Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15284 results about "Ozone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ozone (/ˈoʊzoʊn/), or trioxygen, is an inorganic molecule with the chemical formula O₃. It is a pale blue gas with a distinctively pungent smell. It is an allotrope of oxygen that is much less stable than the diatomic allotrope O₂, breaking down in the lower atmosphere to O₂ (dioxygen). Ozone is formed from dioxygen by the action of ultraviolet light (UV) and electrical discharges within the Earth's atmosphere. It is present in very low concentrations throughout the latter, with its highest concentration high in the ozone layer of the stratosphere, which absorbs most of the Sun's ultraviolet (UV) radiation.

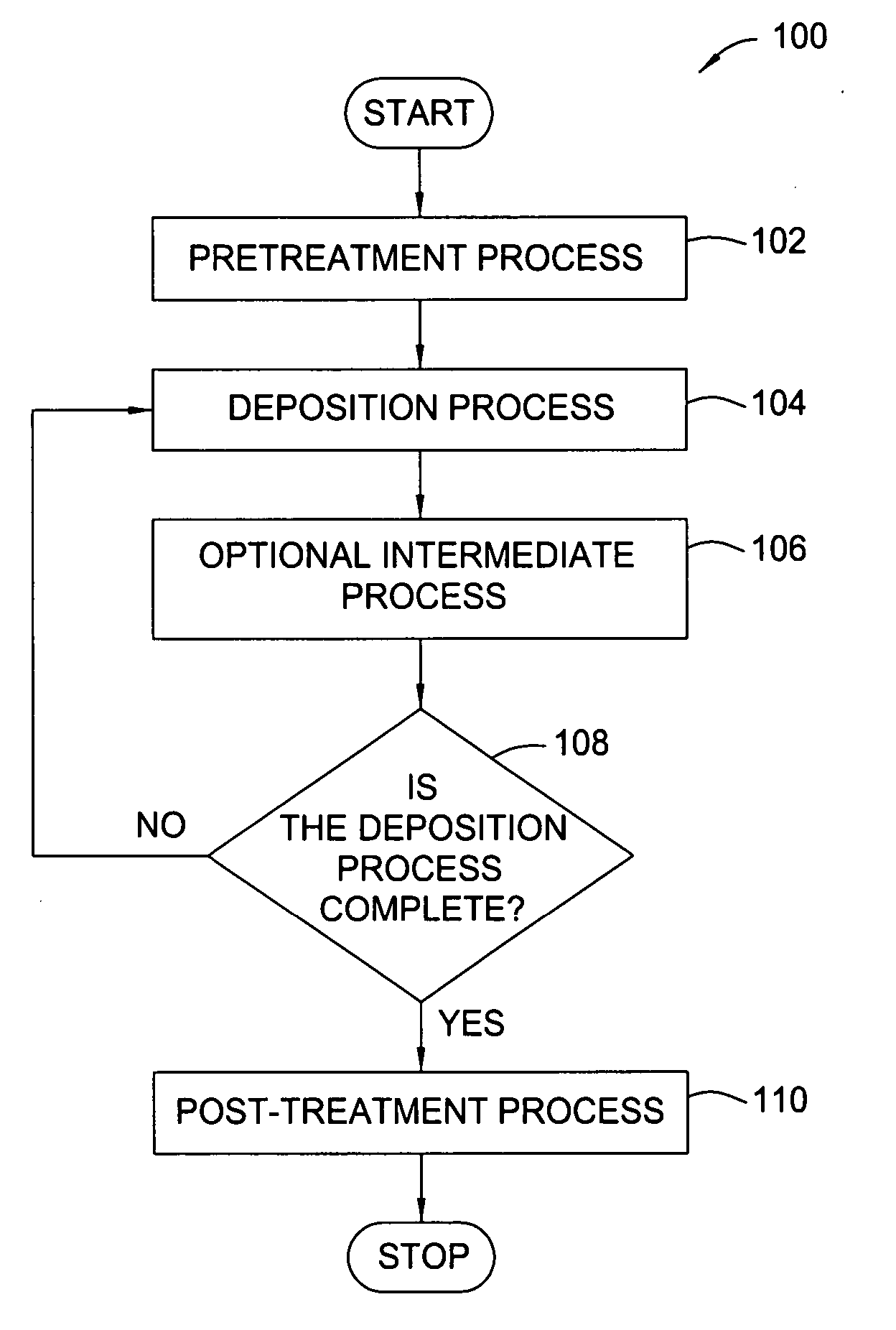

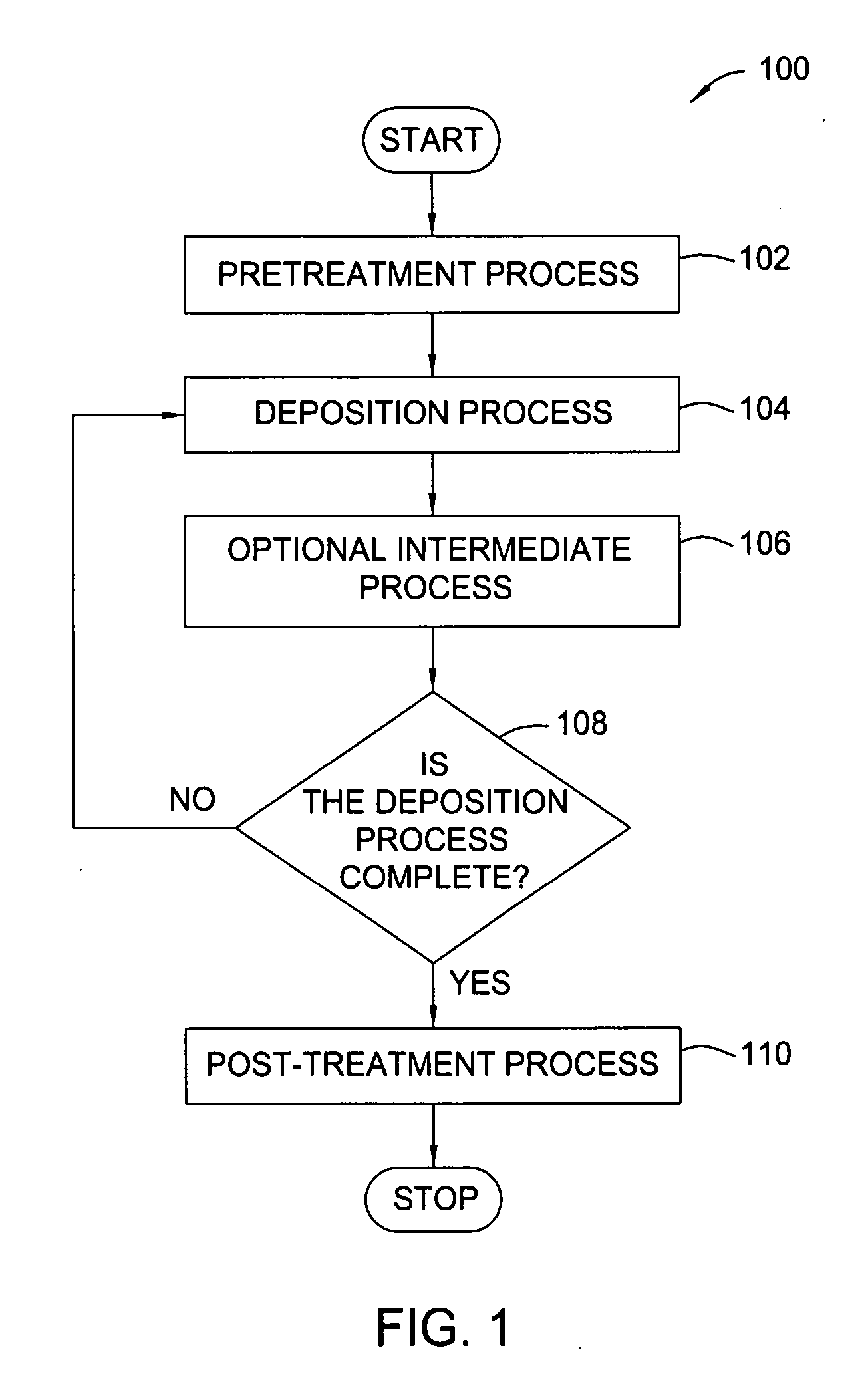

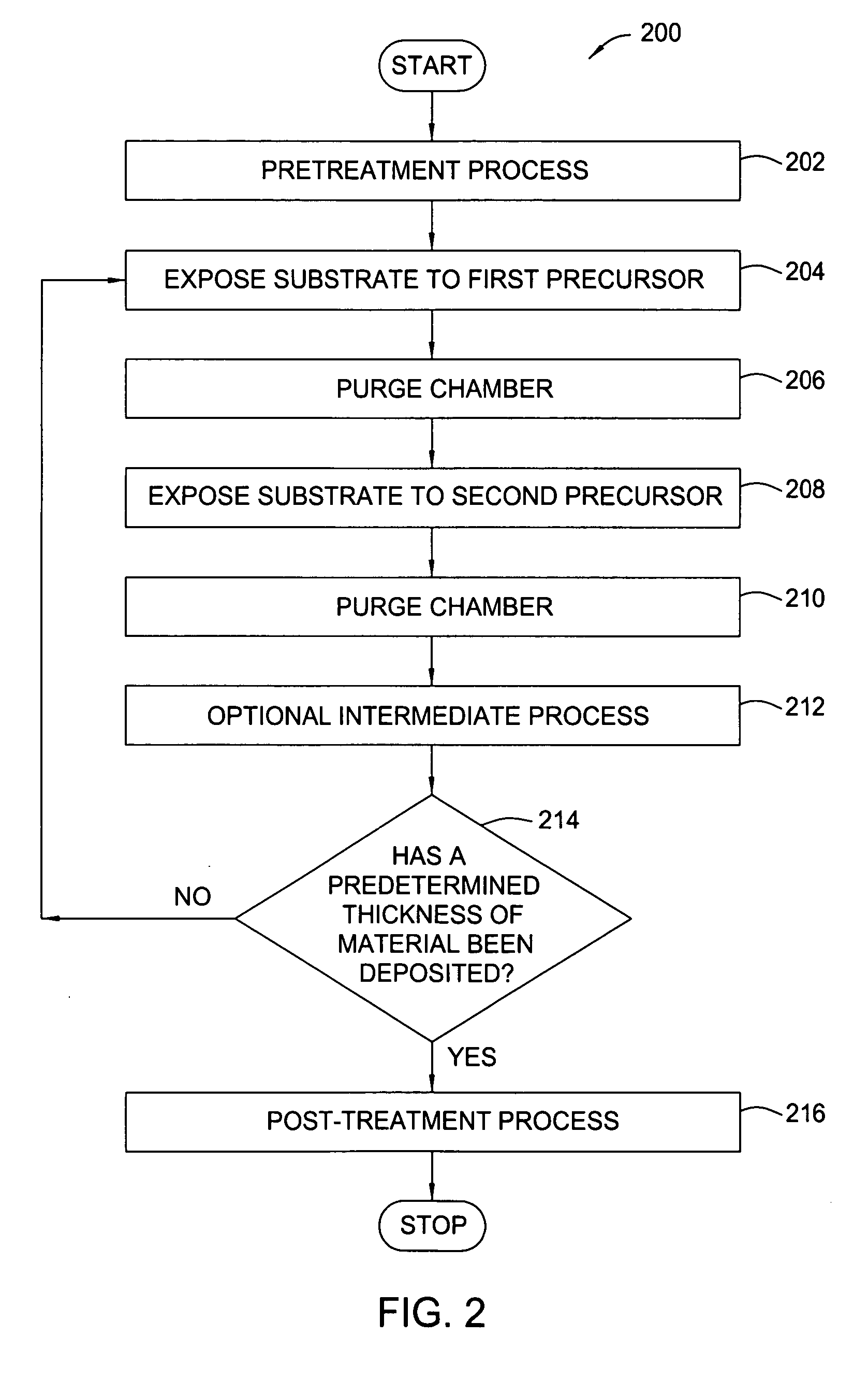

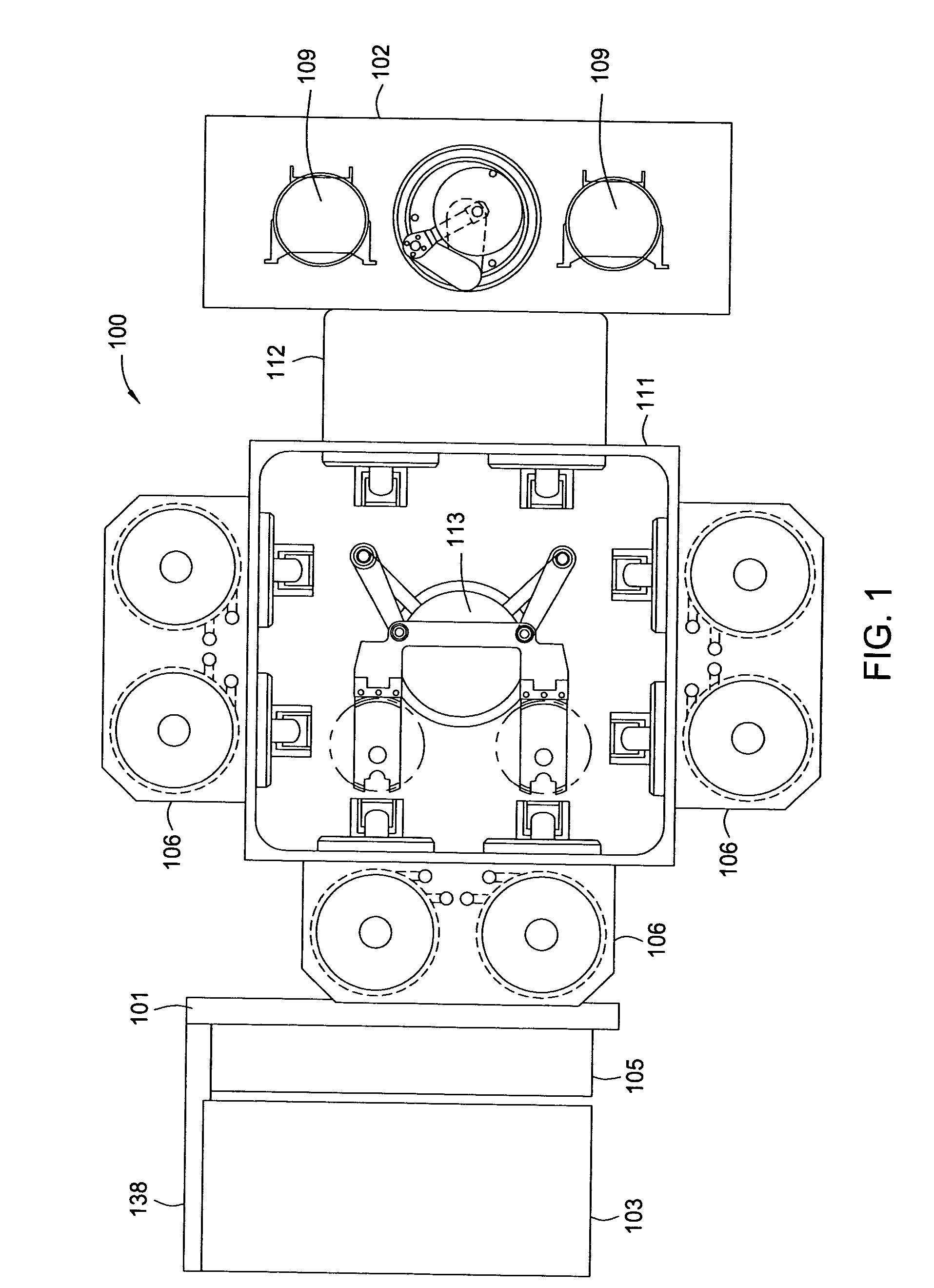

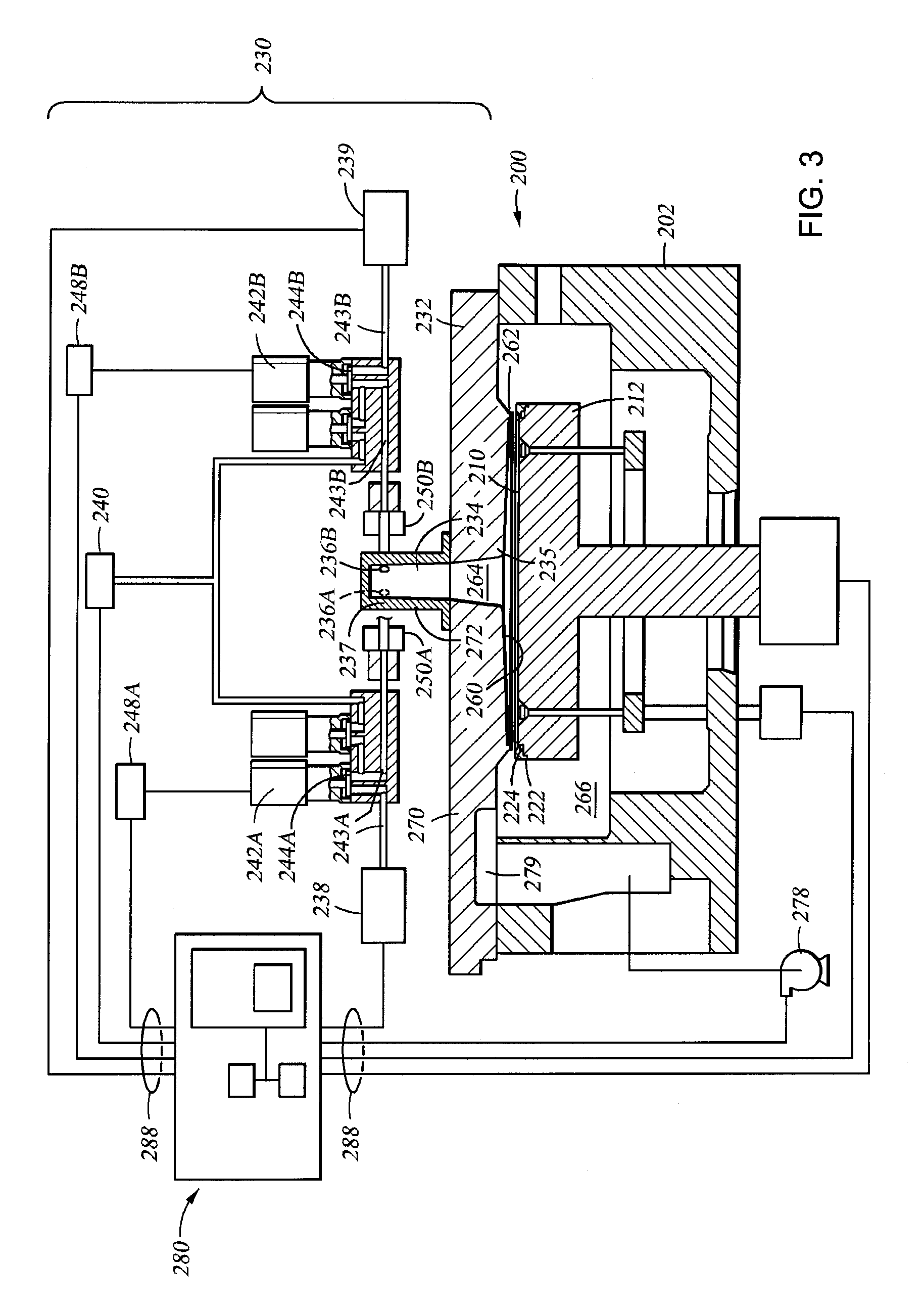

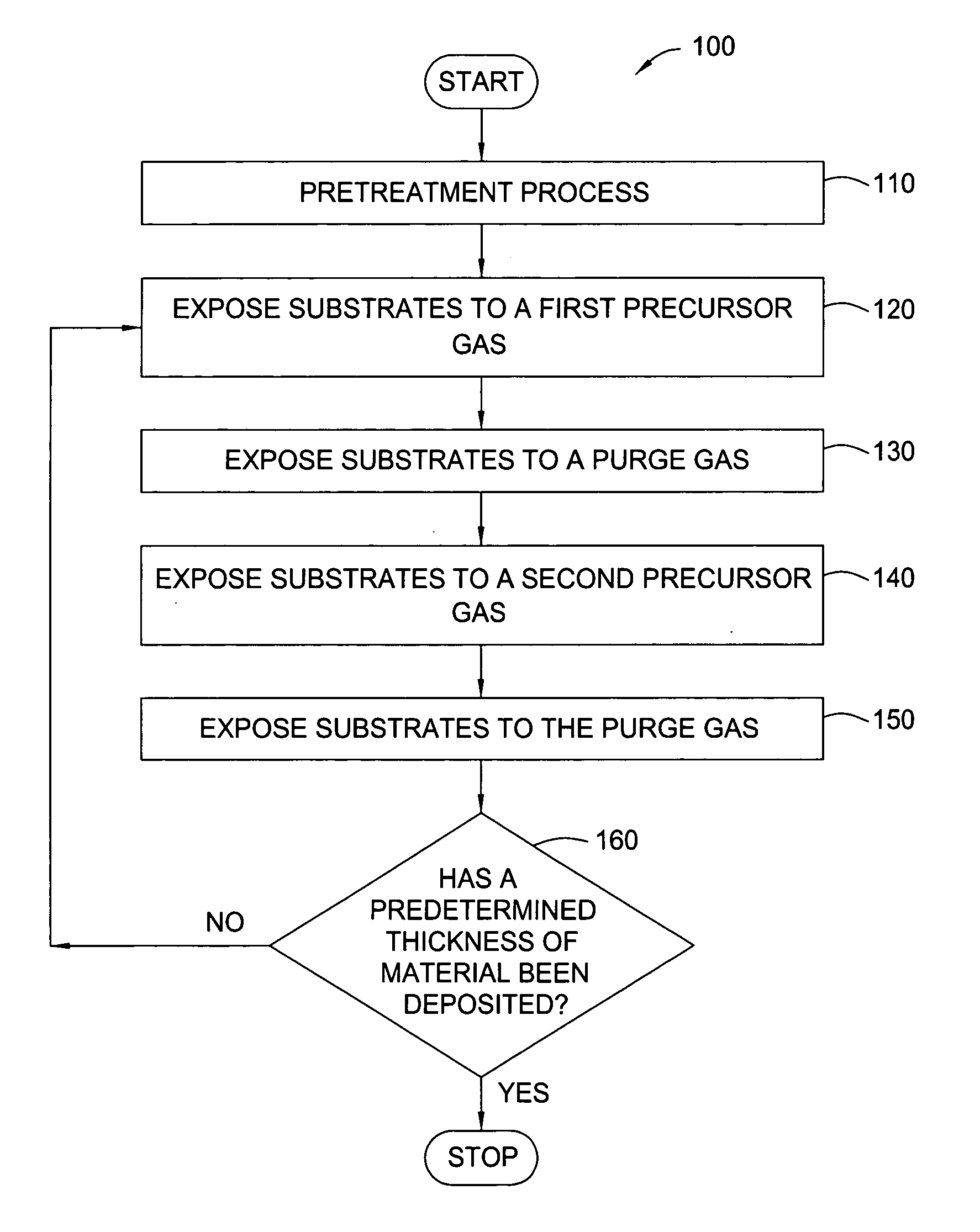

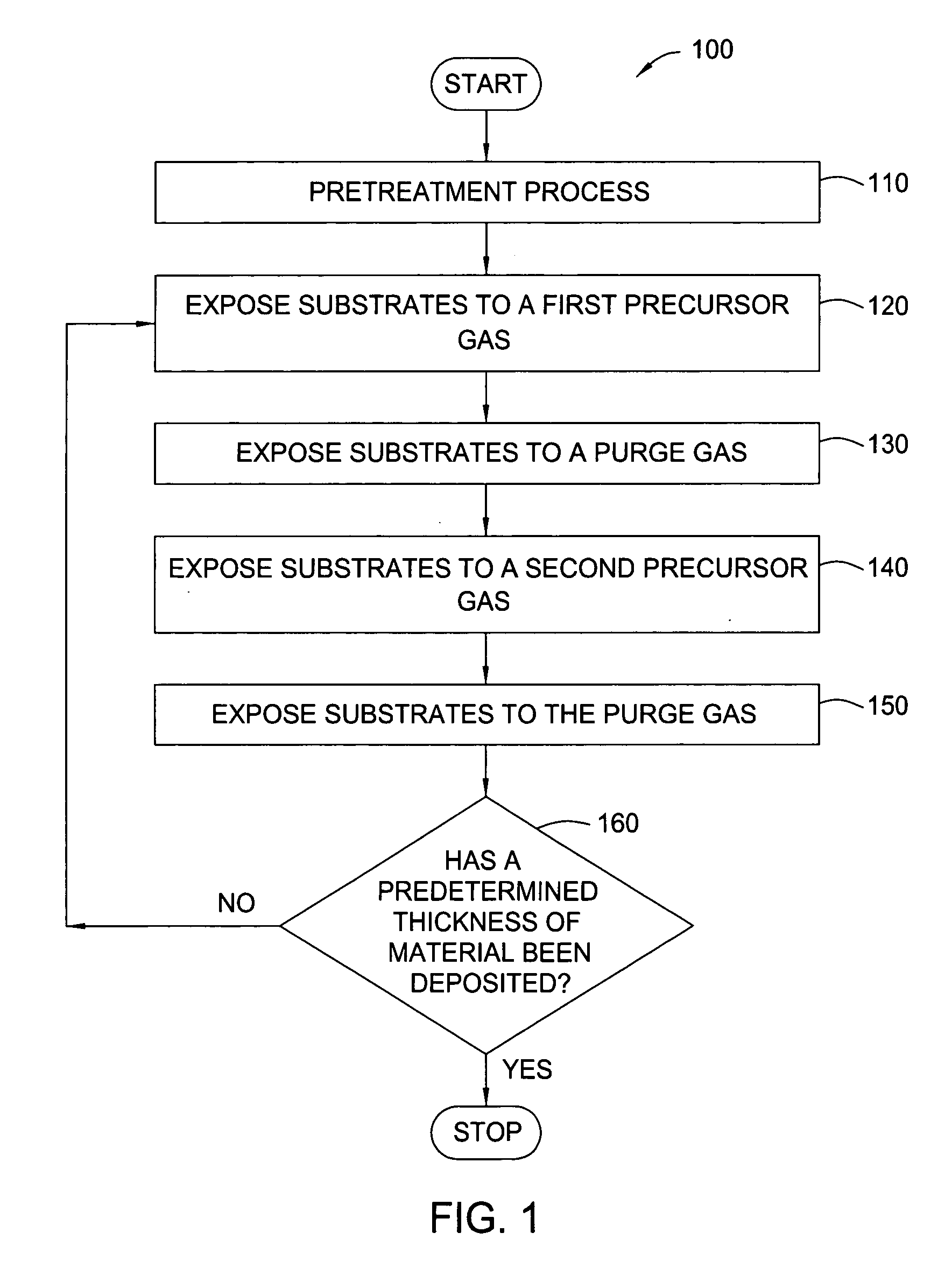

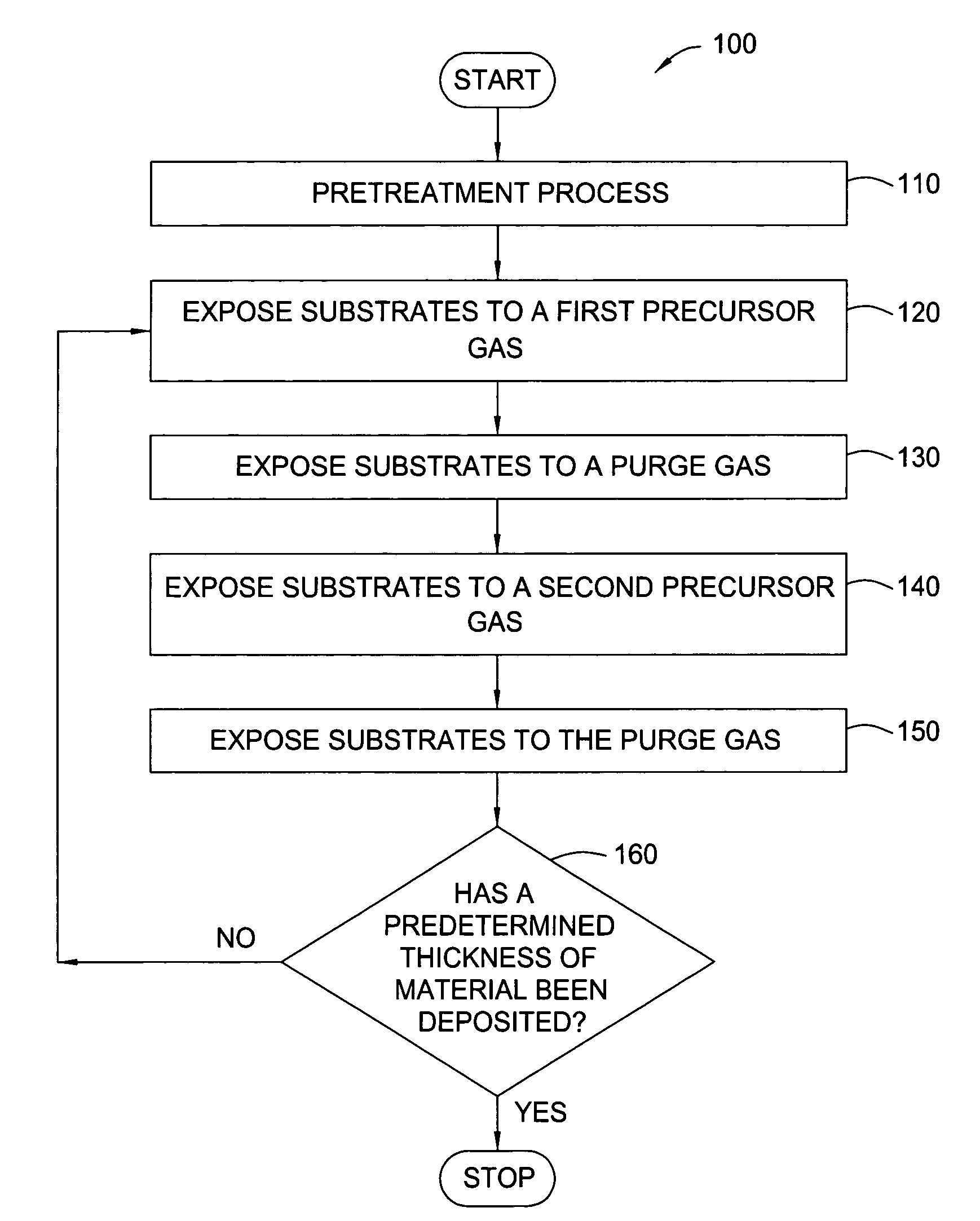

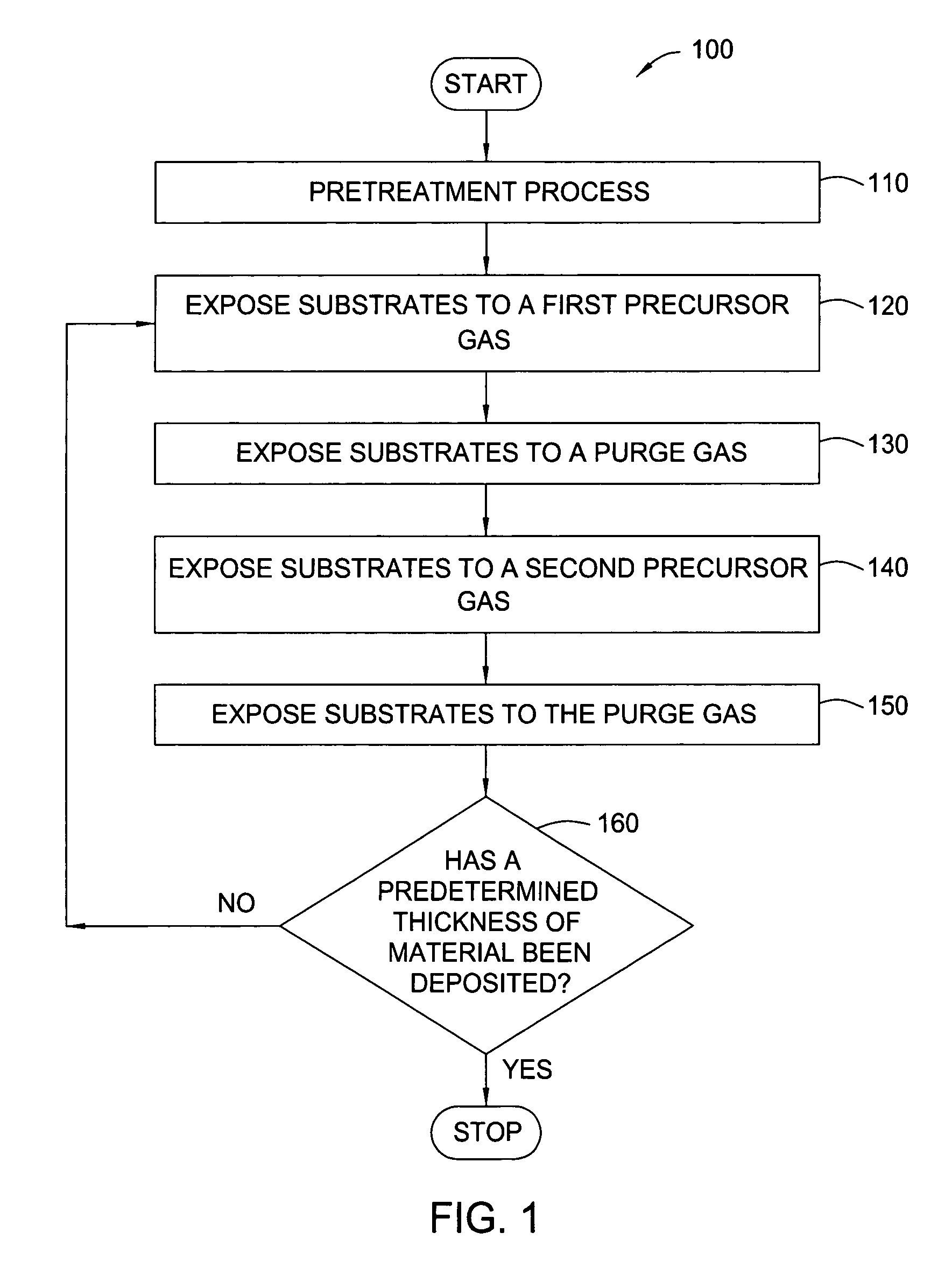

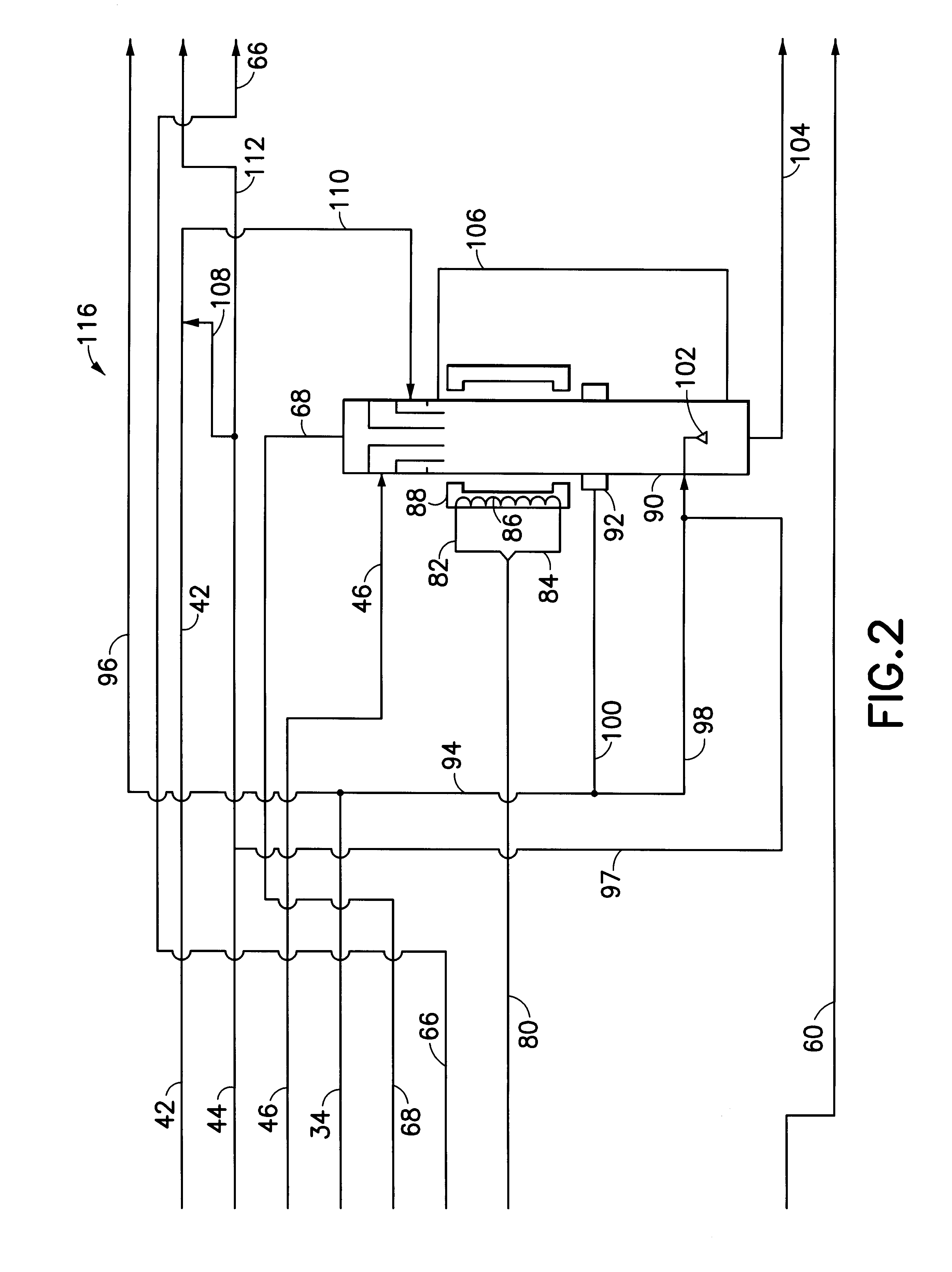

Treatment processes for a batch ALD reactor

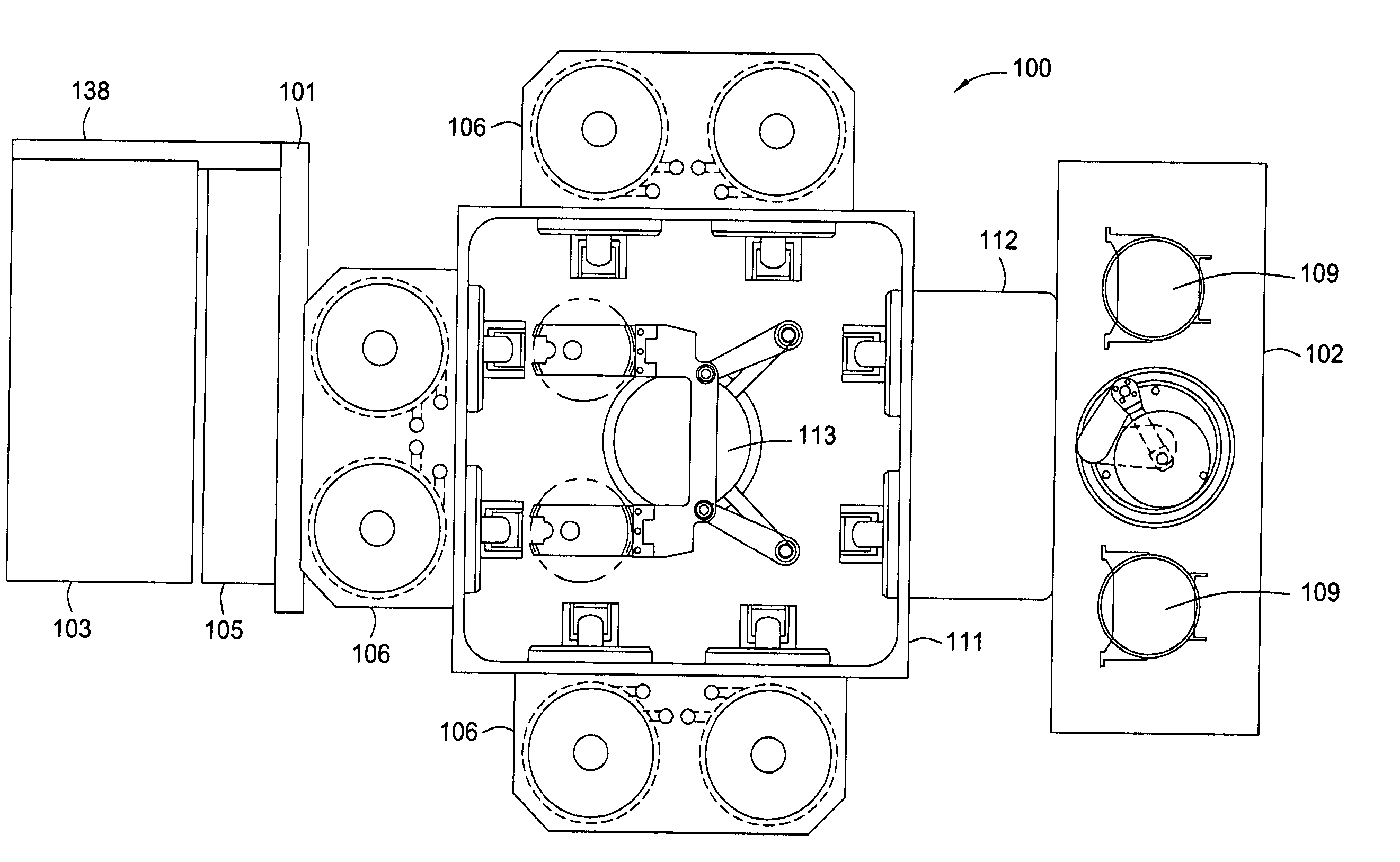

Embodiments of the invention provide treatment processes to reduce substrate contamination during a fabrication process within a vapor deposition chamber. A treatment process may be conducted before, during or after a vapor deposition process, such as an atomic layer deposition (ALD) process. In one example of an ALD process, a process cycle, containing an intermediate treatment step and a predetermined number of ALD cycles, is repeated until the deposited material has a desired thickness. The chamber and substrates may be exposed to an inert gas, an oxidizing gas, a nitriding gas, a reducing gas or plasmas thereof during the treatment processes. In some examples, the treatment gas contains ozone, water, ammonia, nitrogen, argon or hydrogen. In one example, a process for depositing a hafnium oxide material within a batch process chamber includes a pretreatment step, an intermediate step during an ALD process and a post-treatment step.

Owner:APPLIED MATERIALS INC

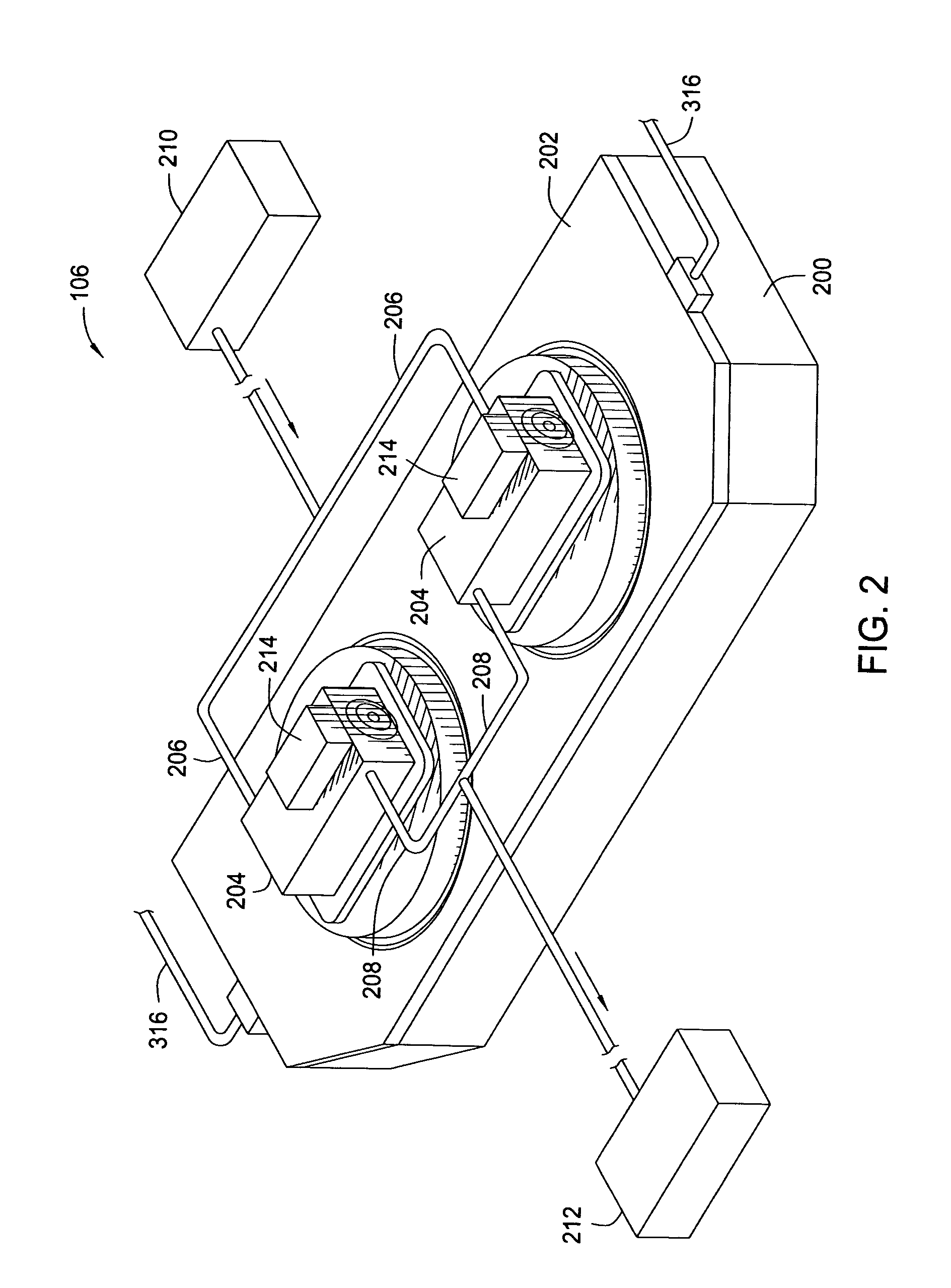

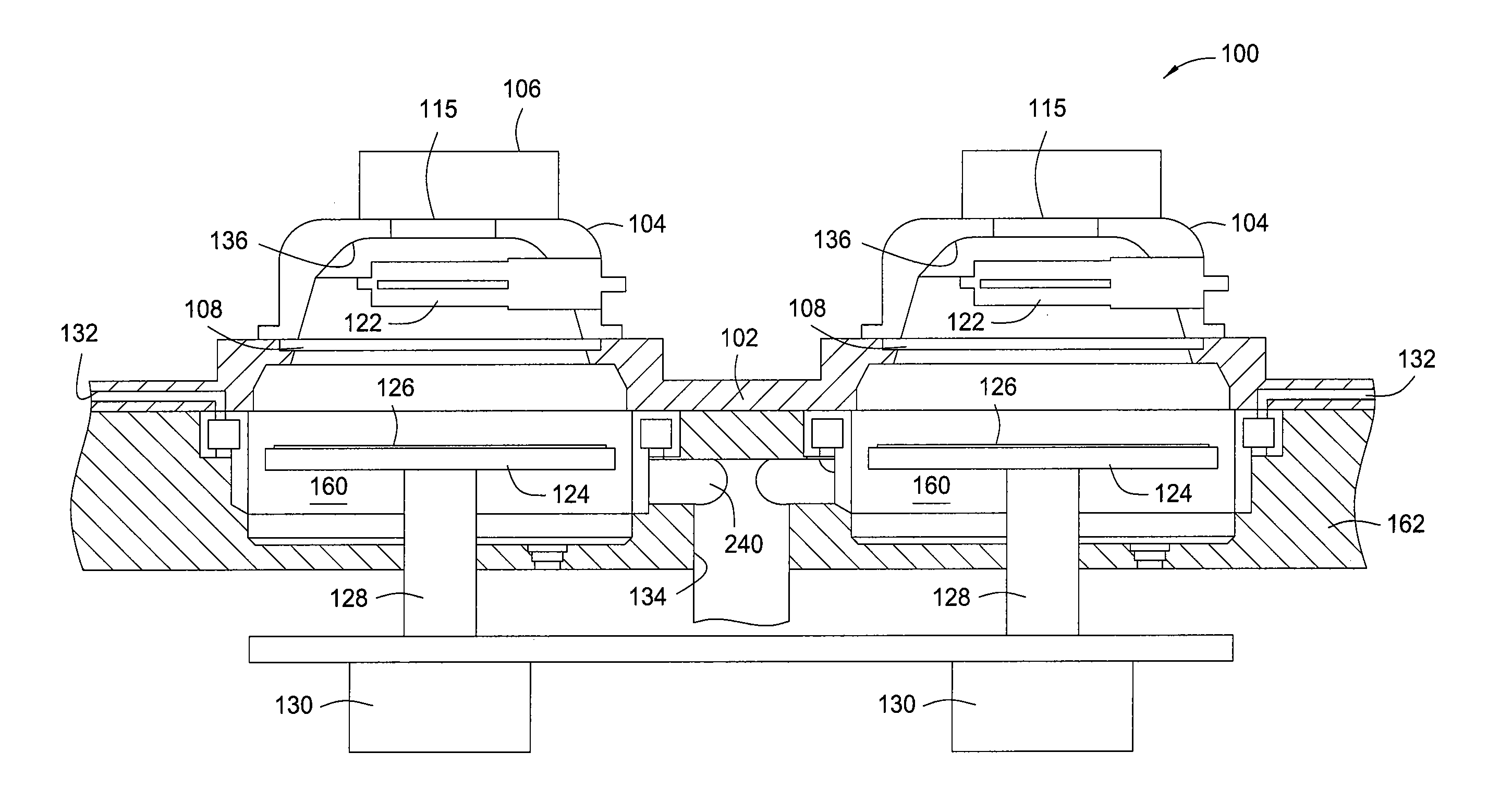

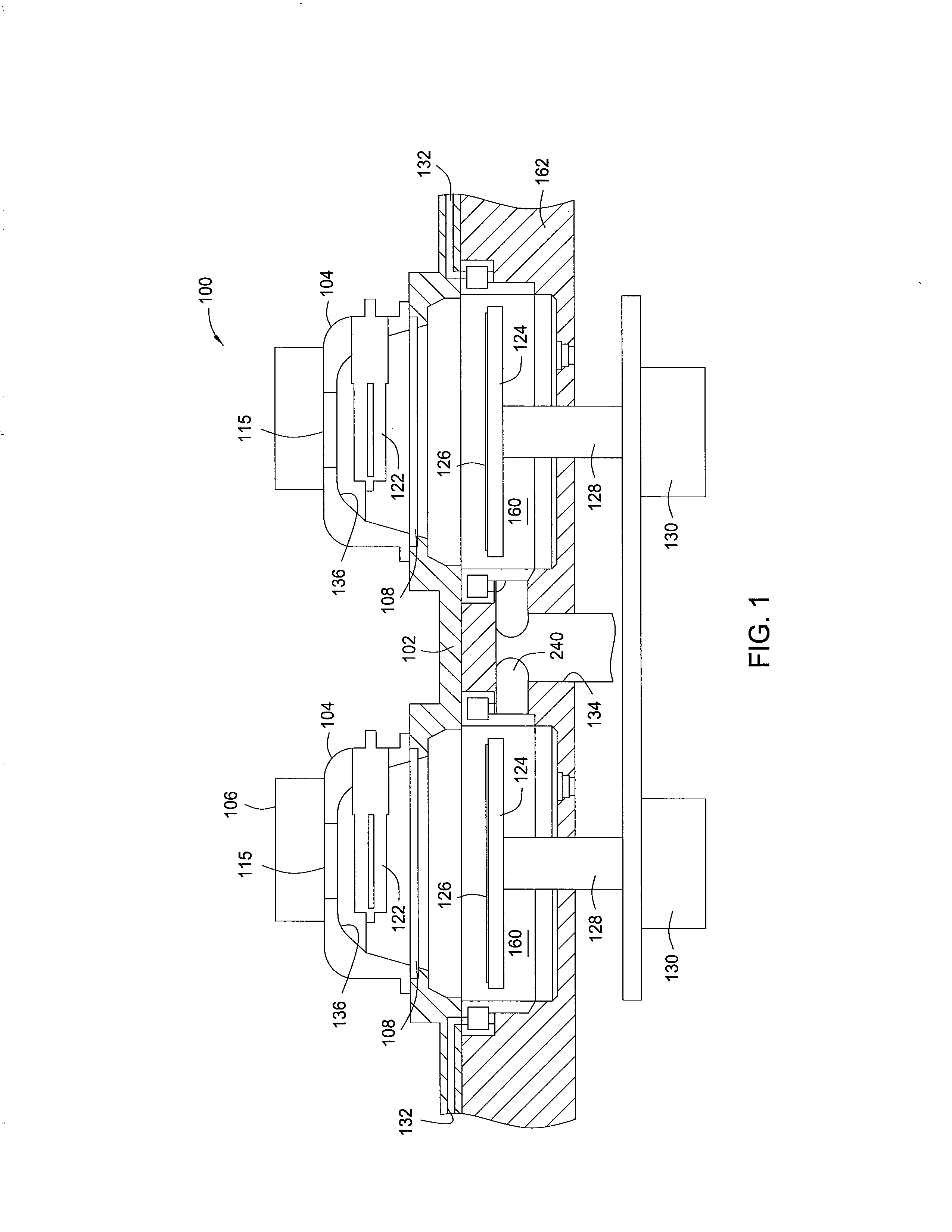

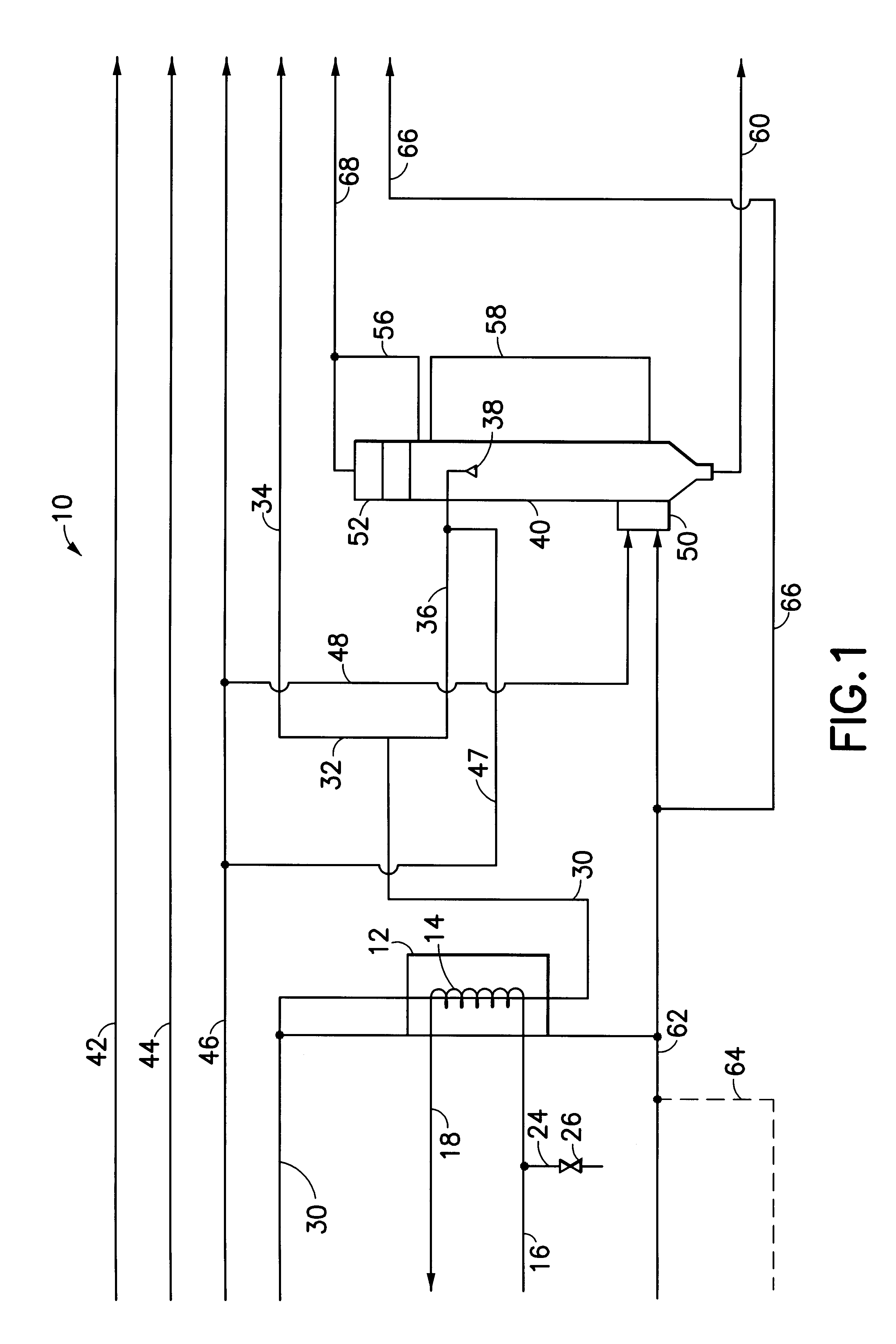

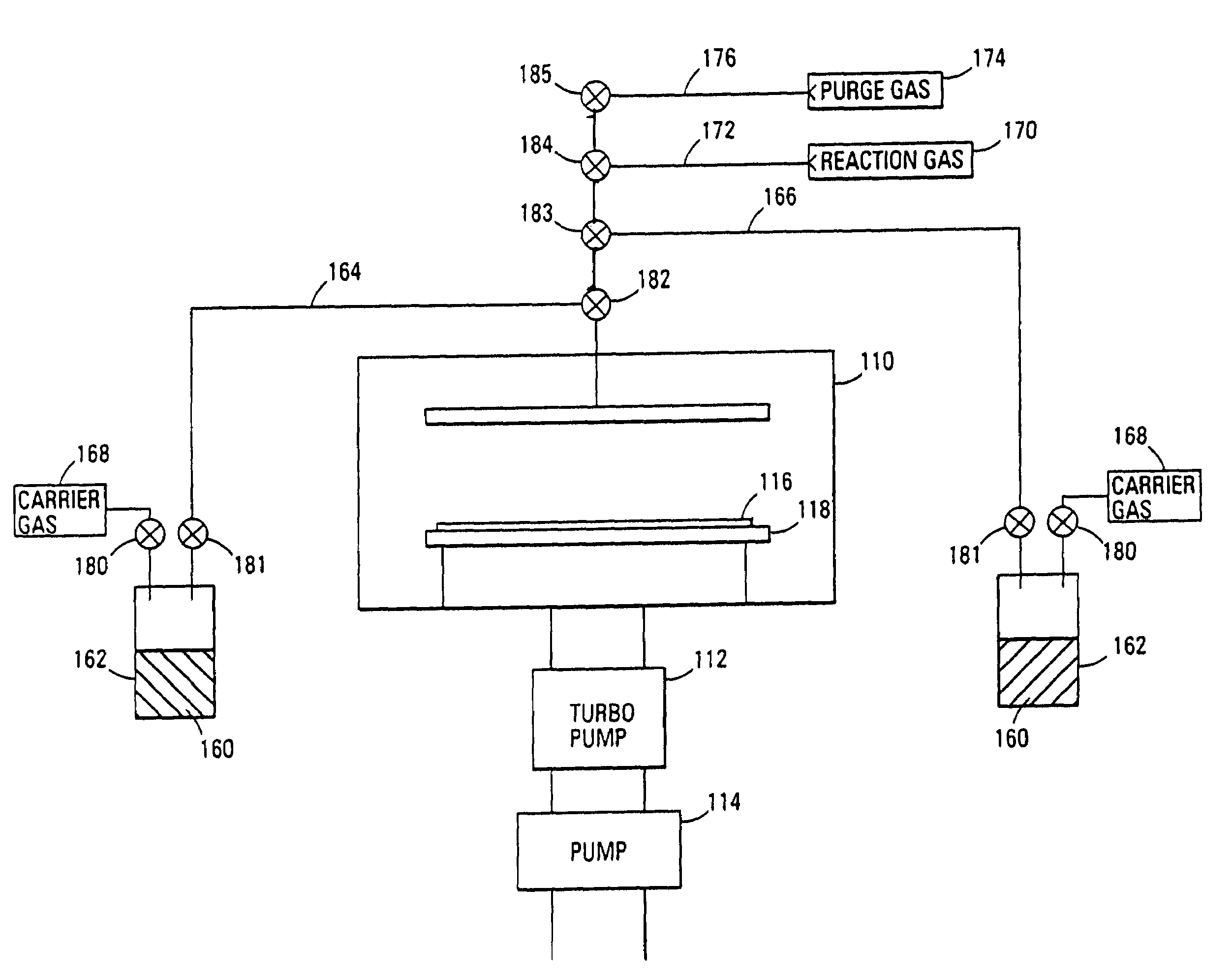

Tandem UV chamber for curing dielectric materials

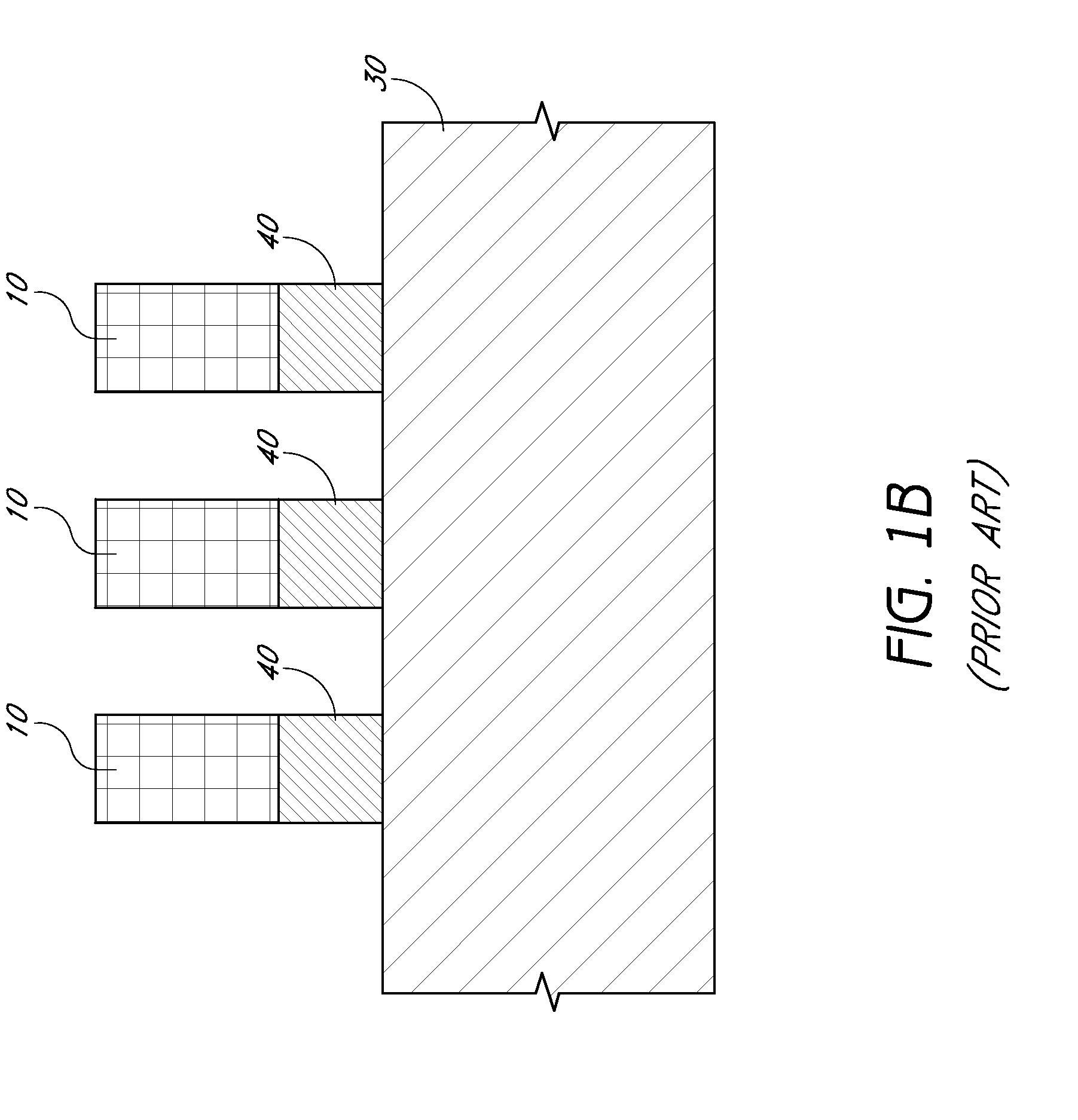

InactiveUS20060251827A1Improve uniformityDrying solid materials with heatSemiconductor/solid-state device manufacturingUltravioletProcess region

An ultraviolet (UV) cure chamber enables curing a dielectric material disposed on a substrate and in situ cleaning thereof. A tandem process chamber provides two separate and adjacent process regions defined by a body covered with a lid having windows aligned respectively above each process region. One or more UV bulbs per process region that are covered by housings coupled to the lid emit UV light directed through the windows onto substrates located within the process regions. The UV bulbs can be an array of light emitting diodes or bulbs utilizing a source such as microwave or radio frequency. The UV light can be pulsed during a cure process. Using oxygen radical / ozone generated remotely and / or in-situ accomplishes cleaning of the chamber. Use of lamp arrays, relative motion of the substrate and lamp head, and real-time modification of lamp reflector shape and / or position can enhance uniformity of substrate illumination.

Owner:APPLIED MATERIALS INC

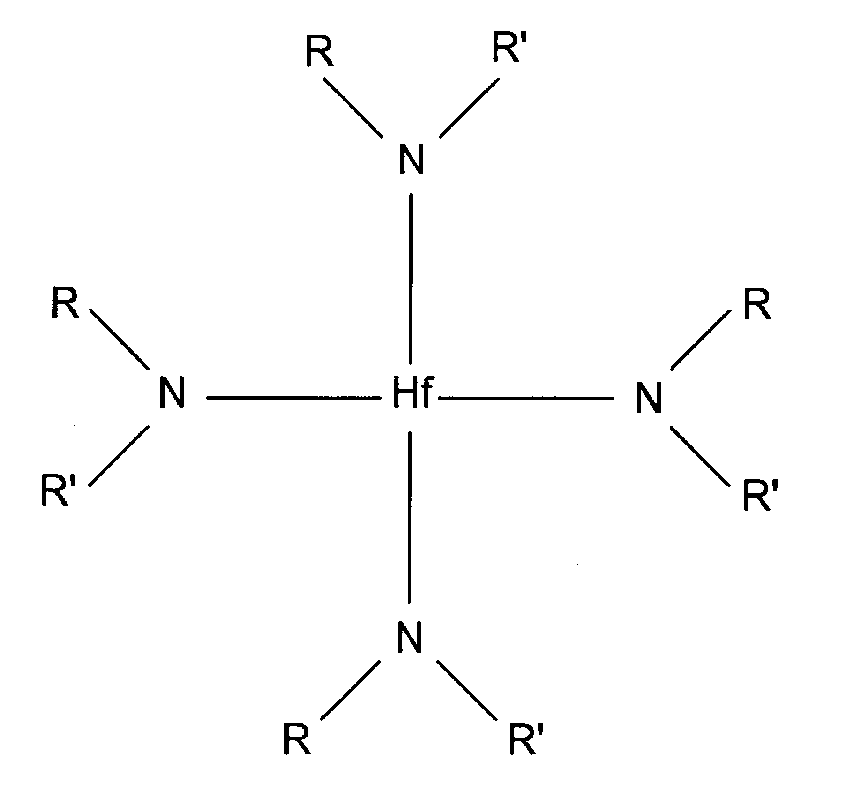

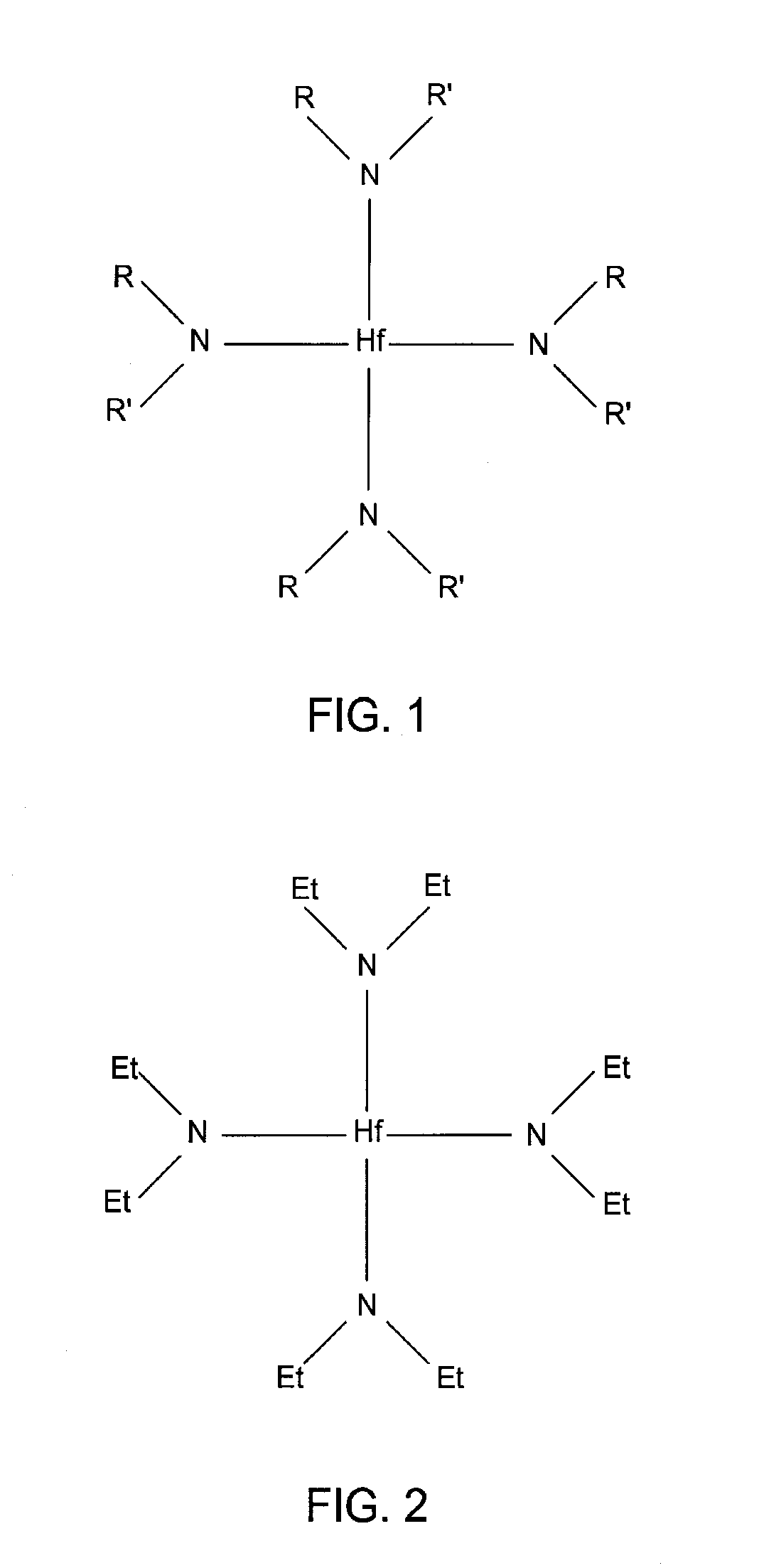

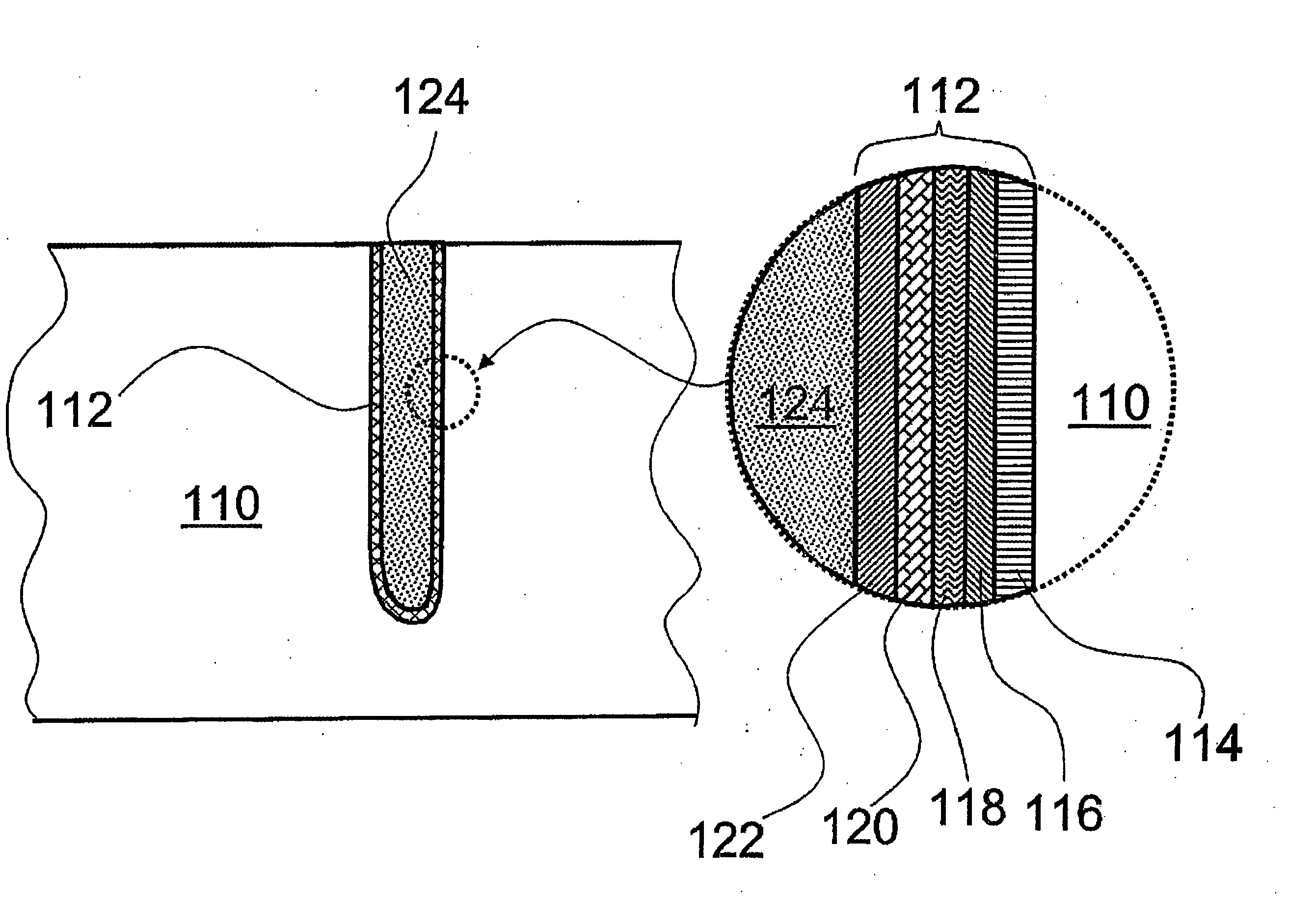

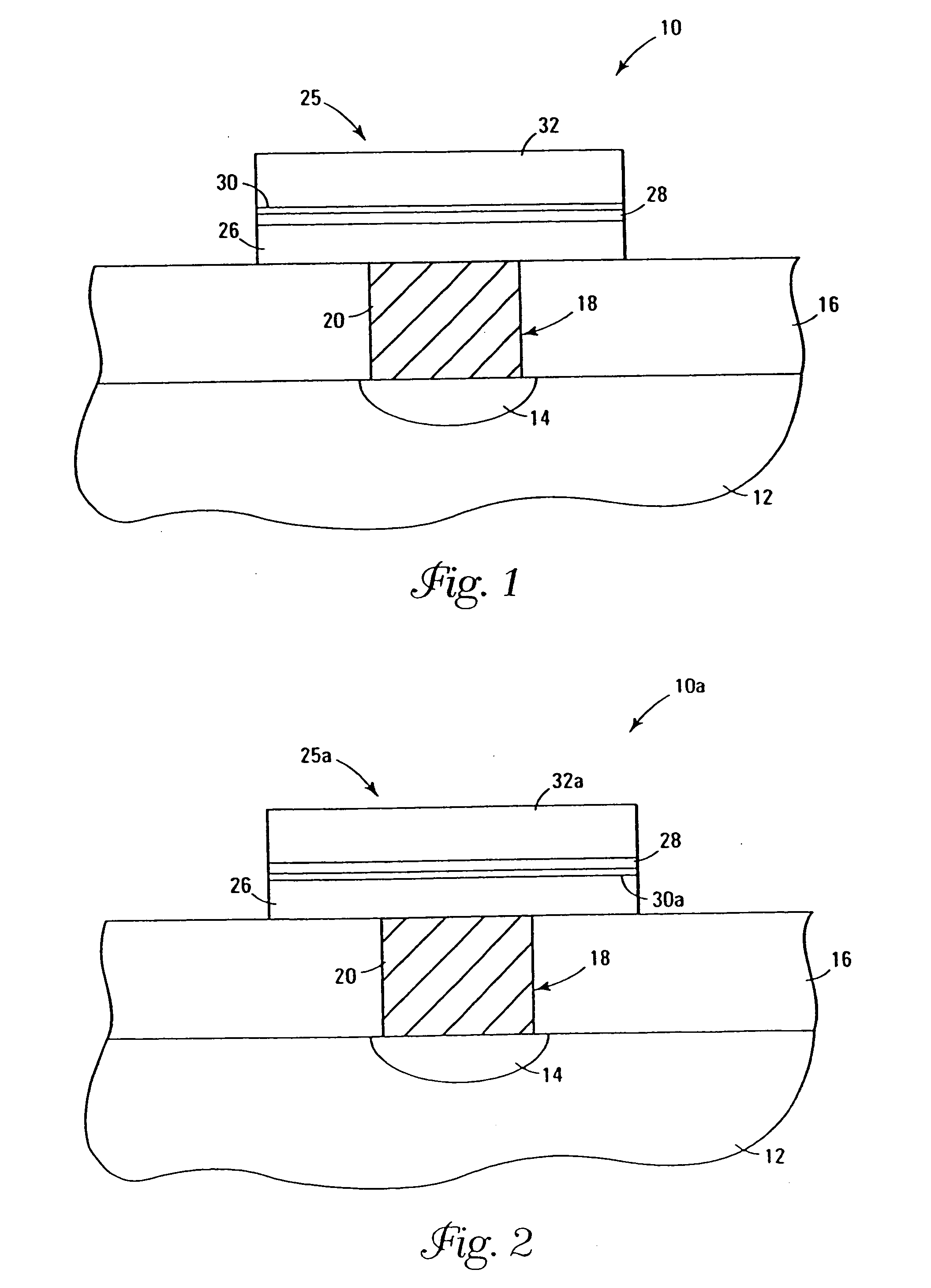

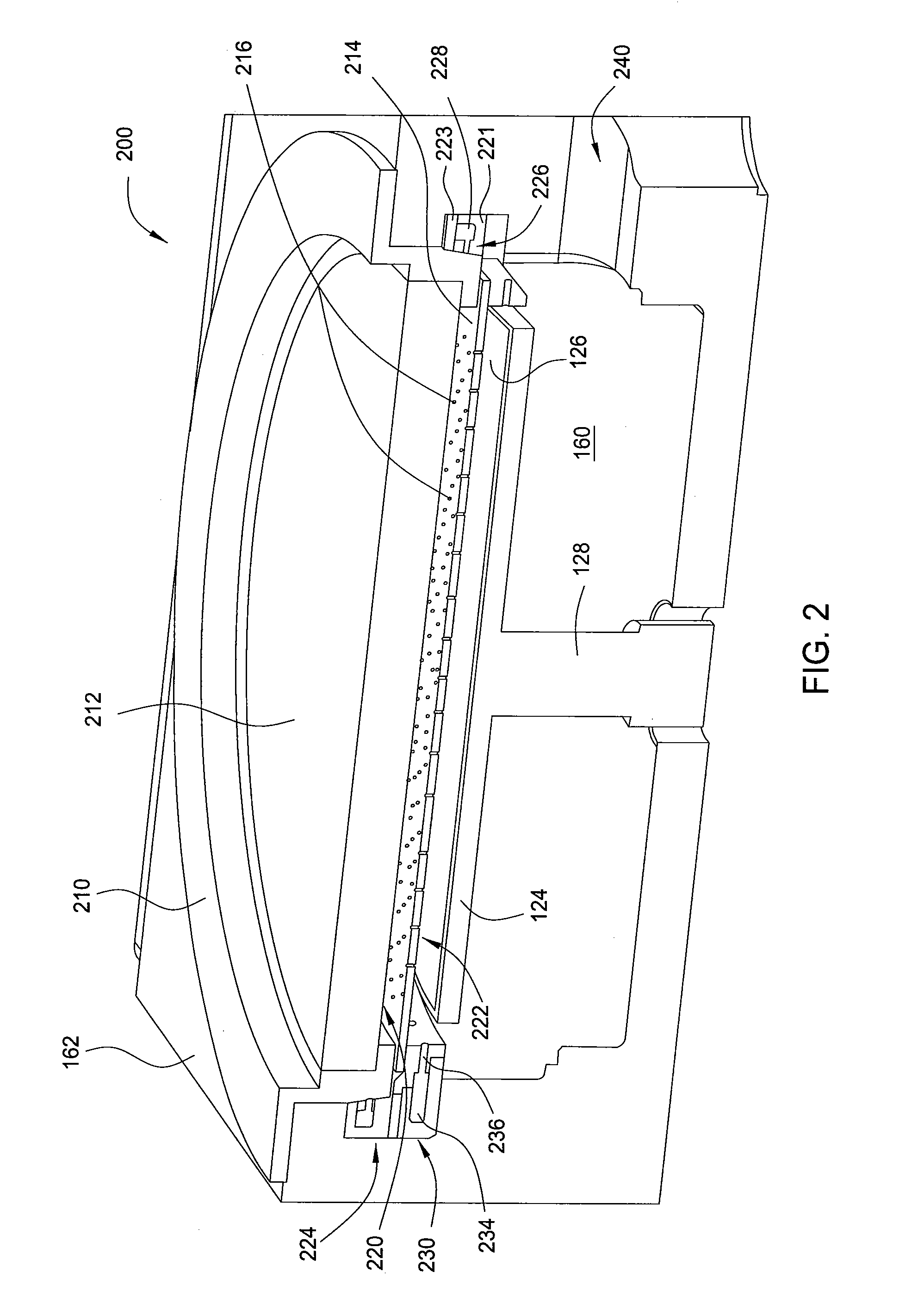

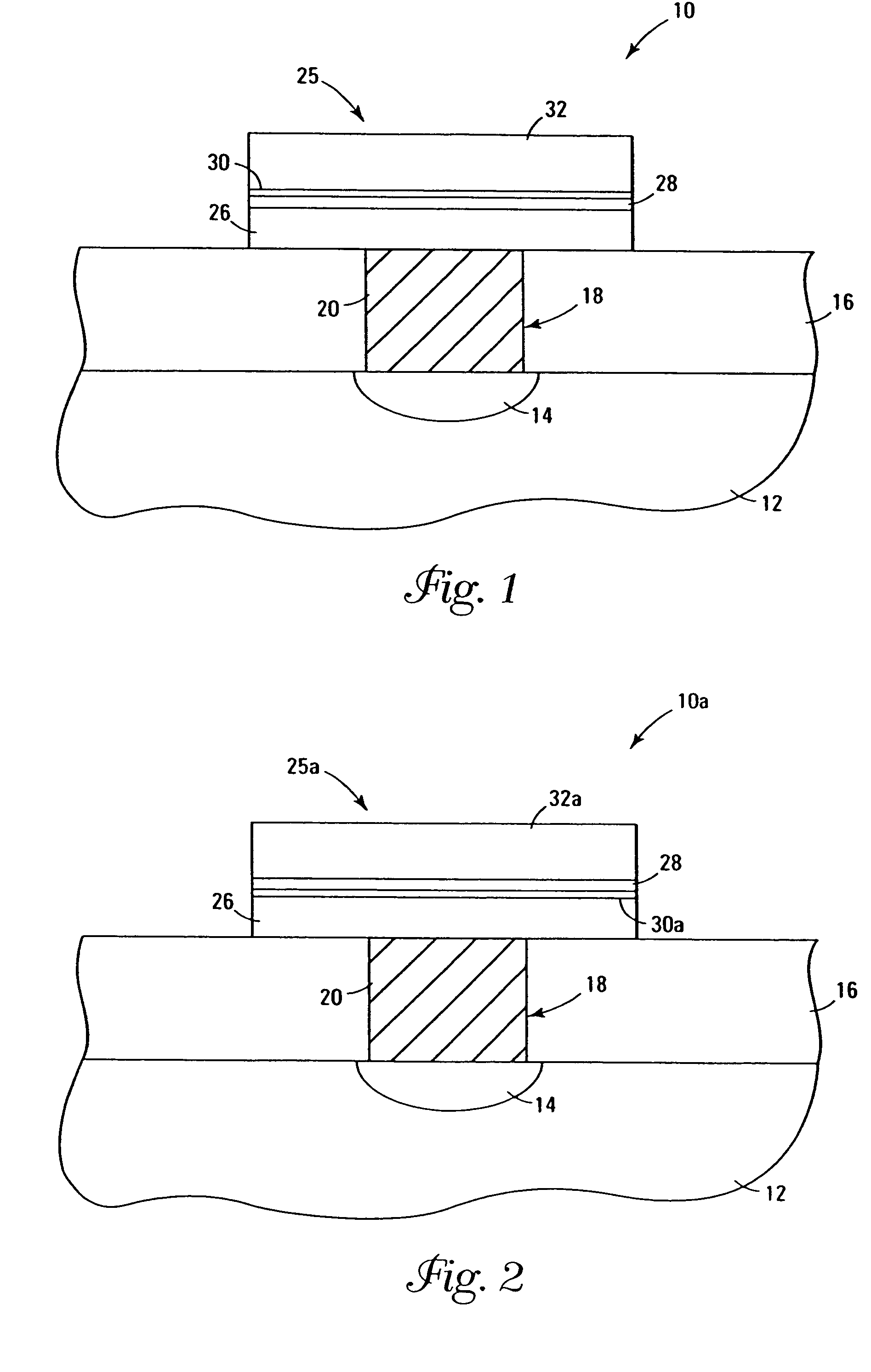

Ald metal oxide deposition process using direct oxidation

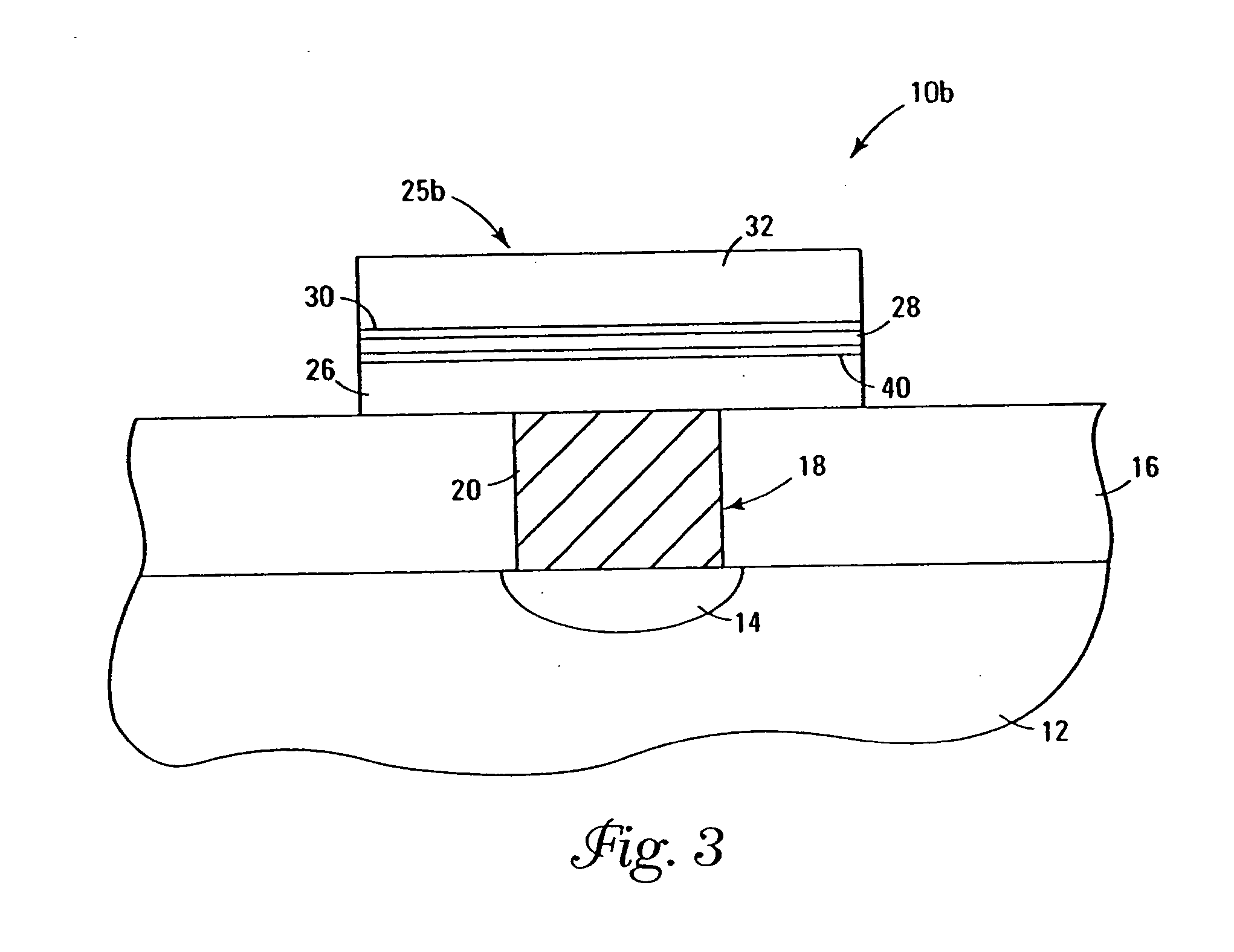

InactiveUS20070059948A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenHafnium

Embodiments of the invention provide methods for forming hafnium materials, such as oxides and nitrides, by sequentially exposing a substrate to hafnium precursors and active oxygen or nitrogen species (e.g., ozone, oxygen radicals, or nitrogen radicals). The deposited hafnium materials have significantly improved uniformity when deposited by these atomic layer deposition (ALD) processes. In one embodiment, an ALD chamber contains an expanding channel having a bottom surface that is sized and shaped to substantially cover a substrate positioned on a substrate pedestal. During an ALD process for forming hafnium materials, process gases form a vortex flow pattern while passing through the expanding channel and sweep across the substrate surface. The substrate is sequentially exposed to chemical precursors that are pulsed into the process chamber having the vortex flow.

Owner:APPLIED MATERIALS INC

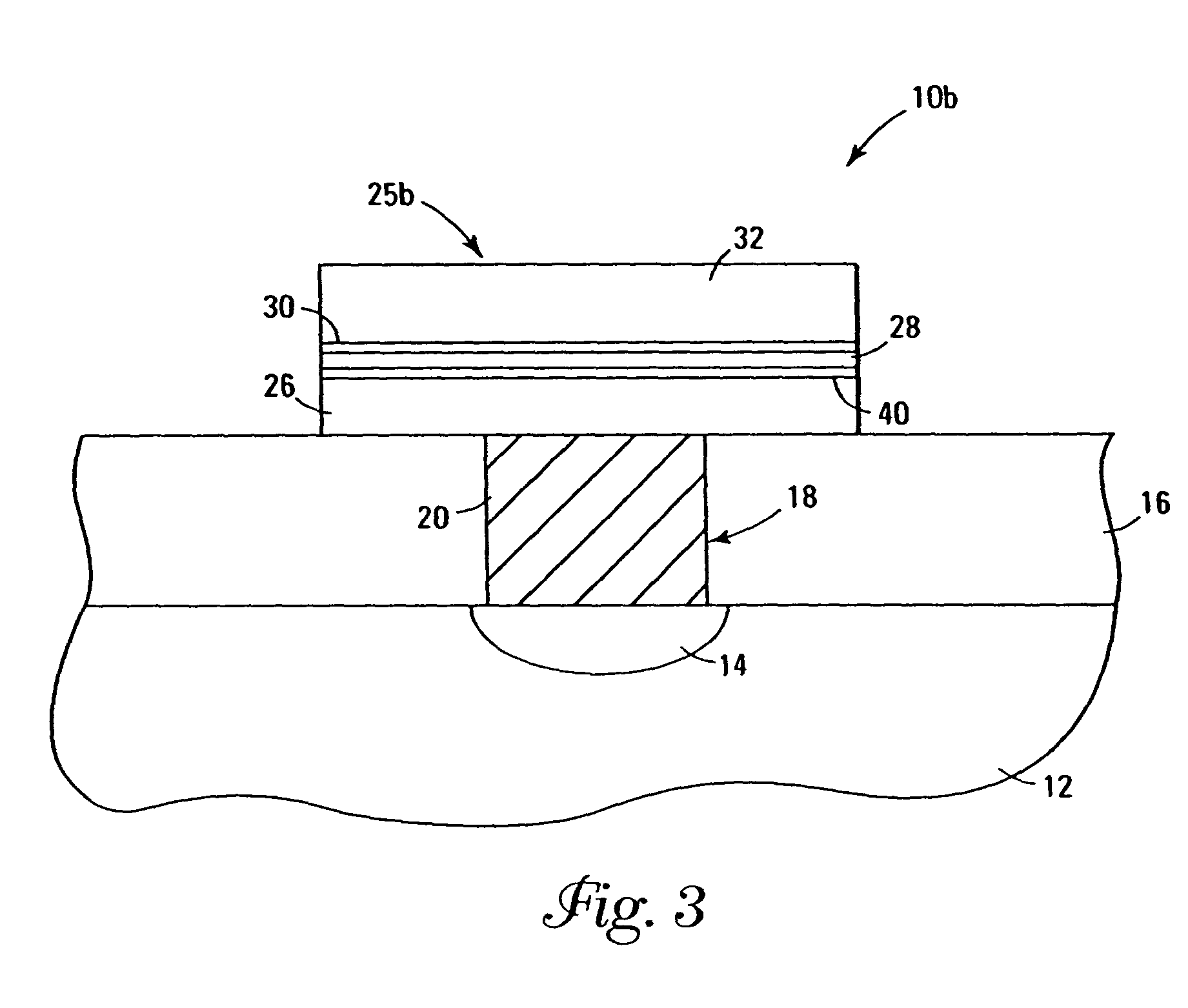

Pretreatment processes within a batch ALD reactor

InactiveUS20070049053A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingWater vaporHafnium

Embodiments of the invention provide methods for forming a material on a substrate which includes exposing a plurality of substrates within a batch process chamber to a first oxidizing gas during a pretreatment process, exposing the substrates sequentially to a precursor and a second oxidizing gas during an ALD cycle and repeating the ALD cycle to form a material on the substrates. In a preferred example, a hafnium precursor is used during the ALD process to form a hafnium-containing material, such as hafnium oxide. In one example, the first and second oxidizing gases are the same oxidizing gases. In a preferred example, the first and second oxidizing gases are different oxidizing gases, such that the pretreatment process contains ozone and the ALD process contains water vapor.

Owner:APPLIED MATERIALS INC

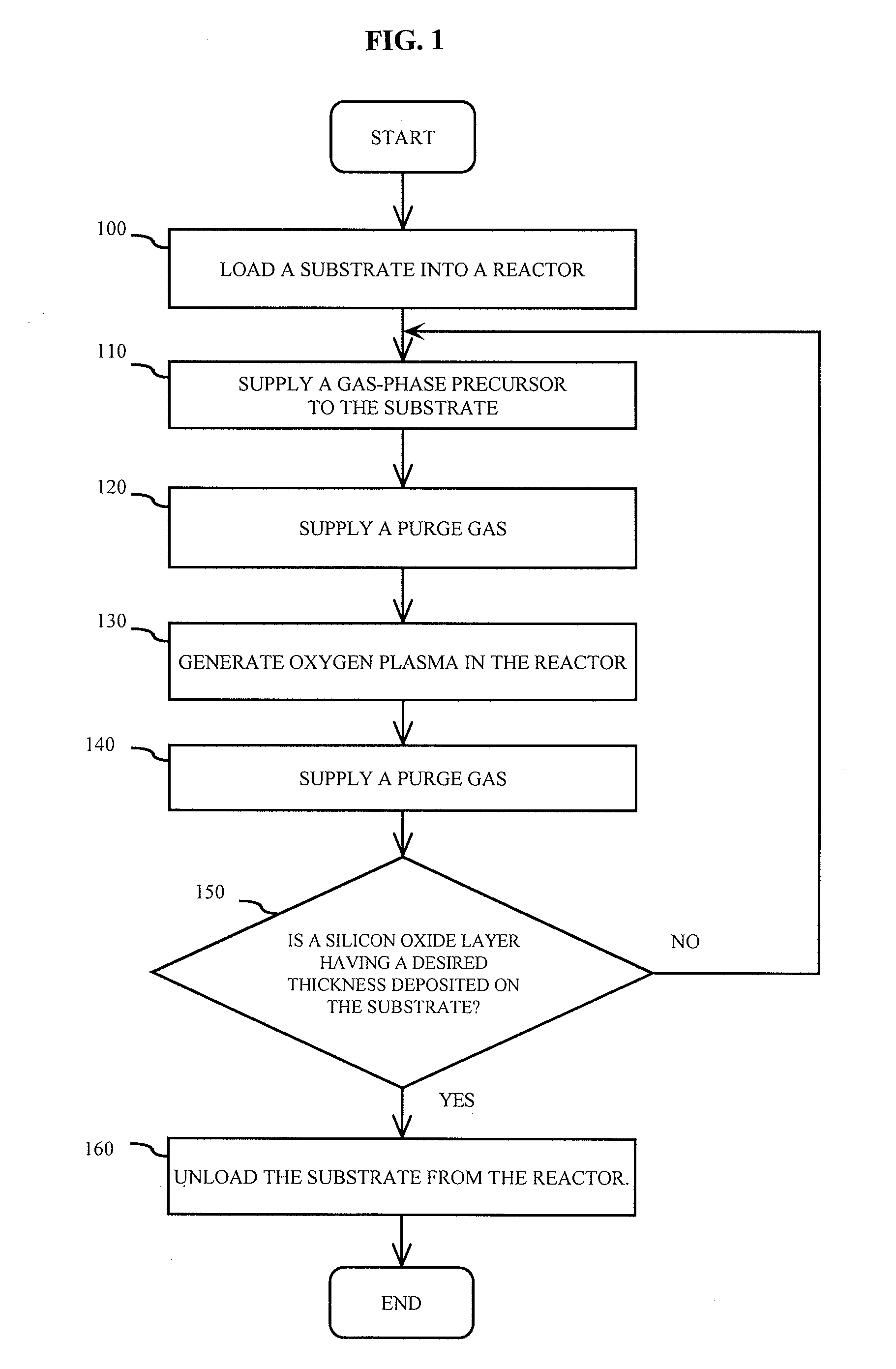

Method of depositing silicon oxide films

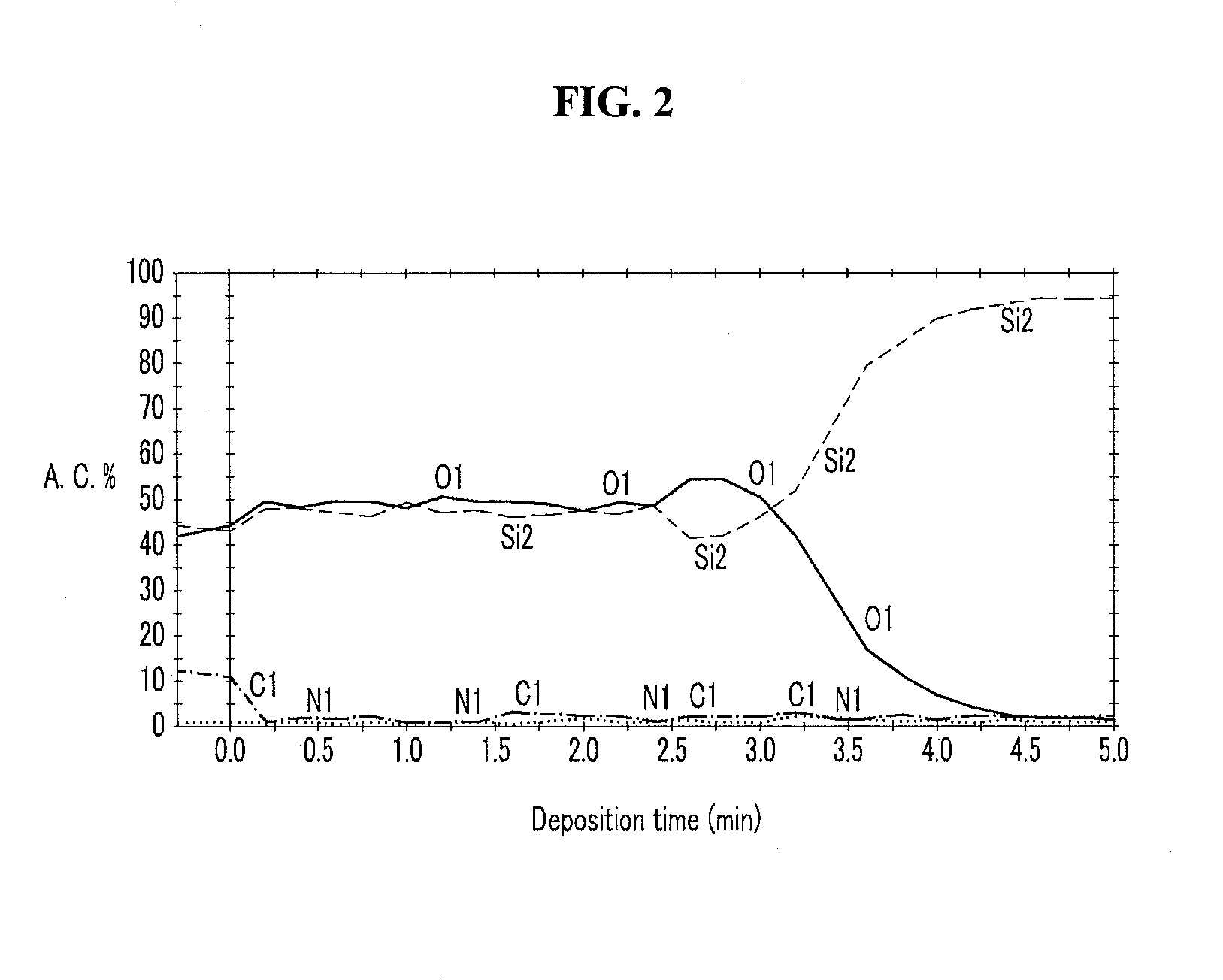

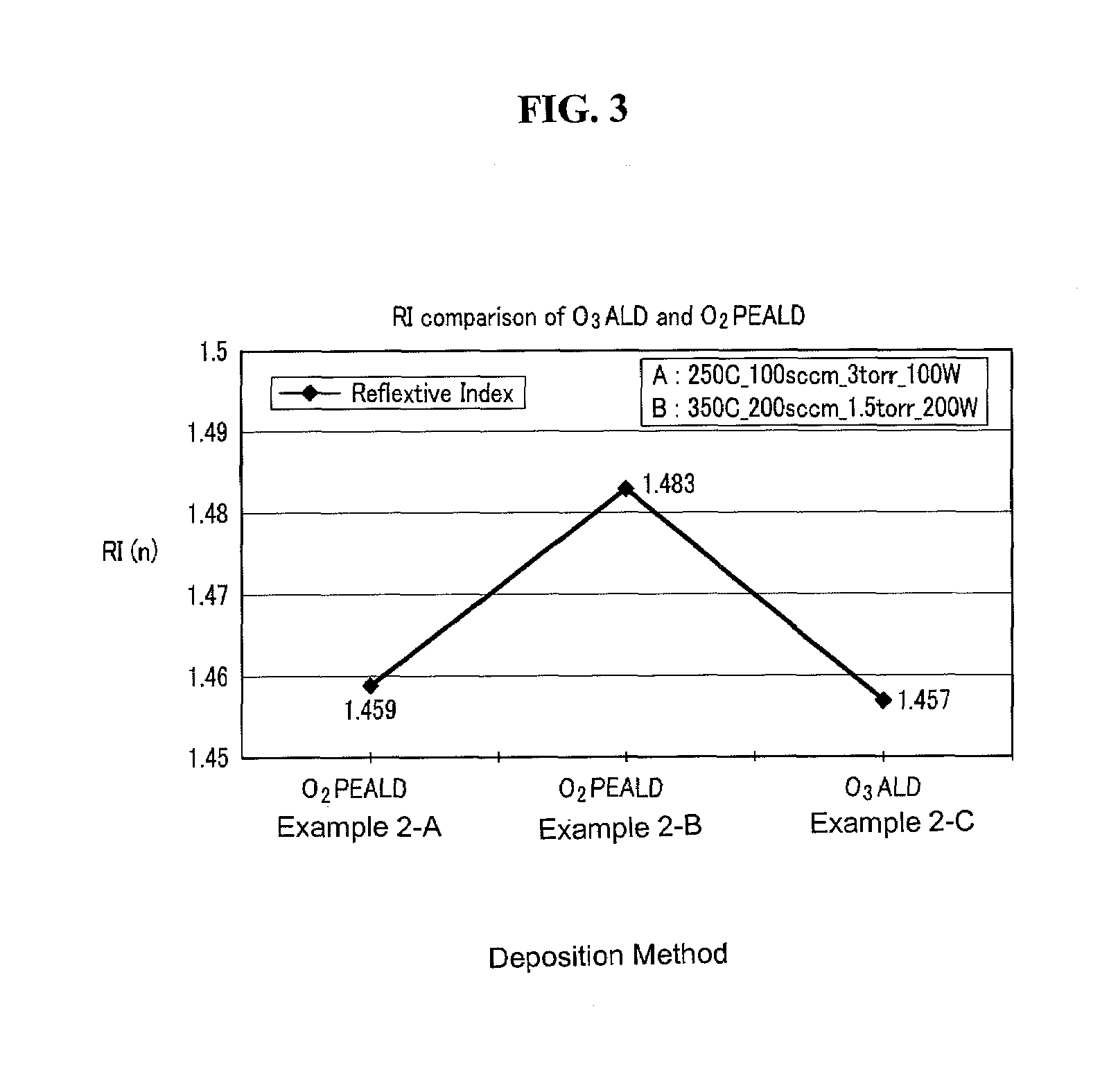

InactiveUS20090041952A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingOxygen plasmaGas phase

Methods of depositing a silicon oxide film are disclosed. One embodiment is a plasma enhanced atomic layer deposition (PEALD) process that includes supplying a vapor phase silicon precursor, such as a diaminosilane compound, to a substrate, and supplying oxygen plasma to the substrate. Another embodiment is a pulsed hybrid method between atomic layer deposition (ALD) and chemical vapor deposition (CVD). In the other embodiment, a vapor phase silicon precursor, such as a diaminosilane compound, is supplied to a substrate while ozone gas is continuously or discontinuously supplied to the substrate.

Owner:ASM KOREA LTD

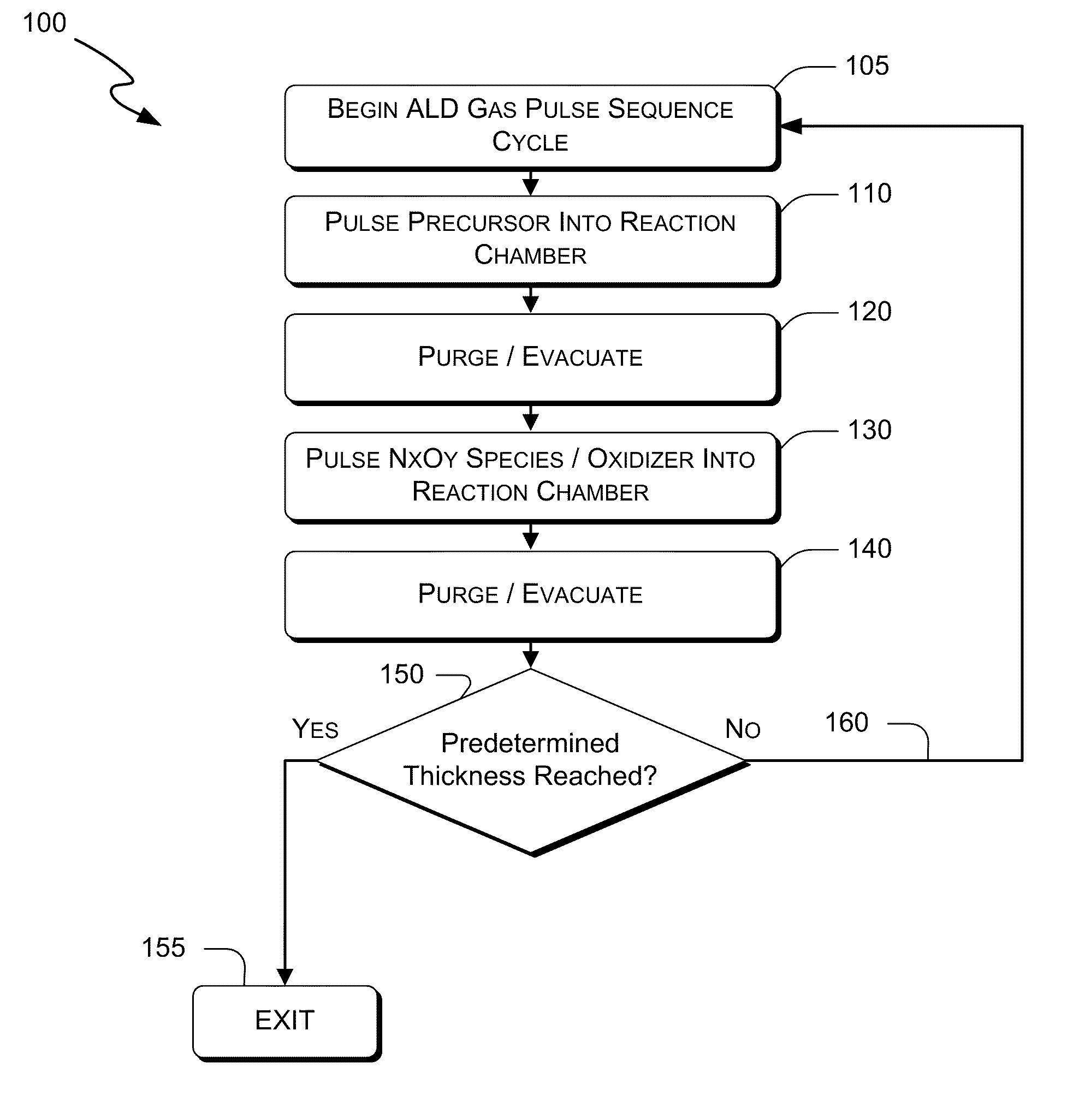

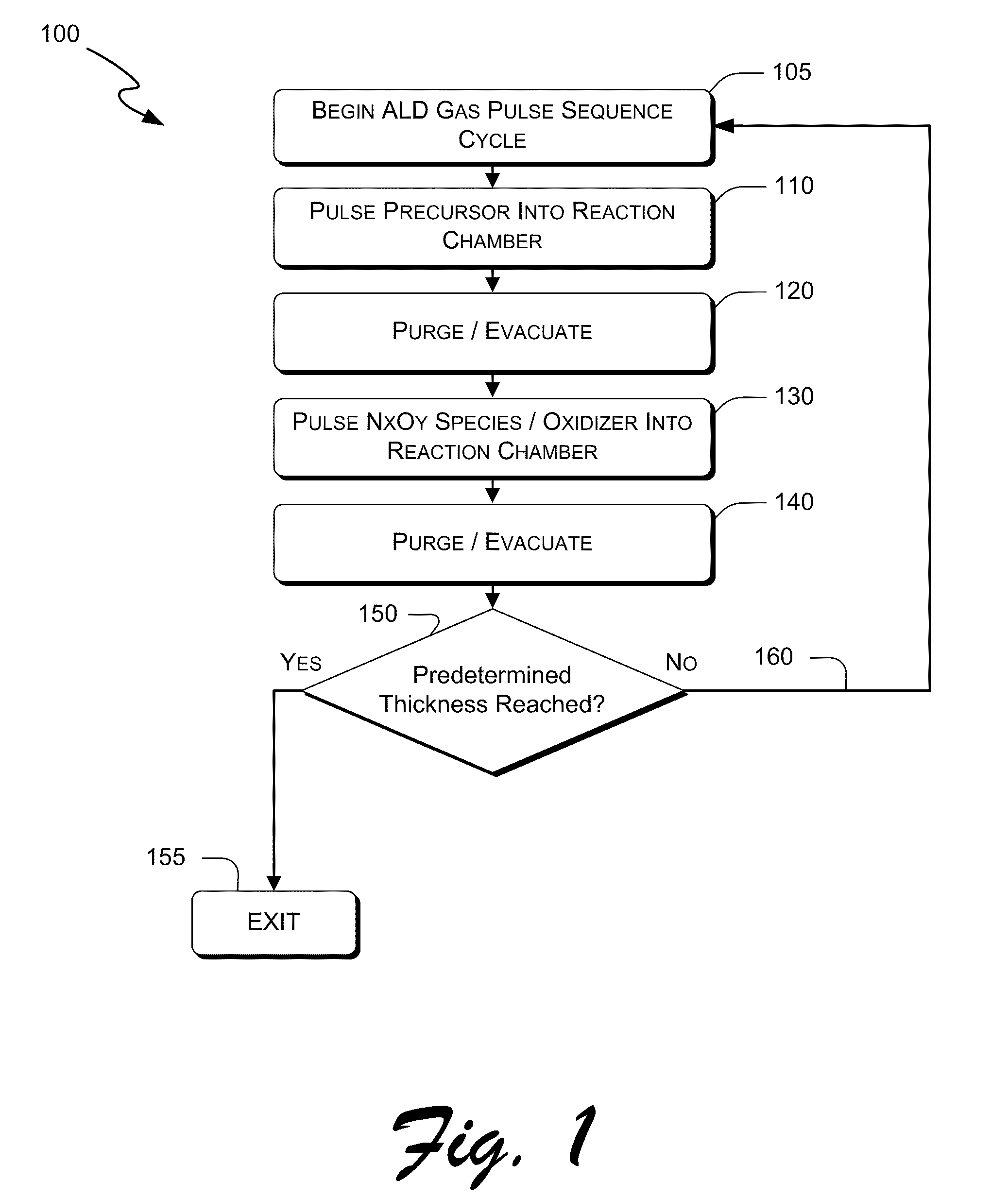

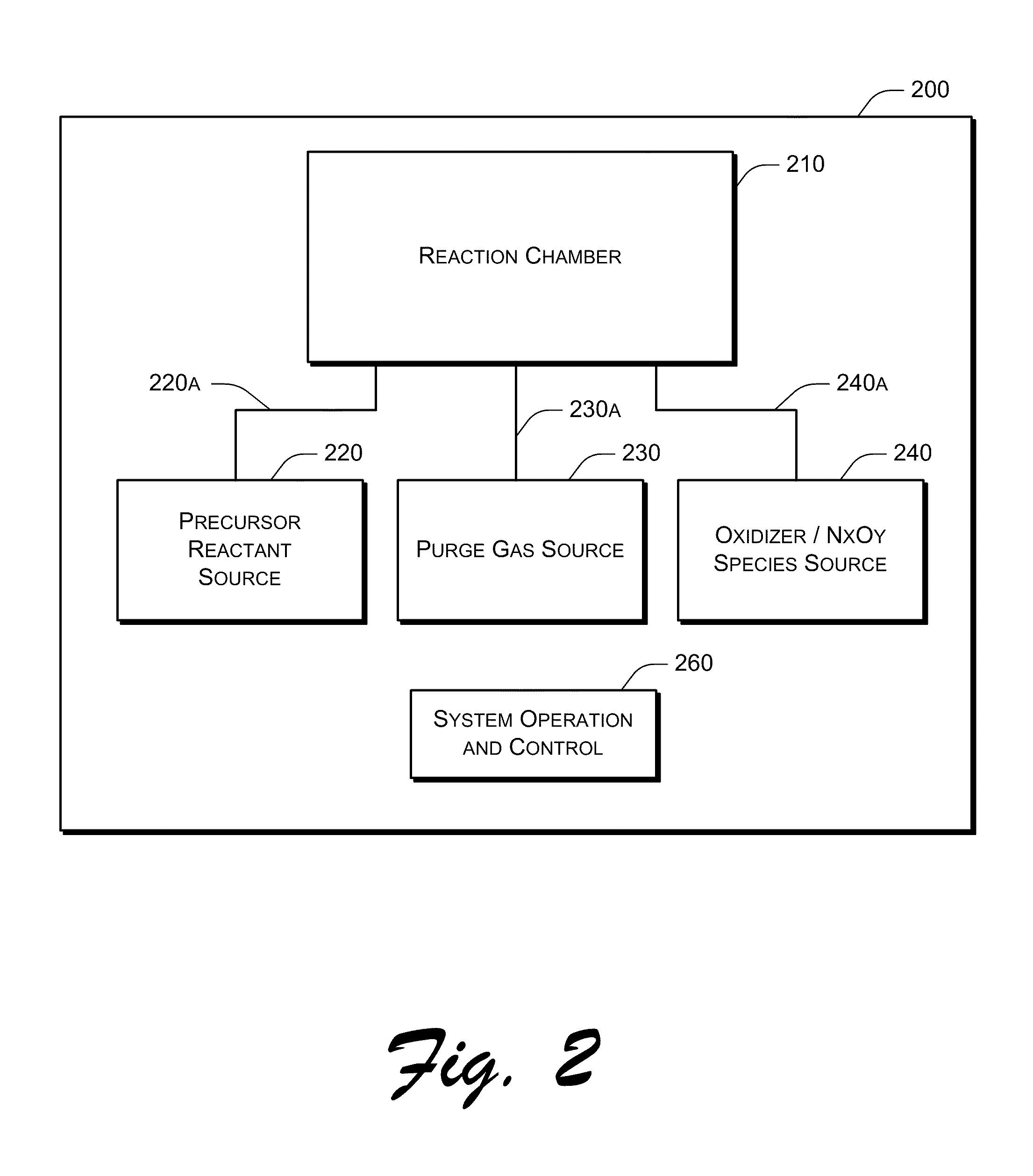

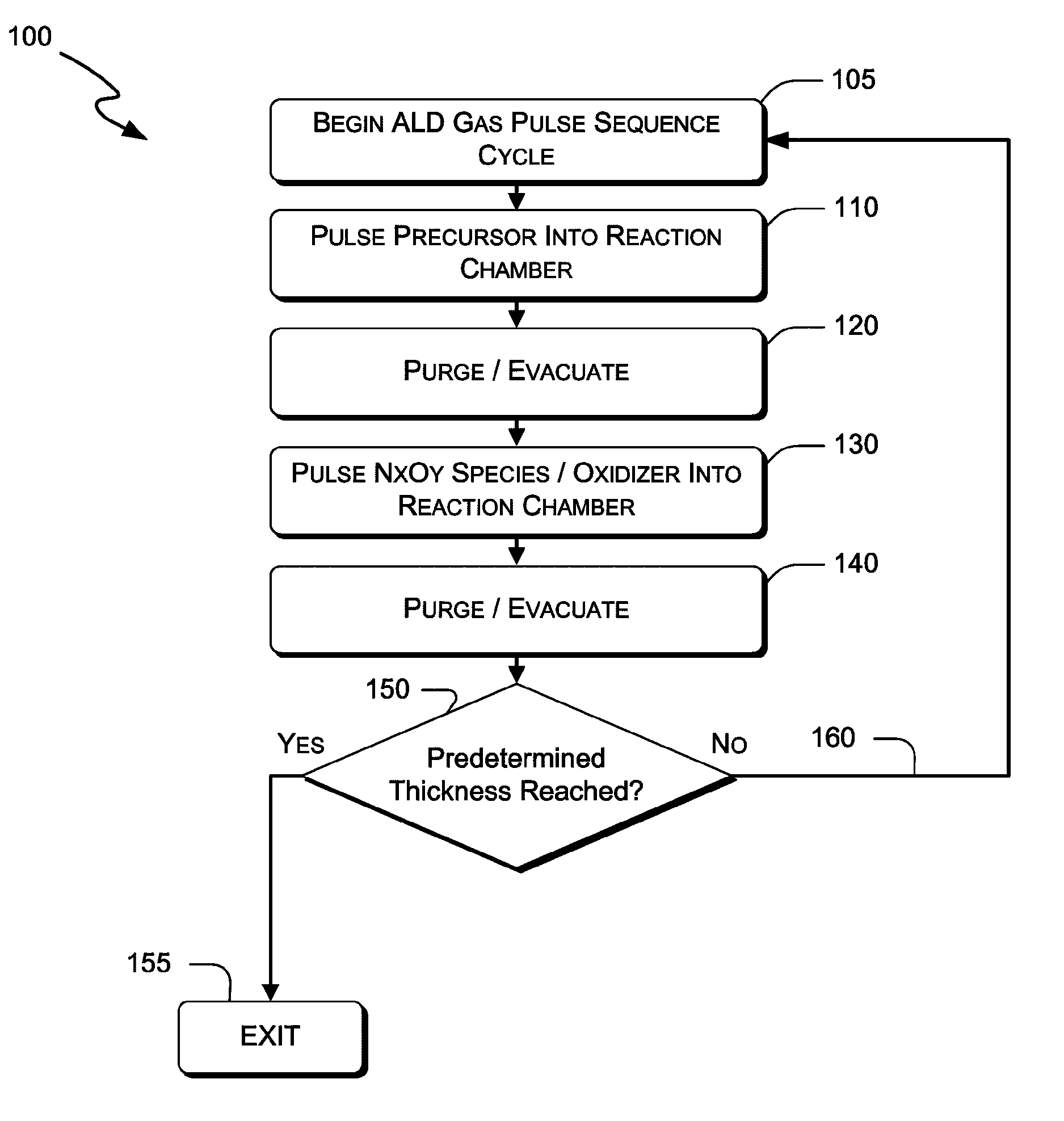

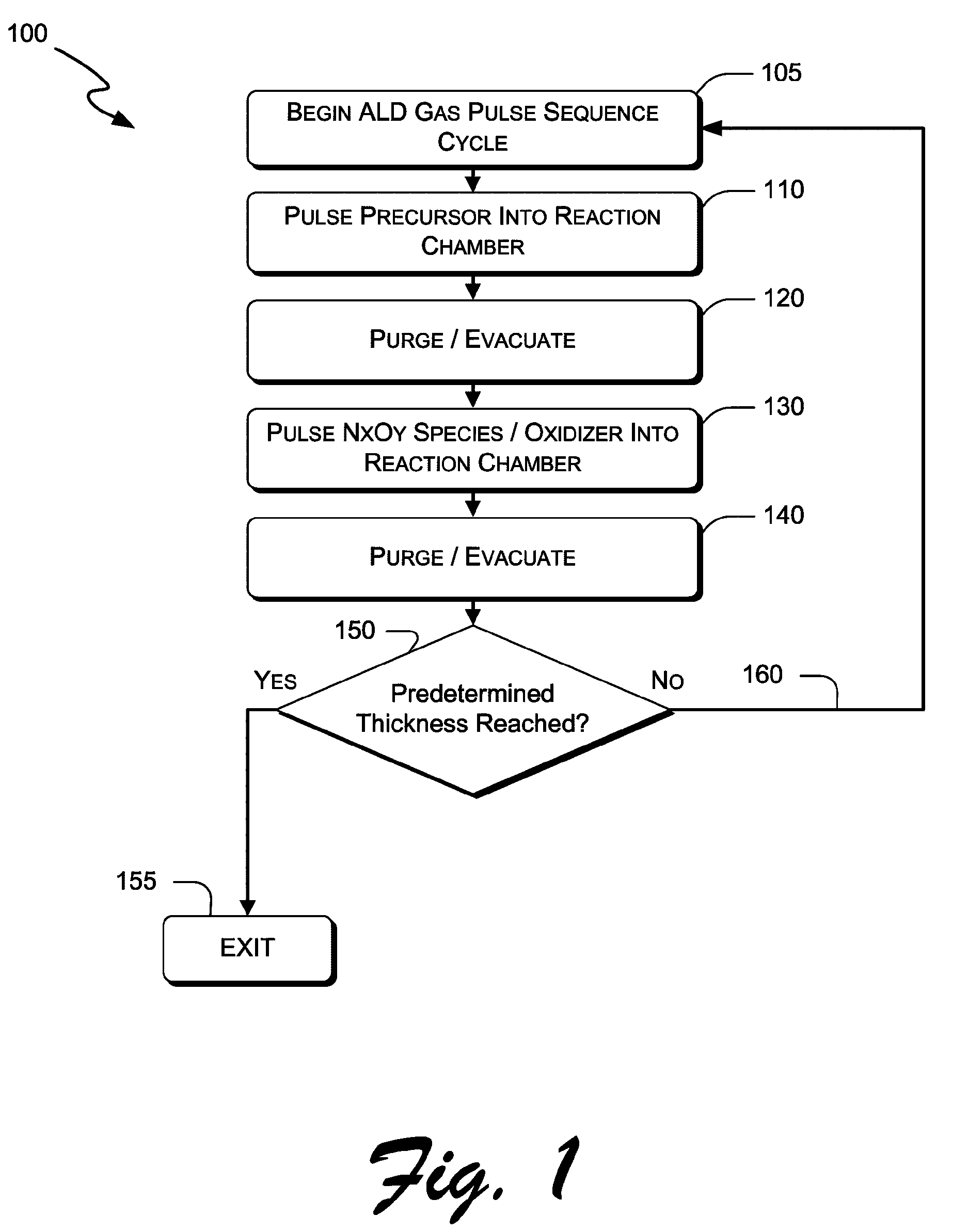

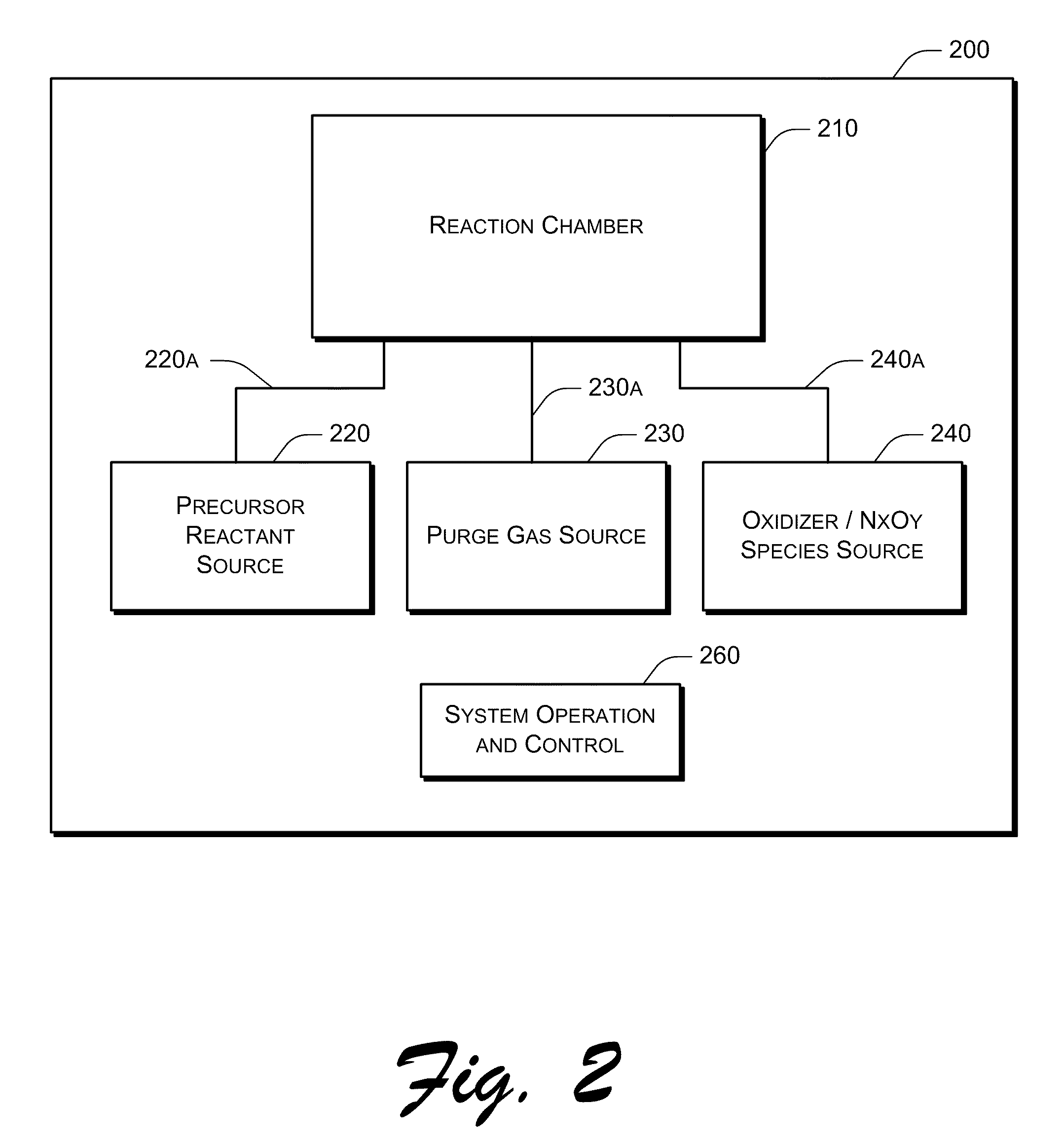

Systems and methods for thin-film deposition of metal oxides using excited nitrogen-oxygen species

ActiveUS20110070380A1Improve deposition efficiencyImprove uniformitySemiconductor/solid-state device manufacturingElectrical discharge ozone preparationNitrogenOxygen

Systems and methods are delineated which, among other things, are for depositing a film on a substrate that is within a reaction chamber. In an exemplary method, the method may comprise applying an atomic layer deposition cycle to the substrate, wherein the cycle may comprise exposing the substrate to a precursor gas for a precursor pulse interval and then removing the precursor gas thereafter, and exposing the substrate to an oxidizer comprising an oxidant gas and a nitrogen-containing species gas for an oxidation pulse interval and then removing the oxidizer thereafter. Aspects of the present invention utilize molecular and excited nitrogen-oxygen radical / ionic species in possible further combination with oxidizers such as ozone. Embodiments of the present invention also include electronic components and systems that include devices fabricated with methods consistent with the present invention.

Owner:ASM IP HLDG BV

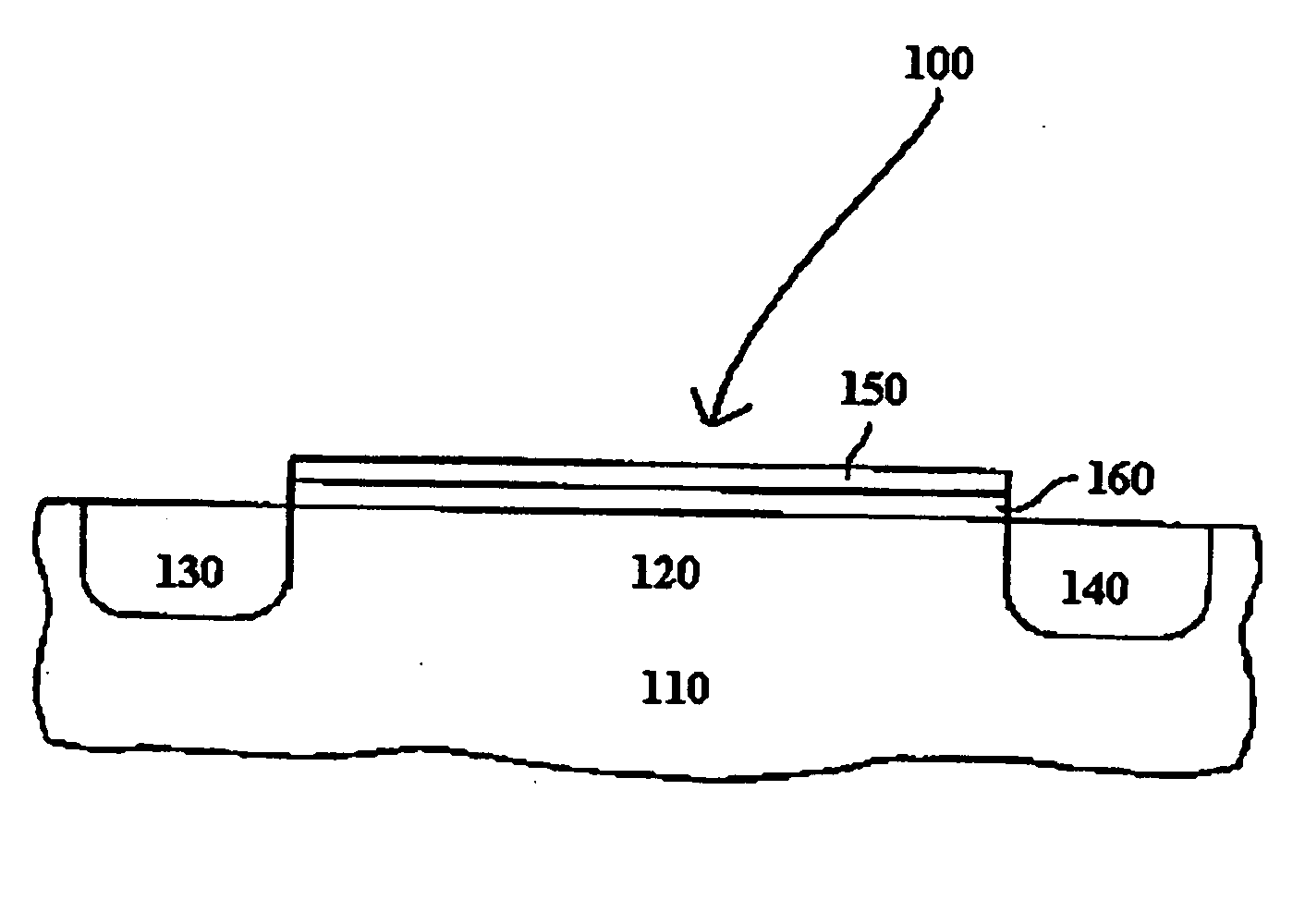

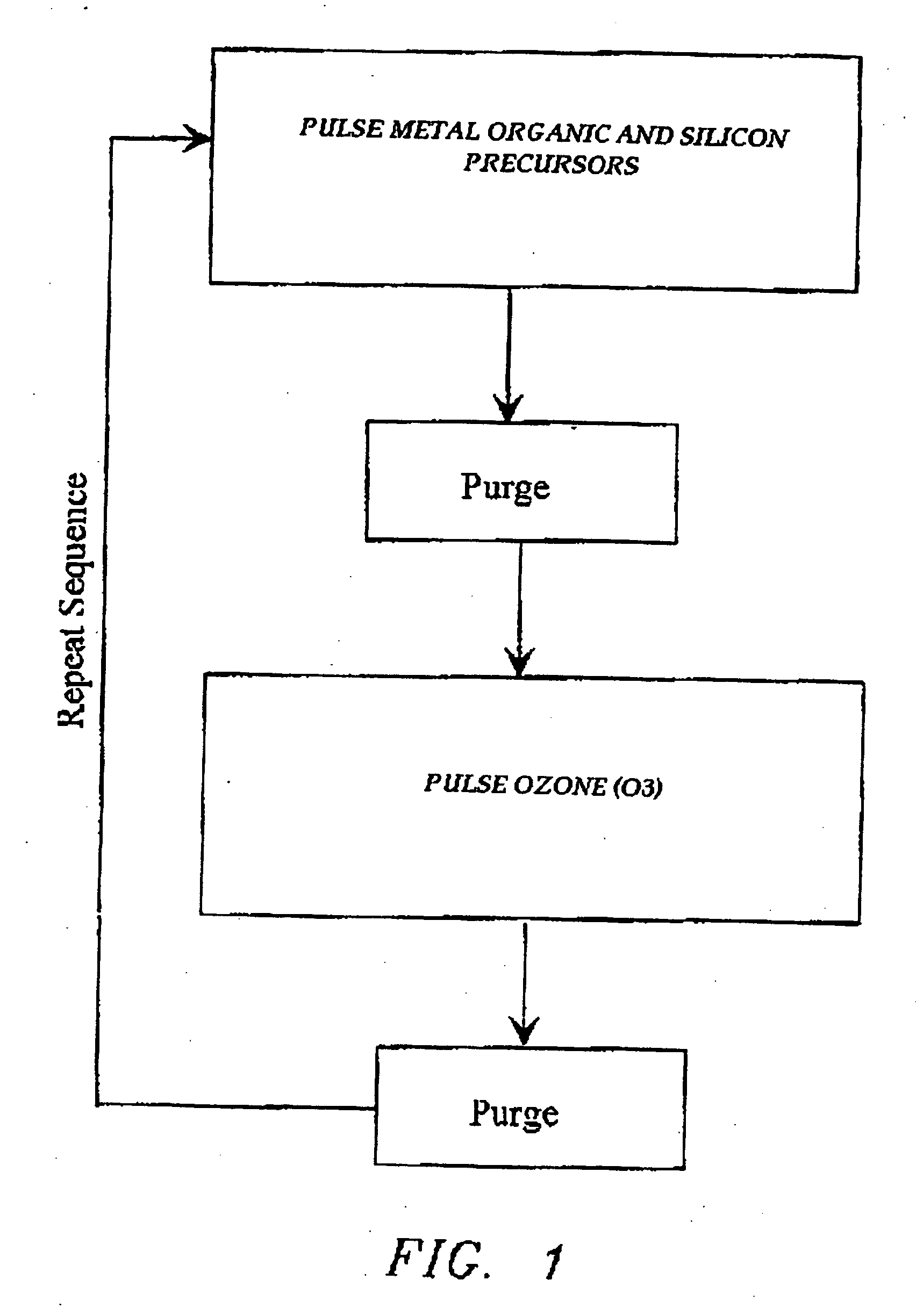

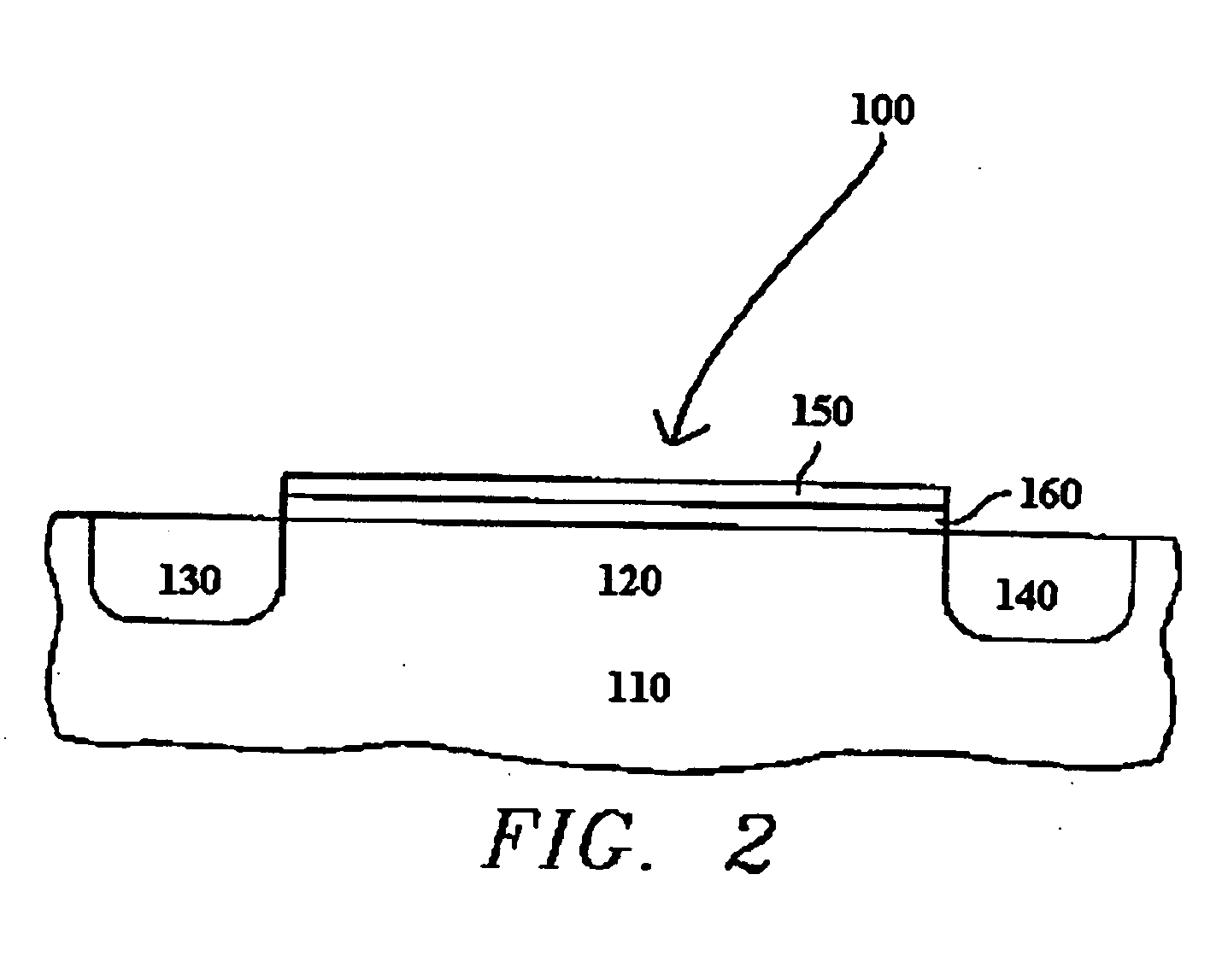

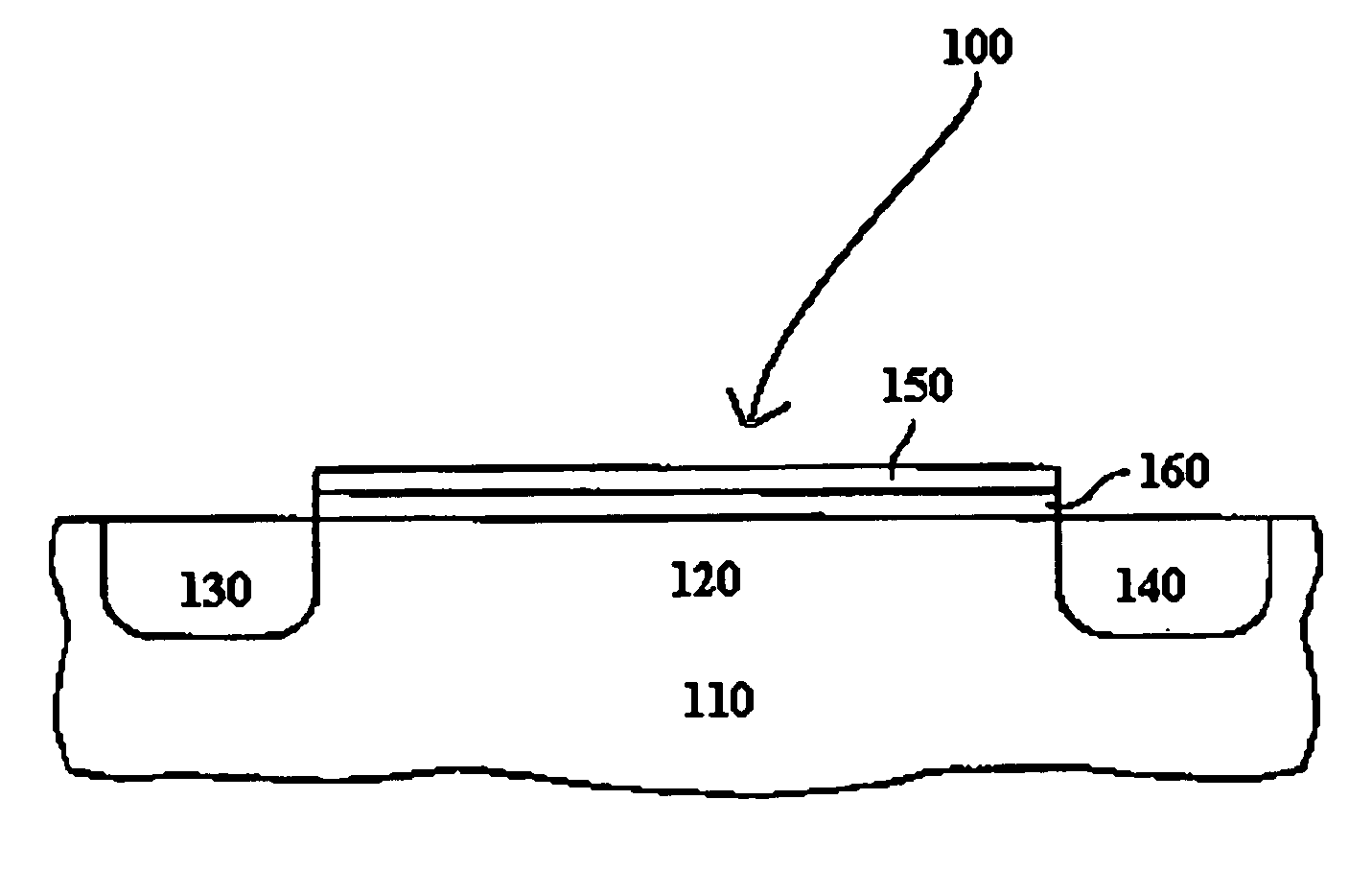

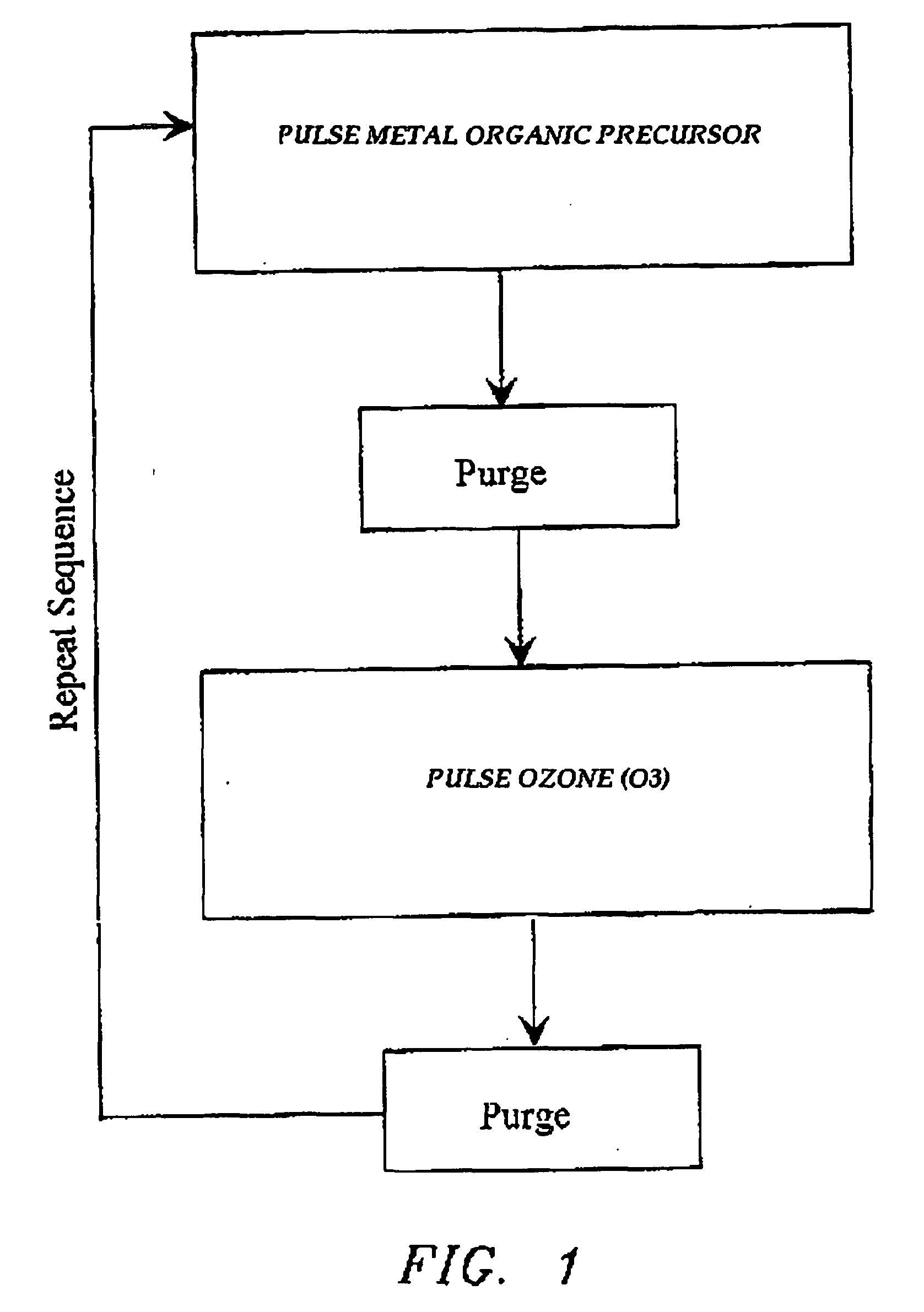

Atomic layer deposition of high k metal silicates

InactiveUS20060228888A1Reduce carbon pollutionReduce stepsSolid-state devicesSemiconductor/solid-state device manufacturingHafniumAtomic layer deposition

The present invention relates to the atomic layer deposition (“ALD”) of high k dielectric layers of metal silicates, including hafnium silicate. More particularly, the present invention relates to the ALD formation of metal silicates using metal organic precursors, silicon organic precursors and ozone. Preferably, the metal organic precursor is a metal alkyl amide and the silicon organic precursor is a silicon alkyl amide.

Owner:AVIZA TECHNOLOGY INC +1

Pretreatment processes within a batch ALD reactor

InactiveUS7402534B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBatch processingWater vapor

Embodiments of the invention provide methods for forming a material on a substrate which includes exposing a plurality of substrates within a batch process chamber to a first oxidizing gas during a pretreatment process, exposing the substrates sequentially to a precursor and a second oxidizing gas during an ALD cycle and repeating the ALD cycle to form a material on the substrates. In a preferred example, a hafnium precursor is used during the ALD process to form a hafnium-containing material, such as hafnium oxide. In one example, the first and second oxidizing gases are the same oxidizing gases. In a preferred example, the first and second oxidizing gases are different oxidizing gases, such that the pretreatment process contains ozone and the ALD process contains water vapor.

Owner:APPLIED MATERIALS INC

Systems and methods for thin-film deposition of metal oxides using excited nitrogen—oxygen species

ActiveUS8883270B2Improve deposition efficiencyEnhance growth rate and uniformitySemiconductor/solid-state device manufacturingElectrical discharge ozone preparationOxygenAtomic layer deposition

Systems and methods are delineated which, among other things, are for depositing a film on a substrate that is within a reaction chamber. In an exemplary method, the method may comprise applying an atomic layer deposition cycle to the substrate, wherein the cycle may comprise exposing the substrate to a precursor gas for a precursor pulse interval and then removing the precursor gas thereafter, and exposing the substrate to an oxidizer comprising an oxidant gas and a nitrogen-containing species gas for an oxidation pulse interval and then removing the oxidizer thereafter. Aspects of the present invention utilize molecular and excited nitrogen-oxygen radical / ionic species in possible further combination with oxidizers such as ozone. Embodiments of the present invention also include electronic components and systems that include devices fabricated with methods consistent with the present invention.

Owner:ASM IP HLDG BV

Atomic layer deposition of high-k metal oxides

InactiveUS20060258078A1Improve thermal stabilityLess growthSolid-state devicesSemiconductor/solid-state device manufacturingDielectric layerTitanium oxide

The present invention relates to the atomic layer deposition (“ALD”) of high k dielectric layers of metal oxides containing Group 4 metals, including hafnium oxide, zirconium oxide, and titanium oxide. More particularly, the present invention relates to the ALD formation of Group 4 metal oxide films using an metal alkyl amide as a metal organic precursor and ozone as a co-reactant.

Owner:AVIZA TECHNOLOGY INC +1

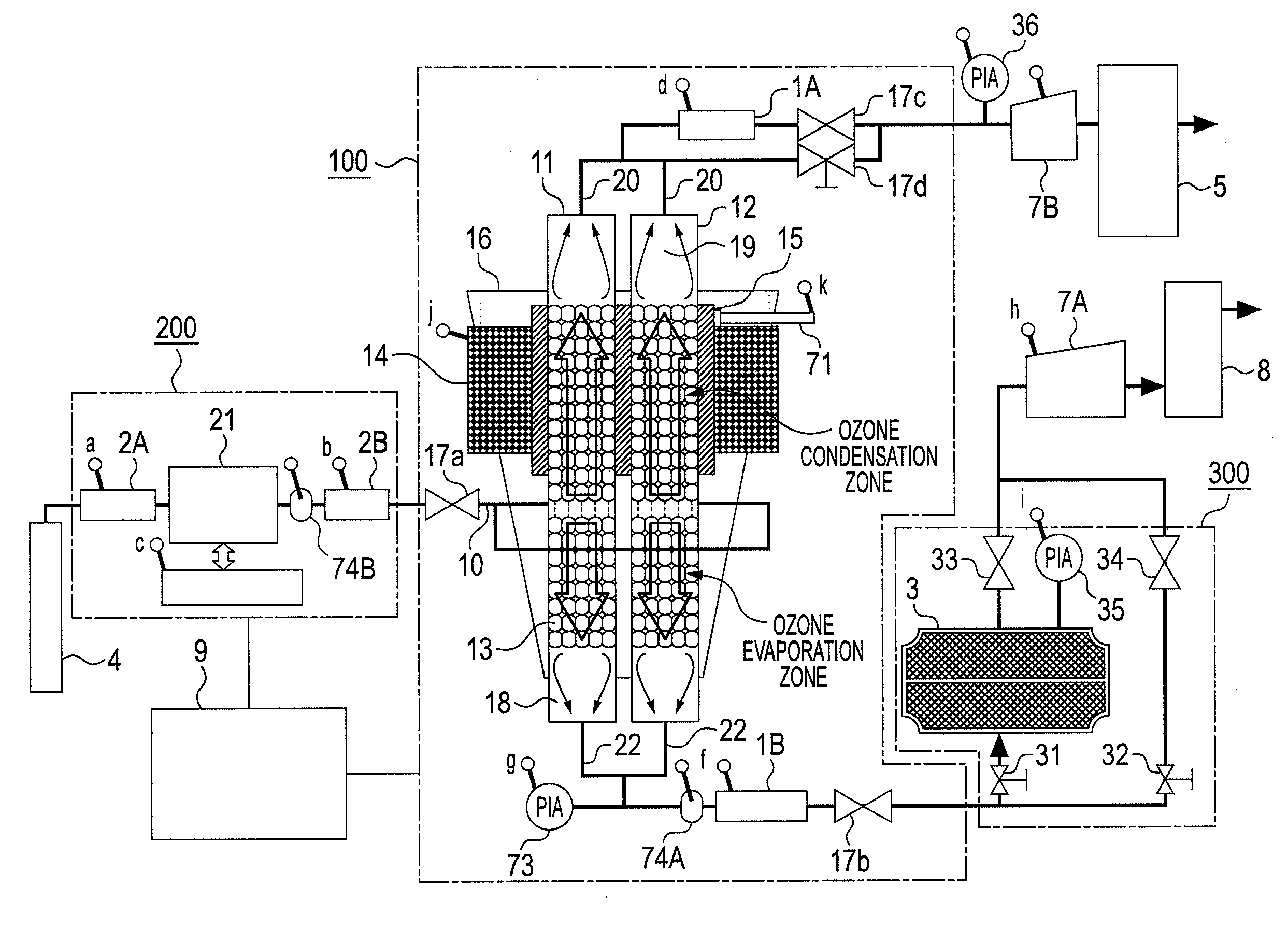

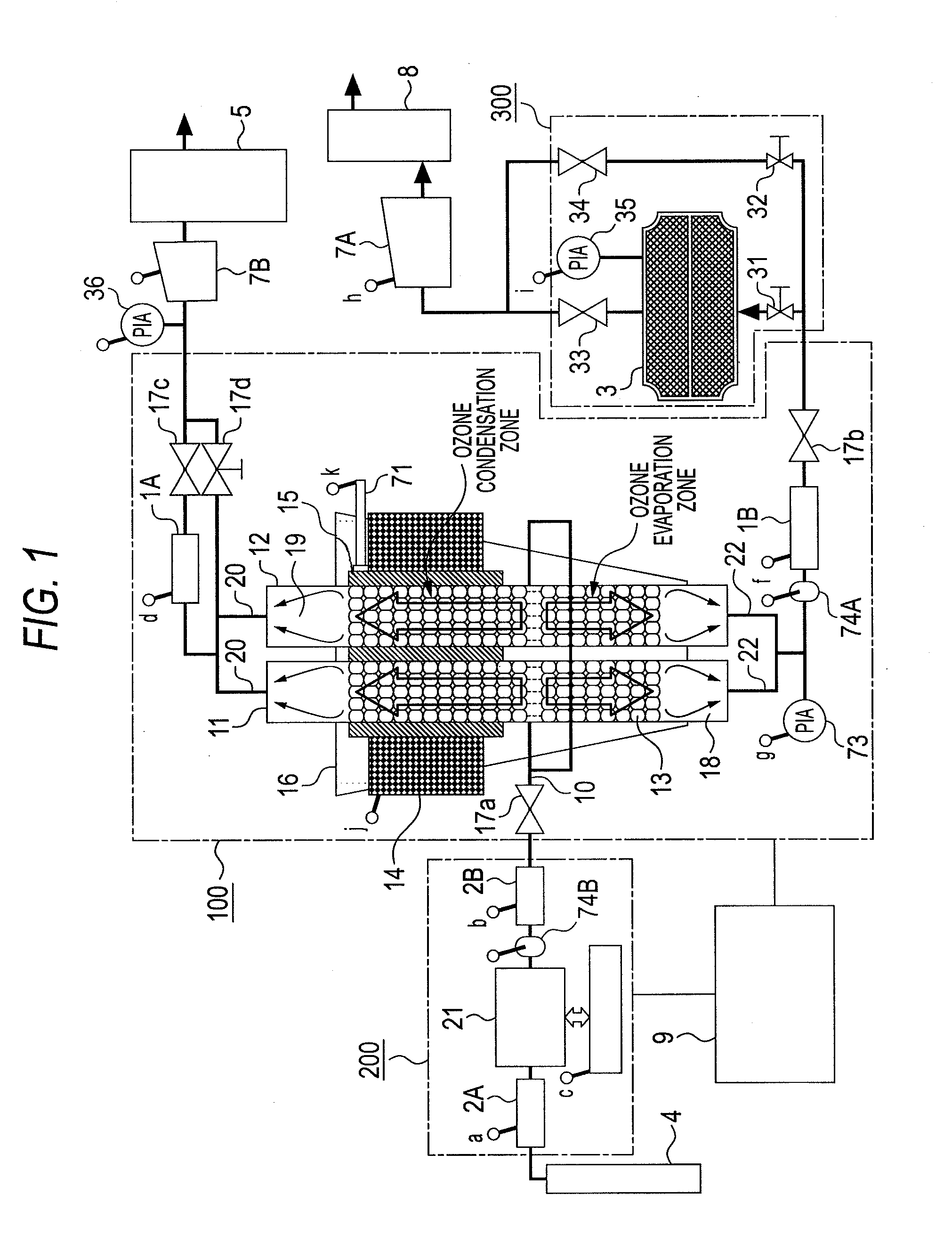

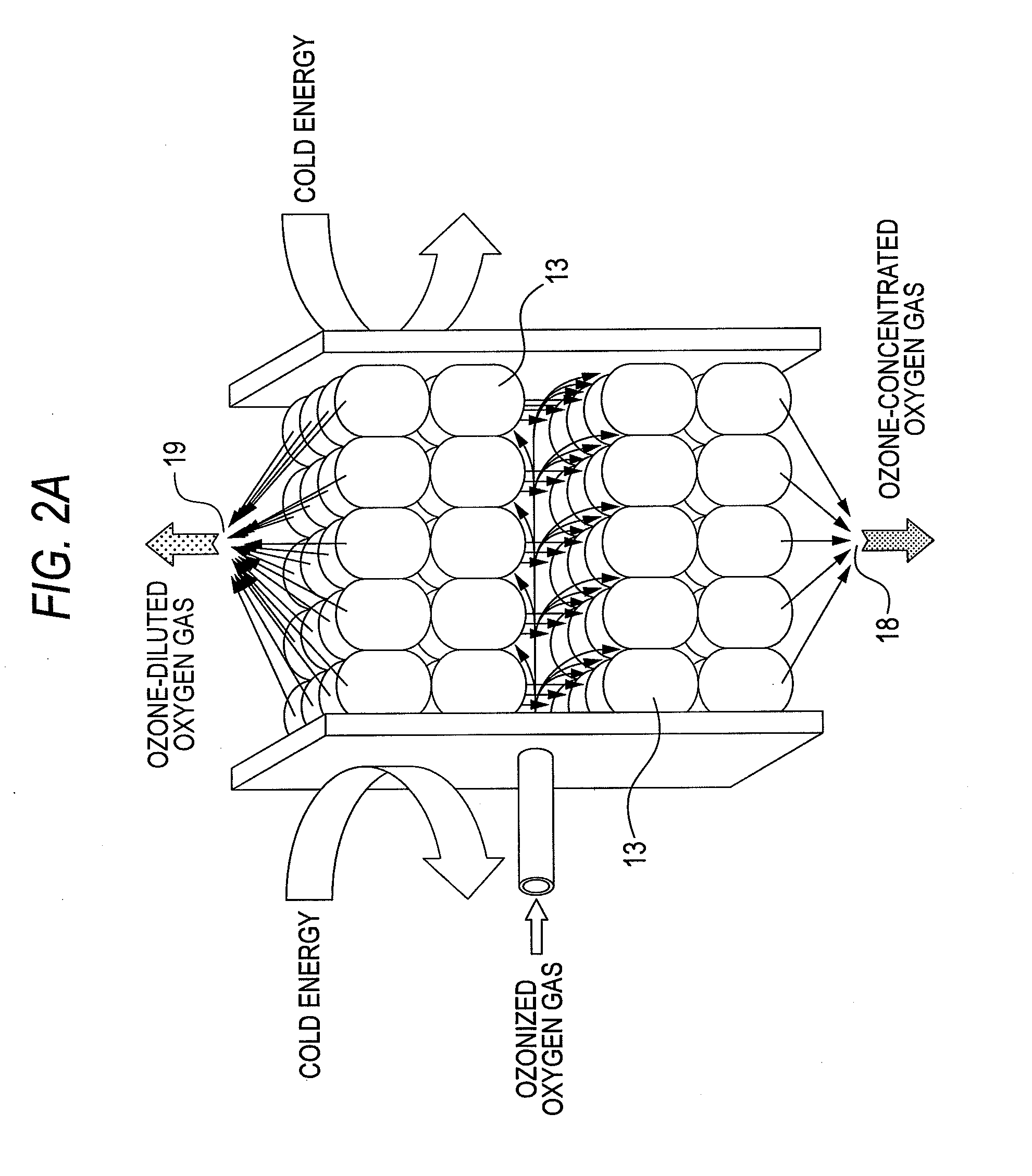

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

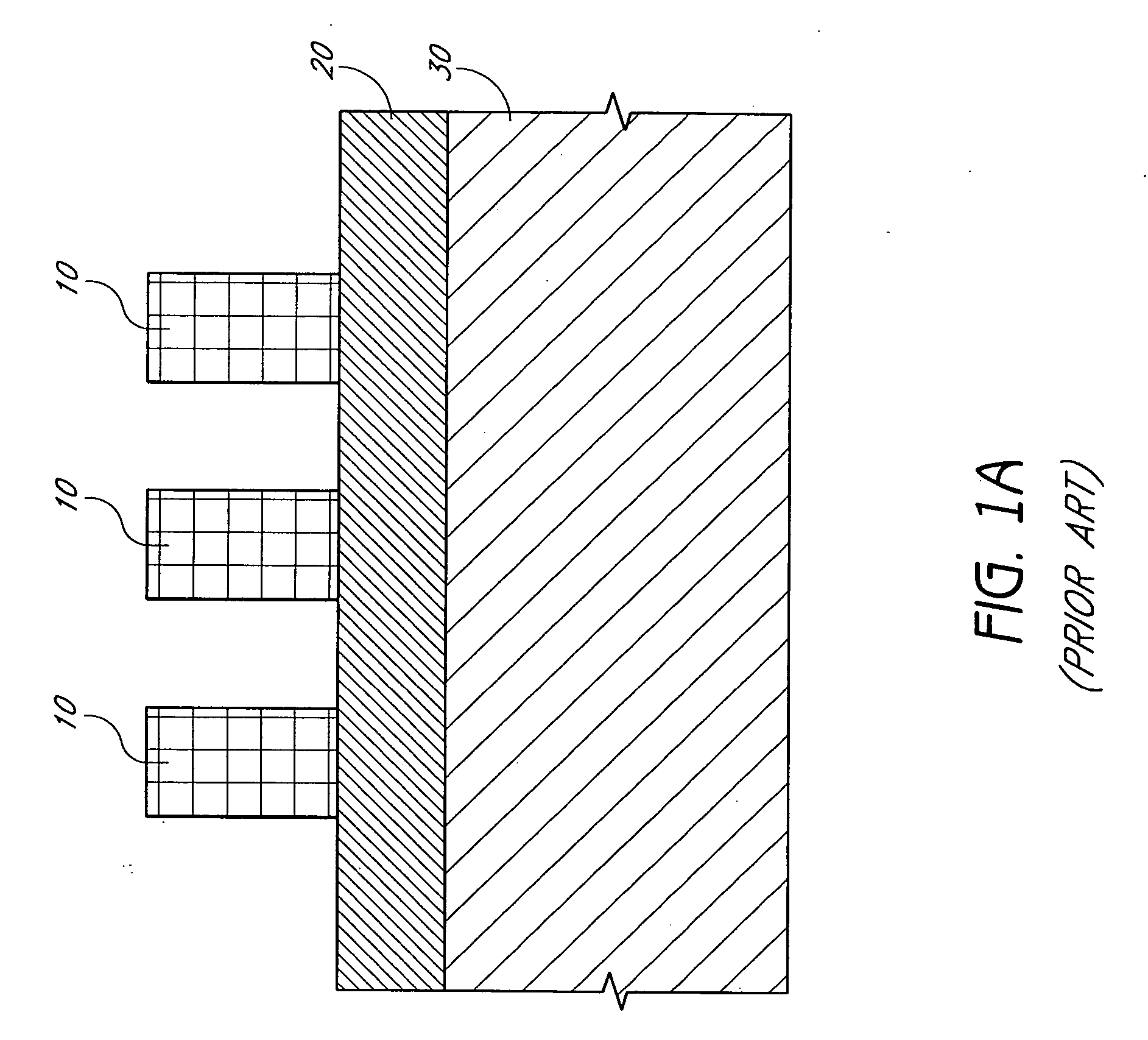

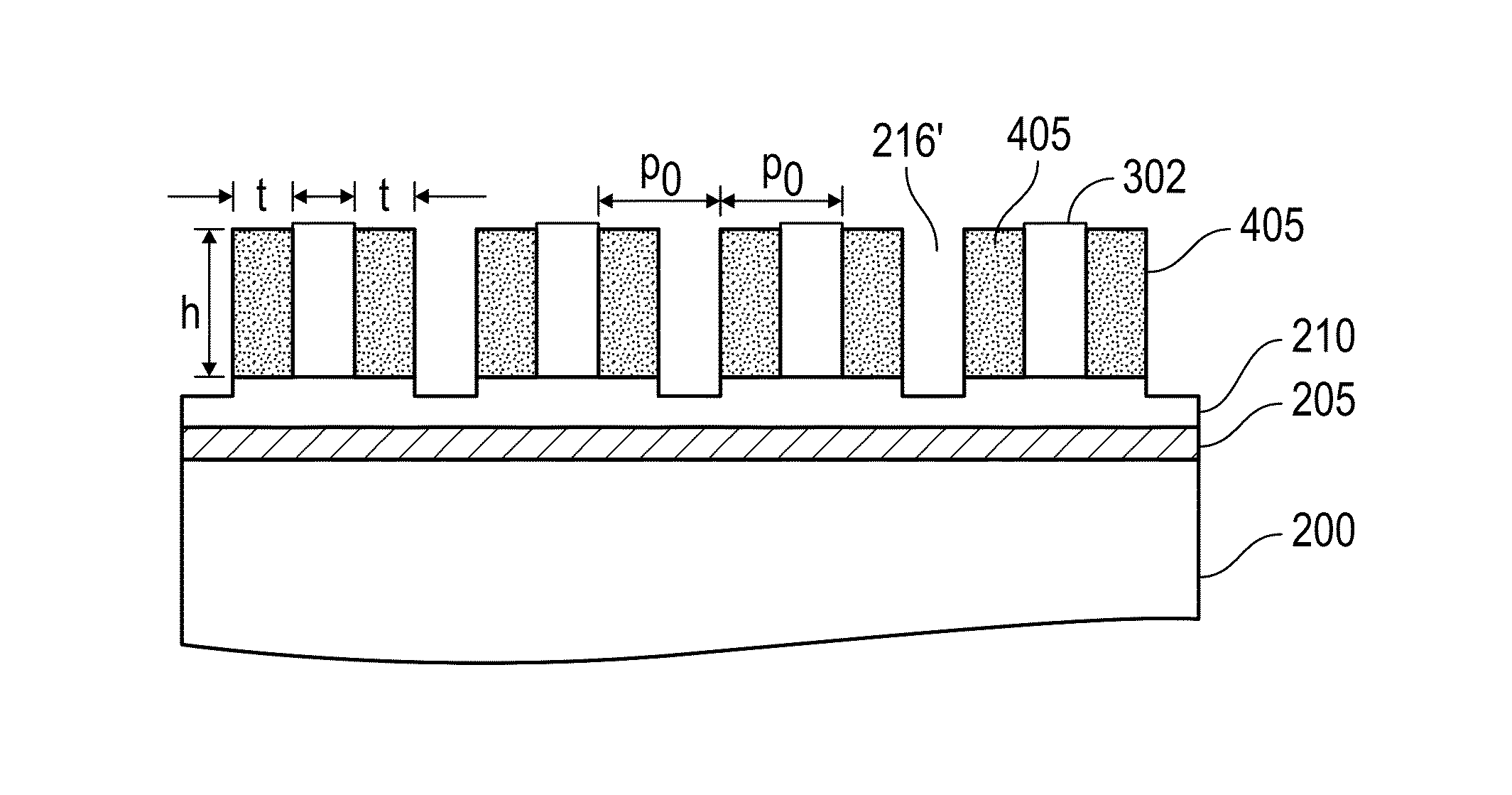

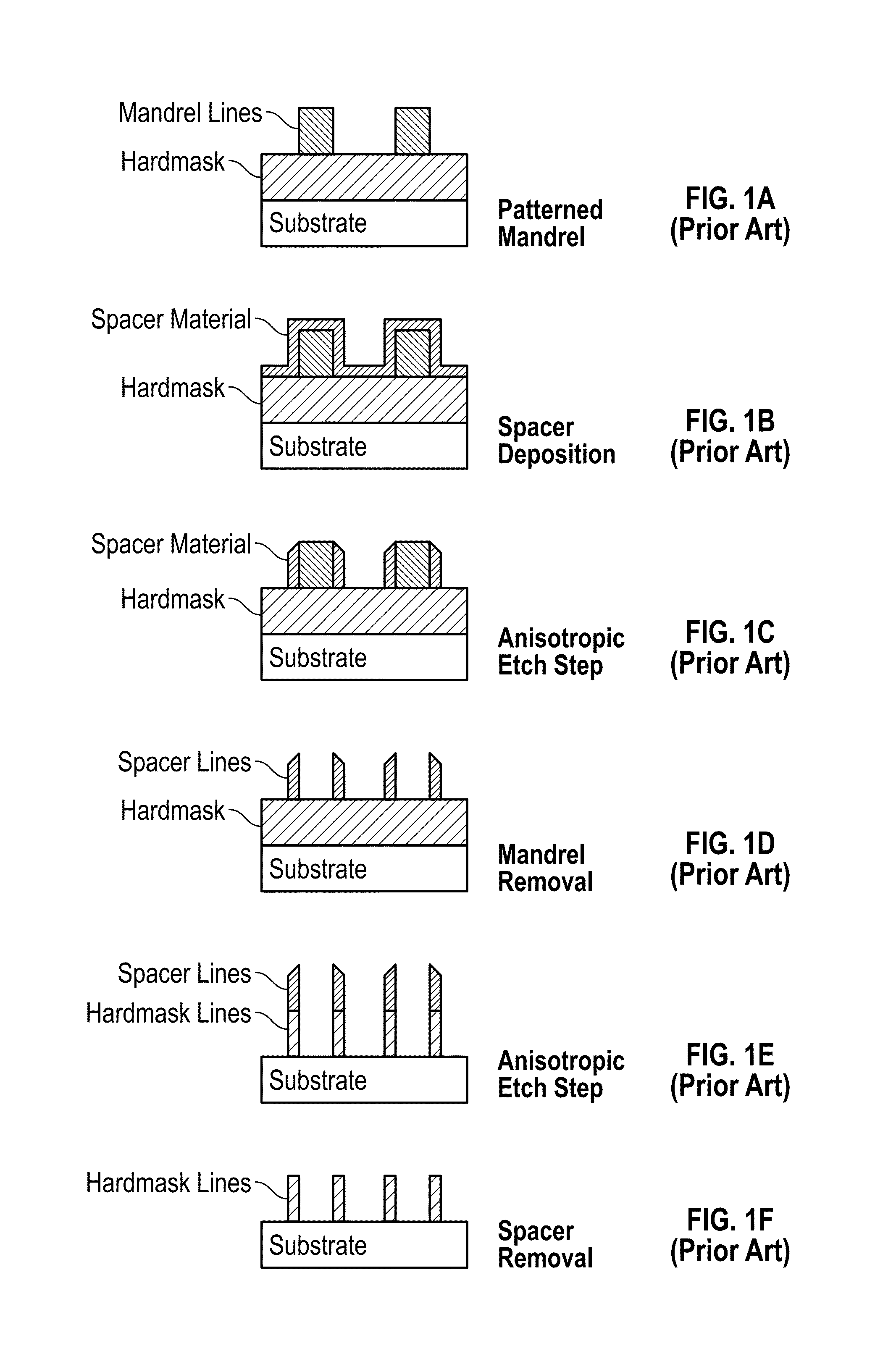

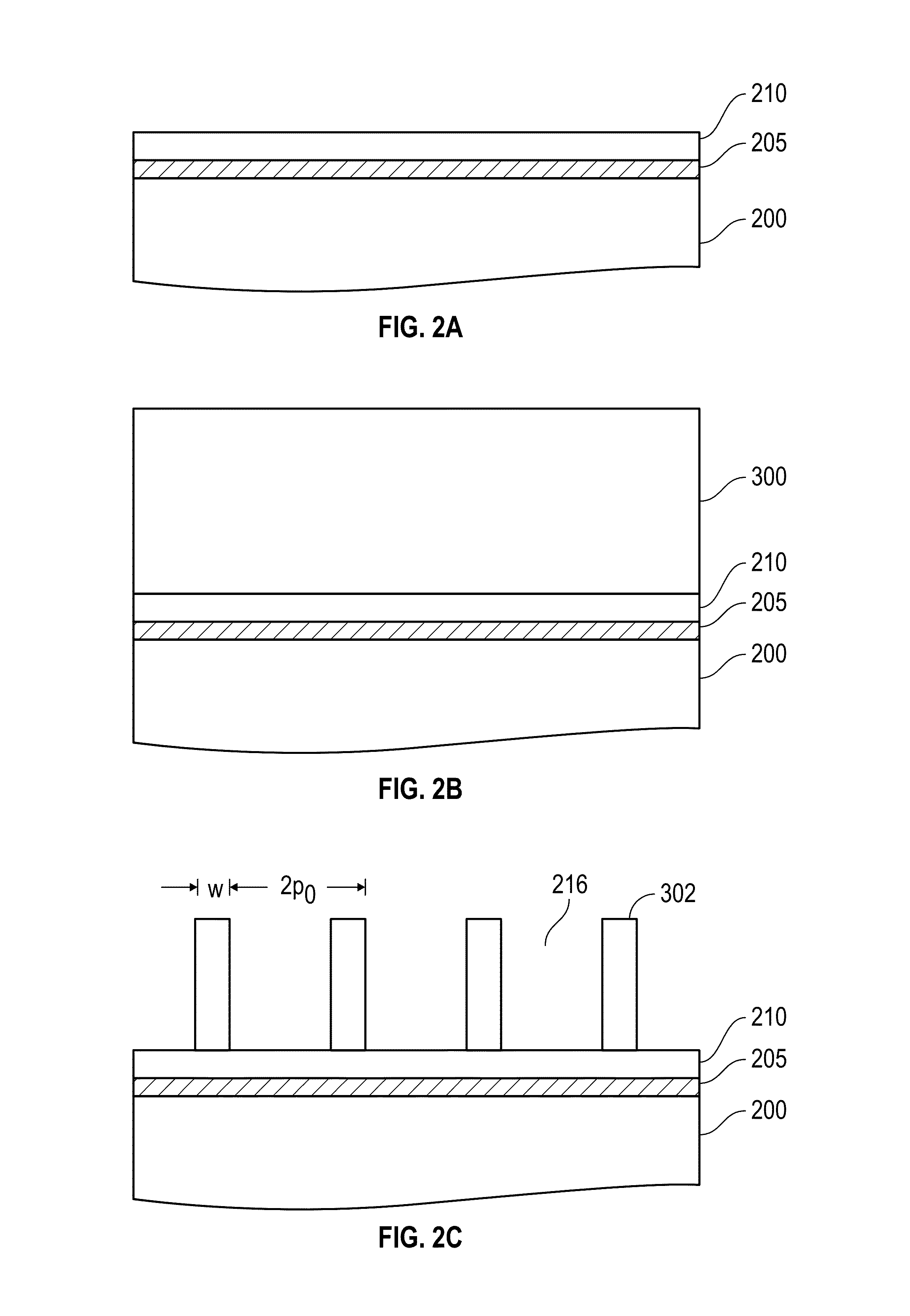

Multiple deposition for integration of spacers in pitch multiplication process

InactiveUS20070049040A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical reactionGas phase

Pitch multiplication is performed using a two step process to deposit spacer material on mandrels. The precursors of the first step react minimally with the mandrels, forming a barrier layer against chemical reactions for the deposition process of the second step, which uses precursors more reactive with the mandrels. Where the mandrels are formed of amorphous carbon and the spacer material is silicon oxide, the silicon oxide is first deposited by a plasma enhanced deposition process and then by a thermal chemical vapor deposition process. Oxygen gas and plasma-enhanced tetraethylorthosilicate (TEOS) are used as reactants in the plasma enhanced process, while ozone and TEOS are used as reactants in the thermal chemical vapor deposition process. The oxygen gas is less reactive with the amorphous carbon than ozone, thereby minimizing deformation of the mandrels caused by oxidation of the amorphous carbon.

Owner:ROUND ROCK RES LLC

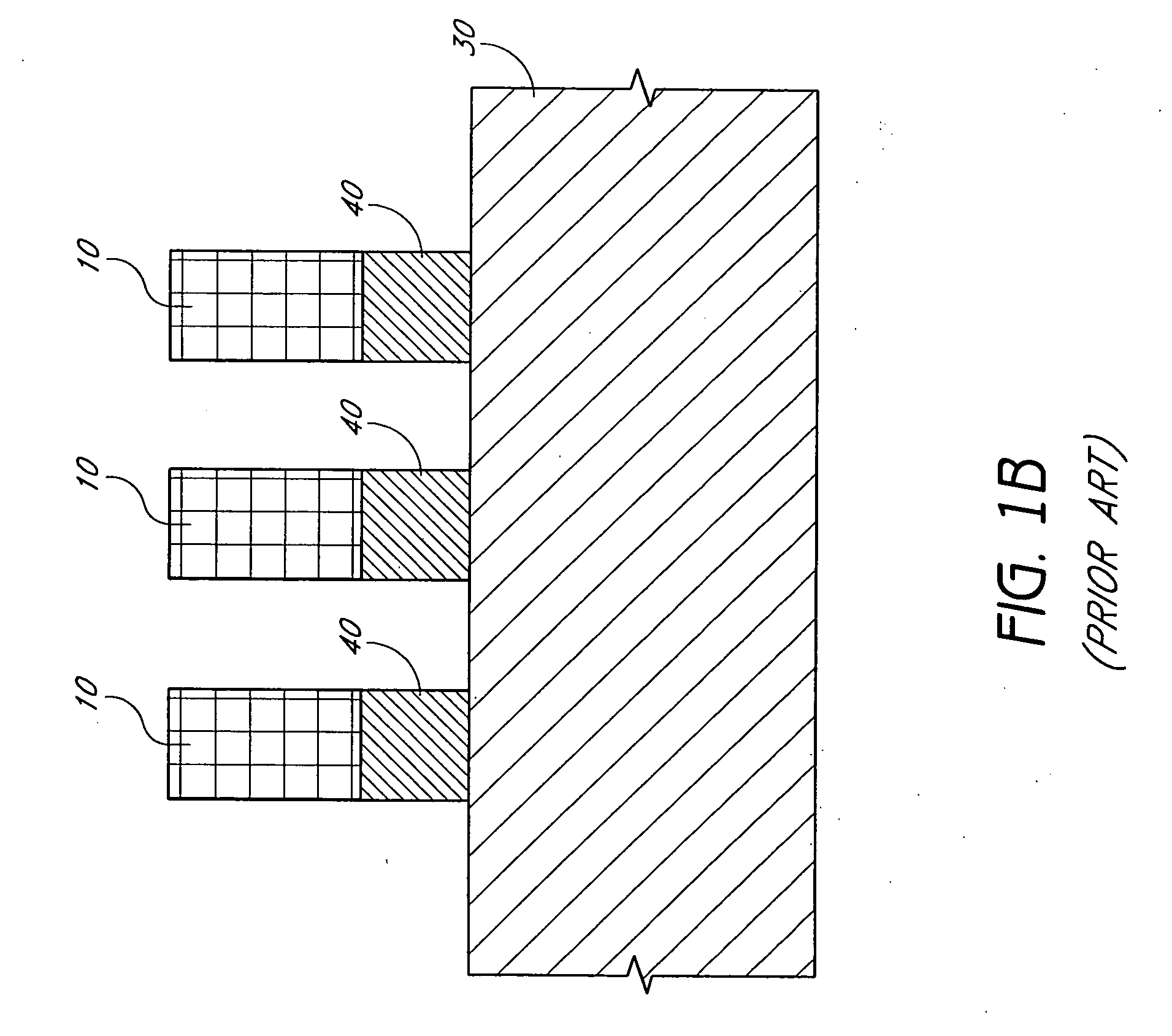

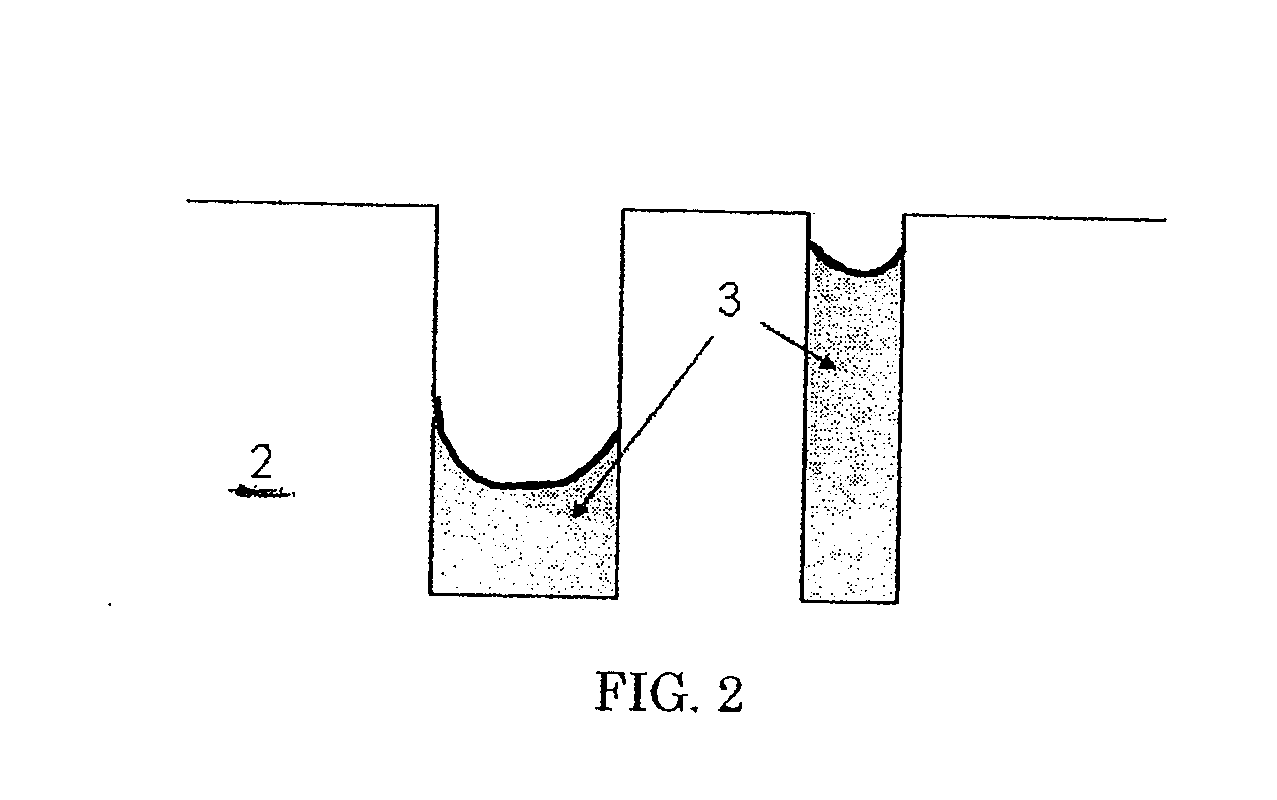

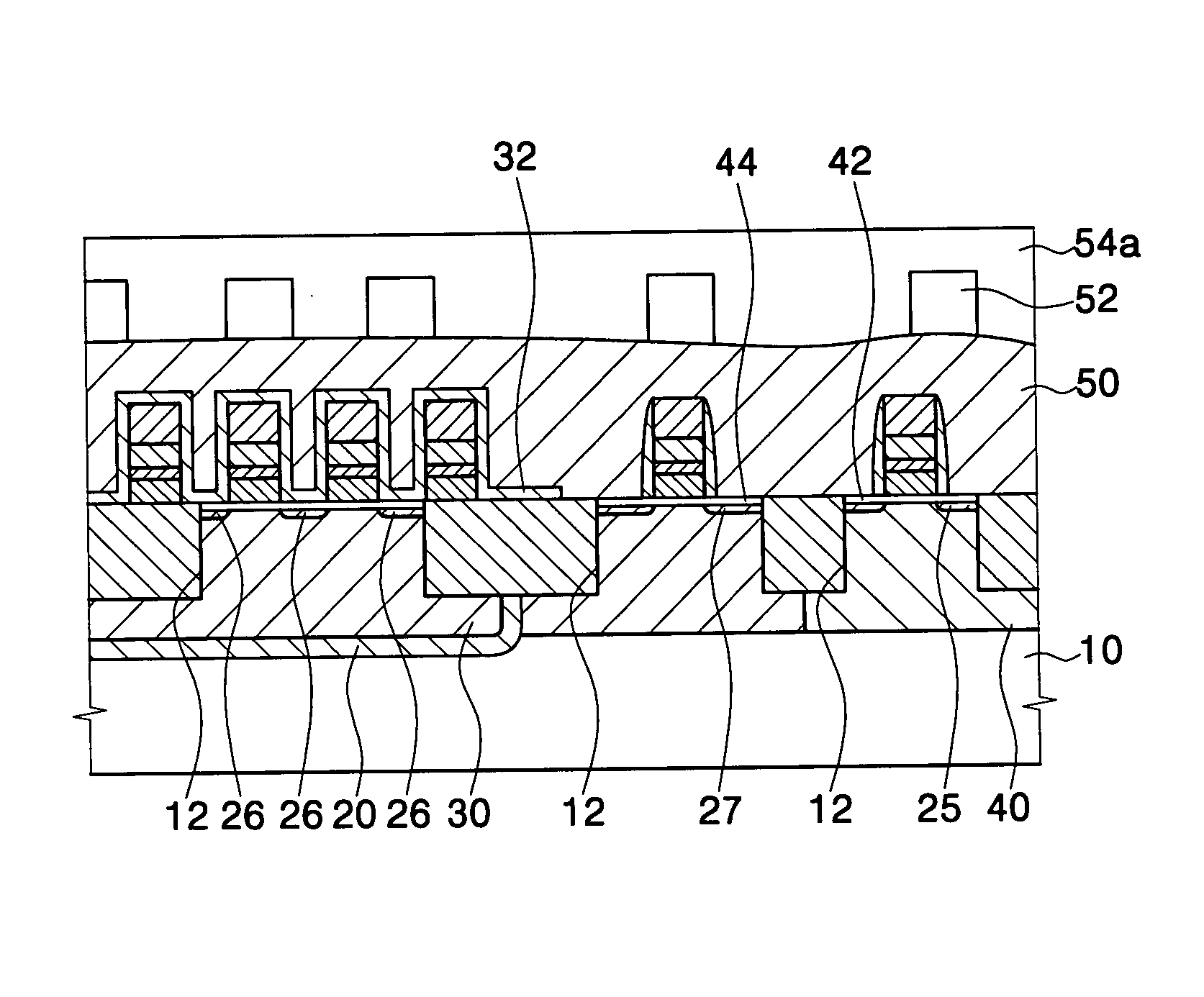

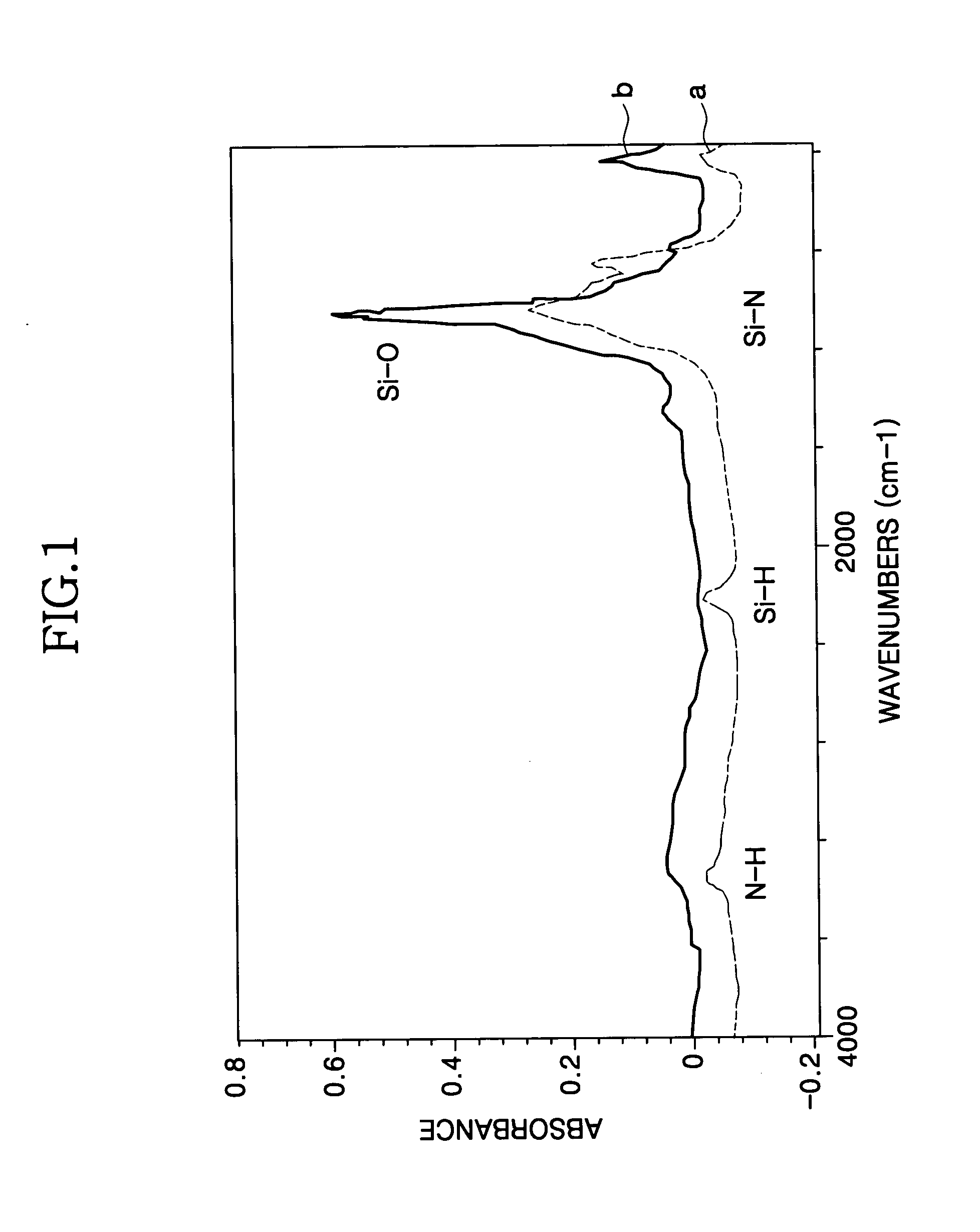

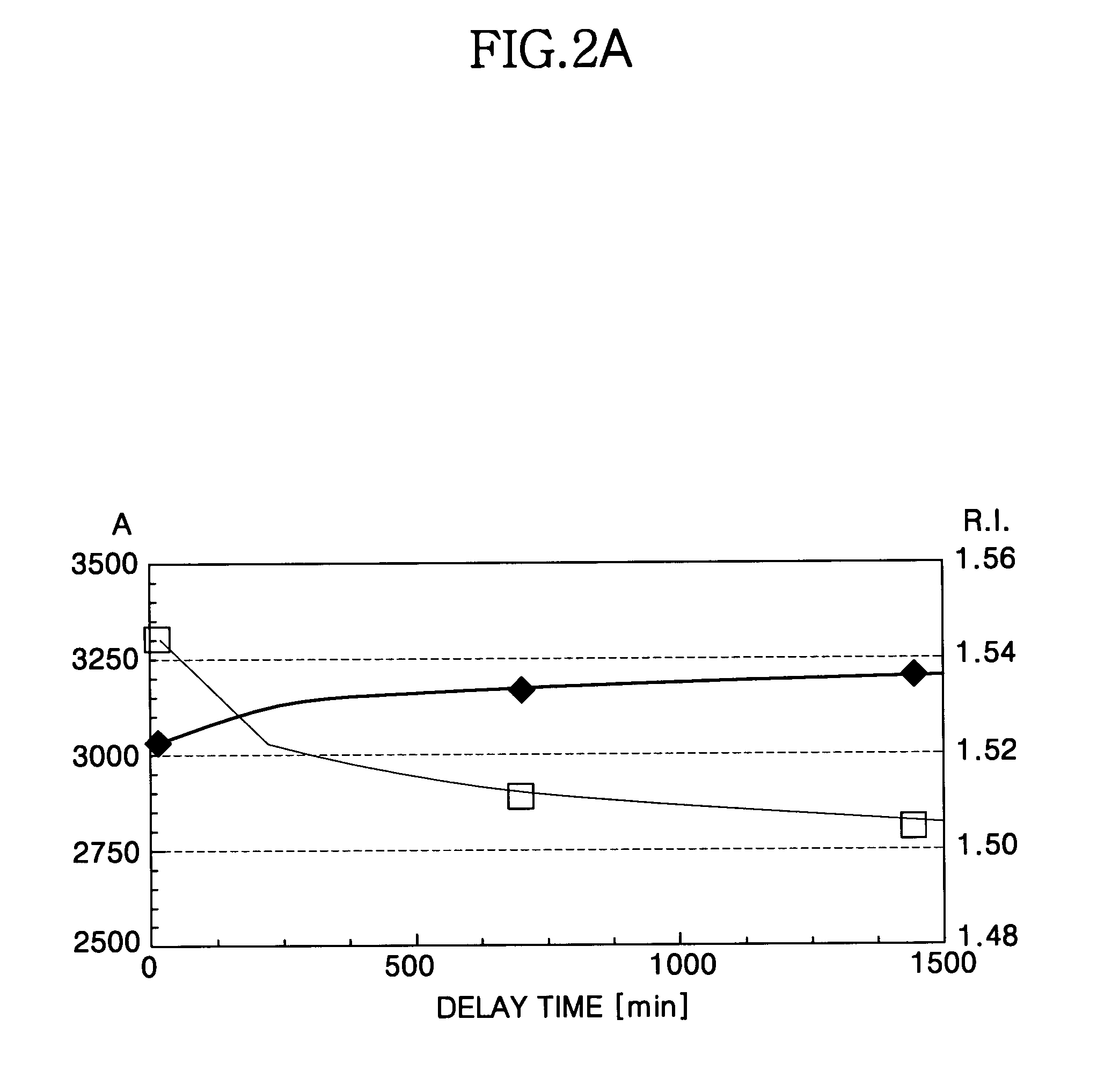

Device isolation technology on semiconductor substrate

A method of forming device isolation regions on a trench-formed silicon substrate and removing residual carbon therefrom includes providing a flowable, insulative material constituted by silicon, carbon, nitrogen, hydrogen, oxygen or any combination of two or more thereof; forming a thin insulative layer, by using the flowable, insulative material, in a trench located on a semiconductor substrate wherein the flowable, insulative material forms a conformal coating in a silicon and nitrogen rich condition whereas in a carbon rich condition, the flowable, insulative material vertically grows from the bottom of the trenches; and removing the residual carbon deposits from the flowable, insulative material by multi-step curing, such as O2 thermal annealing, ozone UV curing followed by N2 thermal annealing.

Owner:ASM JAPAN

Atomic layer deposition of noble metal oxides

Electrically conductive noble metal oxide films can be deposited by atomic layer deposition (ALD)-type processes. In preferred embodiments, Re, Ru, Os and Ir oxides are deposited by alternately and sequentially contacting a substrate with vapor phase pulses of a noble metal precursor and an oxygen source. The noble metal precursor is preferably a betadiketonate compound and the oxygen source is preferably ozone or oxygen plasma. The deposition temperature may be less than about 200° C.

Owner:ASM INTERNATIONAL

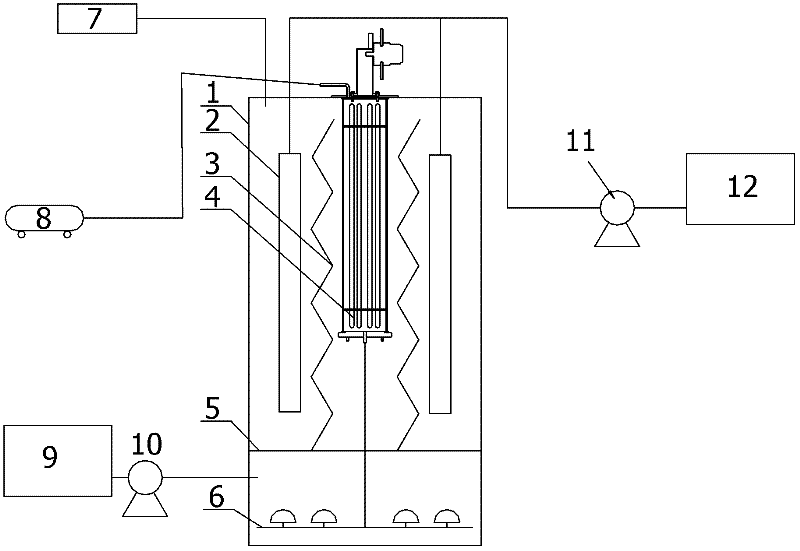

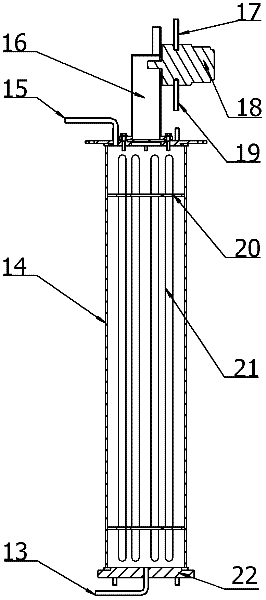

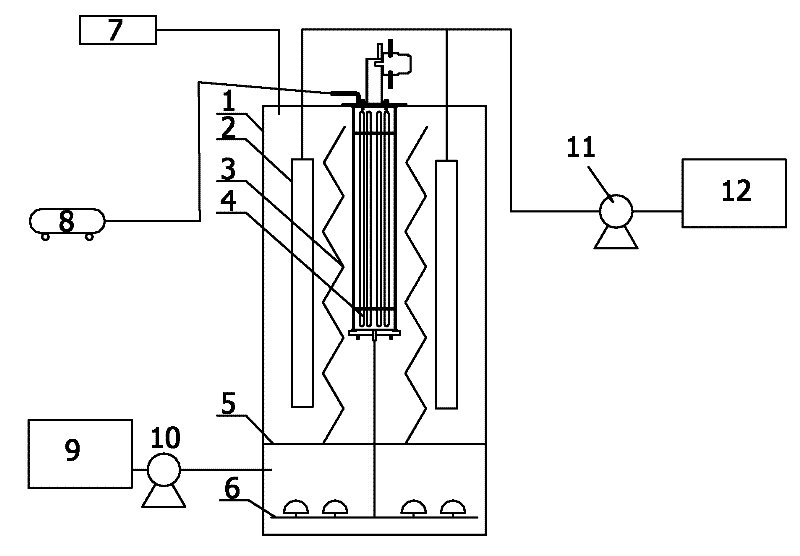

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

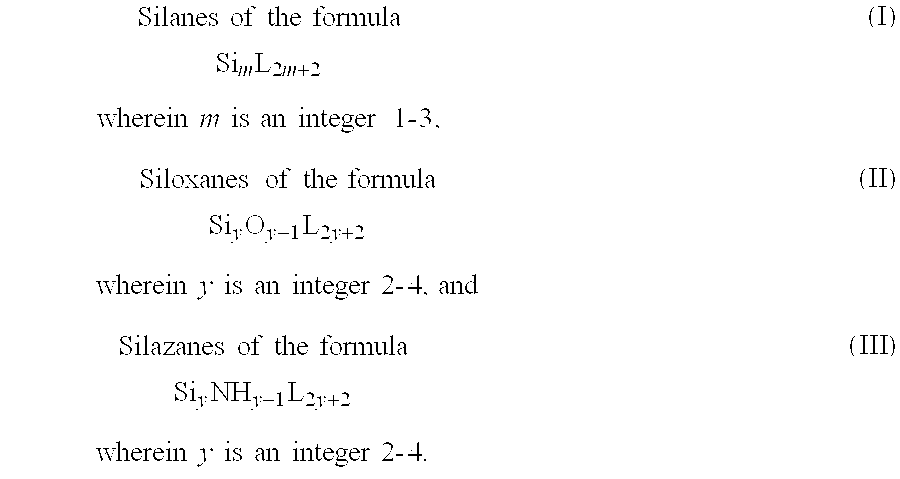

Method of growing oxide films

InactiveUS20030188682A1Easy to prepareExcellent dielectric propertiesPolycrystalline material growthSemiconductor/solid-state device manufacturingSilicon oxideOxygen

Abstract of Disclosure Process for producing silicon oxide containing thin films on a growth substrate by the ALCVD method. In the process, a vaporisable silicon compound is bonded to the growth substrate, and the bonded silicon compound is converted to silicon dioxide. The invention comprises using a silicon compound which contains at least one organic ligand and the bonded silicon compound is converted to silicon dioxide by contacting it with a vaporised, reactive oxygen source, in particular with ozone. The present invention provides a controlled process for growing controlling thin films containing SiO2, with sufficiently short reaction times.

Owner:ASM IP HLDG BV

Multiple deposition for integration of spacers in pitch multiplication process

InactiveUS20080149593A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical reactionGas phase

Pitch multiplication is performed using a two step process to deposit spacer material on mandrels. The precursors of the first step react minimally with the mandrels, forming a barrier layer against chemical reactions for the deposition process of the second step, which uses precursors more reactive with the mandrels. Where the mandrels are formed of amorphous carbon and the spacer material is silicon oxide, the silicon oxide is first deposited by a plasma enhanced deposition process and then by a thermal chemical vapor deposition process. Oxygen gas and plasma-enhanced tetraethylorthosilicate (TEOS) are used as reactants in the plasma enhanced process, while ozone and TEOS are used as reactants in the thermal chemical vapor deposition process. The oxygen gas is less reactive with the amorphous carbon than ozone, thereby minimizing deformation of the mandrels caused by oxidation of the amorphous carbon.

Owner:ROUND ROCK RES LLC

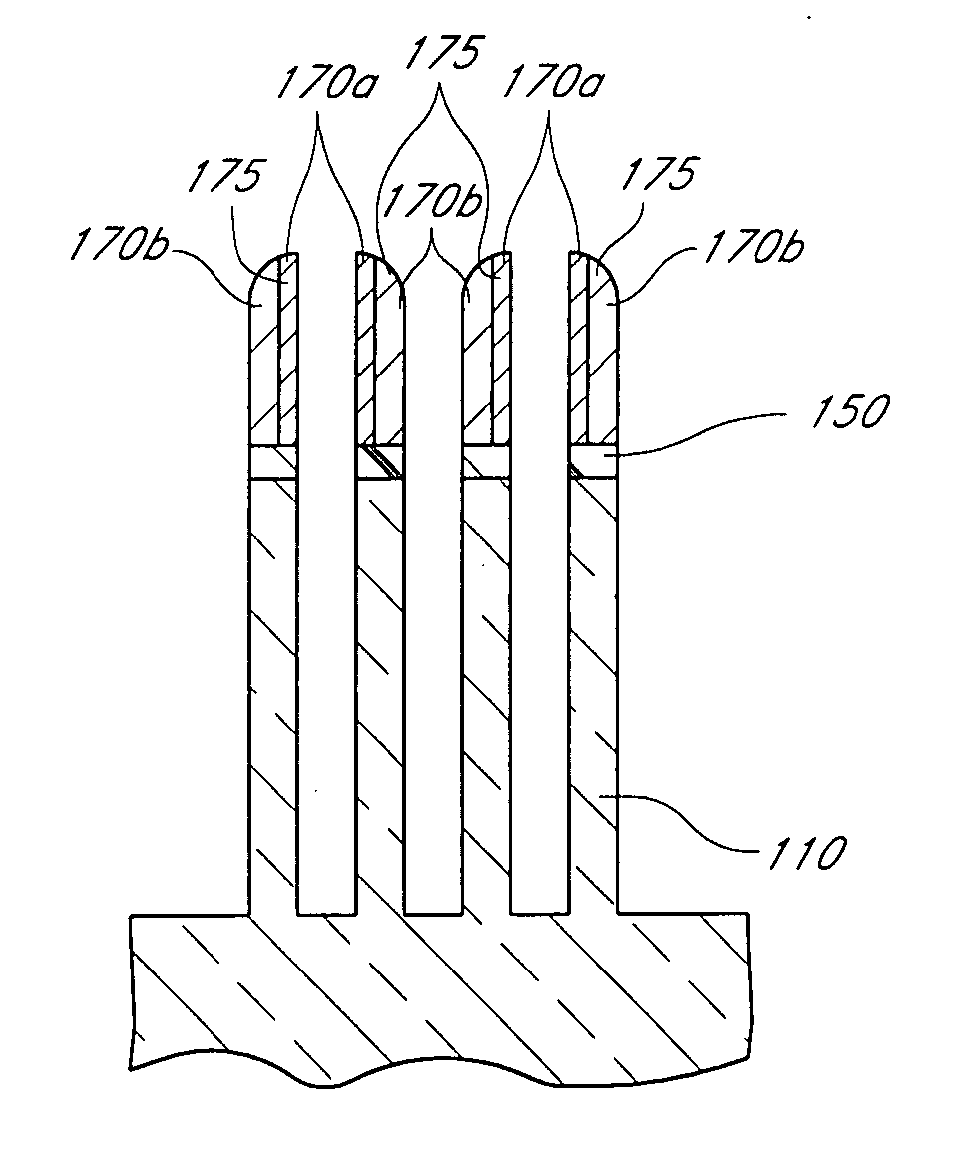

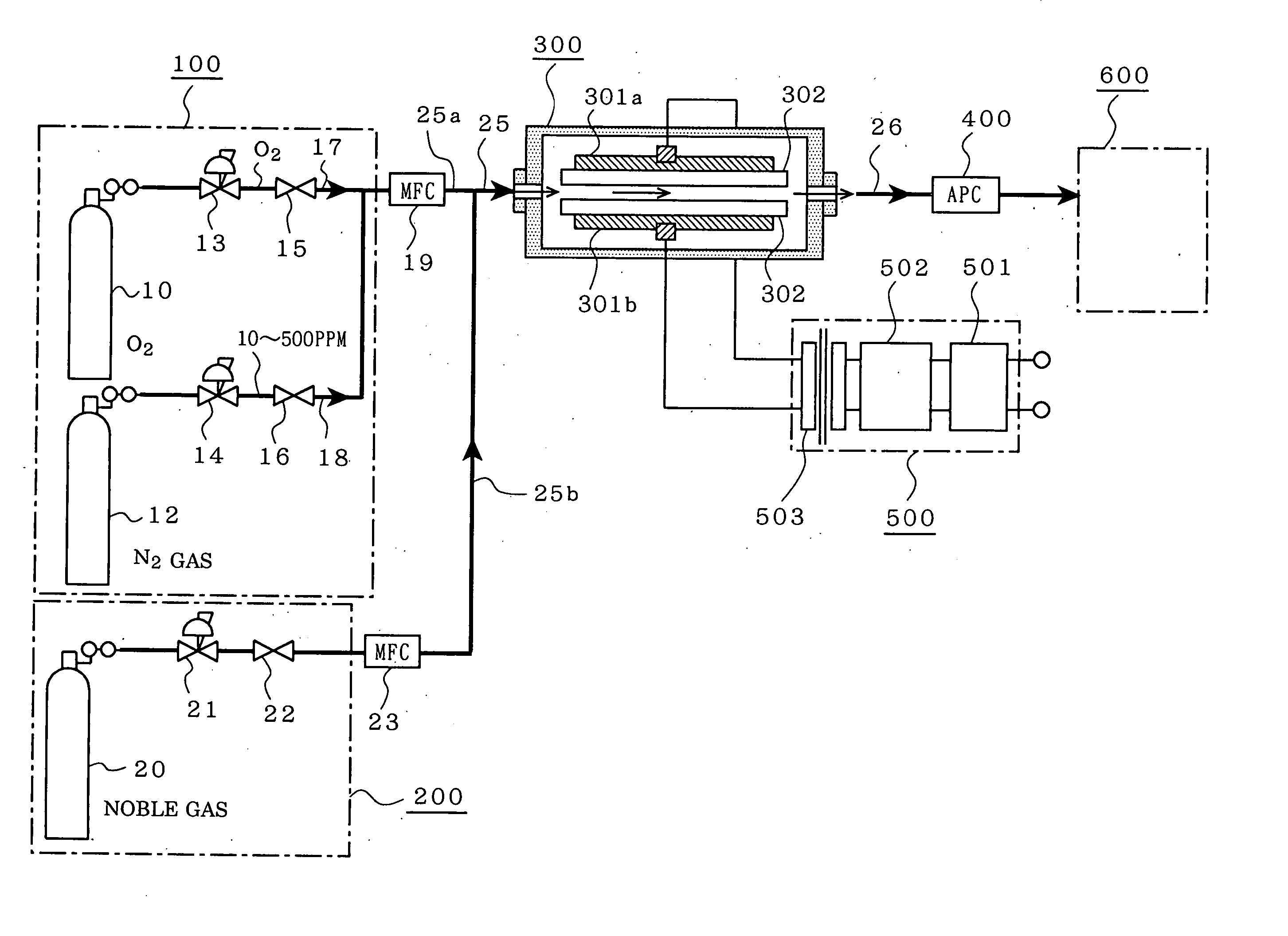

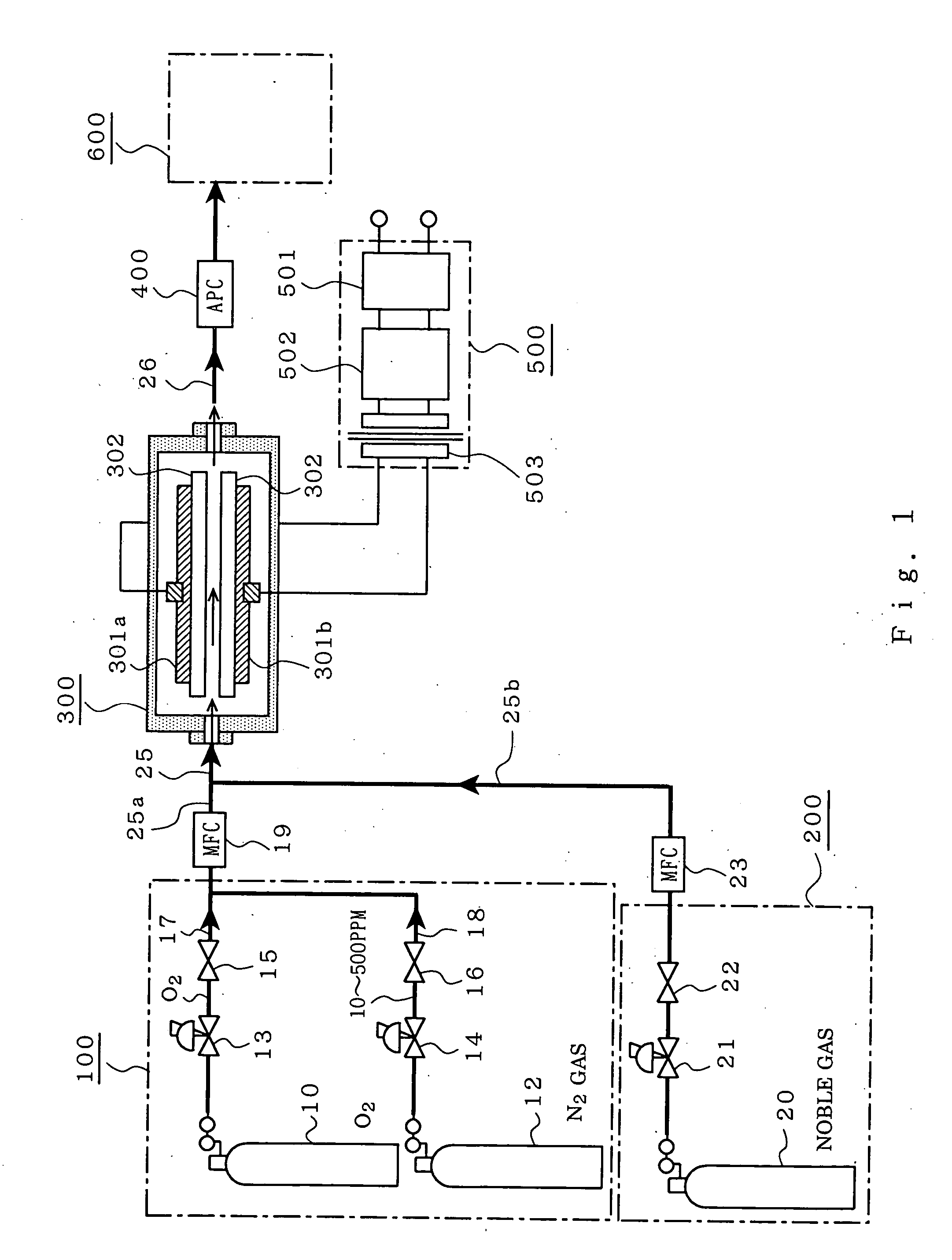

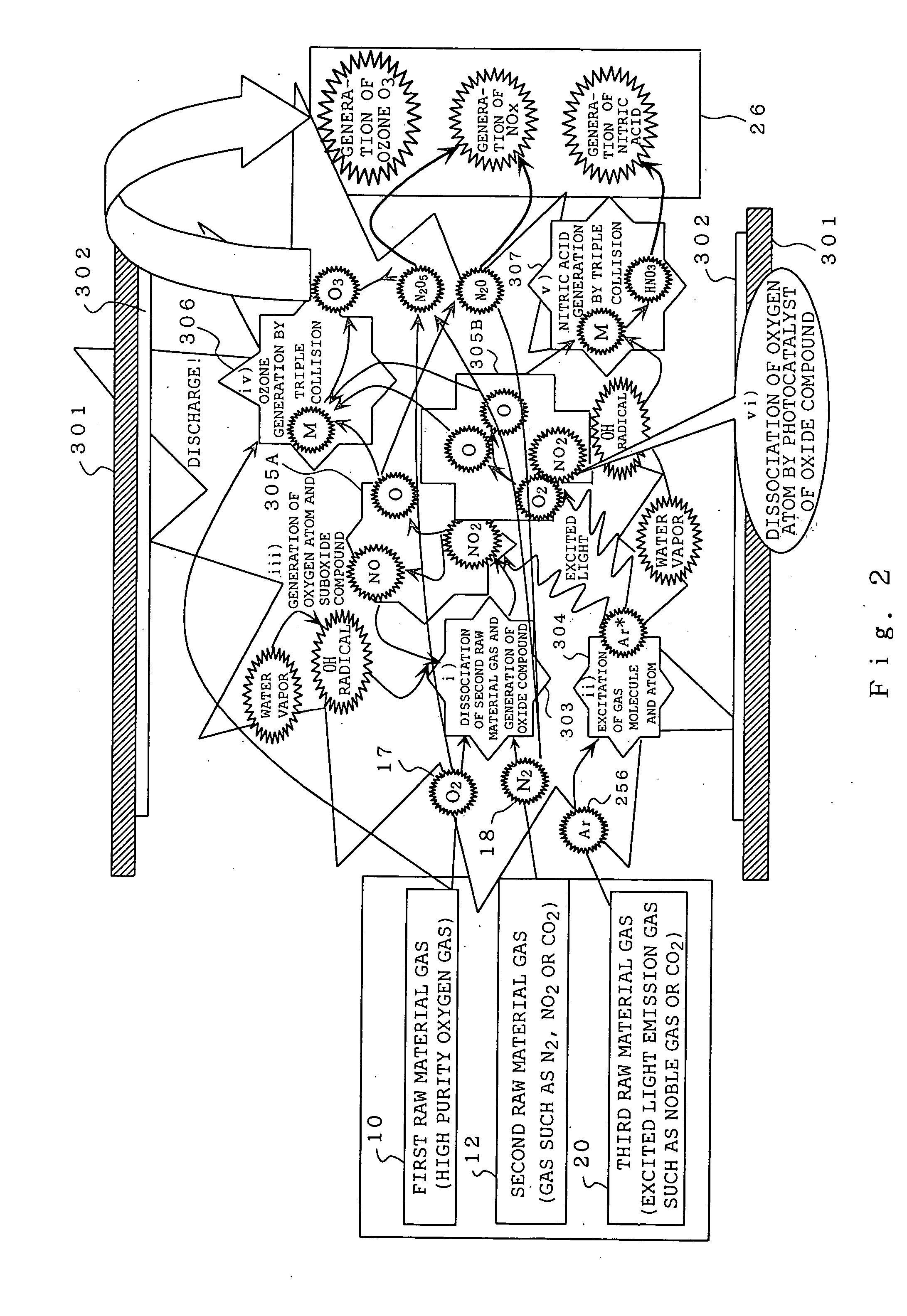

Ozone generator

ActiveUS20040223893A1Physical/chemical process catalystsElectrical discharge ozone preparationAtmospheric sciencesGas supply

An ozone generator for generating ozone by applying a specified process to oxygen by discharge includes a first raw material gas supply unit for supplying the oxygen as a first raw material gas, and a second raw material gas supply unit for supplying an oxide compound gas as a second raw material gas, in which, by excited light, excited and generated by a discharge in the oxygen and the oxide compound gas, the oxide compound gas is dissociated, or the oxide compound gas is excited accelerating dissociation of the oxygen, and ozone is generated. In this way, ozone generation efficiency is raised.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

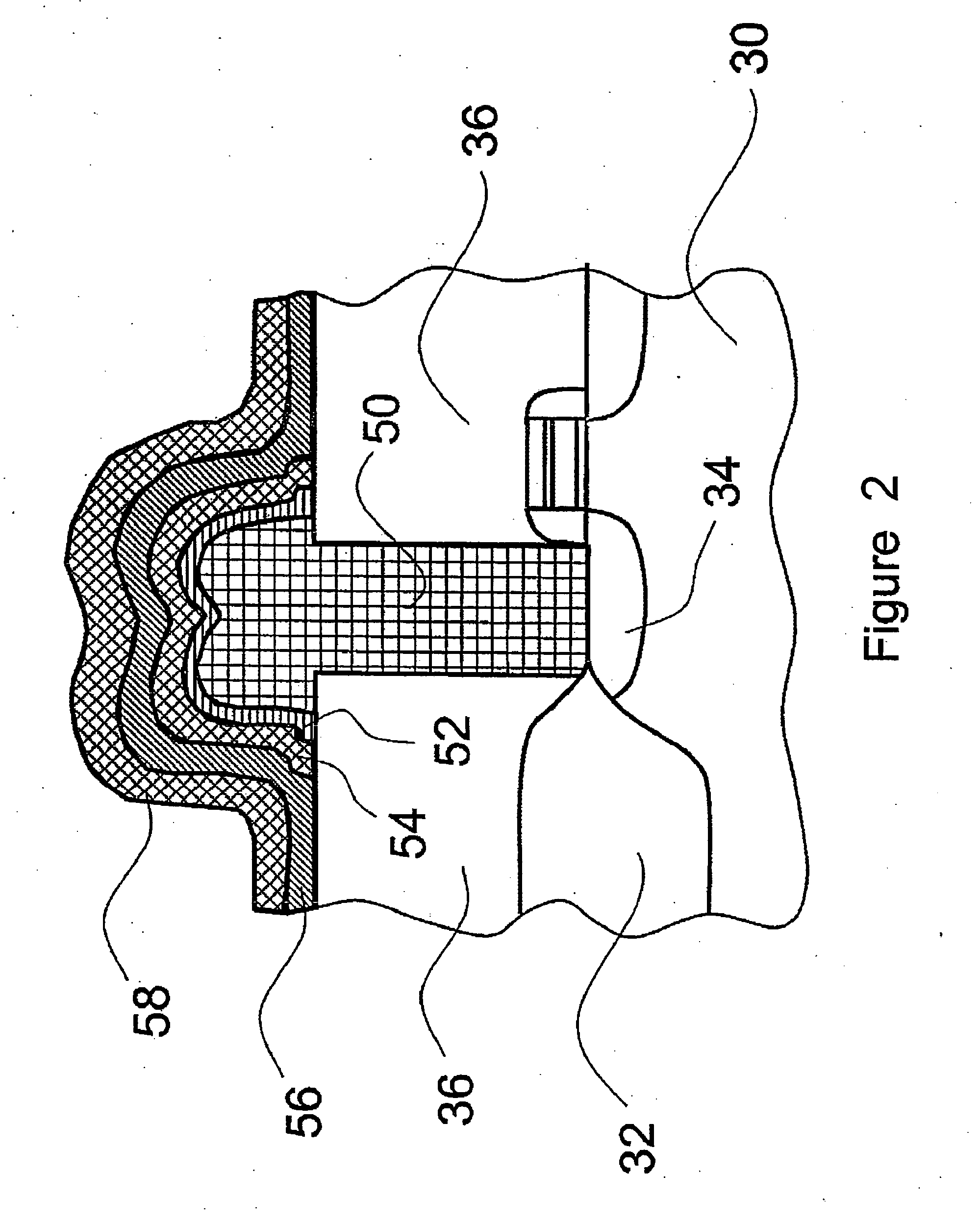

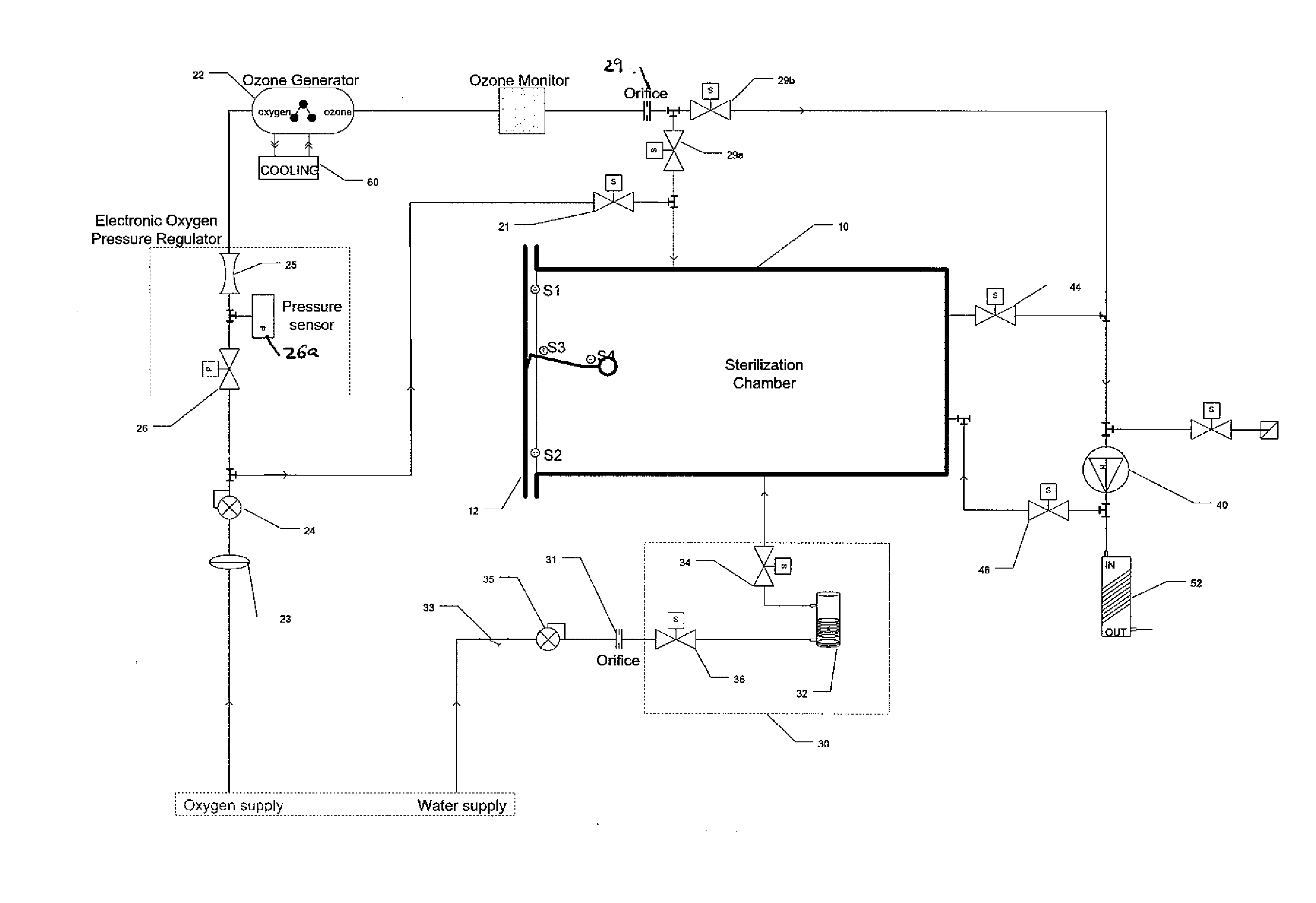

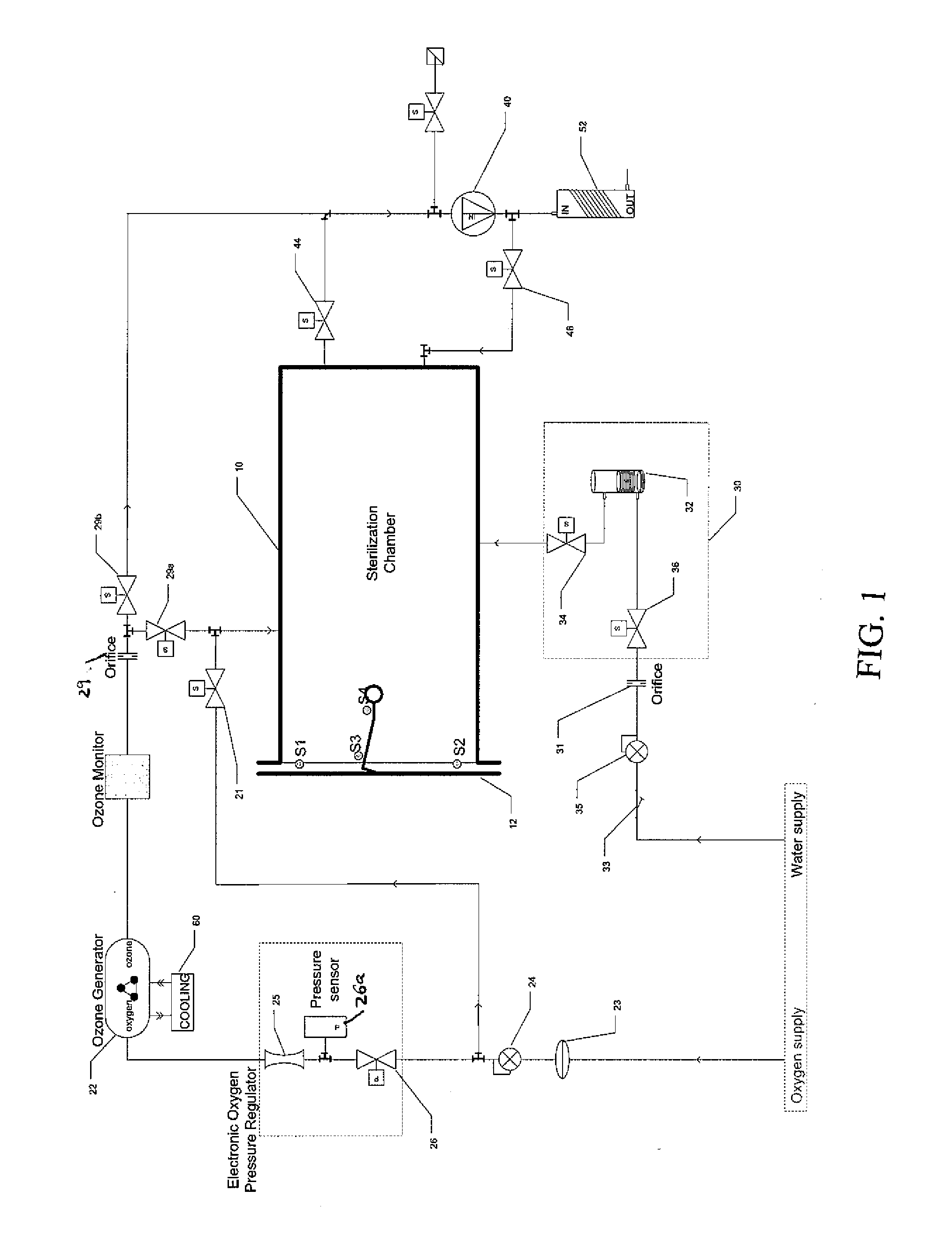

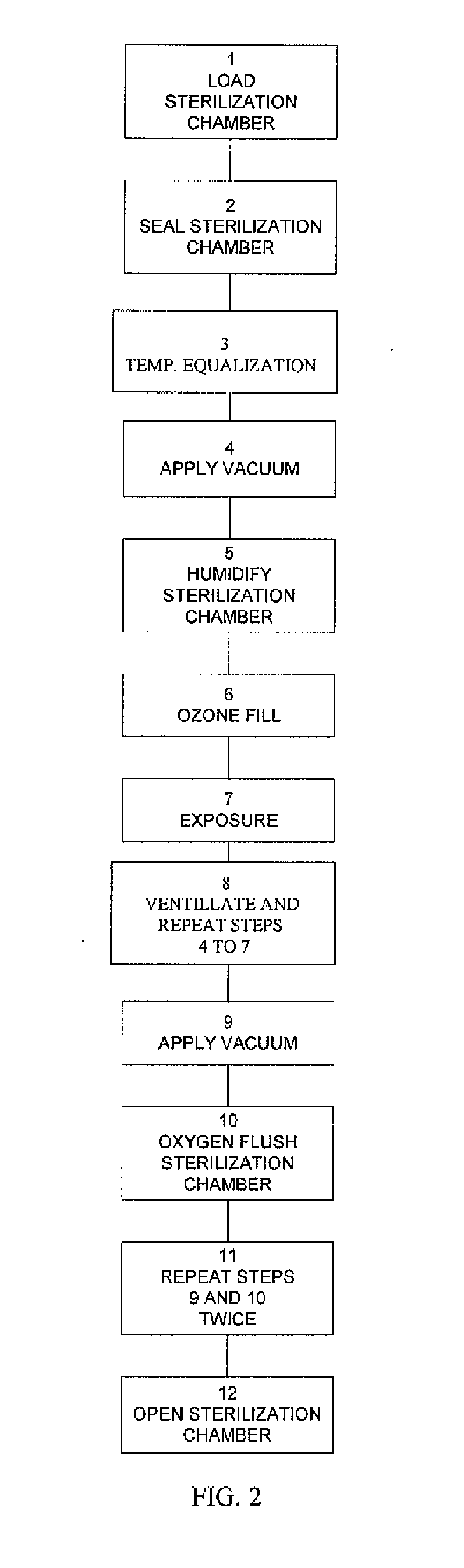

Method and apparatus for ozone sterilization

InactiveUS20070258855A1Avoid condensationPrevent water condensationElectrolysis componentsExhaust apparatusVacuum pressureWater vapor

The present invention provides a method and apparatus for sterilizing articles using an ozone-containing gas, where condensation of water from the sterilization atmosphere during the sterilization process is substantially prevented. The inventive sterilization method includes providing a sterilization chamber and placing an article into the sterilization chamber. The sterilization chamber is sealed prior to equalizing the temperature of the article and the atmosphere in the sterilization chamber. A vacuum is applied to achieve a preselected vacuum pressure in the sterilization chamber. Once the vacuum pressure is set, water vapour is supplied to the sterilization chamber. Ozone-containing gas is then supplied to the sterilization chamber and the sterilization chamber remains sealed for a preselected treatment period, where the sterilization chamber remains sealed throughout the whole process. Finally, vacuum in the sterilization chamber is released.

Owner:STRYKER CORP

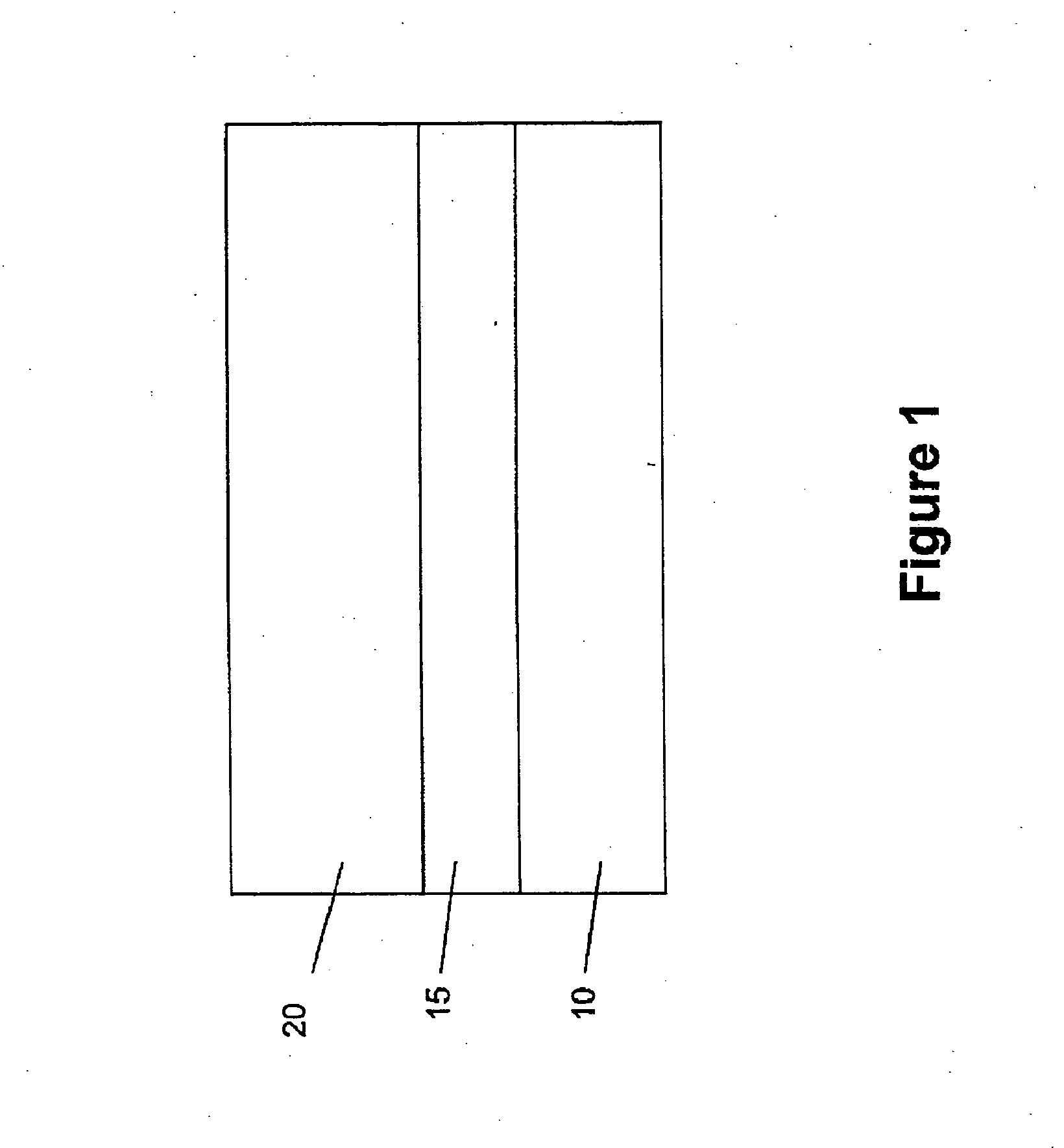

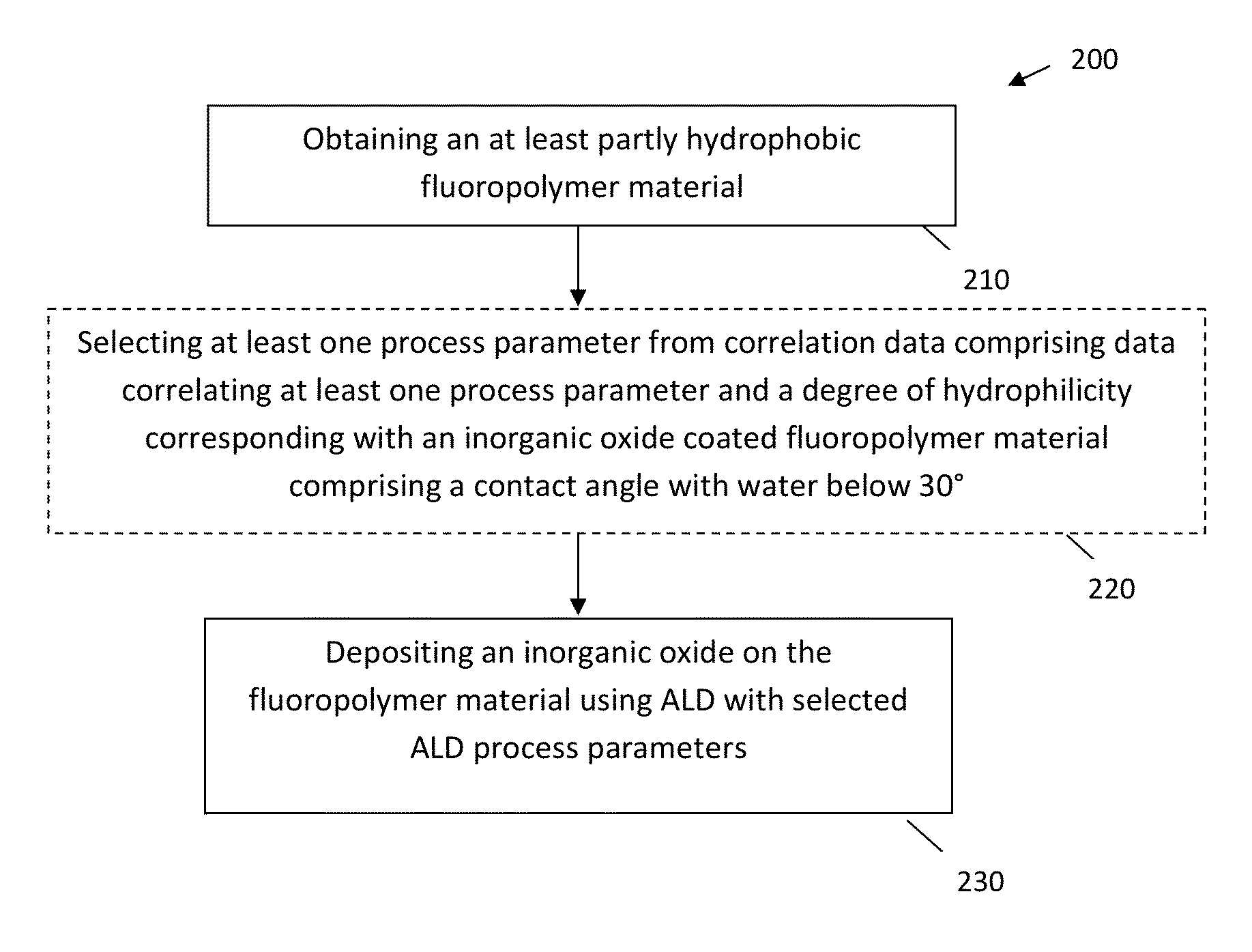

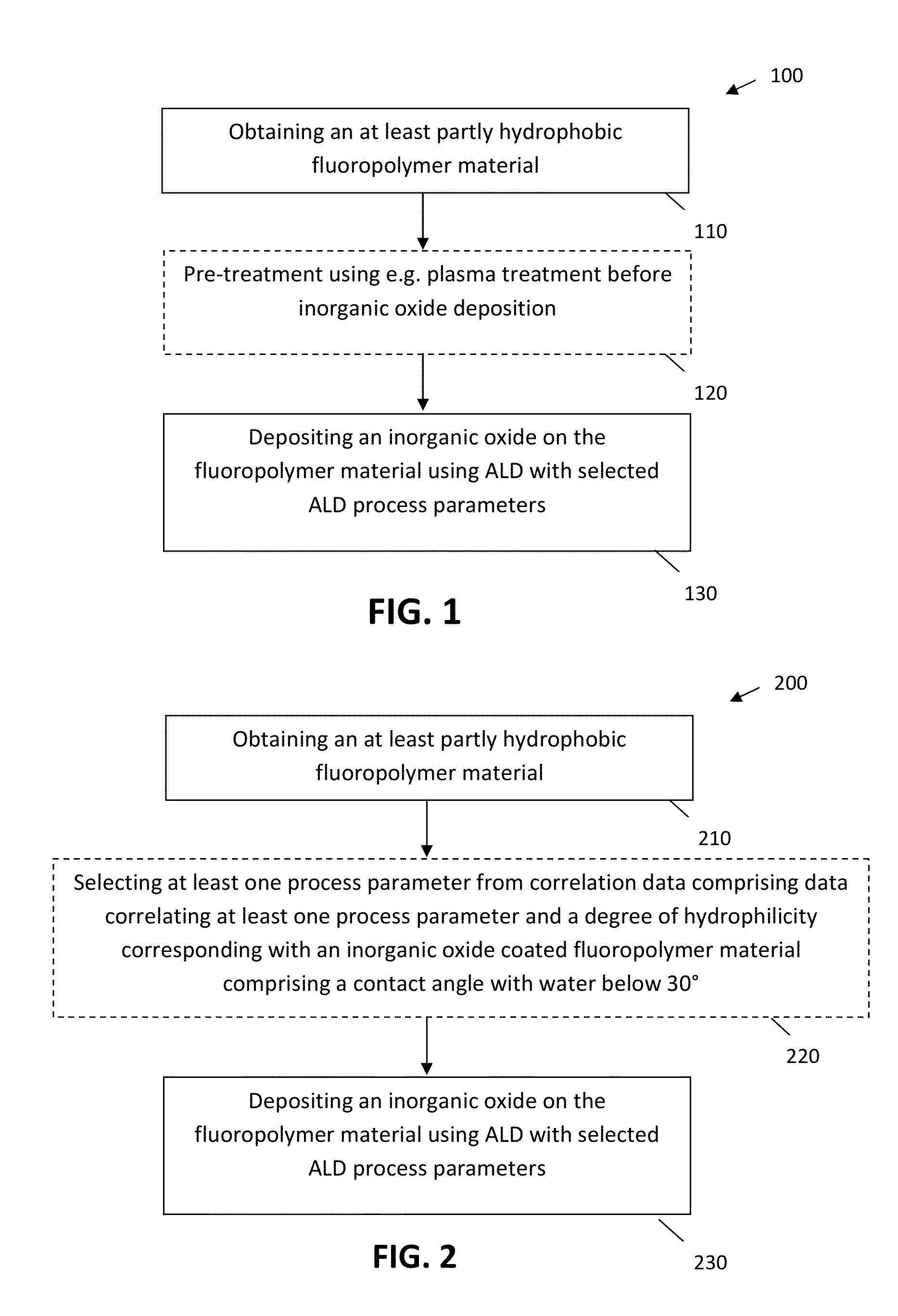

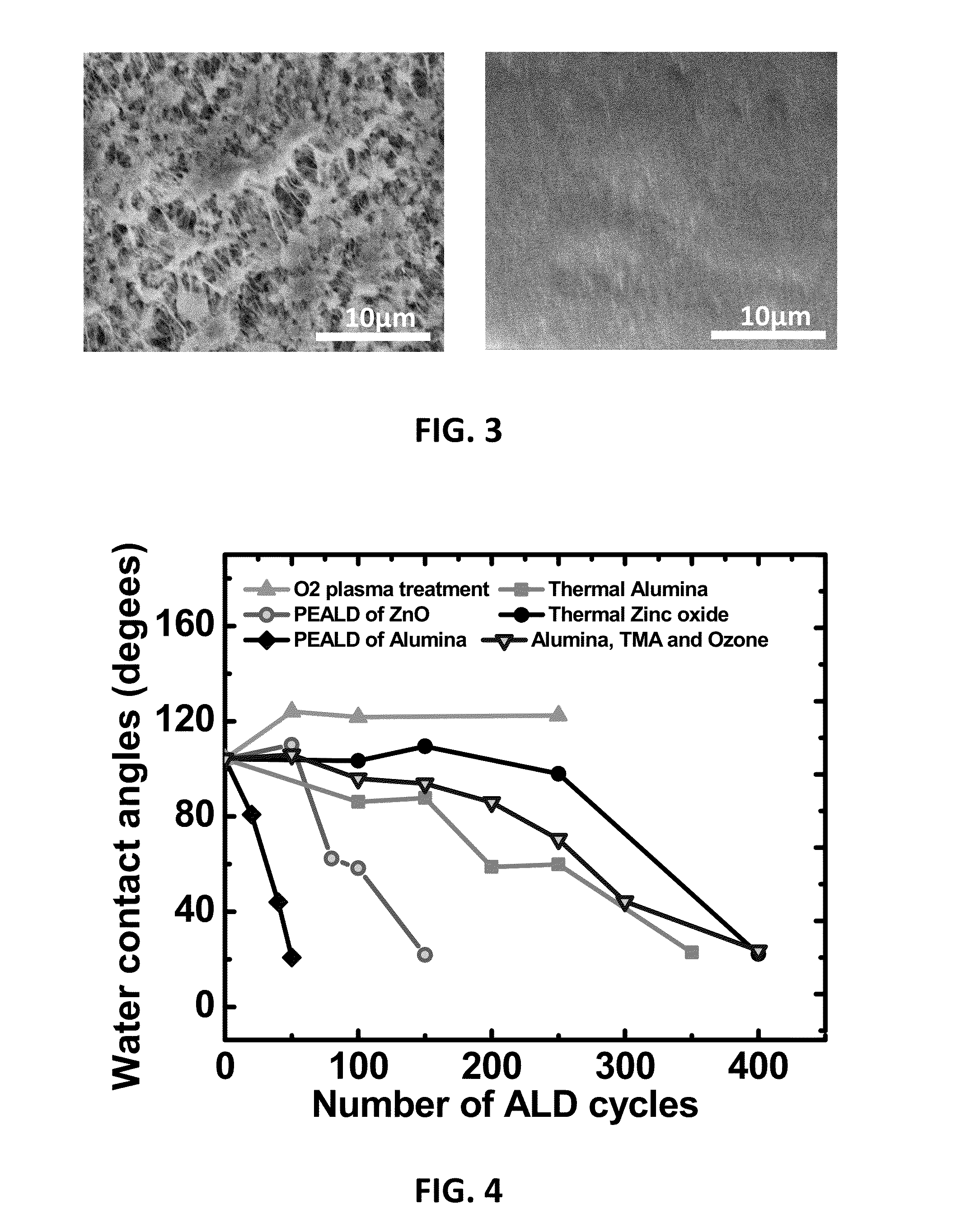

Methods for Obtaining Hydrophilic Fluoropolymers

InactiveUS20150345018A1Rendering fluoropolymers hydrophilicSimple methodSynthetic resin layered productsChemical vapor deposition coatingFluoropolymerPlasma activation

A method is described for providing a hydrophilic effect to a fluoropolymer, e.g. polytetrafluoroethylene (PTFE) material. The method comprises obtaining an at least partly hydrophobic fluoropolymer material, applying a plasma and / or ozone activation step and depositing an inorganic coating using an atomic layer deposition process. Plasma activation step and / or said atomic layer deposition process thereby comprises using process parameters determining a high interaction probability between one or more precursors for the atomic layer deposition process and the fluoropolymer material so as to obtain a coated fluoropolymer material having a contact angle with water below 30°.

Owner:UNIV GENT

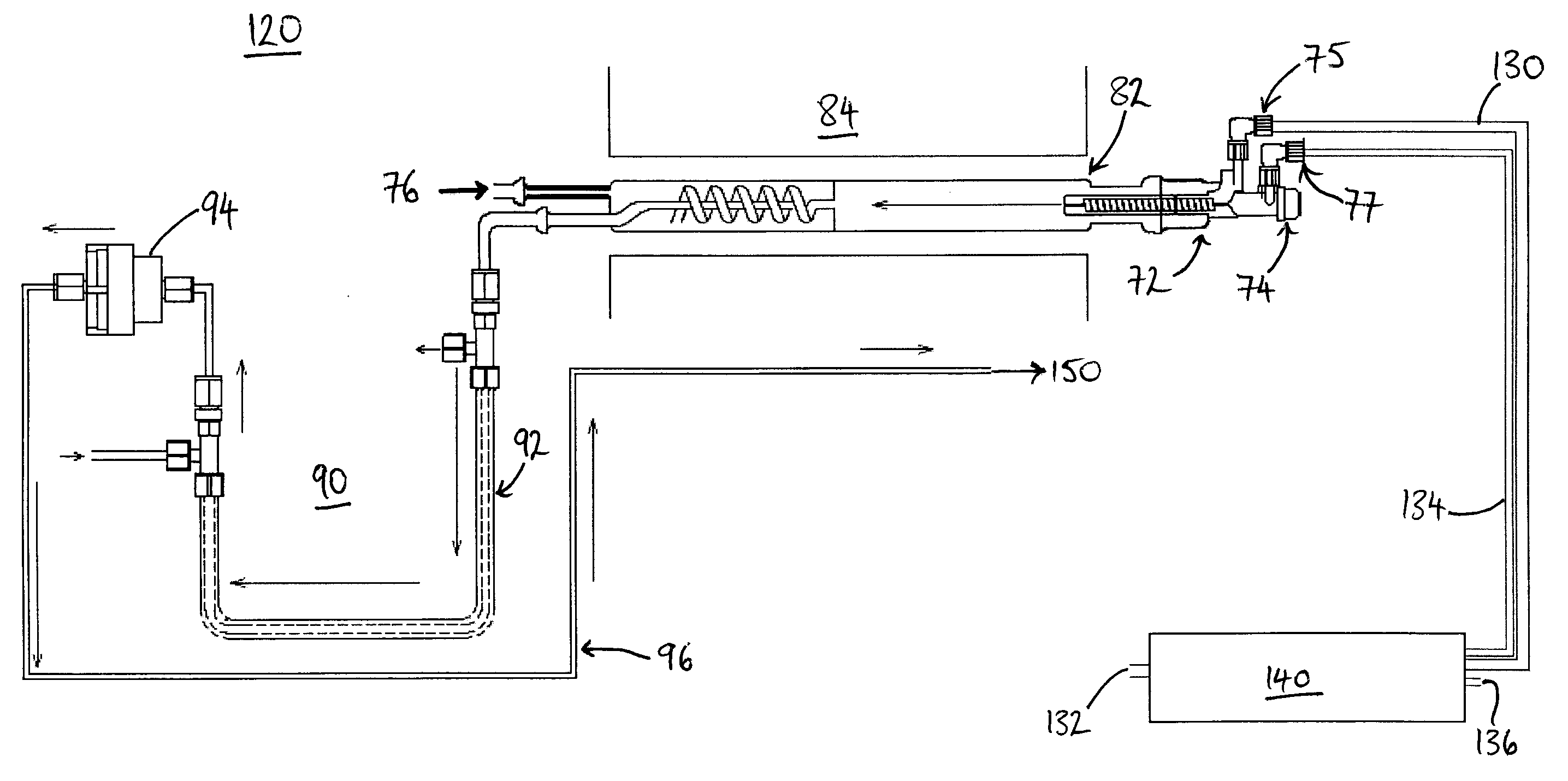

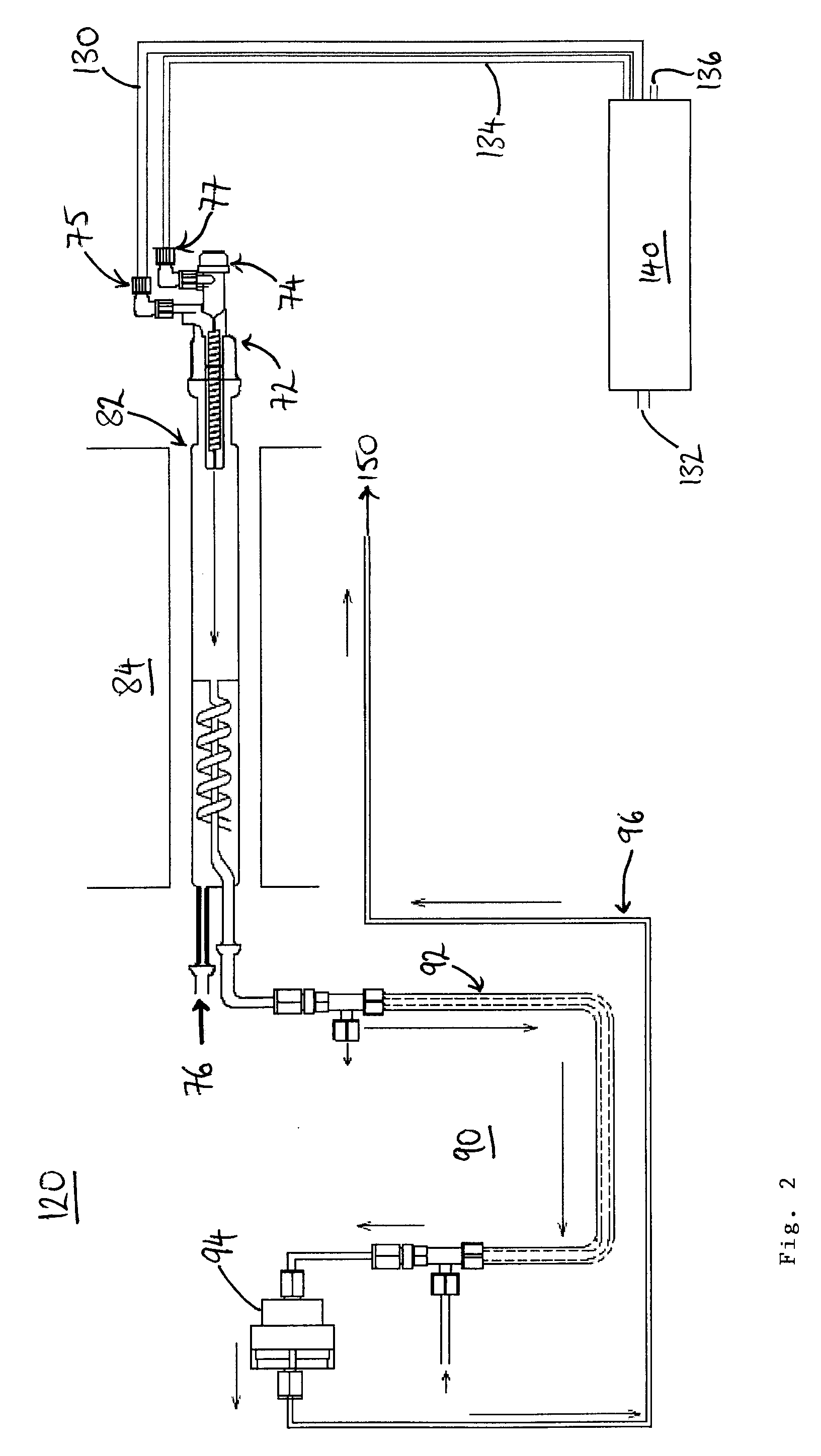

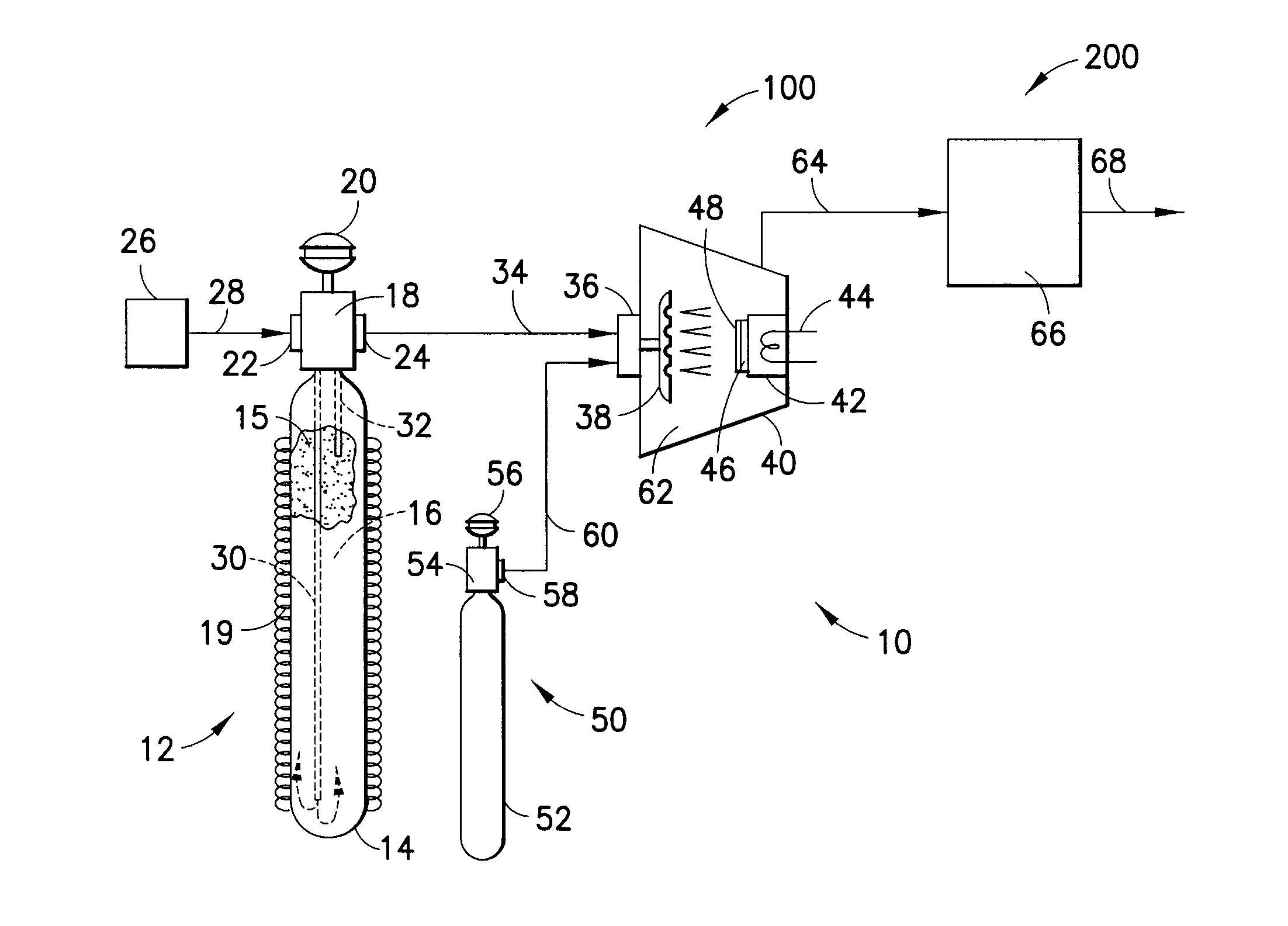

Apparatus and method for generating nitrogen oxides

InactiveUS20080176335A1Possible to useIncrease productionChemical analysis using combustionNitrogen compoundsCombustion chamberWorking temperature

A combustion analyzer apparatus and method for combustion analysing a sample, the analyzer comprising a combustion chamber (82) for receiving a sample for combustion therein to form combustion products, and a fluid supply apparatus for supplying fluid(s) into the chamber. The fluid supply apparatus (130-140) comprises a nitrogen oxides (NOx) generating apparatus (140,190,210,240) and is arranged to supply NOx into the combustion chamber. A yield of sulphur dioxide in the combustion products may thereby be improved. The NOx generating apparatus may be operated at a raised working temperature. The NOx generating apparatus may be provided by an ozonator with a supply of nitrogen and oxygen. A Venturi tube arrangement (246) may draw the generated NOx into a (carrier or oxygen) gas line to the combustion chamber. Ozone may be supplied to the combustion products to convert nitrogen monoxide therein to nitrogen dioxide. The NOx and ozone may be supplied by a single device (210,240).

Owner:THERMO ELECTRON MFG

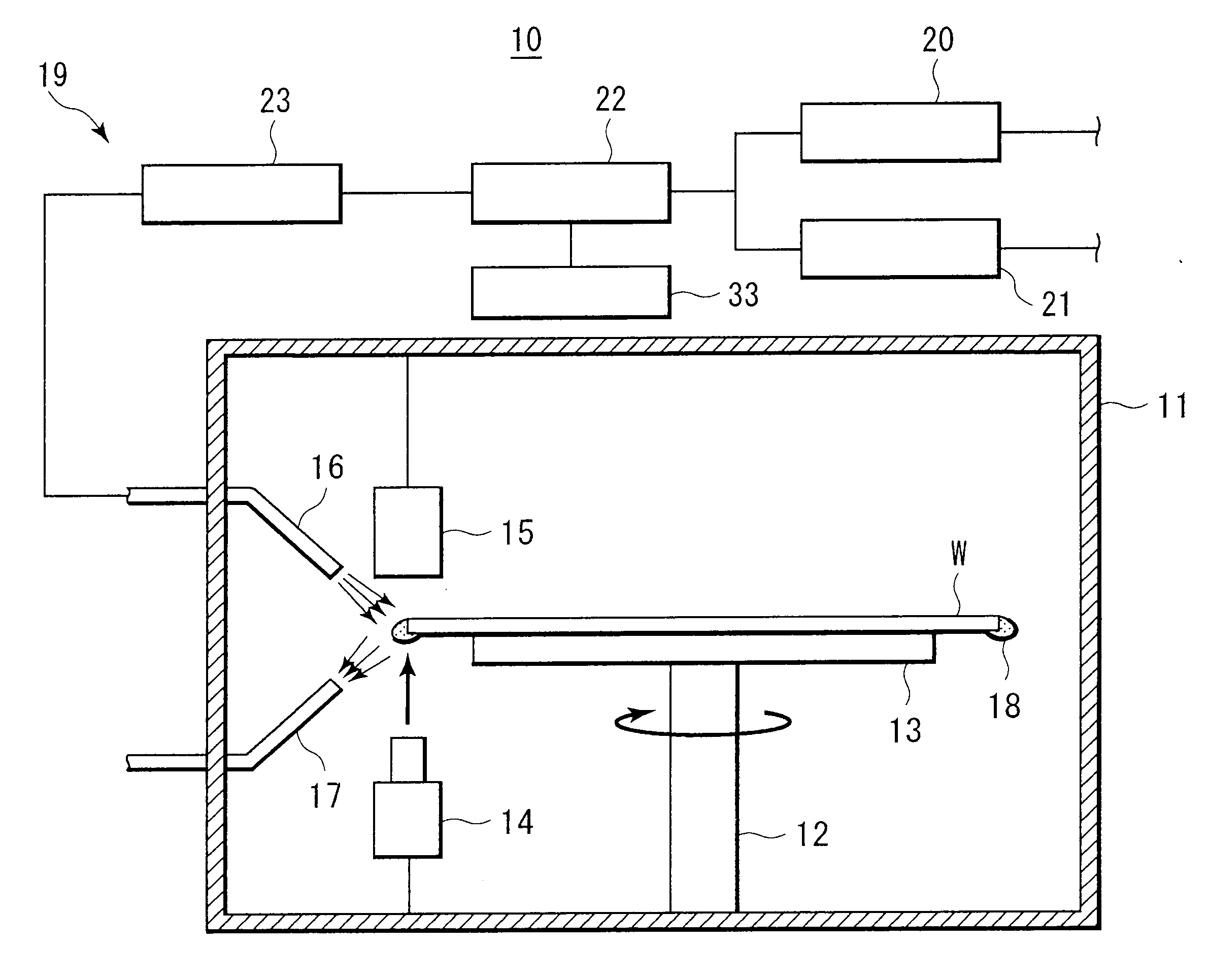

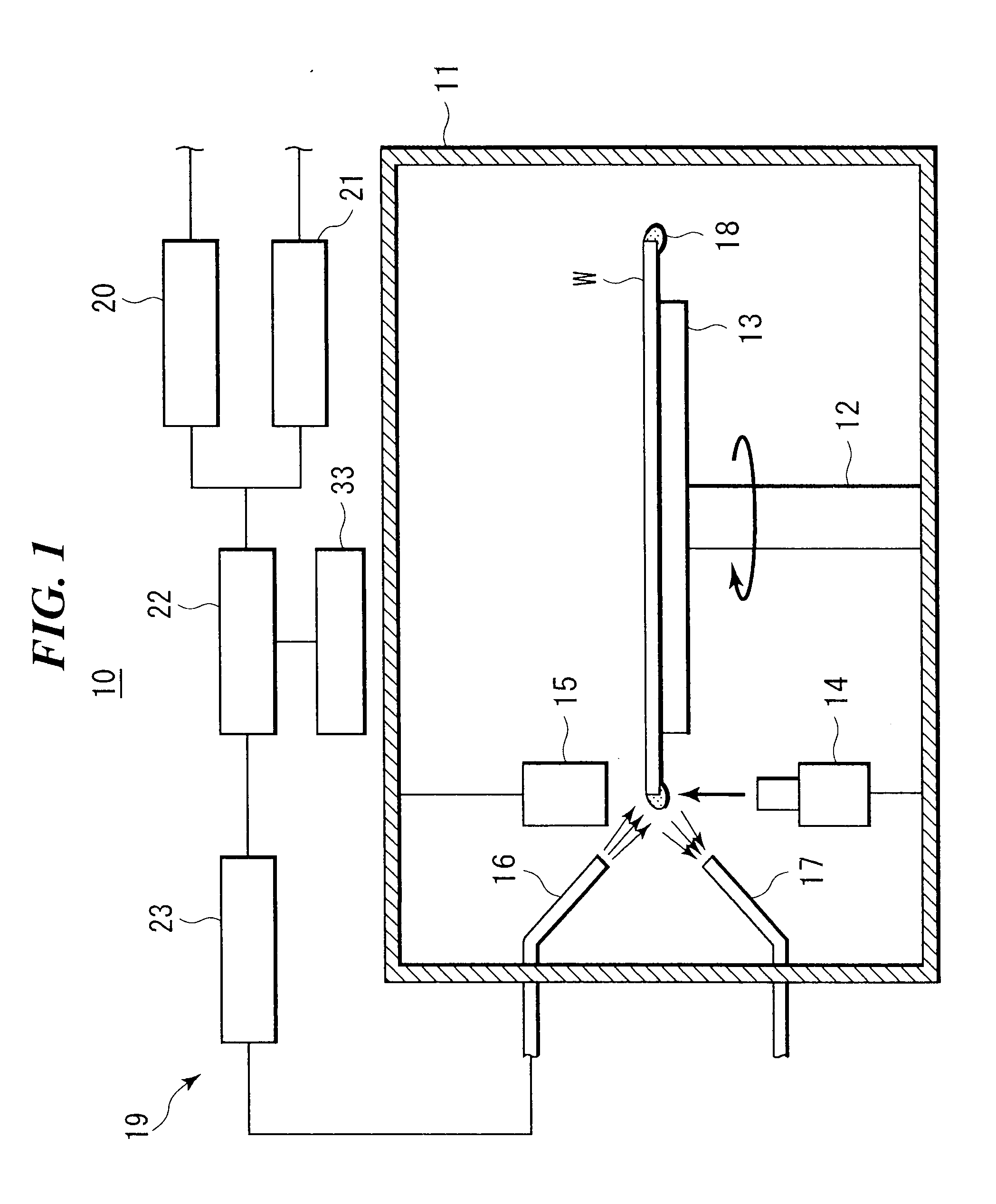

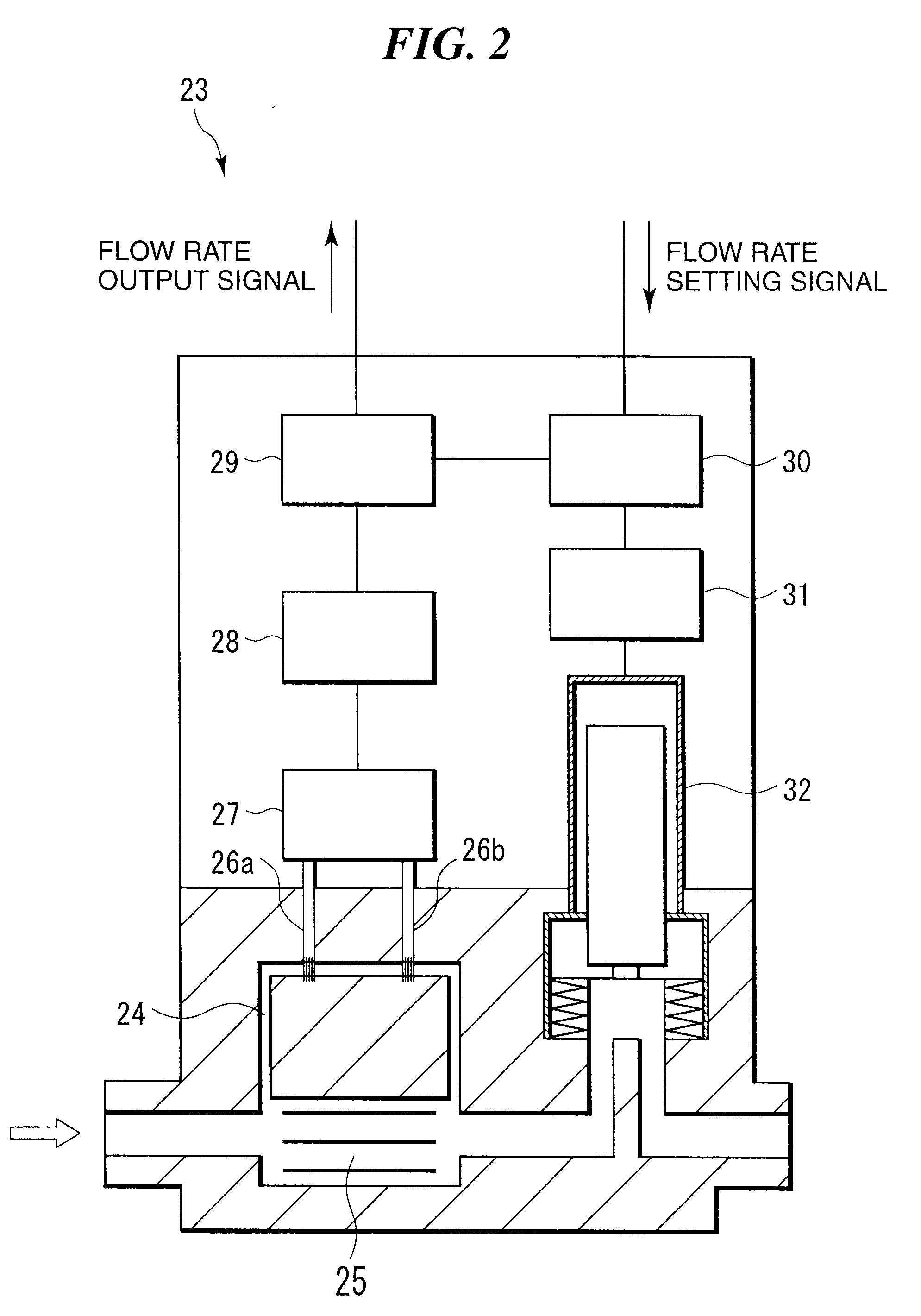

Ozone gas concentration measurement method, ozone gas concentration measurement system, and substrate processing apparatus

ActiveUS20100119439A1Improve concentrationEasy to measurePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSemiconductor/solid-state device manufacturingProduct gasGas concentration

An ozone gas concentration measurement method that can easily measure the concentration of ozone gas. A process gas containing ozone gas is produced from a raw gas containing oxygen gas. The number of moles of gas molecules contained in the process gas is measured. The concentration of the ozone gas contained in the process gas is calculated based on the number of moles of gas molecules contained in the process gas.

Owner:TOKYO ELECTRON LTD

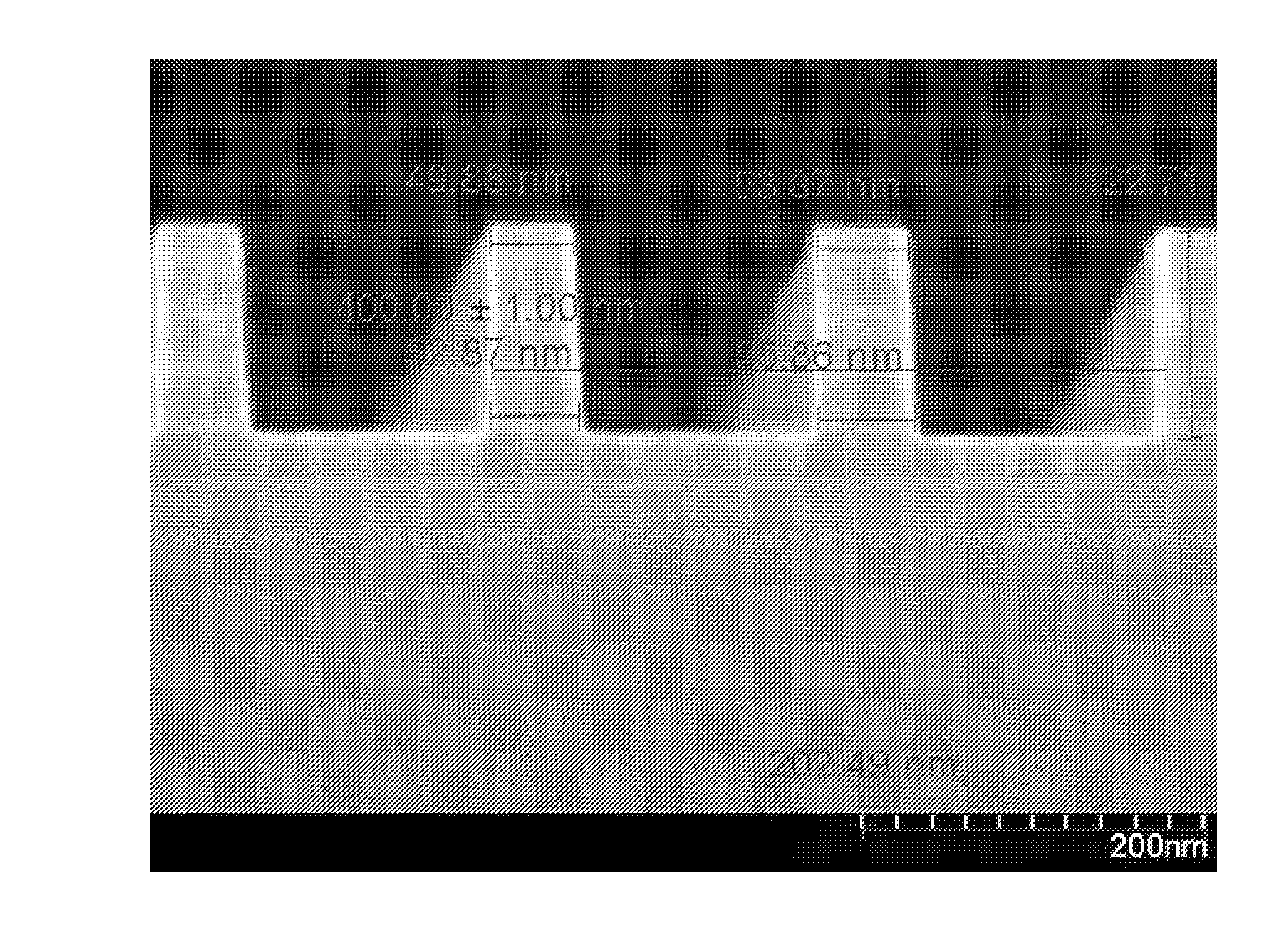

Method for sidewall spacer line doubling using atomic layer deposition of a titanium oxide

A method for sidewall spacer line doubling uses thermal atomic layer deposition (ALD) of a titanium oxide (TiOx) spacer layer. A hardmask layer is deposited on a suitable substrate. A mandrel layer of diamond-like carbon (DLC) is deposited on the hardmask layer and patterned into stripes with tops and sidewalls. A layer of TiOx is deposited, by thermal ALD without the assistance of plasma or ozone, on the tops and sidewalls of the mandrel stripes. Thermal ALD of the TiO2, without energy assistance by plasma or ozone, has been found to cause no damage to the DLC mandrel stripes. After removal of the TiOx from the tops of the mandrel stripes and removal of the mandrel stripes, stripes of TiO2 are left on the hardmask layer and may be used as an etch mask to transfer the pattern into the hardmask layer.

Owner:WESTERN DIGITAL TECH INC

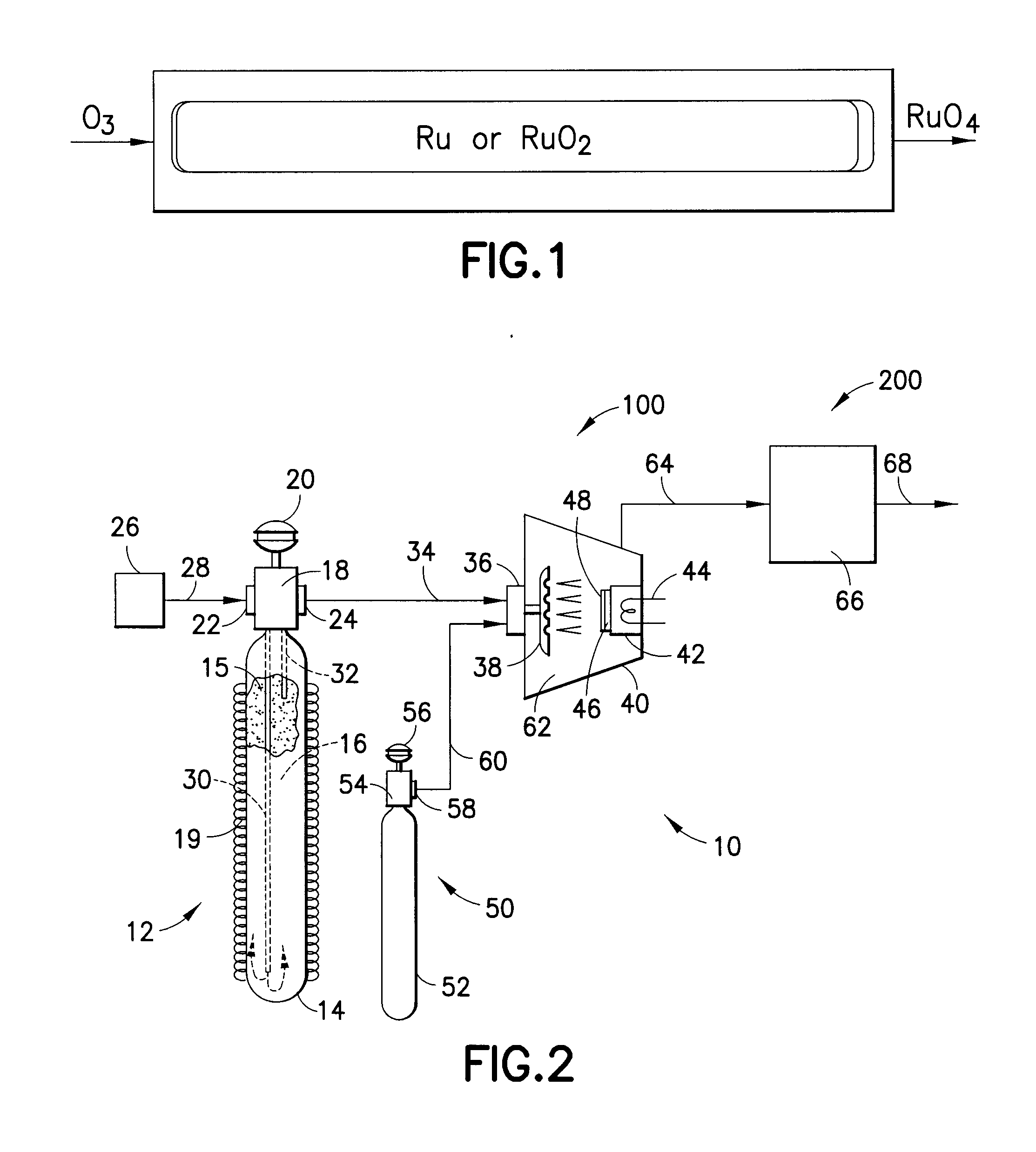

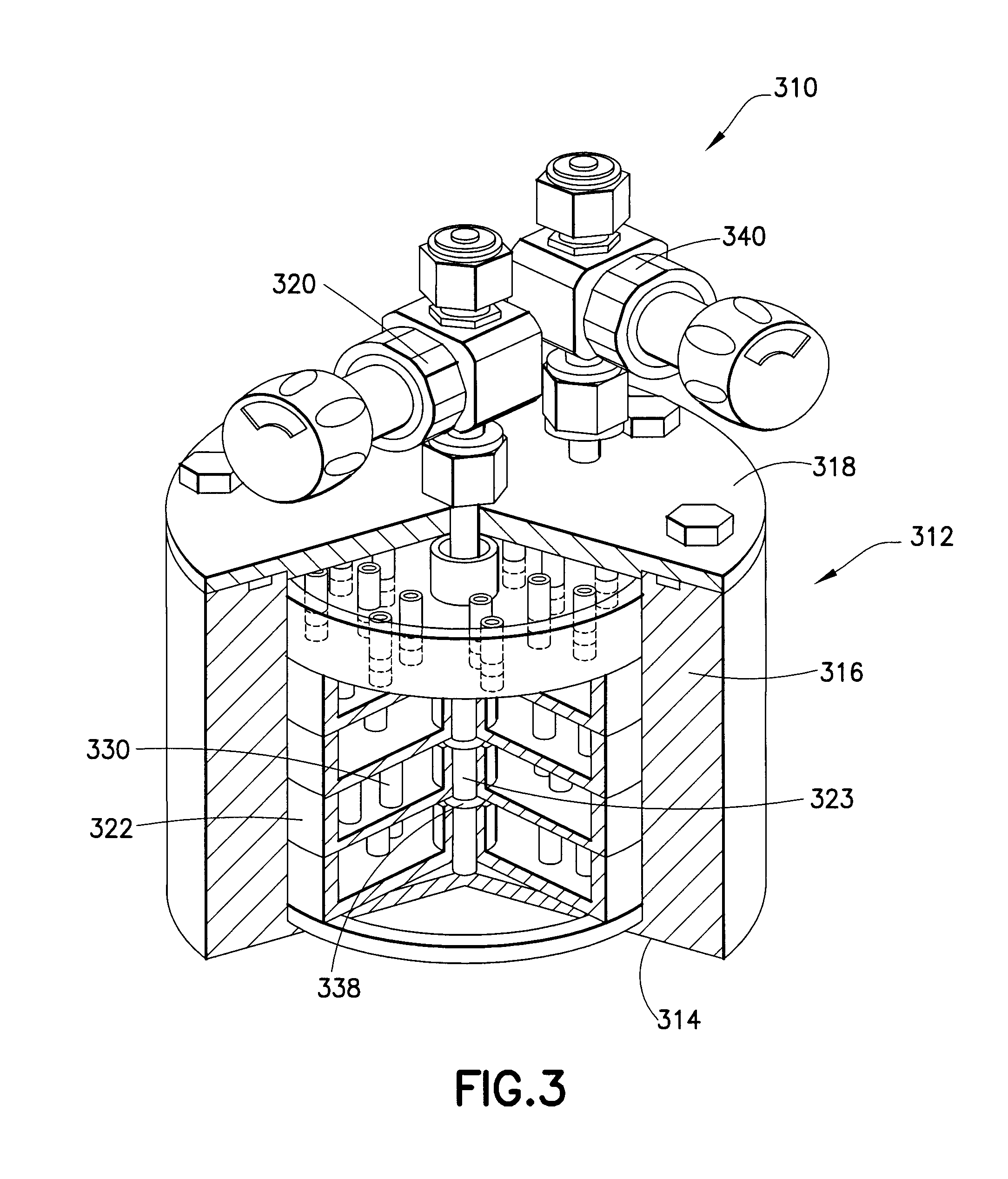

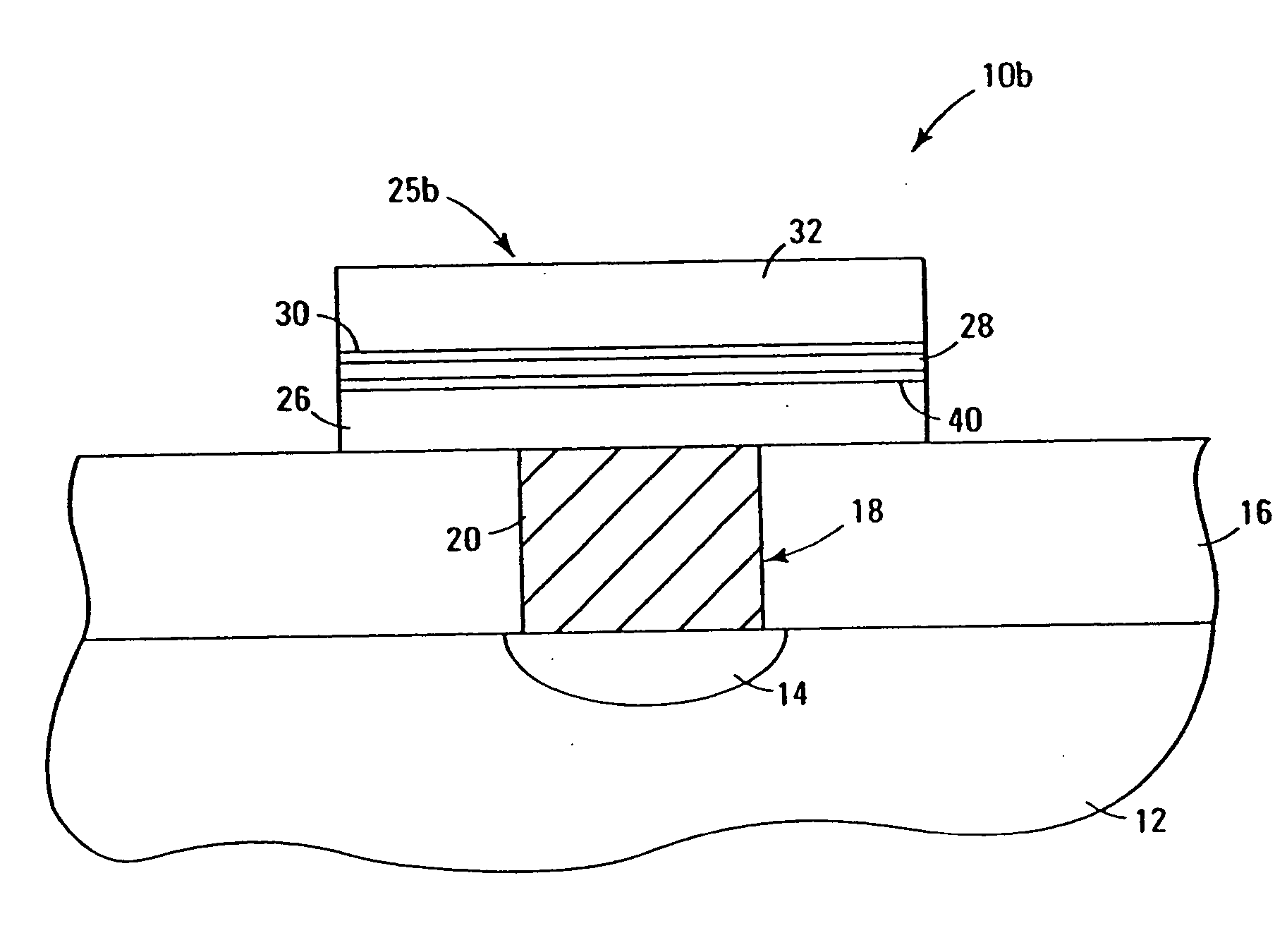

IN SITU GENERATION OF RuO4 FOR ALD OF Ru AND Ru RELATED MATERIALS

Apparatus and method for generating ruthenium tetraoxide in situ for use in vapor deposition, e.g., atomic layer deposition (ALD), of ruthenium-containing films on microelectronic device substrates. The ruthenium tetraoxide can be generated on demand by reaction of ruthenium or ruthenium dioxide with an oxic gas such as oxygen or ozone. In one implementation, ruthenium tetraoxide thus generated is utilized with a strontium organometallic precursor for atomic layer deposition of strontium ruthenate films of extremely high smoothness and purity.

Owner:ENTEGRIS INC

Systems and methods for forming metal oxide layers

InactiveUS20060252244A1Reducing (Easy to controlSemiconductor/solid-state device manufacturingCapacitorsGas phaseDeposition process

A method of forming (and apparatus for forming) a metal oxide layer, preferably a dielectric layer, on a substrate, particularly a semiconductor substrate or substrate assembly, using a vapor deposition process and ozone with one or more metal organo-amine precursor compounds.

Owner:MICRON TECH INC

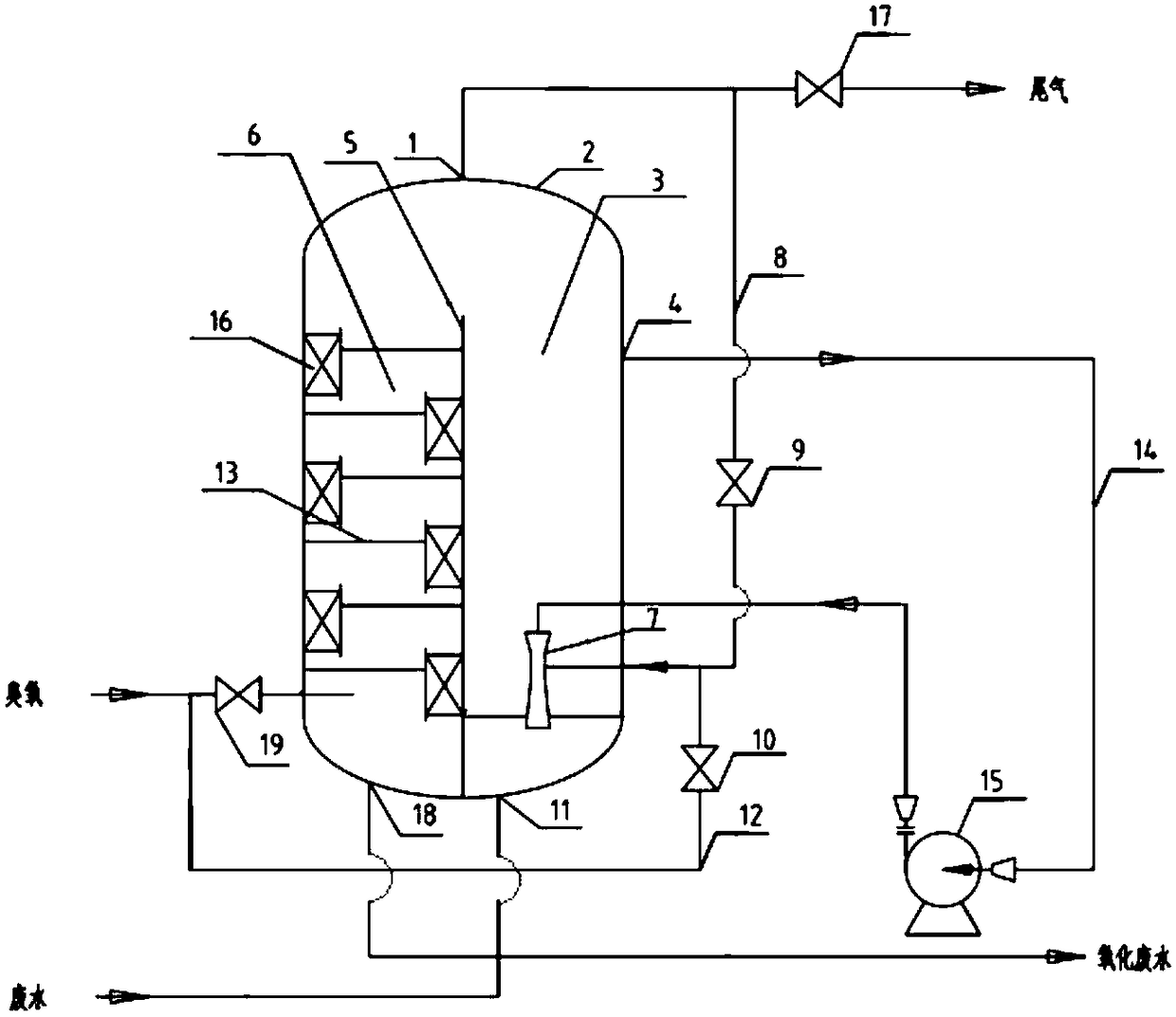

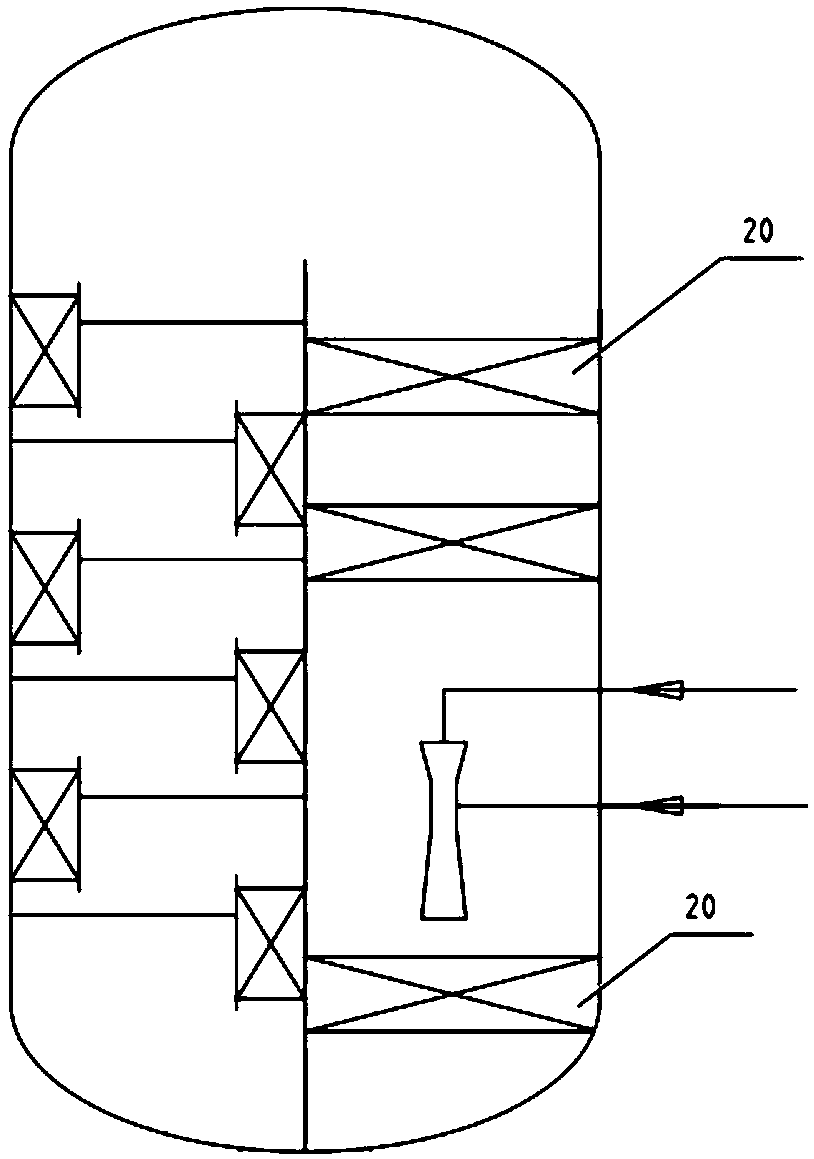

Reactor for catalytically oxidizing wastewater through ozone and application method thereof

PendingCN109437390AEnhanced mass transferReduce backmixingWater/sewage treatment by oxidationWorking fluidChemical oxygen demand

The invention discloses a reactor for catalytically oxidizing wastewater through ozone and an application method thereof. The reactor comprises a reaction chamber, a water inlet, a water outlet, a gasoutlet and a circulating water outlet, wherein a separation plate in the reaction chamber is used for separating the lower part of the reaction chamber into a jet flow reaction chamber and a tower type reaction chamber; the jet flow reaction chamber is internally provided with a first catalysis bed layer and an ejector; the circulating water outlet is connected with a working fluid inlet of the ejector; the gas outlet is connected with a sucked liquid inlet of the ejector through a gas circulating pipe; the water inlet is arranged at the bottom of the jet flow reaction chamber; the tower typereaction chamber is internally provided with a tower plate and a second catalysis bed layer; the water outlet is arranged at the bottom of the tower type reaction chamber; a gas inlet is communicatedwith the lower side of the tower plate and the gas circulating pipe; the gas circulating pipe is connected with a tail gas outlet. The reactor has the advantages of high mass transfer efficiency, rapid reaction speed, high ozone utilization rate, high COD (Chemical Oxygen Demand) removal rate and the like.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Method for seasoning UV chamber optical components to avoid degradation

InactiveUS20130177706A1Pretreated surfacesChemical vapor deposition coatingAnalytical chemistryOptics

Methods for depositing a carbon-based seasoning layer on exposed surfaces of the optical components within a UV processing chamber are disclosed. In one embodiment, the method includes flowing a carbon-containing precursor radially inwardly across exposed surfaces of optical components within the thermal processing chamber from a circumference of the optical components, exposing the carbon-containing precursor to a thermal radiation emitted from a heating source to form a carbon-based seasoning layer on the exposed surfaces of the optical components, exposing the carbon-based seasoning layer to ozone, wherein the ozone is introduced into the processing chamber by flowing the ozone radially inwardly across exposed surfaces of optical components from the circumference of the optical components, heating the optical components to a temperature of about 400° C. or above while flowing the ozone to remove the carbon-based seasoning layer from exposed surfaces of the optical components.

Owner:APPLIED MATERIALS INC

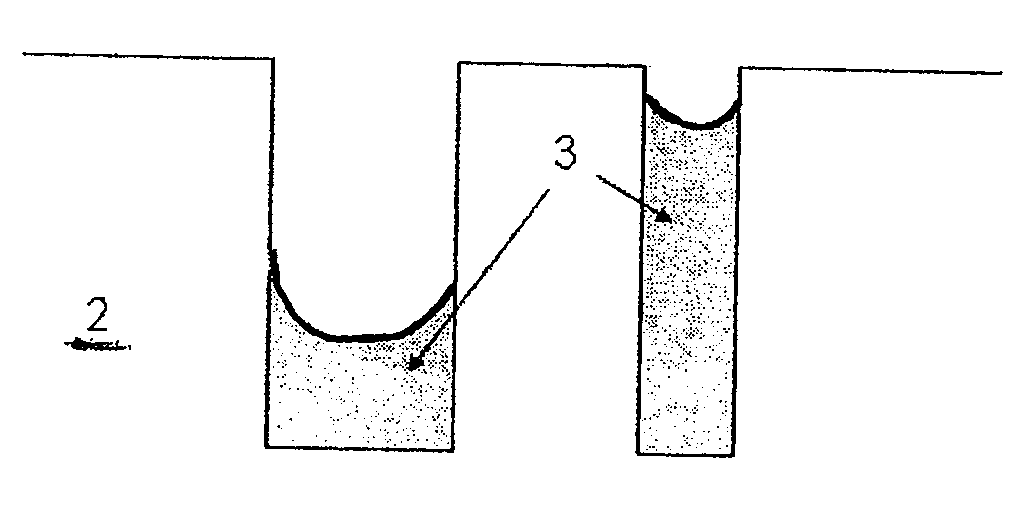

Method for forming a silicon oxide layer using spin-on glass

A method is provided for forming silicon oxide layers during the processing of semiconductor devices by applying a SOG layer including polysilazane to a substrate and then substantially converting the SOG layer to a silicon oxide layer using an oxidant solution. The oxidant solution may include one or more oxidants including, for example, ozone, peroxides, permanganates, hypochlorites, chlorites, chlorates, perchlorates, hypobromites, bromites, bromates, hypoiodites, iodites, iodates and strong acids.

Owner:SAMSUNG ELECTRONICS CO LTD

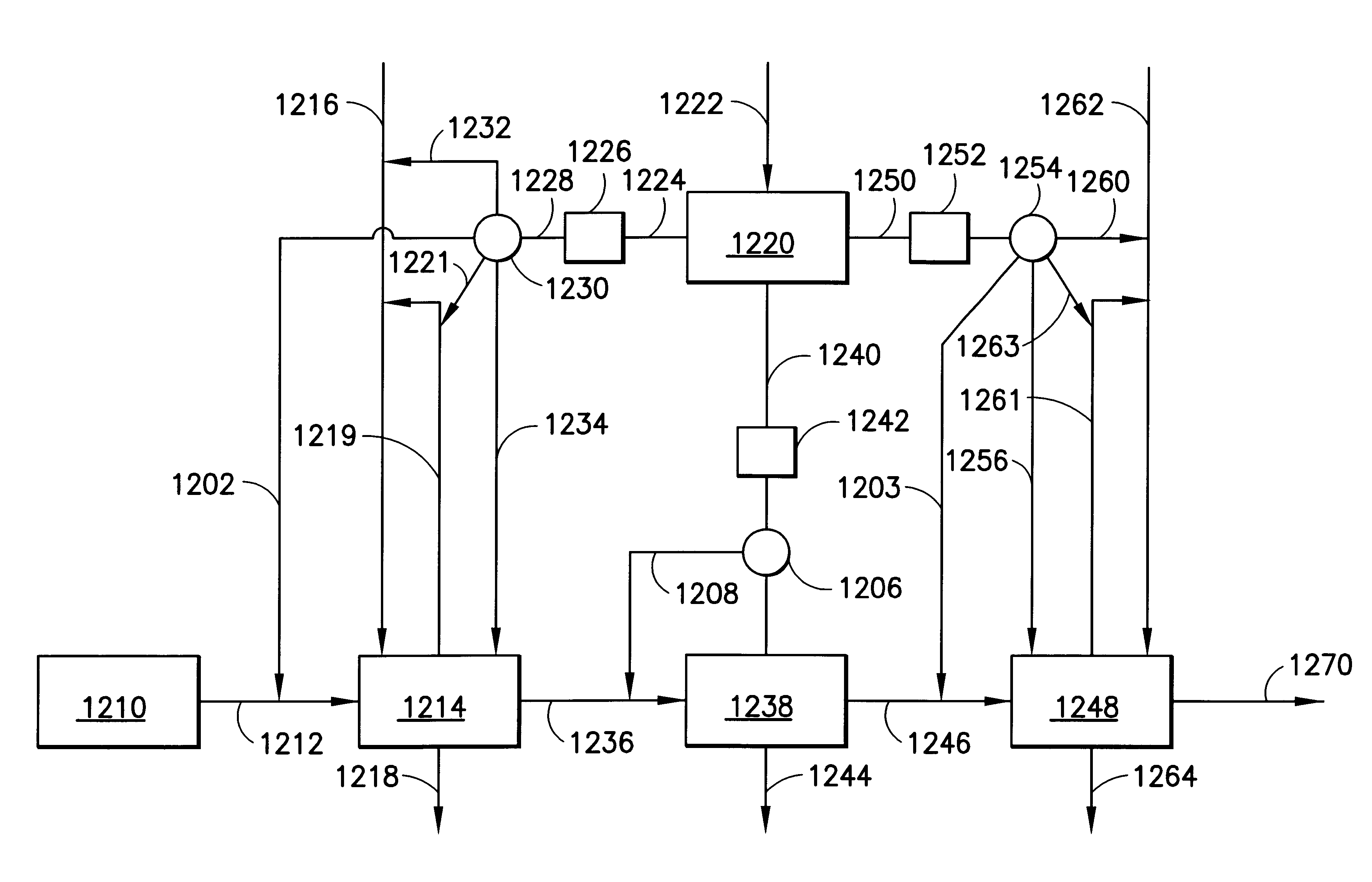

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6322756B1Reduce sensitivityReduces water requiredCombination devicesExhaust apparatusOxygenOxidative treatment

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises an oxidation unit to which an oxygen-containing gas such as ozone may be added, with input of energy (e.g., thermal, radio frequency, electrical, microwave, etc.), to effect oxidation of oxidizable species in the effluent, such as halocompounds (e.g., chlorofluorocarbons, perfluorocarbons), CO, NF3, nitrogen oxides, and sulfur oxides). The effluent gas stream treatment system may include a wet scrubber associated with the oxygen-containing gas source, so that the gas stream is contacted with the oxygen-containing gas during the wet scrubbing operation, to enhance removal of oxidizable species in the gas stream during treatment.

Owner:BHT SERVICES PTE LTD

Systems and method for forming silicon oxide layers

InactiveUS7115528B2Reduce decreaseEasy to controlSemiconductor/solid-state device manufacturingCapacitorsGas phaseSilicon oxide

A method of forming (and apparatus for forming) a metal oxide layer, preferably a dielectric layer, on a substrate, particularly a semiconductor substrate or substrate assembly, using a vapor deposition process and ozone with one or more metal organo-amine precursor compounds.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com