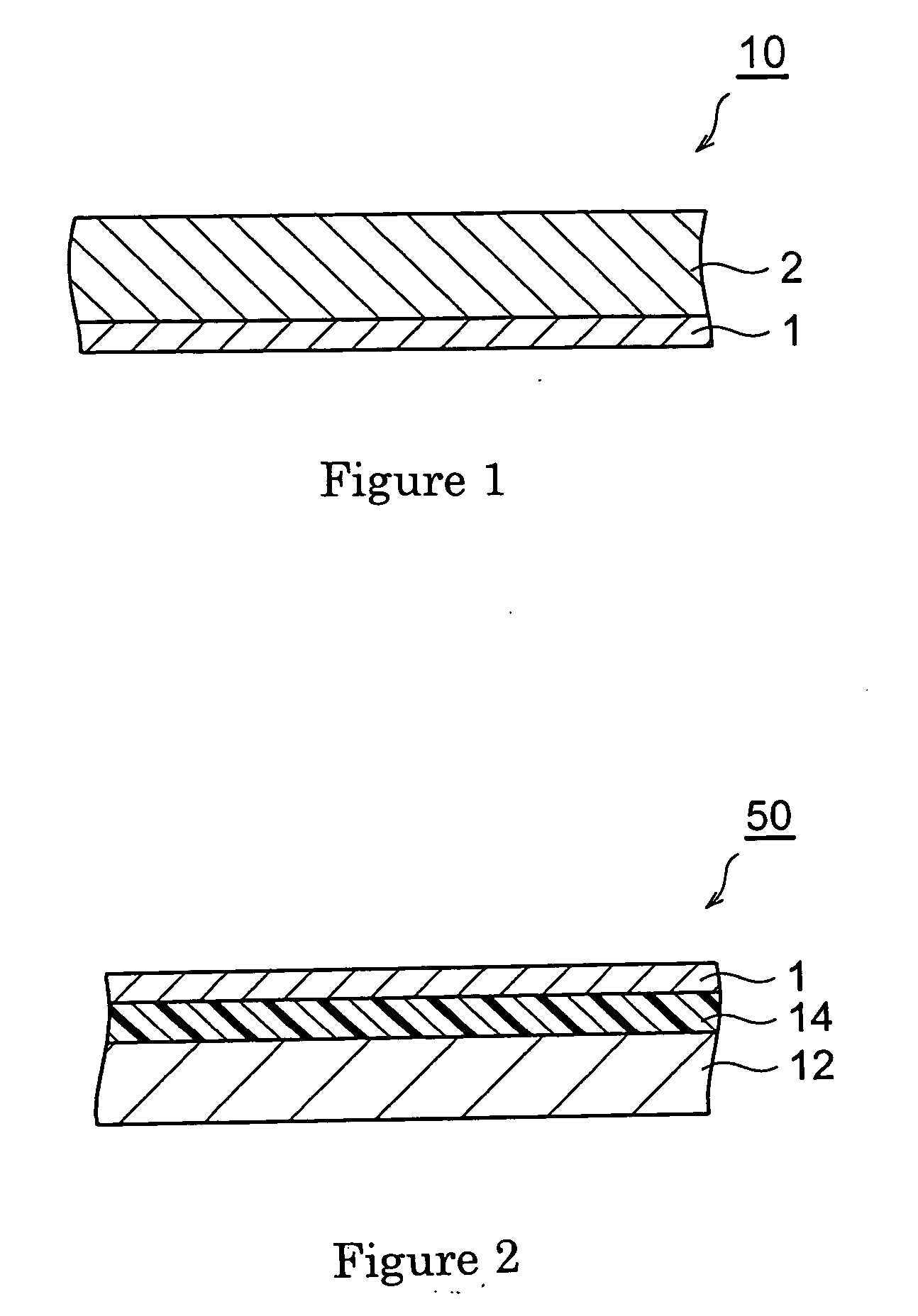

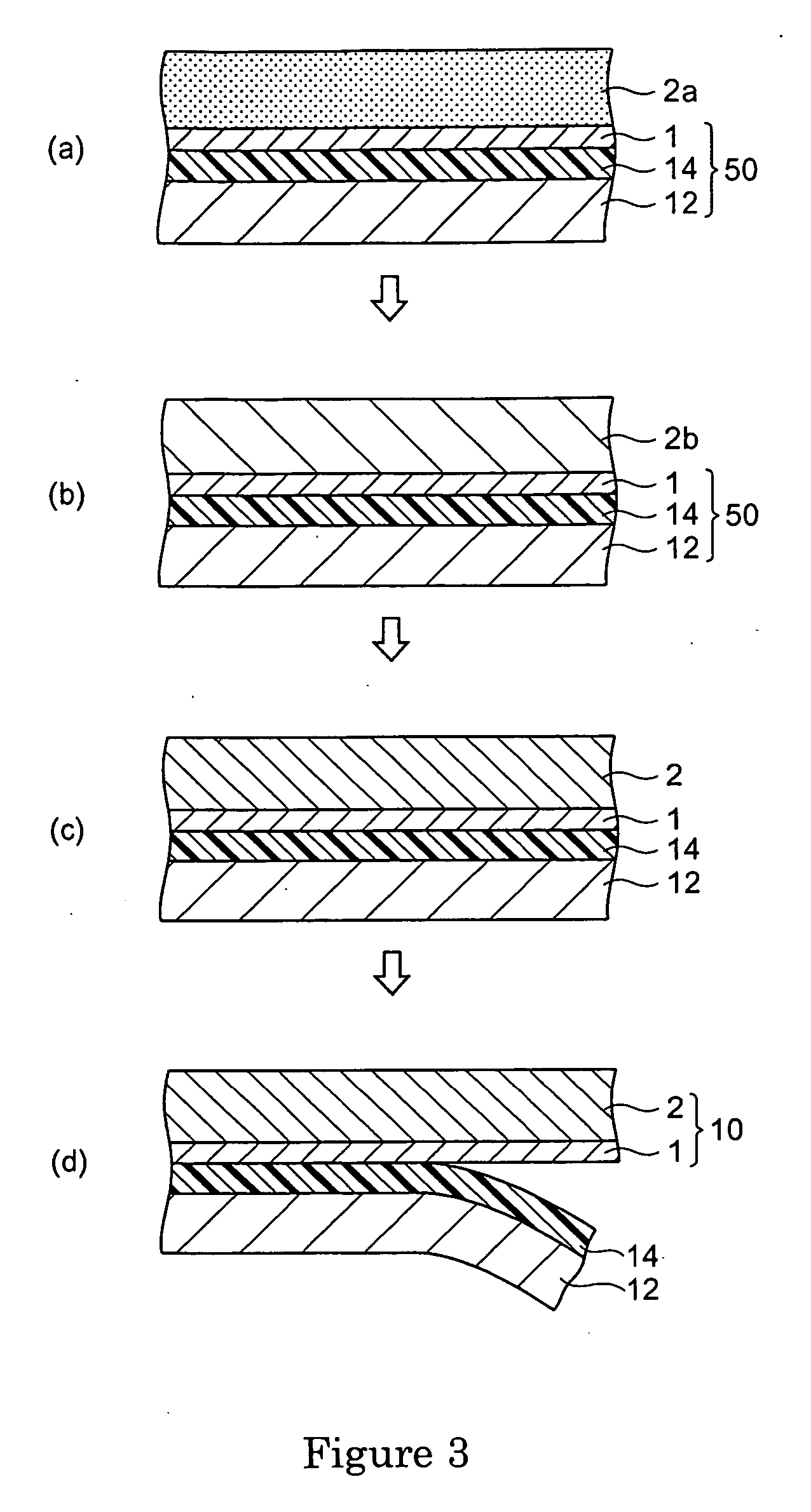

High-quality transfer method of graphene prepared by chemical vapor deposition method

The invention relates to a high-quality transfer method of graphene prepared by a chemical vapor deposition method. The method comprises the following steps: a, spinning a polymethylmethacrylate (PMMA) thin layer having even thickness on the surface of graphene prepared on a copper foil substrate with the chemical vapor deposition method; b, dissolving the copper foil; c, laminating; and d, and removing PMMA. By using the method provided by the invention, graphene can be stably, reliably and high-quality transferred, and the impurities in graphene are less, thereby ensuring the completeness and good property of prepared graphene not to be damaged and meeting the requirement of researching and applying graphene. After the method provided by the invention is adopted, complete and less-impurity-containing graphene can be stably, reliably and high-quality transferred, and thus a reliable guarantee for representation, research and application of graphene is provided.

Owner:SOUTHEAST UNIV

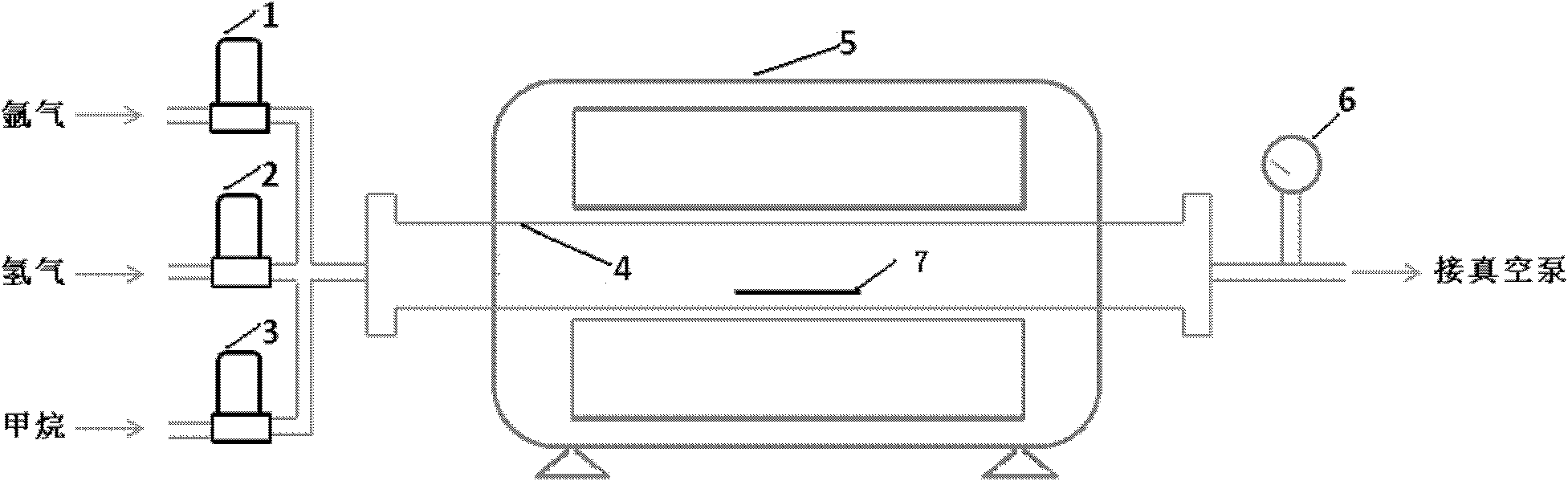

Method for preparing single-layer or multi-layer graphene through chemical vapor deposition

InactiveCN102220566ADefect peak lowImprove crystal qualityMaterial nanotechnologySingle layer grapheneGas phaseCopper foil

The invention discloses a method for preparing single-layer or multi-layer graphene through chemical vapor deposition, and relates to a method for preparing a graphene material. The method comprises the following steps of: placing a metal substrate in a vacuum tubular furnace or a vacuum atmosphere furnace; injecting hydrogen into a vacuum cavity under the situation of removing the oxygen in the vacuum cavity; heating to 800-1,100 DEG C; and injecting a carbon source gas into the vacuum cavity to obtain the metal substrate for depositing graphene. According to the method disclosed by the invention, a graphene film is deposited by cracking methane or other carbon source gases on the metal substrate (such as a copper foil or a nickel foil and the like) at a high temperature by using the chemical vapor deposition method; and therefore, the invention provides a method for preparing the single-layer or multi-layer graphene with an ultra-large area.

Owner:无锡第六元素高科技发展有限公司

Substrate for flexible wiring and method for producing the same

InactiveUS20070077416A1Low water absorptionLayer be enoughPretreated surfacesGlass/slag layered productsPolyesterLiquid crystalline

The present invention provides a substrate for flexible wiring comprises a liquid crystalline polyester layer and a copper foil with a thickness of 5 μm or less. The substrate has a large adhesion between the resin layer and the copper foil, and is sufficient in water absorbing property and electrical properties.

Owner:SUMITOMO CHEM CO LTD

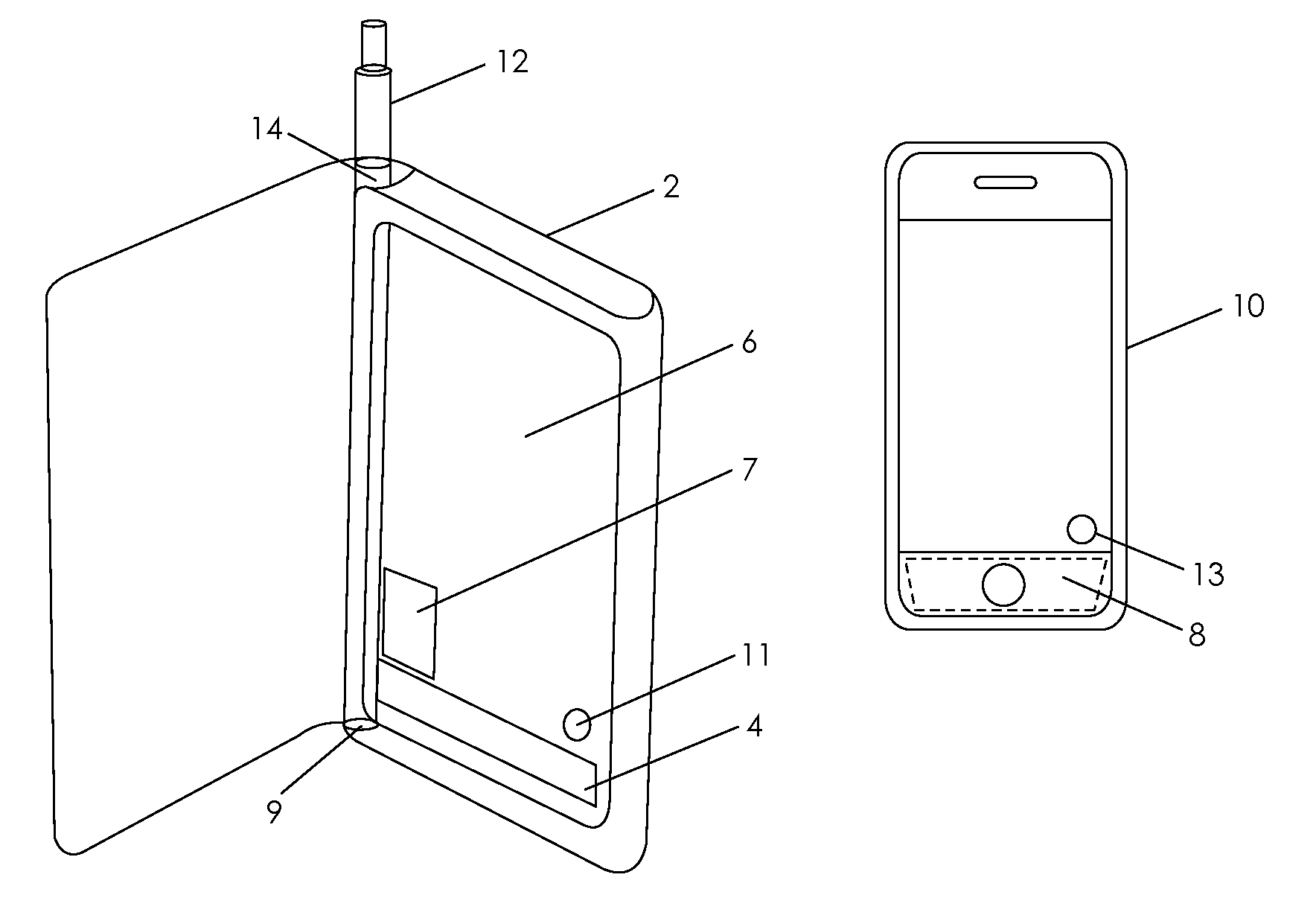

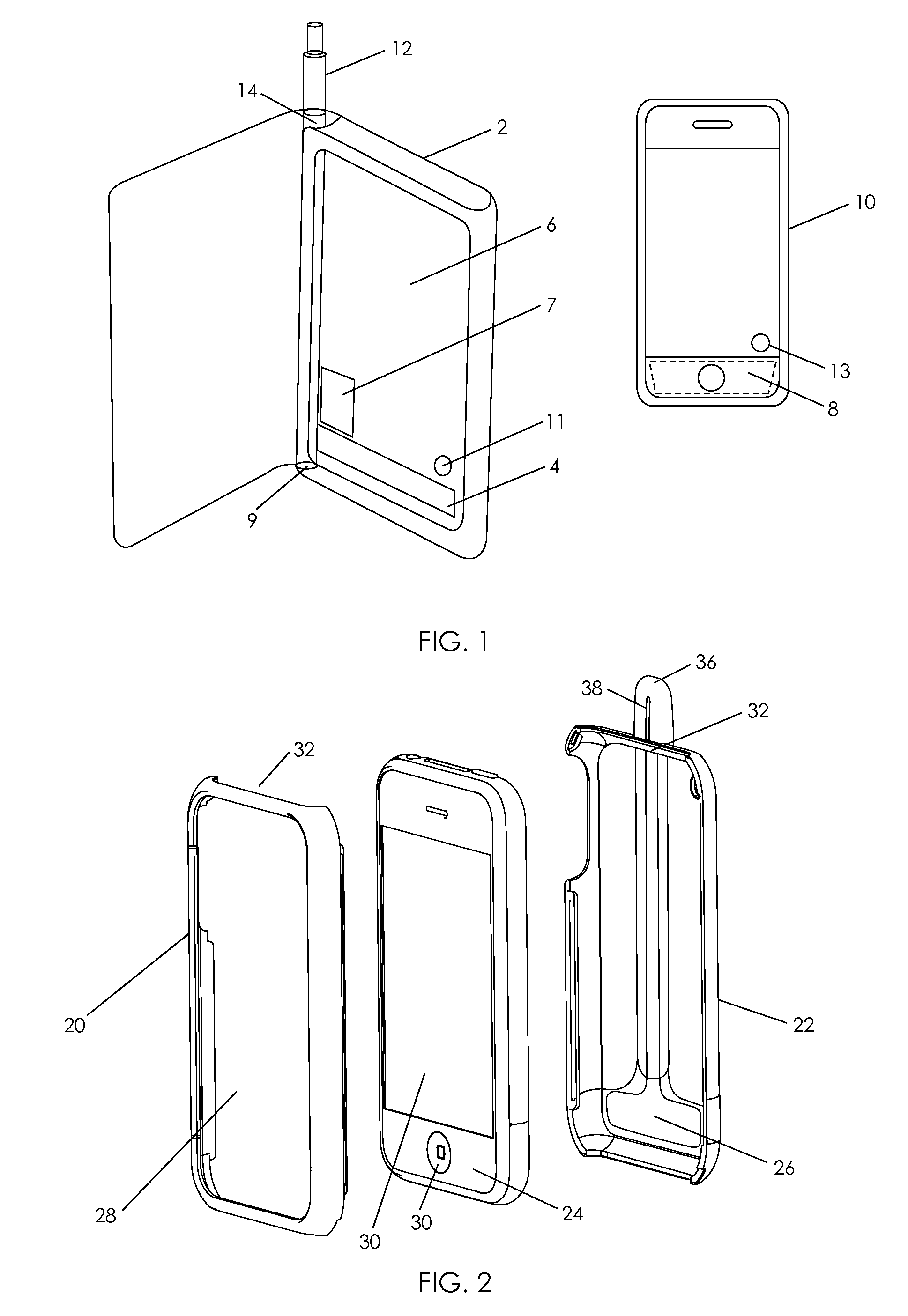

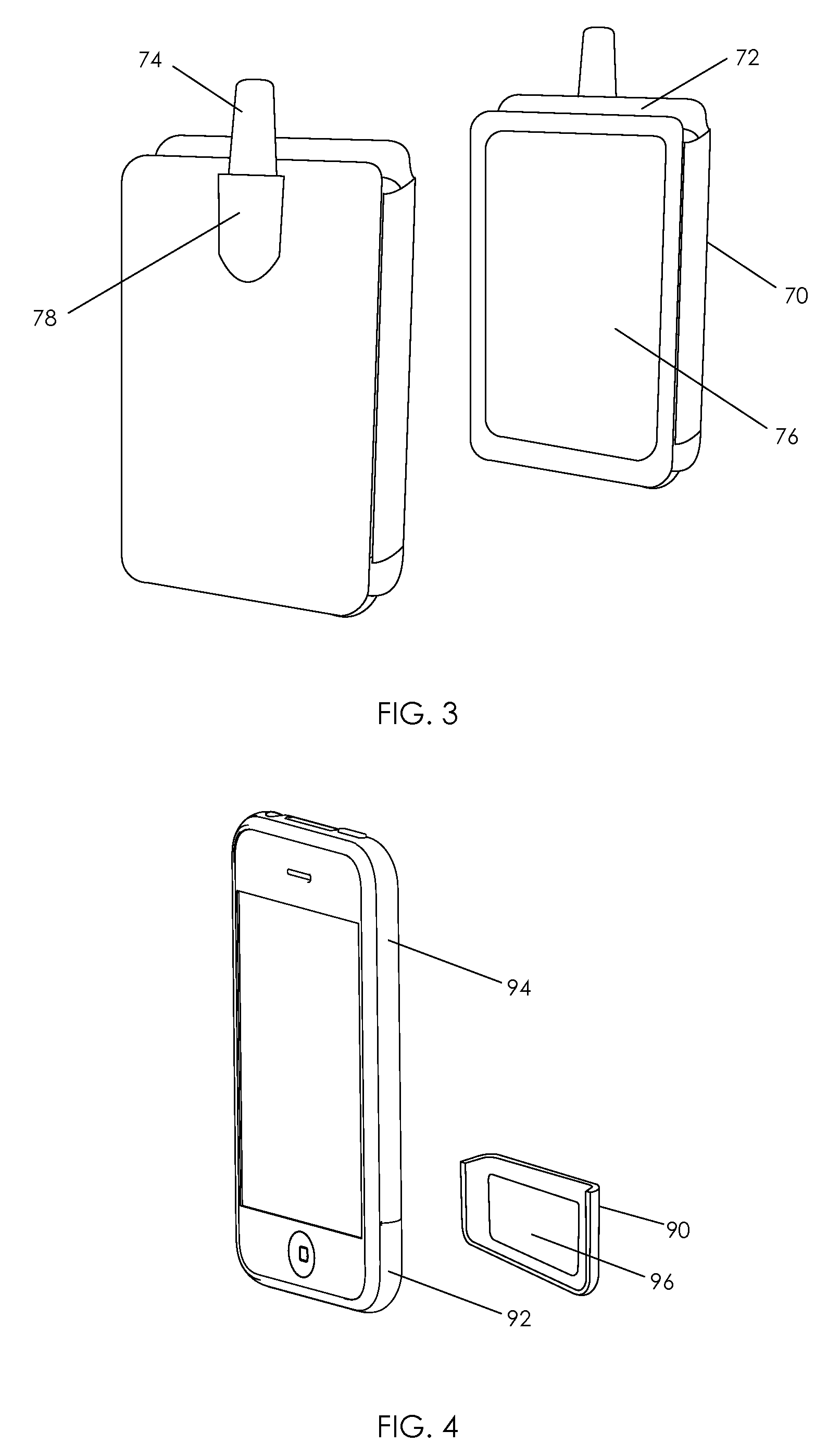

Reception Boosting Accessory

InactiveUS20090181735A1Easy to receiveEnhanced signalSubstation equipmentAntenna detailsAudio power amplifierCoupling

A carrying case for a portable electronic device includes a coupling element that couples to an antenna of the device without establishing a direct electrical connection. The coupling element increases the reception of the device by increasing the effective size of the antenna. The coupling element is designed to correspond to the reception capabilities of the device for which the case is designed. Preferably, the coupling element is a copper foil that is positioned in the case such that it is adjacent the antenna of the device when the device is held within the case. The copper foil is shaped to correspond to a profile of the device. An antenna and signal amplifier can be used in connection with the coupling element to further boost the device's reception capability.

Owner:VINCI BRANDS LLC

High-performance lithium ion battery and preparation process thereof

InactiveCN102347475AImprove electronic conductivityImprove charge and discharge performanceCell electrodesSecondary cellsAluminium foilCopper foil

The invention relates to a high-performance lithium ion battery. According to the battery, an electrode material is subjected to a nano-composite treatment of grapheme and polyaniline; an anode current collector comprises aluminium foil; a cathode current collector comprises copper foil; a conductive agent comprises superconducting carbon black, conductive graphite or acetylene black; a binding agent comprises styrene butadiene rubber, carboxymethylcellulose sodium, polytetrafluoroethylene, polyvinylidene difluoride or hydroxy propyl methylcellulose; a electrolyte comprises liquid electrolyte or a polymer electrolyte containing a conductive polymer, a nano-material, or a mixture comprising the conductive polymer and the nano-material; a membrane is subjected to a high temperature resistant insulation coating treatment, or directly adopts a high temperature resistant insulating porous polymer matrix. A preparation process for the high-performance lithium ion battery comprises: material preparing, coating, drying, rolling, slicing, coil winding or sheet stacking, assembling, liquid injecting, formation and capacity distributing. The lithium ion battery provided by the present invention has characteristics of excellent charge and discharge performance at the large rate, small capacity fading, good heat stability, good safety performance and long electrode cycle life, and can be widely applicable for the fields of electric bicycles, electric motorcycles, electric cars and the like.

Owner:LUNAN RES INST OF COAL CHEM

Noise-suppressing wiring-member and printed wiring board

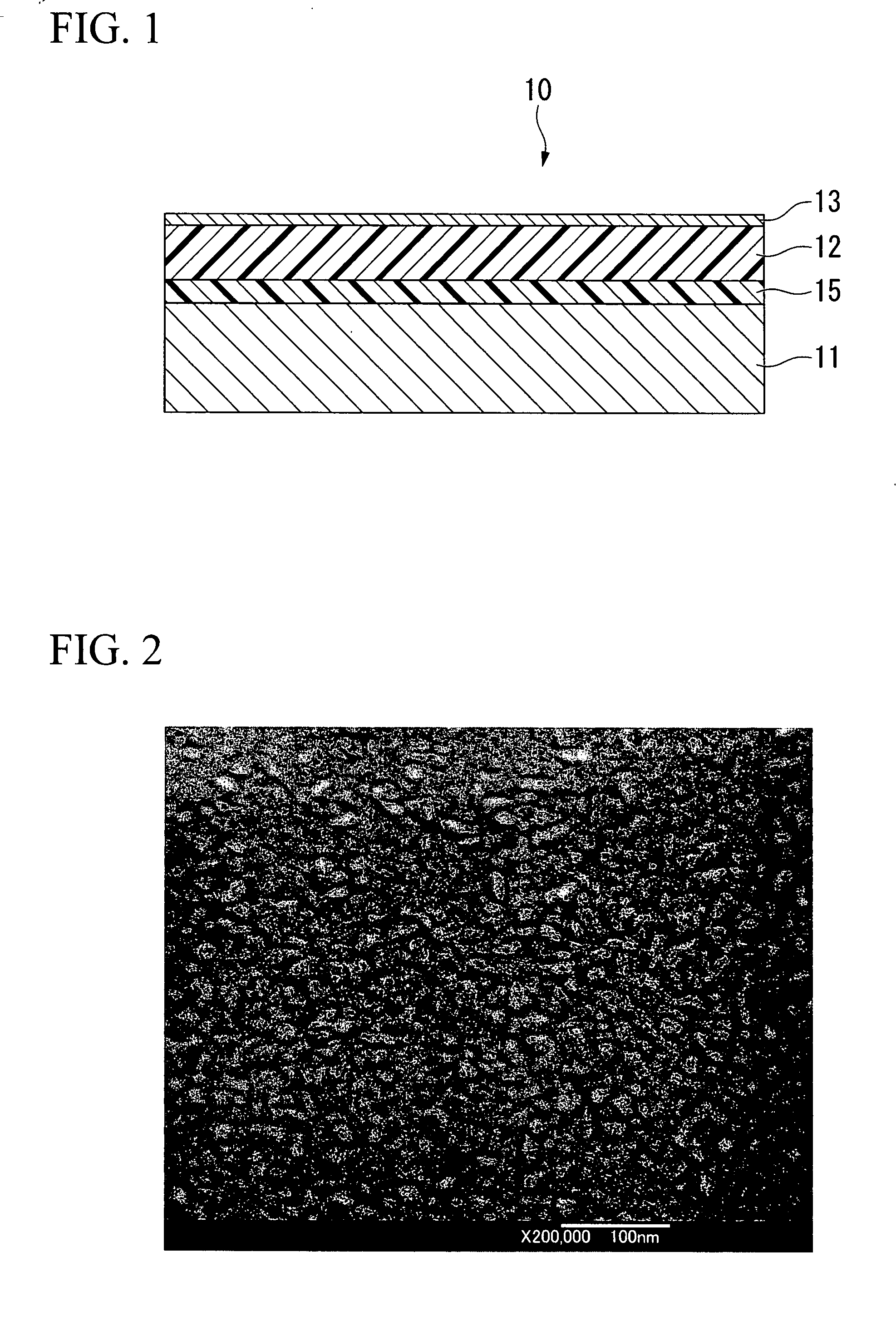

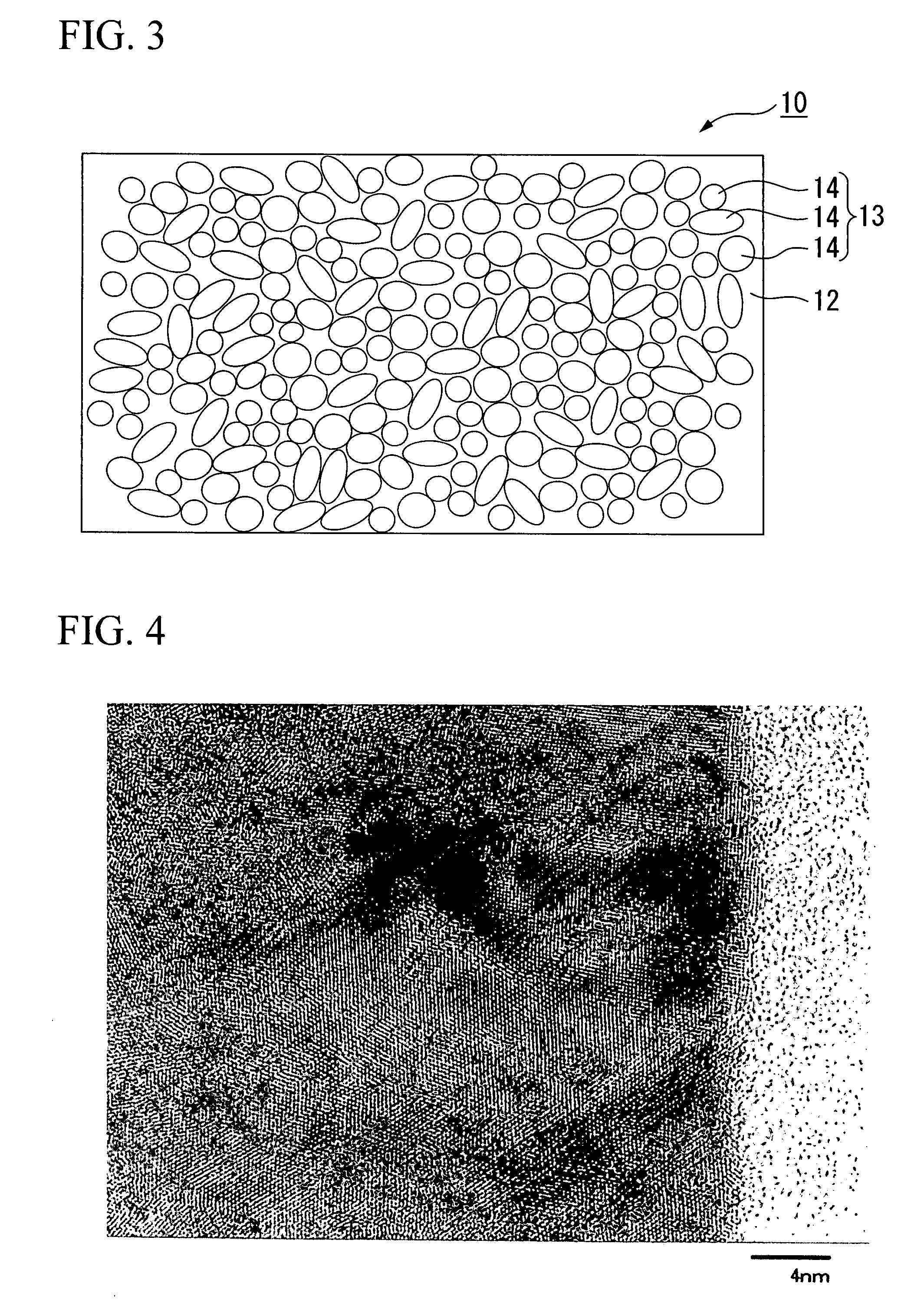

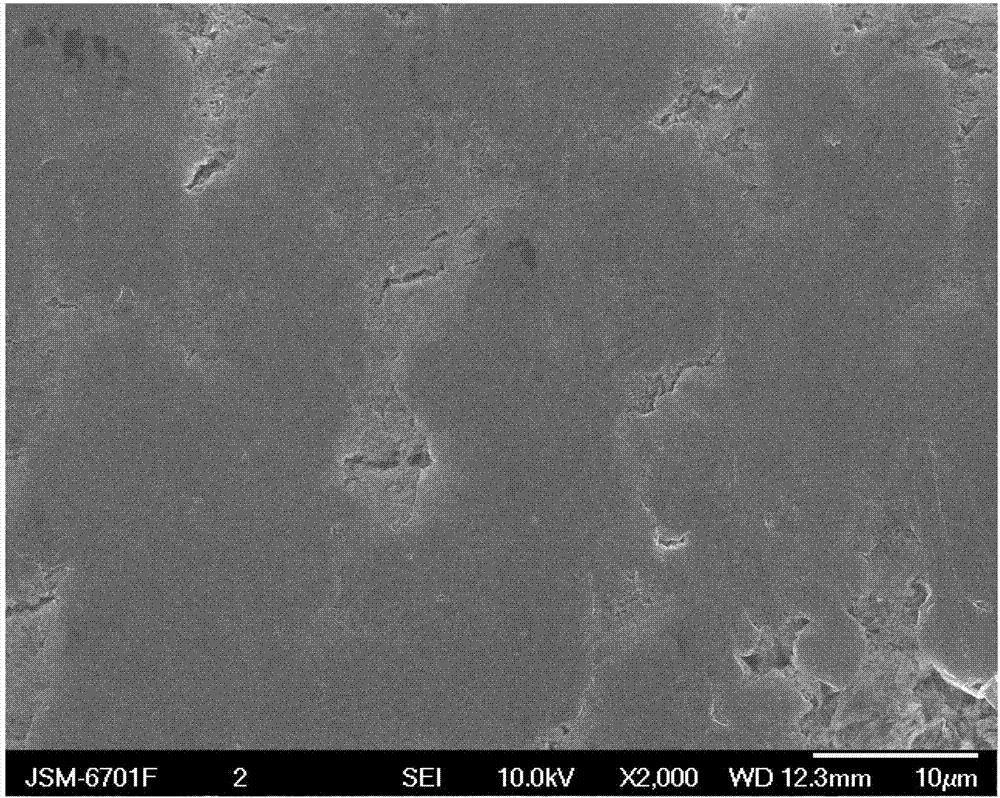

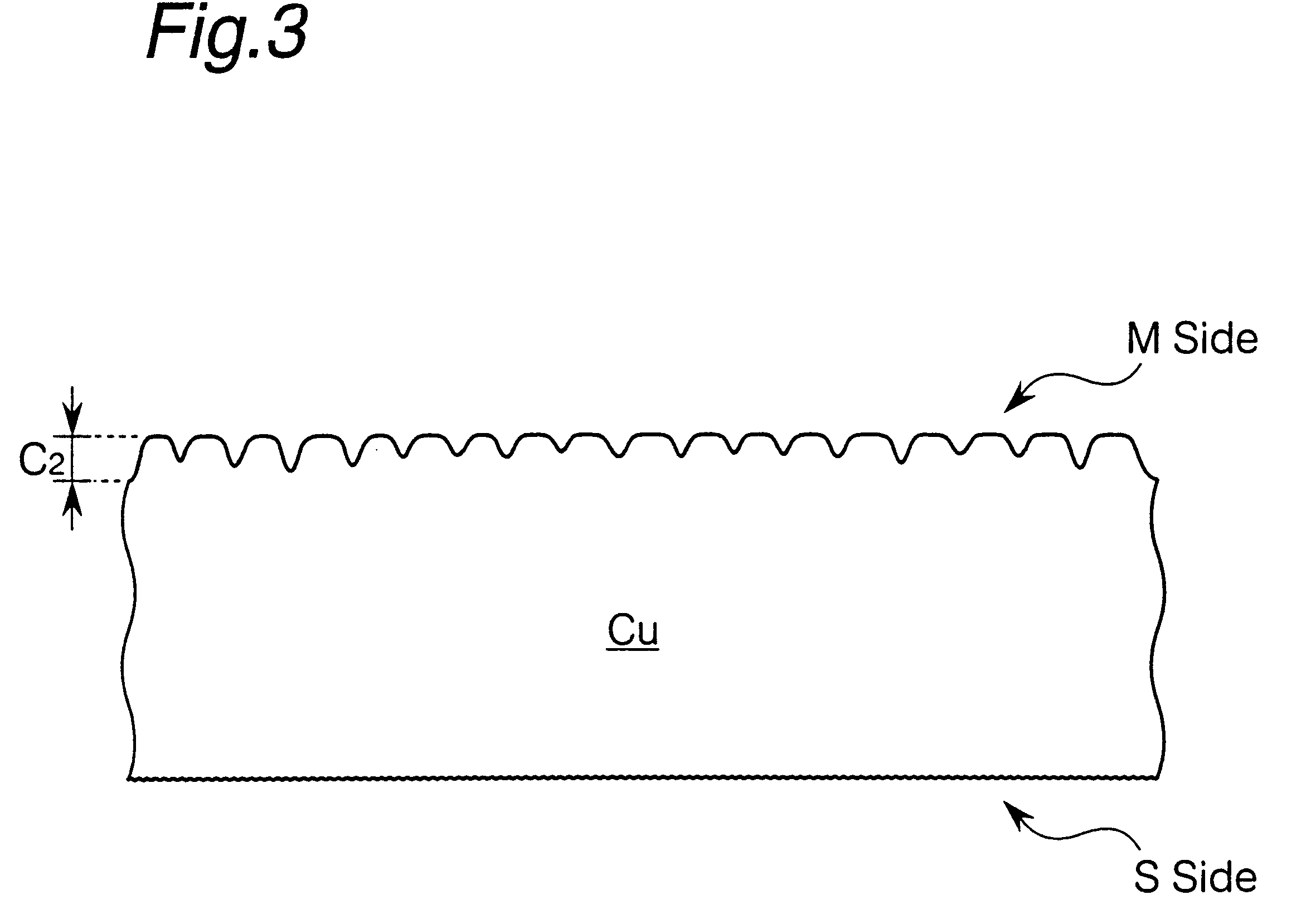

ActiveUS20080049410A1Reduce the amount requiredMagnetic/electric field screeningCross-talk/noise/interference reductionMetallic materialsSurface roughness

The present invention relates to a wiring member including: a copper foil layer having a smooth surface with a surface roughness Rz of 2 μm or less; a noise suppressing layer containing a metallic material or a conductive ceramic and having a thickness of 5 to 200 nm; and an insulating resin layer provided between the smooth surface of the copper foil layer and the noise suppressing layer, and also relates to a printed wiring board equipped with the wiring member. Moreover, the present invention relates to a noise suppressing structure including: a first conductive layer; a second conductive layer; a noise suppressing layer provided between the first conductive layer and the second conductive layer, the noise suppressing layer being to be electromagnetically-coupled with the first conductive layer, the noise suppressing layer comprising a metallic material or a conductive ceramic, and the noise suppressing layer having a thickness of 5 to 300 nm; a first insulating layer provided between the first conductive layer and the noise suppressing layer; and a second insulating layer provided between the second conductive layer and the noise suppressing layer; wherein the noise suppressing structure has: a region (I) in which the noise suppressing layer and the first conductive layer face each other; and a region (II) in which the noise suppressing layer and the first conductive layer do not face each other but the noise suppressing layer and the second conductive layer face each other, the regions (I) and (II) neighboring each other.

Owner:SHIN-ETSU POLYMER CO LTD

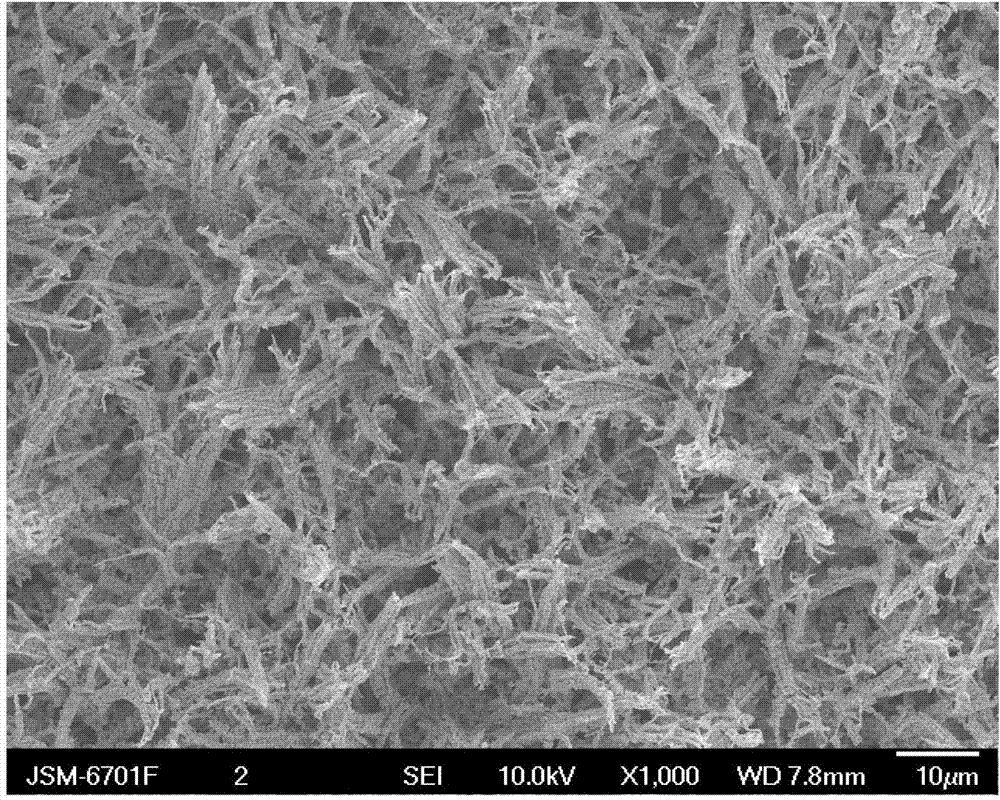

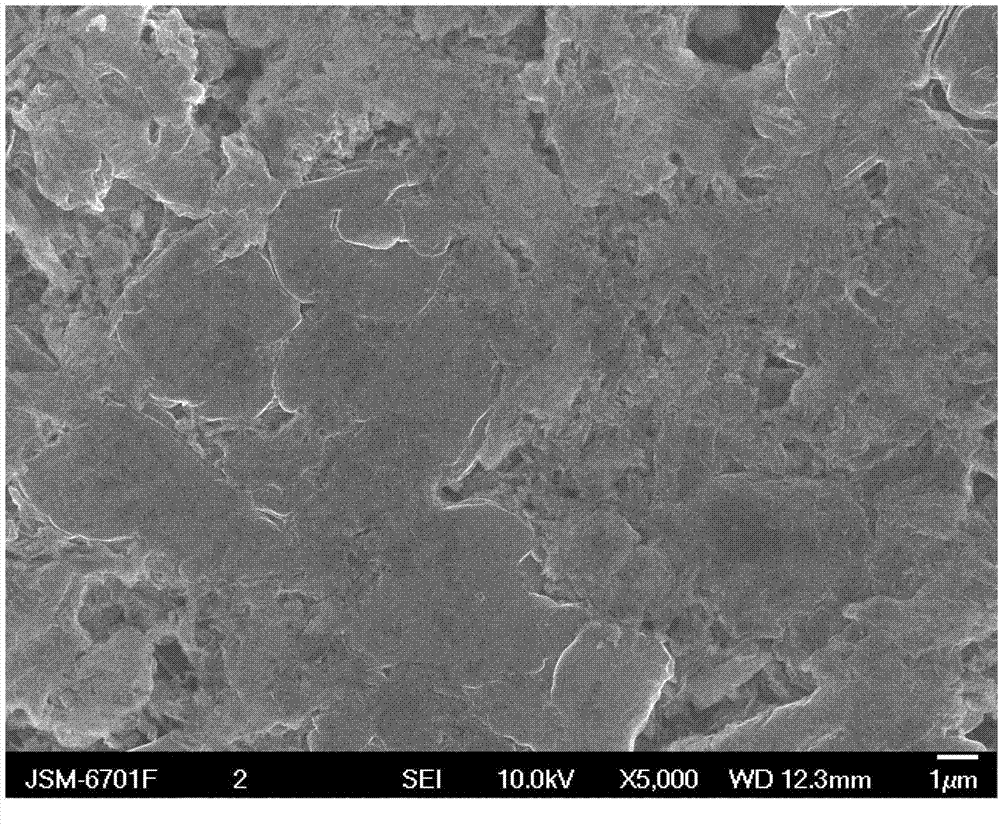

Three-dimensional porous current collector as well as preparation method and use thereof

ActiveCN104716330AFull pore volumeImprove cycle lifeElectrode manufacturing processesElectrode carriers/collectorsCopper foilMetal

The invention discloses a three-dimensional porous current collector which is used as a negative current collector of a metal secondary battery. At least one surface of the three-dimensional porous current collector is provided with a porous structure, sufficient in pore volume and moderate in thickness. Compared with a flat current collector, a metal negative electrode loaded on the three-dimensional porous current collector can be used for effectively restraining the formation of dendritic crystals, so that the safety of the metal negative electrode is improved, the cycle life of the metal negative electrode is long, and the voltage polarization of the metal negative electrode is small. The three-dimensional porous current collector can be prepared from a flat copper foil, and can be prepared through simple steps. The method for preparing the three-dimensional porous current collector is simple, suitable for large-scale production and very high in practicability, and the raw materials are easily available.

Owner:INST OF CHEM CHINESE ACAD OF SCI

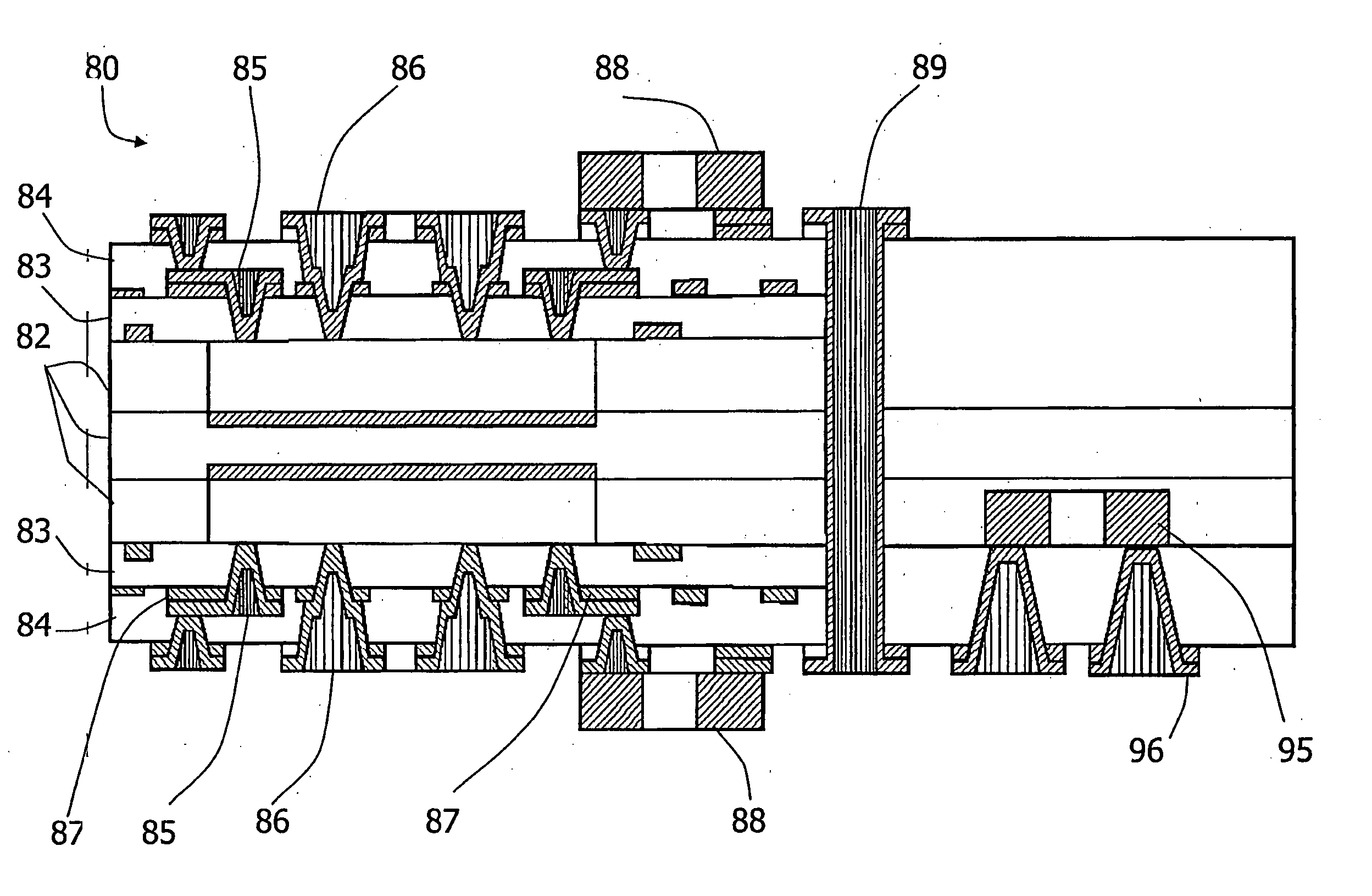

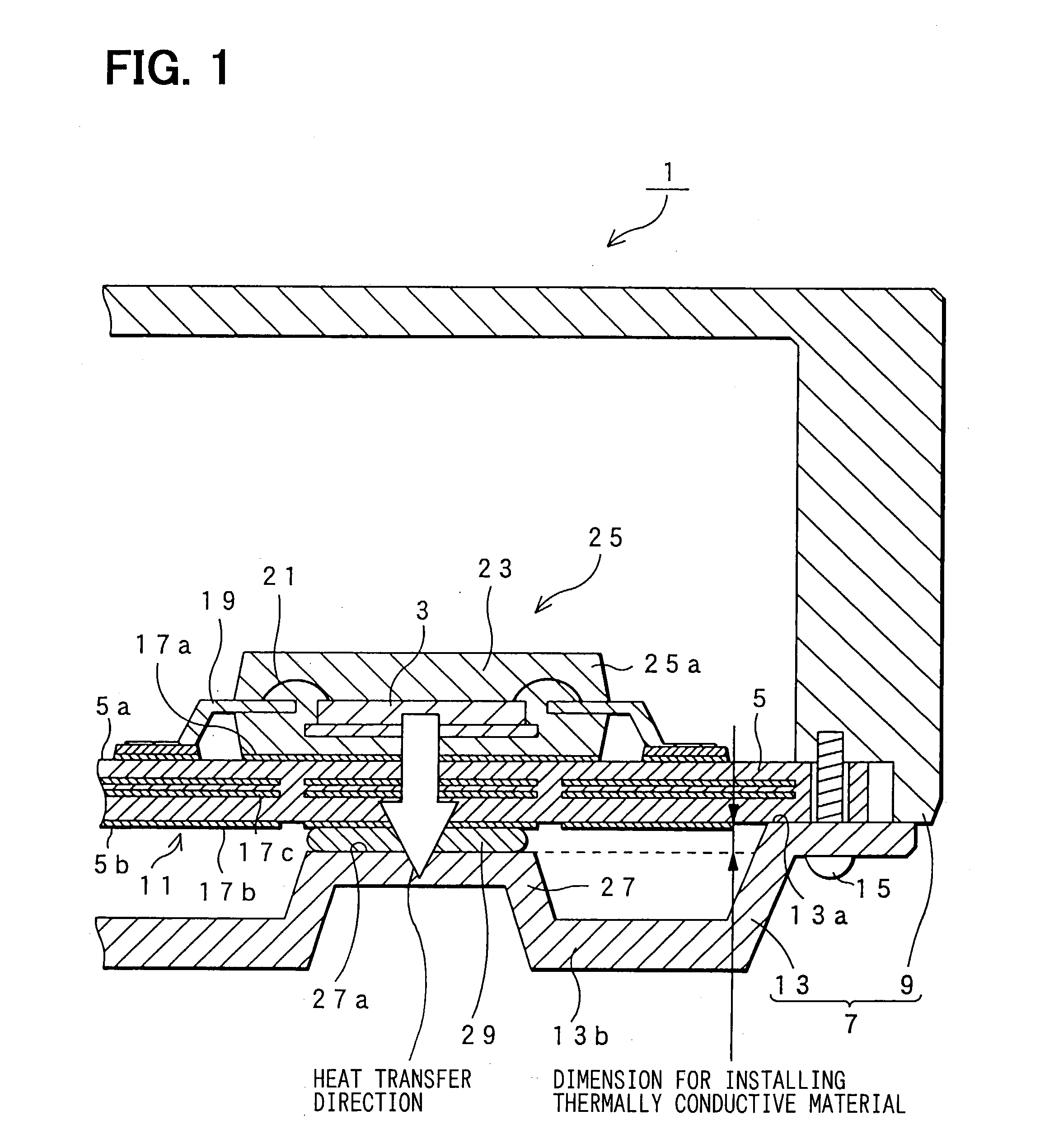

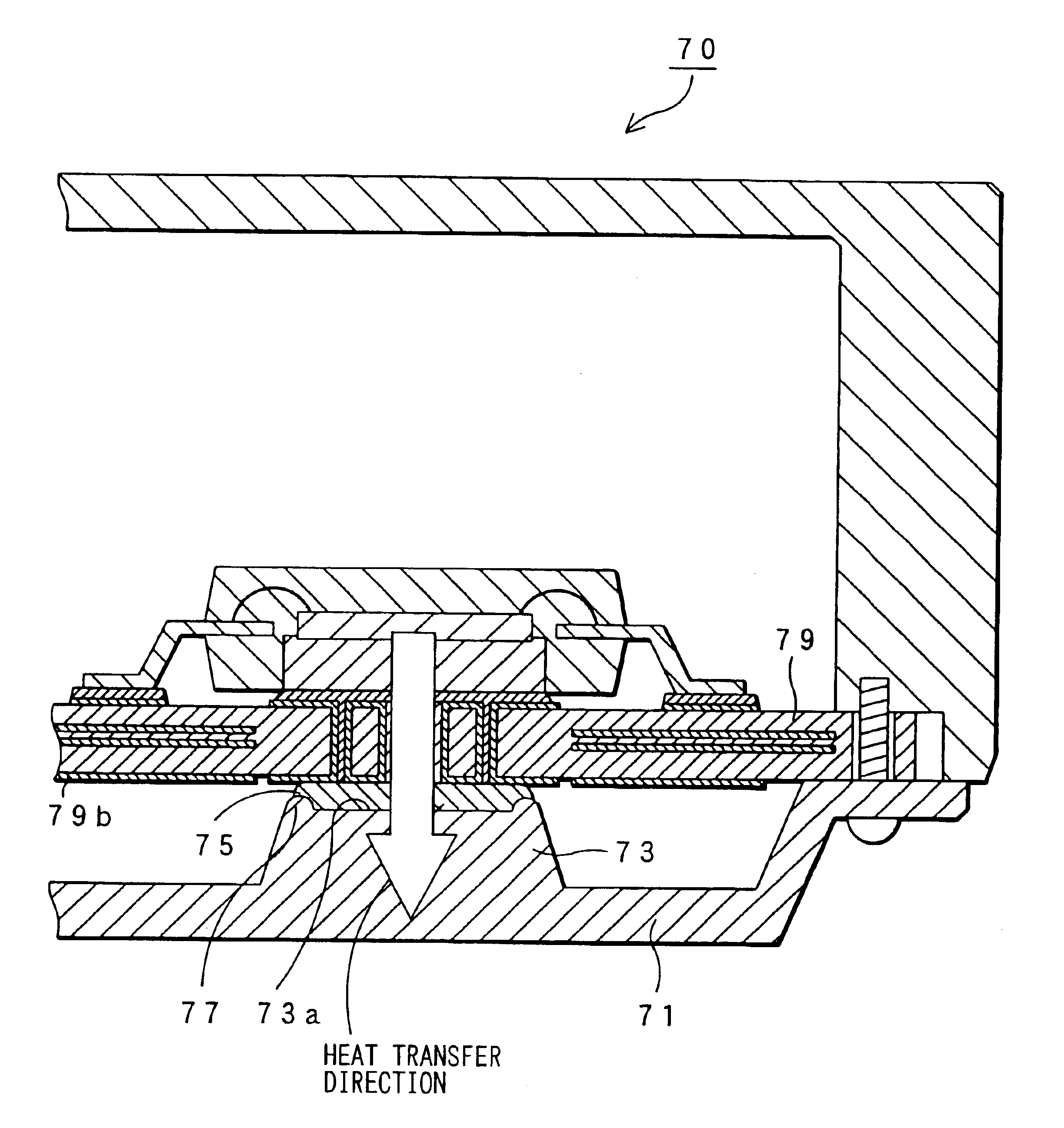

Electronic control unit

InactiveUS6816377B2Semiconductor/solid-state device detailsPrinted circuit aspectsSemi solidEngineering

An electronic control device having a high heat dissipating ability includes a printed board secured to an enclosure and interposed between a case and a cover with screws passing through the printed board. Thermally conductive thin film layers made of copper foil are formed in parallel on a mount face and an opposite mount face of the printed board and inside the printed board so as to be thermally separated from each other. A protrusion is provided on the cover and protrudes beyond a bottom part of the cover toward the position where an electronic component is mounted. A flexible, semi-solid thermally conductive material is placed between an end face of the protrusion and the opposite mount face of the printed board corresponding to the position where the electronic component is mounted to be in contact with the end face and the opposite mount face.

Owner:DENSO CORP

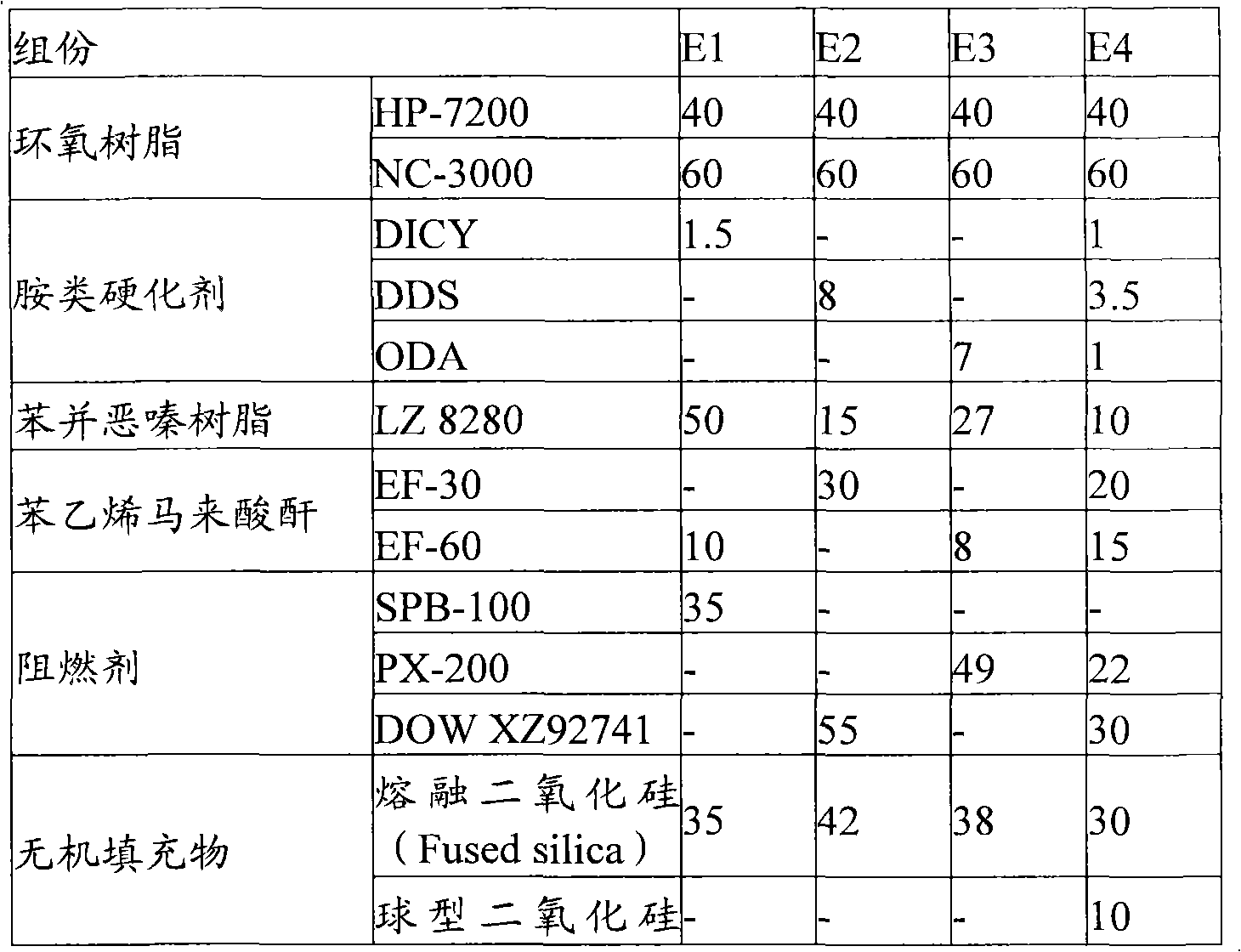

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

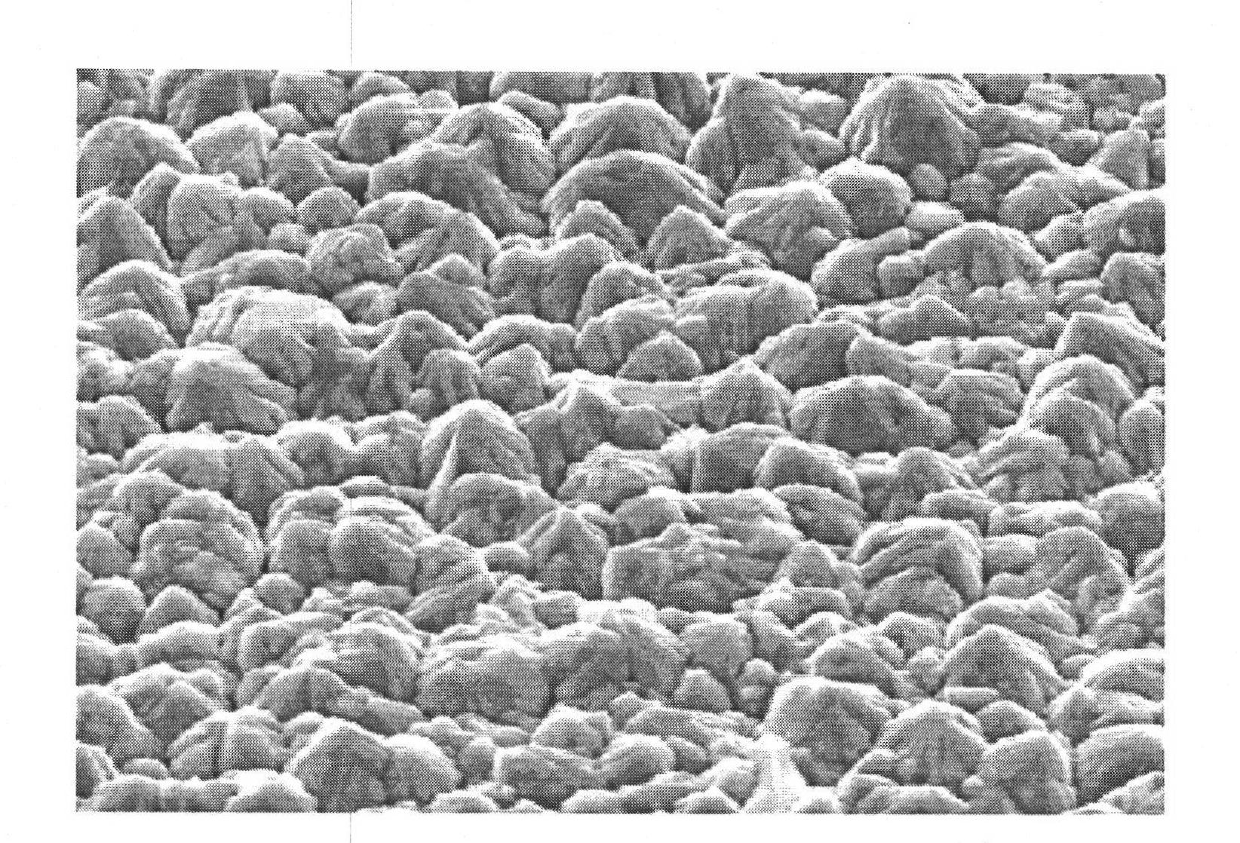

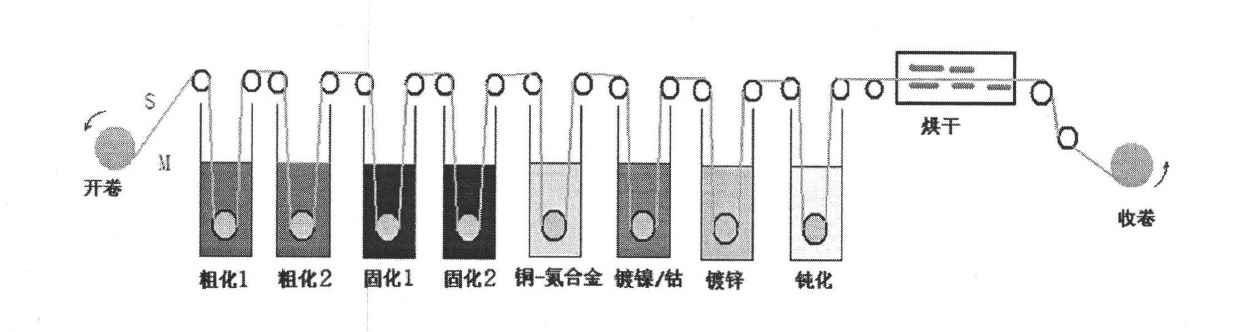

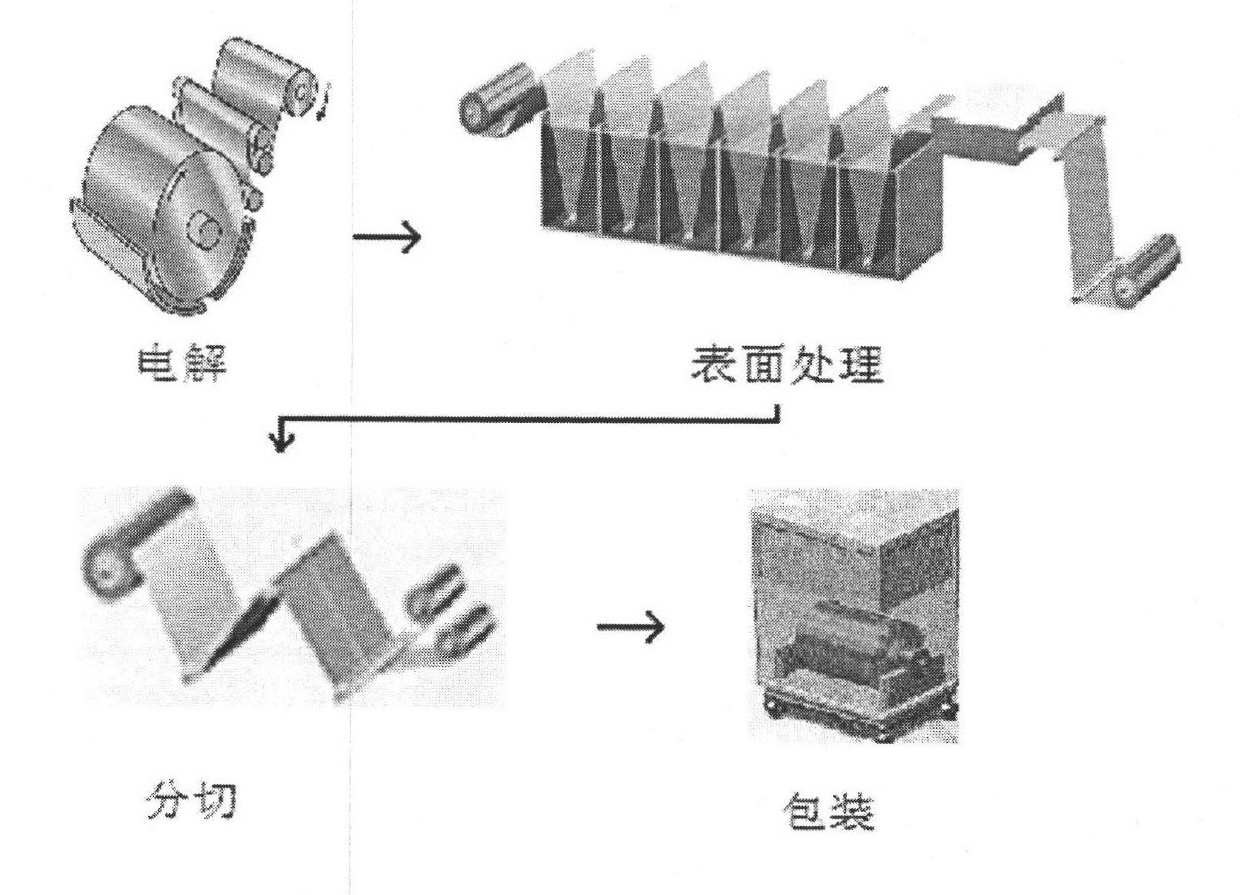

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

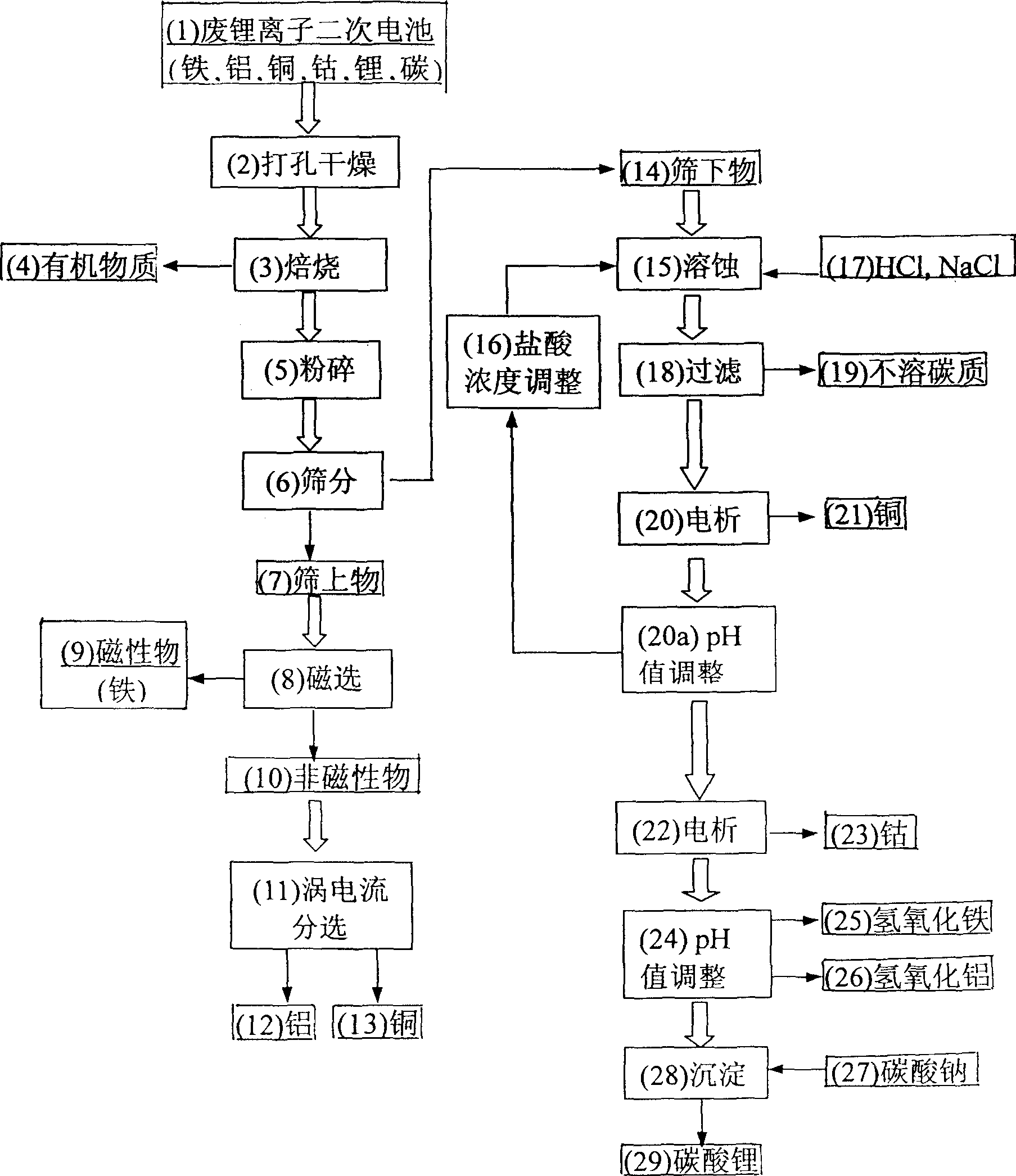

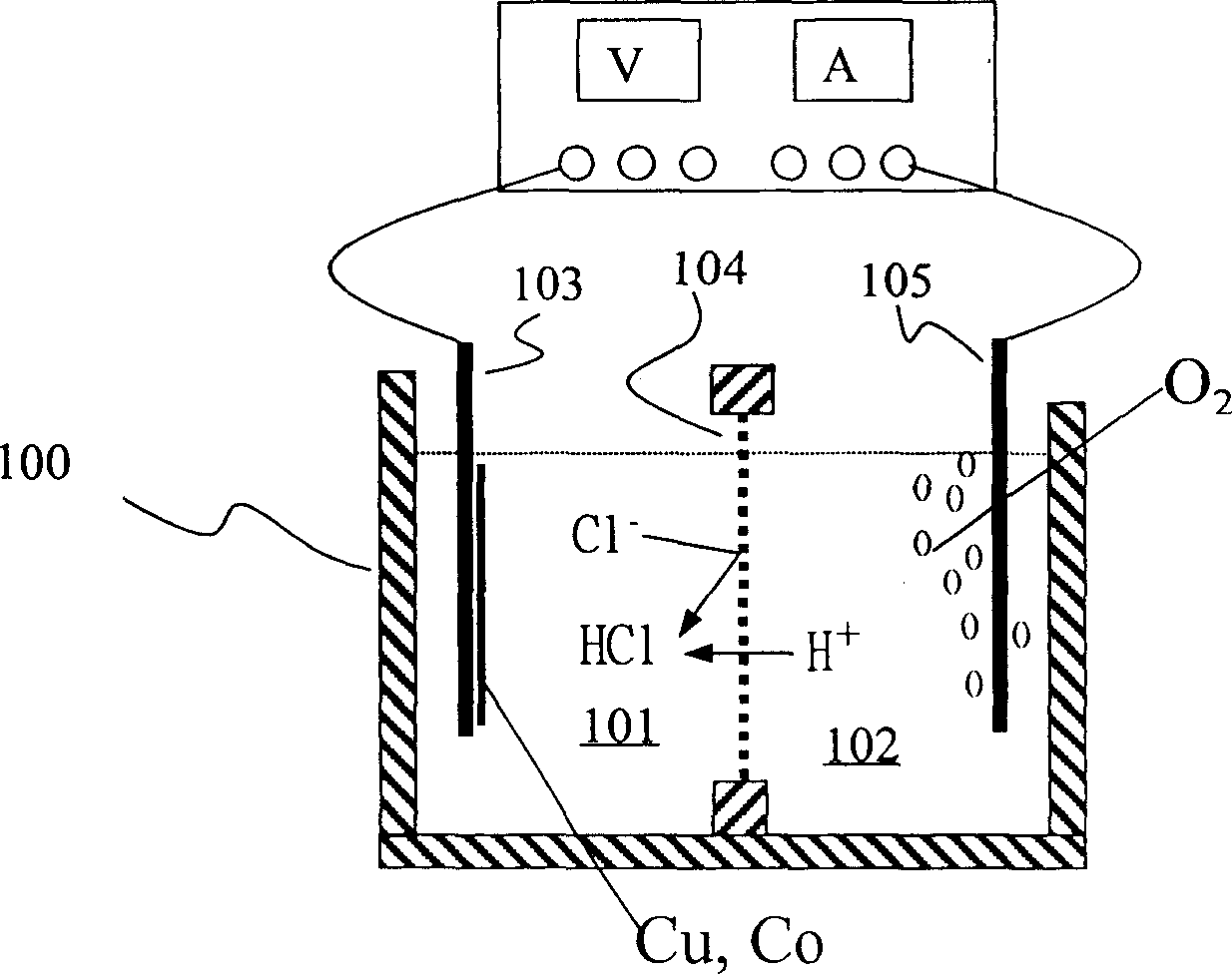

Method for recovering metal from used Li ion cell

InactiveCN1402376ATo achieve the purpose of separationReduce lossWaste accumulators reclaimingBattery recyclingDielectricCopper foil

The invented method includes the physical separation method combining with the preparation procedure of the cleaning wet recycle, providing the features of simple and high purity of the recovered metal. The invention includes following steps. With the disused lithium ion cells being burned in the high-temperature furnace, the organic dielectric is removed. After the smashing and sieving treatment, the oversize material is processed through the magnetic separation and the eddy current sorting so as to obtain the iron case, copper foil and aluminium foil etc. The undersize is processed through the steps of corrosion, filtering and electrolysis so as to obtain copper and cobalt. With carbonic acid radical being added to the solution richen in lithium ion, the high purity carbonate of lithiumis formed so as to recovery lithium.

Owner:IND TECH RES INST

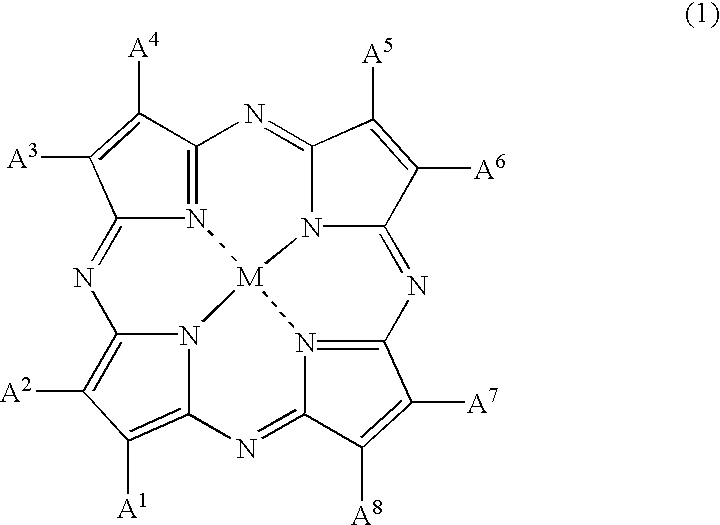

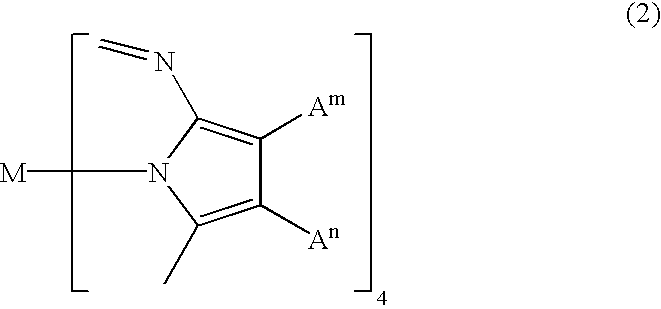

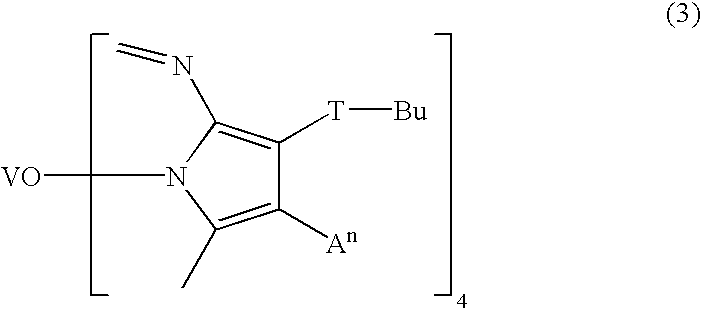

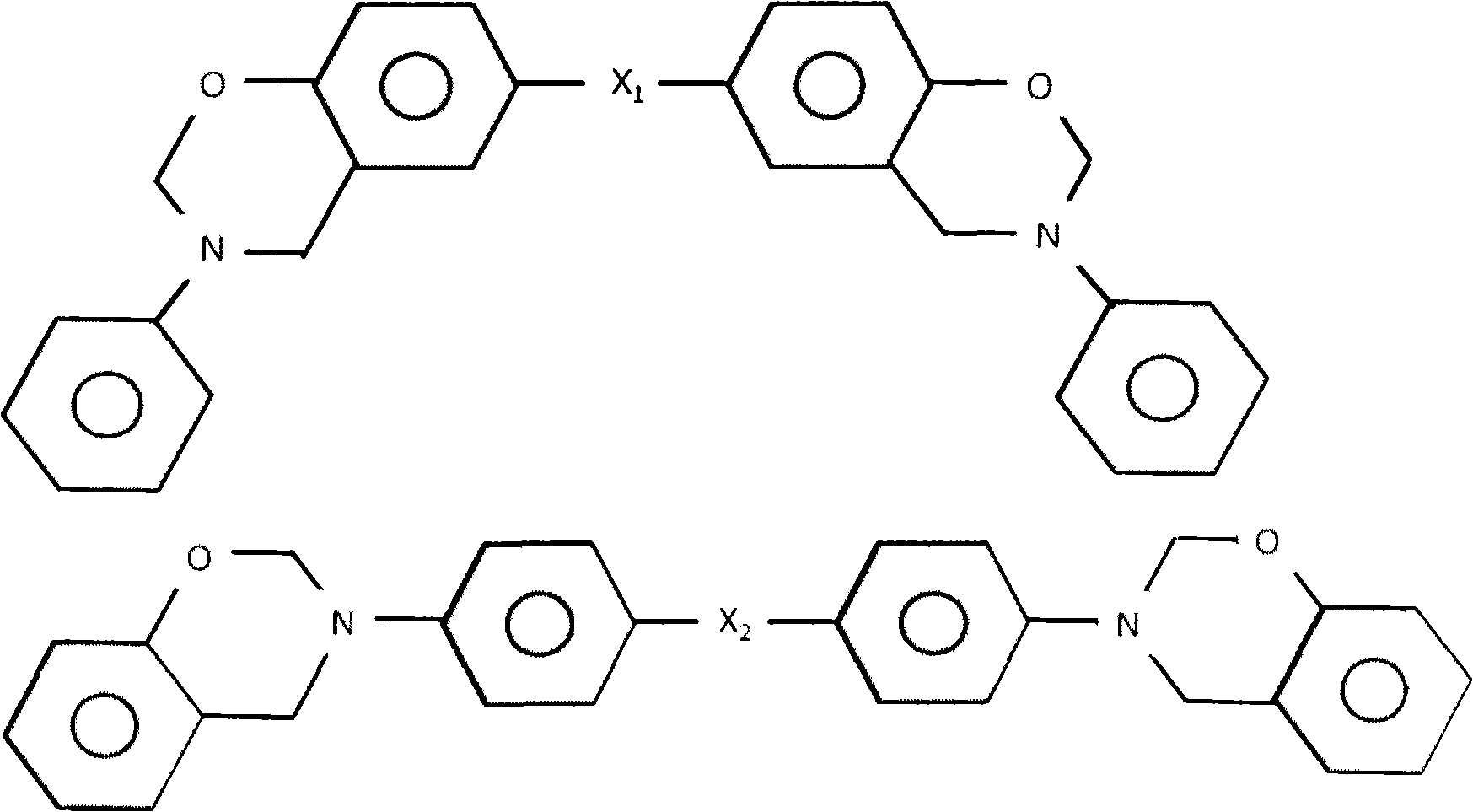

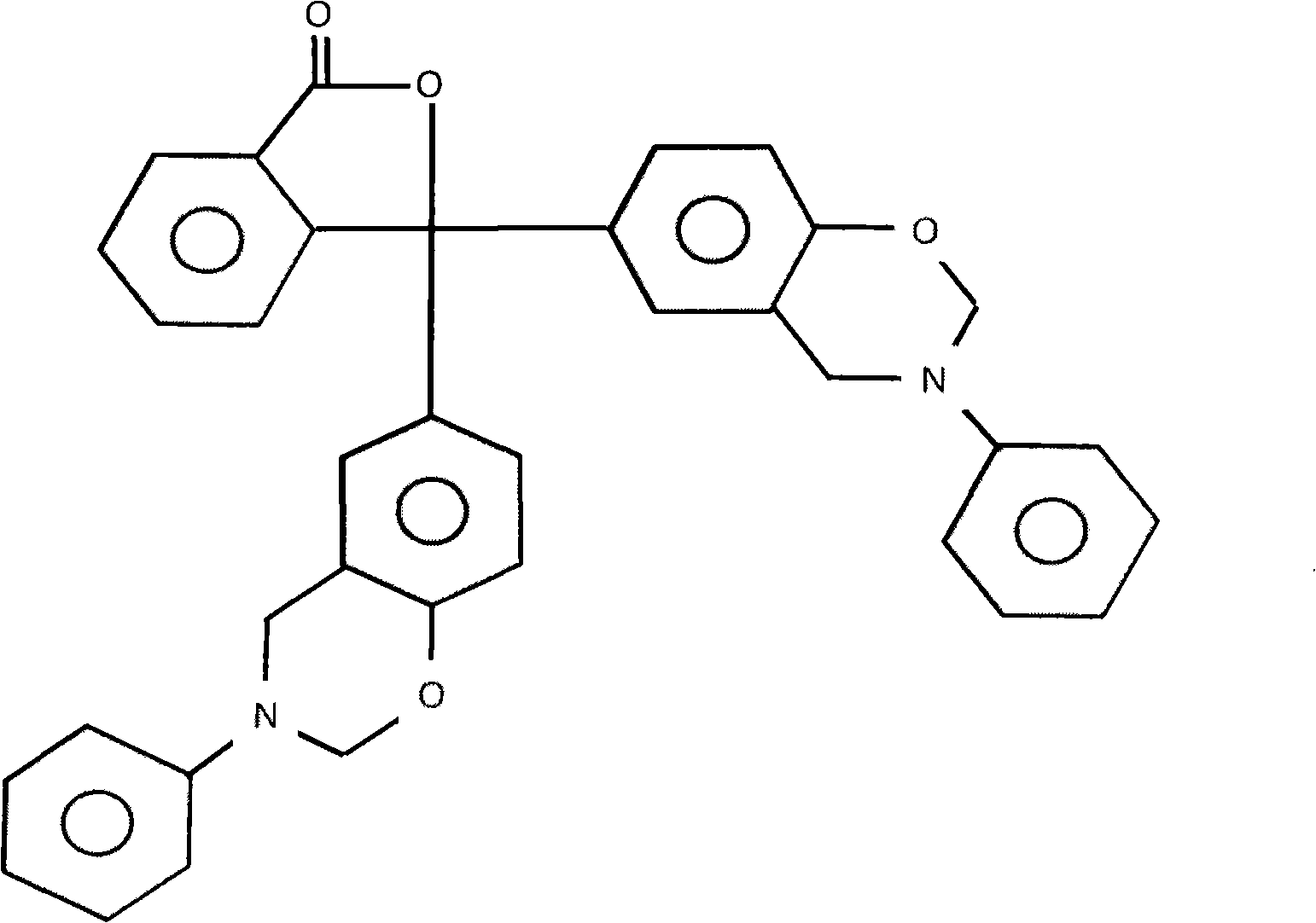

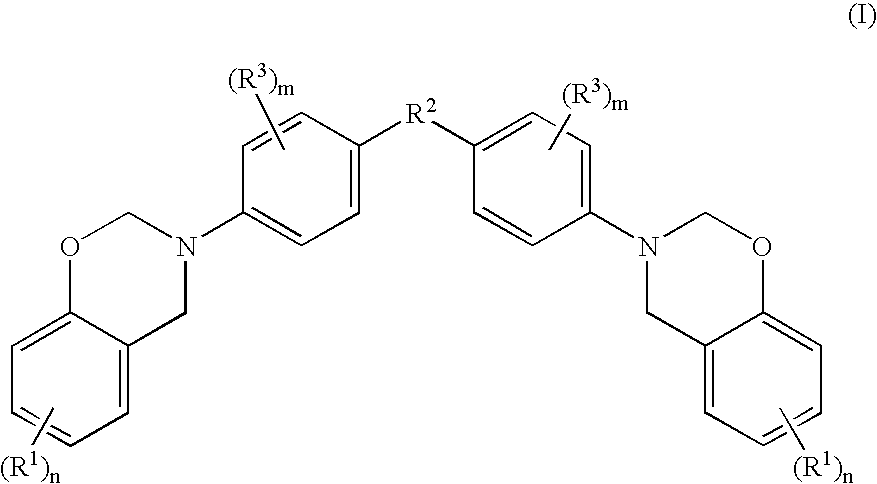

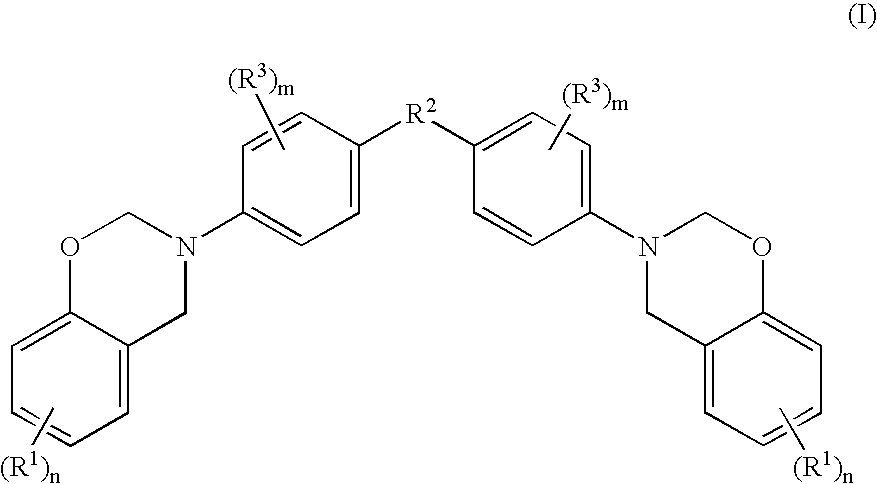

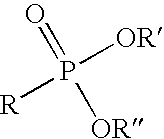

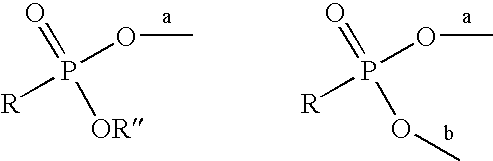

Halogen-free resin composition

Disclosed is a halogen-free resin composition comprising: (A) one or more phosphorus-containing epoxy resins; (B) a hardener; (C) a hardening accelerator; (D) a polyphenylene oxide resin; and (E) a filling material, wherein the hardener of component B has the structure represented by the following formula (I): wherein each symbol is as defined above. The halogen-free resin composition of the present invention without adding halogen has excellent heat resistance and flame retardant property, and excellent dielectric property. The halogen-free resin composition of the present invention is particularly useful in the application of bonding sheets, composite materials, laminated plates, printed circuit boards, copper foil adhesives, inks used for build-up process, semiconductor packaging materials and the like.

Owner:CHANG CHUN PLASTICS CO LTD

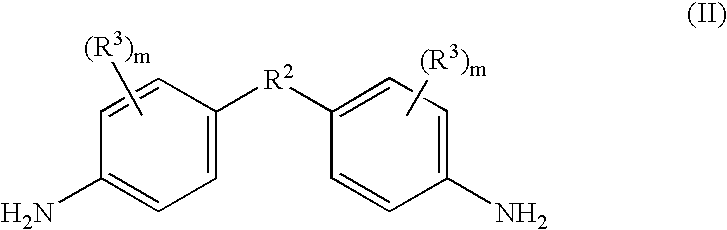

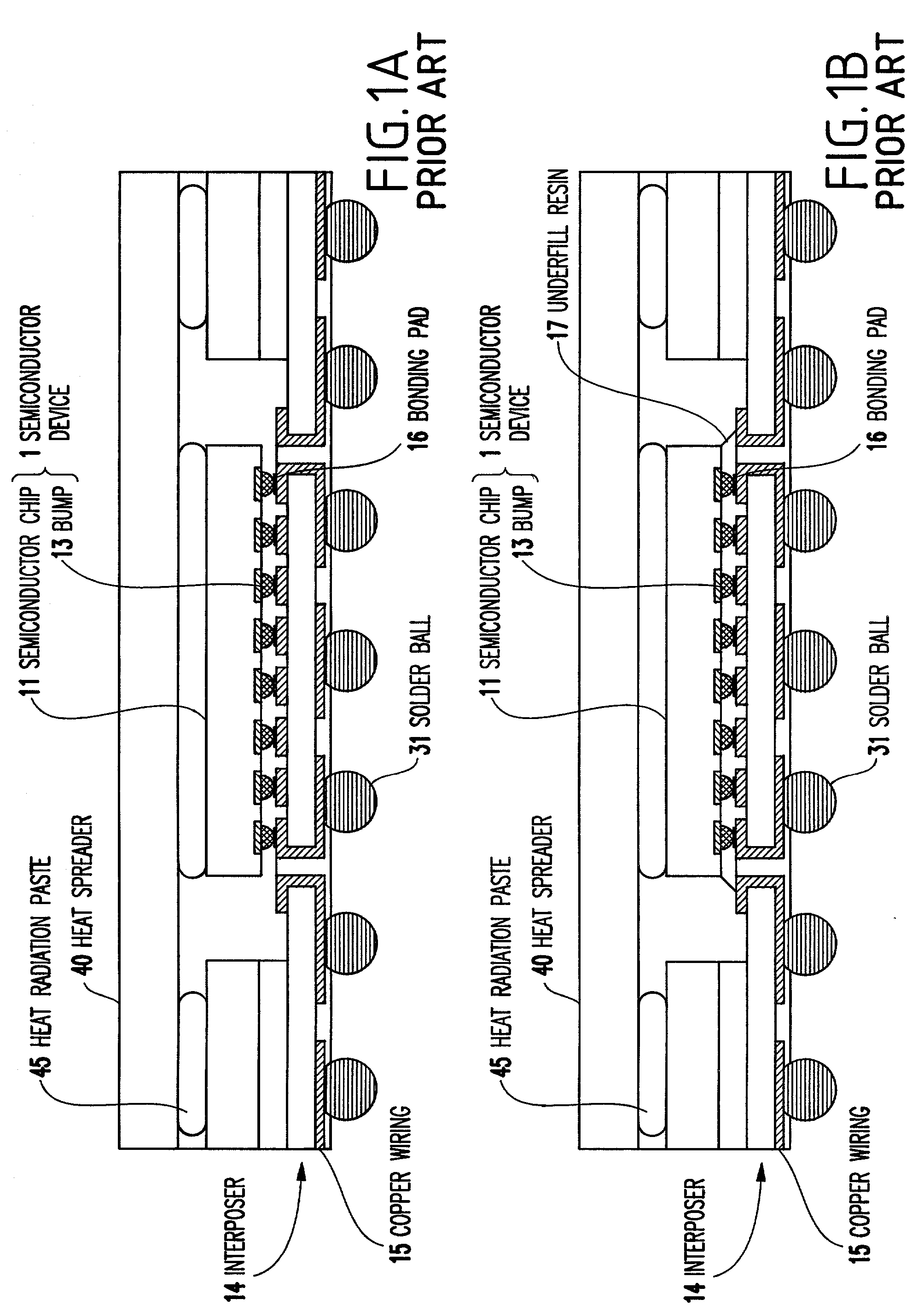

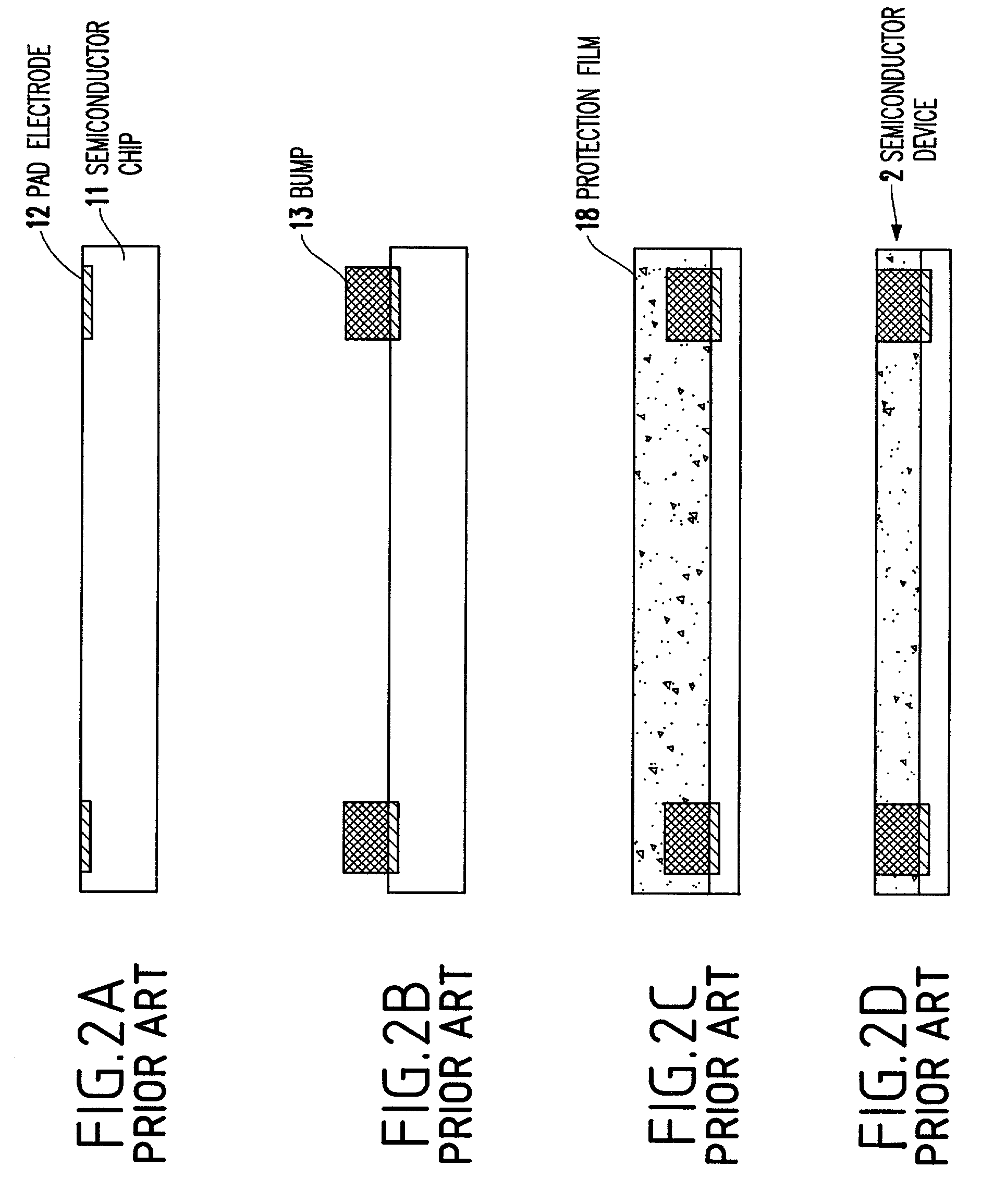

Semiconductor device and manufacturing method of the same

InactiveUS20020132463A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

Semiconductor device 3 comprises semiconductor chip 11, Au ball bumps 21 formed on pad electrodes 12 with a stud bump method, and thermoplastic adhesive layer 22 provided on the surface of semiconductor chip 11 on which pad electrodes 12 are formed, in which the tops of Au ball bumps 21 project from the surface of adhesive layer 22. Reliable bonding can be realized by forming the bumps for electrical connection and the adhesive resin having an adhesion function on the semiconductor chip. In addition, the present invention provides a method of bonding a copper foil to a semiconductor wafer to form a wiring pattern, a multi chip module in which electrical connection is established by bumps bonded to each other through an adhesive layer, and the like.

Owner:NEC ELECTRONICS CORP

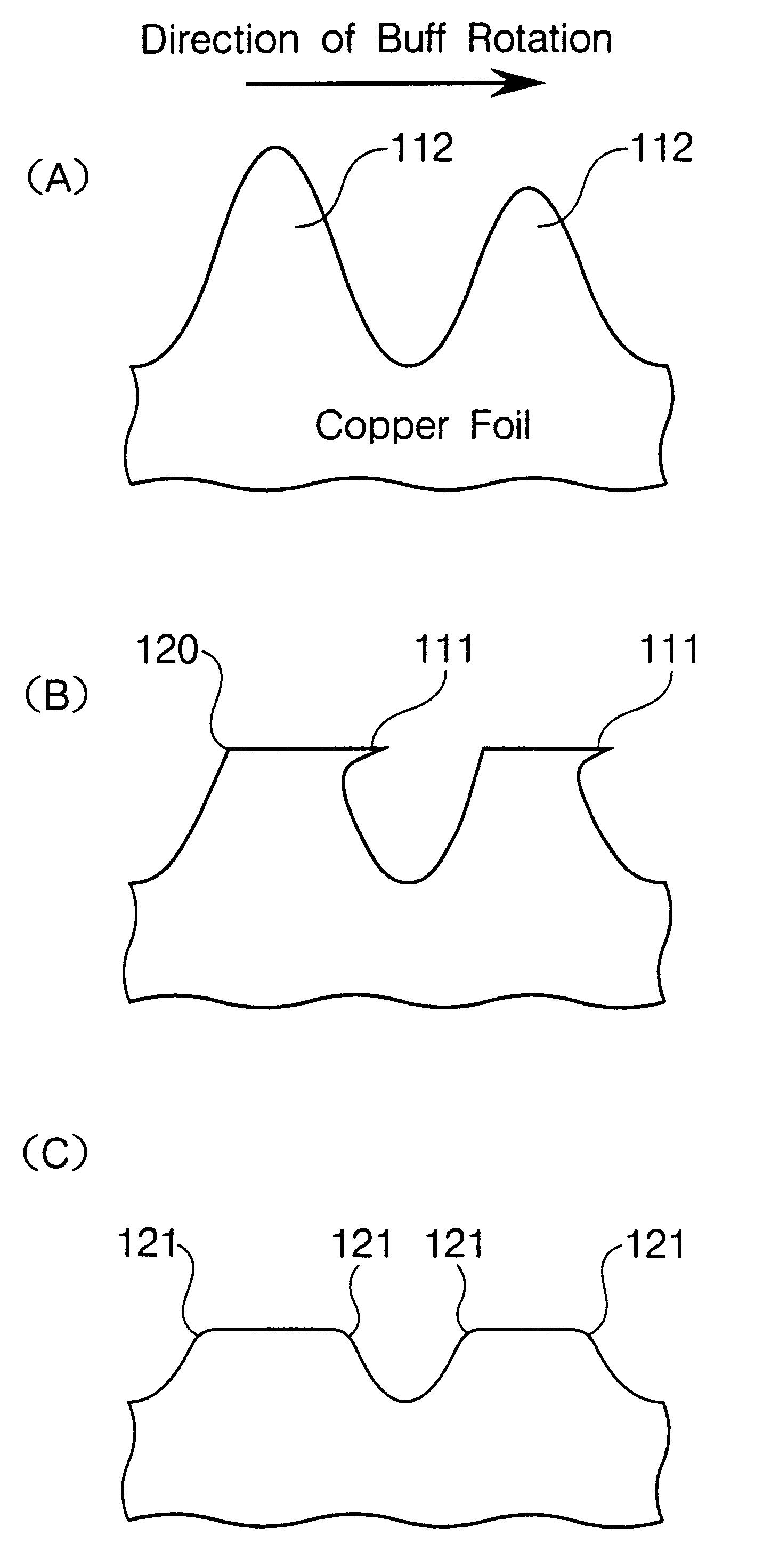

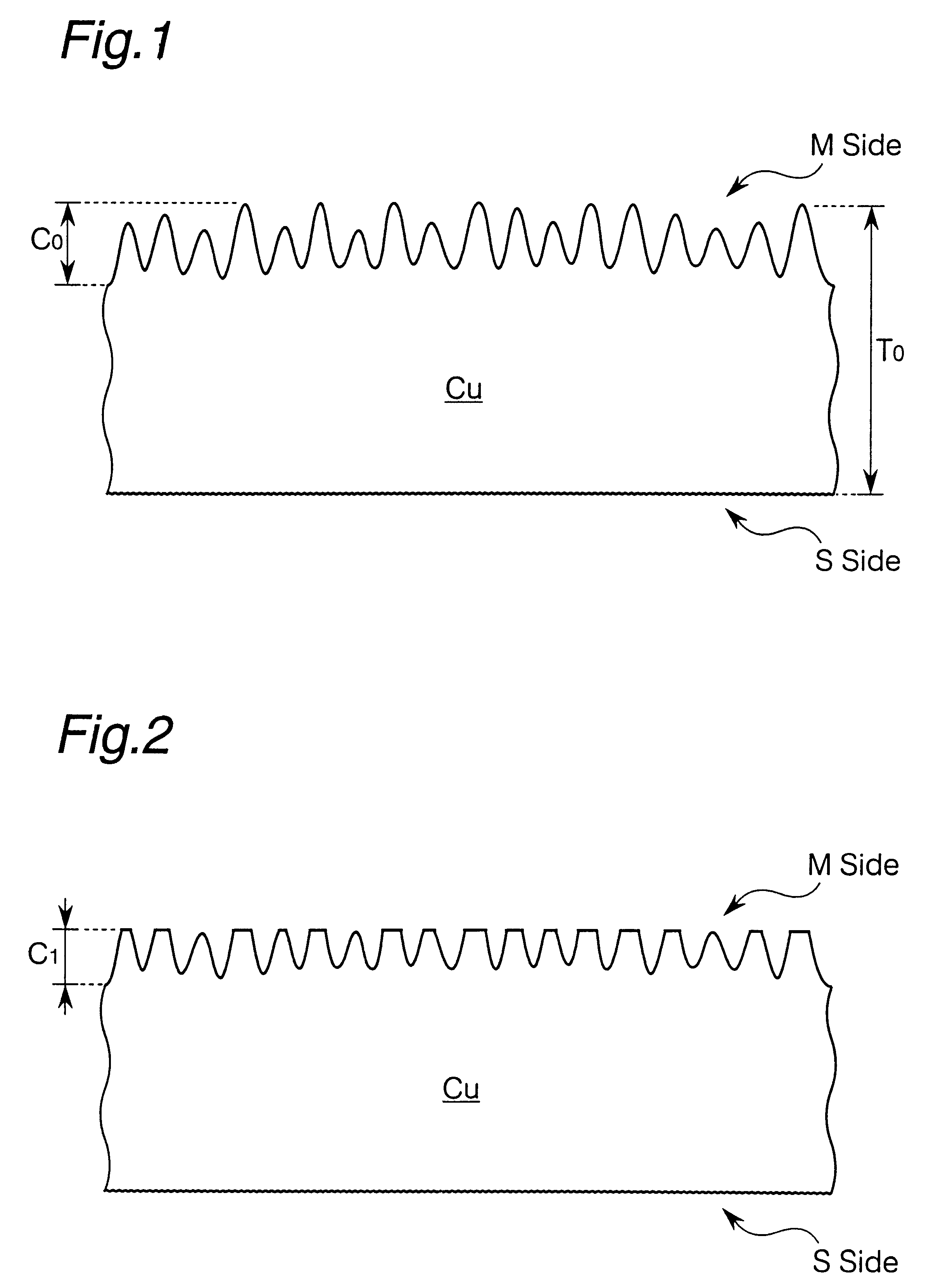

Electrodeposited copper foil with its surface prepared, process for producing the same and use thereof

InactiveUS6475638B1Eliminate deformationHigh peel strengthInsulating substrate metal adhesion improvementLapping machinesSurface roughnessCopper foil

A process for producing an electrodeposited copper foil with its surface prepared, comprising the steps of: subjecting an electrodeposited copper foil having a shiny side and a matte side whose average surface roughness (Rz) is in the range of 2.5 to 10 mum to at least one mechanical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 1.5 to 3.0 mum; and subjecting the matte side having undergone the mechanical polishing to a selective chemical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 0.8 to 2.5 mum. The invention further provides an electrodeposited copper foil with its surface prepared, produced by the above process, and still further provides PWBs and a multilayer laminate of PWBs, produced with the use of the above electrodeposited copper foil with its surface prepared. The mechanical polishing followed by chemical polishing of the matte side enables obtaining an electrodeposited copper foil with its surface prepared, the matte side of which exhibits excellent properties, and hence enables obtaining PWBs and a multilayer PWBs which have excellent properties.

Owner:MITSUI MINING & SMELTING CO LTD

Composite structure with organophosphonate adherent layer and method of preparing

The present invention provides an article comprising: a substrate having a surface and comprising electrodeposited copper foil or copper alloy foil; an adherent layer serving to promote adhesion, comprising at least one organophosphonate or salt thereof covalently bound to the surface; and a functional layer, comprising at least one polymer bound to the adherent layer. The present invention further provides devices comprising a heat source or electronic component and the article described above, wherein the heat source is in thermal contact with the substrate and the electronic component is in electrical contact with the substrate.Also provided is a method of producing the above-described article.

Owner:ACULON

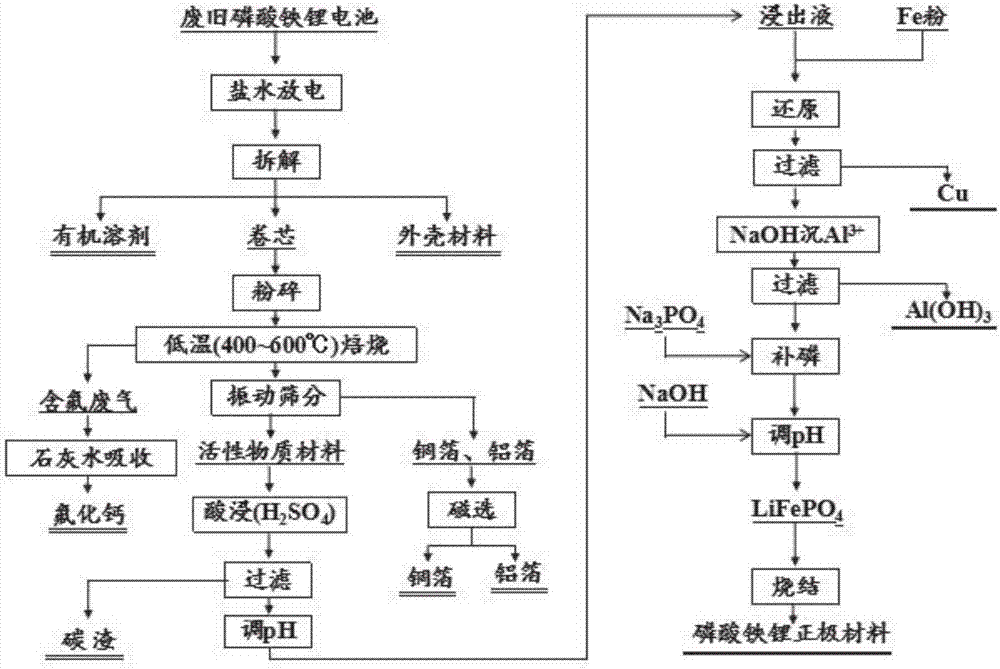

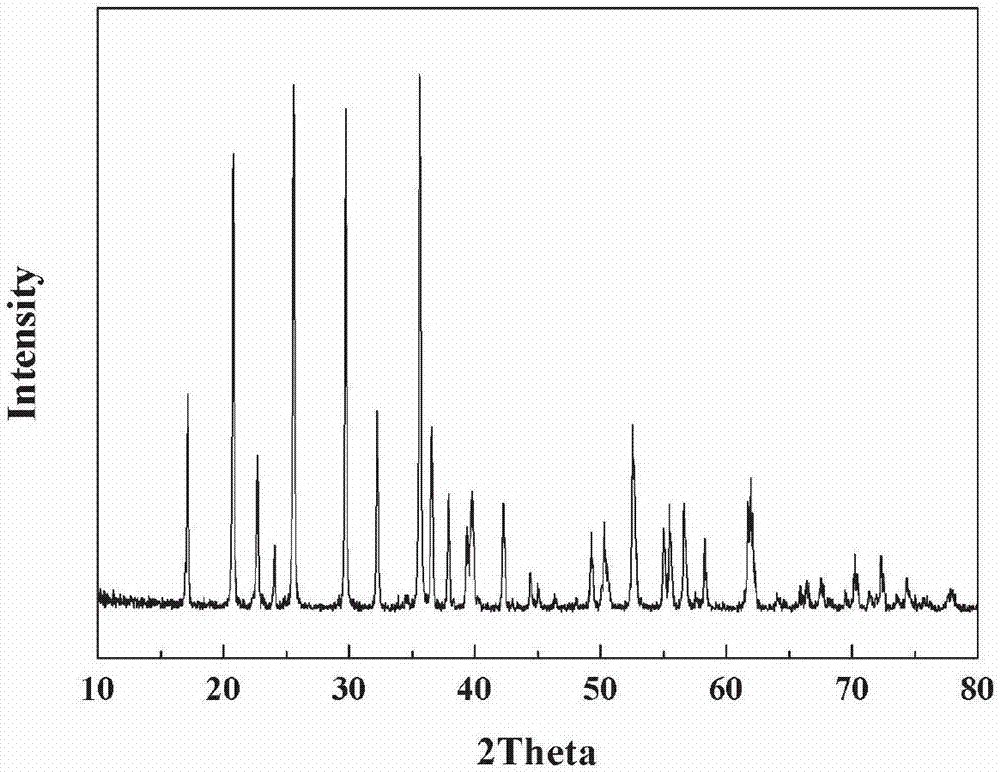

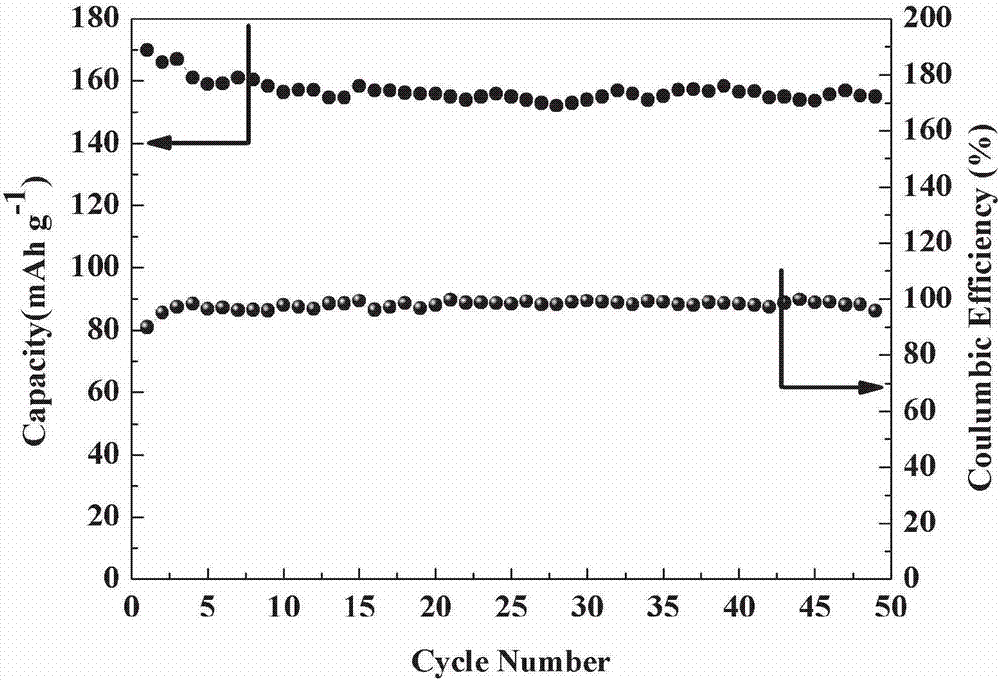

Method for regenerating positive active material from waste lithium iron phosphate batteries

ActiveCN106910889ARealize combination generationQuality assuranceCell electrodesWaste accumulators reclaimingFiltrationCopper foil

The invention discloses a method for regenerating a positive active material from waste lithium iron phosphate batteries. The method comprises the steps as follows: 1) waste lithium iron phosphate batteries are discharged in saline water, and organic solvents, roll cores and casing materials are disassembled; 2) the roll cores are subjected to crushing, calcination and other steps, and active materials, copper foil and aluminum foil are separated through vibrating screening. Fluorine-containing waste gas is absorbed with lime water, the copper foil and the aluminum foil are separated with a magnetic separation method, the active materials are leached out with sulfuric acid, and a leachate and carbon residues are obtained through separation; 3) Cu<2+> in the leachate is reduced to elementary copper by adding iron powder, meanwhile, Fe<3+> is reduced to Fe<2+>, copper and excessive iron residues are filtered out, aluminum is removed through precipitation with an alkaline liquid, the filtrate is supplemented with a phosphorus source after filtration, the pH value is adjusted by adding the alkaline liquid, coarse lithium iron phosphate precipitates are produced, and finally, battery-grade lithium iron phosphate is obtained through sintering. Comprehensive utilization of the waste lithium iron phosphate batteries and regeneration of the active materials are realized with a simple, practical, economical and feasible method, no secondary pollution is produced, and the method is suitable for industrial production.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com