Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36715 results about "Polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most common plastic. As of 2017, over 100 million tonnes of polyethylene resins are produced annually, accounting for 34% of the total plastics market. Its primary use is in packaging (plastic bags, plastic films, geomembranes, containers including bottles, etc.). Many kinds of polyethylene are known, with most having the chemical formula (C₂H₄)ₙ. PE is usually a mixture of similar polymers of ethylene with various values of n. Polyethylene is a thermoplastic; however, it can become a thermoset plastic when modified (such as cross-linked polyethylene).

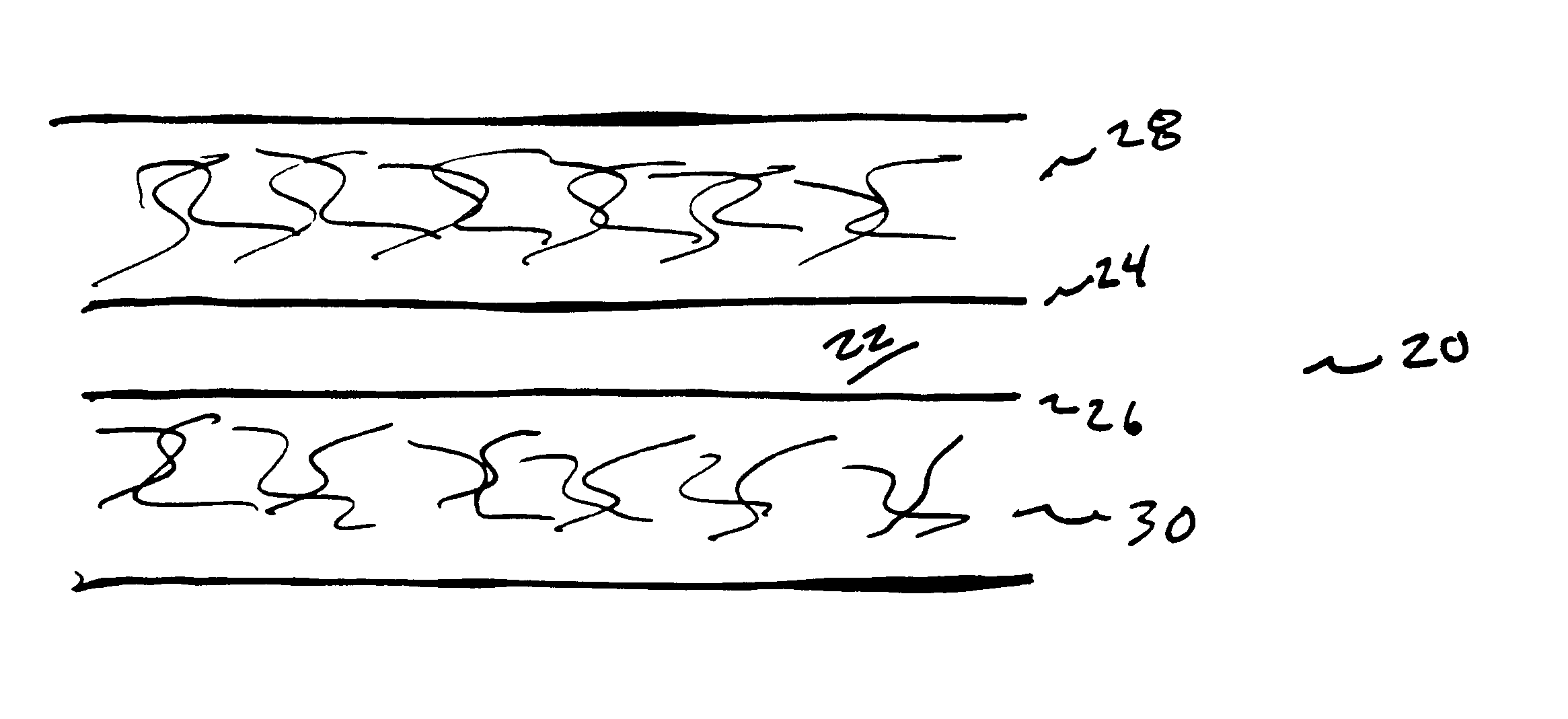

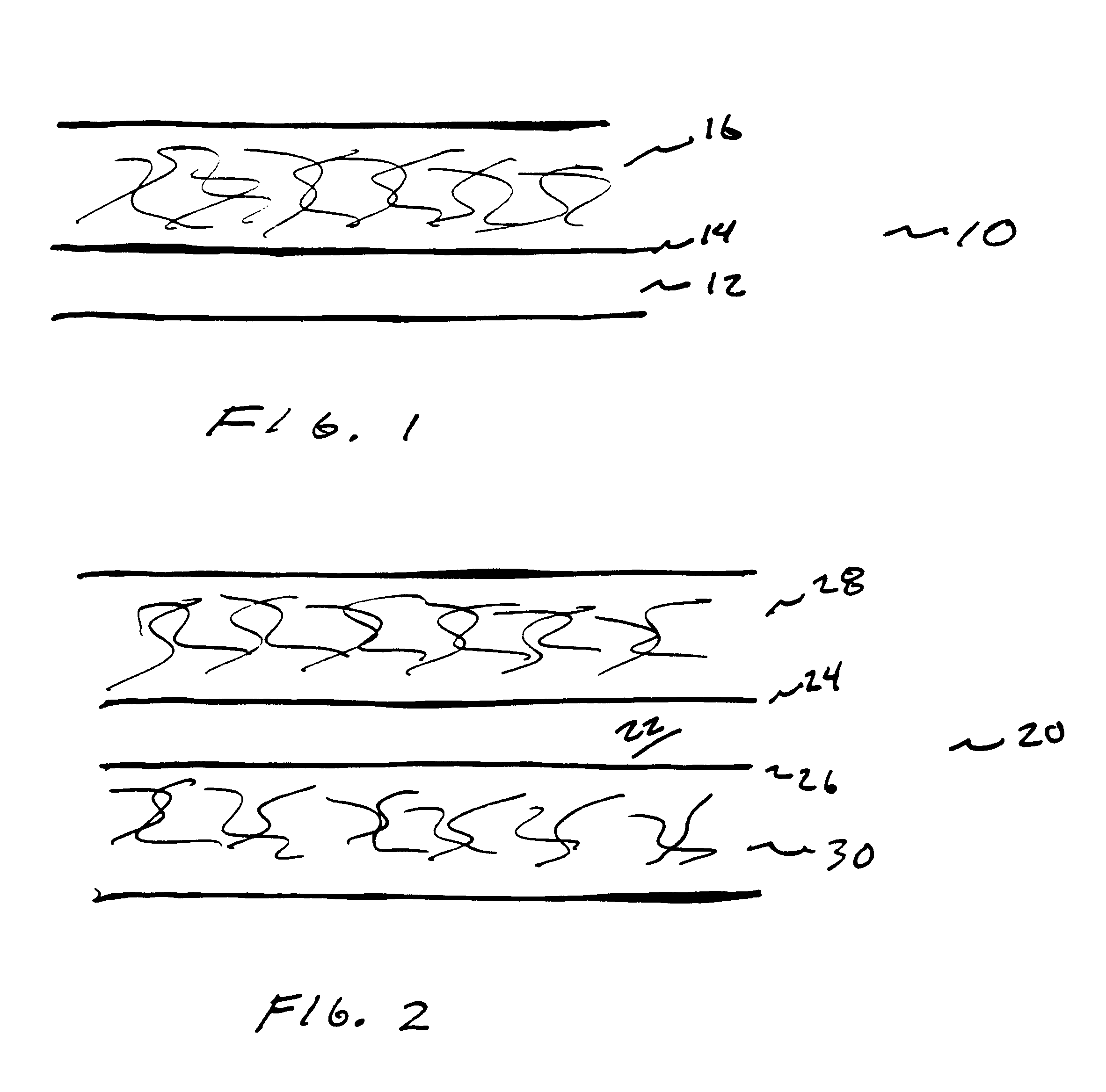

Fluid acquisition layer

A liquid acquisition material for use in an absorbent article. The liquid acquisition material having first fibers and second fibers. The first fibers are chemically cross-linked cellulose fibers and the second fibers are selected from the group consisting of: polyethylene, polypropylene, polyester, rayon, lyocell, and mixtures thereof. The liquid acquisition material has a total dry weight, the first fibers have a first dry weight, and the second fibers have a second dry weight. The first dry weight is from 30 to 95 percent of the total dry weight and the second dry weight is from 5 to 70 percent of the total dry weight.

Owner:THE PROCTER & GAMBLE COMPANY

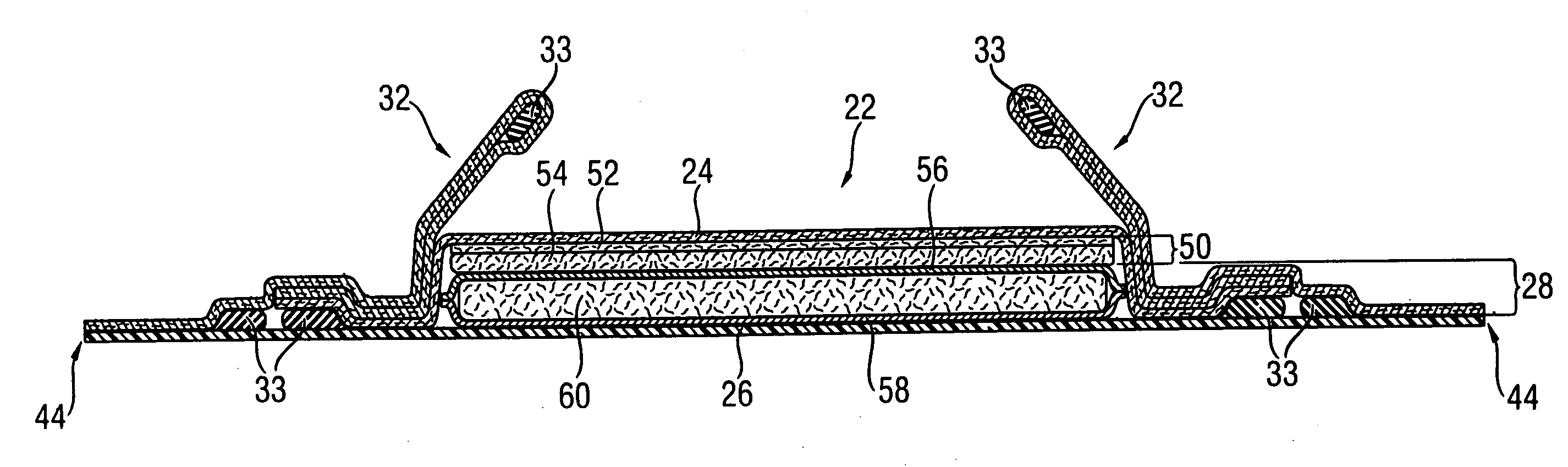

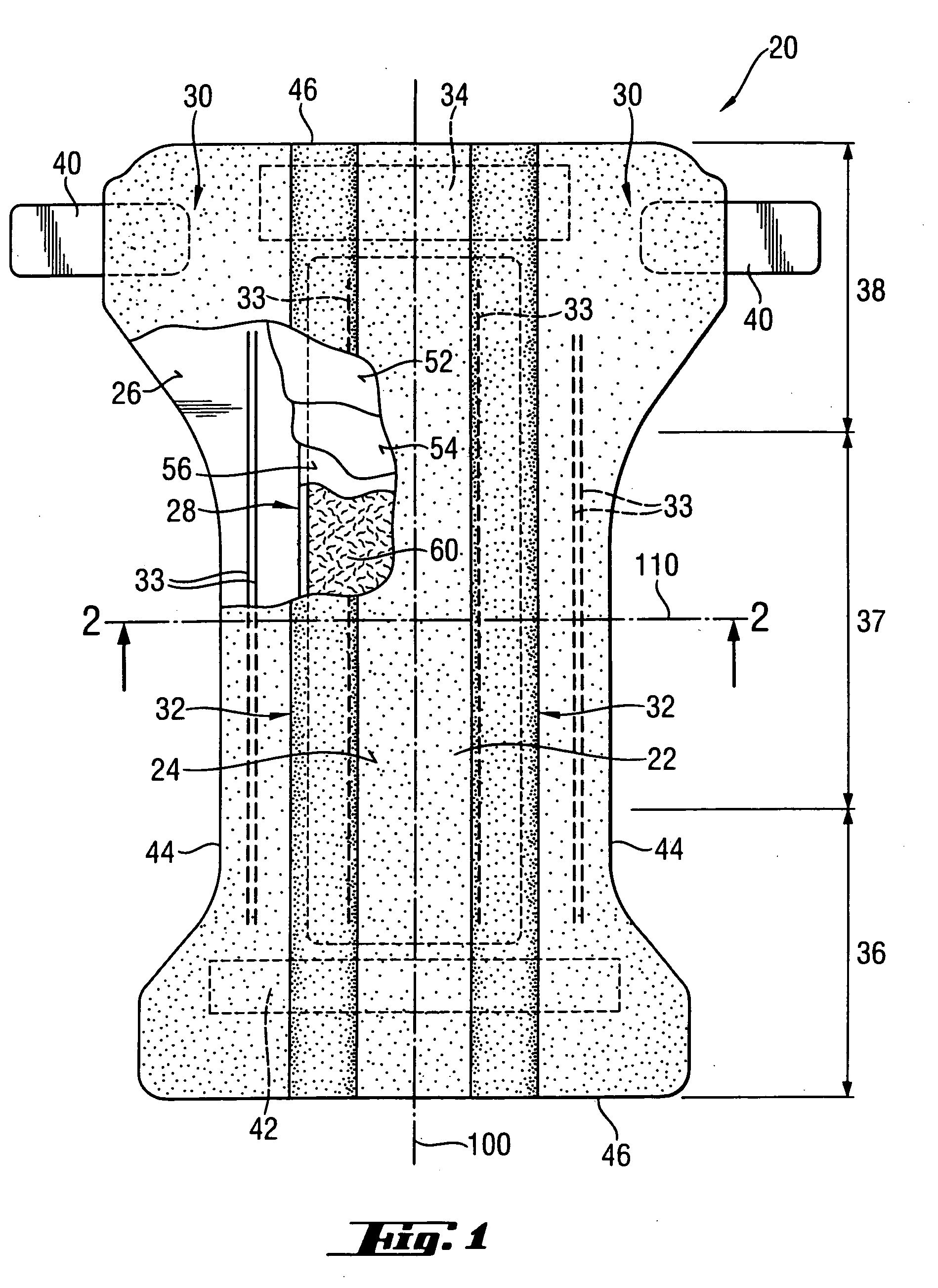

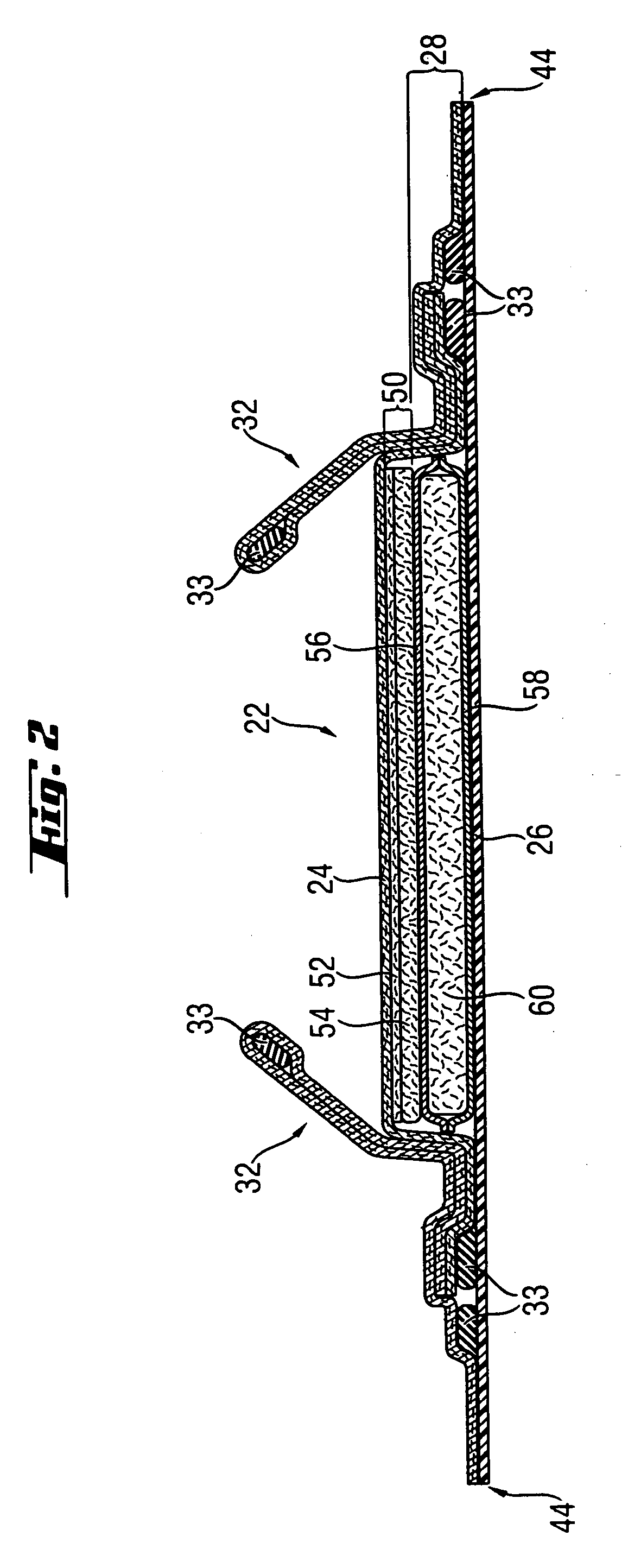

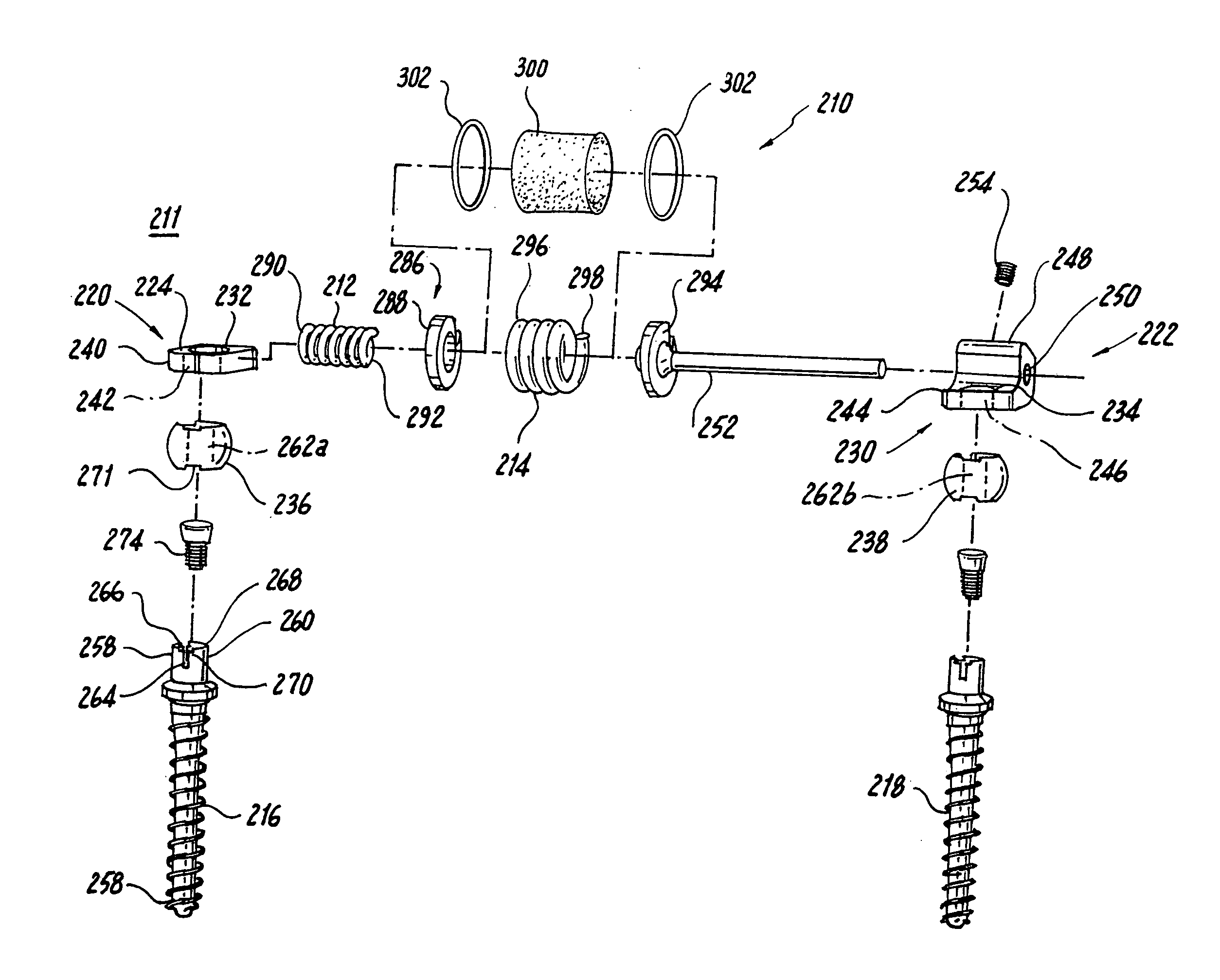

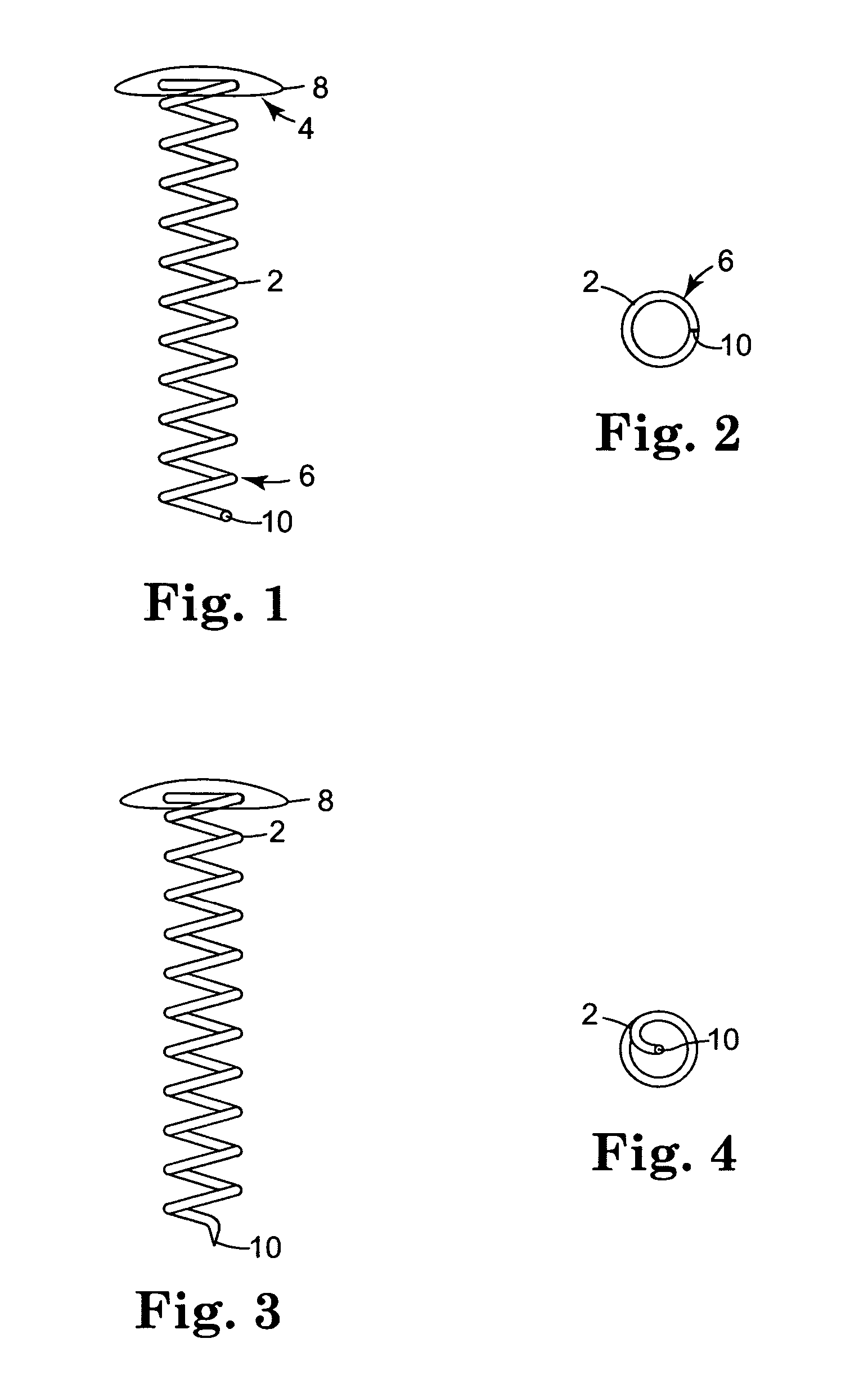

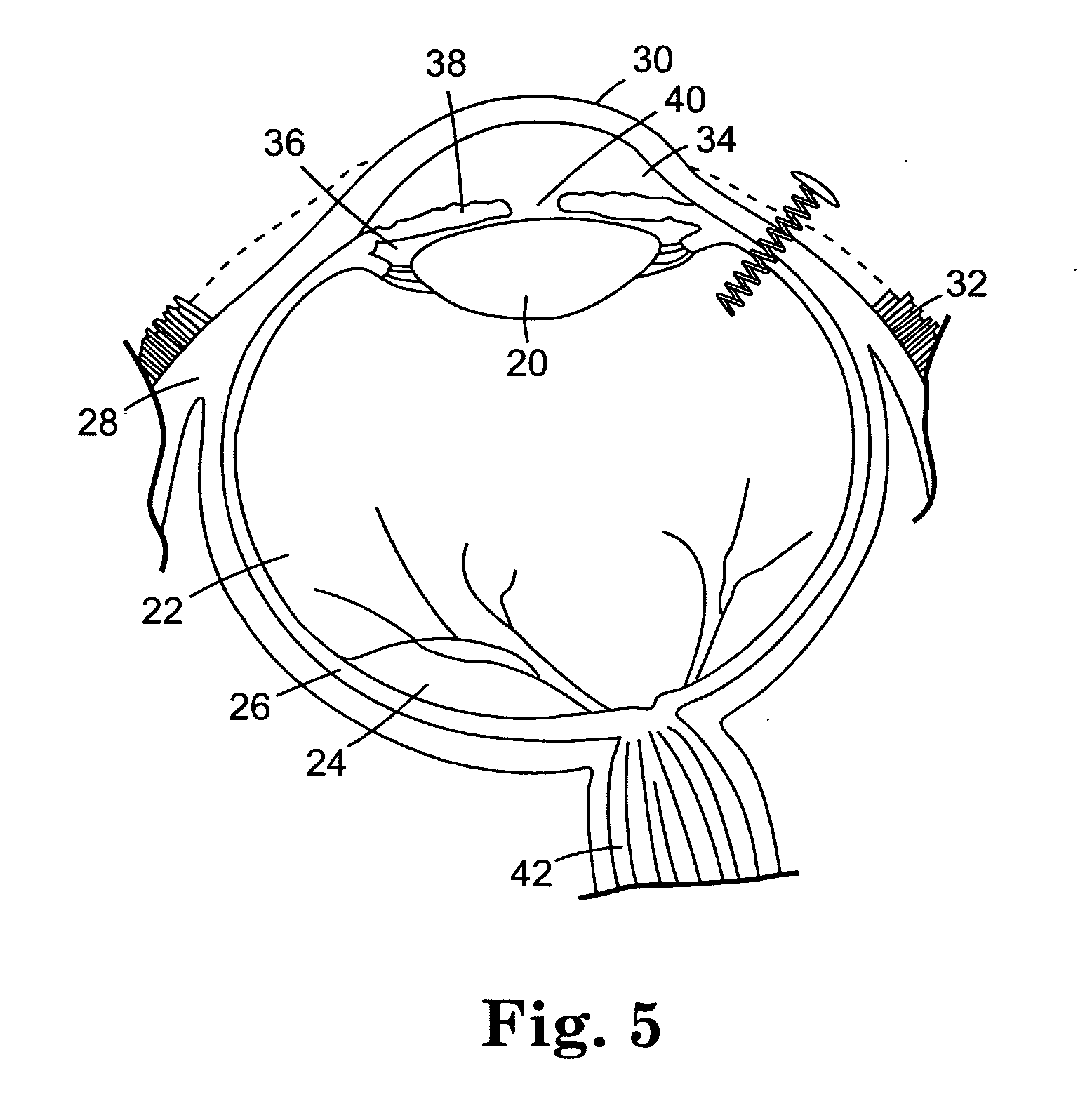

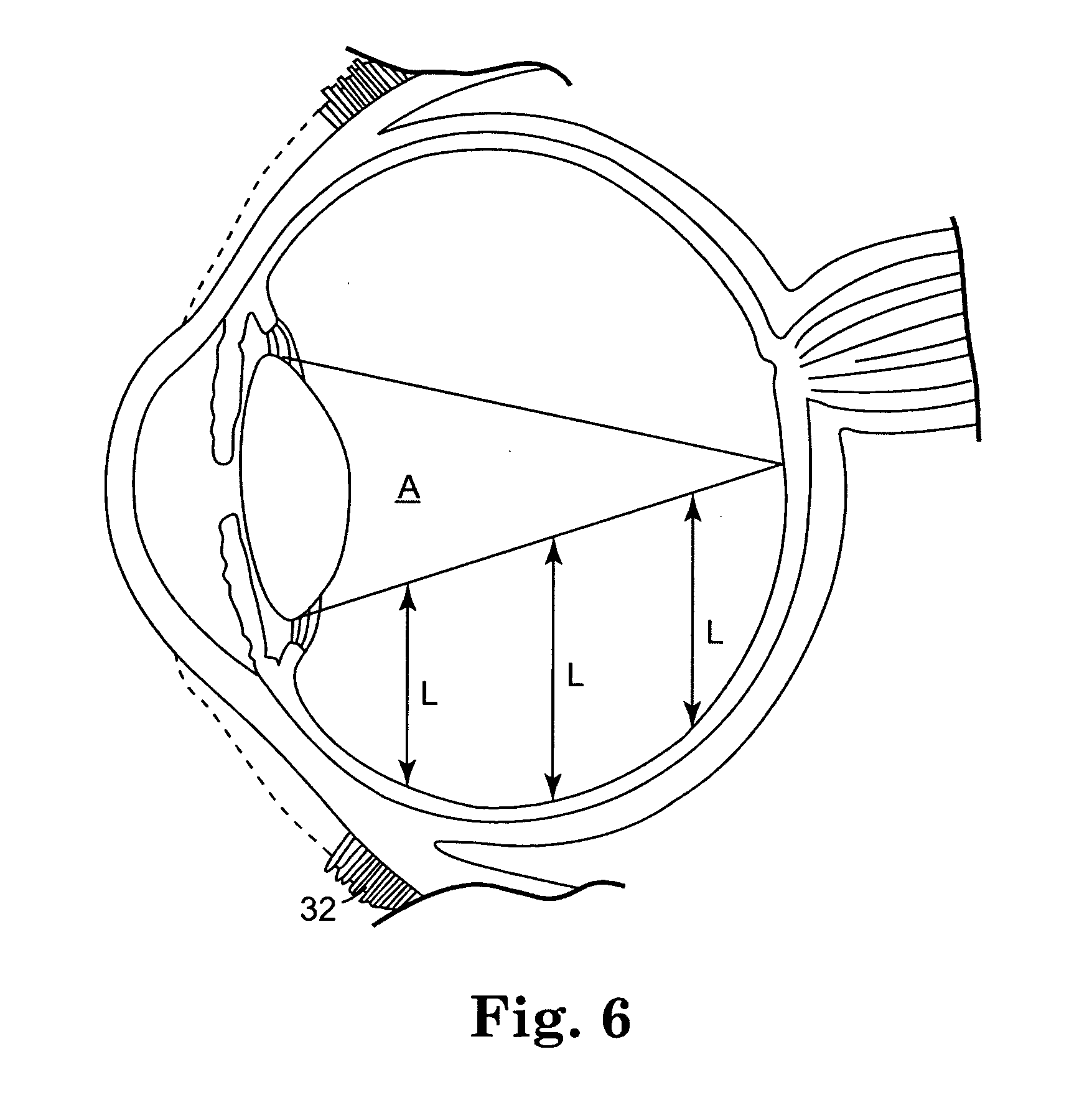

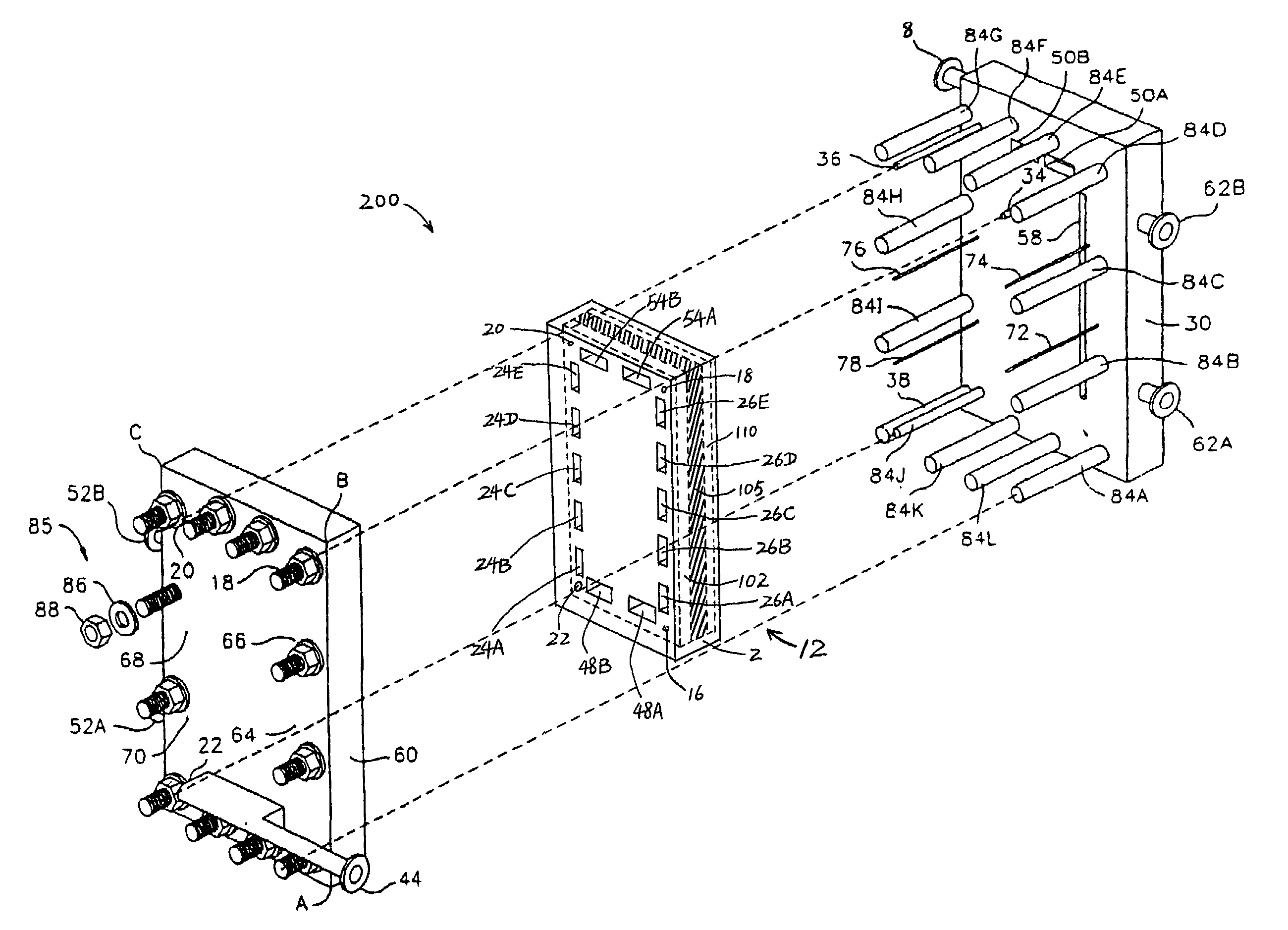

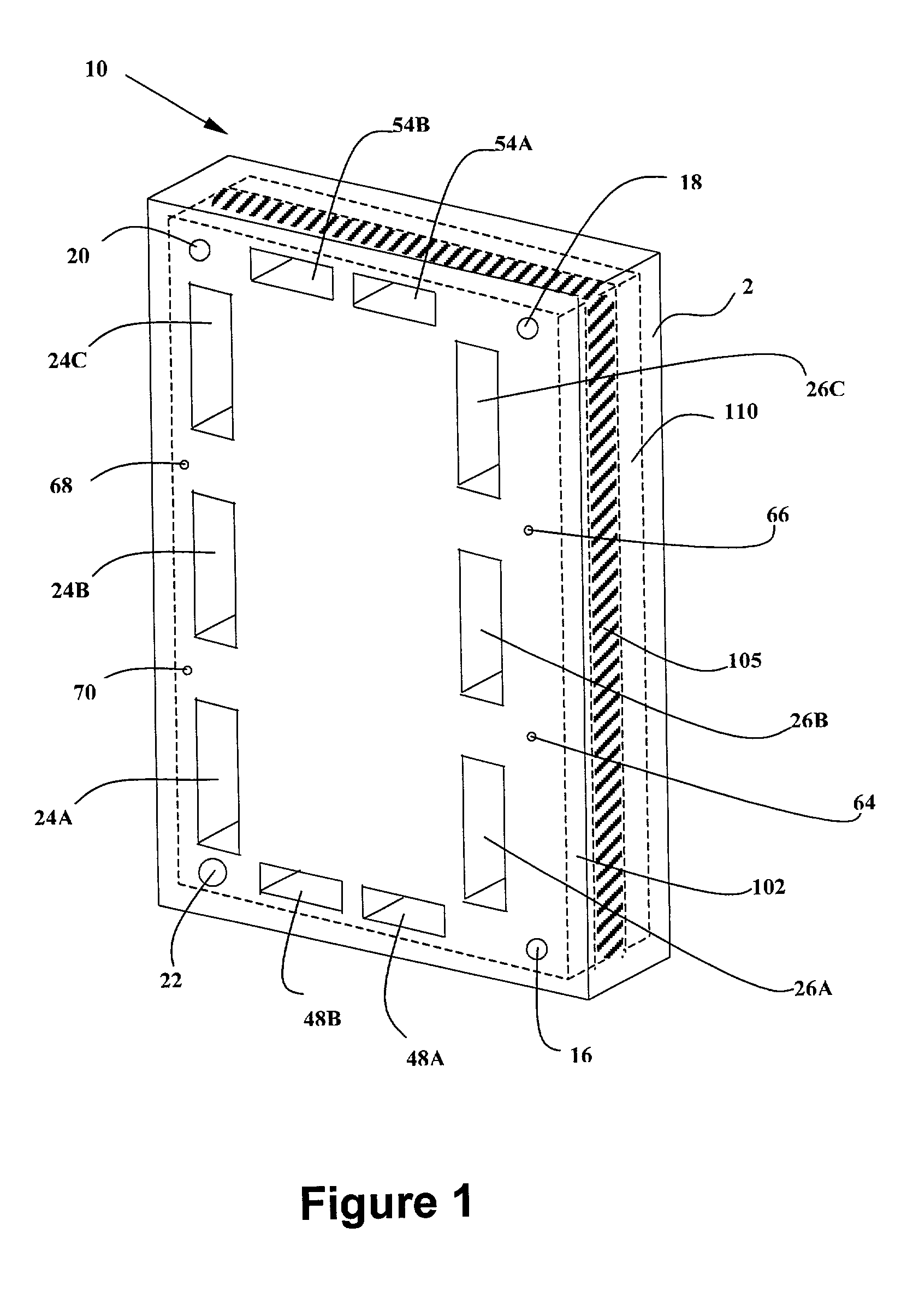

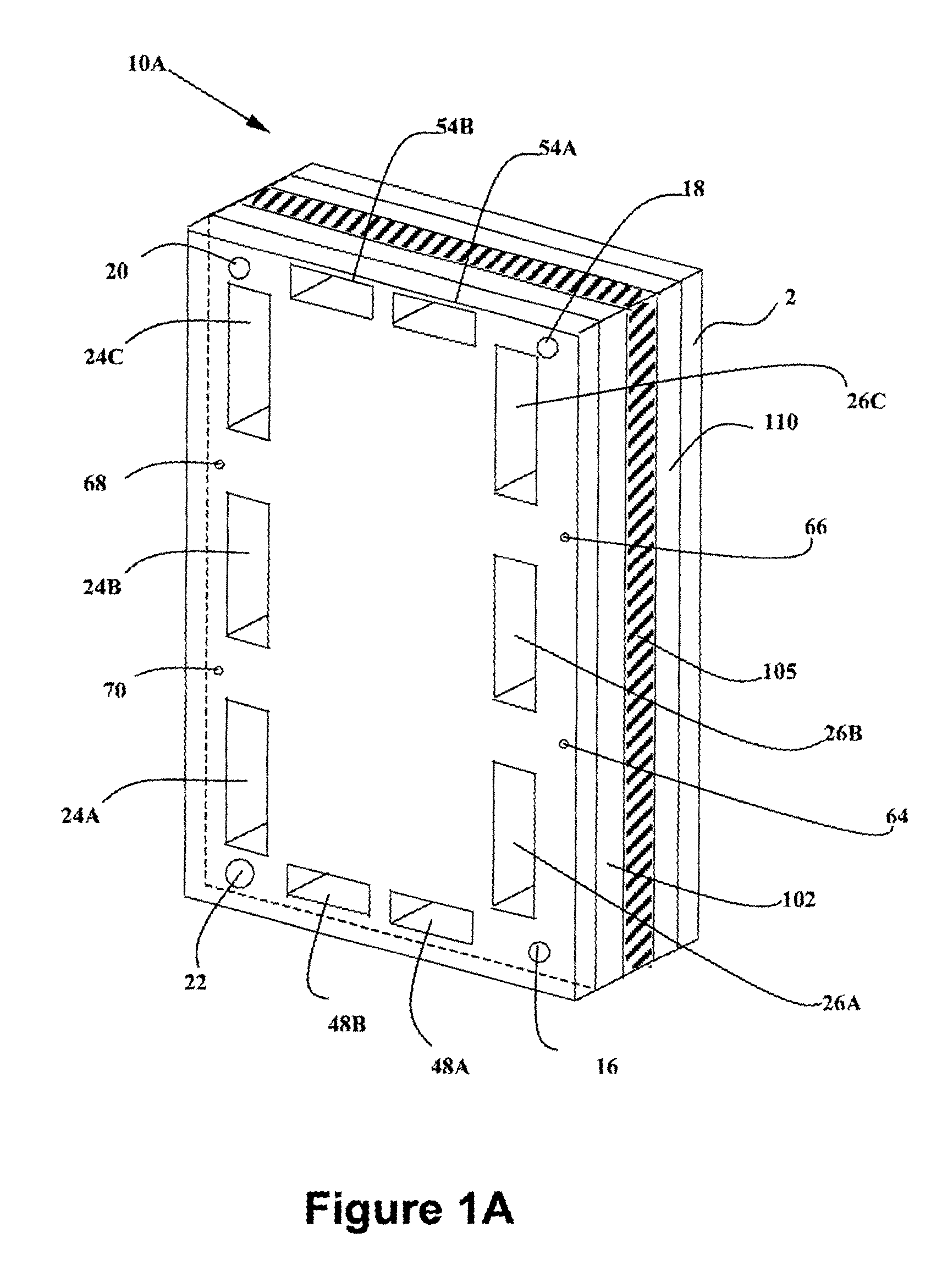

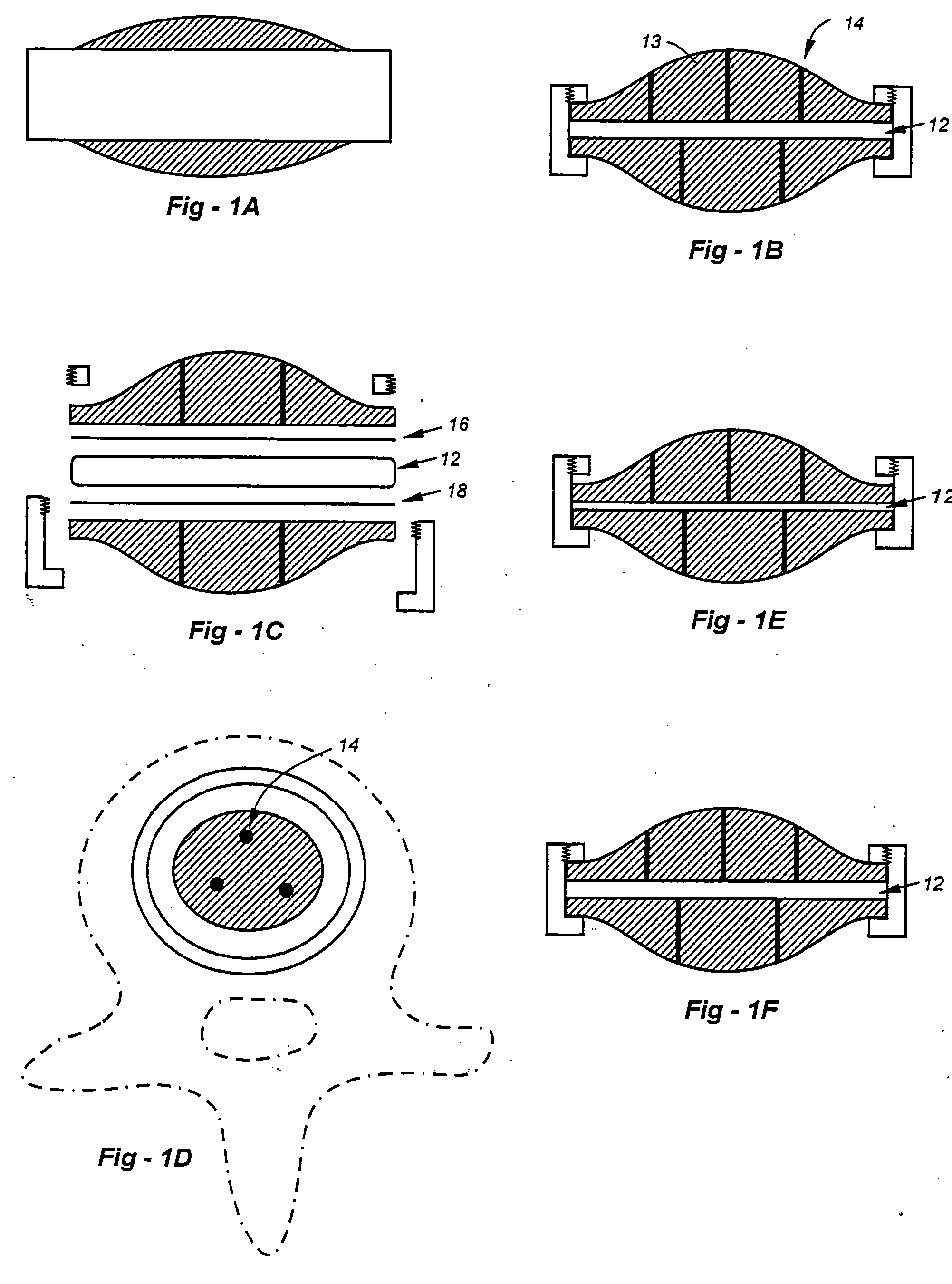

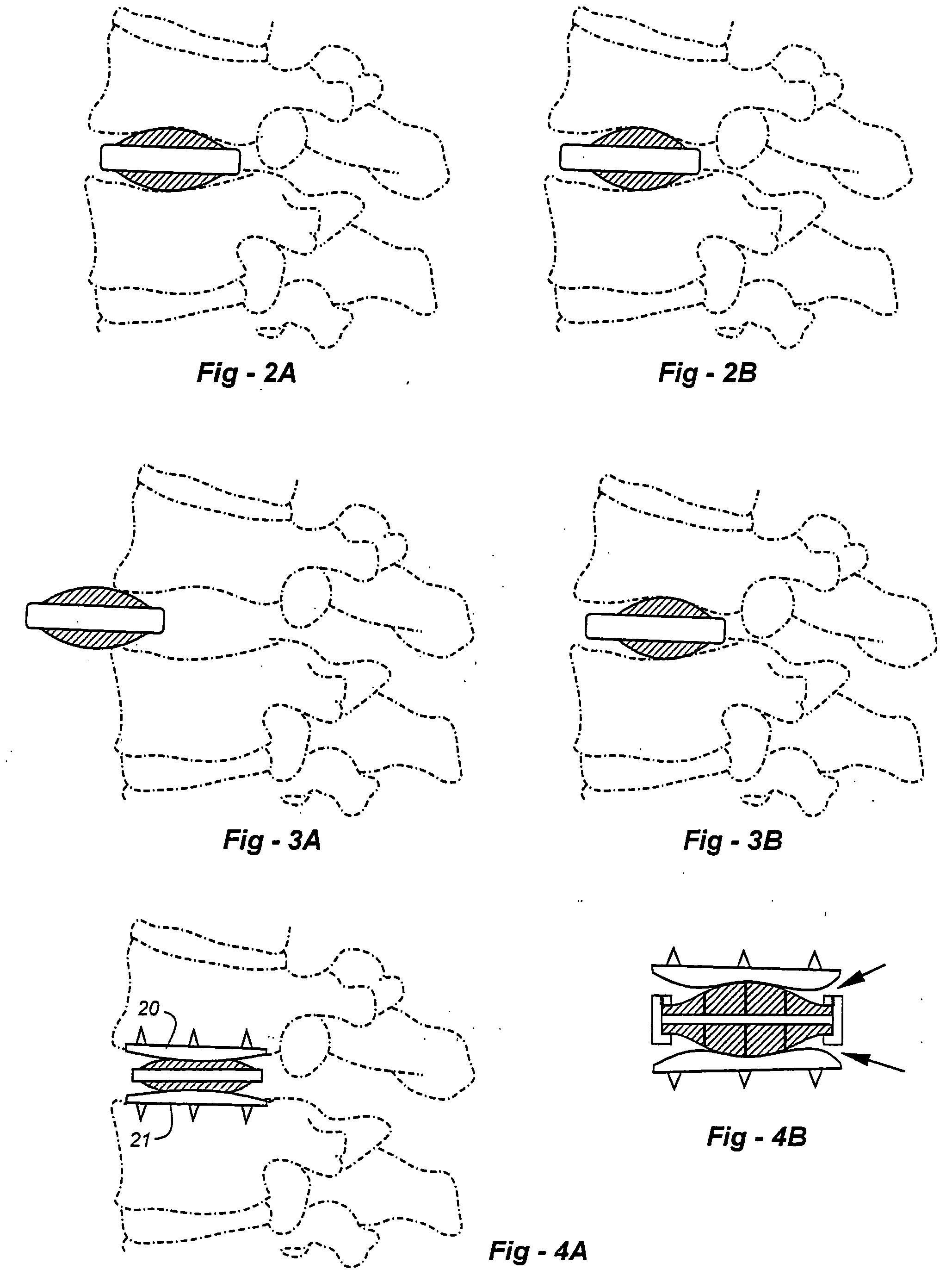

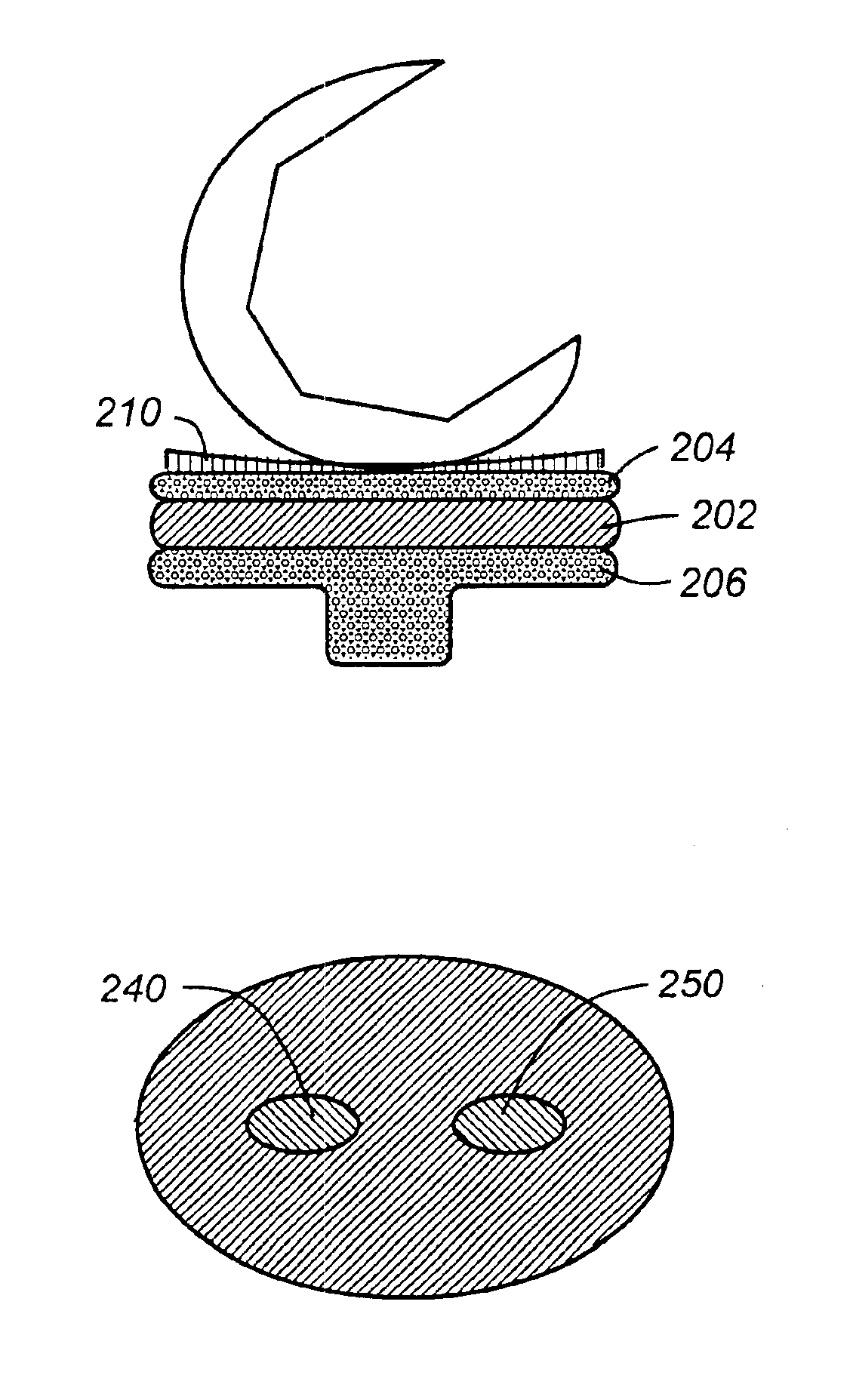

Surgical implant devices and systems including a sheath member

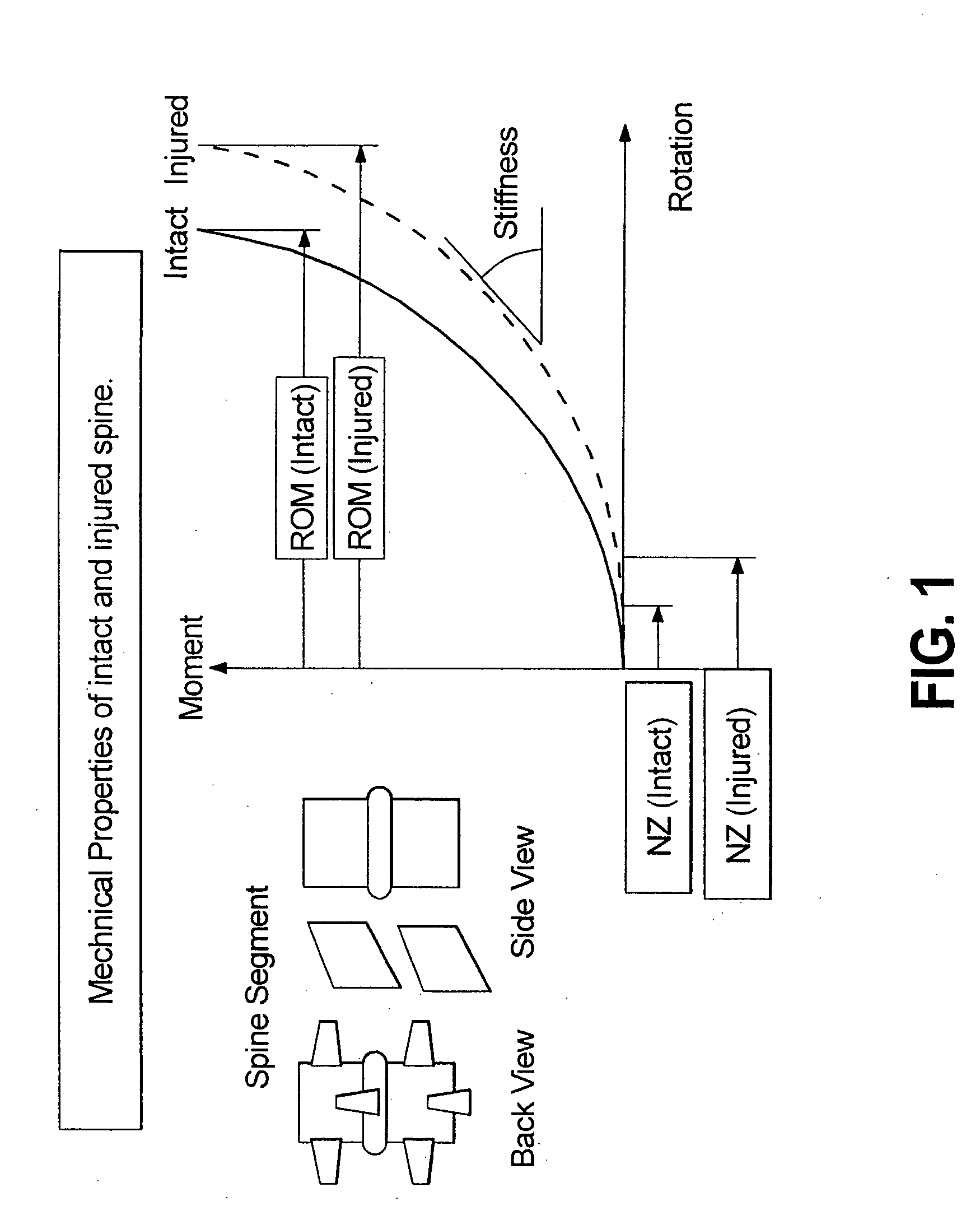

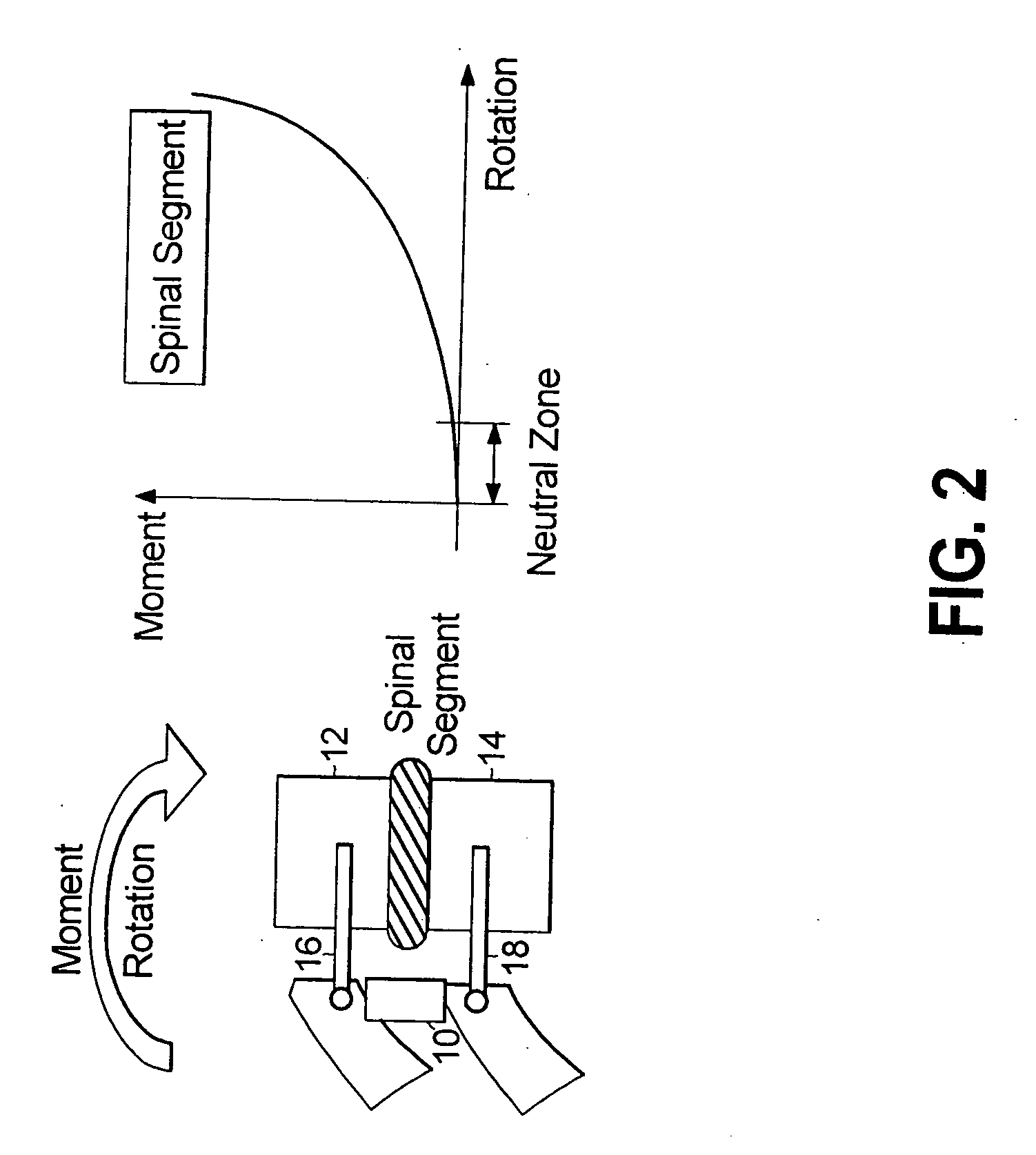

InactiveUS20050177156A1Easy to installImprove clinical outcomesSuture equipmentsInternal osteosythesisAnatomical structuresSpinal column

A surgical implant is provided that includes first and second abutment surfaces between which are positioned a force imparting mechanism. A sheath is positioned between the first and second abutment surfaces, and surrounds the force imparting mechanism. The sheath is fabricated from a material that accommodates relative movement of the abutment members, while exhibiting substantially inert behavior relative to surrounding anatomical structures. The sheath is generally fabricated from expanded polytetrafluoroethylene, ultra-high molecular weight polyethylene, a copolymer of polycarbonate and a urethane, or a blend of a polycarbonate and a urethane. The force imparting member may include one or more springs, e.g., a pair of nested springs. The surgical implant may be a dynamic spine stabilizing member that is advantageously incorporated into a spine stabilization system to offer clinically efficacious results.

Owner:RACHIOTEK

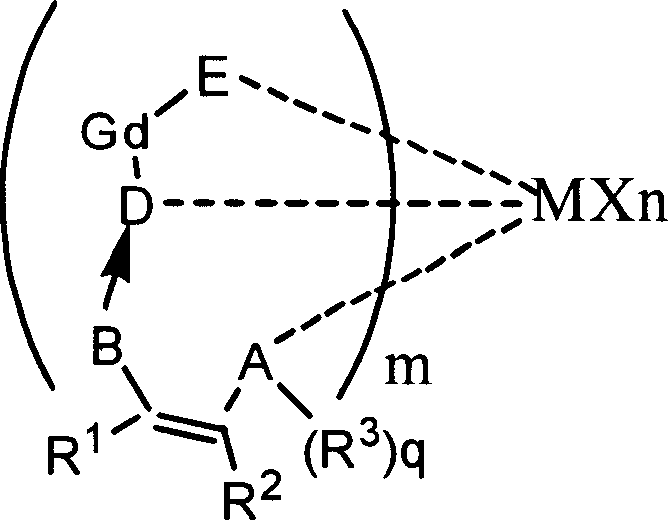

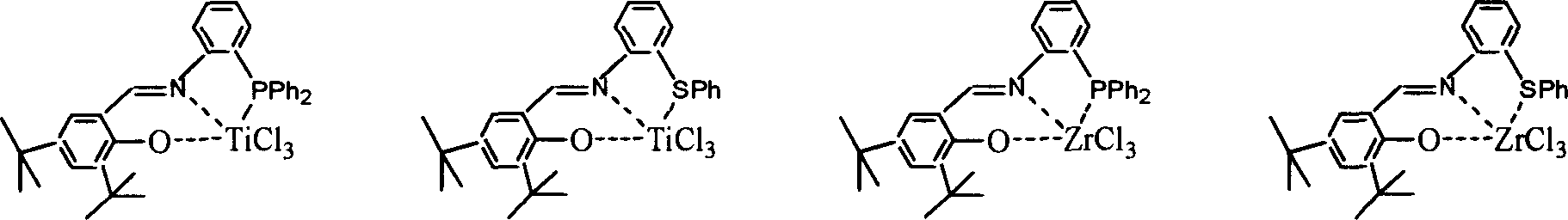

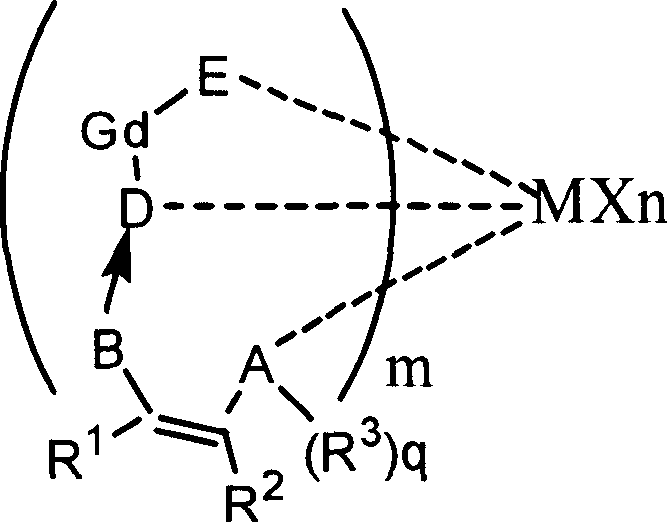

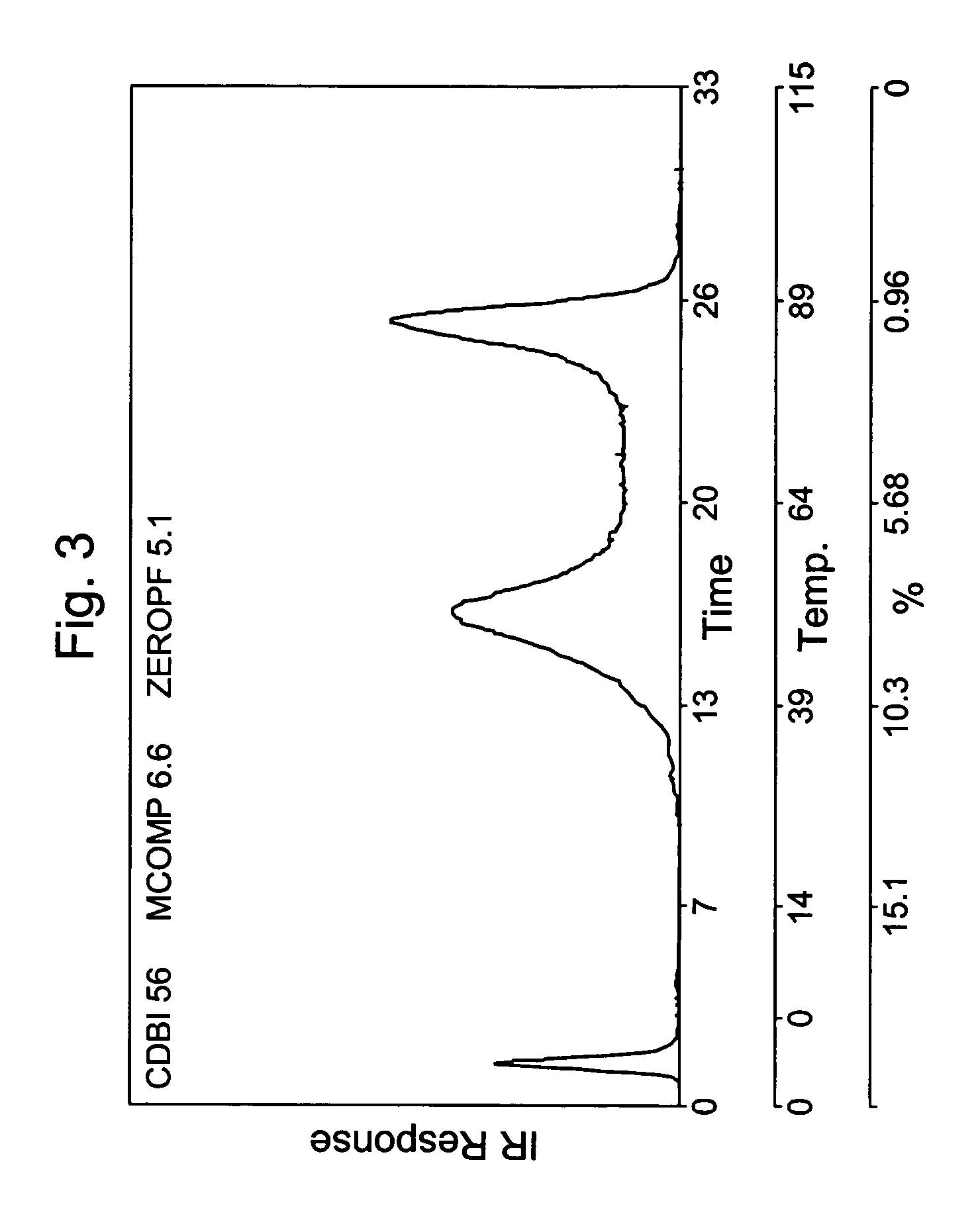

Catalyst composition, method of polymerization, and polymer therefrom

Owner:UNIVATION TECH LLC

Catalyst composition, method of polymerization, and polymer therefrom

InactiveUS6841631B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinMetal

Catalyst compositions and methods, useful in polymerization processes, utilizing at least two metal compounds are disclosed. At least one of the metal compounds is a Group 15 containing metal compound and the other metal compound is preferably a bulky ligand metallocene-type catalyst. The invention also discloses a new polyolefin, generally polyethylene, particularly a multimodal polymer and more specifically, a bimodal polymer, and its use in various end-use applications such as film, molding and pipe.

Owner:UNIVATION TECH LLC

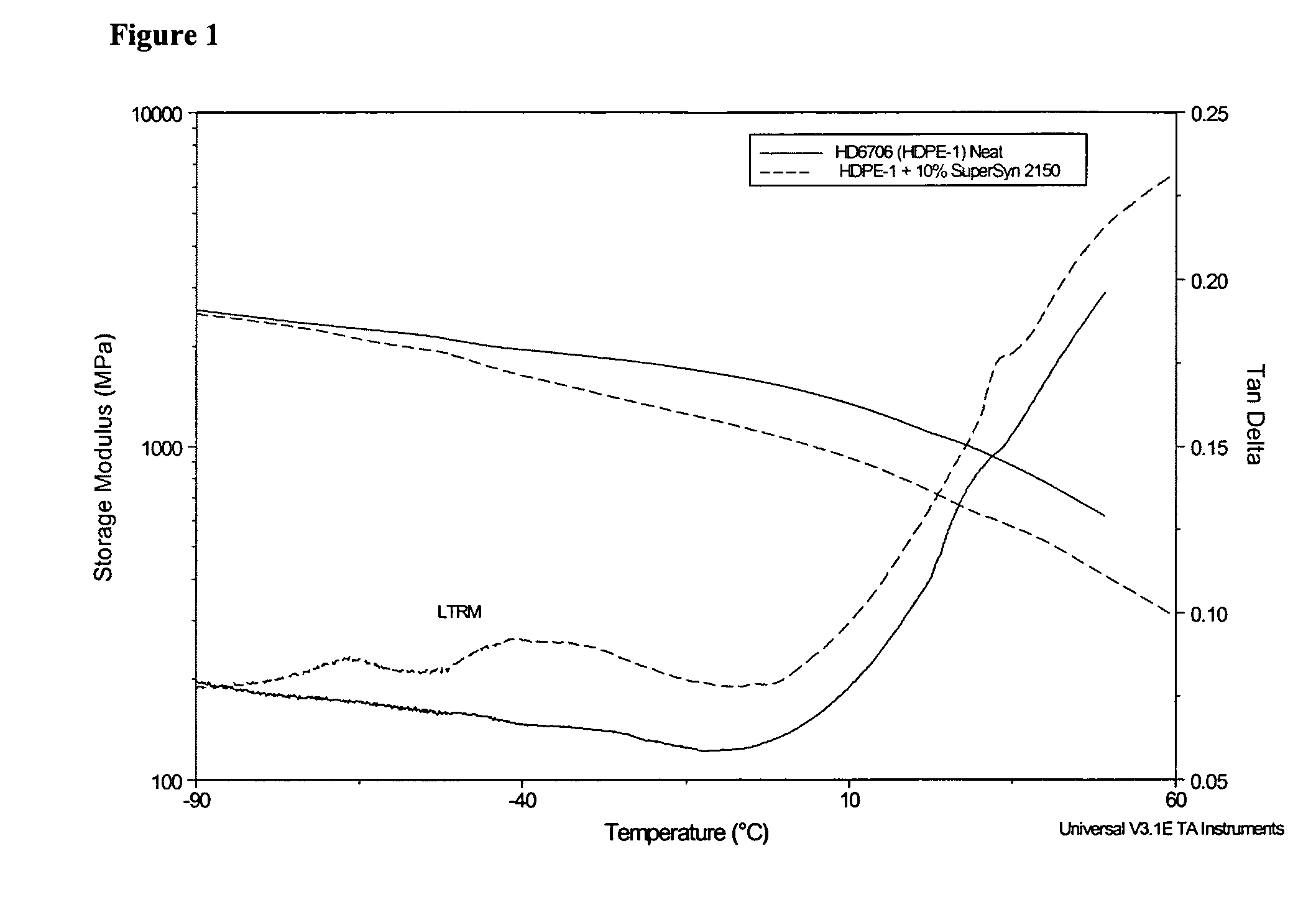

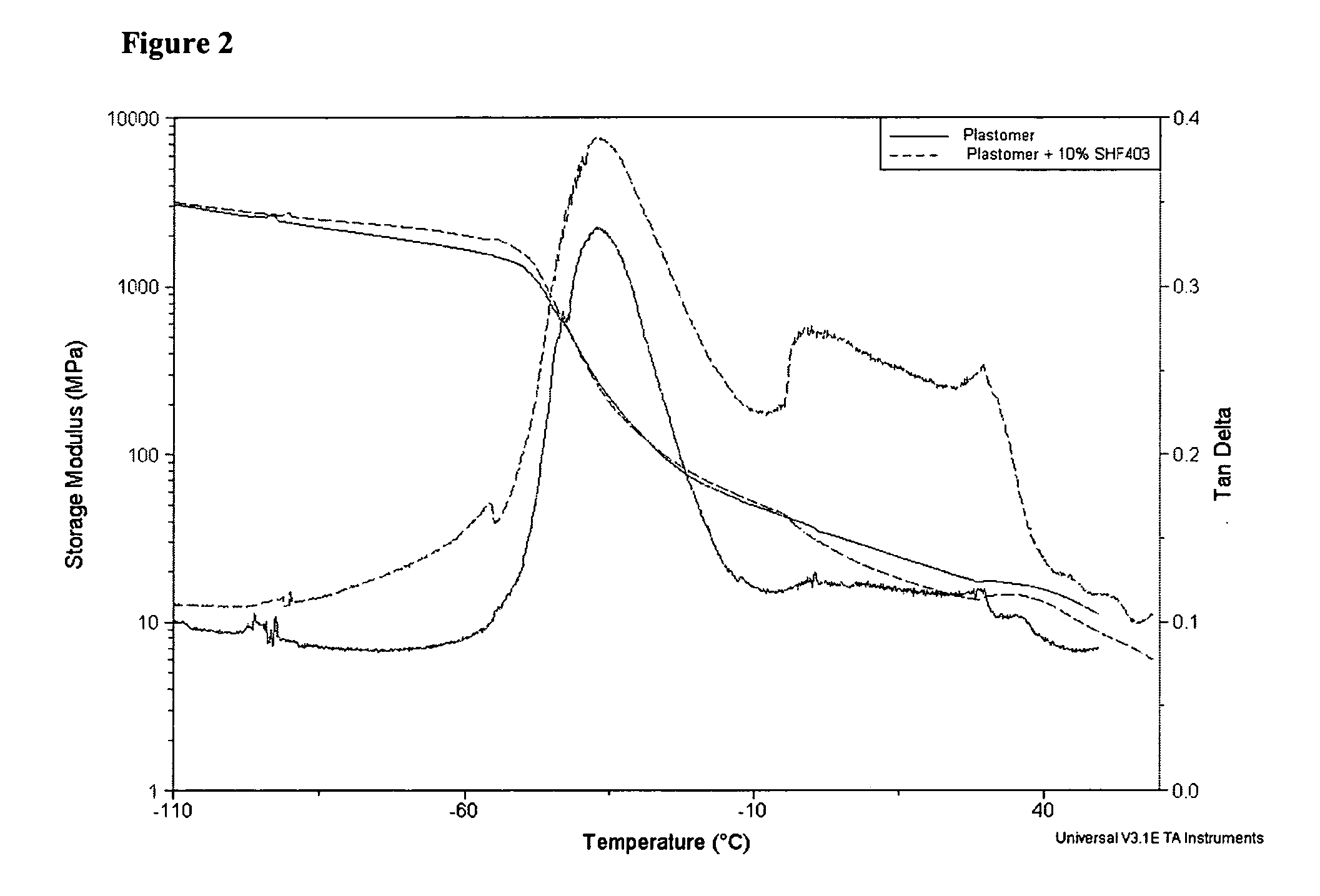

Modified polyethylene compositions

The present invention relates to a composition comprising more than 25 weight % (based on the weight of the composition) of one or more ethylene polymers having an Mw of 20,000 g / mole or more and at least 0.1 weight % of a liquid hydrocarbon modifier where the modifier has: 1) a viscosity index of 120 or more, and 2) an kinematic viscosity of 3 to 3000 cSt at 100° C., and 3) a pour point of −10° C. or less, and 4) a flash point of 200° C. or more; and wherein the modifier contains less than 5 weight % of functional groups selected from hydroxide, aryls, substituted aryls, halogens, alkoxys, carboxylates, esters, acrylates, oxygen, nitrogen, and carboxyl, based upon the weight of the modifier.

Owner:EXXONMOBIL CHEM PAT INC

Controlled release bioactive agent delivery device

InactiveUS20050019371A1Minimize damageInterference minimizationOrganic active ingredientsSenses disorderControlled releaseMeth-

Owner:SURMODICS INC

Carry type non-metallocene calalyst for polymerization of olefine, its preparation method and uses

The invention discloses an equivoluminal dipping loading method of non-metallocene olefin polymeric catalyst as well as application of copolymerizing course within two or more different olefins, which comprises the following steps: dissolving non-metallocene olefin polymeric catalyst in the solvent; mixing solution and carrier; stirring wet solid material evenly; drying; obtaining the load-typed non-metallocene olefin polymeric catalyst; making the solvent and carrier satisfy specific relationship.

Owner:SINOPEC YANGZI PETROCHEM

Fibers and nonwovens comprising polyethylene blends and mixtures

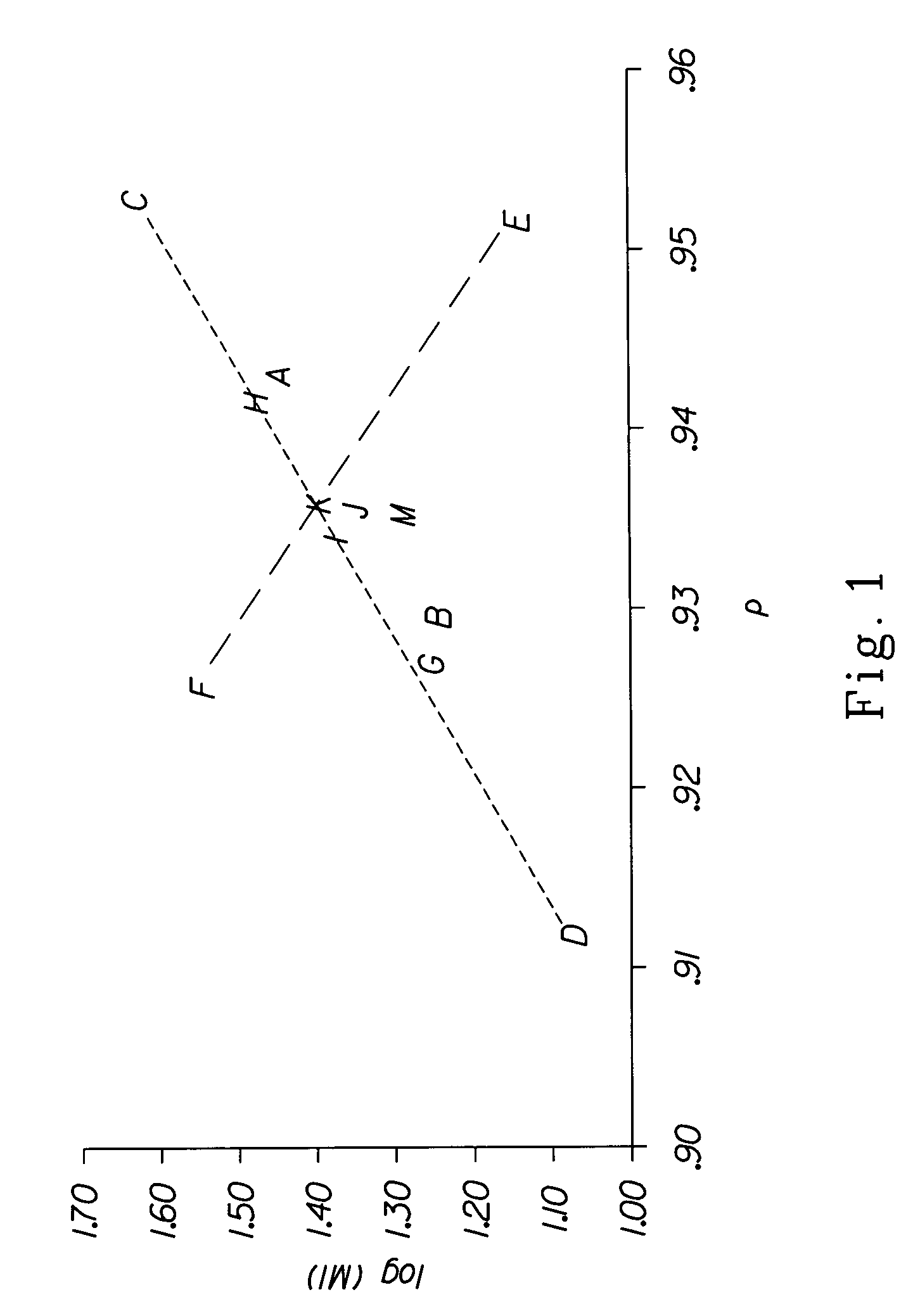

Polymeric blends and polymeric mixtures that incorporate a blend of a first polyethylene and a second polyethylene are described. The first and second polyethylenes have a predetermined relationship for the density and the melt index of the individual polyethylenes. Also described are fibers (including bicomponent fibers) and nonwoven materials made from the fibers where the fibers are extruded using the polymeric blends, and / or the polymeric mixtures.

Owner:PROCTER & GAMBLE CO

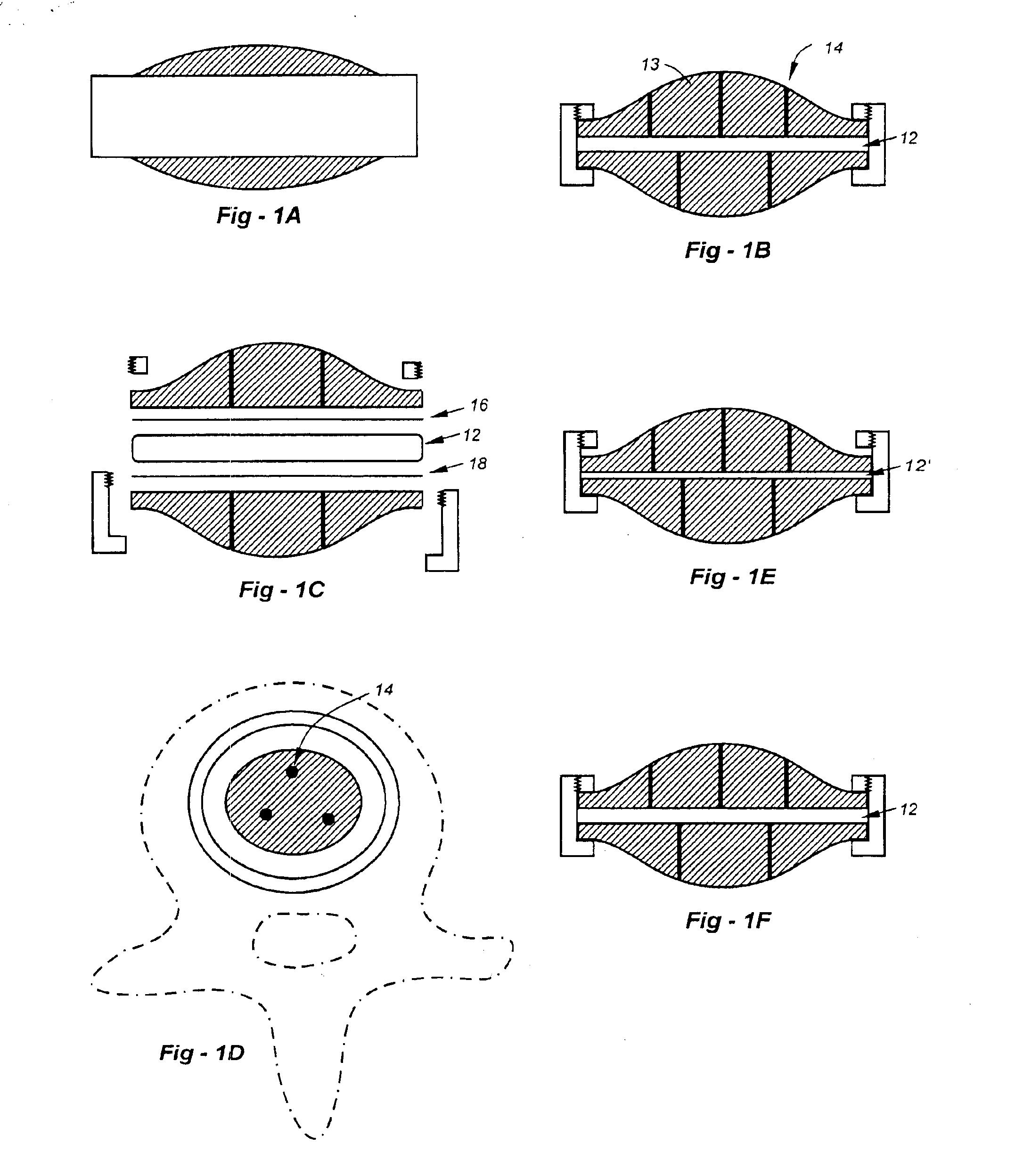

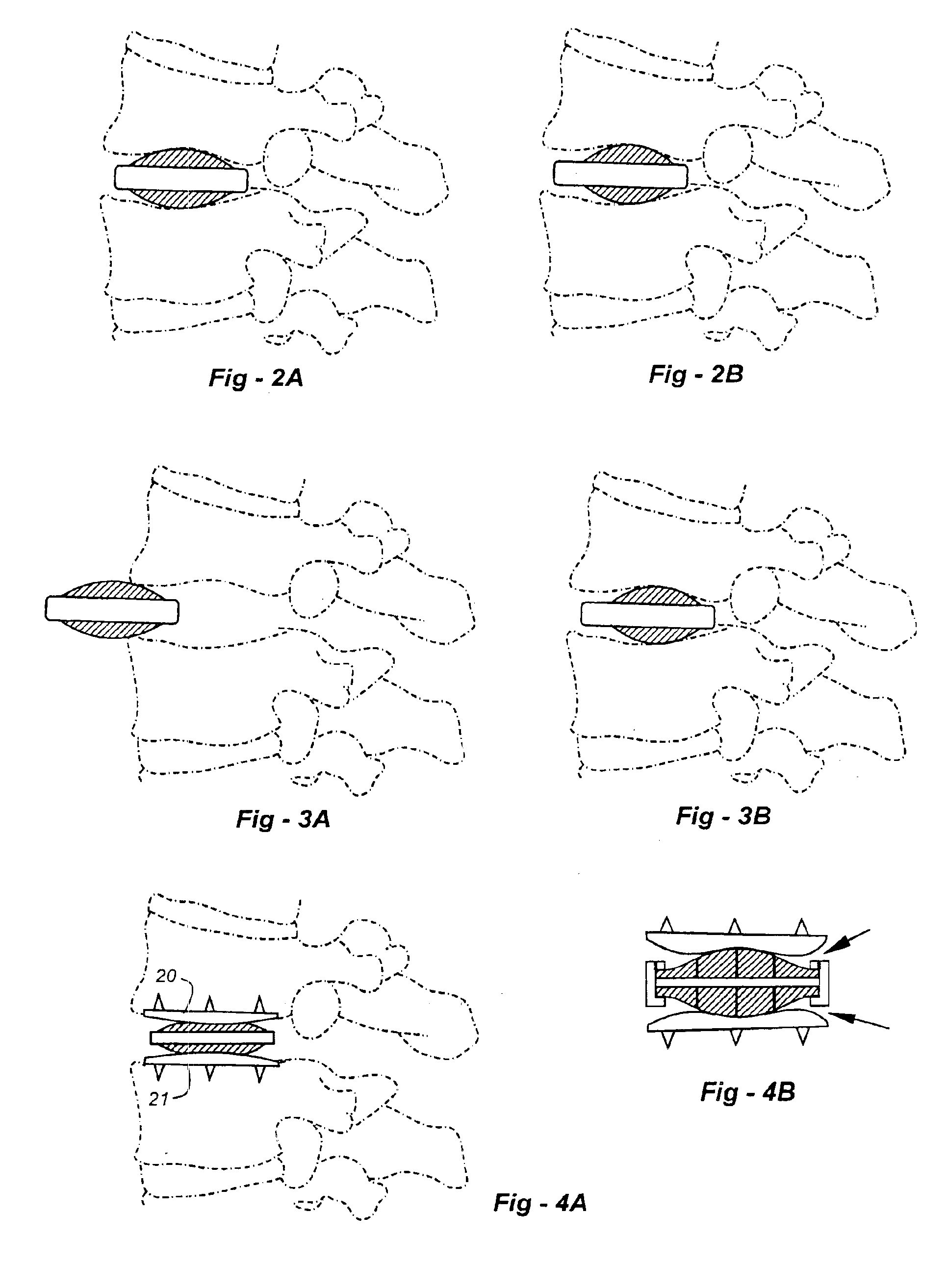

Mechanical apparatus and method for artificial disc replacement

InactiveUS7442210B2Easy to integrateFree from painSuture equipmentsBone implantPolyesterPolypropylene

Owner:OUROBOROS MEDICAL INC

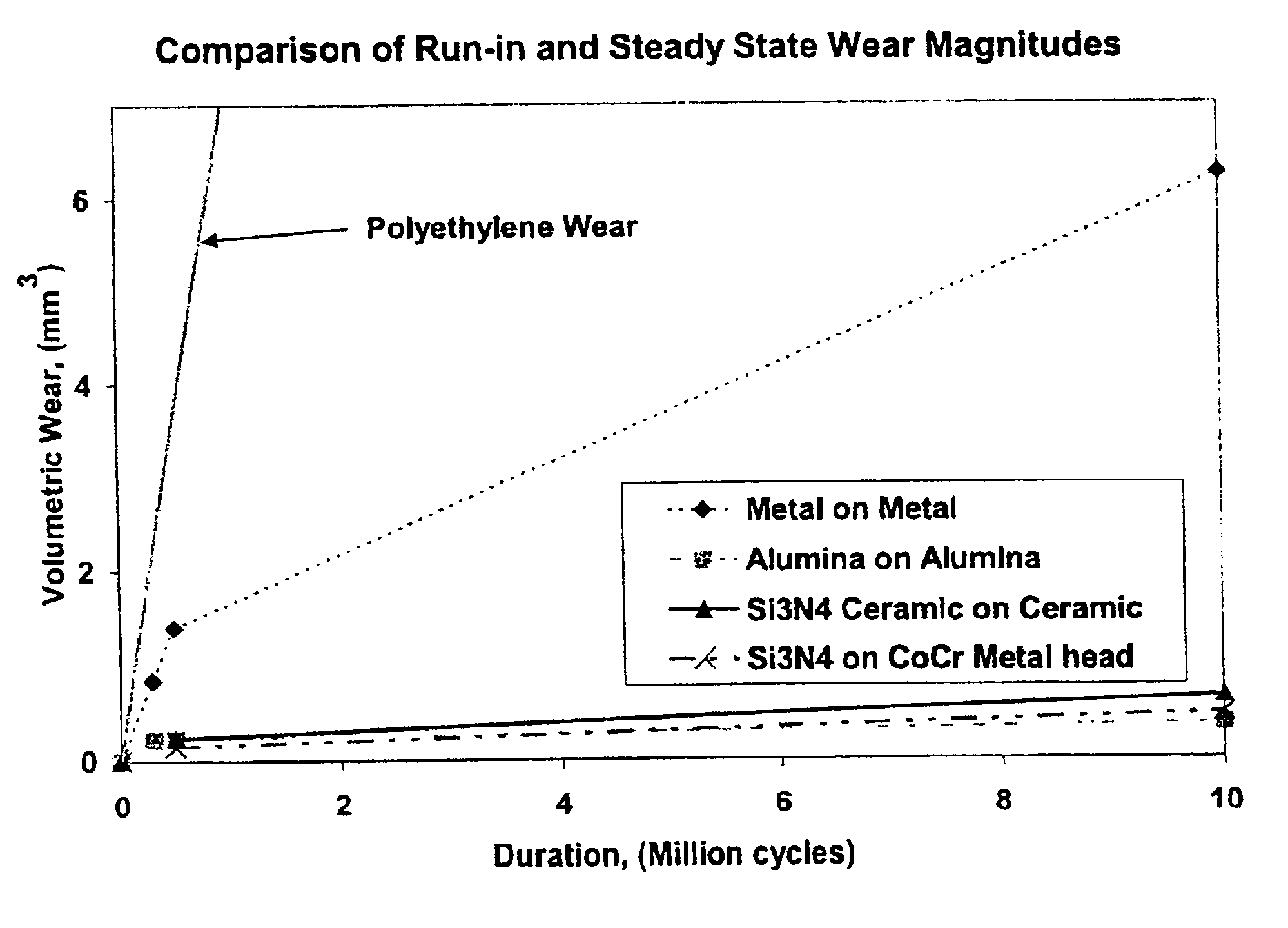

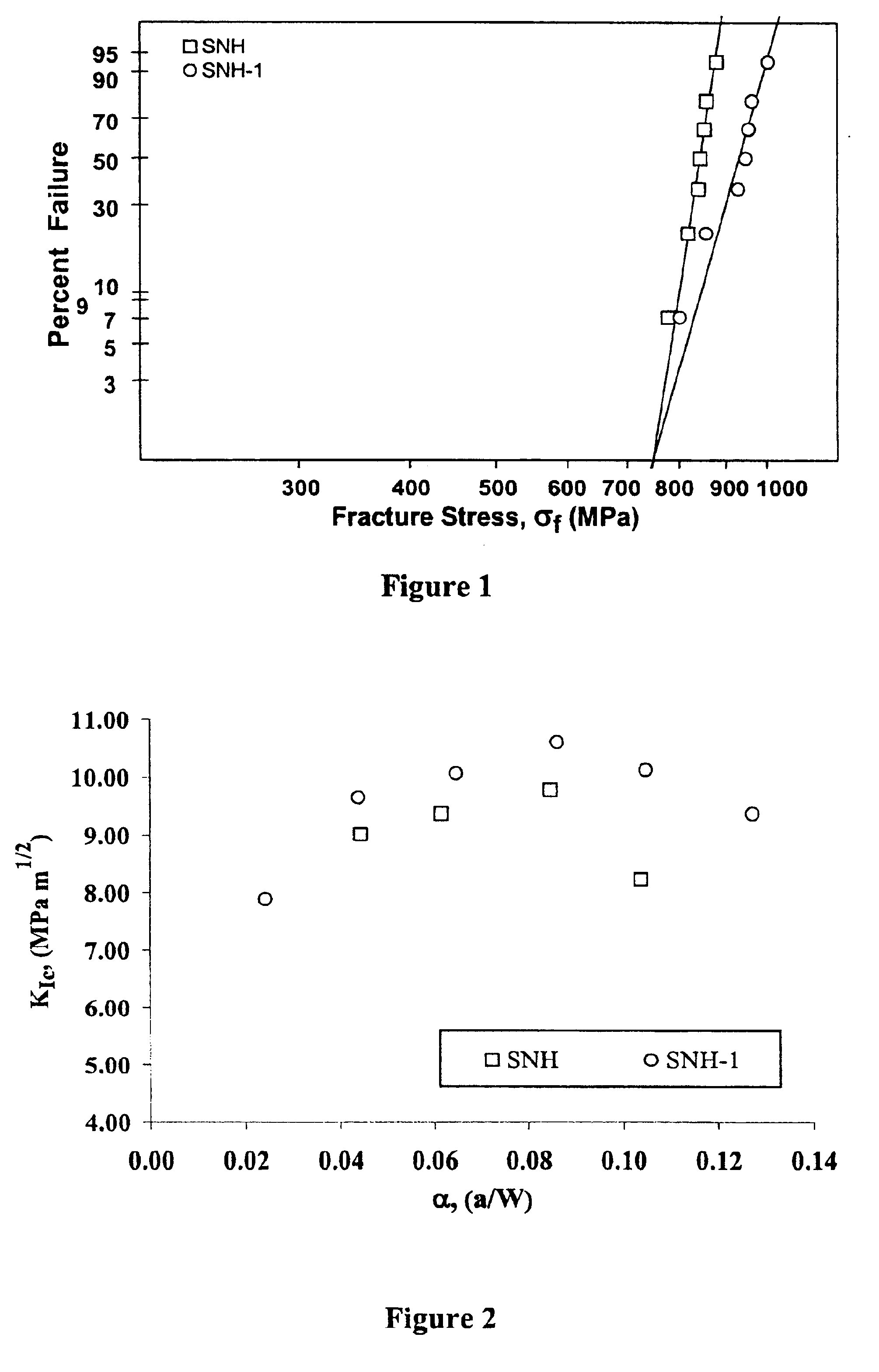

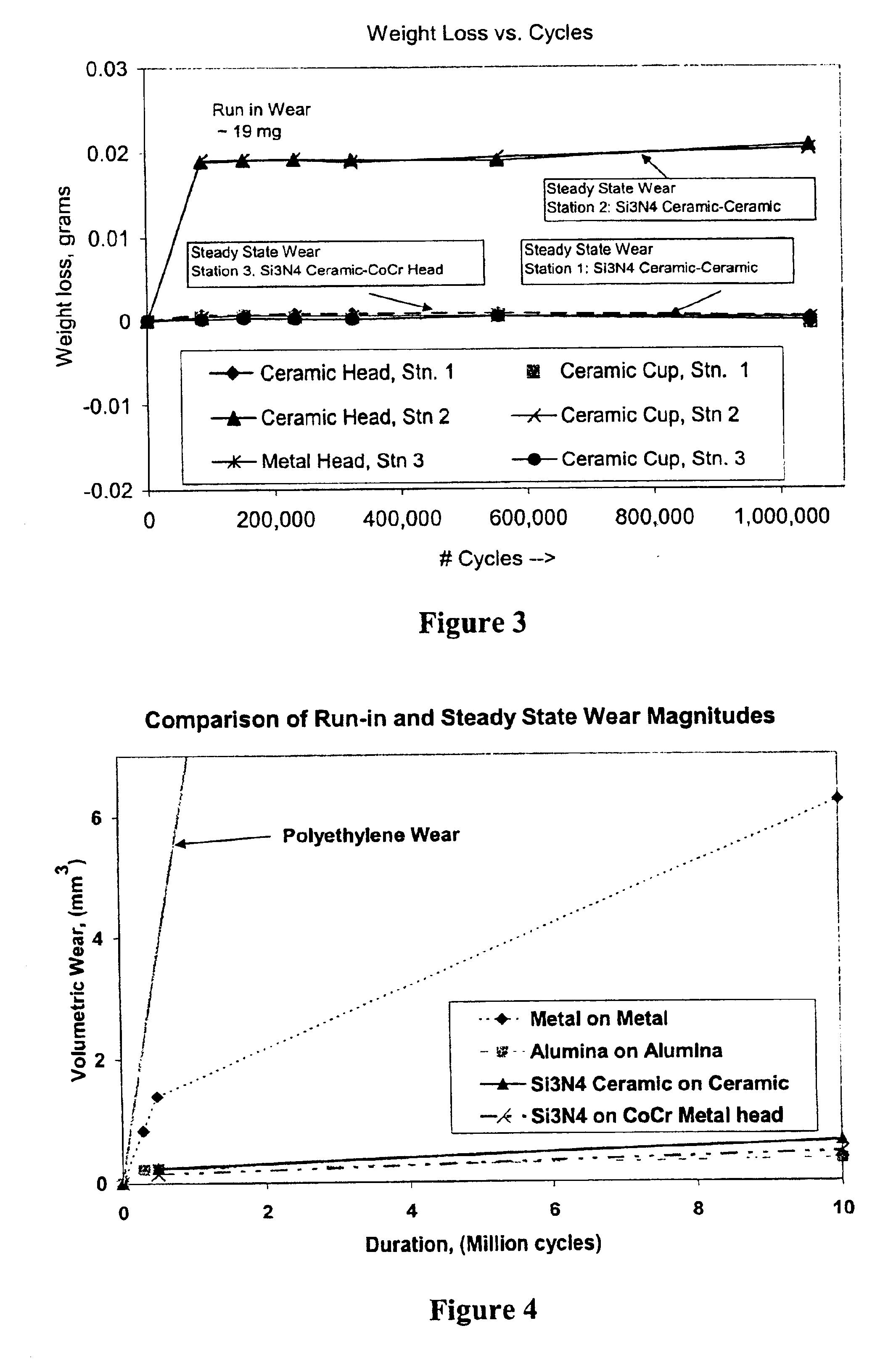

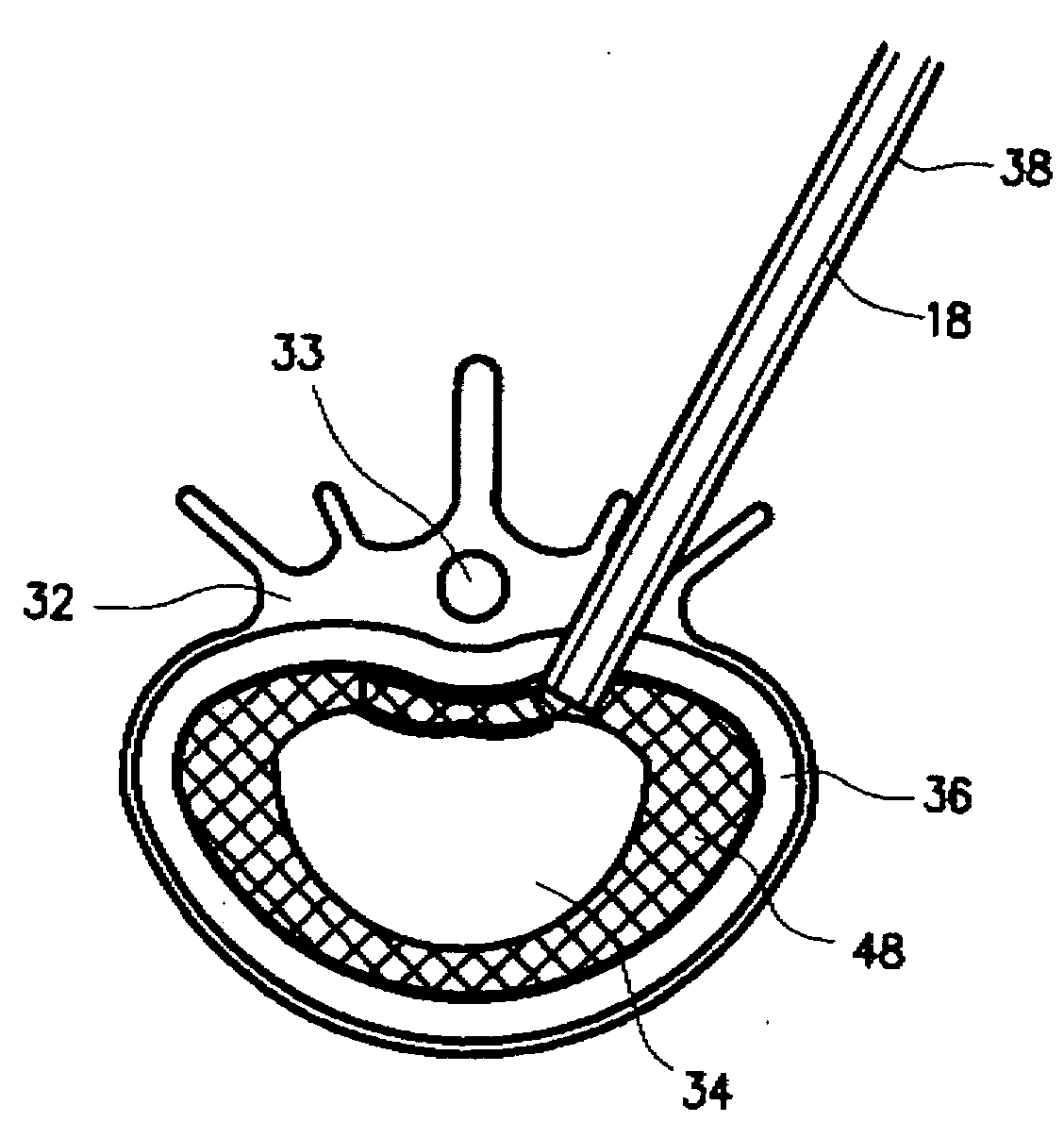

Metal-ceramic composite articulation

InactiveUS6881229B2Minimal productionImprove flexural strengthBone implantJoint implantsHigh fractureIn vivo

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPa1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate polyethylene (PE) wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

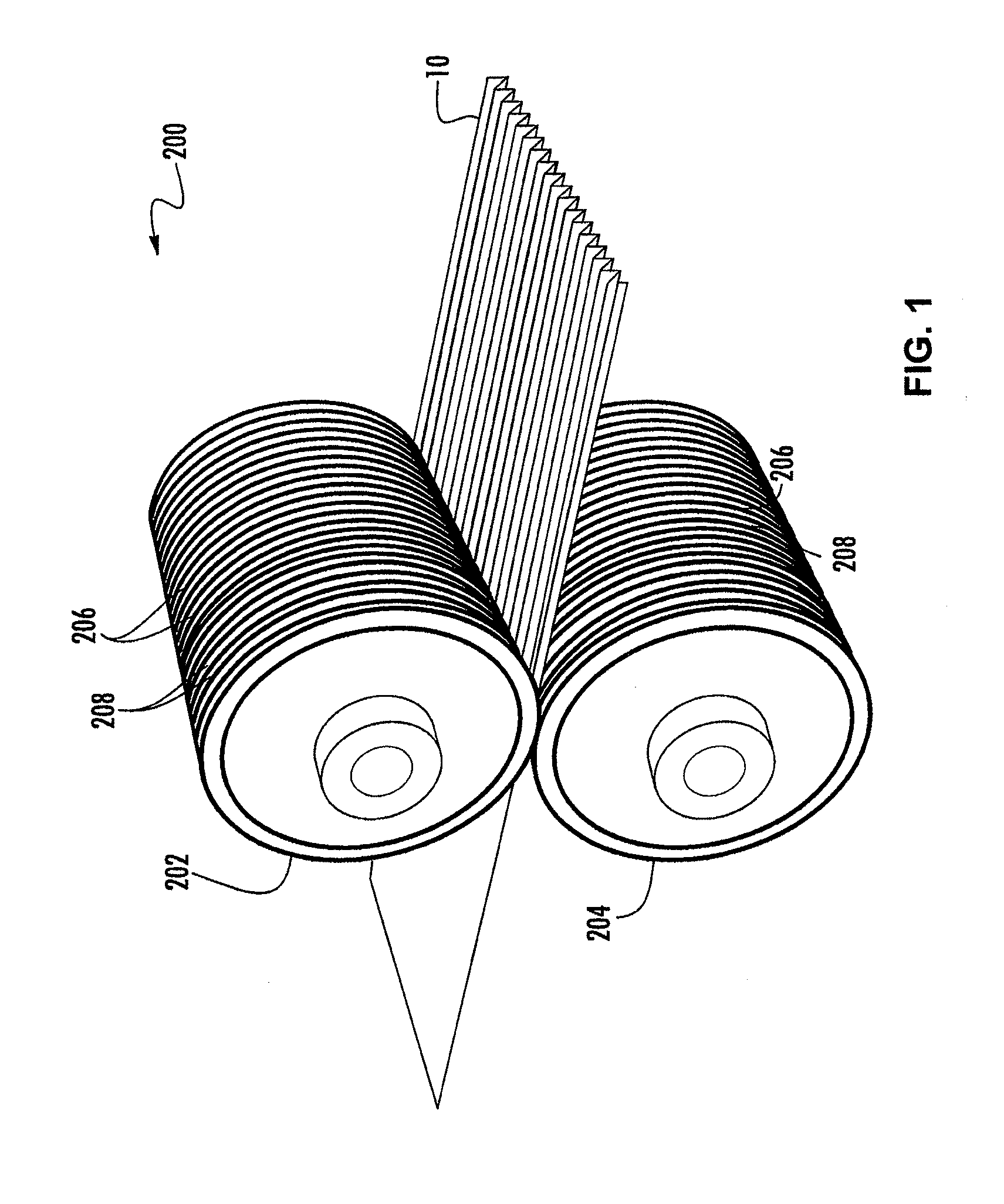

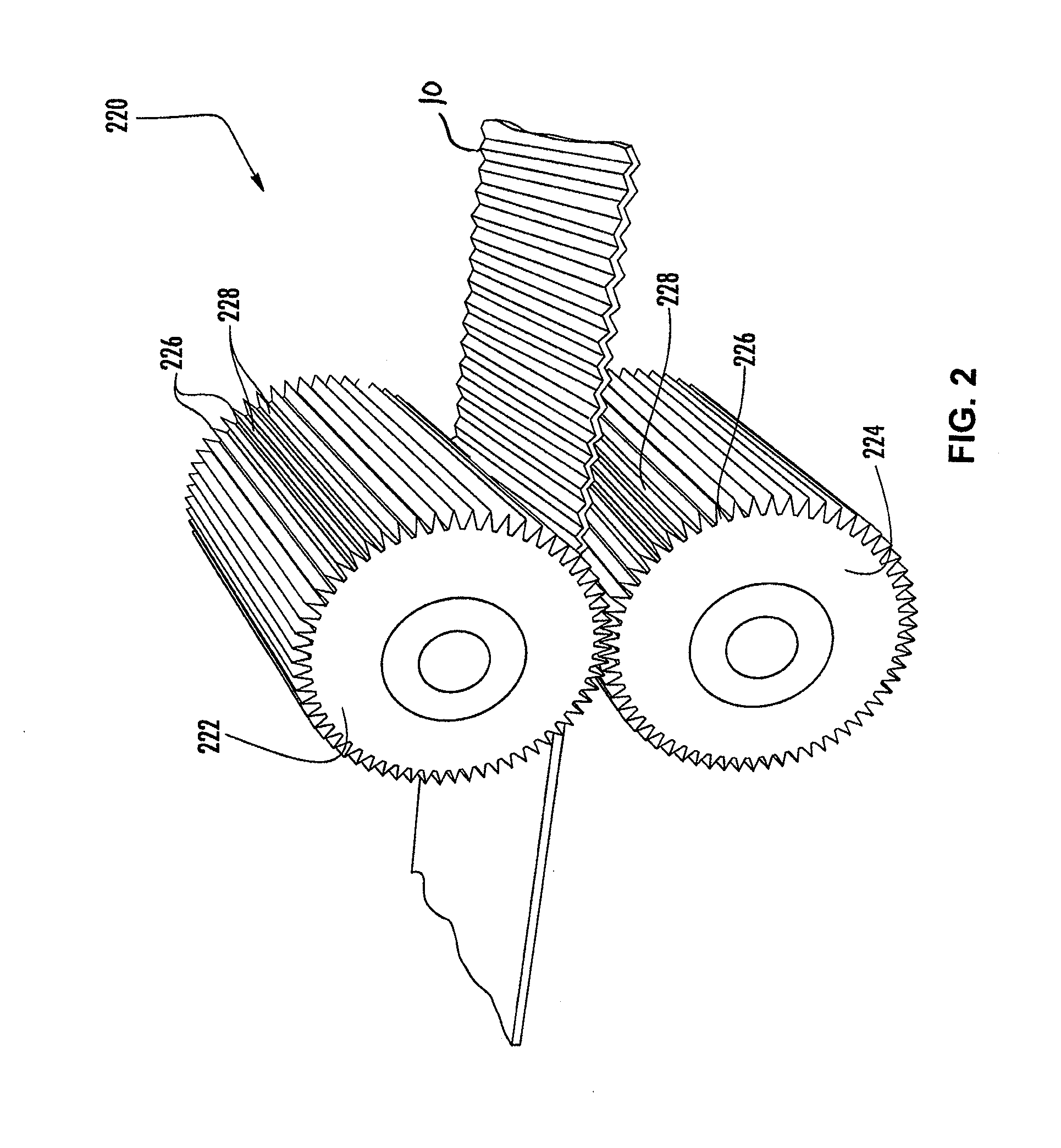

Process for preparing a simulated in situ polyethylene blend

A process comprising:(i) providing a first polyethylene, prepared independently, having a melt index in the range of about 5 to about 3000 grams per 10 minutes and a density in the range of about 0.900 to about 0.975 gram per cubic centimeter and a second polyethylene, prepared independently, having a flow index in the range of about 0.01 to about 30 grams per 10 minutes and a density in the range of about 0.860 to about 0.940 gram per cubic centimeter, the weight ratio of the first polyethylene to the second polyethylene being in the range of about 75:25 to about 25:75;(ii) blending the first polyethylene with the second polyethylene;(iii) melting the blend; and, prior to extrusion or pelletizing,(iv) passing the molten blend through one or more active screens, in the case of two or more active screens, positioned in series, each active screen having a micron retention size in the range of about 2 to about 70, at a mass flux of about 5 to about 100 pounds per hour per square inch.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

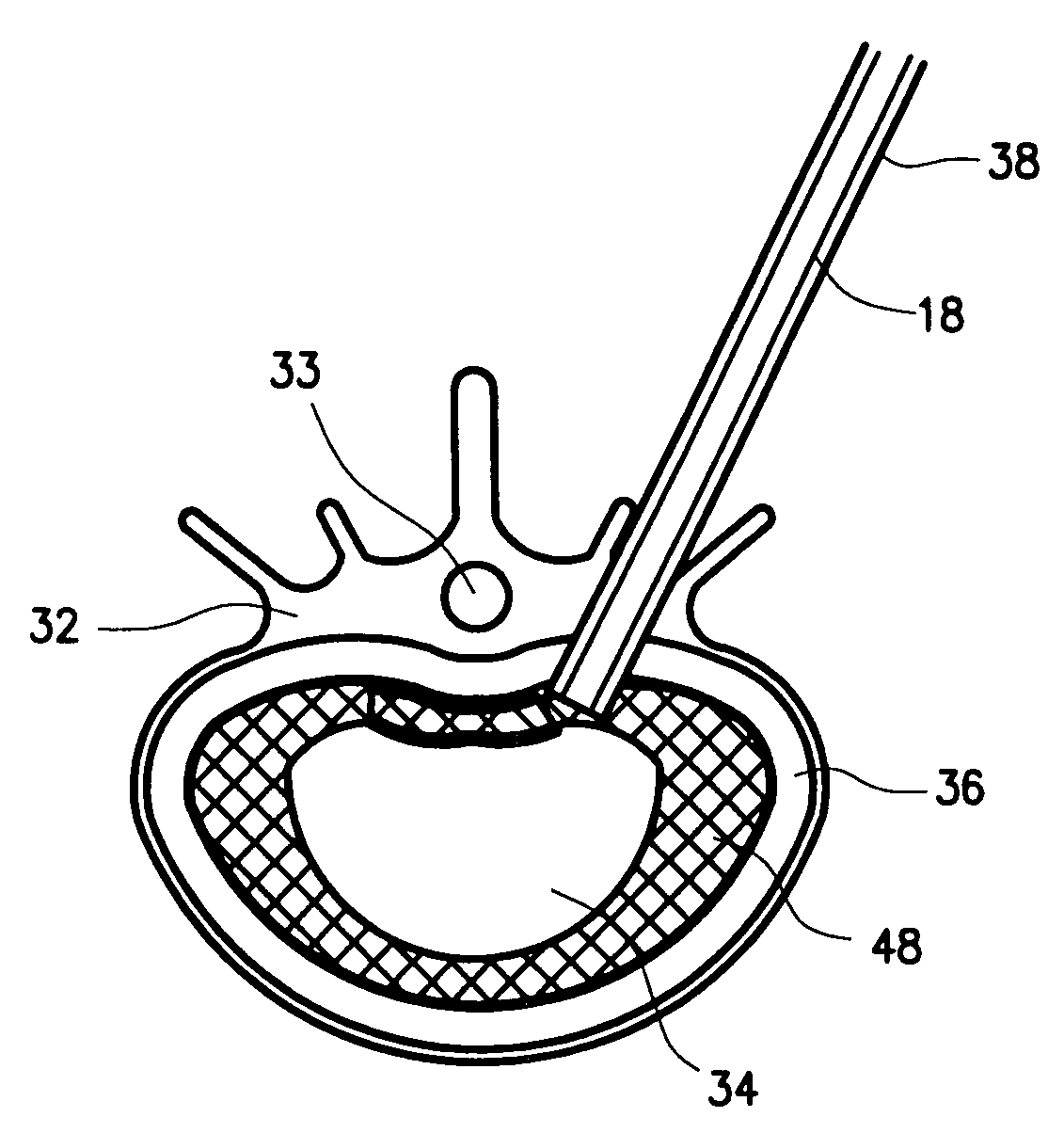

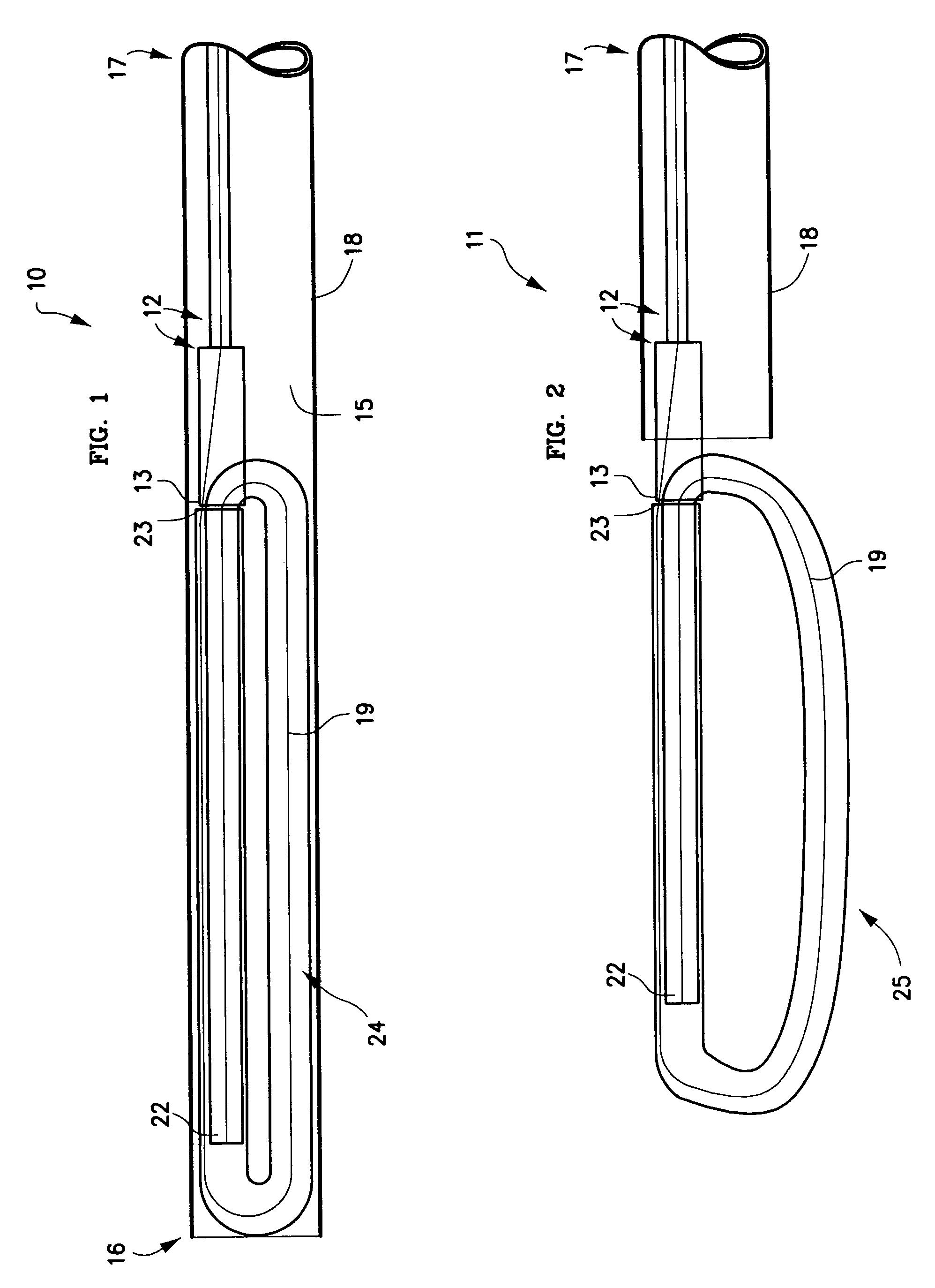

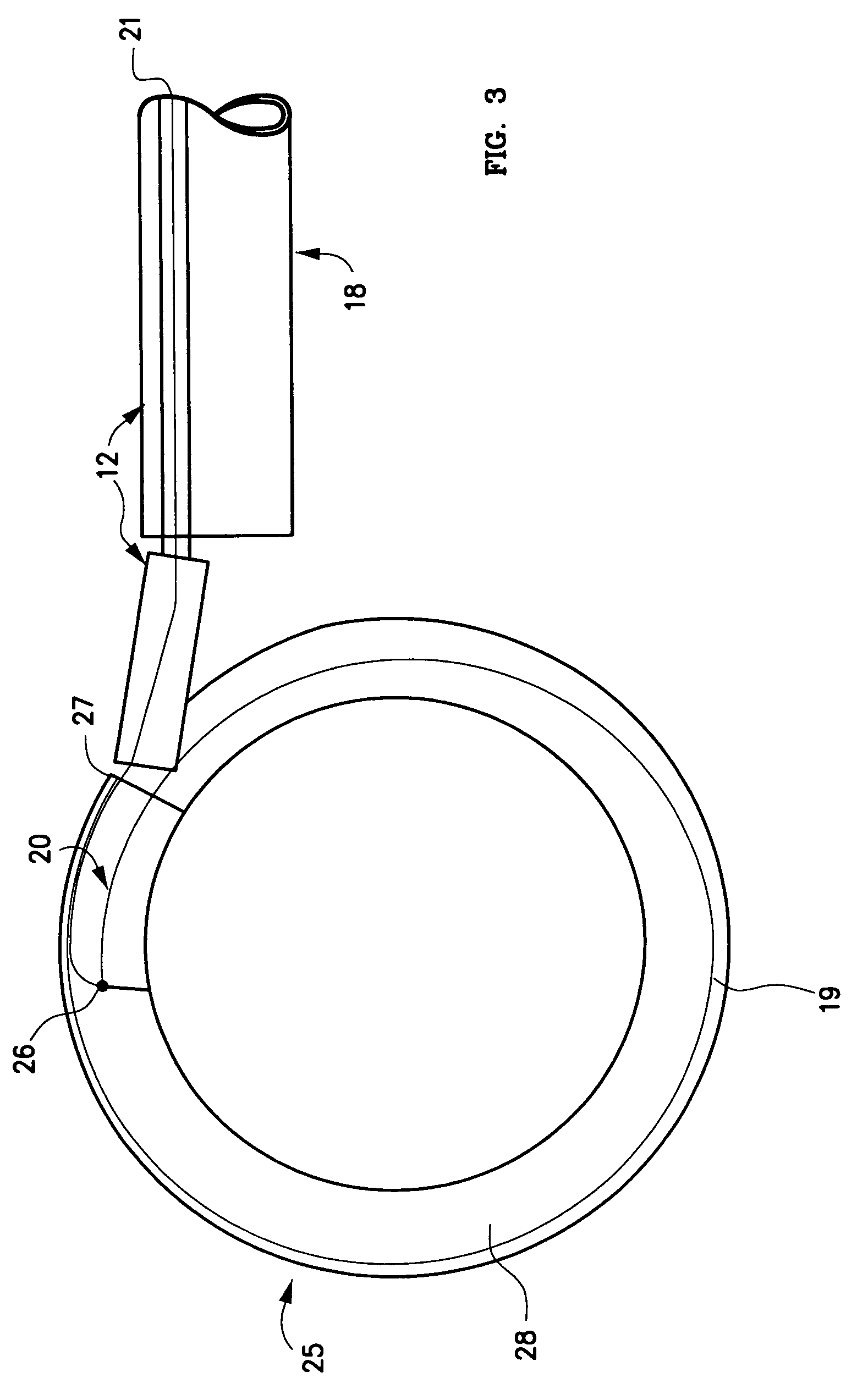

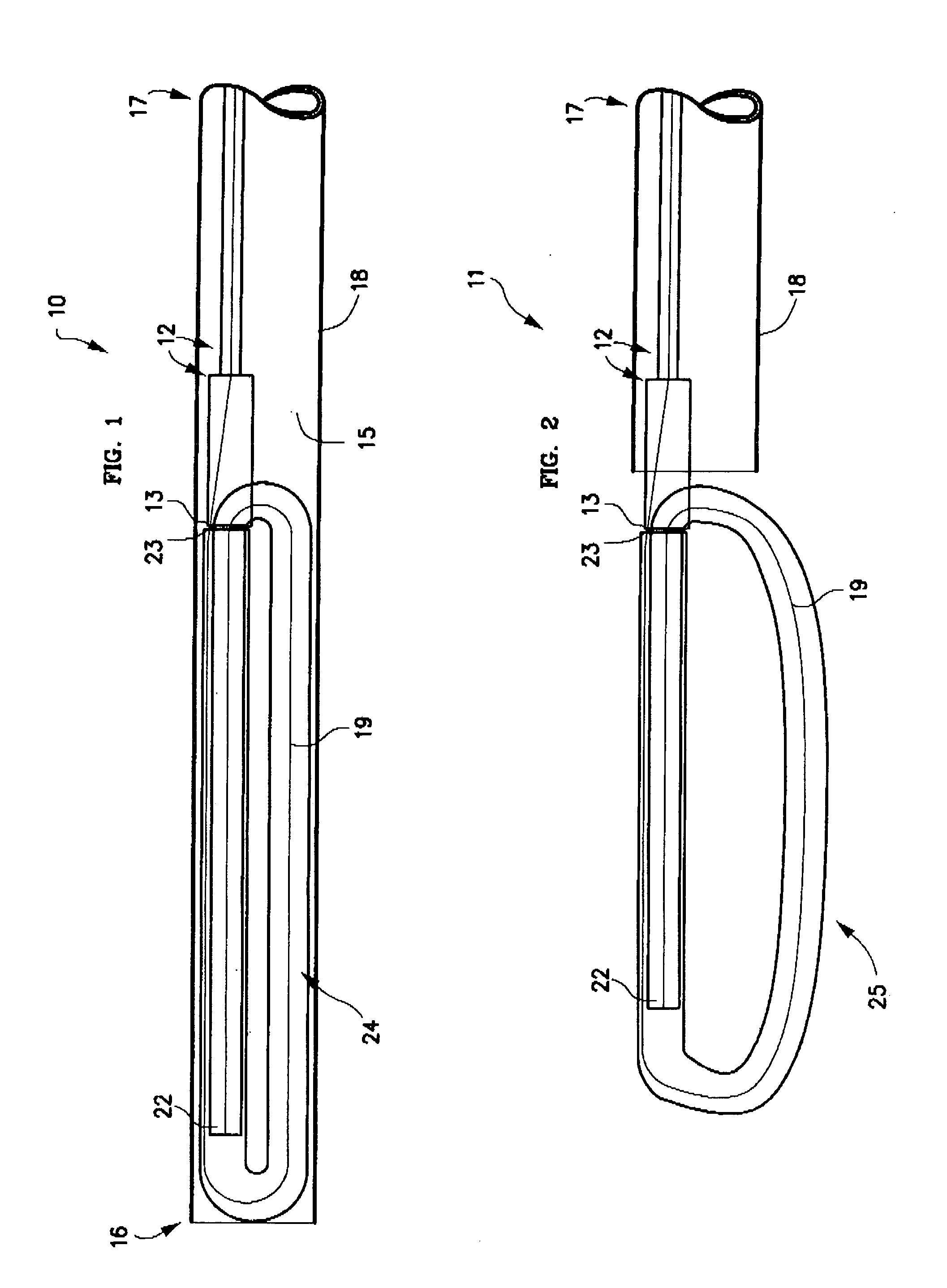

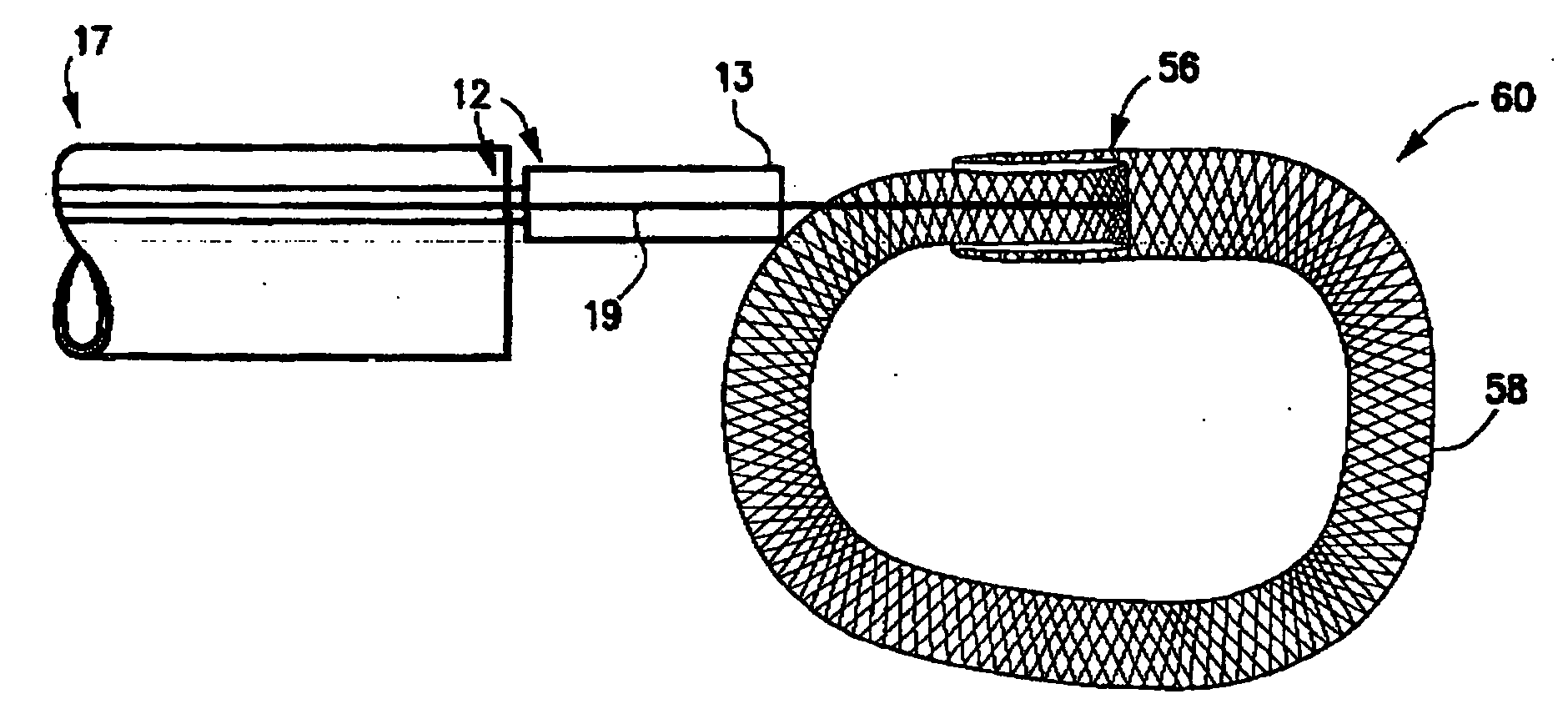

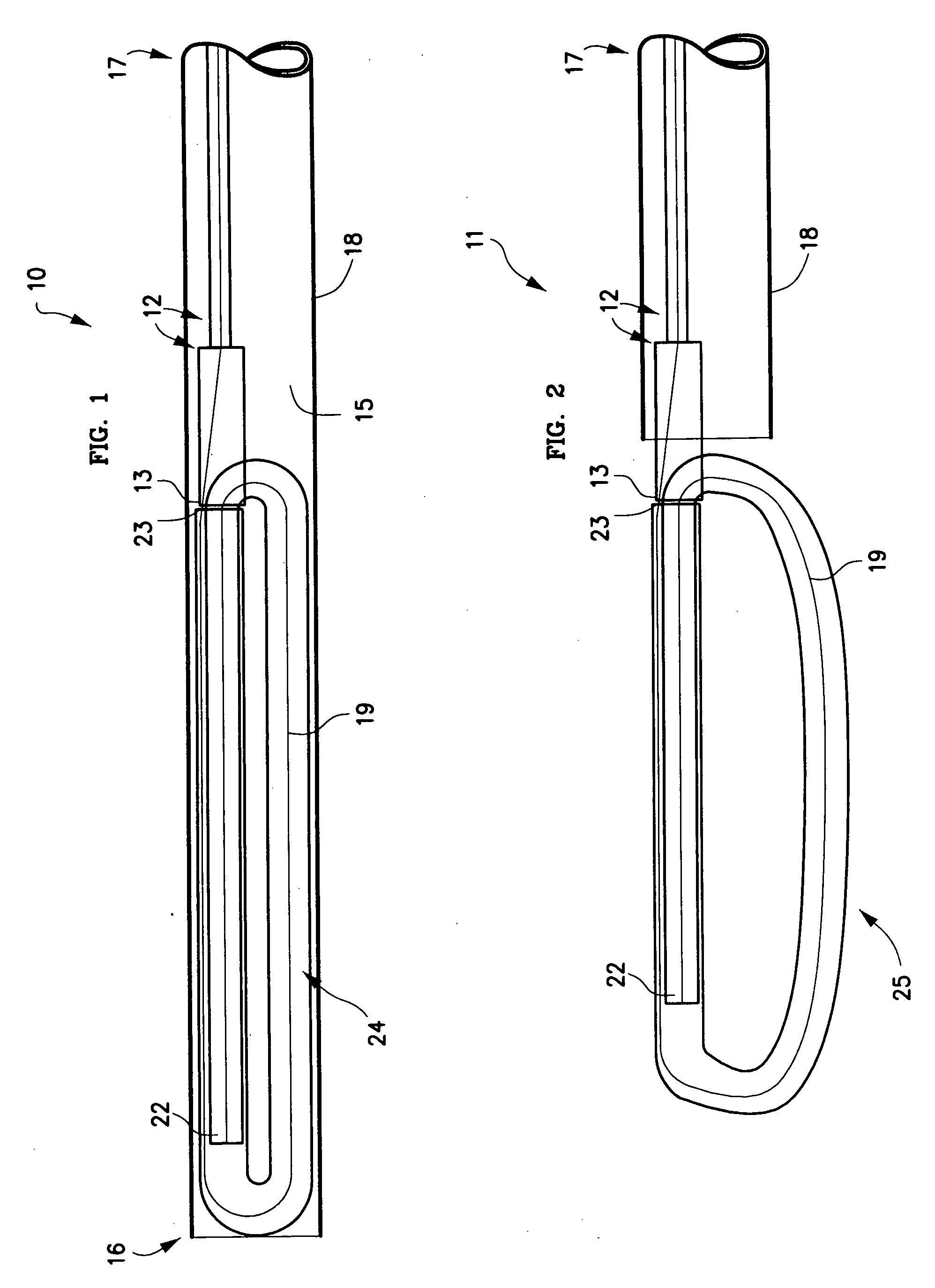

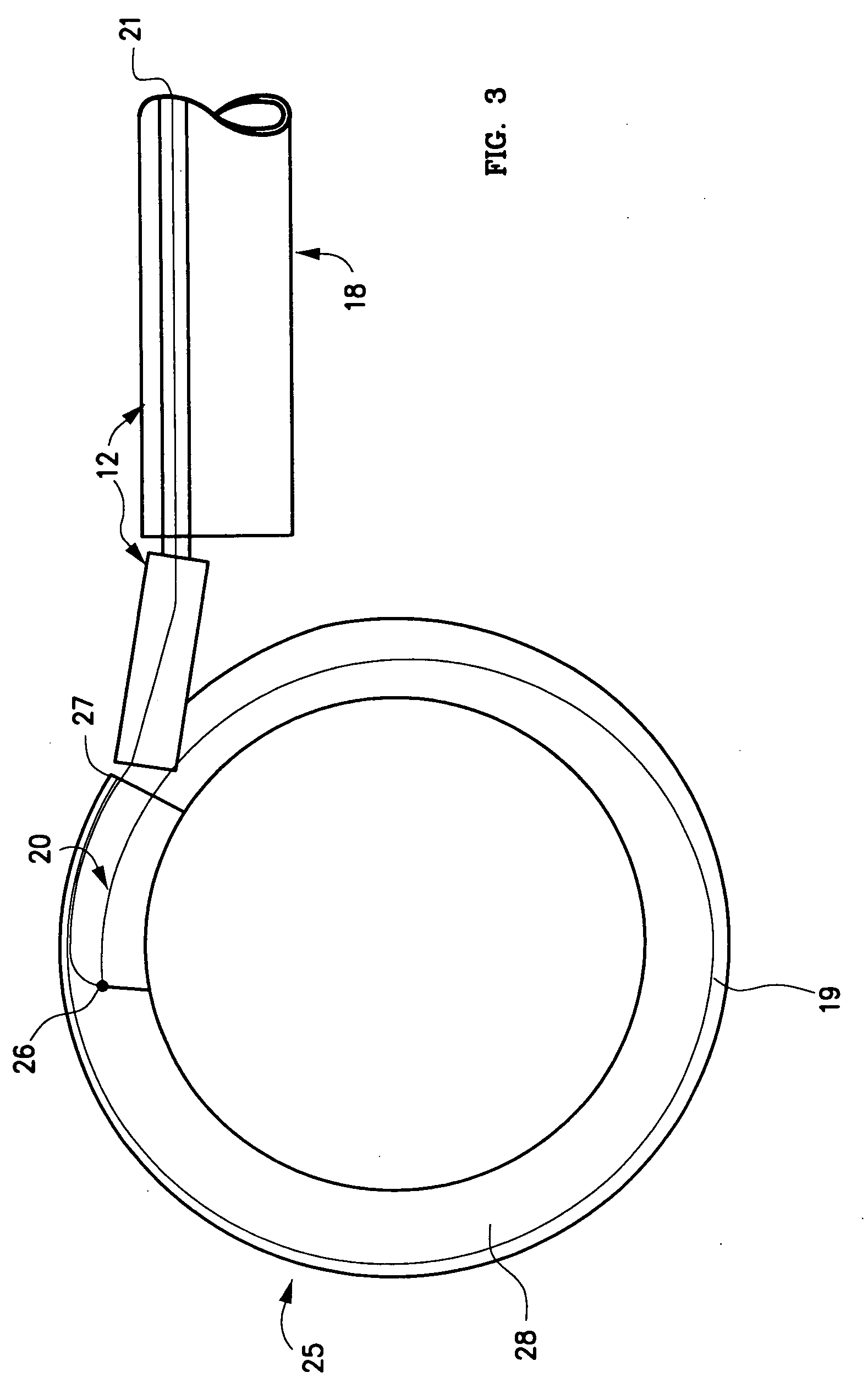

Mechanical apparatus and method for artificial disc replacement

InactiveUS20060287726A1Easy to integrateFree from painSuture equipmentsInternal osteosythesisPolyesterClosed loop

The present invention relates to a device and method which may be used to reinforce the native annulus during spinal surgery. The device is a catheter based device which is placed into the inter-vertebral space following discectomy performed by either traditional surgical or endoscopic approaches. The distal end of the catheter is comprised of an expansile loop which may be increased in diameter by advancement of a portion of the catheter via its proximal end, such proximal end remaining external to the body. The expansile loop may be formed of a woven or braided material and may be made of a polymer such as nylon, polyurethane, polyester, polyethylene, polypropylene or any of the well known and biocompatible polymers. Alternatively the expansile portion of the catheter may be formed from a metallic braid of stainless steel, elgiloy, Nitinol, or other biocompatible metals. The expansile loop may be formed such that when the loop is diametrically contracted the loop feeds into its other end, similar to a snake eating its own tail. Stabilization of the outer portion of the loop and pulling out the inner portion will thereby increase the overall diameter of the loop while maintaining it as a closed loop or torus. The present invention comprises four embodiments and can be used to 1) facilitate disk fusing, 2) perform an artificial replacement of the nucleus, 3) perform an artificial replacement of the annulus, or 4, perform an artificial replacement of both the nucleus and annulus.

Owner:OUROBOROS MEDICAL INC

Three-dimensional fabricating systems for rapidly producing objects

InactiveUS20160288376A1High strengthAdditive manufacturing apparatus3D object support structuresFree Radical SuppressionPolypropylene

This invention relates to rapid prototyping systems, specifically, a composition for a release film comprising one or more base materials selected from the group consisting of silicone, polycarbonate, polyethylene, and polypropylene; and one or more free-radical inhibitors.

Owner:DENTSPLY SIRONA INC

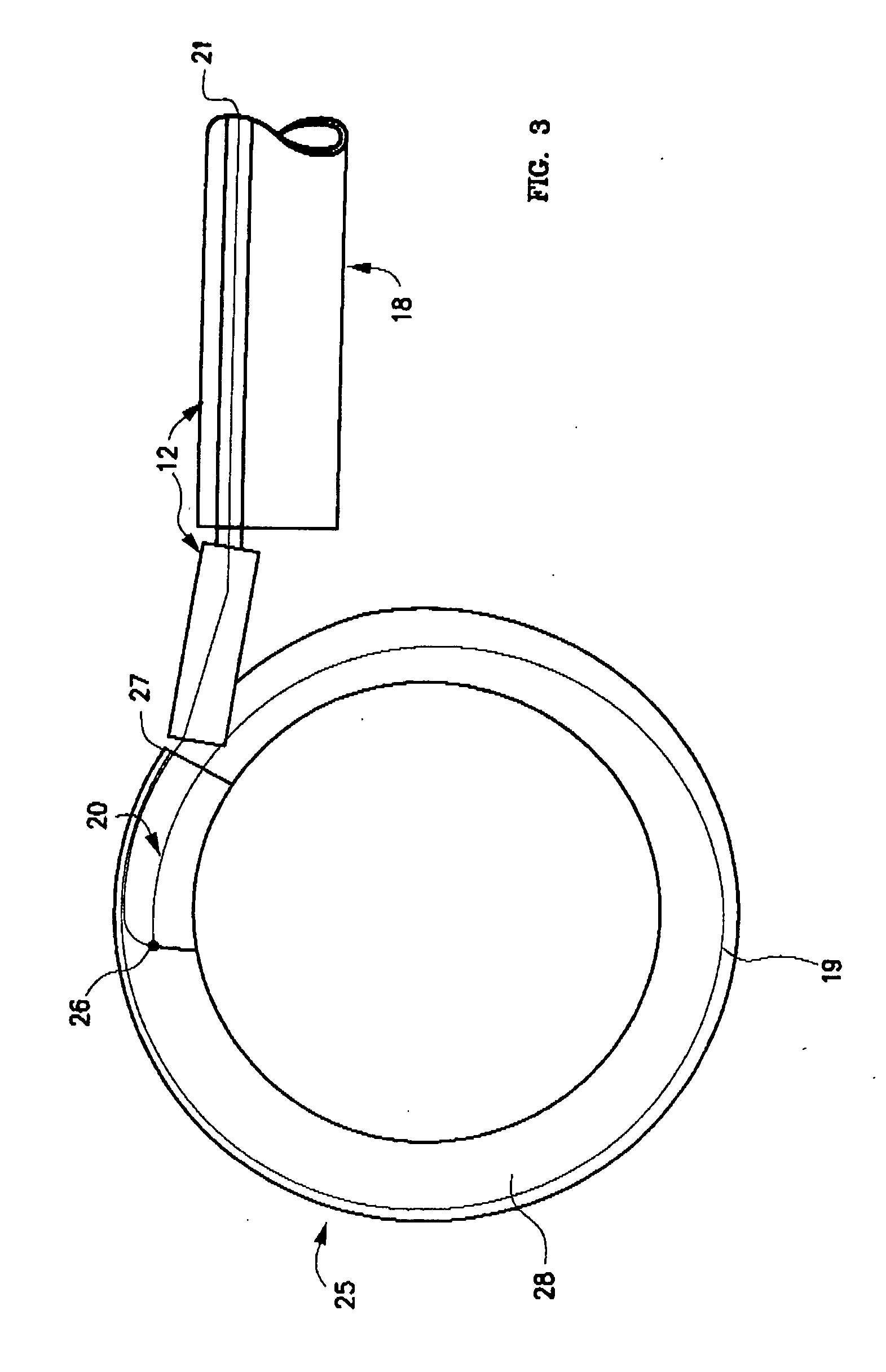

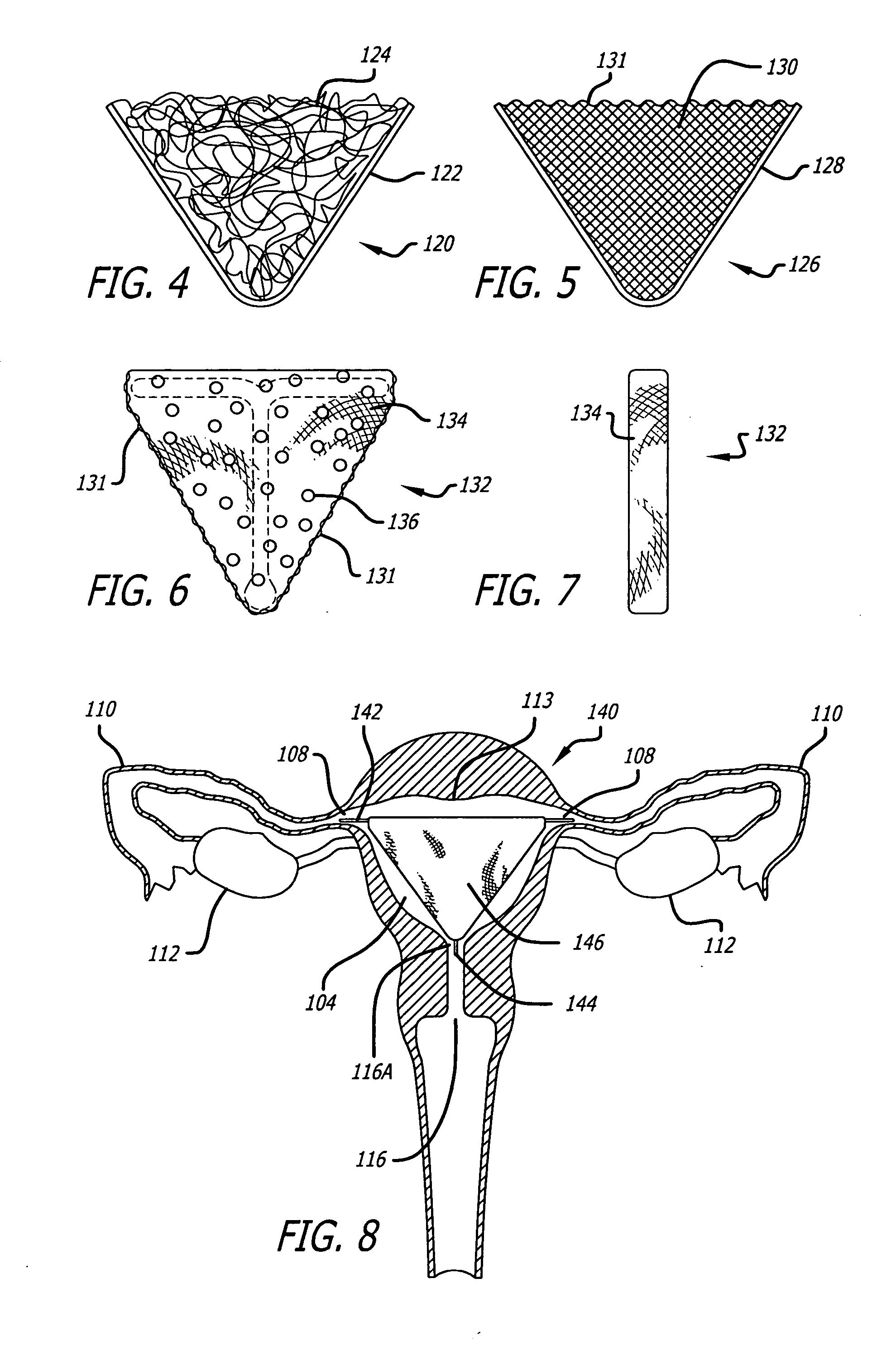

Method and apparatus for creating intrauterine adhesions

InactiveUS20050171569A1Better treat excessive bleedingPromote tissue growthUltrasonic/sonic/infrasonic diagnosticsSuture equipmentsExcessive BleedingGynecology

In general, the present invention contemplates an implantable device for treating excessive bleeding in a body cavity. The device comprises a biocompatible material, for example polyethylene teraphathalate (PET), which is deliverable into the body cavity. The biocompatible material contains an attribute(s) that promotes tissue reaction or growth that results in a tissue response and / or adhesion formation within the body cavity to reduce or stop the excessive bleeding.

Owner:AUB HLDG

Drawn gel-spun polyethylene yarns and process for drawing

ActiveUS6969553B1Synthetic resin layered productsMonocomponent polyolefin artificial filamentYarnSports equipment

Owner:HONEYWELL INT INC

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

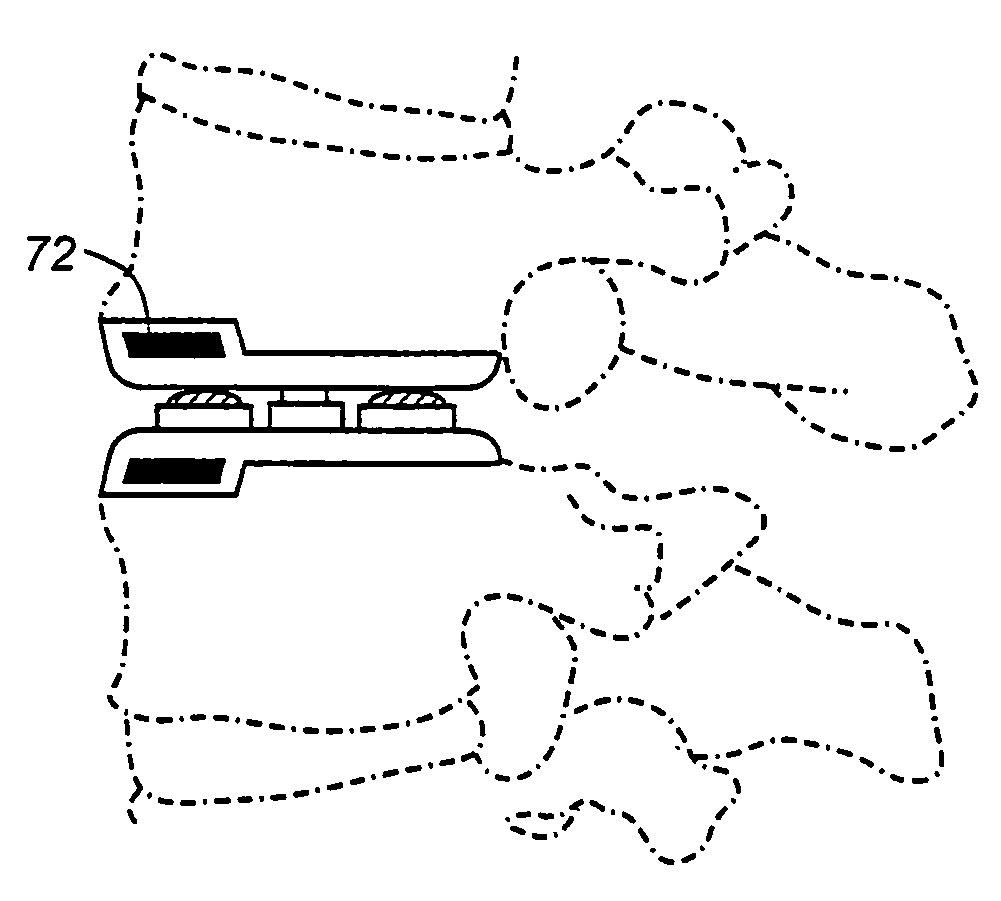

Prosthetic joints with contained compressible resilient members

InactiveUS20050192674A1Improve protectionEliminate shear stressInternal osteosythesisJoint implantsElastomerTotal knee replacement

In a total knee replacement (TKR), the use of a cushion element provides better wear characteristics than polyethylene (“poly”) alone. Since a metal-on-metal, metal-on-ceramic, or ceramic-on-ceramic articulating surface has better wear characteristics than metal on poly, the invention essentially provides cushioning for metal / ceramic-on-metal / ceramic joint replacements. It also allows the use of elastomers for their cushioning properties rather than their surface wear and tensile strength characteristics. The contained compressible elements could also be used as a cushion below polyethylene components, polyethylene over metal components, unicondylar knee replacements, patellar components, and prosthetic components for other parts of the body, including the hip, elbow, shoulder, wrist, and ankle.

Owner:ANOVA

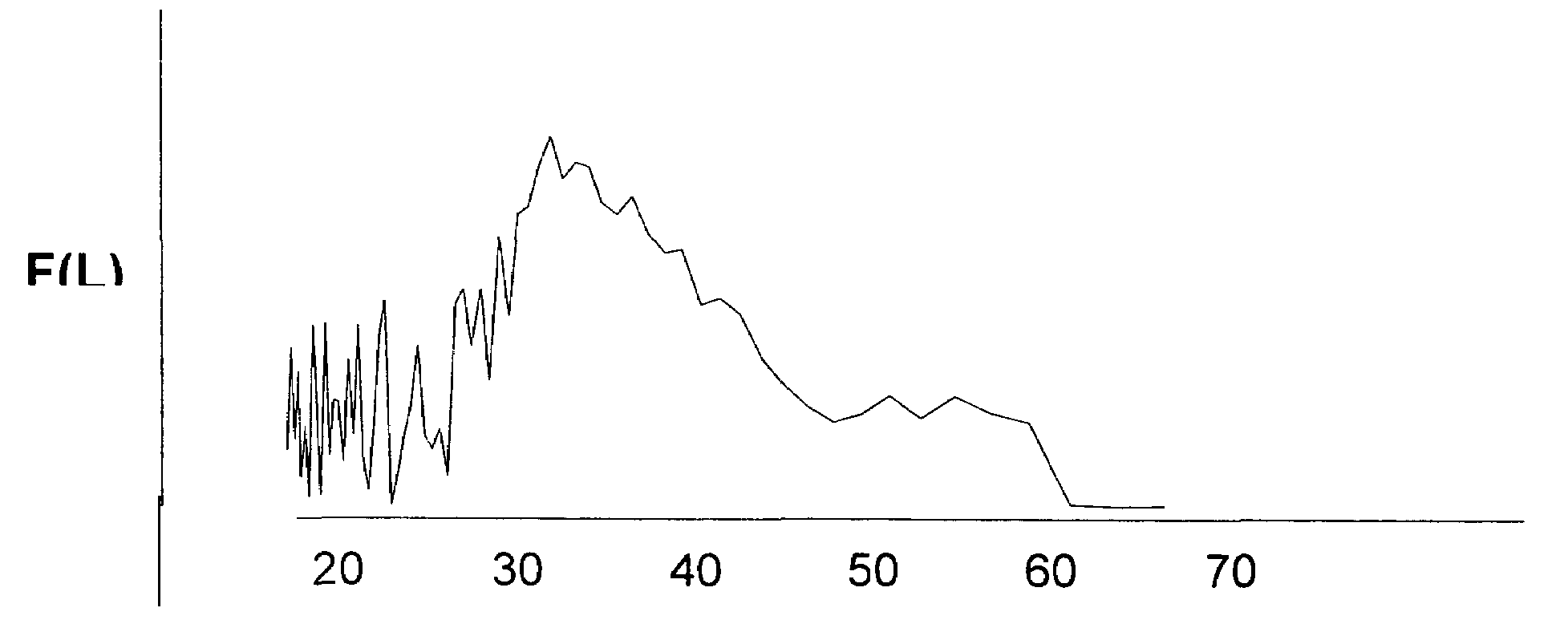

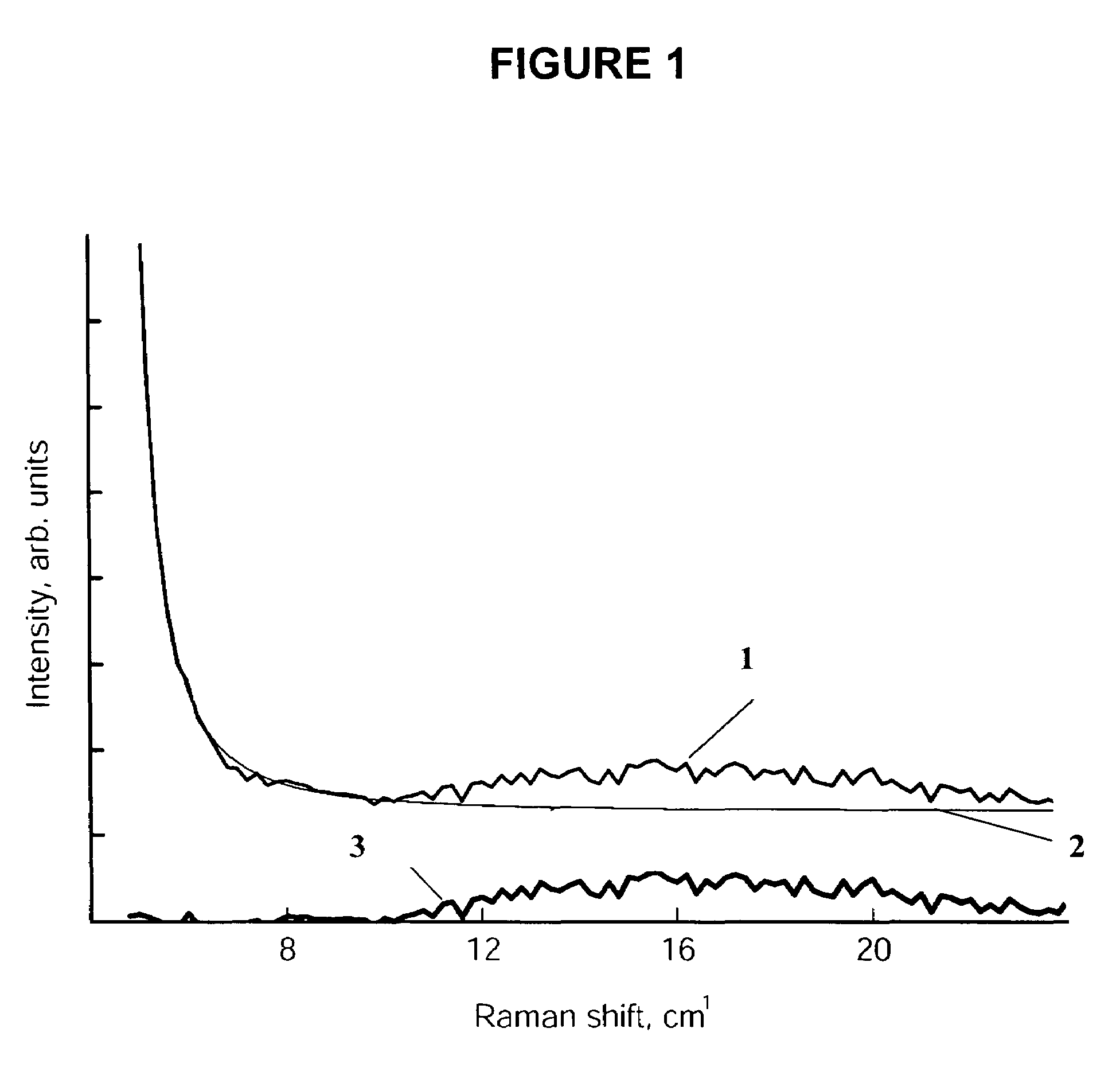

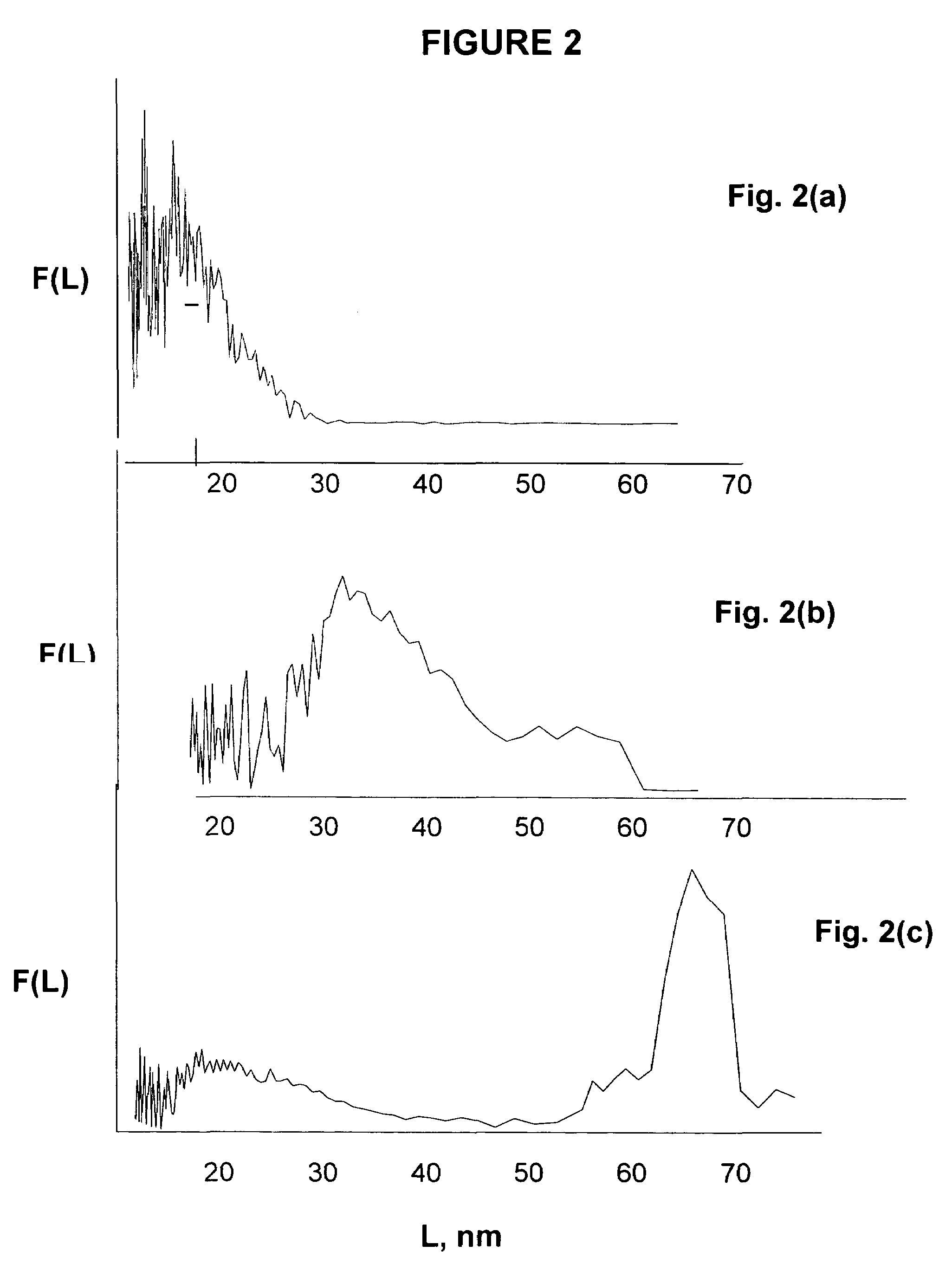

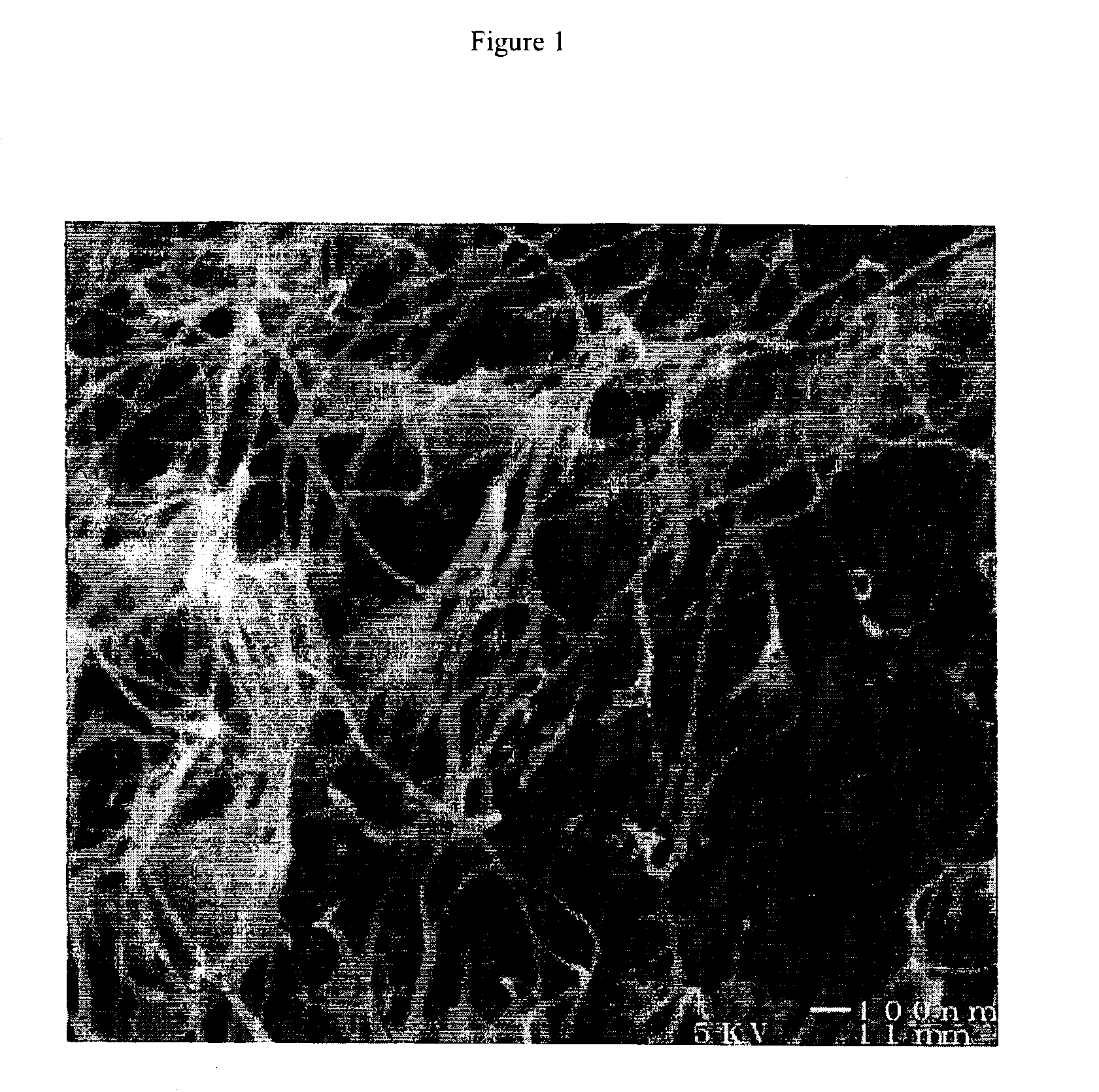

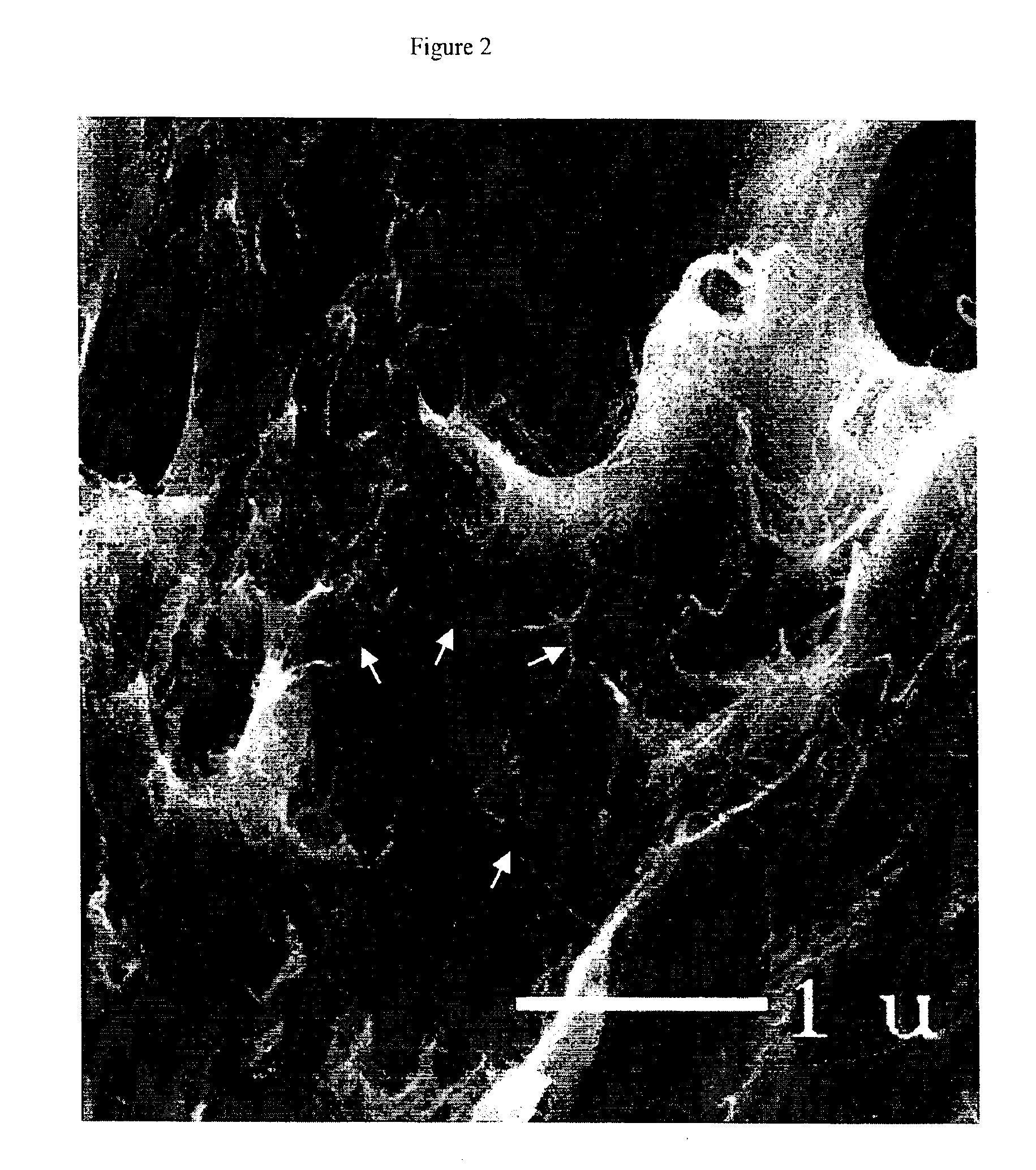

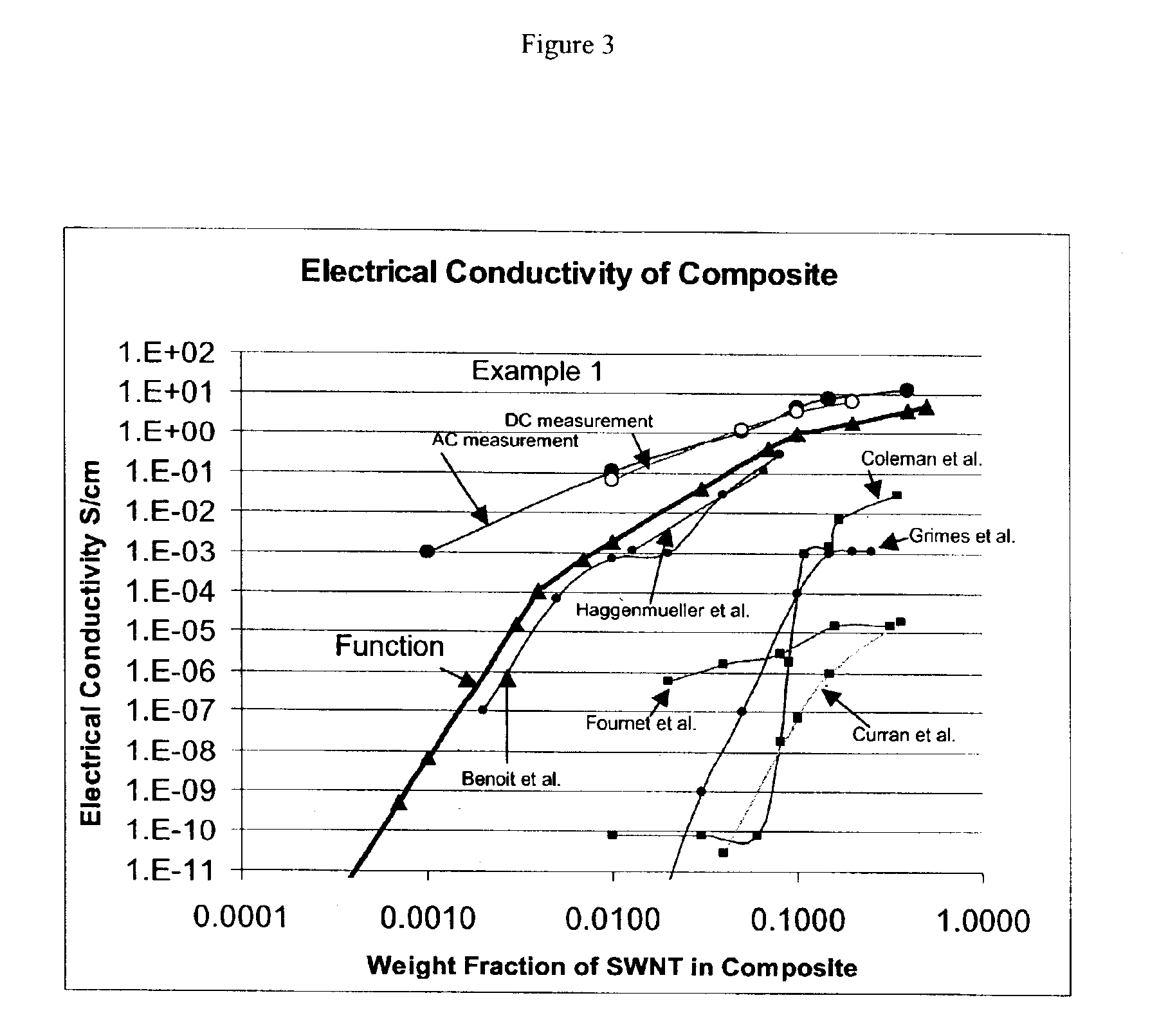

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

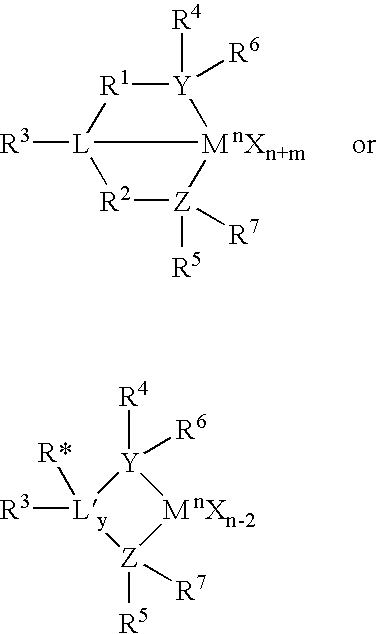

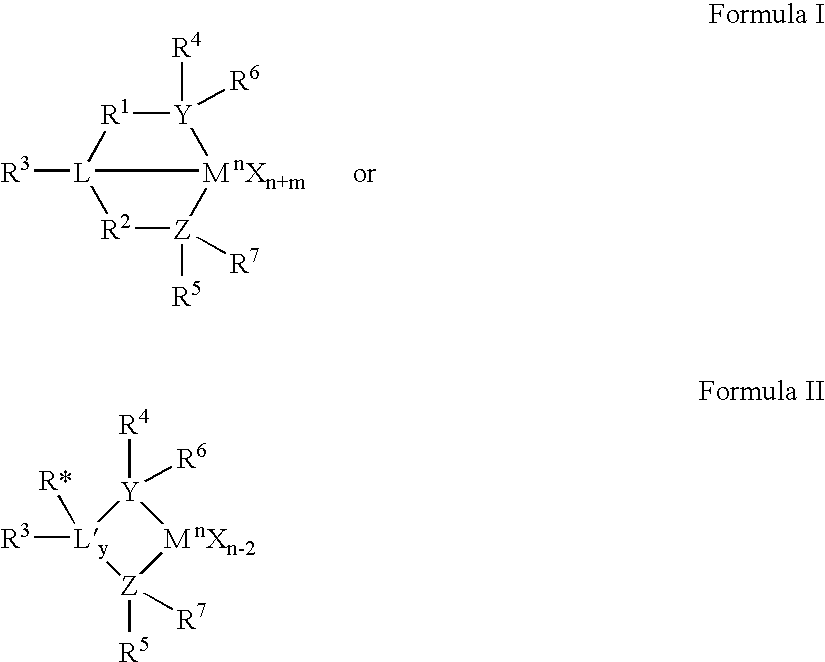

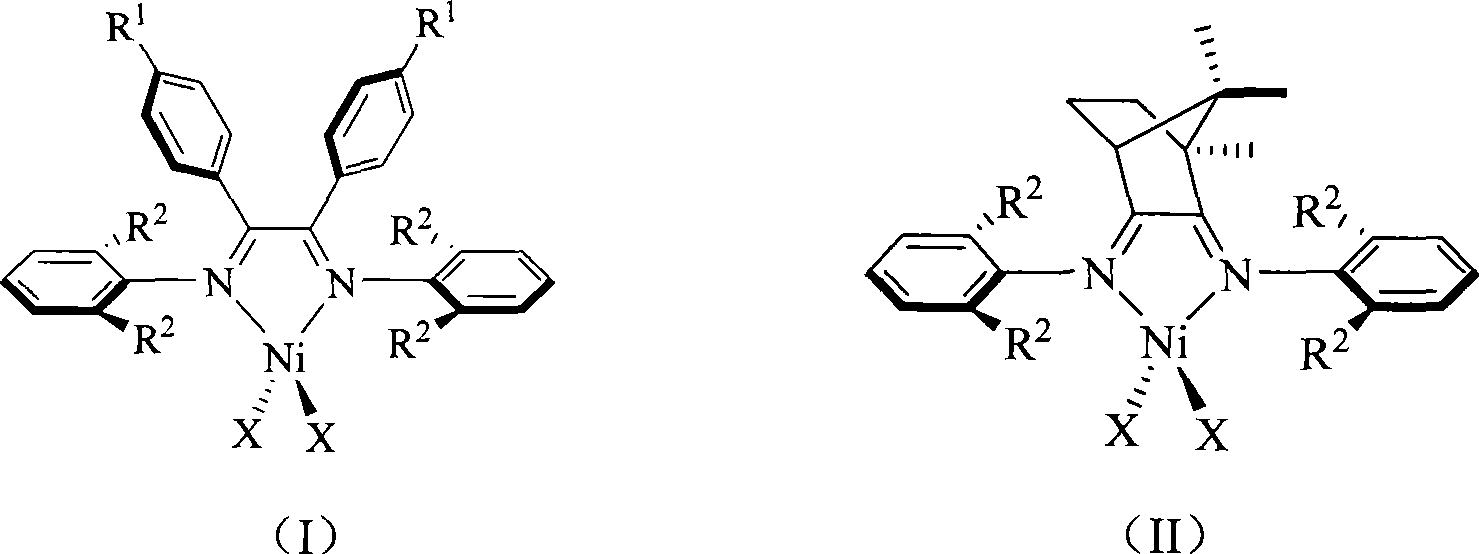

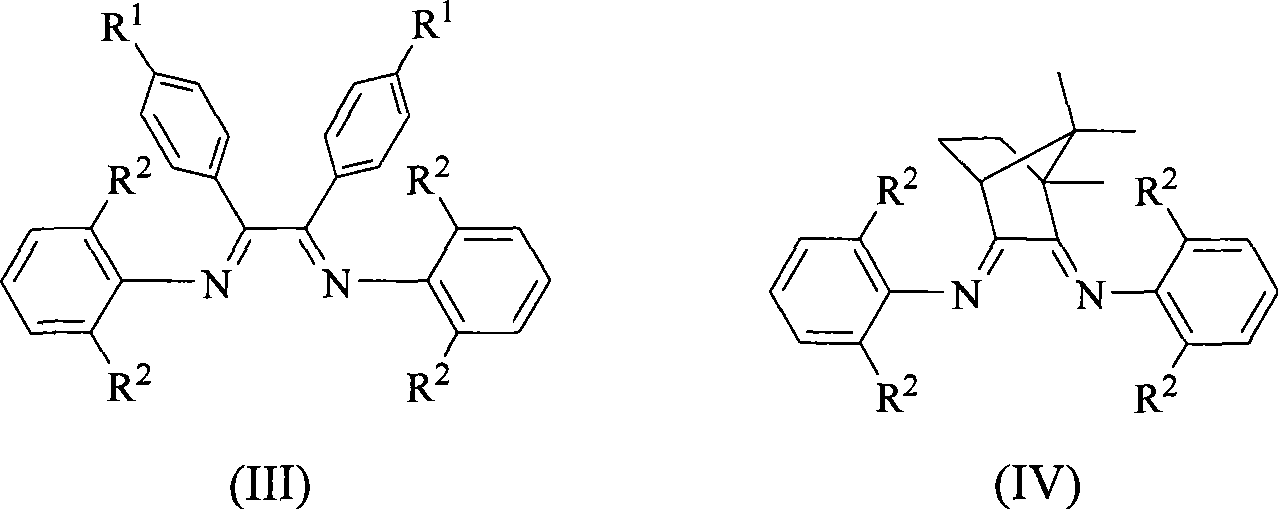

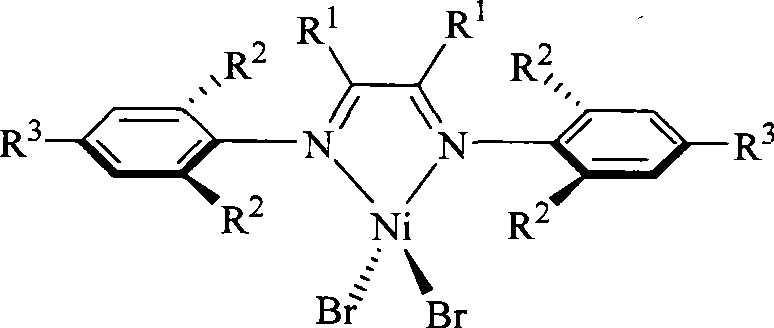

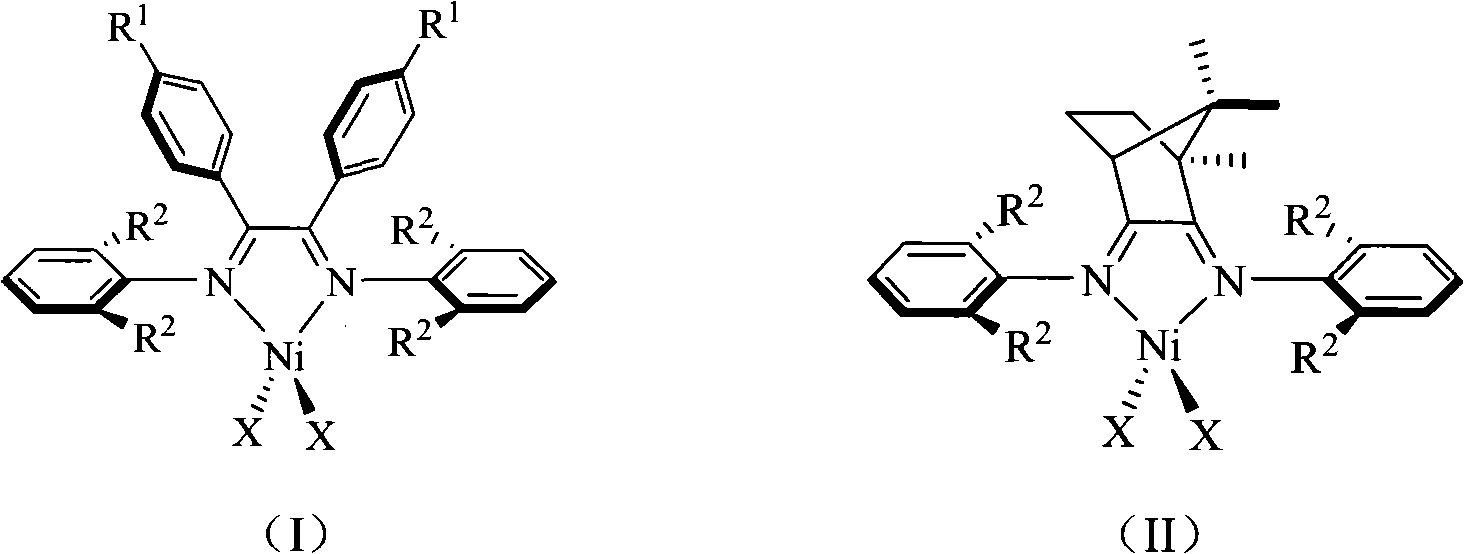

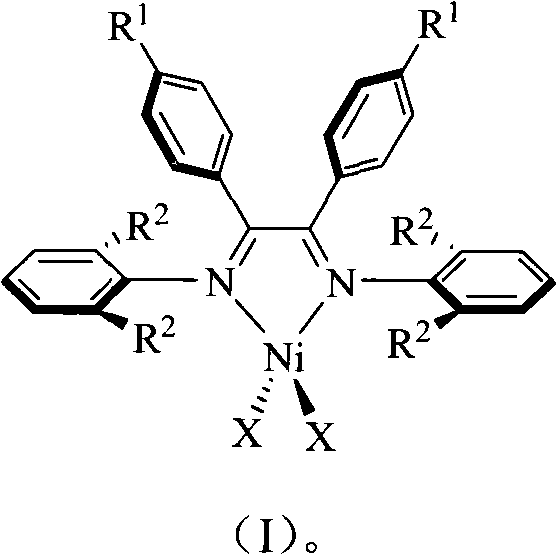

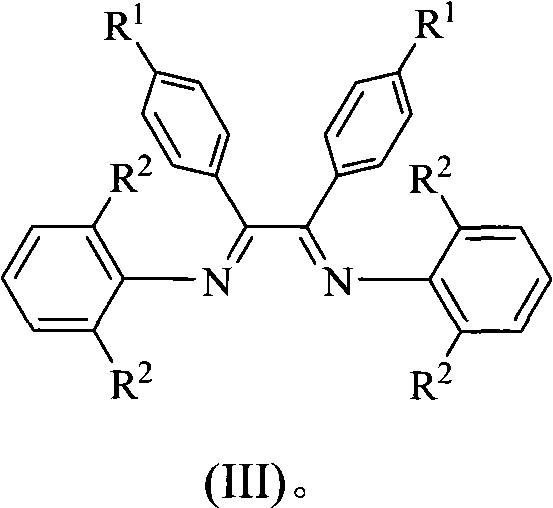

Alpha-nickel diimine compound olefin polymerization catalyst and preparation method thereof, and method for preparing branched polyethylene

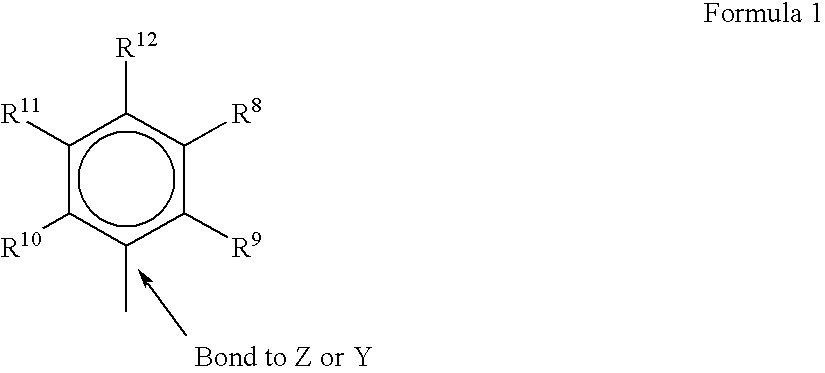

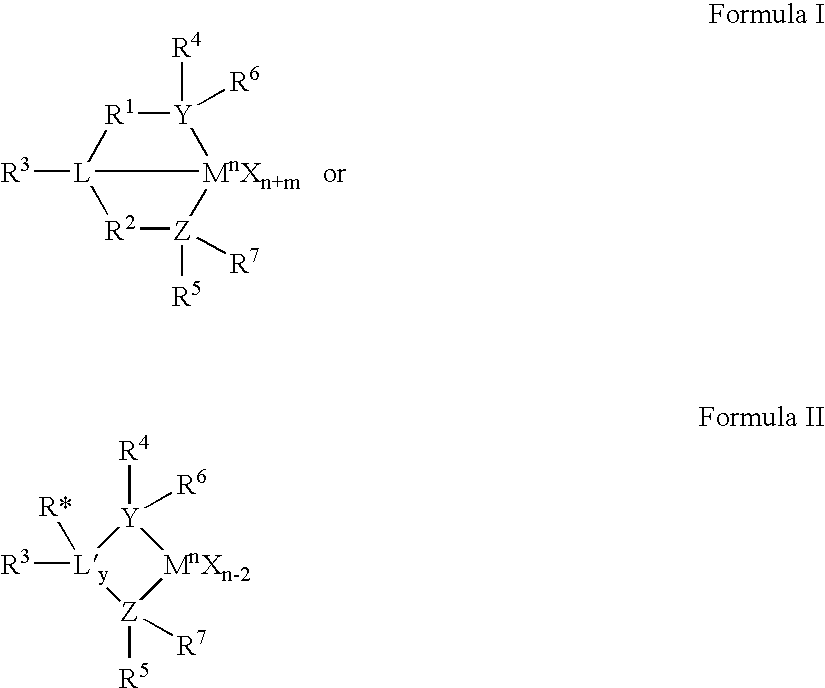

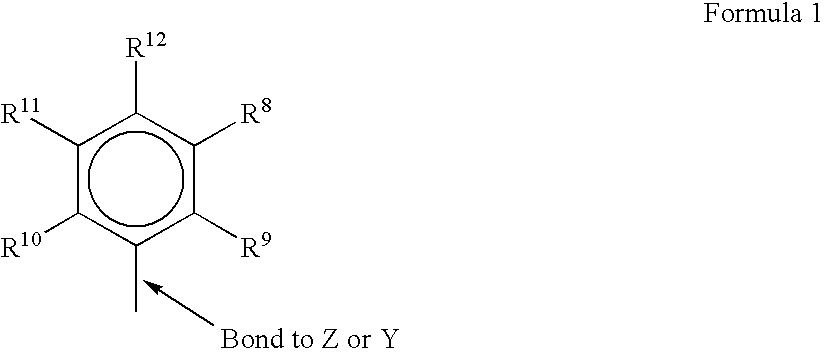

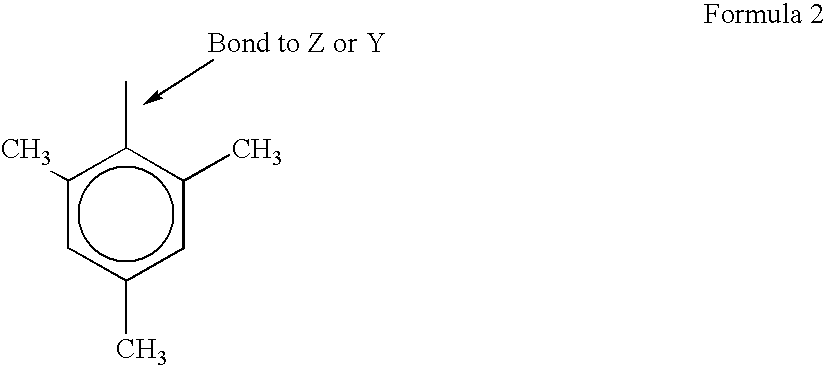

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst and a preparation method thereof, and a method for preparing branched polyethylene. Structural formulas of the alpha-nickel diimine compound olefin polymerization catalyst are shown as a formula (I) and a formula (II), and the preparation method of the alpha-nickel diimine compound olefin polymerization catalyst is simple and low in cost, and can catalyze ethylene polymerization with high activity at a temperature of more than or equal to 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared by catalyzing of the alpha-nickel diimine compound olefin polymerization catalyst has high molecular weight, and can prepare molecular weight which reaches more than 10<2>*kg / mol in the temperature range of between 0 and 80 DEG C.

Owner:SUN YAT SEN UNIV

Mechanical apparatus and method for artificial disc replacement

InactiveUS20060287727A1Increase the diameterEasy to integrateSuture equipmentsBone implantPolyesterClosed loop

The present invention relates to a device and method which may be used to reinforce the native annulus during spinal surgery. The device is a catheter based device which is placed into the inter-vertebral space following discectomy performed by either traditional surgical or endoscopic approaches. The distal end of the catheter is comprised of an expansile loop which may be increased in diameter by advancement of a portion of the catheter via its proximal end, such proximal end remaining external to the body. The expansile loop may be formed of a woven or braided material and may be made of a polymer such as nylon, polyurethane, polyester, polyethylene, polypropylene or any of the well known and biocompatible polymers. Alternatively the expansile portion of the catheter may be formed from a metallic braid of stainless steel, elgiloy, Nitinol, or other biocompatible metals. The expansile loop may be formed such that when the loop is diametrically contracted the loop feeds into its other end, similar to a snake eating its own tail. Stabilization of the outer portion of the loop and pulling out the inner portion will thereby increase the overall diameter of the loop while maintaining it as a closed loop or torus. The present invention comprises four embodiments and can be used to 1) facilitate disk fusing, 2) perform an artificial replacement of the nucleus, 3) perform an artificial replacement of the annulus, or 4, perform an artificial replacement of both the nucleus and annulus.

Owner:OUROBOROS MEDICAL INC

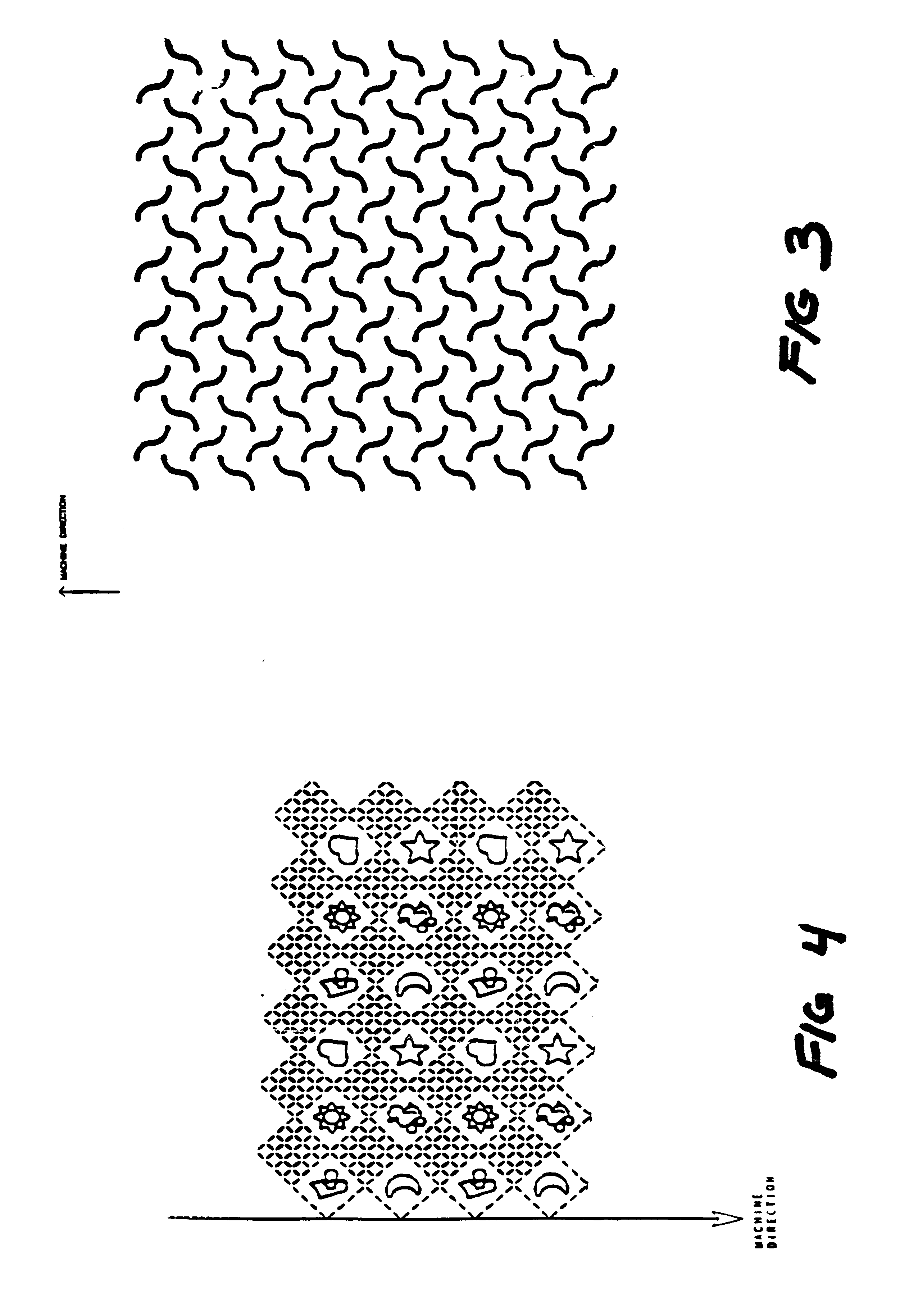

Extensible Nonwoven Fabric

ActiveUS20140276517A1High elongationImprovement in one or moreBaby linensWoven fabricsExtensibilityNonwoven fabric

Extensible nonwoven fabrics having improved elongation, extensibility, abrasion resistance and toughness. In particular, embodiments of the invention are directed to extensible spunbond fabrics comprising a polymeric blend of a metallocene catalyzed polypropylene, polyethylene, and a third polymer component.

Owner:FITESA GERMANY +1

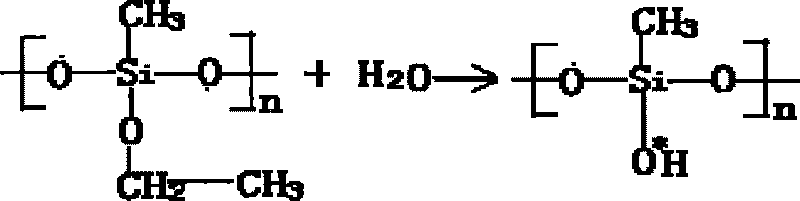

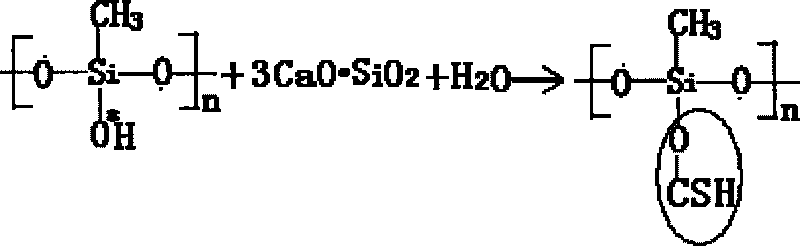

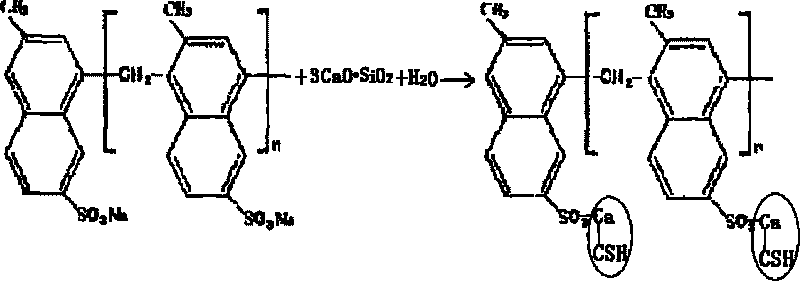

Waterproof roll capable of carrying out chemical bonding and physical crosslinking synergism with concrete

ActiveCN101694114AImprove stabilityIncreased durabilityRoof covering using flexible materialsTextiles and paperAntioxidantPlasticizer

The invention discloses a wet-laying and pre-laying waterproof roll which is made by the following processes: dipping and coating a modified asphalt compound on a blank body, controlling the thickness and sizing, coating a membrane, rolling, and the like, wherein the modified asphalt compound contains modified asphalt, a plasticizer, an antioxidant, a functional auxiliary agent and a filling gent. A preparation method of the waterproof roll comprises the following steps: putting substrate asphalt in a reaction pot, adding a thickening agent, irregular polyethylene and styrene-polybutadiene-styrene segmented copolymer, evenly mixing, heating and stirring for 1.5-2 hours, then reducing the temperature to about 180 DEG C, adding padding, the plasticizer, the antioxidant and the functional auxiliary agent into the reaction pot and stirring for 0.5-1h, evenly mixing and modifying, then conveying into a colloid mill for repeatedly milling to the material, then dipping and coating the modified asphalt on the blank body, controlling the thickness, sizing, coating the membrane and rolling, and finally preparing the waterproof roll which has excellent performance and can carry out chemical bonding and physical crosslinking synergism with the concrete, namely, a CPS waterproof roll for short.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

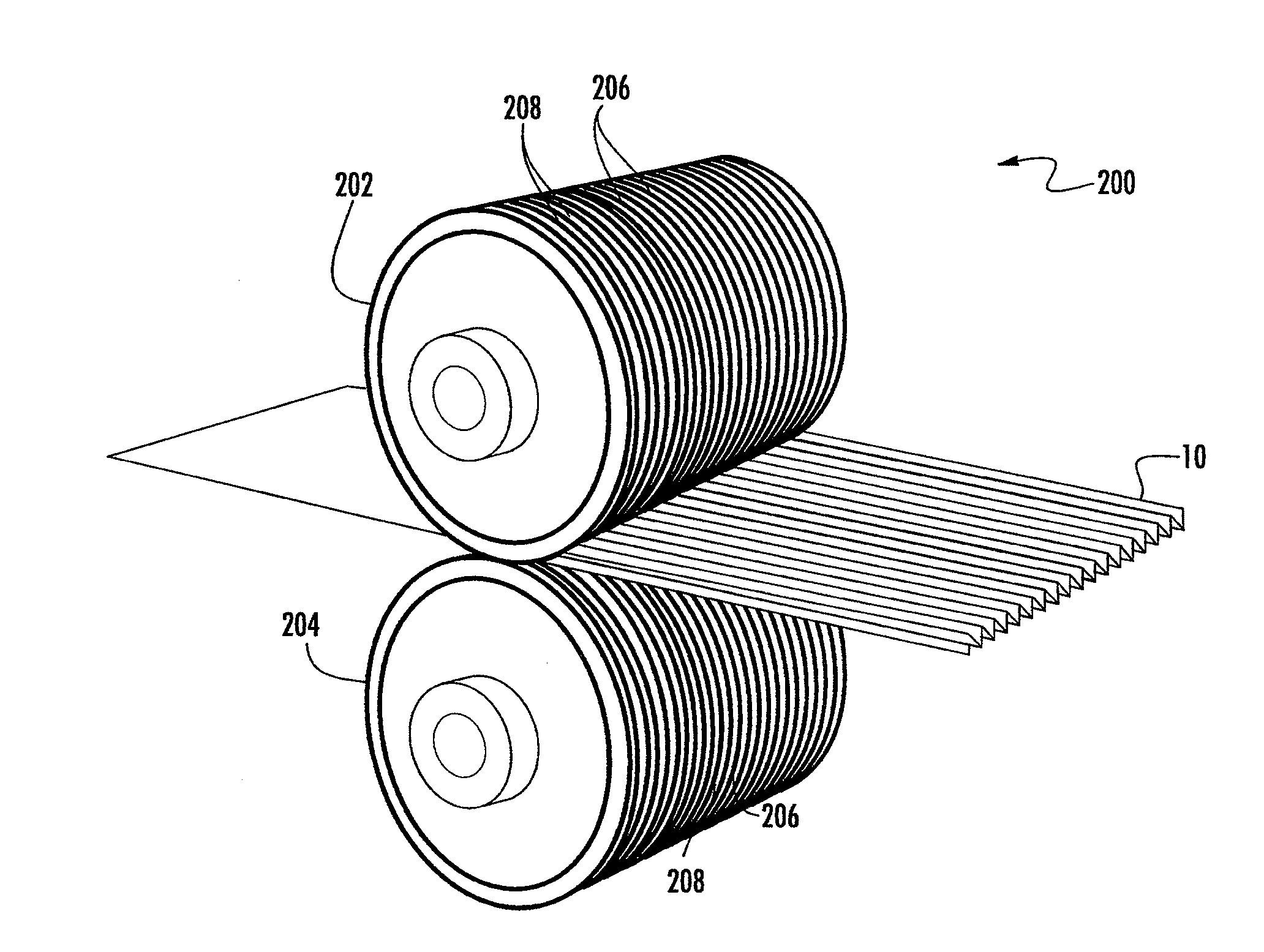

Process for drawing gel-spun polyethylene yarns

InactiveUS20050093200A1Domestic articlesMonocomponent polyolefin artificial filamentProduction rateForced convection

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

High strength polyethylene film

InactiveUS6248831B1Close tolerance in film thicknessGood high speed extrusion bubble stabilitySolubilityAlpha-olefin

A process for production of a polyethylene blend in situ comprising contacting ethylene and at least one alpha-olefin with a magnesium / titanium based catalyst system including a partially activated precursor and a cocatalyst in each of two fluidized bed reactors connected in series, one of the provisos being that the precursor is formed by contacting an alkylaluminum halide with a solid reaction product prepared from a magnesium alkoxide, a titanium tetraalkoxide, and a solubility enhancing agent.

Owner:UNION CARBIDE CORP

Stable breathable elastic garments

InactiveUS6909028B1Good body conformanceImprove breathabilityPersonal careSynthetic resin layered productsPolyvinyl polymerPolymer science

A thermally stable microporous breathable film is provided comprising at least 35% filler, by weight of the filled-film, and a thermoplastic polymer blend of a first polyethylene polymer and a second polyethylene polymer. The first polyethylene polymer comprises 30%-70% by weight of the polymer blend and can have a density between about 0.86 g / cm3 and 0.89 g / cm3 and the second polyethylene polymer can have a density between about 0.90 g / cm3 and 0.92 g / cm3. The filled-film can be uniaxially or biaxially oriented to form a microporous film and / or film laminate having good body conformance and which retains a high WVTR at 37° C. and above.

Owner:KIMBERLY-CLARK WORLDWIDE INC

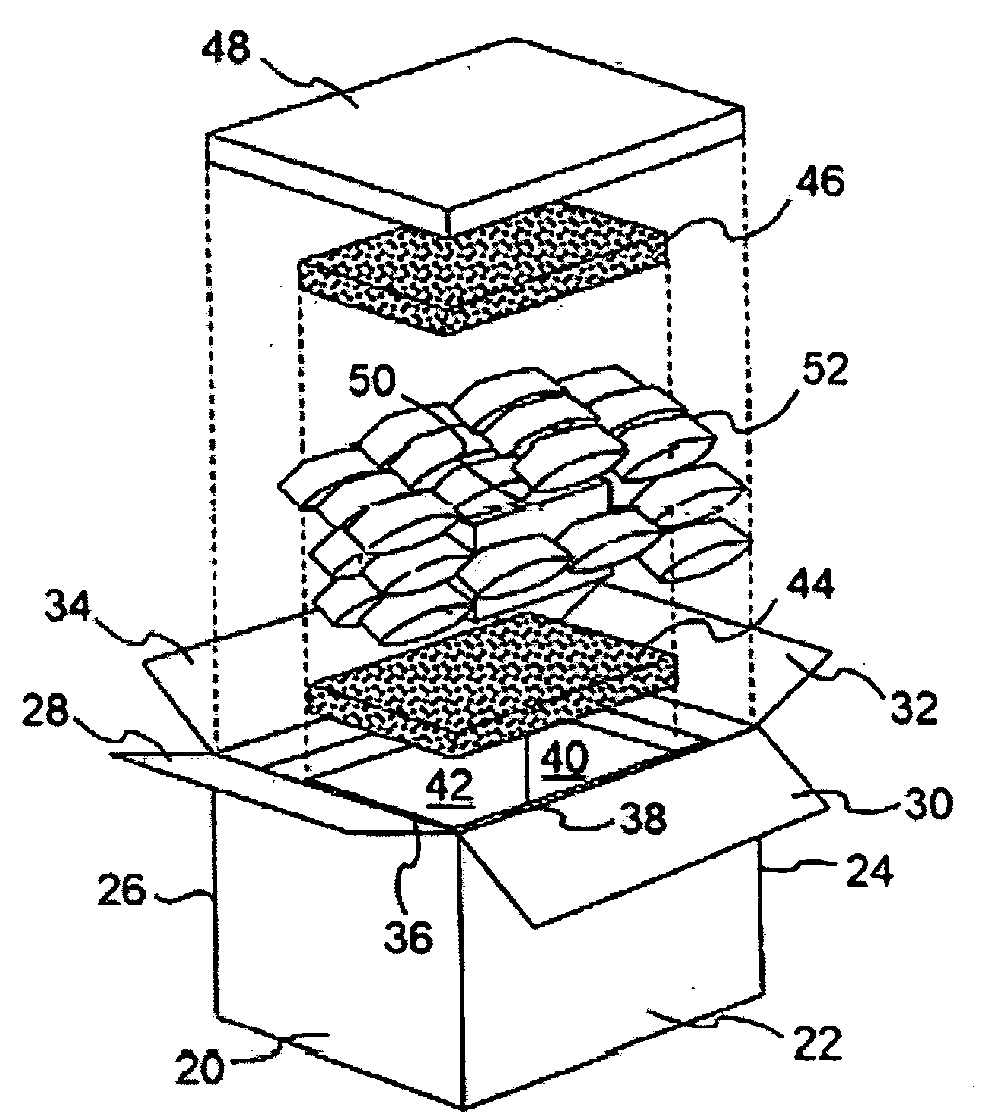

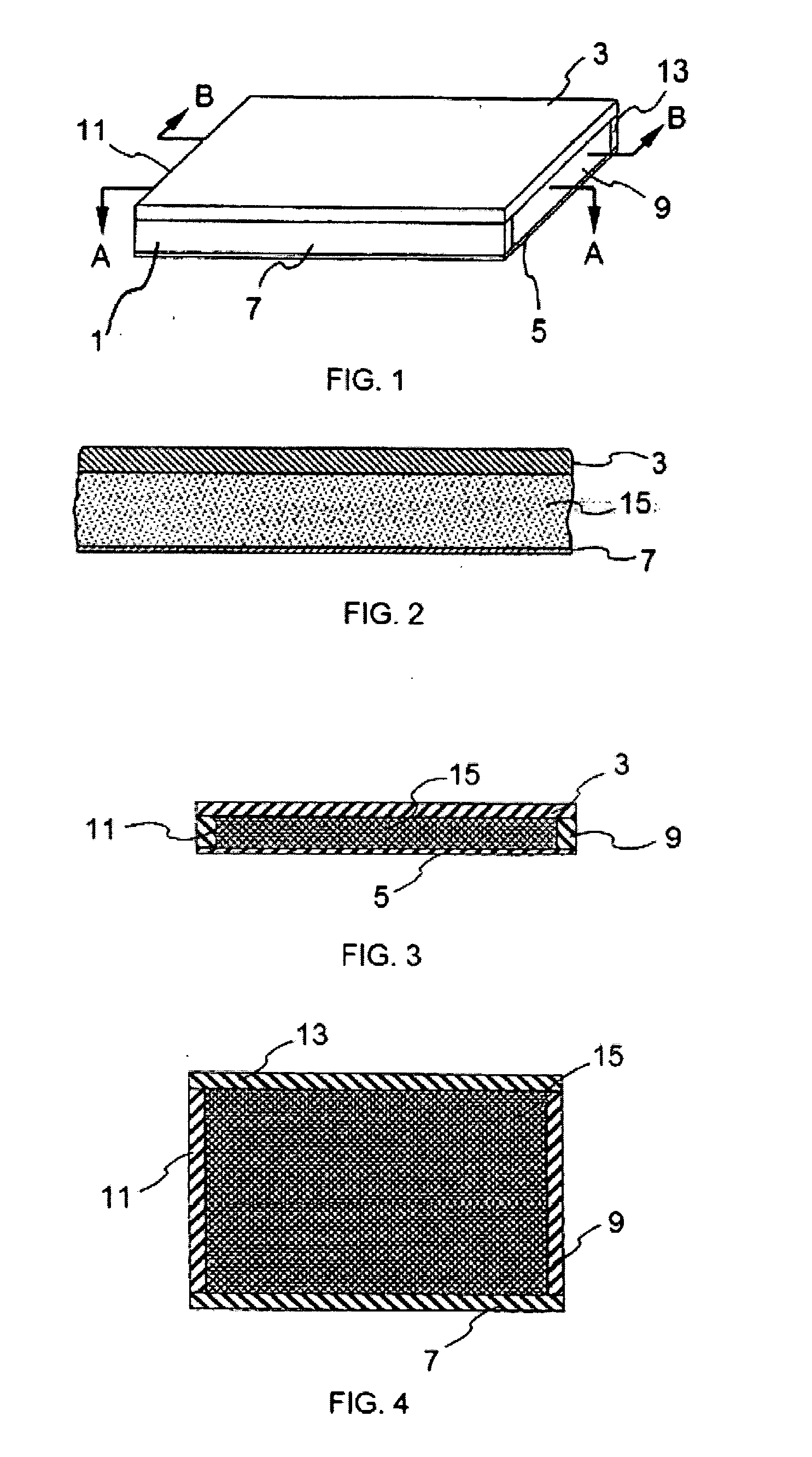

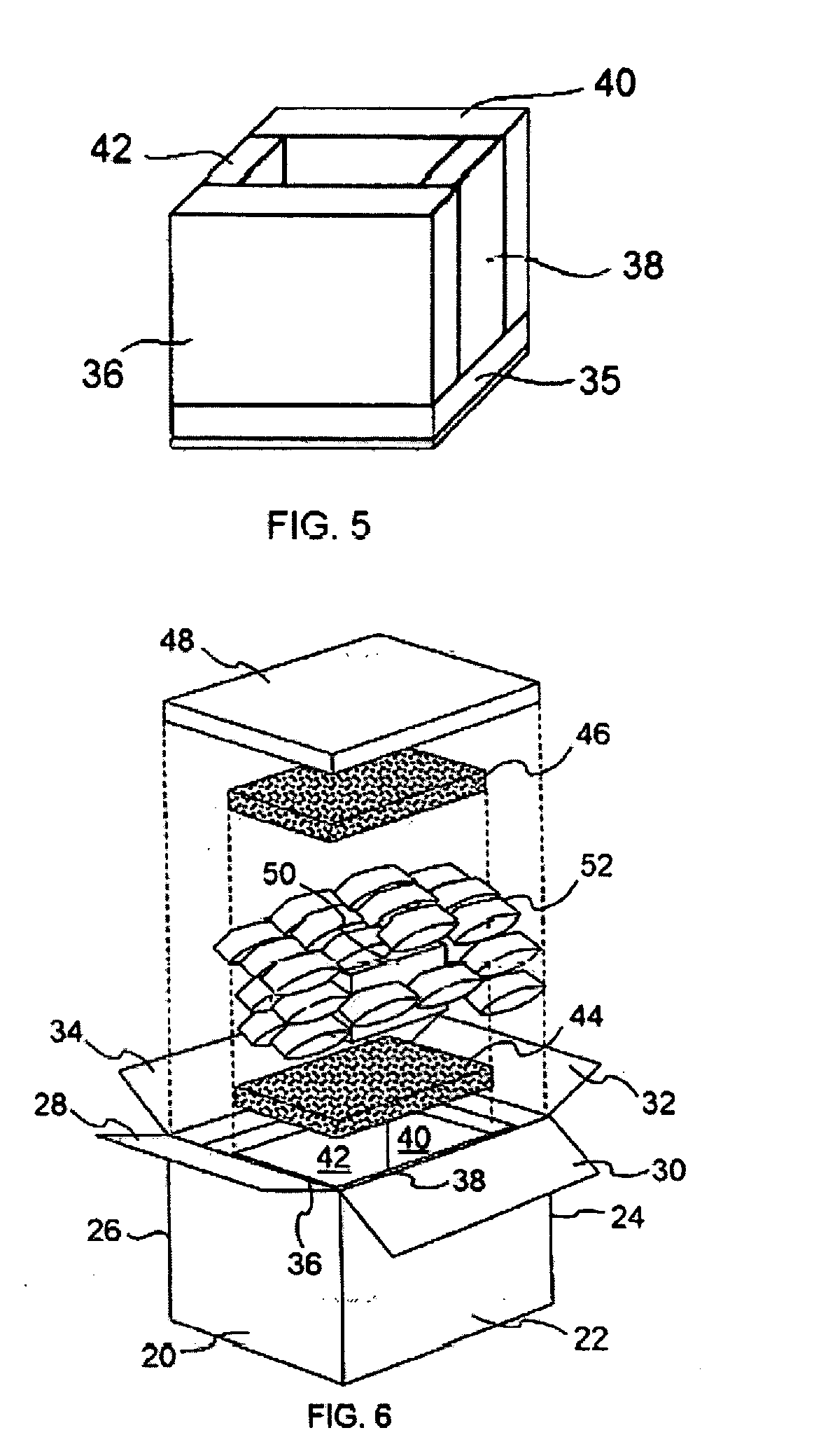

Insulated panels and shipping container incorporating said panels

The invention relates to an insulation panel for use in thermally insulated shipping containers, the panel comprising a rigid core of an insulation material, the core being wholly encompassed within a polyethylene foam envelope. A container made from the panels and a shipping carton is also described.

Owner:FAGERDALA SINGAPORE PTE

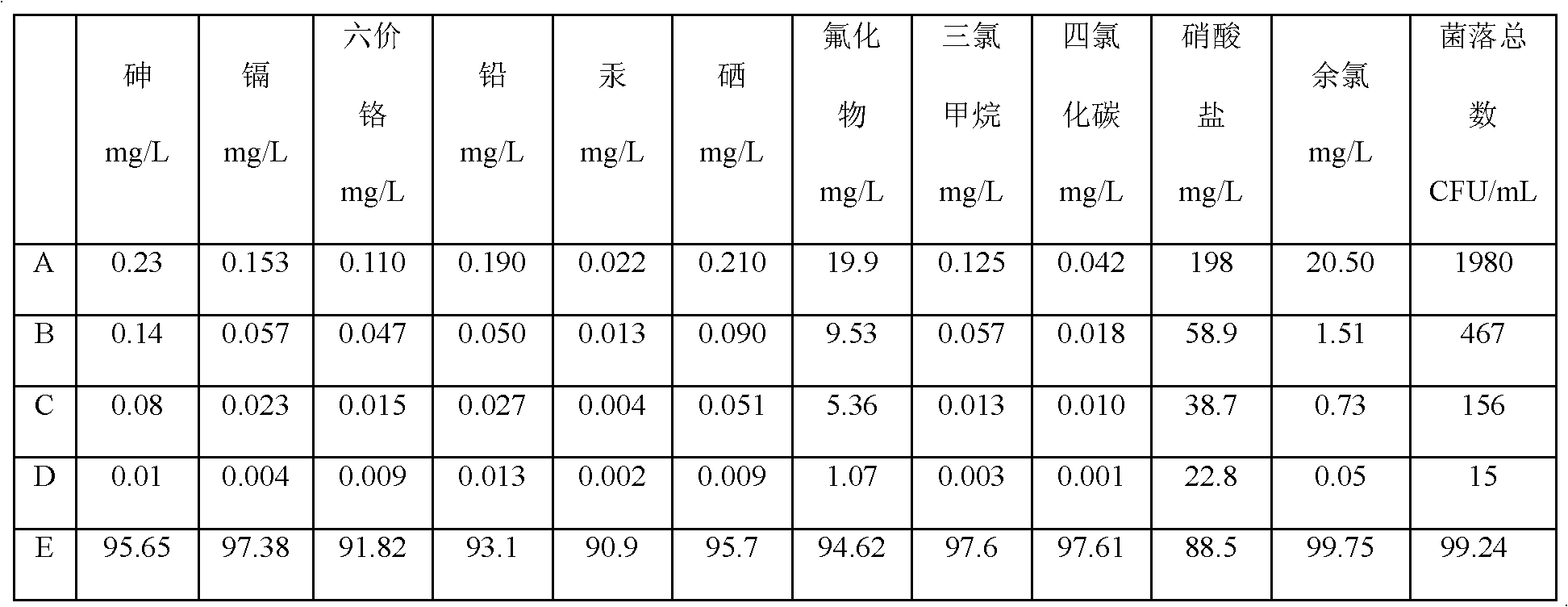

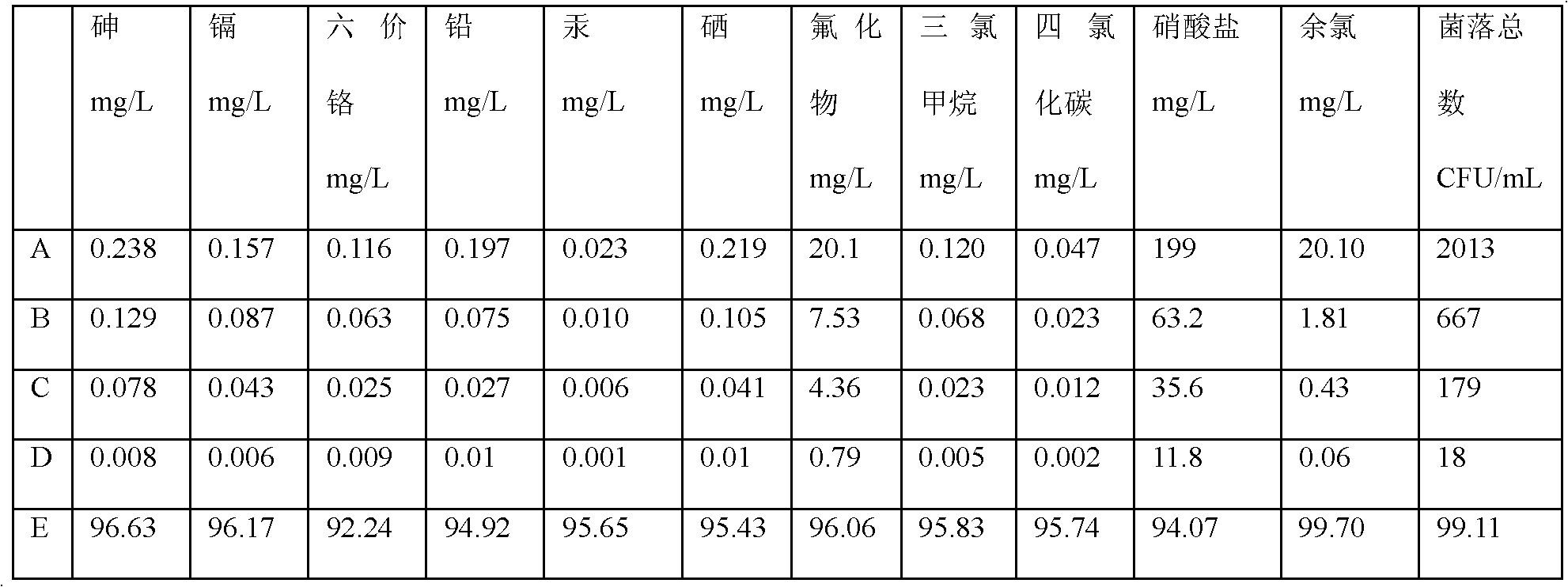

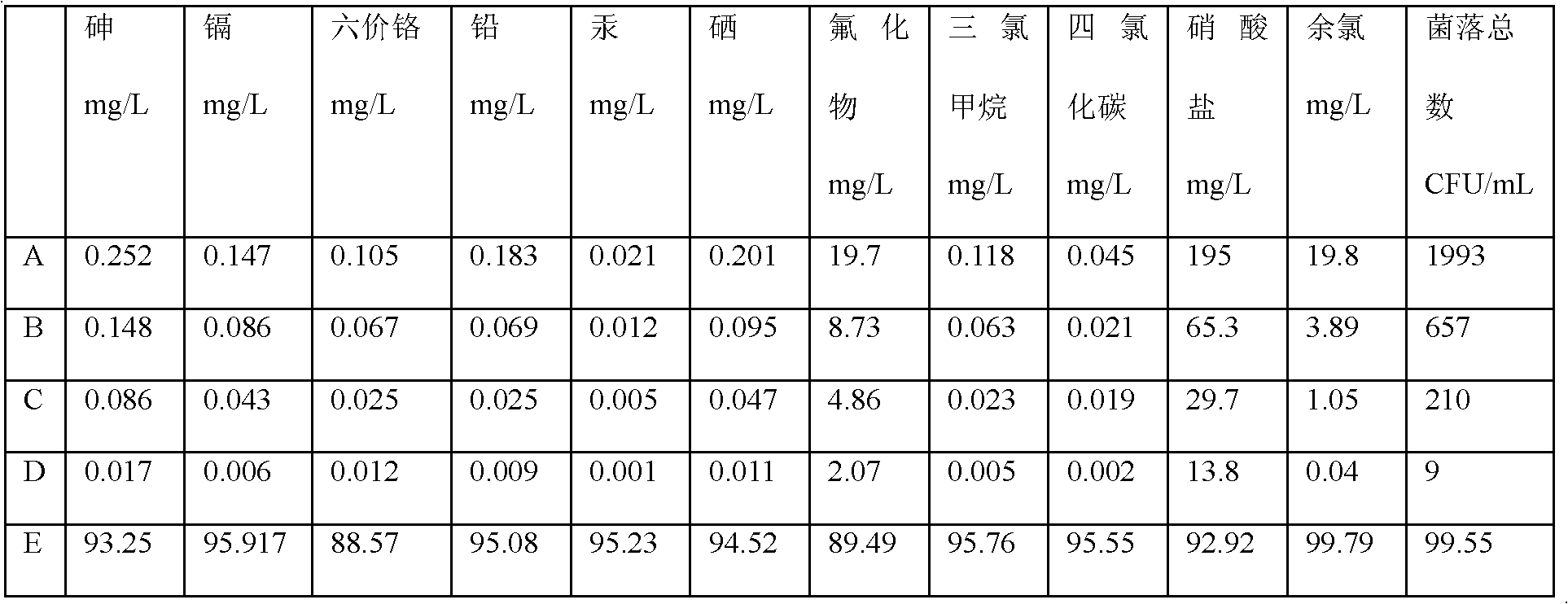

Multifunctional composite absorbing material for purifying water and preparation method thereof

ActiveCN102350298AReduce wasteEfficient removalOther chemical processesWater/sewage treatment bu osmosis/dialysisAcrylic resinCerium

The invention provides a multifunctional composite absorbing material for purifying water and a preparation method thereof, relating to an absorbing material. The invention provides the multifunctional composite absorbing material for purifying water, which can be used for effectively removing a plurality of harmful substances in the water and has higher removal efficiency and lower production cost, and the preparation method thereof. The absorbing material is selected from at least one of absorbing materials A, B and C; the absorbing material A takes a mesoporous adsorption ceramic material as a carrier to load nano metals including nano silver, nano zinc, nano iron and nano cerium; the absorbing material B takes the mesoporous adsorption ceramic material as the carrier to load nano metal oxides including nano titanium dioxide, nano zinc oxide, nano ferric oxide and nano cerium dioxide; and the absorbing material C is prepared from the following raw materials according to the mass ratio: 100-200 parts of active carbon powder, 20-30 parts of polyethylene powder, 10-30 parts of calcium sulfite powder, 10-30 parts of natural zeolite powder, 20-40 parts of macroporous acrylic resin and 10-20 parts of attapulgite powder.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

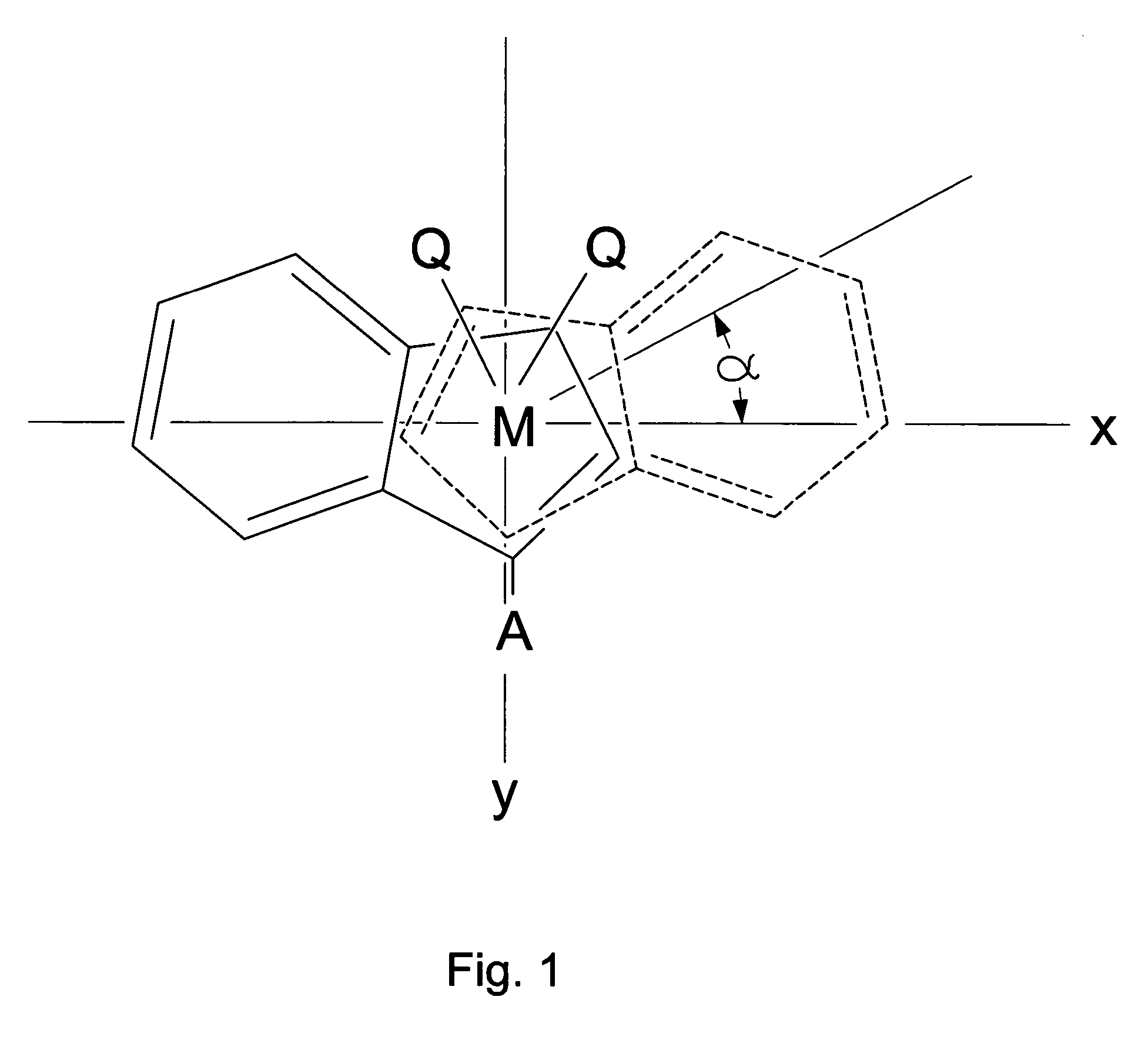

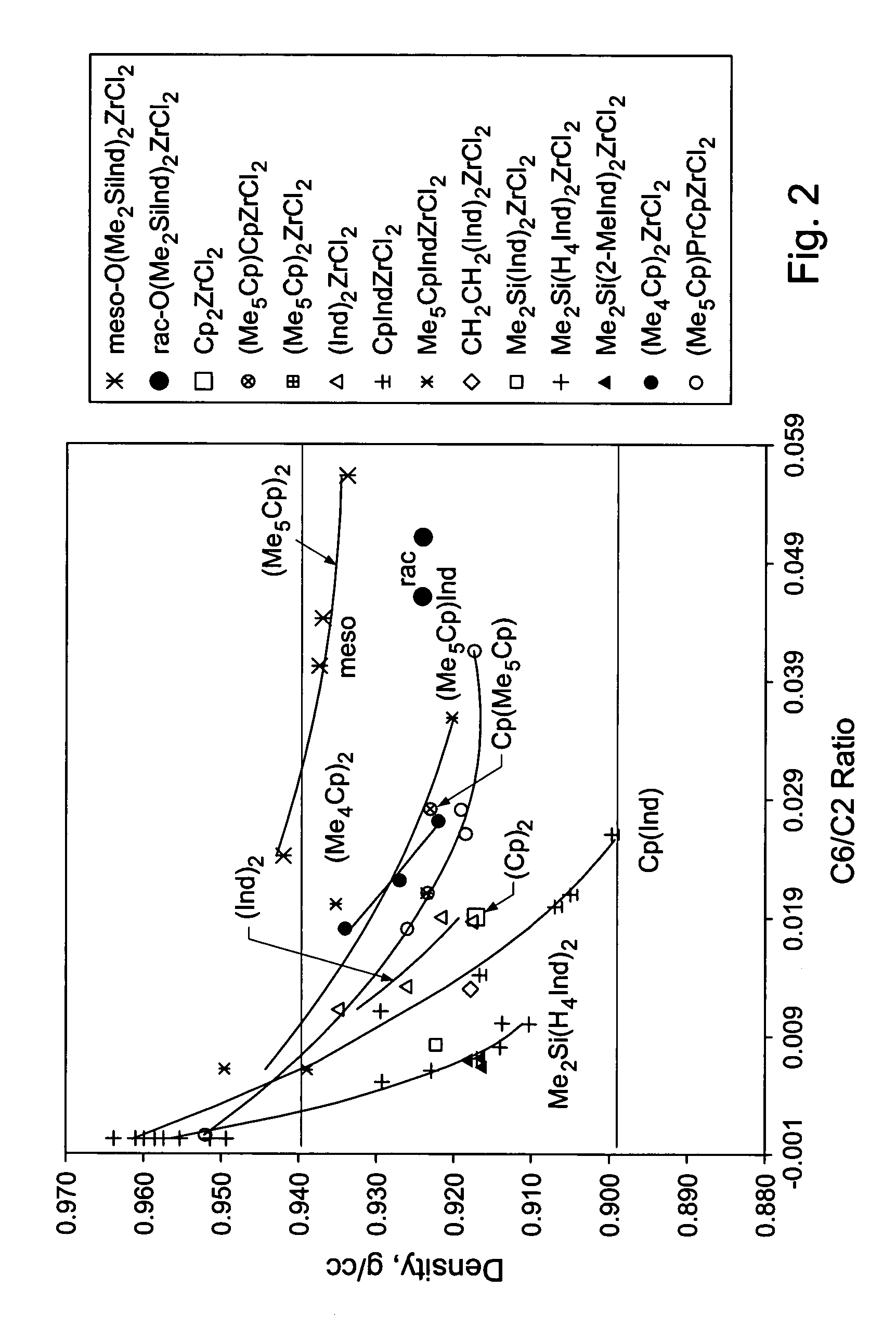

Mixed metallocene catalyst systems containing a poor comonomer incorporator and a good comonomer incorporator

The present invention provides polymerization catalyst compounds, catalyst systems including these catalyst compounds, and to their use in the polymerization of ethylene and at least one comonomer. In particular, the invention provides a catalyst system comprising a poor comonomer incorporating catalyst compound and a good comonomer incorporating catalyst compound. Preferably, the low comonomer incorporating catalyst compound is a metallocene containing at least one substituted or unsubstituted fused ring cyclopentadienyl based ligand which is substantially directed to the front of the molecule, contains a long bridging group, or which contains a methyl substitution pattern which correlates to poor comonomer incorporation. The invention also provides methods of selecting the poor comonomer incorporating metallocene to pair with the good comonomer incorporating metallocene to produce polymers that are easy to process into a variety of articles, especially polyethylene based film, having enhanced properties.

Owner:UNIVATION TECH LLC

Alpha-nickel diimine compound olefin polymerization catalyst, preparation method and method for preparing branched polyethylene

InactiveCN101812145AEasy to prepareLow costNickel organic compoundsBulk chemical productionPolymer scienceDiimine

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst, a preparation method and a method for preparing branched polyethylene. The structural formula of the alpha-nickel diimine compound olefin polymerization catalyst is shown as the formula (I) and the formula (II). The alpha-nickel diimine compound olefin polymerization catalyst has simple preparation method and low cost, and ethylene can be catalyzed to polymerize with high activity at a temperature not lower than 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared from the alpha-nickel diimine compound olefin polymerization catalyst by catalyzing has high molecular weight, and the molecular weight can reach higher than 102x kg / mol within the range of 0-80 DEG C.

Owner:SUN YAT SEN UNIV

Prosthetic joints with contained compressible resilient members

InactiveUS6875235B2Improve protectionEliminate shear stressInternal osteosythesisJoint implantsElastomerTotal knee replacement

In a total knee replacement (TKR), the use of a cushion element provides better wear characteristics than polyethylene (“poly”) alone. Since a metal-on-metal, metal-on-ceramic, or ceramic-on-ceramic articulating surface has better wear characteristics than metal on poly, the invention essentially provides cushioning for metal / ceramic-on-metal / ceramic joint replacements. It also allows the use of elastomers for their cushioning properties rather than their surface wear and tensile strength characteristics. The contained compressible elements could also be used as a cushion below polyethylene components, polyethylene over metal components, unicondylar knee replacements, patellar components, and prosthetic components for other parts of the body, including the hip, elbow, shoulder, wrist, and ankle.

Owner:ANOVA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com