Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16319 results about "Thermal treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal treatment is any waste treatment technology that involves high temperatures in the processing of the waste feedstock. Commonly this involves the combustion of waste materials.

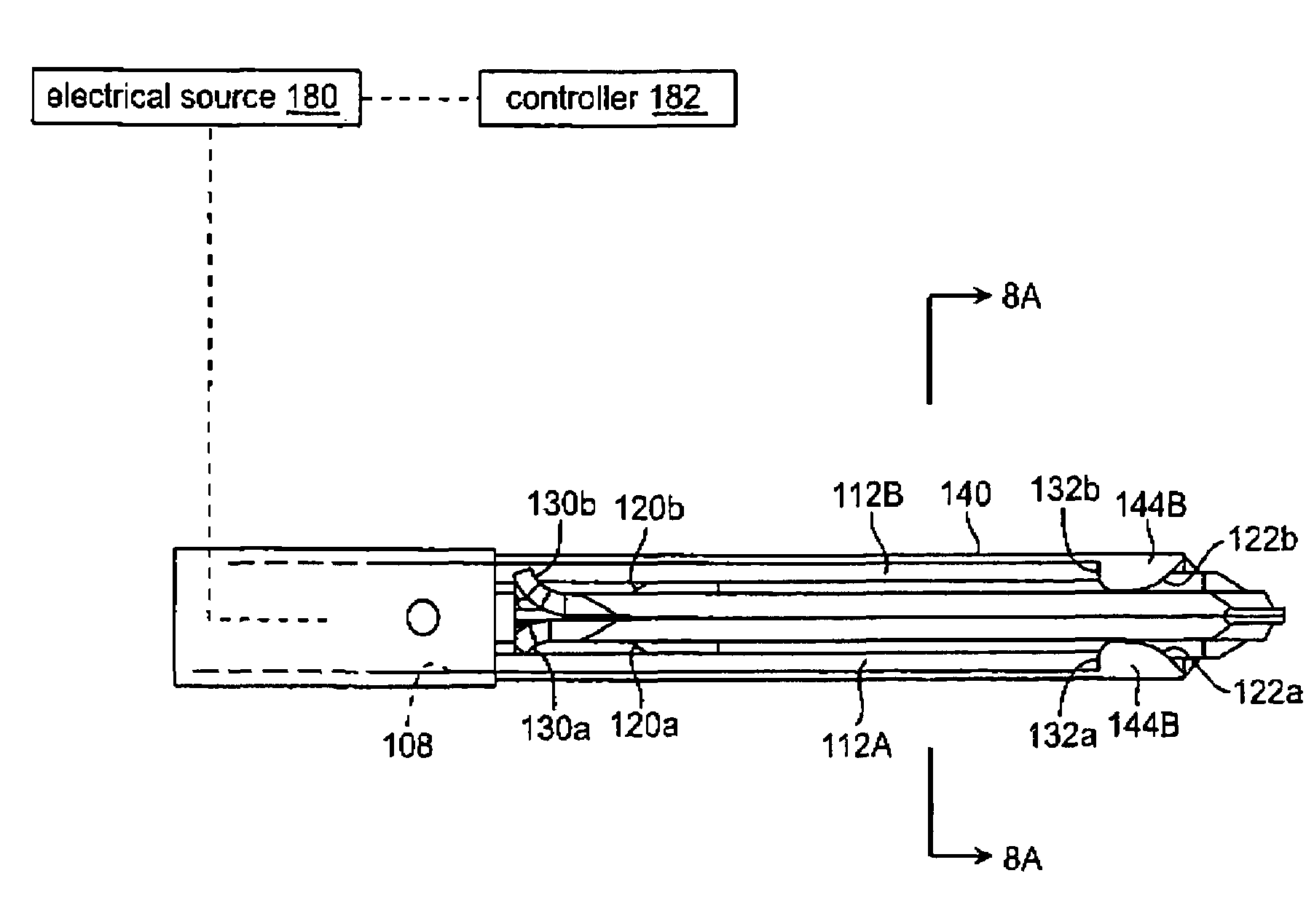

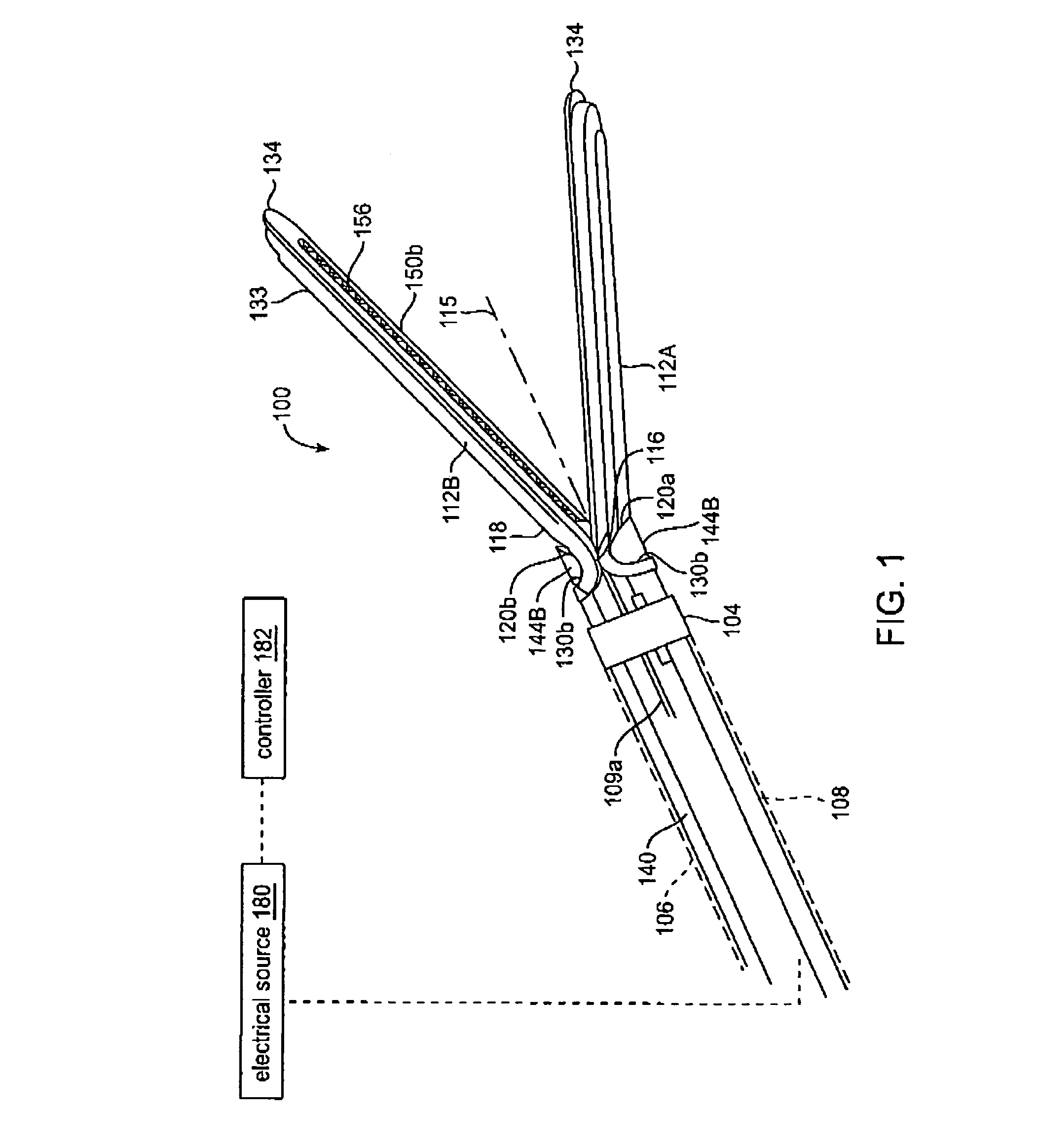

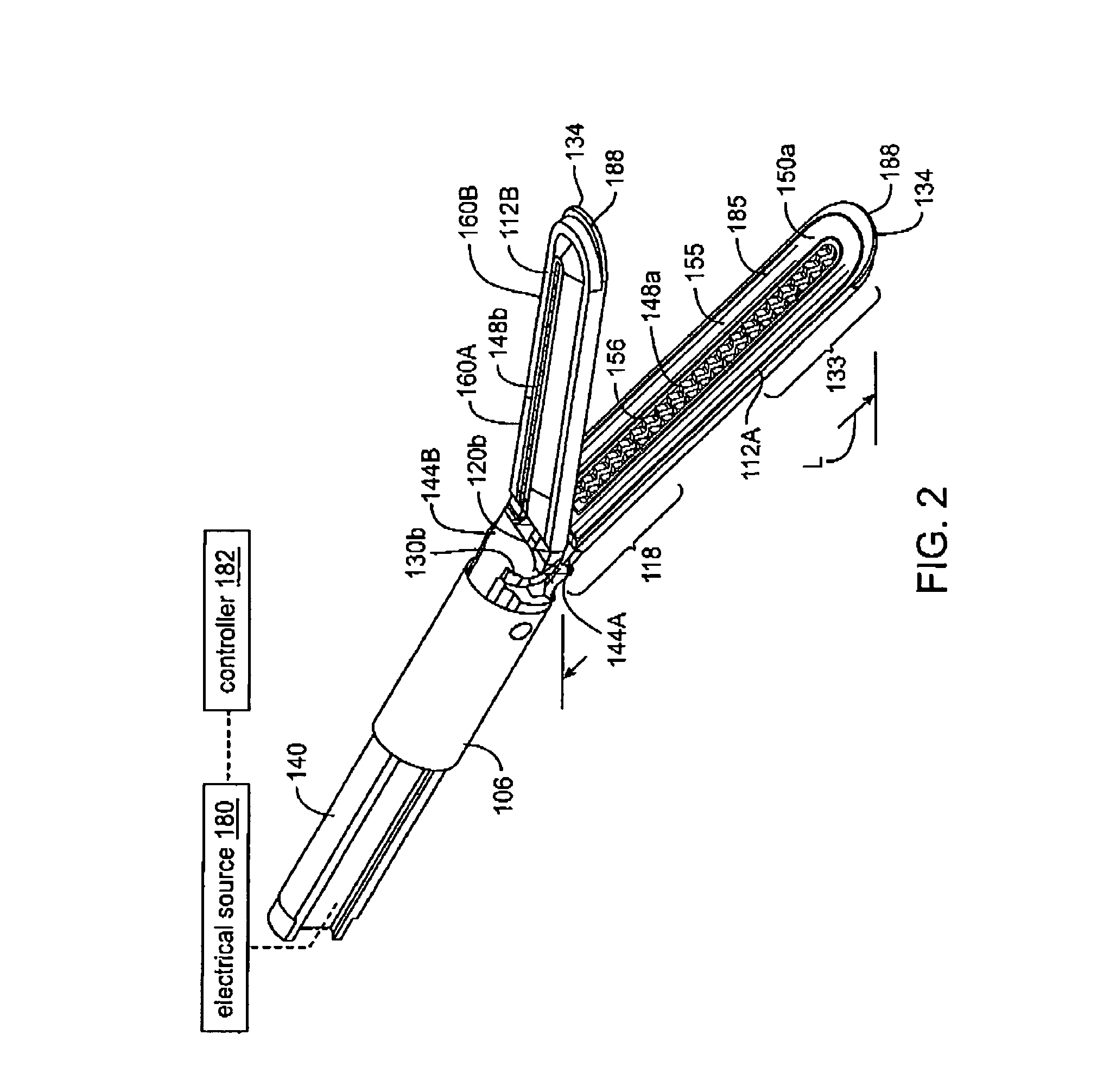

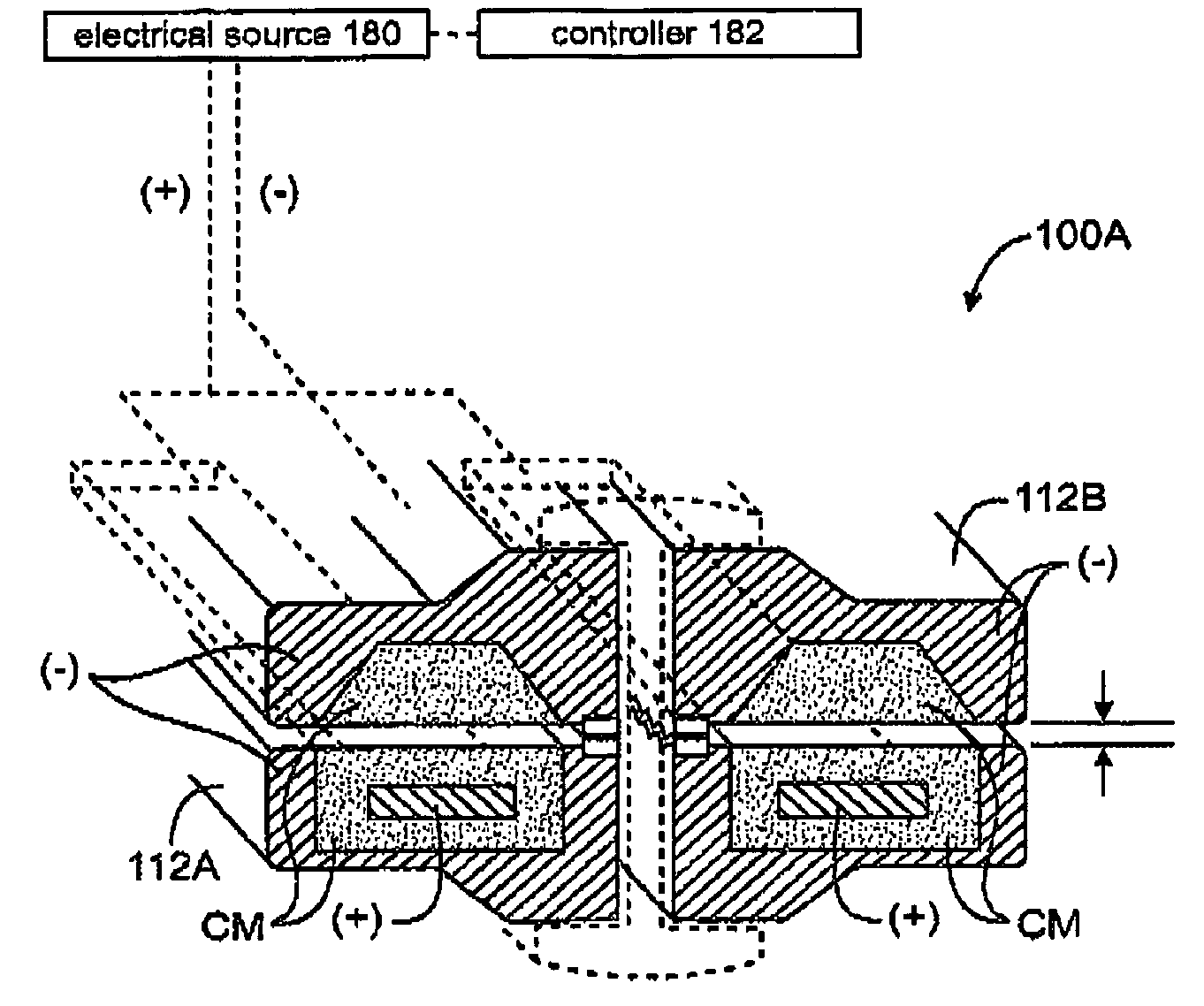

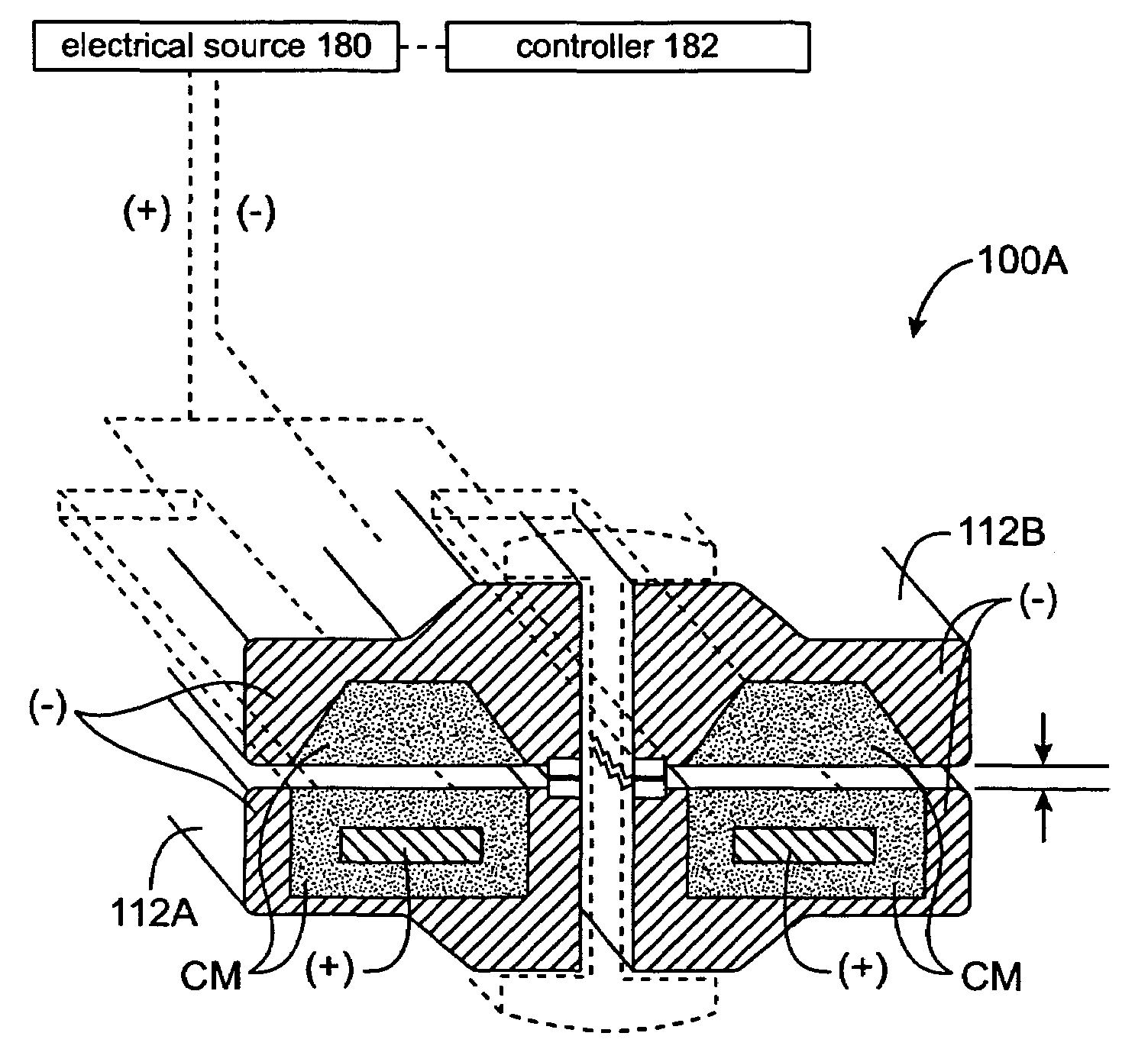

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

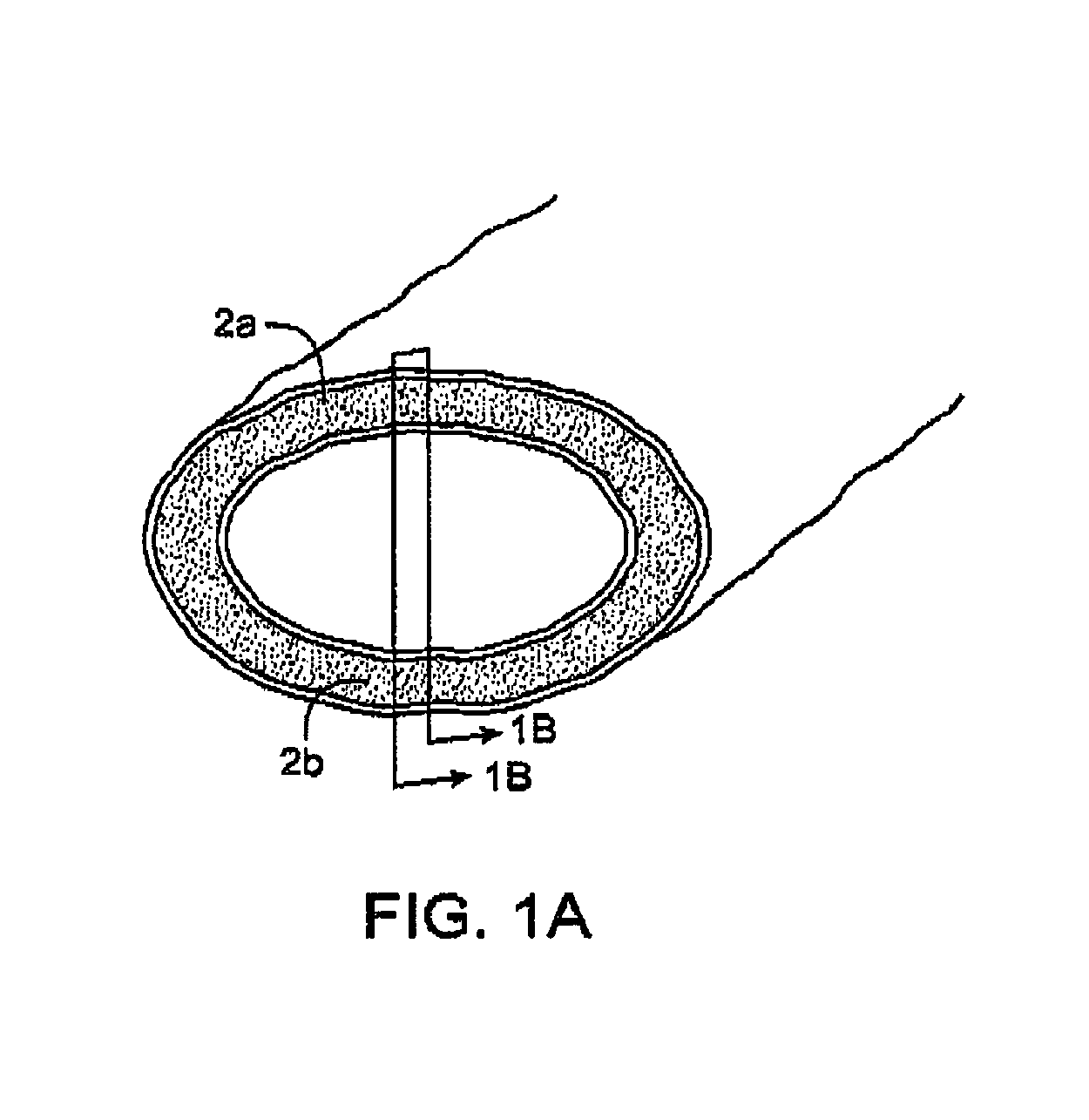

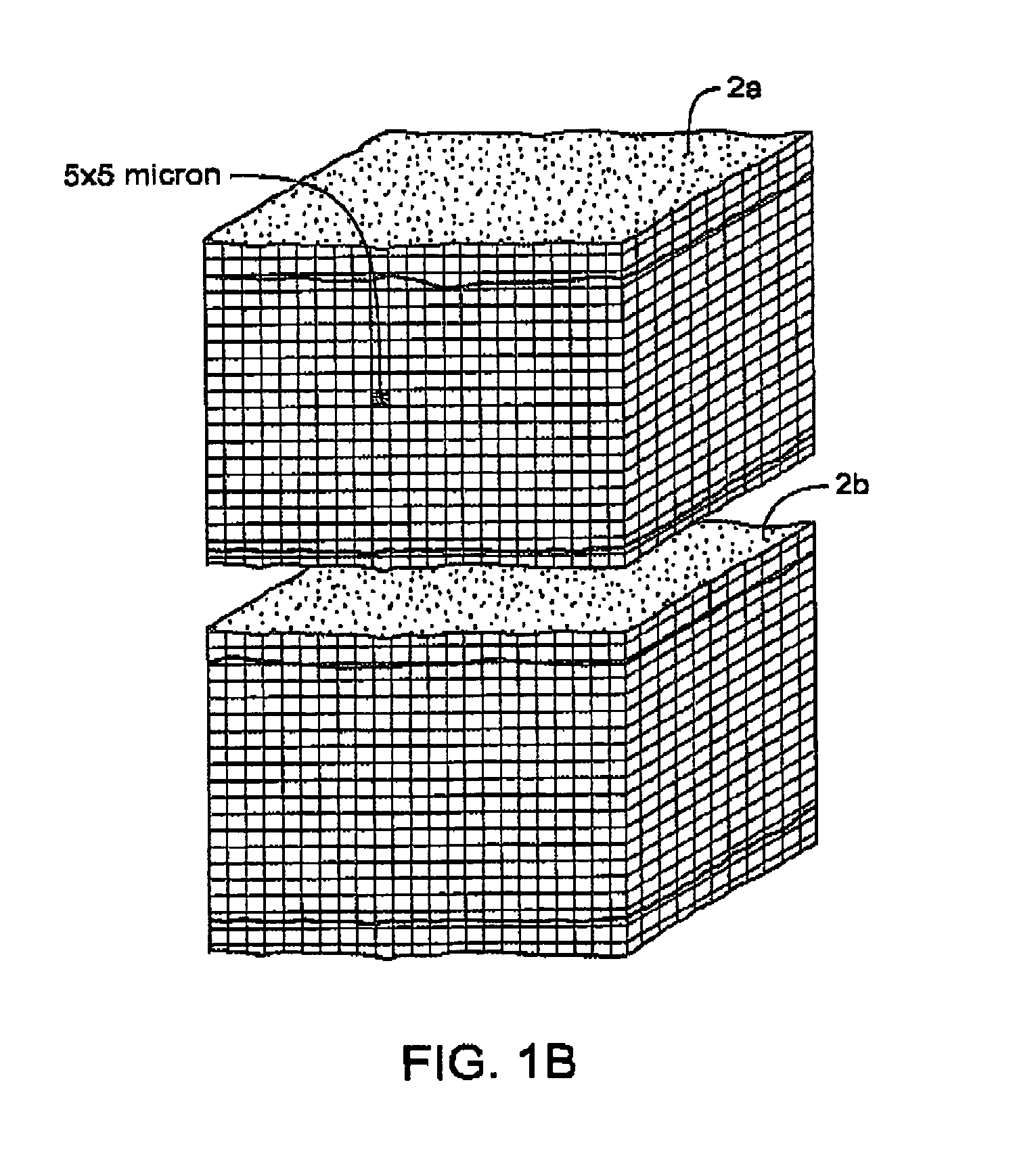

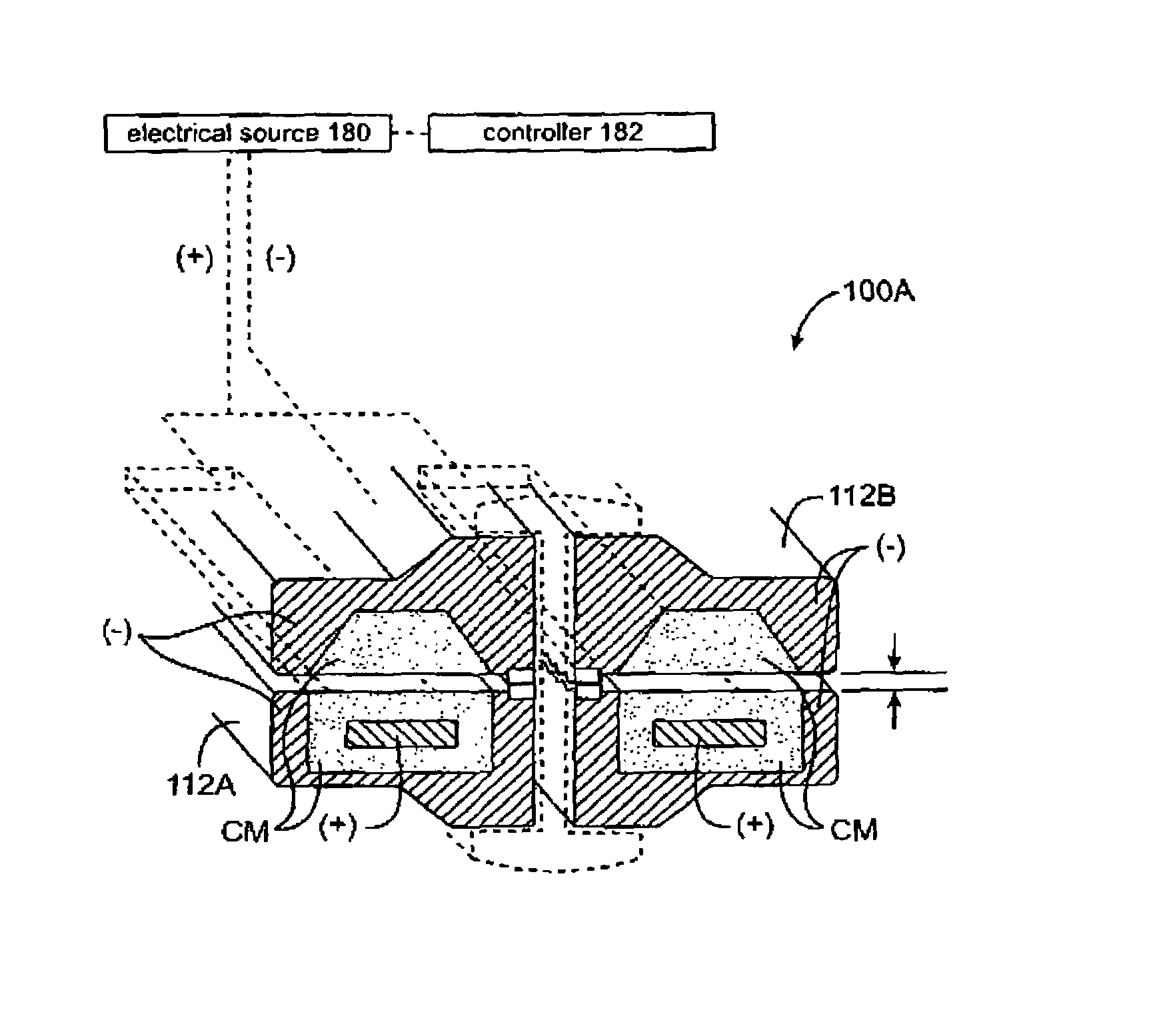

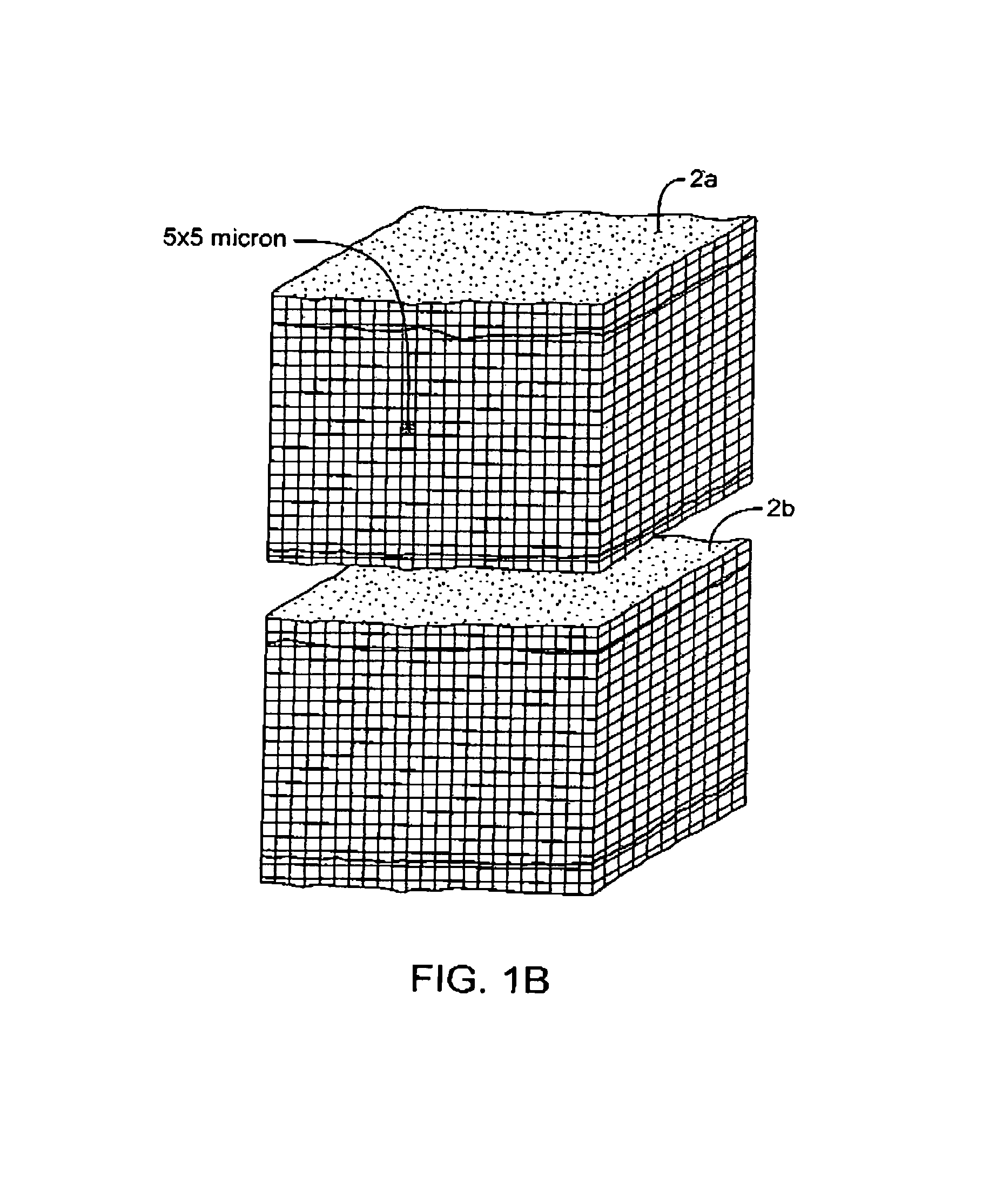

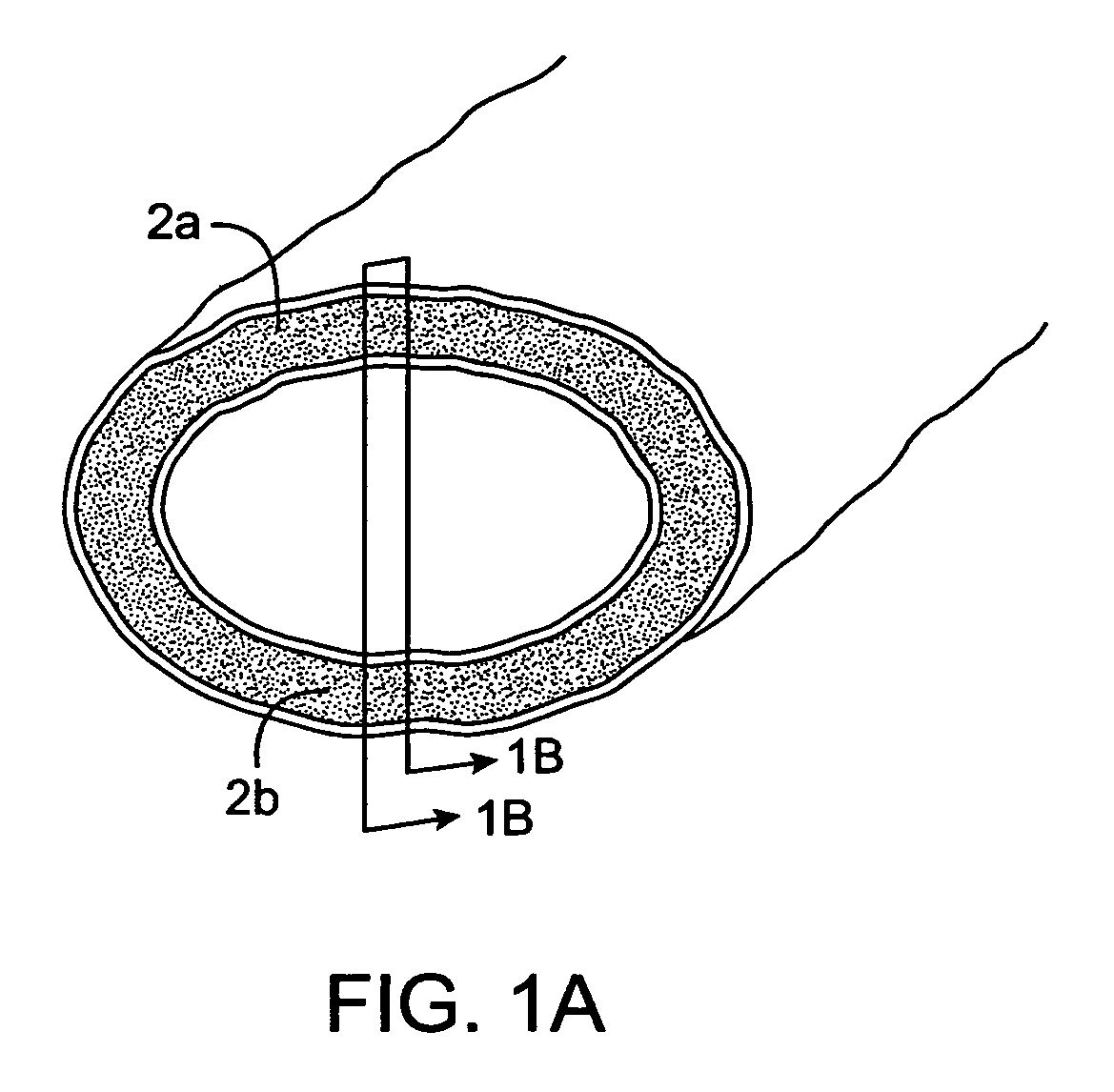

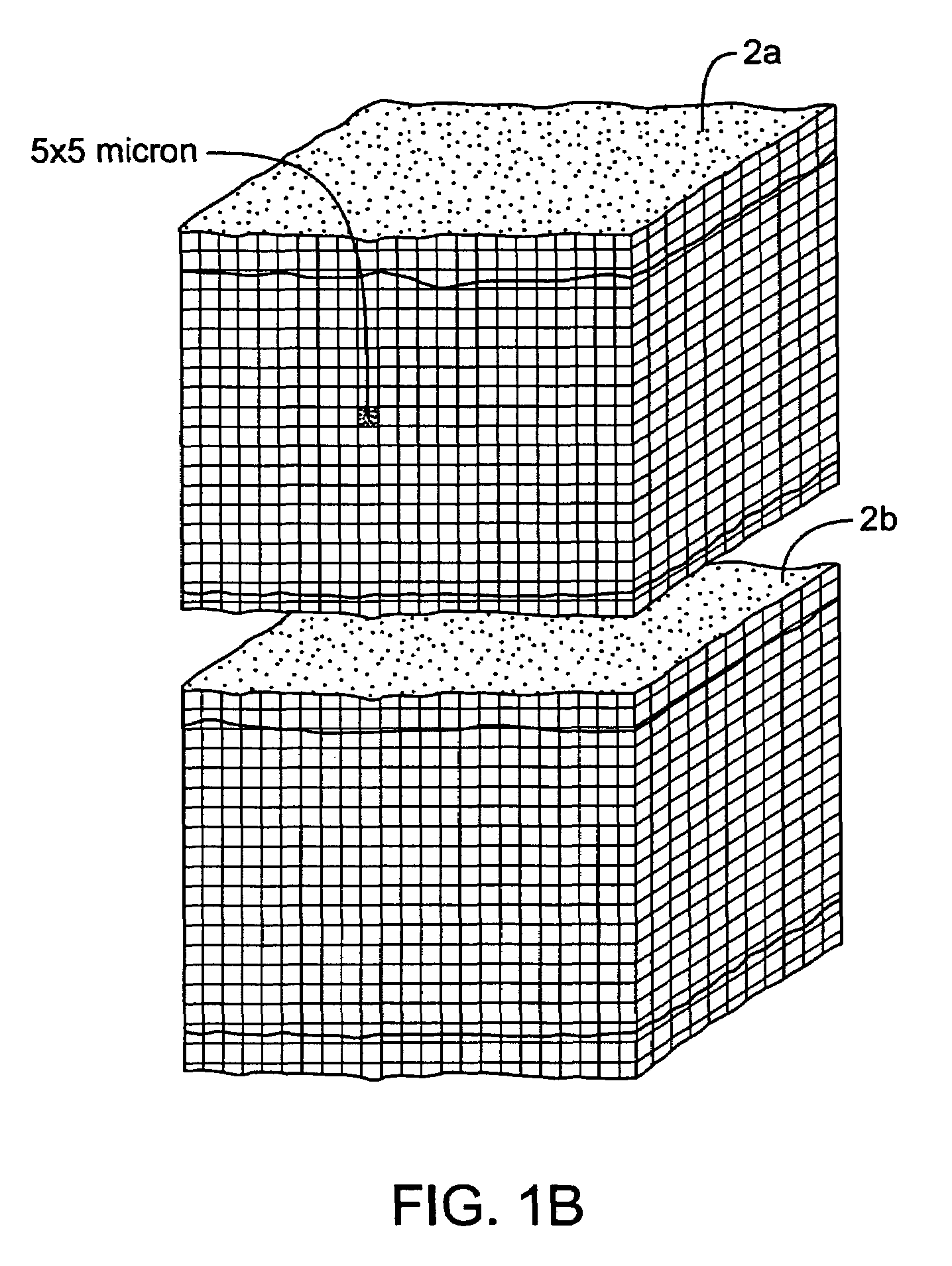

InactiveUS7083619B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

InactiveUS7311709B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleSpatial positioning

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a variable resistive body of a positive temperature coefficient material that has a selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The variable resistive body can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application across micron-scale portions of the engagement surface. In another mode of operation, a variable resistive body will focus conductive heating in a selected portion of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

InactiveUS7112201B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface. In another mode of operation, a conductive-resistive matrix can induce a “wave” of Rf energy density to sweep across the tissue to thereby weld tissue.

Owner:ETHICON ENDO SURGERY INC

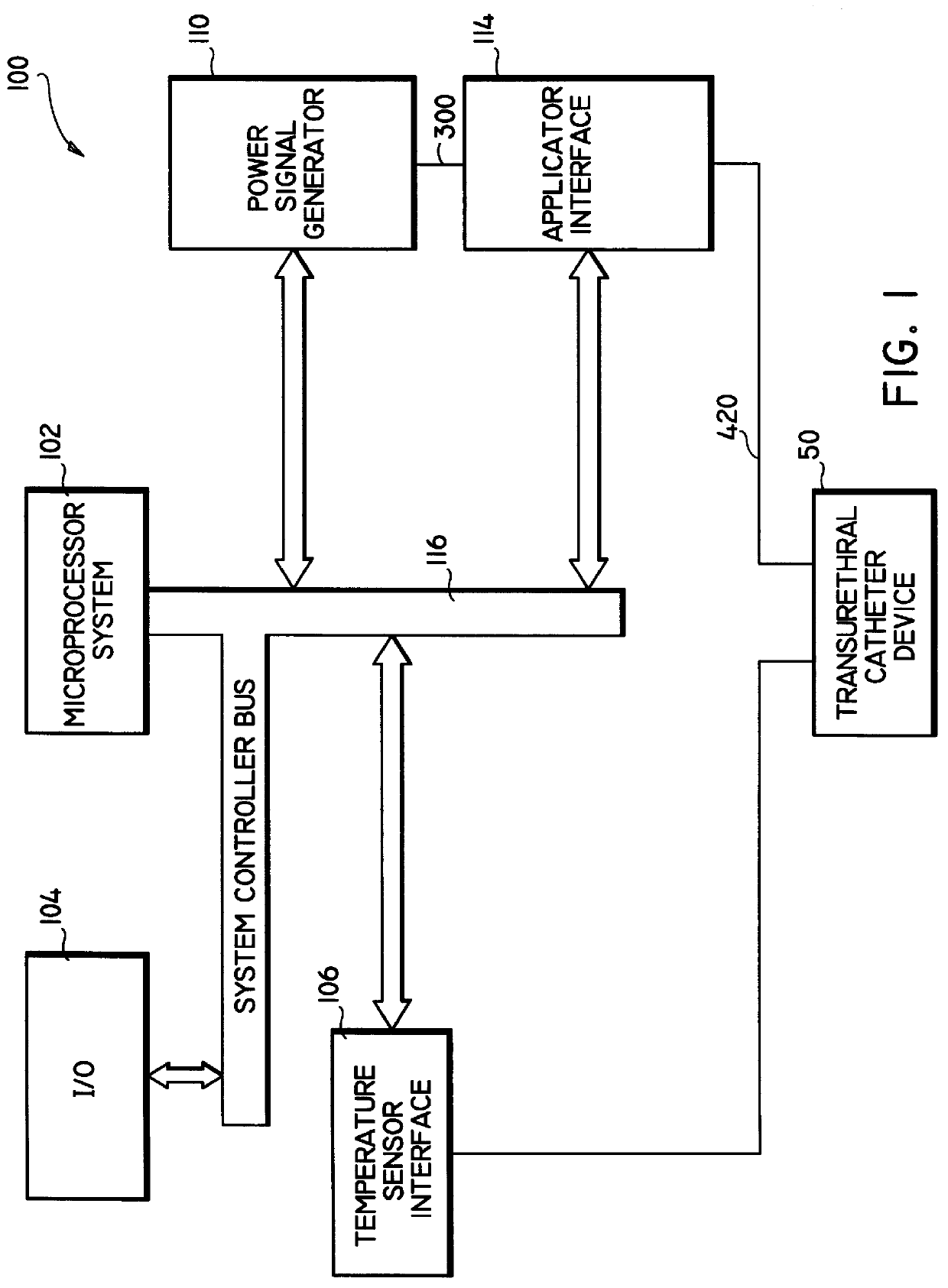

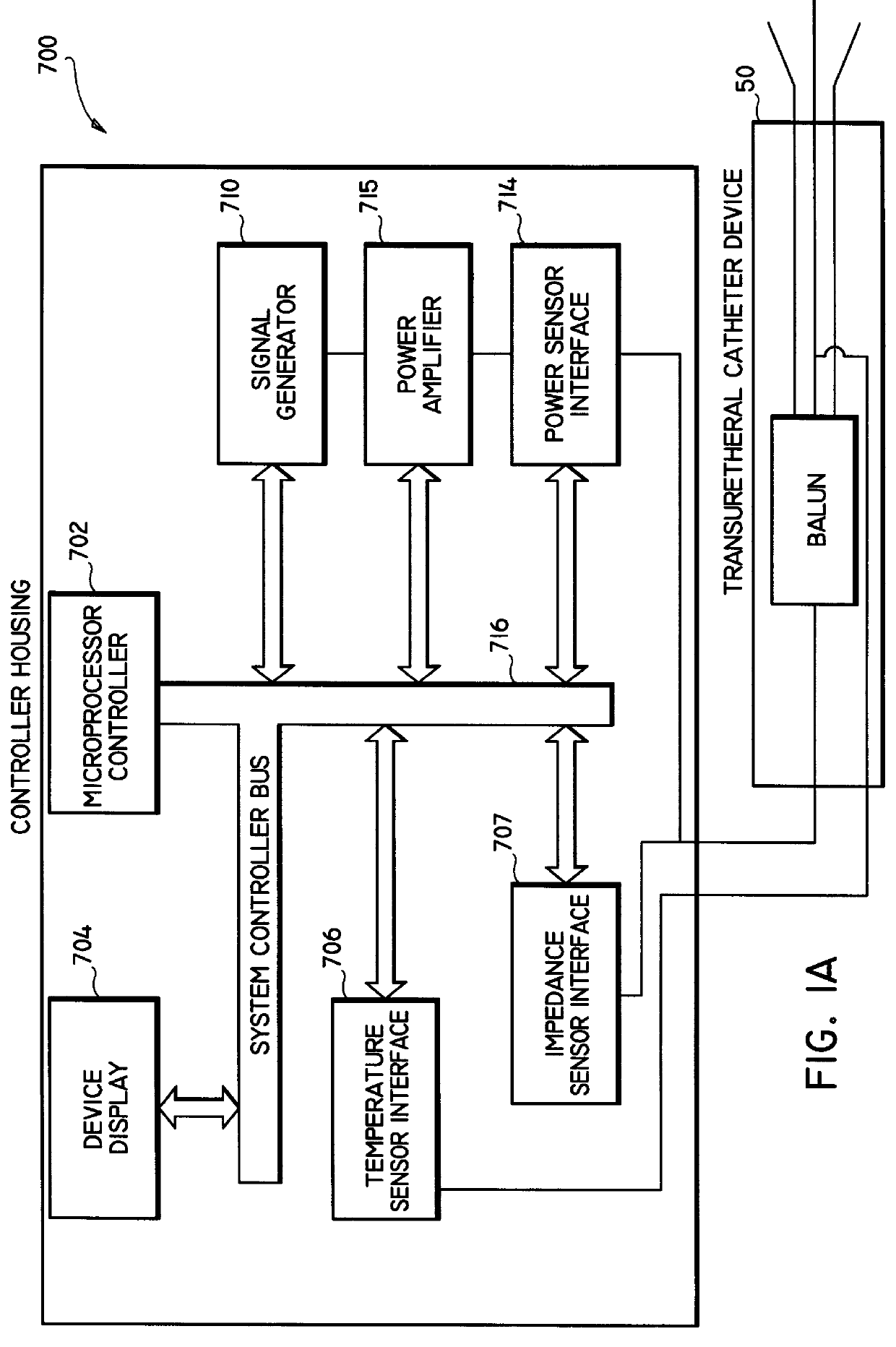

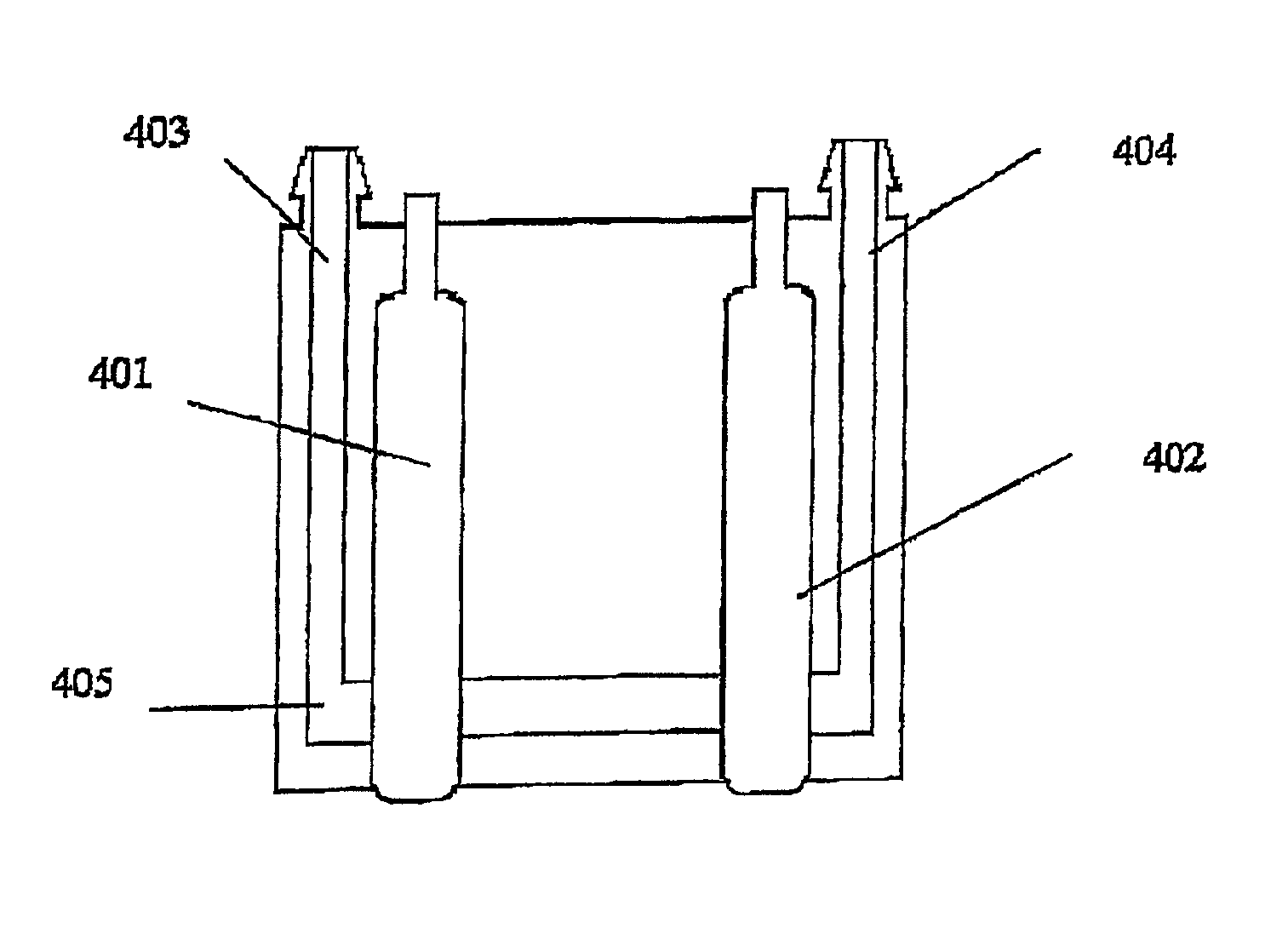

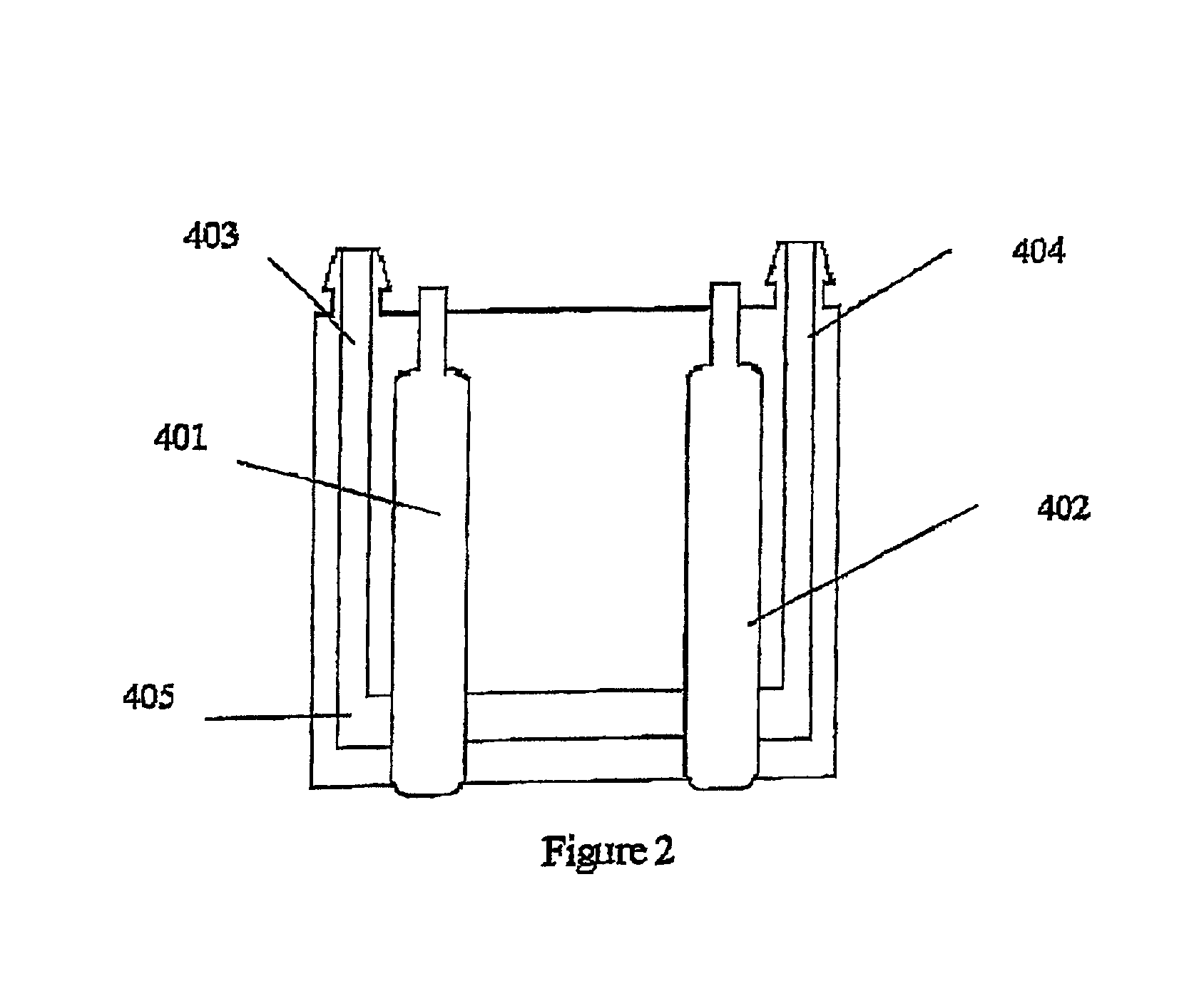

Dynamic heating method and radio frequency thermal treatment

A method and system for the delivery of radiofrequency energy to the tissue, particularly, the prostate, to alleviate the symptoms of BPH is disclosed. The system incorporates a bipolar or multipolar electrode array to create an electric field where the heat created is confined solely to a specific volume of the prostate gland and therefore the heated tissue is defined only by the electrode geometry. The bipolar electrode array provides a variety of three dimensional, symmetric heating patterns within the prostatic tissue depending on the relative electrode lengths and angular separation. The system provides precision tissue temperature and impedance measurements thereby enabling the surgeon to accurately predict heating pattern performance and tissue response to RF heating.

Owner:KASEVICH RAYMOND S

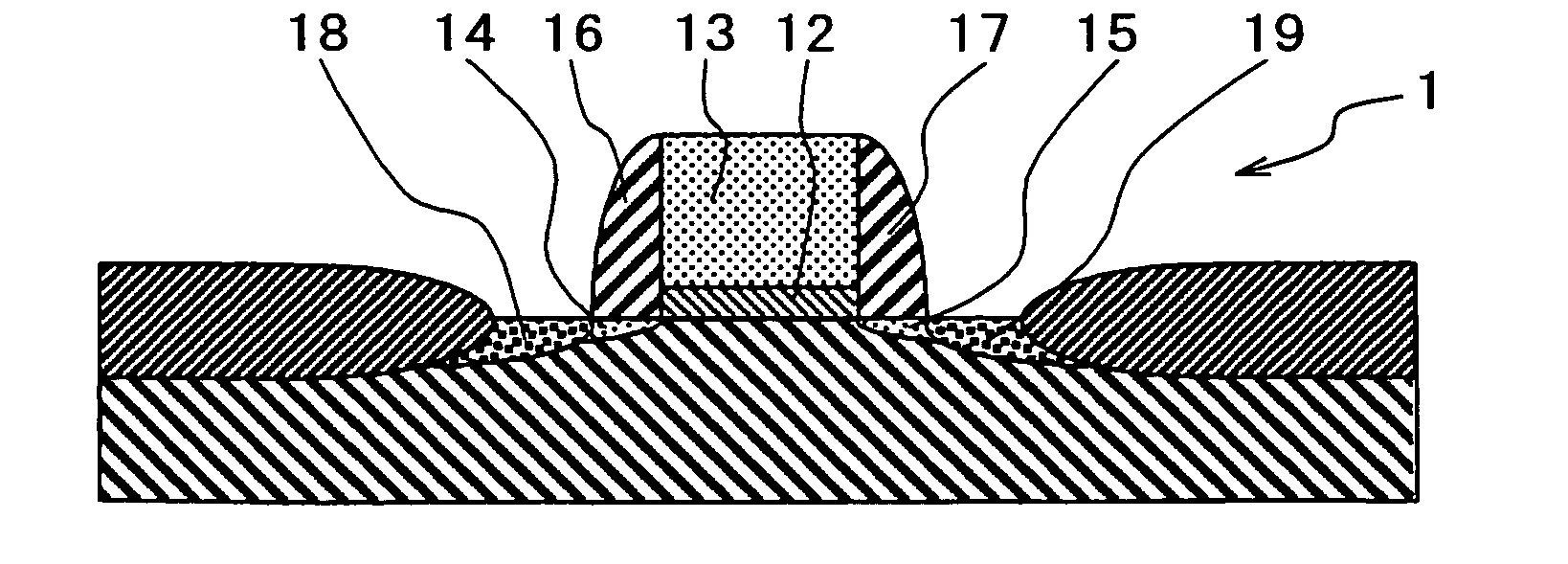

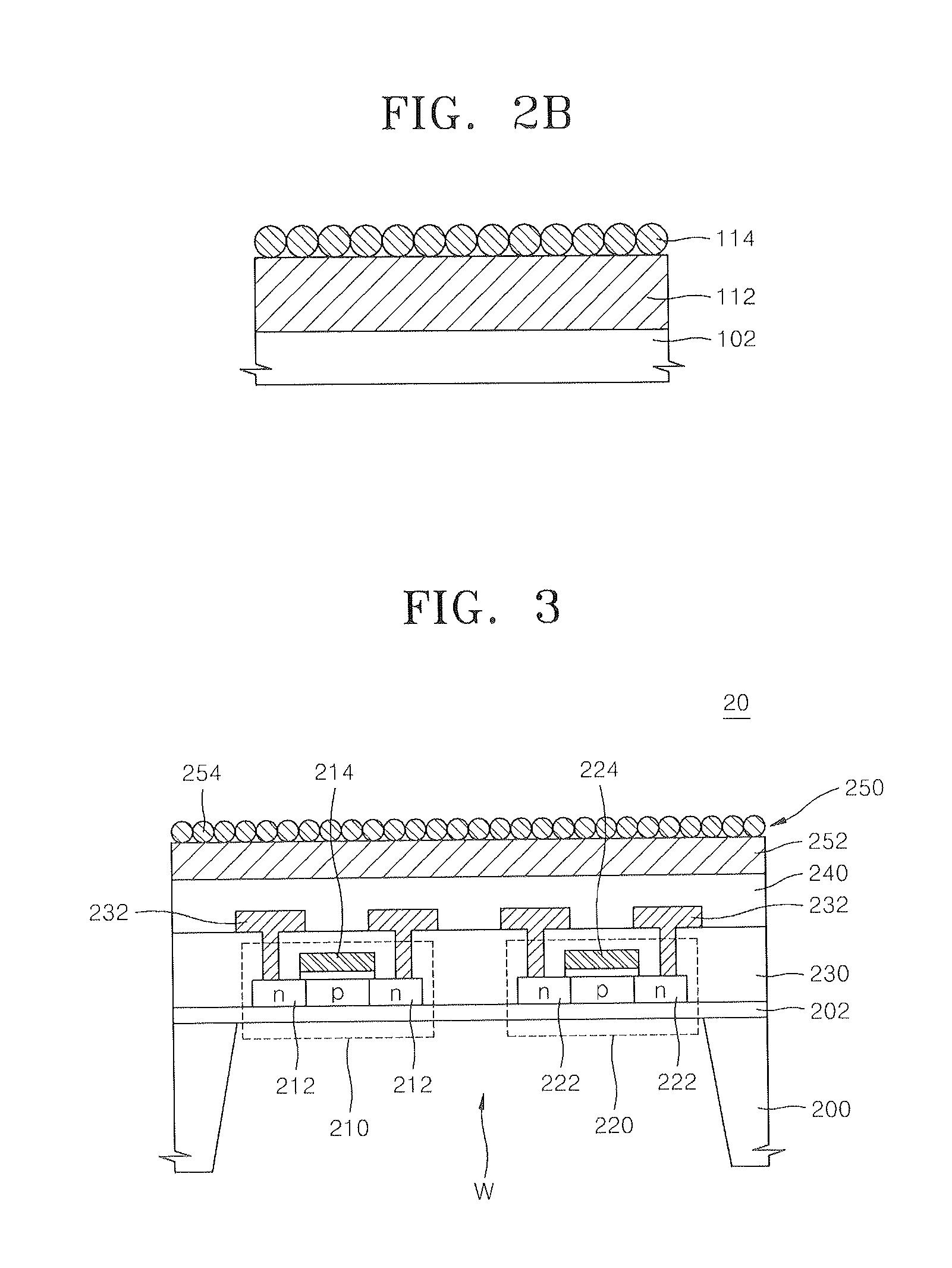

Method for forming a thin film and method for fabricating a semiconductor device

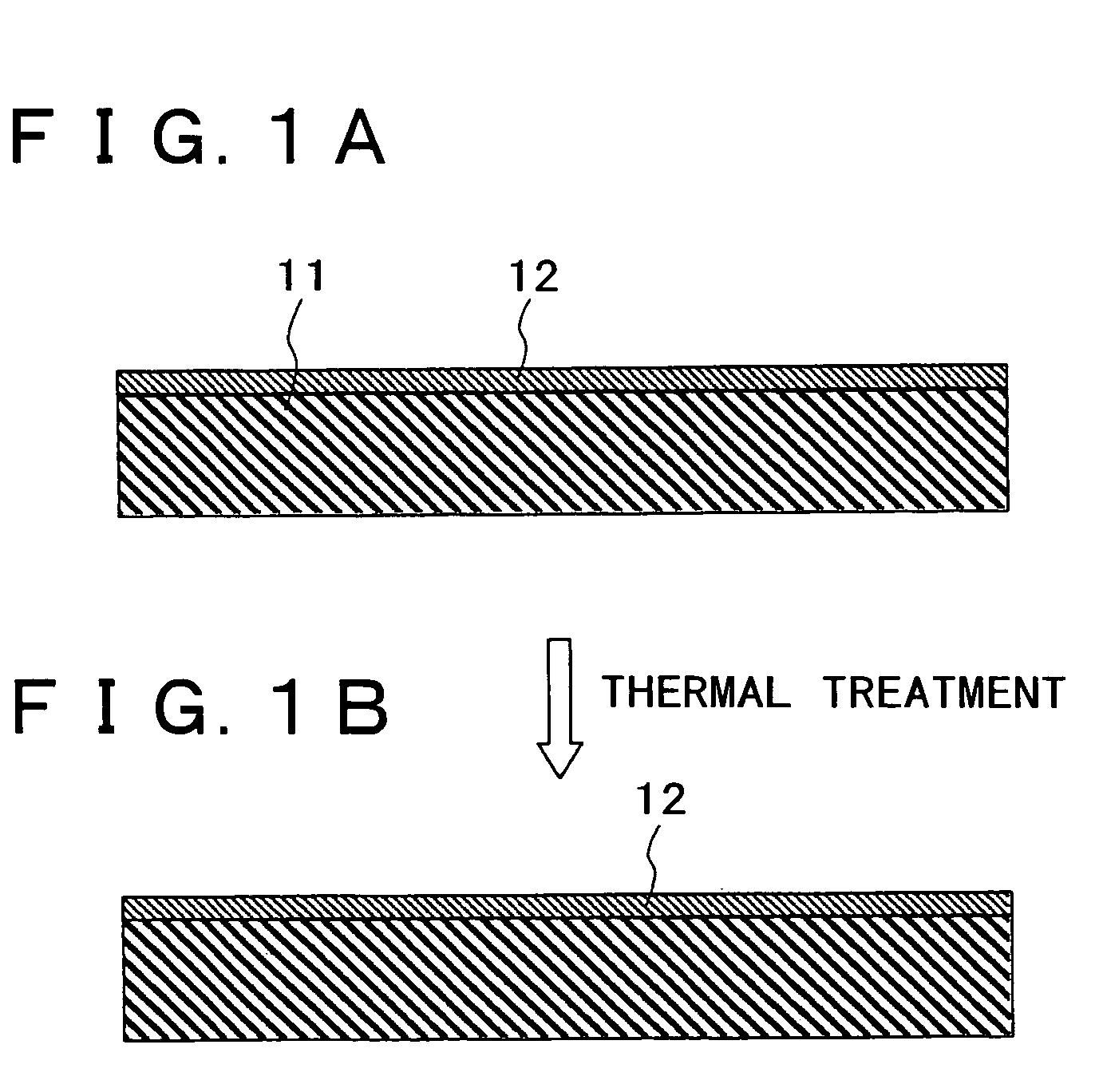

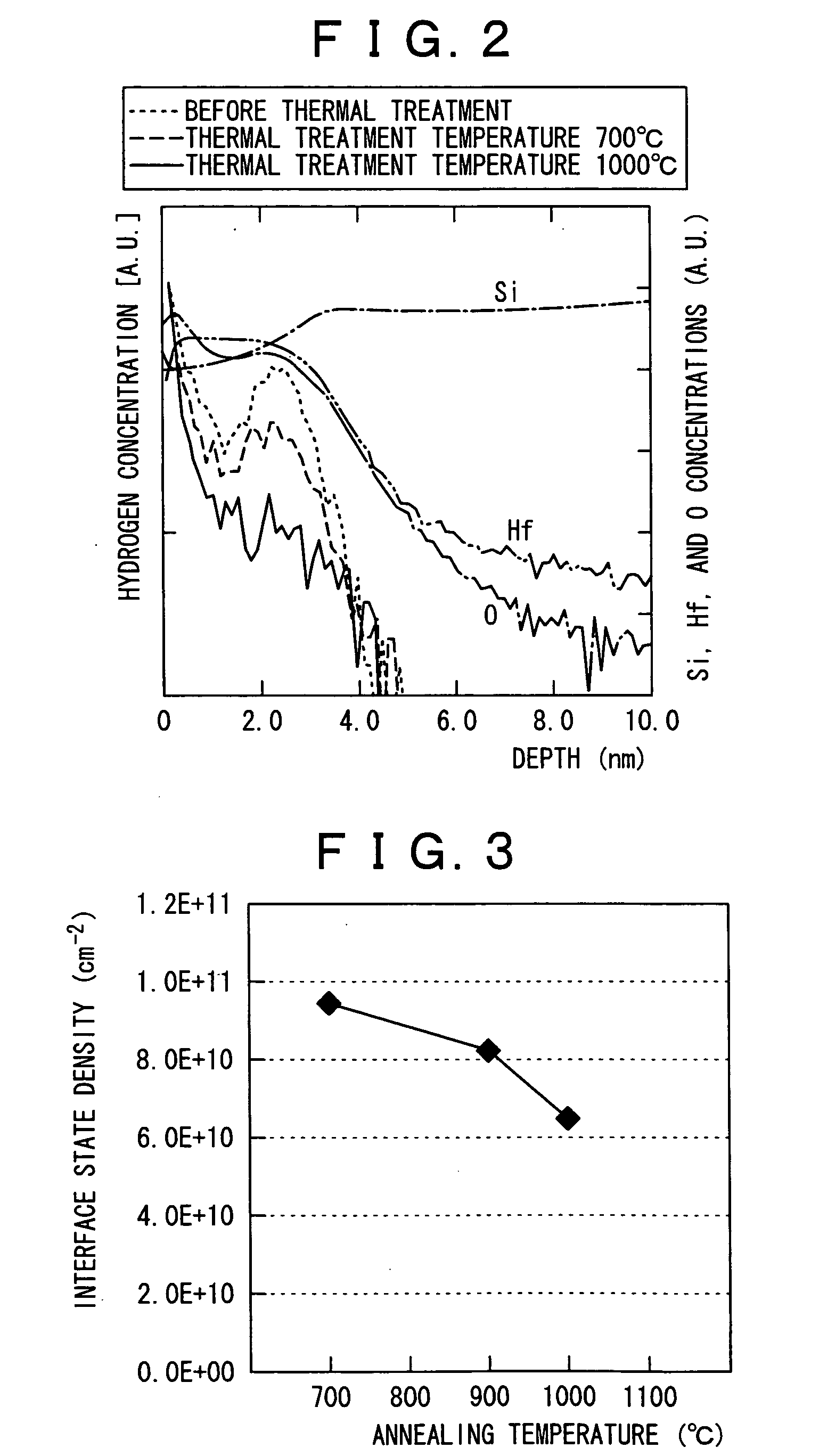

InactiveUS20050070123A1Improve mobility and reliabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricHafnium

By conducting a high temperature annealing in a nitrogen atmosphere at a temperature at which a hafnium silicate film undergoes no phase separation, hydrogen contained in the film is removed and prevention of boron penetration is made possible. The present invention provides a method for forming a thin film including a step of forming a hafnium silicate film on a substrate by an atomic layer deposition method and a step of carrying out thermal treatment on the hafnium silicate film at a thermal treatment temperature equal to or higher than a temperature at which hydrogen contained in the hafnium silicate film is removed and lower than a temperature at which the hafnium silicate film undergoes no phase separation, and a method for fabricating a semiconductor device for forming a gate dielectric film using the method for forming a thin film.

Owner:SONY CORP

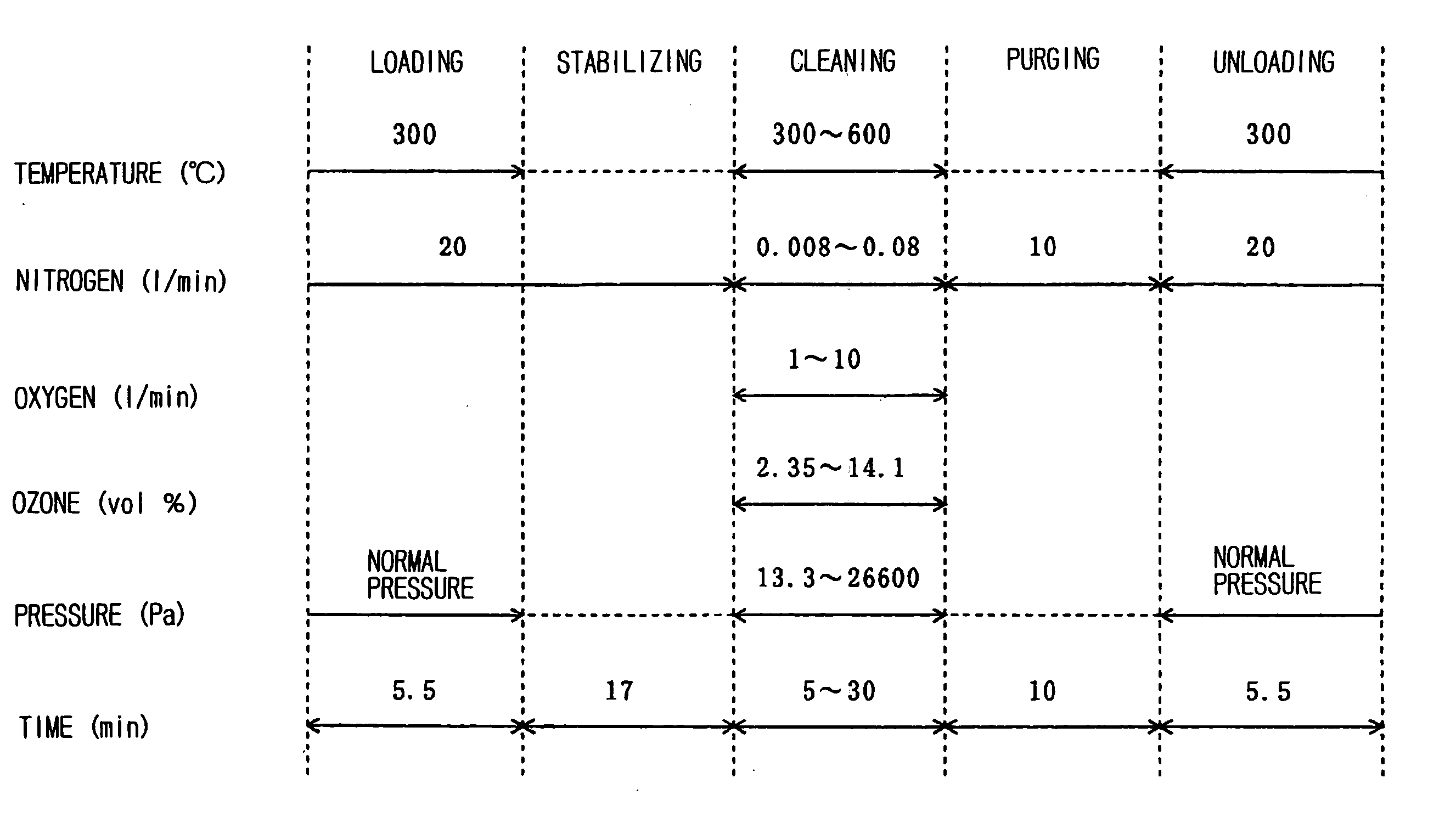

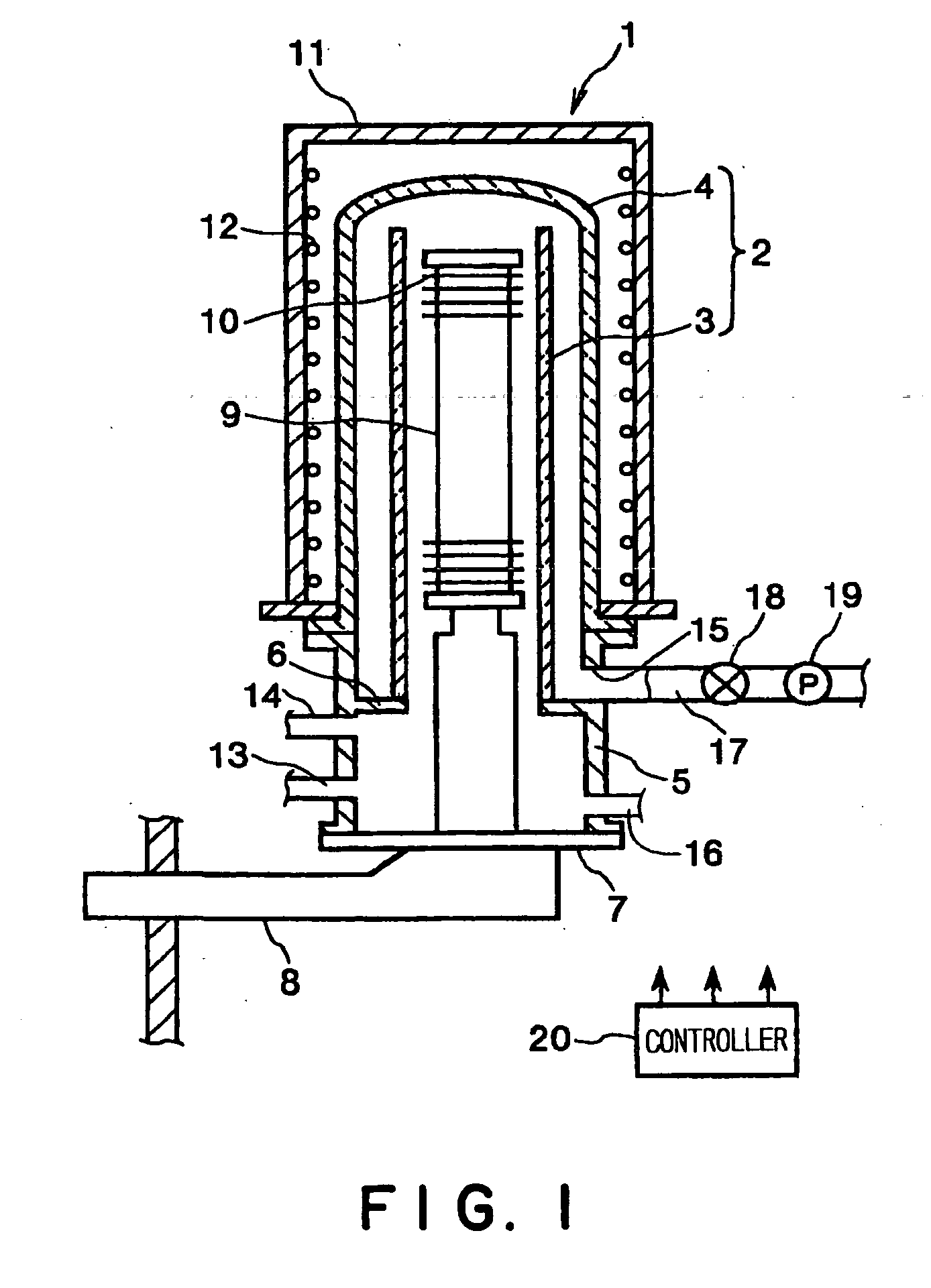

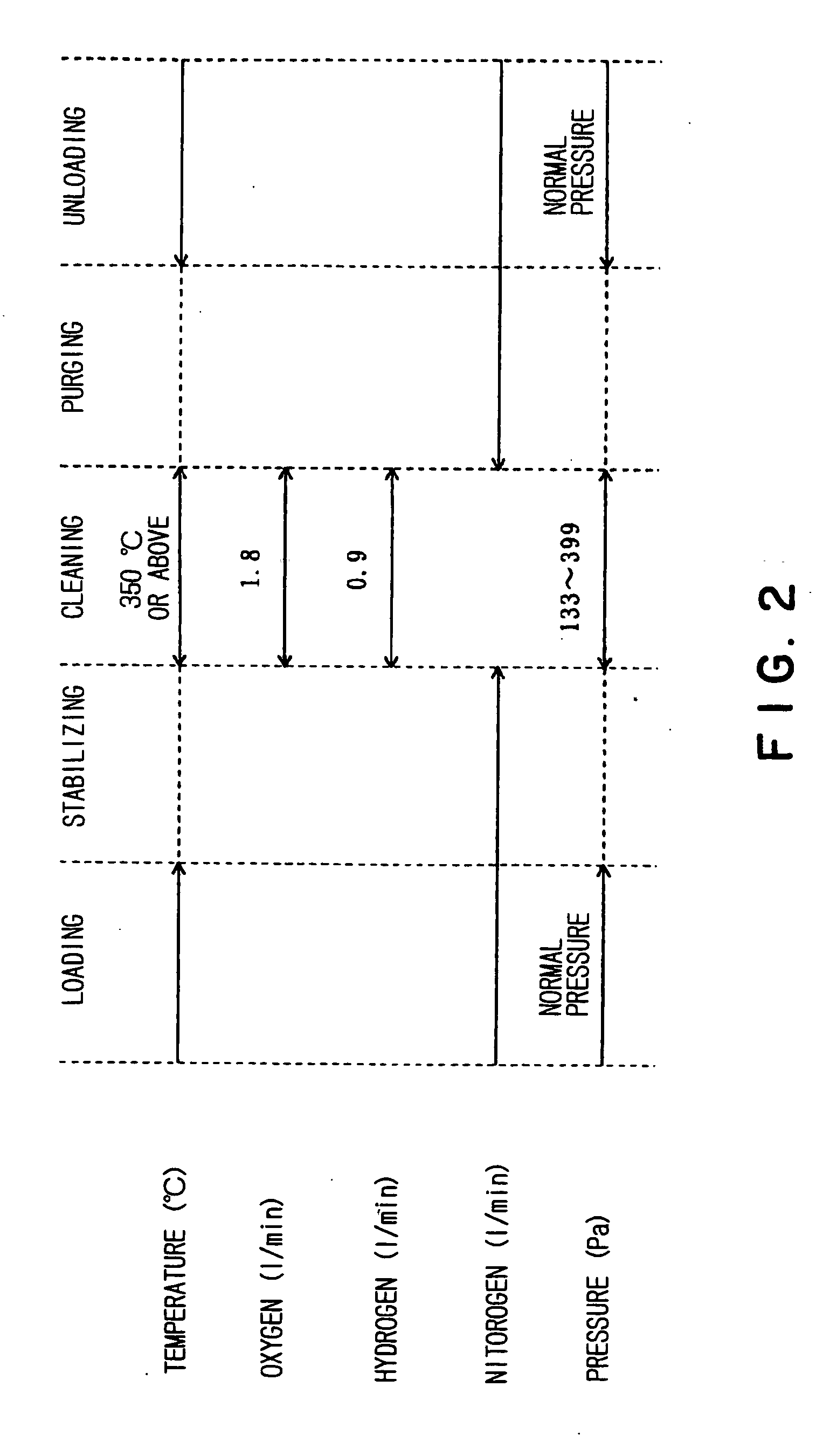

Method and apparatus for treating article to be treated

InactiveUS20040219793A1Efficient removalShort timeAfter-treatment detailsSemiconductor/solid-state device manufacturingCombustionHydrogen

A thermal treatment apparatus 1 includes a reaction tube 2 for containing wafers 10 contaminated with organic substances having a heater 12 capable of heating the reaction tube; a first gas supply pipe 13 for carrying oxygen gas into the reaction tube 2; and a second gas supply pipe 14 for carrying hydrogen gas into the reaction tube 2. Oxygen gas and hydrogen gas are supplied through the first gas supply pipe 13 and the second gas supply pipe 14, respectively, into the reaction tube 2, and the heater 12 heats the reaction tube 2 at a temperature capable of activating oxygen gas and hydrogen gas. A combustion reaction occurs in the reaction tube 2 and thereby the organic substances adhering to the wafers 10 are oxidized, decomposed and removed.

Owner:TOKYO ELECTRON LTD

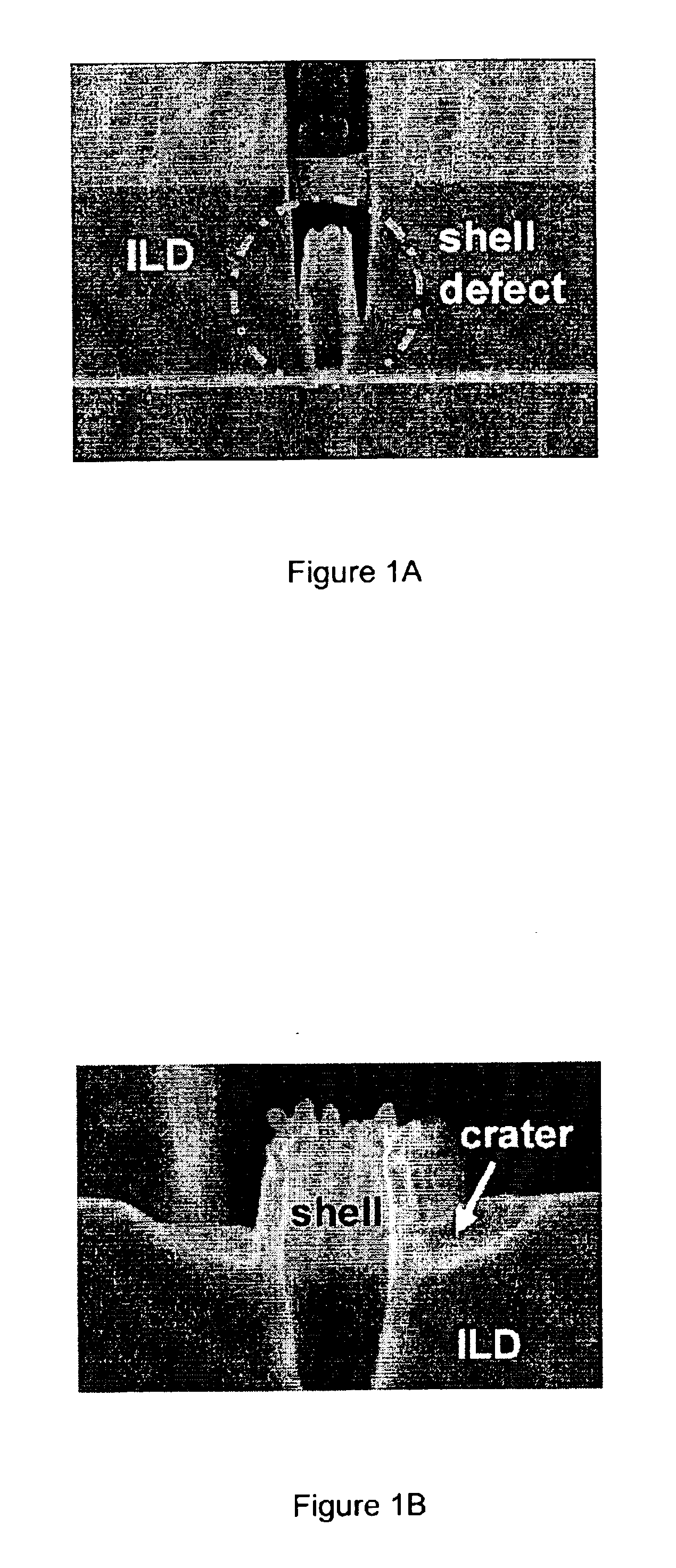

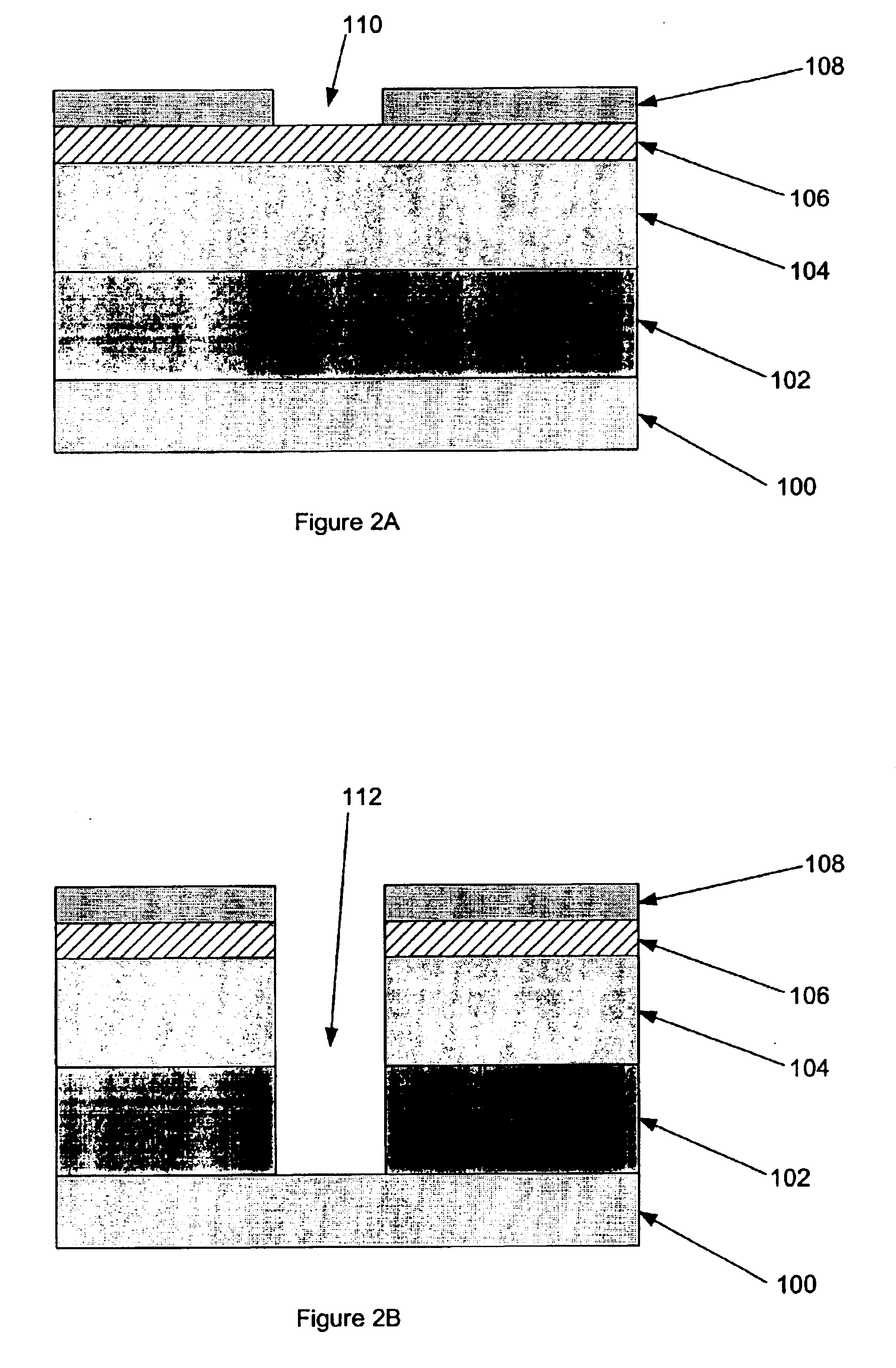

Polymer sacrificial light absorbing structure and method

InactiveUS6876017B2From solid stateSemiconductor/solid-state device detailsSolubilityLithographic artist

Method and structure for optimizing dual damascene patterning with polymeric dielectric materials are disclosed. Certain embodiments of the invention comprise polymeric sacrificial light absorbing materials (“polymer SLAM”) functionalized to have a controllable solubility switch wherein such polymeric materials have substantially the same etch rate as conventionally utilized polymeric dielectric materials, and subsequent to chemical modification of solubility-modifying protecting groups comprising the SLAM materials by thermal treatment or in-situ generation of an acid, such SLAM materials become soluble in weak bases, such as those conventionally utilized to remove materials in lithography treatments.

Owner:INTEL CORP

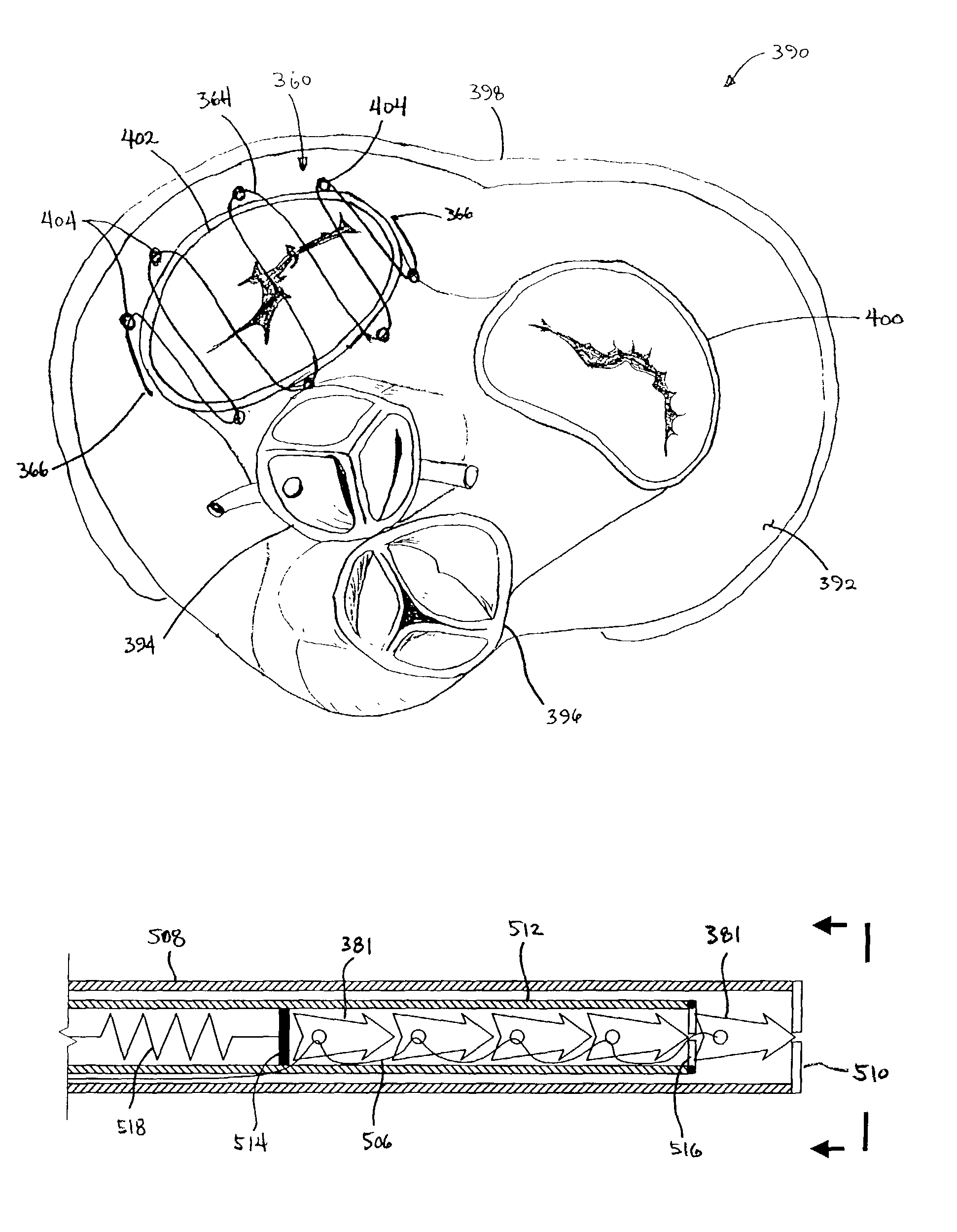

Apparatus and methods for treating tissue

InactiveUS7186262B2Reducing valve diameterFunction increaseSuture equipmentsUltrasound therapyControl mannerTransducer

Apparatus and methods are provided for thermally and / or mechanically treating tissue, such as valvular structures, to reconfigure or shrink the tissue in a controlled manner. Mechanical clips are implanted over the leaflets of a valve, e.g., in the heart, either alone or after thermal treatment to cause the valve to close more tightly. The clips are delivered by a catheter and may be configured to traverse directly over the valve itself or to lie partially over the periphery of the valve to prevent obstruction of the valve channel. The clips can be coated with drugs or a radiopaque coating. Alternatively, individual anchors with a tensioning element, like a suture, may be used to approximate the valves towards each other. The catheter can also incorporate sensors or energy delivery devices, e.g., transducers, on its distal end.

Owner:AURIS HEALTH INC

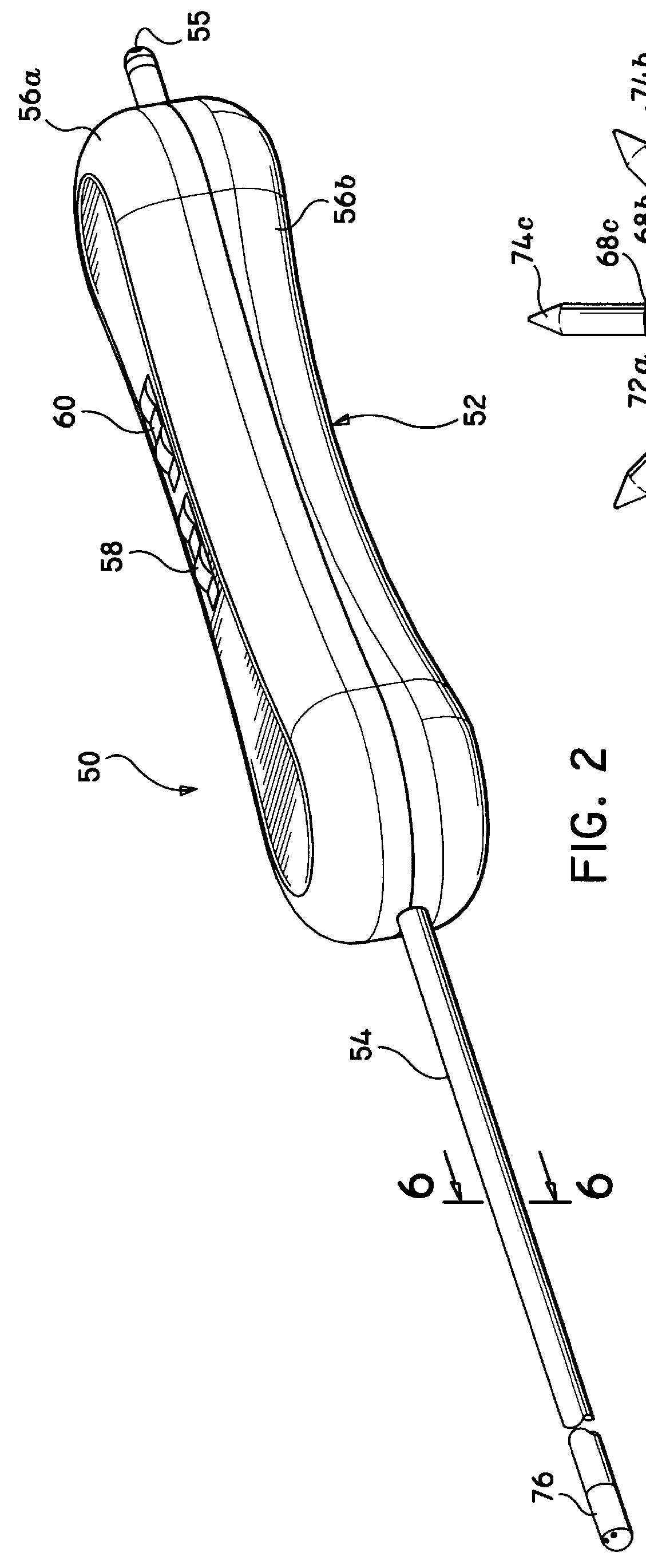

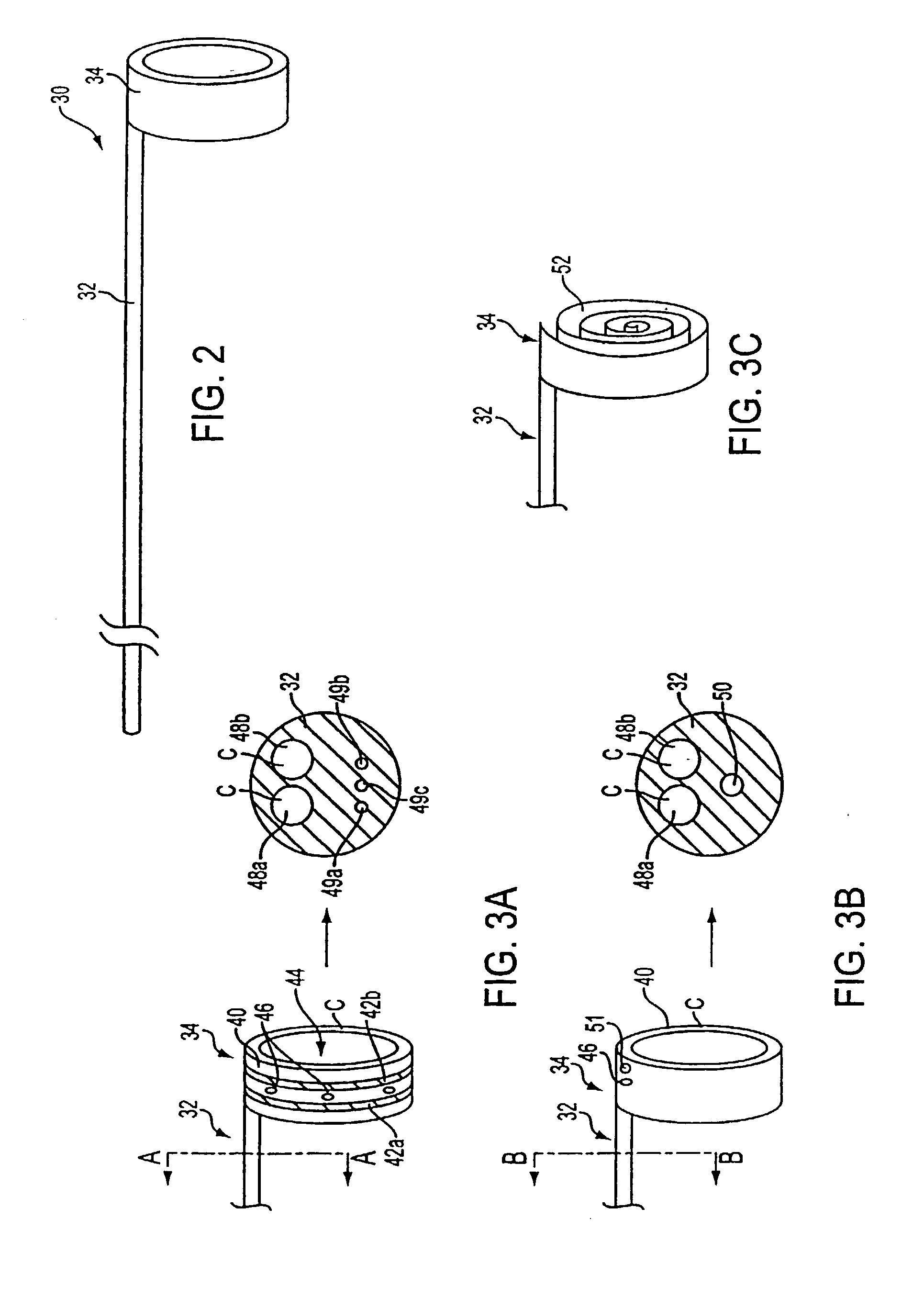

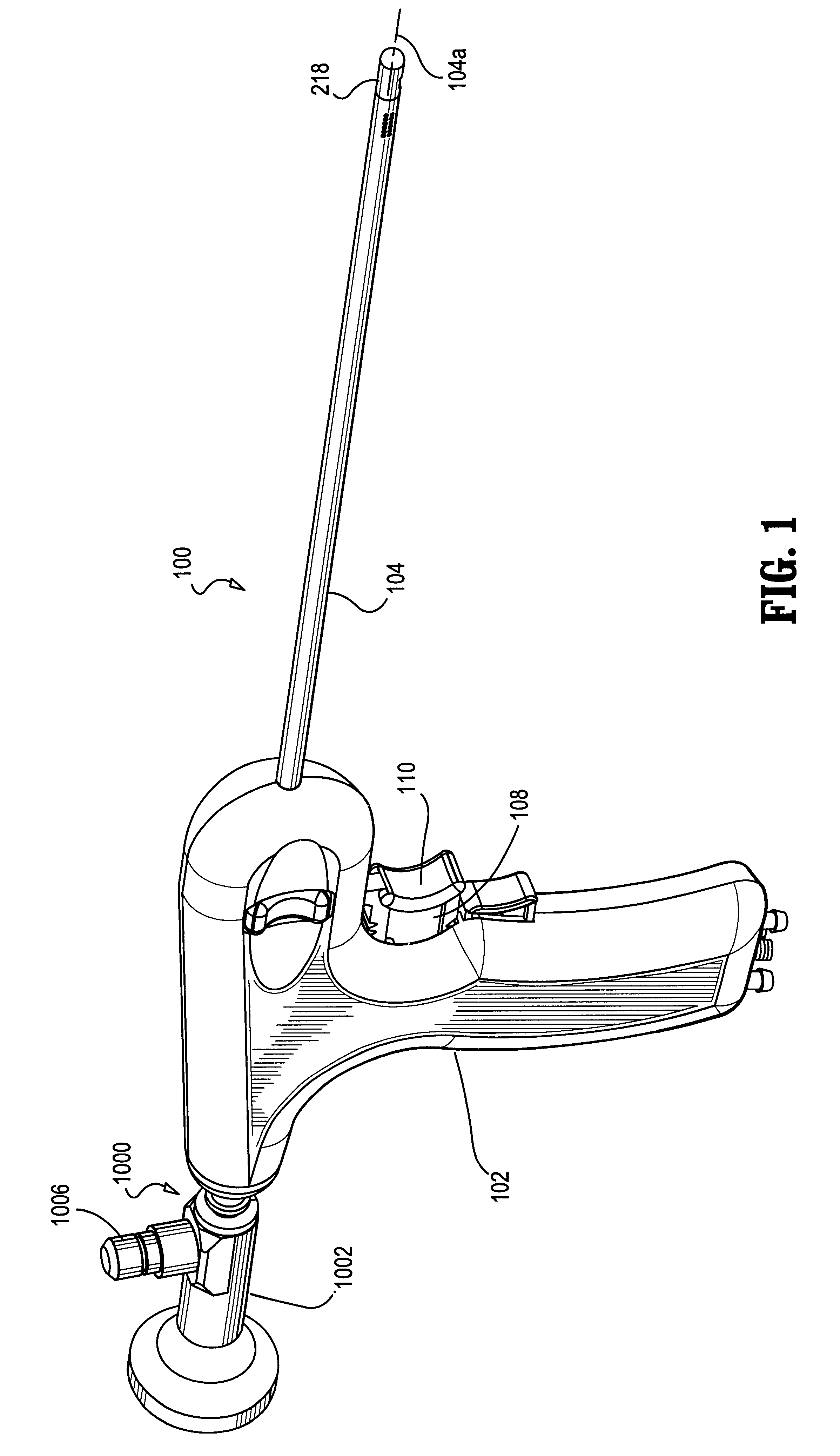

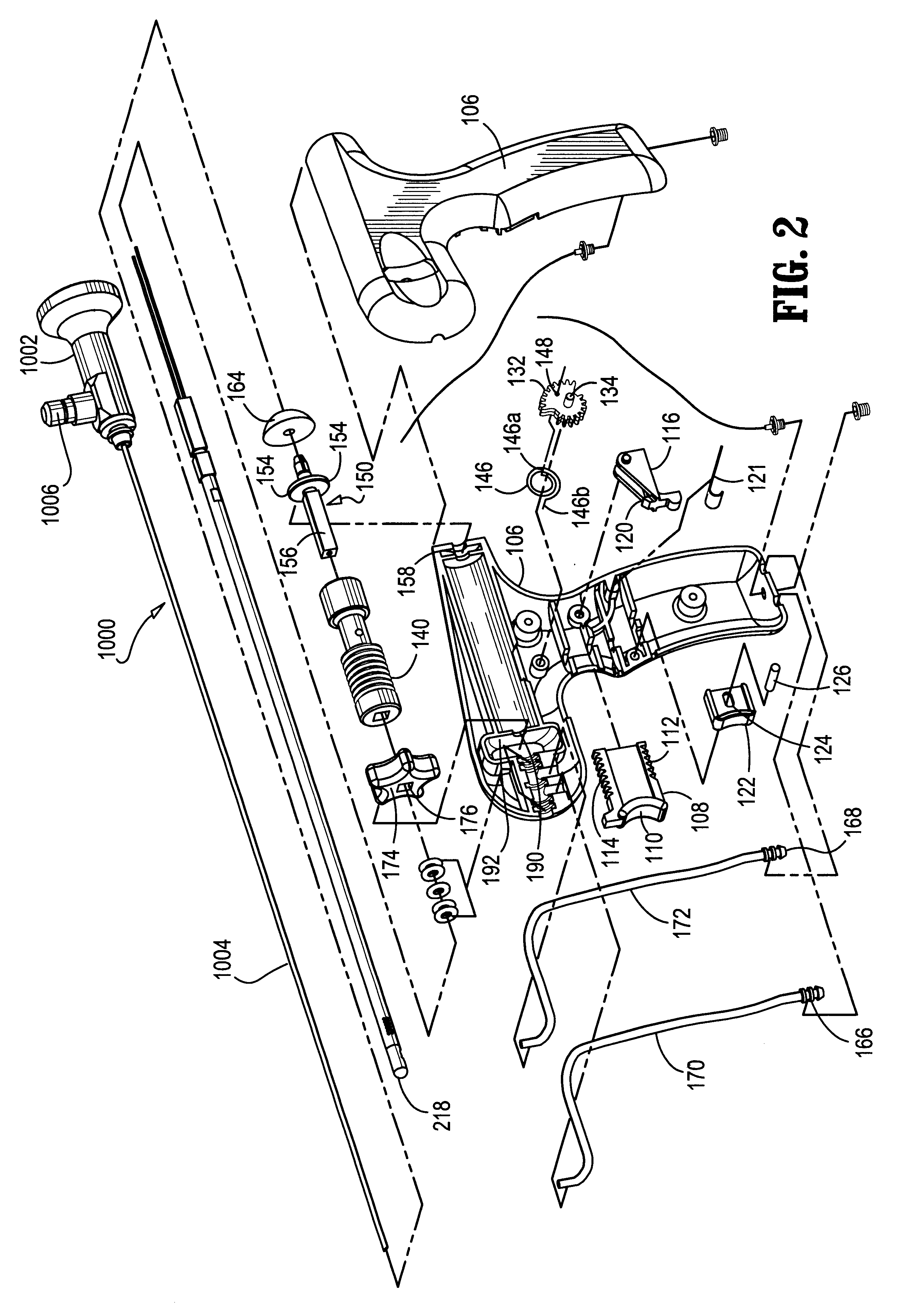

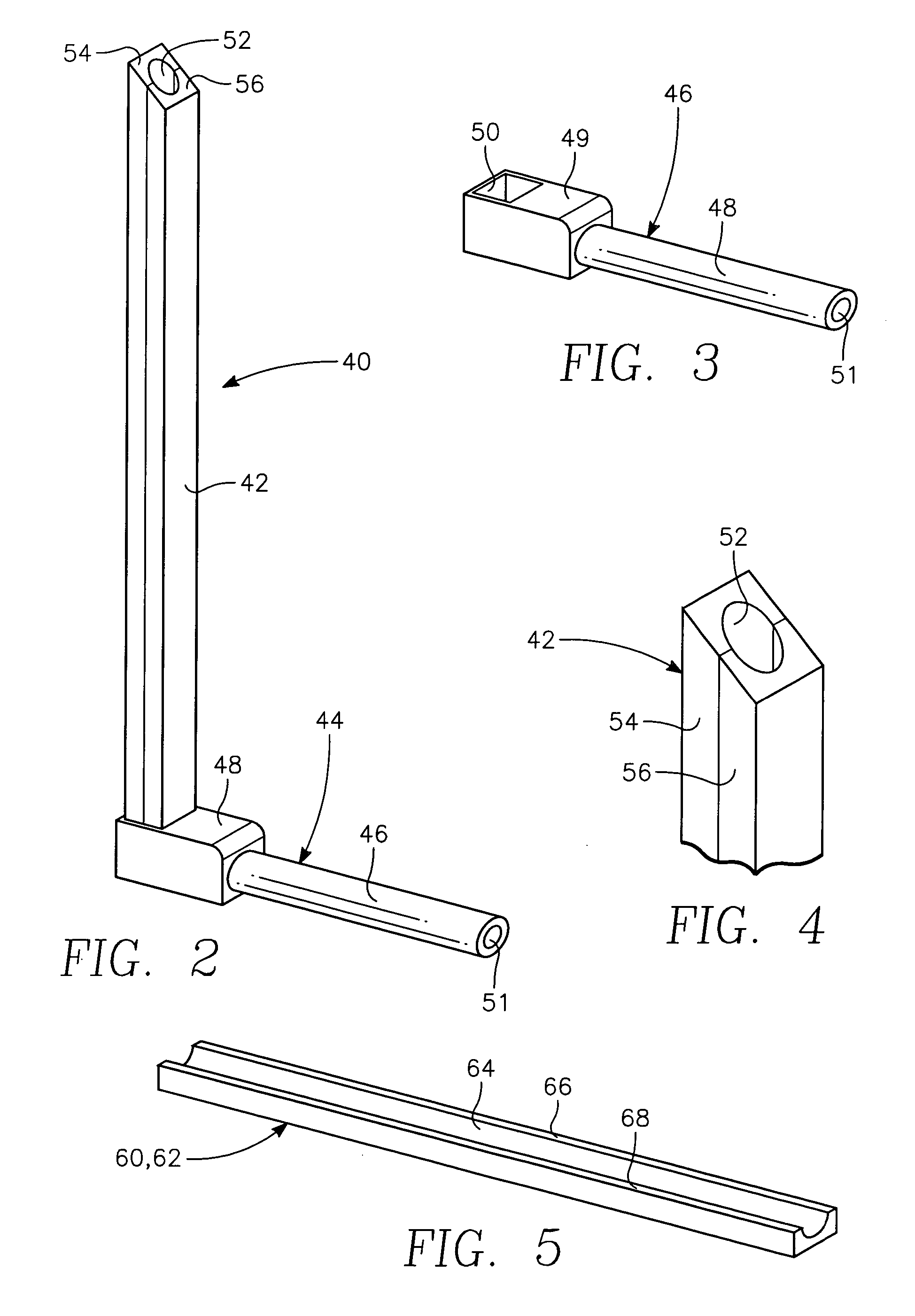

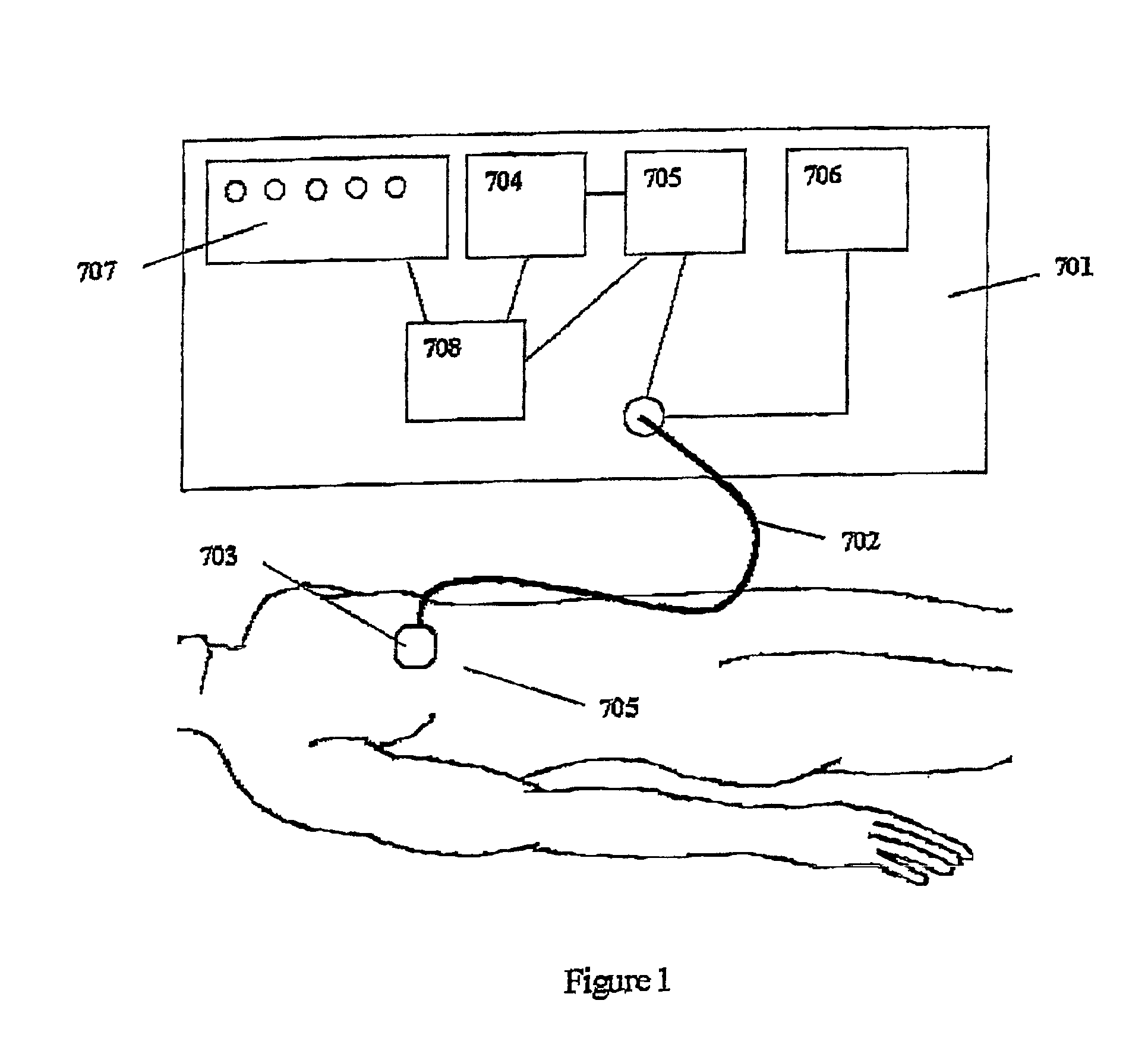

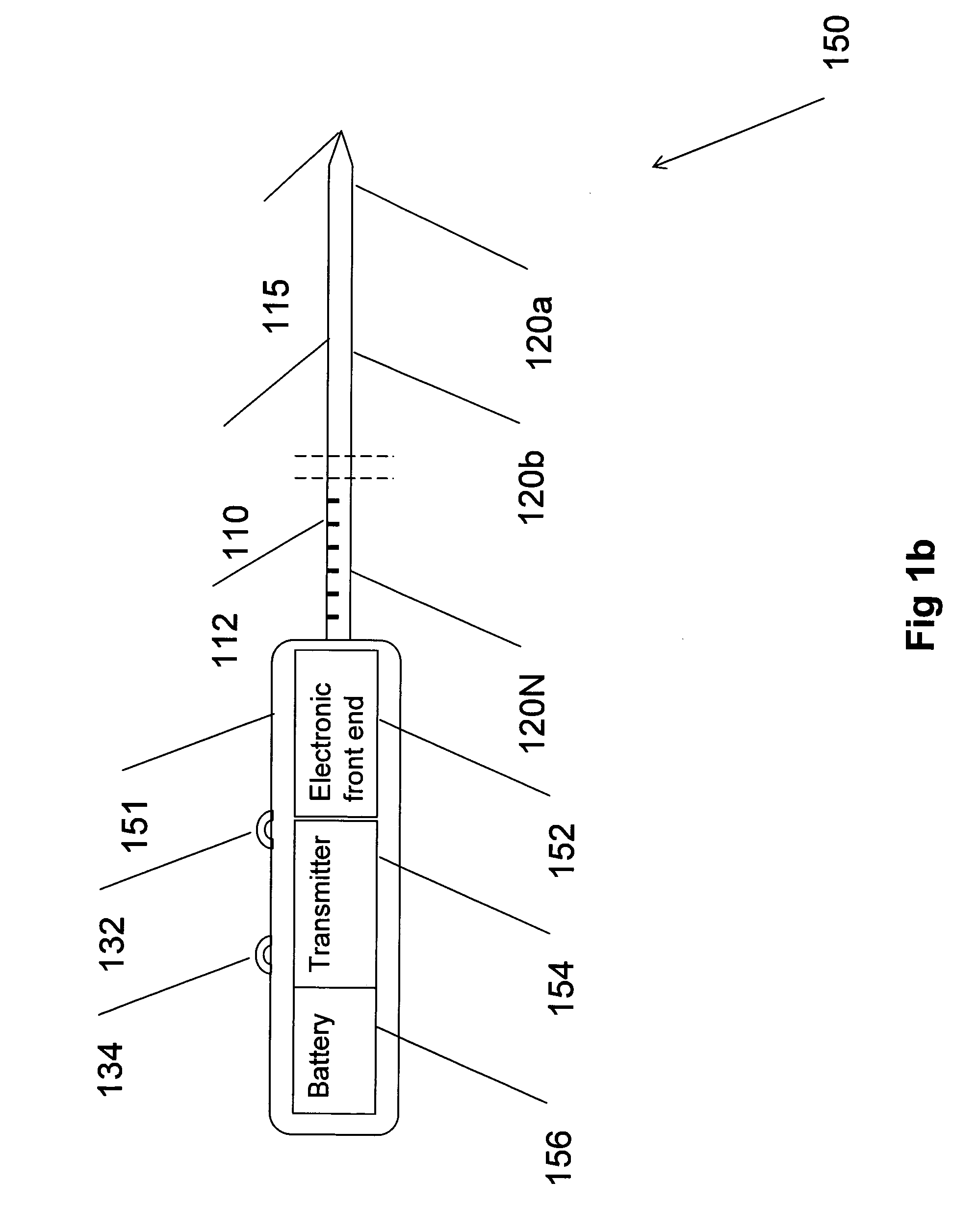

Apparatus and method for thermal treatment of body tissue

An apparatus and method for the thermal treatment of tissue, e.g., prostatic tissue, with RF energy is disclosed. The apparatus includes a handle dimensioned to be grasped with a single hand of a surgeon, an elongated portion extending distally from the handle and defining a longitudinal axis, at least one electrode extending within the elongated portion and movable between a non-deployed position and a fully deployed position, and a trigger mechanism associated with the handle and having a trigger operatively connected to the one electrode. The trigger is movable to selectively and incrementally move the one electrode between the non-deployed position and the fully deployed position. A ratchet mechanism permits movement of the trigger in one direction corresponding to movement of the one electrode toward the fully deployed position while preventing movement of the trigger in a second direction. The elongated portion of the apparatus may be rotatable about the longitudinal axis to reposition the one electrode.

Owner:UNITED STATES SURGICAL CORP

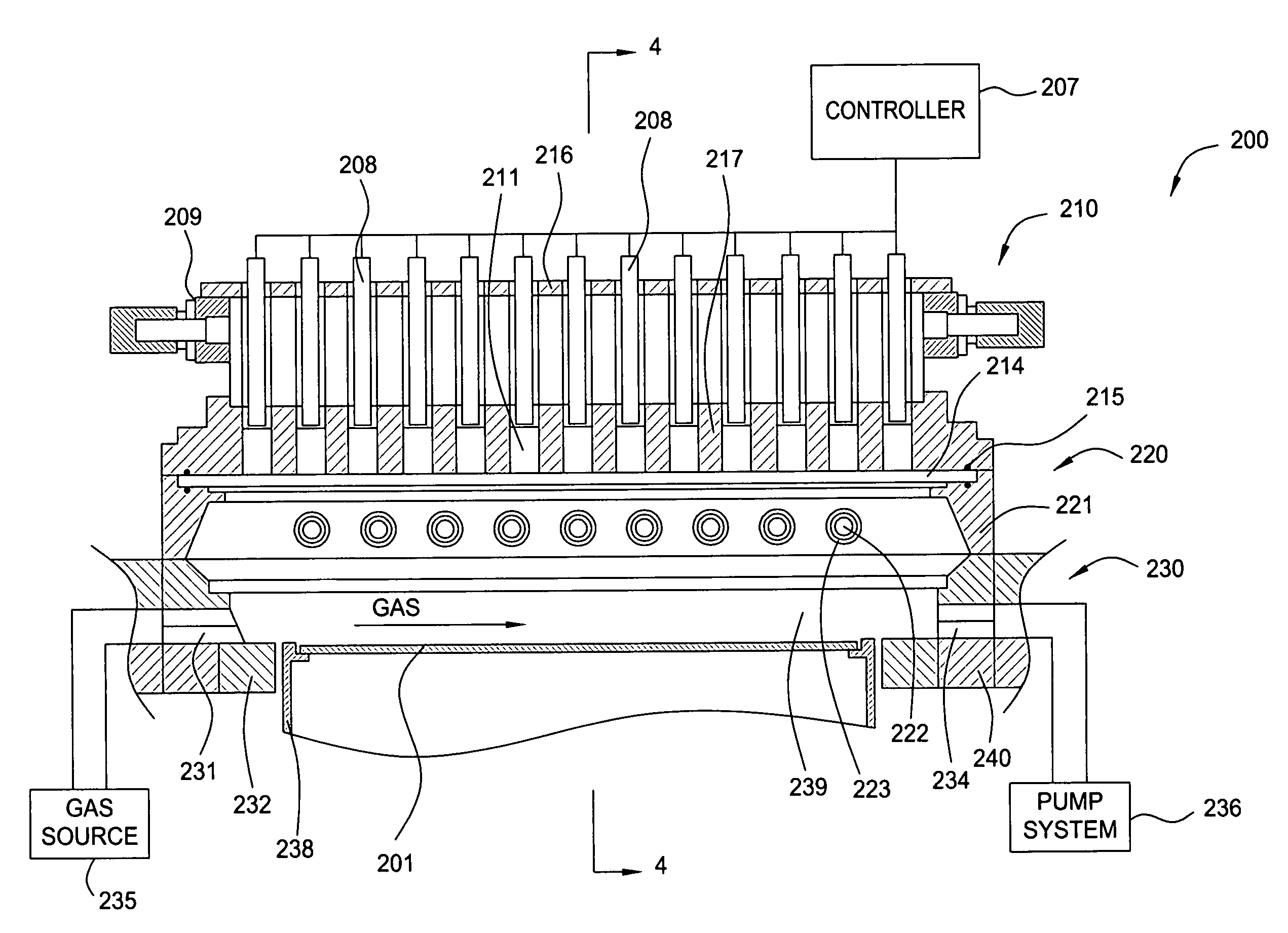

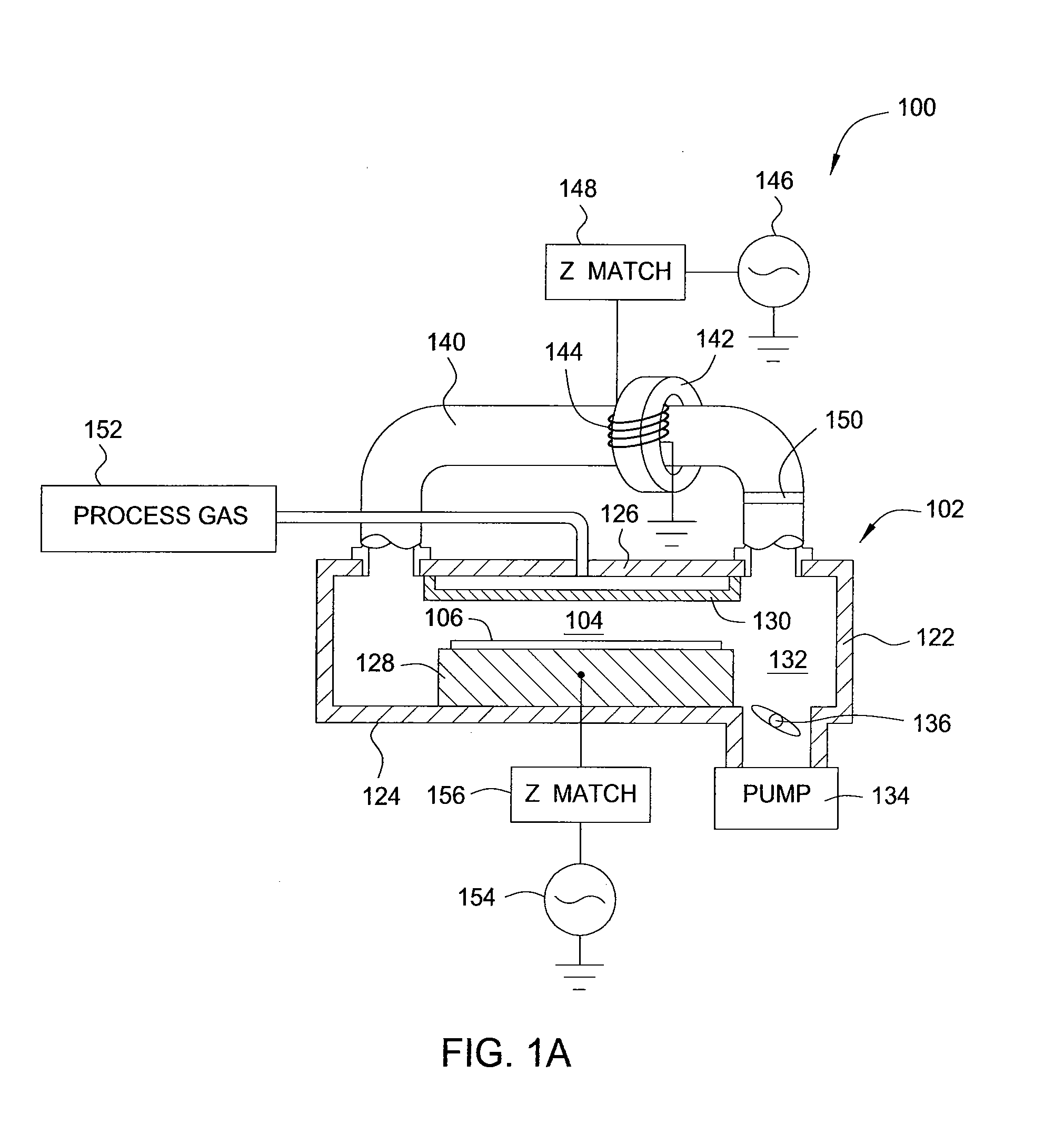

UV assisted thermal processing

InactiveUS7547633B2Material analysis using wave/particle radiationElectric discharge tubesThermodynamicsThermal treatment

The present invention provides methods and apparatus for performing thermal processes to a semiconductor substrate. Thermal processing chambers of the present invention comprise two different energy sources, such as an infrared radiation source and a UV radiation source. The UV radiation source and the infrared radiation source may be used alone or in combination to supply heat, activate electronic, or create active species inside the thermal processing chamber.

Owner:APPLIED MATERIALS INC

Removal of surface dopants from a substrate

InactiveUS20090162996A1Semiconductor/solid-state device detailsSolid-state devicesDopantHigh concentration

A method and apparatus for removing excess dopant from a doped substrate is provided. In one embodiment, a substrate is doped by surfaced deposition of dopant followed by formation of a capping layer and thermal diffusion drive-in. A reactive etchant mixture is provided to the process chamber, with optional plasma, to etch away the capping layer and form volatile compounds by reacting with excess dopant. In another embodiment, a substrate is doped by energetic implantation of dopant. A reactive gas mixture is provided to the process chamber, with optional plasma, to remove excess dopant adsorbed on the surface and high-concentration dopant near the surface by reacting with the dopant to form volatile compounds. The reactive gas mixture may be provided during thermal treatment, or it may be provided before or after at temperatures different from the thermal treatment temperature. The volatile compounds are removed. Substrates so treated do not form toxic compounds when stored or transported outside process equipment.

Owner:APPLIED MATERIALS INC

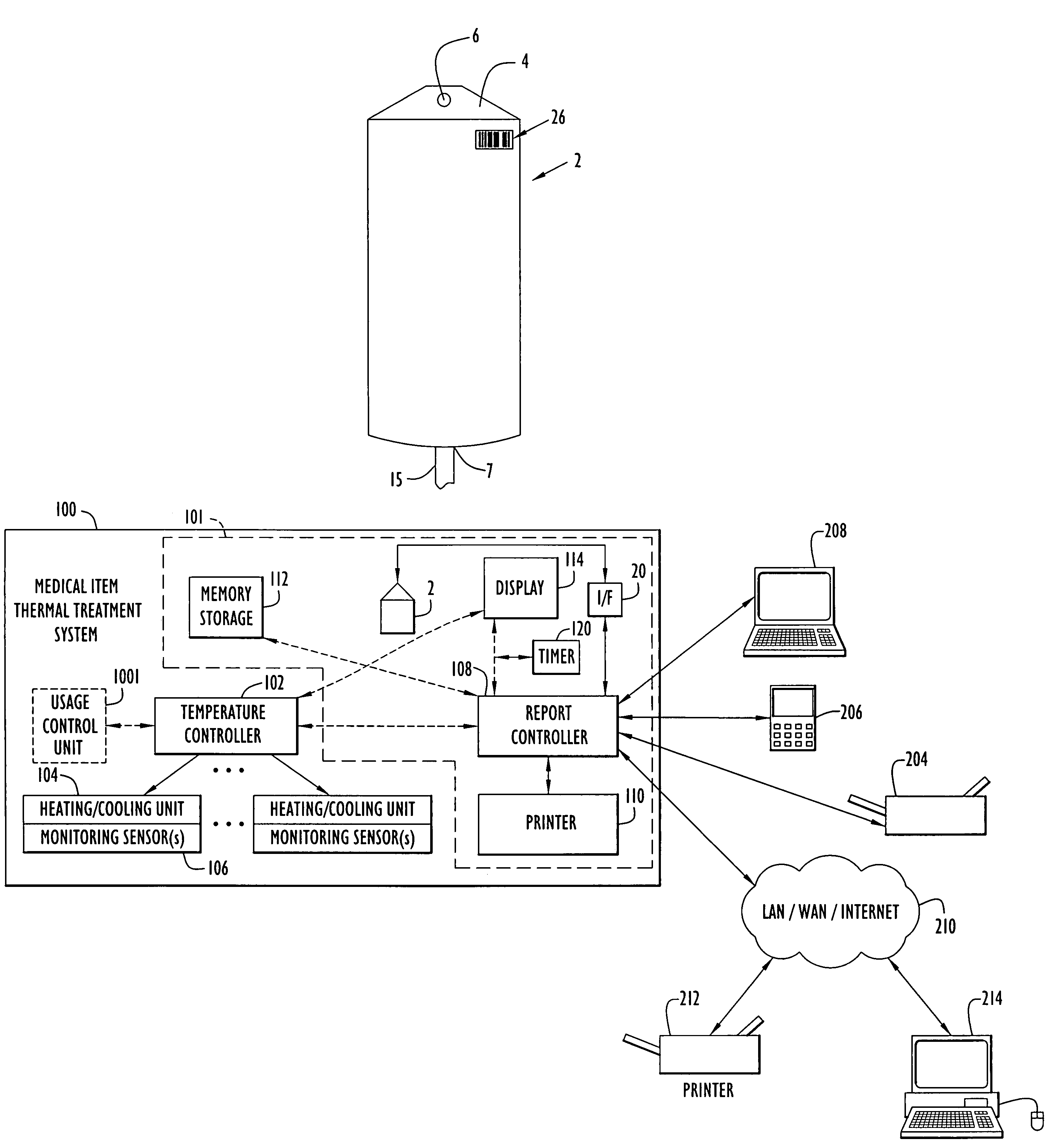

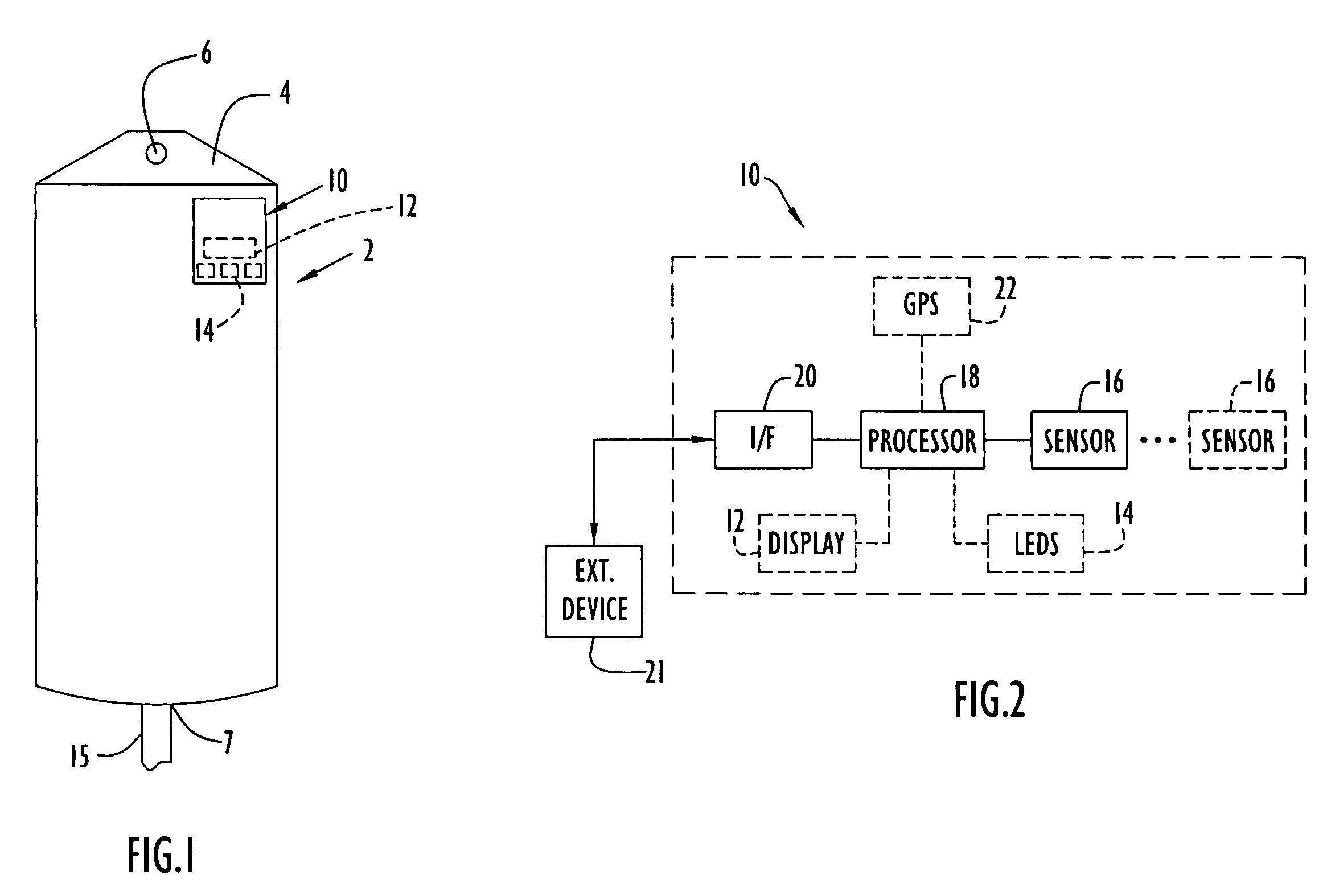

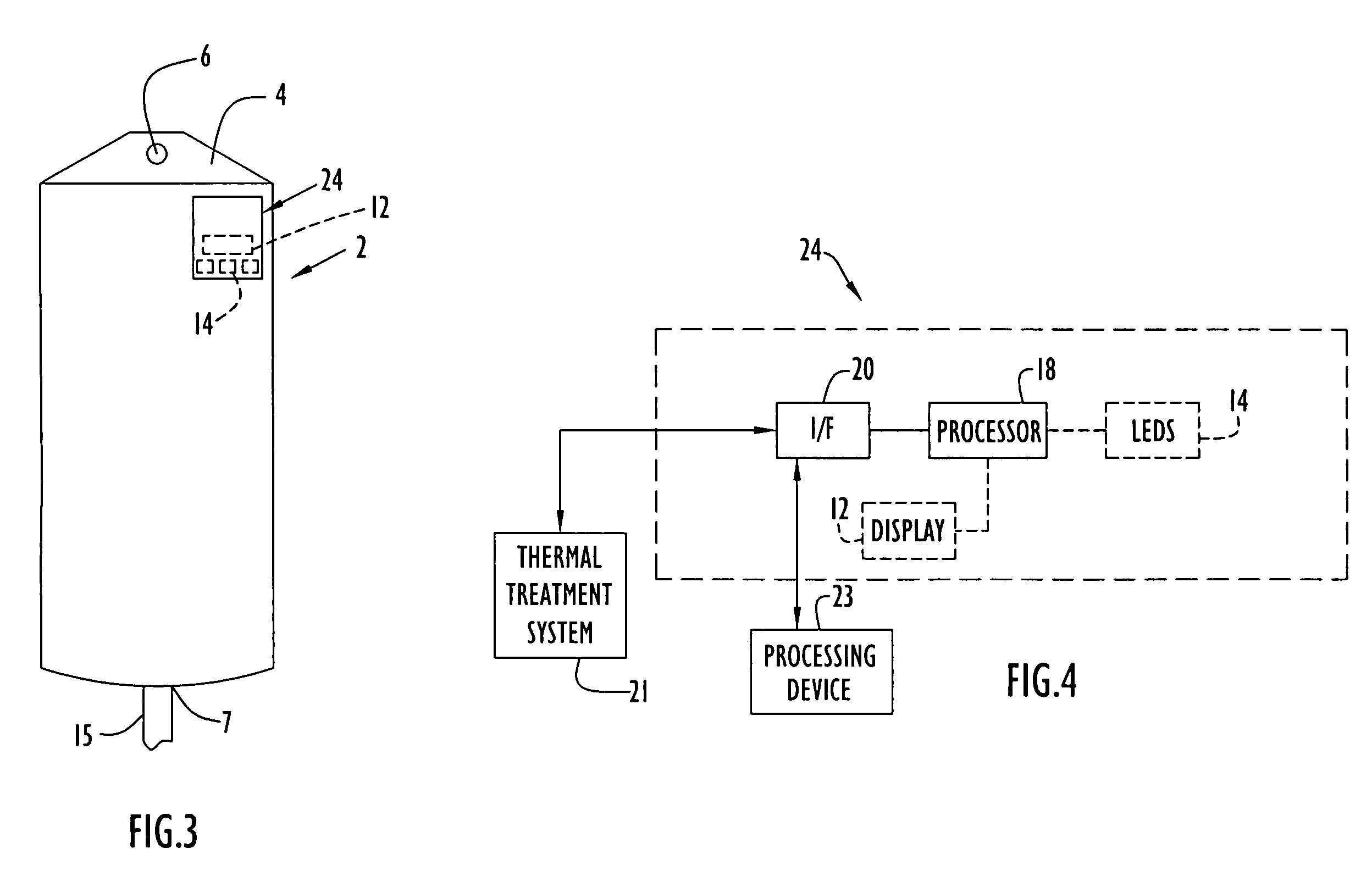

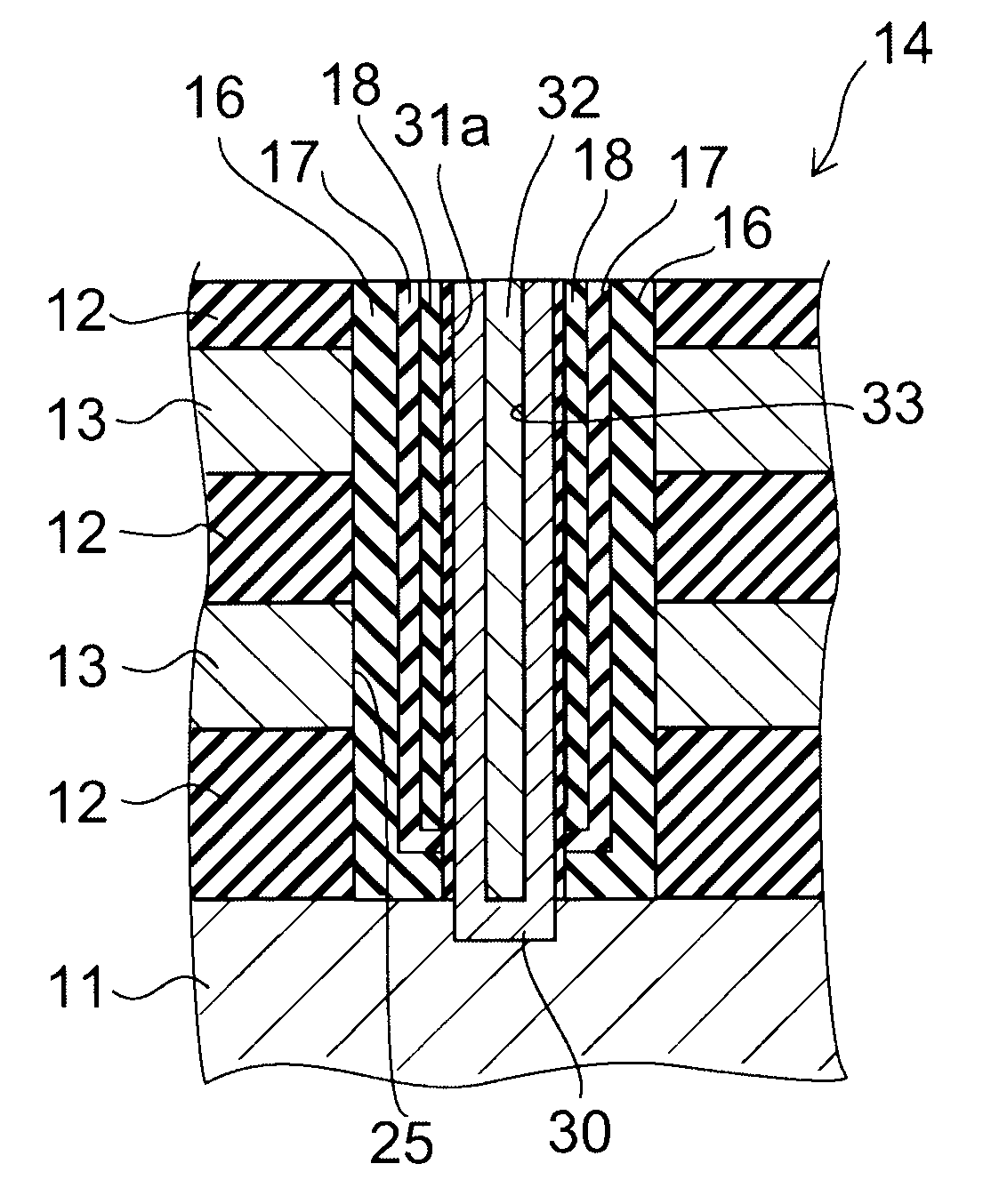

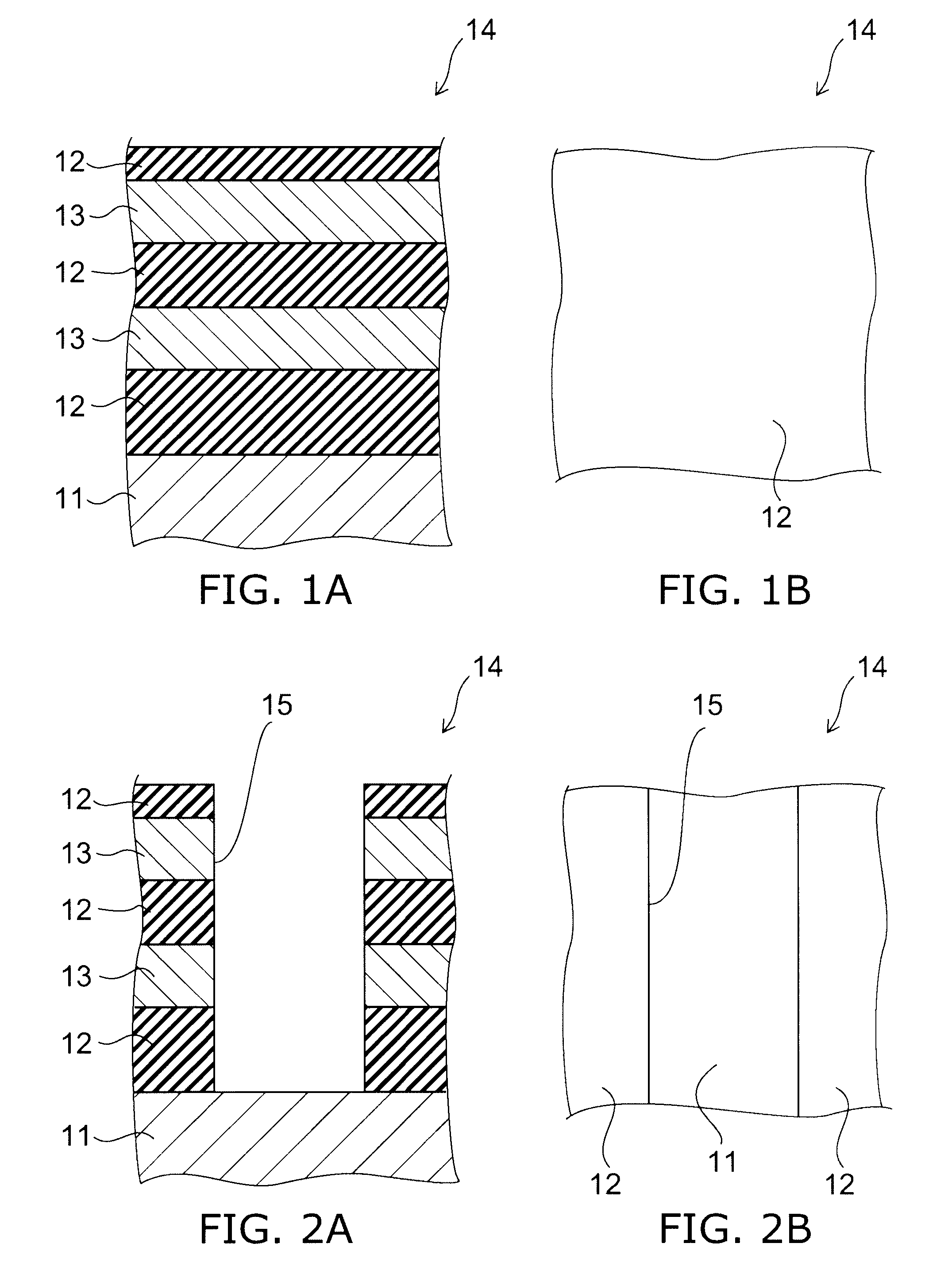

Medical item thermal treatment systems and method of monitoring medical items for compliance with prescribed requirements

Various present invention devices enable adherence to requirements for medical items. A medical item of the present invention includes a monitoring or data recording device to monitor and / or record medical solution conditions. The device may further include indicators to indicate compliance of the medical solution with prescribed requirements (e.g., manufacturer, medical standard or regulation, etc.). The medical item may alternatively include a barcode or transponder to uniquely identify the medical item to a thermal treatment system measuring and storing conditions in a central database. The present invention further includes various thermal treatment systems that monitor medical items for prescribed requirements and display the monitored parameters to medical personnel. In addition, the present invention may place time stamp information on medical items to enable determination by medical personnel of compliance with prescribed requirements.

Owner:PATENTED MEDICAL SOLUTIONS LLC

Nonvolatile semiconductor memory device and method for manufacturing the same

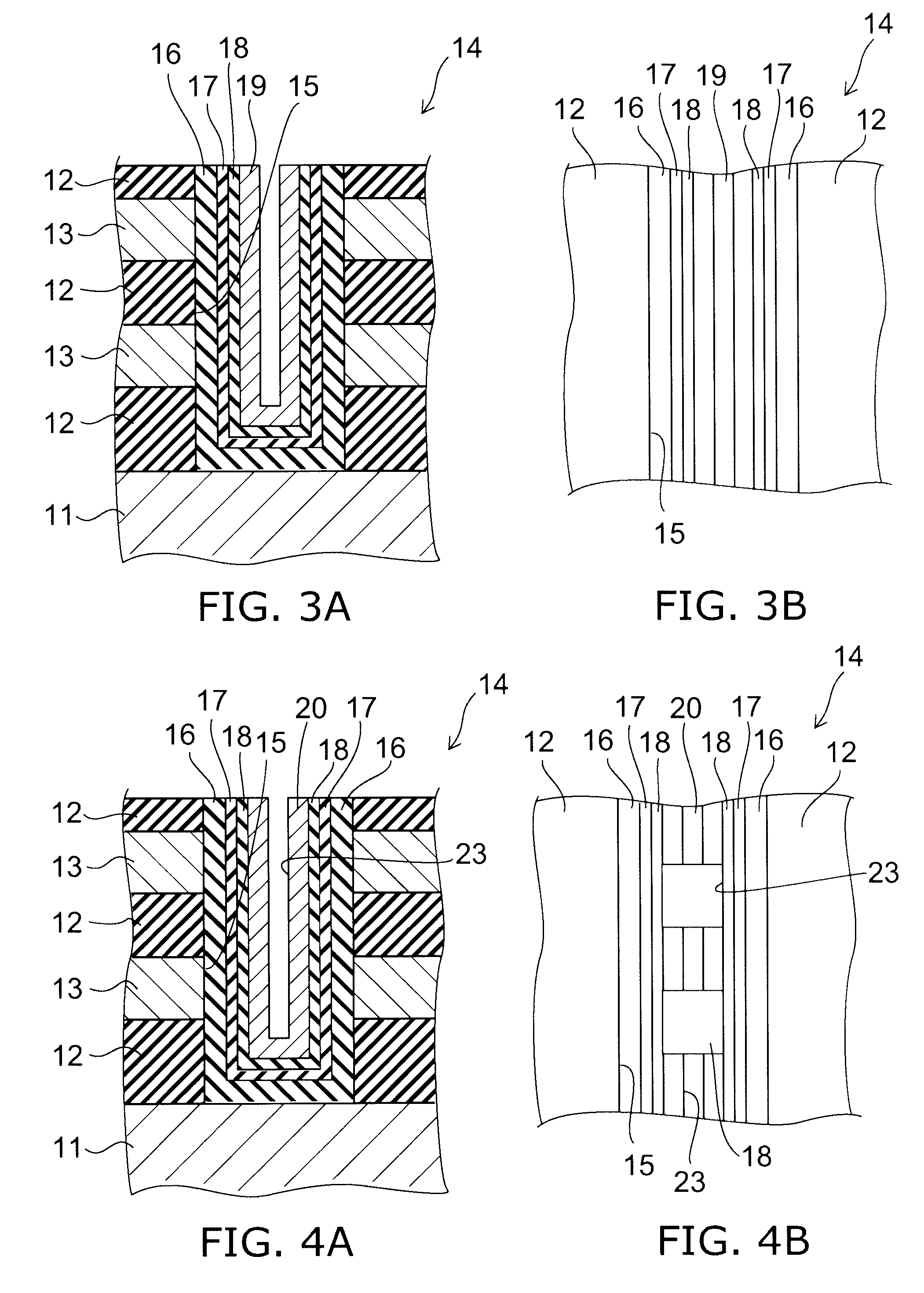

ActiveUS20100140684A1Solid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideThermal treatment

On a silicon substrate is formed a stacked body by alternately stacking a plurality of silicon oxide films and silicon films, a trench is formed in the stacked body, an alumina film, a silicon nitride film and a silicon oxide film are formed in this order on an inner surface of the trench, and a channel silicon crystalline film is formed on the silicon oxide film. Next, a silicon oxide layer is formed at an interface between the silicon oxide film and the channel silicon crystalline film by performing thermal treatment in an oxygen gas atmosphere.

Owner:KIOXIA CORP

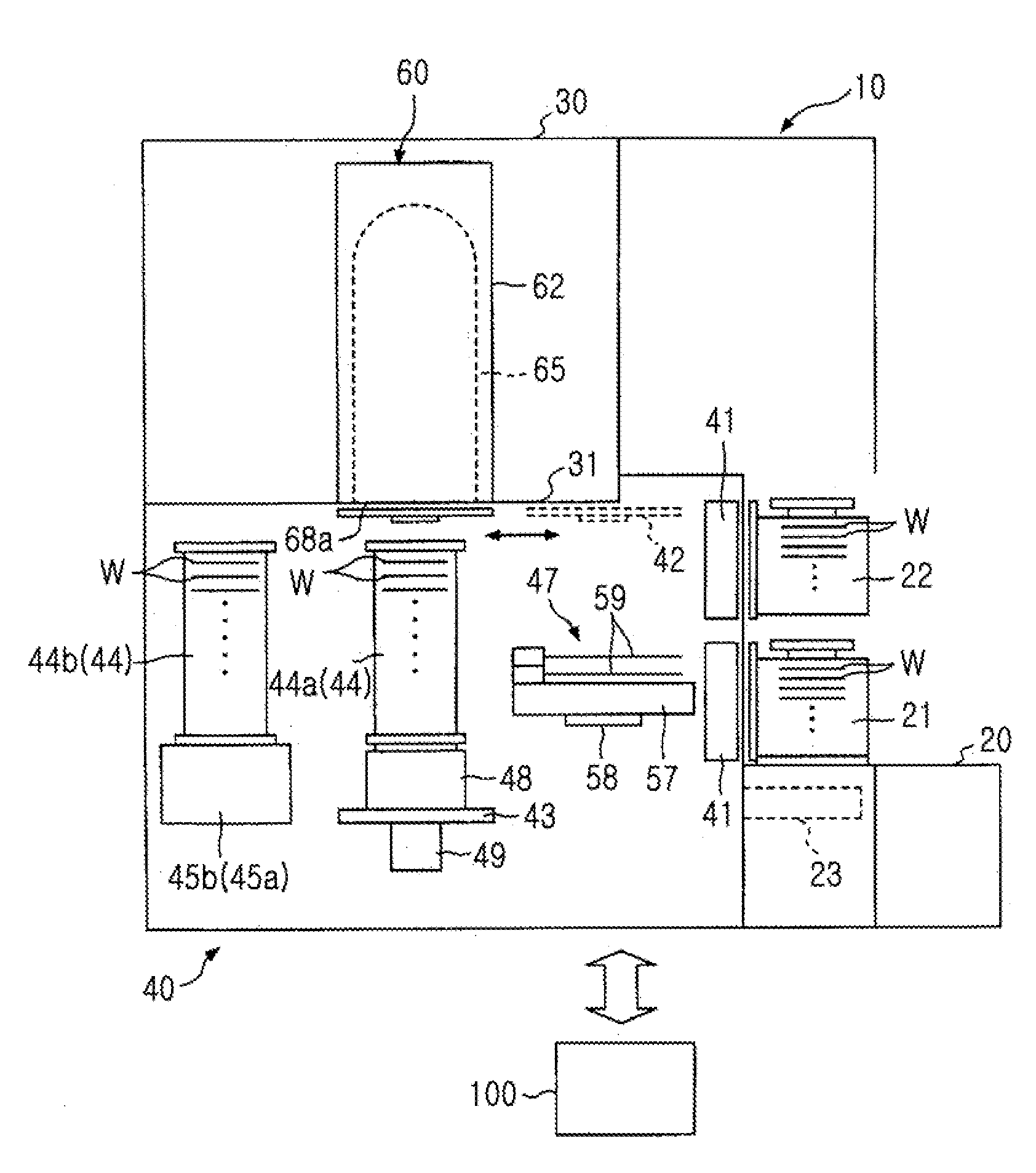

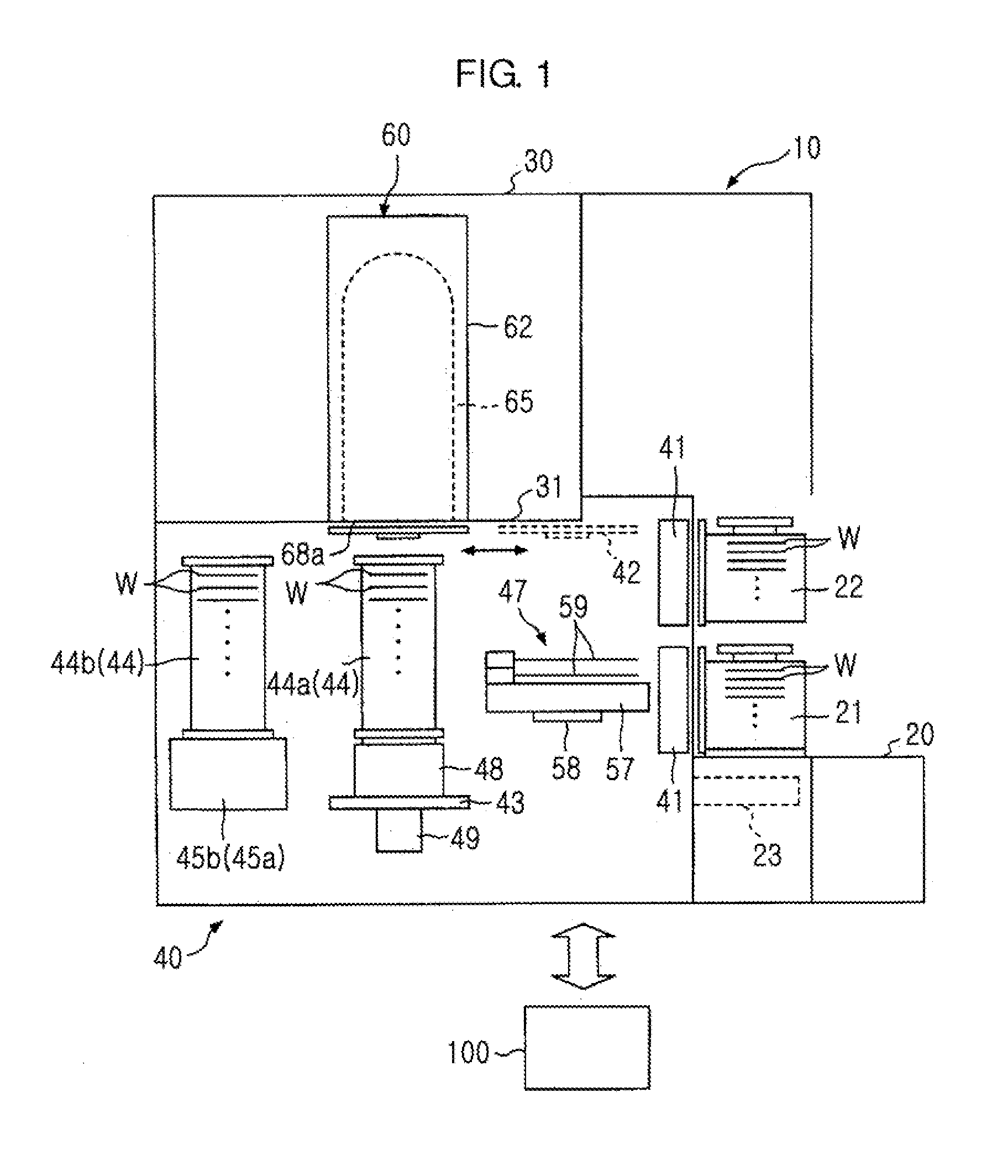

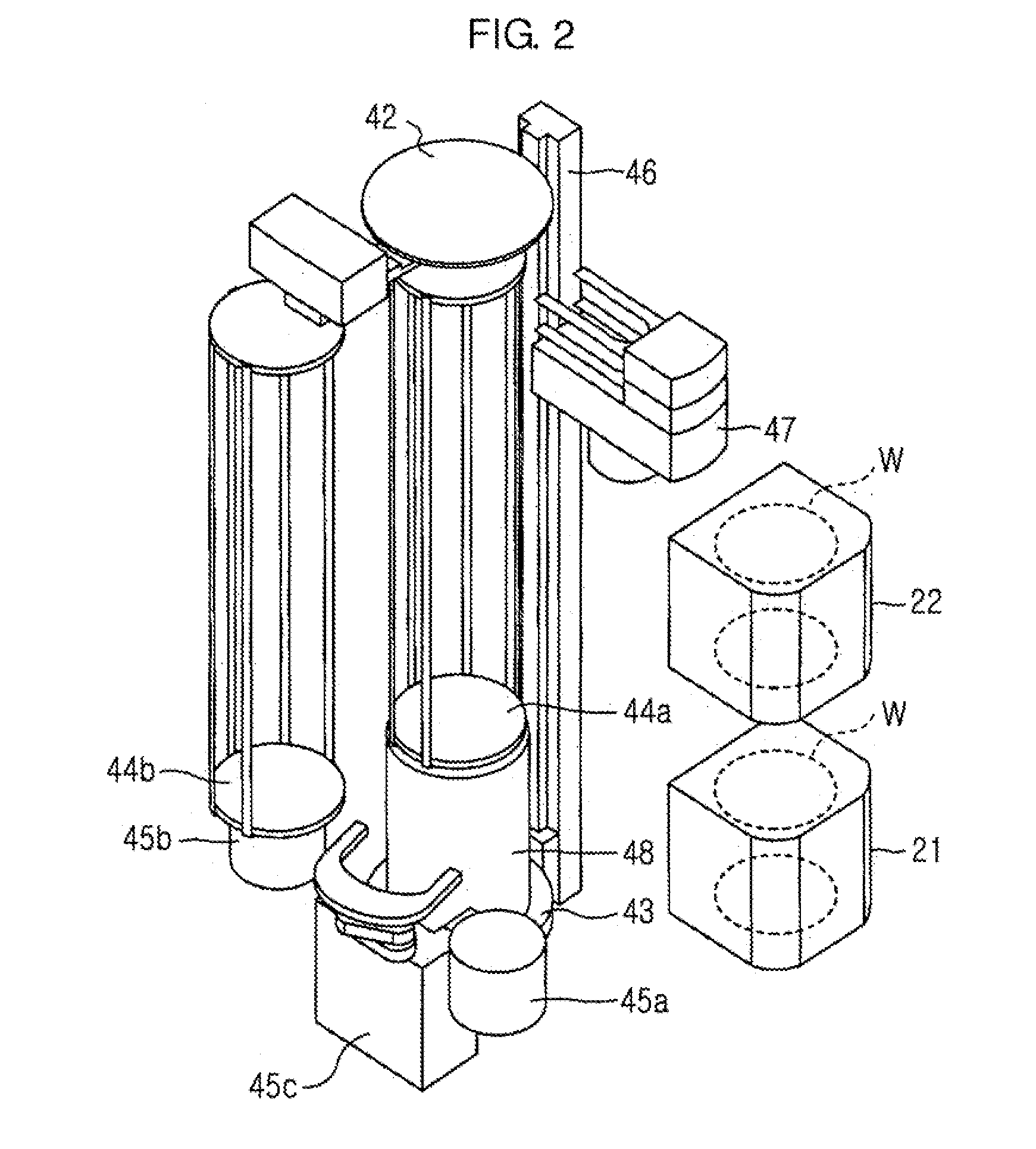

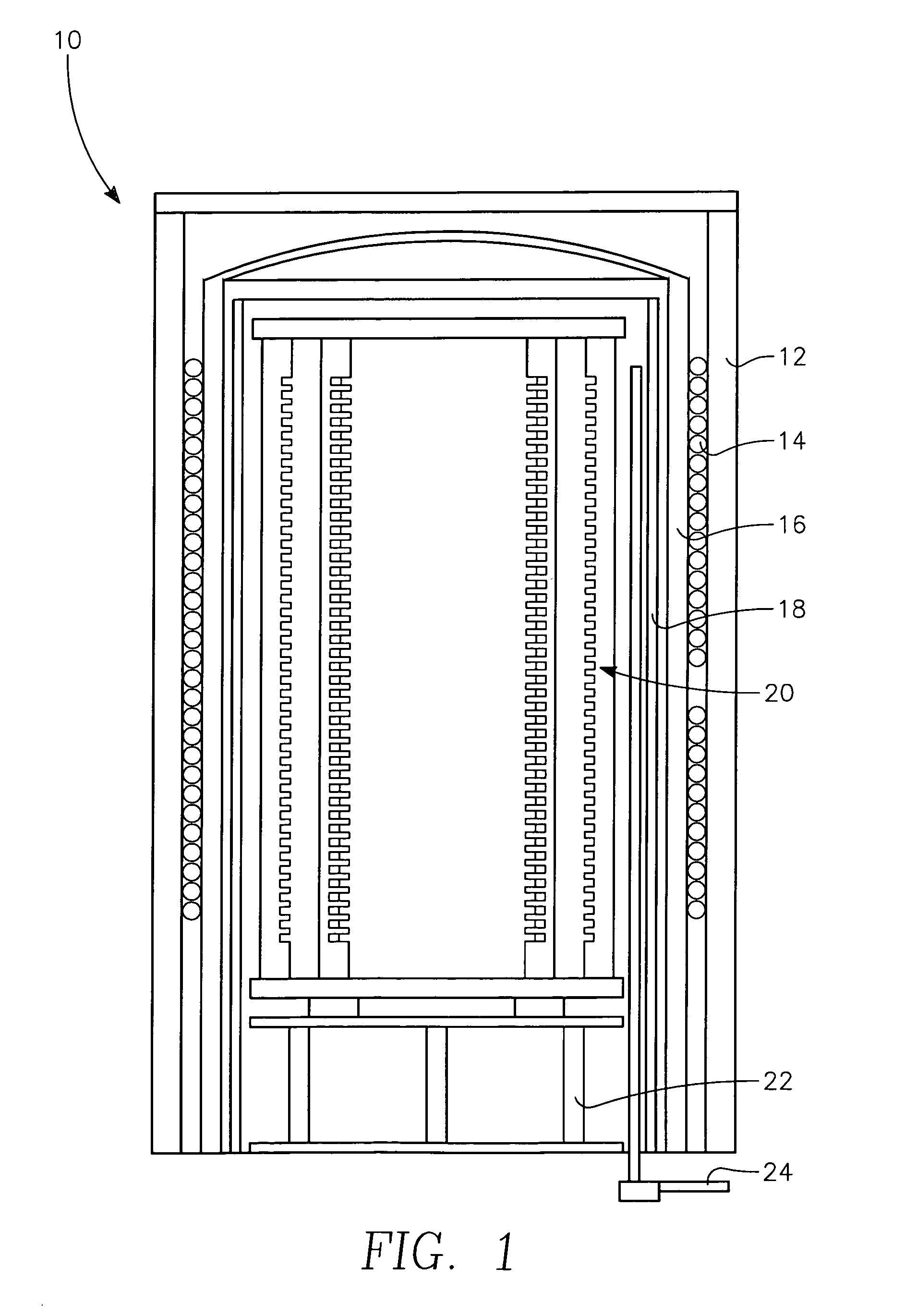

Thermal treatment apparatus, temperature control system, thermal treatment method, temperature control method, and non-transitory computer readable medium embodied with program for executing the thermal treatment method or the temperature control method

InactiveUS20130065189A1Avoid it happening againIncrease power consumptionSemiconductor/solid-state device manufacturingCharge manipulationControl flowTemperature control

A thermal treatment apparatus includes a processing container, a substrate holding unit for holding a plurality of substrates at predetermined intervals in a direction inside the processing container, a heating unit for heating the processing container, a supply unit for supplying gas, a plurality of supply ports provided respectively at different locations in the direction, and a cooling unit for cooling the processing container by supplying the gas into the processing container by the supply unit via each of the supply ports, wherein the supply unit is provided in such a way that the supply unit independently controls flow rates of the gases supplied via each of the supply ports.

Owner:TOKYO ELECTRON LTD

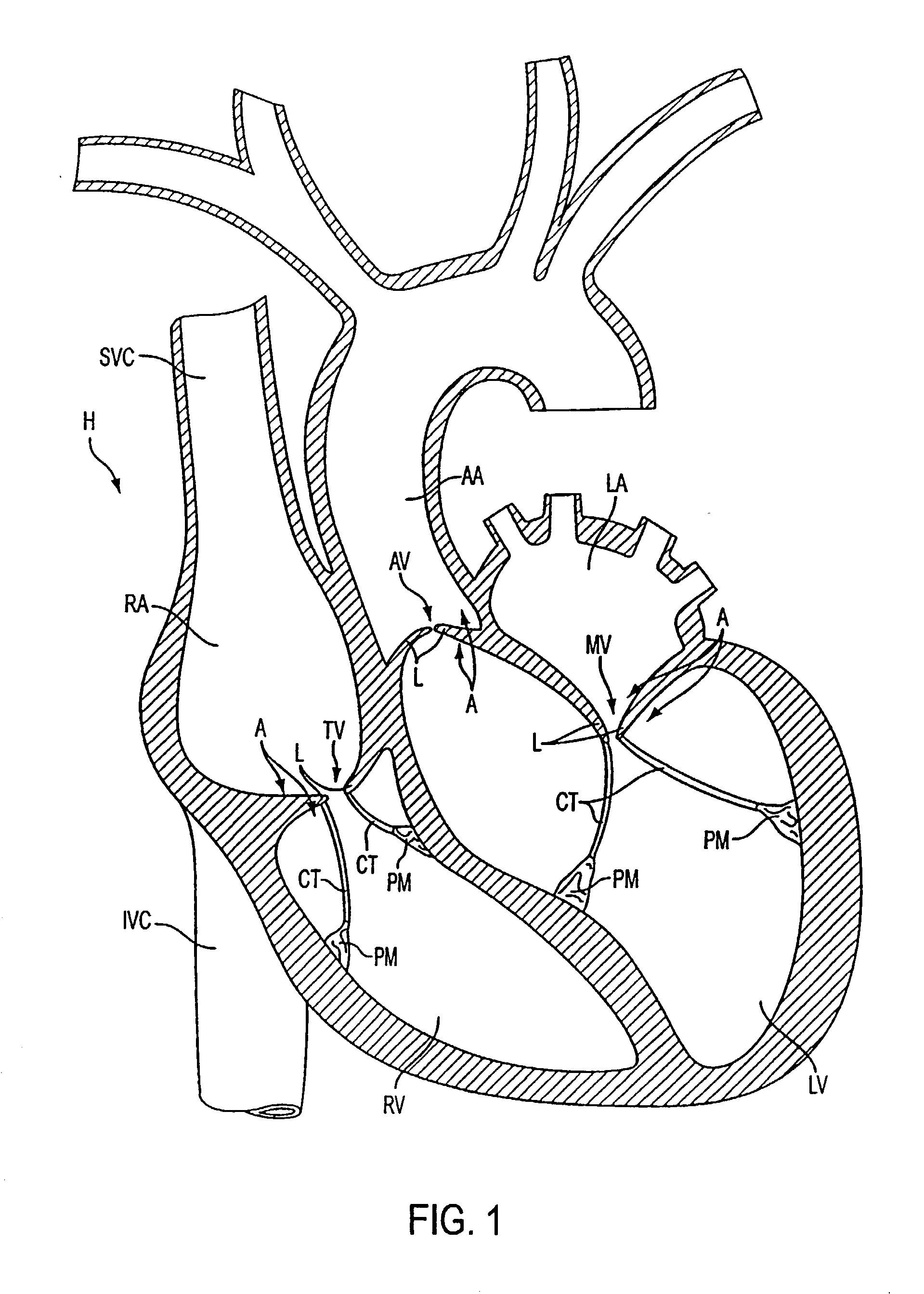

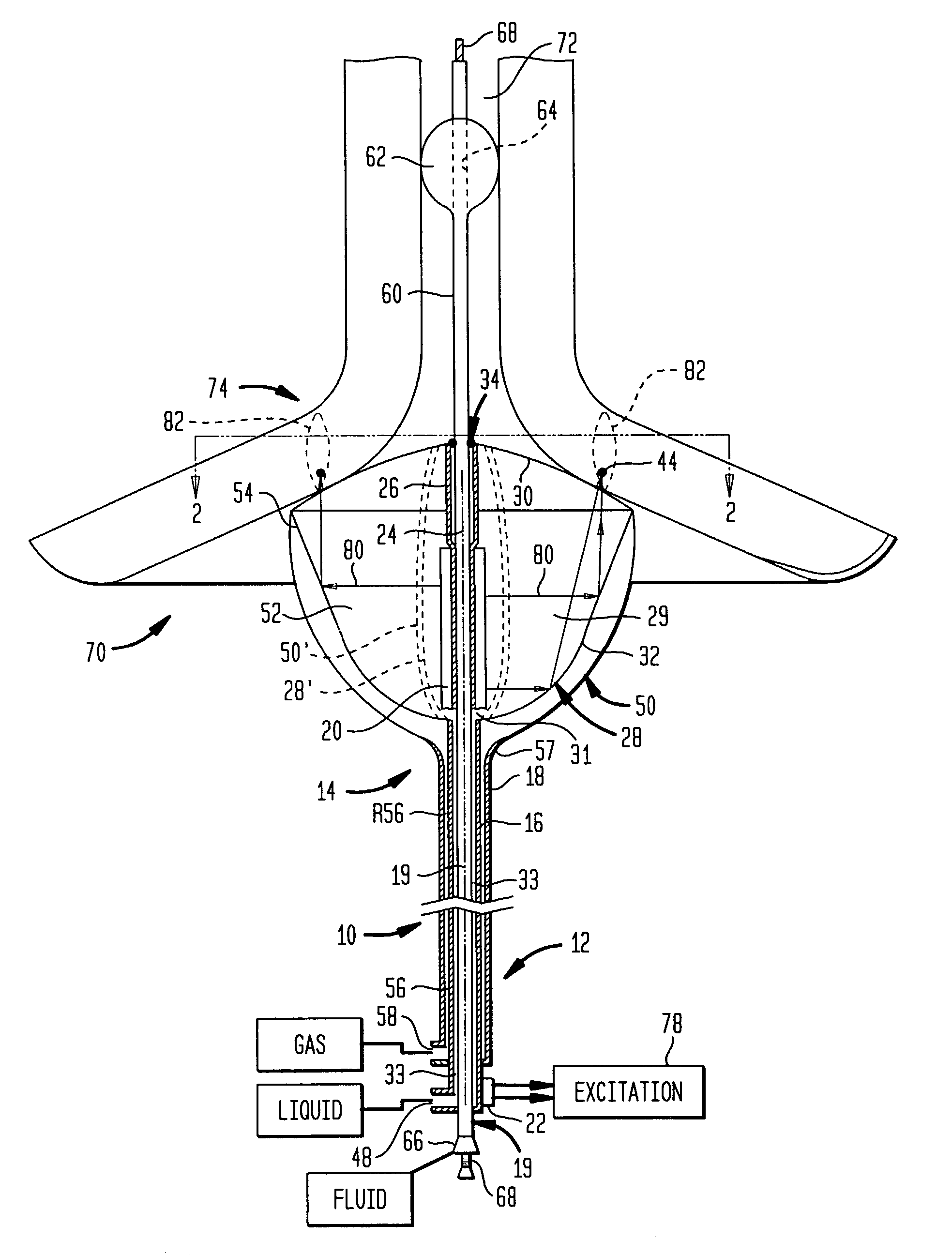

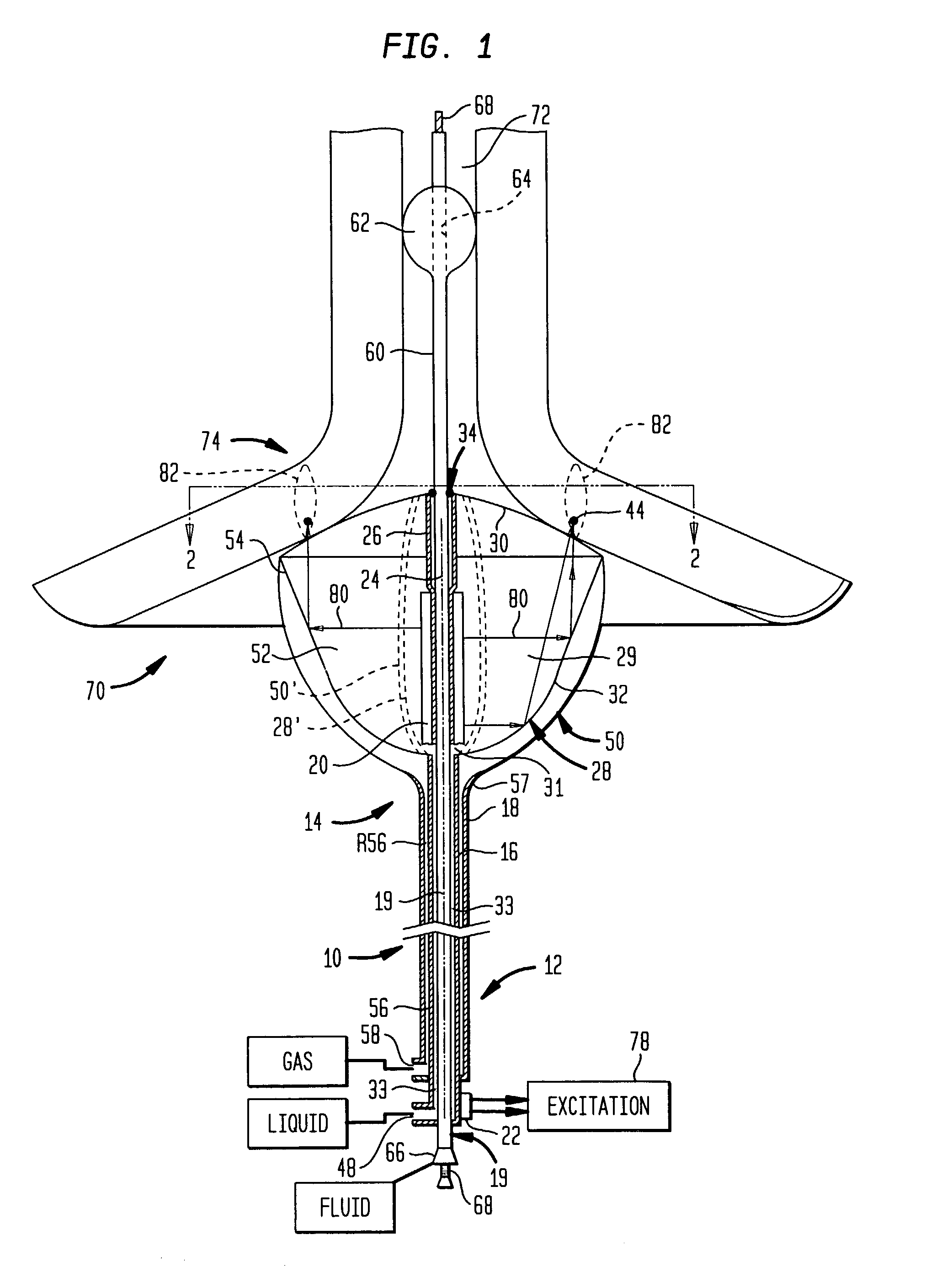

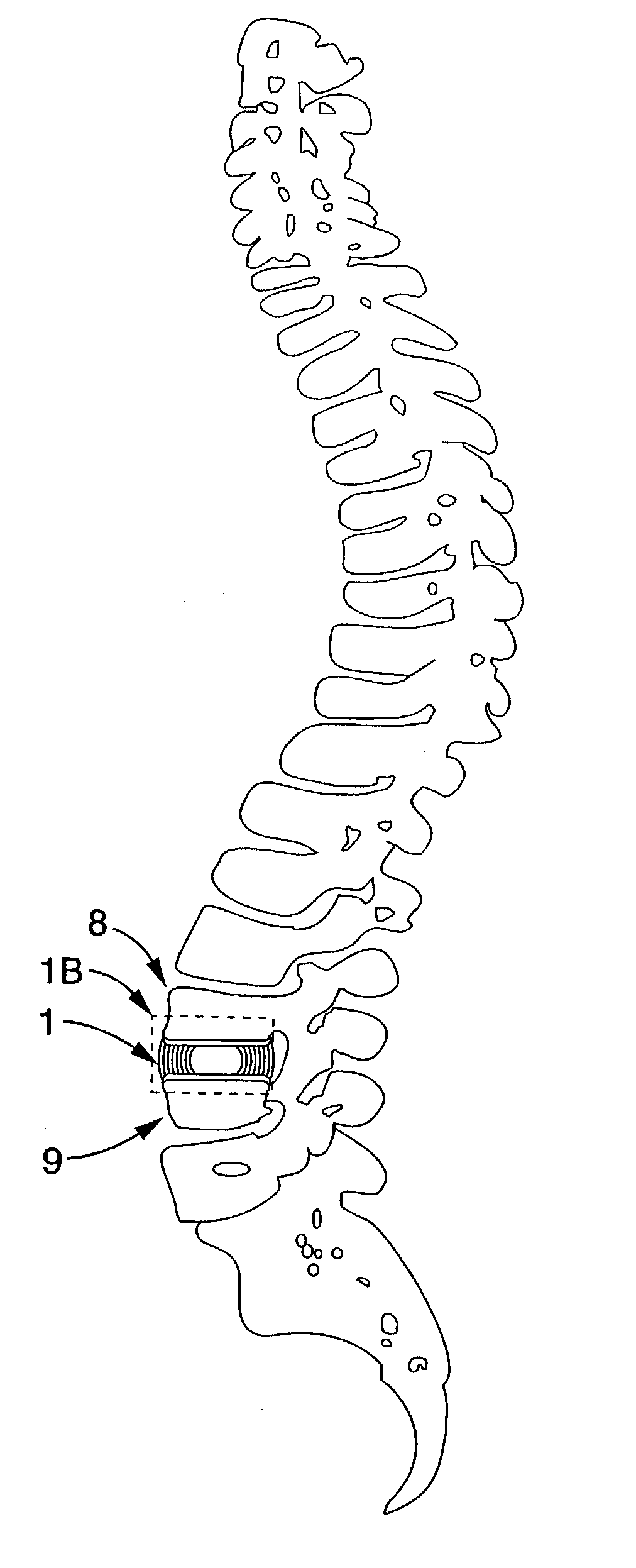

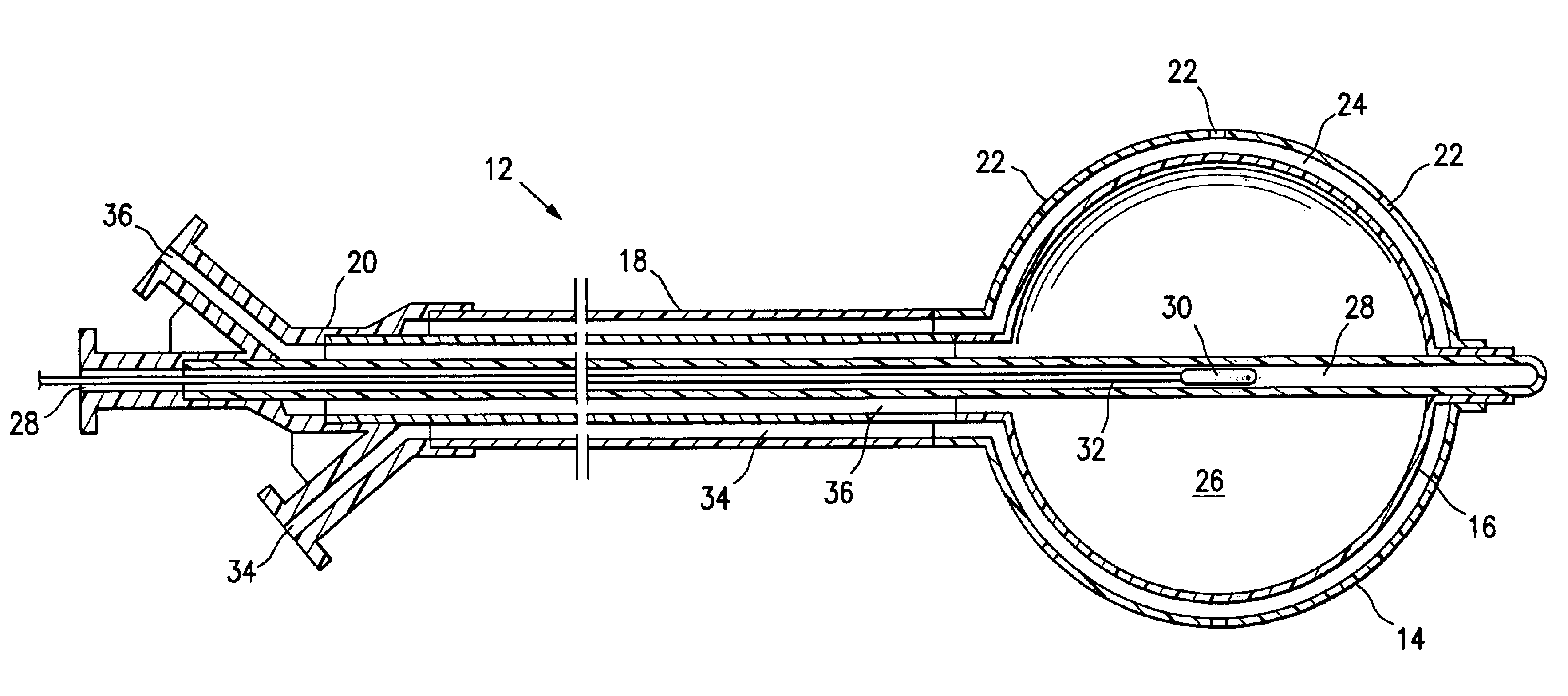

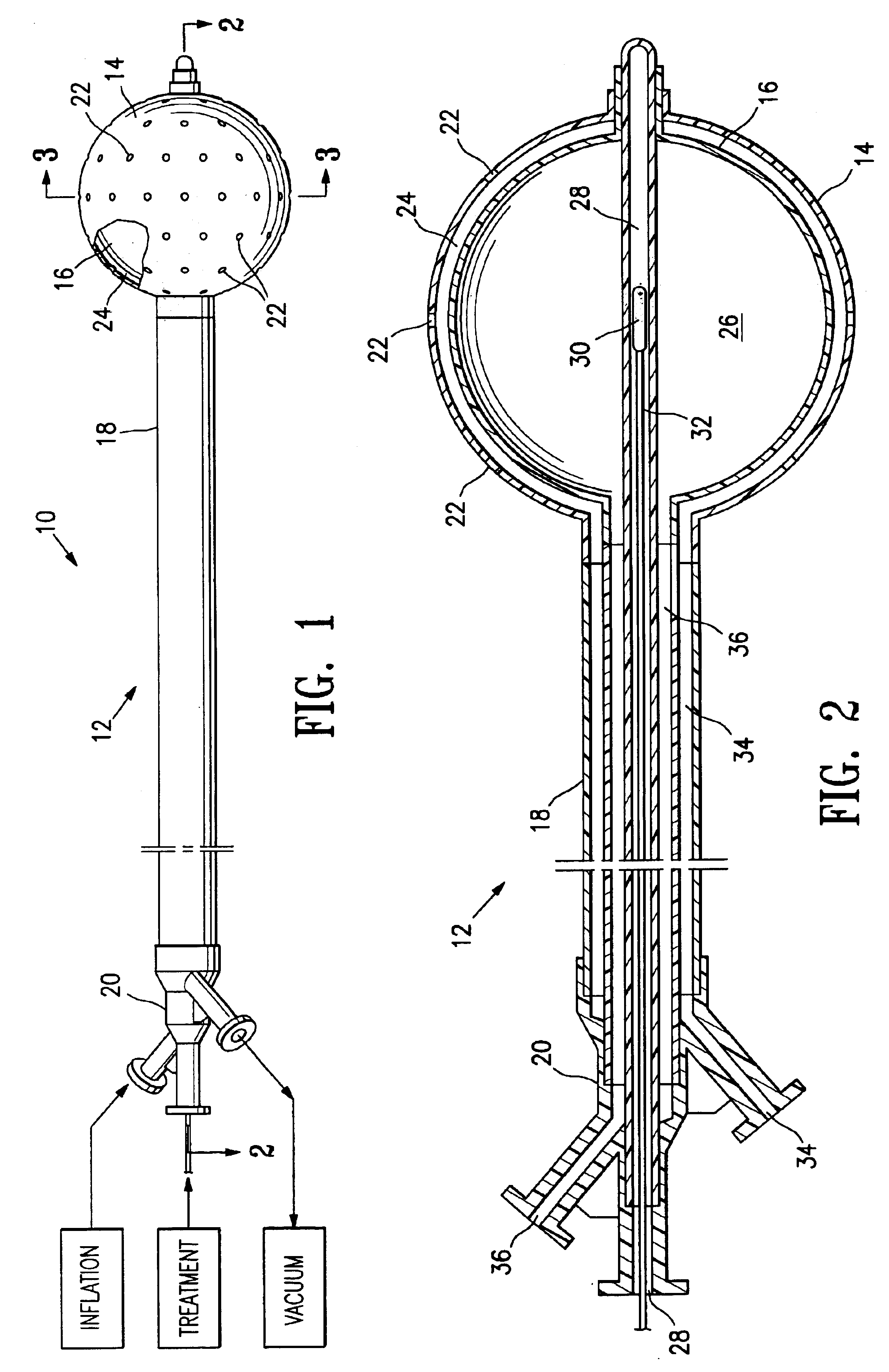

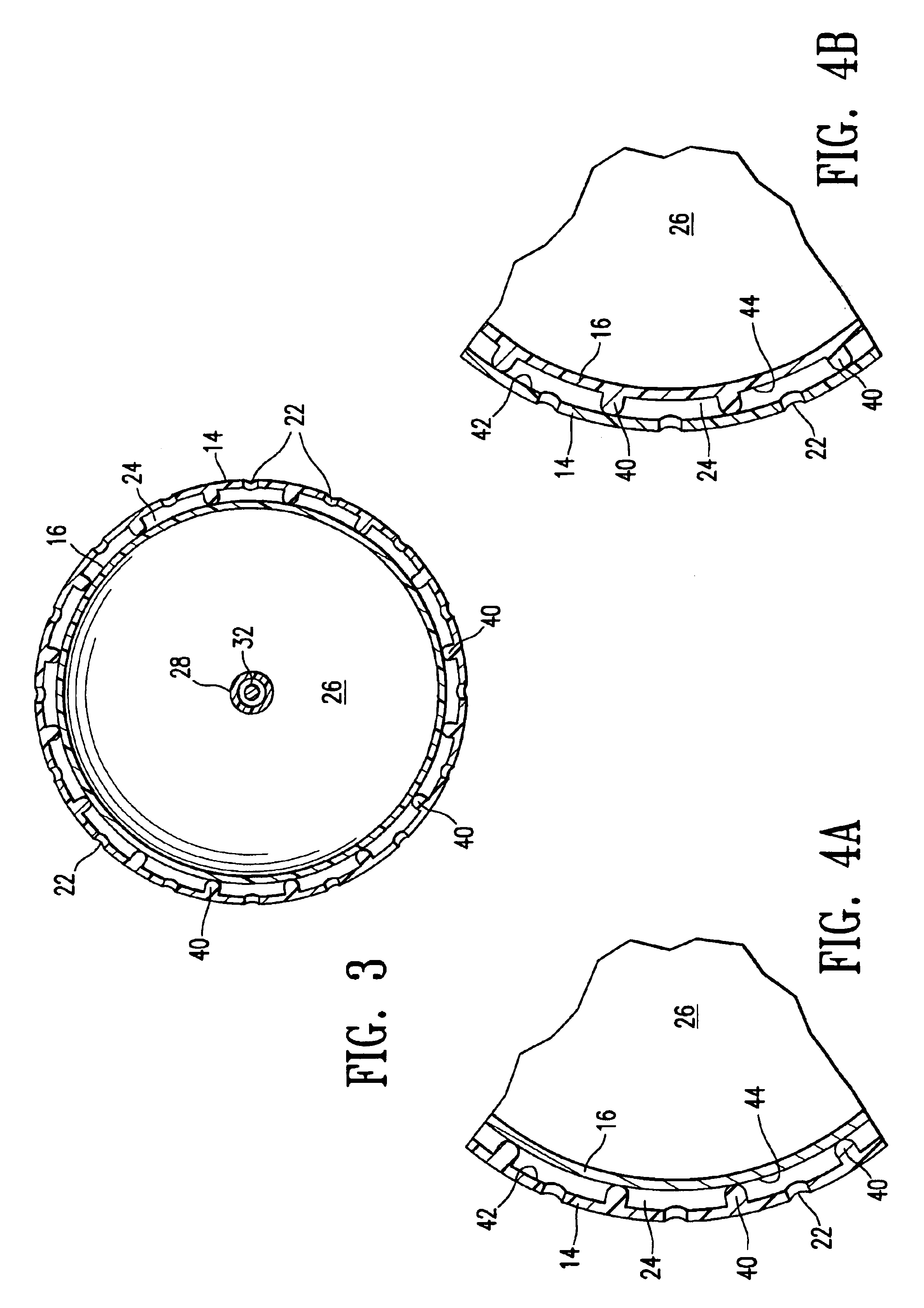

Thermal treatment methods and apparatus with focused energy application

InactiveUS7083614B2Minimize reflectionCollapse of structureUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyMedicineAcoustic energy

A collapsible ultrasonic reflector incorporates a gas-filled reflector balloon, a liquid-filled structural balloon an ultrasonic transducer disposed within the structural balloon. Acoustic energy emitted by the transducer is reflected by a highly reflective interface between the balloons. In a cardiac ablation procedure, the ultrasonic energy is focused into an annular focal region to ablate cardiac tissue extending in an annular path along the wall. Devices for stabilizing the balloon structure and for facilitating collapse and withdrawal of the balloon structure are also disclosed.

Owner:BOSTON SCI SCIMED INC +1

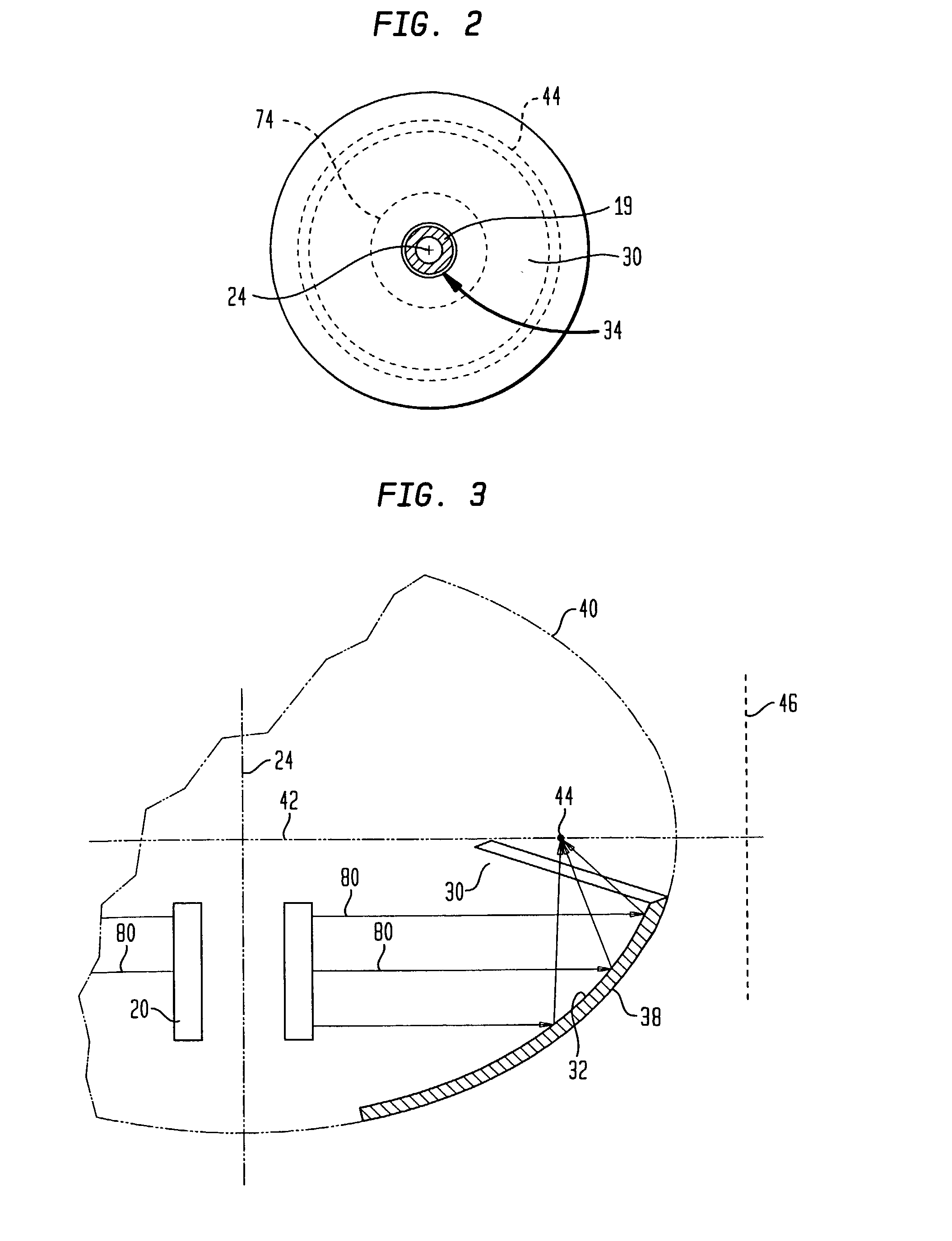

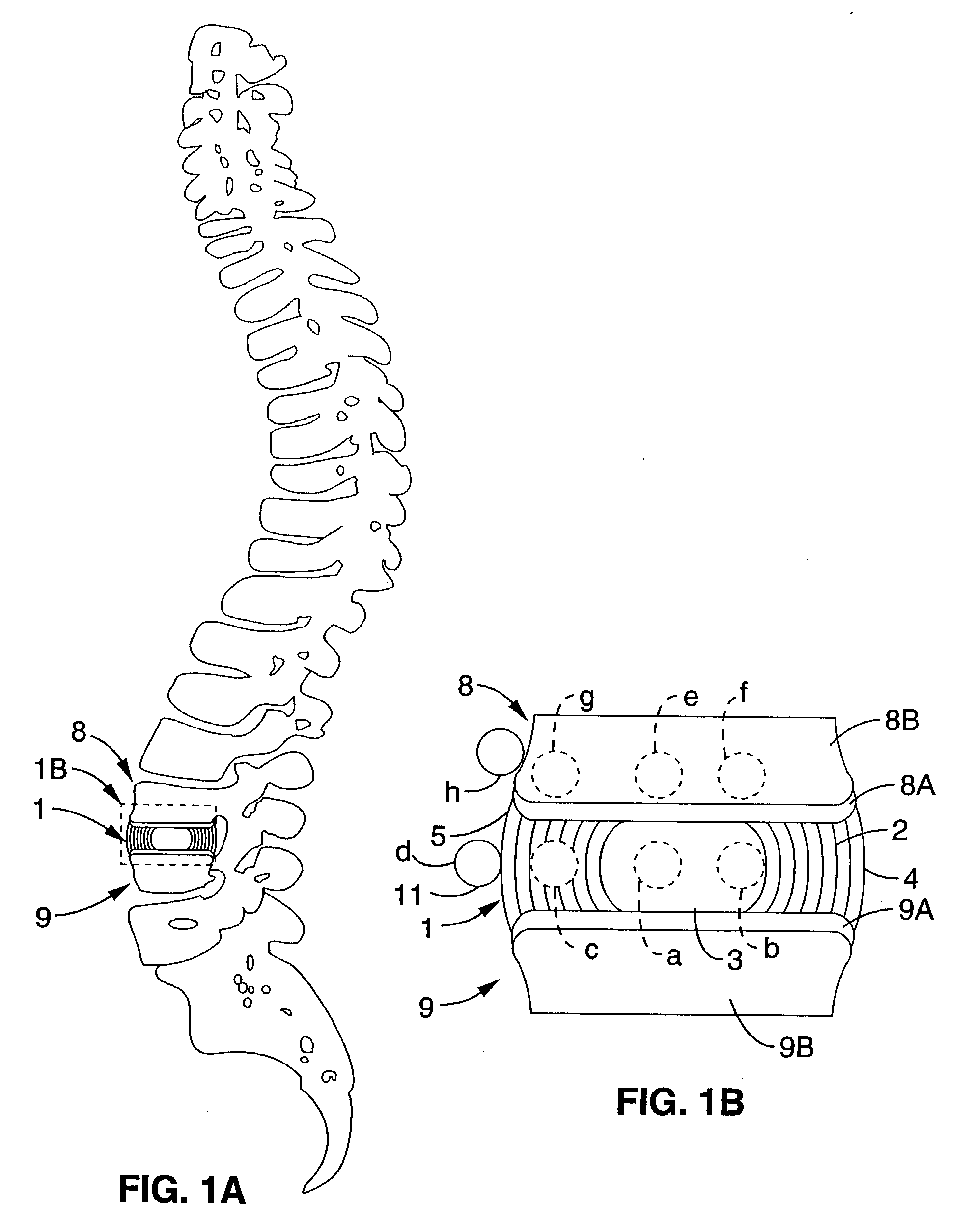

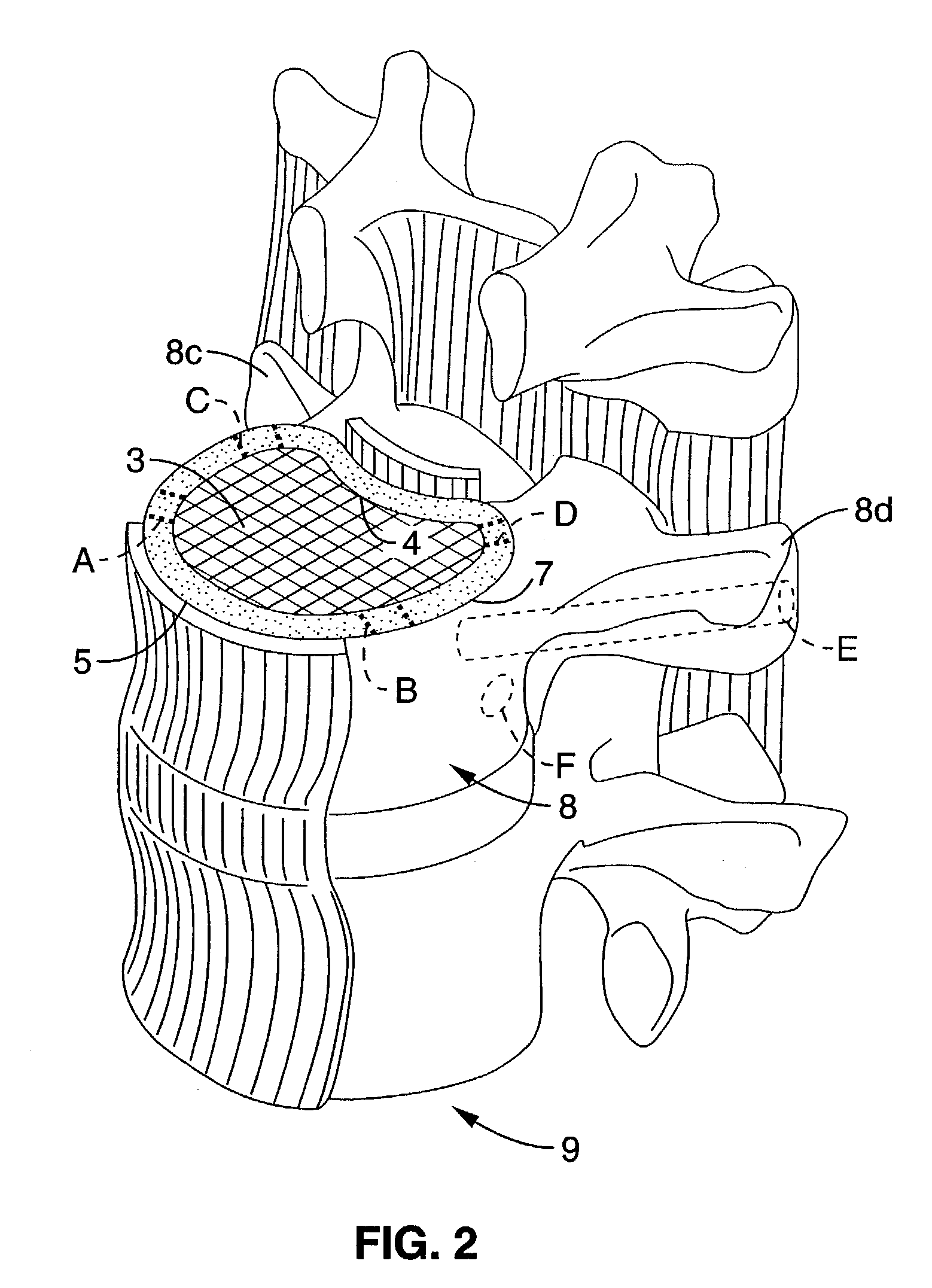

Implantable thermal treatment method and apparatus

A long-term implantable ultrasound therapy system and method is provided that provides directional, focused ultrasound to localized regions of tissue within body joints, such as spinal joints. An ultrasound emitter or transducer is delivered to a location within the body associated with the joint and heats the target region of tissue associated with the joint from the location. Such locations for ultrasound transducer placement may include for example in or around the intervertebral discs, or the bony structures such as vertebral bodies or posterior vertebral elements such as facet joints. Various modes of operation provide for selective, controlled heating at different temperature ranges to provide different intended results in the target tissue, which ranges are significantly effected by pre-stressed tissues such as in-vivo intervertebral discs. In particular, treatments above 70 degrees C., and in particular 75 degrees C., are used for structural remodeling, whereas lower temperatures achieves other responses without appreciable remodeling.

Owner:RGT UNIV OF CALIFORNIA

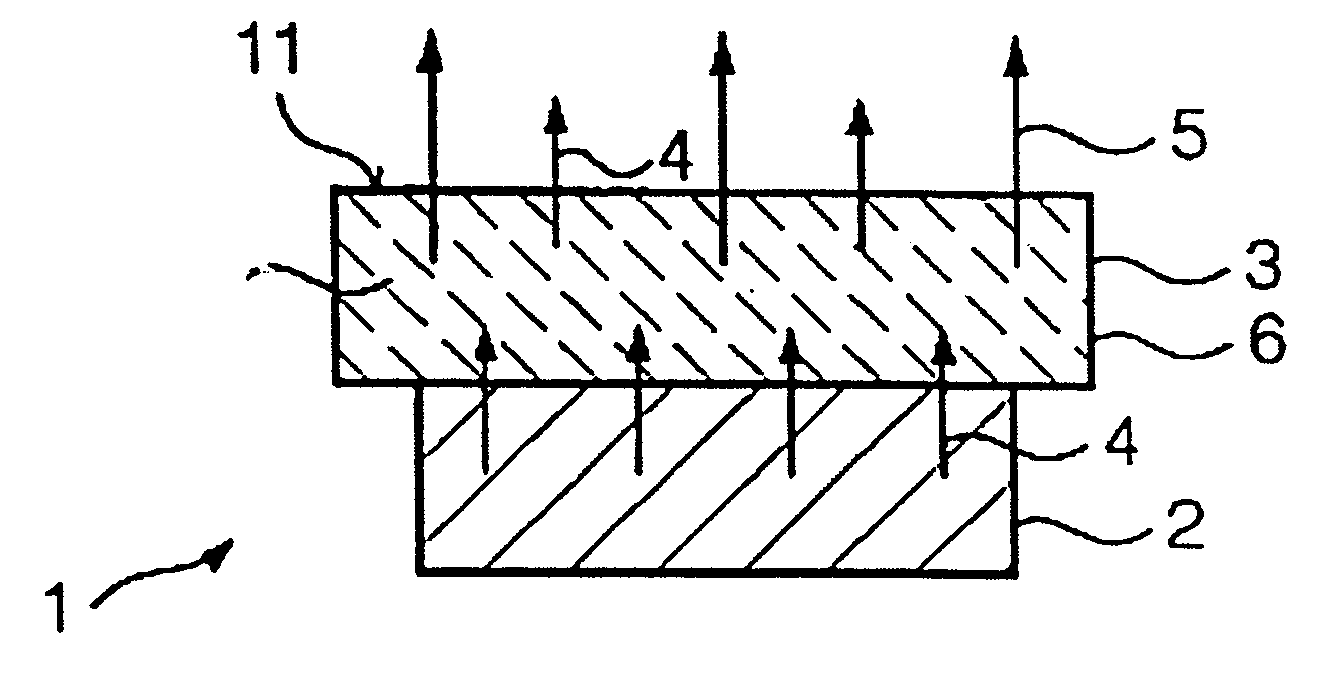

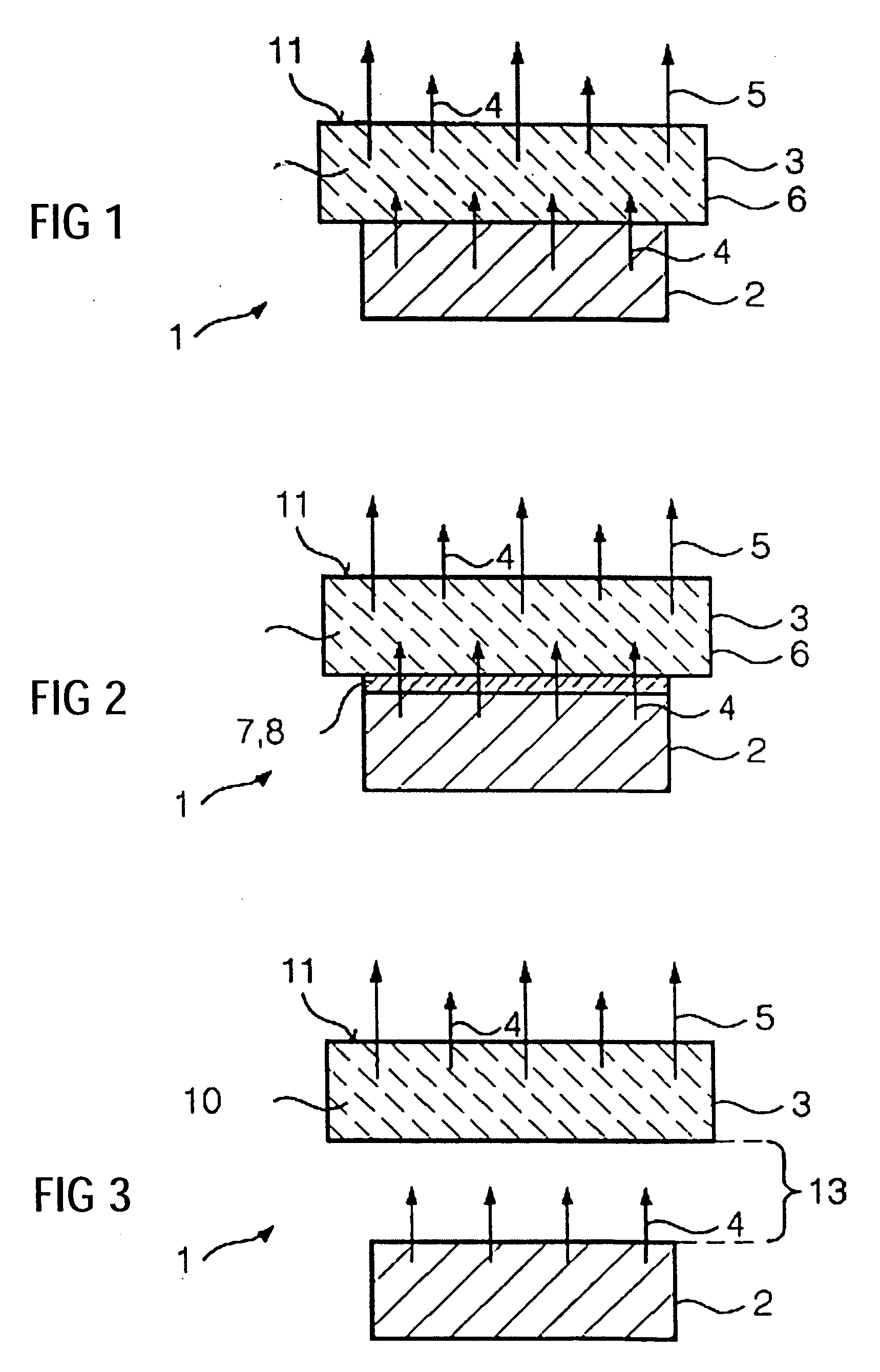

Light source having an LED and a luminescence conversion body and method for producing the luminescence conversion body

ActiveUS20040145308A1Efficient luminescence conversionDischarge tube luminescnet screensLamp detailsDopantSecondary radiation

The invention relates to a light source (1), having at least one LED (2) for emitting a primary radiation (4) and at least one luminescence conversion body (3) having at least one luminescent material for converting the primary radiation (4) into a secondary radiation (5). The luminescence conversion body is a polycrystalline ceramic body. The LED is based on GaInN and emits blue primary radiation. The ceramic body comprises for example a luminescent material based on a cerium-doped yttrium aluminum garnet. This luminescent material emits yellow secondary radiation. Blue primary radiation and yellow secondary radiation penetrate through the luminescence conversion body and are perceived as white light by the observer. In order to produce the luminescence conversion body, provision is made of a polycrystalline ceramic body which is united with a solution of a dopant. By means of a thermal treatment, the dopant (activator) diffuses into the ceramic body, the luminescent material being formed.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH

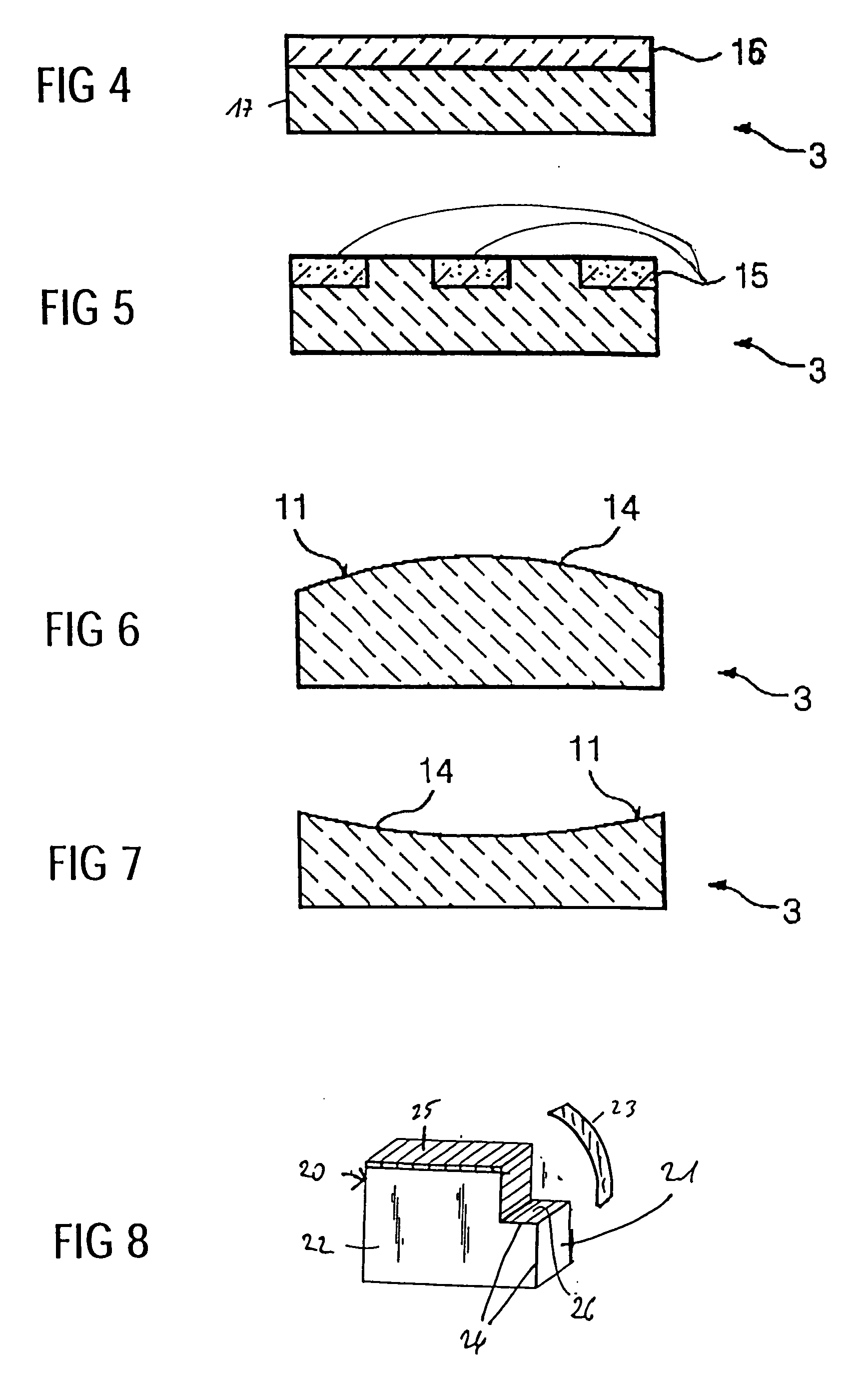

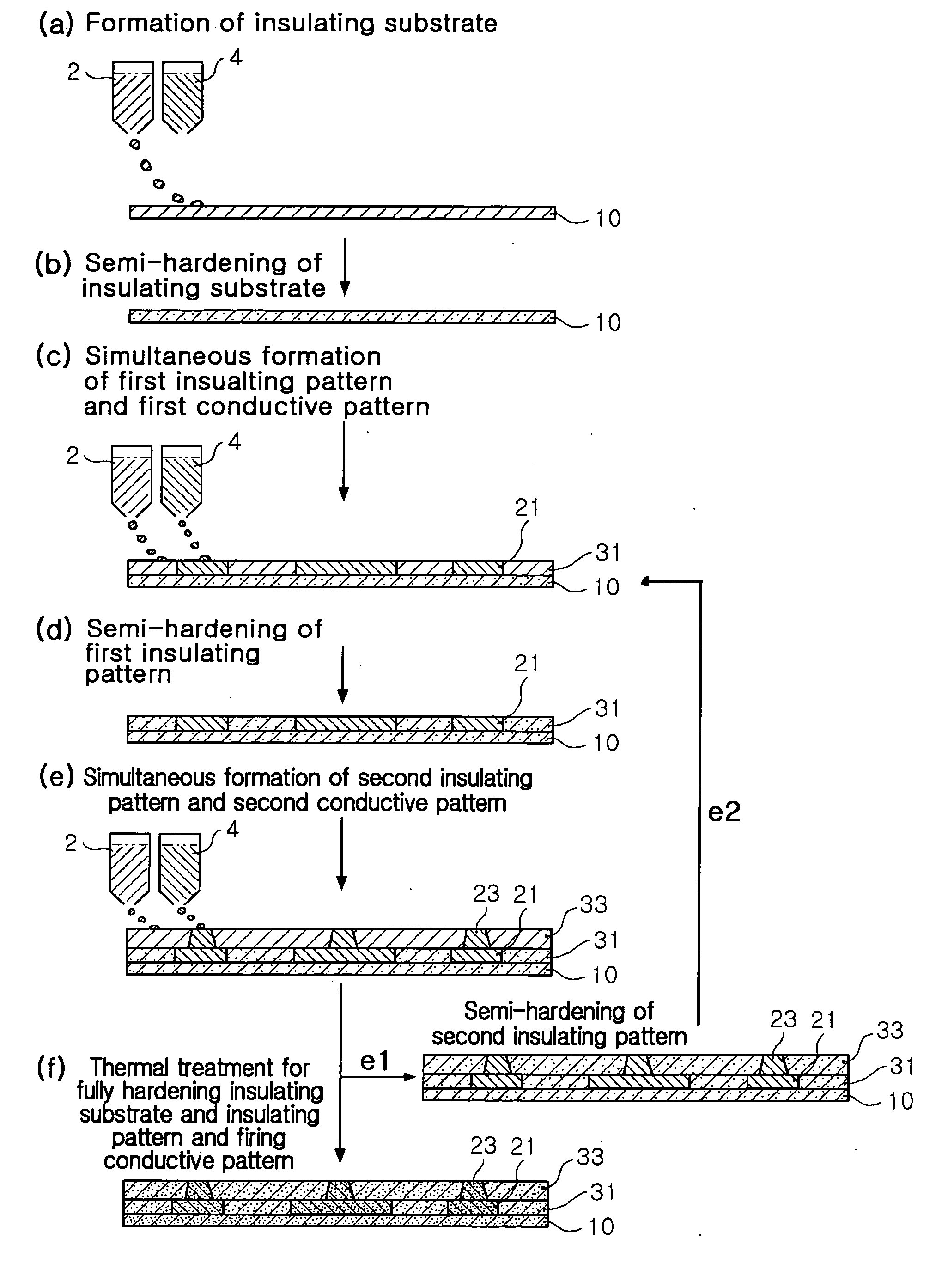

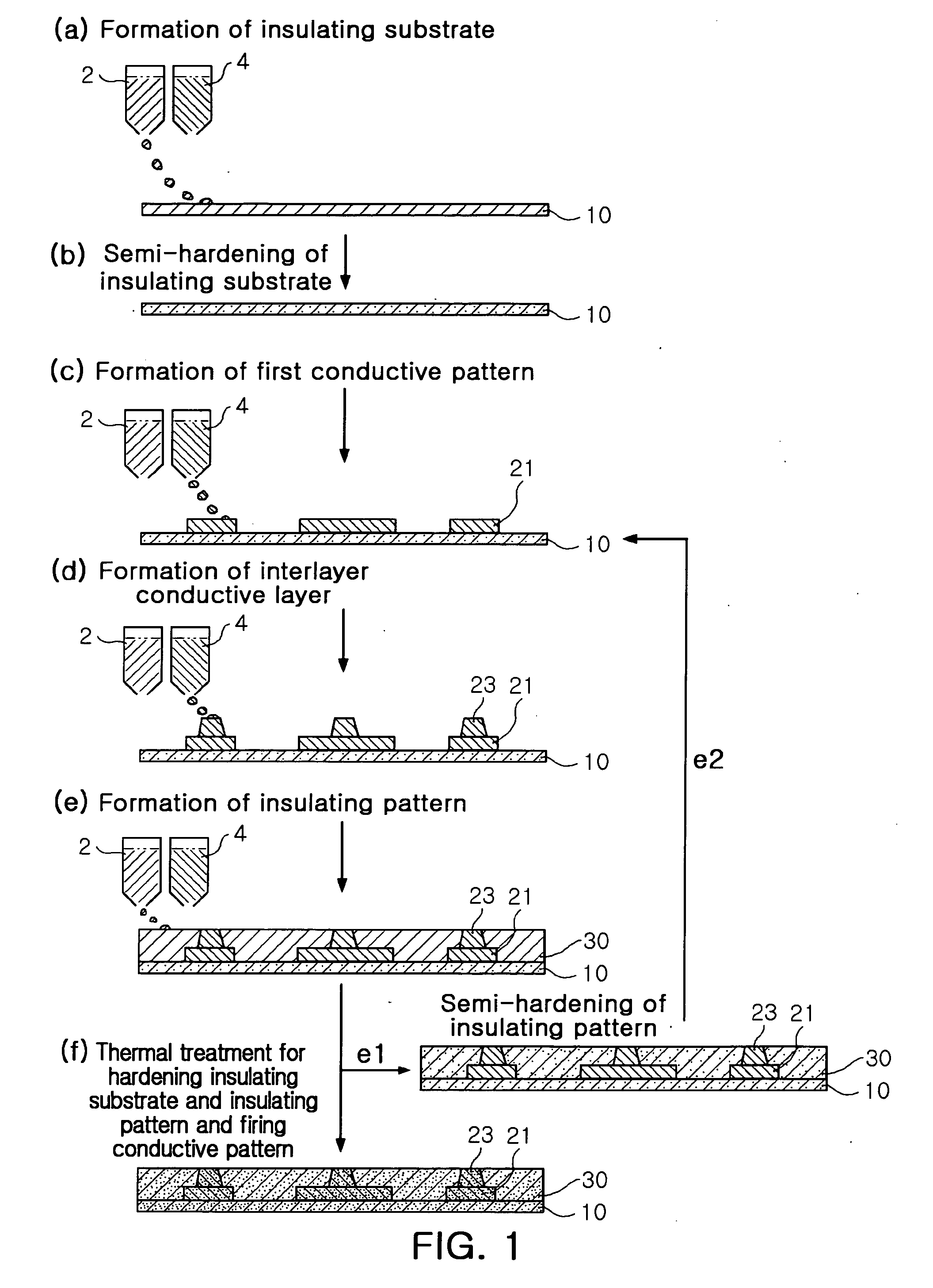

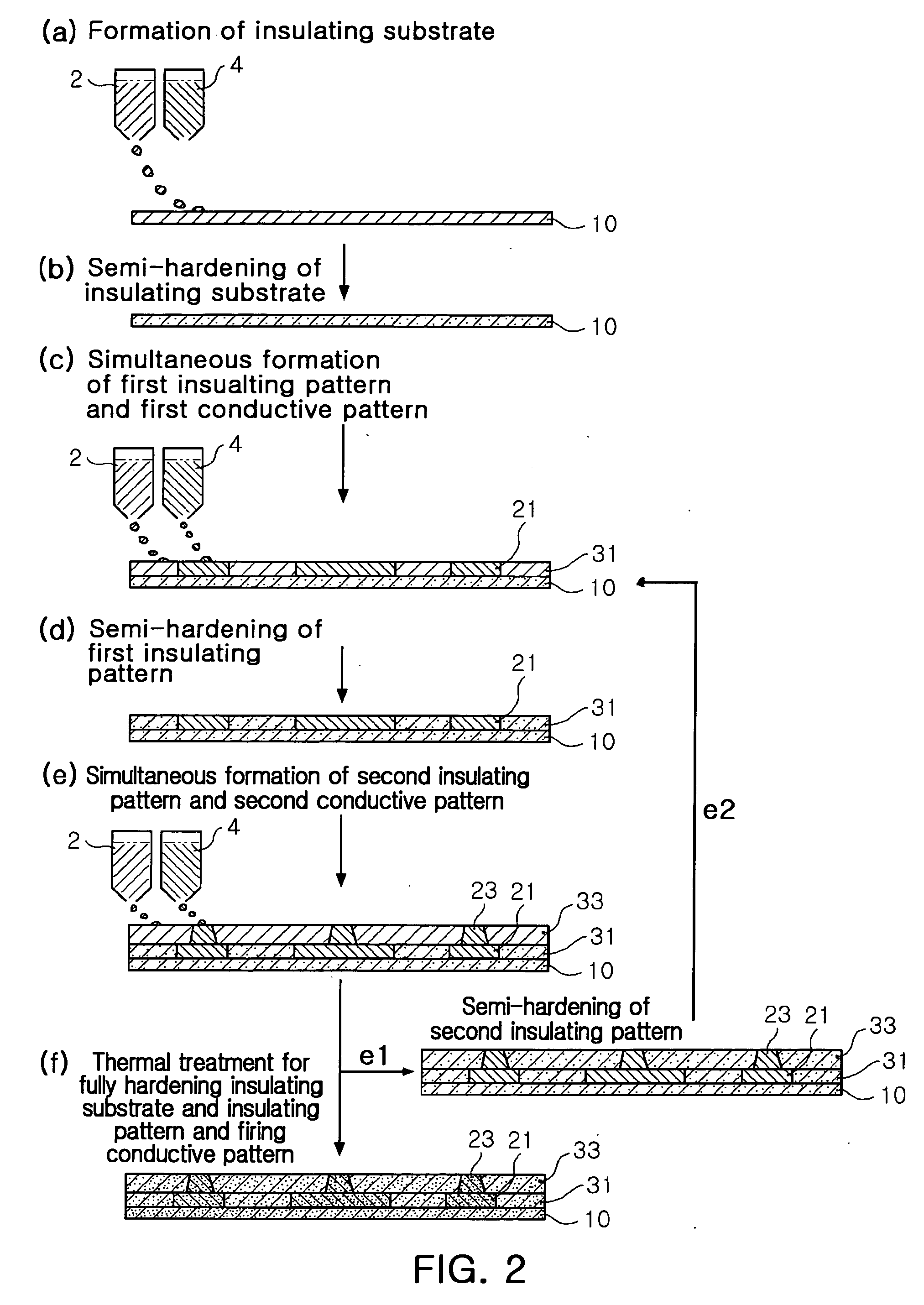

Printed wiring board and method for manufacturing the same

InactiveUS20070128855A1High peel strengthPeel strengthAdditive manufacturing apparatusPrinted circuit aspectsTwo stepThermal treatment

Provided is a method for manufacturing a printed wiring board, which can enhance the peel strength between an insulating layer and a conductive pattern by a two-step process, that is, a semi-hardening and full-hardening of the insulating layer. In the method for manufacturing the printed wiring board having one or more layers of a conductive pattern and an insulating pattern, an insulating pattern is formed on an insulating substrate, and at least one of the insulating substrate and the insulating pattern is semi-hardened. A conductive pattern is formed on the insulating substrate and / or the insulating pattern, thereby providing a stack structure. Then, a thermal treatment is performed on the stack structure to fully harden the semi-hardened insulating substrate and / or insulating pattern, and the conductive pattern is fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

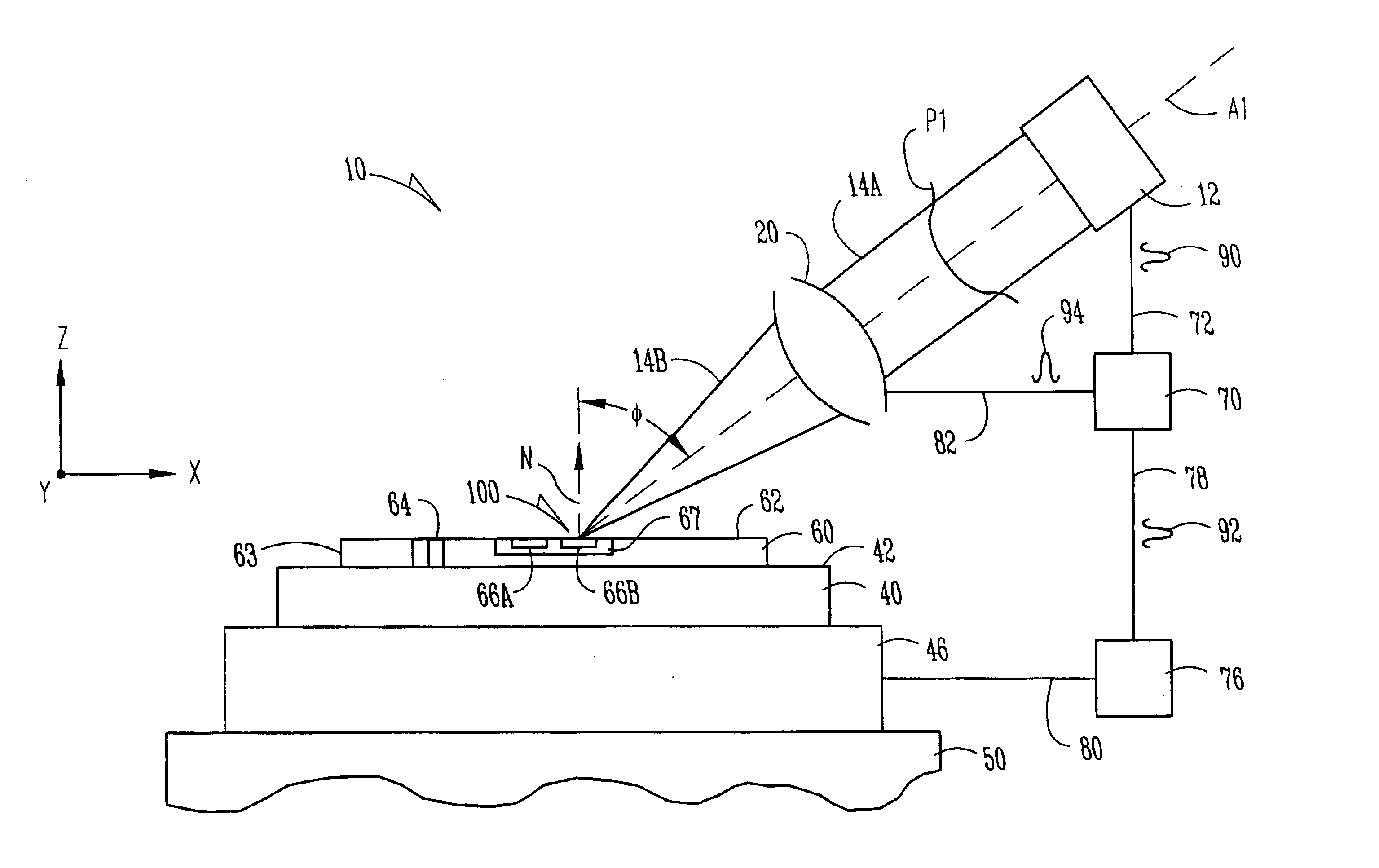

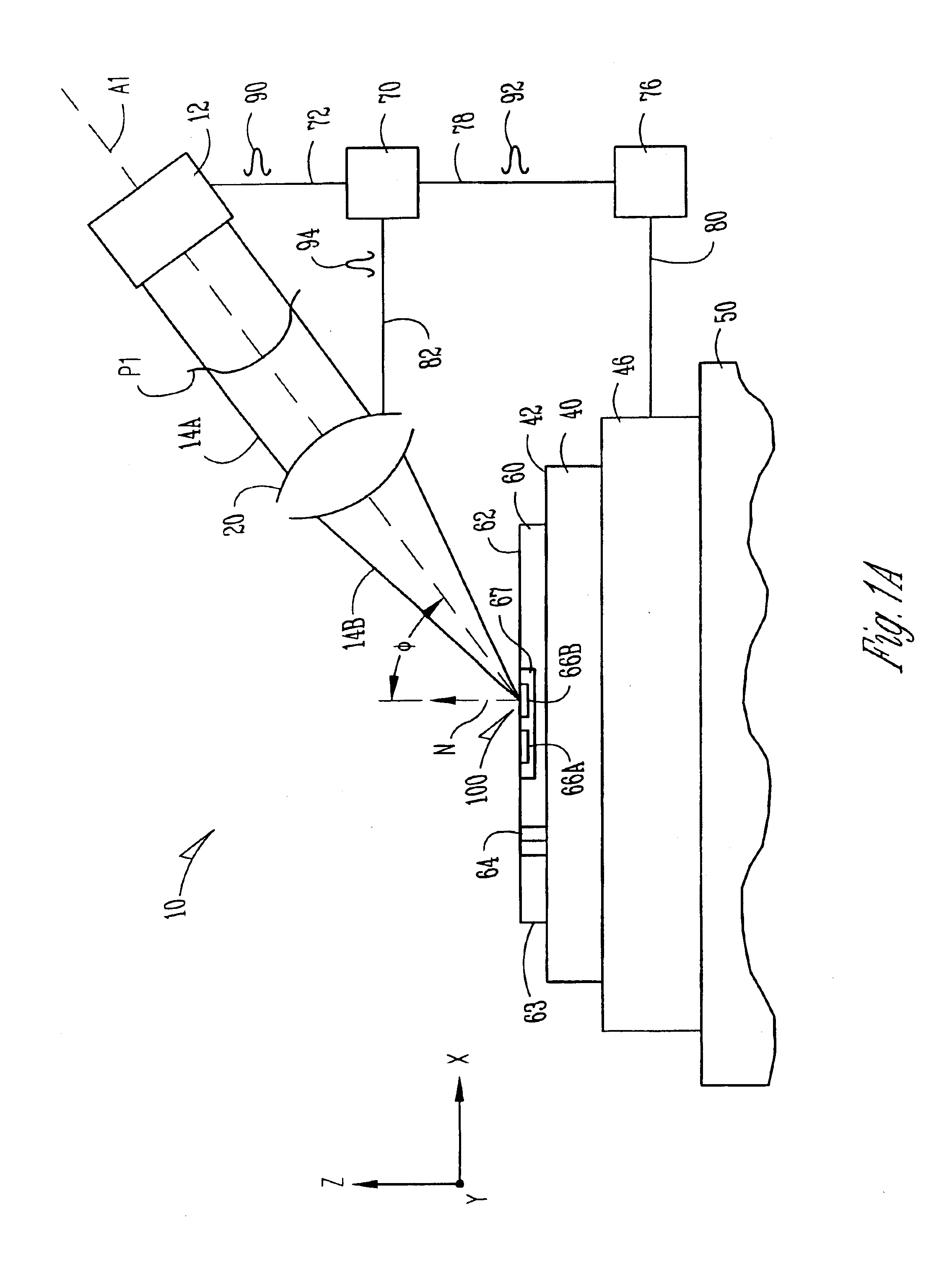

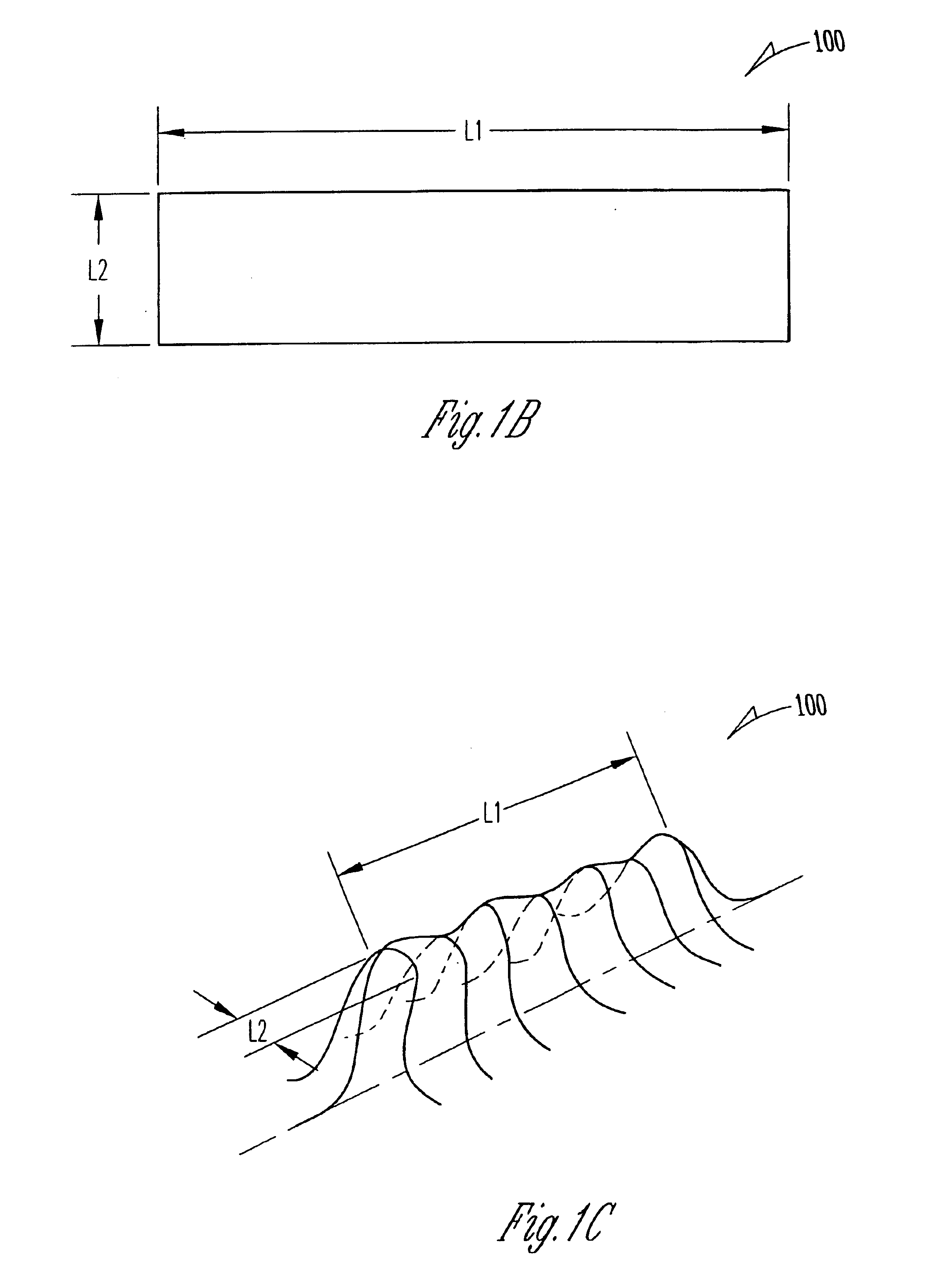

Laser scanning apparatus and methods for thermal processing

InactiveUS6747245B2Laser detailsSemiconductor/solid-state device manufacturingLaser scanningProcess region

Apparatus and methods for thermally processing a substrate with scanned laser radiation are disclosed. The apparatus includes a continuous radiation source and an optical system that forms an image on a substrate. The image is scanned relative to the substrate surface so that each point in the process region receives a pulse of radiation sufficient to thermally process the region.

Owner:VEECO INSTR

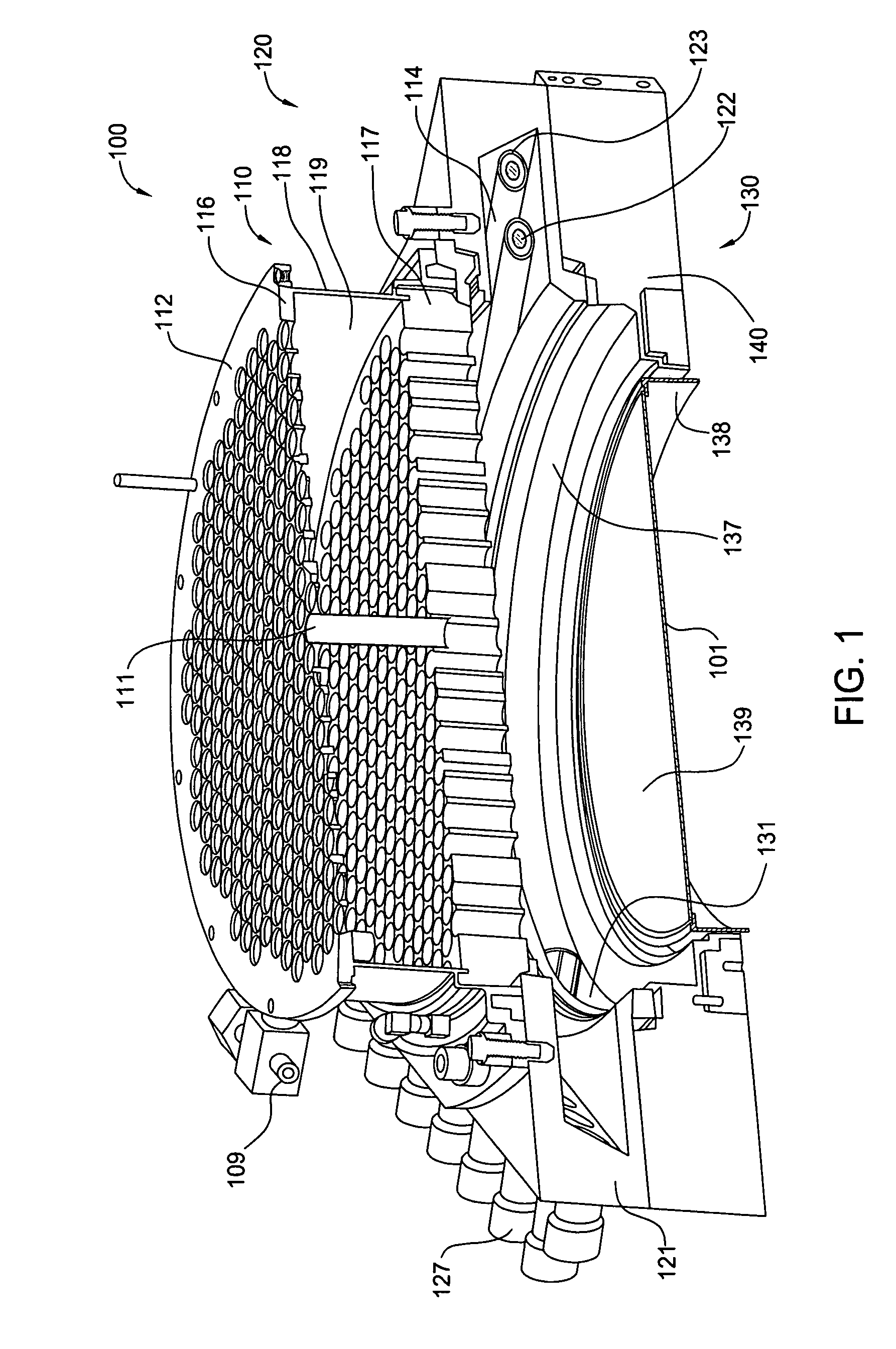

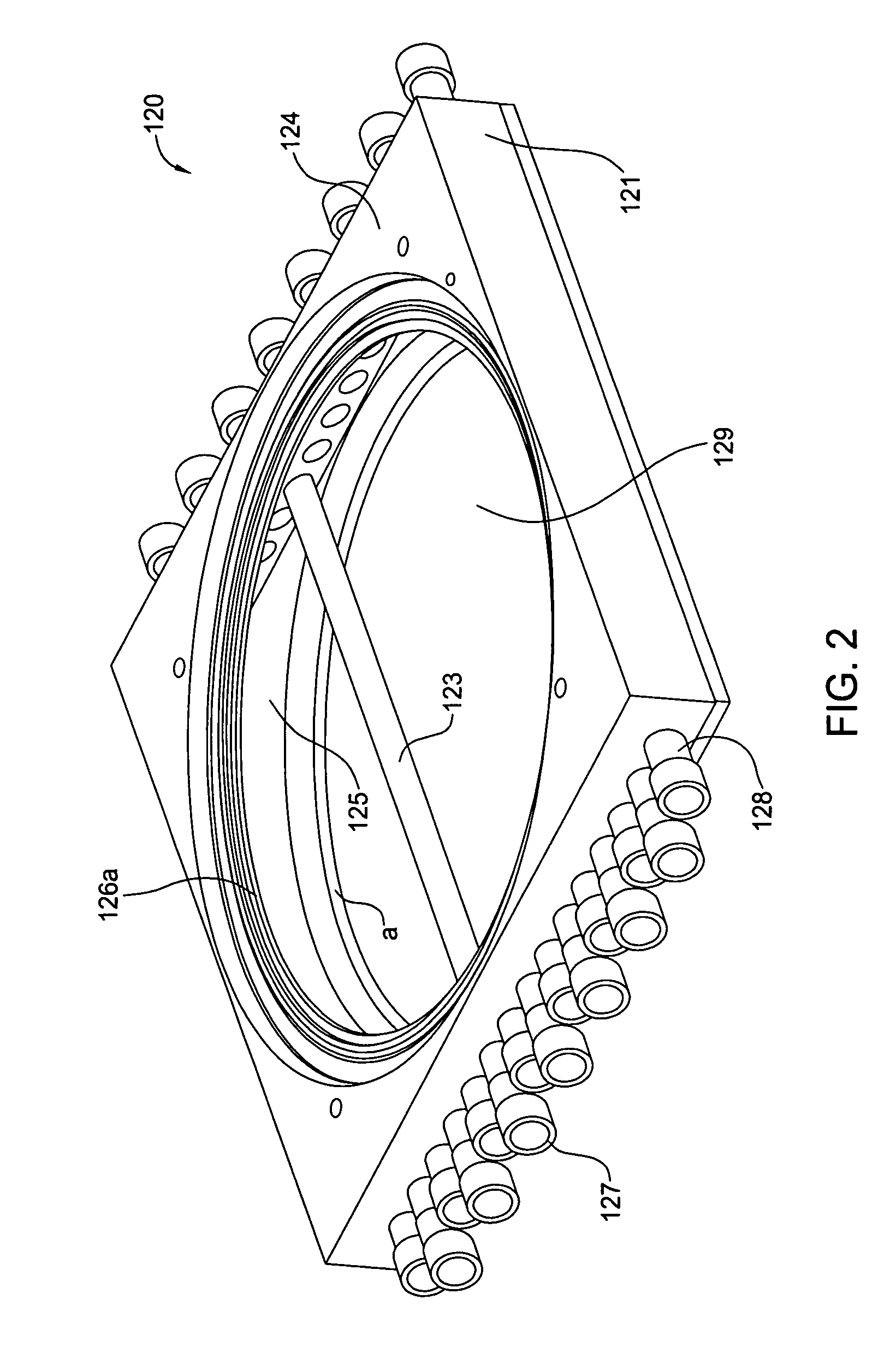

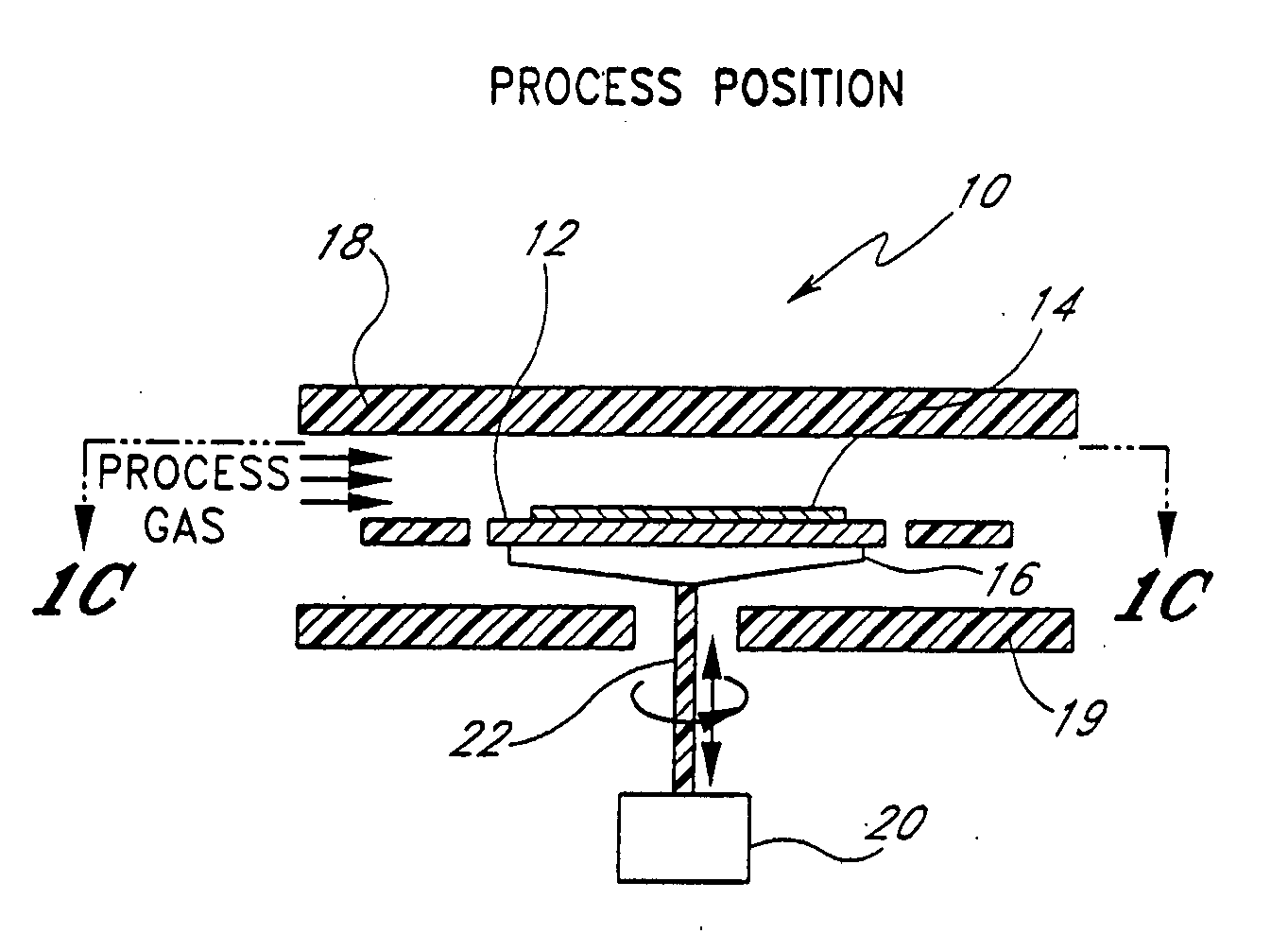

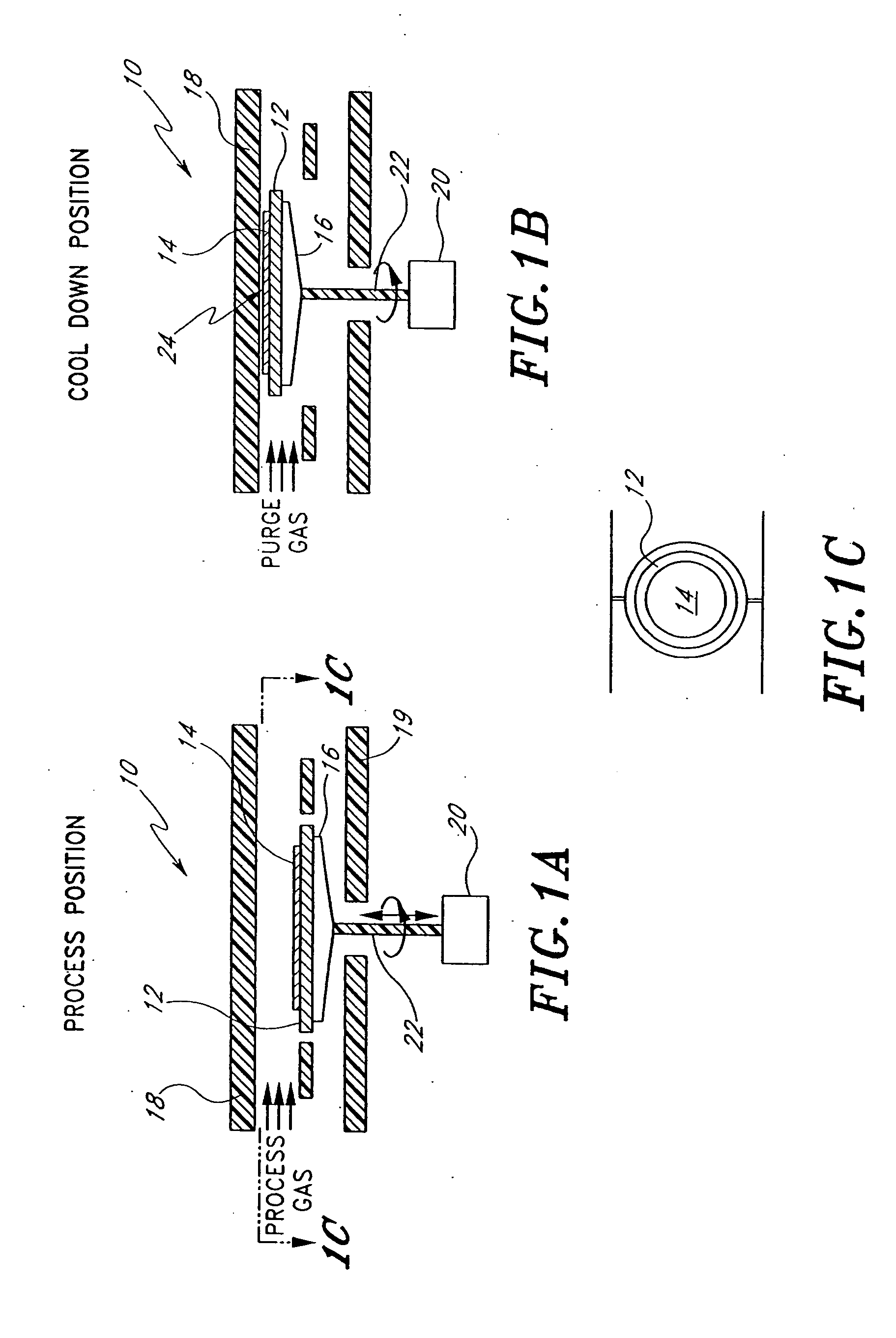

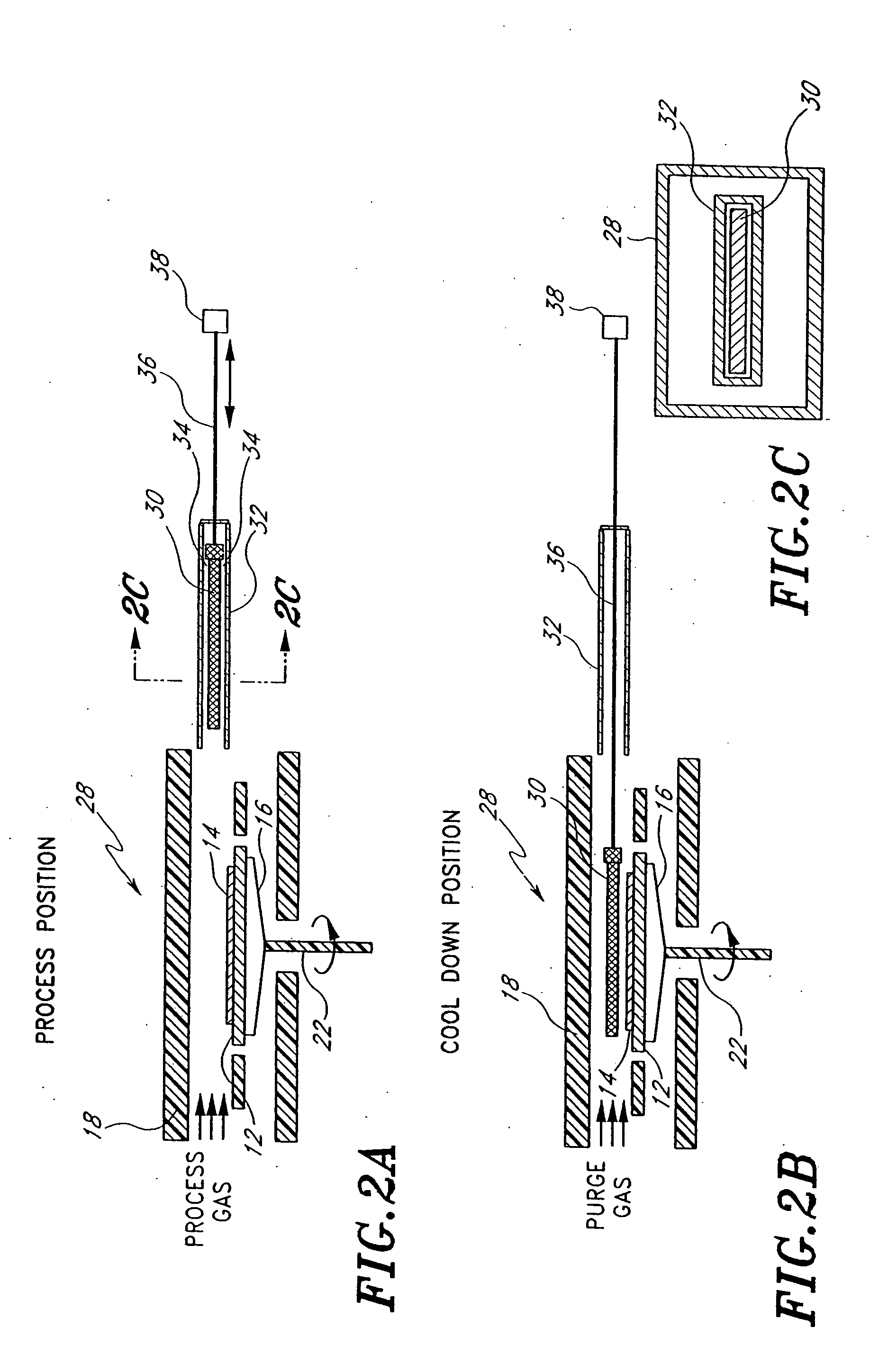

Apparatus for thermal treatment of substrates

InactiveUS20050229855A1Short timeIncrease wafer throughputSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringCold plate

Methods and apparatuses are provided for cooling semiconductor substrates prior to handling. In one embodiment, a substrate and support structure combination is lifted after high temperature processing to a cold wall of a thermal processing chamber, which acts as a heat sink. Conductive heat transfer across a small gap from the substrate to the heat sink speeds wafer cooling prior to handling the wafer (e.g., with a robot). In another embodiment, a separate plate is kept cool within a pocket during processing, and is moved close to the substrate and support after processing. In yet another embodiment, a cooling station between a processing chamber and a storage cassette includes two movable cold plates, which are movable to positions closely spaced on either side of the wafer.

Owner:RAAIJMAKERS IVO

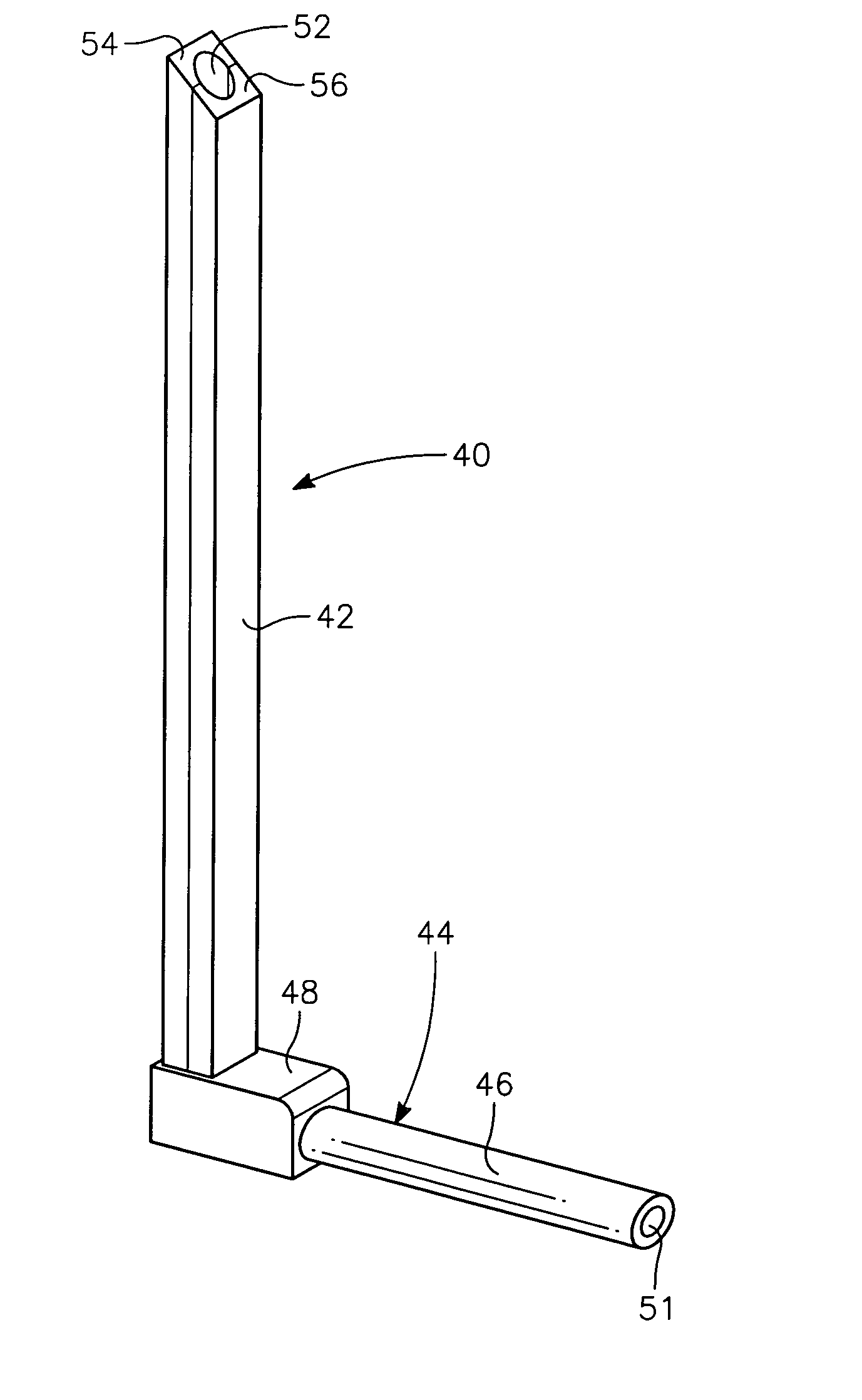

Silicon gas injector and method of making

A gas injector tube usable in a batch thermal treatment oven including two silicon shells joined together with an adhesive formed of a fine silicon powder and a curable silica-forming agent, such as a spin-on glass, which is ultrasonically homogenized. The tube may have a gas outlet on its distal end or be sealed with a silicon cap and have side outlet holes formed along its side. The silicon injector tube may be used in combination with a silicon tower and a silicon liner so that all bulk parts within the furnace hot zone are formed of silicon.

Owner:INTEGRATED MATERIALS

Vacuum device and method for treating tissue adjacent a body cavity

Devices and methods are provided for applying vacuum near to devices for delivering treatments to tissue adjacent a body cavity, effective to draw adjacent tissue near to such devices and to enhance treatment of the tissue. Body cavities include natural body cavities and cavities remaining after removal of tissue such as cancerous tissue. A device may include an inner balloon assembly with an inflation conduit. A sheath assembly having a fluid-permeable sheath wall may enclose the inner balloon assembly. Vacuum applied to the space between the sheath and the inner balloon is useful to draw tissue into contact with the device, improving treatment effectiveness. Methods for treating tissue with such devices and systems are also provided. Treatments may include providing radioactive material for radiation treatment, providing chemotherapeutic material for chemotherapy, providing thermal treatment, and combinations thereof. Systems may include devices of the invention and a vacuum source.

Owner:HOLOGIC INC

System and method for skin treatment using electrical current

InactiveUS6889090B2Improve permeabilityHigh calorific valueElectrotherapyTherapeutic coolingSkin treatmentsVoltage pulse

A system and method for selective thermal treatment of skin irregularities. The system comprises one or more RF electrodes that are adapted to apply RF energy to the skin. An RF pulse generator generates voltage pulses in the RF range at the electrodes, where the voltage pulses have a duration of 2-500 ms. The method comprises applying RF electrodes to the skin and generating voltage pulses at the electrodes in the RF range, where the pulses have a duration in the range of 2-500 ms.

Owner:SYNERON MEDICAL LTD

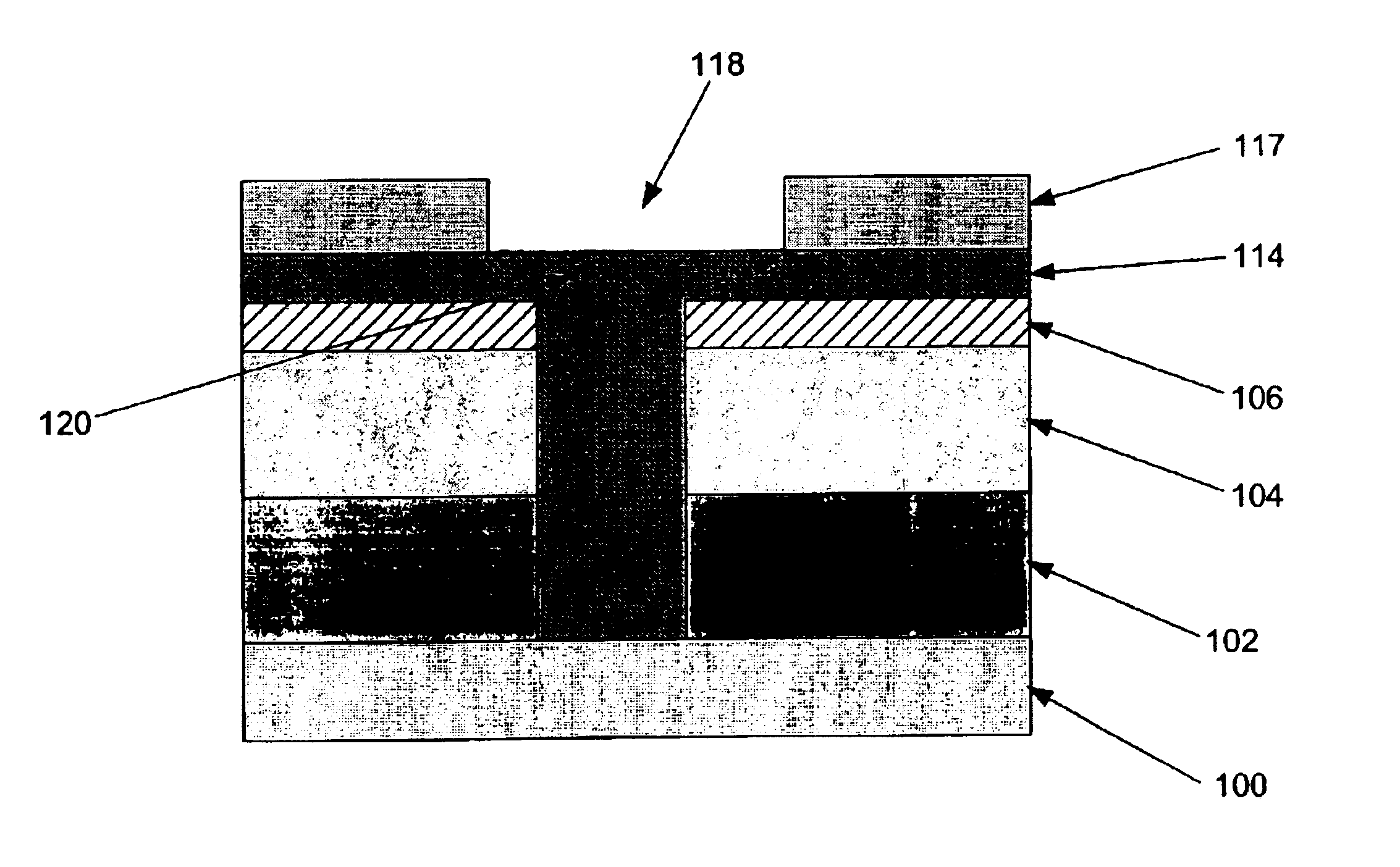

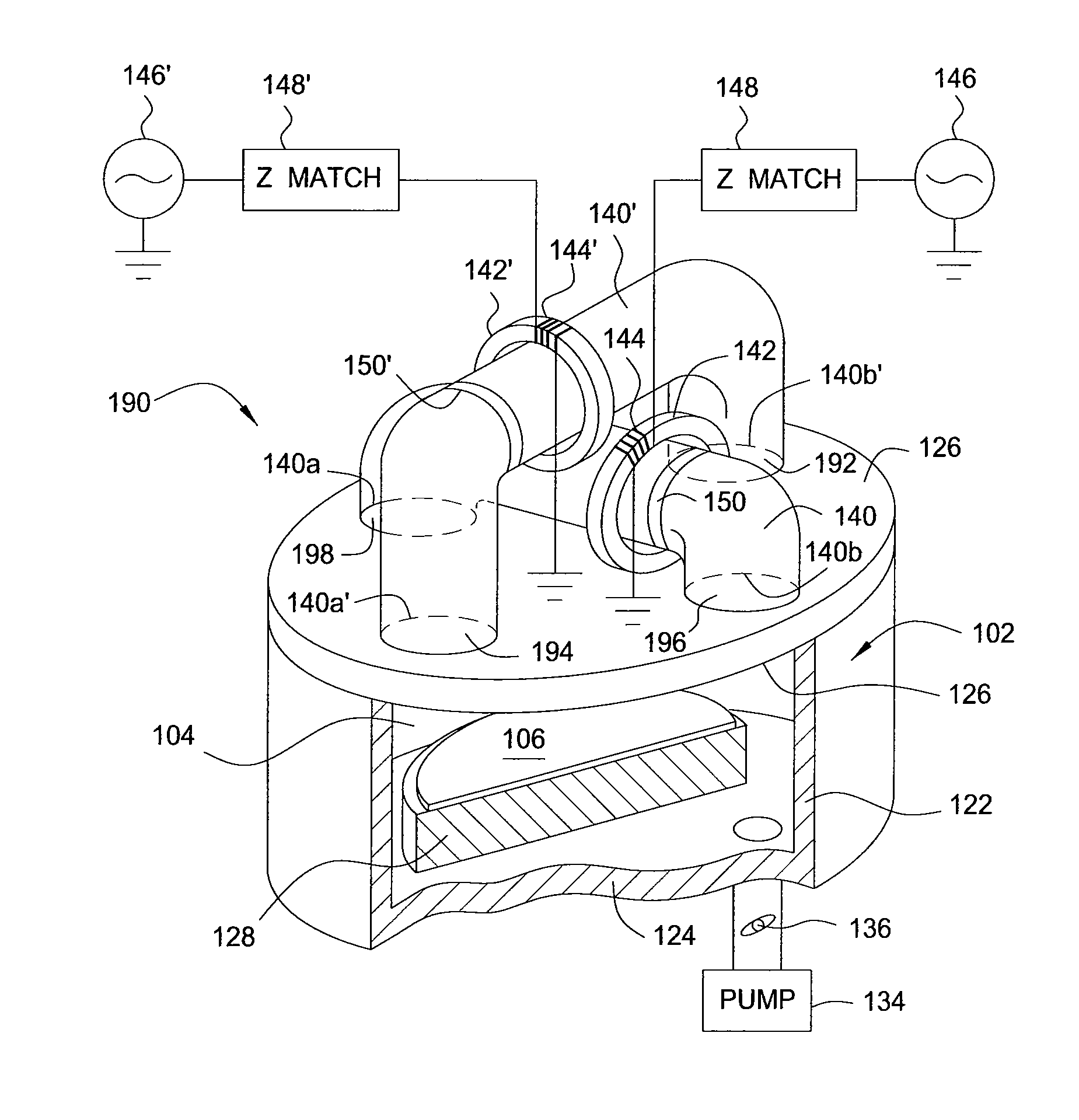

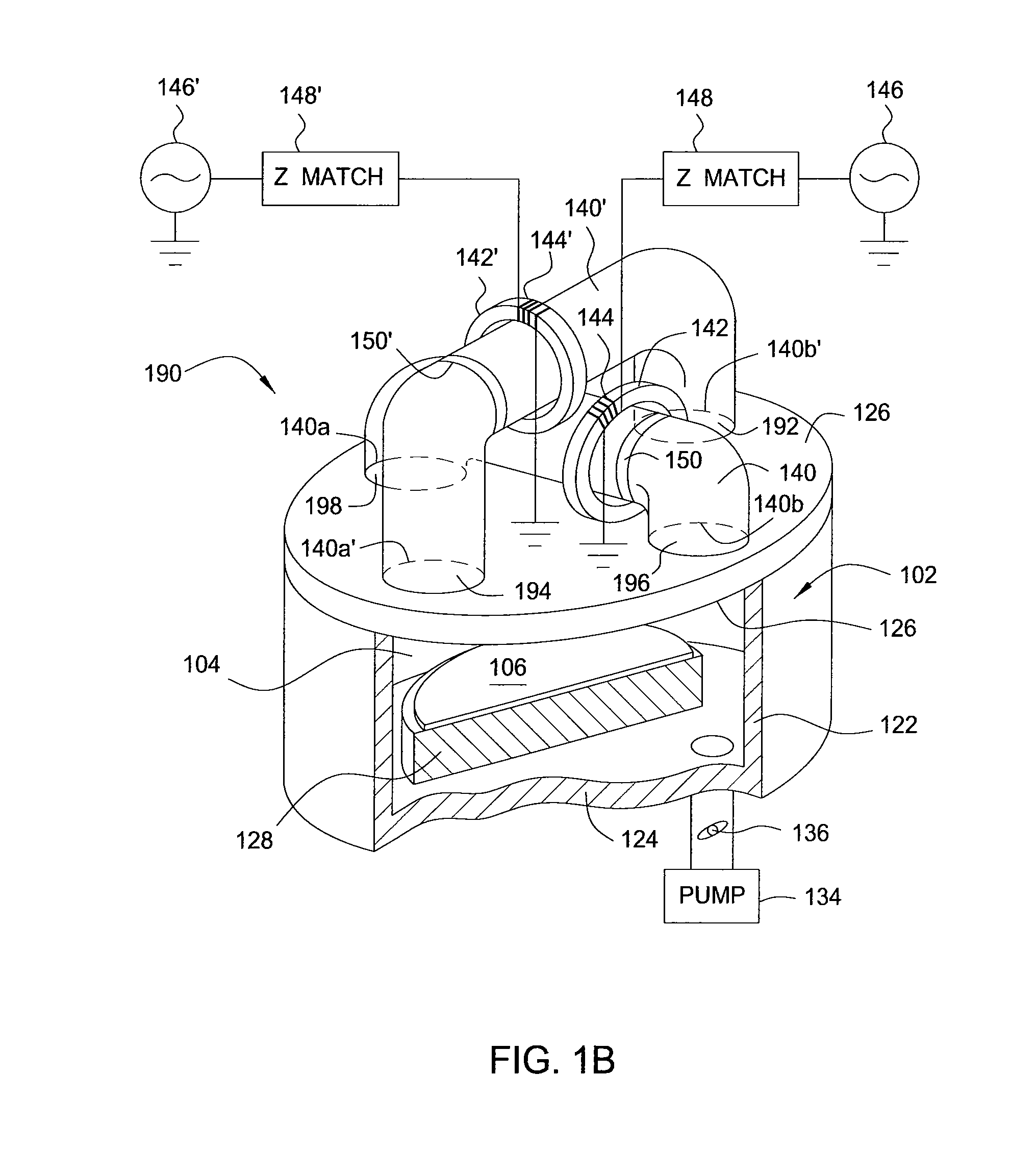

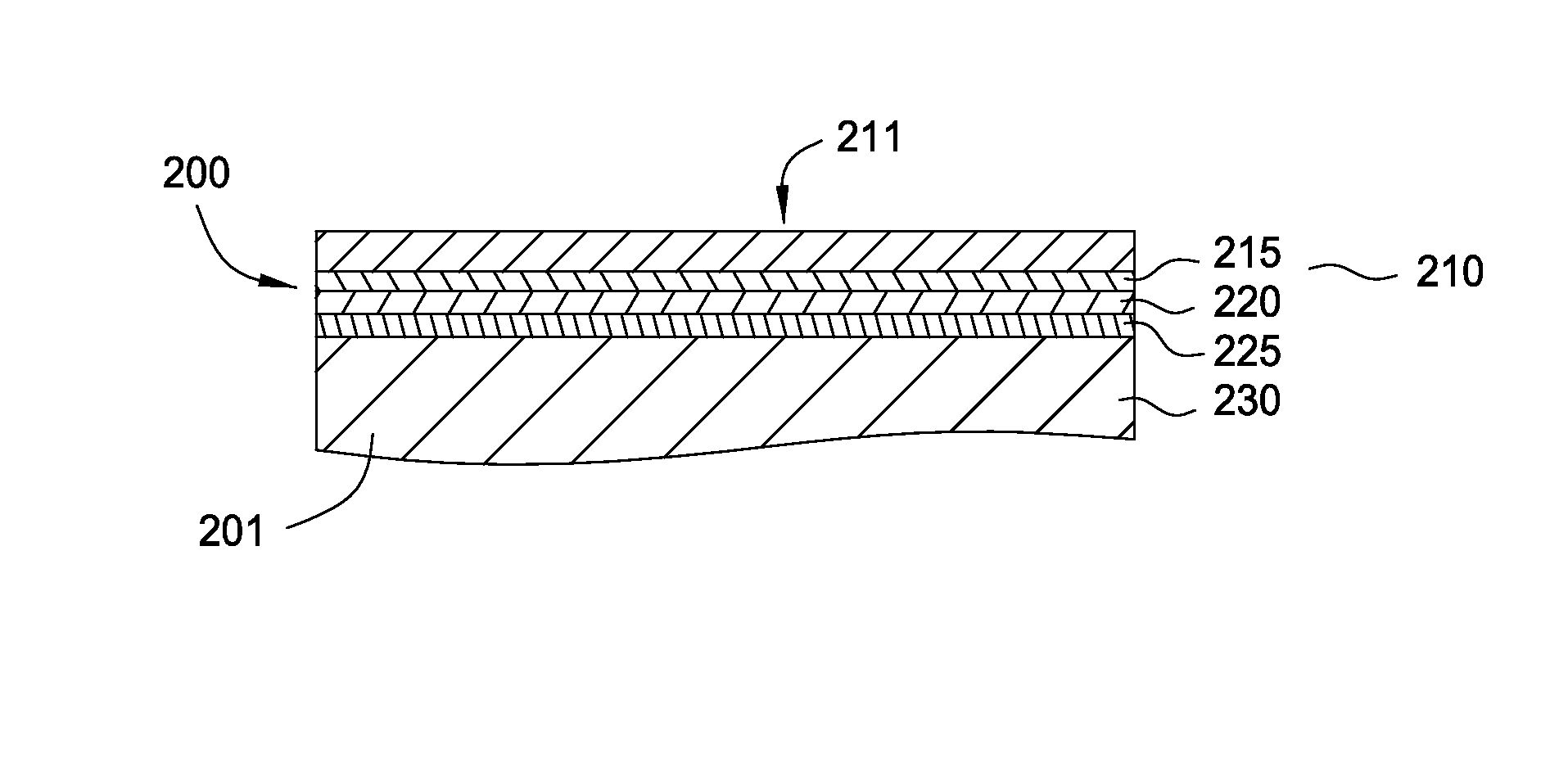

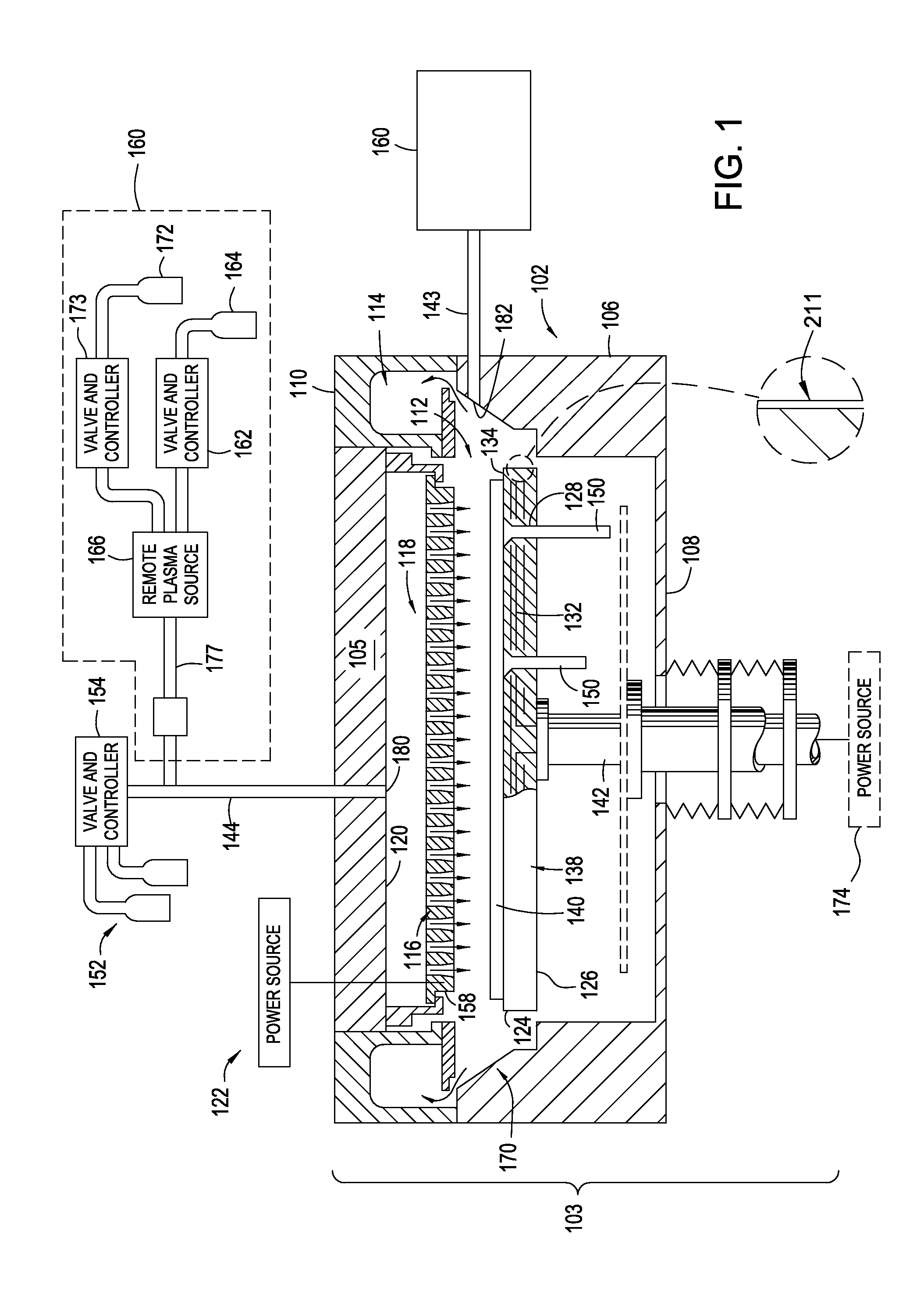

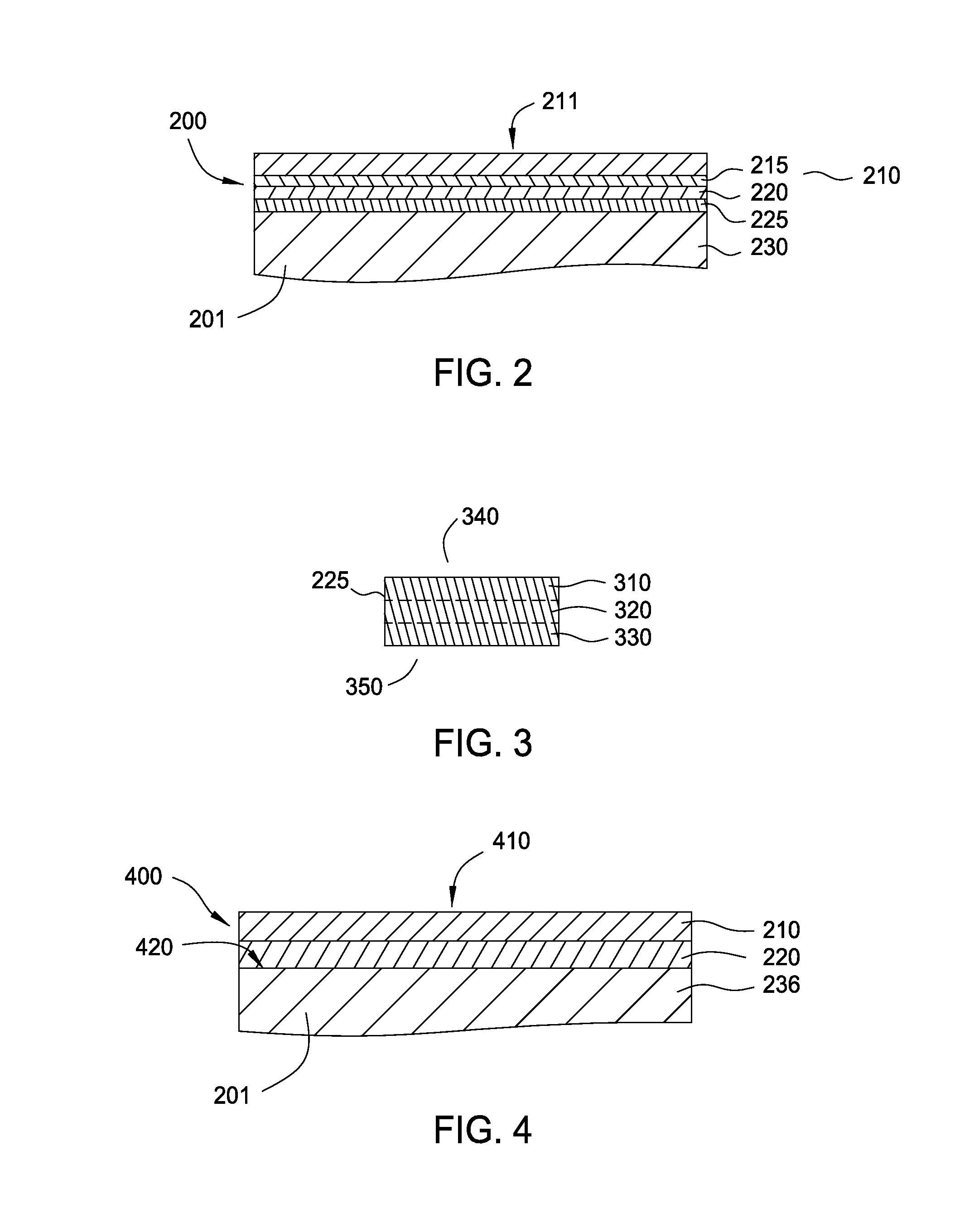

Thermal treated sandwich structure layer to improve adhesive strength

InactiveUS20140272341A1Improve integrityElectric discharge tubesLayered productsRemote plasmaDistribution system

A method and apparatus for cleaning a process chamber are provided. In one embodiment, a process chamber is provided that includes a remote plasma source and a processing chamber. The processing chamber includes a substrate support assembly disposed in the bottom portion of the processing chamber, a gas distribution system configured to provide gas into the processing chamber above the substrate support assembly, a removable liner layer the chamber interior walls. An adhesion layer is disposed on the substrate support. A protective layer is disposed on the adhesion layer. Pluralities of intermediate layers are created between the substrate support layer and the adhesion layer, and the adhesion layer and the protective layer through a thermal treatment in a non-reactive environment.

Owner:APPLIED MATERIALS INC

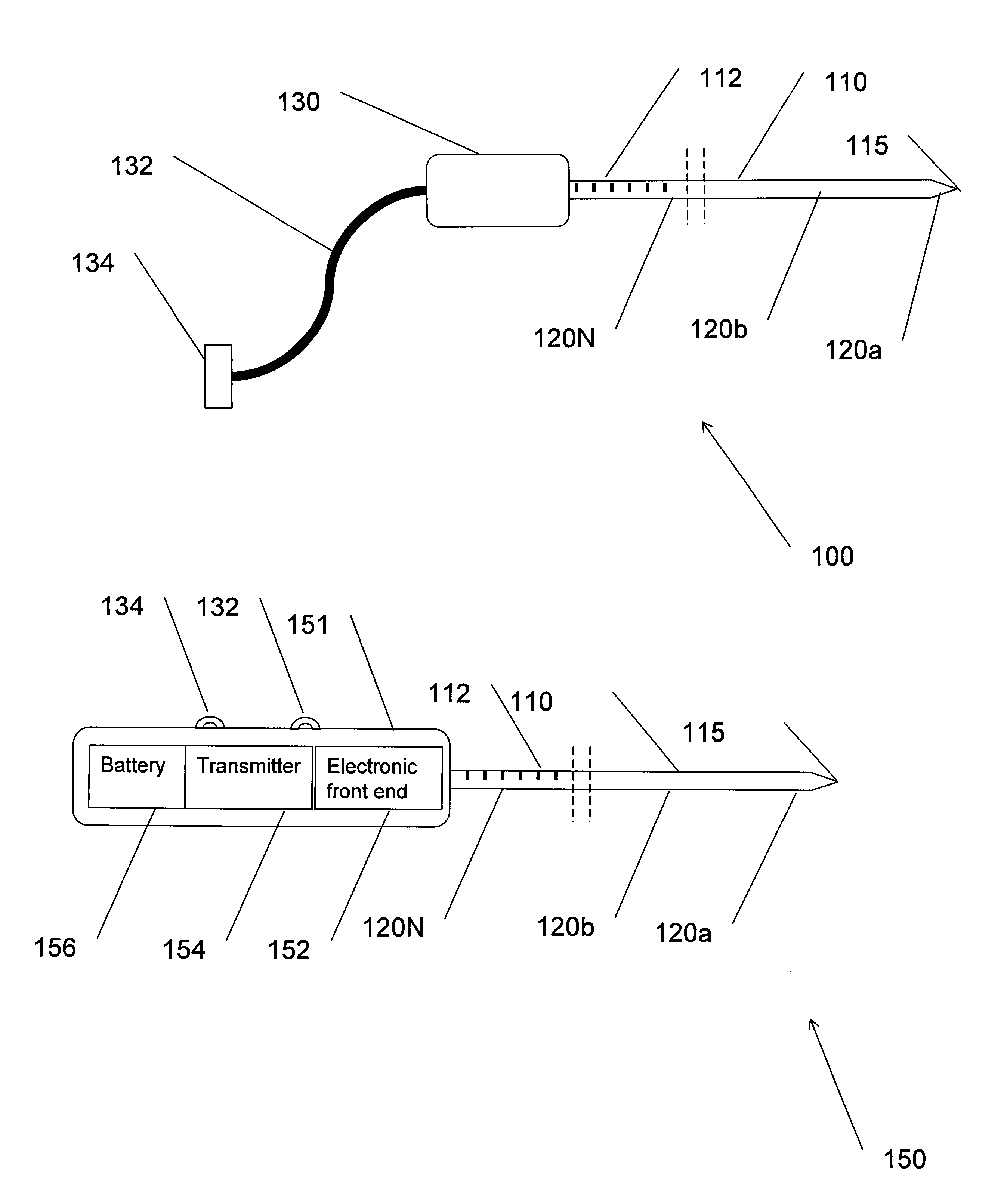

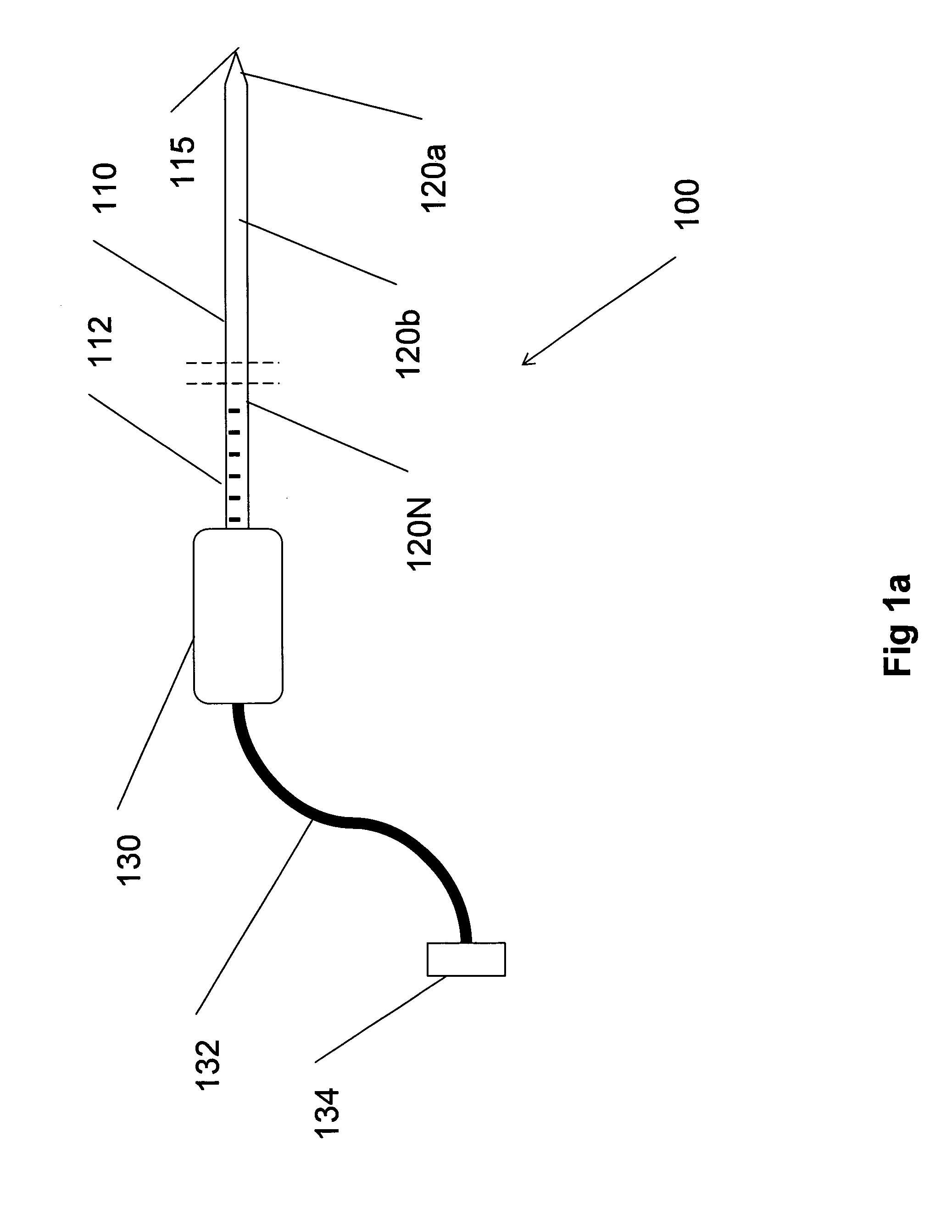

Multiple sensor device for measuring tissue temperature during thermal treatment

ActiveUS8348855B2Easy constructionThermometer detailsLine/current collector detailsThermal probeMultiple sensor

The present invention relates to devices and methods for measuring tissue temperature during thermal treatment of a body. More particularly, the present invention relates to a thermal probe comprising a plurality of thermal sensors operable to measure tissue temperatures during thermal treatments such as cryosurgery. Embodiments of the invention enable simultaneous measurements, using a single probe, of temperatures at a plurality of positions within body tissues. A preferred embodiment enables movement of sensors with respect to tissues while the probe is immobilized by being embedded in frozen tissue.

Owner:BOSTON SCI SCIMED INC

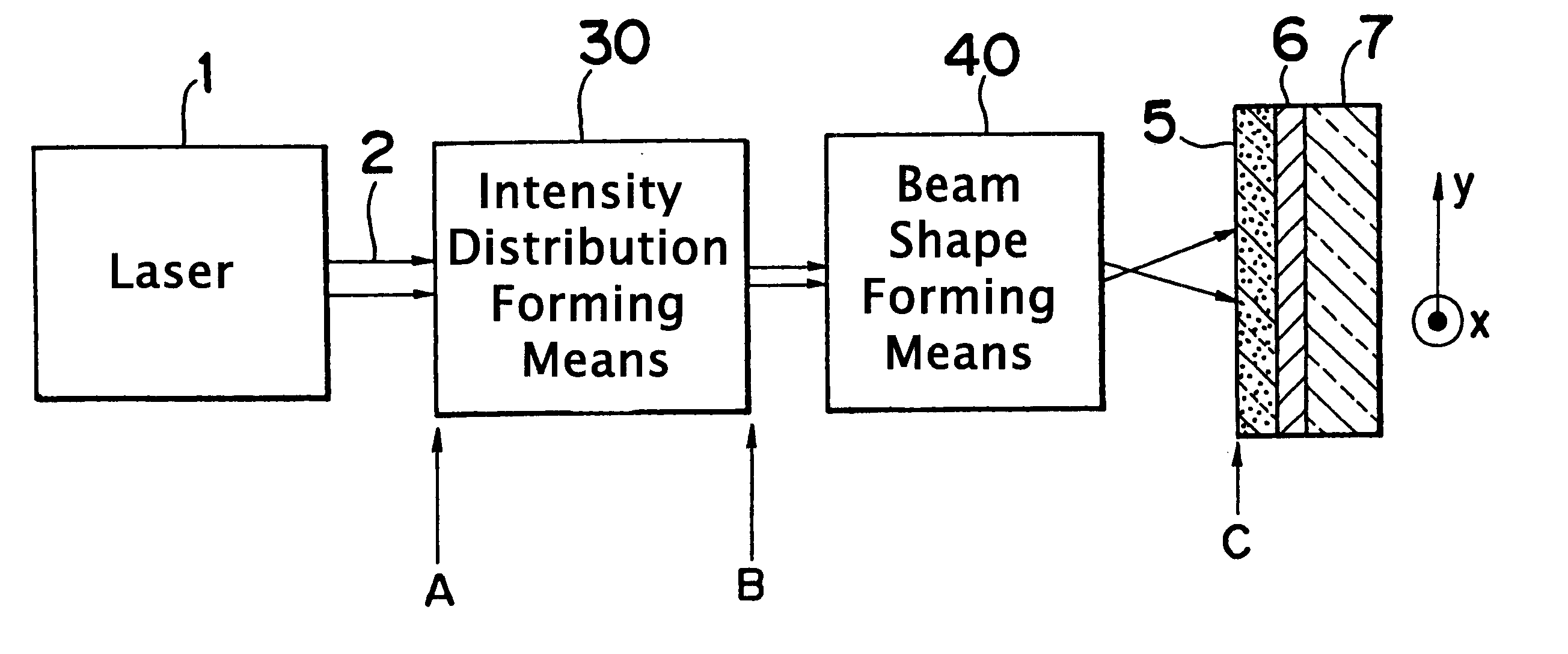

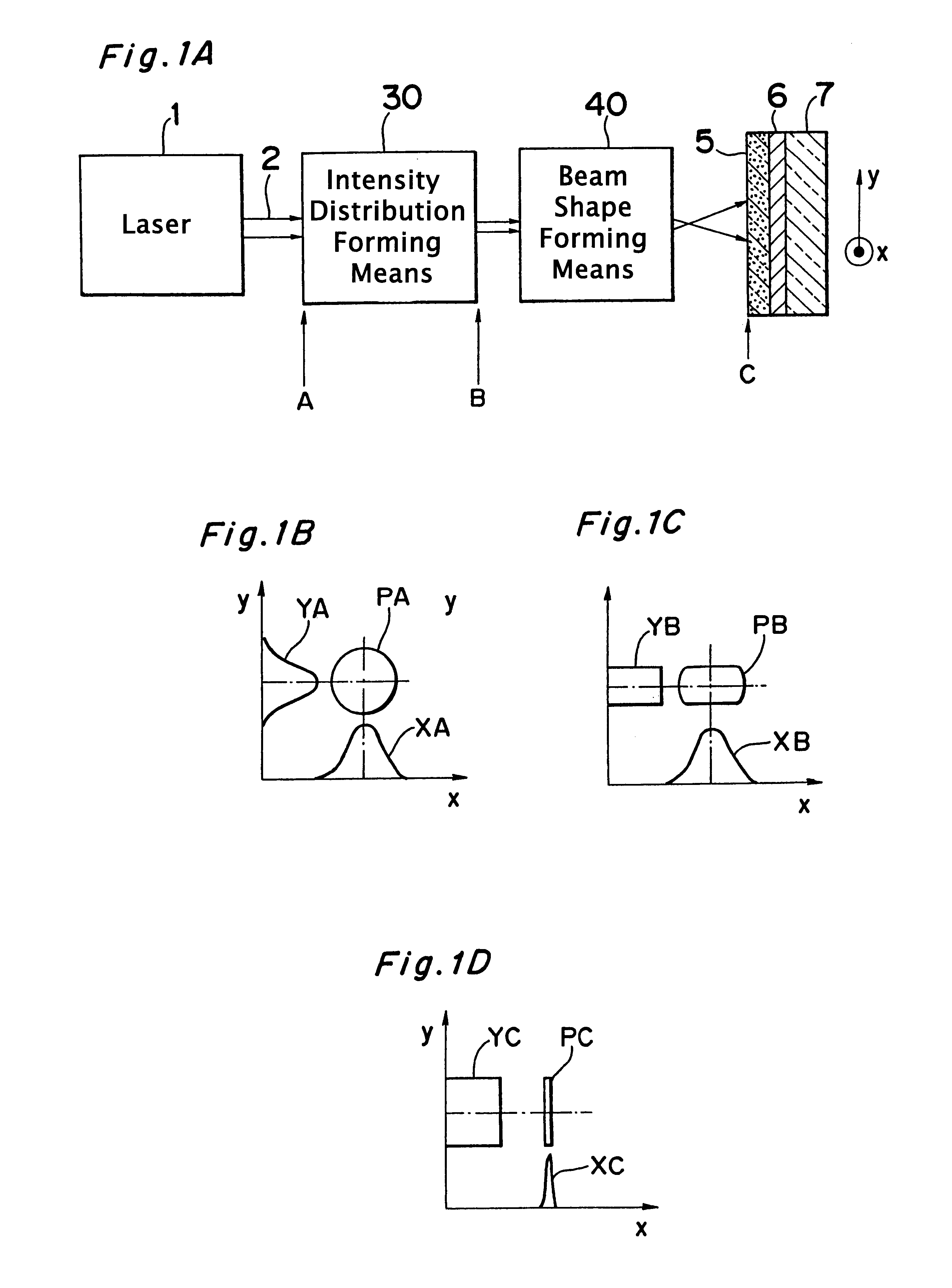

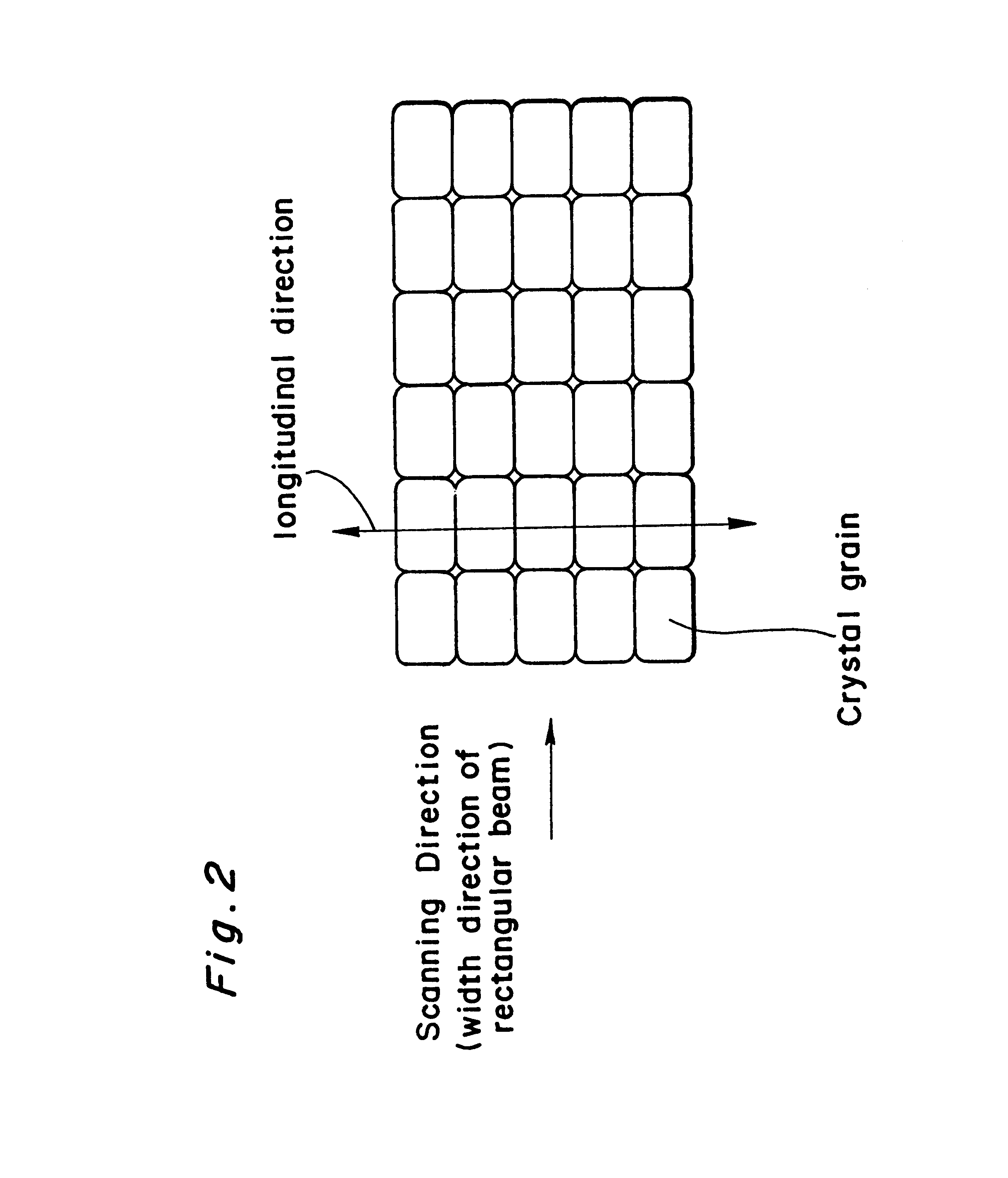

Optical system and apparatus for laser heat treatment and method for producing semiconductor devices by using the same

InactiveUS6437284B1High crystallinityReduced lattice defectsSemiconductor/solid-state device manufacturingMetal working apparatusLight beamOptoelectronics

An optical system that controls laser beam spot profile for forming a high performance thin film by a laser heat treatment process is provided. In the optical system that irradiates a rectangular laser beam on a film formed on a substrate, intensity distribution forming, apparatus makes the intensity distribution uniform in the longitudinal direction while maintaining the properties of the laser beam 2 such as directivity in the direction of shorter side, making it possible to concentrate the light to a limit permitted by the nature of the laser beam and achieve the maximum intensity gradient on the film disposed on the substrate. Thus a steep temperature distribution can be generated on the film disposed on the substrate and, as a result, high performance thin film can be formed.

Owner:MITSUBISHI ELECTRIC CORP

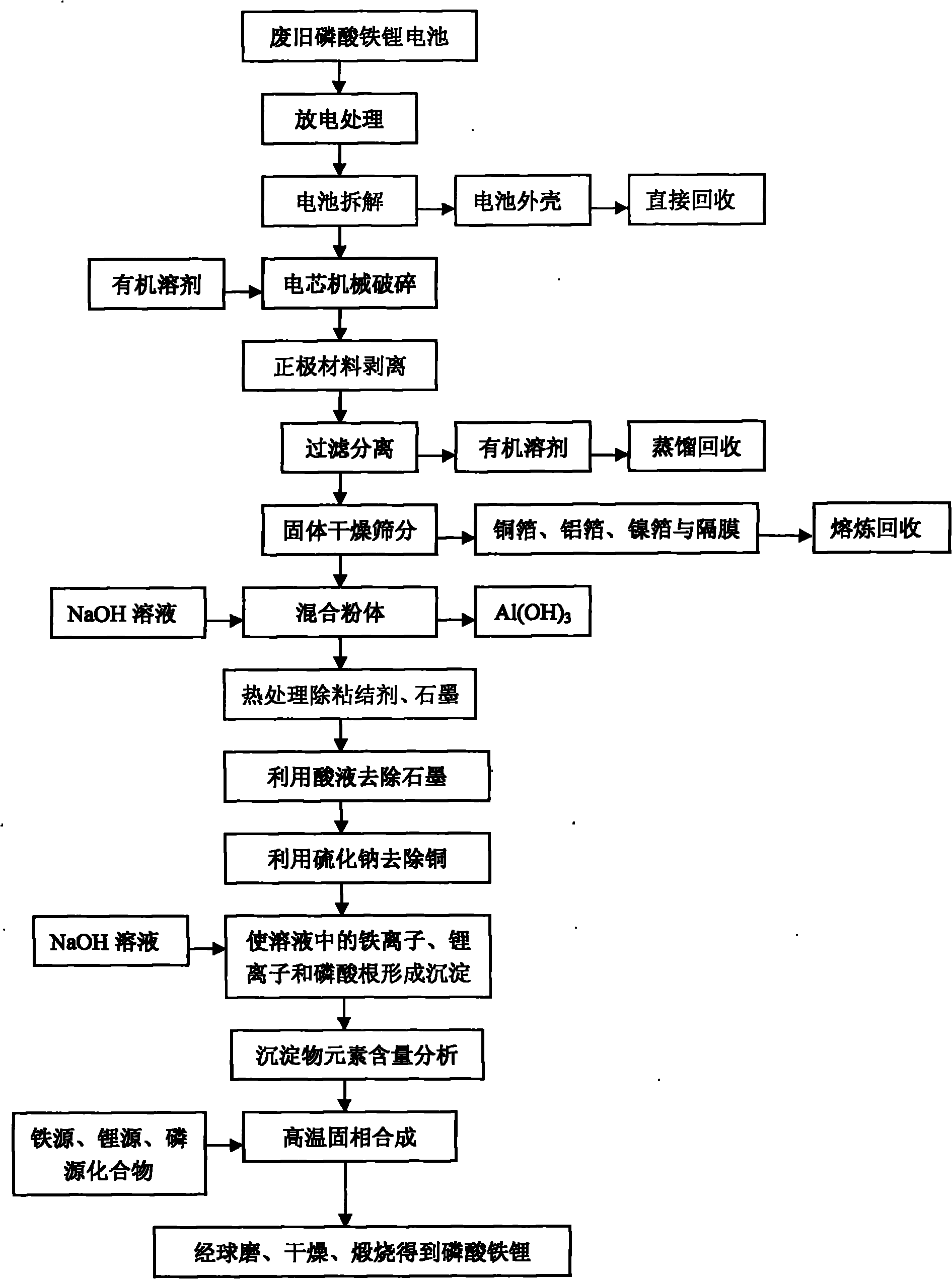

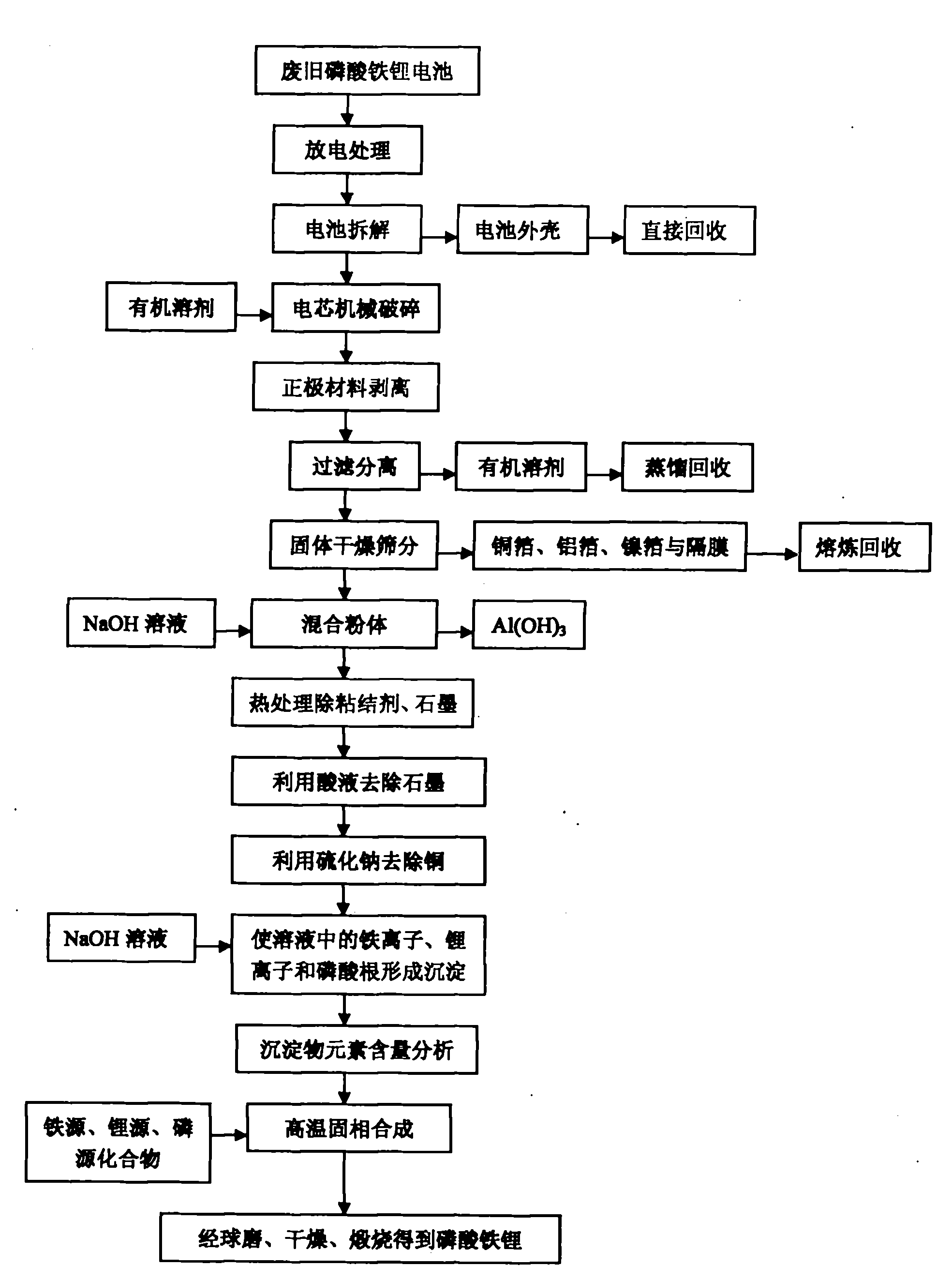

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

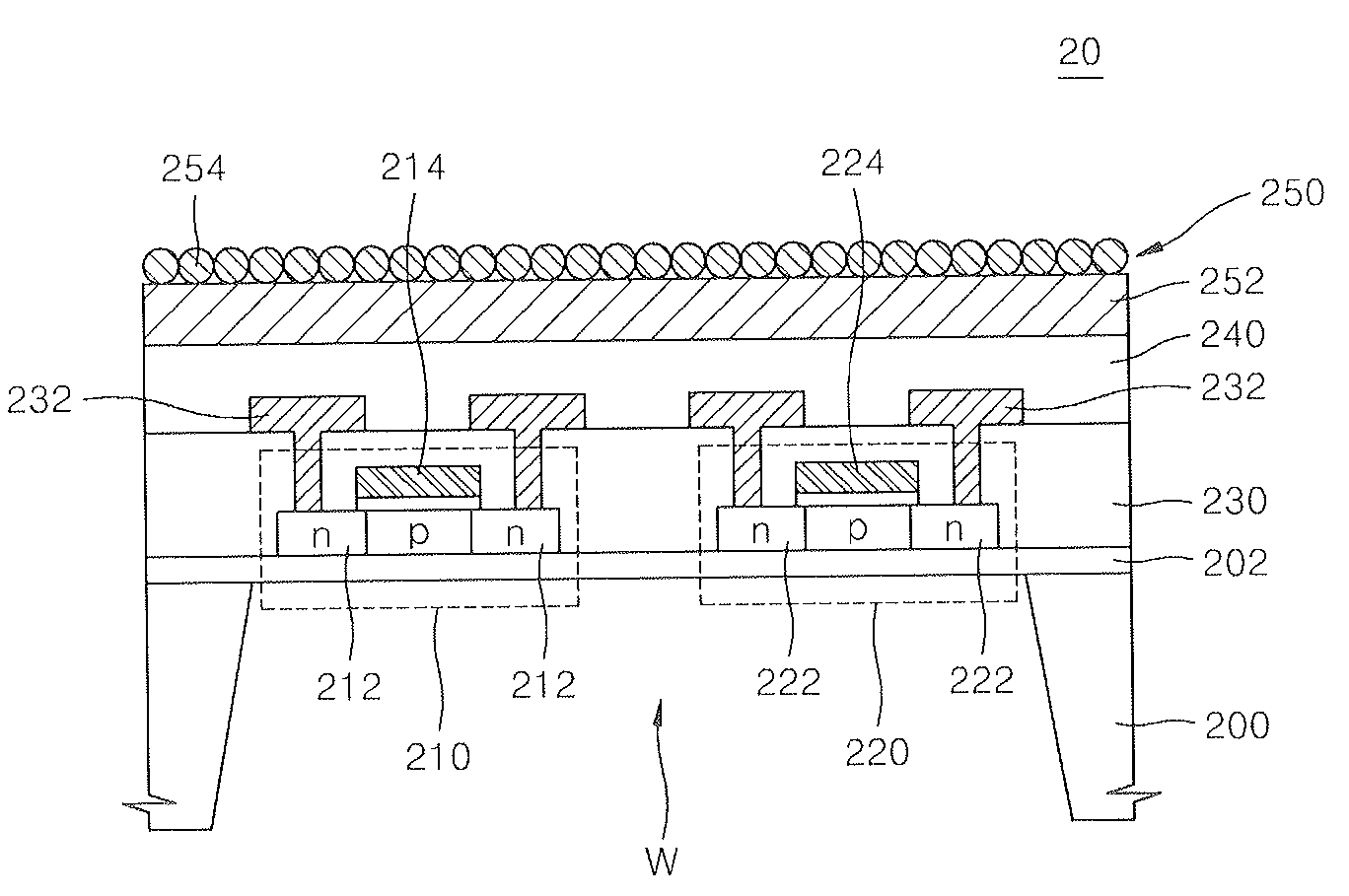

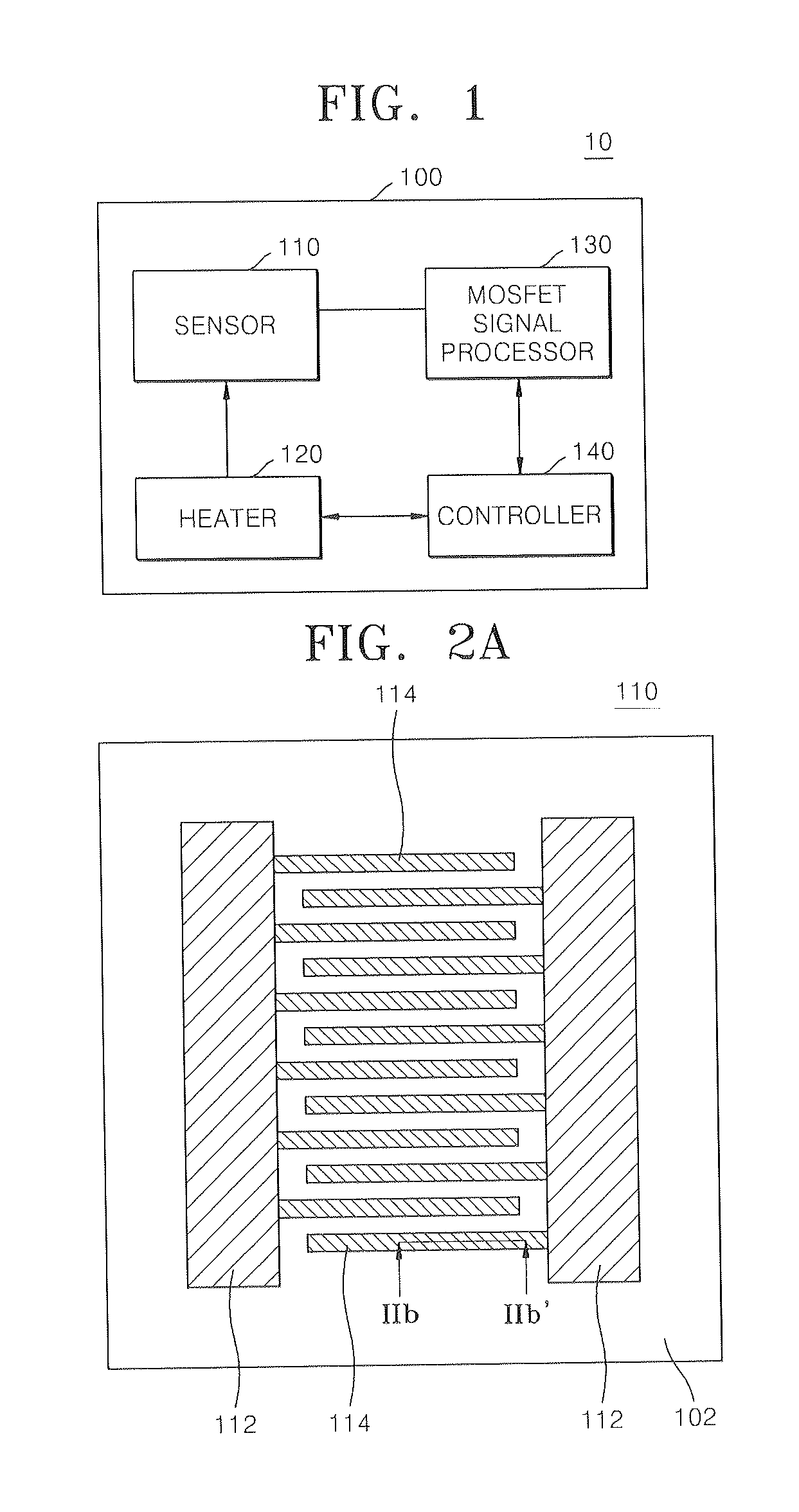

Method of forming sensor for detecting gases and biochemical materials, integrated circuit having the sensor, and method of manufacturing the integrated circuit

InactiveUS20080121946A1Characteristics degradation of an integrated circuit caused by heating the unit devices when forming the sensor can be preventedSemiconductor/solid-state device manufacturingNanosensorsMOSFETNano structuring

A method of forming a sensor for detecting gases and biochemical materials that can be fabricated at a temperature in a range from room temperature to 400° C., a metal oxide semiconductor field effect transistor (MOSFET)-based integrated circuit including the sensor, and a method of manufacturing the integrated circuit are provided. The integrated circuit includes a semiconductor substrate. The sensor for detecting gases and biochemical materials includes a pair of electrodes formed on a first region of the semiconductor substrate, and a metal oxide nano structure layer formed on surfaces of the pair electrodes. A heater is formed to perform thermal treatment to re-use the material detected in the metal oxide nano structure layer. Also, a signal processor is formed by a MOSFET to process a predetermined signal obtained from a quantity change of a current flowing through the pair of electrodes of the sensor. To form the sensor, the metal oxide nano structure layer is formed on surfaces of the pair of electrodes at a temperature in a range from room temperature to 400° C.

Owner:ELECTRONICS & TELECOMM RES INST

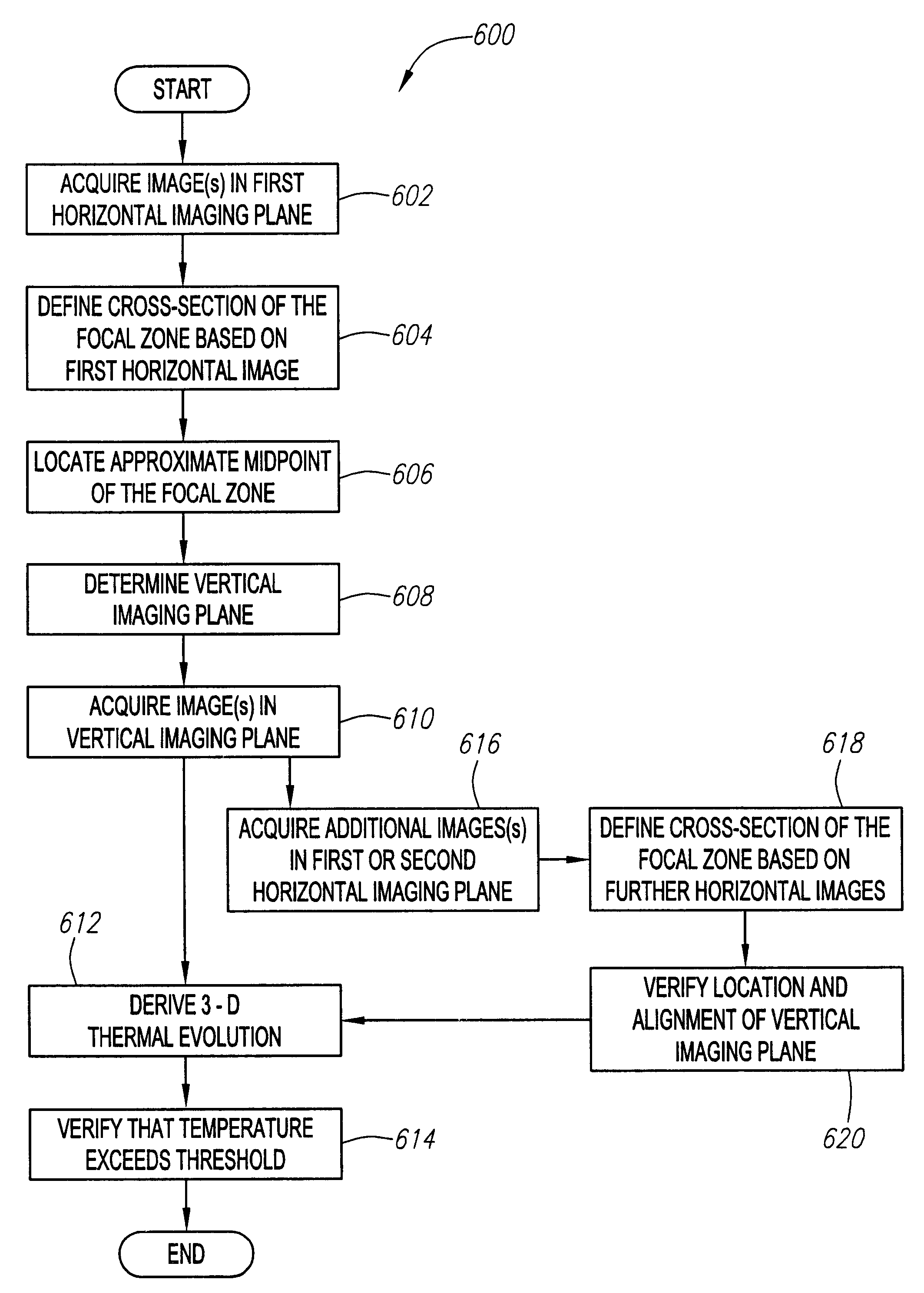

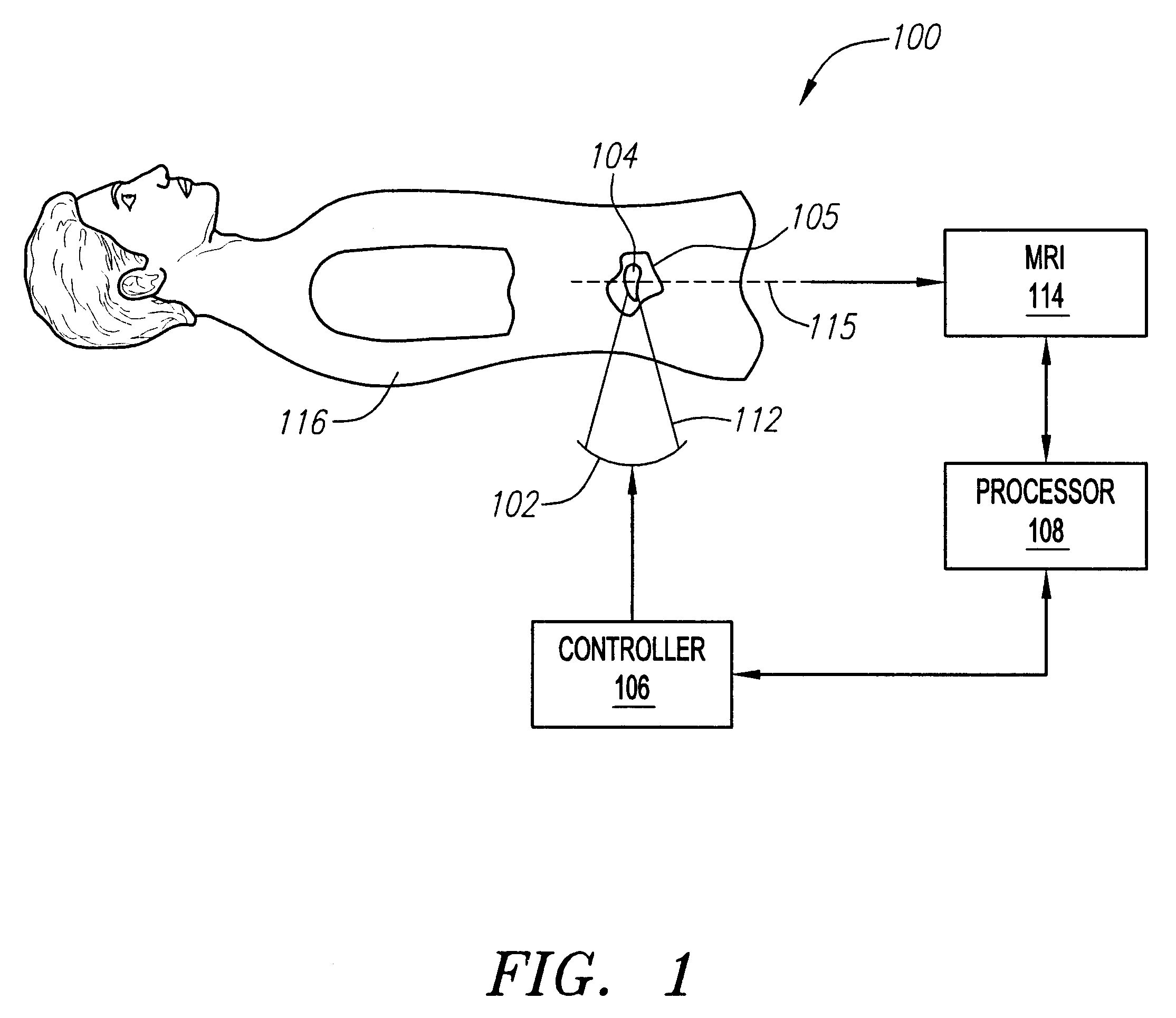

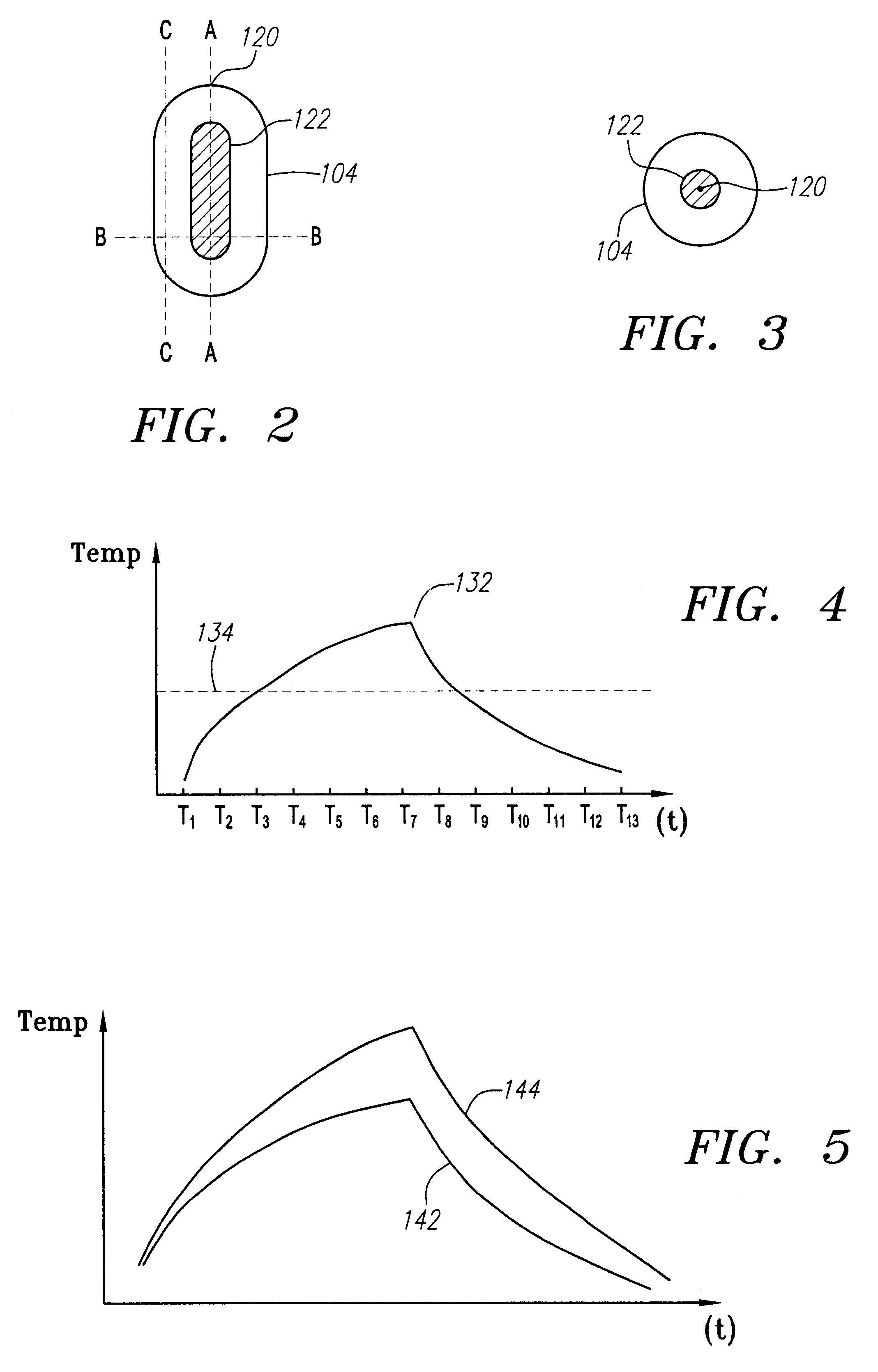

MRI-guided temperature mapping of tissue undergoing thermal treatment

Systems and methods using magnetic resonance imaging for monitoring the temperature of a tissue mass being heated by energy converging in a focal zone that is generally elongate and symmetrical about a focal axis. A first plurality of images of the tissue mass are acquired in a first image plane aligned substantially perpendicular to the focal axis. A cross-section of the focal zone in the first image plane is then defined from the first plurality of images. A second plurality of images are acquired of the tissue mass in a second image plane aligned substantially parallel to the focal axis, the second image plane bisecting the first image plane at approximately a midpoint of the defined focal zone cross-section.

Owner:INSIGHTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com