Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32851 results about "Elastomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An elastomer is a polymer with viscoelasticity (i.e., both viscosity and elasticity) and has very weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of elastic polymer, is often used interchangeably with rubber, although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation, without breaking of covalent bonds, is feasible. At ambient temperatures, such rubbers are thus relatively soft (E ≈ 3 MPa) and deformable. Their primary uses are for seals, adhesives and molded flexible parts. Application areas for different types of rubber are manifold and cover segments as diverse as tires, soles for shoes, and damping and insulating elements. The importance of these rubbers can be judged from the fact that global revenues are forecast to rise to US$56 billion in 2020.

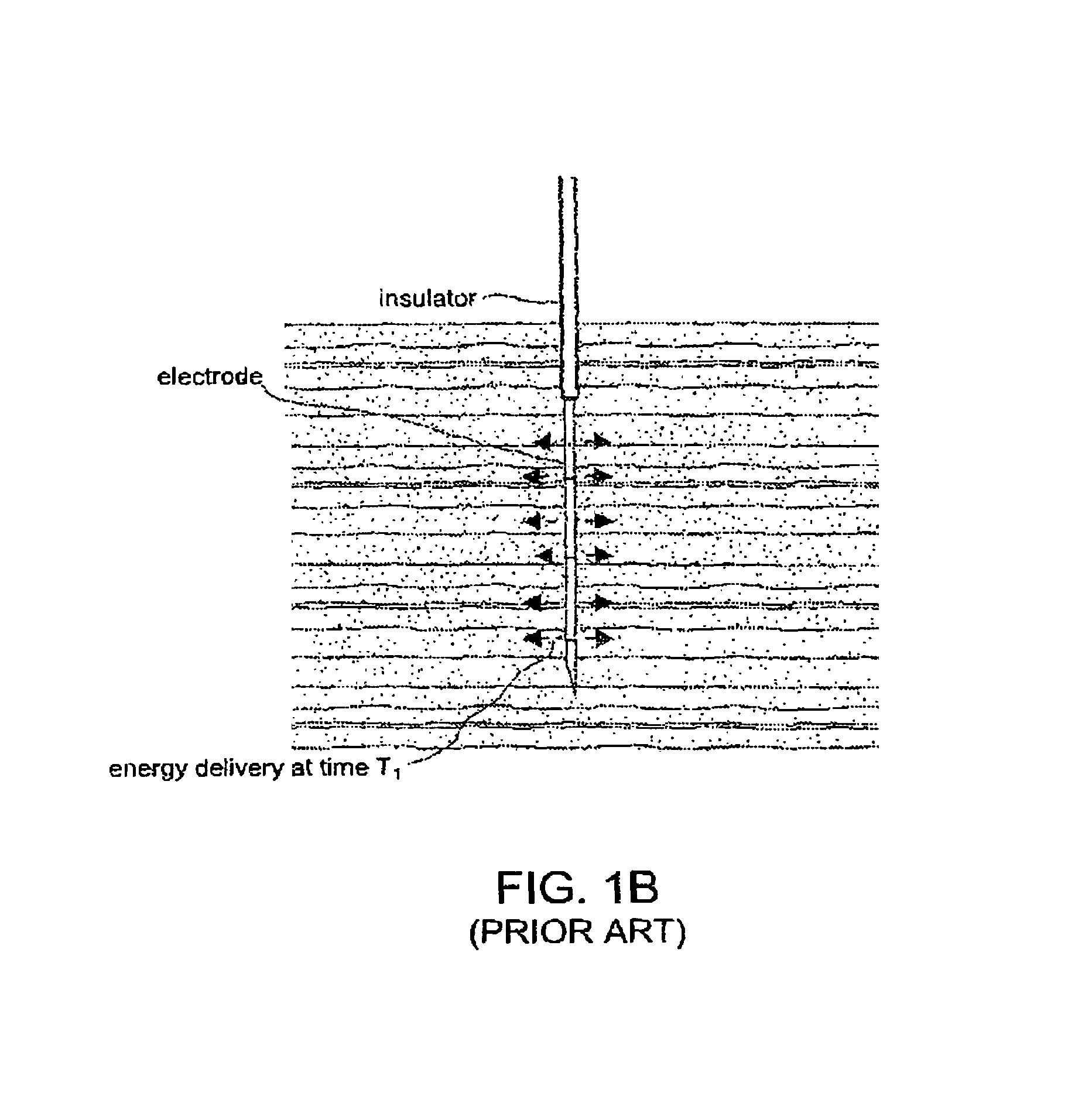

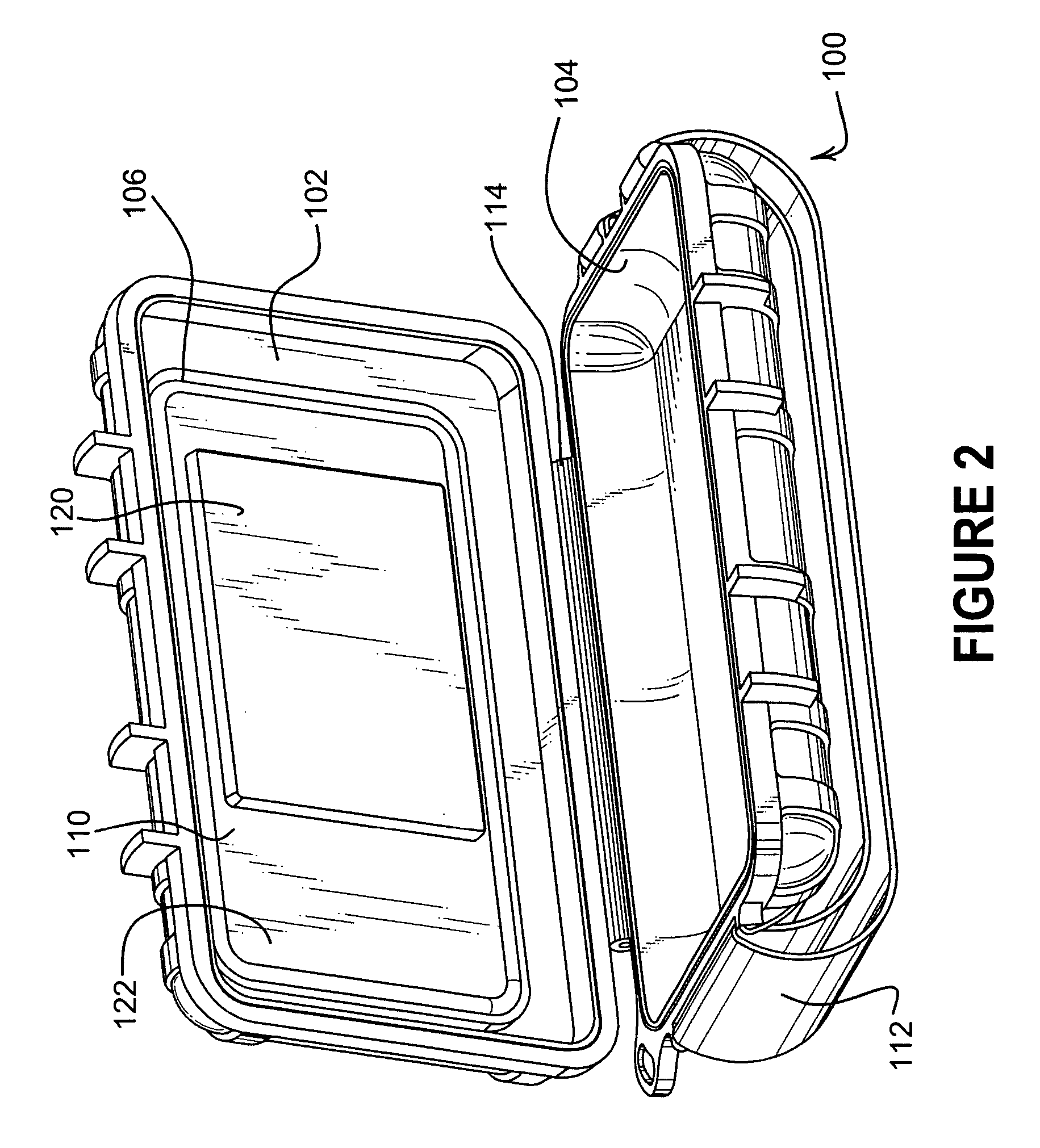

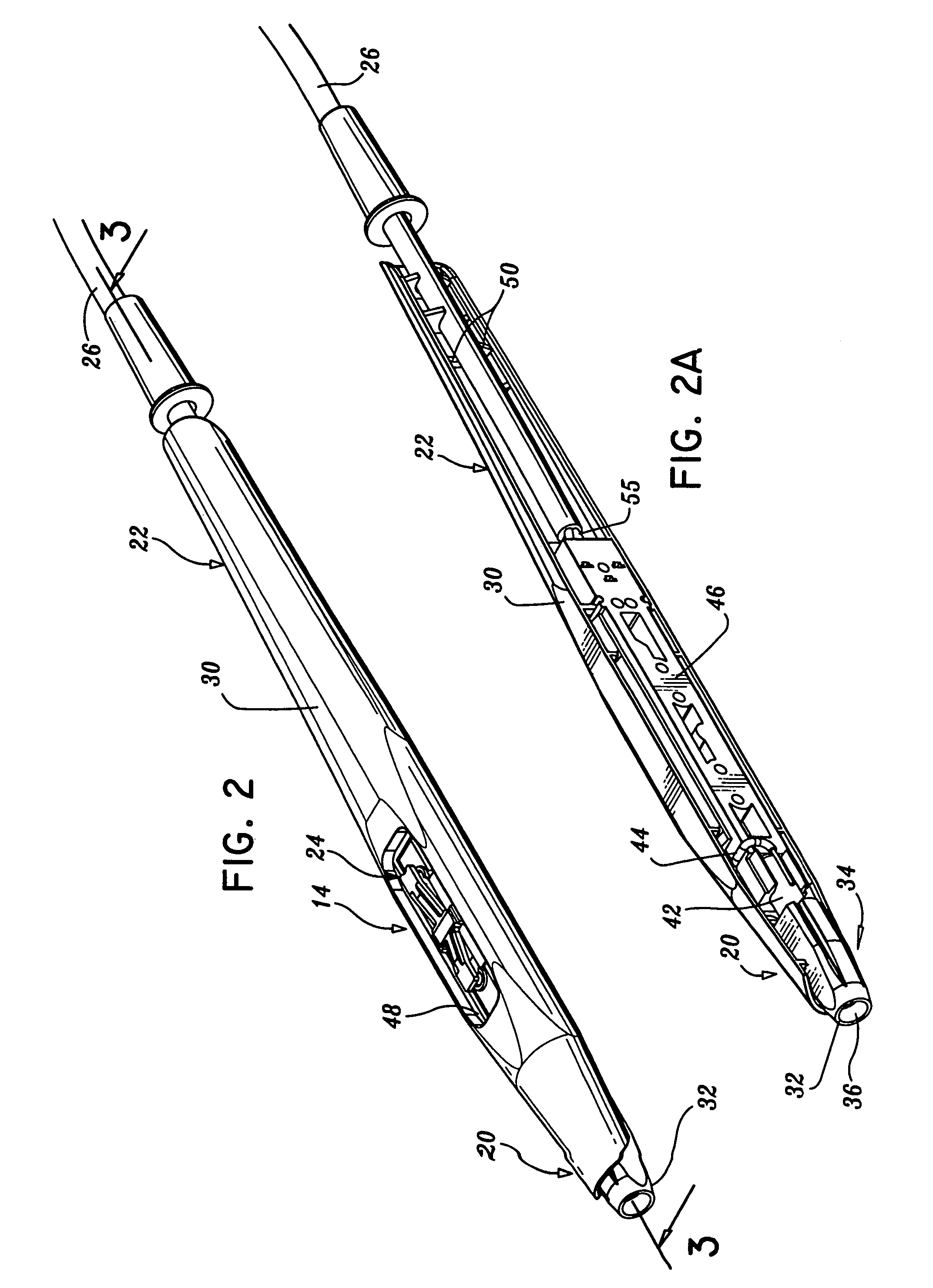

Electrosurgical working end for controlled energy delivery

InactiveUS7125409B2Prevent any substantial dehydrationEnergy efficiencySurgical needlesSurgical instruments for heatingElastomerEngineering

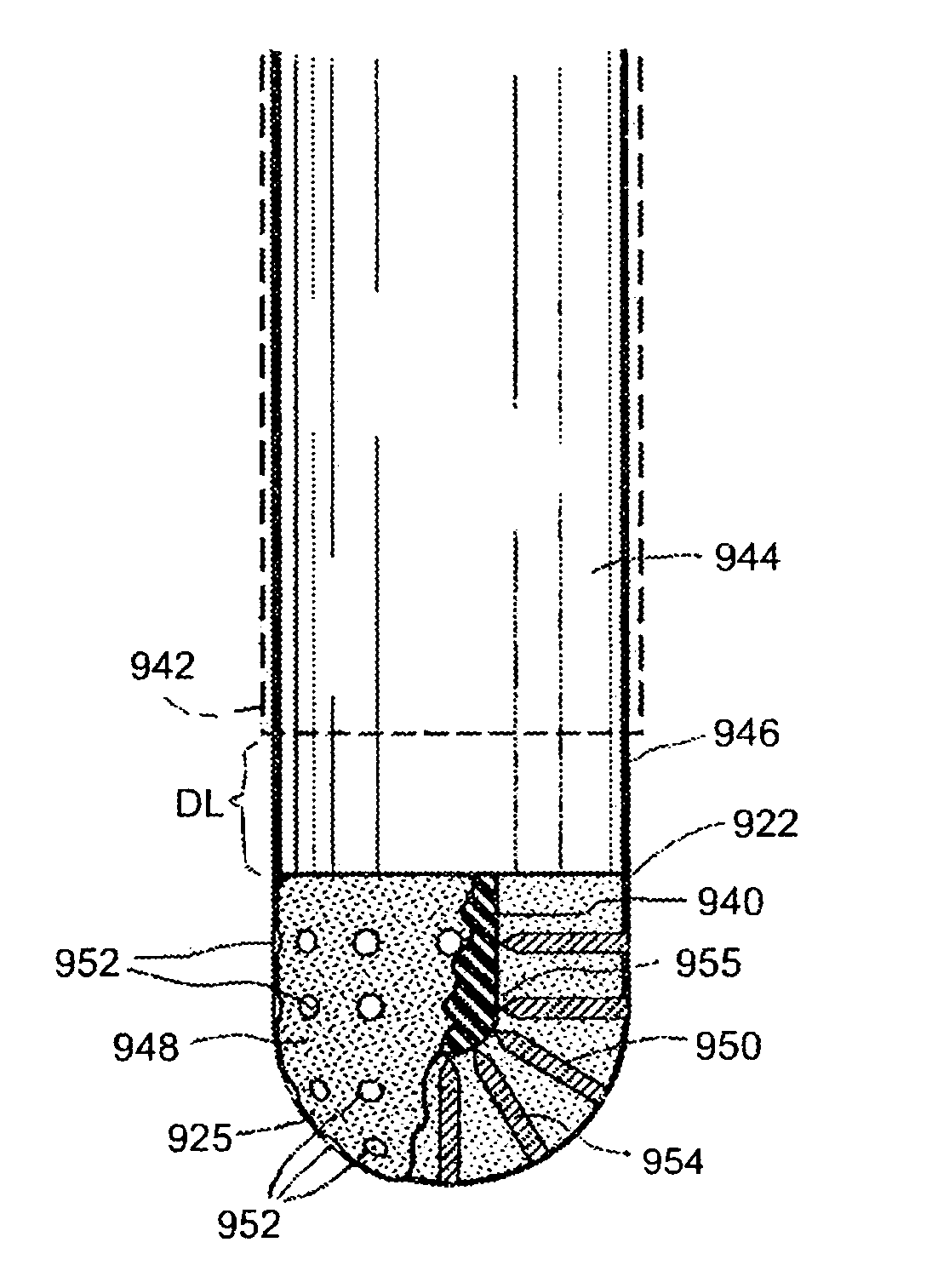

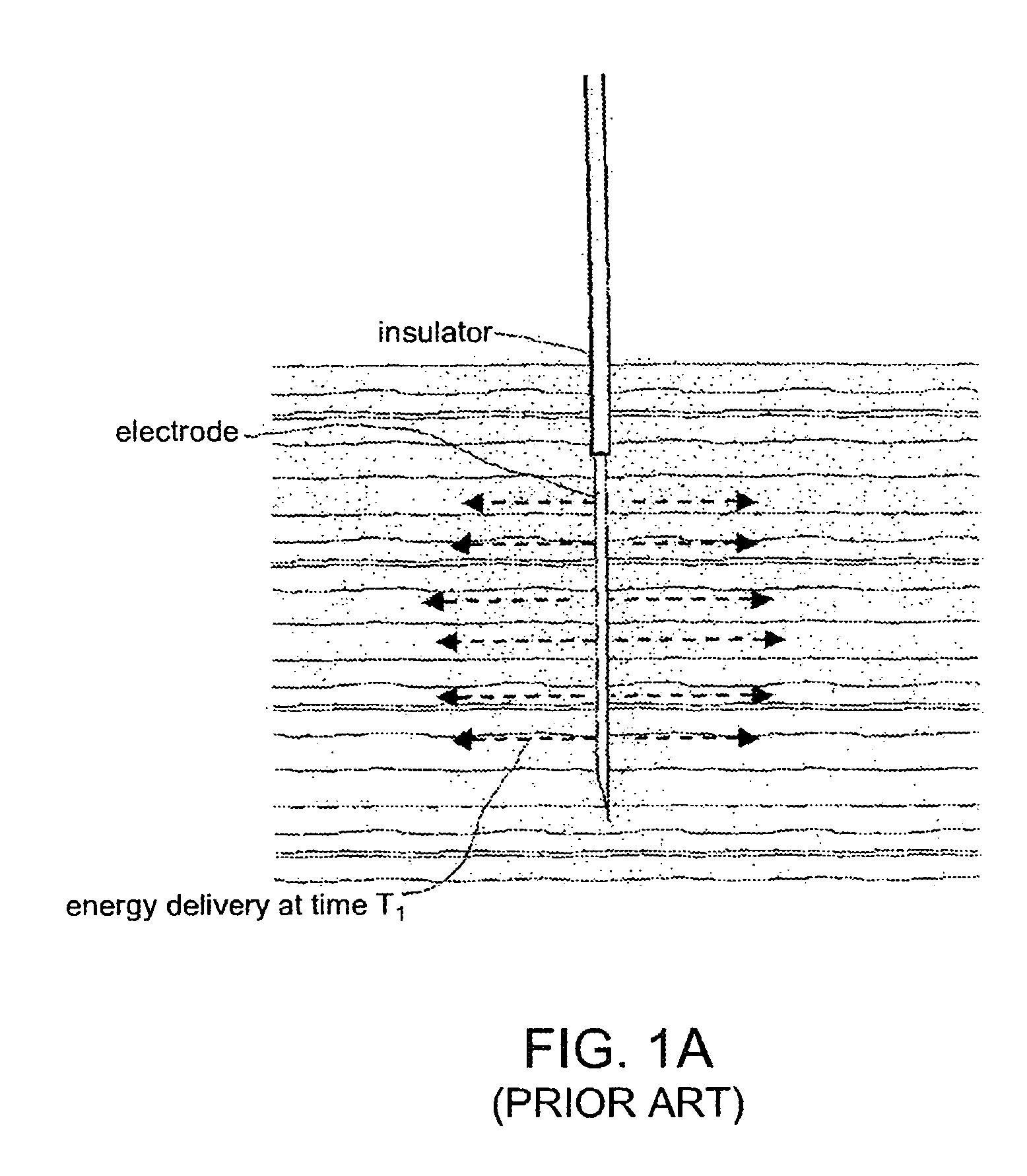

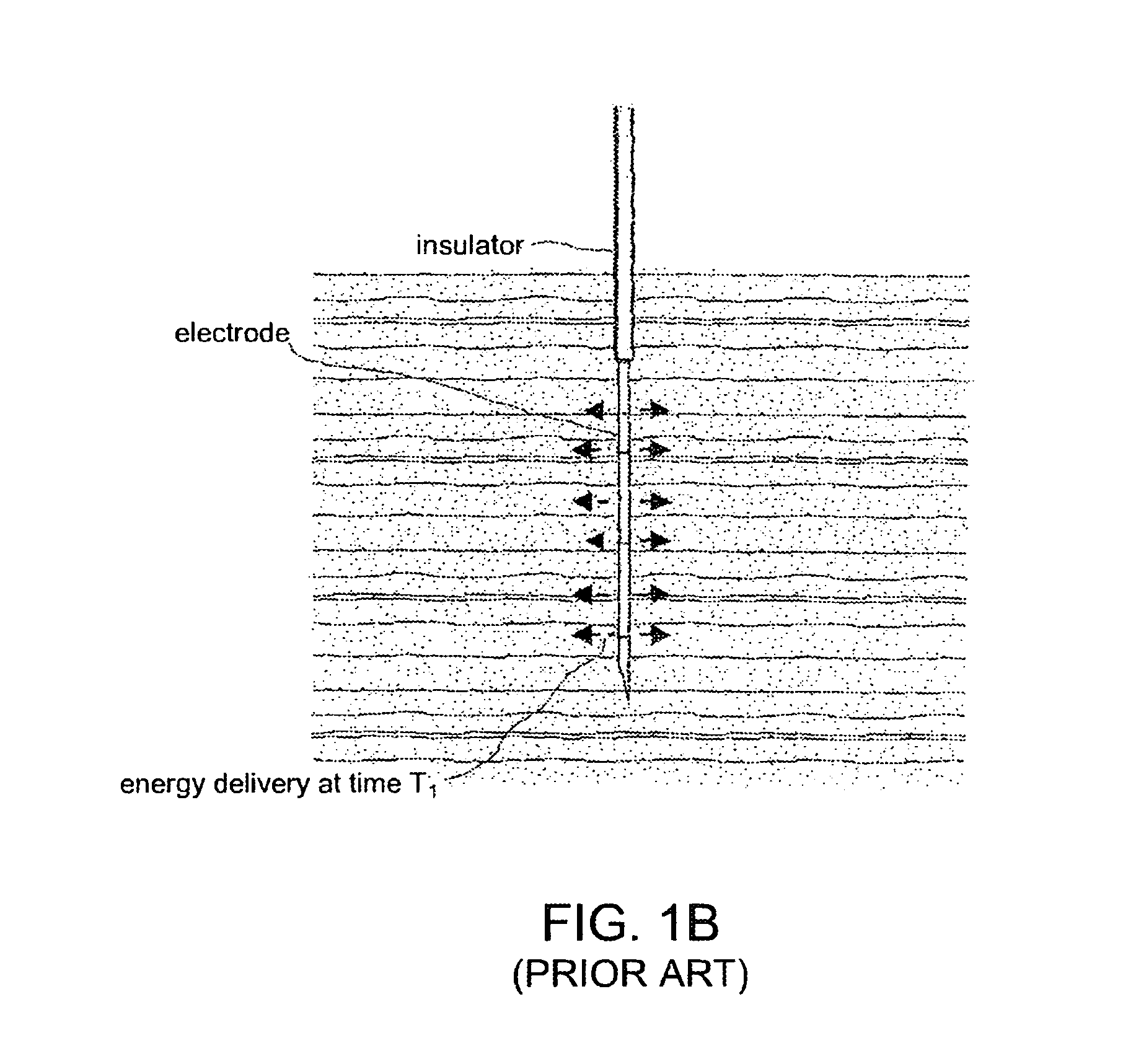

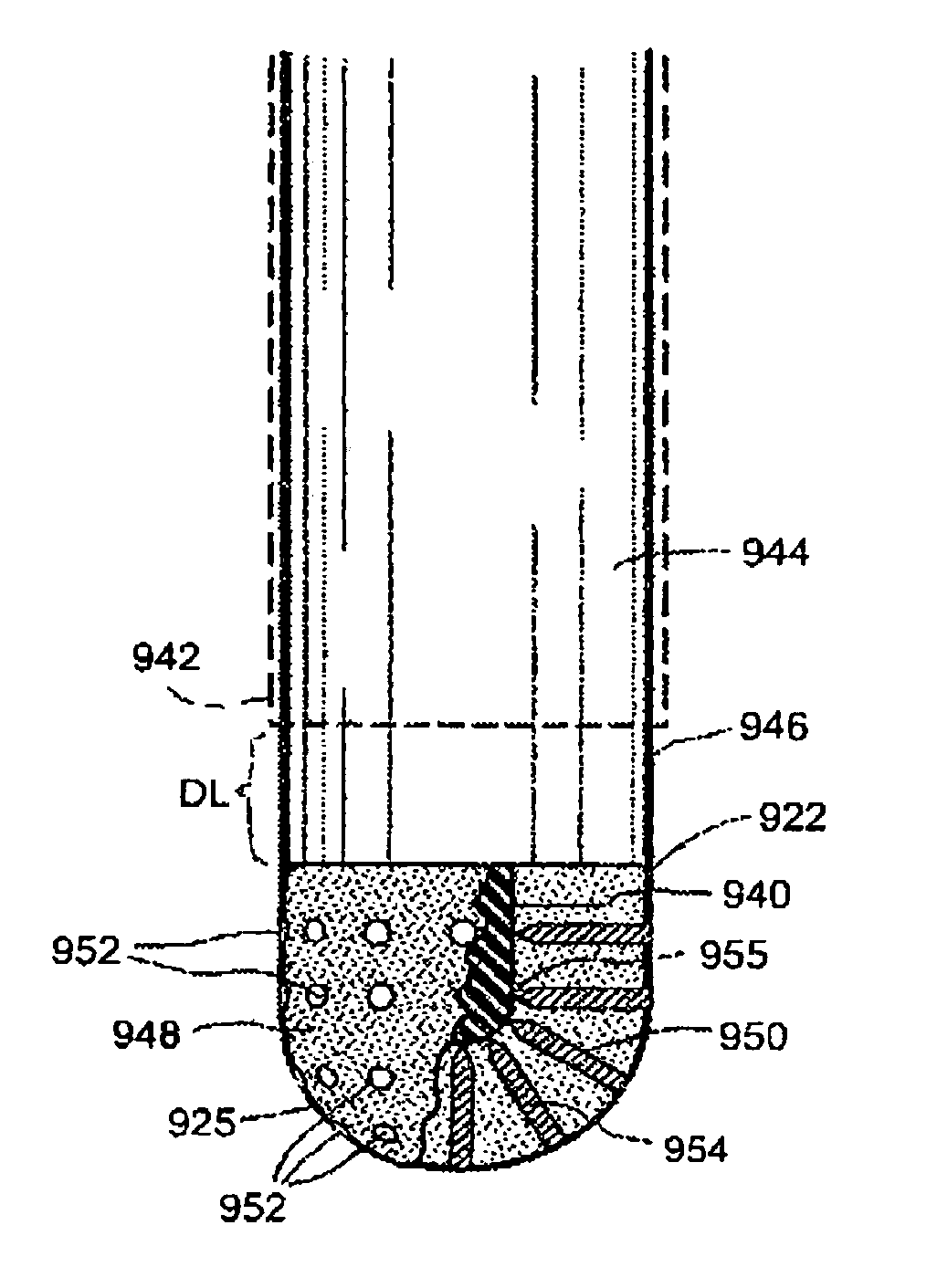

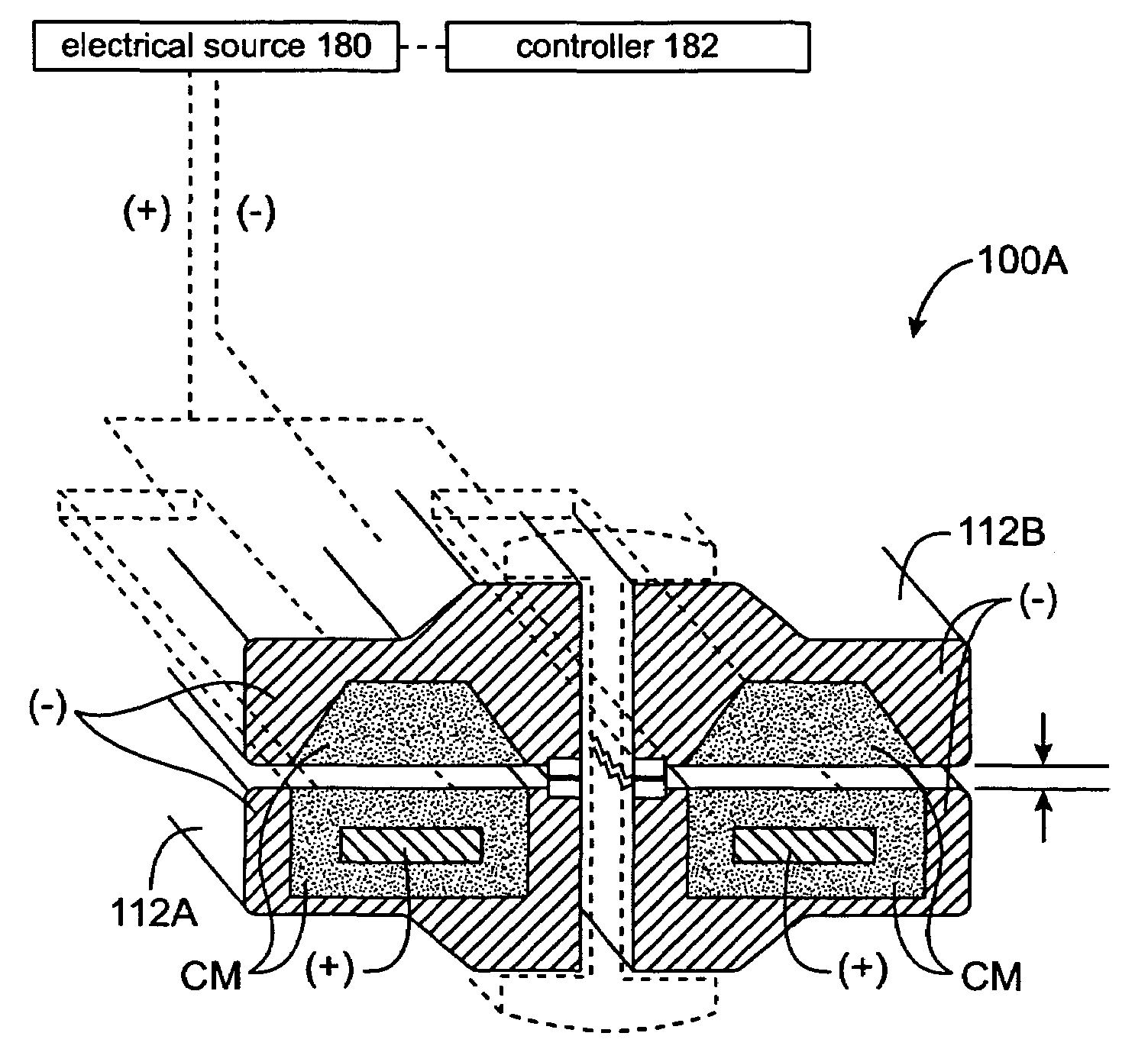

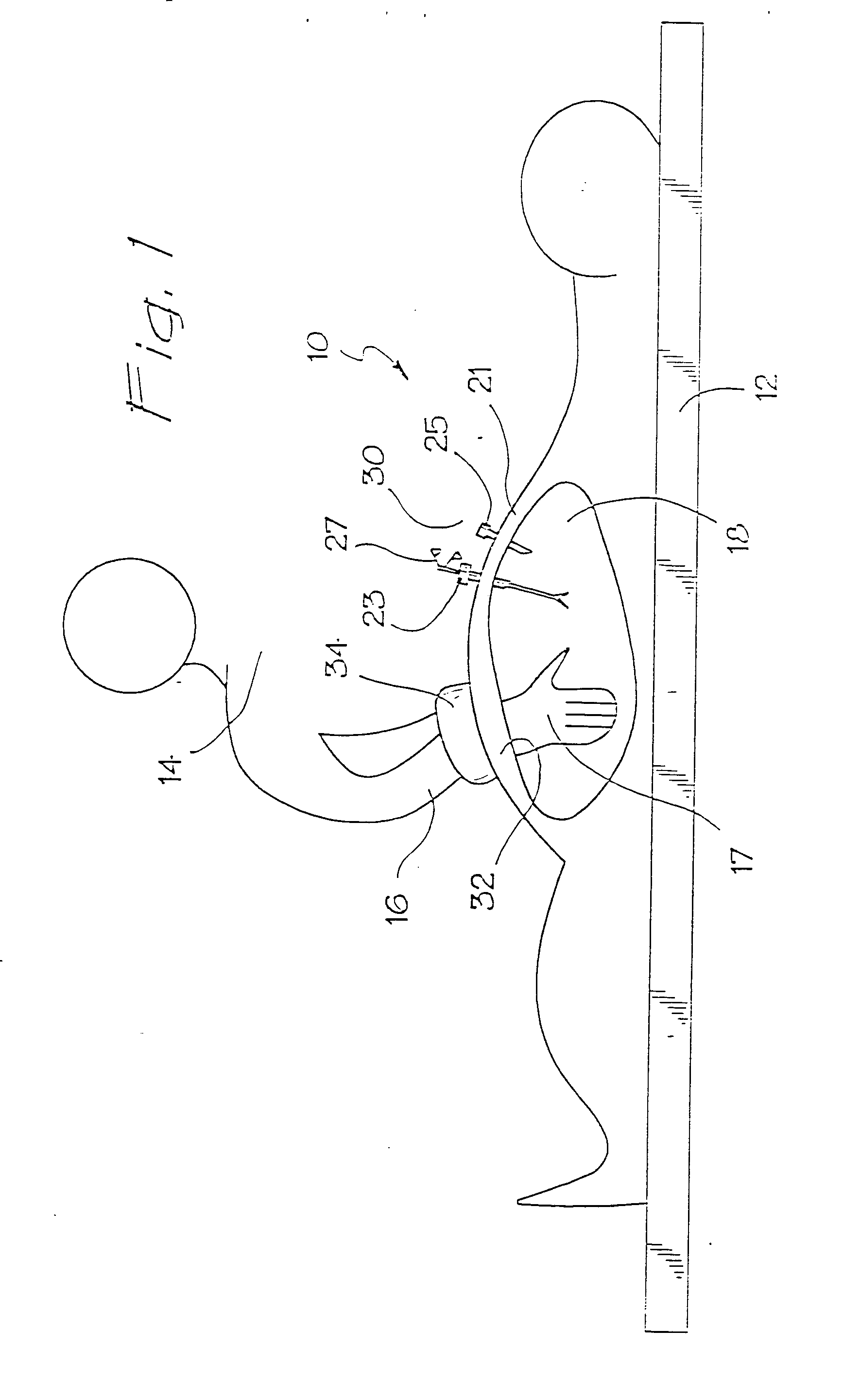

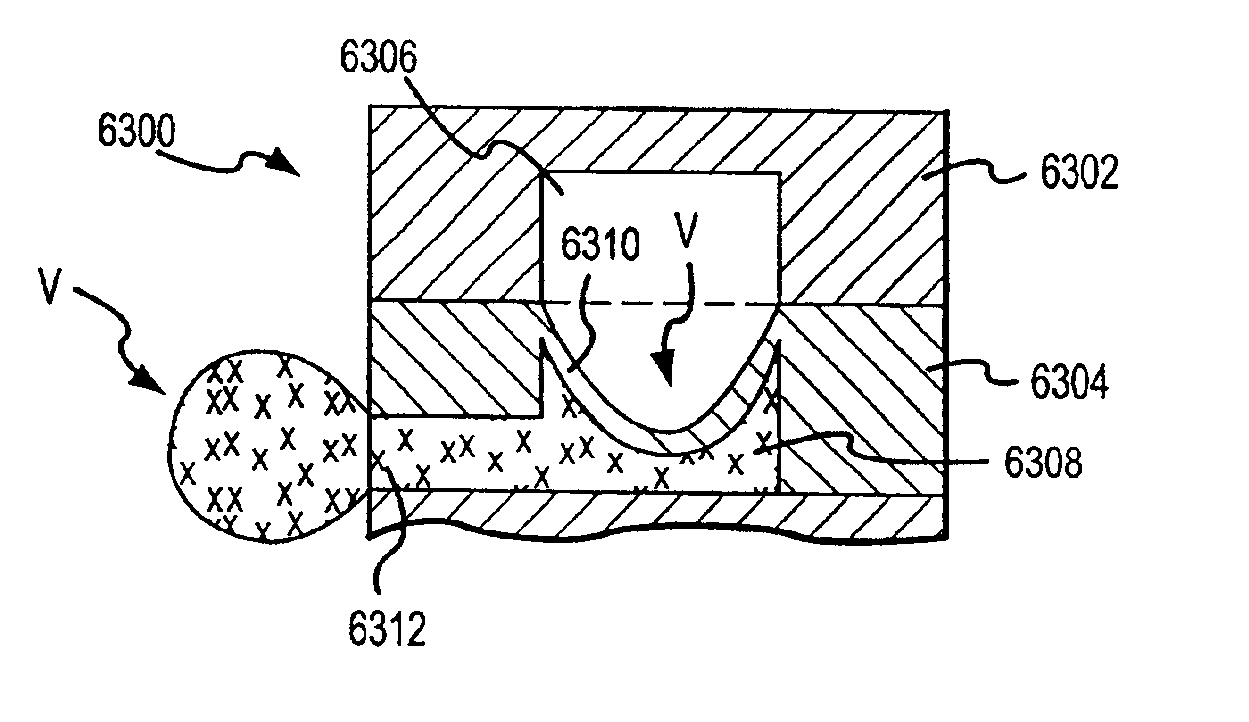

An electrosurgical working end for automatic modulation of active Rf density in a targeted tissue volume. The working end of the probe of the present invention defines a tissue-engagement surface of an elastomeric material with conductive elements that extend therethrough. In one embodiment, the expansion of the elastomeric material can de-couple the conductive elements from an interior electrode based temperature to modulate current flow. In another embodiment, the elastomeric material can couple and de-couple the conductive elements from an interior electrode based on engagement pressure to modulate current flow

Owner:ETHICON ENDO SURGERY INC

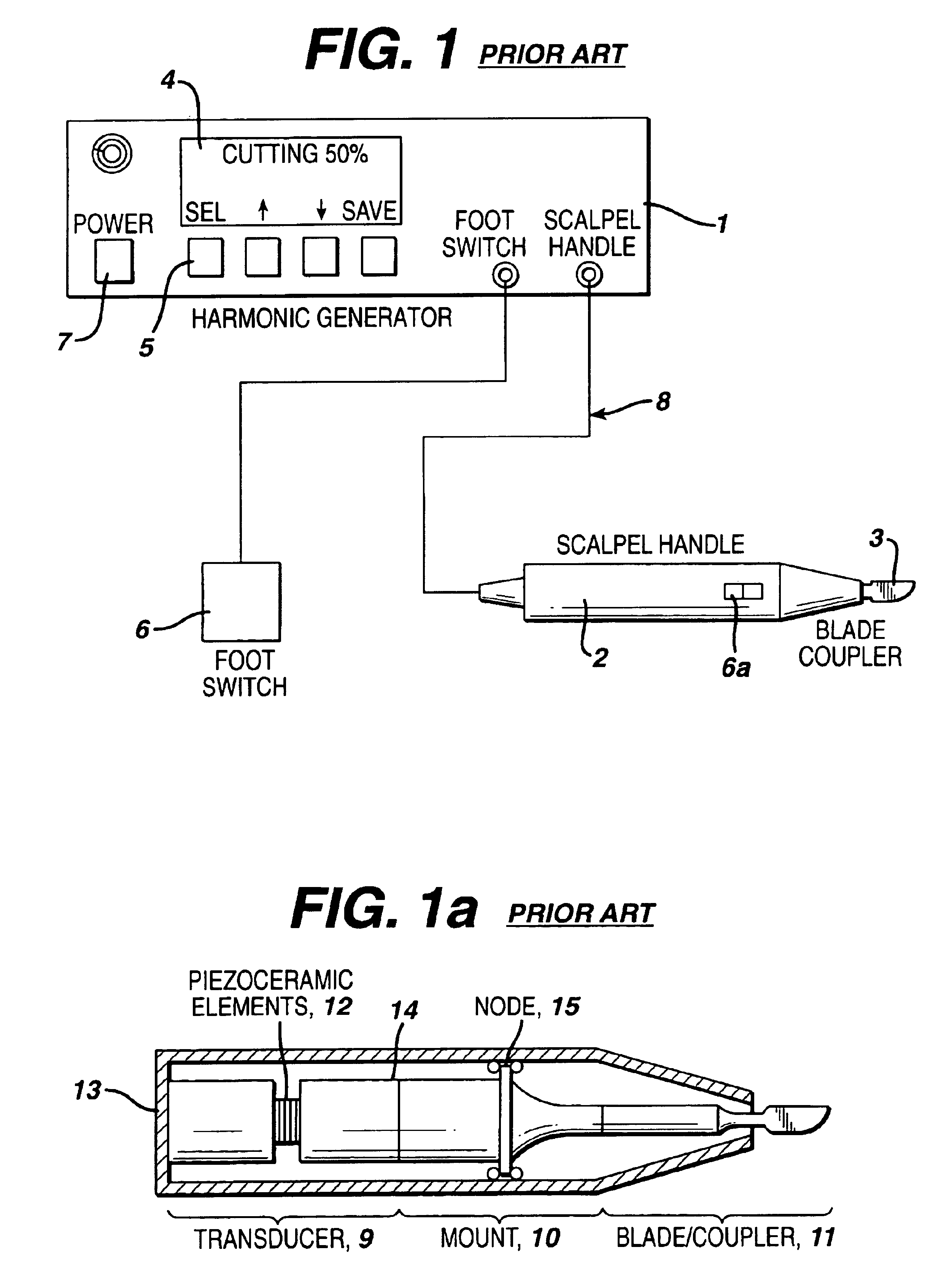

Electrosurgical instrument and method of use

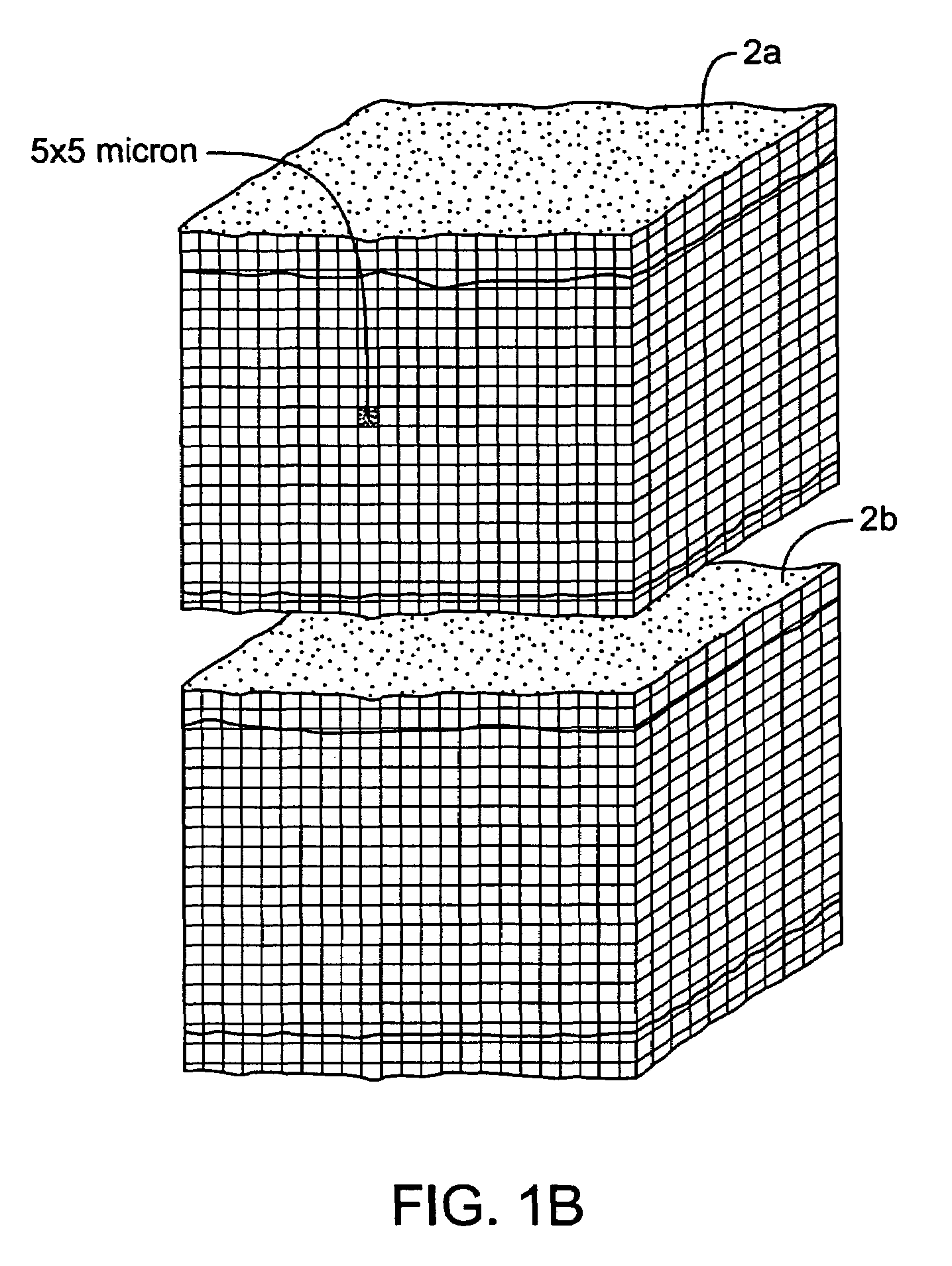

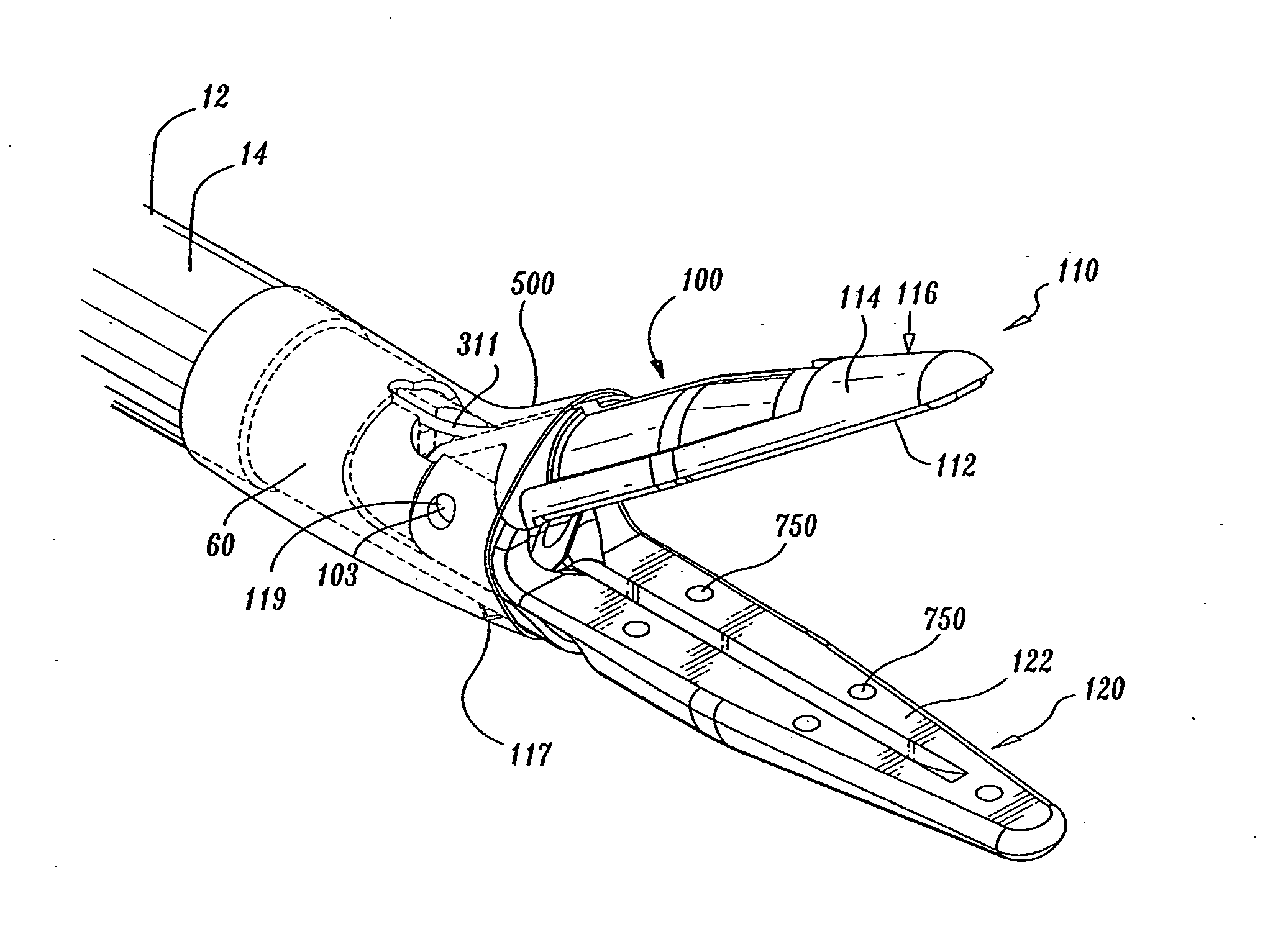

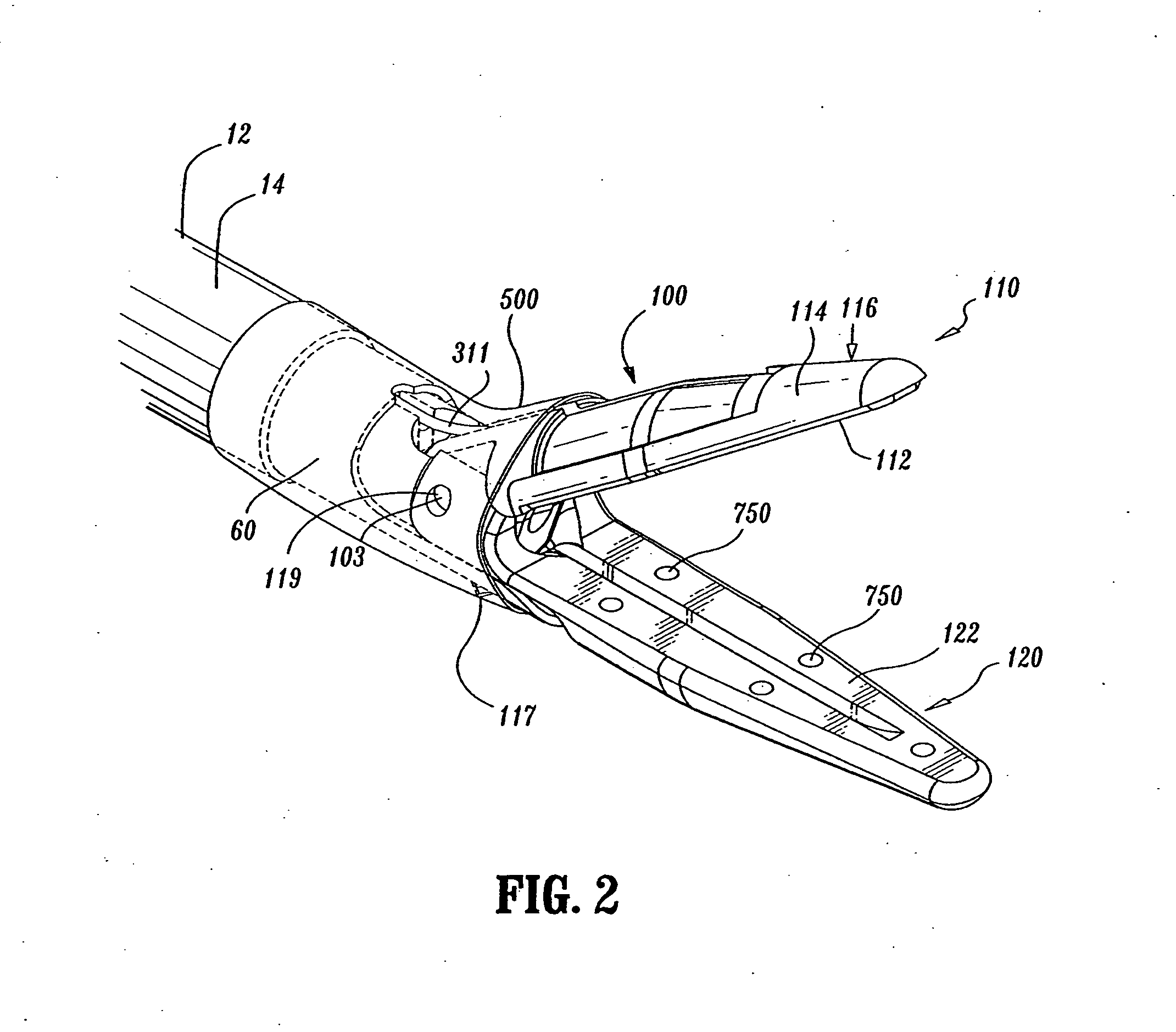

InactiveUS7083619B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

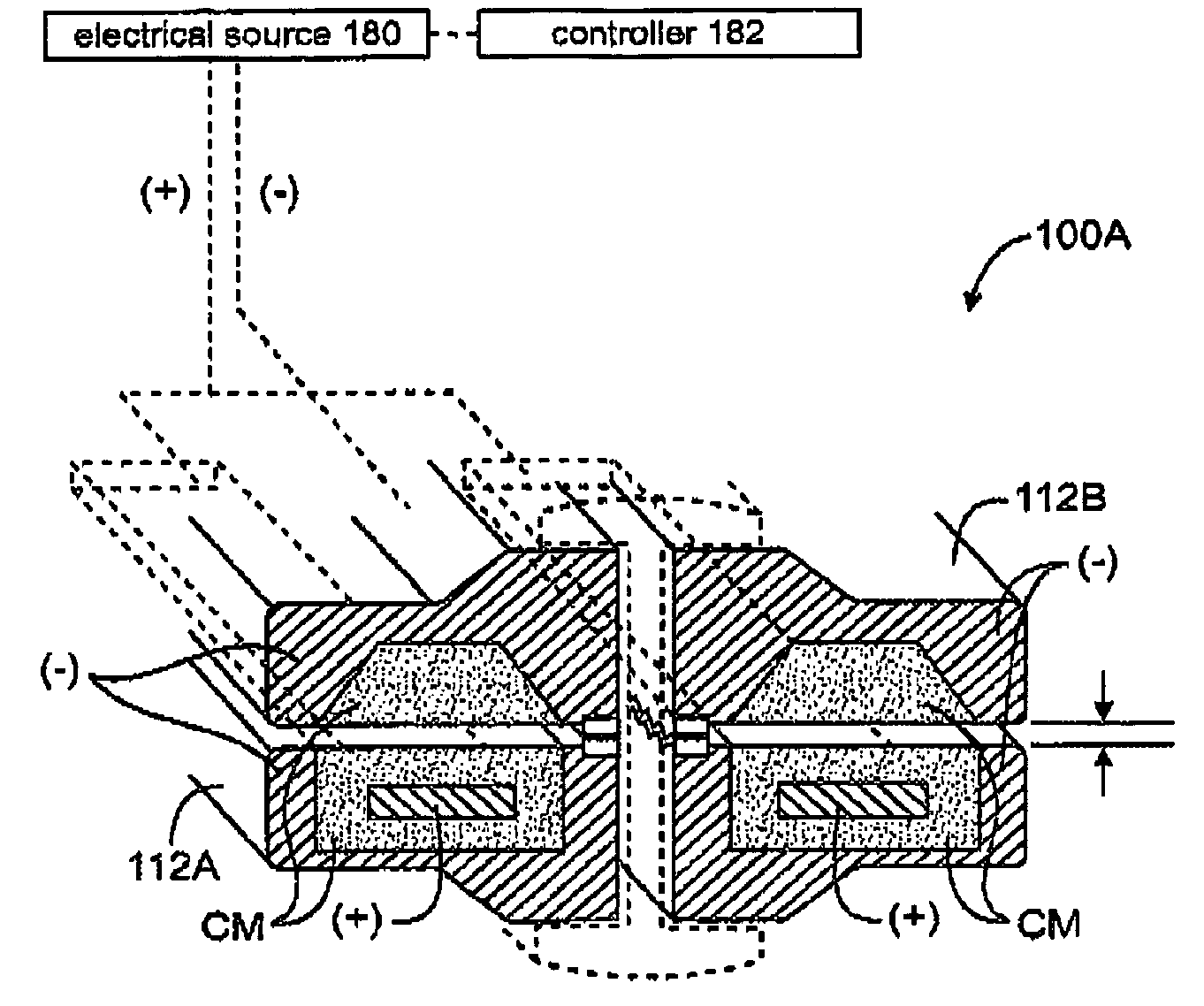

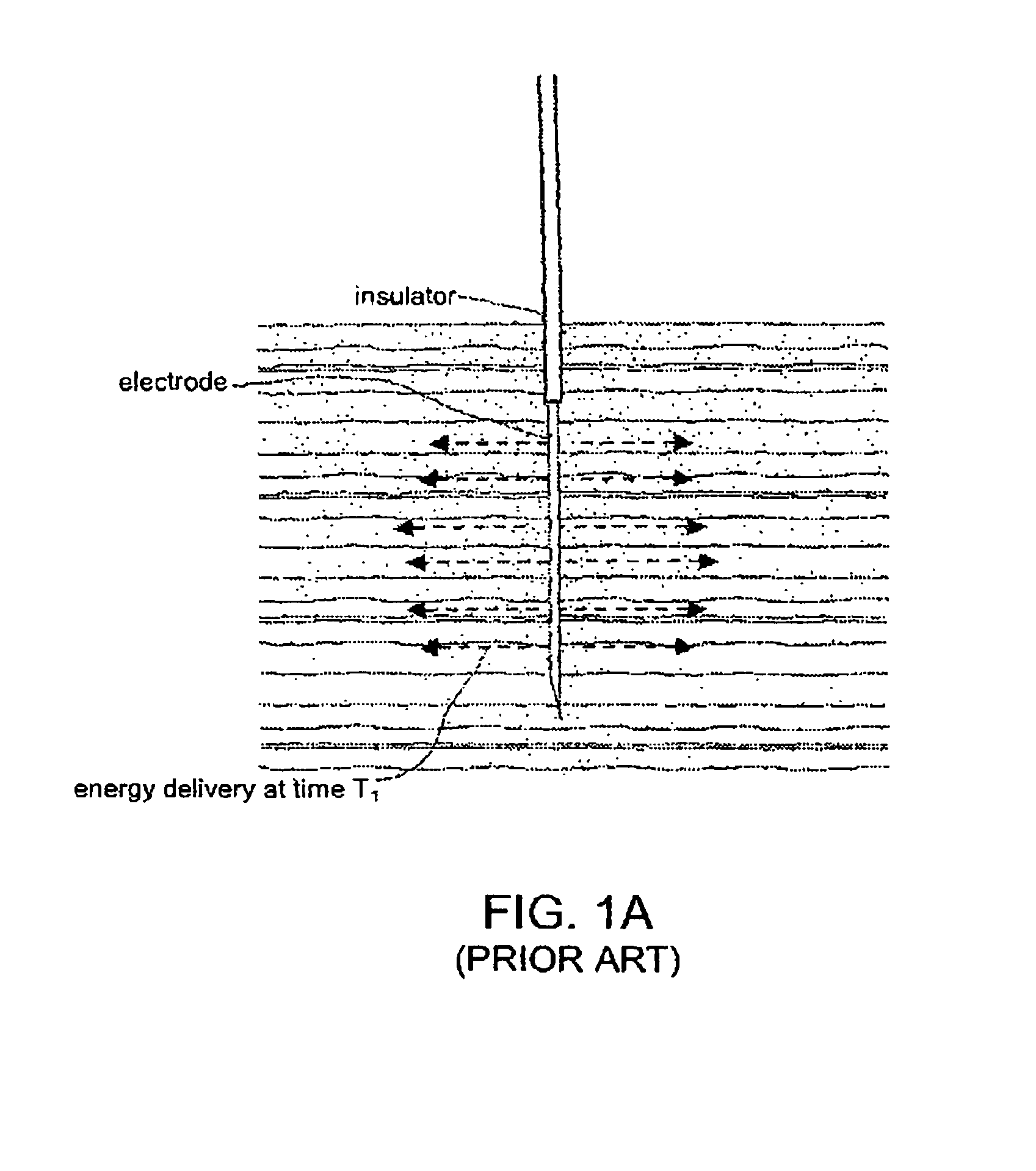

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical working end for controlled energy delivery

InactiveUS7070597B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingCoatingsElastomerVolumetric Mass Density

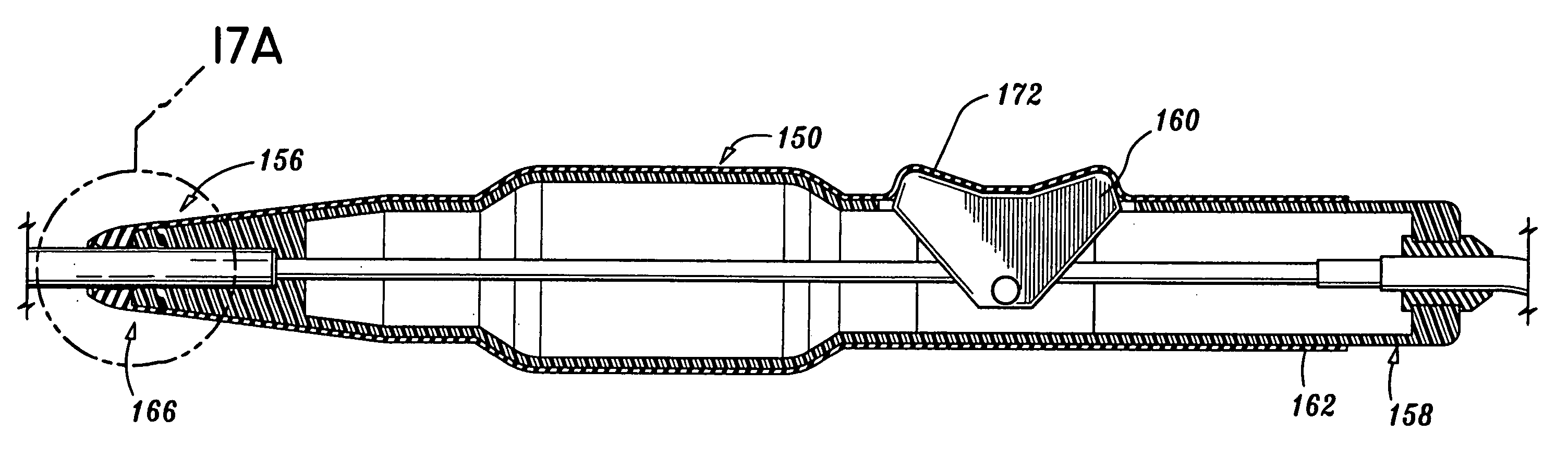

An electrosurgical working end for automatic modulation of active Rf density in a targeted tissue volume. The working end of the probe of the present invention defines a tissue-engagement surface of an elastomeric material with conductive elements that extend therethrough. In one embodiment, the expansion of the elastomeric material can de-couple the conductive elements from an interior electrode based temperature to modulate current flow. In another embodiment, the elastomeric material can couple and de-couple the conductive elements from an interior electrode based engagement pressure to modulate current flow.

Owner:ETHICON ENDO SURGERY INC

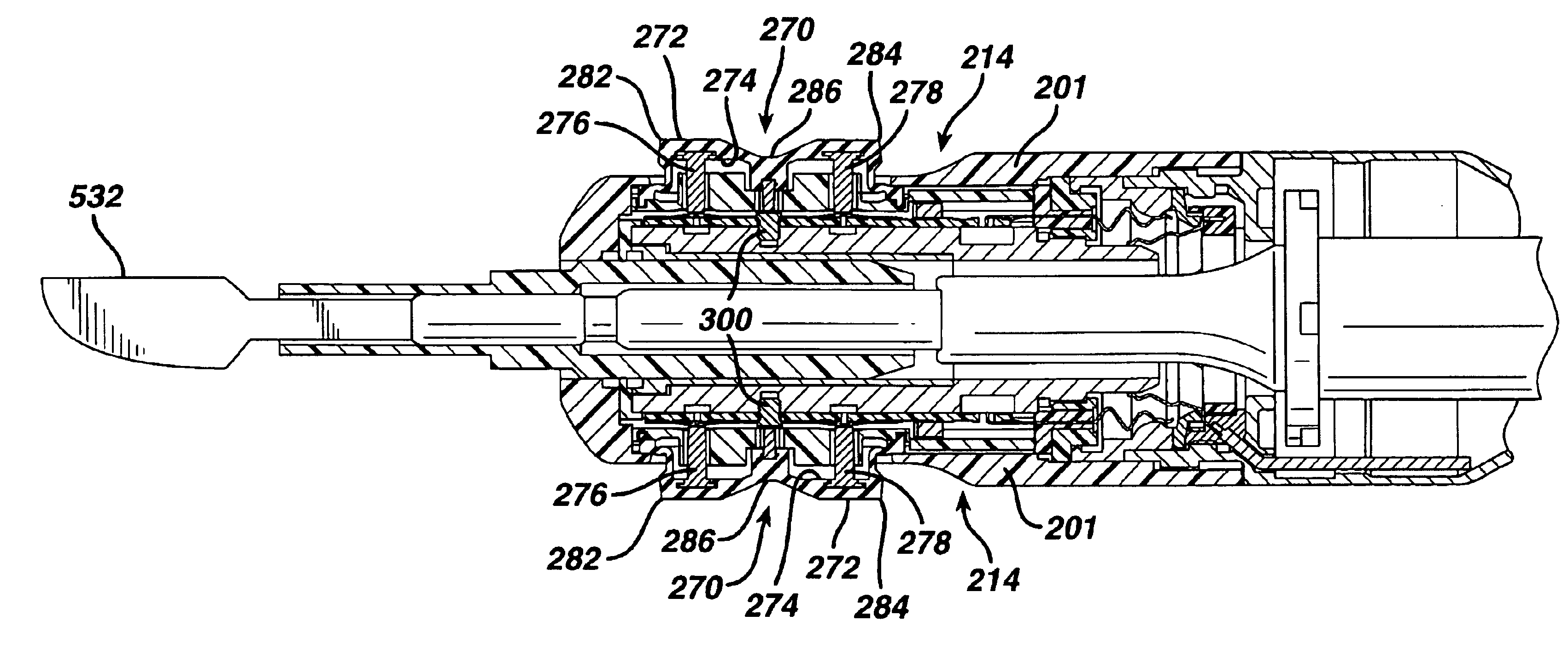

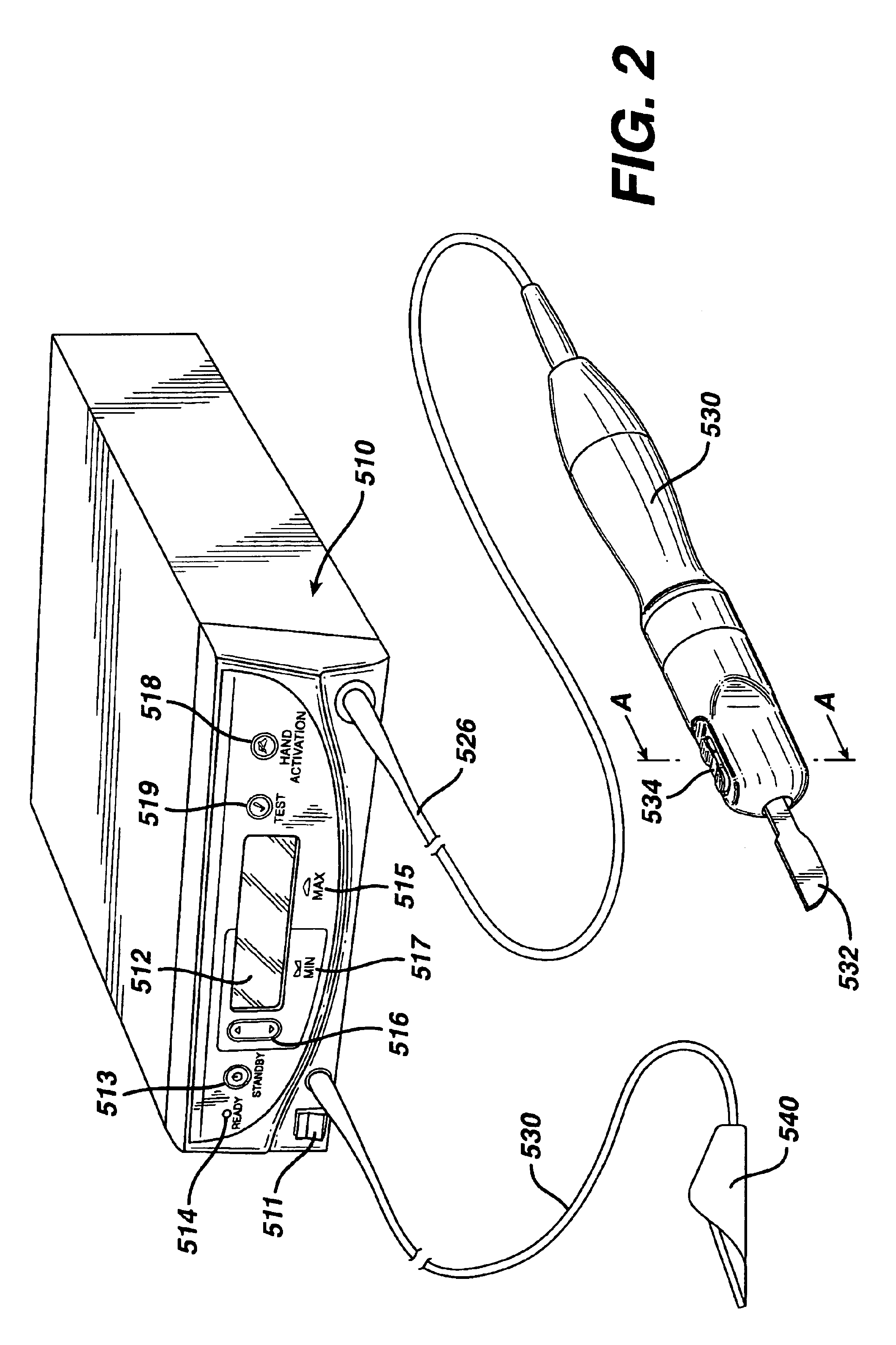

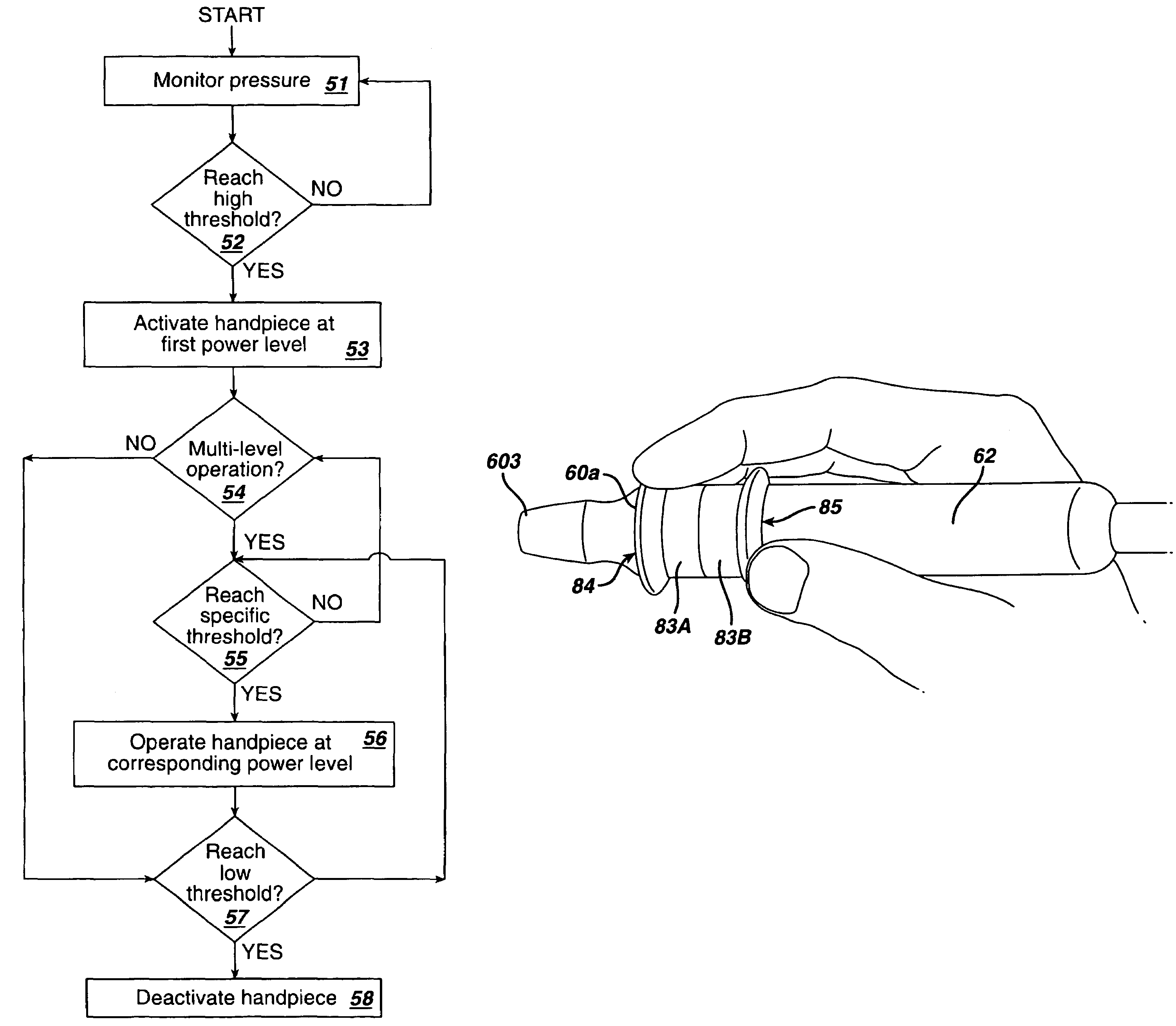

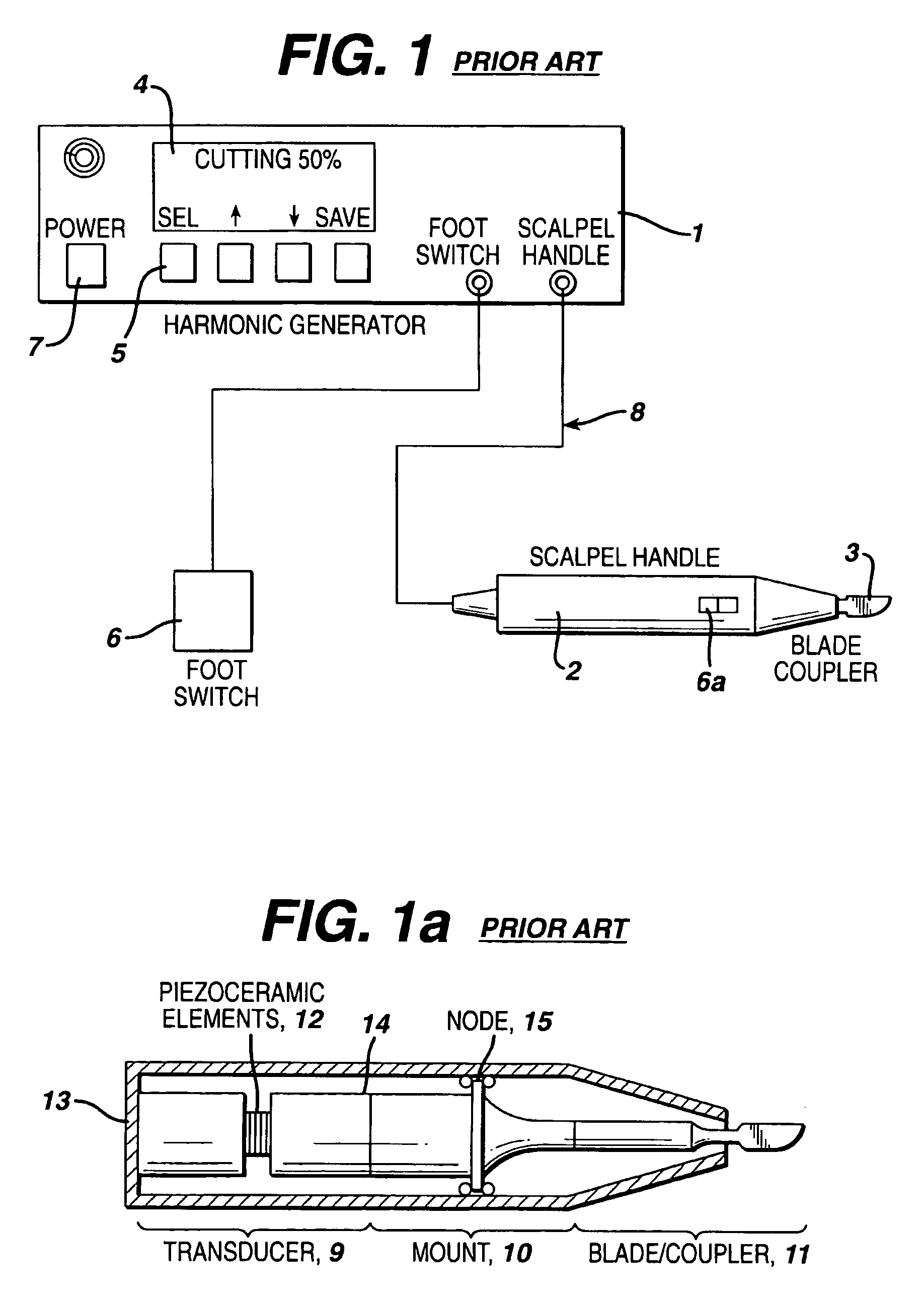

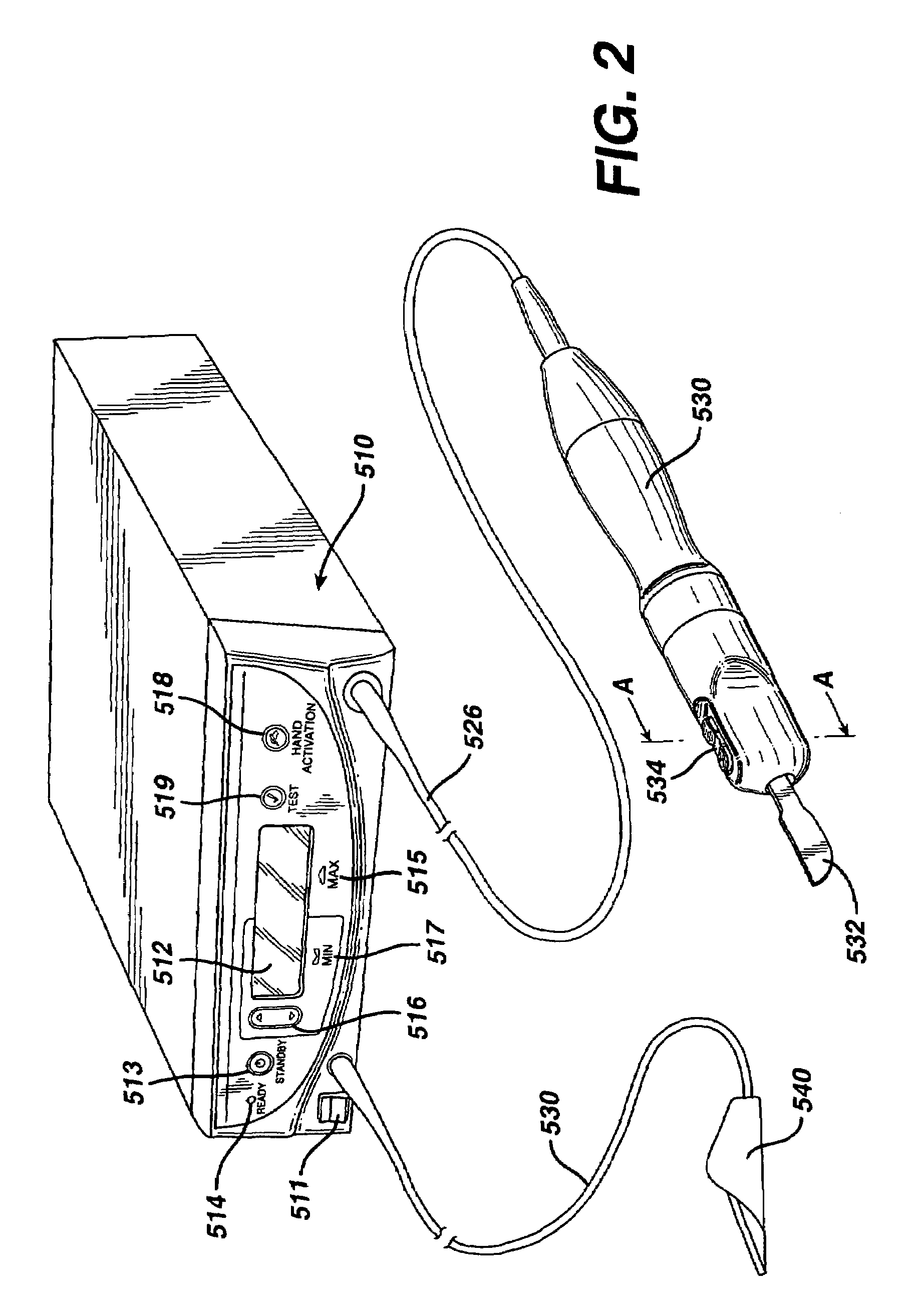

Finger operated switch for controlling a surgical handpiece

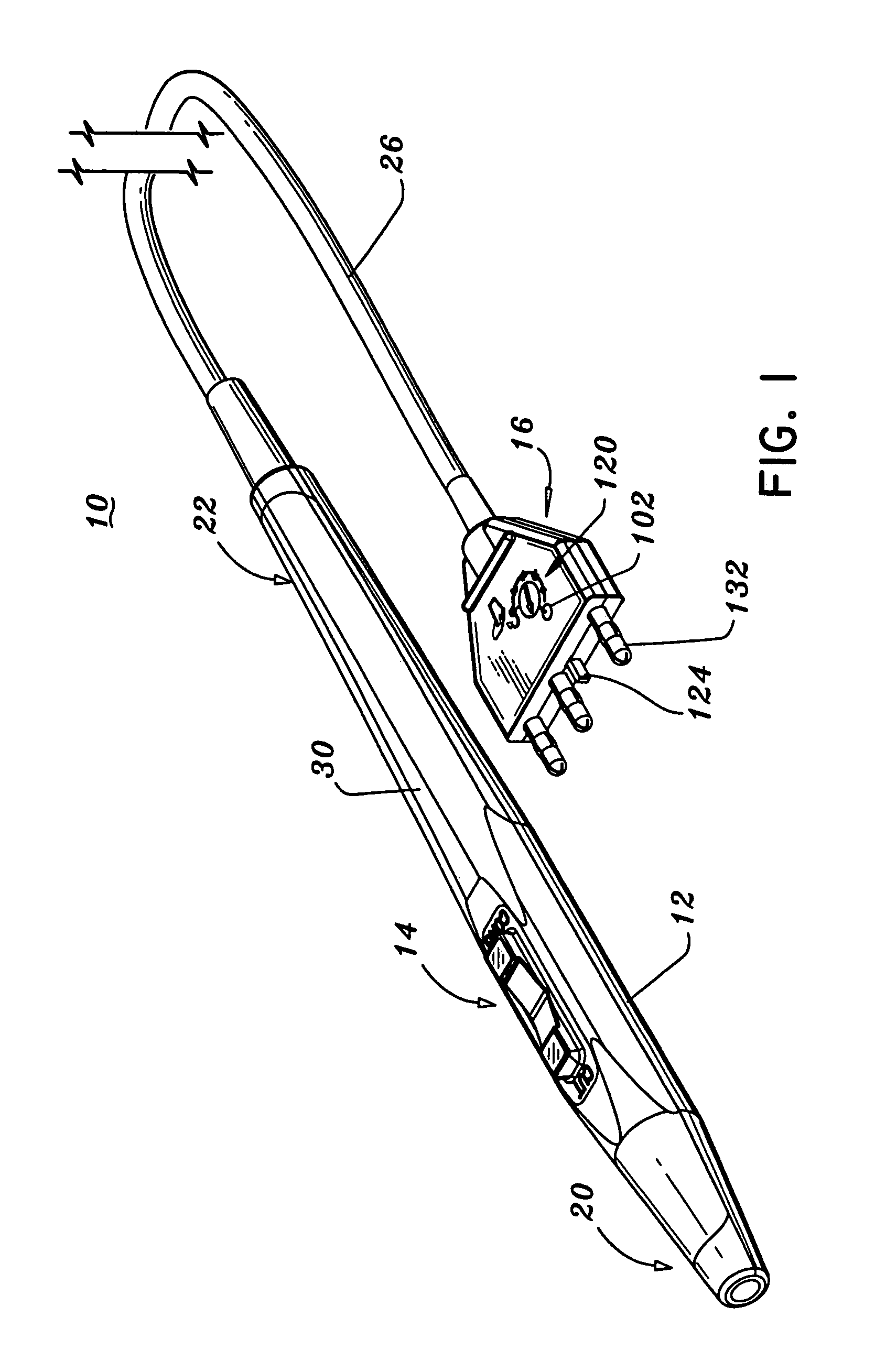

According to the invention, a finger-operated switch for activating and operating an ultrasonic surgical handpiece is provided. The power output of the surgical handpiece is responsive and proportional to the pressure applied to the finger-operated switch. The finger-operated switch includes, but not limited to, force sensitive resistors whose resistance is proportional to the force applied by the finger of the human operator of the surgical handpiece, force sensitive capacitors whose capacitance is proportional to the pressure, deflection or compression of the insulation layer between two electrodes or is proportional to the spacing between the two conductive layers, strain gauges mounted underneath or integral to the housing of the surgical handpiece such that the pressure applied thereto results in an output change in the strain gauges, magnets or ferromagnets encased or embedded in an elastomer with a sensor inside the surgical handpiece that detects the field strength of the magnet and monitors changes relative to the force applied to the handpiece housing, and piezo film or piezo ceramic whose charge or voltage is proportional to the force applied.

Owner:ETHICON ENDO SURGERY INC

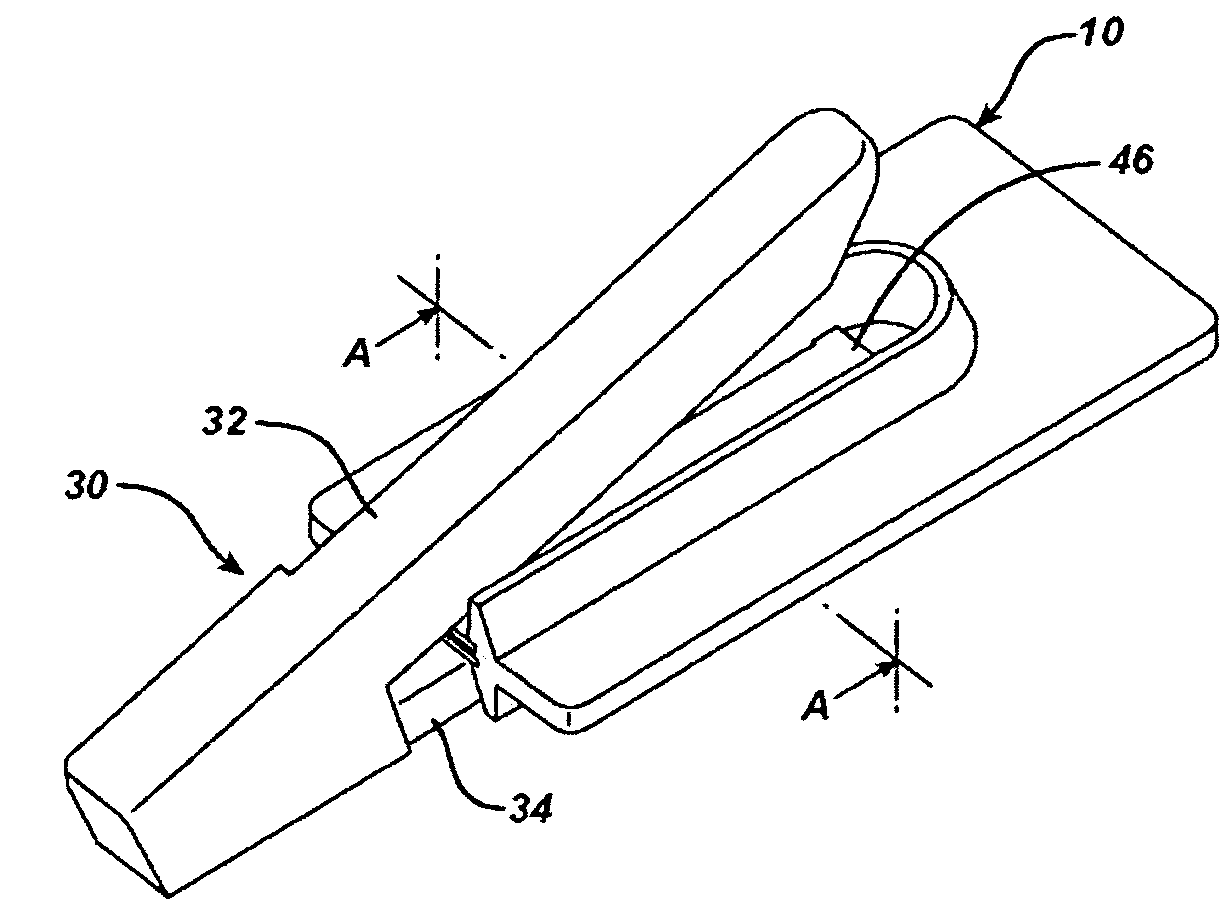

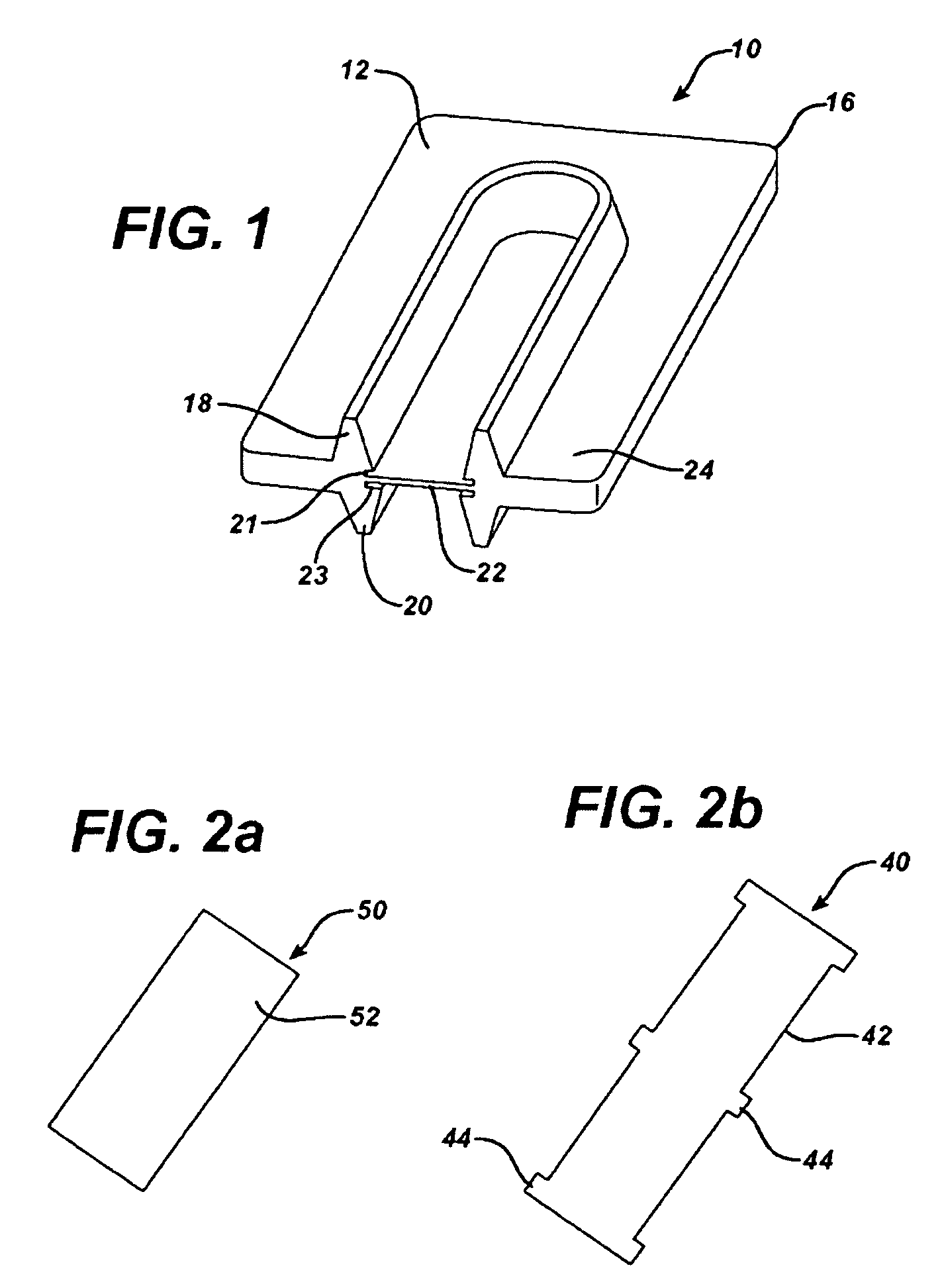

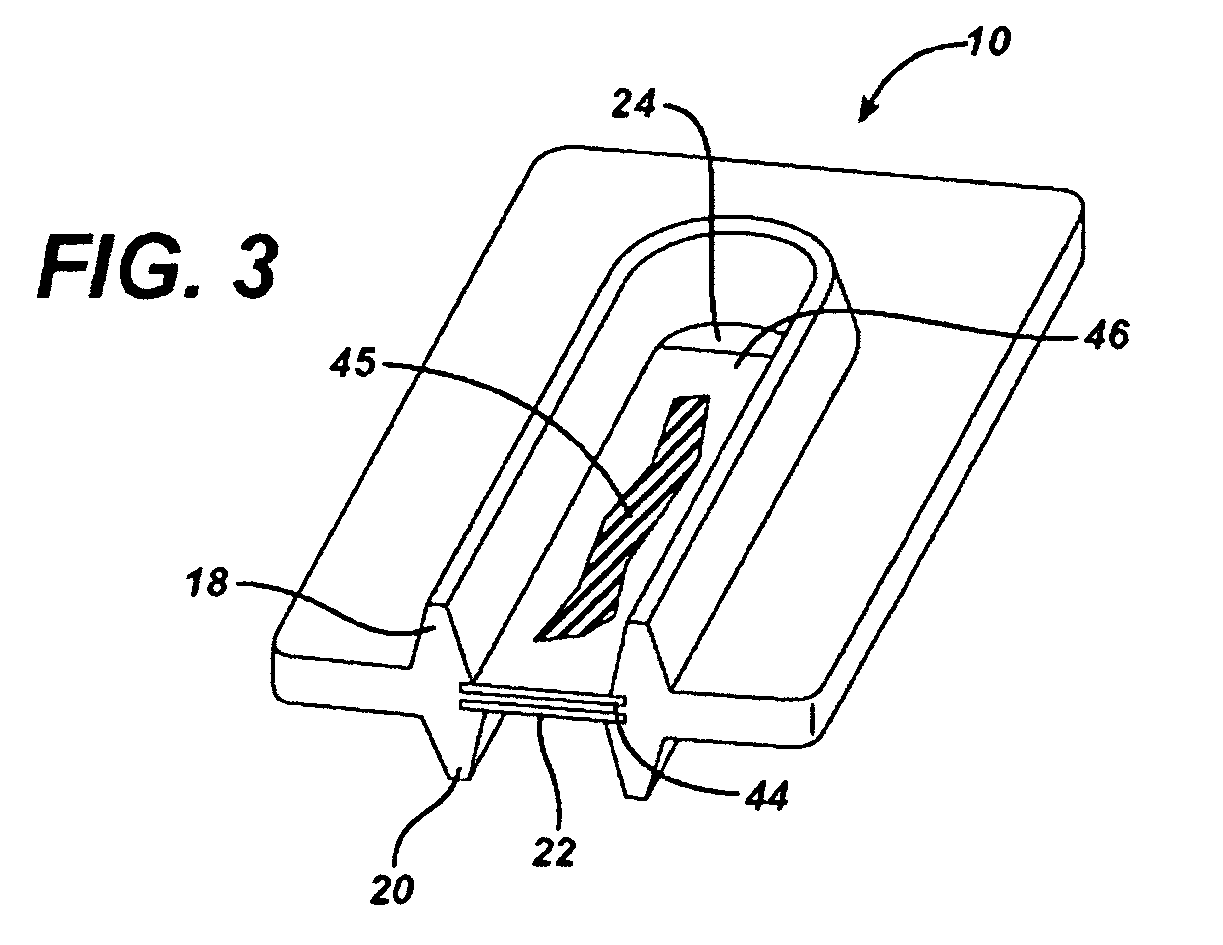

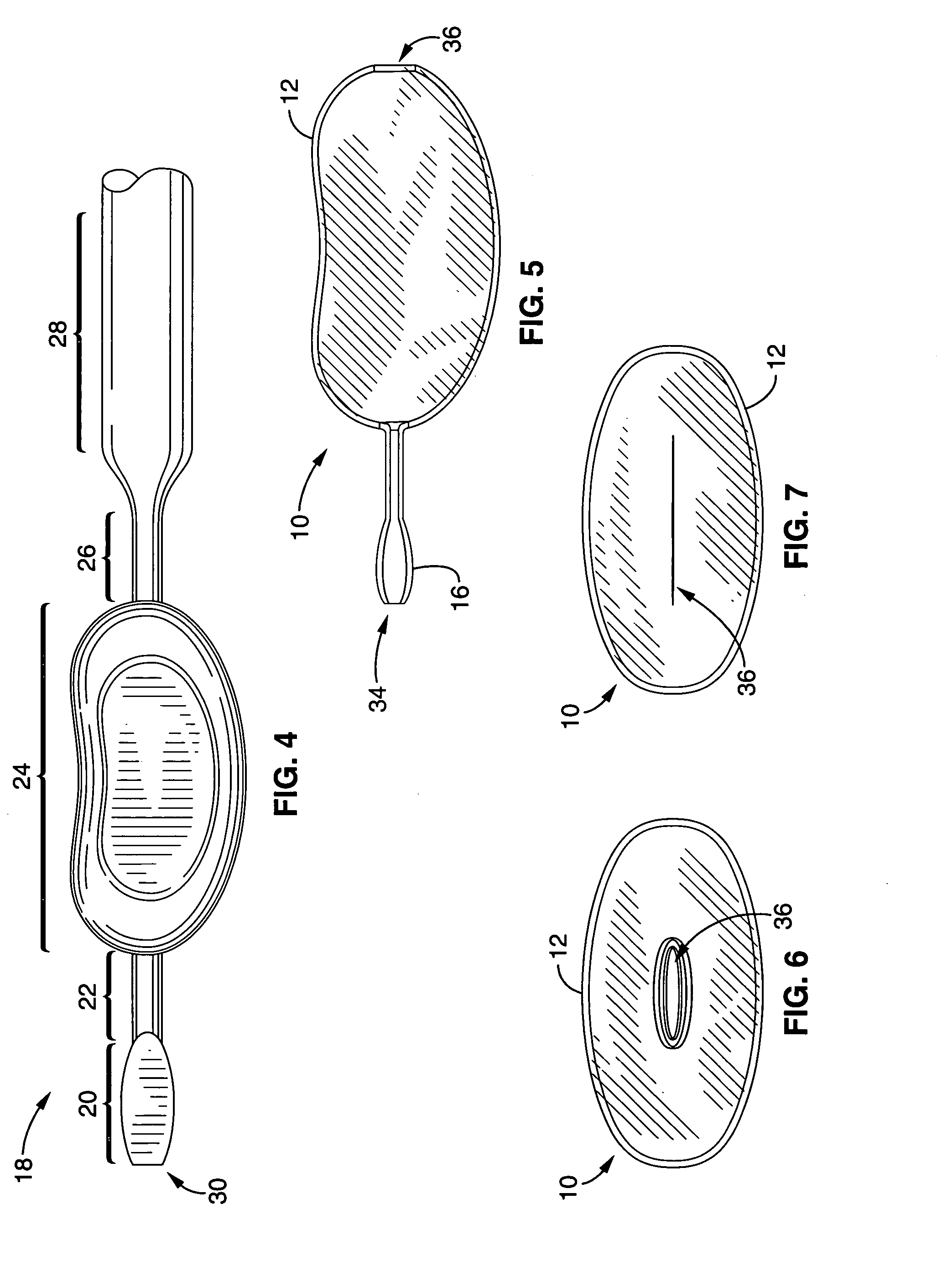

Apparatus and method for attaching a surgical buttress to a stapling apparatus

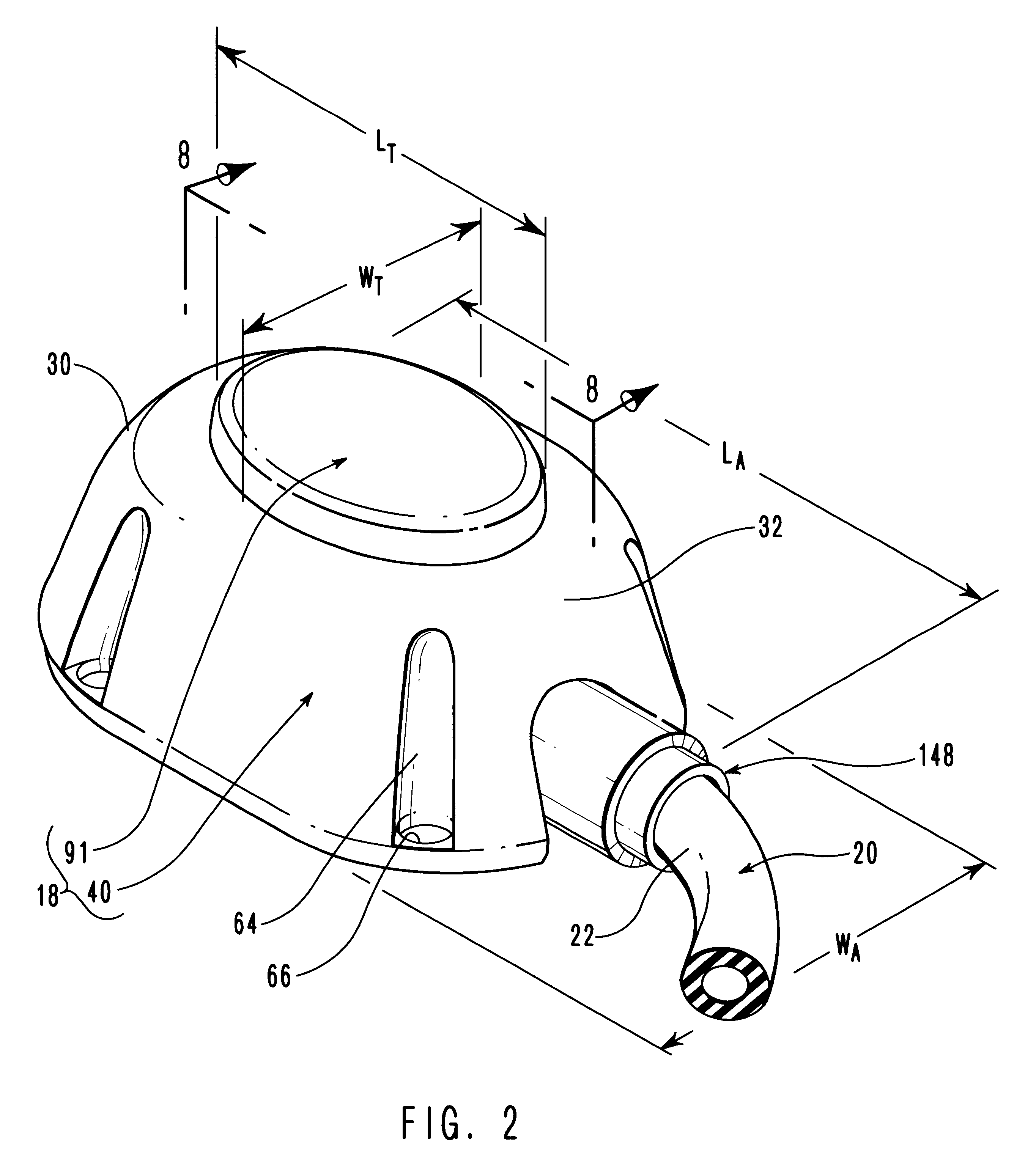

The present invention is an apparatus for equipping a surgical stapling device with a surgical buttress in order to provide reinforced surgical fastener suture lines and includes means for aligning the apparatus with the surgical staple device, an elastomeric foam surgical buttress contained within the alignment means and means for retaining the foam buttress within the alignment means, which alignment means is formed as a unitary body containing a frame, guide channel walls and means for receiving the elastomeric foam surgical buttress.

Owner:ADVANCED TECH & REGENERATIVE MEDICINE

Finger operated switch for controlling a surgical handpiece

ActiveUS7883465B2Ultrasonic/sonic/infrasonic diagnosticsSurgical instrument detailsElastomerCapacitance

According to the invention, a finger-operated switch for activating and operating an ultrasonic surgical handpiece is provided. The power output of the surgical handpiece is responsive and proportional to the pressure applied to the finger-operated switch. The finger-operated switch includes, but not limited to, force sensitive resistors whose resistance is proportional to the force applied by the finger of the human operator of the surgical handpiece, force sensitive capacitors whose capacitance is proportional to the pressure, deflection or compression of the insulation layer between two electrodes or is proportional to the spacing between the two conductive layers, strain gauges mounted underneath or integral to the housing of the surgical handpiece such that the pressure applied thereto results in an output change in the strain gauges, magnets or ferromagnets encased or embedded in an elastomer with a sensor inside the surgical handpiece that detects the field strength of the magnet and monitors changes relative to the force applied to the handpiece housing, and piezo film or piezo ceramic whose charge or voltage is proportional to the force applied.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

InactiveUS7112201B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface. In another mode of operation, a conductive-resistive matrix can induce a “wave” of Rf energy density to sweep across the tissue to thereby weld tissue.

Owner:ETHICON ENDO SURGERY INC

Methods and apparatus for analyzing polynucleotide sequences

The present invention provides an apparatus for analyzing the sequences of polynucleotides. The apparatus comprises (a) flow cell which has at least one microfabricated multilayer elastomeric synthesis channel; and (b) an inlet port and an outlet port. The inlet port and outlet ports are in fluid communication with the flow cell for flowing fluids into and through the flow cell.

Owner:CALIFORNIA INST OF TECH

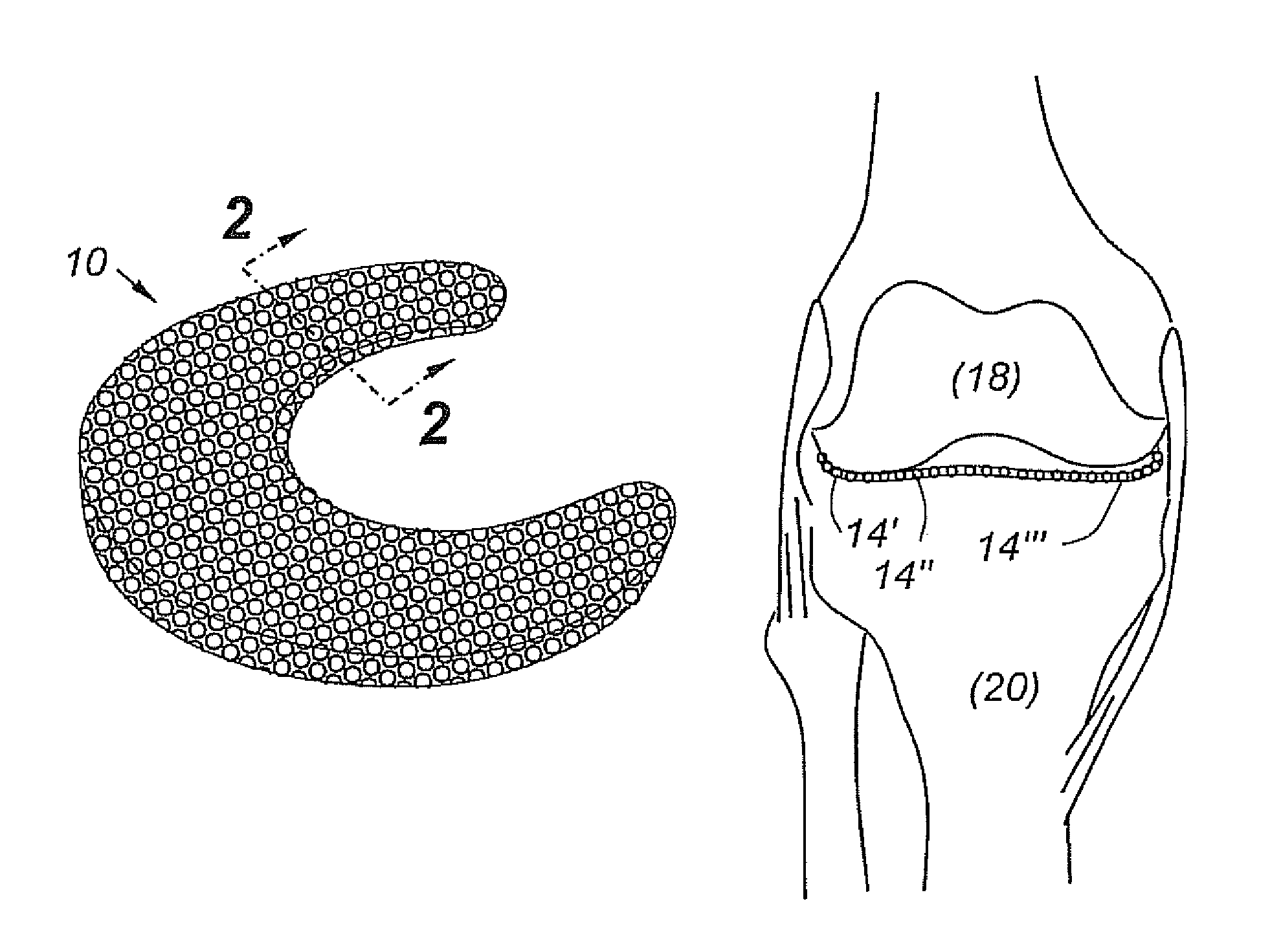

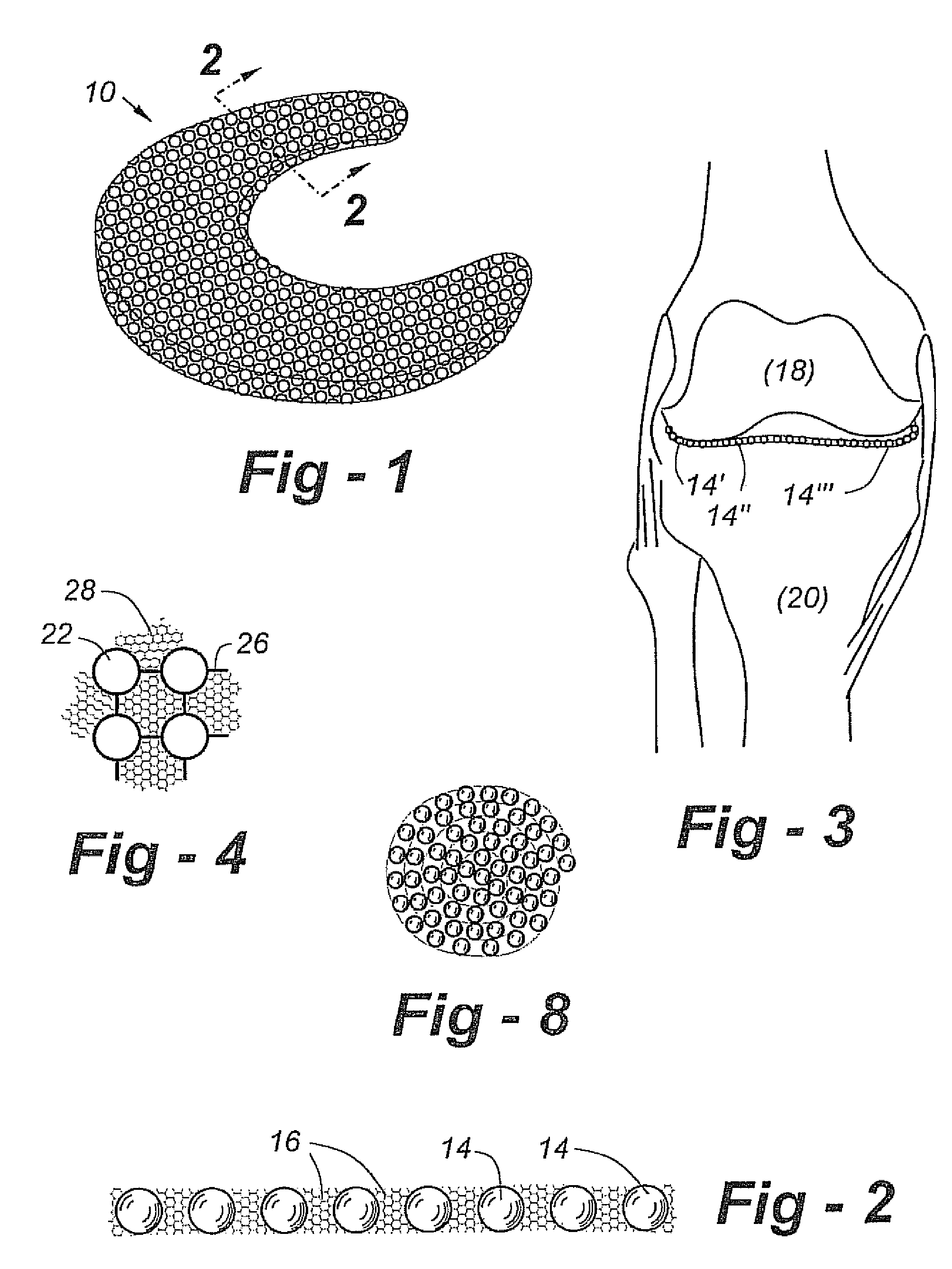

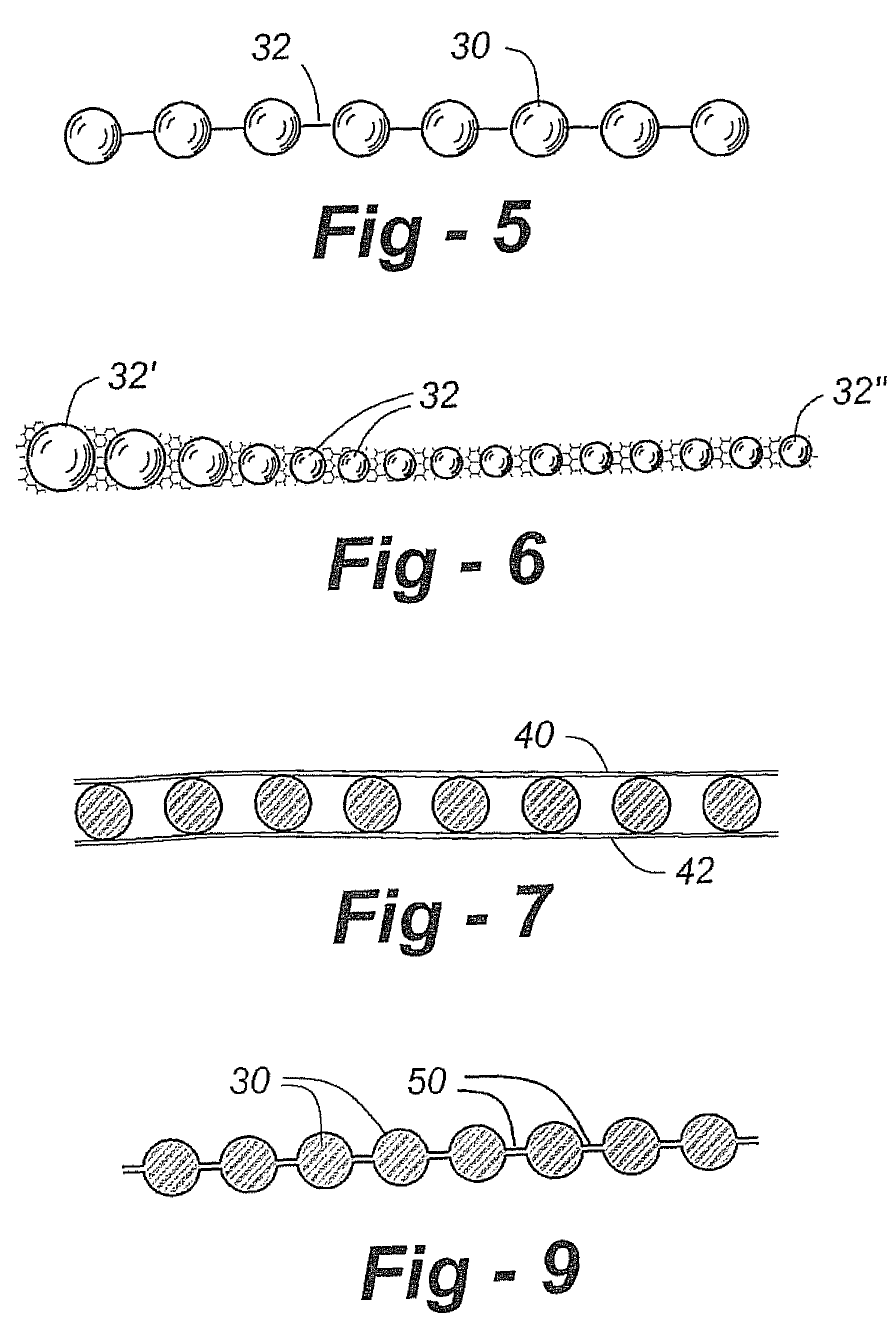

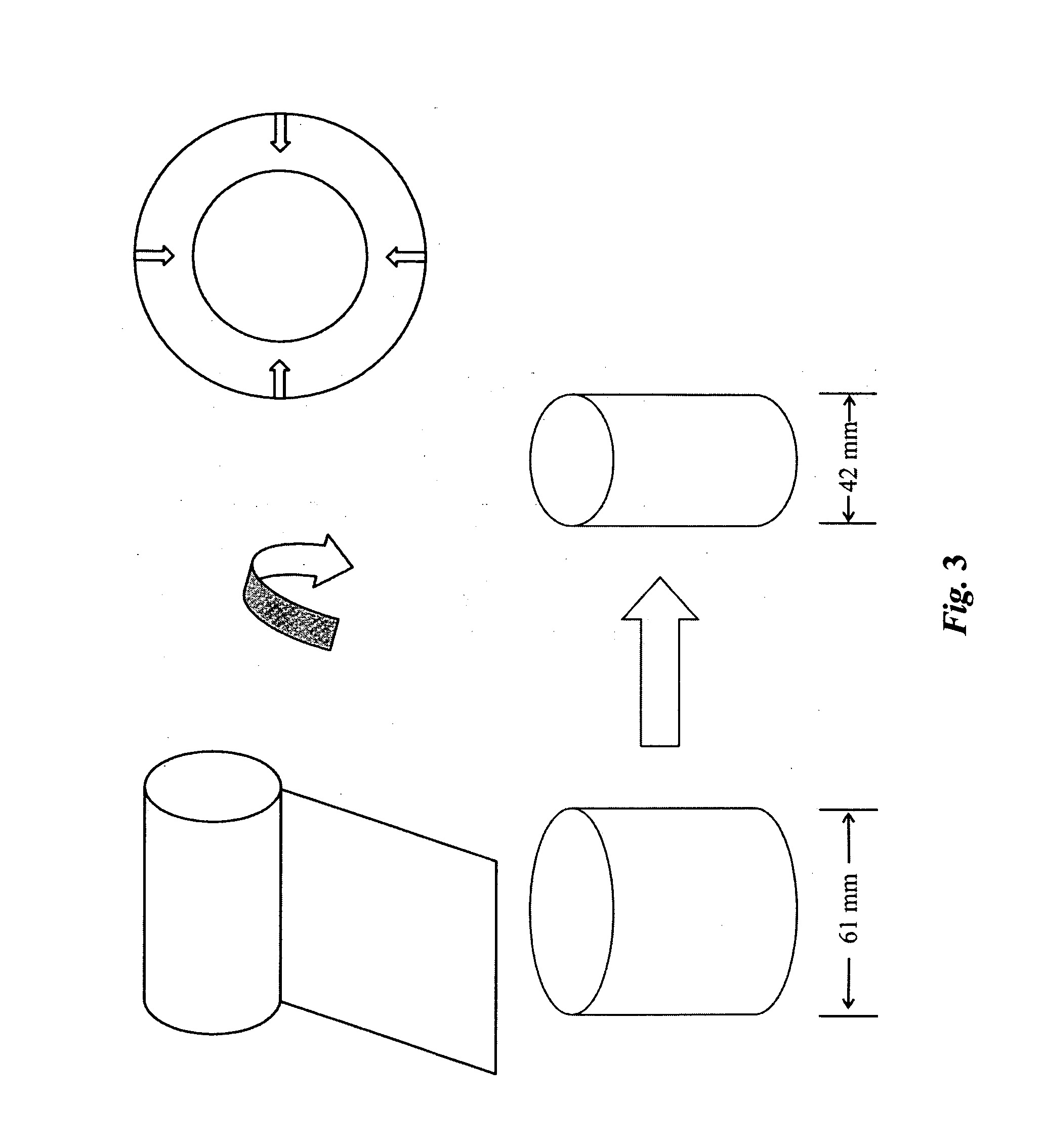

Prosthesis for replacement of cartilage

A cartilage replacement or repair prosthesis comprises a layer of streamlined elastomer elements, preferably in the form of spheres, supported in a matrix material so that the radially opposed surfaces of the spheres are positioned on opposite surfaces of the layer and make contact with the opposed surfaces of the femur and tibia and the forces exerted between these bones extend through the streamlined elements. The matrix material has a substantially lower resistance to deformation than the spheres to control the position of the spheres relative to one another without significantly restraining their load-responsive deformation under forces exerted between the femur and tibia. The layer, with its elastomeric inserts, is sufficiently thin and flexible to allow it to be rolled for arthroscopic insertion into a knee joint.

Owner:SUCCESSOR TRUSTEE OF THE EUGENE RIVIN LIVING TRUST +2

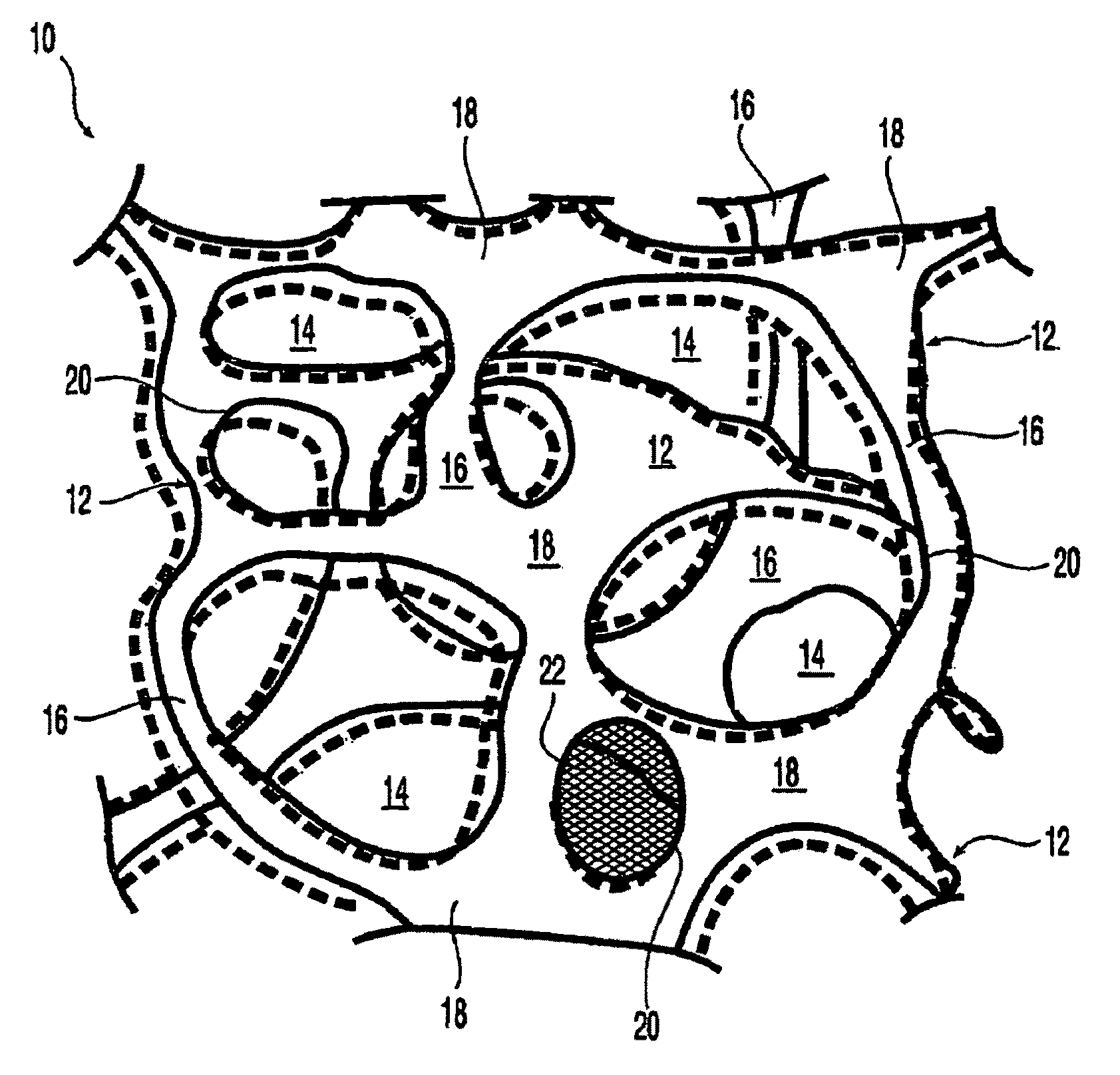

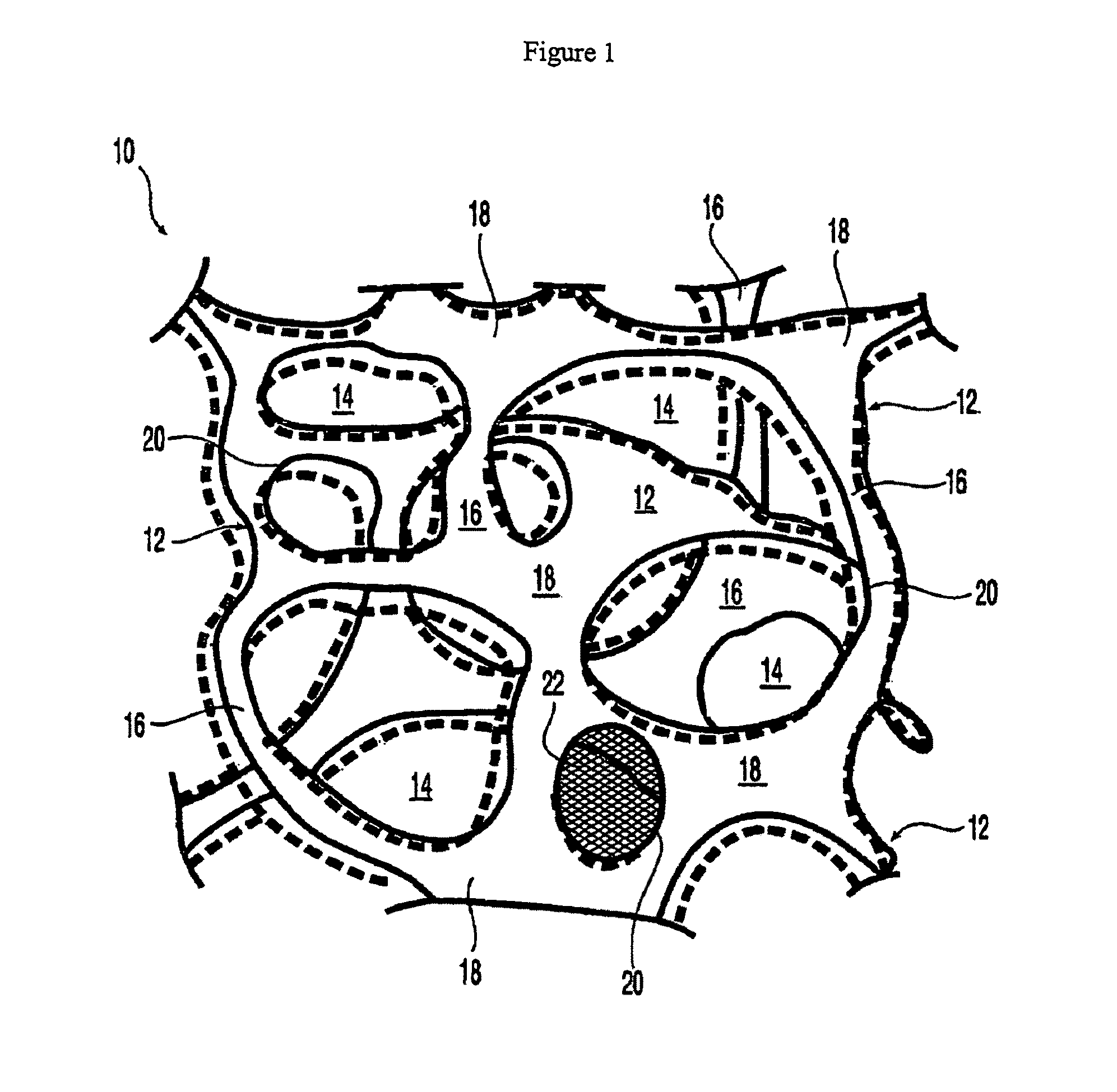

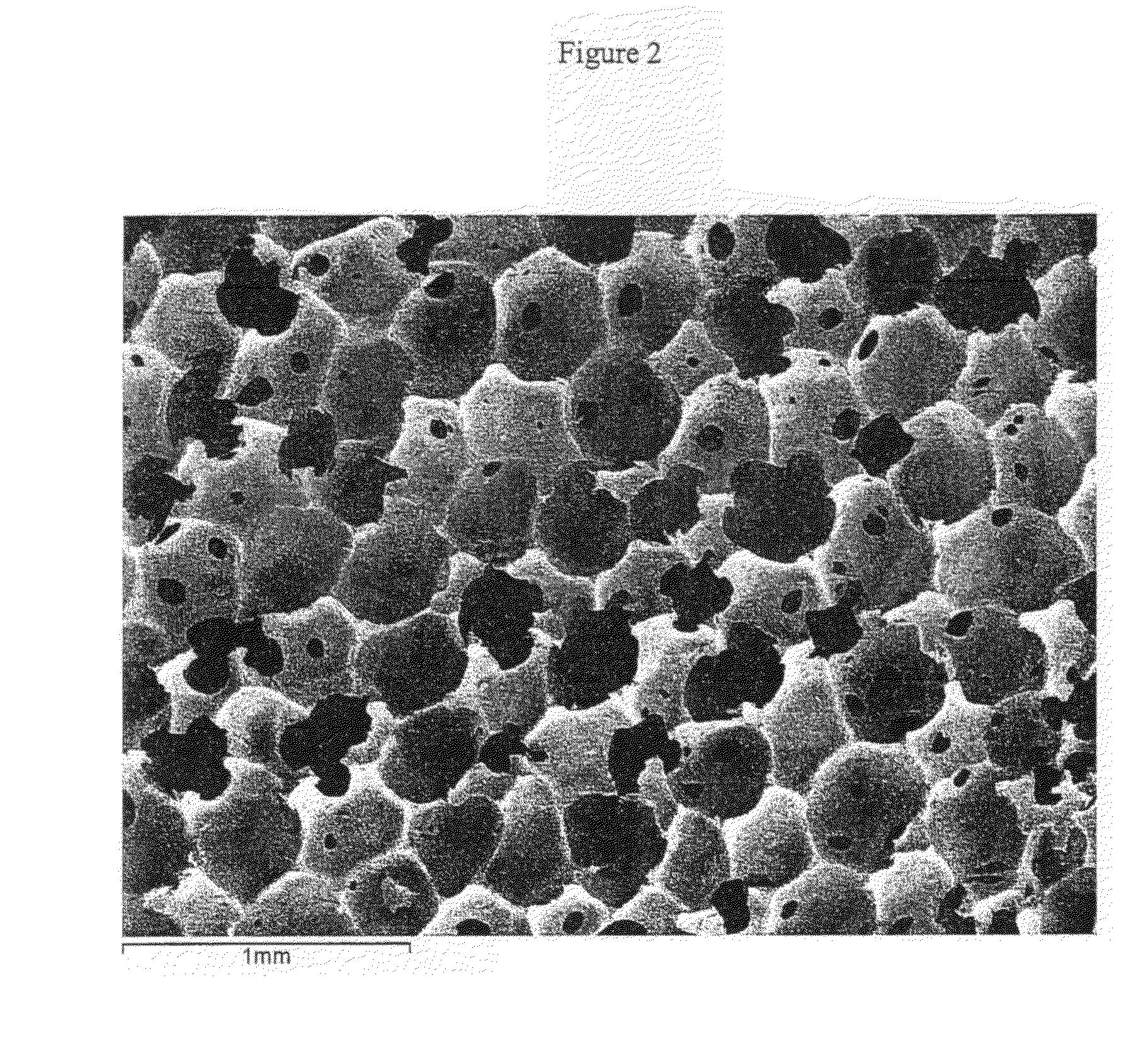

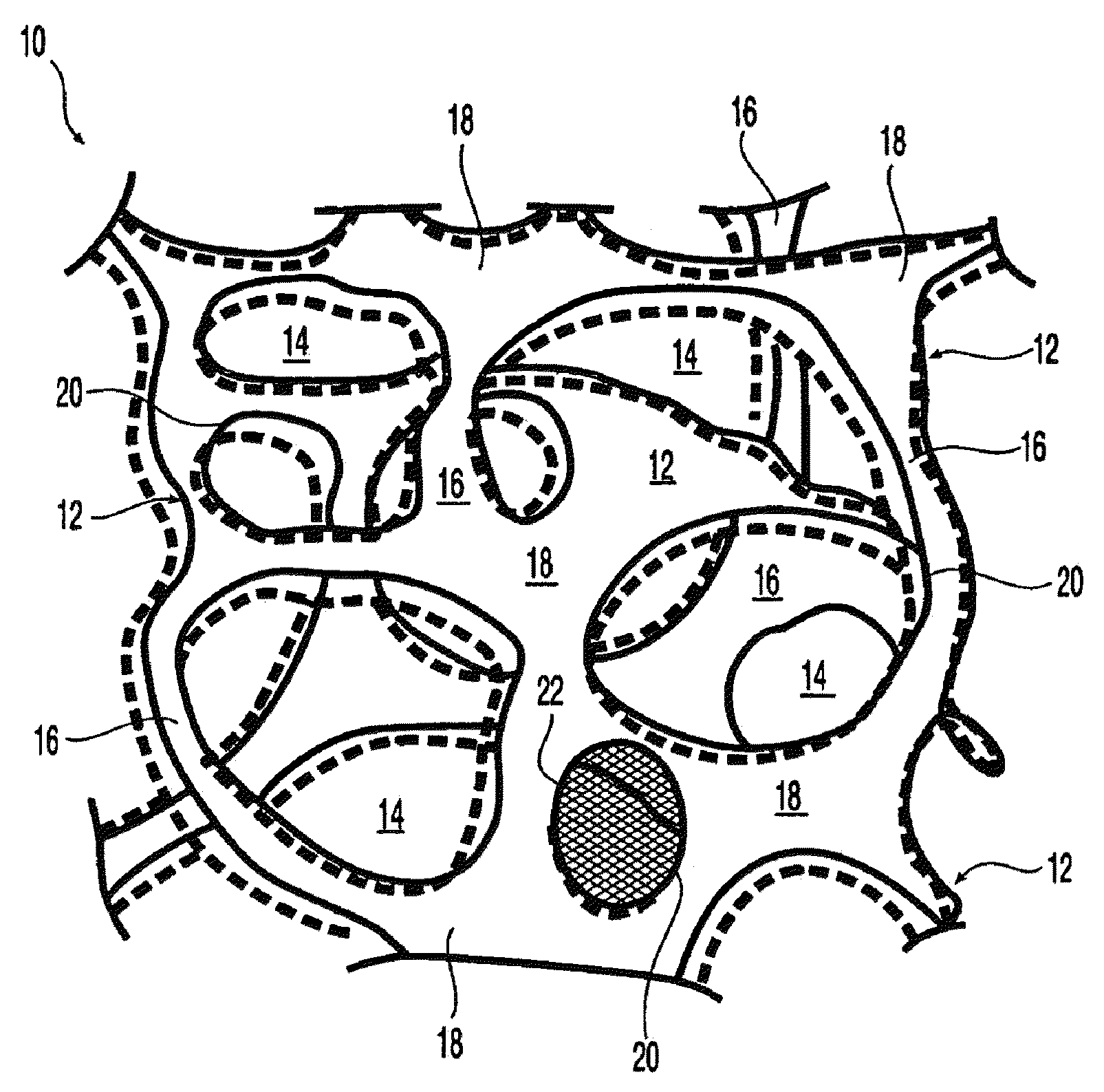

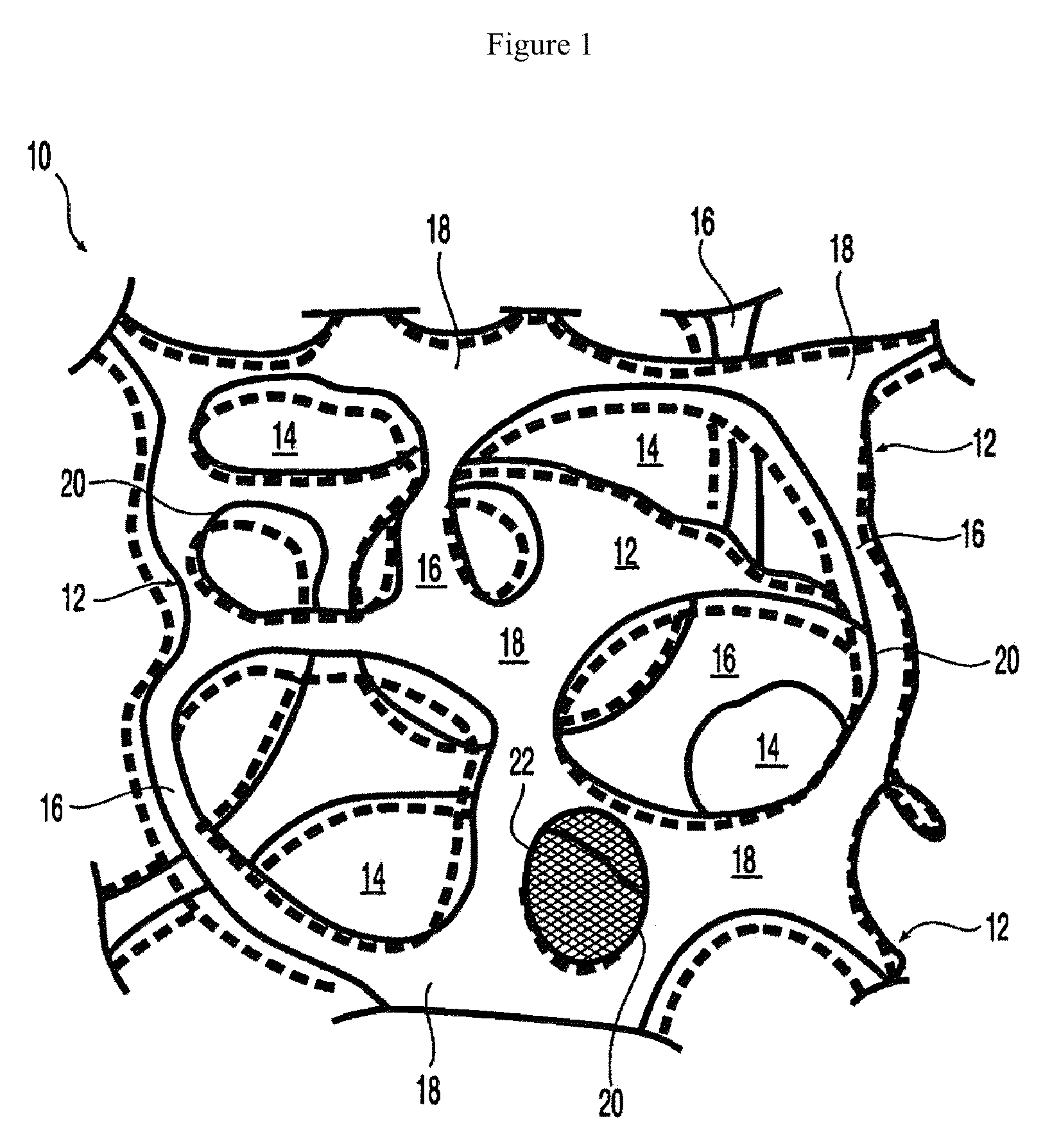

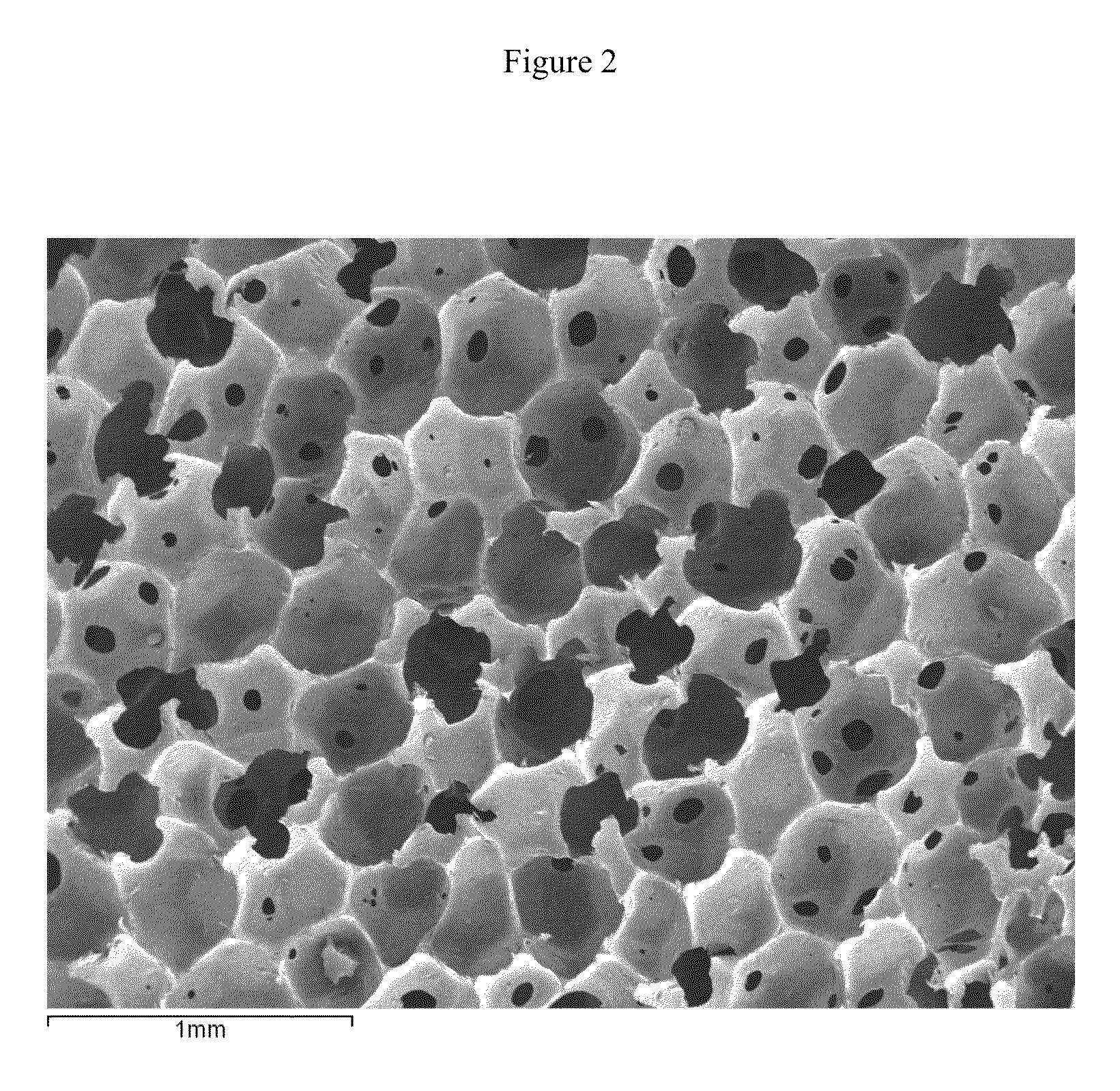

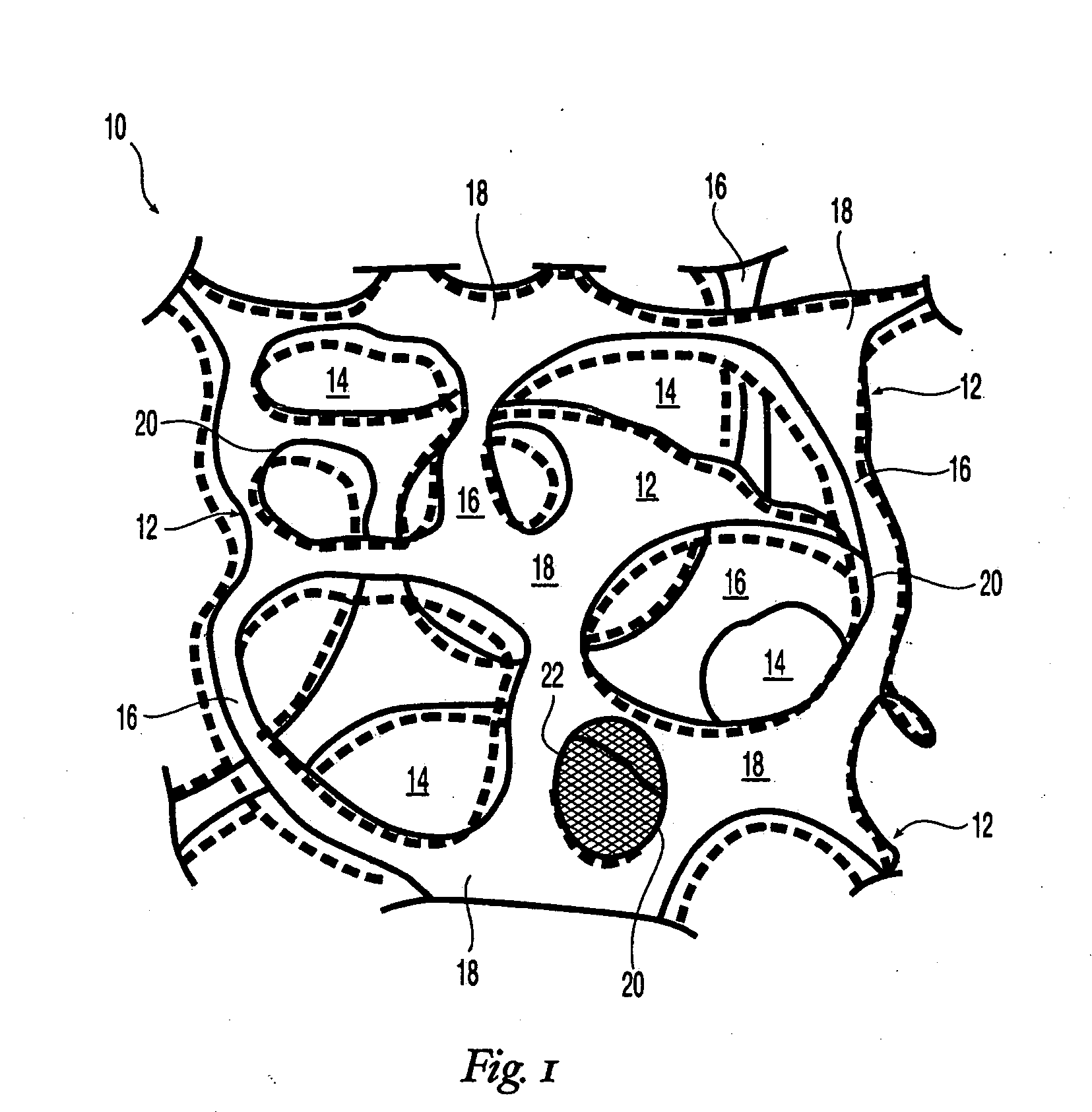

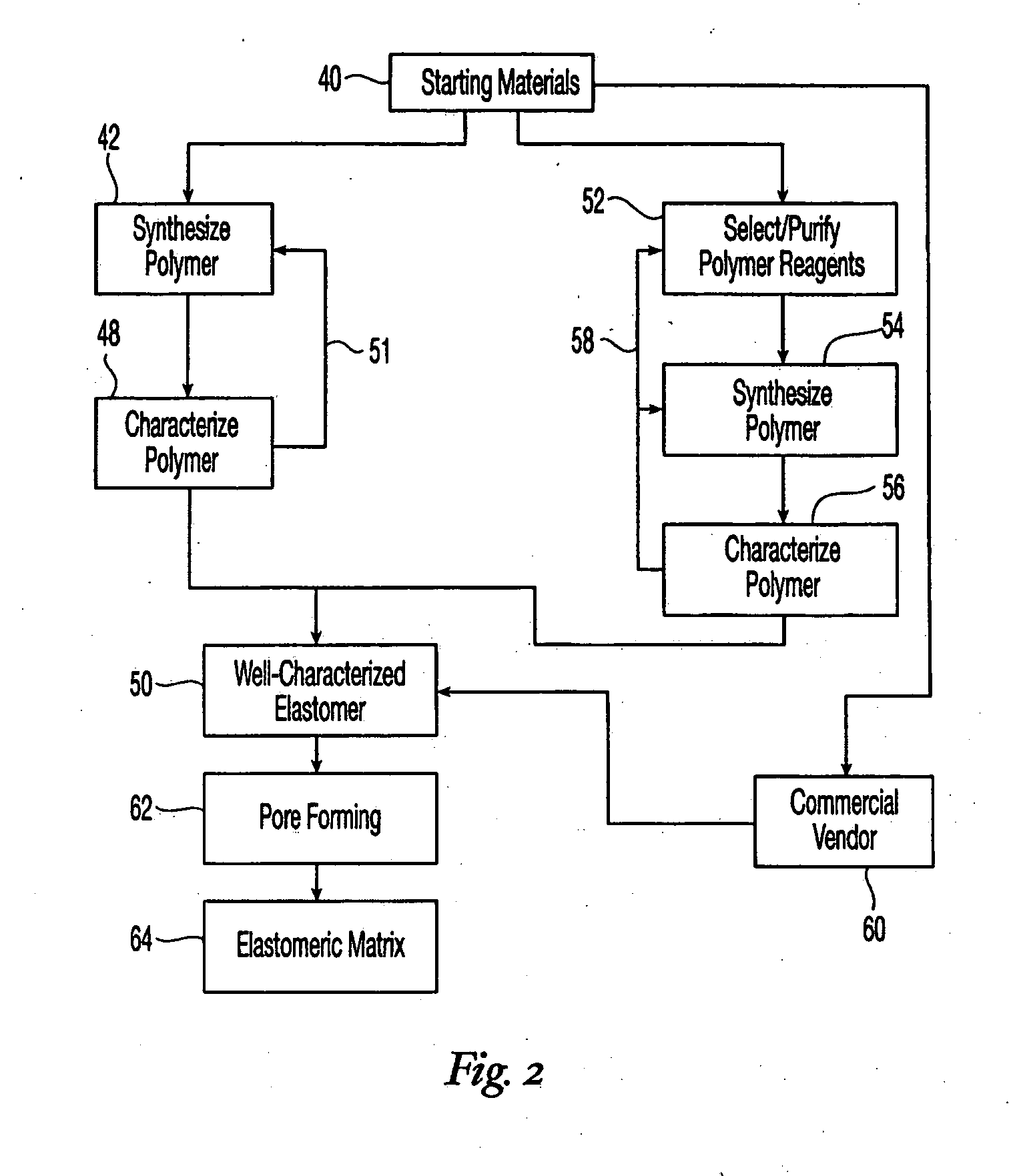

At least partially resorbable reticulated elastomeric matrix elements and methods of making same

ActiveUS8801801B2Small volumeIncrease in sizePolyurea/polyurethane coatingsProsthesisElastomerBiomedical engineering

The present disclosure relates to reticulated elastomeric matrices, and more particularly to at least partially degradable elastomeric elements that are compressible and exhibit resilience in their recovery and that can be employed in diverse applications including, without limitation, biological implantation, especially in humans.

Owner:DSM IP ASSETS BV

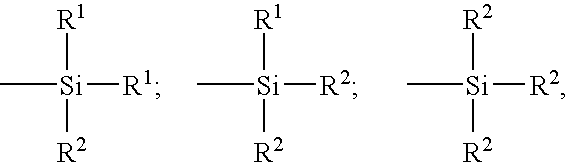

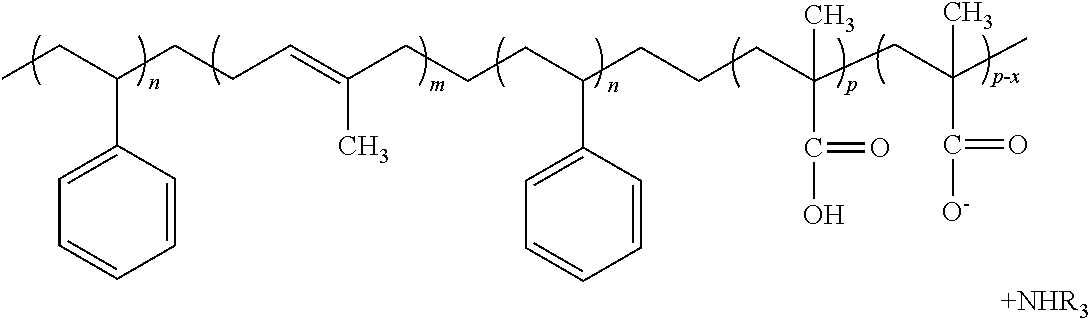

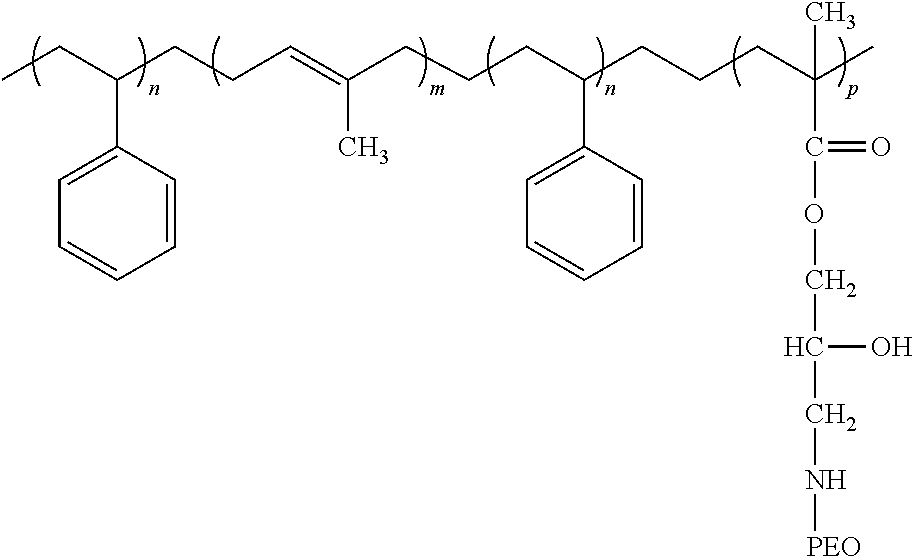

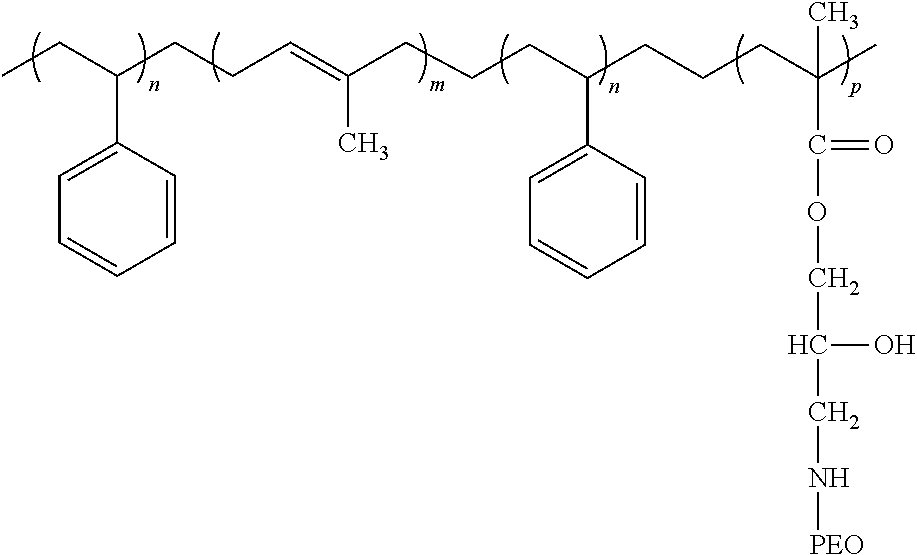

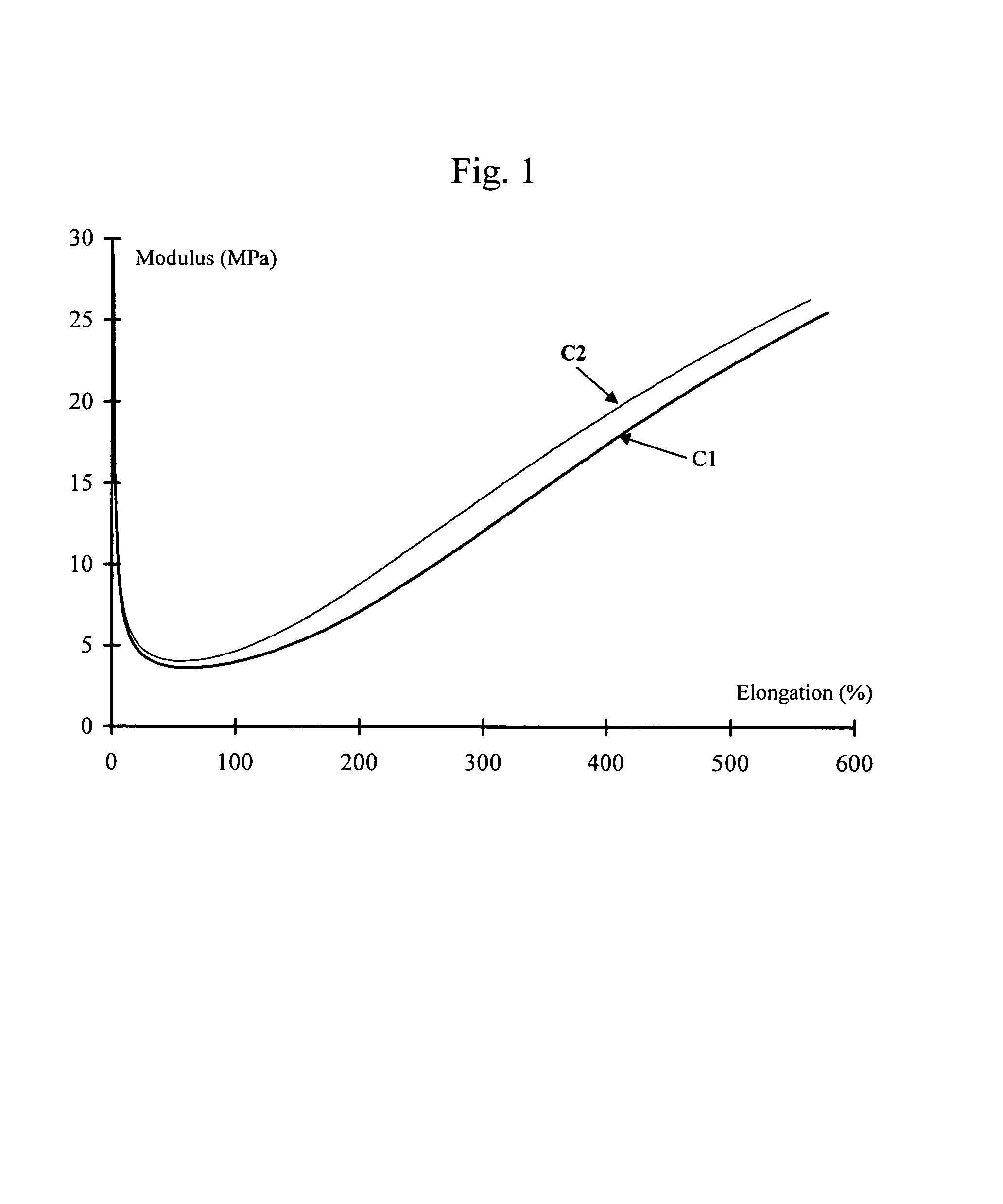

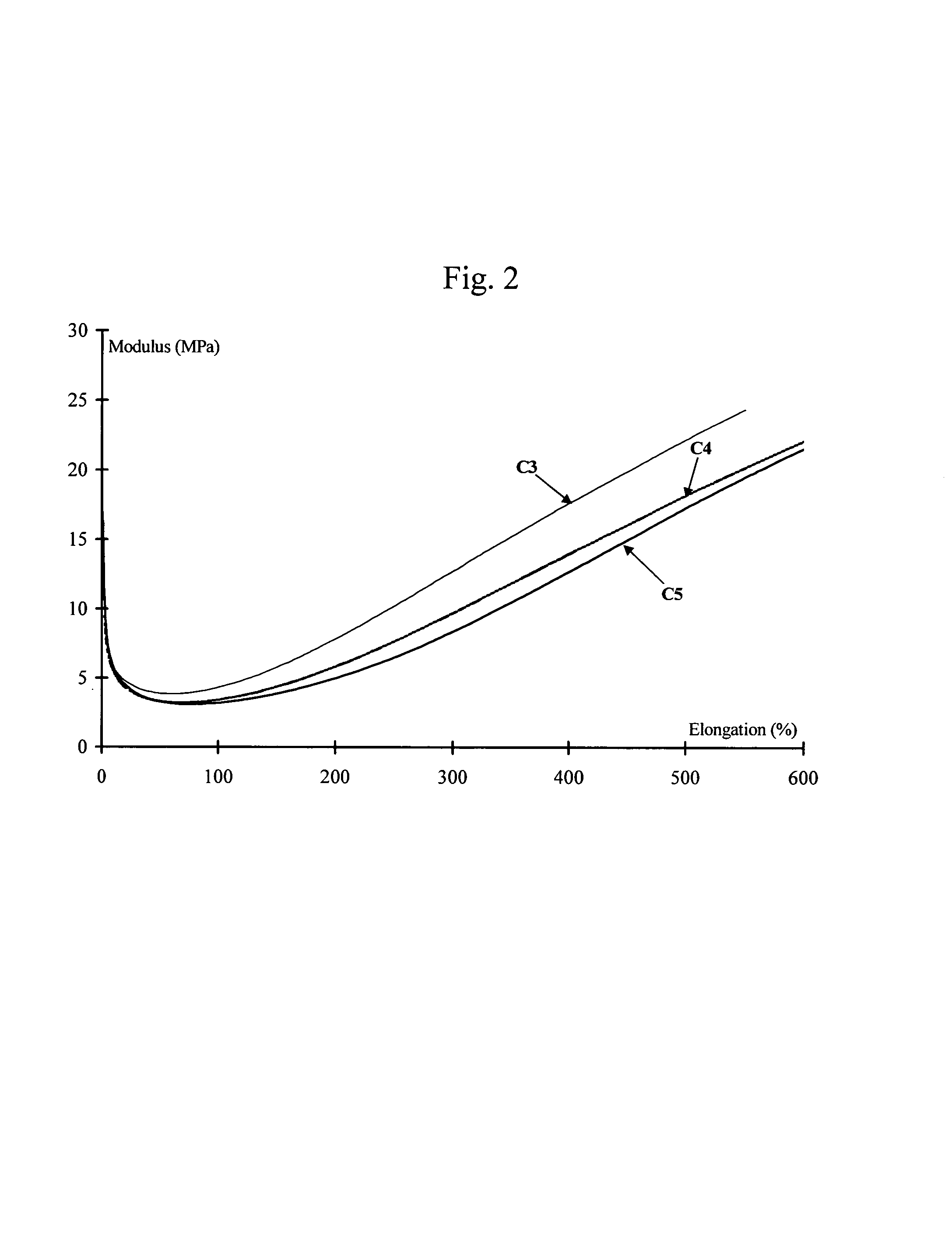

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

At least partially resorbable reticulated elastomeric matrix elements and methods of making same

ActiveUS9050176B2Small volumeIncrease in sizePharmaceutical delivery mechanismPharmaceutical non-active ingredientsElastomerBiomedical engineering

The present disclosure relates to reticulated elastomeric matrices, and more particularly to at least partially degradable elastomeric elements that are compressible and exhibit resilience in their recovery and that can be employed in diverse applications including, without limitation, biological implantation, especially in humans.

Owner:DSM IP ASSETS BV

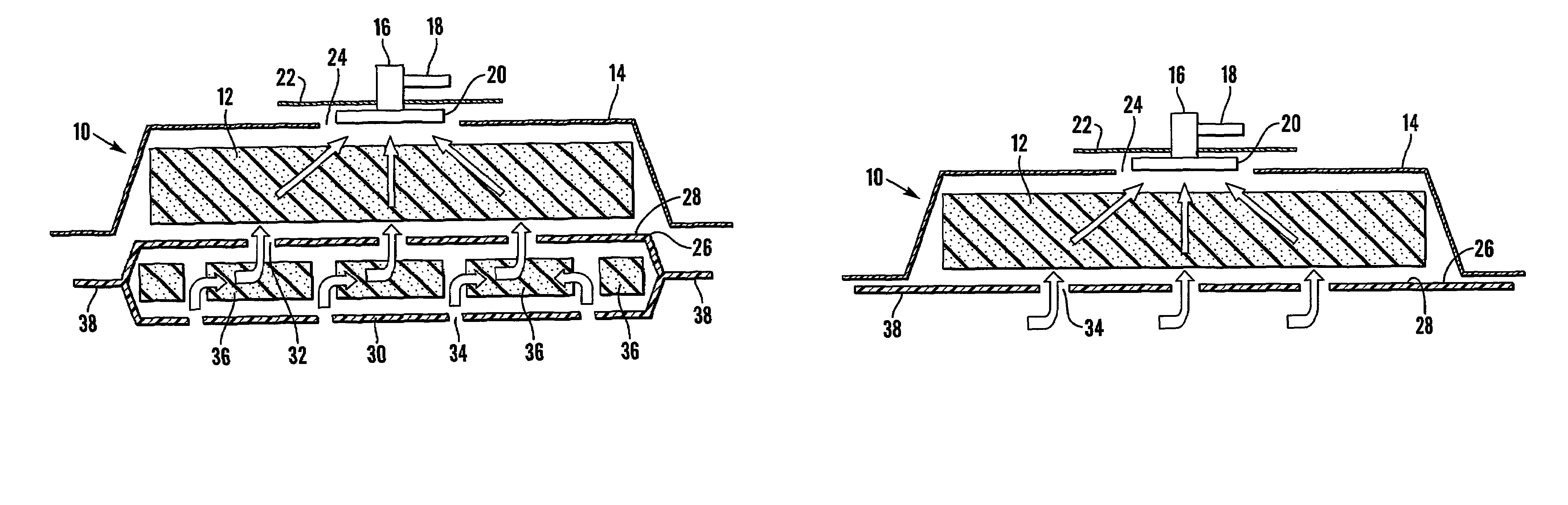

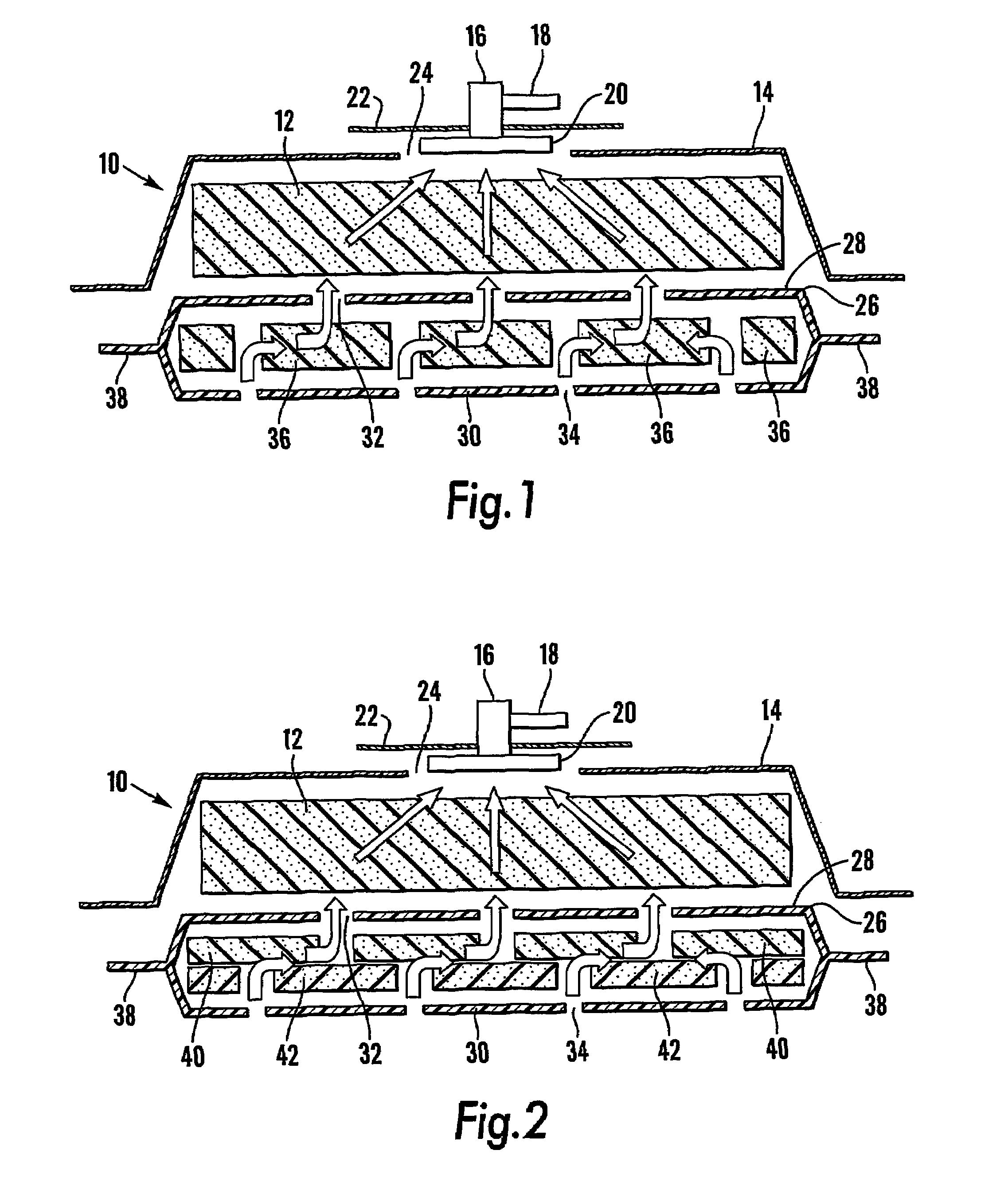

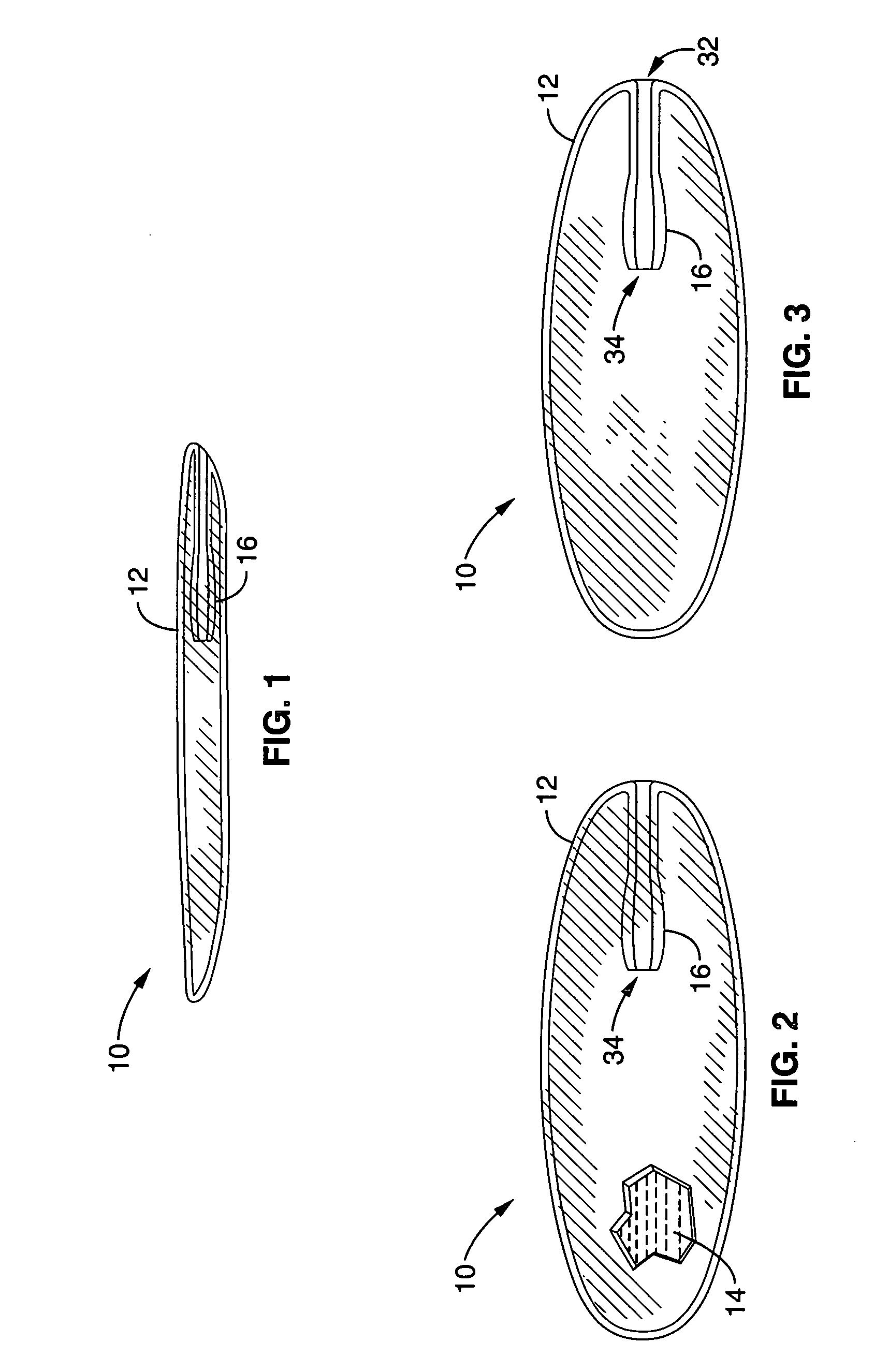

Removable wound closure

InactiveUS7381859B2Promote wound healingMinimizes adhesion formationNon-adhesive dressingsWound drainsElastomerPorosity

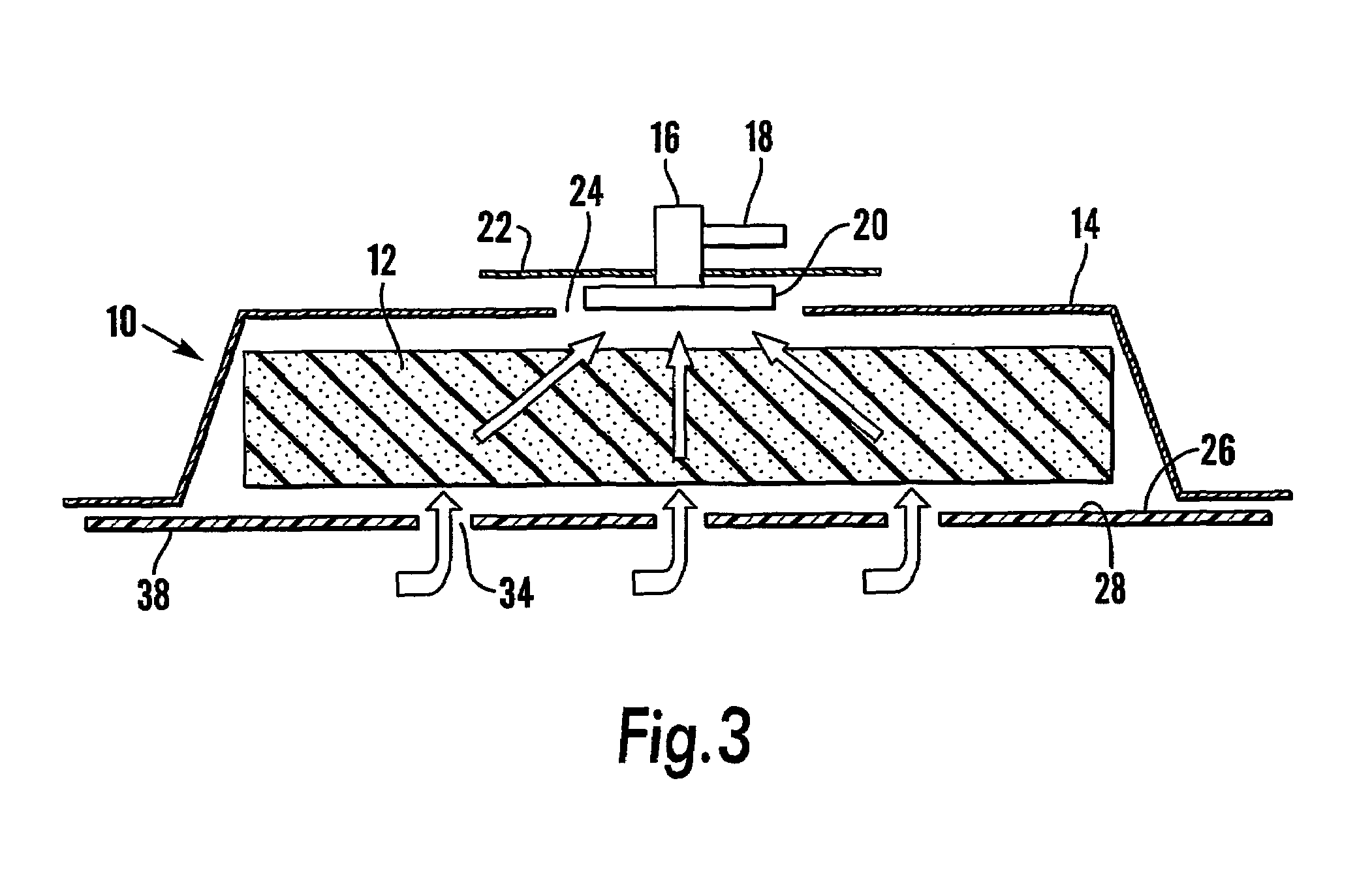

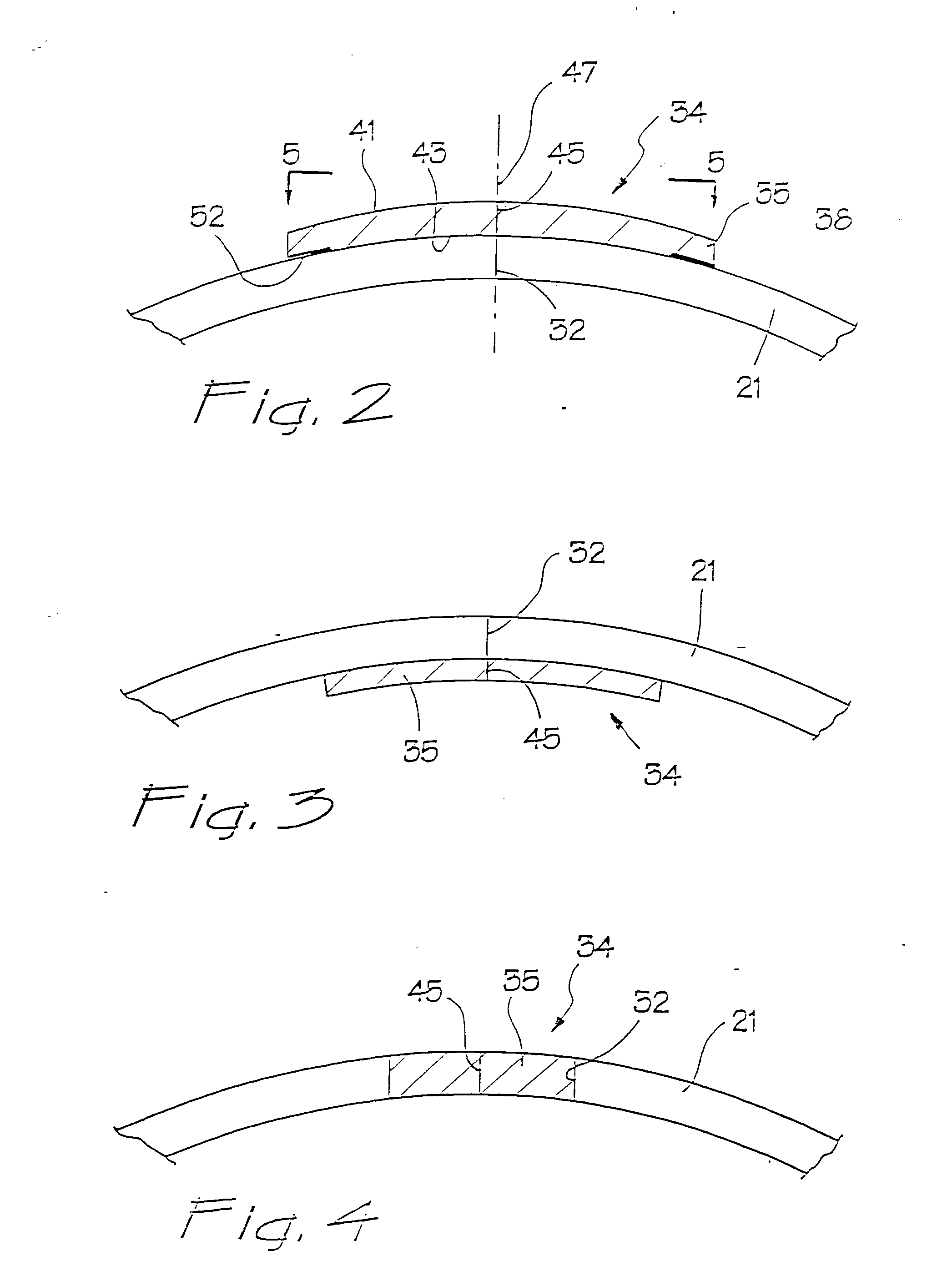

A system and method for the temporary closure of a wound, especially an abdominal wound, to facilitate re-entry, final closure, and long term healing of the wound. An abdominal wound dressing and methods of use are described that enable the application of negative pressure to the wound site in a site healing promoting manner while also limiting the formation of adhesions that would prevent the removal of the dressing. The dressing comprises a layer of porous foam material (36) enclosed by sheets of elastomeric material (38) punctuated by a number of appropriately placed holes (34). Multiple layers of porous foam may also be used. A suction tube connector (16) is provided on an upper surface of a layer of foam (12) for connection to a negative pressure source. At least one layer of foam is enclosed in elastomeric material and is placed in direct contact with the tissue within the open wound. Fluids are drawn by negative pressure through the holes positioned in the elastomeric envelope, and through the foam. If multiple foam layers are employed, the lower layer(s) of foam are of a finer porosity while the upper layer of foam is coarse. An adhesive elastomeric sheet (14) covers the entire wound dressing and seals the edges to the skin surrounding the wound. An appropriate vacuum device is attached to the suction tube connector.

Owner:KCI LICENSING INC

Substrate Coated With A Hydrophilic Elastomer

ActiveUS20110319848A1Improve hydrophilicityGood coating stabilitySynthetic resin layered productsPretreated surfacesElastomerPolymer science

Substrates, coated with a block copolymer comprising at least four blocks being at least two hard blocks, one soft block and one hydrophilic block, wherein a the soft block is sandwiched between the hard blocks.

Owner:THE PROCTER & GAMBLE COMPANY

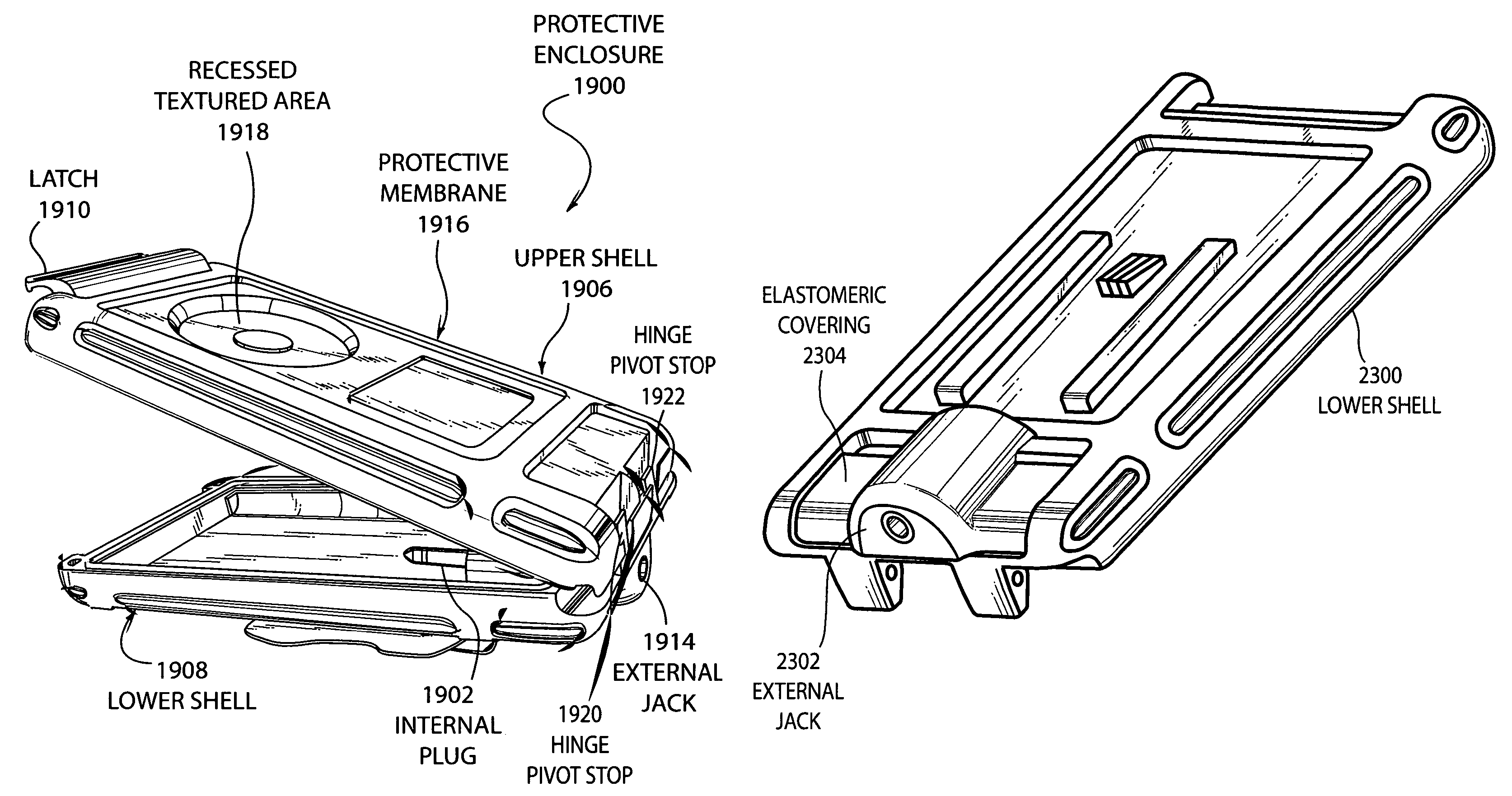

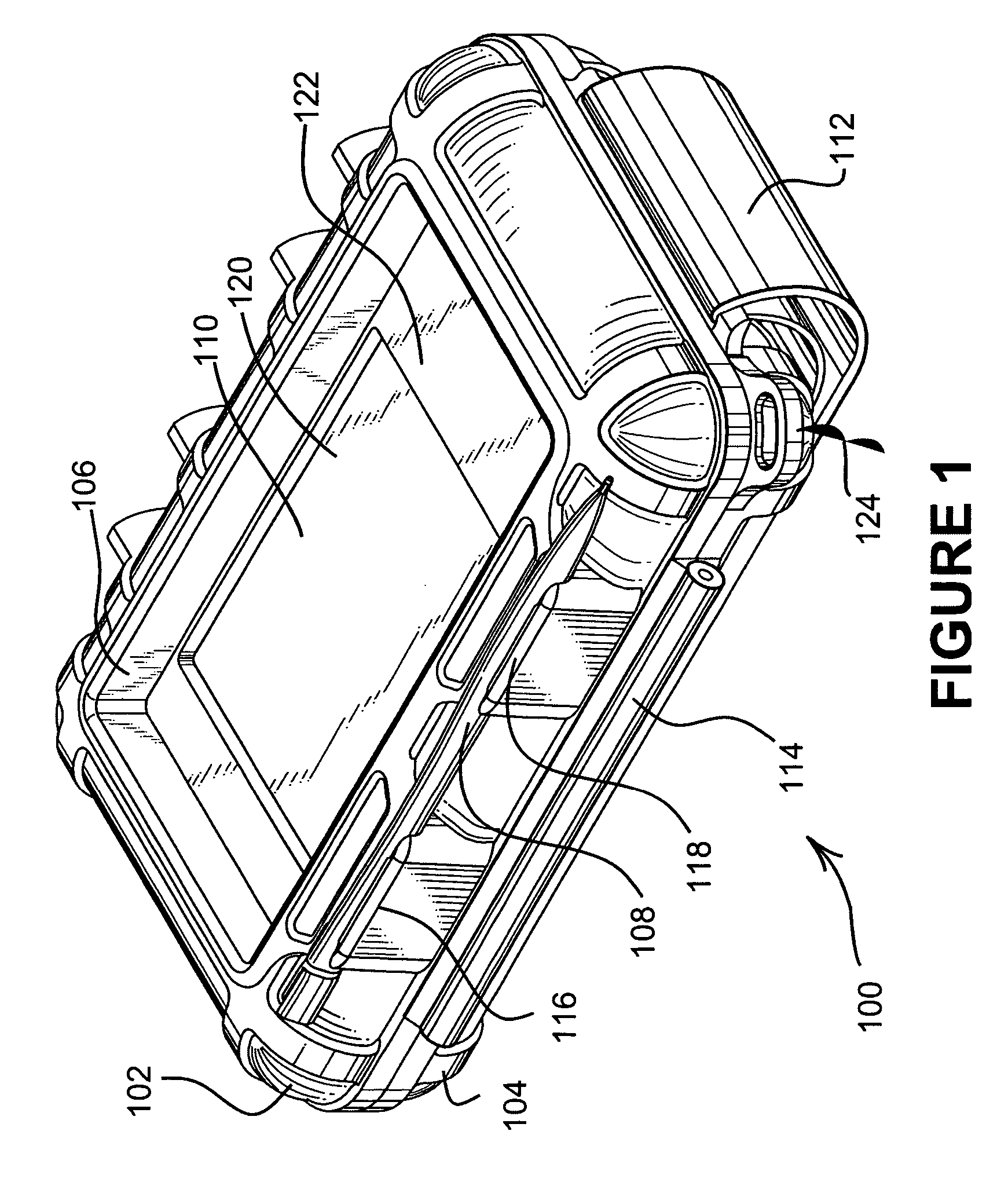

Protective enclosure and watertight adapter for an interactive flat-panel controlled device

InactiveUS7180735B2Stable controlIncrease contactSonic/ultrasonic/infrasonic transmissionDigital data processing detailsElastomerCapacitance

A protective enclosure is disclosed for an interactive flat-panel control device. The protective enclosure is watertight, crush-resistant, and impact-resistant. An electrical adapter may disposed within the protective enclosure and covered with an elastomeric covering that permits a connector of the adapter to flex with respect to the lower shell of the enclosure so that the connector may easily be inserted into an interface jack of the electronic device. The elastomeric covering also provides a watertight seal that enables the protective enclosure to be submersibly watertight. While providing protection, the protective enclosure simultaneously allows smooth and accurate interaction with the interactive flat-panel controlled device. The protective enclosure has a protective membrane that permits RF and touch screen stylus inputs, as well as capacitance, such as from a finger, to be transmitted accurately to the flat-panel control. The hardness and texture of the protective membrane allows a stylus or finger to glide smoothly along the surface of the membrane without catching or sticking. The protective enclosure is further adapted to allow infrared and other communication signals while the device is secured inside the case. Further, electrical connections can be made through the case without affecting the protection afforded the electronic device inside. The protective enclosure may have a removable cable management belt clip that has a flange that retains and prevents entangling of an accessory cable for the interactive flat-panel control device.

Owner:OTTER PRODS

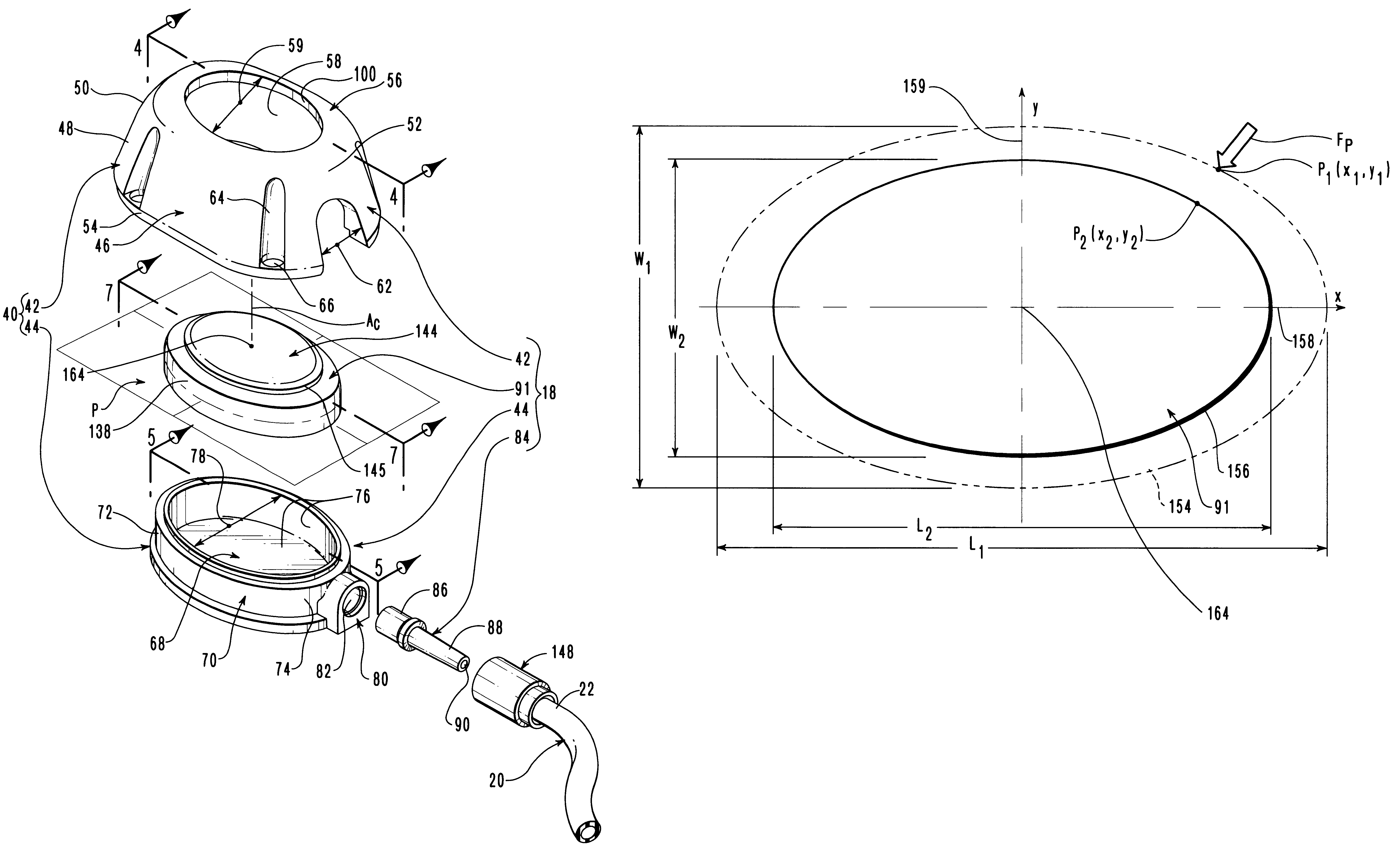

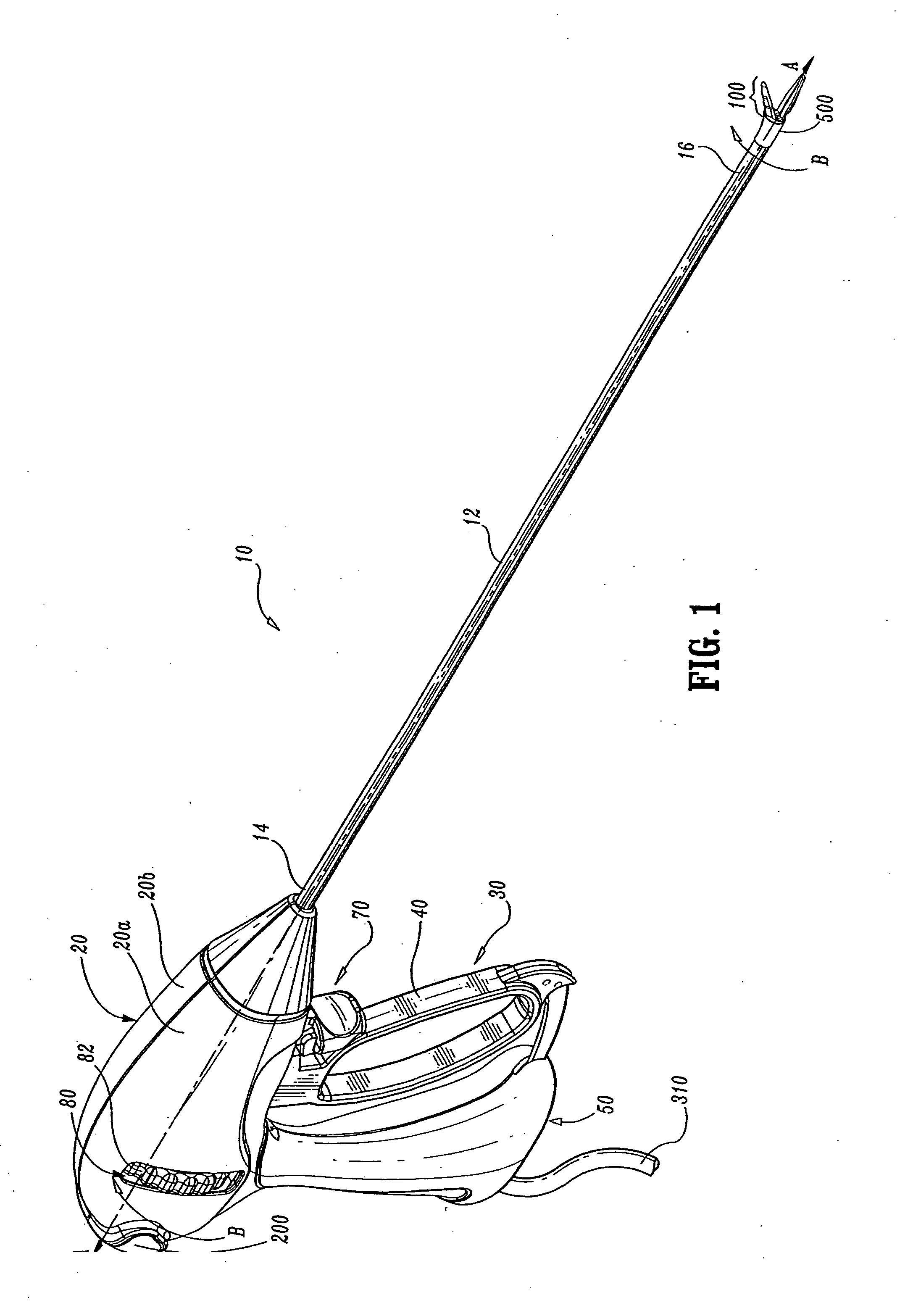

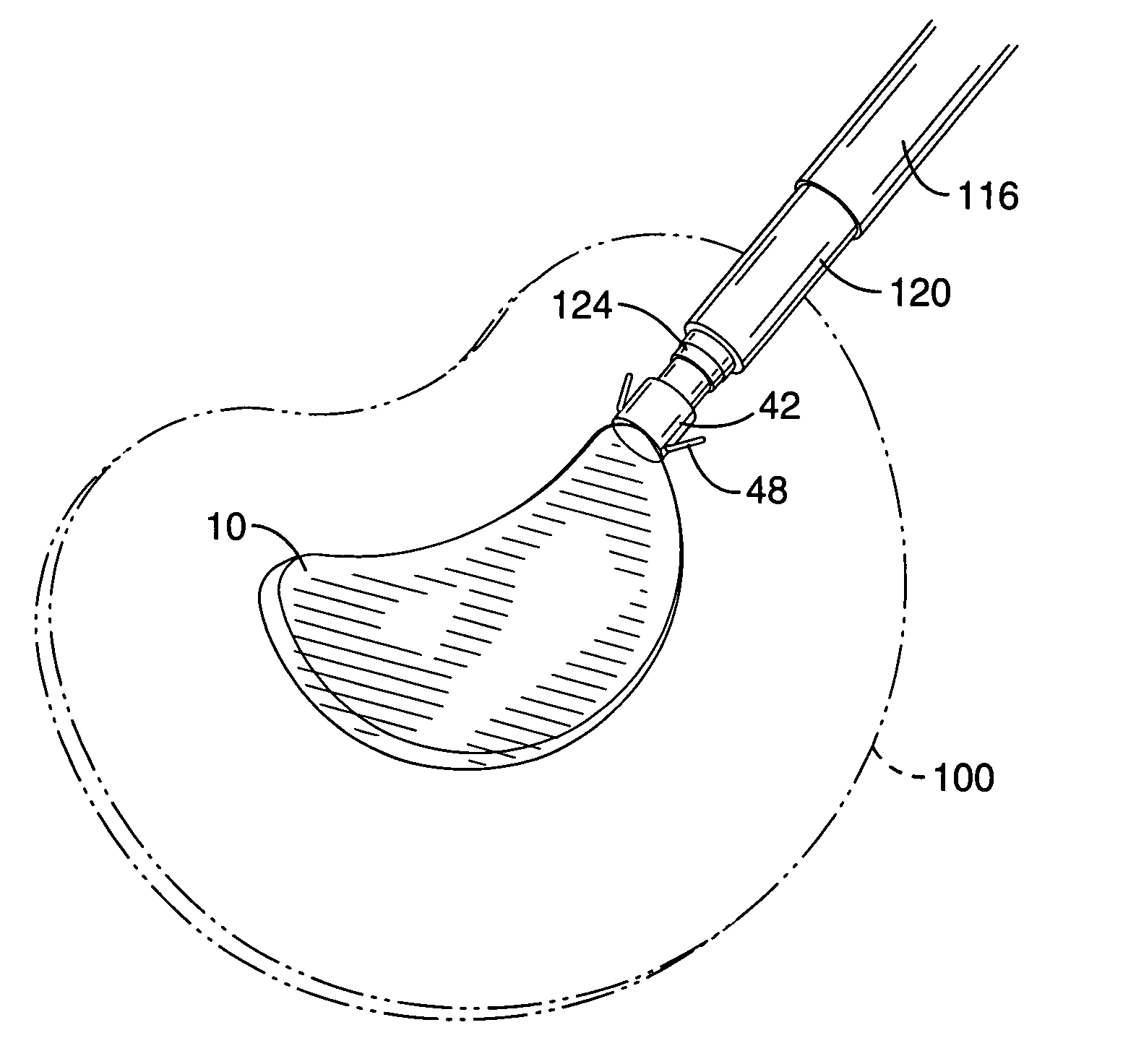

Surgical access apparatus and method

A surgical access device includes a single valve that forms a seal with the body wall and provides an access charnel into a body cavity. The valve has properties for creating a zero seal in the absence of an instrument as well as an instrument seal with instruments having a full range of instrument diameter. The valve can include a gel and preferably an ultragel comprised of an elastomer and an oil providing elongation greater than 1000 percent and durometer less than 5 Shore A. The shore valve can be used as a hand port where the instrument comprises the arm of a surgeon, thereby providing hand access into the cavity. A method for making the surgical access device includes the combining or a gelling agent with an oil, preferably in a molding process. A method for using the device includes steps for creating an opening with the instrument. In a particular process, an organ can be removed from the body cavity through the single valve to create an organ seal while the organ is addressed externally of the body cavity. The valve and method are particularly adapted for laparoscopic surgery wherein the abdominal cavity is insufflated with a gas thereby requiring the zero seal, the instrument seal, and the organ seal in various procedures.

Owner:APPL MEDICAL RESOURCES CORP

Frag shield

Fabric laminates having superior resistance to penetration of fragments, such as shrapnel. The fabrics are formed of high-strength fibers consolidated with from about 7% to about 15% by weight of an elastomeric matrix composition, and in combination with protective layers of a polymer film on each surface of the fabric. The fabrics achieve a significant improvement in fragment resistance compared to fabrics of the prior art, while also maintaining excellent ballistic resistant properties.

Owner:HONEYWELL INT INC

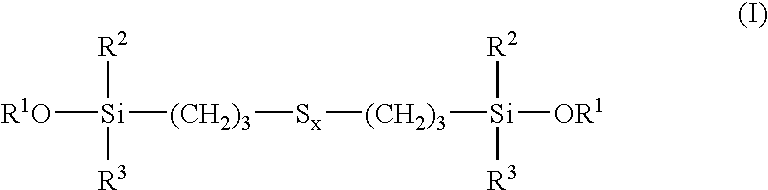

Tire and tread comprising a bis-alkoxysilane tetrasulfide as coupling agent

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

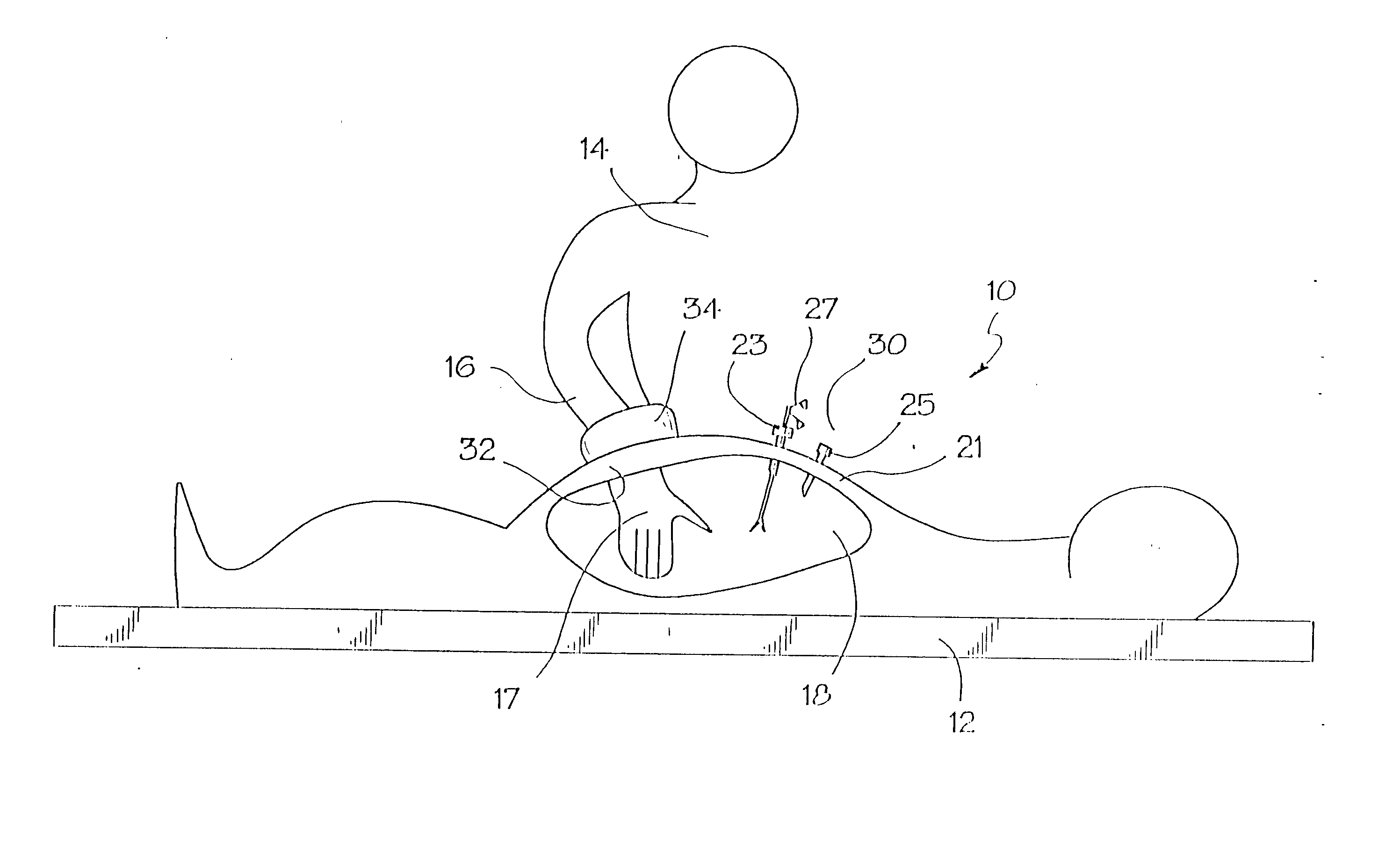

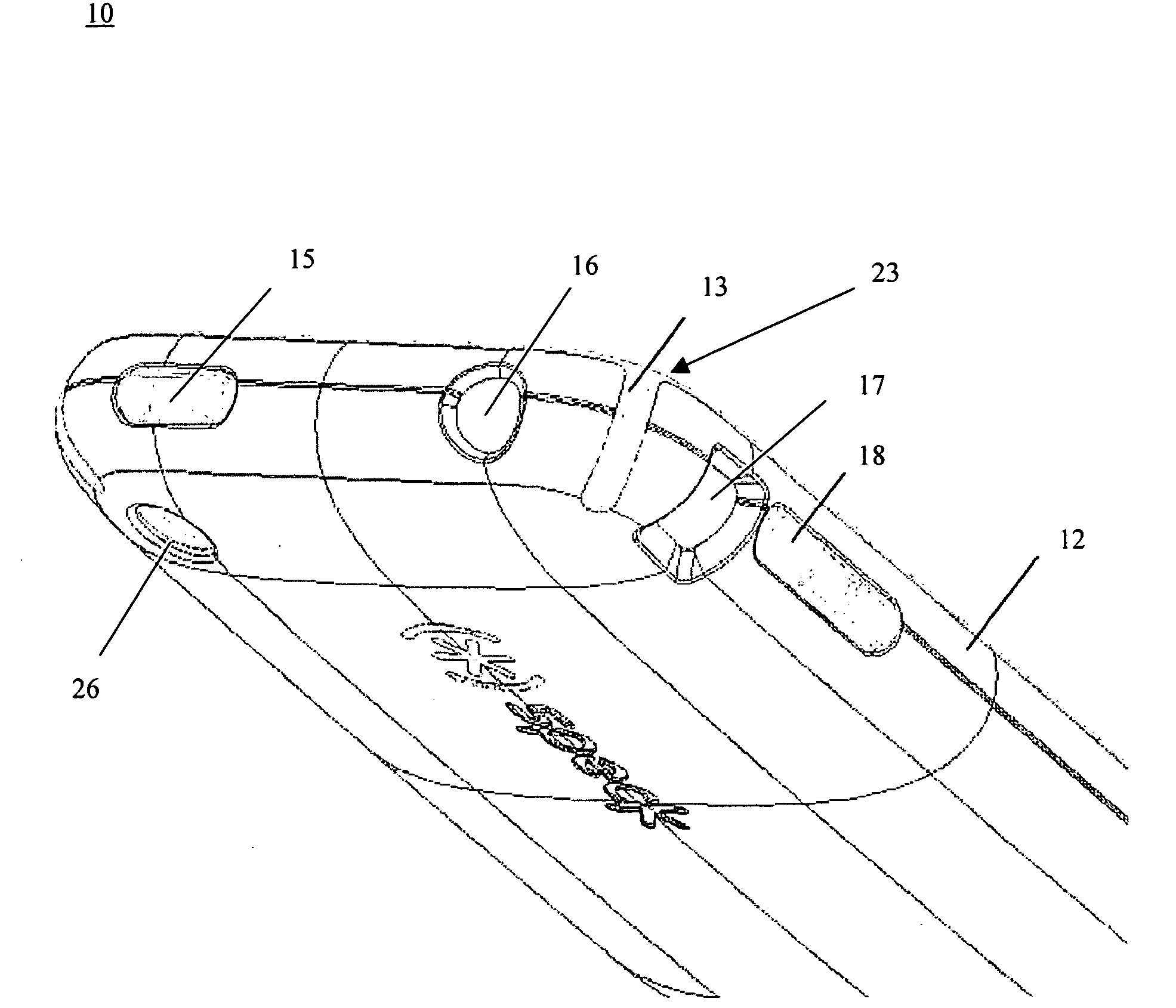

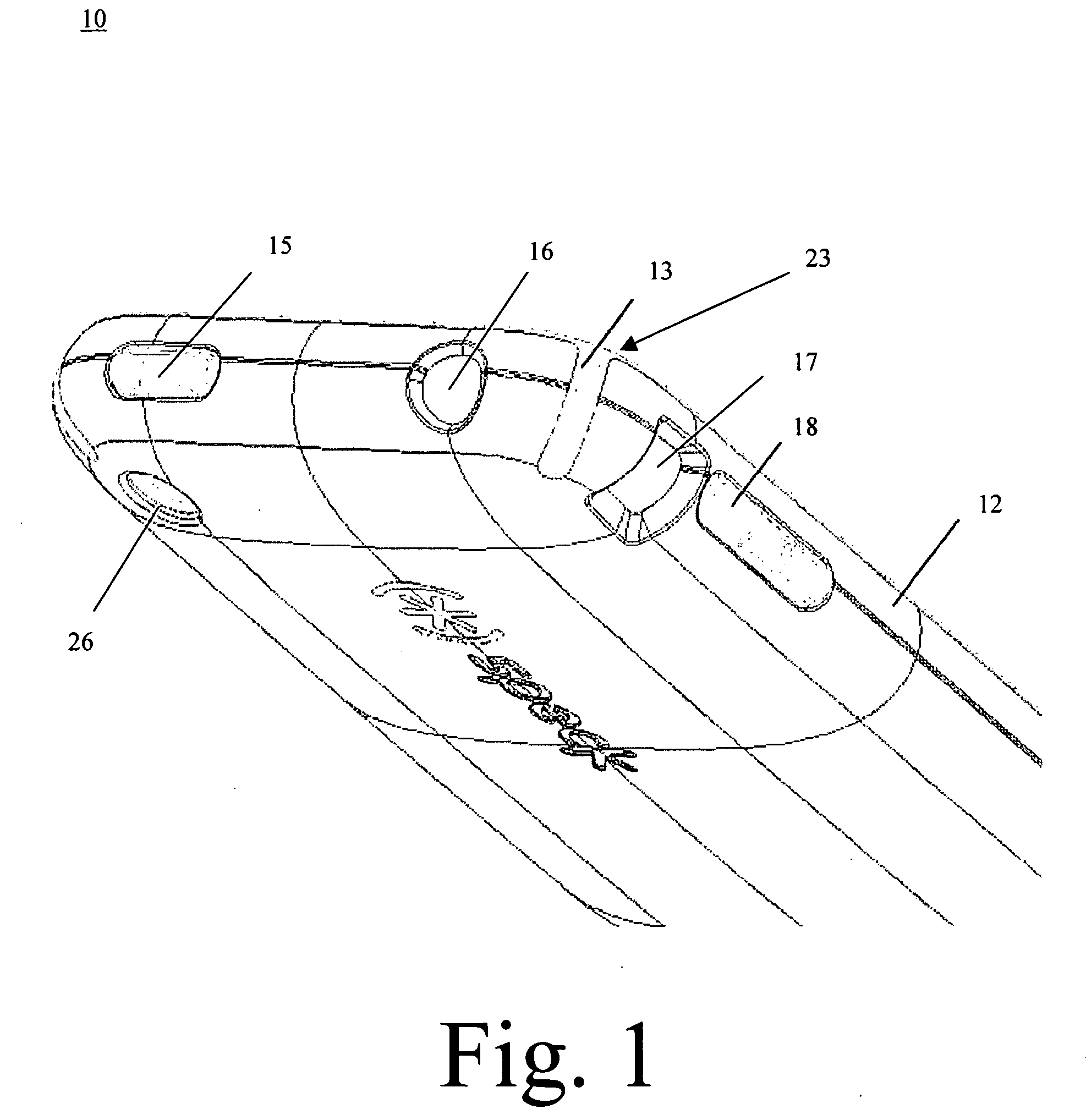

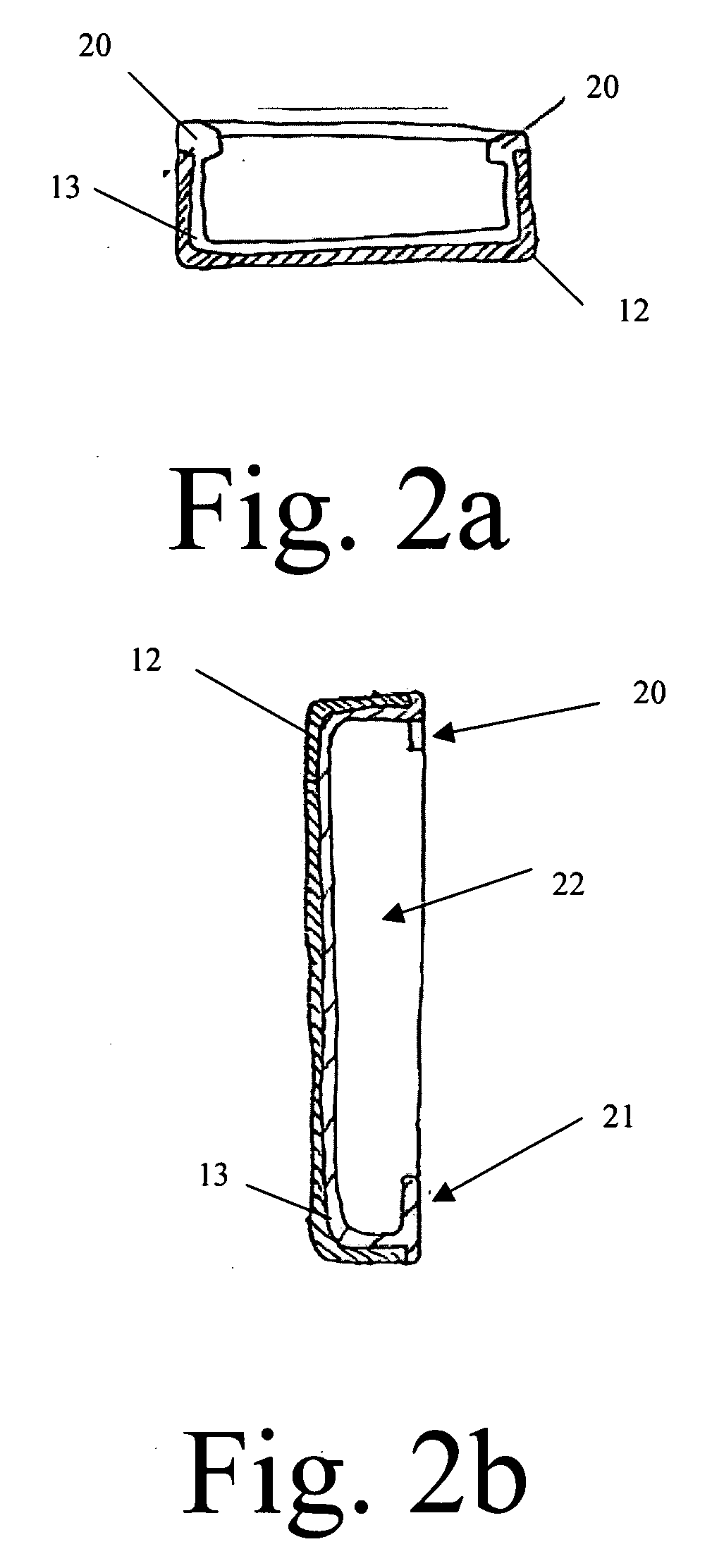

One Piece Co-formed Exterior Hard Shell Case with an Elastomeric Liner for Mobile Electronic Devices

ActiveUS20100203931A1Maximum protectionReduce coefficient of frictionTravelling carriersHoldersElastomerMechanical engineering

A one-piece co-formed exterior hard shell case with an elastomeric liner formed on the interior of the exterior hard shell for mobile electronic devices. This hard protective exterior shell allows the device maximum protection from impacts with sharp objects while the interior elastomeric portion that provides shock protection for the device from impacts. The exterior hard shell part is formed to fit the device closely with a small offset from the devices surface. The exterior hard shell raps around the edges of the device. To allow the shell to be able to be mounted on the device the corners of the hard shell are cut open. This allows each sidewall to flex away when a device is inserted and snap back once it is in place. The elastomeric material fills in the gaps created at the corners of the exterior hard shell to allow flex for mounting.

Owner:SPECULATIVE PROD DESIGN

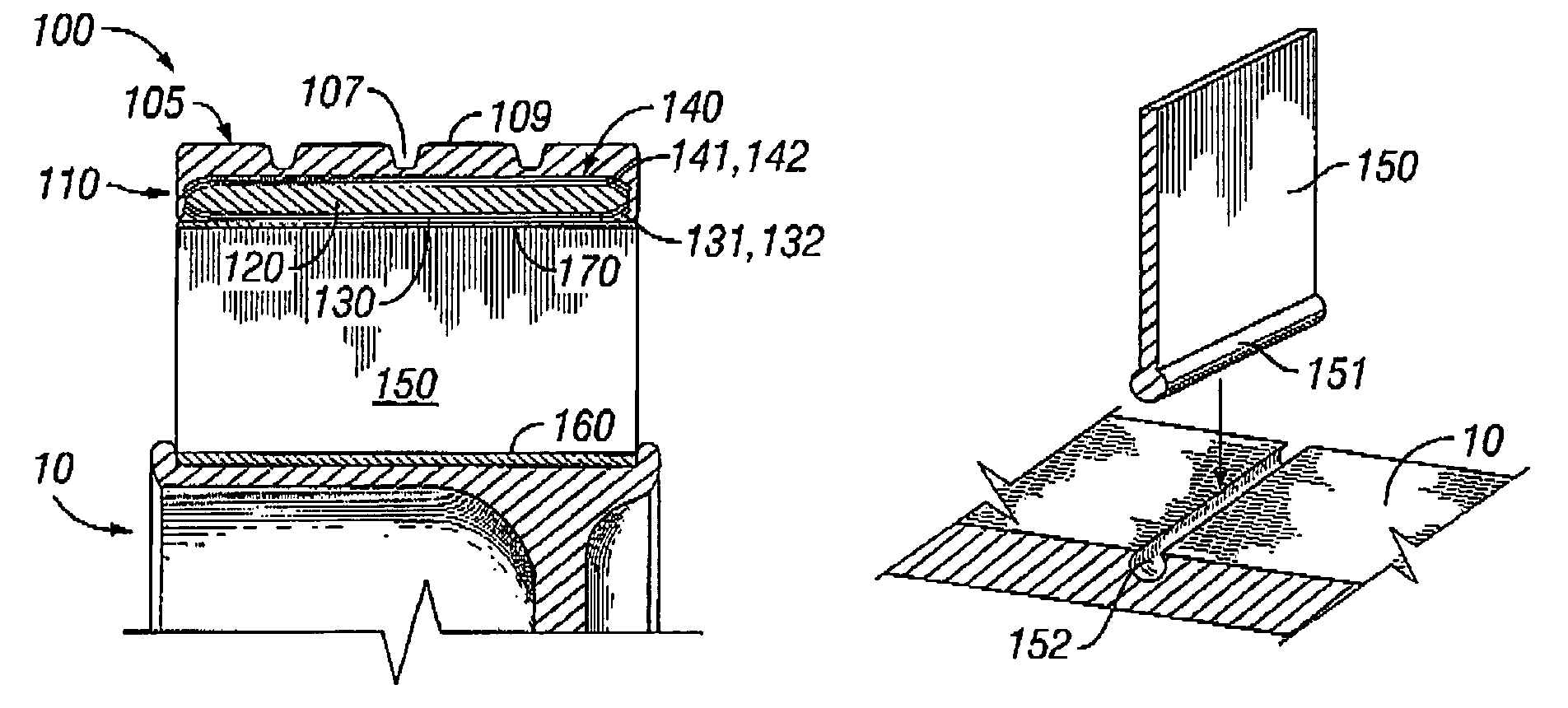

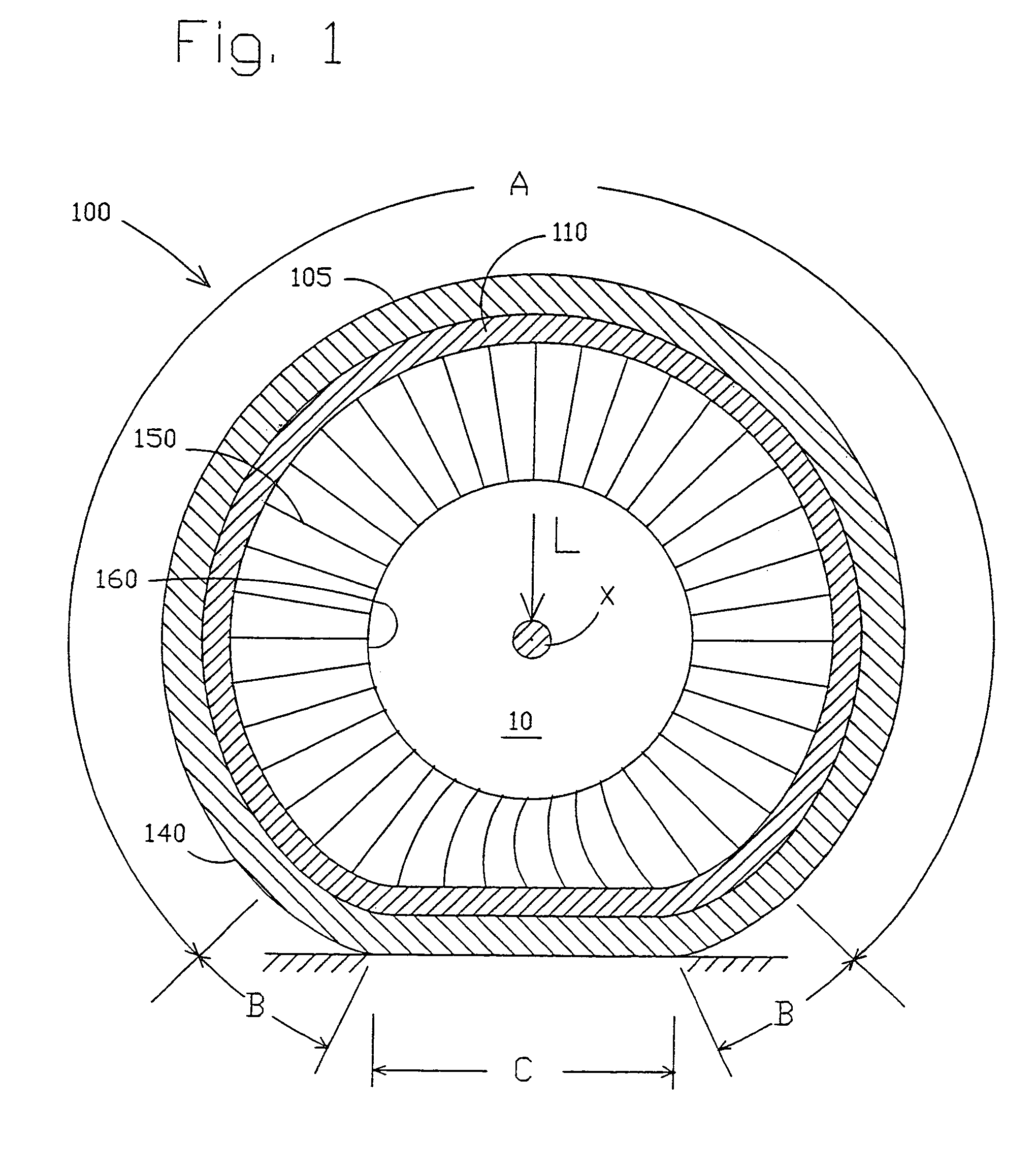

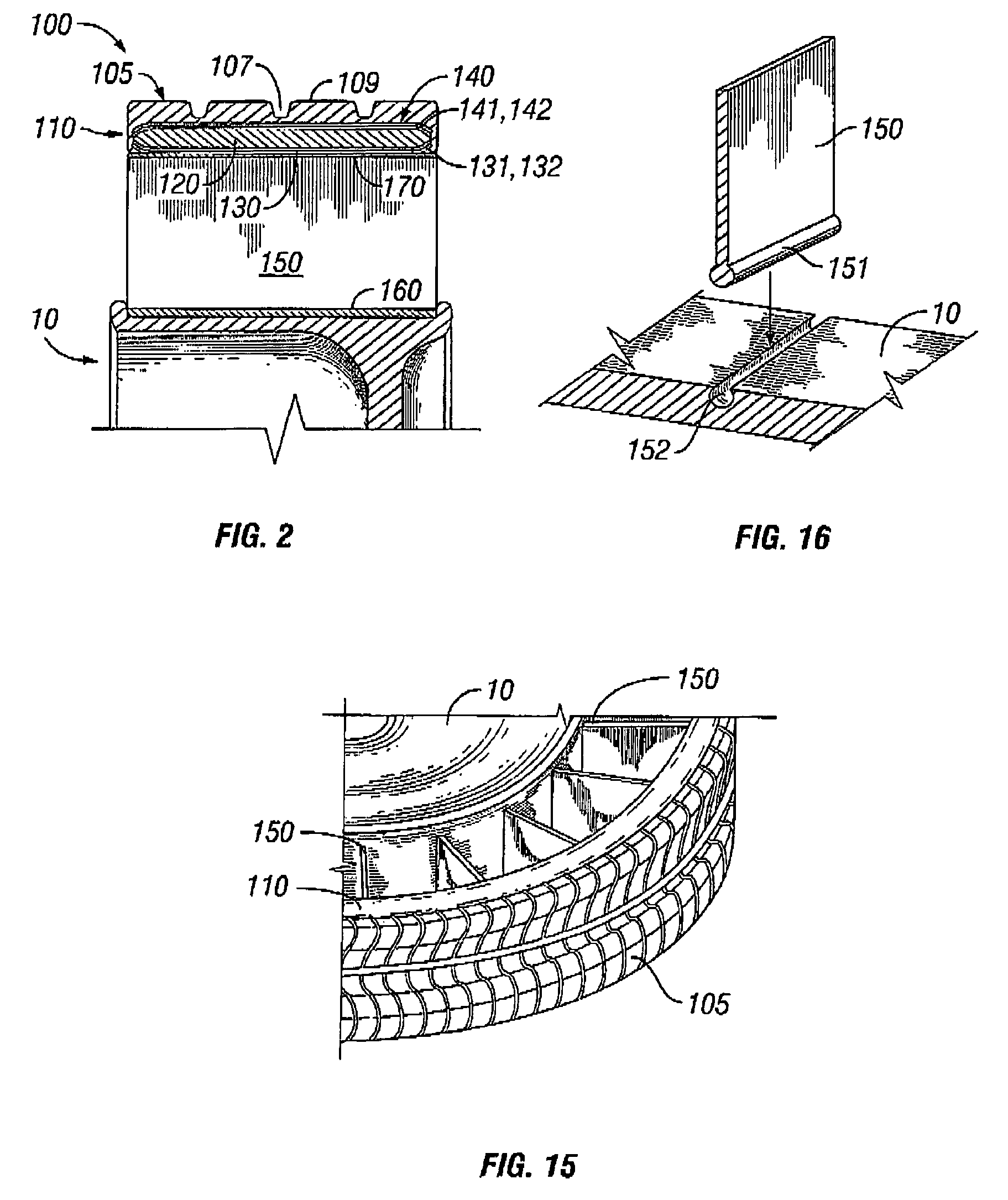

Non-pneumatic tire

InactiveUS7201194B2Supporting massHigh effective radial stiffness in tensionNon-inflatable tyresPneumatic tyre reinforcementsElastomerShear modulus

A structurally supported tire includes a ground contacting tread portion, a reinforced annular band disposed radially inward of the tread portion, and a plurality of web spokes extending transversely across and radially inward from the reinforced annular band and anchored in a wheel or hub. The reinforced annular band comprises an elastomeric shear layer, at least a first membrane adhered to the radially inward extent of the elastomeric shear layer and at least a second membrane adhered to the radially outward extent of the elastomeric shear layer. Each of the membranes has a longitudinal tensile modulus sufficiently greater than the shear modulus of the shear layer so that when under load the ground contacting portion of the tire deforms to a flat contact region through shear strain in the shear layer while maintaining constant the length of the membranes, the web spokes transmitting load forces between the annular band and the hub through tension in the web spokes not connected to the ground contacting portion of the tire.

Owner:MICHELIN RECH & TECH SA

Microfluidic devices and methods of use

InactiveUS20020127736A1Lessening oscillation in velocityReduce oscillation amplitudeSludge treatmentFixed microstructural devicesElastomerThin membrane

A microfluidic device comprises pumps, valves, and fluid oscillation dampers. In a device employed for sorting, an entity is flowed by the pump along a flow channel through a detection region to a junction. Based upon an identity of the entity determined in the detection region, a waste or collection valve located on opposite branches of the flow channel at the junction are actuated, thereby routing the entity to either a waste pool or a collection pool. A damper structure may be located between the pump and the junction. The damper reduces the amplitude of oscillation pressure in the flow channel due to operation of the pump, thereby lessening oscillation in velocity of the entity during sorting process. The microfluidic device may be formed in a block of elastomer material, with thin membranes of the elastomer material deflectable into the flow channel to provide pump or valve functionality.

Owner:CALIFORNIA INST OF TECH

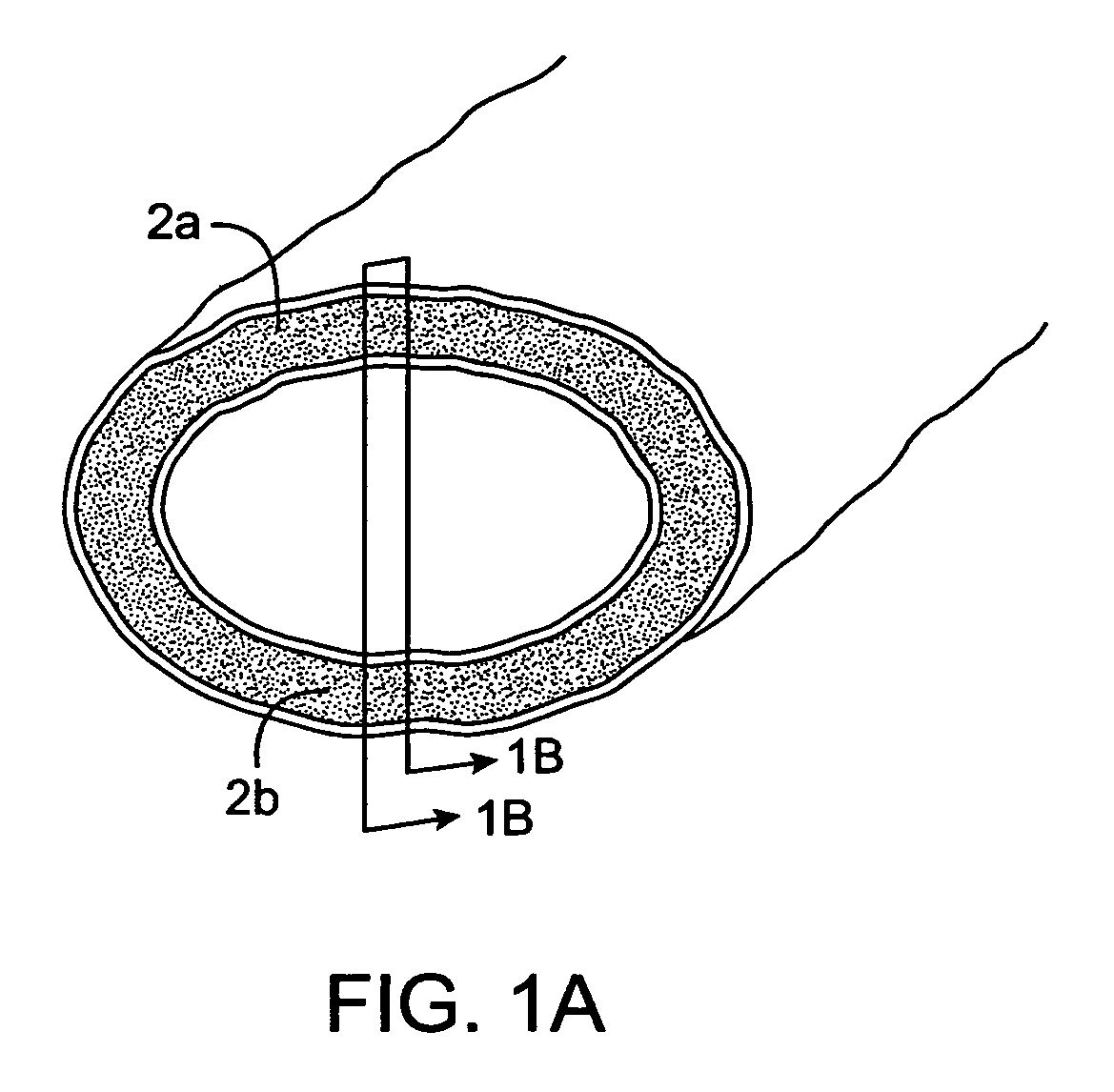

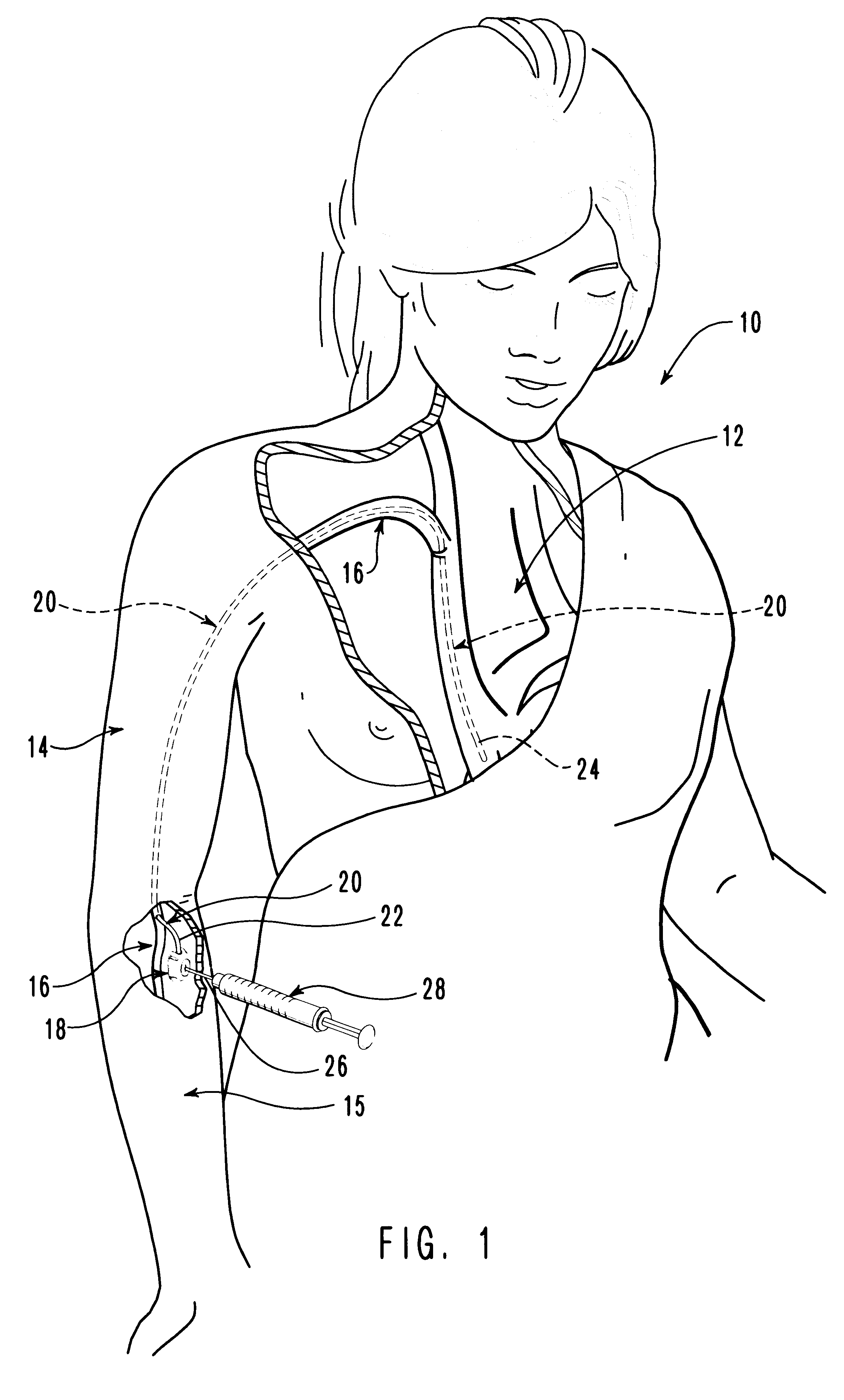

Vascular access port with elongated septum

InactiveUS6213973B1Large target areaPreventing buckling of the septumSurgeryMedical devicesNeedle penetrationHydrostatic pressure

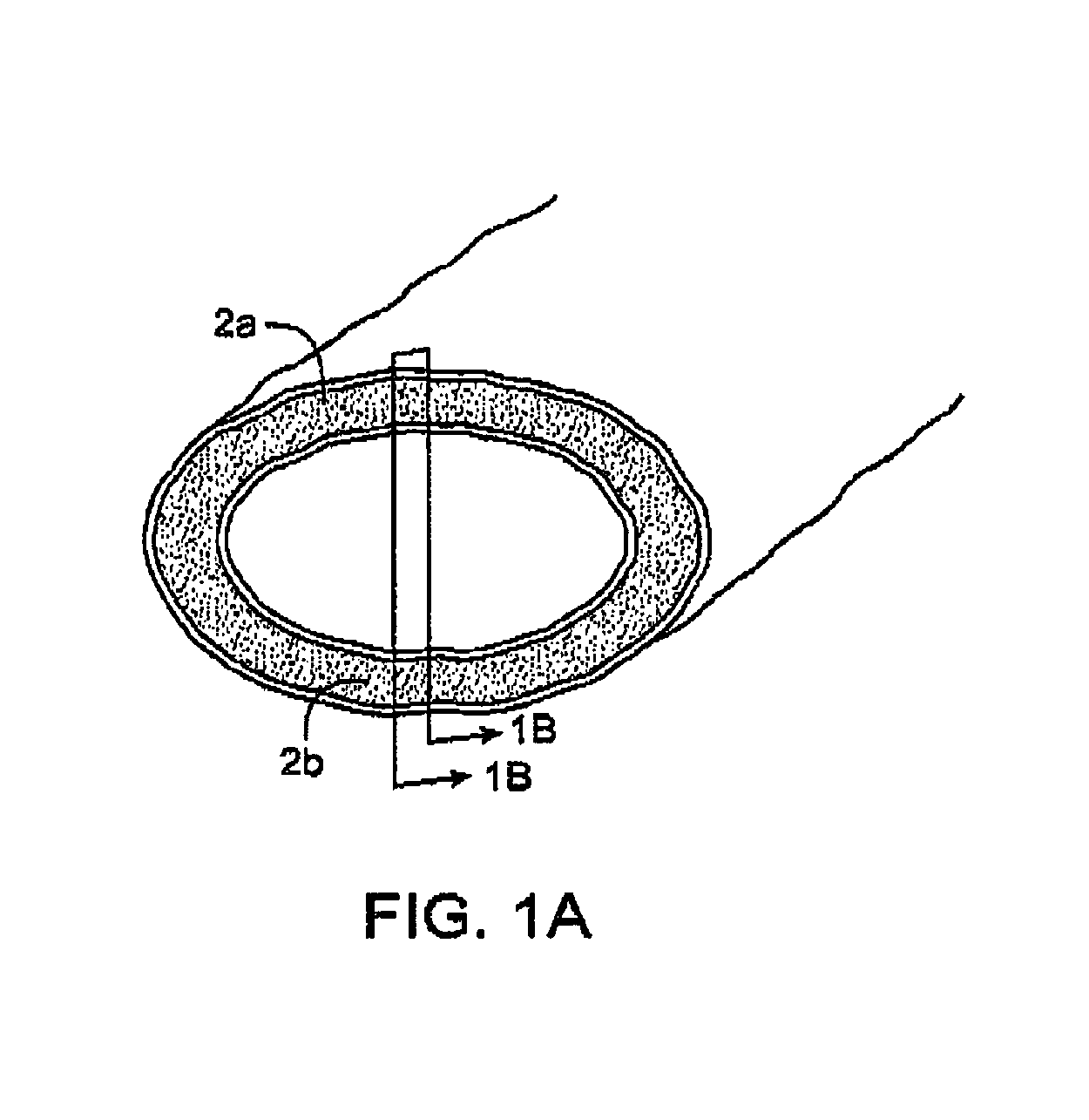

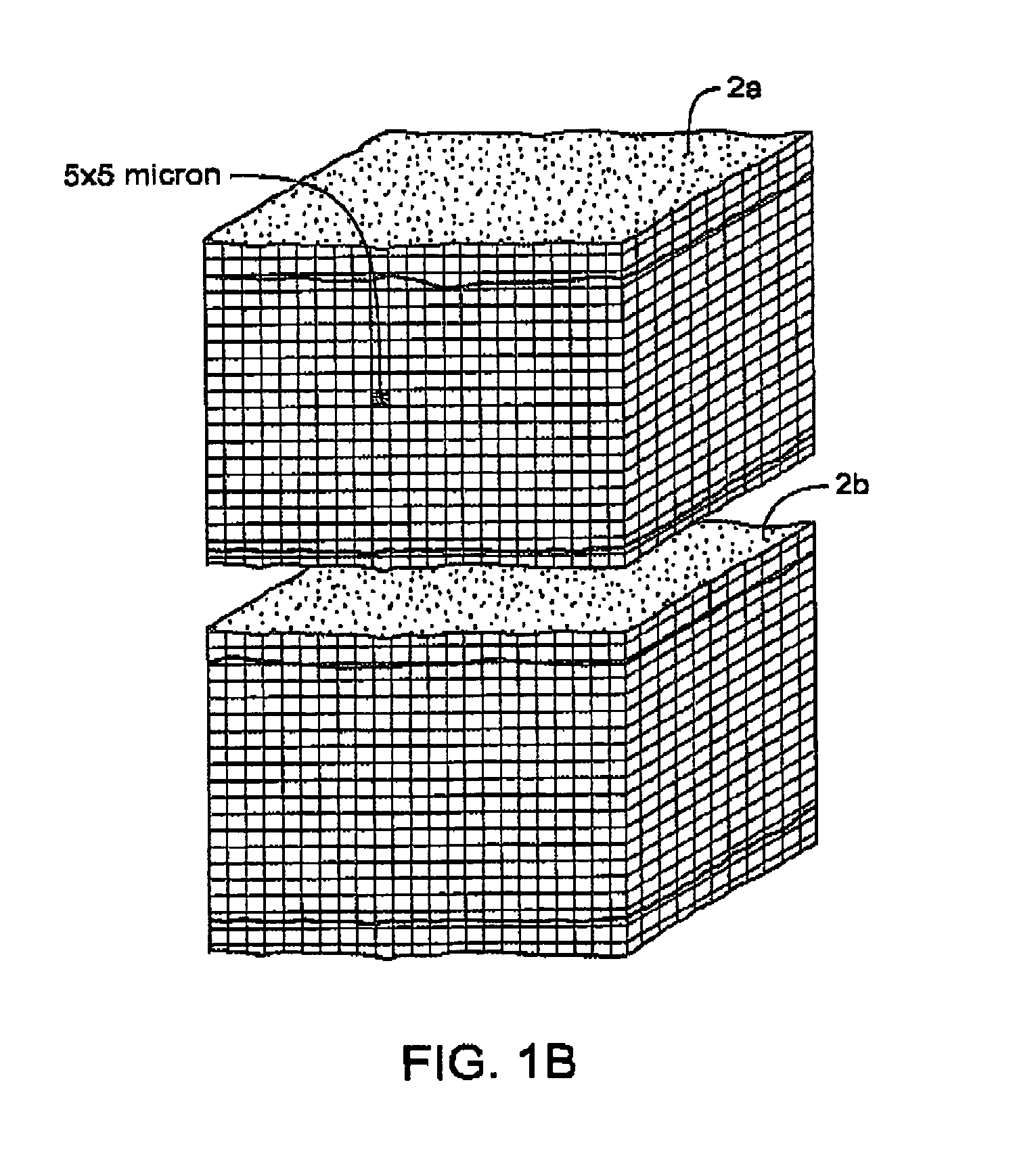

An elongated access port has a needle-impenetrable housing enclosing a fluid reservoir. The housing includes a base having a floor with an upstanding encircling sidewall and a cap having a top wall with a depending encircling skirt. The skirt of the cap receives the sidewall of the base. An access aperture extends through the top wall of the cap to communicate with the fluid reservoir. The access aperture is encircled by a continuous rim having an elongated shape in the plane of the access aperture. The rim of the access aperture may be elliptical, oval, polygonal, or parabolic-ended. An elastomeric, needle-penetrable, generally planar septum is disposed in the access aperture with the periphery of the septum in sealing engagement with the rim of the access aperture. Prior to installation, the septum has a periphery with a cross section in the plane of the septum that is geometrically proportional to and larger than the shape of the access aperture. Installation causes the periphery of the septum to be displaced inwardly by the rim of the access aperture in a direction parallel to the plane of the septum. In view of the relative shapes of the rim of the access aperture and the periphery of the septum, this produces substantially uniform hydrostatic pressure in regions of the installed septum that are subjected in use of the access port to needle penetrations. Opposite faces of the periphery of the septum are urged toward each other between the cap of the housing and the top of the sidewall of the base of the housing.

Owner:CR BARD INC

Insulating boot for electrosurgical forceps

ActiveUS20070078458A1Reduces the potential for strayDiagnosticsSurgical instruments for heatingElastomerEngineering

Either an endoscopic or open bipolar forceps includes a flexible, generally tubular insulating boot for insulating patient tissue, while not impeding motion of the jaw members. The jaw members are movable from an open to a closed position and the jaw members are connected to a source of electrosurgical energy such that the jaw members are capable of conducting energy through tissue held therebetween to effect a tissue seal. A knife assembly may be included that allows a user to selectively divide tissue upon actuation thereof. The insulating boot may be made from a viscoelastic, elastomeric or flexible material suitable for use with a sterilization process including ethylene oxide.

Owner:COVIDIEN AG

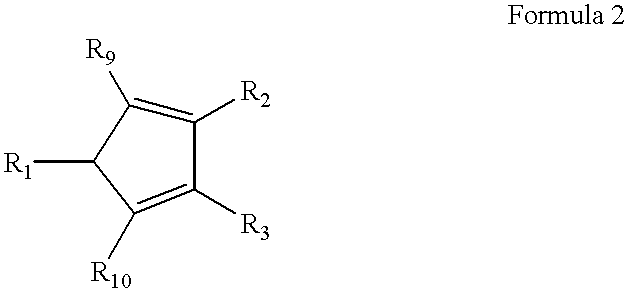

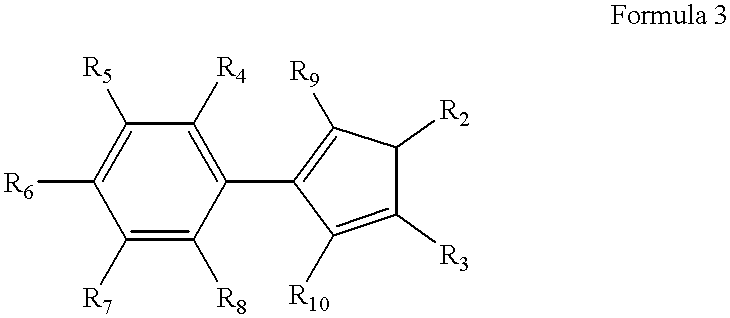

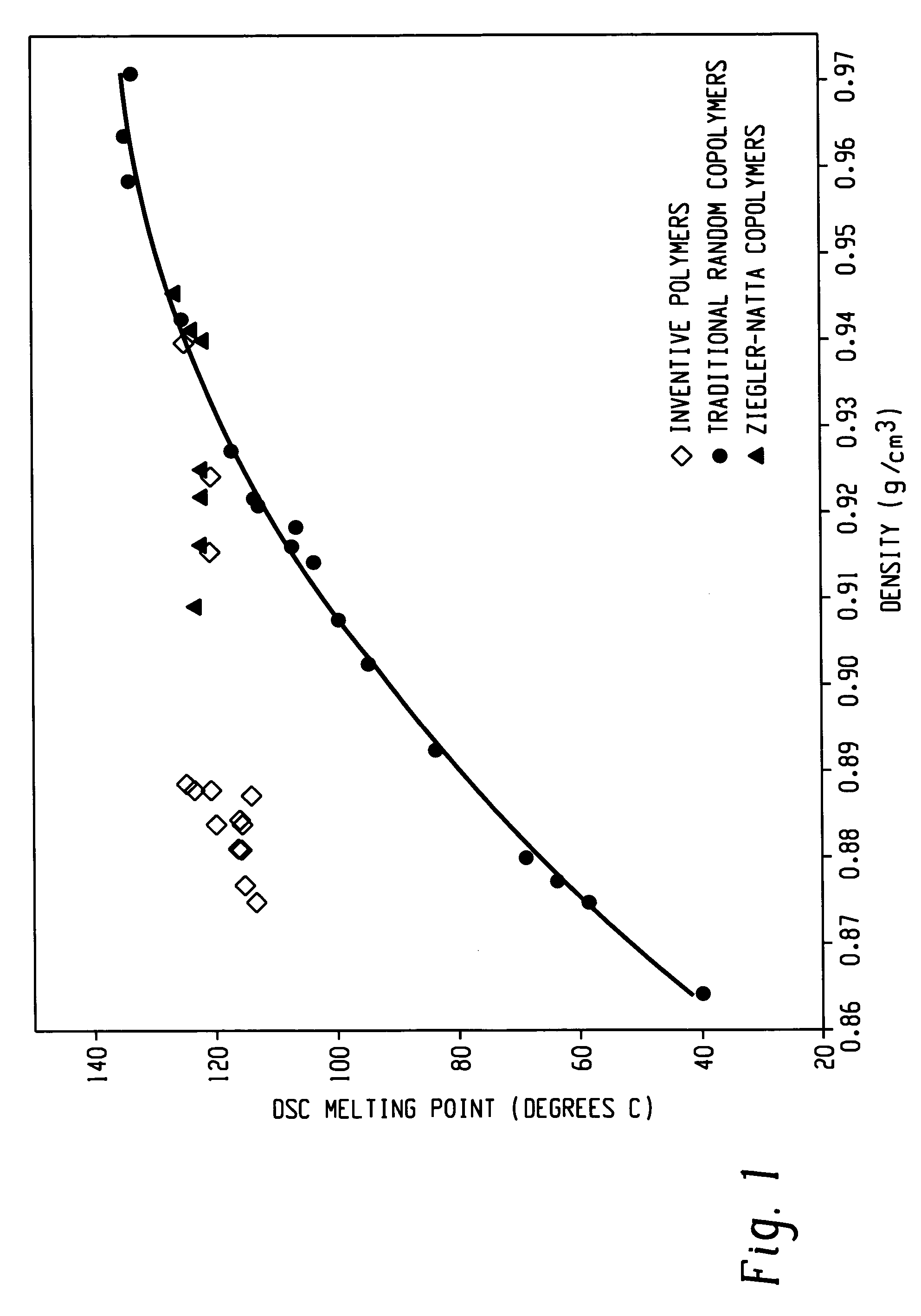

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6169151B1Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolymer science

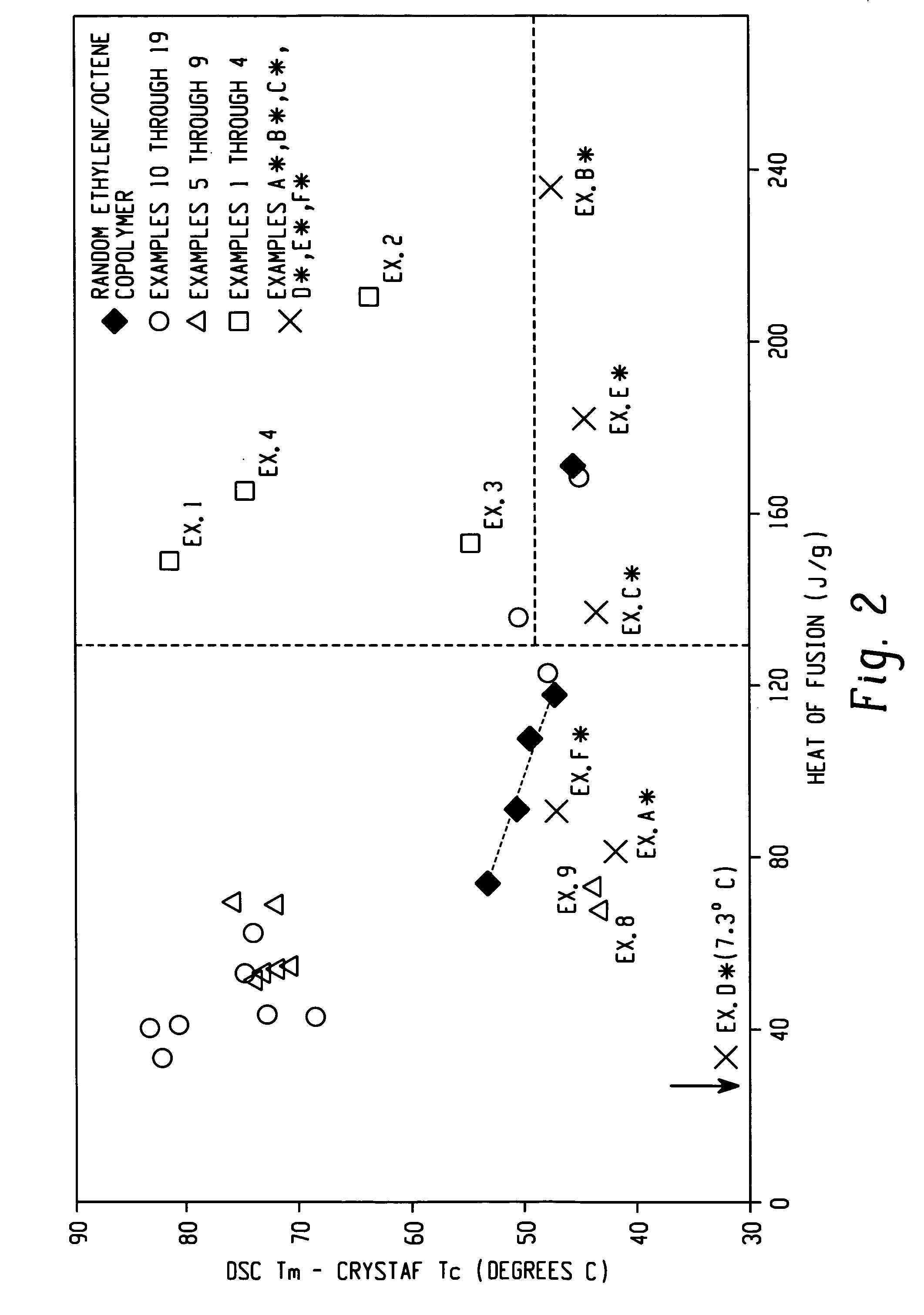

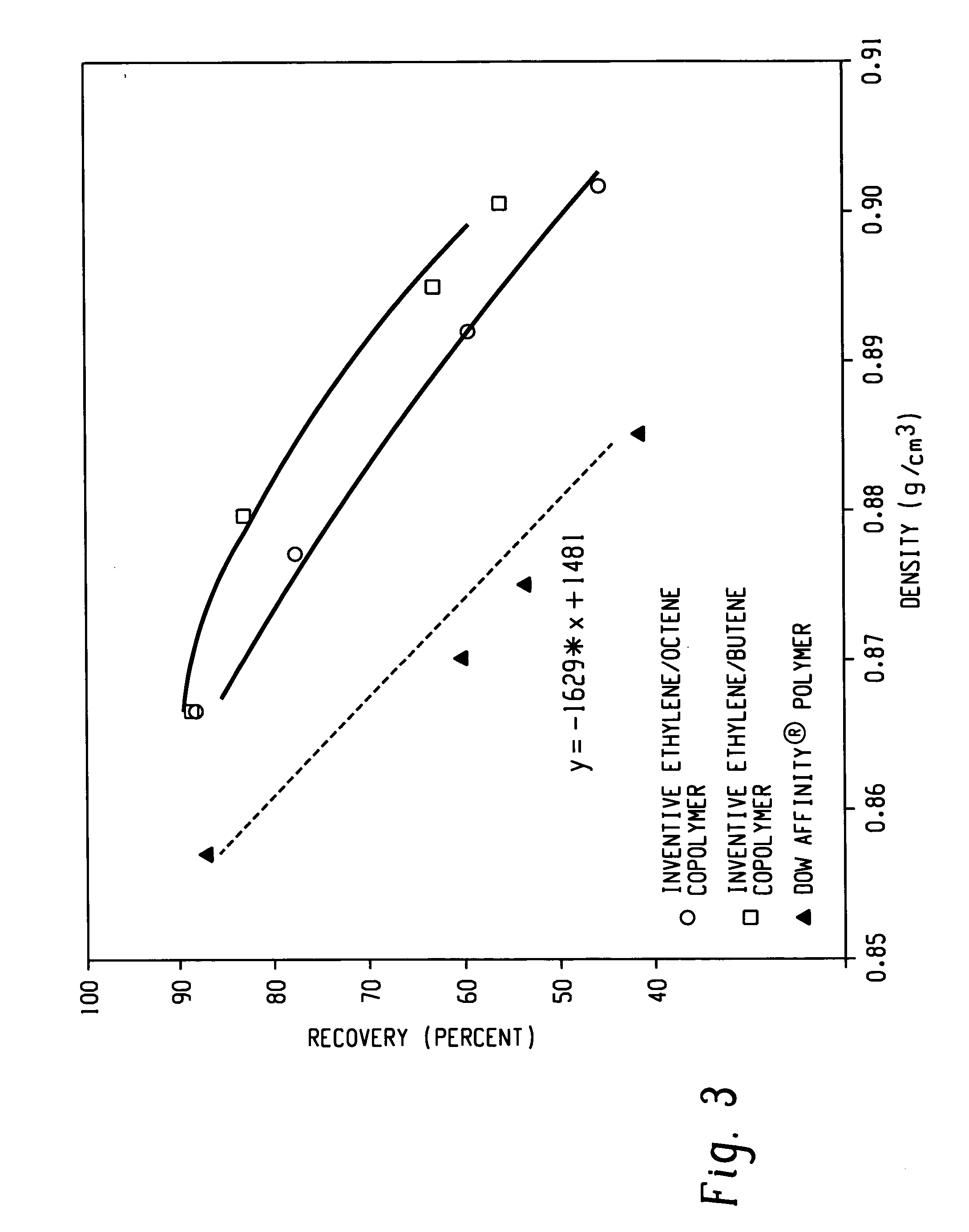

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

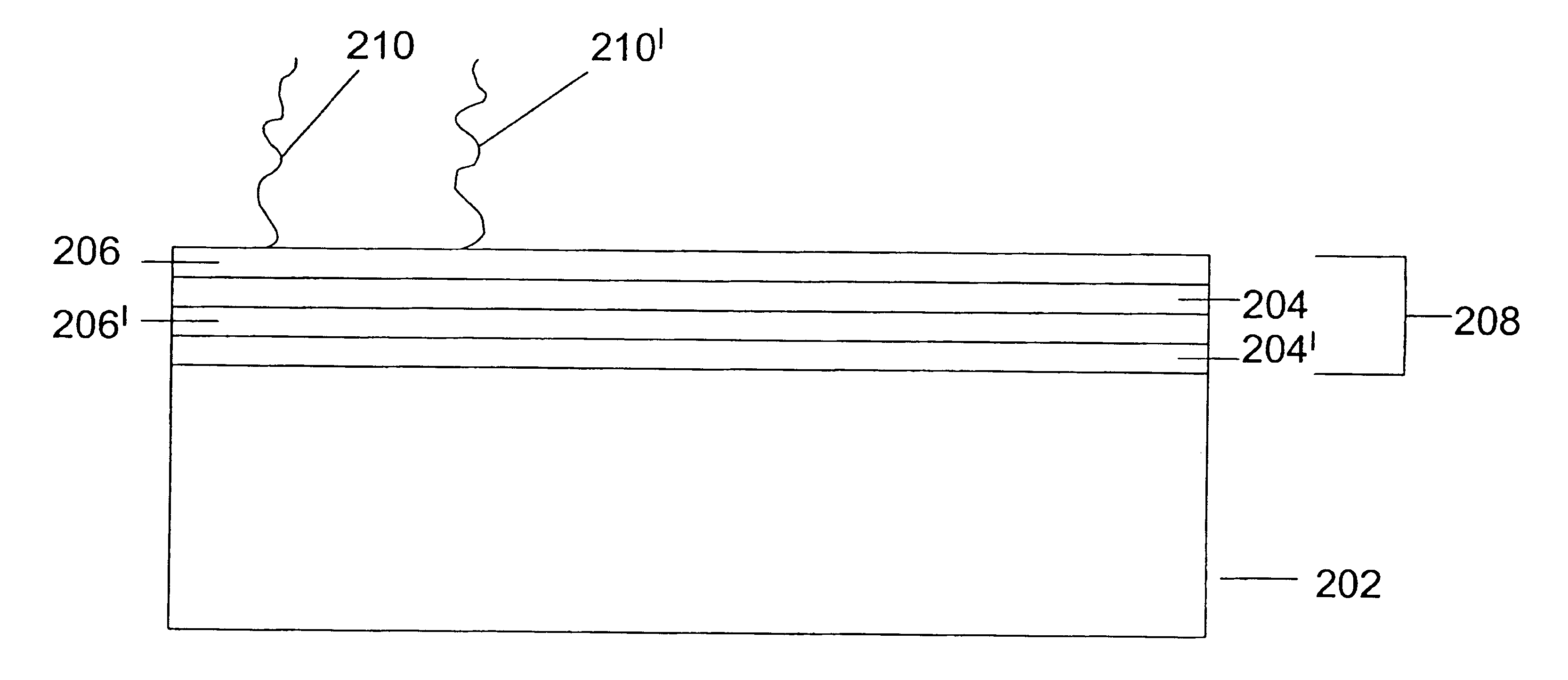

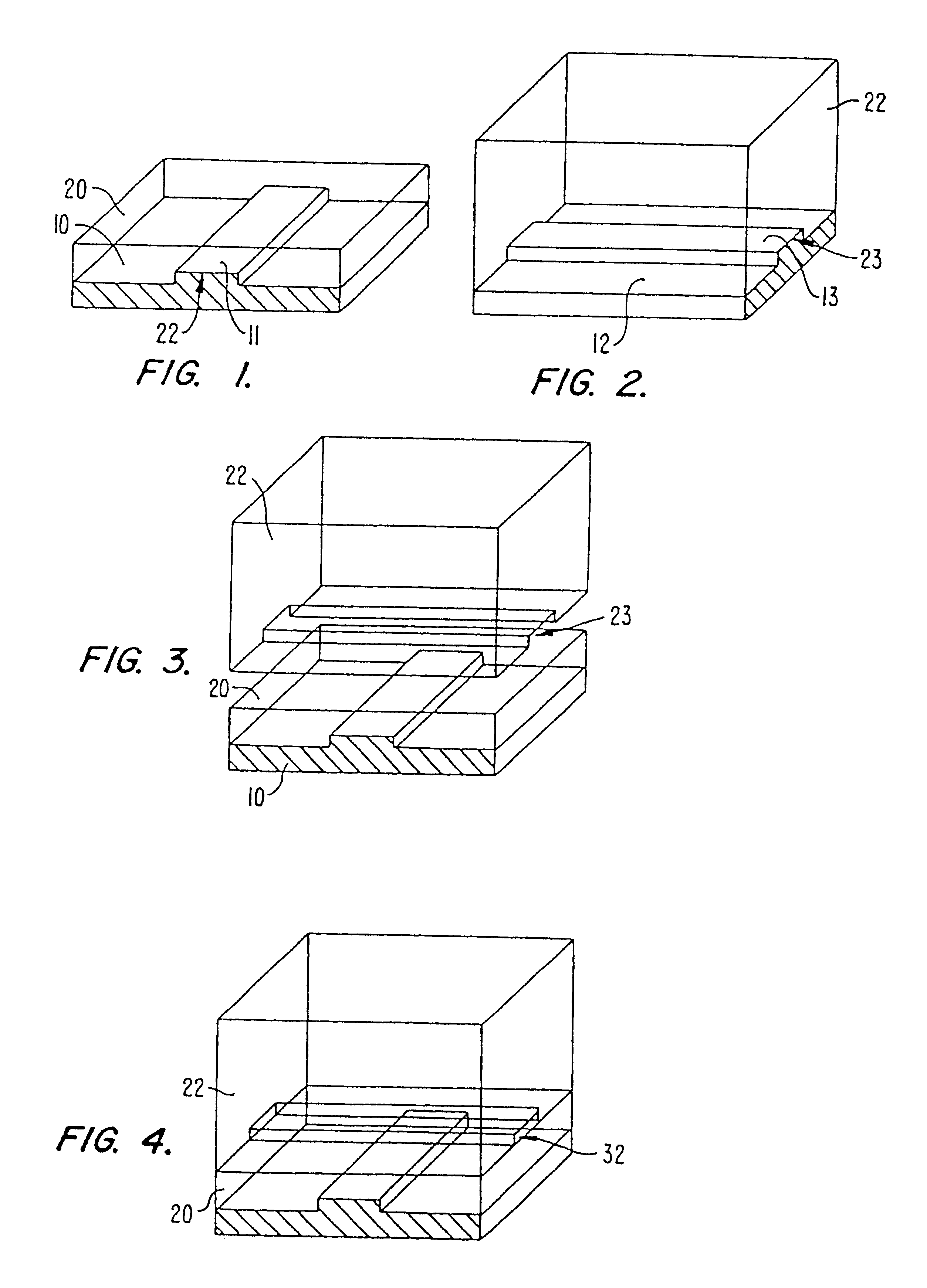

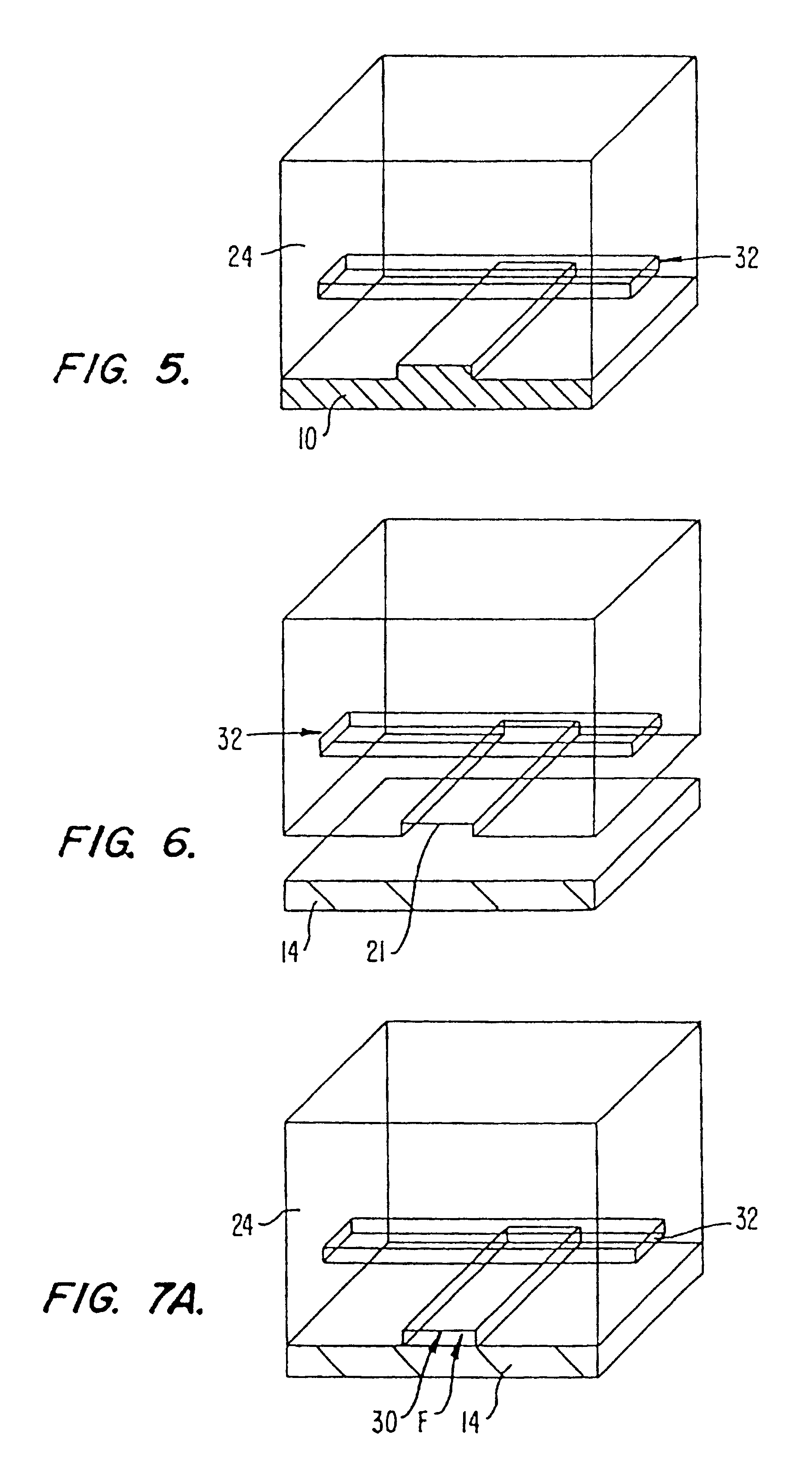

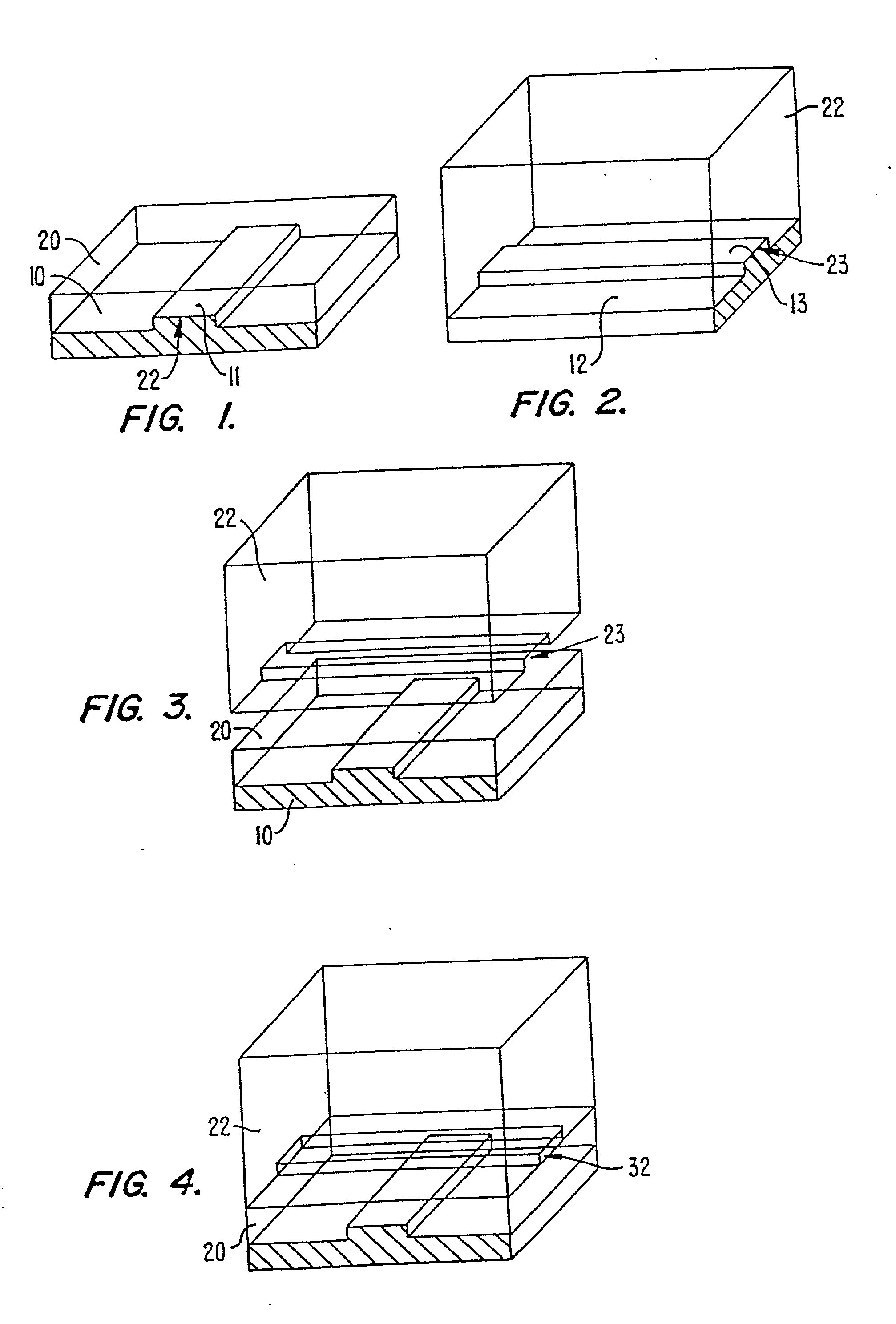

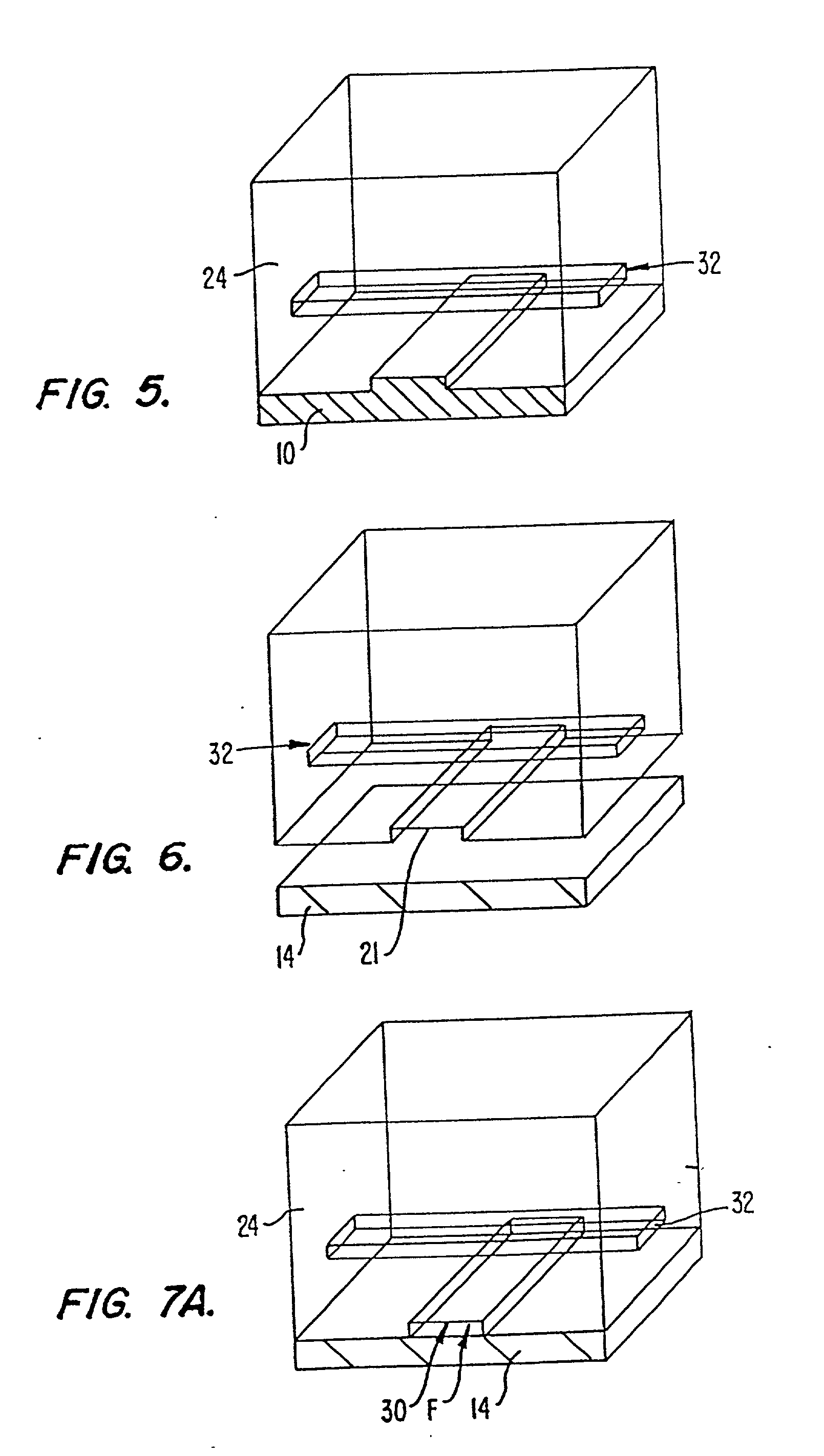

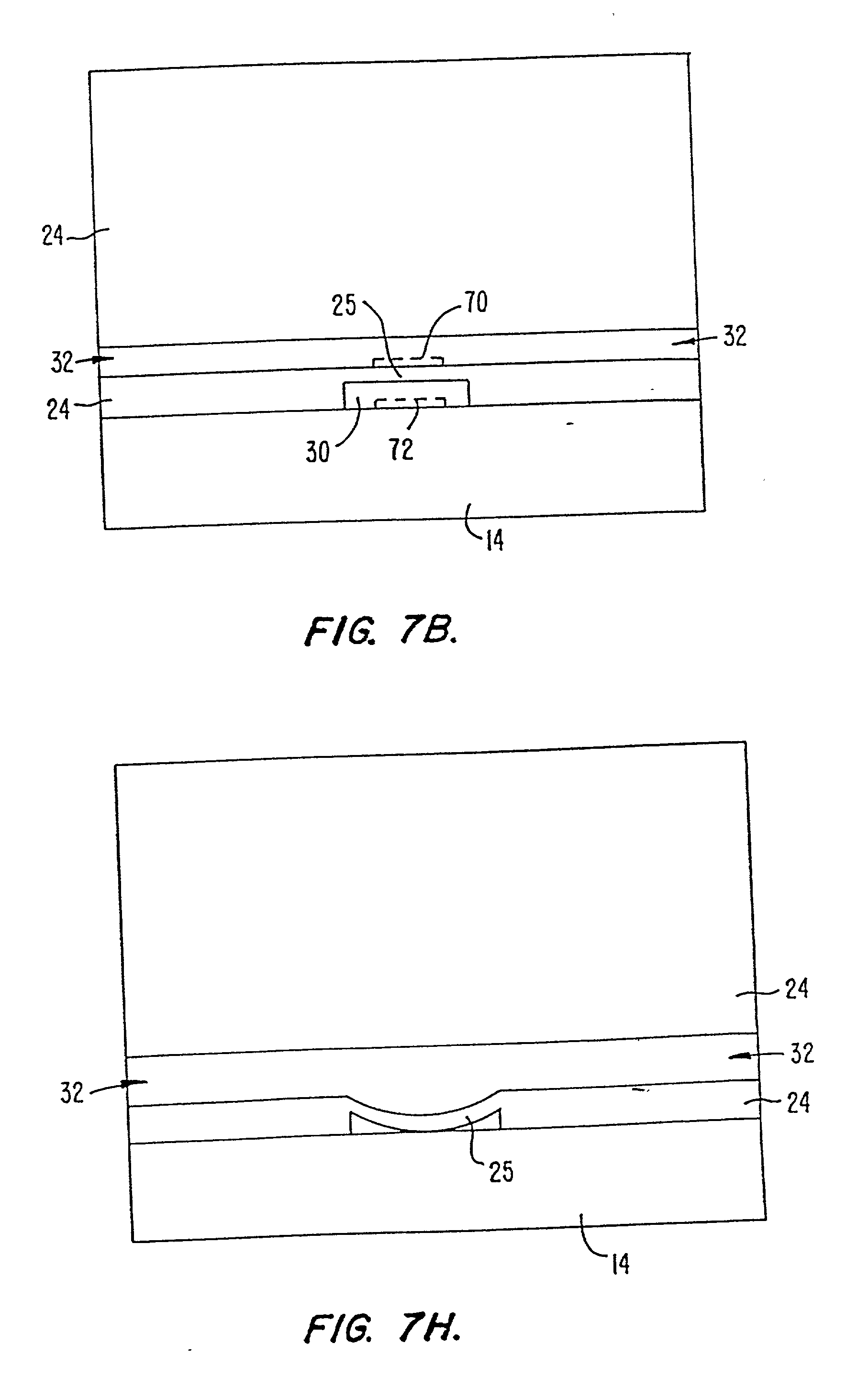

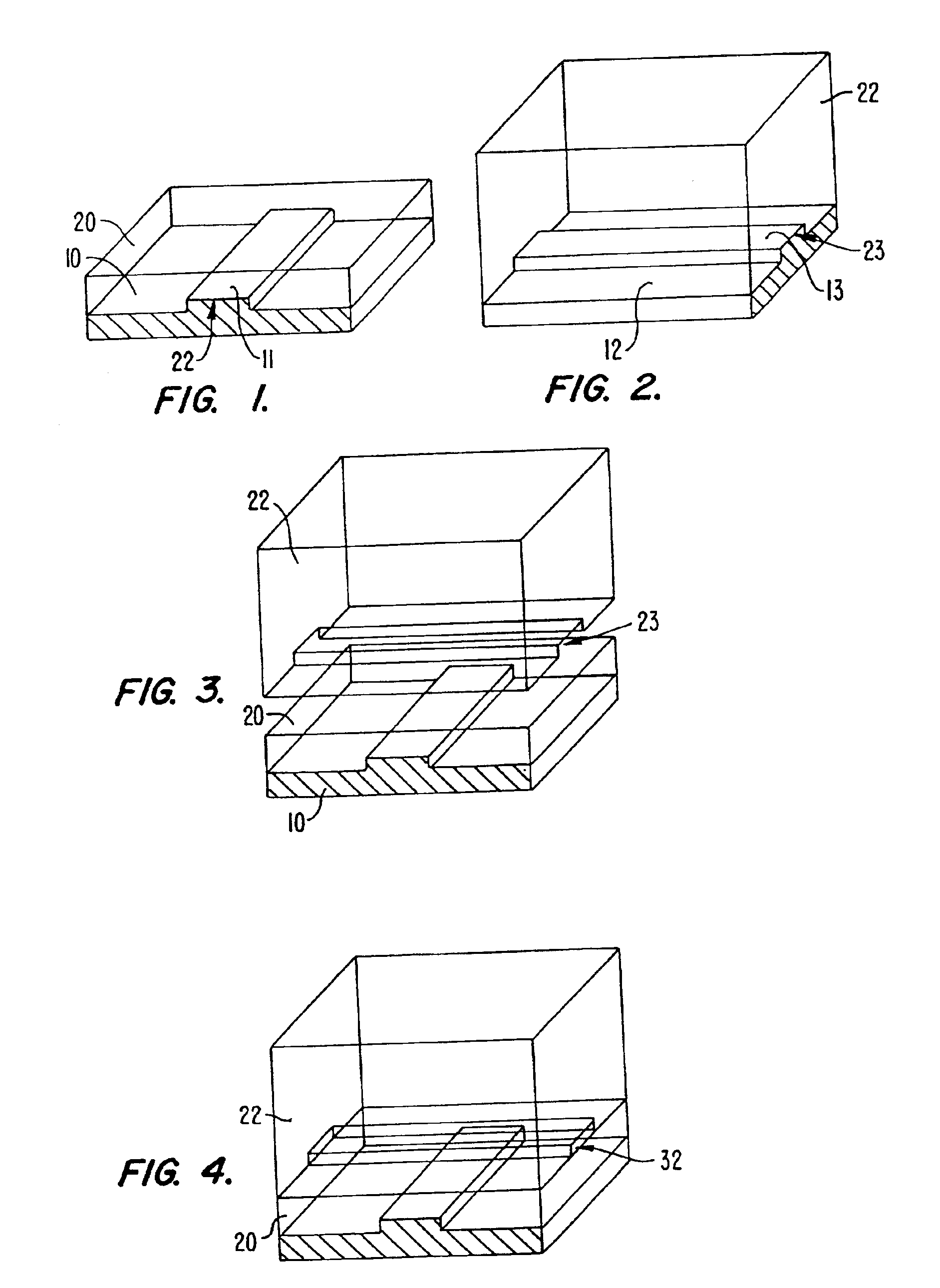

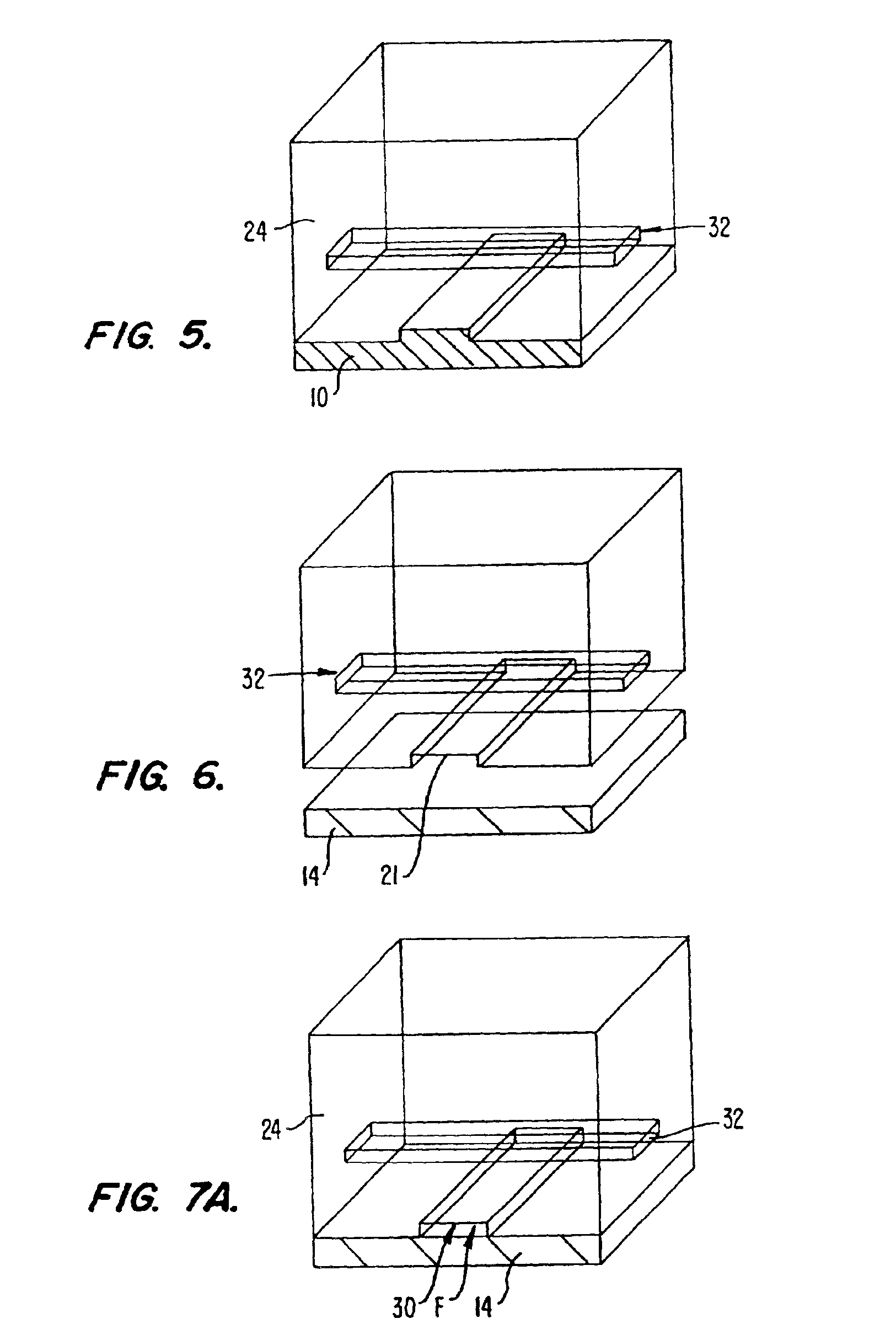

Microfabricated elastomeric valve and pump systems

InactiveUS6899137B2Increase speedSmall sizeFixed microstructural devicesVolume/mass flow measurementElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

High performance reticulated elastomeric matrix preparation, properties, reinforcement, and use in surgical devices, tissue augmentation and/or tissue repair

InactiveUS20070190108A1Different and simple configurationEfficiently employedProsthesisElastomerSurgical operation

This invention relates to reticulated elastomeric matrices, their manufacture, their post-processing, such as their reinforcement, compressive molding or annealing, and uses including uses for implantable devices into or for topical treatment of patients, such as humans and other animals, for surgical devices, tissue augmentation, tissue repair, therapeutic, nutritional, or other useful purposes.

Owner:BIOMERIX CORP

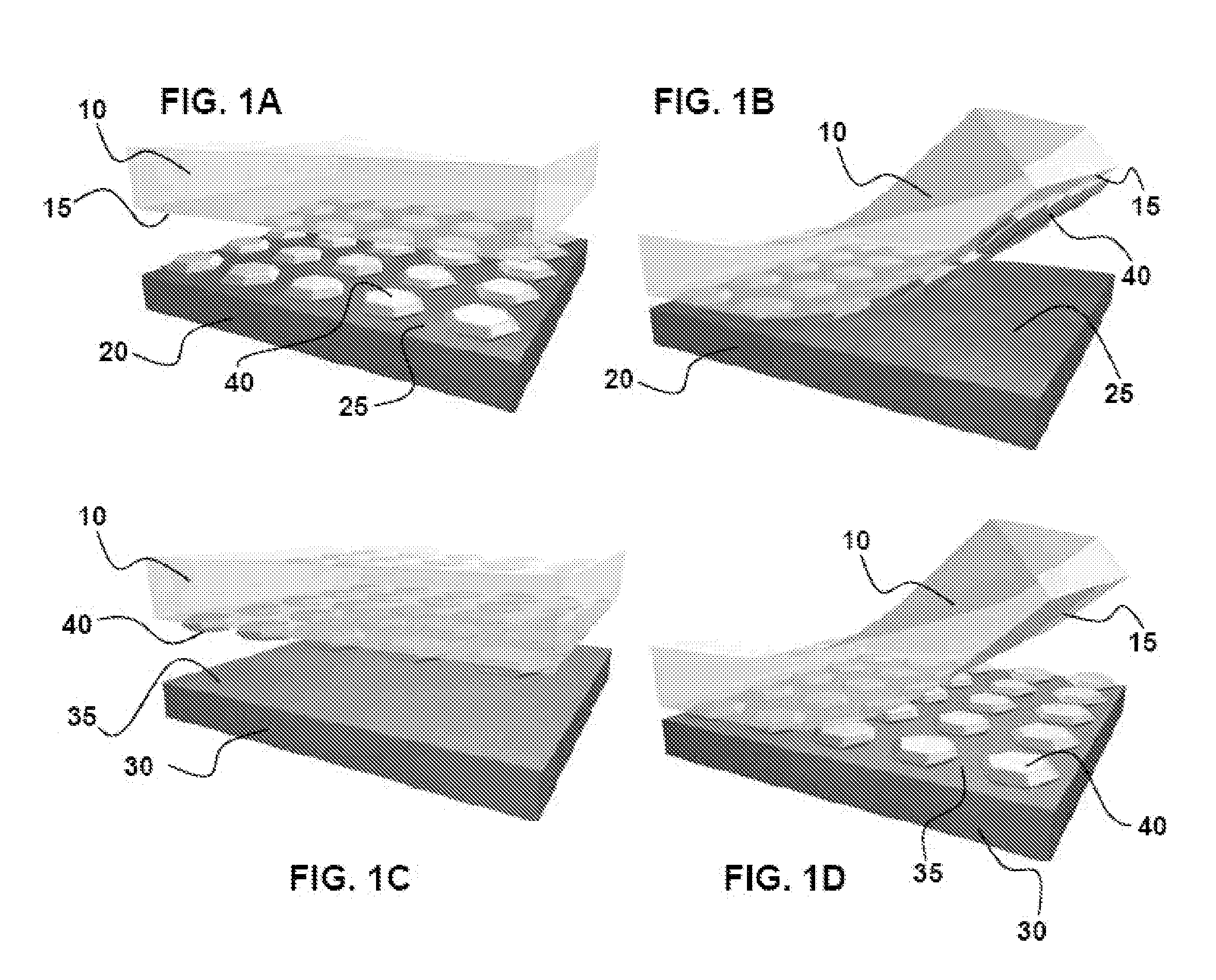

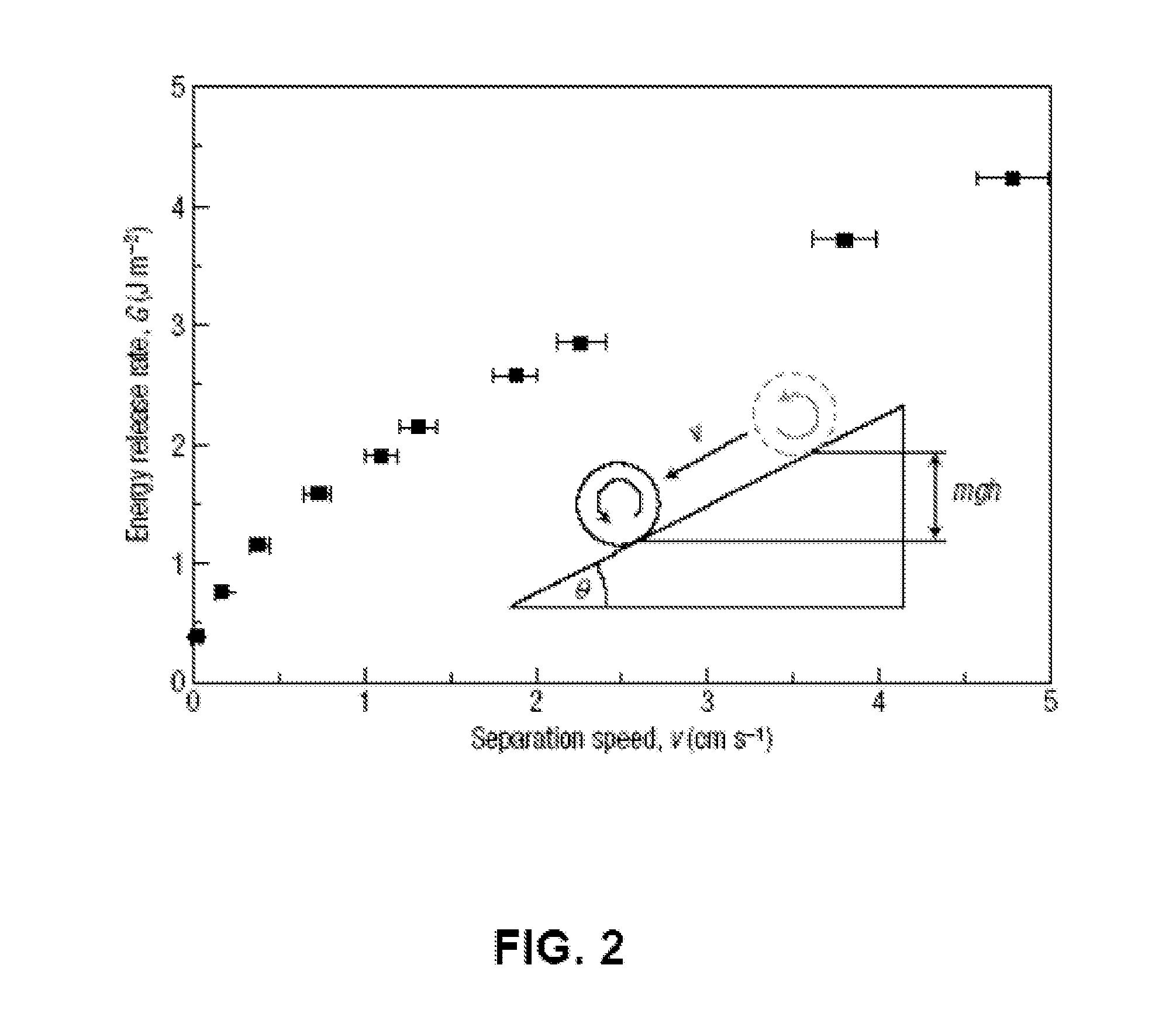

Pattern Transfer Printing by Kinetic Control of Adhesion to an Elastomeric Stamp

ActiveUS20090199960A1Keep the distanceEasy transferFinal product manufactureDecorative surface effectsSpatial OrientationsElastomer

The present invention provides methods, systems and system components for transferring, assembling and integrating features and arrays of features having selected nanosized and / or microsized physical dimensions, shapes and spatial orientations. Methods of the present invention utilize principles of ‘soft adhesion’ to guide the transfer, assembly and / or integration of features, such as printable semiconductor elements or other components of electronic devices. Methods of the present invention are useful for transferring features from a donor substrate to the transfer surface of an elastomeric transfer device and, optionally, from the transfer surface of an elastomeric transfer device to the receiving surface of a receiving substrate. The present methods and systems provide highly efficient, registered transfer of features and arrays of features, such as printable semiconductor element, in a concerted manner that maintains the relative spatial orientations of transferred features.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Cap liners, closures and gaskets from multi-block polymers

A polymer composition comprises at least an ethylene / α-olefin interpolymer and at least one other polymer. The other polymer can be selected from a second ethylene / α-olefin interpolymer, an elastomer, a polyolefin, a polar polymer, and an ethylene / carboxylic acid interpolymer or ionomer thereof. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Also provided are gaskets, bottle cap liners, and closures that comprise or obtained from a compositon comprising at least one ethylene / α-olefin interpolymer and at least one polyolefin. The gaskets are capable of compression sealing various containers, without contaminating the contents. Liquid containers particularly benefit from the use of the novel gasket materials disclosed herein.

Owner:DOW GLOBAL TECH LLC

Electrosurgical device having a dielectric seal

A method of manufacturing a seal in an electrosurgical device includes placing components of the electrosurgical device within an elongated housing section, the housing section including an actuator opening, introducing the housing section within a mold filled with a liquid thermoplastic elastomer and allowing the elastomer to flow within the housing, forming an elastomeric inwardly-extending lip portion circumferentially surrounding an opening at a distal end of the electrosurgical device for introducing an electrode therein, and allowing the molded elastomer to cure and become integral with the housing to seal the components within the molded elastomer contained within the housing section. The method may also include the step of forming an elastomeric actuator seal around the actuator opening.

Owner:COVIDIEN AG

Systems, devices and methods for treatment of intervertebral disorders

InactiveUS20060149380A1Increase heightMinimally invasiveSuture equipmentsSpinal implantsFiberElastomer

A bioactive / biodegradable nucleus implant for repairing degenerated intervertebral discs that is inflated inside the nucleus space after the degenerated nucleus has been removed to re-pressurize the nuclear space within the intervertebral disc. The implant is inflated with a high molecular weight fluid, gel or combination of fluid and elastomer, preferably an under-hydrated HA hydrogel / growth factor mixture with or without host cells. The implant includes an internal, integral, self-sealing valve that allows one-way filling of the implant after it is placed within the disc, and is made from a material that allows fibrous in growth thereby stabilizing the implant. A variety of substances can be incorporated into the implant to promote healing, prevent infection, or arrest pain.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com