Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40339 results about "Punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet. The punch often passes through the work into a die. A scrap slug from the hole is deposited into the die in the process. Depending on the material being punched this slug may be recycled and reused or discarded.

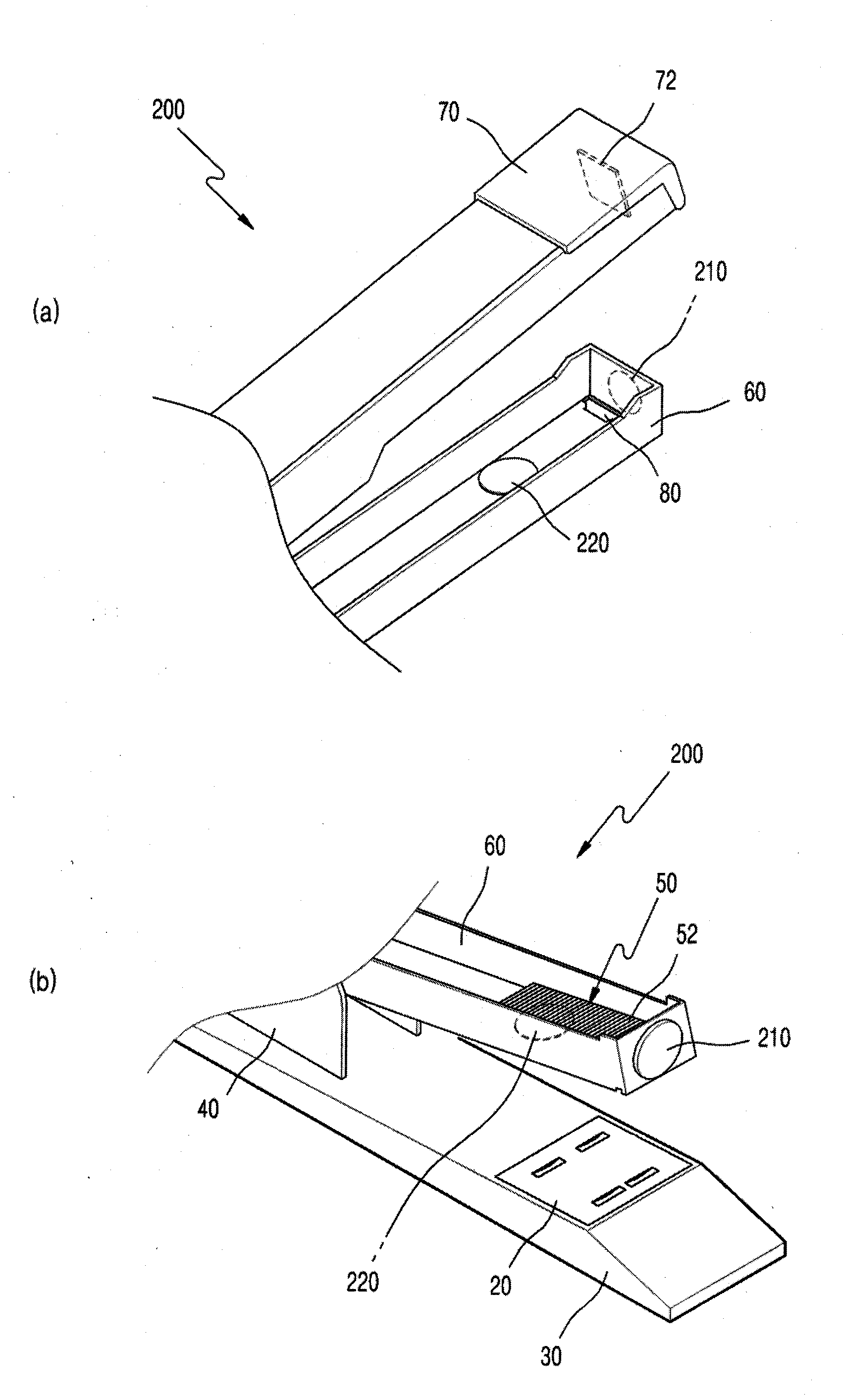

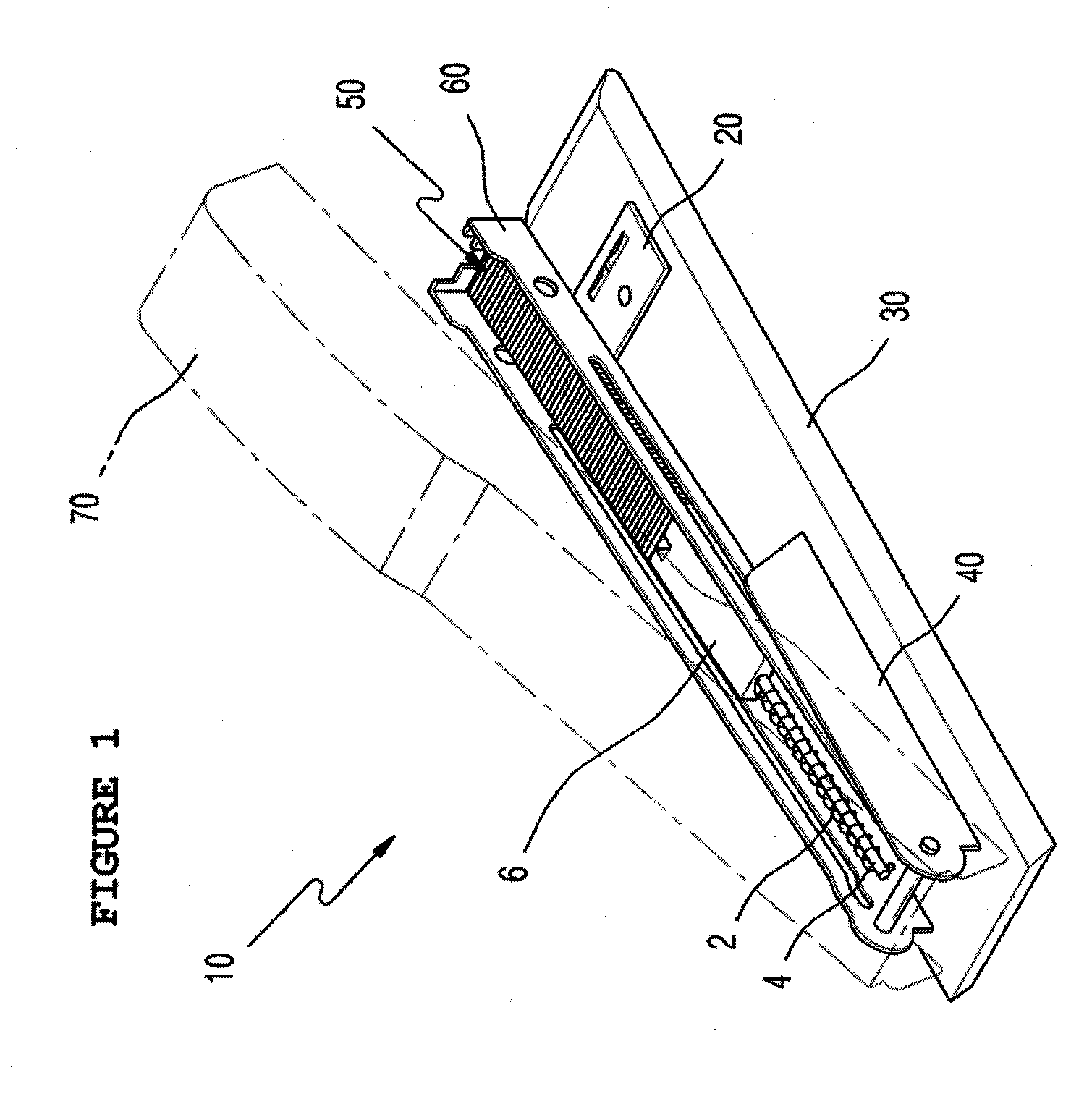

Structure of staple magazine having permanent magnet

The present invention uses the principle in which staples made of iron are attracted in a direction in which magnetic attraction force is generated. Using this principle, a permanent magnet is provided on a front wall of a staple magazine, so that a staple cartridge is attracted towards an ejection slot of the staple magazine by the magnetic attraction force of the permanent magnet. When a handle having a punching blade is pushed, the frontmost staple in the staple cartridge, which is aligned with the ejection slot, is ejected by the punching blade to staple paper sheets. After the frontmost staple is ejected, the staple cartridge is automatically moved to and brought into close contact with the front wall of the staple magazine such that a subsequent staple, which is in a frontmost position, is aligned with the ejection slot to prepare for a subsequent stapling operation.

Owner:UHM HYUN DUK

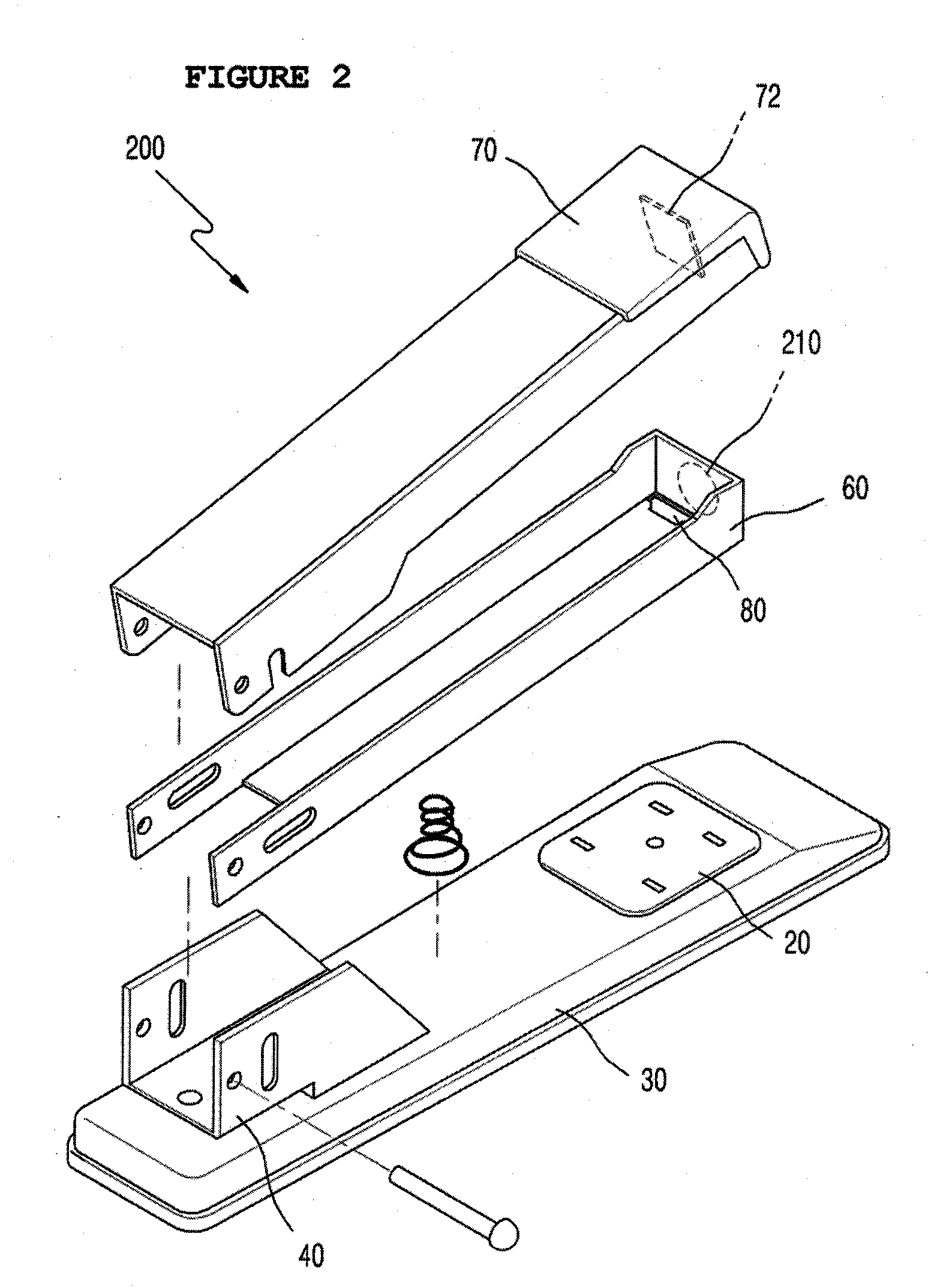

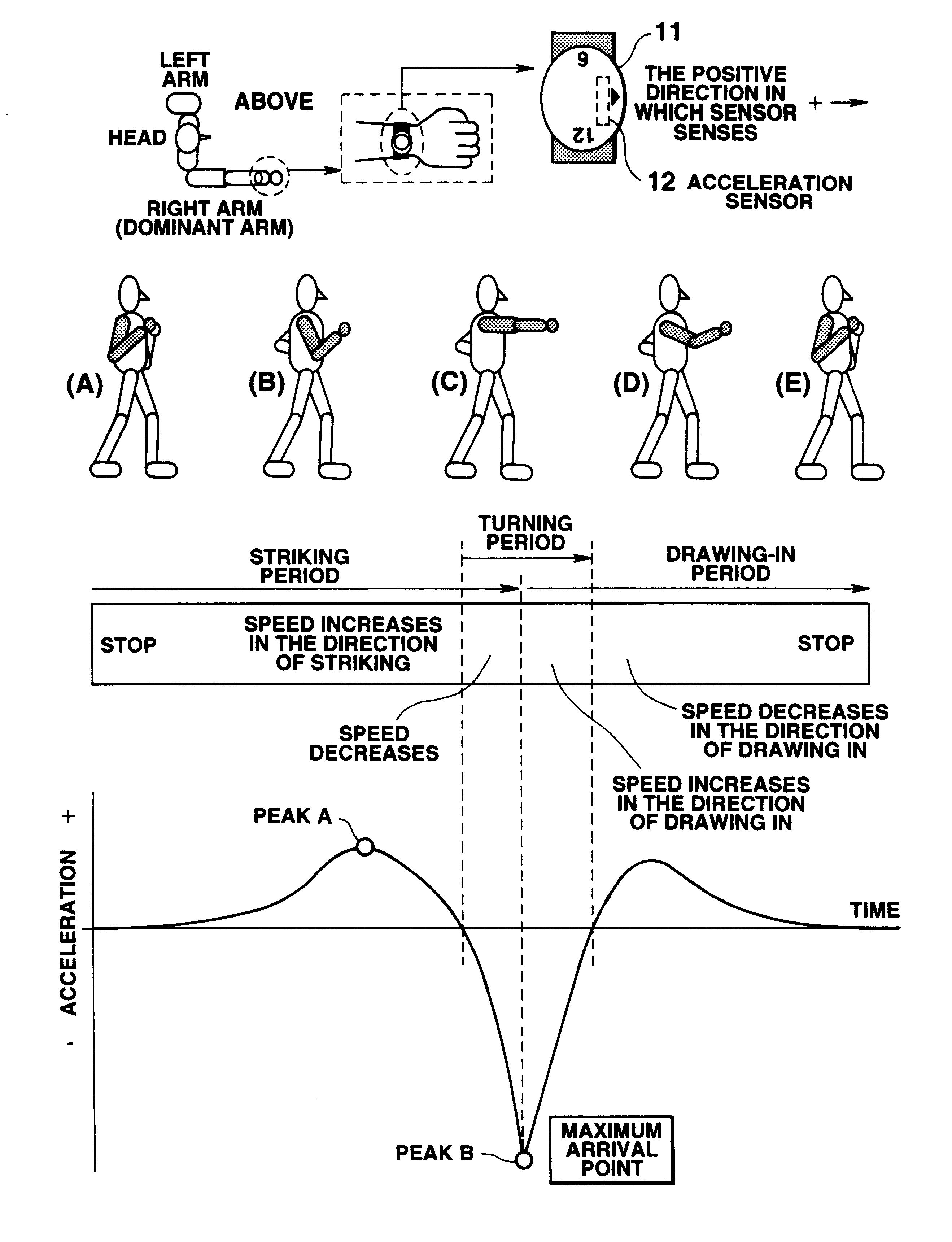

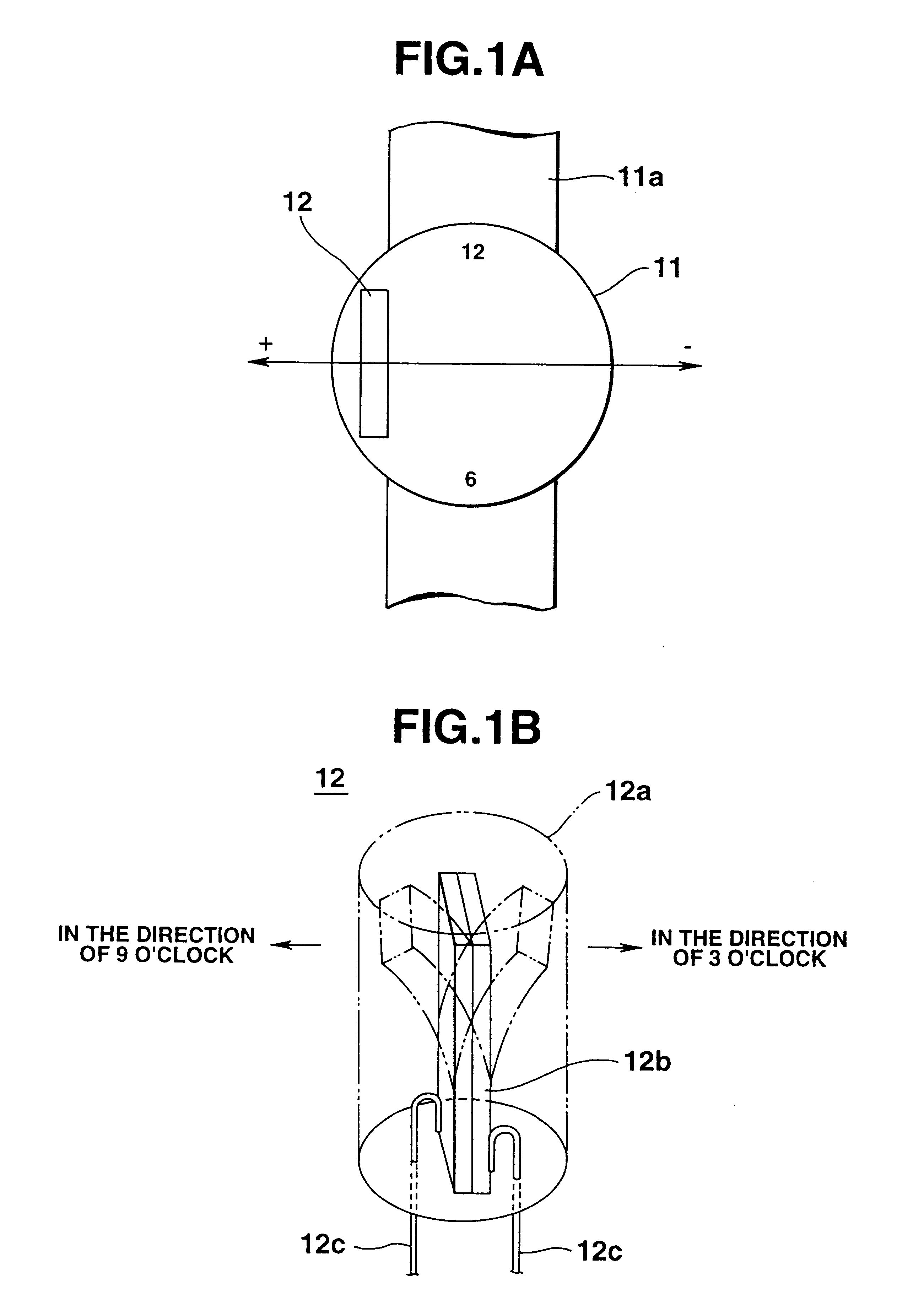

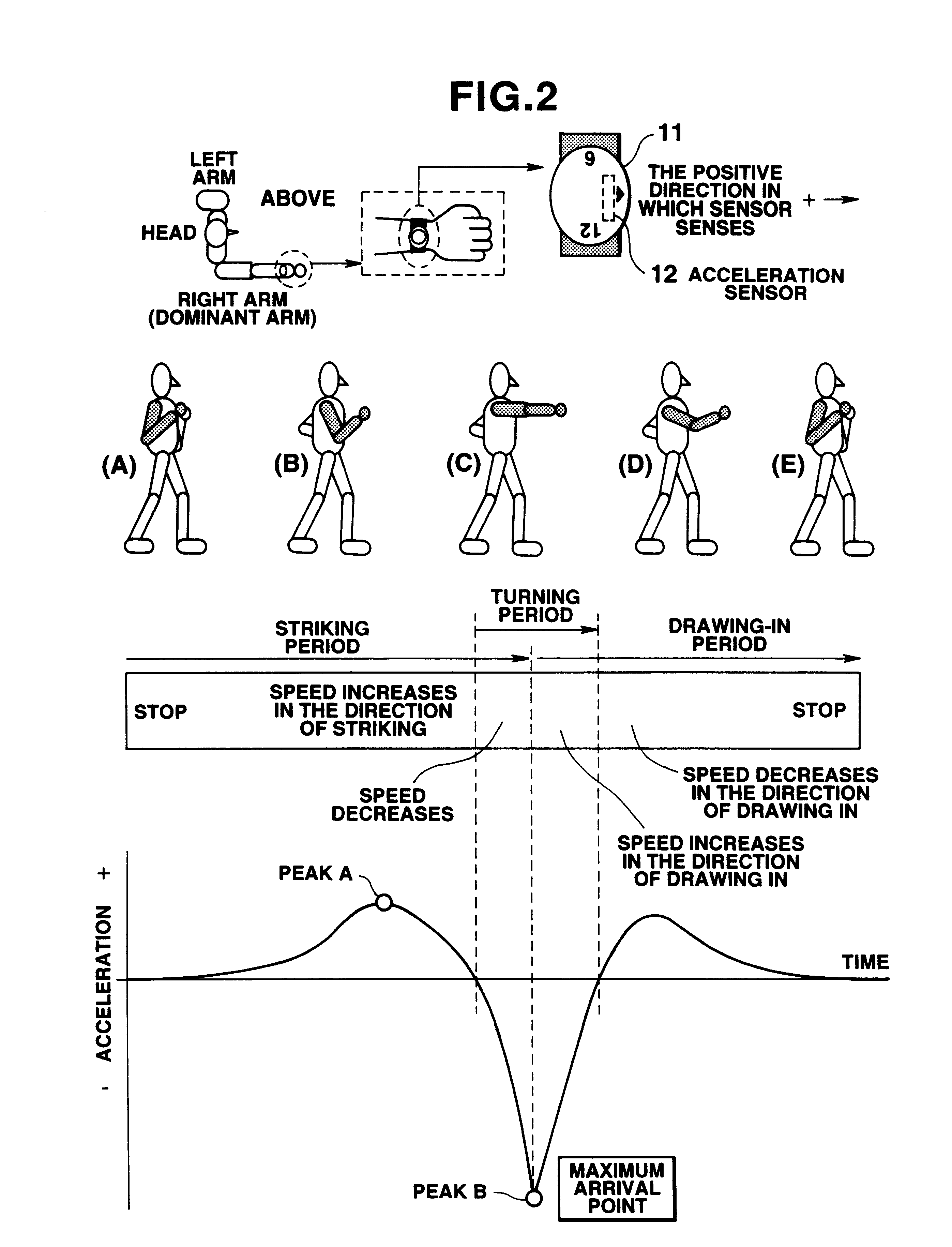

Movement measuring device, electronic game machine including movement measuring device, and method of playing game machine

InactiveUS6183365B1Easily sensing speed and impact forceCompact structureInput/output for user-computer interactionAcceleration measurement using interia forcesPunchingEngineering

A movement measuring device determines the speed of the body's specific movement on the basis of the maximum value of the acceleration sensed by an acceleration sensing unit attached to the body, when the body has made a specific movement. For example, when the player wears the device on his arm and makes a punching motion, the punching speed is found from the maximum acceleration resulting from the punching action. Furthermore, a game device obtains data indicating the magnitude of a specific movement of the body, on the basis of the acceleration sensed by an acceleration sensing unit, and then decides the outcome of the game on the basis of the strength and weakness of the punch. This enables the user to easily play a fighting sport game involving the player's actual punching motions anywhere.

Owner:CASIO COMPUTER CO LTD

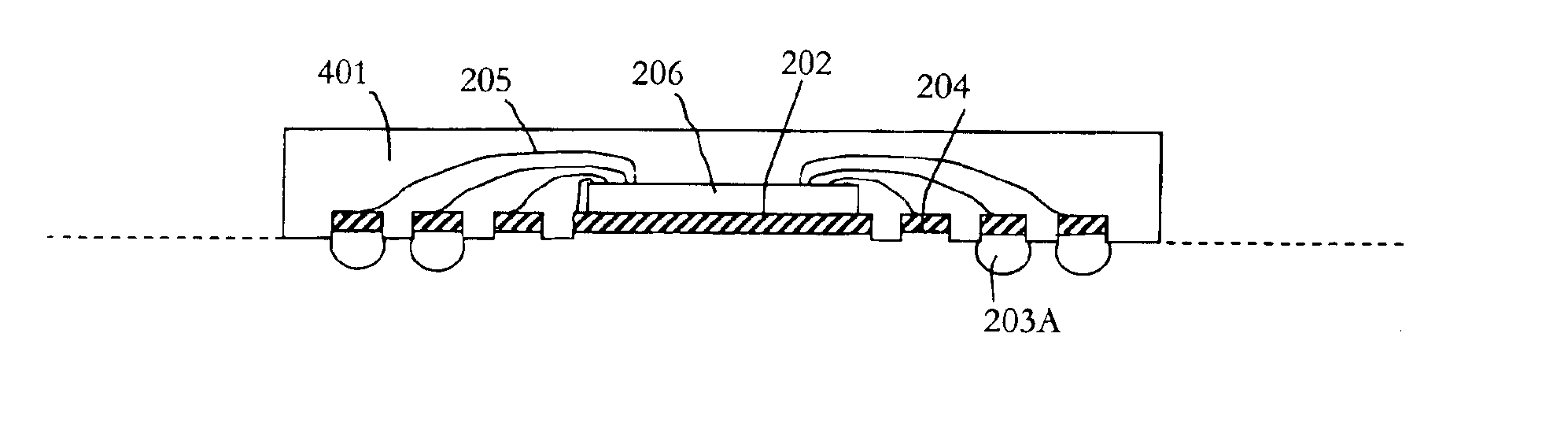

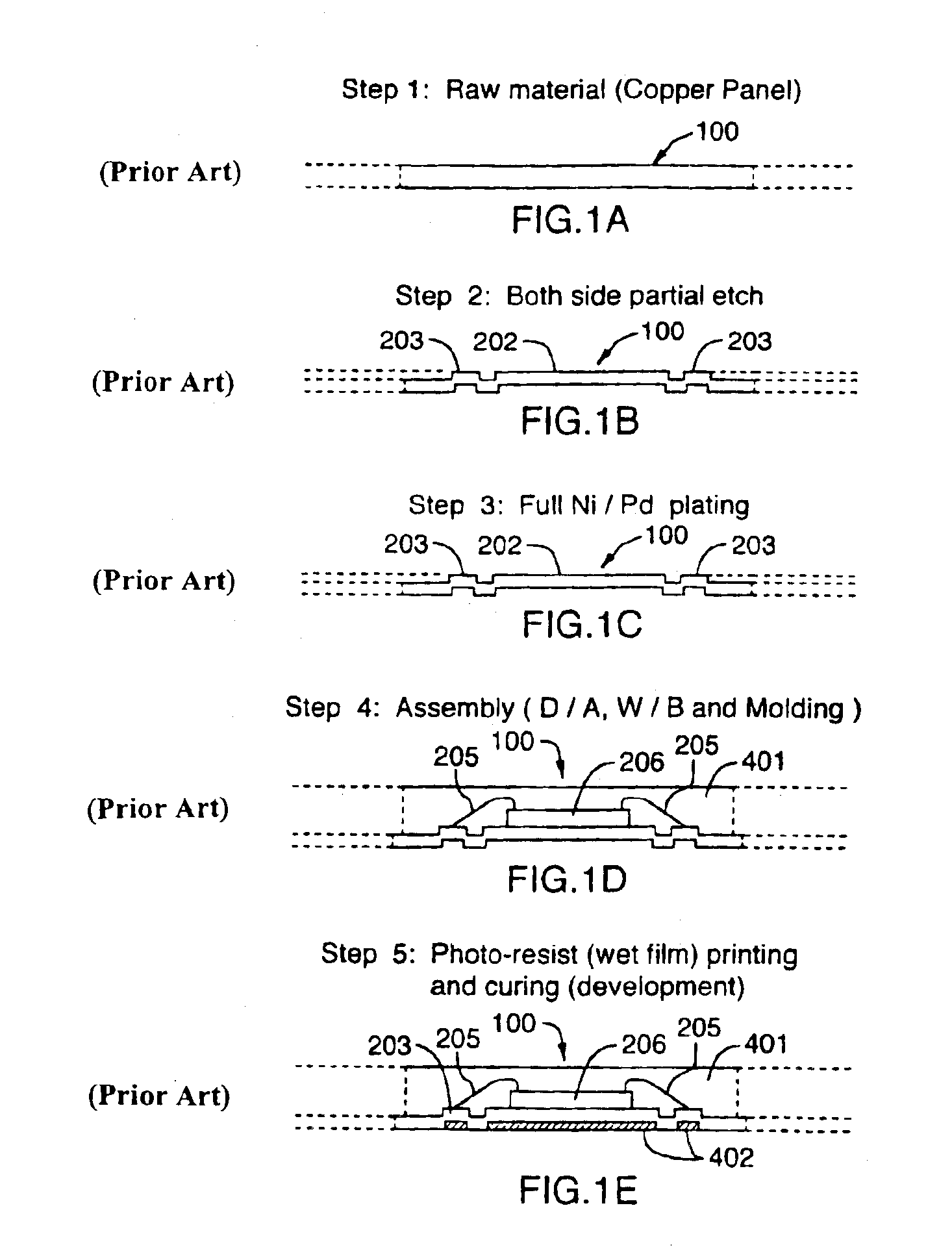

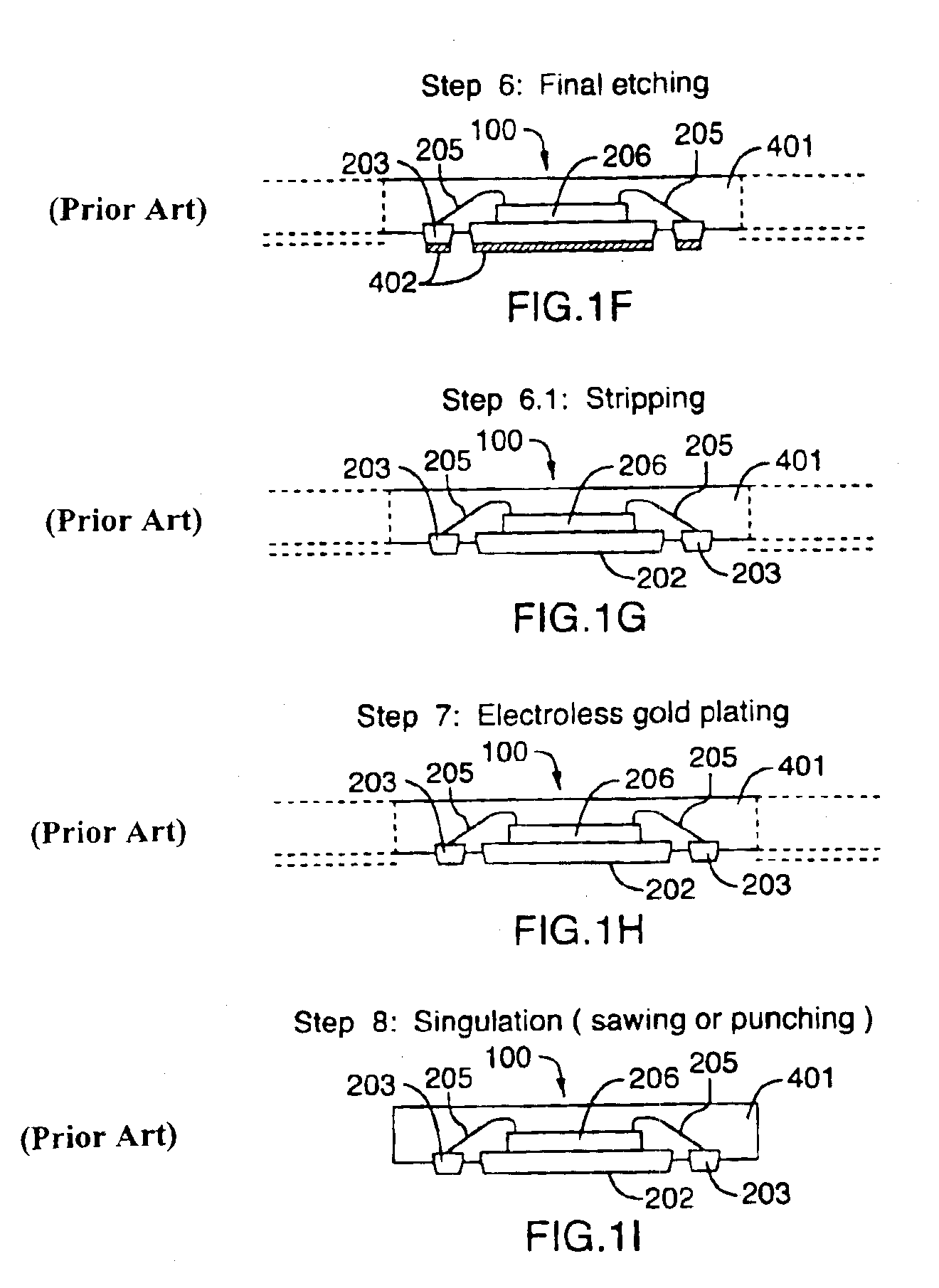

Leadless plastic chip carrier with etch back pad singulation

InactiveUS6933594B2Improve interlockEasy alignmentSemiconductor/solid-state device detailsSolid-state devicesEtchingPunching

A leadless plastic chip carrier is constructed by half etching one or both sides of the package design onto a leadframe strip so as to create unique design features such as power and / or ground ring surrounding the die attach pad, interlocking rivet head construction for the contact pads, and an interlocking pattern for the die attach pad. After wire bonding and molding, a further etching is performed to isolate and expose contact pads. Singulation of individual chip packages from the leadframe strip is then performed by saw singulation or die punching.

Owner:UTAC HEADQUARTERS PTE LTD

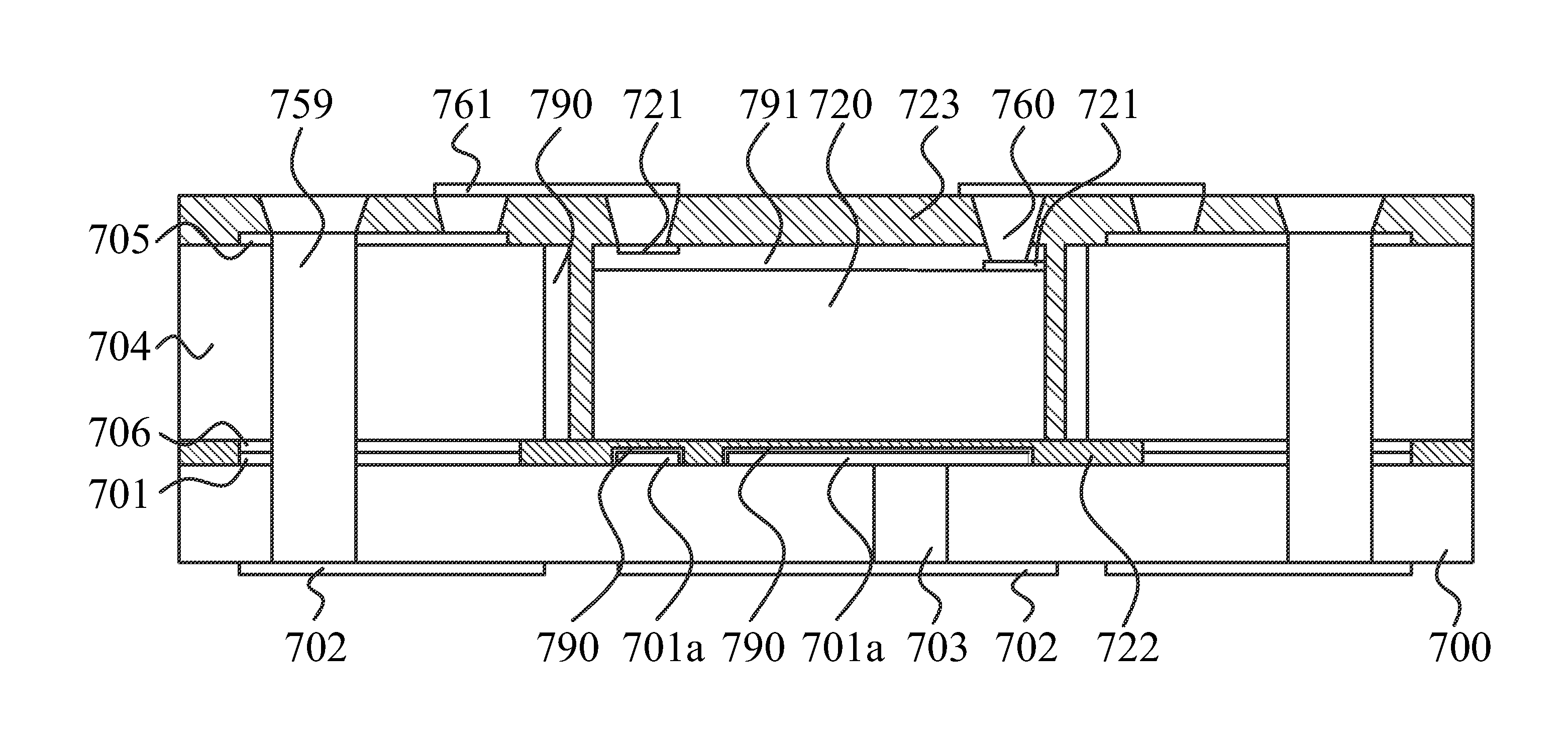

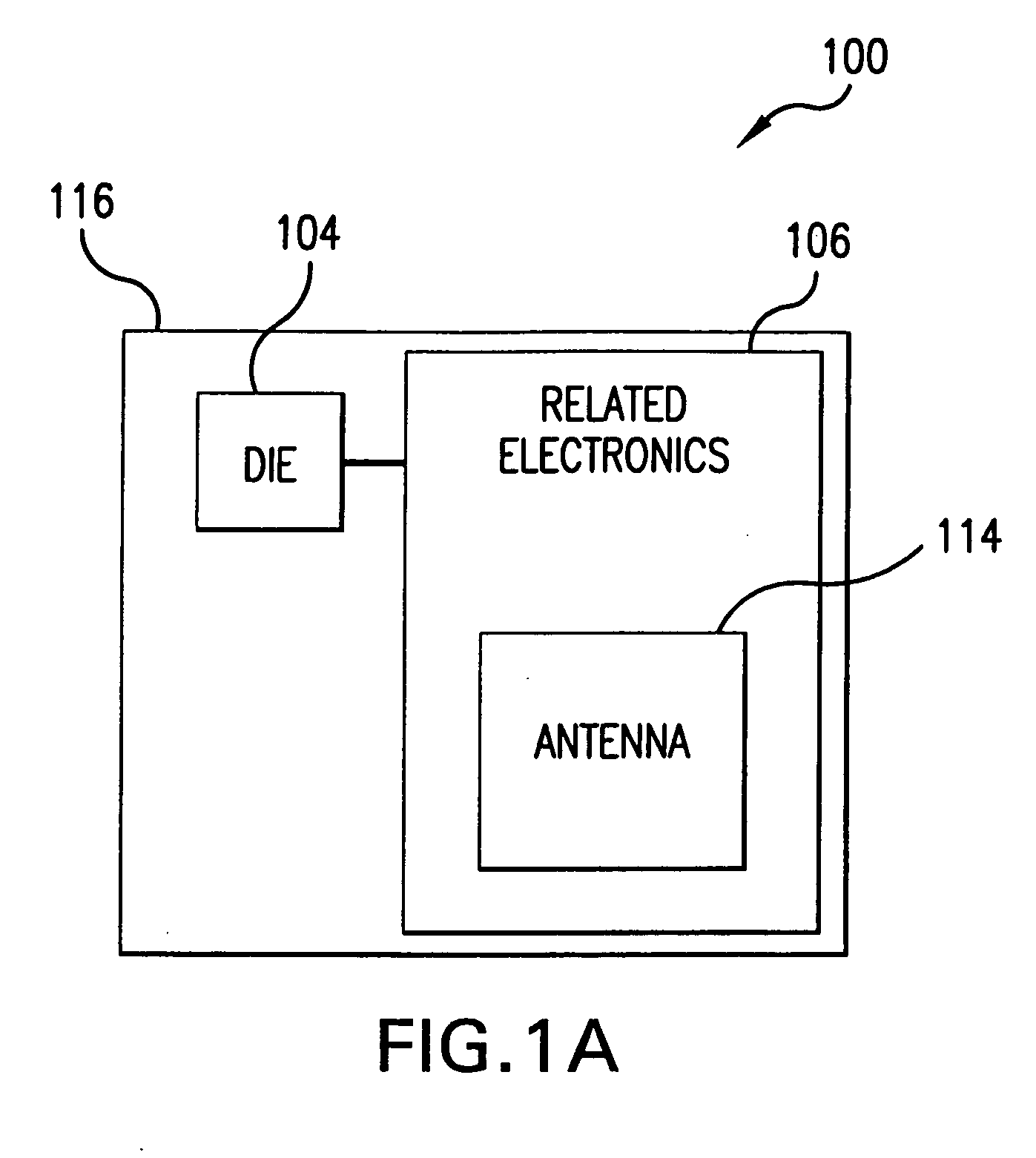

Semiconductor Device Package Structure and Method for the Same

InactiveUS20100301474A1Shrink wellShrinkage sizeSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerPunching

The present invention discloses a semiconductor device package and the method for the same. The method includes preparing a first substrate and a second substrate; opening a die opening window through the second substrate by using laser or punching; preparing an adhesion material; attaching the first substrate to the second substrate by the adhesion material; aligning a die by using the aligning mark of the die metal pad and attaching the die onto the die metal pad with force by the adhesion material; forming a first dielectric layer on top surfaces of the second substrate and the die and pushing the first dielectric layer into gap between the side wall of the die and the side wall of the die opening window under vacuum condition; opening a plurality of via openings in the first dielectric layer; and forming a redistribution layer in the plurality of via openings and on the first dielectric layer.

Owner:KING DRAGON INT

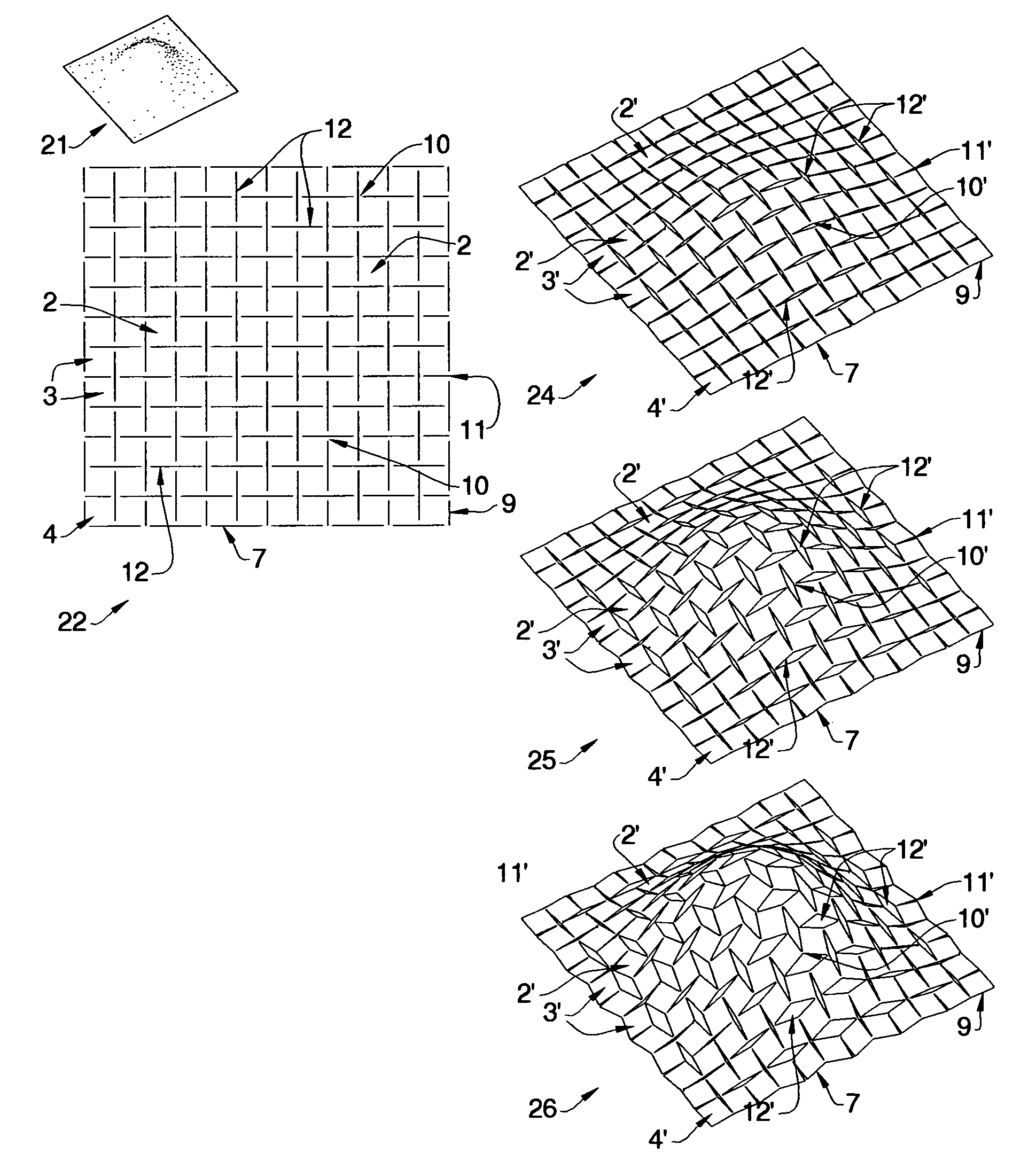

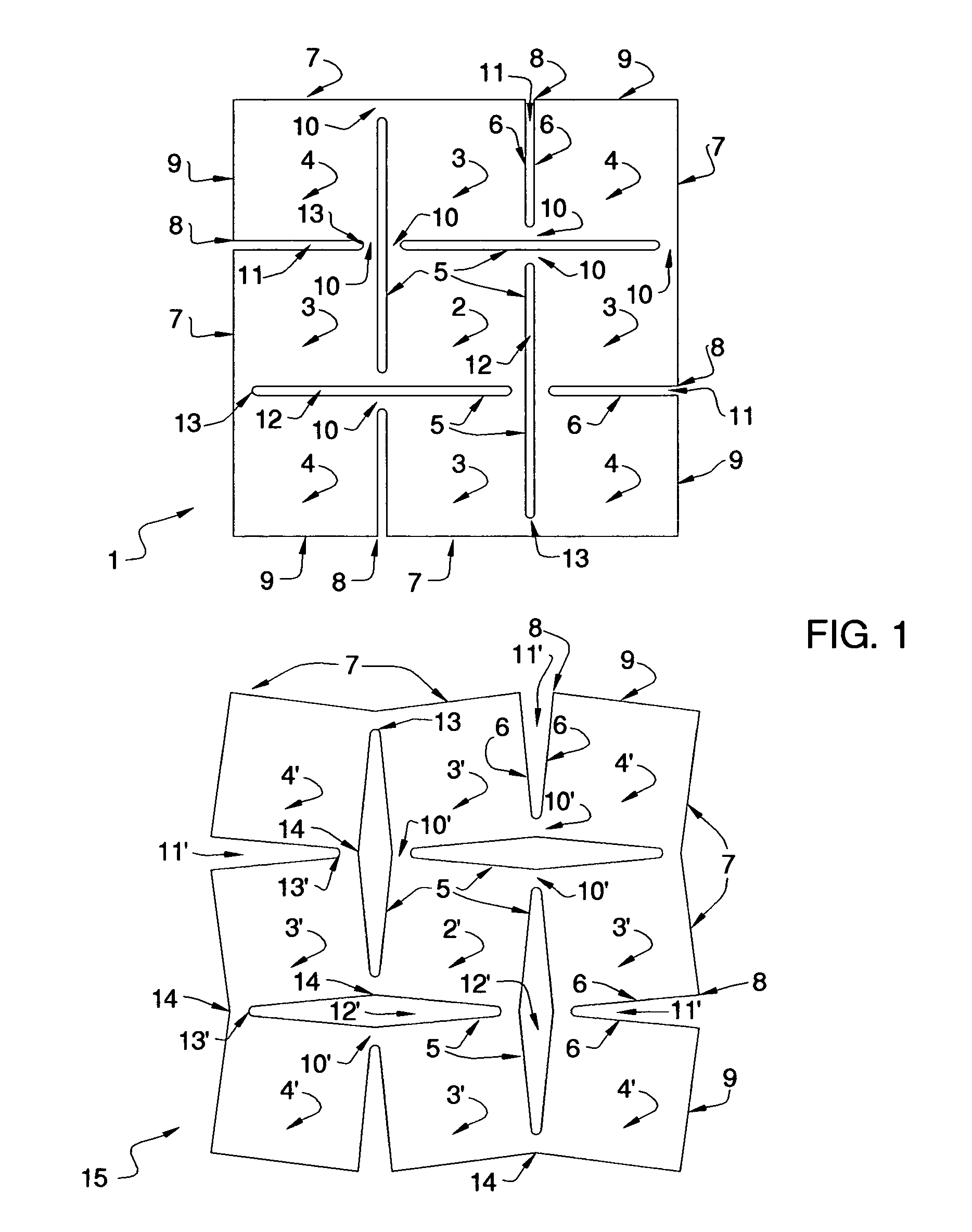

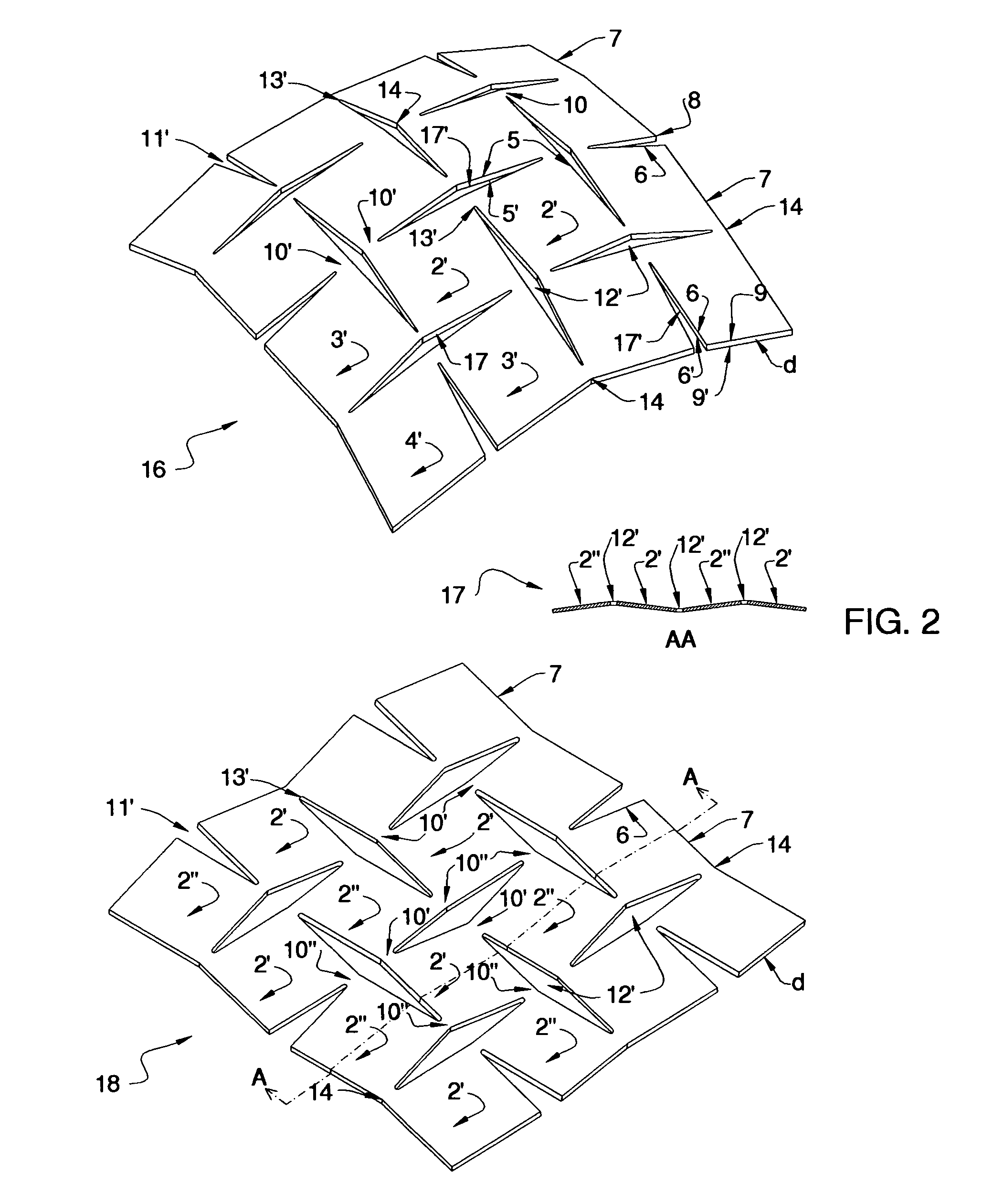

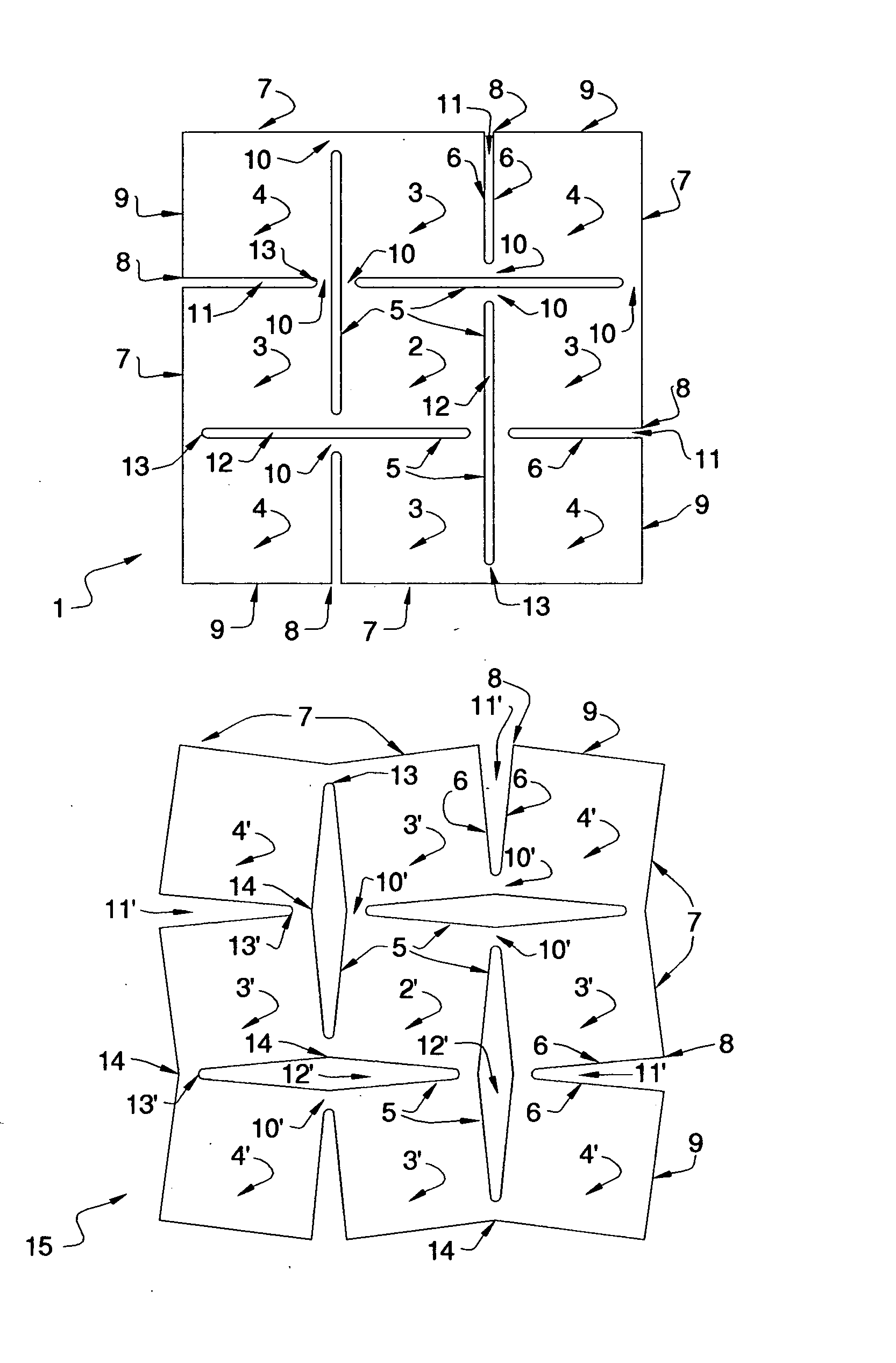

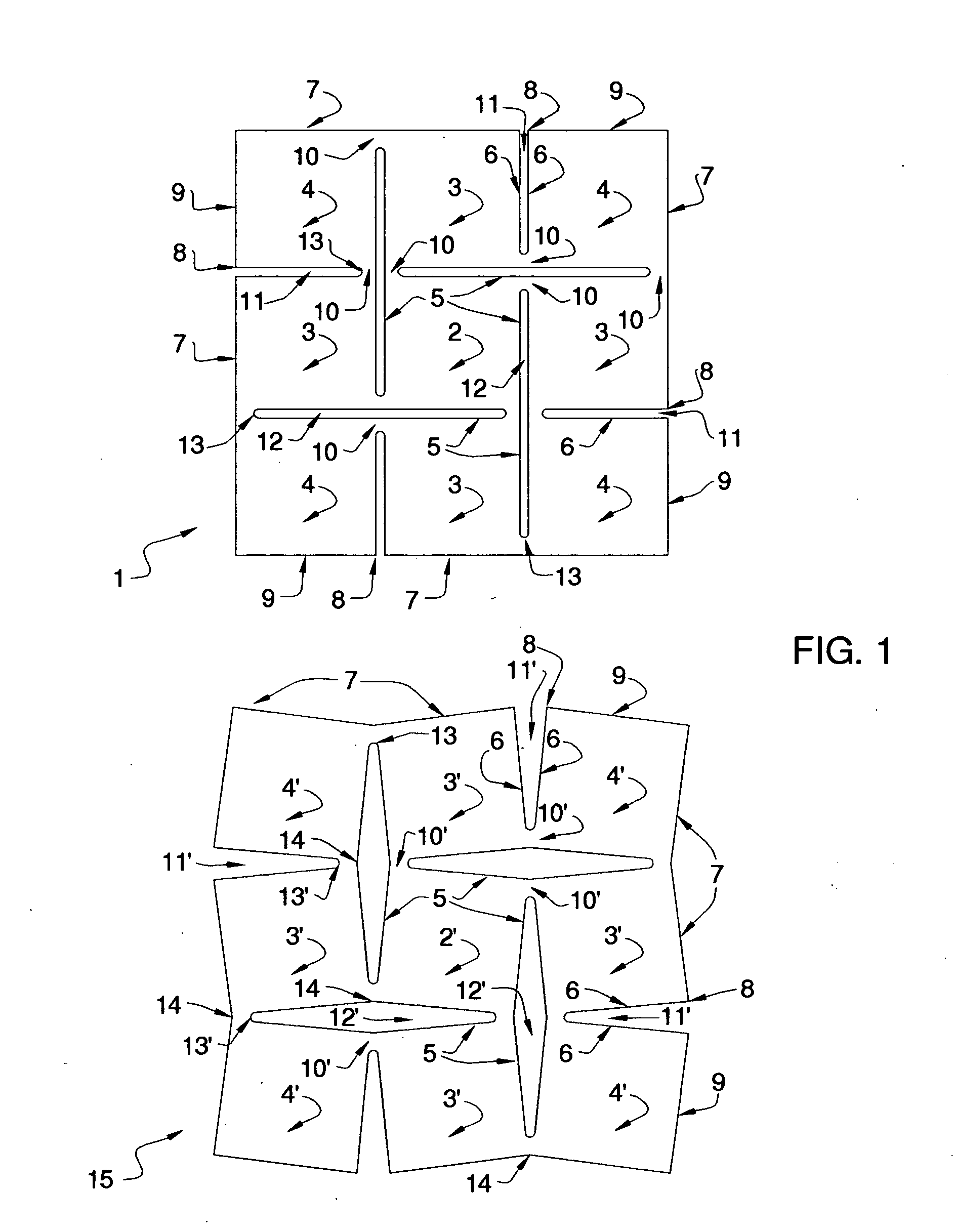

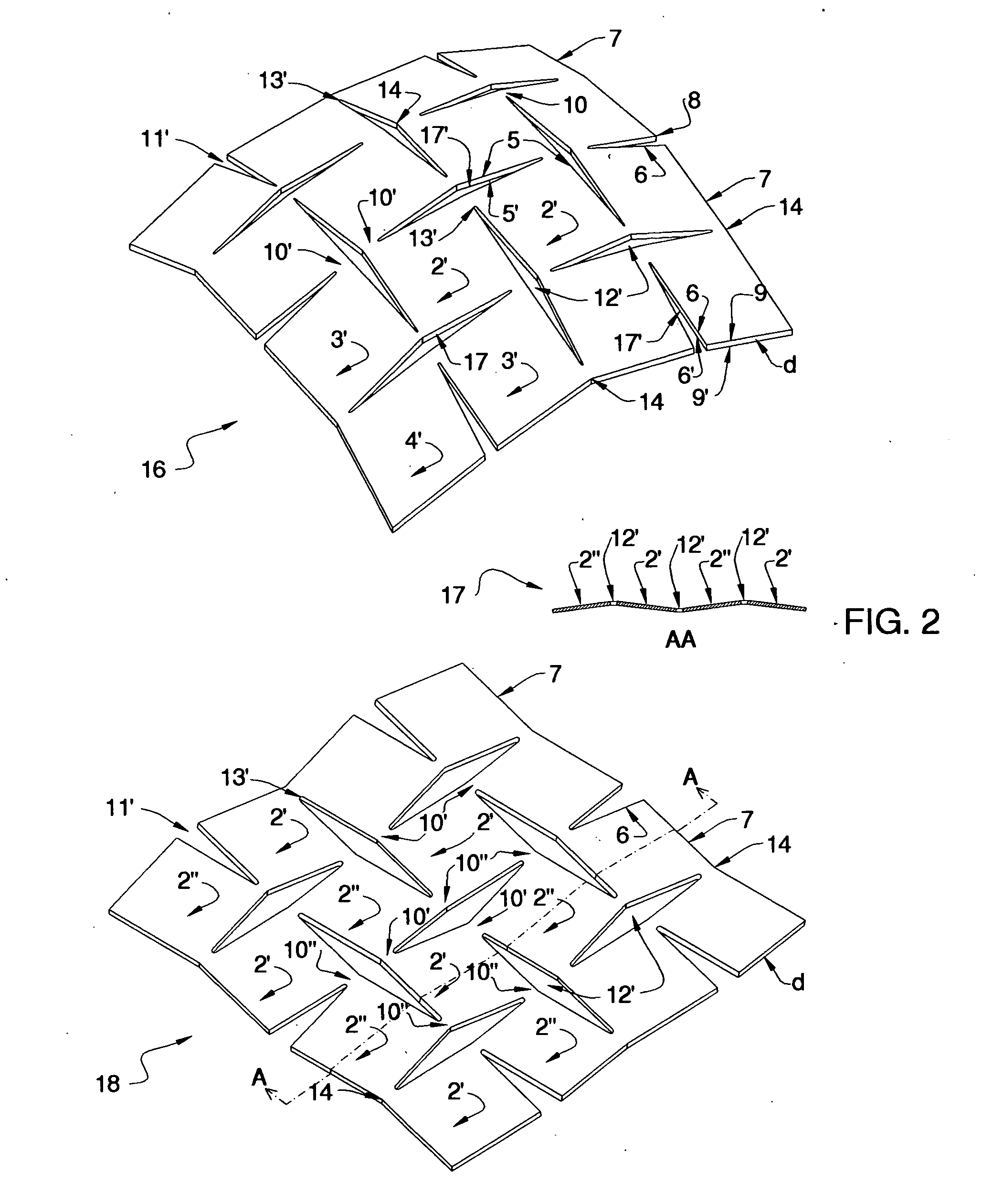

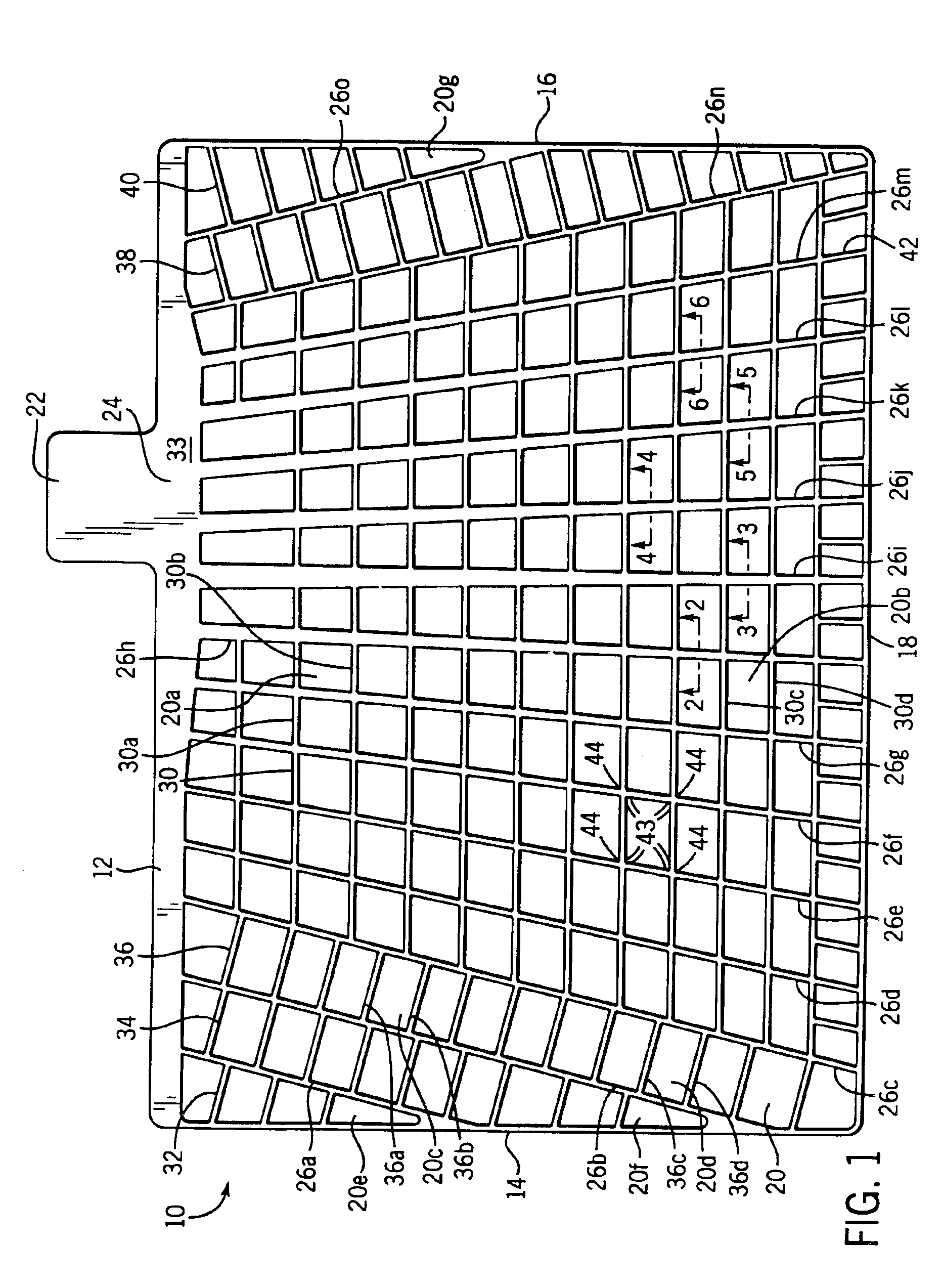

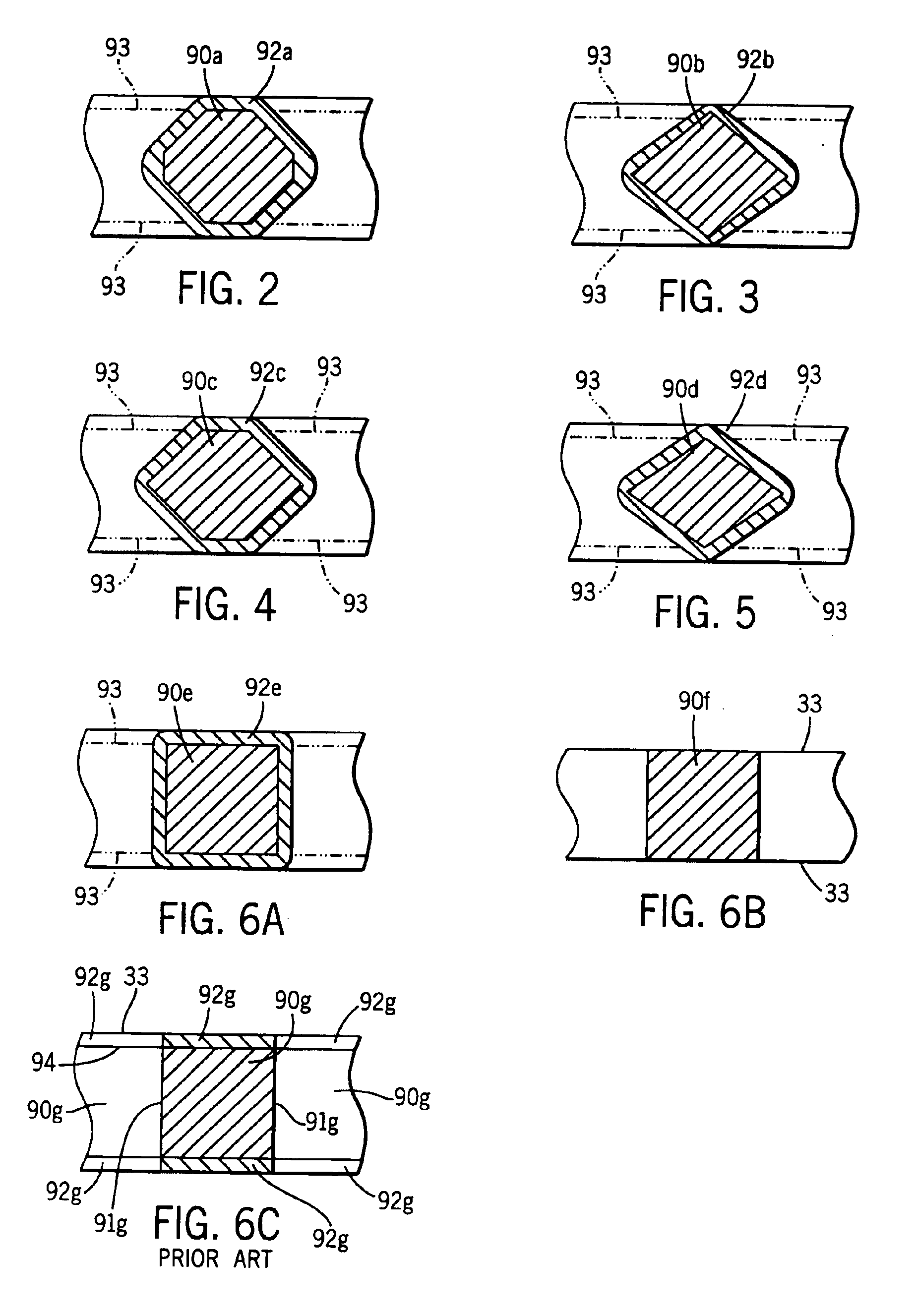

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

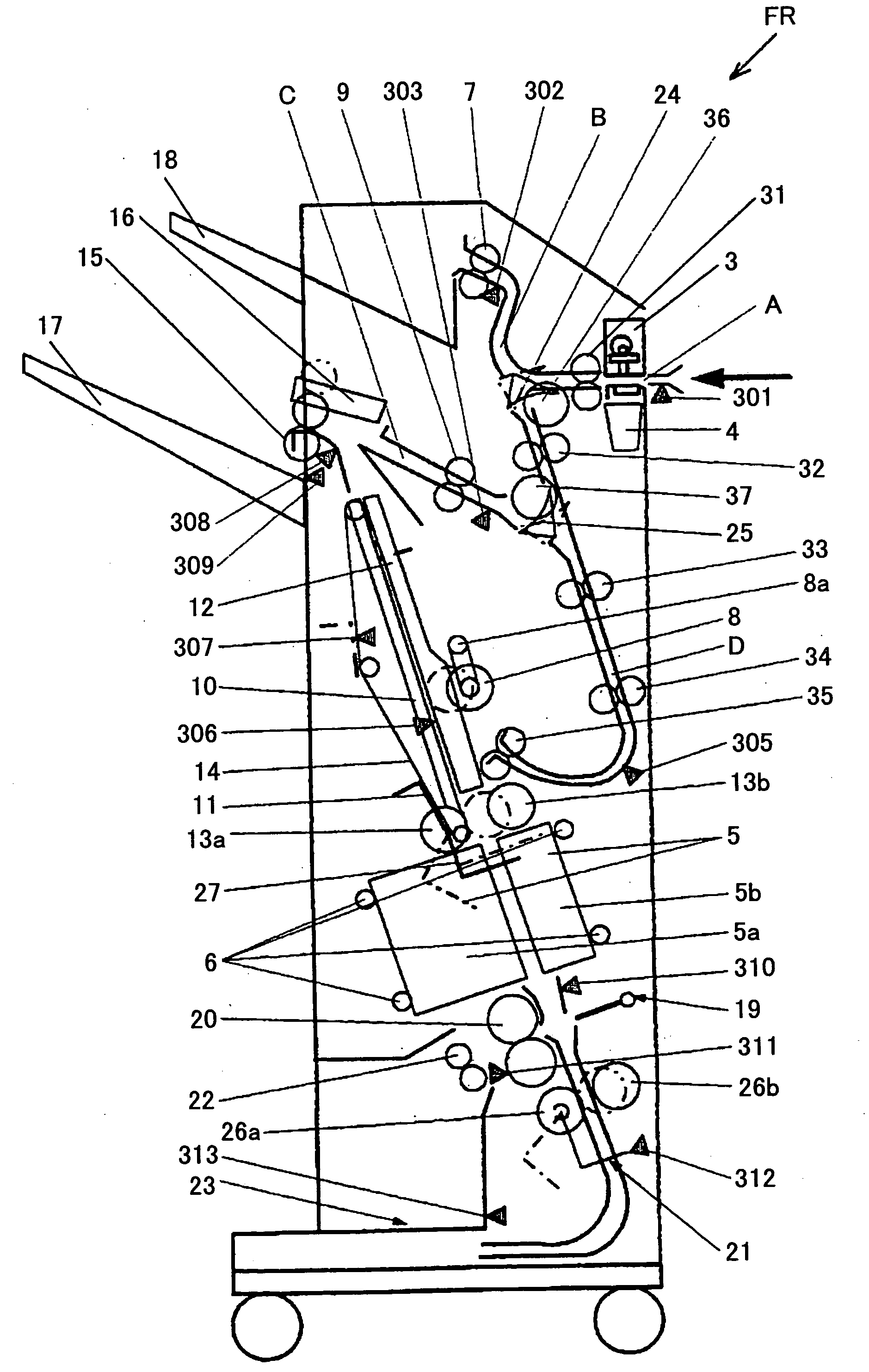

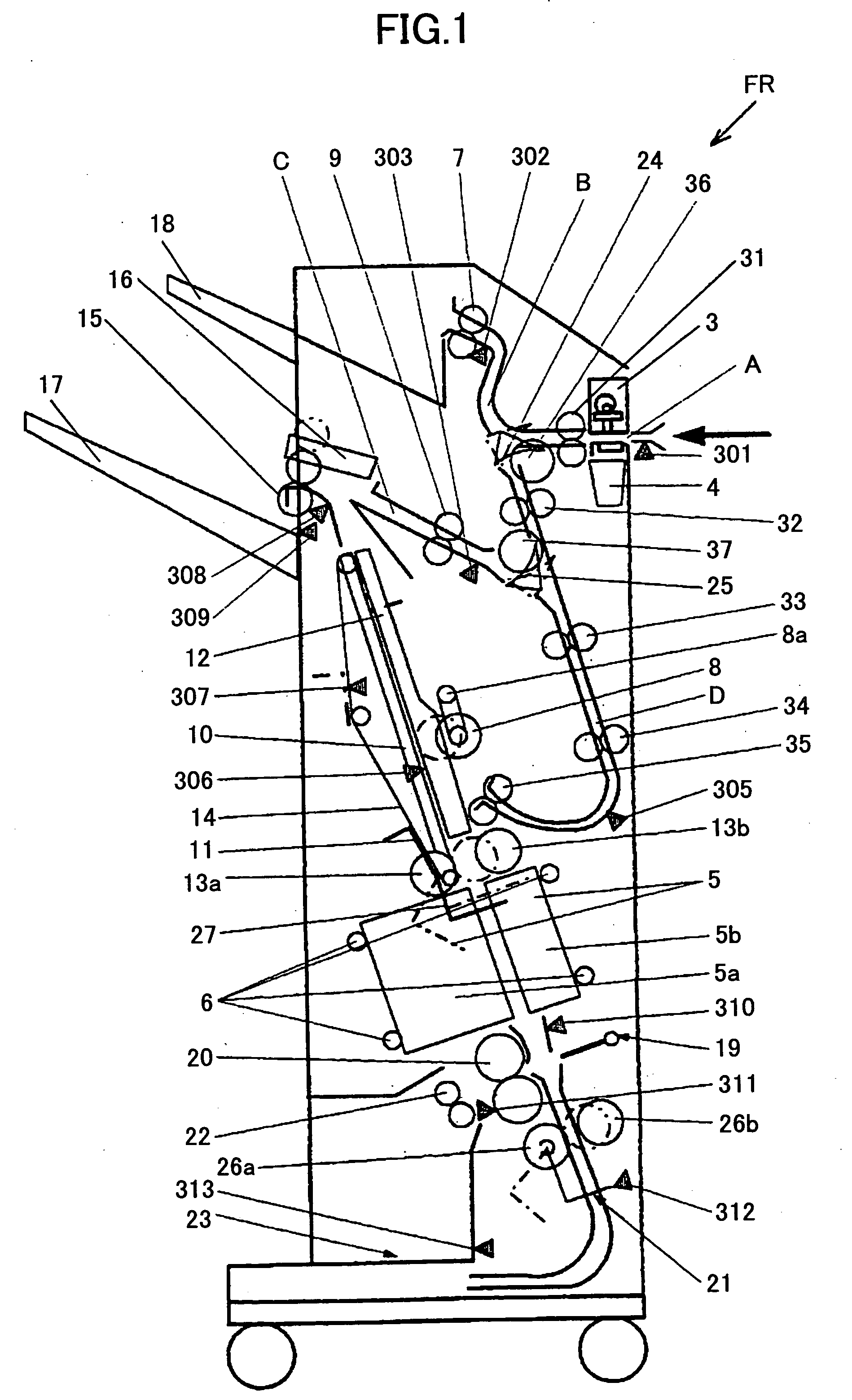

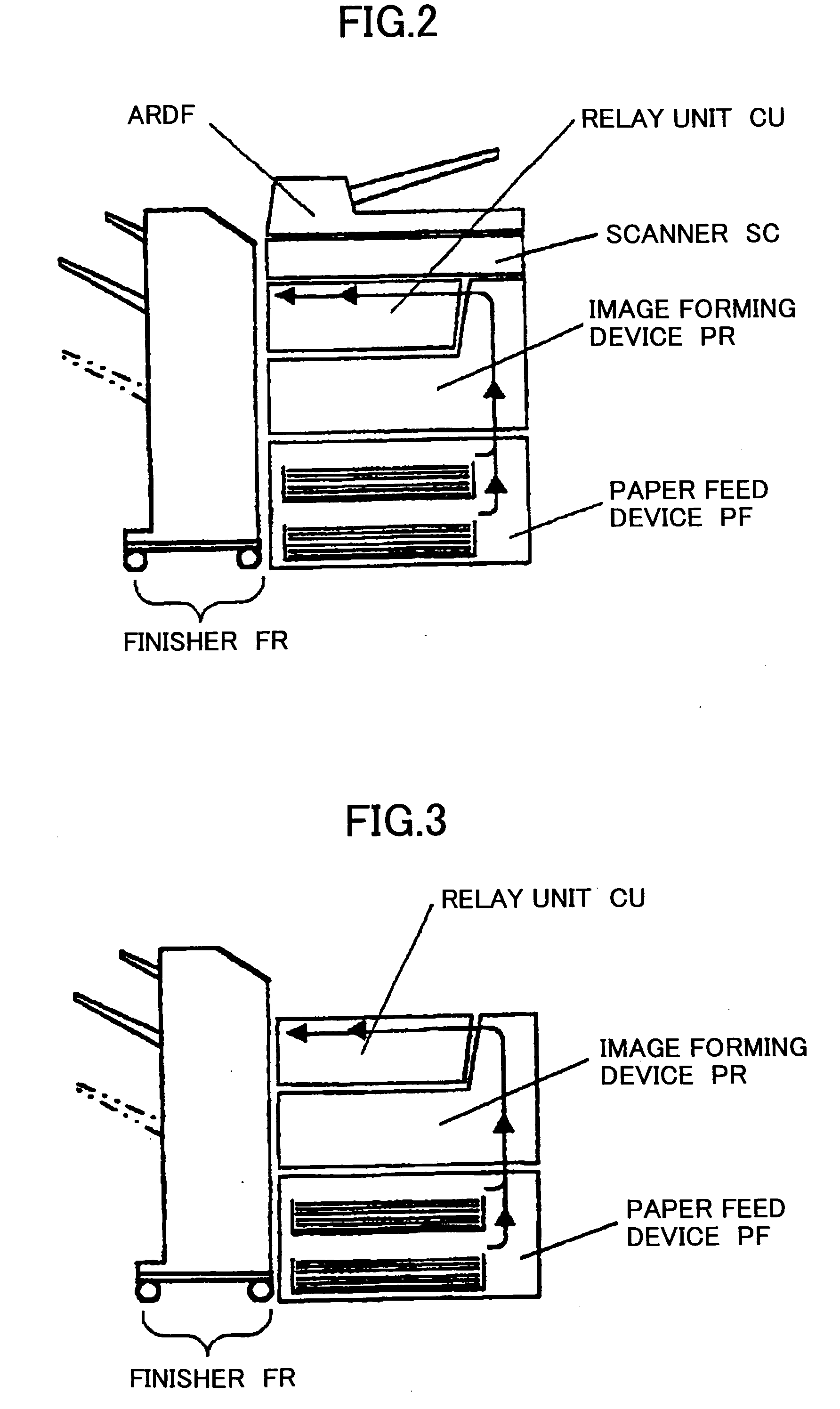

Sheet punch device, sheet processing device, image forming system, program, and recording medium

InactiveUS20050000336A1High-speed sheetGood motor stop precisionAutomatic control devicesFeeding apparatusPunchingEngineering

A sheet punch device for punching a sheet with a punch edge comprises a motor performing a punching operation and a position detection unit detecting a position of the punch edge. A control unit controls the motor and the position detection unit, wherein the control unit causes the position detection unit to detect a position of the punch edge at a time of or prior to a motor stop in a first driving operation of the motor to perform the punching operation, and, when the detected position deviates from a desired position, the control unit performs restarting of the motor so that the punch edge is brought close to the desired position.

Owner:RICOH KK

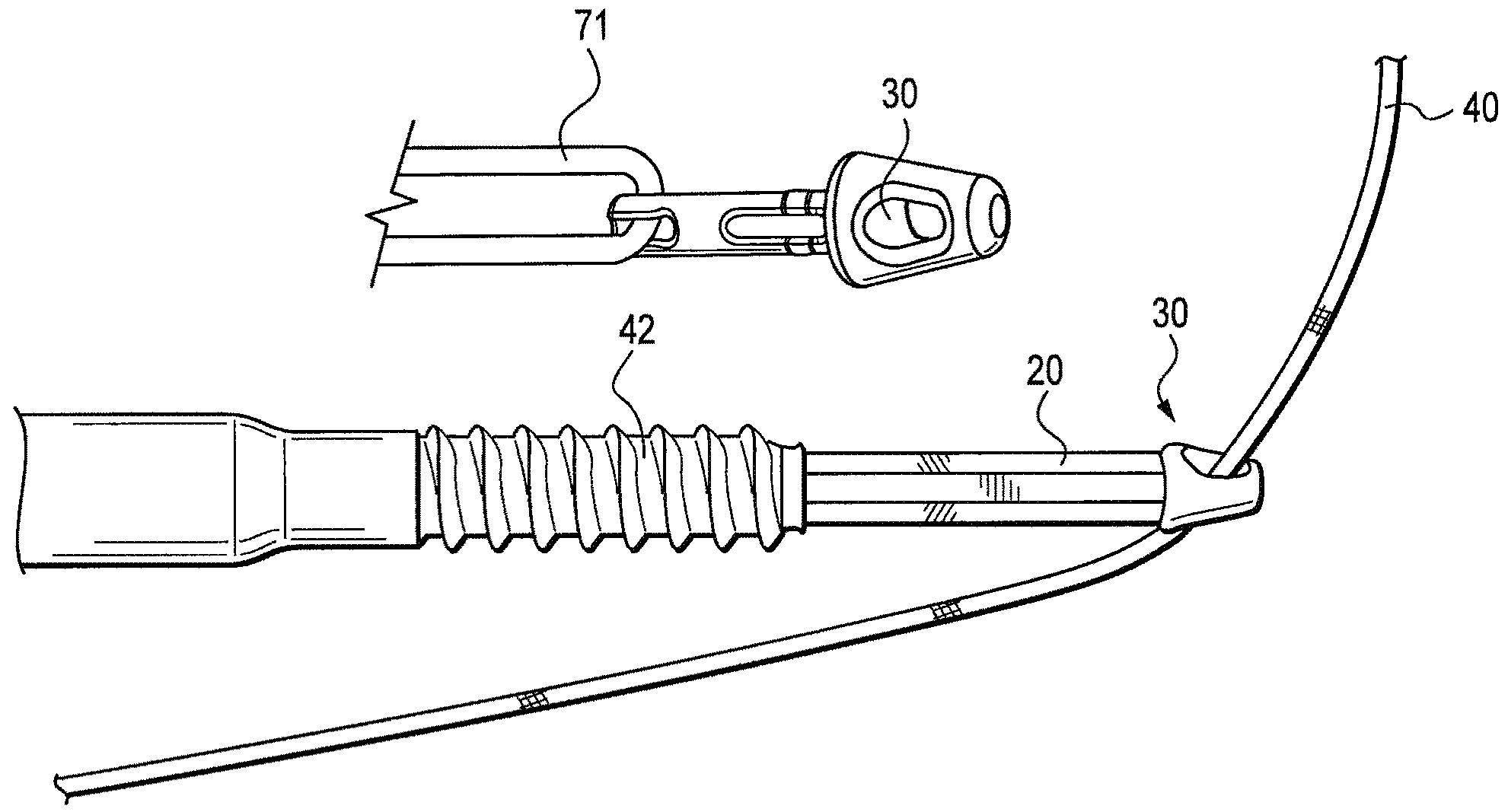

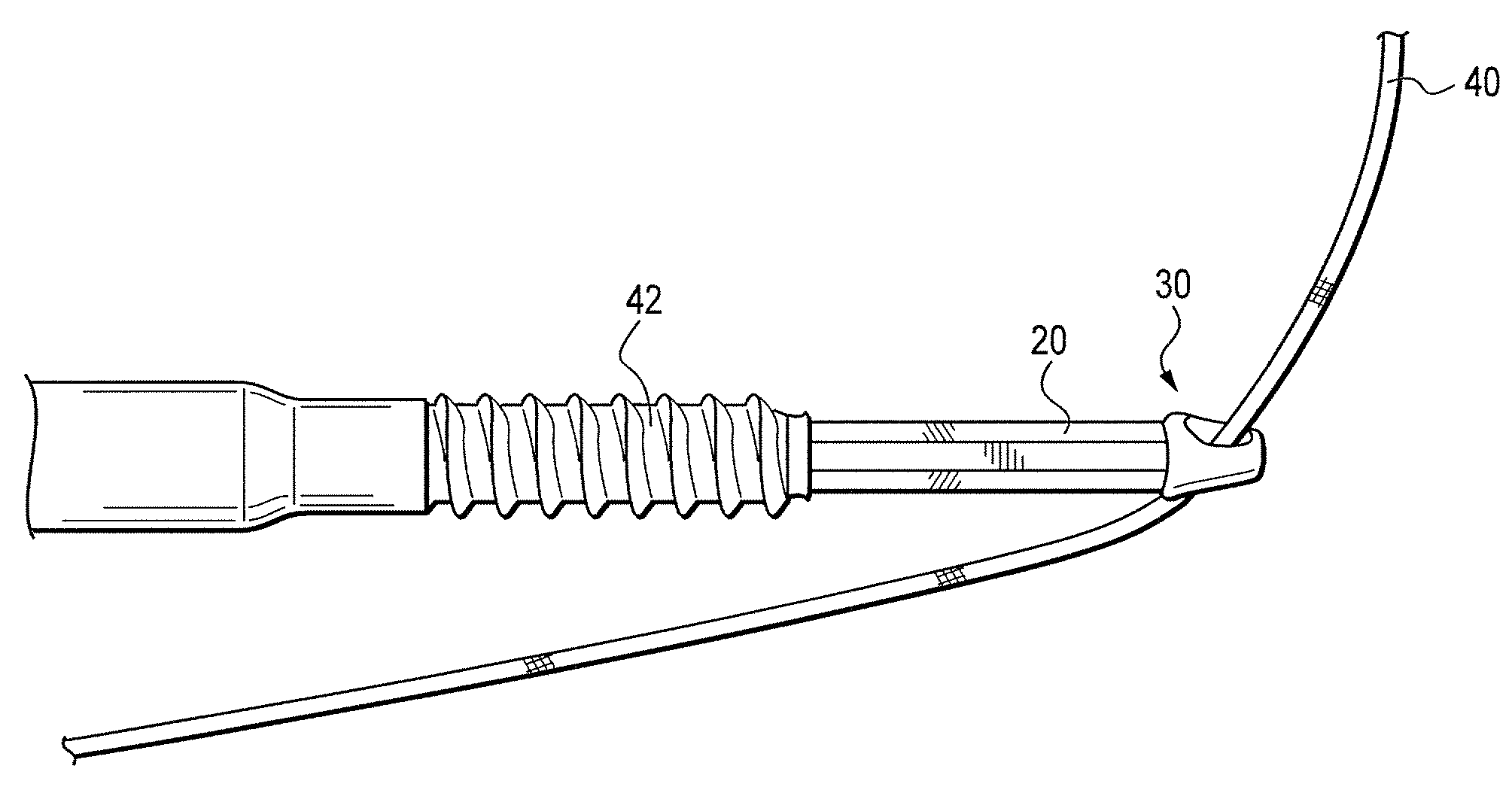

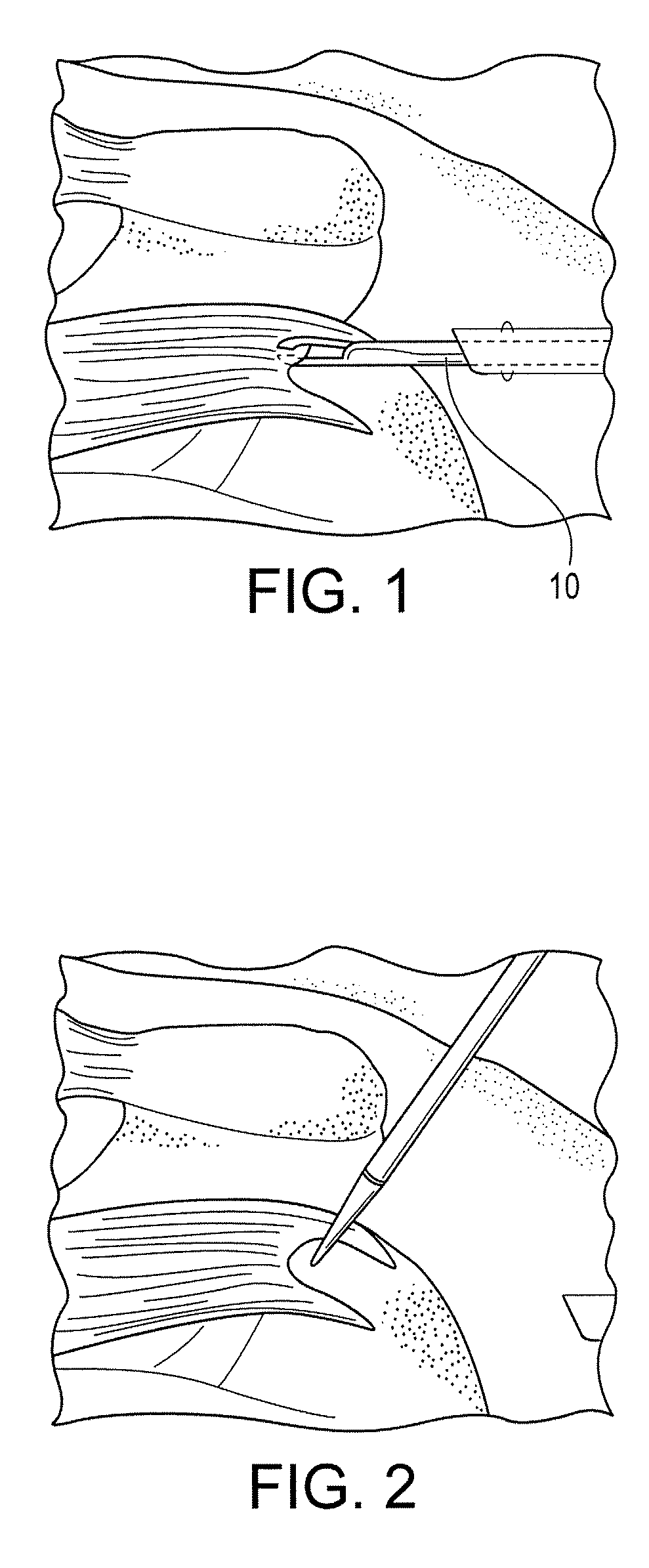

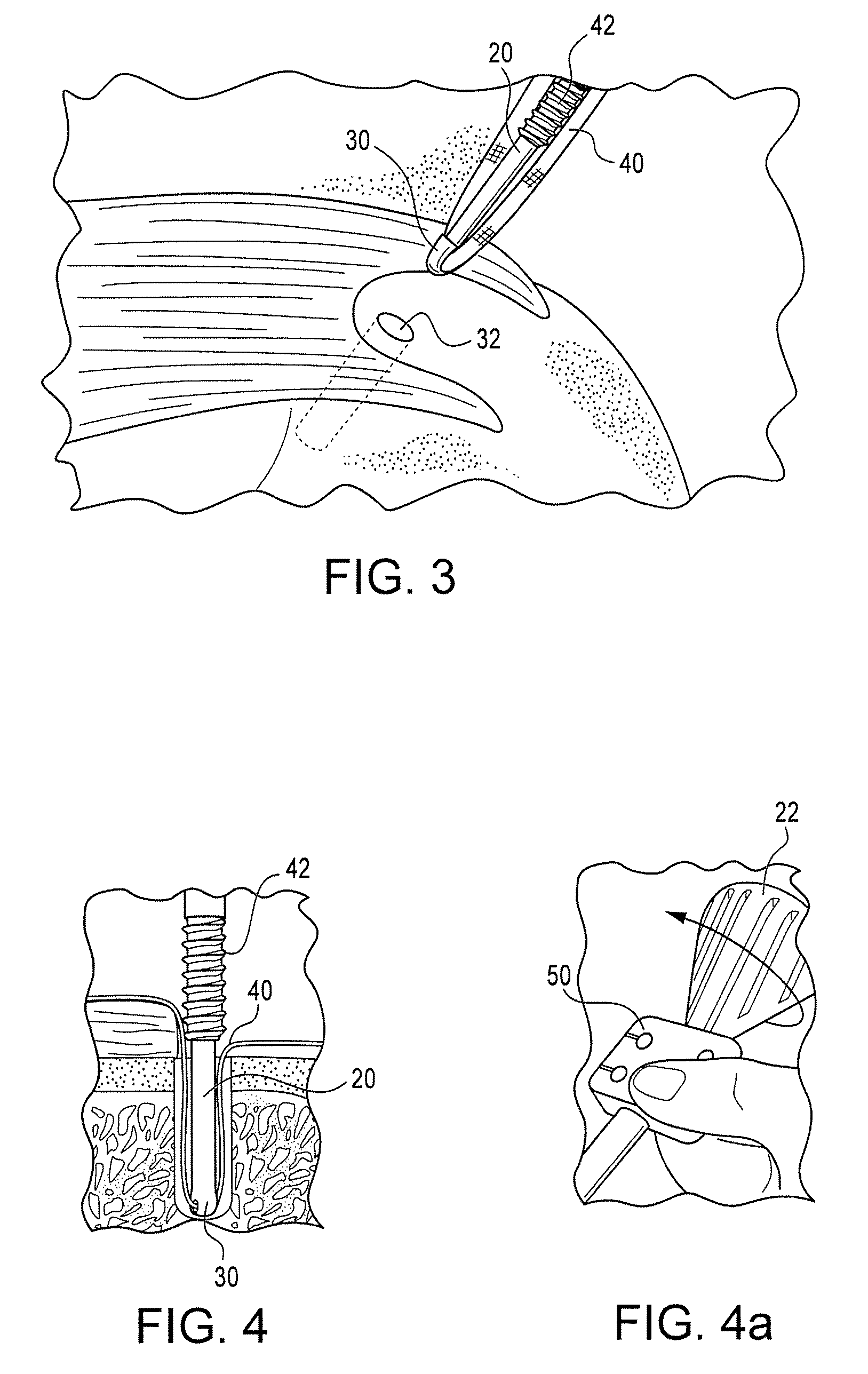

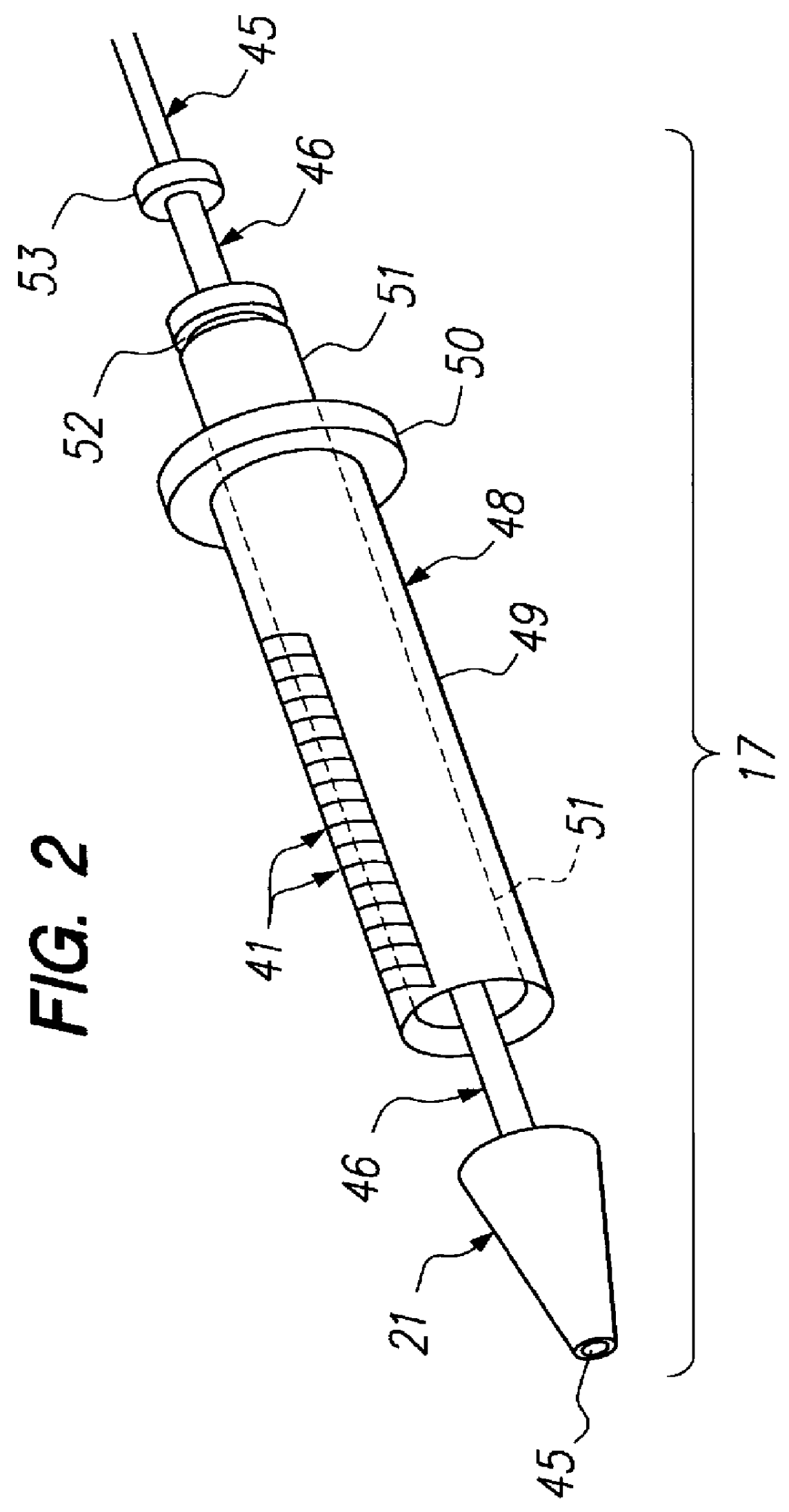

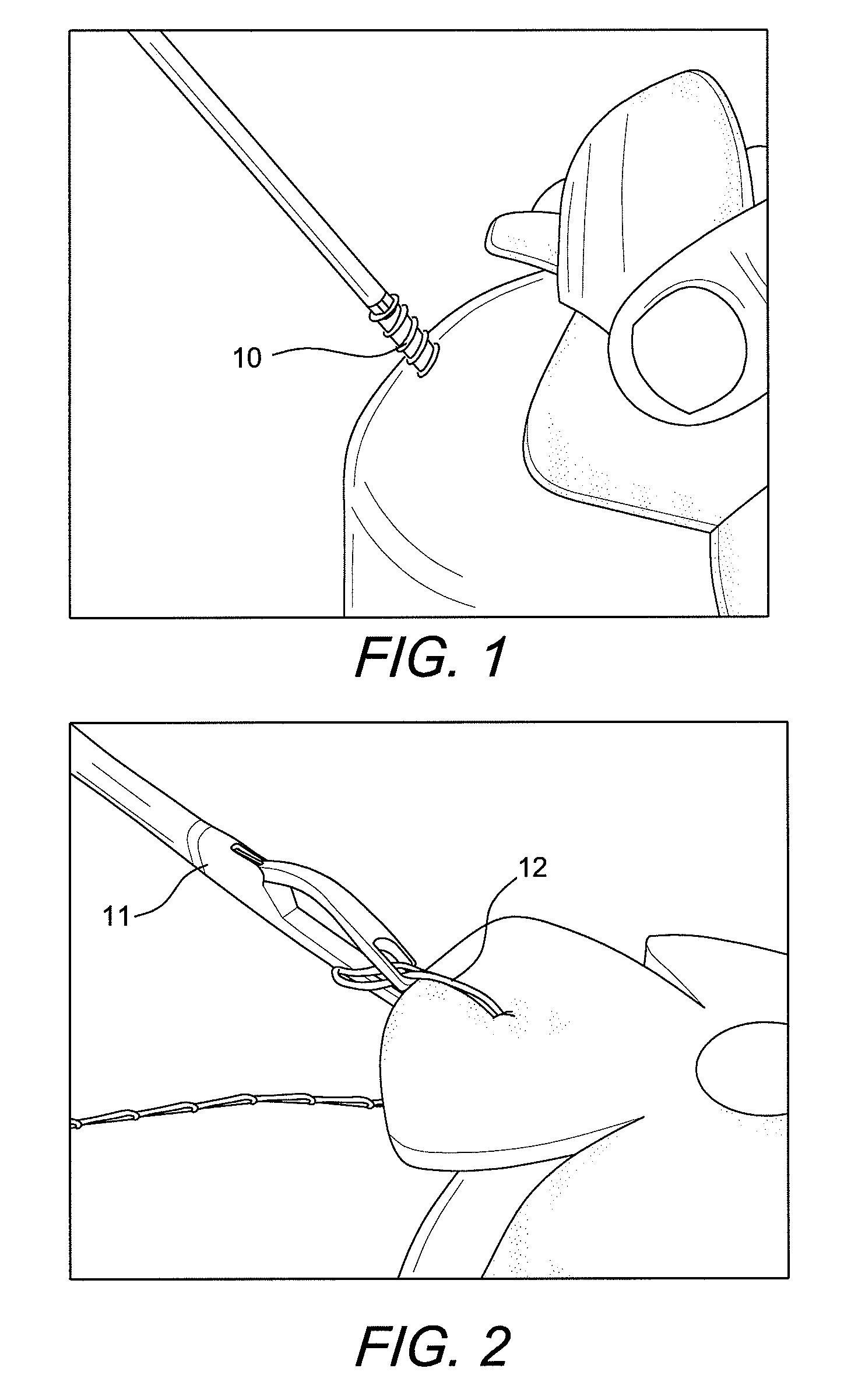

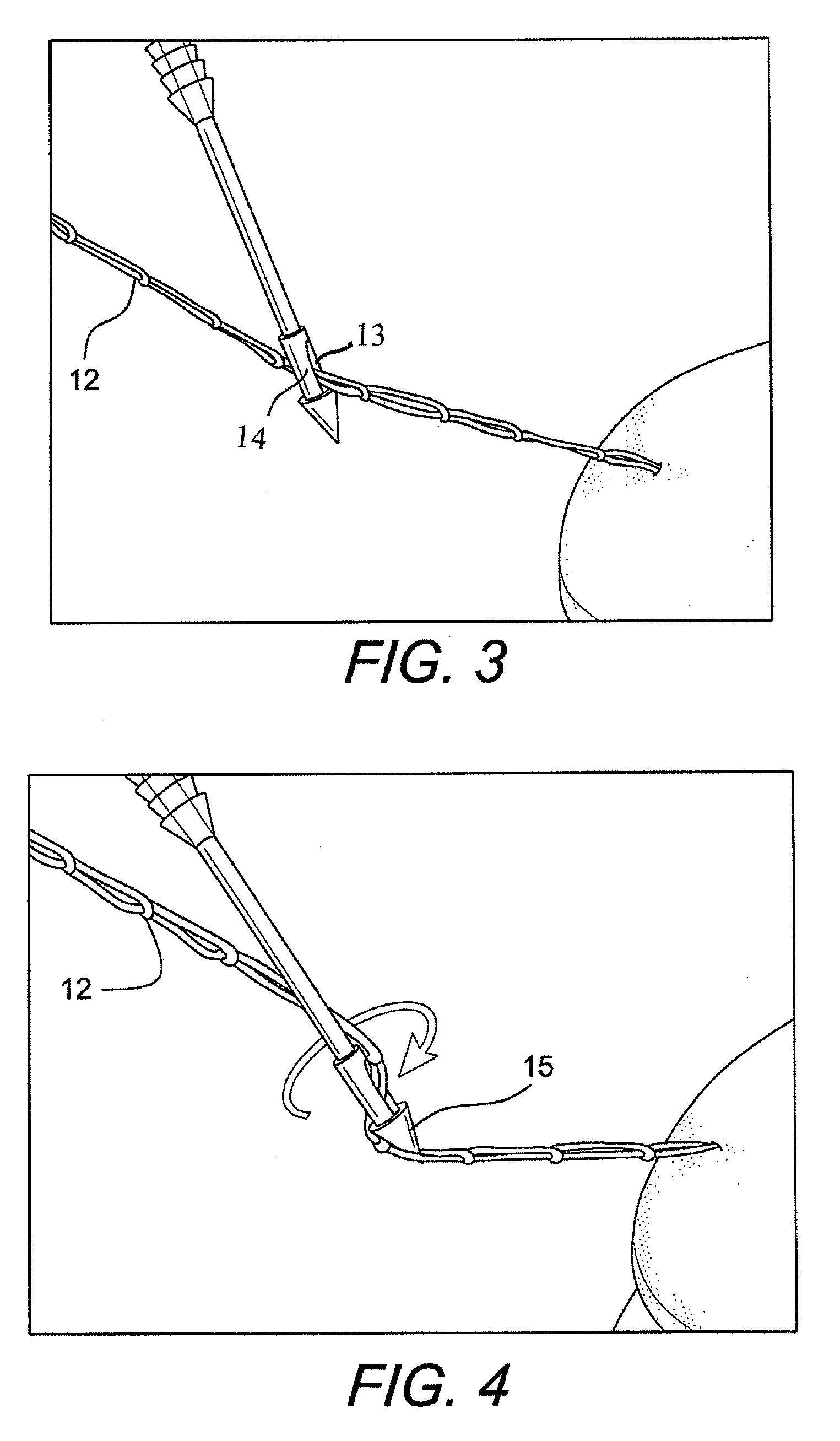

Swivel anchor for knotless fixation of tissue

A method and device for knotless fixation of tissue. A swivel anchor having a rotatable implant is used to capture suture for surgical tissue repair without requiring suture knots. The implant may be provided with a conical metal tip which is self-punching and avoids the need for pre-drilling a hole in bone. The implant includes a closed aperture to allow free sliding of a suture strand. The swivel anchor is secured in a hole in bone by advancing a fixation device, such as a cannulated interference screw, over the body of the implant.

Owner:ARTHREX INC

Self-punching swivel anchor and method for knotless fixation of tissue

A method and device for knotless fixation of tissue. A swivel anchor having a rotatable implant is used to capture suture for surgical tissue repair without requiring suture knots. The implant may be provided with a conical metal tip which is self-punching and avoids the need for pre-drilling a hole in bone. The implant includes a closed aperture to allow free sliding of a suture strand. The swivel anchor is secured in a hole in bone by advancing a fixation device, such as a cannulated interference screw, over the body of the implant.

Owner:ARTHREX

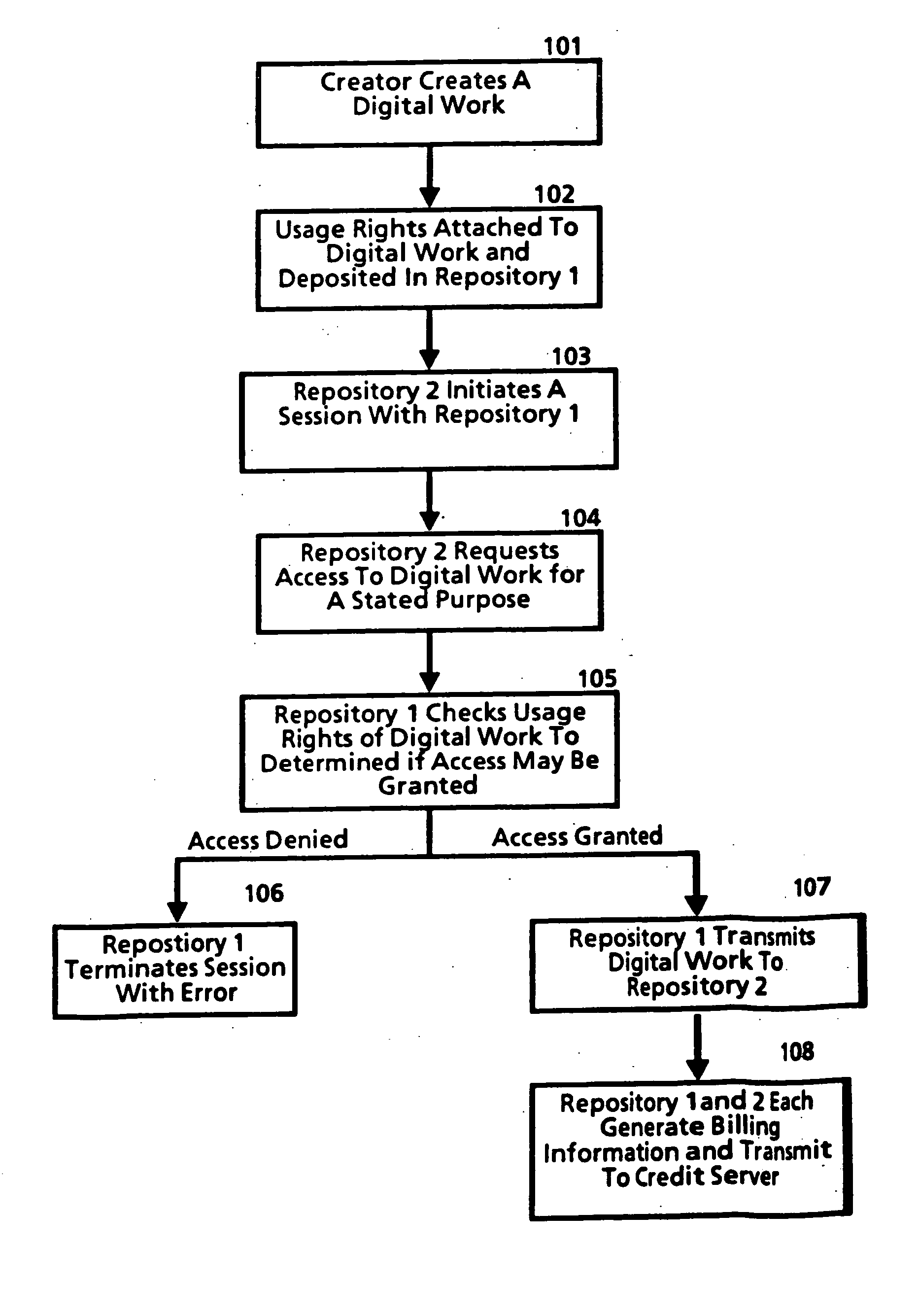

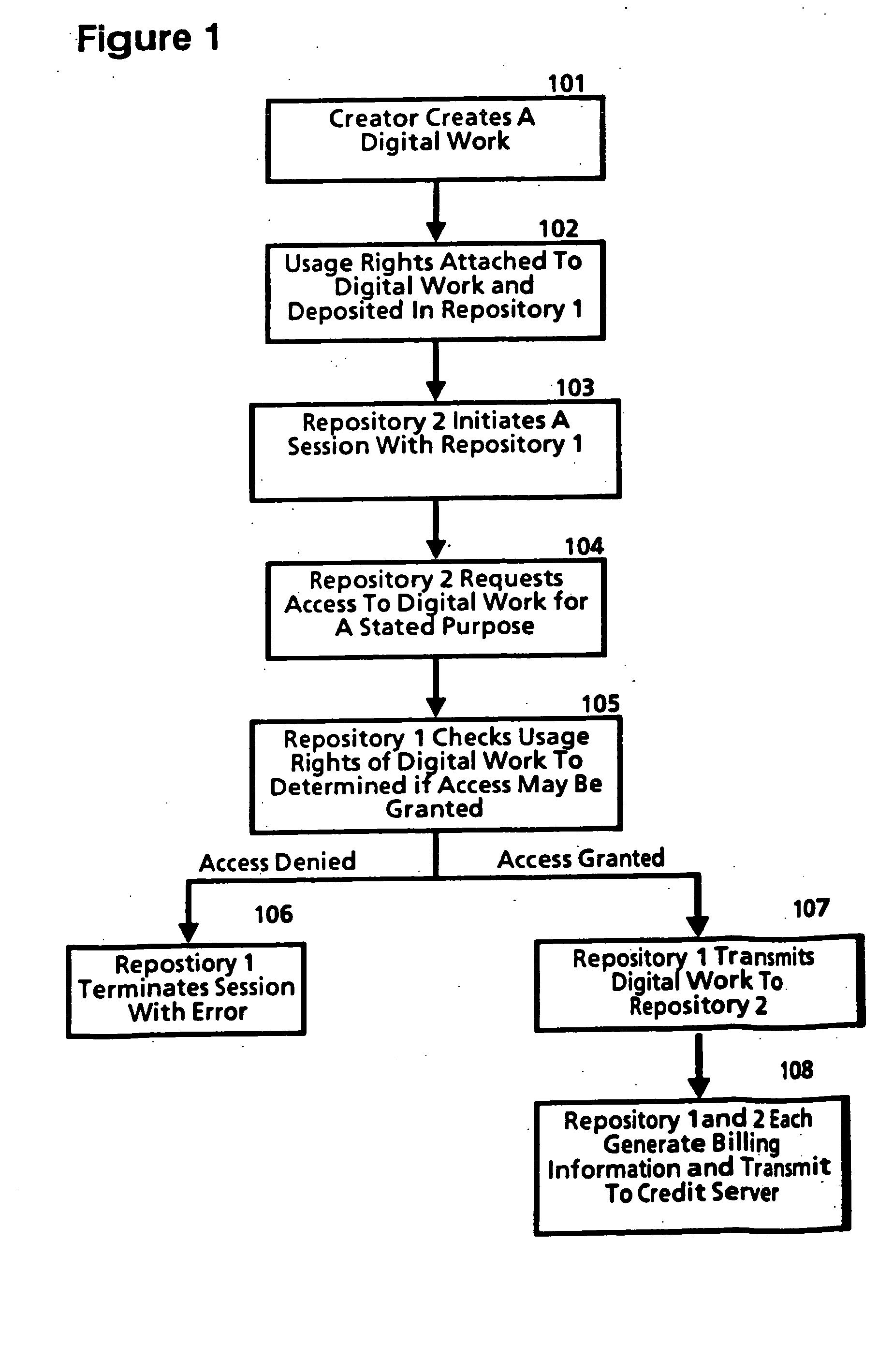

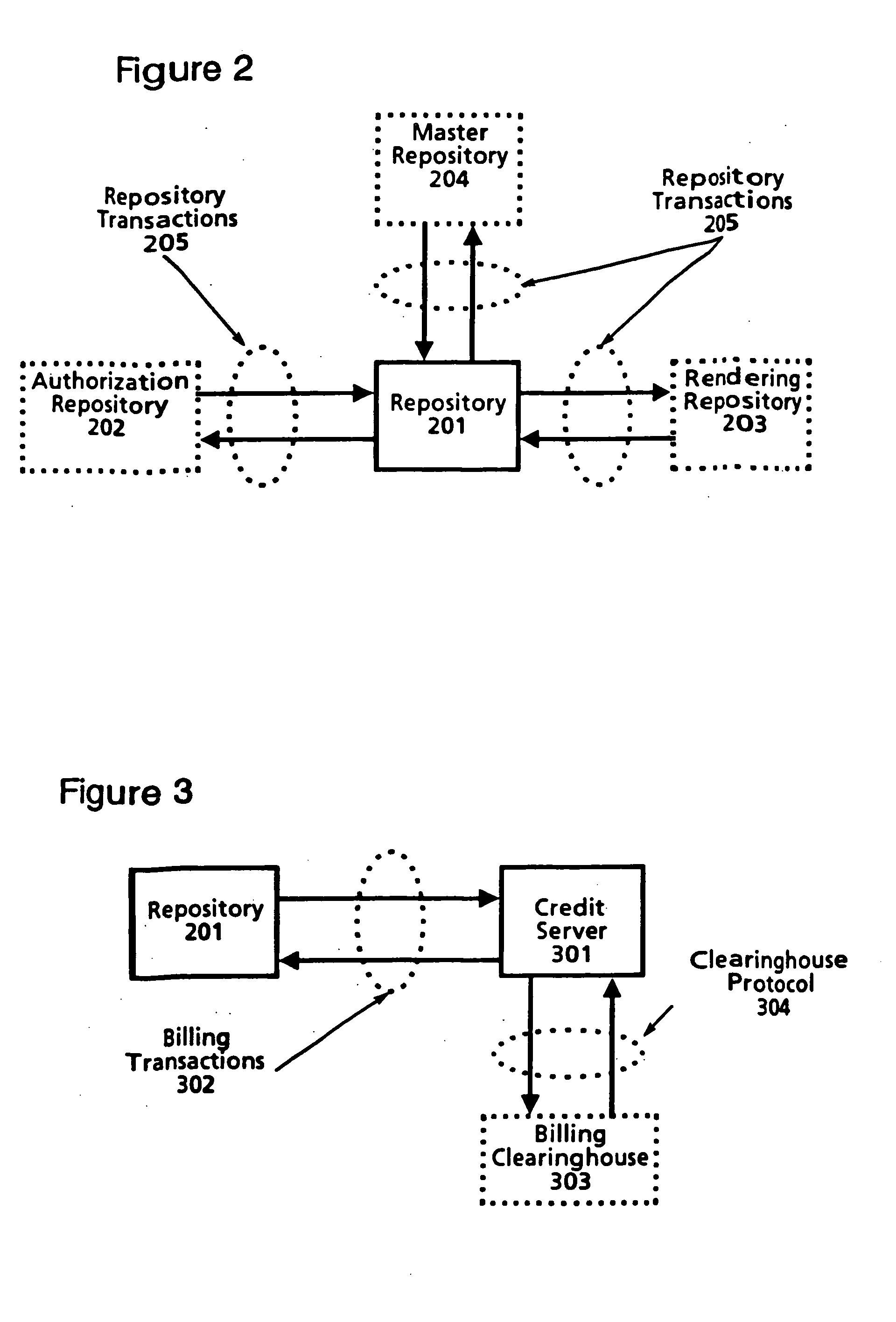

System for controlling the distribution and use digital works using digital tickets

InactiveUS20050108173A1Great security and controlPrevent digital ticket forgeryMetering/charging/biilling arrangementsPulse modulation television signal transmissionPunchingDigital work

A system for controlling the distribution and use of digital works using digital tickets. In the present invention, a “digital ticket” is used to entitle the ticket holder to exercise some usage right with respect to a digital work. Usage rights are used to define how a digital work may be used or distributed. Each usage right may specify a digital ticket which must be present before the right may be exercised. Digital works are stored in repositories which enforce a digital works usage rights. Each repository has a “generic ticket agent” which punches tickets. In some instances only the generic ticket agent is necessary. In other instances, punching by a “special ticket agent” residing on another repository may be needed.

Owner:CONTENTGUARD HLDG

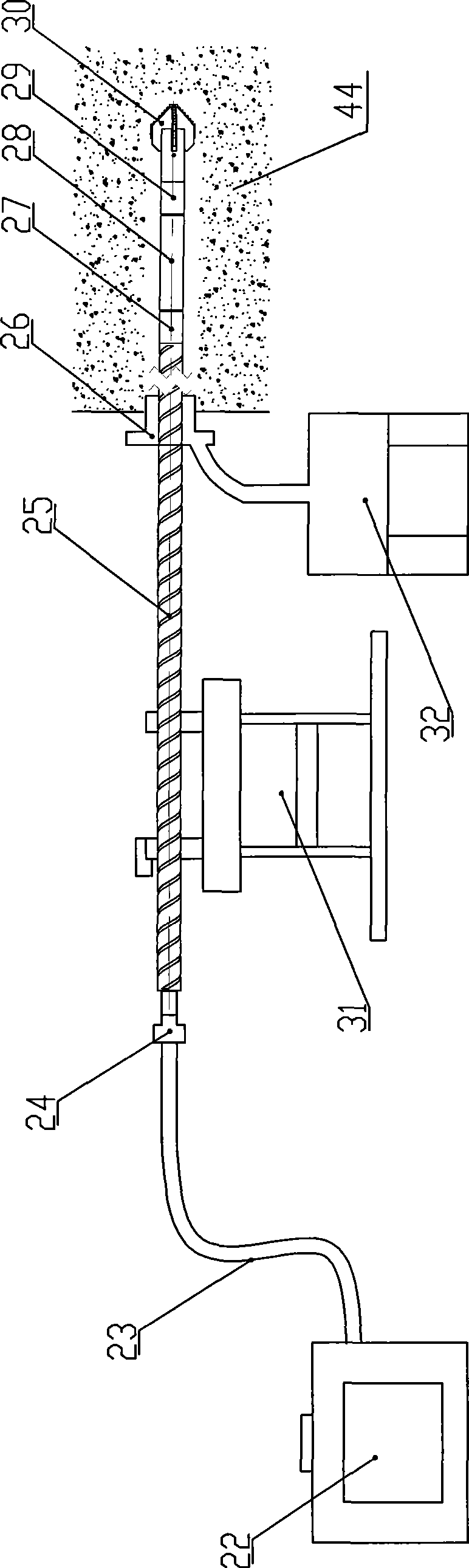

In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

InactiveCN101532391AGuaranteed cleanlinessAvoid enteringDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

The invention discloses an in-hole drilling tool integrating drilling, slotting and punching a coal seam and a using method thereof. The in-hole drilling tool comprises a water supple device or an air supple device, a high-pressure sealing drill pipe, a slotting and punching valve and a drill bit. The water supply device and the air supply device are connected with the high-pressure sealing drill pipe at an orifice. The slotting and punching valve is installed between the high-pressure sealing drill pipe and the drill bit. The in-hole drilling tool is essentially used for drilling and anti-reflective outburst eliminating after drilling of soft outburst coal seam. The using method is as follows: after the drilling construction is finished, a water supplier with a pressure release valve is used for starting a high-pressure pumping station to improve the pressure and the flux for water supply; high-pressure water current at the pumping station drives the slotting and punching valve to act for closing an axial liquid passage and opening a radial liquid passage; and high-pressure jet current realizes slotting or punching through a cutting nozzle or a punching nozzle. The invention has novel design and easy operation, is safe and reliable, improves the outburst elimination efficiency and realizes the integrated operation of drilling, slotting or punching and outburst eliminating.

Owner:HENAN POLYTECHNIC UNIV

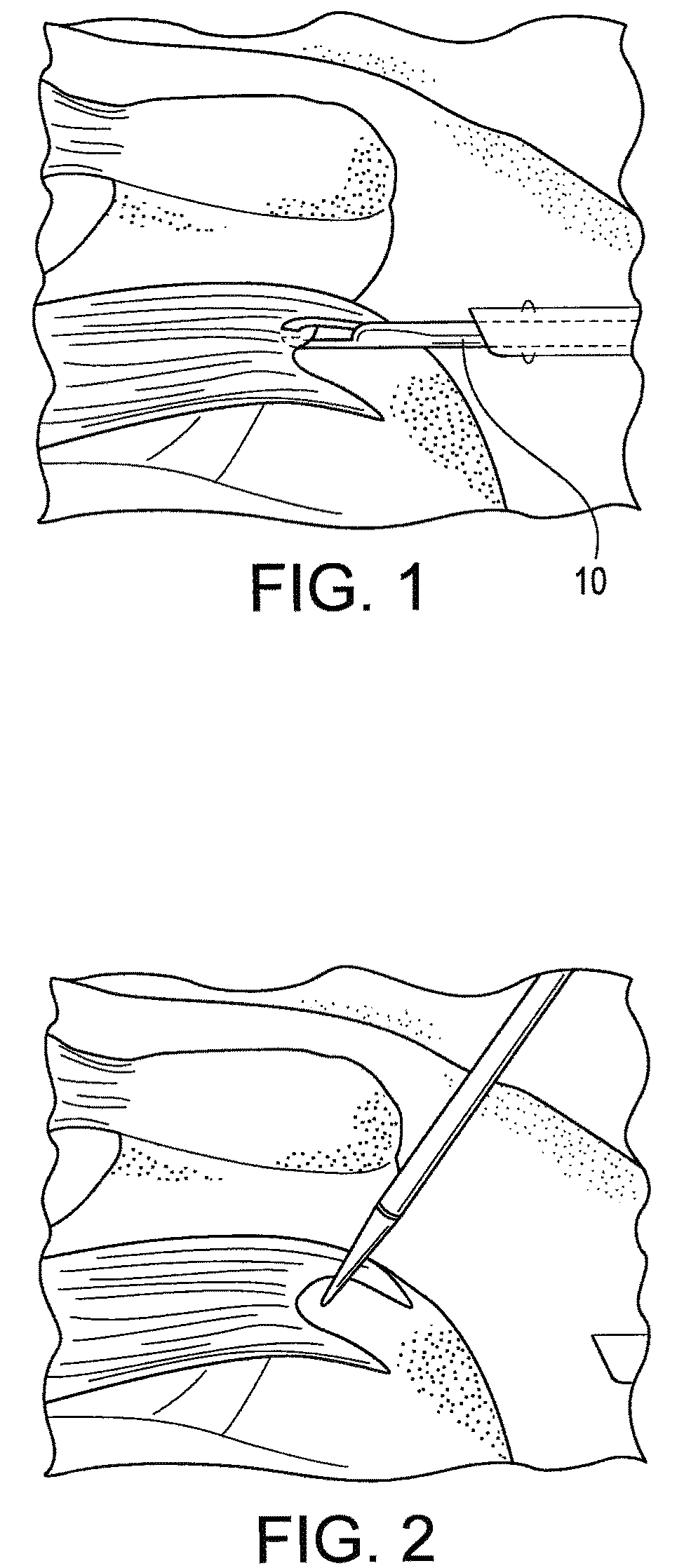

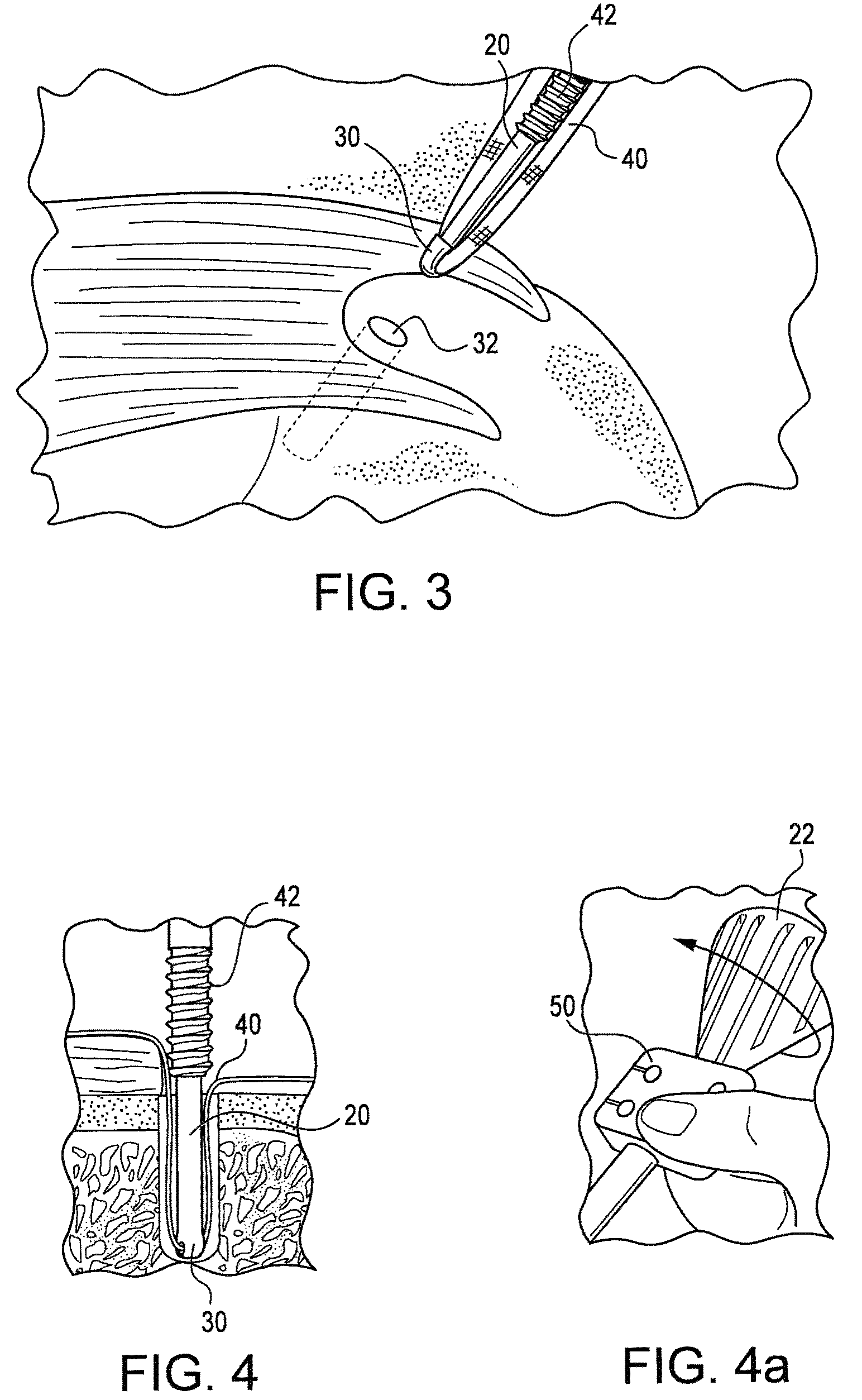

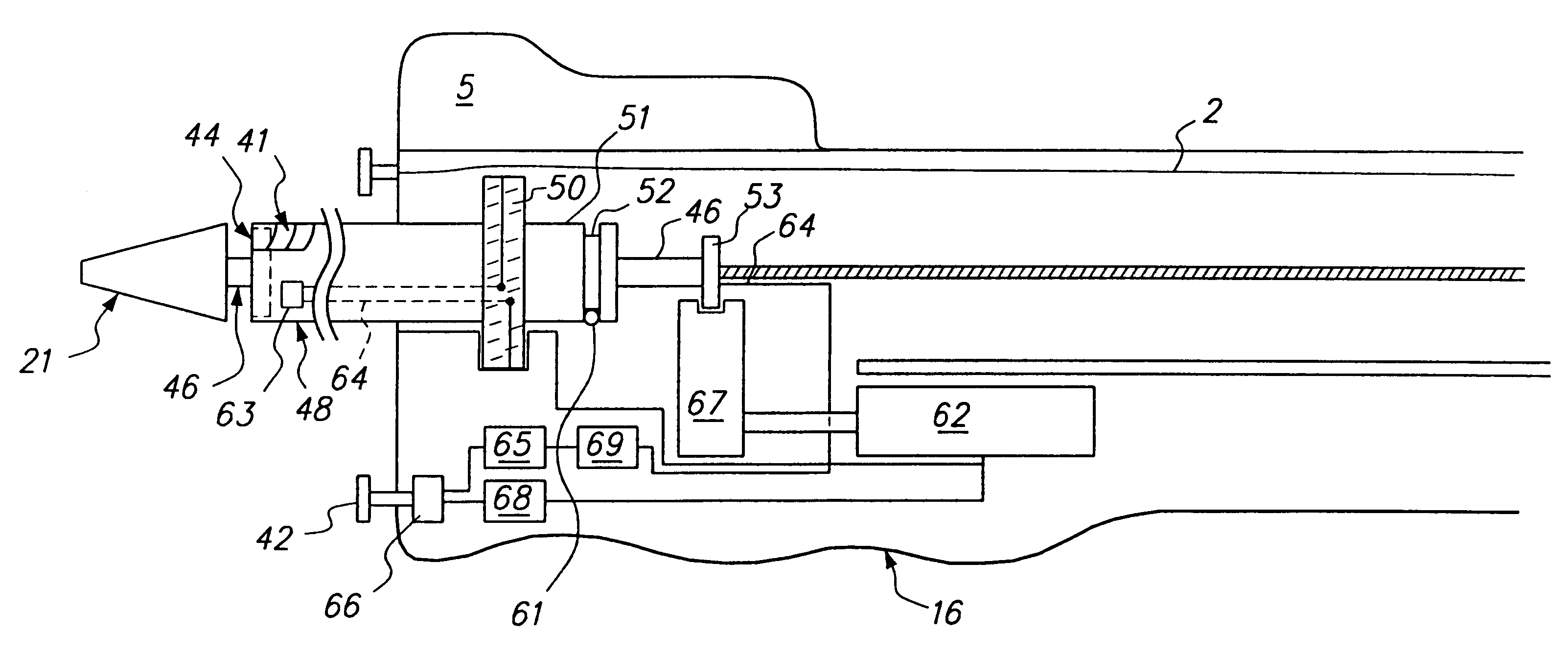

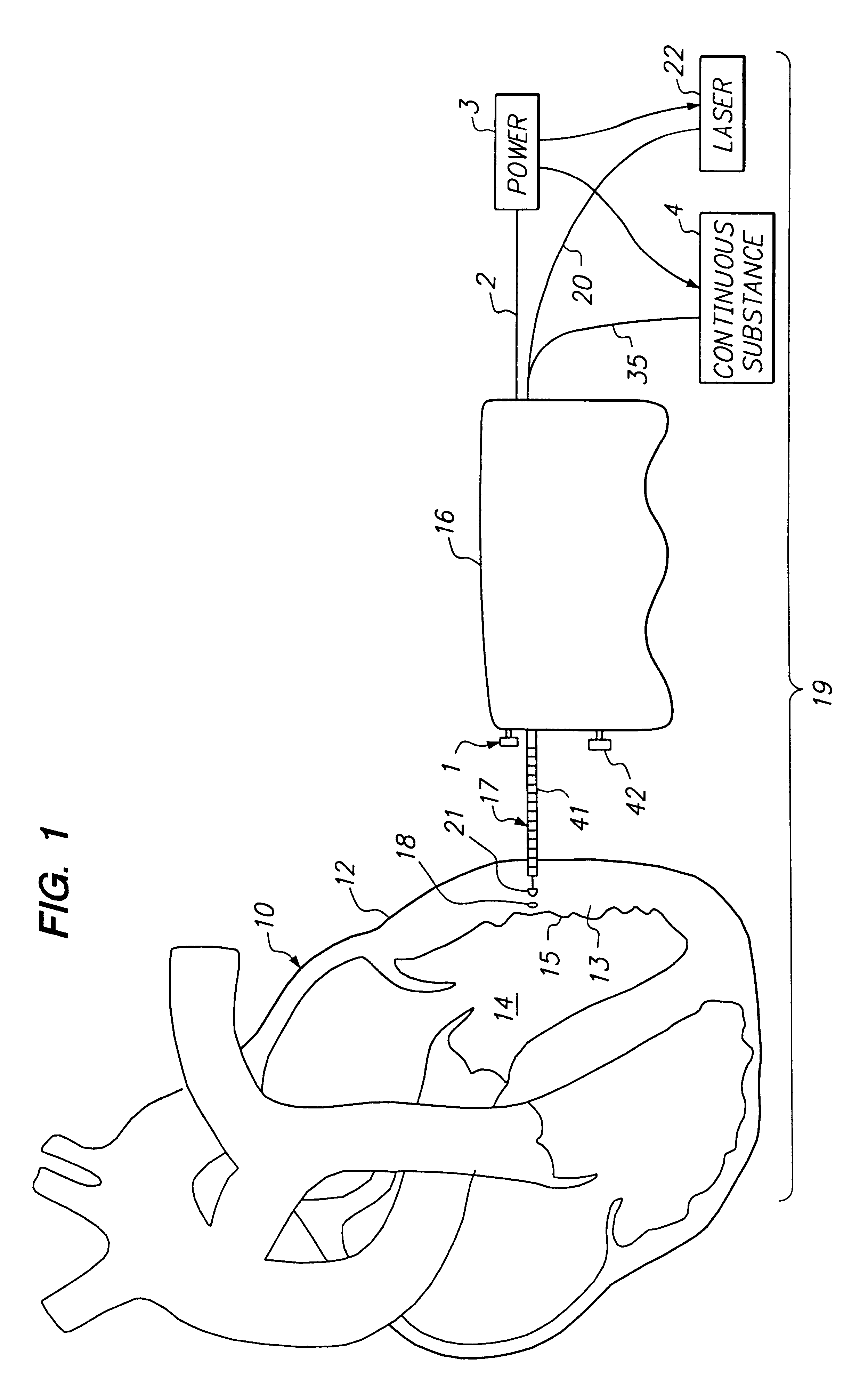

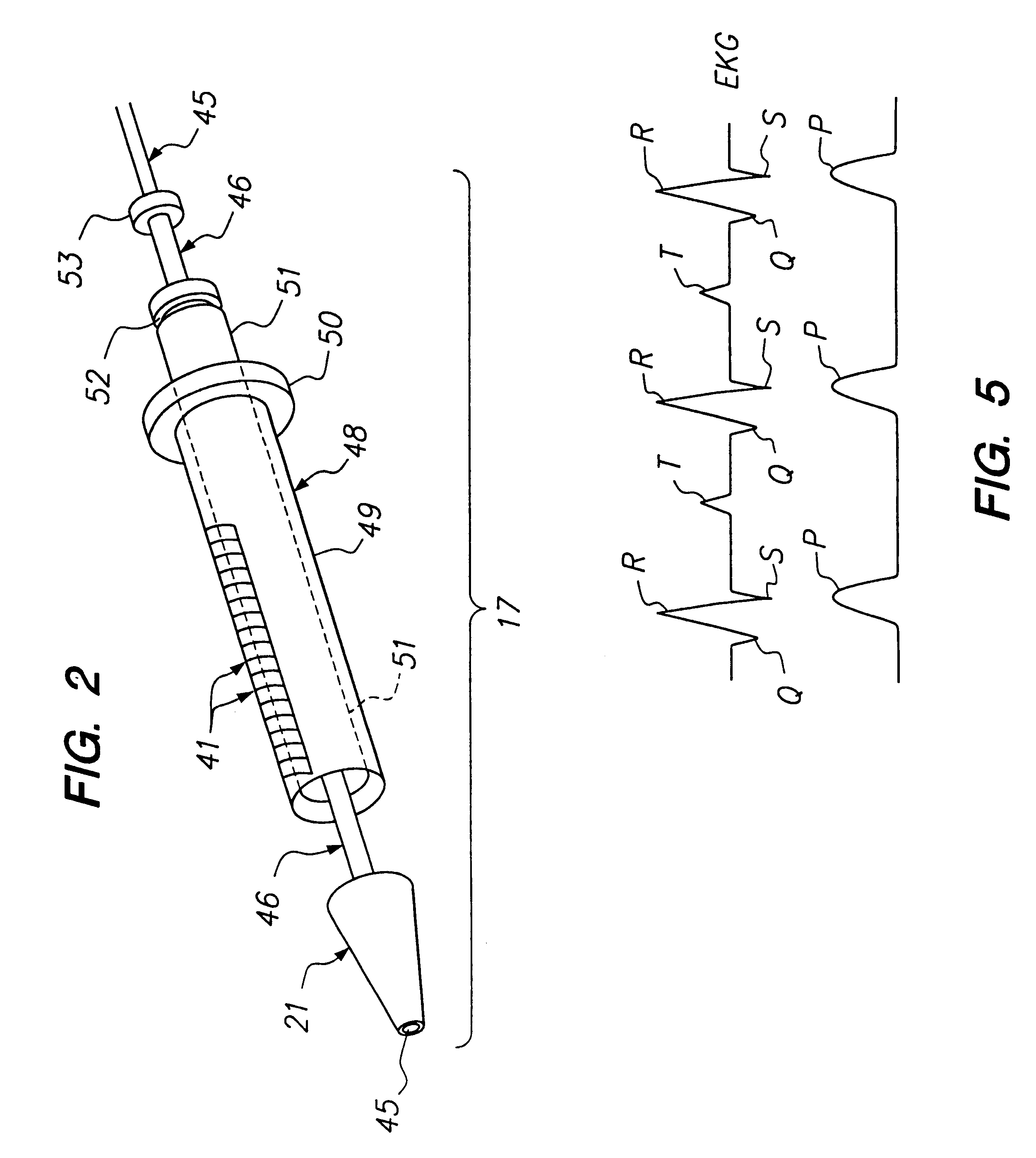

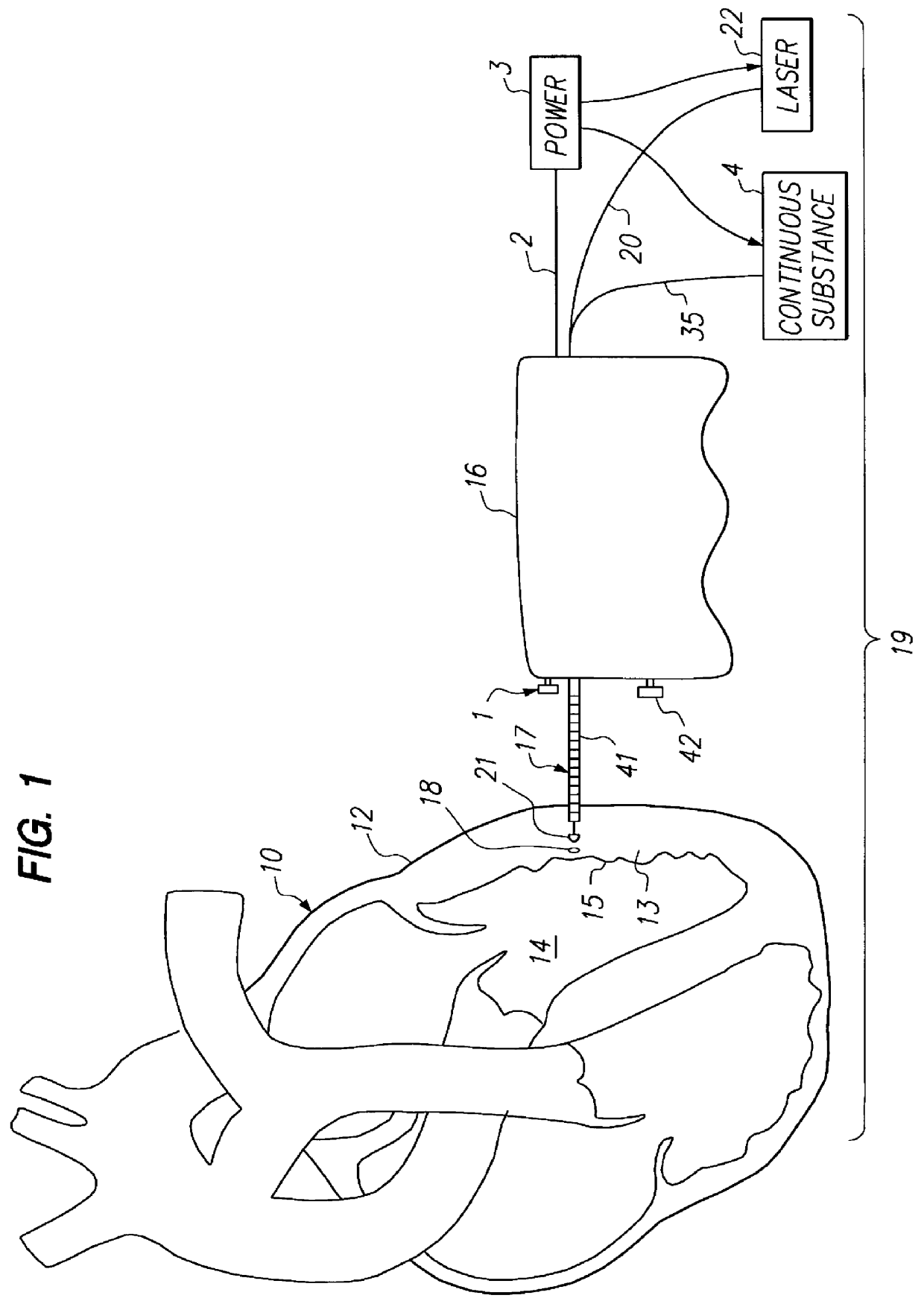

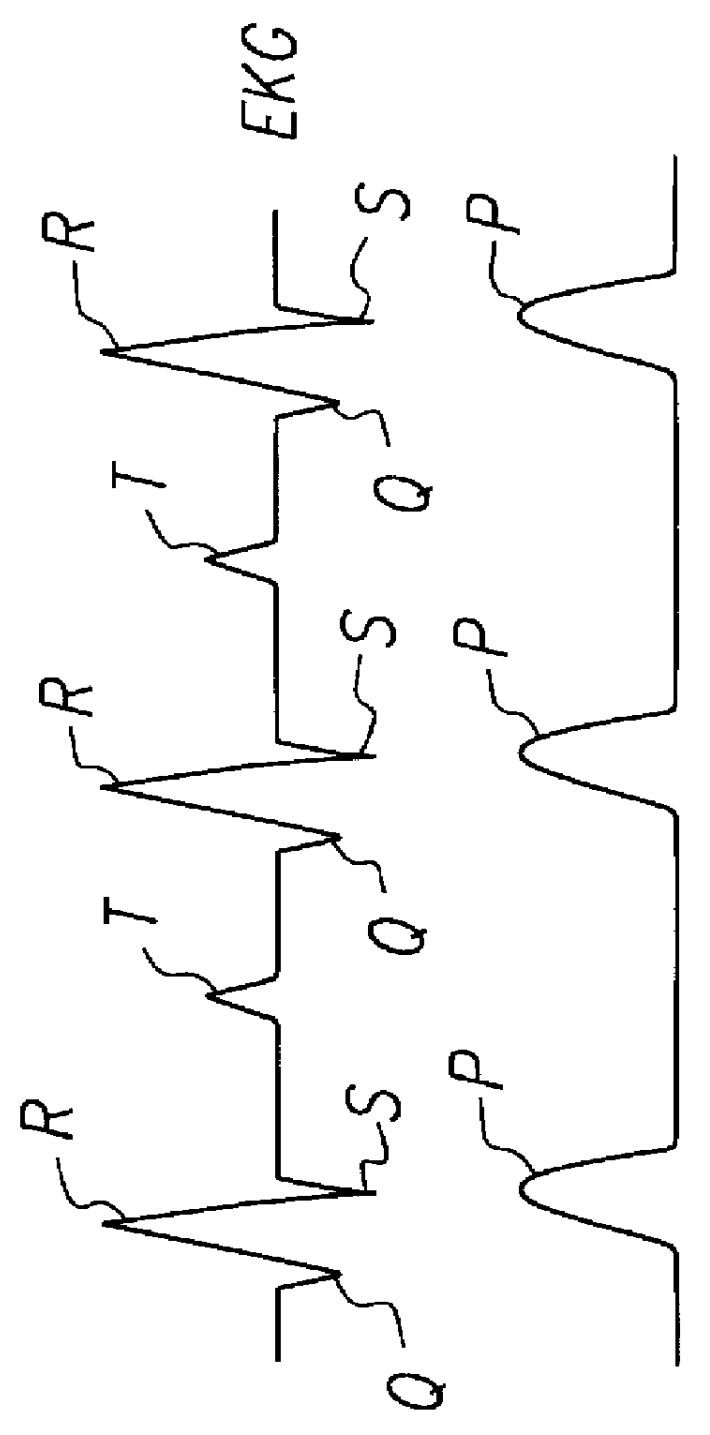

Method and apparatus for creation of drug delivery and/or stimulation pockets in myocardium

An apparatus and method for creating drug-filled pockets within muscle tissue, such as myocardium of the heart for increasing angiogenesis. More particularly, the apparatus has an excising assembly with a dilator tip for penetrating and advancing through the surface and body of a muscle or organ, such as the heart. Preferably, the dilator tip has a low level laser optical fiber emission to ease the passage of the excising assembly and provide thermal damage which also stimulates angiogenesis. More preferably, the dilator tip also disperses a pharmacologically active substance as the apparatus is passed through the tissue and / or creates pockets. The excising assembly is connected to a hand-held control device from which the operator pushes a switch to activate a punching mechanism within the excising assembly. The punching mechanism cuts a discrete piece of muscle tissue and traps it within the excising assembly leaving a pocket in the remaining muscle tissue. The excising assembly may also optionally release a bolus of the pharmacologically active substance into the pocket so created. Most preferably, there is a timing mechanism to measure the contraction of the heart, and the timing mechanism is synchronized with the operator's switch on the hand-held device to ensure that the punching occurs at maximum contraction of systole. A measurement guide determines how much excised tissue is trapped in the reservoir of the excising assembly. At a threshold level of filling, the surgeon will remove the excising assembly from the hand-held control device and open the punching mechanism for release of tissue. More preferably, the threshold level of filling will automatically turn off the switch to the punching mechanism to indicate to the surgeon the need to empty the excising assembly of tissue.

Owner:ECLIPSE SURGICAL TECH

Finishing apparatus

InactiveUS6928259B2Easily and rapidly finishVariations in punched hole positions can be suppressedElectrographic process apparatusArticle deliveryPunchingImage formation

A finishing apparatus 4 has an image forming apparatus 1 for forming an image by an image formation module and a finisher 3 for finishing for a record sheet 2 on which an image is already formed from the image forming apparatus 1. The finisher 3 has a punching unit 5 for punching a hole in the record sheet 2. The finishing apparatus 4 further includes mark recorder 6 for recording a mark M to determine the punch position on the record sheet 2 before punching.

Owner:FUJIFILM BUSINESS INNOVATION CORP

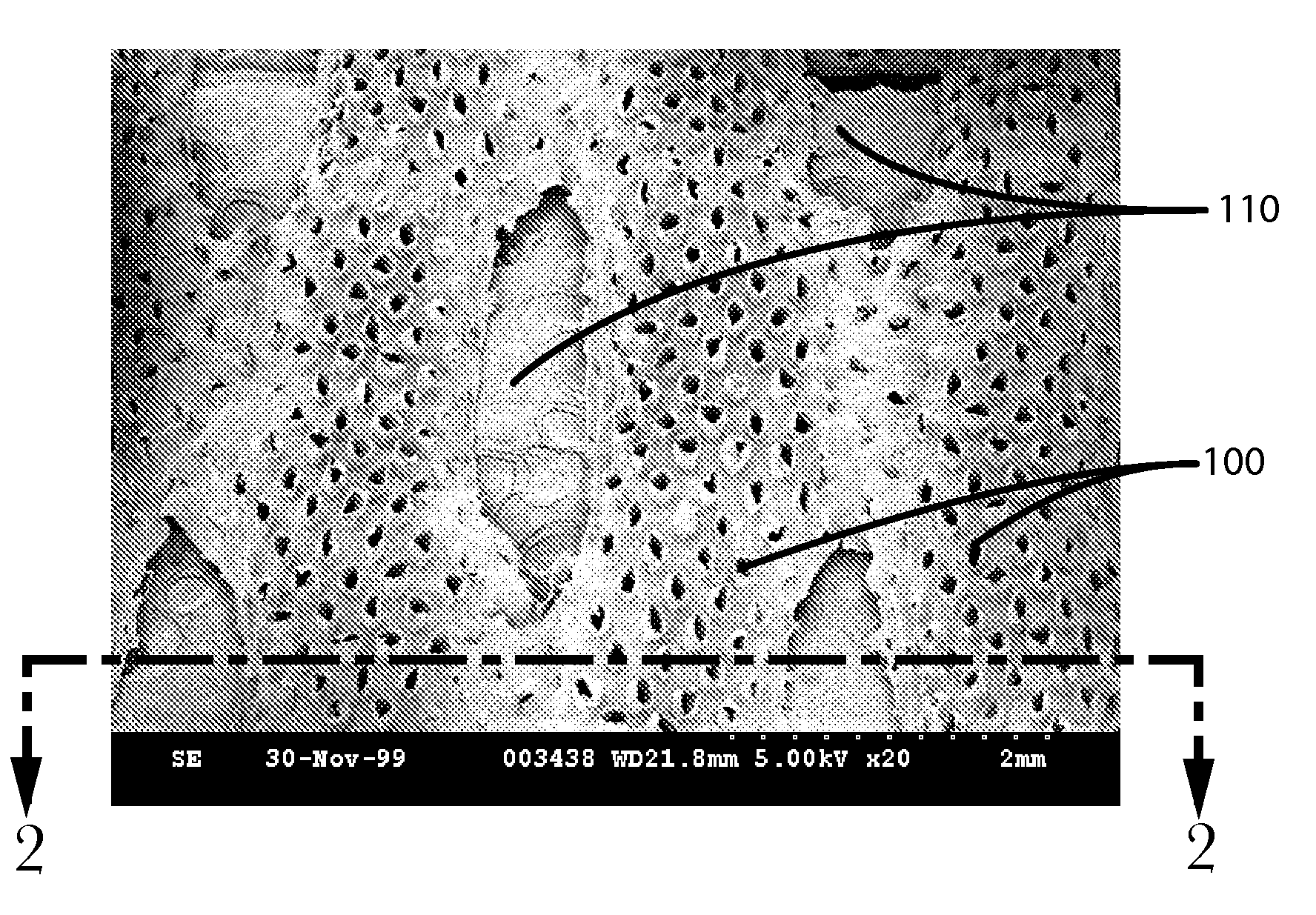

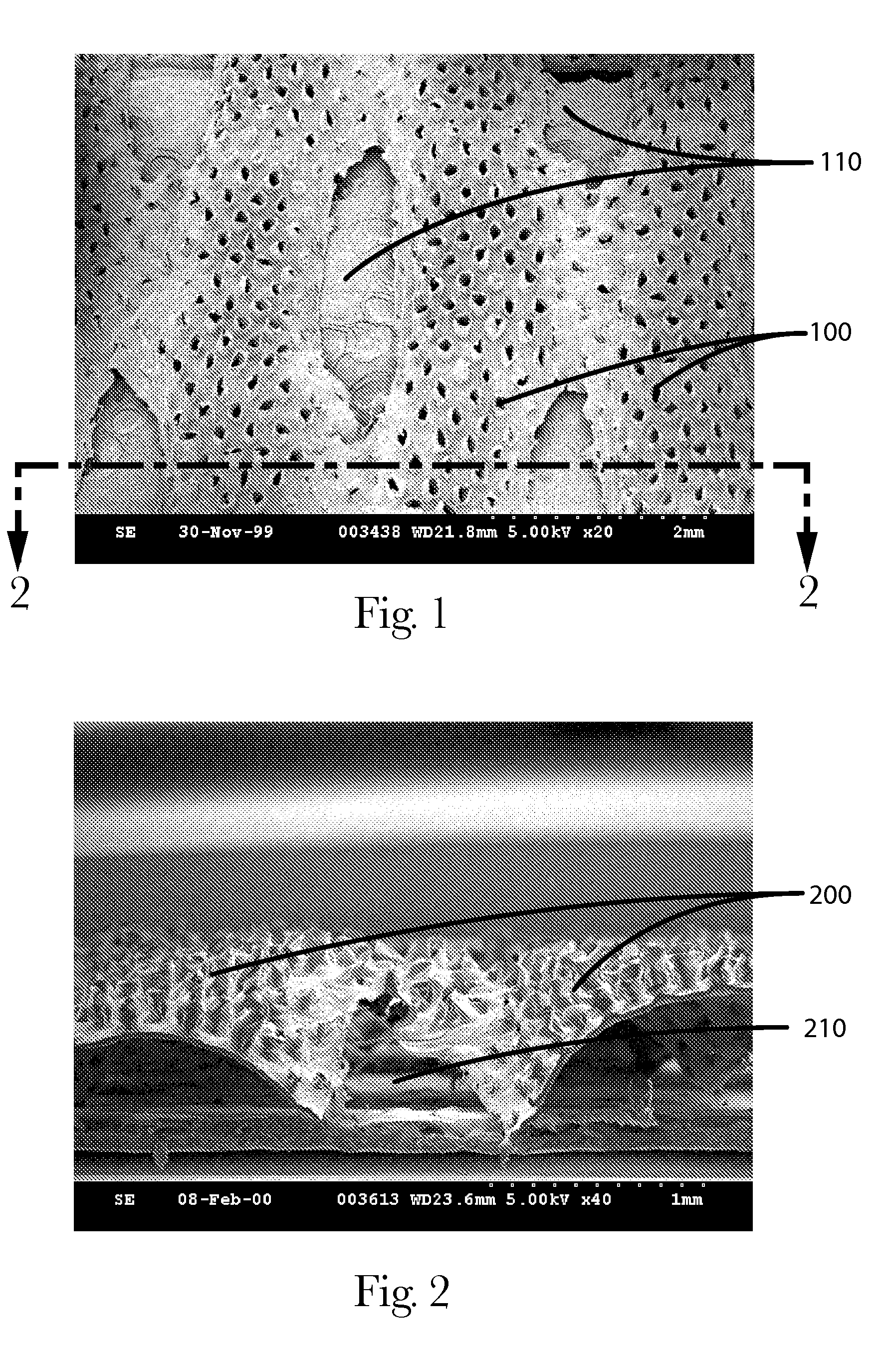

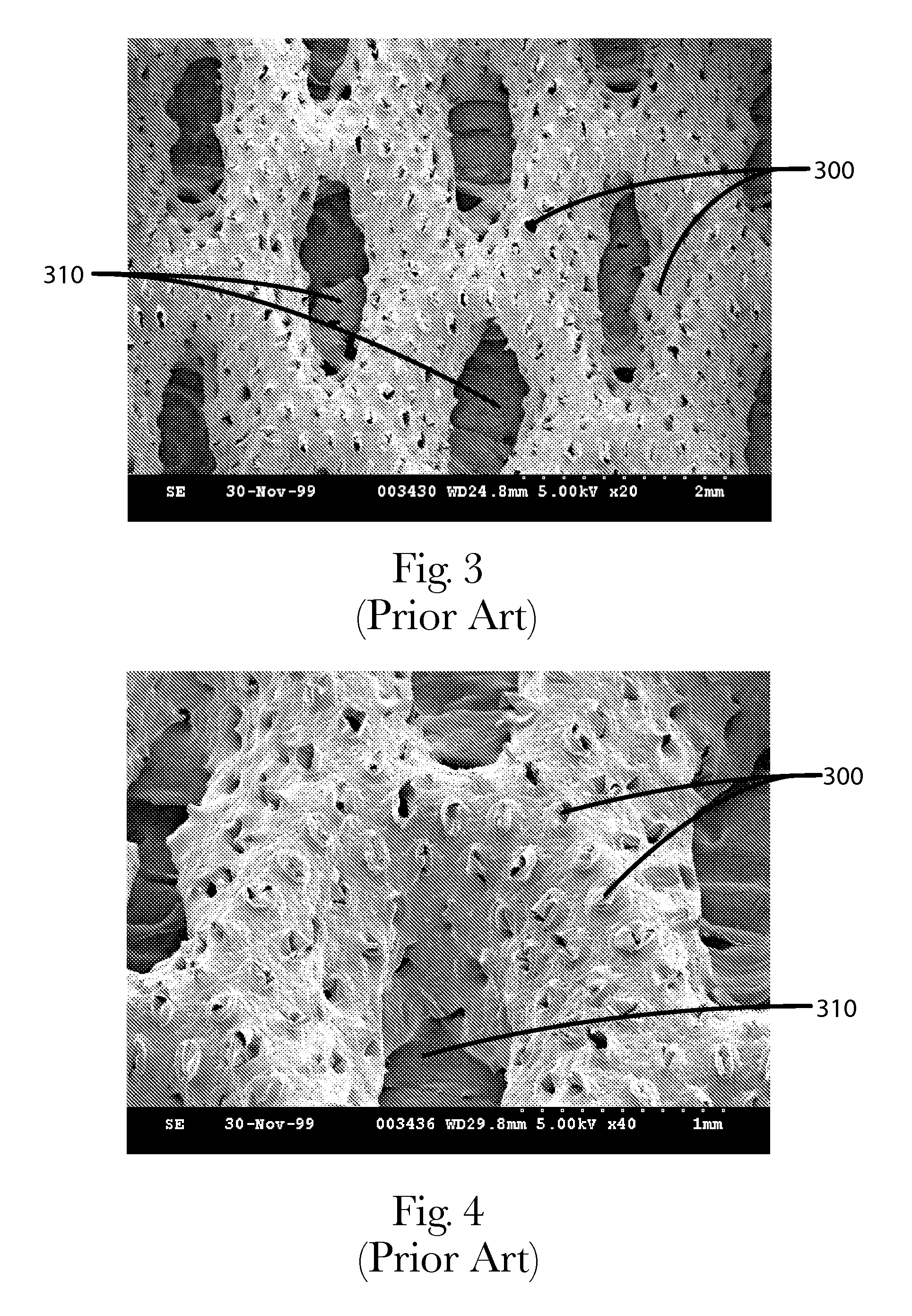

Apertured polymeric film webs and absorbent articles using such webs

A method for making an apertured polymeric film web, the method comprising the steps of:a. providing a polymeric film web;b. providing a first process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, flocking, ultrasonics, printed hair, brushing, and combinations thereof;c. providing a second process, different from the first process, the second process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, ultrasonics, stretch rupturing, hydrocutting, hydrosonics, slitting, ring-rolling, and combinations thereof;d. forming three dimensional surface structures in the polymeric film web by the first process; ande. forming fluid transport apertures in the polymeric film web by the second process.

Owner:THE PROCTER & GAMBLE COMPANY

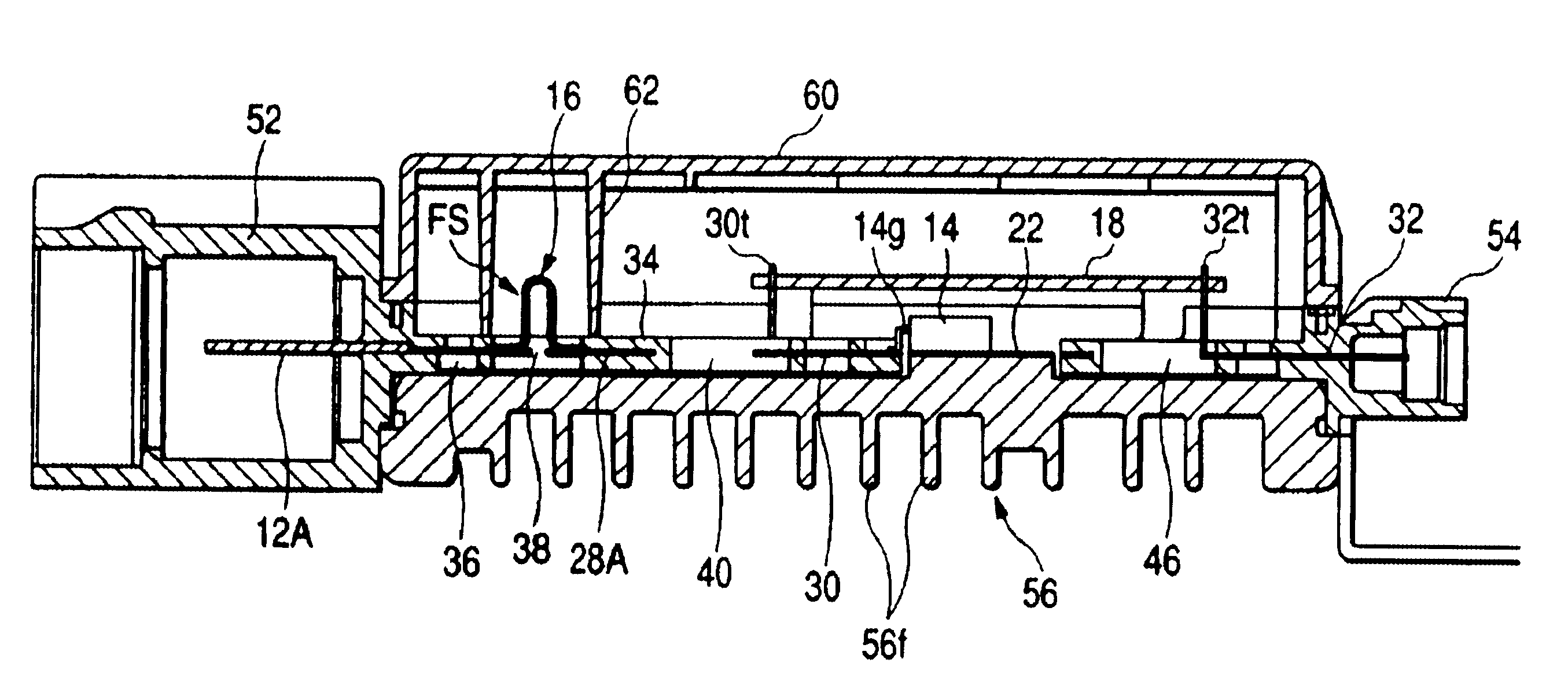

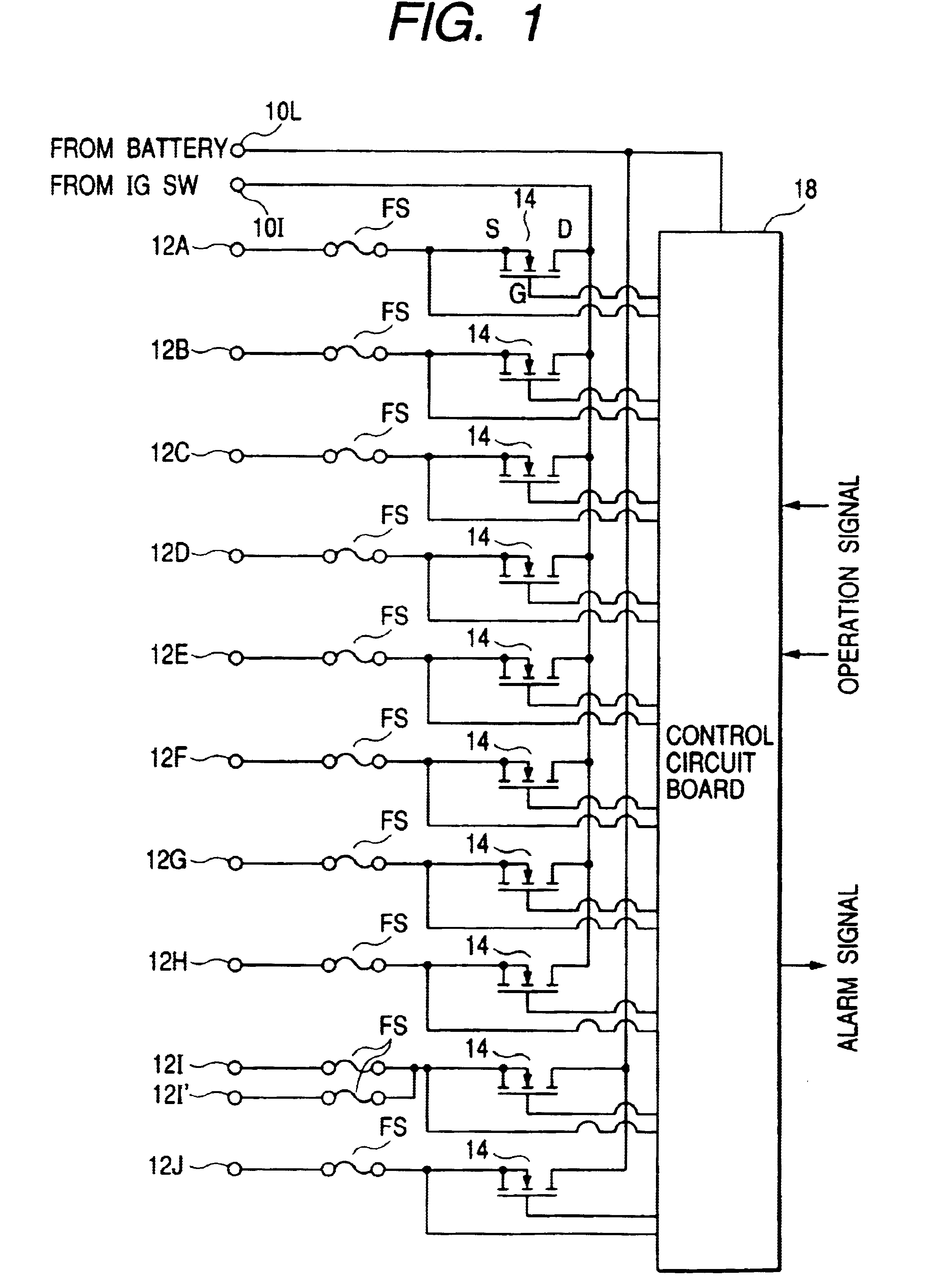

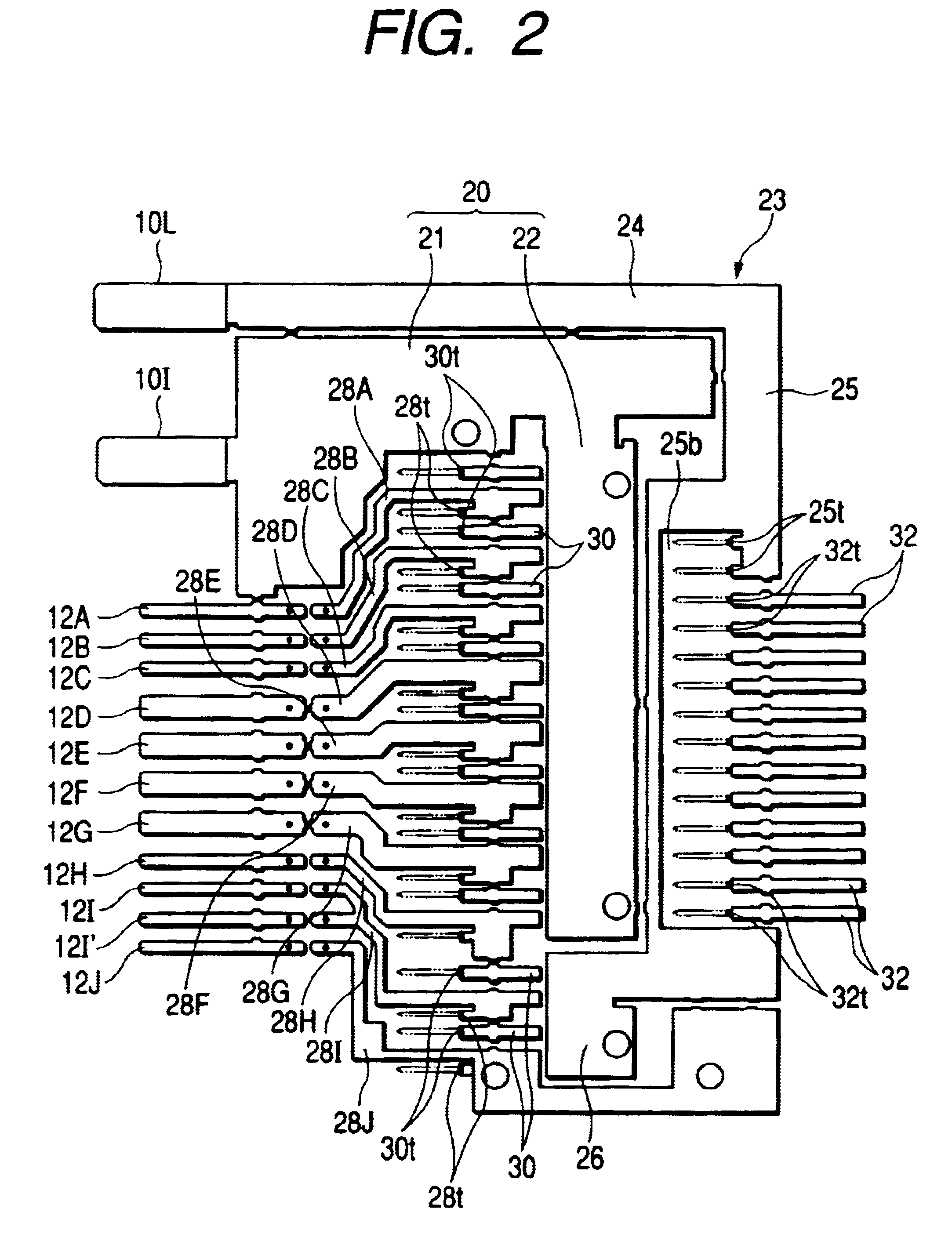

Power distributor for a vehicle and production method thereof

InactiveUS6724627B2Simple structureAssembly precisionSemiconductor/solid-state device detailsSolid-state devicesPunchingDistributor

In the power distributor using a semiconductor switching element, input terminals 10I and 10L, output terminals 12A-12J, connected to the element, and more preferably, the board terminals 30 and 32, are structured by a metallic plate, and arranged on the same plane perpendicular to the plate thickness. The metallic plate can be integrated by the resin mold, thereby the structure can be greatly simplified. The metallic plate can be produced by a greatly simple method by which, after the punching out of the metallic plate and the molding of the resin mold, a predetermined portion of the metallic plate is cut and the semiconductor switching element is mounted, and it can contribute to also the reduction of the cost.

Owner:AUTONETWORKS TECH LTD +2

Battery grid

InactiveUS6953641B2Extend battery lifeImprove adhesionElectrode carriers/collectorsLead-acid accumulator electrodesPunchingEngineering

A method of forming battery grids or plates that includes the step of applying a lead alloy coating to a continuous strip of interconnected battery grids formed from a lead alloy grid material is disclosed. The battery grids may be formed by a continuous battery grid making process such as strip expansion, strip punching, or continuous grid casting. In one version of the method, the grid wires of a continuous strip of battery grids produced by a punching process are immersed in a melt of the lead alloy coating. In another version of the method, the grid wires of a continuous strip of battery grids produced by a punching process are deformed such that the grid wires have a cross-section other than the rectangular cross-section produced by the punching process and the strip of interconnected grids is immersed in a melt of the lead alloy coating. The method increases the cycle life of a battery.

Owner:CPS TECH HLDG LLC

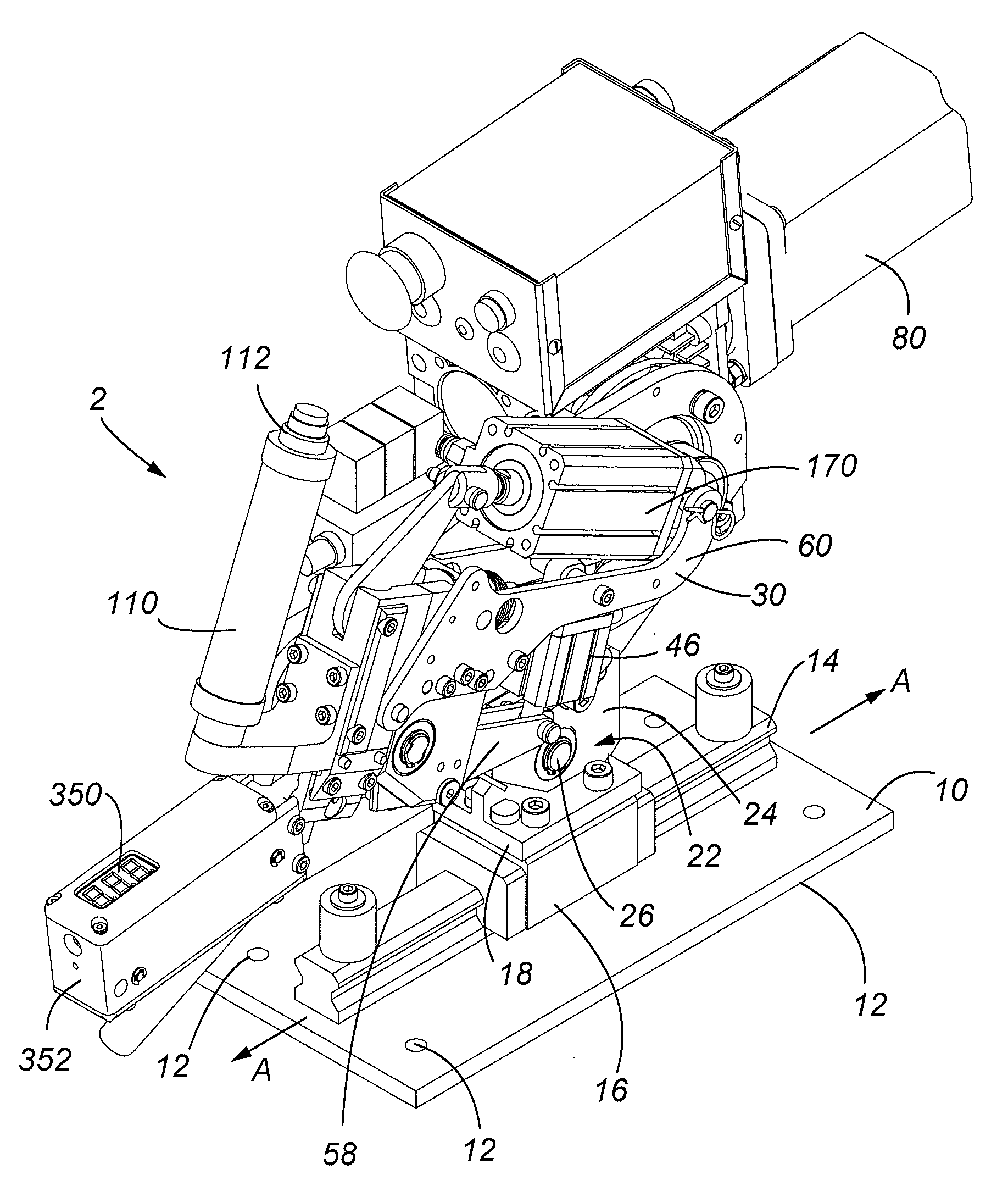

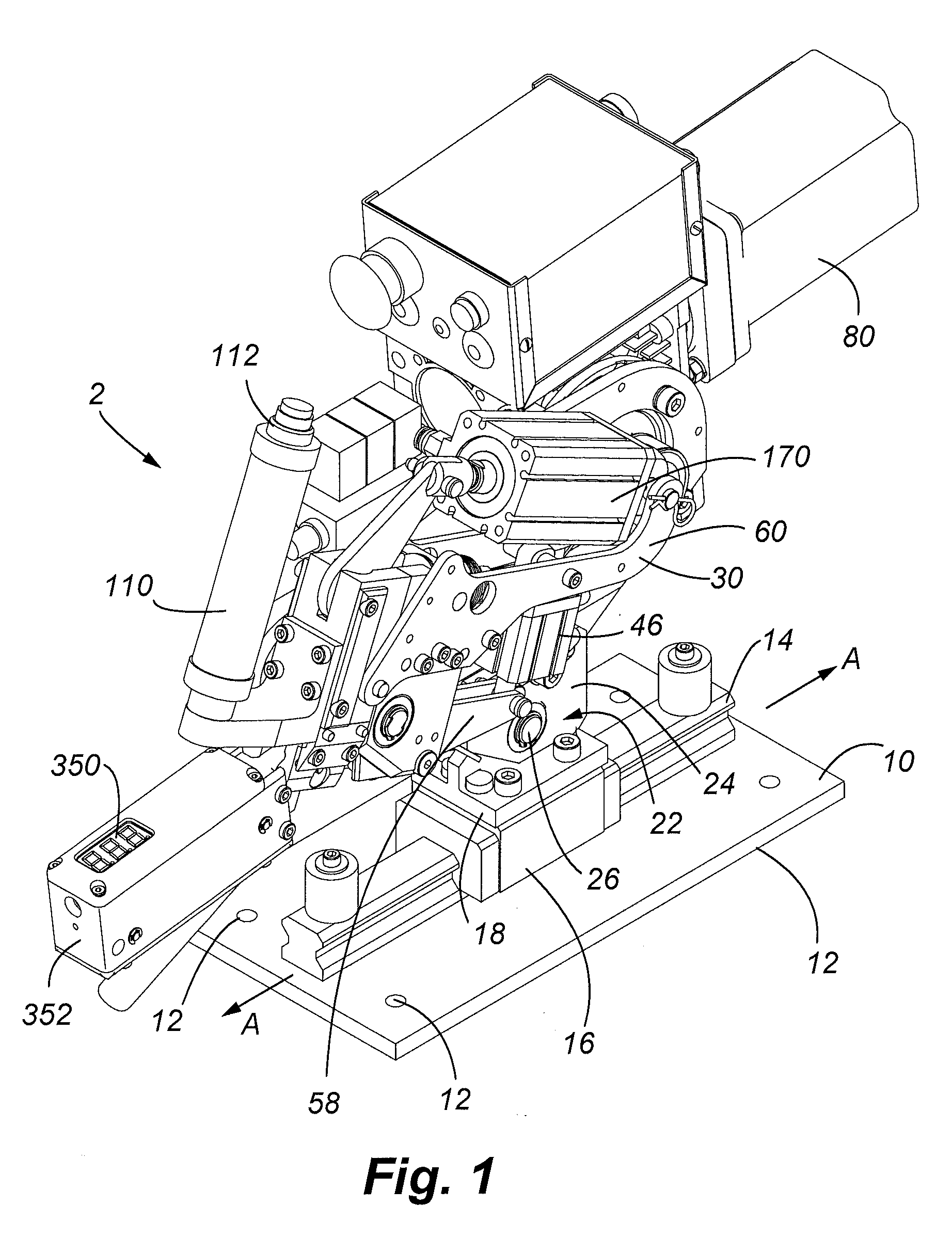

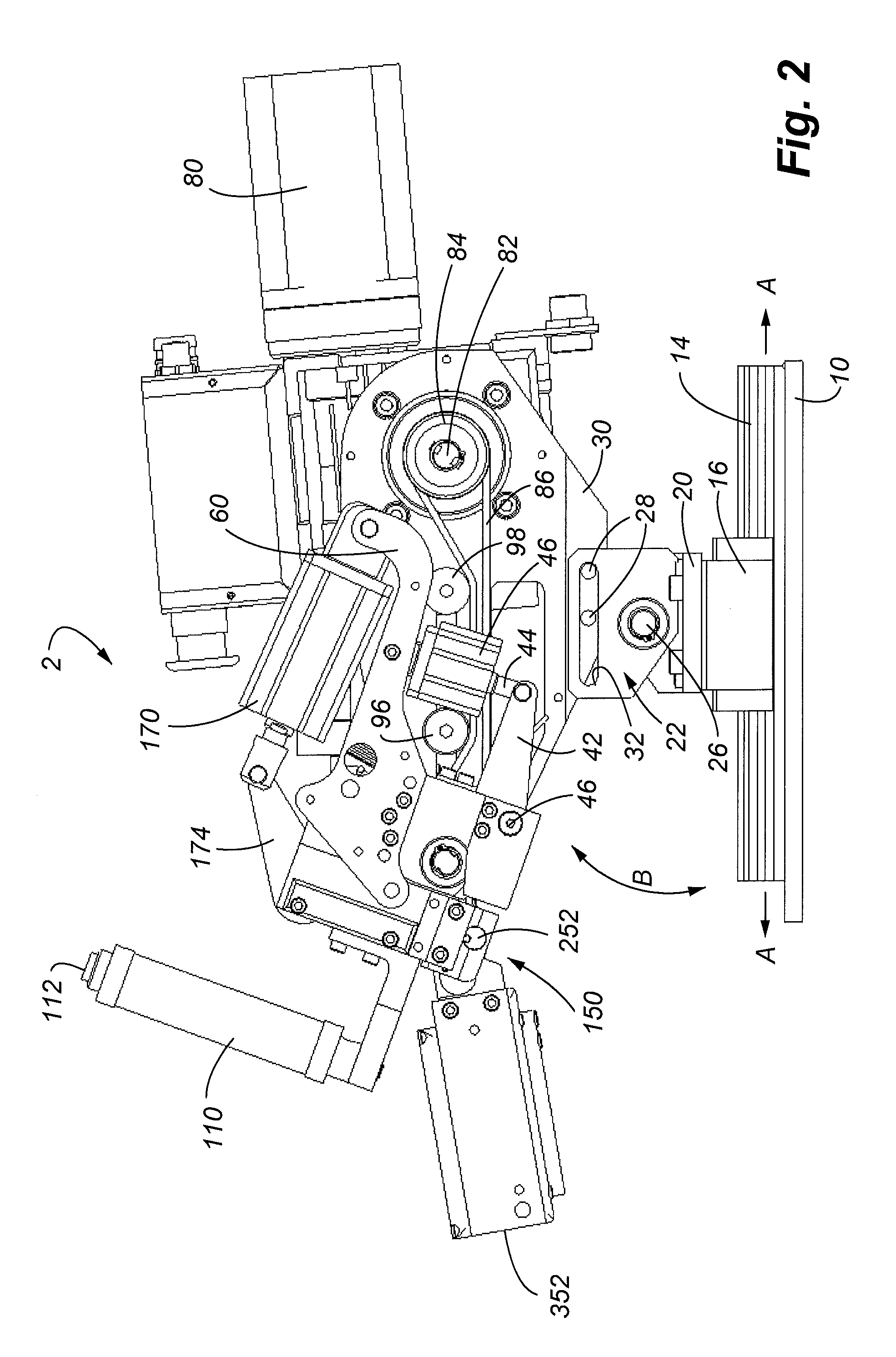

Stationary band clamping apparatus

ActiveUS20090114308A1Easy accessEnhances operational repeatabilityWire articlesBinding material applicationPunchingEngineering

A tensioning device is provided that includes a separable punching and cutting mechanism. Provided is an impact head that holds a buckle while the band that resides within the buckle is tensioned. After a predetermined tension is achieved, a mechanism is used to lock the band with respect to the buckle then to cut the band. Various data related to tension and cutting performance may also be outputted by the invention.

Owner:BAND IT IDEX

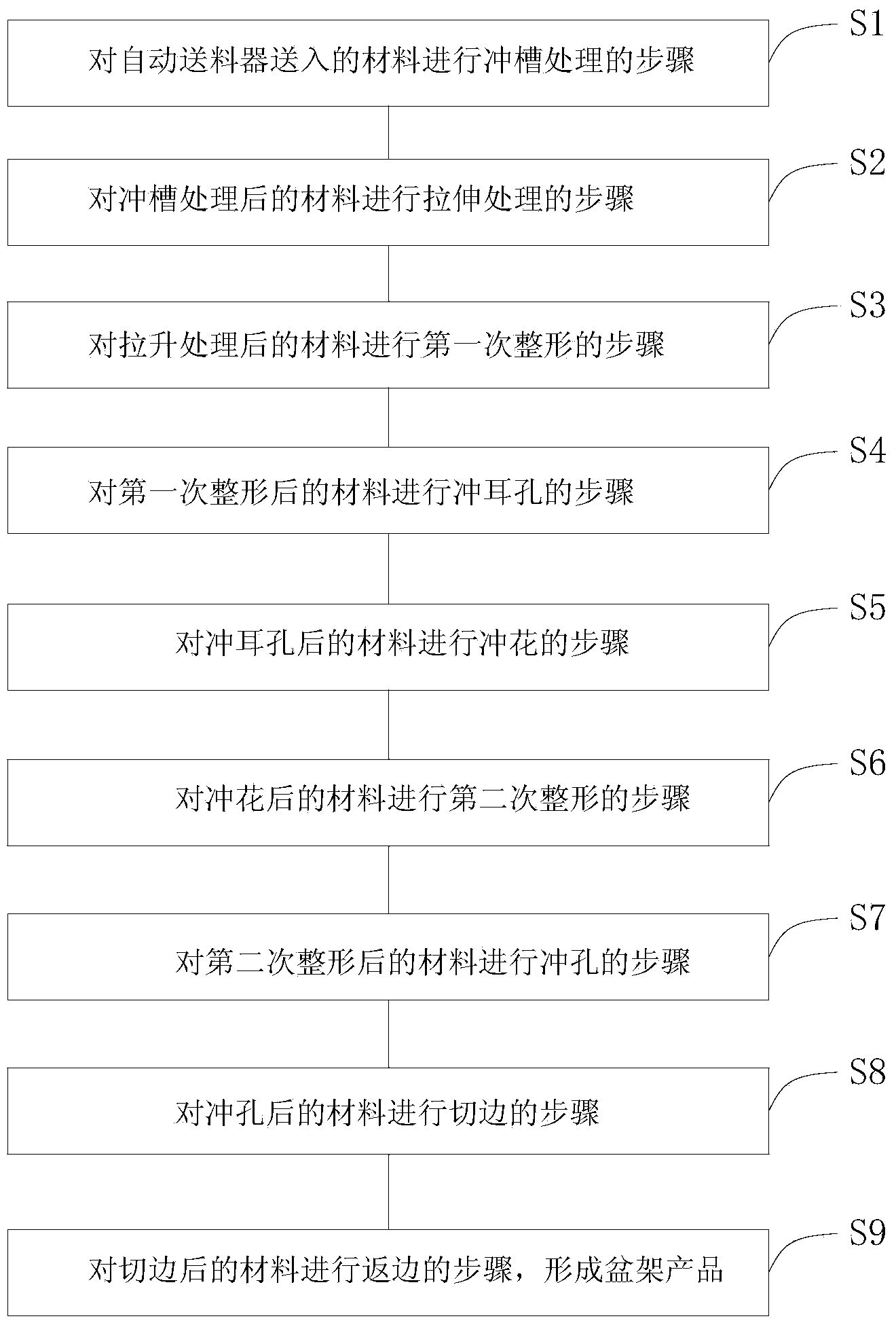

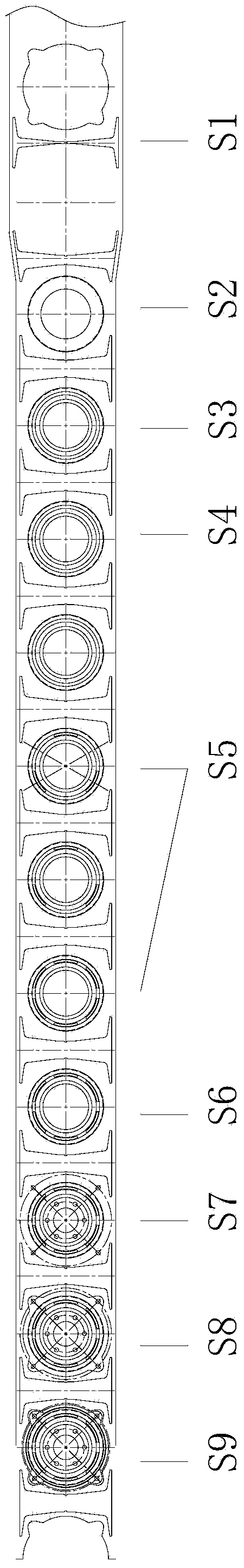

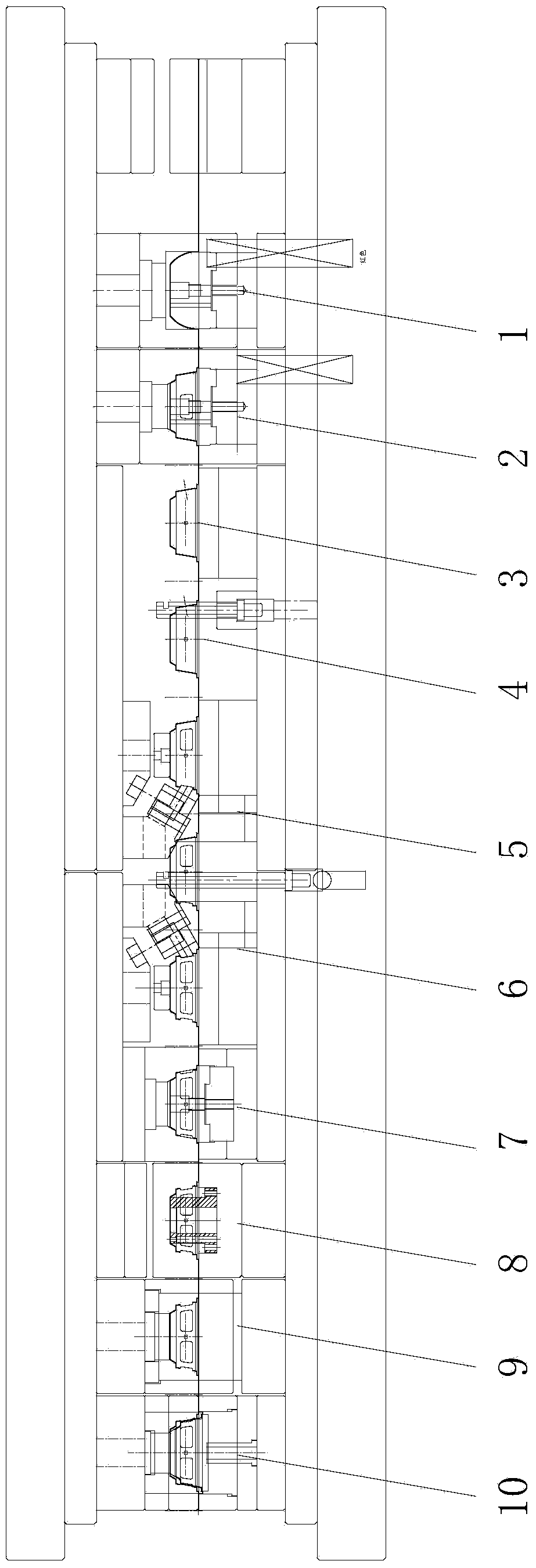

Basin stand automatic feeding progressive die production technology

The invention relates to the technical field of dies, and discloses a basin stand automatic feeding progressive die production technology. According to the basin stand automatic feeding progressive die production technology, an automatic feeder is adopted to send a material to a set of a progressive die to be subjected to the following steps, including, S1, performing groove punching treatment on the material sent by the automatic feeder, S2, stretching the material after the groove punching treatment, S3, shaping the stretched material for the first time, S4, performing ear-hole punching on the material after the first shaping, S5, performing pattern punching on the material after the ear-hole punching, S6, shaping the material for the second time after the pattern punching, S7, punching the material after the second shaping, S8, trimming the material after the punching, and S9, performing side returning on the trimmed material to form a basin stand product. The basin stand automatic feeding progressive die production technology greatly improves production efficiency and reduces production cost.

Owner:启东市天汾电动工具技术创新中心

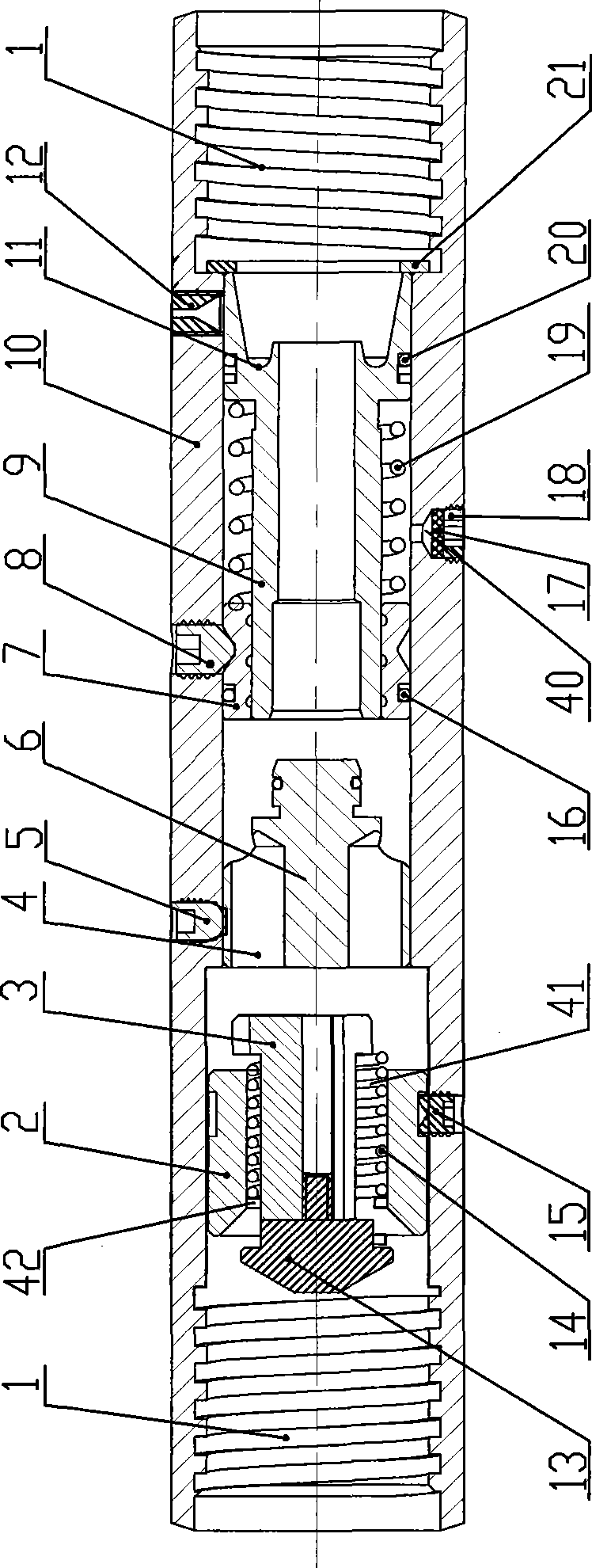

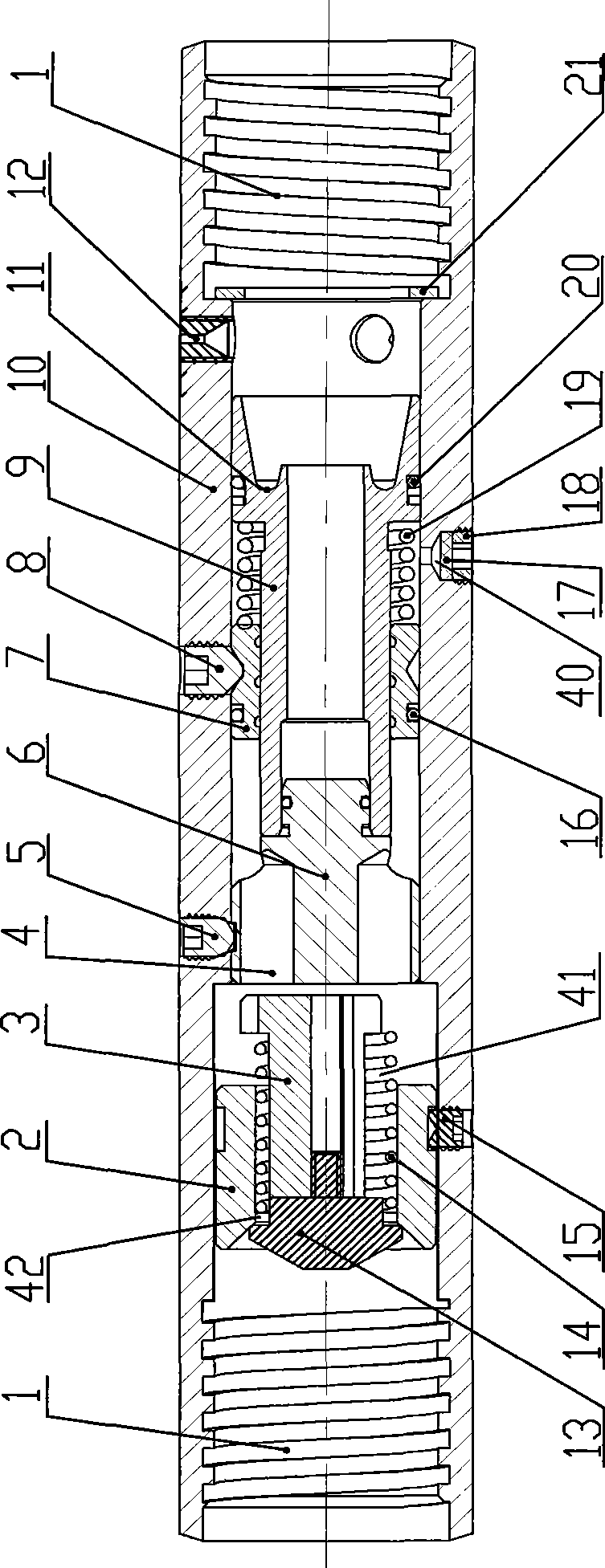

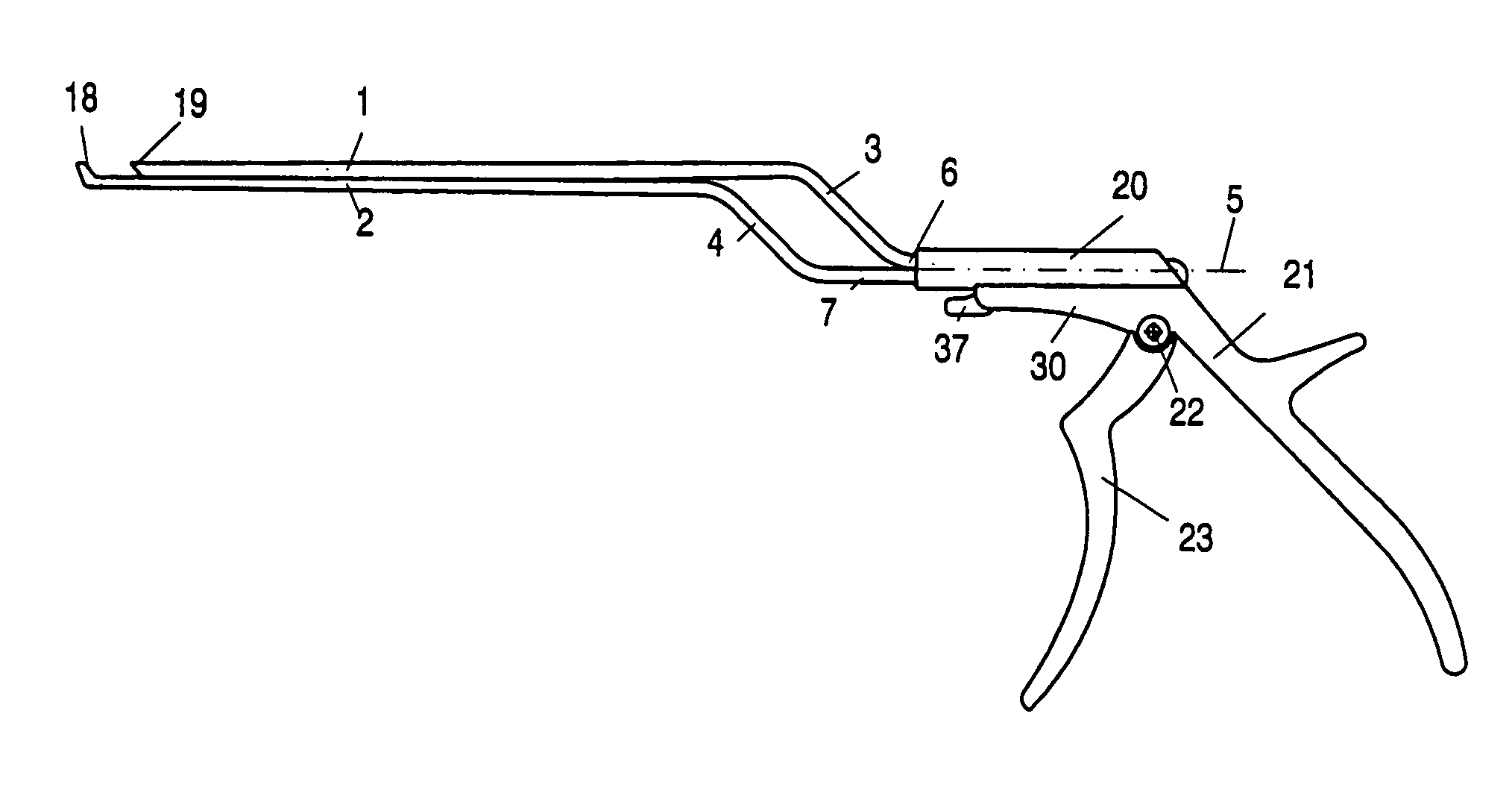

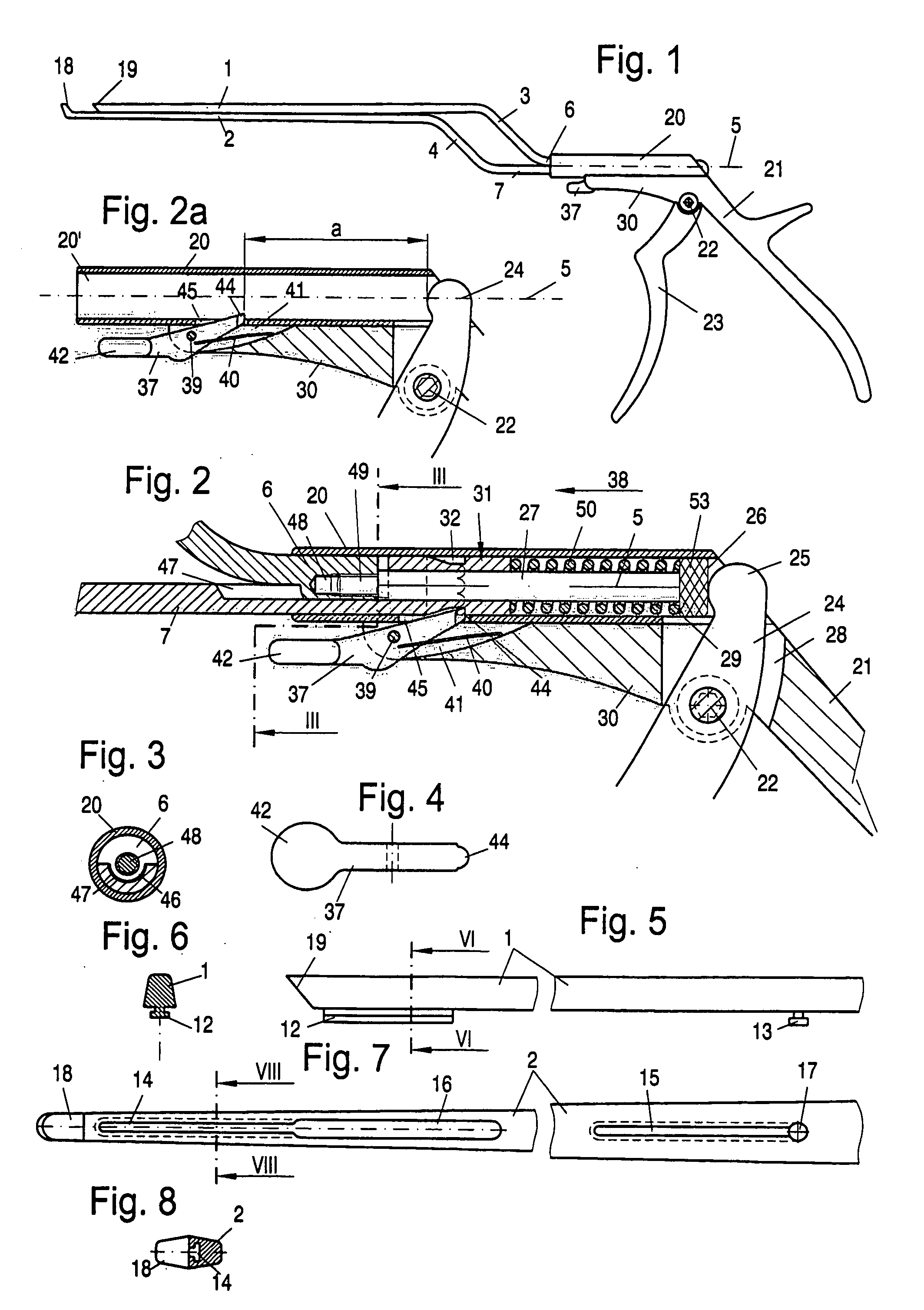

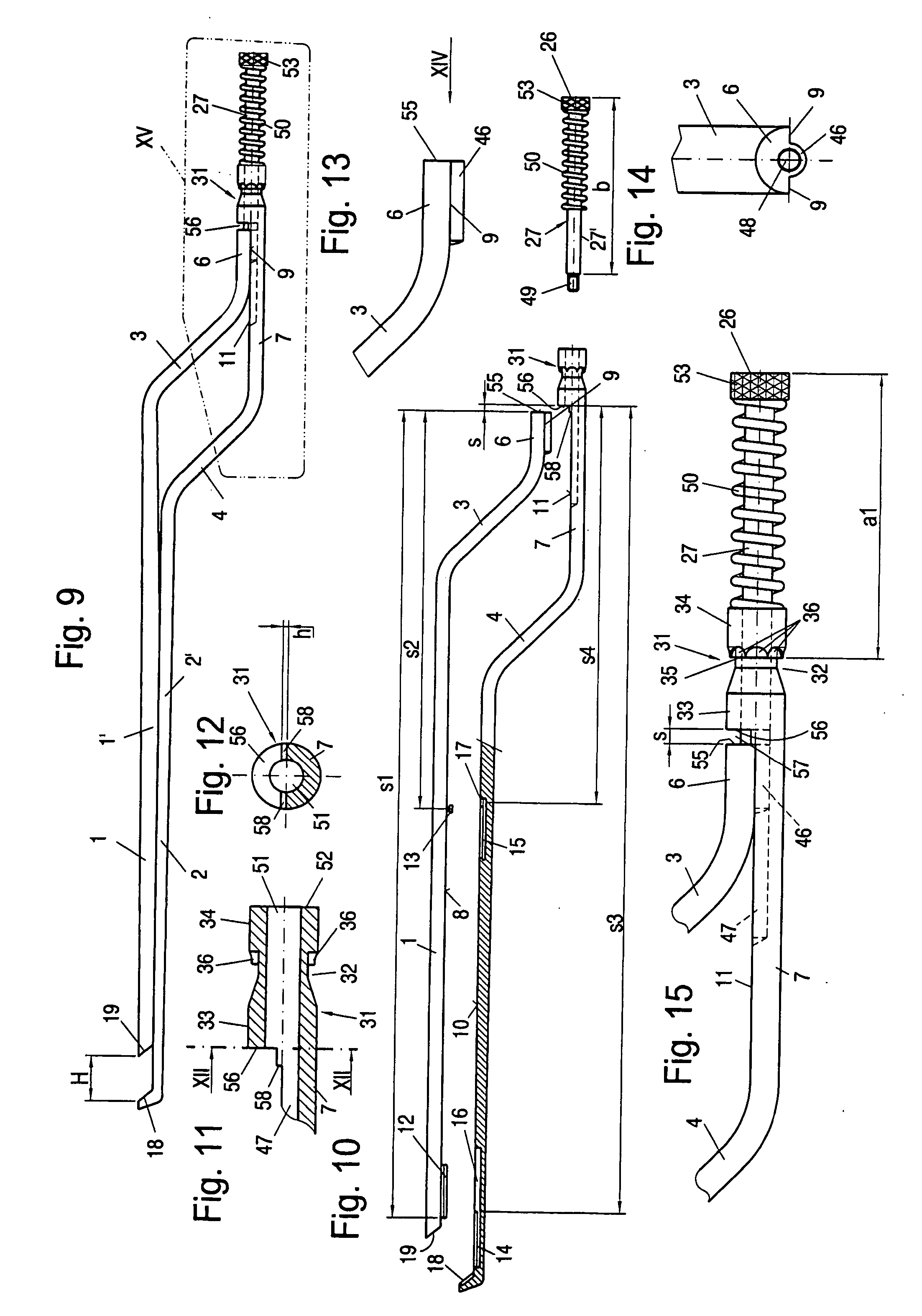

Surgical punching instrument

A surgical punching instrument with a fixed handle (21) is attached to a tubular guide part (20). An actuating lever (23) is mounted on the fixed handle (21) in a pivotingly movable manner and is in connection with a plunger (27) via a short lever arm (24). This plunger is in turn connected to a punching slide (1) and is mounted for actuating same against the action of a compression spring in an axially movable manner in a rearward mounting part (31) of a punching bar (2), which is guided rotatably by an at least partially cylindrical guide section (33, 34) and lockably in different rotated positions in the guide part (20). The punching bar is in contact in the guide part (20) with an axial stop acting in the direction of actuation with a ring shoulder (35) and it is locked in an axially detachable manner. The axial stop, with which the ring shoulder (35) is in contact, comprises a spring-loaded locking lever (37), which passes through a guide slot (45) of the guide part (20) radially into a cylindrical cavity (20′) of the guide part (20), in which the guide section (33, 34) of the mounting part (31) of the punching bar (2) is guided.

Owner:JORG WENZLER MEDIZINTECHN

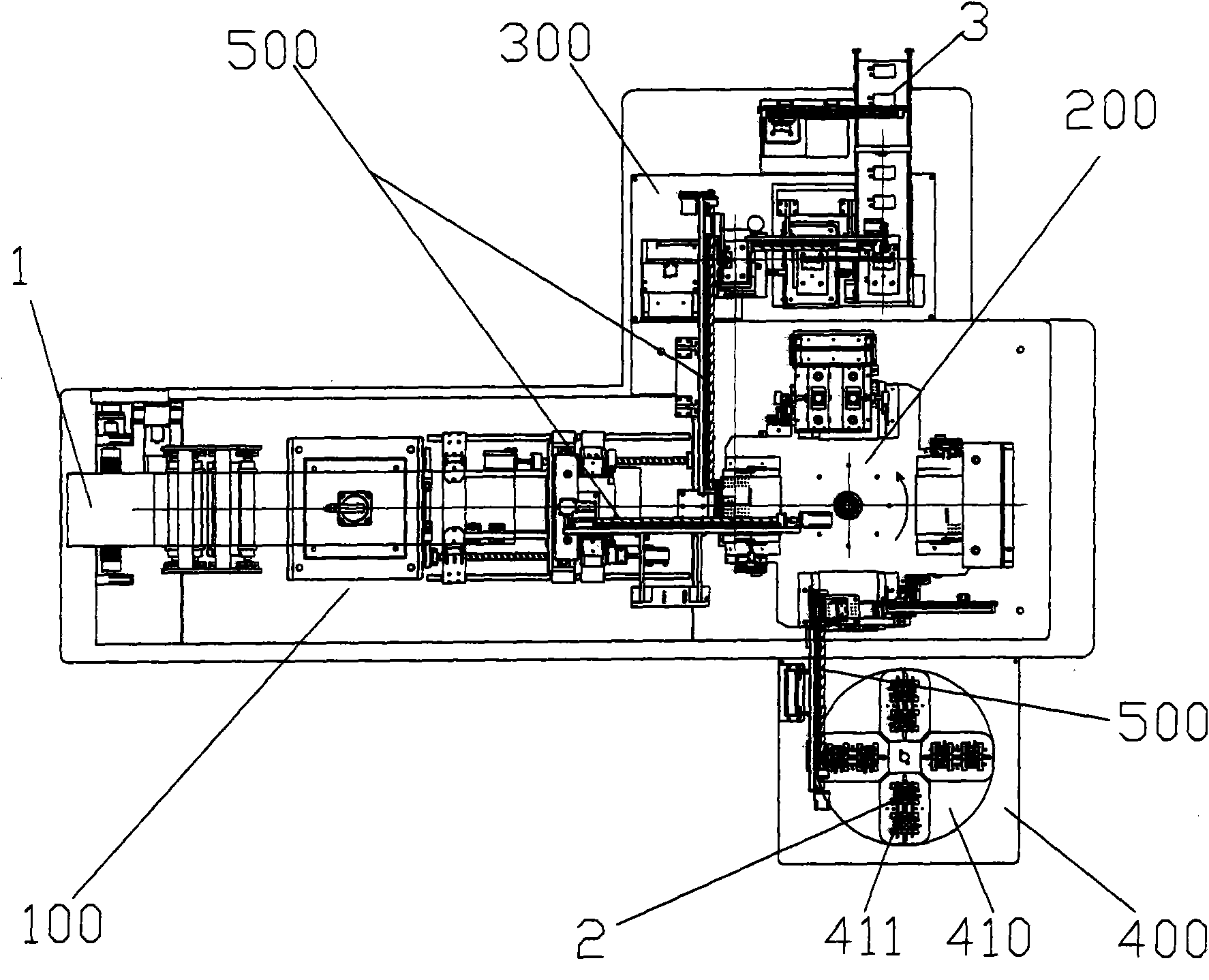

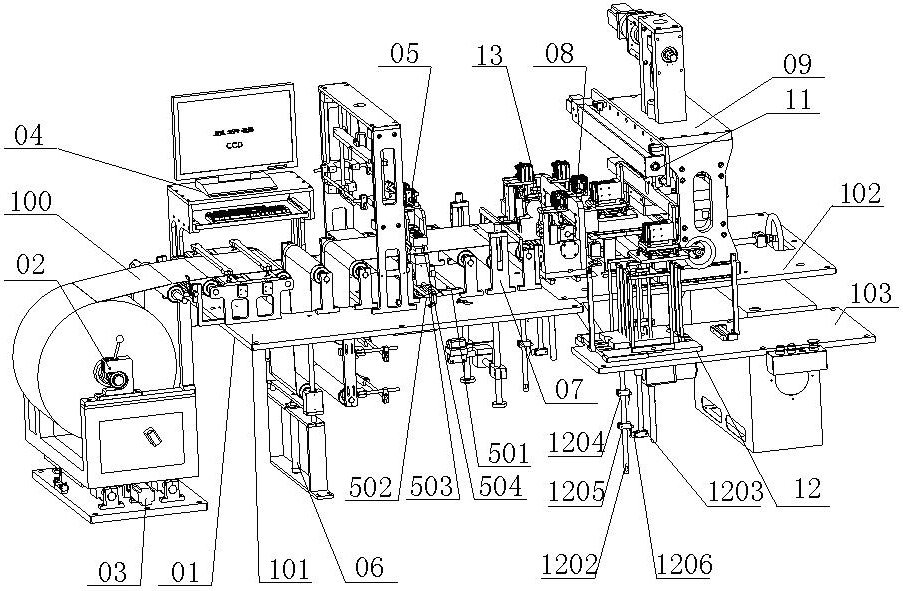

Battery assembling and packaging device

ActiveCN101789525AIncrease the level of automationImprove performanceFinal product manufactureNon-aqueous electrolyte cellsProduction linePunching

The invention relates to a battery assembling and packaging device, comprising an aluminium plastic film forming flaking unit, an assembling and packaging unit, an electrode group charging unit and an auxiliary unit. Aluminium plastic film punching and forming, electrode group feeding and automatic assembly of the two are sequentially realized, then top edge and side edge of packaging bag are sealed and adhered, and test classification is carried out on packaging product, thus automation of batter production line can be effectively improved. The invention has the advantages of convenient operation, high production efficiency, reliable product performance, low production cost and less waste.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

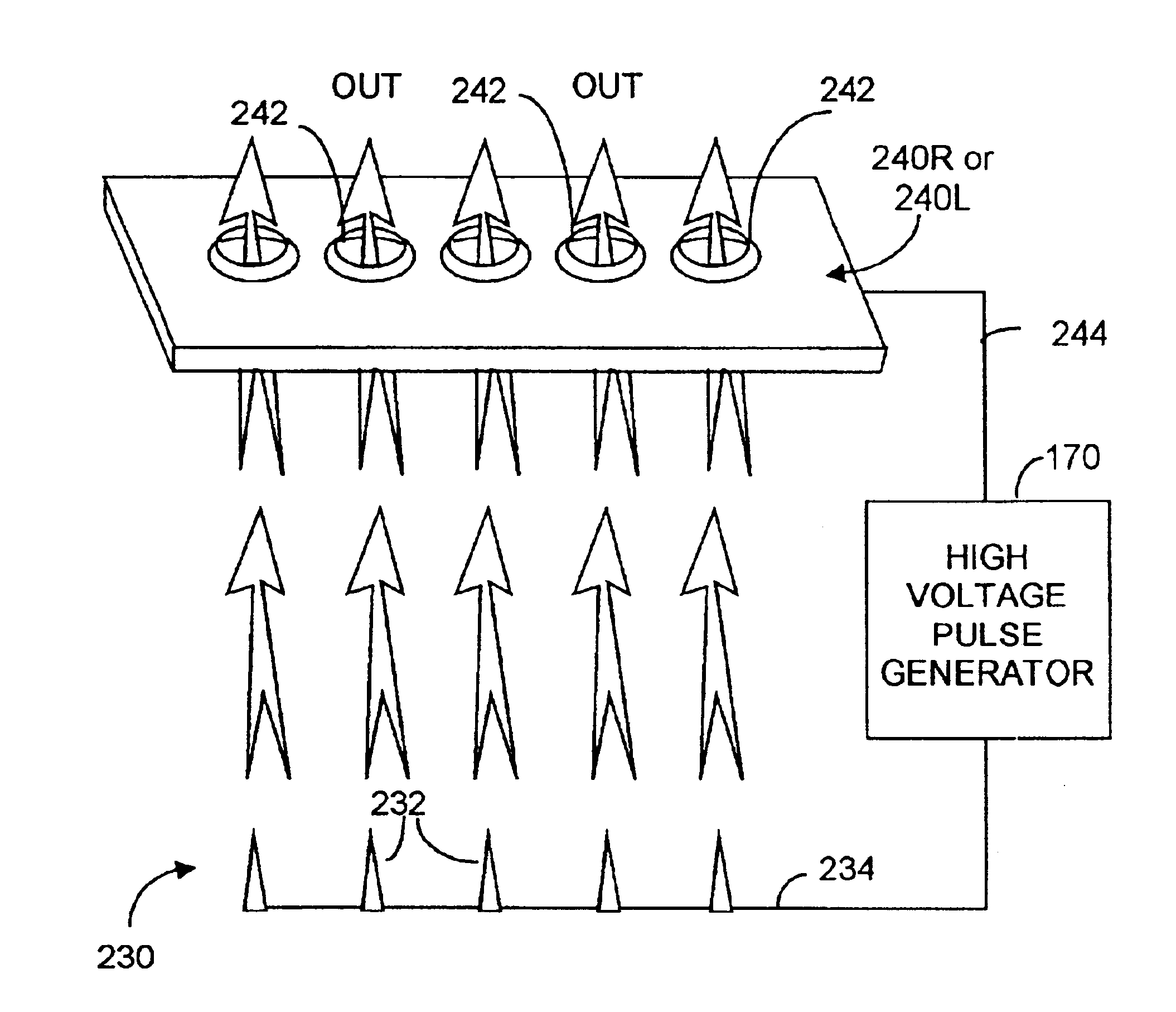

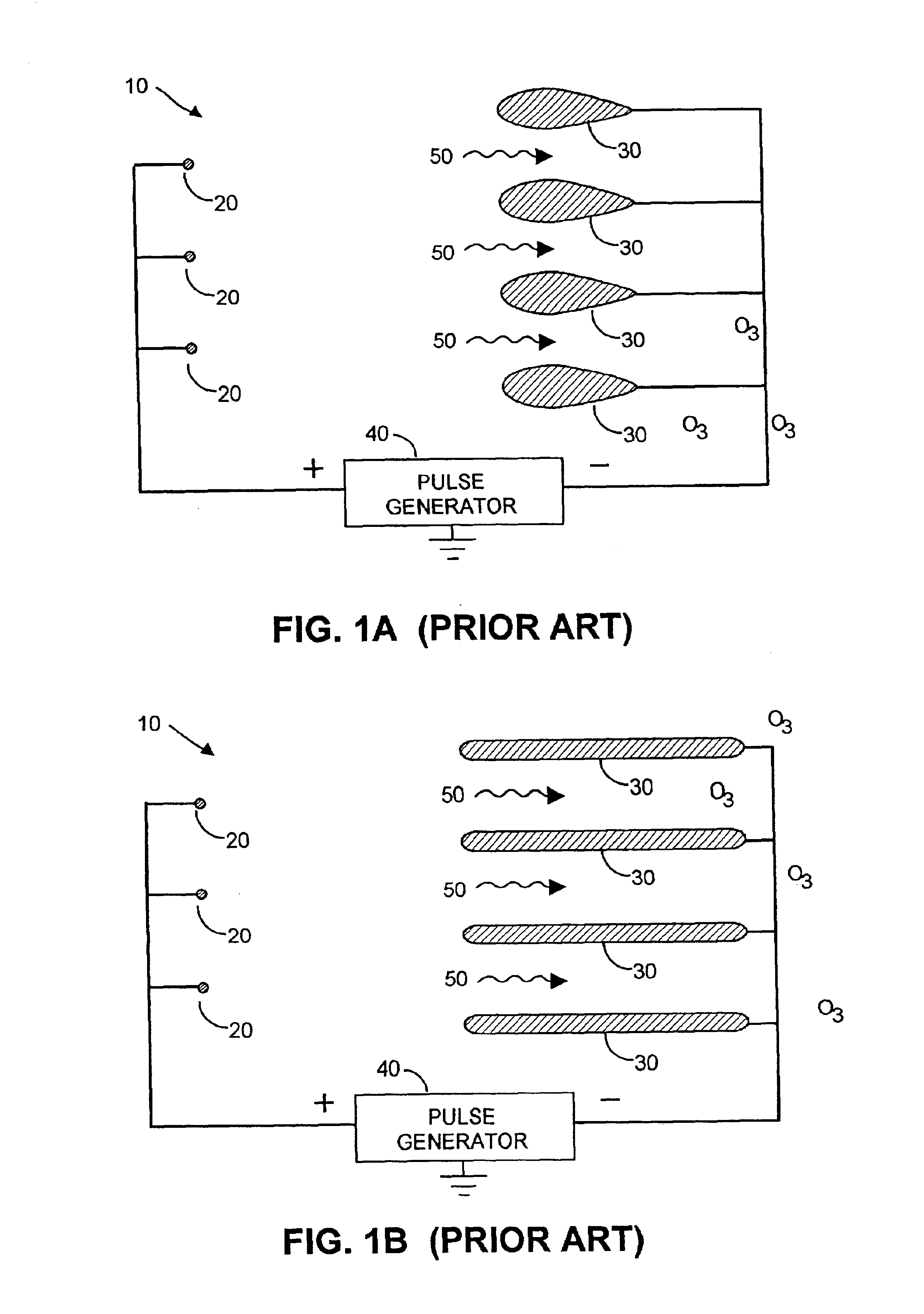

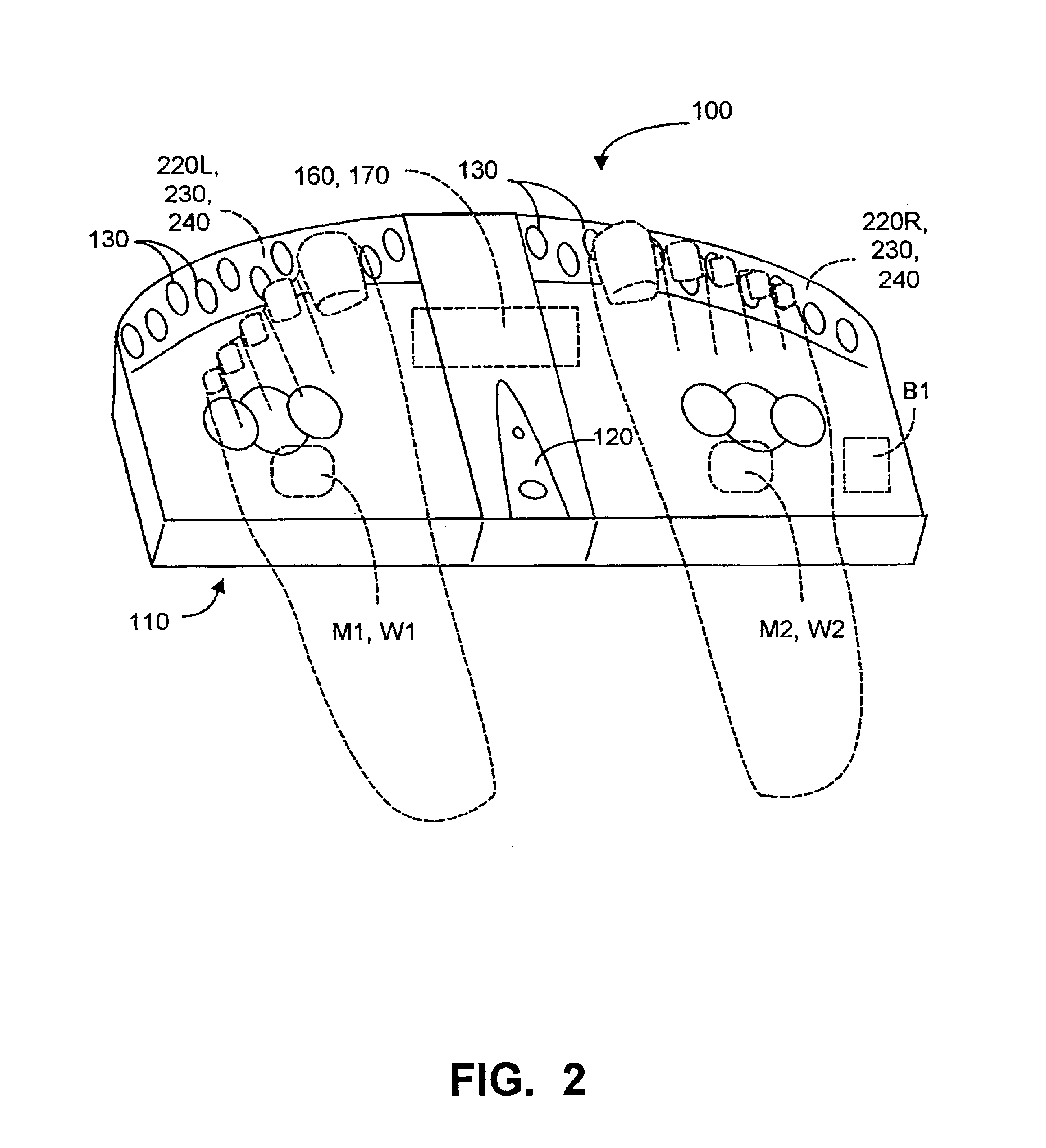

Electro-kinetic air transporter-conditioner with a multiple pin-ring configuration

InactiveUS6863869B2Increase humidityEliminate odorMechanical apparatusLighting and heating apparatusSOCKSPunching

A system massages a user's feet and generates an electro-kinetic airflow that contains safe amounts of ozone that can deodorize the user's feet or socks. The system includes an ion generator comprising a high voltage pulse generator whose output pulses are coupled between left and right first and second electrode arrays. Preferably the first electrode array includes first and second pointed electrodes, and the second electrode array includes annular-like electrodes having a central opening coaxial with the associated pointed electrode. Preferably the annular-like electrodes are formed from a single sheet of metal by extrusion or punching such that the surface of the annular-like electrodes is smooth and continuous through the opening and into a collar region through which the air flows. Particulate matter in the ambient air electrostatically adheres to the smooth continuous surface of the annular-like electrodes.

Owner:TESSERA INC

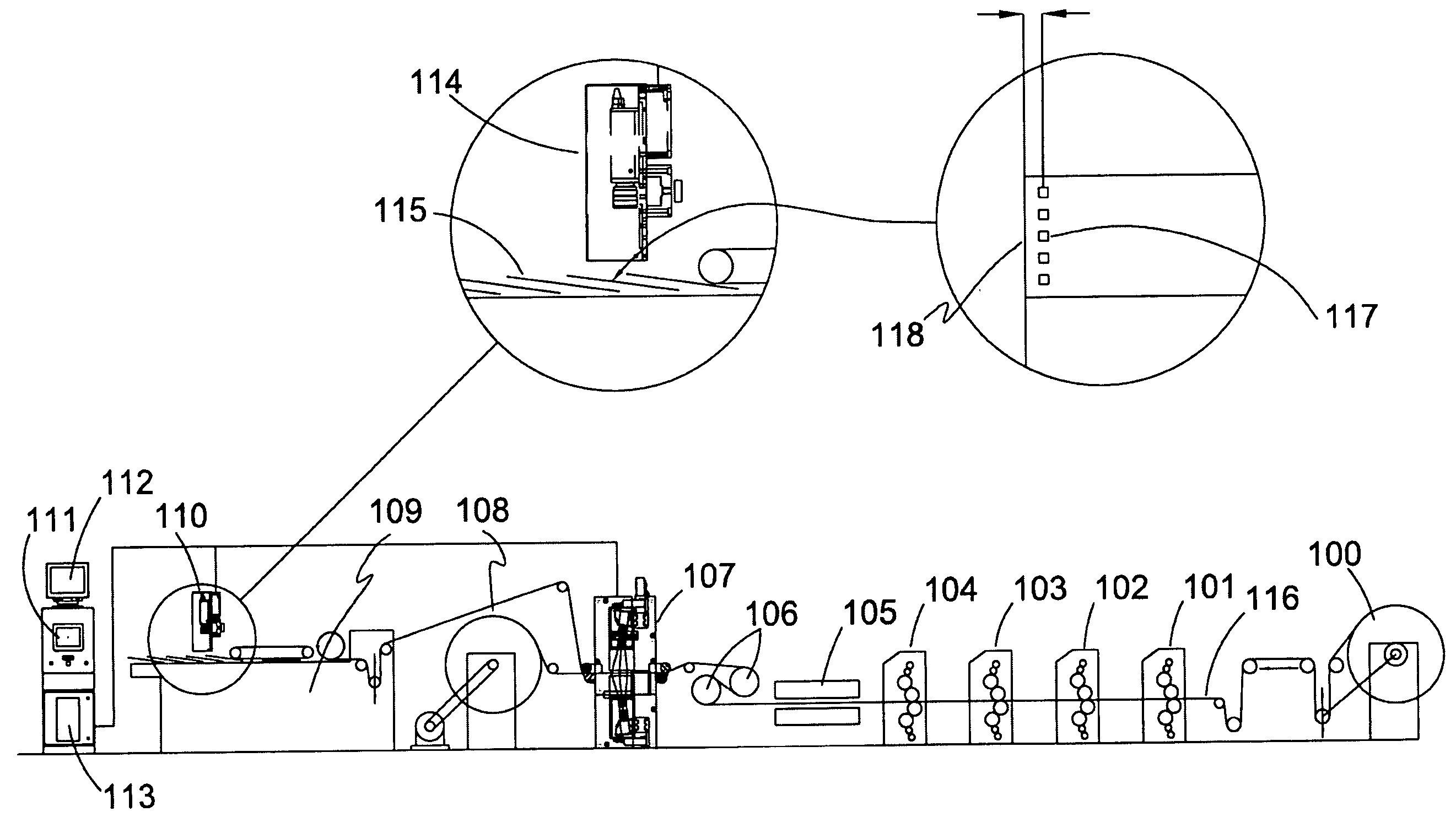

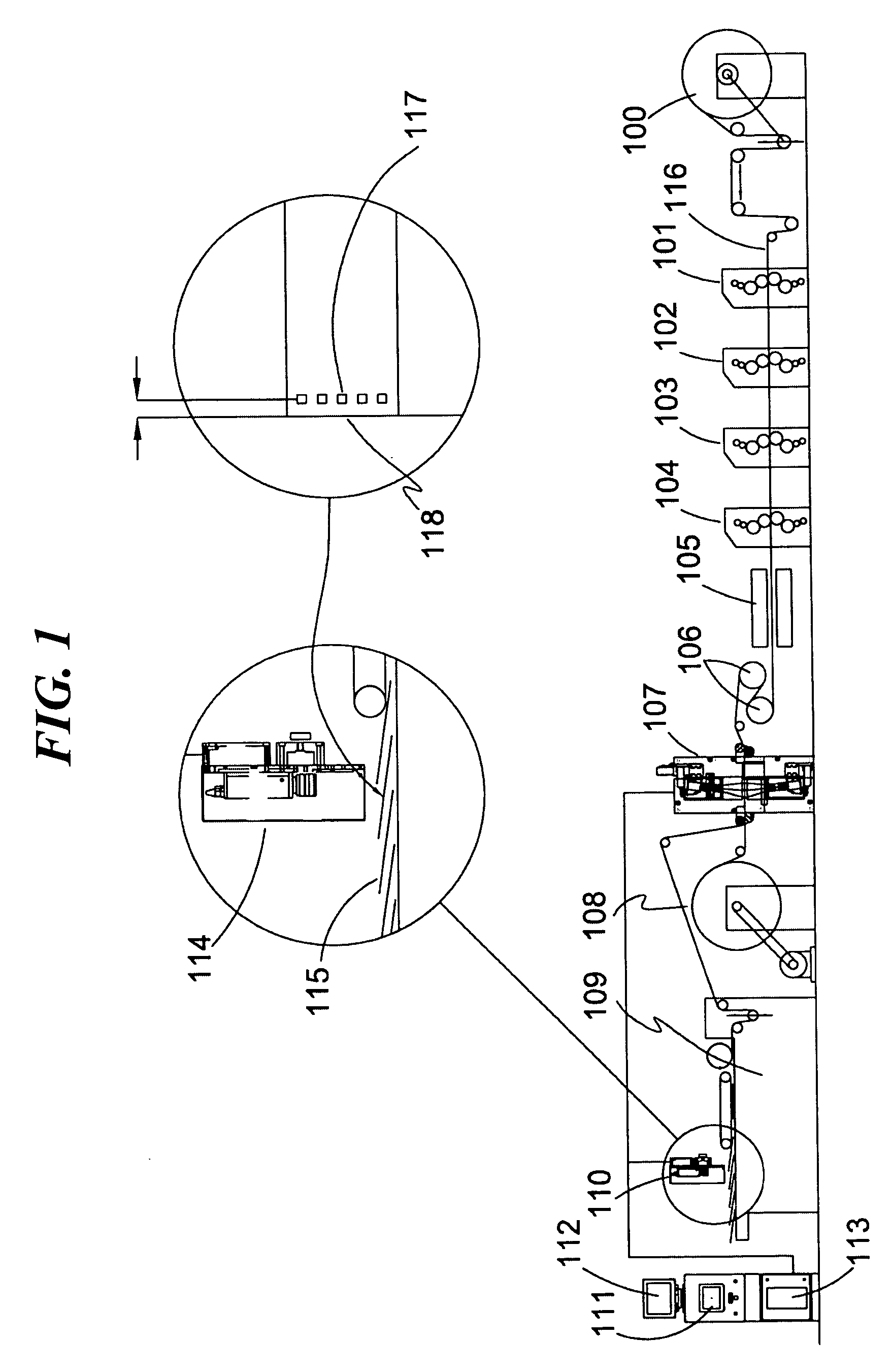

System and method for register mark recognition

InactiveUS20040163562A1Minimize timeReduce material wastePlaten pressesInvestigating moving sheetsOperator interfacePunching

A system, method, and process that determine and automatically correct registration errors between printed objects and mechanically produced objects using advanced image processing techniques is disclosed. Means are also presented for maintaining all registered functions to within very close tolerances during normal running, with other means for rapidly obtaining initial registration with substantial savings in material waste. The disclosed system and method / process are compatible with the printing and converting industry in which rolls of material are processed by printing a number of colors that require close registration especially in pictorial representation. These roll-fed printing machines are quite versatile and in addition to the printing of any number of colors on both front and back can perform any number of additional operations on the printed web at the same time. Some of these additional operations can be the punching of line holes, scoring, perforation and die cutting all of which impart a specific shape mechanically on the printed web. All of these functions must be initially registered to each other and maintained within close tolerances during normal running conditions. The presently disclosed registration system permits these initial registration procedures to be performed with high accuracy, speed, and across a wide variety of web materials and colors. The system generally applies to any web material (5701) on which register marks (5702) are applied, wherein images of the web are obtained (5703) and image processed (5704) under optional control of an operator interface display (5705), resulting in web press motor control (5706) to affect improved print registration on the web material (5701).

Owner:CC1

Method for creation of drug delivery and/or stimulation pockets in myocardium

An apparatus and method for creating drug-filled pockets within muscle tissue, such as myocardium of the heart for increasing angiogenesis. More particularly, the apparatus has an excising assembly with a dilator tip for penetrating and advancing through the surface and body of a muscle or organ, such as the heart. Preferably, the dilator tip has a low level laser optical fiber emission to ease the passage of the excising assembly and provide thermal damage which also stimulates angiogenesis. More preferably, the dilator tip also disperses a pharmacologically active substance as the apparatus is passed through the tissue and / or creates pockets. The excising assembly is connected to a hand-held control device from which the operator pushes a switch to activate a punching mechanism within the excising assembly. The punching mechanism cuts a discrete piece of muscle tissue and traps it within the excising assembly leaving a pocket in the remaining muscle tissue. The excising assembly may also optionally release a bolus of the pharmacologically active substance into the pocket so created. Most preferably, there is a timing mechanism to measure the contraction of the heart, and the timing mechanism is synchronized with the operator's switch on the hand-held device to ensure that the punching occurs at maximum contraction of systole. A measurement guide determines how much excised tissue is trapped in the reservoir of the excising assembly. At a threshold level of filling, the surgeon will remove the excising assembly from the hand-held control device and open the punching mechanism for release of tissue. More preferably, the threshold level of filling will automatically turn off the switch to the punching mechanism to indicate to the surgeon the need to empty the excising assembly of tissue.

Owner:ECLIPSE SURGICAL TECH

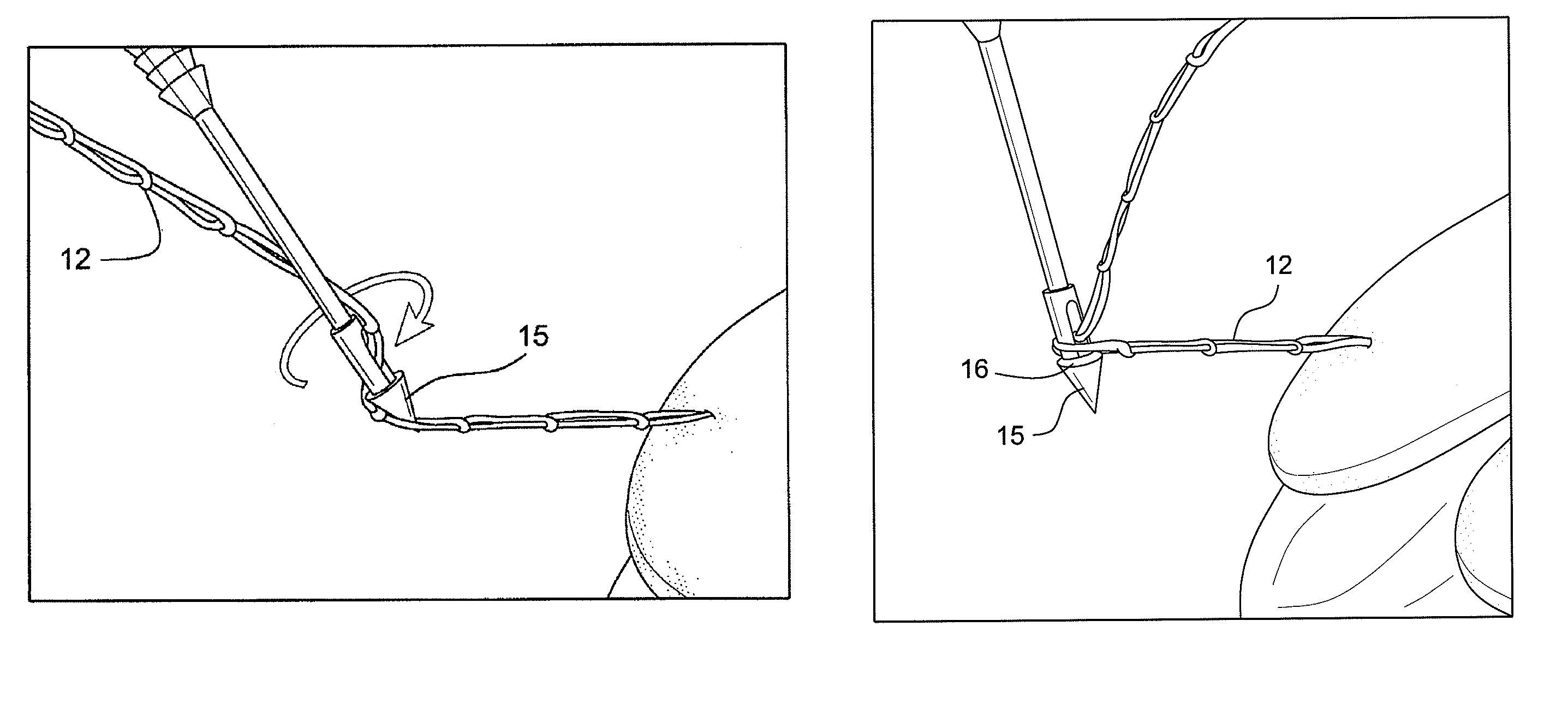

Technique for tissue fixation by capturing and anchoring a link of suture chain attached to tissue

A method and device for knotless fixation of tissue. The method utilizes a push-in type anchor (for example, a self-punching anchor) and a suture chain that includes a plurality of loops. A first portion of the suture chain is secured to the tissue to be fixated. The suture chain is next secured to the push-in type anchor (for example, by passing the suture chain through an eyelet of the anchor). The anchor is then advanced along the suture chain to bring a tip of the anchor above a chosen loop or link of the suture chain. The tip of the anchor is pushed through the chosen loop so that the tip locks the chosen loop in place (for example, by capturing both sides of the link above a shoulder of the anchor). With the captured link, the anchor is advanced into a pilot hole or socket formed in the bone to fixate the tissue. The captured link provides a hard stop that does not slip, in addition to frictional interference between the anchor and the bone socket.

Owner:ARTHREX

Method for manufacturing pure titanium seamless tubes

ActiveCN101708511ASimple processImprove efficiencyMetal rolling arrangementsRoll speed control devicePunchingTitanium

The invention relates to a method for manufacturing pure titanium seamless tubes. The method is characterized by comprising the following steps of: preparing tube blank bars; machining the tube blank bars; diagonally rolling and punching holes: heating blank to 700 to 980 DEG C, punching holes once or twice by utilizing a two-roll diagonally rolling mill group, wherein molybdenum mandrels or water-cooled mandrels are utilized, the inclined angle of punching roll is 8 degrees, the number of revolutions of the roll is 40 to 90 basic speed to 195 r / min; preparing the pierced billet after punching hole, wherein the specifications of the pierced billet are that the outside diameter is phi 72 to phi 125mm,the wall thickness is 5 to 20mm, and the length is; carrying out cold rolling; and carrying out heat treatment on finished product, detecting performance and entering warehouse. The invention has the characteristics of high production efficiency, low production cost, high material yield, short production period, low device investment, better product quality, and the like. The produced pure titanium seamless tubes have good quality, the mechanical properties accord with state requirements, and the pure titanium seamless tubes can meet the need for large-scale industrial production.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL

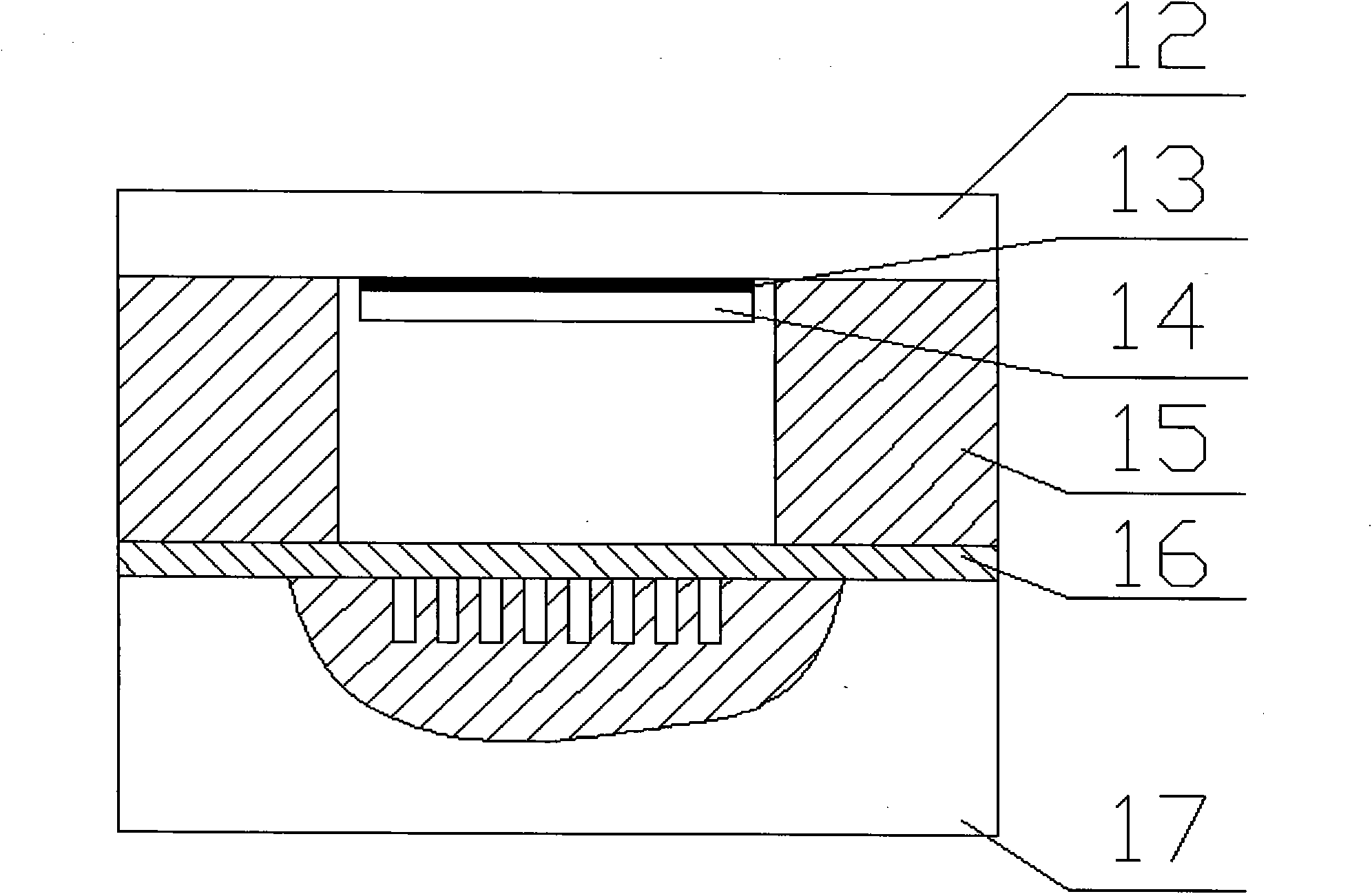

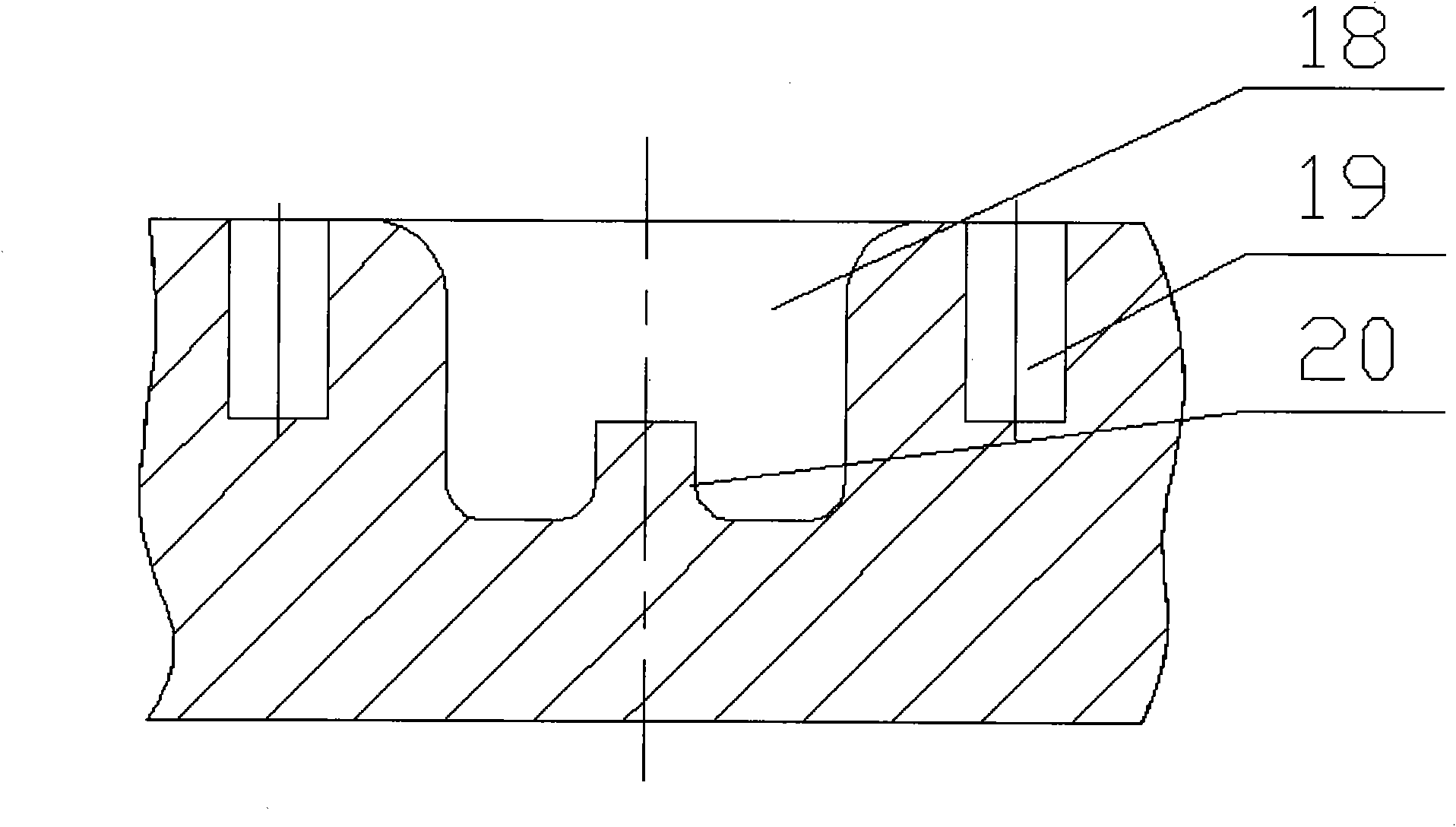

Laser indirect compound micro plastic forming device and method

InactiveCN102009268APrecise and controllable parametersGood repeatabilityLaser beam welding apparatusPunchingLaser processing

The invention discloses a laser indirect compound micro plastic forming device, belonging to the field of laser processing technology of parts of MEMS (Micro-electromechanical Systems). The laser indirect compound micro plastic forming device consists of a laser loading system, a forming system and a control system. In a laser indirect compound micro plastic forming method, pulse laser is used for driving a flying plate to move at a high speed; after moving for a certain distance, the flying plate collides with a target workpiece on a special compound micro die at a high speed; and the collided target workpiece gets high-energy momentum and is extruded between the flying plate and the special compound micro die. Since the target workpiece is limited by the special compound micro die, the target workpiece forms the shape of the special compound micro die during the extruding process. The special compound micro die is provided with hollowing dies and terrace dies which are arranged in arrays, so that the compound process of drawing, punching and trimming and batch forming of the target workpiece can be realized by primary impacting, and the hollowing dies and the terrace dies on thespecial compound micro die can be designed according to the forming and quantity of the target workpieces as required so that the batch forming of the target workpiece can be realized under differentforming requirements.

Owner:JIANGSU UNIV

Method, system, and apparatus for transfer of dies using a pin plate

InactiveUS20050015970A1Solid-state devicesSemiconductor/solid-state device manufacturingPunchingEngineering

A method and system for device assembly and a method, system, and apparatus for transfer of dies using a pin plate are described herein. A die plate is received having dies. The body of the die plate has a plurality of holes extending therethrough. Each die covers a corresponding hole on a first surface of the die plate. The die plate is positioned to be closely adjacent to the web of substrates. The punching device has a plurality of punching members extending from an outer surface. The punching device is planar or alternatively cylindrical. The punching device is applied to a second surface of the die plate to cause a set of the punching members to extend through a set of holes in the die plate, causing dies to be transferred from the die plate to one or more destination substrates or other surfaces.

Owner:SYMBOL TECH INC

Process for manufacturing low-silicon low-carbon deep punching/drawing steel

ActiveCN101343677ARelaxation of sulfur content requirementsReduce manufacturing costManufacturing convertersProcess efficiency improvementExtensibilitySlag

The invention discloses a production method of low-silicon and low-carbon deep punching / drawing steel, bottom-blowing argon is performed in the whole process of converter smelting, and a single slag / double slag technique is adopted to pour out the dephosphorized slag, high-basicity slag is produced in later period, the dualistic basicity of final slag R is more than 3.5, the terminal temperature of molten steel is 1620 DEG C to 1650 DEG C, and tapping ( P ) is less than 0.012 percent. The molten steel is refined by adopting low-silicon and low-carbon high-basicity reductive slag in a LF furnace refining station, thus to manufacture reductive slag for desulphurisation, and the ( Al ) in the molten steel is less than 0.005 percent. The molten steel refined by the LF furnace is vacuum-treated by a RH vacuum furnace, the carbon and the silicon in the molten steel is circularly removed, the molten steel is continuously casted into a casting blank through a CSP sheet bar conticaster, the casting blank is sent into CSP sheet bar heat continuous rolling mill and rolled into a coiled sheet after being heated in a roller hearth soaking furnace, a hot rolled coiled sheet is coldrolled into cold rolled coiled sheet through a cold tandem mill or a single mill after being acidwashed, and leveled through a leveling machine after being annealed by a cover furnace, and a leveling divided coil is stretched and divided. The production method has the advantages that the production cost of the working procedure is saved, the consumption of the refractory consumption of the converter is reduced, the equipment investment is saved, the process of the production technique is steady and smooth, the n value of the cold rolled plate is bigger than 0.23, the r value thereof is bigger than 2.1, and the deep punching performance and the extensibility are good.

Owner:湖南华菱涟钢特种新材料有限公司 +1

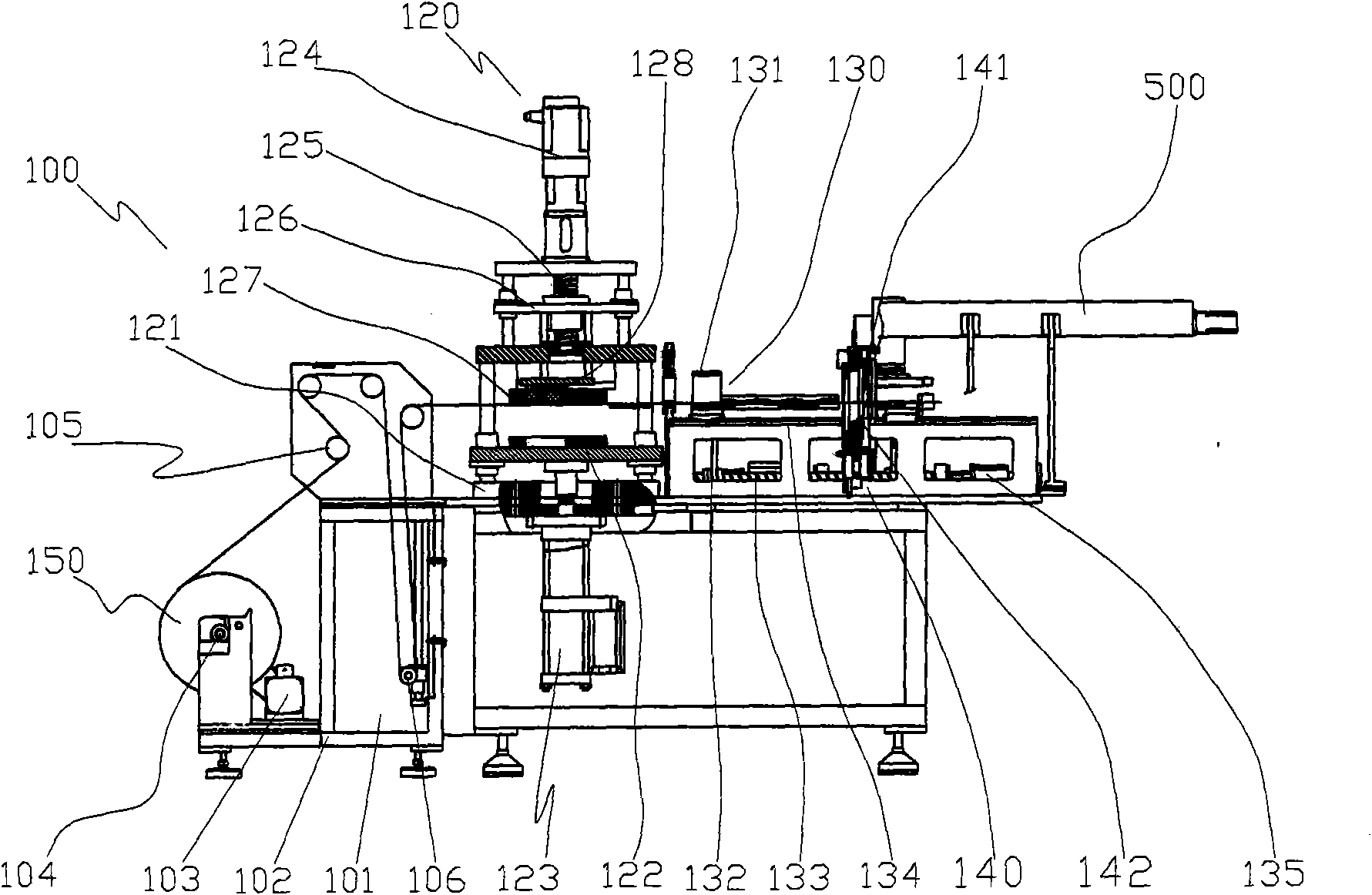

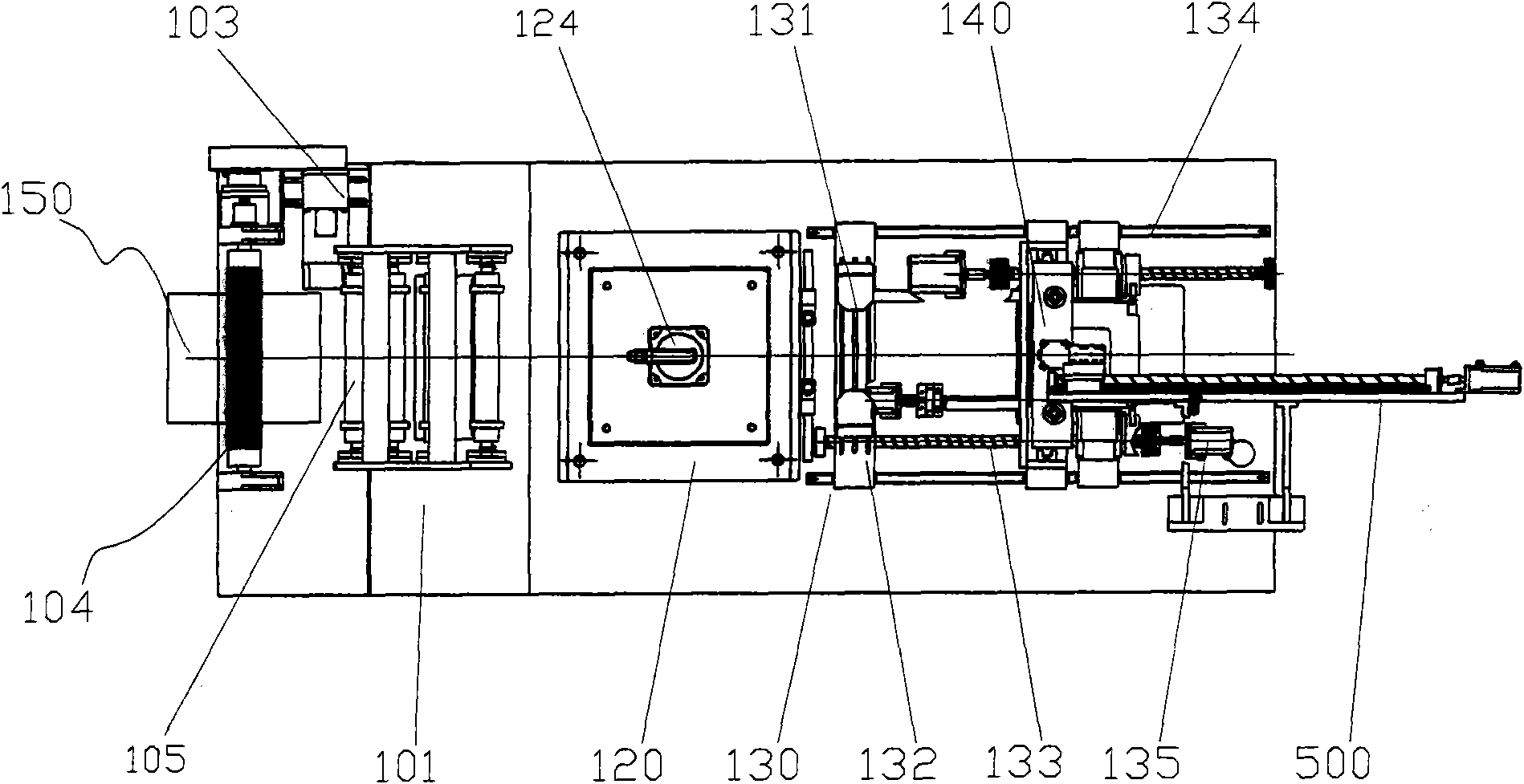

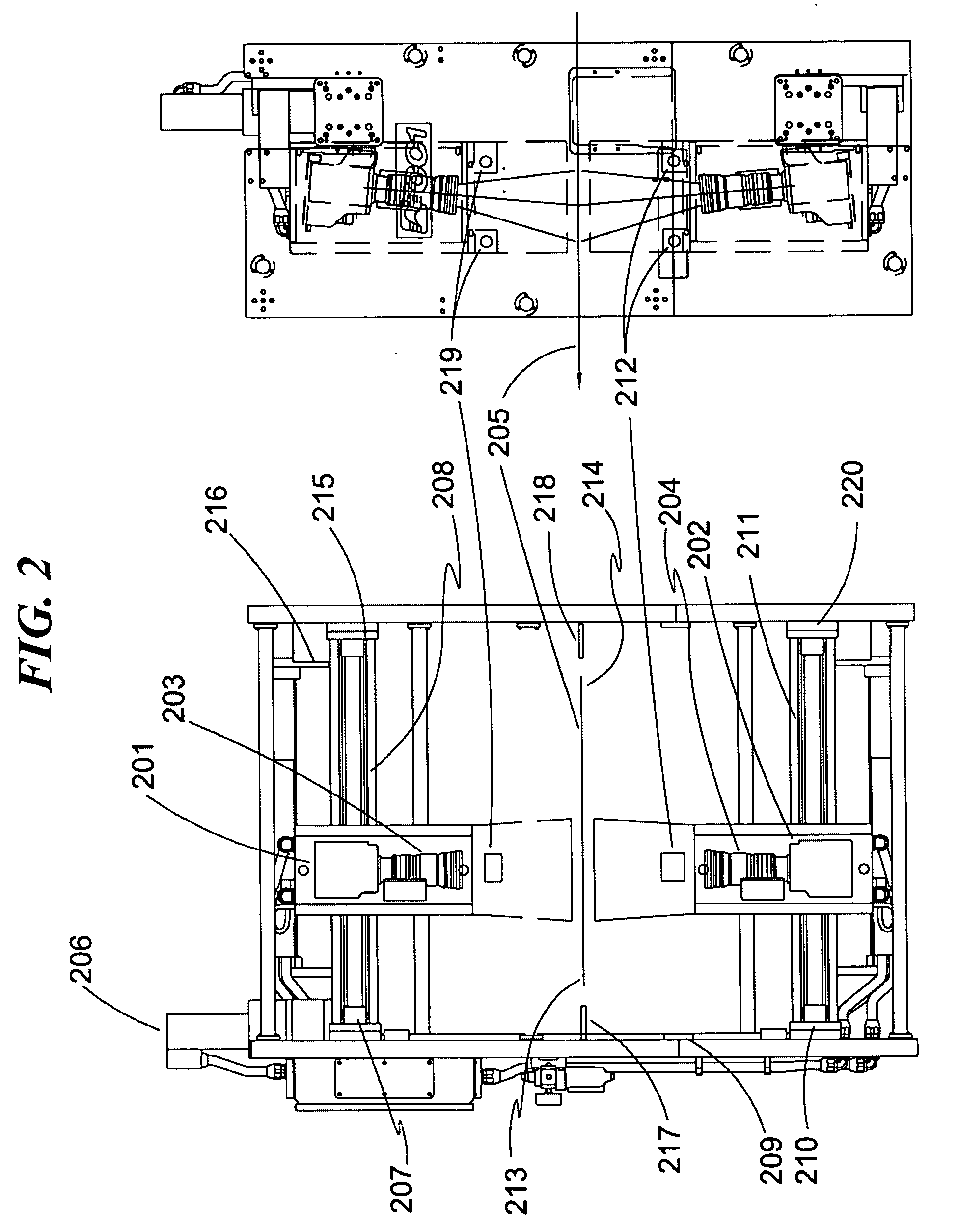

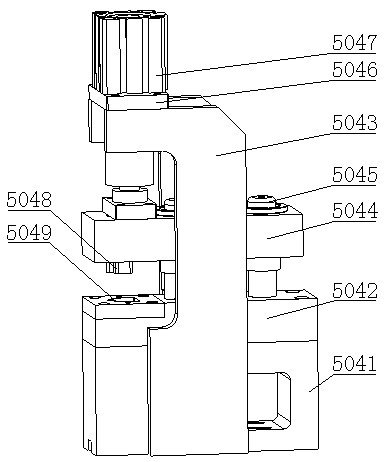

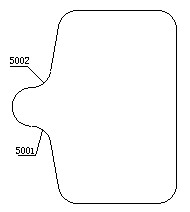

Electrode sheet forming machine

ActiveCN102306744AReduce manufacturing costExpanded range of specificationsElectrode manufacturing processesMetal-working feeding devicesPunchingAgricultural engineering

The present invention discloses an electrode sheet forming machine. The electrode sheet forming machine comprises a support mechanism, an unwinding mechanism, an unwinding rectification mechanism, an unwinding traction mechanism, a tension mechanism, a forming mechanism and a material collecting mechanism. The electrode sheet forming machine is characterized in that: the forming mechanism comprises a chamfer clipping mechanism, a constant length cutting mechanism and an electrode lug punching mechanism, wherein the chamfer clipping mechanism, the constant length cutting mechanism and the electrode lug punching mechanism are sequentially arranged on an electrode sheet belt in an unwinding direction; the chamfer clipping mechanism is provided for carrying out clipping for both sides of the electrode sheet belt to form the chamfer of each single electrode sheet, the constant length cutting mechanism is provided for carrying out constant length cutting for the electrode sheet belt to formthe single electrode sheet, the electrode lug punching mechanism is provided for punching the electrode lug of the single electrode sheet. Compare to the prior art, with the present invention, the die cost is saved.

Owner:深圳市和合自动化有限公司

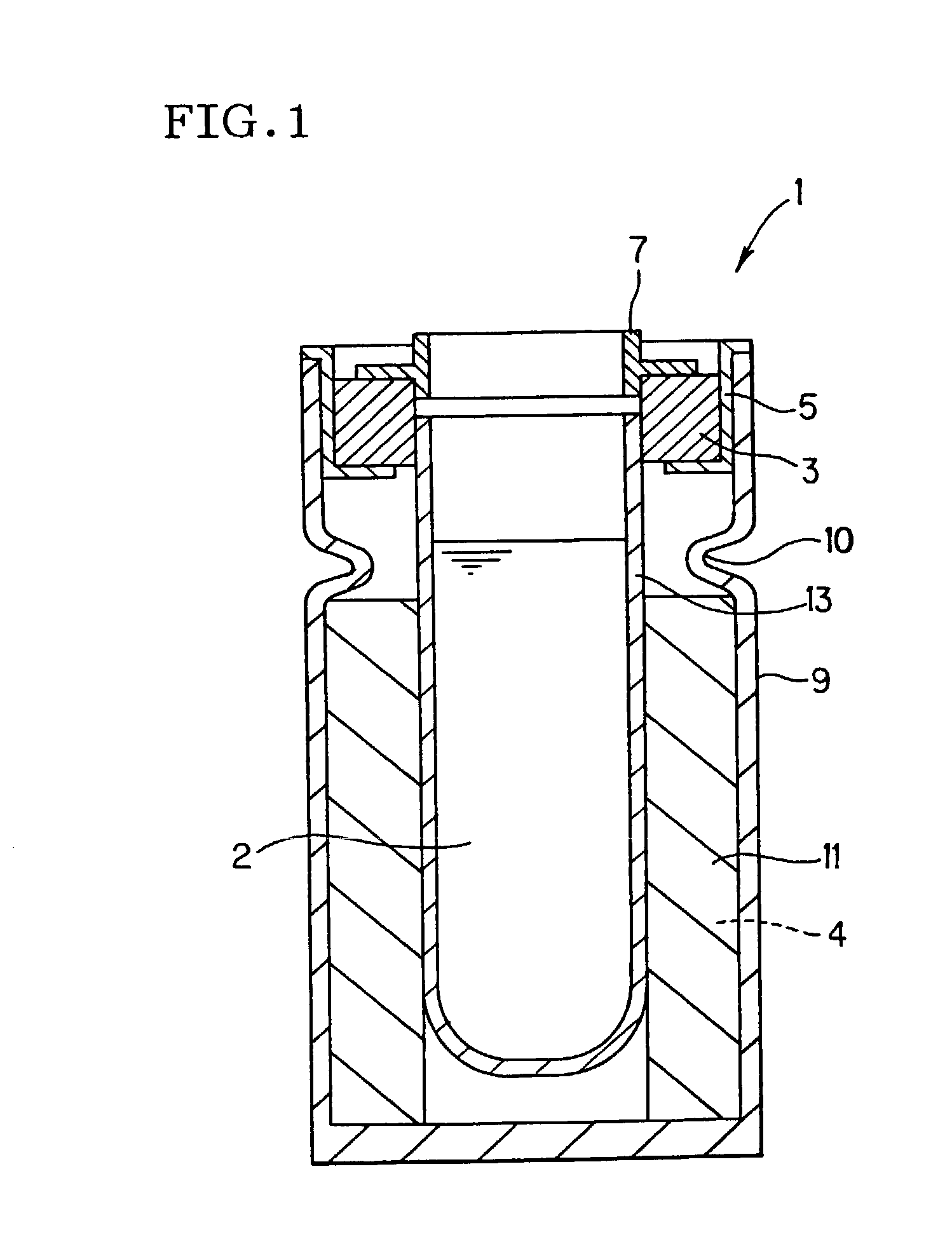

Current collector of positive electrode and sodium-sulfur battery using the same

InactiveUS20030054255A1Electrode carriers/collectorsSolid electrolyte cellsHigh resistanceGlass fiber

A current collector of positive electrode enabling a NaS battery to be excellent in the charge recovery characteristic and low in internal resistance is provided, which collector has a high resistance layer formed by needle-punching glass fibers with 5 to 15 mum fiber diameters into a felt substrate made of carbon fibers or graphite fibers by needle-punching from the one surface of the substrate. The density of the glass fibers needle-punched into the substrate is gradually decreased in the direction from the above mentioned surface to the other surface of the substrate, and the deepest portions of the needle-punched glass fibers reach the depths of 85 to 100% of the substrate thickness.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com