Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1070results about How to "Improve deposition efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

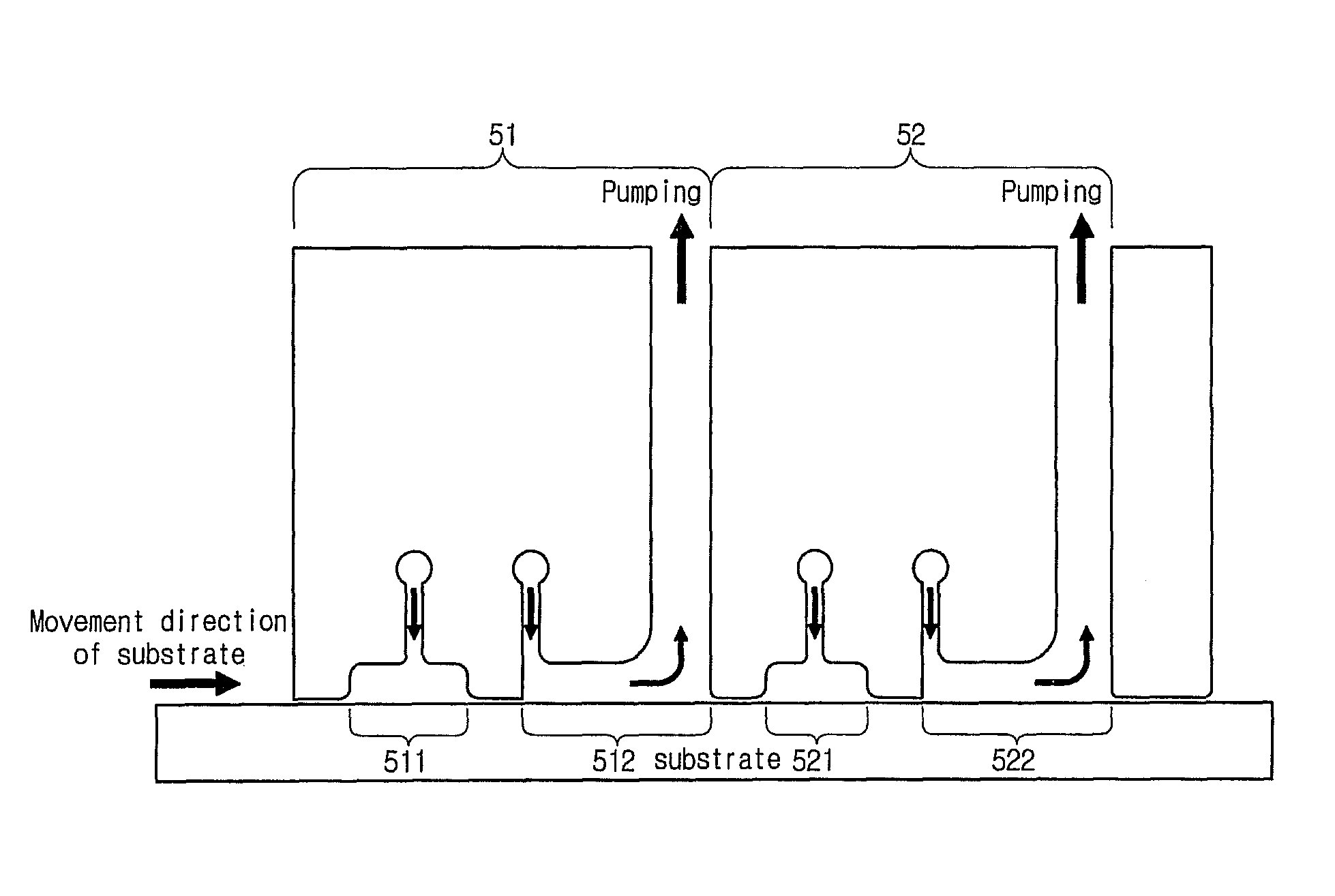

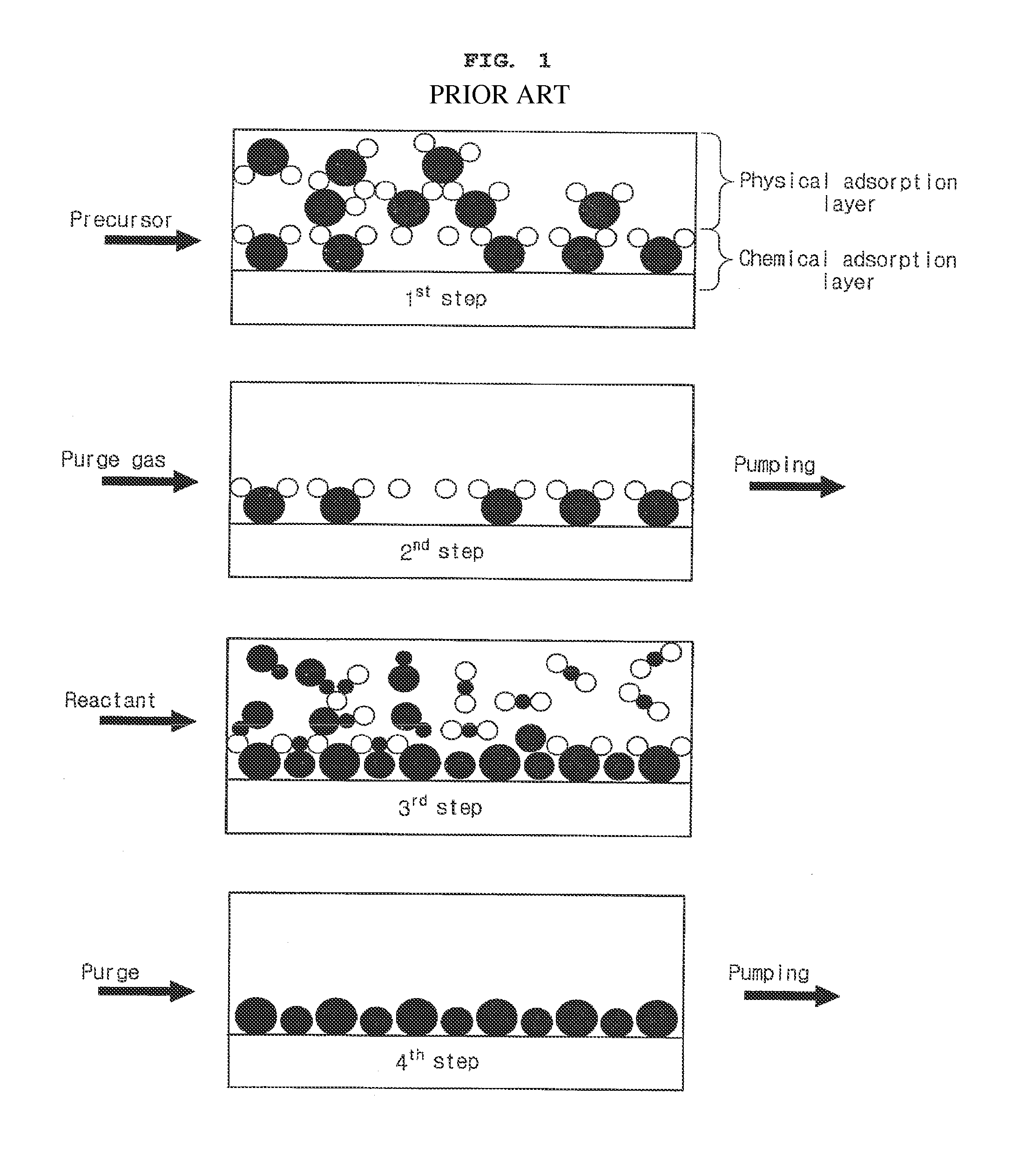

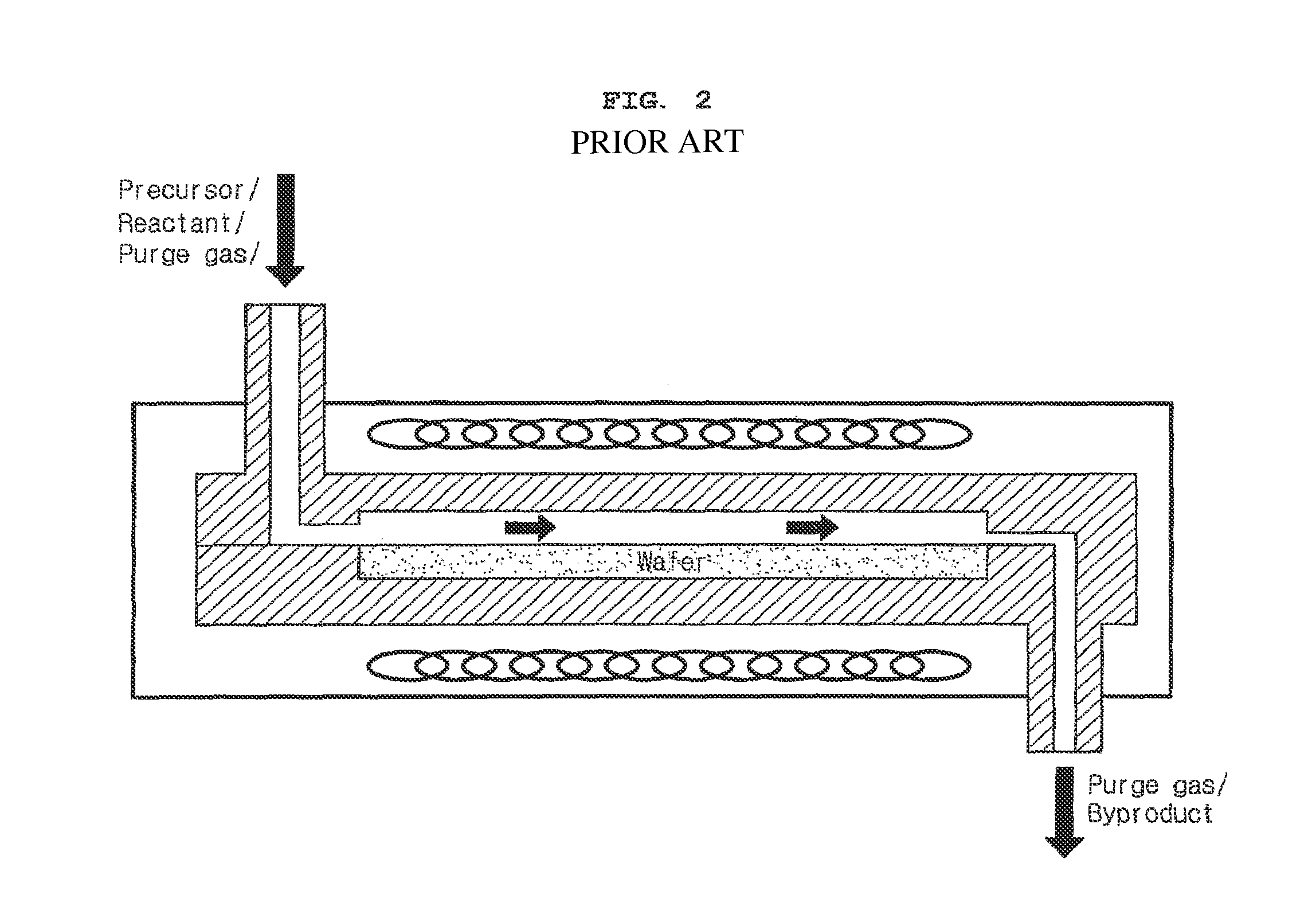

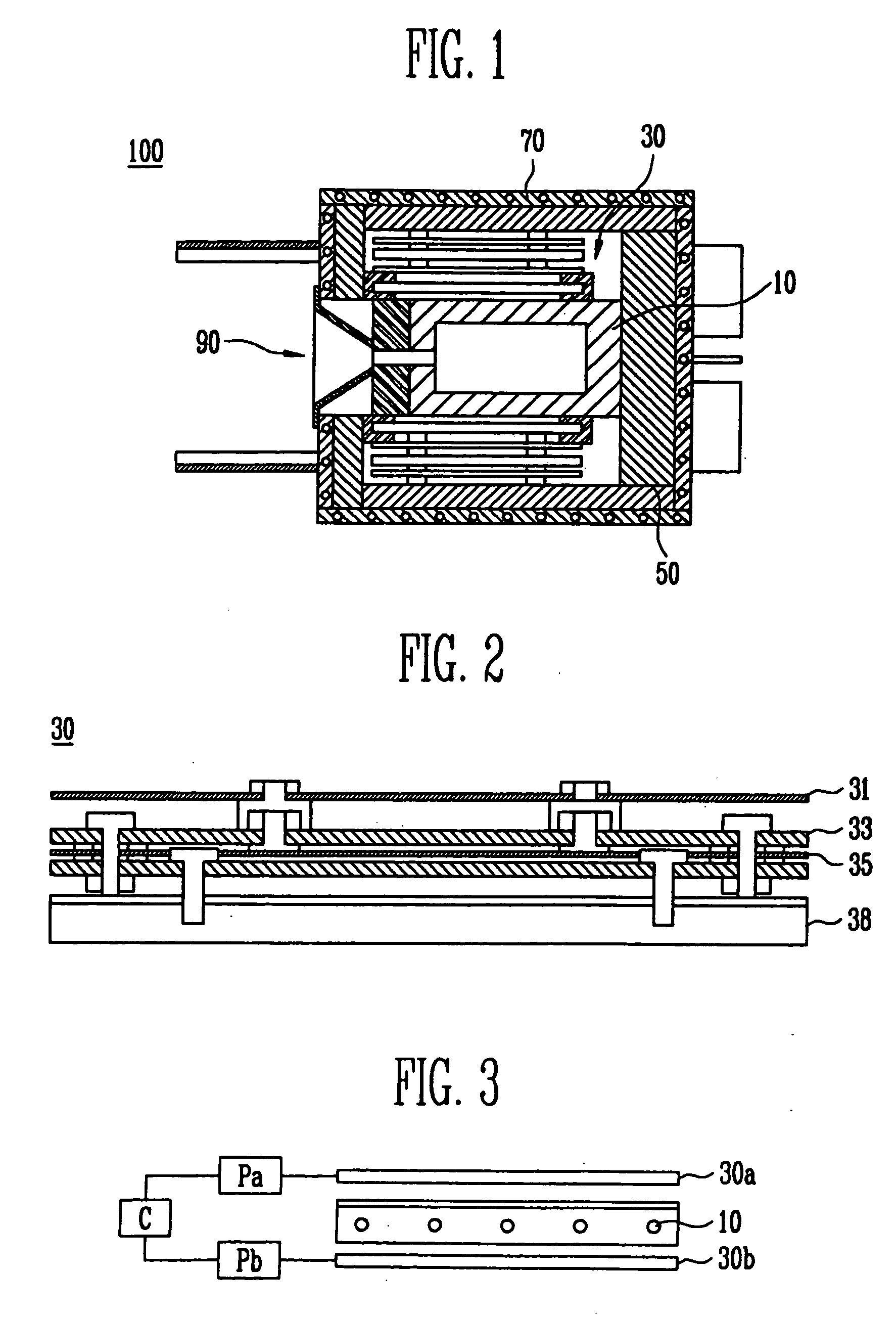

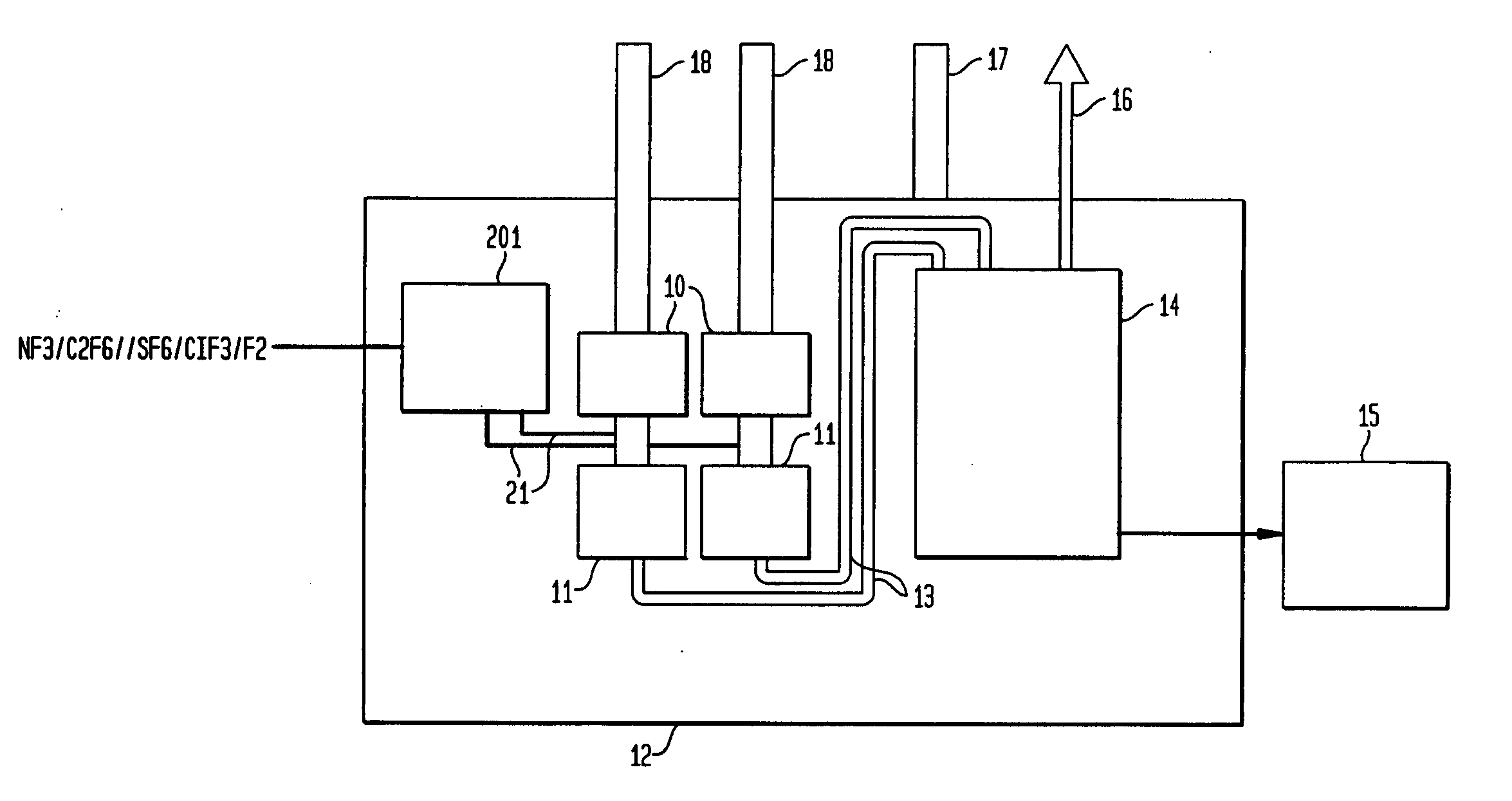

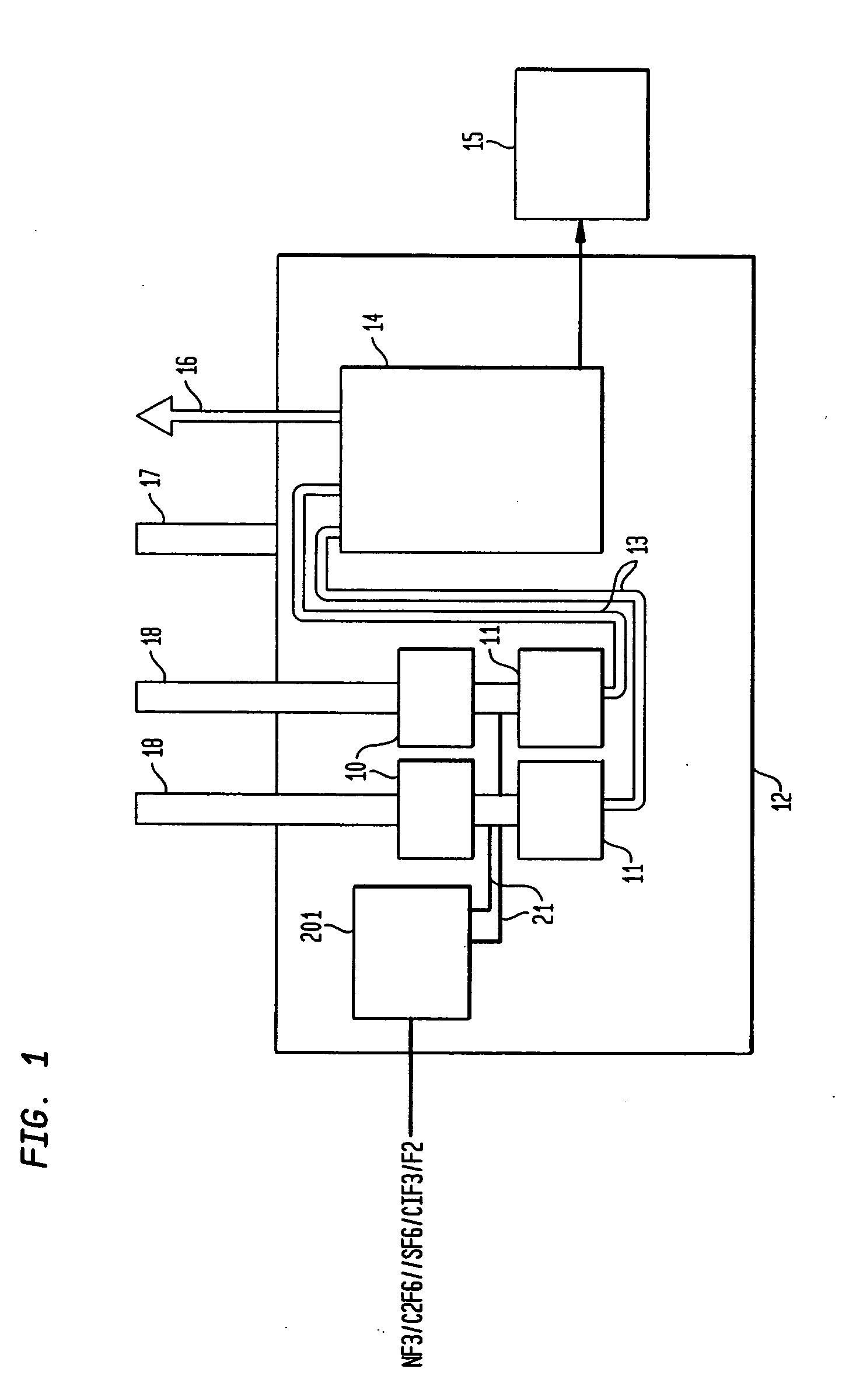

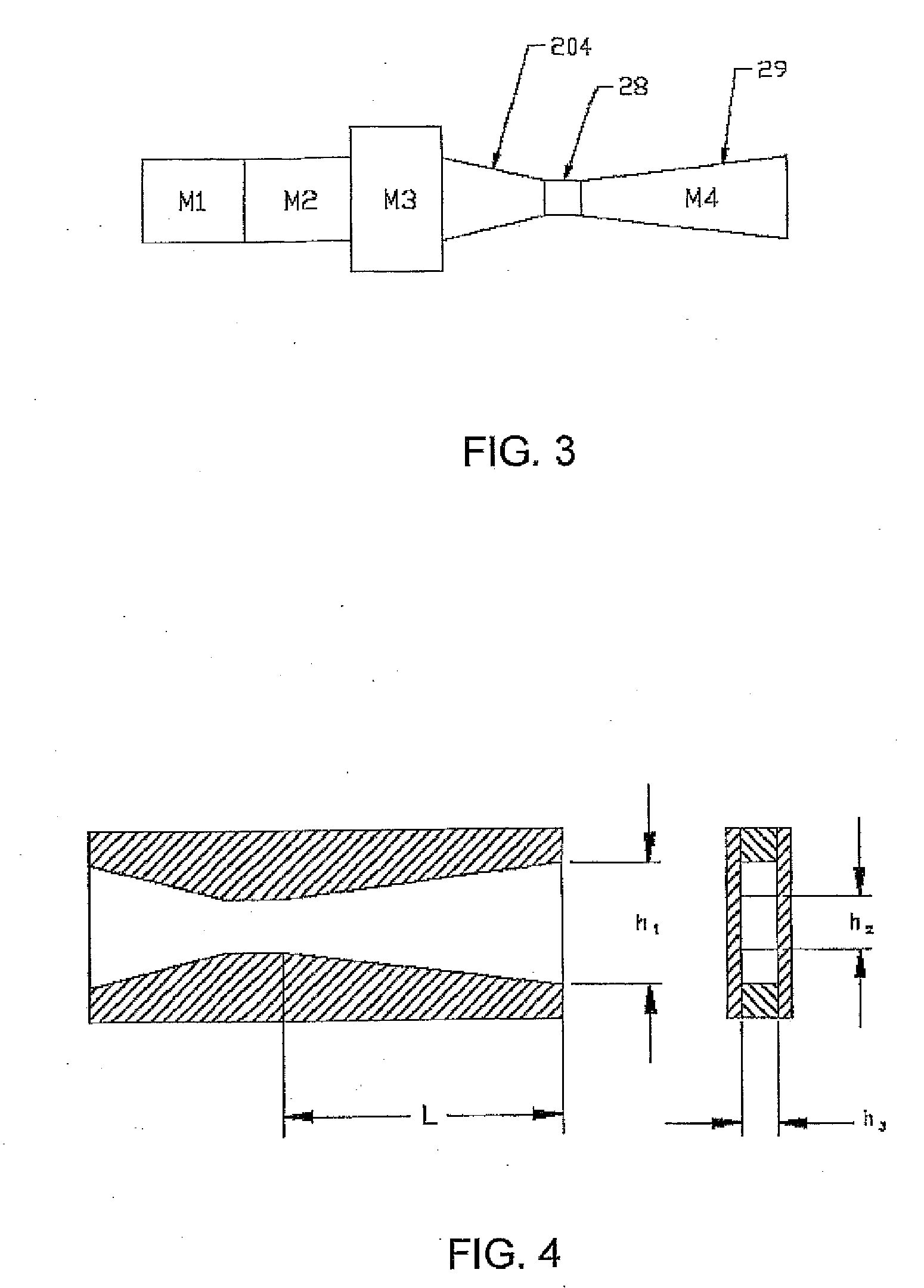

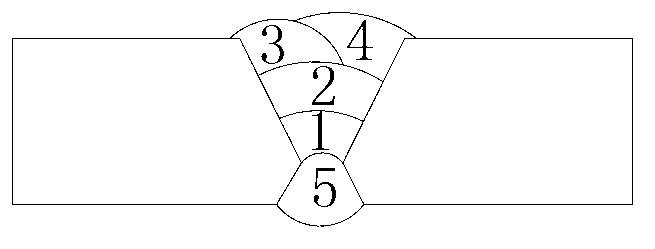

Vapor deposition reactor

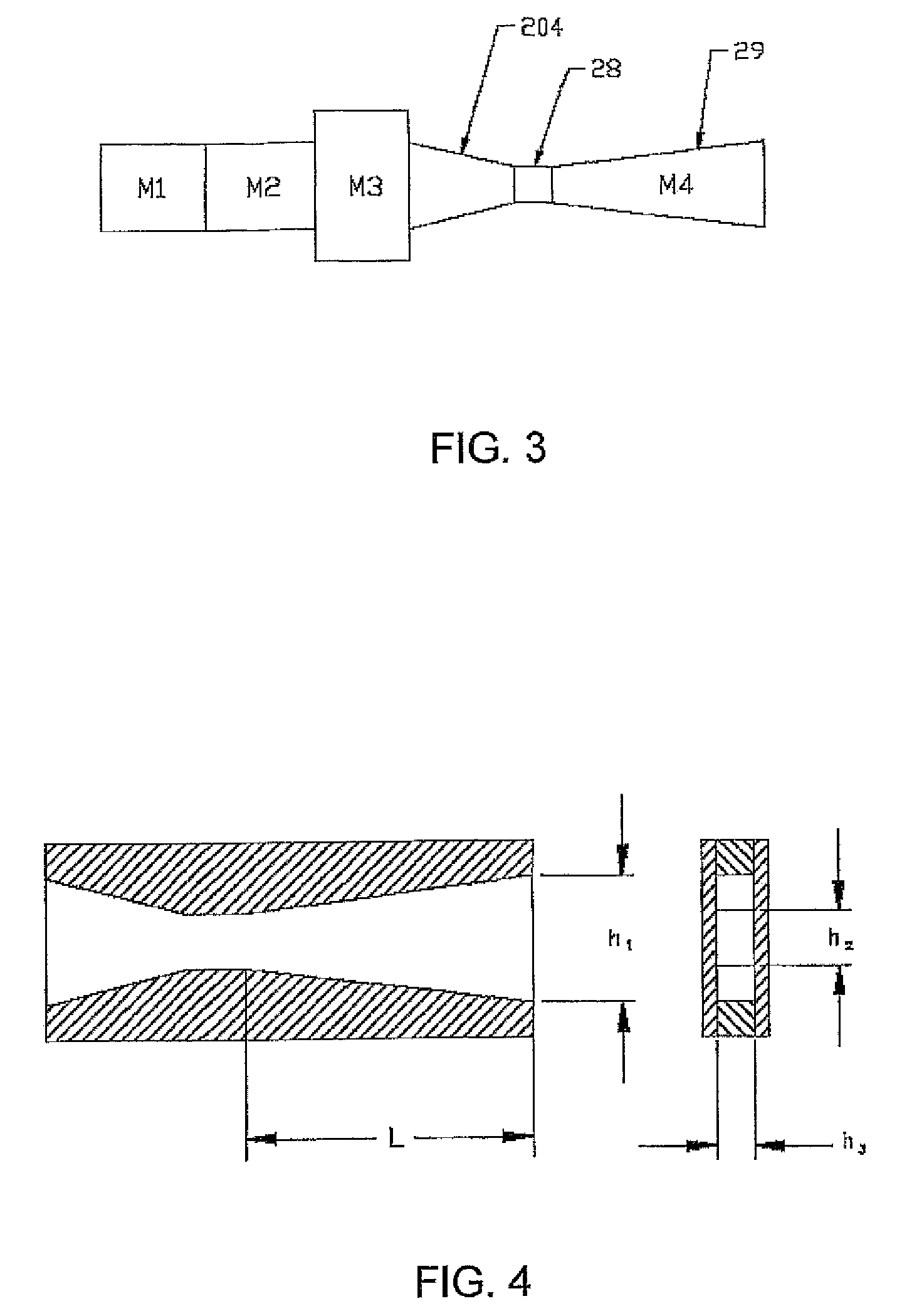

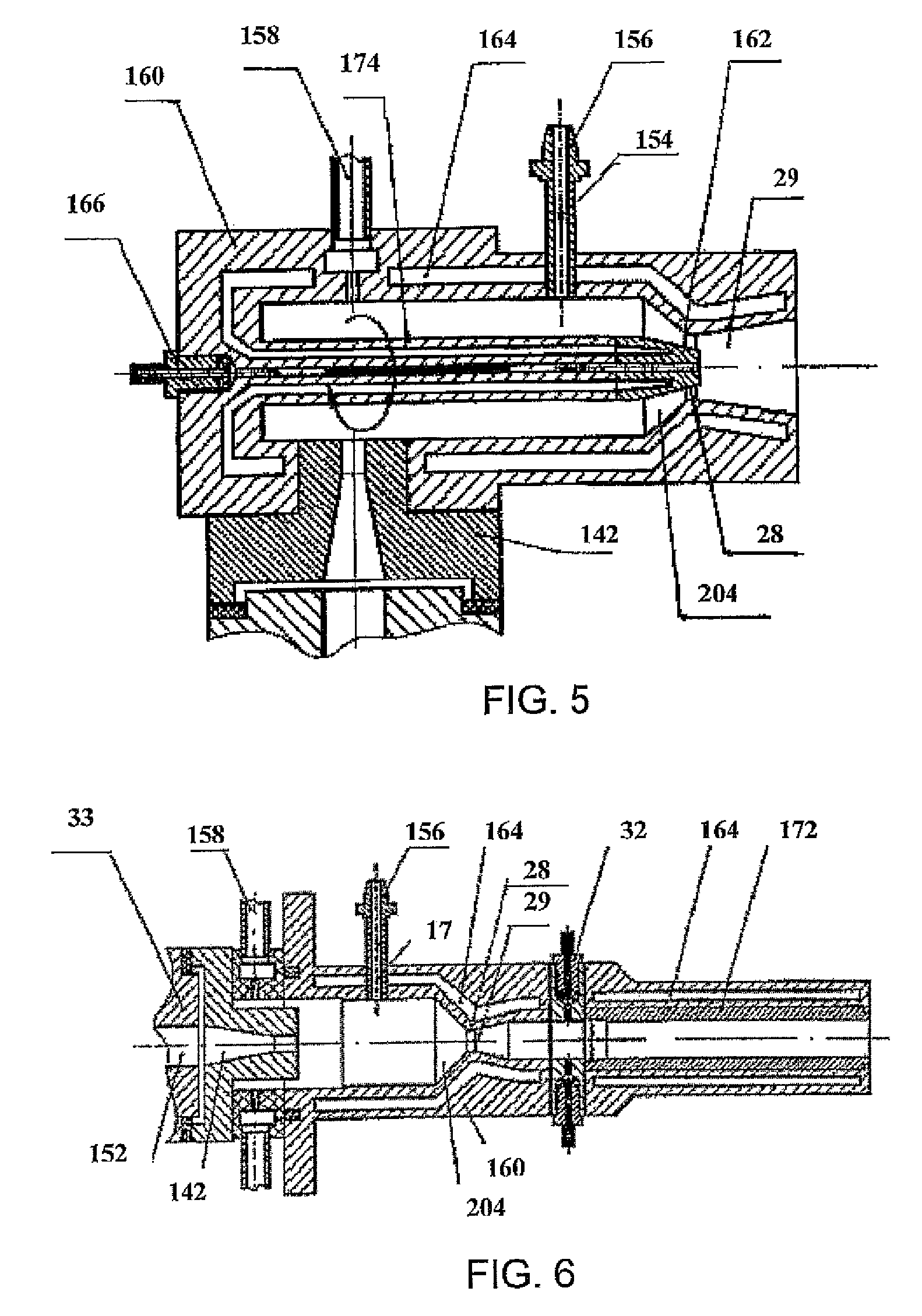

InactiveUS20090165715A1Improve deposition efficiencyShorten the timeChemical vapor deposition coatingRemote plasmaMicrowave

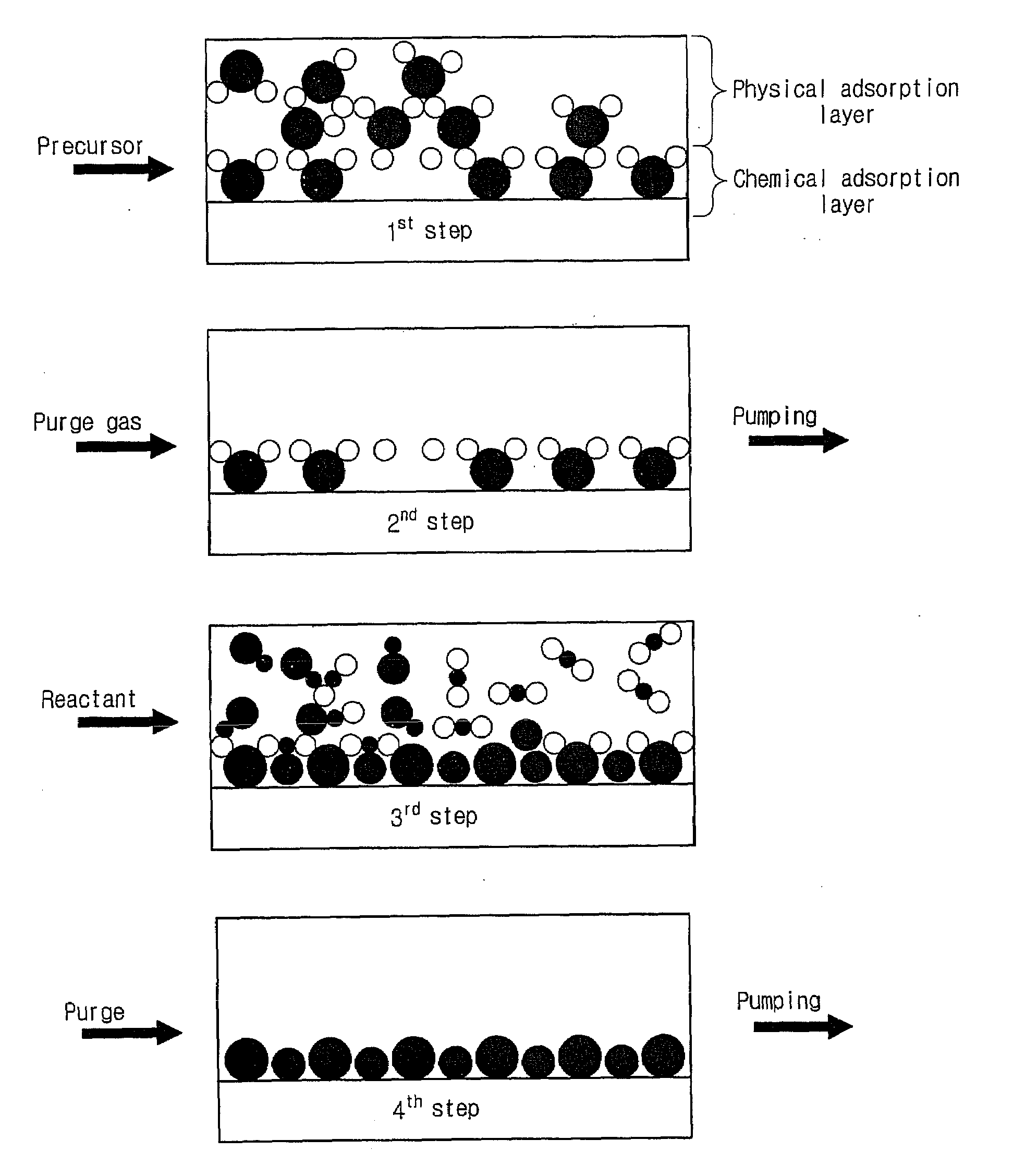

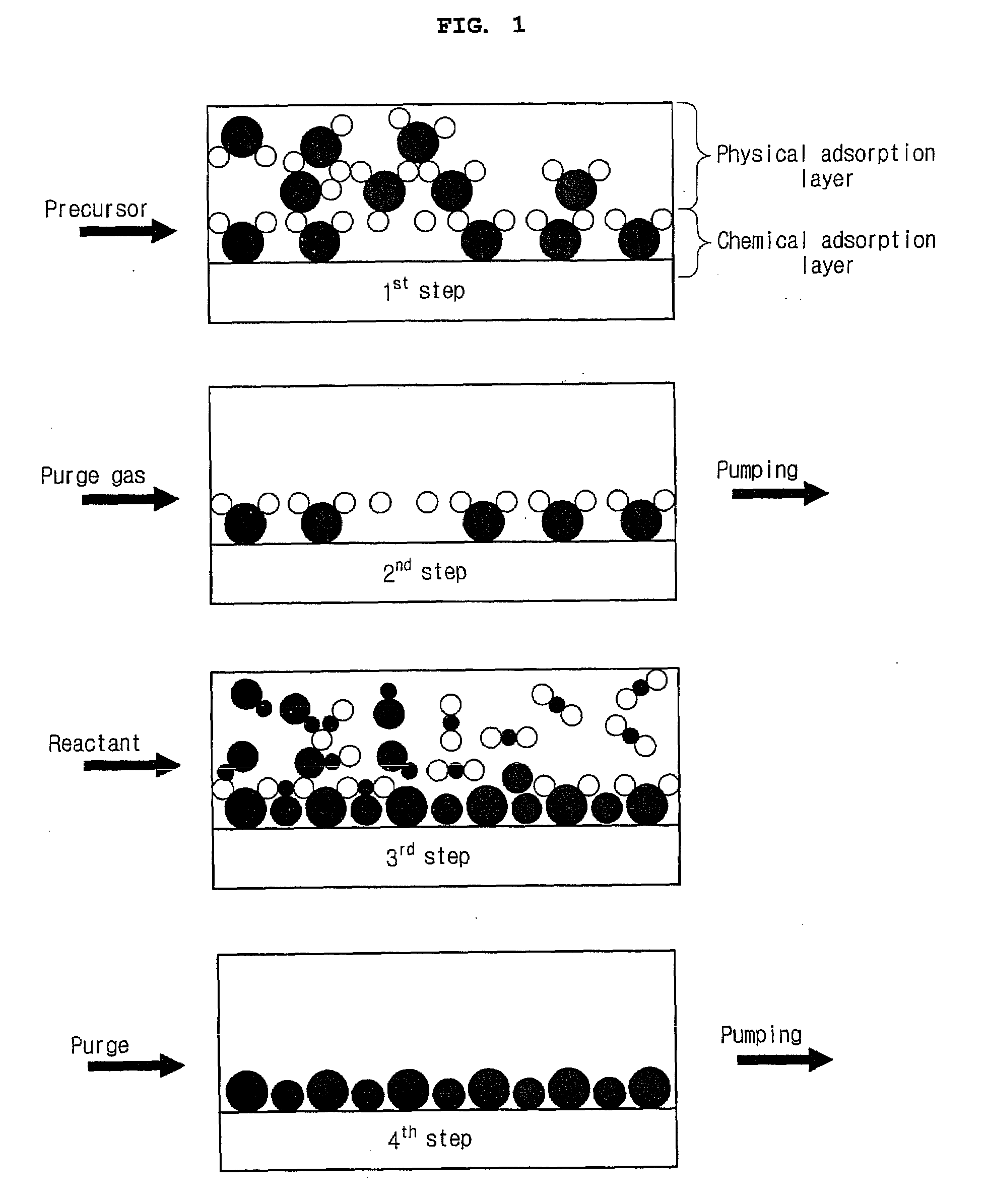

A vapor deposition reactor has a configuration where a substrate or a vapor deposition reactor moves in a non-contact state with each other to allow the substrate to pass by the reactor and an injection unit and an exhaust unit are installed as a basic module of the reactor for receiving a precursor or a reactant and for receiving and pumping a purge gas, respectively. With the use of a small-size inlet for the reactor, homogeneous film properties are obtained, the deposition efficiency of precursors is improved, and an amount of time required for a purge / pumping process can be reduced. In addition, since the reactor itself is configured to reflect each step of ALD, it does not need a valve. Moreover, the reactor makes it easier for users to apply remote plasma, use super high frequencies including microwave, and UV irradiation.

Owner:VEECO ALD

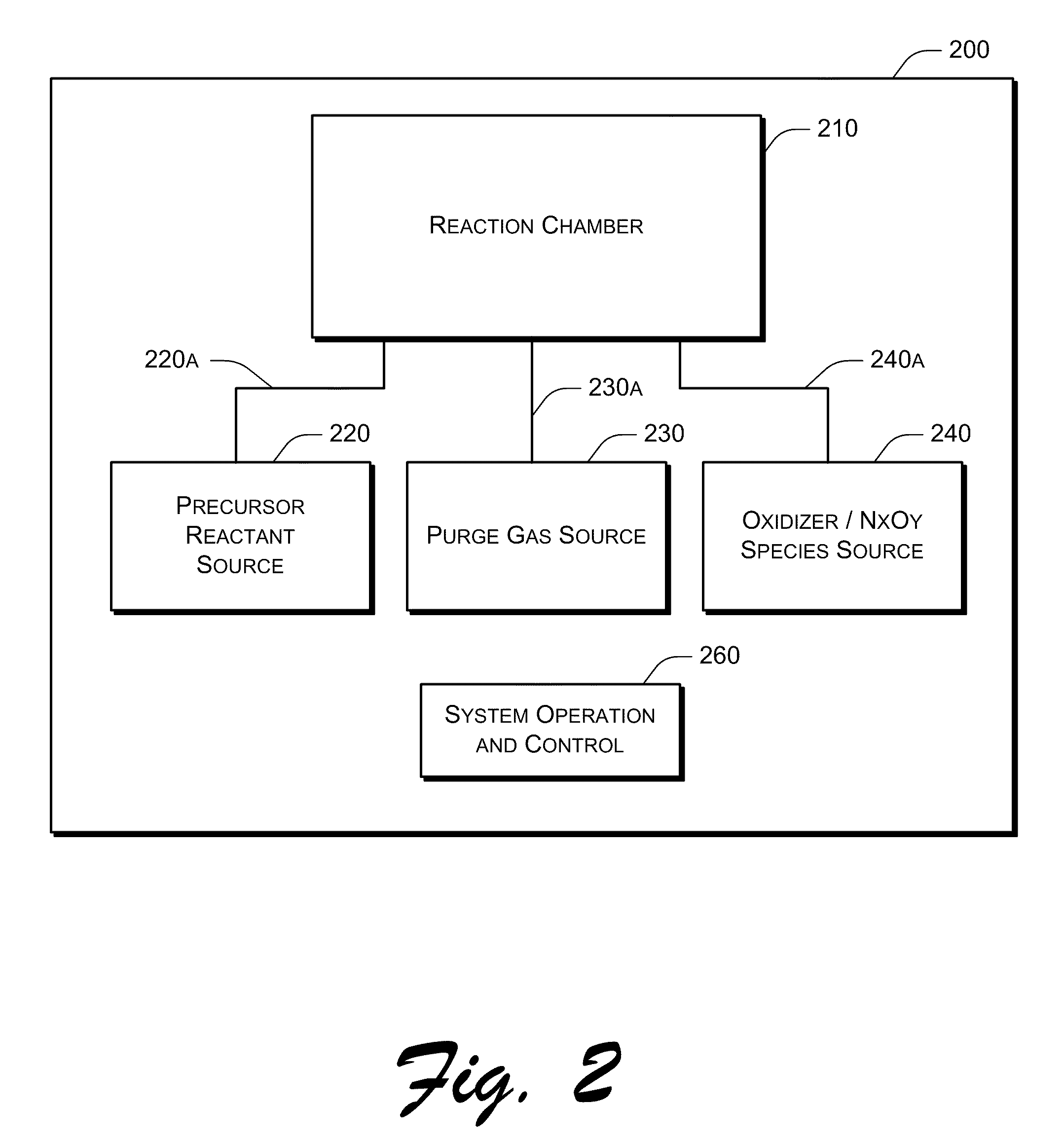

Systems and methods for thin-film deposition of metal oxides using excited nitrogen-oxygen species

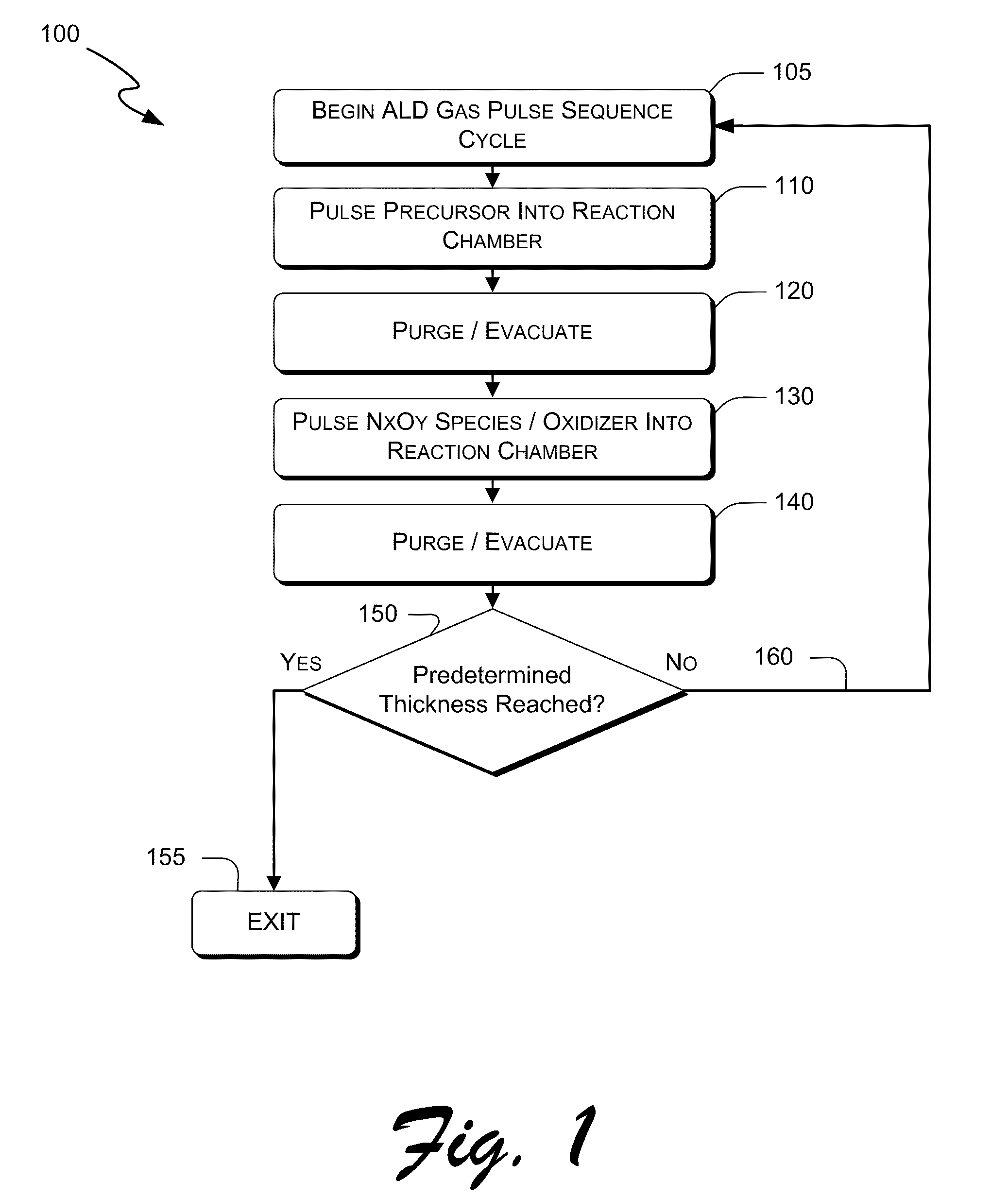

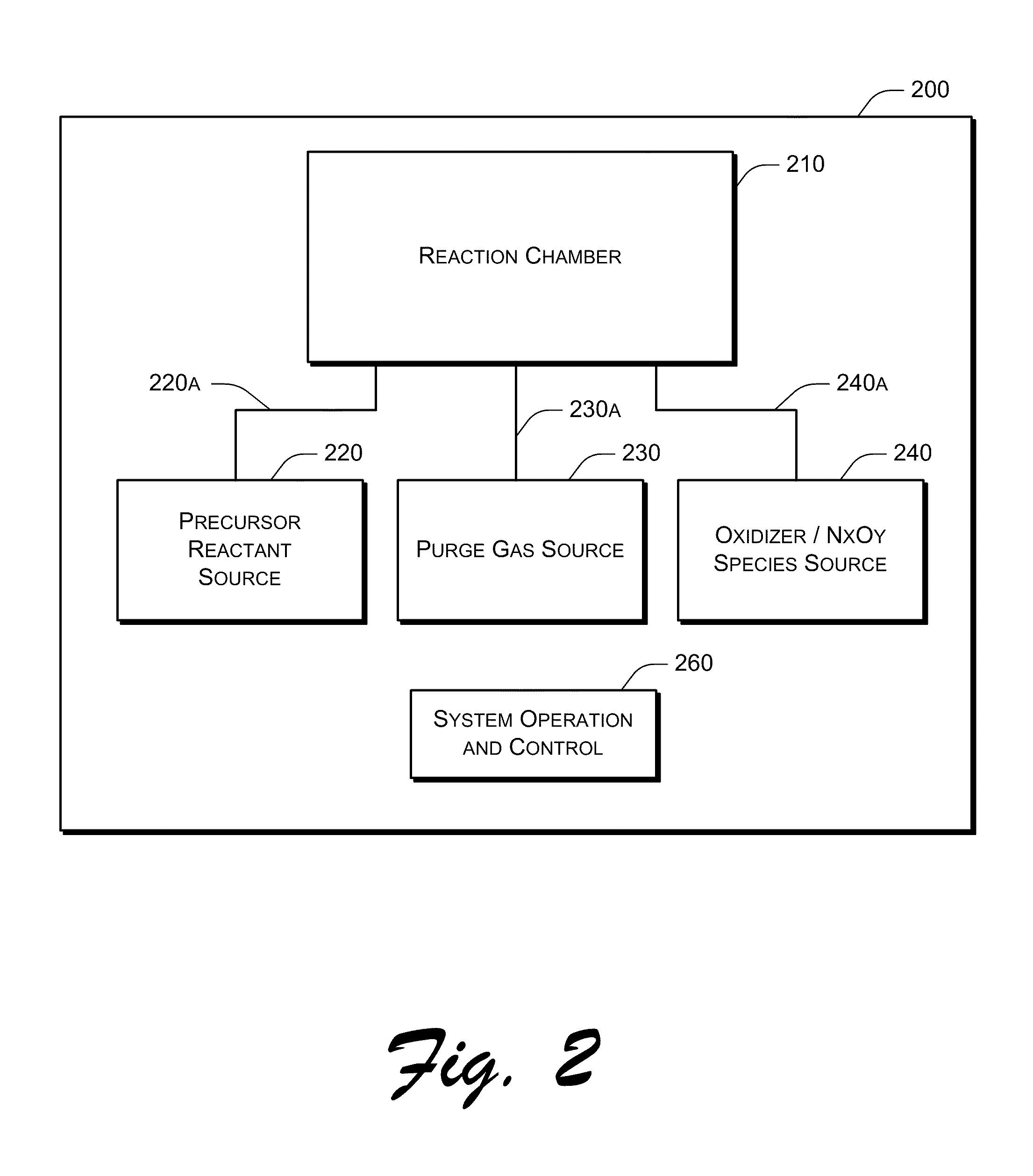

ActiveUS20110070380A1Improve deposition efficiencyImprove uniformitySemiconductor/solid-state device manufacturingElectrical discharge ozone preparationNitrogenOxygen

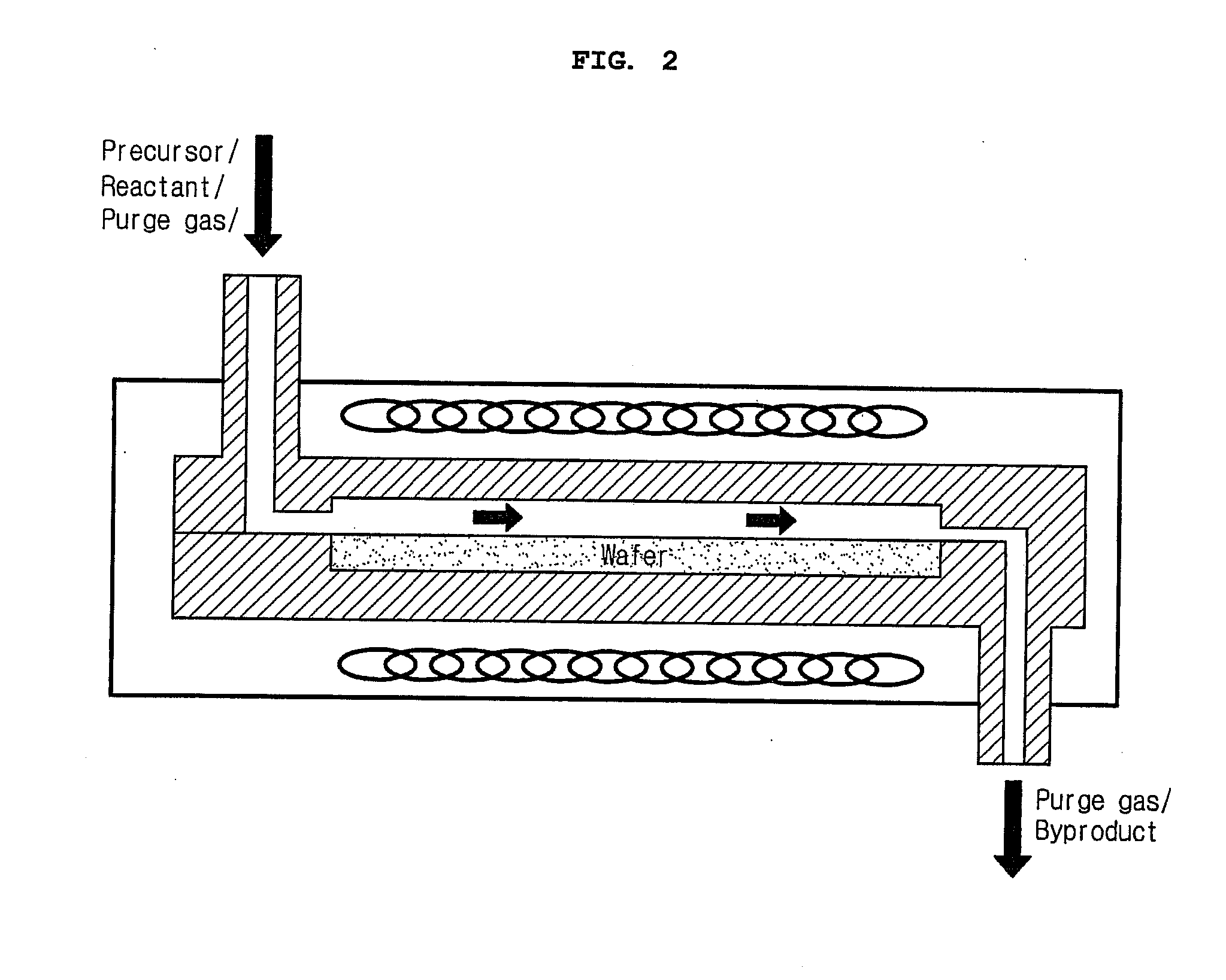

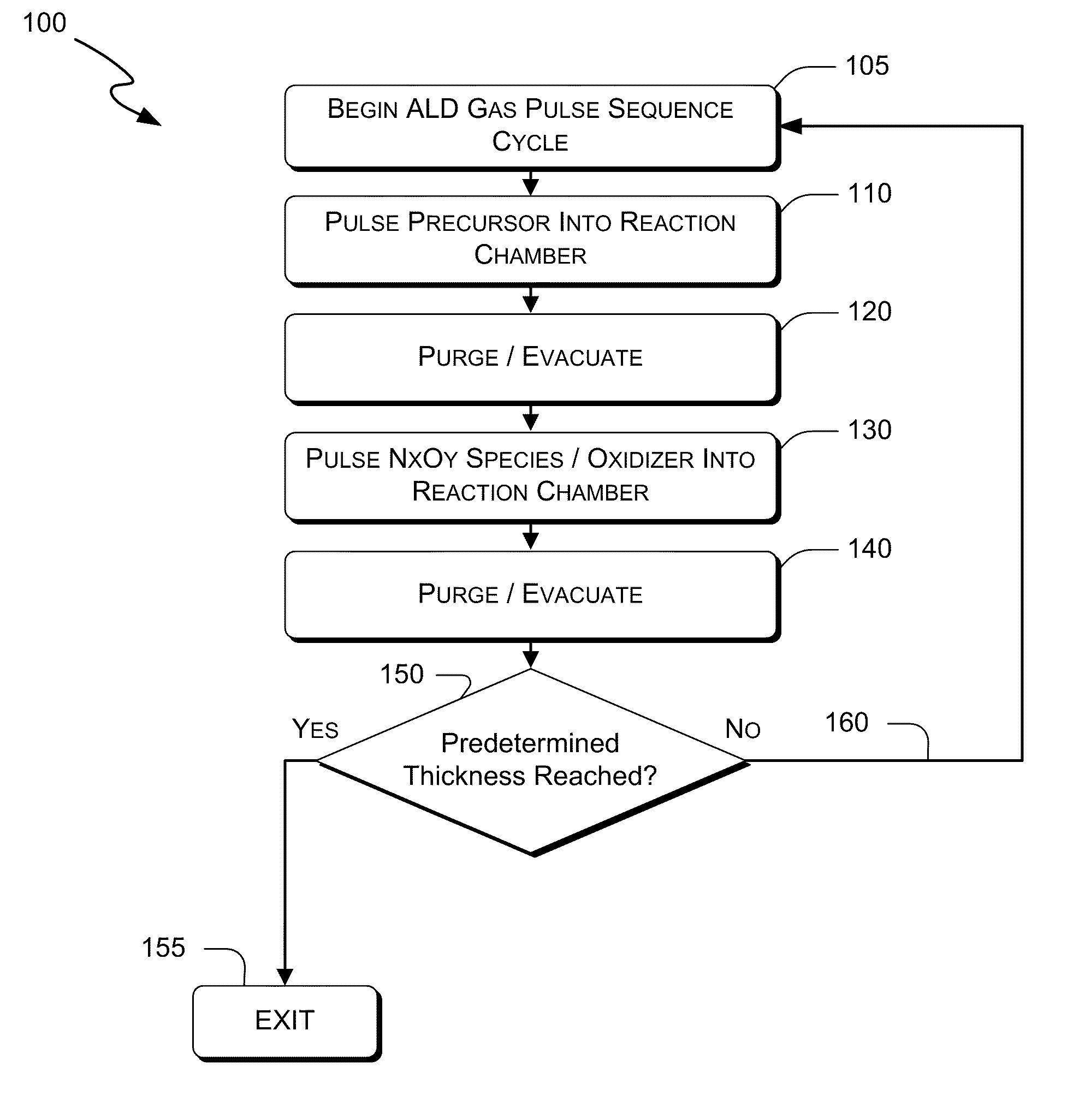

Systems and methods are delineated which, among other things, are for depositing a film on a substrate that is within a reaction chamber. In an exemplary method, the method may comprise applying an atomic layer deposition cycle to the substrate, wherein the cycle may comprise exposing the substrate to a precursor gas for a precursor pulse interval and then removing the precursor gas thereafter, and exposing the substrate to an oxidizer comprising an oxidant gas and a nitrogen-containing species gas for an oxidation pulse interval and then removing the oxidizer thereafter. Aspects of the present invention utilize molecular and excited nitrogen-oxygen radical / ionic species in possible further combination with oxidizers such as ozone. Embodiments of the present invention also include electronic components and systems that include devices fabricated with methods consistent with the present invention.

Owner:ASM IP HLDG BV

Systems and methods for thin-film deposition of metal oxides using excited nitrogen—oxygen species

ActiveUS8883270B2Improve deposition efficiencyEnhance growth rate and uniformitySemiconductor/solid-state device manufacturingElectrical discharge ozone preparationOxygenAtomic layer deposition

Systems and methods are delineated which, among other things, are for depositing a film on a substrate that is within a reaction chamber. In an exemplary method, the method may comprise applying an atomic layer deposition cycle to the substrate, wherein the cycle may comprise exposing the substrate to a precursor gas for a precursor pulse interval and then removing the precursor gas thereafter, and exposing the substrate to an oxidizer comprising an oxidant gas and a nitrogen-containing species gas for an oxidation pulse interval and then removing the oxidizer thereafter. Aspects of the present invention utilize molecular and excited nitrogen-oxygen radical / ionic species in possible further combination with oxidizers such as ozone. Embodiments of the present invention also include electronic components and systems that include devices fabricated with methods consistent with the present invention.

Owner:ASM IP HLDG BV

Vapor deposition reactor

InactiveUS8333839B2Improve deposition efficiencyShorten the timeChemical vapor deposition coatingMicrowaveRemote plasma

A vapor deposition reactor has a configuration where a substrate or a vapor deposition reactor moves in a non-contact state with each other to allow the substrate to pass by the reactor and an injection unit and an exhaust unit are installed as a basic module of the reactor for receiving a precursor or a reactant and for receiving and pumping a purge gas, respectively. With the use of a small-size inlet for the reactor, homogeneous film properties are obtained, the deposition efficiency of precursors is improved, and an amount of time required for a purge / pumping process can be reduced. In addition, since the reactor itself is configured to reflect each step of ALD, it does not need a valve. Moreover, the reactor makes it easier for users to apply remote plasma, use super high frequencies including microwave, and UV irradiation.

Owner:VEECO ALD

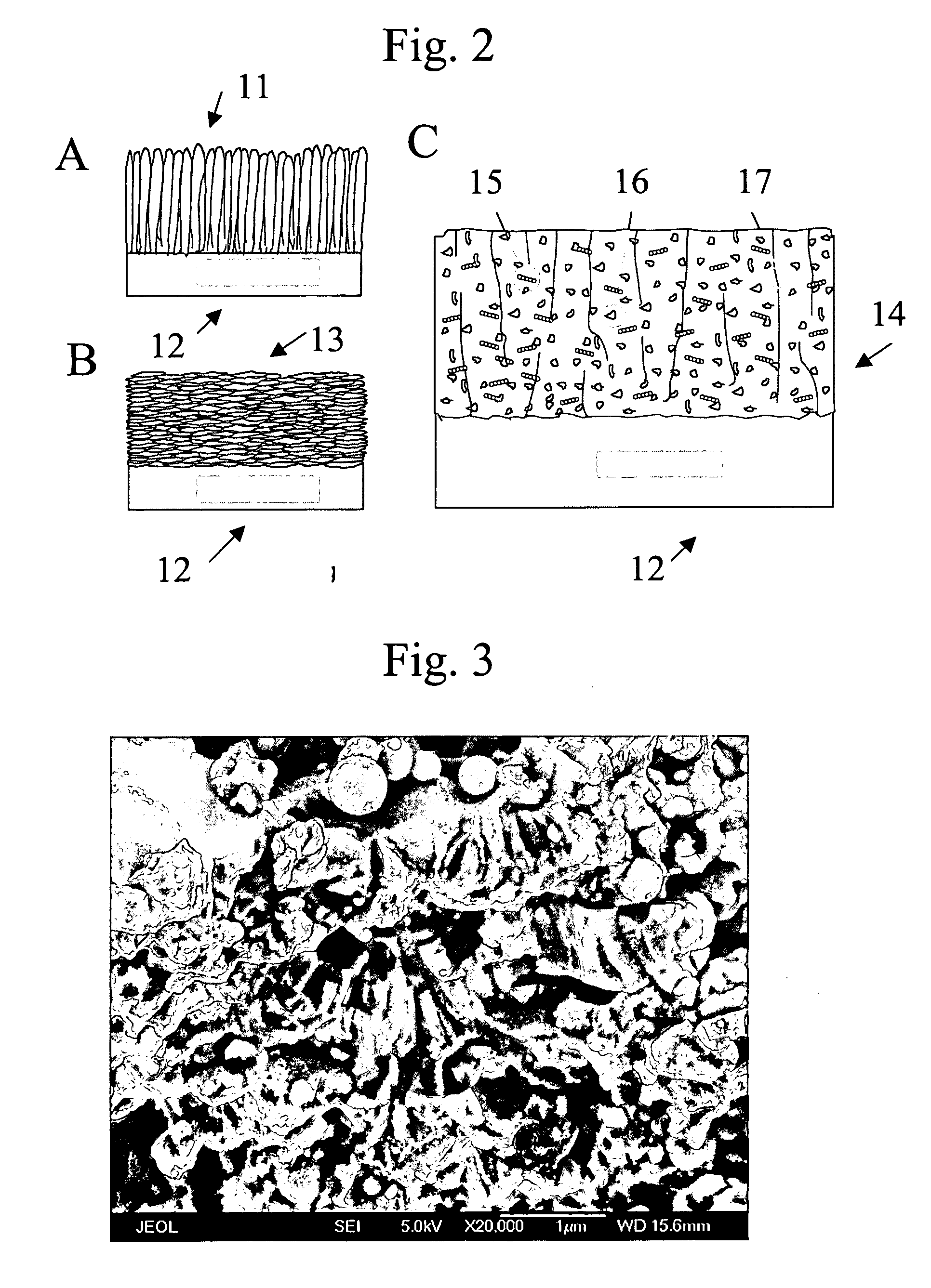

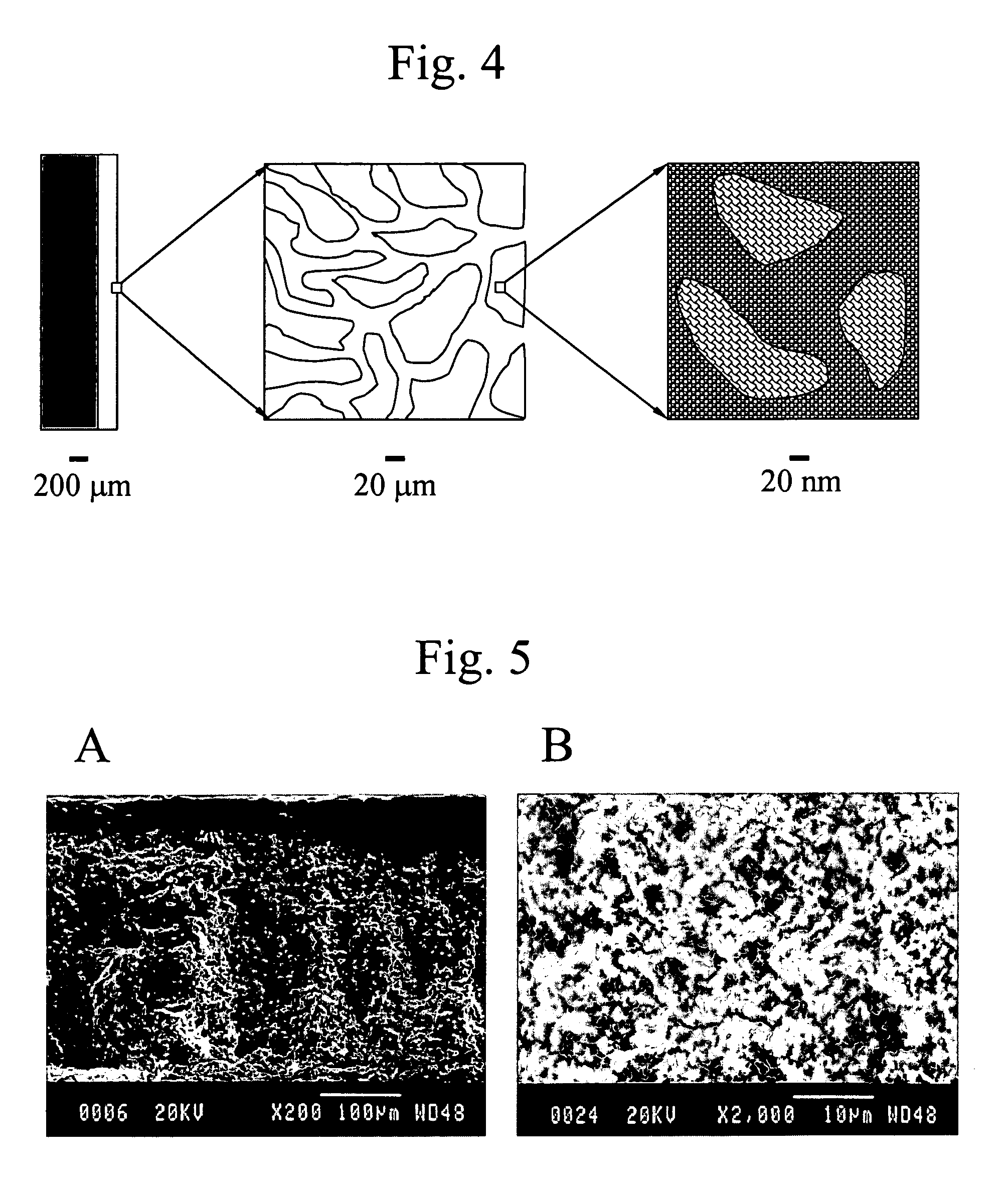

Coatings, materials, articles, and methods of making thereof

ActiveUS20040229031A1Low costSufficient powerMaterial nanotechnologyLiquid surface applicatorsHot zoneMaterials science

Owner:UNIV OF CONNECTICUT +2

Apparatus for depositing an organic layer and method for controlling a heating unit thereof

InactiveUS20070077358A1Improve heating efficiencyMinimize timeVacuum evaporation coatingSputtering coatingCrucibleEvaporation

An apparatus for depositing an organic layer and a method for controlling the heating unit thereof are provided. The apparatus includes a crucible positioned in a deposition chamber and containing materials for evaporation. The apparatus also includes a heating unit having first and second heat sources for heating the crucible. A housing isolates the heat emitted from the heating unit and an outer wall anchors the crucible. A nozzle sprays the materials evaporated from the crucible. The first and second heat sources are positioned on first and second sides of the crucible, respectively, and are independently controlled to minimize the time required to stabilize the deposition rate.

Owner:SAMSUNG DISPLAY CO LTD

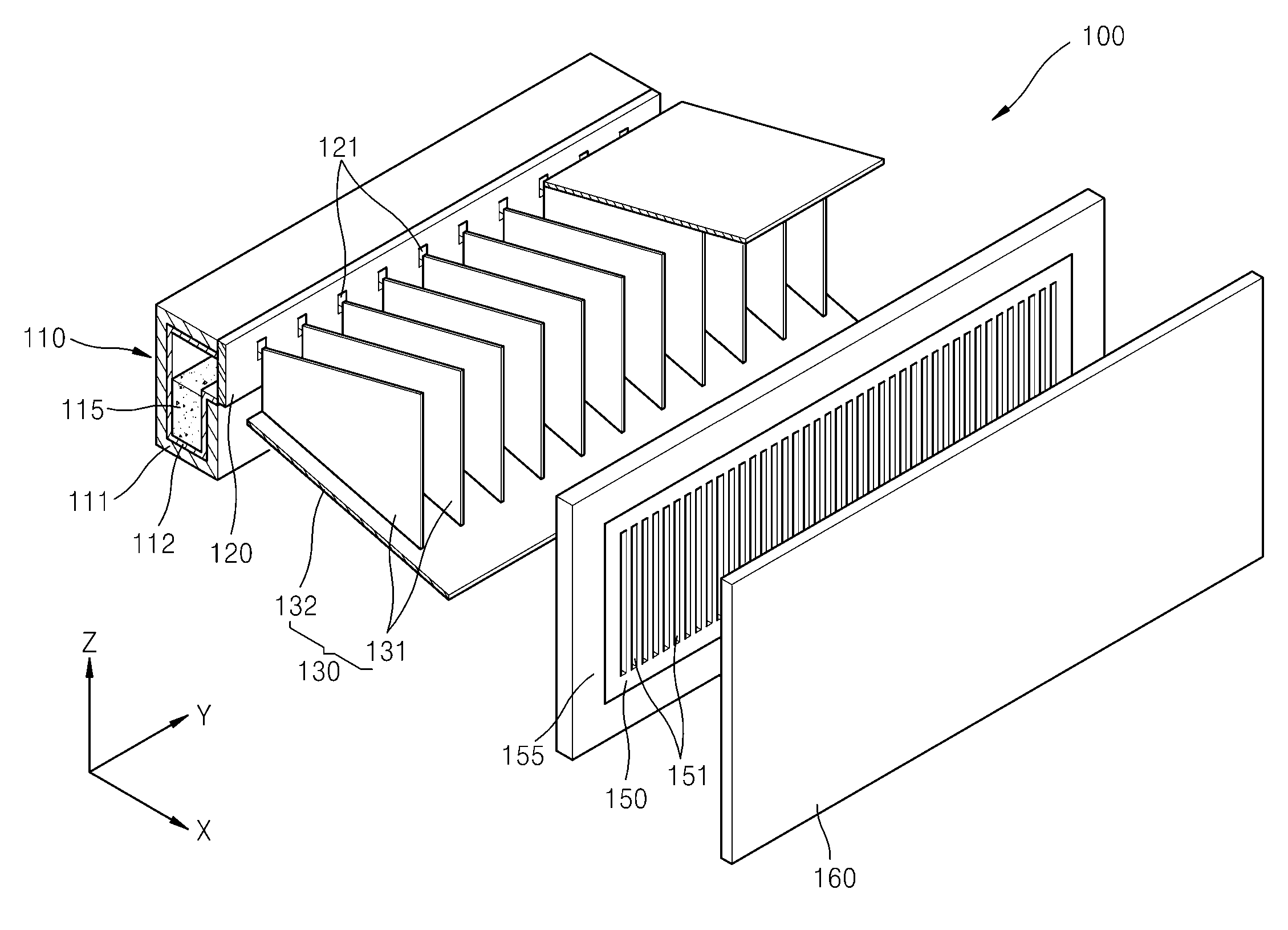

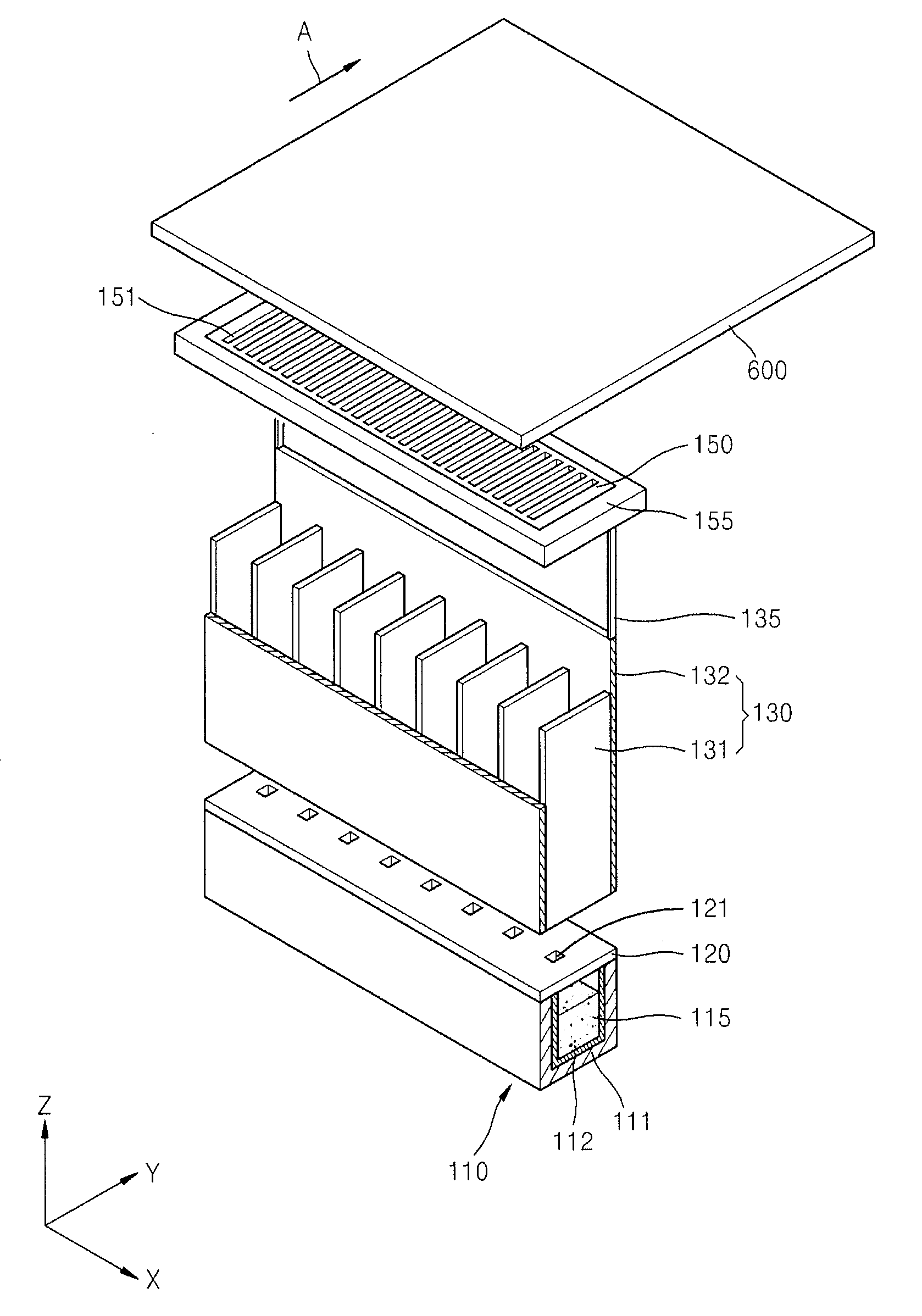

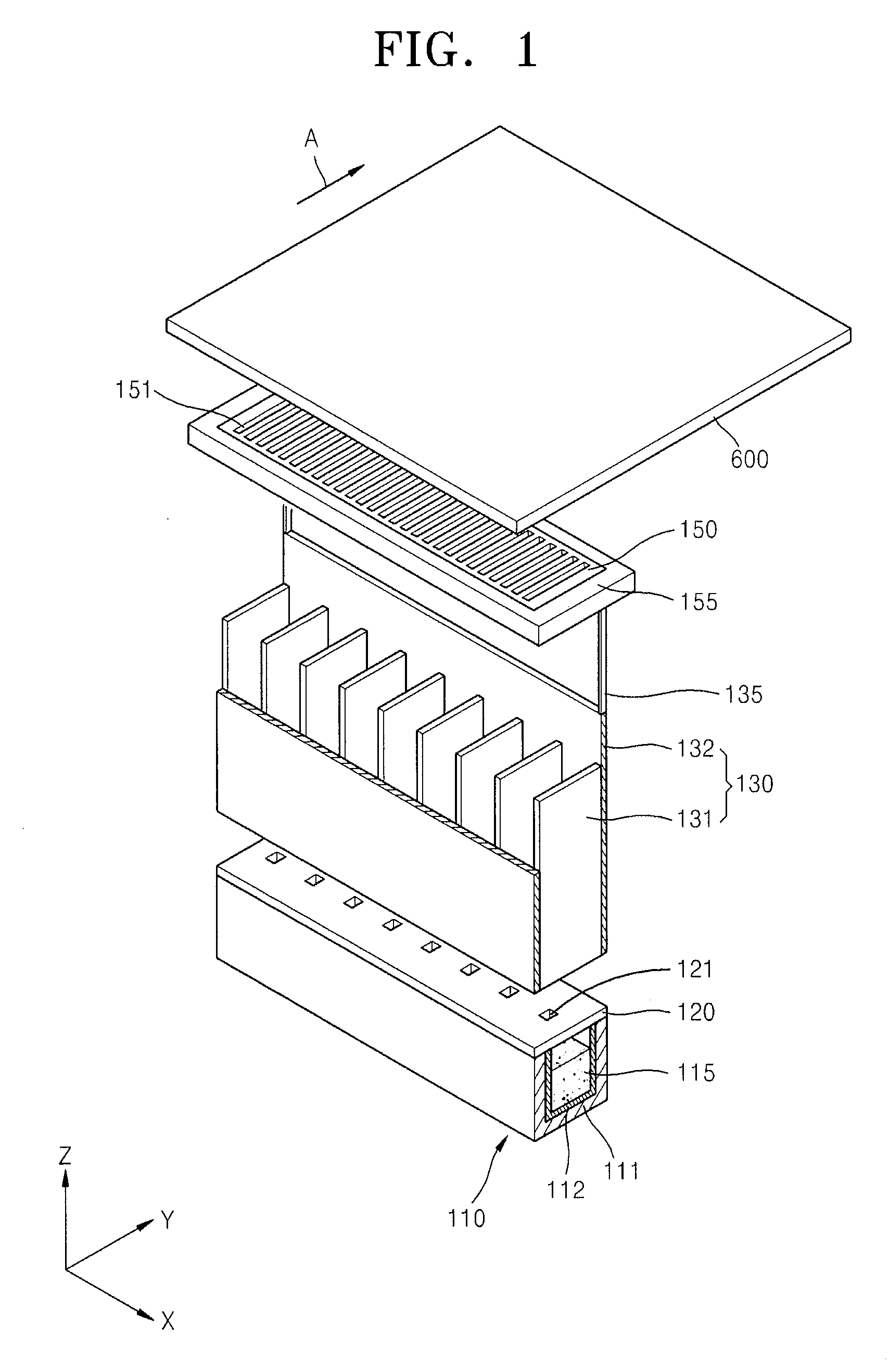

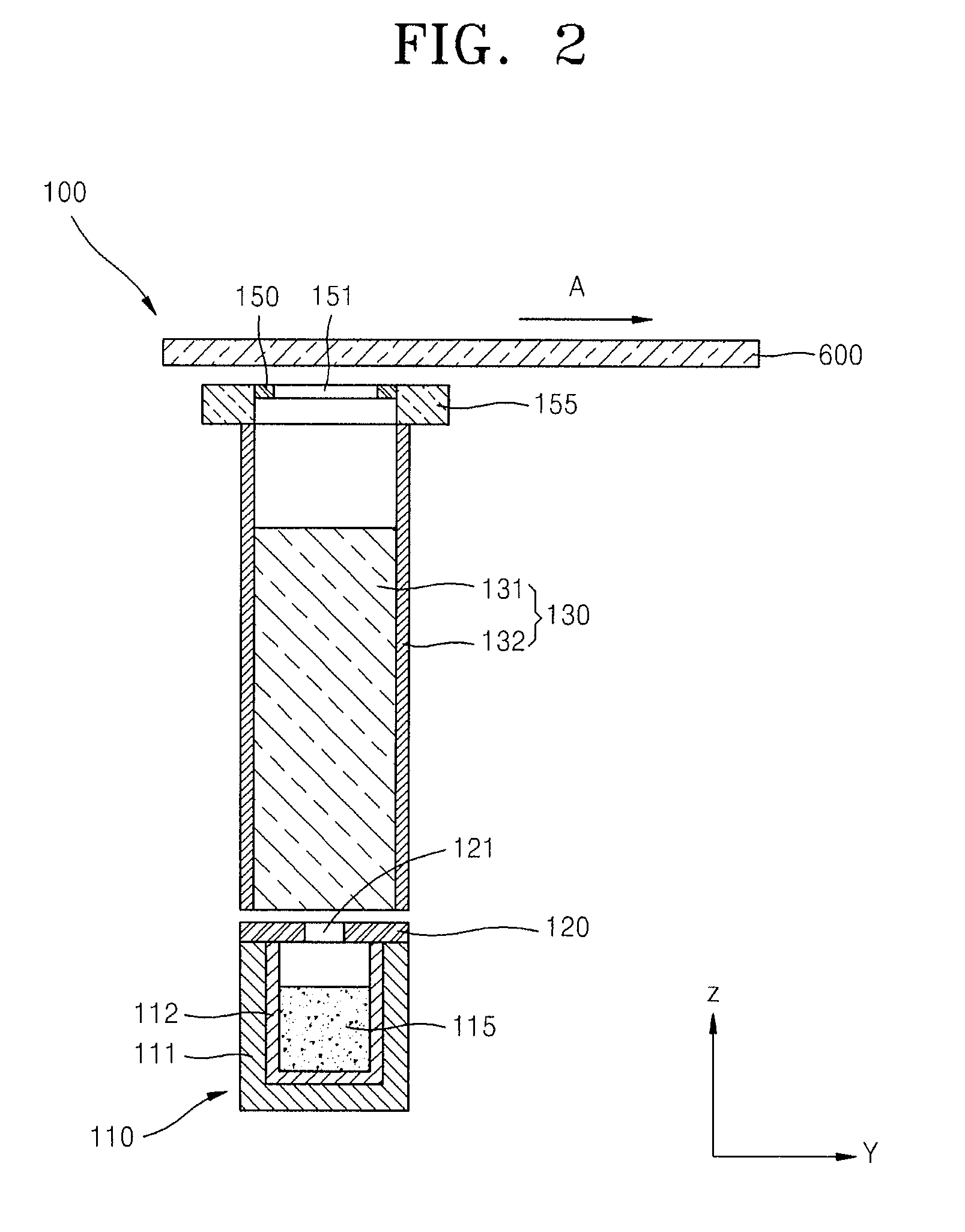

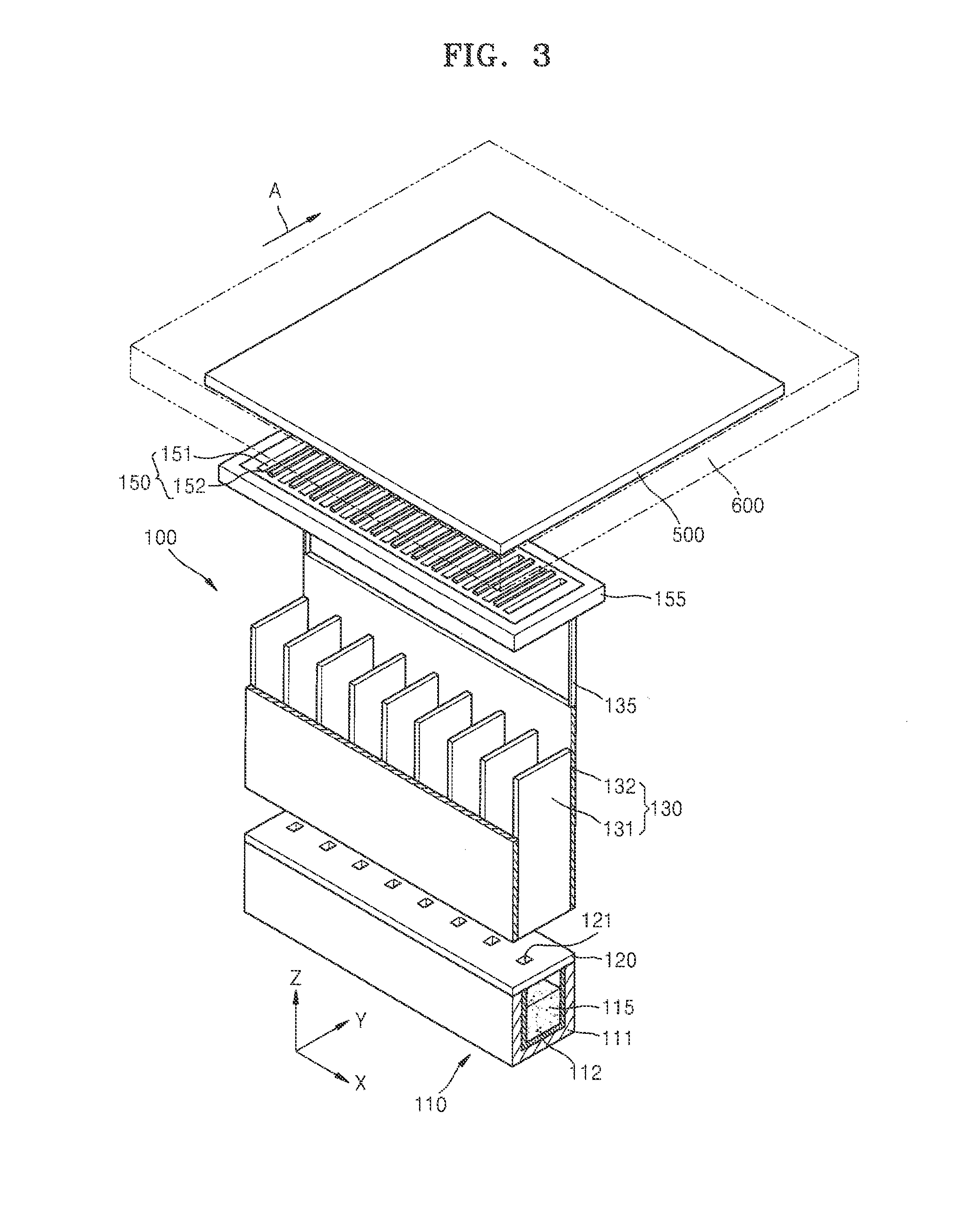

Thin film deposition apparatus

ActiveUS20100297349A1Easy to manufactureImprove manufacturing yieldVacuum evaporation coatingSputtering coatingEngineeringNozzle

A thin film deposition apparatus used to produce large substrates on a mass scale and improve manufacturing yield. The thin film deposition apparatus includes a deposition source; a first nozzle disposed at a side of the deposition source and including a plurality of first slits arranged in a first direction; a second nozzle disposed opposite to the first nozzle and including a plurality of second slits arranged in the first direction; and a barrier wall assembly including a plurality of barrier walls arranged in the first direction so as to partition a space between the first nozzle and the second nozzle.

Owner:SAMSUNG DISPLAY CO LTD

Personal care composition in the form of an article having a hydrophobic surface-resident coating

InactiveUS20100291165A1Conveniently and quickly dissolvedEfficient use ofCosmetic preparationsHair cosmeticsPersonal careMedicine

The present invention relates to personal care compositions, especially those personal care compositions in the form of an article that is a porous, dissolvable solid structure. The article has a hydrophobic surface-resident coating that can provide enhanced deposition efficiency of hydrophobic actives contained therein.

Owner:THE PROCTER & GAMBLE COMPANY

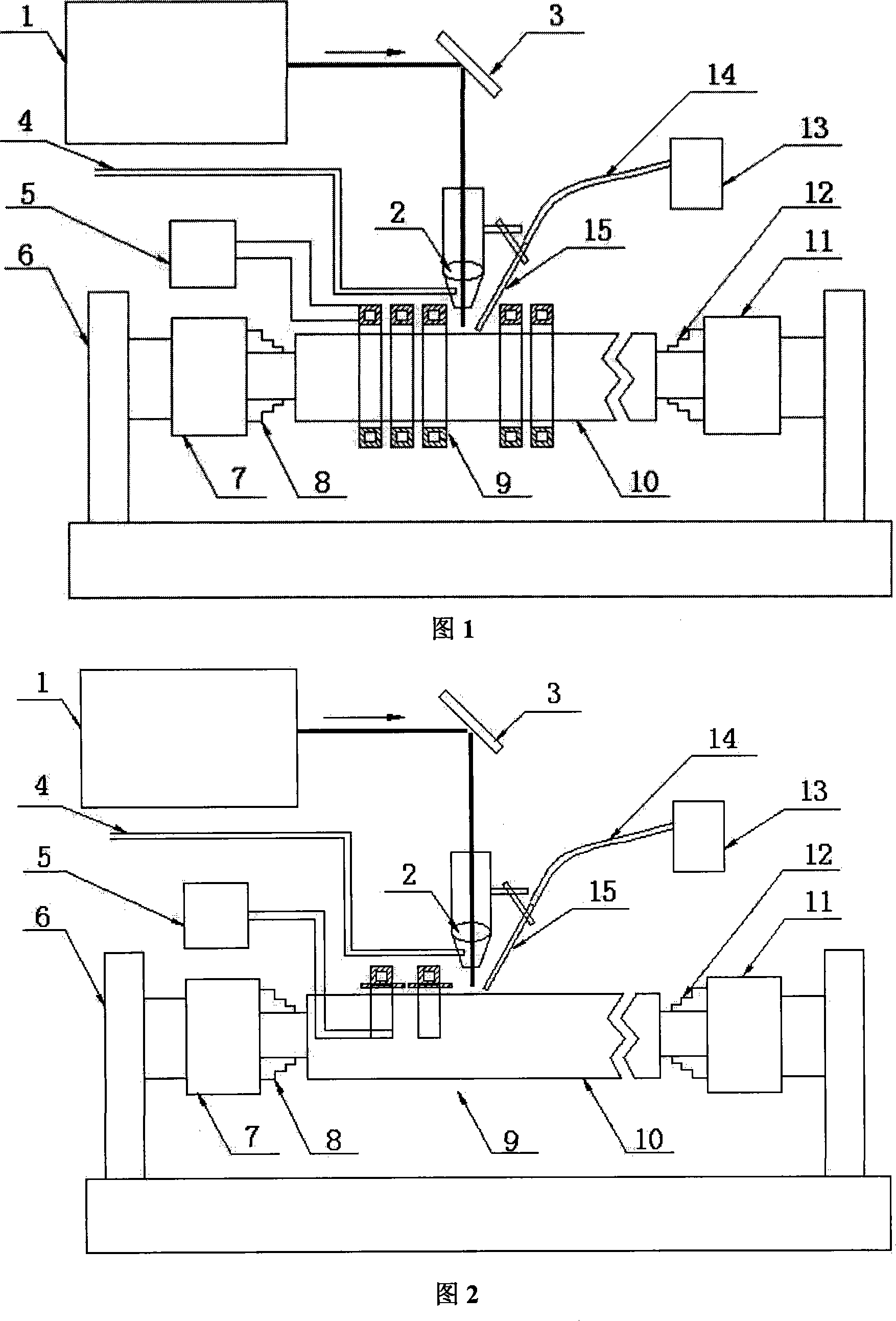

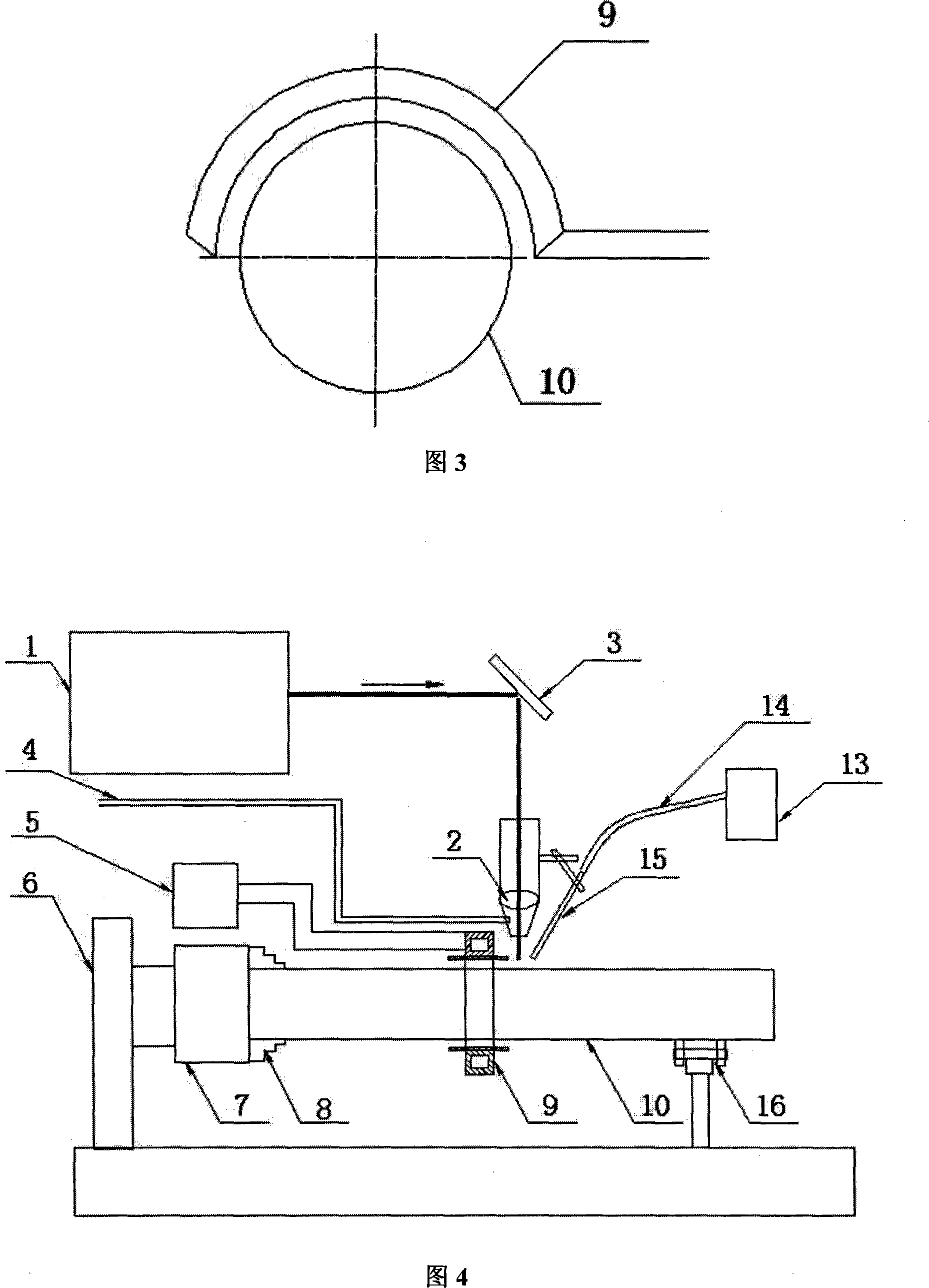

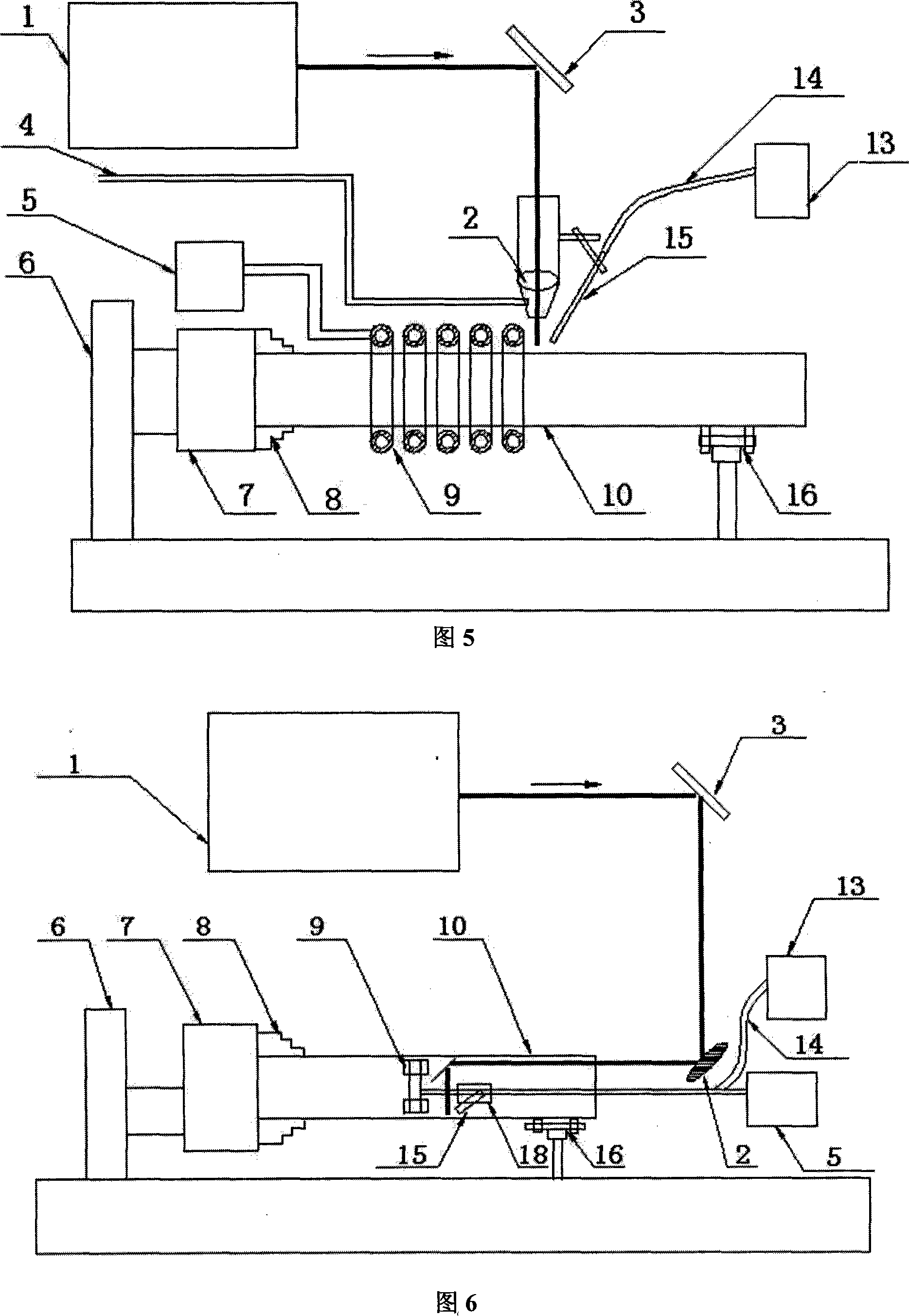

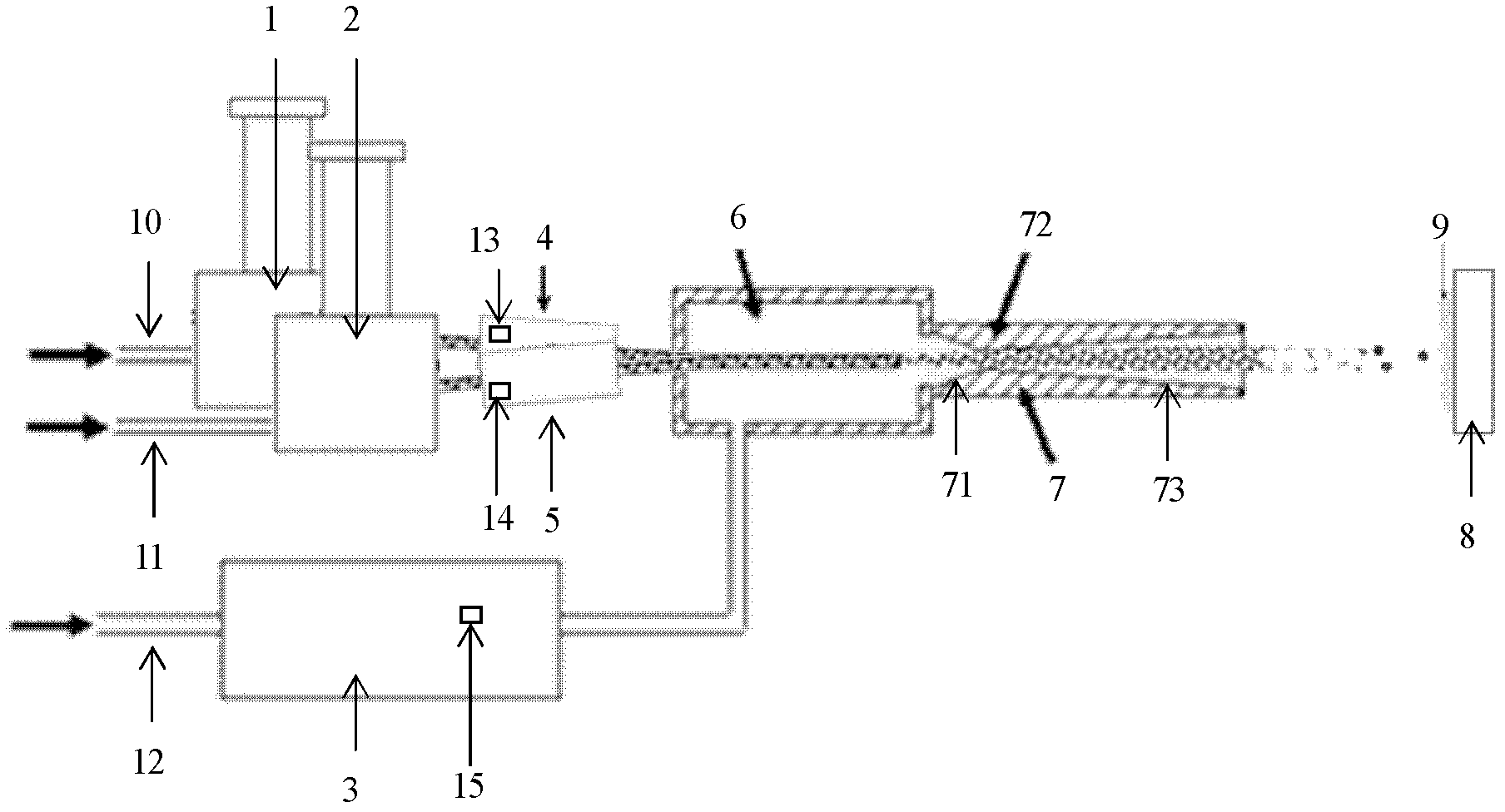

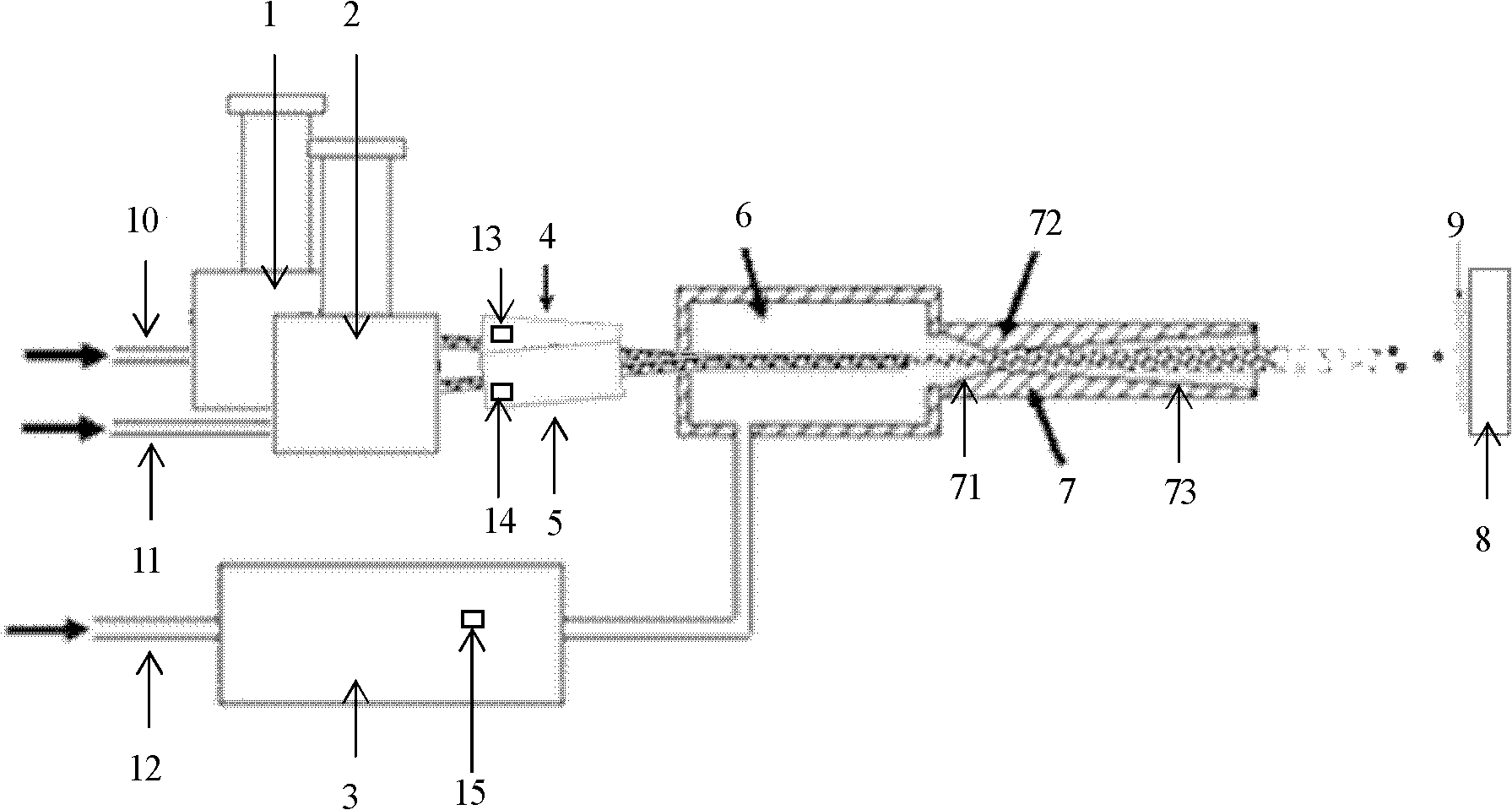

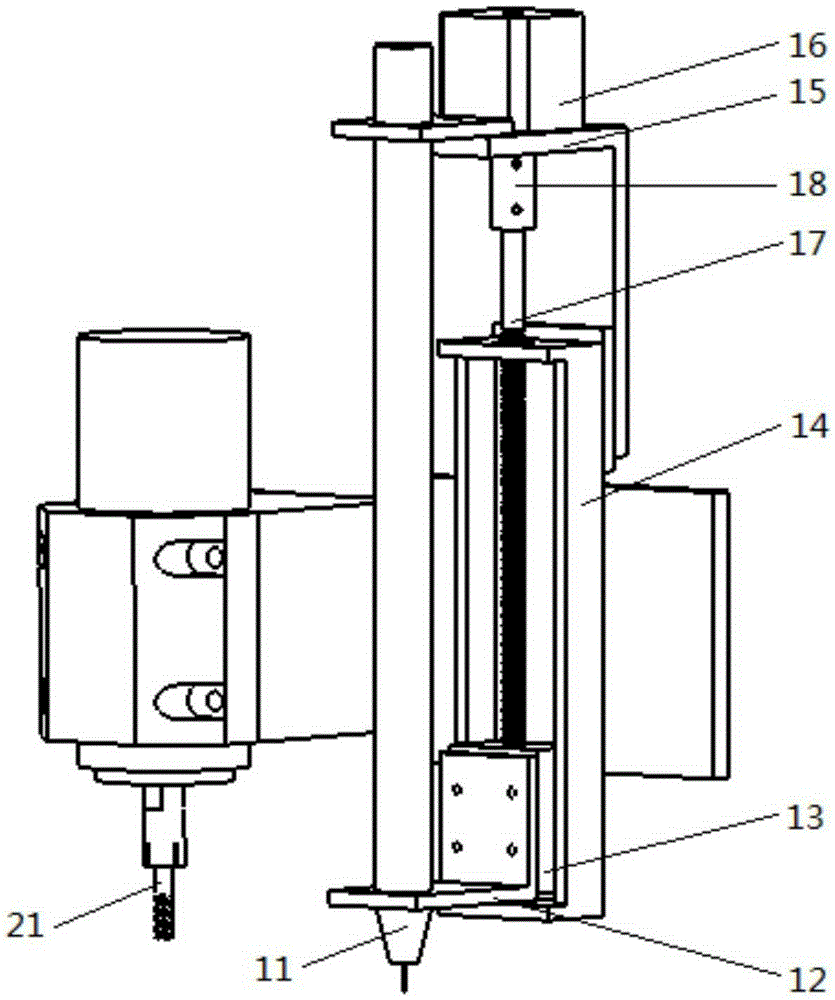

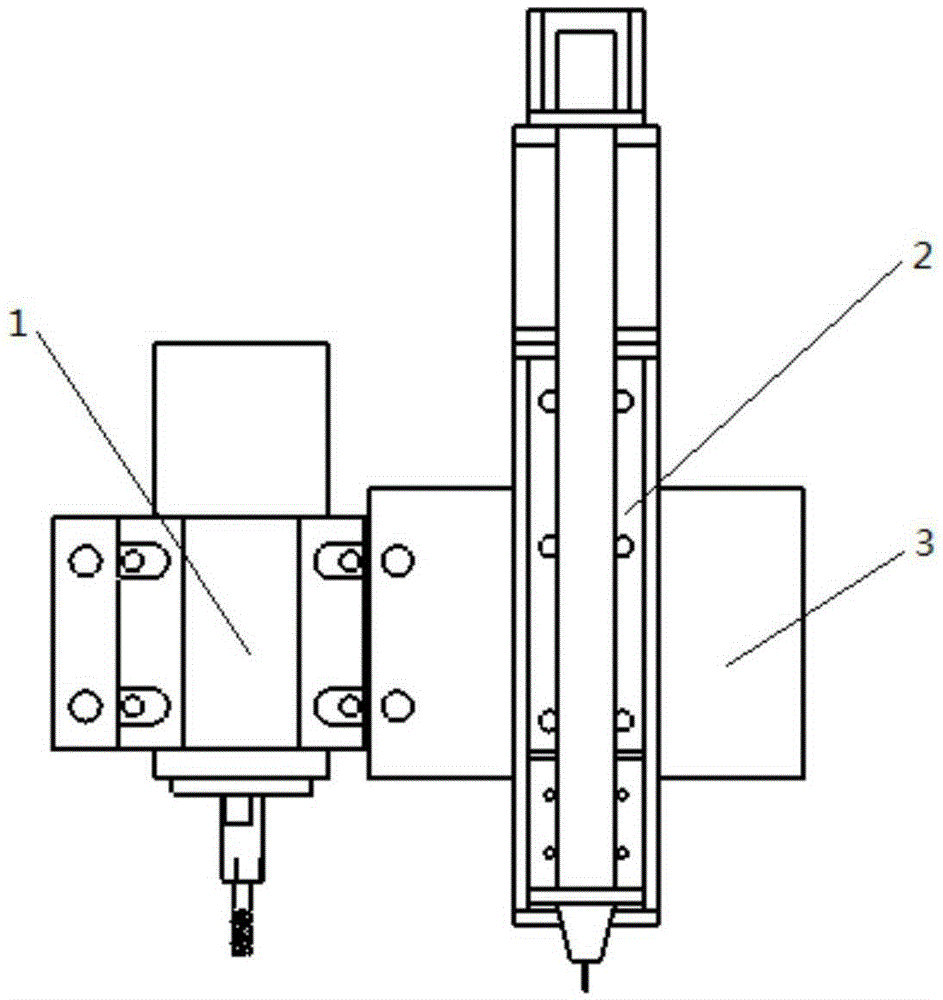

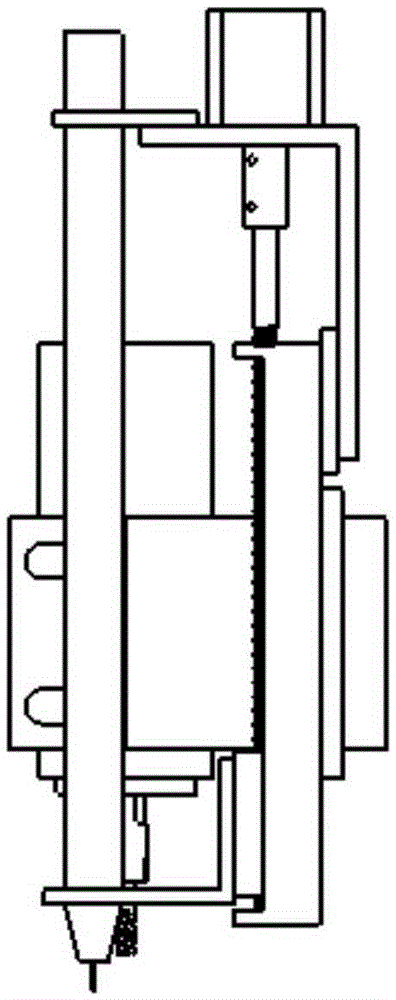

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

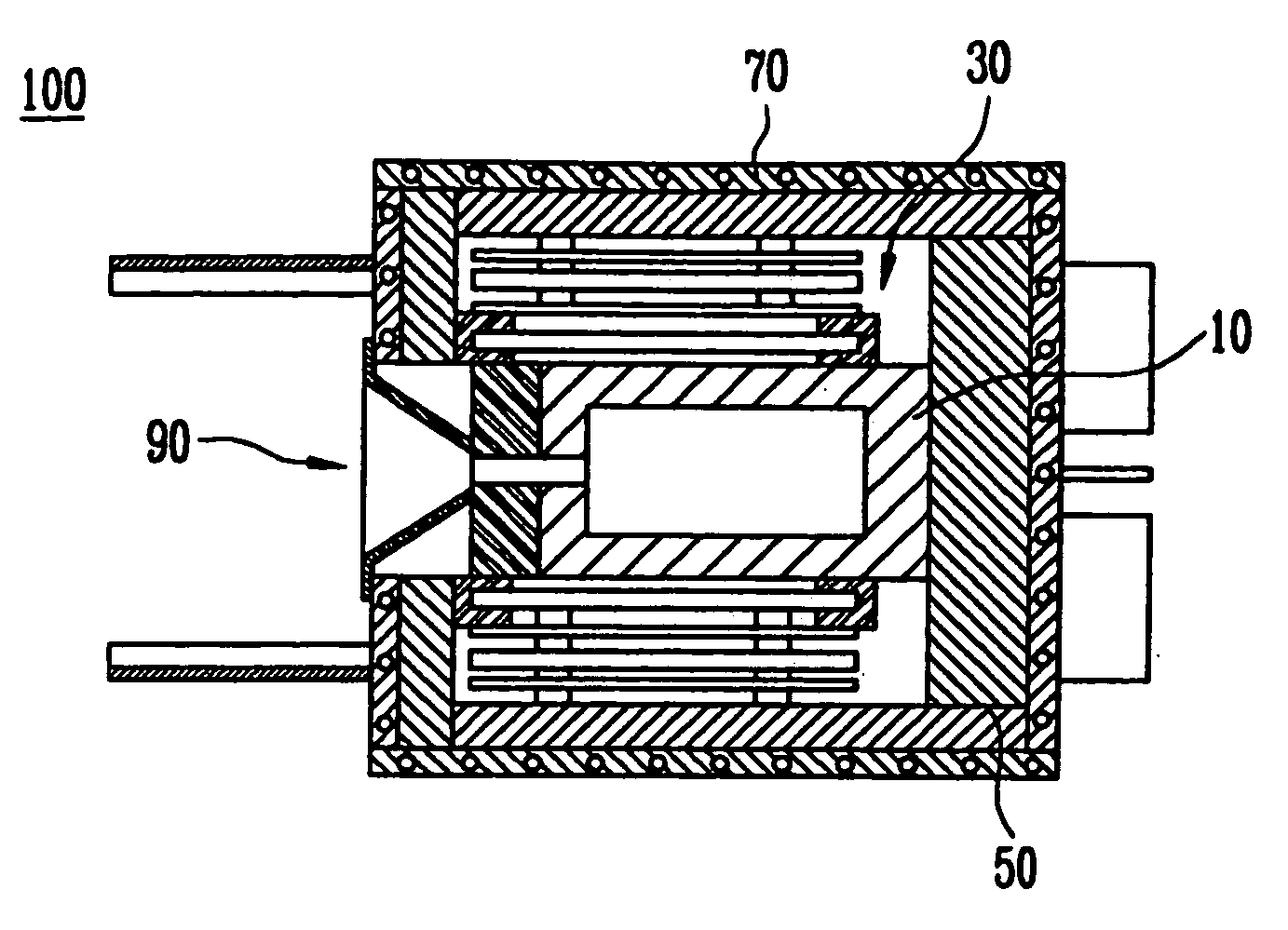

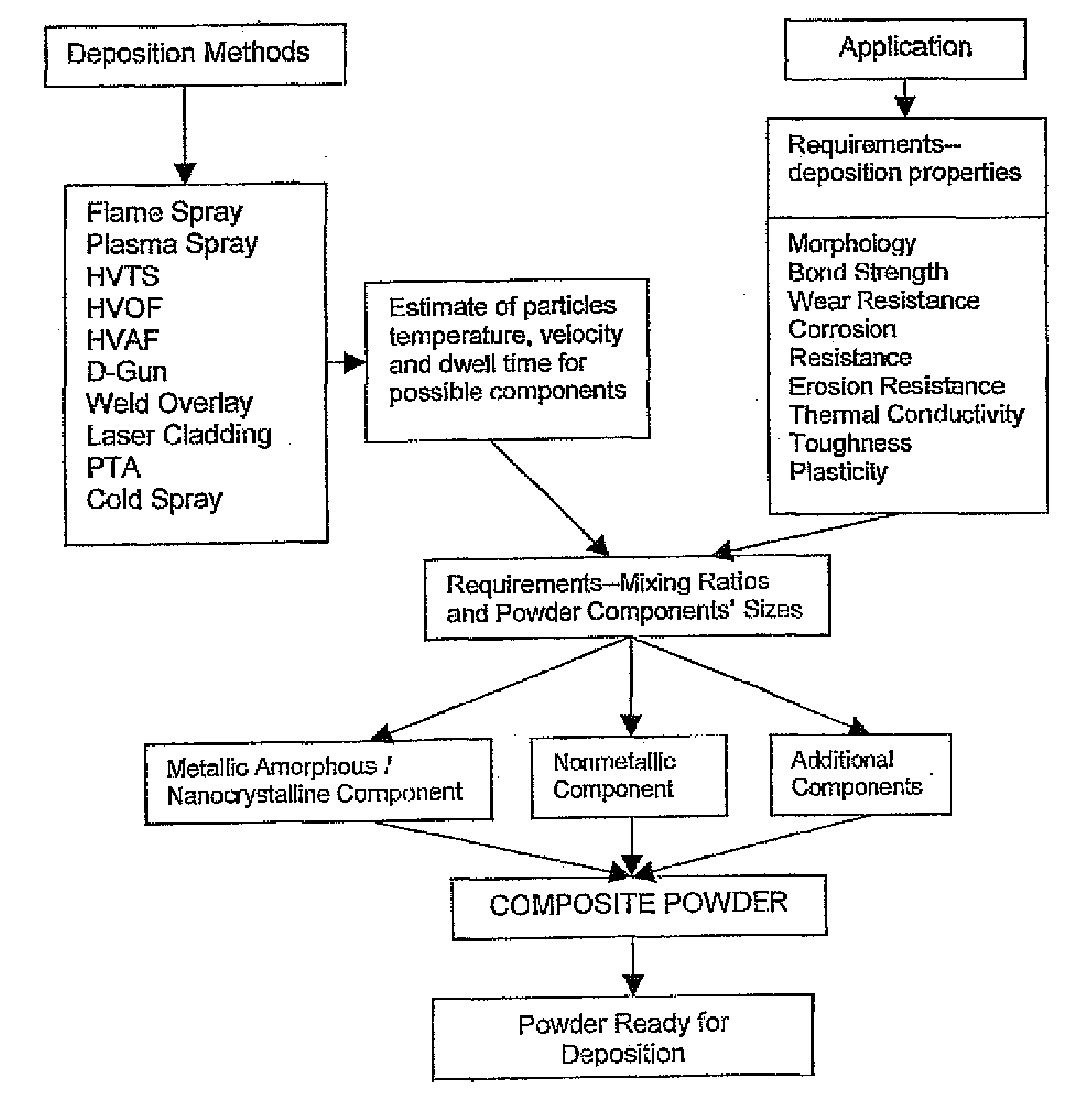

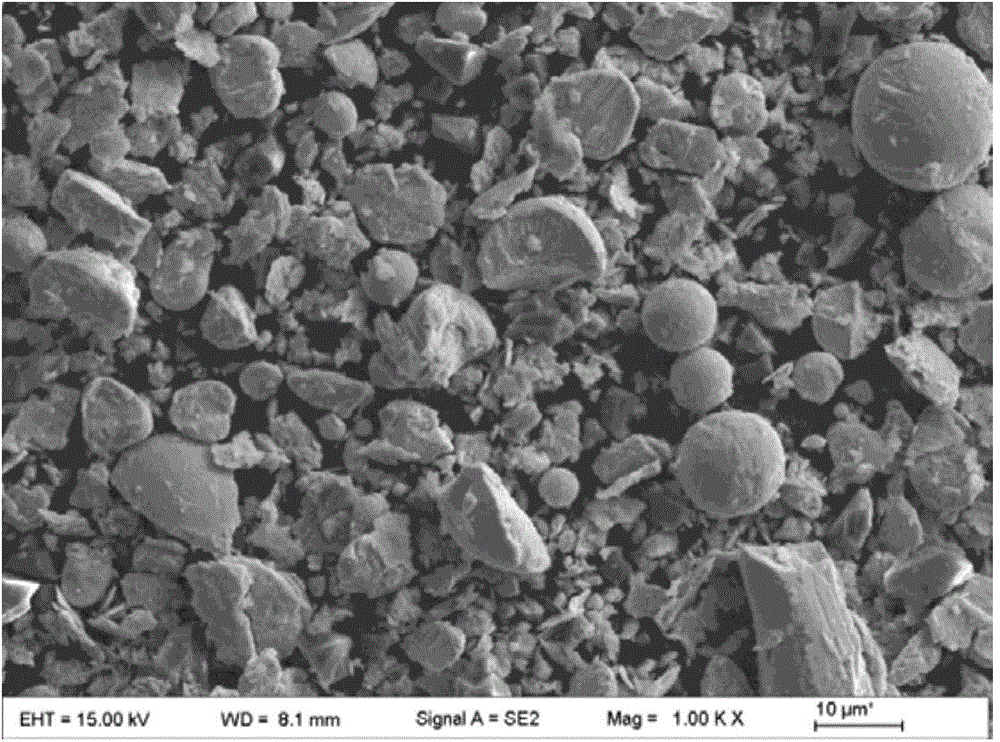

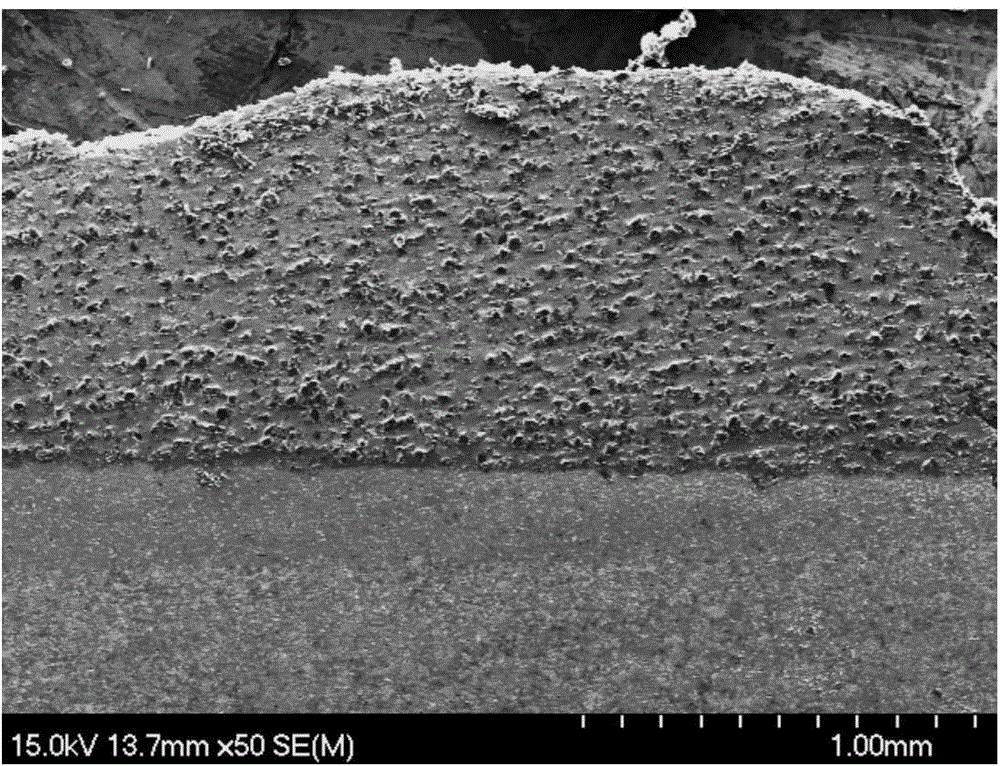

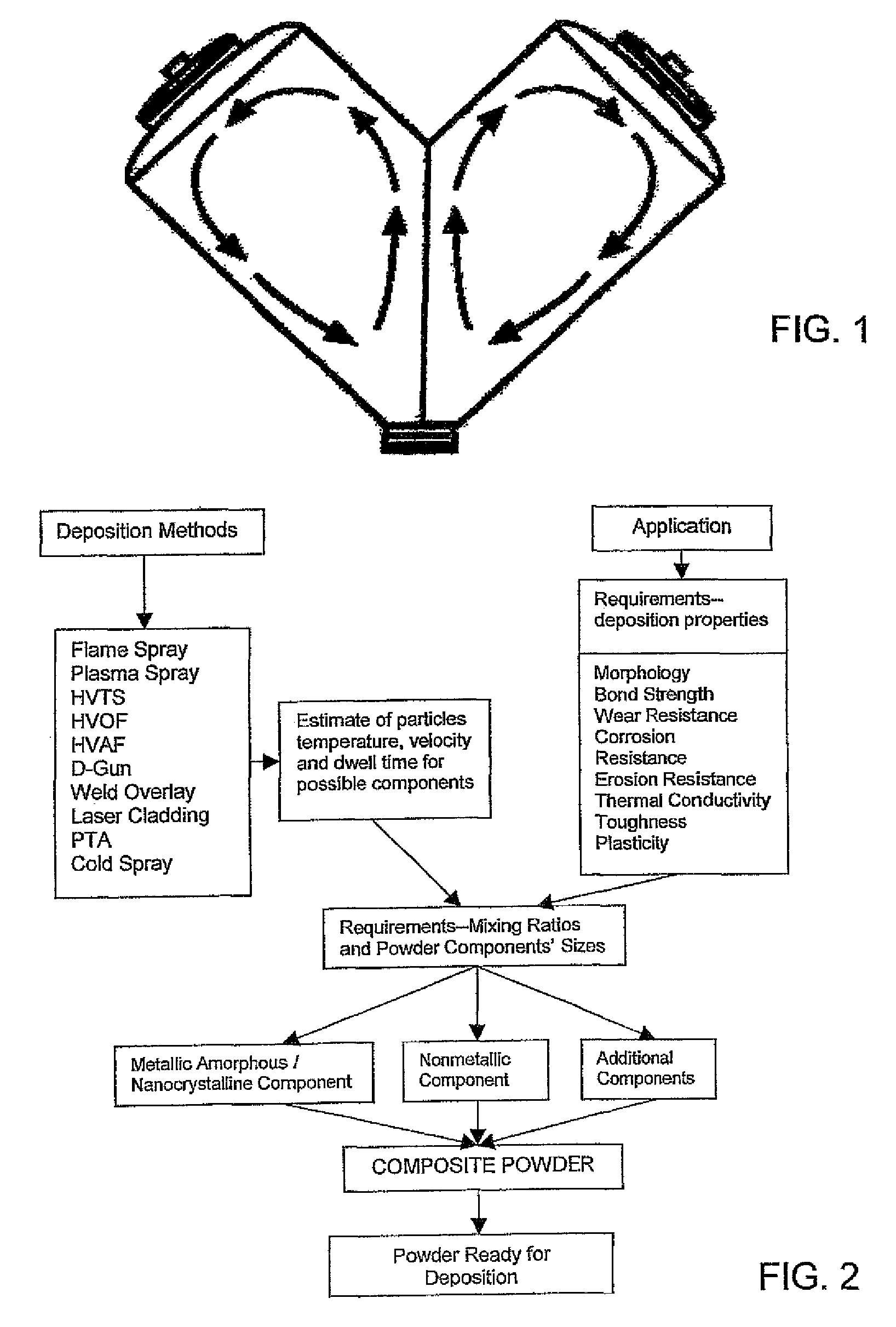

Deposition System, Method And Materials For Composite Coatings

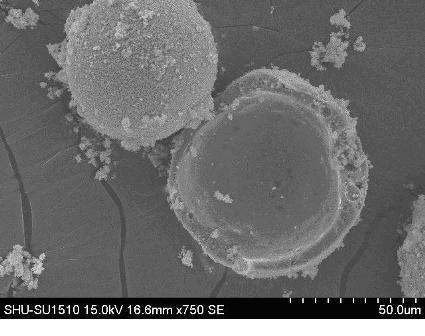

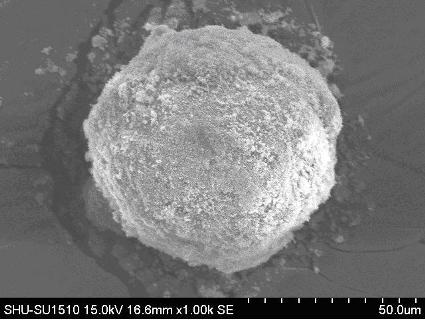

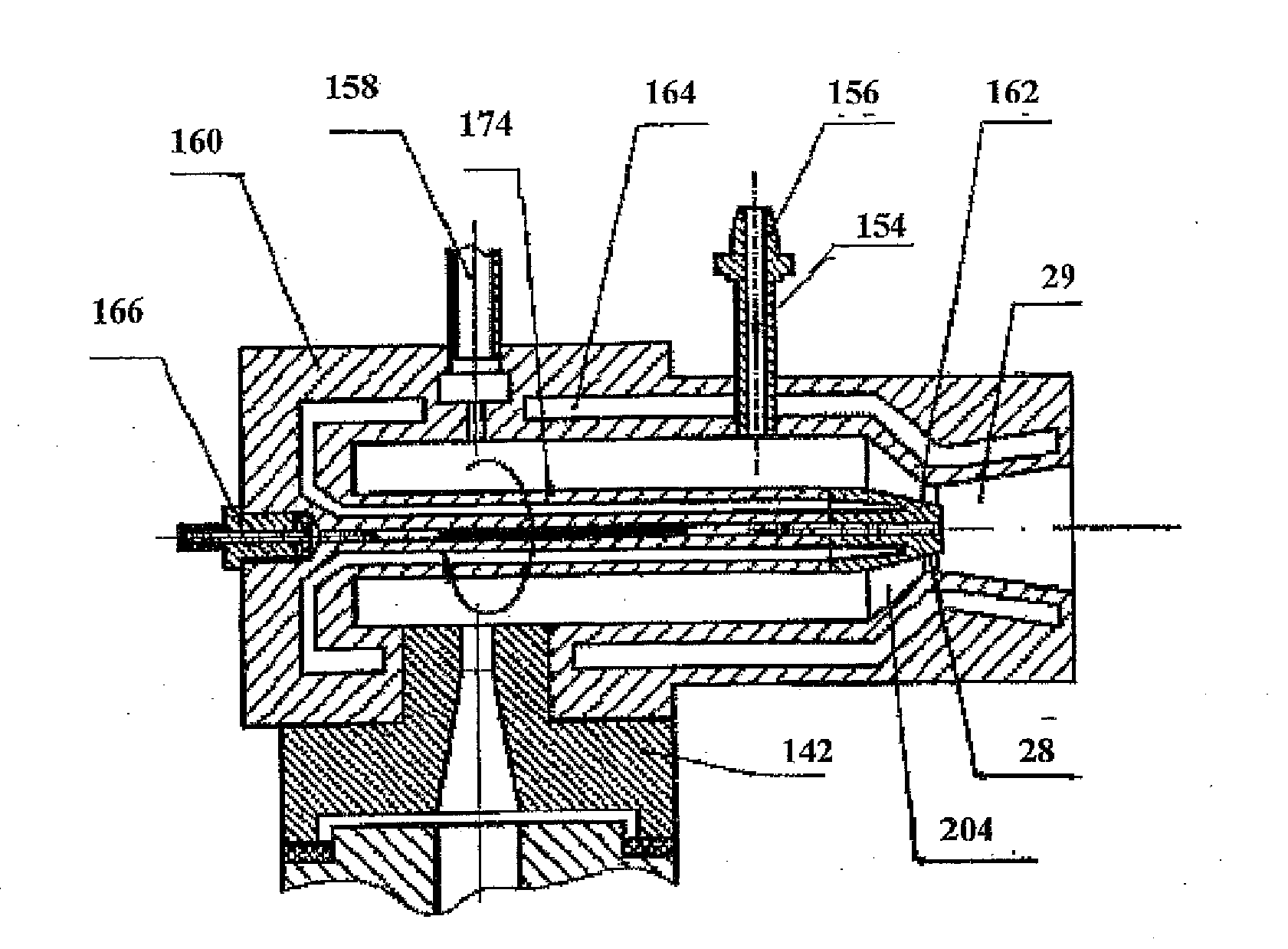

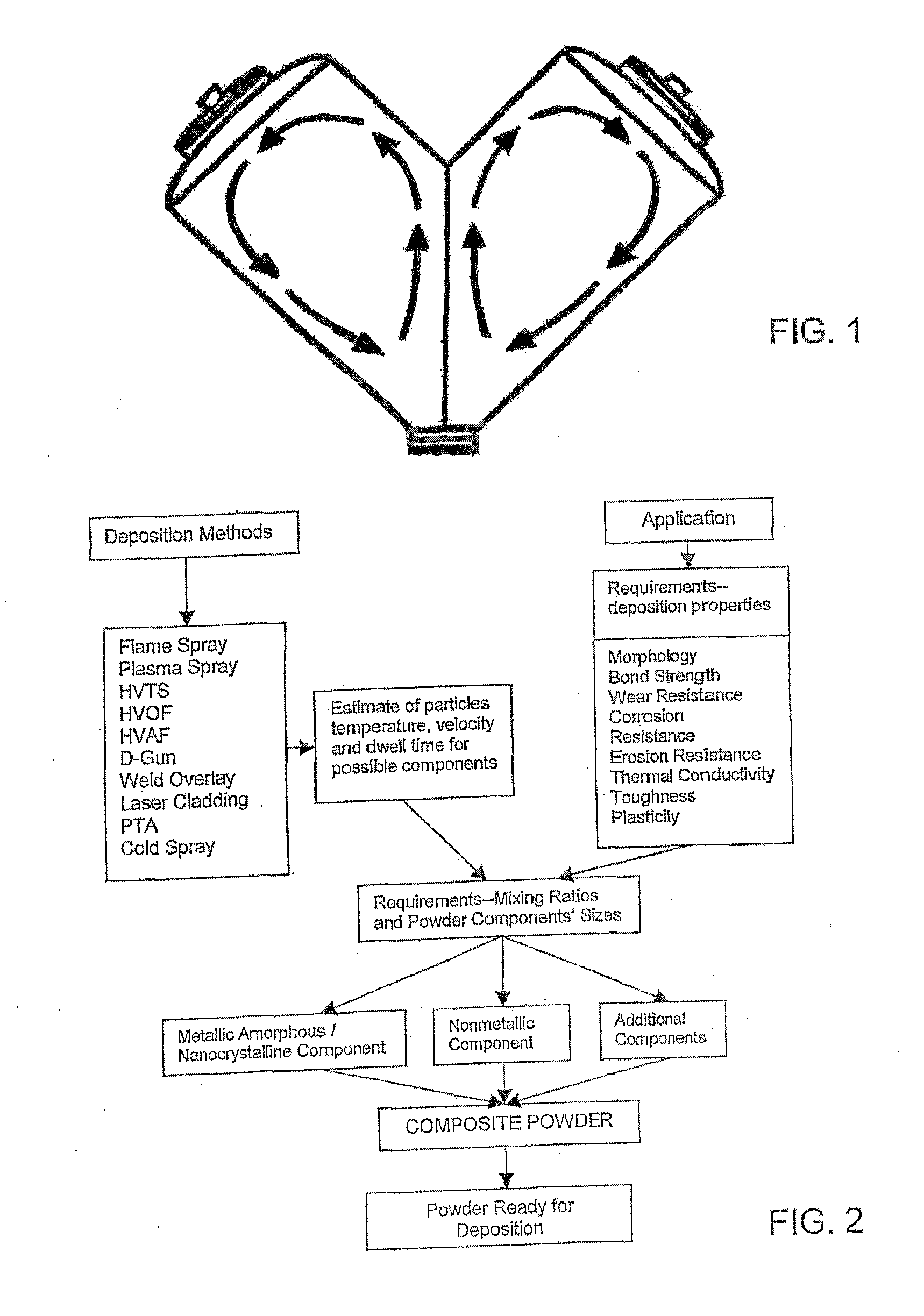

InactiveUS20070243335A1Improve corrosion resistanceImprove structural performanceMolten spray coatingMetal-working apparatusHigh wear resistanceNanocrystal

A composite powder for a deposition of a composite coating comprises a nonmetallic component and a metallic component, the metallic component having an amorphous structure or a nanocrystalline structure. The metallic component may include an amorphous metallic alloy. The metallic alloy may include constituents having the amorphous structure. The metallic component may include a combination of the metallic alloy existing in the amorphous state and constituents of the amorphous metallic alloy in the amorphous state. The composite metal-ceramic powders are used for depositing composite coatings on a selected surface. Disclosed are several methods and systems for producing such composite powders. Disclosed are also several methods and systems for depositing composite coatings. Advantageously, the deposited coatings exhibit high corrosion resistance, high wear resistance, and excellent structural properties.

Owner:BELASHCHENKO VLADIMIR E

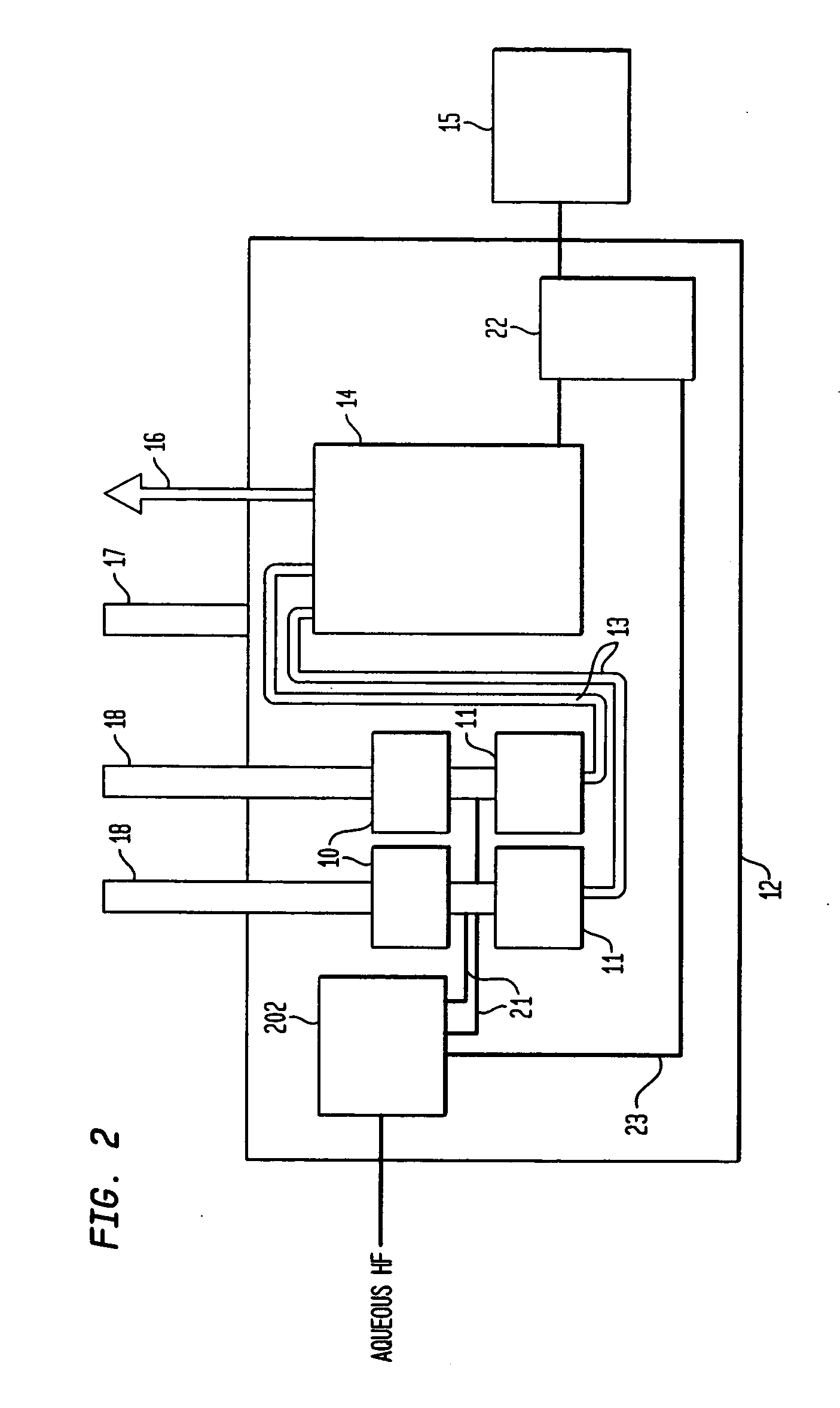

Method and apparatus for maintaining by-product volatility in deposition process

InactiveUS20050250347A1Improve deposition efficiencyReduce the amount requiredElectric discharge tubesFinal product manufactureDeposition processFluorine containing

A method and apparatus for introducing a fluorine-containing flow stream to a deposition process to maintain process by-product volatility and reduce or eliminate by-product formation and / or interference.

Owner:EDWARDS VACUUM INC

Cold spray device and method for preparing metal composite gradient quasicrystal coating

InactiveCN102527544AHigh speedLow spraying temperatureLiquid spraying apparatusSpecial surfacesForming gasGas heater

The invention relates to the field of surface coating preparation and particularly relates to a cold spray device and method for preparing a metal composite gradient quasicrystal coating. A quasicrystal powder feeder and a metal or alloy powder feeder of the device are respectively connected to a gas-solid mixing chamber through a pipeline to form a dual-channel powder feeding structure, a quasicrystal heater and a metal or alloy powder heater are respectively arranged on the pipelines, a gas heater is connected with the gas-solid mixing chamber through a pipeline and a supersonic flow nozzle is arranged at an outlet of the gas-solid mixing chamber. One path of the gas source compressed gas enters into the quasicrystal powder feeder, one path enters into the metal powder feeder, and one path enters into the heater, the gas and the powders enter into the supersonic flow nozzle via the gas-solid mixing chamber to form gas-solid dual-phase flow, solid particles in the gas-solid dual-phase flow are injected onto the surface of a workpiece and generate severe plastic deformation and finally deposit on the surface of the workpiece. The method provided by the invention can solve the problems of fragility and phase change and the like of coatings, and can be used for preparing two-component or multi-component alloy quasicrystal gradient coatings of various series.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

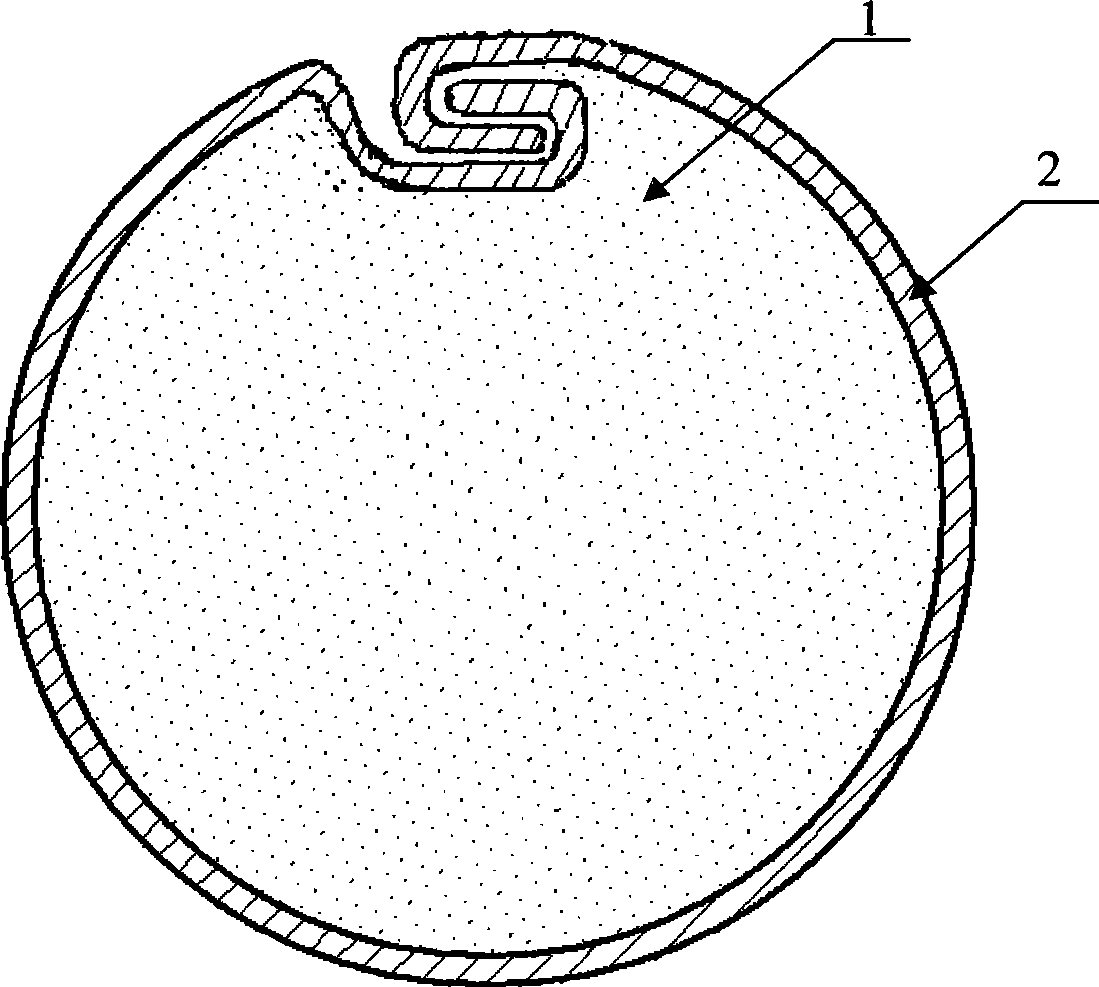

Large-diameter flux-cored wire for revolving body or wear-resistant composite board overlaying welding

InactiveCN101497152AHigh deposition efficiencyImprove productivityWelding/cutting media/materialsSoldering mediaWear resistantGas protection

The invention discloses a large diameter flux-cored wire for resurfacing welding of a revolving body or a wear resistant composite board. The shape of the longitudinal cross-section of the flux-cored wire is an O shape, the diameter of the flux-cored wire phi is between 4.2 and 6.0mm, and the longitudinal length of the flux-cored wire can be determined freely; the wall thickness of the flux-cored wire is between 0.1 and 0.8mm, and wall interfaces are connected by lock seams; and a powder material with the particle size between -50 and +200 meshes or the powder material and steel wires are wrapped in the wall of the flux-cored wire, wherein the steel wires are positioned in the geometric centre of the longitudinal cross-section of the flux-cored wire, arranged longitudinally along the flux-cored wire and have the same length as the flux-cored wire. The flux-cored wire has high deposition efficiency, is applicable to modes such as submerged arc surfacing welding, open arc surfacing welding, gas protection arc surfacing and the like, and improves the productivity greatly.

Owner:SHANDONG UNIV

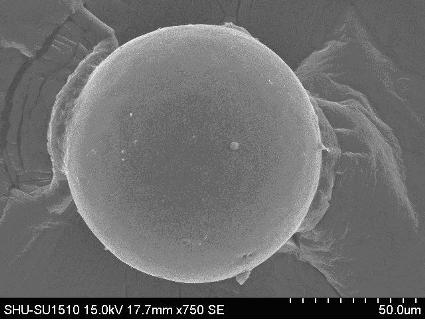

Method for preparing hollow glass microsphere coating titanium dioxide

InactiveCN102002263AEasy to depositExtended service lifePigment treatment with organosilicon compoundsReflecting/signal paintsFiltrationDistilled water

The invention discloses a method for preparing titanium dioxide for coating surfaces of hollow glass microspheres. The method comprises: washing the hollow glass microspheres with alkali liquor to remove impurities and etching to improve activity; performing surface activation and modification by using a silane coupling agent; mixing the activated hollow glass microspheres and distilled water in a mass ratio of 1:10; fully stirring at 40 to 90 DEG C; in the stirring process, dripping solution of titanium sulfate at a constant speed with in 2 to 6 hours according to a mass ratio of the hollow glass microspheres to the titanium sulfate of 1:0.8-1:1.6; slowly adding alkali liquor, keeping the pH value of the reaction system between 5 and 7, and stirring first at a speed of 400r / min for the first 1 / 5 of reaction time and then at a speed of 100 to 300r / min for the rest 4 / 5 of reaction time; and after the reaction is finished, standing, performing suction filtration, washing with distilled water, drying and calcining. The hollow glass microspheres coated with the titanium dioxide can serve as filler for reflective and thermal-insulation coating. Compared with common hollow glass microspheres, the hollow glass microspheres can be used for preparing and synthesizing high-performance coating combining various thermal-insulation mechanisms.

Owner:SHANGHAI UNIV

Deposition System, Method And Materials For Composite Coatings

InactiveUS20100189910A1Improve corrosion resistanceImprove structural performanceLiquid surface applicatorsMolten spray coatingHigh wear resistanceNanocrystal

A composite powder for a deposition of a composite coating comprises a nonmetallic component and a metallic component, the metallic component having an amorphous structure or a nanocrystalline structure. The metallic component may include an amorphous metallic alloy. The metallic alloy may include constituents having the amorphous structure. The metallic component may include a combination of the metallic alloy existing in the amorphous state and constituents of the amorphous metallic alloy in the amorphous state. The composite metal-ceramic powders are used for depositing composite coatings on a selected surface. Disclosed are several methods and systems for producing such composite powders. Disclosed are also several methods and systems for depositing composite coatings. Advantageously, the deposited coatings exhibit high corrosion resistance, high wear resistance, and excellent structural properties.

Owner:BELASHCHENKO VLADIMIR E

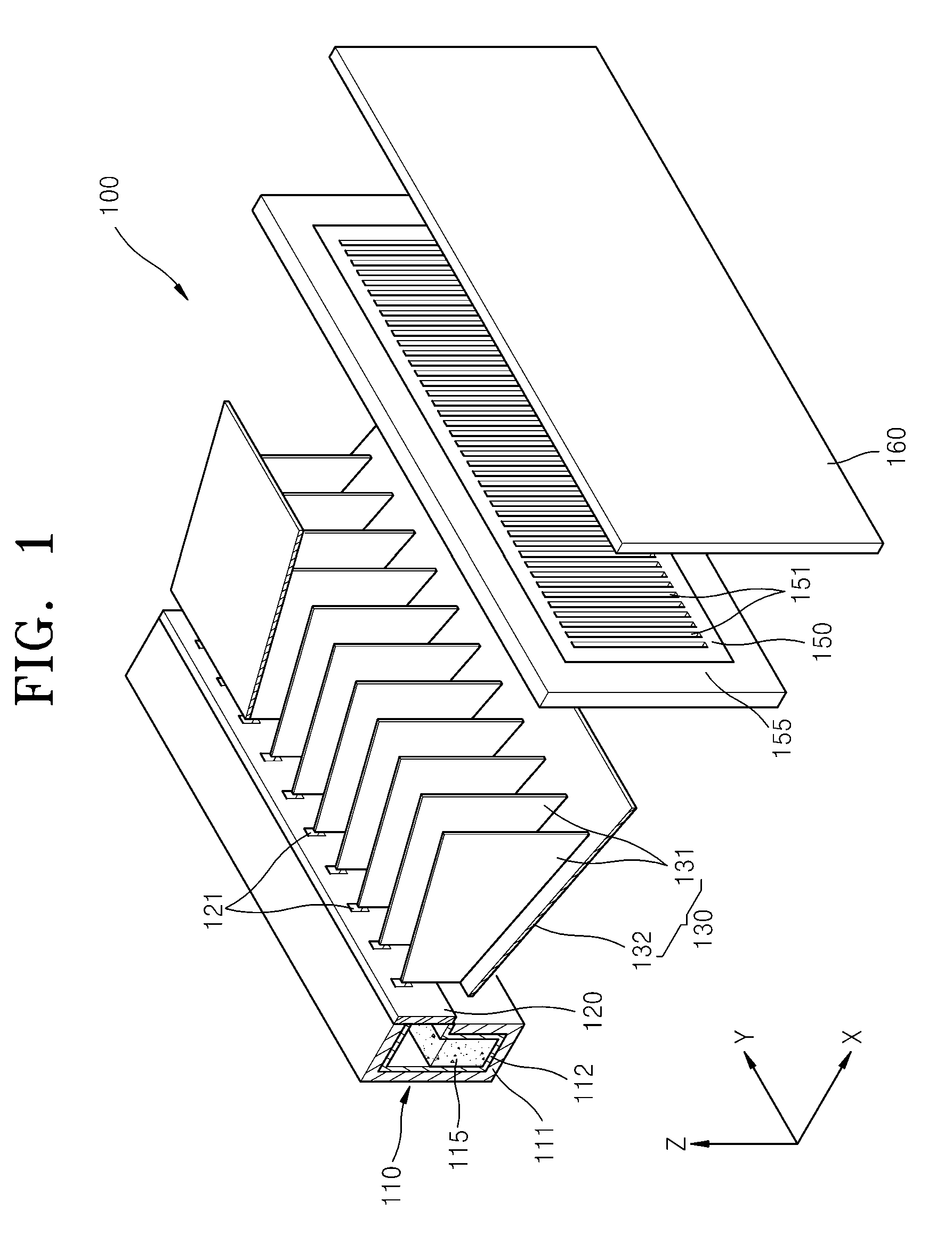

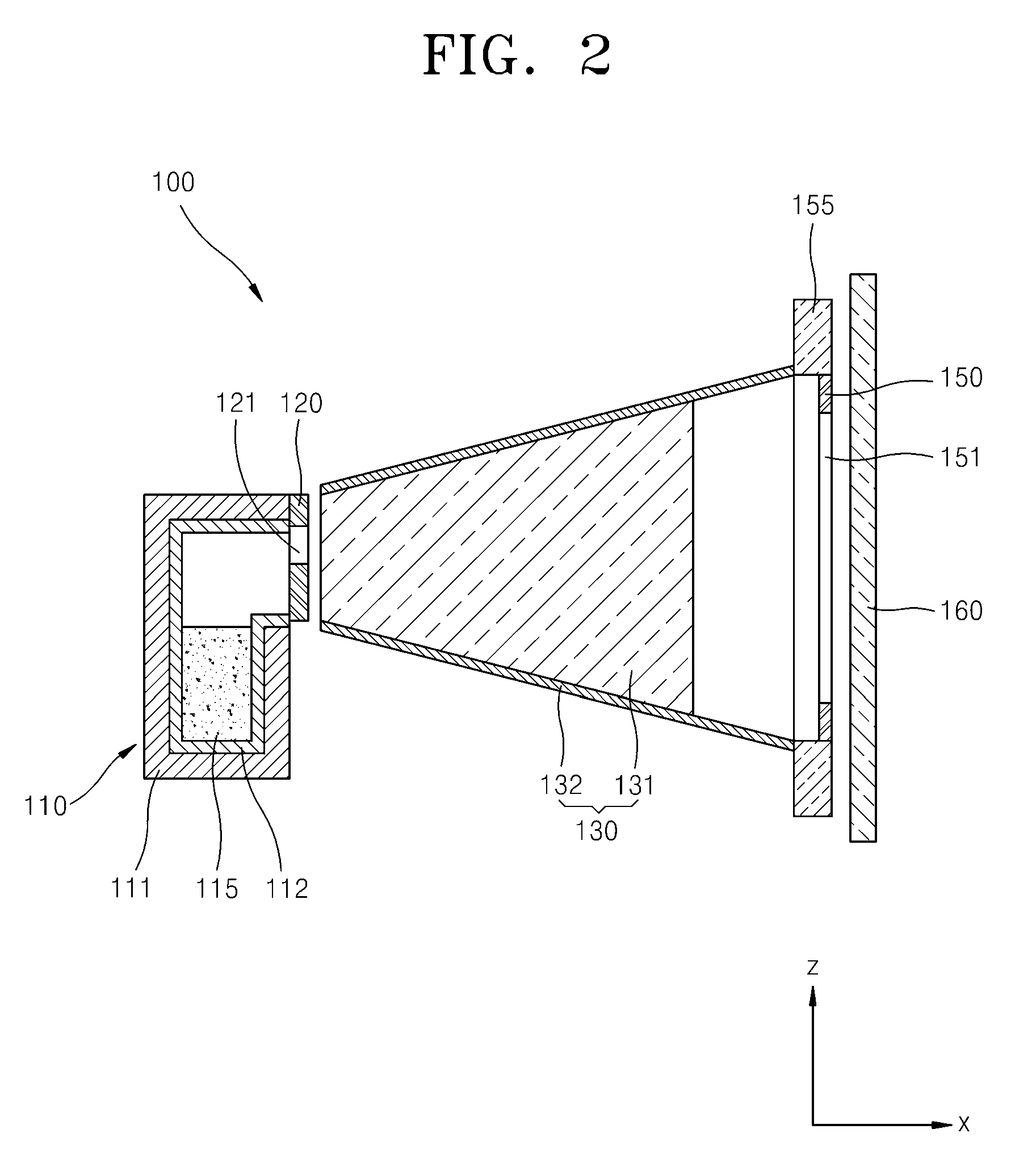

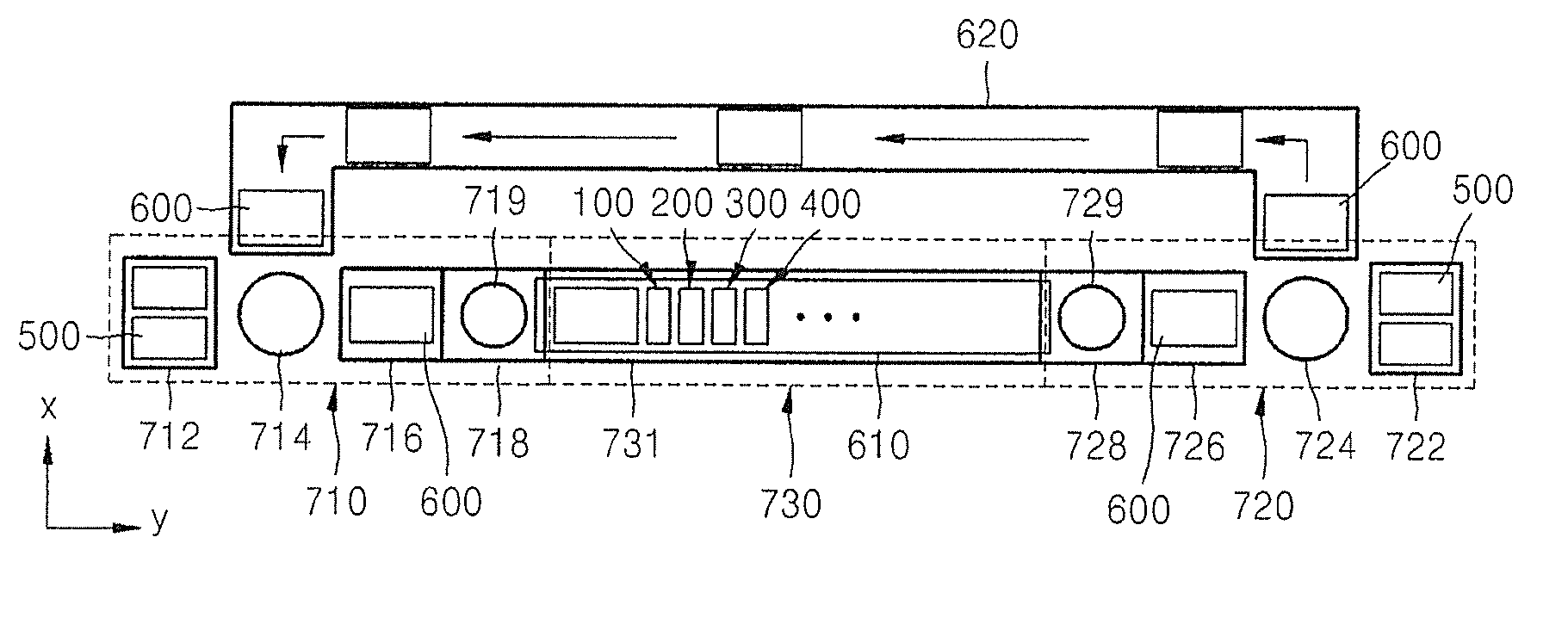

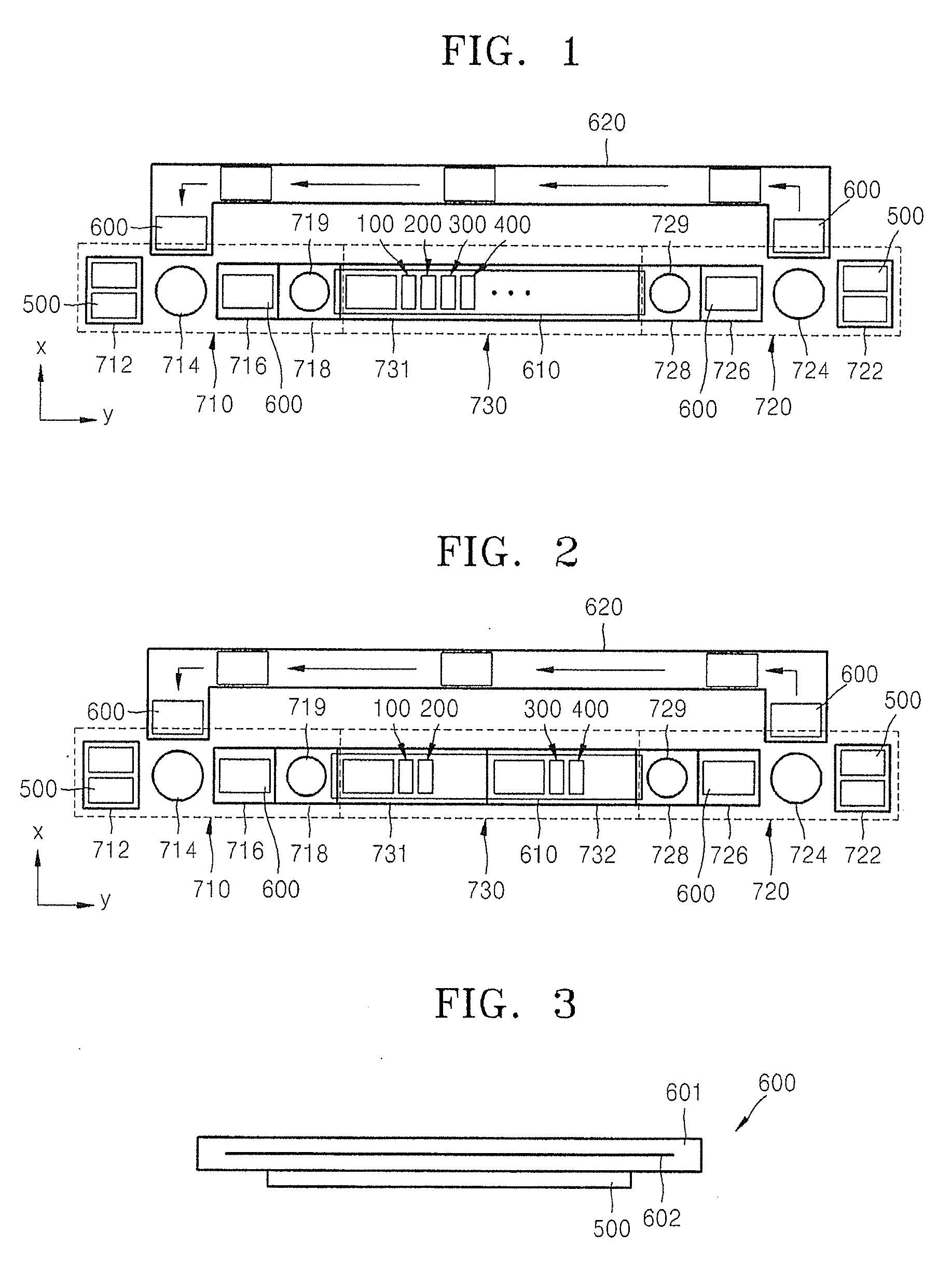

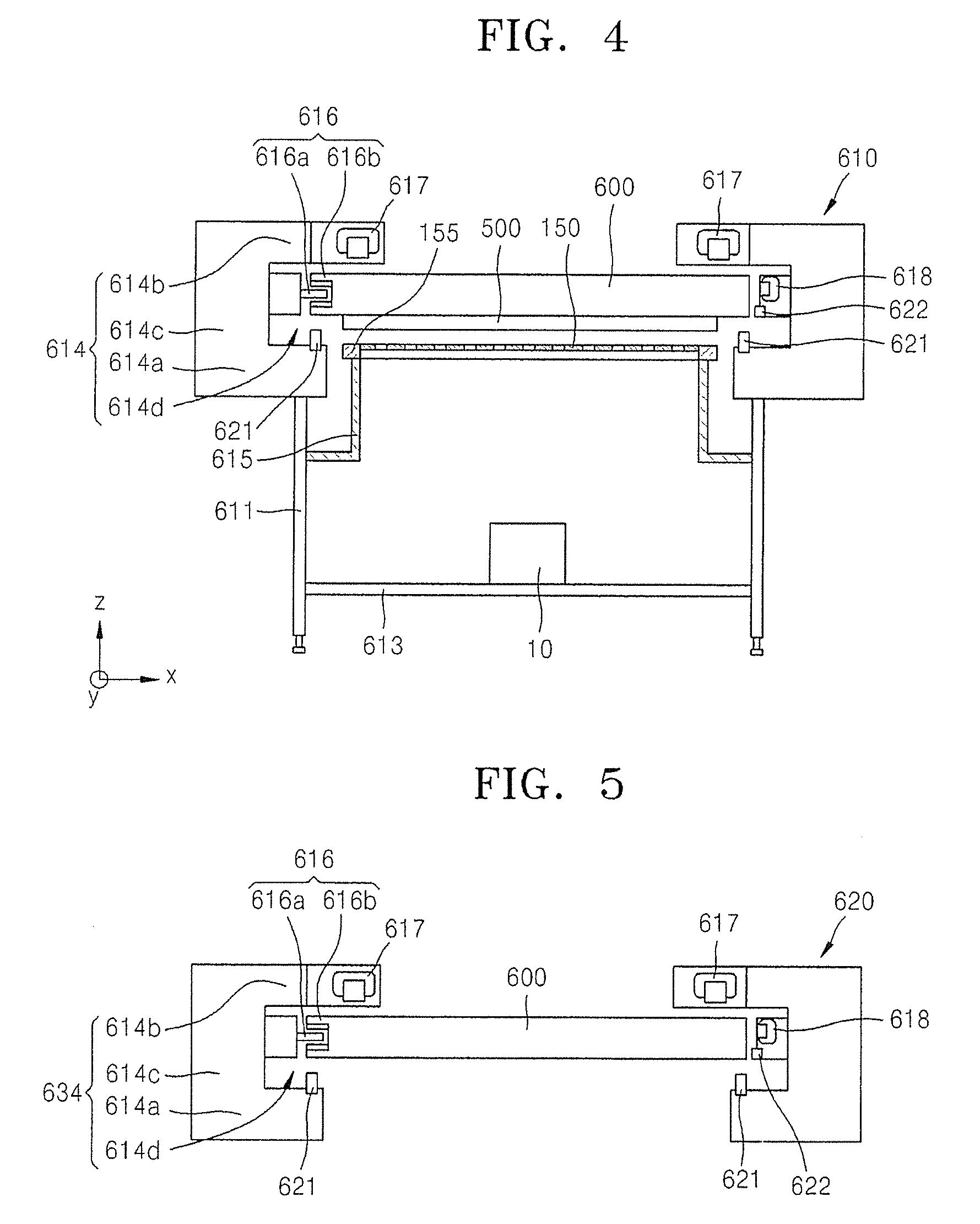

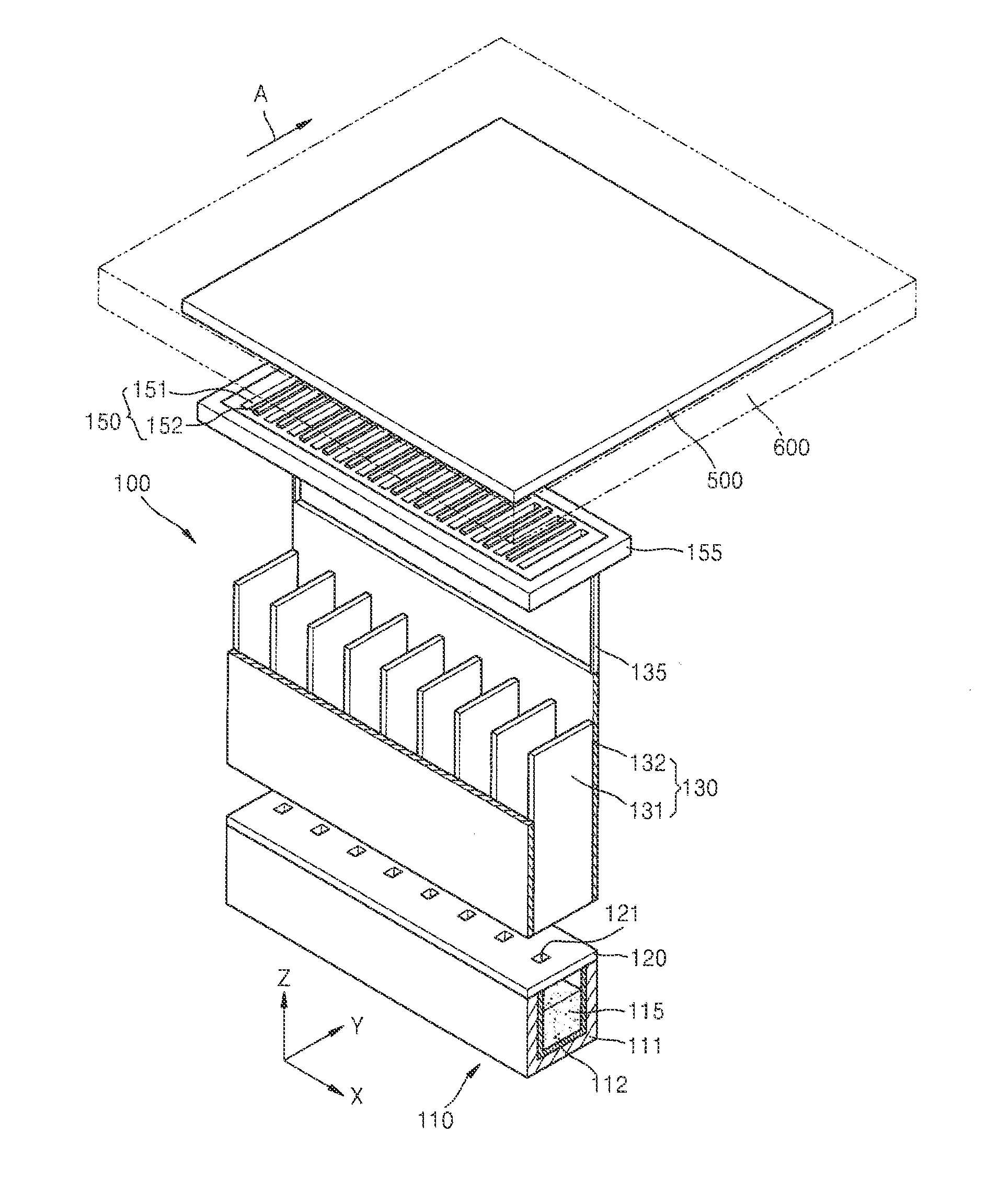

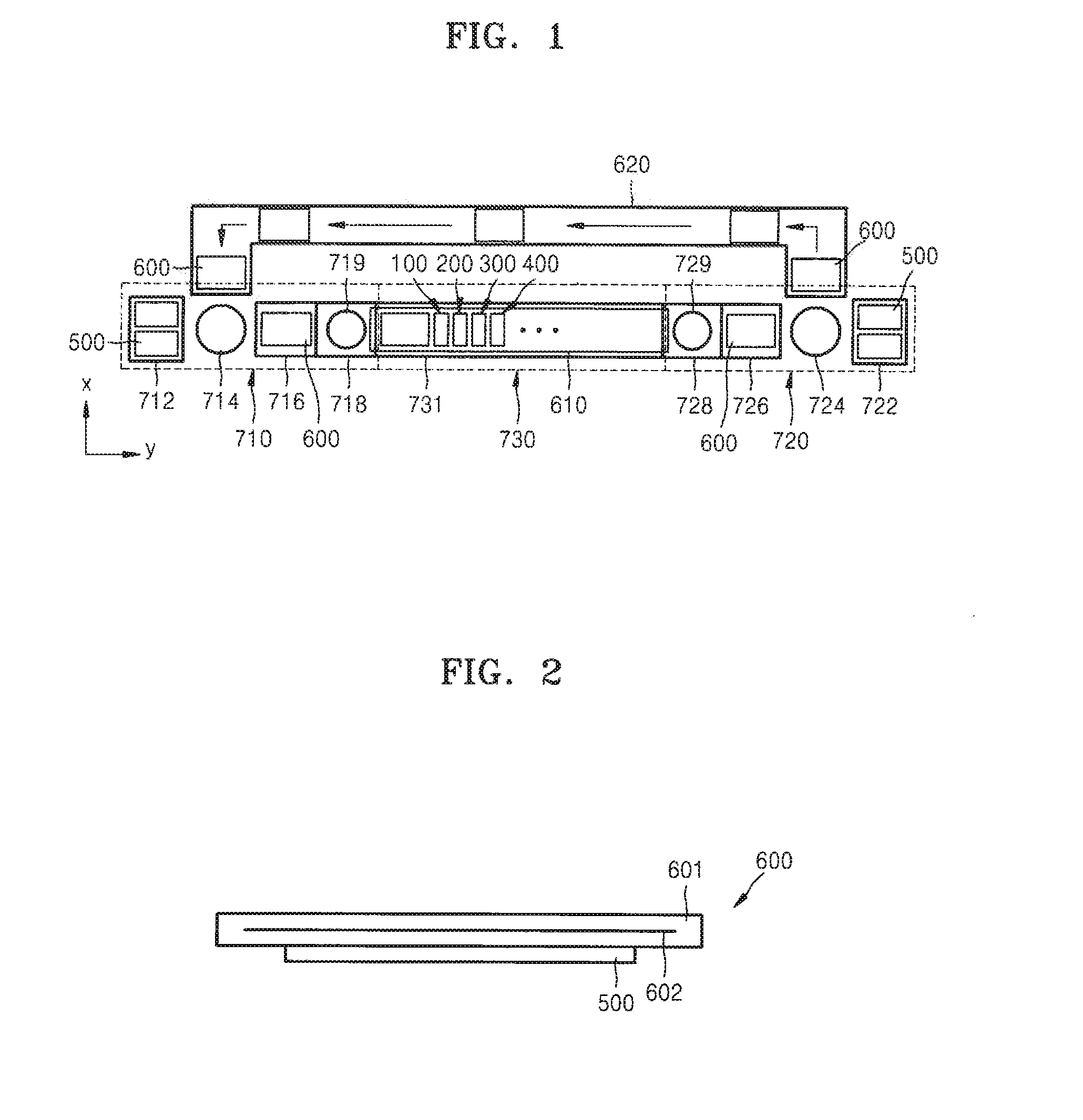

Organic layer deposition apparatus and method of manufacturing organic light-emitting display device by using the same

ActiveUS20130009177A1Easy to manufactureImprove manufacturing yieldLiquid surface applicatorsSpraying apparatusDisplay deviceOrganic layer

An organic layer deposition apparatus, and a method of manufacturing an organic light-emitting display device using the organic layer deposition apparatus. The organic layer deposition apparatus includes: an electrostatic chuck that fixedly supports a substrate that is a deposition target; a deposition unit including a chamber maintained at a vacuum and an organic layer deposition assembly for depositing an organic layer on the substrate fixedly supported by the electrostatic chuck; and a first conveyer unit for moving the electrostatic chuck fixedly supporting the substrate into the deposition unit, wherein the first conveyer unit passes through inside the chamber, and the first conveyer unit includes a guide unit having a receiving member for supporting the electrostatic chuck to be movable in a direction.

Owner:SAMSUNG DISPLAY CO LTD

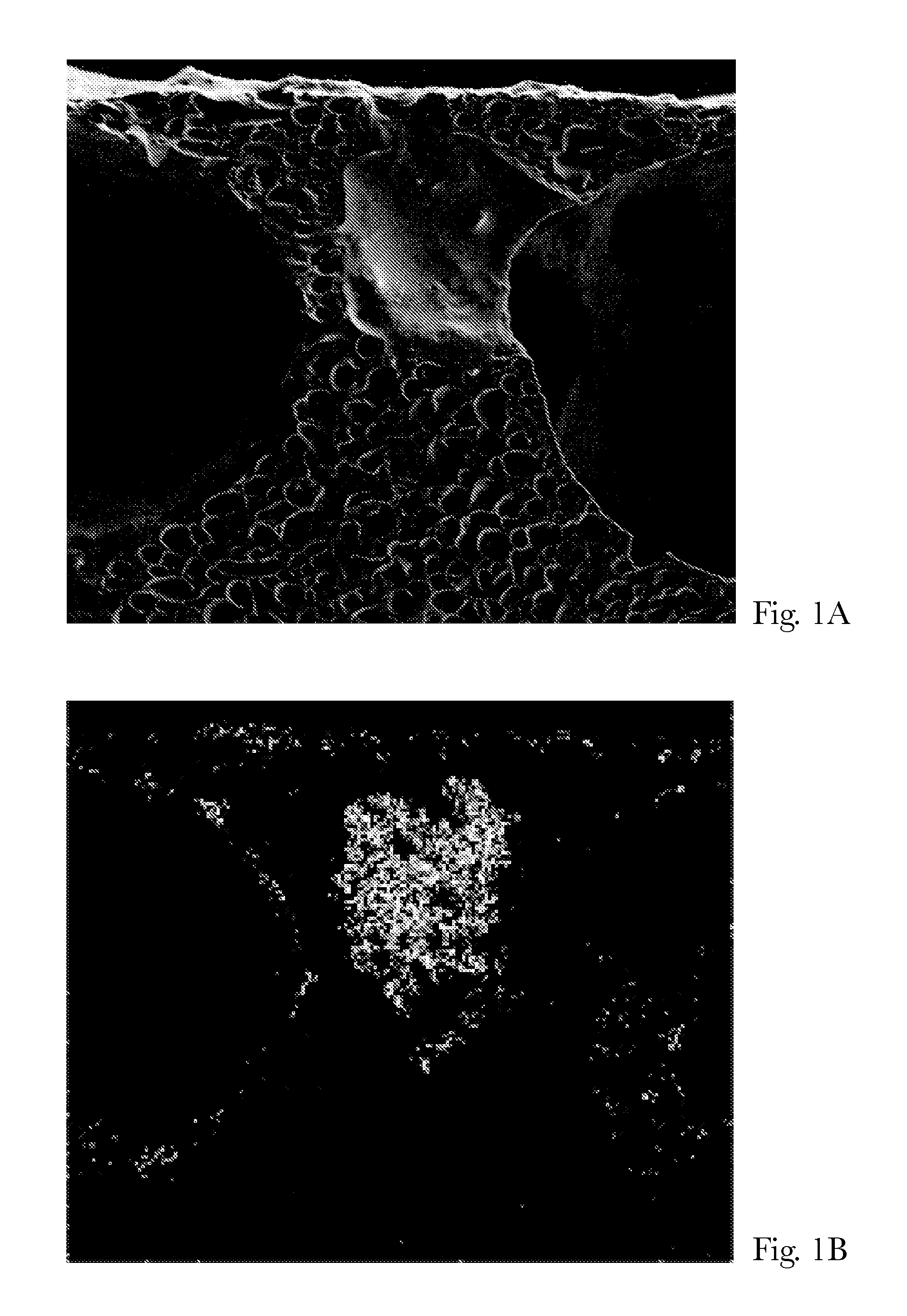

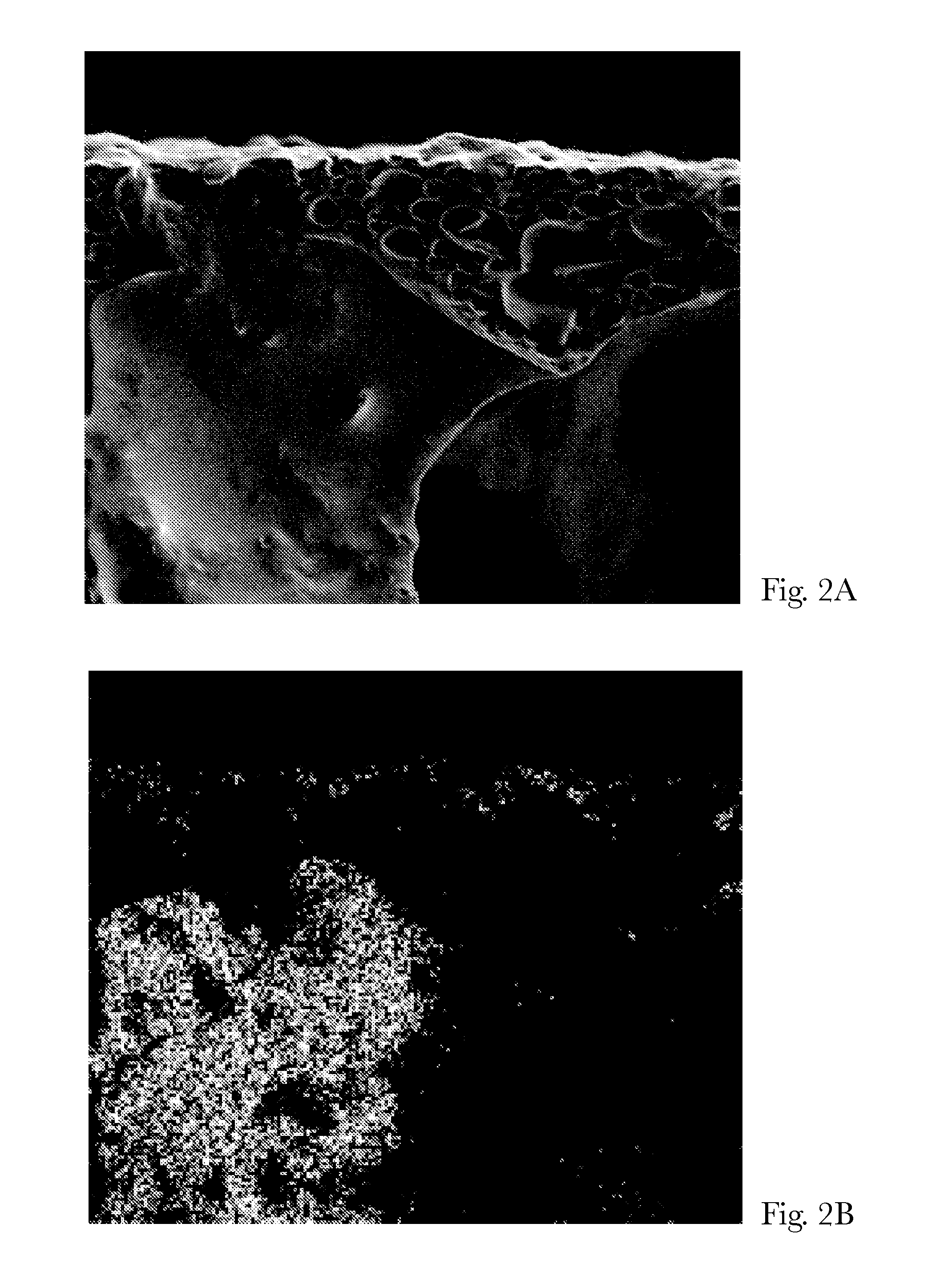

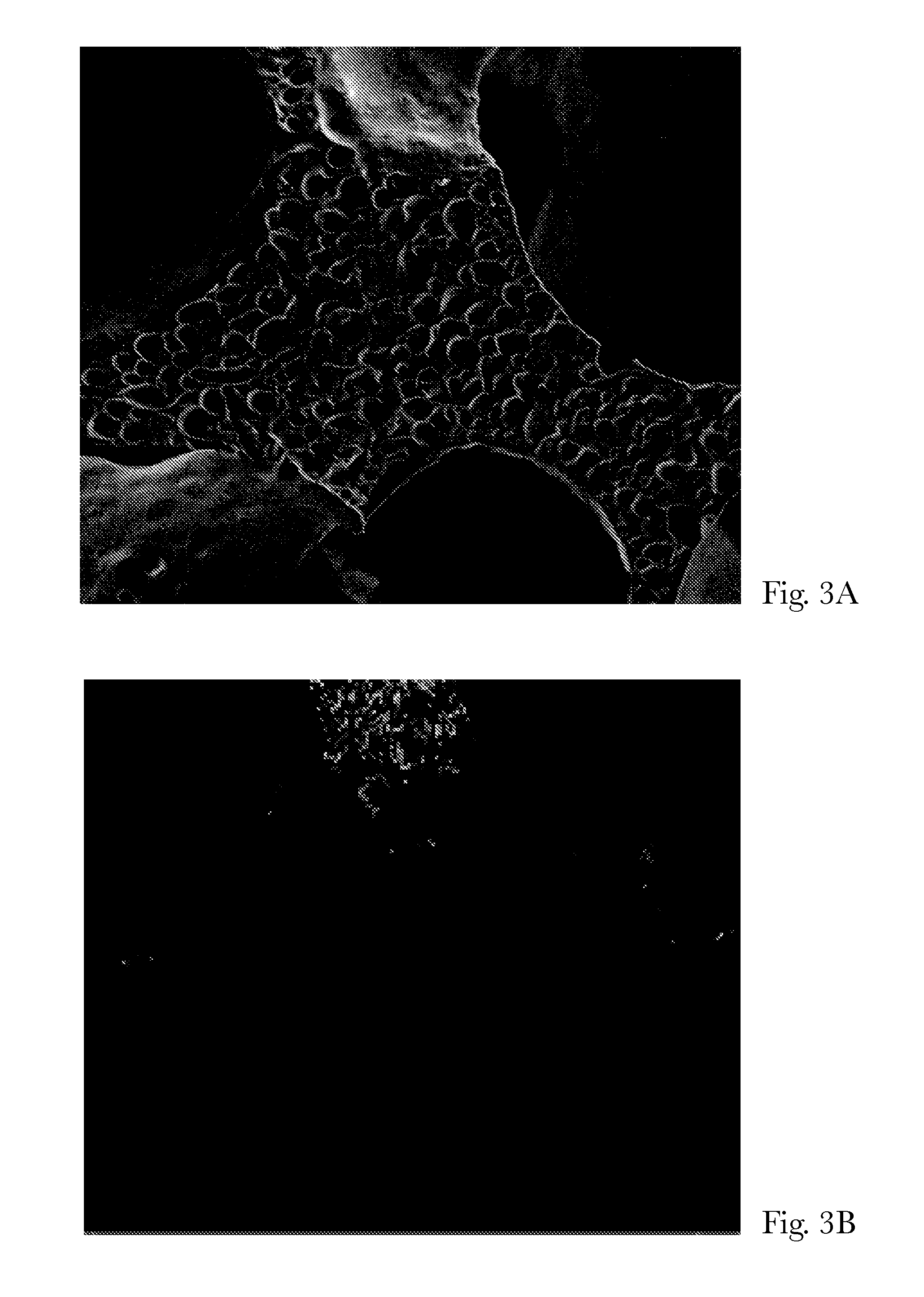

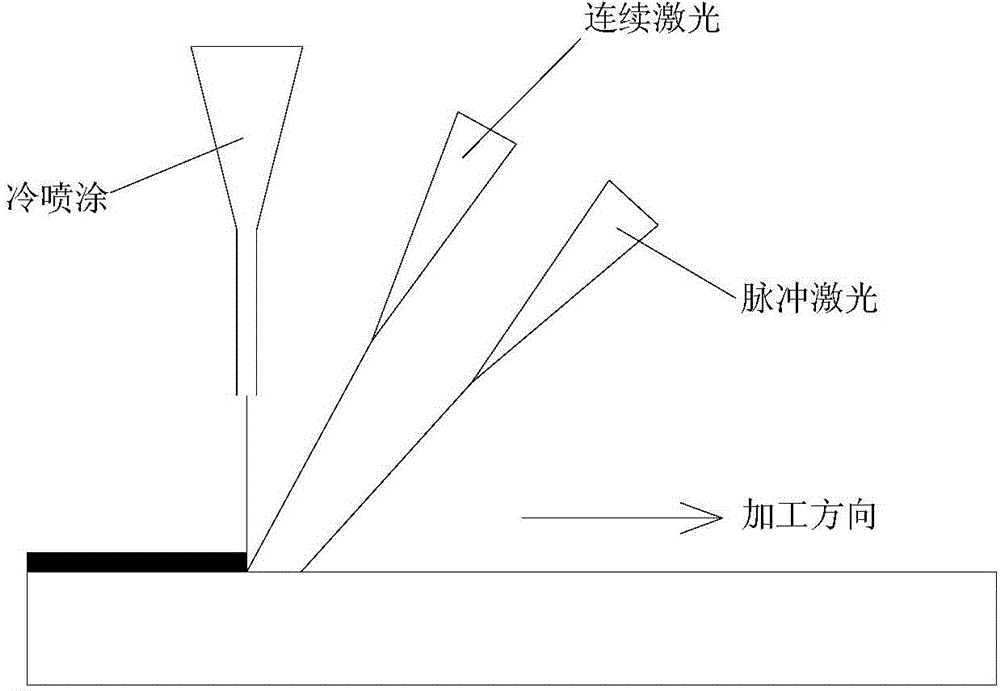

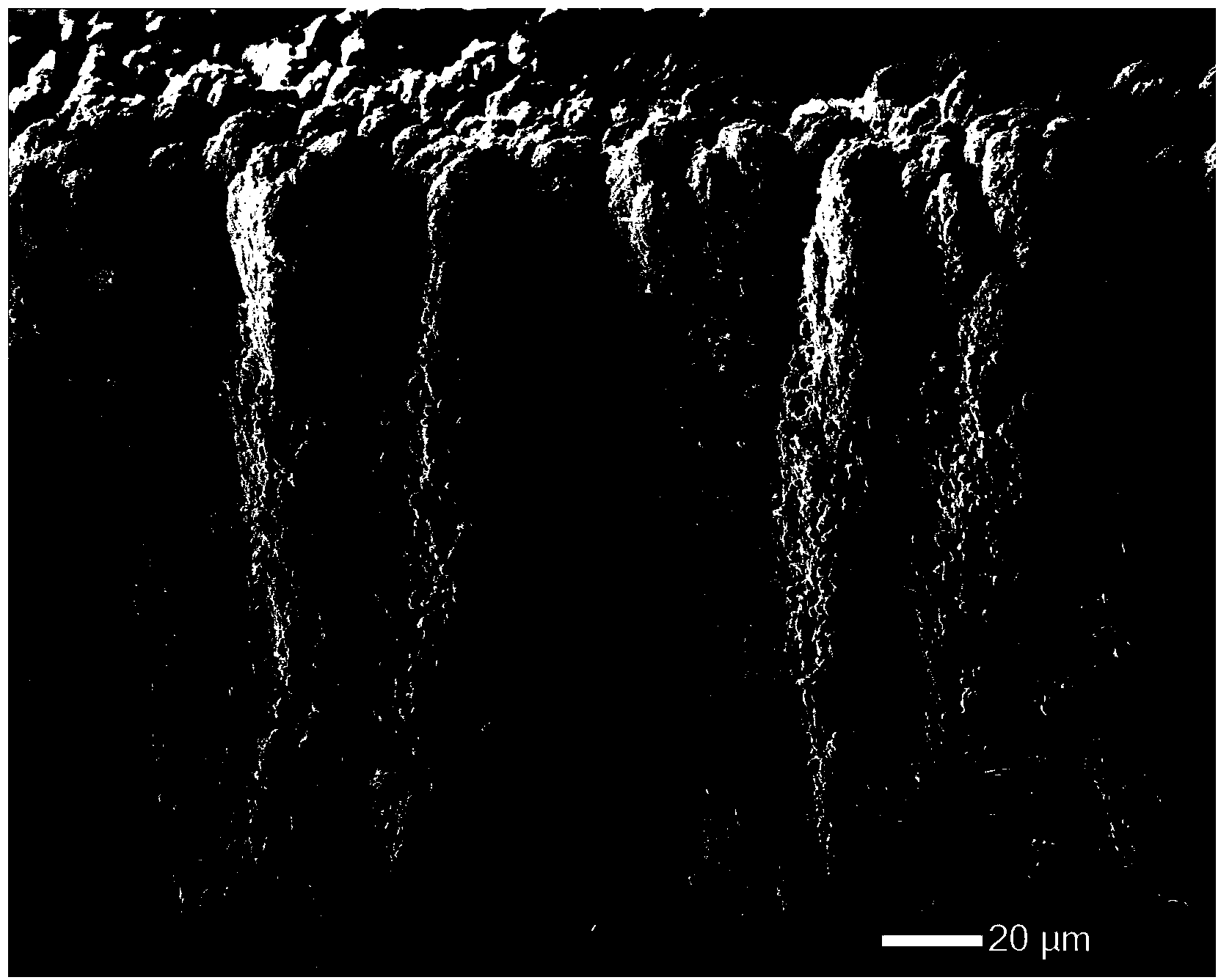

Metal-based/diamond laser composite coating and preparation method thereof

ActiveCN104018156AAvoid easy decompositionInhibition of dissolutionMovable spraying apparatusLaser beam welding apparatusCompound aHardness

The invention discloses a metal-based diamond laser composite coating and a preparation method thereof. The preparation method comprises the following steps: firstly selecting high-hardness metal powder and diamond powder with proper grain size and shape, uniformly mixing the high-hardness metal powder and the diamond powder by using a ball-milling method, and finally preparing the composite coating on a matrix by using a method of synchronously compounding a laser texturing technology, a laser heat treatment technology and a cold spraying technology. The thickness of the composite coating is over 1mm, and the diamond volume content in the coating is more than 45%. The preparation of the composite coating by using the high-hardness metal powder as the diamond binding phase is realized, and the binding strength of the composite coating and the matrix is improved through the pulse texturing treatment, and finally the stable and high-quality high-hardness metal-based / diamond composite high wear-resisting coating is prepared, and the integration, the automation and the efficiency of the matrix surface treatment and the coating deposition treatment are realized.

Owner:ZHEJIANG UNIV OF TECH +1

Deposition system, method and materials for composite coatings

InactiveUS7670406B2Improve corrosion resistanceImprove structural performanceMolten spray coatingMetal-working apparatusHigh wear resistanceNanocrystal

A composite powder for a deposition of a composite coating comprises a nonmetallic component and a metallic component, the metallic component having an amorphous structure or a nanocrystalline structure. The metallic component may include an amorphous metallic alloy. The metallic alloy may include constituents having the amorphous structure. The metallic component may include a combination of the metallic alloy existing in the amorphous state and constituents of the amorphous metallic alloy in the amorphous state. The composite metal-ceramic powders are used for depositing composite coatings on a selected surface. Disclosed are several methods and systems for producing such composite powders. Disclosed are also several methods and systems for depositing composite coatings. Advantageously, the deposited coatings exhibit high corrosion resistance, high wear resistance, and excellent structural properties.

Owner:BELASHCHENKO VLADIMIR E

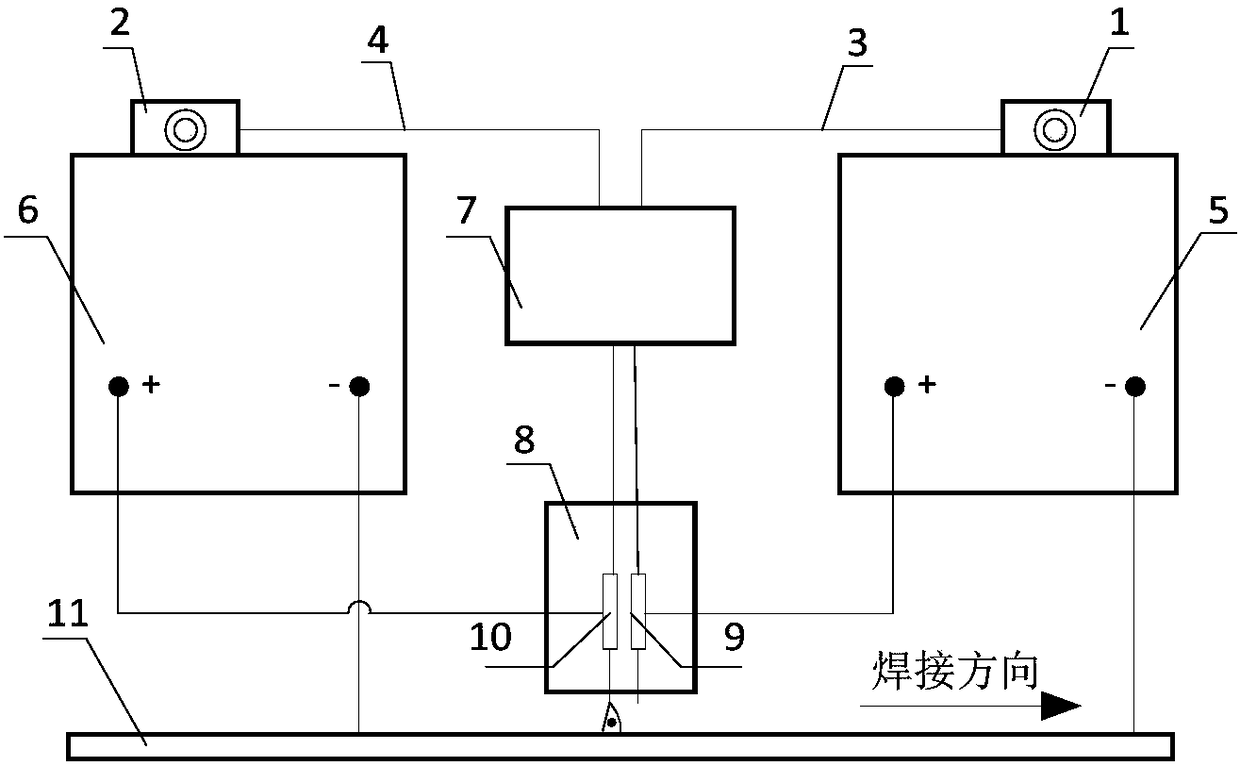

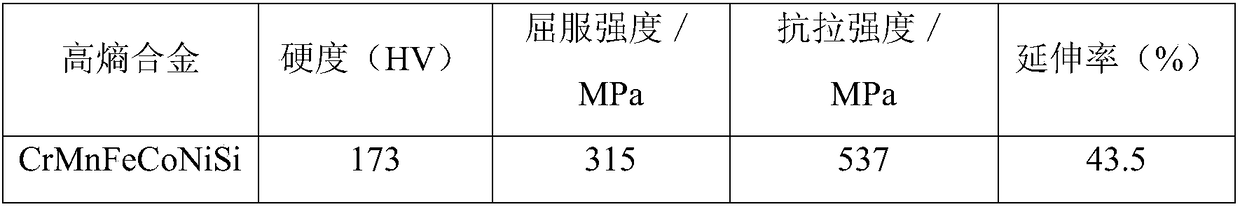

Double-arc fuse collaborative additive manufacturing method of high-entropy alloy

ActiveCN108326427AEasy to adjust ingredientsEasy to adjust grain sizeAdditive manufacturing apparatusLaser beam welding apparatusManufacturing technologyHigh entropy alloys

The invention relates to the technical field of high-entropy alloys, and specifically discloses a double-arc fuse collaborative additive manufacturing method of a high-entropy alloy. The method is characterized in that raw materials are supplied based on a formula of the high-entropy alloy, wherein the raw materials include an alloy strip and flux core powder; the alloy strip and the flux core powder are prepared into a flux cored welding wire; and then a double-arc fuse collaborative additive manufacturing method is carried out to obtain a part or a blocky alloy as requirement. The method isstable in processes, high in cladding efficiency, high in preparation efficiency, wide in heat input adjusting range, low in cost, convenient to adjust the components of the alloy and the size of crystal grains; in addition, the method is applicable to manufacturing of massive high-entropy alloys as well as precise high-entropy alloy parts.

Owner:SHIJIAZHUANG TIEDAO UNIV

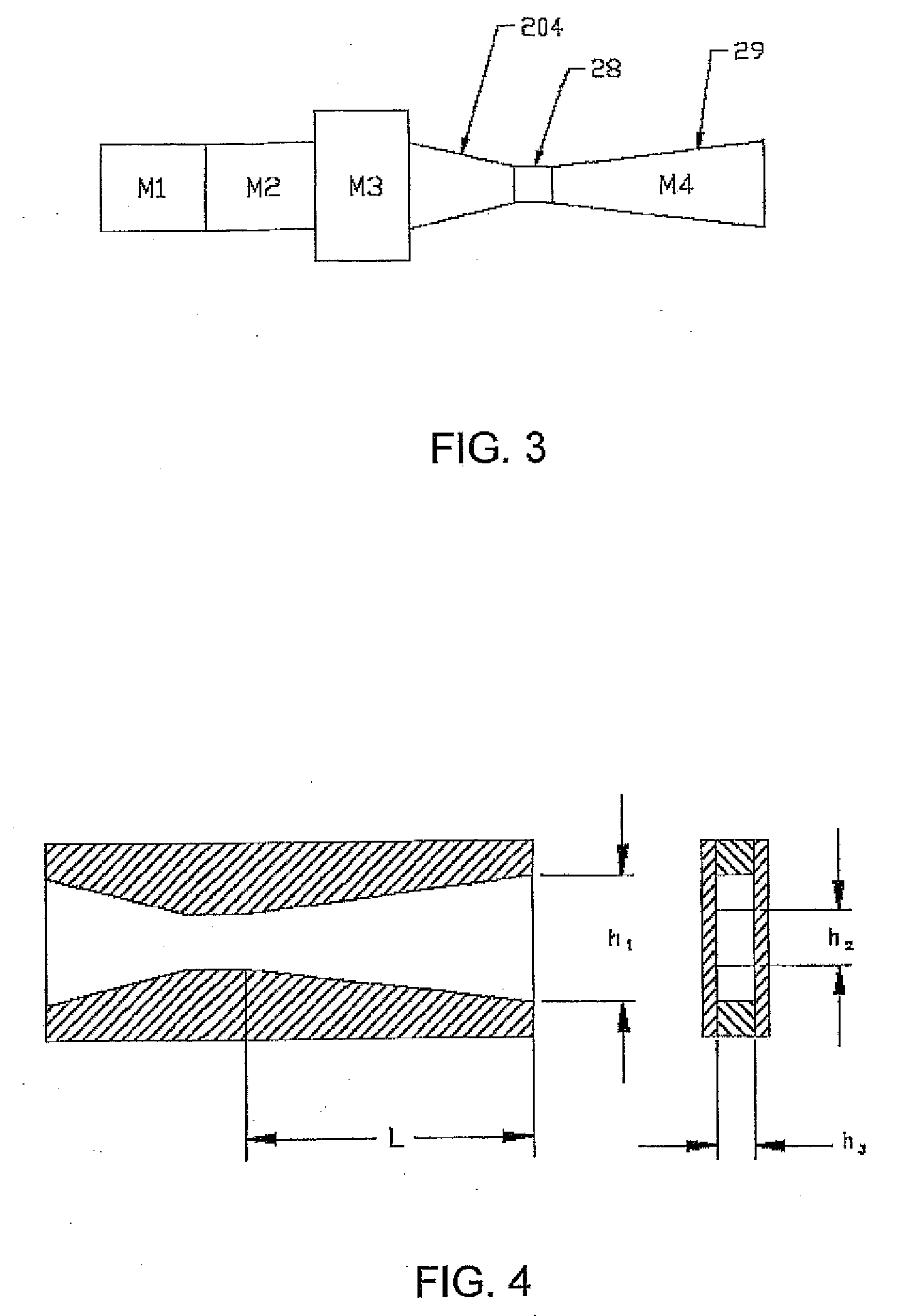

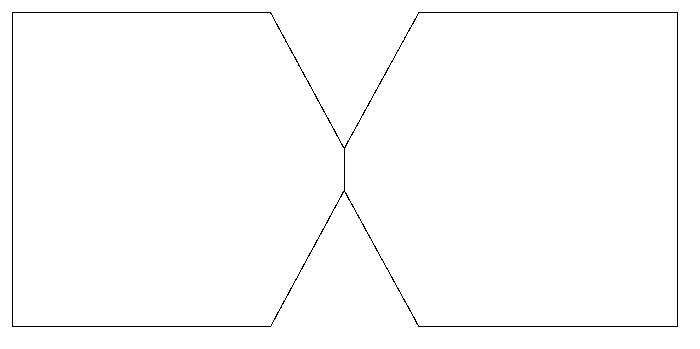

Thin film deposition apparatus, method of manufacturing organic light-emitting display device by using the apparatus, and organic light-emitting display device manufactured by using the method

ActiveUS20110266944A1Easy to manufactureImprove manufacturing yieldDischarge tube luminescnet screensLamp detailsDisplay deviceEngineering

Each of thin film deposition assemblies of a thin film deposition apparatus includes: a deposition source that includes a deposition material; a deposition source nozzle unit arranged at a side of the deposition source and including a plurality of deposition source nozzles arranged in a first direction; a patterning slit sheet arranged opposite to the deposition source nozzle unit and having a plurality of patterning slits arranged in the first direction; and a barrier plate assembly including a plurality of barrier plates arranged in the first direction, the barrier plate assembly being arranged between the deposition source nozzle unit and the patterning slit sheet. The thin film deposition apparatus and the substrate are separated from each other and are movable relative to each other. The deposition material includes a material to produce the thin film of a red (R), green (G) or blue (B) emission layer, or an auxiliary layer.

Owner:SAMSUNG DISPLAY CO LTD

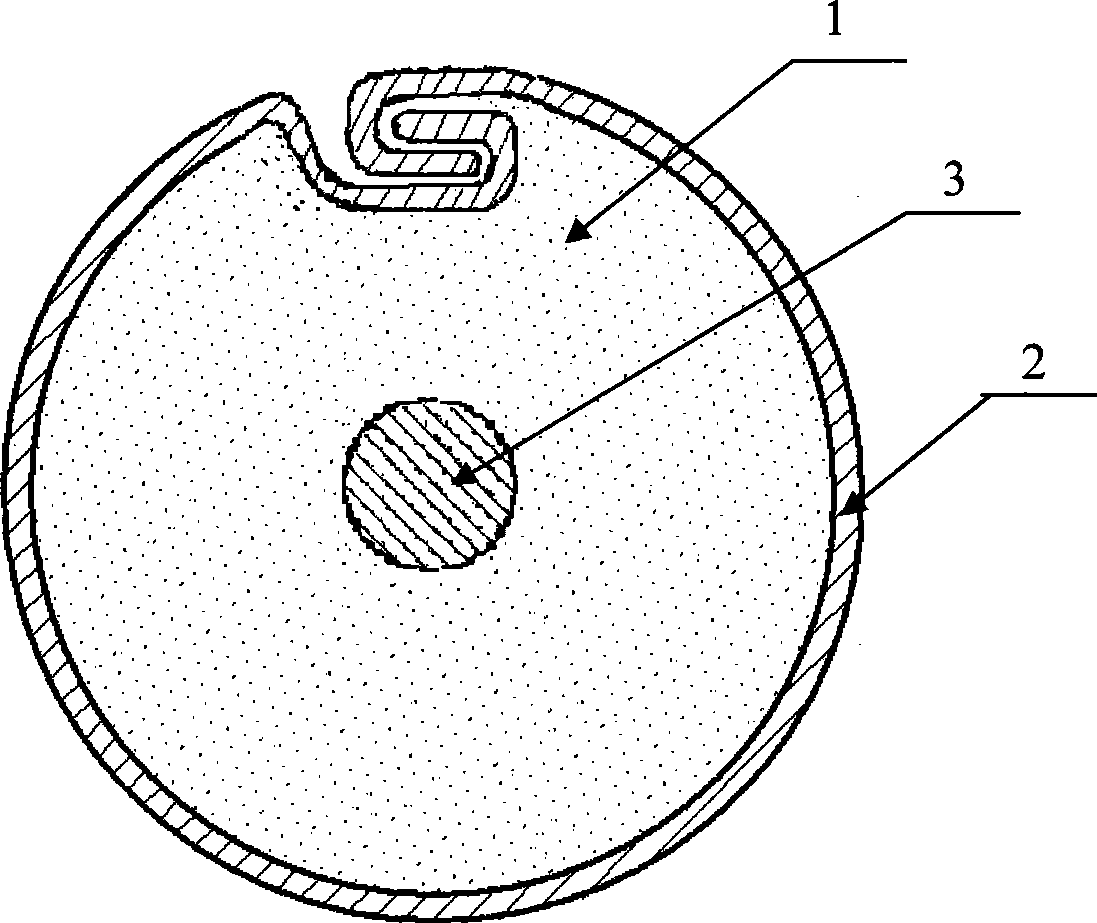

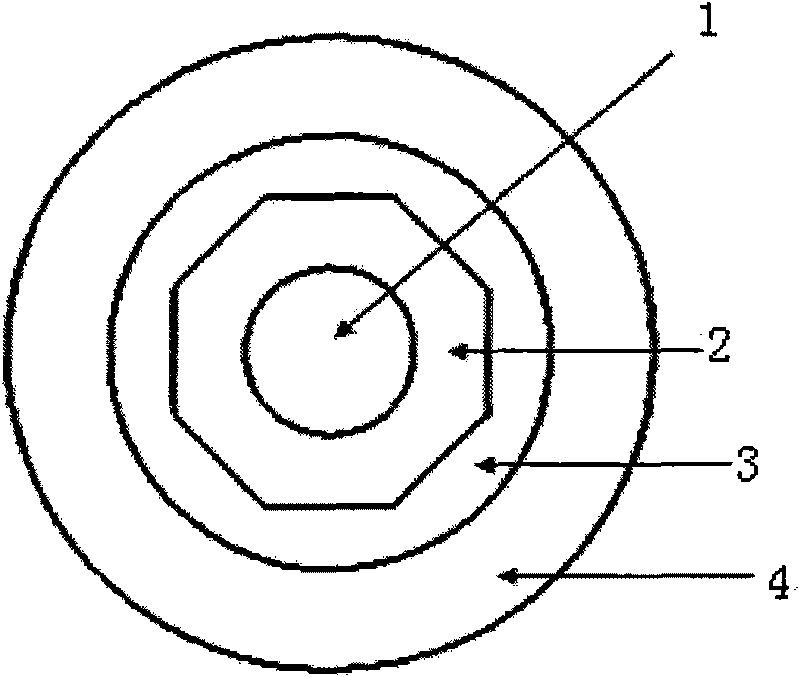

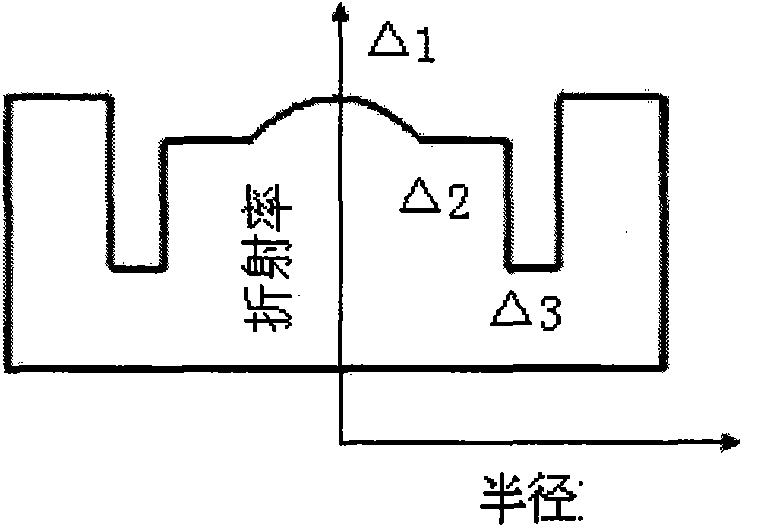

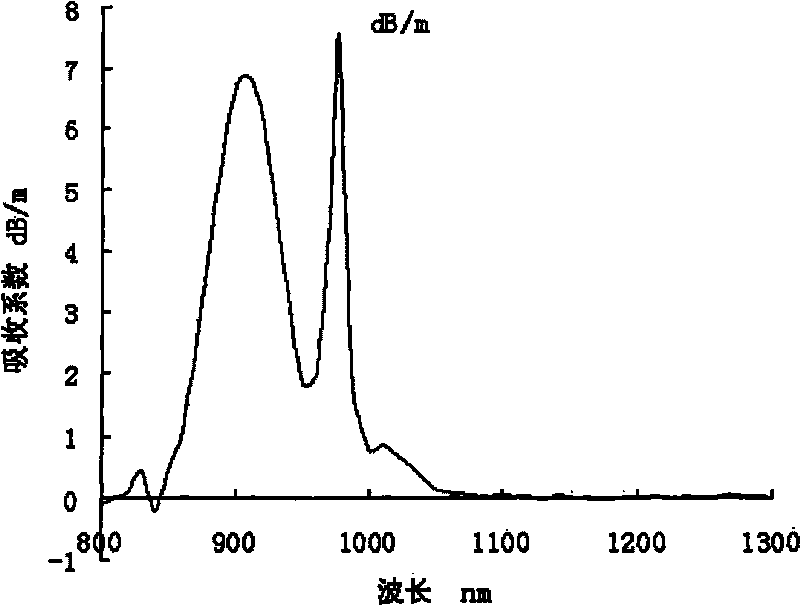

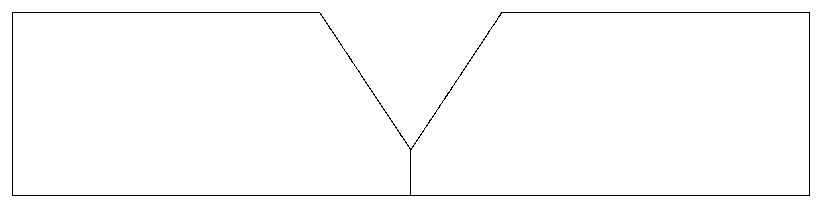

Large-mode active optical fiber and manufacture method thereof

ActiveCN101738682AIncrease powerHigh energy storage densityGlass making apparatusOptical fibre with graded refractive index core/claddingFiberRefractive index

The invention relates to optical fiber and a manufacture method thereof, in particular to large-mode active optical fiber and a manufacture method thereof. The large-mode active optical fiber is formed by drawing a fiber core and a quartz glass inner cladding, a quartz glass outer cladding and a coating which are sequentially coated on the outer surface of the fiber core, wherein the fiber core is formed by depositing, melting and collapsing silicon tetrachloride doped with rare-earth ions in a quartz glass tube; the refractive index of the fiber core is a gradually changed refractive index, and a fiber core refractive index section parameter alpha is not smaller than 1 and not larger than 3; and the appearance of the quartz glass inner cladding is in a regular gengon shape. The large-mode active optical fiber has the advantages of large mode and similar single-mode output, improves the capacity of bearing laser power and the energy storage density of the active optical fiber, improves the light beam quality of output laser, solves the problem of hollow ring of the output laser, greatly improves the reliability of high-power optical fiber laser devices and the utilization rate of raw materials and reduces the manufacture cost.

Owner:FENGHUO COMM SCI & TECH CO LTD

Method for welding Q500qE ultralow-carbon bainite steel for bridge

ActiveCN103286427ASolve welding process problemsAvoid cold cracksArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention provides a method for welding Q500qE ultralow-carbon bainite steel for a bridge. The method is excellent in joint mechanical performance and high in welding efficiency and specifically includes that aiming at specific chemical components, applicable technical conditions and different plate thicknesses of the Q500qE ultralow-carbon bainite steel for the bridge, preheating temperature before welding, groove types and welding process parameters are determined; a welding joint type adopts butt joint, penetration angle joint or ship position T-shaped angle joint; a welding method adopts submerged arc welding, CO2 gas shielded semiautomatic welding or shielded metal arc welding. By the welding method, the joint type and thickness specifications of a bridge structure are comprehensively covered, the technical scheme is simple, convenient and high in adaptivity, all implementing effects meet technical requirements of standards related to building of bridge steel and the bridge structure, and the method is of great significance in promoting upgrading of the bridge steel and development of large-span steel bridge building technology. The method can be applied to building of the bridge structure, can also be applied to welding of other ultrathin-carbon bainite steel and is high in adaptivity.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Organic layer deposition apparatus and method of manufacturing organic light-emitting display device by using the same

ActiveUS20120299023A1Easy to manufactureBroaden applicationLiquid surface applicatorsVacuum evaporation coatingOrganic layerDisplay device

An organic layer deposition apparatus for forming an organic layer on a substrate includes: a deposition source configured to discharge a deposition material; a deposition source nozzle unit arranged at a side of the deposition source and including a plurality of deposition source nozzles; and a patterning slit sheet facing the deposition source nozzle unit and including a plurality of patterning slits and at least one spacer arranged between a pair of adjacent patterning slits of the plurality of patterning slits, the patterning slit sheet being smaller than the substrate in at least one of a first direction or a second direction perpendicular to the first direction, and the substrate is spaced apart from the organic layer deposition apparatus by a predetermined distance, and at least one of the substrate or the organic layer deposition apparatus is movable relative to the other.

Owner:SAMSUNG DISPLAY CO LTD

High-temperature abradable seal coating

InactiveCN101653998AReduce oxidation rateStop the spreadMolten spray coatingLayered productsSurface layerAlloy

The invention relates to high-temperature abradable seal coating with single-layer or multi-layer structure, wherein the high-temperature abradable seal coating with single-layer structure is providedwith a bonding bottom layer sprayed on a base body, and an oxygen barrier layer and a seal surface layer are sequentially sprayed on the bonding bottom layer; on the basis of the high-temperature abradable seal coating with single-layer structure, at least another seal surface layer is needed to be sprayed on the seal surface layer to form the high-temperature abradable seal coating with multi-layer structure; the bonding bottom layer is made of NiCrAlY or NiCoCrAlY alloy powder, the oxygen barrier layer is made of composite agglomerated powder of nano yttria, partially stable zirconia and nano Alpha-Al2O3, and the seal surface layer is made of nano Y-PSZ based high-temperature seal coating materials. The high-temperature abradable seal coating has better high temperature stability, thermal shock resistance and abradability during the use.

Owner:WUHAN UNIV OF TECH

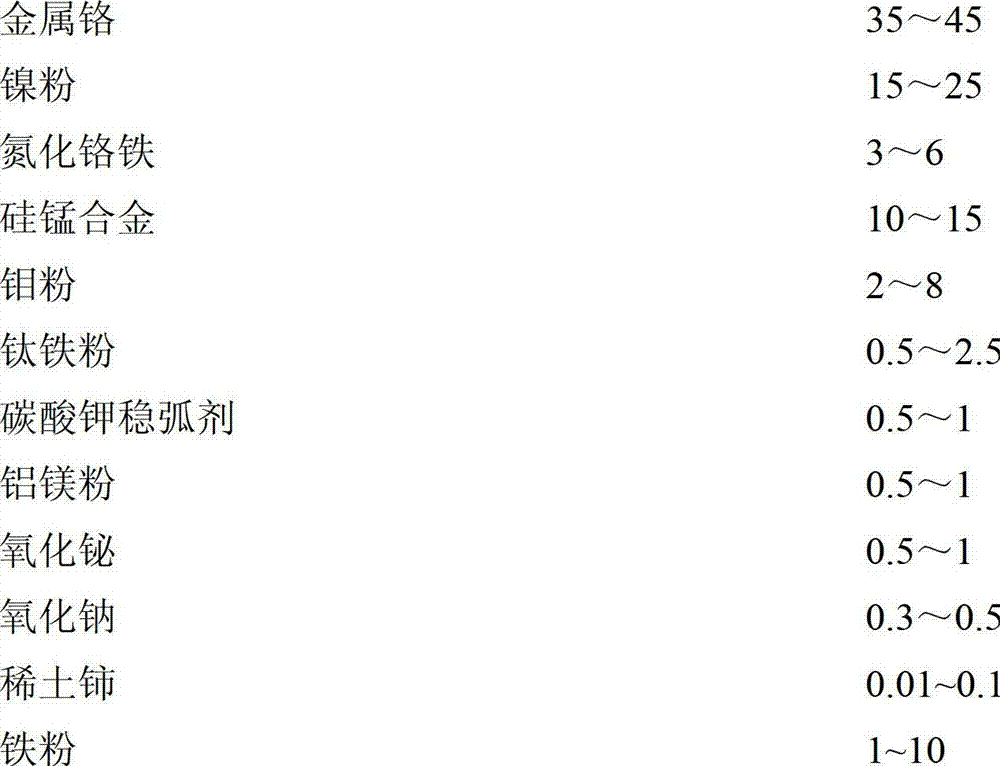

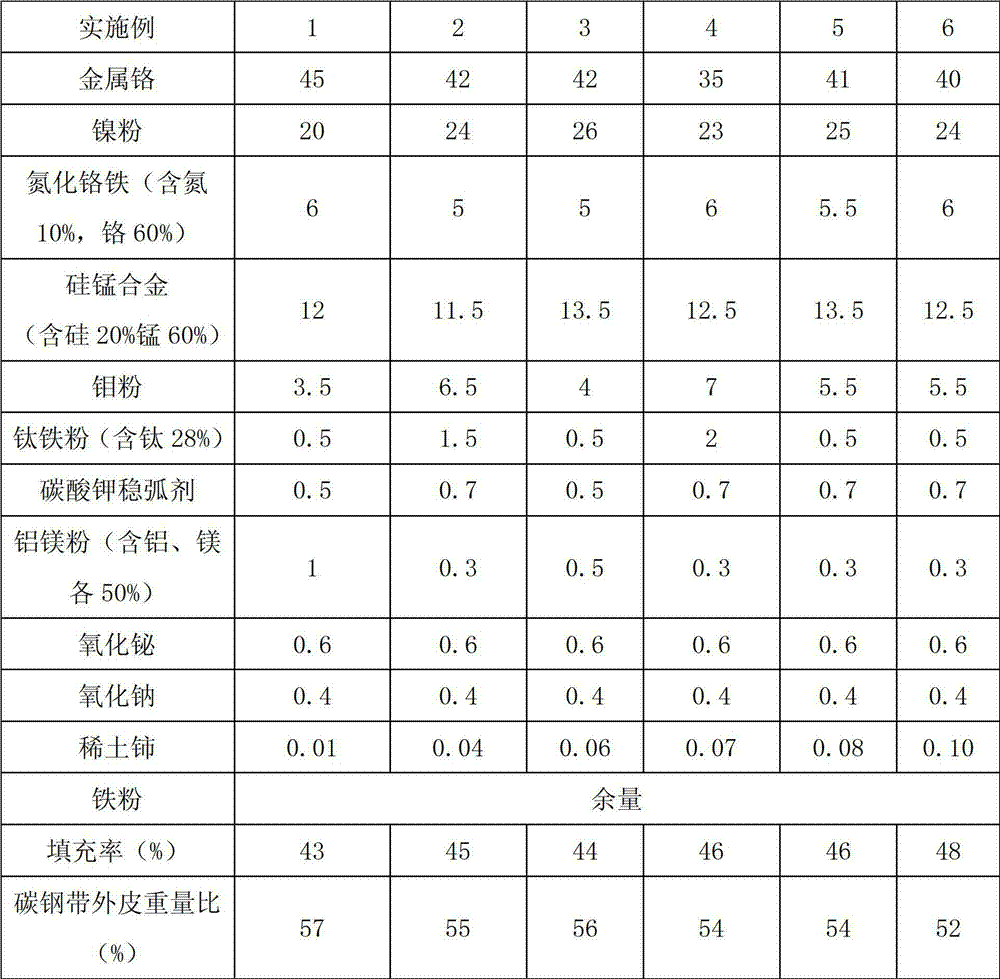

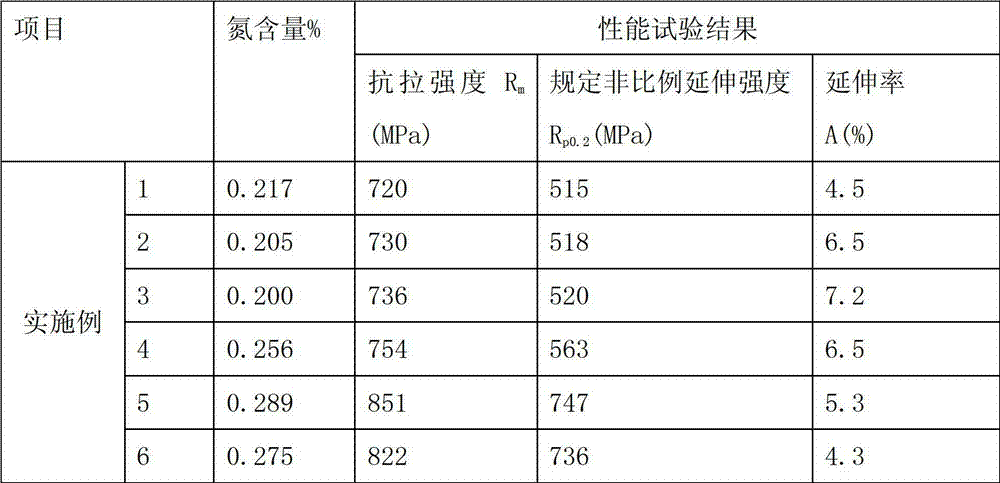

Metal powder-cored type nitrogen austenite stainless steel flux-cored wire and method for manufacturing same

ActiveCN103042321AEffective combinationGood wire qualityWelding/cutting media/materialsSoldering mediaCeriumMechanical property

The invention relates to a metal powder-cored type nitrogen austenite stainless steel flux-cored wire and a method for manufacturing the same. The metal powder-cored type nitrogen austenite stainless steel flux-cored wire comprise a carbon steel cored shell and powder filled in the shell, and is characterized in that the powder comprises, by weight, from 35% to 45% of metal chromium, from 15% to 25% of nickel powder, from 3% to 6% of ferrochromium nitride, from 10% to 15% of silicon-magnesium alloy, from 2% to 8% of molybdenum powder, from 0.5% to 2.5% of ferrotitanium powder, from 0.5% to 1% of potassium carbonate arc stabilizers, from 0.5% to 1% of aluminum-magnesium powder, from 0.5% to 1% of bismuth oxide, from 0.3% to 0.5% of sodium oxide, from 0.01% to 0.1% of rare-earth cerium and from 1% to 10% of iron powder, and the weight of the powder ranges from 40% to 50% of the total weight of the wire. Compared with the prior art, the metal powder-cored type nitrogen austenite stainless steel flux-cored wire has the advantages that weld metal has excellent mechanical properties such as good toughness and high strength after the wire is applied to welding high-nitrogen steel, and a corrosion resistant effect is good.

Owner:北方材料科学与工程研究院有限公司 +2

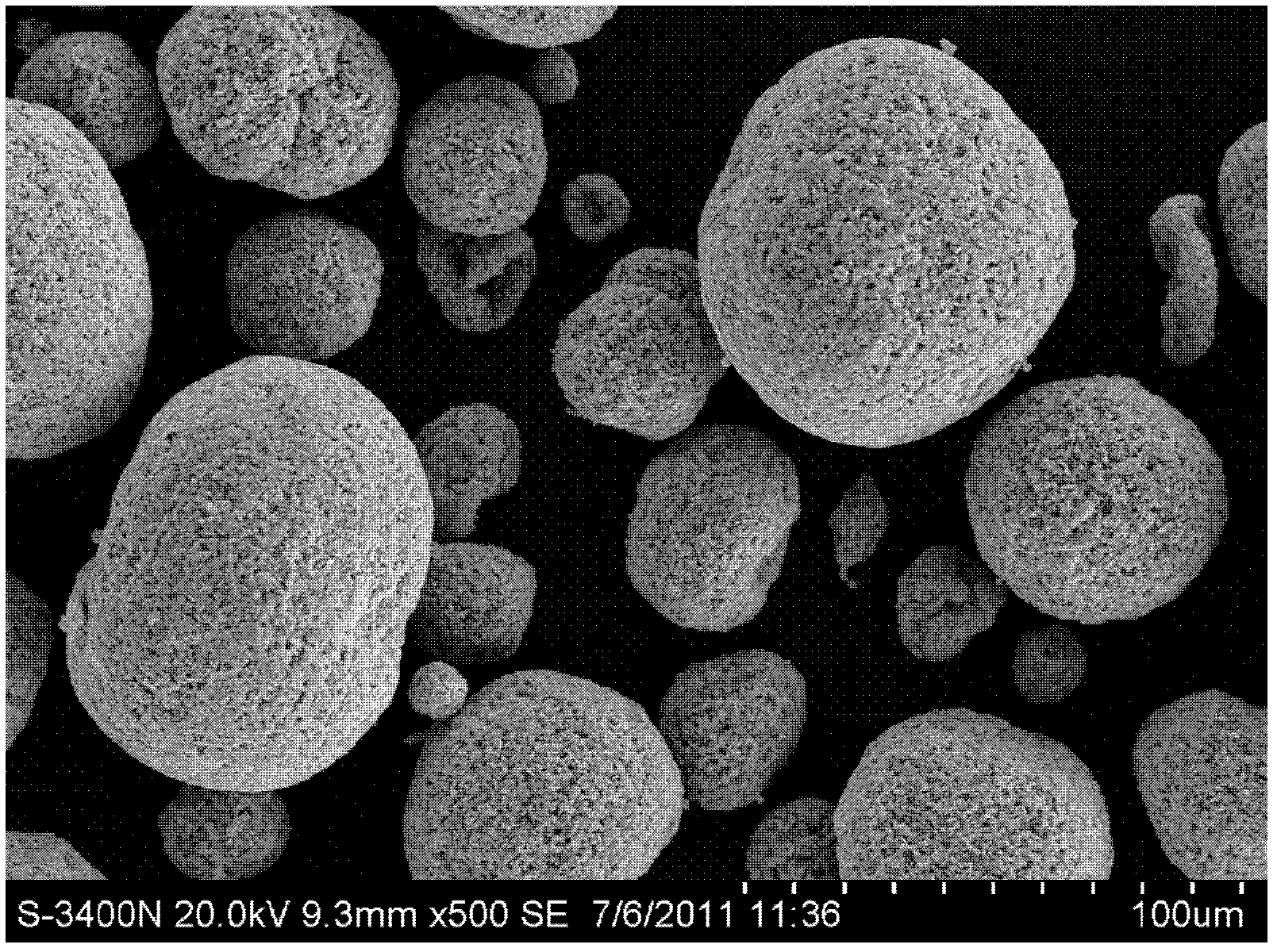

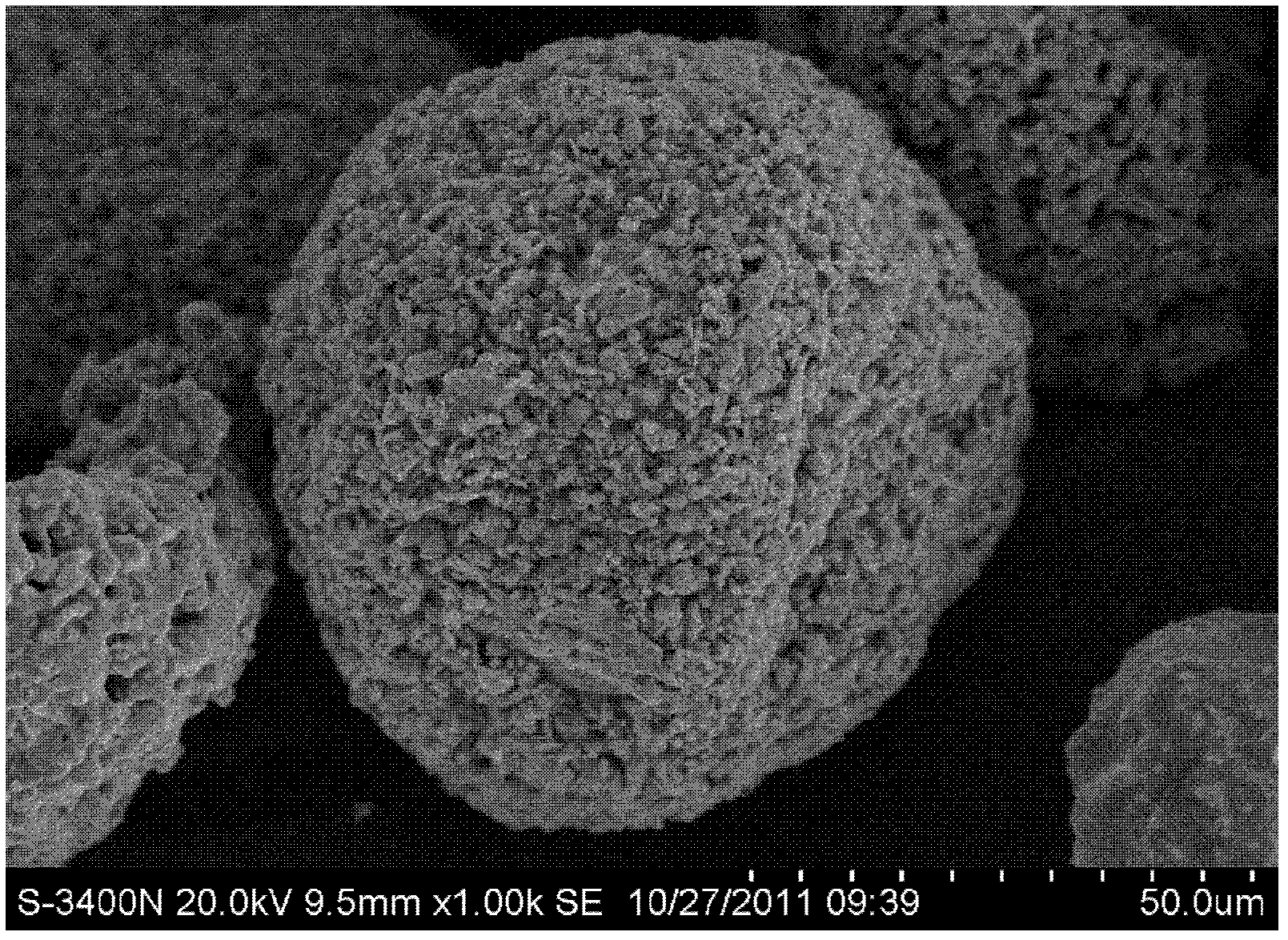

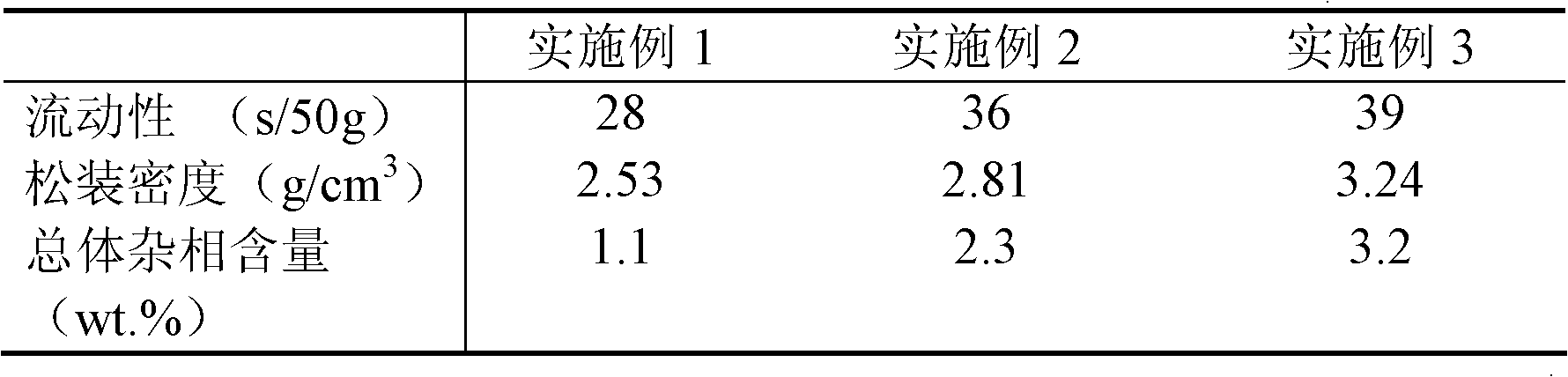

Preparation method of coating containing TiB2 metal ceramic composite powder for thermal spraying piston ring

InactiveCN102581292AImprove deposition efficiencyGuaranteed contentMolten spray coatingThermal sprayingPolyvinyl alcohol

The invention relates to a preparation method of a coating containing TiB2 metal ceramic composite powder for a thermal spraying piston ring, belonging to the field of composite power body technology. The preparation method provided by the invention comprises the following steps: firstly, adopting a ball-milling method to perform mixing and wet grinding on 25-75wt.% TiB2 powder, 25-10wt.% NiCr alloy powder and 50-15wt.% Mo metal powder to obtain mixed powder with the particle size less than 3 micrometers; then mixing the mixed powder with adhesion agent PVA (Polyvinyl Alcohol), dispersing agent and deionized water in proportion in to slurry, performing atomization and granulation of the slurry at the drying temperature rang of 150-250 DEG C and under the atomizing disc frequency range of 140-190Hz through a spray drying device; and finally performing densification treatment on the powder through heat treatment technology and plasma balling technology. For the composite powder prepared by the preparation method of the invention, the particle size is uniformly distributed, the spherical degree, the densification degree and the mobility are good, the deposition efficiency of TiB2 can be improved, and the metal ceramic coating with good wear-resisting property can be prepared.

Owner:BEIJING UNIV OF TECH

Electric arc adding and milling device

ActiveCN105414981ASolve the problem of insufficient machining accuracySimple processOther manufacturing equipments/toolsEngineeringAdditive layer manufacturing

The invention discloses an electric arc adding and milling device belonging to the technical field of electric arc adding. The electric arc adding and milling device comprises an electric arc adding unit and a milling unit, wherein the milling unit comprises a milling head; the milling unit is connected with the electric arc adding unit; and the electric arc adding unit comprises a welding gun, a supporting plate, a slide block, a fixing groove, a fixing plate, a stepping motor and a lead screw, wherein one end of the welding gun is fixed together with the slide block, the other end of the welding gun passes through a through hole of the supporting plate, both the supporting plate and the fixing plate are fixed together with the stepping motor, the fixing groove is fixed together with the fixing plate, an output shaft of the stepping motor is connected with the lead screw, and the lead screw passes through a threaded through hole formed in the slide block. The electric arc adding and milling device can be used for realizing additive manufacturing and cutting at one step, so that workpieces are more precisely machined, and the using requirement is met.

Owner:HUAZHONG UNIV OF SCI & TECH

Plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with long service lifer, high insulation performance and composite structure, and preparation method thereof

ActiveCN103966539AImprove deposition efficiencyPollution controlMolten spray coatingVacuum evaporation coatingLanthanideNanostructure

The invention discloses a plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with a long service life, a high insulation performance and a composite structure, and a preparation method thereof, and belongs to the technical field of thermal barrier coating. The ceramic layer material comprises lanthanum zirconate or cerate; the thermal barrier coating comprises a bonding layer, a first ceramic layer and a second ceramic layer which are prepared on a base body, wherein the first ceramic layer adopts a YSZ coating; the second ceramic layer comprises the lanthanum zirconate or cerate; in the preparation method of the ceramic layer, the pressure of a vacuum chamber is lower than 1 mbar; through adjusting parameters of spraying electric power, current, gas flow rate, temperature of the basal body, powder feeding rate, spraying distance and the like, the YSZ coating layer and the lanthanide thermal barrier coating ceramic layer which are provided with microstructures of columnar crystal structures, layered structures, layered structures and columnar crystal structures, or nano- structured coating and the like can be obtained. The service life of the thermal barrier coating is long and the heat-insulating property is favorable.

Owner:BEIHANG UNIV

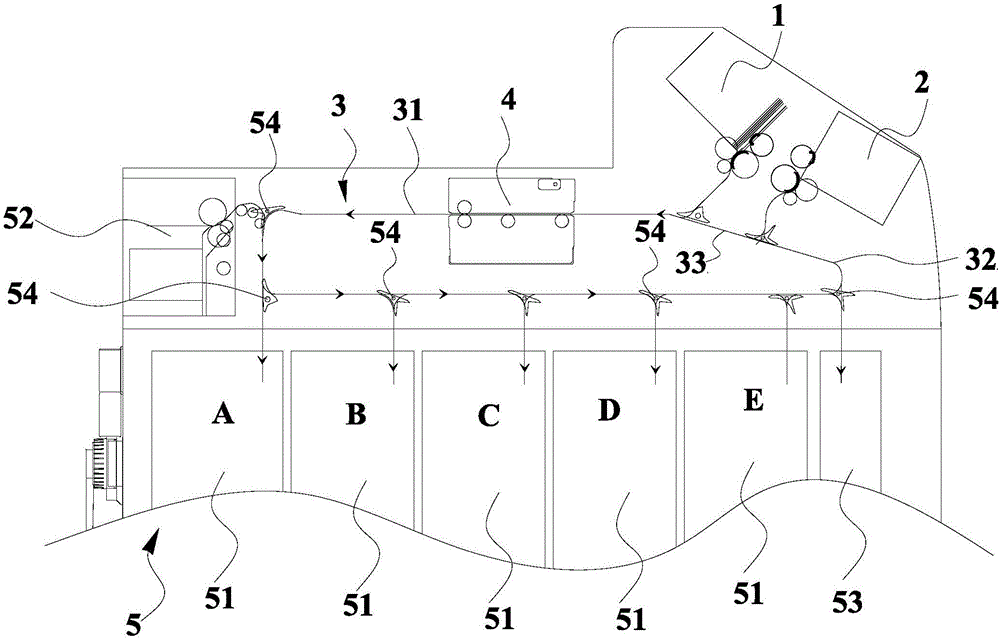

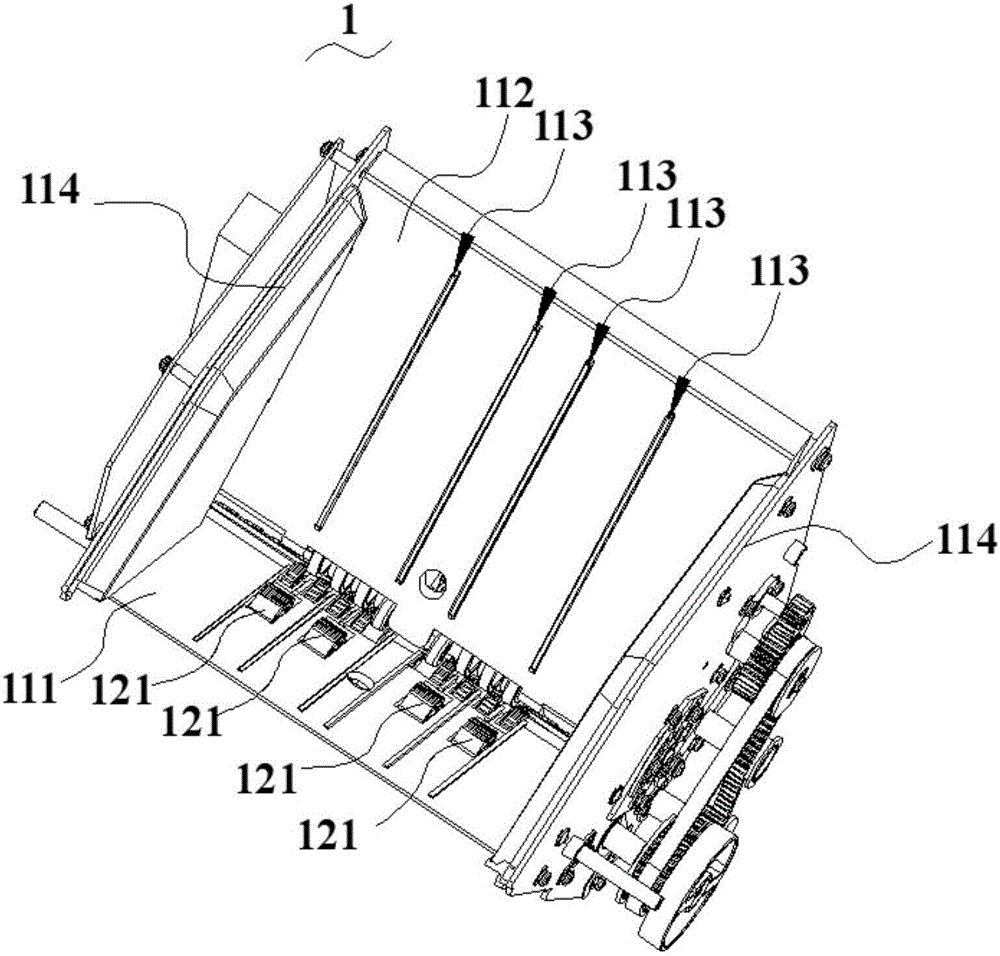

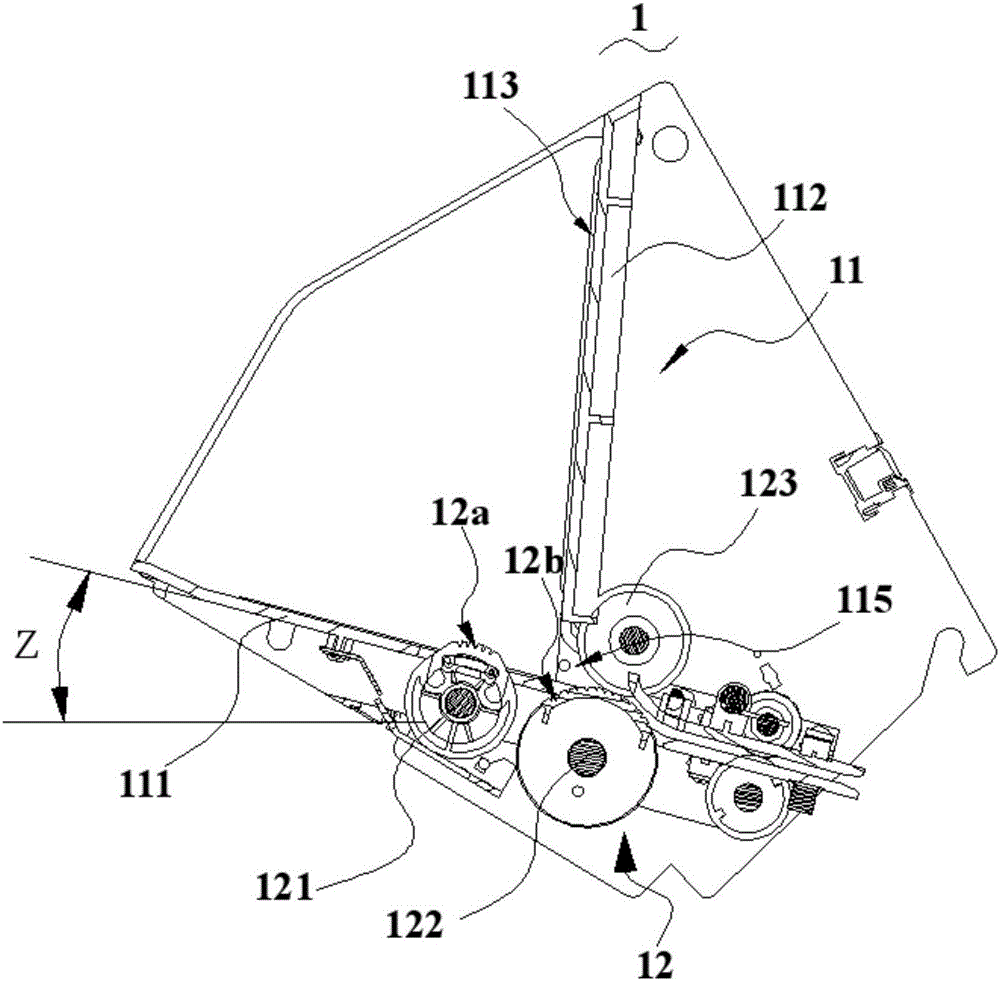

Cash recycling system

PendingCN106384460AAchieve continuityImprove deposit efficiencyComplete banking machinesATM accessoriesPhase detectorEngineering

The invention relates to the technical field of ATM equipment, and provides a cash recycling system. The cash recycling system comprises a cash saving device, a cash taking device, a channel assembly, a cash detector, a cash box assembly and a control system, wherein the cash box assembly communicates to the channel assembly; the channel assembly comprises a first channel and a second channel; the cash saving device communicates to the first channel; and the cash taking device communicates to the second channel. The cash recycling system provided by the invention is provided with the cash saving device special for saving cashes and the cash taking device special for taking the cashes; in a cash saving process, the cashes pass through the first channel and are subjected to real and counterfeit detection one by one through the cash detector at the cash saving device; if the cashes are real, the cashes are directly conveyed into the cash box assembly; and if the cashes are defective cashes, the cashes are directly conveyed to the cash taking device. Therefore, saving of the real cashes and withdrawing of the defective cashes can be executed separately, the cash saving process is more continuous, the cash saving efficiency is greatly improved, and the waiting time is shortened.

Owner:SHENZHEN YIHUA COMP +2

Open arc overlaying wire material with strong abrasive resistance for grinding roller and grinding disk

InactiveCN101658980AReduce splashFine particleWelding/cutting media/materialsSoldering mediaTitanium nitrideNanometre

The present invention provides an open arc overlaying wire material with strong abrasive resistance for a grinding roller and a grinding disk, which consists of a steel sheet and powder arranged in the steel sheet. A nano additive (A) is added into the powder, wherein the nano additive (A) can be one or any combination of three of nano TiN (titanium nitride), nano SiN (silicon nitride) and nano SiC (silicon carbide). The powder contains 3 to 5 weight percent of the nano additive (A). The nano additive (A) has the functions of strengthening dispersion of nano ceramic phases, improves cohesion strength, rupture strength and combination strength of a cladding layer material and has good high-temperature stability; and the nano additive (A) improves self lubricity of the material, improves theabrasive resistance of cladding layer metals and prolongs service life of the grinding roller and the grinding disk processed by overlaying. The service life of the grinding roller and the grinding disk processed by the overlaying is improved by 1.5 to 2 times than that processed by open arc overlaying; and the cladding efficiency is improved by 10 to 20 percent so as to save the overlaying wirematerial. The open arc overlaying wire material has light fume and less molten metal spatter in the process of overlaying, and a weld pass is smooth after the material is molded.

Owner:JIANGXI HENGDA HI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com