Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15883 results about "Microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

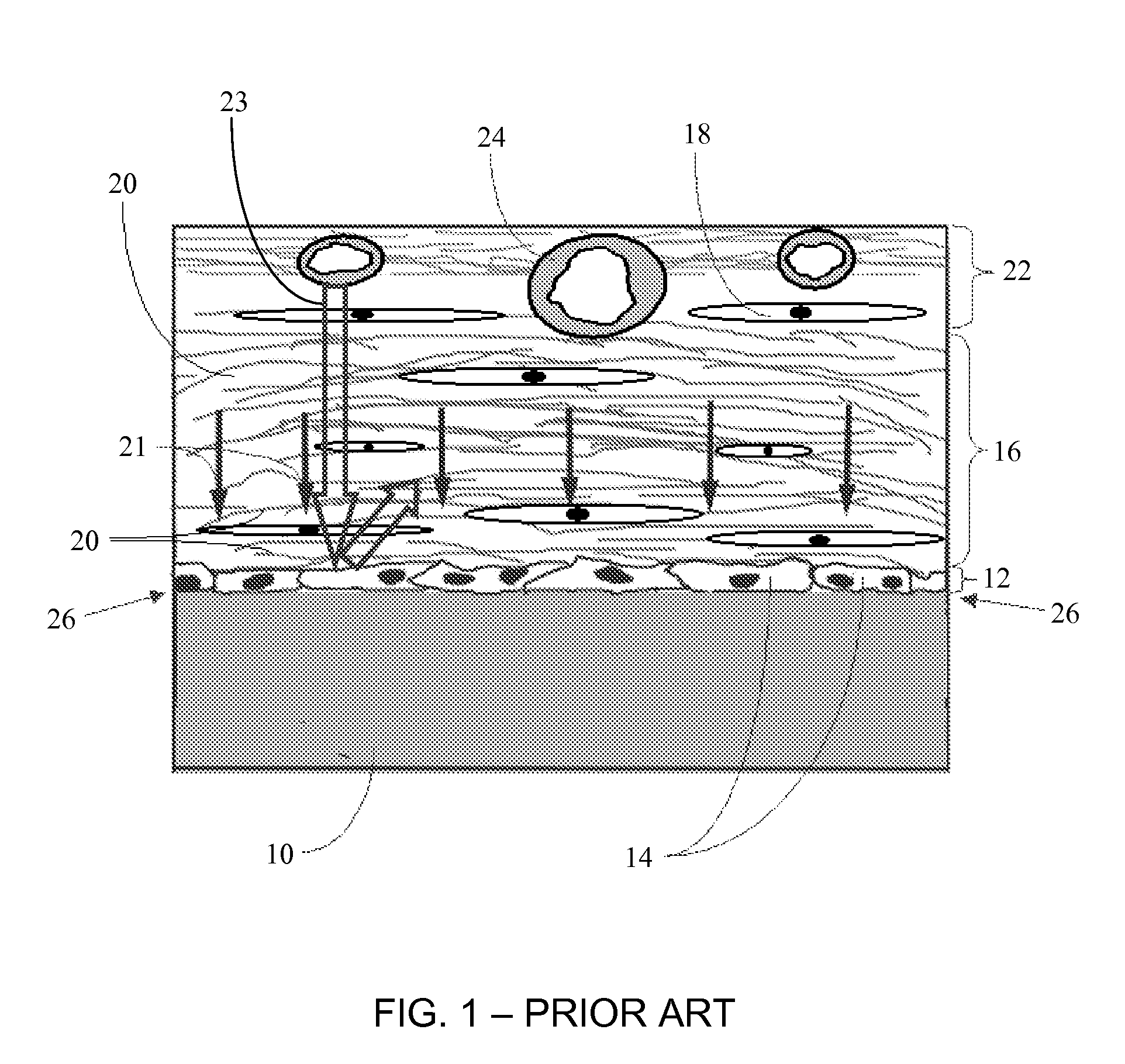

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure’s influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can take many forms but the primary ones are the pores. Even if those pores play a very important role in the definition of the characteristics of a material, so does its composition. In fact, for many materials, different phases can exist at the same time. These phases have different properties and if managed correctly, can prevent the fracture of the material.

Porous tissue scaffoldings for the repair of regeneration of tissue

InactiveUS6333029B1Promote growthPromote regenerationPeptide/protein ingredientsAntipyreticRepair tissueOpen cell

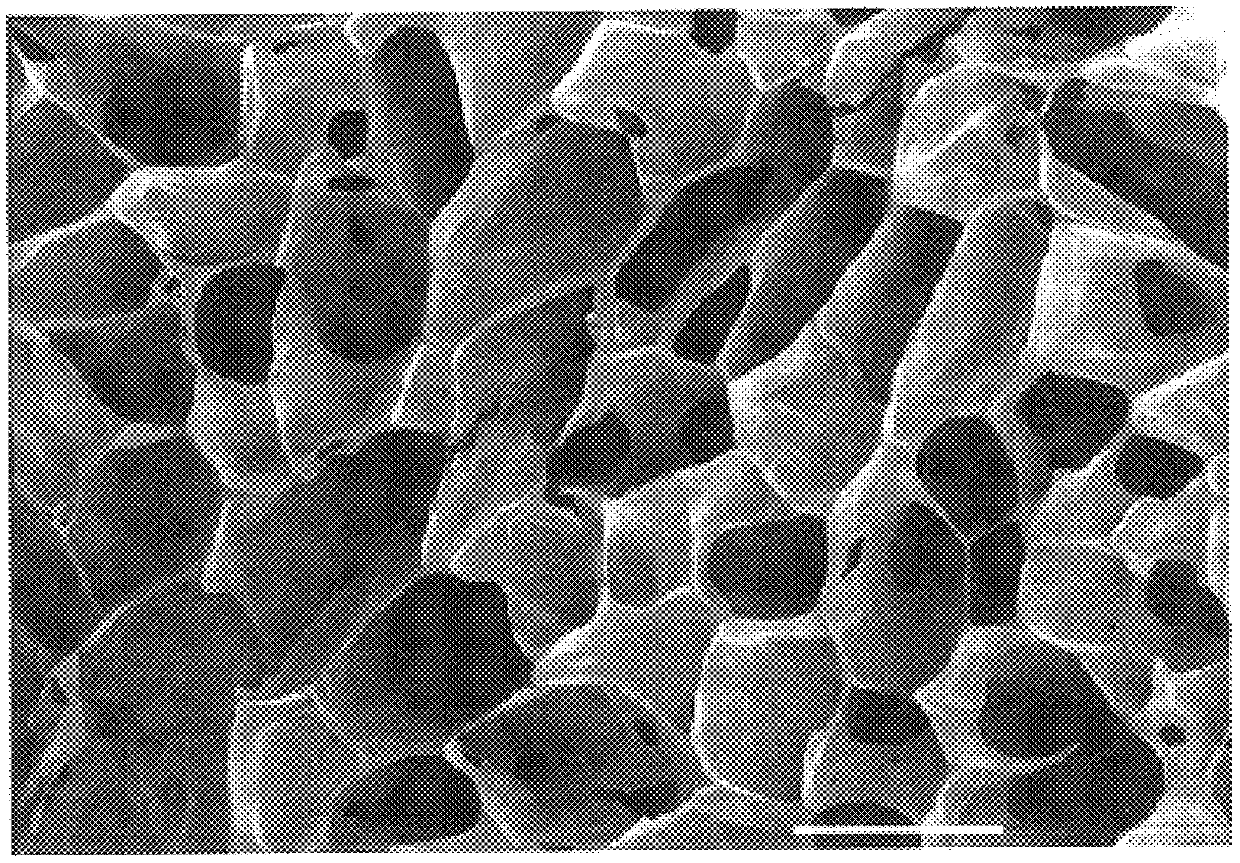

The present patent describes a three-dimensional inter-connected open cell porous foams that have a gradient in composition and / or microstructure through one or more directions. These foams can be made from a blend of absorbable and biocompatible polymers that are formed into foams having a compositional gradient transitioning from predominately one polymeric material to predominately a second polymeric material. These gradient foams are particularly well suited to tissue engineering applications and can be designed to mimic tissue transition or interface zones.

Owner:ETHICON ENDO SURGERY INC

Bioabsorbable Polymer, Bioabsorbable Composite Stents

InactiveUS20080249608A1Simple and inexpensive to manufactureVarying of ductilityStentsSurgeryMetallic materialsMedical device

Biocompatible materials may be configured into any number of implantable medical devices including intraluminal stents. The biocompatible material may comprise metallic and non-metallic materials in hybrid structures. In one such structure, a device may be fabricated with one or more elements having an inner metallic core that is biodegradable with an outer shell formed from a polymeric material that is biodegradable. Additionally, therapeutic agents may be incorporated into the microstructure or the bulk material.

Owner:CORDIS CORP

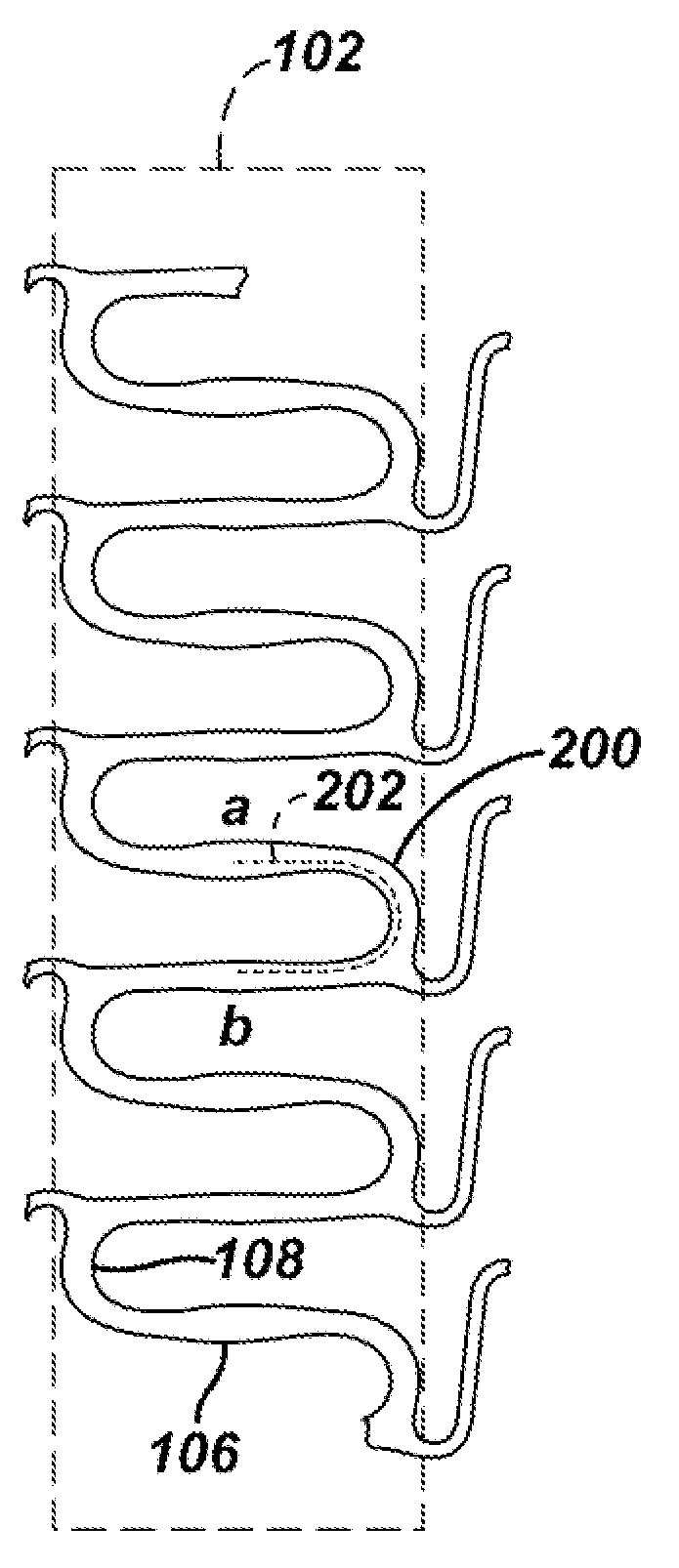

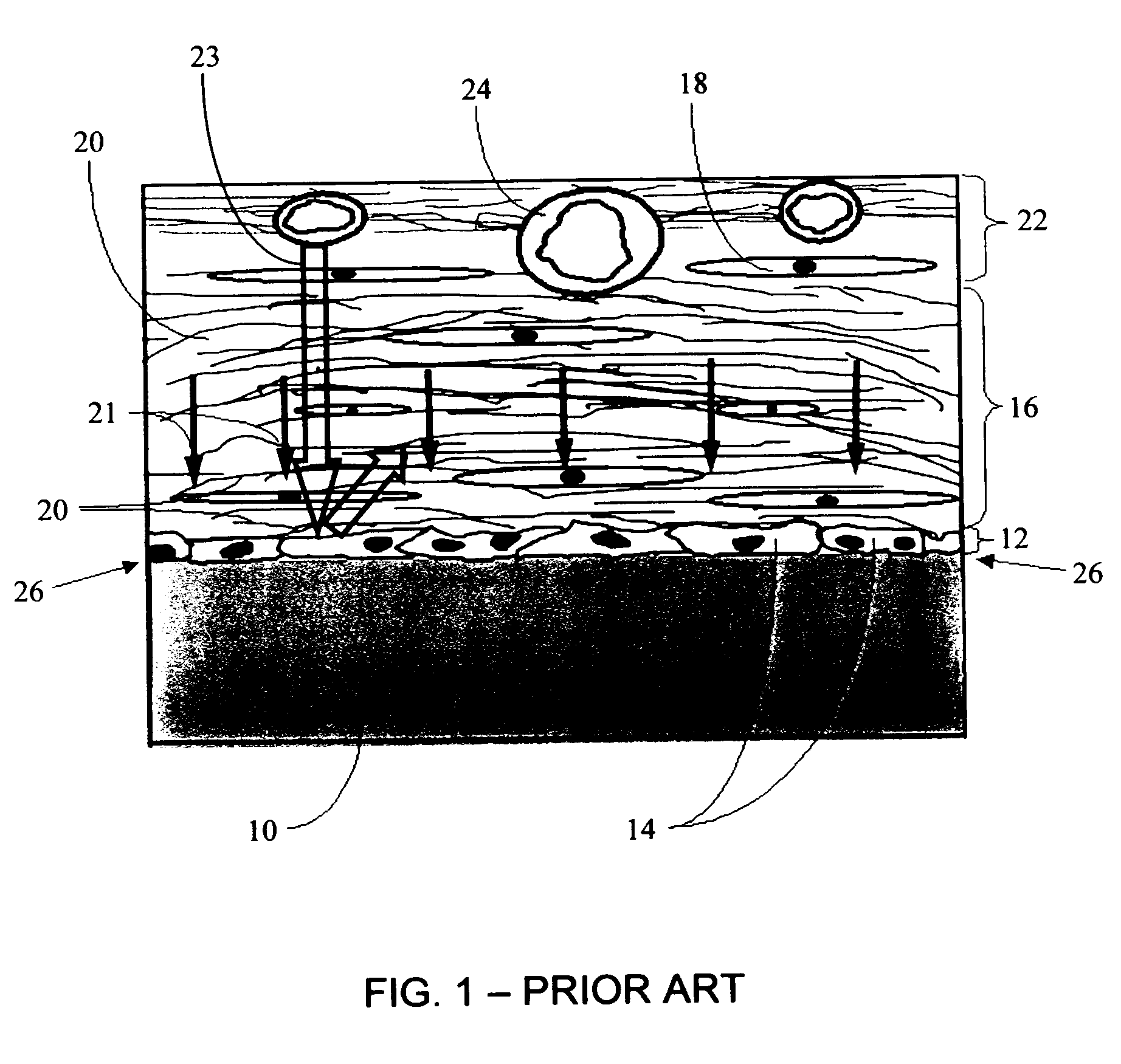

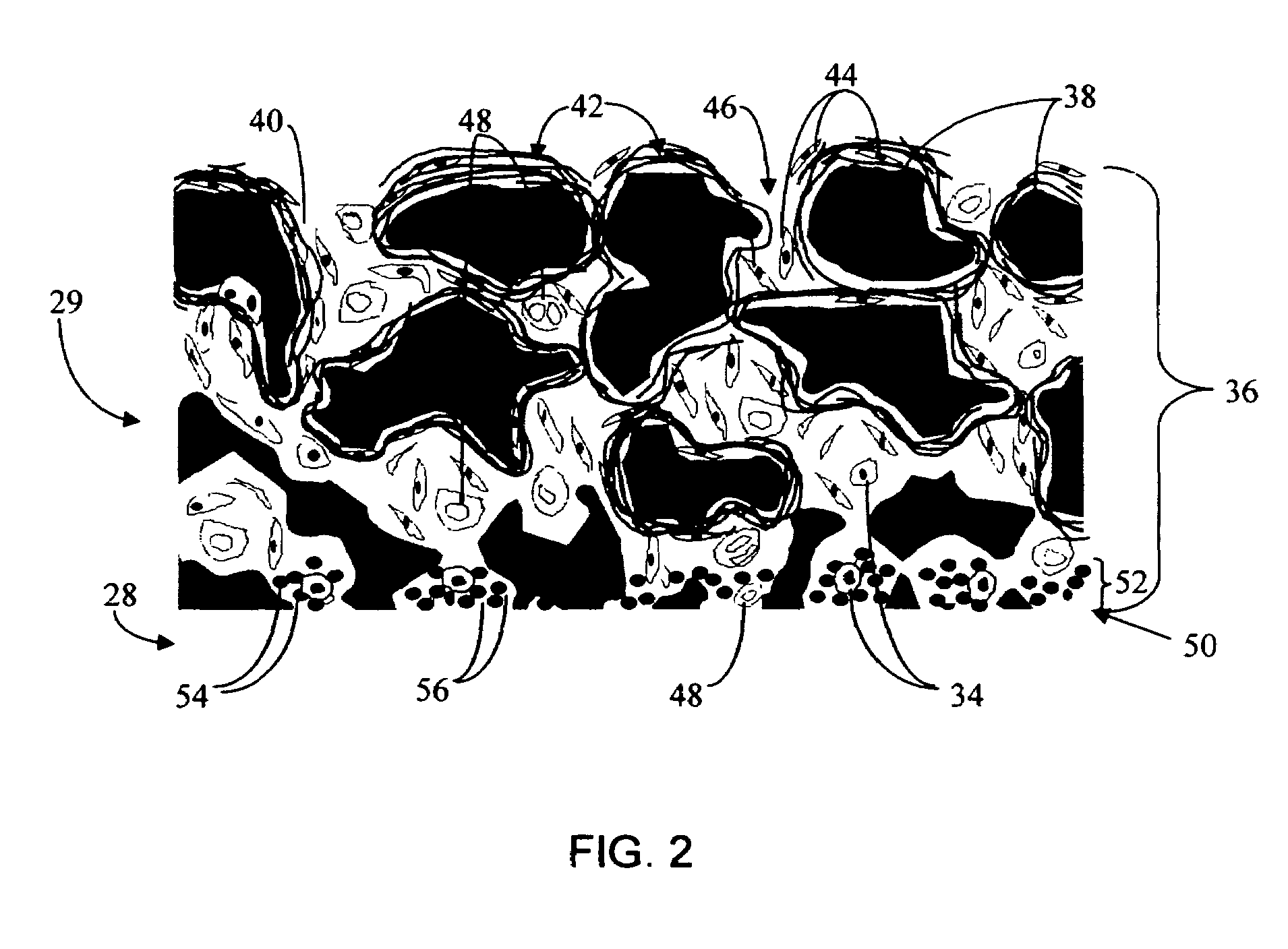

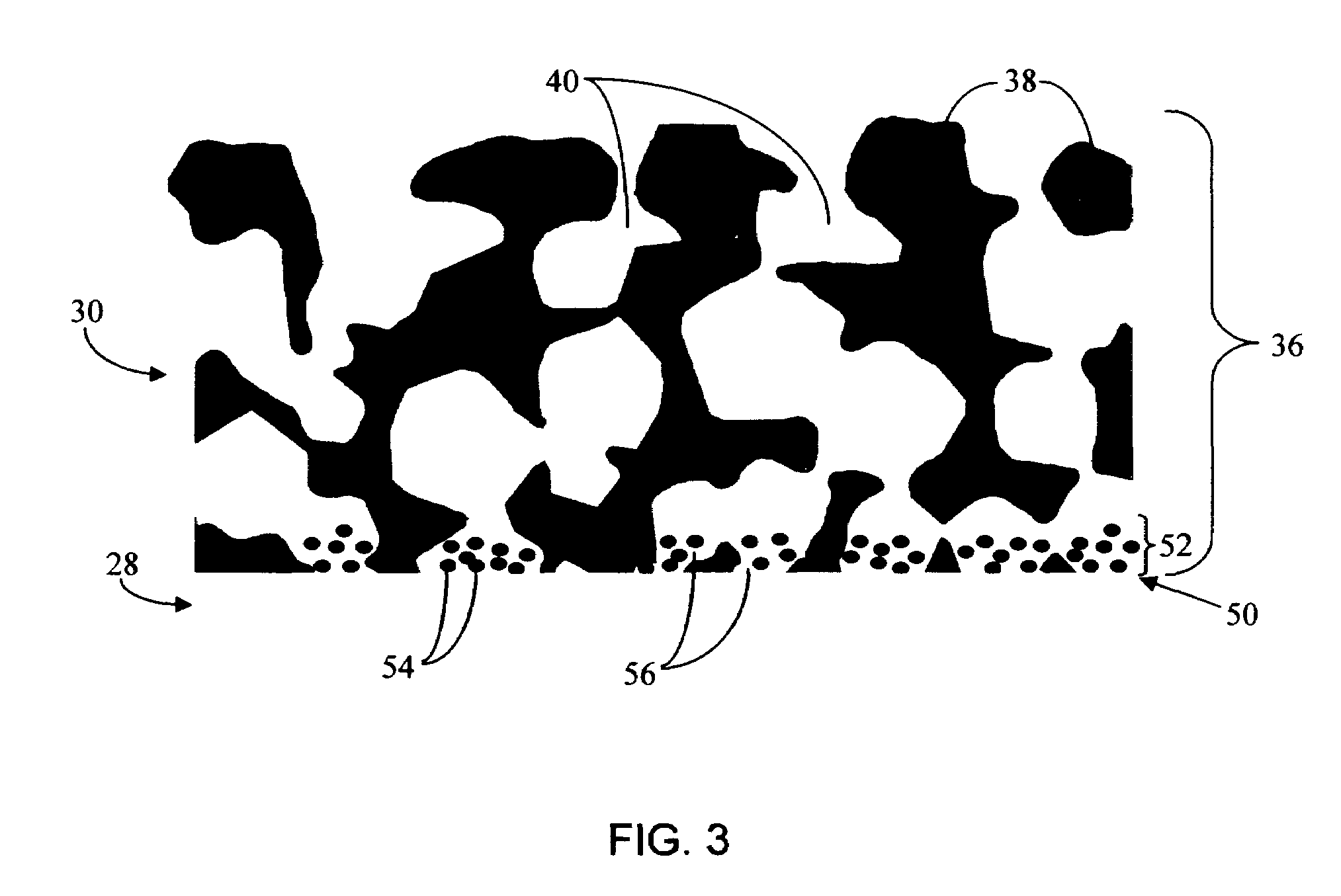

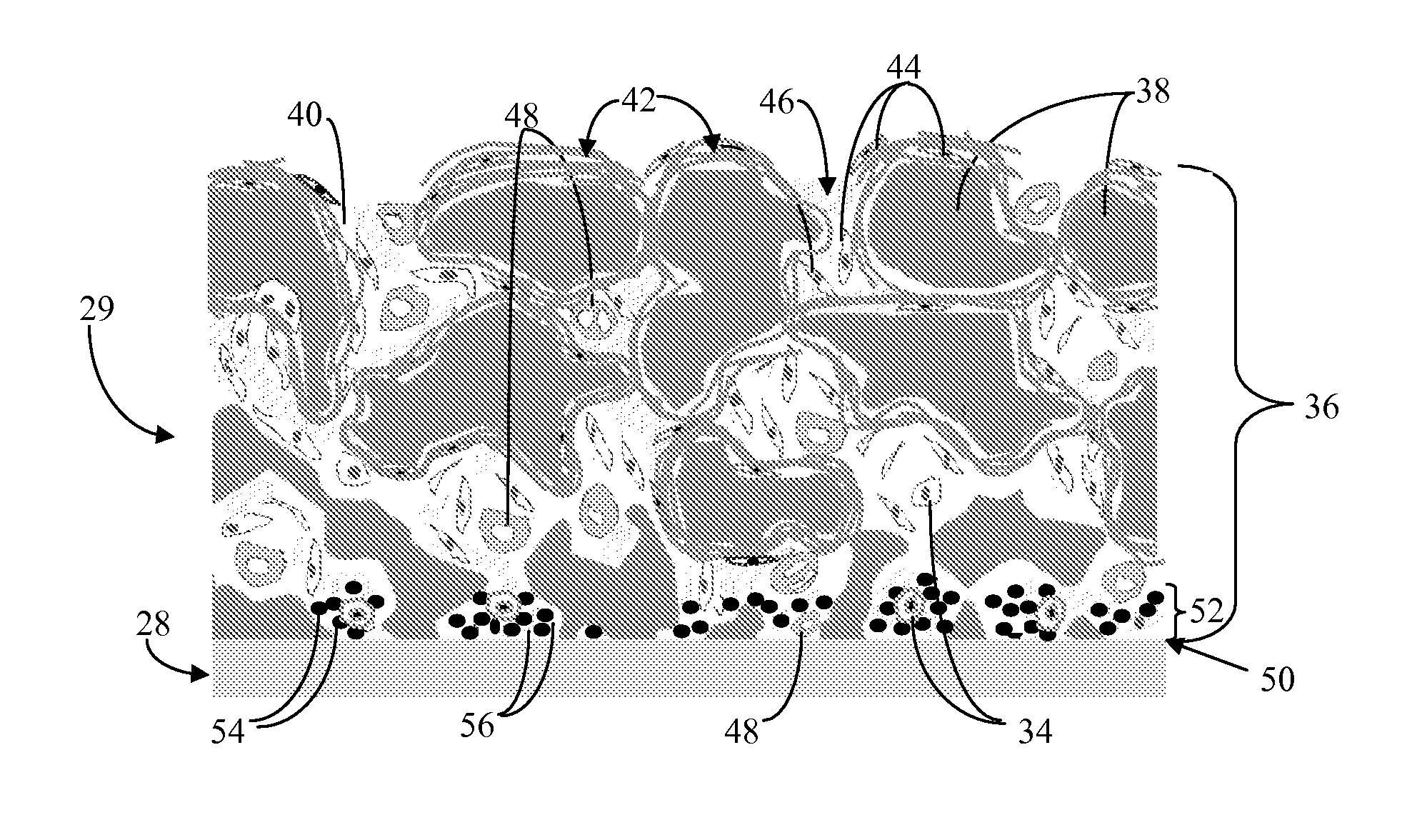

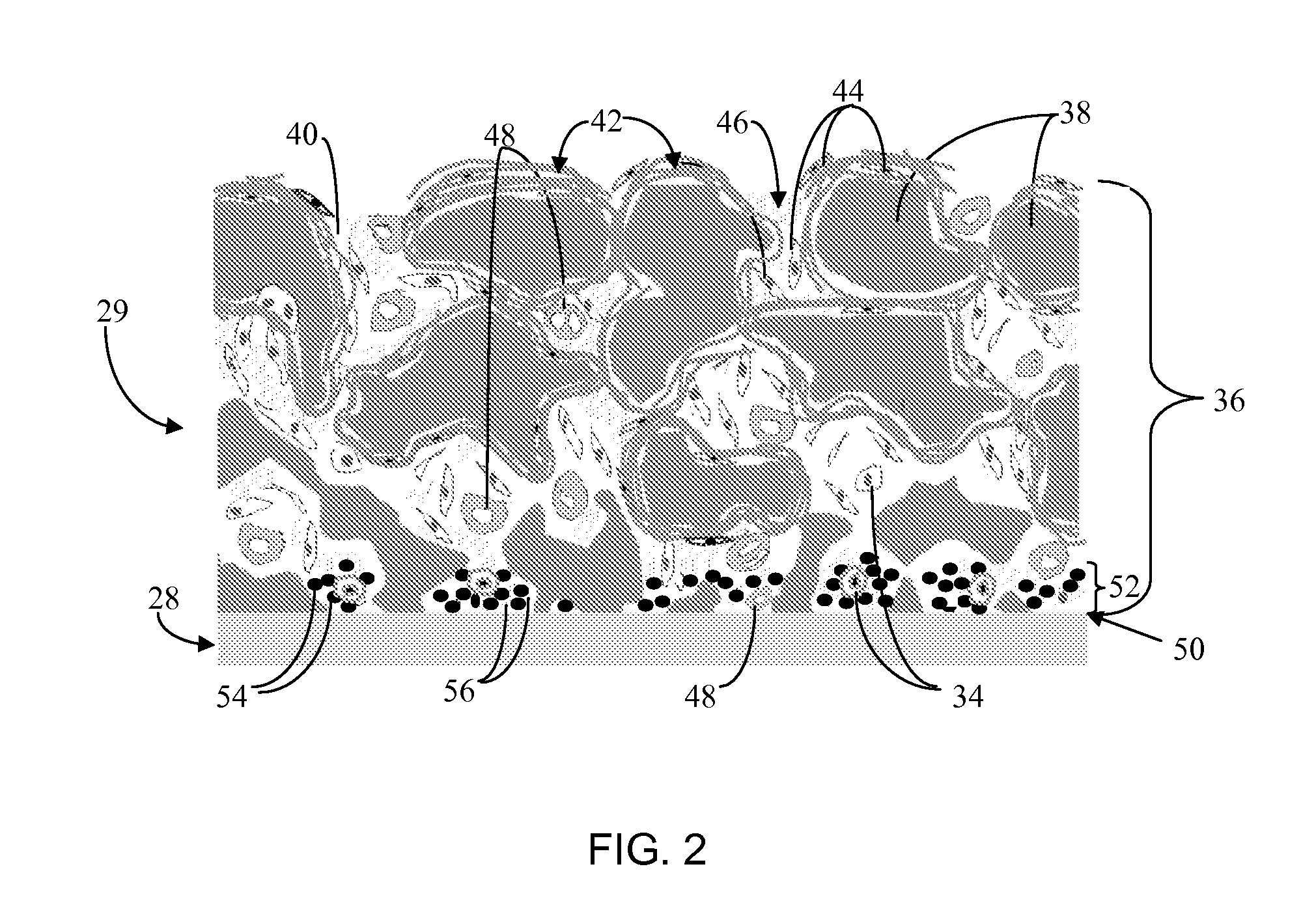

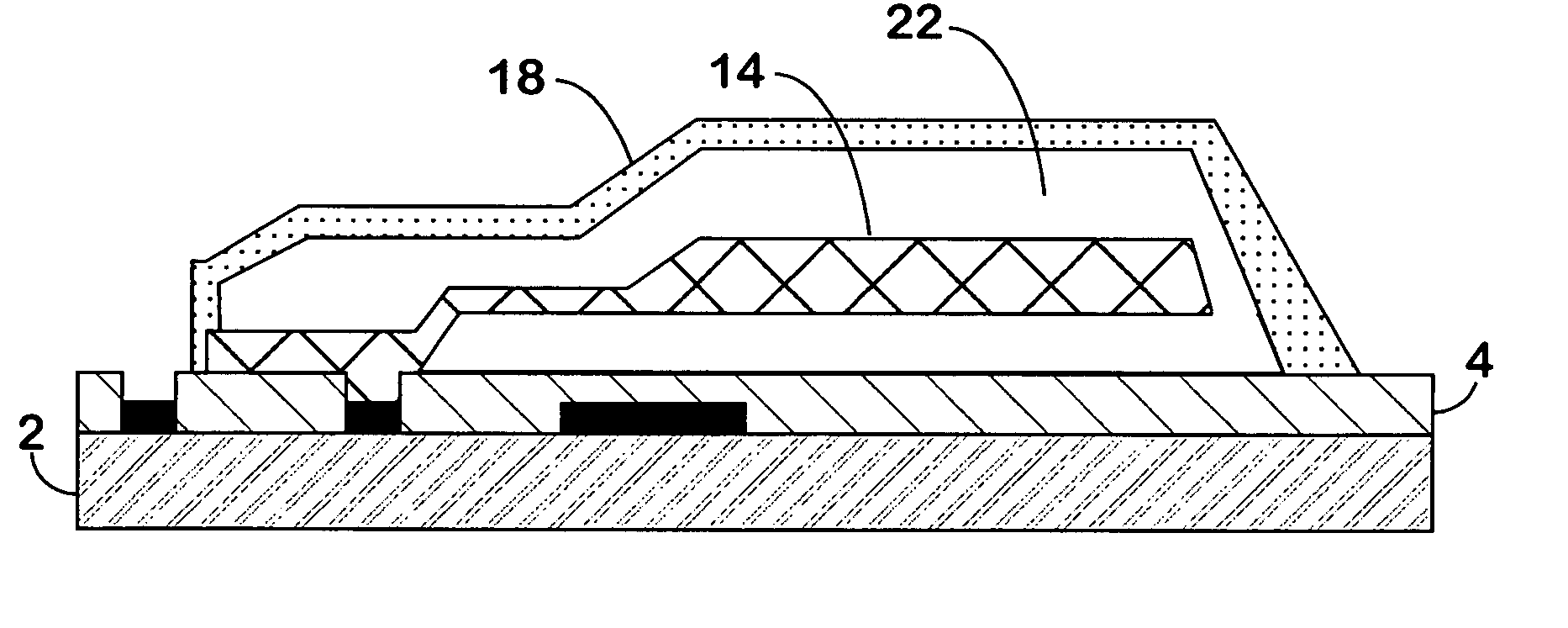

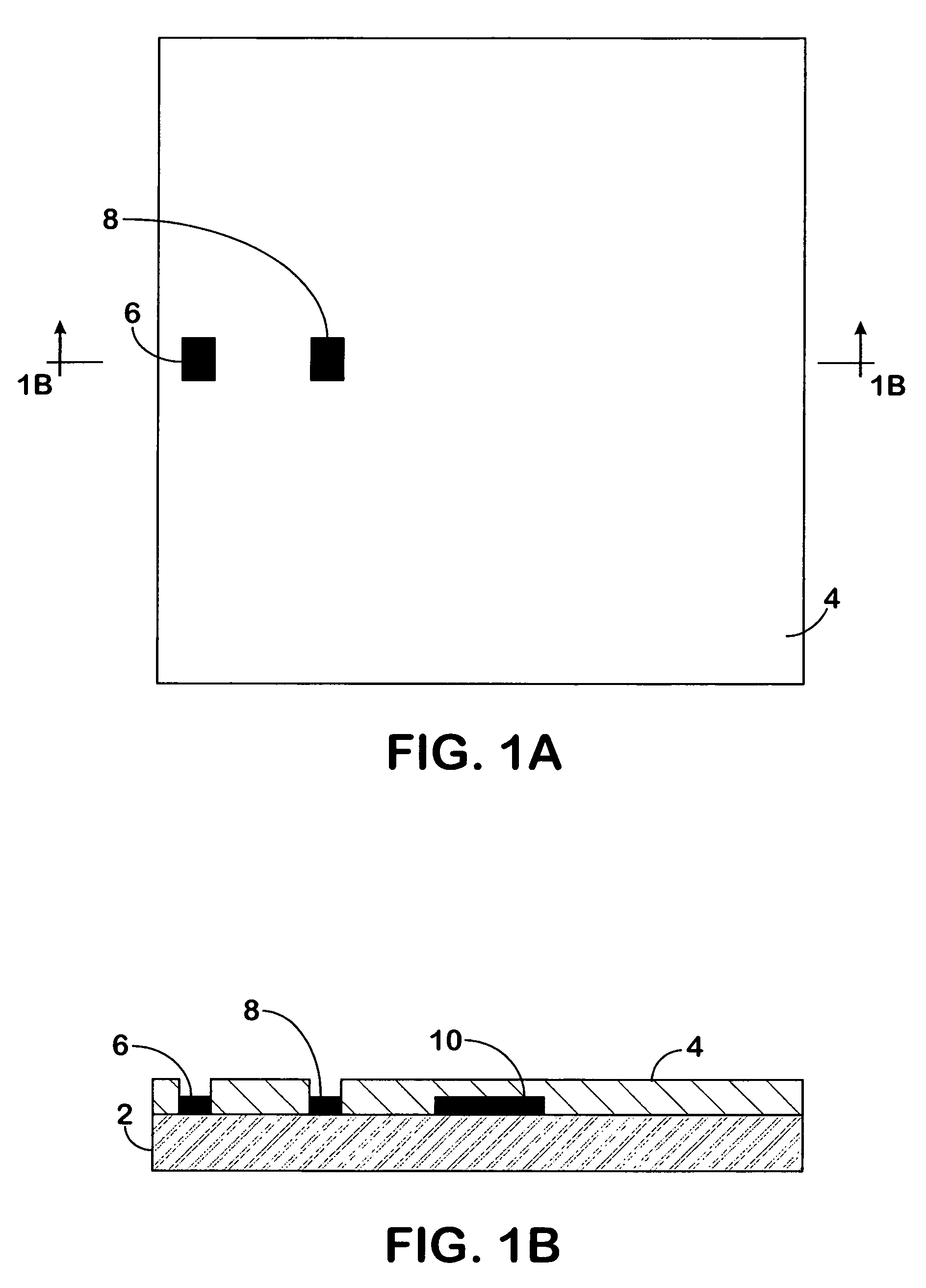

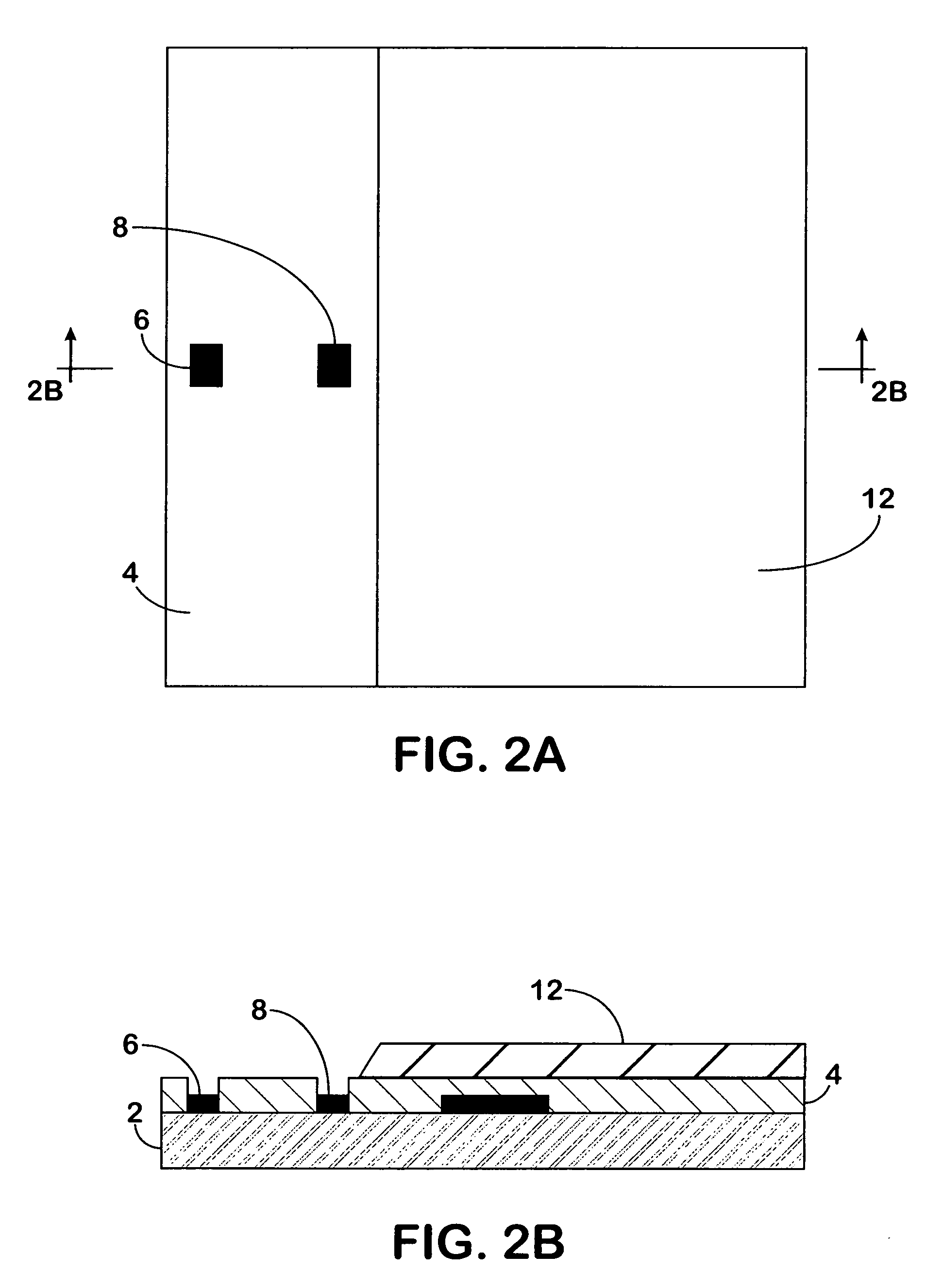

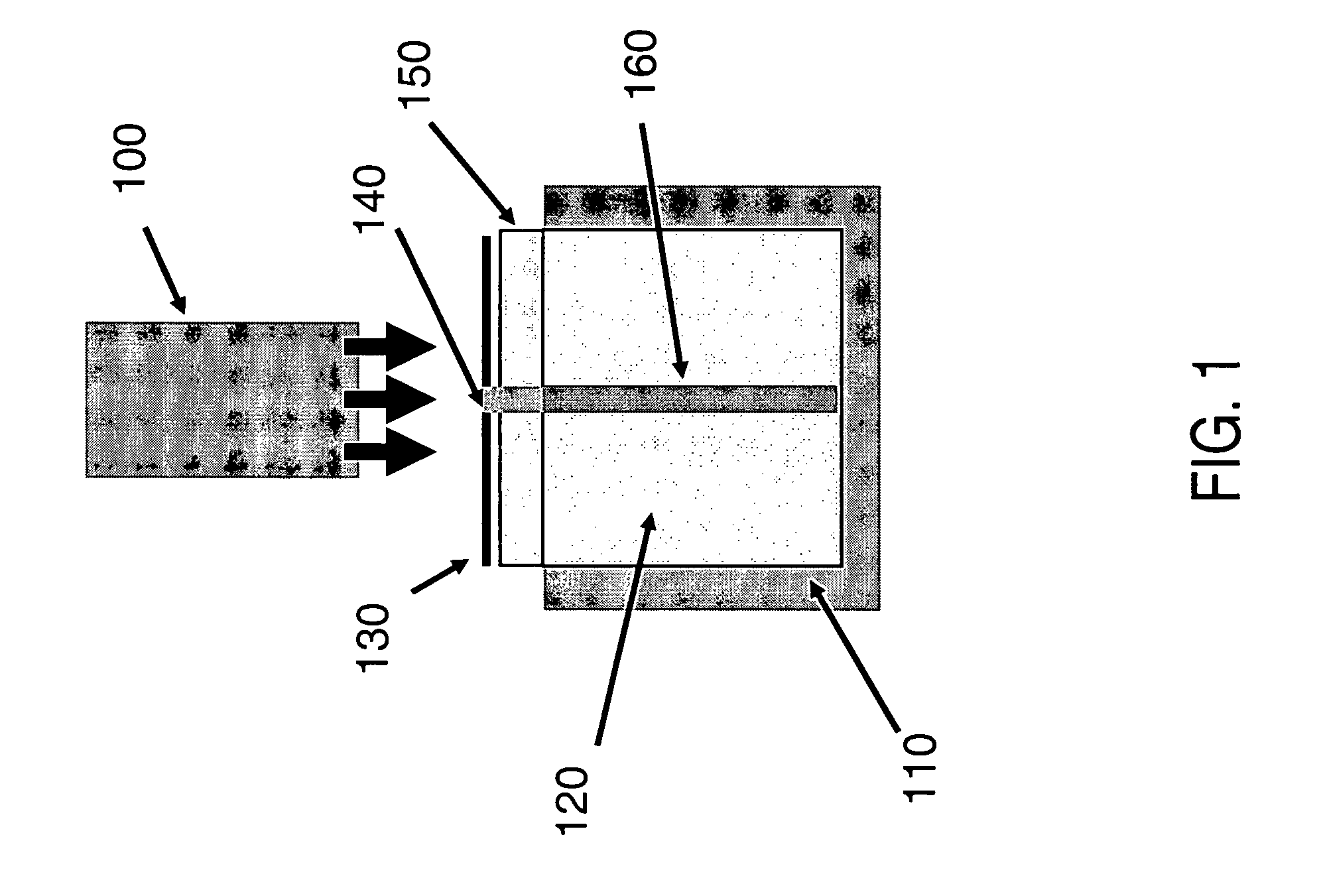

Biointerface membrane with macro-and micro-architecture

Disclosed herein are biointerface membranes including a macro-architecture and a micro-architecture co-continuous with and bonded to and / or located within at least a portion of the macro-architecture. The macro- and micro-architectures work together to manage and manipulate the high-level tissue organization and the low-level cellular organization of the foreign body response in vivo, thereby increasing neovascularization close to a device-tissue interface, interfering with barrier cell layer formation, and providing good tissue anchoring, while reducing the effects of motion artifact, and disrupting the organization and / or contracture of the FBC. The biointerface membranes of the preferred embodiments can be utilized with implantable devices such as devices for the detection of analyte concentrations in a biological sample (for example, from a body), cell transplantation devices, drug delivery devices, electrical signal delivering or measuring devices, and / or combinations thereof.

Owner:DEXCOM

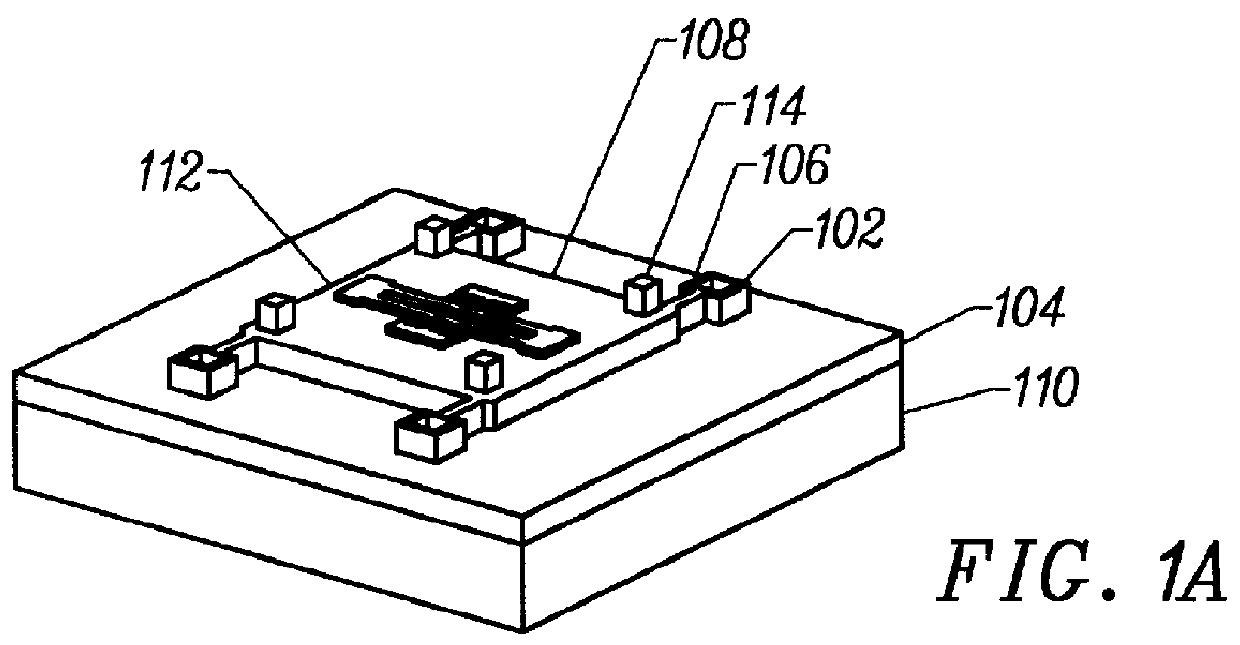

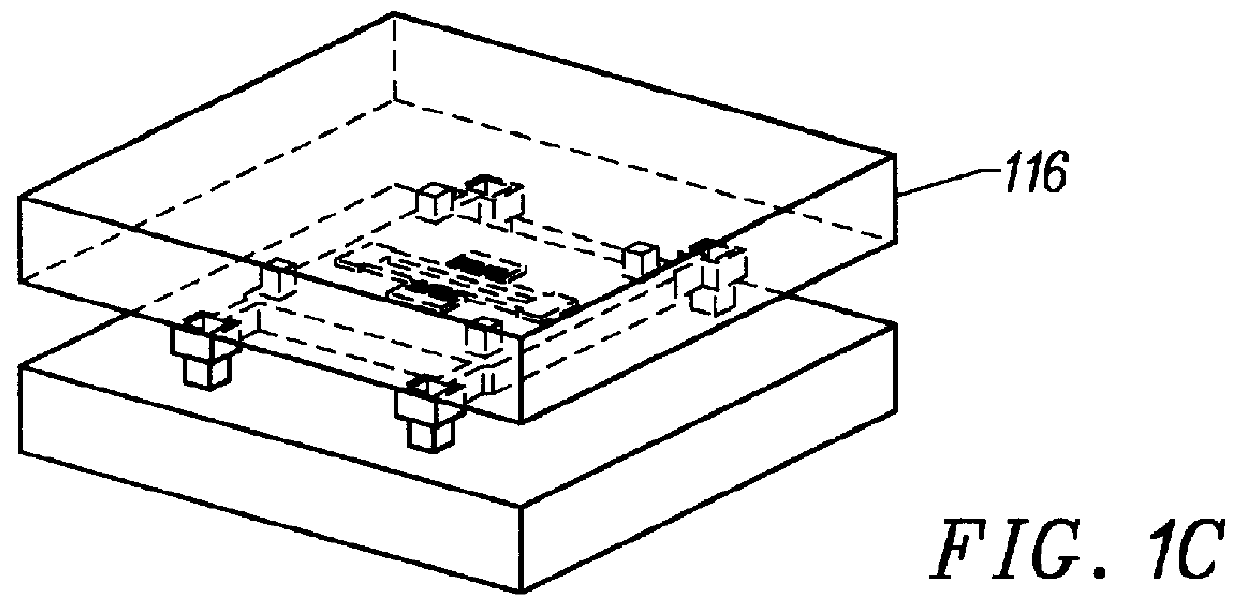

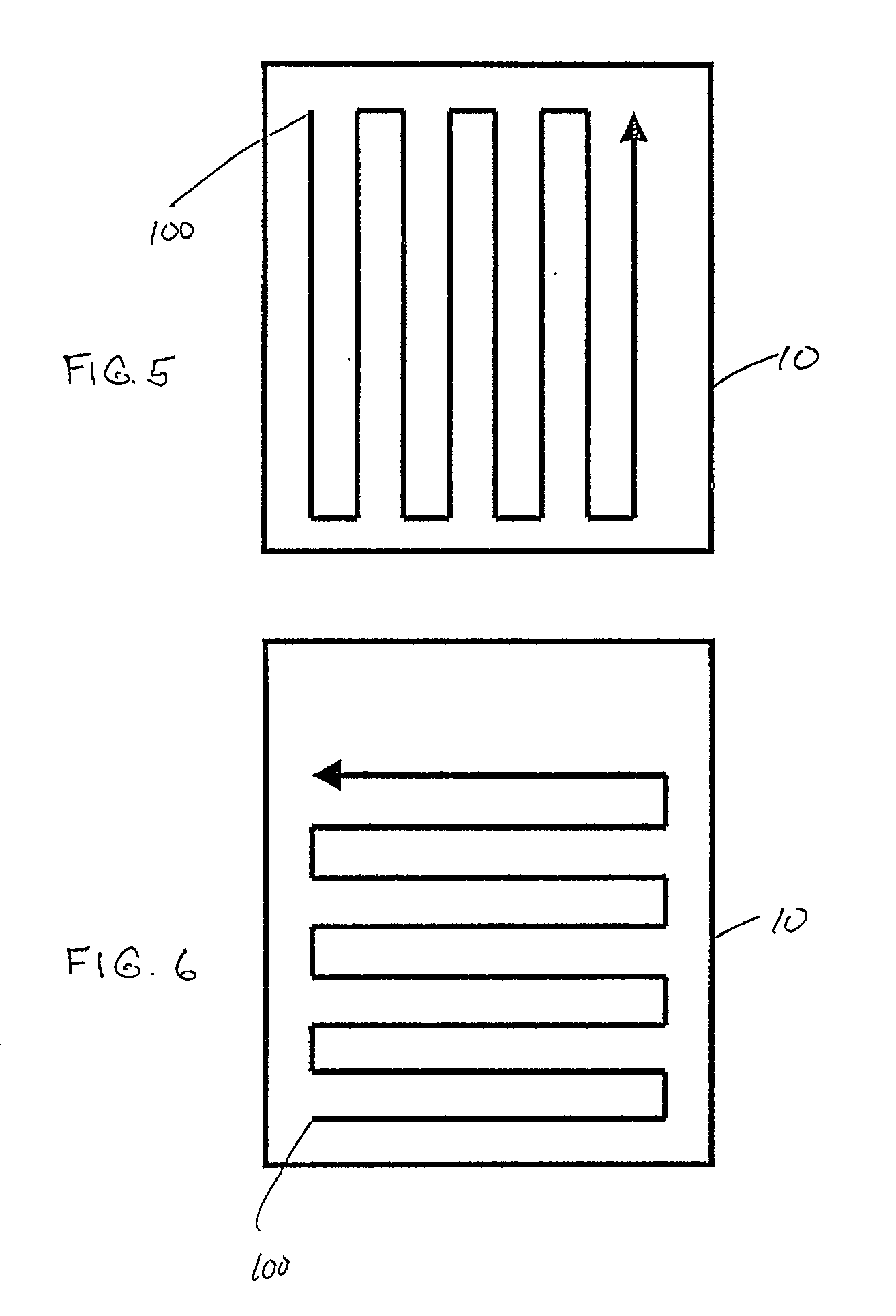

Non-planar microstructures for manipulation of fluid samples

This invention comprises an apparatus and method for the manipulation of materials, including particles, cells, macromolecules, such as proteins, nucleic acids and other moieties, in fluid samples. The apparatus comprises an enclosed chamber on a chip having an internal microstructure with surface area substantially greater than the facial surface area of the internal structure. Generally the internal microstructure comprises a continuous network of channels, each of which has a depth substantially greater than its width. The network may comprise a single channel, a single channel with multiple branches, multiple channels, multiple channels with multiple branches, and any combination thereof. The internal structure may present an inert, non-reactive surface, or be coated with a reactive ligand, or be electrically conductive and optionally be coated with an electrical insulator. Discrete portions of the internal structure may differ in structural and surface properties. Multiple chips may be linked together to create a multiplexed array of chambers, optionally linked to other analytical devices.

Owner:CEPHEID INC

Biointerface with macro- and micro-architecture

Owner:DEXCOM INC

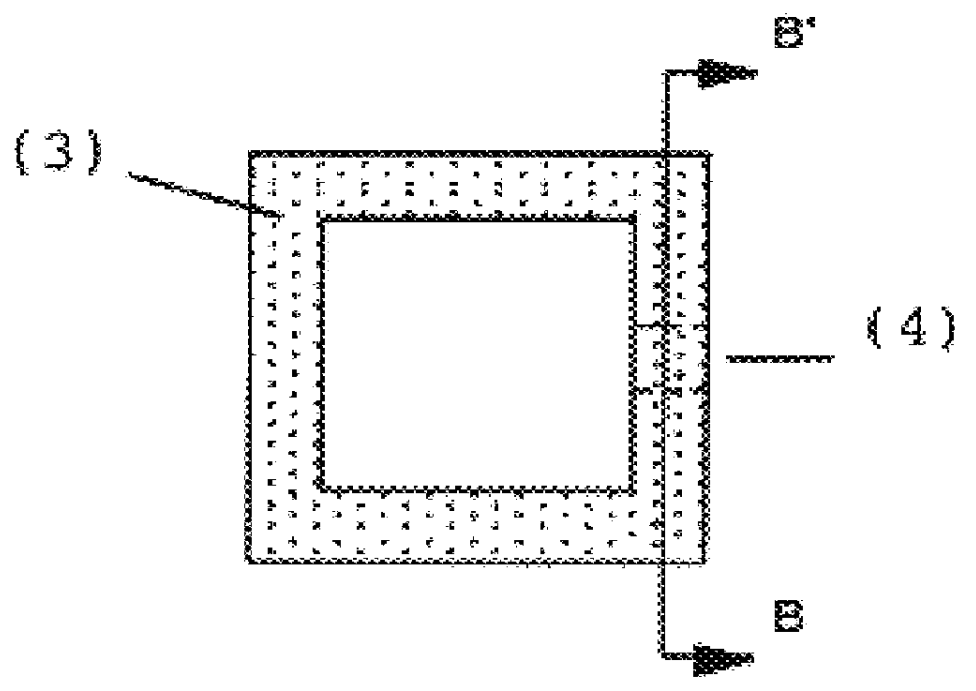

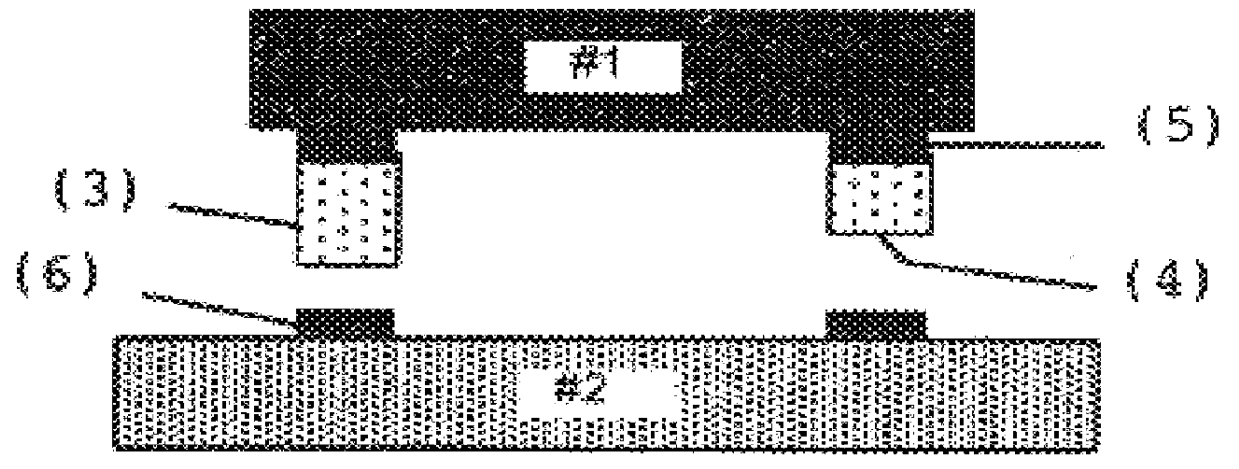

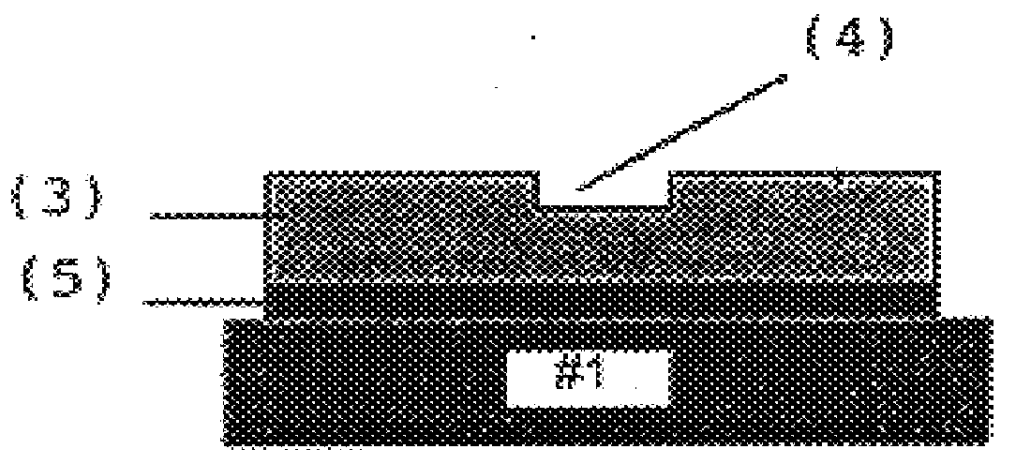

Method of fabrication of a microstructure having an internal cavity

InactiveUS6297072B1Easy to manufactureImprove air tightnessAcceleration measurement using interia forcesDecorative surface effectsInternal cavityMicrostructure

A method of fabricating a microstructure having an inside cavity. The method includes depositing a first layer or a first stack of layers in a substantially closed geometric configuration on a first substrate. Then, performing an indent on the first layer or on the top layer of said first stack of layers. Then, depositing a second layer or a second stack of layers substantially with said substantially closed geometric configuration on a second substrate. Then, aligning and bonding said first substrate on said second substrate such that a microstructure having a cavity is formed according to said closed geometry configuration.

Owner:CP CLARE +1

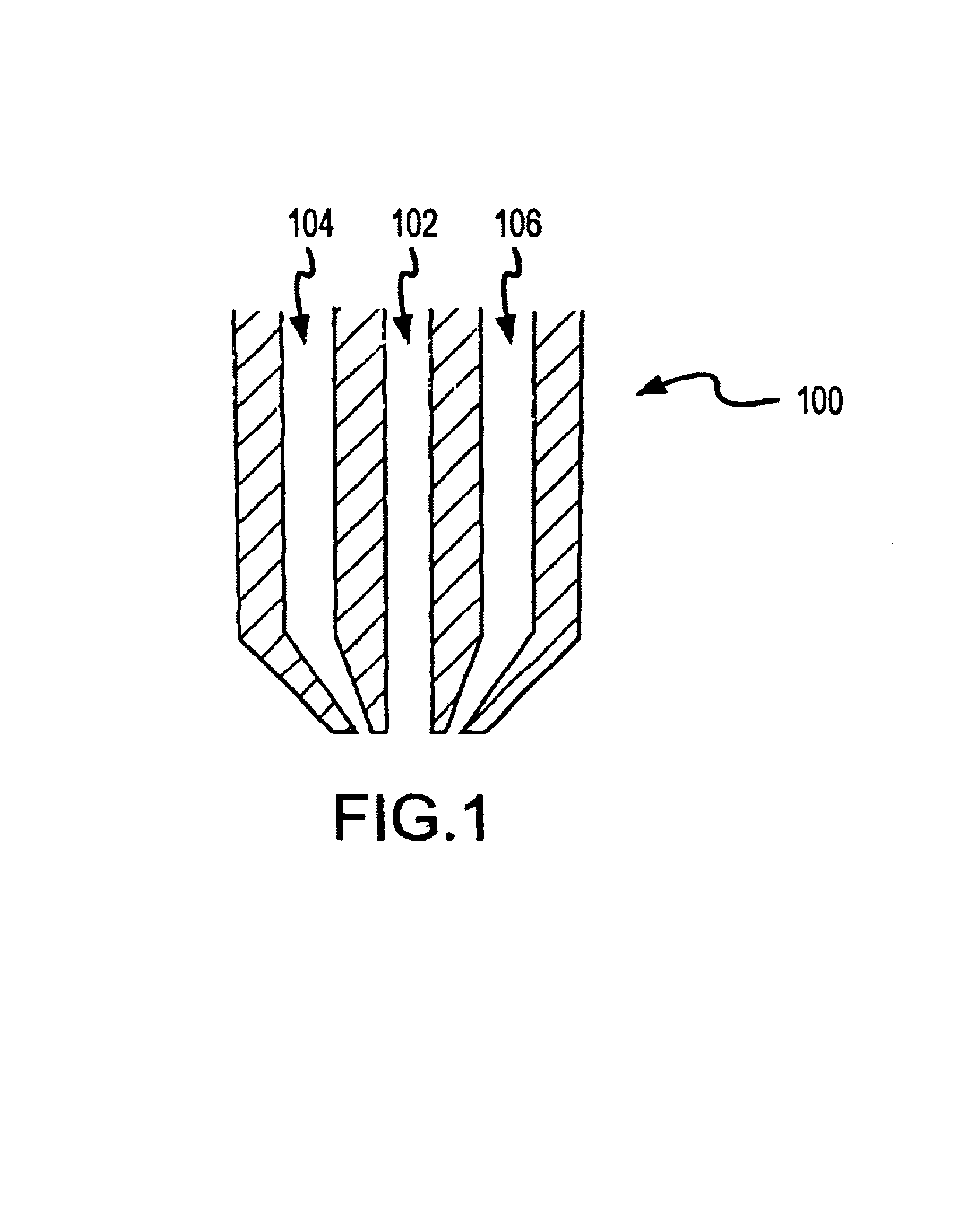

Coaxial waveguide microstructures and methods of formation thereof

ActiveUS7012489B2Printed circuit aspectsCircuit fluid transportElectrical conductorCoaxial waveguides

Provided are coaxial waveguide microstructures. The microstructures include a substrate and a coaxial waveguide disposed above the substrate. The coaxial waveguide includes: a center conductor; an outer conductor including one or more walls, spaced apart from and disposed around the center conductor; one or more dielectric support members for supporting the center conductor in contact with the center conductor and enclosed within the outer conductor; and a core volume between the center conductor and the outer conductor, wherein the core volume is under vacuum or in a gas state. Also provided are methods of forming coaxial waveguide microstructures by a sequential build process and hermetic packages which include a coaxial waveguide microstructure.

Owner:CUBIC CORPORATION

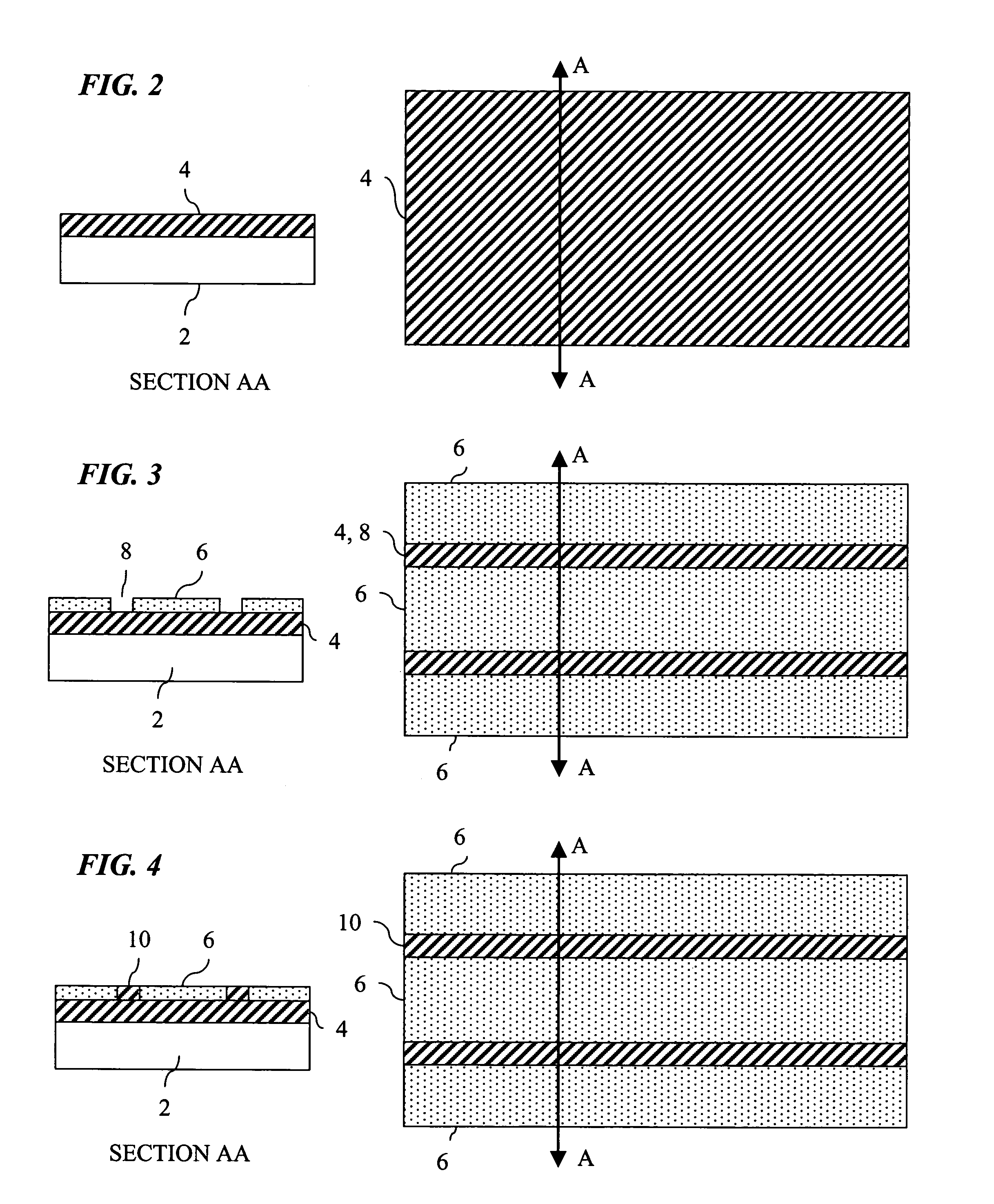

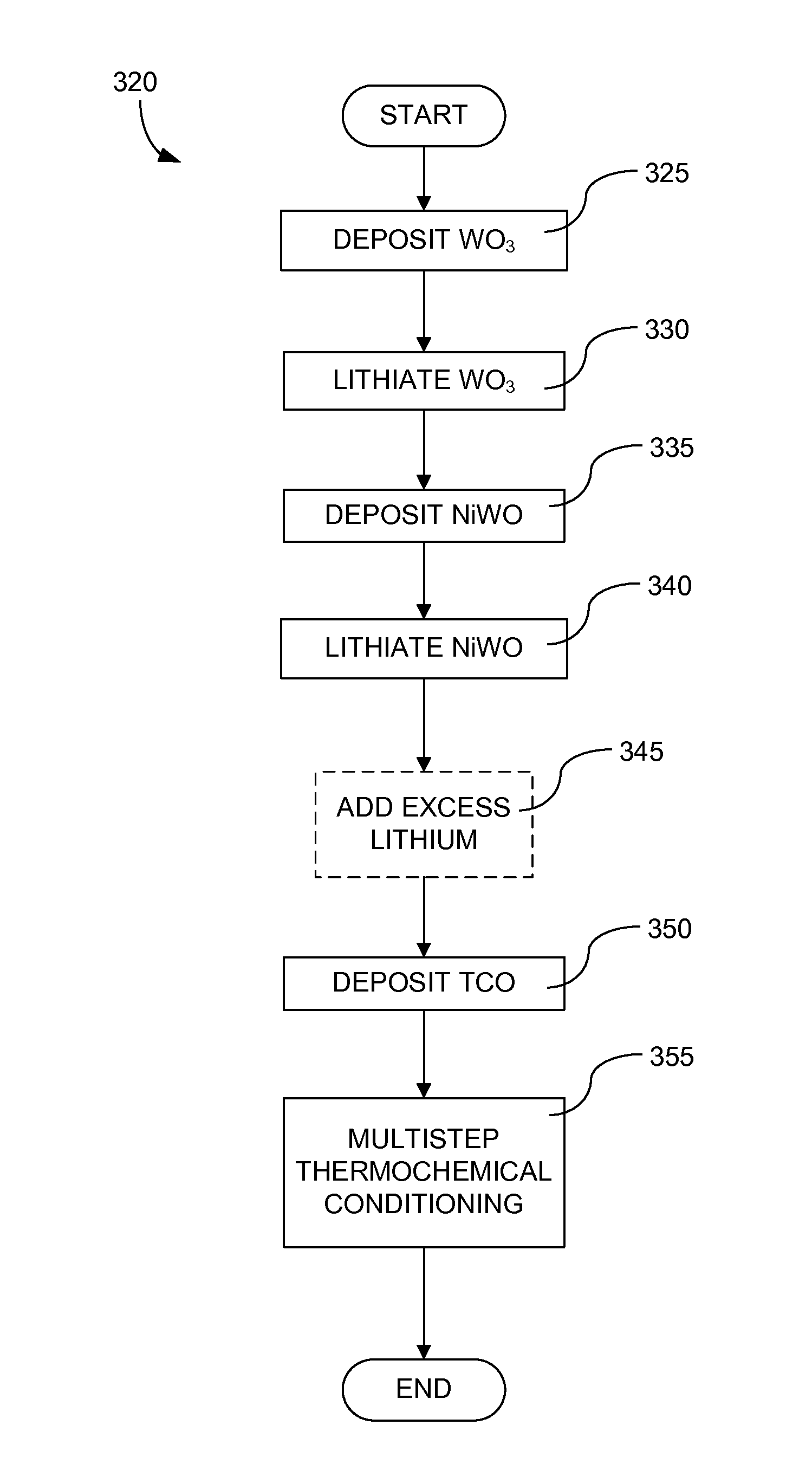

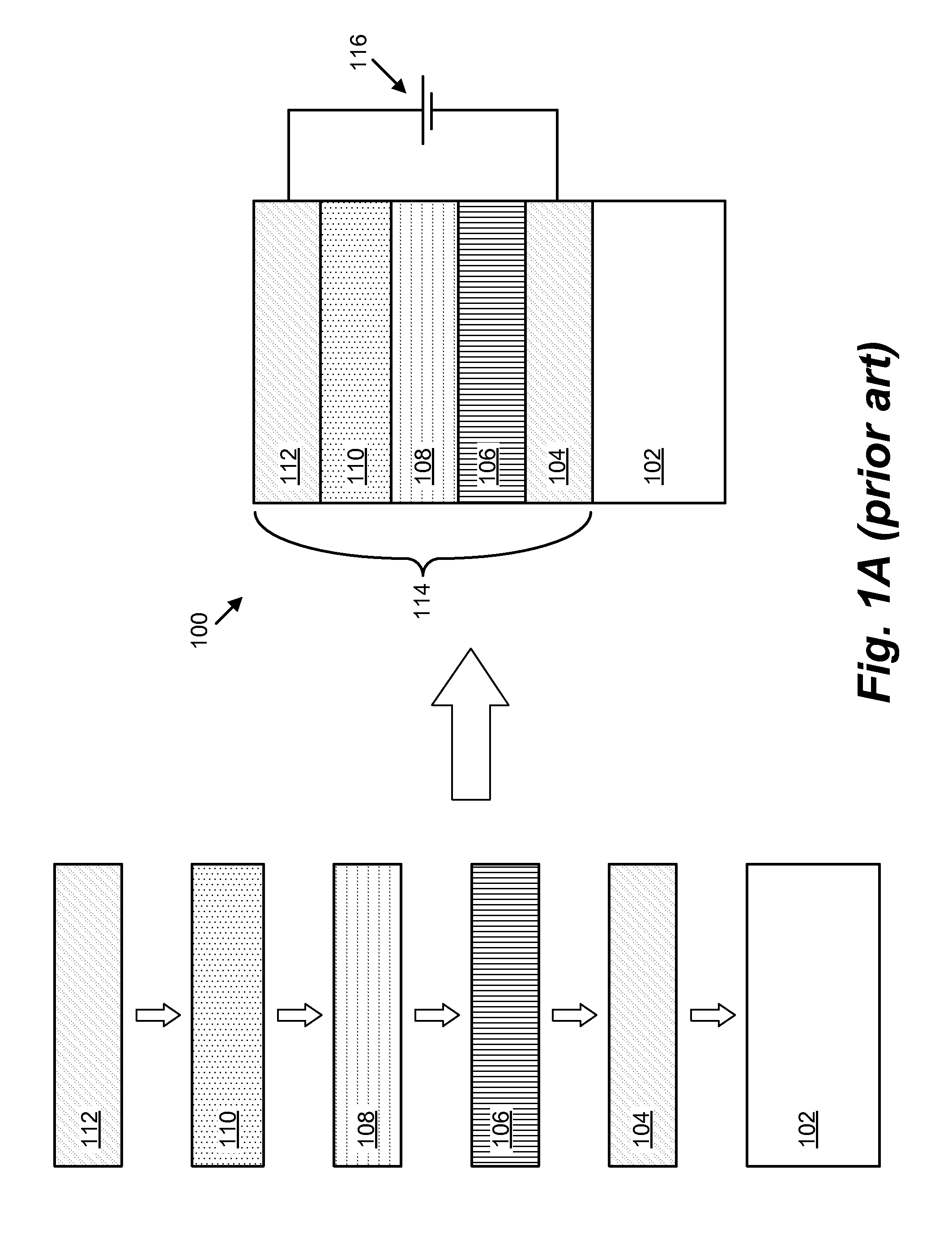

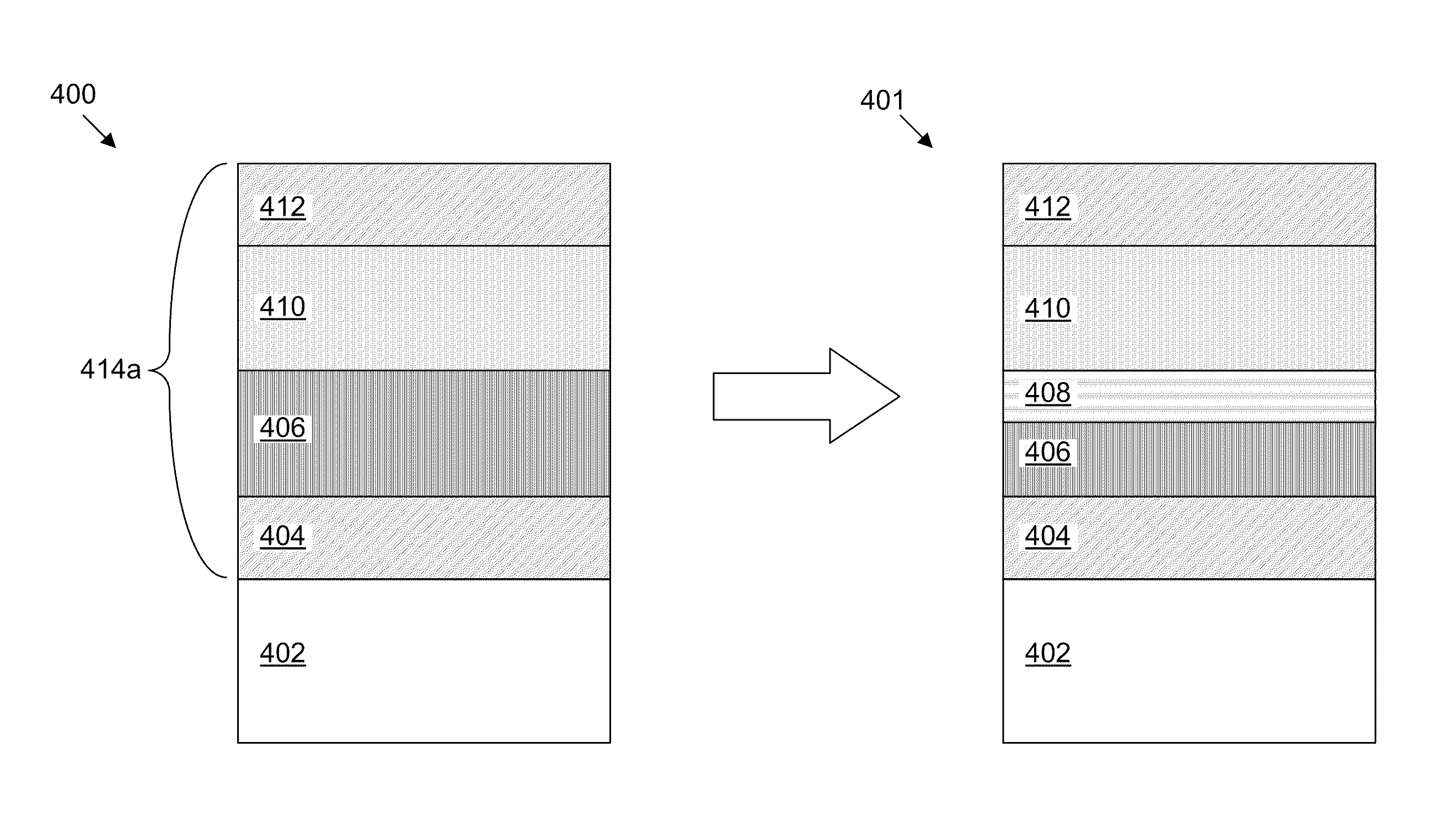

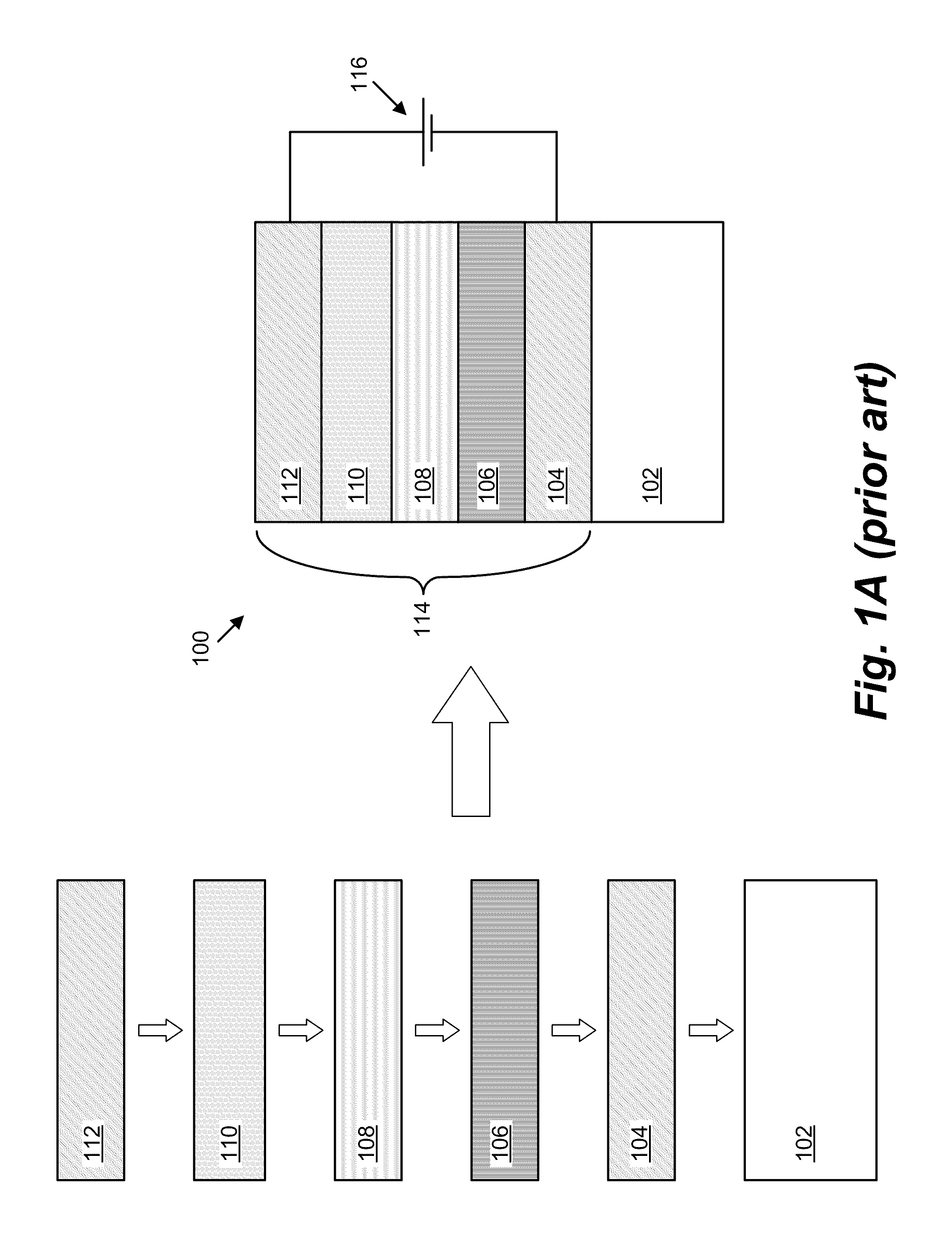

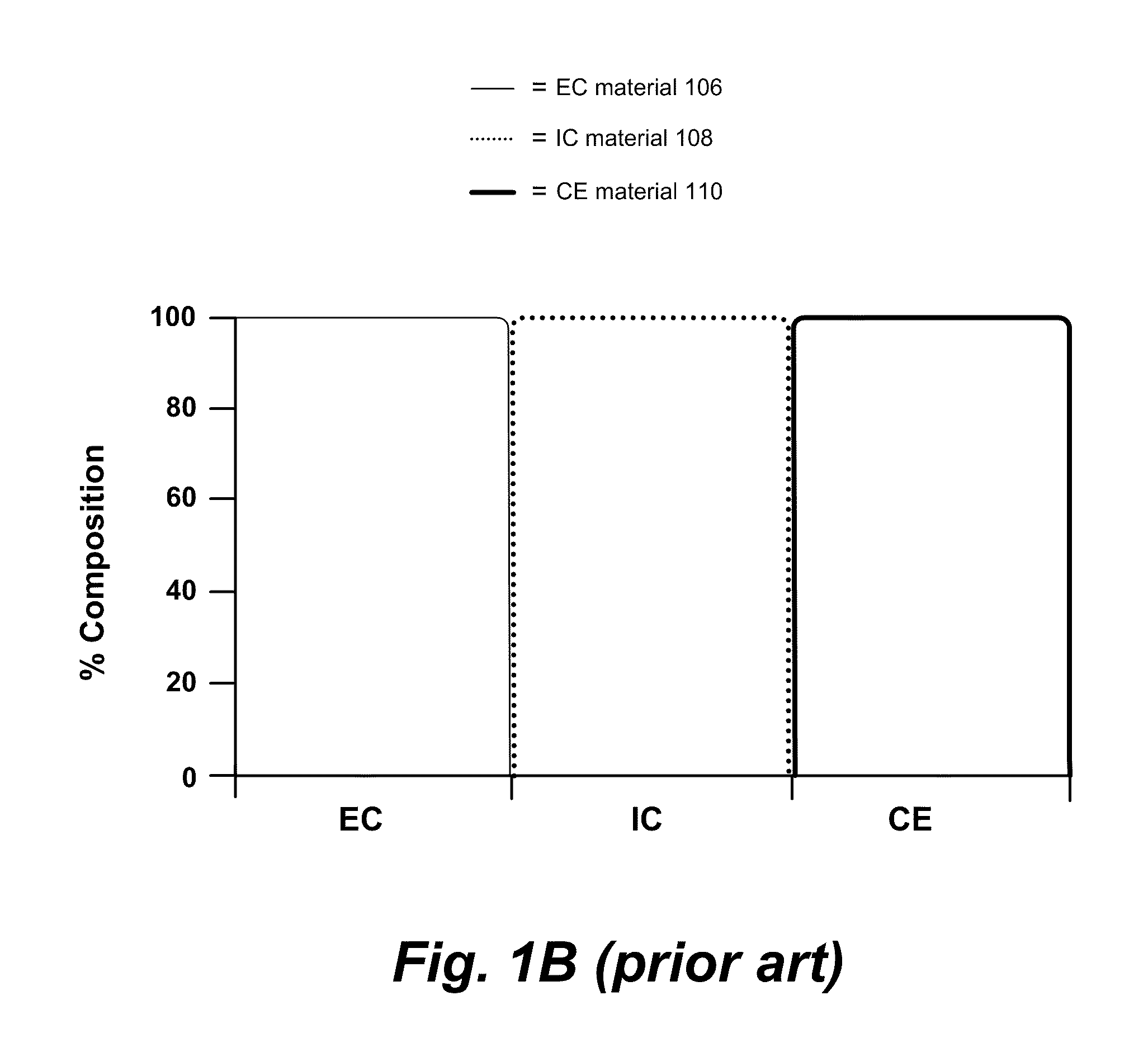

Electrochromic devices

ActiveUS20110266138A1Improve conductivityIncrease resistanceVacuum evaporation coatingSputtering coatingElectricityOptoelectronics

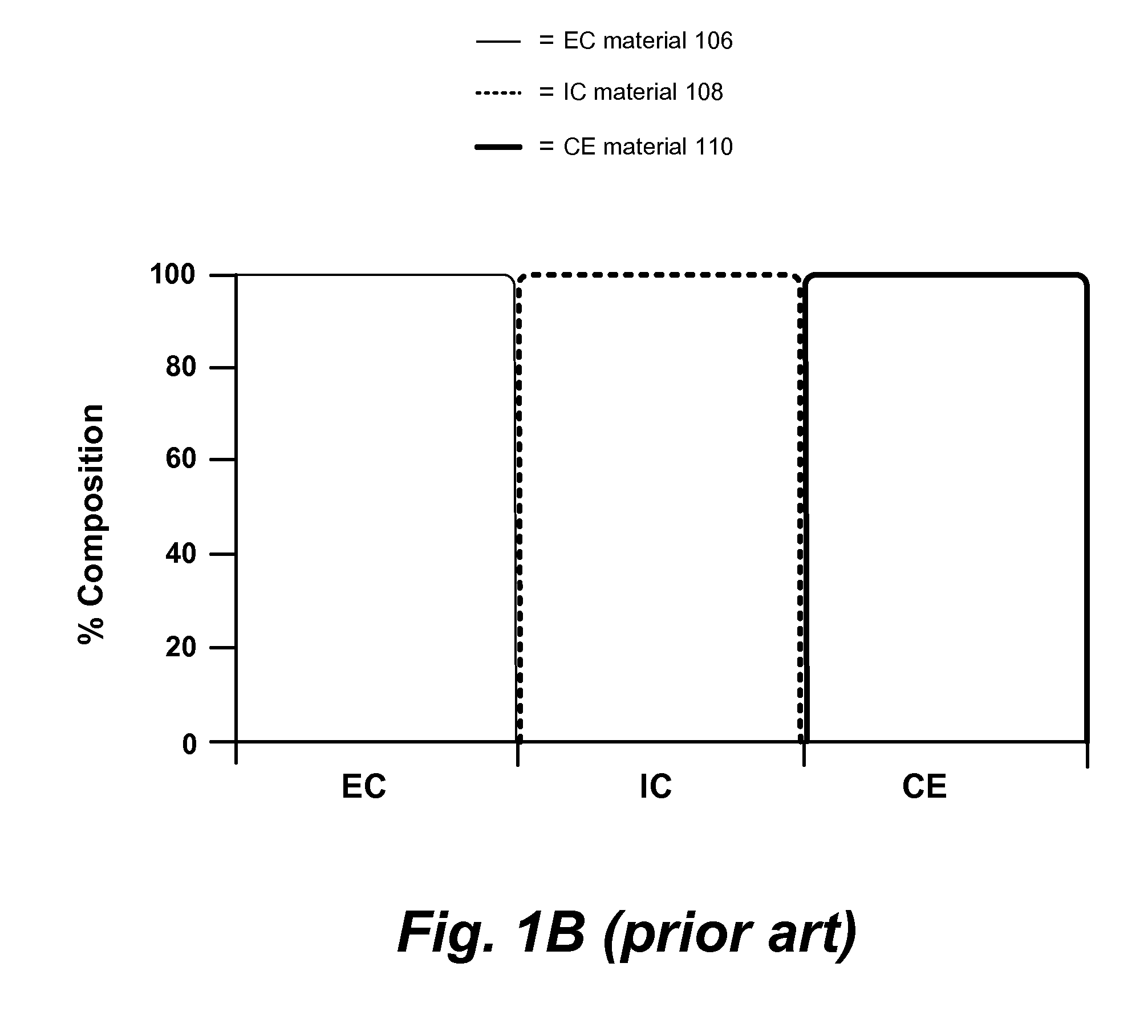

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically-insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically-insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

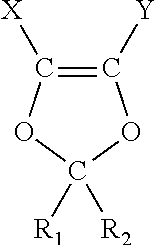

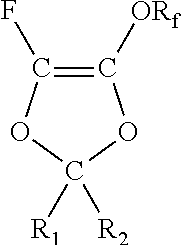

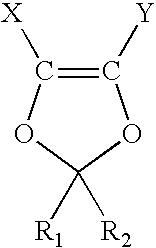

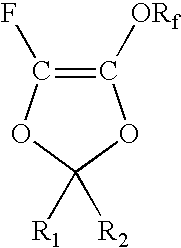

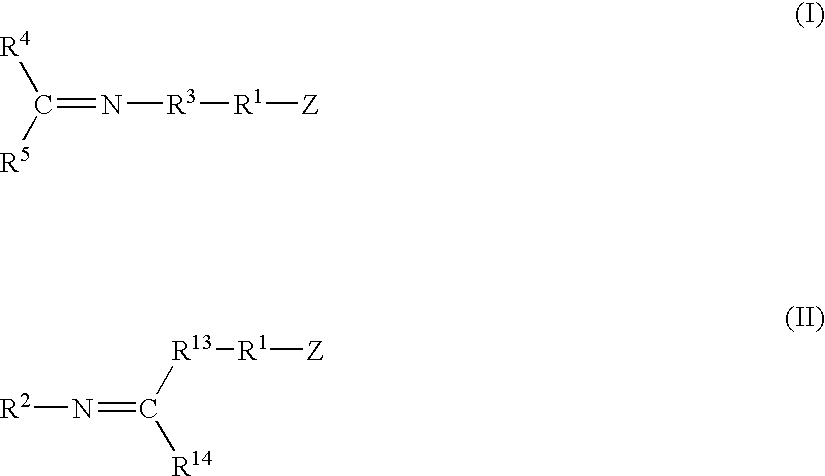

Modified polymers prepared with lanthanide-based catalysts

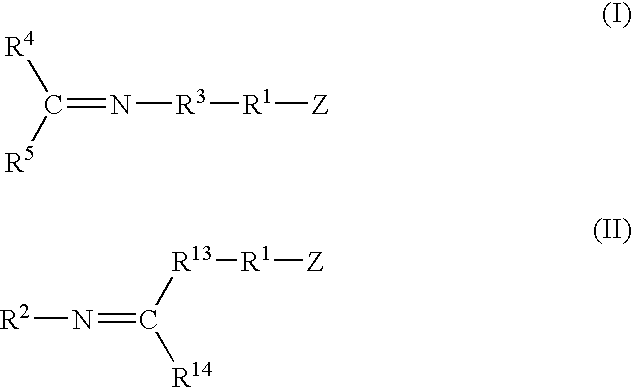

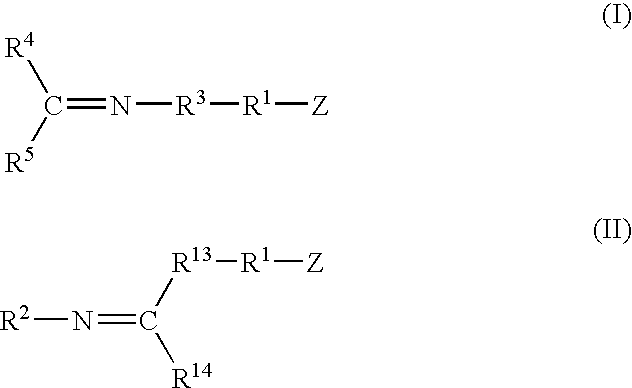

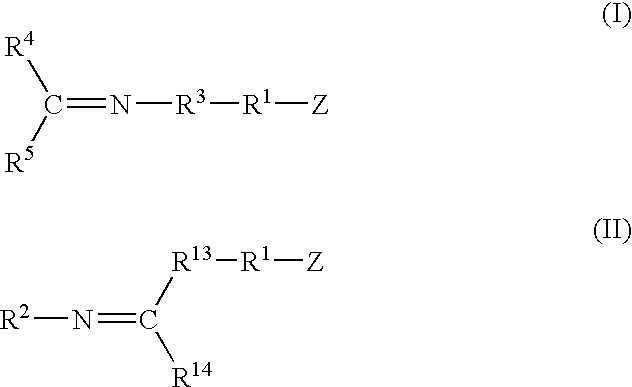

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2, R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

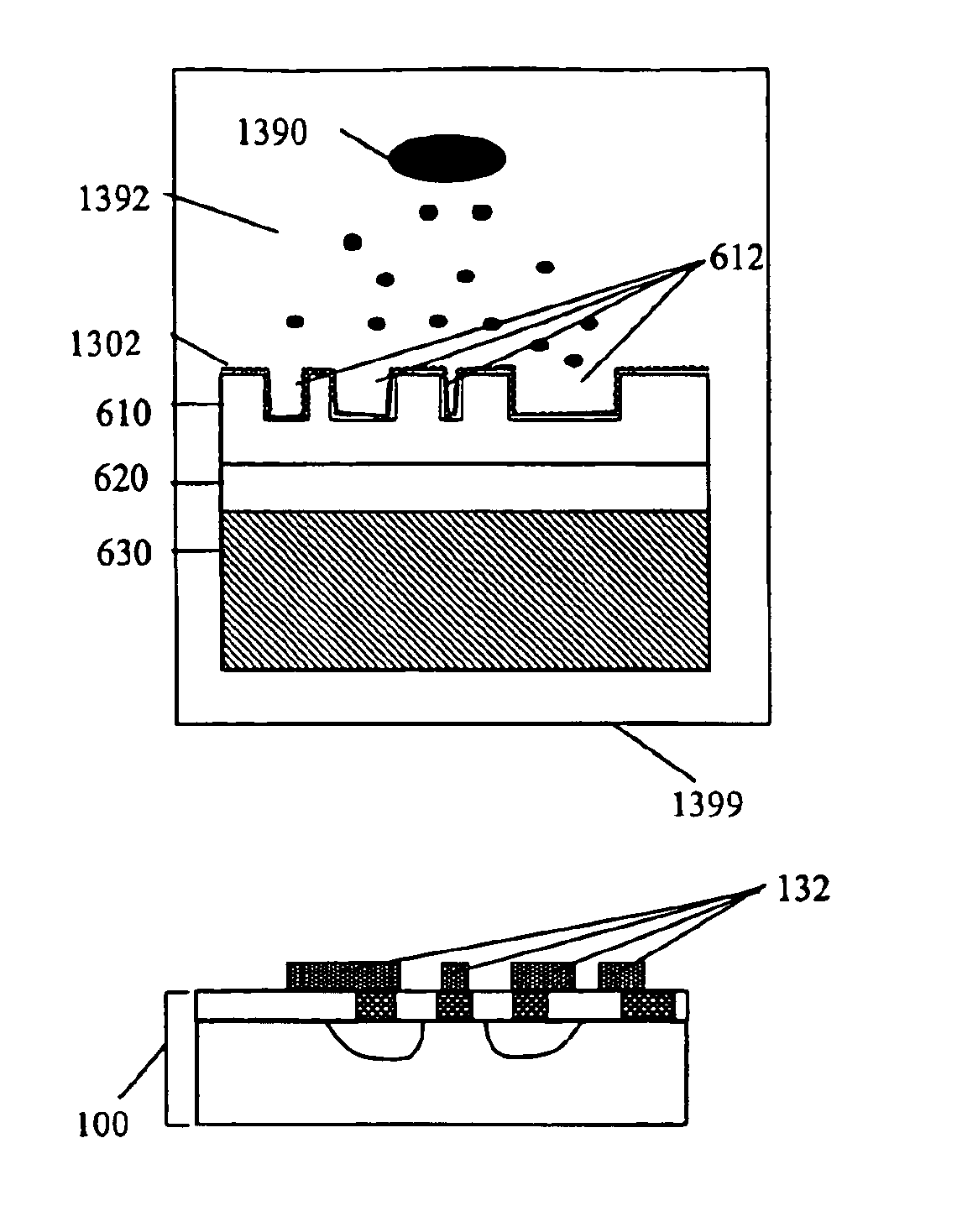

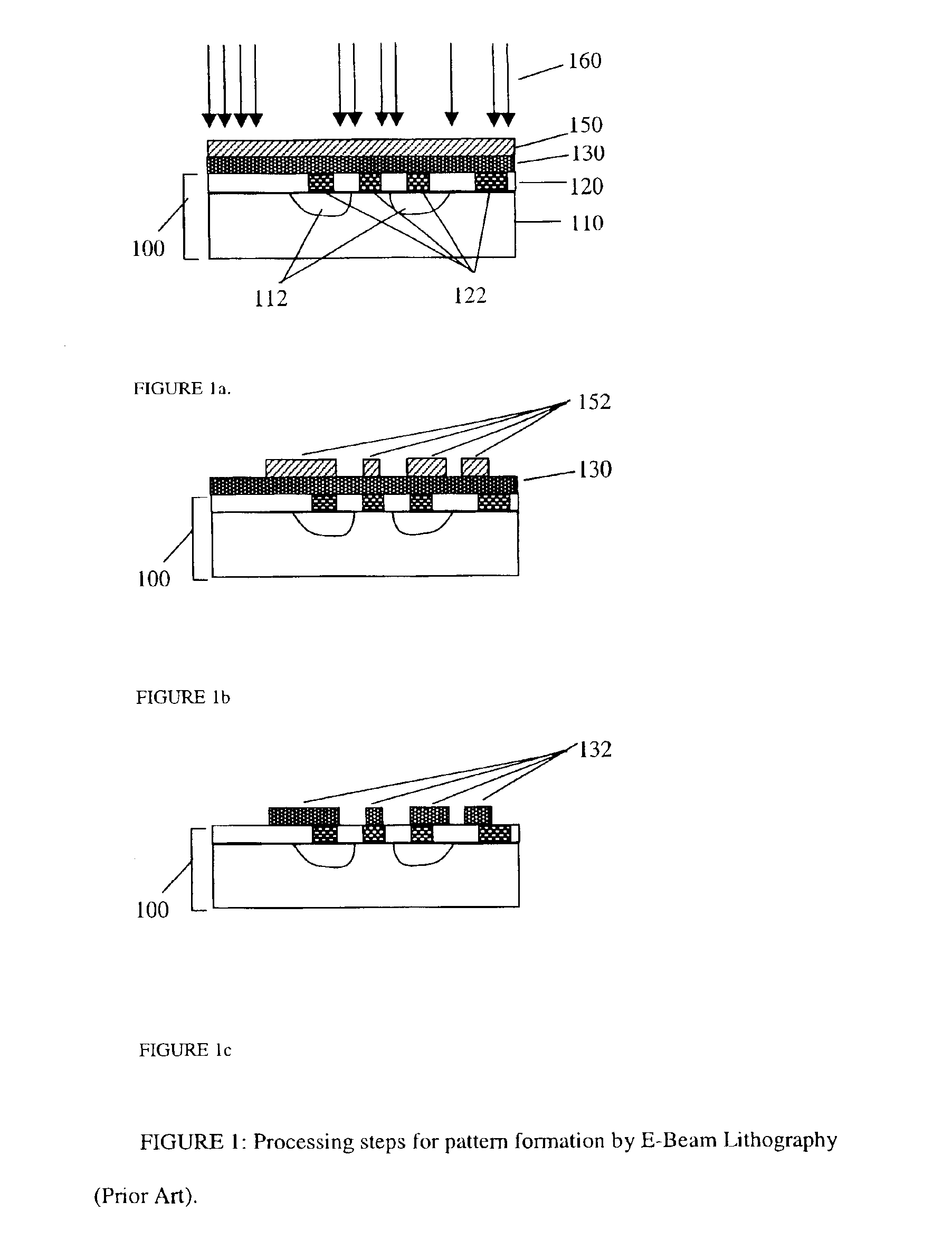

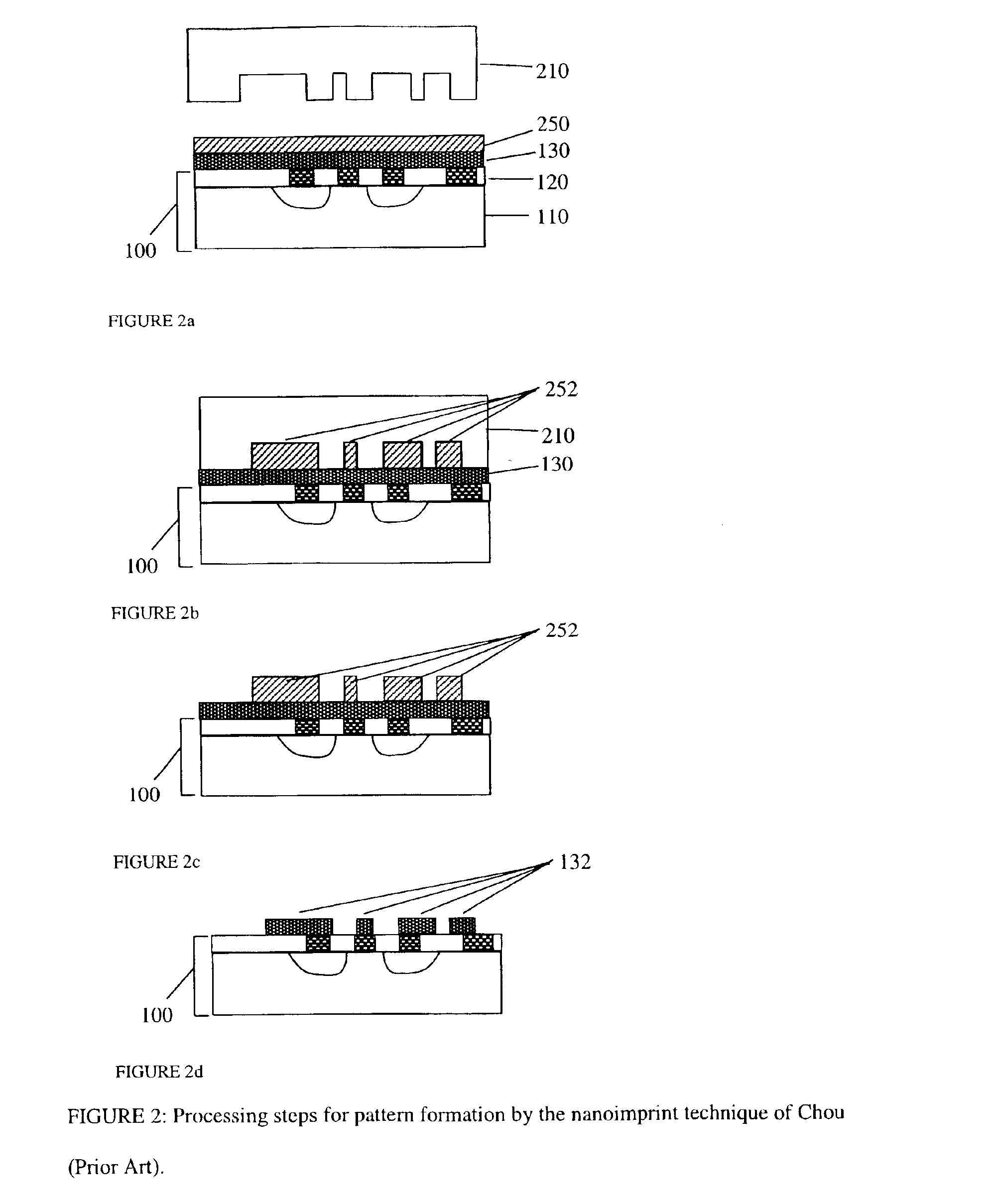

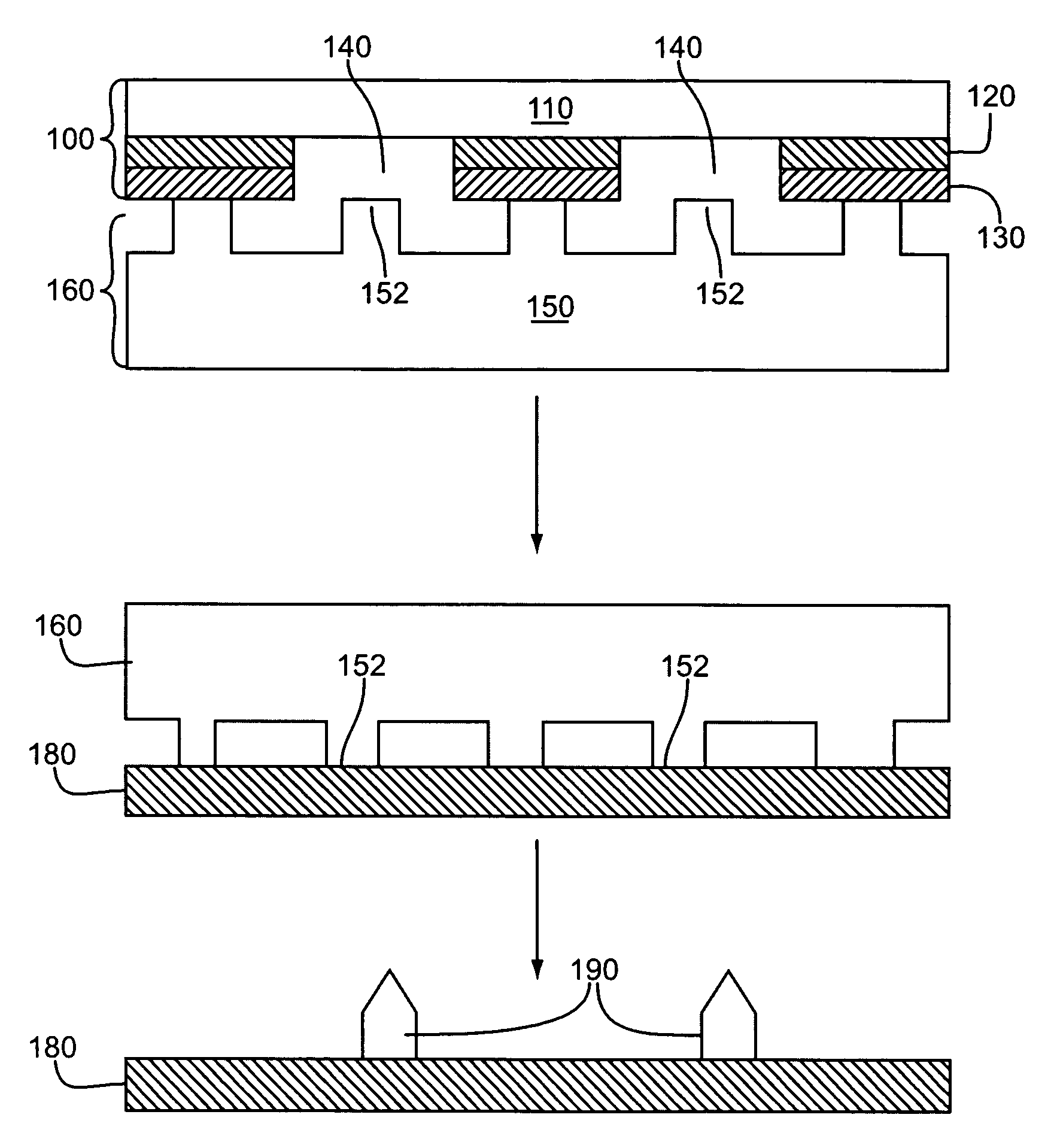

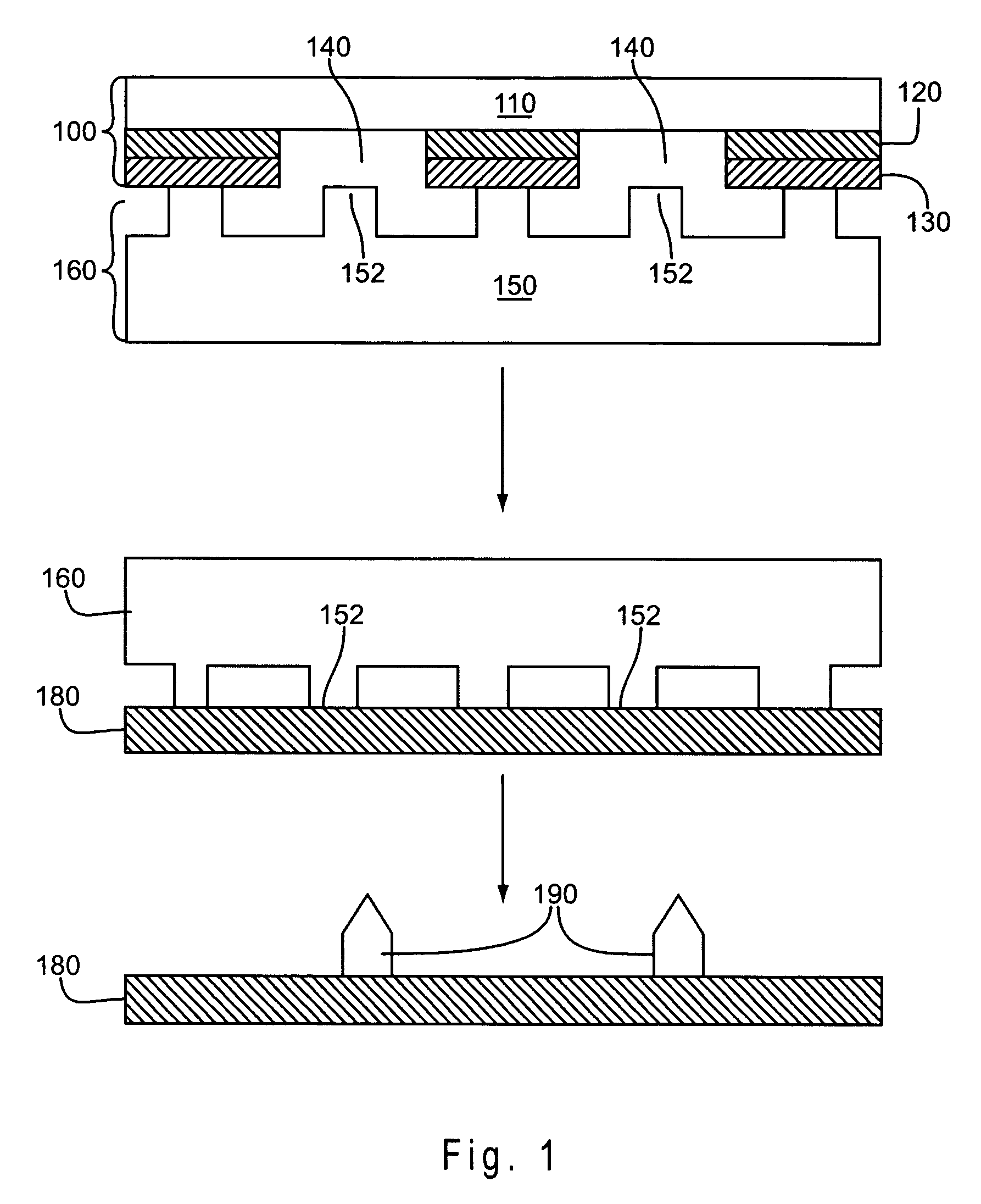

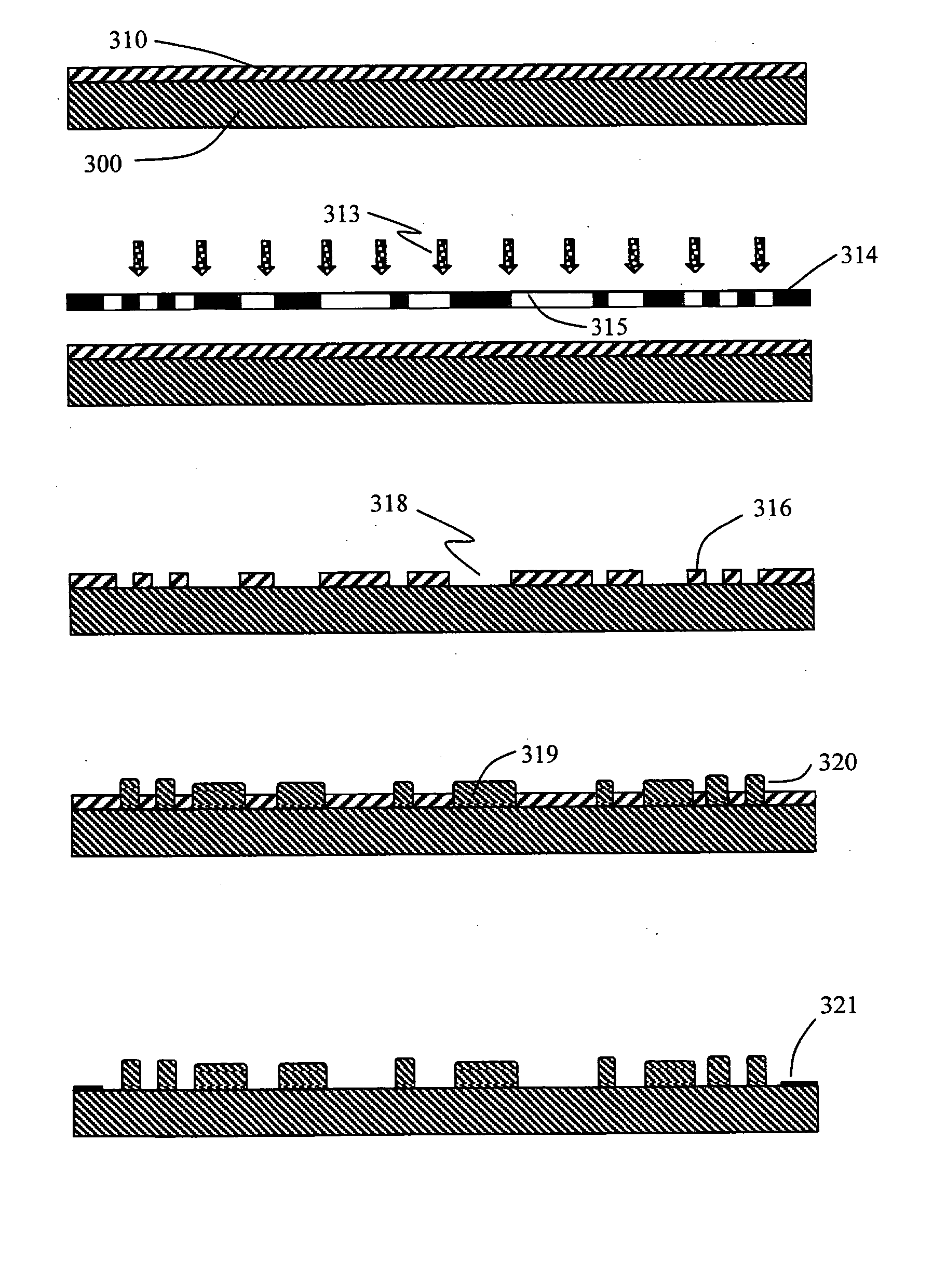

Replication and transfer of microstructures and nanostructures

InactiveUS6849558B2Facilitates pattern transferCheap to makeNanostructure manufactureDecorative surface effectsEngineeringMicroscopic scale

A method for the duplication of microscopic patterns from a master to a substrate is disclosed, in which a replica of a topographic structure on a master is formed and transferred when needed onto a receiving substrate using one of a variety of printing or imprint techniques, and then dissolved. Additional processing steps can also be carried out using the replica before transfer, including the formation of nanostructures, microdevices, or portions thereof. These structures are then also transferred onto the substrate when the replica is transferred, and remain on the substrate when the replica is dissolved. This is a technique that can be applied as a complementary process or a replacement for various lithographic processing steps in the fabrication of integrated circuits and other microdevices.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

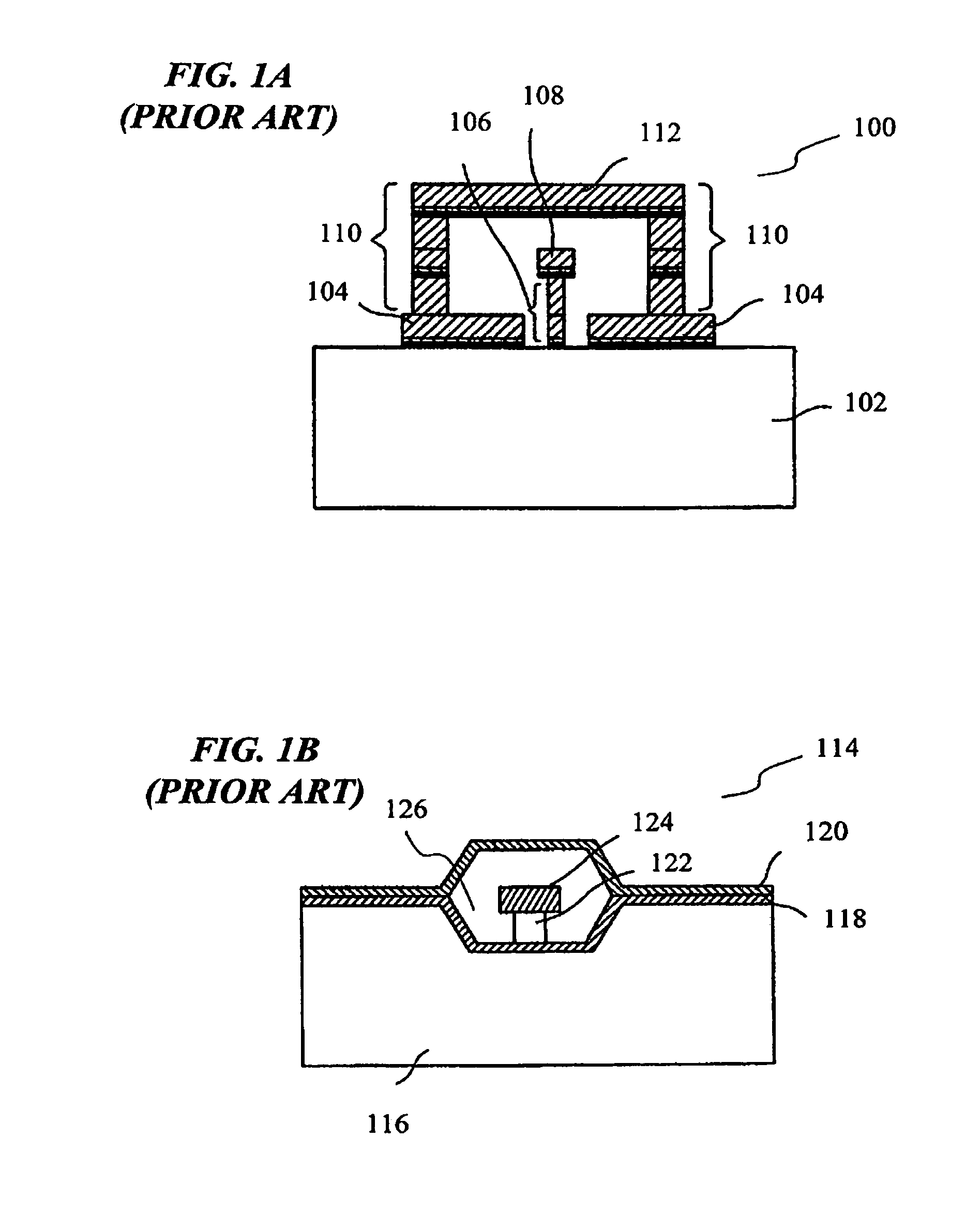

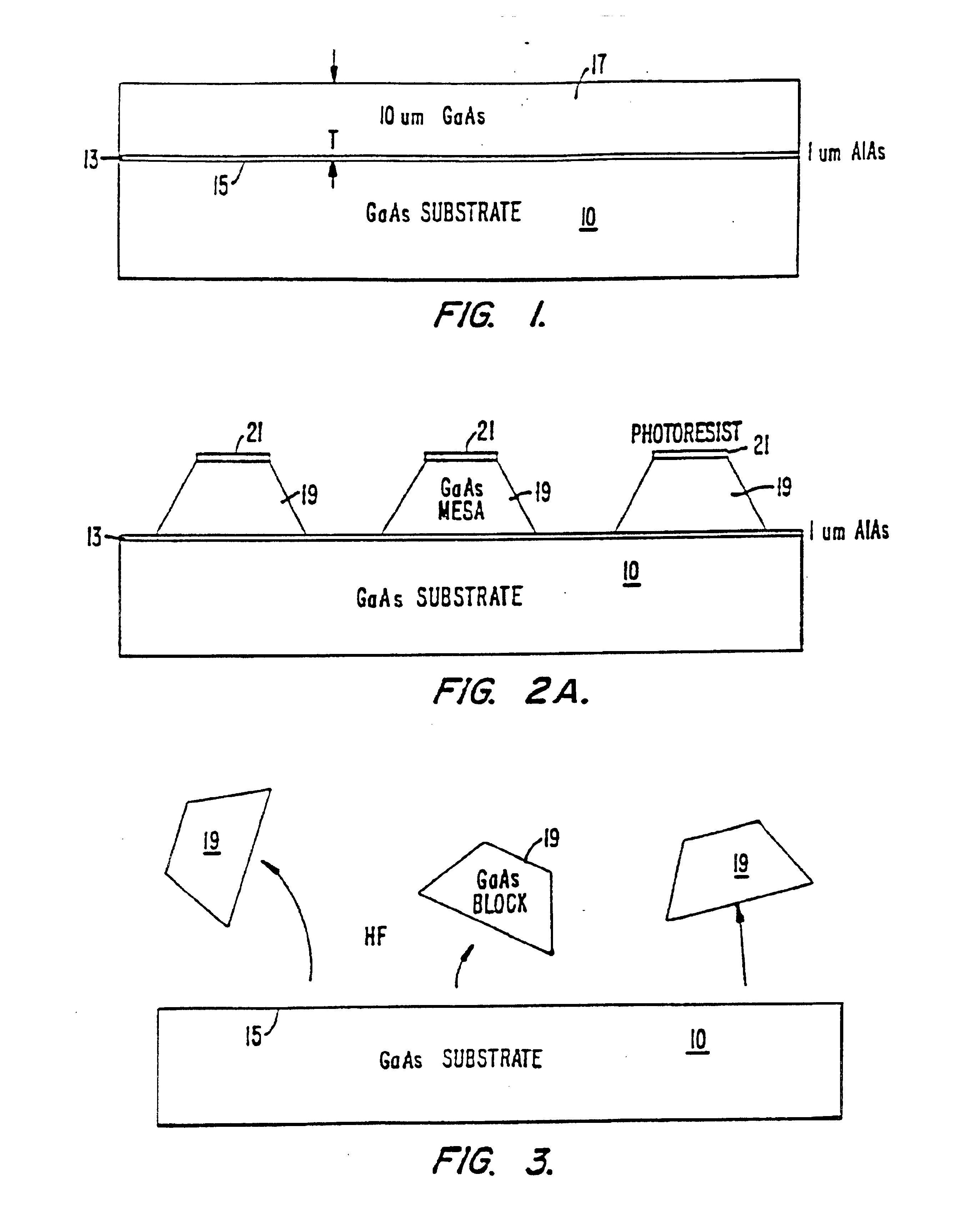

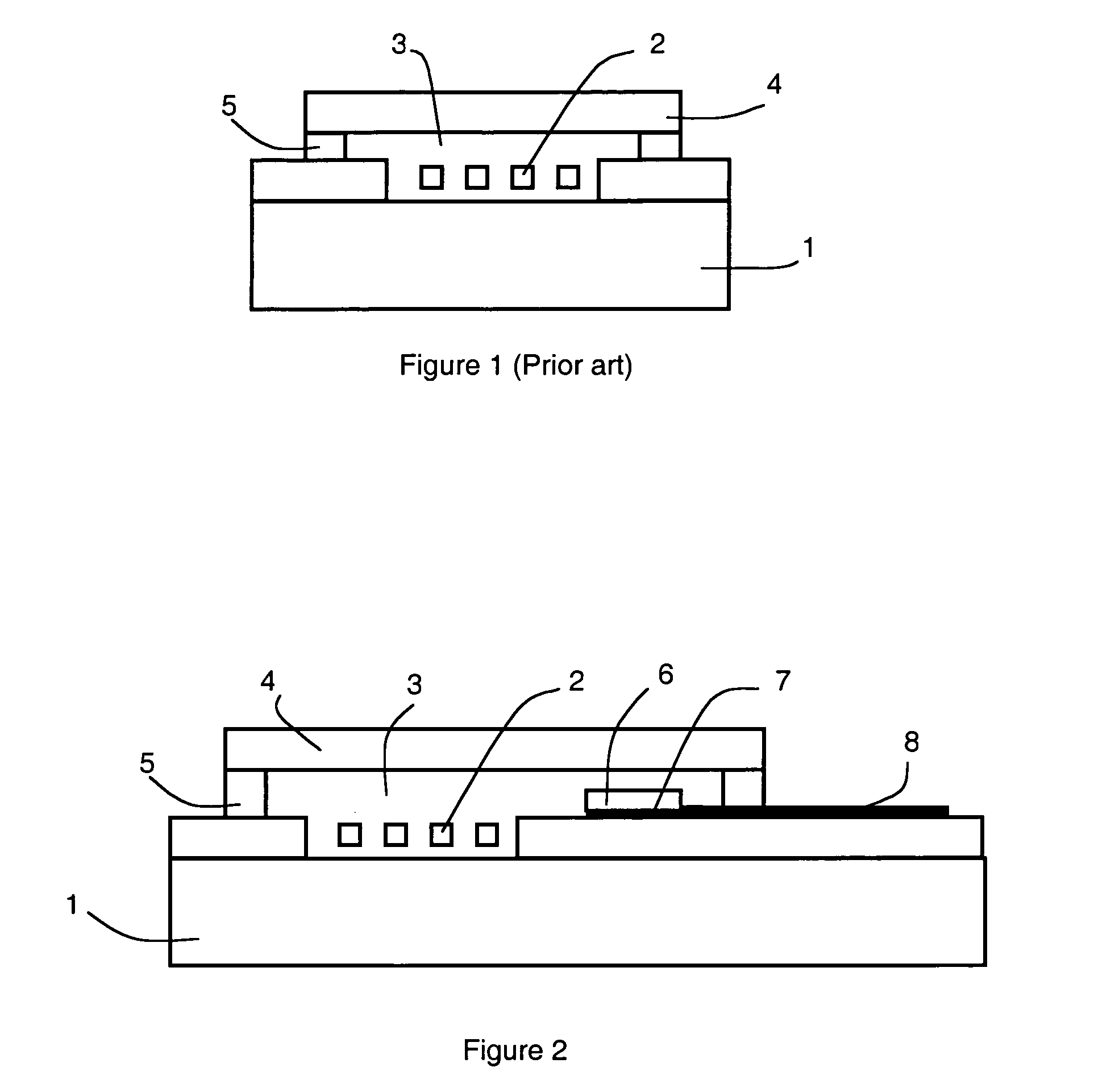

Manufacture of MEMS structures in sealed cavity using dry-release MEMS device encapsulation

InactiveUS7008812B1Eliminates undesirable liquid surface tensionIncrease etch rateAcceleration measurement using interia forcesSolid-state devicesMaterials sciencePlasma etching

The disclosed fabrication methodology addresses the problem of creating low-cost micro-electro-mechanical devices and systems, and, in particular, addresses the problem of delicate microstructures being damaged by the surface tension created as a wet etchant evaporates. This disclosure demonstrates a method for employing a dry plasma etch process to release encapsulated microelectromechanical components.

Owner:CYMATICS LAB CORP

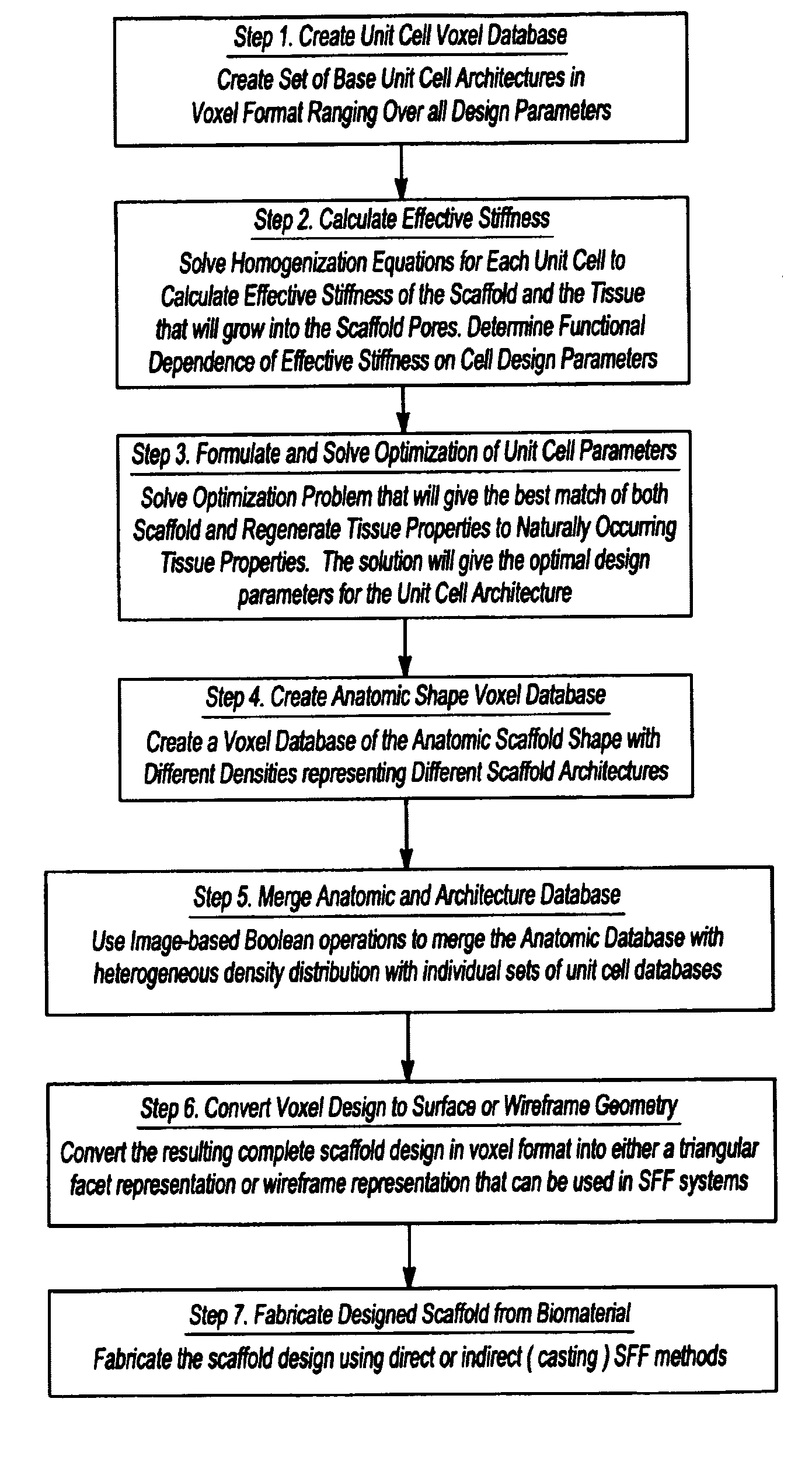

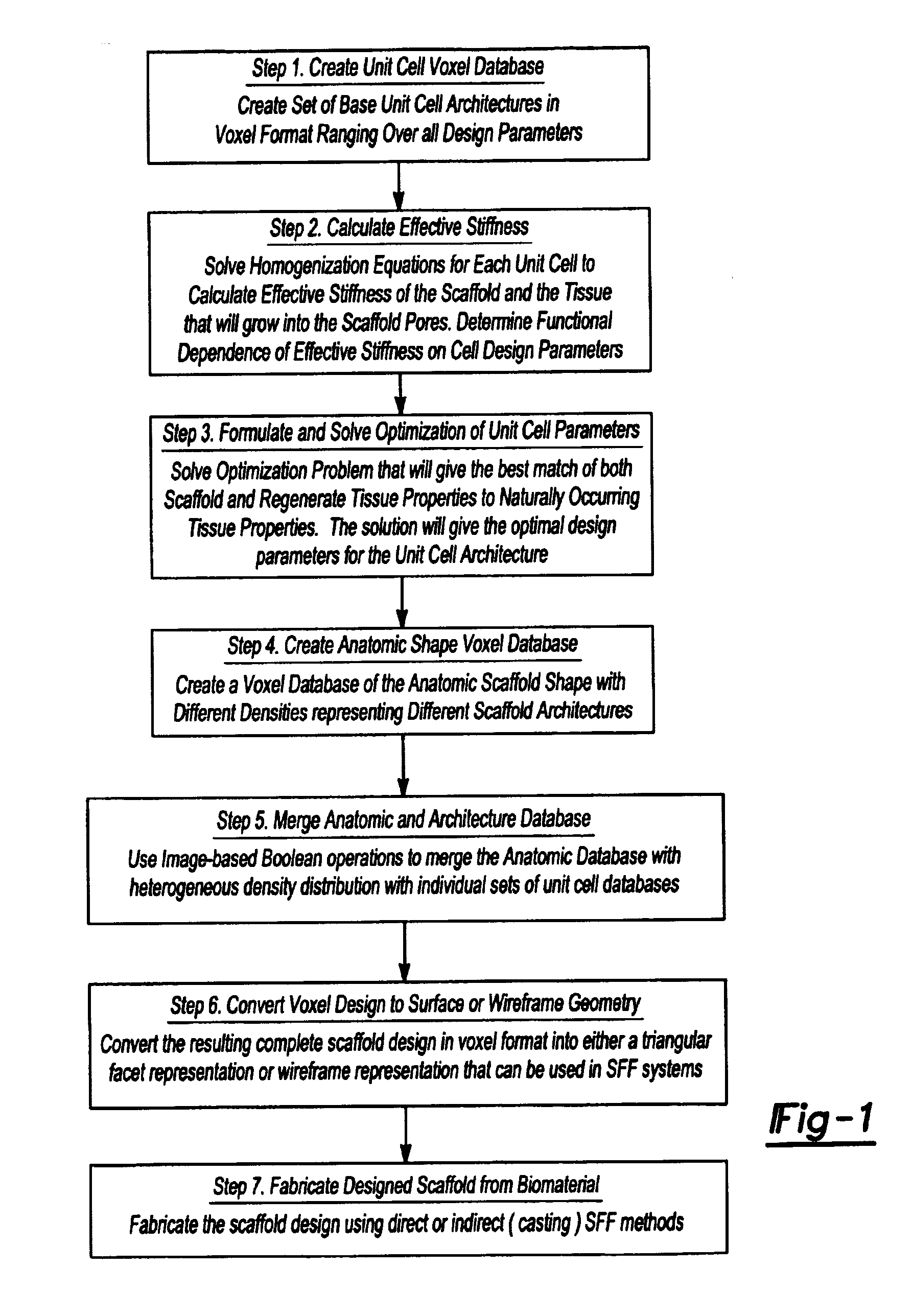

Design methodology for tissue engineering scaffolds and biomaterial implants

A design methodology is provided for creating biomaterial scaffolds optimized for in vivo function with any 3D anatomic shape. The method creates all designs using voxel based design techniques. It also provides for optimization of implant and scaffold microstructure to best match functional and biofactor delivery (including cells, genes and proteins) requirements. The voxel based design techniques readily allow combination of any scaffold or implant microstructure database with any complex 3D anatomic shape created by CT or MRI scanners. These designs can be readily converted to formats for layered manufacturing or casting.

Owner:HOLLISTER SCOTT J +2

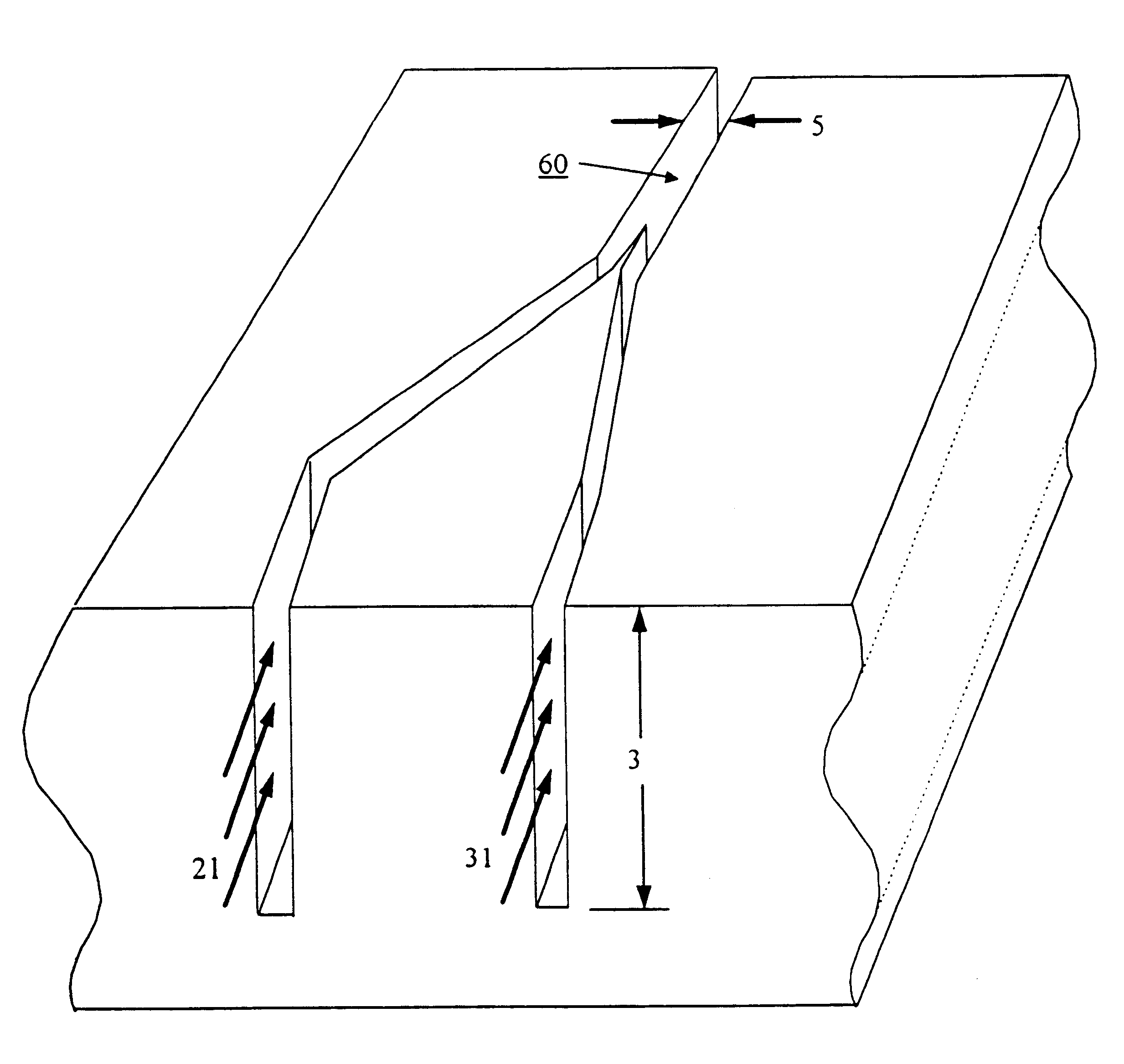

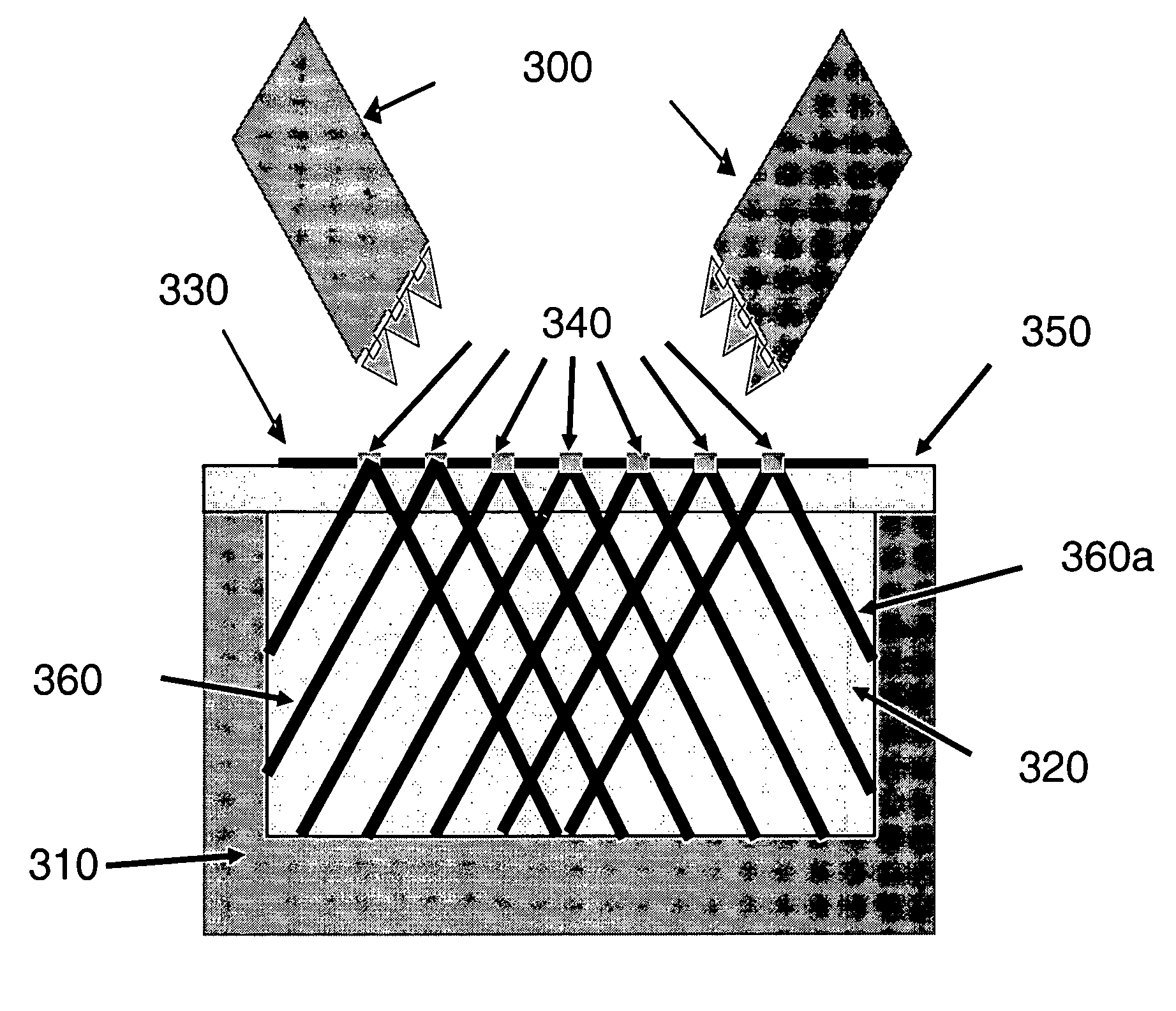

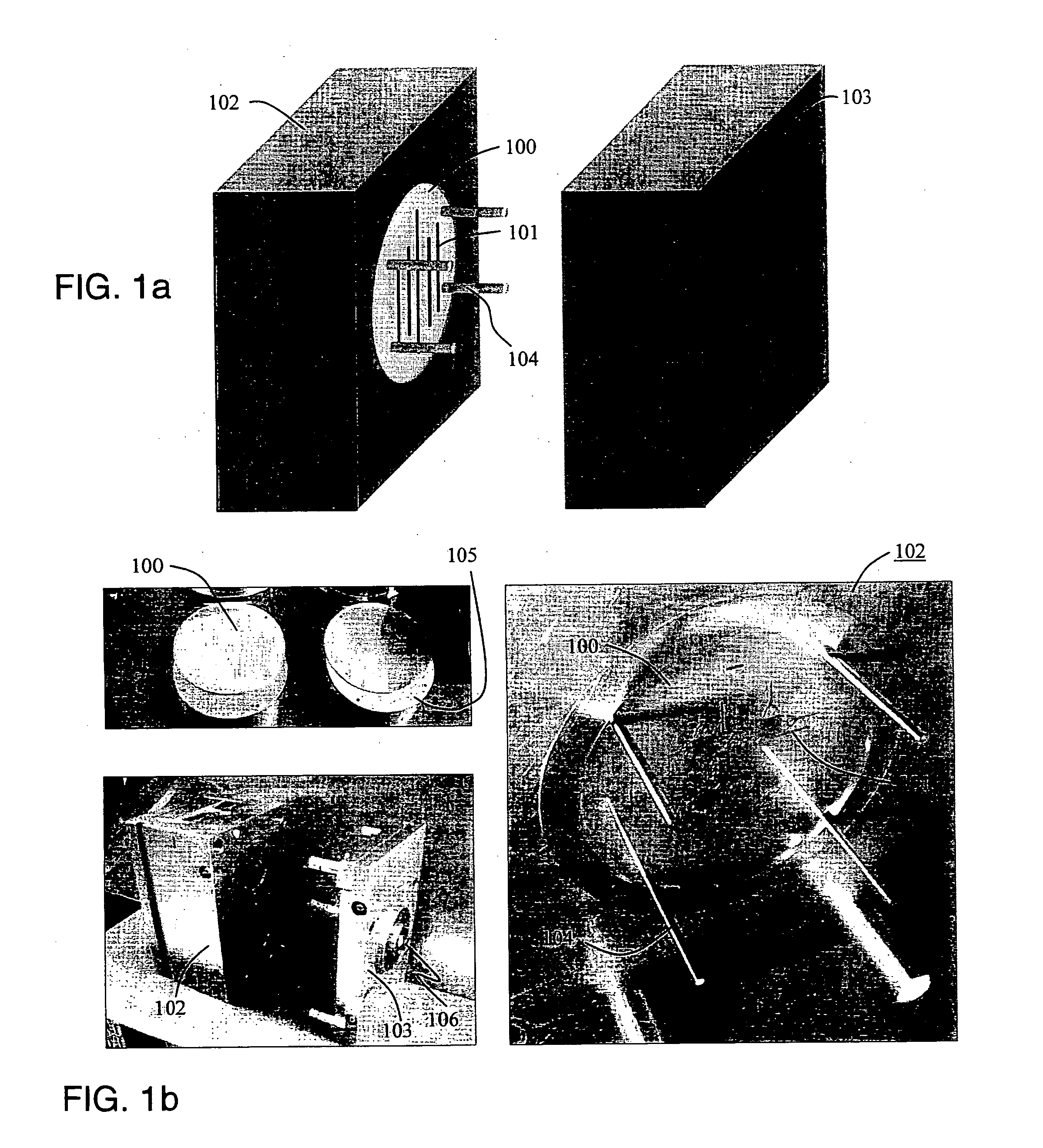

Optically oriented three-dimensional polymer microstructures

A method and system of creating one or more waveguides and / or patterning these waveguides to form a 3D microstructure that uses mask and collimated light. In one embodiment, the system includes at least one collimated light source selected to produce a collimated light beam; a reservoir having a photo-monomer adapted to polymerize by the collimated light beam; and a mask having at least one aperture and positioned between the at least one collimated light source and the reservoir. Here, the at least one aperture is adapted to guide a portion of the collimated light beam into the photo-monomer to form the at least one polymer waveguide through a portion of a volume of the photo-monomer.

Owner:HRL LAB

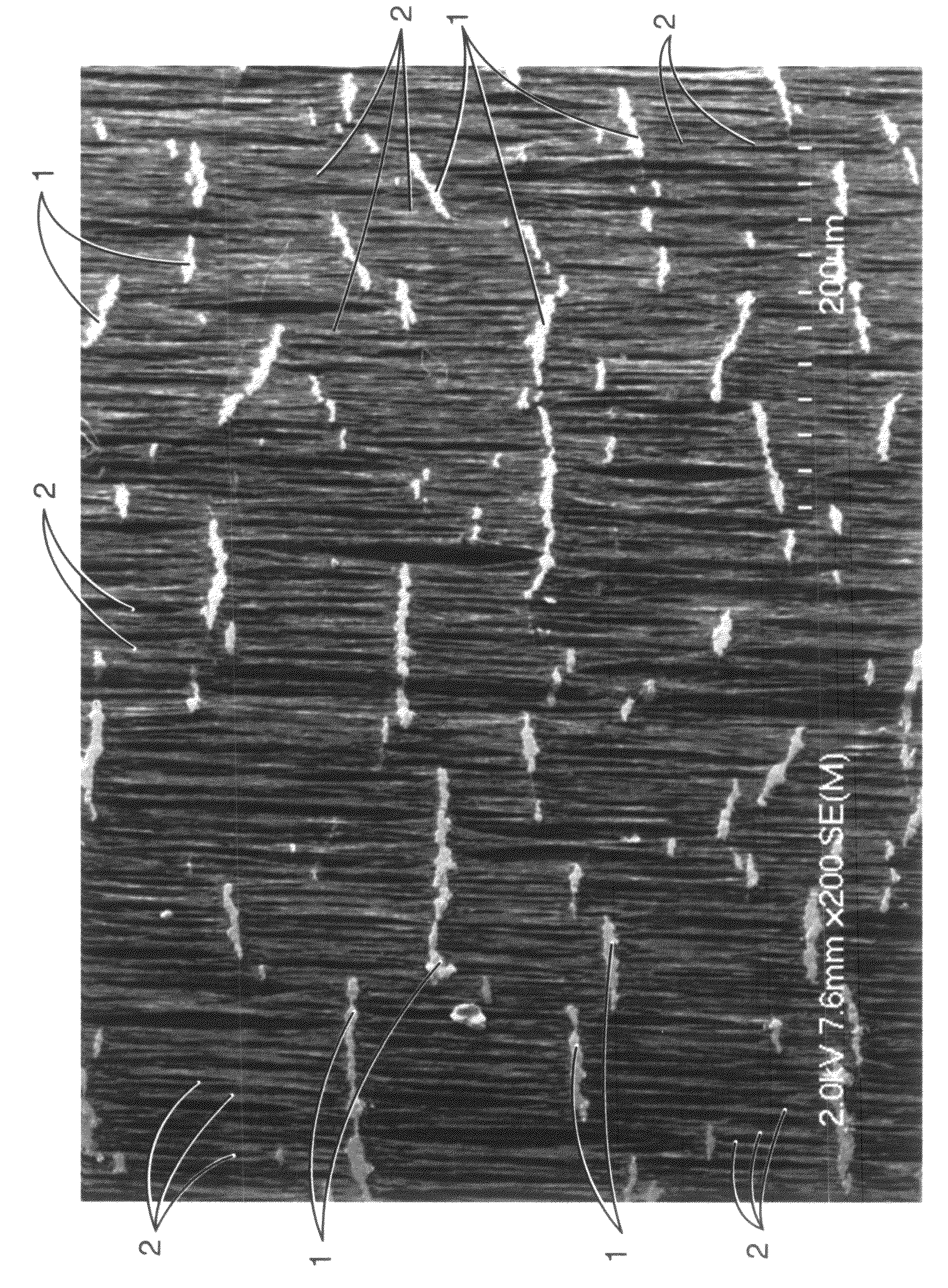

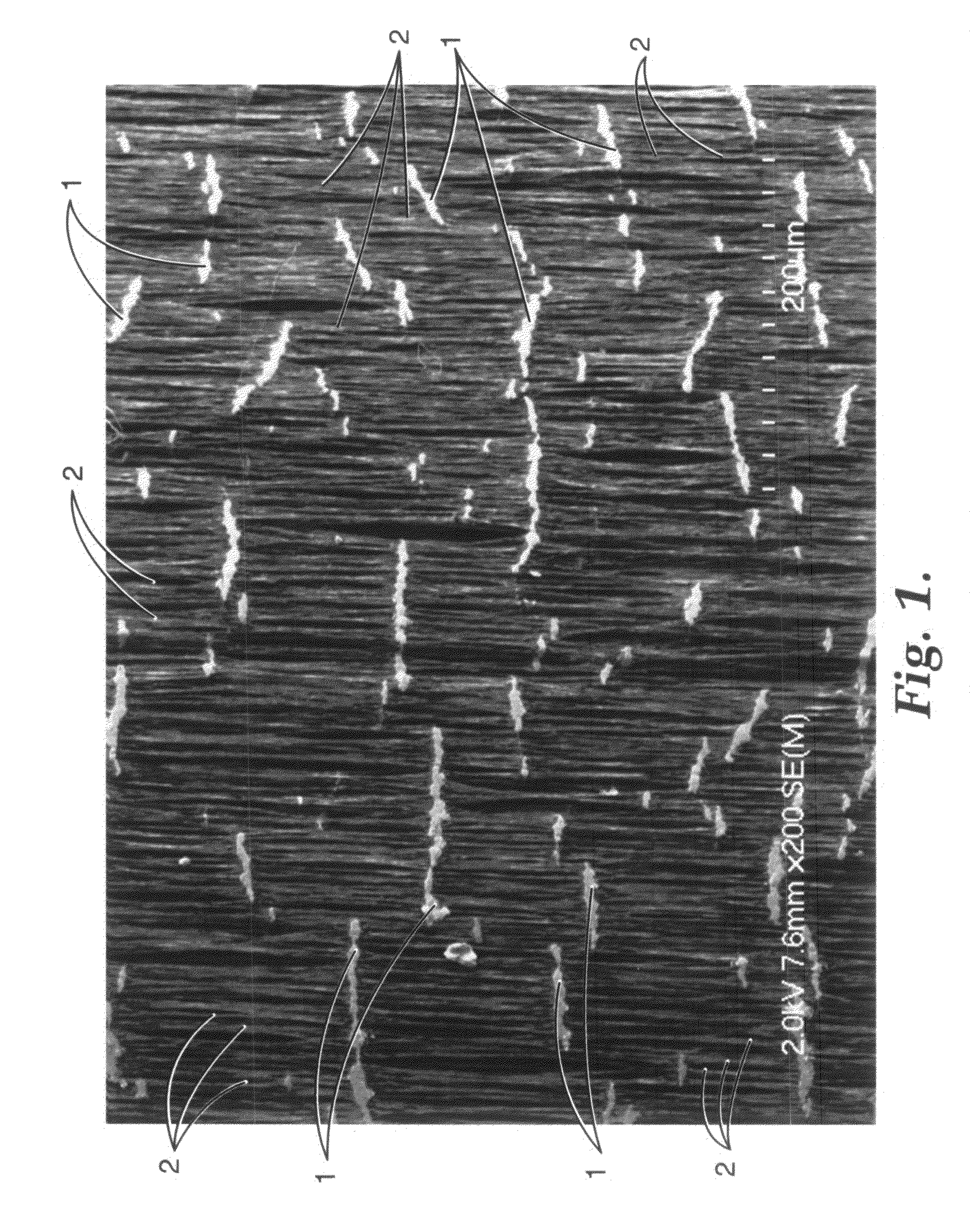

Expandable TFE copolymers, method of making, and porous, expended articles thereof

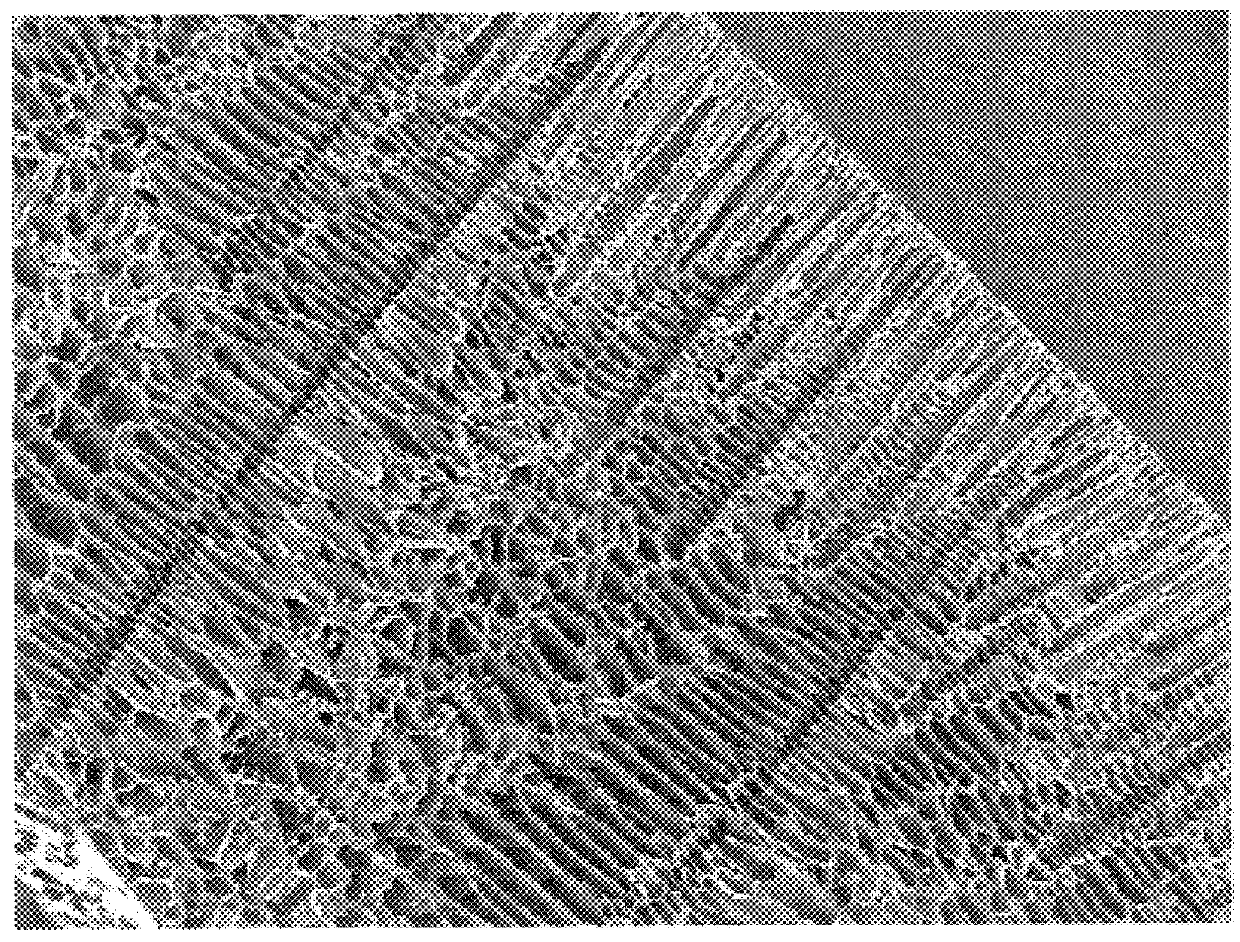

A process for the polymerization of a true tetrafluoroethylene (TFE) copolymer of the fine powder type is provided, wherein the copolymer contains polymerized comonomer units of at least one comonomer other than TFE in concentrations of at least or exceeding 1.0 weight percent, and which can exceed 5.0 weight percent, wherein the copolymer is expandable, that is, the copolymer may be expanded to produce strong, useful, expanded TFE copolymeric articles having a microstructure of nodes interconnected by fibrils.

Owner:WL GORE & ASSOC INC

Electrochromic devices

ActiveUS8300298B2Improve conductivityIncrease resistanceDoors/windowsVacuum evaporation coatingElectricityOptoelectronics

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

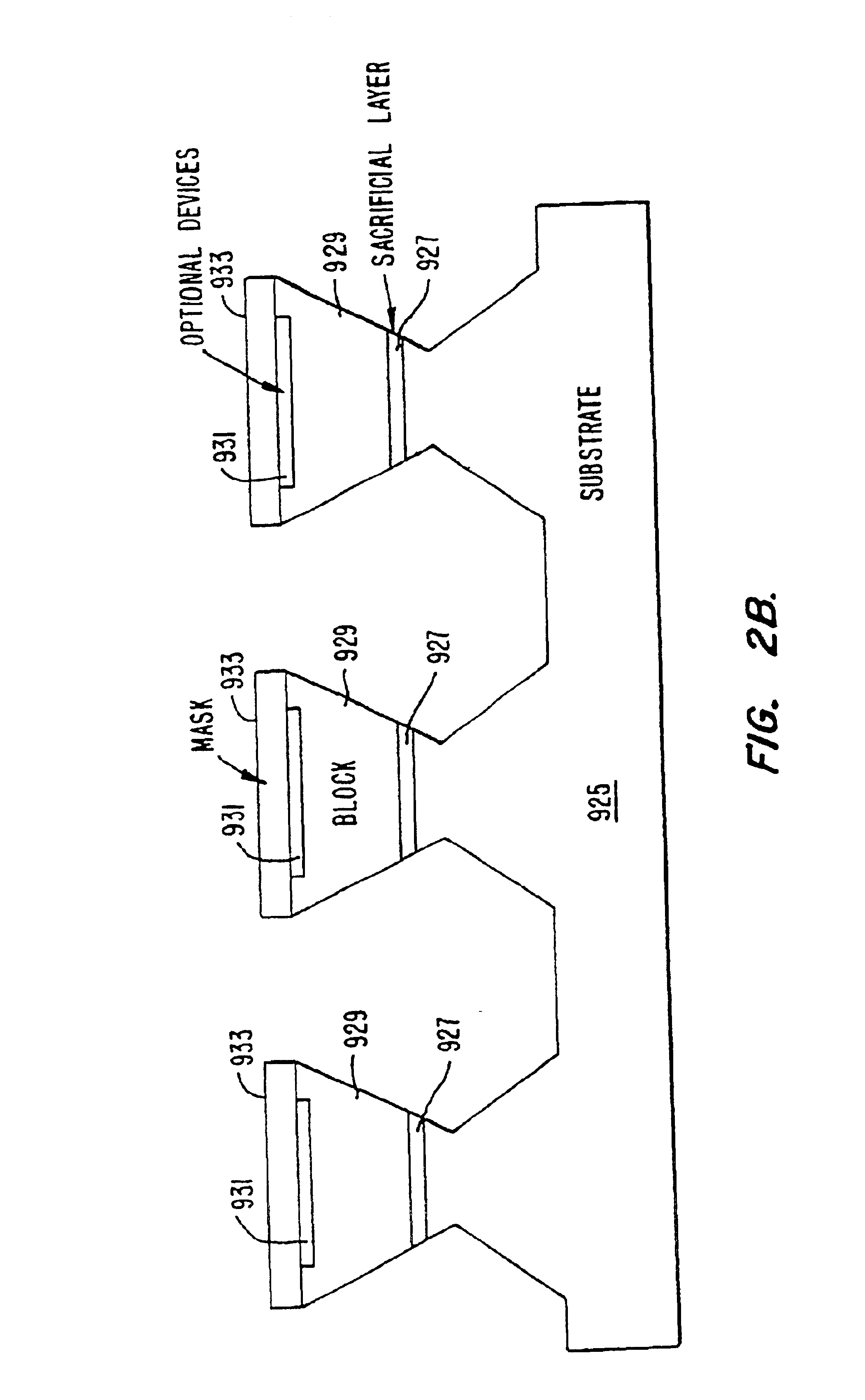

Wafer-to-wafer transfer of microstructures using break-away tethers

InactiveUS6142358AReduce tensionSemiconductor/solid-state device detailsWelding/cutting auxillary devicesOptoelectronicsMicrostructure

Break-away tethers to secure electronic, mechanical, optical, or other microstructures, during release from one substrate and transfer to another. Microstructures are fabricated with integrated tethers attaching them to a first substrate. The structures are undercut by etching and contacted and bonded to a second substrate. First and second substrates are separated, breaking the tethers.

Owner:RGT UNIV OF CALIFORNIA

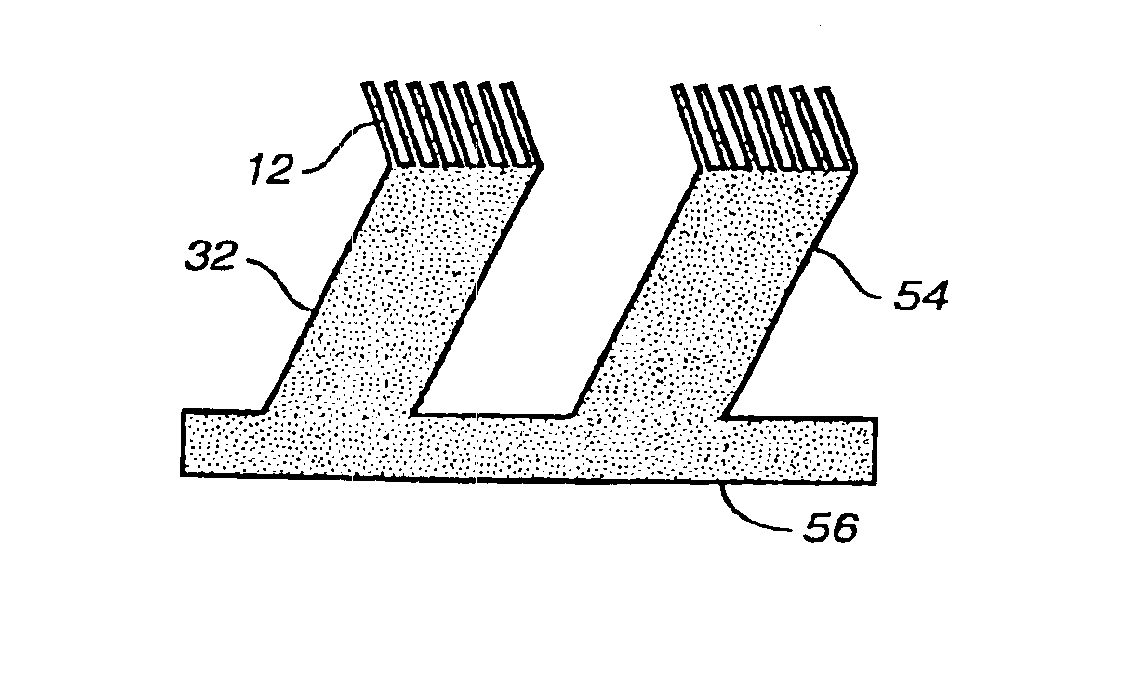

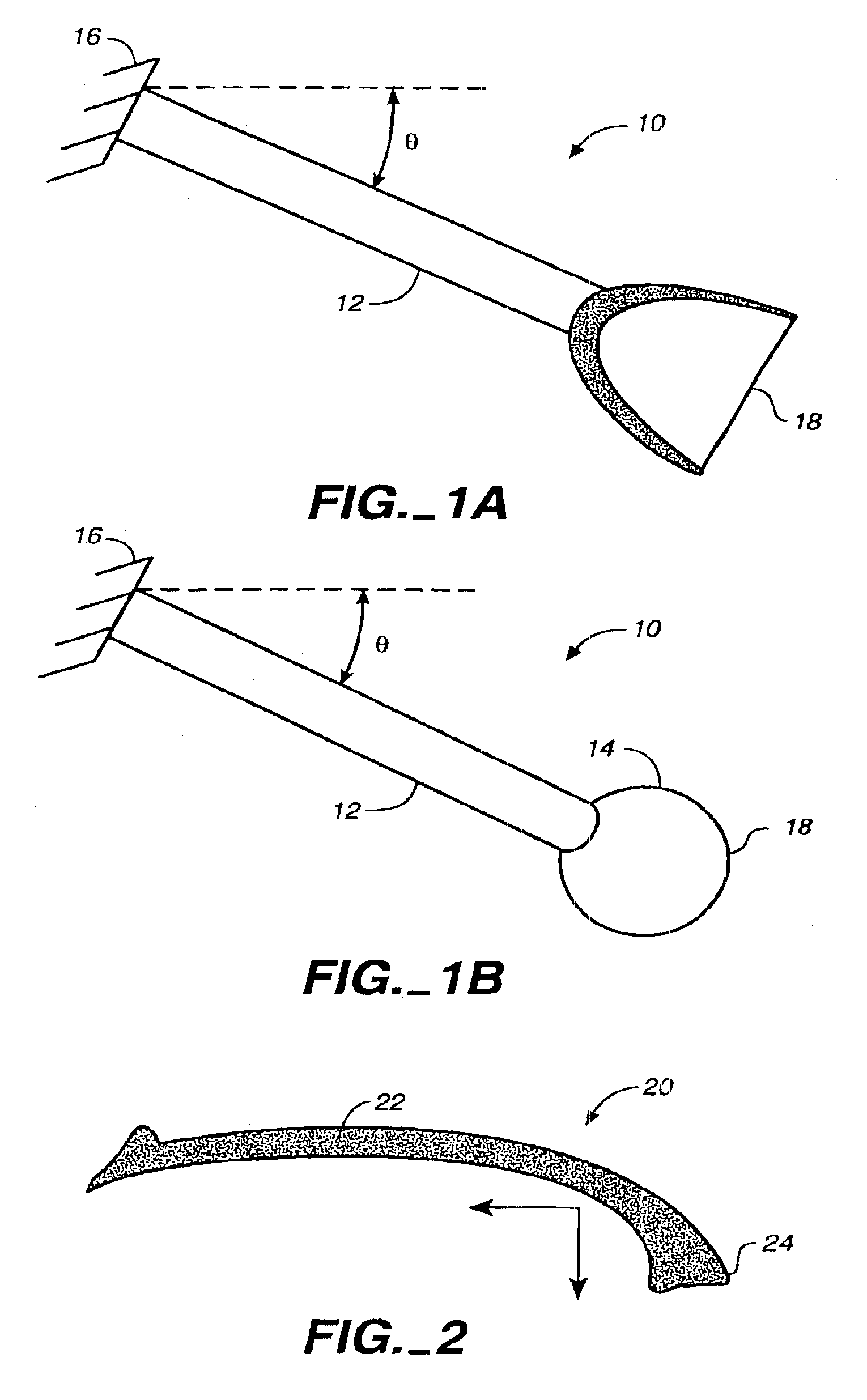

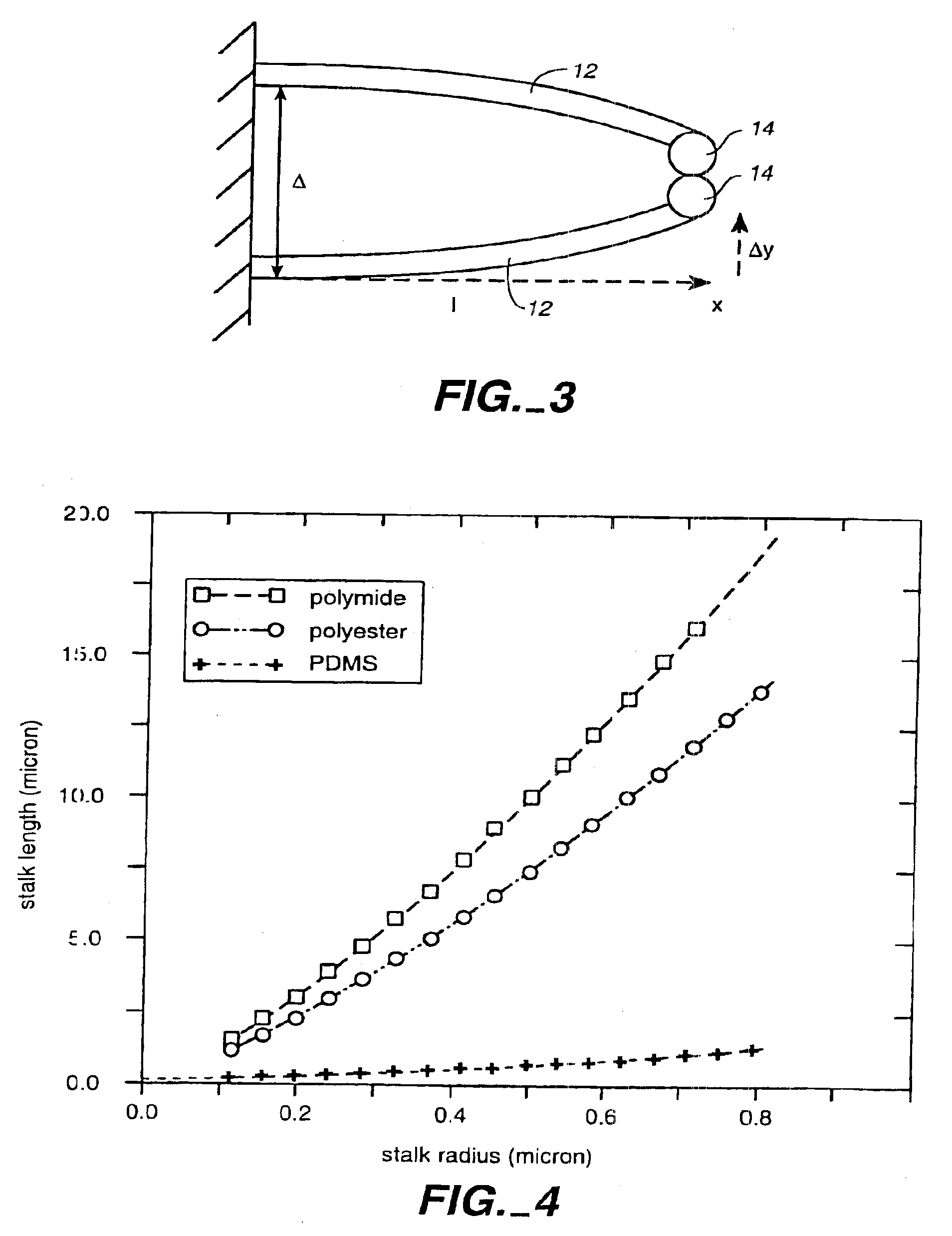

Adhesive microstructure and method of forming same

InactiveUS6872439B2Improve adhesionEasy to disengageSnap fastenersMaterial nanotechnologyMicroscopic scaleOblique angle

A fabricated microstructure comprising at least one protrusion capable of providing an adhesive force at a surface of between about 60 and 2,000 nano-Newtons. A stalk supports the protrusion at an oblique angle relative to a supporting surface. The microstructure can adhere to different surfaces.

Owner:RGT UNIV OF CALIFORNIA

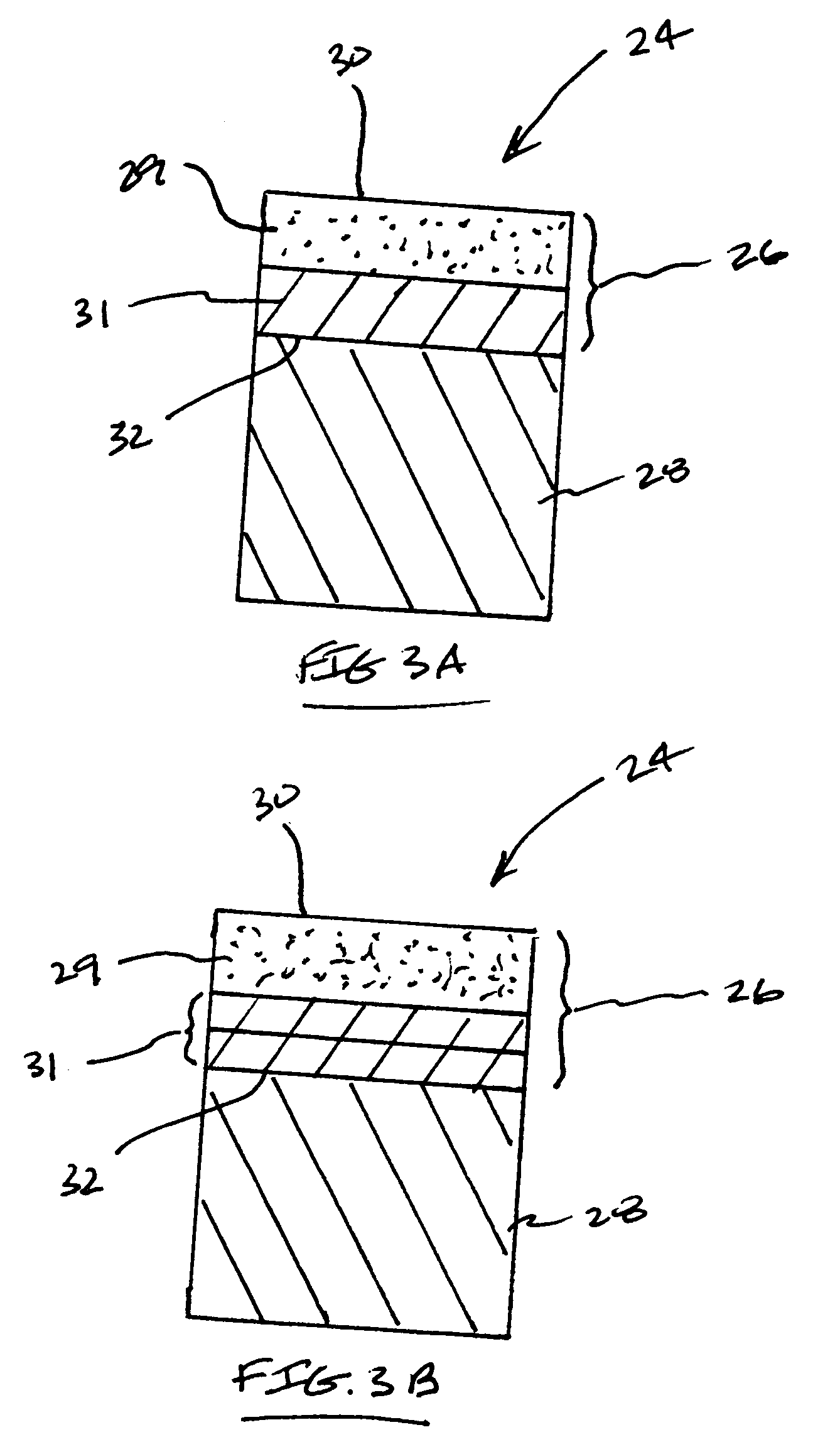

Thermally stable diamond bonded materials and compacts

InactiveUS20050263328A1Improve thermal stabilityGood adhesionDrill bitsConstructionsMaterials scienceTemperature and pressure

Thermally stable diamond bonded materials and compacts include a diamond body having a thermally stable region and a PCD region, and a substrate integrally joined to the body. The thermally stable region has a microstructure comprising a plurality of diamond grains bonded together by a reaction with a reactant material. The PCD region extends from the thermally stable region and has a microstructure of bonded together diamond grains and a metal solvent catalyst disposed interstitially between the bonded diamond grains. The compact is formed by subjecting the diamond grains, reactant material, and metal solvent catalyst to a first temperature and pressure condition to form the thermally stable region, and then to a second higher temperature condition to both form the PCD region and bond the body to a desired substrate.

Owner:SMITH INT INC

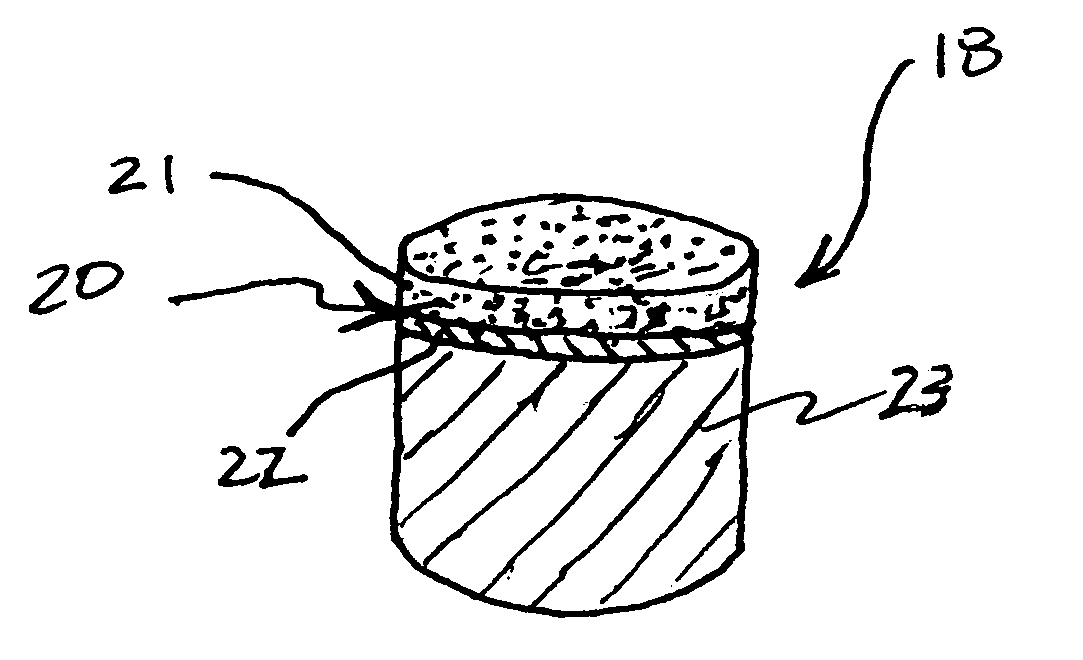

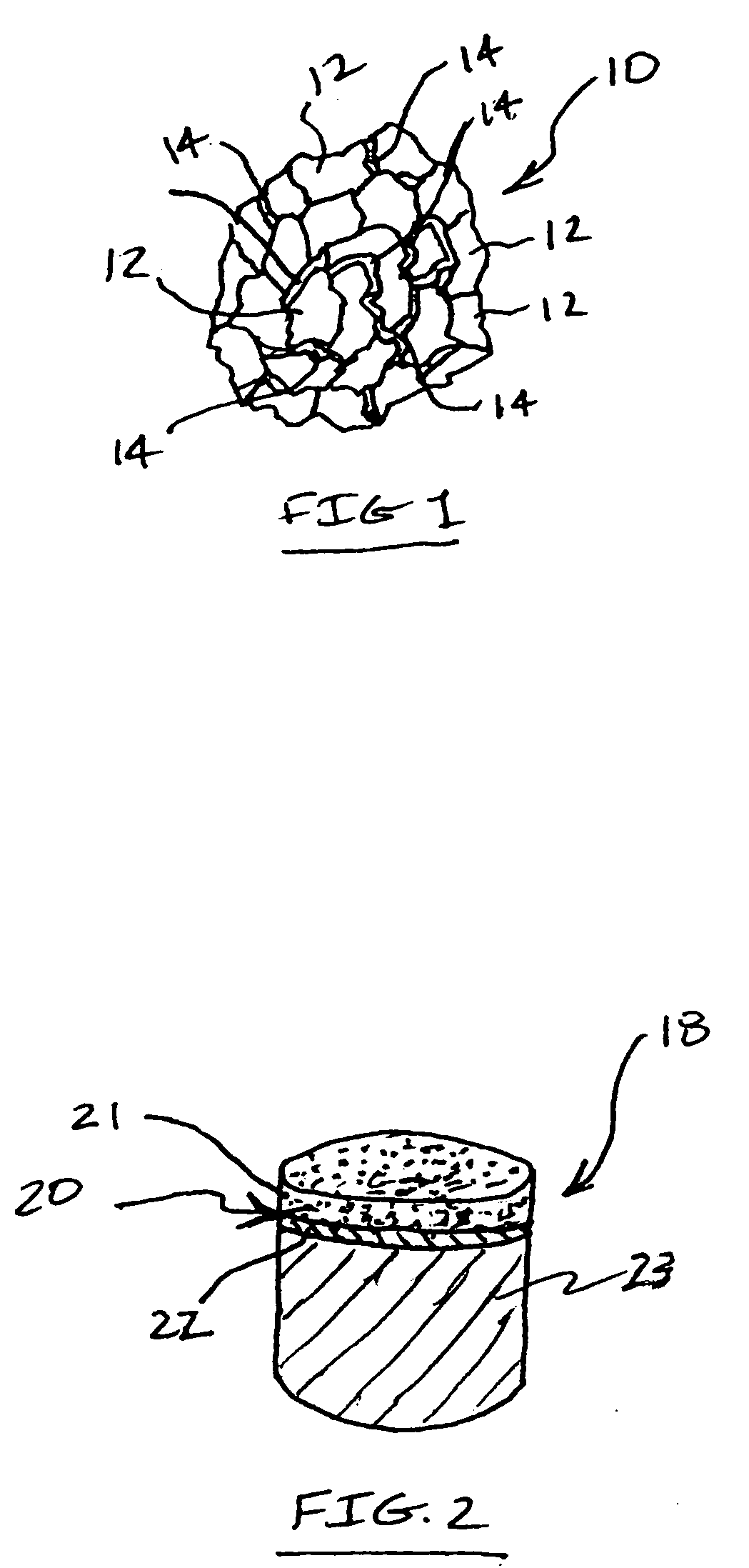

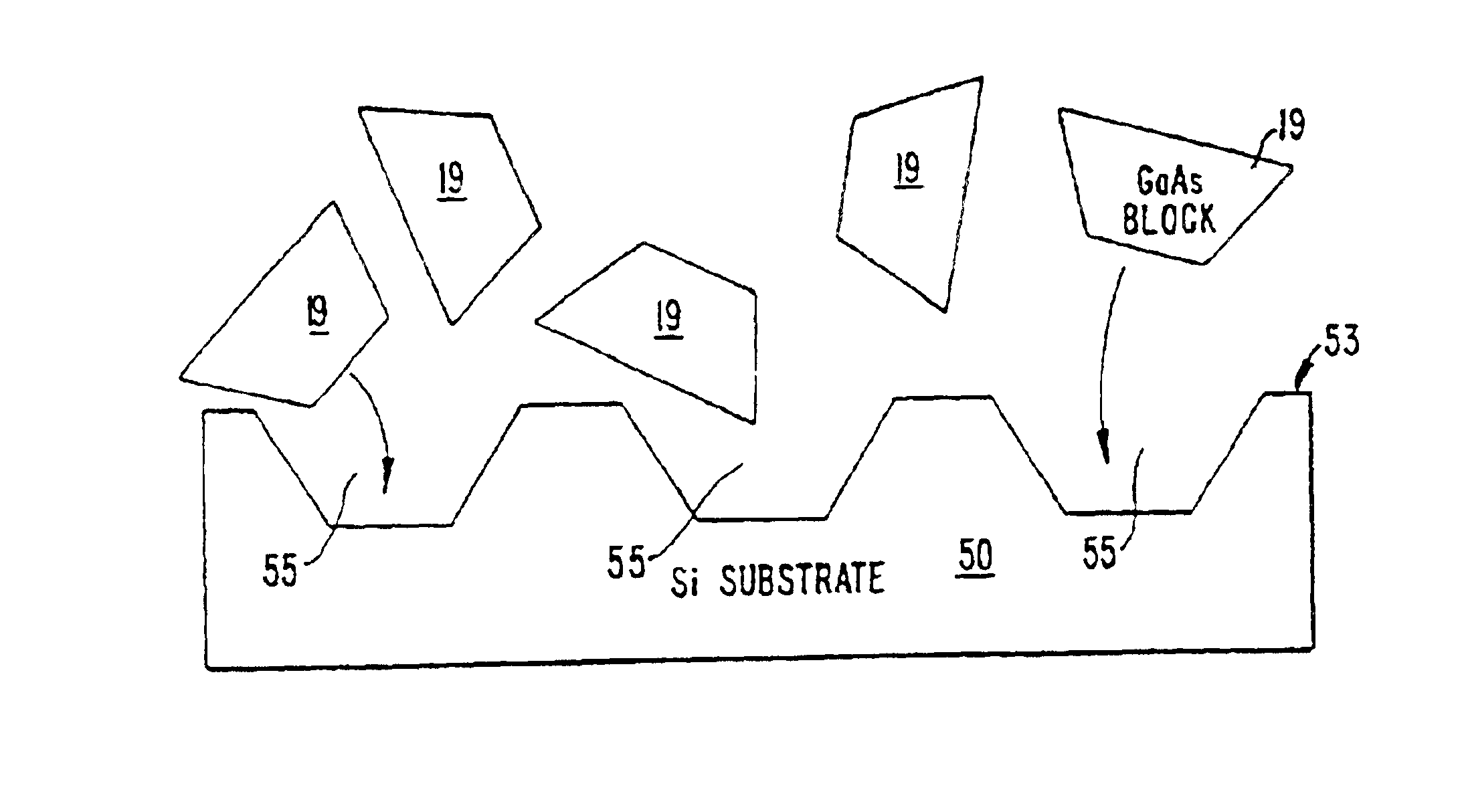

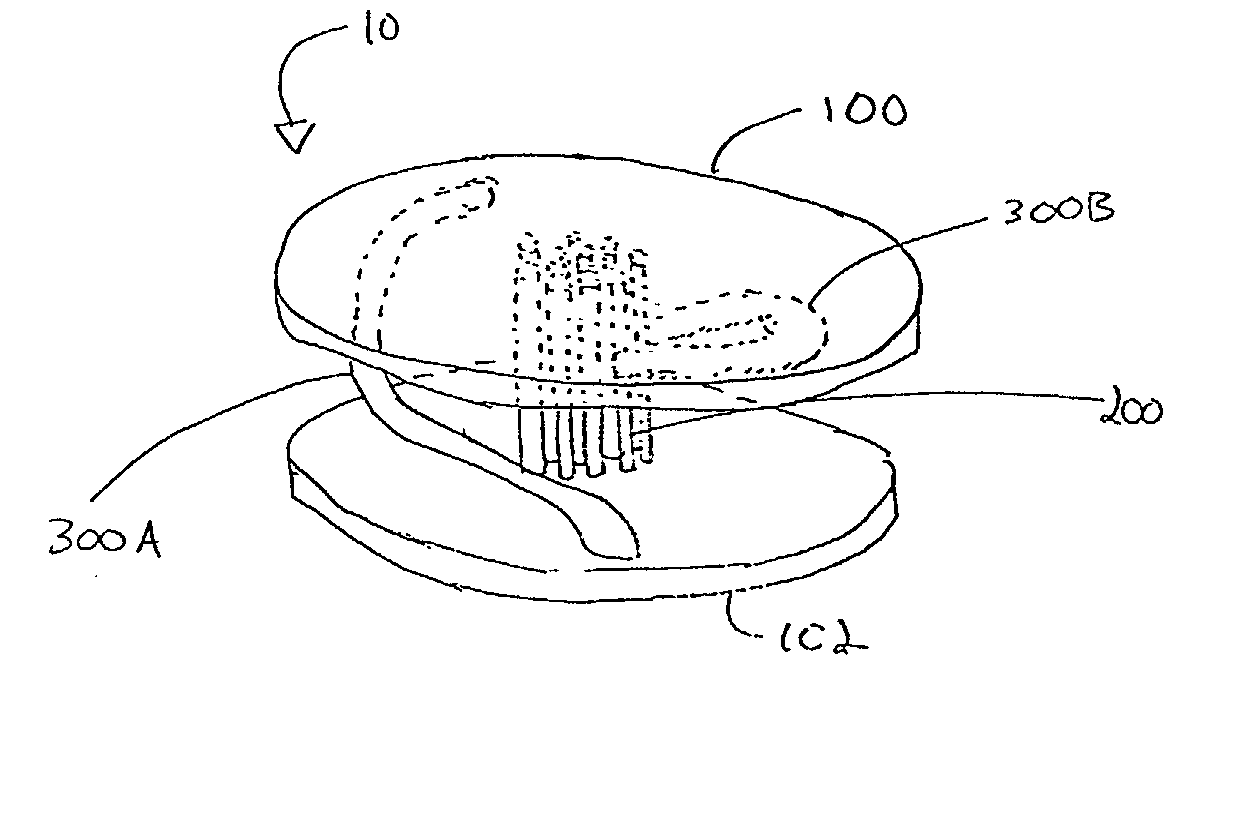

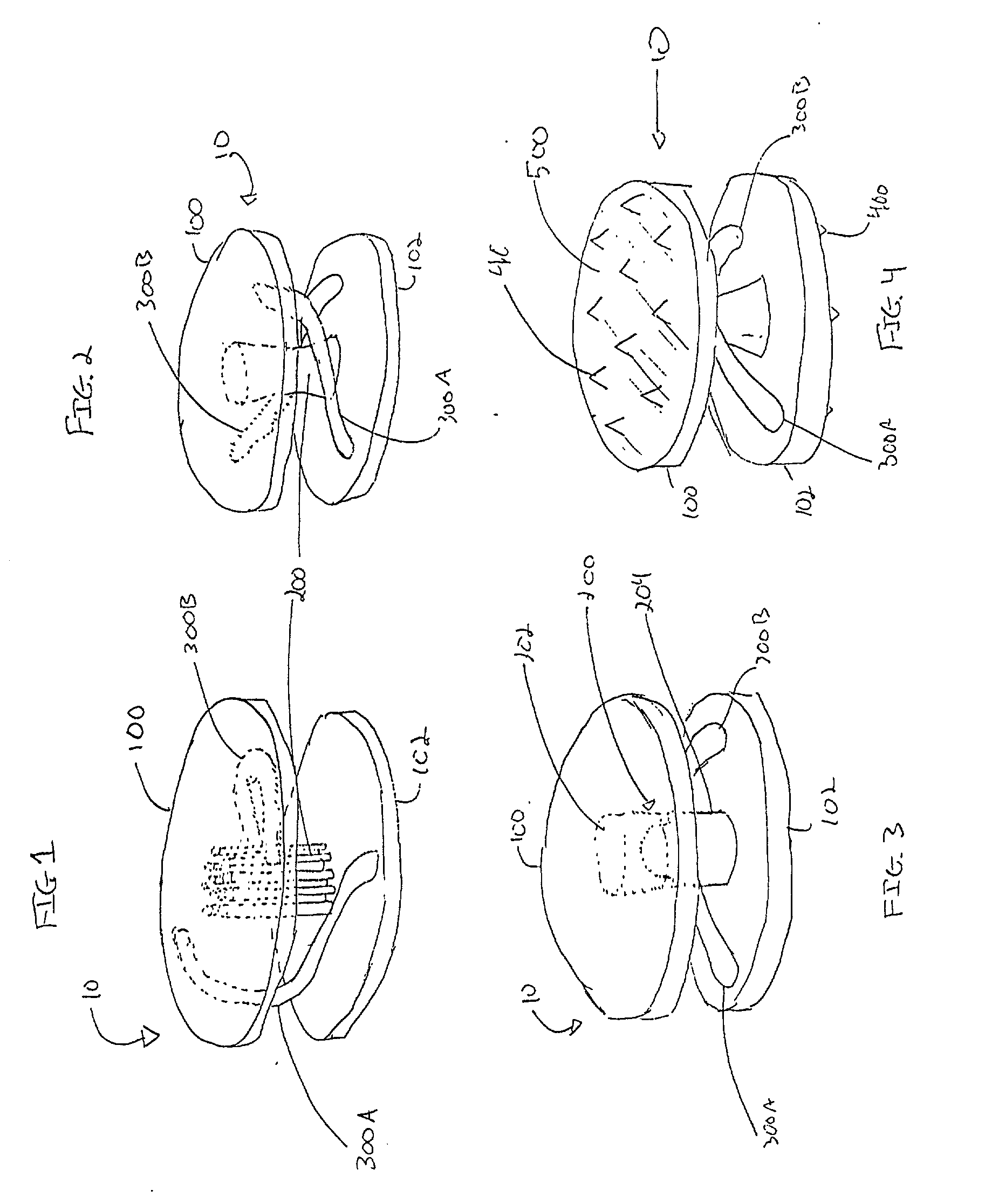

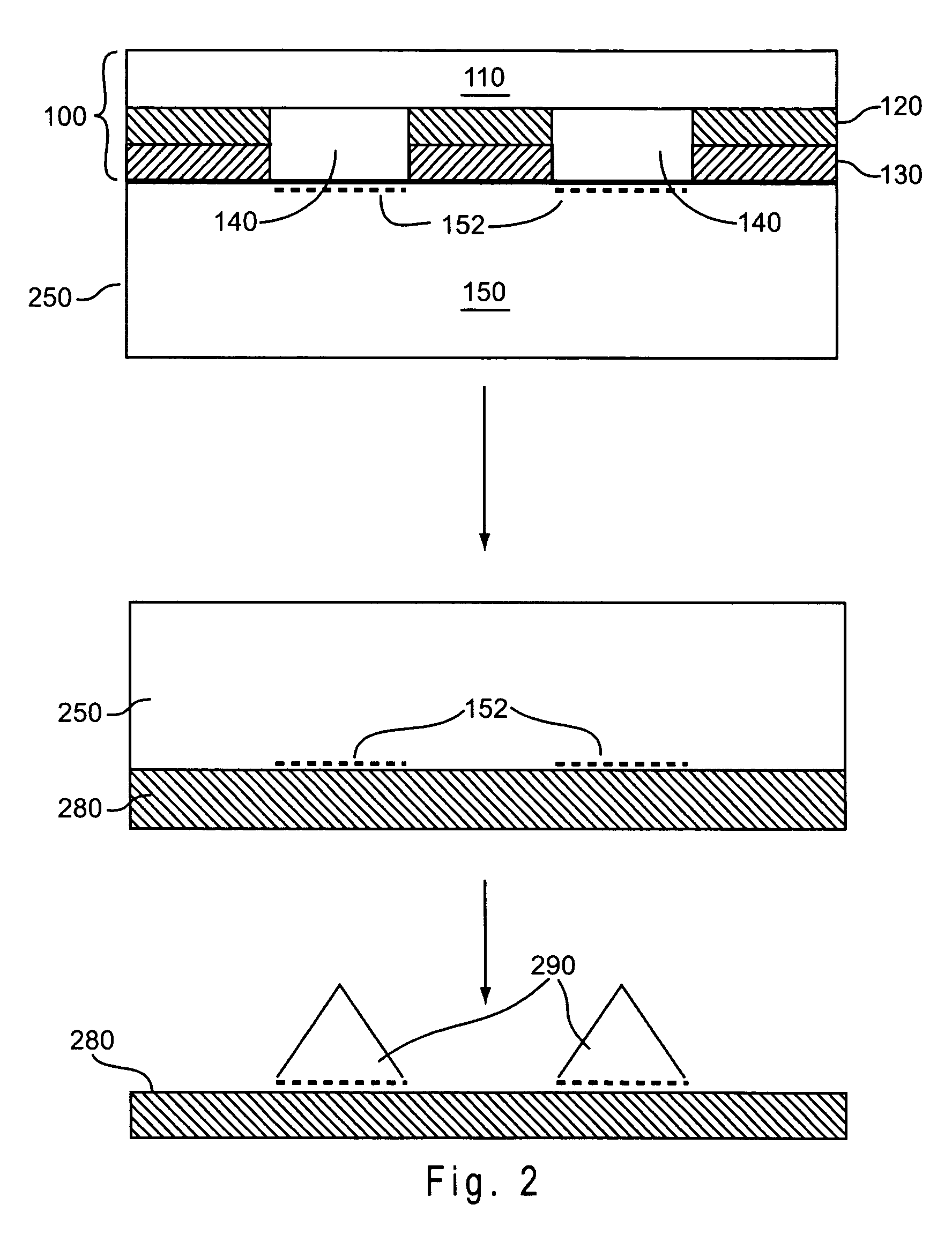

Method and apparatus for fabricating self-assembling microstructures

InactiveUS6864570B2Promote circulationEvenly distributedTransistorSemiconductor laser arrangementsFluid transportSelf assemble

A method and apparatus for assembling microstructures onto a substrate through fluid transport. The microstructures being shaped blocks self-align into recessed regions located on a substrate such that the microstructure becomes integral with the substrate. The improved method includes a step of transferring the shaped blocks into a fluid to create a slurry. Such slurry is then dispensed evenly or circulated over the top surface of a substrate having recessed regions thereon. The microstructure via the shape and fluid tumbles onto the surface of the substrate, self-aligns, and engages into a recessed region.

Owner:RGT UNIV OF CALIFORNIA

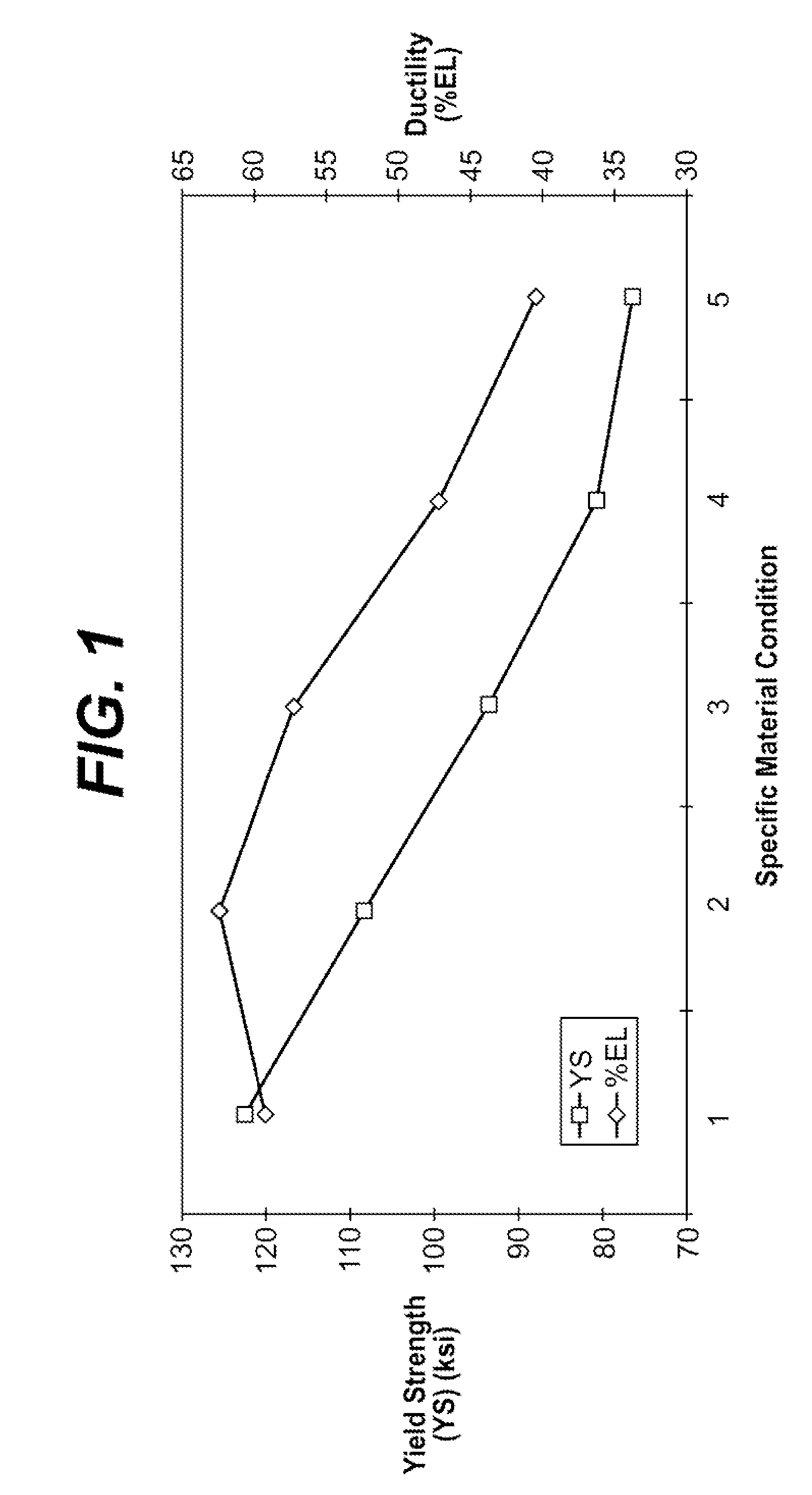

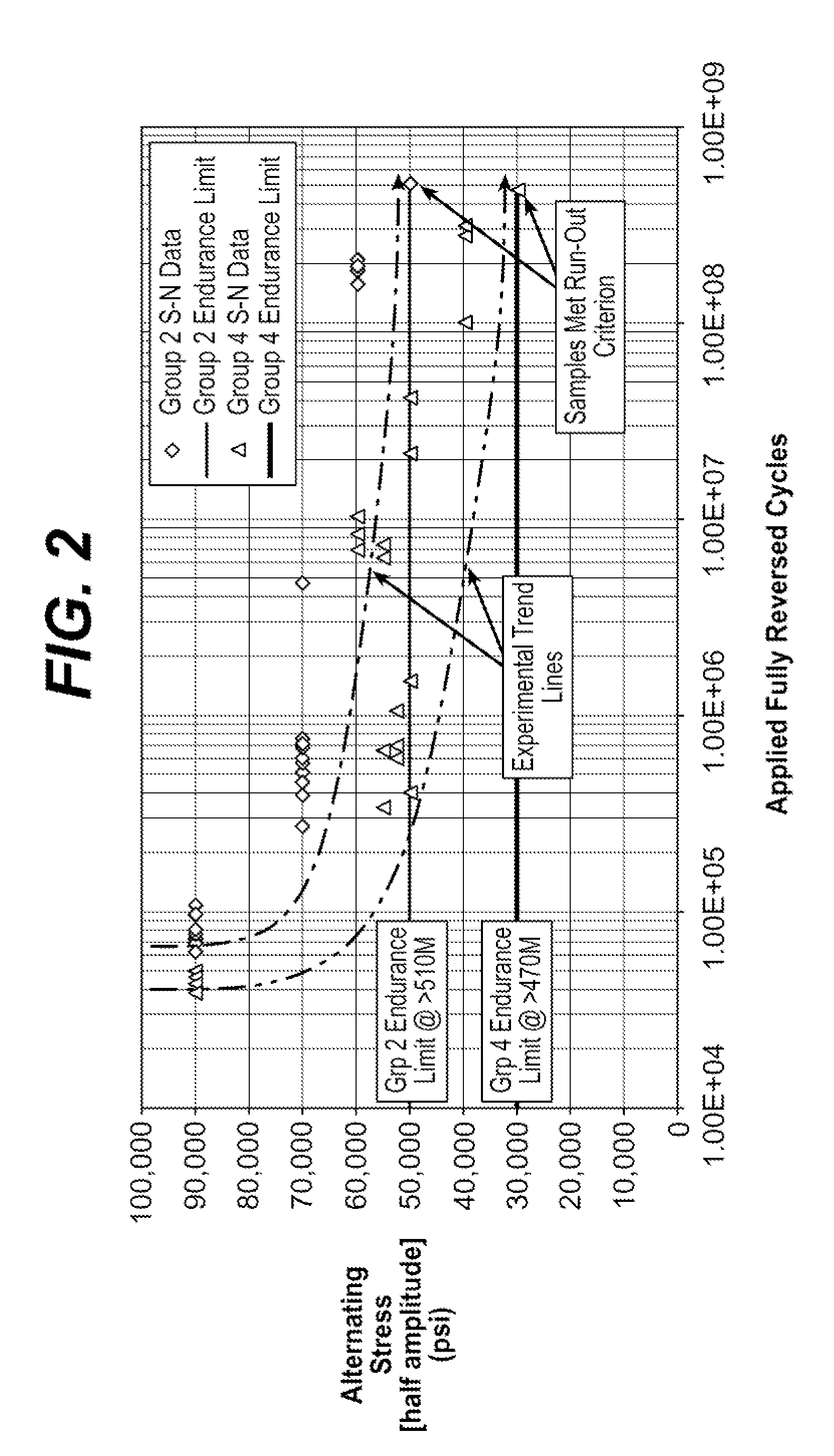

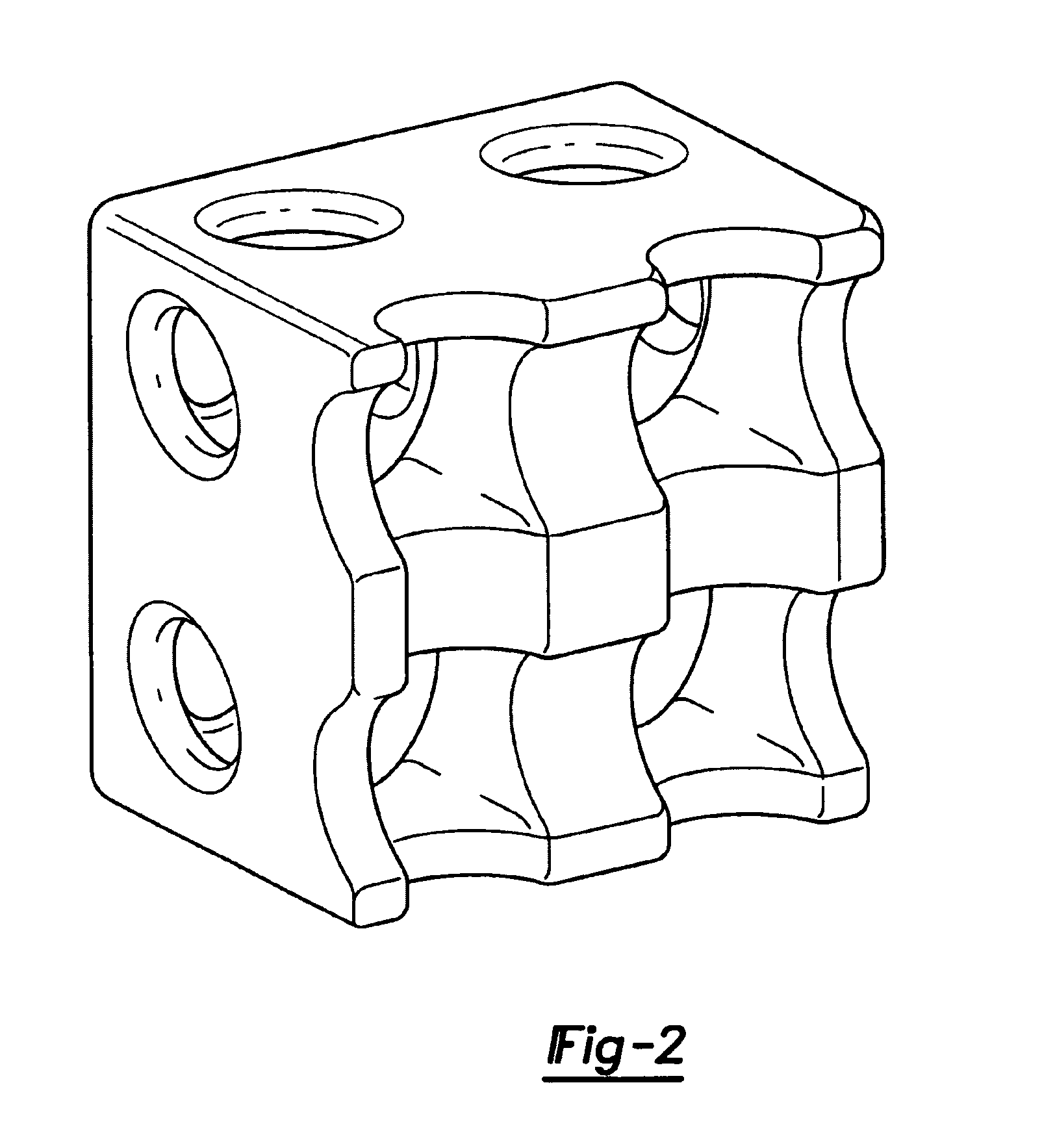

Orthopedic implant and method of making metal articles

The present application is directed to an orthopedic implant. More specifically, the orthopedic implant is suitable for arthroplasty procedures where optimized multifunctional behavior of the implant is desired. In some embodiments the implant is suitable for the replacement of a spinal disc. In one embodiment, the present application is directed to an orthopedic implant including a first plate a second plate and a flexible support. The flexible support may have a single connection to the first plate and a single connection to the second plate and may vary in cross section. The first plate, the second plate and the flexible support may be unitarily formed. This application is also directed to methods of producing metal articles having microstructure for improved mechanical properties. Such methods may be suitable for the production of medical devices. In one embodiment, the method includes directing a stream including a particulate material in a pattern corresponding to at least a portion of a structure of an orthopedic implant and fusing at least a portion of the particulate material with a laser.

Owner:DEPUY ACROMED INC

Expandable TFE copolymers, method of making, and porous, expended articles thereof

ActiveUS20090093602A1Improve the extrusion effectStretch smoothlyThin material handlingFiberTetrafluoroethylene

A process for the polymerization of a true tetrafluoroethylene (TFE) copolymer of the fine powder type is provided, wherein the copolymer contains polymerized comonomer units of at least one comonomer other than TFE in concentrations of at least or exceeding 1.0 weight percent, and which can exceed 5.0 weight percent, wherein the copolymer is expandable, that is, the copolymer may be expanded to produce strong, useful, expanded TFE copolymeric articles having a microstructure of nodes interconnected by fibrils.

Owner:WL GORE & ASSOC INC

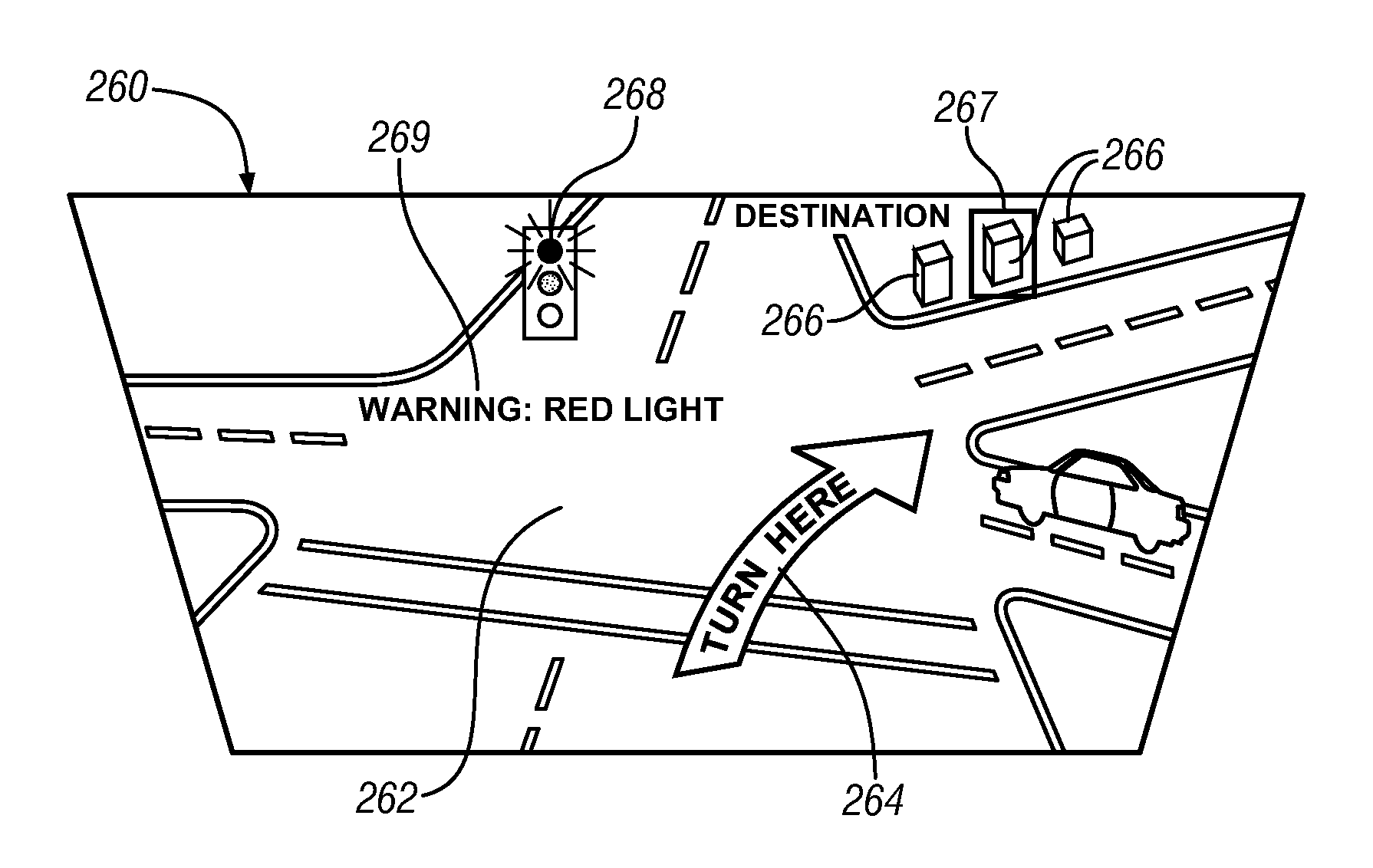

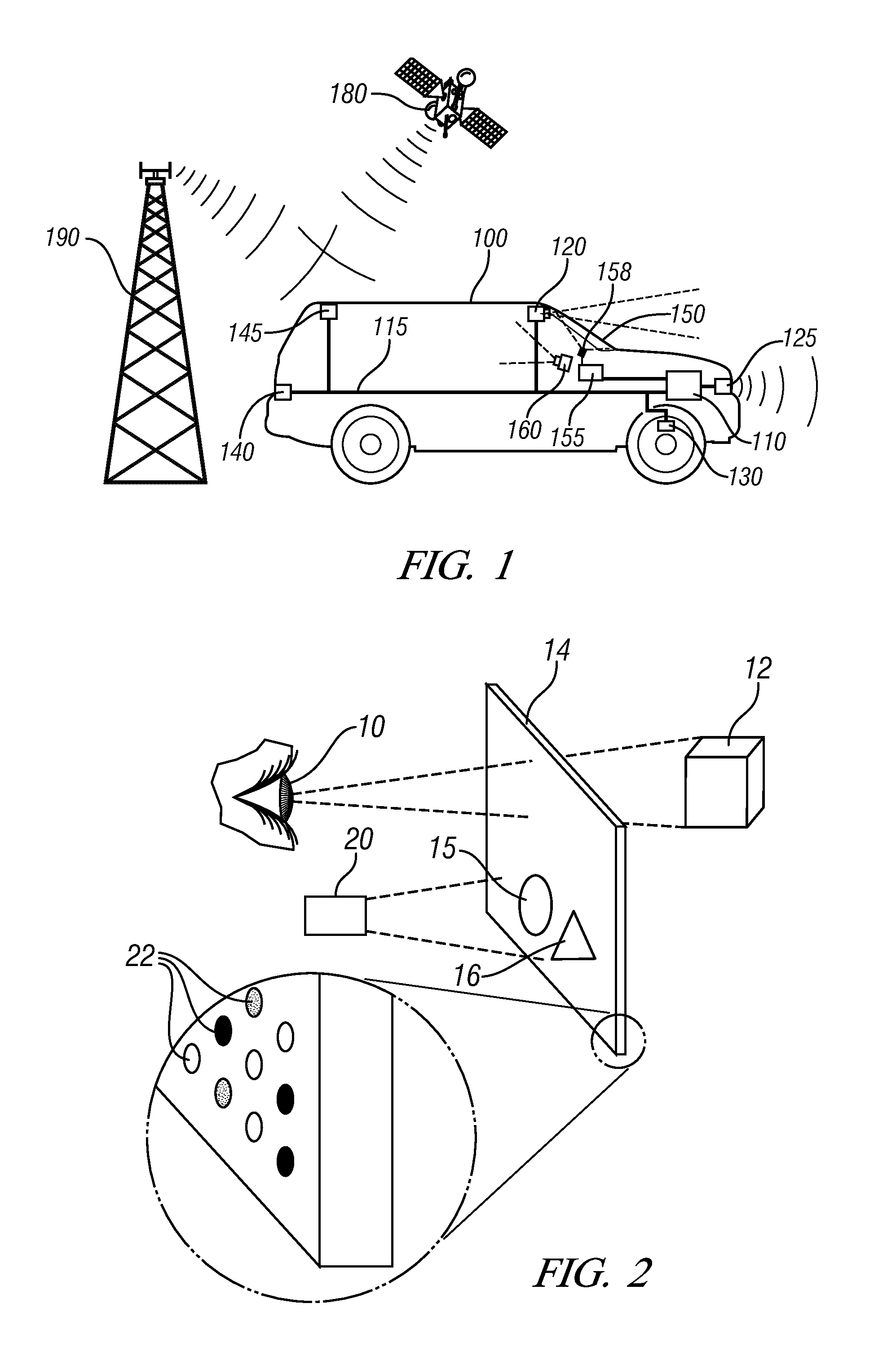

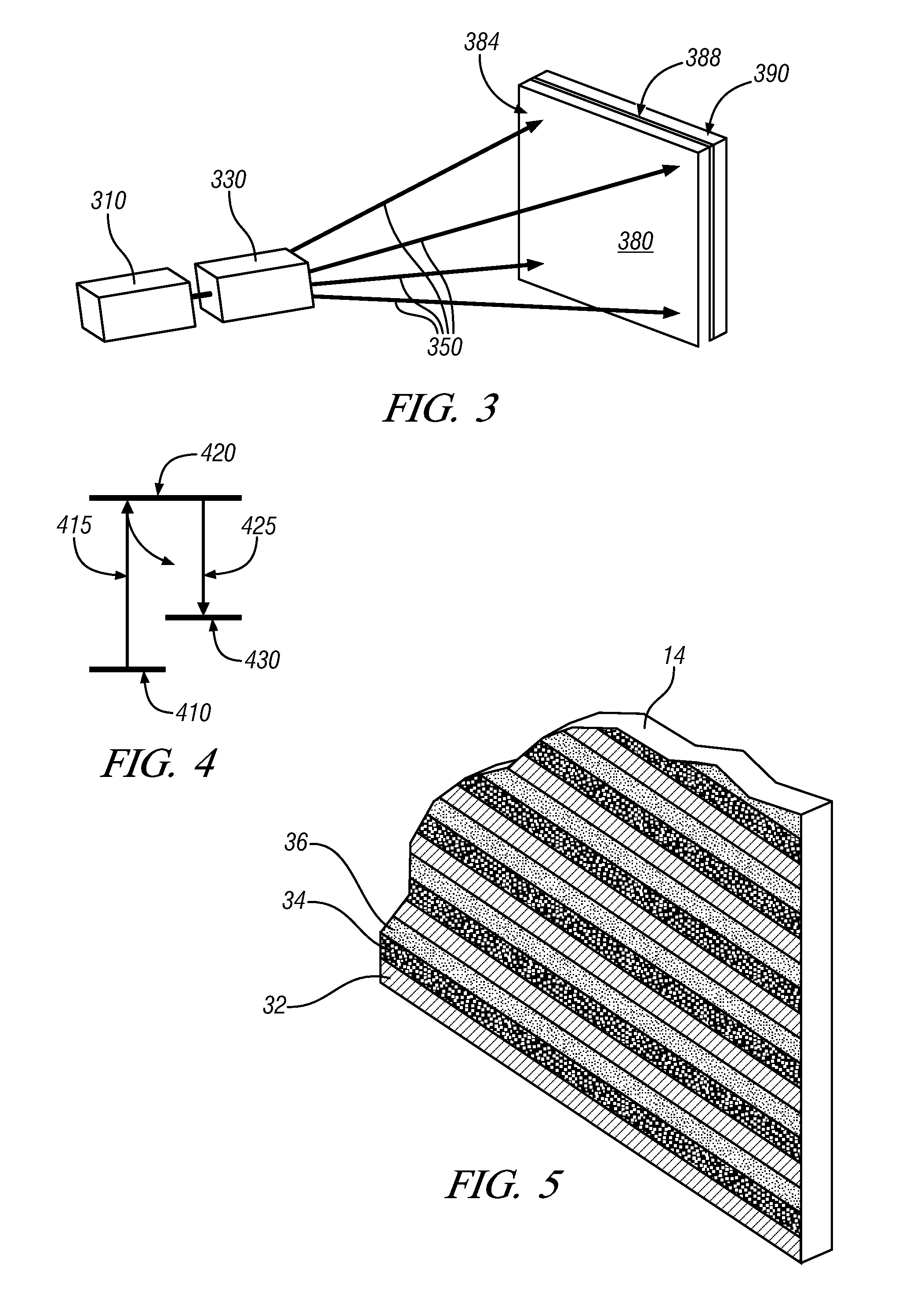

Point of interest location marking on full windshield head-up display

ActiveUS20100253542A1Instruments for road network navigationIndication of parksing free spacesGraphicsHead-up display

A substantially transparent windscreen head up display includes one of light emitting particles or microstructures over a predefined region of the windscreen permitting luminescent display while permitting vision through the windscreen. A method to display a graphic identifying a point-of-interest upon the substantially transparent windscreen head up display of a vehicle includes monitoring the point-of-interest, monitoring a GPS digital map device, determining a graphic describing the location of the point-of-interest based upon data from the GPS digital map device for display upon the substantially transparent windscreen head up display, and displaying the graphic upon the substantially transparent windscreen head up display.

Owner:GM GLOBAL TECH OPERATIONS LLC

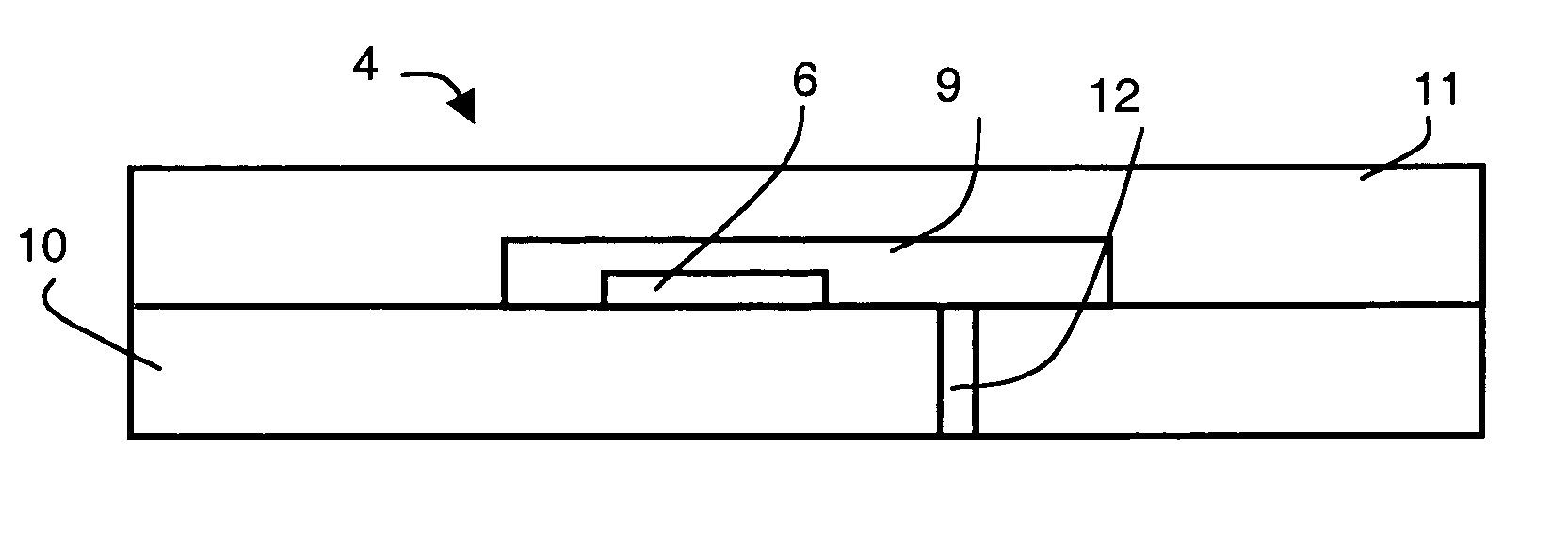

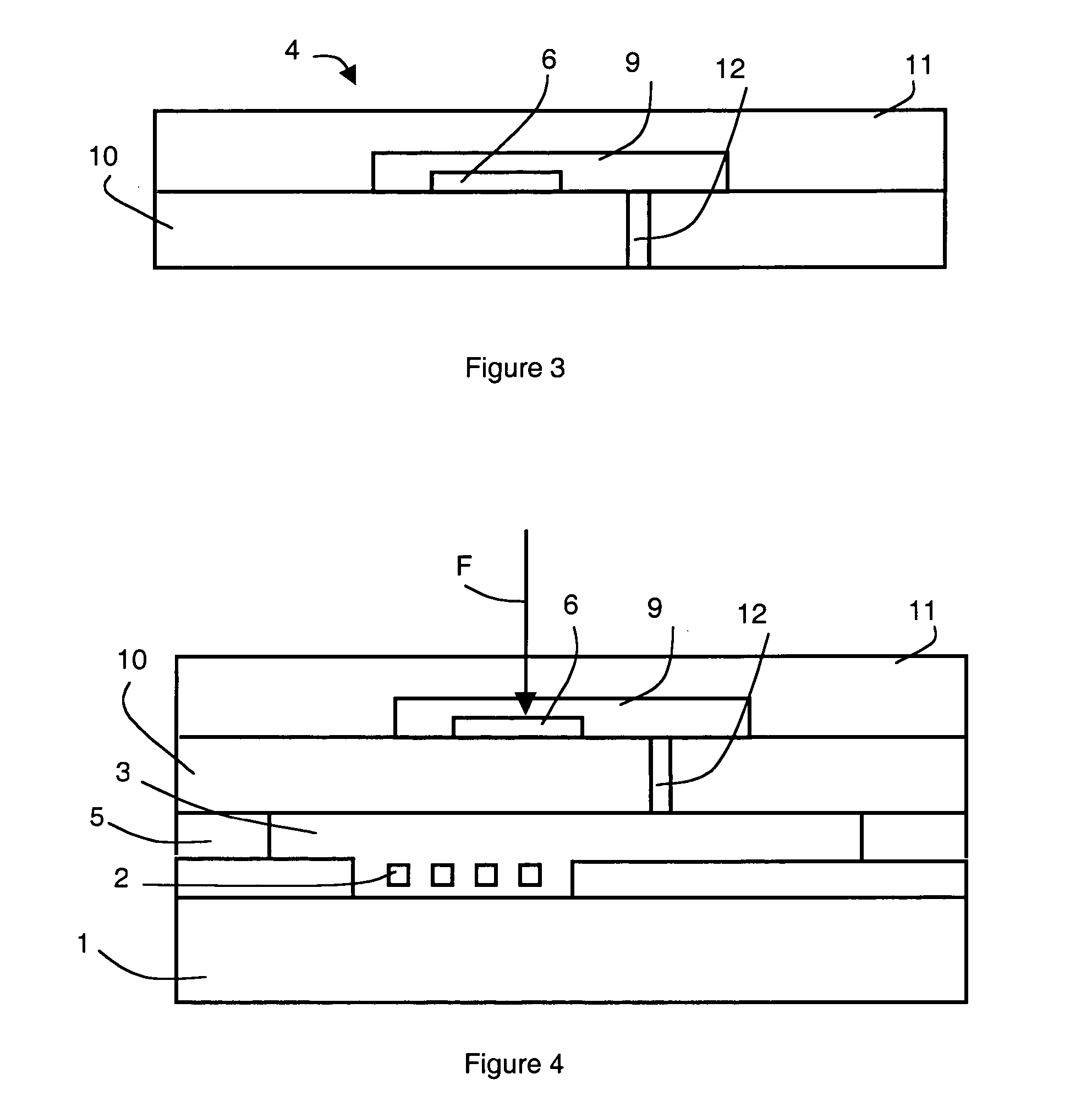

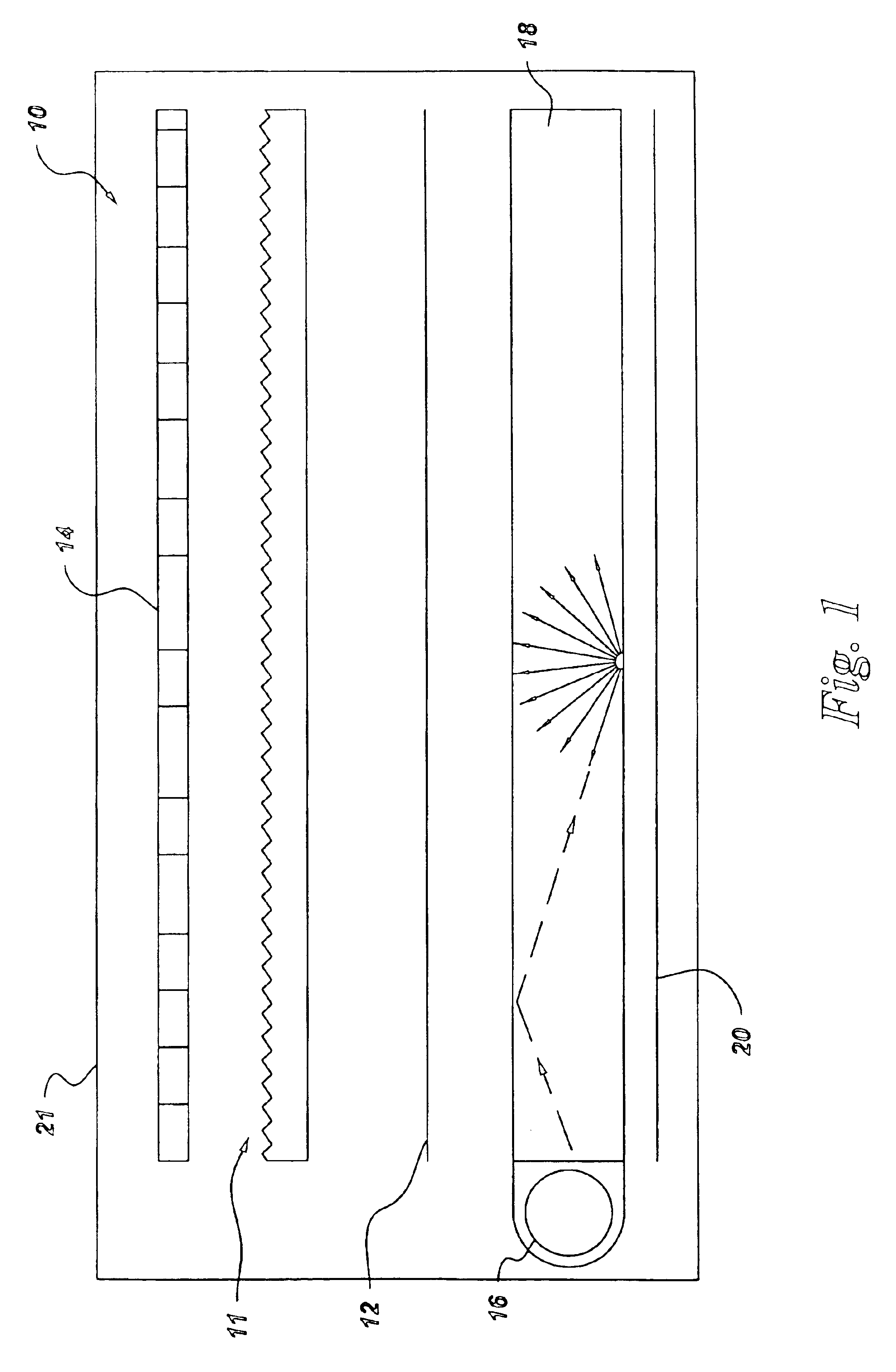

Integrated electromechanical microstructure comprising pressure adjusting means in a sealed cavity and pressure adjustment process

ActiveUS20040080035A1Simple processEasy to controlSemiconductor/solid-state device detailsSolid-state devicesCombustionEngineering

The integrated electromechanical microstructure comprises a base substrate and a cavity closed by a protective cover. Means for adjusting the pressure in the cavity after the protective cover has been sealed comprise at least one element made of pyrotechnic material combustion whereof releases gas into the cavity. The pressure in the cavity can thus be adjusted independently from the sealing process. Selective ignition of the elements made of pyrotechnic material can be achieved by heating electrical resistors or by laser beams coming from outside the microstructure and directed selectively towards the elements made of pyrotechnic material through a transparent zone of the protective cover.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

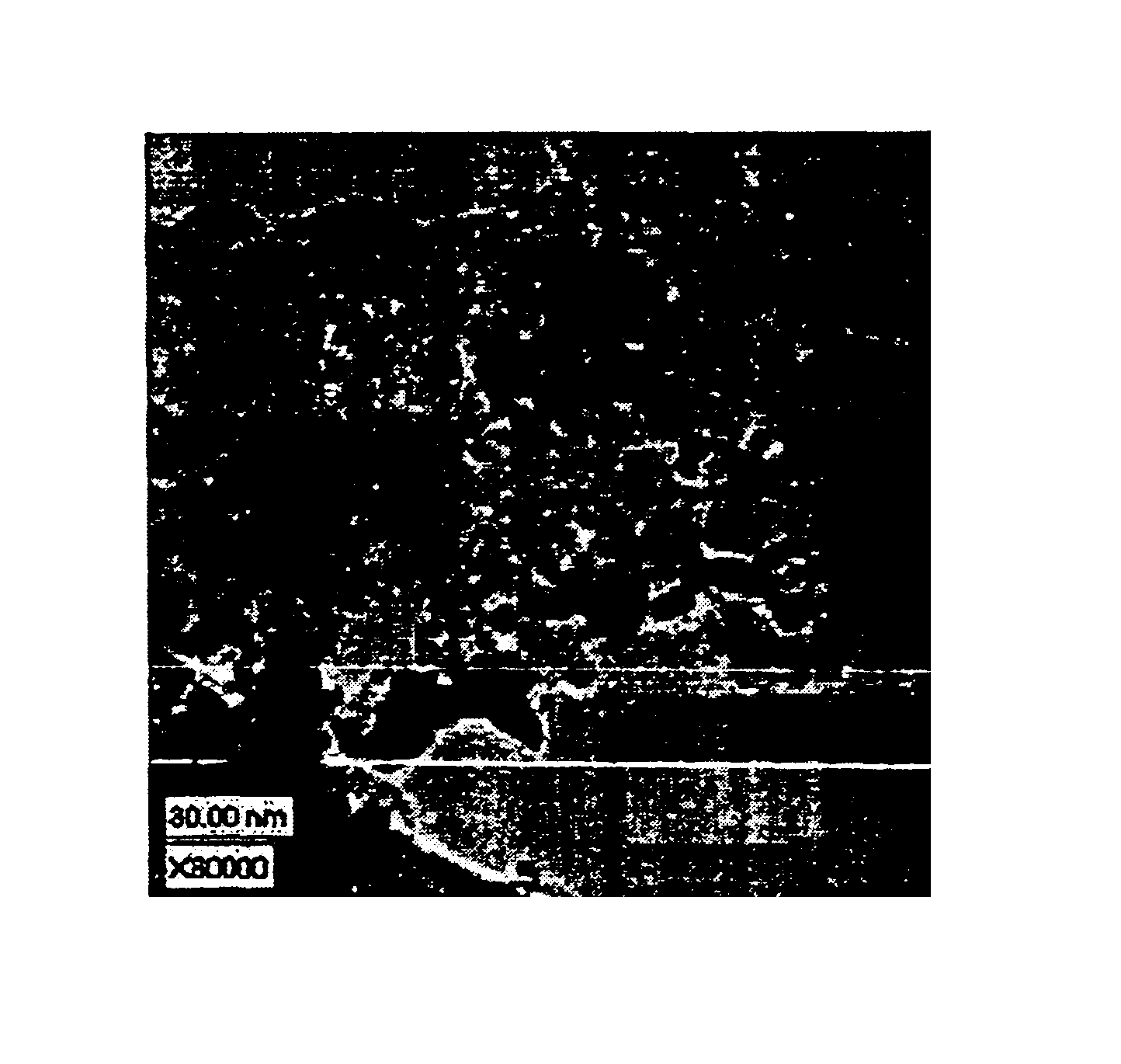

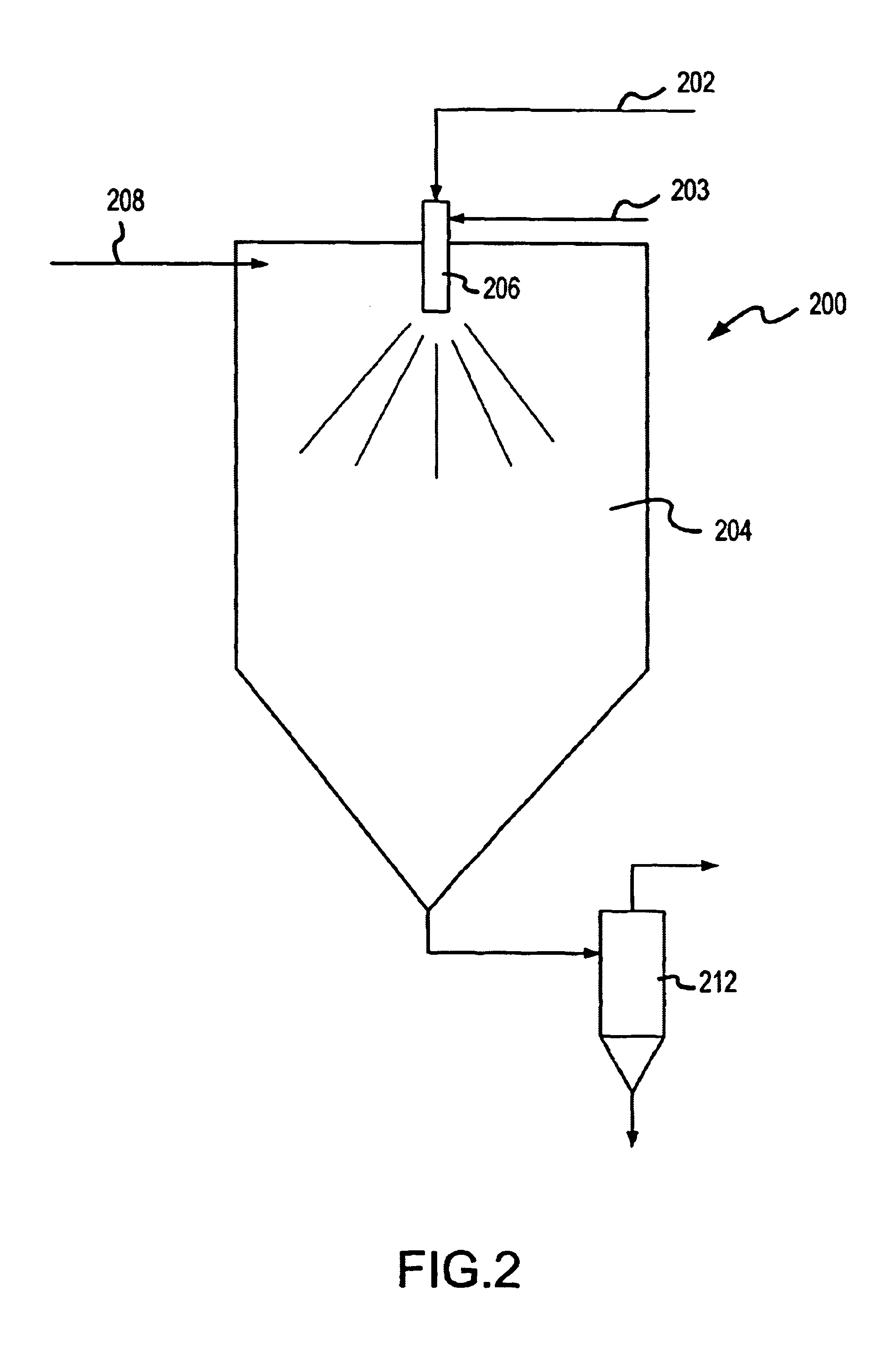

Electrocatalyst powders, methods for producing powders and devices fabricated from same

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

Modified polymers prepared with lanthanide-based catalysts

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2 R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

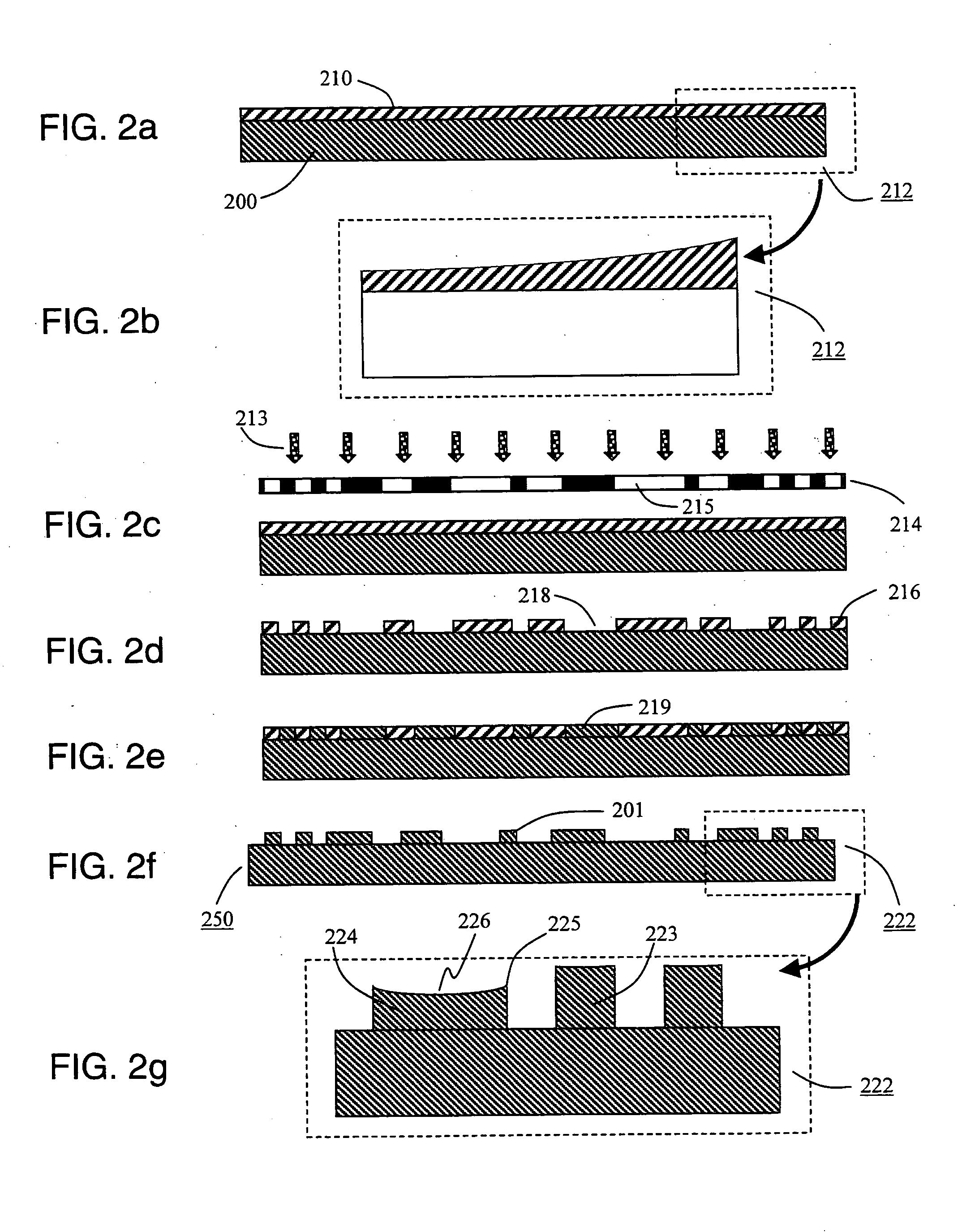

Decal transfer lithography

ActiveUS7662545B2Photography auxillary processesPhotosensitive materialsElastomerLithographic artist

A method of making a microstructure includes selectively activating a portion of a surface of a silicon-containing elastomer, contacting the activated portion with a substance, and bonding the activated portion and the substance, such that the activated portion of the surface and the substance in contact with the activated portion are irreversibly attached. The selective activation may be accomplished by positioning a mask on the surface of the silicon-containing elastomer, and irradiating the exposed portion with UV radiation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Microstructure-bearing articles of high refractive index

InactiveUS6844950B2High refractive indexLiquid crystal compositionsImpression capsPolymer scienceMeth-

Blends of oligomeric urethane multi(meth)acrylate; optionally at least one other monomer selected from the group consisting of acrylic monomers, styrenic monomers and ethylenically unsaturated nitrogen heterocycles, preferably a polyol multi(meth)acrylate; and nanoparticles of an ethylenically unsaturated, preferably (meth)acrylic-functionalized, titanium or zirconium compound can be cured by ultraviolet radiation in contact with a photoinitiator to produce optical resinous articles having high refractive indices, haze ratings of at most 5% and other properties which may be tailored according to the desired use.

Owner:SABIC INNOVATIVE PLASTICS IP BV

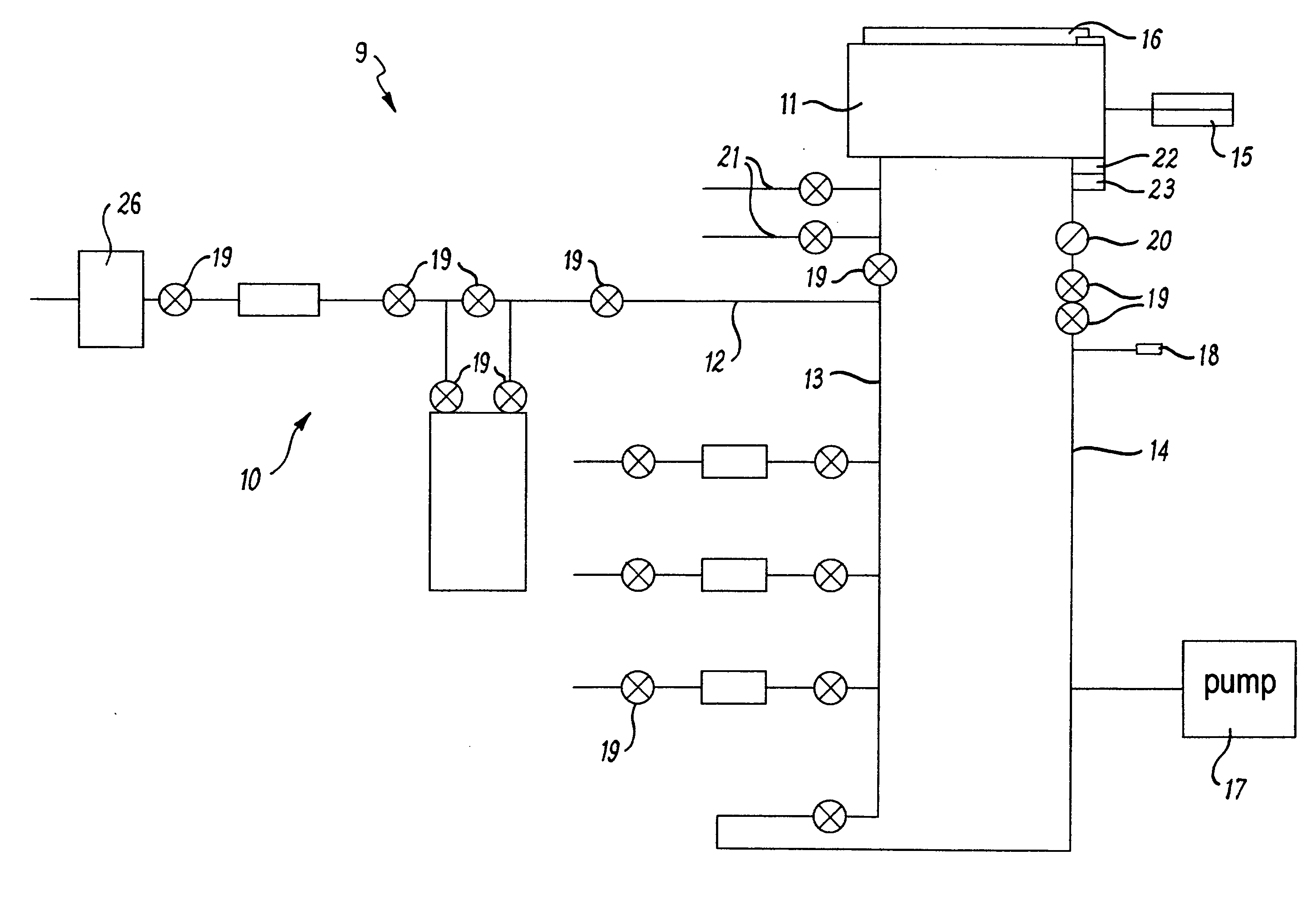

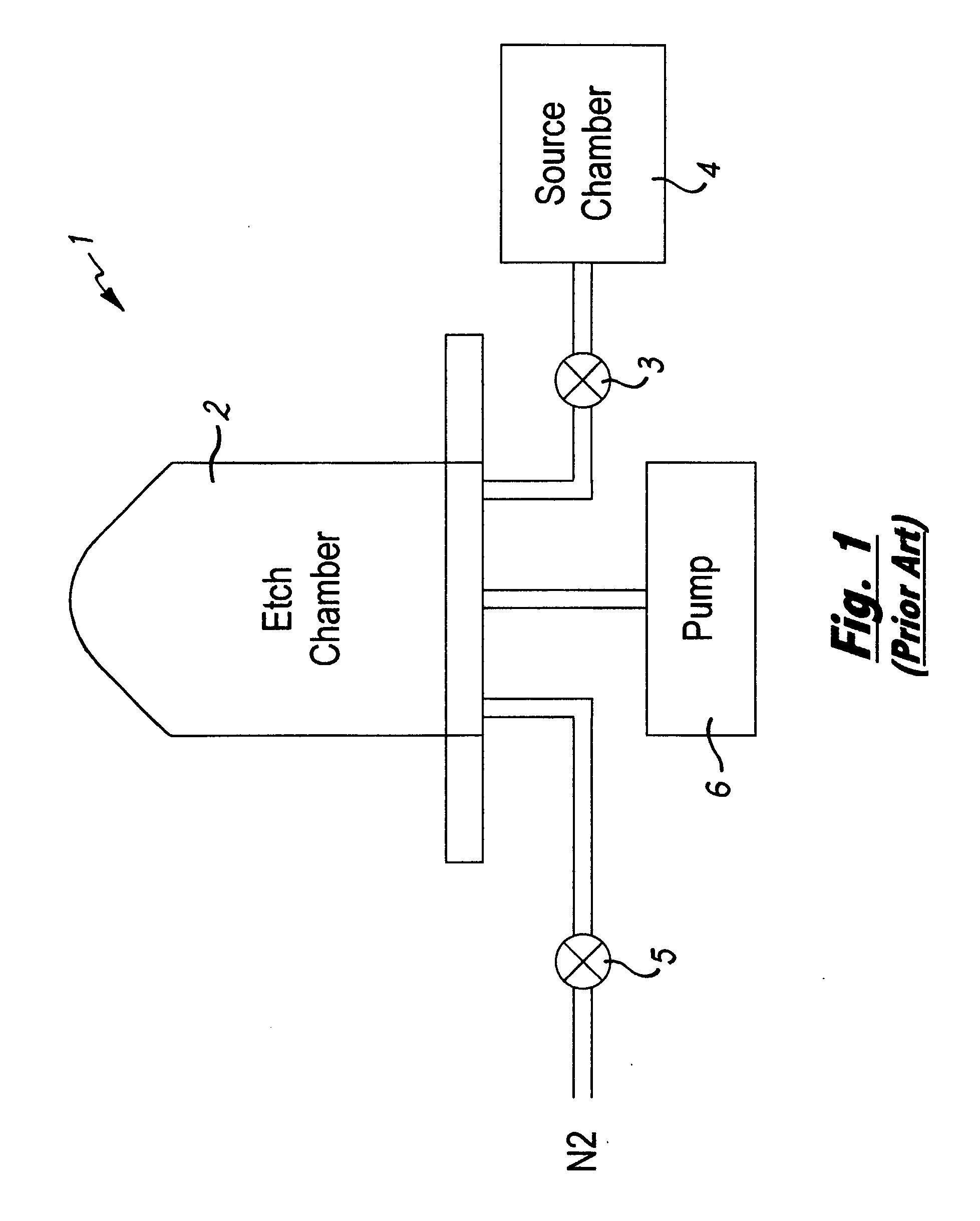

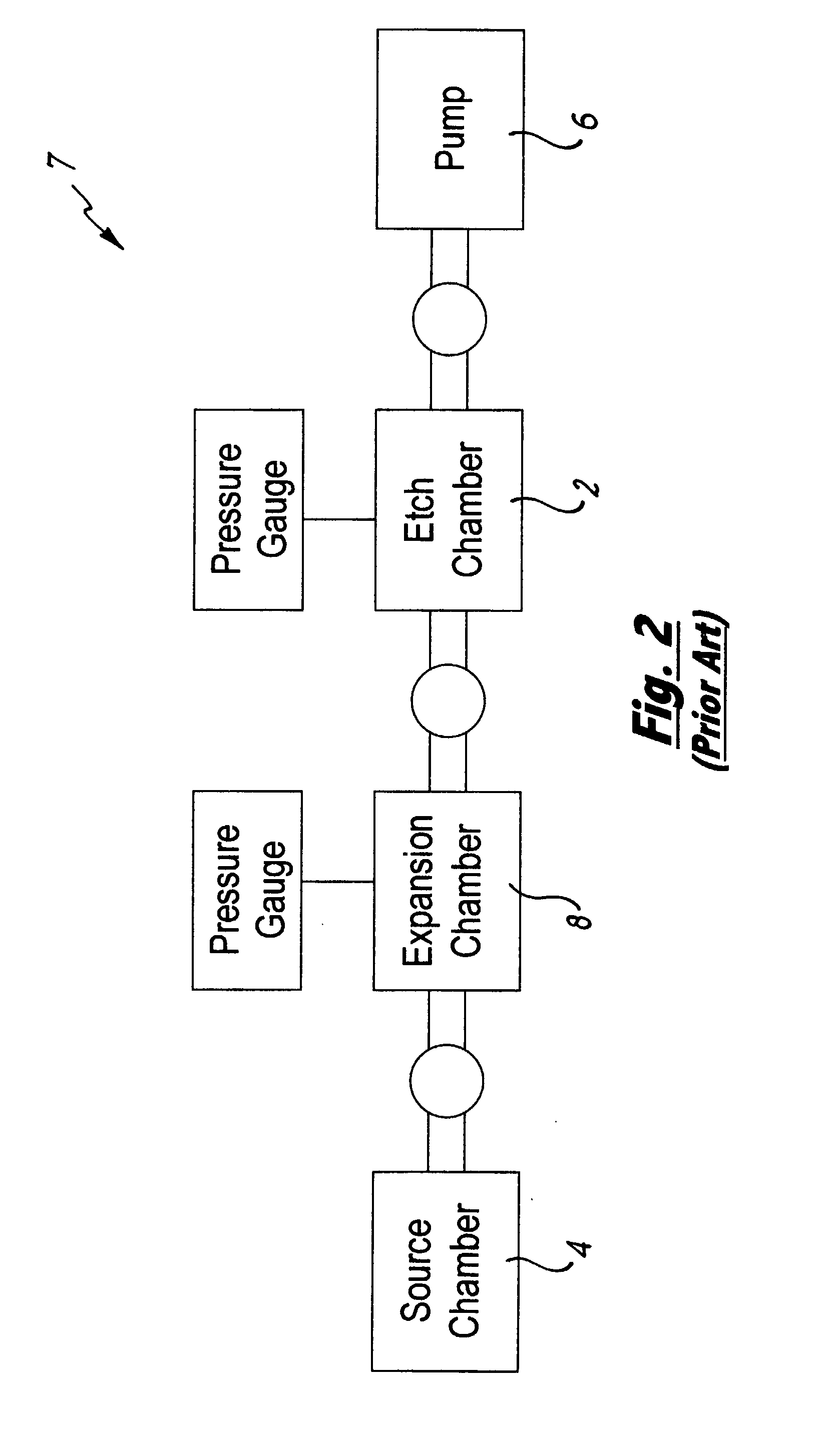

Method and Apparatus for the Etching of Microstructures

InactiveUS20080035607A1Increase partial pressureIncrease ratingsElectric discharge tubesDecorative surface effectsEtchingContinuous flow

An apparatus and method for providing an etching gas source for etching one or more microstructures located within a process chamber. the apparatus has a gas source supply line attached to a gas source and one or more chambers for containing an etching material. In use, the etching material is transformed into an etching material vapor within one or more of the chamber and the gas supply line provides a supply of carrier gas to the etching material vapor and also supplies the etching material vapor transported by the carrier gas to the process chamber. Advantageously, the apparatus of the invention does not require the incorporation of any expansion chambers or other complicated mechanical features in order to achieve a continuous flow of etching gas.

Owner:MEMSSTAR

Microfabricated structures and processes for manufacturing same

InactiveUS20050067286A1Minimize surface roughnessEasy to controlElectroforming processesMicroelectromechanical systemsManufacturing technologyCompound (substance)

Various techniques for the fabrication of highly accurate master molds with precisely defined microstructures for use in plastic replication using injection molding, hot embossing, or casting techniques are disclosed herein. Three different fabrication processes used for master mold fabrication are disclosed wherein one of the processes is a combination of the other two processes. In an embodiment of the first process, a two-step electroplating approach is used wherein one of the metals forms the microstructures and the second metal is used as a sacrificial support layer. Following electroplating, the exact height of the microstructures is defined using a chemical mechanical polishing process. In an embodiment of the second process, a modified electroforming process is used for master mold fabrication. The specific modifications include the use of Nickel-Iron (80:20) as a structural component of the master mold, and the use of a higher saccharin concentration in the electroplating bath to reduce tensile stress during plating and electroforming on the top as well as sides of the dummy substrate to prevent peel off of the electroform. The electroforming process is also well suited towards the fabrication of microstructures with non-rectangular cross sectional profiles. Also disclosed is an embodiment of a simple fabrication process using direct deposition of a curable liquid molding material combined with the electroforming process. Finally, an embodiment of a third fabrication process combines the meritorious features of the first two approaches and is used to fabricate a master mold using a combination of the two-step electroplating plus chemical mechanical polishing approach and the electroforming approach to fabricate highly accurate master molds with precisely defined microstructures. The microstructures are an integral part of the master mold and hence the master mold is more robust and well suited for high volume production of plastic MEMS devices through replication techniques such as injection molding.

Owner:CINCINNATI UNIVERISITY OF THE

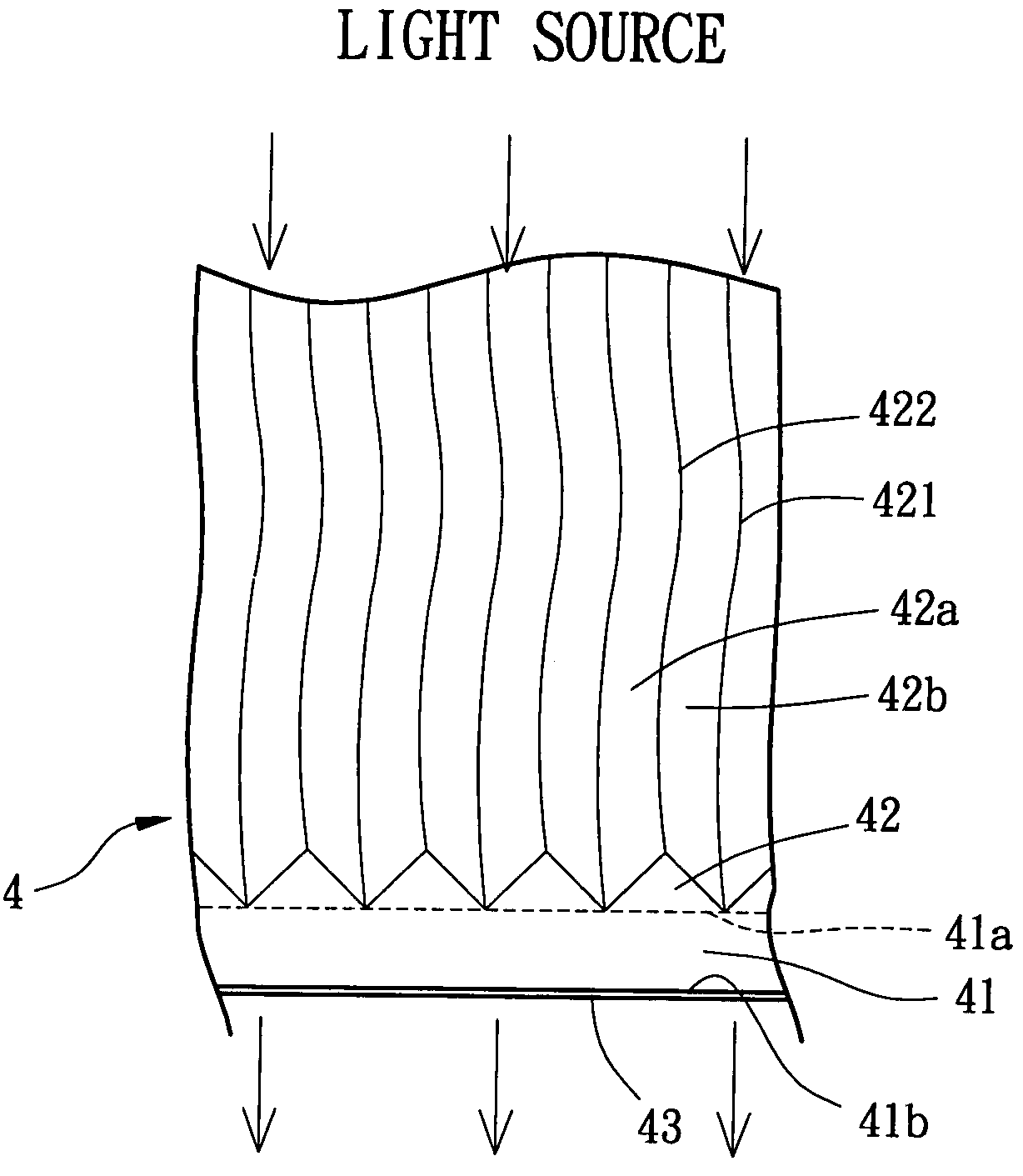

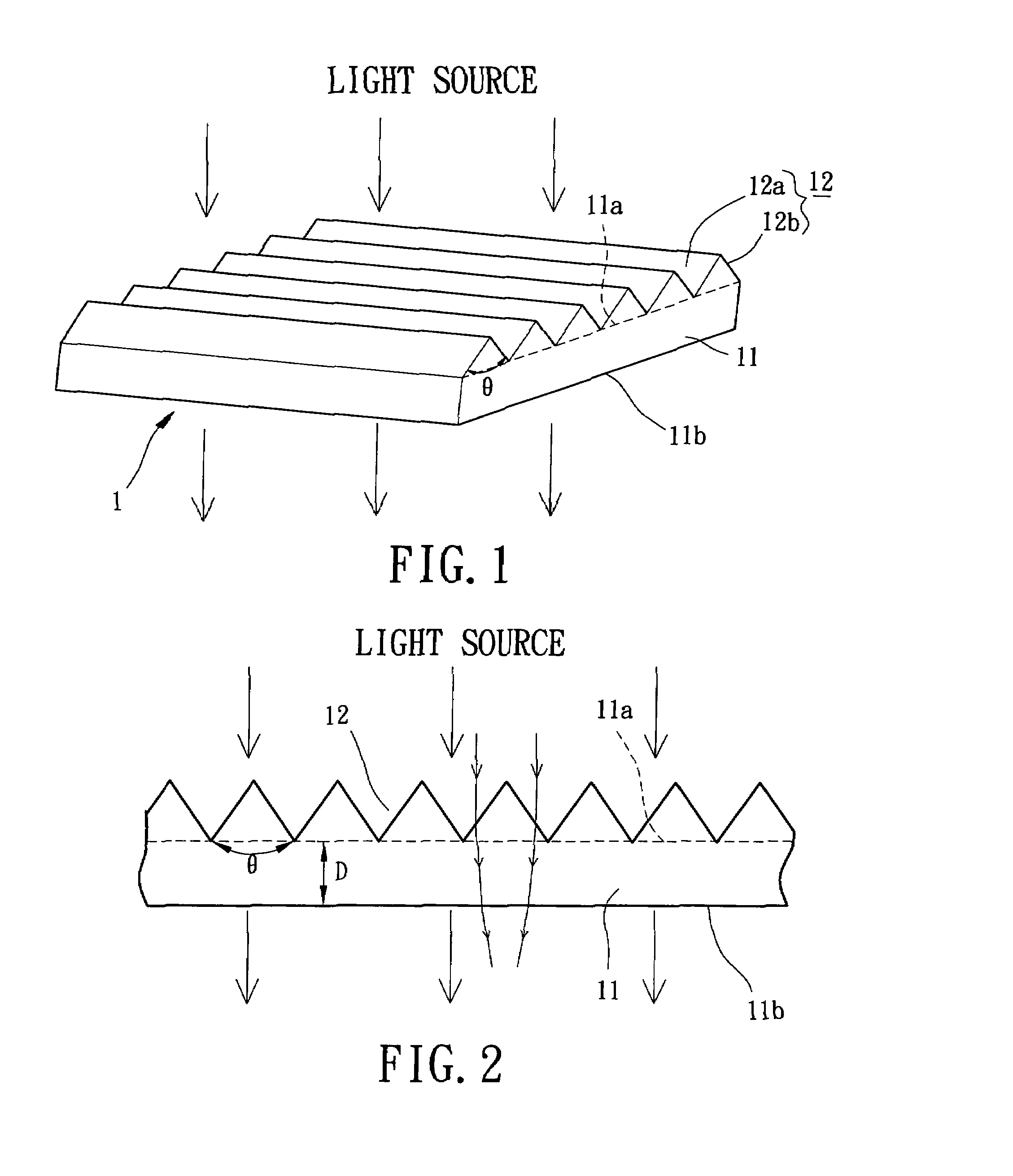

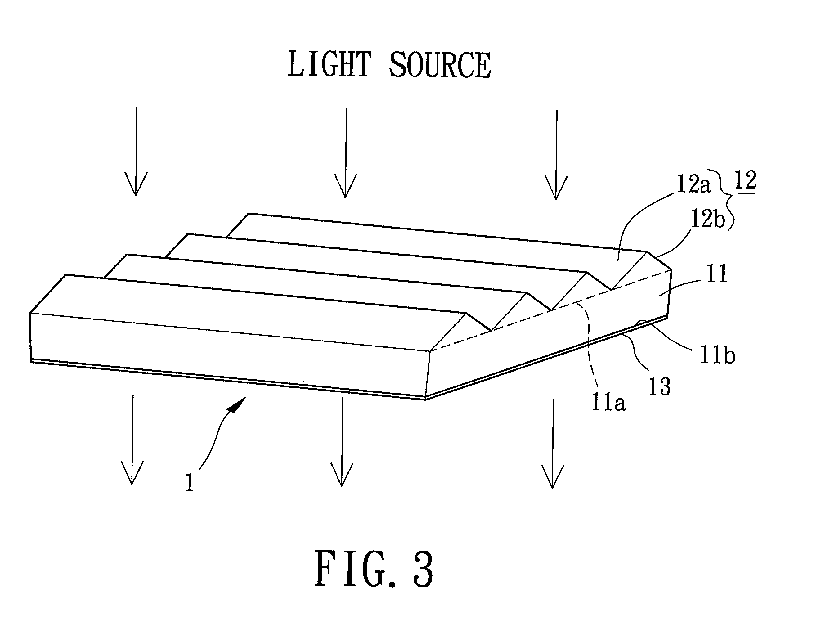

Brightness enhancement film having a light-guiding structure

ActiveUS7269328B2Increase brightnessAvoid abrasionsCoupling light guidesOptical waveguide light guideLight guideLight emission

A brightness enhancement film having a light-guiding structure includes a substrate, which has a light-guiding layer and a plurality of light-refracting microstructures. The substrate has a light incident surface and a light emission surface opposite thereto. The light-refracting microstructures are arranged on the light incident surface of the substrate and are provided for varying surface curvatures to refract incident light. The light-guiding layer is arranged on the light emission surface of the substrate and is provided for guiding refracted light to generate homogeneous light to emit therefrom.

Owner:ZHEJIANG JINHUI OPTOELECTRONIC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com