Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10190 results about "Copper alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

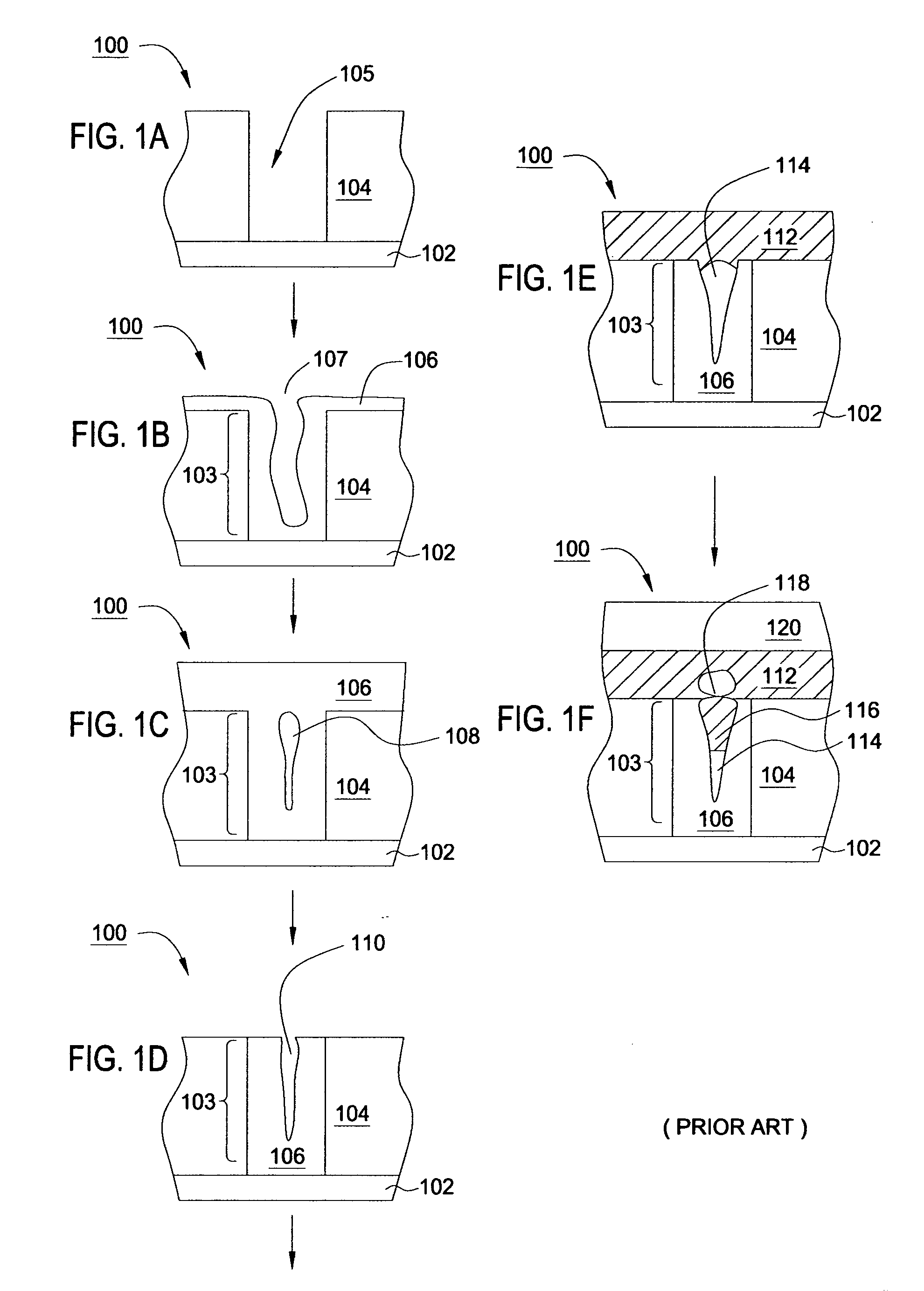

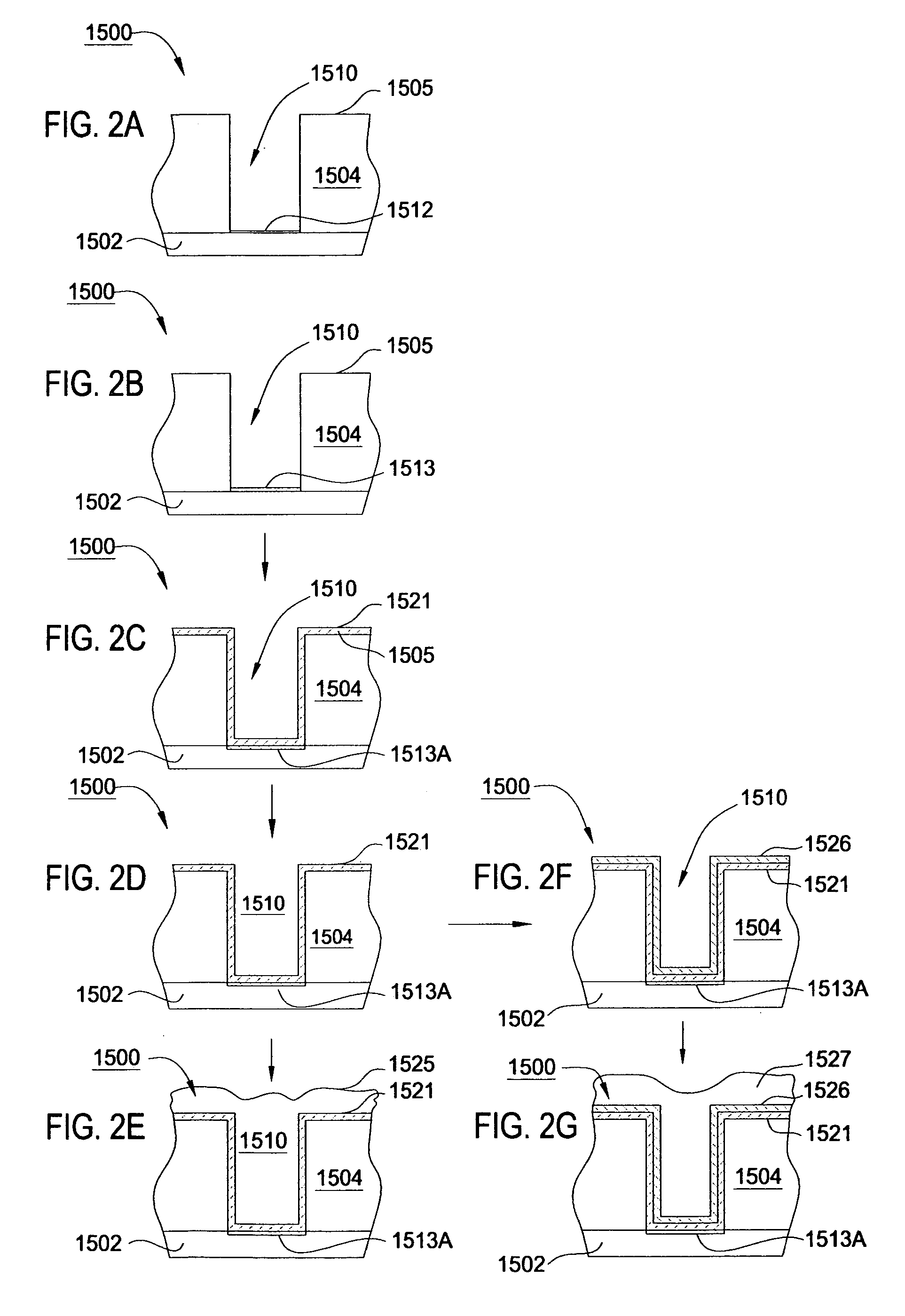

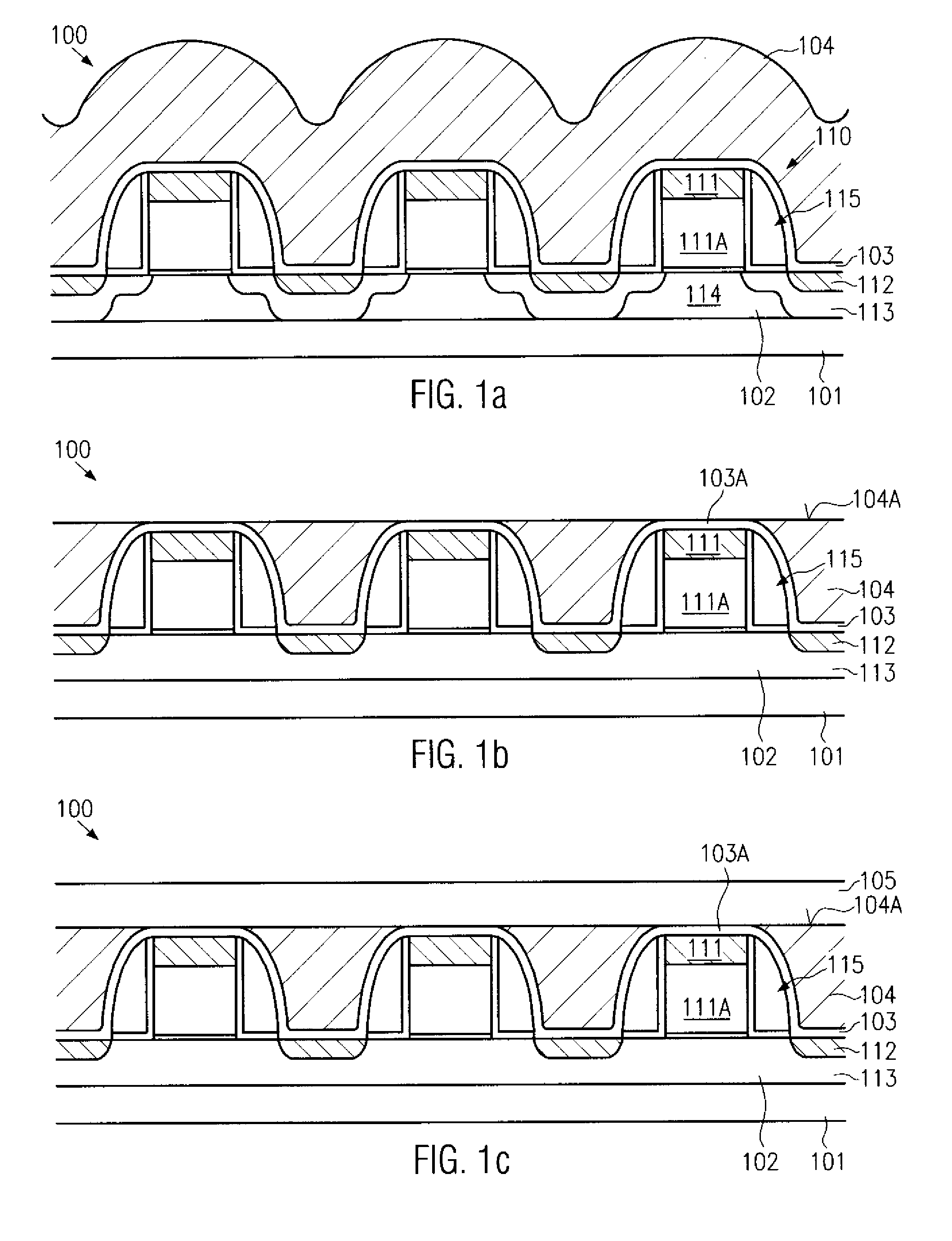

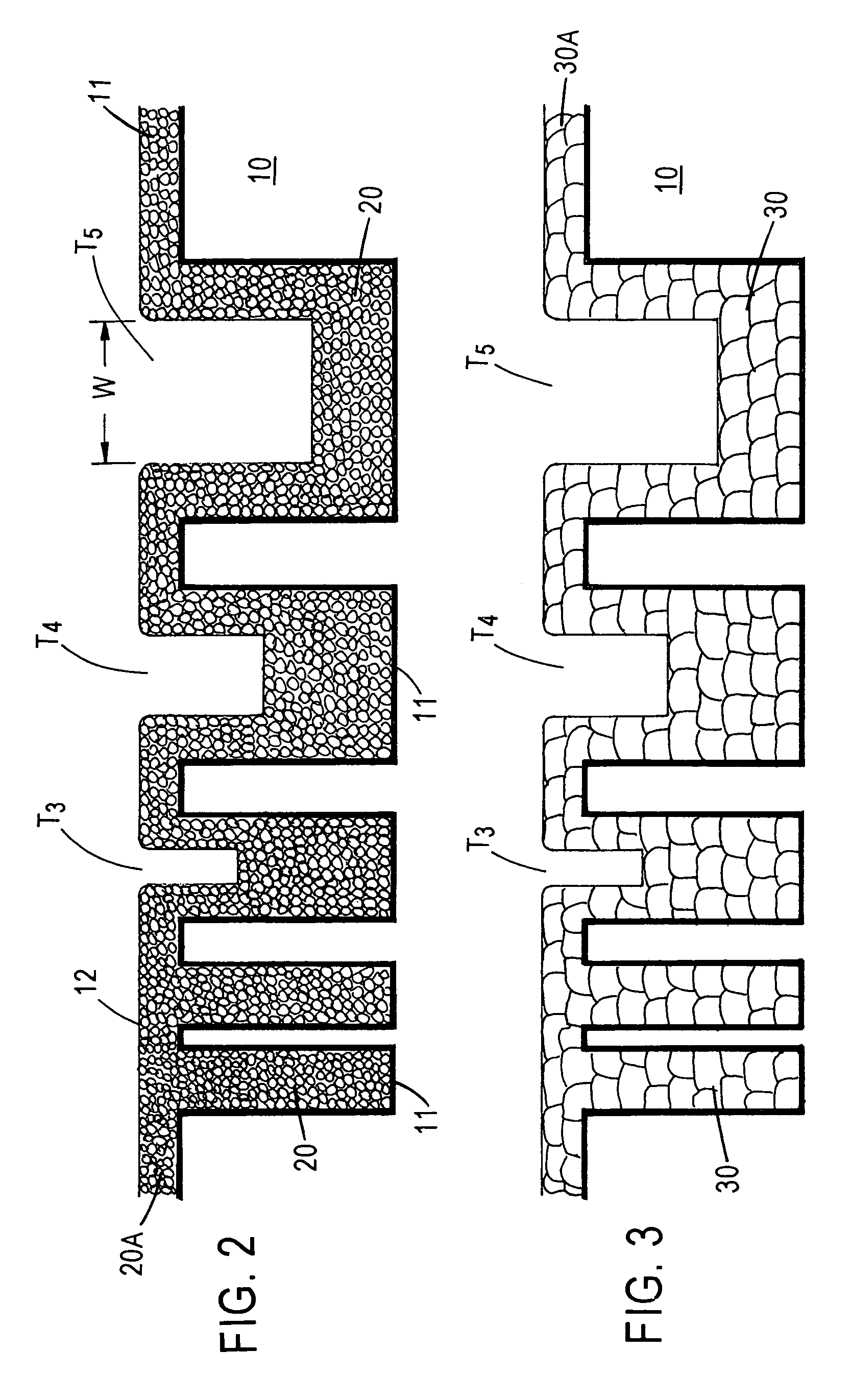

Contact metallization scheme using a barrier layer over a silicide layer

ActiveUS20060251800A1Material nanotechnologySemiconductor/solid-state device detailsDevice materialElectroless deposition

Embodiments of the invention generally provide methods of filling contact level features formed in a semiconductor device by depositing a barrier layer over the contact feature and then filing the layer using an PVD, CVD, ALD, electrochemical plating process (ECP) and / or electroless deposition processes. In one embodiment, the barrier layer has a catalytically active surface that will allow the electroless deposition of a metal on the barrier layer. In one aspect, the electrolessly deposited metal is copper or a copper alloy. In one aspect, the contact level feature is filled with a copper alloy by use of an electroless deposition process. In another aspect, a copper alloy is used to from a thin conductive copper layer that is used to subsequently fill features with a copper containing material by use of an ECP, PVD, CVD, and / or ALD deposition process. In one embodiment, a portion of the barrier layer is purposely allowed to react with traces of residual oxide at the silicon junction of the contact level feature to form a low resistance connection.

Owner:APPLIED MATERIALS INC

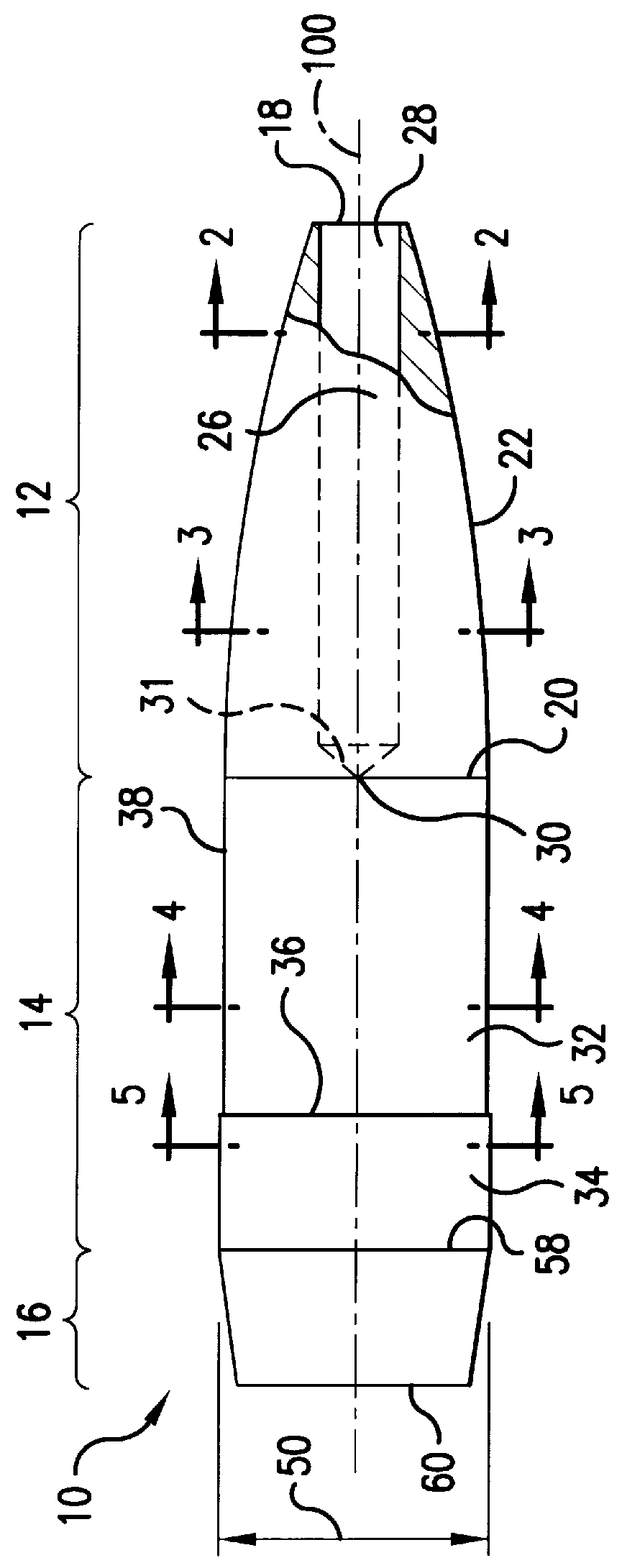

High accuracy projectile

InactiveUS6070532AMinimizes bullet jumpImprove accuracyAmmunition projectilesTraining ammunitionEngineeringGun barrel

A projectile having improved accuracy when fired over long ranges is formed from a monolithic block of a copper alloy. Proceeding from a nose to a heel of the projectile, is a fore portion with arcuate side walls, a body portion of substantially constant cross-sectional area that minimally contacts a rifled gun barrel, a drive band having a diameter effective to seal propellant gases and an aft portion that continuously decreases in diameter terminating at the heel. A cylindrical bore extends from an opened end at the nose to a closed end proximate to a transition plane between the fore portion and the body portion.

Owner:OLIN CORP

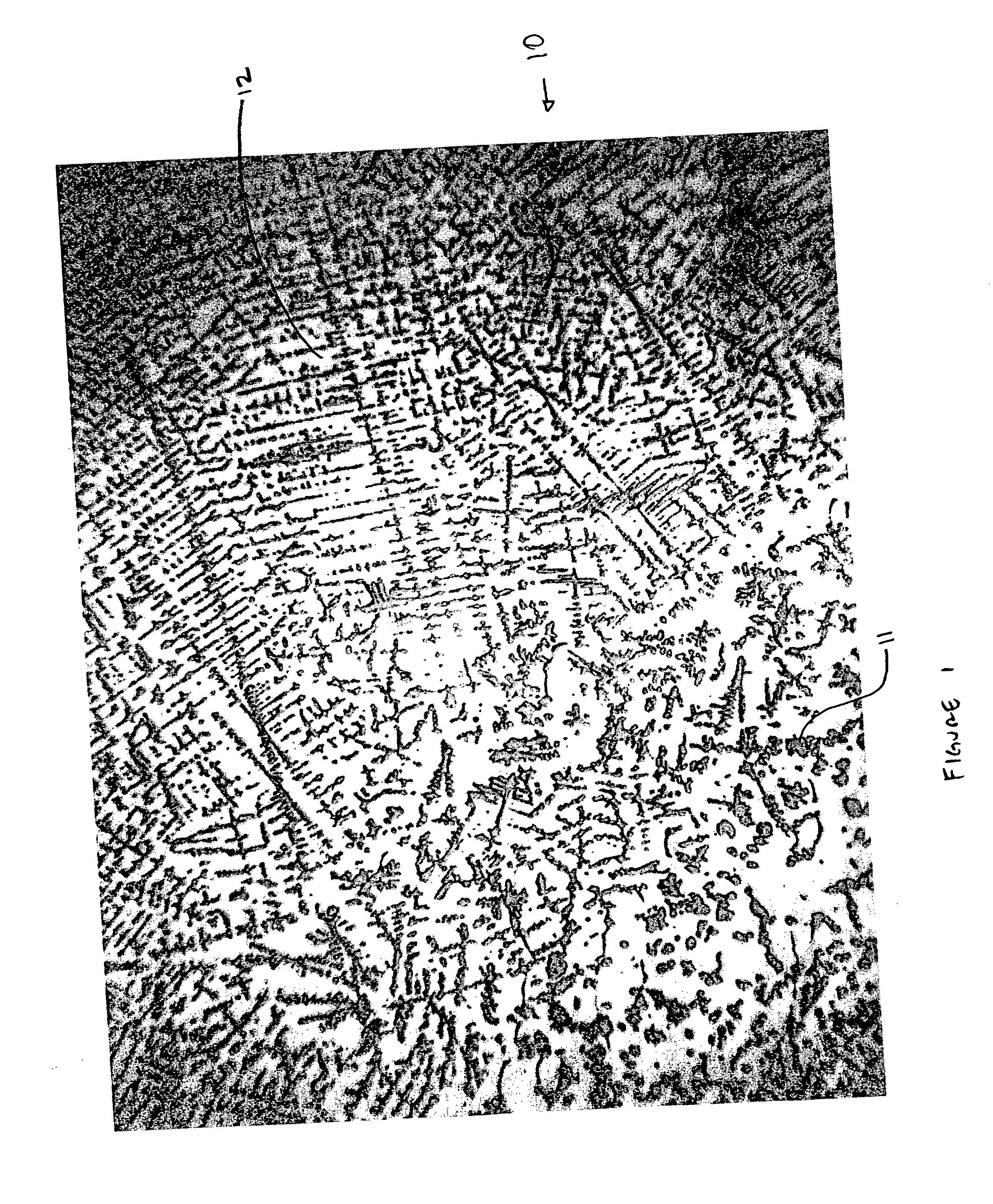

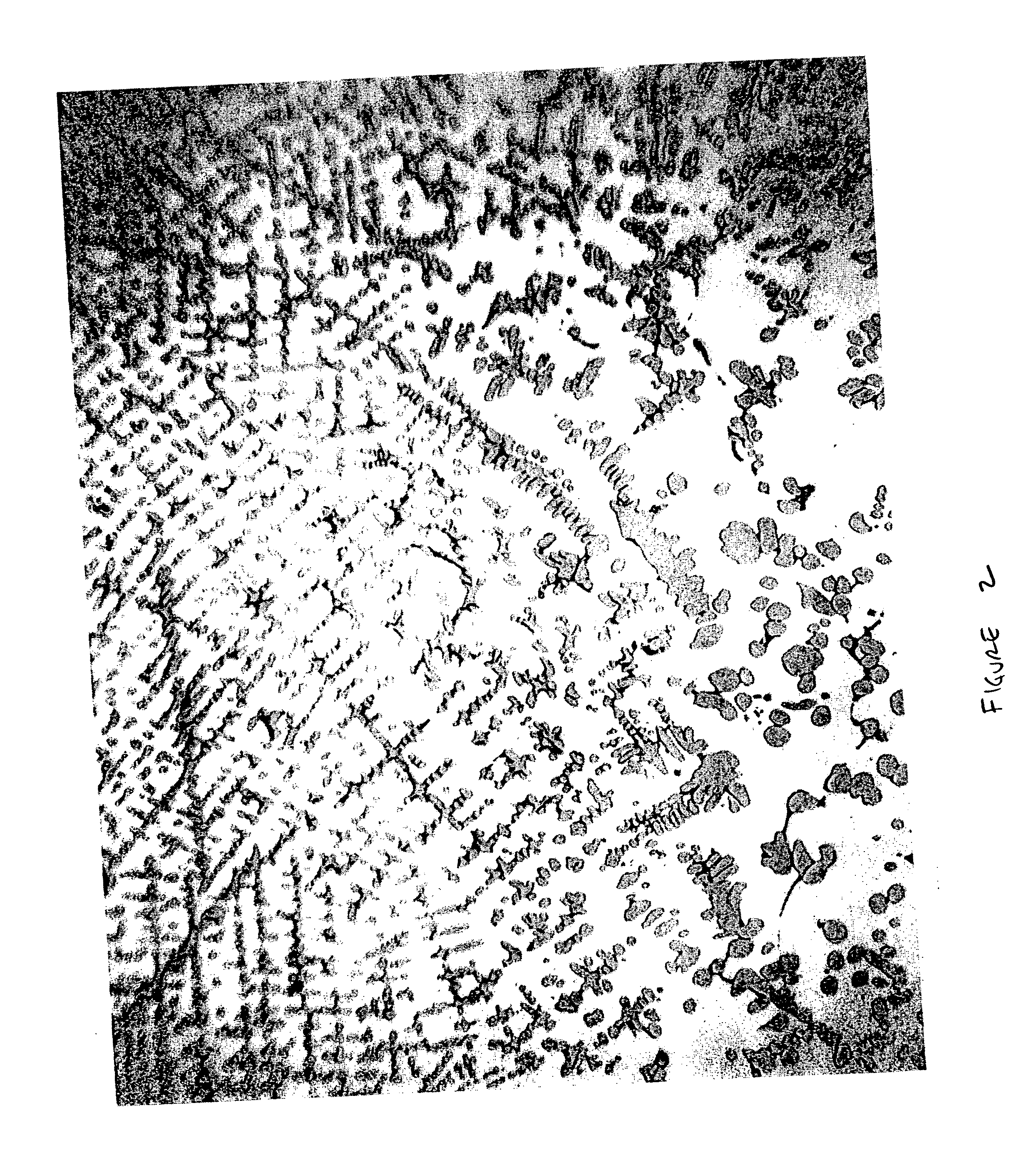

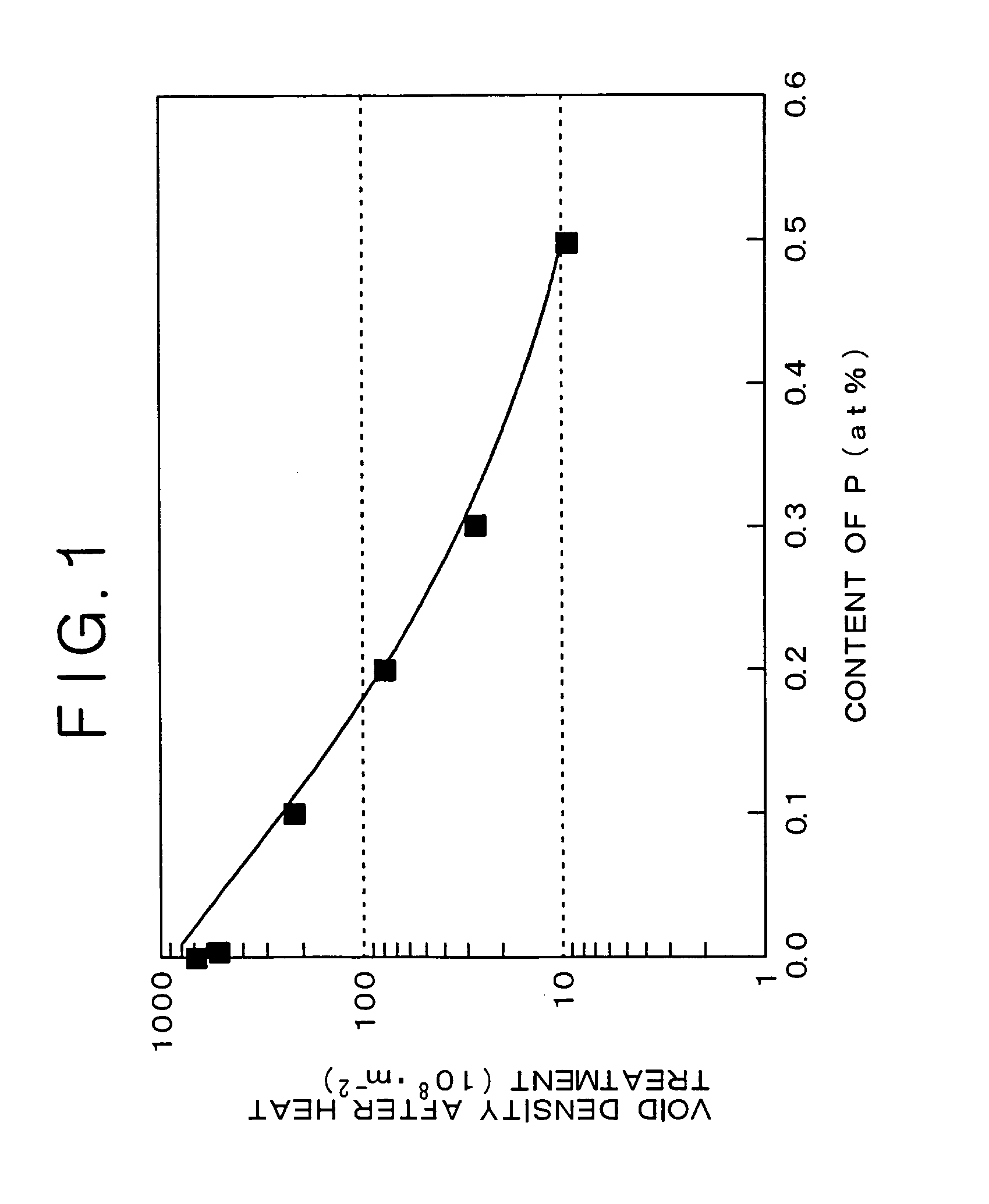

Copper alloy and process for producing the same

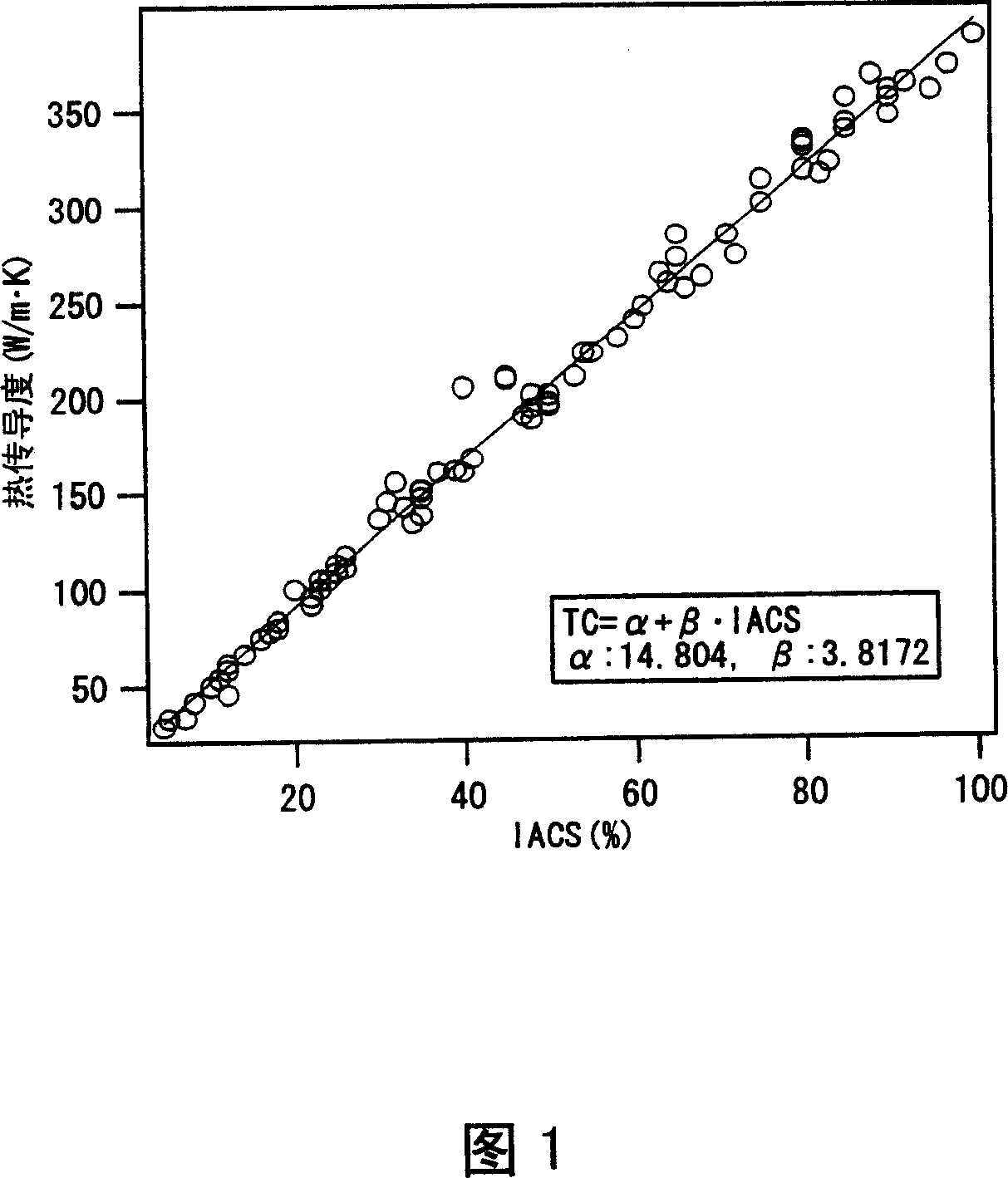

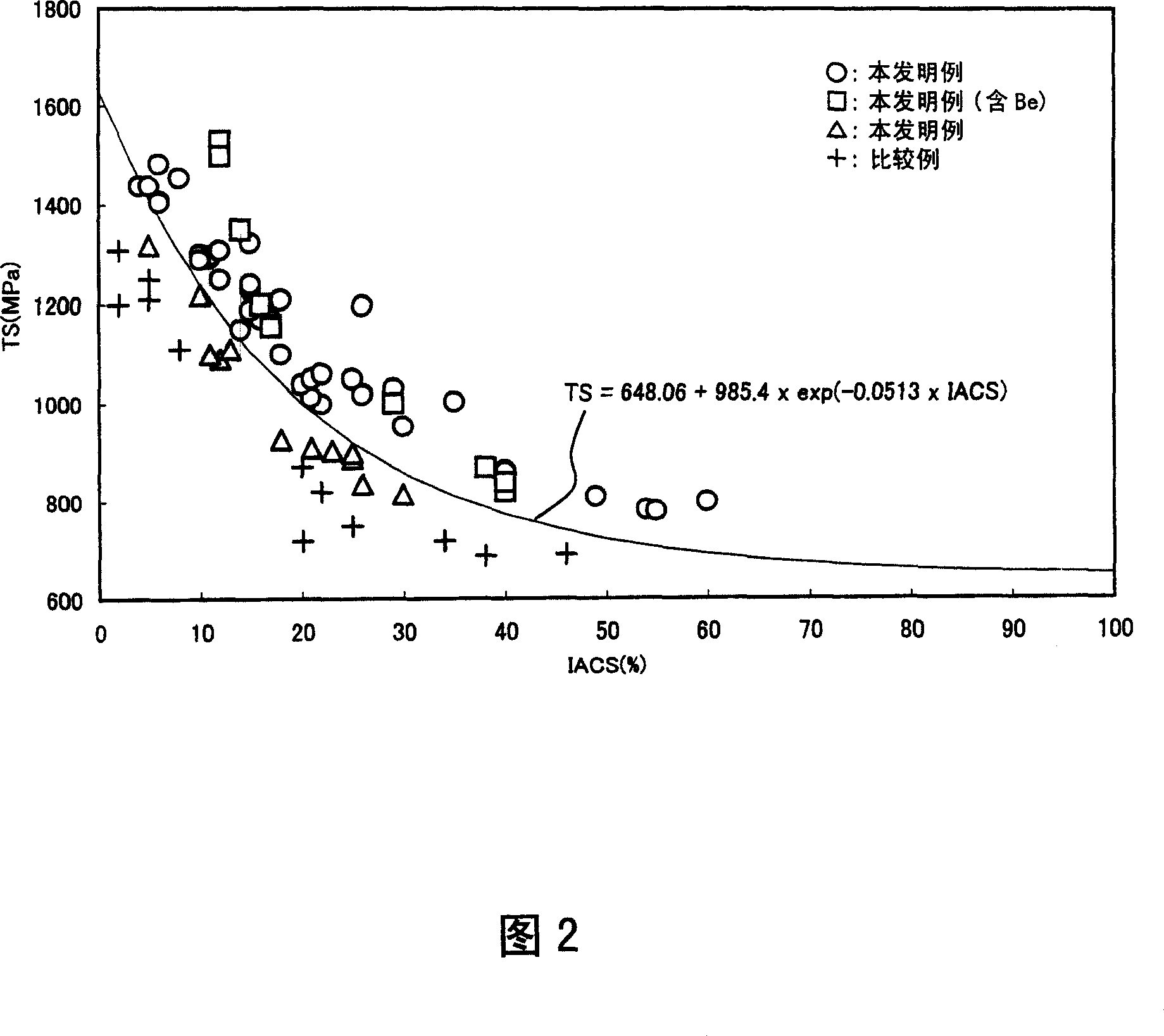

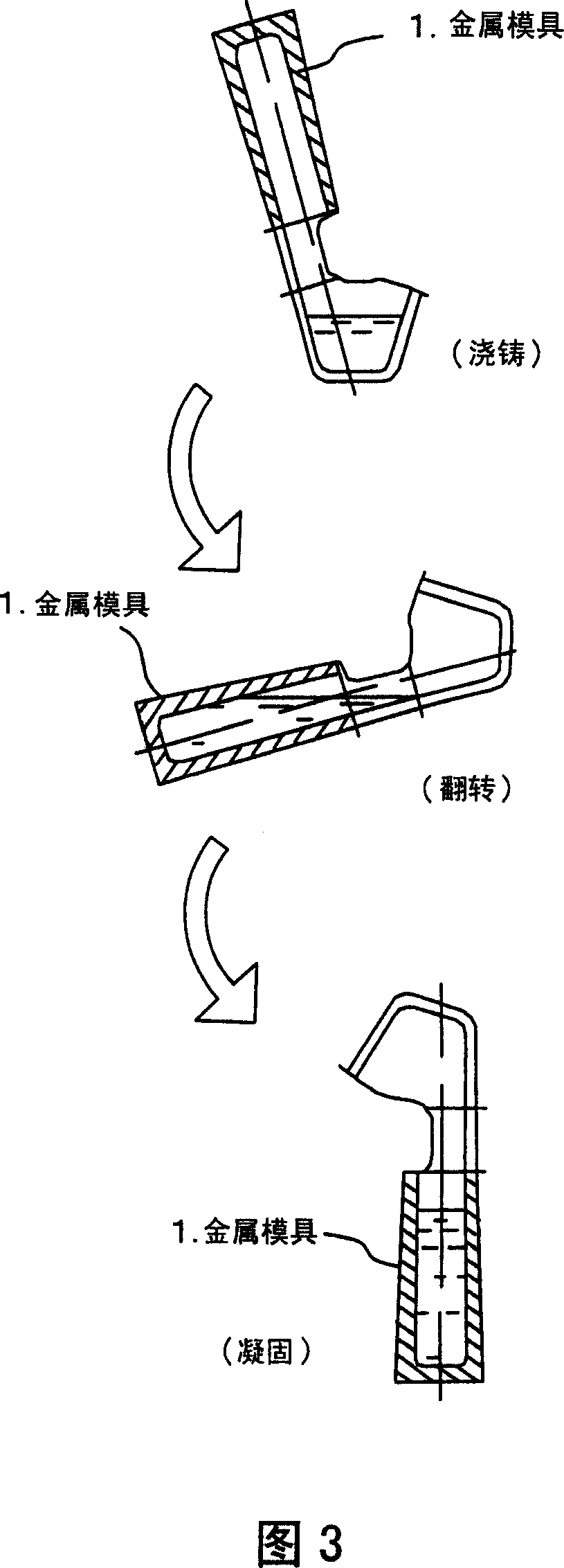

A copper alloy that has a specific chemical composition, the balance being Cu and impurities, in which the relationship between the total number N and the diameter X satisfies the following formula (1). This copper alloy is obtained by cooling a bloom, a slab, a billet or an ingot in at least a temperature range from the temperature of the bloom, the slab, the billet or the ingot just after casting to 450 DEG C, at a cooling rate of 0.5 DEG C / s or more. After the cooling, working in a temperature range of 600 DEG C or lower and further heat treatment of holding for 30 seconds or more in a temperature range of 150 to 750 DEG C are desirably performed. The working and the heat treatment are most desirably performed for a plurality of times. logN 0.4742 + 17.629 exp - 0.1133 X wherein N means the total number of precipitates and inclusions, having a diameter of not smaller than 1 [mu]m which are found in 1 mm 2 of the alloy; and X means the diameter in [mu]m of the precipitates and the inclusions having a diameter of not smaller than 1 [mu]m.

Owner:SUMITOMO METAL IND LTD

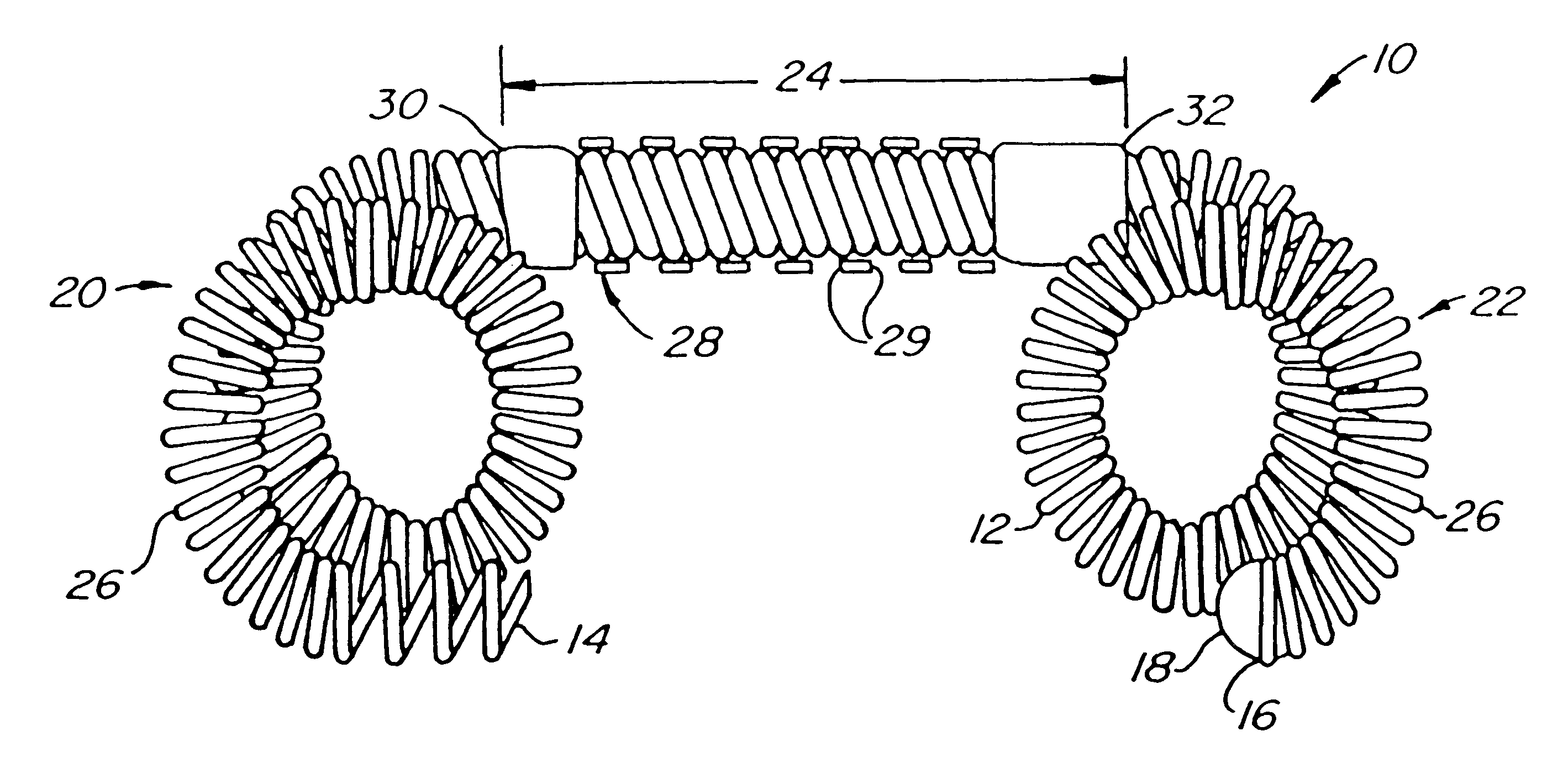

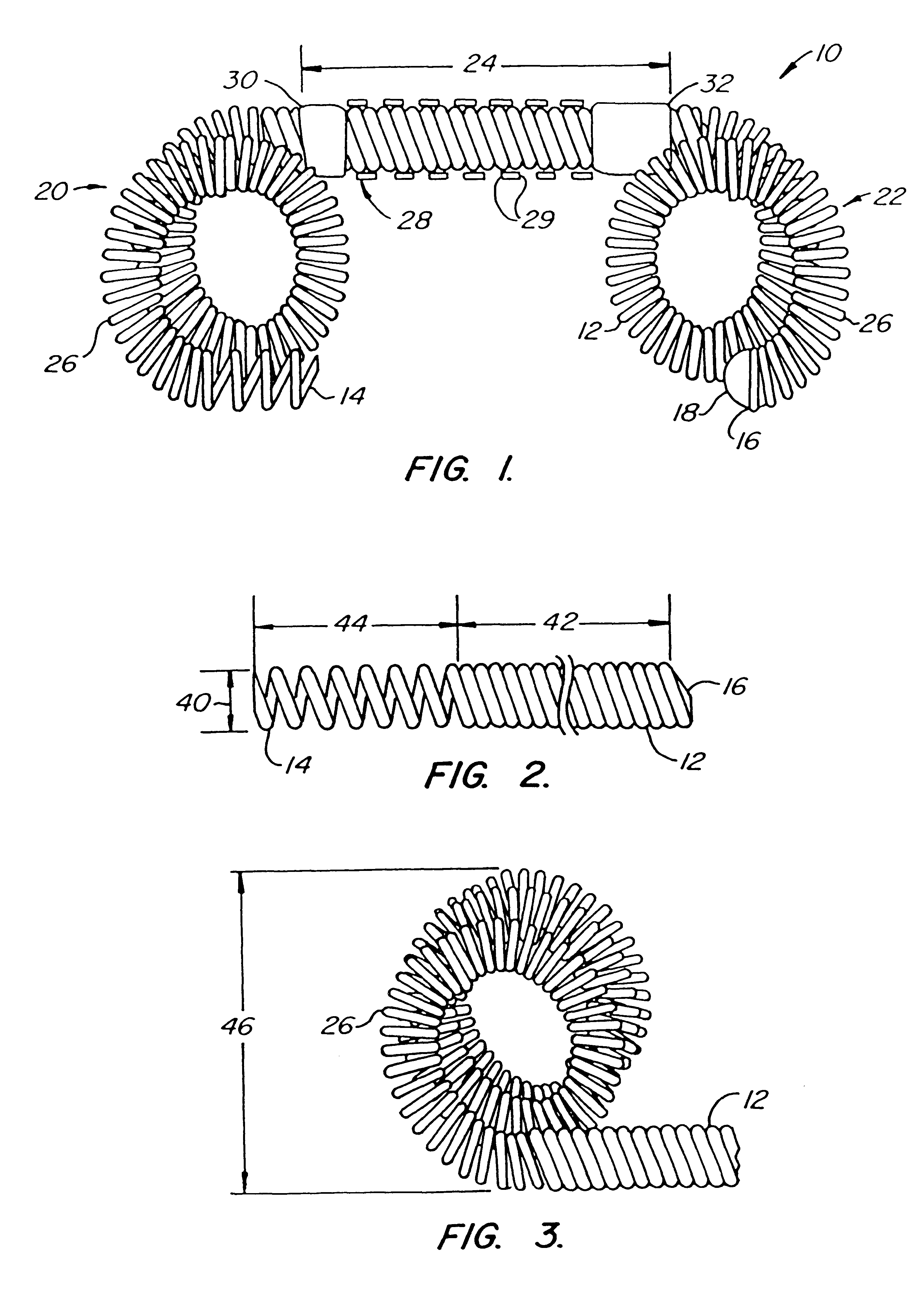

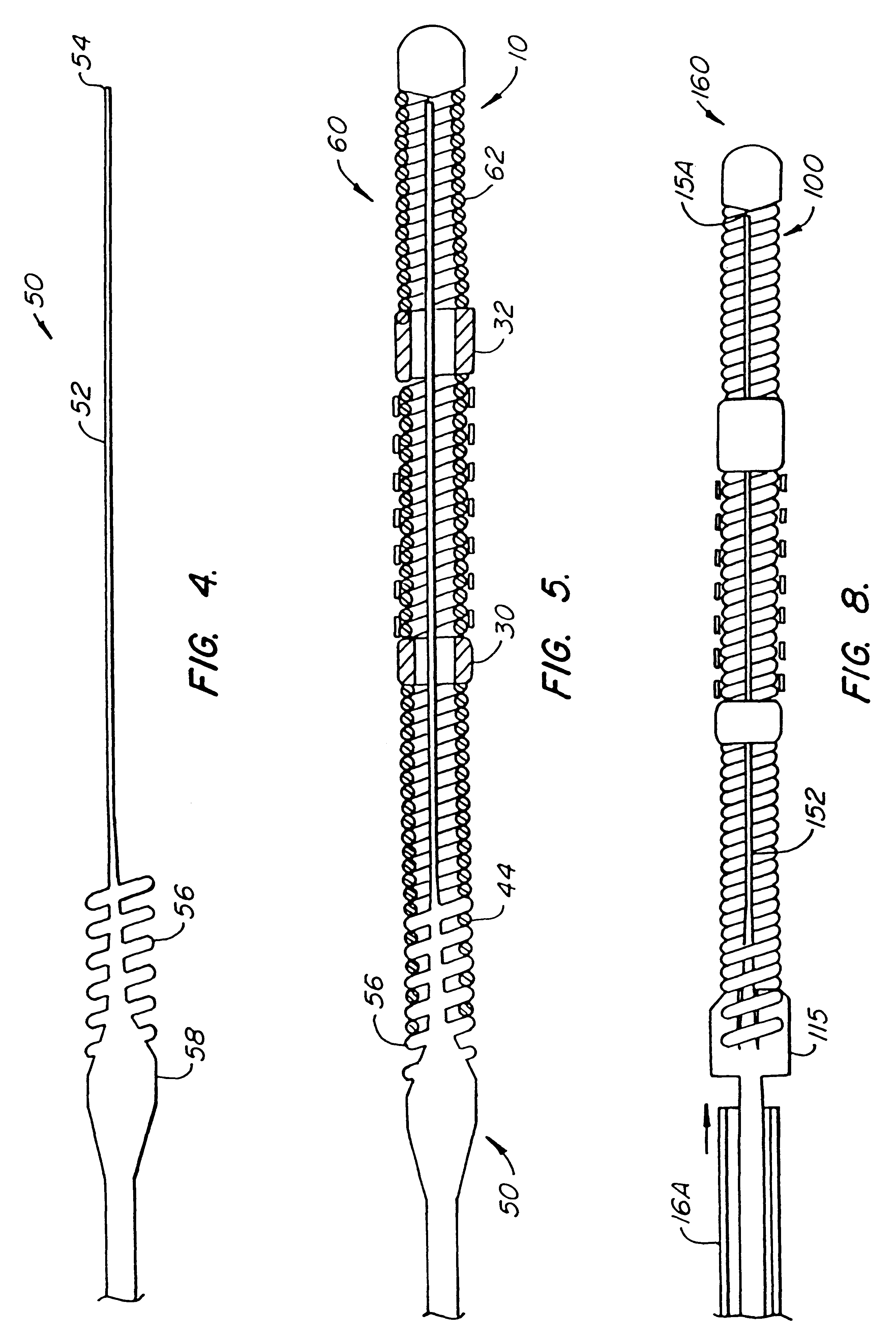

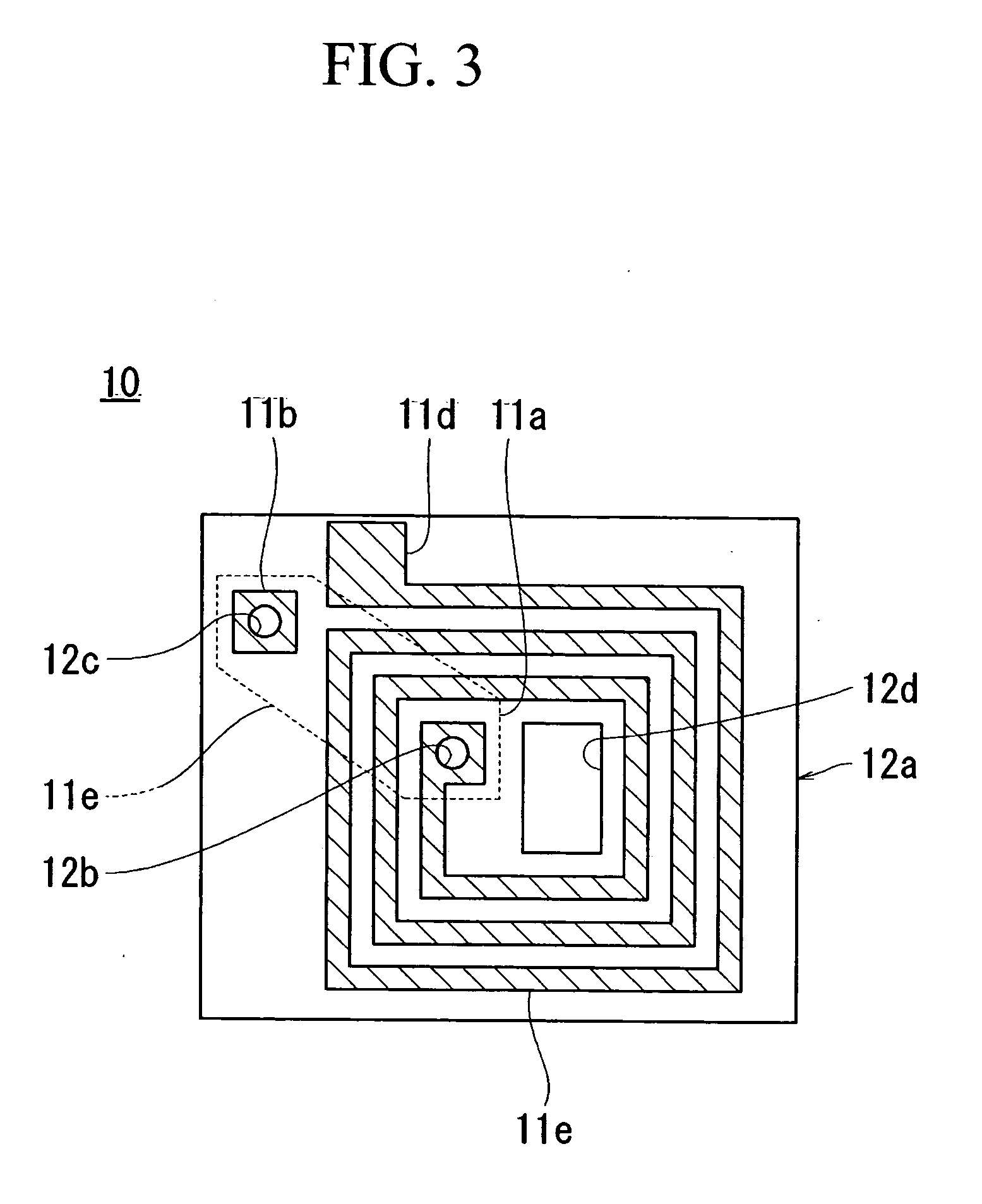

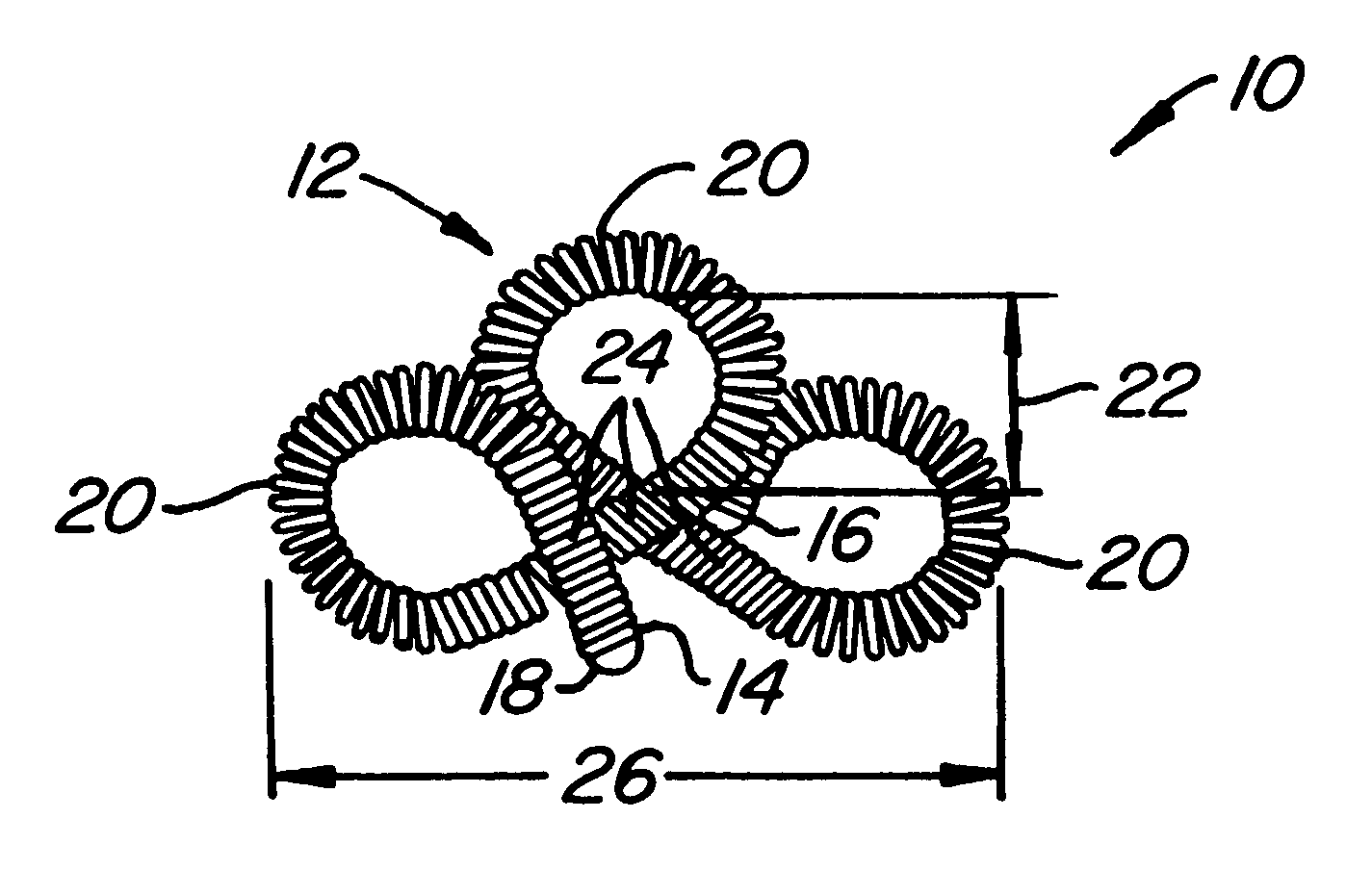

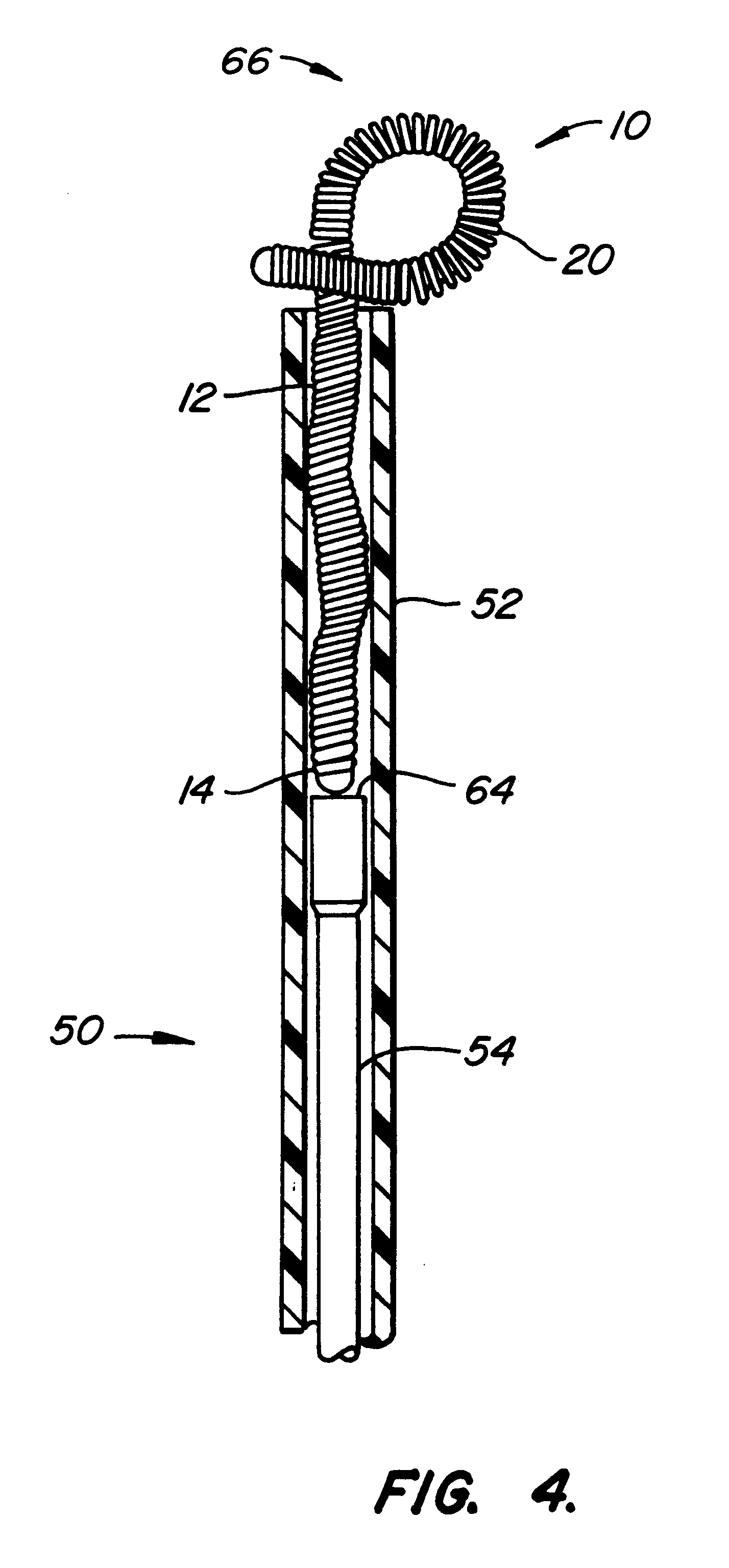

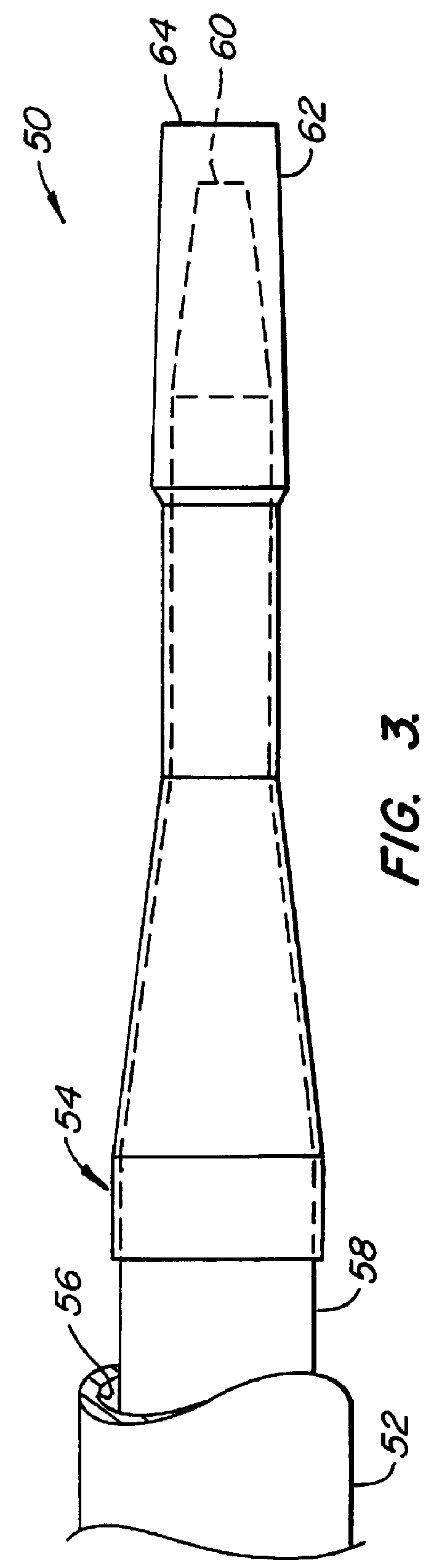

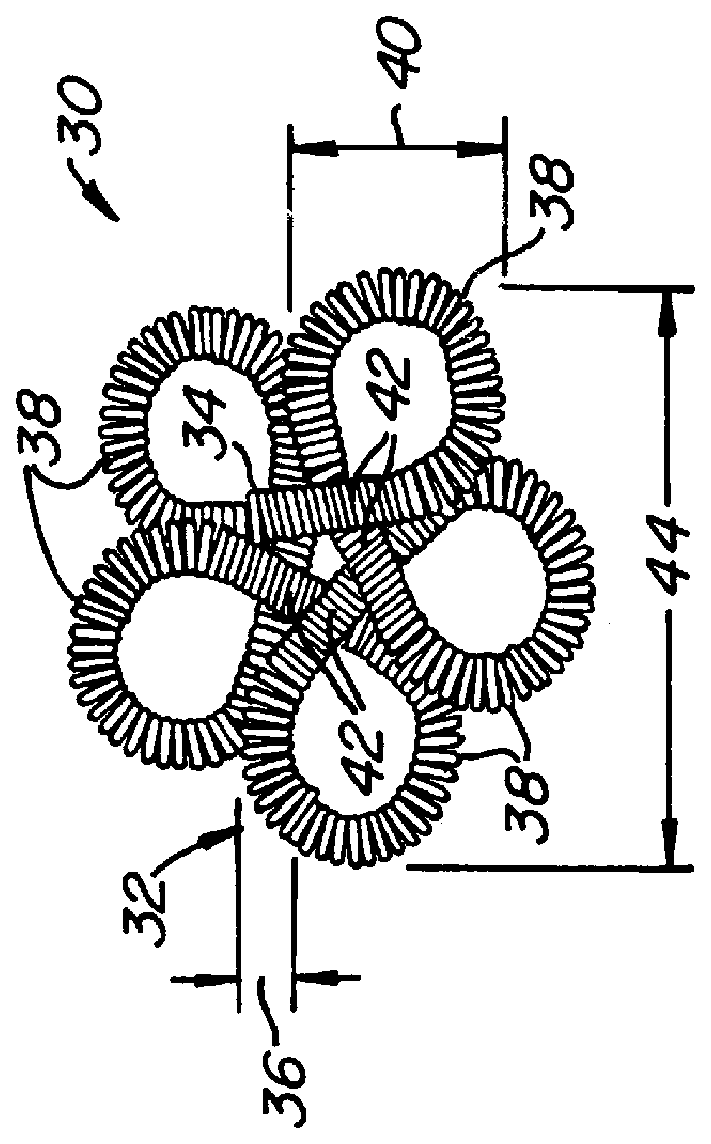

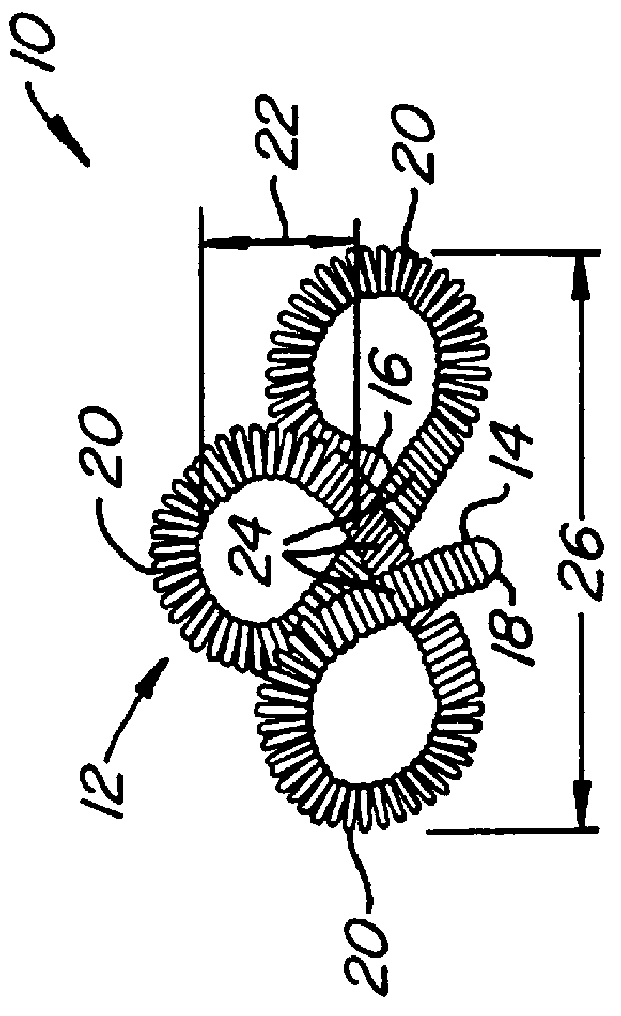

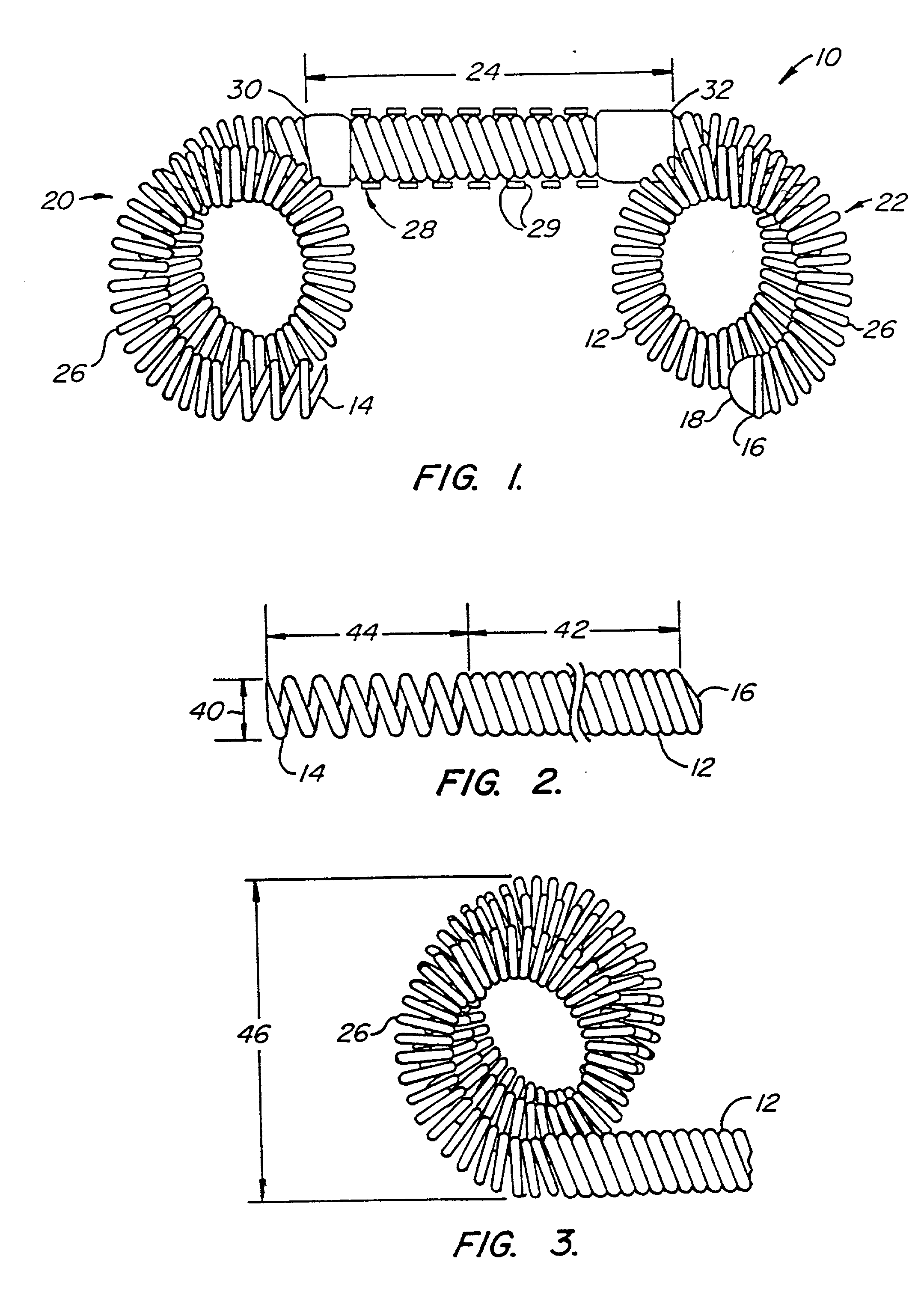

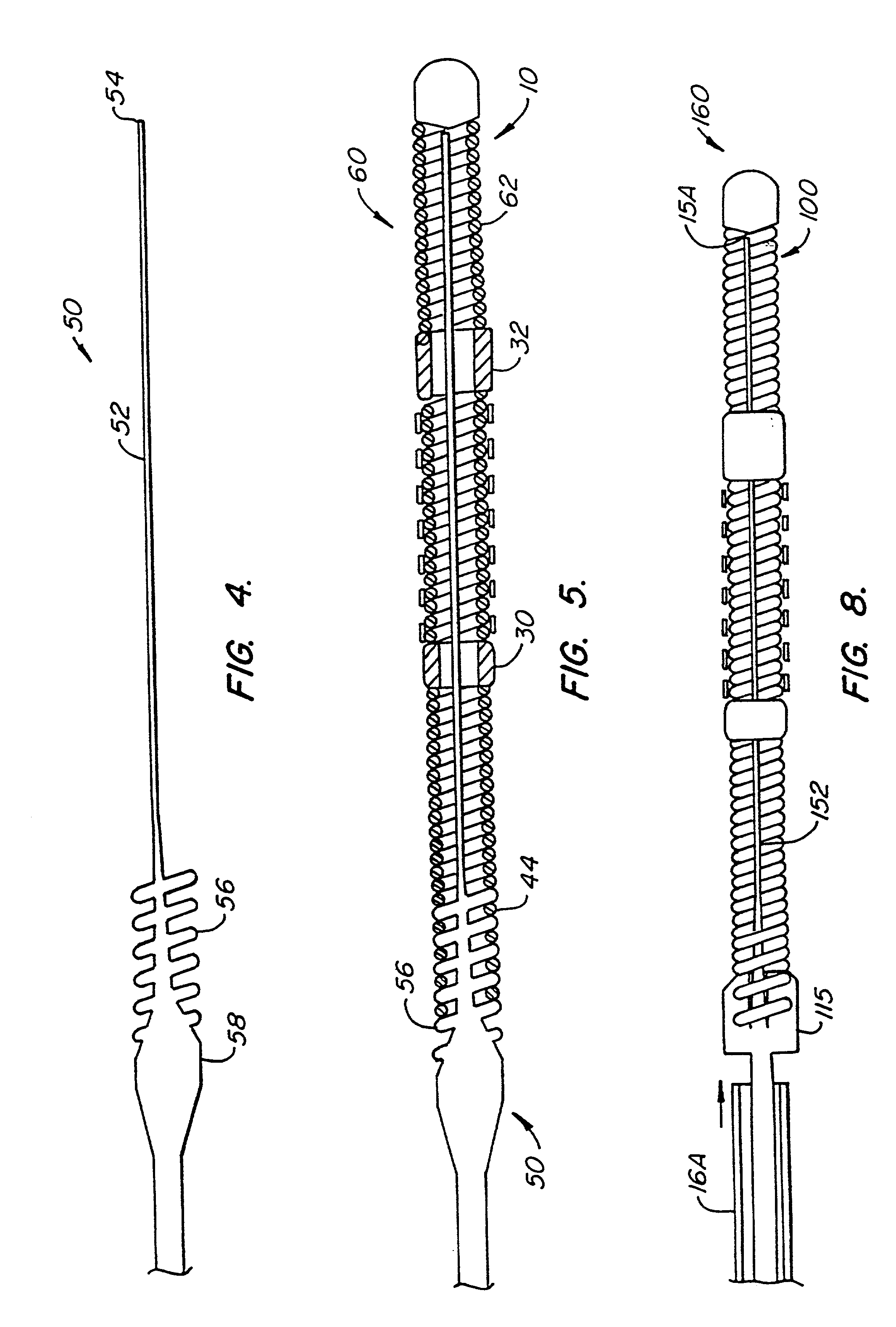

Contraceptive transcervical fallopian tube occlusion devices and methods

The invention provides intrafallopian devices and non-surgical methods for their placement to prevent conception. The efficacy of the device is enhanced by forming the structure at least in part from copper or a copper alloy. The device is anchored within the fallopian tube by a lumen-traversing region of the resilient structure which has a helical outer surface, together with a portion of the resilient structure which is biased to form a bent secondary shape, the secondary shape having a larger cross-section than the fallopian tube. The resilient structure is restrained in a straight configuration and transcervically inserted within the fallopian tube, where it is released. Optionally, permanent sterilization is effected by passing a current through the resilient structure to the tubal walls.

Owner:BAYER ESSURE

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

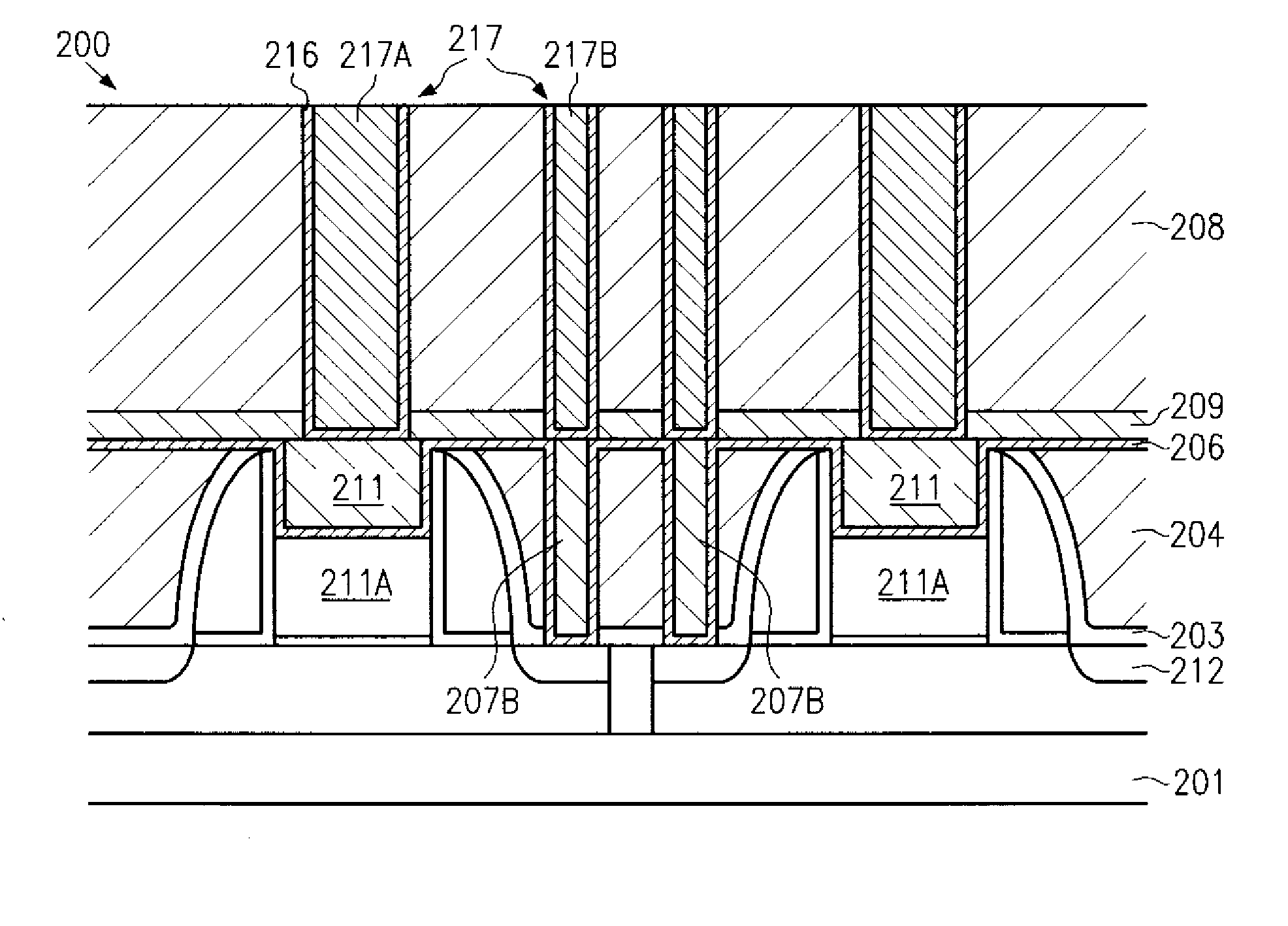

Semiconductor device comprising a contact structure based on copper and tungsten

ActiveUS20070099414A1Reduce resistanceLower resistanceTransistorSemiconductor/solid-state device detailsInter layerDevice material

By providing contact plugs having a lower plug portion, formed on the basis of well-established tungsten-based technologies, and an upper plug portion, which may comprise a highly conductive material such as copper or a copper alloy, a significant increase in conductivity of the contact structure may be achieved. For this purpose, after the deposition of a first dielectric layer of the inter-layer stack, a planarization process may be performed so as to allow the formation of the lower plug portions on the basis of tungsten, while, after the deposition of the second dielectric layer, a corresponding copper-based technology may be used for forming the upper plug portions of significantly enhanced conductivity.

Owner:GLOBALFOUNDRIES US INC

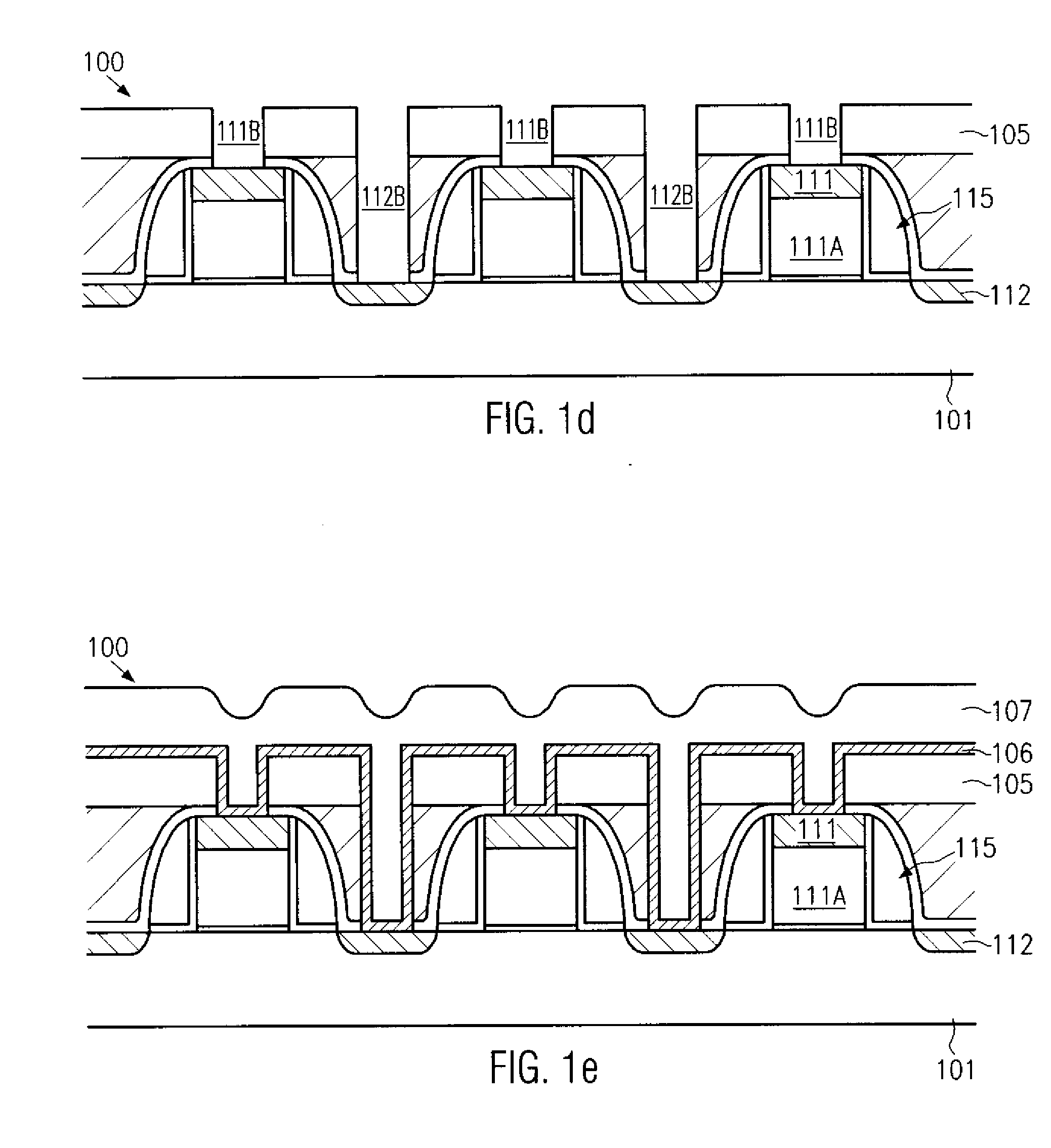

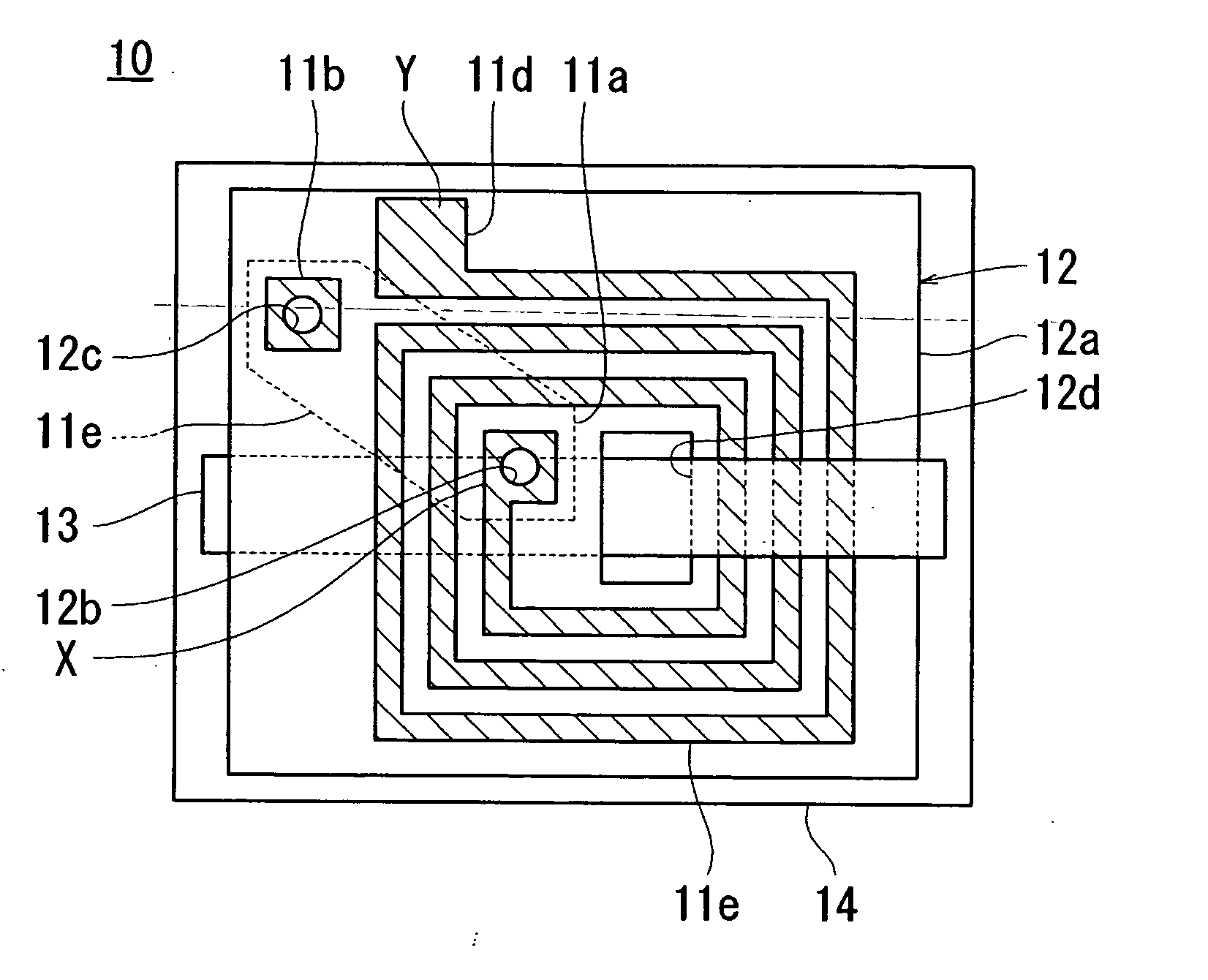

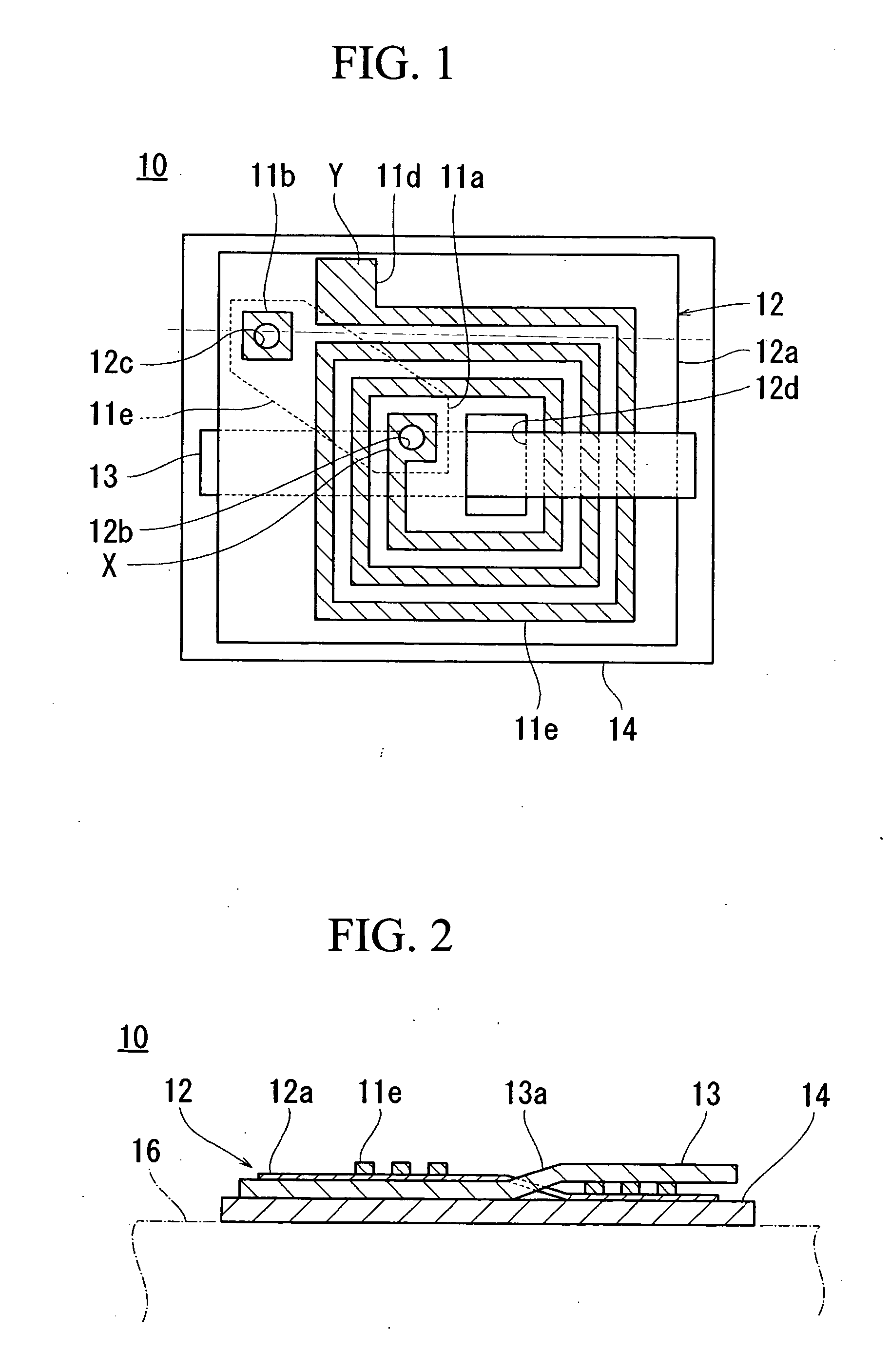

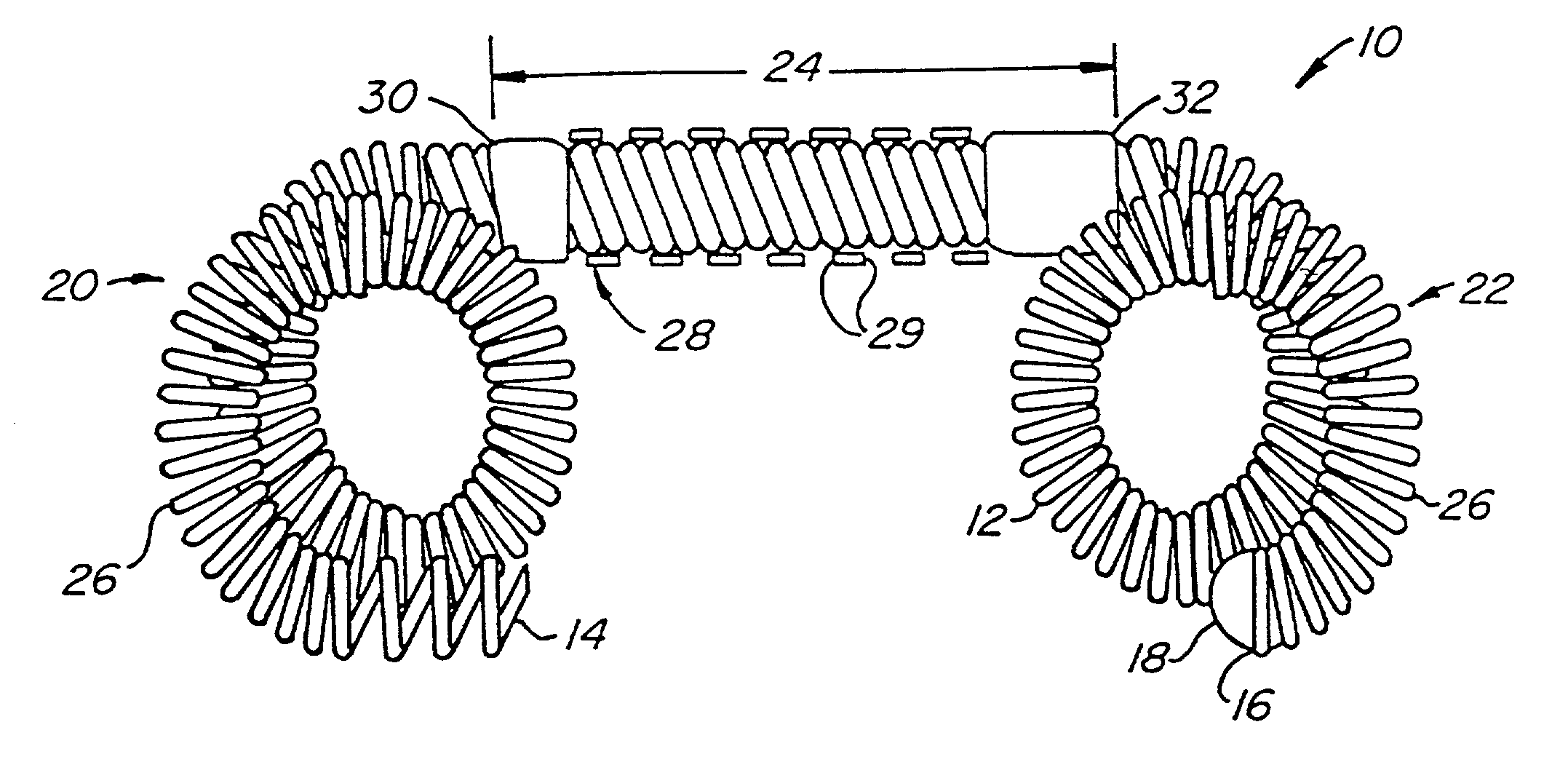

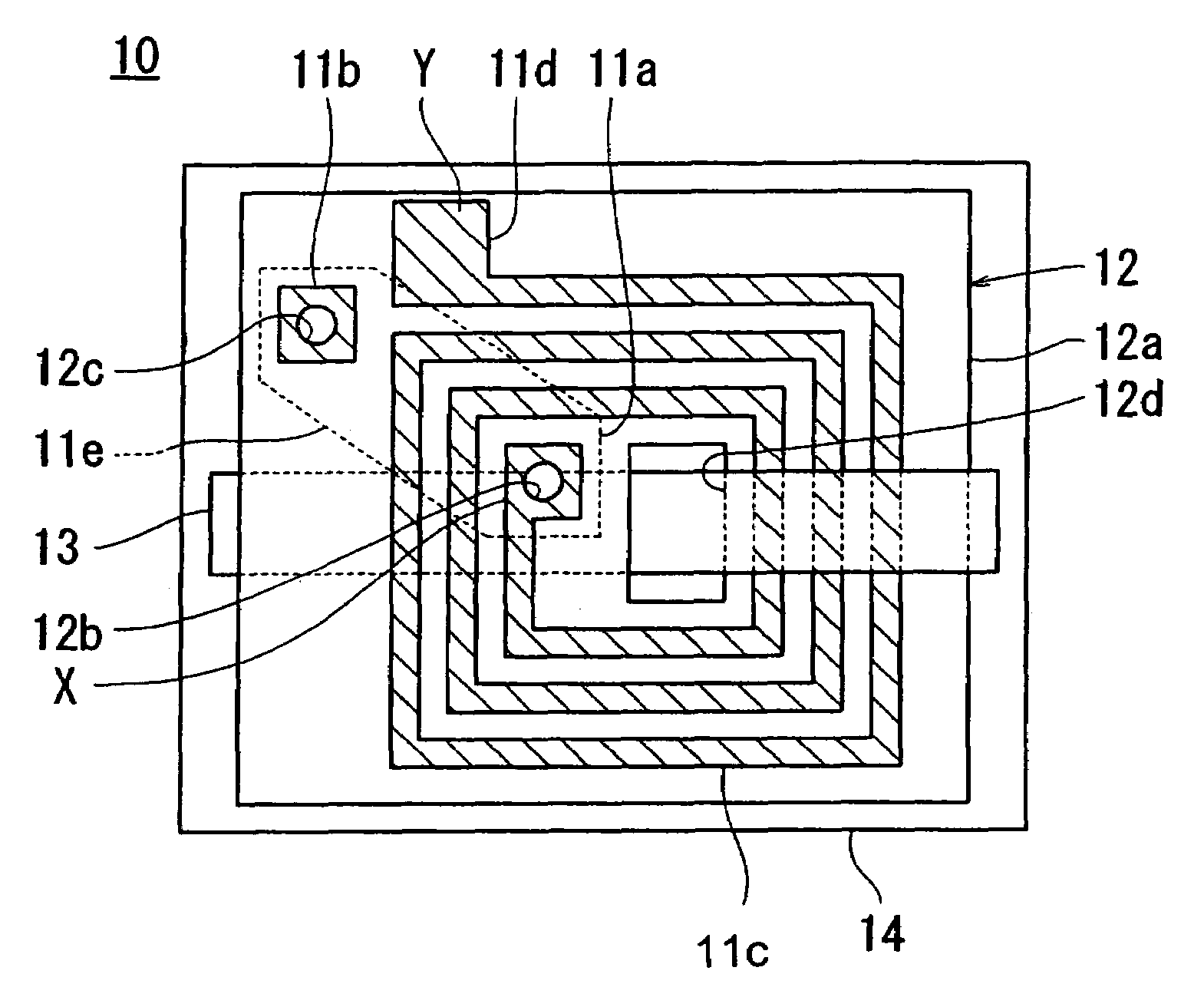

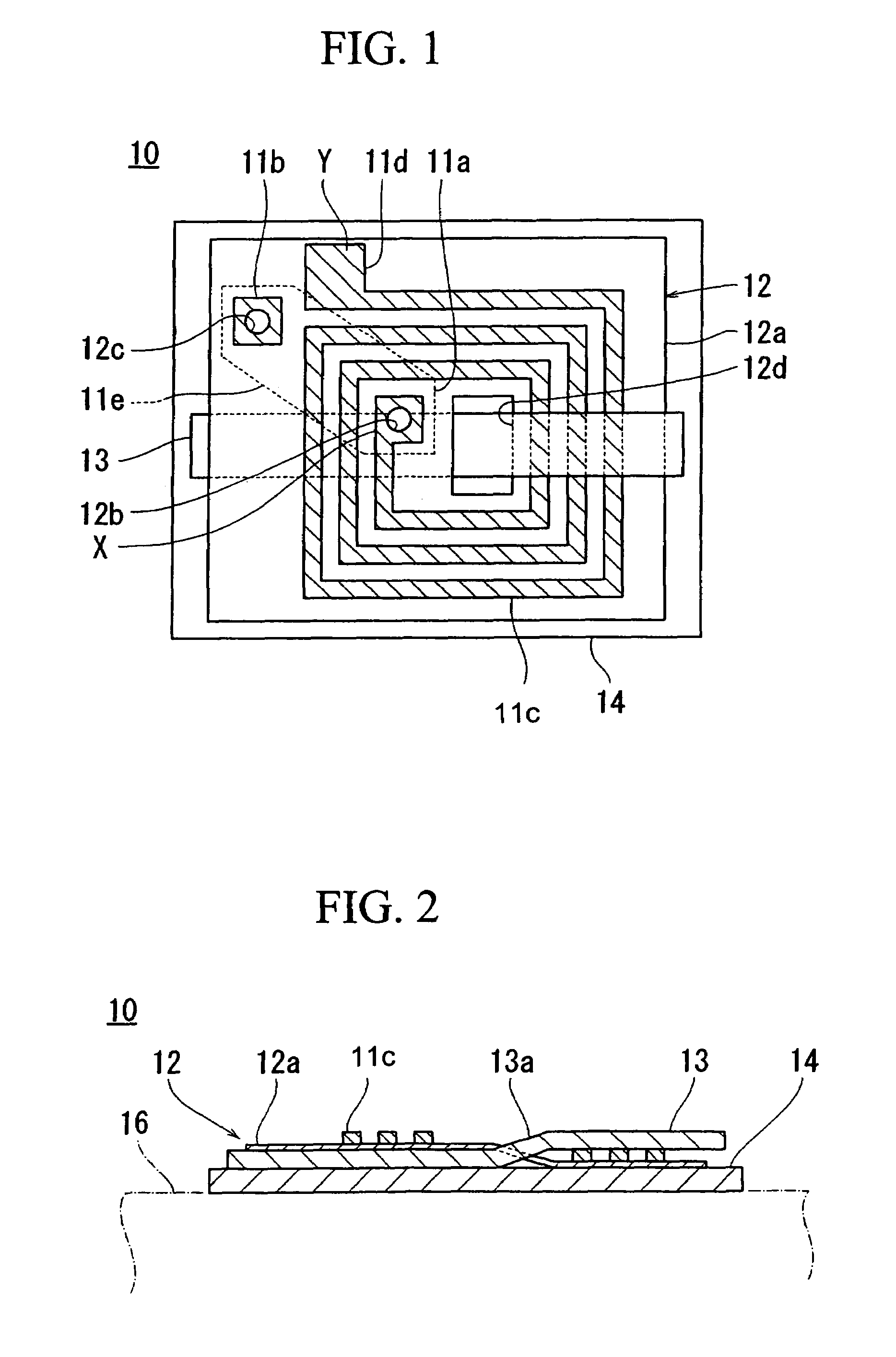

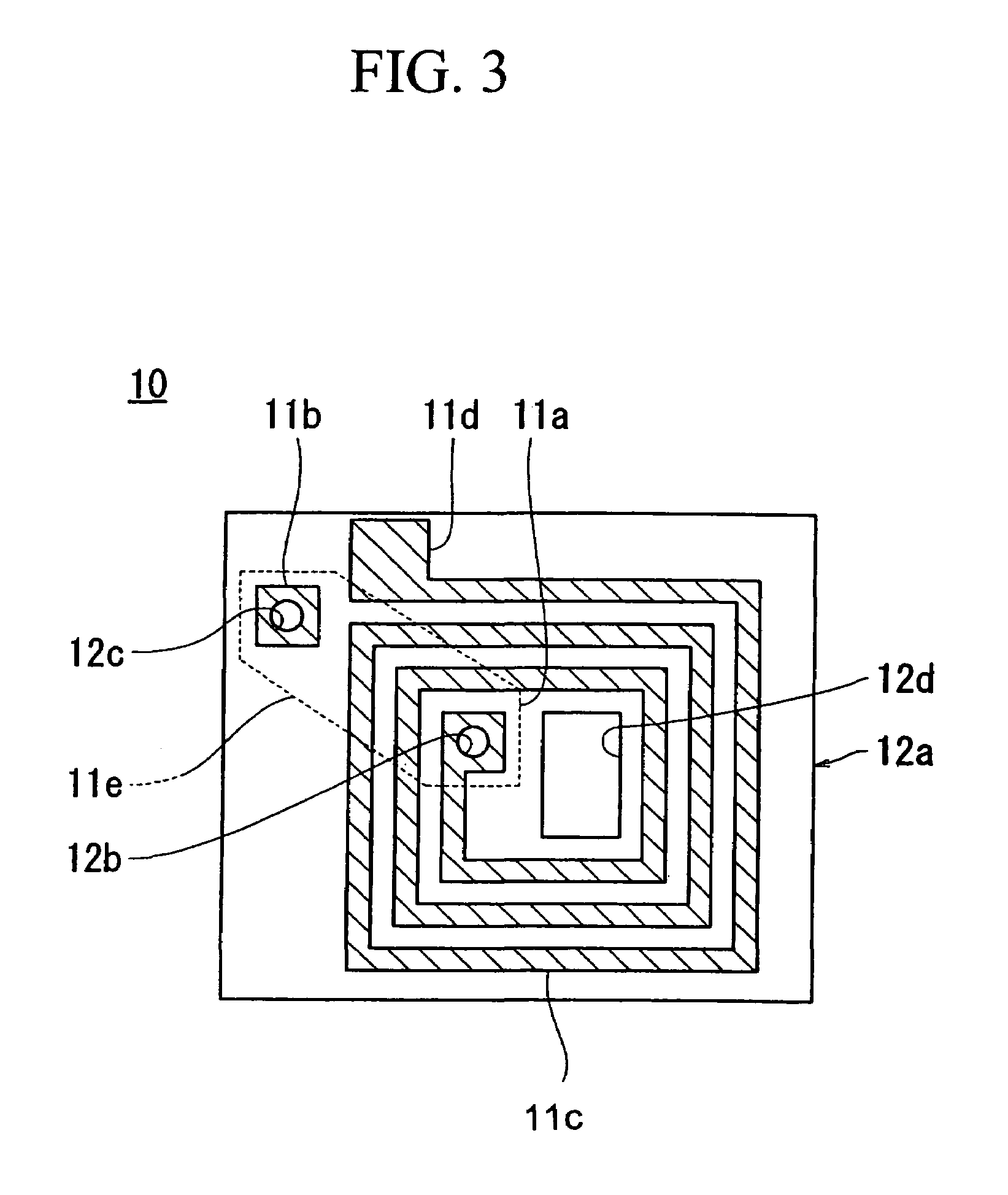

Antenna coil and rfid-use tag using it, transponder-use antenna

InactiveUS20050007296A1Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterAir coreNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

Contraceptive transcervical fallopian tube occlusion devices and their delivery

InactiveUS6176240B1Good curative effectLess readily restrainedFallopian occludersFemale contraceptivesObstetricsSalpingostomy

The invention provides intrafallopian devices and non-surgical methods for their placement to prevent conception. The efficacy of the device is enhanced by forming the structure at least in part from copper or a copper alloy. The device is anchored within the fallopian tube by imposing a secondary shape on a resilient structure, the secondary shape having a larger cross-section than the fallopian tube. The resilient structure is restrained in a straight configuration and transcervically inserted within the fallopian tube, where it is released. The resilient structure is then restrained by the walls of the fallopian tube, imposing anchoring forces as it tries to resume the secondary shape.

Owner:BAYER ESSURE

Electrically affixed transcervical fallopian tube occlusion devices

InactiveUS6145505AGood curative effectLess readily restrainedFallopian occludersFemale contraceptivesObstetricsSalpingostomy

The invention provides intrafallopian devices and non-surgical methods for their placement to prevent conception. The efficacy of the device is enhanced by forming the structure at least in part from copper or a copper alloy. The device is anchored within the fallopian tube by imposing a secondary shape on a resilient structure, the secondary shape having a larger cross-section than the fallopian tube. The resilient structure is restrained in a straight configuration and transcervically inserted within the fallopian tube, where it is released. The resilient structure is then restrained by the walls of the fallopian tube, imposing anchoring forces as it tries to resume the secondary shape.

Owner:BAYER ESSURE

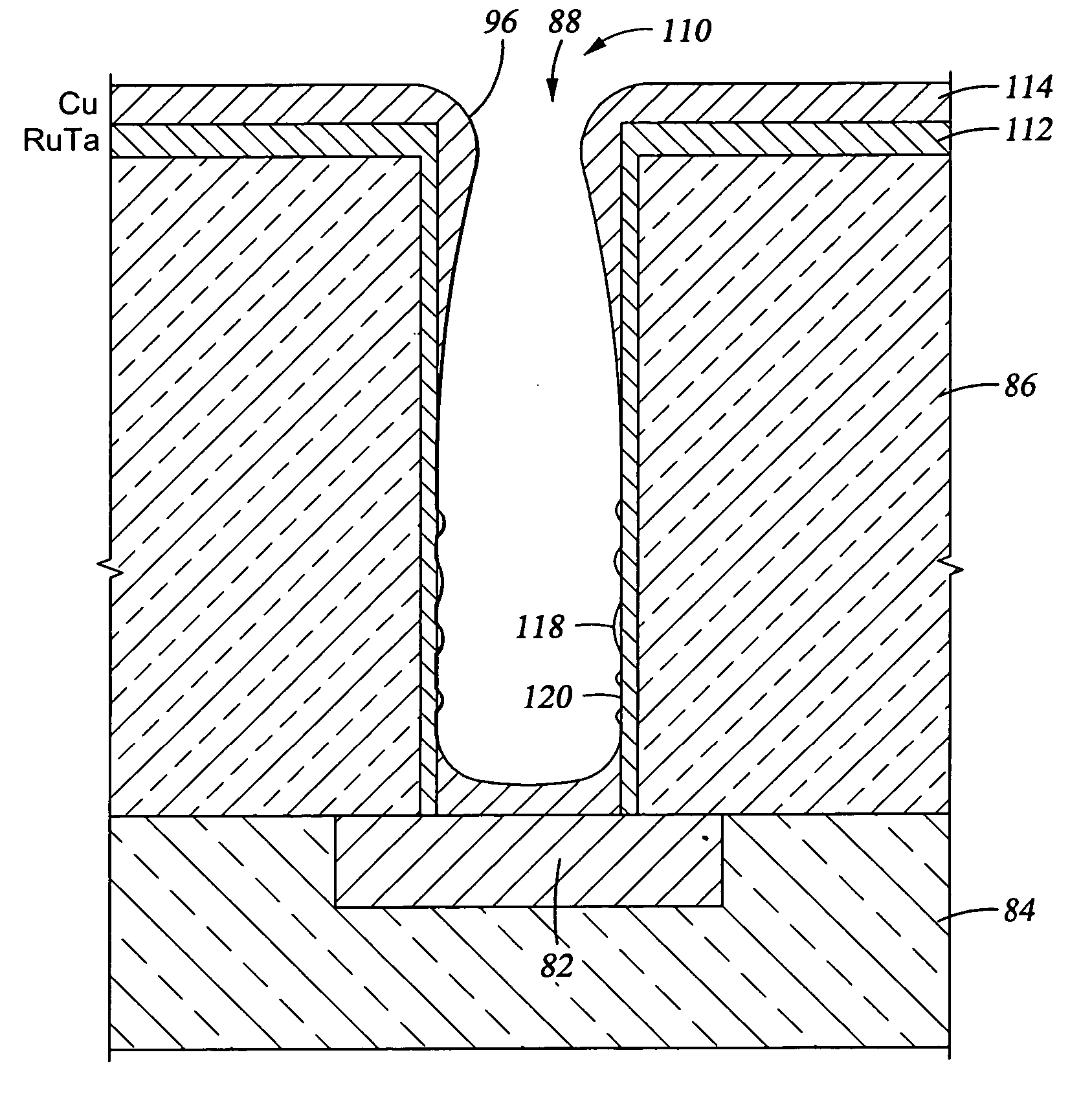

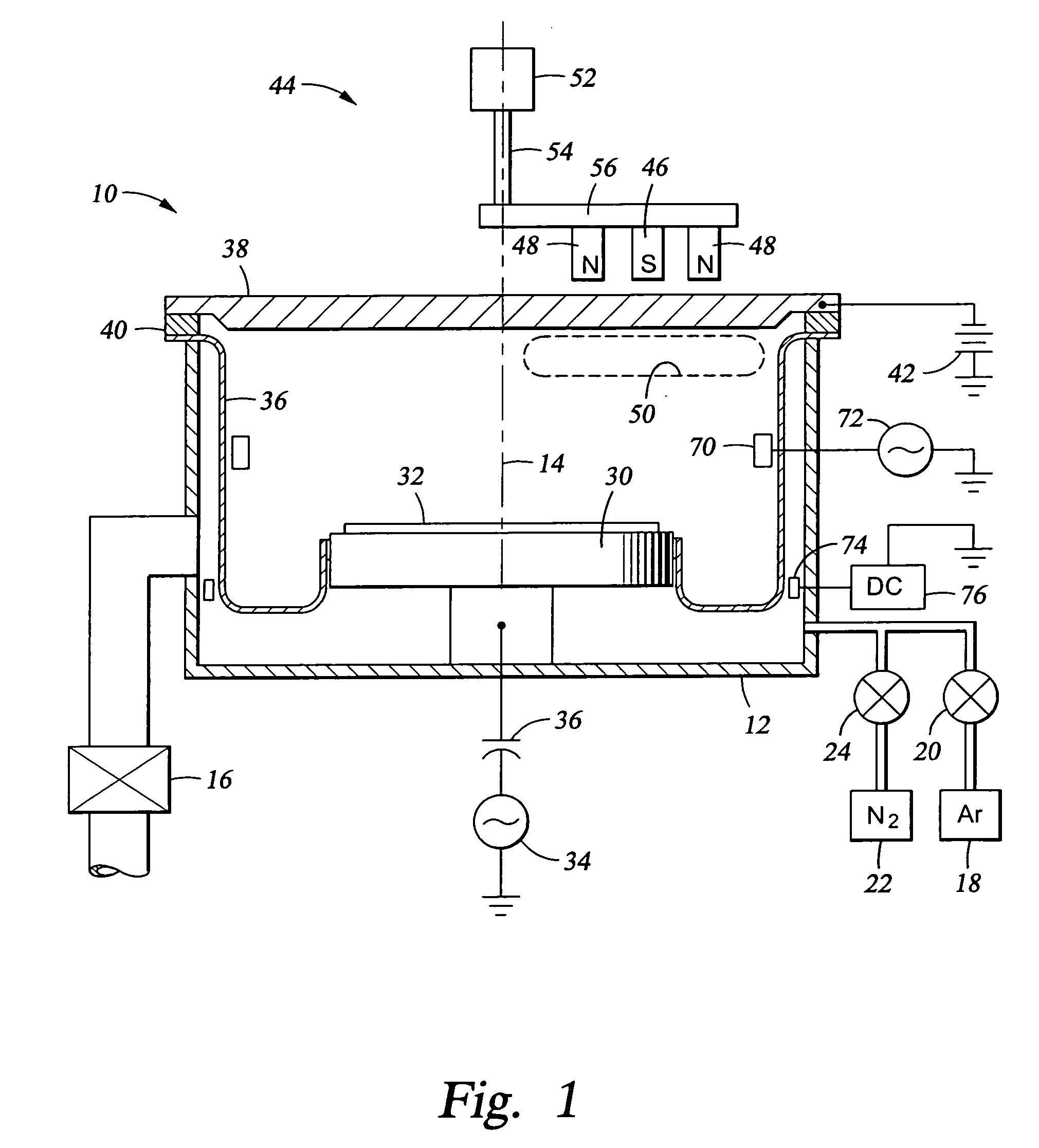

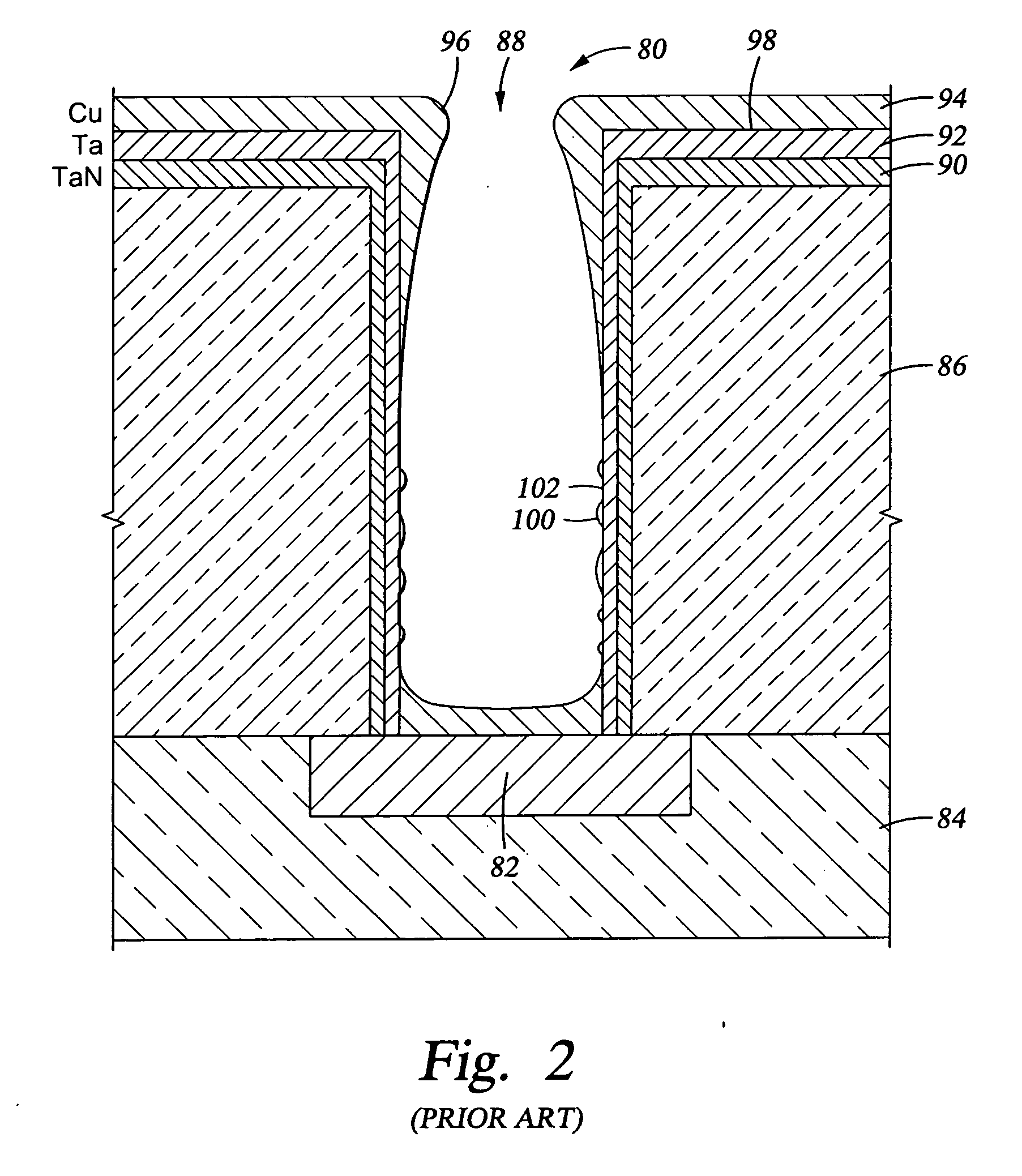

Integrated process for sputter deposition of a conductive barrier layer, especially an alloy of ruthenium and tantalum, underlying copper or copper alloy seed layer

InactiveUS20070059502A1Effective interfacial barrierGood suitSemiconductor/solid-state device detailsVacuum evaporation coatingMoisture barrierRefractory metals

A fabrication method and a product for the deposition of a conductive barrier or other liner layer in a vertical electrical interconnect structure. One embodiment includes within a a hole through a dielectric layer a barrier layer of RuTaN, an adhesion layer of RuTa, and a copper seed layer forming a liner for electroplating of copper. The ruthenium content is preferably greater than 50 at % and more preferably at least 80 at % but less than 95 at %. The barrier and adhesion layers may both be sputter deposited. Other platinum-group elements substitute for the ruthenium and other refractory metals substitute for the tantalum. Aluminum alloying into RuTa when annealed presents a moisture barrier. Copper contacts include different alloying fractions of RuTa to shift the work function to the doping type.

Owner:APPLIED MATERIALS INC

Contraceptive transcervical fallopian tube occlusion devices and methods

InactiveUS20020020417A1Good curative effectLess readily restrainedFallopian occludersDiagnosticsPower flowSalpingostomy

The invention provides intrafallopian devices and non-surgical methods for their placement to prevent conception. The efficacy of the device is enhanced by forming the structure at least in part from copper or a copper alloy. The device is anchored within the fallopian tube by a lumen-traversing region of the resilient structure which has a helical outer surface, together with a portion of the resilient structure which is biased to form a bent secondary shape, the secondary shape having a larger cross-section than the fallopian tube. The resilient structure is restrained in a straight configuration and transcervically inserted within the fallopian tube, where it is released. Optionally, permanent sterilization is effected by passing a current through the resilient structure to the tubal walls.

Owner:BAYER ESSURE

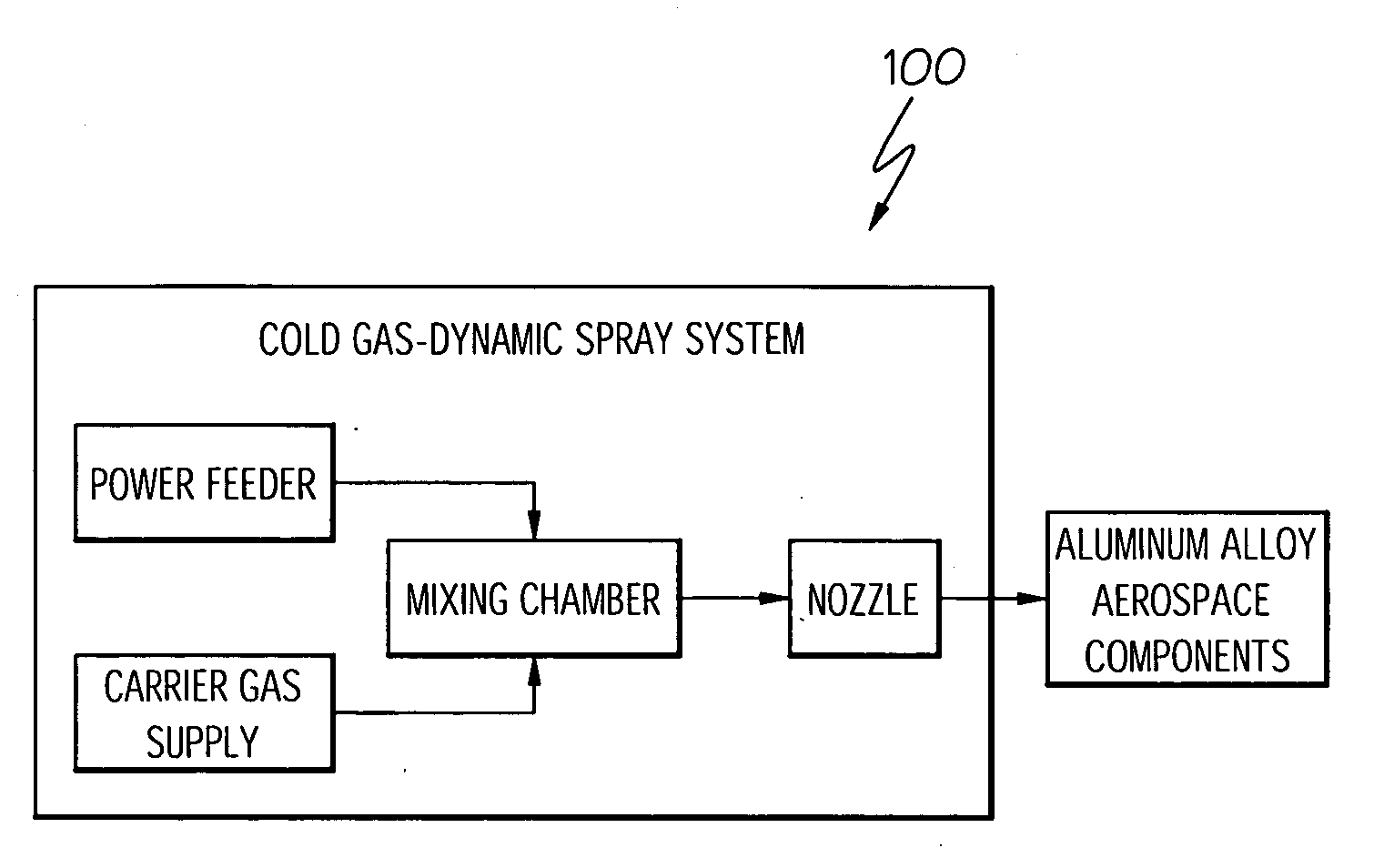

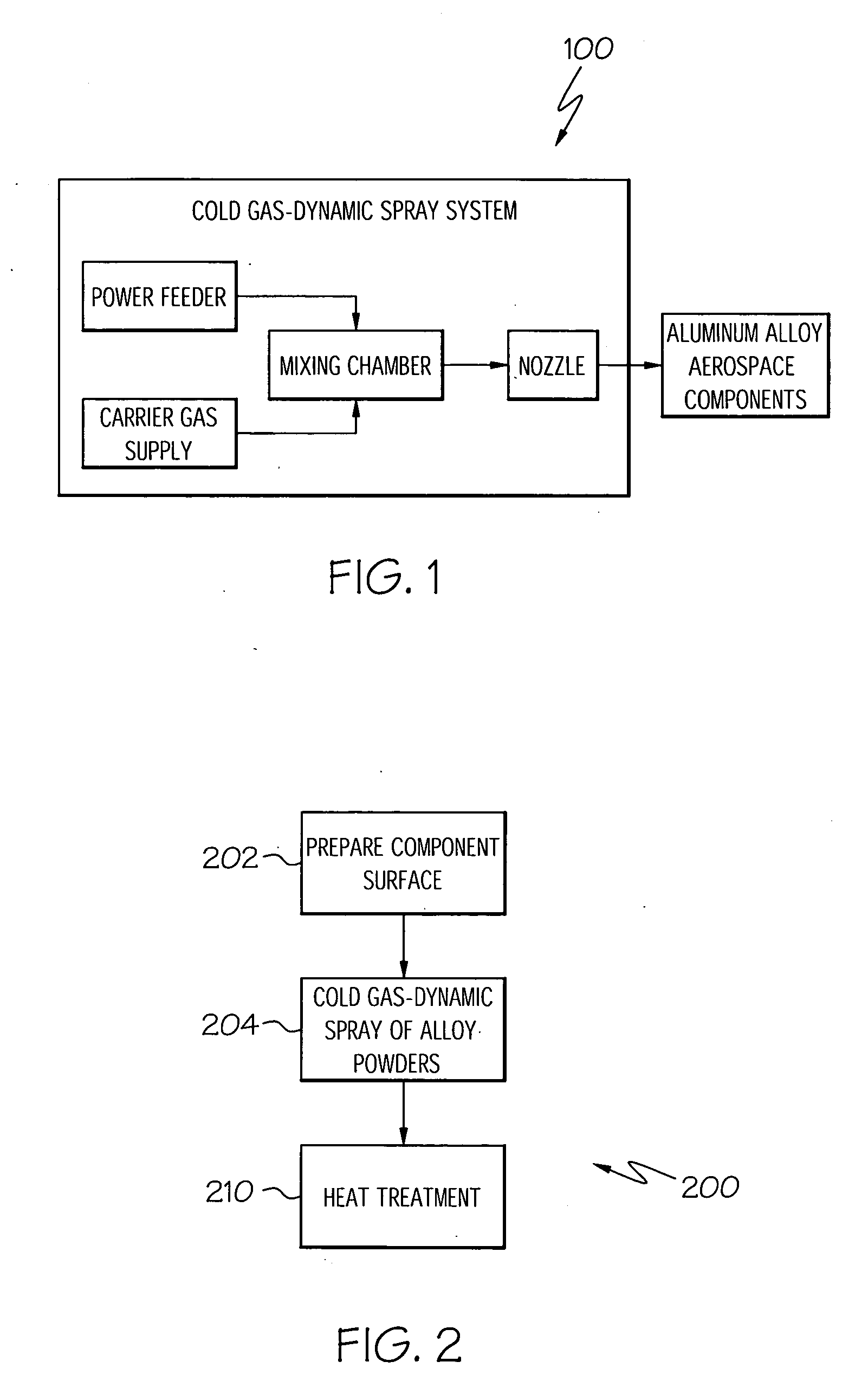

Aluminum articles with wear-resistant coatings and methods for applying the coatings onto the articles

InactiveUS20060093736A1Liquid surface applicatorsSuperimposed coating processWear resistantTitanium alloy

A method for coating a surface of a component formed from aluminum or an alloy thereof includes the step of cold gas-dynamic spraying a powder material on the component surface to form a coating, the powder material comprising at least one alloy from the group consisting of titanium, a titanium alloy, nickel, a nickel alloy, iron, an iron alloy, aluminum, an aluminum alloy, copper, a copper alloy, cobalt, and a cobalt alloy. In one embodiment, the method further includes the step of heat treating the turbine component after the cold gas-dynamic spraying.

Owner:HONEYWELL INT INC

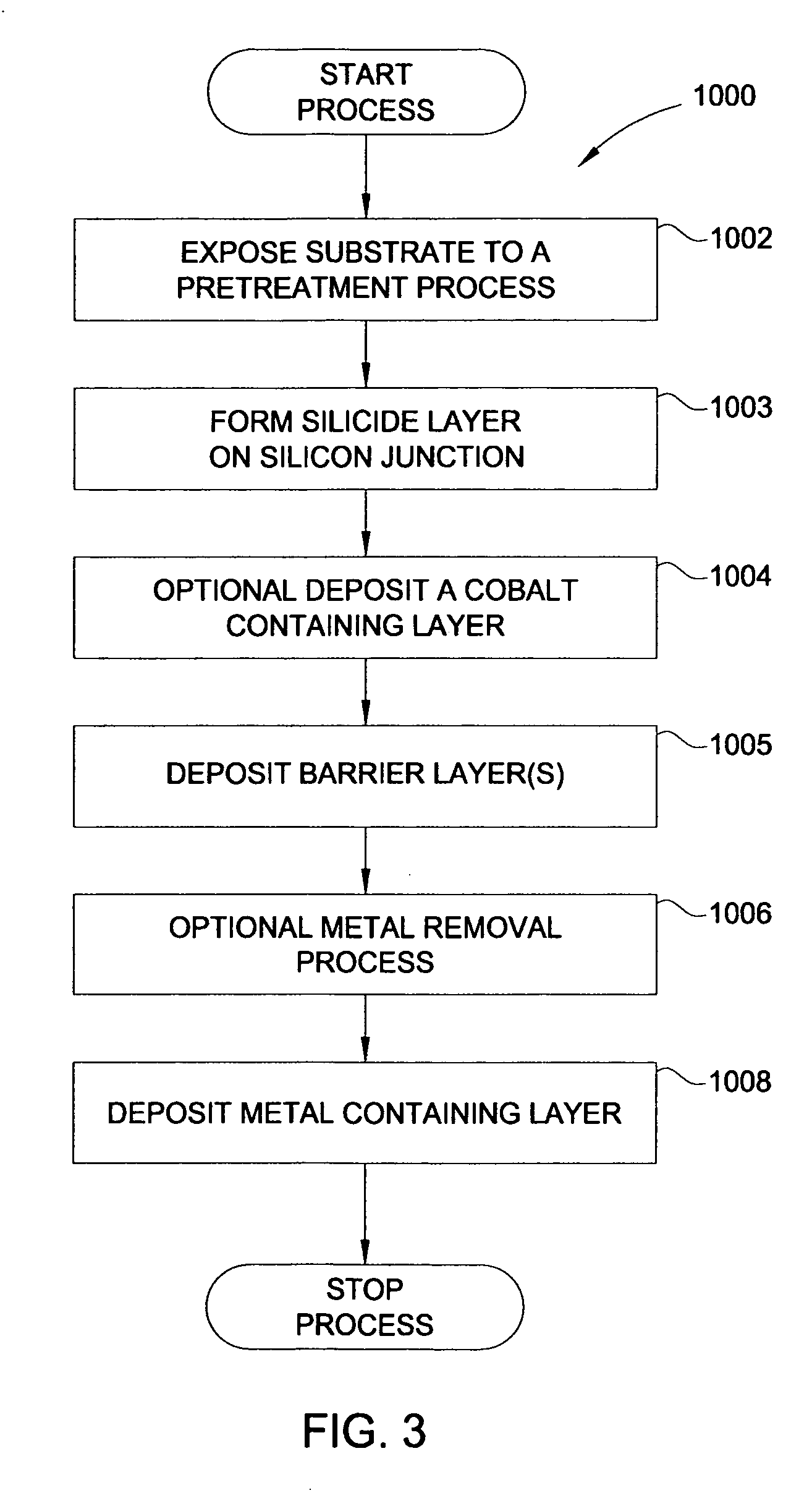

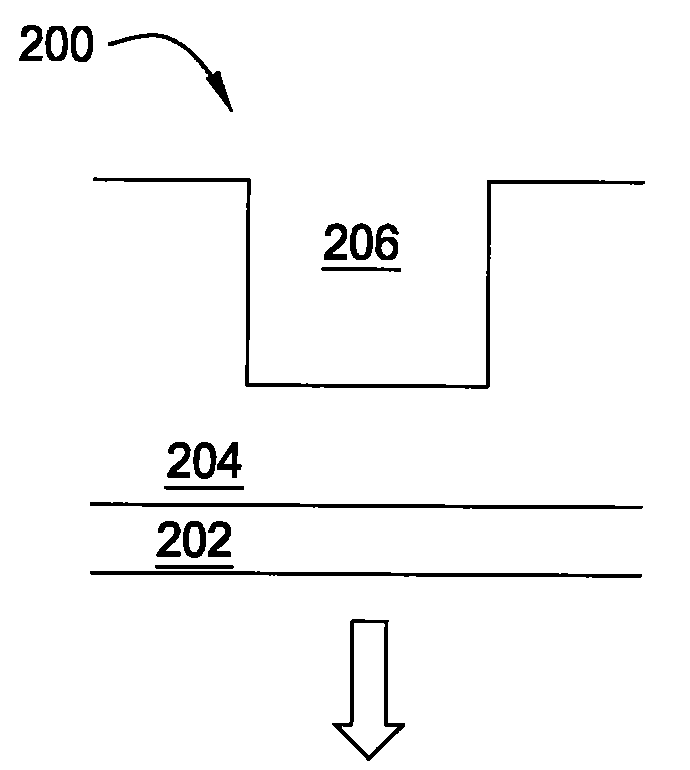

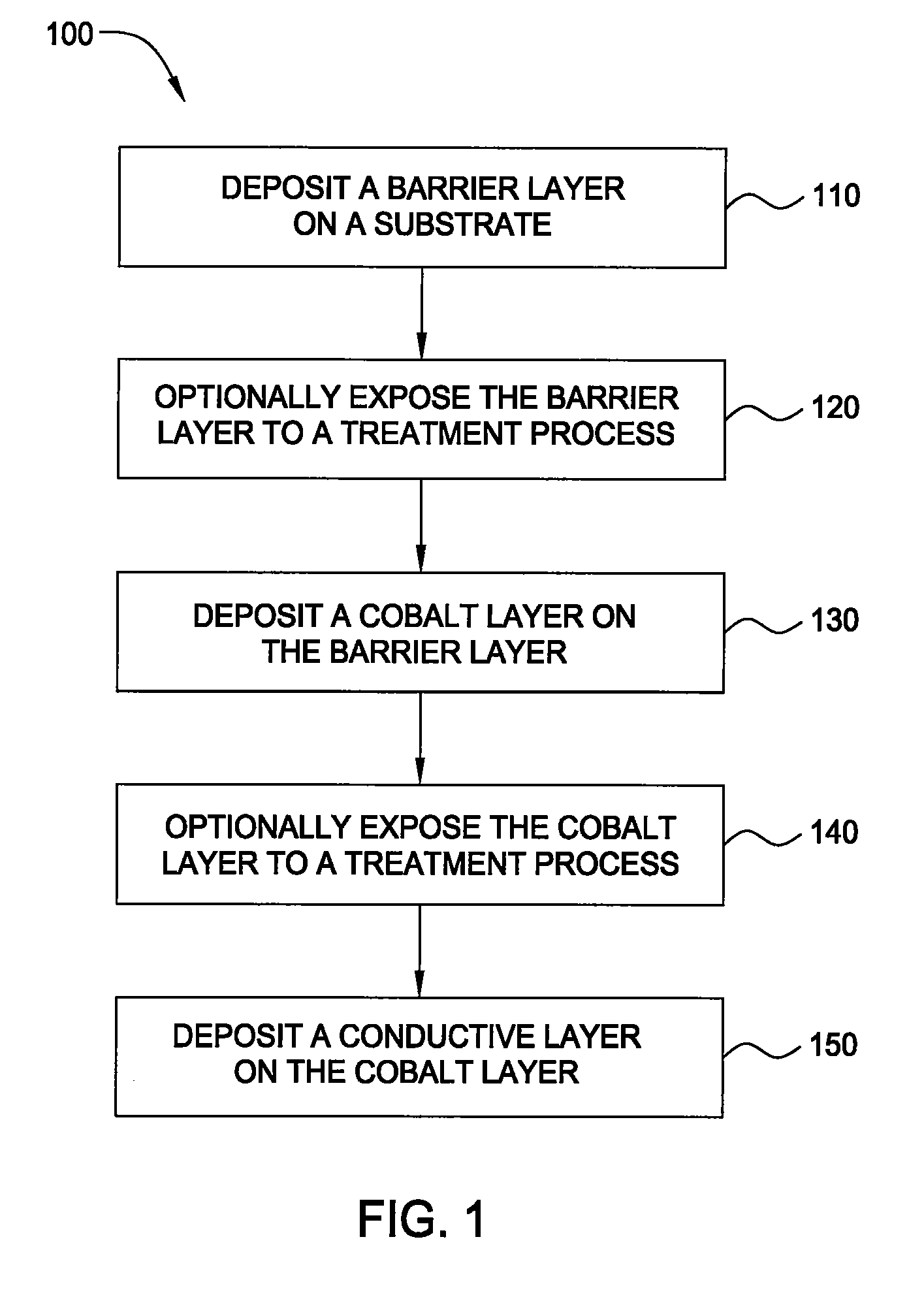

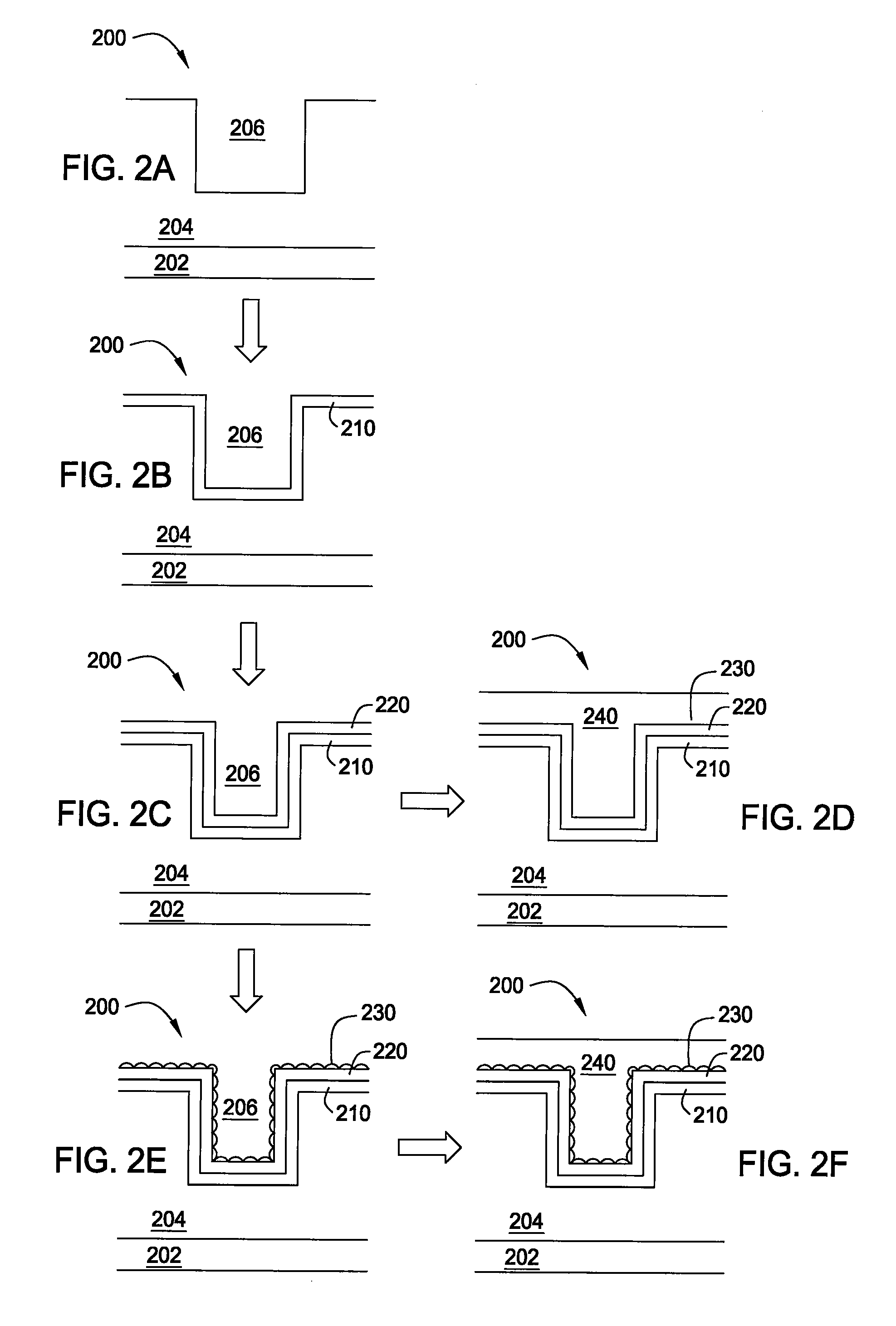

Cobalt deposition on barrier surfaces

ActiveUS20090053426A1Pretreated surfacesSemiconductor/solid-state device manufacturingHydrogenRemote plasma

Embodiments of the invention provide processes for depositing a cobalt layer on a barrier layer and subsequently depositing a conductive material, such as copper or a copper alloy, thereon. In one embodiment, a method for depositing materials on a substrate surface is provided which includes forming a barrier layer on a substrate, exposing the substrate to dicobalt hexacarbonyl butylacetylene (CCTBA) and hydrogen to form a cobalt layer on the barrier layer during a vapor deposition process (e.g., CVD or ALD), and depositing a conductive material over the cobalt layer. In some examples, the barrier layer and / or the cobalt layer may be exposed to a gas or a reagent during a treatment process, such as a thermal process, an in situ plasma process, or a remote plasma process.

Owner:APPLIED MATERIALS INC

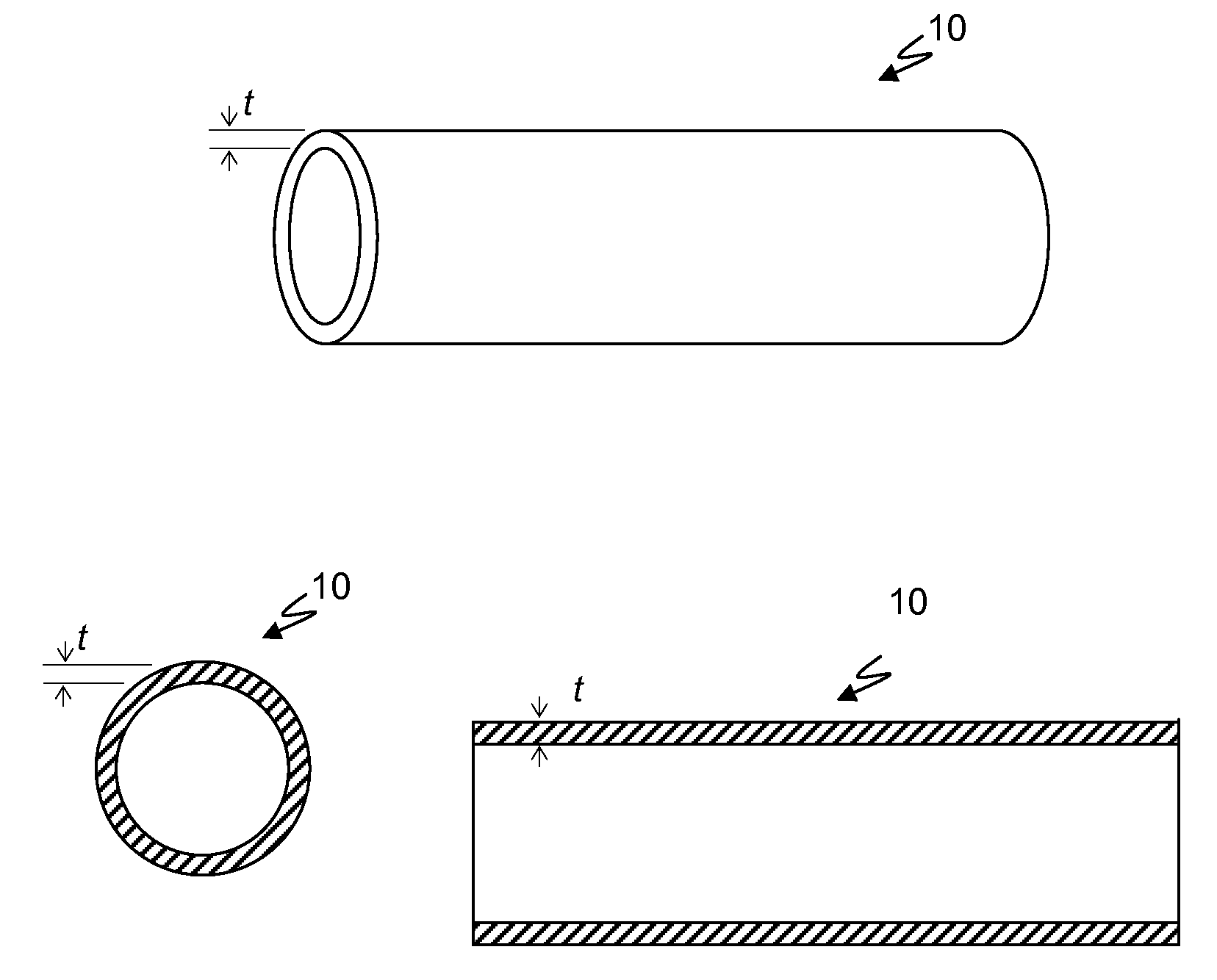

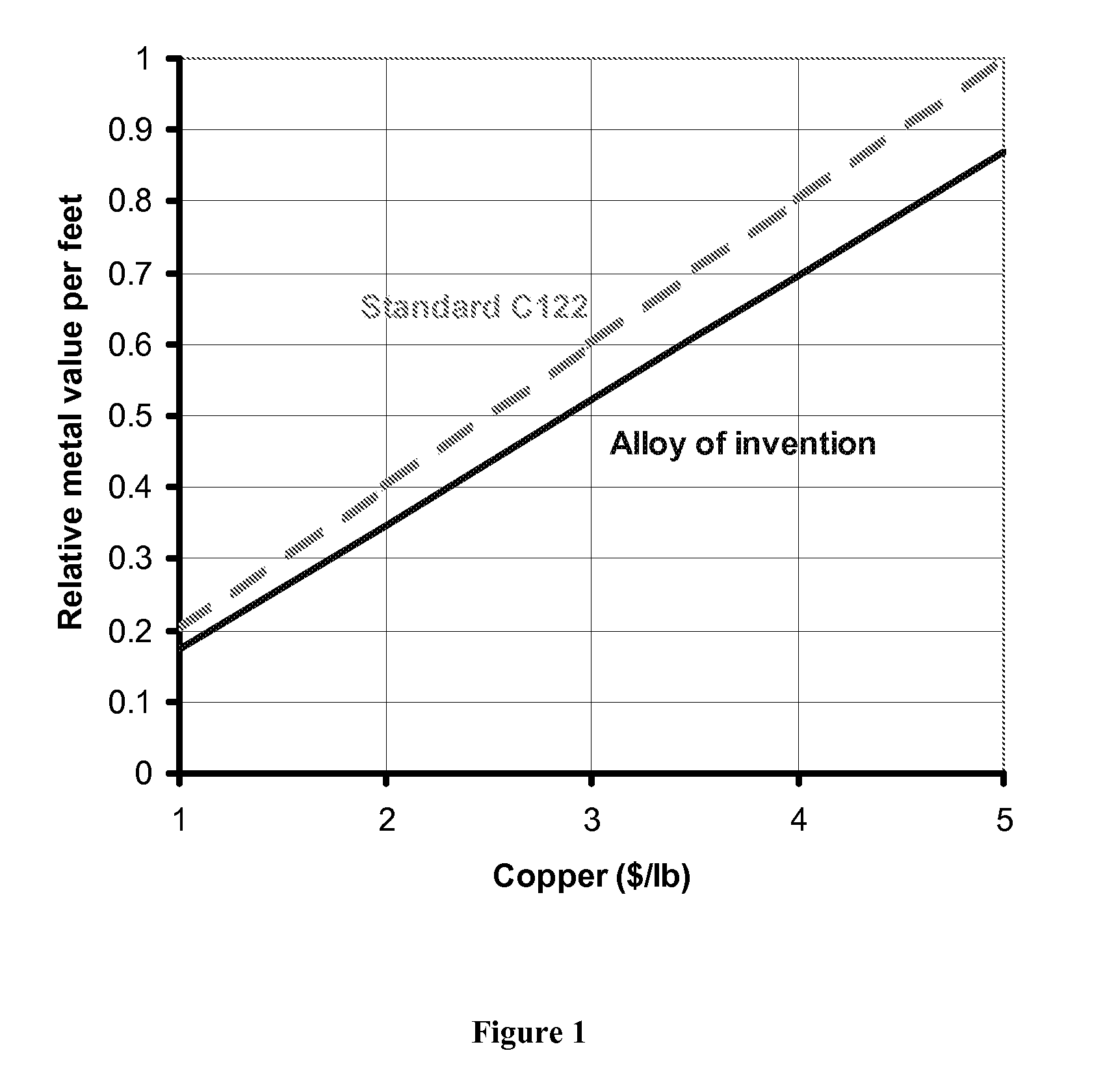

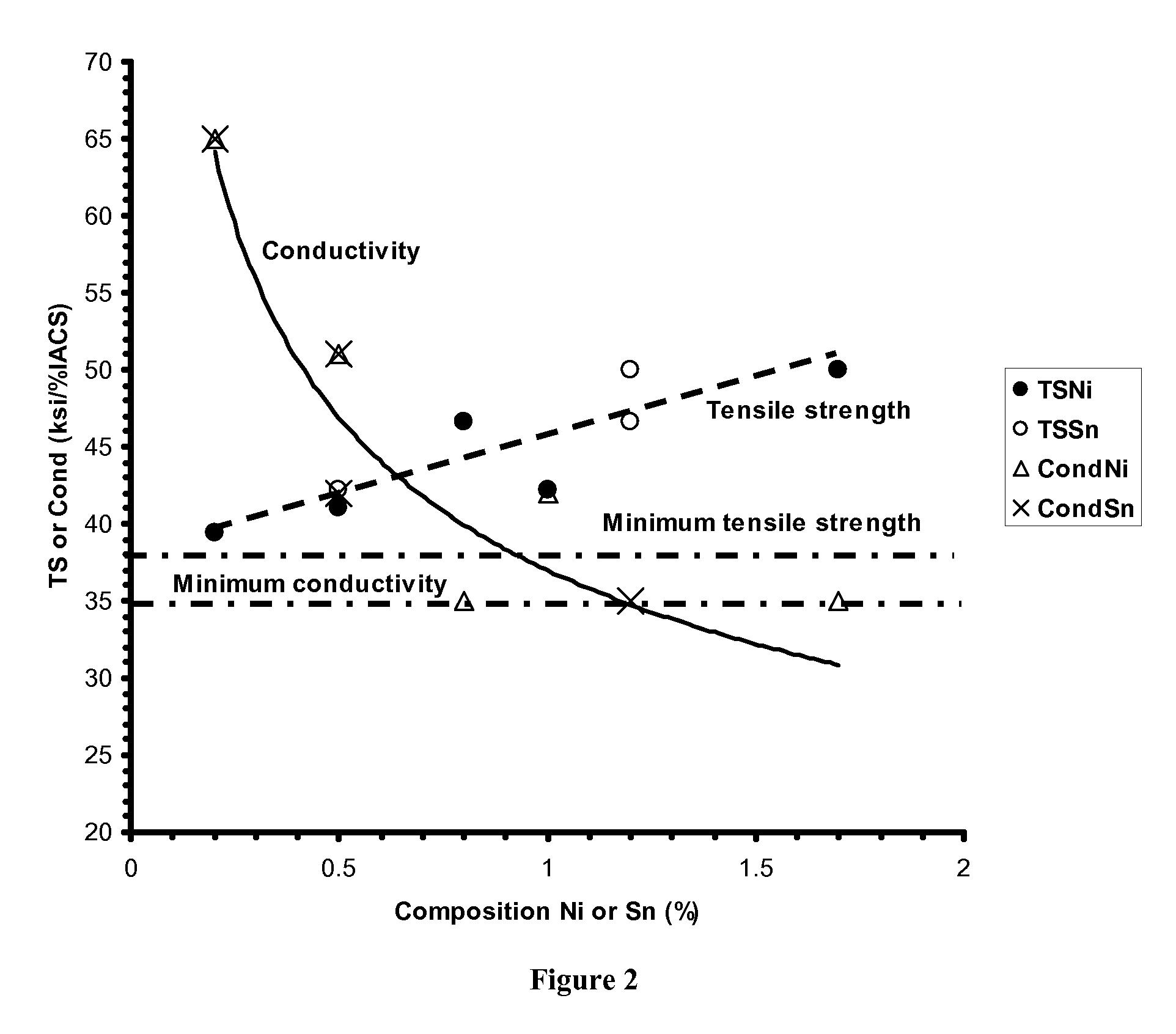

Copper Alloy for Heat Exchanger Tube

InactiveUS20110005739A1High tensile strengthEasy to processTubular elementsPlate heat exchangerHigh pressure

An alloy comprising copper, nickel, tin and, optionally, phosphorus which can be used in, for example, a copper alloy tube for heat exchangers that provides excellent fracture strength and processability for reducing the weight of the tube and for use in high pressure applications with cooling media such as carbon dioxide.

Owner:VIRTUS PRECISION TUBE LLC

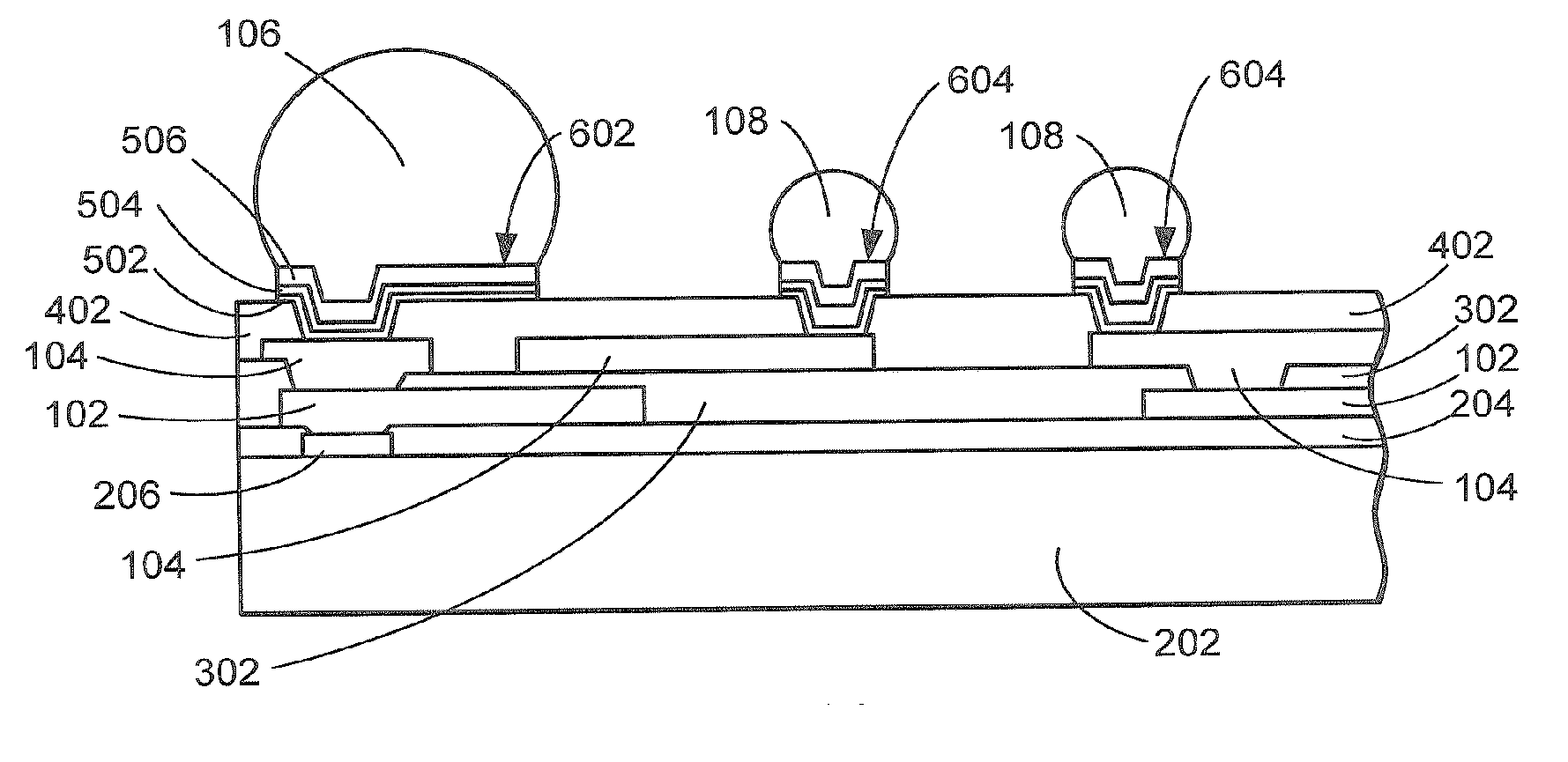

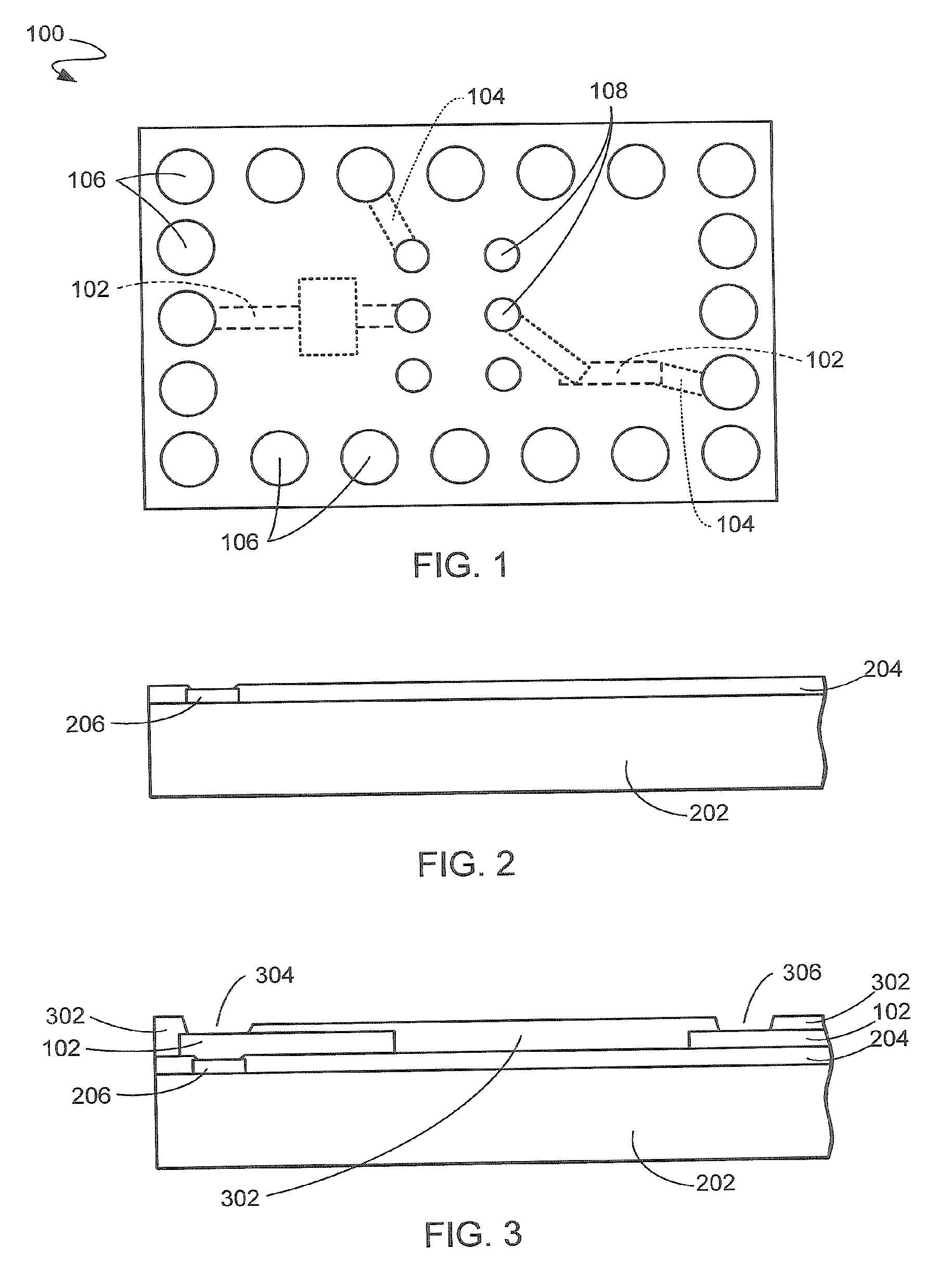

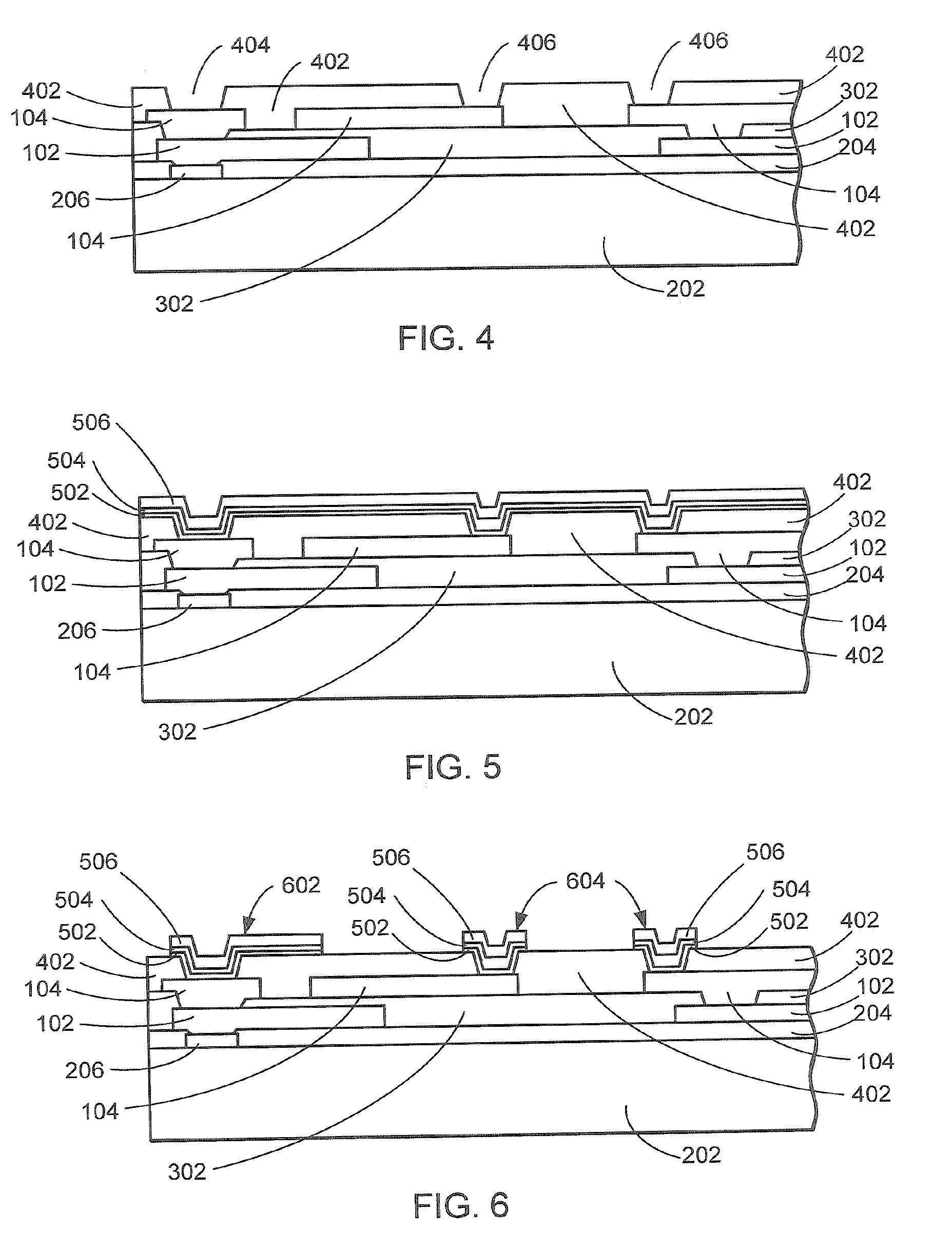

Integrated circuit solder bumping system

ActiveUS20070069346A1Semiconductor/solid-state device detailsSolid-state devicesRedistribution layerInsulation layer

An integrated circuit solder bumping system provides a substrate and forms a redistribution layer on the substrate. An insulation layer is formed on the redistribution layer. The insulation layer has a plurality of openings therethrough. A first UBM layer of titanium is deposited on the insulation layer and in the openings therethrough. A second UBM layer of chromium / copper alloy is deposited on the first UBM layer. A third UBM layer of copper is deposited on the second UBM layer. UBM pads of at least two different sizes are formed from the UBM layers. Solder paste is printed over at least some of the UBM pads. The solder paste is reflowed to form at least smaller solder bumps on at least some of the UBM pads. Bigger solder bumps are formed on at least some of the UBM pads.

Owner:JCET SEMICON (SHAOXING) CO LTD

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

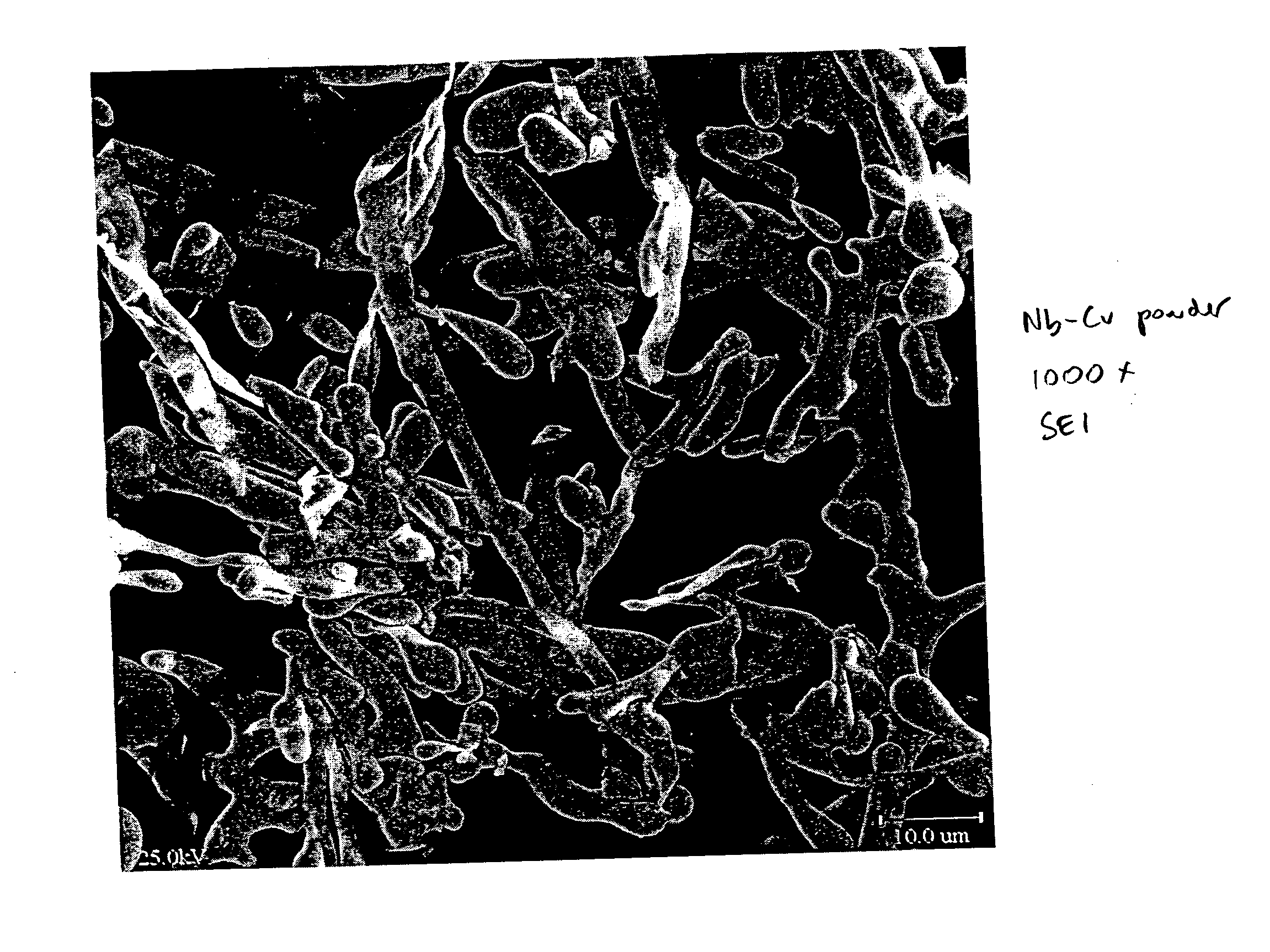

Method for producing metal fibers

InactiveUS20050000321A1Transportation and packagingMetal-working apparatusO-Phosphoric AcidMetal fibers

A method of producing metal fibers including melting a mixture of at least a fiber metal and a matrix metal, cooling the mixture to form a bulk matrix comprising at least a fiber phase and a matrix phase and removing at least a substantial portion of the matrix phase from the fiber phase. Additionally, the method may include deforming the bulk matrix. In certain embodiments, the fiber metal may be at least one of niobium, a niobium alloy, tantalum and a tantalum alloy and the matrix metal may be at least one of copper and a copper alloy. The substantial portion of the matrix phase may be removed, in certain embodiments, by dissolving of the matrix phase in a suitable mineral acid, such as, but not limited to, nitric acid, sulfuric acid, hydrochloric acid and phosphoric acid.

Owner:ATI PROPERTIES

Plating bath and process for depositing alloy containing tin and copper

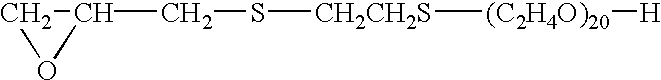

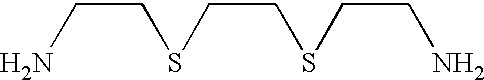

InactiveUS6607653B1Avoid depositionImprove stabilityPrinted circuit manufactureSemiconductor devicesBismuthSulfur containing

The present invention provides a tin-copper alloy plating bath, tin-copper-bismuth alloy plating bath or tin-copper-silver alloy plating bath containing a soluble metal compound and a specific sulfur-containing compound. The plating bath of the present invention is an alloy plating bath containing tin and copper, the bath being capable of preventing deposition of copper on a tin anode by substitution, having low dependence of plated coating composition on current density, high bath stability and resistance to turbidness.

Owner:ISHIHARA CHEM +1

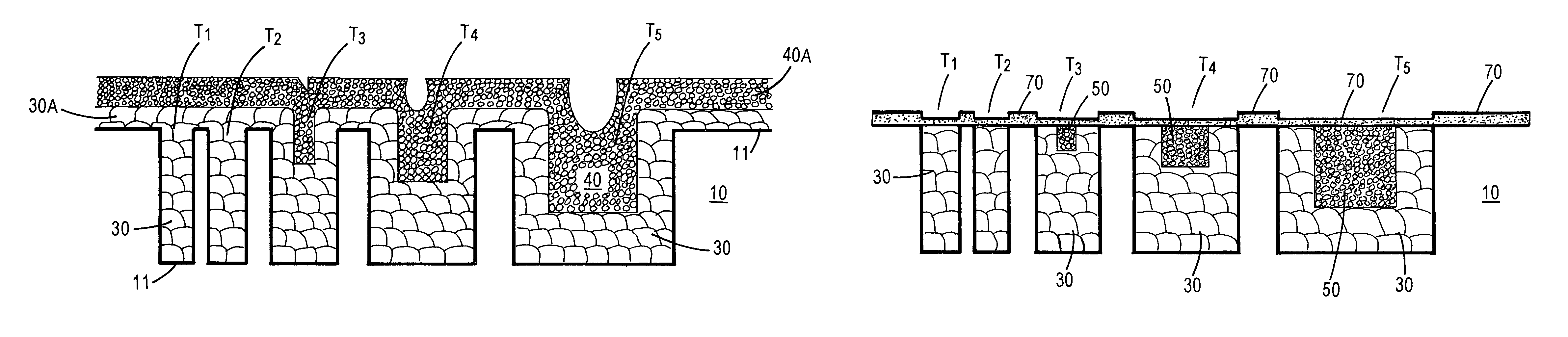

Antenna coil, and RFID-use tag using it, transponder-use antenna

InactiveUS7088304B2Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterEngineeringNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

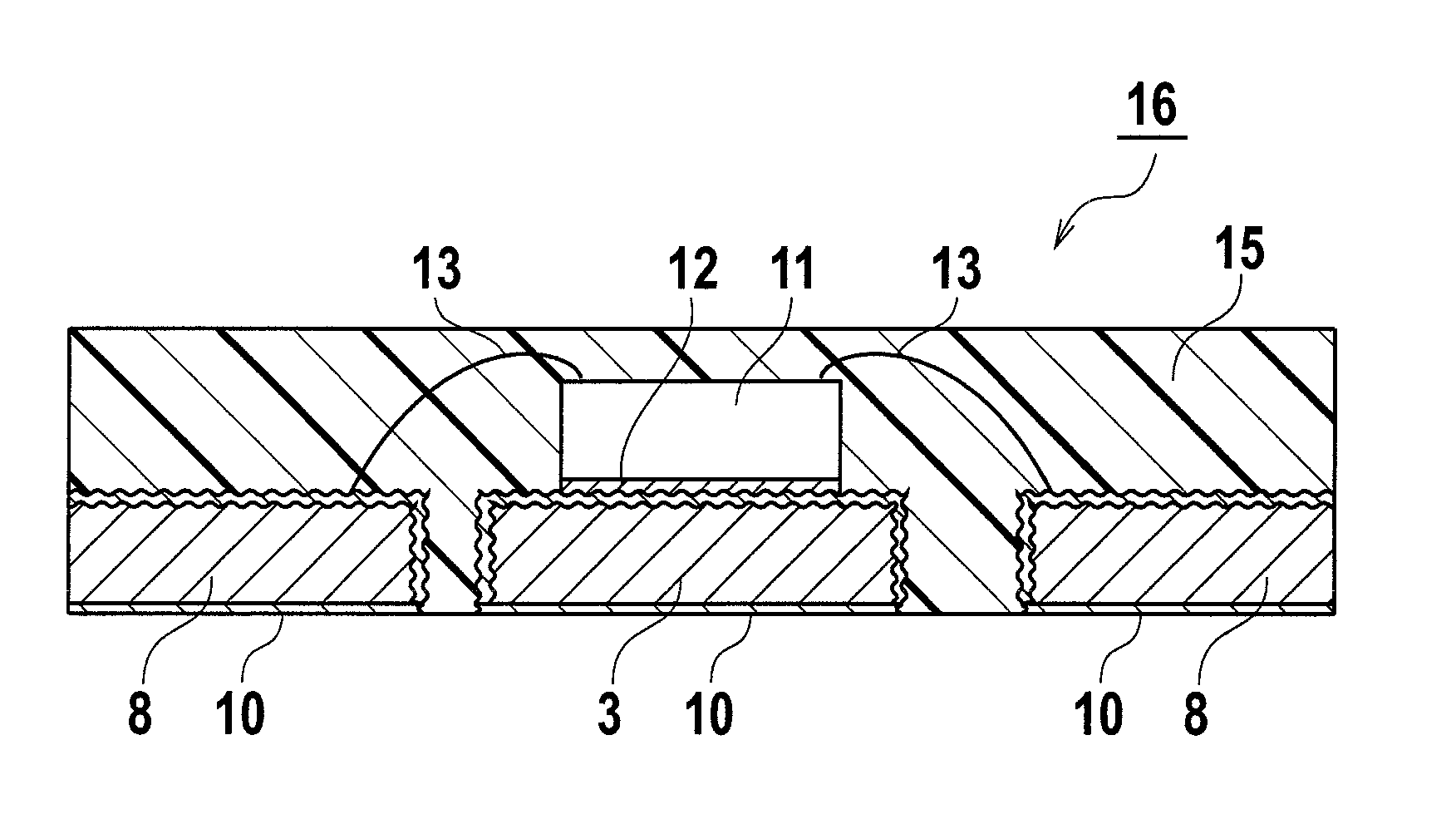

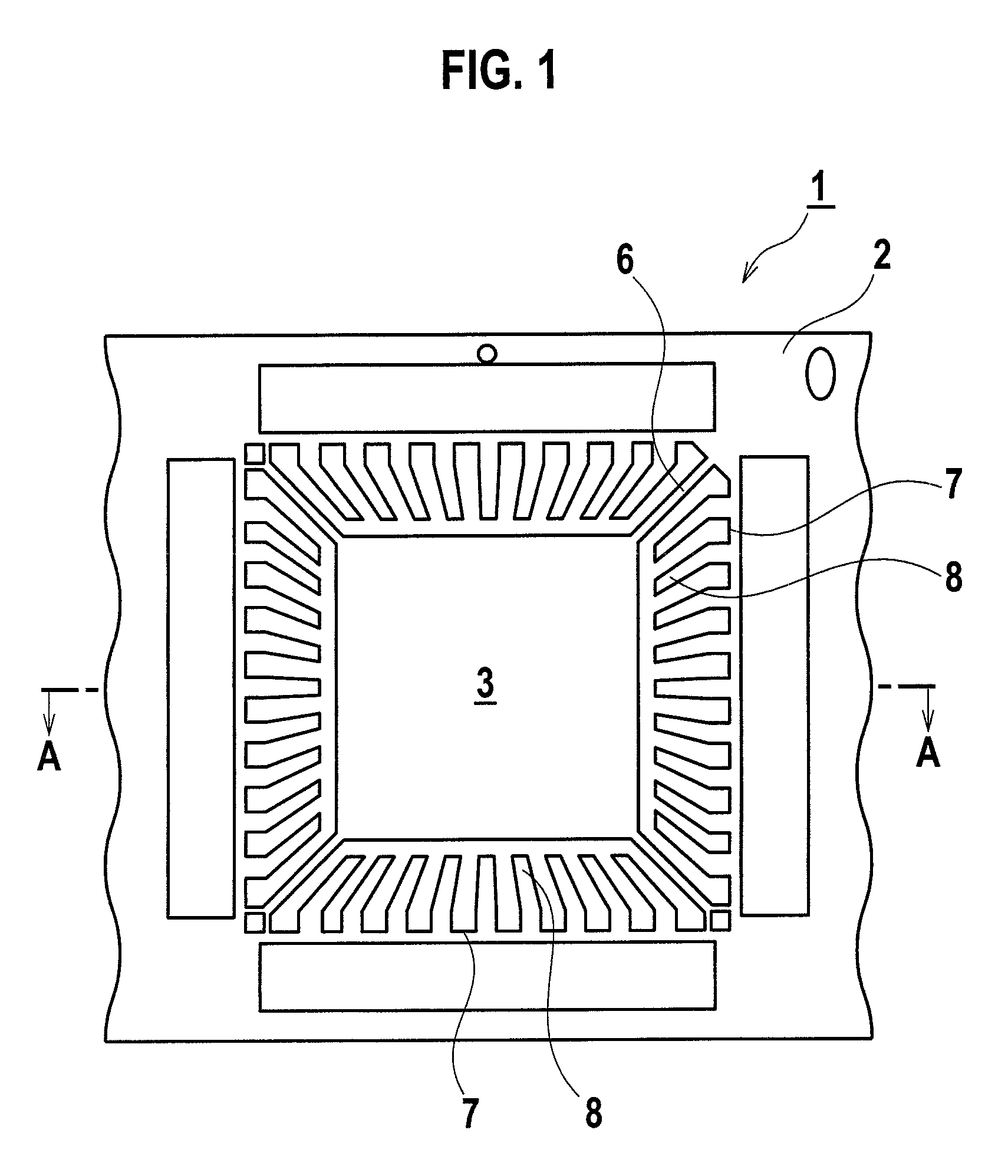

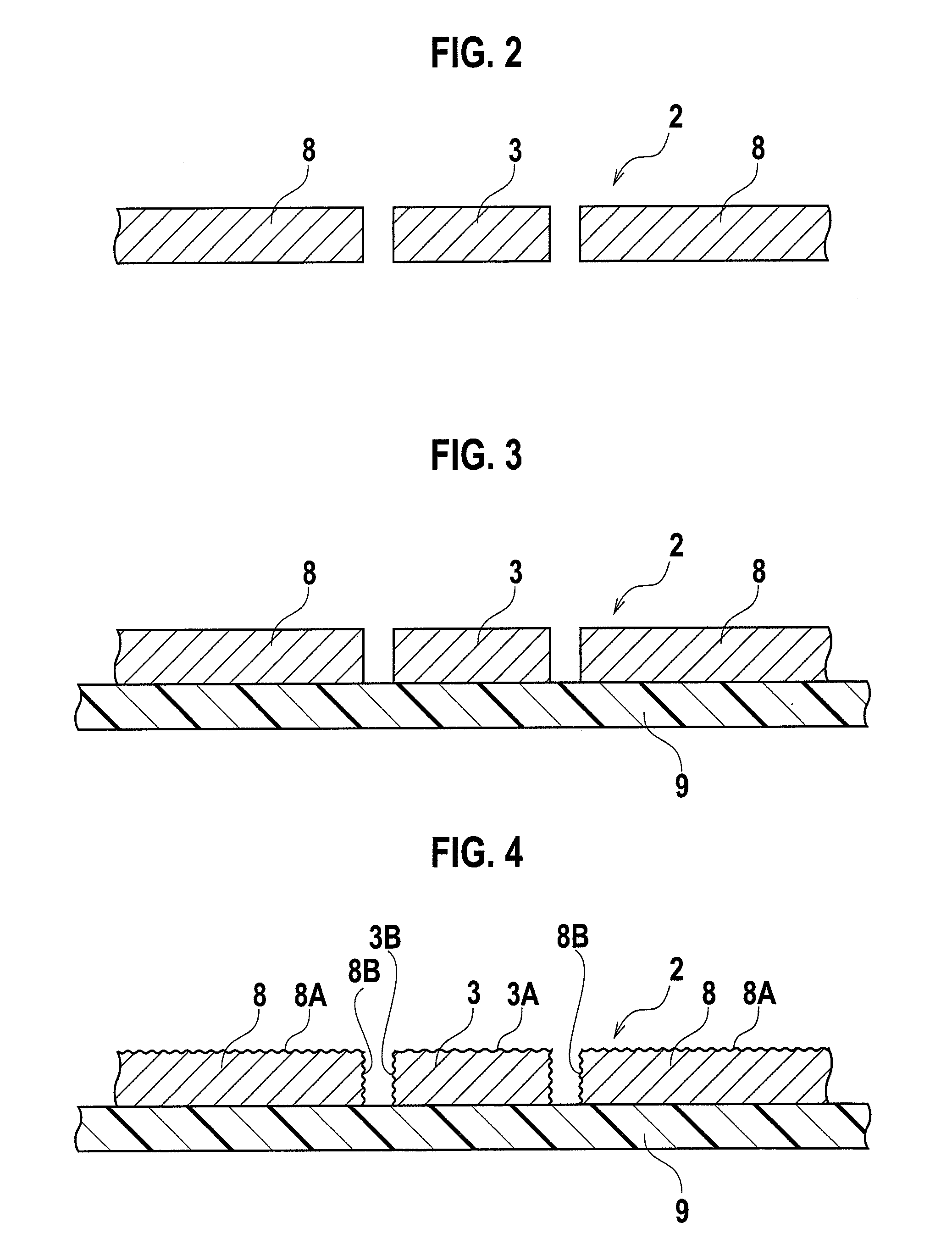

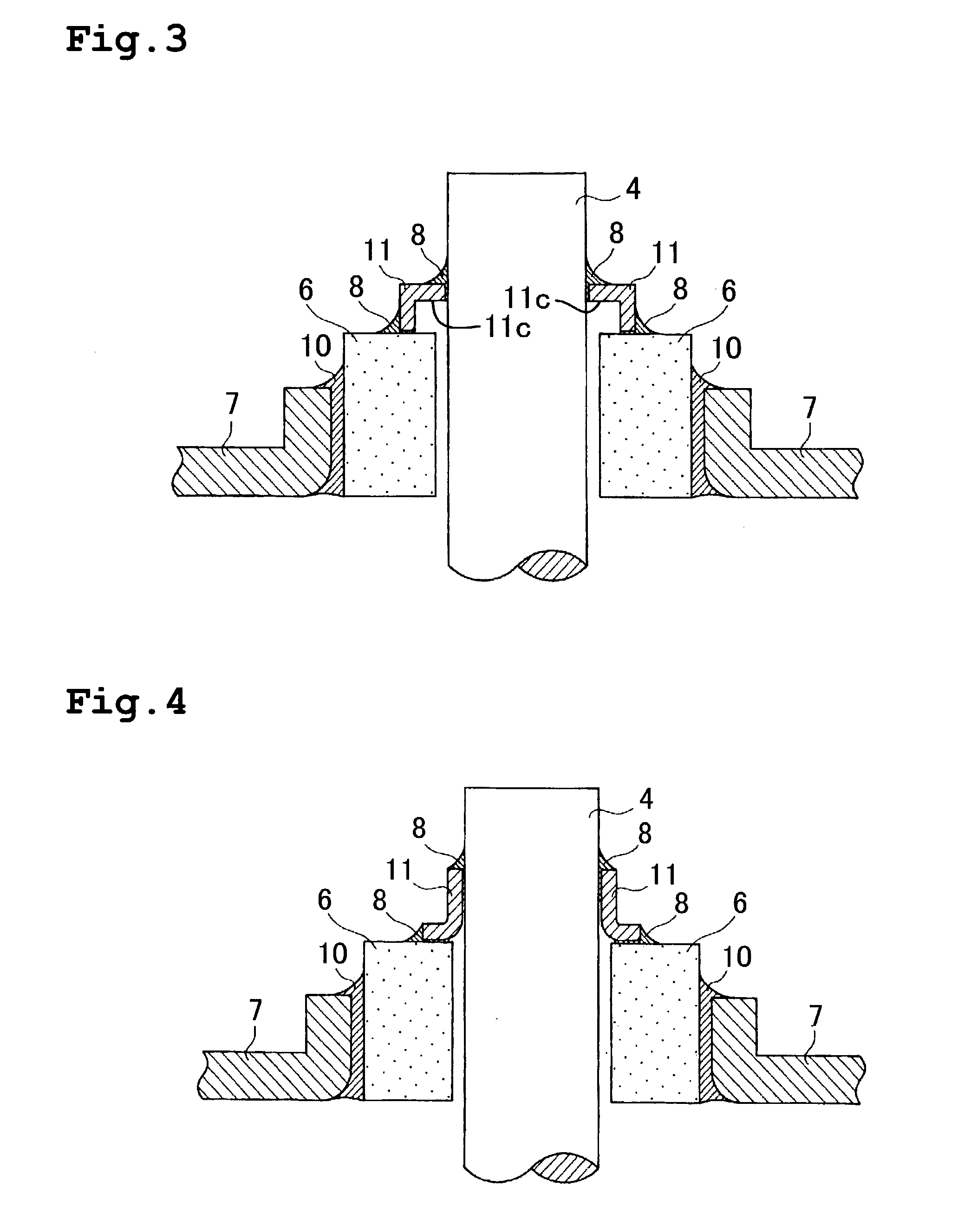

Circuit member, manufacturing method for circuit members, semiconductor device, and surface lamination structure for circuit member

ActiveUS20090039486A1High bonding strengthPrinted circuit assemblingLine/current collector detailsRough surfaceElectrical connection

A circuit member includes a frame substrate formed, by patterning a rolled copper plate or a rolled copper alloy plate, with a die pad portion for a semiconductor chip to be mounted thereon, and a lead portion for an electrical connection to the semiconductor chip, having rough surfaces formed as roughed surfaces on upsides and lateral wall sides of the die pad portion and the lead portion, and smooth surfaces formed on downsides of the die pad portion and the lead portion, and the die pad portion and the lead portion are buried in a sealing resin, having a downside of the lead portion exposed.

Owner:DAI NIPPON PRINTING CO LTD

Method for producing metal fibers

Owner:ATI PROPERTIES

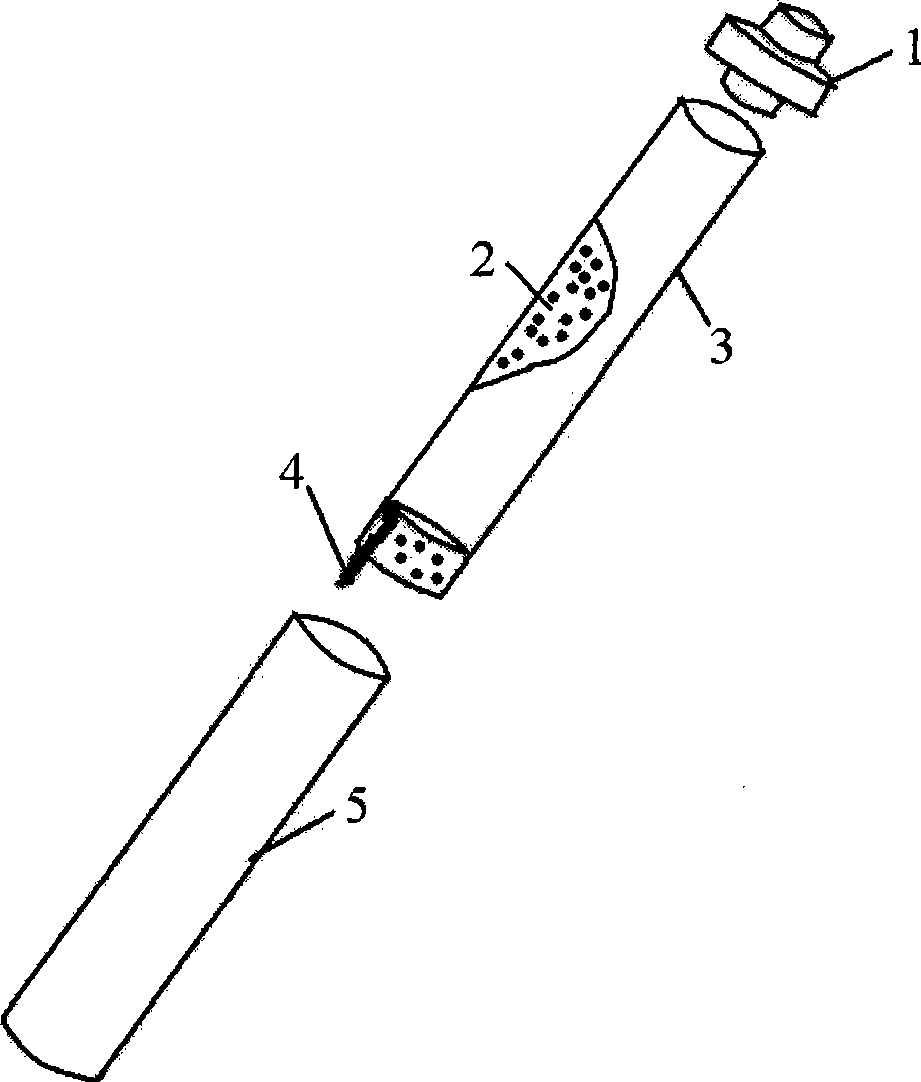

Manual thermit welding electrode and preparation and using methods thereof

ActiveCN101444876AFirmly connectedEasy to weldWelding/cutting media/materialsAlumino-thermic welding apparatusSlagEngineering

The invention discloses a manual thermit welding electrode and preparation and using method thereof which belong to the technical field of welding. A welding compound of the welding electrode comprises a thermit, a slag forming constituent and an alloying agent. Raw materials are weighed according to the proportion and arranged in a ball mill, a grinding ball and a milling medium are added, and the welding compound is obtained by drying after wet grinding; the welding compound is filled in a cylinder which is made of paper, a lead wire is arranged at one end of the cylinder, and the other end is sealed by a plastic plug, thereby forming the thermit welding electrode; the welding electrode is arranged in a sleeve which is made of paper and sealed for preservation. When in use, the sleeve is fixed on the plug at the back end of the welding electrode, the sleeve is held by a hand, and the lead wire at the front end of the welding electrode is ignited, and then the manual welding or cutting operation can be carried out. The welding electrode is small, lightweight and portable, the welding and the cutting operations are simple, rapid and safe, the welding and the cutting operations can be carried out anytime and anywhere, and the welding electrode can be applied in the welding and the cutting of steels, stainless steels or copper alloy materials.

Owner:TSINGHUA UNIV

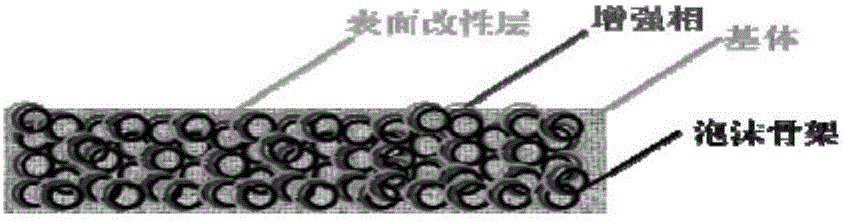

Foam skeleton structure reinforced metal-matrix composite material and preparation method

ActiveCN105779804AImprove thermal conductivityImprove conductivityChemical vapor deposition coatingThree-dimensional spaceCarbon nanotube

The invention discloses a foam skeleton structure reinforced metal-matrix composite material and a preparation method thereof. The composite material comprises a foam skeleton, a surface strengthening material and a matrix, wherein the foam skeleton is made of foam metal, foamed ceramics or foamy carbon; the surface strengthening material is a high heat conduction material adopting a diamond film, a graphene film, a carbon nanotube and the like; the metal matrix material adopts one of copper, aluminum, a copper alloy, an aluminum alloy and the like. A reinforcing phase and a matrix phase of the prepared composite material keep continuous distribution in three-dimensional space, an interpenetrating network structure is formed, the influence of a composite interface on the thermal properties of the material can be weakened effectively, good plasticity and toughness of the metal matrix are not reduced, the reinforcing phase can become a whole, the heat conduction efficiency of a reinforcing body is realized to the greatest extent, the heat conductivity, the electric conductivity and the mechanical strength of the composite material are greatly improved compared with the traditional composite material, and the composite material is a multifunctional composite material with great potential.

Owner:CENT SOUTH UNIV

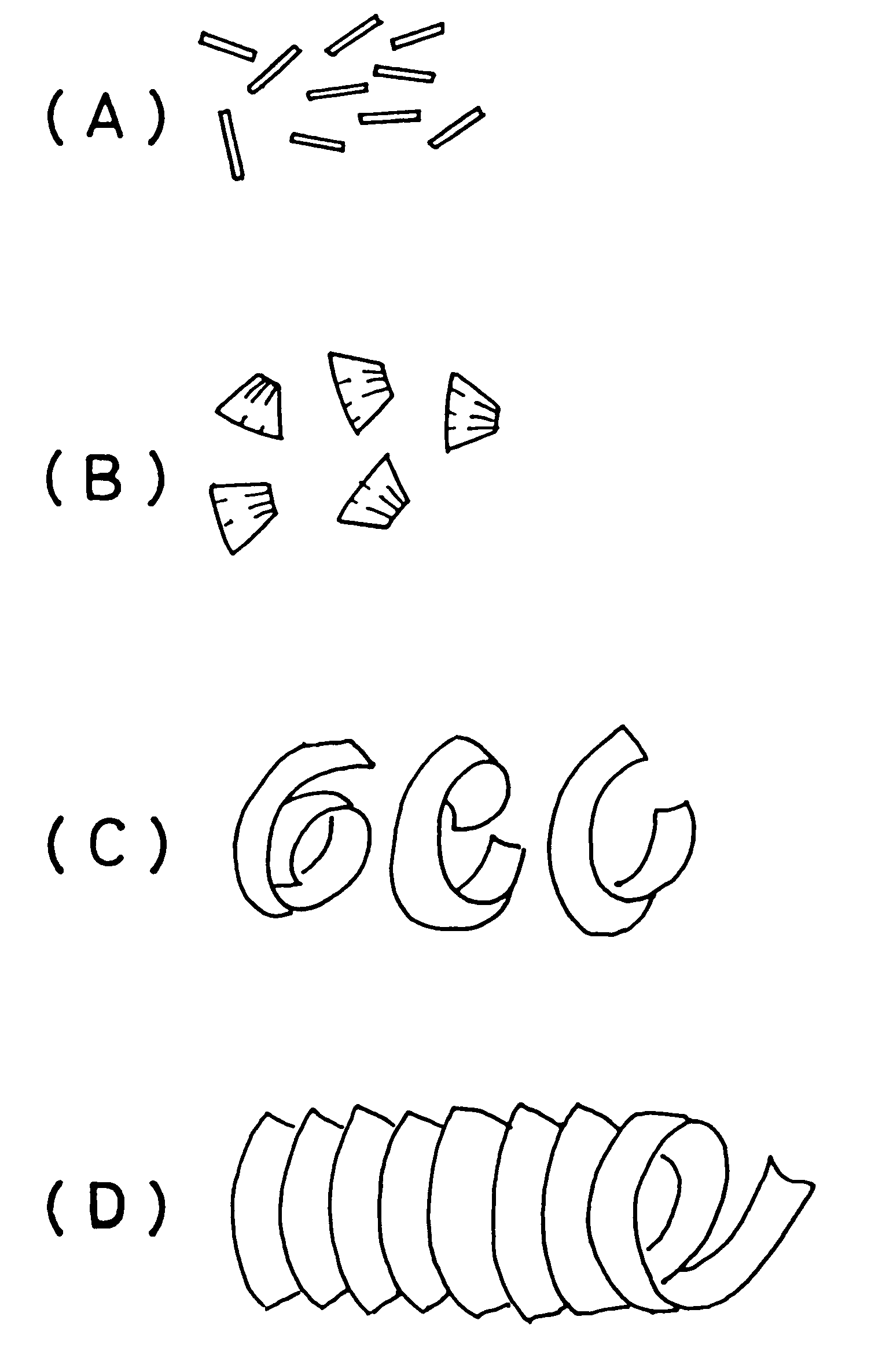

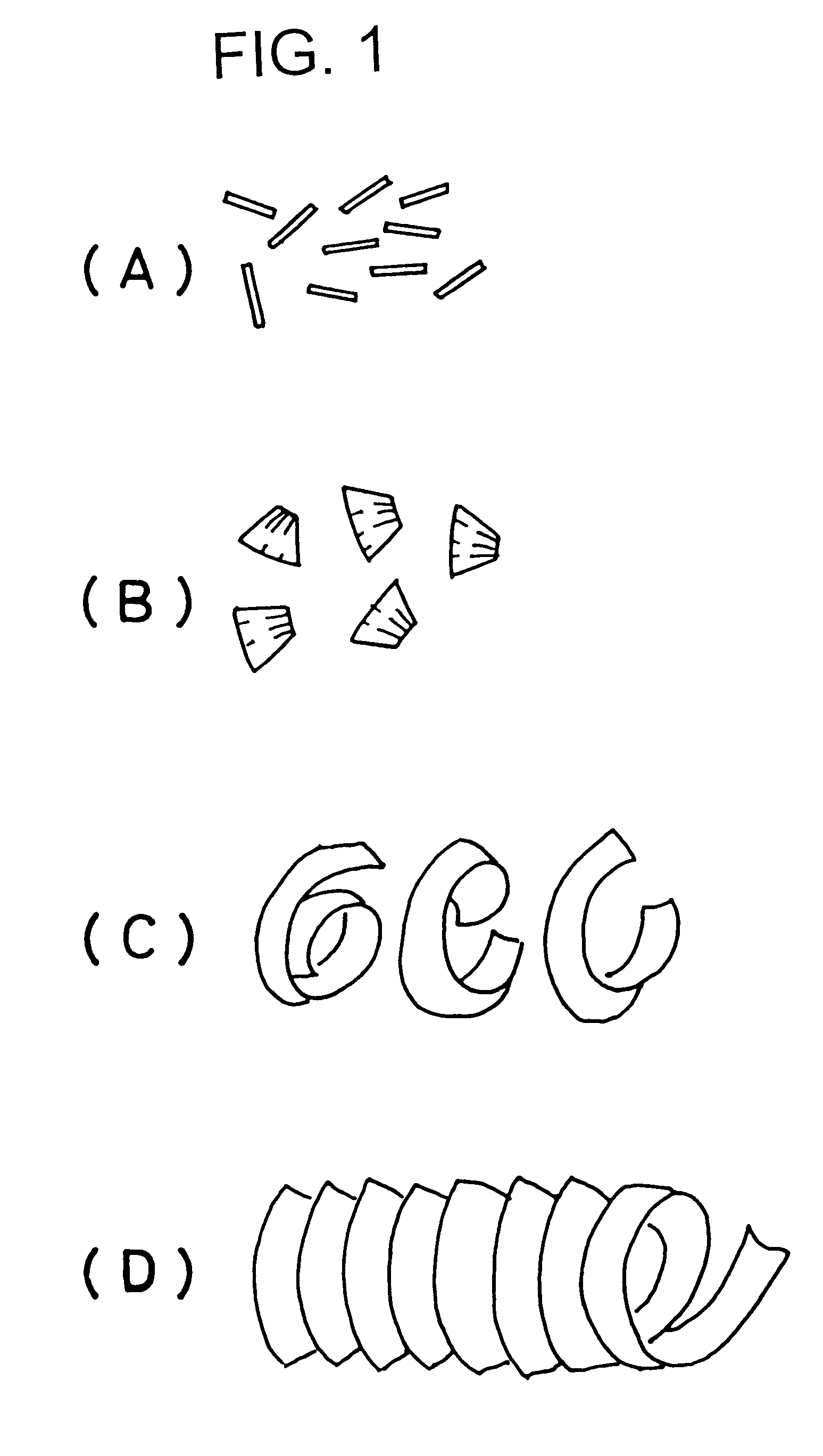

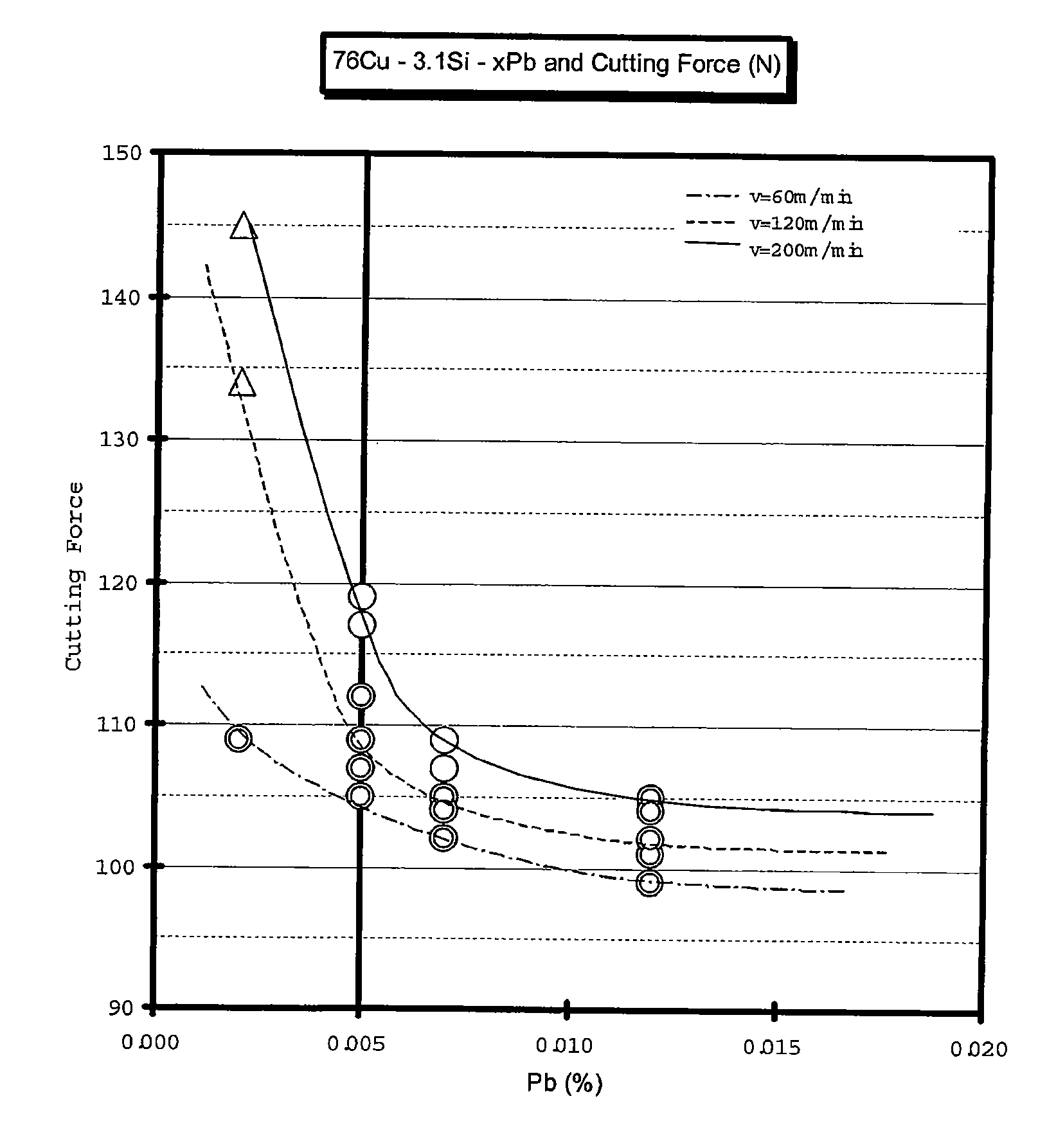

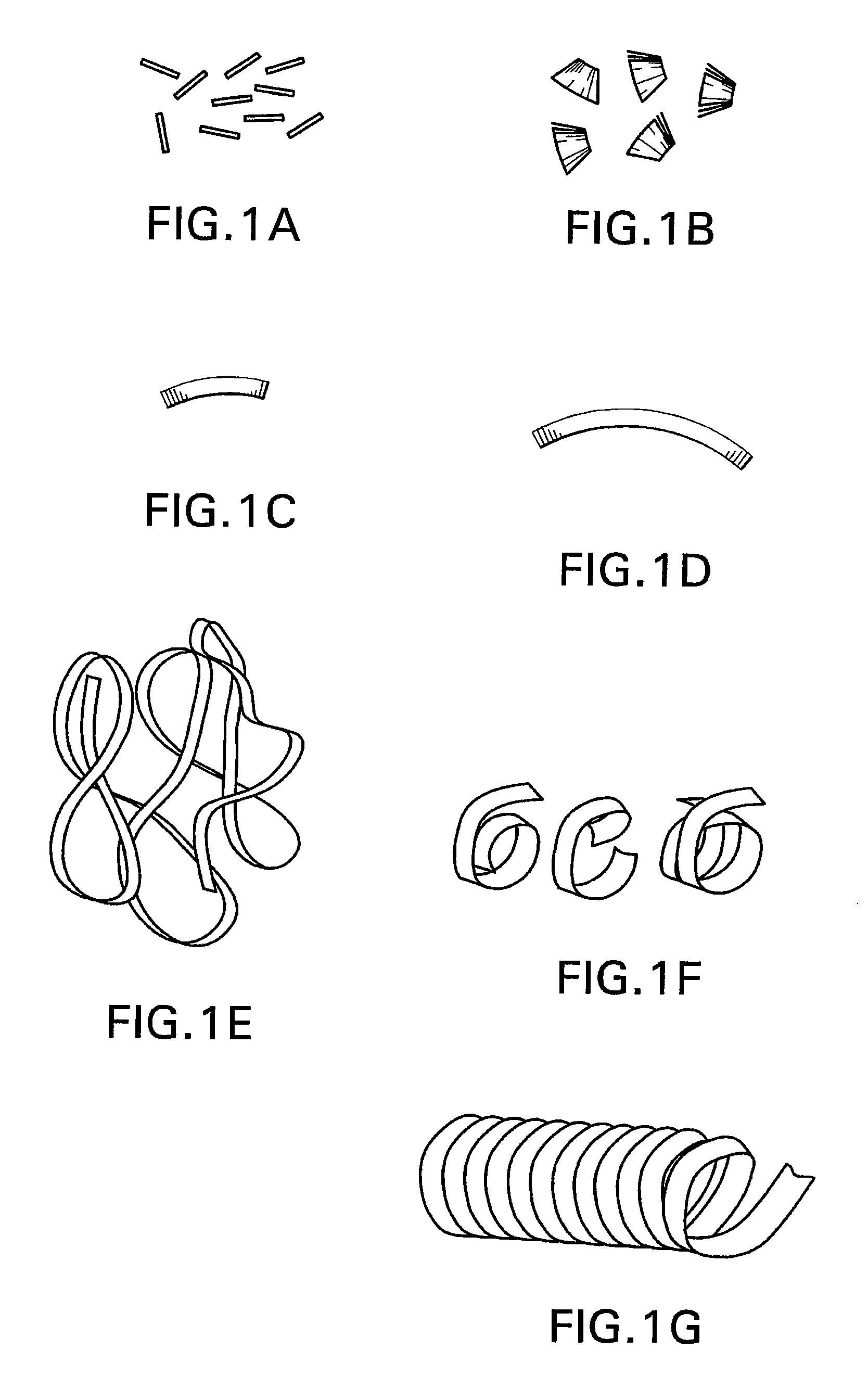

Lead-free free-cutting copper alloys

A lead-free free-cutting copper alloy having 69 to 79 percent, by weight, of copper; greater than 3 percent, by weight, of silicon; and a remaining percent, by weight, of zinc. The alloy preferable has greater than 3.0 percent and less than or equal to 4.0 percent, by weight, of silicon; and at least one element selected from among 0.02 to 0.4 percent, by weight, of bismuth, 0.02 to 0.4 percent, by weight, of tellurium, and 0.02 to 0.4 percent, by weight, of selenium. The alloy also preferable has at least one element selected from among 0.3 to 3.5 percent, by weight, of tin, 1.0 to 3.5 percent, by weight, of aluminum, and 0.02 to 0.25 percent, by weight, of phosphorus. In further embodiments, the alloy has at least one element selected from among 0.02 to 0.15 percent, by weight, of antimony, and 0.02 to 0.15 percent, by weight, of arsenic.

Owner:MITSUBISHI SHINDOH CO LTD

Copper alloy with no lead

This invention relates to a Pb-free Cu alloy, especially a Pb-free machinable Cu alloy, which is composed of: Cu 55.0-89%, Zn 3.0-45%, Sn 0.1-10%, Ni 0.1-2.0%, Si 0-5.0%, Bi 0.1-5.0%, Se 0-3.0%, Al 0.01-1.0%, P 0.05-0.15%, and RE 0.01-0.5%. RE, Bi, Se and P are added respectively in the forms of RE-Cu intermediate alloy, Cu-Bi intermediate alloy, Cu-Se intermediate alloy and P-Cu intermediate alloy, or RE, Bi, Se and P are added respectively in the forms of Bi-Se alloy and P-Cu alloy. This invention can eliminate harmful effects on environment and human bodies caused by Pb during production and recovery process. The Cu alloy has good machinability, mechanical properties, processability and fluidity, and has no thermal splitting. The production method is simple, and can produce the Cu alloy by using the present apparatus for producing lead-brass alloy. Besides, the contents of Se, Bi and RE are low,.

Owner:JIANGXI UNIV OF SCI & TECH

Free-cutting copper alloy containing very low lead

The free-cutting copper alloy according to the present invention contains a greatly reduced amount of lead in comparison with conventional free-cutting copper alloys, but provides industrially satisfactory machinability. The free-cutting alloys comprise 71.5 to 78.5 percent, by weight, of copper, 2.0 to 4.5 percent, by weight, of silicon, 0.005 percent up to but less than 0.02, by weight, of lead, and the remaining percent, by weight, of zinc.

Owner:SANBO SHINDO KOGYO CO LTD

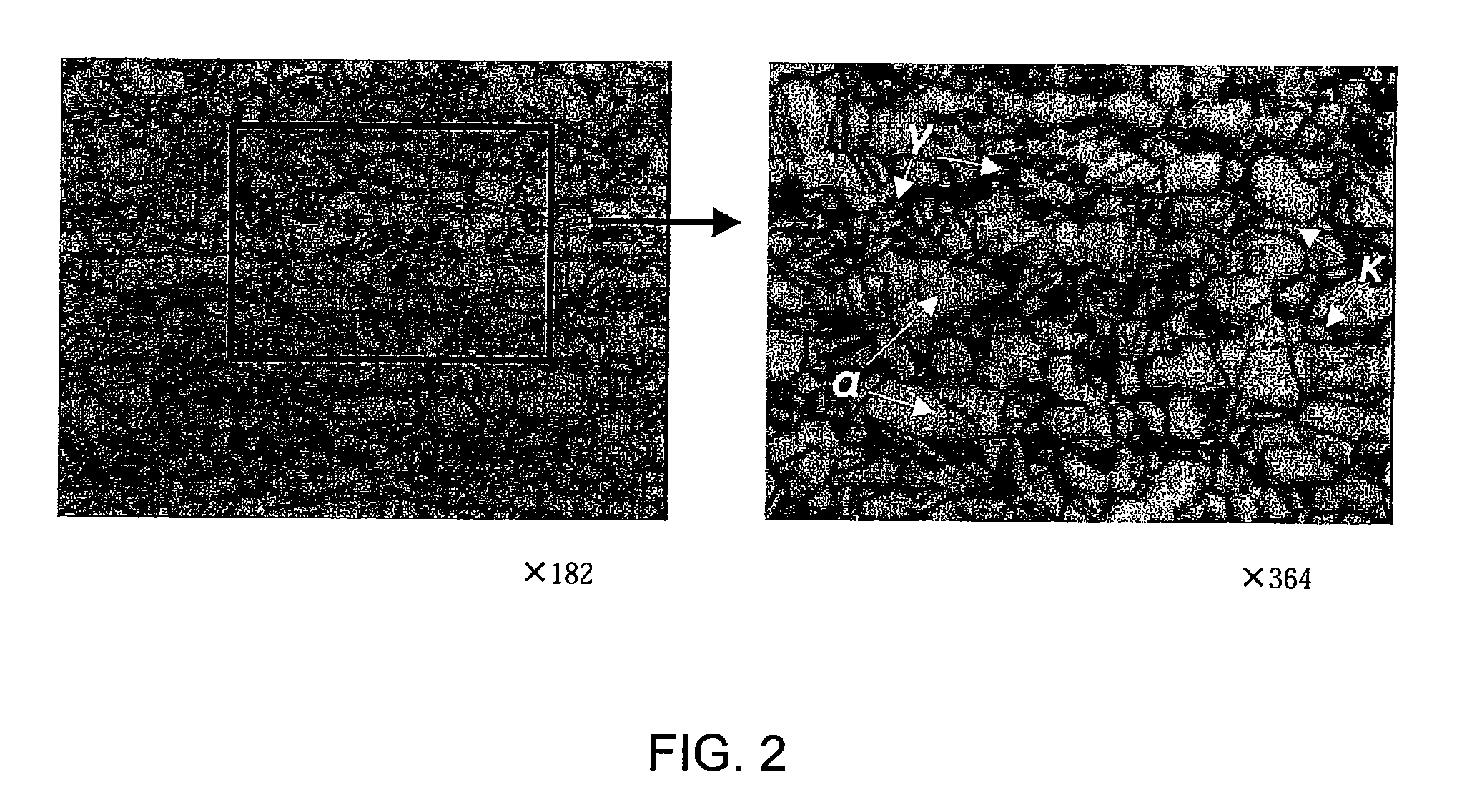

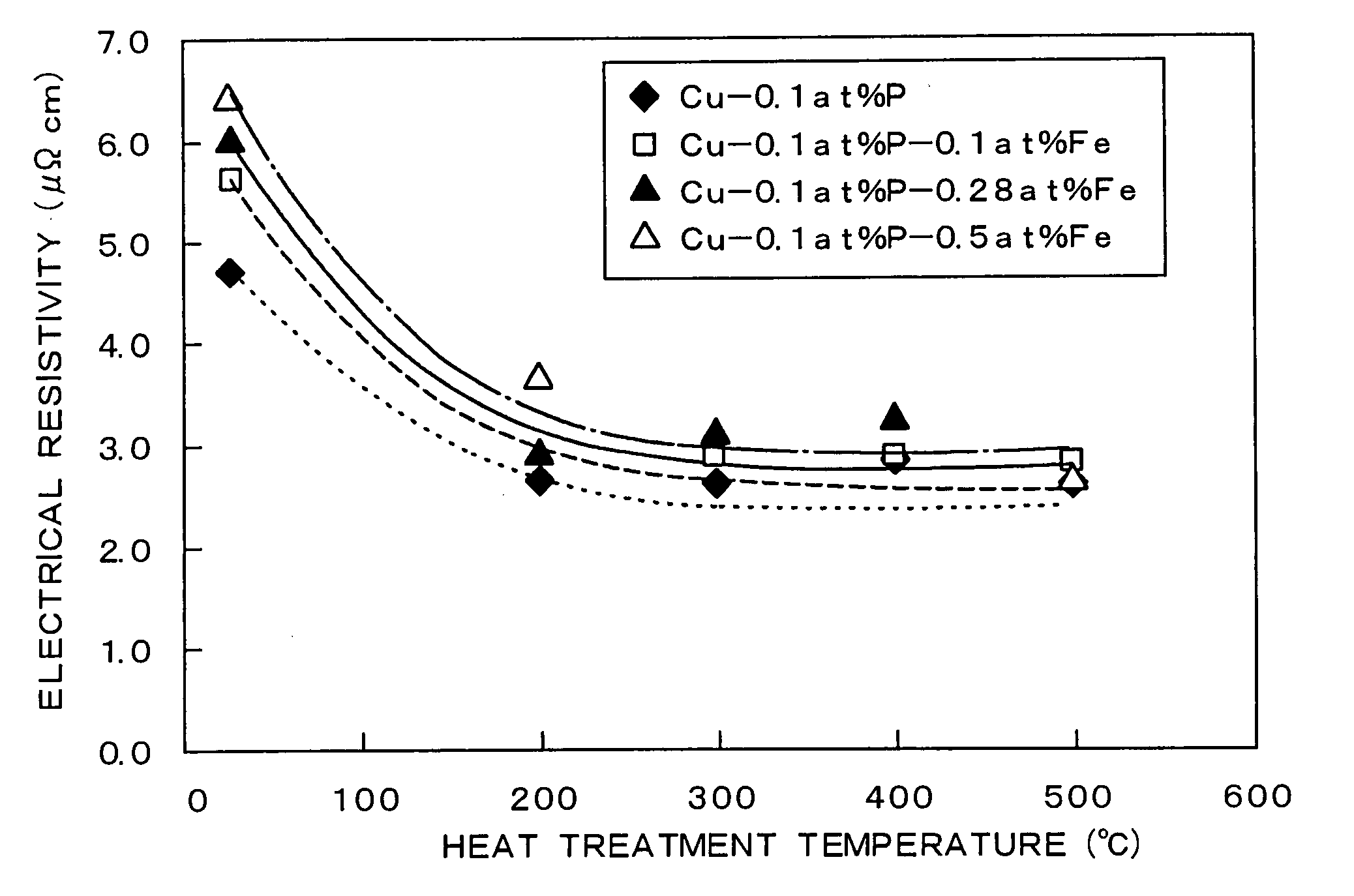

Copper alloy thin films, copper alloy sputtering targets and flat panel displays

InactiveUS20060091792A1Low resistivityInhibition formationDischarge tube luminescnet screensCathode ray tubes/electron beam tubesAlloy thin filmFlat panel display

A Cu alloy thin film contains Fe and P with the balance being substantially Cu, in which the contents of Fe and P satisfy all the following conditions (1) to (3), and in which Fe2P is precipitated at grain boundaries of Cu after heat treatment at 200° C. to 500° C. for 1 to 120 minutes: 1.4NFe+8NP<1.3 (1)NFe+48NP>1.0 (2)12NFe+NP>0.5 (3)wherein NFe represents the content of Fe (atomic percent); and NP represents the content of P (atomic percent).

Owner:KOBE STEEL LTD

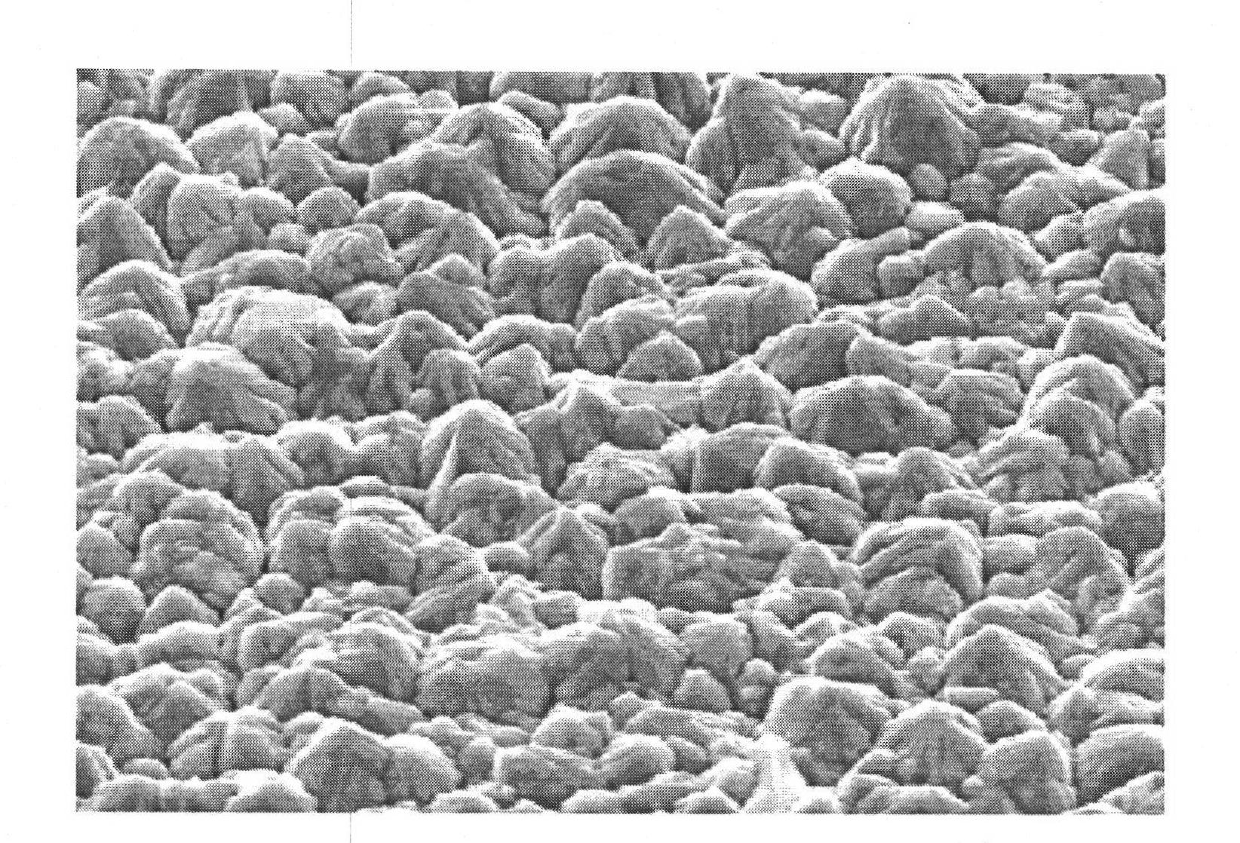

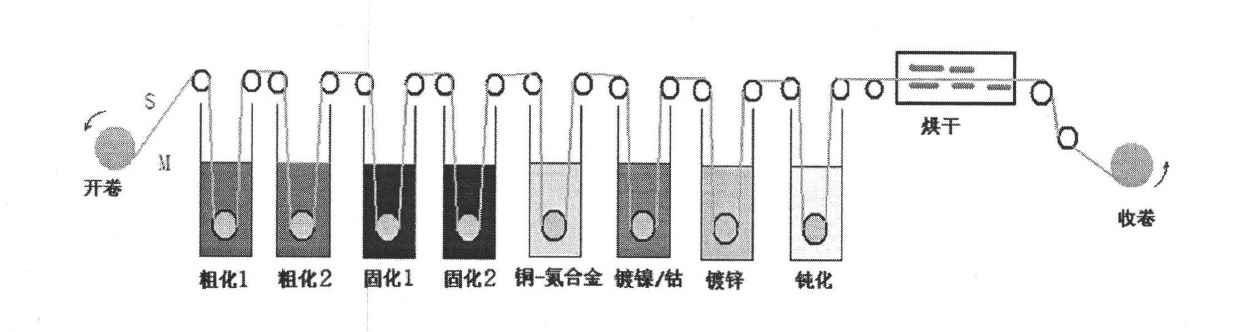

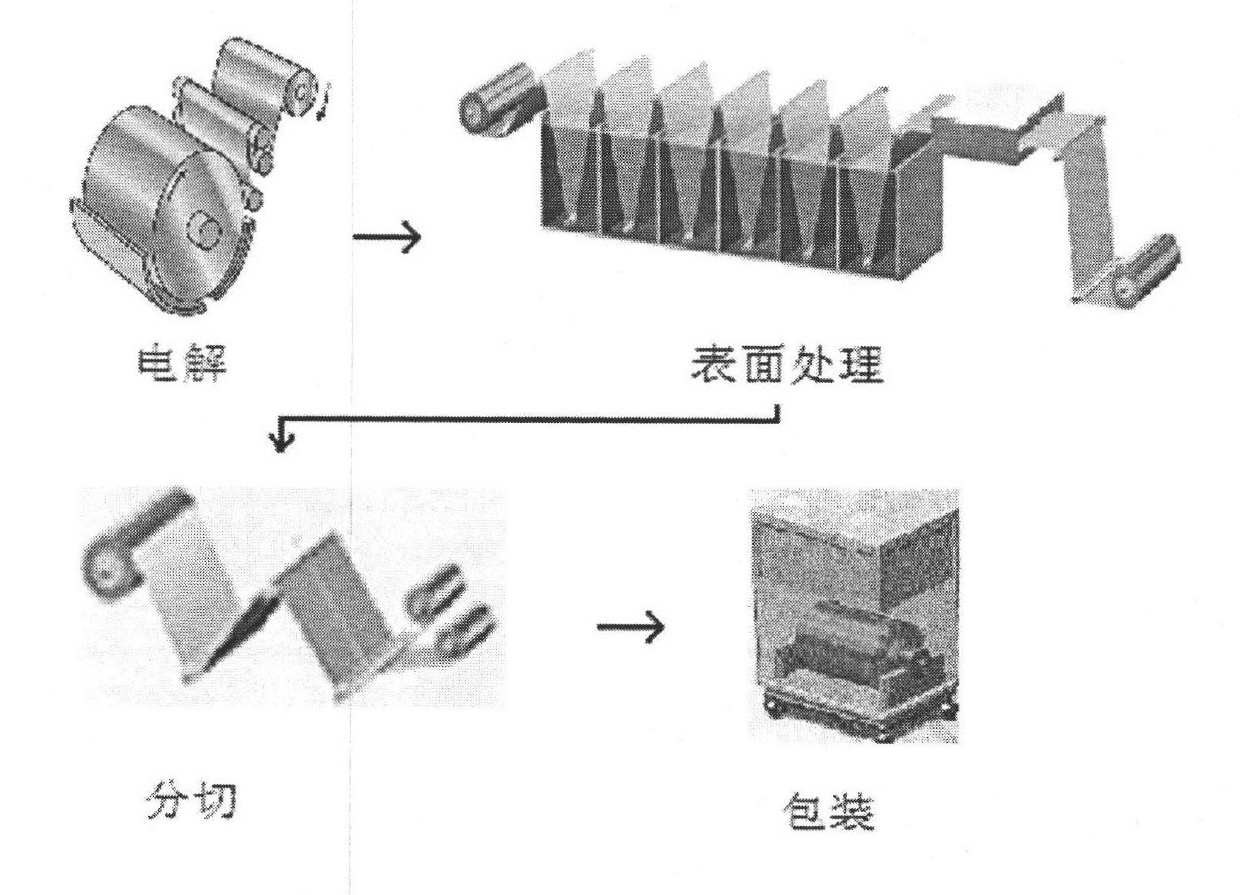

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

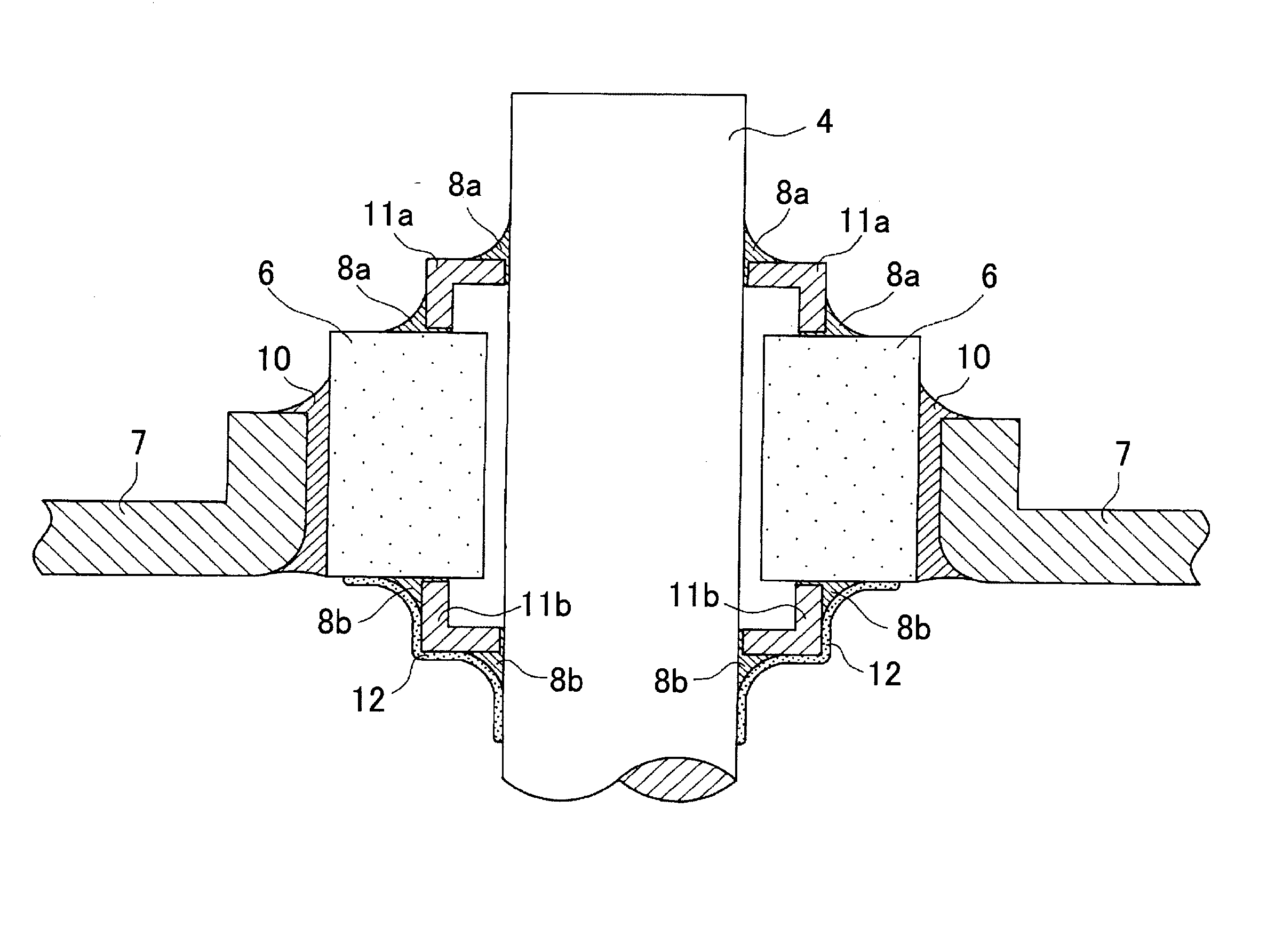

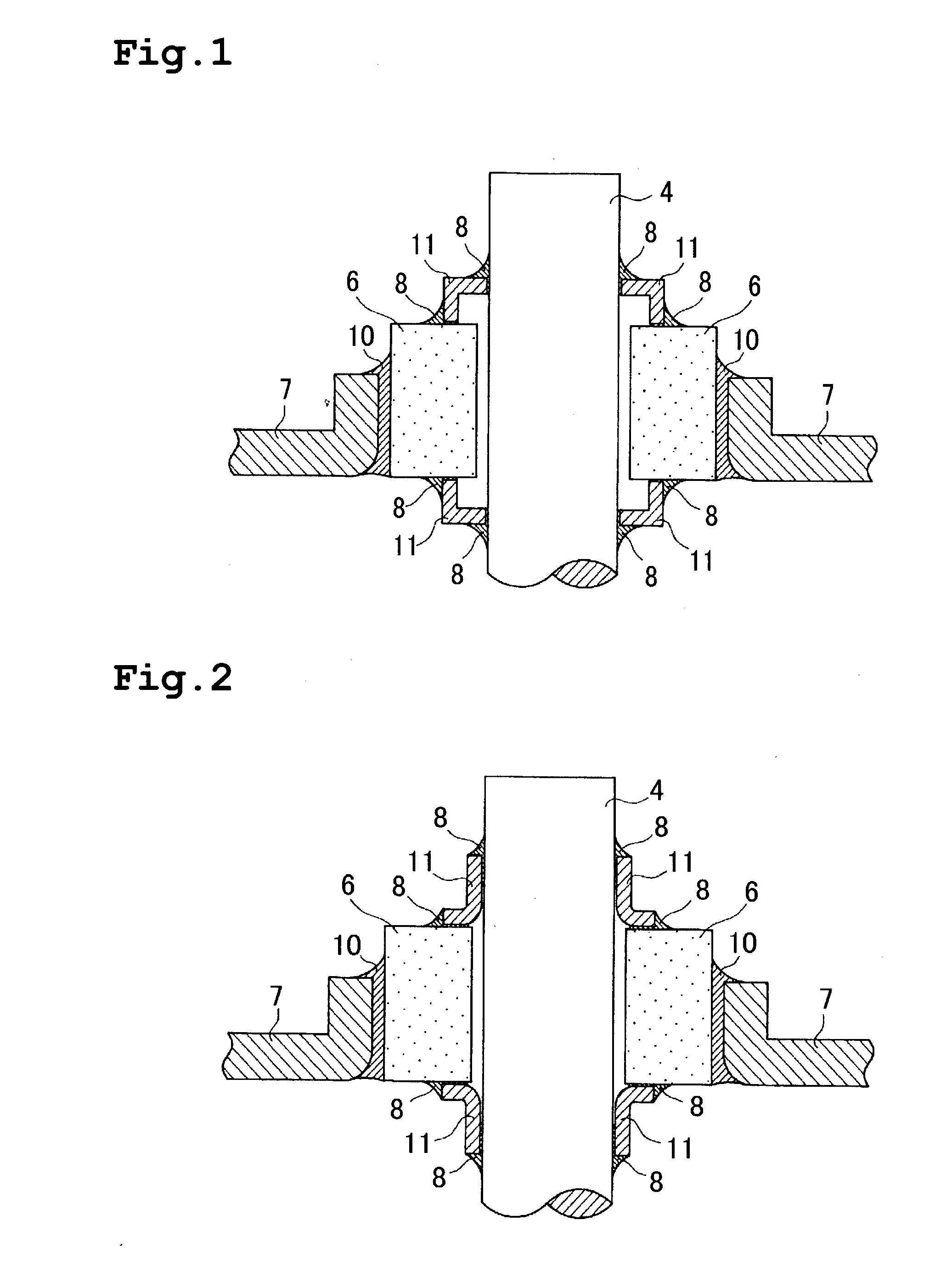

Battery

InactiveUS20030143460A1Avoid crackingReliable crackingFinal product manufactureSmall-sized cells cases/jacketsMetalCopper alloy

An insulating sleeve 6 made of ceramic hermetically fixed into an opening in a terminal supporting plate 7 in a battery sheath made of metal, a positive terminal 4 made of an aluminum alloy or negative terminal 5 made of a copper alloy is inserted in the insulating sleeve, and a metallic ring is fitted over the positive terminal 4 or negative terminal 5. The inner edge of the metallic ring 11 and the positive terminal 4 or negative terminal 5 are hermetically fixed to each other by an aluminum-based brazing metal 8 or copper-based brazing metal 9, and the outer edge of the metallic ring 11 and the insulating sleeve 6 are hermetically fixed to each other by an aluminum-based brazing metal 8 or copper-based brazing metal 9.

Owner:GS YUASA INT LTD

Copper interconnects with metal capping layer and selective copper alloys

ActiveUS6979625B1Reduce voidsImproved resistance to electromigrationSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectLayer interface

High reliable copper interconnects are formed with copper or a low resistivity copper alloy filling relatively narrow openings and partially filling relatively wider openings and a copper alloy having improved electromigration resistance selectively deposited in the relatively wider openings. The filled openings are recessed and a metal capping layer deposited followed by CMP. The metal capping layer prevents diffusion along the copper-capping layer interface while the copper alloy filling the relatively wider openings impedes electromigration along the grain boundaries.

Owner:ADVANCED MICRO DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com