Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19661 results about "Cobalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt is a chemical element with the symbol Co and atomic number 27. Like nickel, cobalt is found in the Earth's crust only in chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, produced by reductive smelting, is a hard, lustrous, silver-gray metal.

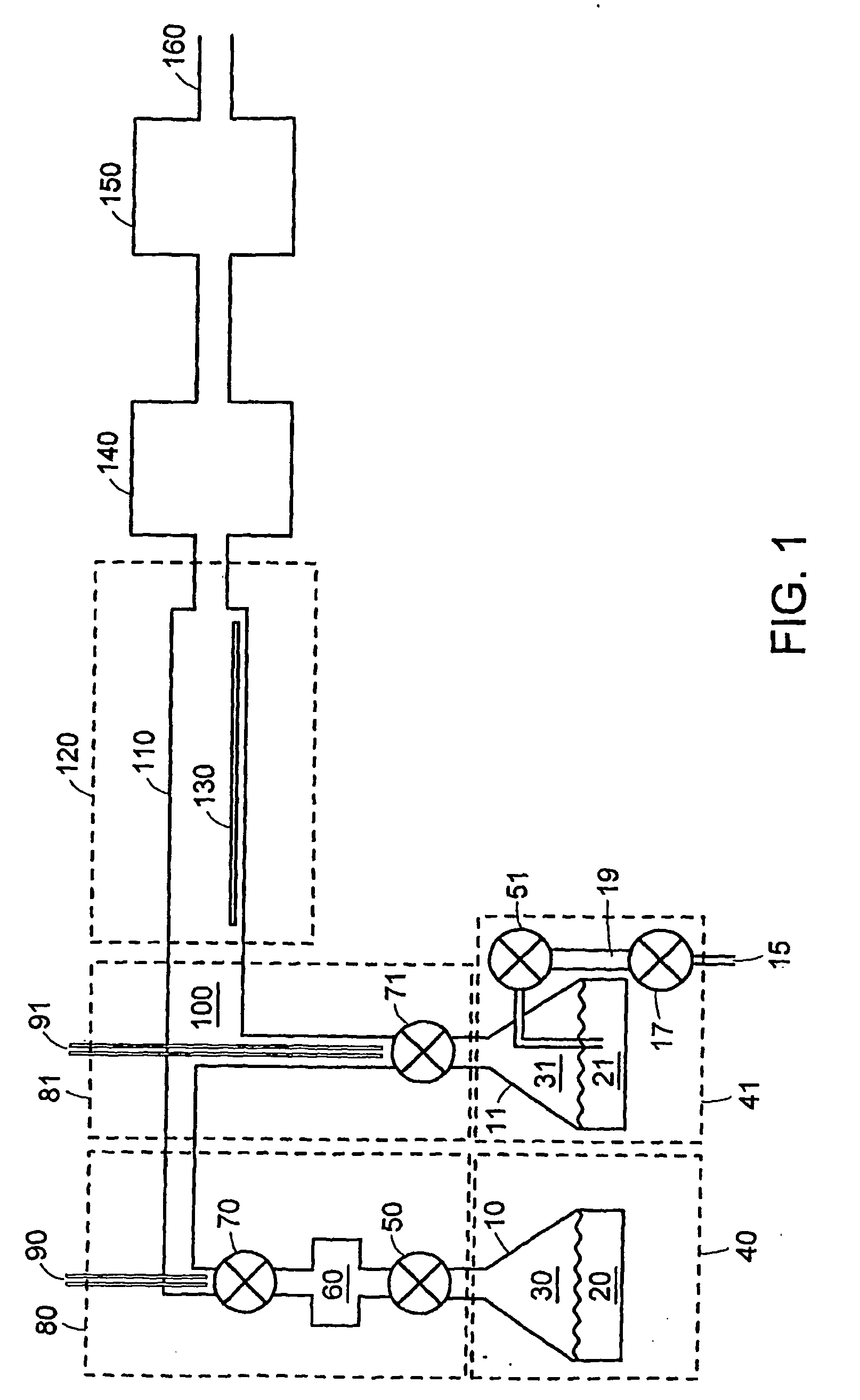

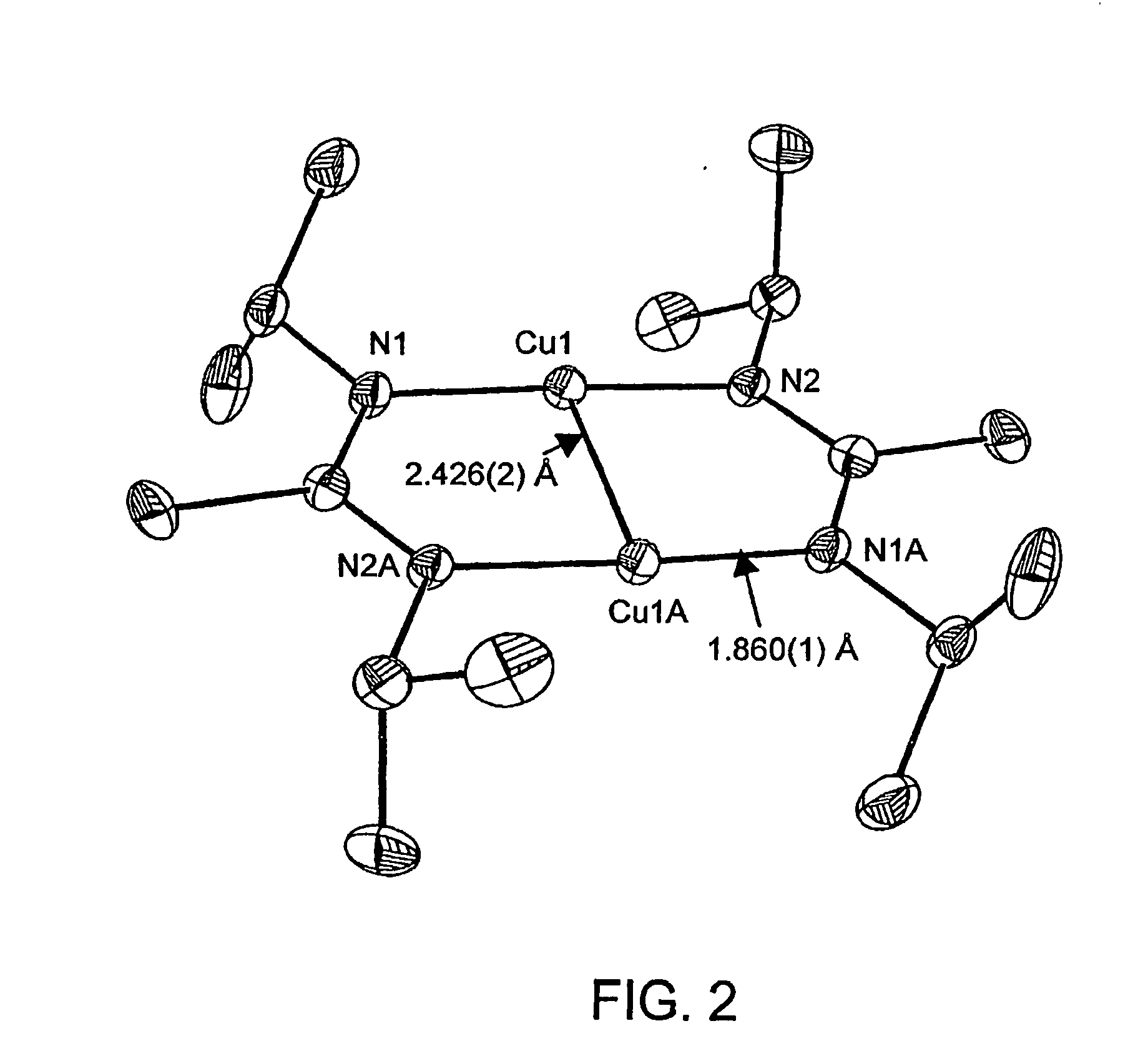

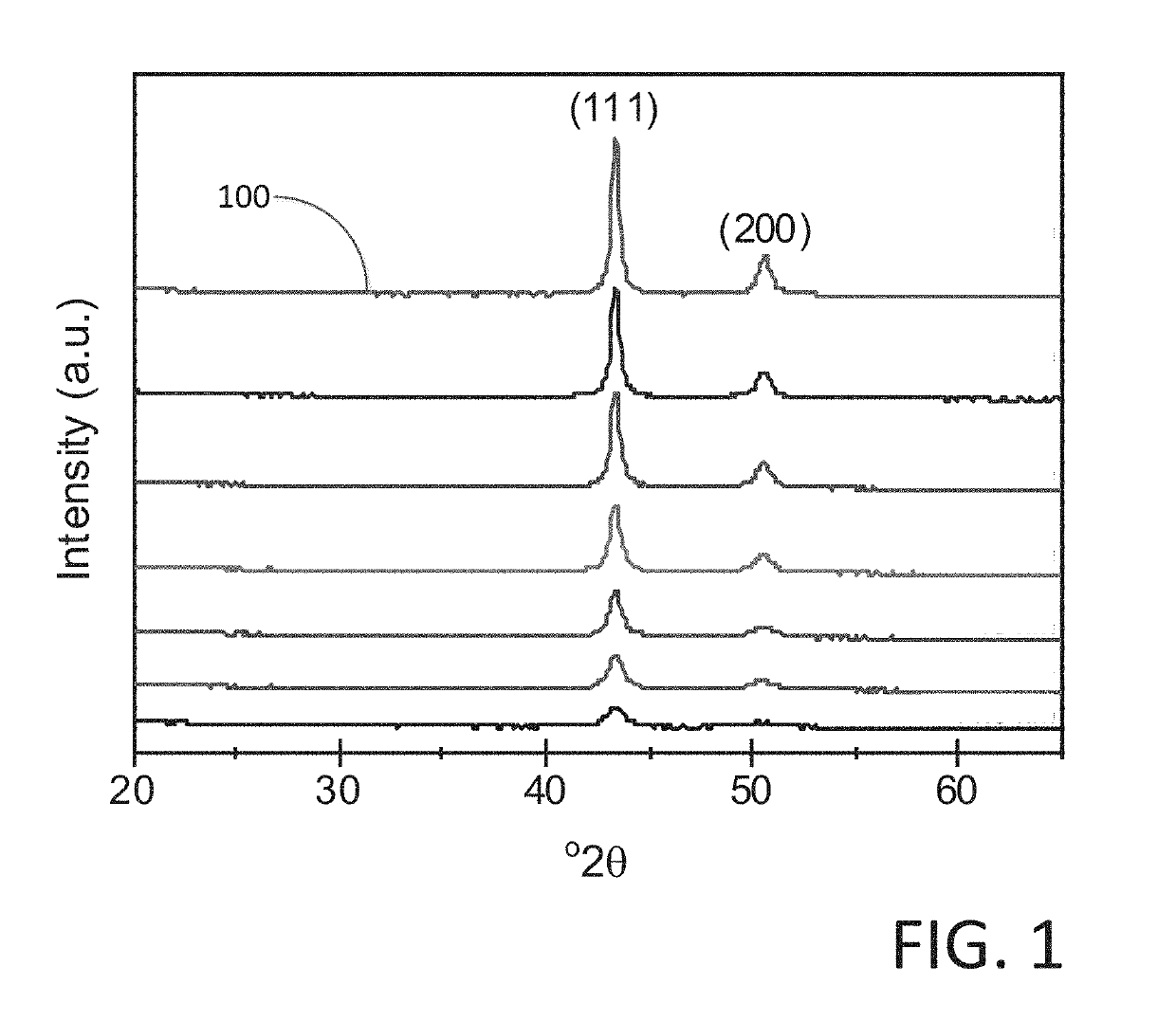

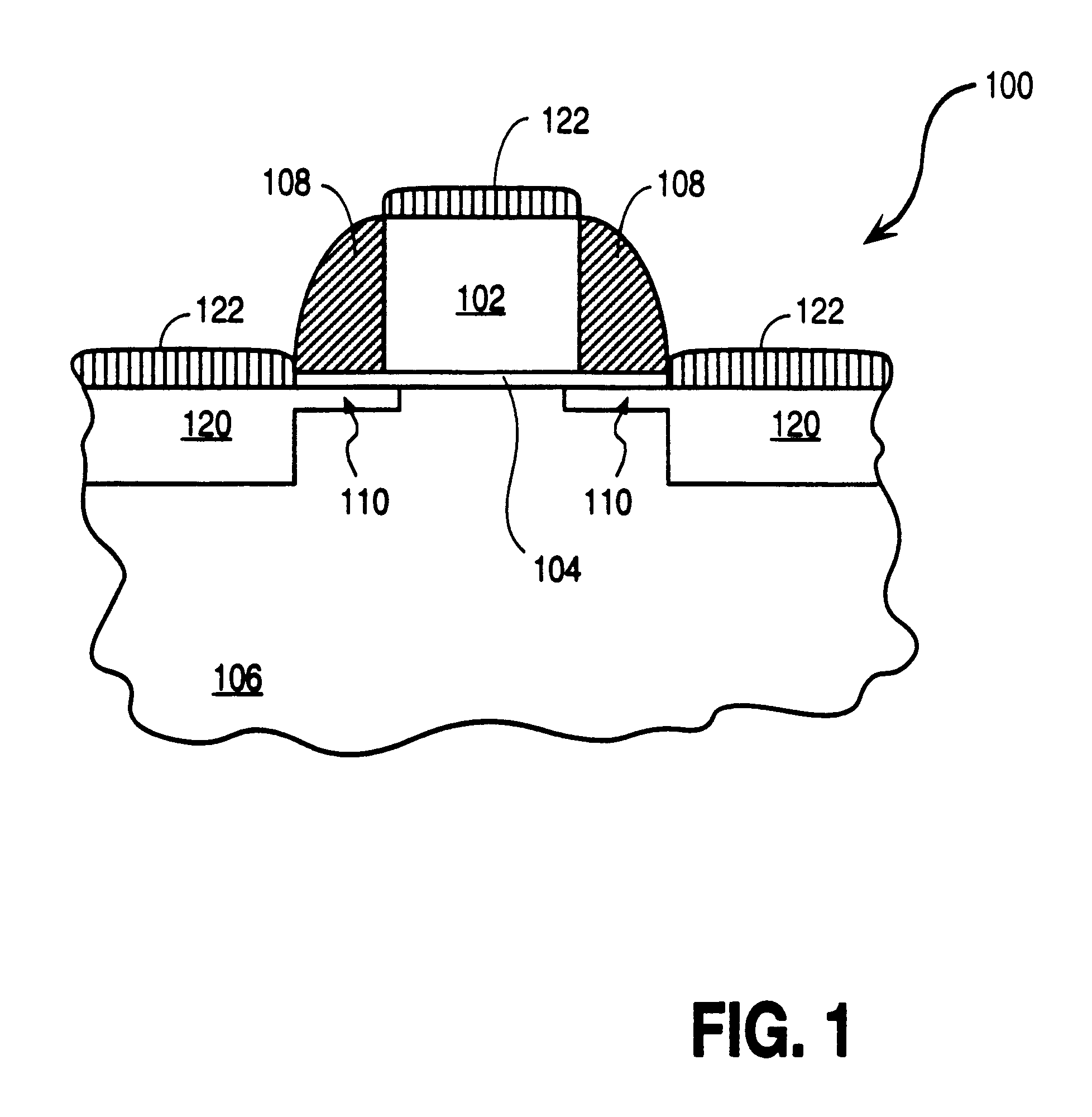

Atomic layer deposition using metal amidinates

ActiveUS20060141155A1Improve conductivityReduce the temperatureGroup 8/9/10/18 element organic compoundsGroup 5/15 element organic compoundsHydrogenWater vapor

Metal films are deposited with uniform thickness and excellent step coverage. Copper metal films were deposited on heated substrates by the reaction of alternating doses of copper(I) NN′-diisopropylacetamidinate vapor and hydrogen gas. Cobalt metal films were deposited on heated substrates by the reaction of alternating doses of cobalt(II) bis(N,N′-diisopropylacetamidinate) vapor and hydrogen gas. Nitrides and oxides of these metals can be formed by replacing the hydrogen with ammonia or water vapor, respectively. The films have very uniform thickness and excellent step coverage in narrow holes. Suitable applications include electrical interconnects in microelectronics and magnetoresistant layers in magnetic information storage devices.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

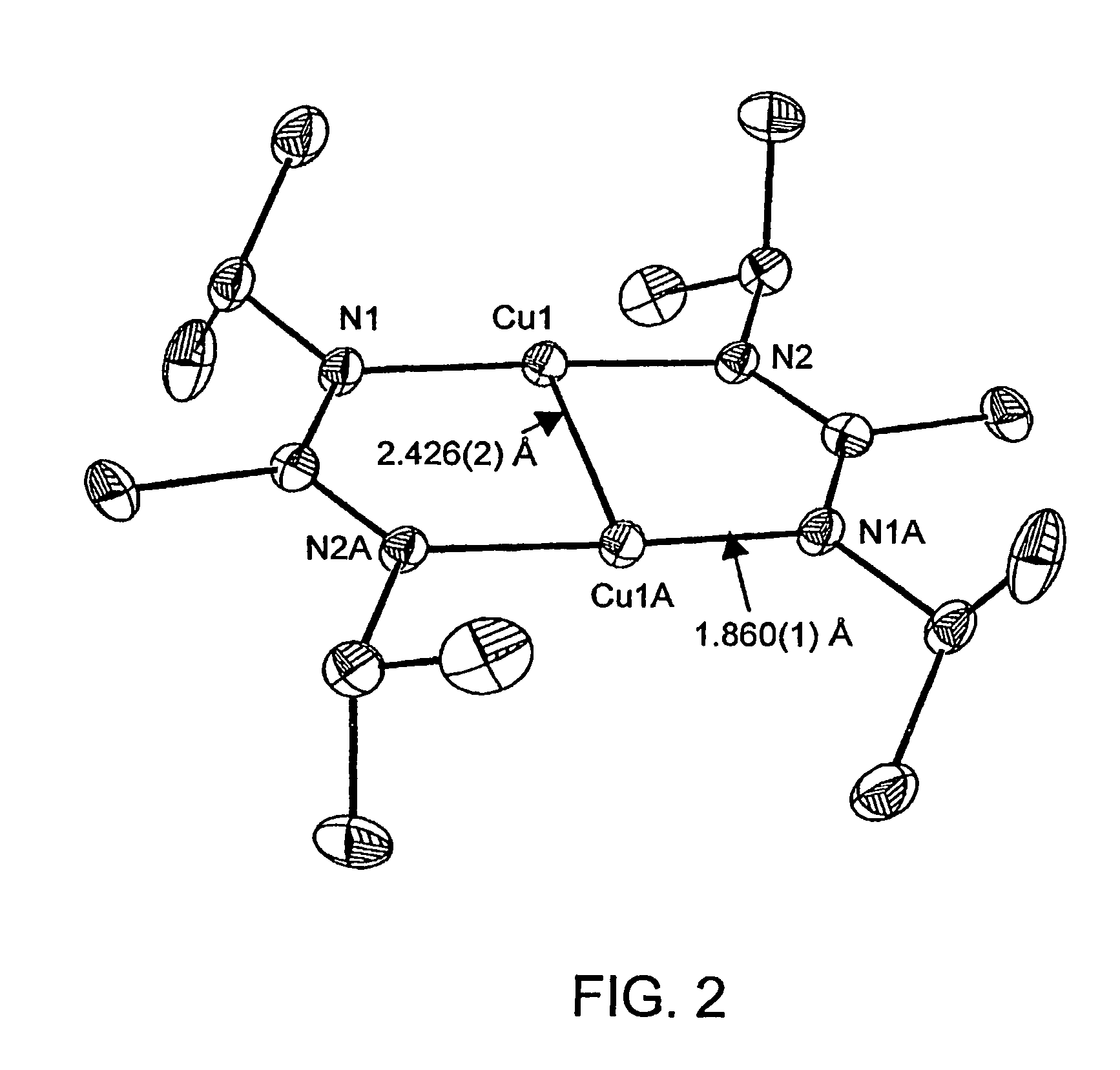

Selective cobalt deposition on copper surfaces

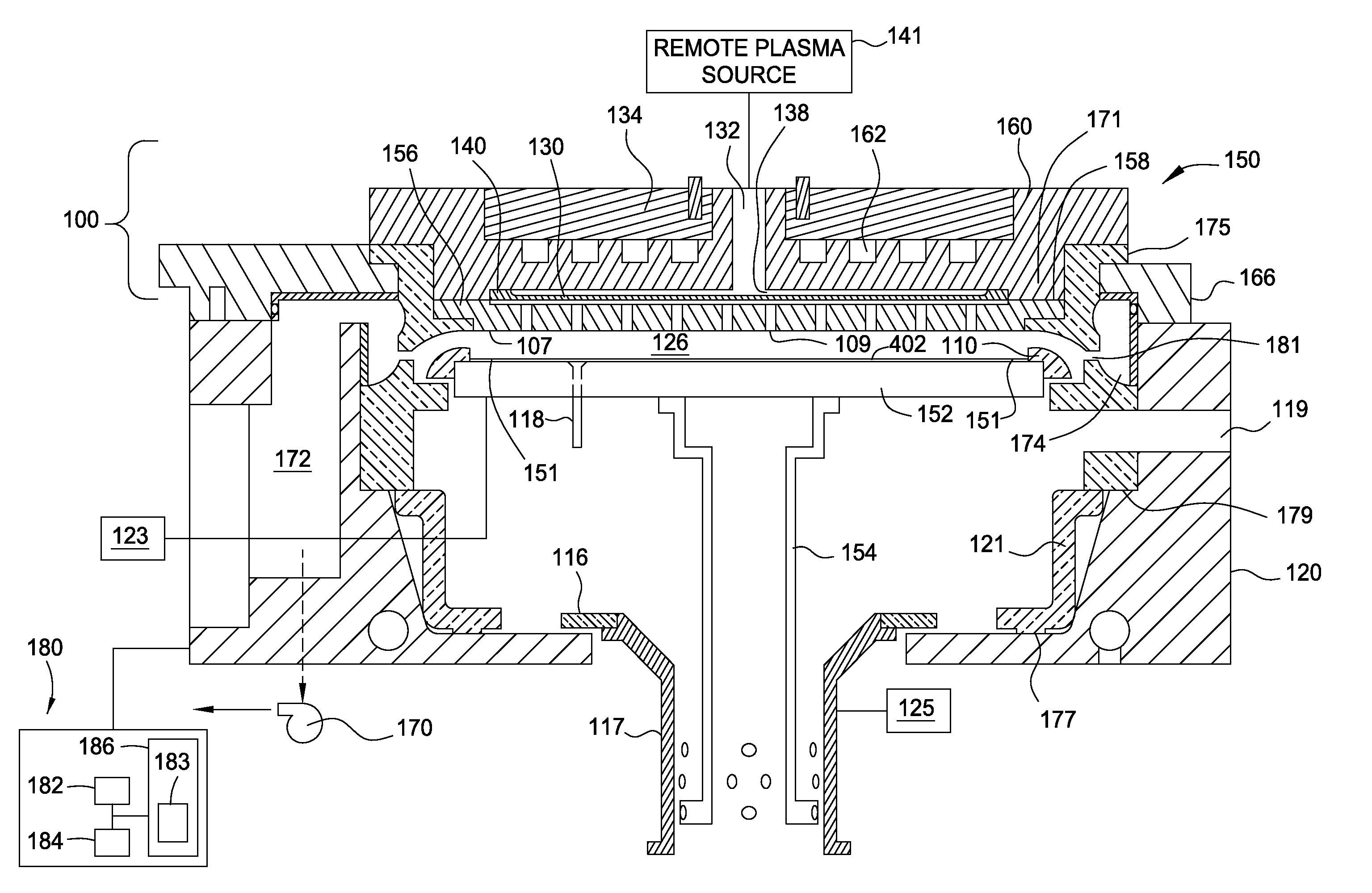

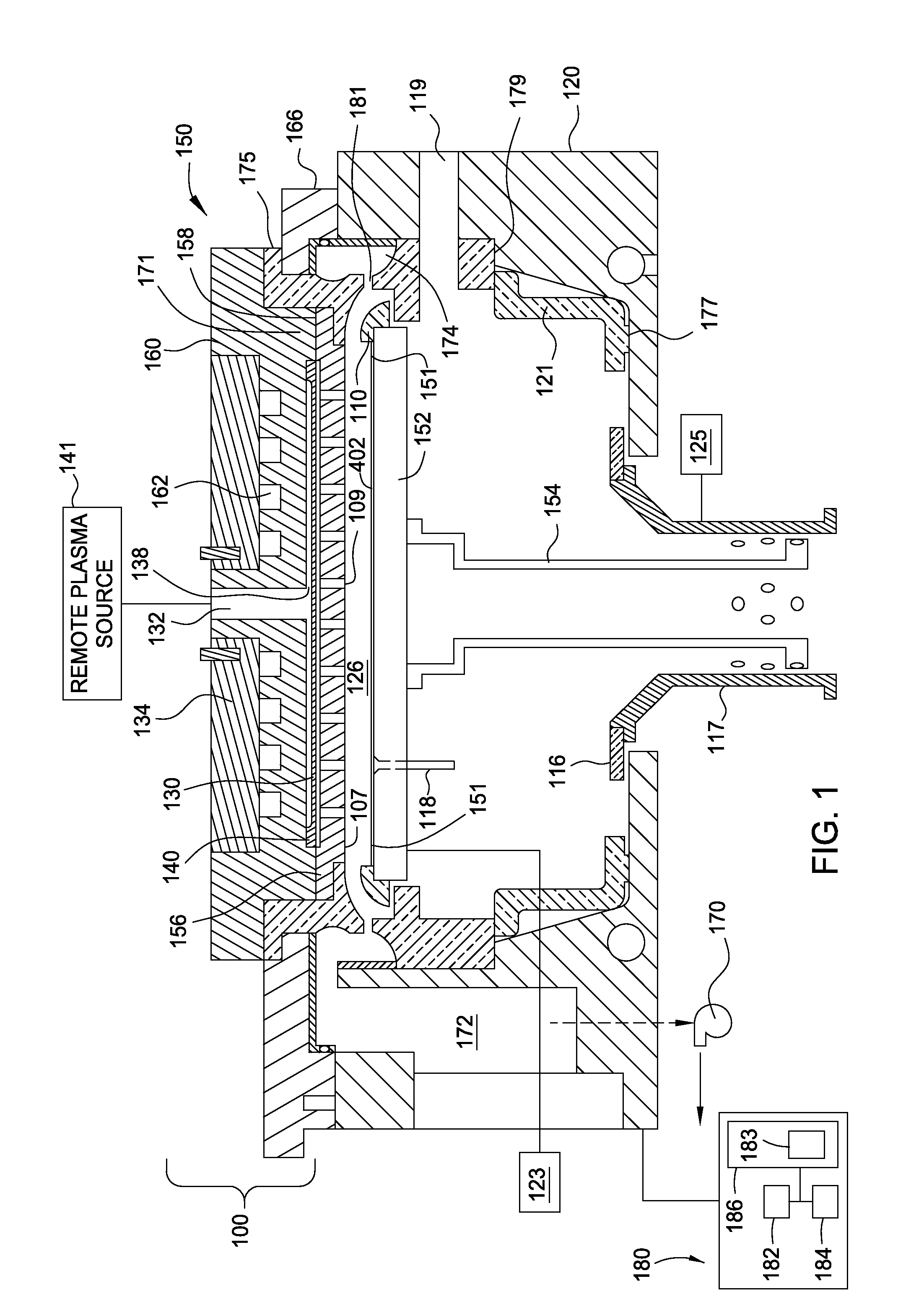

InactiveUS20090269507A1Pretreated surfacesSemiconductor/solid-state device manufacturingGas phaseDielectric surface

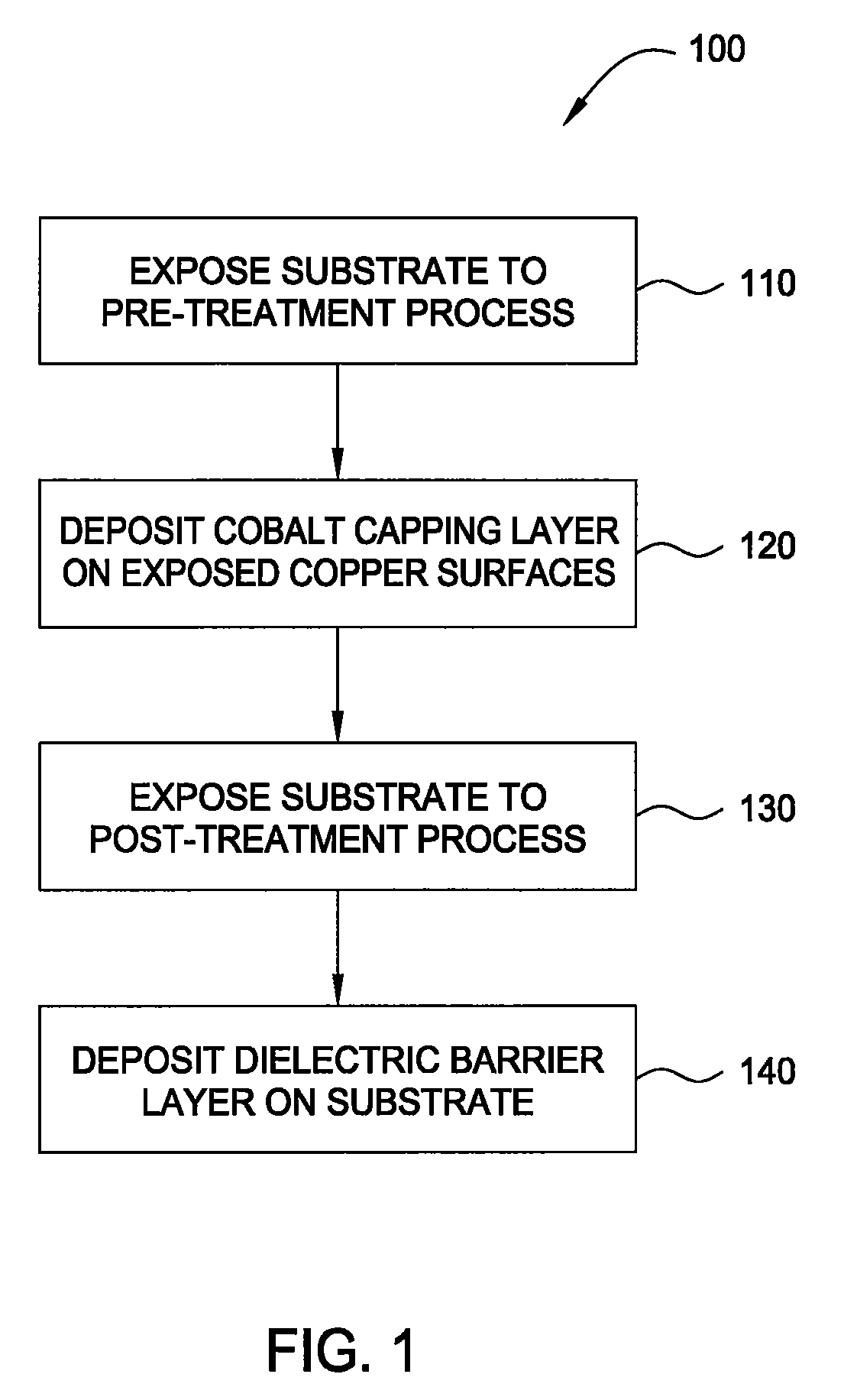

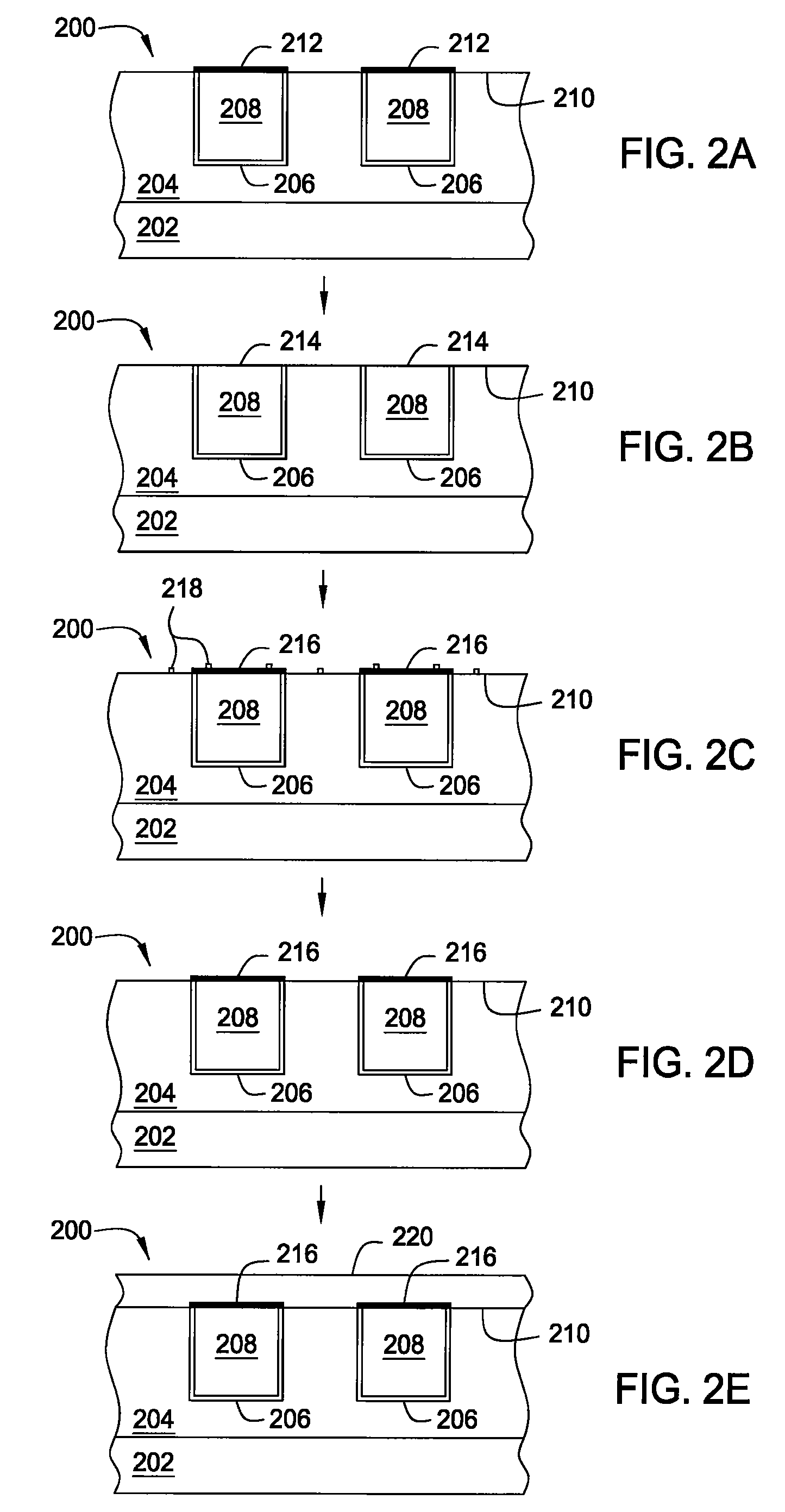

Embodiments of the invention provide processes to selectively form a cobalt layer on a copper surface over exposed dielectric surfaces. In one embodiment, a method for capping a copper surface on a substrate is provided which includes positioning a substrate within a processing chamber, wherein the substrate contains a contaminated copper surface and a dielectric surface, exposing the contaminated copper surface to a reducing agent while forming a copper surface during a pre-treatment process, exposing the substrate to a cobalt precursor gas to selectively form a cobalt capping layer over the copper surface while leaving exposed the dielectric surface during a vapor deposition process, and depositing a dielectric barrier layer over the cobalt capping layer and the dielectric surface. In another embodiment, a deposition-treatment cycle includes performing the vapor deposition process and subsequently a post-treatment process, which deposition-treatment cycle may be repeated to form multiple cobalt capping layers.

Owner:APPLIED MATERIALS INC

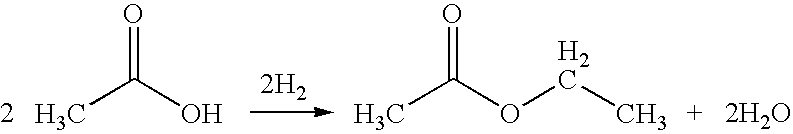

Process for catalytically producing ethylene directly from acetic acid in a single reaction zone

InactiveUS20100030001A1High selectivityHigh yieldHydrocarbonsBulk chemical productionAcetic acidHydrogen

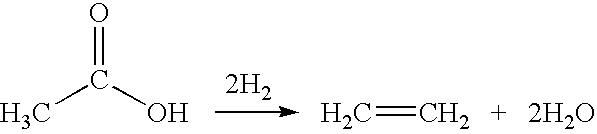

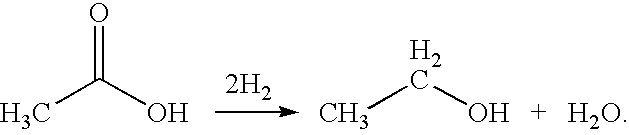

A process for the selective production of ethylene by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethylene in a single reaction zone is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either a copper supported on iron oxide, copper-aluminum catalyst, cobalt supported on H-ZSM-5, ruthenium-cobalt supported on silica or cobalt supported on carbon selectively produces ethylene in a vapor phase at a temperature in the range of about 250° C. to 350° C.

Owner:CELANESE INT CORP

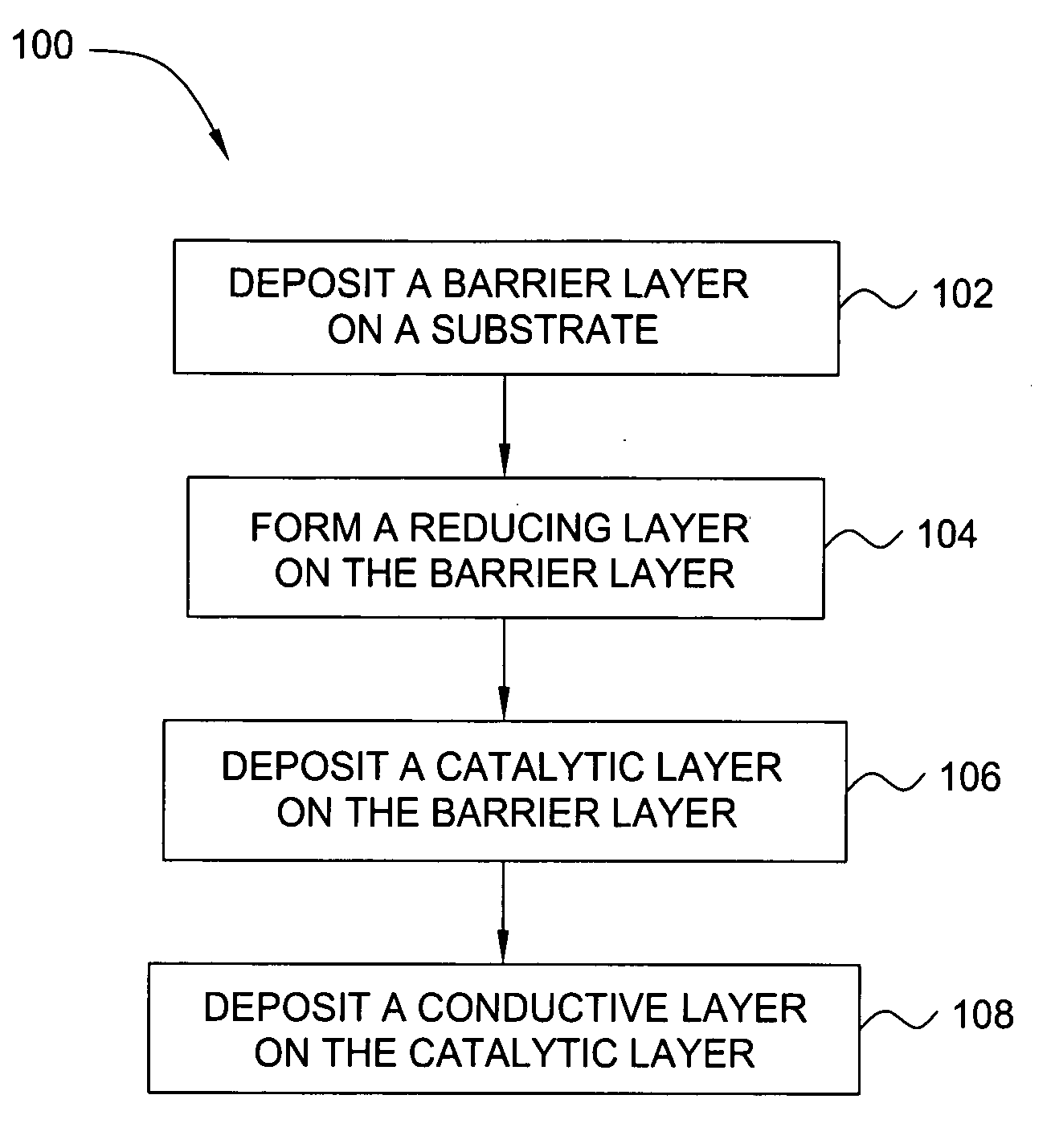

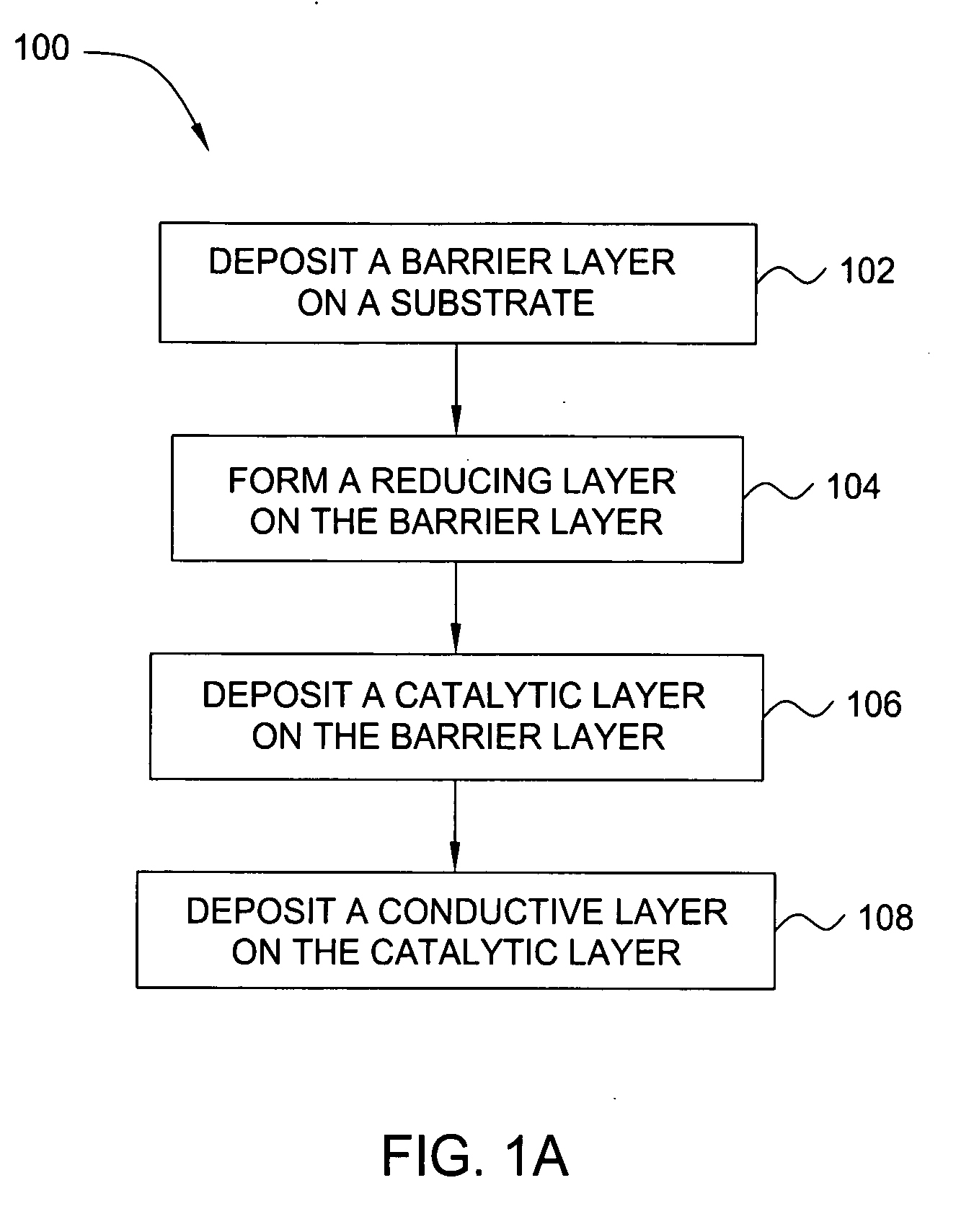

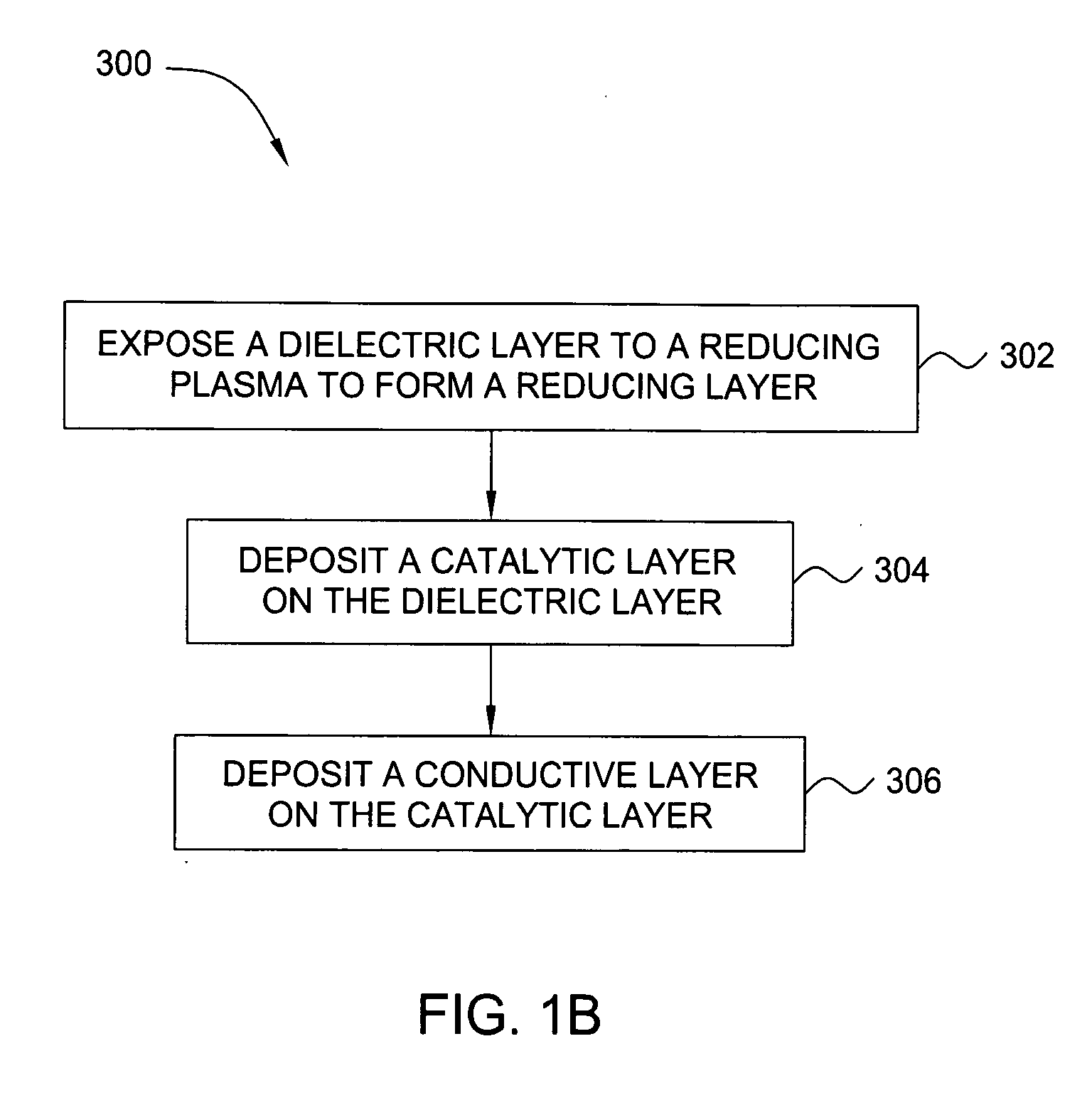

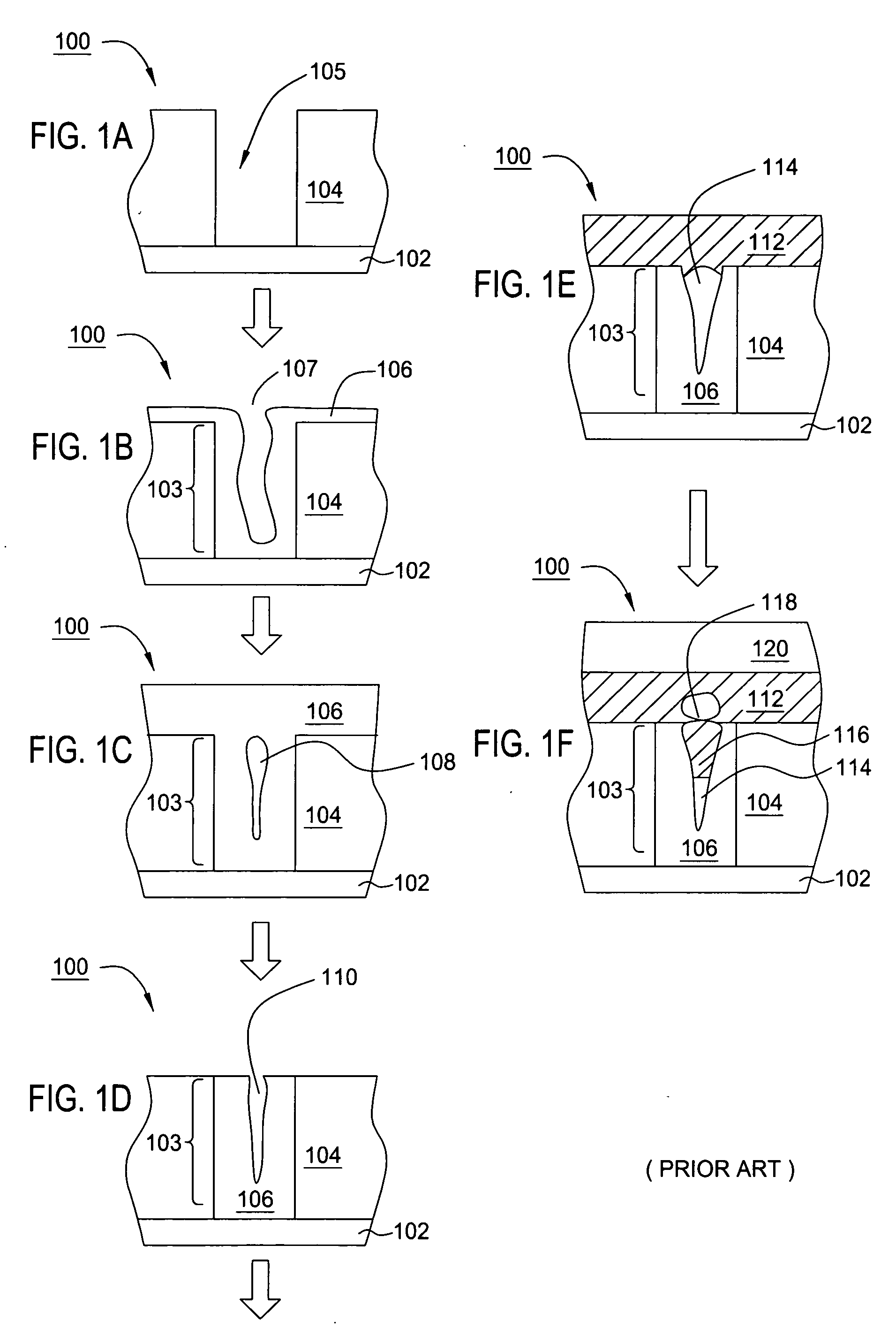

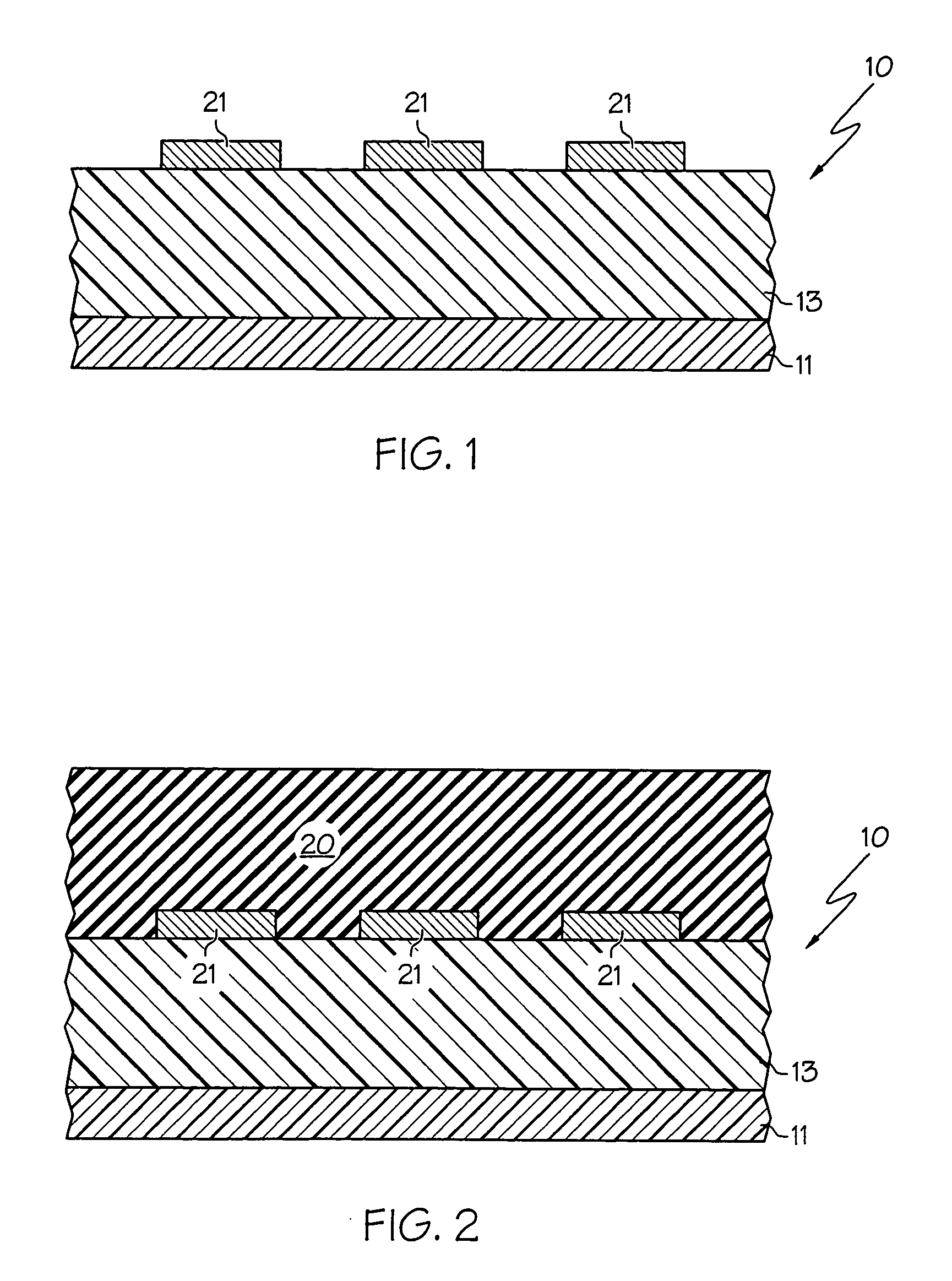

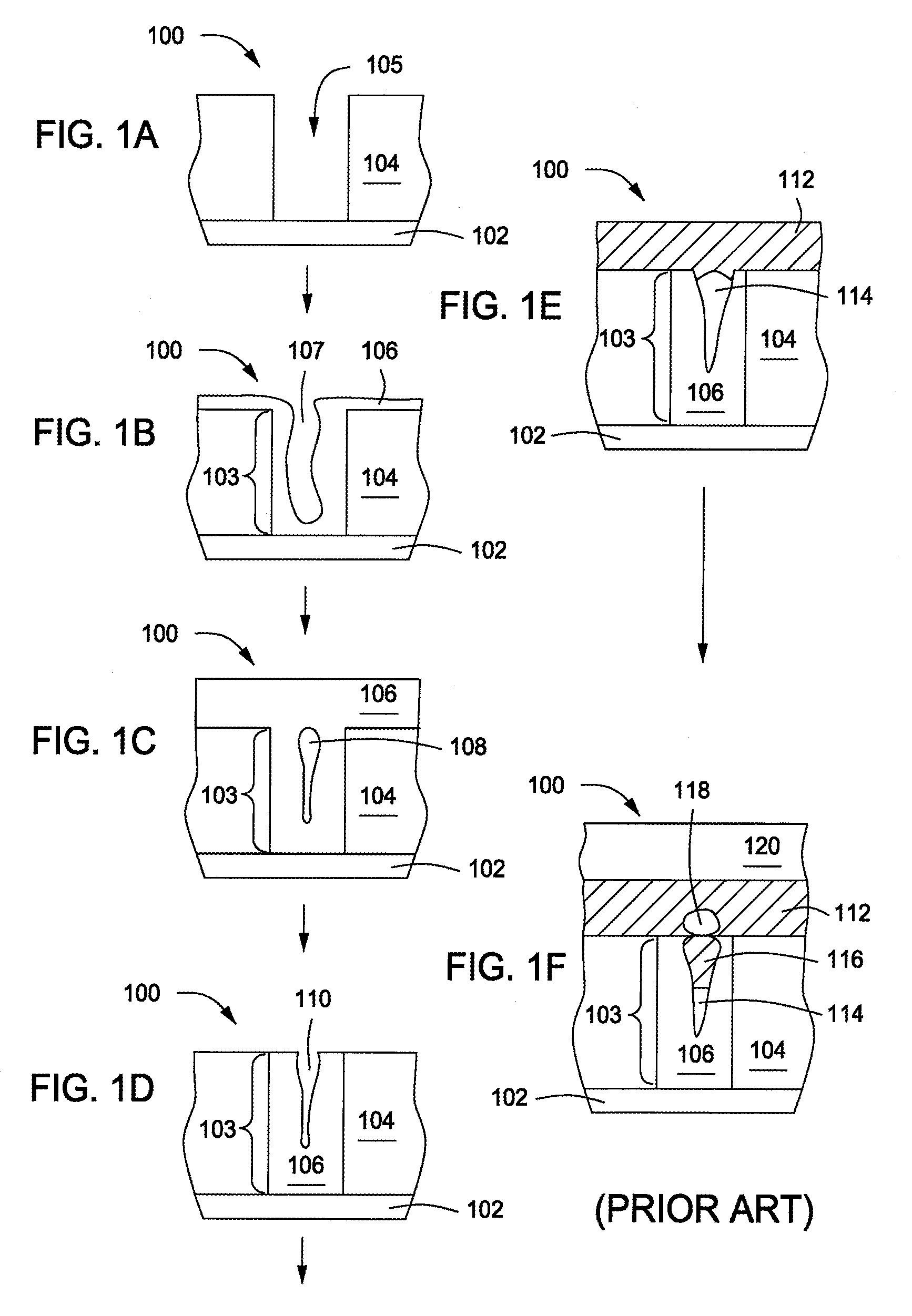

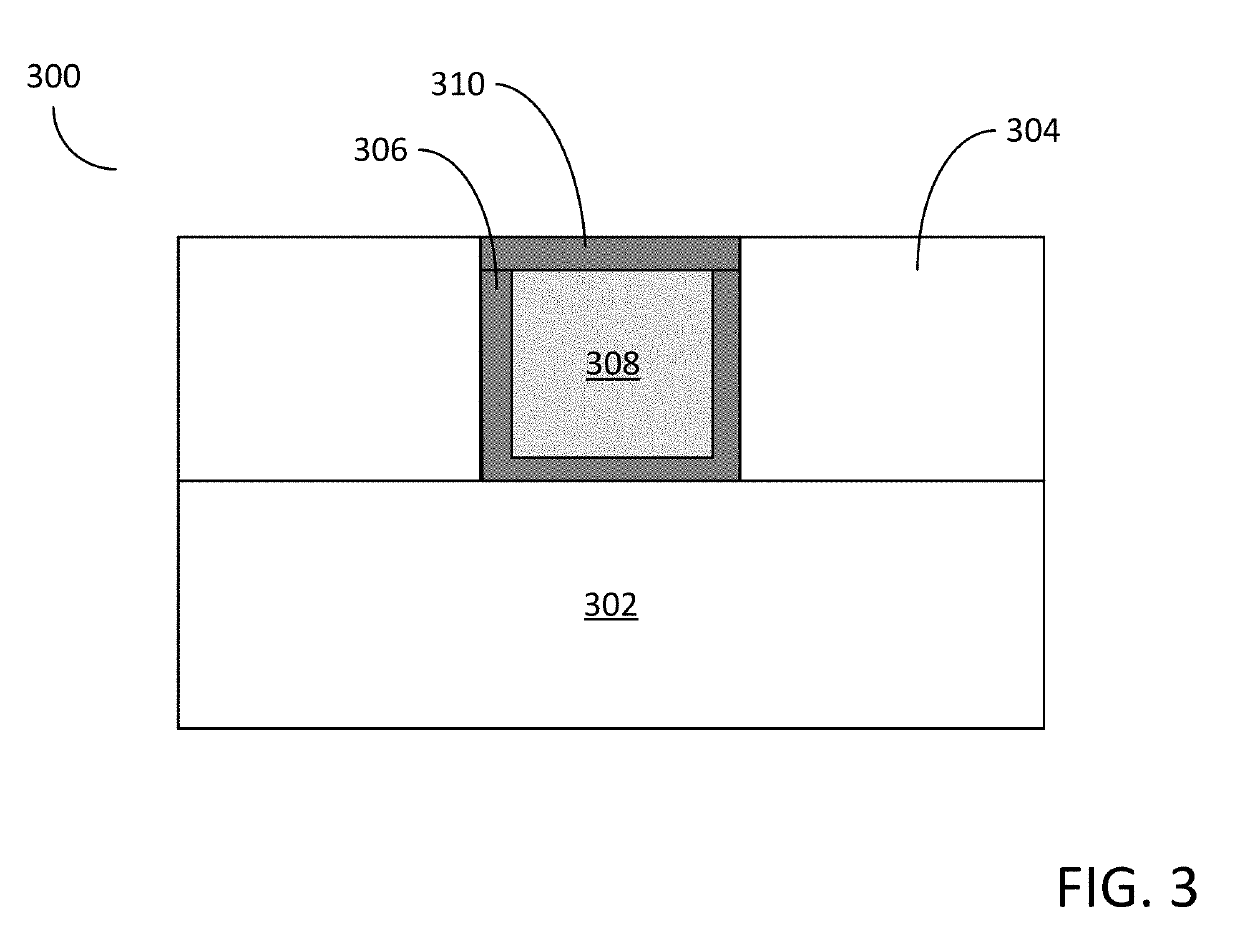

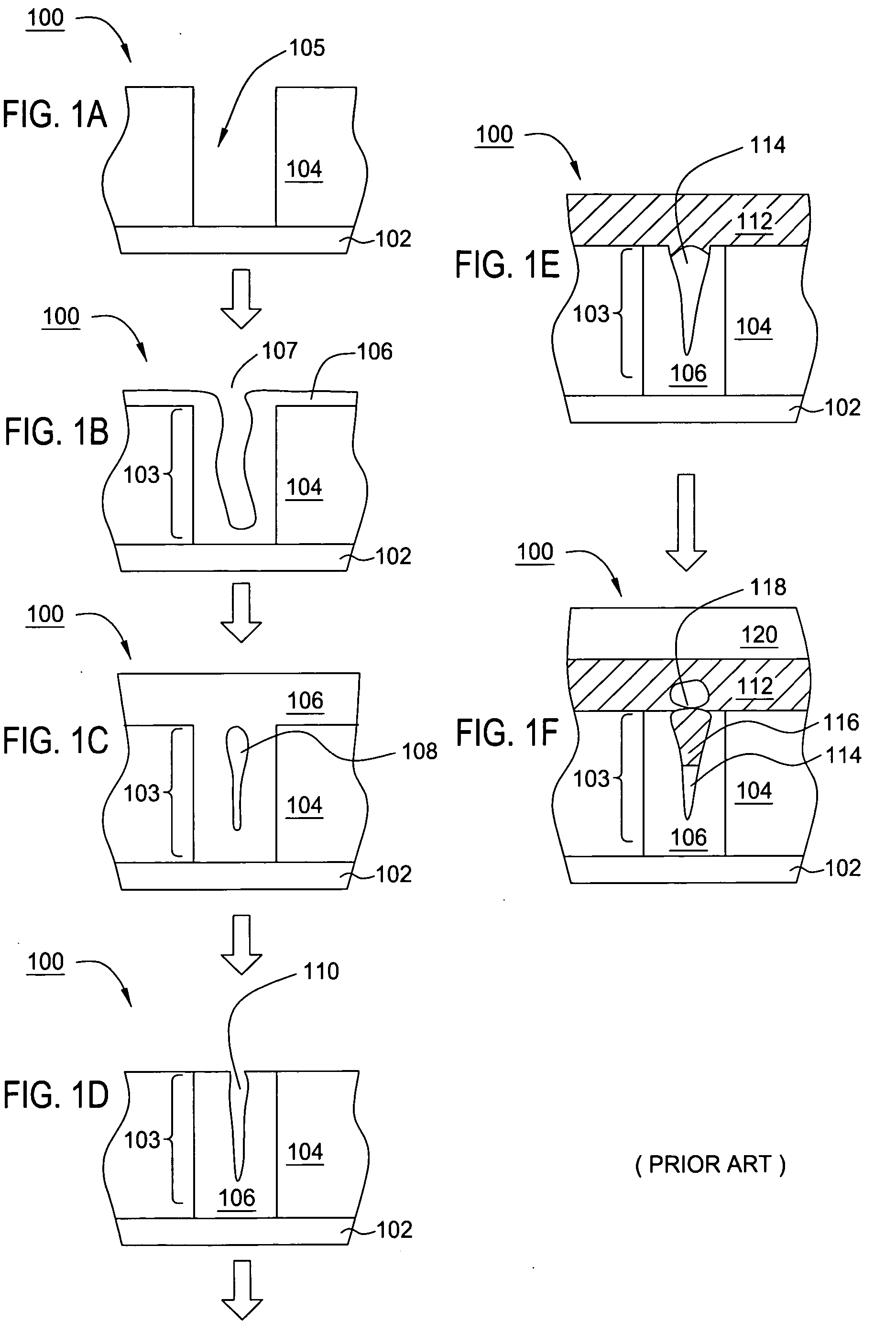

Deposition of an intermediate catalytic layer on a barrier layer for copper metallization

InactiveUS20060240187A1Solid-state devicesSemiconductor/solid-state device manufacturingIridiumSilanes

In one embodiment, a method for depositing a conductive material on a substrate is provided which includes exposing a substrate containing a barrier layer to a volatile reducing precursor to form a reducing layer during a soak process, exposing the reducing layer to a catalytic-metal precursor to deposit a catalytic metal-containing layer on the barrier layer, and depositing a conductive layer (e.g., copper) on the catalytic metal-containing layer. The volatile reducing precursor may include phosphine, diborane, silane, a plasma thereof, or a combination thereof and be exposed to the substrate for a time period within a range from about 1 second to about 30 seconds during the soak process. The catalytic metal-containing layer may contain ruthenium, cobalt, rhodium, iridium, nickel, palladium, platinum, silver, or copper. In one example, the catalytic metal-containing layer is deposited by a vapor deposition process utilizing ruthenium tetroxide formed by an in situ process.

Owner:APPLIED MATERIALS INC

Process for forming cobalt and cobalt silicide materials in copper contact applications

InactiveUS20080268635A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingElectroless depositionCopper

Embodiments of the invention described herein generally provide methods for forming cobalt silicide layers and metallic cobalt layers by using various deposition processes and annealing processes. In one embodiment, a method for forming a cobalt silicide material on a substrate is provided which includes treating the substrate with at least one preclean process to expose a silicon-containing surface, depositing a cobalt silicide material over the silicon-containing surface, and depositing a copper material over the cobalt silicide material. In another embodiment, a metallic cobalt material may be deposited over the cobalt silicide material prior to depositing the copper material. In one example, the copper material may be formed by depositing a copper seed layer and a copper bulk layer on the substrate. The copper seed layer may be deposited by a PVD process and the copper bulk layer may be deposited by an ECP process or an electroless deposition process.

Owner:APPLIED MATERIALS INC

Selective deposition

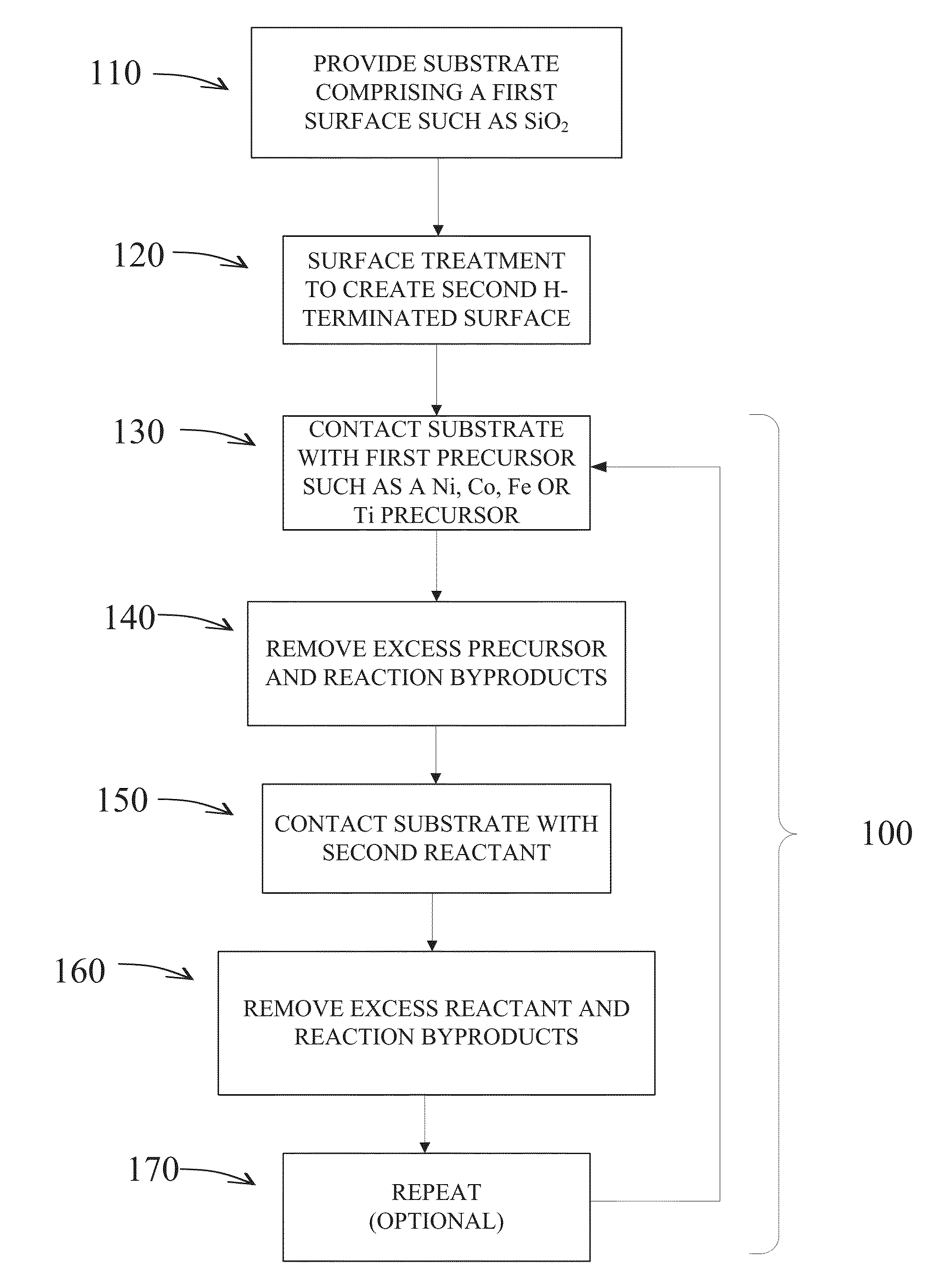

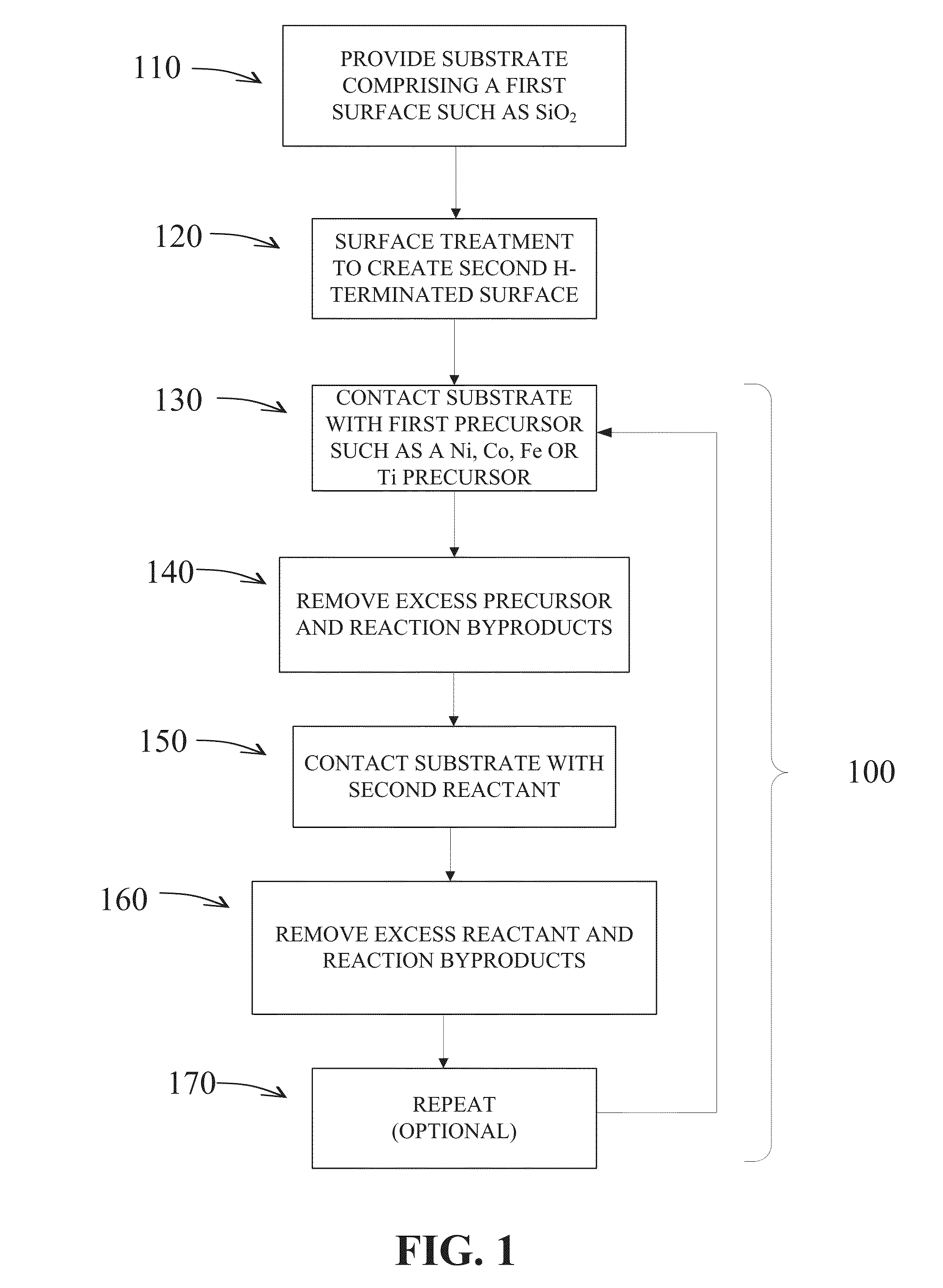

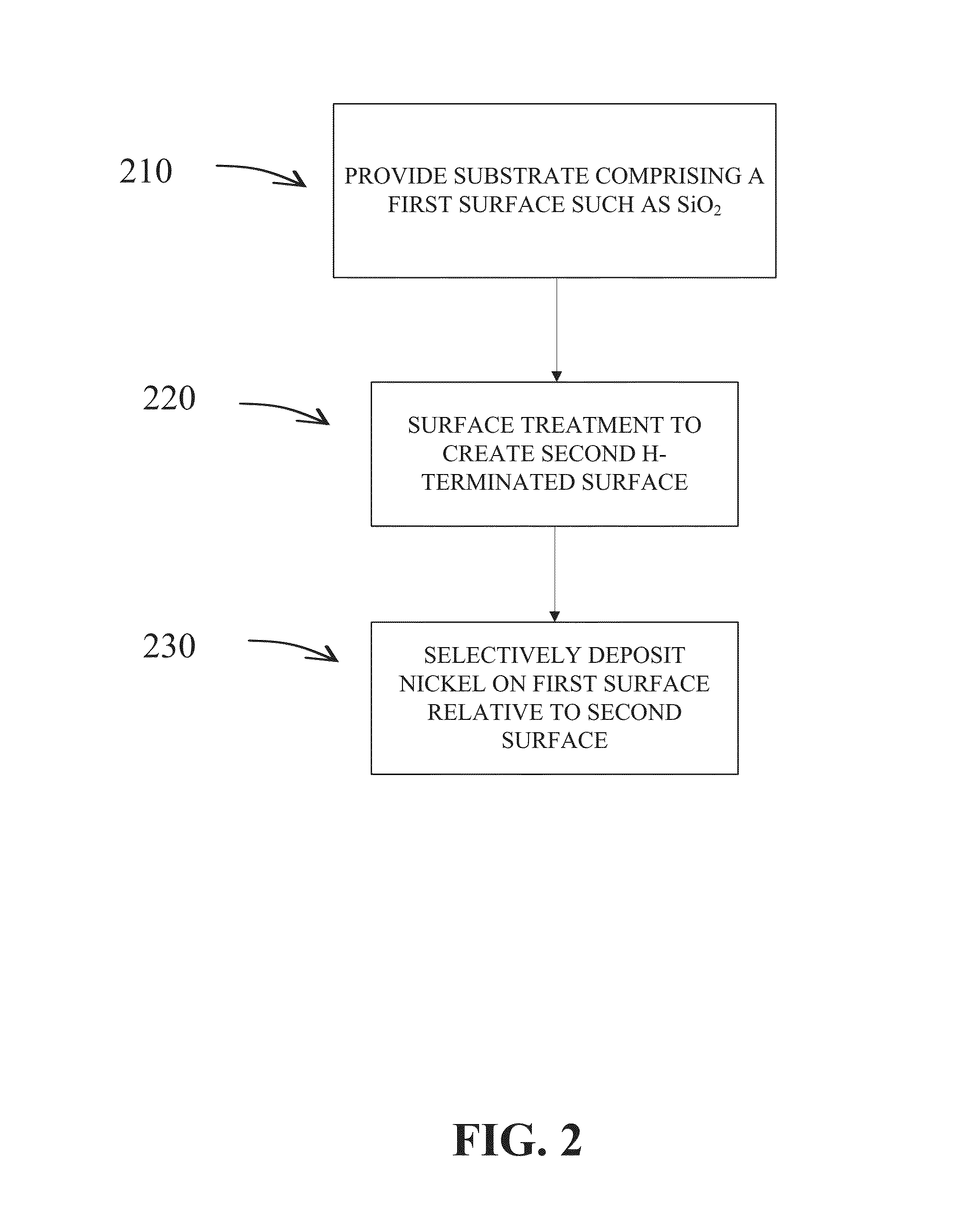

Methods are provided for selectively depositing a surface of a substrate relative to a second, different surface. An exemplary deposition method can include selectively depositing a material, such as a material comprising nickel, nickel nitride, cobalt, iron, and / or titanium oxide on a first surface, such as a SiO2 surface, relative to a second, different surface, such as a H-terminated surface, of the same substrate. Methods can include treating a surface of the substrate to provide H-terminations prior to deposition.

Owner:ASM IP HLDG BV

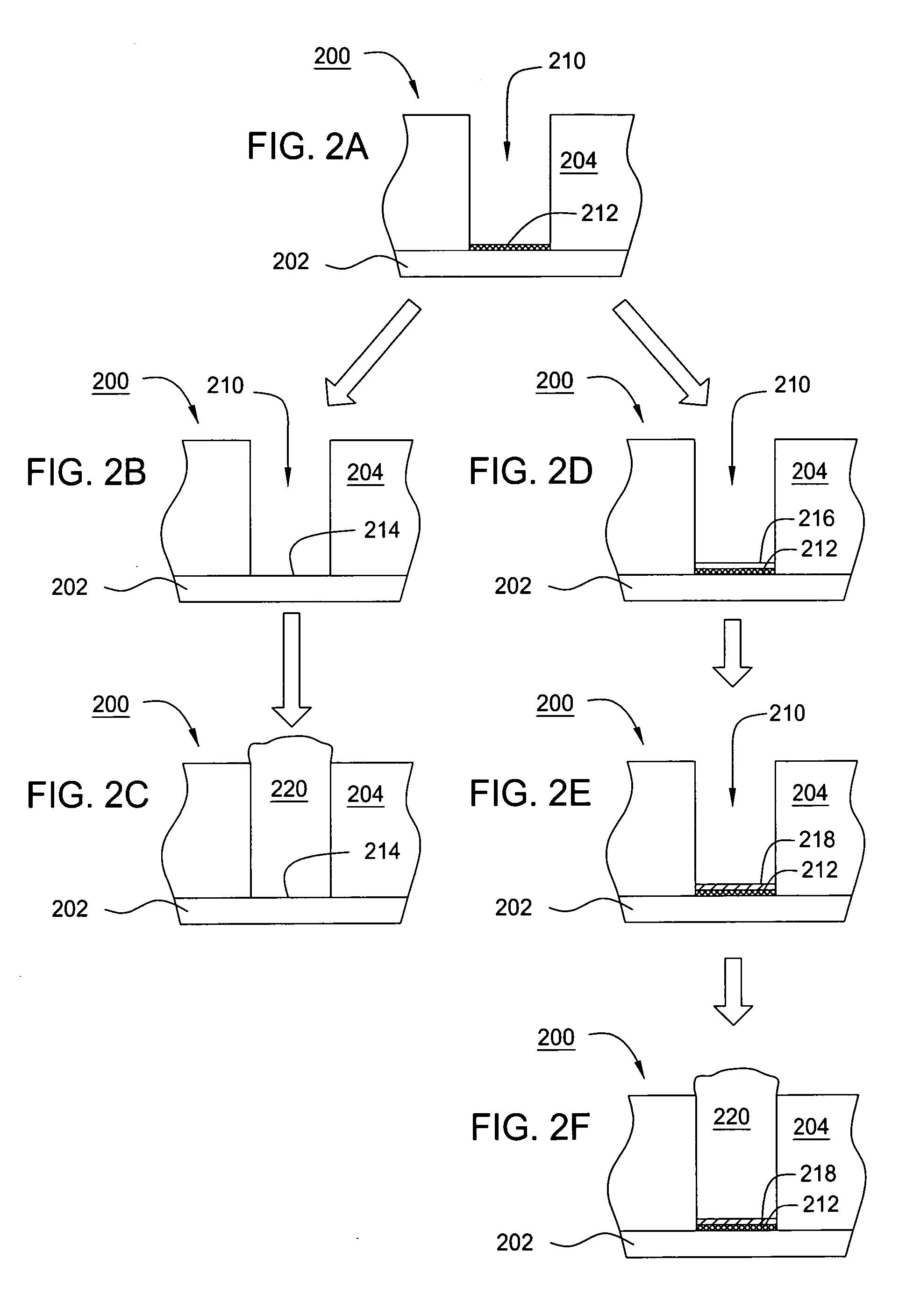

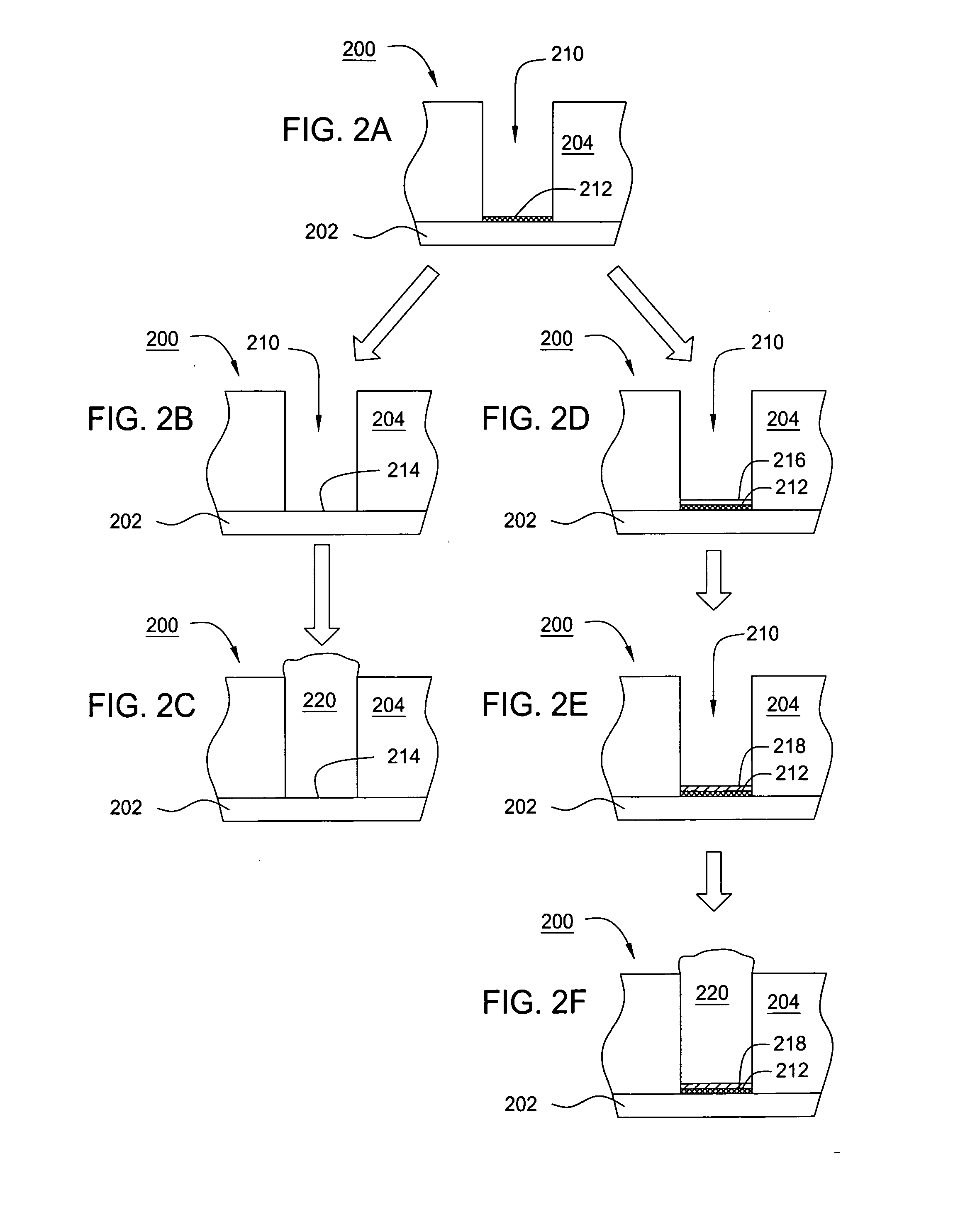

Electroless deposition process on a silicon contact

ActiveUS20060264043A1Material nanotechnologySemiconductor/solid-state device manufacturingSalicideAlloy

Embodiments as described herein provide methods for depositing a material on a substrate during electroless deposition processes, as well as compositions of the electroless deposition solutions. In one embodiment, the substrate contains a contact aperture having an exposed silicon contact surface. In another embodiment, the substrate contains a contact aperture having an exposed silicide contact surface. The apertures are filled with a metal contact material by exposing the substrate to an electroless deposition process. The metal contact material may contain a cobalt material, a nickel material, or alloys thereof. Prior to filling the apertures, the substrate may be exposed to a variety of pretreatment processes, such as preclean processes and activations processes. A preclean process may remove organic residues, native oxides, and other contaminants during a wet clean process or a plasma etch process. Embodiments of the process also provide the deposition of additional layers, such as a capping layer.

Owner:APPLIED MATERIALS INC

Electroless plating of metal caps for chalcogenide-based memory devices

InactiveUS20060094236A1Good electrical contactSemiconductor/solid-state device manufacturingPlatinumSulfur

A method of forming a metal cap over a conductive interconnect in a chalcogenide-based memory device is provided and includes, forming a layer of a first conductive material over a substrate, depositing an insulating layer over the first conductive material and the substrate, forming an opening in the insulating layer to expose at least a portion of the first conductive material, depositing a second conductive material over the insulating layer and within the opening, removing portions of the second conductive material to form a conductive area within the opening, recessing the conductive area within the opening to a level below an upper surface of the insulating layer, forming a cap of a third conductive material over the recessed conductive area within the opening, the third conductive material selected from the group consisting of cobalt, silver, gold, copper, nickel, palladium, platinum, and alloys thereof, depositing a stack of a chalcogenide based memory cell material over the cap, and depositing a conductive material over the chalcogenide stack.

Owner:MICRON TECH INC

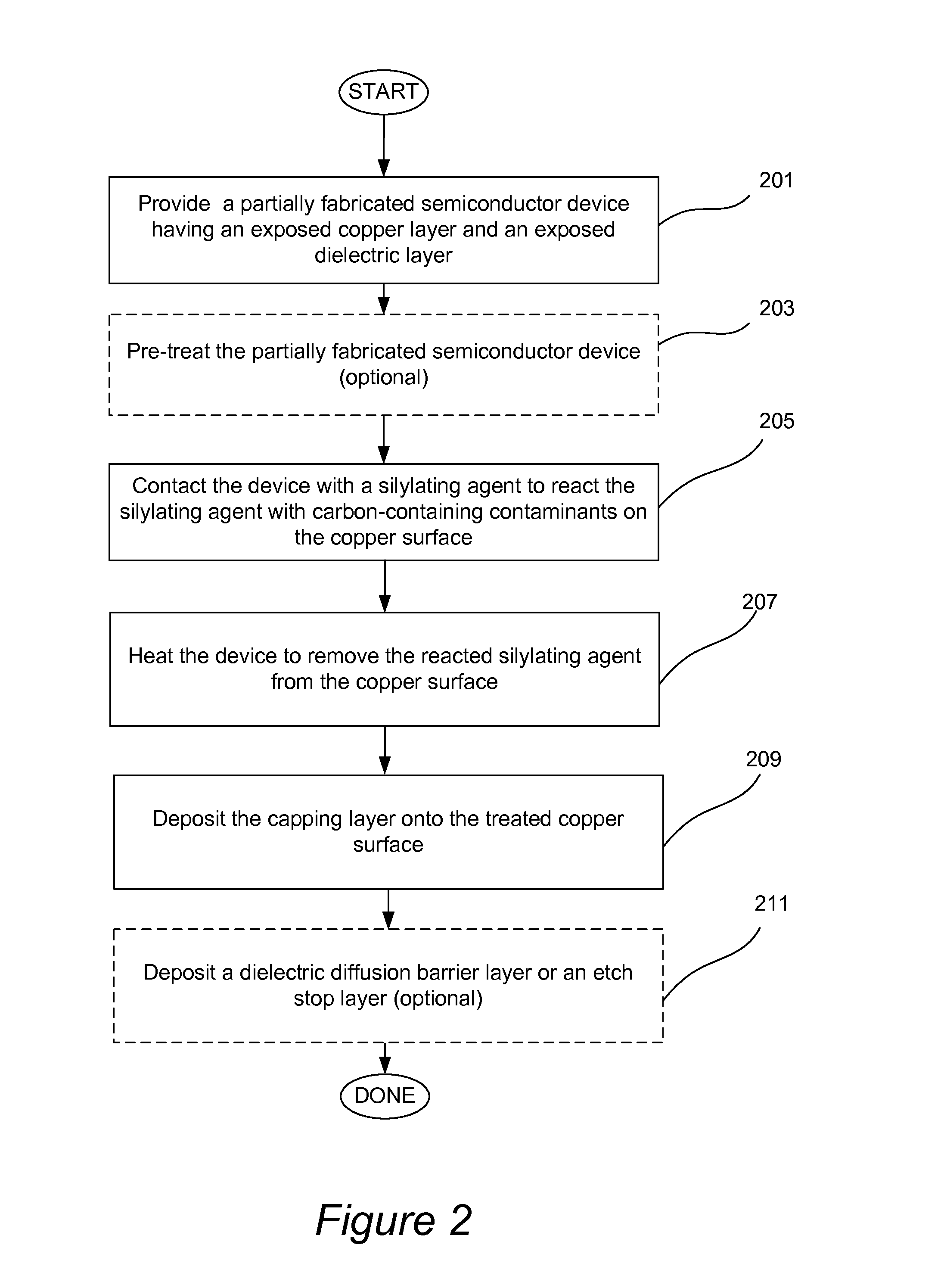

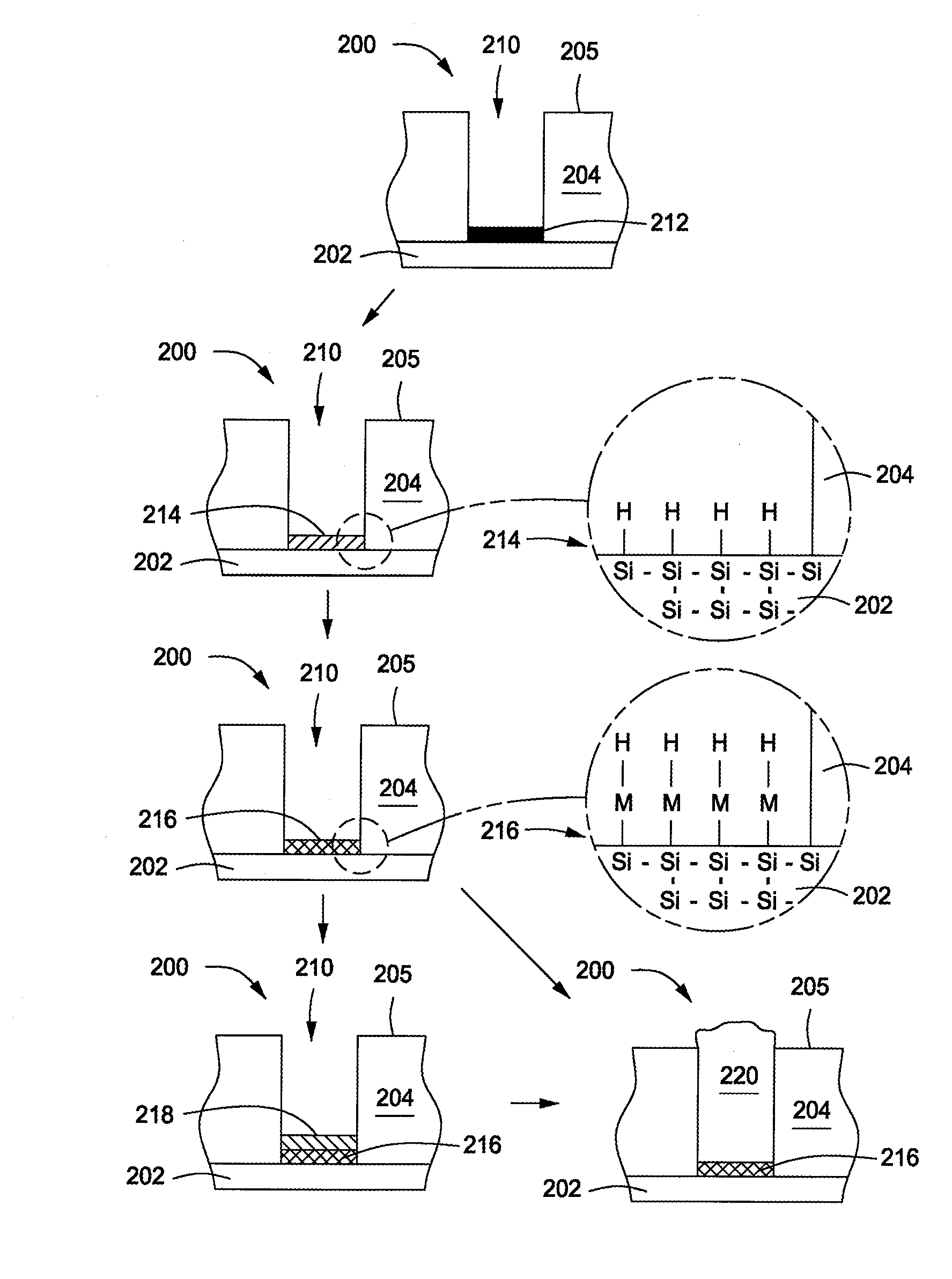

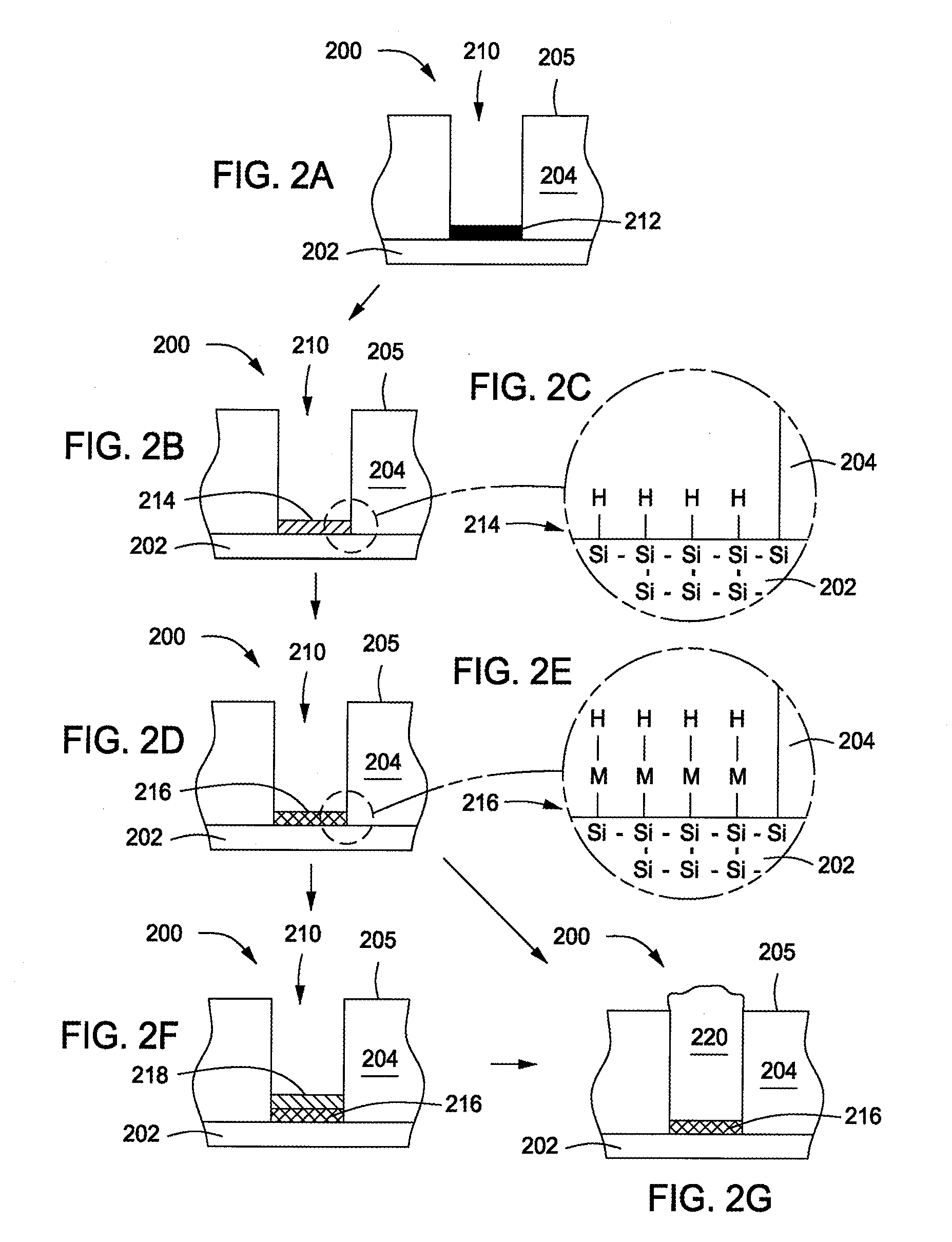

Cleaning of carbon-based contaminants in metal interconnects for interconnect capping applications

InactiveUS20150380296A1Avoid depositionLow deposition rateLiquid surface applicatorsSemiconductor/solid-state device manufacturingMetal interconnectSilylation

Protective caps residing at an interface between copper lines and dielectric diffusion barrier layers are used to improve various performance characteristics of interconnects. The caps, such as cobalt-containing caps or manganese-containing caps, are selectively deposited onto exposed copper lines in a presence of exposed dielectric using CVD or ALD methods. The deposition of the capping material is affected by the presence of carbon-containing contaminants on the surface of copper, which may lead to poor or uneven growth of the capping layer. A method of removing carbon-containing contaminants from the copper surface prior to deposition of caps involves contacting the substrate containing the exposed copper surface with a silylating agent at a first temperature to form a layer of reacted silylating agent on the copper surface, followed by heating the substrate at a higher temperature to release the reacted silylating agent from the copper surface.

Owner:LAM RES CORP

Method of selectively depositing a thin film material at a semiconductor interface

InactiveUS20070108404A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingDevice formMetal silicide

Embodiments of the invention provide processes to form a high quality contact level connection to devices formed on a substrate. In one embodiment, a method for depositing a material on a substrate is provided which includes exposing the substrate to a buffered oxide etch solution to form a silicon hydride layer during a pretreatment process, depositing a metal silicide layer on the substrate, and depositing a first metal layer (e.g., tungsten) on the metal silicide layer. The buffered oxide etch solution may contain hydrogen fluoride and an alkanolamine compound, such as ethanolamine diethanolamine, or triethanolamine. The metal silicide layer may contain cobalt, nickel, or tungsten and may be deposited by an electroless deposition process. In one example, the substrate is exposed to an electroless deposition solution containing a solvent and a complexed metal compound.

Owner:APPLIED MATERIALS INC

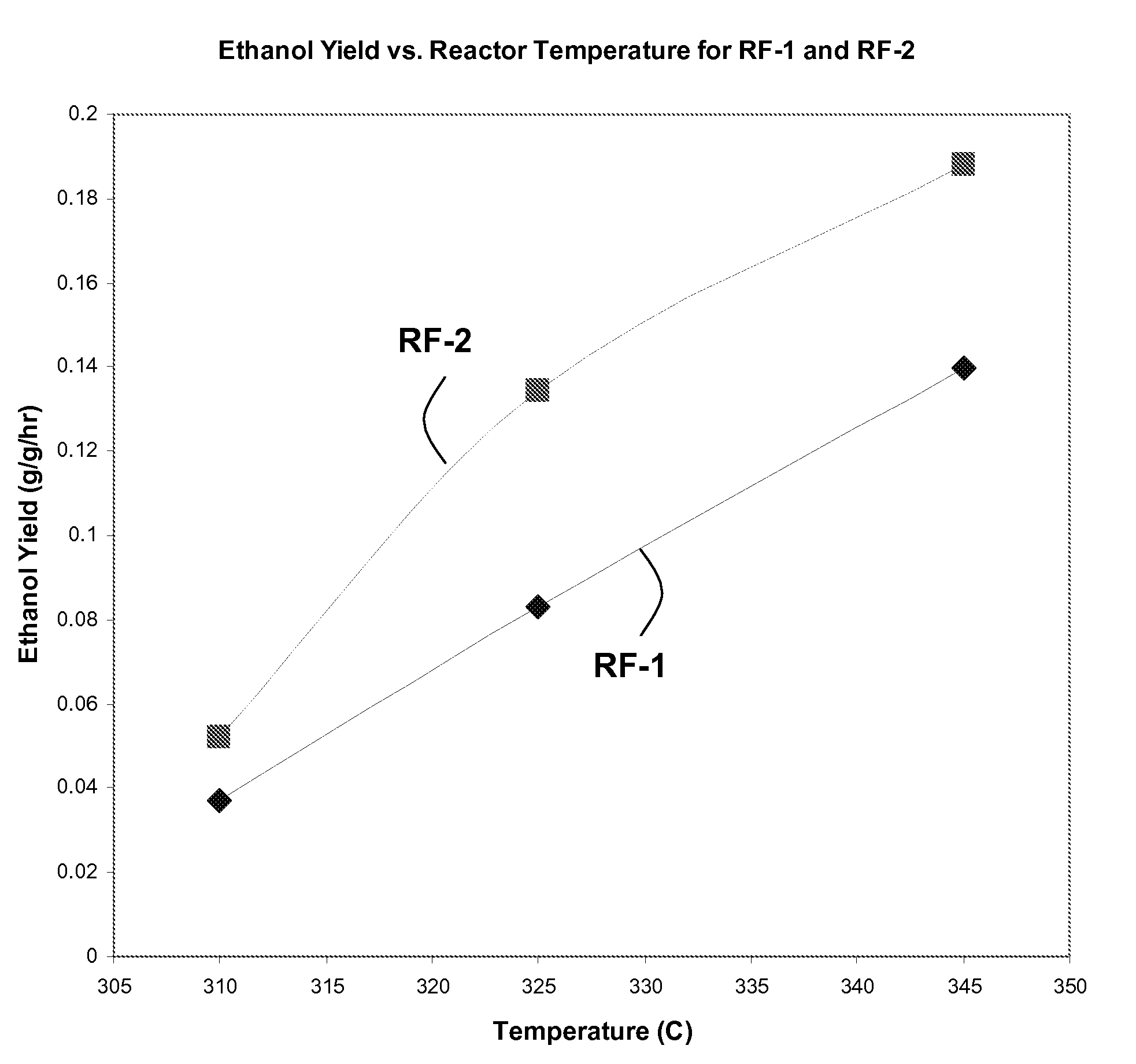

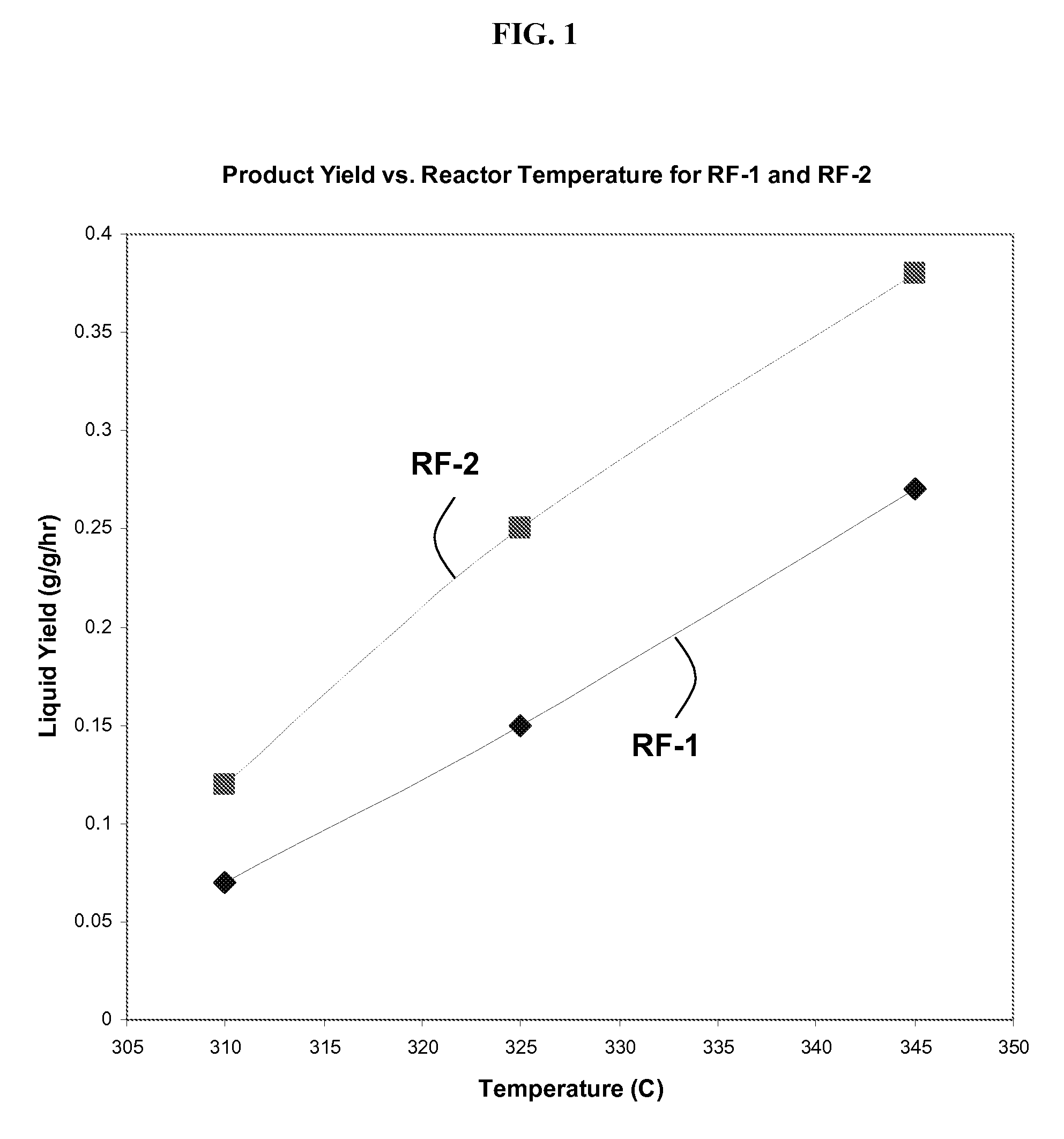

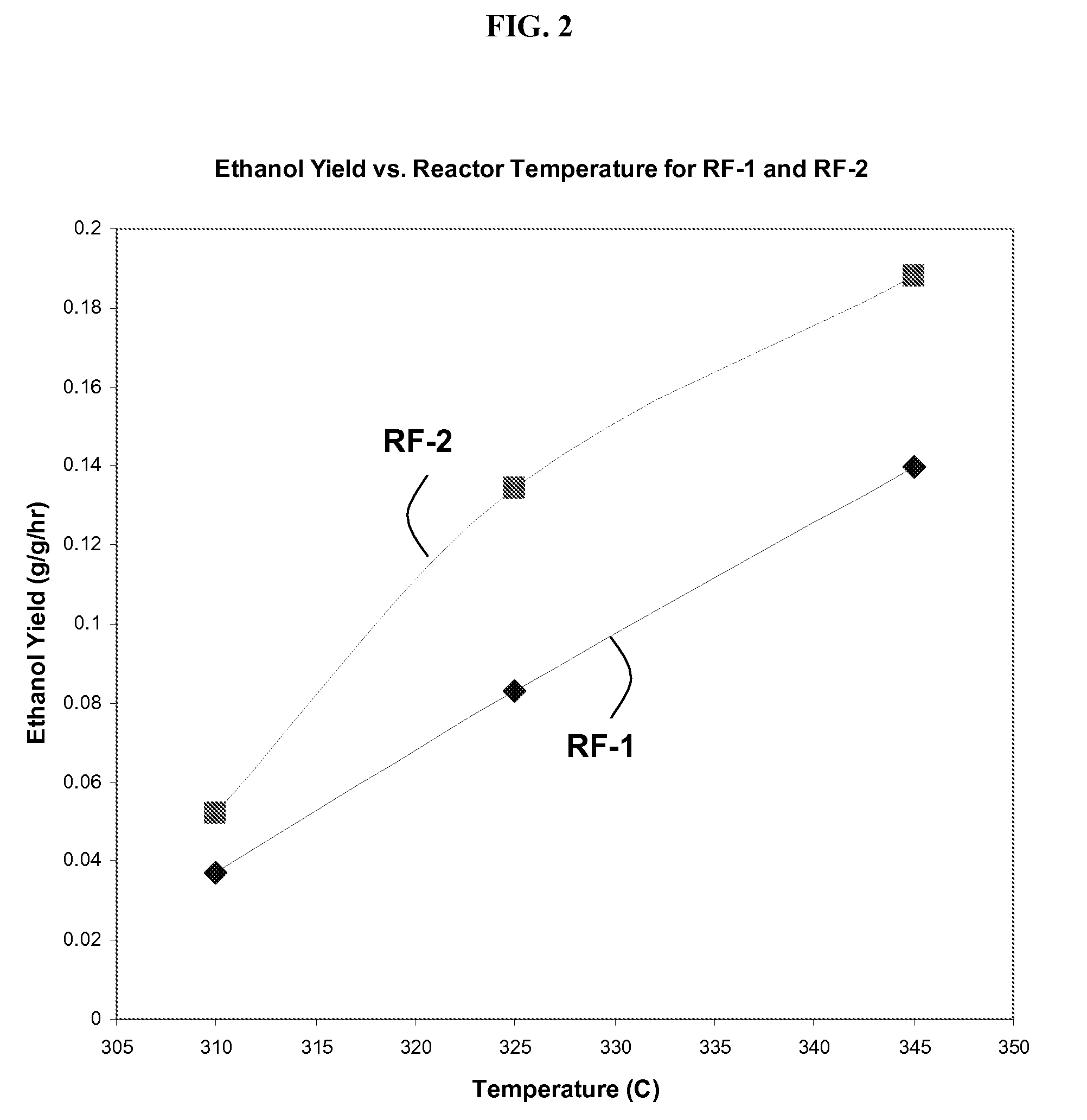

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

Atomic layer deposition using metal amidinates

ActiveUS20090291208A1Good step coverageImprove conductivityGroup 8/9/10/18 element organic compoundsCopper organic compoundsHydrogenWater vapor

Metal films are deposited with uniform thickness and excellent step coverage. Copper metal films were deposited on heated substrates by the reaction of alternating doses of copper(I) NN′-diispropylacetamidinate vapor and hydrogen gas. Cobalt metal films were deposited on heated substrates b the reaction of alternating doses of cobalt(II) bis(N,N′-diispropylacetamidinate) vapor and hydrogen gas. Nitrides and oxides of these metals can be formed by replacing the hydrogen with ammonia or water vapor, respectively. The films have very uniform thickness and excellent step coverage in narrow holes. Suitable applications include electrical interconnects in microelectronics and magnetoresistant layers in magnetic information storage devices.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

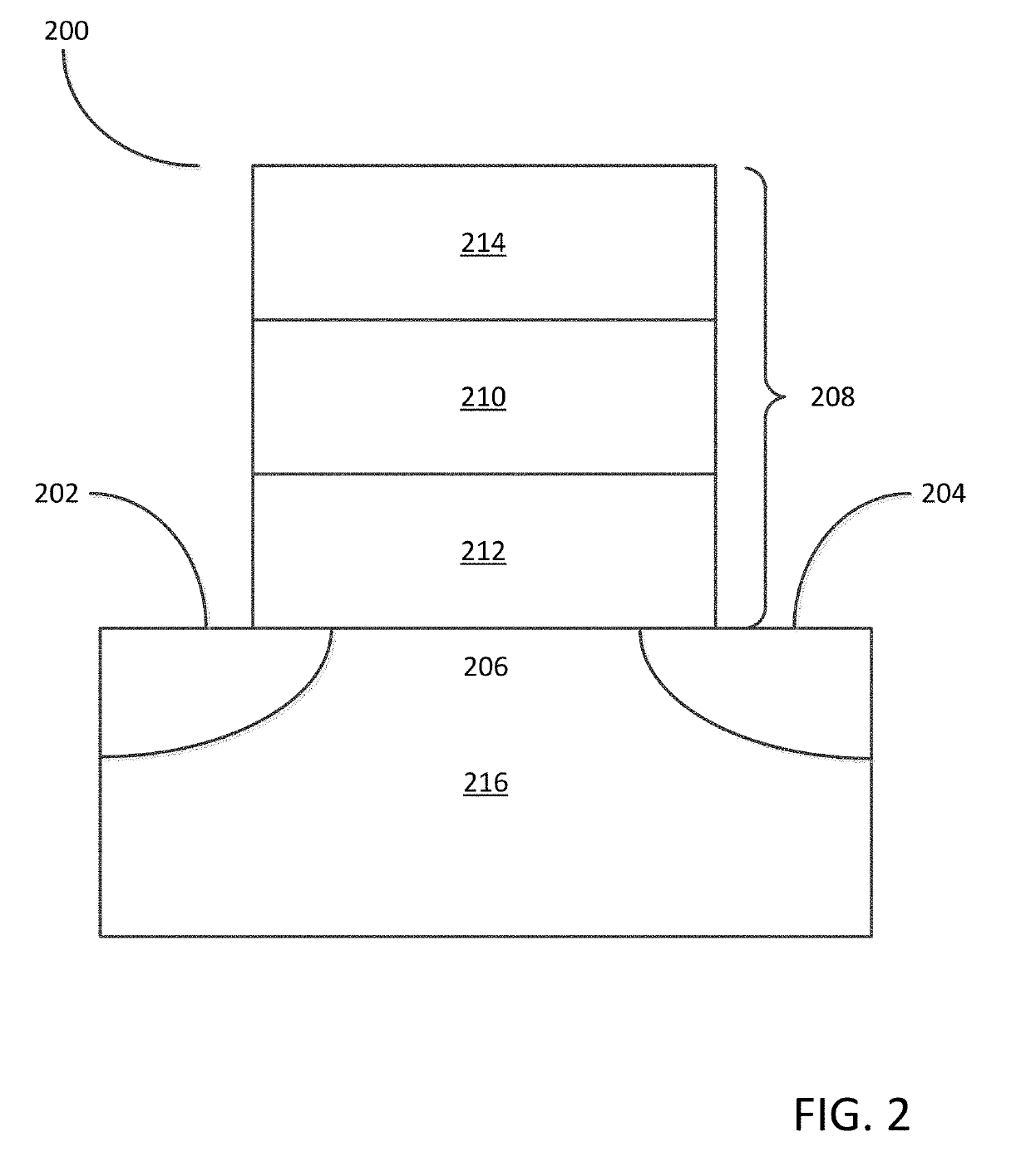

Methods for forming a metallic film on a substrate by a cyclical deposition and related semiconductor device structures

ActiveUS20190252196A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrazine compoundOptoelectronics

Methods for forming a metallic film on a substrate by cyclical deposition are provided. In some embodiments methods may include contacting the substrate with a first reactant comprising a non-halogen containing metal precursor comprising at least one of copper, nickel or cobalt and contacting the substrate with a second reactant comprising a hydrocarbon substituted hydrazine. In some embodiments related semiconductor device structures may include at least a portion of a metallic interconnect formed by cyclical deposition processes.

Owner:ASM IP HLDG BV

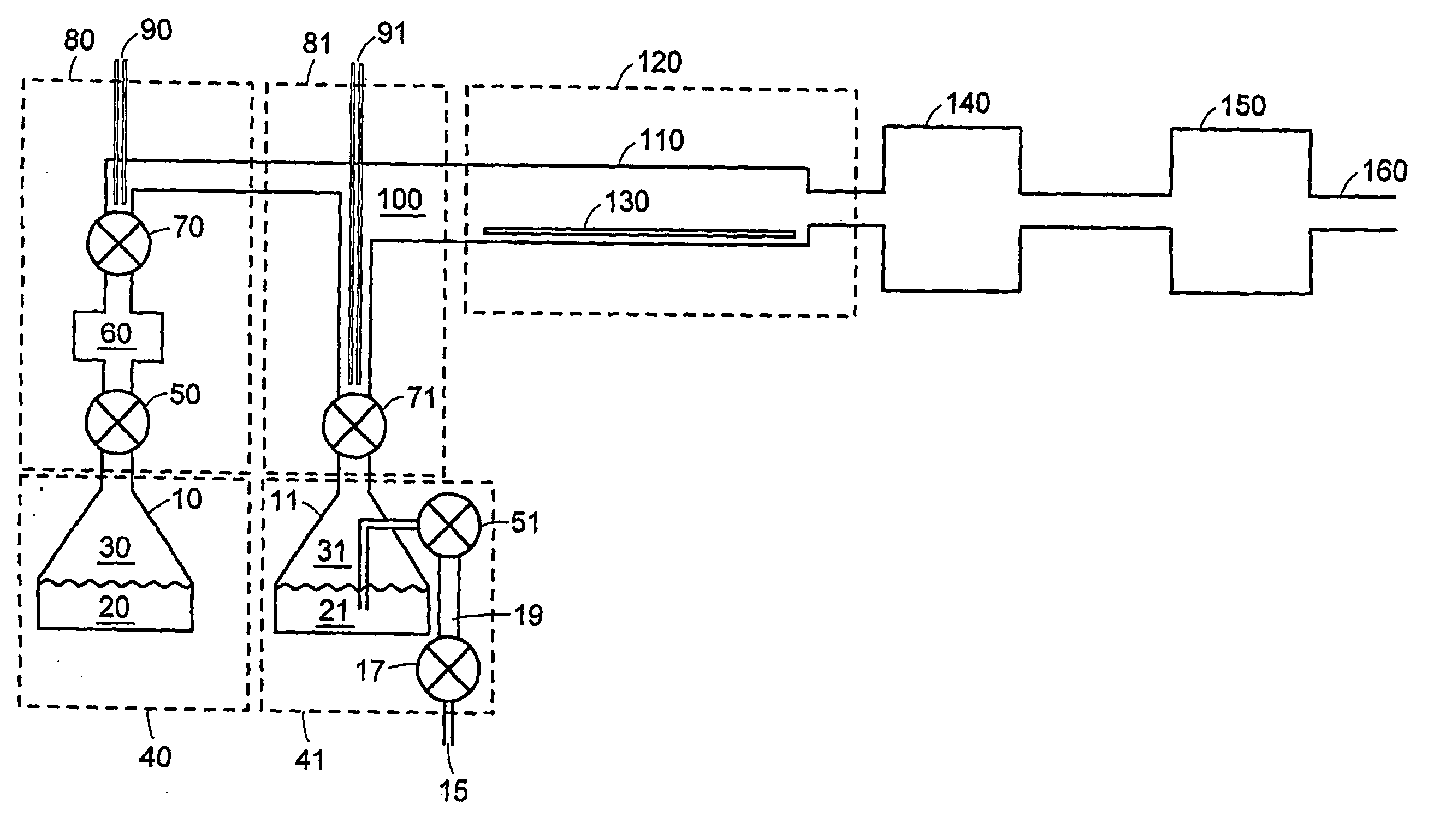

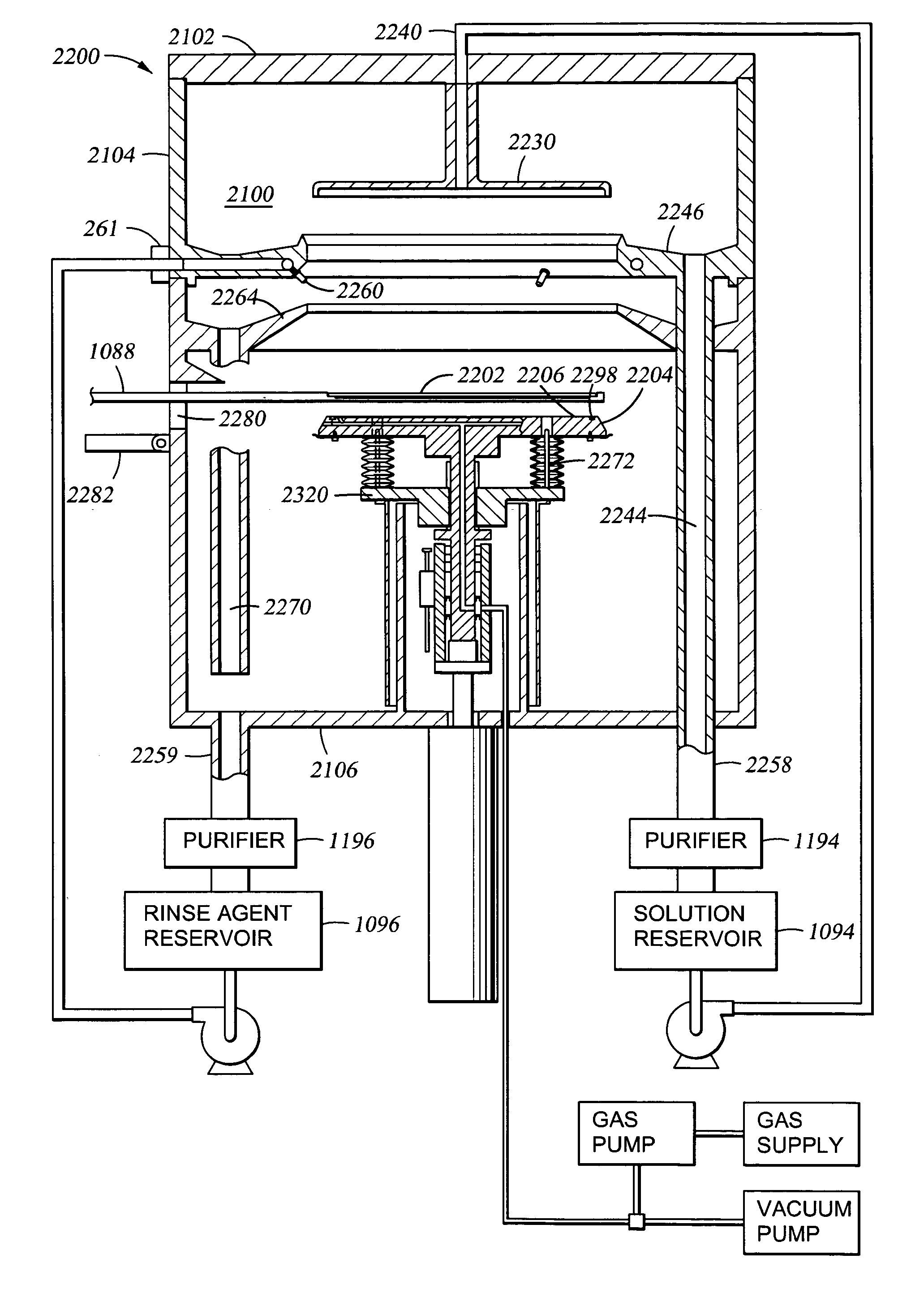

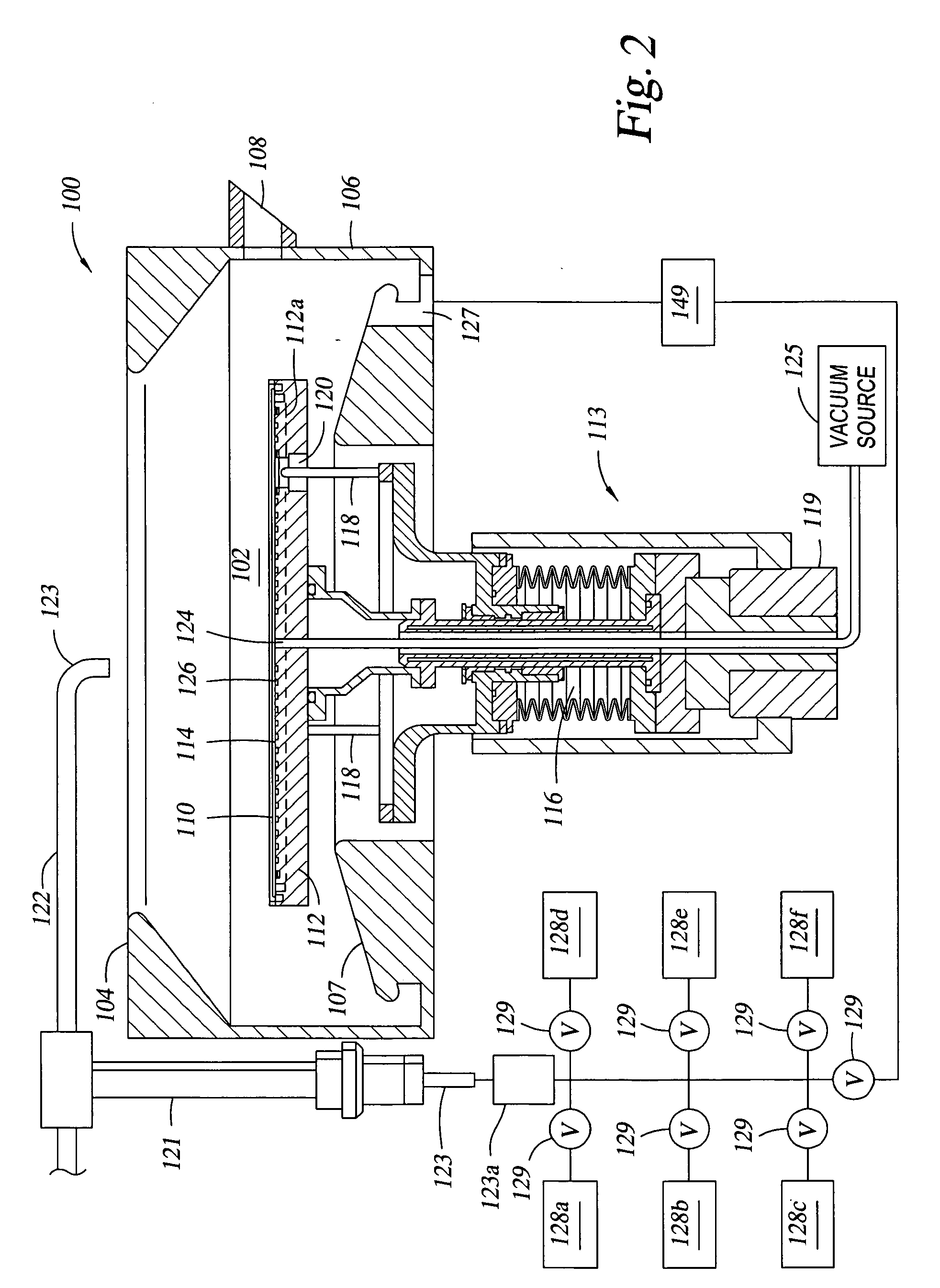

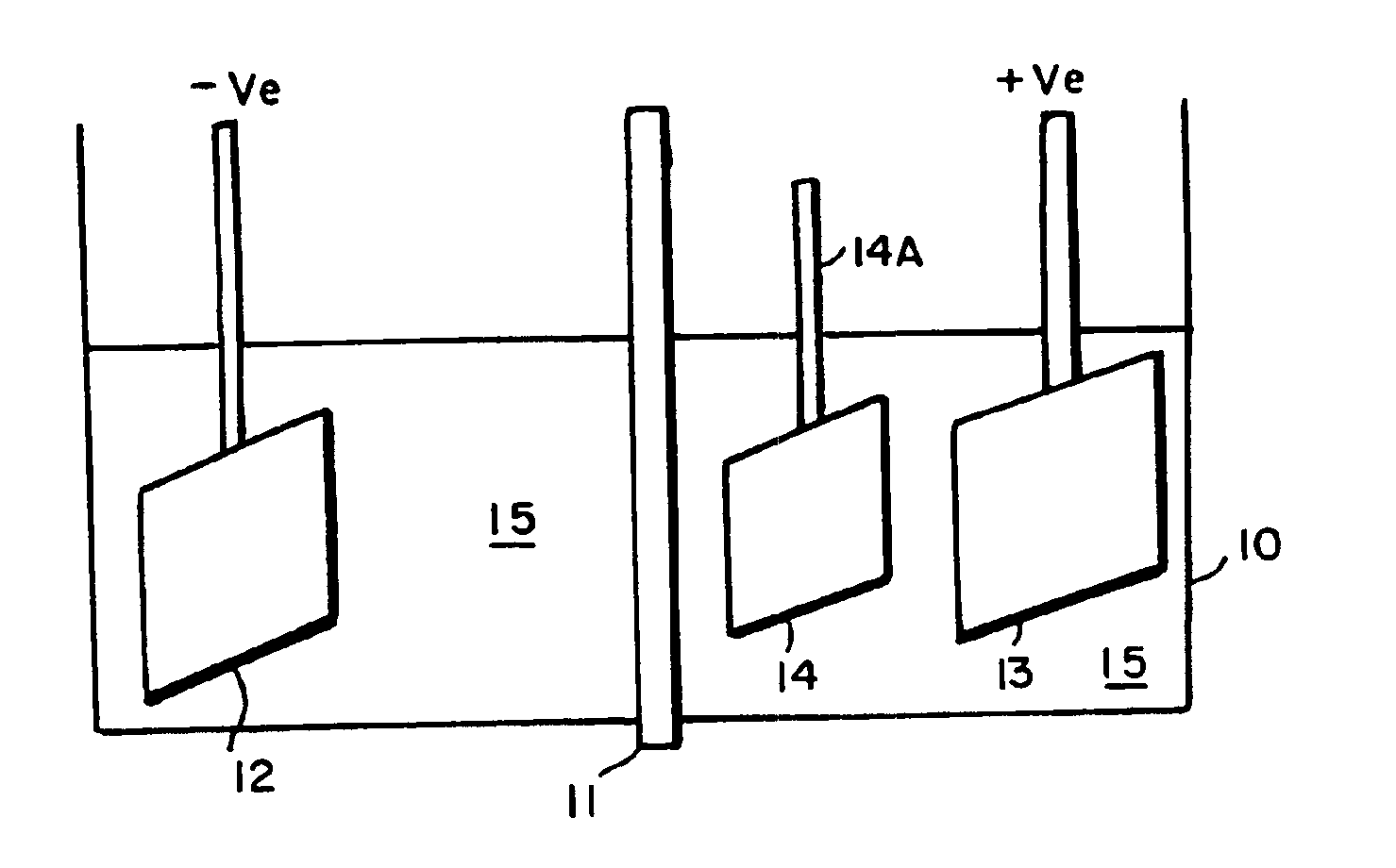

Electroless deposition apparatus

An apparatus and a method of depositing a catalytic layer comprising at least one metal selected from the group consisting of noble metals, semi-noble metals, alloys thereof, and combinations thereof in sub-micron features formed on a substrate. Examples of noble metals include palladium and platinum. Examples of semi-noble metals include cobalt, nickel, and tungsten. The catalytic layer may be deposited by electroless deposition, electroplating, or chemical vapor deposition. In one embodiment, the catalytic layer may be deposited in the feature to act as a barrier layer to a subsequently deposited conductive material. In another embodiment, the catalytic layer may be deposited over a barrier layer. In yet another embodiment, the catalytic layer may be deposited over a seed layer deposited over the barrier layer to act as a “patch” of any discontinuities in the seed layer. Once the catalytic layer has been deposited, a conductive material, such as copper, may be deposited over the catalytic layer. In one embodiment, the conductive material is deposited over the catalytic layer by electroless deposition. In another embodiment, the conductive material is deposited over the catalytic layer by electroless deposition followed by electroplating or followed by chemical vapor deposition. In still another embodiment, the conductive material is deposited over the catalytic layer by electroplating or by chemical vapor deposition.

Owner:APPLIED MATERIALS INC

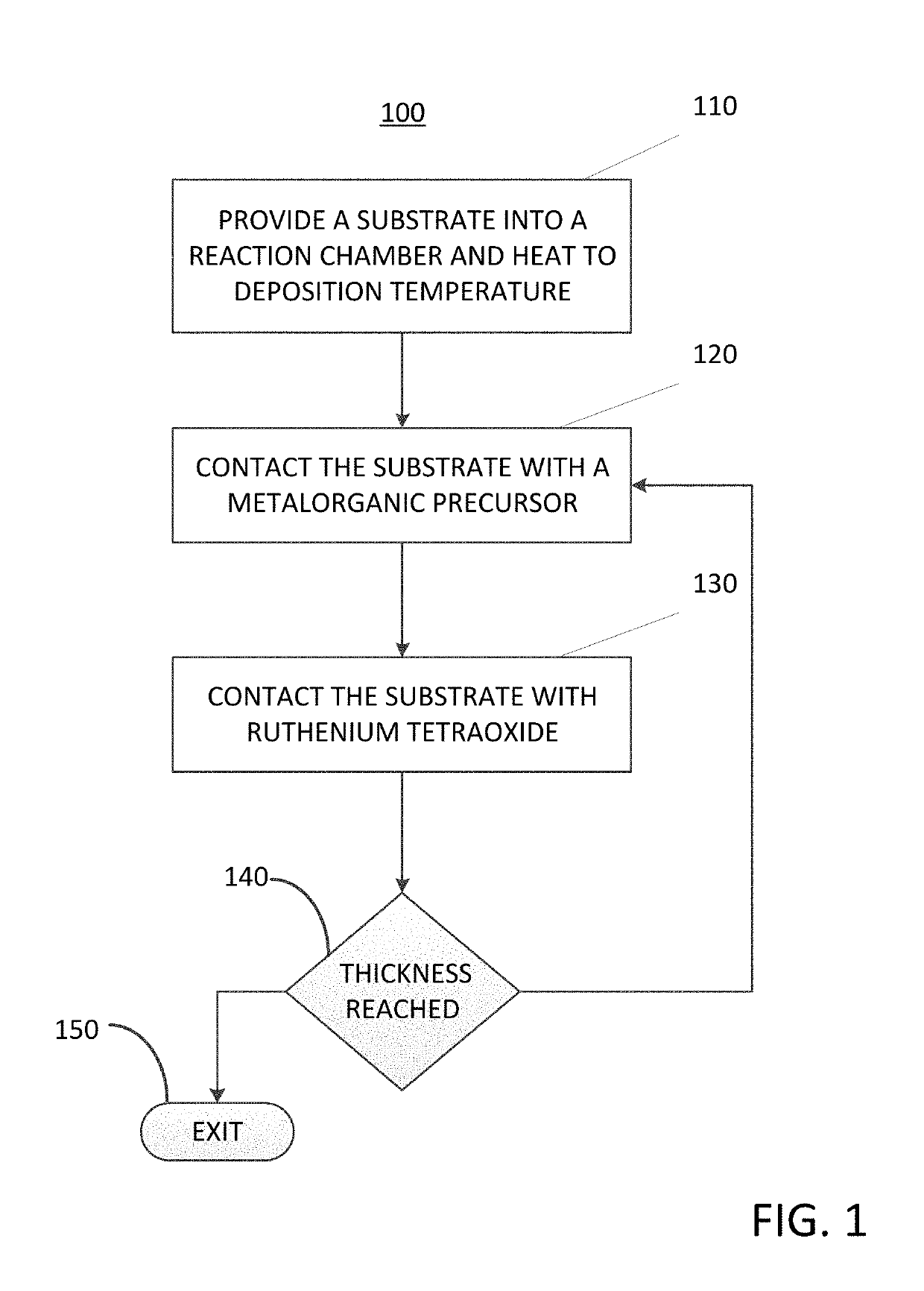

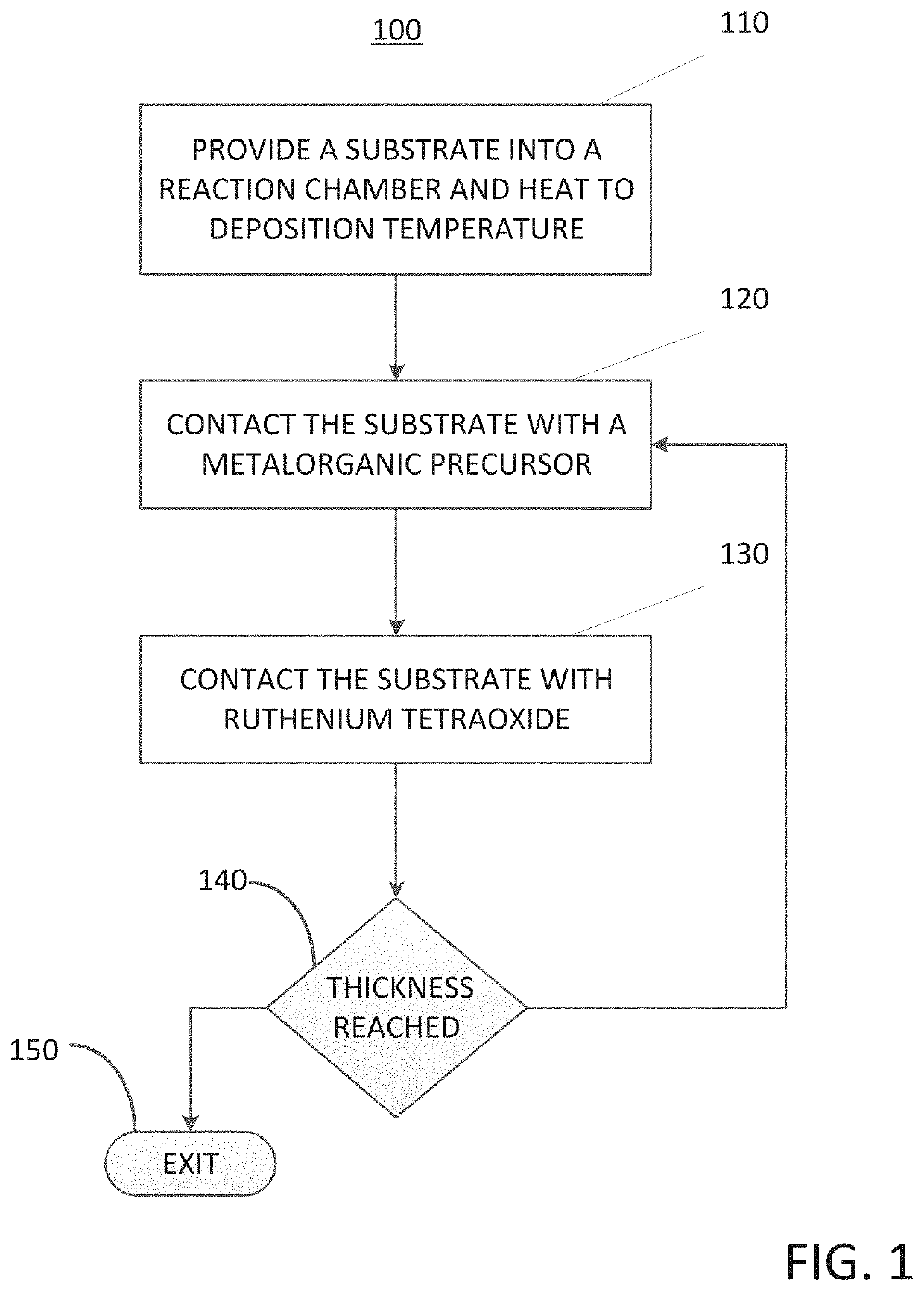

Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process

A method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process is disclosed. The method may include: contacting the substrate with a first vapor phase reactant comprising a metalorganic precursor, the metalorganic precursor comprising a metal selected from the group consisting of a cobalt, nickel, tungsten, molybdenum, manganese, iron, and combinations thereof. The method may also include; contacting the substrate with a second vapor phase reactant comprising ruthenium tetroxide (RuO4); wherein the ruthenium-containing film comprises a ruthenium-metal alloy. Semiconductor device structures including ruthenium-metal alloys deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

Electroless deposition process on a silicide contact

InactiveUS20060246217A1Material nanotechnologySemiconductor/solid-state device manufacturingSalicideElectroless deposition

Embodiments as described herein provide methods for depositing a material on a substrate during electroless deposition processes, as well as compositions of the electroless deposition solutions. In one embodiment, the substrate contains a contact aperture having an exposed silicon contact surface. In another embodiment, the substrate contains a contact aperture having an exposed silicide contact surface. The apertures are filled with a metal contact material by exposing the substrate to an electroless deposition process. The metal contact material may contain a cobalt material, a nickel material, or alloys thereof. Prior to filling the apertures, the substrate may be exposed to a variety of pretreatment processes, such as preclean processes and activations processes. A preclean process may remove organic residues, native oxides, and other contaminants during a wet clean process or a plasma etch process. Embodiments of the process also provide the deposition of additional layers, such as a capping layer.

Owner:APPLIED MATERIALS INC

Cobalt salicidation method on a silicon germanium film

A method of forming a cobalt germanosilicide film is described. According to the present invention a silicon germanium alloy is formed on a substrate. A cobalt film is then formed on the silicon germanium alloy. The substrate is then heated to a temperature of greater than 850° C. for a period of time less than 20 seconds to form a cobalt germanium silicide film.

Owner:INTEL CORP

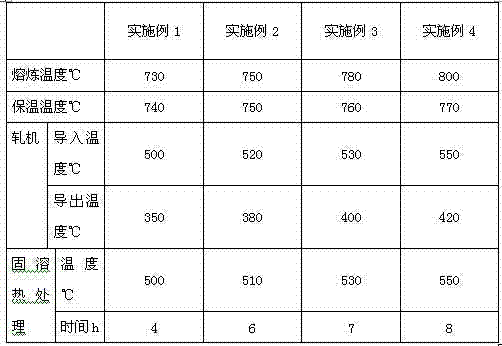

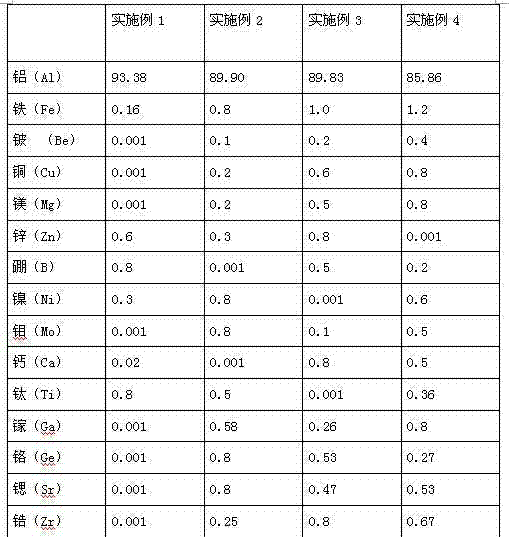

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

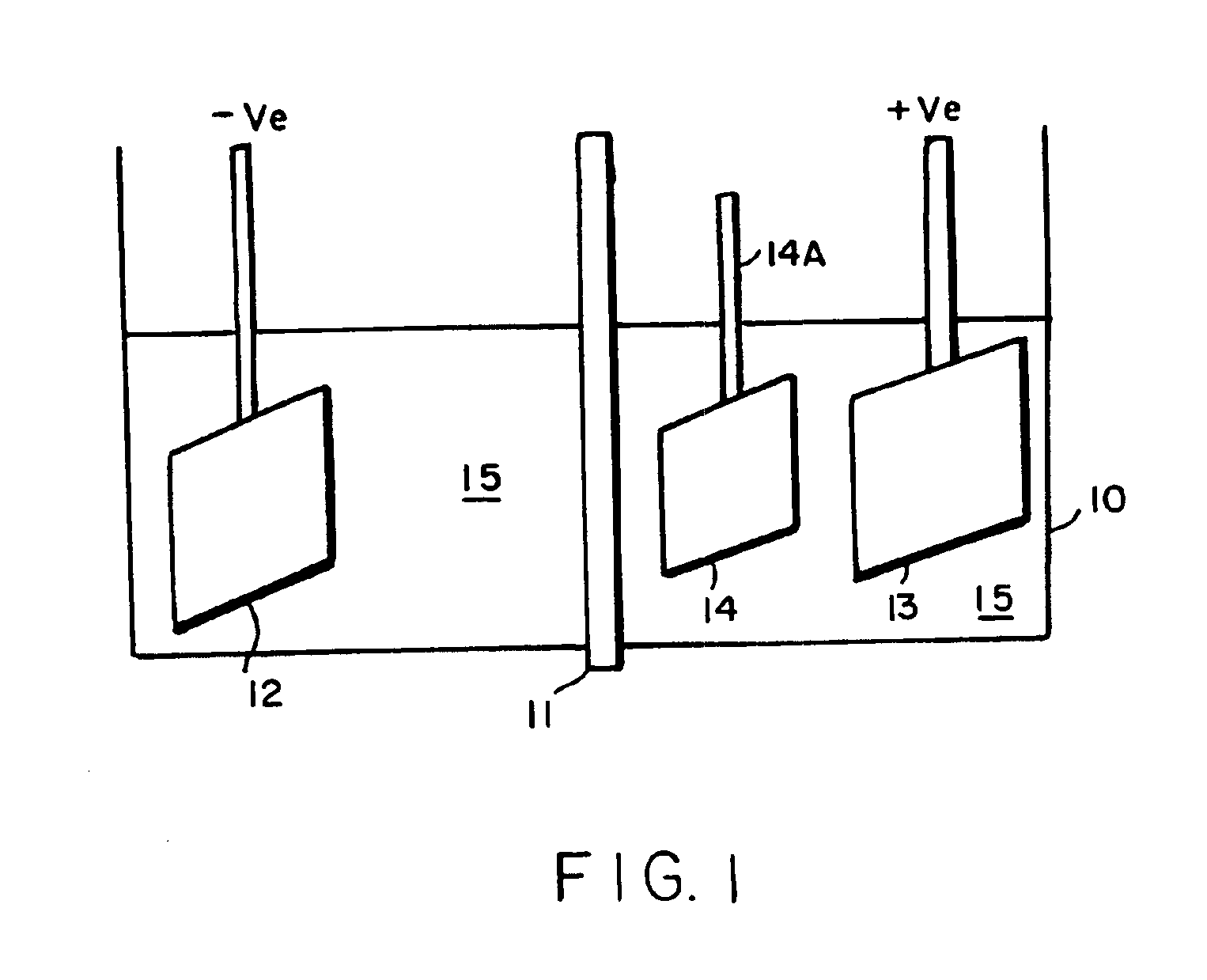

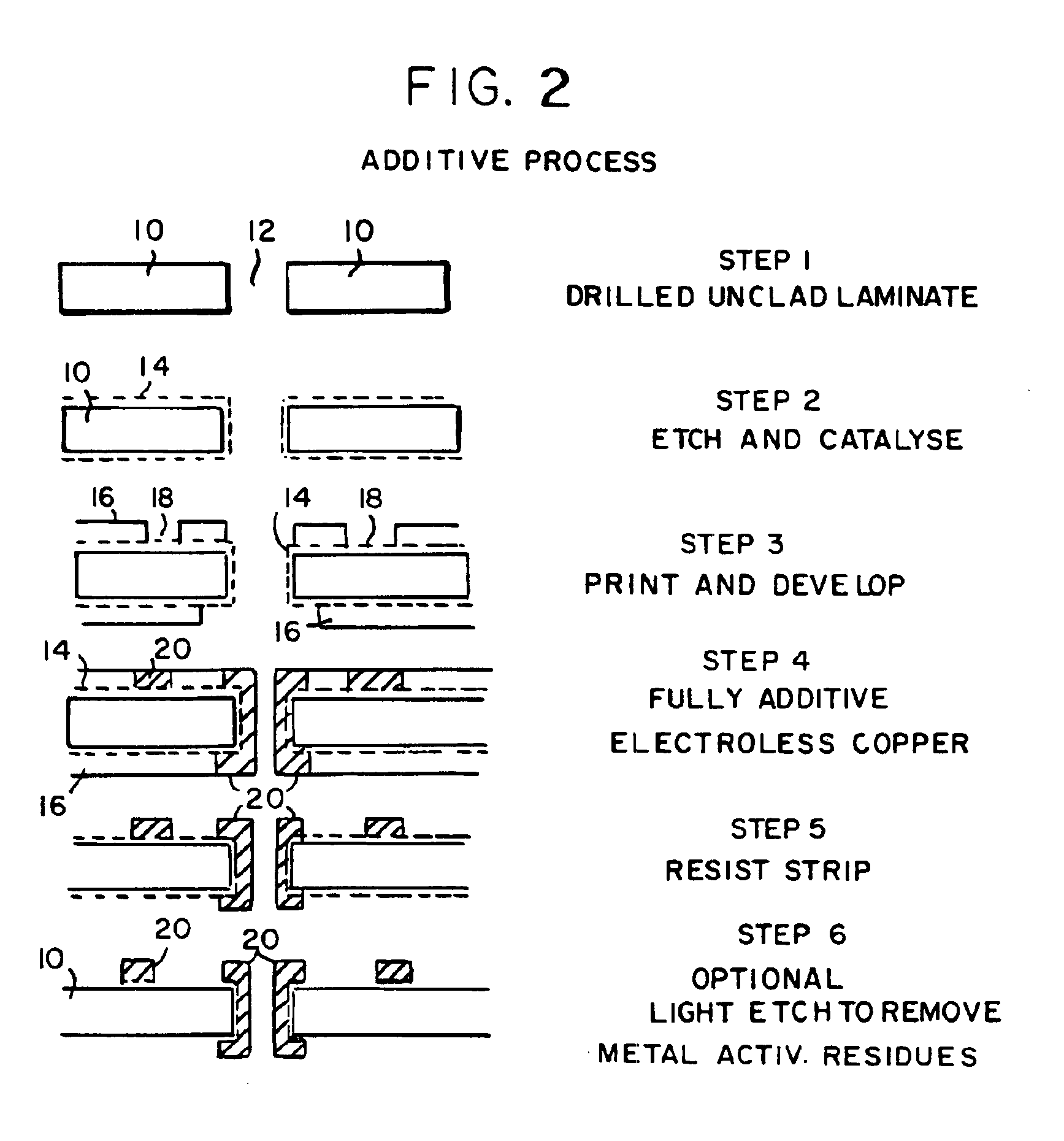

Electroless plating processes

InactiveUS6861097B1Reducing problem encounteredSimple methodPaper/cardboard articlesDecorative surface effectsPolymeric surfaceOxidation state

The invention includes processes for combined polymer surface treatment and metal deposition. Processes of the invention include forming an aqueous solution containing a metal activator, such as an oxidized species of silver, cobalt, ruthenium, cerium, iron, manganese, nickel, rhodium, or vanadium. The activator can be suitably oxidized to a higher oxidation state electrochemically. Exposing a part to be plated (such as an organic resin, e.g. a printed circuit board substrate) to the solution enables reactive hydroxyl species (e.g. hydroxyl radicals) to be generated and to texture the polymer surface. Such texturing facilitates good plated metal adhesion. As part of this contacting process sufficient time is allowed for both surface texturing to take place and for the oxidized metal activator to adsorb onto said part. The part is then contacted with a reducing agent capable of reducing the metal activator to a lower ionic form, or a lower oxidation state. That reduction can result in the formation of metallic catalytic material over the surface of the part. The reduced metal activator can then function to catalyze the electroless deposition of metal such as copper from solution by contacting the part with the plating solution.

Owner:SHIPLEY CO LLC

Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process

A method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process is disclosed. The method may include: contacting the substrate with a first vapor phase reactant comprising a metalorganic precursor, the metalorganic precursor comprising a metal selected from the group consisting of a cobalt, nickel, tungsten, molybdenum, manganese, iron, and combinations thereof. The method may also include; contacting the substrate with a second vapor phase reactant comprising ruthenium tetroxide (RuO4); wherein the ruthenium-containing film comprises a ruthenium-metal alloy. Semiconductor device structures including ruthenium-metal alloys deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

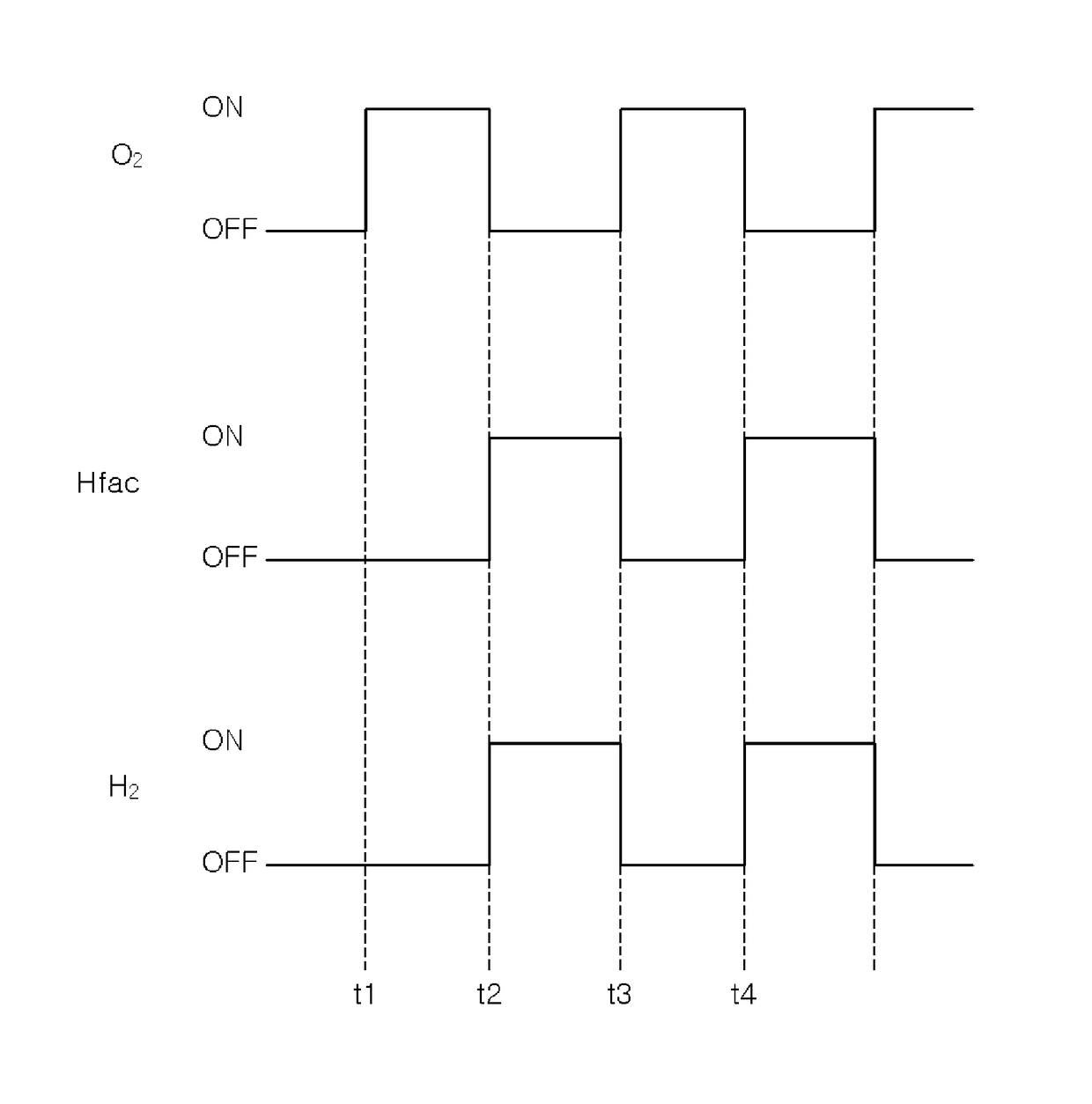

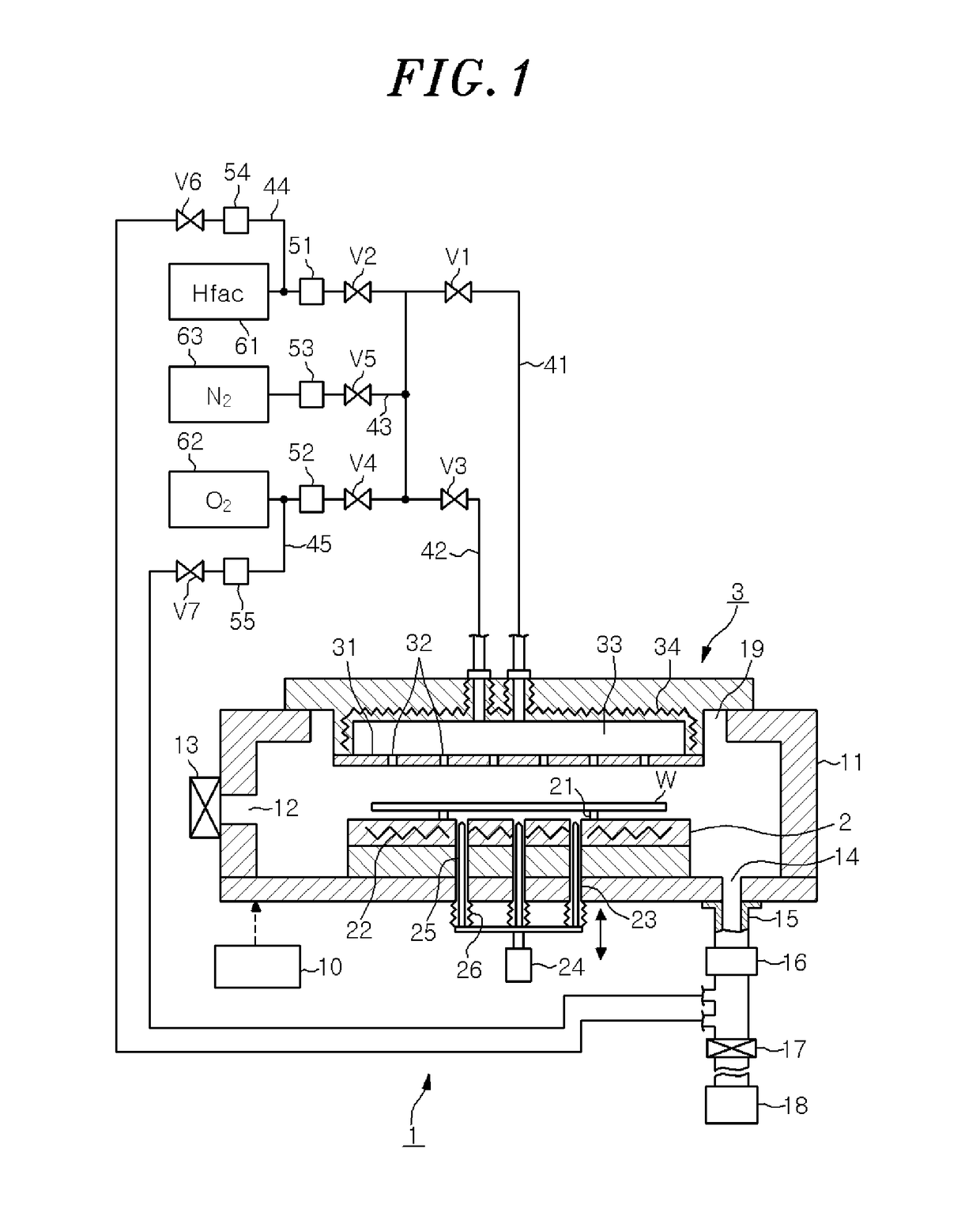

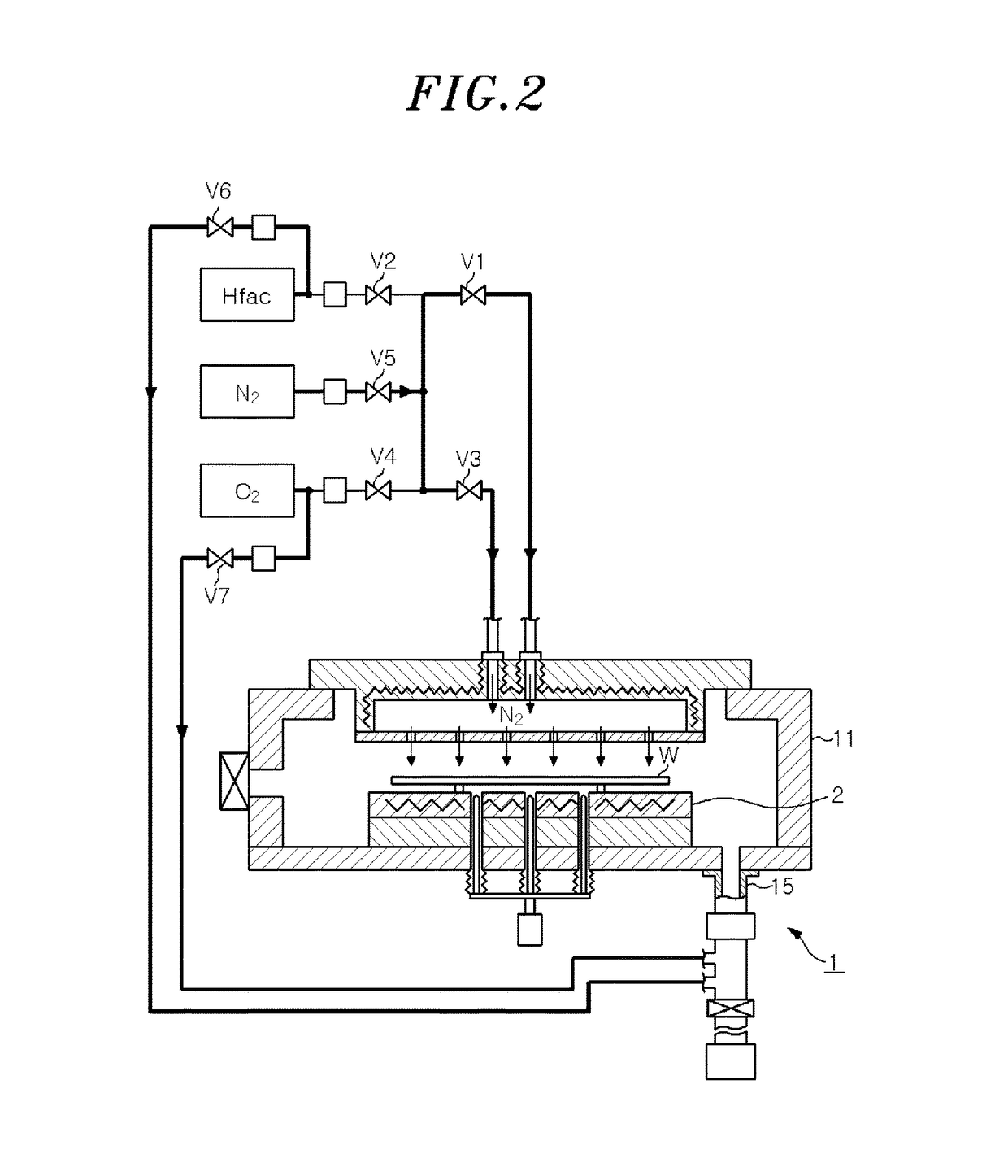

Etching method and etching apparatus

ActiveUS9991138B2Avoid decompositionSemiconductor/solid-state device detailsSolid-state devicesProduct gasCobalt

An etching method includes a step of etching a cobalt film formed on a surface of a target object by supplying an etching gas containing β-diketone and an oxidizing gas for oxidizing the cobalt film to the target object. The supply of the etching gas and the oxidizing gas is carried out such that a flow rate ratio of the oxidizing gas to the etching gas is ranging from 0.5% to 50% while heating the target object to a temperature lower than or equal to 250° C.

Owner:TOKYO ELECTRON LTD +1

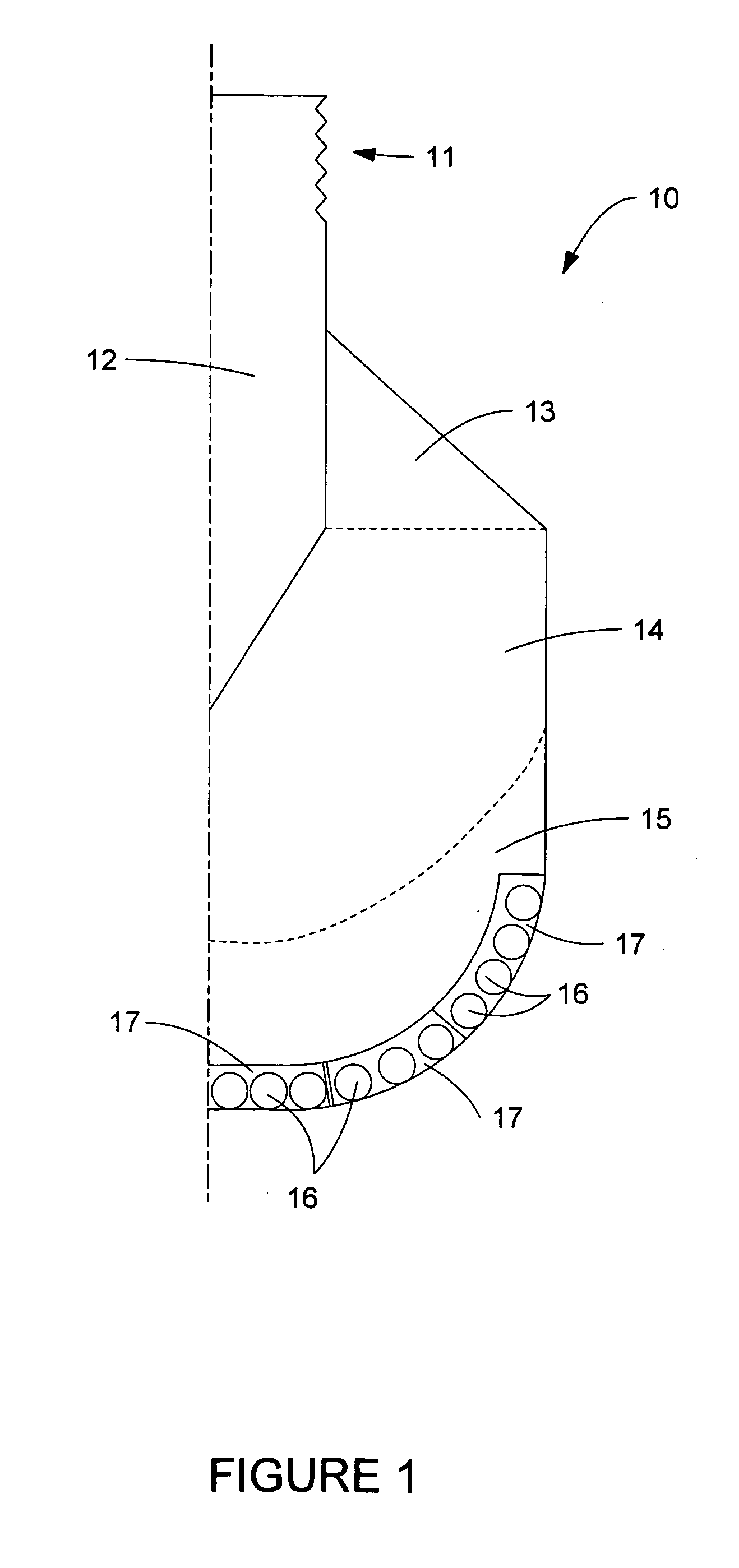

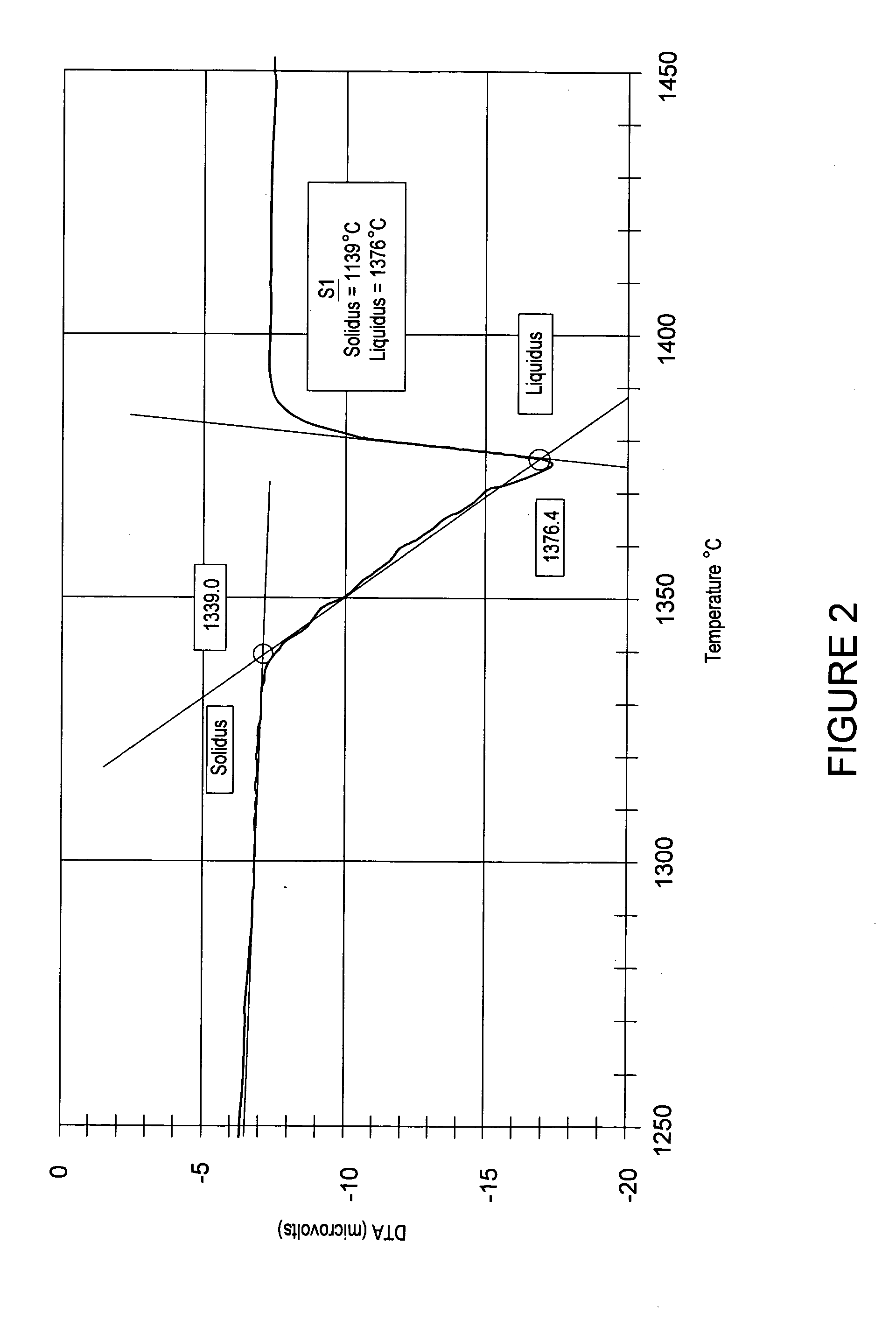

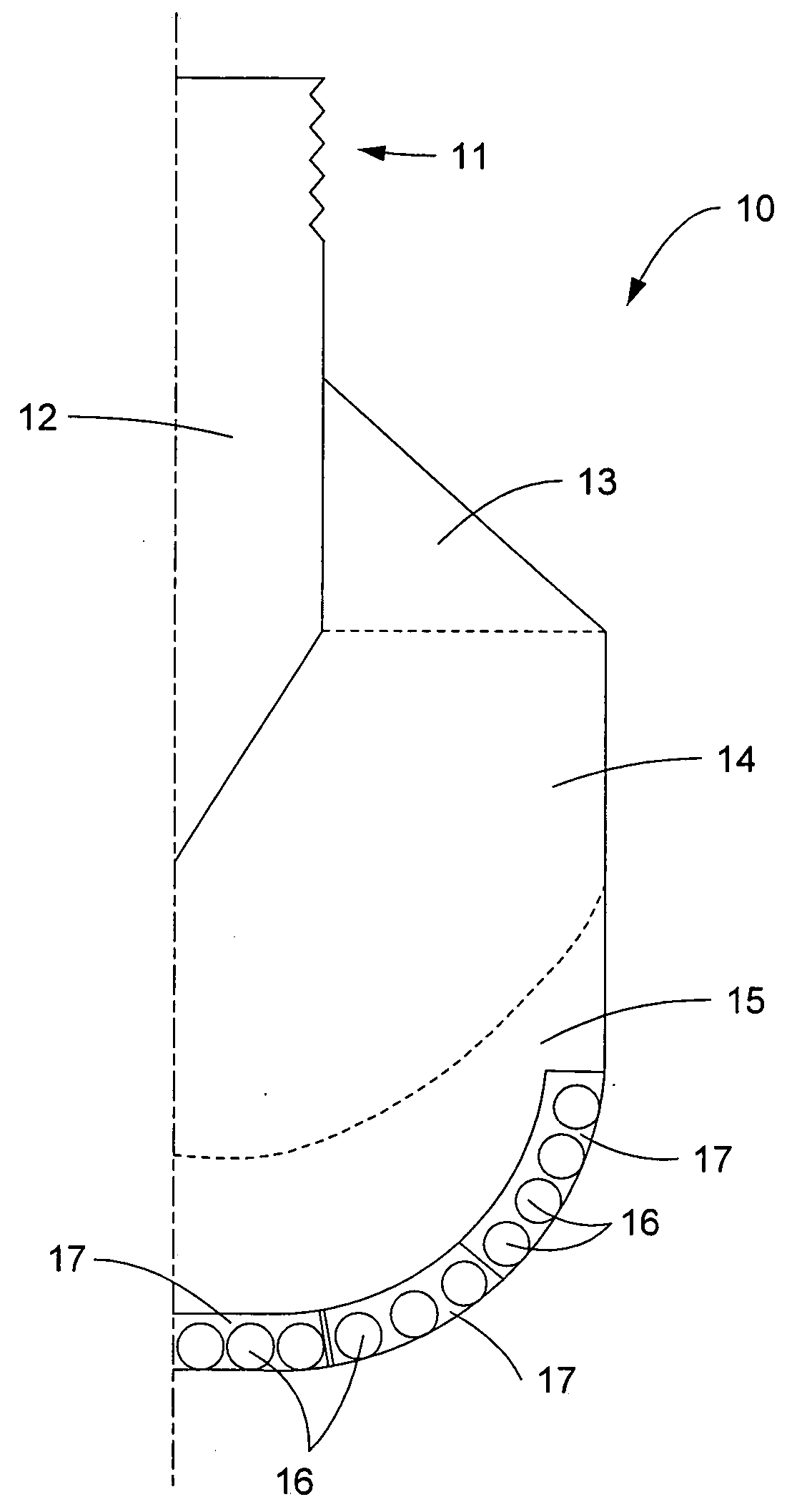

Earth-boring bits

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

Method for producing alcohols by hydrogenation of carbonyl compounds

InactiveUS6486366B1Less amountHigh strengthSugar derivativesOrganic compound preparationCobaltPt element

A method for preparation of alcohols by catalytic hydrogenation of carbonyl compounds with hydrogen or hydrogen-containing gases in the presence of a hydrogenation catalyst of Raney type, where the catalyst is used in the form of hollow bodies, Preferred as catalytically active components are nickel, cobalt, copper, iron, platinum, palladium or ruthenium.

Owner:DEGUSSA AG

Earth-boring bits

InactiveUS20050211475A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsMetal-working drilling toolsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:ATI PROPERTIES +1

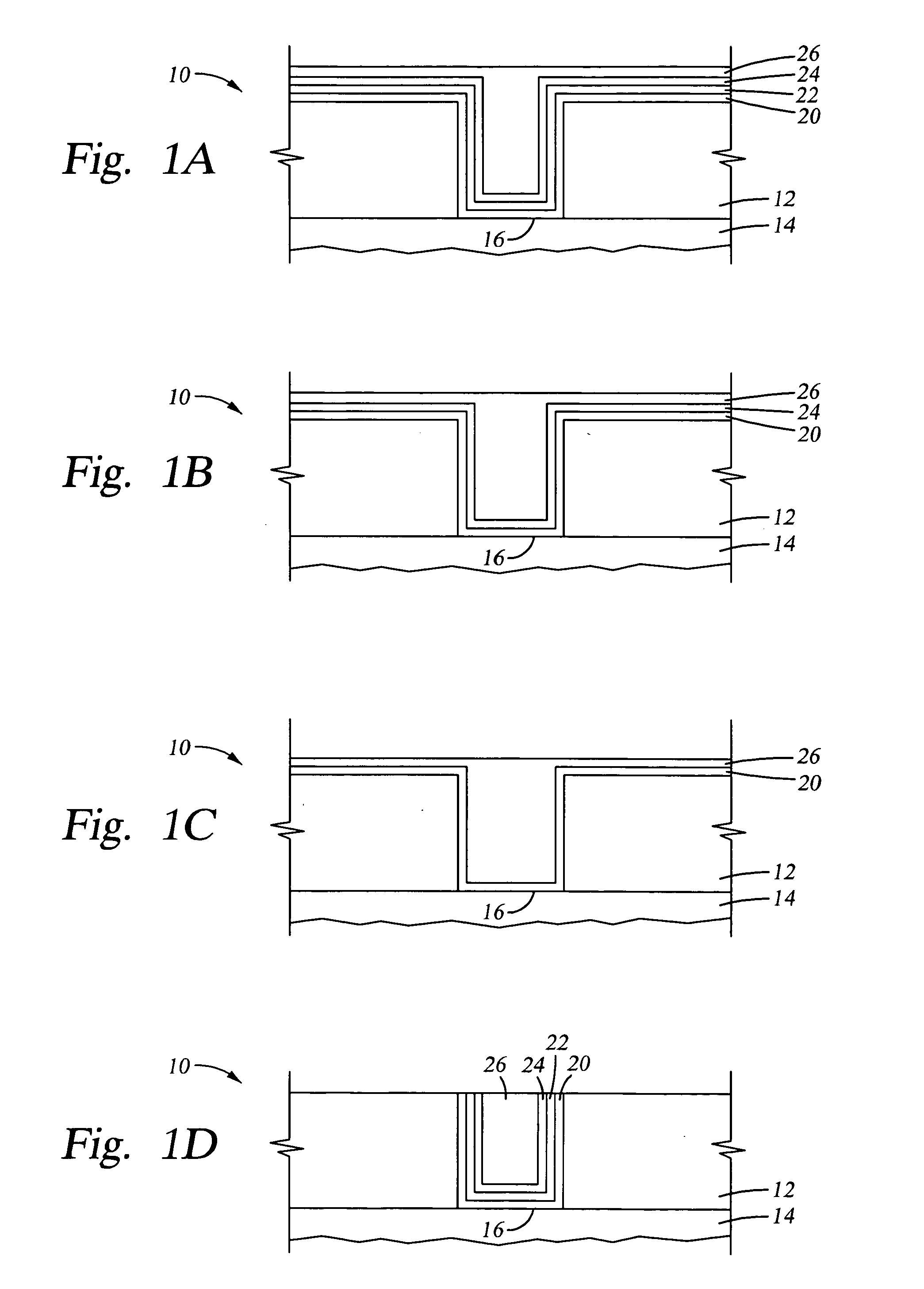

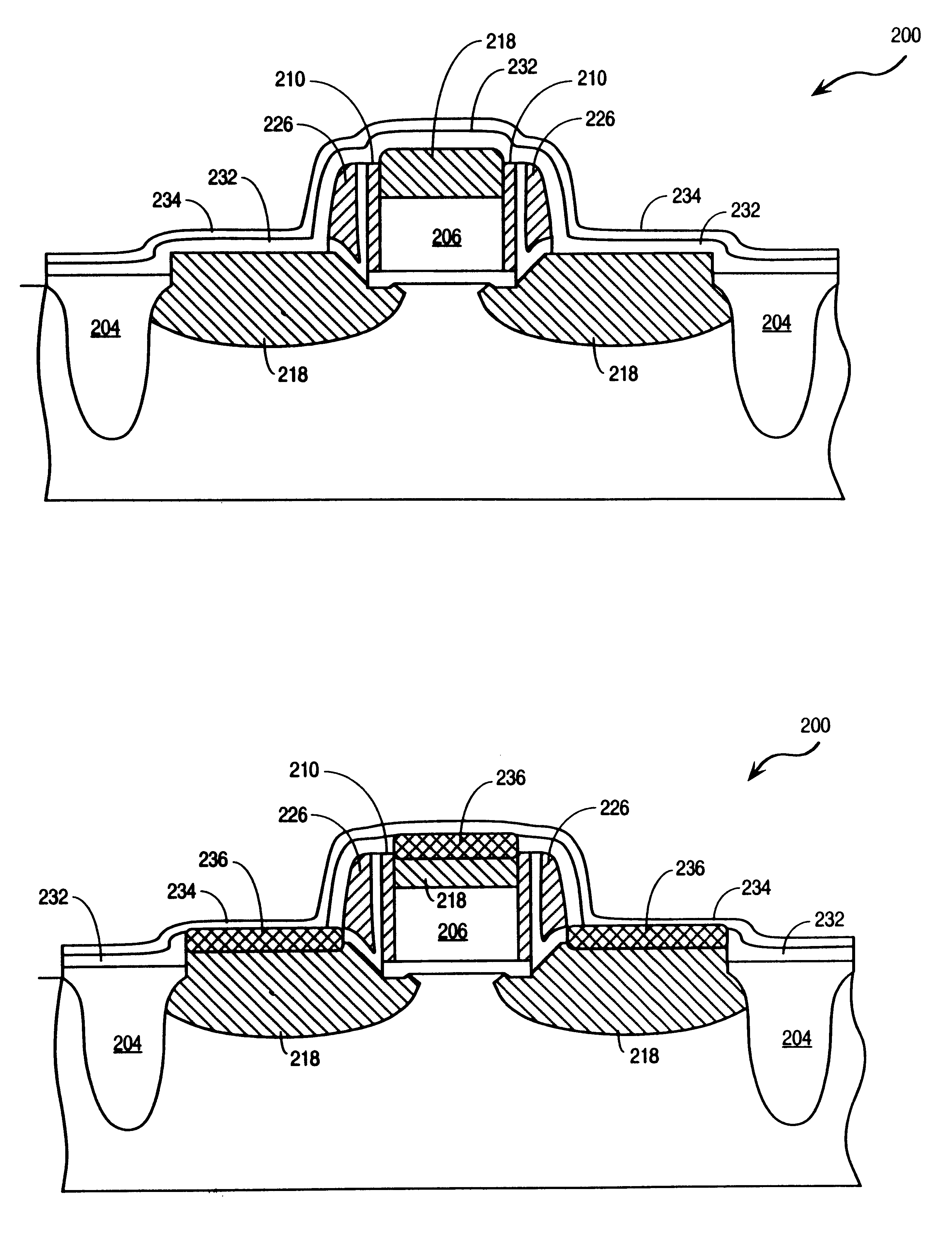

Process for forming cobalt-containing materials

InactiveUS20070202254A1Pretreated surfacesSemiconductor/solid-state device manufacturingCobaltCobalt silicide

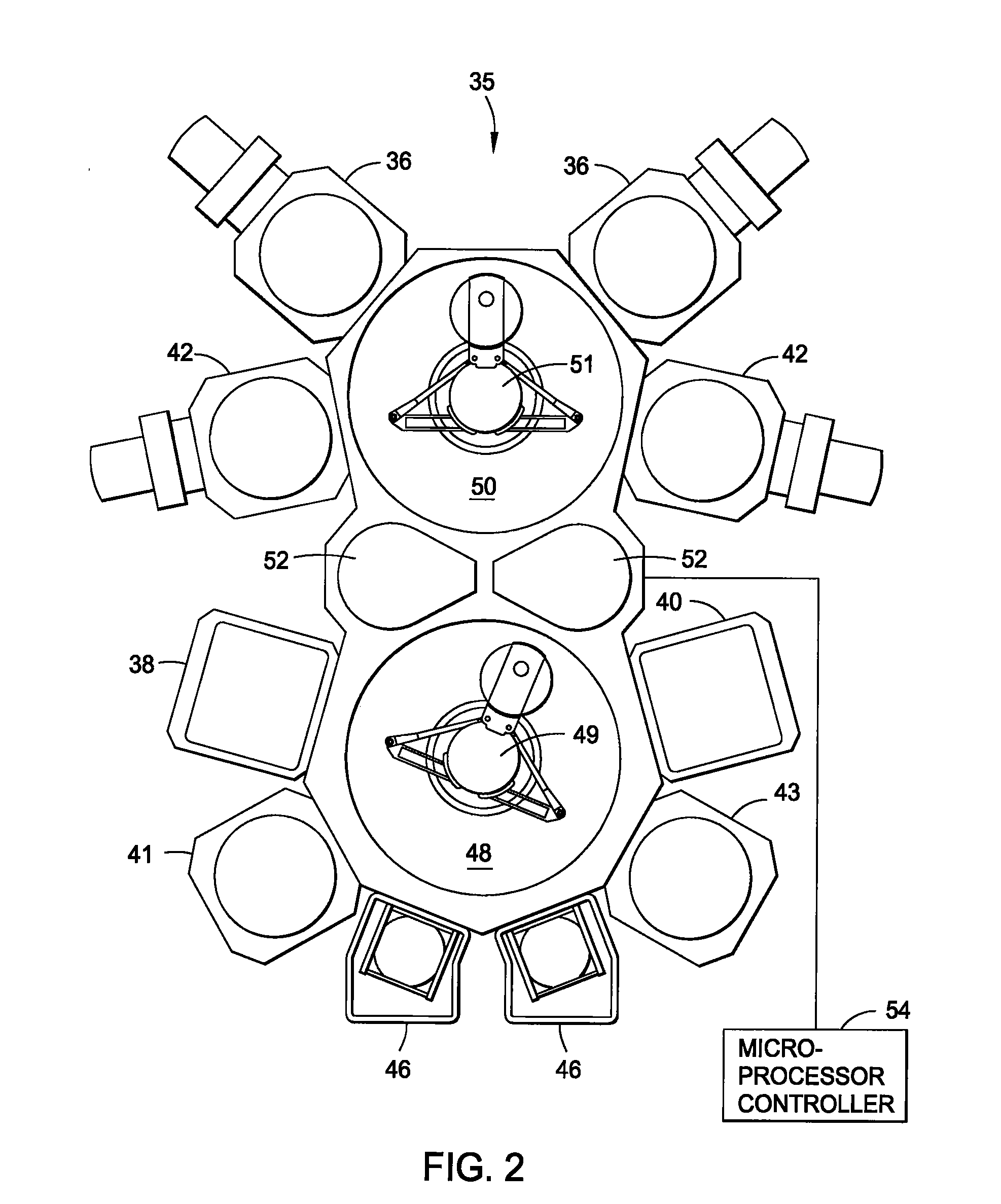

Embodiments of the invention described herein generally provide methods and apparatuses for forming cobalt silicide layers, metallic cobalt layers, and other cobalt-containing materials. In one embodiment, a method for forming a cobalt silicide containing material on a substrate is provided which includes exposing a substrate to at least one preclean process to expose a silicon-containing surface, depositing a cobalt silicide material on the silicon-containing surface, depositing a metallic cobalt material on the cobalt silicide material, and depositing a metallic contact material on the substrate. In another embodiment, a method includes exposing a substrate to at least one preclean process to expose a silicon-containing surface, depositing a cobalt silicide material on the silicon-containing surface, expose the substrate to an annealing process, depositing a barrier material on the cobalt silicide material, and depositing a metallic contact material on the barrier material.

Owner:APPLIED MATERIALS INC

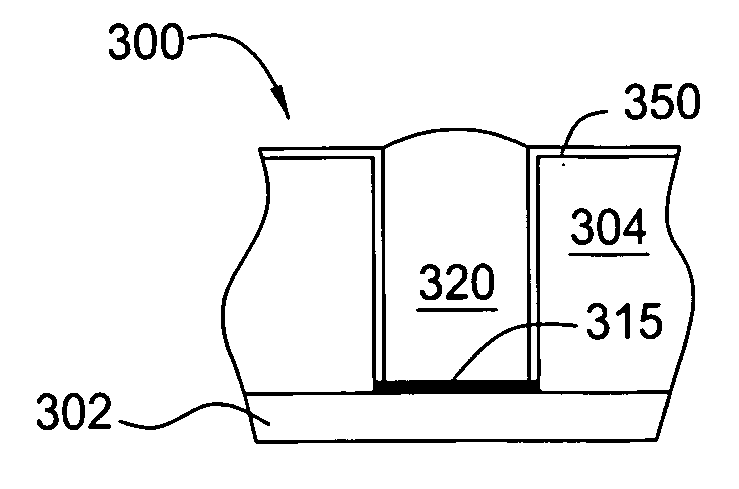

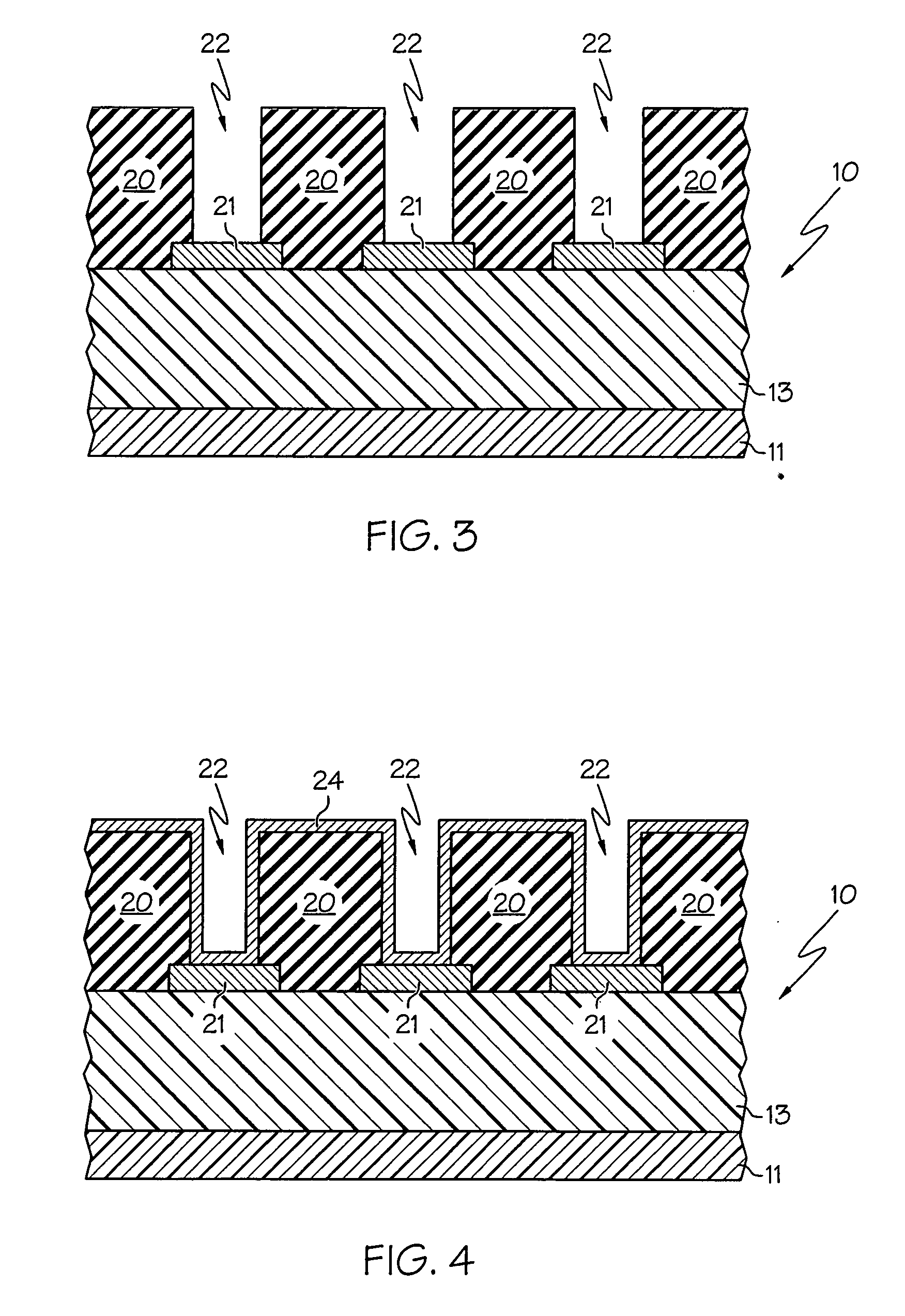

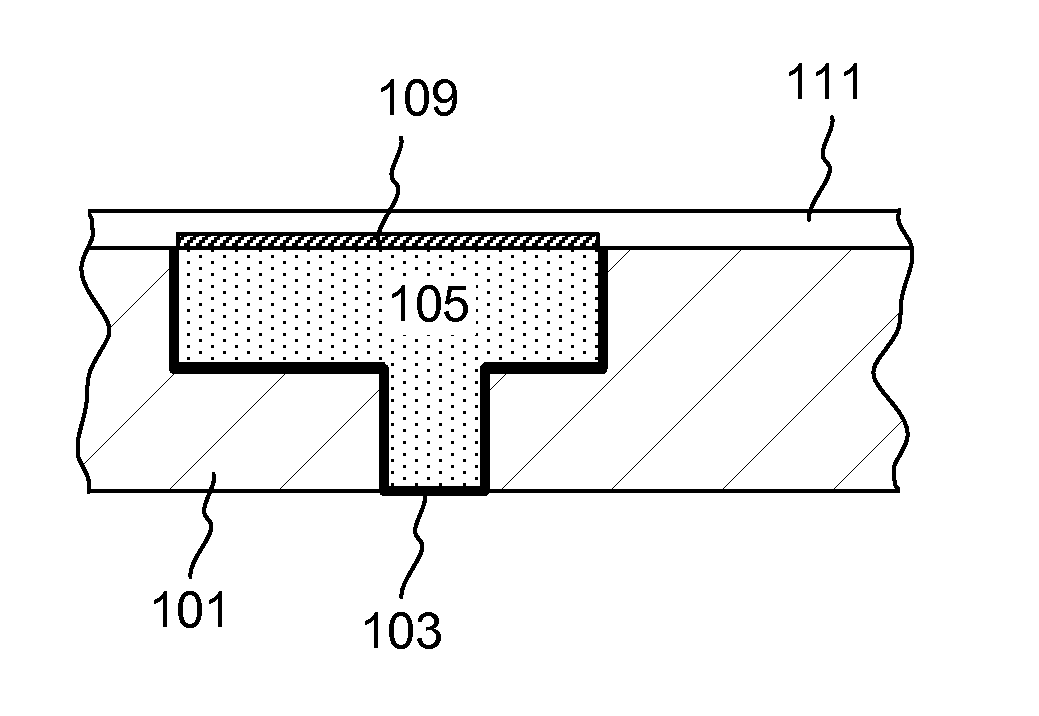

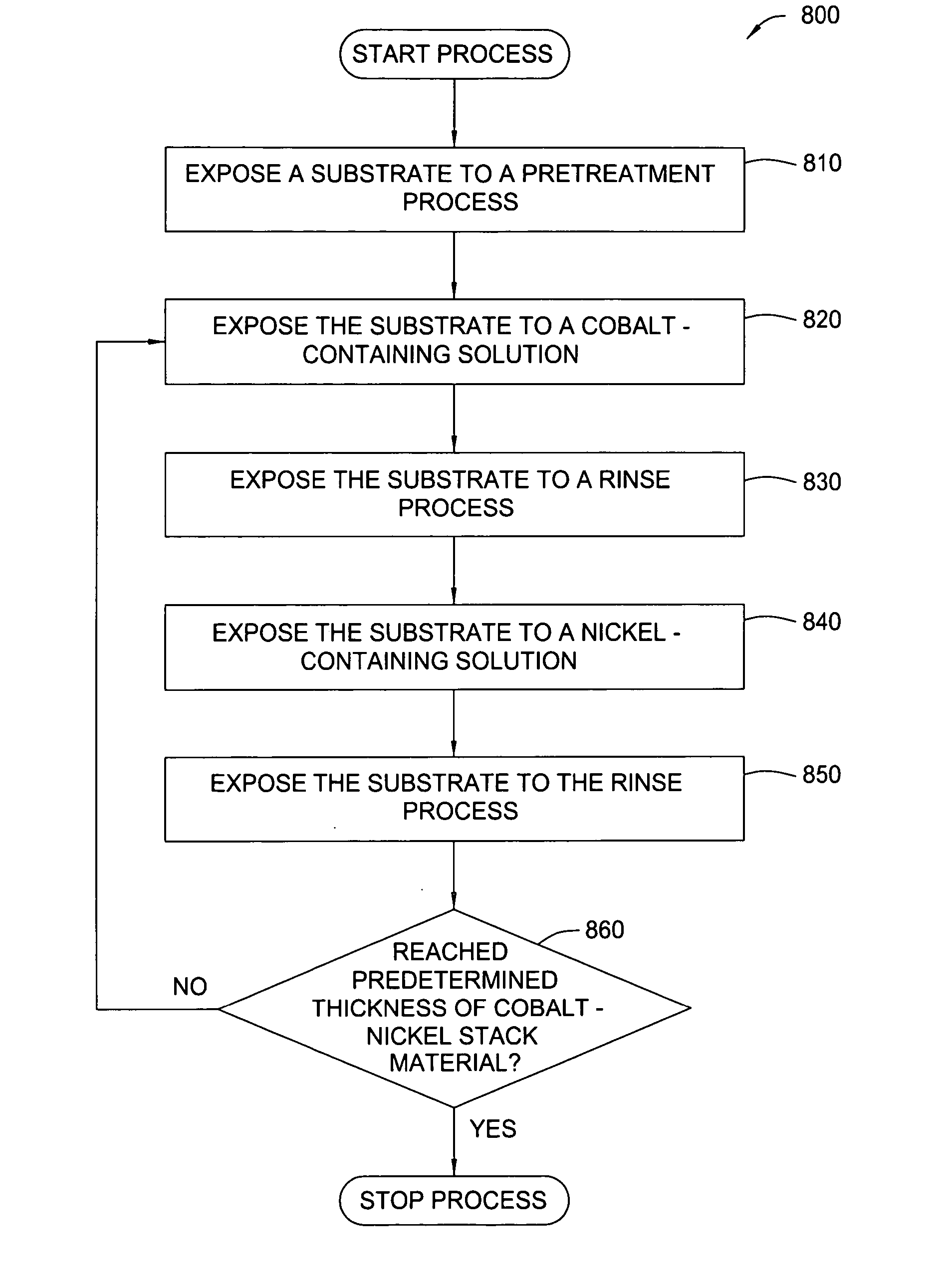

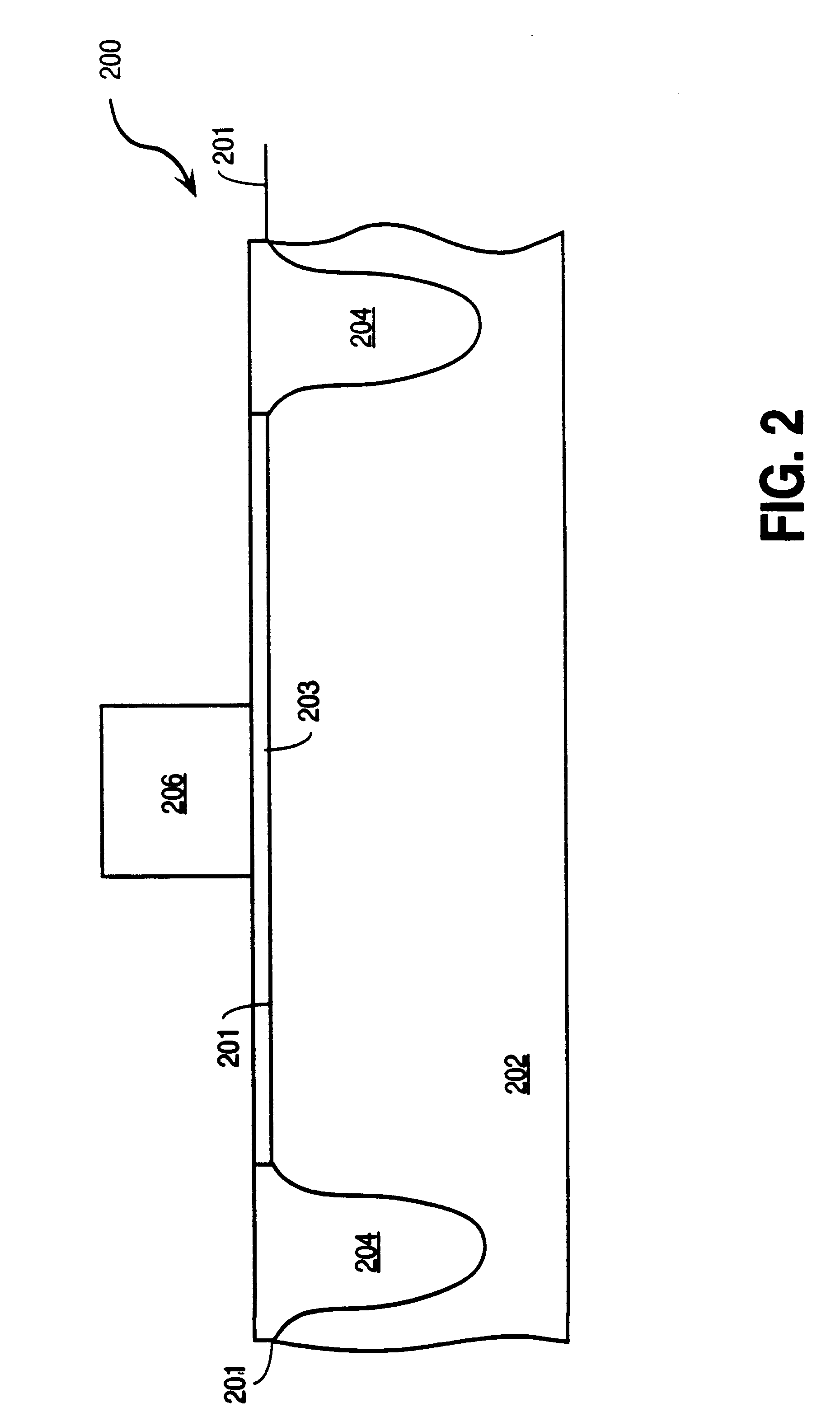

Method of enabling seamless cobalt gap-fill

ActiveUS20150093891A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCobaltHydrogen annealing

Methods for depositing a metal layer in a feature definition of a semiconductor device are provided. In one implementation, a method for depositing a metal layer for forming a semiconductor device is provided. The method comprises performing a cyclic metal deposition process to deposit a metal layer on a substrate and annealing the metal layer disposed on the substrate. The cyclic metal deposition process comprises exposing the substrate to a deposition precursor gas mixture to deposit a portion of the metal layer on the substrate, exposing the portion of the metal layer to either a plasma treatment process or hydrogen annealing process and repeating the exposing the substrate to a deposition precursor gas mixture and exposing the portion of the metal layer to either a plasma treatment process or hydrogen annealing process until a predetermined thickness of the metal layer is achieved.

Owner:APPLIED MATERIALS INC

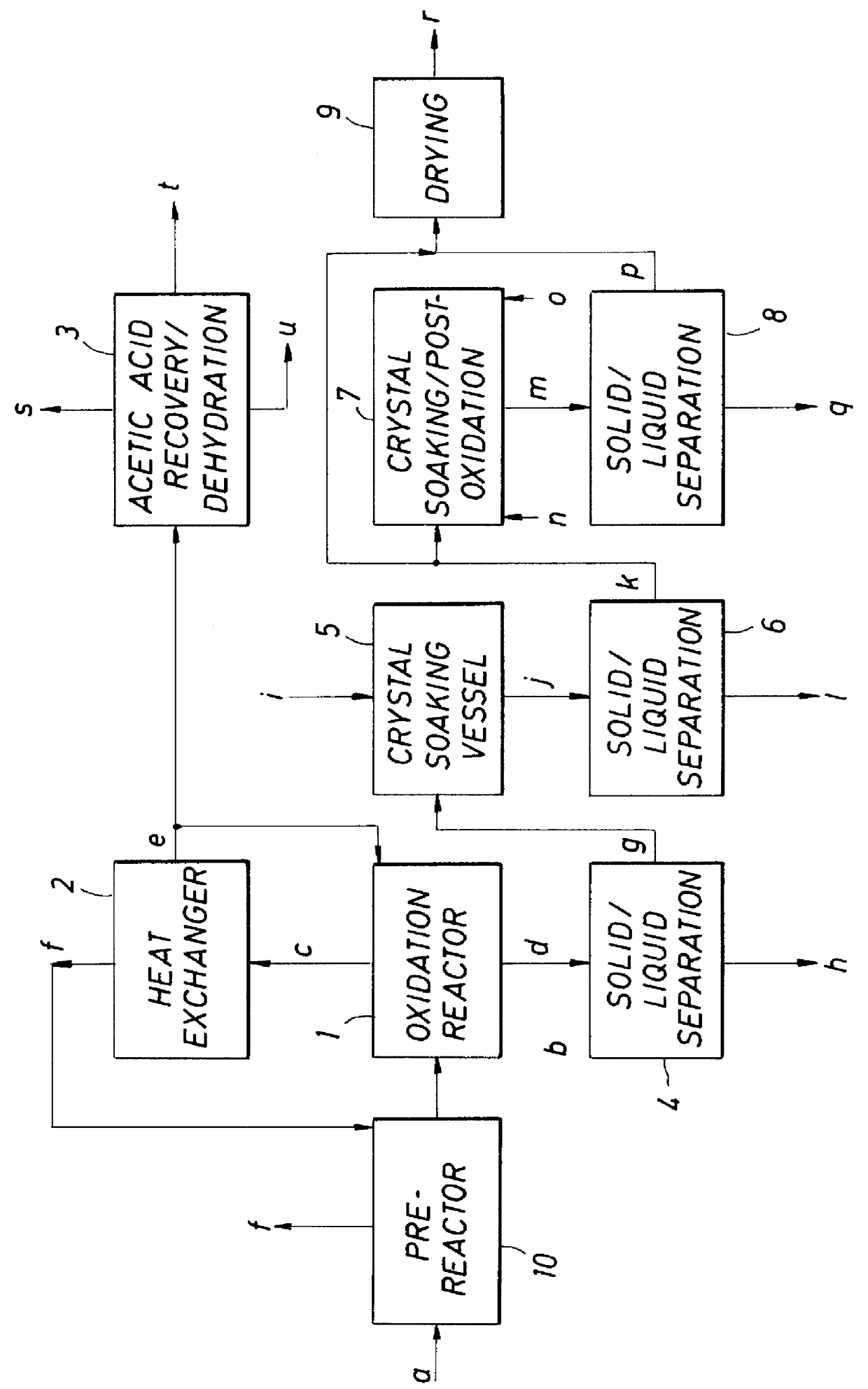

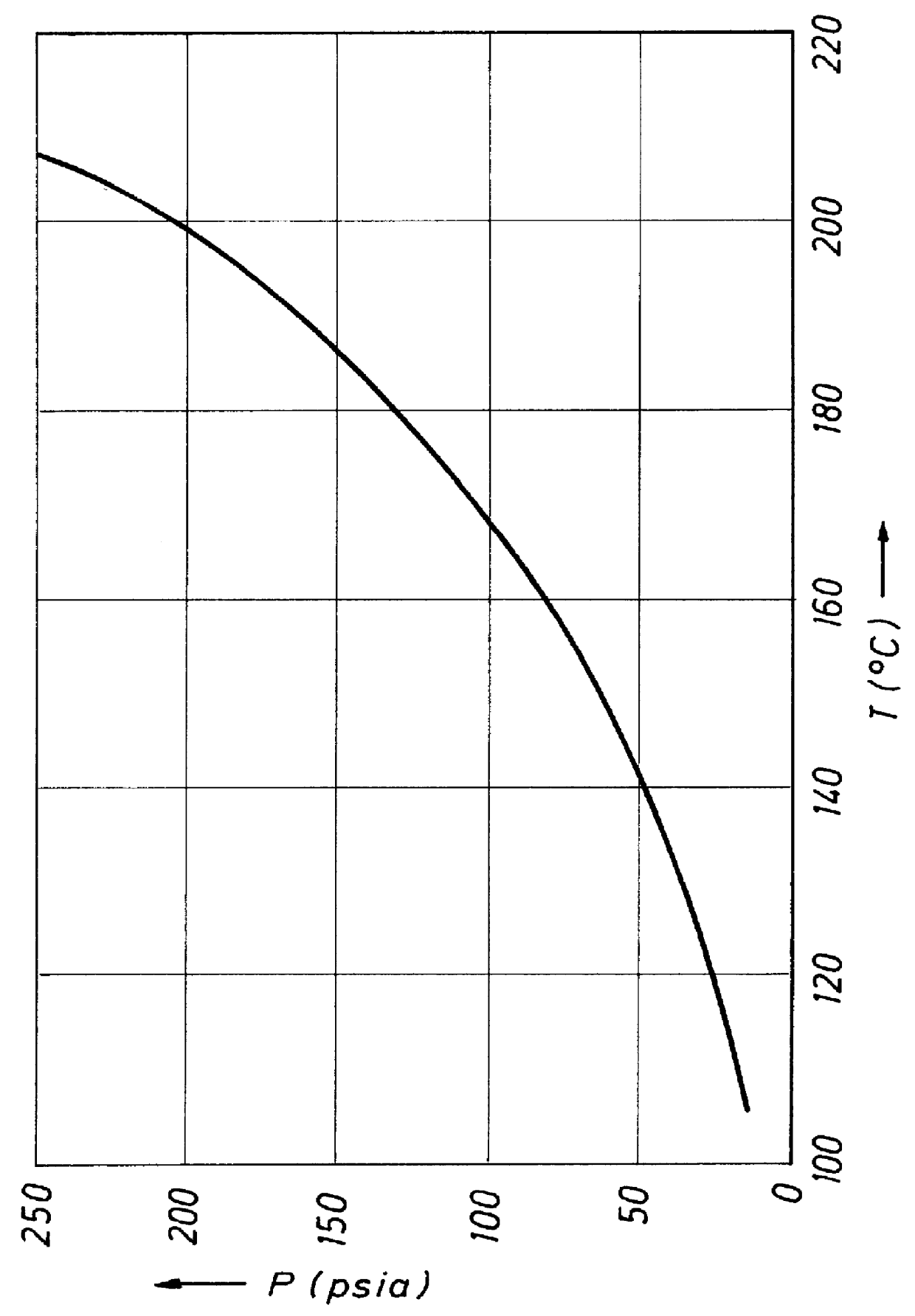

Method to produce aromatic dicarboxylic acids using cobalt and zirconium catalysts

InactiveUS6153790AAvoid problemsEfficient removalOrganic compound preparationChemical recyclingOrganic acidWater vapor

A process to produce terephthalic acid is provided, the process including the steps of: providing a feed stream comprising a dialkyl substituted aromatic and in an organic acid solvent: contacting the feed stream with an oxidant, the oxidant containing at least 50% by volume oxygen and at an oxygen partial pressure of at least 1 psia, at a temperature between about 80 DEG C. and about 130 DEG C., in the presence of a catalyst system comprising zirconium and cobalt, wherein the contacting is done in a stirred tank reactor; removing from the stirred tank reactor a vapor stream comprising the organic acid, water vapor and unreacted oxidant; condensing at least a portion of the organic acid and water from the vapor stream; separating at least a portion of the water from the organic acid back to the stirred tank reactor; returning at least a portion of the condensed organic acid back to the stirred tank reactor; continuously recovering from the stirred tank reactor a product comprising a diacid substituted aromatic; isolating solid crystals of diacid substituted aromatic from the reactor product; and recovering from the solid crystals a diacid substituted aromatic having a purity of preferably at least 97% by weight.

Owner:SHELL OIL CO

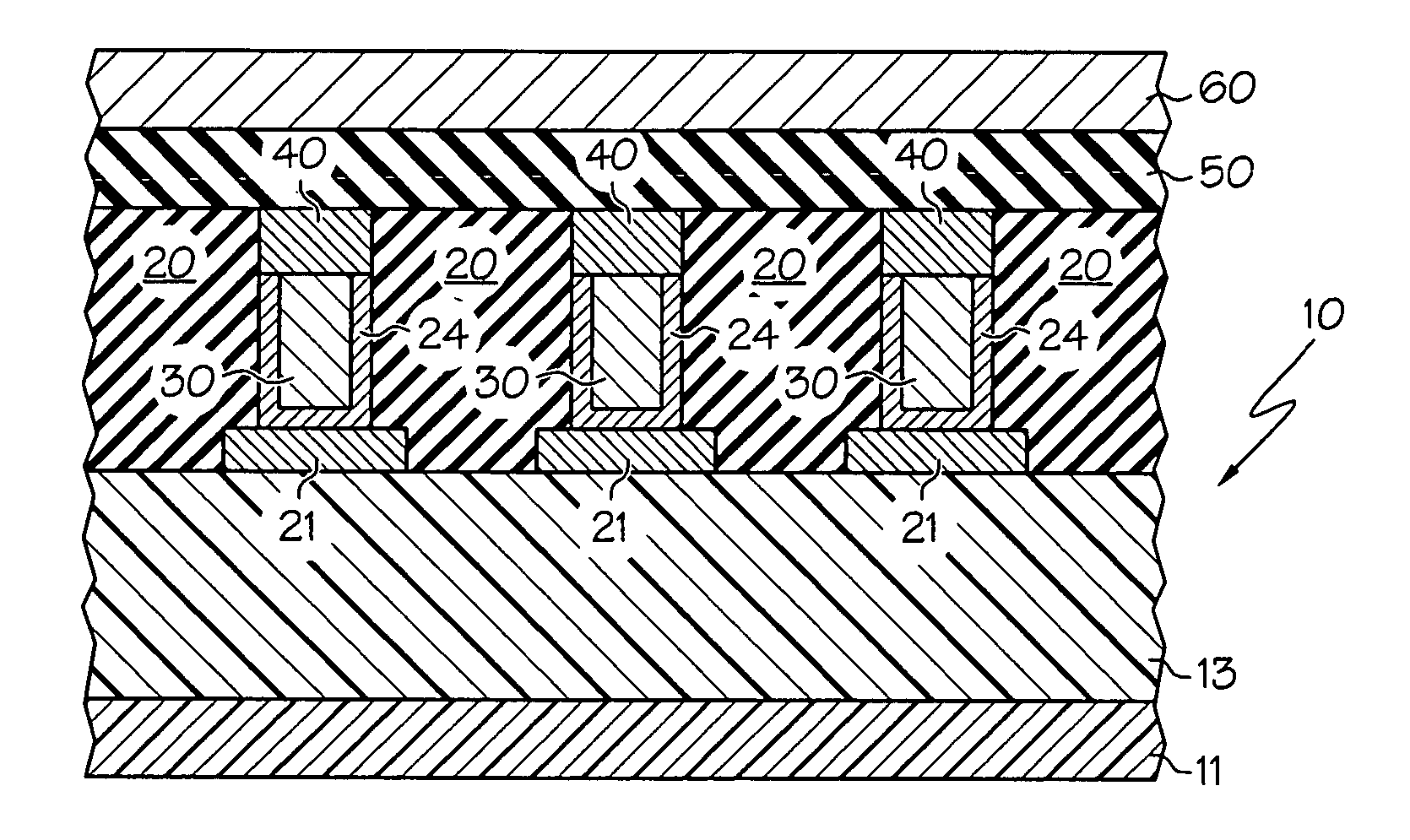

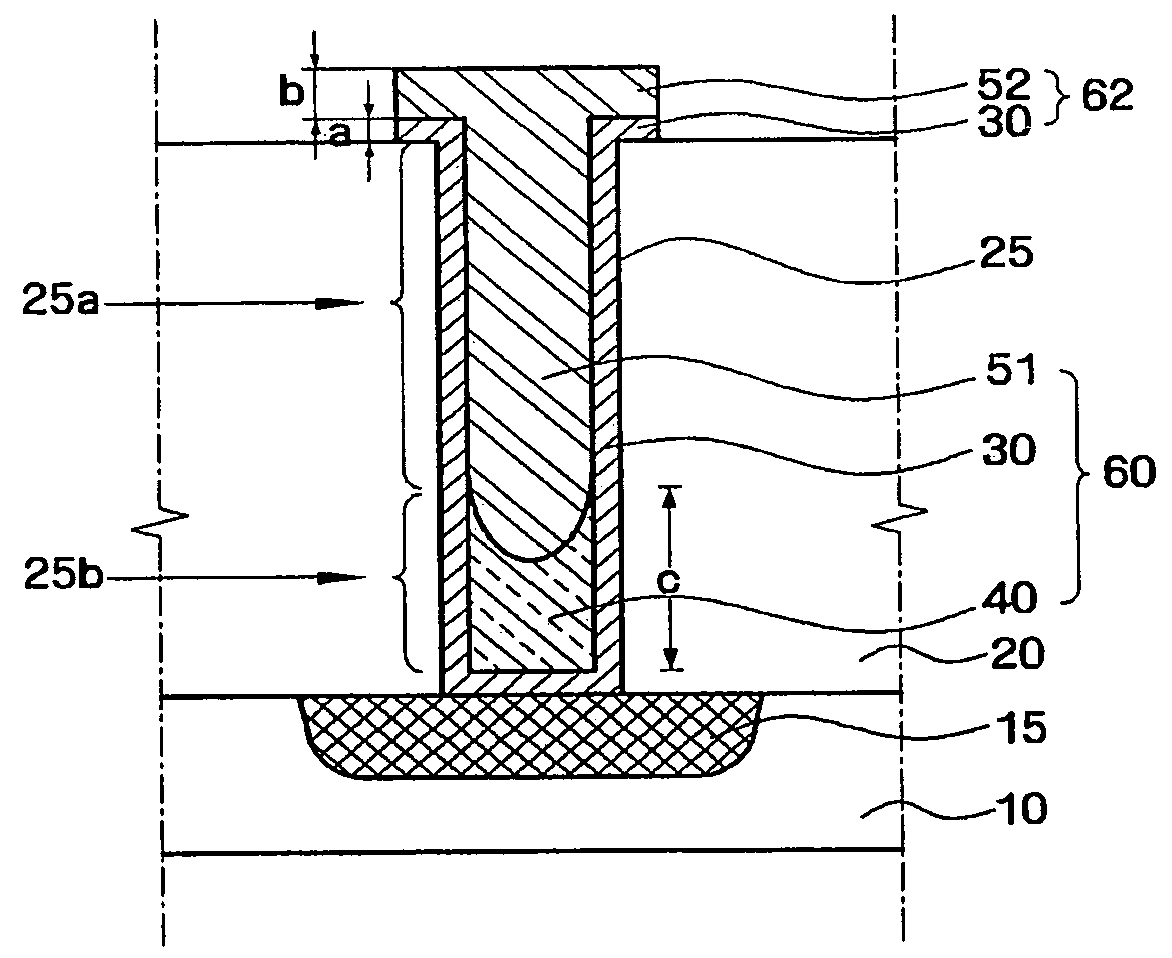

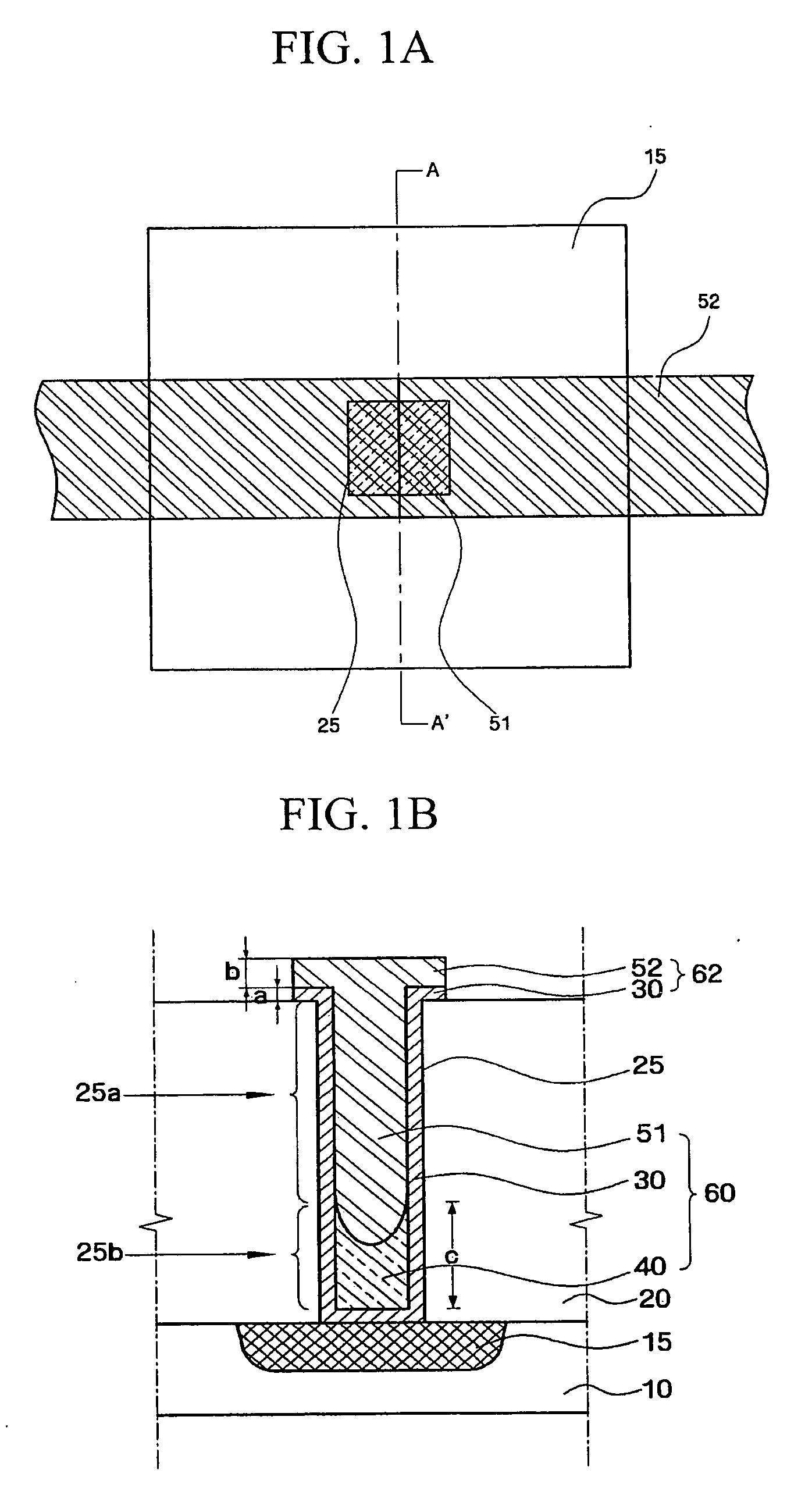

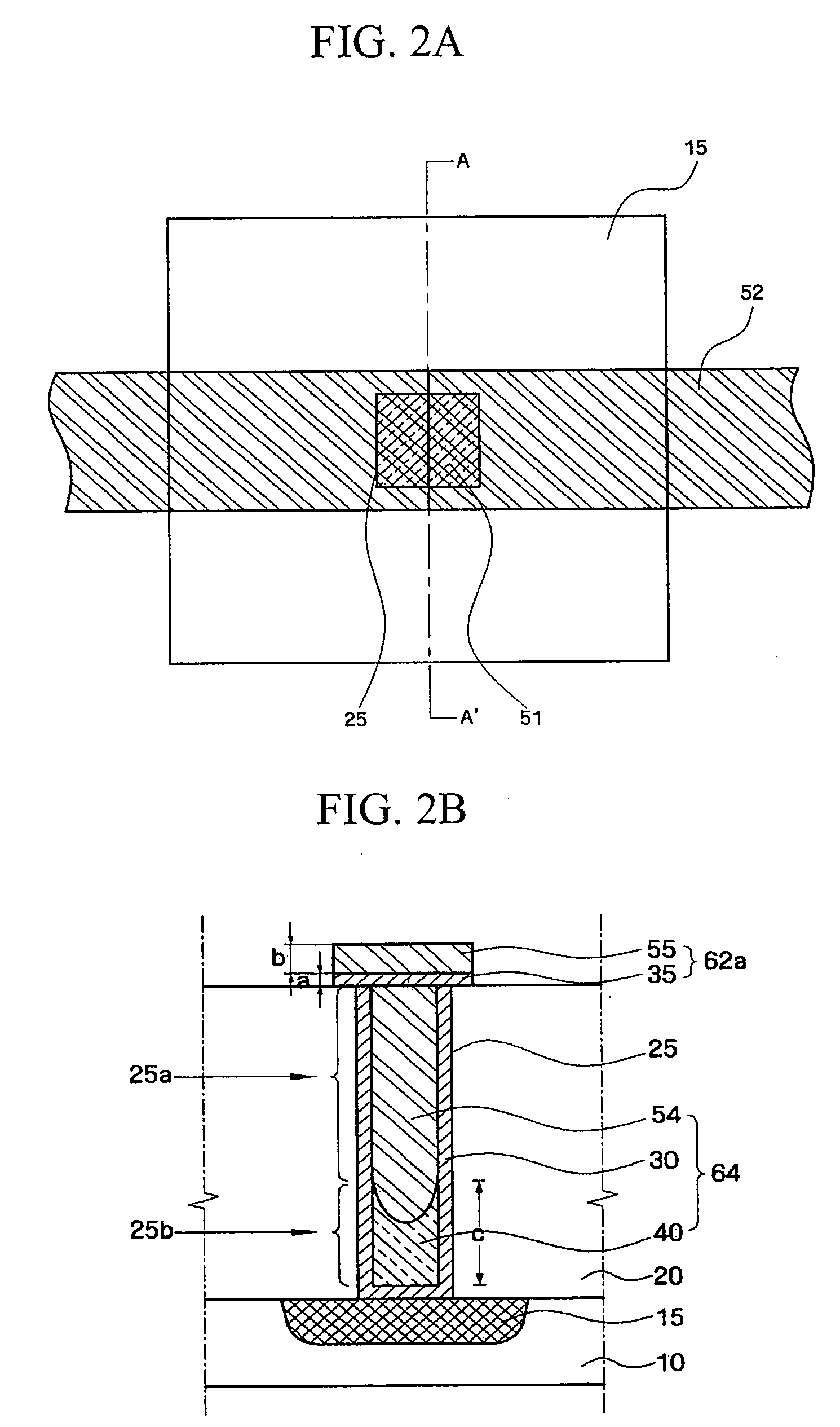

Semiconductor device including interlayer interconnecting structures and methods of forming the same

InactiveUS20090026618A1Low-resistivity connectivityReduce capacitanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialConductive materials

In a method of forming a semiconductor device, and a semiconductor device formed according to the method, an insulating layer is provided on an underlying contact region of the semiconductor device. An opening is formed in the insulating layer to expose the underlying contact region. A seed layer is provided on sidewalls and a bottom of the opening, the seed layer comprising cobalt. A barrier layer of conductive material is provided in a lower portion of the opening, the seed layer being exposed on sidewalls of an upper portion of the opening. A metal layer is provided on the barrier layer in the opening to form an interlayer contact, the metal layer contacting the seed layer at the sidewalls of the upper portion of the opening.

Owner:SAMSUNG ELECTRONICS CO LTD

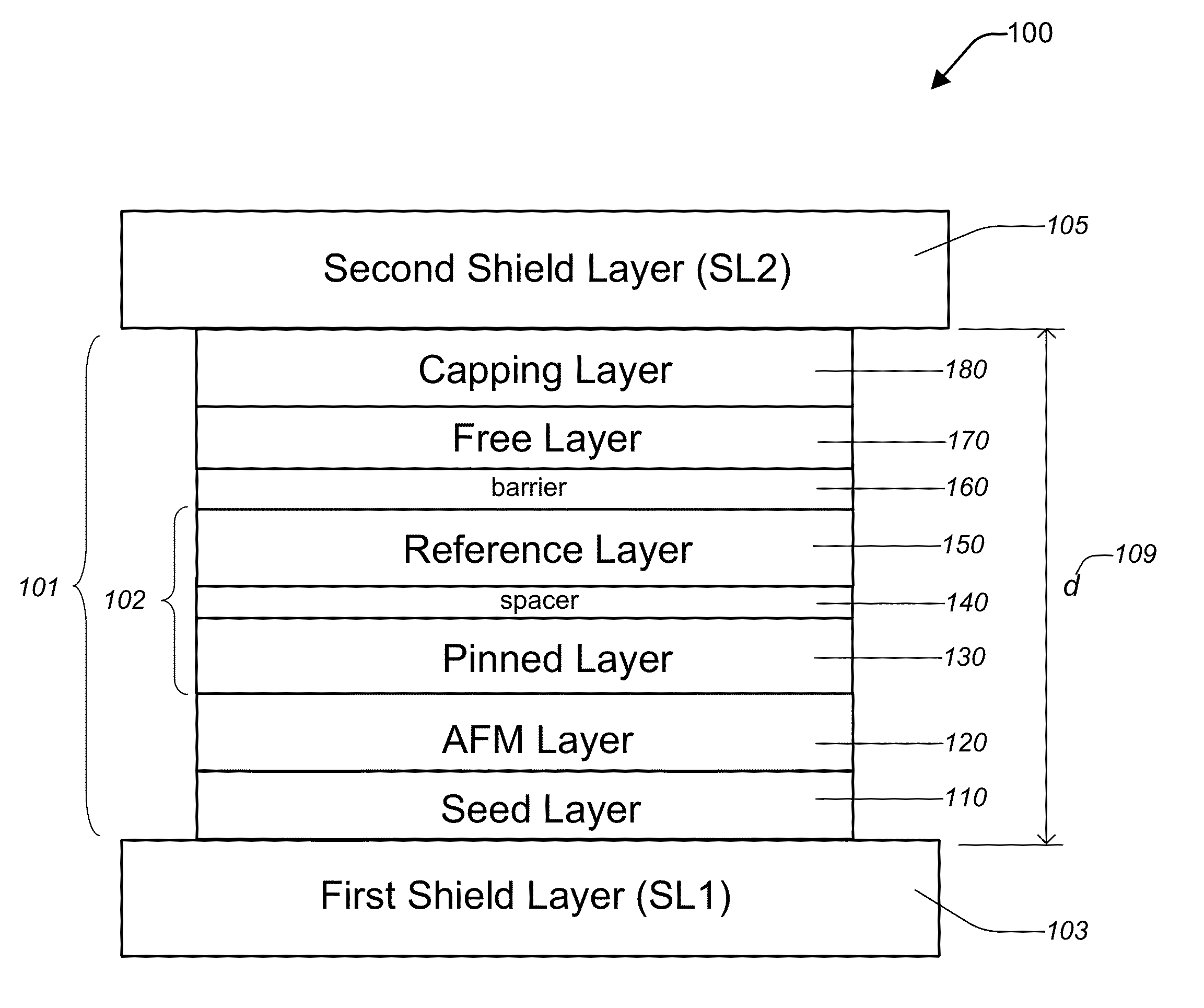

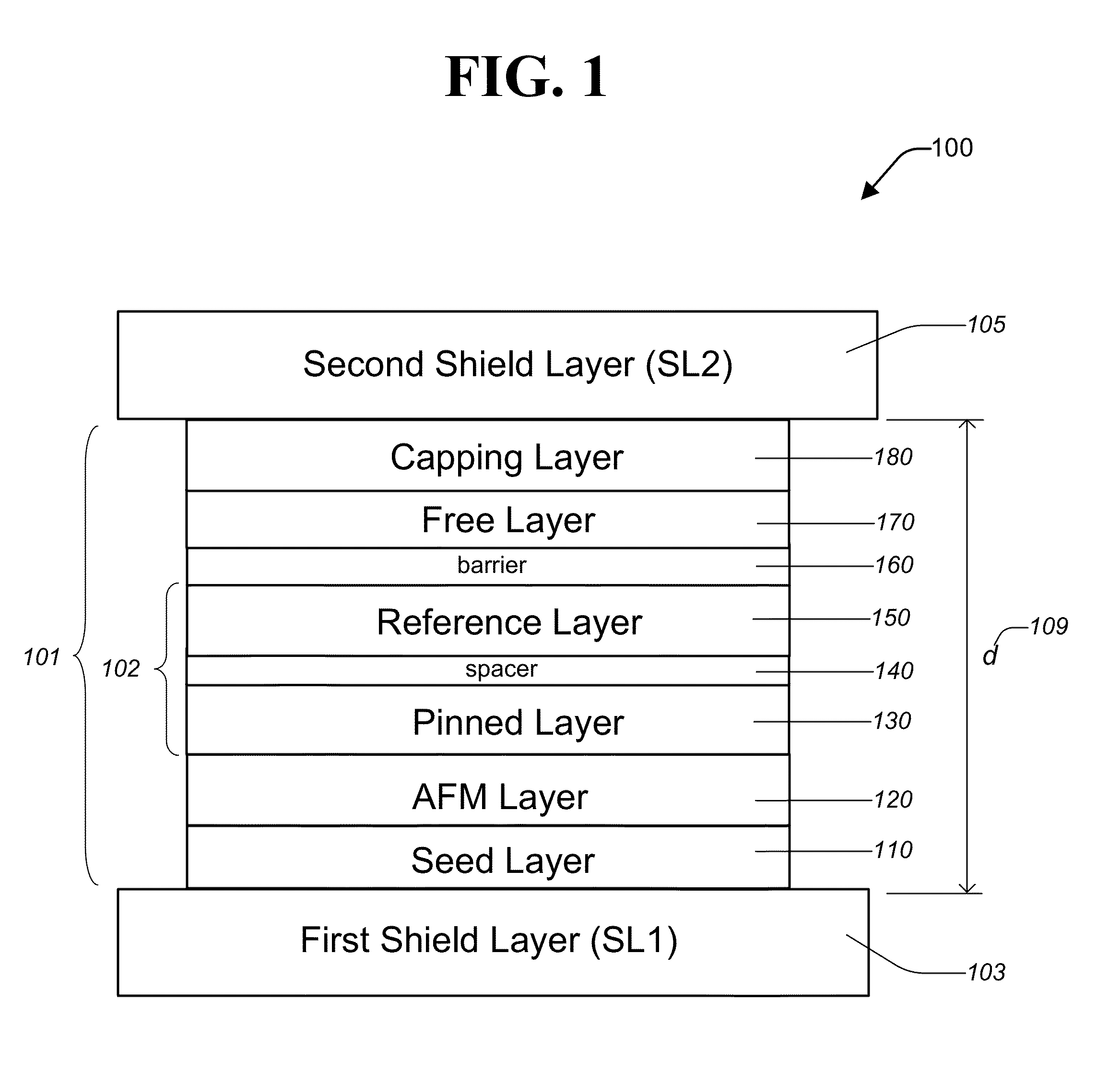

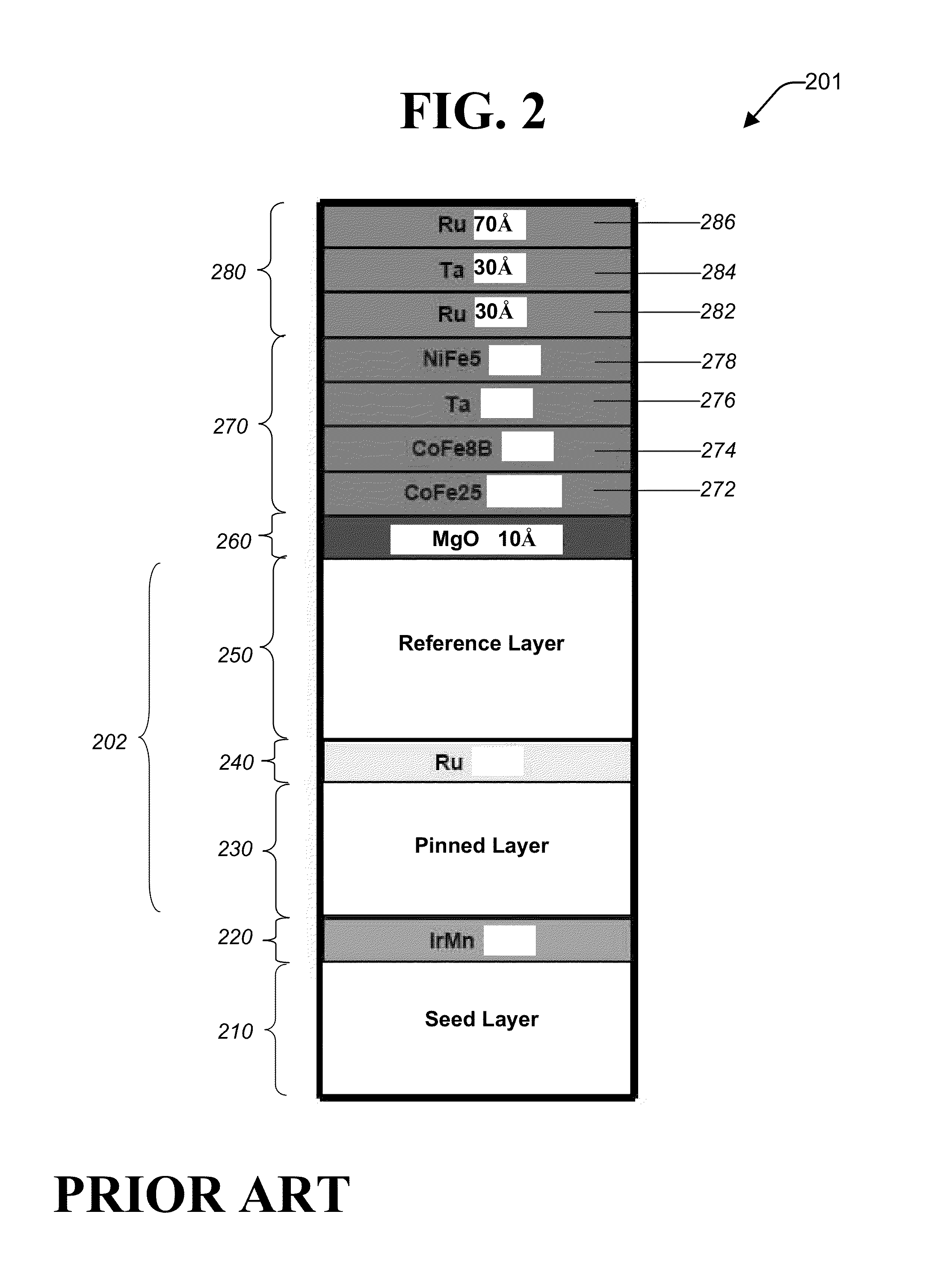

Magnetoresistive sensors having an improved free layer

ActiveUS8498084B1Reduce thicknessGilbert damping constantMagnetic measurementsRecord information storageSpin polarizationCobalt

A magnetoresistive sensor having a novel free layer and a method of producing the same are disclosed. The magnetoresistive sensor comprises a pinned layer, a barrier layer disposed over the pinned layer, and a free layer disposed over the barrier layer. The free layer comprises a first magnetic layer disposed over the barrier layer. The first magnetic layer has a positive spin polarization, a positive magnetostriction, and a polycrystalline structure. The free layer further comprises a second magnetic layer disposed over the first magnetic layer. The second magnetic layer has a negative magnetostriction and comprises at least cobalt (Co) and boron (B).

Owner:WESTERN DIGITAL TECH INC

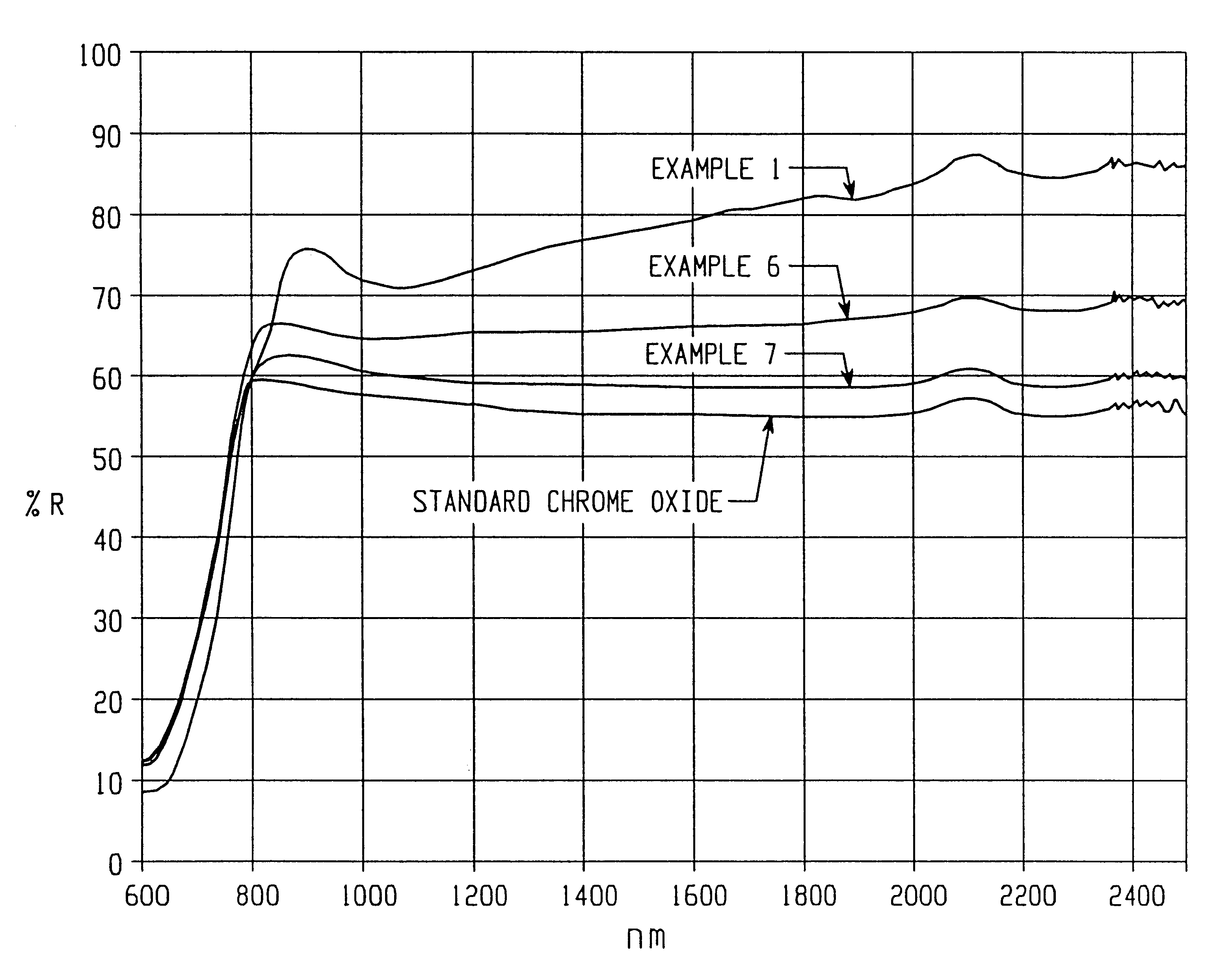

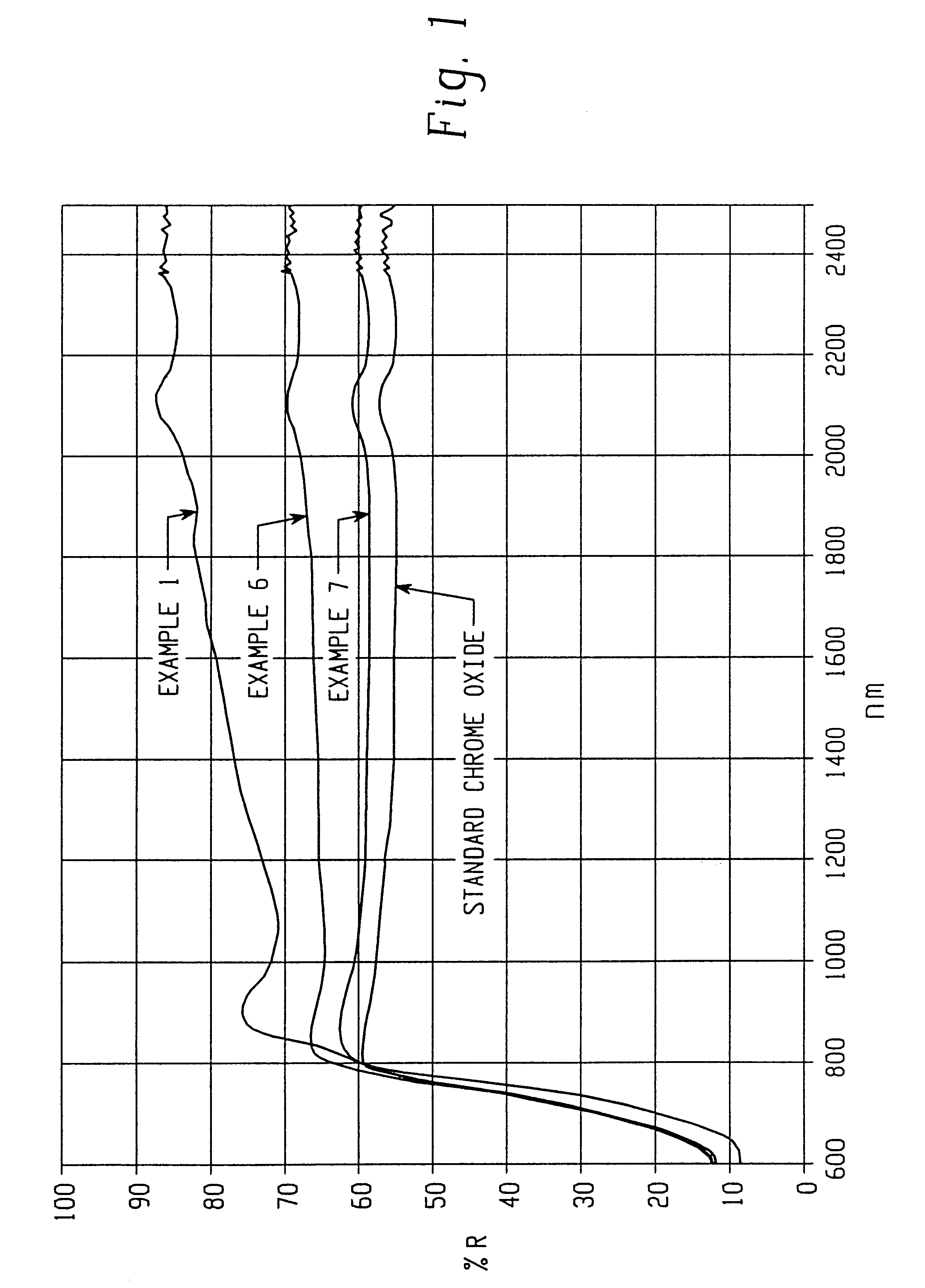

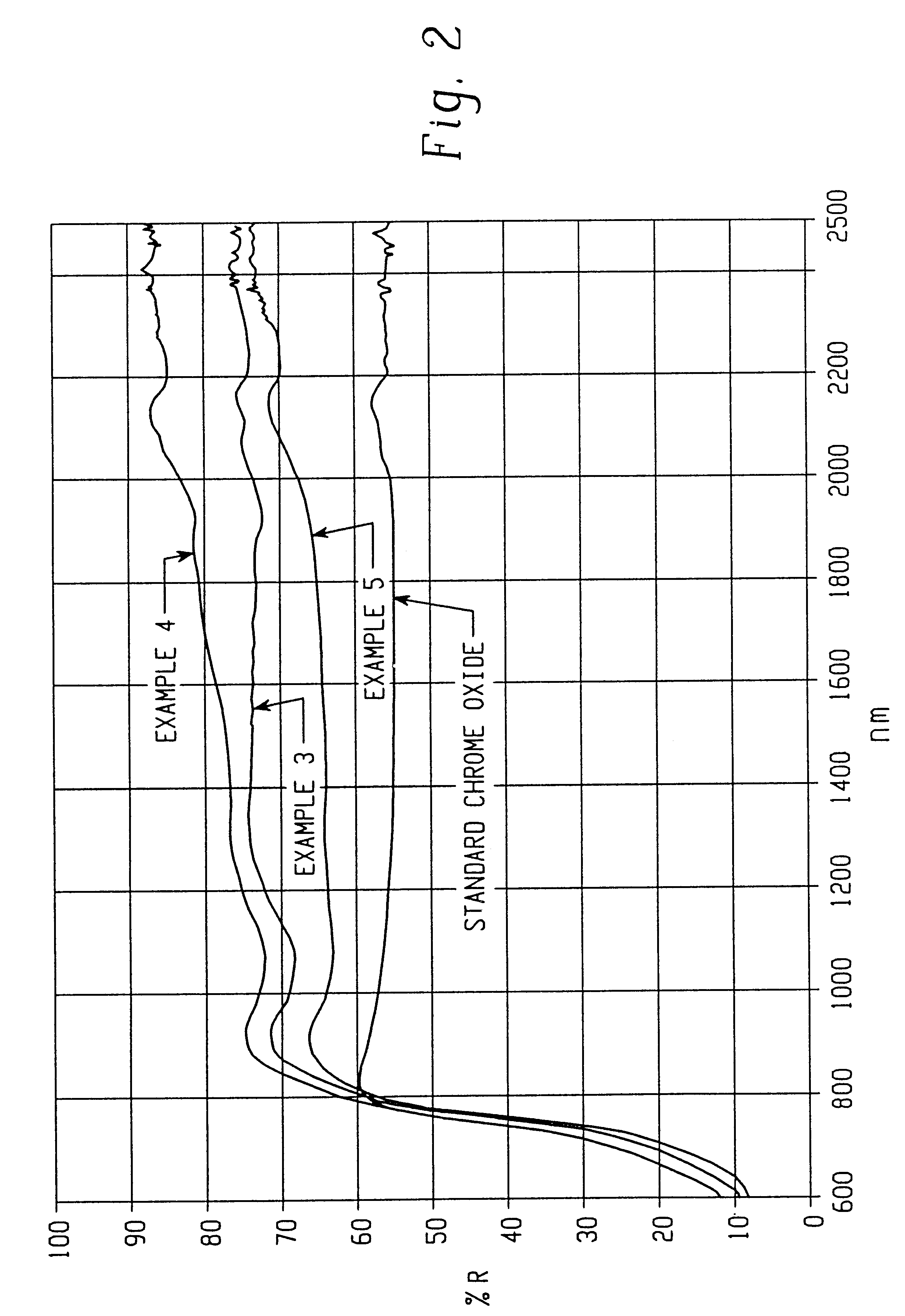

Infrared reflective color pigment

InactiveUS6454848B2Reduce heat buildupReduce energy costsInorganic pigment treatmentCoatingsIndiumCobalt

The present invention provides new solid solutions having a corundum-hematite crystalline structure which are useful as inorganic color pigments. Solid solutions according to the present invention include a host component having a corundum-hematite crystalline structure which contains as guest components one or more elements from the group consisting of aluminum, antimony, bismuth, boron, chrome, cobalt, gallium, indium, iron, lanthanum, lithium, magnesium, manganese, molybdenum, neodymium, nickel, niobium, silicon, tin, titanium, vanadium, and zinc. Solid solutions according to the present invention are formed by thoroughly mixing compounds, usually metal oxides or precursors thereof, which contain the host and guest components and then calcining the compounds to form the solid solutions having the corundum-hematite crystalline structure. Some of the new solid solutions according to the present invention exhibit relatively low Y CIE tri-stimulus values and relatively high near infrared reflectance.

Owner:FERRO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com