Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13223 results about "Triethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triethanolamine aka Trolamine (abbr. as TEOA or TELA to distinguish it from TEA which is for triethylamine) is a viscous organic compound that is both a tertiary amine and a triol. A triol is a molecule with three alcohol groups. Approximately 150,000 tonnes were produced in 1999. It is a colourless compound although samples may appear yellow because of impurities.

Method of selectively depositing a thin film material at a semiconductor interface

InactiveUS20070108404A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingDevice formMetal silicide

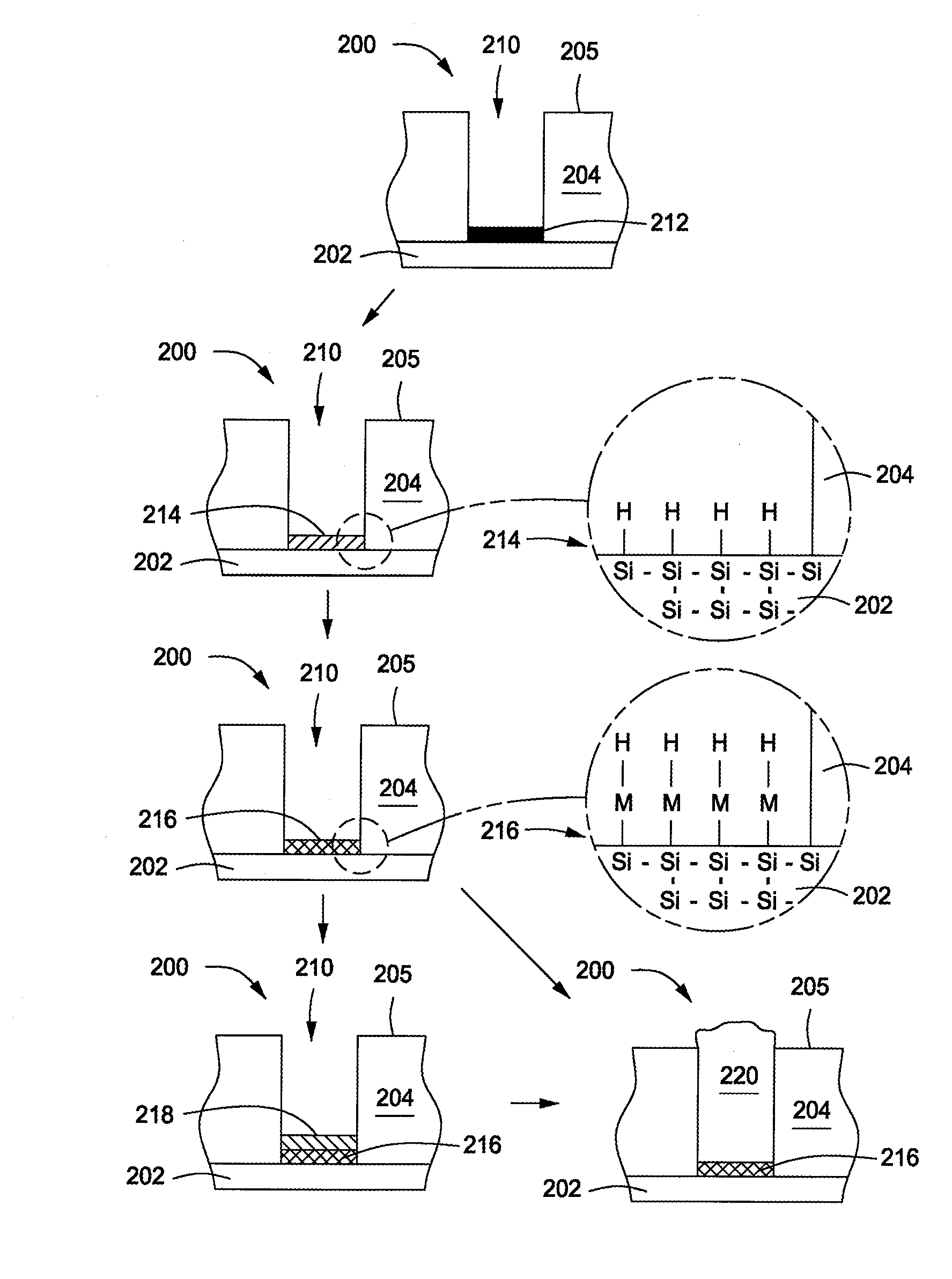

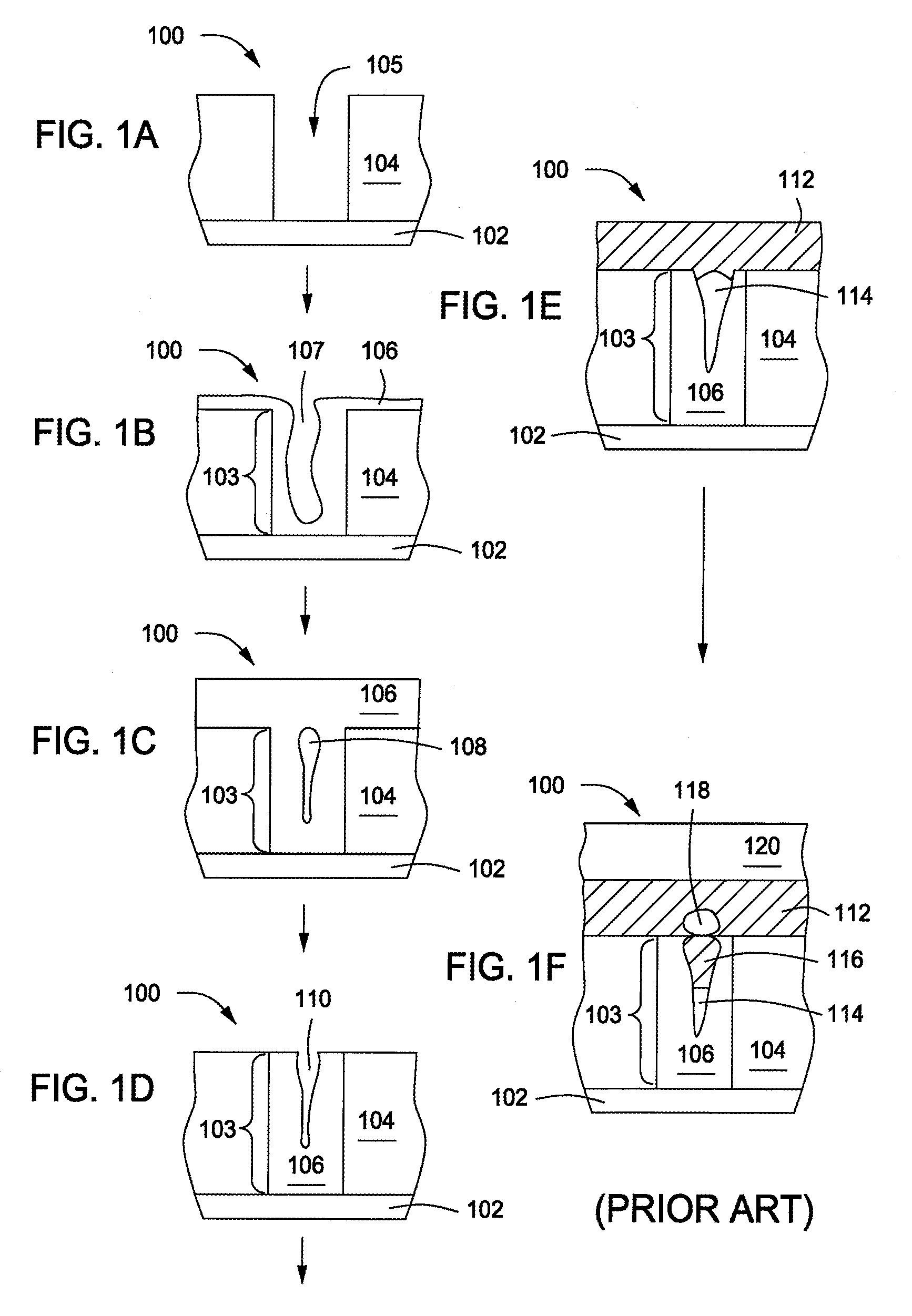

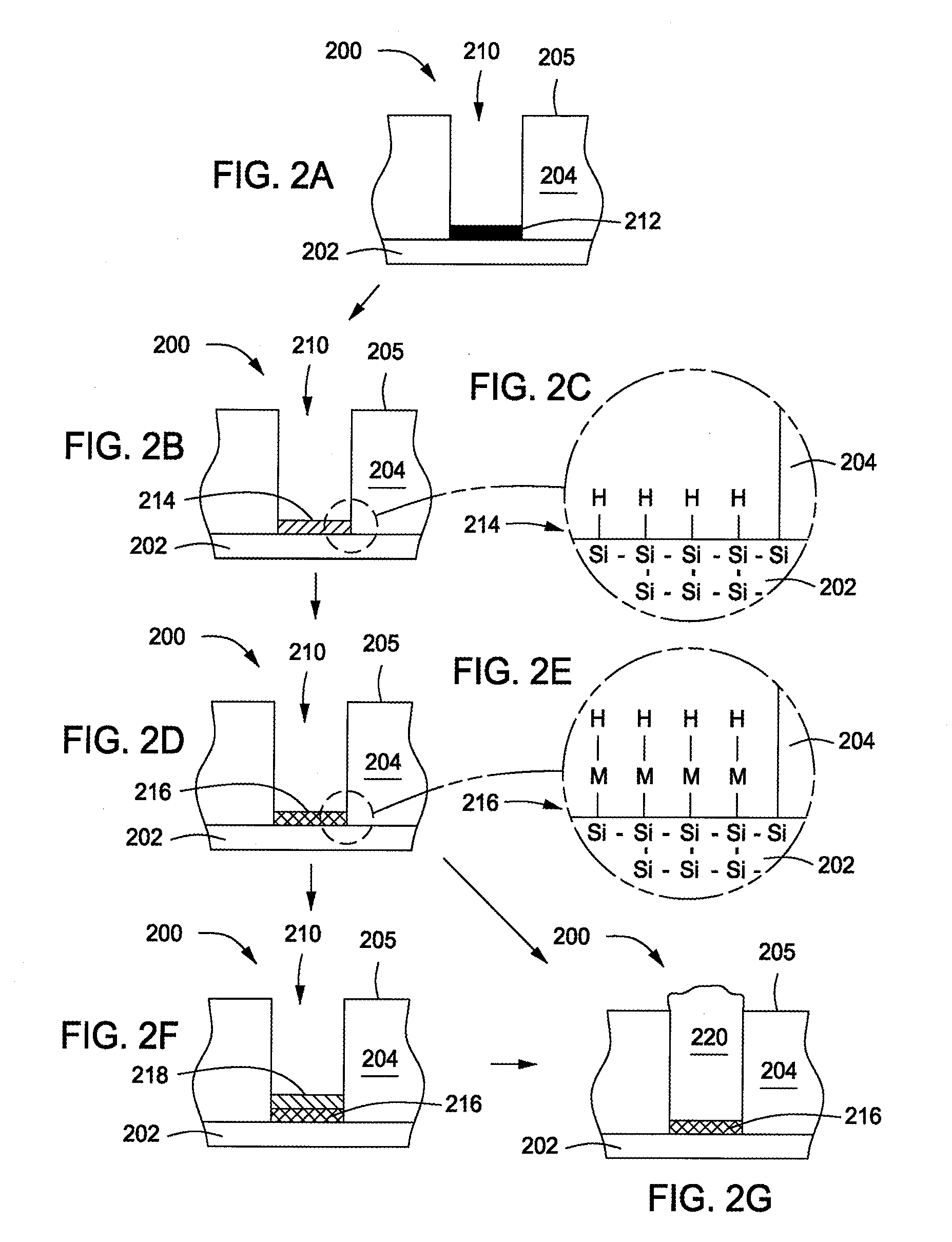

Embodiments of the invention provide processes to form a high quality contact level connection to devices formed on a substrate. In one embodiment, a method for depositing a material on a substrate is provided which includes exposing the substrate to a buffered oxide etch solution to form a silicon hydride layer during a pretreatment process, depositing a metal silicide layer on the substrate, and depositing a first metal layer (e.g., tungsten) on the metal silicide layer. The buffered oxide etch solution may contain hydrogen fluoride and an alkanolamine compound, such as ethanolamine diethanolamine, or triethanolamine. The metal silicide layer may contain cobalt, nickel, or tungsten and may be deposited by an electroless deposition process. In one example, the substrate is exposed to an electroless deposition solution containing a solvent and a complexed metal compound.

Owner:APPLIED MATERIALS INC

Treatment of skin wounds using polyenylphosphatidylcholine and alkanolamines

InactiveUS6932963B2Minimize scarringReduce inhibitionBiocideCosmetic preparationsSOYBEAN SEED OILTriethanolamine

Polyenylphosphatidylcholine in combination with an alkanolamine are topically applied to treat skin wounds, promote healing, and minmize scar formation. Typical compositions contain from about 0.25% to about 12% of a polyenylphosphatidylcholine preparation obtained from natural sources such as soybean oil which contains at least about 25% by weight, preferably about 40% or more, dilinoeoylphosphatidylcholine, and from about 0.1% to about 10% by weight of an alkanolamine such as ethylaminoethanol, methylaminoethanol, dimethylaminoethanol, isopropanolamine, triethanolamine, isopropanoldimethylamine, ethylethanolamine, 2-butanolamine, choline, serine, or mixtures thereof. Dimethylaminoethanol is a particularly preferred alkanolamine. Tyrosine is an adjunct ingredient in many embodiments.

Owner:N V PERRICONE

Alkaline liquid laundry detergent compositions comprising polyesters

InactiveUS9365806B2Maximize the benefitsEasy to cleanOrganic detergent compounding agentsSurface-active detergent compositionsPolyesterLiquid laundry detergent

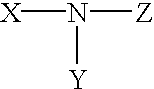

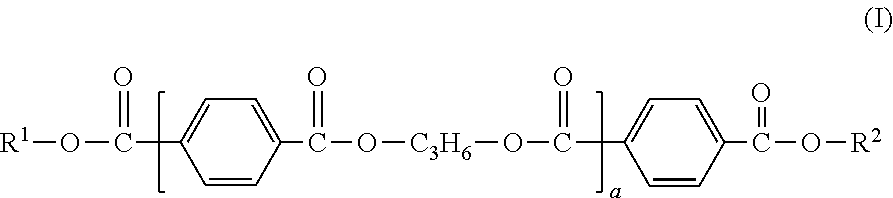

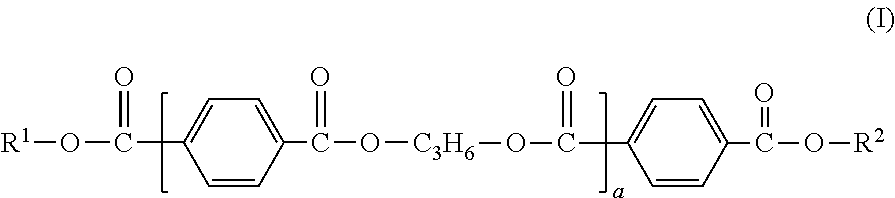

An alkaline liquid laundry detergent composition comprising at least 1 wt % triethanolamine, at least 5 wt % non-soap surfactant and at least 0.5 wt % of a polyester according to the following formula (I) wherein R1 and R2 independently of one another are X—(OC2H4)n-(OC3H6)m wherein X is C1-4 alkyl, the —(OC2H4) groups and the —(OC3H6) groups are arranged blockwise and the block consisting of the —(OC3H6) groups is bound to a COO group or are HO—(C3H6), n is based on a molar average a number of from 12 to 120, preferably 40 to 50, m is based on a molar average a number of from 1 to 10, and a is based on a molar average a number of from 4 to 9. The inventive compositions comprise polyesters that have an advantageous stability in their alkaline environment and also possess advantageous soil release properties.

Owner:CONOPCO INC D B A UNILEVER

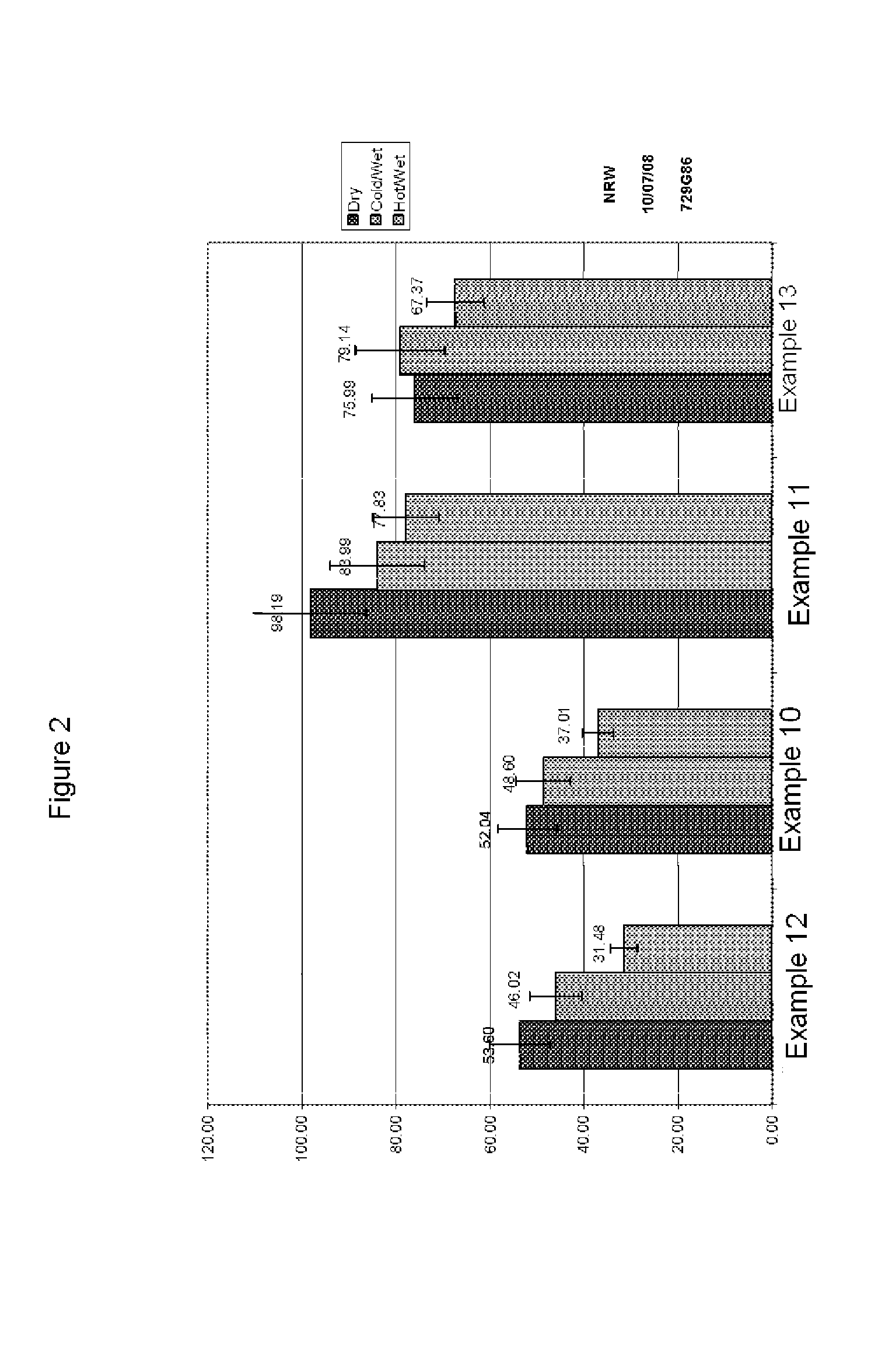

Extended binder compositions

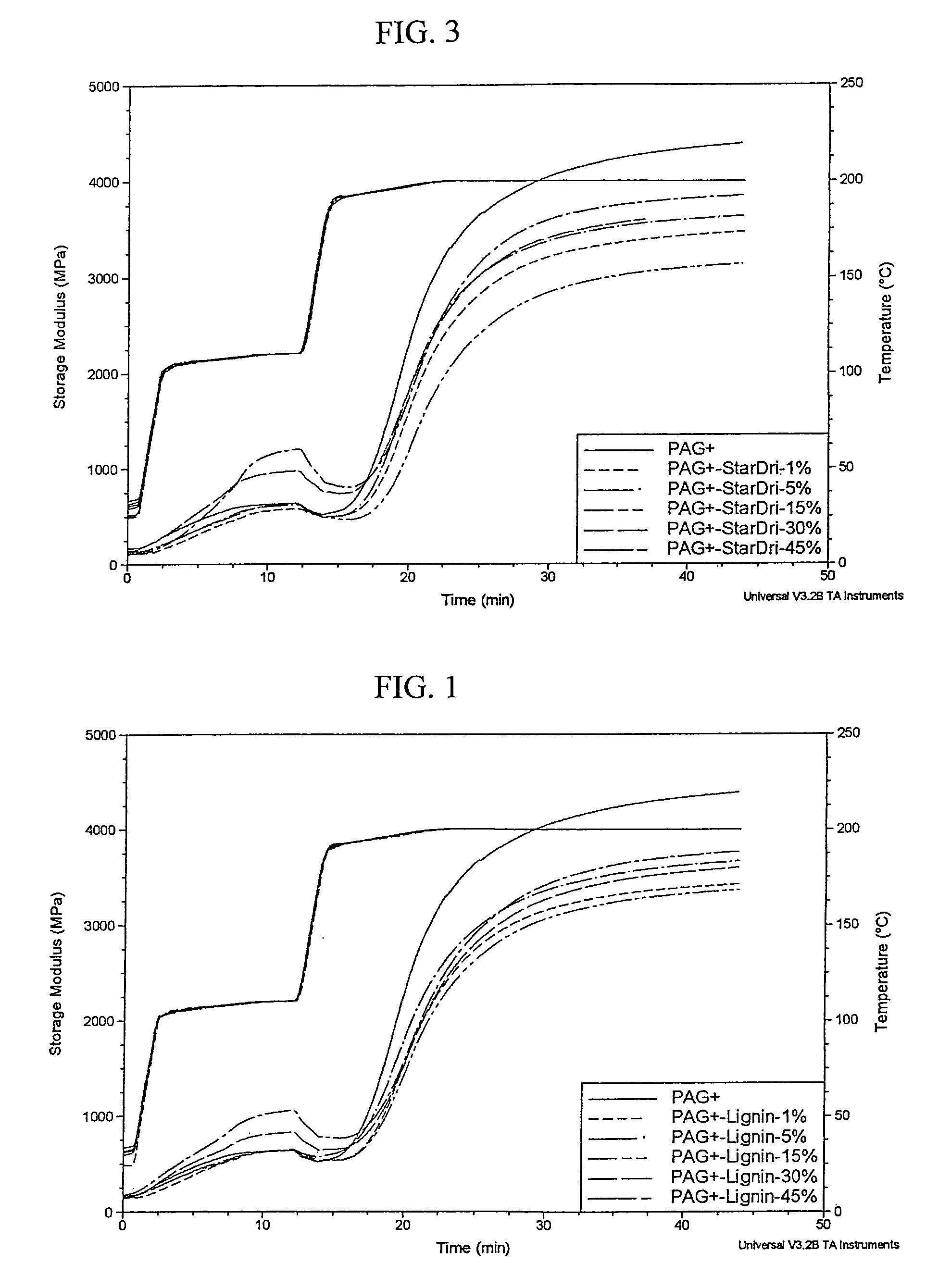

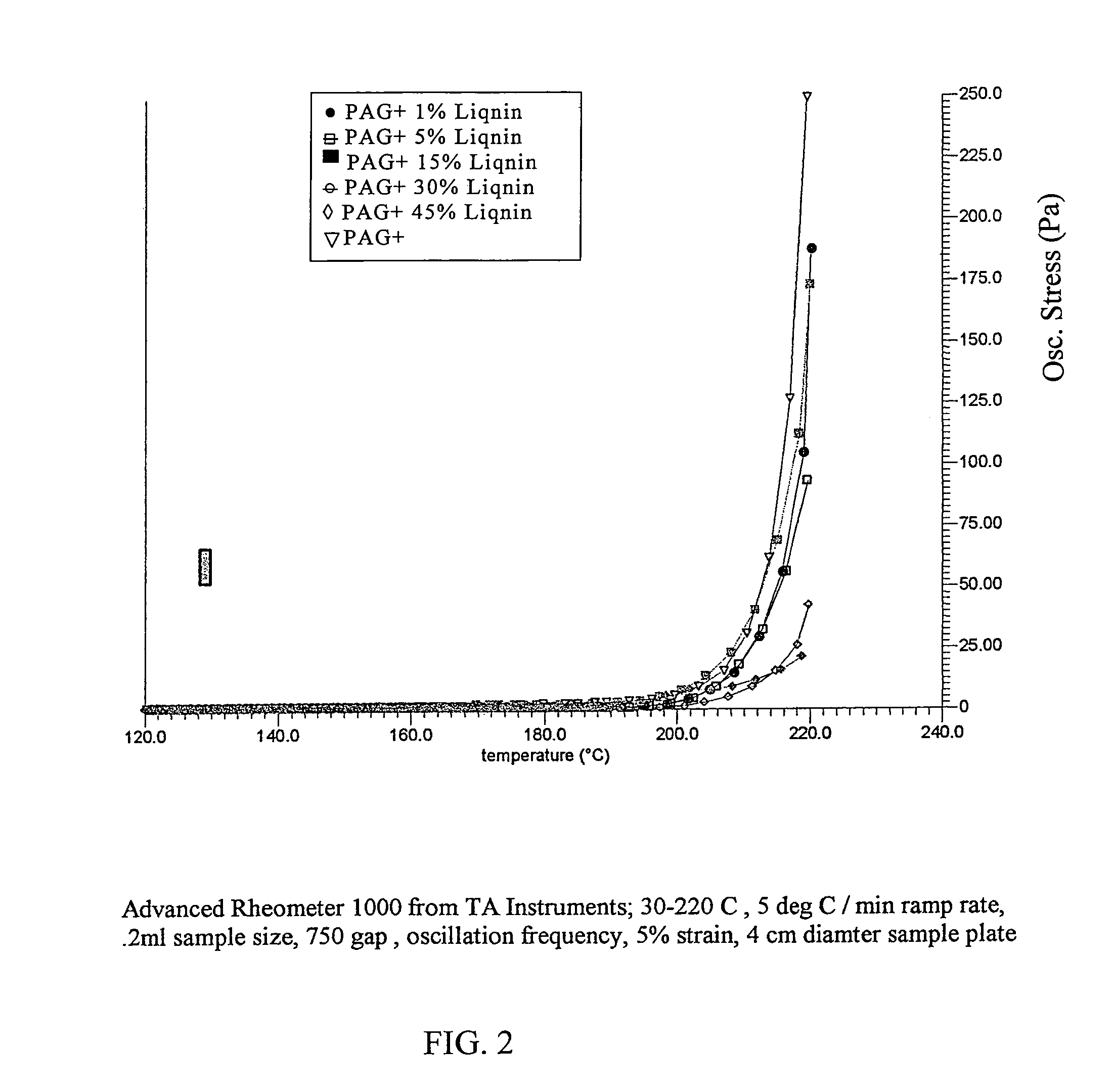

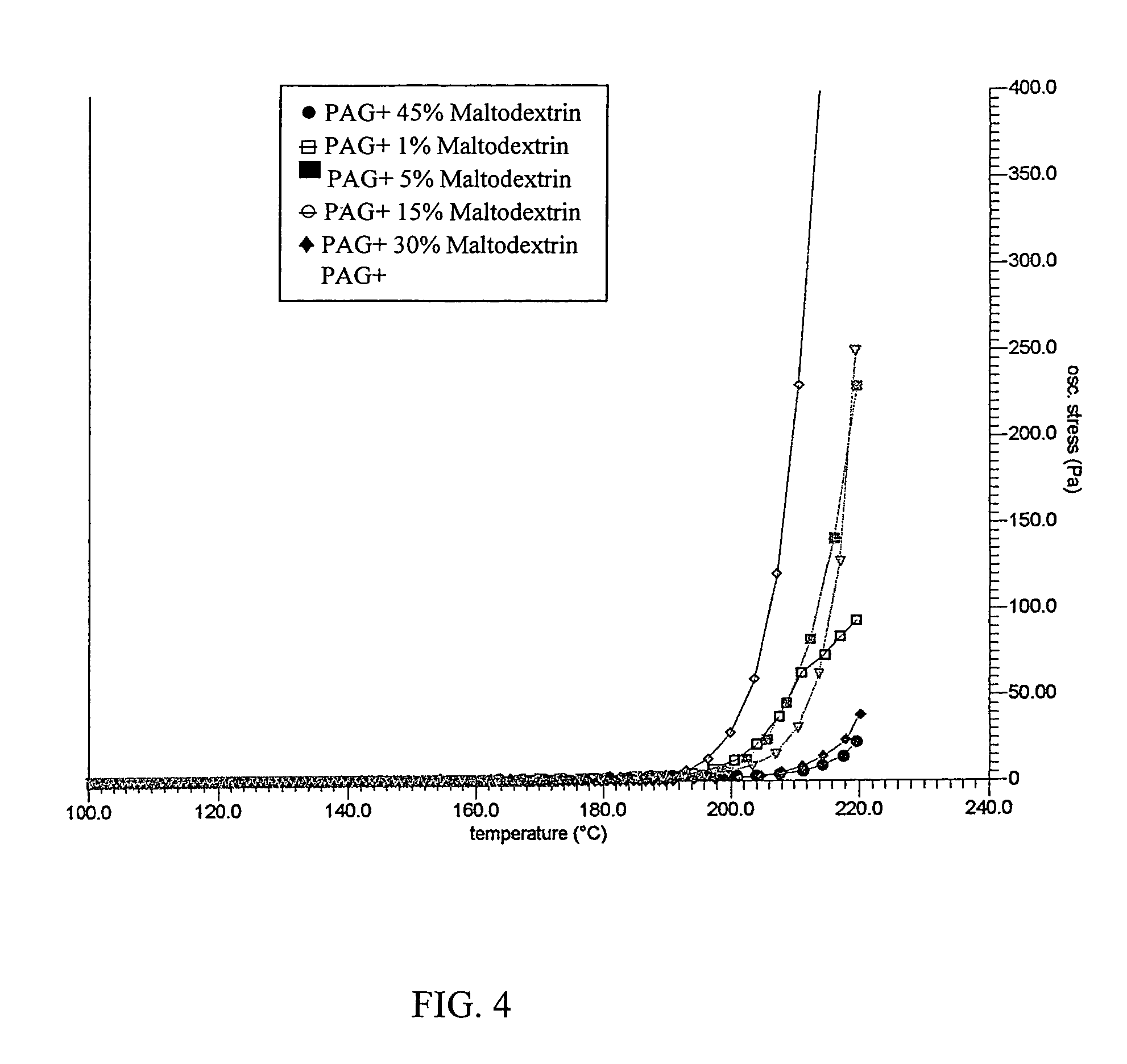

The present invention provides a variety of extended polyacrylic acid based binder compositions comprising a low molecular weight polyacrylic acid (typically hypophosphite or sulfite terminated), a crosslinking agent (such as triethanolamine or glycerol) and one or more water soluble materials, such as lignin, low molecular weight starch and soybean protein. The extended binder composition of the present invention provides a lower cost binder composition without degrading the performance and may be selected to alter one or more characteristics of the basic binder composition such binder wetting, emulsion compatibility, dust suppression and wash water flow properties.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Stainless steel cleaning agent

InactiveCN101135056AImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

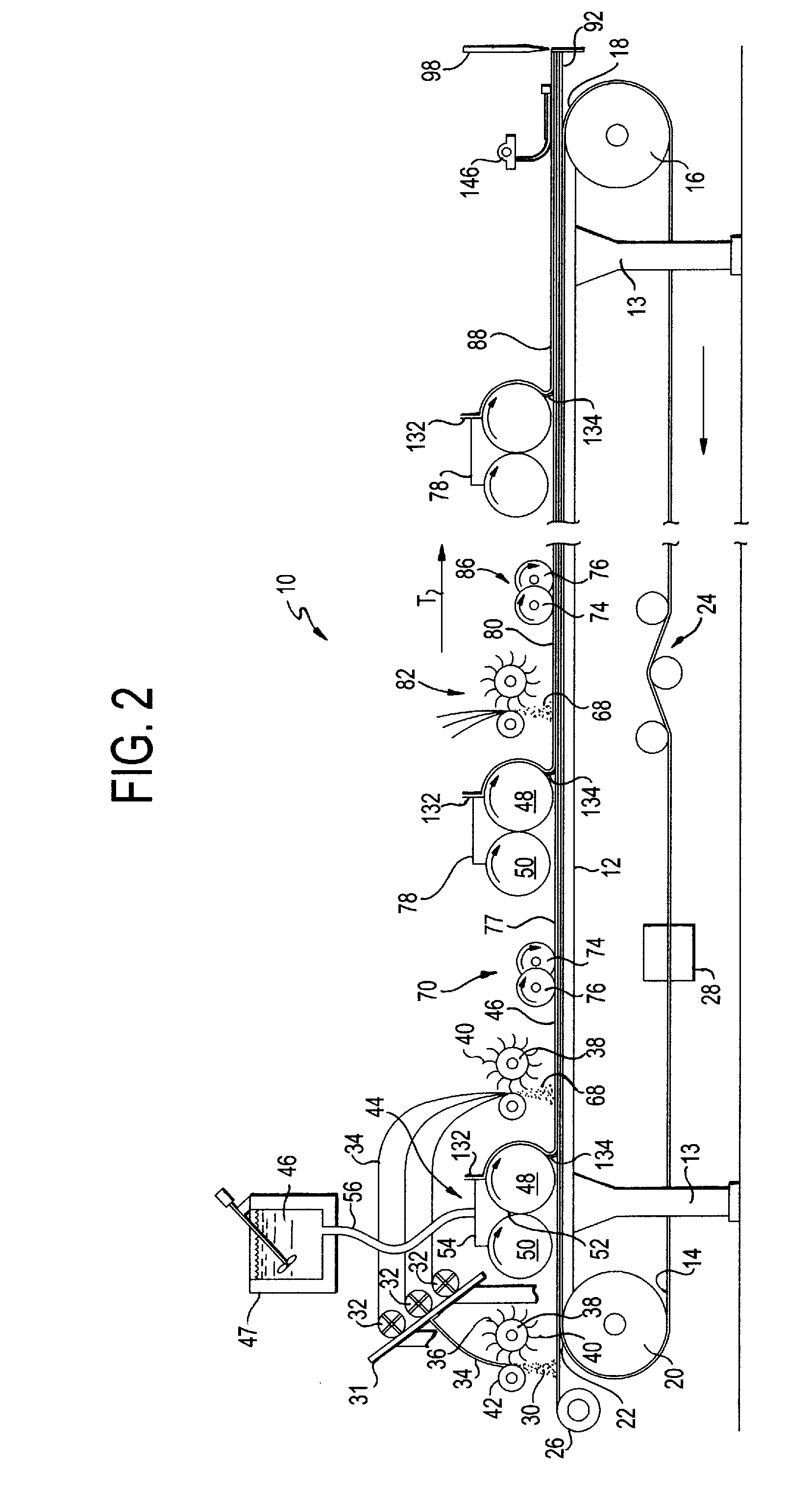

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

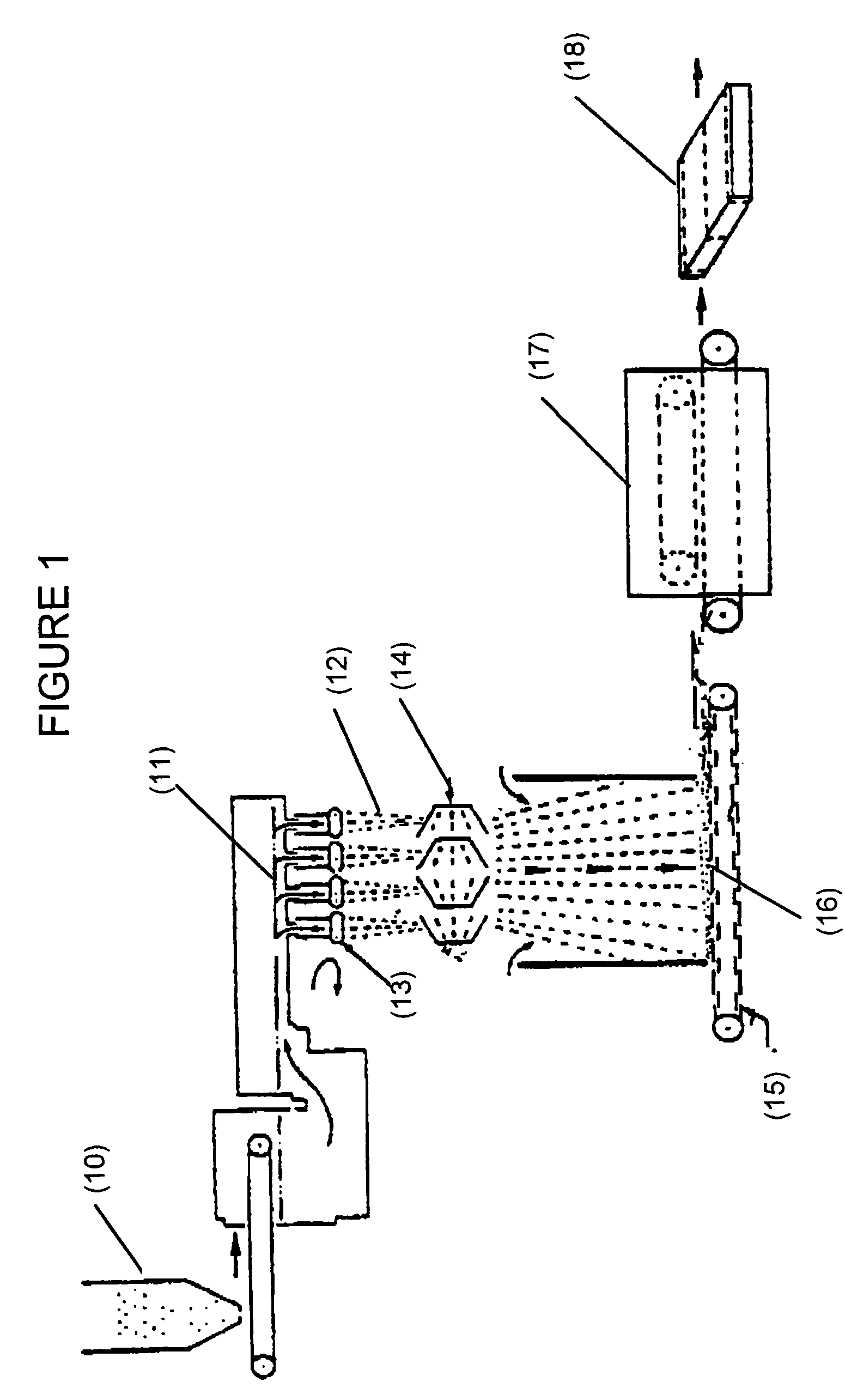

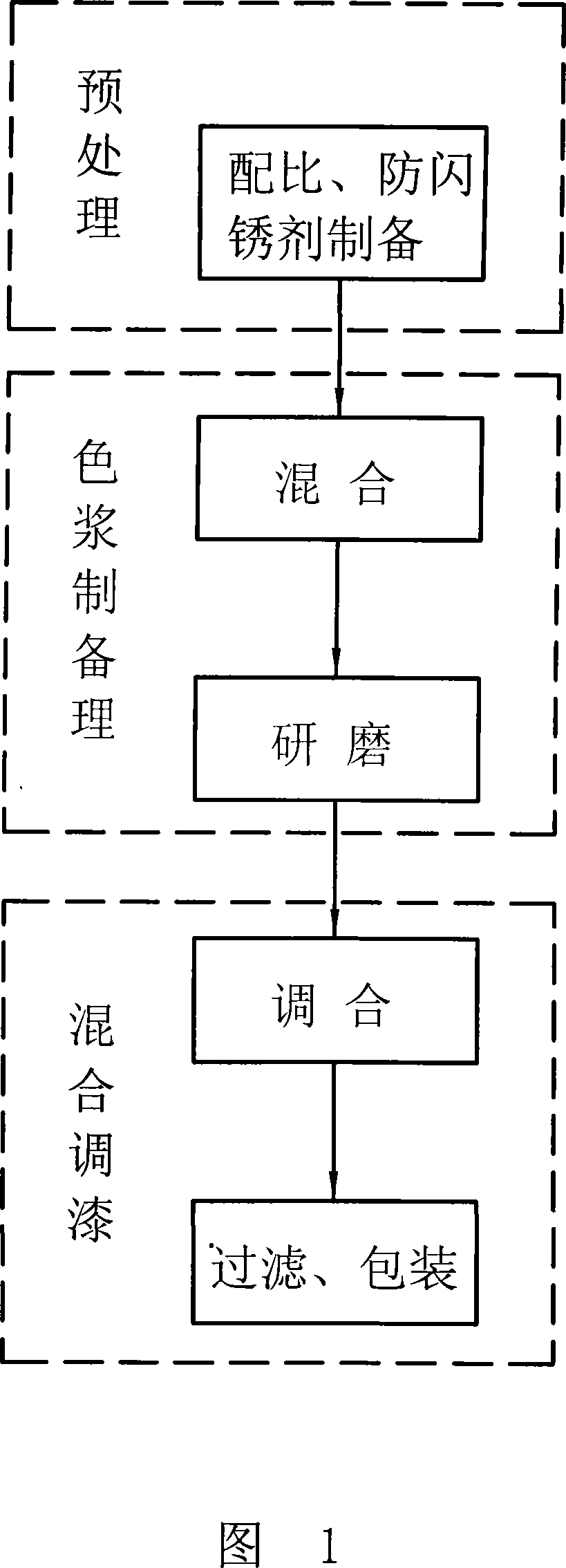

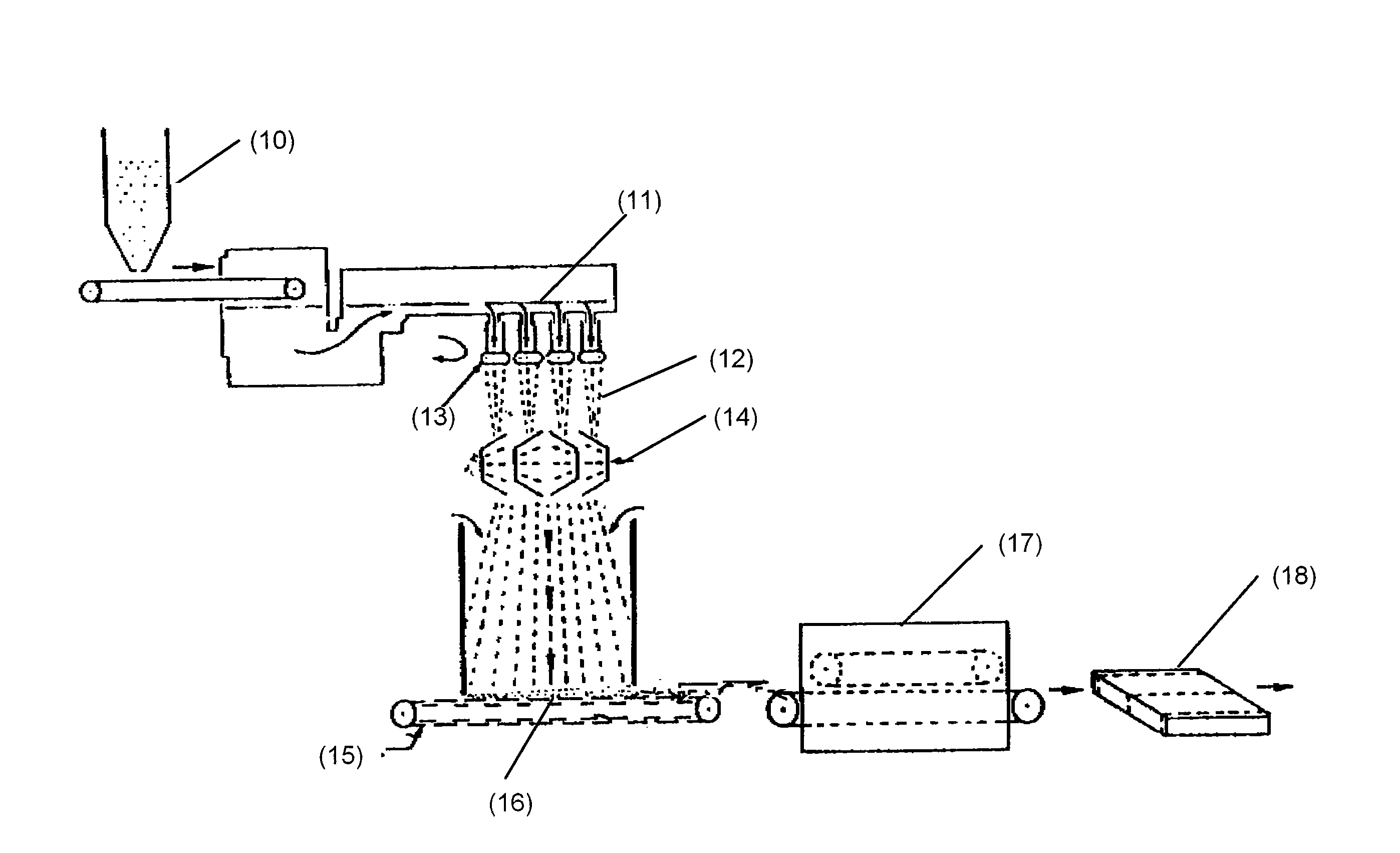

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, an ammine, a primary alkanolamines (preferably monoethanolamine), a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

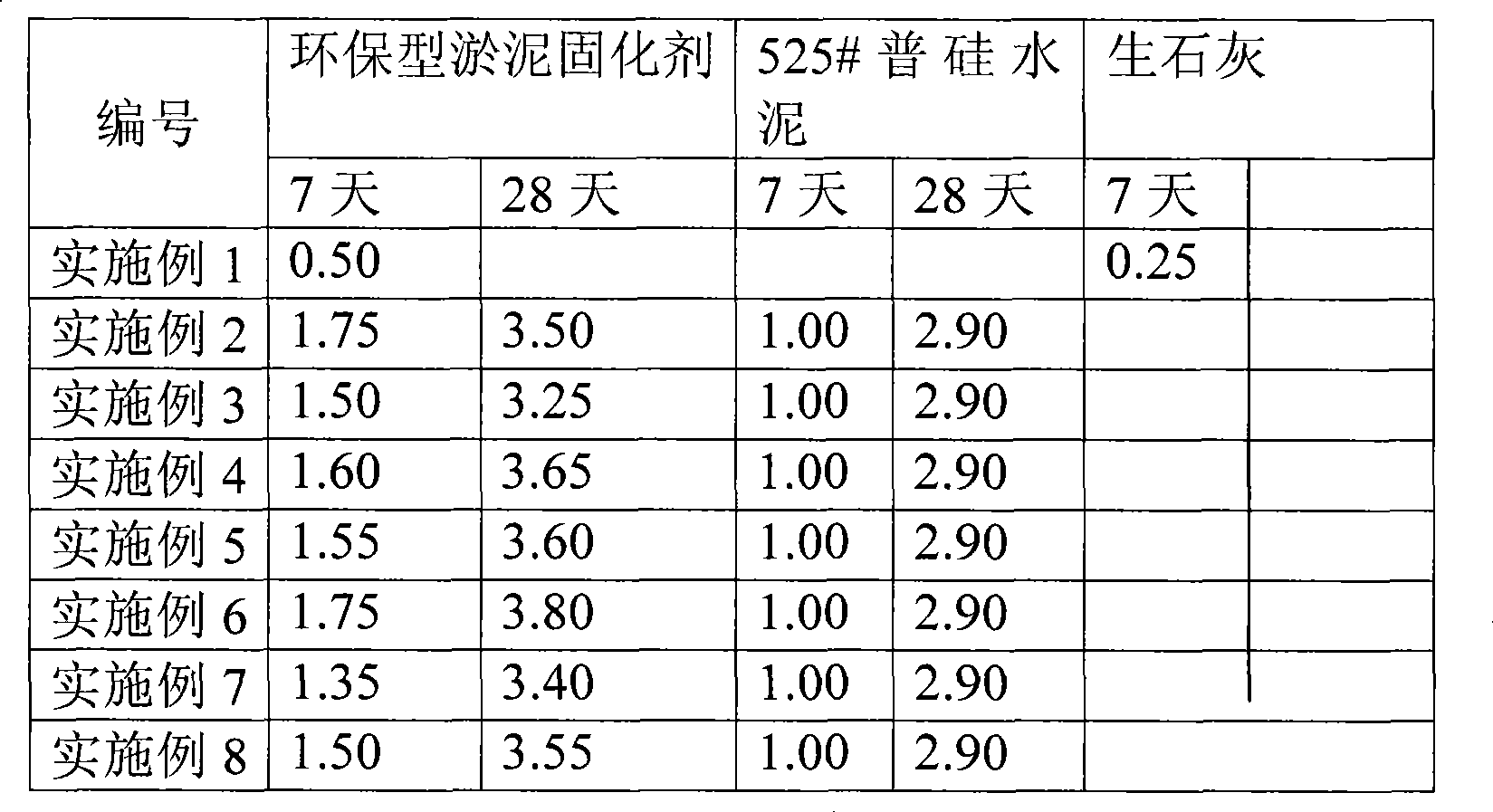

Environment-friendly type sludge firming agent

InactiveCN101381194AImprove curing abilityImprove curing effectSludge treatment by de-watering/drying/thickeningRoad engineeringSlag

The invention provides an environment-friendly silt curing agent, which is manufactured through the following steps: one or two among fly ash, calcium sulfate, sodium sulfate, sodium carbonate and potassium carbonate, one or two among slag, slag combination, potassium hydroxide, calcium oxide, sodium silicate or silicon dioxide, one or two among carbide slag, lime or gypsum, as well as one or two among triethanol amine surfactant, calcium lignosulfonate or sodium lignosulfonate form a plurality of optimal compound formulations according to respective attributes, are optimized, compounded, ground till the Brinell specific surface areas are between 300 and 900 m2 / kg respectively and then mixed, wherein particle sizes are between 0.00040 and 0.5 mm. As a large amount of waste is utilized, the curing agent saves raw materials, solves the problems about waste discharge and environmental pollution, controls waste through waste, and has important significance to environmental protection. The invention aims to provide the environment-friendly silt curing agent which has strong adaptability to a plurality of types of silt and soil, is good in curing effect, good in durability after curing and capable of utilizing industrial waste, and can be widely applied to fill engineering, embanking or embankment reinforcement engineering, road engineering and other fields.

Owner:天津渤海环保工程有限公司 +1

Process for making an ink jet ink

A process for making an ink jet ink comprising: a) providing a dispersion containing a pigment, a hydrocarbon carrier, and a polyamine / fatty acid condensation polymer dispersant; b) mixing the pigment dispersion with rigid milling media less than 100 mu m; c) introducing the mixture of step (b) into a mill; d) milling the mixture from step (c) until the pigment particle size is below about 100 nanometers (nm); e) adding to the mixture during or after step d) or f) (below) a stabilizer selected from the group consisting of a polyether polyol; a modified polyester resin; an acrylic polymer; an alkylol ammonium salt of a block copolymer having acidic groups; ethoxylated triethanolamine; a high molecular weight block copolymer having an amine functionality; sorbitan sesquioleate; polyhydroxy stearic acid; butylated polyvinyl pyrrolidone; poly(vinylpyrrolidone / 1-hexadecene); and poly(p-tert-butylstyrene-co-styrene-co-2-sulfoethyl-lithium methacrylate); f) separating the milling media from the mixture milled in step (d); and g) diluting the mixture to obtain an ink jet ink having a pigment concentration suitable for ink jet printers.

Owner:EASTMAN KODAK CO

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

Self-leveling cementitious composition with controlled rate of strength development and ultra-high compressive strength upon hardening and articles made from same

ActiveUS20090239977A1High strengthImprove the immunitySolid waste managementTriethanolamineFiber reinforcement

A self-leveling cementitious mixture with excellent flow properties and which hardens with a controlled rate of strength development to an ultra-high compressive strength composite composition for use in making articles such as cementitious armor panel with ballistic and blast resistant properties including: a continuous phase resulting from the curing of an aqueous mixture, in the absence of silica flour, of inorganic cement binder, inorganic mineral filler having a particle size of about 150-450 microns, pozzolanic mineral filler, polycarboxylate based self-leveling agent and water. The cementitious mixture may include alkanolamine, such as triethanolamine, and acid or acid salt, such as tartaric acid. The cementitious composition may be reinforced with reinforcing fibers, e.g. glass fibers, in an amount of about 0.5-6.0% by volume of the overall cementitious composition. The fibers are uniformly dispersed in the cementitious composition before it is cured to form a final cementitious armor panel.

Owner:UNITED STATES GYPSUM CO +1

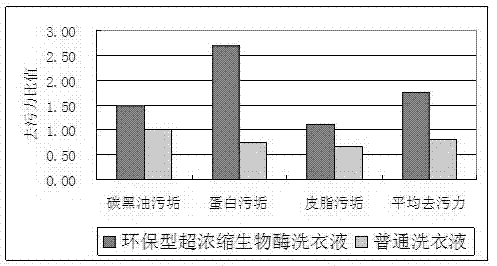

Environment-friendly type hyperconcentration biological enzyme liquid laundry detergent and preparation method thereof

ActiveCN102242022ANo pollution in the processReduce consumptionNon-ionic surface-active compoundsDetergent mixture composition preparationHydrotropePhosphate

The invention relates to a detergent for daily use, and specifically relates to an environment-friendly type hyperconcentration biological enzyme liquid laundry detergent and a preparation method thereof. The prepared product in the invention is mobile liquid with low viscosity, contains no phosphates, fluorescent brightening agents or alkylphenol polyoxyethylene, and has no pollution to environment. The production process for the product is simple; preparation and mass production of the product are easy; the product can be widely used for washing of various fabrics and clothing and is both applicable to hand wash and machine wash. The environment-friendly type hyperconcentration biological enzyme liquid laundry detergent comprises, by weight, 0.5 to 50 parts of fatty alcohol polyoxyethylene ether sodium sulfate-70, 0.5 to 50 parts of fatty alcohol polyoxyethylene ether-9, 0.5 to 30 parts of sodium alkylbenzene sulfonate-60, 0.2 to 15 parts of triethanolamine, 0.1 to 10 parts of sodium citrate, 0 to 5 parts of citric acid, 0 to 5 parts of aliphatic acid, 0.02 to 8 parts of biological enzyme, 0.1 to 20 parts of an enzyme stabilizer, 0.5 to 30 parts of a solvent, 0 to 15 parts of a hydrotropic agent, 0 to 5 parts of a bactericide, 0.001 to 5 parts of an antiseptic, 0 to 3 parts of essence and 1.0 to 40 parts of softened water.

Owner:上海开米科技有限公司

Water-based cleaner

ActiveCN101538512ACause wasteAvoid cleaning costsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSodium metasilicate

A water-based cleaner is prepared by surfactant primary washing part, alkaline auxiliary washing part, solvent part, preservative and water; wherein the surfactant primary washing part is compounded by anion and nonionic surfactant; the alkaline auxiliary agent part selects trolamine, sodium metasilicate pentahydrate which has dispersive action on dirt and EDTA disodium which has chelation on metallic ions, and excludes phosphate accessory aid which pollutes water quality. The solvent part selectes alcohol, glycol ether or natural orange oil extract D-limonene which have good safety performance, strong solvency and little environmental pollution. The preservative selects food grade preservative propylparaben which is safe and nontoxic. The invention adopts concentrate formula, the preparation method is simple, users can dilute the product according to object to be washed and the degree of dirt, and operate with reasonable using concentration, thus avoiding the waste of washing cost due to excessive concentration and the waste of energy. The inventive water-based cleaner reduces package cost and transportation cost, and has no adverse effect on the environment.

Owner:SHANGHAI JIUSHENG IND

High-antiwear cutting fluid

InactiveCN104277900AImprove anti-wear performanceLow costLubricant compositionLanthanum fluoridePolyethylene glycol

The invention discloses a high-antiwear cutting fluid, which comprises the following raw materials in parts by weight: 10-25 parts of soybean oil, 5-15 parts of rapeseed oil, 8-25 parts of 2-ethylhexyl oleate, 15-30 parts of fatty alcohol-polyoxyethylene ether, 3-8 parts of disodium sulphonatoacetate, 1-5 parts of copper / silica composite nano materials, 5-12 parts of citric acid-modified lanthanum fluoride nanoparticles, 20-40 parts of an imidazoline-ammonium salt corrosion inhibitor, 3-15 parts of glycerin, 2-15 parts of triethanolamine, 2-6 parts of borax, 0.5-1.5 parts of benzotriazole, 8-20 parts of polyethylene glycol and 30-50 parts of water. The high-antiwear cutting fluid is excellent in antiwear, cooling, lubrication, cleaning and antirust functions, and is low in cost and strong in stability.

Owner:CHAOHU GUANGFENG METAL PROD

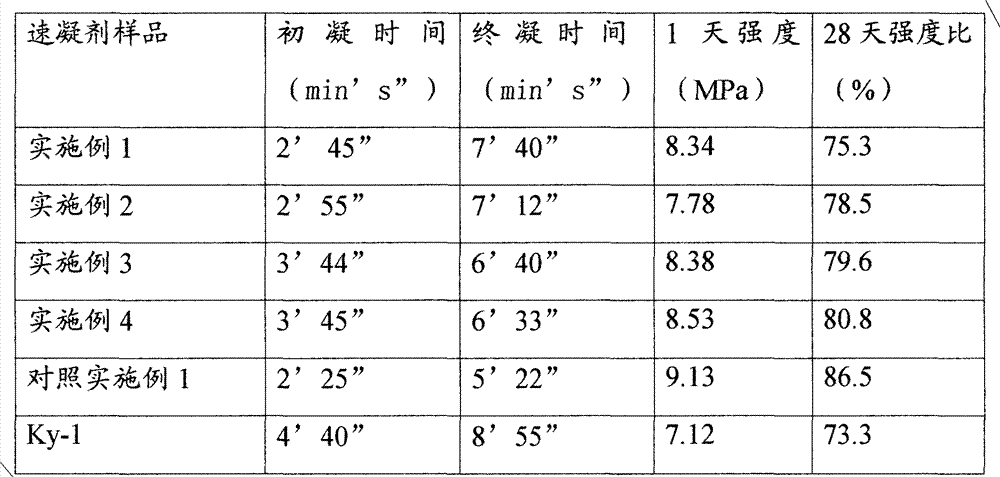

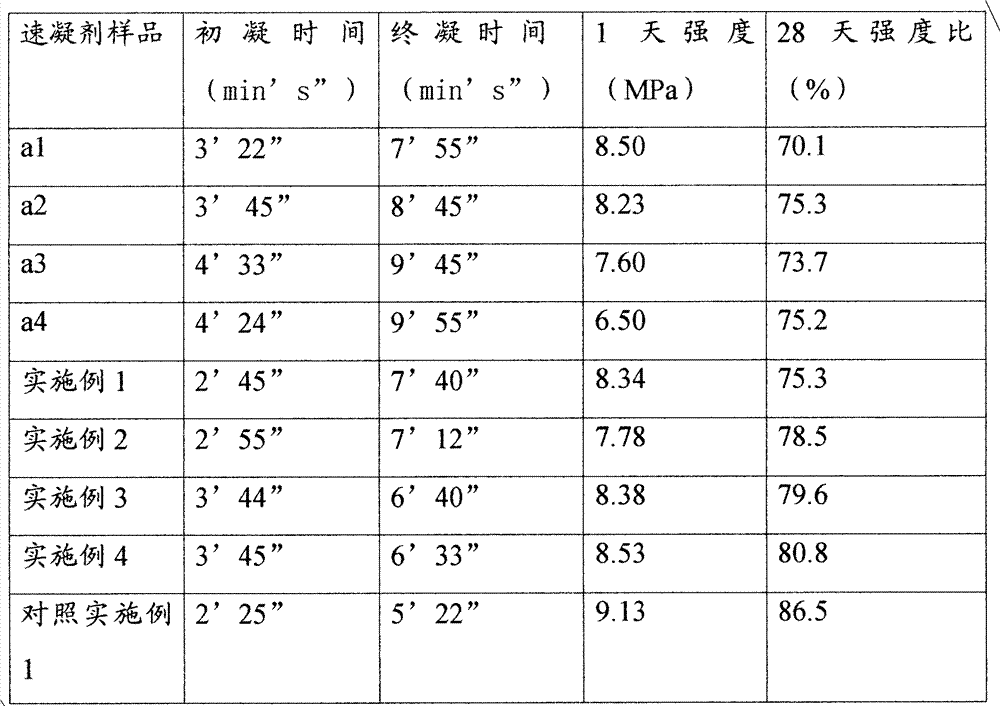

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

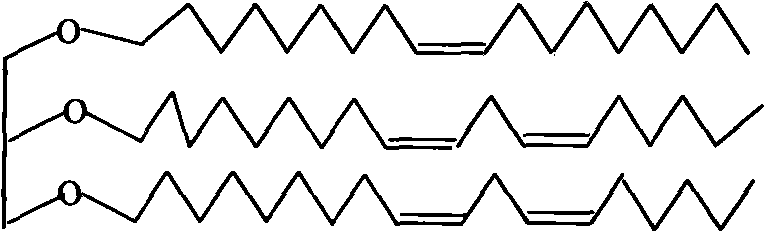

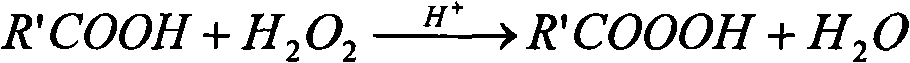

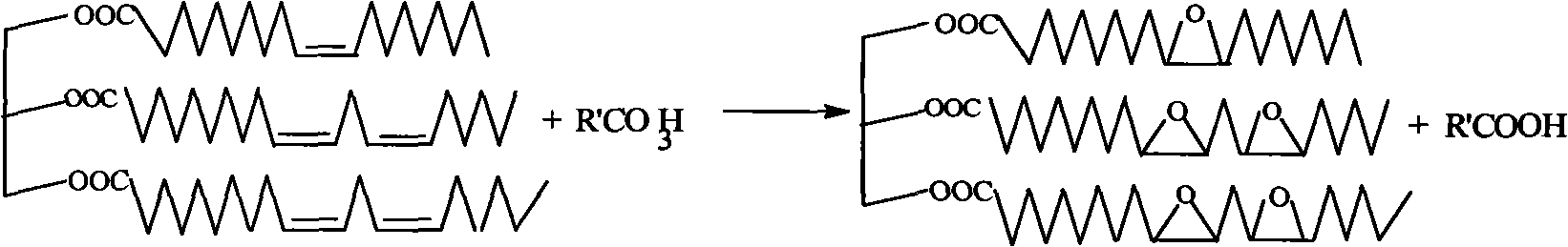

Method for preparing hard polyurethane foam plastics with soybean oil

ActiveCN101314632AImprove water resistanceImprove heat resistancePolyesterFatty acid glycerol esters

The invention provides a method for preparing hard polyurethane foam plastics from soybean oil. The method comprises the steps as follows: (1) carrying out epoxidation including the sub-steps of subjecting soybean oil and epoxidizing agent to reaction to obtain epoxidized soybean oil; (2) carrying out ring-opening reaction including the sub-steps of subjecting epoxidized soybean oil and nucleophilic reagent of reactive hydrogen to the ring-opening reaction of epoxy chemical bond in the presence of a catalyst to obtain mixed hydroxyl fatty acid glyceride; (3) carrying out alcoholysis and esterification including the sub-steps of adding alcohol, heating for alcoholysis to obtain mixed hydroxyl fatty acid monoester, i.e. soybean oil based polyol, and esterifying with organic acid and acid anhydride to generate polyester polyol; and (4) sequentially adding 80-150 weight parts of isocyanate, 0.3-4 weight parts of triethanolamine and 0.5-4 weight parts of foam stabilizer to 100 weight parts of soybean oil based polyol, intensively stirring, adding 0.5-3 weight parts of distilled water, and uniformly foaming while stirring at the high speed.

Owner:NANTONG HAIERMA TECH CO LTD

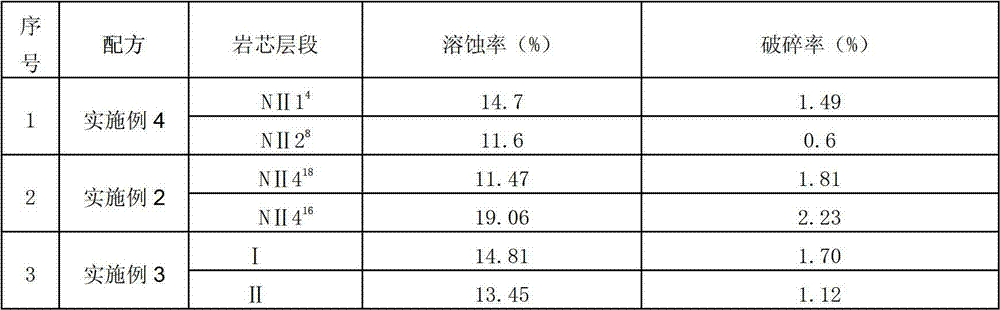

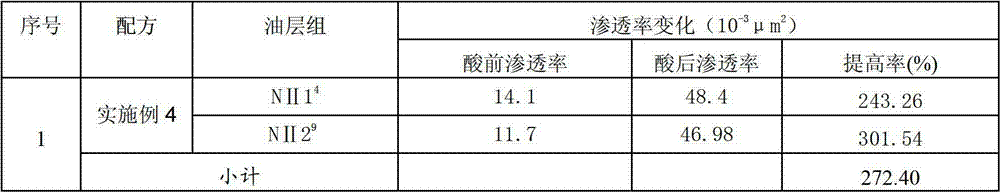

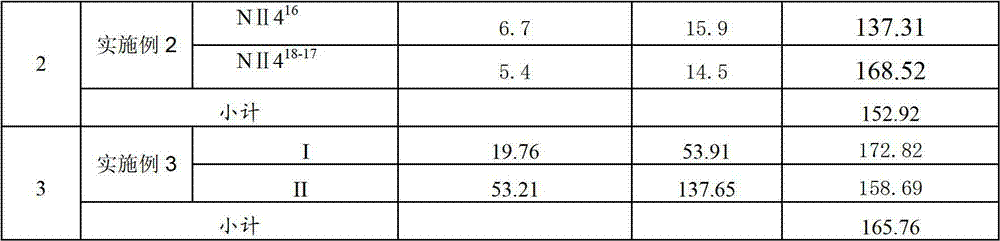

Acidizing block remover suitable for complex lithologic reservoir

ActiveCN102775980ASuppressed ionizationRestore permeabilityDrilling compositionSolventFluoboric acid

The invention relates to an acidizing block remover suitable for a complex lithologic reservoir. The acidizing block remover suitable for the complex lithologic reservoir comprises the following components by weight: 0-12% of hydrochloric acid, 0-3% of ammonium bifluoride, 0-10% of sulfamic acid, 0-5% of fluoboric acid, 0-3% of boric acid, 0-4% of alcohol, 0-2% of triethanolamine, 3% of glacial acetic acid, 4.0-6.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 0.5-1.0% of penetrating agent, 2.0% of clay stabilizer and 45-88.5% of water. The problems that the lithologic and physical property differences of oil fields are large, the oil fields are in staggered distribution, and the acidizing debugging construction effect of a common water injection well is not ideal are mainly solved. The acidizing block remover suitable for the complex lithologic reservoir can effectively corrode the strata minerals and obstruent, does not destroy a rock skeleton, can prevent secondary precipitation caused by sensitive mineral, improves the water absorbing capacity of the reservoir, and increases the daily increasing water injection rate of an average single-well measure.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Wet urea additive process for simultanously desulfurizing and denitrification

InactiveCN1377722AReduce volumeGuarantee sustainableDispersed particle separationAir quality improvementEthylenediaminePhosphate

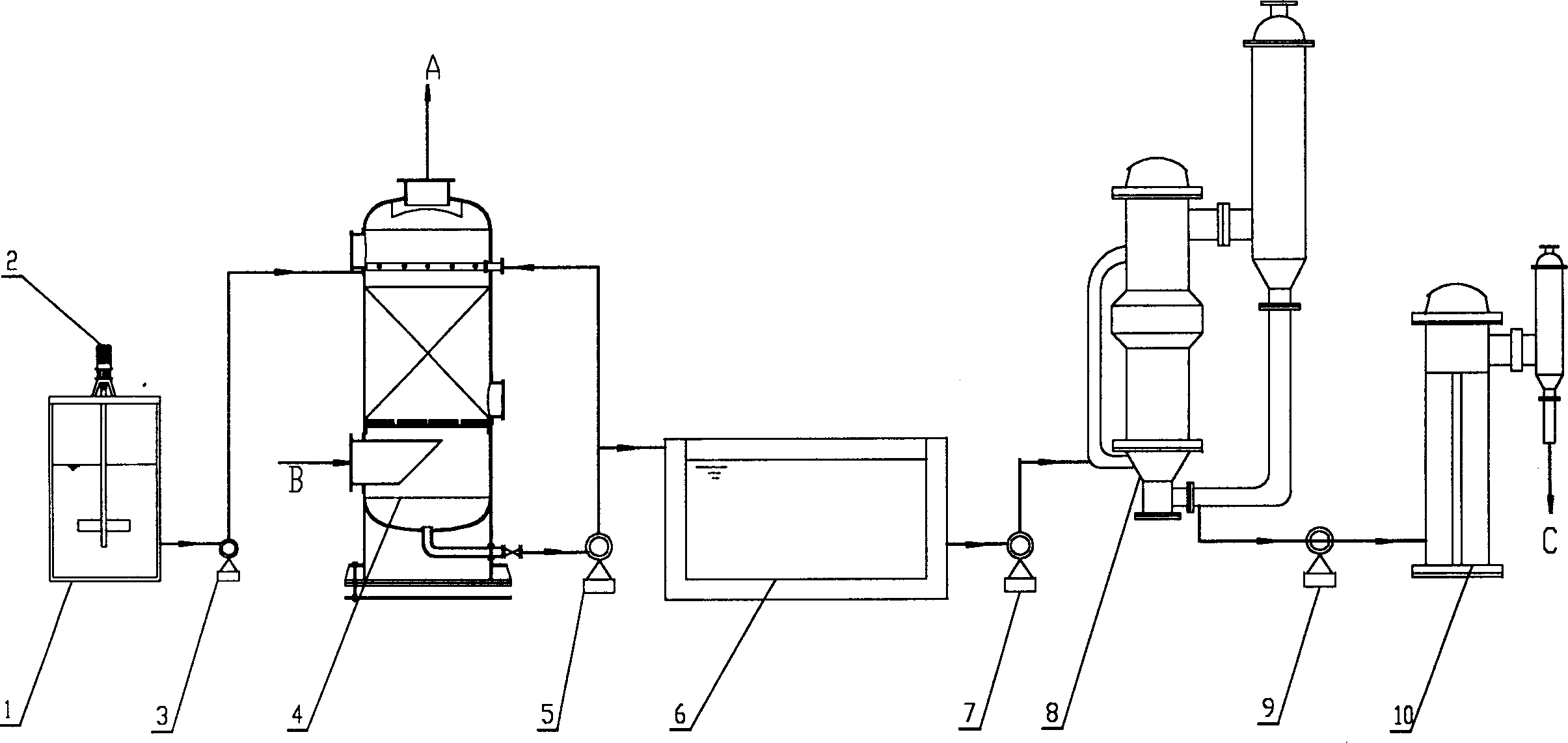

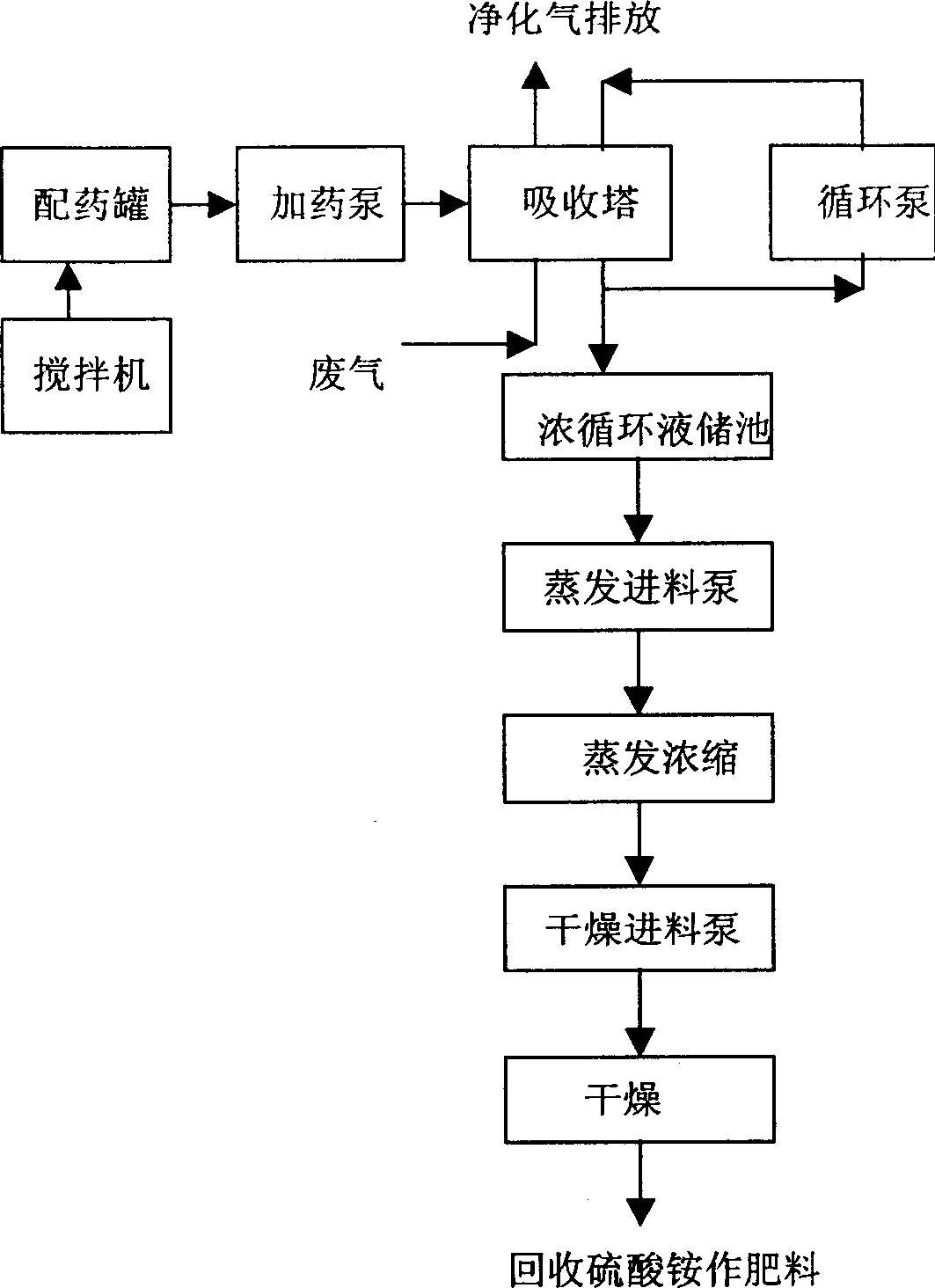

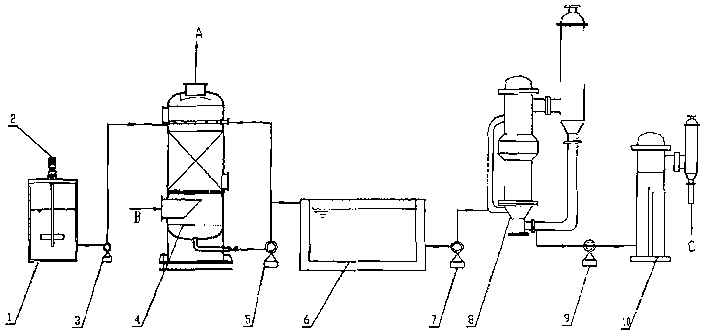

The present invention relates to flue gas purifying treatment technology. The equipment consists of chemical compounding tank with stirrer, chemical adding pump, adsorber tower, circulating pump, storing pond for concentrated absorbent liquid, evaporating inlet pump, evaporator, drying inlet pump and drying machine connected via pipeline. It desulfurizes and denitrificates simultaneously through the mixed reaction of flue gas and absorbent liquid in the absorber tower with urea as absorbent and organic amine or phosphate as additive. It has an SO2 eliminating rate up to 95% and NOx eliminating rate up to 80%, with the recovered ammonium sulfate being used as fertilizer.

Owner:国家环境保护总局华南环境科学研究所

Self-leveling cementitious composition with controlled rate of strength development and ultra-high compressive strength upon hardening and articles made from same

ActiveUS8030377B2Reduce the amount requiredModifies its propertySolid waste managementGlass fiberPolymer science

A self-leveling cementitious mixture with excellent flow properties and which hardens with a controlled rate of strength development to an ultra-high compressive strength composite composition for use in making articles such as cementitious armor panel with ballistic and blast resistant properties including: a continuous phase resulting from the curing of an aqueous mixture, in the absence of silica flour, of inorganic cement binder, inorganic mineral filler having a particle size of about 150-450 microns, pozzolanic mineral filler, polycarboxylate based self-leveling agent and water. The cementitious mixture may include alkanolamine, such as triethanolamine, and acid or acid salt, such as tartaric acid. The cementitious composition may be reinforced with reinforcing fibers, e.g. glass fibers, in an amount of about 0.5-6.0% by volume of the overall cementitious composition. The fibers are uniformly dispersed in the cementitious composition before it is cured to form a final cementitious armor panel.

Owner:UNITED STATES GYPSUM CO +1

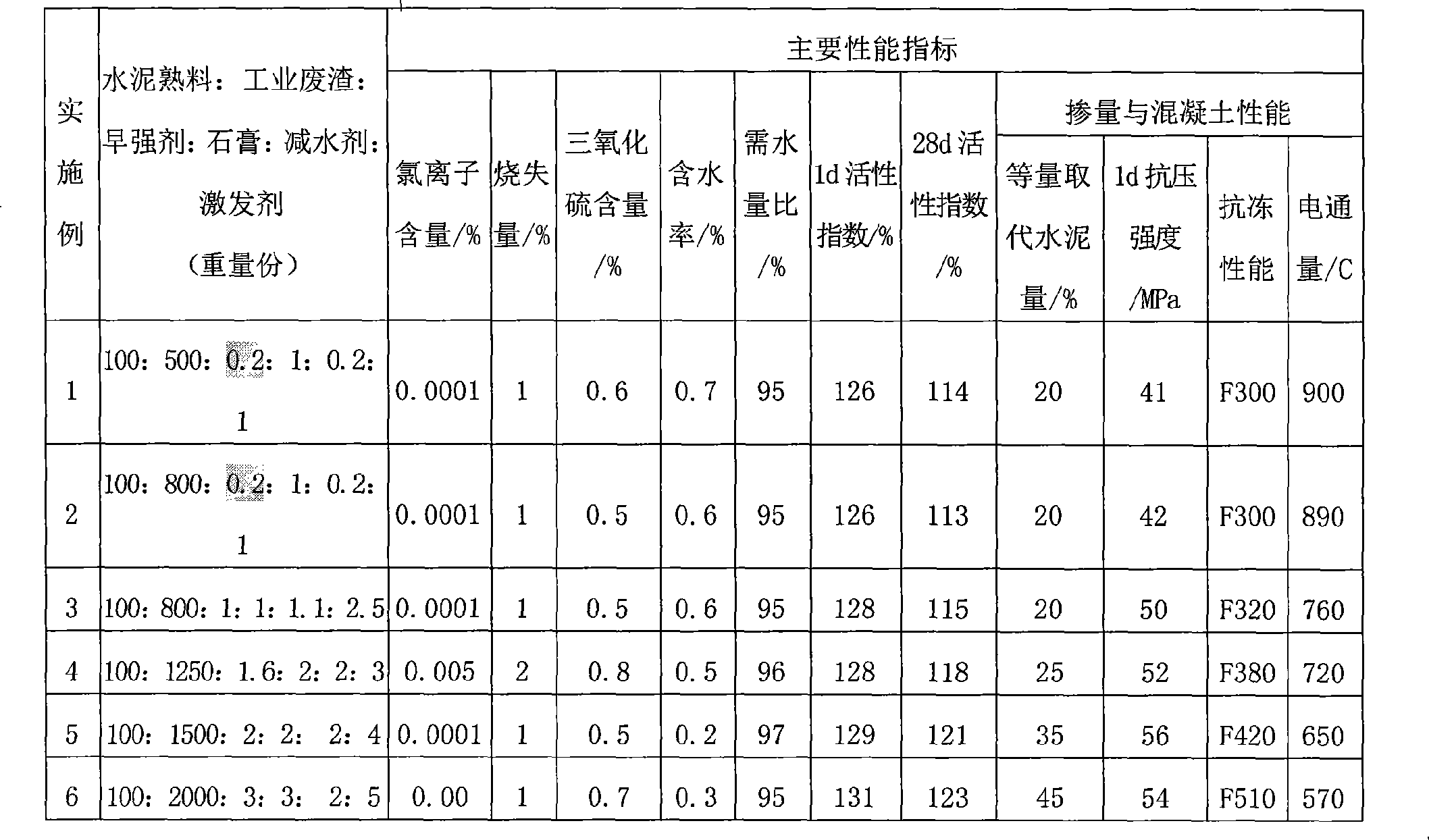

Blending material for high-early-strength concrete

InactiveCN101508557AImprovement of early strength and high strengthReduce dosageSolid waste managementHigh strength concreteCalcium formate

The invention relates to an admixture for high early strength of concrete, characterized in that the admixture is formed by mixing and stirring cement clinkers, industrial residues, early strength agents, plaster, water reducing agents and excitants. The parts by weight of the components are as follows: 100 parts of cement clinkers, 500-2000 parts of industrial residues, 0.2-3 parts of early strength agents, 1-3 parts of plaster, 0.2-2 parts of water reducing agents and 1-5 parts of excitants. The excitant is the mixture of aluminum hydroxide, calcium nitrite and calcium nitrate; wherein, the aluminum hydroxide accounts for 50% of the mixture while the calcium nitrite and the calcium nitrate are in any proportion; the early strength agent is the mixture of trolamine, lithium carbonate and calcium formate, wherein, the trolamine accounts for 50% of the mixture while the lithium carbonate and the calcium formate are in any proportion. The admixture for concrete provided by the invention has high activity index and low content of harmful ions. Adding the admixture can obviously improve the demoulding strength, long-term mechanical property and durability of the concrete.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

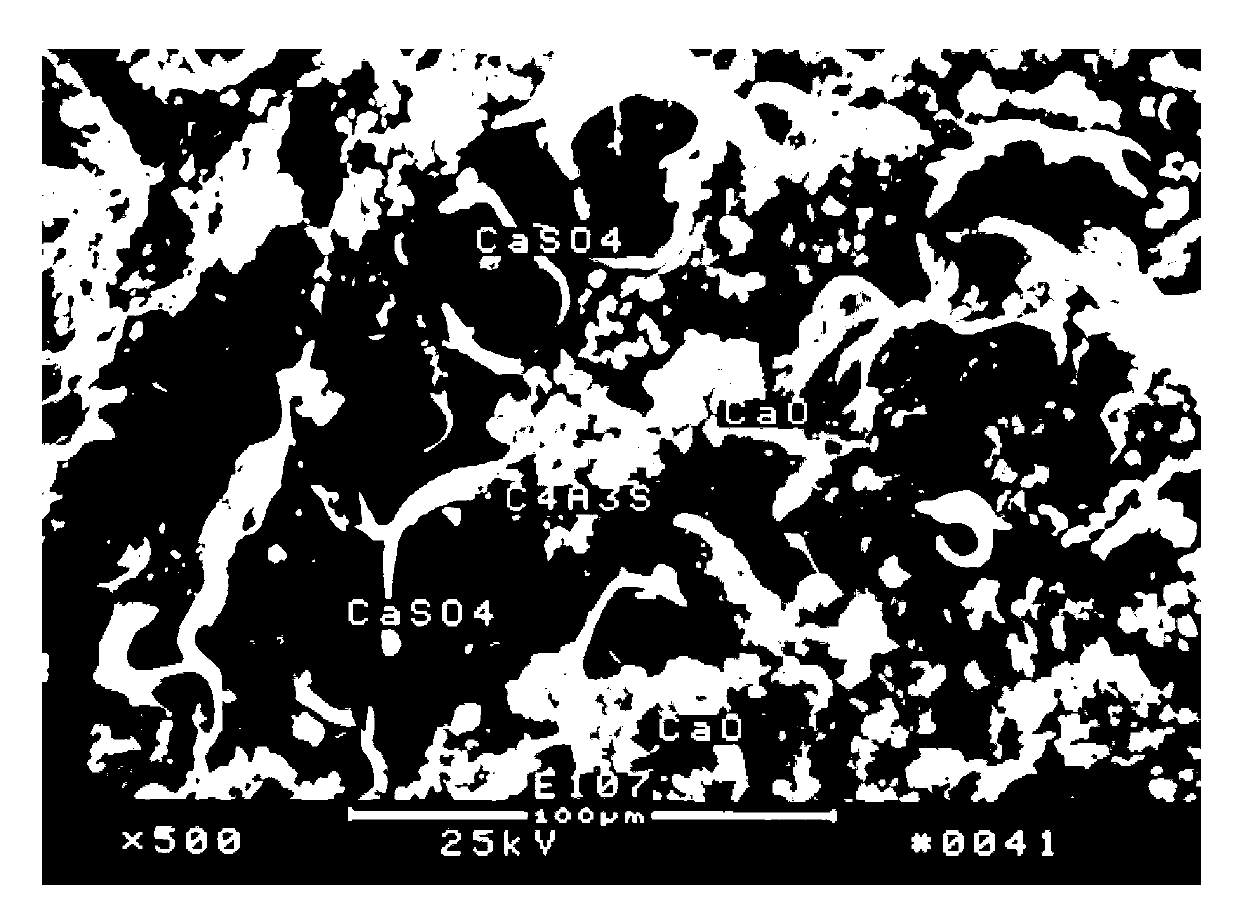

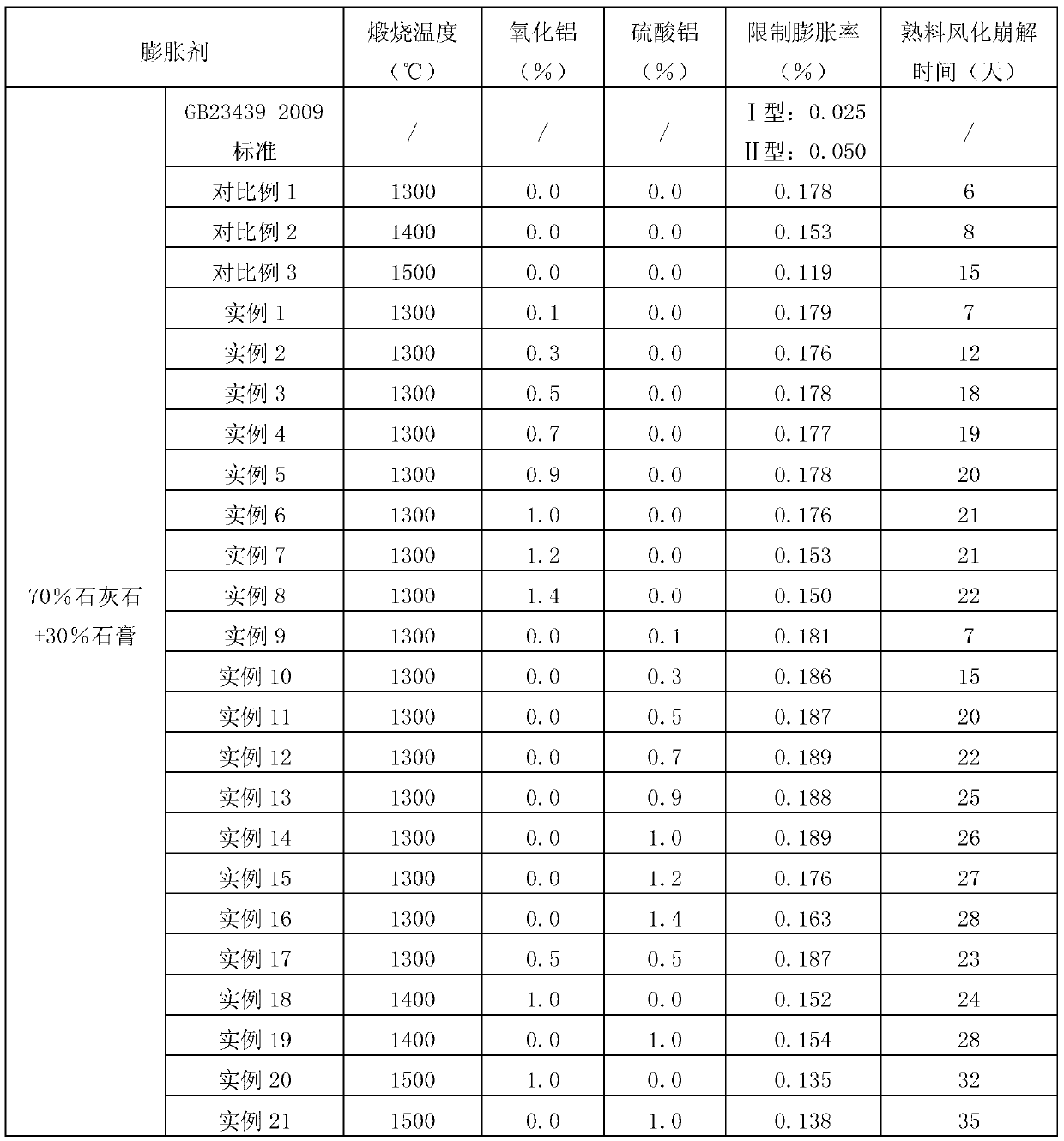

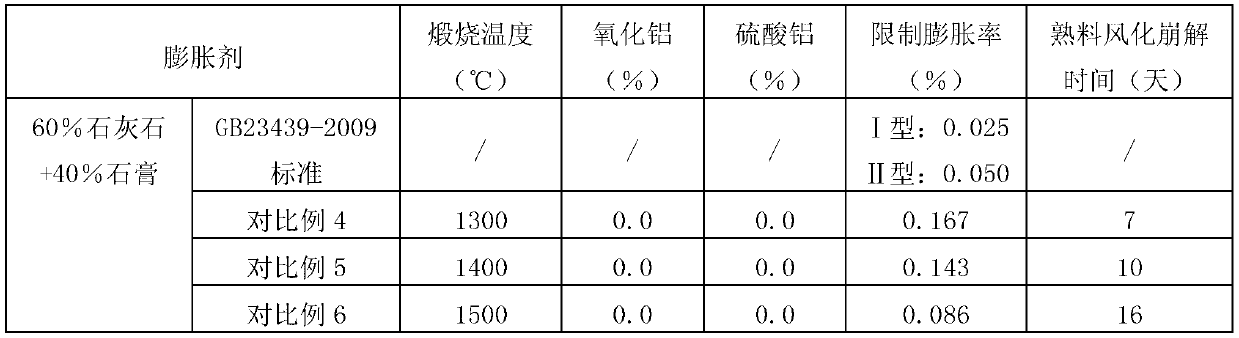

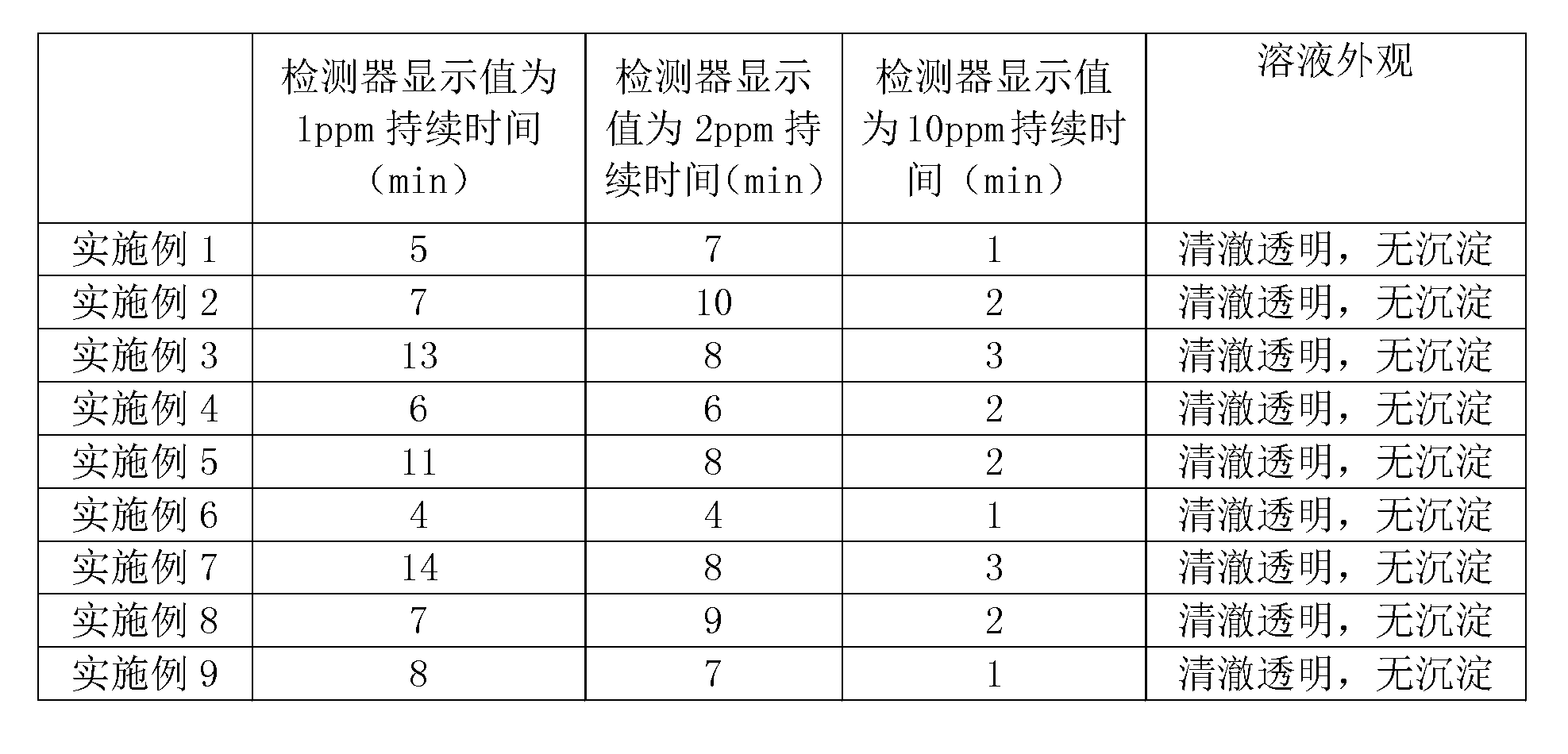

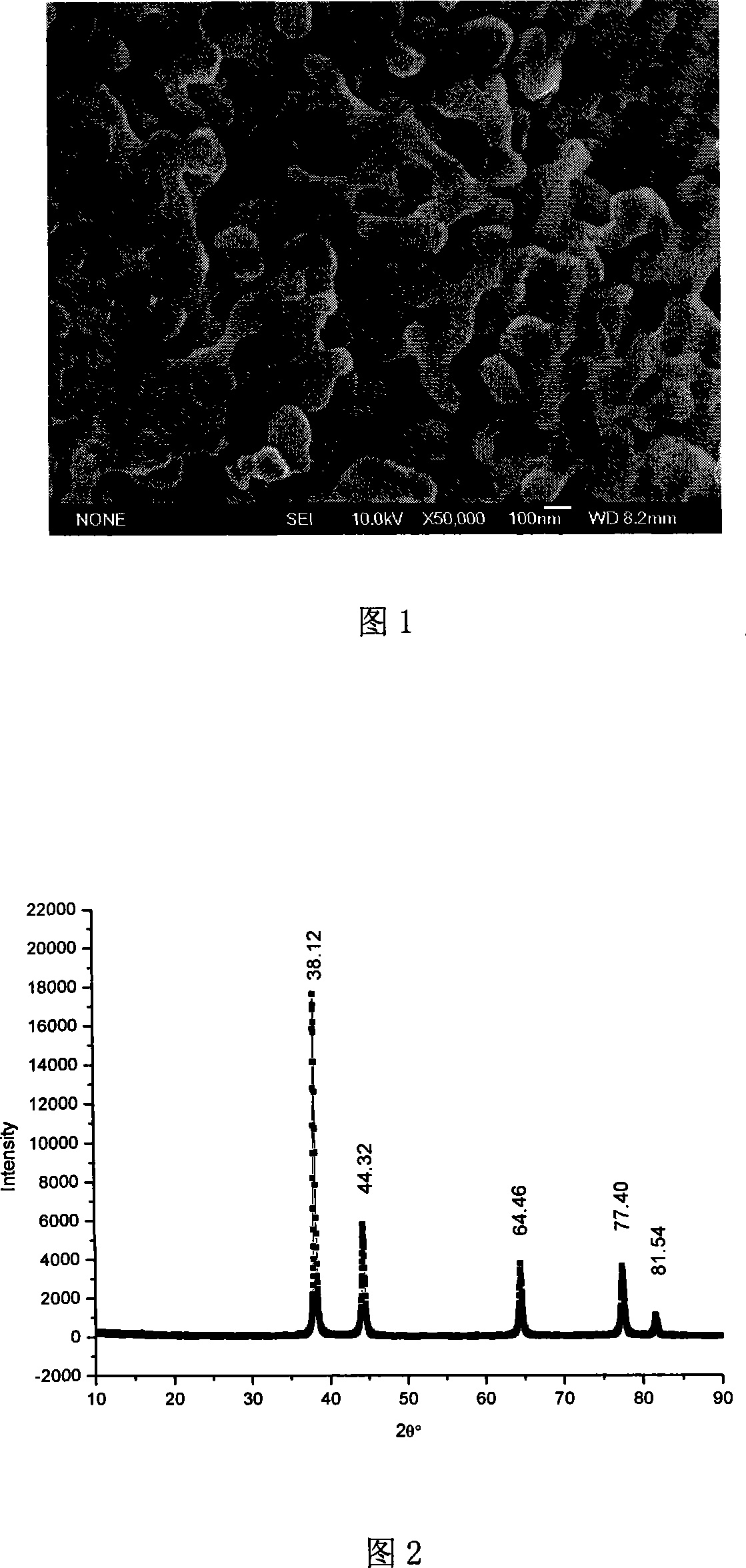

Gypsum and calcium oxide melt inclusion expansion clinker, concrete expansion agent, and preparation method and application thereof

The invention relates to a gypsum and calcium oxide melt inclusion expansion clinker, a concrete expansion agent, and a preparation method and application thereof, belonging to the field of construction materials. The expansion clinker provided by the invention is prepared by mixed grinding and high-temperature burning of limestone, gypsum and aluminum oxide and / or aluminum sulfate. The concrete expansion agent is prepared by grinding the expansion clinker together with a calcium sulphoaluminate cement clinker, calcium stearate or / and triethanolamine until the specific surface area is 140-400 m<2> / kg. According to the invention, the expansion clinker has high restrained expansion rate and high clinker weathering resistance; the concrete expansion agent has the functions of cracking resistance, seepage resistance, shrinkage compensation and the like, and has the advantage of long product shelf life (up to 6 months). The concrete expansion agent can be used for cracking resistance and seepage resistance of a common concrete structure, and can greatly enhance the durability of the concrete.

Owner:CHINA BUILDING MATERIALS ACAD

Sulfur removal agent suitable for production of oil-gas well

InactiveCN102698576ASimple recipeAffect normal productionDispersed particle separationPropanolAlcohol

The invention relates to a sulfur removal agent suitable for the production of an oil-gas well. The sulfur removal agent comprises the following components in percentage by mass: 10 to 25 percent of hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, 5 to 20 percent of alcohol amine, 5 to 20 percent of small molecular alcohol and the balance of water. The alcohol amine is one or a mixture of more thantwo of monoethanolamine, ethyleneglycol amine, diisopropanolamine, methyldiethanolamine and triethanolamine; and the small molecular alcohol is one or a mixture of more than two of methanol, ethanol and propanol. The sulfur removal agent has a simple formula, can be soluble with water, and can effectively reduce the content of hydrogen sulfide in crude oil or natural gas; simultaneously, productsgenerated by the sulfur removal agent and the hydrogen sulfide are water-soluble, and cannot block a mineshaft and influence the normal production of the oil-gas well; and the sulfur removal agent can achieve effects at the temperature of 30 to 120 DEG C and can be quickly reacted with the hydrogen sulfide.

Owner:SOUTHWEST PETROLEUM UNIV

Renewable engine fuel

InactiveUS20080168706A1Efficient propulsion technologiesLiquid carbonaceous fuelsCarbon numberAlkane

The present invention provides fully renewable engine fuels derived completely from biomass sources. The fully renewable engine fuel is comprised of one or more low carbon number esters, one or more pentosan-derivable furans, one or more aromatic hydrocarbon, one or more C4-C10 straight chain alkanes derivable from polysaccharides, and one or more bio-oils. In addition, the fuel may contain triethanolamine. Such a lower octane renewable fuel may be utilized, for example, in automobile fuel, 100 LL aviation fuel applications, and turbine engine applications. These ethanol-based, fully renewable fuels may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100LL aviation fuel (known as AvGas), as well as high octane, rocket, diesel, and turbine engine fuels.

Owner:SWIFT ENTERPRISES

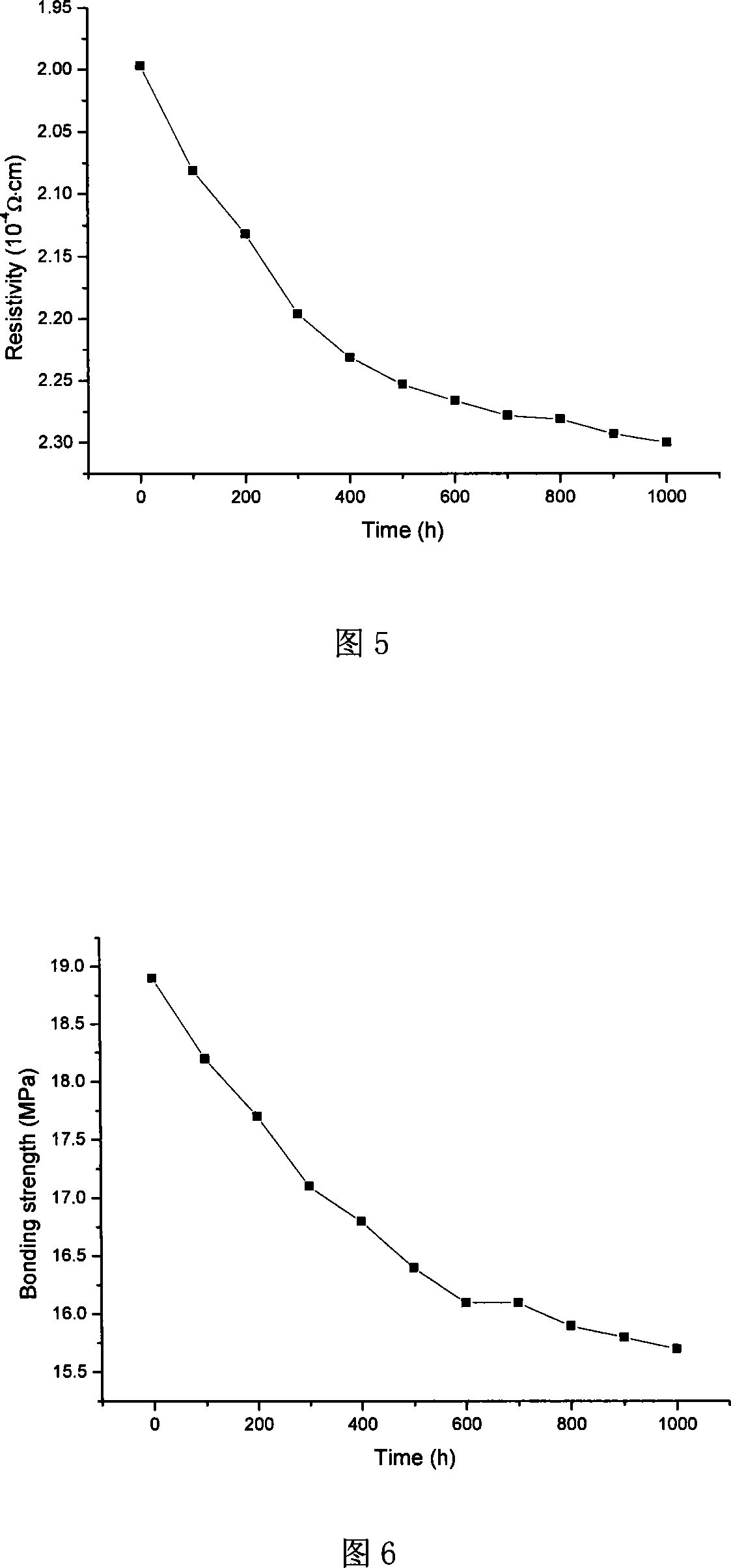

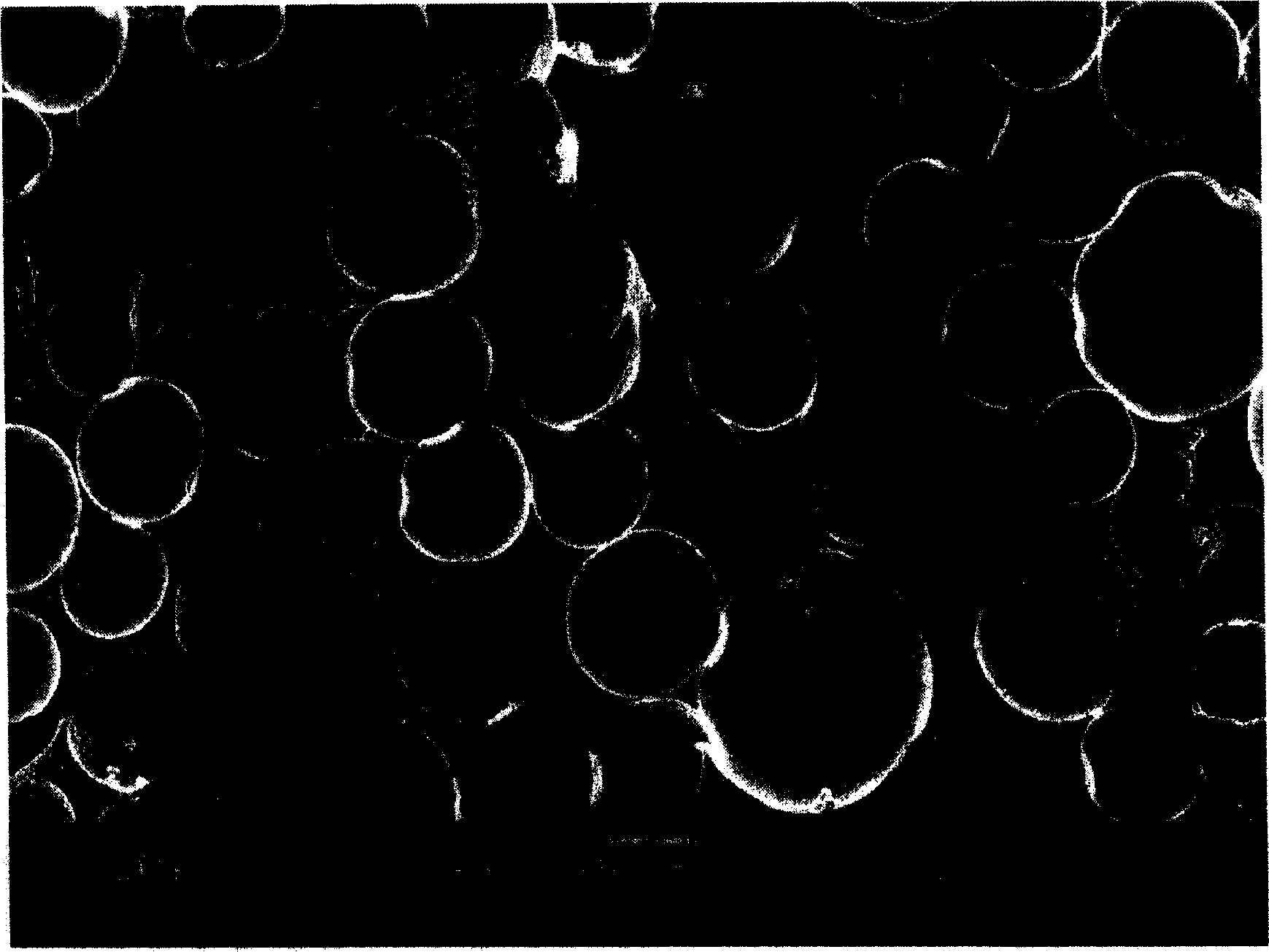

Conductive adhesive added with short rod type nano silver powder and preparation method thereof

ActiveCN101215450AImprove conductivityImprove mechanical propertiesNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPlastic materials

The invention relates to conductive adhesive which is added with short rod shaped silver powder and a process for preparation, which belong to the technical field of preparing technology for plastic material which is used to pack micro-electronics. The invention is characterized in that mixing silver powder of the short rod shaped silver powder and micrometer silver powder are taken as conductive filler and added into epoxide resin basal bodies to prepare utility conductive adhesive with high performance. The components and the percentage composition of the conductive adhesive are that polymeric matrix epoxide resin E-51 is 24-40%, conductive silver powder particles are 50-70%, wherein the short rod shaped silver powder is 10% and the micrometer silver powder is 40-60%, toughening agent dibutylphthalate is 2.4-4.0%, and curing agent triethanolamine is 3.6-6.0%. The preparation of the micrometer silver powder adopts silver nitrate, polyvinylpyrrolidone surface active agent and hydrazine hydrate reducing agent 5% as raw materials and prepared through liquid phase reducing reaction. The usage mass ratio of the silver nitrate and the polyvinylpyrrolidone is 1:1. Since the conductive adhesive which is prepared by the invention is added with the micrometer silver powder, thereby the electrical conductivity and the mechanical properties are increased, and the invention has better antiaging performance.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com