Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49700results about "Process efficiency improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

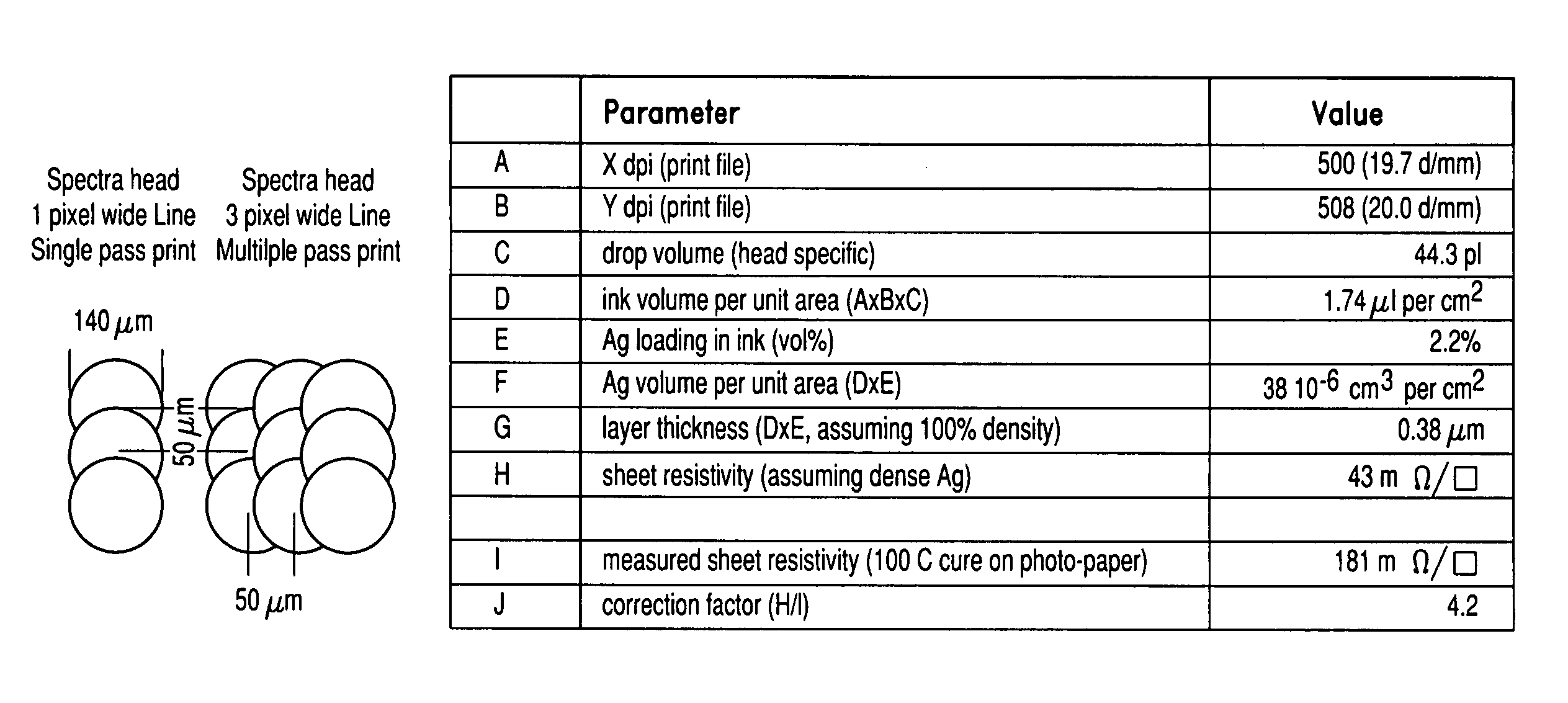

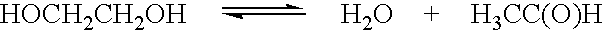

Metal nanoparticle compositions

InactiveUS20060189113A1Low processing (curing)Improve mechanical propertiesMaterial nanotechnologyTransportation and packagingNanometreViscosity

Owner:CABOT CORP

Surface-functionalized mesoporous carbon materials

ActiveUS9249241B2Effectively and efficiently functionalizedPractical and cost-effective for large scale productionProcess efficiency improvementPolyvinyl polymerSolvent

A functionalized mesoporous carbon composition comprising a mesoporous carbon scaffold having mesopores in which polyvinyl polymer grafts are covalently attached, wherein said mesopores have a size of at least 2 nm and up to 50 nm. Also described is a method for producing the functionalized mesoporous composition, wherein a reaction medium comprising a precursor mesoporous carbon, vinyl monomer, initiator, and solvent is subjected to sonication of sufficient power to result in grafting and polymerization of the vinyl monomer into mesopores of the precursor mesoporous carbon. Also described are methods for using the functionalized mesoporous carbon, particularly in extracting metal ions from metal-containing solutions.

Owner:UT BATTELLE LLC

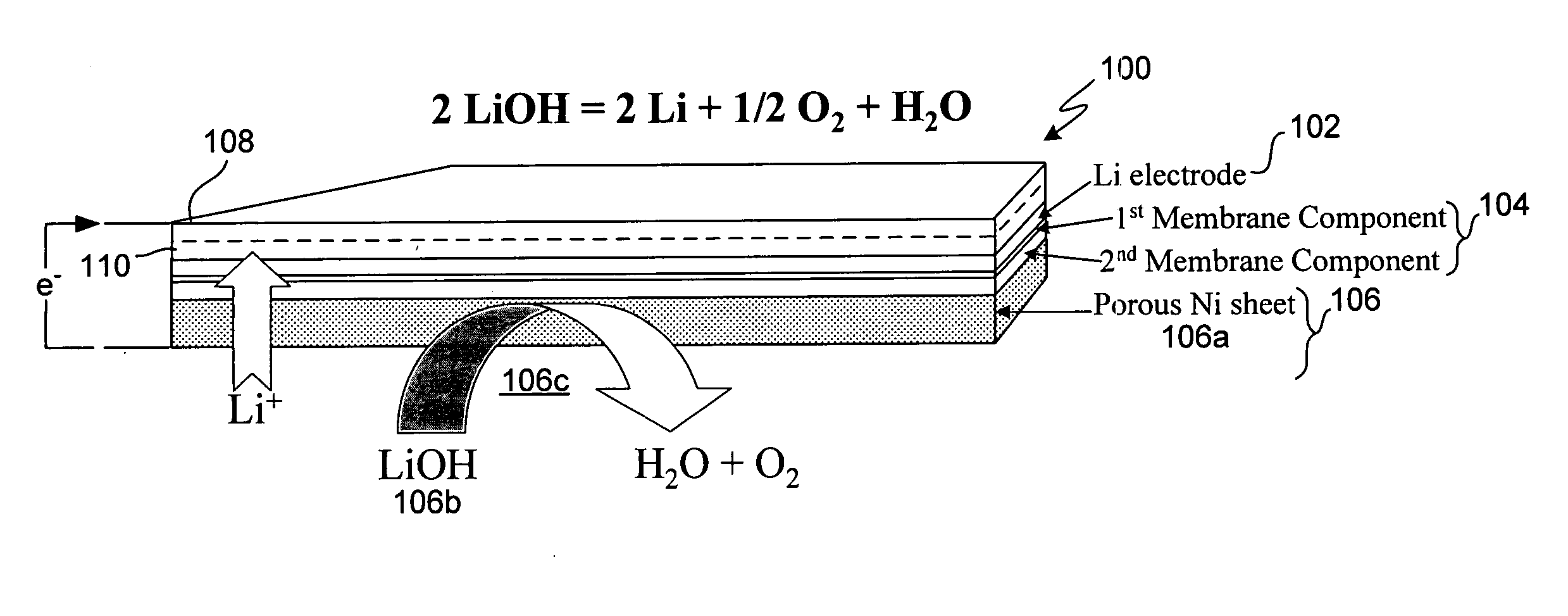

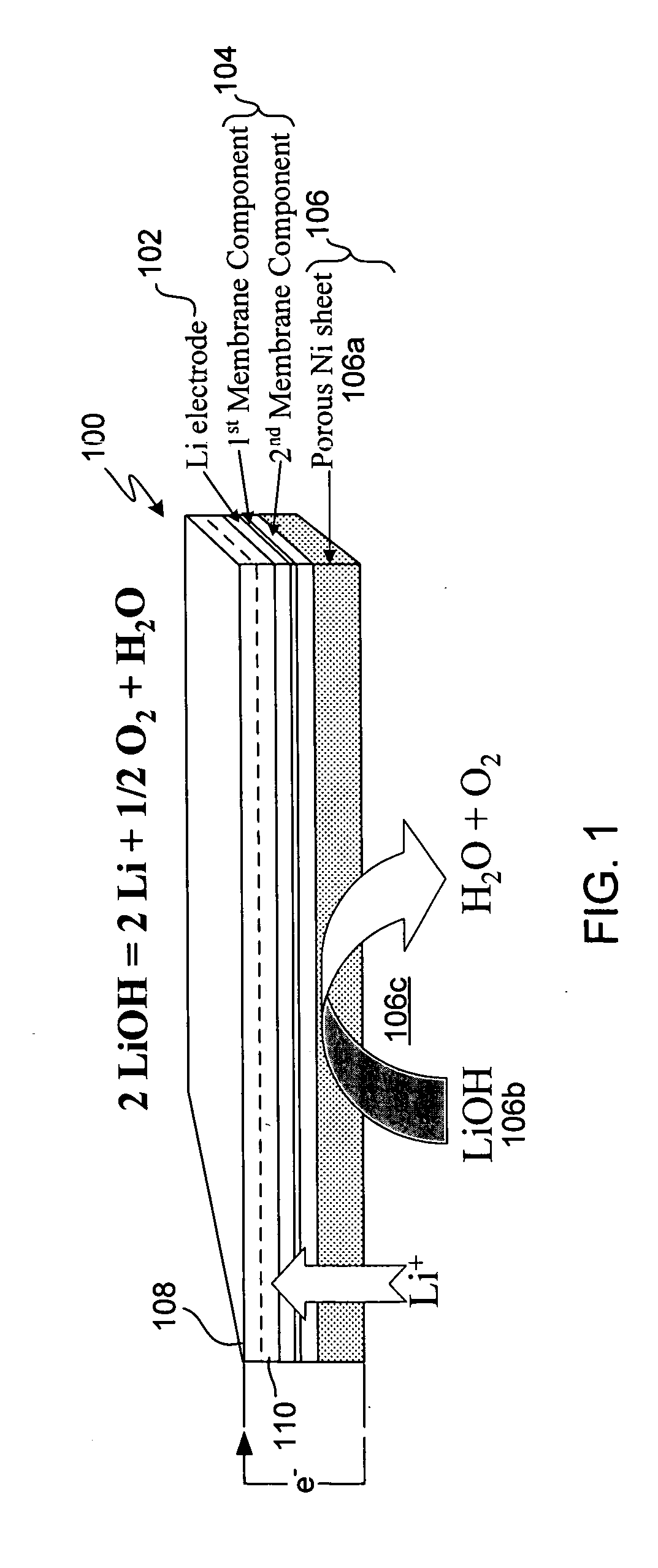

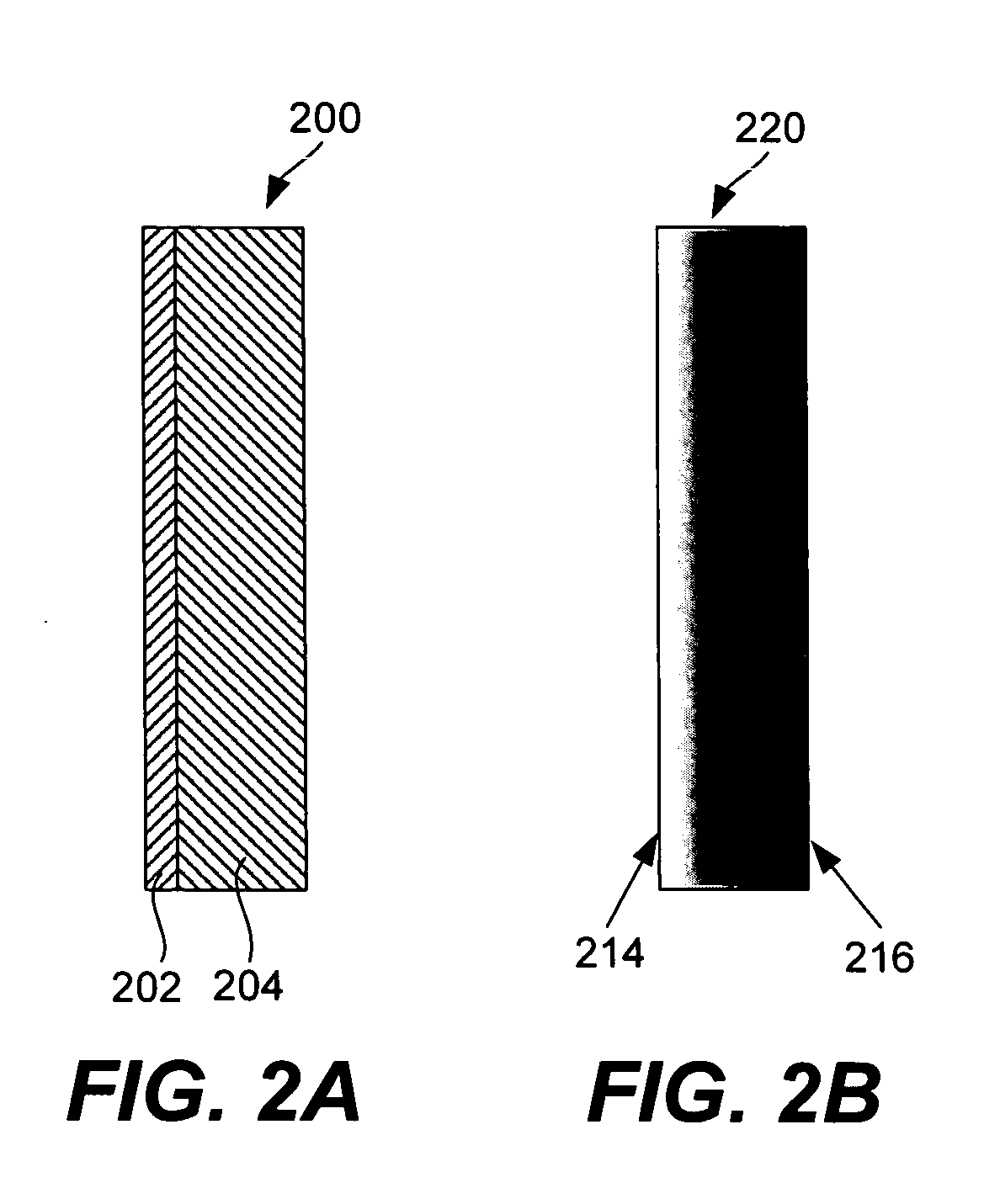

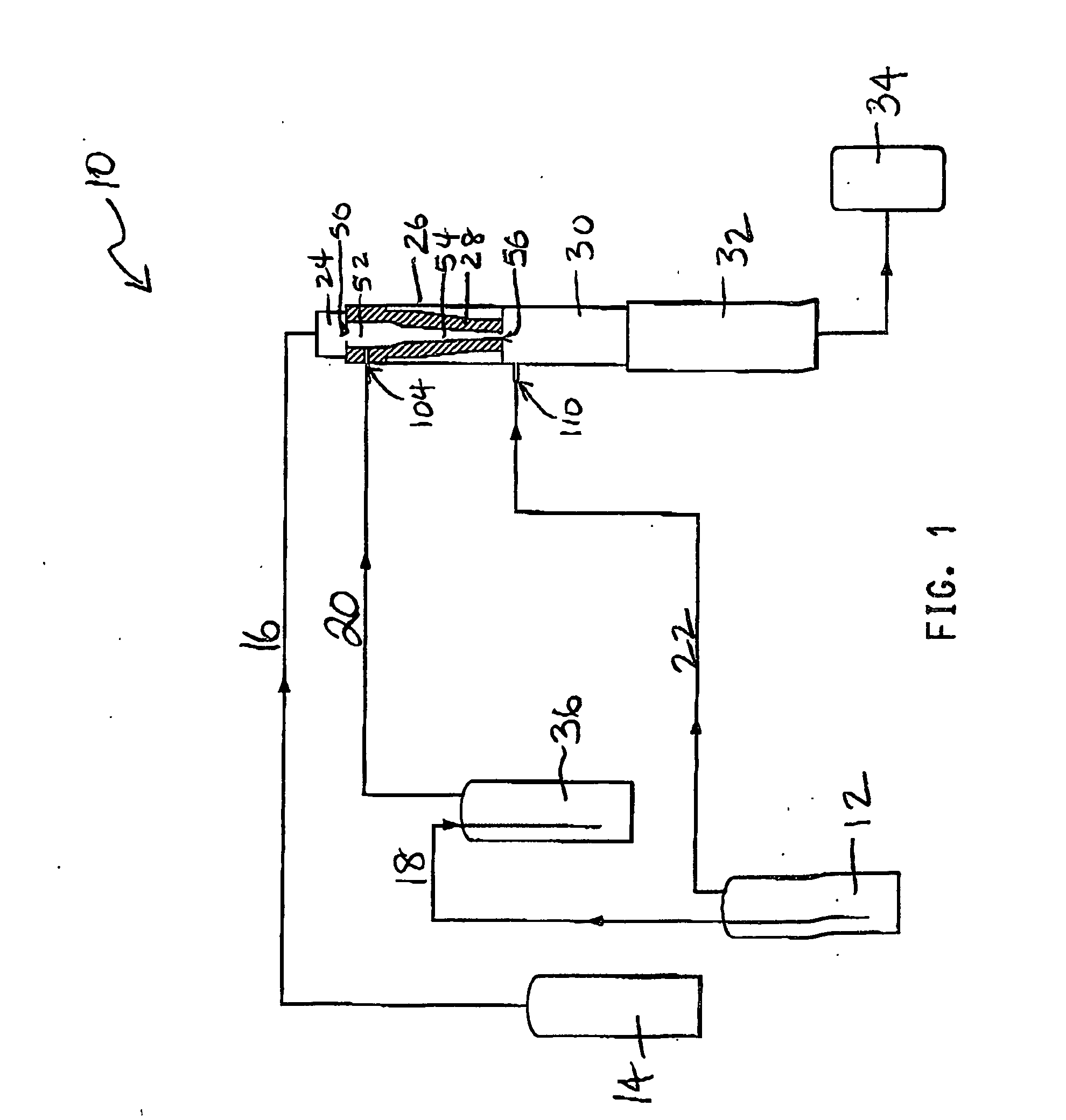

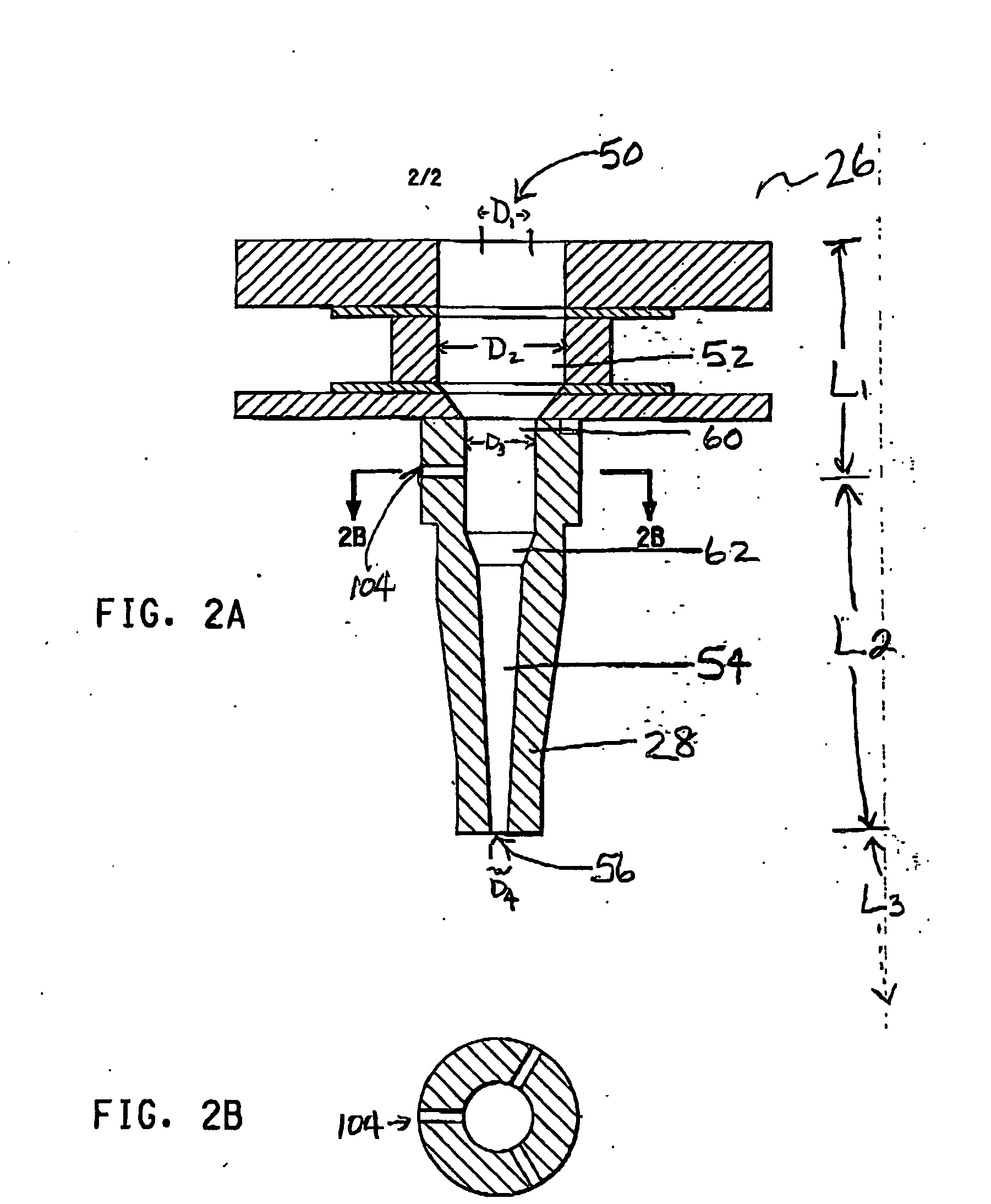

Active metal electrolyzer

InactiveUS20050100793A1Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

Electro-winning of active metal (e.g., lithium) ions from a variety of sources including industrial waste, and recycled lithium and lithium-ion batteries is accomplished with an electrolyzer having a protected cathode that is stable against aggressive solvents, including water, aqueous electrolytes, acid, base, and a broad range of protic and aprotic solvents. The electrolyzer has a highly ionically conductive protective membrane adjacent to the alkali metal cathode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the cathode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or anode material in conjunction with the cathode. The electrolyzer can be configured and operated to claim or reclaim lithium or other active metals from such sources.

Owner:POLYPLUS BATTERY CO INC

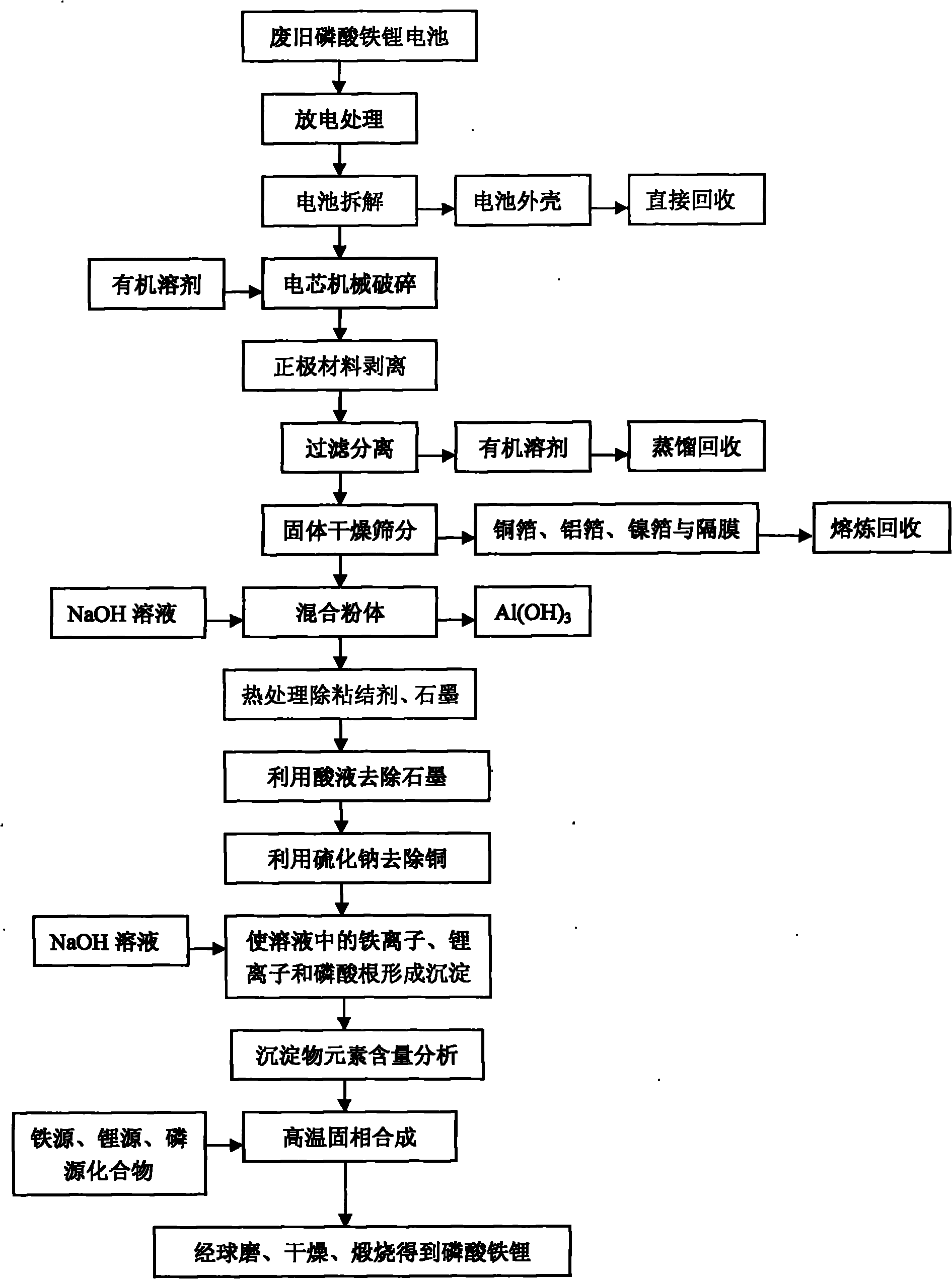

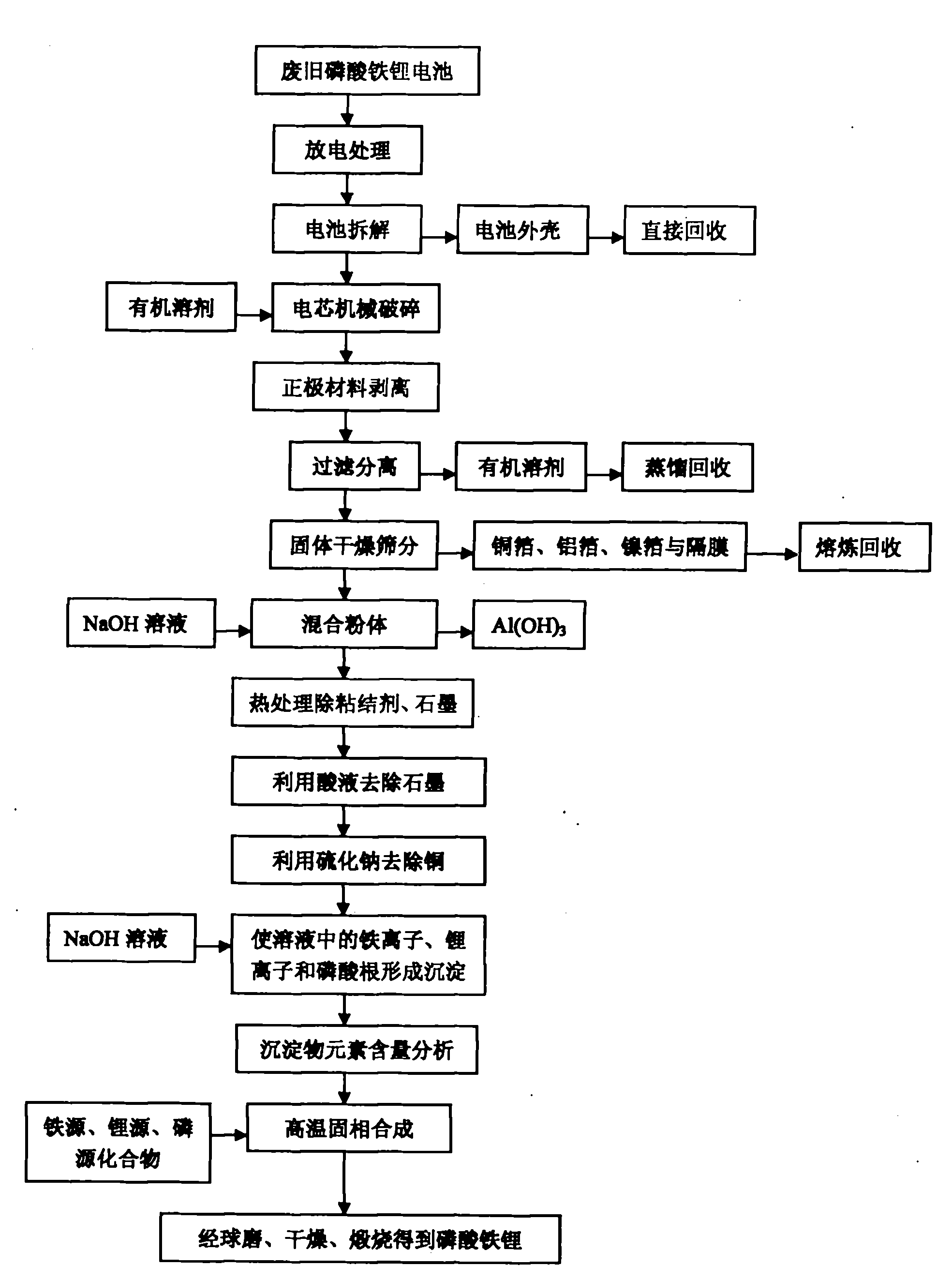

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

Rapid solar-thermal conversion of biomass to syngas

ActiveUS20080086946A1Improve reaction kineticsWide rangeElectrical coke oven heatingSolar heating energySyngasReactor design

Methods for carrying out high temperature reactions such as biomass pyrolysis or gasification using solar energy. The biomass particles are rapidly heated in a solar thermal entrainment reactor. The residence time of the particles in the reactor can be 5 seconds or less. The biomass particles may be directly or indirectly heated depending on the reactor design. Metal oxide particles can be fed into the reactor concurrently with the biomass particles, allowing carbothermic reduction of the metal oxide particles by biomass pyrolysis products. The reduced metal oxide particles can be reacted with steam to produce hydrogen in a subsequent process step.

Owner:UNIV OF COLORADO THE REGENTS OF

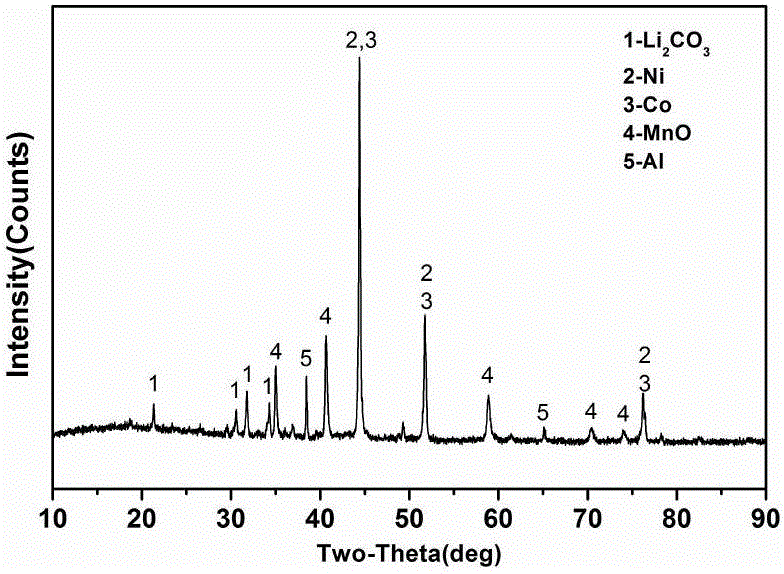

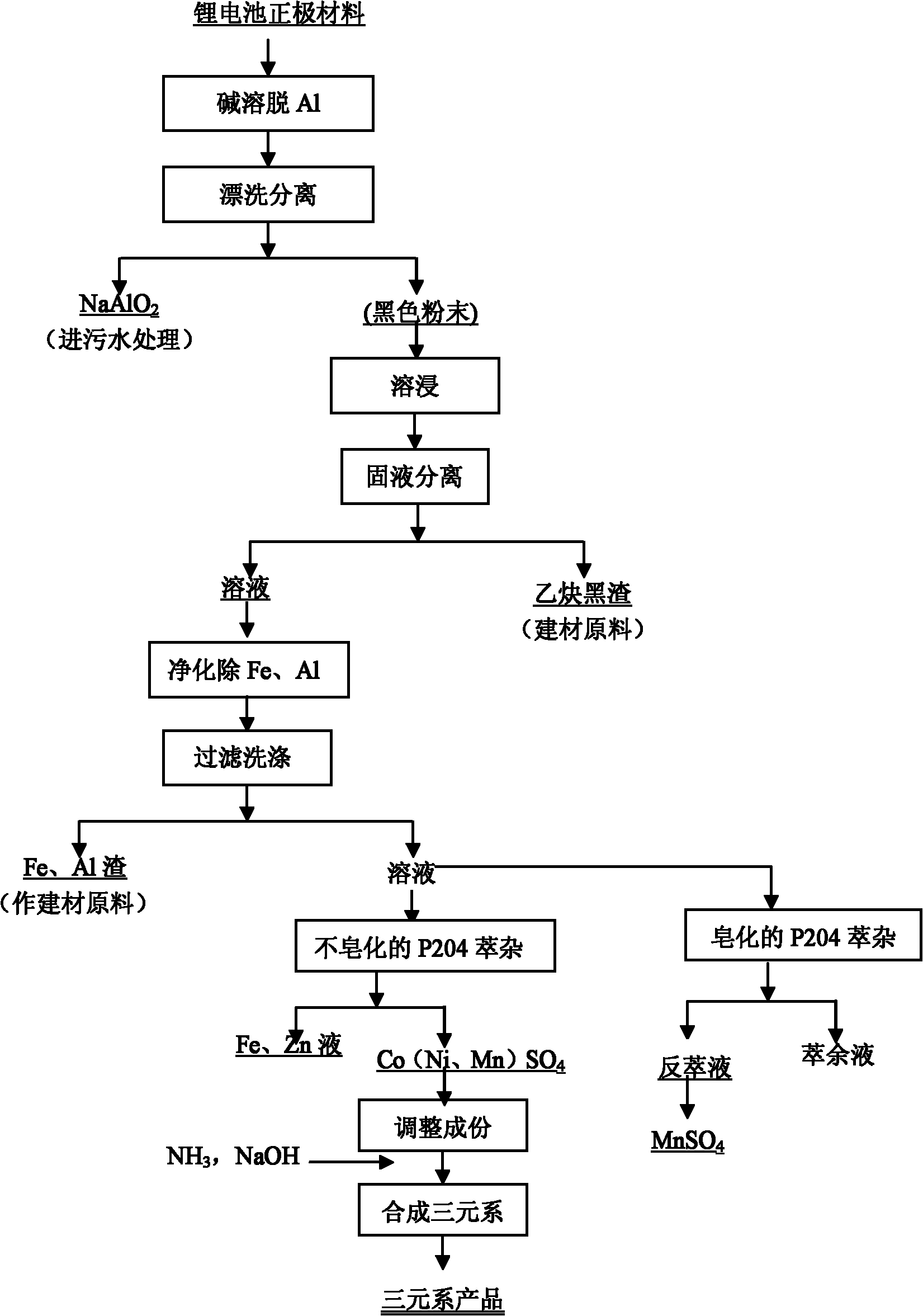

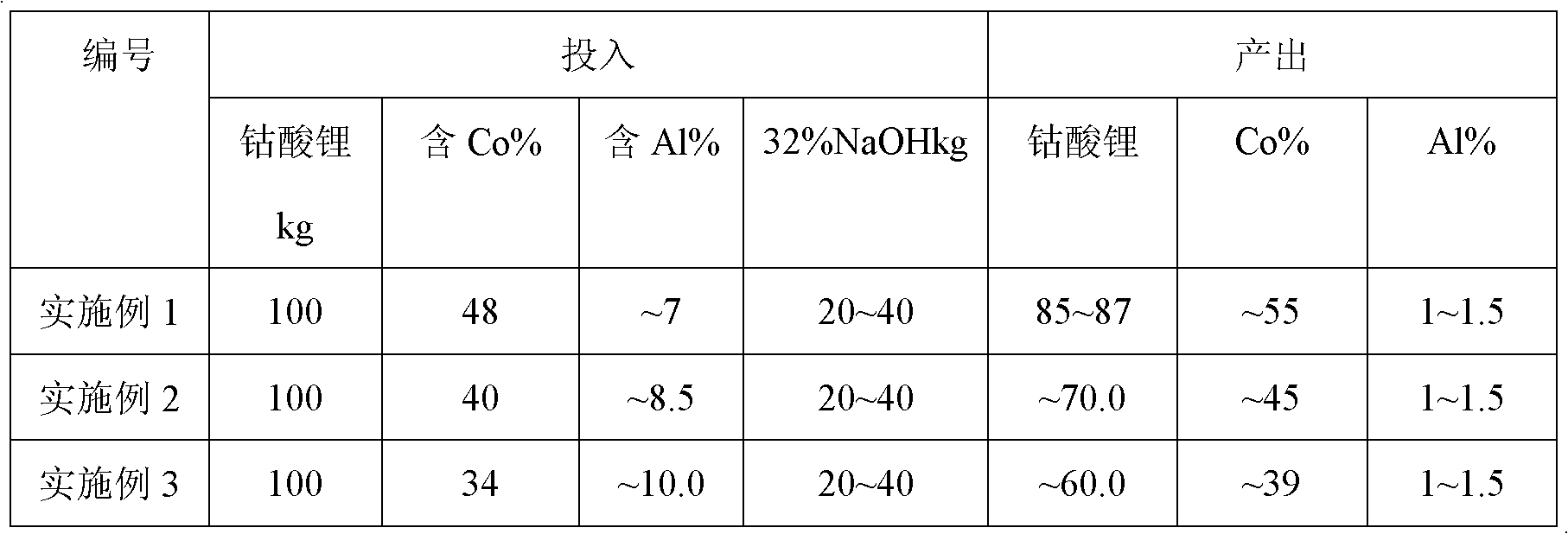

Method for comprehensively recovering valuable metals from waste lithium-ion battery material

ActiveCN106129511AEfficient recyclingHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementManganeseAmmonia

The invention discloses a method for comprehensively recovering valuable metals from a waste lithium-ion battery material. The method is characterized by comprising the steps of mixing a waste lithium-ion battery positive electrode material with a reducing agent, or mixing simply crushed whole battery with a carbon reducing agent; carrying out reducing roasting treatment at the temperature of 500-750 DEG C; firstly carbonizing and leaching a roasted product through CO2 to obtain a lithium bicarbonate water solution for preparing an Li2CO3 product; and leaching valuable elements of cobalt, nickel, manganese and the like from liquid leached residues through oxidation acid leaching or oxidation ammonia leaching, carrying out extracting and purifying and then preparing the corresponding compound product. The method is simple in technology and short in flow; the reagent cost is low; and valuable metal elements of lithium, the cobalt, the nickel, the manganese and the like in the waste lithium-ion battery material can be efficiently recovered.

Owner:GUANGDONG GUANGHUA SCI TECH

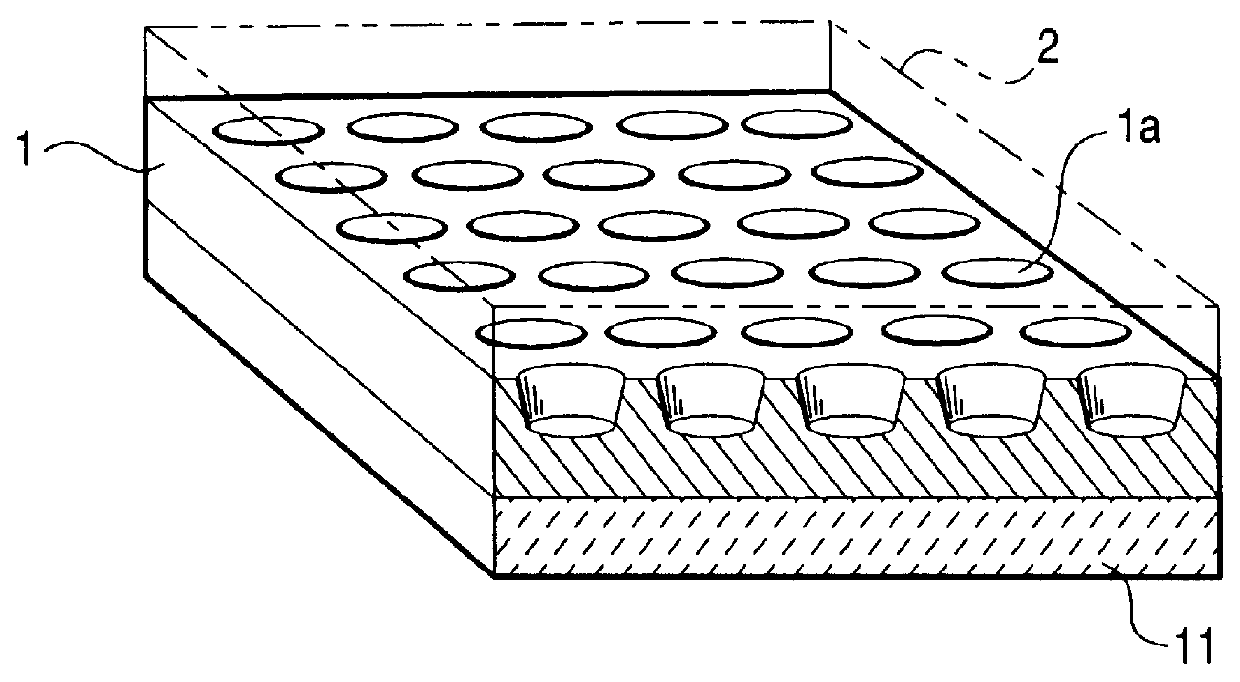

Method of producing a reduced metal, and traveling hearth furnace for producing same

InactiveUS6126718ALow gangue and ash contentSmall amountProcess efficiency improvementGas emission reductionHearthMetal

Producing reduced metal by charging and stacking a raw material containing a metal-containing material and a solid reducing material on a horizontally moving hearth of a traveling hearth furnace, by disposing a solid reducing material layer on the hearth, forming concave portions at the solid reducing material surface, stacking the raw material on the surface of the solid reducing material layer, reducing raw material by at least once heating and melting the material on the hearth to separate metal and gangue and ash ingredients, and discharging metal from the hearth.

Owner:KAWASAKI STEEL CORP

Process for extracting lithium from salt lake brine by adsorptive method

InactiveCN1511964AEasy to makeNo pollutionProcess efficiency improvementLithium chlorideLithium carbonate

The present invention relates to adsorption process of extracting lithium from salt lake brine, and the process is suitable for producing lithium carbonate and lithium chloride with lithium-containing Qinghai saline lake brine, including concentrated lithium-containing Qinghai saline lake brine. The process includes sun shining saline lake brine to obtain concentrated lithium containing brine, adsorption of lithium ion with aluminum salt adsorbent, eluting adsorbed lithium ion with water, and refining and concentrating the elutriant to obtain material for preparing lithium carbonate and lithium chloride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for recovering rare earth from rare earth-containing aluminum-silicon materials

ActiveCN101705380AAvoid enteringLess fixed investmentProcess efficiency improvementMolecular sieveSelective leaching

The invention relates to a method for recovering rare earth from rare earth-containing aluminum-silicon materials, which comprises the following steps: taking the rare earth-containing aluminum-silicon materials including rare earth-loaded molecular sieves, catalyst wastes, and the like as raw materials, conducting prioritized selective leaching by acid so as to lead the majority of the rare earth and a small amount of aluminum to be dissolved and separated from silicon and other impurities, leading the rare earth to form precipitates and be separated from the aluminum by adopting a double salt precipitation or oxalate precipitation method, and then recovering and purifying the rare earth. The method has the advantages of directly realizing the extraction of the rare earth from the aluminum-silicon materials including the molecular sieves and the like, with over 98% purity of the obtained rare earth, and avoiding impurities such as aluminum, silicon and the like entering the rare earth; and meanwhile, the technology also has the characteristics of little fixed investment, low production cost and easiness for realizing industrialized production.

Owner:GRIREM ADVANCED MATERIALS CO LTD

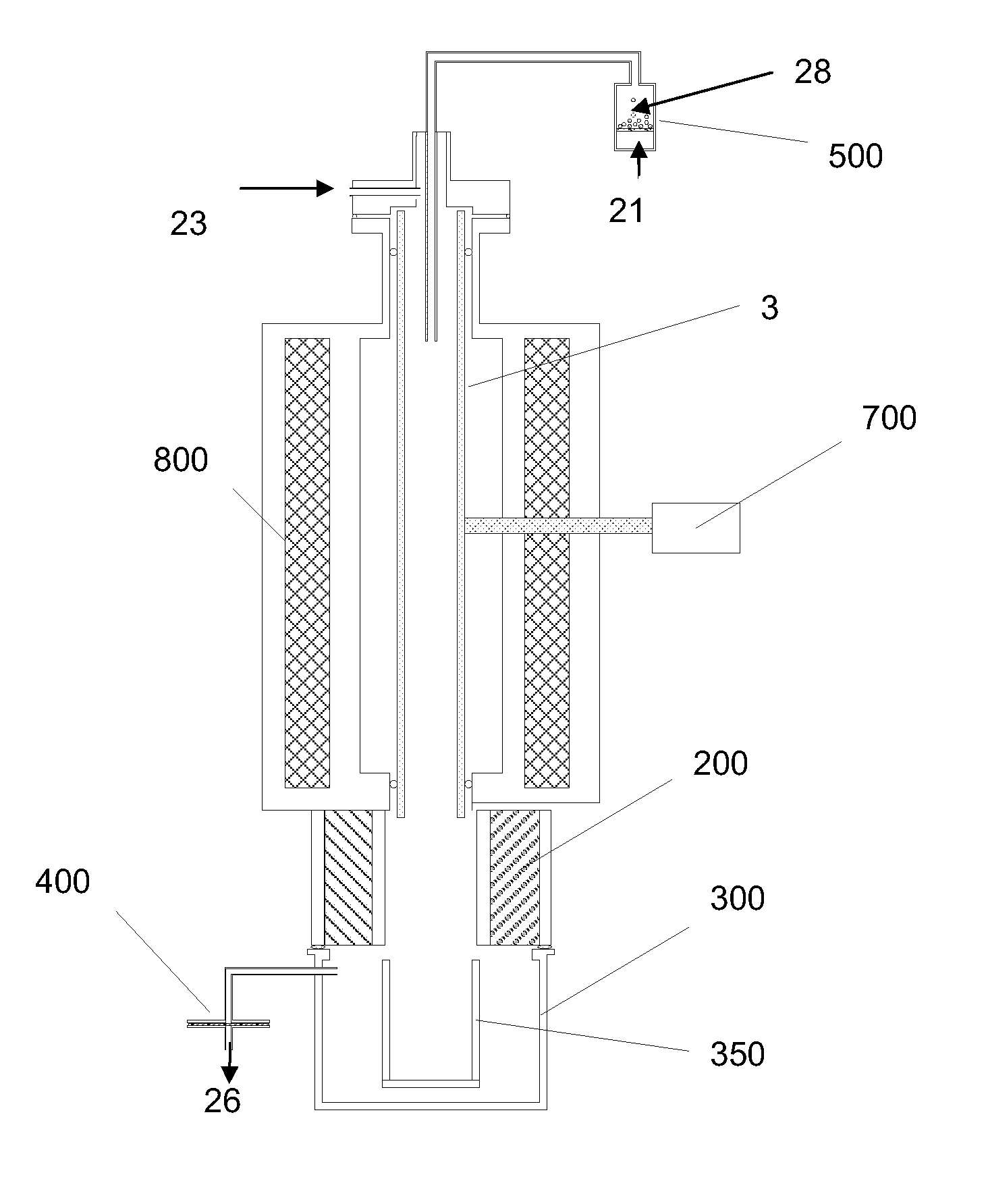

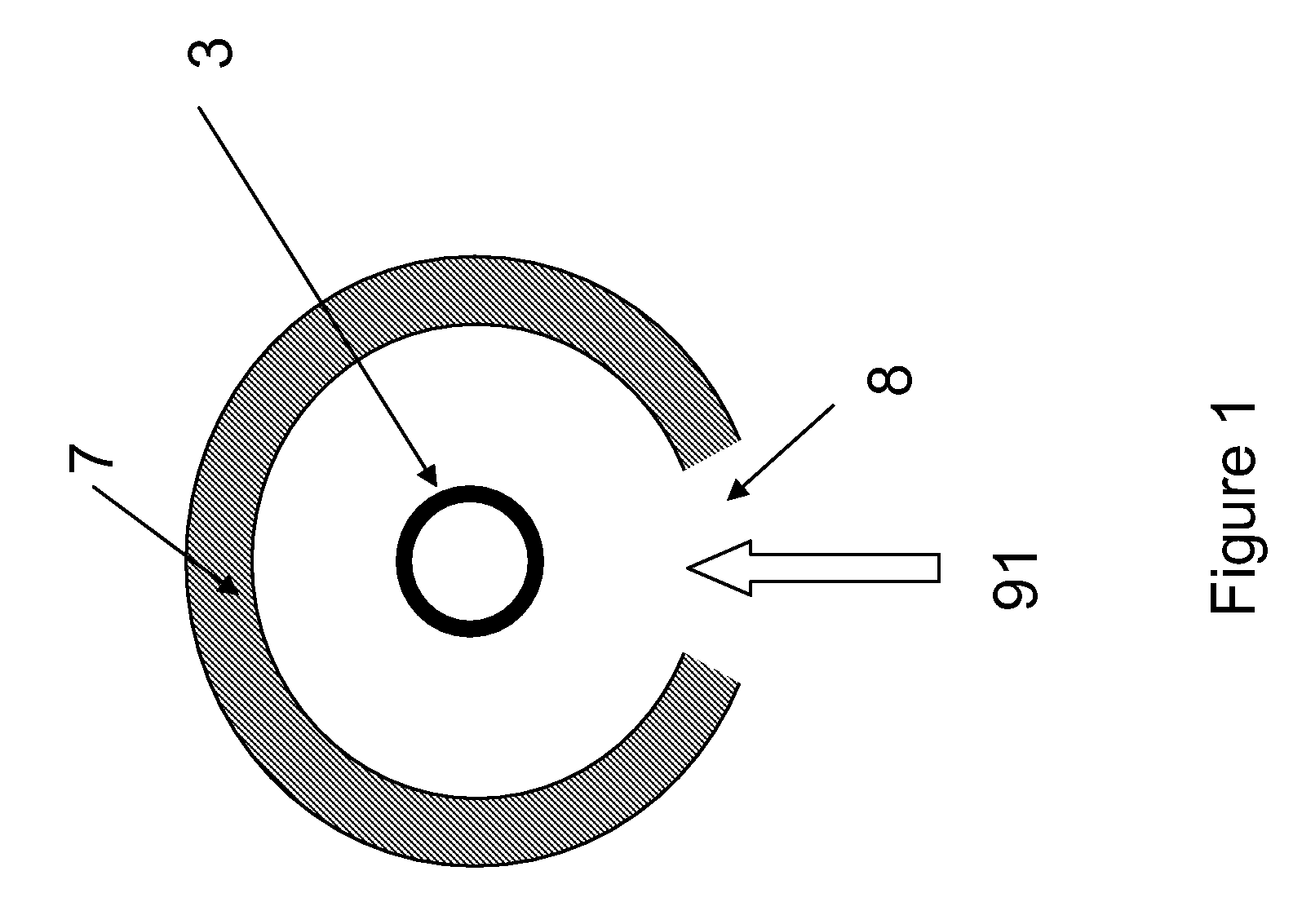

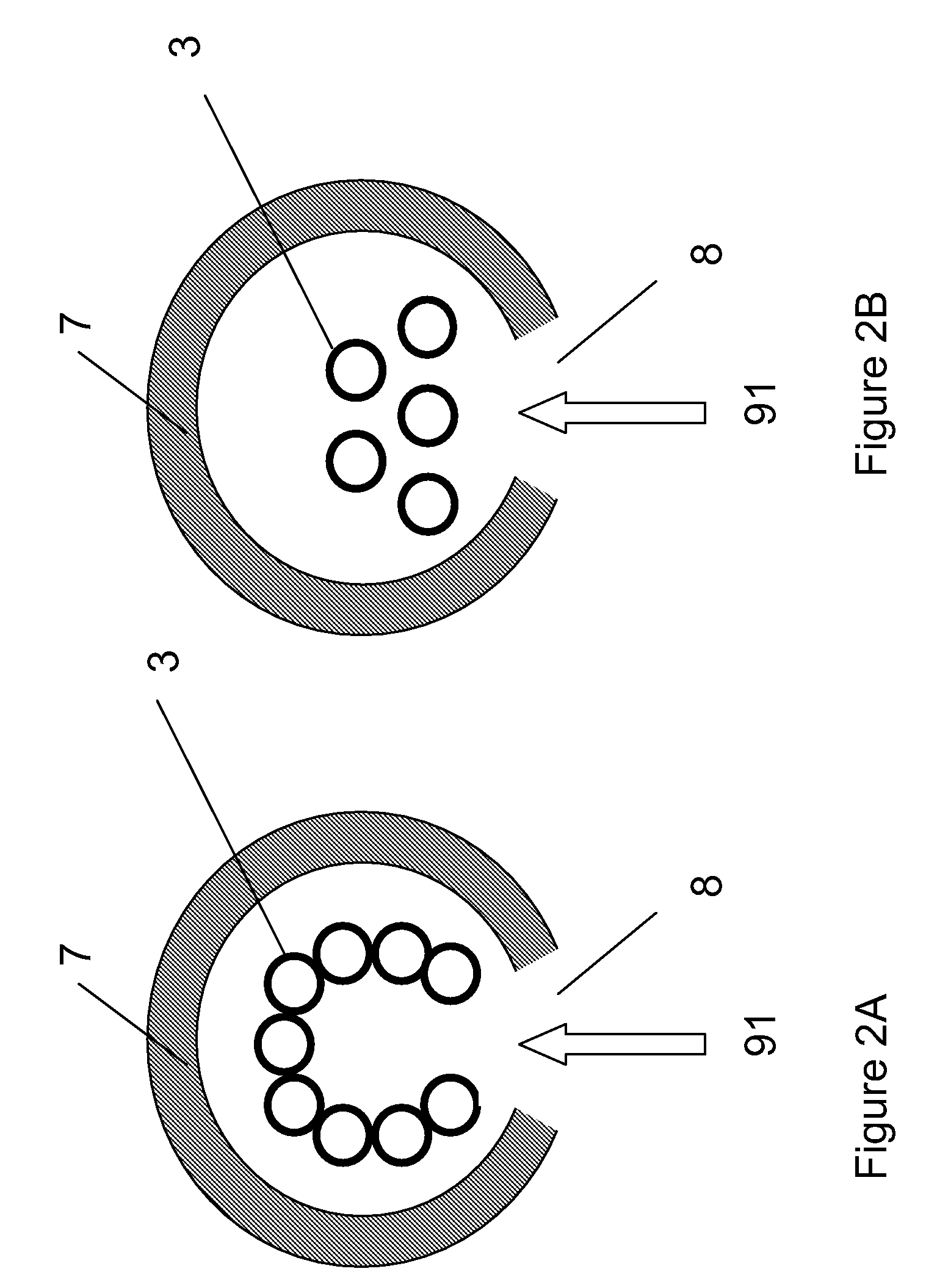

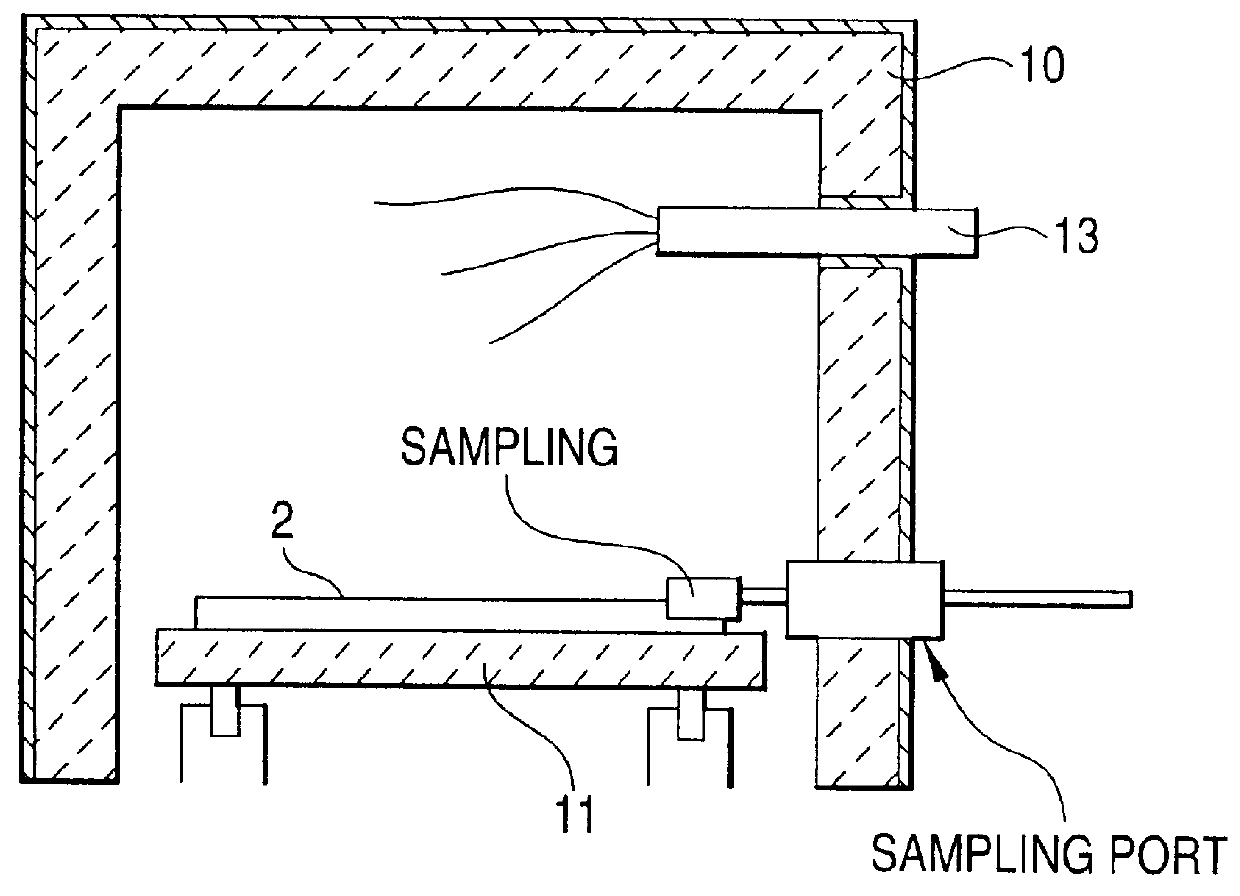

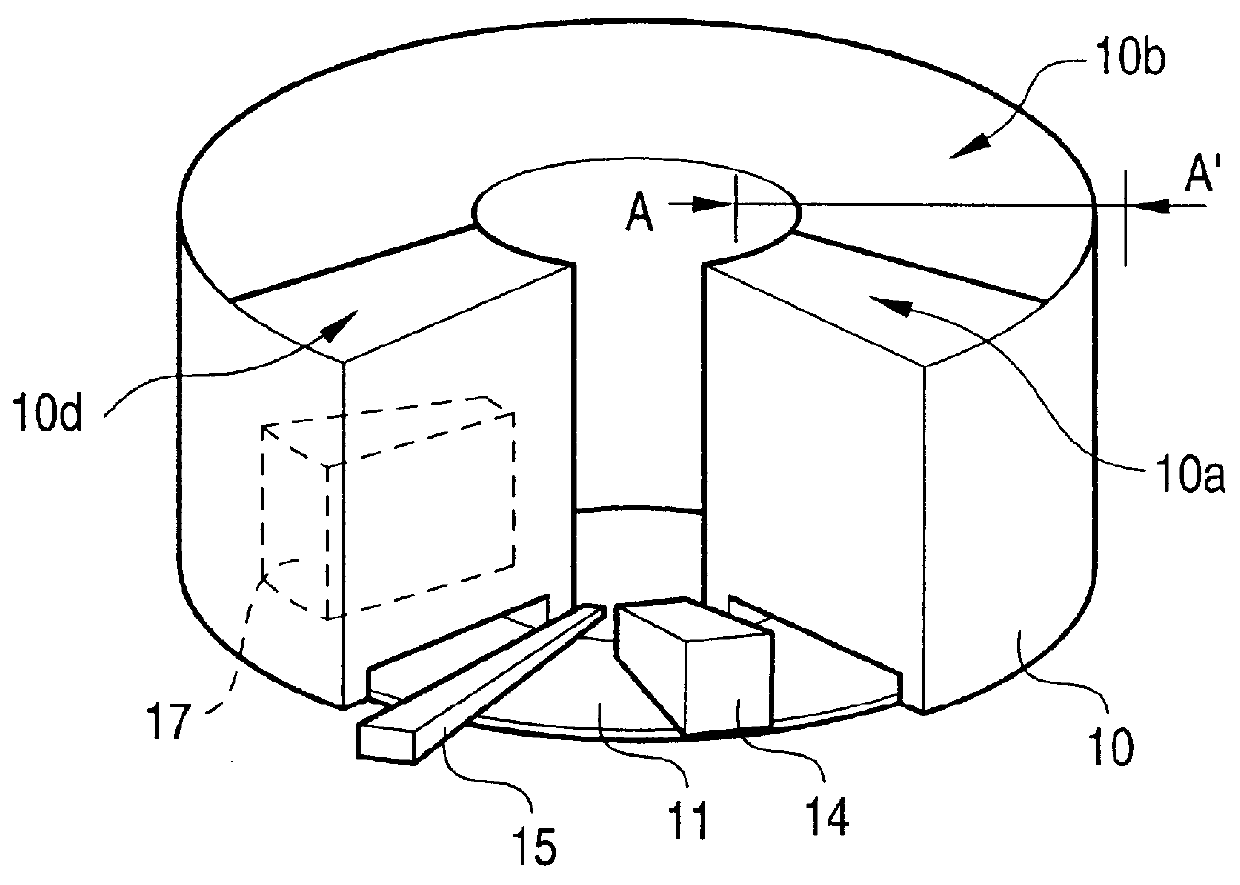

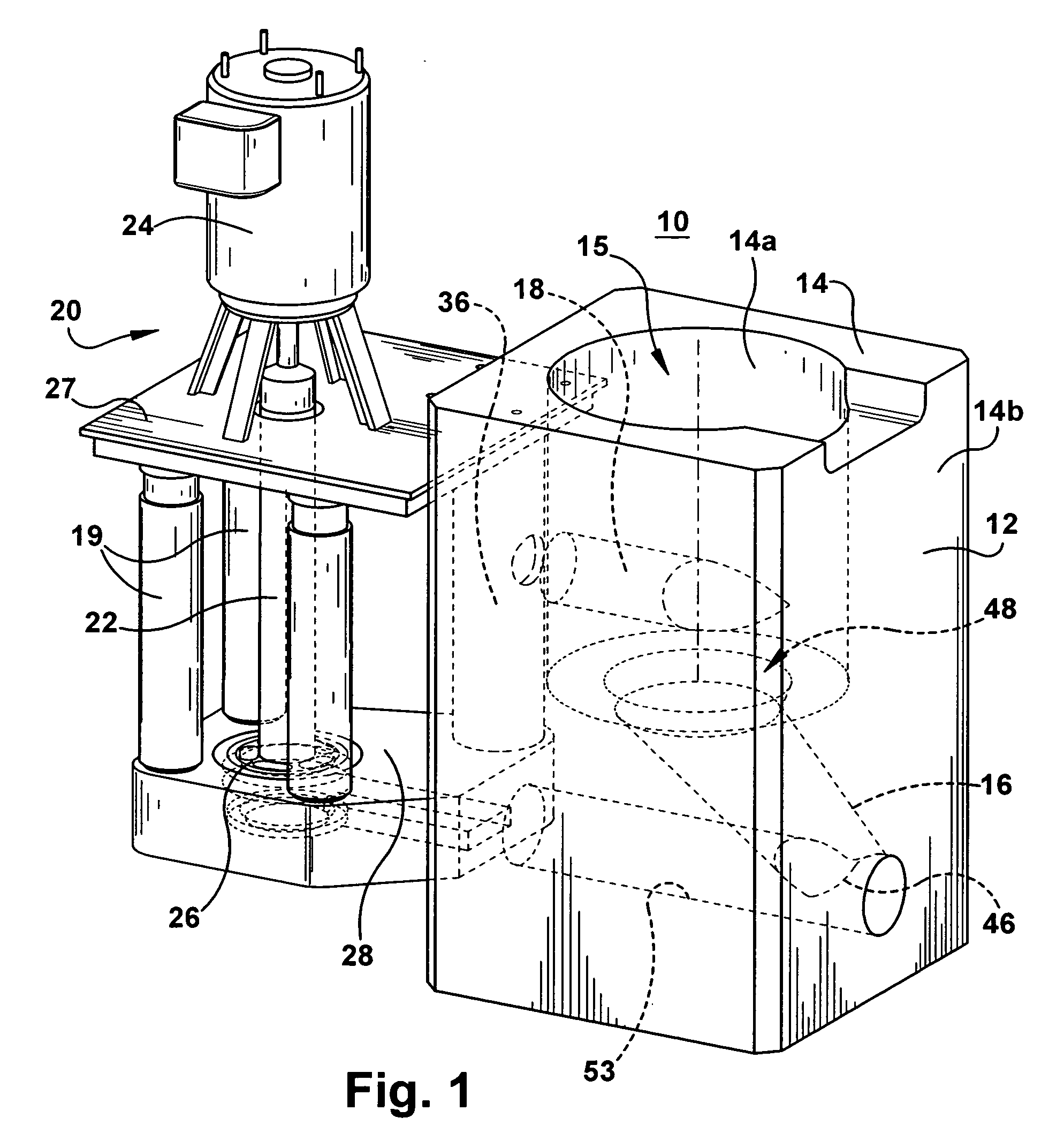

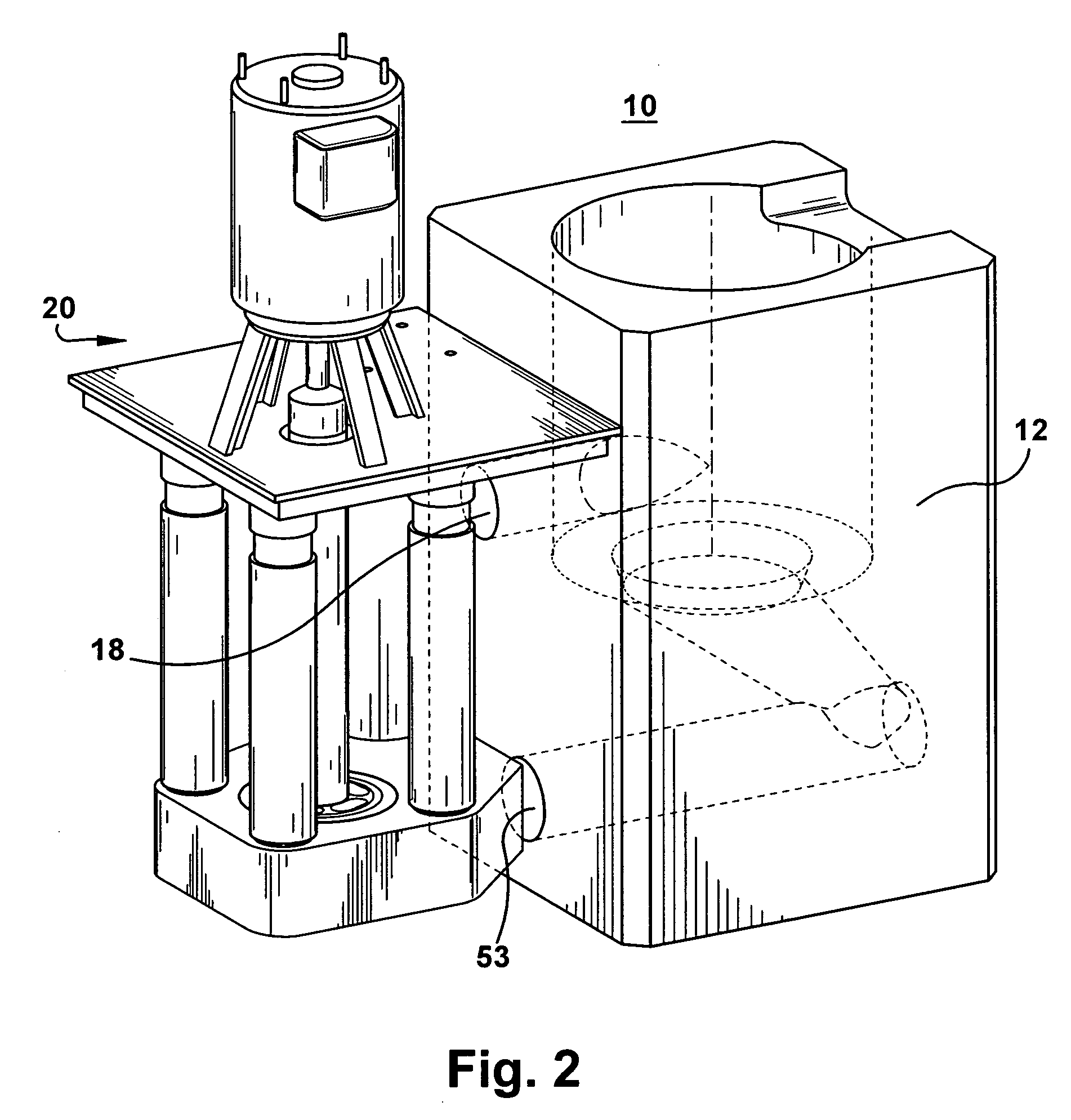

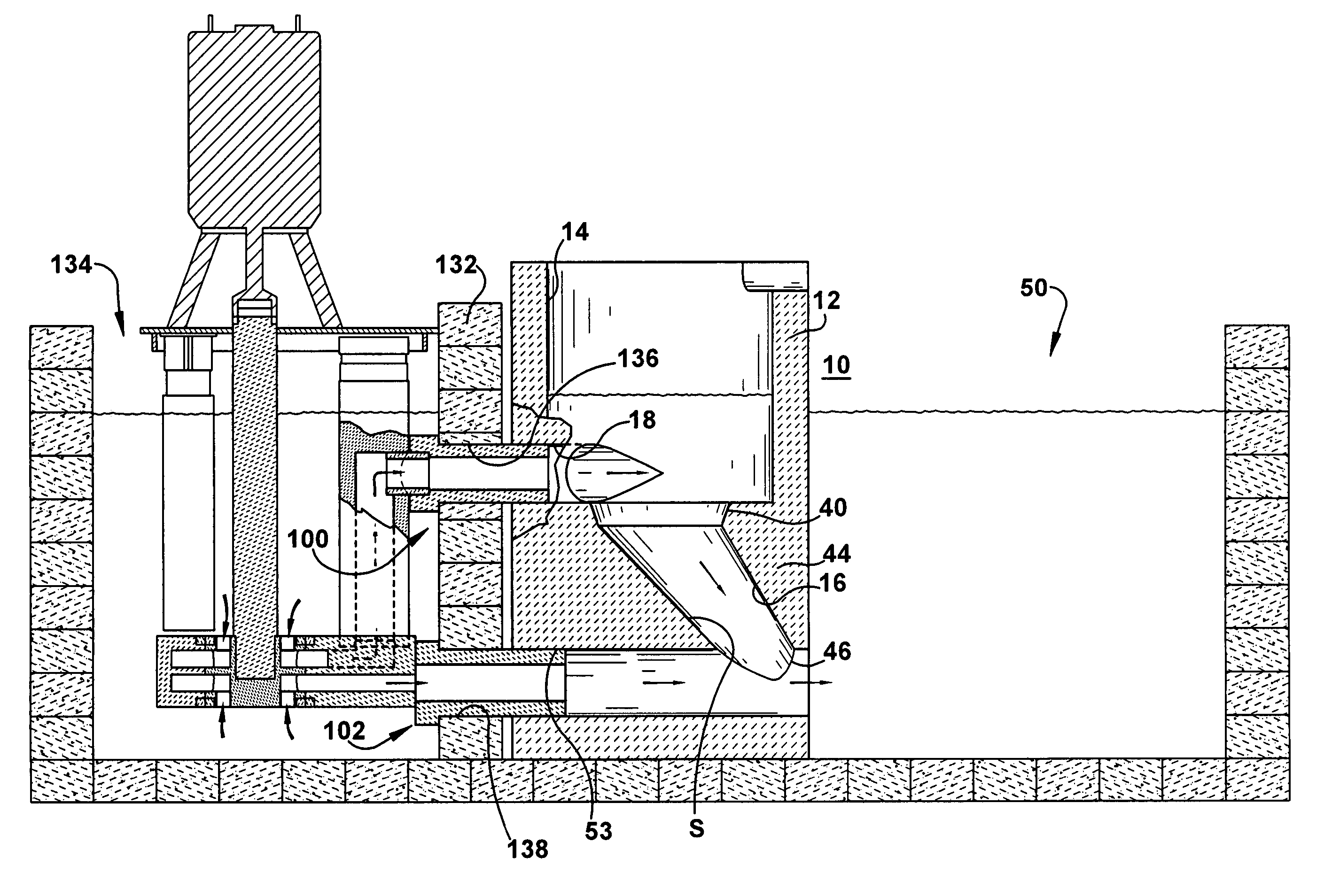

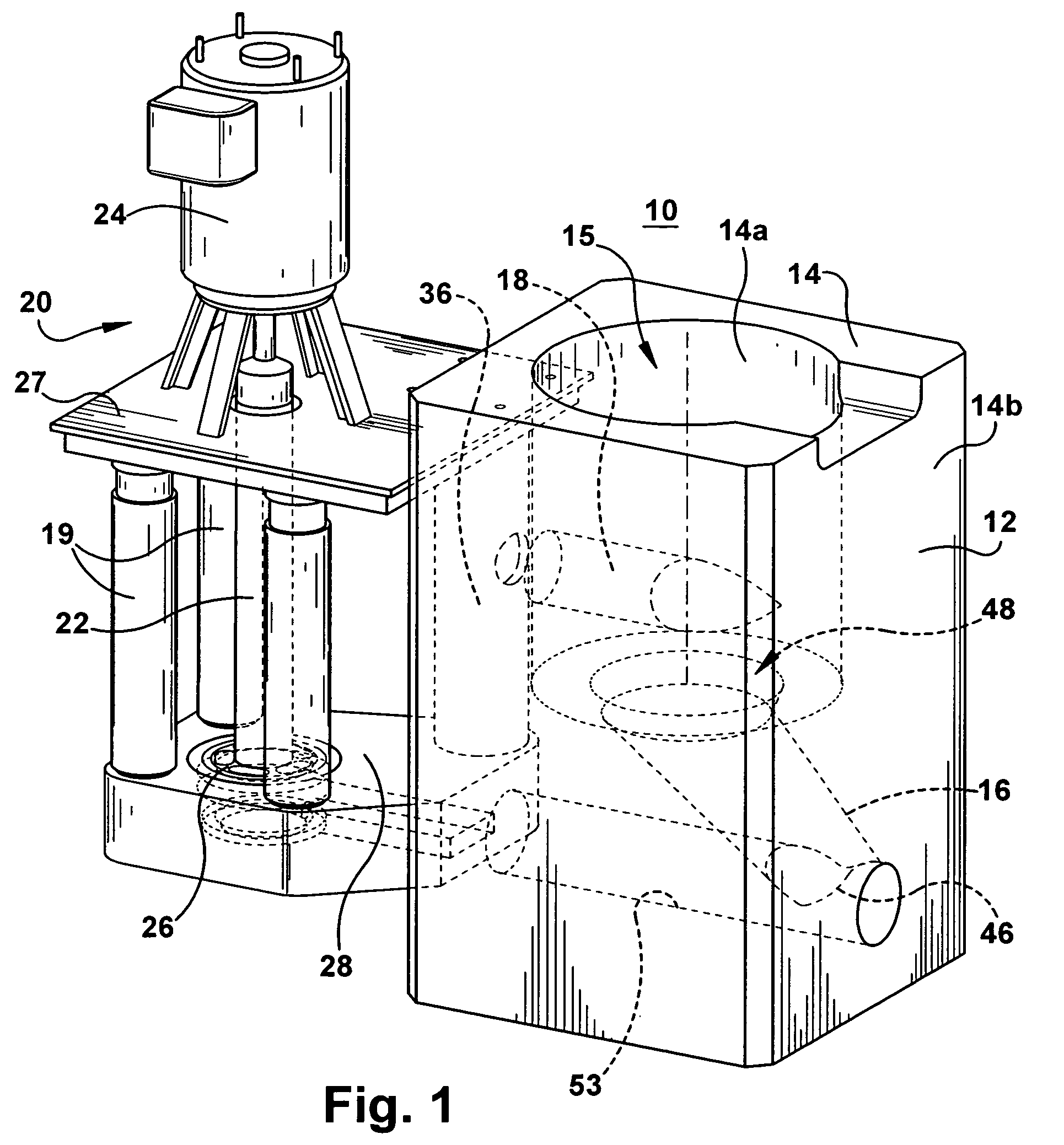

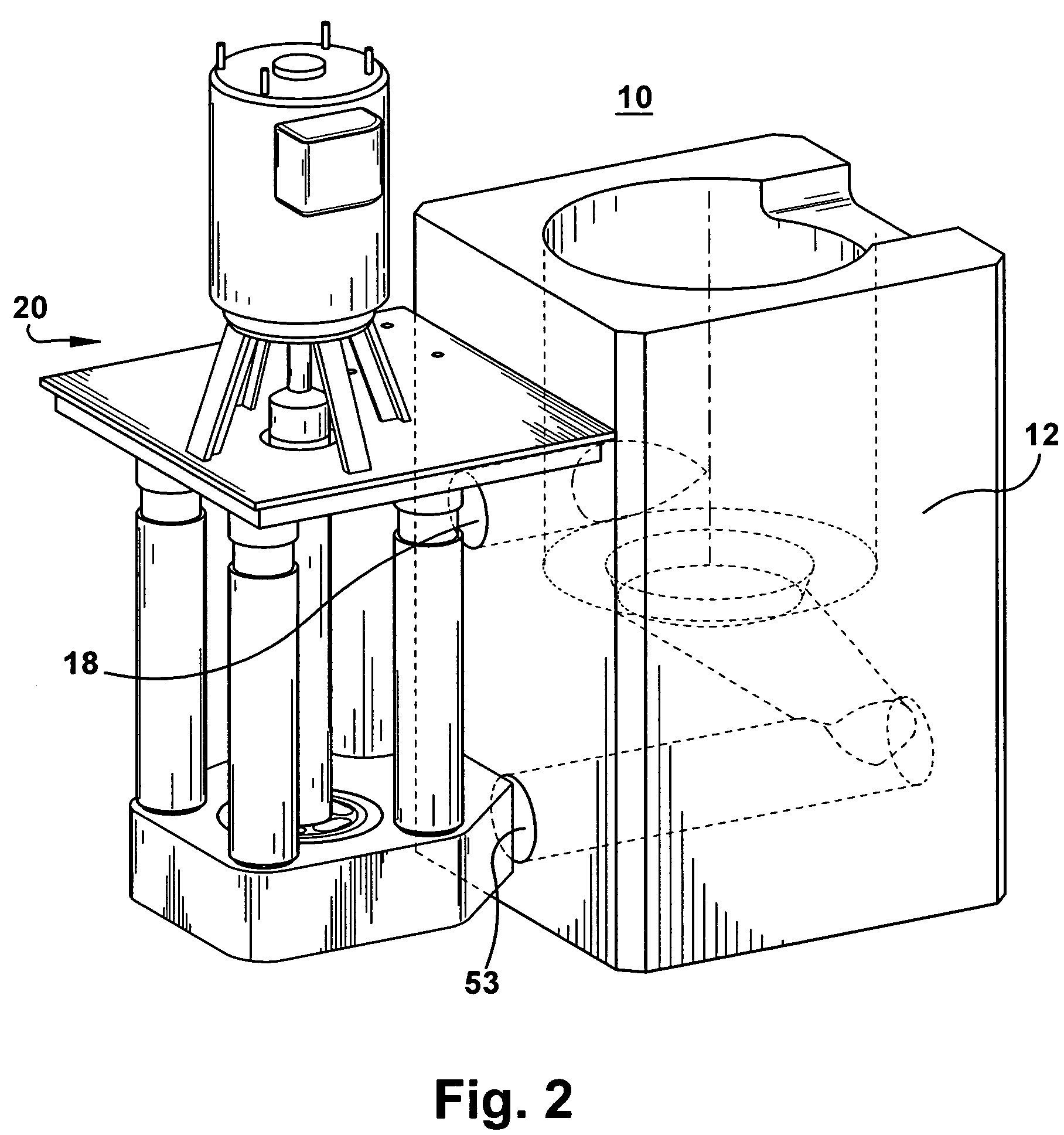

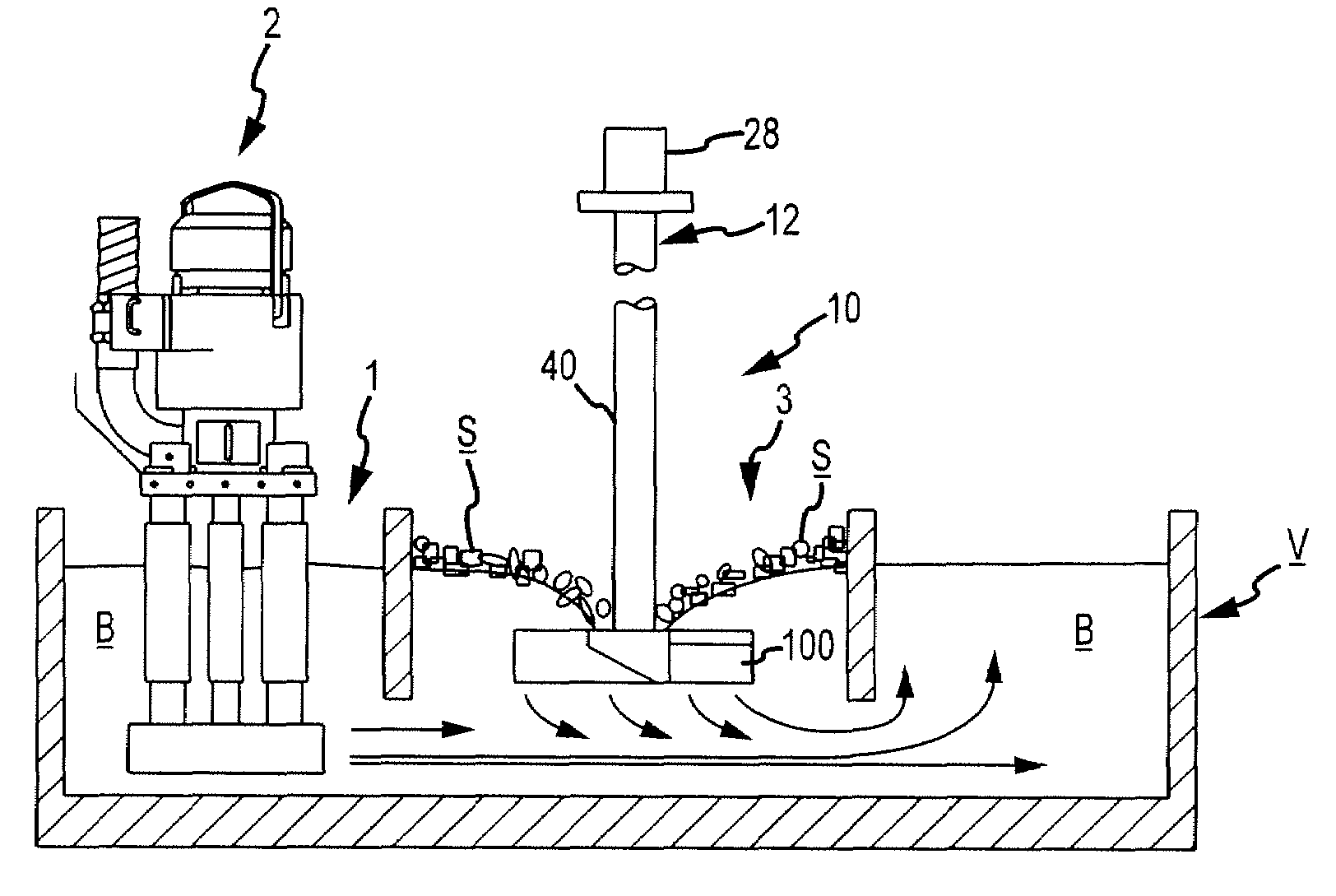

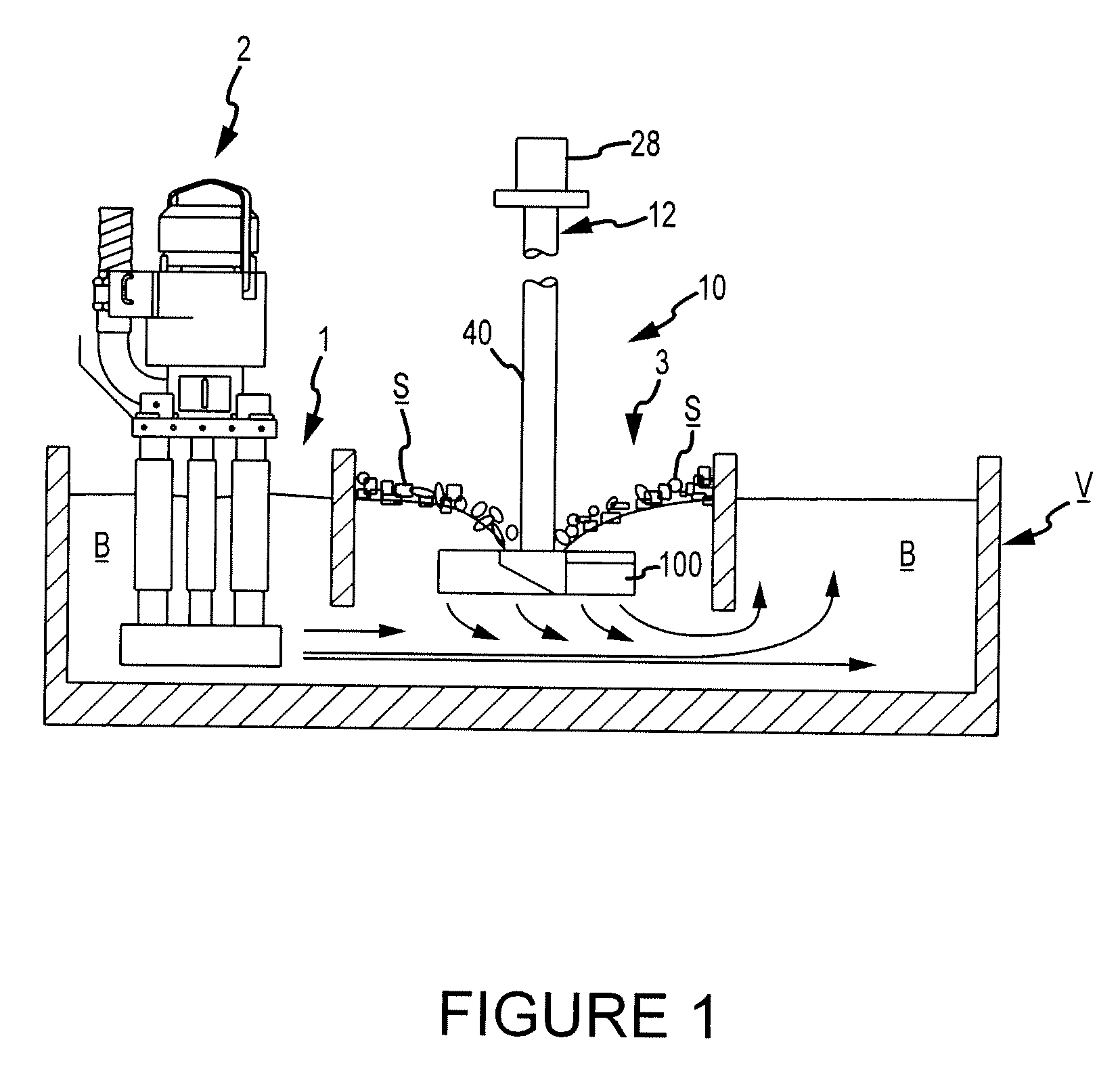

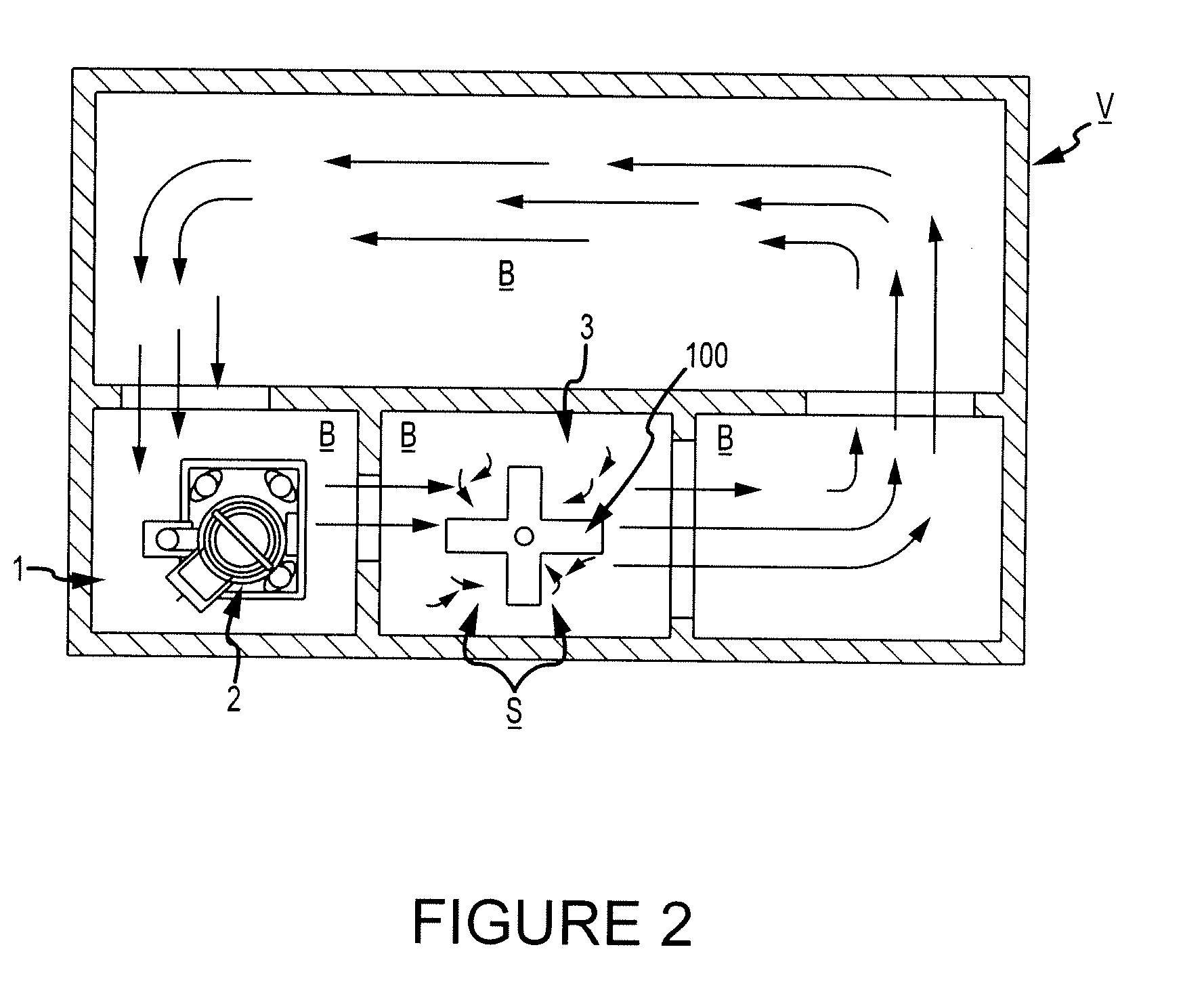

Vortexer apparatus

ActiveUS20060180963A1Facilitates submergence and meltingMaintain temperatureStirring devicesCharge manipulationImpellerPositive pressure

The present invention features a vortexer apparatus including a vessel comprising an exterior surface, an interior surface containing fluid and a mouth for receiving material at an upper end portion of the interior surface. In one application the material is metal scrap that is melted in molten metal as the fluid. All components that contact the molten metal are formed of refractory material. An outlet passageway extends downwardly from the interior surface. A vessel inlet opening is located between the exterior and interior surfaces above the outlet passageway. A center line passes through a center of the interior surface and the vessel inlet opening is disposed at a location offset from the center line. A pump is adapted to pump fluid into the vessel effective to form a vortex of fluid in the vessel. The base and impeller are configured and arranged effective to provide molten metal leaving the base outlet with a positive pressure. An outlet conduit extends from the base outlet to near the vessel inlet opening and can be maintained at a temperature above which molten metal solidifies, along its entire length. Instead of the vortexer vessel, the inventive vortexer apparatus may integrate a chamber of a furnace (e.g., a charge well). The chamber may be rectangularor include arcuate portions. Corner inserts may be used to provide the chamber with an oval or generally circular shape that may facilitate the vortex. One feature of the invention is a vortex vessel that includes an offset inlet opening and lower circulation opening. Also featured is a baffle impeller that may be vaned or barrel type. In addition, the invention features a pump having upper and lower impeller chambers separated by a web in the base, and impeller outlets that are isolated from fluid communication with each other.

Owner:THUT BRUNO H

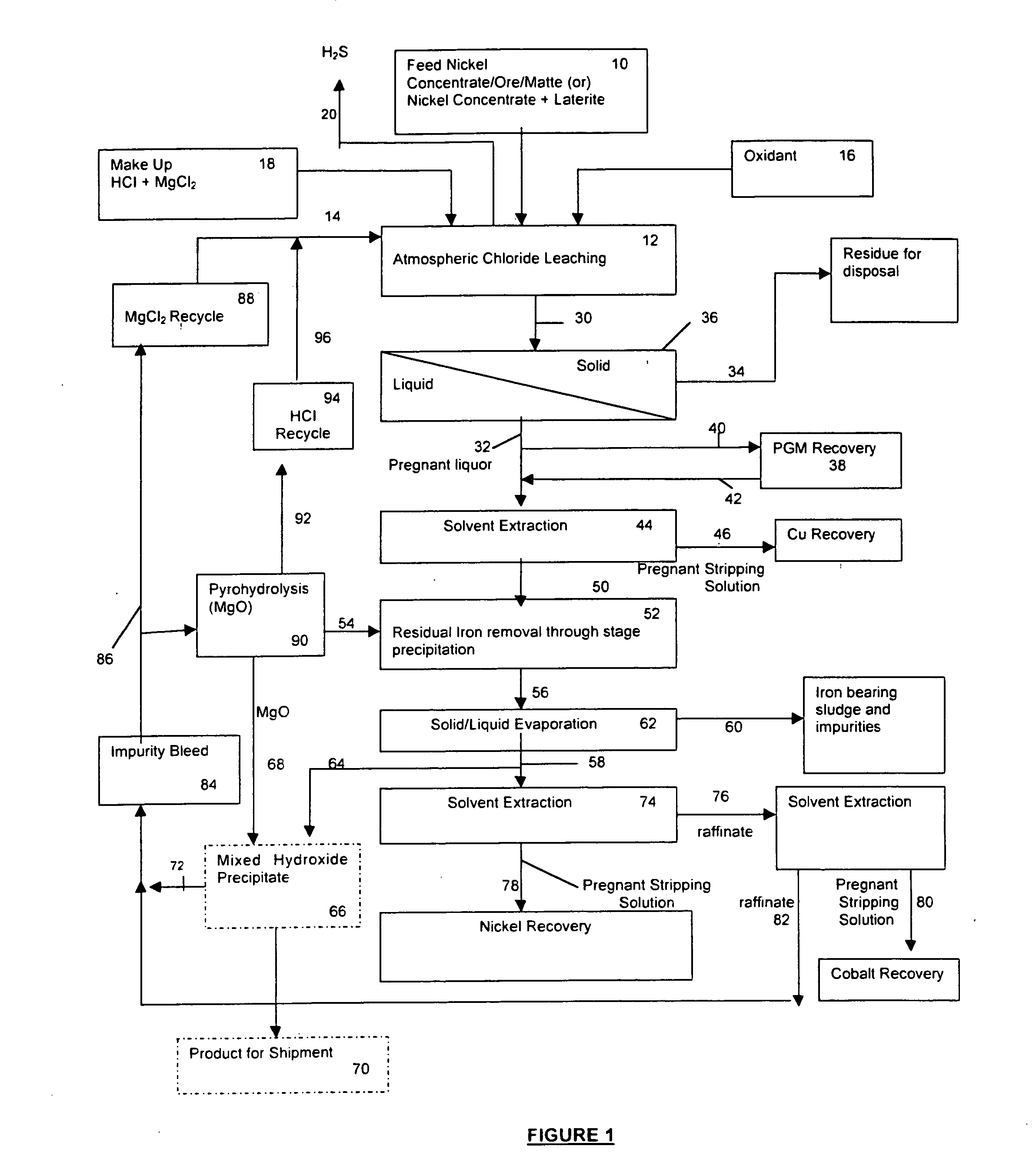

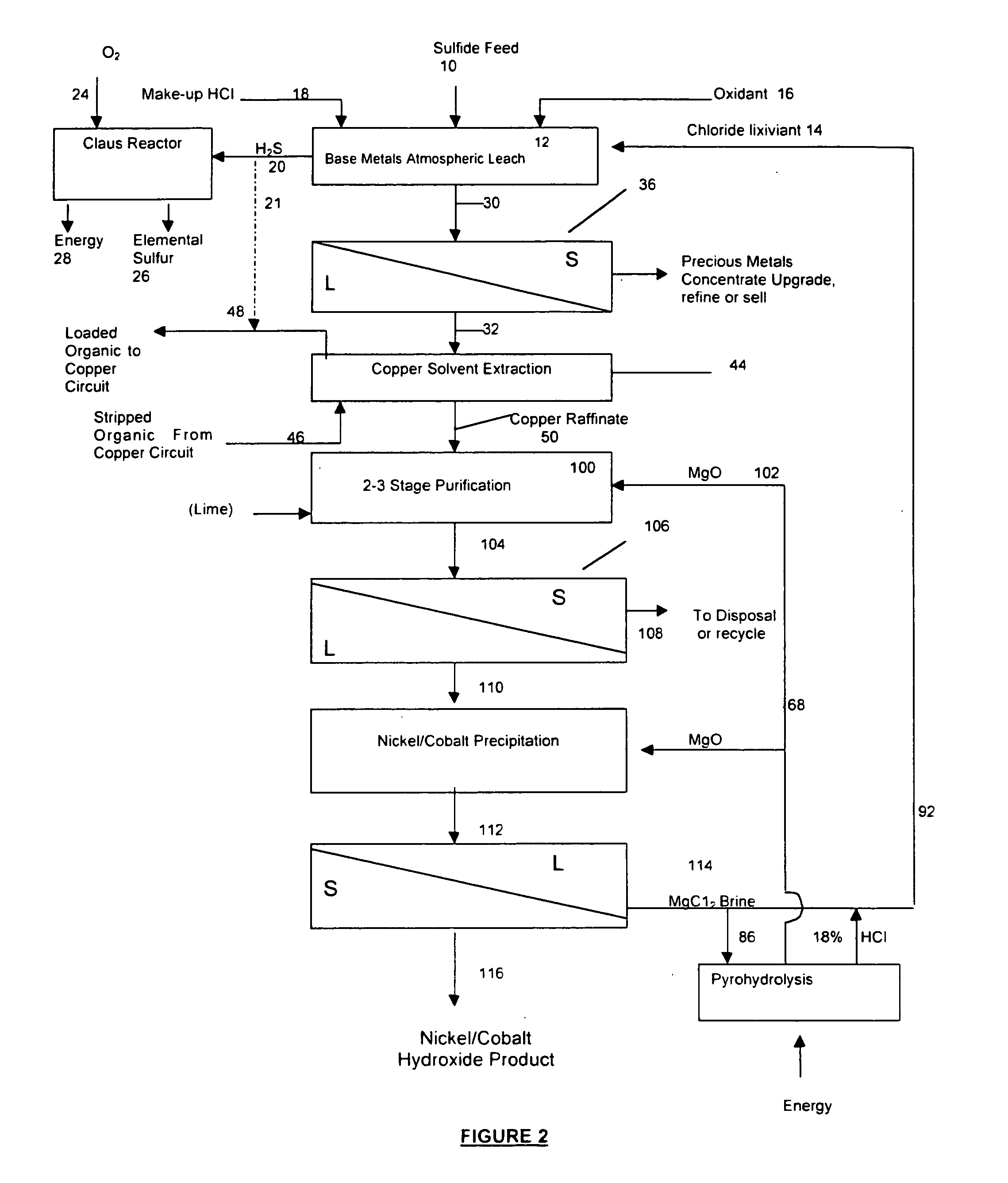

Process for the recovery of value metals from base metal sulfide ores

InactiveUS20050118081A1Simple gas/liquidReduce the amount requiredSulfur compoundsSolid sorbent liquid separationSulfideDissolution

A process for leaching a value metal from a base metal sulfide ore, comprising the step of leaching the ore with a lixiviant comprising a chloride, an oxidant and hydrochloric acid is disclosed. The leaching is controlled, by use of low concentrations of hydrochloric acid and a redox potential, to effect formation of hydrogen sulfide from the base metal sulfide ore. The hydrogen sulfide is stripped from the leach solution, thereby reducing the amount of sulfate generated in the leach to very low levels. The leaching may also be conducted to limit the co-dissolution of platinum group metals and gold with the base value metals. The leach forms a value metal-rich leachate and a solids residue. The solids residue may be subsequently leached to recover the platinum group metals and gold. The value metal-rich leachate can be is oxidized and neutralized to recover the value base metals. In an embodiment, the chloride is magnesium chloride and lixiviant solution is regenerated.

Owner:JAGUAR NICKEL INC

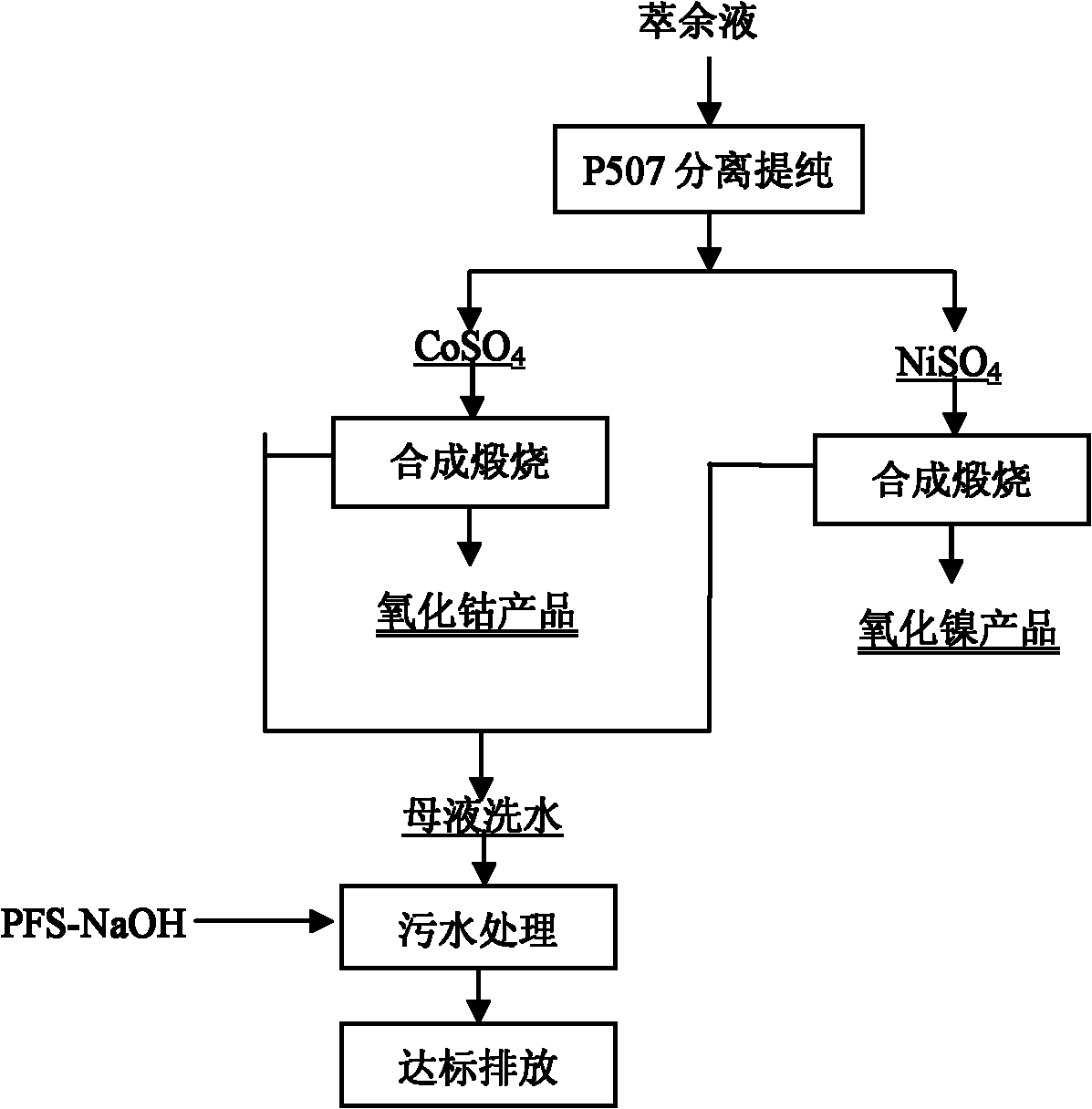

Method for recovering cobalt, nickel and manganese from waste lithium cells

ActiveCN101871048ANo pollution in the processReduce consumptionProcess efficiency improvementRecovery methodAlkaline earth metal

The invention discloses a method for recovering cobalt, nickel and manganese from waste lithium cells. Most of the conventional recovery methods can hardly guarantee the product quality. The technical scheme adopted by the invention is as follows: (1) the anode materials of waste lithium cells are immerged in low-concentration alkali solution, and because the anode materials do not react with the alkali solution, the anode materials shed from aluminum sheets to become black powder; (2) for the black powder, dilute sulfuric acid is first adopted for low-acid dissolution, Na2SO5 or Na2SO3 or Fe powder added with concentrated sulfuric acid is then adopted for reduction and dissolution, and finally, 3 to 6mol / L of sulfuric acid is adopted for high-acid dissolution; (3) solid-liquid separation is carried out on the substance obtained in step 2; (4) reagent is adopted for precipitating and deeply removing alkaline earth impurities. The method has the advantages of simple operation, low auxiliary material consumption, high product purity, high metal yield and no environment pollution, and is an ideal method for recovering cobalt, nickel and manganese from waste lithium cells.

Owner:ZHEJIANG HUAYOU COBALT +1

Vortexer apparatus

ActiveUS7497988B2Facilitates submergence and meltingMaintain temperatureStirring devicesCharge manipulationImpellerPositive pressure

Owner:THUT BRUNO H

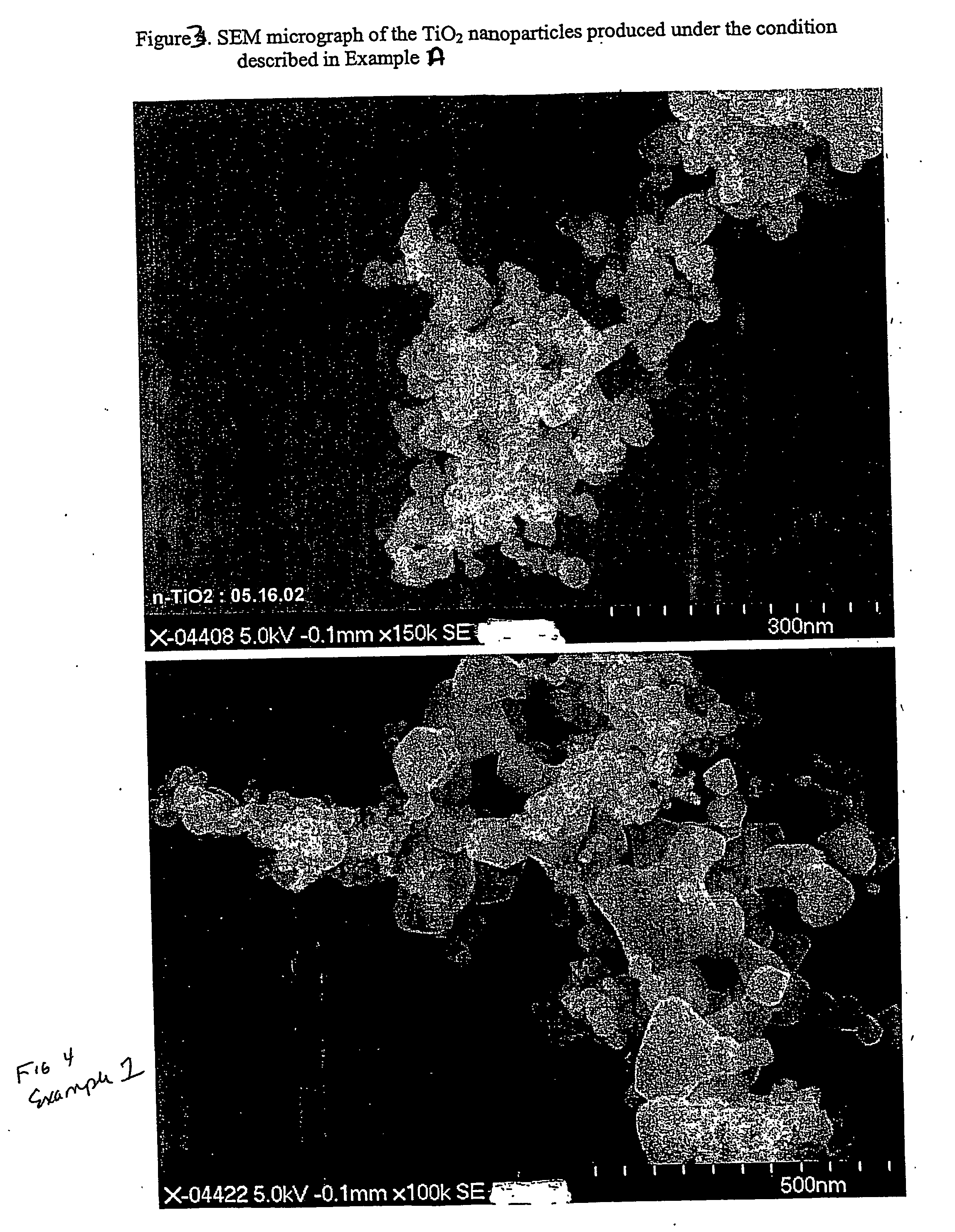

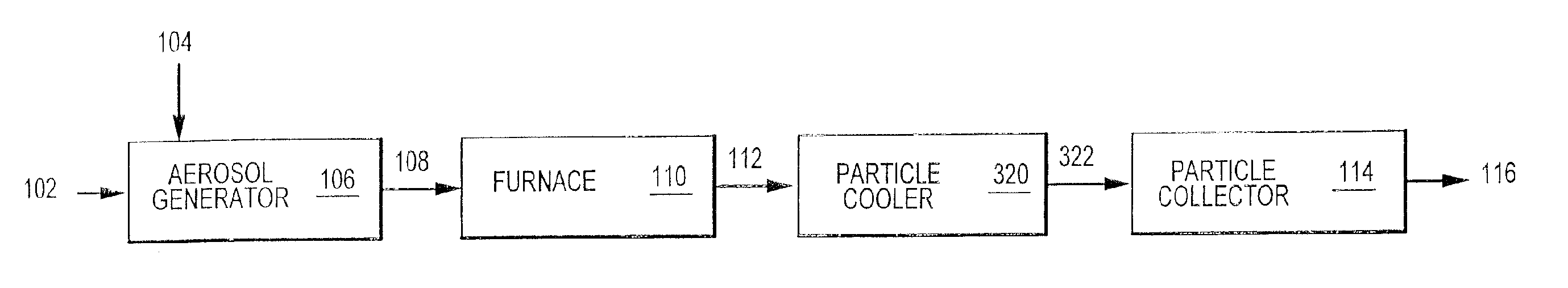

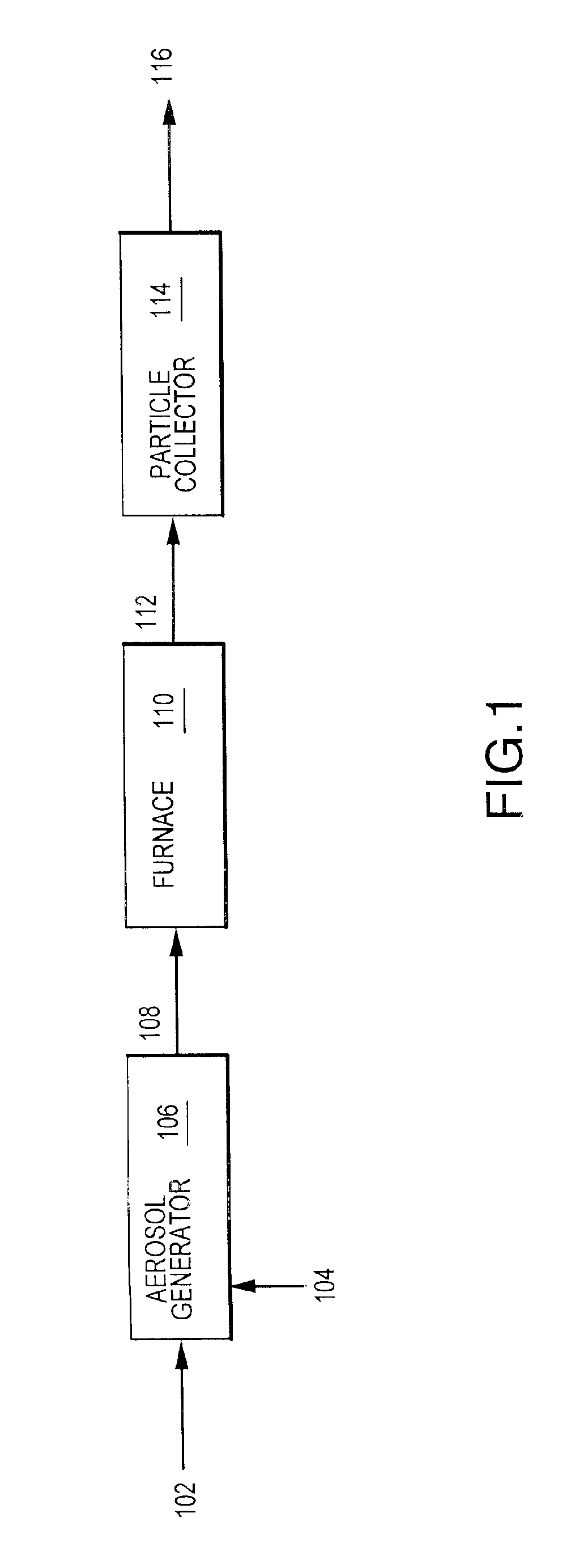

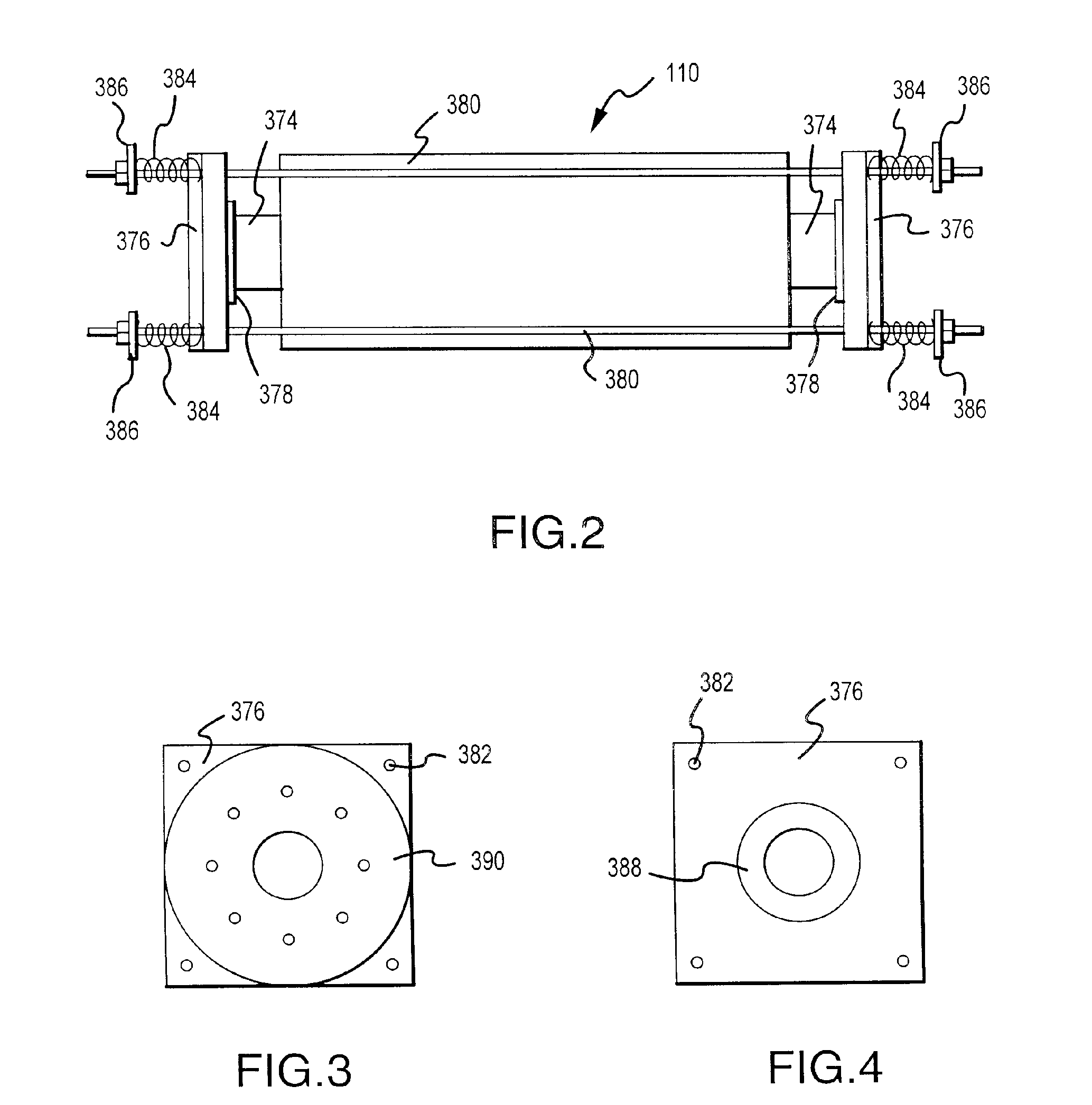

Method of producing nanoparticles using a evaporation-condensation process with a reaction chamber plasma reactor system

InactiveUS20060159596A1Reduce the temperatureMaterial nanotechnologyNanostructure manufactureNanoparticleReaction zone

The present invention provides a method and apparatus for the controlled synthesis of nanoparticles using a high temperature process. The reactor chamber includes a high temperature gas heated by means such as a plasma torch, and a reaction chamber. The homogenizer includes a region between the reactant inlets and the plasma (the spacer zone) to ensure that feeds from the reactant inlets are downstream of the recirculation zone induced by the high temperature gas. It also includes a region downstream of the reactant inlets that provides a nearly I dimensional (varying only in the axial direction) flow and concentration profile in the reaction zone to produce nanoparticles with narrow size distribution.

Owner:EI DU PONT DE NEMOURS & CO

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

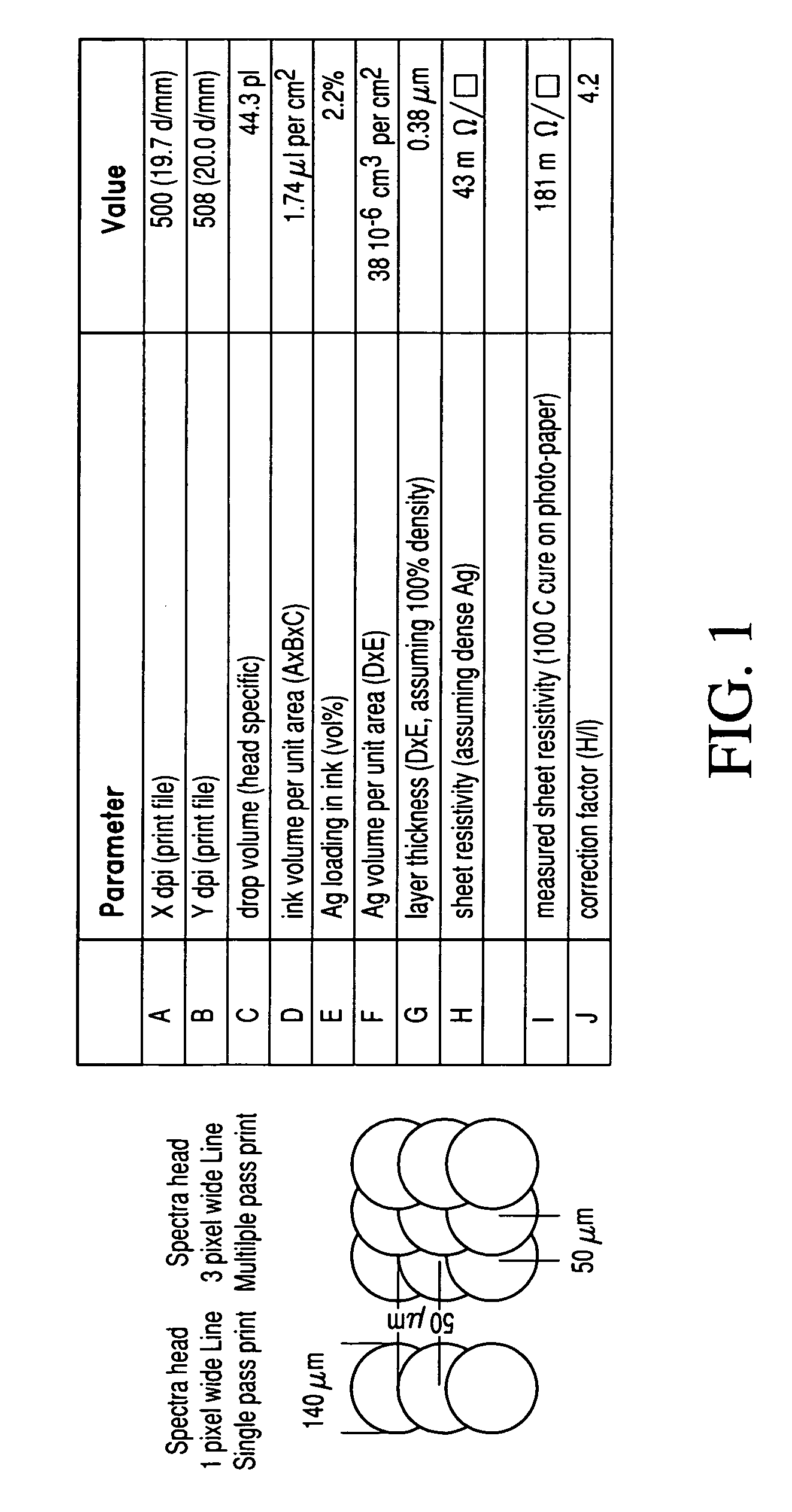

Separation of metal nanoparticles

ActiveUS20060159603A1Easy to separateAccelerated precipitationMaterial nanotechnologyPowder deliveryPolyolProton

A process for the production of metal nanoparticles. Nanoparticles are formed by combining a metal compound with a solution that comprises a polyol and a substance that is capable of being adsorbed on the nanoparticles. The nanoparticles are precipitated by adding a nanoparticle-precipitating liquid in a sufficient amount to precipitate at least a substantial portion of the nanoparticles and of a protic solvent in a sufficient amount to improve the separation of the nanoparticles from the liquid phase.

Owner:SICPA HLDG SA

Calcification vanadium slag sintering method

InactiveCN101161831AEasy temperature controlShorten roasting timeProcess efficiency improvementSlagCalcification

The invention discloses a method of vanadium slag direct entering high temperature roasting furnace calcify roasting, that is, high calcium vanadium slag or ordinary vanadium slag and lime or limestone are mixed uniformly without the gradual heating up process from low temperature to high temperature, the mixture enters into the roasting furnace of more than 600 DEG C for calcified roasting., the vanadium of the vanadium slag is changed into vanadium acid calcium, vanadium of the roasting clinker is dissolved into the solution under the leaching function of sulphuric acid solution, vanadium oxide and the like vanadium products are further made. The invention needs no gradual heating up process from low temperature to high temperature of the prior sodium treatment roasting, thereby reducing roasting time, improving productivity of unit and reducing production cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

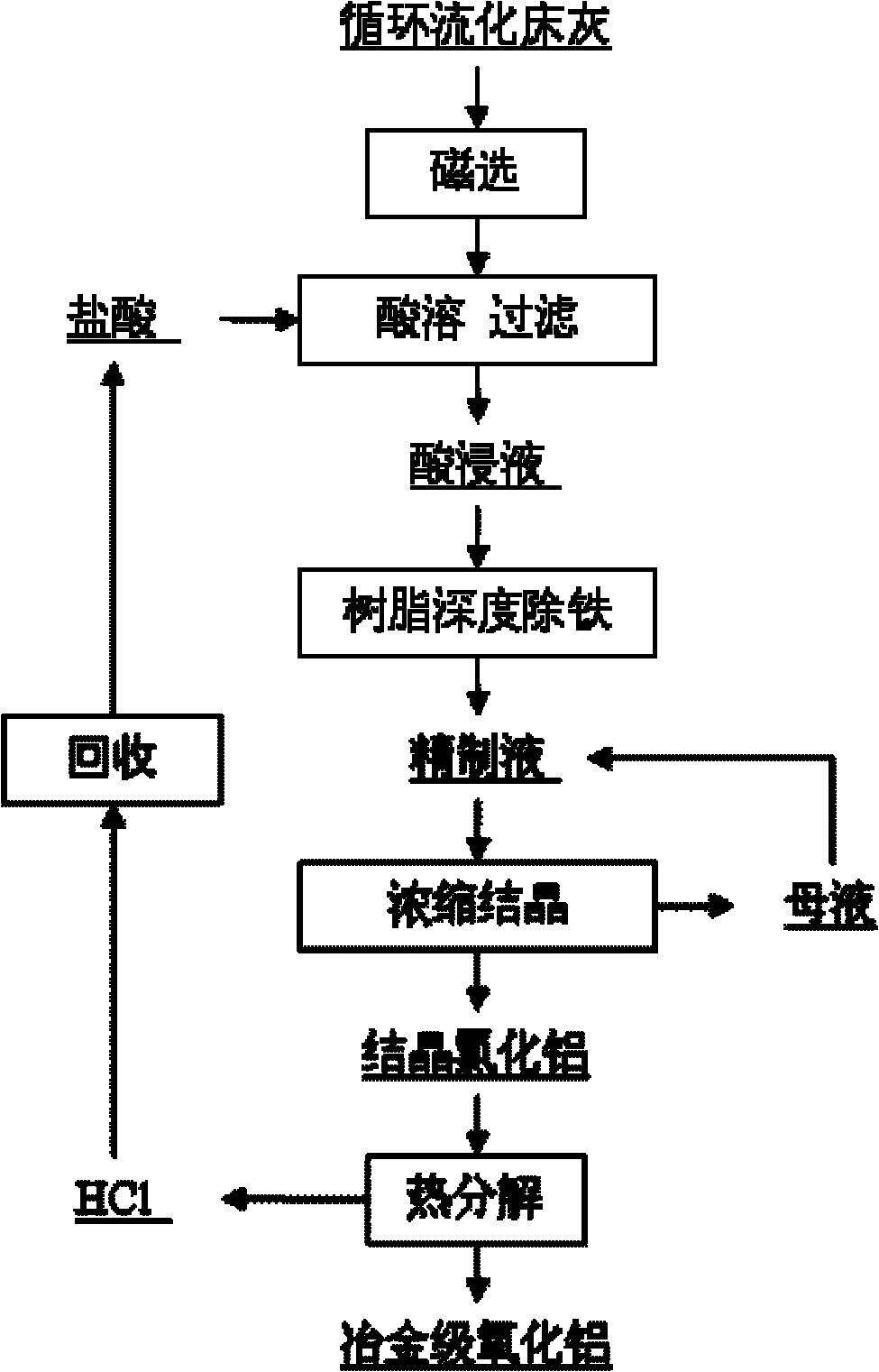

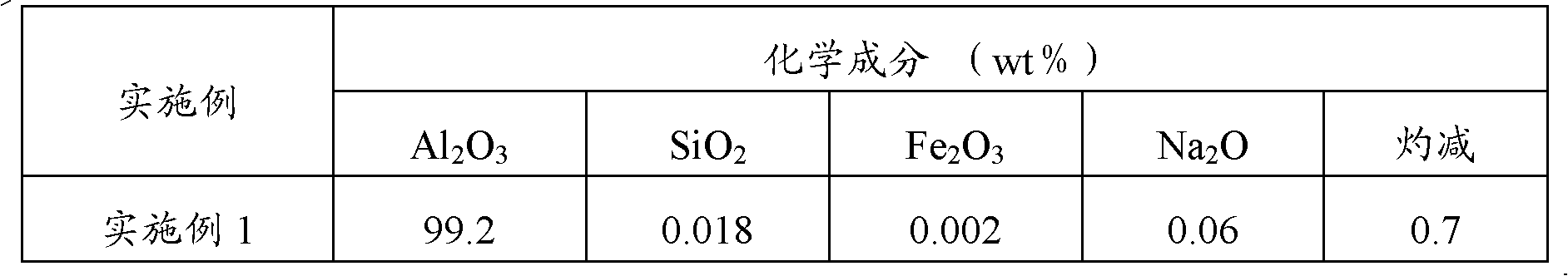

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

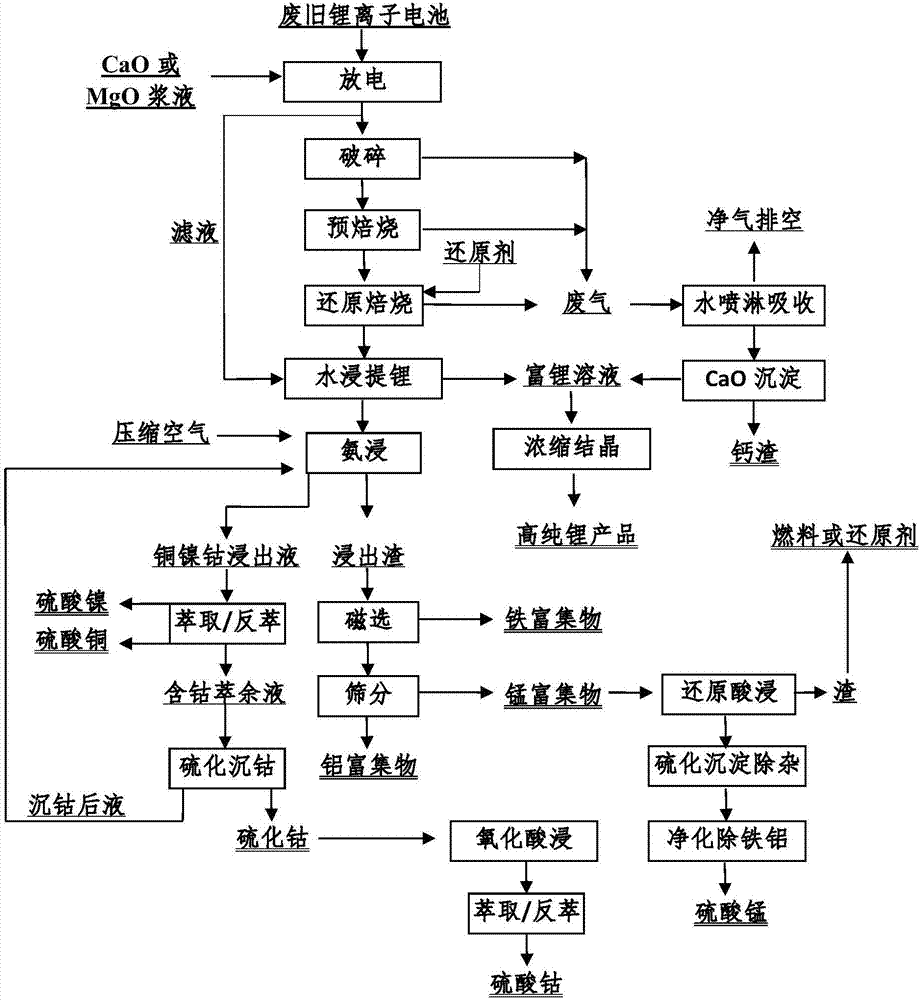

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

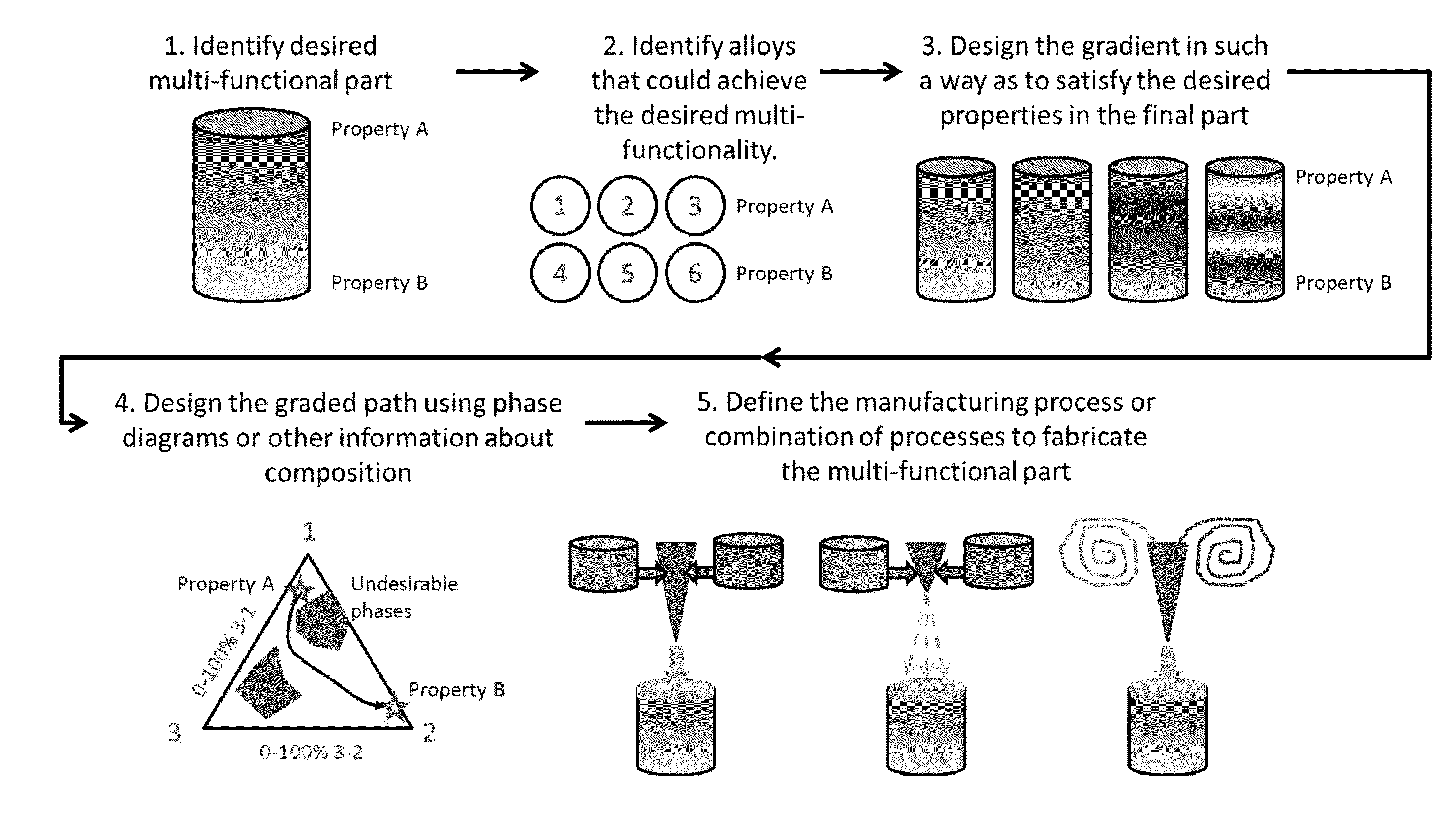

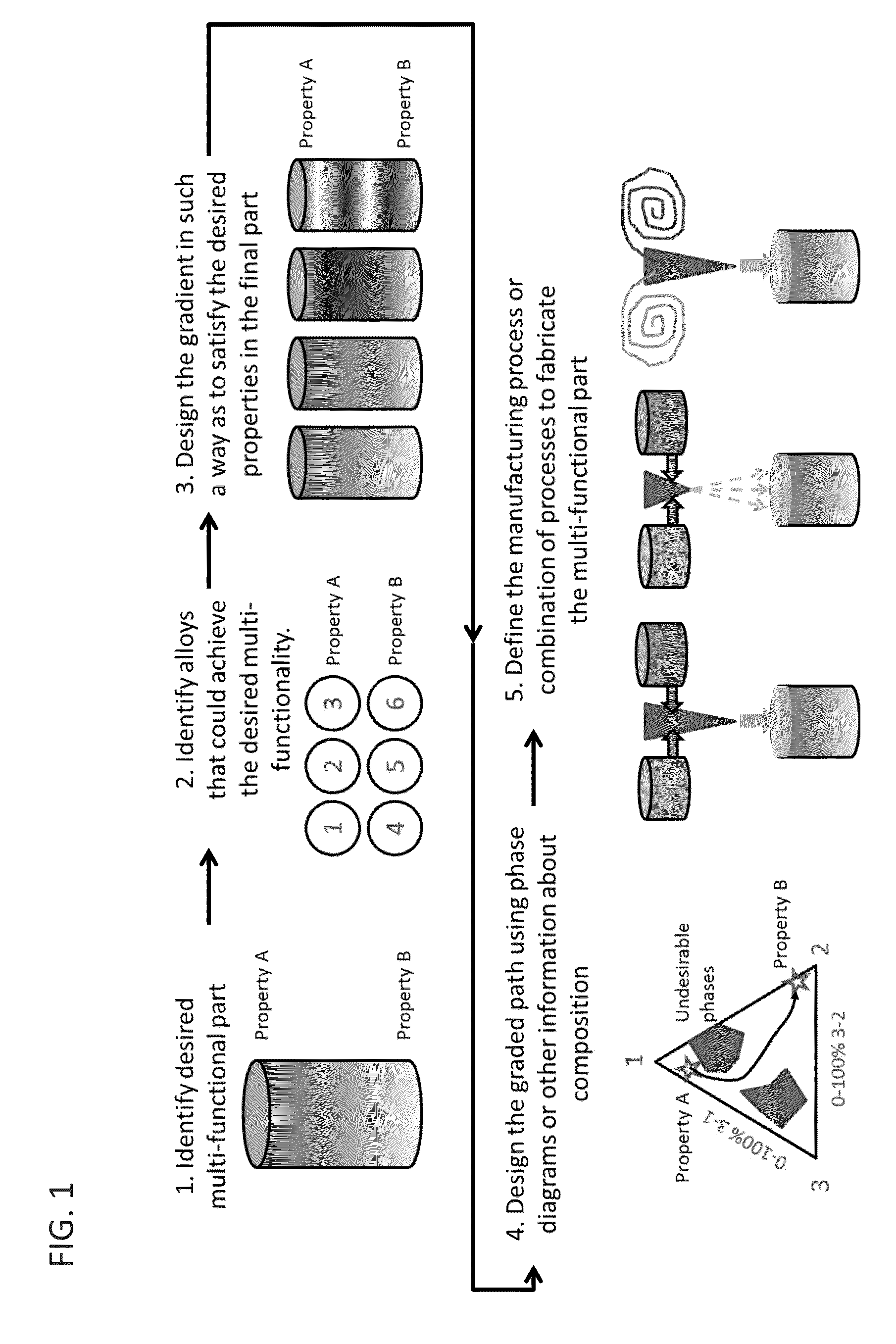

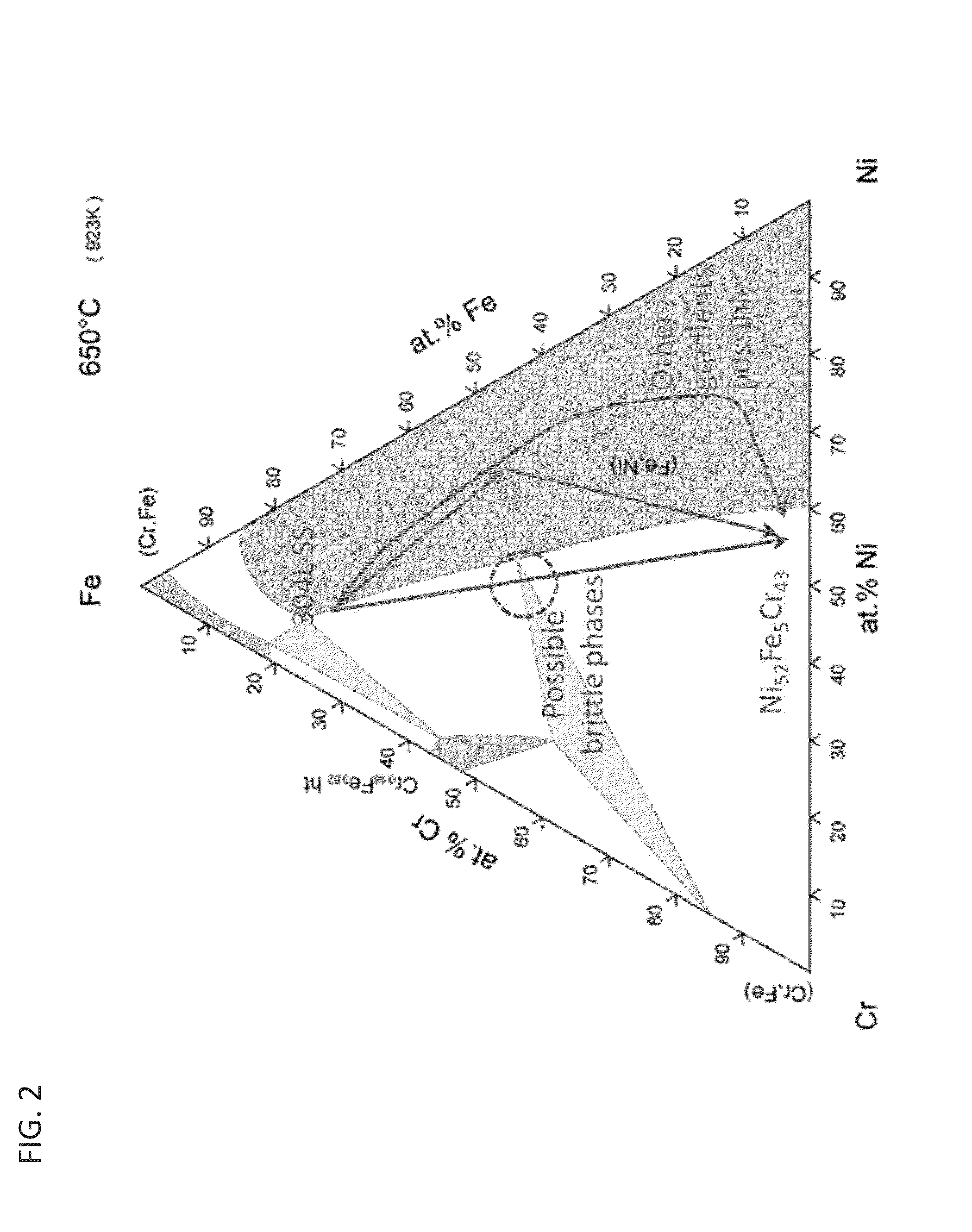

Methods for fabricating gradient alloy articles with multi-functional properties

ActiveUS20150044084A1High speedSufficient cooling rateAdditive manufacturingMolten spray coatingMetal alloyGradient material

Systems and methods for fabricating multi-functional articles comprised of additively formed gradient materials are provided. The fabrication of multi-functional articles using the additive deposition of gradient alloys represents a paradigm shift from the traditional way that metal alloys and metal / metal alloy parts are fabricated. Since a gradient alloy that transitions from one metal to a different metal cannot be fabricated through any conventional metallurgy techniques, the technique presents many applications. Moreover, the embodiments described identify a broad range of properties and applications.

Owner:CALIFORNIA INST OF TECH

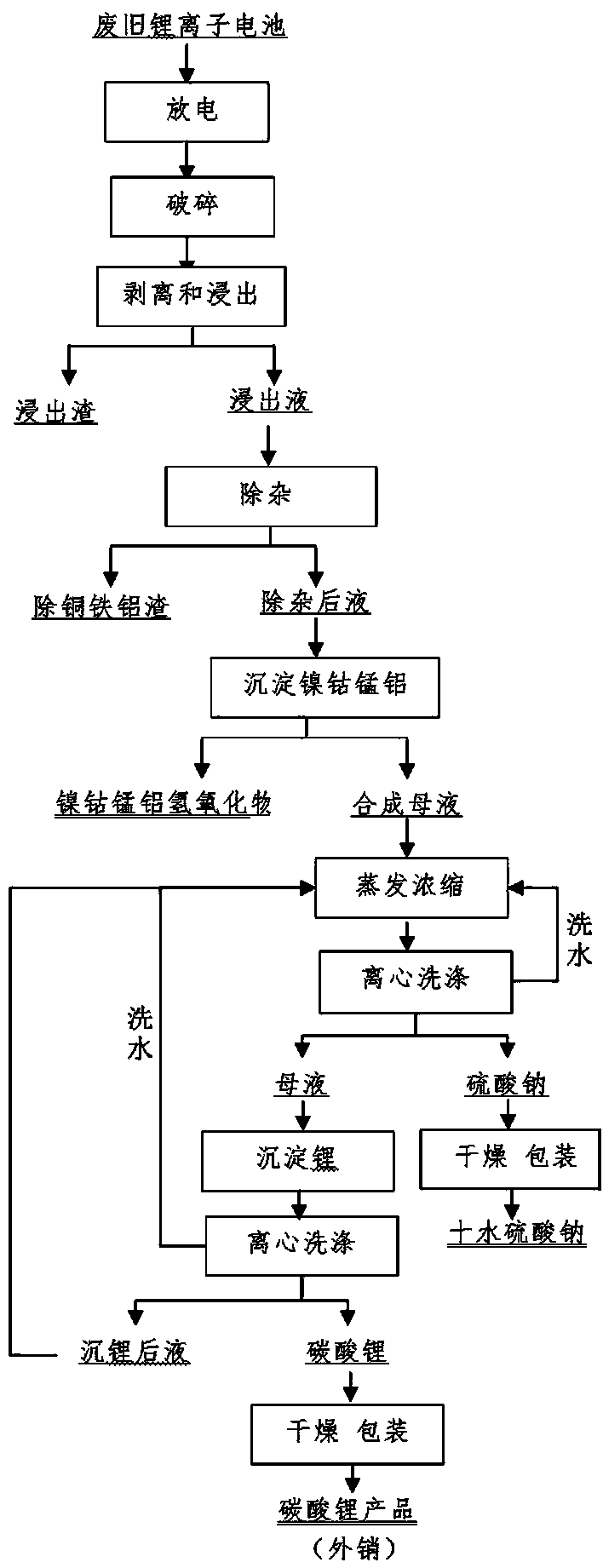

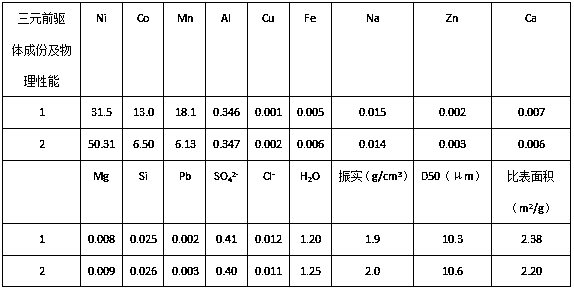

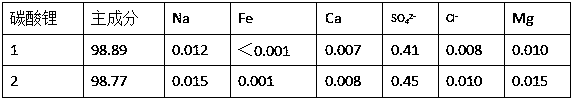

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

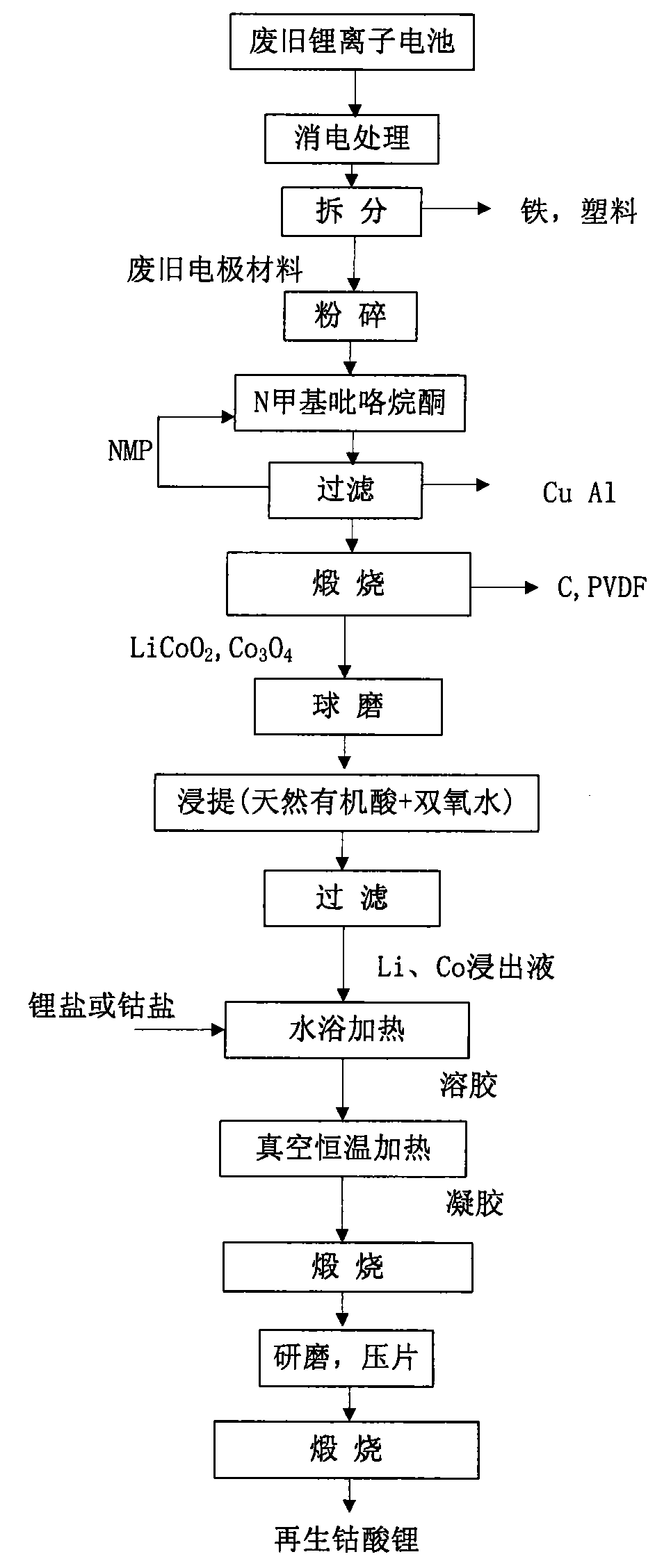

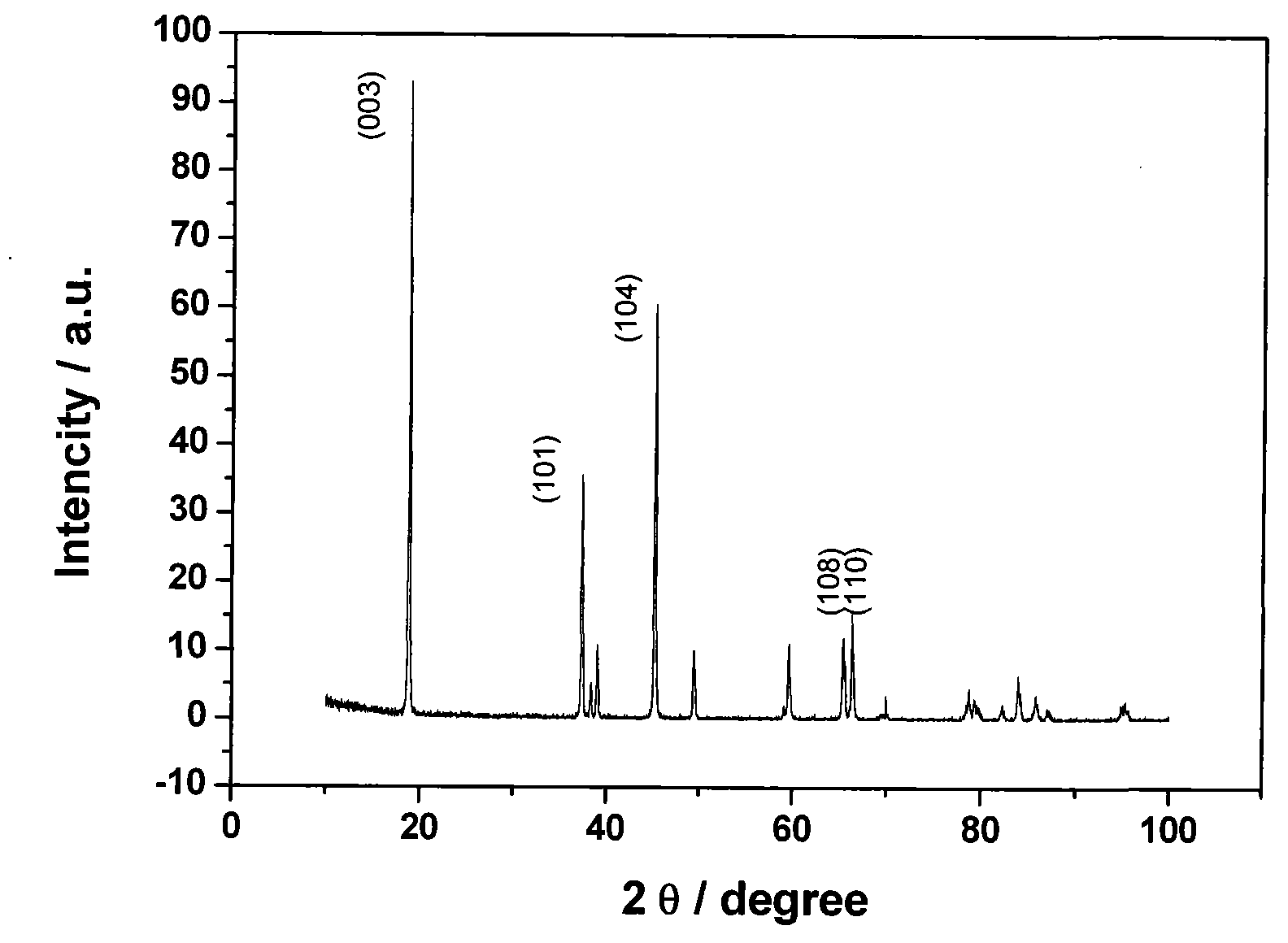

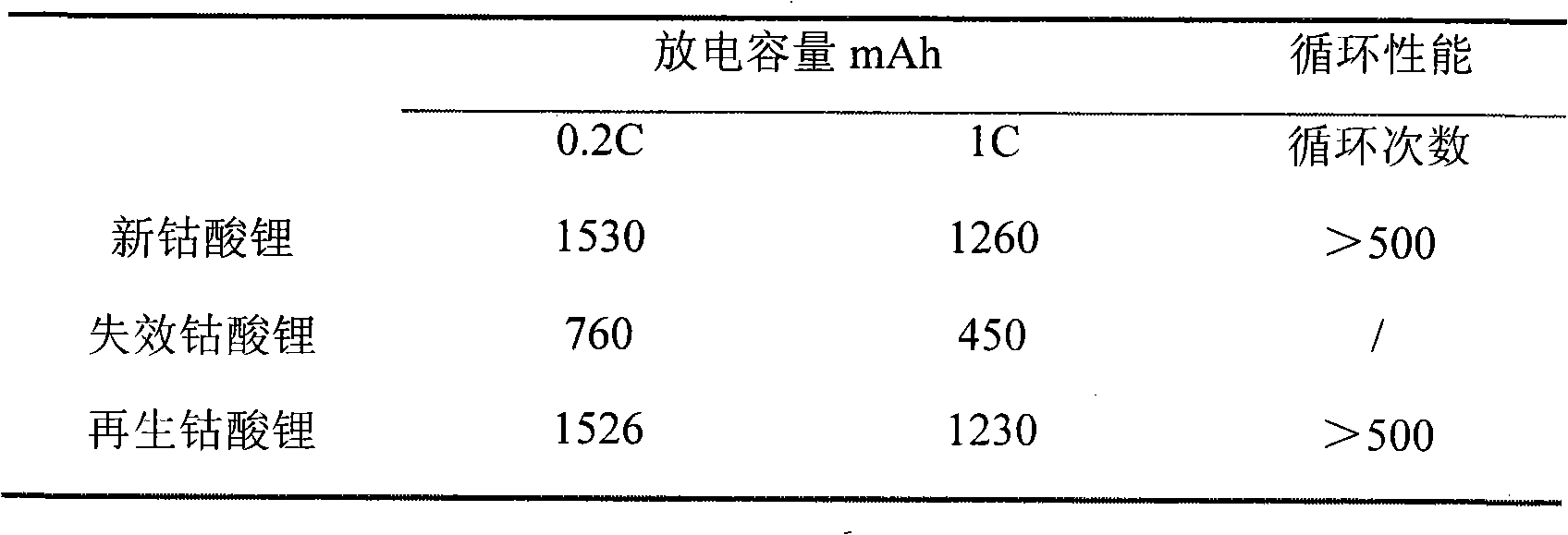

Method for recovering and preparing lithium cobalt oxide by using disused lithium battery

ActiveCN101673859ASolve the hazardSolve resource problemsLithium compoundsWaste accumulators reclaimingWater bathsOrganic acid

The invention relates to a method for recovering and preparing lithium cobalt oxide by using a disused lithium battery, belonging to the technical field of recovery and recycle of electrode materials.The method comprises the steps of: discharging, disassembling, smashing, NMP processing and burning a disused lithium battery sequentially, to obtain a disused LiCoO2 material; ball-milling the disused LiCoO2 material and adding natural organic acid and hydrogen peroxide to obtain a solution of Li<+> and Co<2+>; adding lithium salt or cobalt salt after filtering, and then heating by water bath; dropwise adding ammonia water in the solution to prepare a xerogel; and performing secondary burning to obtain an electrode material of lithium cobalt oxide. The method has the advantages that the electrochemical properties of the electrode material of the disused lithium battery can be recycled with obvious effect as well as simple and easy operation; the natural organic acid used in the process of acid dipping has small damage to apparatus; and the method is environment friendly and efficient, and has low cost, simple technique, high recovery rate and industrialized promotion.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

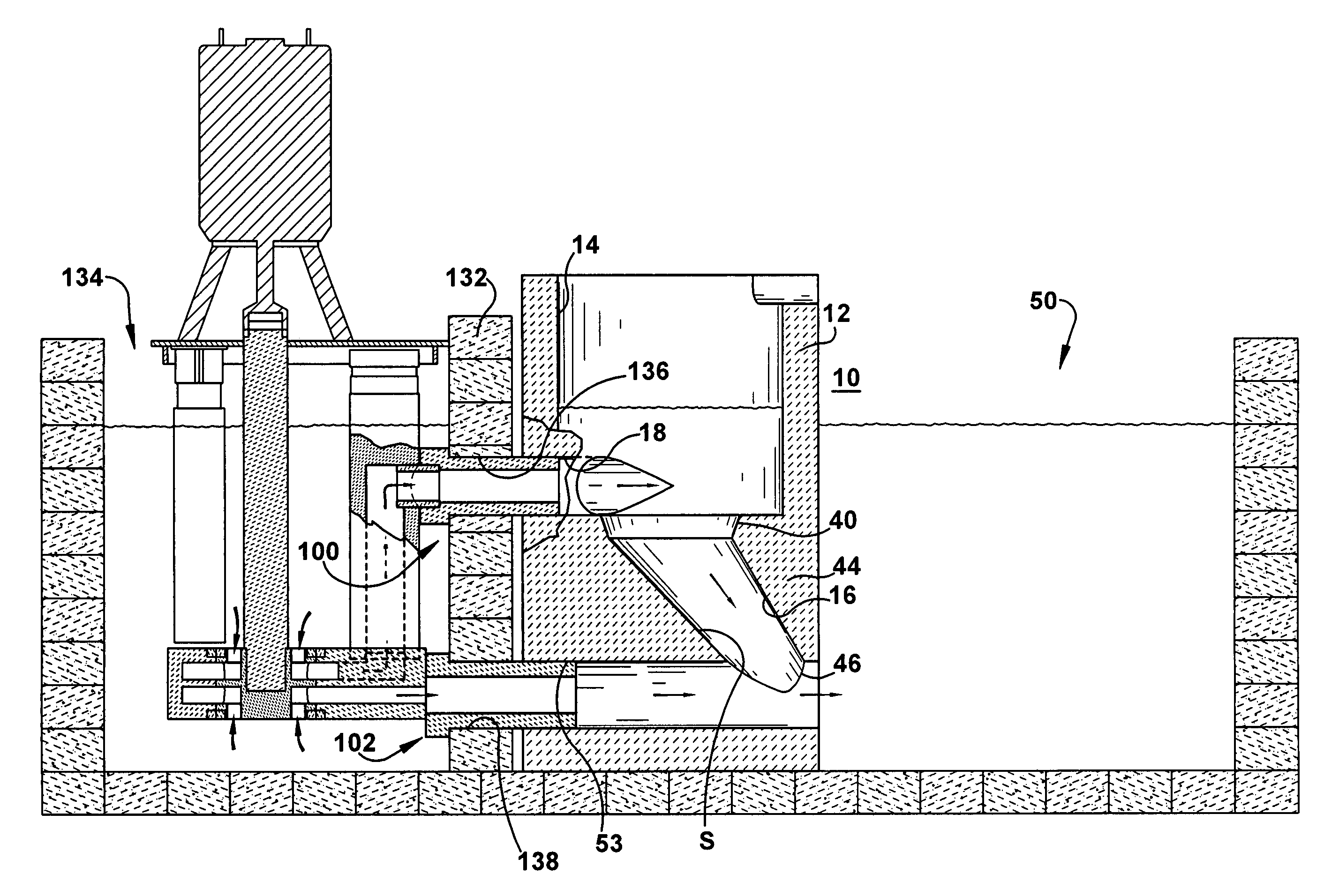

Scrap melter and impeller therefore

InactiveUS20080230966A1Reduce jammingReduce cloggingMelt-holding vesselsStirring devicesImpellerDrive shaft

A device for submerging scrap metal includes: (a) a drive source, (b) a drive shaft having a first end and a second end, the first end being connected to the drive source, and (d) an impeller connected to the second end of the drive shaft, the impeller preferably having two or more outwardly-extending blades. Preferably, each of the blades has a portion that directs molten metal at least partially downward. The impeller design leads to lower operating speeds, lower vibration, longer component life and less maintenance. Additionally, the impeller preferably has a connective portion. The connective portion is used to connect the impeller to the shaft and preferably comprises a nonthreaded, tapered bore extending through the impeller.

Owner:COOPER PAUL V

Method of making iron and steel

InactiveUS6149709AEasy to getLess impurity contentProcess efficiency improvementElectric furnaceHigh energyRefractory

Molten iron is prepared by (1) providing iron oxide and a carbonaceous reducing agent, (2) preparing a shaped product from the carbonaceous reducing agent and the iron oxide, (3) preparing solid reduced iron from the shaped product, wherein the solid reduced iron has a metallization of at least 60%, a specific gravity of at least 1.7, and a carbon content of at least 50% of the theoretical amount required for reducing the iron oxide remaining in the solid reduced iron, and, (4) before substantial cooling occurs, heating the solid reduced iron in an arc heating-type melting furnace at a high temperature. The molten iron can be prepared efficiently from iron ores of relatively low iron content without causing erosion of refractories, at high energy and high reduction efficiencies, and by a simple operation in a simple facility.

Owner:KOBE STEEL LTD

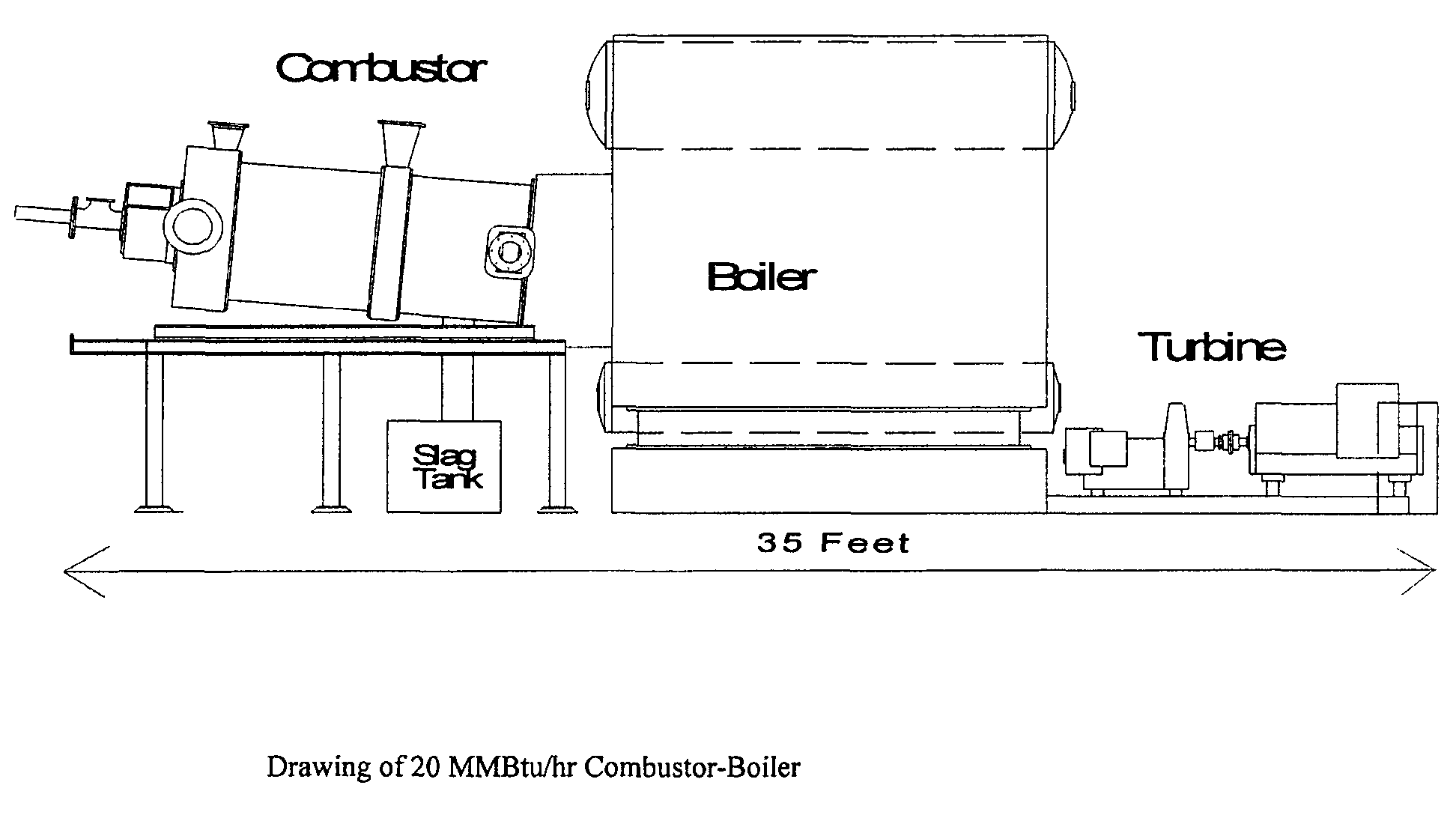

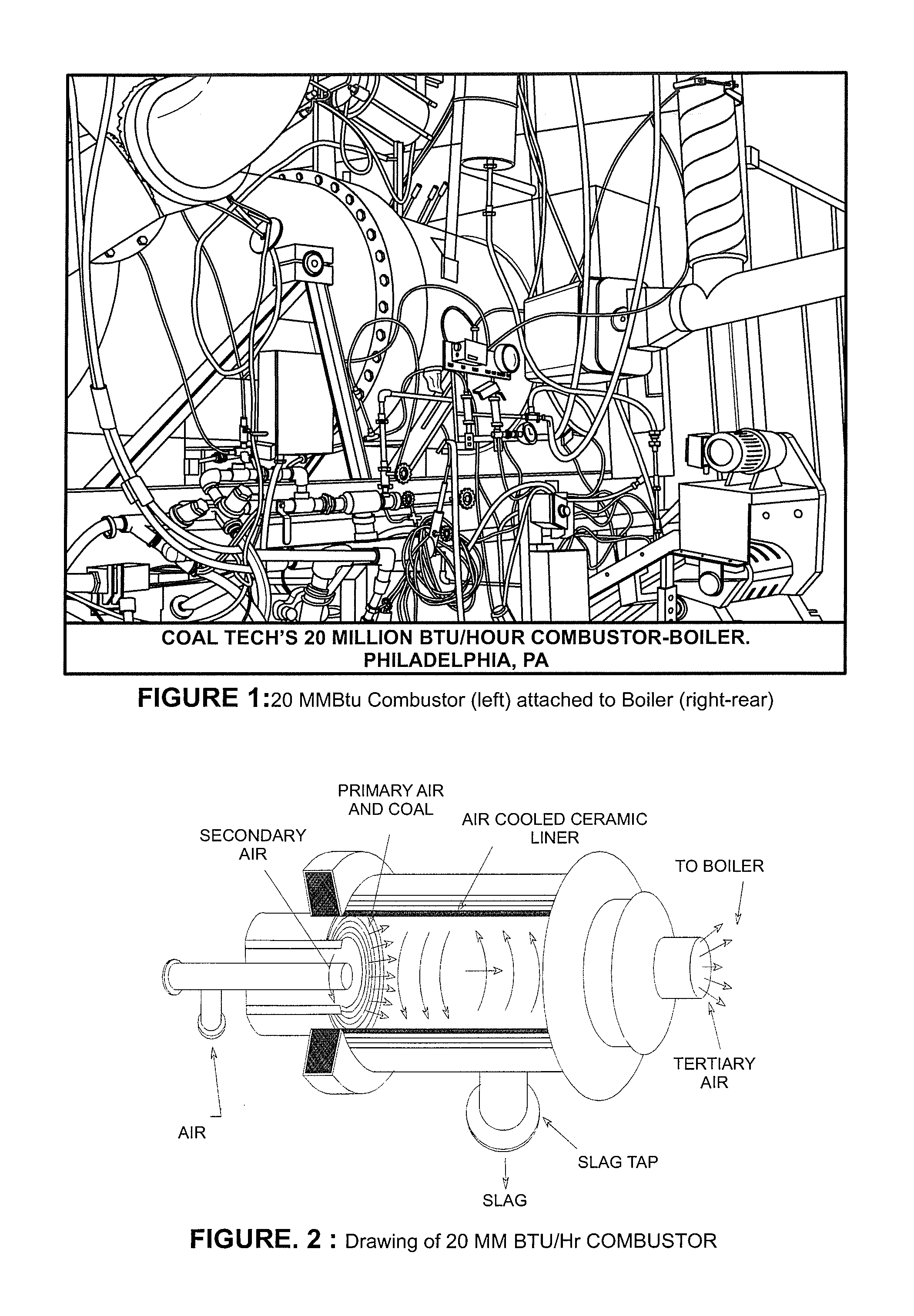

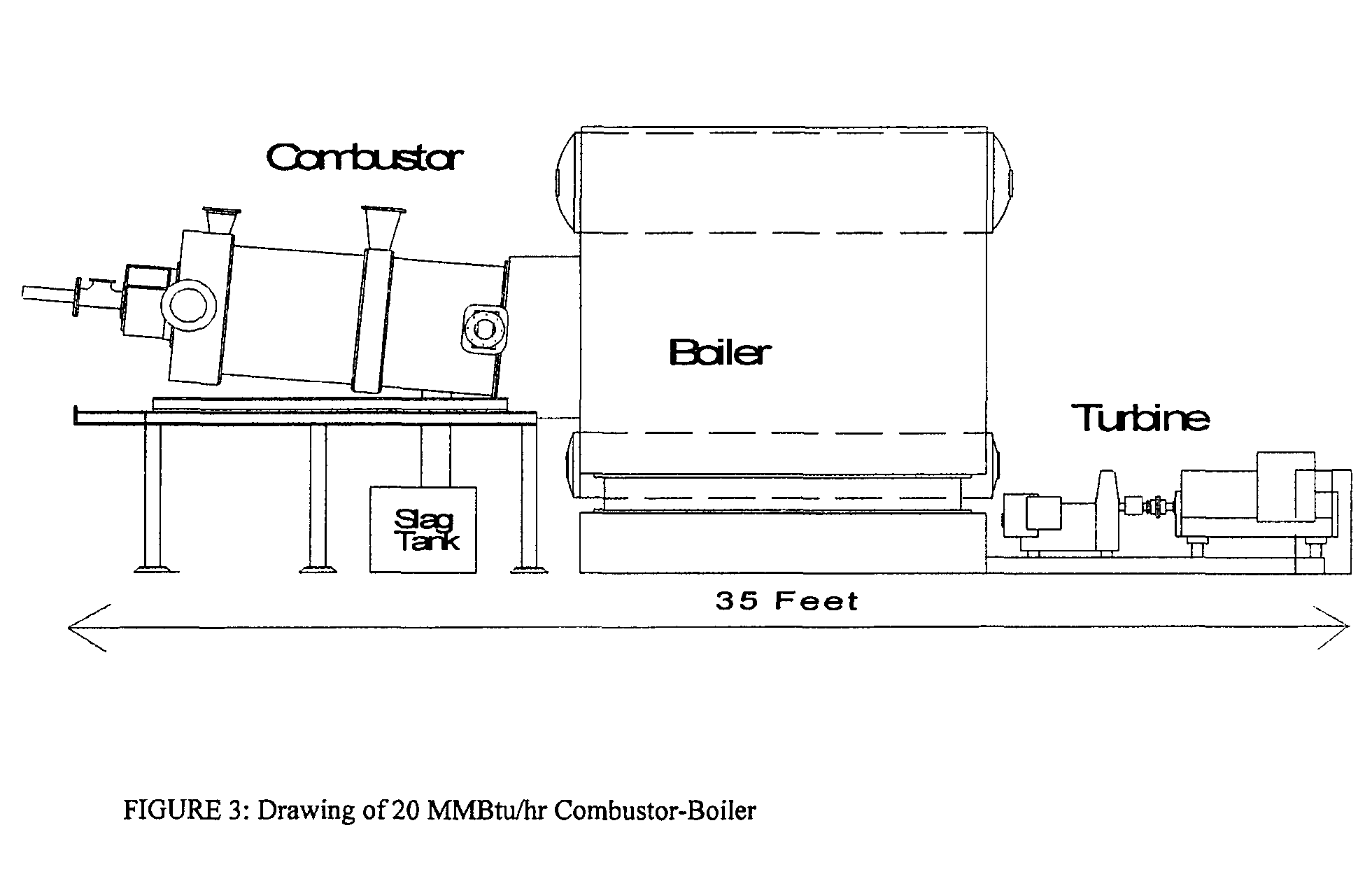

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

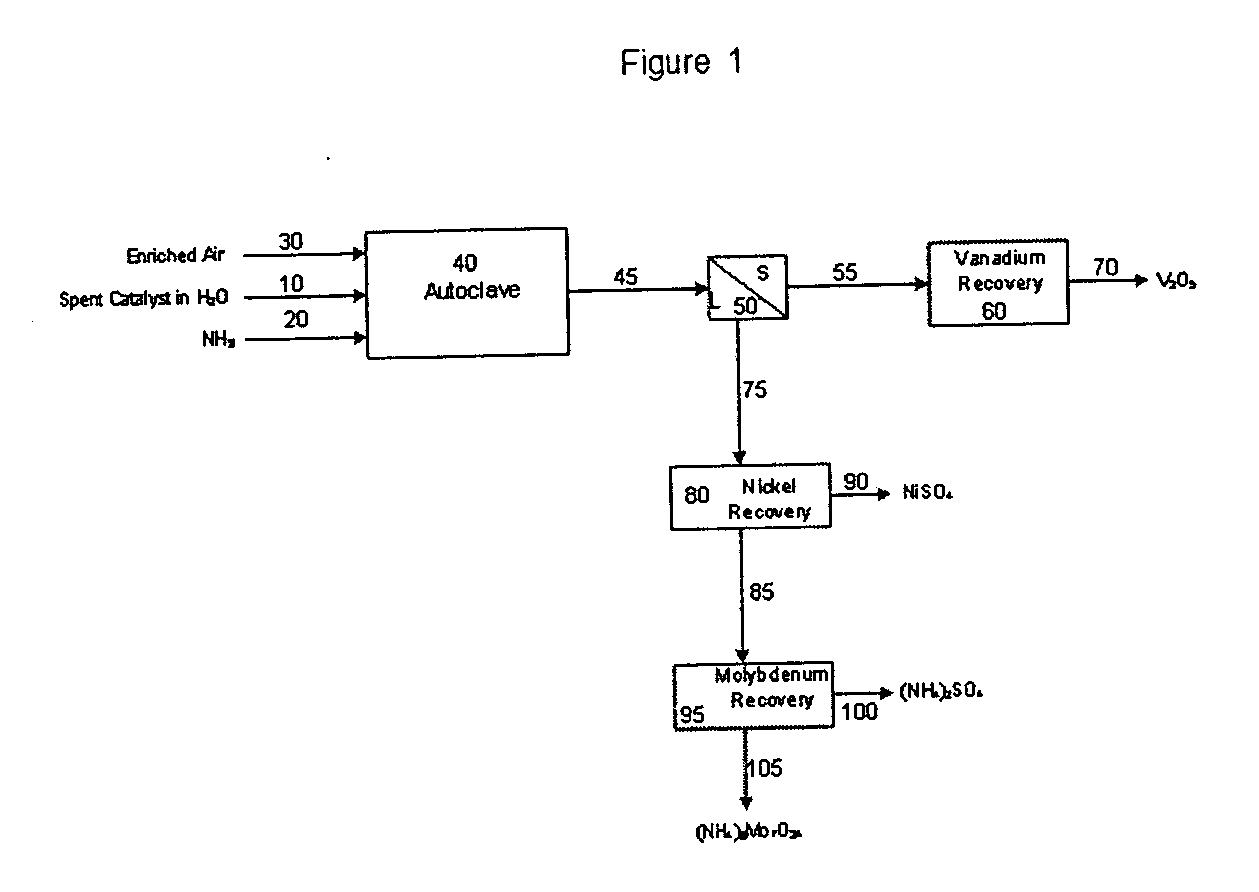

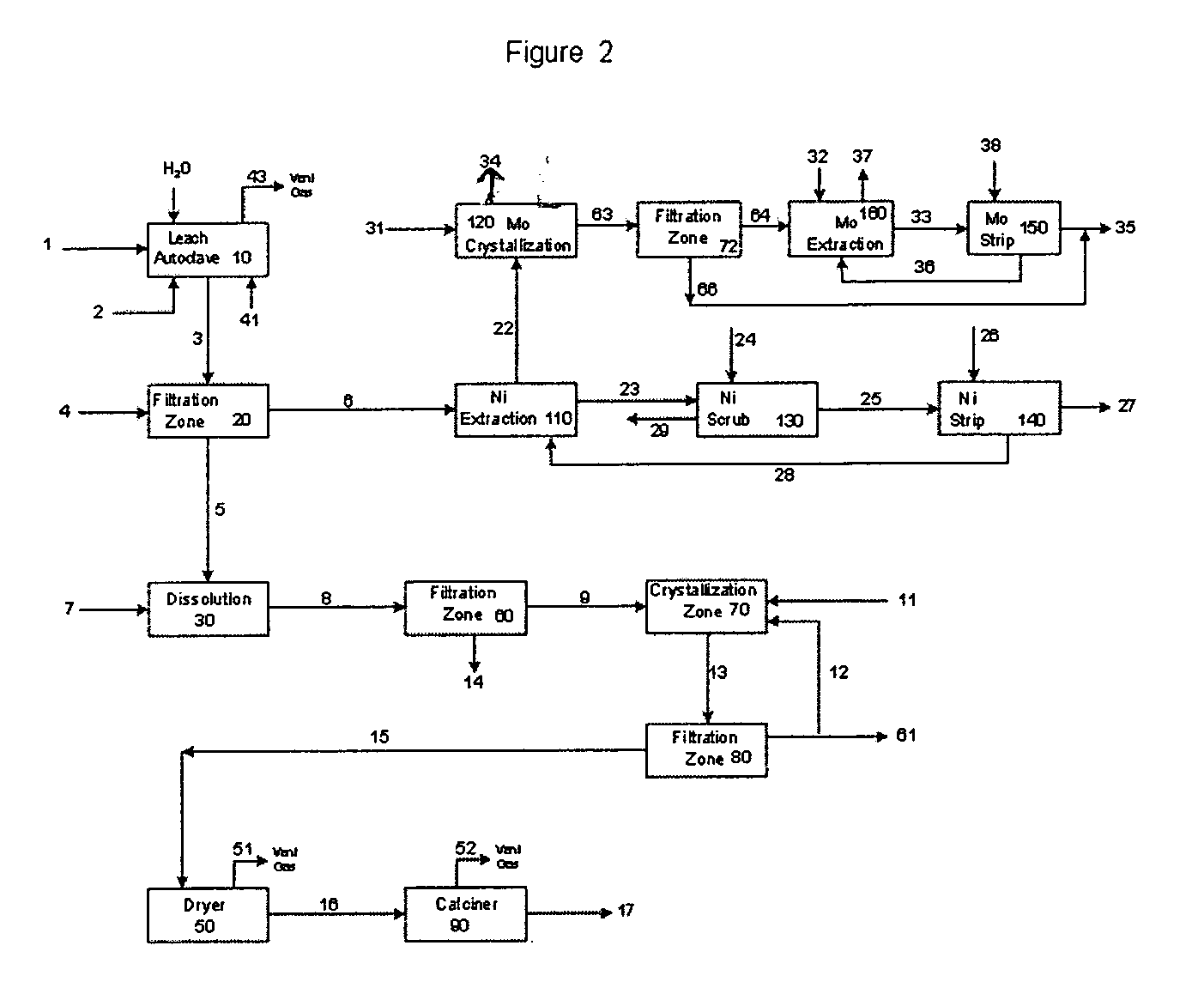

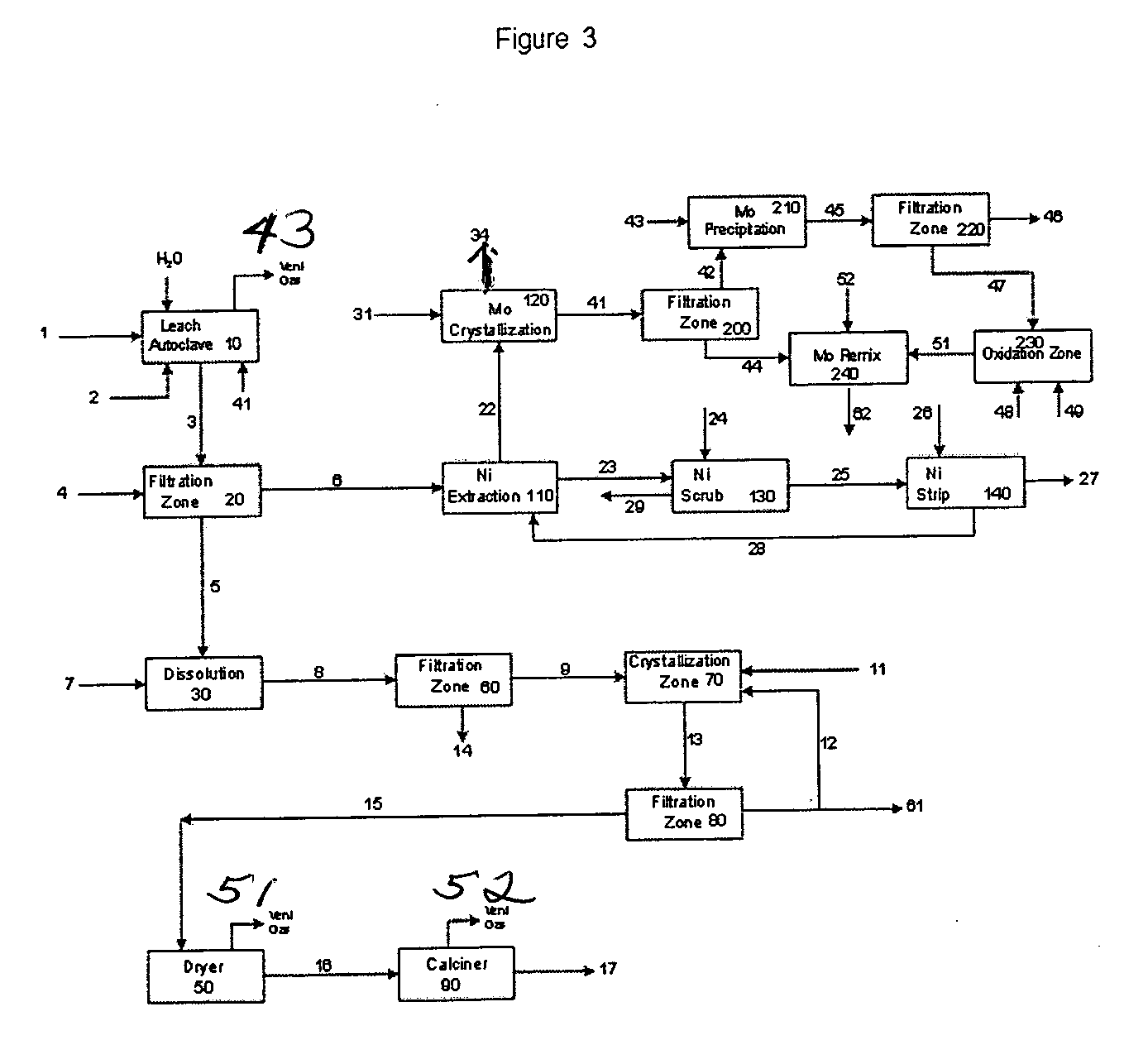

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

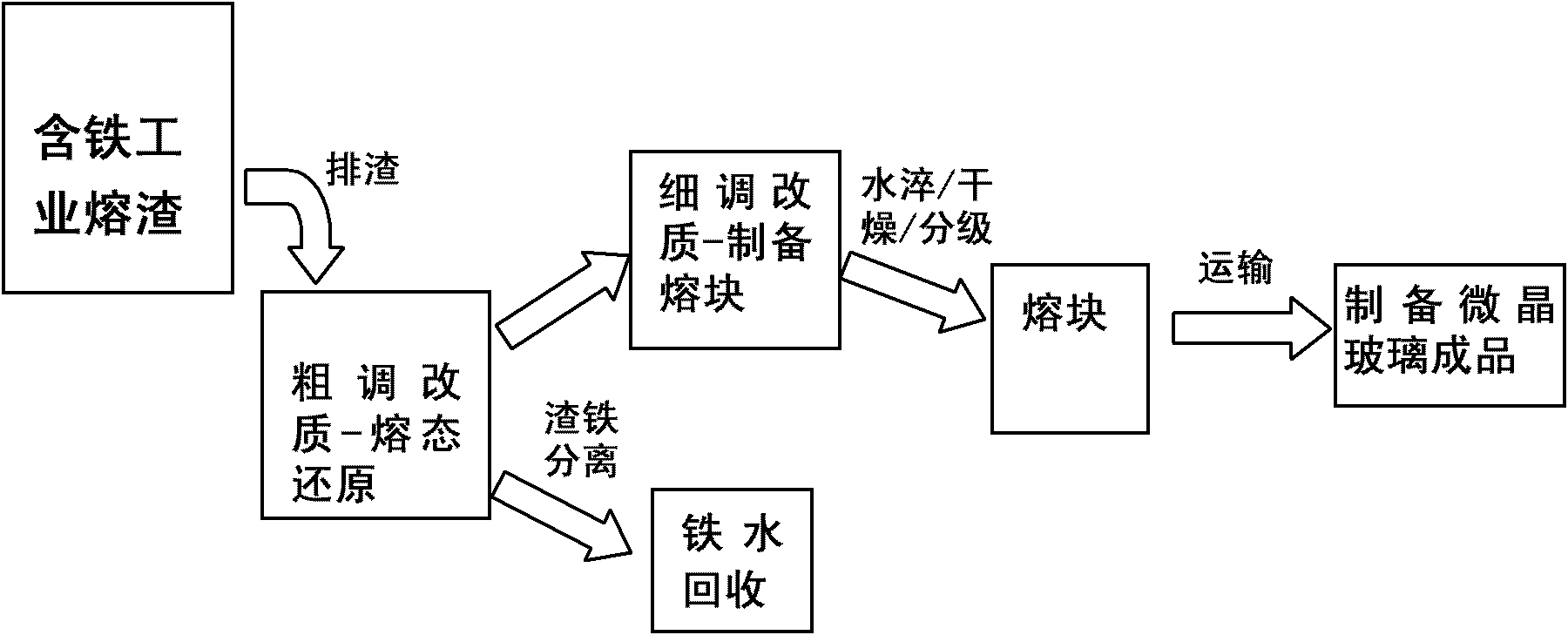

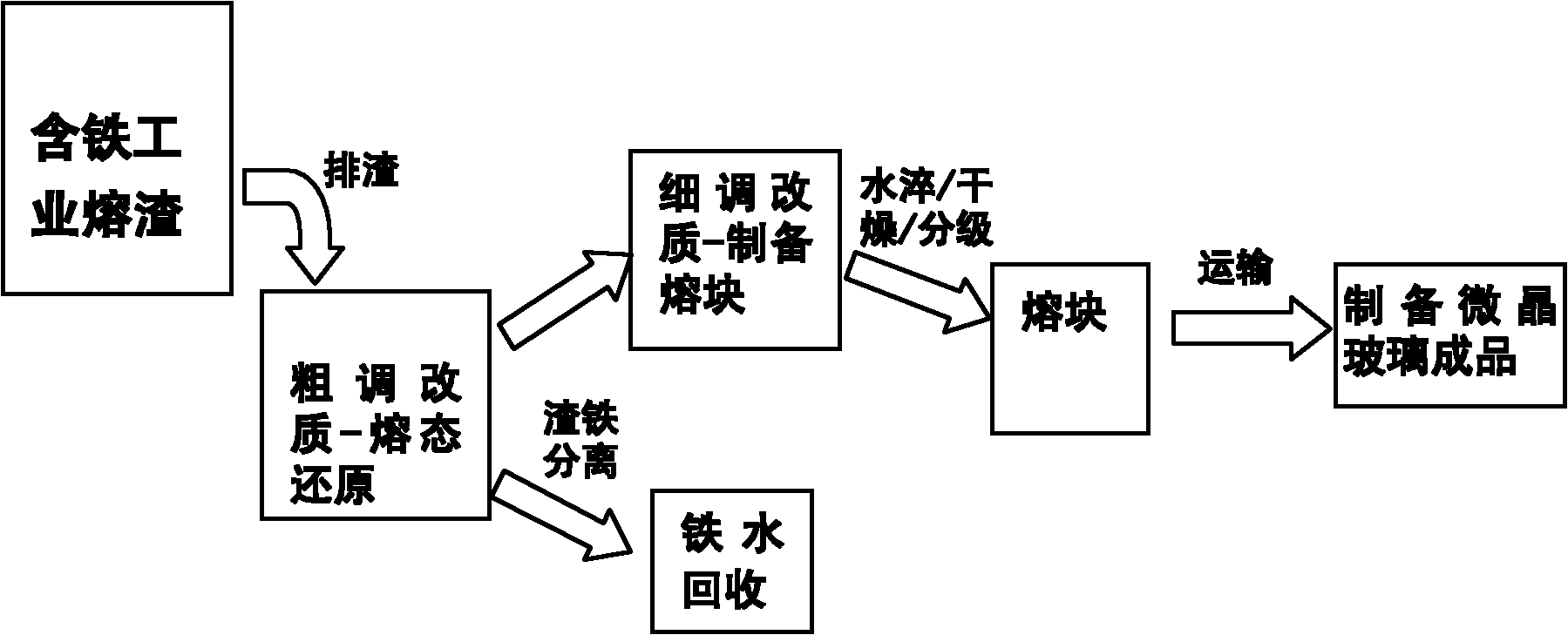

Method for recycling iron on line from iron-containing industrial slag and preparing glass ceramics frit

InactiveCN101914639AGuaranteed slag compositionRecycling and recovery technologiesProcess efficiency improvementMaterials preparationSlag

The invention relates to a method for recycling iron on line from iron-containing industrial slag and preparing a glass ceramics frit, belonging to the technical field of resource comprehensive utilization and material preparation and mainly comprising a two-step method process of iron-containing industrial slag online rough adjustment and modification for reducing iron and fine adjustment and modification for preparing the frit. The method comprises the steps of: discharging high-temperature iron-containing slag into a high-temperature furnace device, and simultaneously adding a reducing agent and a modifying agent to ensure that slag components are adjusted to reach the optimal component point in which iron oxide is reduced; after fully reacted, separating reduced molten iron from the slag, and recycling to obtain high-temperature molten iron; further adding a modifying agent and an adjusting agent into the slag remained after the separation to ensure that the slag components are adjusted to achieve the quality requirement of slag glass ceramics on the frit; and water-hardening, drying and grading the qualified slag to prepare the glass ceramics frit. The invention realizes multiple purposes that the heat of the slag is directly utilized and metal iron is recycled to prepare a high addition value product as well as solid wastes are massively utilized, and the like.

Owner:UNIV OF SCI & TECH BEIJING

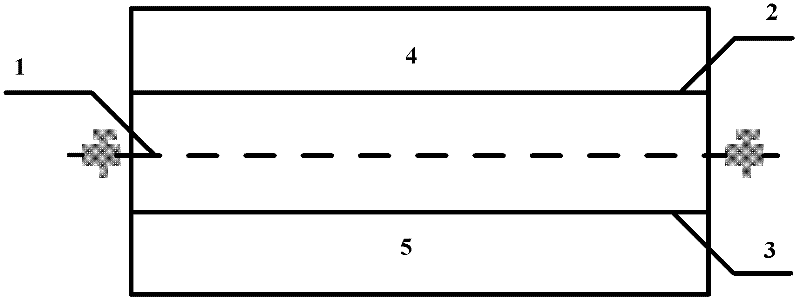

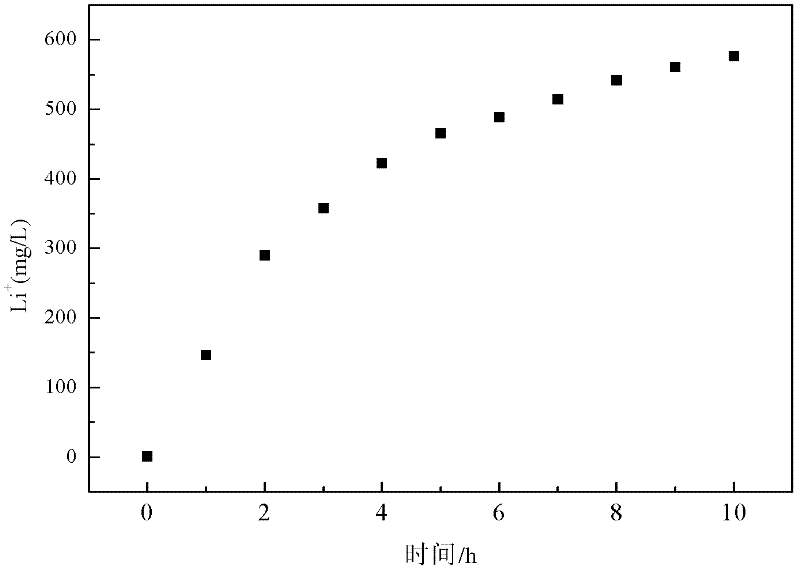

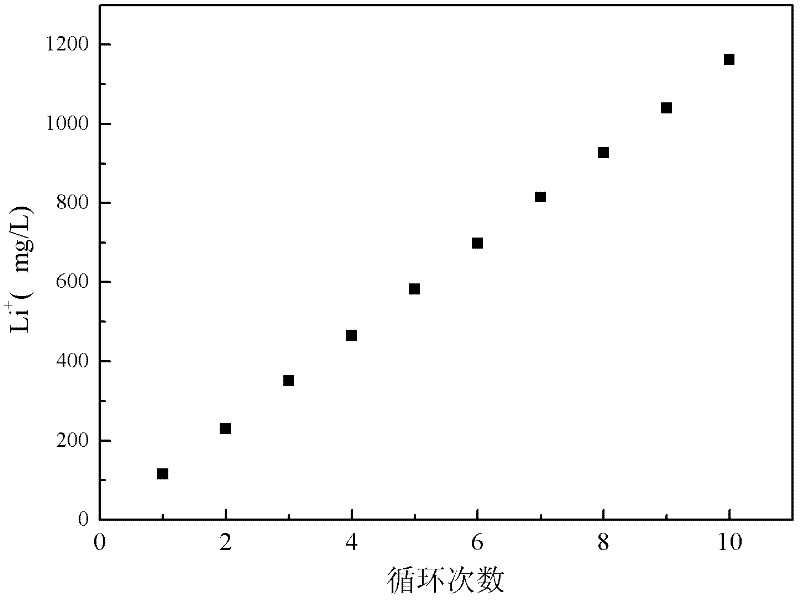

Method and device for separating magnesium and lithium and enriching lithium from salt lake brine

ActiveCN102382984AGood choiceImprove stabilityProcess efficiency improvementSupporting electrolyteIon-exchange membranes

The invention relates to a method and a device for separating magnesium and lithium and enriching the lithium from salt lake brine. The method comprises the following steps of: separating an electrodialyzing device into two areas by using an anion exchange membrane, namely a lithium salt chamber and a brine chamber, filling the salt lake brine in the brine chamber, and filling a supporting electrolyte solution which does not contain Mg<2+> in the lithium salt chamber; placing a conducting matrix coated by an ionic sieve in the brine chamber as a cathode; placing the conducting matrix coated by a lithium-embedded ionic sieve in the lithium salt chamber as an anode; under the driving of an external electric potential, embedding Li <1+> in the brine in the brine chamber into the ionic sieve to form the lithium-embedded ionic sieve, and recovering the lithium-embedded ionic sieve into the ionic sieve after the lithium-embedded ionic sieve in the lithium salt chamber releases the Li <1+> into a conducting solution; and discharging a liquid in the brine chamber after the lithium is embedded, adding the salt lake brine again, alternatively placing electrodes in the two chambers, and repeating and circulating operations. Through the method and the device for separating magnesium and lithium and enriching lithium in the salt lake brine, the separation of the lithium and other ions is effectively realized, and a lithium-enriched solution is synchronously obtained. The method has a short flow and low production cost, is simple to operate, can be operated continuously, and is easy to industrially apply.

Owner:CENT SOUTH UNIV

Popular searches

Metal-working apparatus Semiconductor/solid-state device manufacturing Inks Anti-corrosive paints Non-conductive material with dispersed conductive material Liquid/solution decomposition chemical coating Printed circuit manufacture Solid/suspension decomposition chemical coating Chemical vapor deposition coating Organic electrolyte cells

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com