Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Level aluminum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

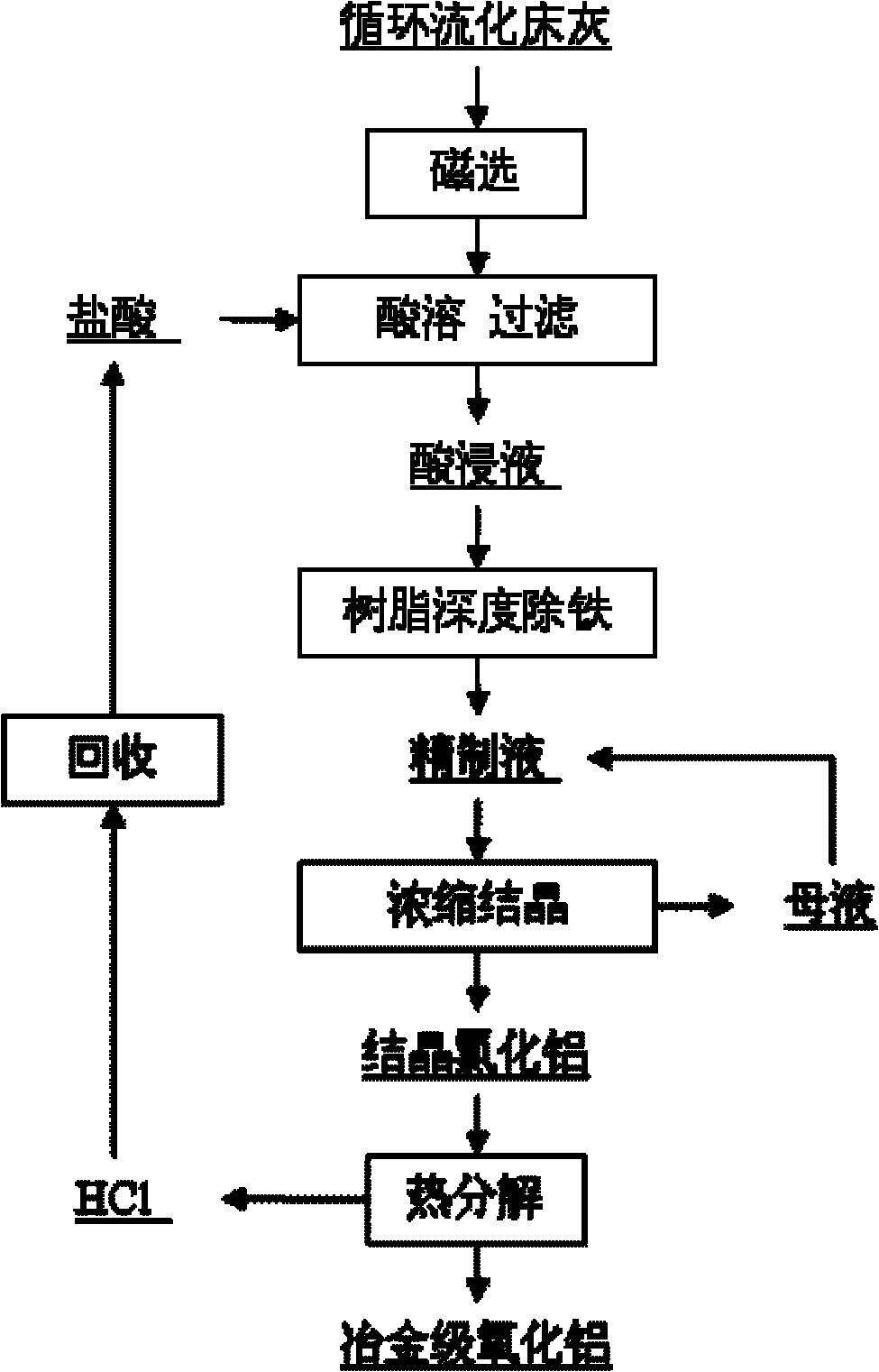

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

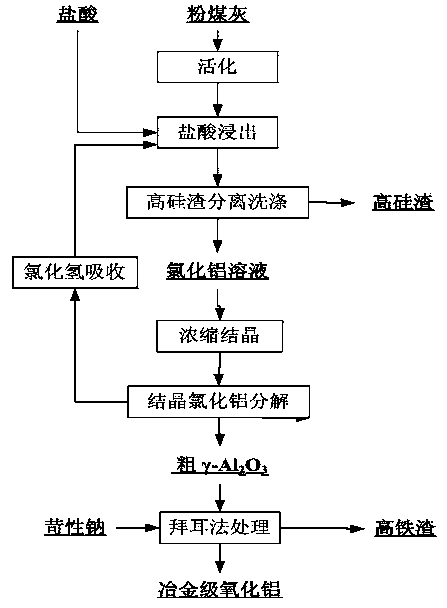

Method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid

ActiveCN103663511AEffective leachingAchieve cycleAluminium oxides/hydroxidesAluminium chlorideSteelmaking

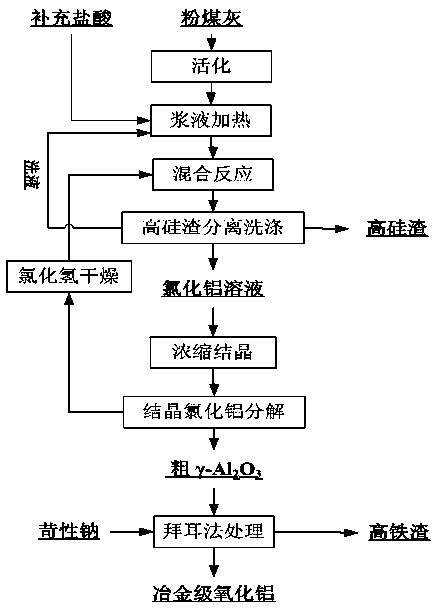

The invention discloses a method for producing aluminum oxide through treatment and utilization of industrial solid wastes and particularly relates to a method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid. The method comprises the following steps: activating coal ashes; mixing the activated coal ashes with 15%-36% hydrochloric acid, wherein a molar ratio of HCl in the hydrochloric acid to aluminum oxide and iron oxide in the coal ashes is 4-9; feeding mixed serous fluid into a reactor, heating to 90 DEG C-230 DEG C, wherein reaction time is 1 hour-8 hours; carrying out solid-liquid separation after reacting and cooling to obtain aluminum chloride liquid and high-silicon residue, and evaporating, concentrating or drying to obtain crystallized aluminum chloride; decomposing the crystallize aluminum chloride to obtain crude gamma-Al2O3 and a hydrogen chloride gas; and preparing metallurgical-level aluminum oxide by gamma-Al2O3 through a Bayer process, wherein the residue is high-iron residue and can be used as a steelmaking material. According to the method, any auxiliary agent is not added, so that aluminum oxide in the coal ashes can be effectively leached out, and the leaching rate of the aluminum oxide can reach over 85%.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

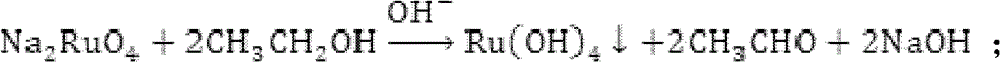

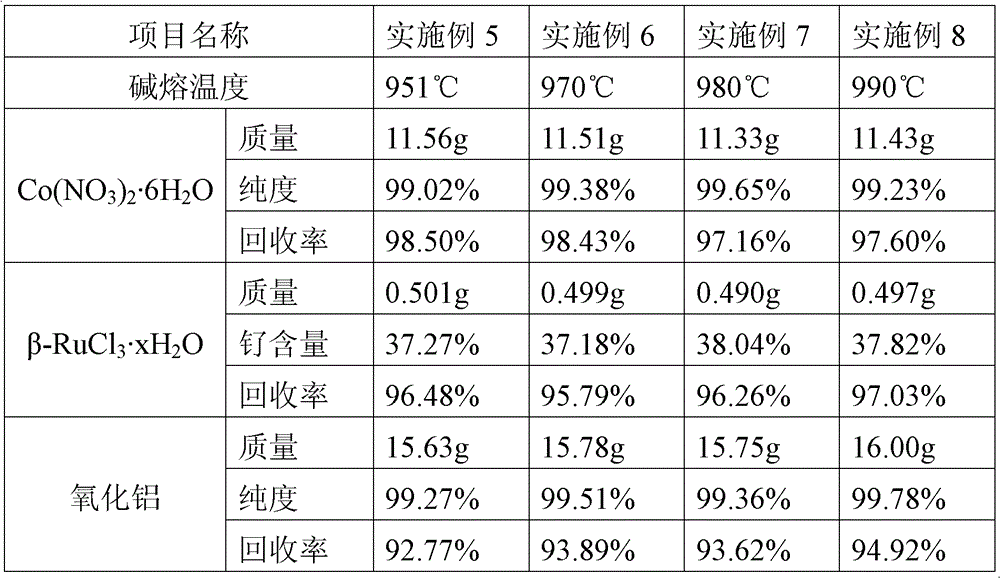

Method for comprehensively recovering metallic cobalt, ruthenium and aluminum from Fischer-Tropsch synthesis dead catalyst Co-Ru/Al2O3

ActiveCN102796873AHigh purityOperational securityProductsAluminium compoundsDistillationAluminium hydroxide

The invention discloses a method for comprehensively recovering metallic cobalt, ruthenium and aluminum from a Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3, and the method can be used for effectively separating and comprehensively recovering valuable metallic cobalt, ruthenium and aluminum from the Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3. The method comprises the steps of: firstly carrying out hydrocarbon removal and reductive treatment on the dead catalyst; effectively separating cobalt slag in an alkali fusion step; and carrying out acid leaching on the cobalt slag, oxalate or oxalate deposited cobalt, reducing cobalt oxalate, dissolving the metallic cobalt via nitric acid and the like to obtain Co(NO3)2.6H2O. Ruthenate is obtained by the steps of alkali fusion and deionized water leaching; and steps of ethanol reduction, concentrated hydrochloric acid dissolution, reduced pressure distillation and the like are carried out on the ruthenate to obtain a beta-RuCl1.xH2O product which is high in purity. By using a CO2 carbon dioxide decomposition method, the parameters such as reaction temperature, CO2 flow velocity, pH value of reaction destination and the like are controlled and aluminum hydroxide is prepared from meta-aluminate solution; high-temperature calcination is carried out to obtain aluminum oxide; and the product quality meets the quality requirement of first-level aluminum oxide of national standard and the process is economic and environment-friendly. According to the invention, the metallic recovery rate is high, wherein the recovery rate of cobalt is greater than or equal to 97%, the recovery rate of ruthenium is greater than or equal to 95% and the recovery rate of aluminum is greater than or equal to 92%.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

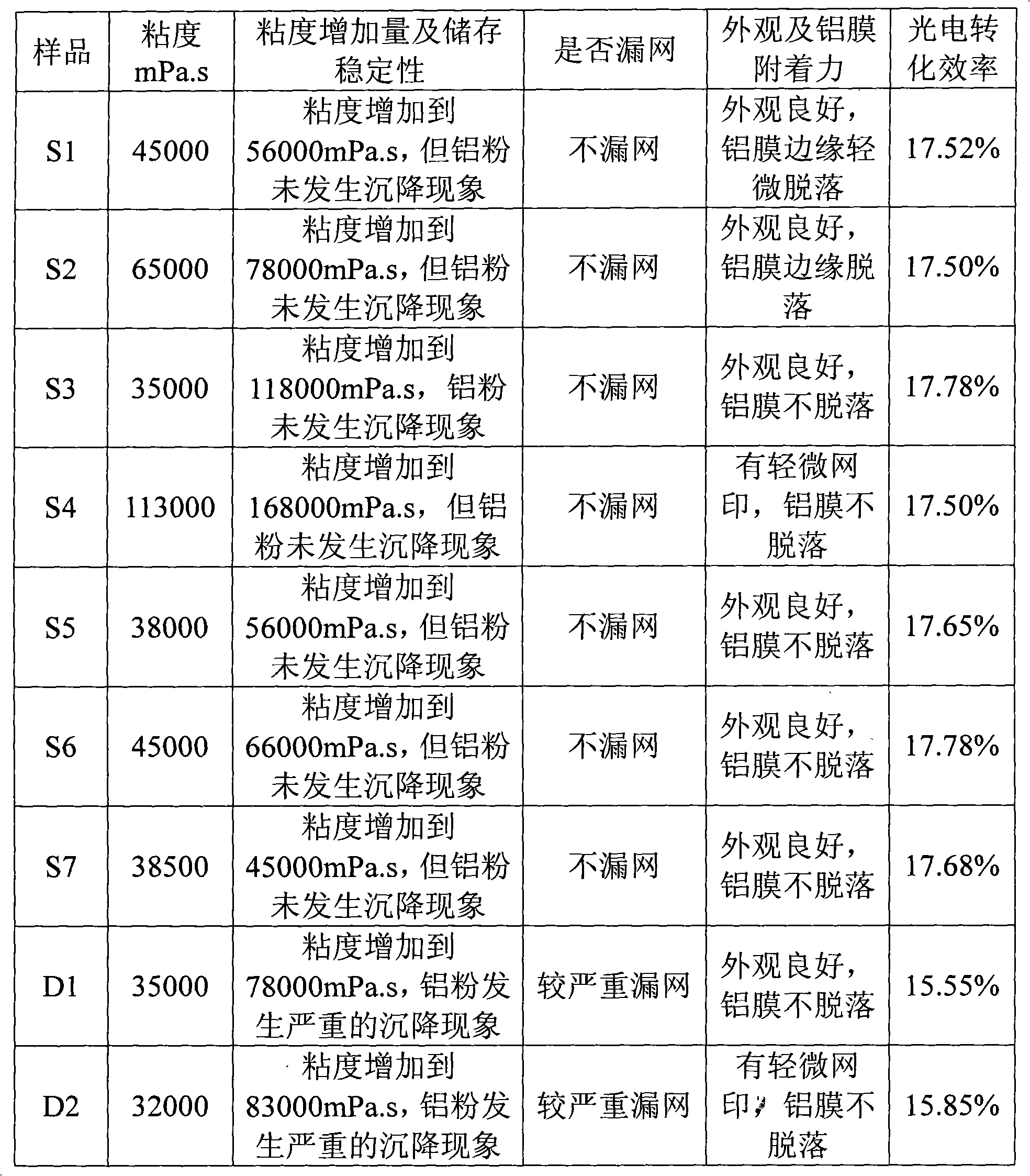

Solar cell conductive slurry and preparation method thereof

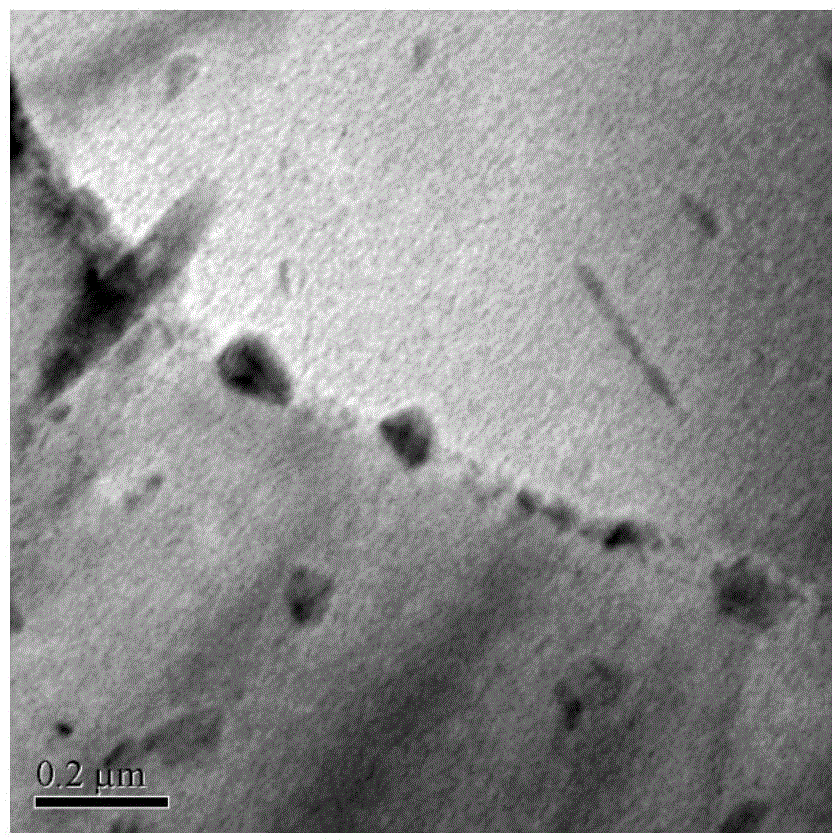

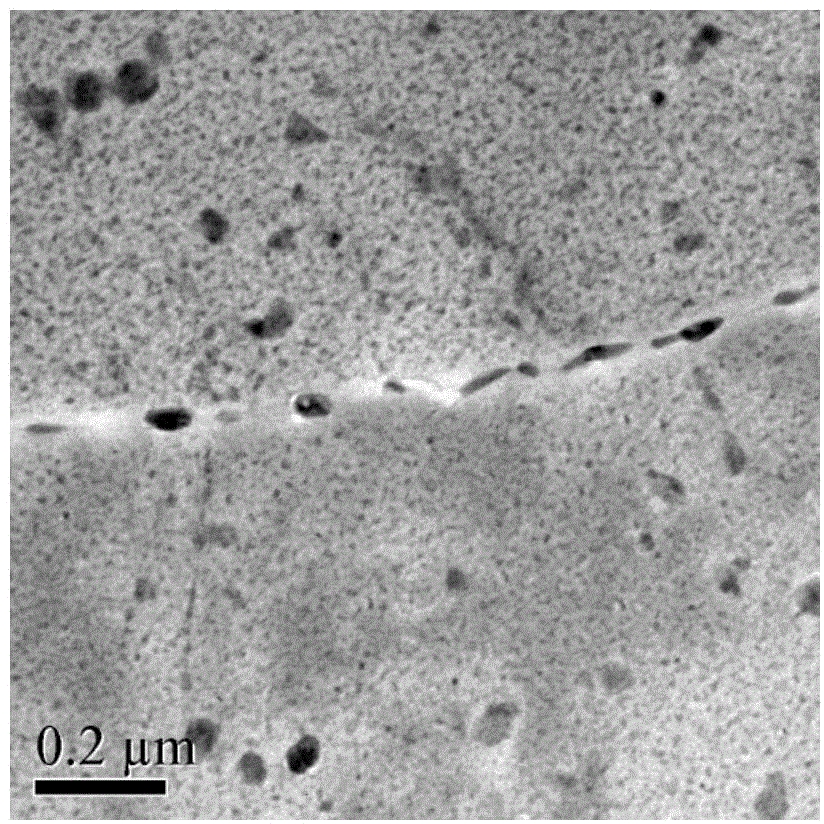

ActiveCN101901844ANo sedimentation and caking phenomenonPrinting does not affectNon-conductive material with dispersed conductive materialPhotovoltaic energy generationLevel aluminumScreen printing

The invention belongs to the field of solar cells and particularly discloses solar cell conductive slurry and a preparation method thereof. The solar cell conductive slurry comprises first-level aluminum powder, second-level aluminum powder, glass powder and an organic carrier, wherein the median particle diameter D50 of the first-level aluminum powder is between 2 and 8 mu m; and the median particle diameter D50 of the second-level aluminum powder is between 20 and 100 nanometers. The conductive slurry does not escape from a screen during screen printing, has high storage stability and is not easy to settle or agglomerate.

Owner:BYD CO LTD

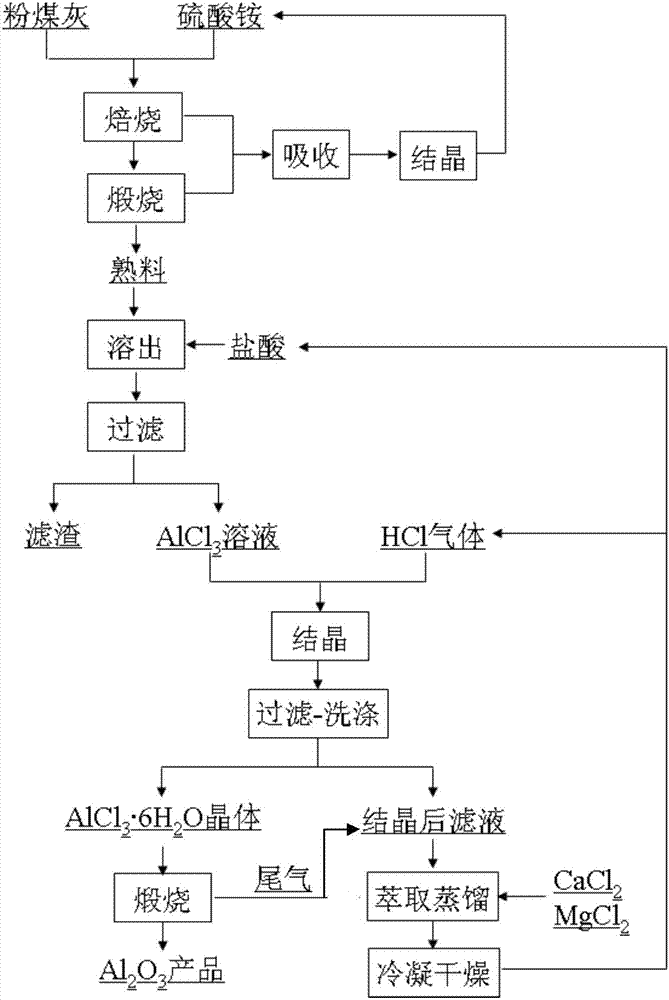

Process method for extracting aluminum oxide in coal ash of pulverized coal furnace by using acid method

InactiveCN106966415ARealize direct recyclingEasy roasting operationAluminium oxides/hydroxidesExtractive distillationBiological activation

The invention relates to a process method for extracting aluminum oxide in coal ash of a pulverized coal furnace by using an acid method. The process method comprises the following steps; adding ammonium sulfate into the coal ash of the pulverized coal furnace for activating, and performing the high-temperature calcination to obtain activated coal ash clinker, adding hydrochloric acid, heating and dissolving out, to obtain aluminum chloride digesting liquor; pumping hydrogen chloride gas into the digesting liquor for crystallizing, performing the solid-liquid separation and washing to obtain high-purity aluminum chloride hexahydrate crystal and waste acid solution, calcining the crystal to generate metallurgy-level aluminum oxide; adding inorganic salt chloride, such as calcium chloride or magnesium chloride, into the waste acid, heating, extractive-distilling and recycling the hydrochloric acid and the hydrogen chloride gas for the dissolving out and crystallization working procedures, performing the absorption-crystallization to tail gas generated in the roasting-calcining activation to generate ammonium sulfate, and realizing the cyclic utilization of materials, wherein the obtained solid residue with abundant silicon dioxide can be used for generating white carbon black or the materials for building. The process method is capable of realizing the reduced recycling of the coal ash of the pulverized coal furnace, and realizing the full cyclic utilization of the materials. The purity of the obtained aluminum oxide product is the first level, the quality of the metallurgy-level aluminum oxide is standard, and the extraction efficiency is up to 84.6%-90.4%.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

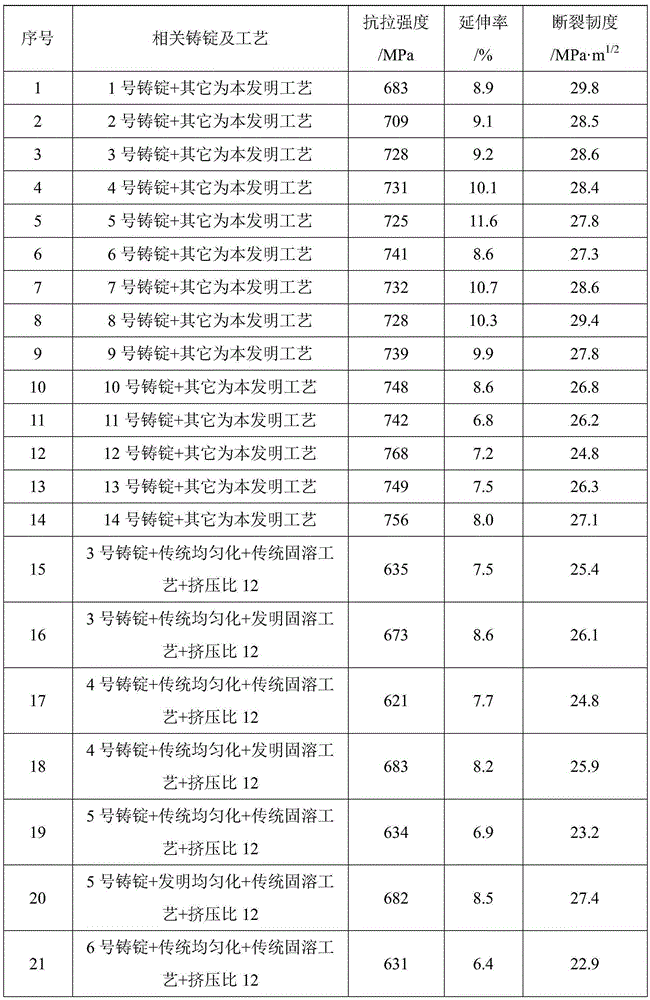

Preparing method for 700-MPa-level aluminum alloy extruded section

The invention provides a preparing method for a 700-MPa-level aluminum alloy extruded section. The 700-MPa-level aluminum alloy extruded section is prepared from, by weight percentage, 7.8% to 10.3% of Zn, 1.3% to 2.0% of Mg, 1.3% to 2.0% of Cu, 0.08% to 0.15% of Zr, smaller than or equal to 0.15% of Si, smaller than or equal to 0.15% of Fe, smaller than or equal to 0.15% of other impurities and the balance Al, wherein the weight percentage of each kind of the impurities is smaller than or equal to 0.05%. The preparing method includes the steps that the raw materials are prepared according to alloy components, fused, subjected to furnace refining and standing, and then cast into an alloy ingot with the required specification; and the alloy ingot is subjected to preferred three-stage homogenizing, then formed through a preferred extrusion technology and can be used for part machining after heat treatment. The novel aluminum alloy extruded section is even in microscopic structure and stable in performance, and the ultimate tensile strength can be higher than 700 MPa; and meanwhile elongation is higher than 8%, fracture toughness is higher than 26 MPa.m<1 / 2>, the current aerospace material selecting requirement is met, and meanwhile the aluminum alloy extruded section can be widely applied to the fields of the nuclear industry, transportation, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preparing aluminum oxide by using hydrochloric acid treatment coal ash

ActiveCN103663510AGuaranteed concentration of hydrochloric acidAvoid Corrosion HazardsSolid waste disposalAluminium oxides/hydroxidesAluminium chlorideSlag

The invention discloses a method for preparing aluminum oxide by using hydrochloric acid treatment coal ash. The method comprises the steps: activating coal ash; mixing the activated coal ash with hydrochloric acid with the concentration of 5-10 percent; feeding mixed slurries into a heat exchanger to be heated to be between 90 and 200 DEG C; feeding the heated slurries into a reactor; adding hydrogen chloride gas into the reactor and reacting for 1-8 hours; separating solid from the liquid after reaction is finished and the temperature is reduced to obtain aluminum chloride and ferric chloride solution and high silicon slag; evaporating and condensing or drying to obtain crystallized aluminum chloride and ferric chloride; heating and decomposing the crystallized aluminum chloride to obtain coarse gamma-Al2O3 containing a large number of impurities and hydrogen chloride gas; and treating coarse gamma-Al2O3 by using the Bayer process to prepare metallurgical-level aluminum oxide, wherein residual slag is high iron slag and can be used an iron-making raw material. According to the method, the problem of severe corrosion of the equipment can be avoided, aluminum oxide in the coal ash is effectively leached, and the produced aluminum oxide can meet the industrial requirement of electrolytic aluminum.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

800MPa-level aluminum alloy extruded section and preparation method thereof

The invention discloses a 800MPa-level aluminum alloy extruded section and a preparation method thereof, belongs to the technical field of metal materials, and provides a large-size 800MPa-level aluminum alloy extruded section which can be used for semicontinuous casting method preparation. The 800MPa-level aluminum alloy extruded section comprises the following components in percentage by weight:9.0-12.5% of Zn, 2.5-3.5% of Mg, 0.8-1.5% of Cu, 0.08-0.15% of Zr, 0.05-0.25% of Sc, less than or equal to 0.10% of Fe, less than or equal to 0.10% of Si, less than or equal to 0.15% of other impurities and the balance of Al, wherein the percentage of each impurity is less than or equal to 0.05%. The 800MPa-level aluminum alloy extruded section is prepared through the steps of batching the raw materials according to the alloy components, melting the raw materials, carrying out furnace refining and standing, and casting an alloy ingot with a required specification by adoption of a semicontinuous casting method; and carrying out tertiary homogenization processing and extrusion process forming in the conditions that the thickness of the extruded section is not smaller than 40mm and the widthis not smaller than 150mm, and carrying out thermal treatment for using. The novel aluminum alloy extruded section is uniform in microscopic structure and stable in performance; in the L direction, the tensile strength can be above 800MPa, the yield strength can be up to 750MPa and the ductility is higher 8%; in the the LT direction, the tensile strength can be up to 750MPa, the yield strength can be up to 700MPa and the ductility is higher than 6%; and the prepared section can be widely applied in the fields of aviation, spaceflight, nuclear industry, transportation, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

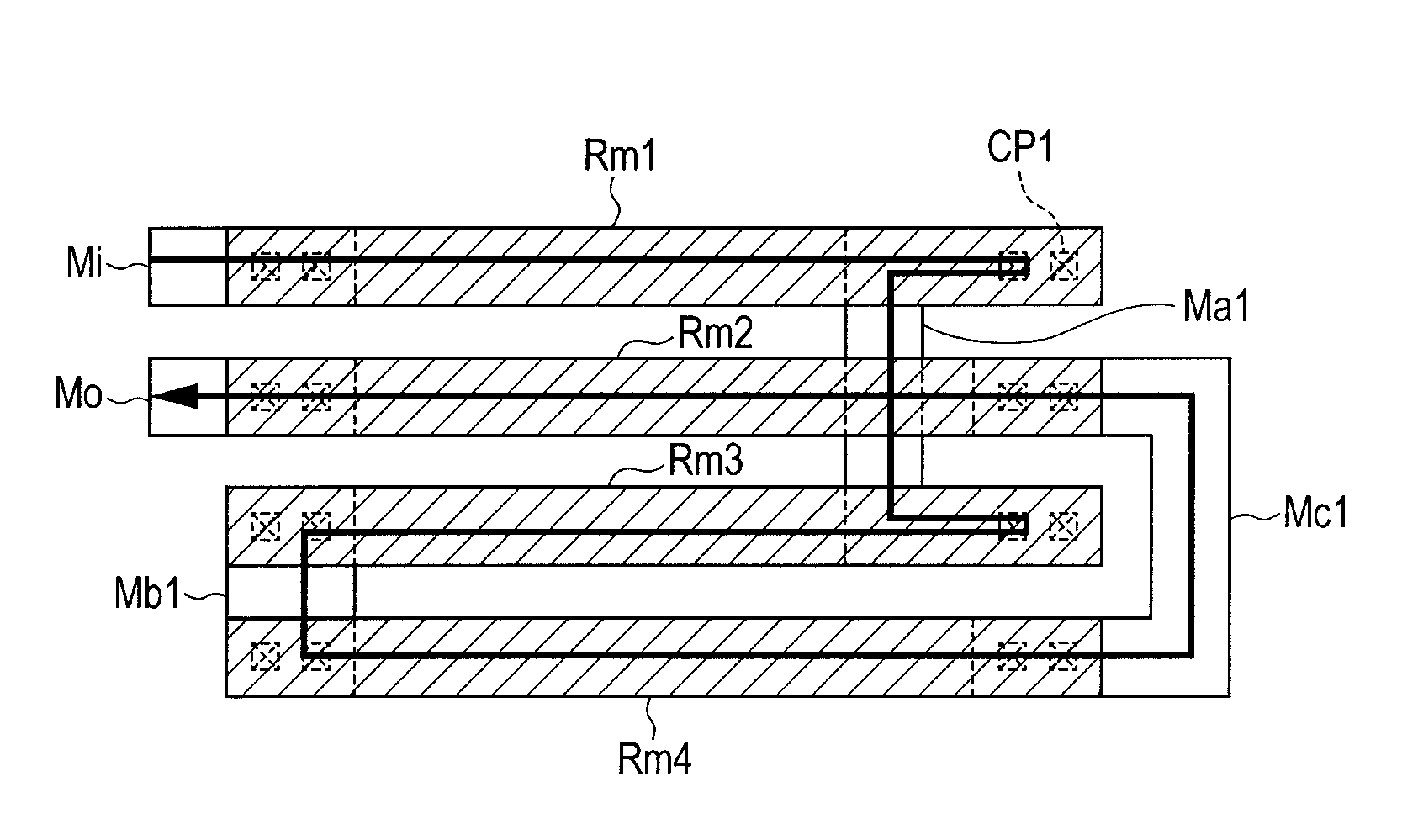

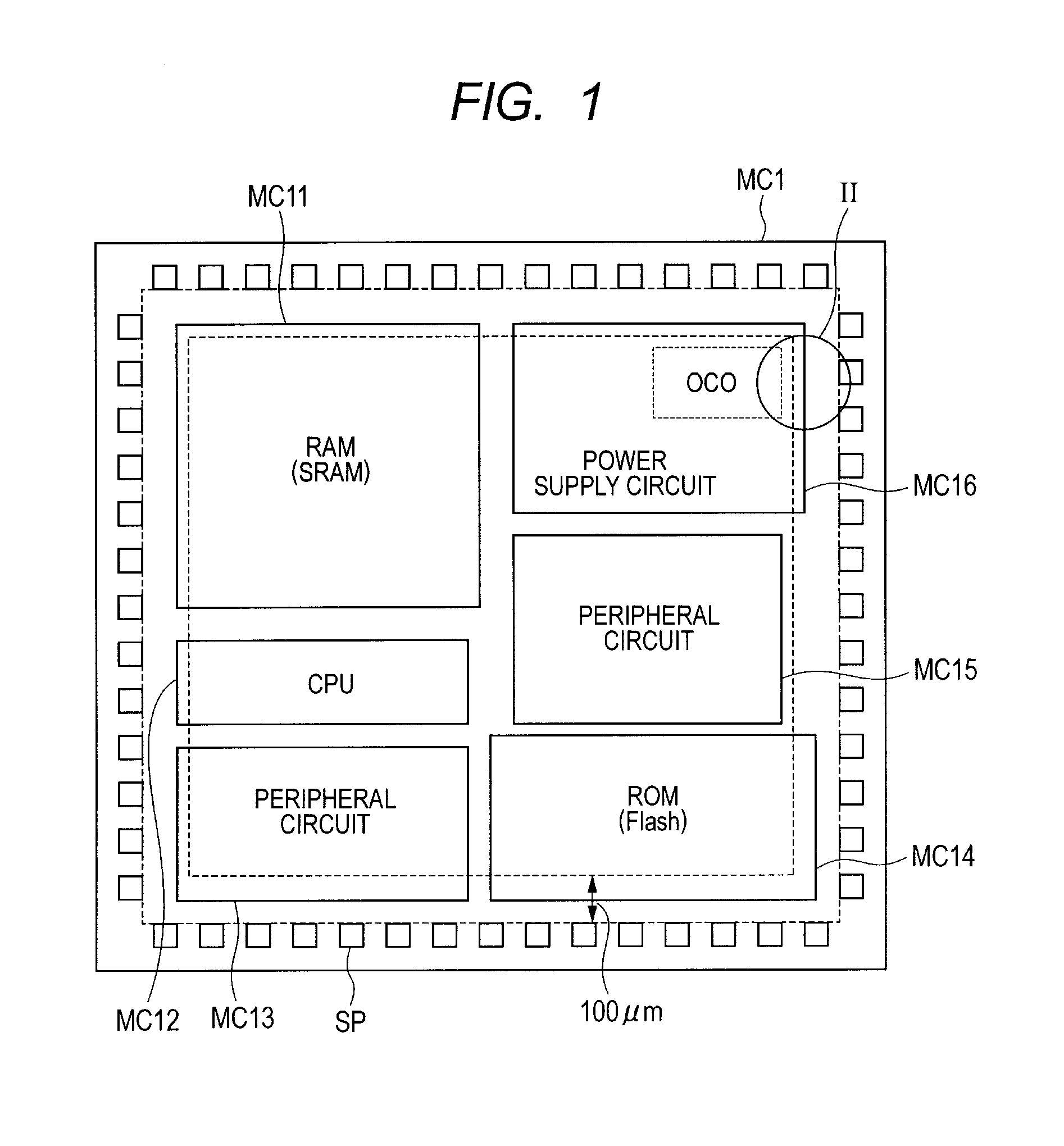

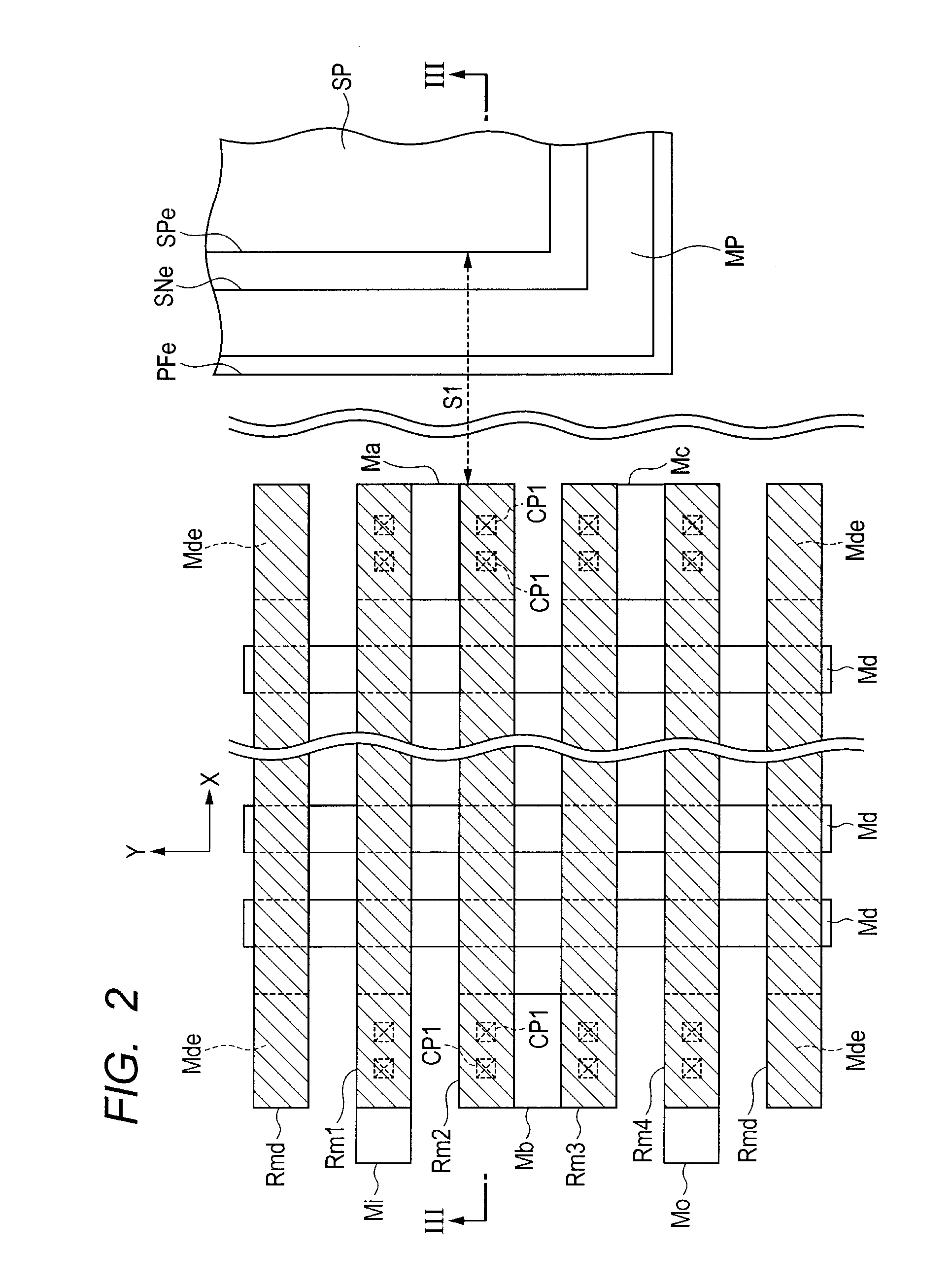

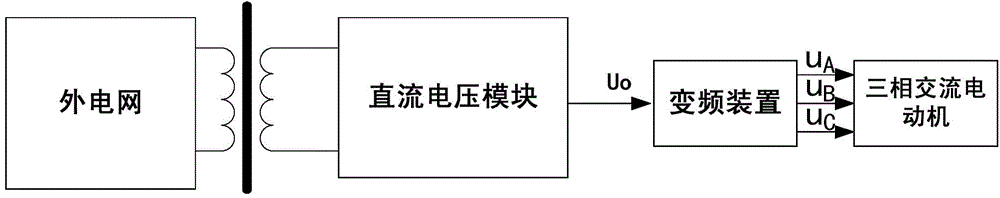

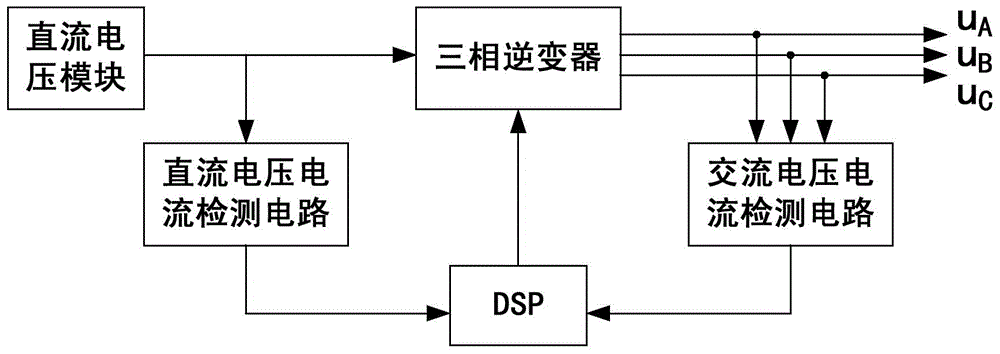

Semiconductor device and manufacturing method thereof

ActiveUS20110180901A1Variation in resistanceSemiconductor/solid-state device detailsSolid-state devicesLevel aluminumElectrical resistance and conductance

To provide a semiconductor device having a structure free from variations in resistance even when a stress is applied thereto; and a manufacturing method of the device. The semiconductor device has a metal resistor layer in a region between a passivation film and an uppermost level aluminum interconnect. This makes it possible to realize a high-precision resistor having few variations in resistance due to a mold stress that occurs in a packaging step or thereafter and therefore, makes it possible to form a high-precision analog circuit.

Owner:RENESAS ELECTRONICS CORP

Fusion casting technology for aluminum alloy flat ingot for packaging tin

The invention relates to a fusion casting technology for an aluminum alloy flat ingot for a packaging tin. Through smelting temperature control, electromagnetic stirring and melt refining, the slag content, nitrogen content and alkali metal content in melt are effectively reduced, uniformity of alloy components is guaranteed, and a low-liquid-level aluminum alloy flat ingot casting machine is adopted for controlling the casting speed and water flow in the casting process; and casting cracks and feather crystals are avoided, the product yield is greatly increased, and the product production rate is increased.

Owner:GUANGXI UNIV

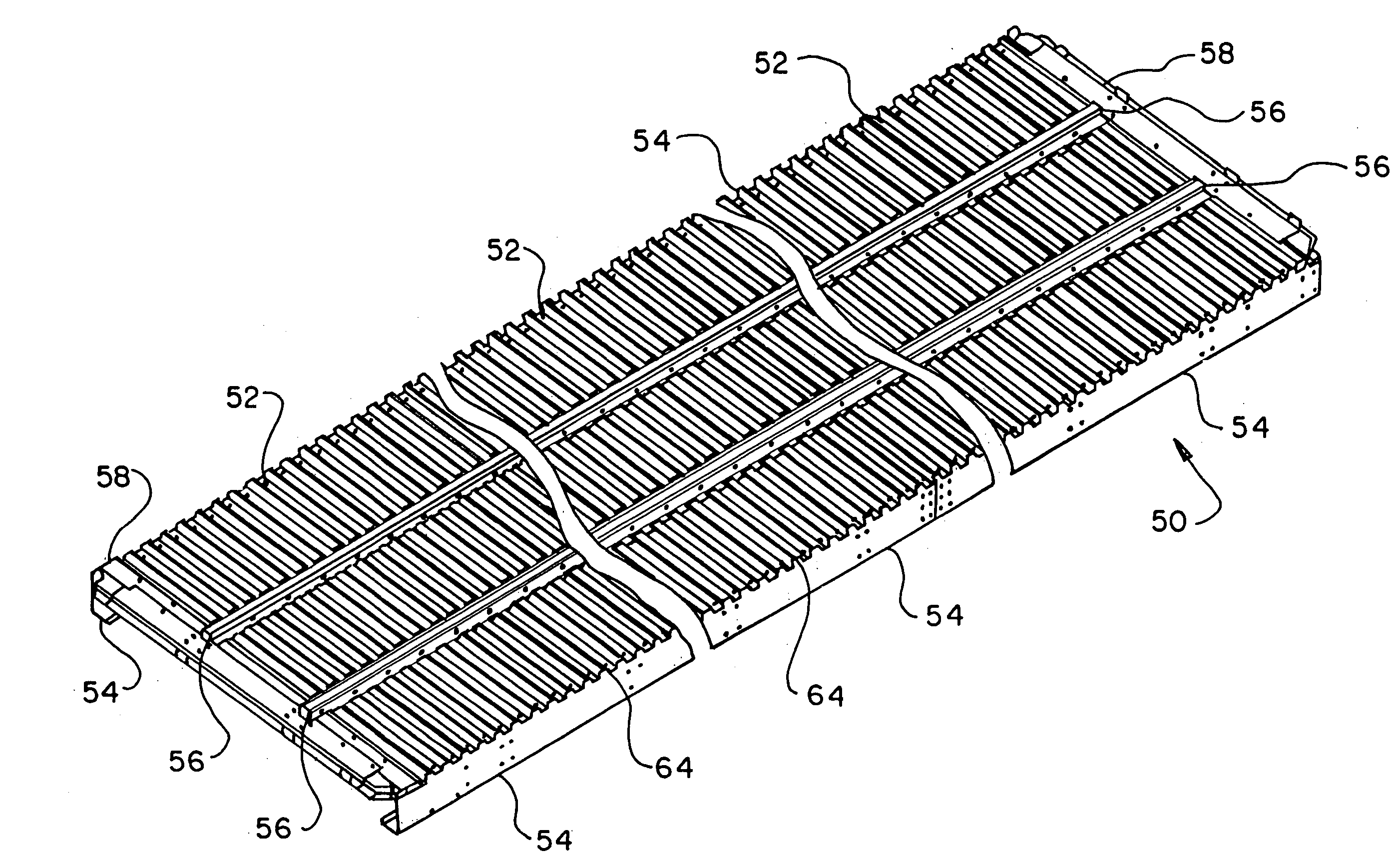

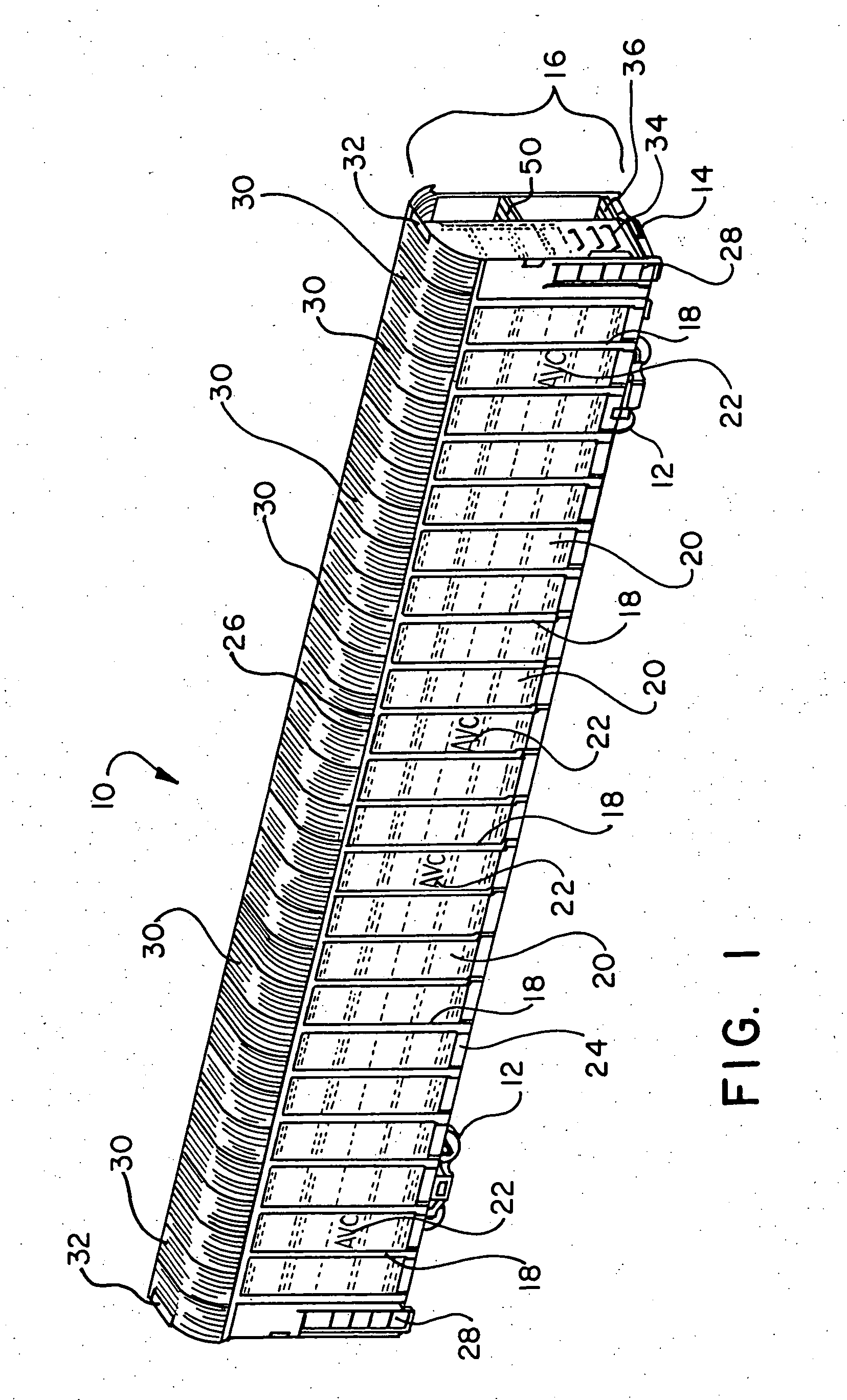

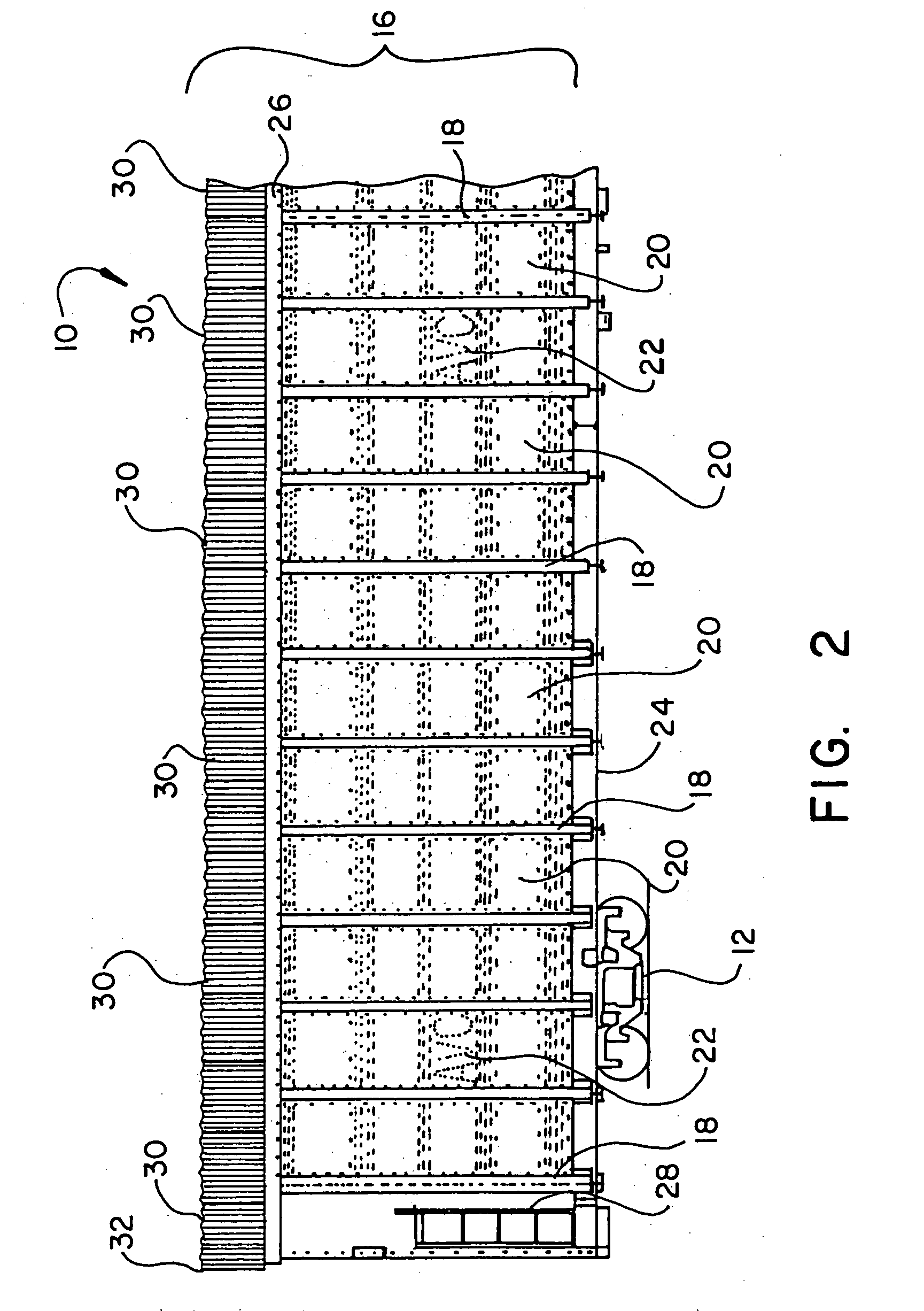

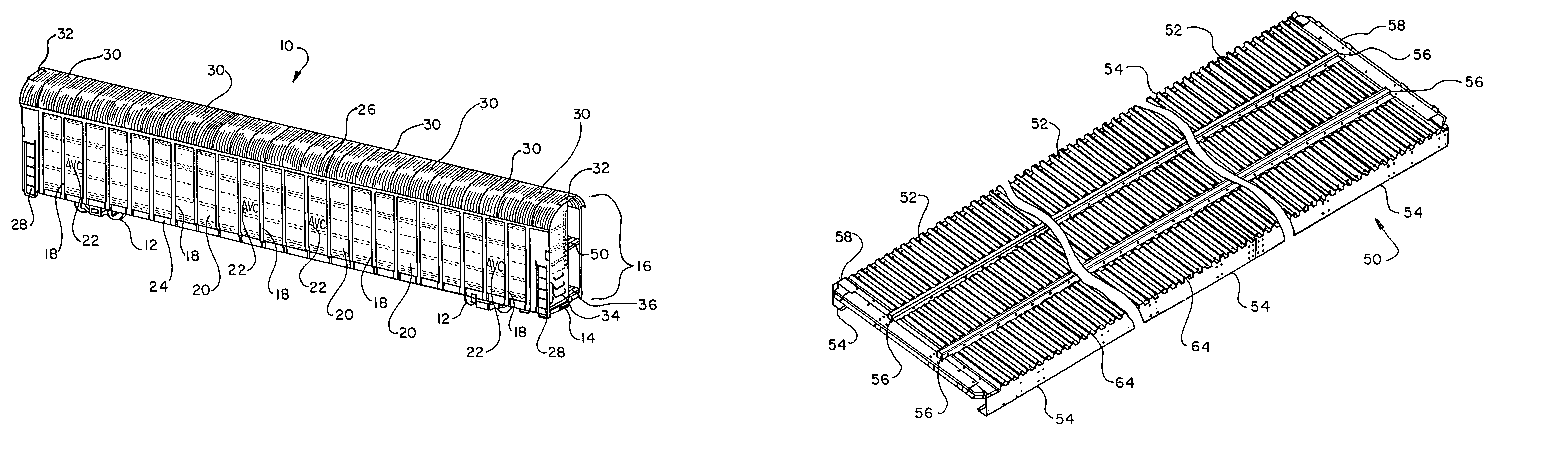

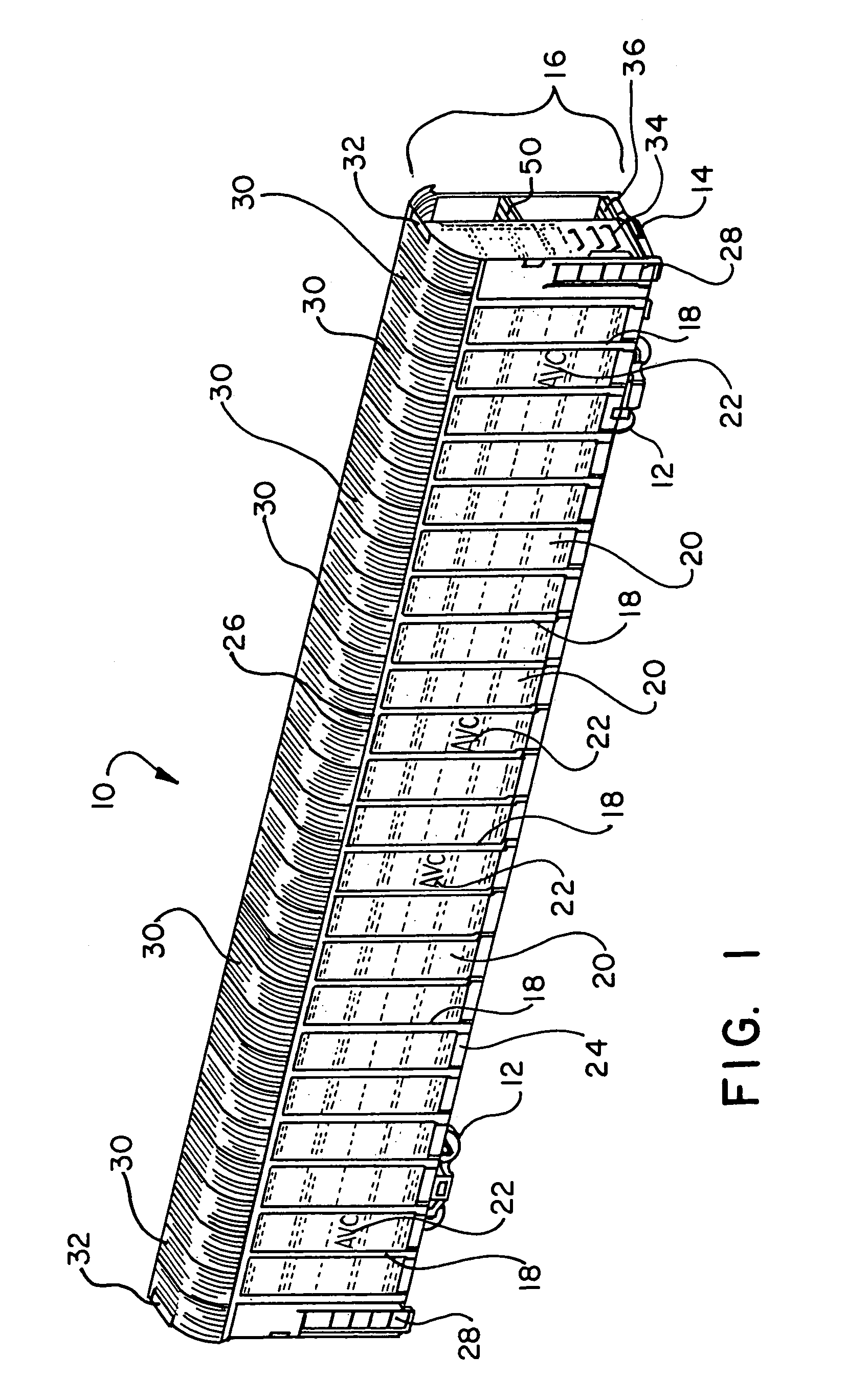

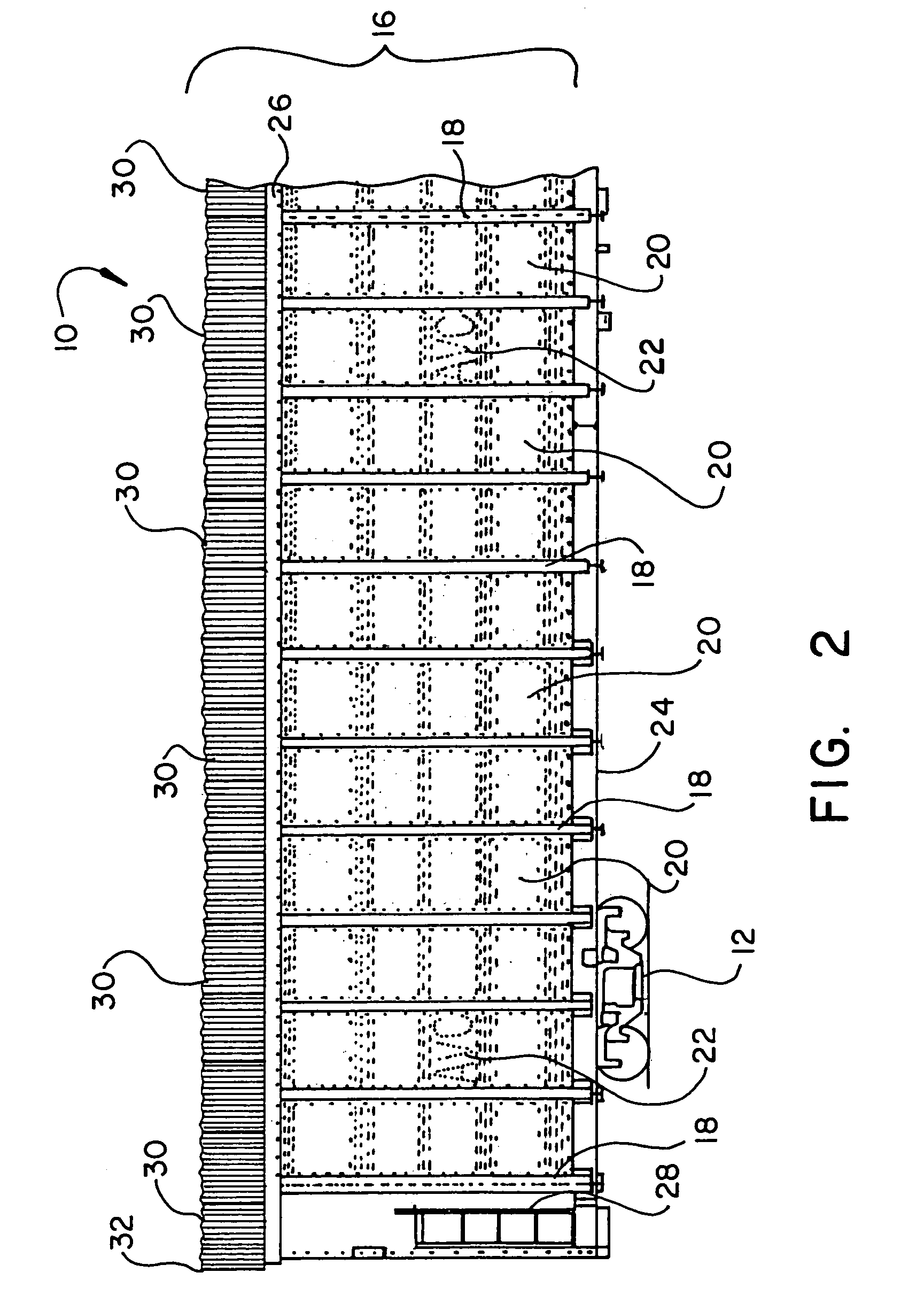

Aluminum vehicle carrier railcar

A bi-level aluminum vehicle carrier railcar (10) includes an integrated aluminum roofing structure (30), aluminum side panels (18, 20), and aluminum decking structure (36, 50) attached to a steel underframe. The decking structure (36, 50) is supported on side stakes (18) of the side panels (18, 20) with the decking structure (36, 50) including overlapping extruded aluminum decking plates with (38, 52) anti-skid features. The anti-skid features include a media blasted finish to a portion of the surface of the decking and extruded ribs (64) in a portion of the decking. The roofing structure (30) includes overlapping, arched corrugated aluminum panels (30), wherein the roof panels (30) remain uncoated.

Owner:JAC OPERATIONS

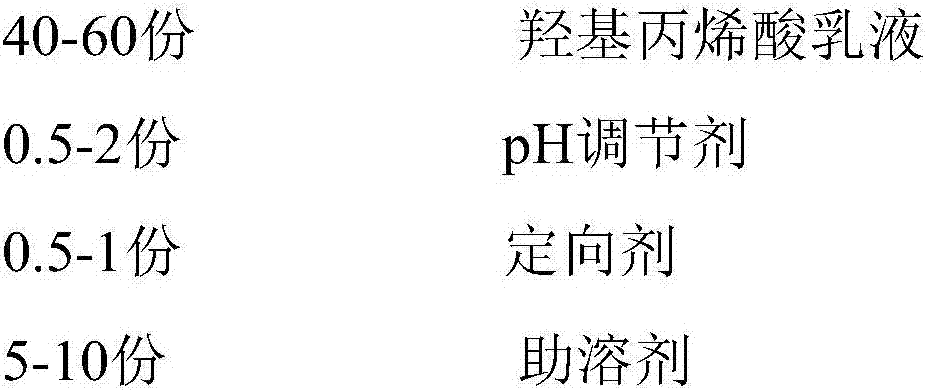

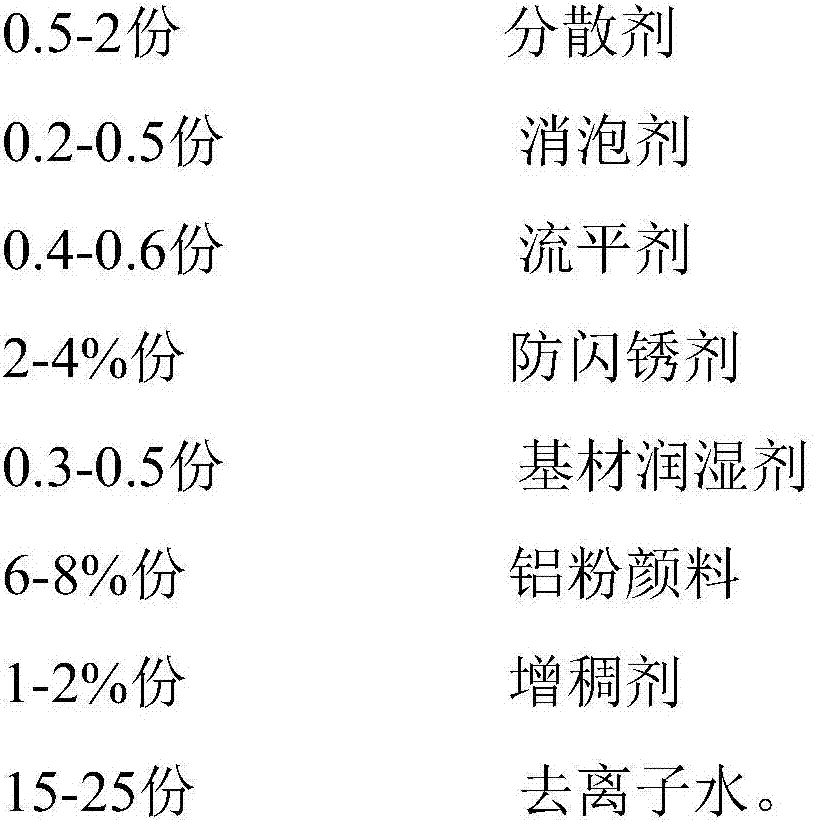

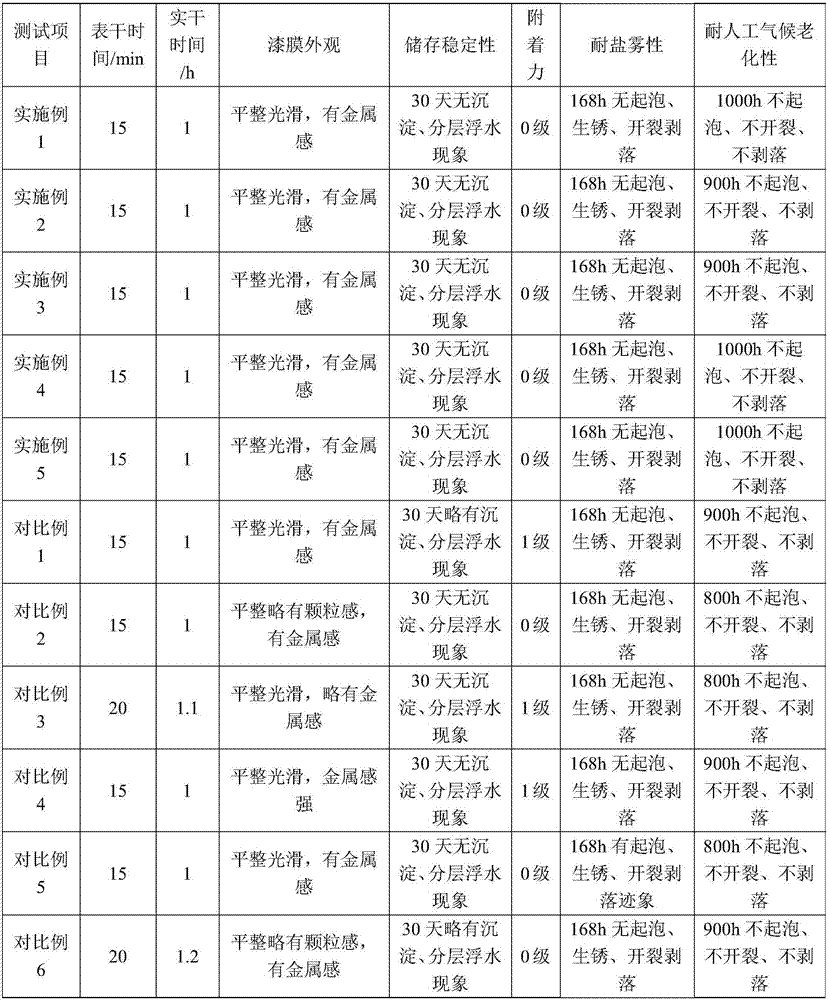

Water-based quick drying anticorrosive storage-stable silver powder dipping paint and preparation method thereof

The invention provides a water-based quick drying anticorrosive storage-stable silver powder dipping paint and a preparation method thereof. The silver powder dipping paint is prepared from the following components: 40 to 60 parts of hydroxyl acrylic emulsion, 6 to 8 parts of aluminum powder pigment, 0.5 to 1 part of a directional agent, 1 to 2 parts of a thickening agent, 2 to 4 parts of a flash rust resisting agent, 5 to 10 parts of a cosolvent, 2 to 5.5 parts of a functional additive and 15 to 25 parts of deionized water, wherein the aluminum powder pigment is micron-level aluminum powder of which the surface is coated with a silica film and the average particle diameter of the micron-level aluminum powder is 5 to 12mu m and the average thickness of the silica film is 2 to 5nm. The water-based quick drying anticorrosive storage-stable silver powder dipping paint disclosed by the invention has the advantages that the drying time is short; a formed paint film is smooth and flat and has metal texture; in addition, the water-based quick drying anticorrosive storage-stable silver powder dipping paint has high adhesion to the surface of an object, better salt spray resistance and artificial aging resistance and better storage stability; the phenomena of precipitation, layering and floating after the water-based quick drying anticorrosive storage-stable silver powder dipping paint is stood for a long time can be avoided, therefore, a good application prospect can be achieved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

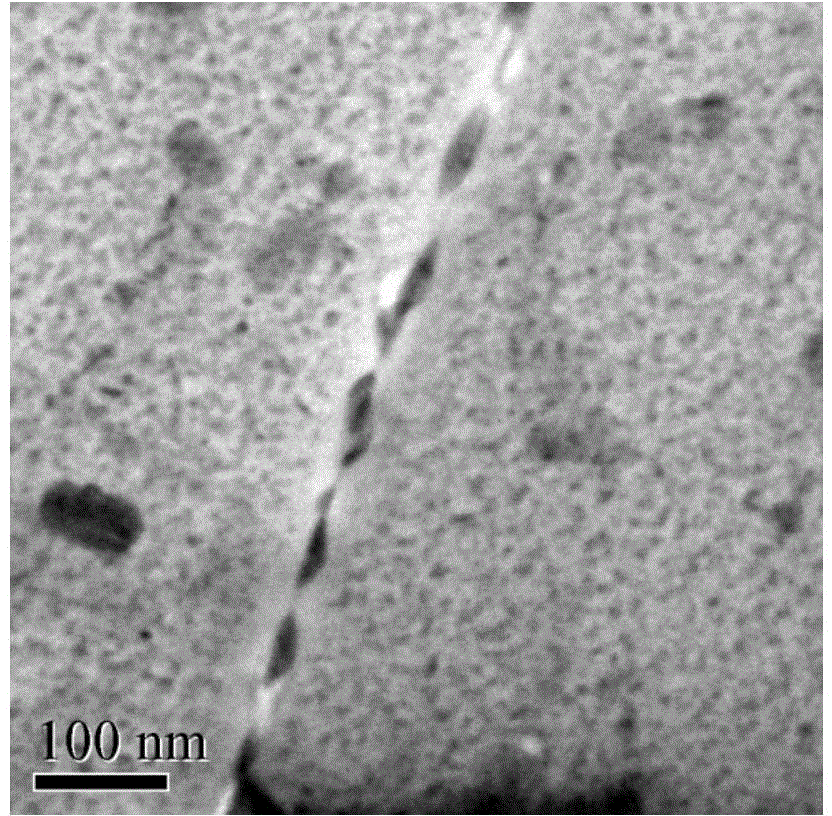

Coprecipitation-carbothermic reduction method for preparing aluminum nitride powder

The invention discloses a coprecipitation-carbothermic reduction method for preparing aluminum nitride powder, belonging to the field of ceramic powder preparation. An aluminum source is aluminum ammonium sulfate, a carbon source is carbon black, and precipitation is ammonium bicarbonate. The aluminum source and the carbon source are proportioned according to molar ratio; and the precipitation and the aluminum source are proportioned according to molar ratio. The preparation method comprises the following steps of: firstly, respectively solving the ammonium bicarbonate and the aluminum ammonium sulfate in a proper amount of deionized water, and then adding the carbon black to the aqueous solution of aluminum ammonium sulfate and stirring uniformly to obtain a mixed solution of the aluminum ammonium sulfate and the carbon black; mixing the mixed solution of the aluminum ammonium sulfate and the carbon black with the solution of ammonium bicarbonate uniformly to obtain uniform precipitation of the aluminum source and the carbon black, discharging water from the prepared precipitation of the aluminum source and the carbon black through a piece of filter cloth and drying to obtain a precursor; and reacting the precursor under a certain condition, carrying out subsequent decarbonization treatment on reaction products to obtain the aluminum nitride powder. The invention is beneficial to the synthesis of high-purity and fine-grain nanometer-level aluminum nitride ceramic powder under lower reaction temperature condition; in addition, the invention has simple device, strong process controllability and reliability and low production cost, and is suitable for the industrialized production.

Owner:厦门钜瓷科技有限公司

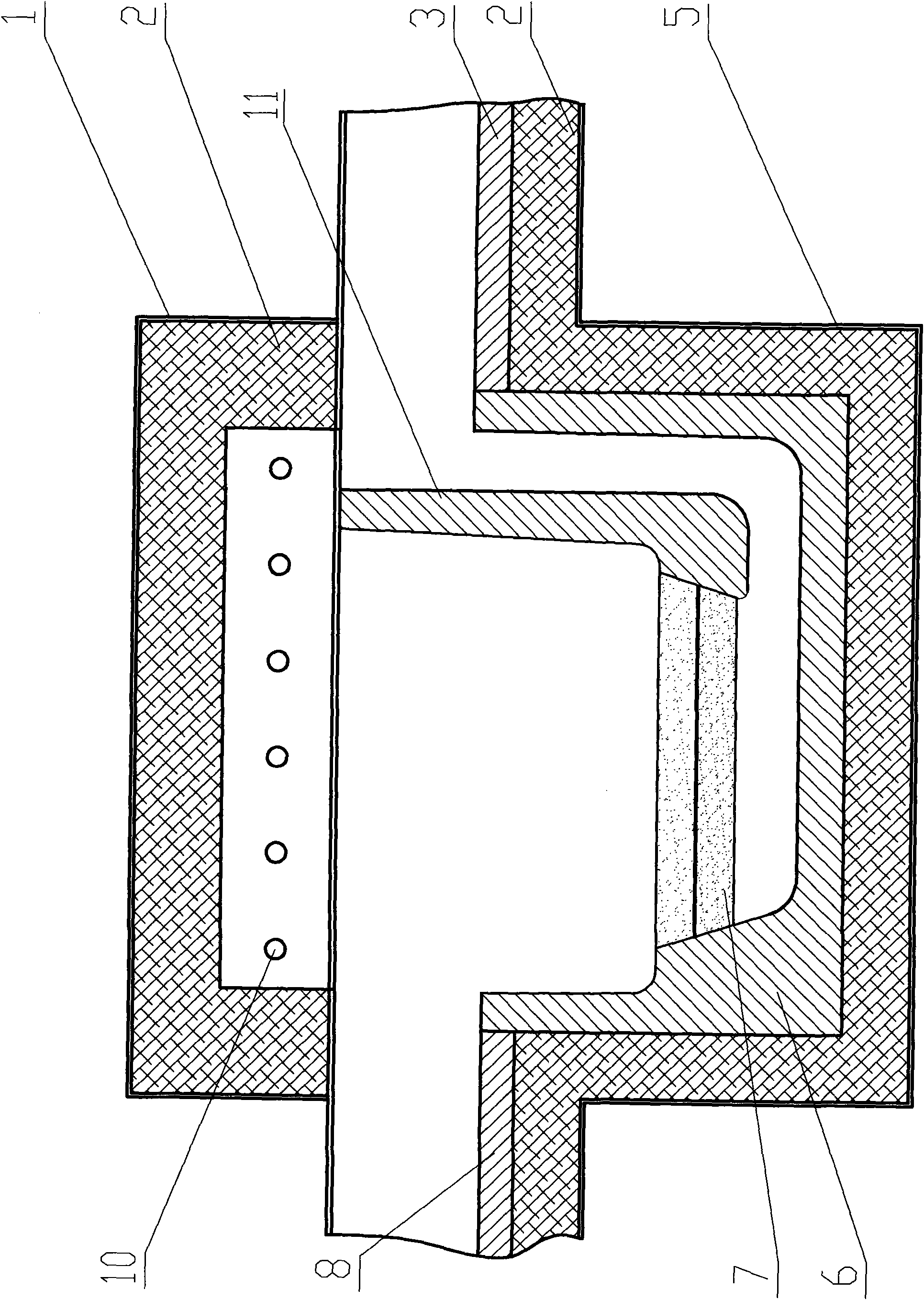

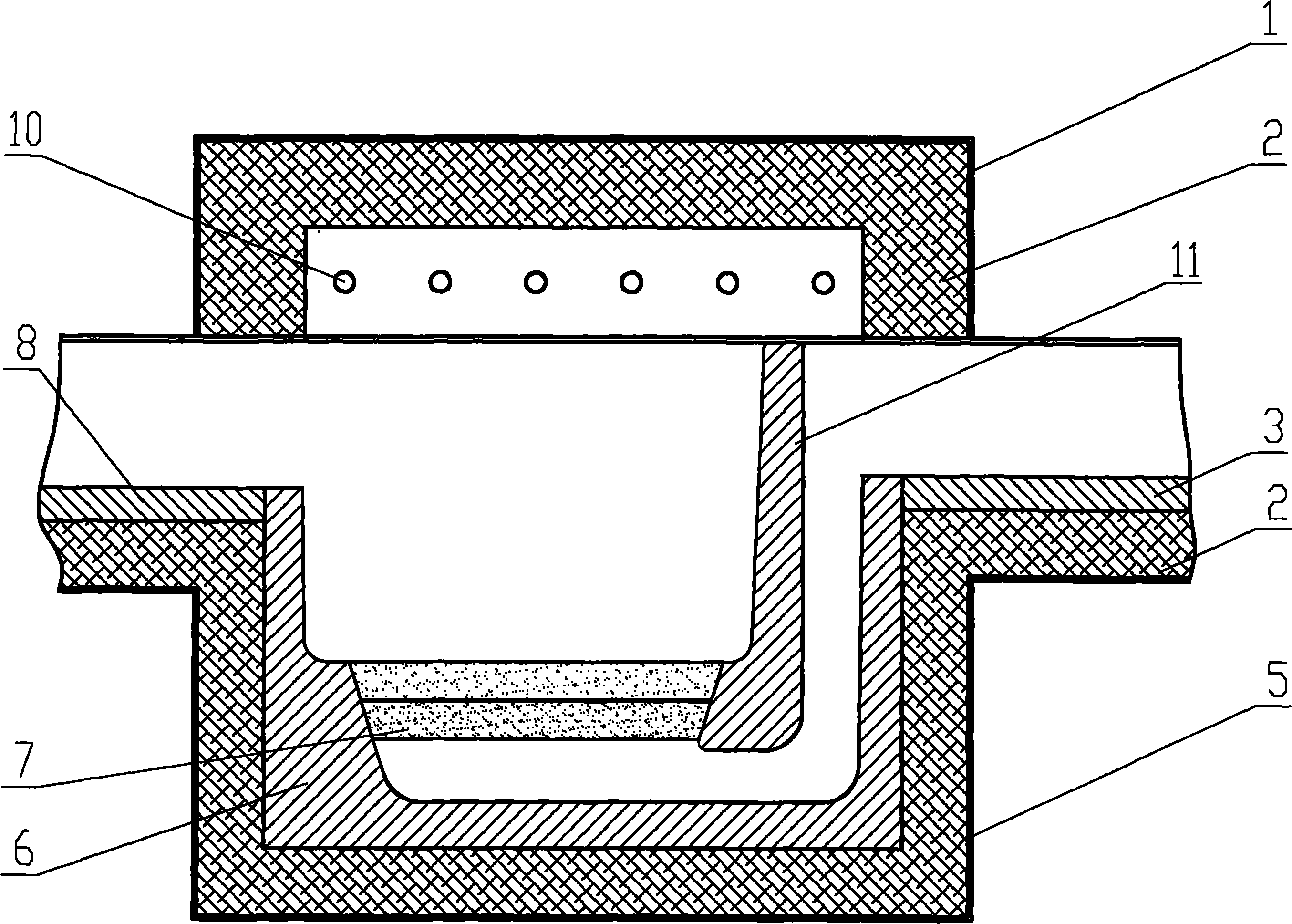

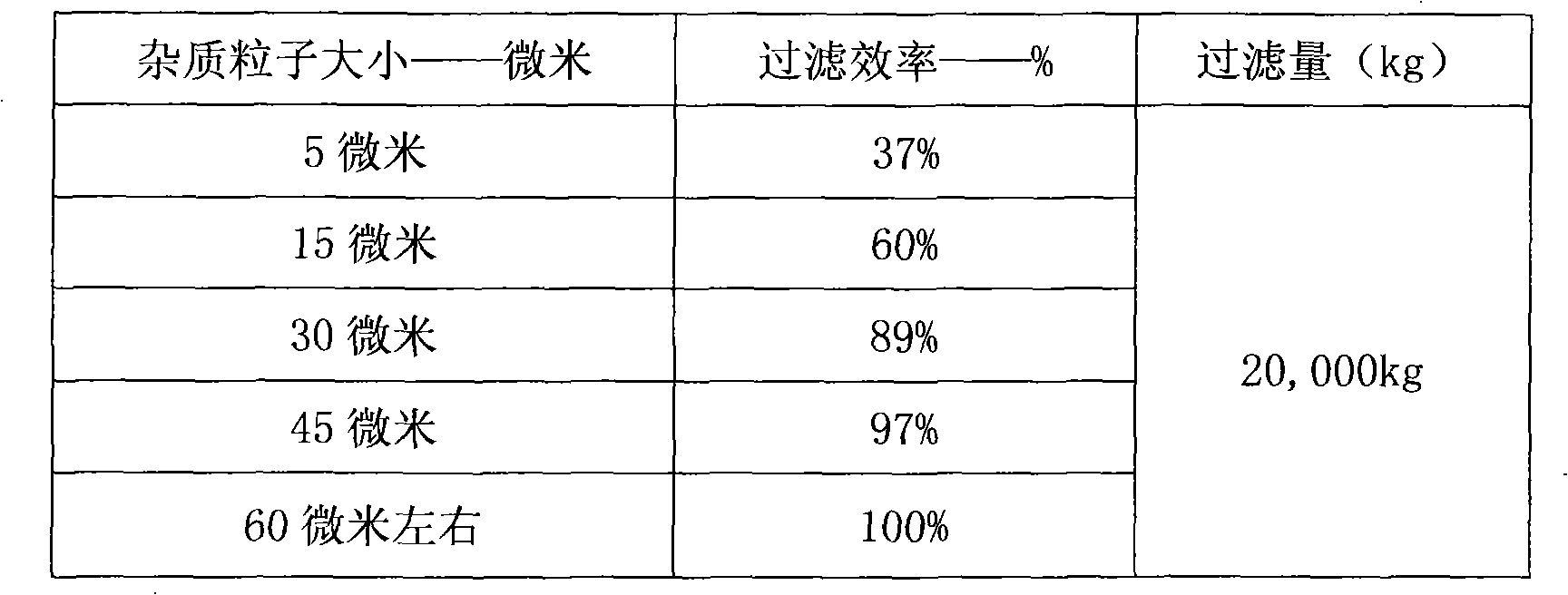

Duplex-structure foamed ceramic filter plate, manufacture method thereof and aluminum melt filtering device

InactiveCN101869794AReduce the likelihood of passingReduce temperature lossCeramicwareStationary filtering element filtersLevel aluminumFiltration

The invention relates to a filter in metal smelting process, in particular to a duplex-structure foamed ceramic filter plate, a manufacture method thereof and an aluminum melt filtering device. The duplex-structure foamed ceramic filter plate is prepared by mixing the following raw materials in parts by weight: 35-40 parts of aluminum dihydrogen phosphate, 1-2 parts of pyrogenic silica, 1-2 parts of kaolin, 1-2 parts of aerogel, 55-60 parts of Alpha alumina, 1-2 parts of defoamer, 0.5-1 part dispersant, and the like. The invention is mainly characterized in that the foamed ceramic filter plates with different hole meshes are stacked and combined into a whole by utilizing the manufacture characteristics of the foamed ceramic filter plates to produce a double-layer or multilayer stacked combination body containing the foamed ceramic filter plates with different hole meshes, and then, the stacked combination body is arranged in a filter box body for filtering aluminum melt. As the stacked conjoined structure is adopted, the air exhaust flow and the plate body floating phenomenon in the original method are reduced, and the multi-stage filtration is easy to realize; therefore, the invention really realizes the double-level or multi-level aluminum melt filtering method which has high precision and efficiency and is economic and convenient.

Owner:HUNAN HUAKE MACHINERY

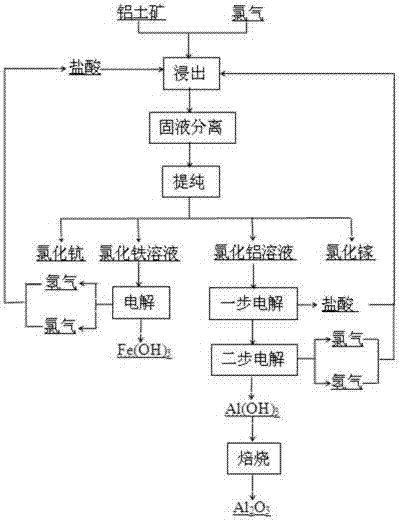

Method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide

ActiveCN107128959AHigh degree of automationHigh purityAluminium compoundsRare earth metal chloridesAluminium chlorideElectrolysis

The invention relates to a method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide. The method comprises the following steps: carrying out hydrochloric acid leaching, solid-liquid separation and purification on bauxite on bauxite, so as to obtain an iron chloride mixed solution and an aluminum chloride mixed solution; respectively separating and purifying the iron chloride mixed solution and the aluminum chloride mixed solution, so as to obtain scandium chloride, gallium chloride, an aluminum chloride water solution and an iron chloride water solution; setting electrolytic voltage and current density, and respectively carrying out two-stage electrolysis on the aluminum chloride water solution and the iron chloride water solution, so as to respectively obtain aluminum hydroxide, hydrogen and chlorine as well as iron hydroxide, hydrogen and chlorine; preparing a hydrochloric acid solution by using the generated hydrogen and chlorine, and returning the hydrochloric acid solution to a leaching stage for recycling; and roasting aluminum hydroxide, so as to obtain metallurgy level aluminum oxide or chemical aluminum oxide. Compared with a traditional acid method, the electrolysis method for recycling aluminum oxide in the bauxite and processing the bauxite has the advantages that the evaporation step and equipment, the concentration step and equipment are omitted, the operation is simplified, meanwhile, the cost is substantially lowered, and the product has relatively high purity.

Owner:NORTHEASTERN UNIV

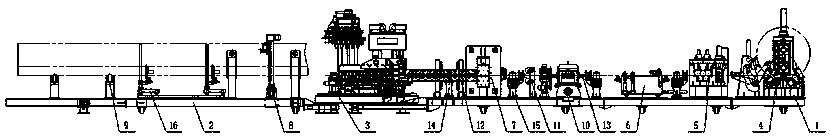

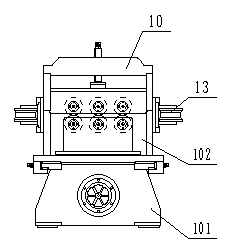

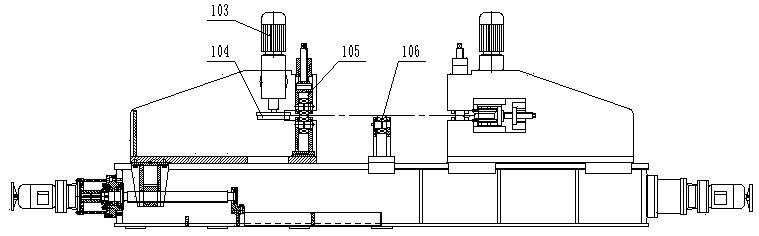

Magnesium aluminum alloy spiral welded pipe production unit

ActiveCN103722347AQuality assuranceAvoid damageOther manufacturing equipments/toolsLevel aluminumButt welding

The invention relates to a magnesium aluminum alloy spiral welded pipe production unit, and belongs to the technical field of magnesium aluminum alloy pipe producing devices. The magnesium aluminum alloy spiral welded pipe production unit is reasonable in structure, low in production cost and high in production efficiency; and the quality of machined magnesium aluminum alloy tubes is high. According to the technical scheme, one end of a front axle is hinged to the bottom of a forming machine; one end of a rear axle is fixed on the bottom of the forming machine; the front axle is coaxially provided with an uncoiler, a pinch leveller, a cutting butt welding machine and a delivery machine sequentially; the uncoiler is used for shoveling aluminum coils; the pinch leveller is used for leveling aluminum belts; the cutting butt welding machine is used for performing butt welding connection on the aluminum belts; the delivery machine serves as a power source of the unit; the rear axle is sequentially provided with an outer welding device and a plurality of supporting rollers; the supporting rollers are used for supporting a welded pipe; the aluminum belts welded by using the cutting butt welding machine enter the delivery machine after passing through an edge milling machine and a film sticking machine; and the delivery machine drives the aluminum belts to pass through a pre-bending machine and enter the forming machine, and the aluminum belts are then pressed into tubes. The magnesium aluminum alloy spiral welded pipe production unit is widely used for producing magnesium aluminum alloy tubes.

Owner:太原华欣诚机电设备有限公司

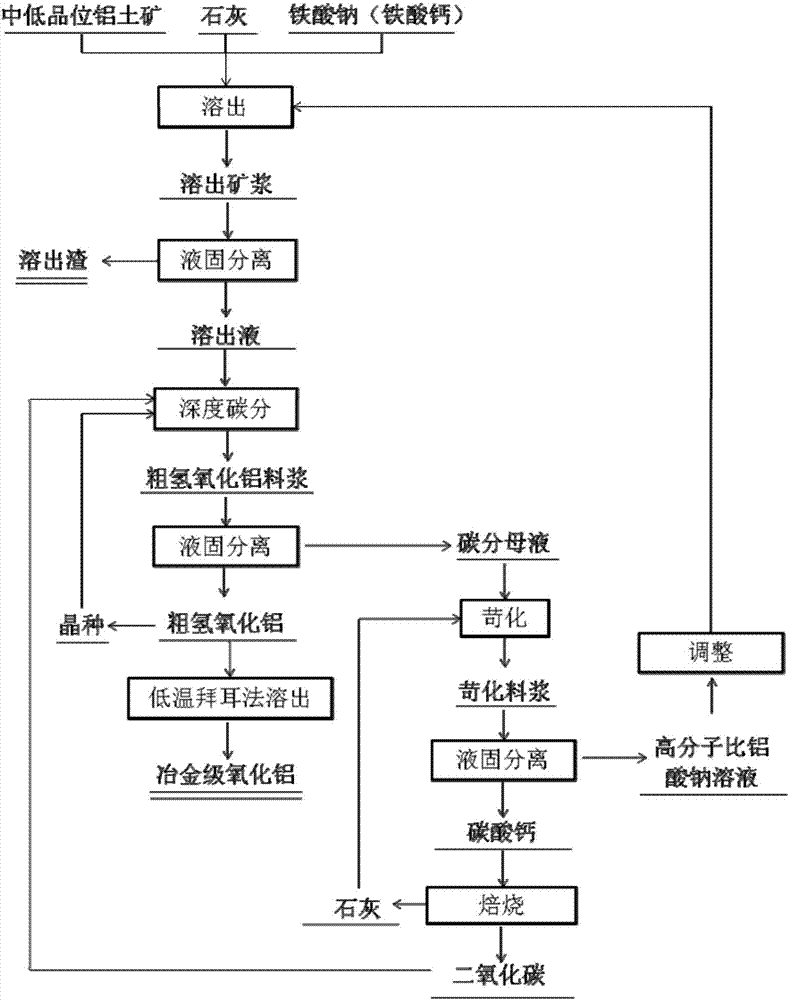

Method for treating medium- and low-grade bauxite to produce metallurgical-level aluminum oxide by one-step andradite alkali heat method

InactiveCN107188209AHigh dissolution rateShort process and high efficiencyAluminium compoundsAndraditeAluminium hydroxide

The invention relates to a method for treating medium- and low-grade bauxite to produce metallurgical-level aluminum oxide by a one-step andradite alkali heat method. The method comprises the following steps of S1, crushing and finely grinding the medium- and low-grade bauxite into mineral powder; S2, mixing and preparing the mineral powder, sodium ferrite or calcium ferrite, activated lime and circulating mother liquor into raw-material mineral pulp; S3, subjecting the raw-material mineral pulp to an alkali heat dissolving-out reaction; S4, diluting dissolved-out mineral pulp, and subjecting diluted liquor to liquid-solid separation; S5, introducing a carbon dioxide gas into a low-molecular-ratio sodium aluminate solution to carry out carbonation decomposition, so as to obtain crude aluminum hydroxide and carbonation-decomposed mother liquor; S6, subjecting the crude aluminum hydroxide to bayer-process treatment, so as to obtain the metallurgical-level aluminum oxide. According to the method provided by the invention, through adding the lime and the sodium ferrite or the calcium ferrite in a dissolving-out procedure, andradite-type slag instead of conventional dissolved-out slag is generated in the dissolving-out procedure; the dissolving-out rate of the aluminum oxide can be improved greatly; meanwhile, the metallurgical-level aluminum oxide is prepared; the method has the characteristics of being short in flow path and high in efficiency; the zero release of a material is realized.

Owner:NORTHEASTERN UNIV

Strong alkali-resistant aluminum oxide bubble bricks and preparation method thereof

InactiveCN108455975APromotes hard-to-sinter problemsImprove sintering strengthCeramicwareMicro nanoBrick

The invention discloses strong alkali-resistant aluminum oxide bubble bricks. The strong alkali-resistant aluminum oxide bubble bricks are prepared from aluminum oxide hollow balls used as aggregates,aluminum oxide micro powder and aluminum titanate which are used as matrixes and a methylcellulose solution used as a binding agent. In addition, the invention further discloses a preparation methodof the strong alkali-resistant aluminum oxide bubble bricks. The problem that a product is difficult to sinter is solved by the micro-nano-level aluminum oxide micro powder, so that the sintering intensity is enhanced; chemical components of the raw materials are high in purity, so that the product contains a small number of harmful chemical components and is high in corrosion resistance; by introduction of the aluminum titanate with a low thermal expansion coefficient and a high melting point, the alkaline corrosion resistance and the high-temperature thermal shock property of the product areimproved.

Owner:江苏三恒高技术窑具有限公司

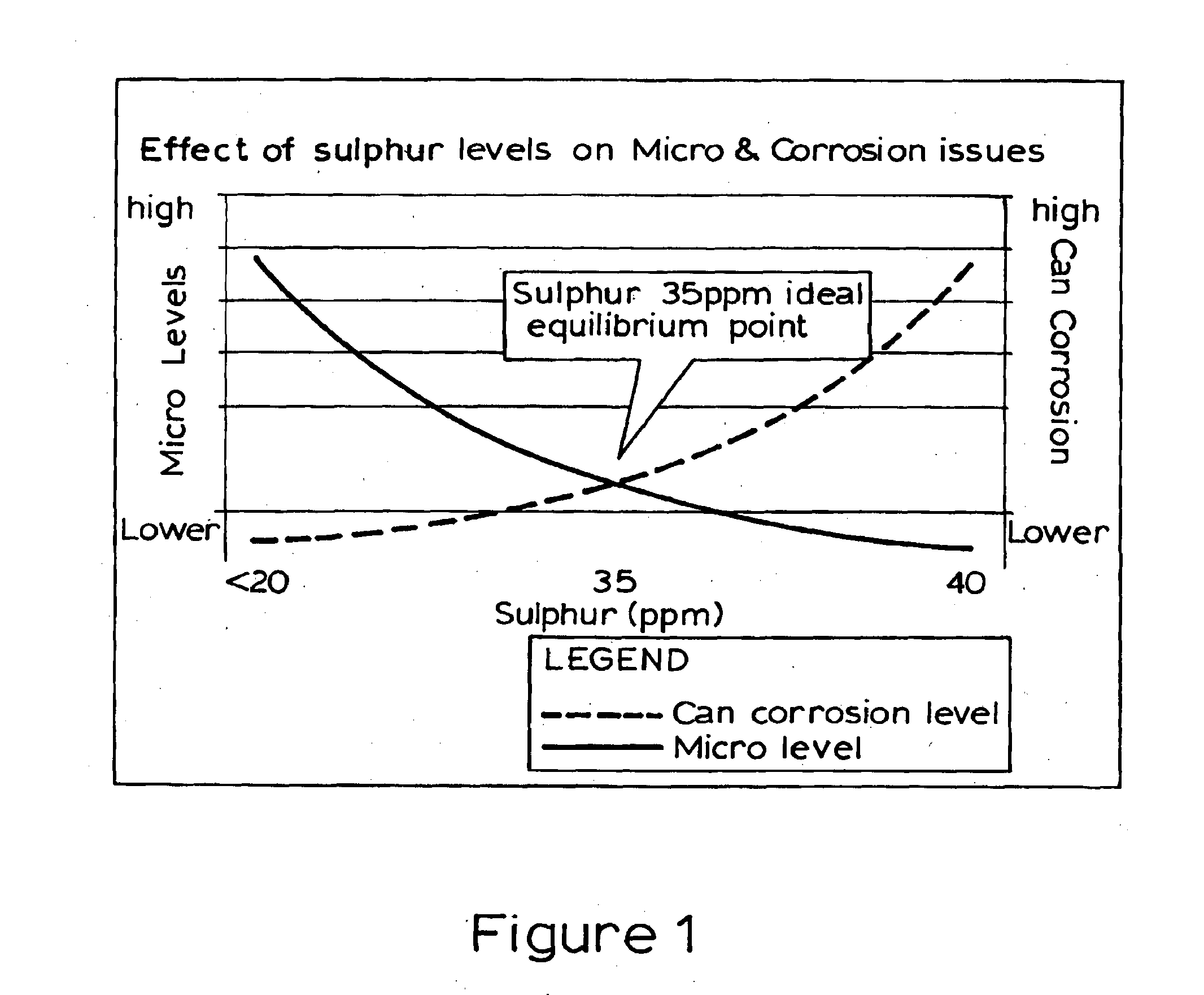

Wine packaged in aluminium containers

PendingUS20160201019A1Low oxygenProtecting wineSemi-permeable membranesMilk preservationLevel aluminumProcess engineering

Owner:INTELLIGENT PACKAGING PTY LTD

Aluminum vehicle carrier railcar

A bi-level aluminum vehicle carrier railcar (10) includes an integrated aluminum roofing structure (30), aluminum side panels (18, 20), and aluminum decking structure (36, 50) attached to a steel underframe. The decking structure (36, 50) is supported on side stakes (18) of the side panels (18, 20) with the decking structure (36, 50) including overlapping extruded aluminum decking plates with (38, 52) anti-skid features. The anti-skid features include a media blasted finish to a portion of the surface of the decking and extruded ribs (64) in a portion of the decking. The roofing structure (30) includes overlapping, arched corrugated aluminum panels (30), wherein the roof panels (30) remain uncoated.

Owner:JAC OPERATIONS

580Mpa-level aluminum alloy pipe for drill stem and manufacturing method thereof

The invention discloses a 580Mpa-level aluminum alloy pipe for a drill stem and a manufacturing method of the 580Mpa-level aluminum alloy pipe for the drill stem. The 580Mpa-level aluminum alloy pipe for the drill stem comprises, by weight, 6.0-7.5 percent of Zn, 1.7-2.3 percent of Mg, 1.7-2.6 percent of Cu, 0.1-0.3 percent of Fe, 0.1-0.3 percent of Ni, 0.1-0.2 percent of Zr, 0.01-0.02 percent of Ti and the balance Al and inevitable impurities. The manufacturing method of the 580Mpa-level aluminum alloy pipe for the drill stem comprises the steps of smelting, casting, pipe blank homogenizing treatment, pipe blank reheating, squeezing, solid dissolving, prestretching deformation and ageing. By the adoption of the 580Mpa-level aluminum alloy pipe for the drill stem, the strength is improved, the pipe has good plasticity, good toughness, good corrosion resistance and good fatigue resistance, and the tensile property and the ductility of the pipe both reach ISO specifications.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

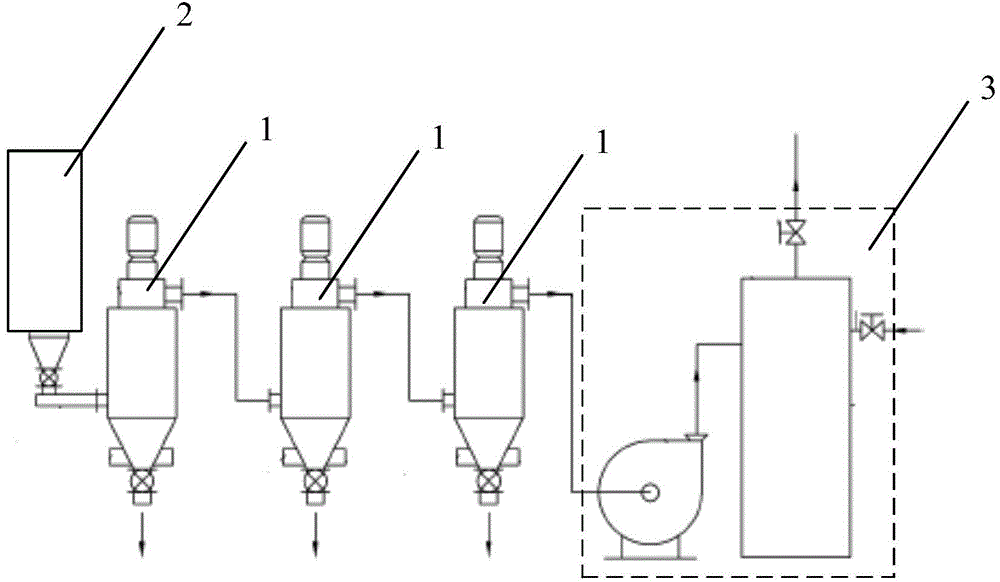

Intelligent superfine aluminum power production system

InactiveCN104549771ASolve the technical problem of wide particle size distributionReduce computing timeCentrifugesCycloneLevel aluminum

The invention relates to a superfine aluminum powder production system which comprises a molten aluminum cyclone atomization cooling device and a plurality of levels of aluminum powder classification devices, wherein the molten aluminum cyclone atomization cooling device comprises a molten aluminum atomization device, a cyclone generator and a cooling tank; the cyclone generator is arranged on the bottom spraying part of the molten aluminum atomization device, and the cooling tank is connected to the lower side of the cyclone generator and is used for cooling aluminum mist into aluminum powder; the powder outlet of a front-level aluminum powder classification device is connected with the powder inlet of a rear-level aluminum powder classification device; the powder inlet of a first-level aluminum powder classification device is connected with the power outlet of the cooling tank; the powder outlet of a tail-level aluminum powder classification device is connected with the air inlet of a cyclone duster; the cyclone duster is applicable to filtering out residual aluminum powder in nitrogen gas; all the aluminum powder classification devices are same in structure and comprise centrifugal classifiers, buffer tanks and material conveying tanks, wherein the buffer tanks are applicable to collecting coarse powder separated out from a current-level aluminum powder classification device, and the material conveying tanks are applicable to conveying the coarse powder in the buffer tanks to an aluminum powder packaging unit.

Owner:JIANGSU TIANYUAN METAL POWDER

Method for electrically converting aluminum chloride into aluminum oxide

ActiveCN107177858AHigh degree of automationShort processCellsAluminium oxide/hydroxide preparationAluminium chlorideElectrolysis

The invention belongs to the technical field of electrolysis, particularly relates to a method for electrically converting aluminum chloride into aluminum oxide, and aims at obtaining metallurgy-level aluminum oxide or chemical aluminum oxide products in short process at low energy consumption by means of wide aluminum chloride resources so as to avoid or solve the problems that in the prior art, energy consumption is high, the cost is high, and pollution is severe. According to the electrolysis method, aluminum chloride can be directly converted into aluminum compound precipitates, and an electrolysis technology is high in automation degree and short in process. Compared with a traditional aluminum oxide preparation method, the method has the advantages that the evaporation and concentration process and equipment thereof are omitted, therefore, the production cost can be reduced, and the production efficiency can be improved; aluminum oxide is produced through the electrolysis technology, the purity of by-products including chlorine and hydrogen in the production process is high, the by-products can be directly dried and utilized, electrolyte is recycled after being filtered, no pollution product is generated in the process, and environmental friendliness and harmlessness are achieved; metallurgy-level aluminum oxide or chemical aluminum oxide is obtained by roasting the aluminum compounds obtained through electrolysis, and the obtained product is high in purity.

Owner:NORTHEASTERN UNIV

Complex component instrument-level composite material and preparation method thereof

The invention discloses a complex component instrument-level composite material and a preparation method thereof, and relates to the field of aluminum alloy material preparation, in particular to thecomplex component instrument-level composite material and the preparation method thereof. The problem that in the quenching and cold-hot impact process of the heat treatment process of an existing instrument-level aluminum-based composite material, cracking is caused by internal stress releasing is solved. The complex component instrument-level composite material is prepared from a SiC reinforcement body and an aluminum alloy matrix through squeeze casting in a composite mode, and the volume fraction of the SiC reinforcement body is 40%-60%. The method comprises the steps of 1 prefabricated body preparing, 2 matrix aluminum alloy smelting, 3 squeeze casting and 4 heat treating. According to the complex component instrument-level composite material and the preparation method thereof, the novel solid solution enhanced aluminum alloy is adopted for instrument-level composite material preparation, the cold-hot impact process such as quenching is not needed in the heat treatment process ofthe composite material, and the quenching cracking risk is eliminated; and the complex component instrument-level composite material prepared through the method is suitable for manufacturing high-precision complex structural parts.

Owner:HARBIN INST OF TECH

Multifunctional insulation board

InactiveCN106982482ADeliciousNo loss of nutritionOhmic-resistance heating detailsLevel aluminumScreen printing

The multifunctional insulation board discloses a multifunctional insulation board. The multifunctional insulation board comprises a sealing panel and an insulation board body, wherein the sealing panel is embedded with the insulation board body, a material of the sealing panel is toughened glass, the insulation board body comprises a screen printing layer, a far-infrared heating layer, an insulation board bound edge and a ventilation insulation floor, the screen printing layer and the far-infrared heating layer are fixed on the ventilation insulation floor, the far-infrared heating layer is provided with a relay, the insulation board bound edge comprises an indicating lamp, a switch button and a power source wire, height of the insulation board bound edge is 20mm, a material of the insulation board bound edge is automotive-level aluminum alloy, and the ventilation insulation floor is provided with ventilation holes and a foot pad. The multifunctional insulation board is advantaged in that continuous insulation of food and drinks can be realized, delicious taste is constantly kept, nutrition lock without loss is realized, in a quite code weather, hands and feet can be directly heated through the multifunctional insulation board, the one-object multi-purpose effect is realized, slow food stewing, clothes article drying and physiotherapy warm keeping are realized, and a simple and fashionable life idea is advocated.

Owner:GUANGDONG TANJIN ELECTRONICS TECH CO LTD

Production method of monocrystalline aluminum hydroxide

ActiveCN102070167ALow oil absorptionHigh hardnessAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideSodium aluminate

The invention relates to a production method of monocrystalline aluminum hydroxide, in particular to a method for producing monocrystalline aluminum hydroxide by decomposing aluminate steel fine liquid in the production process of aluminum oxide. The method is characterized by comprising the following steps: (1) adding sodium oxalate into the sodium aluminate fine liquid to carry out decomposition reaction, filtering the decomposition product, and sufficiently washing the product with hot water to obtain seed crystals; and (2) adding the seed crystals obtained in the step (1) into the sodium aluminate fine liquid to carry out decomposition reaction, filtering the reaction product, and washing the product to obtain the monocrystalline aluminum hydroxide product. The monocrystalline aluminum hydroxide product prepared by the production method provided by the invention is transparent, has the characteristics of high hardness, uniform granularity, low oil absorption rate and the like, is micropowder filler with good properties, and can be used as the precursor of monocrystalline aluminum oxide granules; and the high chemical purity, granularity and physical and chemical properties of the monocrystalline aluminum hydroxide product can satisfy the production requirements of non-metallurgical level aluminum oxide, thus effectively lowering the production cost of non-metallurgical level aluminum oxide.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

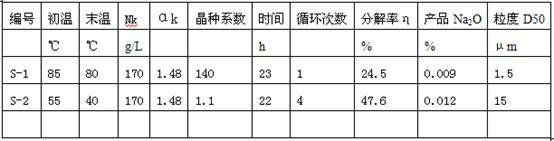

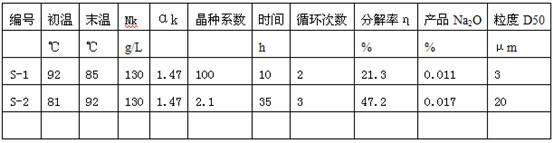

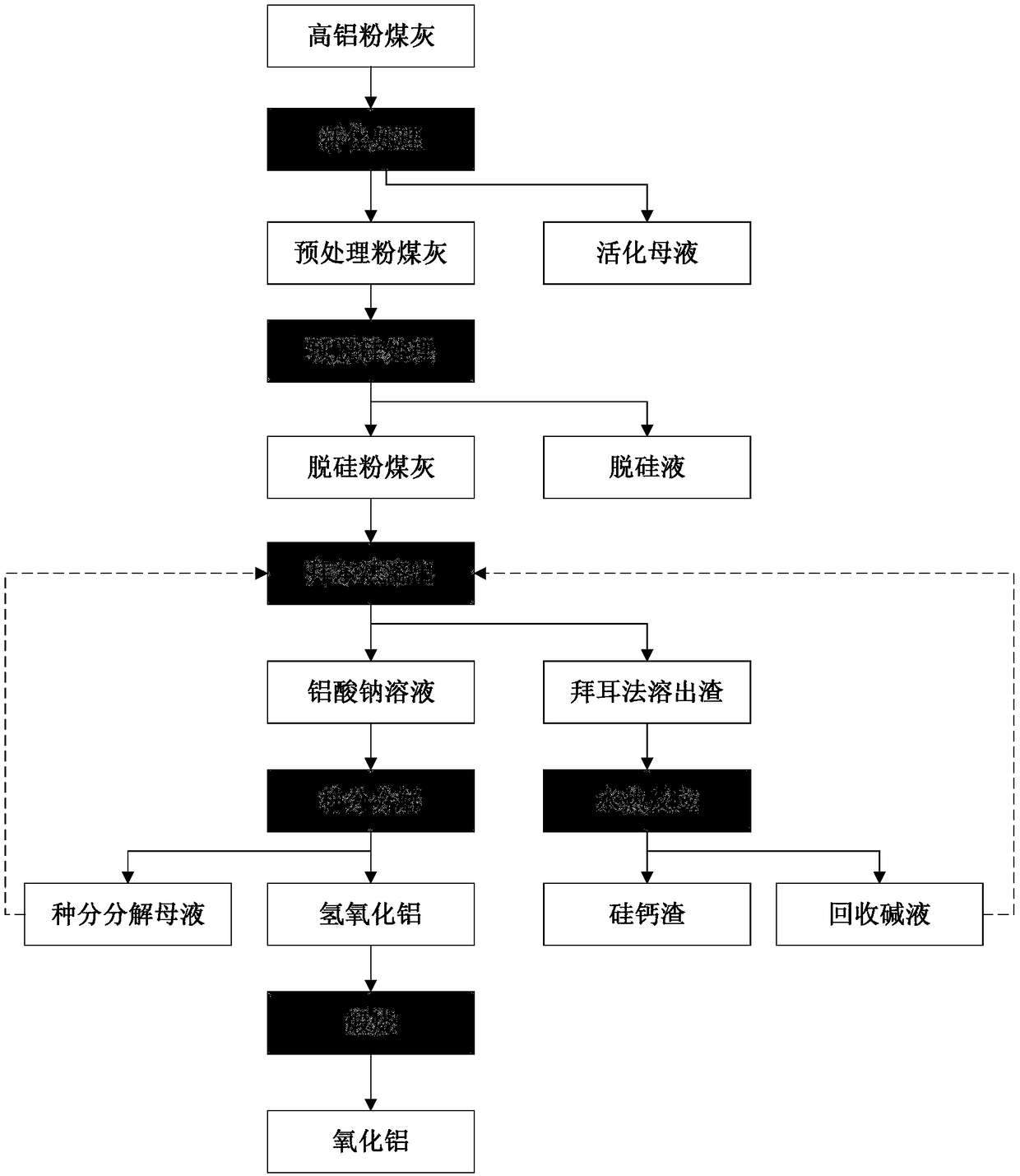

Method for extracting aluminum oxide from high-alumina coal ash

InactiveCN108622920AImprove desiliconization efficiencyIncrease Al-Si RatioAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionAluminium hydroxide

The invention provides a method for extracting aluminum oxide from high-alumina coal ash. The method comprises the following steps: activating the high-alumina coal ash, and performing solid-liquid separation to obtain pretreated coal ash and activated mother liquid; performing pre-desiliconization treatment on the pretreated coal ash, and performing solid-liquid separation to obtain desiliconizedcoal ash and desiliconized liquid; performing Bayer dissolution on the desiliconized coal ash, and performing solid-liquid separation on dissolved slurry to obtain a sodium aluminate solution and Bayer dissolved slag; performing hydrothermal reaction on the Bayer dissolved slag and lime milk, and performing solid-liquid separation to obtain silicon-calcium slag and a recycled alkaline solution; performing seed precipitation decomposition on the sodium aluminate solution to obtain aluminum hydroxide and seed precipitation decomposition mother liquid; and calcining the aluminum hydroxide to obtain aluminum oxide. According to the method disclosed by the invention, after the high-alumina coal ash is activated and desiliconized, the aluminum oxide is extracted by adopting a Bayer process, sothat a high-quality metallurgy-level aluminum oxide product can be obtained, and alkali in the Bayer dissolved slag can be recycled; and the method has the process characteristics of low cost, low energy consumption and the like and has the advantage of simplicity in operation.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Jacquard tie equipment of harness cord device

The invention discloses jacquard tie equipment of harness cord device. The jacquard tie equipment comprises upright columns on two sides, wherein T-shaped beams are arranged on the upright columns; cross beams are fixed on the T-shaped beams; a simulating plate and an undersea plate are arranged on the cross beams; the T-shaped beams are connected with the upright columns in a sliding mode; chains are fixed on the T-shaped beams; one end of each chain is fixed on the T-shaped beams, and the other end of each chain is fixed on the upright columns; the chains are wound on chain rollers; an oil cylinder is fixed on each upright column; each chain roller is fixed on a piston rod of each oil cylinder; square pipes are fixed on the left sides and right sides of the upright columns on the two sides; a cross frame is fixed on the square pipes on one side, and an adjusting rod is fixed on the square pipes on the other side; an adjusting rod is fixed on the cross frame; a connecting sheet is fixed between the two adjusting rods, and two aluminum alloy fixed beams are erected on the connecting sheet; a plurality of fixed rods are fixed on the two aluminum alloy fixed beams, and leveling aluminum alloys are arranged on the fixed rods; and a comber board frame bracket is fixed on the cross frame, and a comber board frame is fixed on the comber board frame bracket. By the jacquard tie equipment, the harness cord device can be manufactured conveniently and quickly.

Owner:ZHEJIANG KD TEXTILE MACHINERY

7150 aluminum alloy slab ingot melting and casting process

The invention relates to a 7150 aluminum alloy slab ingot melting and casting process. According to the 7150 aluminum alloy slab ingot melting and casting process, by controlling melting temperature, electromagnetic stirring and melt refining, the slag content, the hydrogen content and the alkali metal content in a melt are lowered effectively, and uniformity of alloy components is ensured. The casting speed and water flow during casting are controlled by a low-liquid-level aluminum alloy slab ingot casting machine, casting cracks and feather crystals are avoided, the product yield is improved greatly, and the product production efficiency is improved.

Owner:GUANGXI UNIV

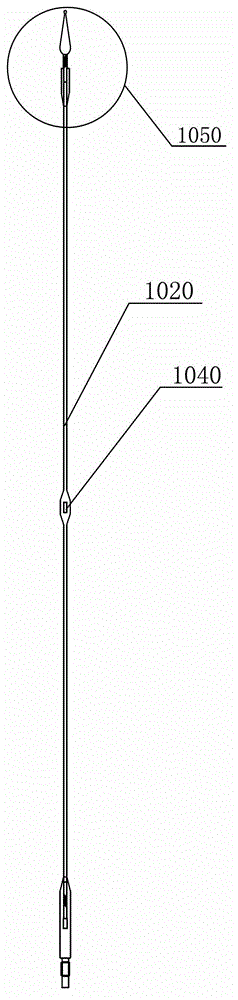

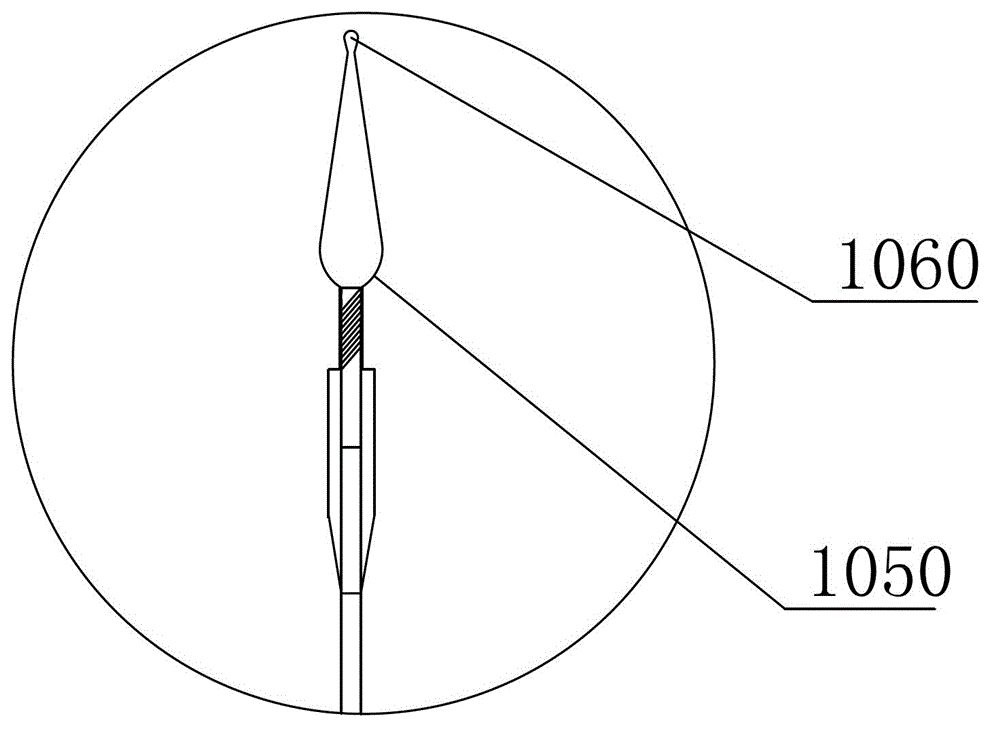

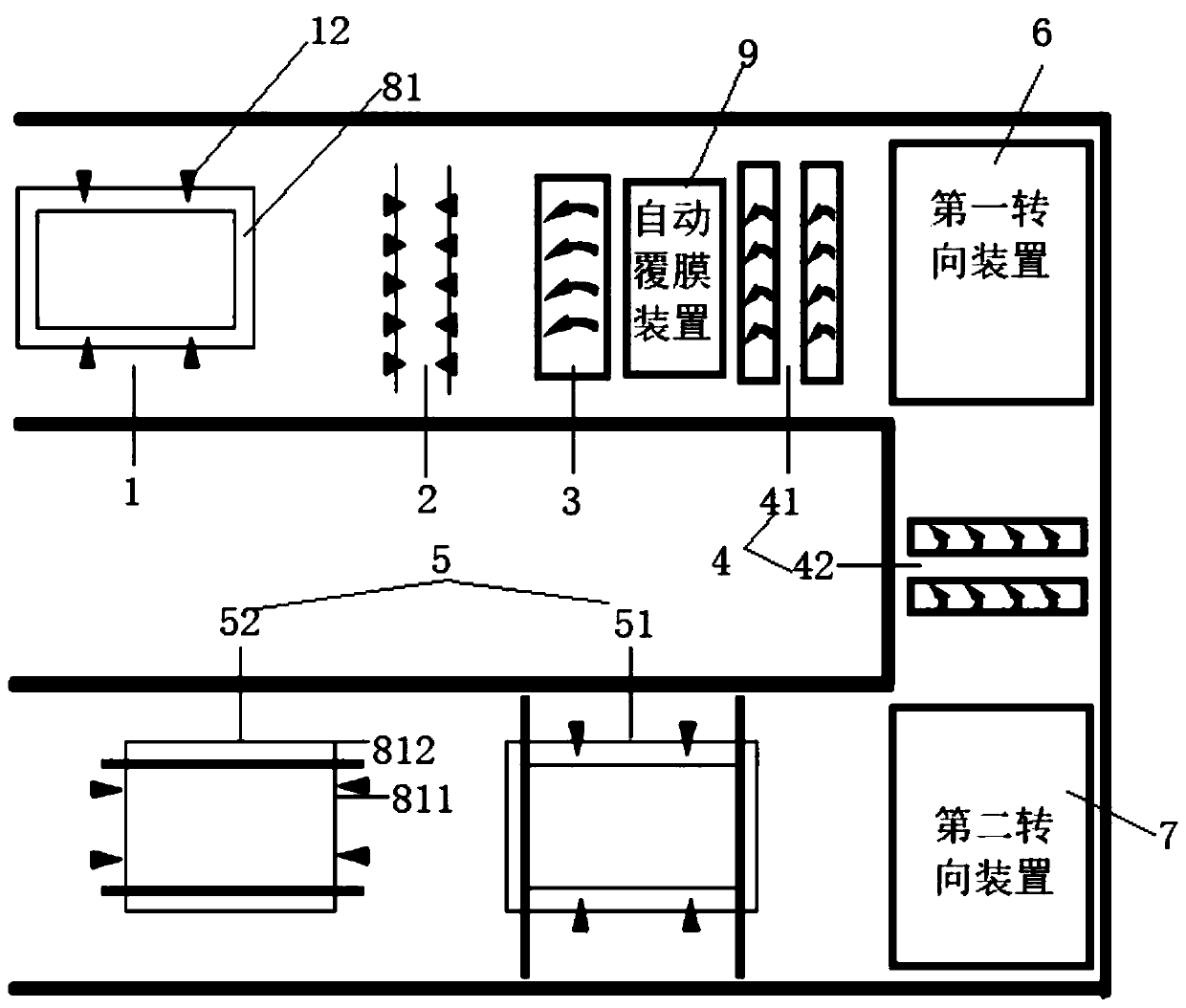

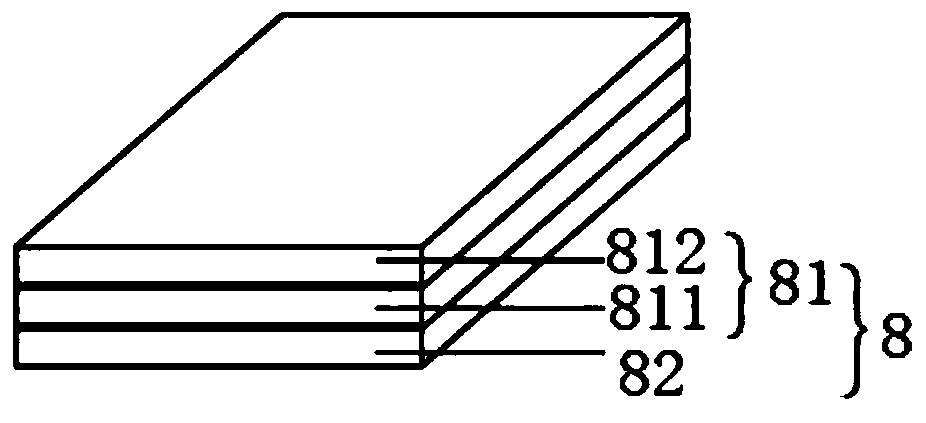

Novel film laminating forming process for aluminum-based copper-clad plate

InactiveCN111591002AAchieve levelingRealize fully automatic processLamination ancillary operationsControlling laminationLevel aluminumPunching

The invention provides a novel film laminating forming process for an aluminum-based copper-clad plate. The process comprises the steps that 1, an aluminum substrate is conveyed to a positioning device to be positioned; 2, the positioned aluminum substrate is conveyed to a dust removal device to be subjected to dust removal; 3, the aluminum substrate subjected to dust removal is conveyed to an automatic film laminating device to be laminated; 4, the aluminum substrate laminated is conveyed to an automatic leveling device to be leveled; and 5, the leveled aluminum substrate is conveyed to an automatic cutting device to be cut, and a finished aluminum plate is formed. The aluminum substrate is automatically conveyed to the automatic film laminating device, the automatic leveling device and the automatic cutting device in sequence, the film laminating process, leveling and cutting are integrated into a complete full-automatic process, the labor requirement is reduced, and the efficiency is high. The positioning device is additionally arranged before film covering, so that deviation is avoided; and dust removal is conducted before film covering, thus avoiding direct film covering without dust removal, which may cause a problem that dust and impurities are easily adsorbed by a protective film due to the electrostatic effect, and an aluminum surface is easily crushed and scrapped during client punching plate forming.

Owner:SHENZHEN CHUANGHUI ALLIANCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com