Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Quasicrystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

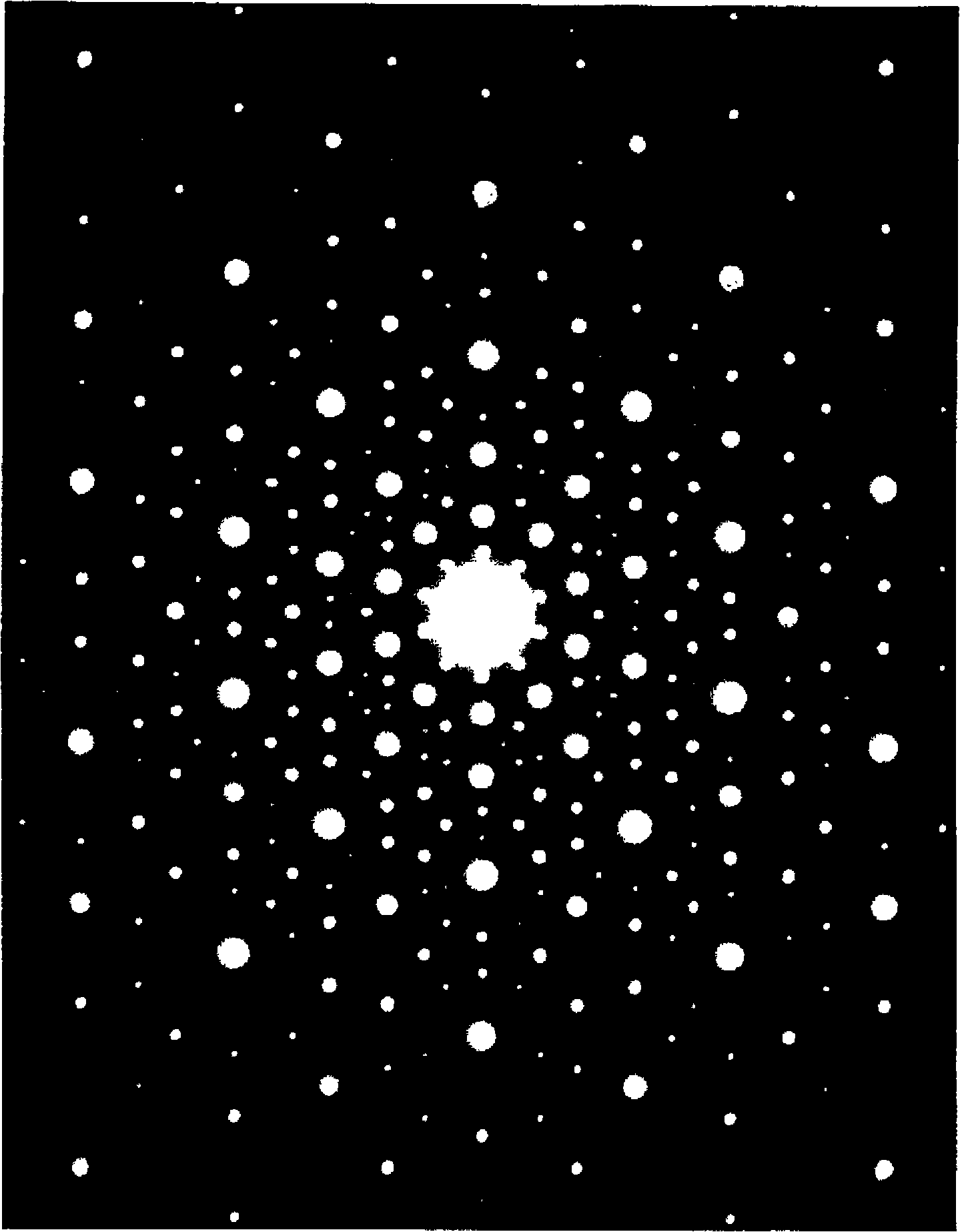

A quasiperiodic crystal, or quasicrystal, is a structure that is ordered but not periodic. A quasicrystalline pattern can continuously fill all available space, but it lacks translational symmetry. While crystals, according to the classical crystallographic restriction theorem, can possess only two-, three-, four-, and six-fold rotational symmetries, the Bragg diffraction pattern of quasicrystals shows sharp peaks with other symmetry orders — for instance, five-fold.

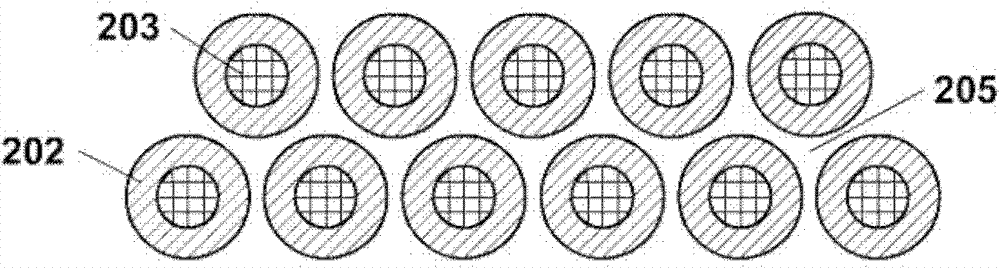

Light emitting diode structures

ActiveUS20060062540A1Improve isotropyImprove extraction efficiencySolid-state devicesNanoopticsRefractive indexPhotonics

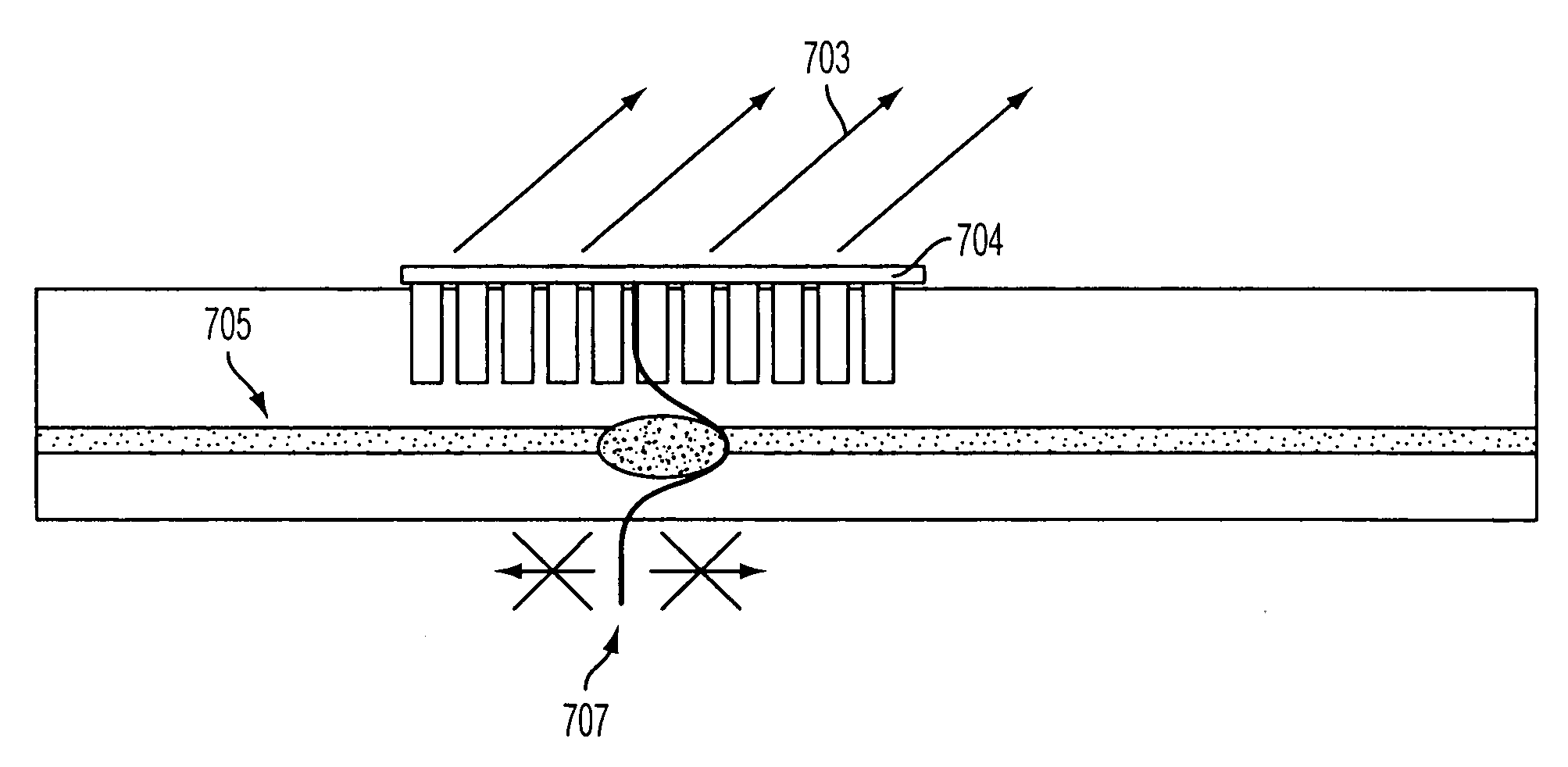

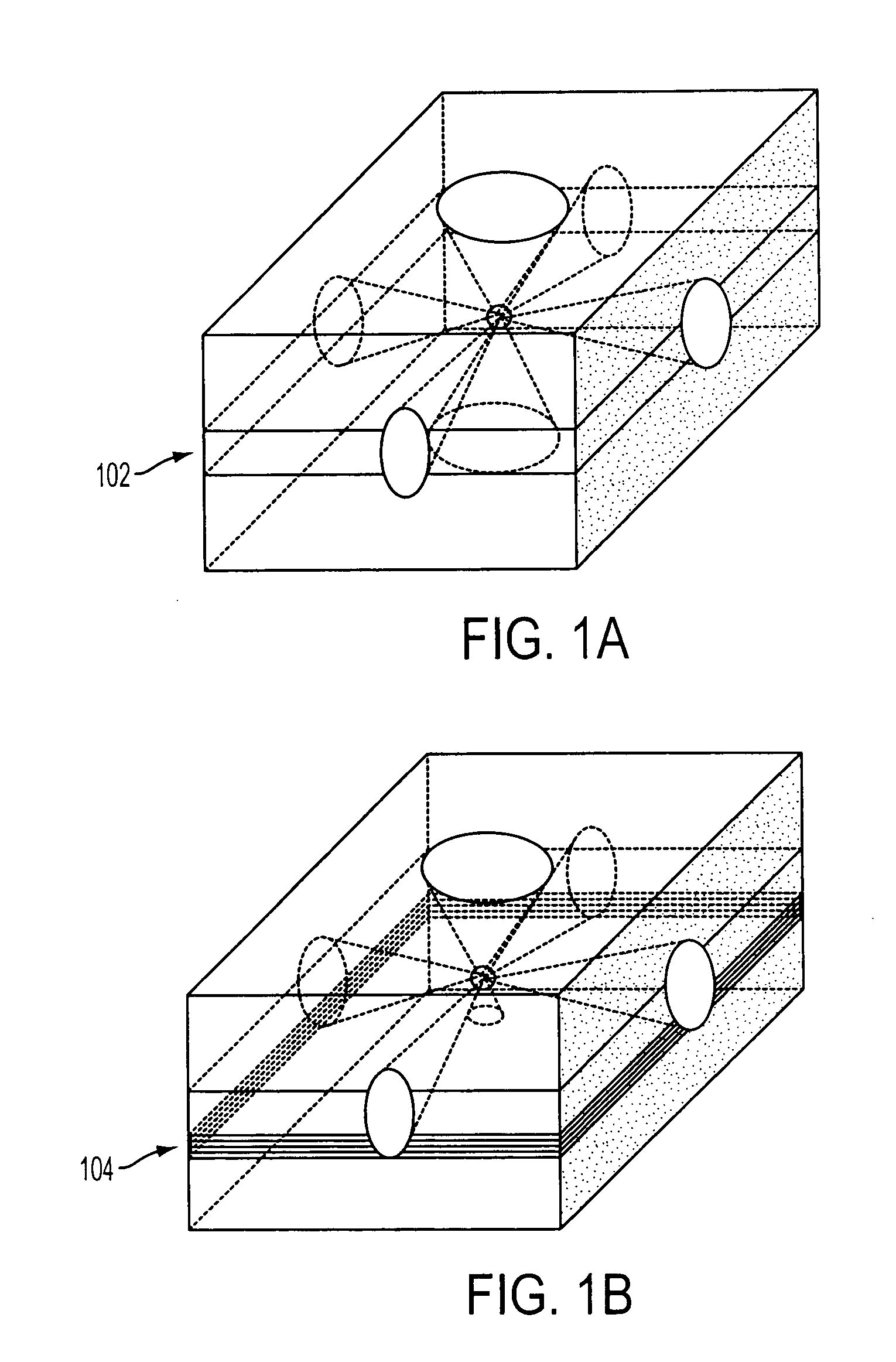

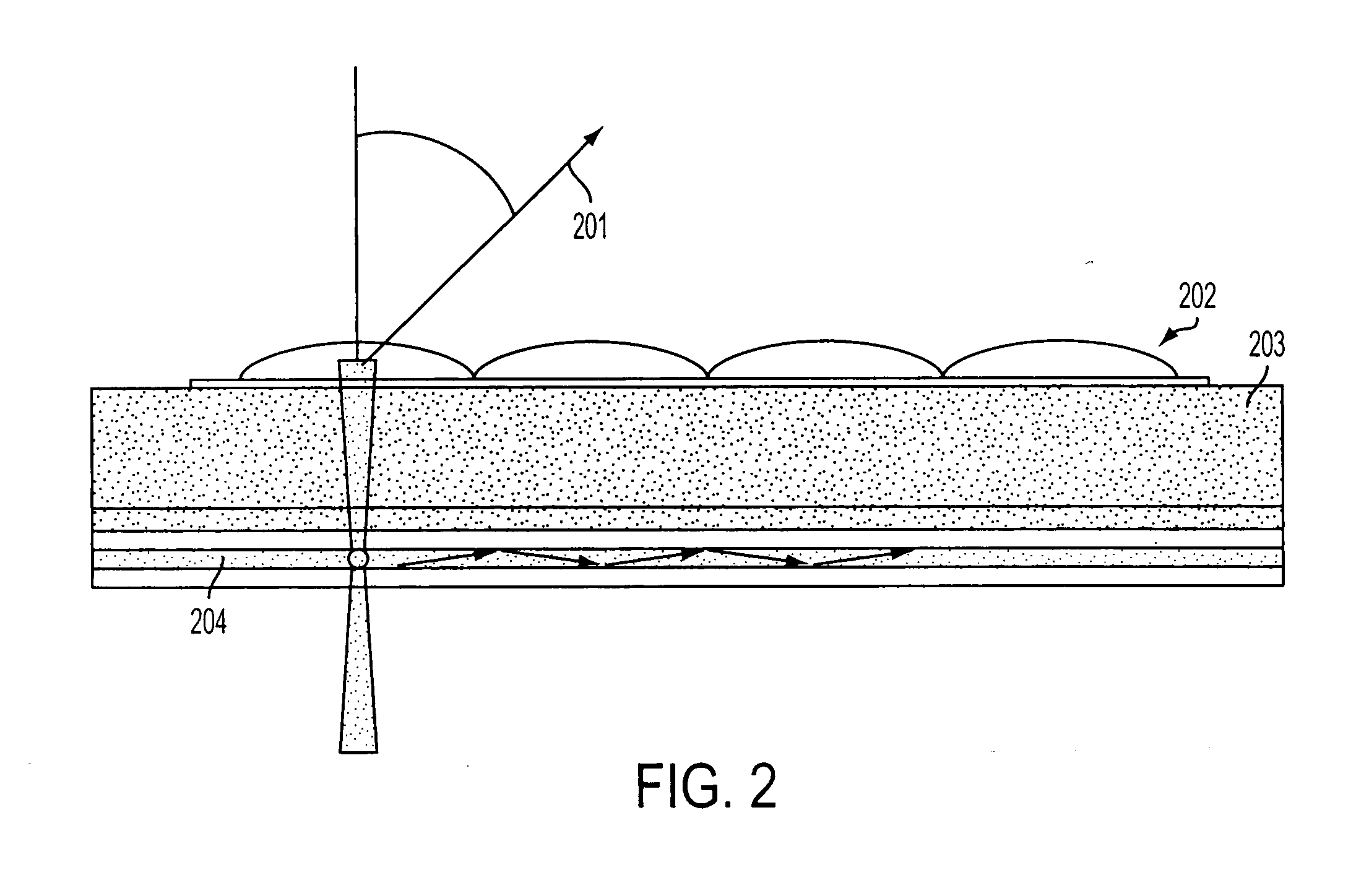

According to one aspect of the present invention, a light emitting diode (LED) structure including an active core layer and at least one substrate layer having a first refractive index, comprises a 2-dimensional photonic quasicrystal in the structure, the photonic quasicrystal comprising an array of regions having a second refractive index, the array exhibiting long range order but short range disorder. The long range order is associated with diffractive properties of the structure and gives rise to uniform-far field diffraction patterns from the LED. The present invention enjoys the benefit of improved light extraction from LEDs without undesirable far field illumination patterns.

Owner:QUANTUM NIL LTD +1

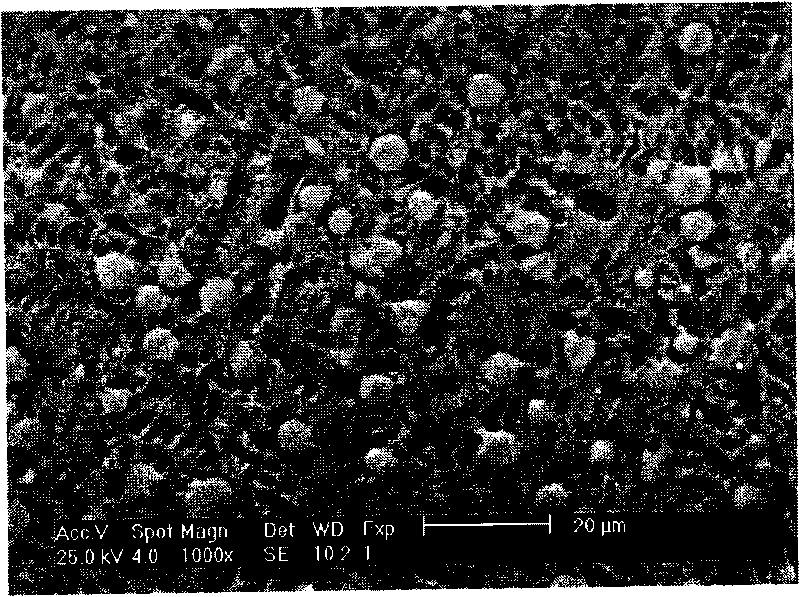

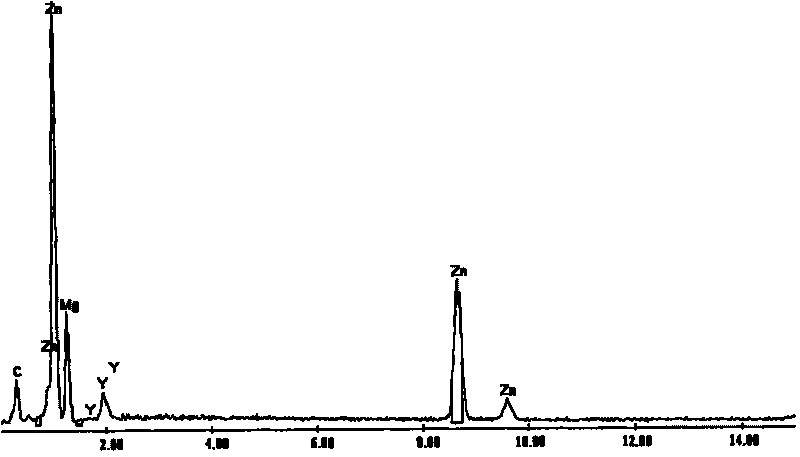

Authigenic quasicrystal reinforced high plastic deformation magnesium alloy

The high molding distortion magnesium alloy with the autogeny allowing the crystal wnganced belongs to the metal technical domain. The invention team and the weight percent: 2-10% Zn, 0.5-6%Gd, 0-1.0%Zr, the impurity element Fe is below 0.005%, the rest is Mg. the invention alloy contains the allowing crystal phase, it is formed into the casting group as the formation of the branch crystal, the allowing crystal phase crushed to distribute along the distorting direction through the extrusion or the rolling hot distorting technology, at the same time, the dispersion distributing twice allowing crystal phase is separated out on the inner group body and the edge of the crystal during the extrusion and the rolling to improve the capability of the alloy. The allowing crystal and the group body has the good interface connecting function, it can harmonize distortion and delay the stress concentrate. So the mold distortional capability of the magnesium alloy can be improved highly. It can be used to produce the magnesium alloy distortional material with the higher distortional capability to resisting the extrusion, the rolling and the pressing. The alloy has the upper model ability and matched with the middling intensity; the resisting intension under the room temperature: 260MPa-320MPa; the extending percent: 20%-26%.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

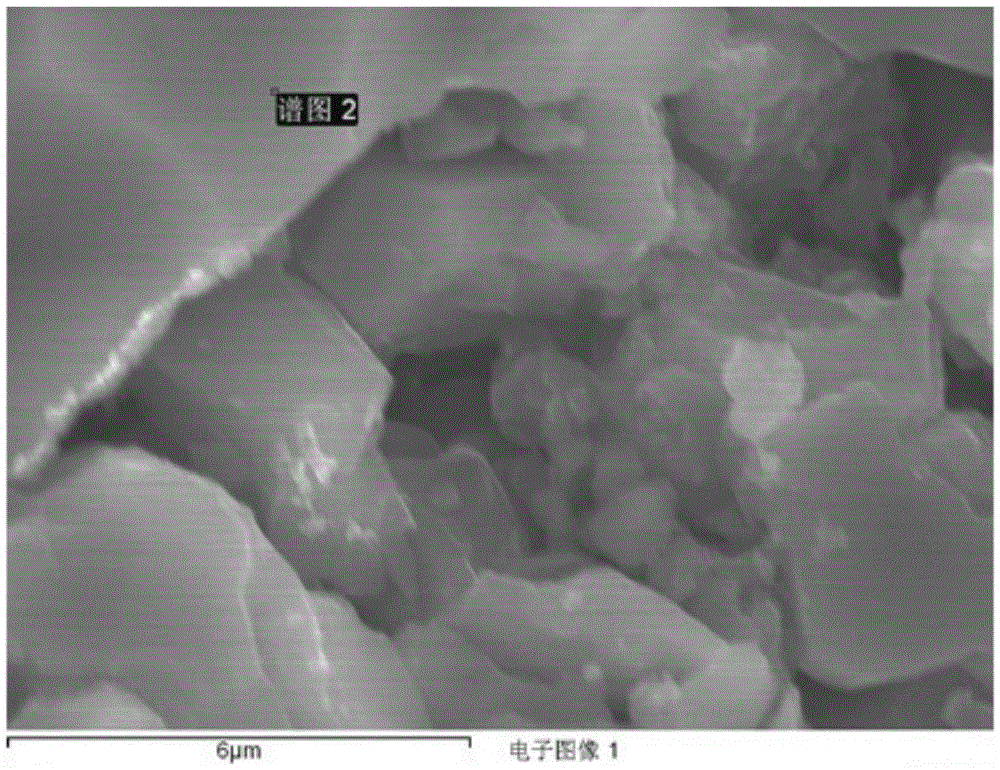

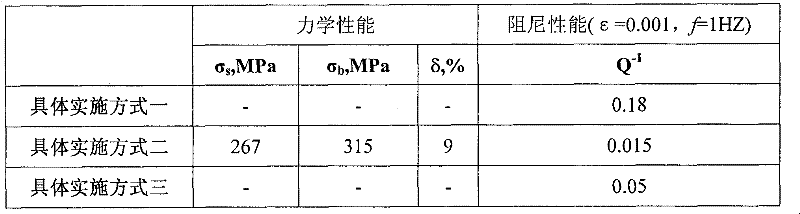

High-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and manufacturing method thereof

InactiveCN101805864ASolve the mechanical propertiesImprove mechanical propertiesQuasicrystalDislocation

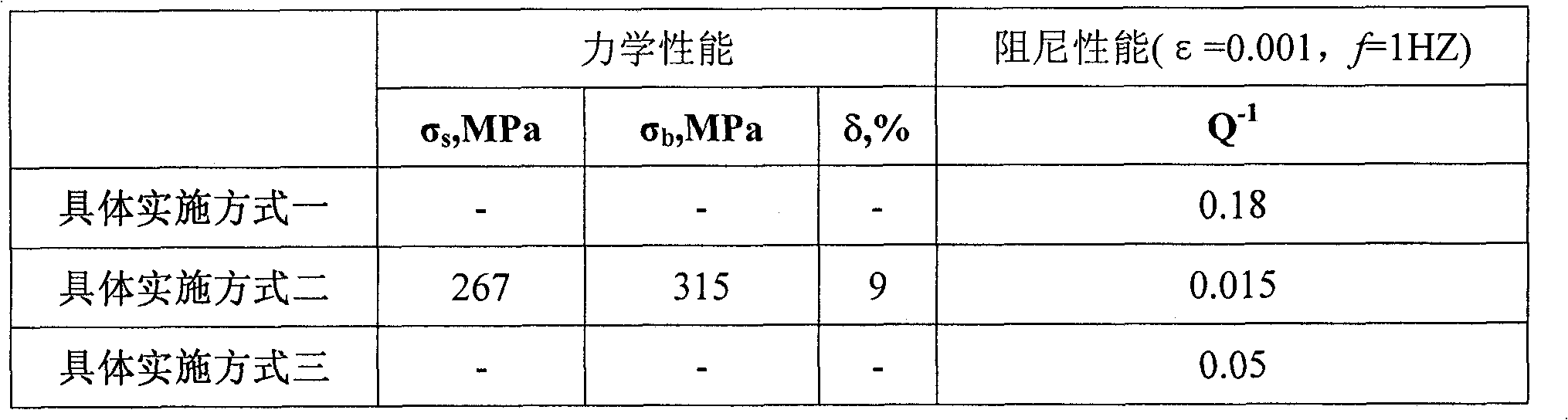

The invention relates to high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and a manufacturing method thereof. The high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy is characterized by comprising the following alloying element components distributed in the alloy and the content value thereof in percent by weight: 1.0%-4.0% of Cu, 0.3%-1.5% of Mn, 0.3%-4.0% of Y, 1.0%-5.5% of Zn and the balance of magnesium. In order to solve the conflict of the damping property and the mechanical property of the magnesium alloy, the invention puts forward the fact that a Zn element and a Y element are added in the high-damping Mg-Cu-Mn alloy so that the Mg, the Zn and the Y form quasicrystals and / or long-prepared phases in the alloy, the quasicrystals or the long-prepared phases can introduce a great amount of new movable dislocations in a magnesium matrix, the damping property of the magnesium alloy is improved through movable dislocations newly increased in the magnesium matrix, and then the conventional heat extrusion is carried out on the alloy so that the mechanical property of the alloy is improved. The invention has the advantages of simple process, strong transportability, easy operation and lower cost and solves the problem that the Mg alloy has limited application due to high damping property and low mechanical property, and the used equipment is conventional and general equipment.

Owner:CHONGQING UNIV

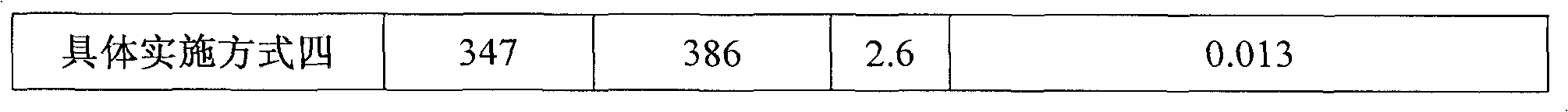

Squeeze casting method for mixed-particle-reinforced type aluminum matrix composite

The invention relates to a squeeze casting method for a mixed-particle-reinforced type aluminum matrix composite. The squeeze casting method for the mixed-particle-reinforced type aluminum matrix composite aims at the problem that the tension strength and the hardness of an aluminum matrix composite are low. According to the squeeze casting method, an aluminum alloy serves as a matrix material, aluminum-copper-iron-beryllium quasicrystal and zirconium carbonate serve as reinforcing agents, an al-sc master alloy serves as a modificator, the aluminum alloy, aluminum-copper-iron-beryllium quasicrystal, the zirconium carbonate and the al-sc master alloy are subjected to melting in a vacuum melting furnace, mechanical stirring, argon bottom blowing protecting, squeezing and heat treatment, and then the mixed-particle-reinforced type aluminum matrix composite is prepared. According to the squeeze casting method, the technology is advanced, the processes are rigorous, and data are precise, full and accurate; the mechanical performance of the aluminum matrix composite is enhanced greatly, the tension strength reaches to 409 MPa, the hardness reaches to 150.2 HV, and the elongation reaches to 4.7%; and the squeeze casting method for the mixed-particle-reinforced type aluminum matrix composite is an advanced method.

Owner:WENXI COUNTY REGAL MAGNESIUM

Preparation method of quasicrystal reinforced fast hardening high strength deformation magnesium alloy

A quasi-crystal reinforced high-strength deformable Mg-alloy is a thin Mg-Zn-RE-Zr band quickly solidified by 2D sheet flows. Its preparing process features that the percentage of quasi-crystal phase is controlled by controlling the thickness of thin band and the dispersity of molten body in two fast solidifying stages, and the size of quasi-crystal phase can be controlled by controlling the parameters in squeezer procedure. Its advantages are high strength (500MPa) and extensibility (10%) and low density.

Owner:XIAN UNIV OF TECH

Degradable Mg-Zn-Y-Ca intravascular stent material and preparation method thereof

The invention relates to a degradable Mg-Zn-Y-Ca intravascular stent material and a preparation method thereof, which belong to the fields of design and manufacture of metal materials. The intravascular stent material is characterized by comprising the following chemical components in percentage by weight (wt%): Zn 1.00 to 4.00, Y 0.10 to 1.00, Ca 0.01 to 0.50 and the balance of Mg; the chemical components are subjected to sub-rapid solidification at (200+ / -10) K / S and heat treatment of heating at 320 to 420 DEG C and heat preservation for 20 to 30h; and the texture characteristic of the intravascular stent material is that: even and fine spherical quasicrystalline phases Mg3YZn6 are dispersed and distributed on an alpha-Mg matrix. The potential difference between the spherical quasicrystalline phases Mg3YZn6 and magnesium is lower so that the formation of a galvanic cell is restrained and galvanic corrosion is alleviated; the sphericity quasicrystal Mg3YZn6 has good corrosion resistance and can obviously enhance the corrosion resistant performance of magnesium alloy; and at the same time, the quasicrystal also has the characteristics of high hardness, low friction coefficient, low interface energy and the like and can greatly enhance the mechanical performance of the magnesium alloy.

Owner:TAIYUAN UNIV OF TECH

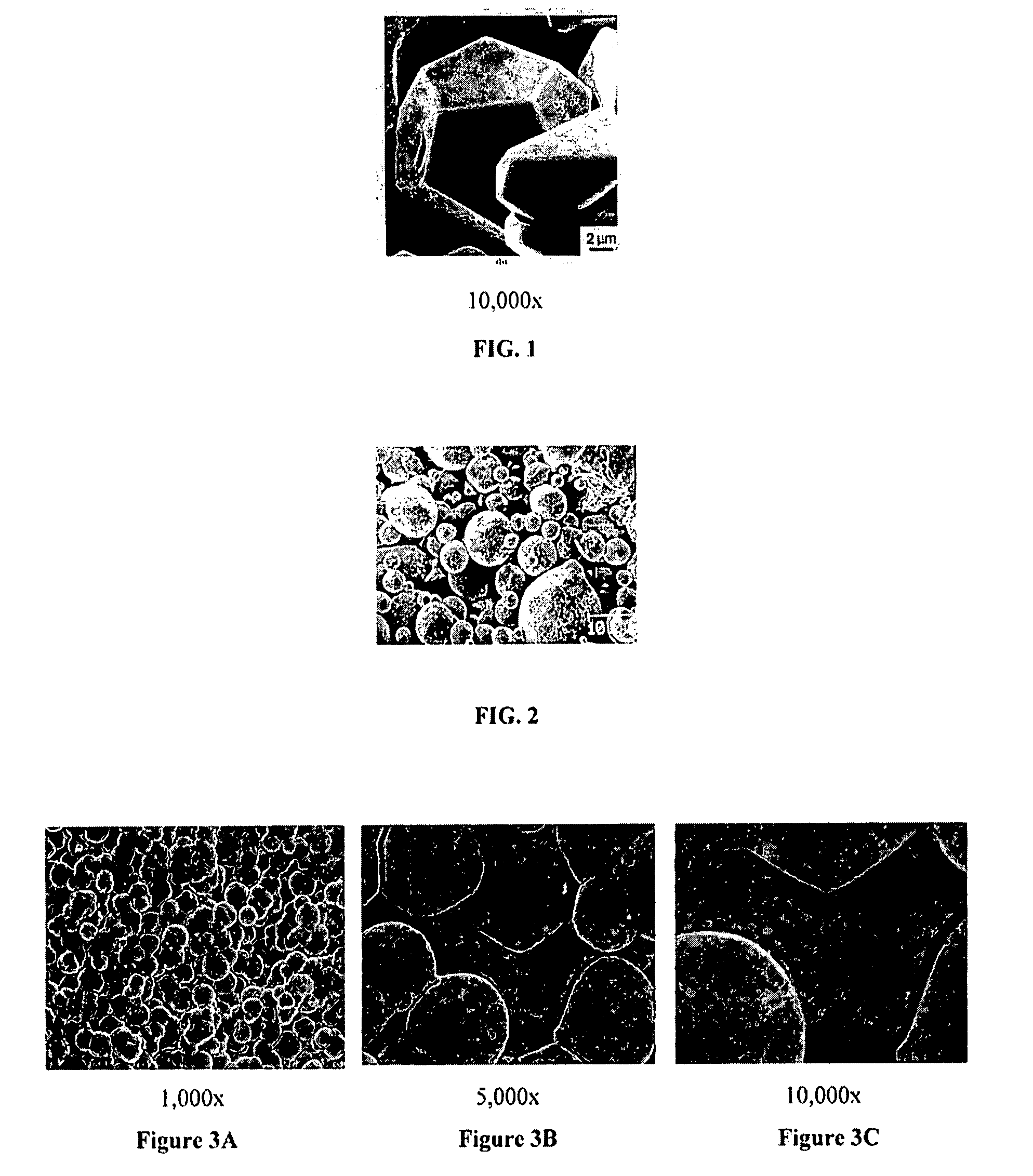

Compositions and coatings including quasicrystals

Composite coating compositions, composite metallic coatings derived from these compositions, and methods of forming the composite coating compositions and composite metallic coatings, wherein the compositions and coatings comprise particles of at least one quasicrystalline metal alloy and at least one elemental metal. The methods include electrocodepositing suspended quasicrystalline metal alloy particles and dissolved metal ions onto a substrate. Preferably, the substrate is disposed in an aqueous bath containing at least one dissolved metal ion species and at least one suspended quasicrystalline metal alloy powder species. The compositions and coatings enhance the wear, friction, hardness, corrosion, and non-stick characteristics of the substrate.

Owner:LYNNTECH

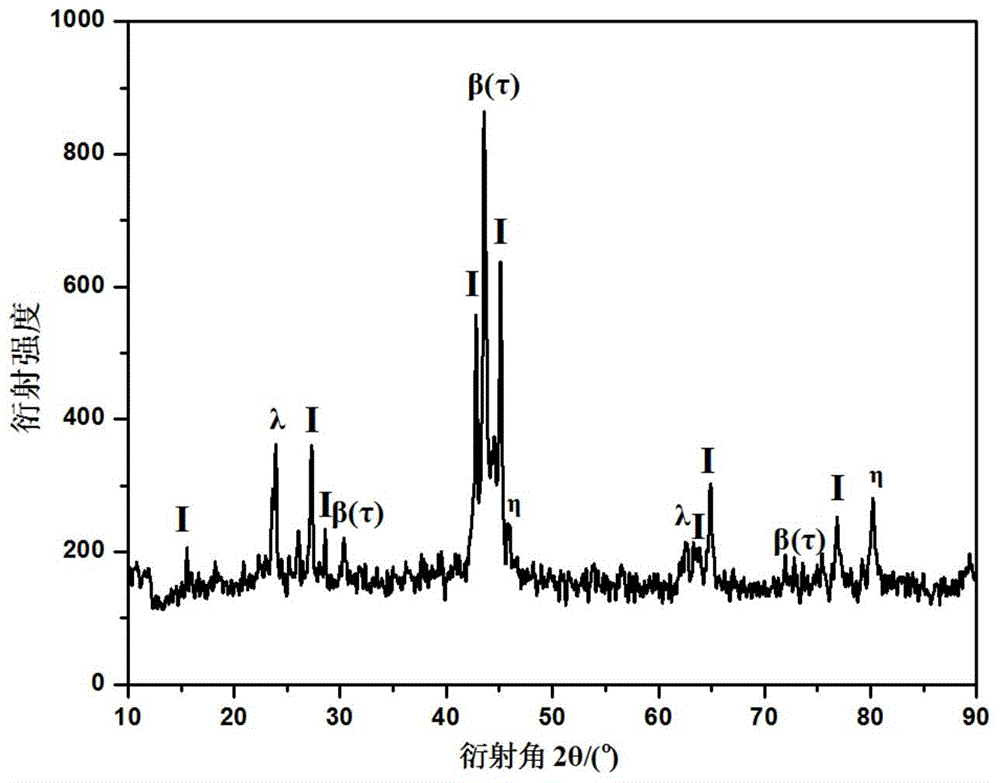

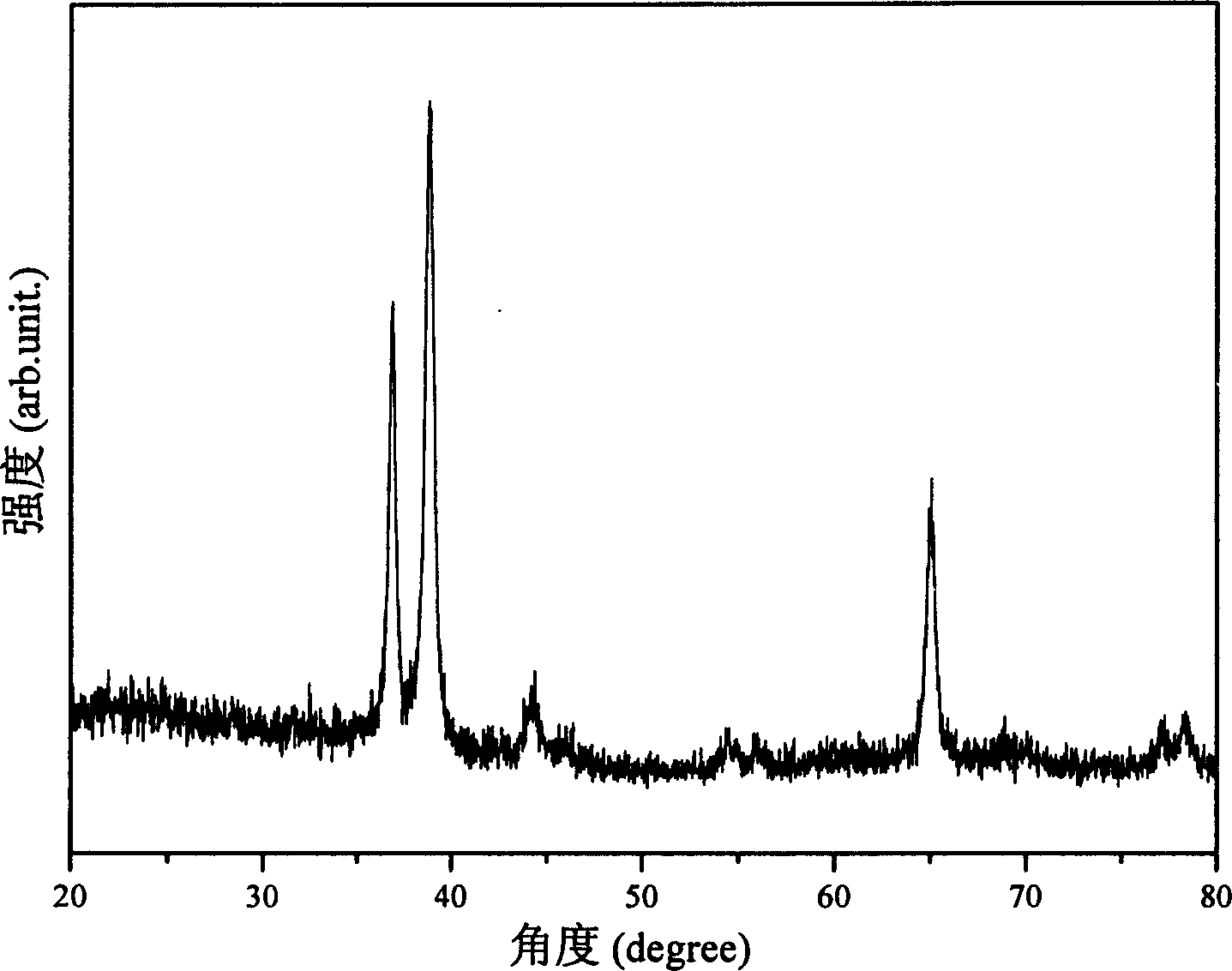

Preparation method of aluminum, copper and iron quasicrystal

The invention relates to a preparation method of an aluminum, copper and iron quasicrystal. In order to solve the problem that process defects exist as the preparation method of the aluminum, copper and iron quasicrystal is difficult, the preparation method comprises the following steps: smelting and casting, quickly cooling, thermally treating and annealing and quenching to prepare an aluminum, copper and iron quasicrystal block material by adopting a medium-frequency induction smelting furnace casting method. The preparation method of the aluminum, copper and iron quasicrystal disclosed by the invention is advanced in process, accurate and full in data; the I phase of the quasicrystal is Al61.92Cu26.21Fe11.87, the product purity is high, the I phase content of the quasicrystal is 98%, the mechanical performances are stable, the hardness is 796HV, and therefore, the preparation method can be applied to various industrial fields and is a very ideal preparation method of the aluminum, copper and iron quasicrystal.

Owner:ZHONGBEI UNIV

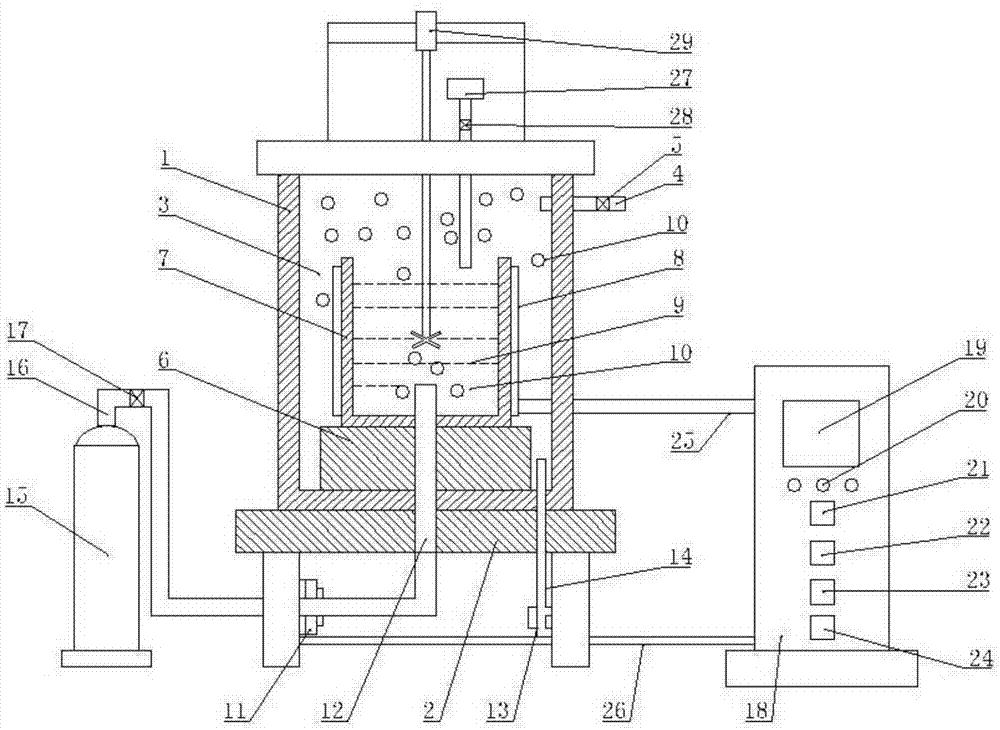

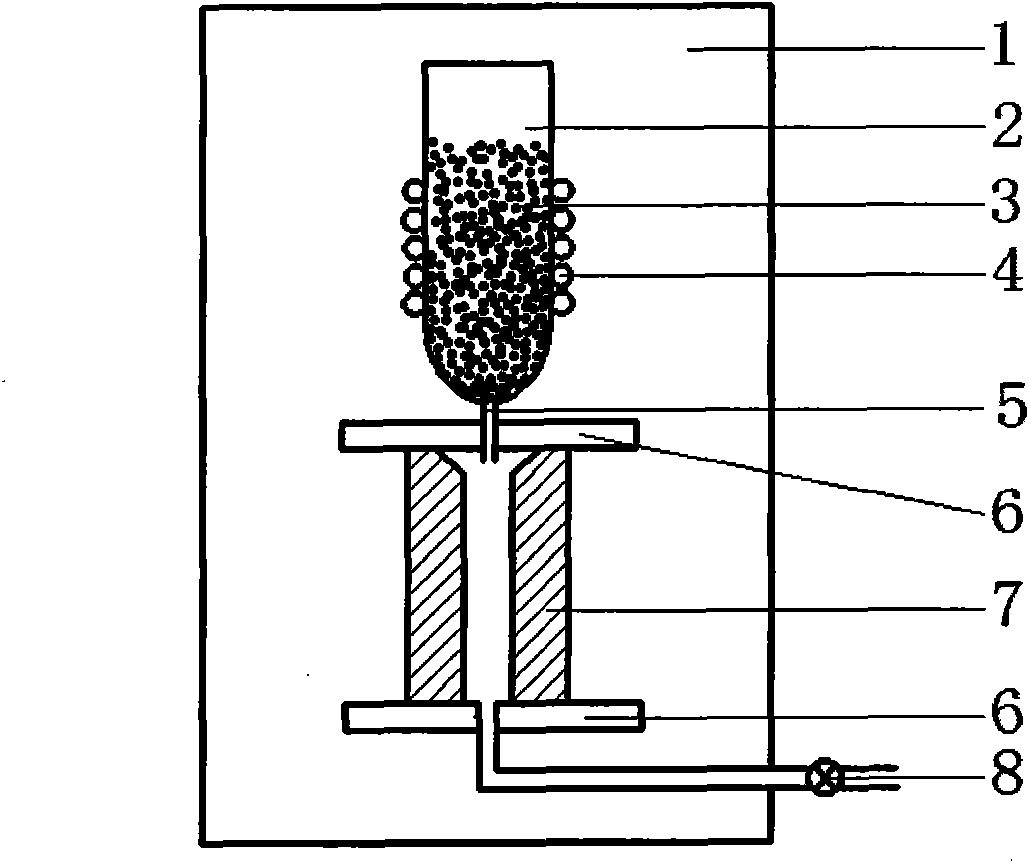

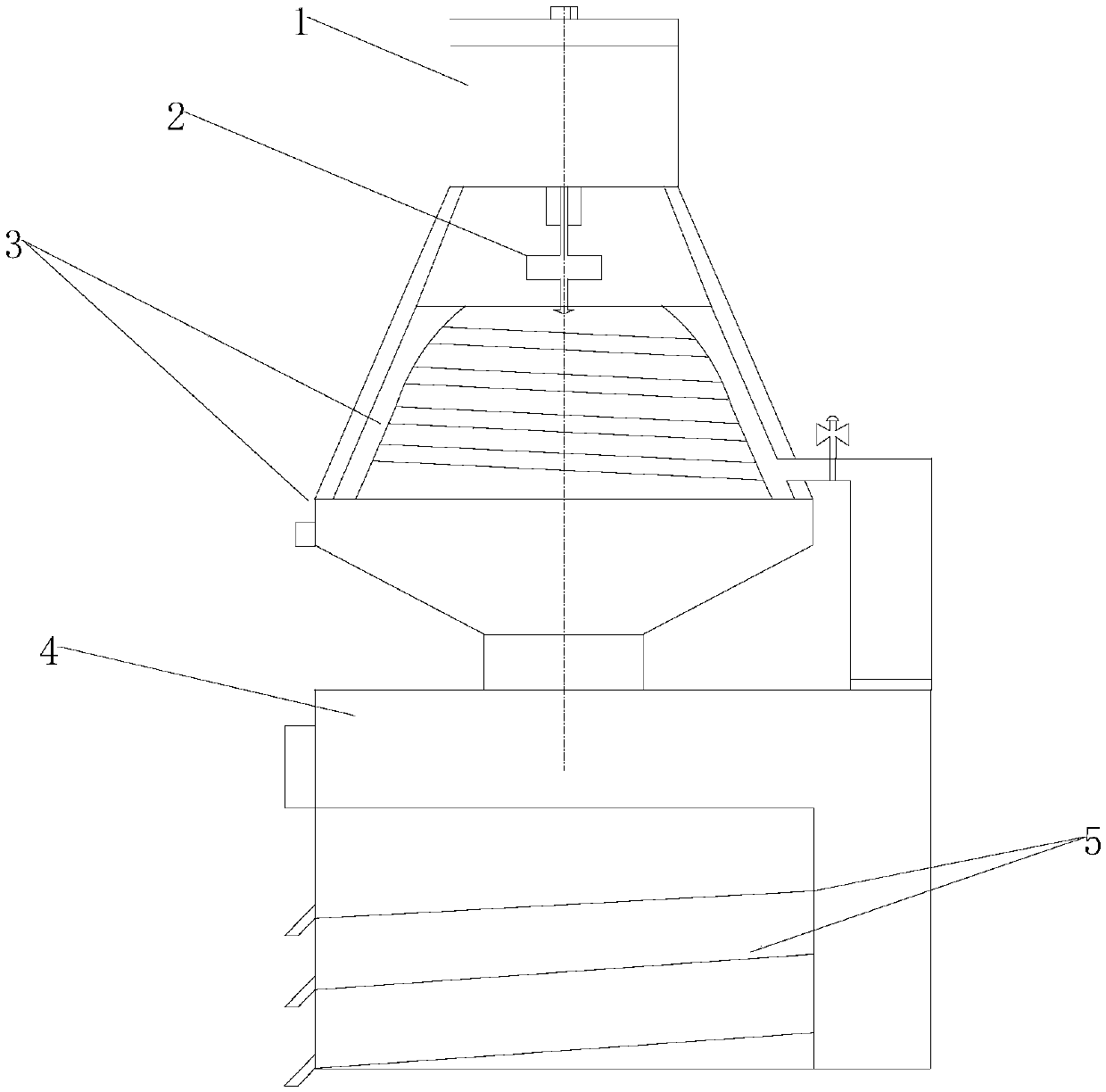

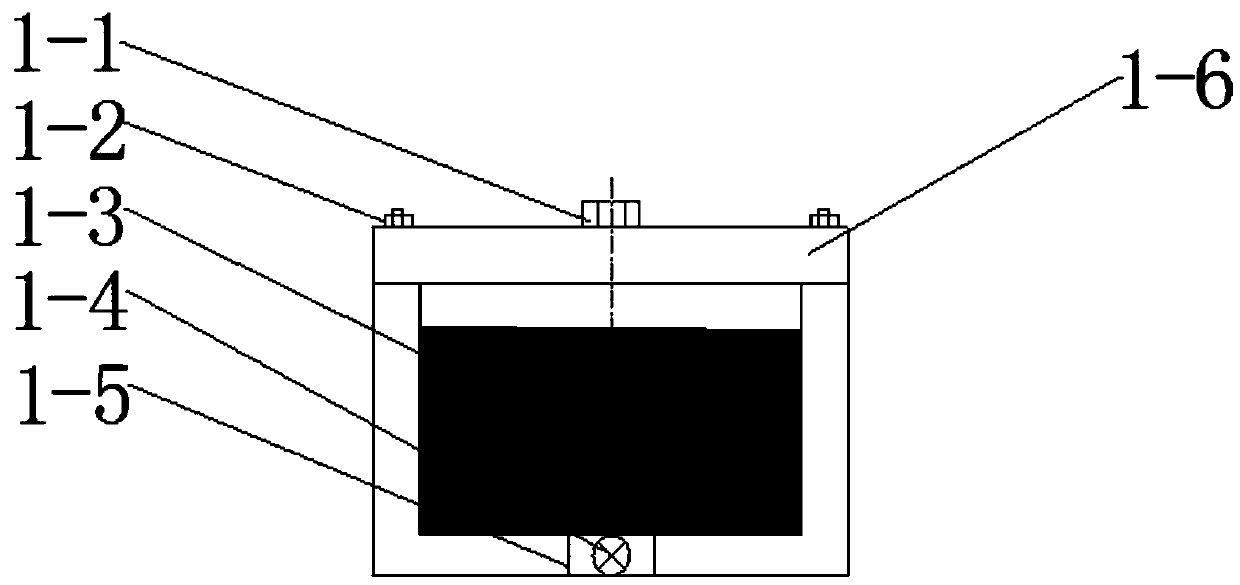

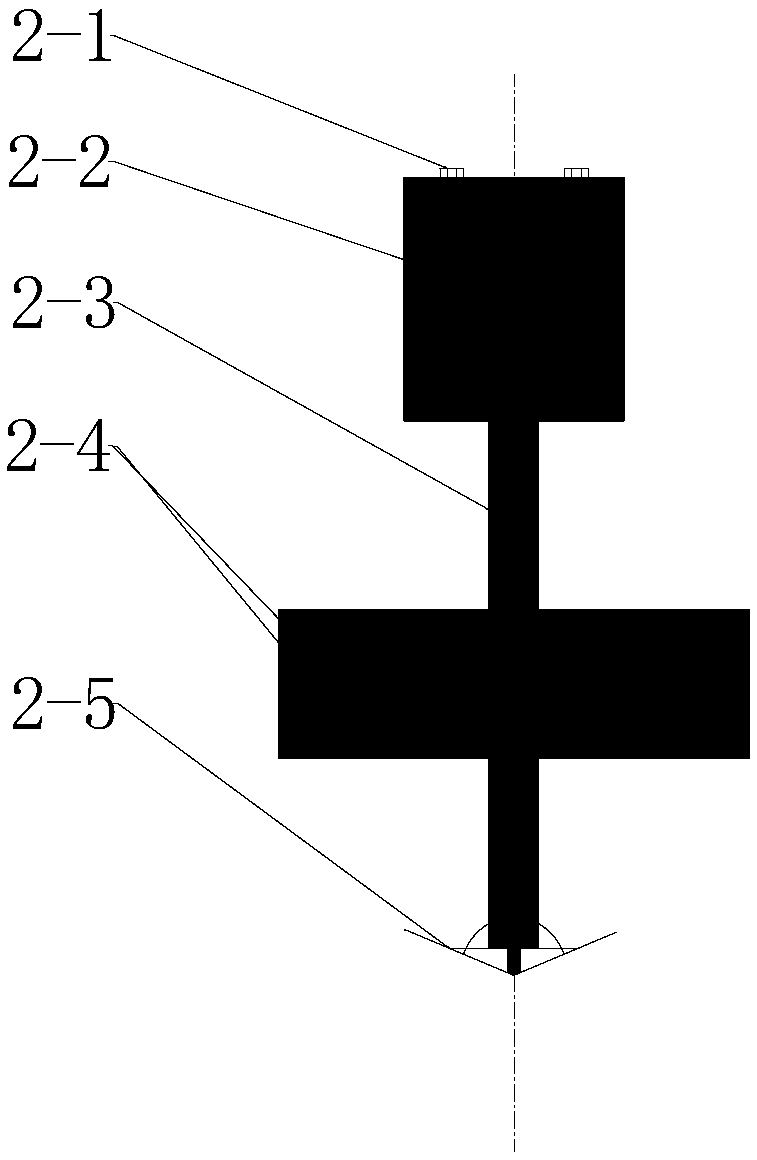

Device for preparing metal amorphous powder through ultrasonic atomization recooling method

The invention relates to an amorphous powder ultrasonic atomization device, in particular to novel ultrasonic atomization metal amorphous powder preparing equipment integrating fusion, ultrasonic atomization, a liquid nitrogen and water secondary recooling system, vacuum drying and discharging screening and collecting. A vacuum fusion crucible is used for fusing raw materials into metal fusion liquid. The metal fusion liquid becomes atomized globular liquid drops under the effect of an ultrasonic atomizer. The metal liquid drops are quickly cooled through liquid nitrogen and cooling water to form metal particles. The metal particles are dried through a vacuum drying oven. The dried metal particles are screened and collected. The amorphous powder preparing method is suitable for metal, quasicrystals and microcrystals.

Owner:CHANGZHOU UNIV

Regular icosahedron titanium-base quasi-crystal material with hydrogen-storage function and its preparing method

InactiveCN1709564AStrong ability to form quasicrystalsEasy to operateOther chemical processesHigh energyTitanium

The invention provides a kind of single icosahedron quasicrystal material with hydrogen storing function. Its component is Ti100-x-y-zZrxNiyCuz, thereinto, 10 < x < 45, 5 < y < 20, 1 < z < 10. the forming ability of the alloy quasicrystal is strong, and the formed quasicrystal material is single icosahedron structure. It is thermodynamics is stable, and has good hydrogen storing function. It can be applied in gaseous state hydrogen storing material and battery cathode material; meantime, it provides a kind of producing method of the material: according to the count of the component formula of the quasicrystal material, choose powders of Ti, Zr, Ni, and Cu of 100 holes per cm2 chemical purity, encase them in the ball milling pot of the high energy ball mill, the ball material rate is 20 : 1, ball mill for 100 - 200 hours under the protection of argon, seal the ball milled alloy powders in the quartz tube, have heat processing at 1 í‡ 10-3 Pa, the heat processing temperature is 480 - 650 Deg. C, the time is 0.5 - 6 hours. Its craft is simple, the operational ability is strong, and it is easy to be industrialized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Quasicrystal-strengthened Mg-6Zn-3Y alloy with ultrafine solidification texture and preparation method thereof

The invention discloses a quasicrystal-strengthened Mg-6Zn-3Y alloy with an ultrafine solidification texture and a preparation method thereof. The quasicrystal-strengthened Mg-6Zn-3Y alloy consists of the following chemical components in percentage by weight: 87.0 to 93.0 percent of Mg, 3.0 to 10.0 percent of Zn and 0.5 to 3.0 percent of Y. The Mg-6Zn-3Y alloy with the ultrafine solidification texture, which contains nanoscale granular quasicrystals, is prepared from normal-pressure as-cast Mg-Zn-Y alloy material under GPa-level ultrahigh pressure as solidification pressure, temperature and solidification cooling rate are controlled. The as-cast texture is characterized in that: the granular quasicrystals are evenly and dispersely distributed on the ultrafine Alpha-Mg matrix, wherein the secondary dendrite arm spacing between Alpha-Mg dendrites is 7Mu m to 10Mu m, the diameter of the granular quasicrystal is 50nm to 100nm, and the volume of the granular quasicrystals accounts for 25 to 35 percent of the total volume of the alloy. The invention adopts a cubic press, solidification process parameters are controlled, i.e., the solidification pressure is 6GPa, the solidification temperature is 1300DEG C, and the solidification rate is 300K / S. Theultrafin quasicrystal-strengthened Mg-6Zn-3Y alloy has high mechanical properties and good thermal stability.

Owner:东北大学秦皇岛分校

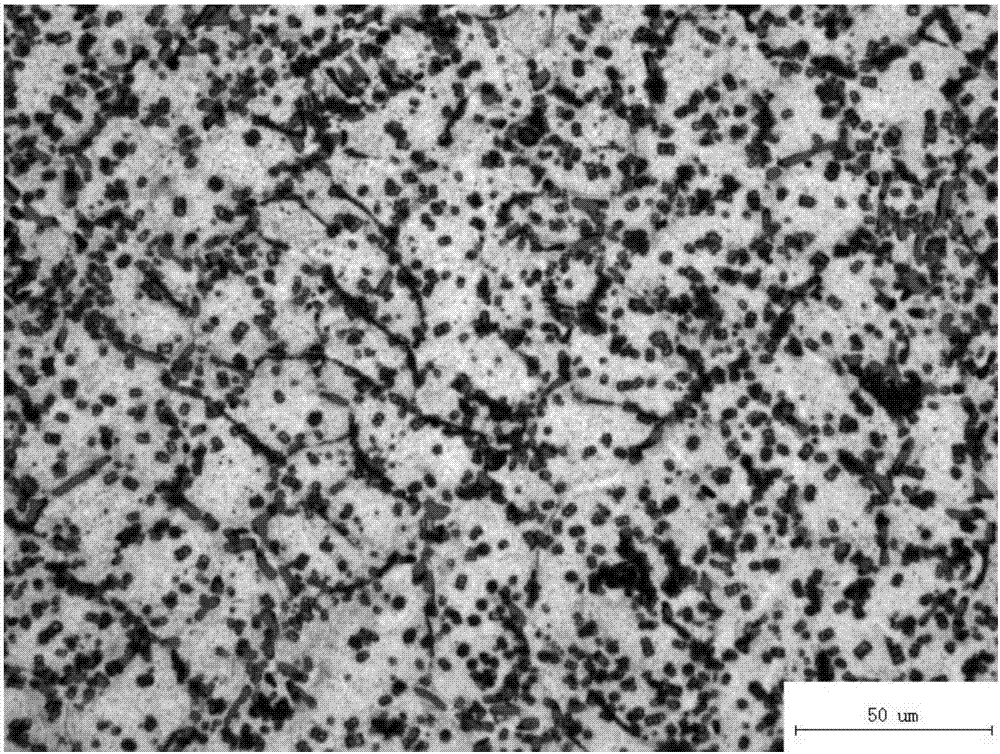

Magnesium base spherical quasicrystal master alloy and preparation method thereof

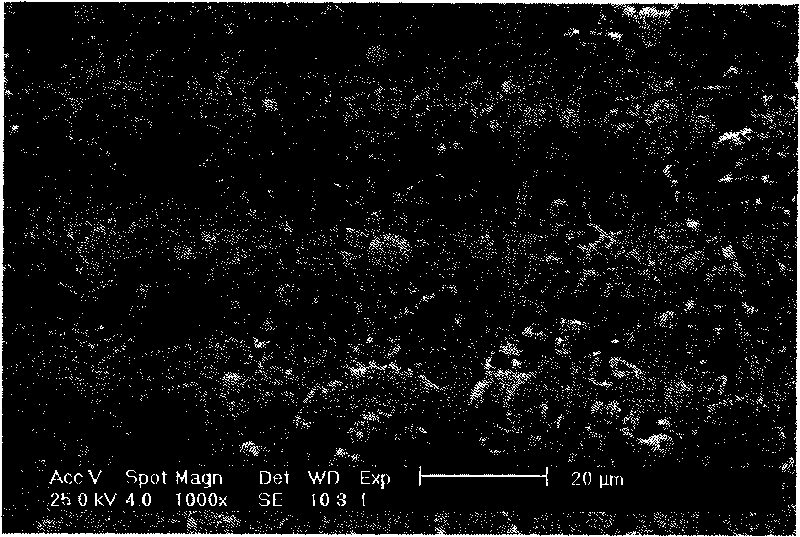

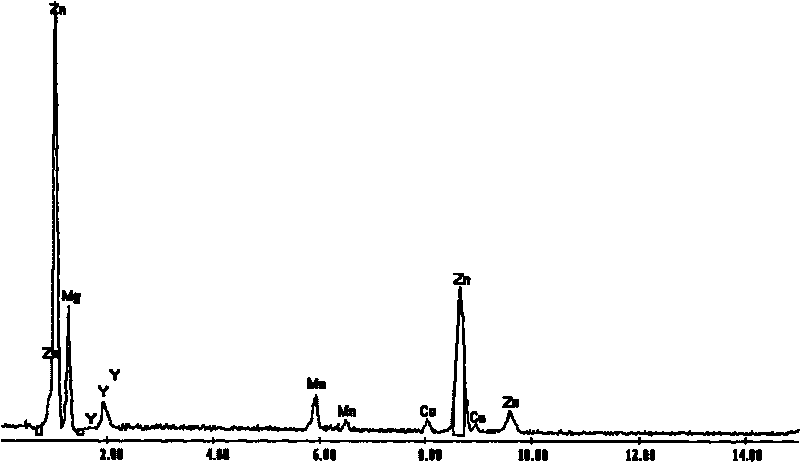

The invention provides a magnesium base spherical quasicrystal master alloy and a preparation method thereof, relating to magnesium base alloys with zinc as a submaster component. The alloy is Mg-Zn-Y-Mn-Cu quinary magnesium base icosahedral spherical quasicrystal master alloy, comprising the following chemical components: 55.0-65.0% of Mg, 30.0-40.0% of Zn, 2.5-5.5% of Y, 0.10-1.50% of Mn and 0.10-0.50% of Cu, wherein the diameter of the spherical quasicrystal is 2-7mu m and the mean diameter is 6mu m. The volume of the spherical quasicrystal is 35-45% of the total volume of the alloy. The preparation method is characterized by adopting control of the solidification rate, namely pouring the alloy melt into a casting mold capable of controlling the cooling rate, wherein the solidification rate is controlled between 72.2K / s and 88.6K / s. The product of the invention can better improve the mechanical property of the alloy materials while enhancing the magnesium alloy substrate, has simple process, low requirement on equipment and wide raw material sources, is convenient to realize industrialized production and saves resources.

Owner:HEBEI UNIV OF TECH

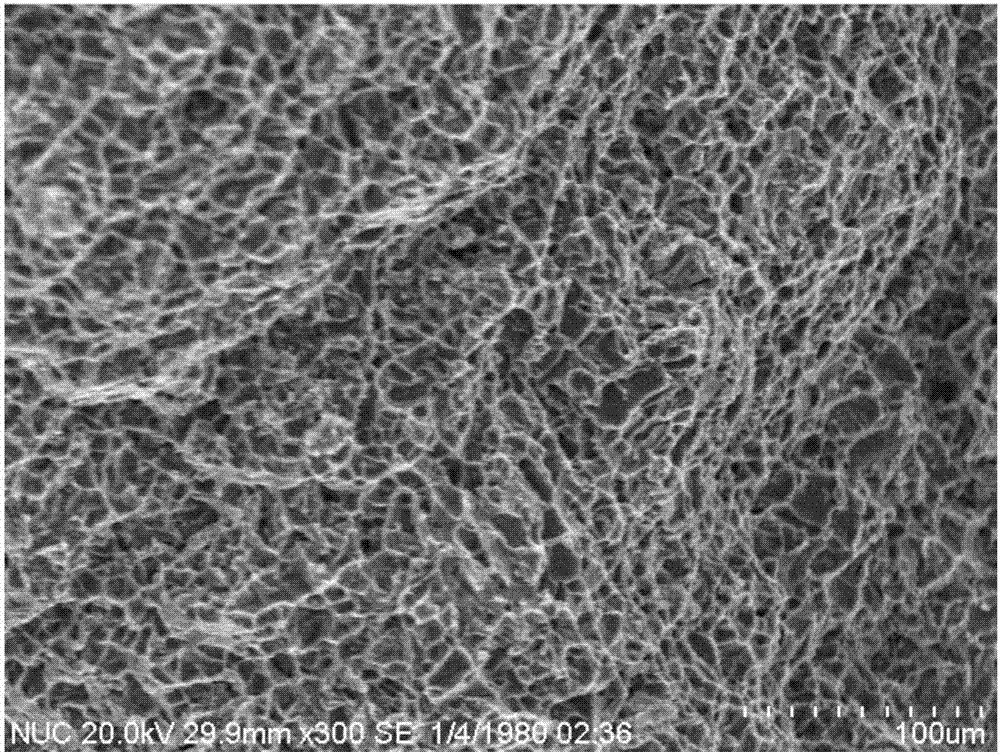

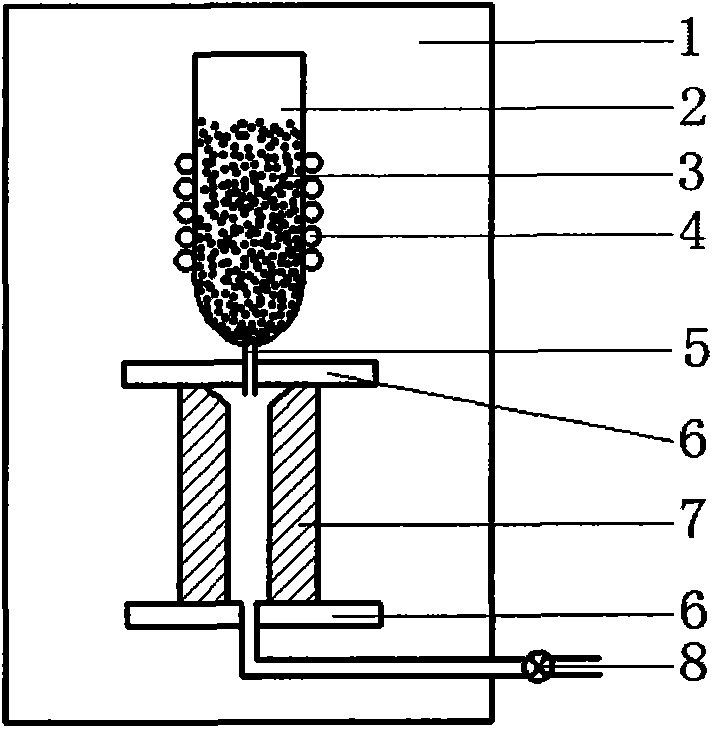

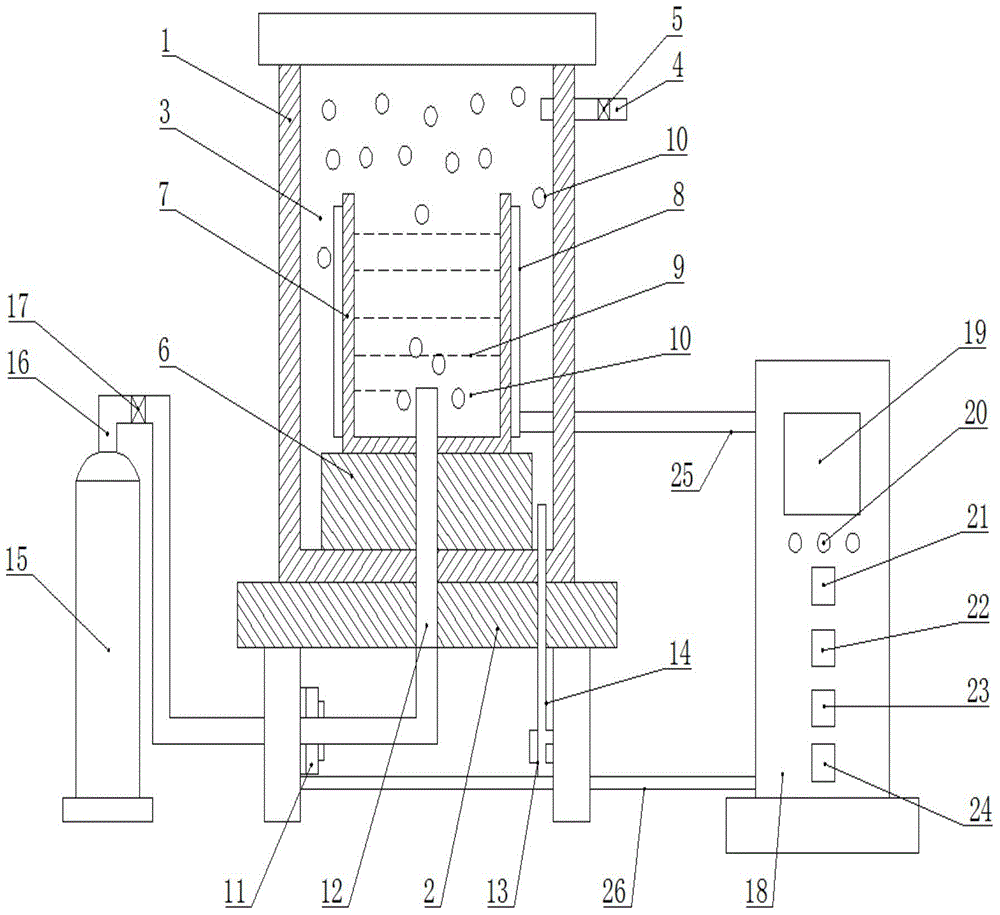

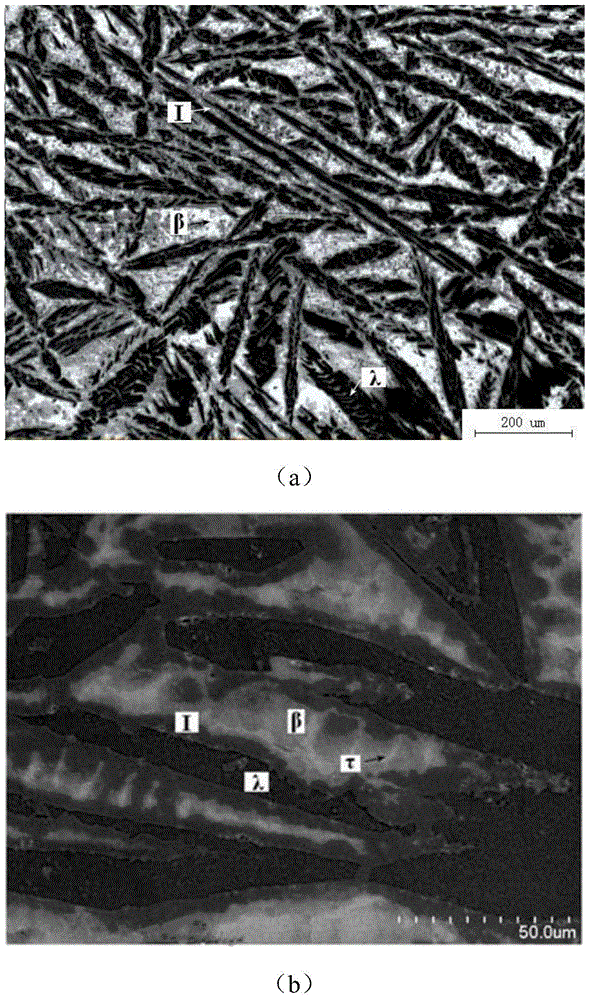

Method of semi-solid indirect squeeze casting for magnesium-based composite material

ActiveUS20200206808A1Improve mechanical propertiesAdvanced technologyMagnesium matrix compositeQuasicrystal

The present invention relates to a method of semi-solid indirect squeeze casting for Mg-based composite material, which aims at improving the mechanical property of the cast by adding magnesium zinc yttrium quasicrystal of high hardness, high elastic modulus and excellent matrix binding property acting as the reinforcement into the magnesium alloy matrix and manufacturing the cast through smelting using a vacuum atmosphere smelting furnace, agitating with ultrasonic wave assisted vibration in the rotating impeller jet agitation furnace and indirect squeeze casting against the problem of poor wettability, easy agglomeration, inhomogeneous distribution between the reinforcement particles and the matrix materials and poor properties of the manufactured cast. The manufacturing method of the present invention has advanced technologies and detailed and accurate data. The cast has excellent microstructure compactness, no shrinkage cavities and shrinkage defects and the primary phase in the metallographic structure consists of spherical and near-spherical crystalline grains, wherein dendritic crystalline grains almost disappear and the size of the crystalline grain is obviously refined. The tensile strength of the Mg-based composite material cast reaches to 225 Mpa, the elongation rate thereof reaches to 6.5% and the hardness thereof reaches to 86 HV. So the manufacturing method of the present invention is an advanced semi-solid indirect squeeze casting method for the Mg-based composite material.

Owner:ZHONGBEI UNIV

Method for preparing nano aluminum-copper-iron quasicrystal powder

The invention relates to a method for preparing nano aluminum-copper-iron quasicrystal powder. In the method, high heat released in an aluminum thermal reduction reaction is used for melting of reaction products and self-purification of high-temperature alloy melt, the separation of a target product from by-products are completed quickly according to the density difference between the products to obtain high-purity alloy melt, a rapid solidification technique is used to prepare a blocky nano aluminum-copper-iron quasicrystal material, and the blocky nano aluminum-copper-iron quasicrystal material is subjected to mechanical ball milling to obtain the quasicrystal powder. The nano aluminum-copper-iron quasicrystal powder prepared by the method has the advantages of high quasicrystal content, small crystallite dimension and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

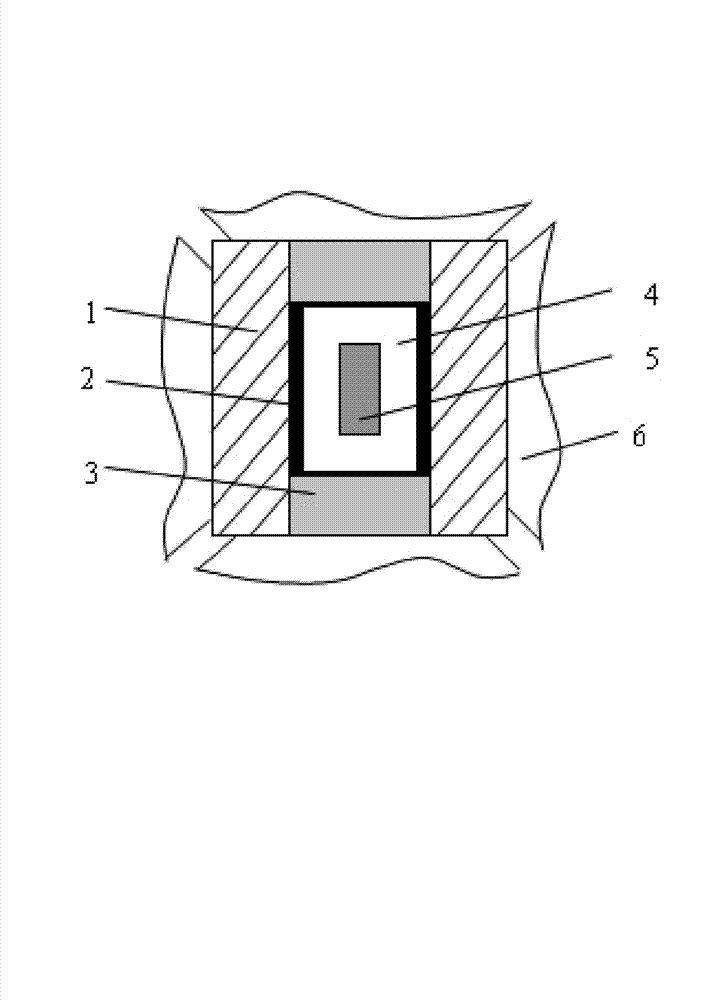

Photonic quasicrystal graph sapphire substrate and manufacturing method thereof and light emitting diode and preparation method thereof

InactiveCN102244170AImprove internal quantum efficiencyImprove light extraction efficiencySemiconductor devicesPhosphoric acidPhotonic crystal structure

The invention relates to a sapphire substrate and a manufacturing method thereof and a light emitting diode adopting the sapphire substrate and a preparation method thereof. The surface of the sapphire substrate is provided with a graph structure of a photonic quasicrystal structure. The proportion of the area of a C surface of the sapphire substrate, which is exposed in the graph structure, in the whole bottom area of the sapphire substrate is low. The surface of the sapphire substrate is provided with the graph structure of the photonic quasicrystal structure; the graph structure is formed in a mode that sub regions are periodically arrayed and has the lattice constant of 0.2 to 5mum; a space between each two adjacent sub regions is of a V shape or a similar V shape; the sub regions extend to the side wall of the C surface of the sapphire substrate and are at an angle of 25 to 60 degrees with the C surface of the sapphire substrate; and the proportion of the C surface of the sapphire substrate, which is exposed in the graph structure, is lower than 20 percent. The manufacturing method of the sapphire substrate comprises the following steps of: forming the photonic crystal structure on the surface of the sapphire substrate; and then carrying out anisotropic etching on the side wall of the photonic crystal structure by using a phosphoric acid / sulphuric acid mixed solution so as to form the photonic quasicrystal graph structure.

Owner:JIANGSU E LITE SEMICON

Compositions and coatings including quasicrystals

Composite coating compositions, composite metallic coatings derived from these compositions, and methods of forming the composite coating compositions and composite metallic coatings, wherein the compositions and coatings comprise particles of at least one quasicrystalline metal alloy and at least one elemental metal. The methods include electrocodepositing suspended quasicrystalline metal alloy particles and dissolved metal ions onto a substrate. Preferably, the substrate is disposed in an aqueous bath containing at least one dissolved metal ion species and at least one suspended quasicrystalline metal alloy powder species. The compositions and coatings enhance the wear, friction, hardness, corrosion, and non-stick characteristics of the substrate.

Owner:LYNNTECH

Light emitting diode structures

ActiveUS7509012B2Improve isotropyImprove extraction efficiencySolid-state devicesNanoopticsPhotonicsRefractive index

According to one aspect of the present invention, a light emitting diode (LED) structure including an active core layer and at least one substrate layer having a first refractive index, comprises a 2-dimensional photonic quasicrystal in the structure, the photonic quasicrystal comprising an array of regions having a second refractive index, the array exhibiting long range order but short range disorder. The long range order is associated with diffractive properties of the structure and gives rise to uniform-far field diffraction patterns from the LED. The present invention enjoys the benefit of improved light extraction from LEDs without undesirable far field illumination patterns.

Owner:QUANTUM NIL LTD +1

Magnesium base spherical quasicrystal master alloy and preparation method thereof

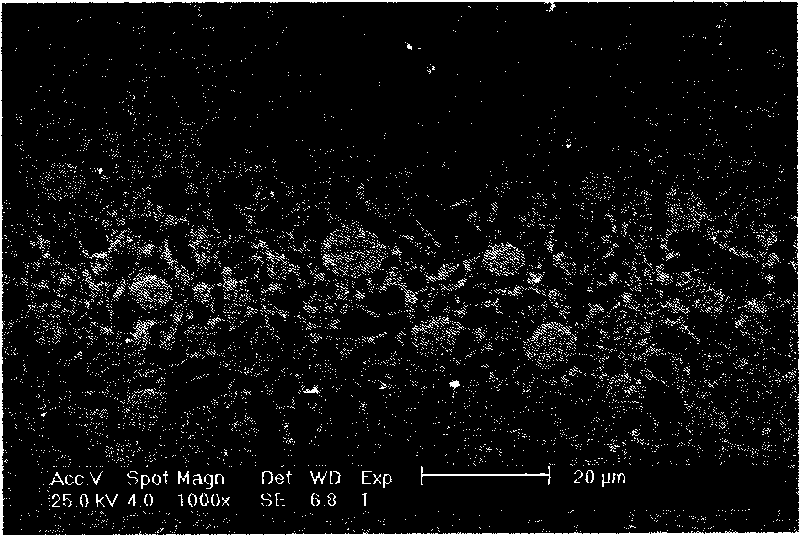

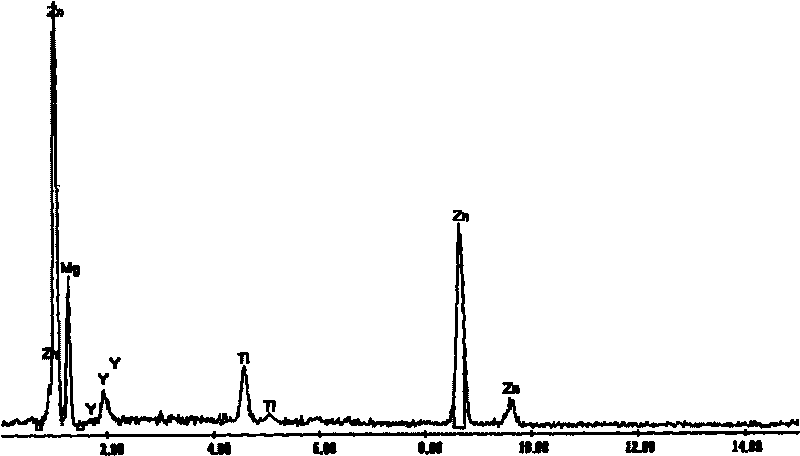

The invention provides a magnesium base spherical quasicrystal master alloy and a preparation method thereof, relating to magnesium base alloys with zinc as a submaster component. The alloy is Mg-Zn-Y-Ti quaternary magnesium base icosahedral spherical quasicrystal master alloy, comprising the following chemical components: 55.0-65.0% of Mg, 30.0-40.0% of Zn, 2.5-5.5% of Y and 0.1-0.5% of Ti, wherein the diameter of the spherical quasicrystal is 6-10mu m and the mean diameter is 8 mu m. The volume of the spherical quasicrystal is 30-40% of the total volume of the alloy. The preparation method is characterized by adopting control of the solidification rate, namely pouring the alloy melt into a casting mold capable of controlling the cooling rate, wherein the solidification rate is controlled between 52.6K / s and 68.4K / s. The product of the invention can better improve the mechanical property of the alloy materials while enhancing the magnesium alloy substrate, has simple process, low requirement on equipment and wide raw material sources, is convenient to realize industrialized production and saves resources.

Owner:HEBEI UNIV OF TECH

Quasicrystal and alumina mixed particulate reinforced magnesium-based composite material and method for manufacturing the same

ActiveUS20160230251A1Improve tensile propertiesHigh elongationParticulatesMagnesium matrix composite

A reinforced magnesium matrix composite includes a quasicrystal and alumina mixture particles reinforcement phase and a magnesium alloy matrix, where the weight ratio of the quasicrystal and alumina mixture particles reinforcement phase to the magnesium alloy matrix is (4-8) to 100; the magnesium alloy matrix including by weight 1000 parts of magnesium, 90 parts of aluminum, 10 parts of zinc, 1.5-5 parts of manganese, 0.5-1 part of silicon and 0.1-0.5 part of calcium; the quasicrystal and alumina mixture particles reinforcement phase including by weight 40 parts of magnesium, 50-60 parts of zinc, 5-10 parts of yttrium and 8-20 parts of nanometer alumina particles of which the diameter is 20-30 nm; and the quasicrystal and alumina mixture particles reinforcement phase having a size of 100-200 mesh.

Owner:ZHONGBEI UNIV

Quasicrystal patterning transparent film electrode used for intelligent light modulation film

The invention discloses a quasicrystal patterning transparent film electrode used for an intelligent light modulation film and a preparation method for the same, and a related intelligent modulation film and a preparation method for the same. The quasicrystal patterning transparent film electrode is a graphene / quasicrystal patterning metal mesh composite transparent conductive film electrode; the graphene / quasicrystal patterning metal mesh composite transparent conductive film electrode consists of a substrate, a quasicrystal patterning metal mesh and a graphene layer; the intelligent light modulation films consists of two graphene / quasicrystal patterning metal mesh composite transparent conductive film electrodes which are opposite in a staggermanner and a light ray modulation unit clamped between the two graphene / quasicrystal patterning metal mesh composite transparent conductive film electrodes, wherein the light ray modulation layer is doped with a backing, the stagger portion is provided with a lead out electrode, and the device is packaged by a packaging material. The graphene / quasicrystal patterning metal mesh composite transparent conductive film electrode can effectively eliminate the optical effect produced by the metal grid in the light modulation film and enables the light modulation film to be applied in the light modulation device having higher requirements.

Owner:北京京城鸿业科技有限公司

Quasicrystal particle strengthening magnesium-based amorphous alloy endogeny composite material and preparation method thereof

The invention provides a magnesium-based amorphous alloy endogeny composite material. A quasicrystal particle strengthening magnesium-based amorphous alloy matrix is stabilized by applying thermodynamics so as to form a quasicrystal-amorphous double-phase composite structure. Experiments prove that the composite structure can be used for effectively improving the plasticity and the strength of materials and is the magnesium-based amorphous composite material having a good application prospect. The invention also provides a preparation method of the quasicrystal-amorphous endogeny composite structure. The preparation method comprises the following specific steps: firstly. slowly cooling an alloy melt to a room temperature so as to obtain a primary quasicrystal phase strengthening quasicrystal-crystal composite tissue with certain size, shape and volume content, then heating so as to ensure that the crystal tissue is molten, and quasicrystal particles are kept stable, thus obtaining a semi-solid melt; finally retaining unmelted quasicrystal particles through a rapid solidification technology, and turning the melt into an amorphous phase, thus obtaining the quasicrystal-amorphous endogeny composite material. The preparation method is simple, easy to operate and strong in controllability and suitable for large-scale industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

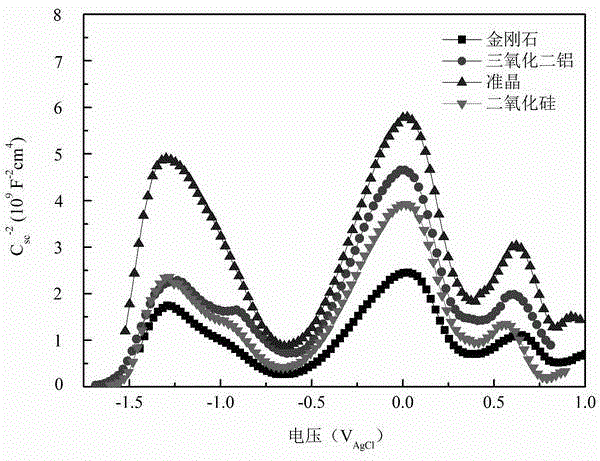

Quasicrystal-containing magnesium alloy with high corrosion resistance and preparation method and application thereof

The invention relates to the field of magnesium alloy, specifically to a quasicrystal-containing magnesium alloy with high corrosion resistance and a preparation method and an application thereof, especially to a quasicrystal-containing magnesium alloy material which has good uniform corrosion and high pitting resistance in a NaCl aqueous solution at room temperature and a method for preparing the alloy material. According to the invention, the poor corrosion resistance problem of magnesium alloy is solved. Through reasonable selection of alloying elements, a quasicrystal phase is introduced into a magnesium alloy matrix so as to prepare the quasicrystal-containing Mg-Li alloy with high corrosion resistance. The quasicrystal-containing magnesium alloy can be a quasicrystal phase reinforced magnesium alloy of the alpha-Mg monophase field and alpha-Mg+beta-Li diphasic filed, and contains the following components: by weight, 0-11.5% of Li, 5-10% of Zn, 0.5-2% of Y and the balance Mg. A product is obtained after alloy smelting and subsequent homogenization treatment. The treatment technology is simple and convenient to operate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-strength magnesium alloy and process for production thereof

The invention provides a high-strength magnesium alloy which is improved in high-temperature strength without using any expensive rare earth element with cost reduction and a process for the production of the alloy. A high-strength magnesium alloy represented by the composition formula: Mg100-(a+b)ZnaXb(wherein X is at least one member selected from among Zr, Ti and Hf and a and b are contents of Zn and X respectively as represented in at% and satisfy the relationships (1), (2) and (3): (1) a / 28 = b = a / 9, (2) 2 < a < 10, and (3) 0.05 < b < 1.0), wherein Mg-Zn-X quasicrystals and approximants thereof in theform of fine particles are dispersed in a Mg mother phase; and a process for the production of the high-strength magnesium alloy which comprises melting Mg in an inert atmosphere to form molten Mg, adding Mg-Zn-X quasicrystals (wherein X is at least one of Zr, Ti and Hf) to the molten Mg to form a molten alloy, casting the molten alloy, and heat-treating the cast alloy to precipitate the quasicrystals and approximants thereof in the Mg mother phase.

Owner:TOYOTA JIDOSHA KK

Preparation method for Al6Mn quasicrystal

The invention relates to a preparation method for a Al6Mn quasicrystal. The method mainly includes the steps that pure Al powder and pure Mn powder are evenly mixed according to the atomic ratio of 6:1, arranged into a hard alloy mould, and pressed in a hydraulic tablet press to obtain a reserved block; the reserved block is mounted into a boron nitride crucible, a pre-dried tubular graphite oven body, the boron nitride crucible, a boron nitride piece, a pyrophyllite piece and a graphite piece are assembled and placed in an ultrahigh-pressure environment, the setting pressure is controlled to be the isostatic pressure ranging from 3 GPa to 5 GPa, and the temperature is controlled to rise to 700-850 DEG C and kept for 30-60 minutes; and the temperature is decreased to 480-580 DEG C and kept for 1-3 hours. The preparation method is simple in process, low in energy consumption and high in efficiency, and the content of prepared quasicrystal is high.

Owner:YANSHAN UNIV

Quasicrystal phase reinforced LPSO structured Mg-Zn-Y magnesium alloy and preparation method thereof

The invention relates to a quasicrystal phase reinforced LPSO structured Mg-Zn-Y magnesium alloy and a preparation method thereof. The magnesium alloy is composed of the following components in percentage by mass: 5.51-13.58% of Zn, 11.30-13.35% of Y and the balance of Mg. On the basis of an LPSO structure Mg-Zn-Y magnesium alloy, the quasicrystal phase reinforced LPSO structured Mg-Zn-Y magnesium alloy is prepared by adding 2-16% by mass of Mg-Zn-Y quasicrystal interalloy in a process of smelting the LPSO structure Mg-Zn-Y magnesium alloy through a reasonable process means. The good advantage of high high-temperature creep resistance of the LPSO structure Mg-Zn-Y magnesium alloy is retained, and the strength and plasticity of the alloy are improved, so that the comprehensive performance of the novel alloy is obviously improved. The obtained composite magnesium alloy material has wide application prospect in the fields of rail transits, automobiles, electronics, communication and the like.

Owner:UNIV OF JINAN

High-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and manufacturing method thereof

InactiveCN101805864BSolve the mechanical propertiesImprove mechanical propertiesQuasicrystalDislocation

The invention relates to high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and a manufacturing method thereof. The high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy is characterized by comprising the following alloying element components distributed in the alloy and the content value thereof in percent by weight: 1.0%-4.0% of Cu, 0.3%-1.5% of Mn, 0.3%-4.0% of Y, 1.0%-5.5% of Zn and the balance of magnesium. In order to solve the conflict of the damping property and the mechanical property of the magnesium alloy, the invention puts forward the fact that a Zn element and a Y element are addedin the high-damping Mg-Cu-Mn alloy so that the Mg, the Zn and the Y form quasicrystals and / or long-prepared phases in the alloy, the quasicrystals or the long-prepared phases can introduce a great amount of new movable dislocations in a magnesium matrix, the damping property of the magnesium alloy is improved through movable dislocations newly increased in the magnesium matrix, and then the conventional heat extrusion is carried out on the alloy so that the mechanical property of the alloy is improved. The invention has the advantages of simple process, strong transportability, easy operationand lower cost and solves the problem that the Mg alloy has limited application due to high damping property and low mechanical property, and the used equipment is conventional and general equipment.

Owner:CHONGQING UNIV

Magnesium-based spherical quasicrystal master alloy and preparation method thereof

The invention provides a magnesium-based spherical quasicrystal master alloy and a preparation method thereof, which relates to a magnesium-based alloy taking zinc as a secondary main component. The alloy is a Mg-Zn-Y-C quaternary magnesium-based icosahedral spherical quasicrystal master alloy comprising the following chemical components: 55.0 to 65.0 percent of Mg, 30.0 to 40.0 percent of Zn, 2.5 to 5.5 percent of Y, and 0.1 to 0.5 percent of C, wherein the diameter of spherical quasicrystals is 3 to 7 mu m; the average diameter of the spherical quasicrystals is 6 mu m; and the volume of the spherical quasicrystals accounts for 40 to 48 percent of the total volume of the alloy. The preparation method is characterized by adopting control over solidification rate, namely pouring molten alloy into a casting mold with cooling rate controllable and controlling the solidification rate in a range between 68.4 and 84.8 K / s. The alloy can improve the mechanical properties of alloy material better when a magnesium alloy matrix is reinforced, and has the advantages of simple process, not high demand for equipment, extensive sources of raw materials, convenience for realizing industrialized production and resource conservation.

Owner:HEBEI UNIV OF TECH

Preparation method for Al-Pd-Mn quasicrystal

The invention relates to a preparation method for a Al-Pd-Mn quasicrystal. The Al-Pd-Mn quasicrystal includes, by atomic ratio, 70%-72% of Al, 18%-21% of Pd and 7%-12% of Mn. The method includes the steps that high-purity Al powder, high-purity Pd powder and high-purity Mn powder are evenly mixed, injected into a hard alloy mould, and pressed in a hydraulic tablet press under 2-4 MPa for 100-300 seconds to obtain a reserved block; the reserved block is mounted into a boron nitride crucible, a pre-dried tubular graphite oven body, the boron nitride crucible, a boron nitride piece, a pyrophyllite piece and a graphite piece are assembled and placed in a six-surface diamond presser, setting pressure is controlled to be isostatic pressure ranging from 3 GPa to 6 GPa, and the temperature is controlled to rise to 850-950 DEG C and kept for 30-60 minutes; and the temperature is decreased to 650-850 DEG C and is kept for two to six hours. The preparation method is simple in process, low in energy consumption and high in efficiency; the quasicrystal is prepared from the raw materials at a time only with conventional equipment; the prepared quasicrystal has excellent quality performance and good mechanical performance and can be widely applied.

Owner:YANSHAN UNIV

Photonic quasicrystal graph sapphire substrate and manufacturing method thereof and light emitting diode and preparation method thereof

InactiveCN102244170BImprove light extraction efficiencyHigh chance of total reflectionSemiconductor devicesPhotonic crystal structurePhysical chemistry

Owner:JIANGSU E LITE SEMICON

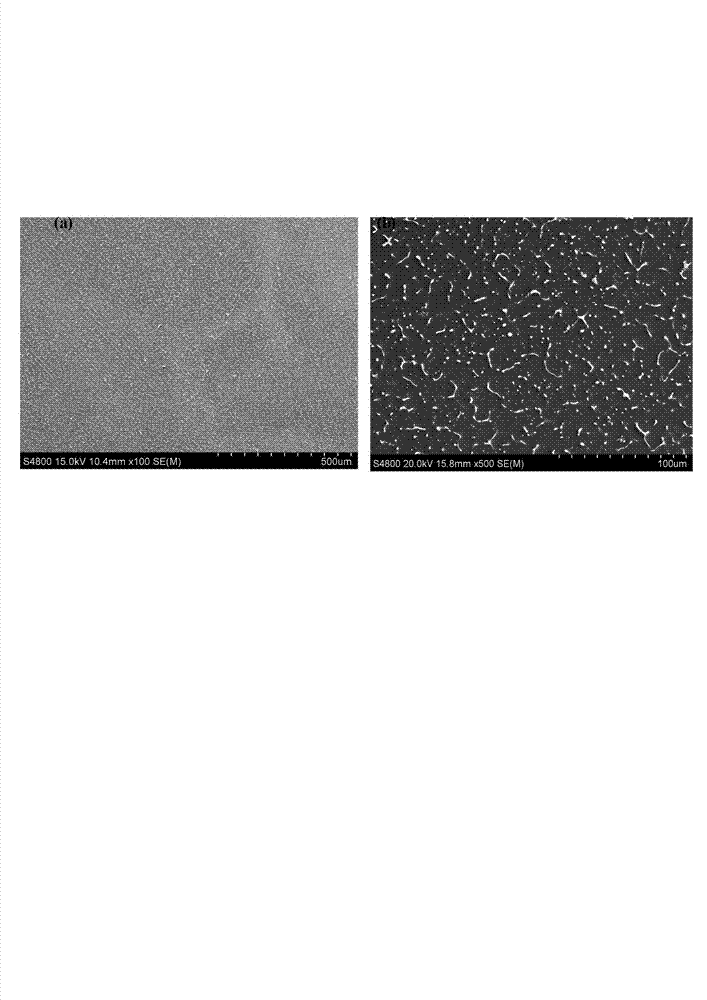

Abrasive particle abrasion pretreatment method for preparing compact passivation film on stainless steel surface

ActiveCN105603414AImprove corrosion resistanceHigh ratio of hard to elasticPolishing machinesAbrasion apparatusPretreatment methodWear particle

The invention discloses an abrasive particle abrasion pretreatment method for preparing a compact passivation film on a stainless steel surface, and belongs to the technical field of stainless steel surface treatment. The abrasive particles used by the pretreatment method comprise quasicrystal and a similar phase (the content is greater than 50%); the Vickers hardness of the abrasive particles is greater than or equal to 5GPa; and the hardness-elasticity ratio is 0.04-0.1. Finishing pretreatment is carried out on the stainless steel surface by an abrasive; stainless steel finishing and fine machining and surface activation can be simultaneously achieved; and quasicrystal abrasive particles have high hardness-elasticity ratio, self-sharpening property and non-sticky performance, have good processing sharpness on the stainless steel surface and can effectively avoid a lot of scratches on a workpiece surface, and are not easily adhered to or embedded into the workpiece surface. The compact and intact passivation film can be obtained by the pretreatment method combined with an existing passivation film preparation technology; the anti-corrosion capability of the stainless steel is improved; the technology is simple; the effect is obvious; resources are saved; and the abrasive particle abrasion pretreatment method can be widely applied.

Owner:DALIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com