Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2722 results about "Continuous flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous-flow manufacturing, or Repetitive-Flow Manufacturing, is an approach to discrete manufacturing that contrasts with batch production. It is associated with a just-in-time and kanban production approach, and calls for an ongoing examination and improvement efforts which ultimately requires integration of all elements of the production system. The goal is an optimally balanced production line with little waste, the lowest possible cost, on-time and defect-free production.

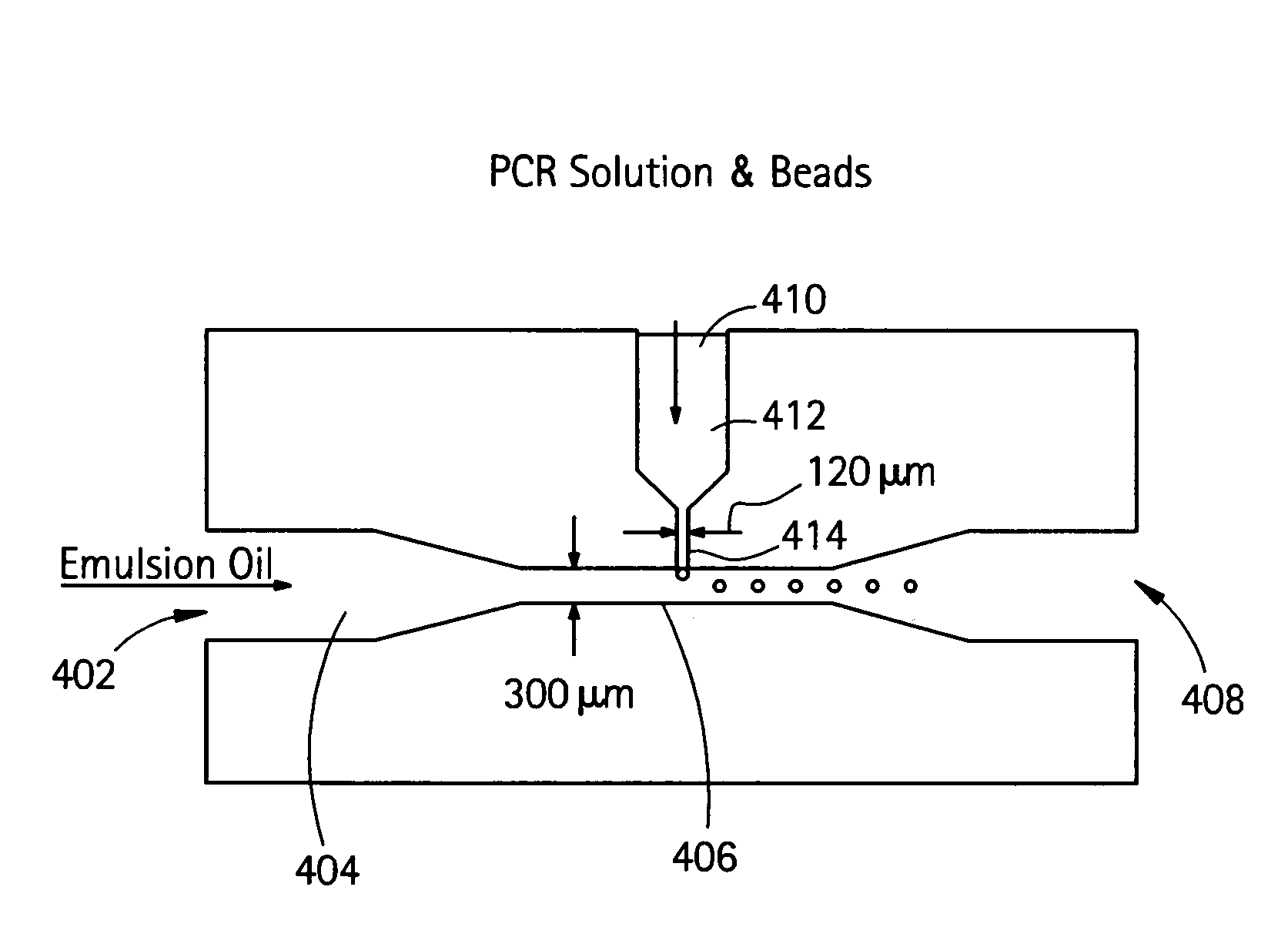

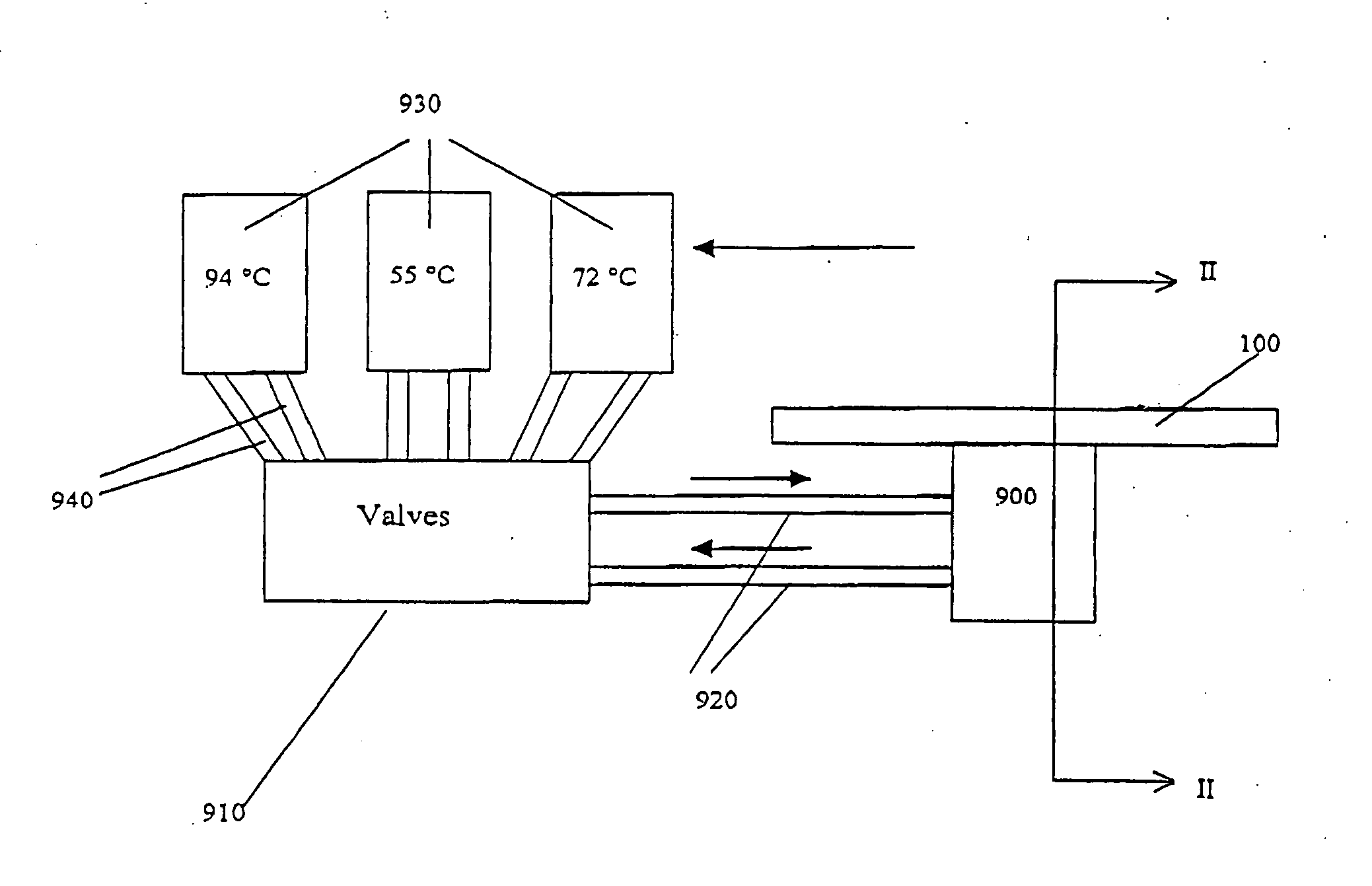

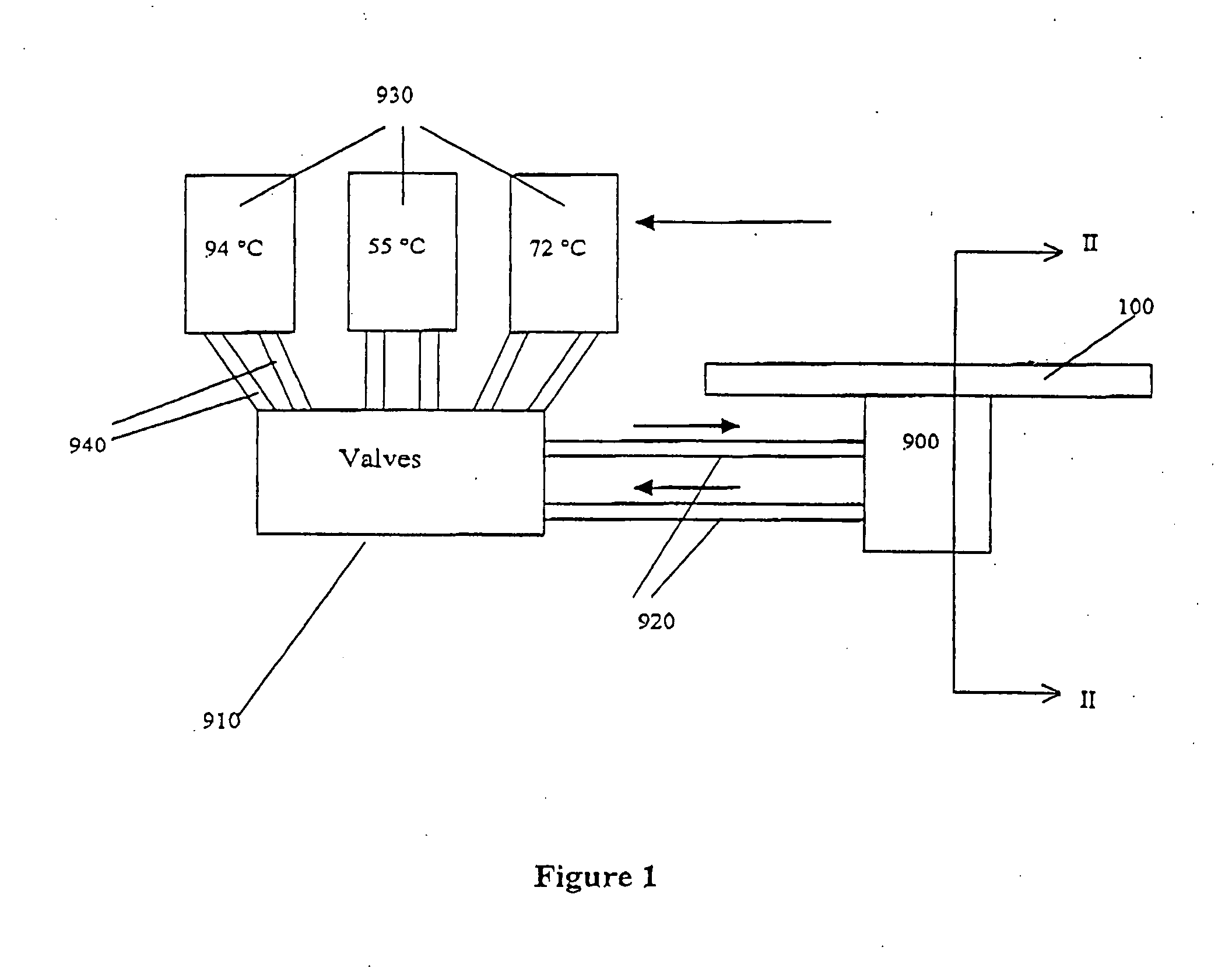

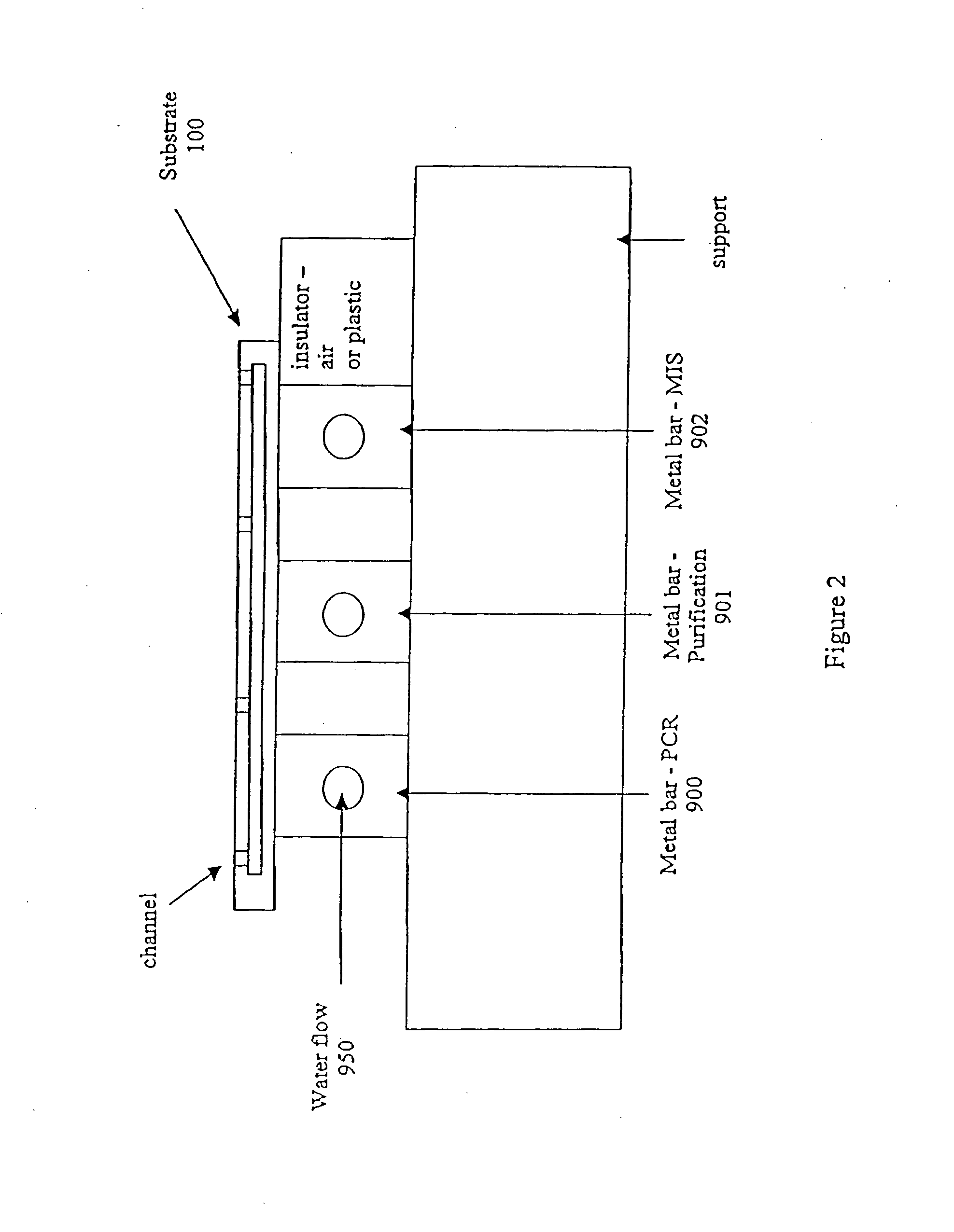

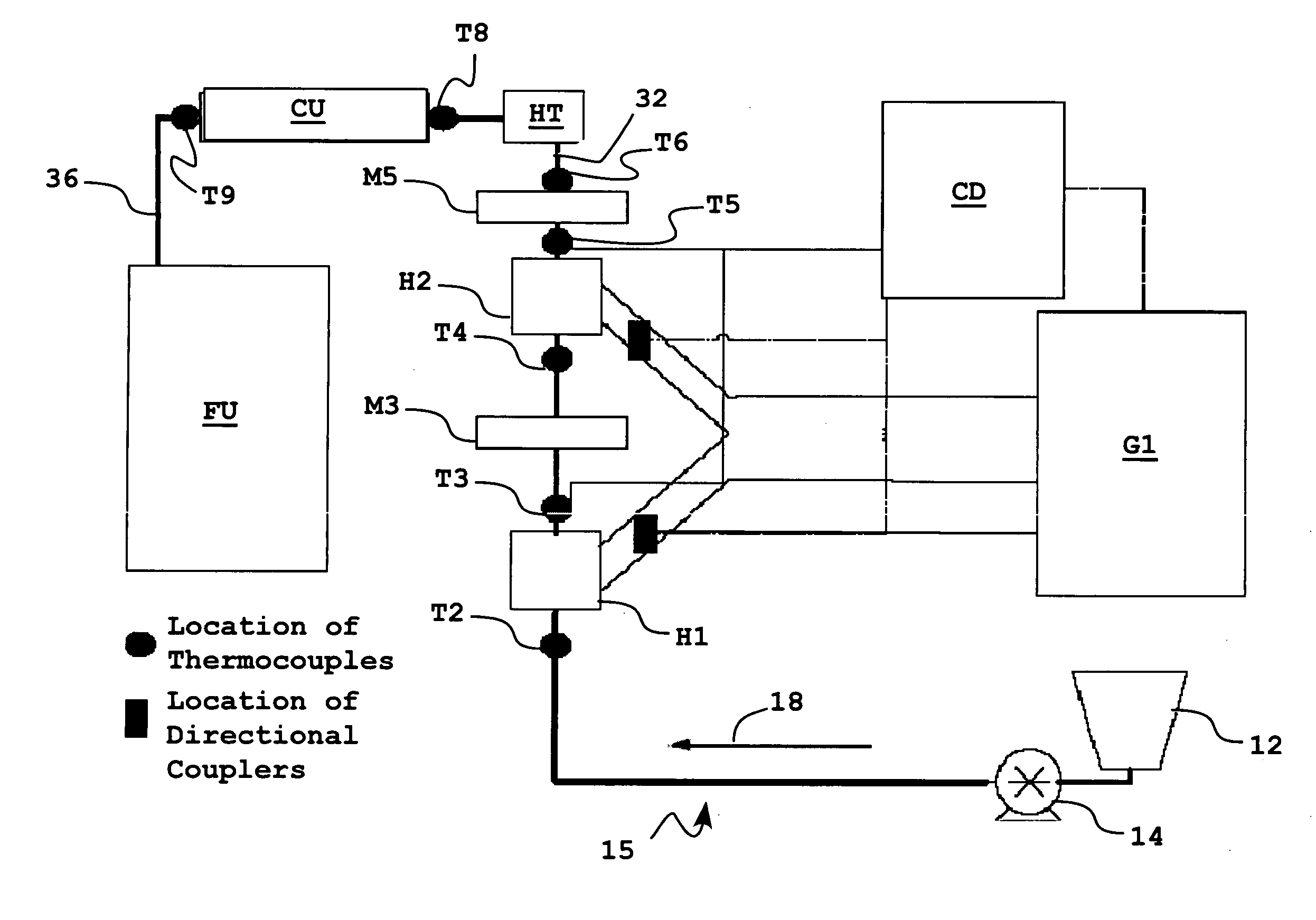

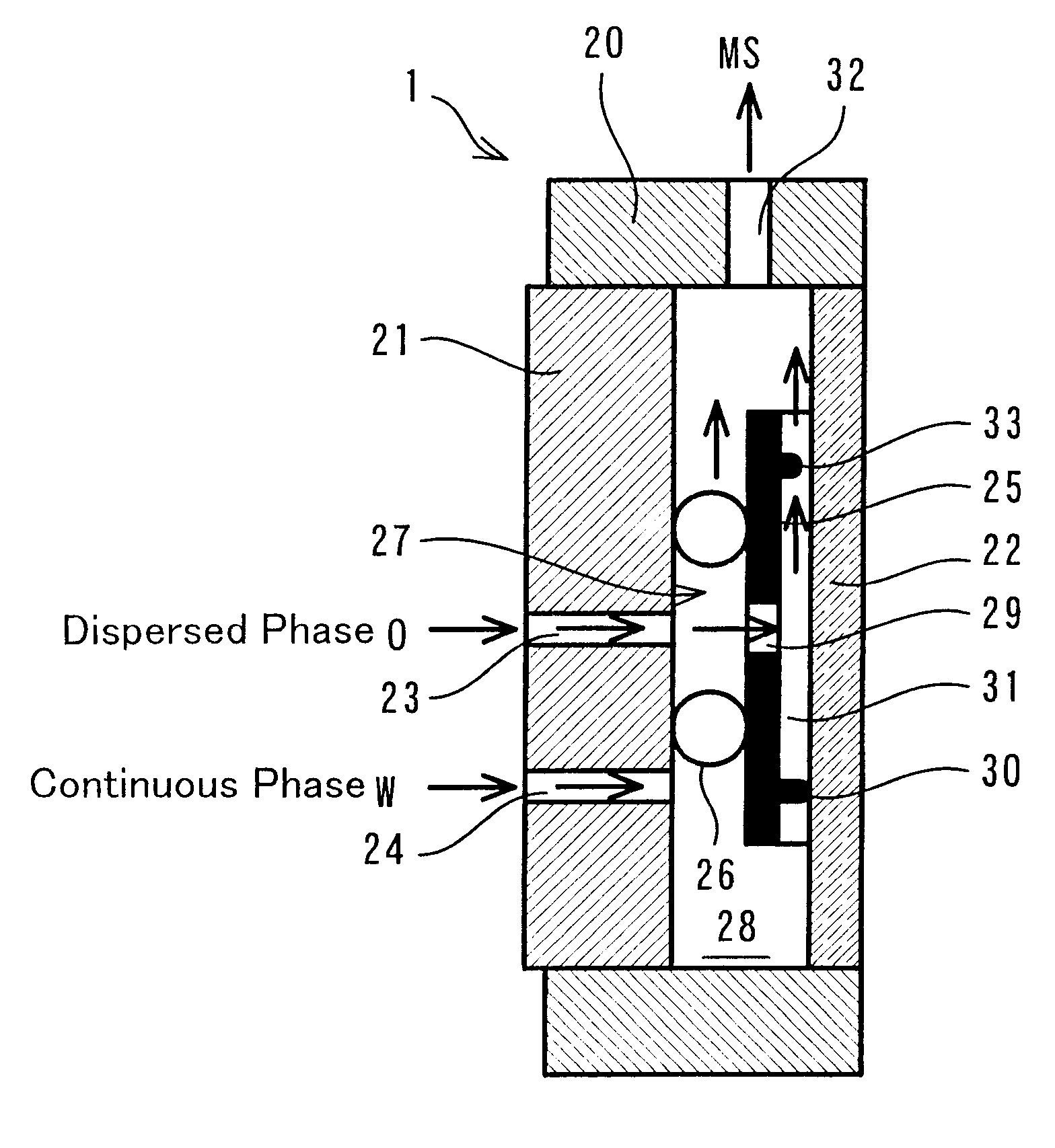

Nucleic acid amplification with continuous flow emulsion

InactiveUS20050227264A1Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

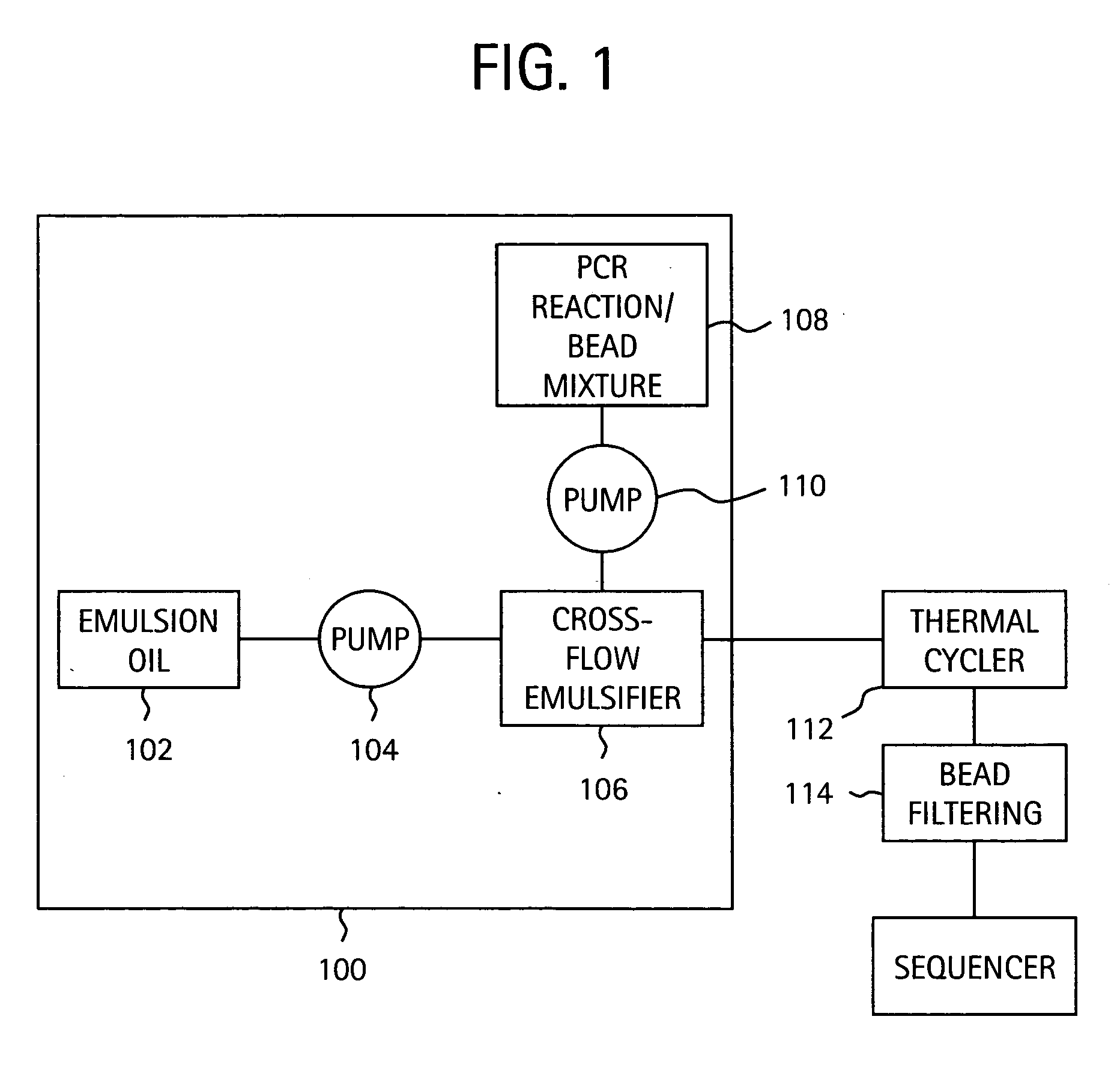

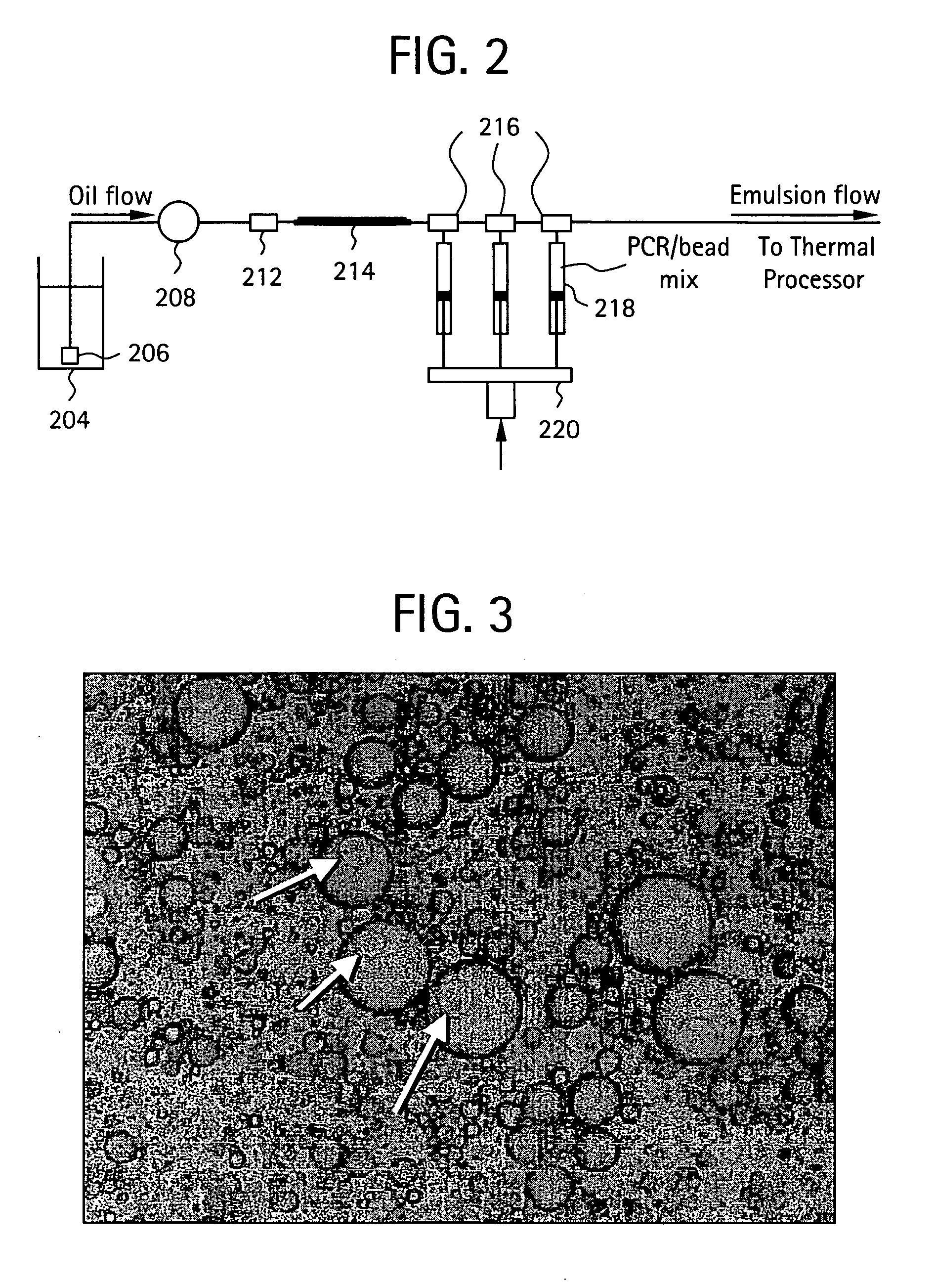

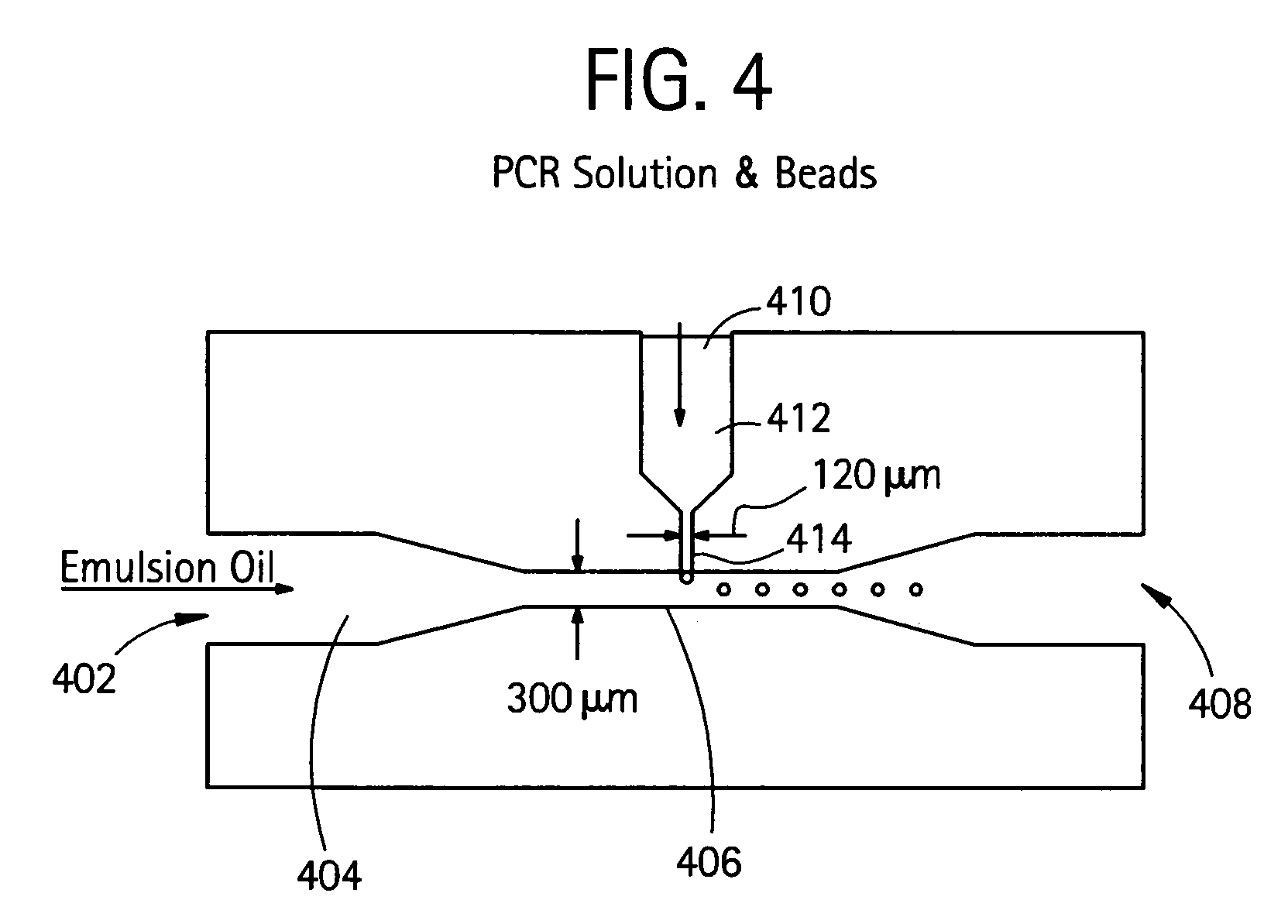

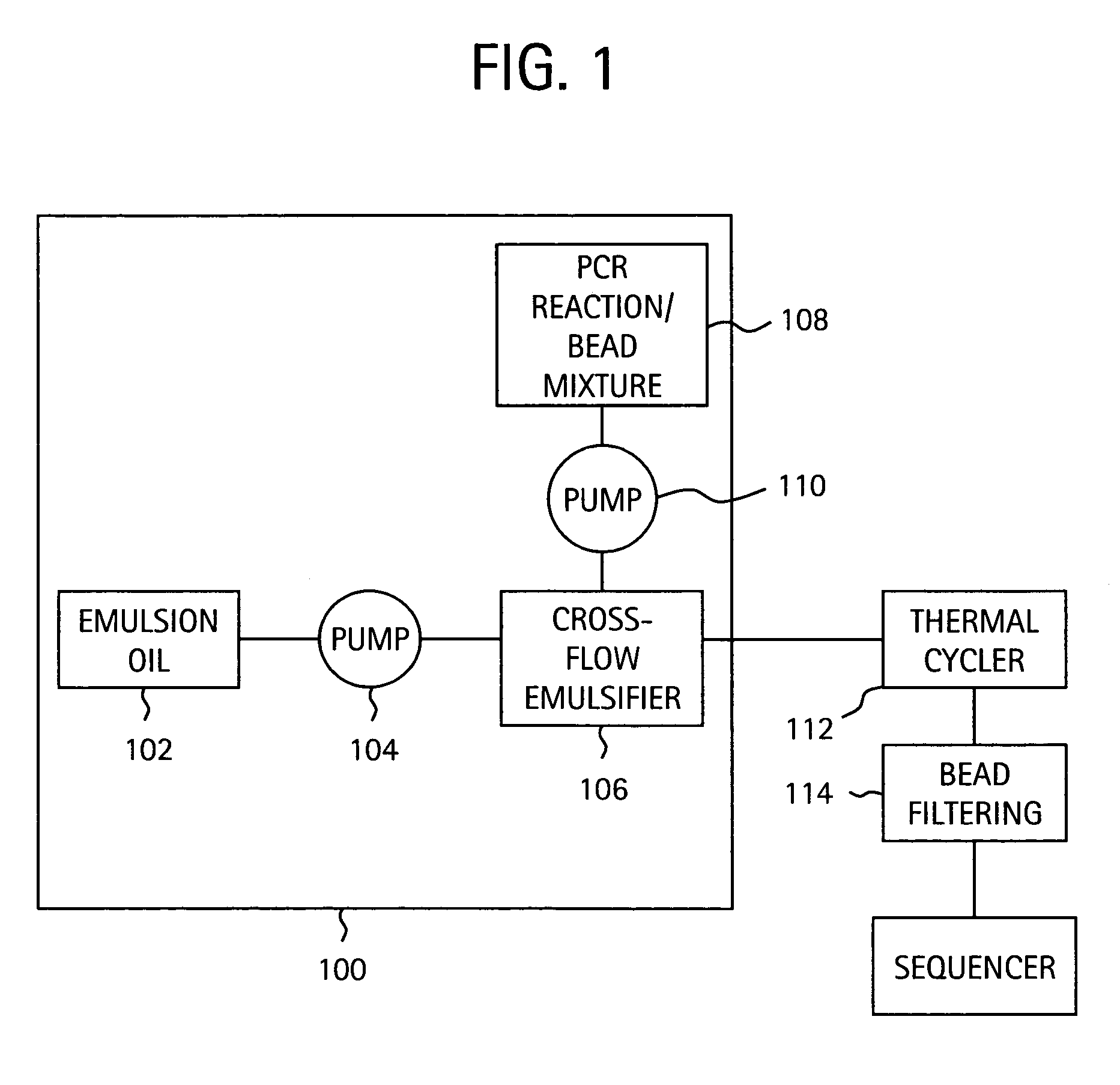

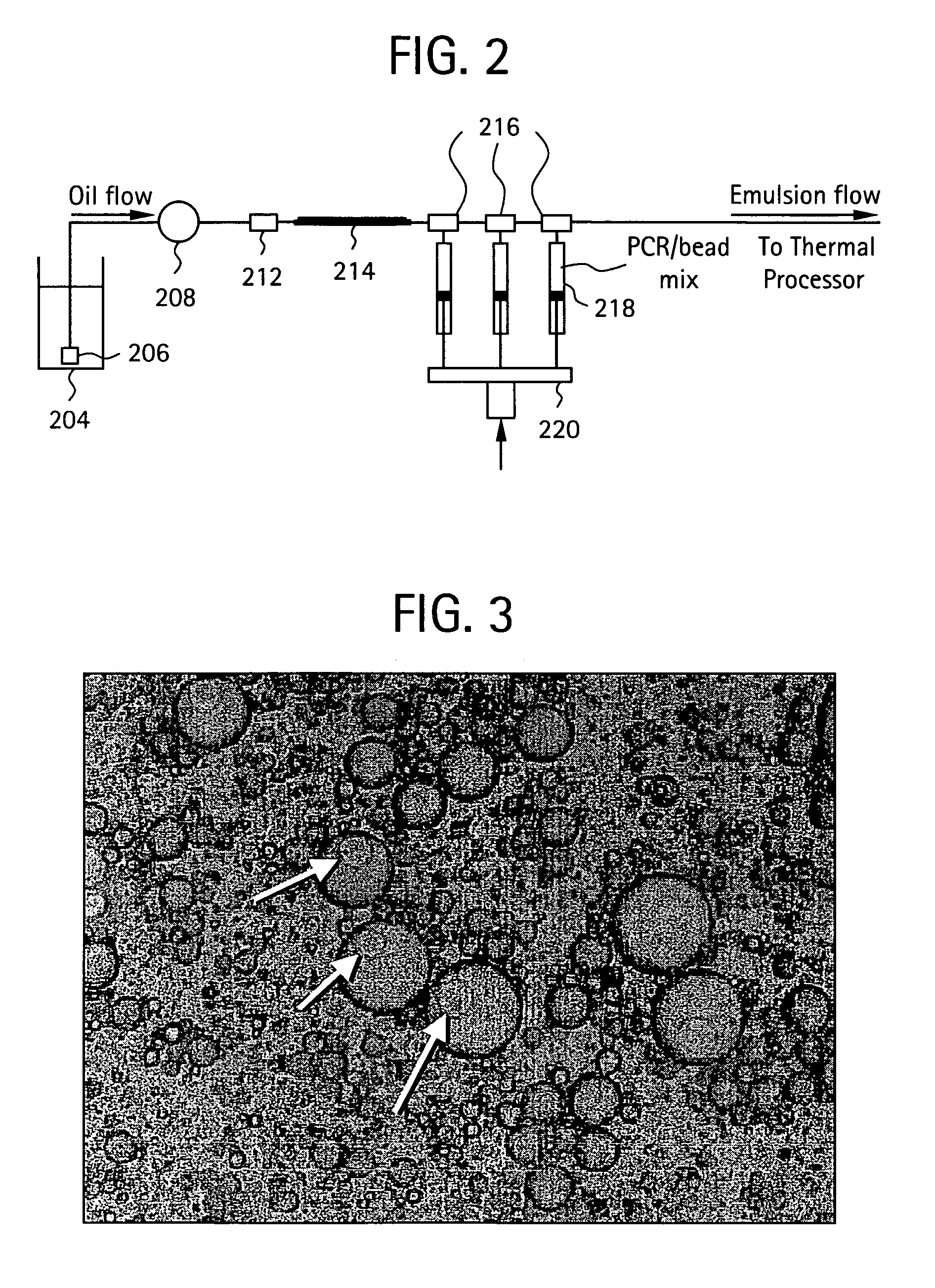

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

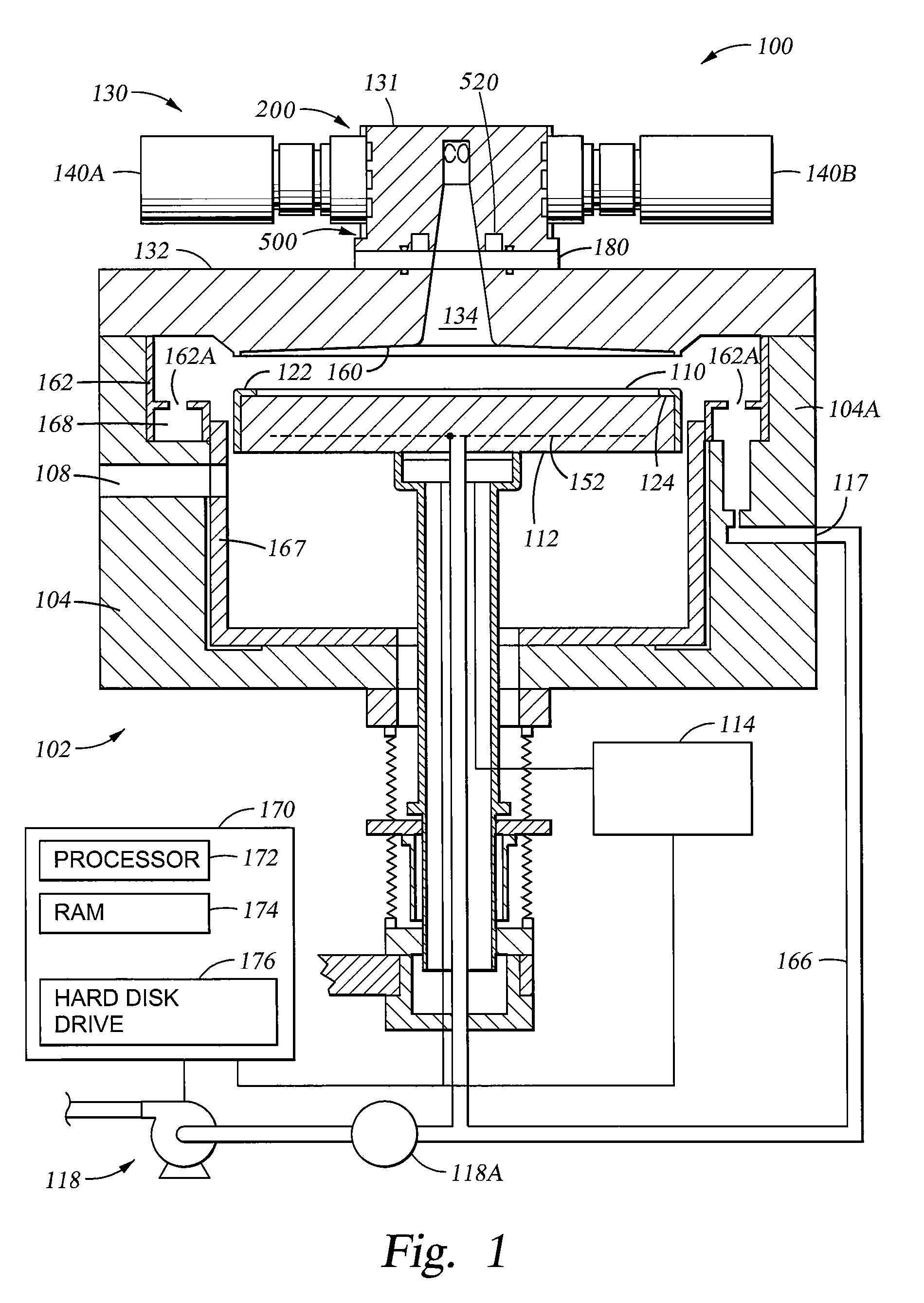

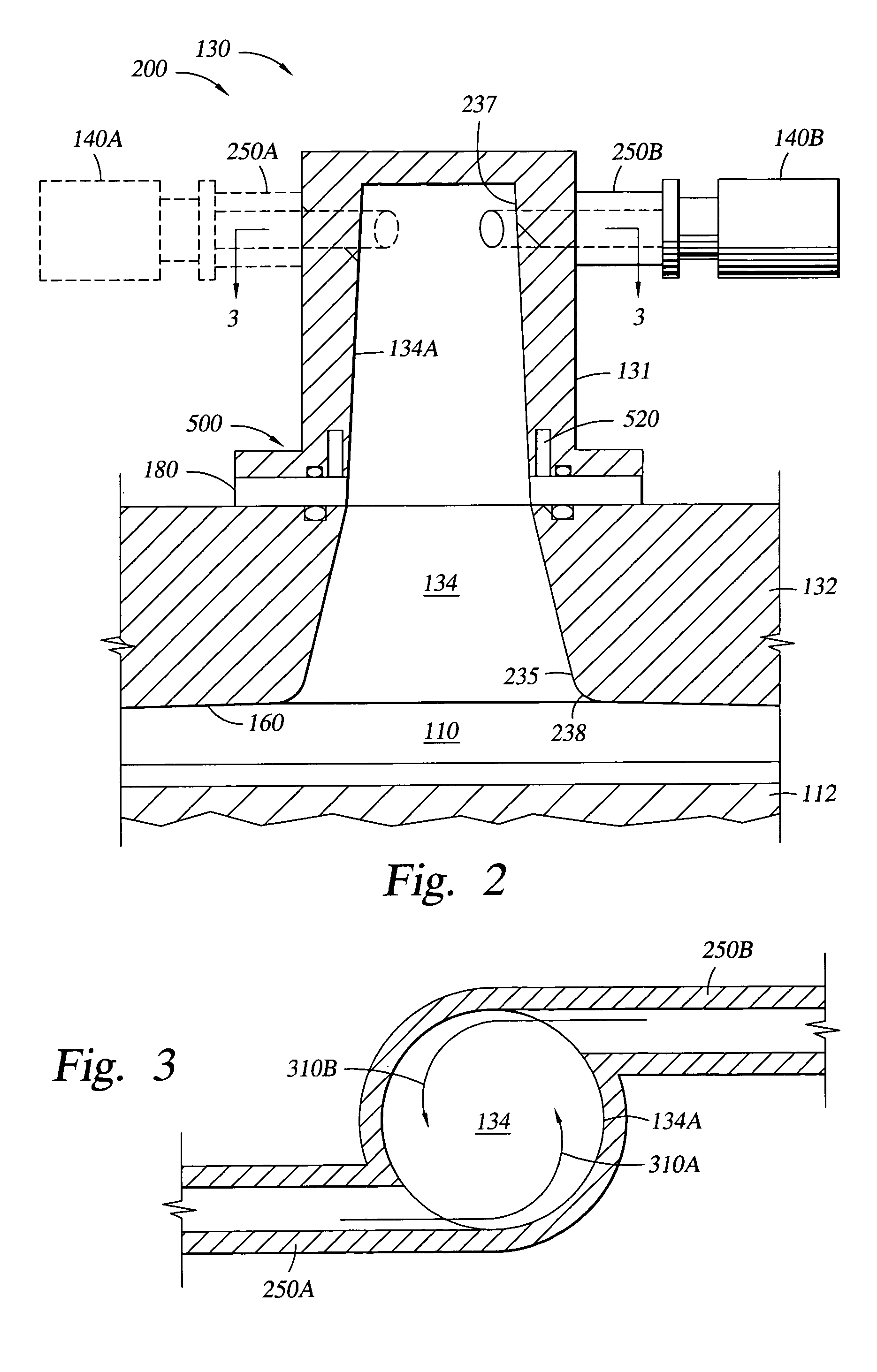

Apparatus and method for hybrid chemical processing

ActiveUS7204886B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingContinuous flowEngineering

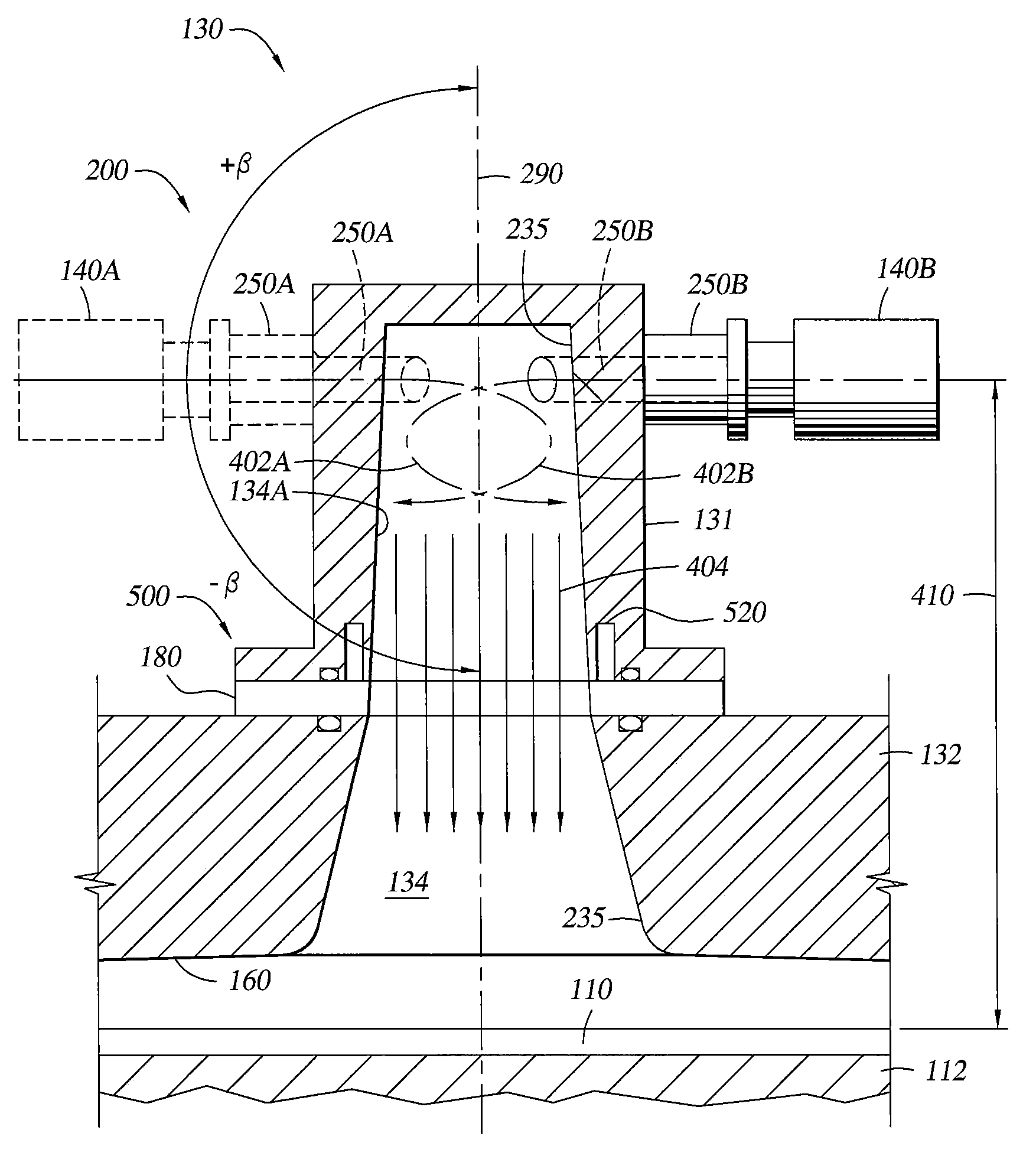

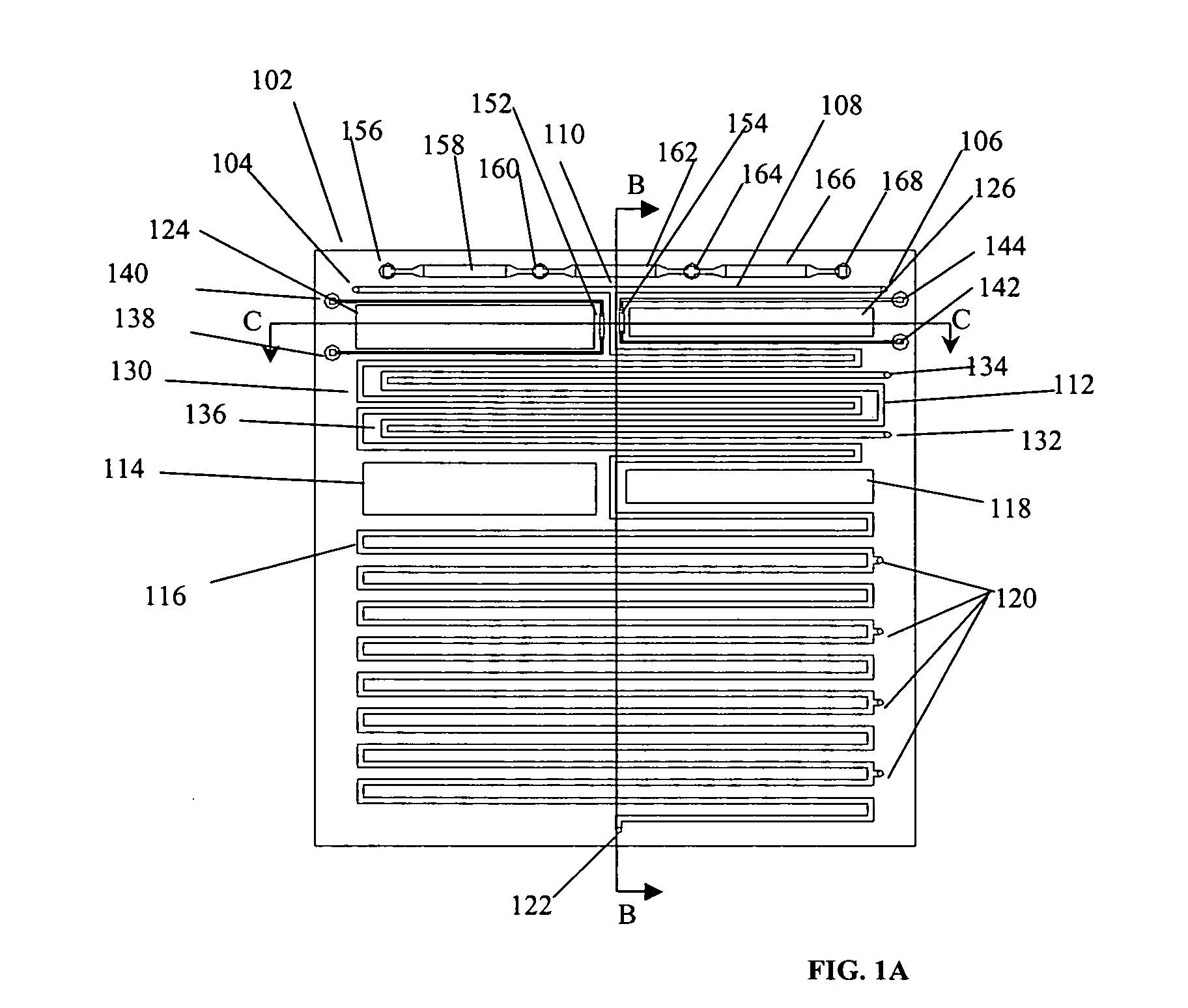

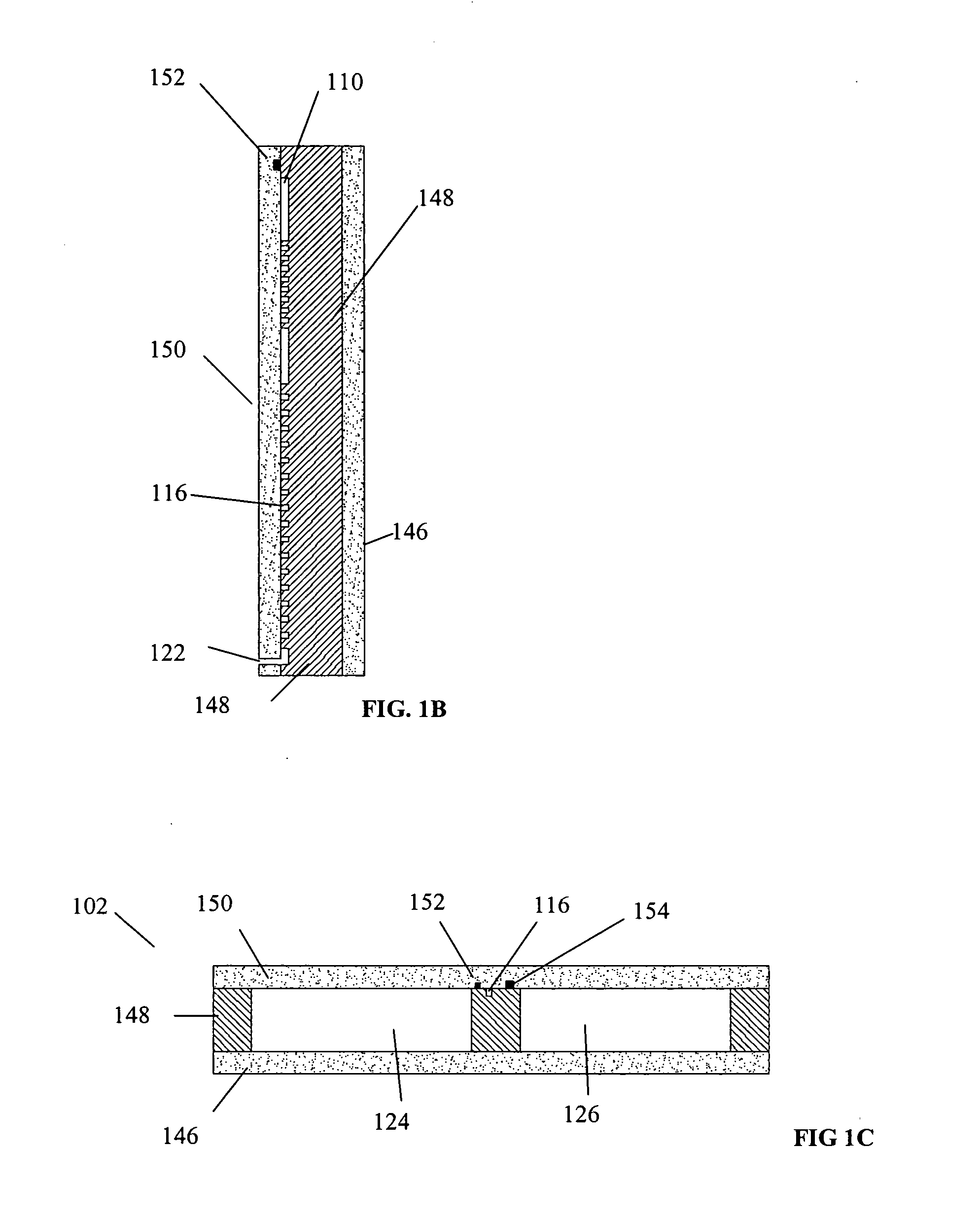

A method and apparatus for performing multiple deposition processes is provided. In one embodiment, the apparatus includes a chamber body and a gas distribution assembly disposed on the chamber body. In one embodiment, the method comprises positioning a substrate surface to be processed within a chamber body, delivering two or more compounds into the chamber body utilizing a gas distribution assembly disposed on the chamber body to deposit a film comprising a first material, and then delivering two or more compounds into the chamber body utilizing a gas distribution assembly disposed on the chamber body to deposit a film comprising a second material. In one aspect of these embodiments, the gas distribution assembly includes a gas conduit in fluid communication with the chamber body, two or more isolated gas inlets equipped with one or more high speed actuating valves in fluid communication with the gas conduit, and a mixing channel in fluid communication with the gas conduit. The valves are adapted to alternately pulse one or more compounds into the gas conduit, and the mixing channel is adapted to deliver a continuous flow of one or more compounds into the gas conduit.

Owner:APPLIED MATERIALS INC

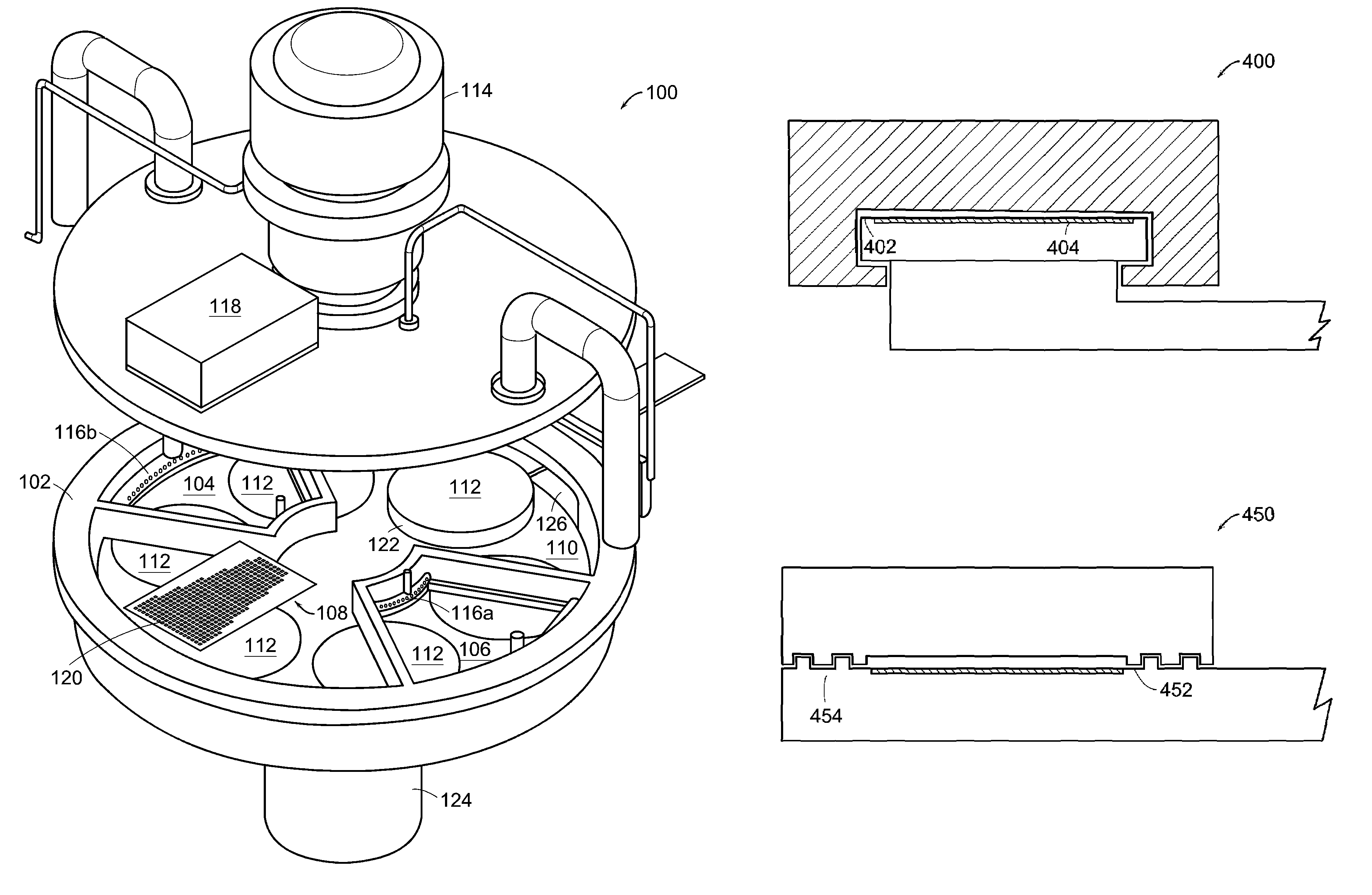

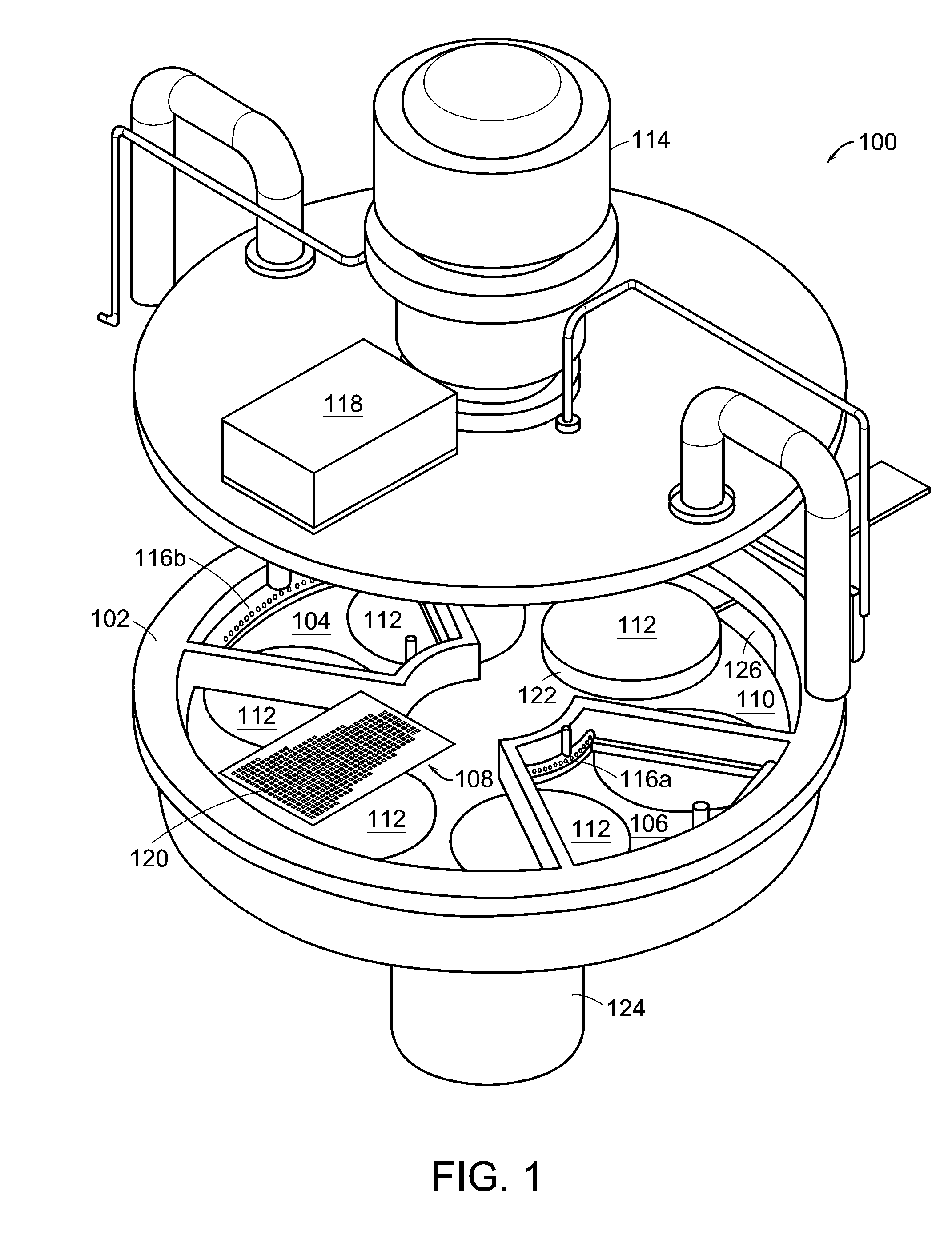

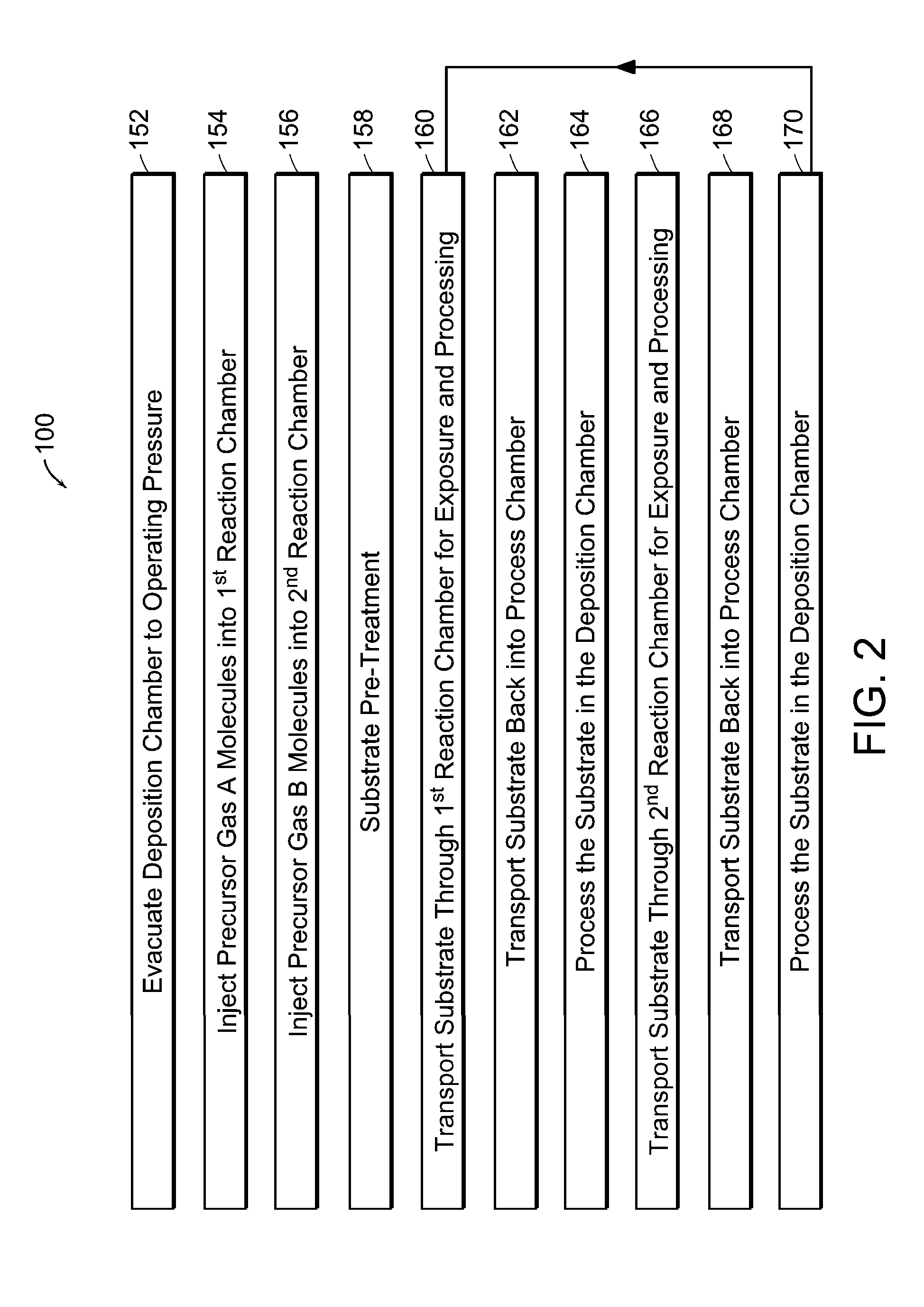

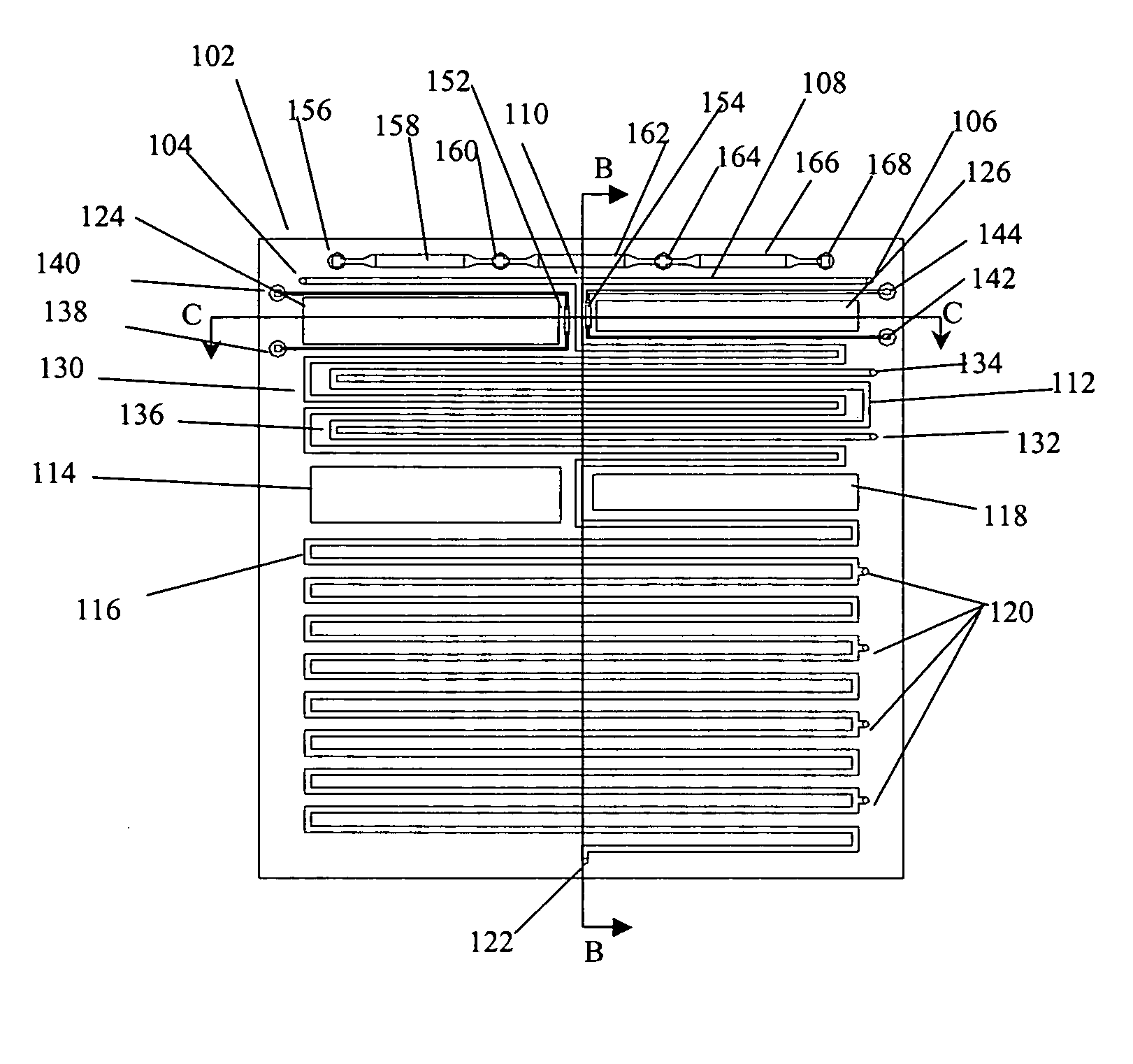

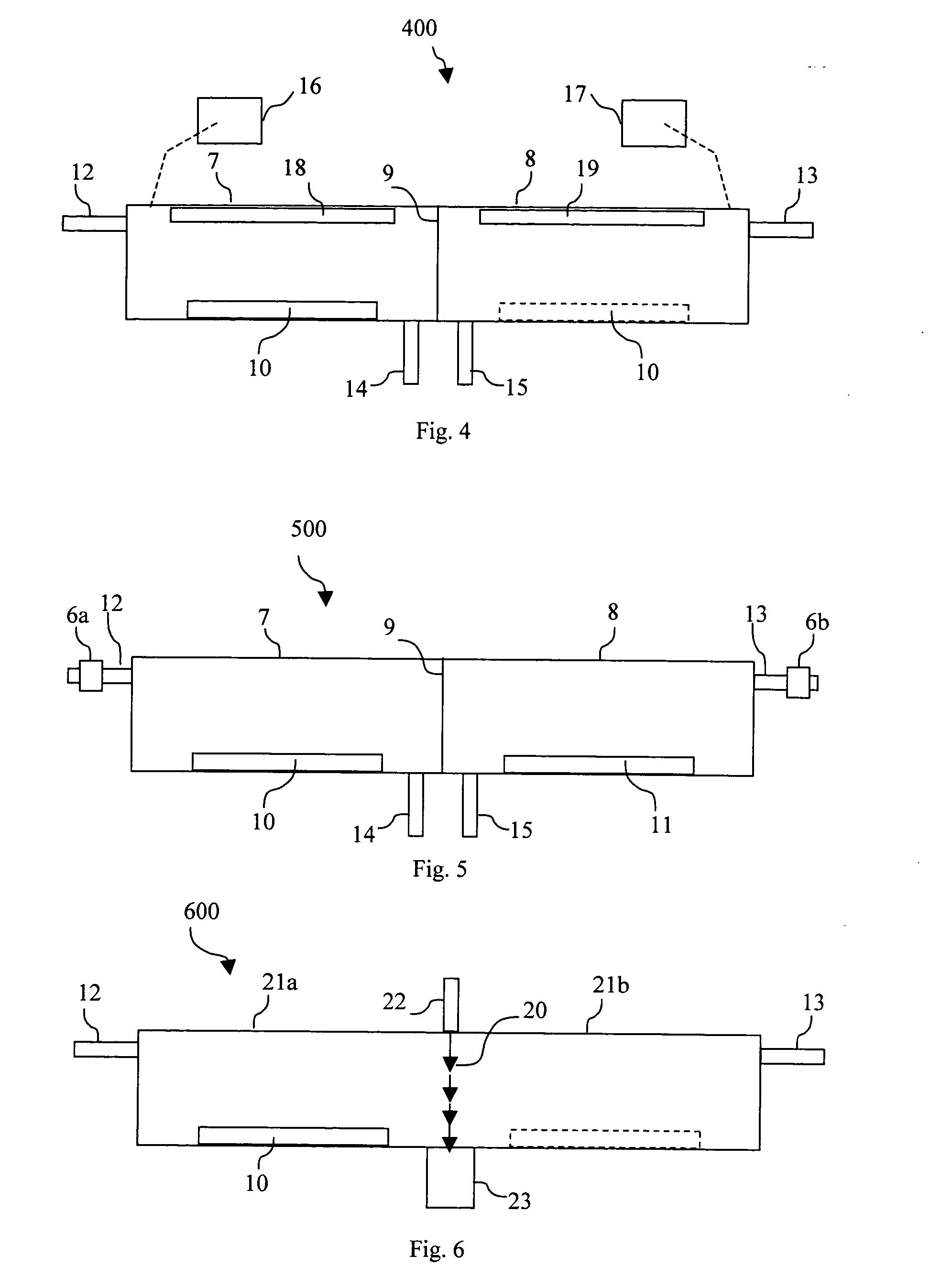

Continuous flow deposition system

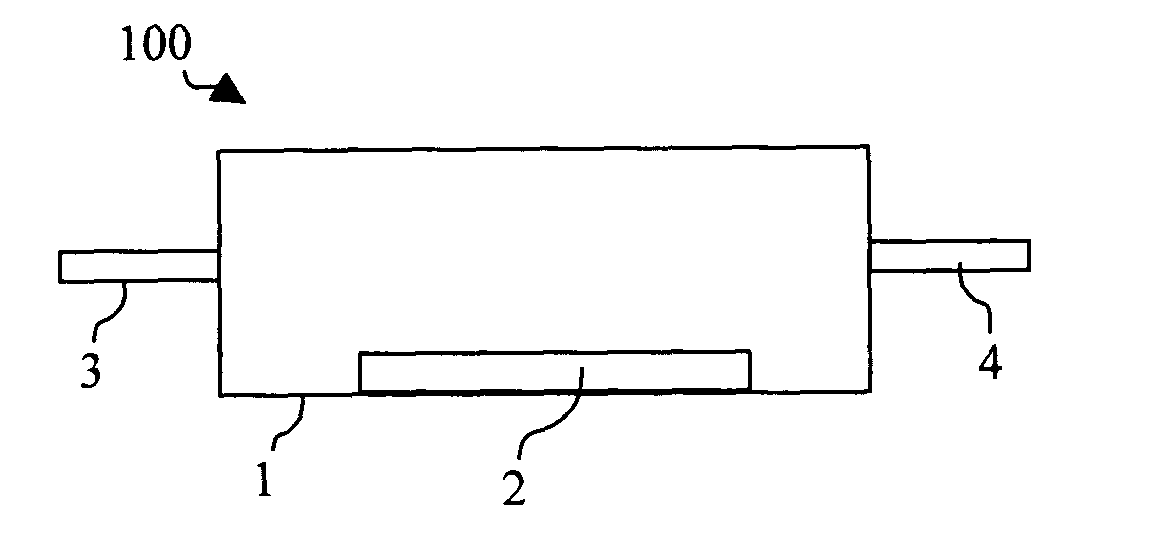

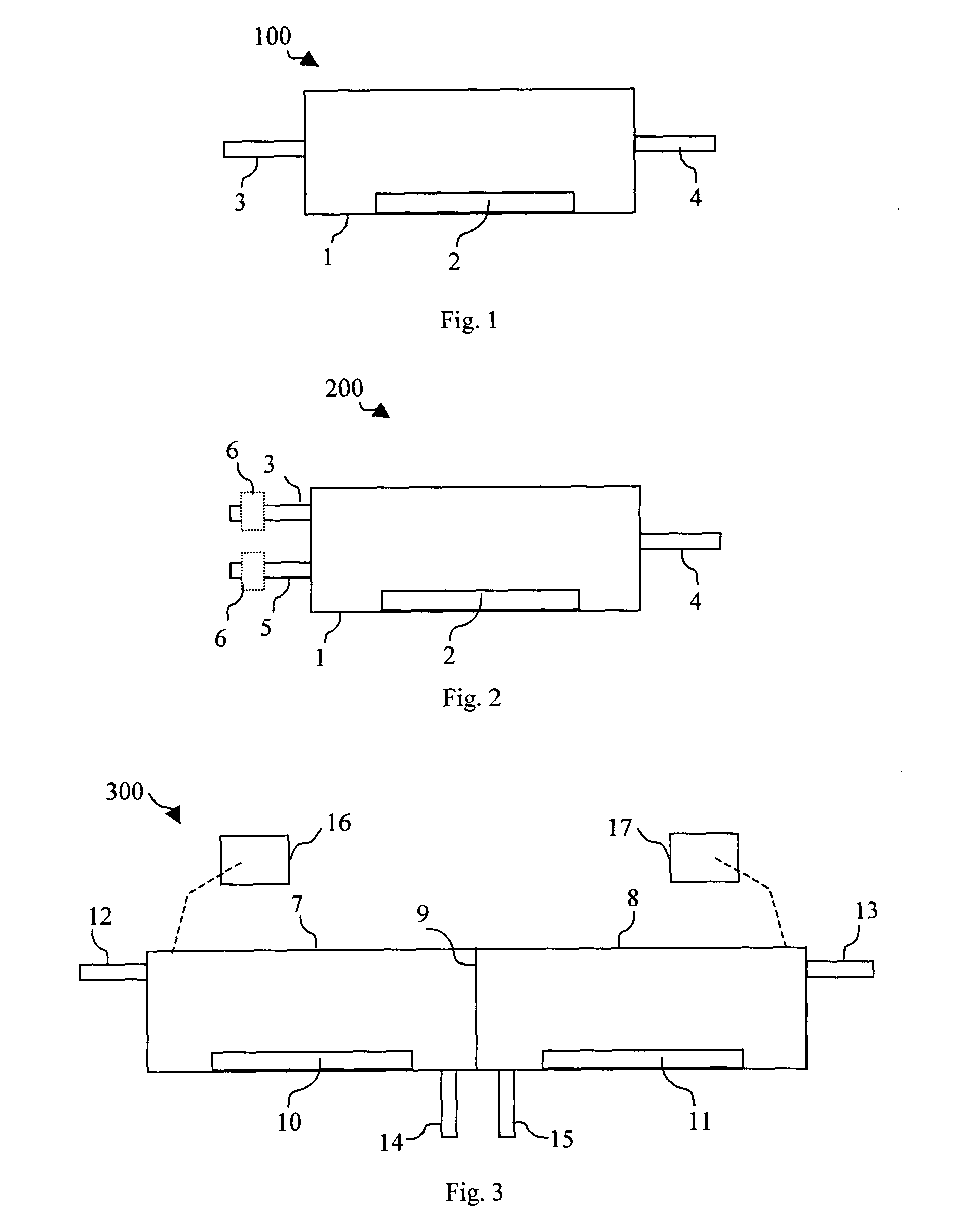

An atomic layer deposition system is described that includes a deposition chamber. A first and second reaction chamber are positioned in the deposition chamber and contain a first and a second reactant species, respectively. A monolayer of the first reactant species is deposited on a substrate passing through the first reaction chamber. A monolayer of the second reactant species is deposited on a substrate passing through the second reaction chamber. A transport mechanism transports a substrate in a path through the first reaction chamber and through the second reaction chamber, thereby depositing a film on the substrate by atomic layer deposition. The shape of the first and the second reaction chambers are chosen to achieve a constant exposure of the substrate to reactant species when the transport mechanism transports the substrate in the path through the respective reaction chambers at the constant transport rate.

Owner:VEECON INSTR

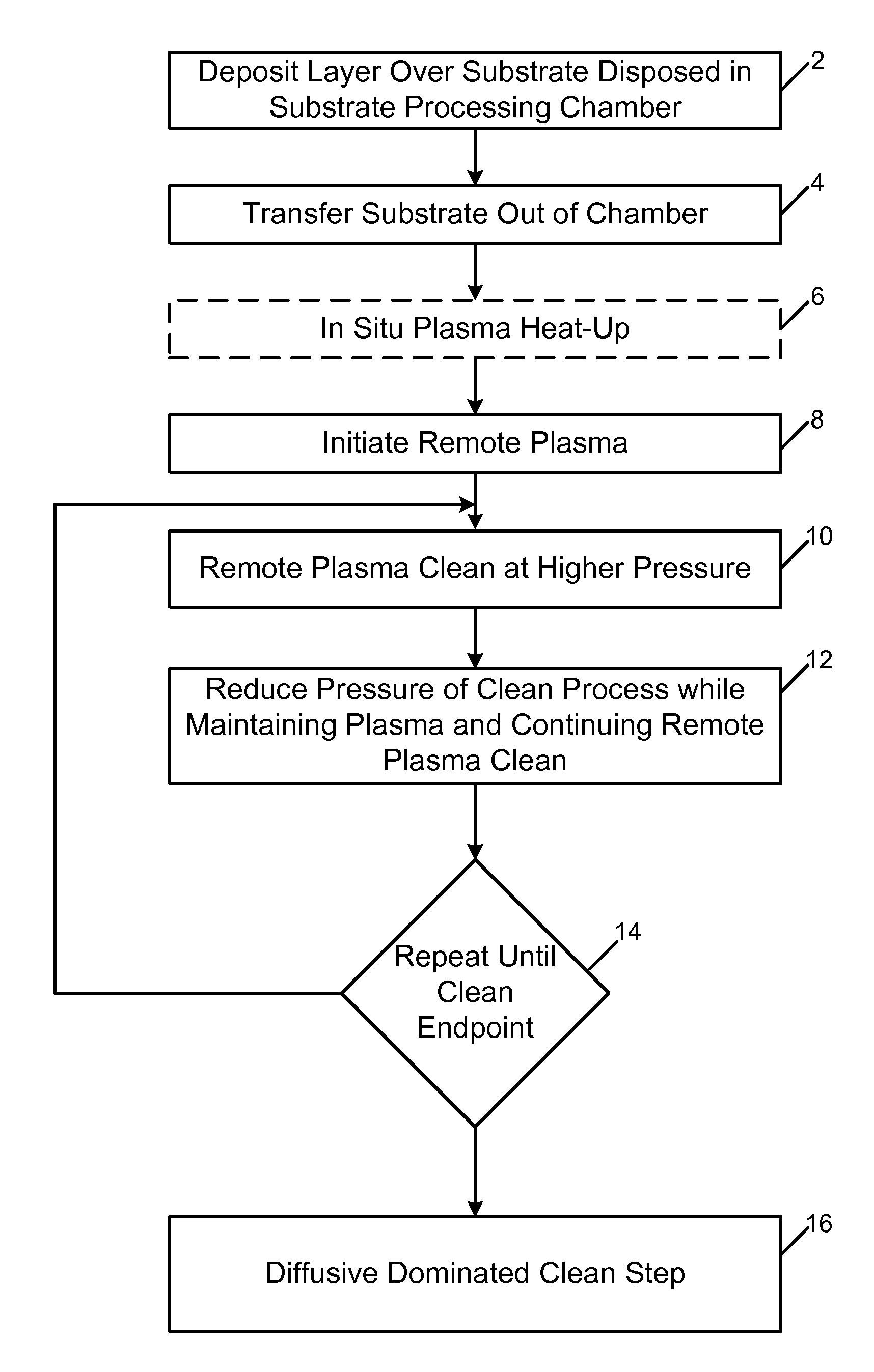

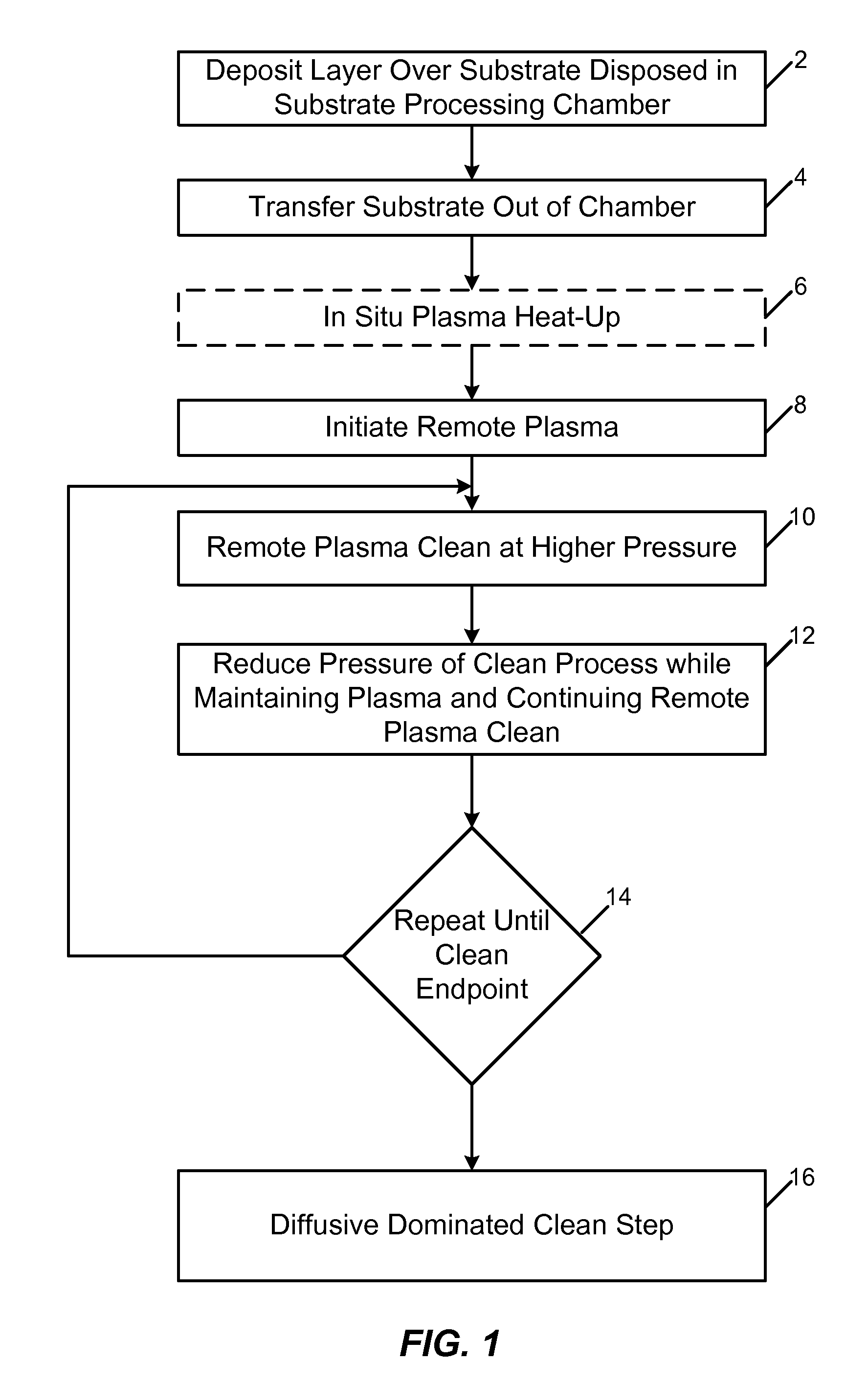

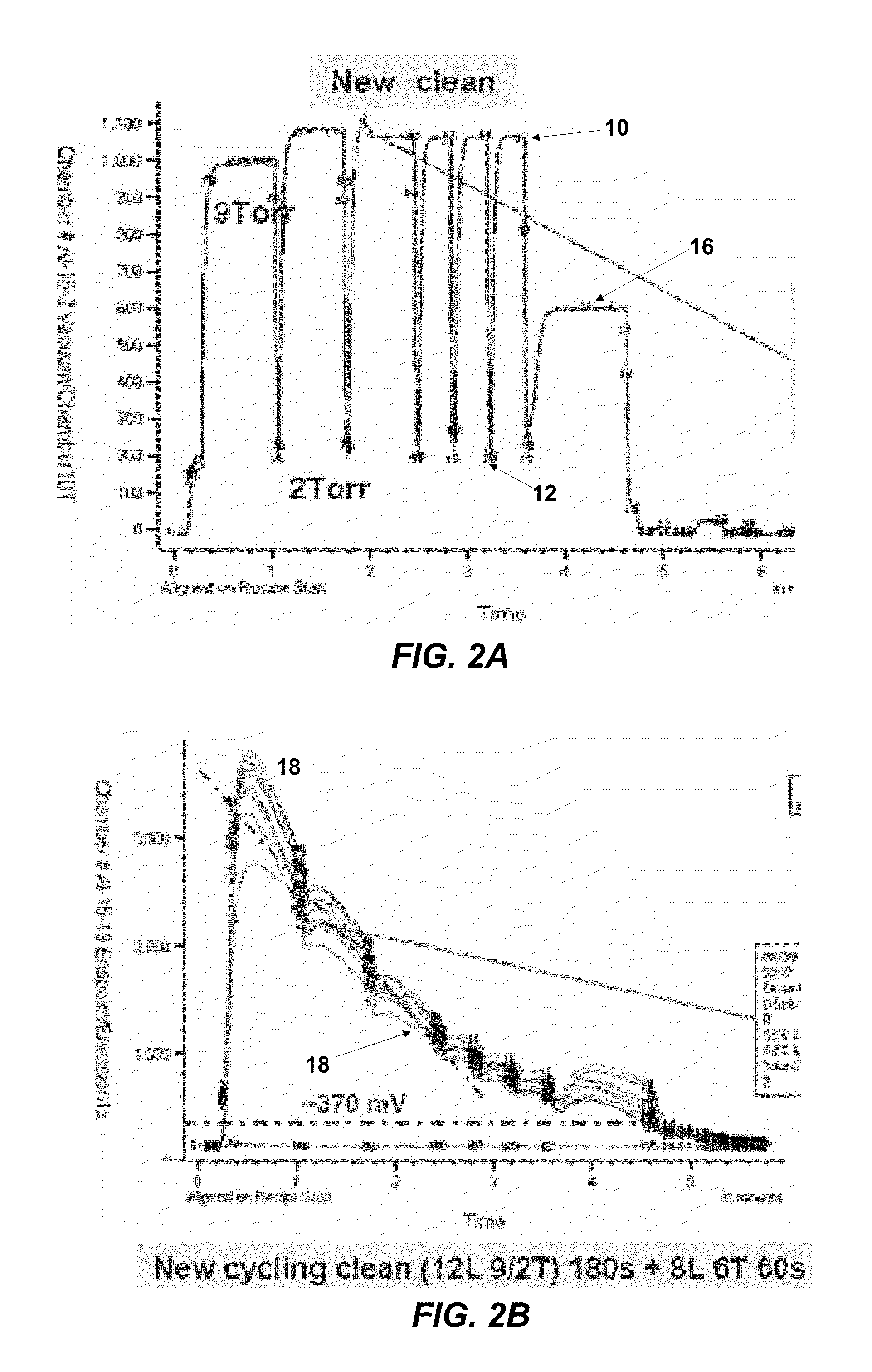

Remote plasma clean process with cycled high and low pressure clean steps

InactiveUS7967913B2Hollow article cleaningSemiconductor/solid-state device manufacturingRemote plasmaContinuous flow

A remote plasma process for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber after processing a substrate disposed in the substrate processing chamber. In one embodiment, the substrate is transferred out of the substrate processing chamber and a flow of a fluorine-containing etchant gas is introduced into a remote plasma source where reactive species are formed. A continuous flow of the reactive species from the remote plasmas source to the substrate processing chamber is generated while a cycle of high and low pressure clean steps is repeated. During the high pressure clean step, reactive species are flown into the substrate processing chamber while pressure within the substrate processing chamber is maintained between 4-15 Torr. During the low pressure clean step, reactive species are flown into the substrate processing chamber while reducing the pressure of the substrate processing chamber by at least 50 percent of a high pressure reached in the high pressure clean step.

Owner:APPLIED MATERIALS INC

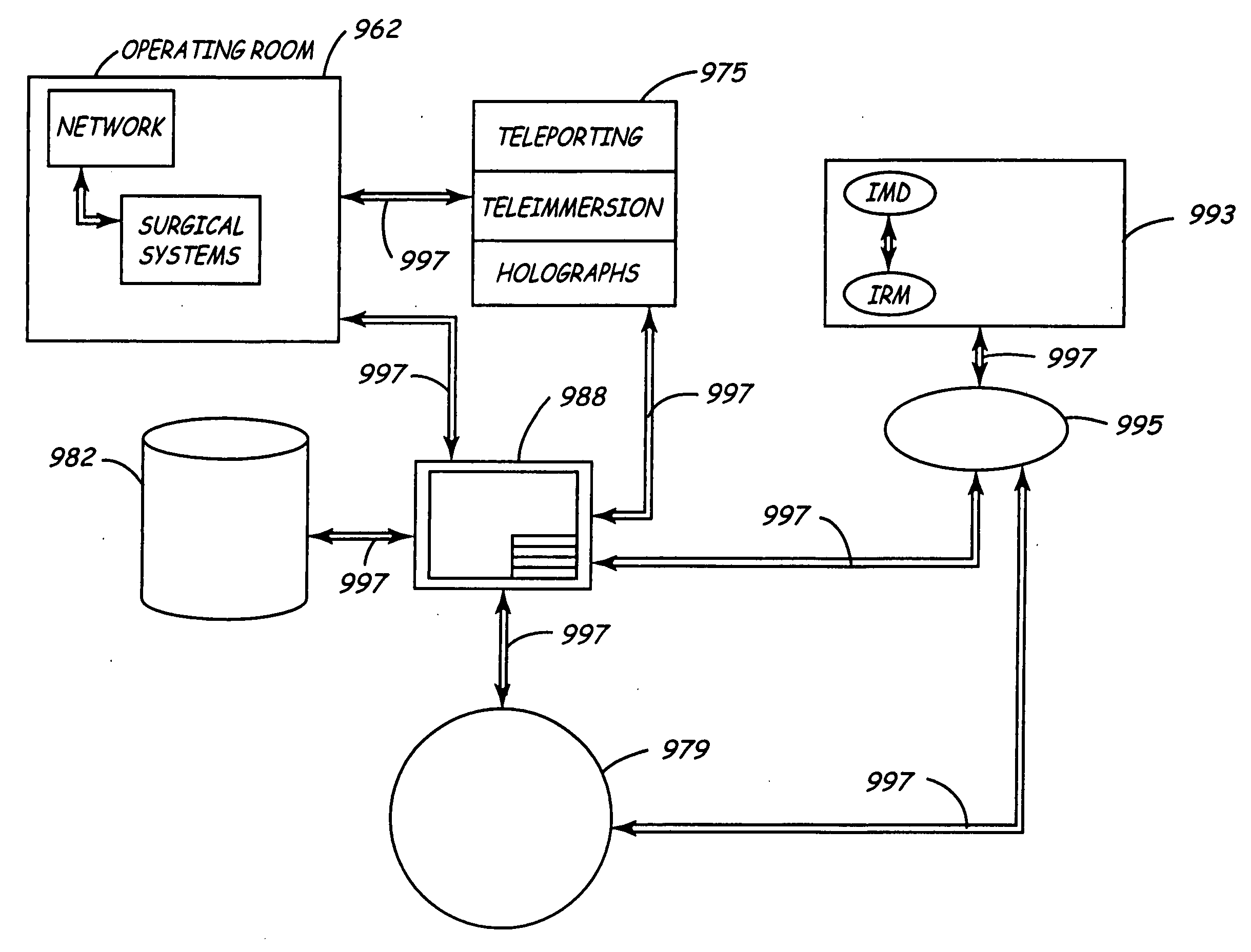

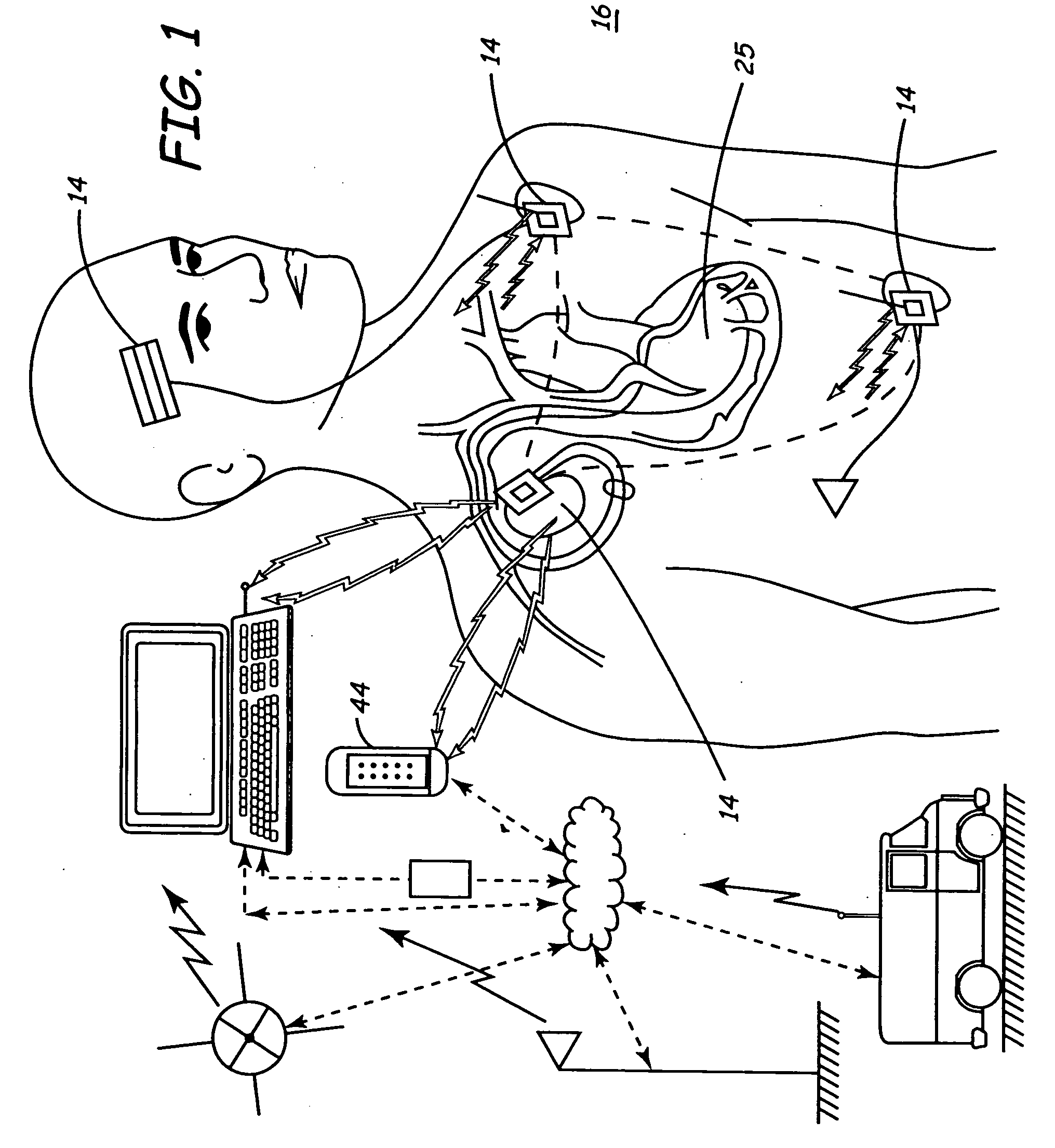

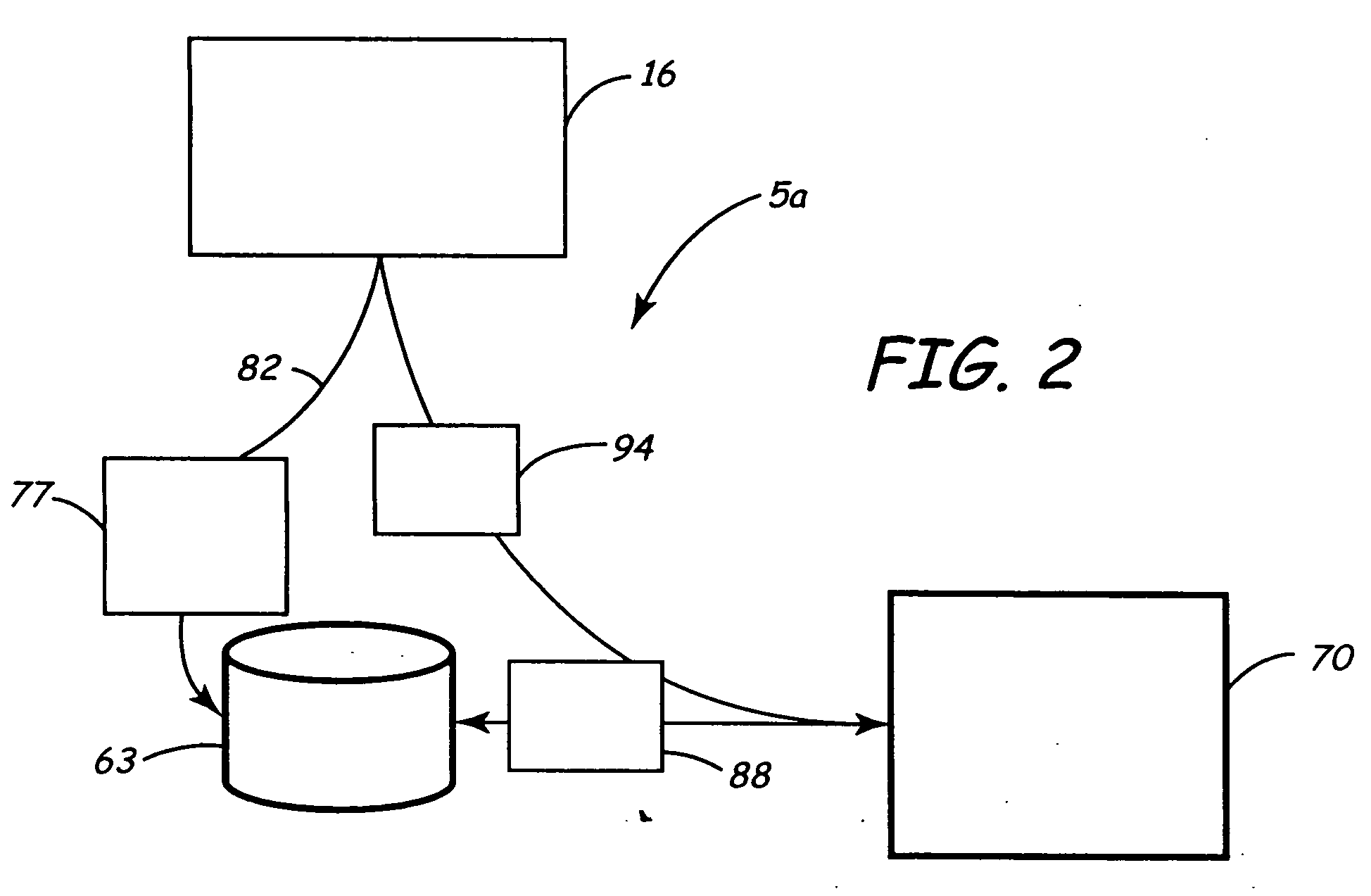

Medical device systems implemented network scheme for remote patient management

A system and method for computer enabled network patient management of medical devices used in chronic disease management. Utilizing web site and push alert notification of alert level physiologic data derived via analysis of continuous stream wireless data transmissions from a patient, a full cycle improvement over existing modalities is achieved. Proxy and medical device user integration and access is enabled to achieve further contribution to the technical advantages of the system.

Owner:MEDTRONIC INC

Microfluidic chemical reactor for the manufacture of chemically-produced nanoparticles

InactiveUS20050129580A1Maintain propertiesMaterial nanotechnologyPolycrystalline material growthProcess functionNanoparticle

The present invention discloses microfluidic modules for making nanocrystalline materials in a continuous flow process. The microfluidic modules include one or more flow path with mixing structures and one or more controlled heat exchangers to process the nanocrystalline materials and reagents in the flow path. The microfluidic modules can be interconnected to form microfluidic reactors that incorporate one or more process functions such as nucleation, growth, and purification.

Owner:LAKE SHORE CRYOTRONICS INC

Atmospheric pressure molecular layer CVD

InactiveUS20050084610A1Reducing physisorptionHigh purityChemical vapor deposition coatingChemical physicsControl system

An Atomic Layer CVD process and apparatus deposits single and or multiple minelayers of material sequentially at atmospheric pressure. Sequential monolayer depositions are separated in time and in space by combinations of physical barriers and / or gas curtains and / or by physical movement of substrates from one deposition chamber or location to another Pulse and / or continuous flows of reactant and purge gases are used in alternate embodiments of the present invention. Reactant injection, purge gas flow and exhaust flows at separated deposition chambers or locations are controlled by coordination of dedicated gas manifolds and control systems for each spatially or temporally separated deposition process or location.

Owner:SELITSER SIMON I

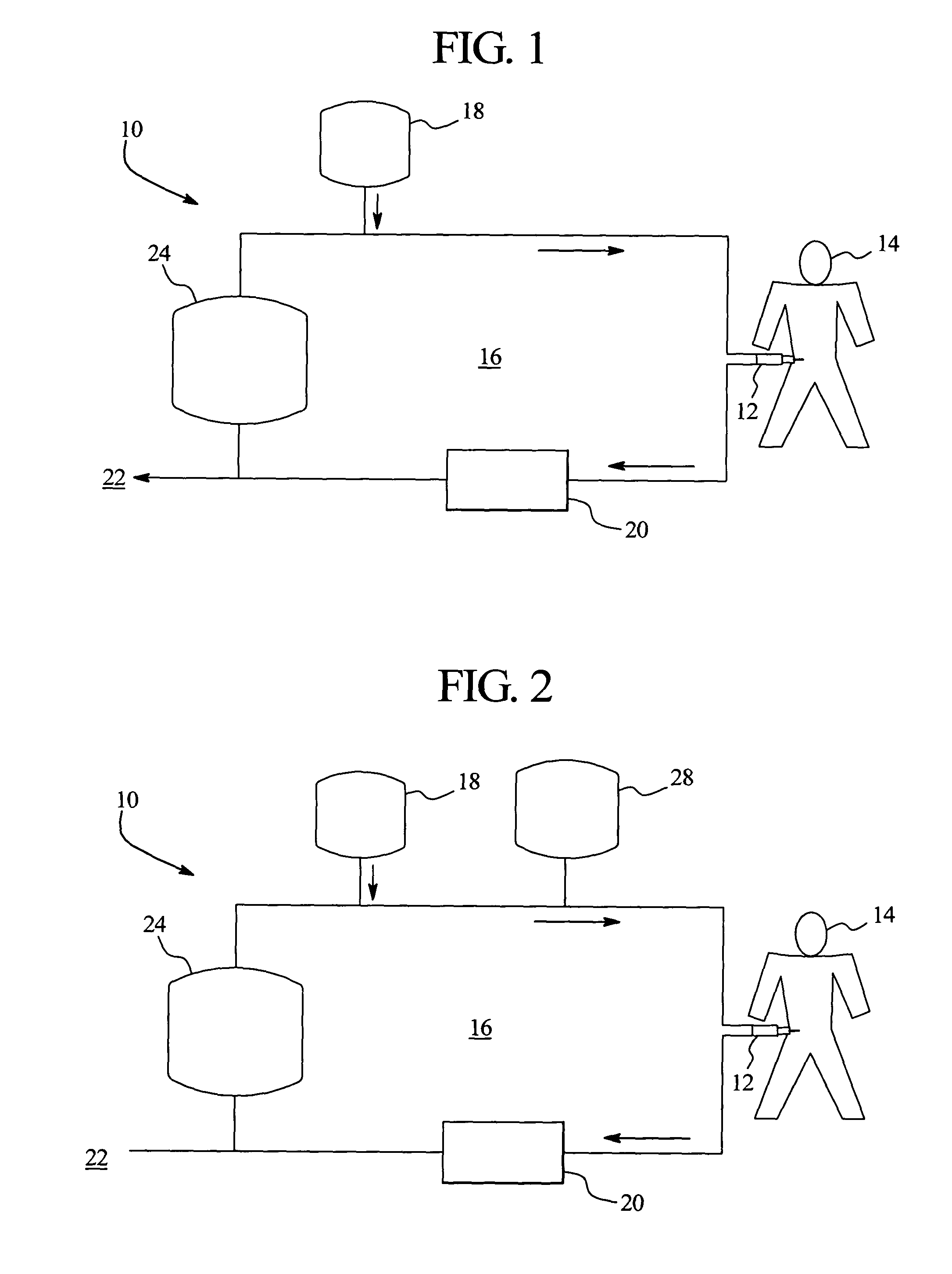

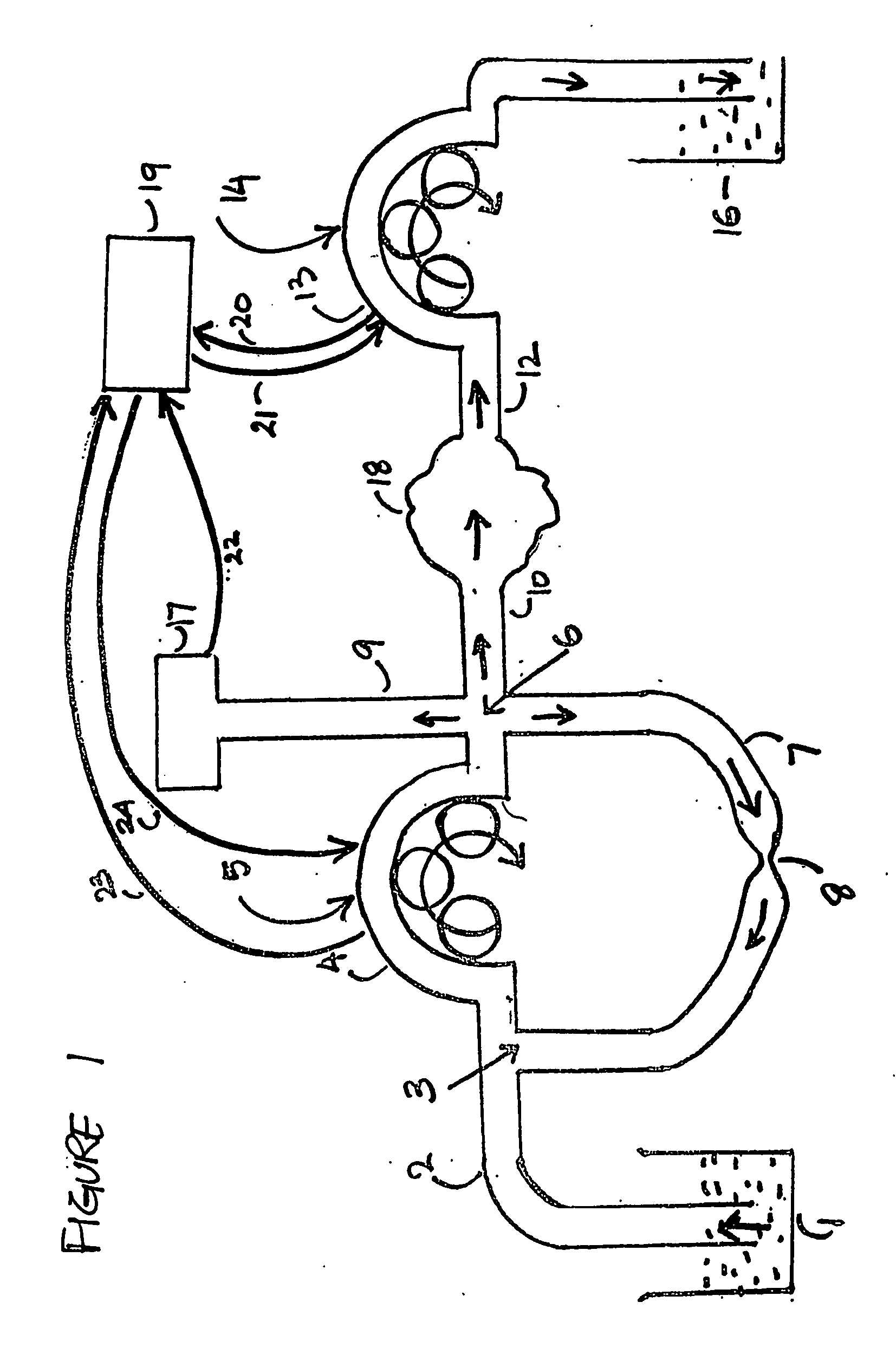

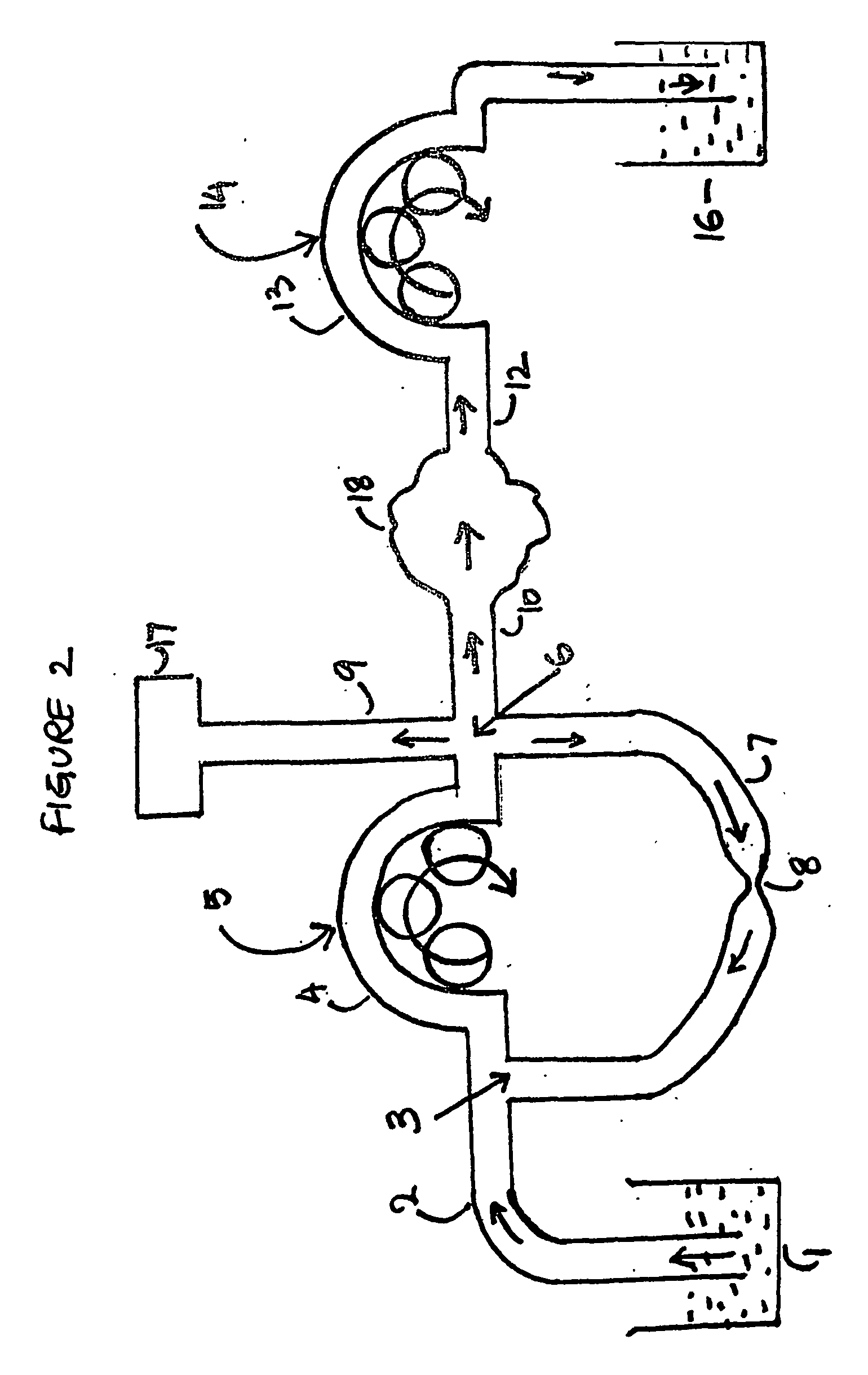

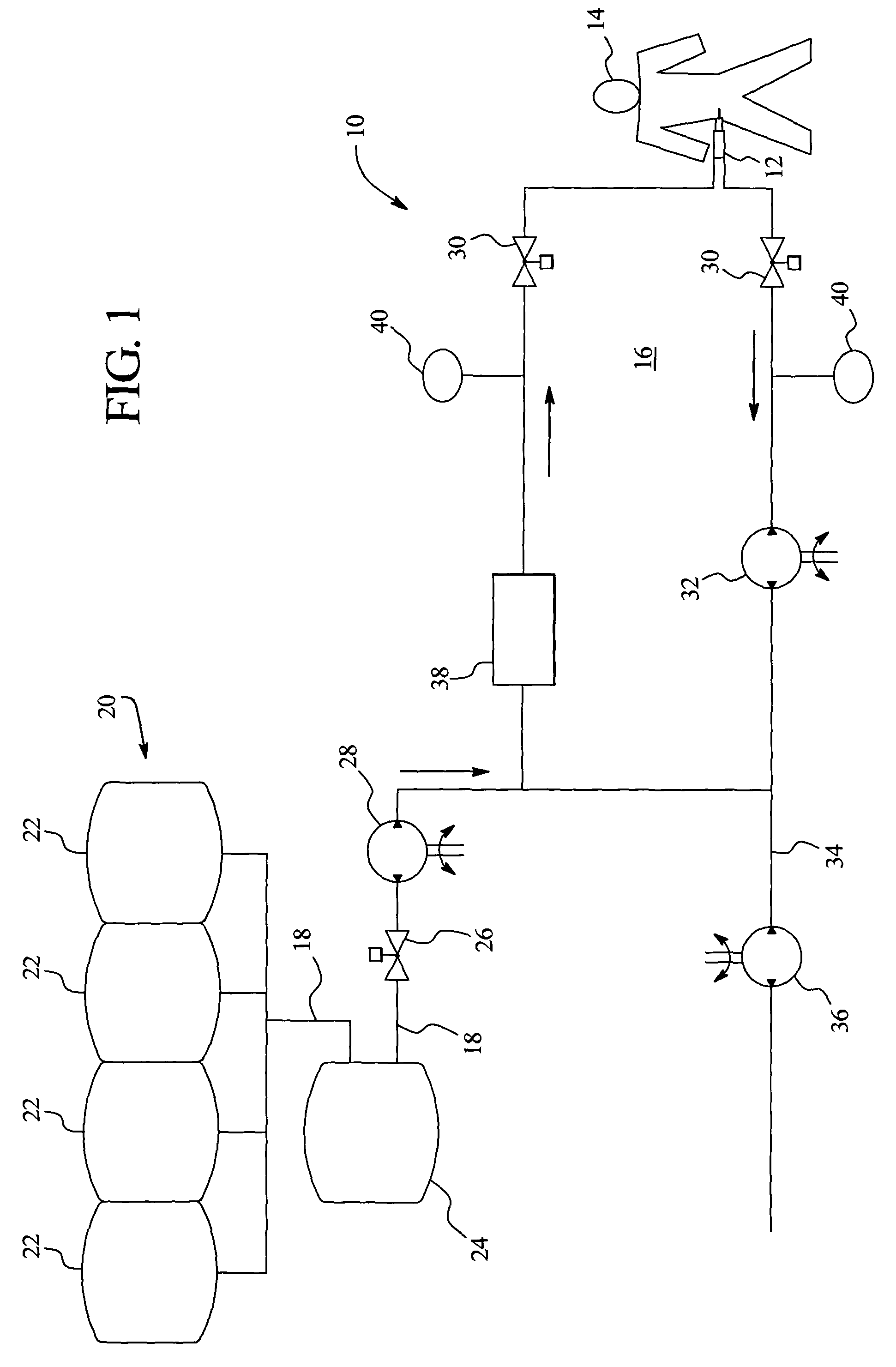

Systems and methods for peritoneal dialysis

ActiveUS7208092B2Strengthen the systemImprove methodSemi-permeable membranesSolvent extractionContinuous flowIntensive care medicine

Systems and methods relating to dialysis therapy, particularly continuous flow dialysis therapy, are provided. The present invention includes a single closed fluid path along which a minimal amount of therapy fluid including dialysate is fed into, continuously circulated and cleaned such that a therapeutic effective amount of solutes, excess water and the like can be removed from the patient connected to the closed fluid loop during treatment.

Owner:BAXTER INT INC +1

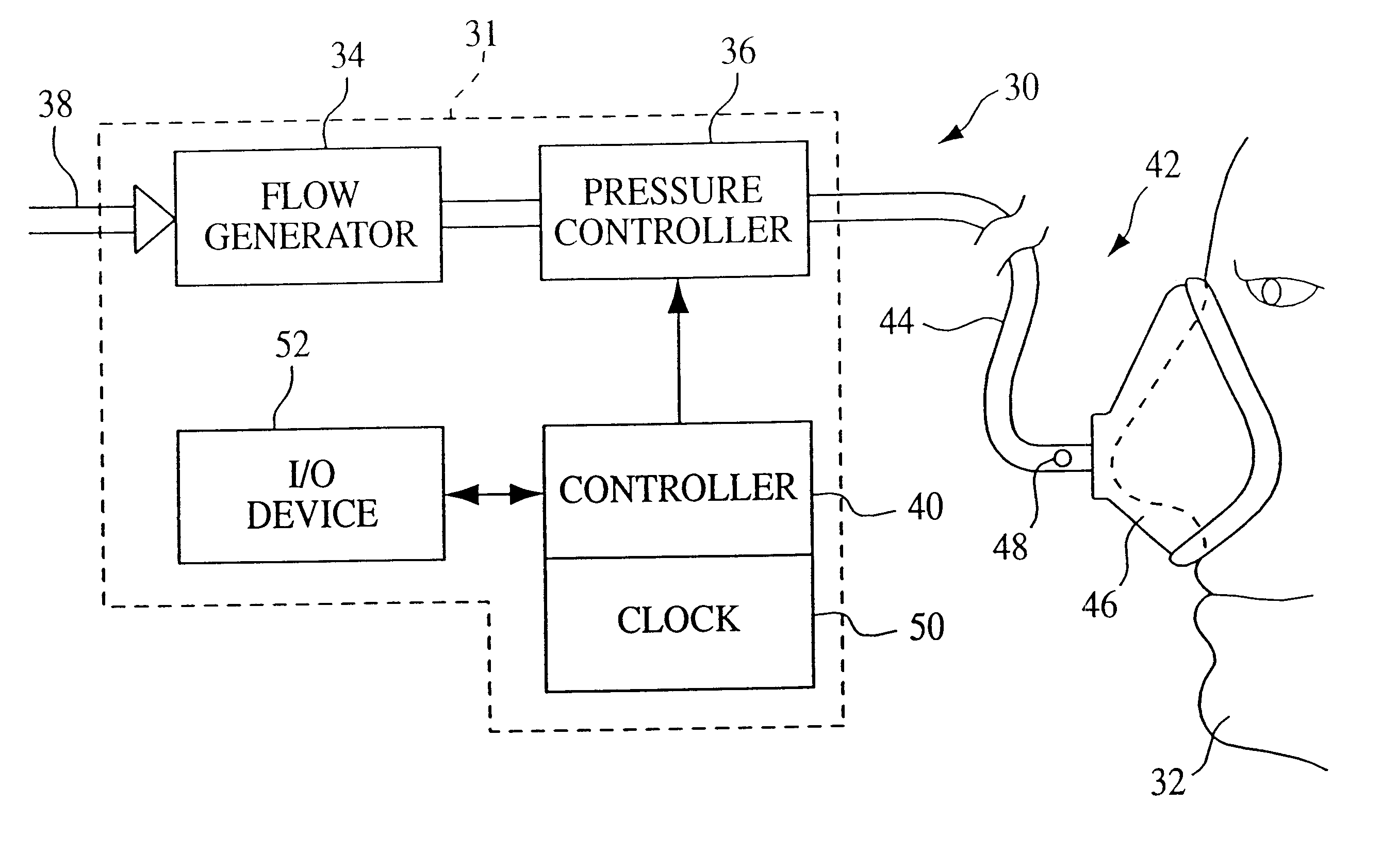

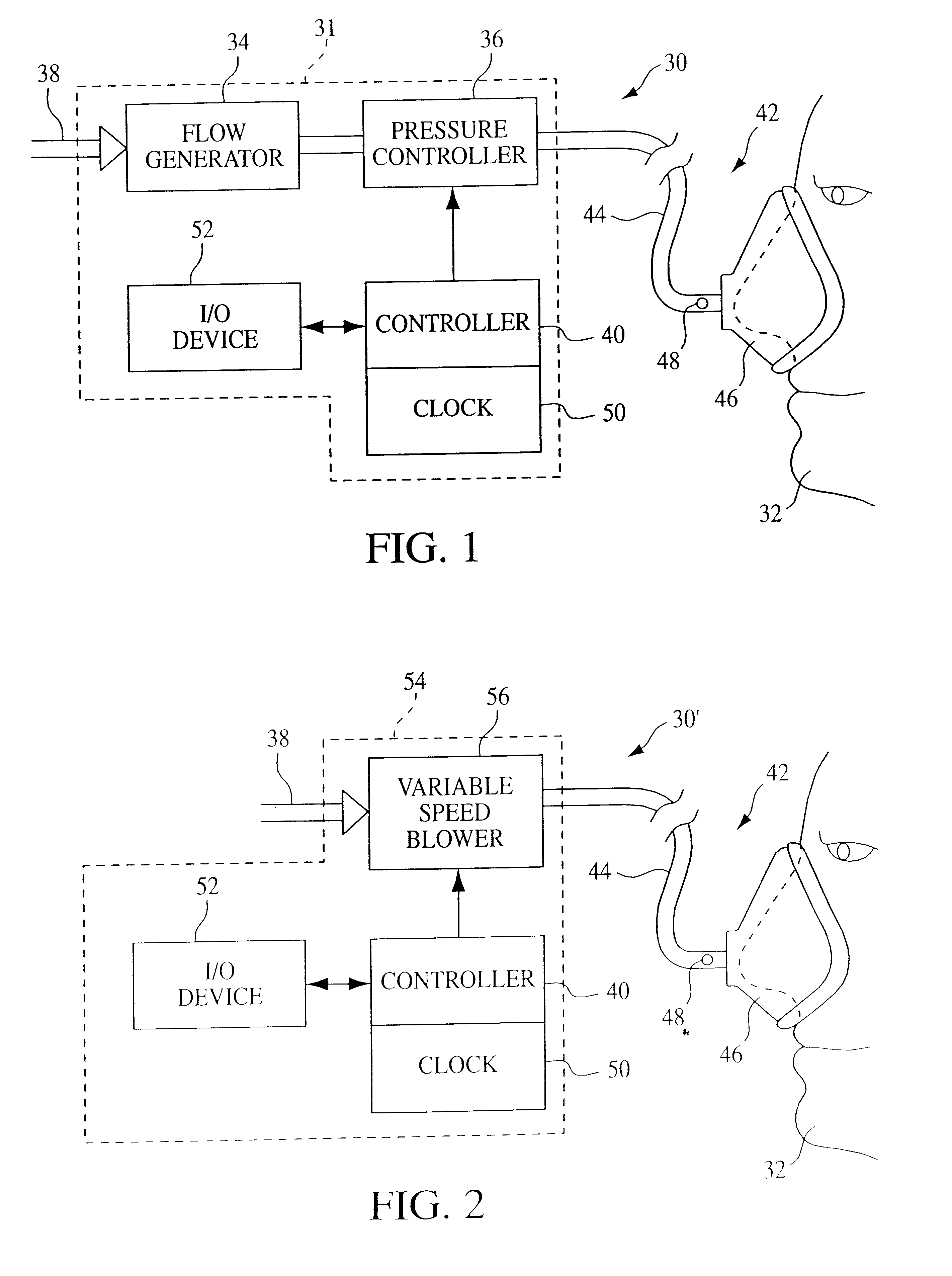

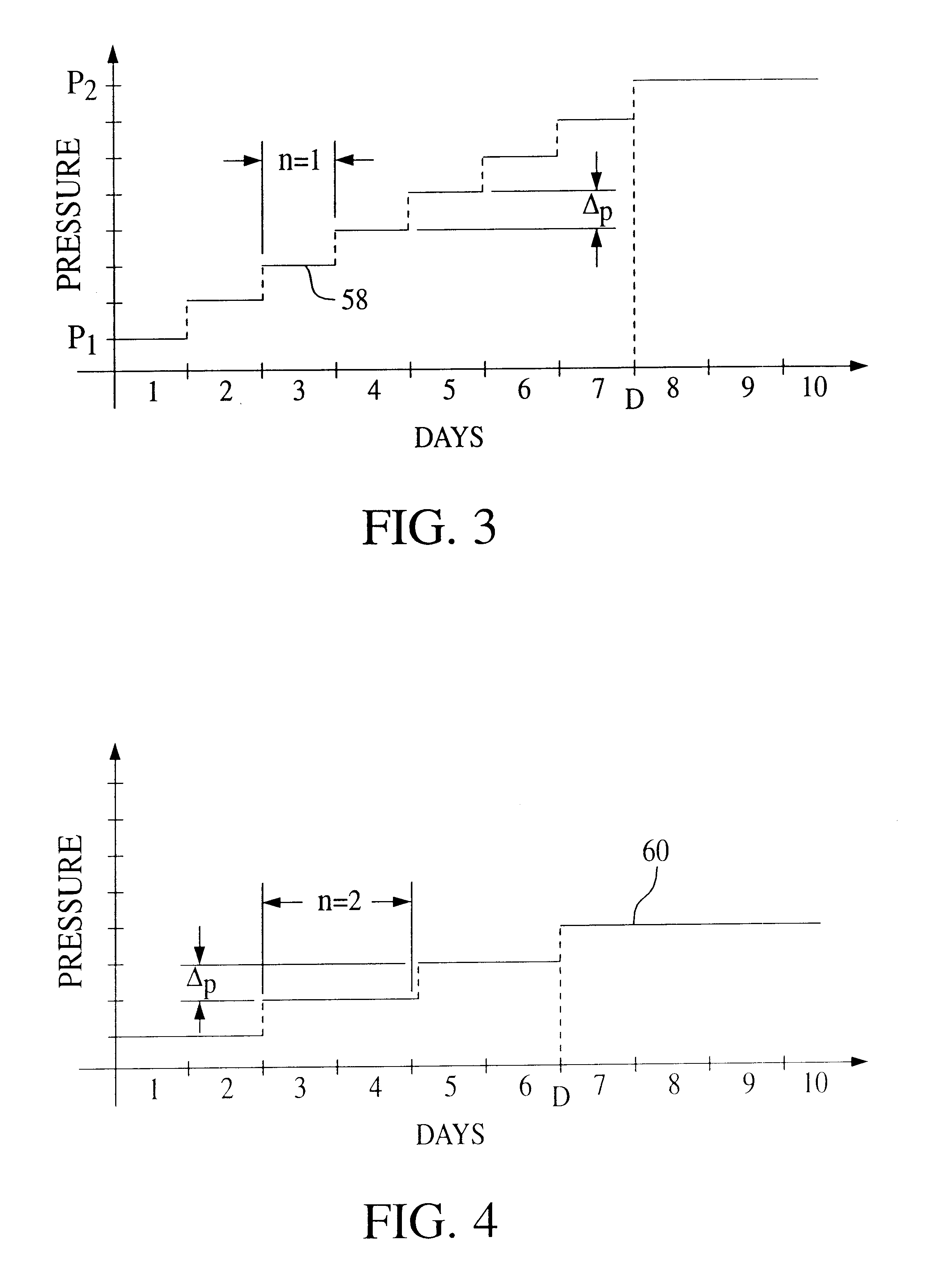

Apparatus and method of providing continuous positive airway pressure

InactiveUS6401713B1RespiratorsOperating means/releasing devices for valvesInitial treatmentInitial therapy

A pressure support system and method in which a gas flow generating system provides a continuous flow of breathing gas at selectable pressure levels. A patient circuit and interface communicate the continuous flow of breathing gas to the airway of a patient. A controller causes the gas flow generating system to provide the continuous flow of breathing gas to the patient at a first pressure level P1 in an initial therapy session. Thereafter, the pressure level of the continuous flow of breathing gas is increased from the first pressure level P1 to a final pressure level P2 over a first predetermined number D of days. More specifically, in one embodiment, the pressure level is incrementally increased by a predetermined incremental amount DELTAp after n therapy sessions taking place on separate days over this first predetermined number D of days. As a result, the current therapy pressure in each therapy session that takes place on separate days following the initial therapy session is incrementally and automatically increased.

Owner:RIC INVESTMENTS LLC

Nucleic acid amplification with continuous flow emulsion

InactiveUS7927797B2Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

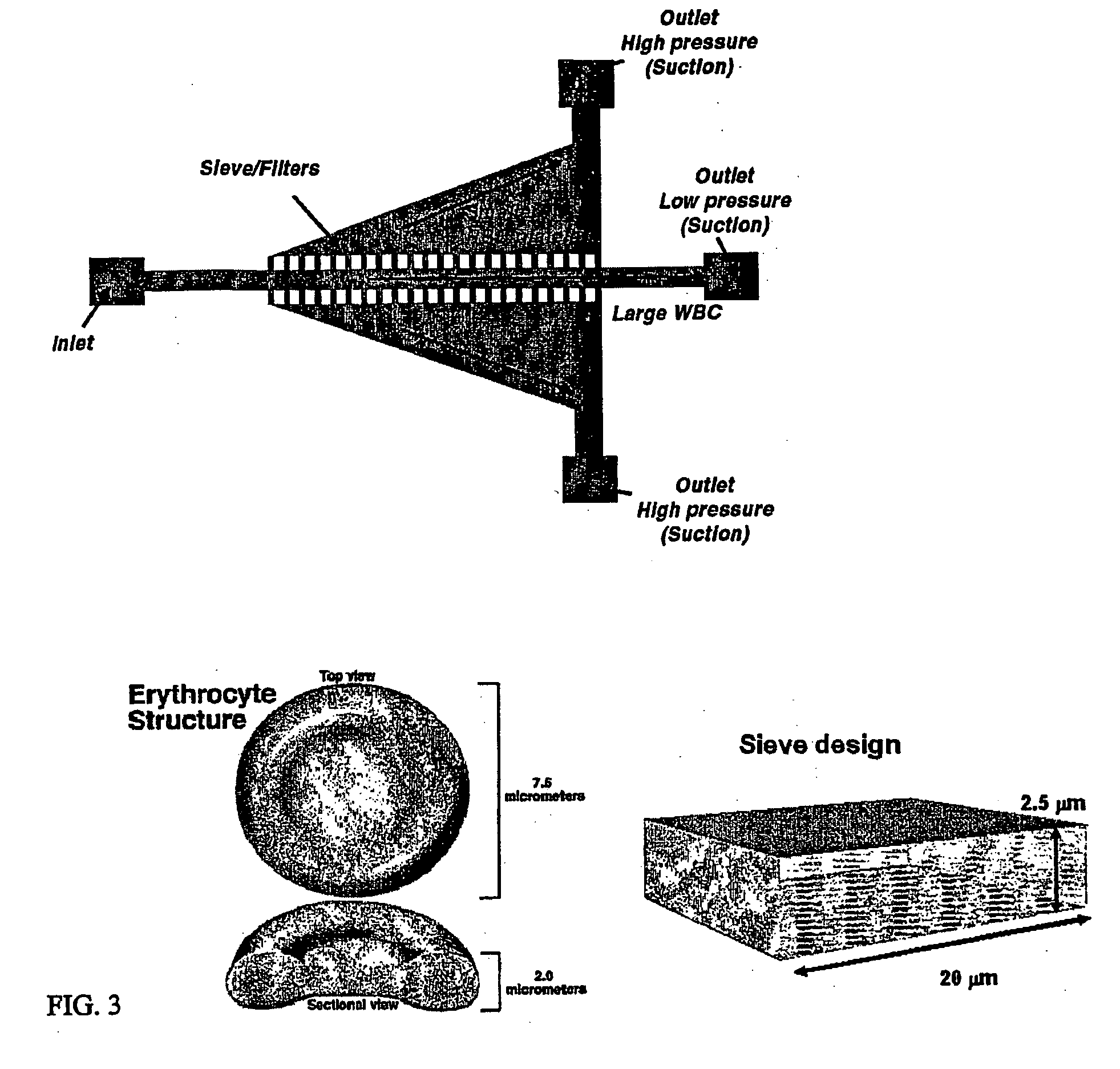

Microfluidic systems for size based removal of red blood cells and platelets from blood

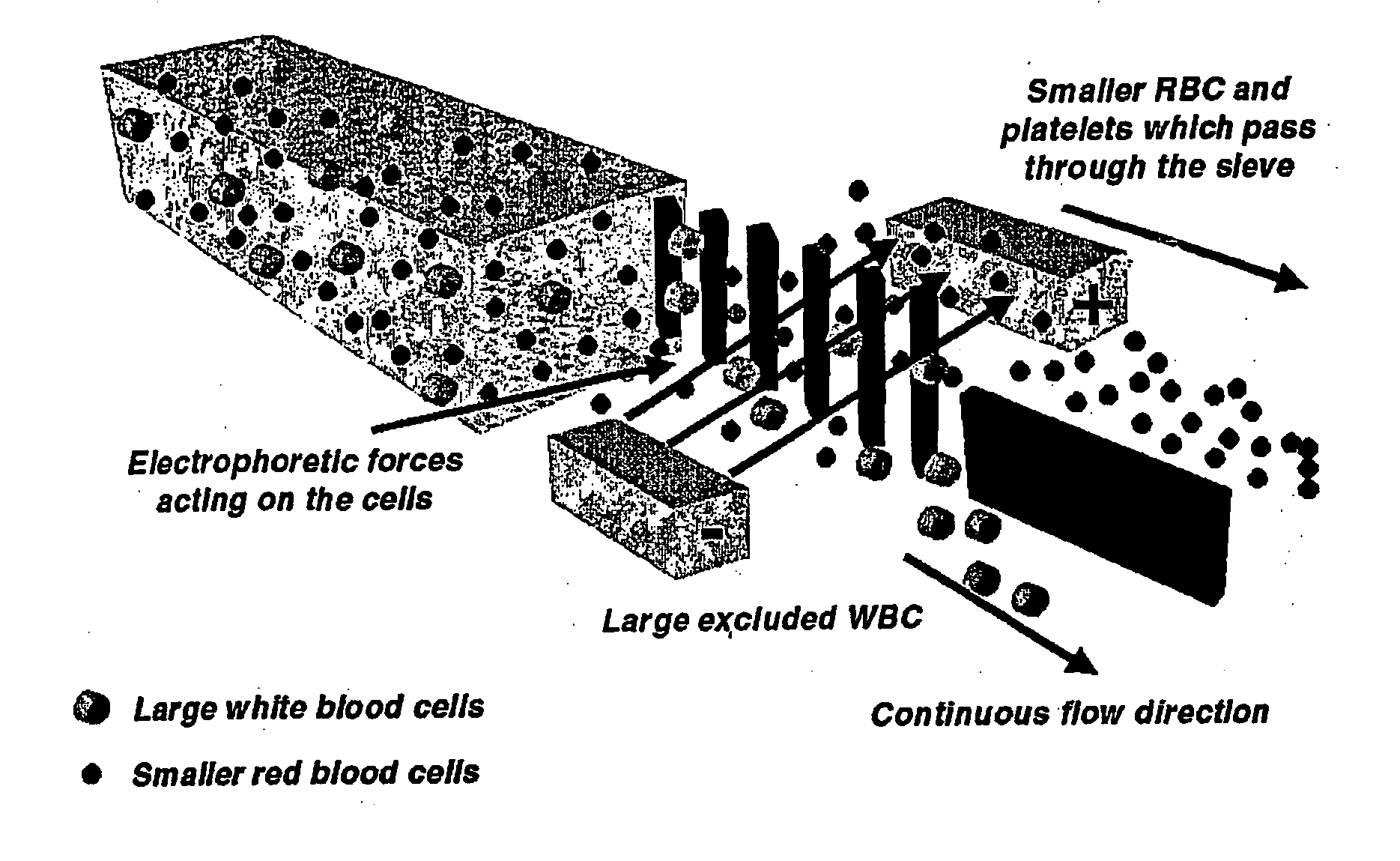

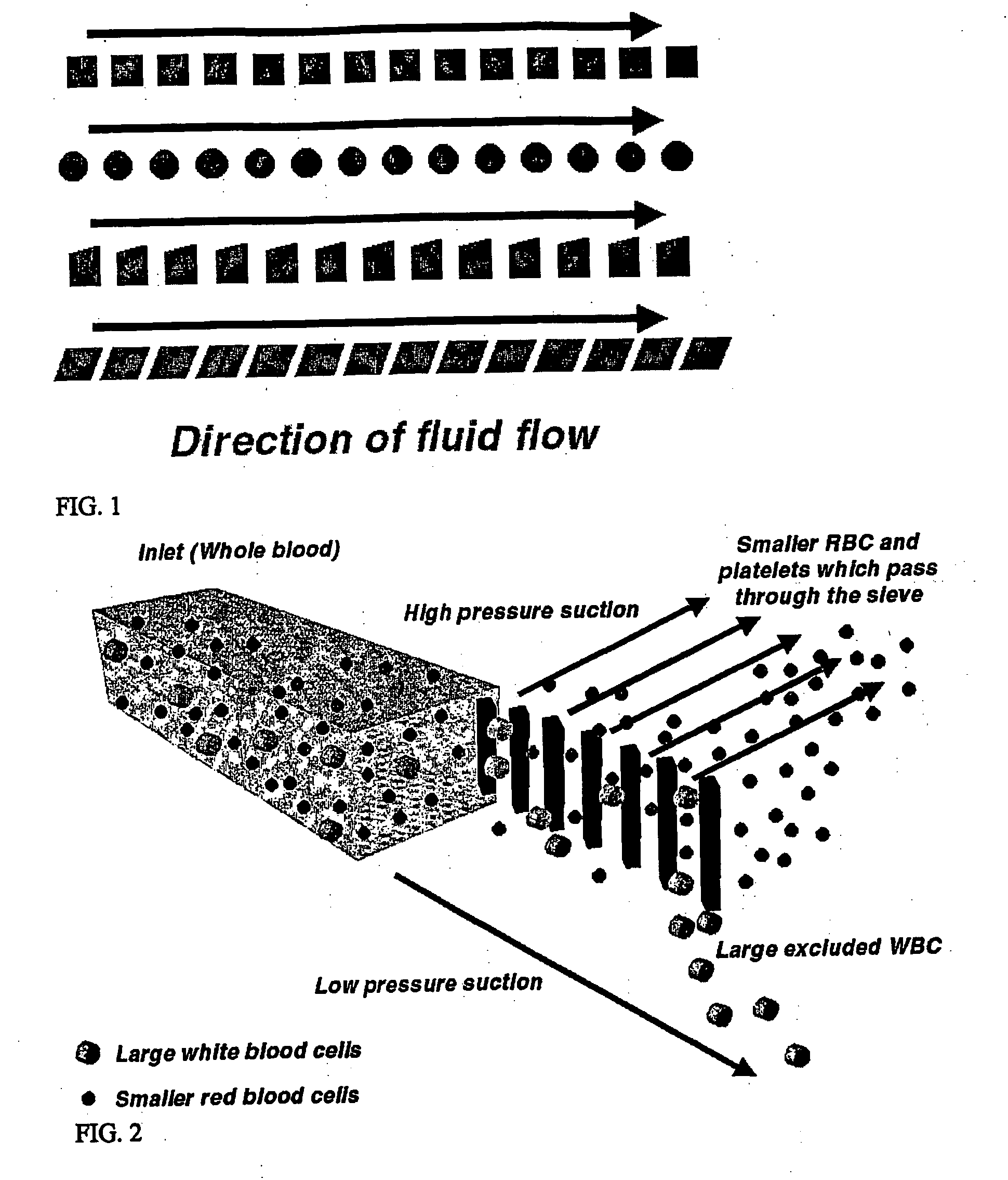

The invention features devices and methods for enriching a sample in one or more desired particles. An exemplary use of these devices and methods is for the enrichment of cells, e.g., white blood cells in a blood sample. In general, the methods of the invention employ a device that contains at least one sieve through which particles of a given size, shape, or deformability can pass. Devices of the invention have at least two outlets, and the sieve is placed such that a continuous flow of fluid can pass through the device without passing through the sieve. The devices also include a force generator for directing selected particles through the sieve. Such force generators employ, for example, diffusion, electrophoresis, dielectrophoresis, centrifugal force, or pressure-driven flow.

Owner:THE GENERAL HOSPITAL CORP

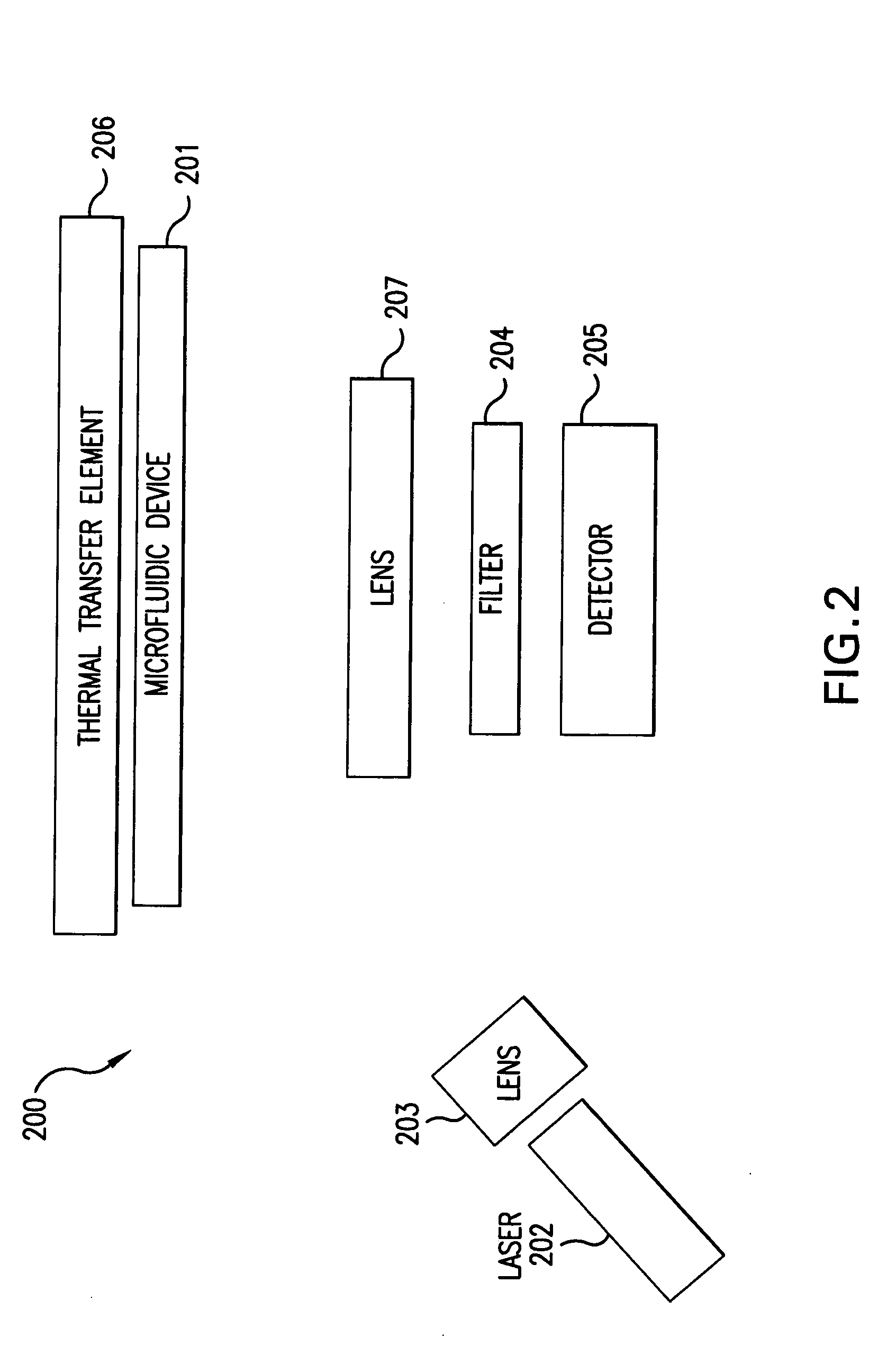

Method for carrying out a biochemical protocol in continuous flow in a microreactor

InactiveUS20050282224A1Reduce in quantityImprove throughputBioreactor/fermenter combinationsFixed microstructural devicesMicroreactorTwo temperature

Devices and methods for carrying out a chemical or biochemical protocol are disclosed. In one embodiment, the chemical or biochemical protocol is performed by cycling at least one thermal transfer member between at least two temperatures while liquid samples on which the chemical or biochemical protocol is to be performed are continuously moving through at least one temperature regulated zone upon which the at least one thermal transfer member acts. In some embodiments, the device comprises a sample transport member that comprises liquid samples in sample receiving regions. The sample transport member moves the samples continuously through a temperature regulated zone which cycles between at least two temperatures while the liquid samples are moving through a temperature regulated zone on which at least one thermal transfer member acts. In some embodiments, the sample receiving regions comprise wells, hydrophillic films or hydrophillic filaments.

Owner:SERONO GENETICS INST SA +1

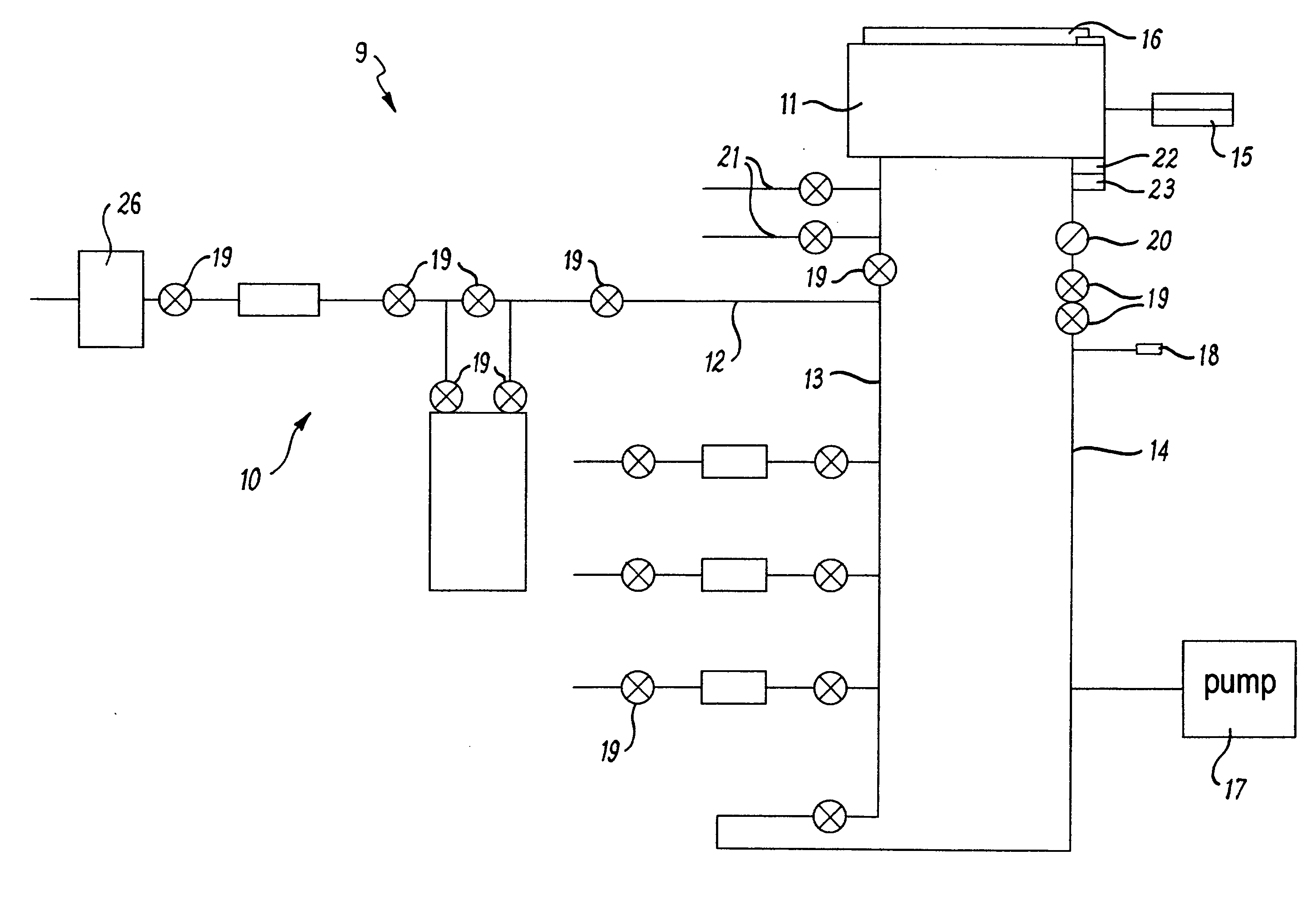

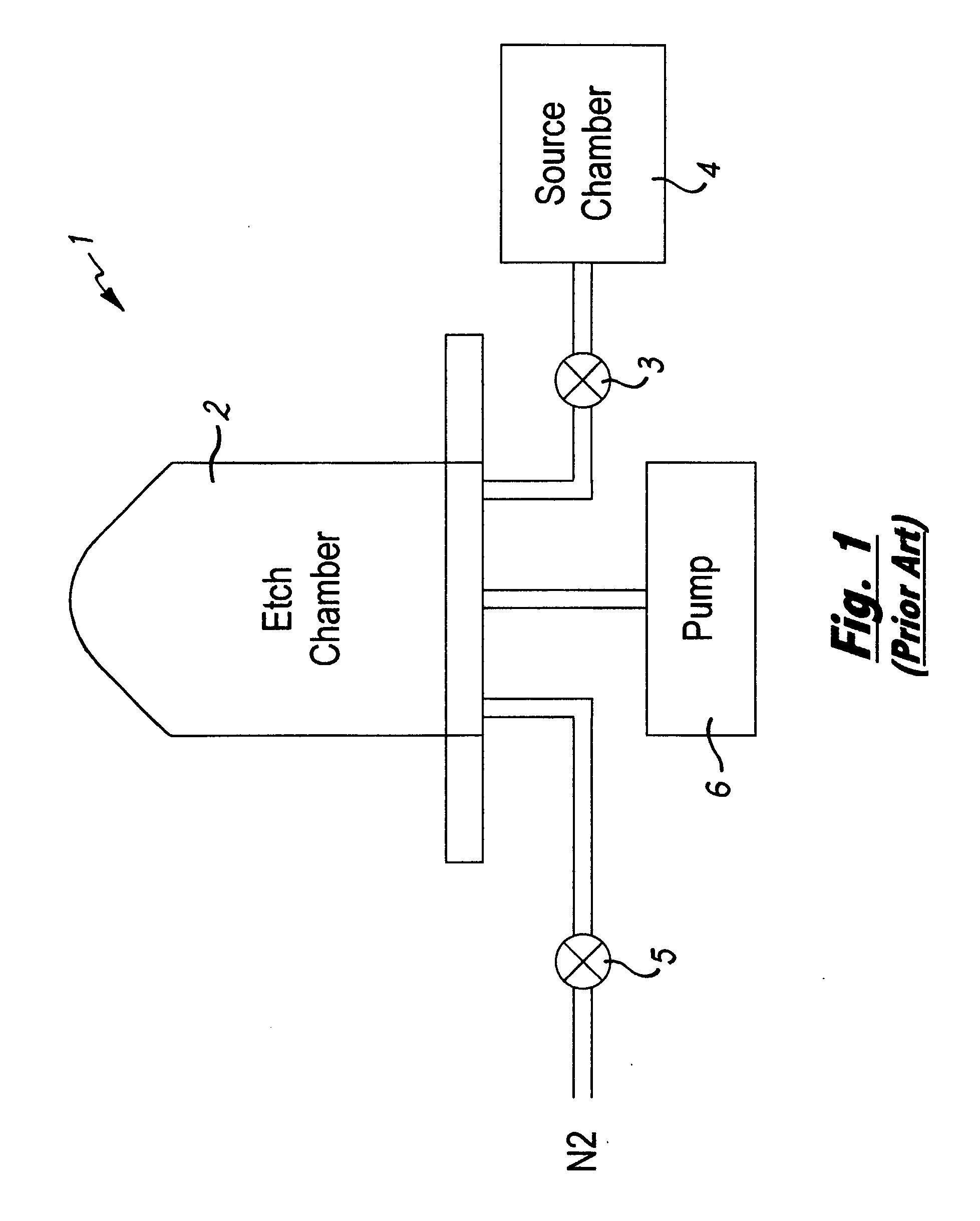

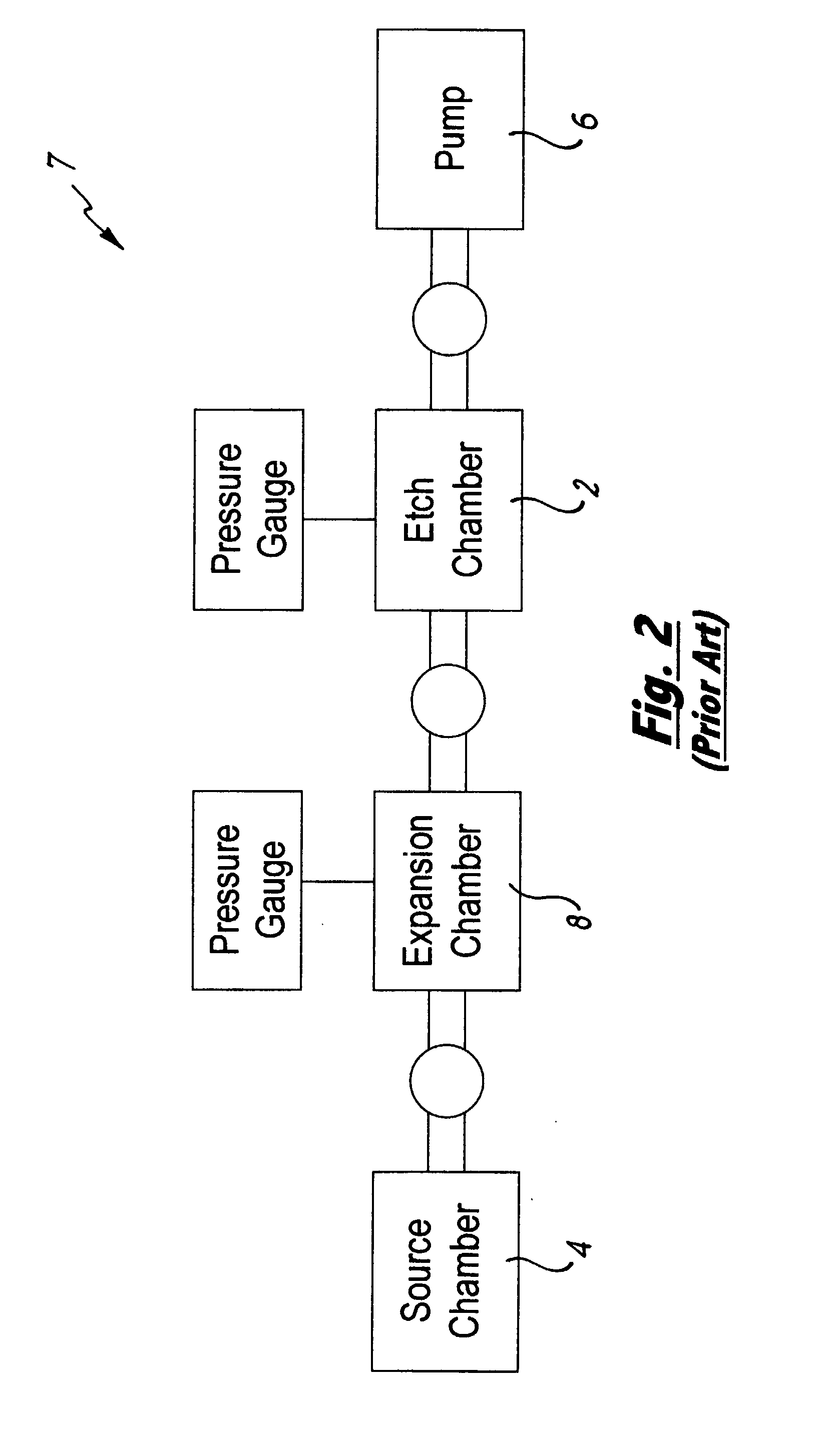

Method and Apparatus for the Etching of Microstructures

InactiveUS20080035607A1Increase partial pressureIncrease ratingsElectric discharge tubesDecorative surface effectsEtchingContinuous flow

An apparatus and method for providing an etching gas source for etching one or more microstructures located within a process chamber. the apparatus has a gas source supply line attached to a gas source and one or more chambers for containing an etching material. In use, the etching material is transformed into an etching material vapor within one or more of the chamber and the gas supply line provides a supply of carrier gas to the etching material vapor and also supplies the etching material vapor transported by the carrier gas to the process chamber. Advantageously, the apparatus of the invention does not require the incorporation of any expansion chambers or other complicated mechanical features in order to achieve a continuous flow of etching gas.

Owner:MEMSSTAR

Smoke evacuation system for continuously removing gas from a body cavity

ActiveUS20180221598A1Prevent over-pressurizationEasy to adjustCannulasSurgical needlesProduct gasContinuous flow

An evacuation system for continuously removing gas from a body cavity of a patient during an endoscopic surgical procedure is disclosed, which includes an inlet flow path leading to a first trocar communicating with the body cavity through which an essentially continuous flow of gas is delivered to the body cavity, an outlet flow path leading from a second trocar communicating with the body cavity though which an essentially continuous flow of gas is removed from the body cavity, a pump communicating at least with the outlet flow path for removing an essentially continuous flow of gas from the surgical cavity, and a processor operatively associated with the pump for controlling at least the essentially continuous flow of gas from the body cavity.

Owner:CONMED CORP

Rotary blood pump and control system therefor

Owner:TC1 LLC +1

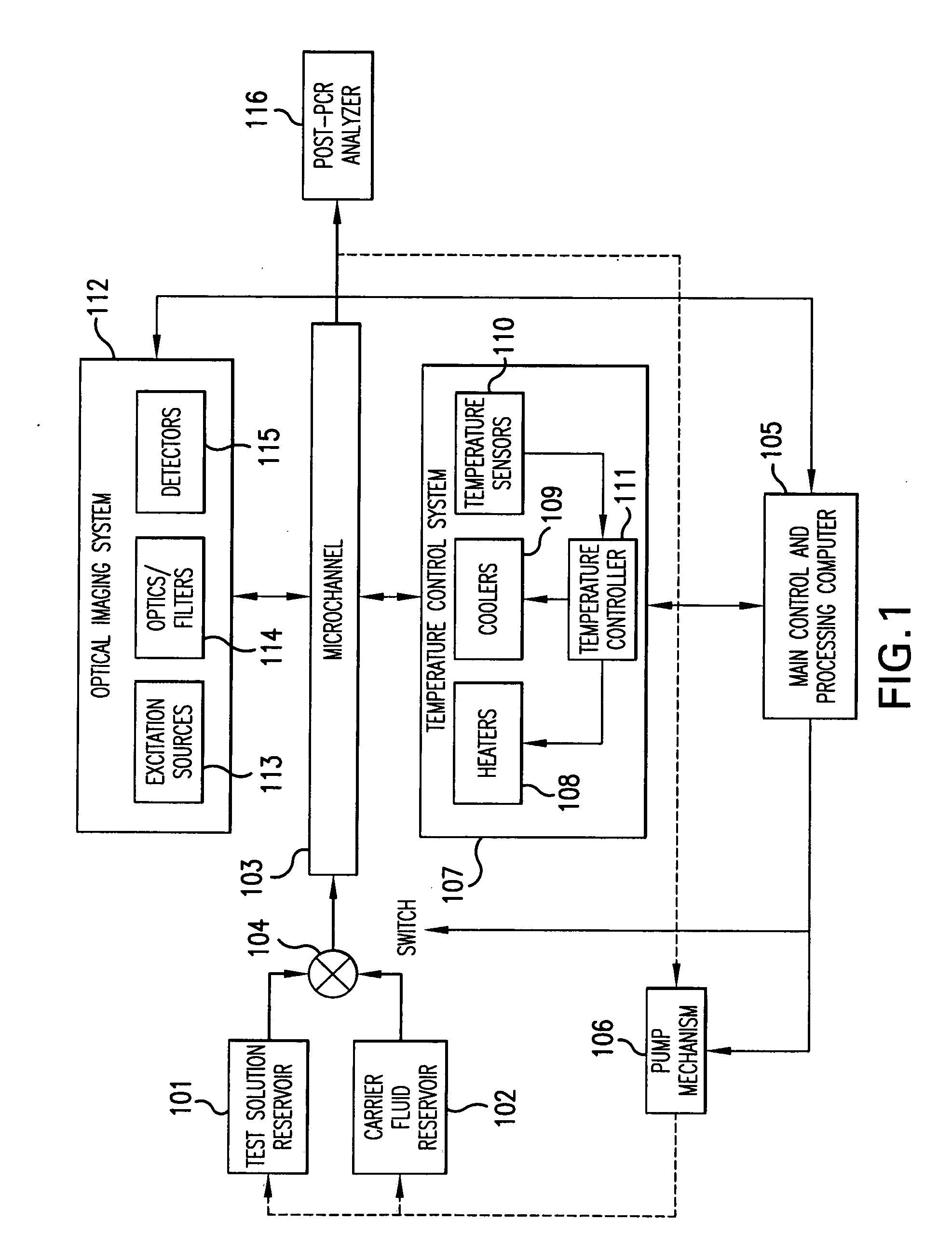

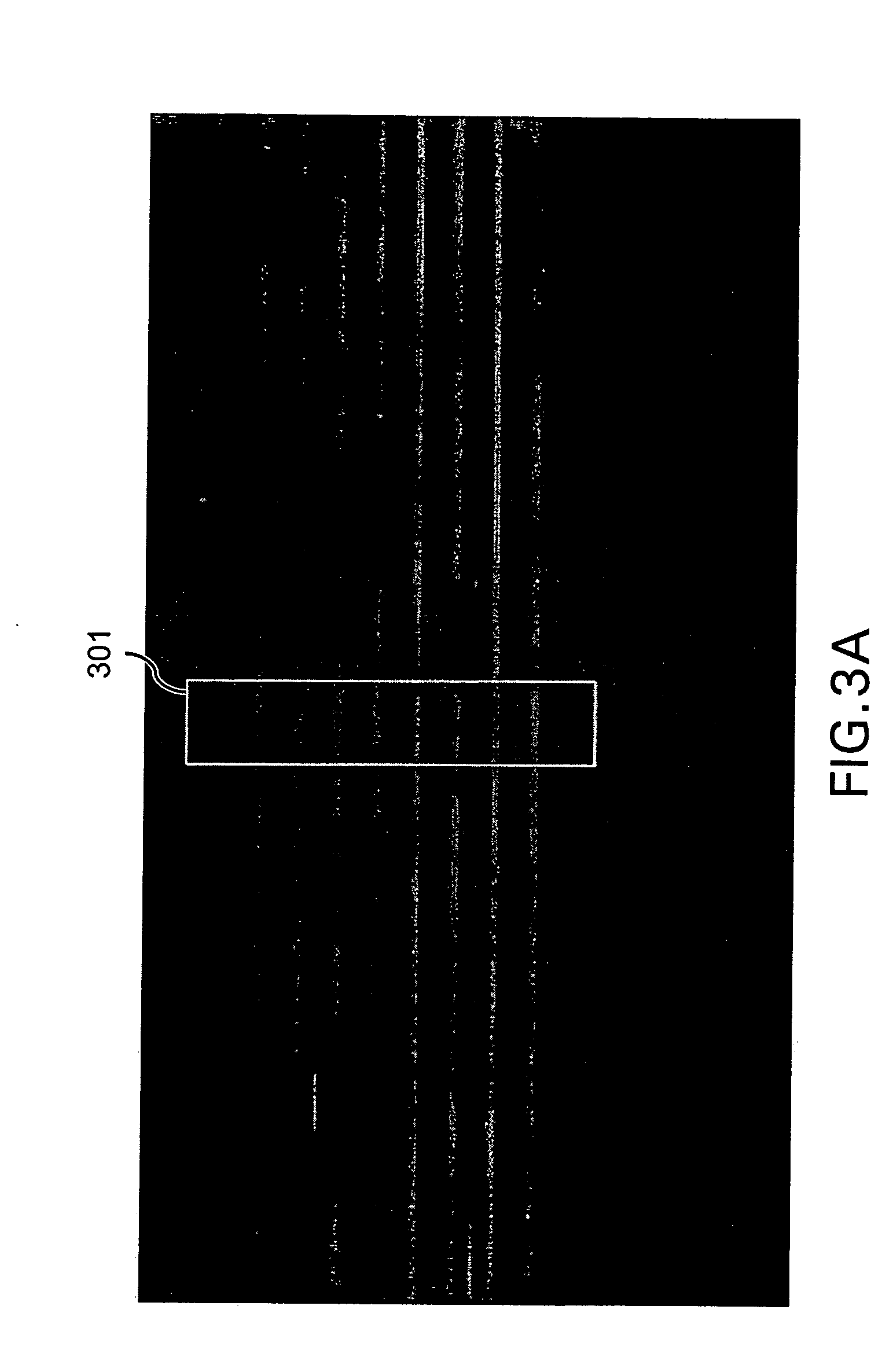

Real-time PCR in micro-channels

The present invention relates to methods for amplifying nucleic acids in micro-channels. More specifically, the present invention relates to methods for performing a real-time polymerase chain reaction (PCR) in a continuous-flow microfluidic system and to methods for monitoring real-time PCR in such systems.

Owner:CANON USA

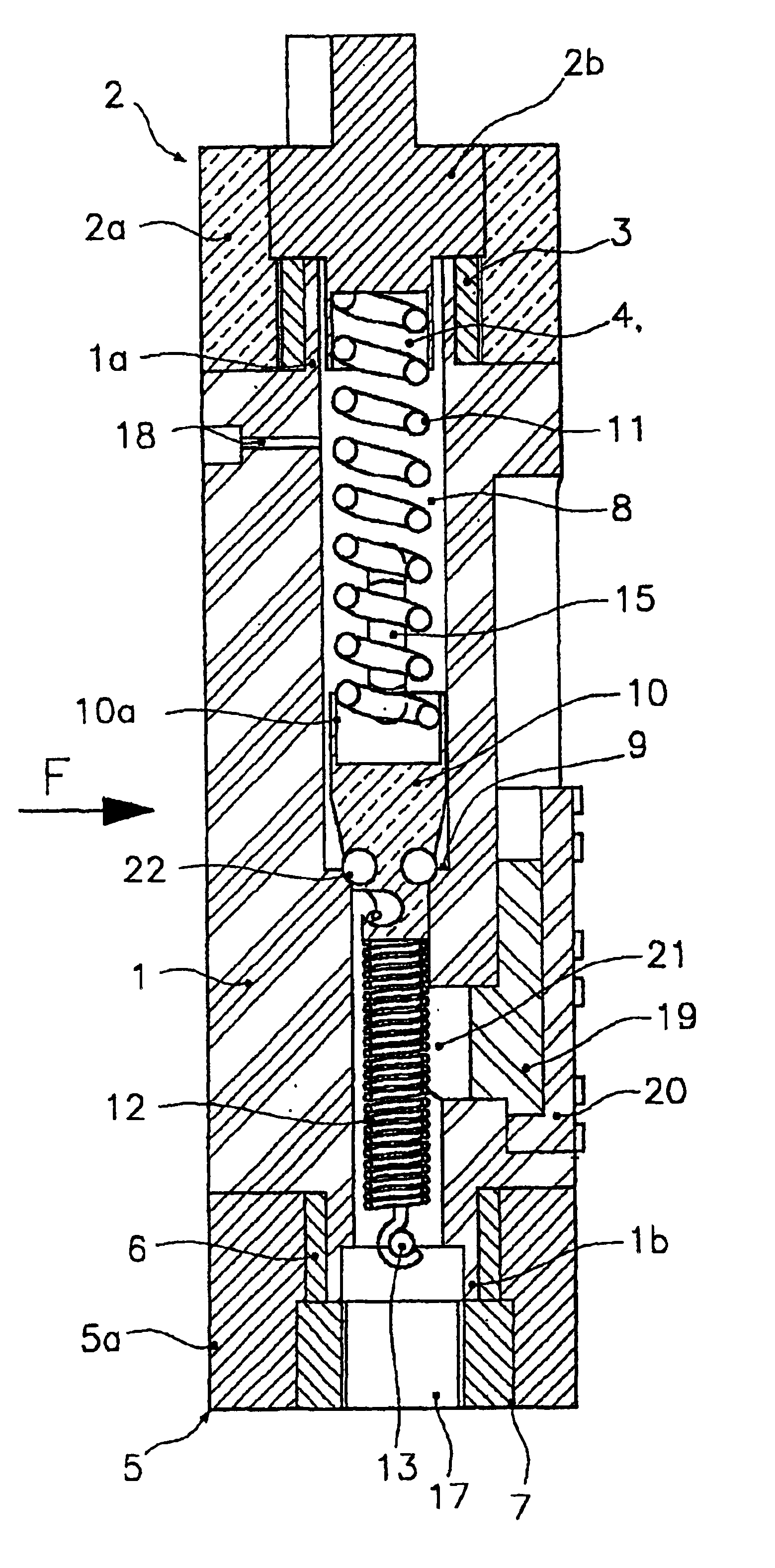

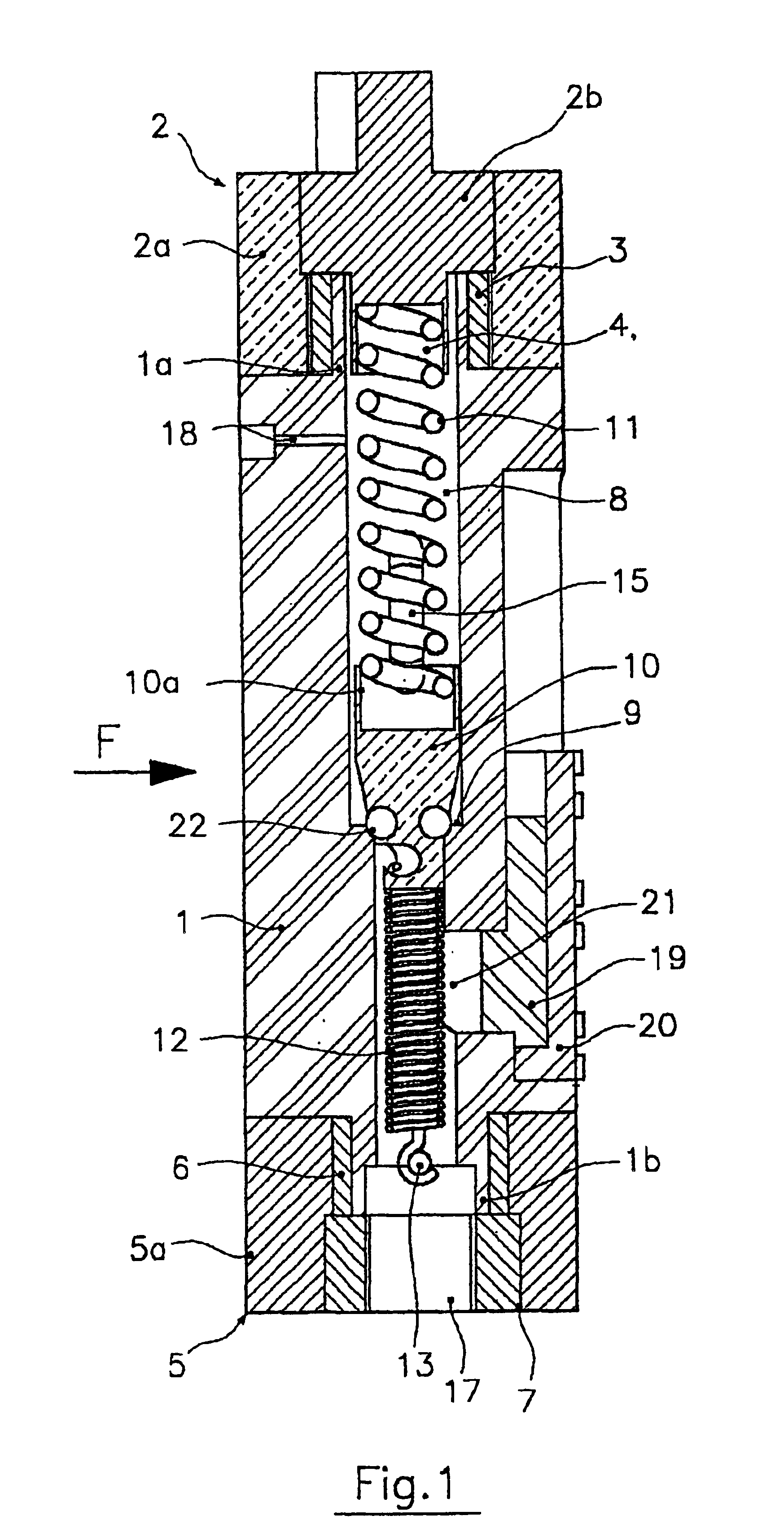

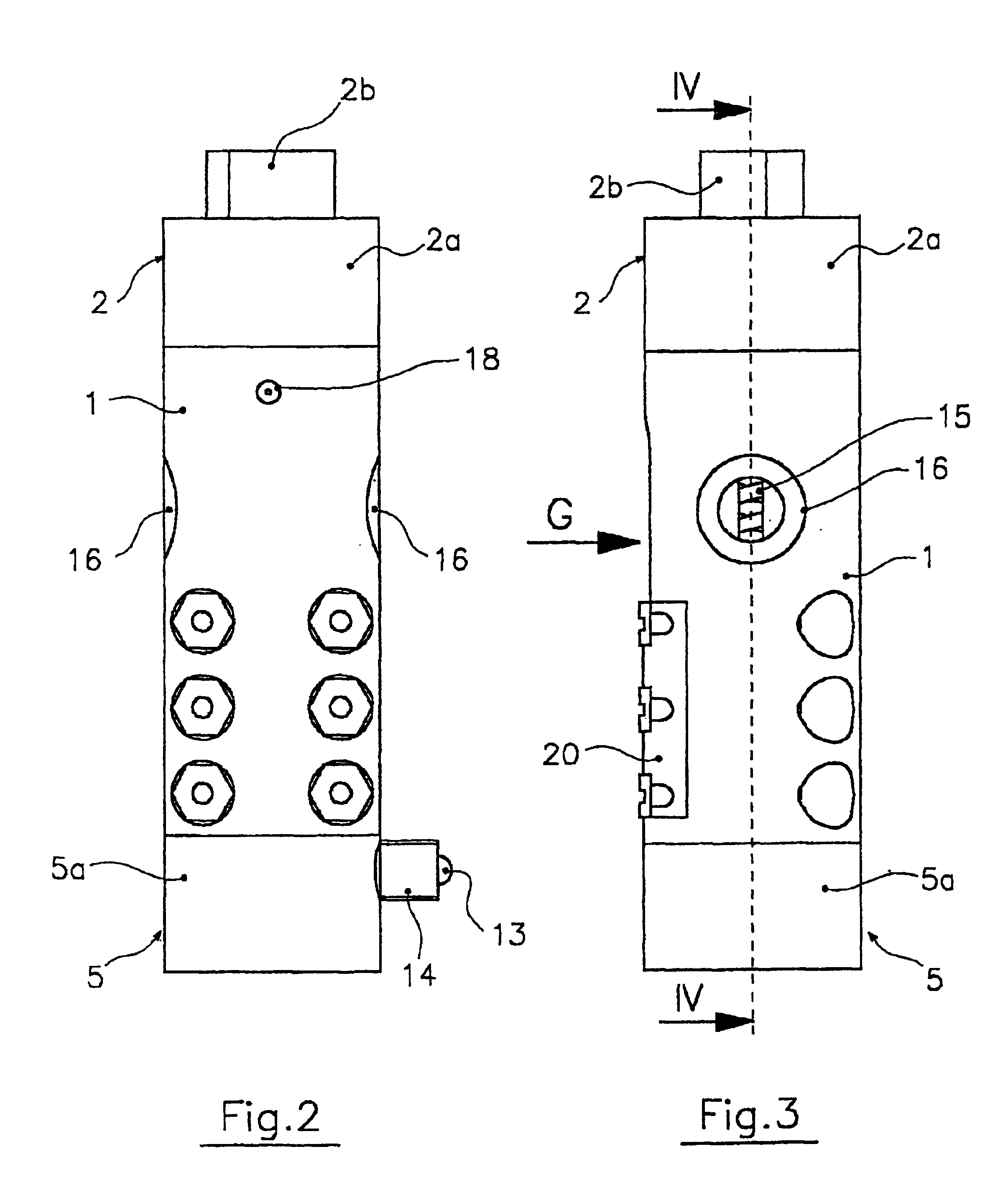

Proportional valve with shape memory alloy actuator

InactiveUS6840257B2Limited sizeReduce weightTemperature control without auxillary powerOperating means/releasing devices for valvesClosed loopAlloy

A proportional valve is disclosed for controlling the outlet pressure of a fluid flowing therethrough. The valve comprises a valve body having an inlet port and an outlet port for the fluid. The valve also has an inner chamber, within which there is formed a valve seat that may be opened and closed variably by a shutter axially movable from and towards the valve seat. Movement of the shutter is controlled by a shape memory alloy (SMA) actuating member operating antagonistically to an elastic member, the temperature of the fluid being lower than the transition temperature of the shape memory alloy. The actuating member and the elastic member are connected to the body valve at opposite sides relative to the valve seat. A power control circuit is also provided for circulating an electric current through the actuating member so as to heat the same by Joule effect from a temperature lower than the transition temperature to one that is higher. At least one vent hole is formed in the valve body for putting a portion of the chamber upstream of the valve seat into fluid communication with the outside or a collection network. The actuating member is housed in that portion of chamber corresponding to the inlet port of the fluid, whereby a continuous flow of fluid around the actuating member is ensured for accelerating the cooling process. A closed-loop control circuit for the power control circuit controls the circulating current as a function of a pressure signal generated by fluid pressure sensing means and in such a way as to offset the retarding effect produced by the fluid during heating of the actuating member.

Owner:ARENA ALBERTO +2

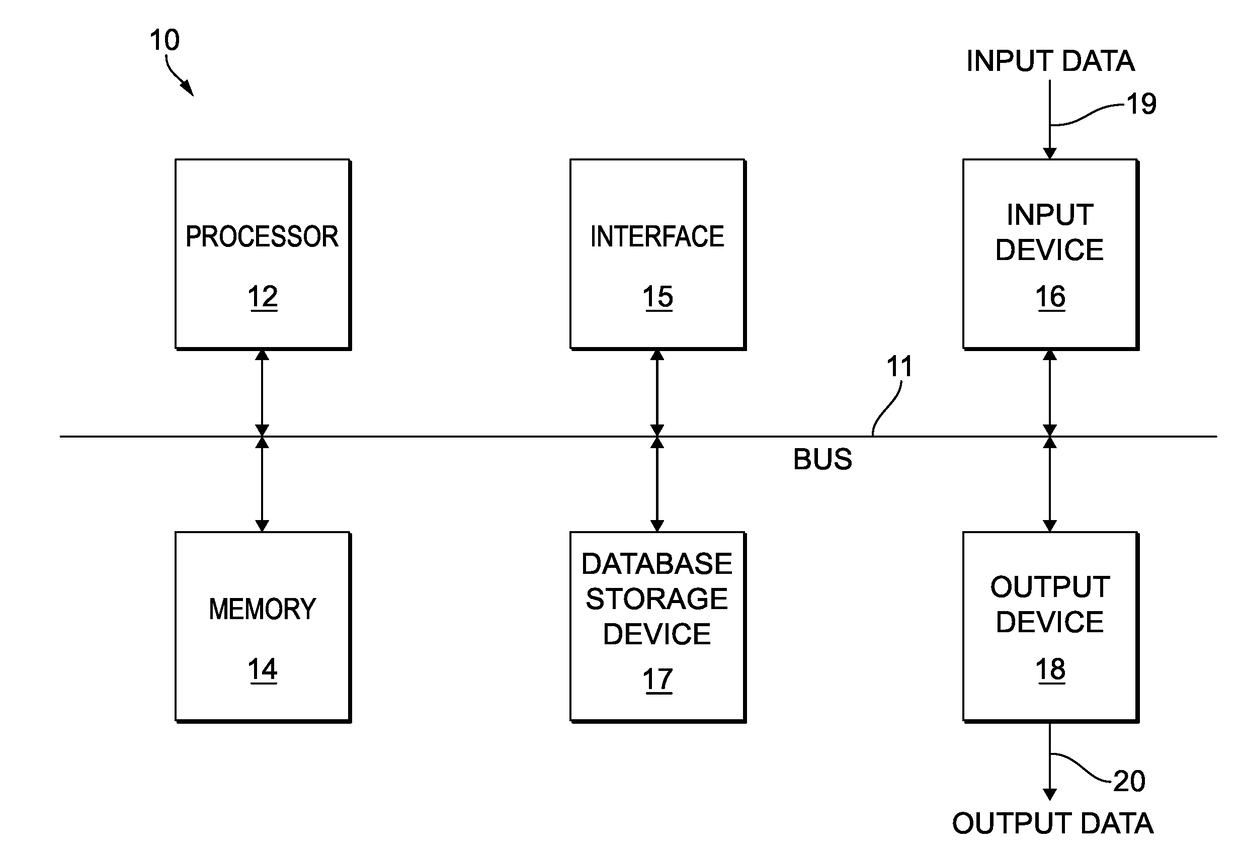

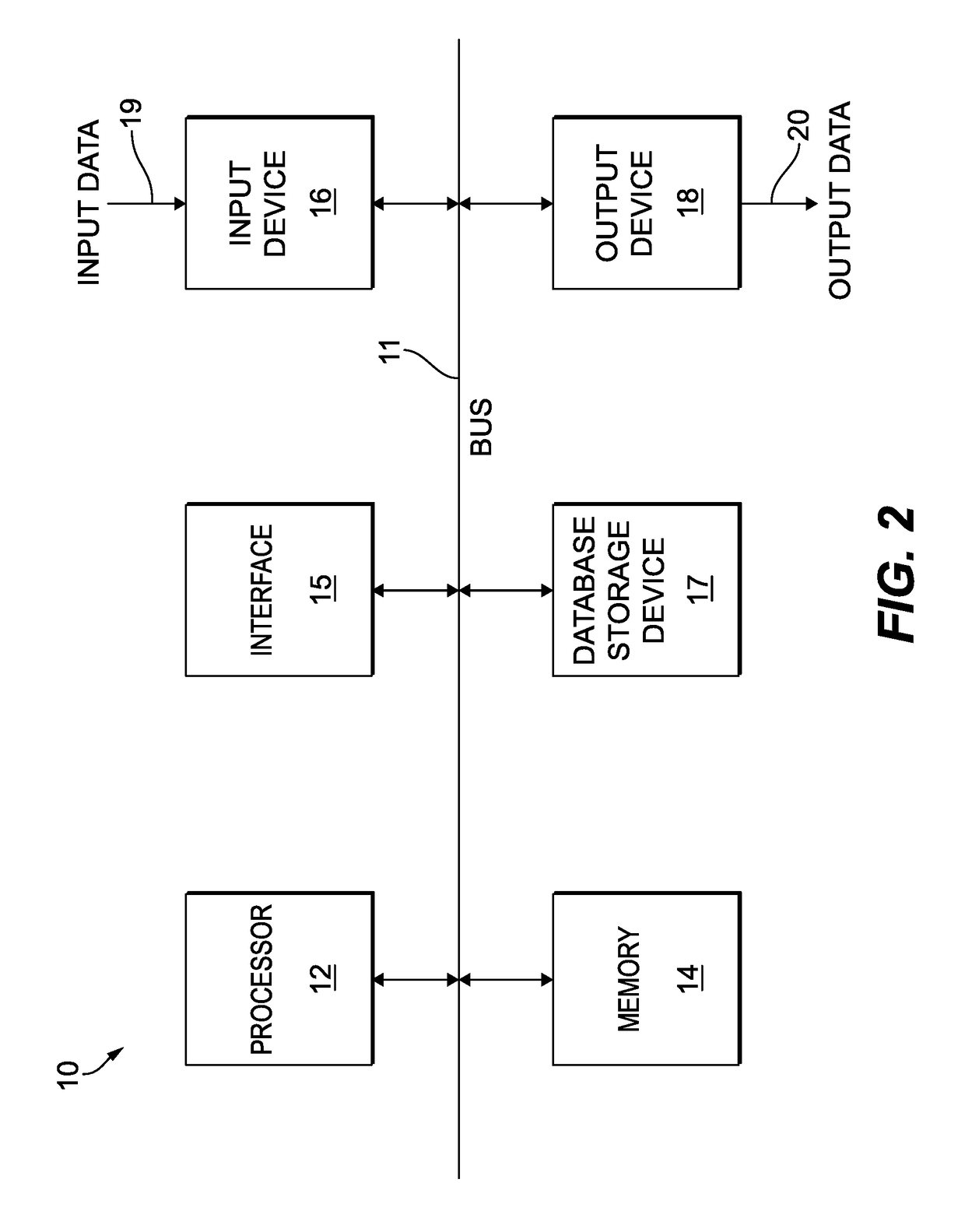

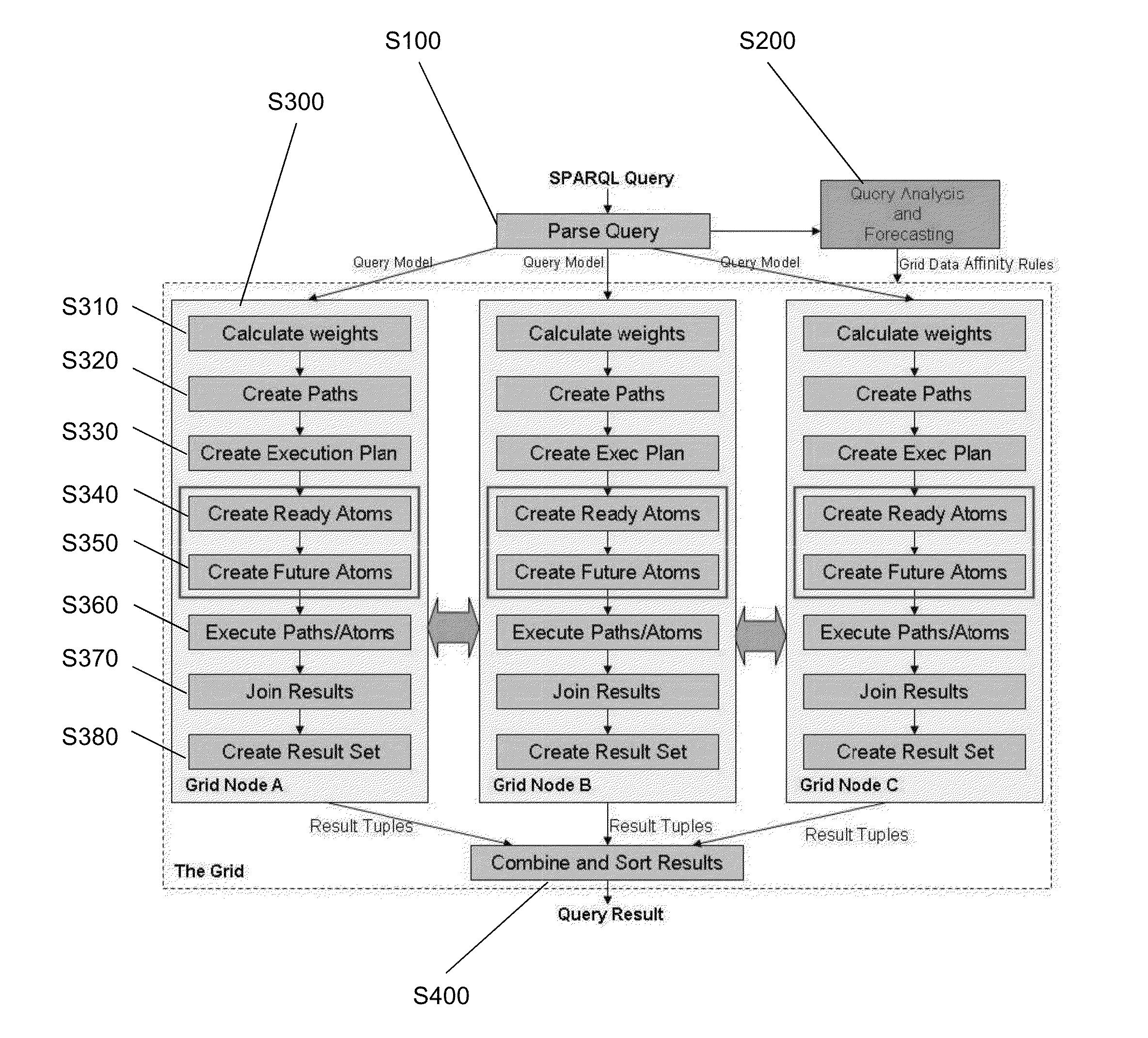

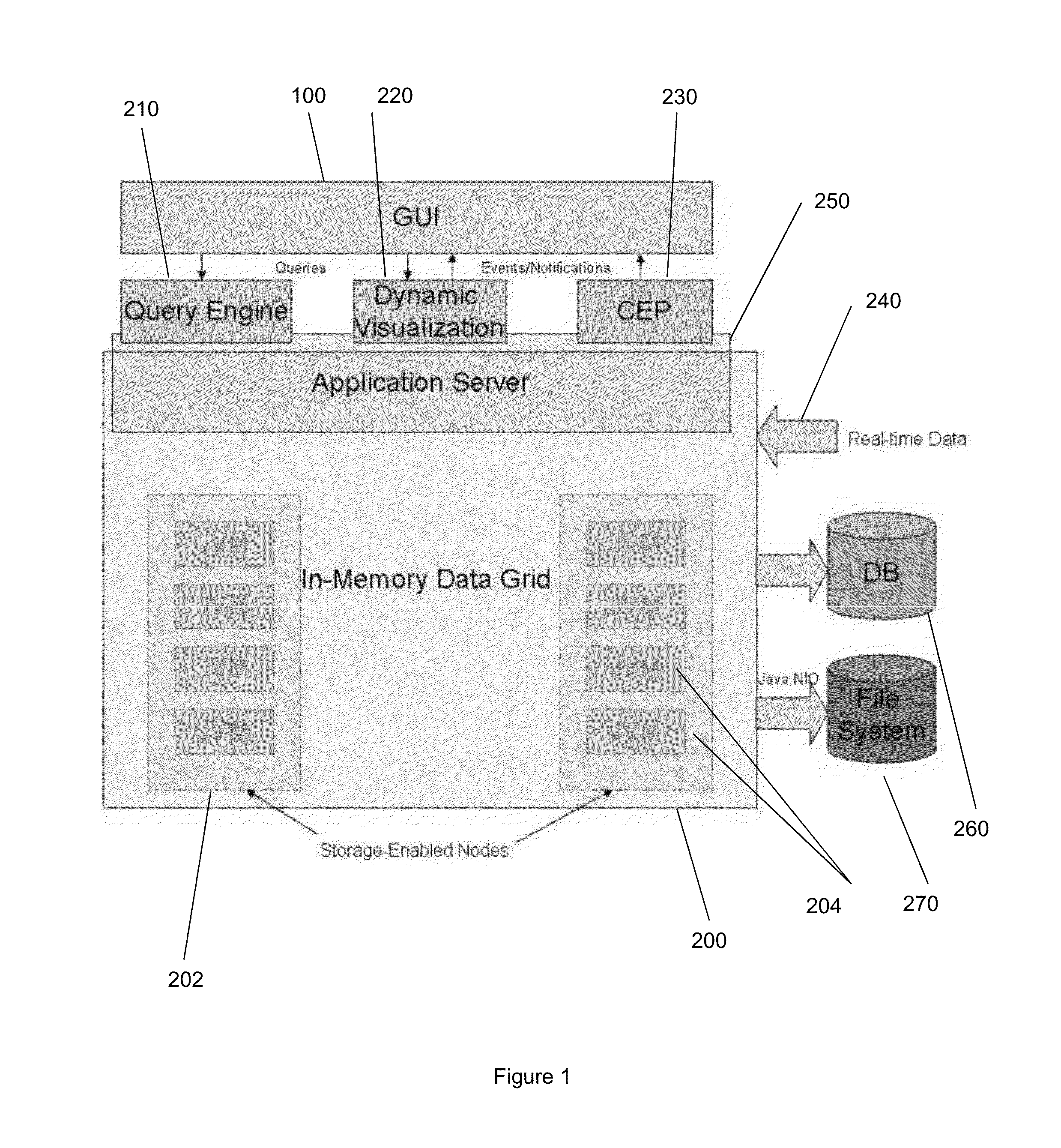

Method and system for processing data queries

ActiveUS20130262443A1Digital data information retrievalDigital data processing detailsGranularityContinuous flow

The invention relates to a method and system that provide a high performance and extremely scalable triple store within the Resource Description Framework (or alternative data models), with optimized query execution. An embodiment of the invention provides a data storage and analysis system to support scalable monitoring and analysis of business processes along multiple configurable perspectives and levels of granularity. This embodiment analyses data from processes that have been already executed and from ongoing processes, as a continuous flow of information. This embodiment provides defining and monitoring processes based on no initial domain knowledge about the process and such that the process will be built only from the incoming flow of information. Another embodiment of the invention provides a grid infrastructure that allows storage of data across many grid nodes and distribution of the workload, avoiding the bottleneck represented by constantly querying a database.

Owner:KHALIFA UNIV OF SCI & TECH +2

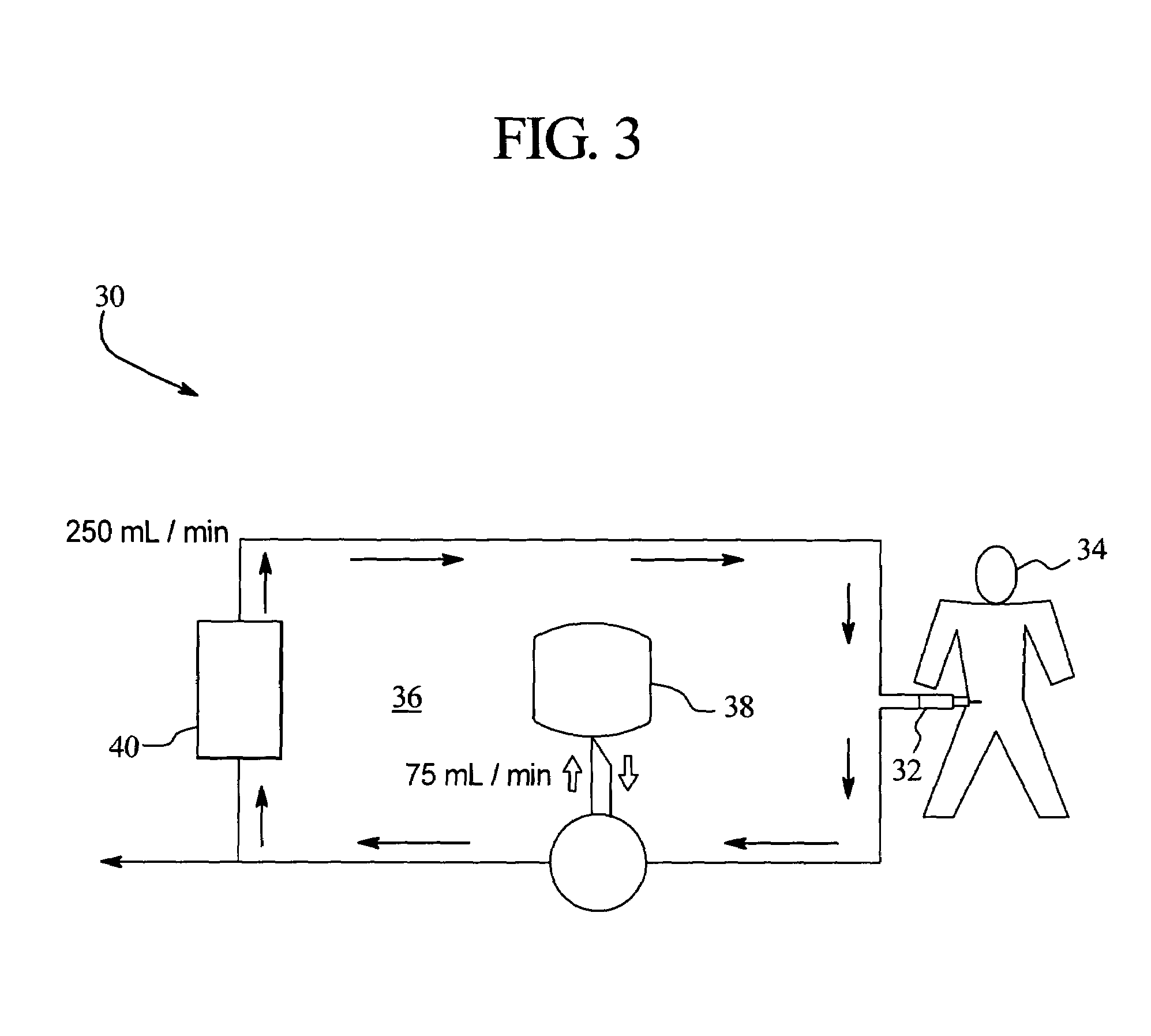

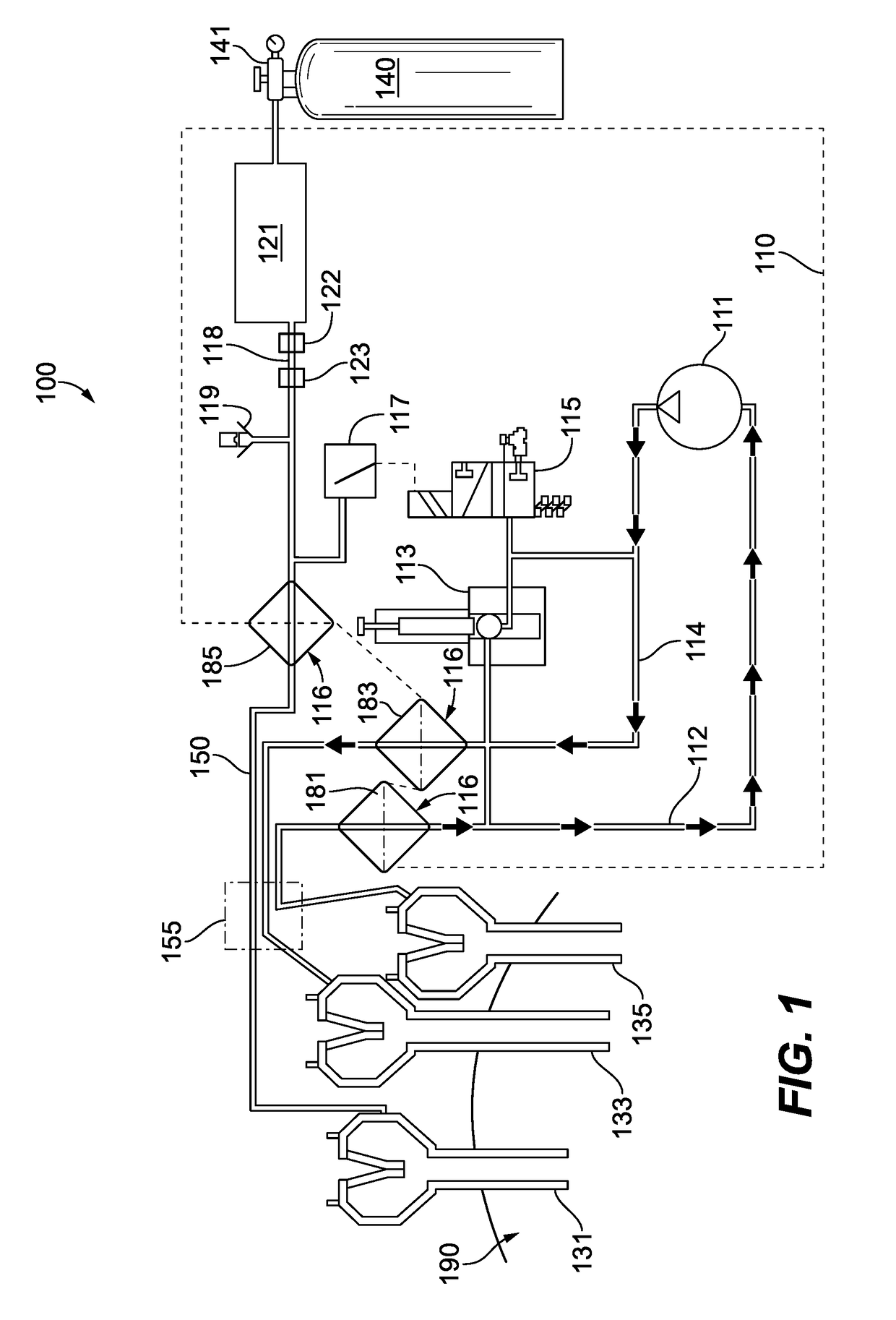

System for distending body tissue cavities by continuous flow irrigation

ActiveUS20070021713A1Shorten the timeMinimize exposureEnemata/irrigatorsMedical devicesContinuous flowEndoscopic Procedure

The present invention provides a system and a method for distending a body tissue cavity of a subject by continuous flow irrigation such that minimal or negligible fluid turbulence is present inside the cavity, such that any desired cavity pressure can be created and maintained for any desired outflow rate. The present invention also provides a method for accurately determining the rate of fluid loss, into the subject's body system, during any endoscopic procedure without utilizing any deficit weight or fluid volume calculation or flow rate sensor. The system and the methods of the present invention described above can be used in any endoscopic procedure requiring continuous flow irrigation few examples of such endoscopic procedures being hysteroscopic surgery, arthroscopic surgery, trans uretheral surgery, endoscopic surgery of the brain and endoscopic surgery of the spine.

Owner:ARTHREX

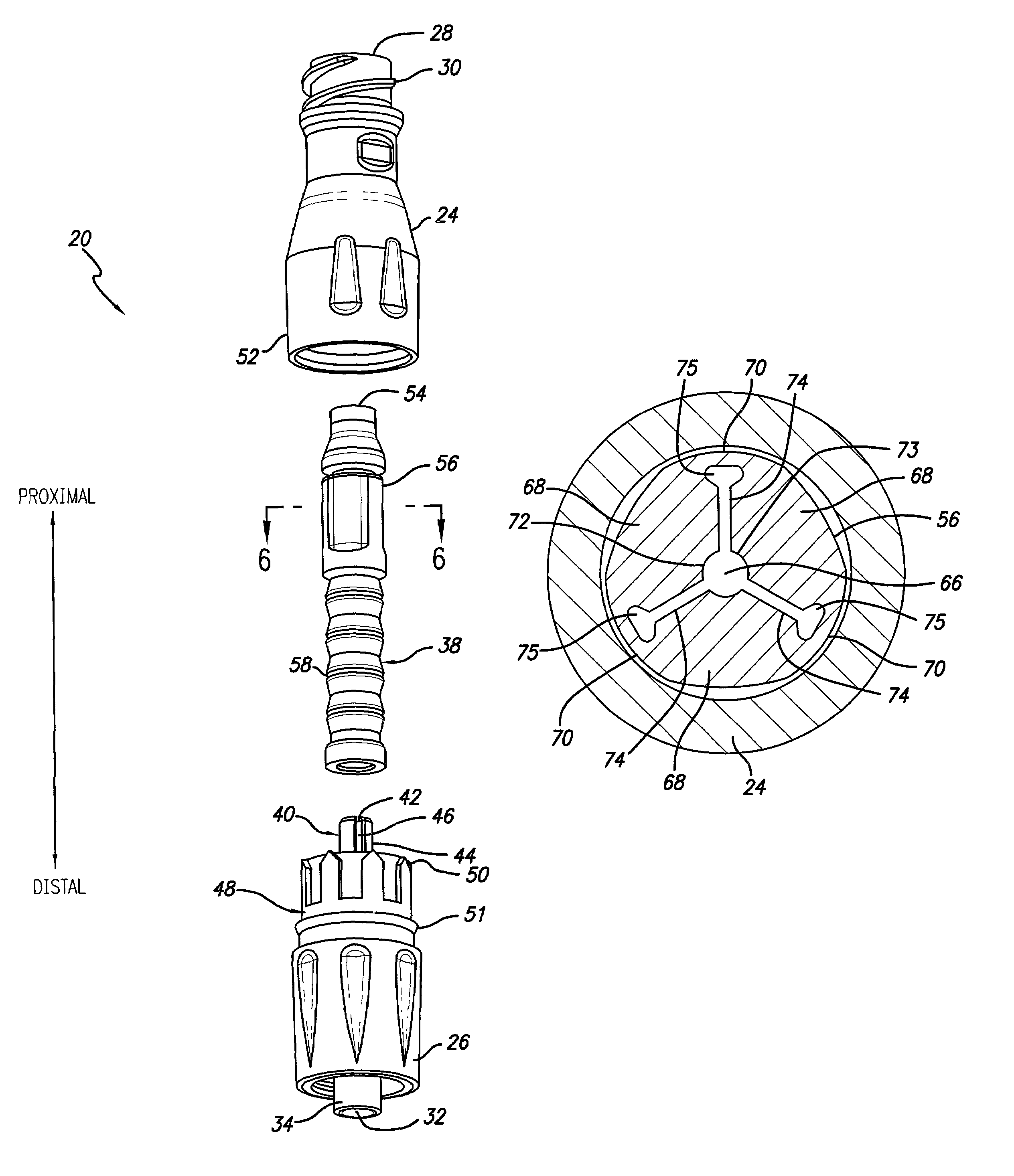

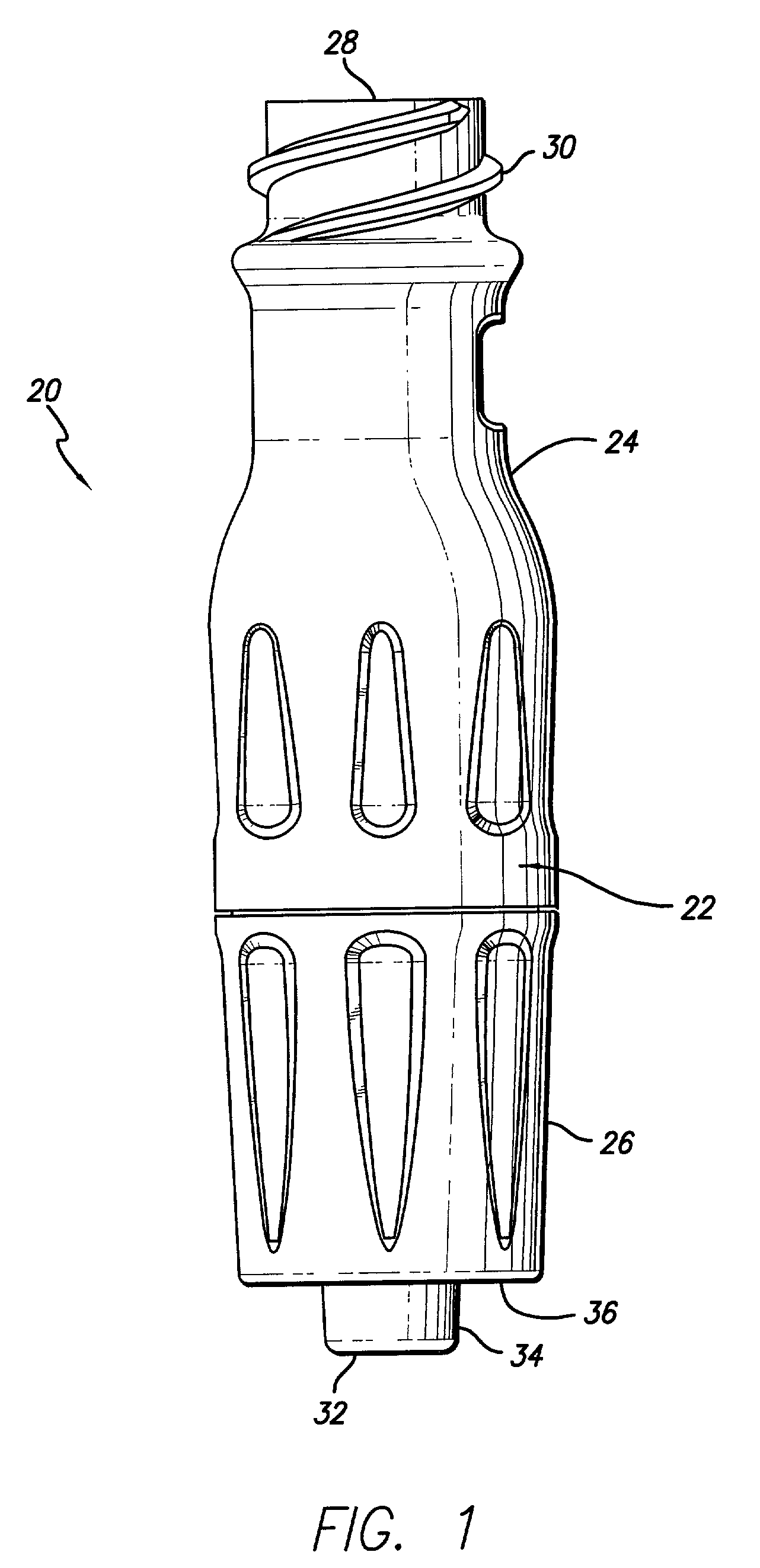

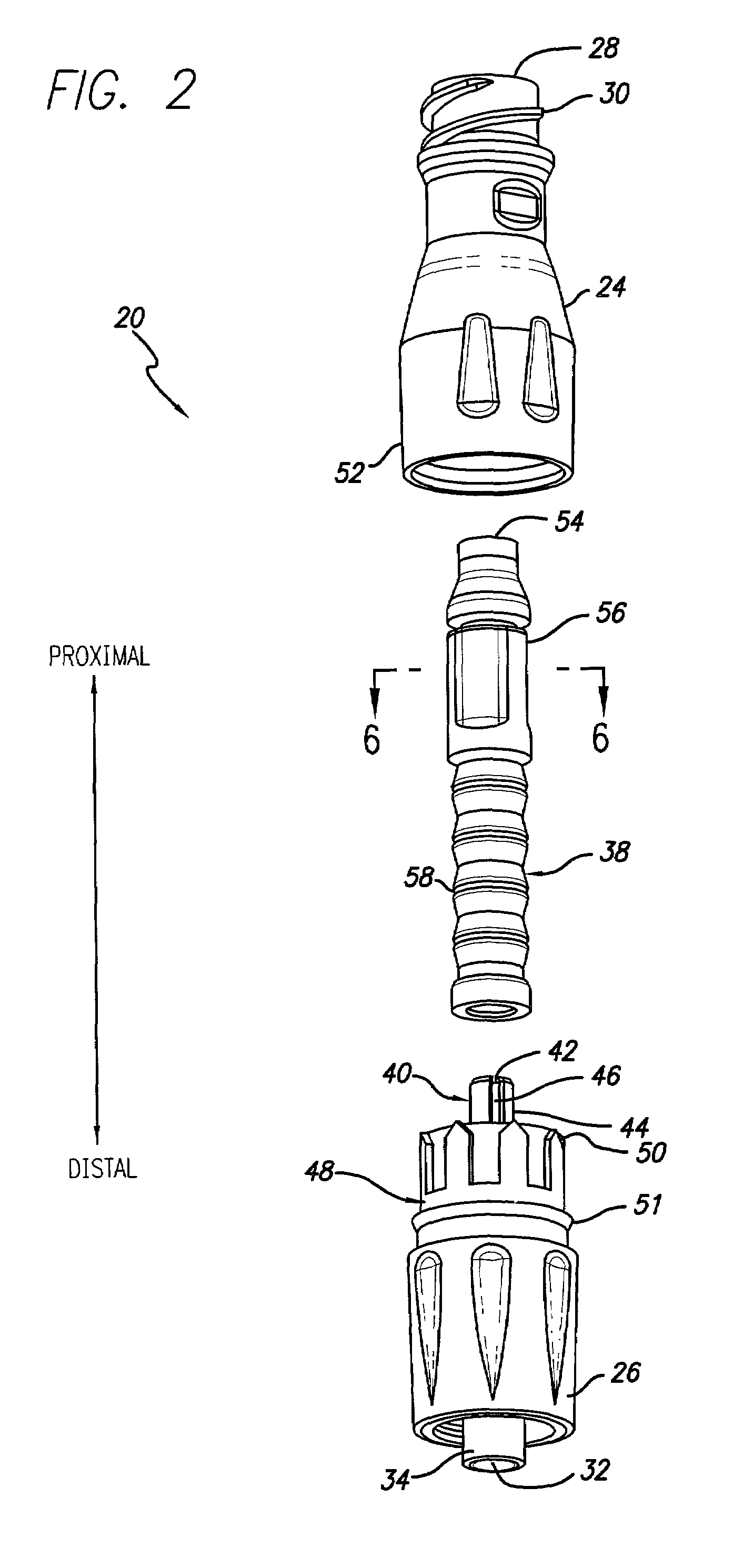

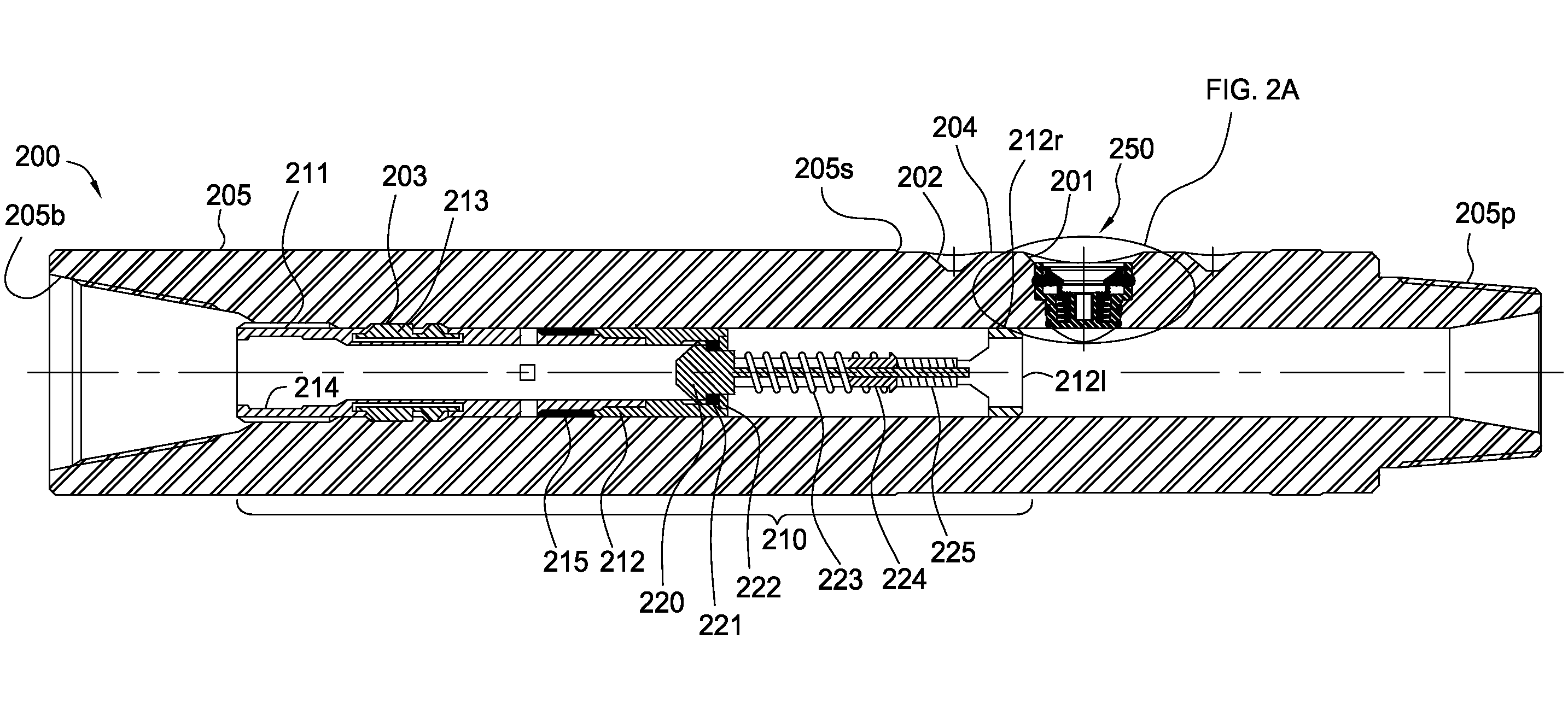

Needle-free medical connector with expandable valve mechanism and method of fluid flow control

A needle-free medical connector includes a housing with a first port and a second port. The connector also includes a piston element defining a fluid passageway between the first and second ports. The piston element is movable between flow and non-flow positions. The piston element has an expandable section having a variable inner width and volume that forms a part of the flow path through the connector. As the piston is compressed to the flow position, the expandable section is expanded in width by movement over a flow post thereby maintaining or increasing the volume of the fluid passageway through the connector. The expandable section has a configuration permitting the continuous flow of fluid through its entirety.

Owner:CAREFUSION 303 INC

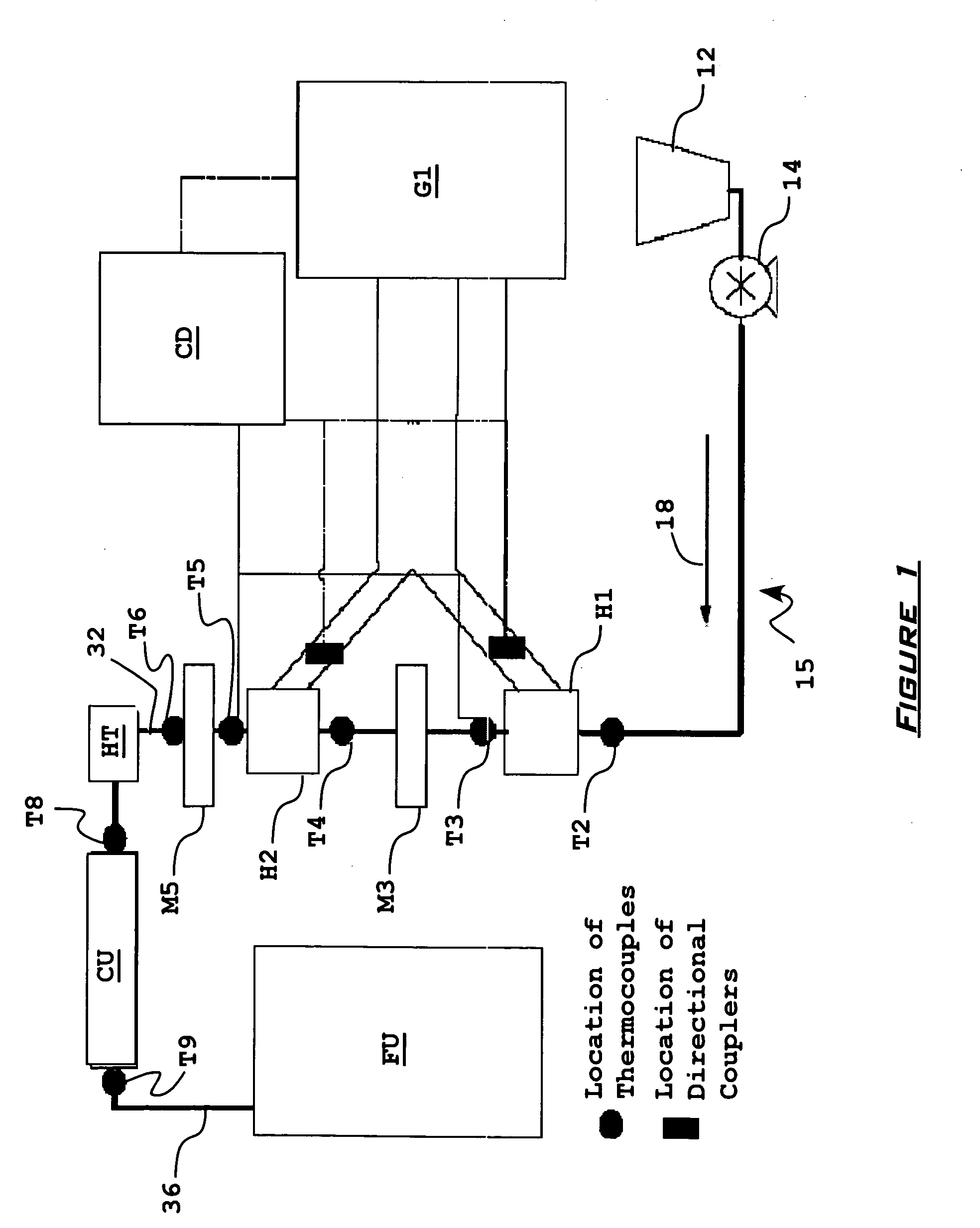

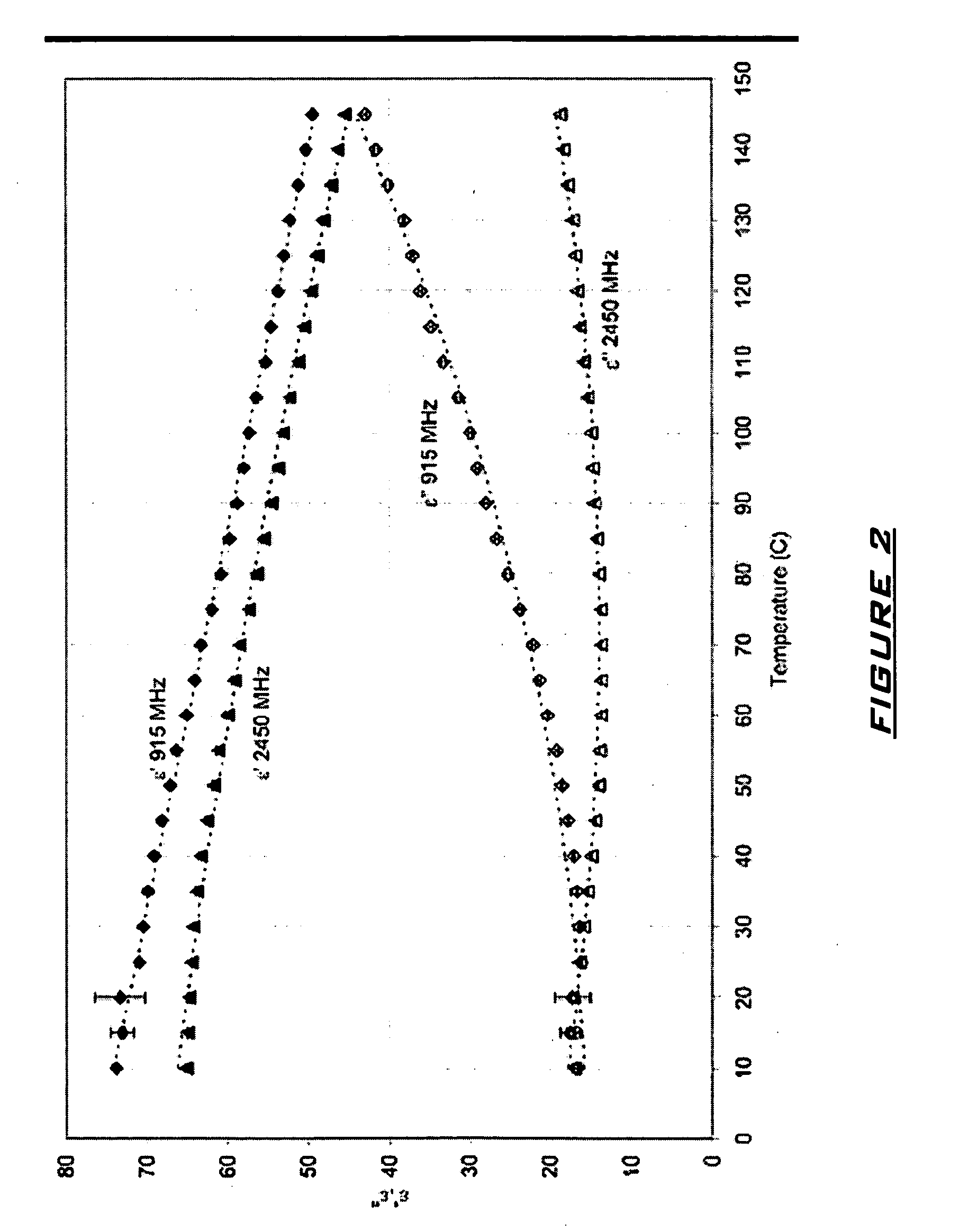

Methods and apparatuses for thermal treatment of foods and other biomaterials, and products obtained thereby

InactiveUS20060151533A1Speed up heat exchangeImproved physical contactOpening closed containersBottle/container closureMedicineContinuous flow

Methods and apparatuses for thermally treating flowable materials using electromagnetic radiation, and foods and materials obtained thereby. Also provided are methods of continuous flow thermal treatment of biomaterials, apparatuses for performing the same, and products prepared using the methods and / or apparatuses.

Owner:SIMUNOVIC JOSIP +6

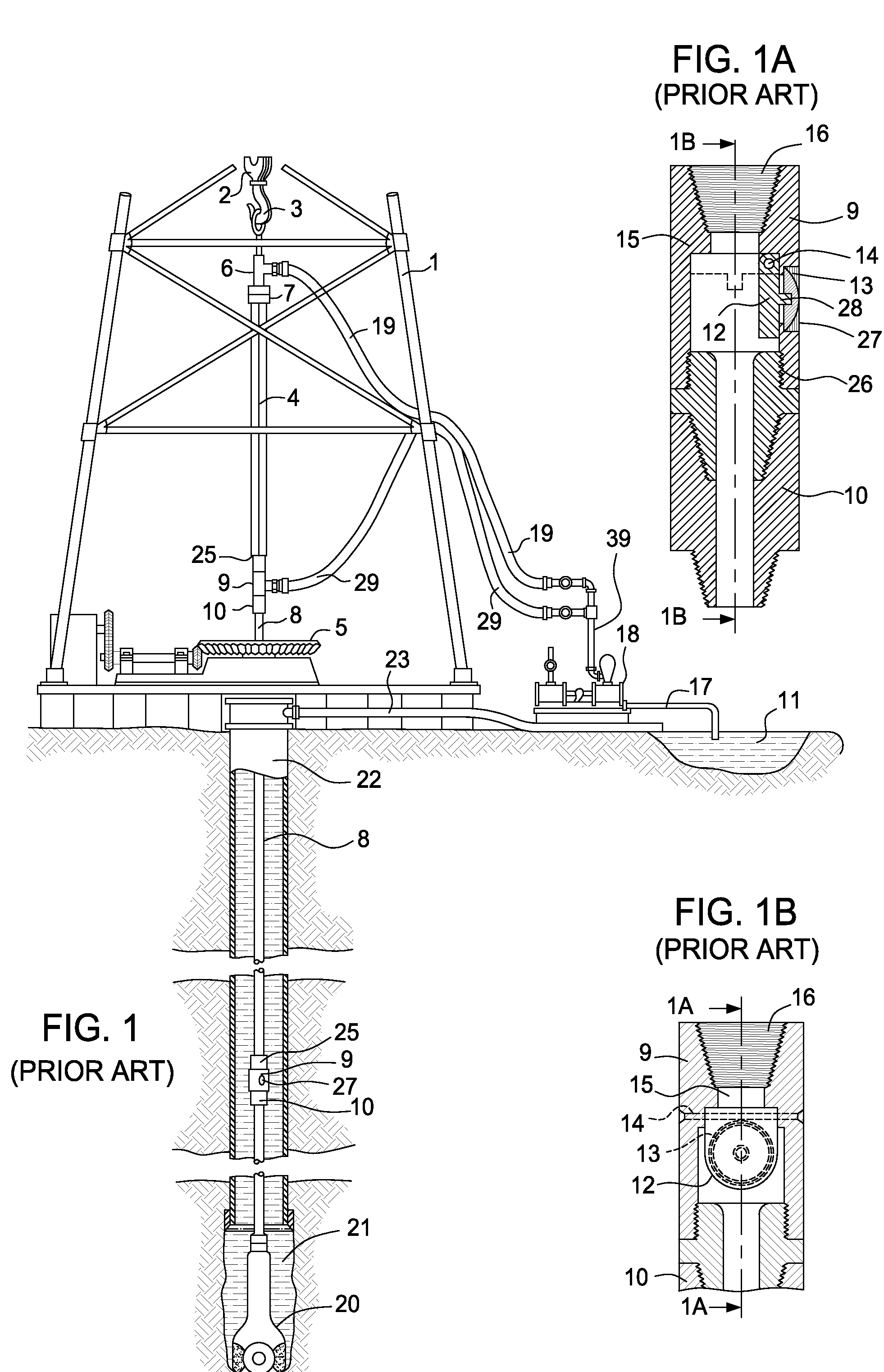

Continuous flow drilling systems and methods

In one embodiment, a method for drilling a wellbore includes injecting drilling fluid into a top of a tubular string disposed in the wellbore at a first flow rate. The tubular string includes: a drill bit disposed on a bottom thereof, tubular joints connected together, a longitudinal bore therethrough, and a port through a wall thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The cuttings and drilling fluid (returns) flow to the surface via an annulus defined between the tubular string and the wellbore. The method further includes rotating the drill bit while injecting the drilling fluid; remotely removing a plug from the port, thereby opening the port; and injecting drilling fluid into the port at a second flow rate while adding a tubular joint or stand of joints to the tubular string. The injection of drilling fluid into the tubular string is continuously maintained between drilling and adding the joint or stand to the drill string. The method further includes remotely installing a plug into the port, thereby closing the port. The first and second flow rates may be substantially equal or different.

Owner:WEATHERFORD TECH HLDG LLC

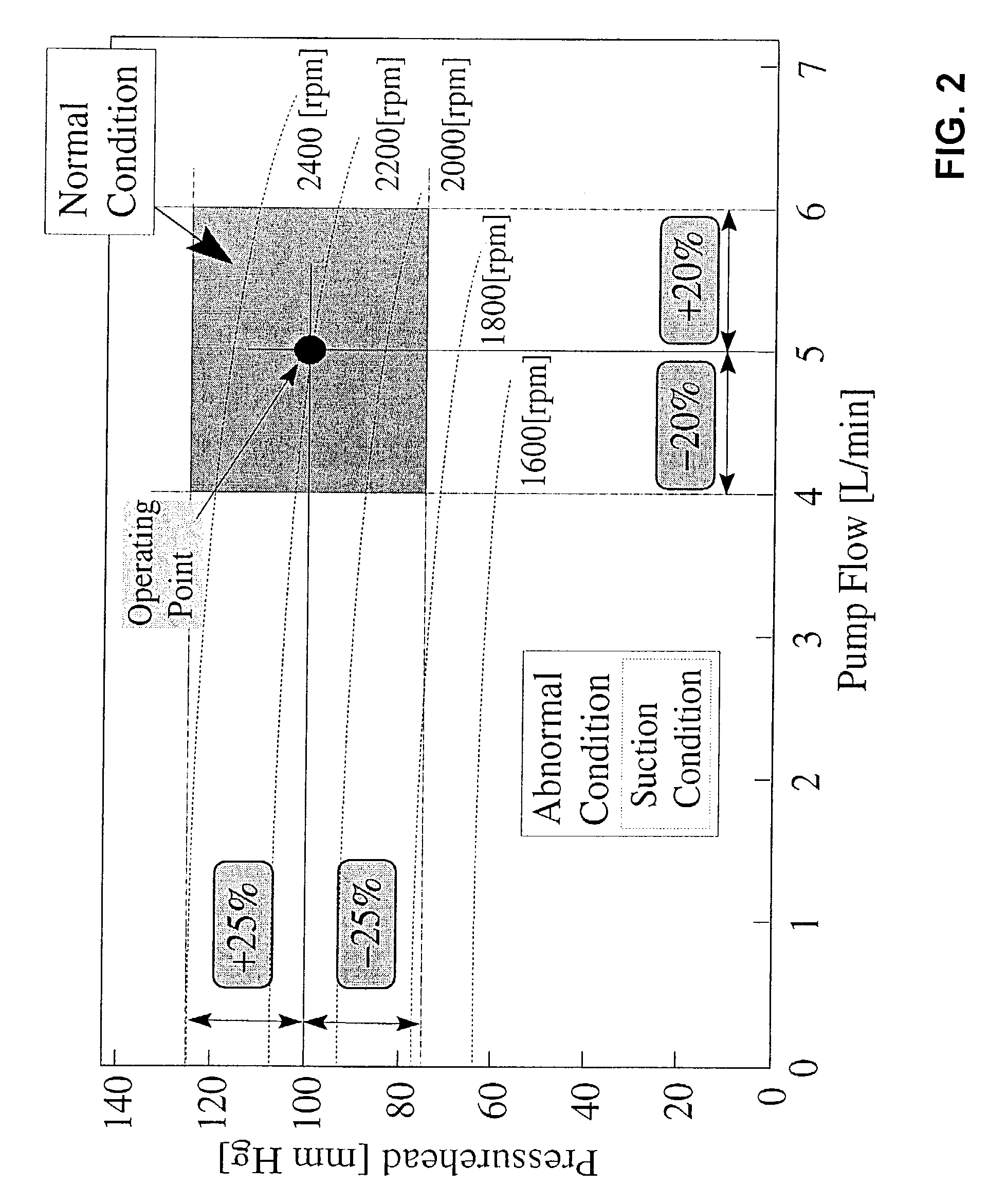

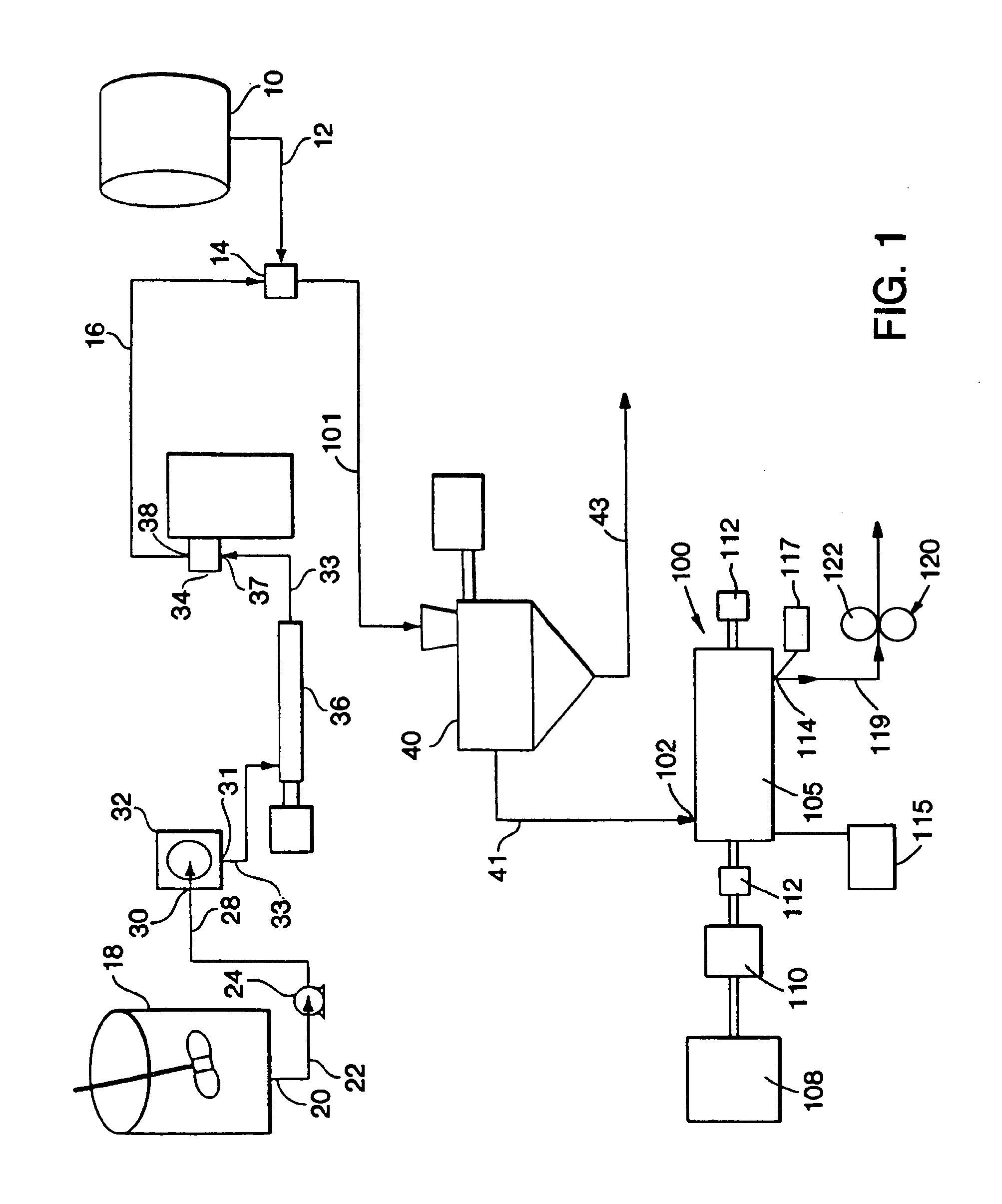

Methods and apparatus for controlling a continuous flow rotary blood pump

A control system for a continuous flow rotary blood pump is provided. A normal operating range of the blood pump is established. The normal operating range may comprise a normal pump flow range and a normal pressure head range. A target rotational speed of the pump is set in accordance with the normal operating range. A current operating condition of the blood pump is determined. The current operating condition may comprise a current pump flow, a current pressure head, and a current rotational speed of the pump. The current operating condition is compared with the normal operating range. An appropriate control algorithm is selected from a plurality of available control algorithms based on the comparison. The target rotational speed of the pump is adjusted using the selected control algorithm to maintain or recover the normal operating range.

Owner:HITMAC USA +1

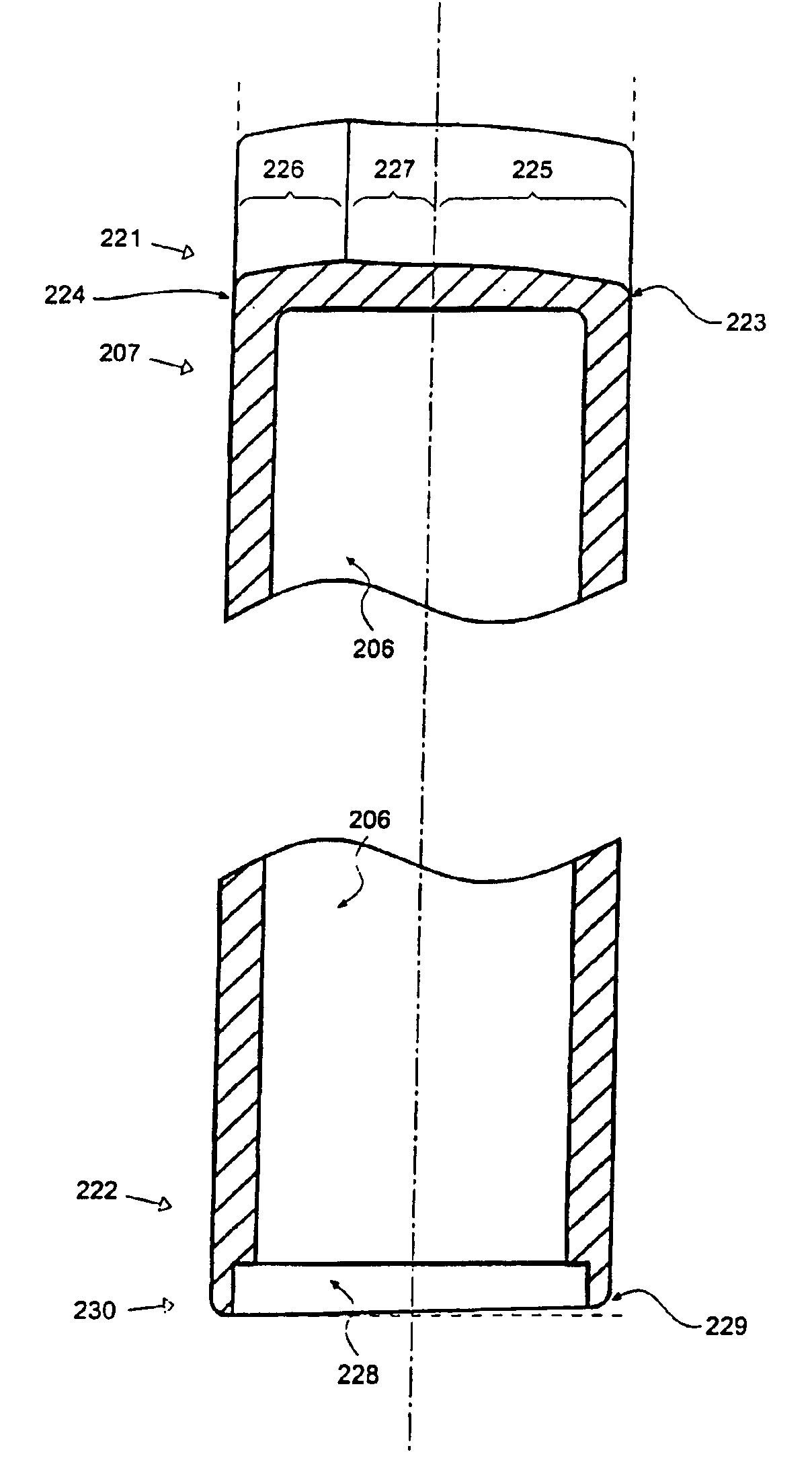

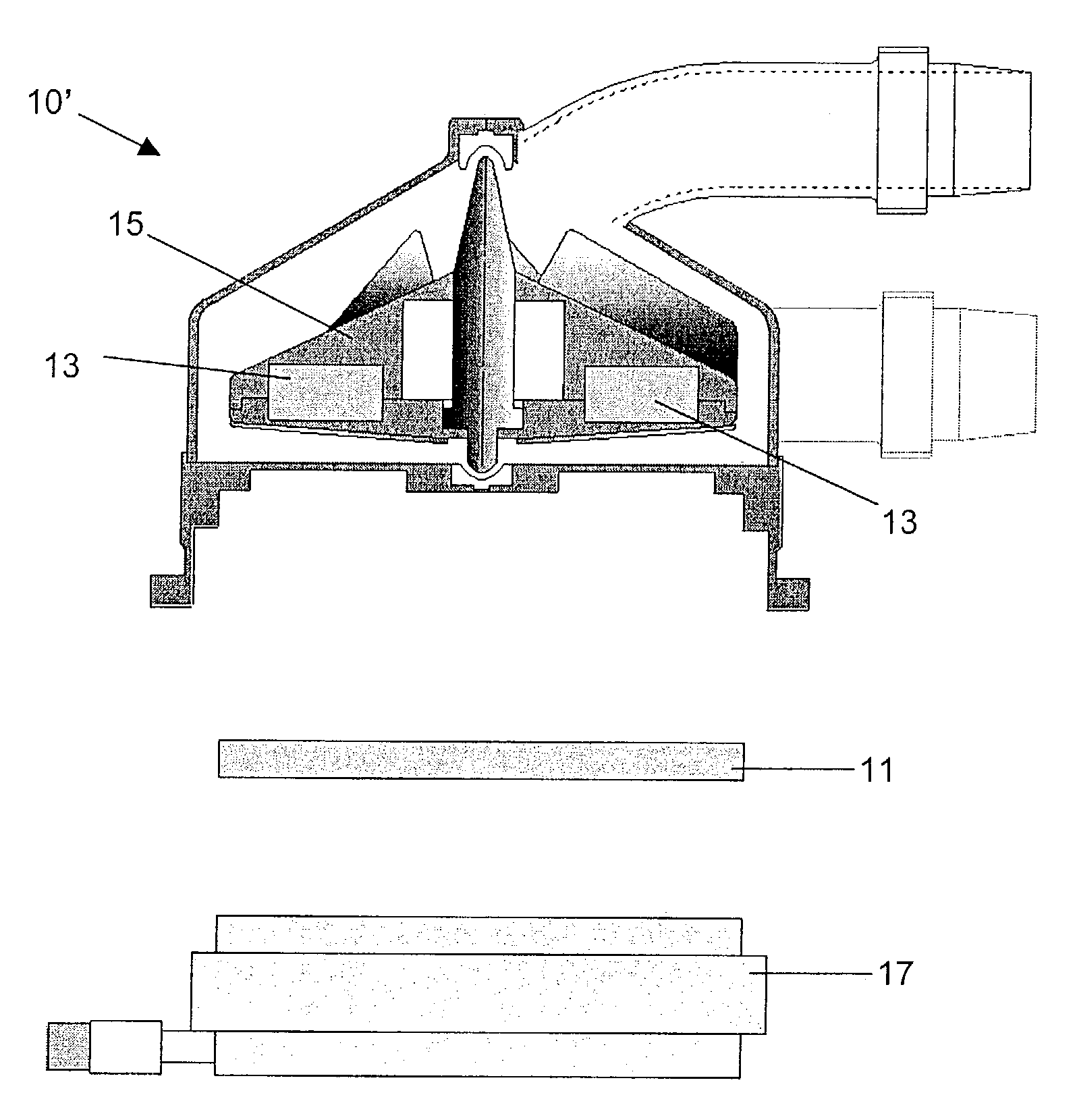

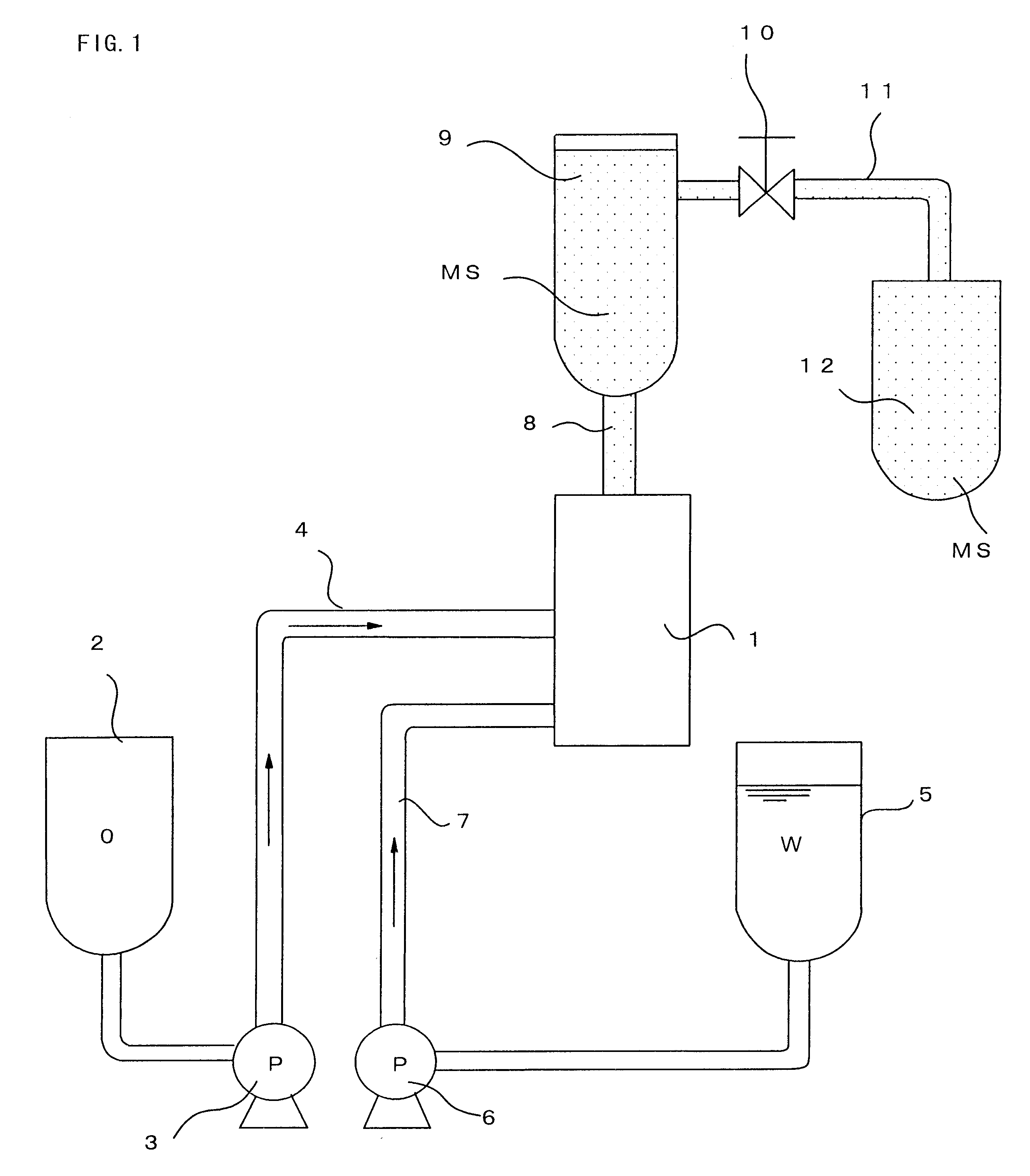

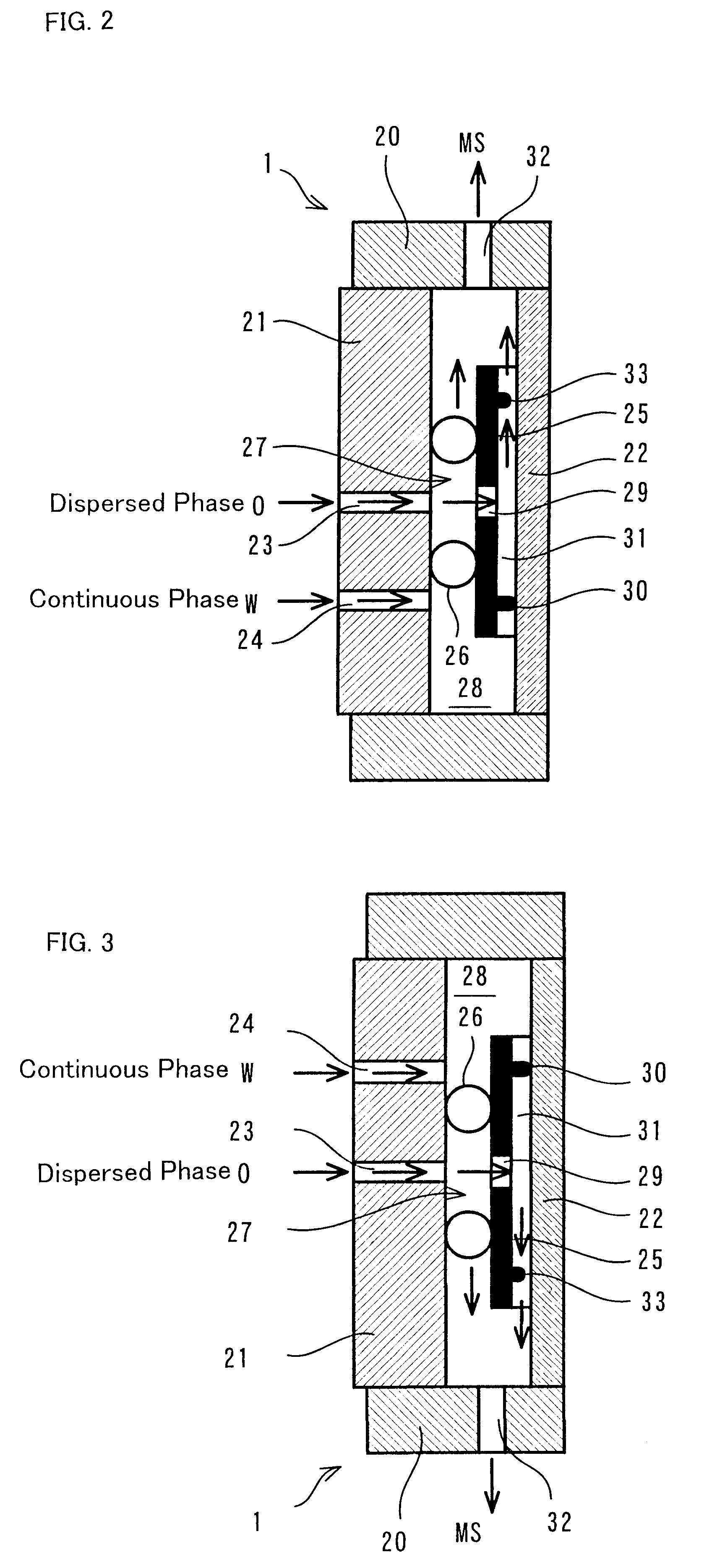

Continuous manufacturing method for microspheres and apparatus therefor

In an apparatus for continuously manufacturing microspheres, a dispersed phase (O) is supplied to a chamber 27 for the dispersed phase inside of a bulkhead member 26 via a supply port 23. Thereafter, the dispersed phase enters into a gap 31 between a plate 22 via a supply port 29 in a base 25. The dispersed phase which enters into the gap 31 grows microspheres (particles) having a certain diameter while passing through a microchannel 33 by pressure applied by, for example, a pump, and is mixed with a continuous phase (W), so that microspheres are produced. The thus-produced microspheres float or are suspended in the continuous phase without needing any particular external force in response to their specific gravity, allowing the microspheres to be generated and withdrawn from a withdrawal port 32 at a significantly reduced pressure in comparison to conventional methods and apparatus.

Owner:NAT FOOD RES INST +1

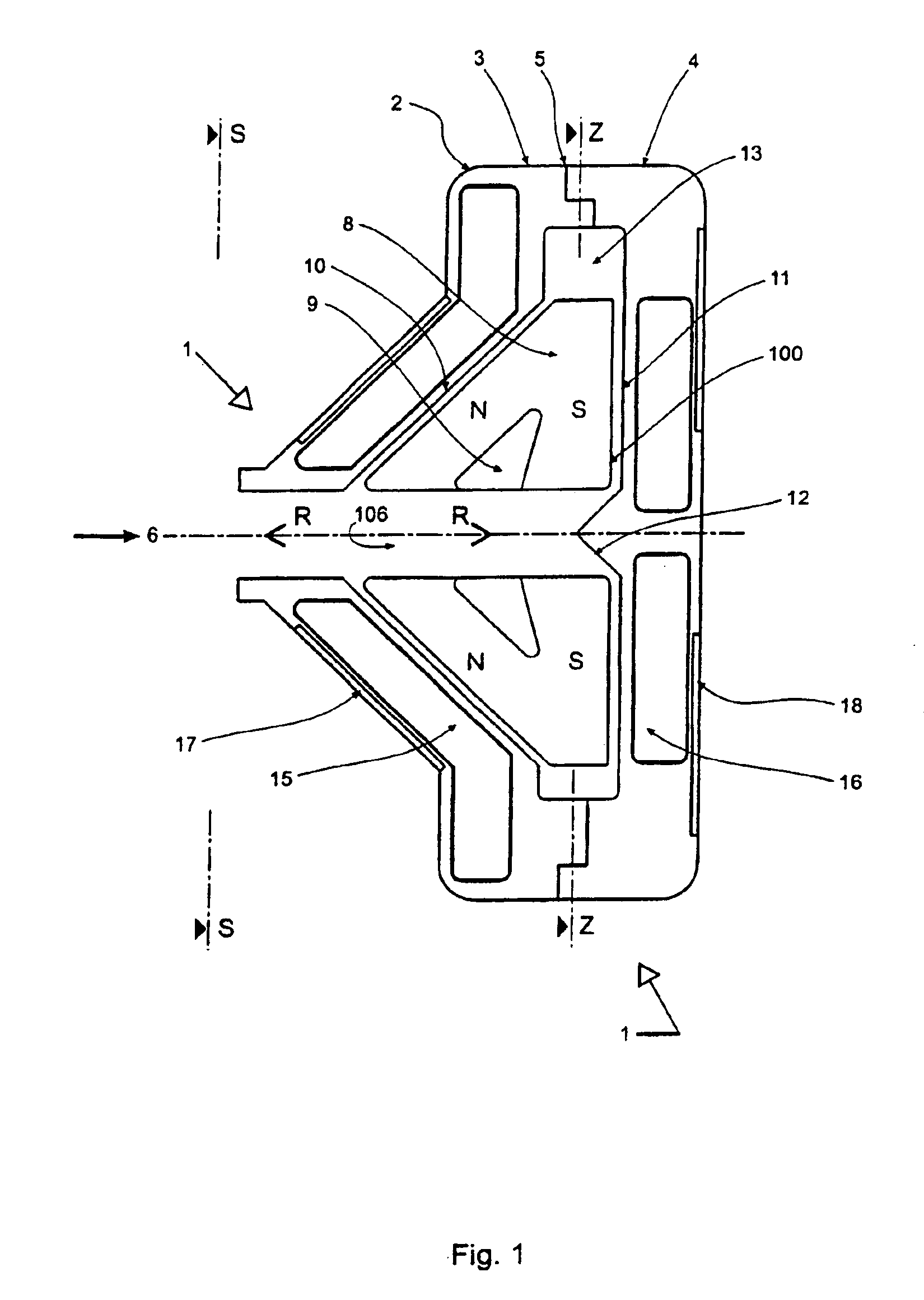

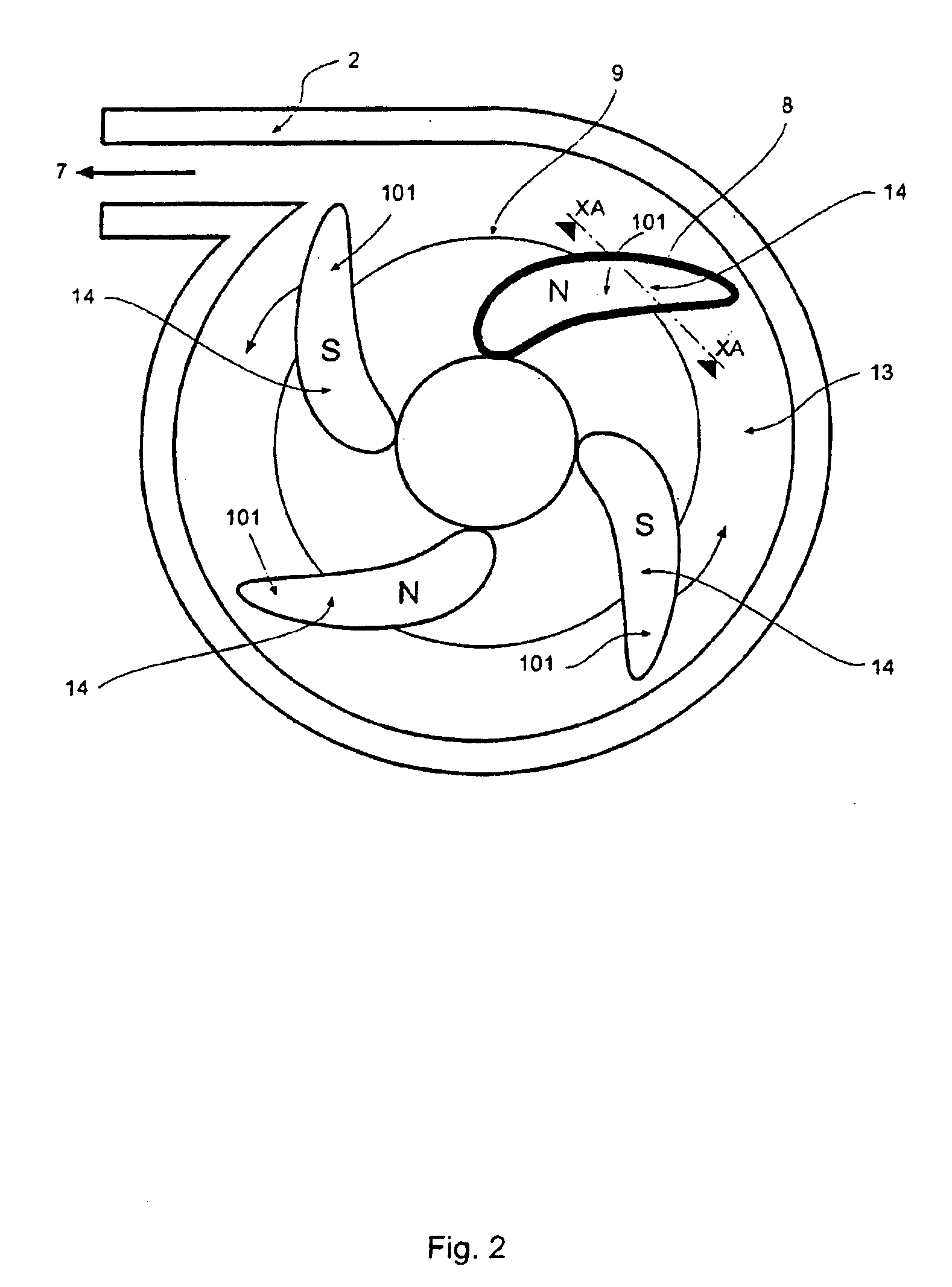

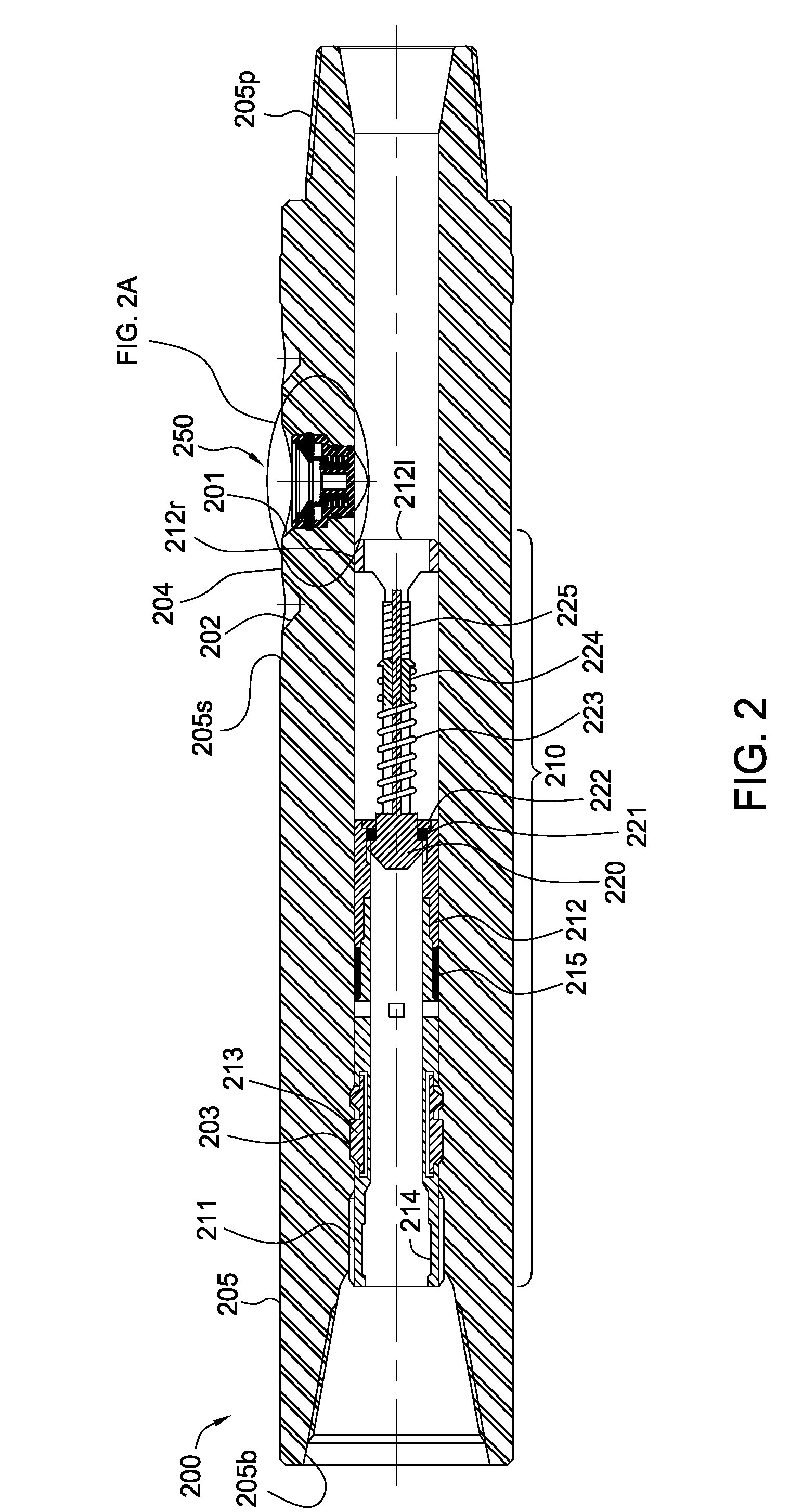

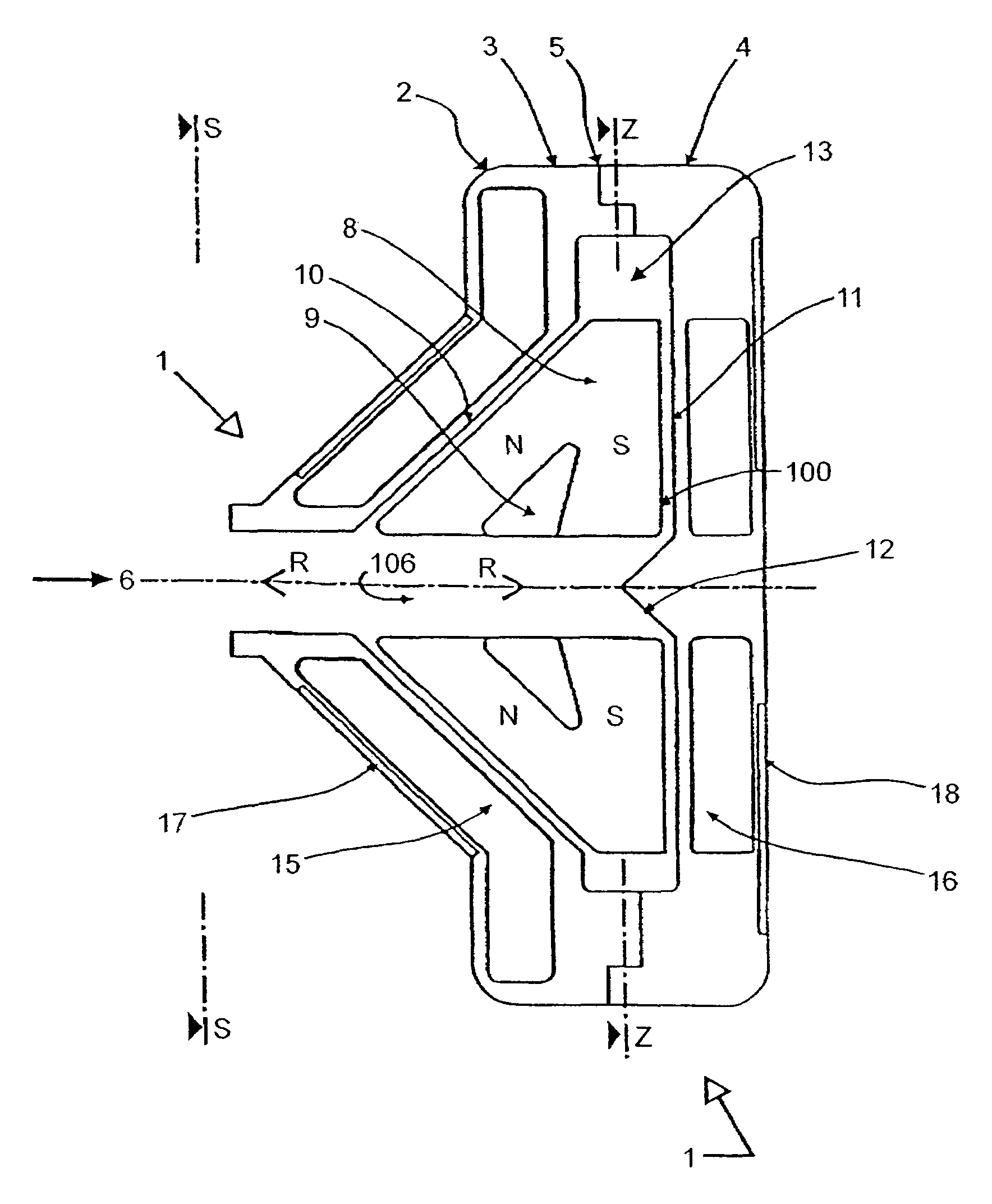

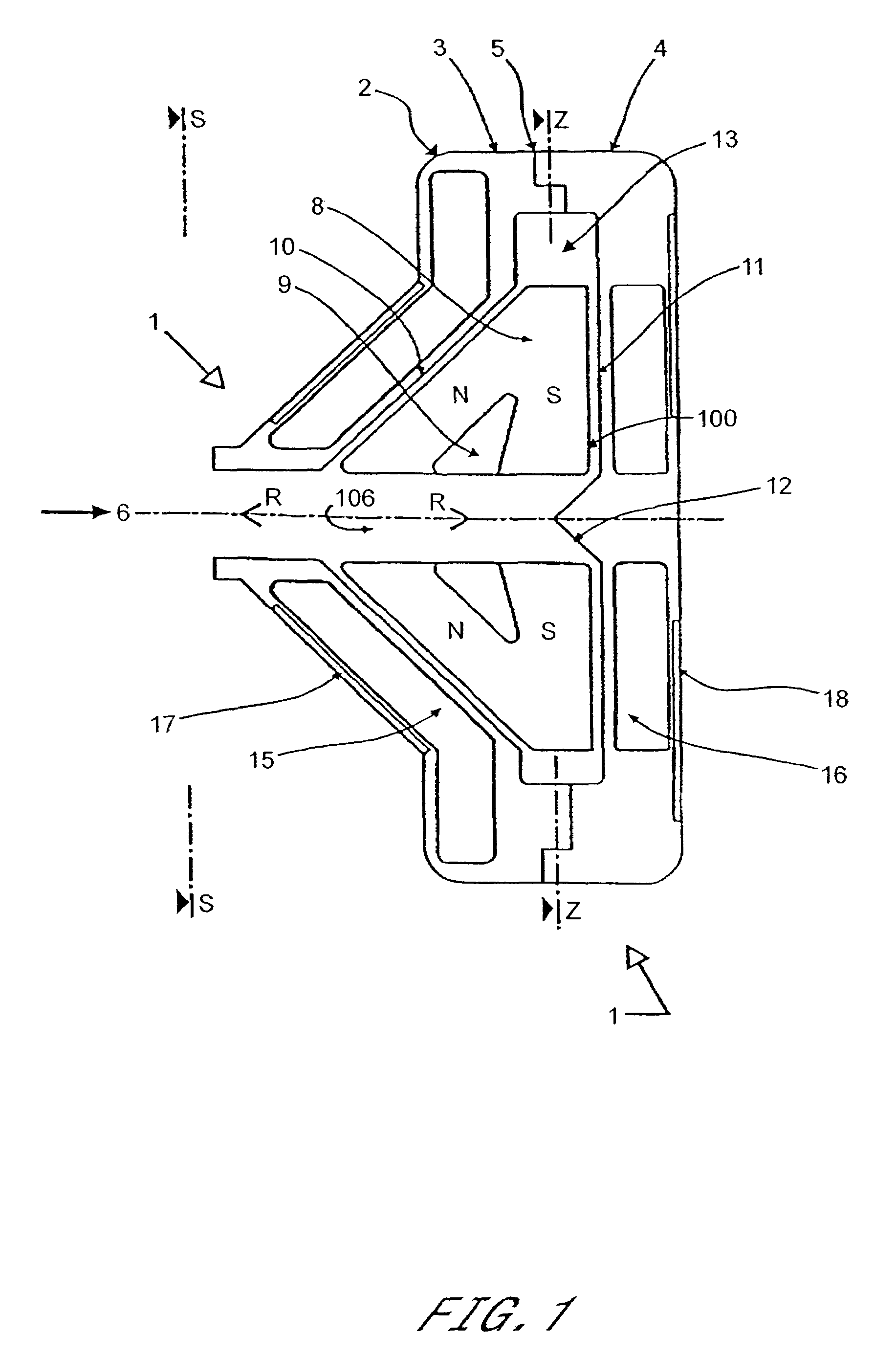

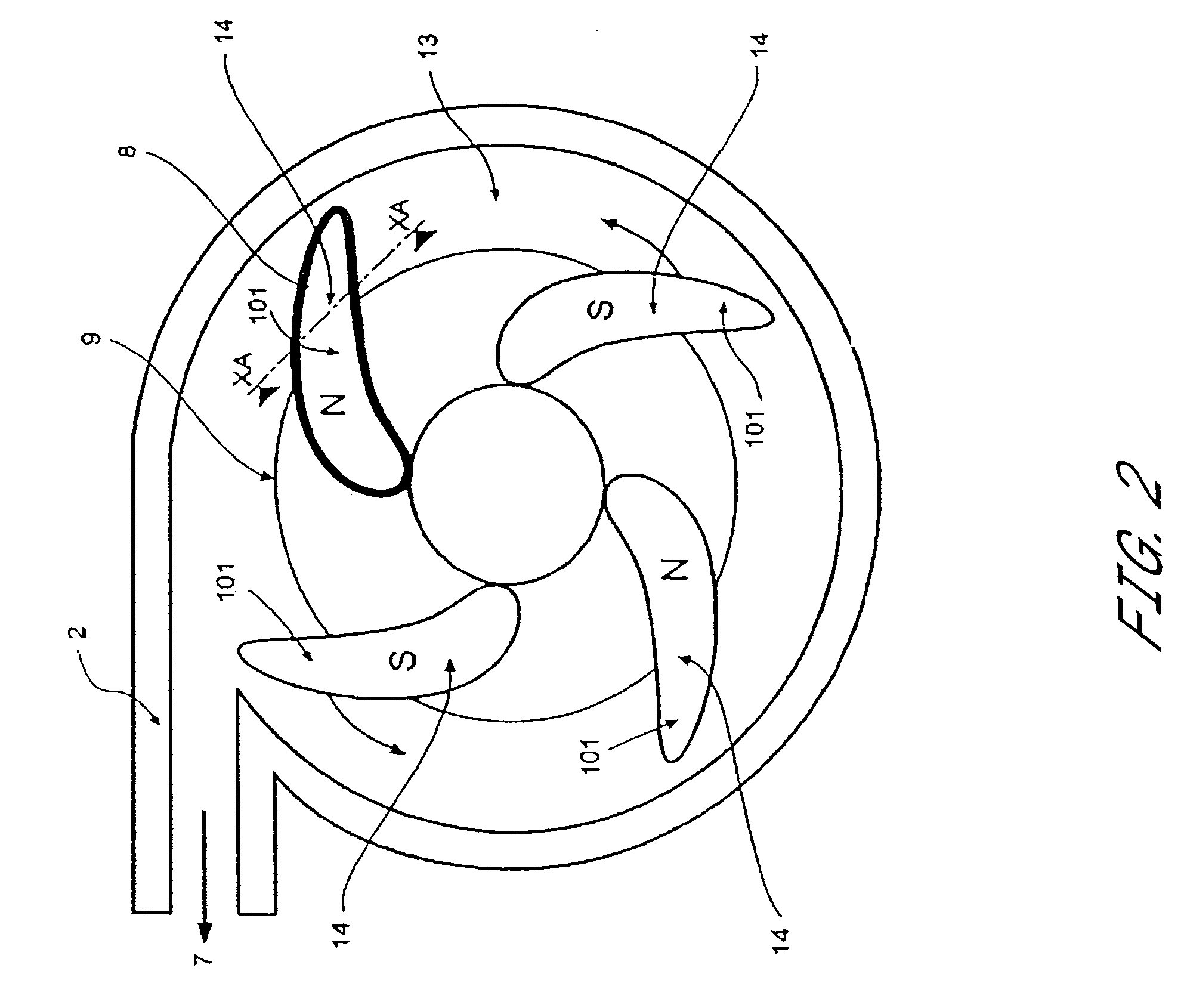

Rotary pump with exclusively hydrodynamically suspended impeller

A pump assembly 1, 33, 200 adapted for continuous flow pumping of blood. In a particular form the pump 1, 200 is a centrifugal pump wherein the impeller 100, 204 is entirely sealed within the pump housing 2, 201 and is exclusively hydrodynamically suspended therein as the impeller rotates within the fluid 105 urged by electromagnetic means external to the pump cavity 106, 203. Hydrodynamic suspension is assisted by the impeller 100, 204 having deformities therein such as blades 8 with surfaces tapered from the leading edges 102, 223 to the trailing edges 103, 224 of bottom and top edges 221, 222 thereof.

Owner:TC1 LLC +2

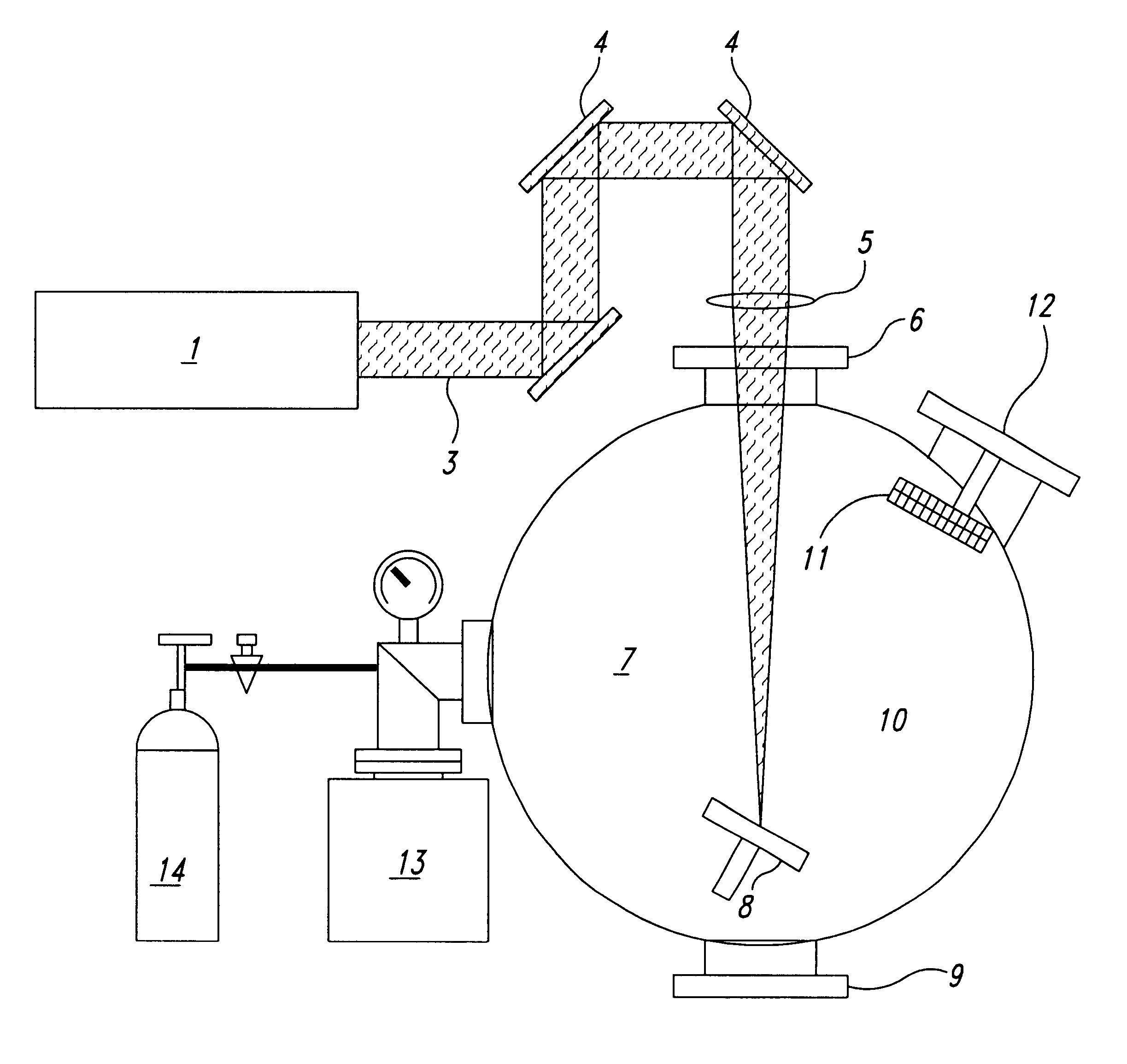

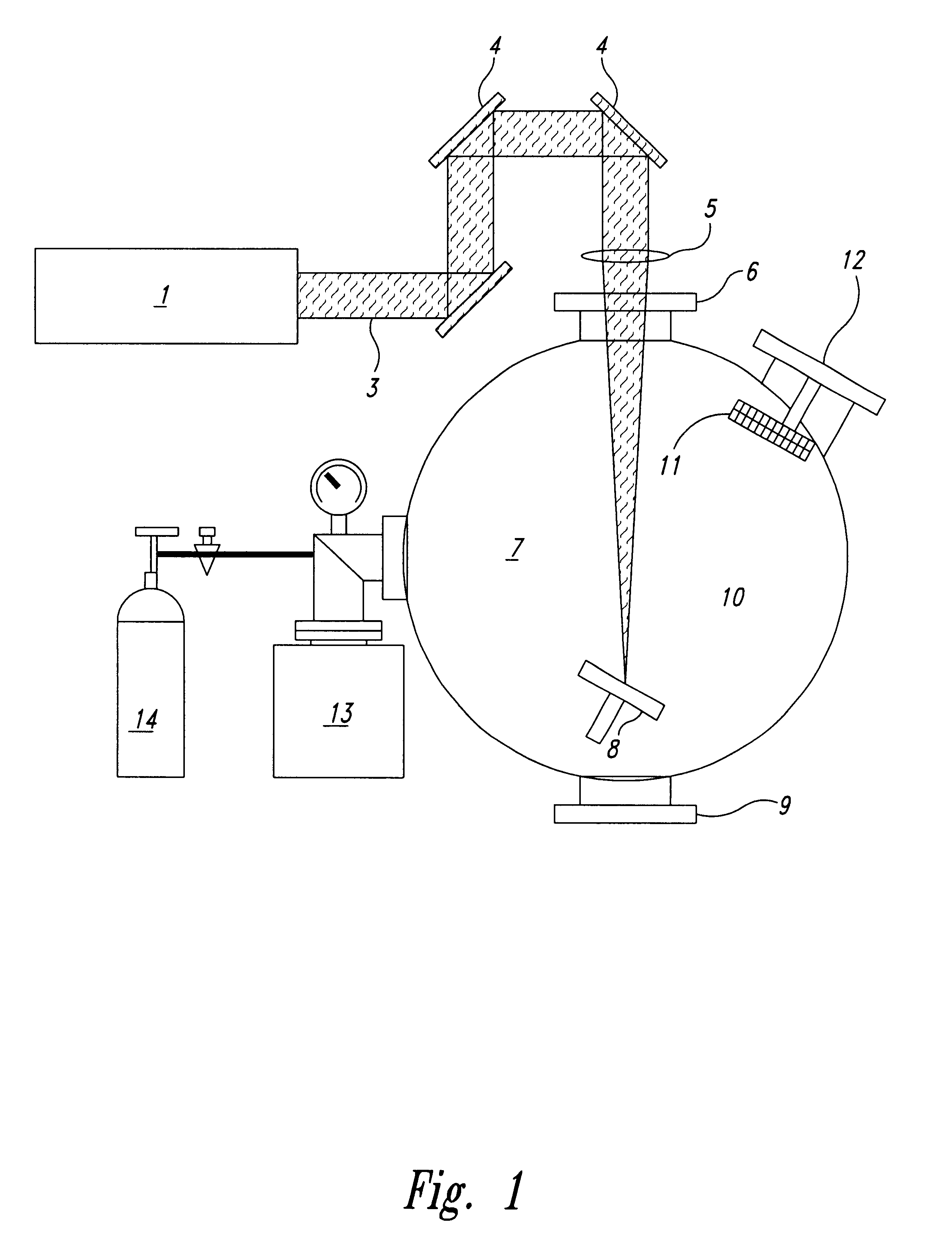

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

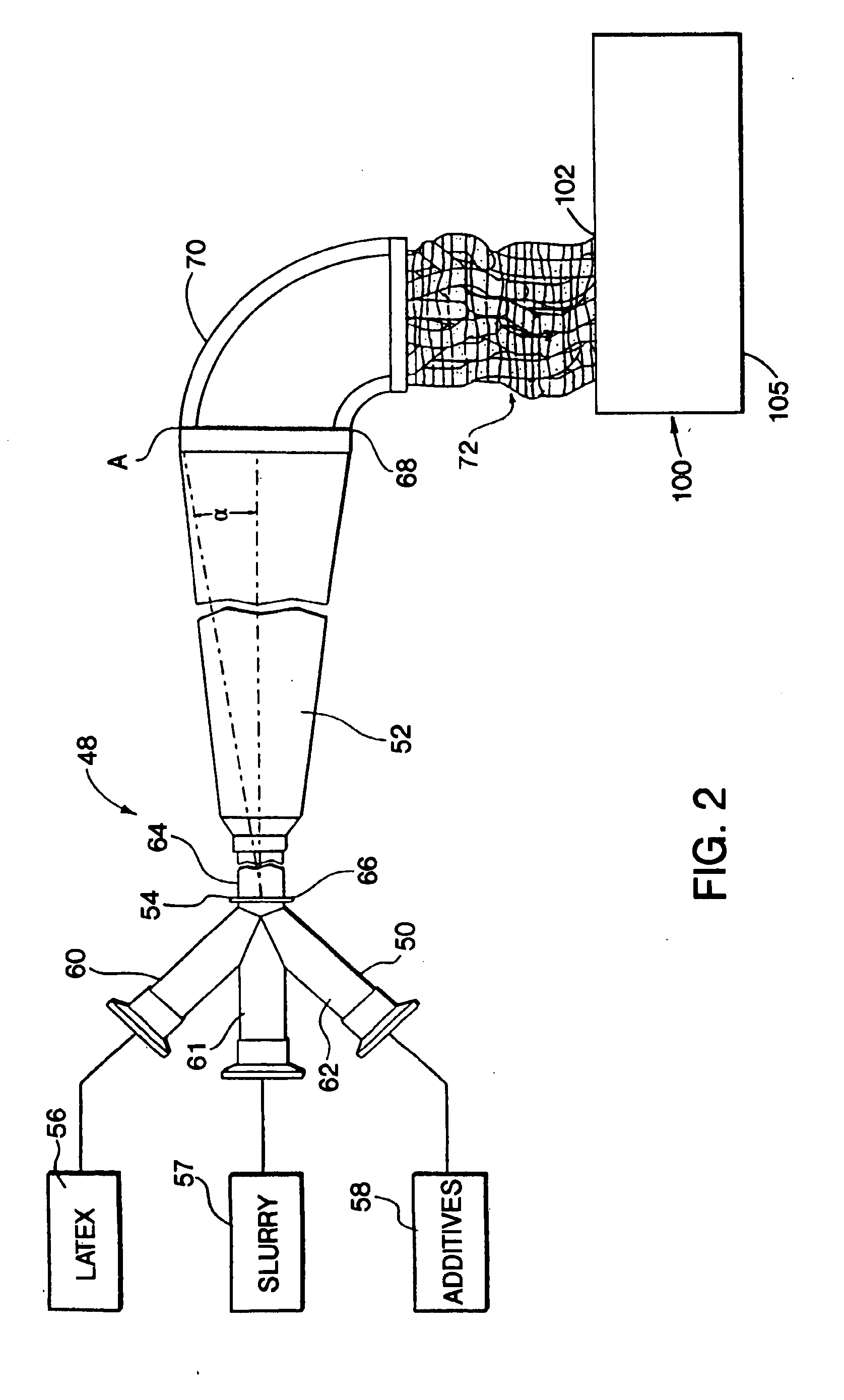

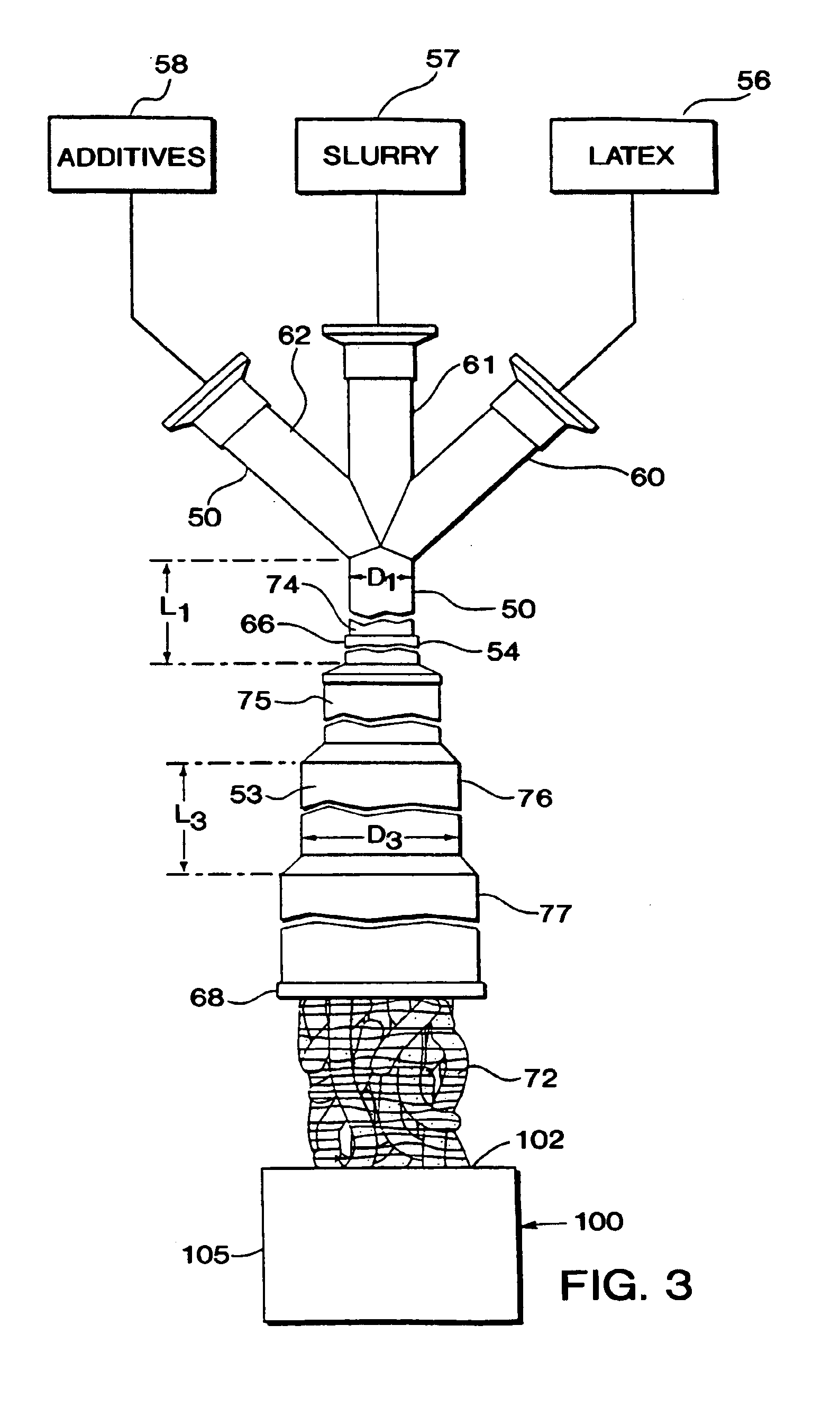

Method and apparatus for producing and treating novel elastomer composites

InactiveUS6929783B2Facilitate controlling and changing operating parameterImprove economyLiquid degasificationSpecial tyresParticulatesMasterbatch

Elastomer masterbatch is processed in a continuous compounder having multiple parallel elongate rotors axially oriented in an elongate processing chamber. Optionally, additional materials are compounded into the masterbatch, e.g., additives, other elastomeric compositions, etc. Preferably, the masterbatch then is further processed in an open mill. Excellent control of Mooney Viscosity is achieved.In certain preferred embodiments, elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a coagulated mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end without need of adding acid or salt solution or other coagulation step. The coagulated elastomer and particulate filler composite is fed into the aforesaid continuous compounder for processing and control of its moisture level and Mooney Viscosity. Novel elastomer composites are produced. Such novel elastomer composites combine material properties and characteristics, such as choice of filler, elastomer, level of filler loading, moisture level, Mooney Viscosity, balance between molecular weight and amount of bound rubber, and macro-dispersion not previously achieved.

Owner:CABOT CORP

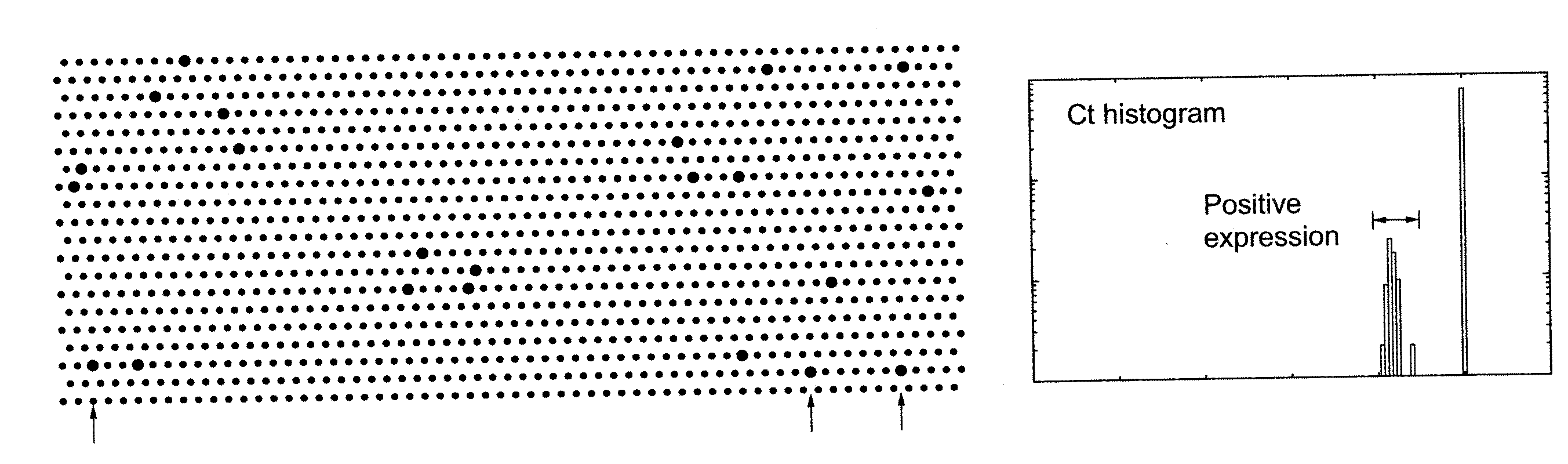

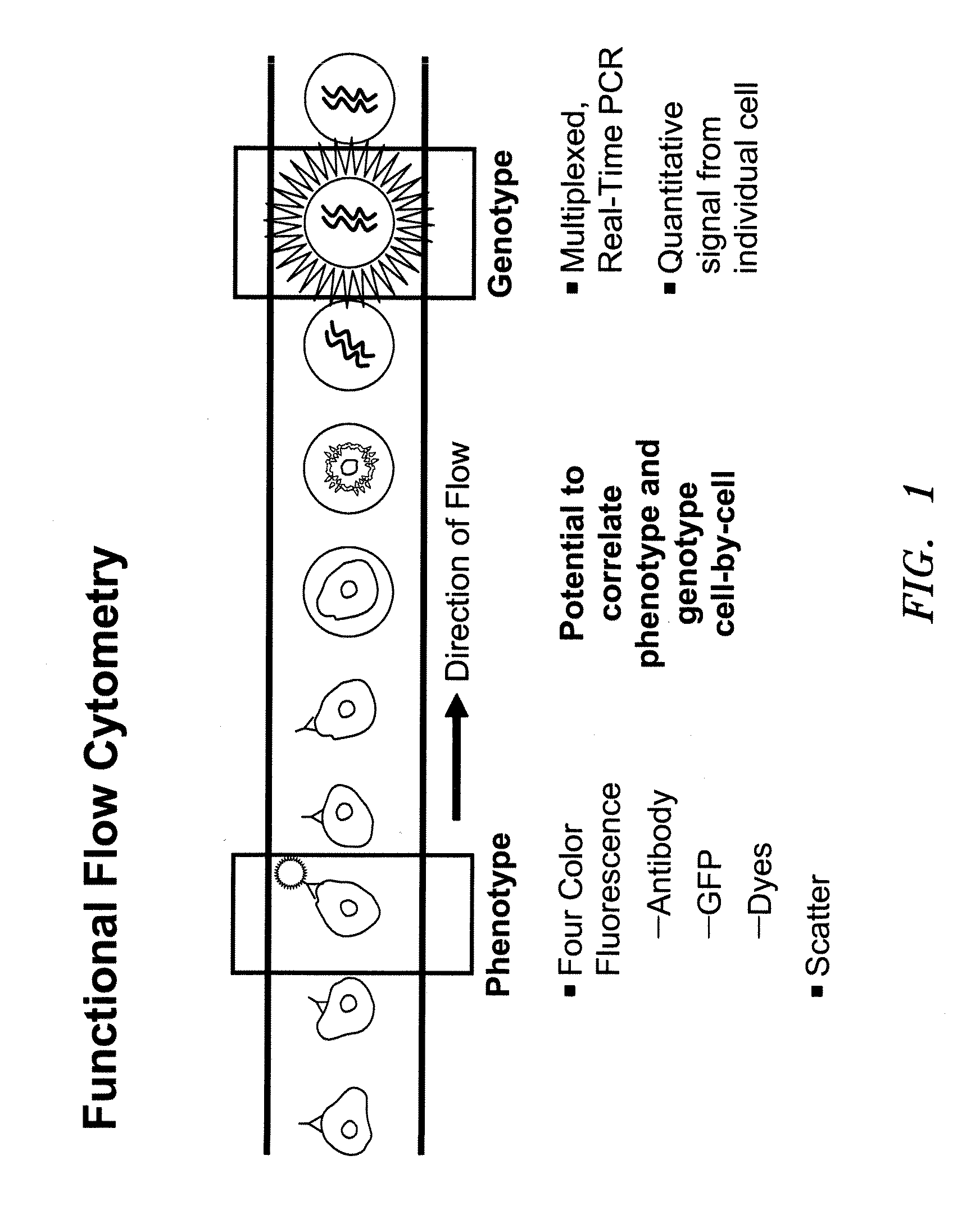

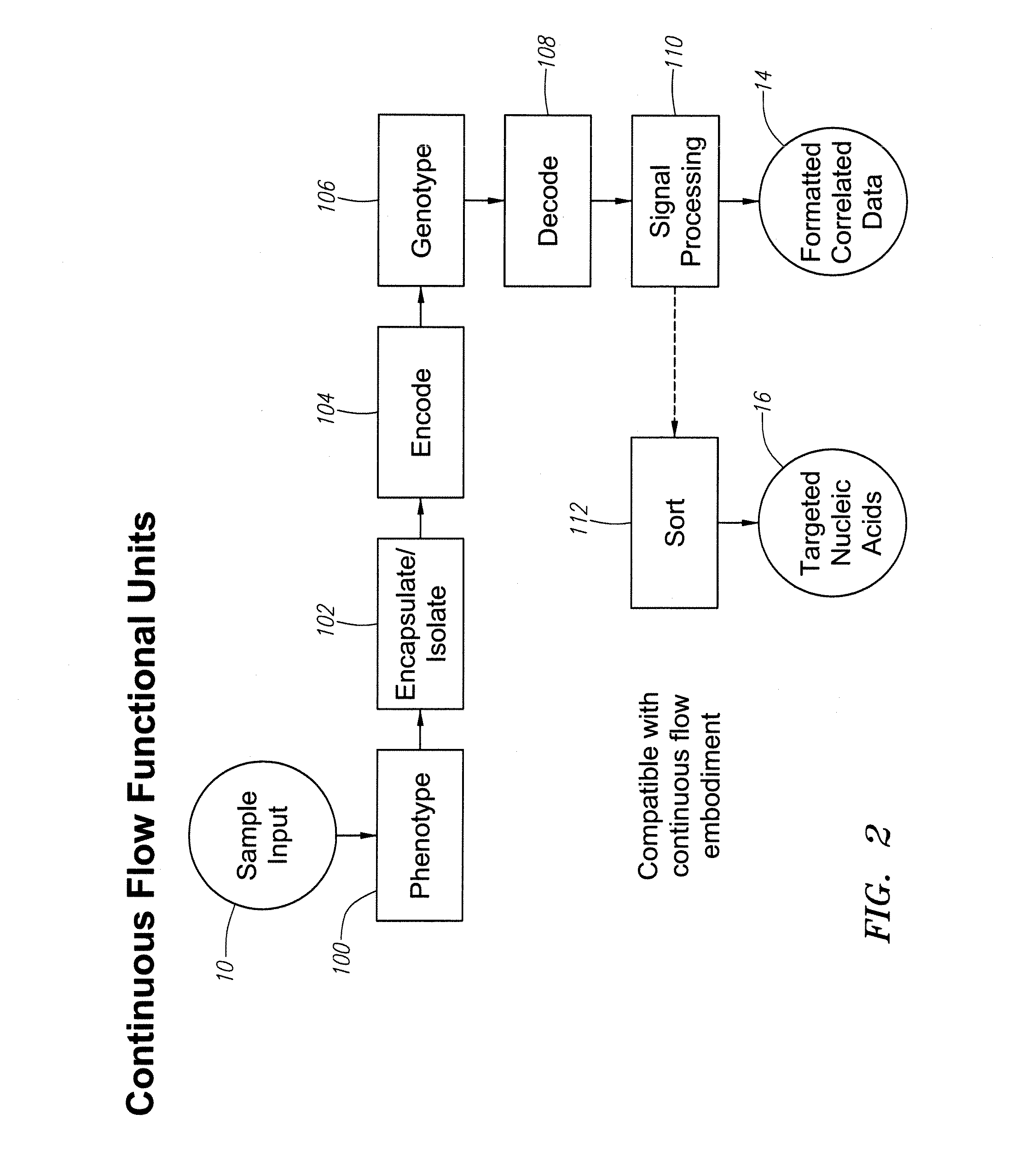

Methods and Devices for Correlated, Multi-Parameter Single Cell Measurements and Recovery of Remnant Biological Material

InactiveUS20090042737A1Reduces number of point of interrogationHeating or cooling apparatusLibrary screeningPhenotype genotypeGenotype Analysis

Methods and apparatus are provided for analysis and correlation of phenotypic and genotypic information for a high throughput sample on a cell by cell basis. Cells are isolated and sequentially analyzed for phenotypic information and genotypic information which is then correlated. Methods for correlating the phenotype-genotype information of a sample population can be performed on a continuous flow sample within a microfluidic channel network or alternatively on a sample preloaded into a nano-well array chip. The methods for performing the phenotype-genotype analysis and correlation are scalable for samples numbering in the hundreds of cells to thousands of cells up to the tens and hundreds of thousand cells.

Owner:PROGENITY INC

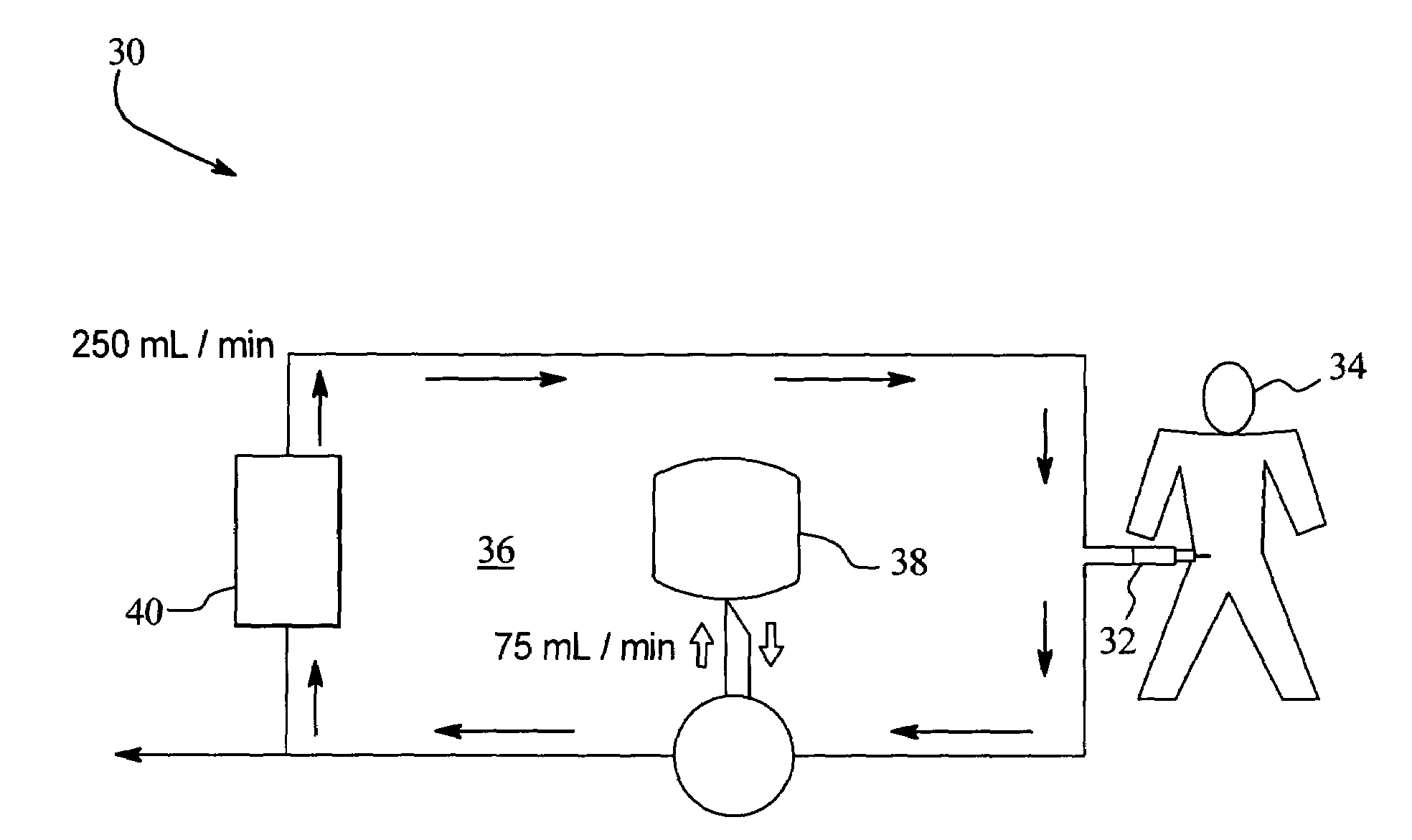

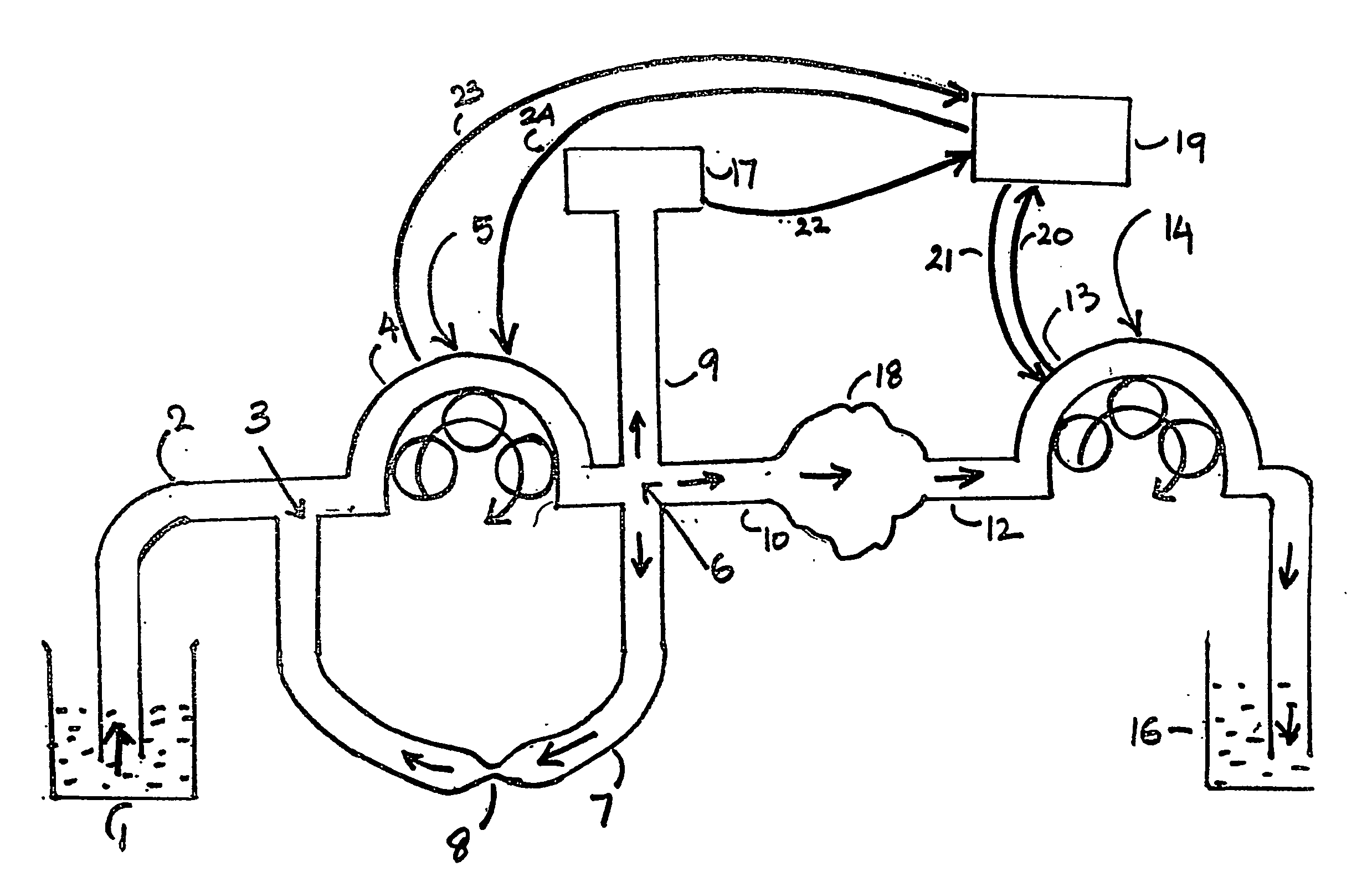

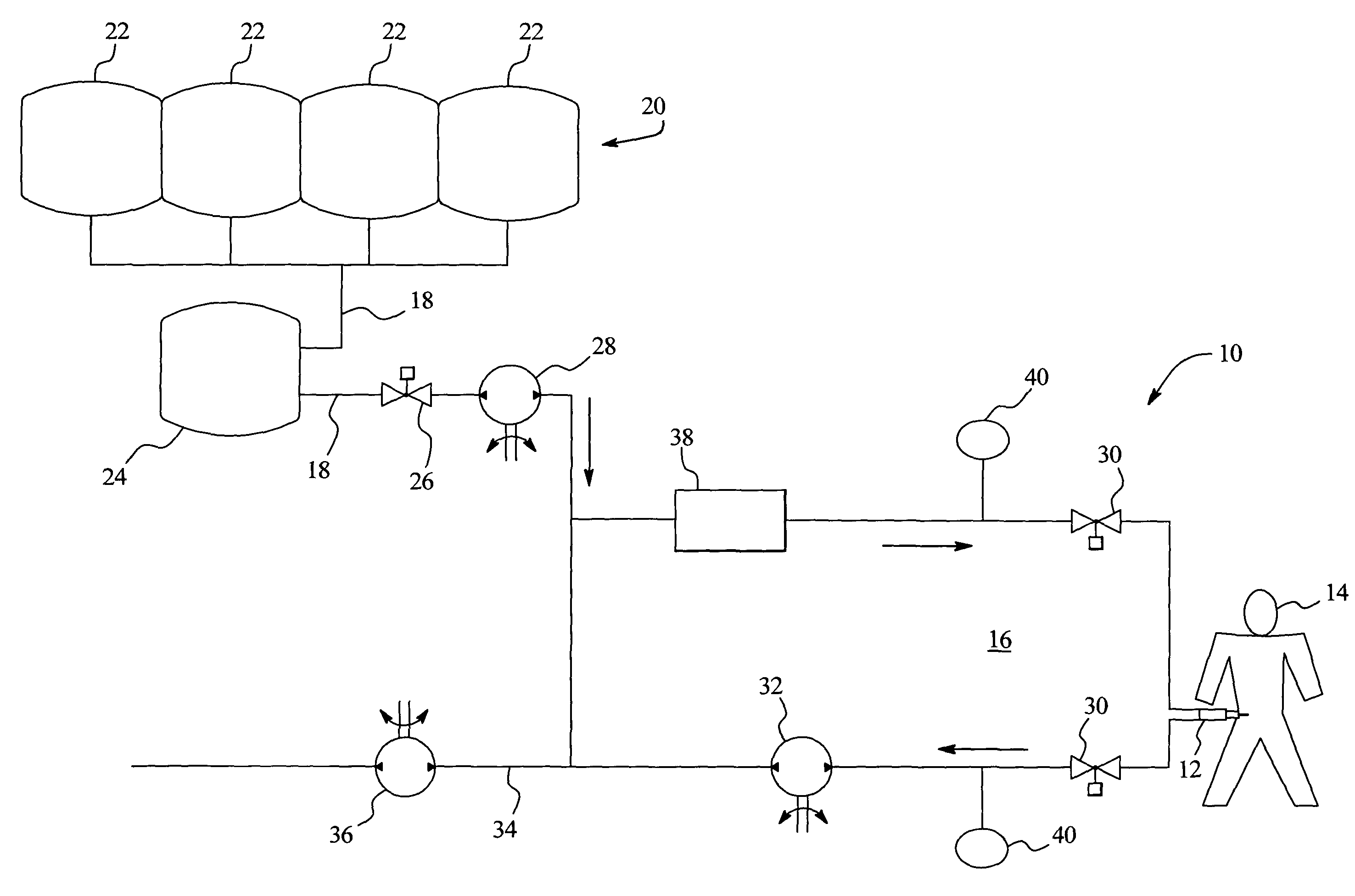

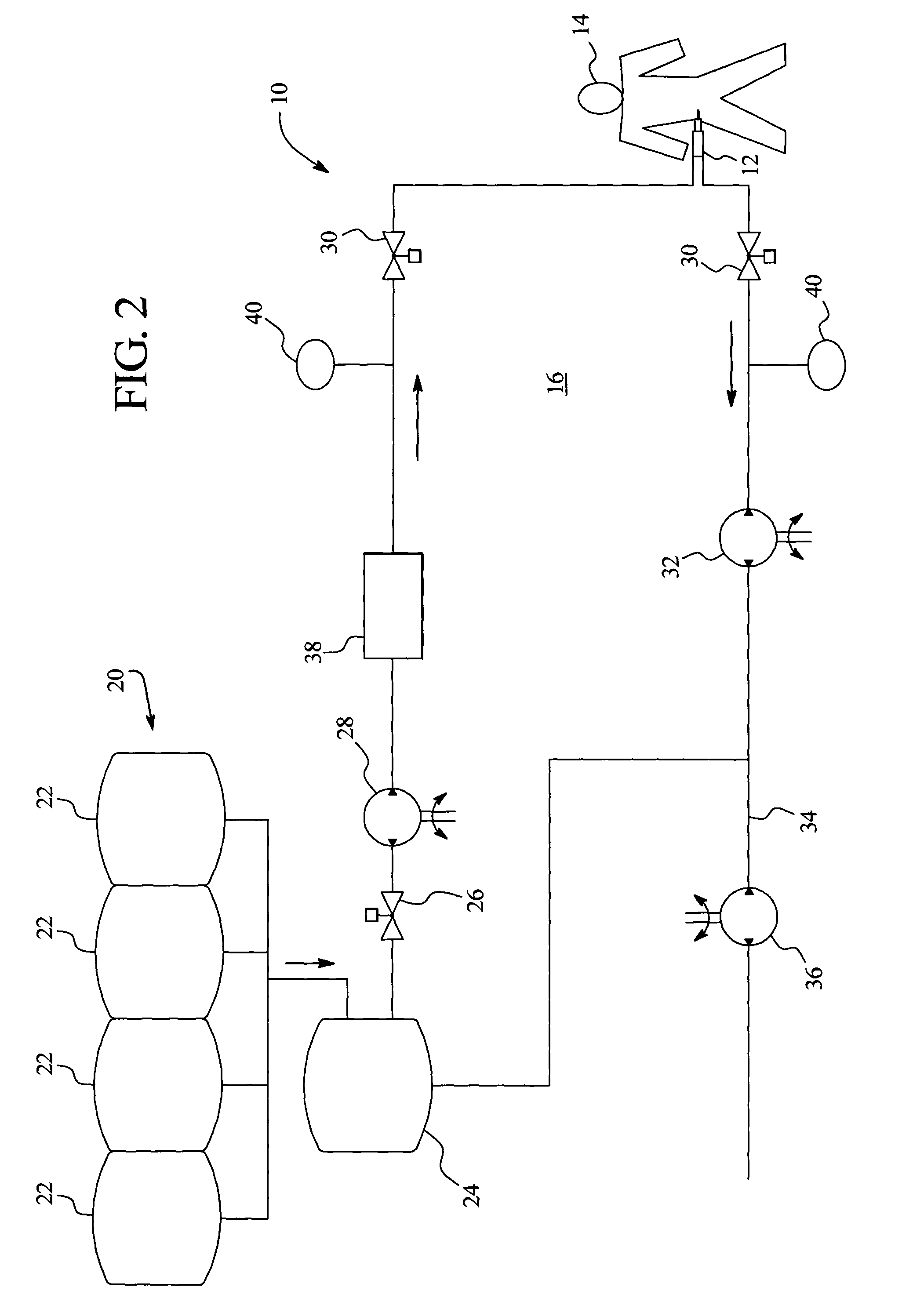

Systems and methods for performing peritoneal dialysis

ActiveUS7922686B2Strengthen the systemImprove methodPeritoneal dialysisProsthesisCycle rateContinuous flow

Systems and methods for providing multiple pass continuous flow dialysis therapy are provided. The present invention includes a fluid circuit connected to a patient via a catheter thereby defining a fluid loop along which a therapy fluid including a dialysate can be continuously circulated into, through and out of a peritoneal cavity of a patient to remove a therapeutically effective amount of excess water and solutes including uremic toxins. The feed rate and discharge rate of therapy fluid into the fluid loop can be controllably regulated in proportion to the circulation rate of fluid in the fluid loop such that the therapy fluid can pass a multiple number of times along the fluid loop prior to discharge.

Owner:BAXTER INT INC +1

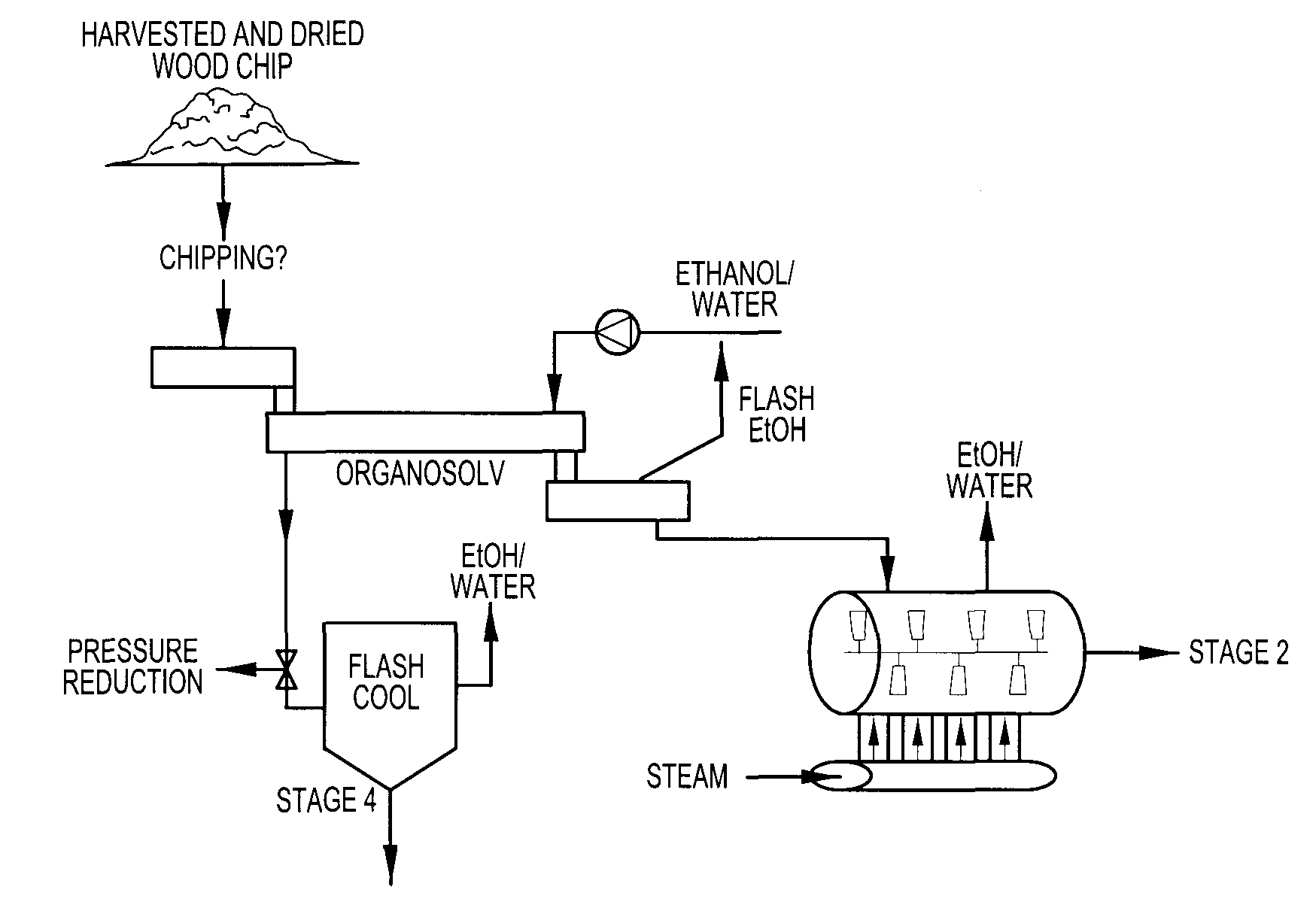

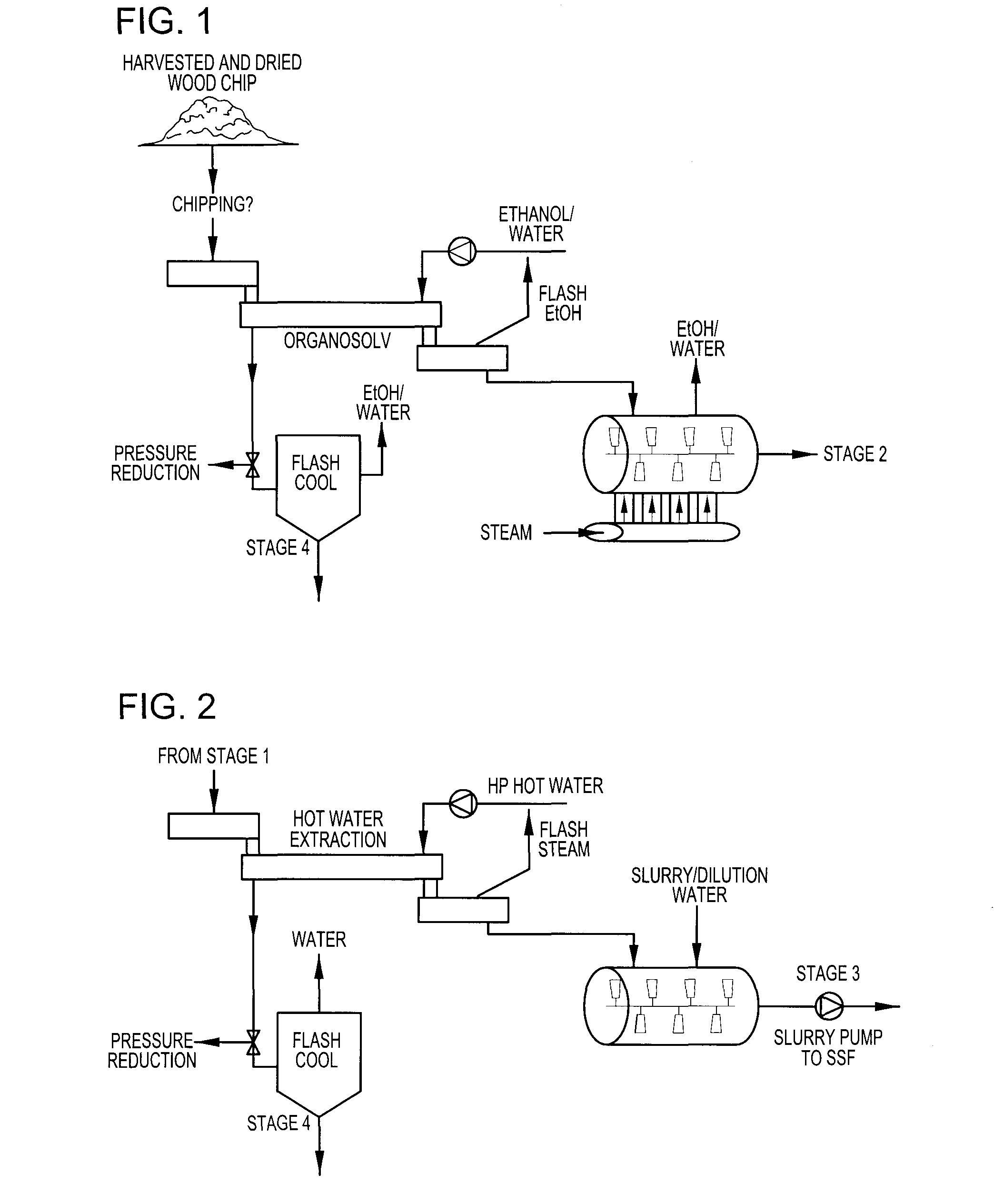

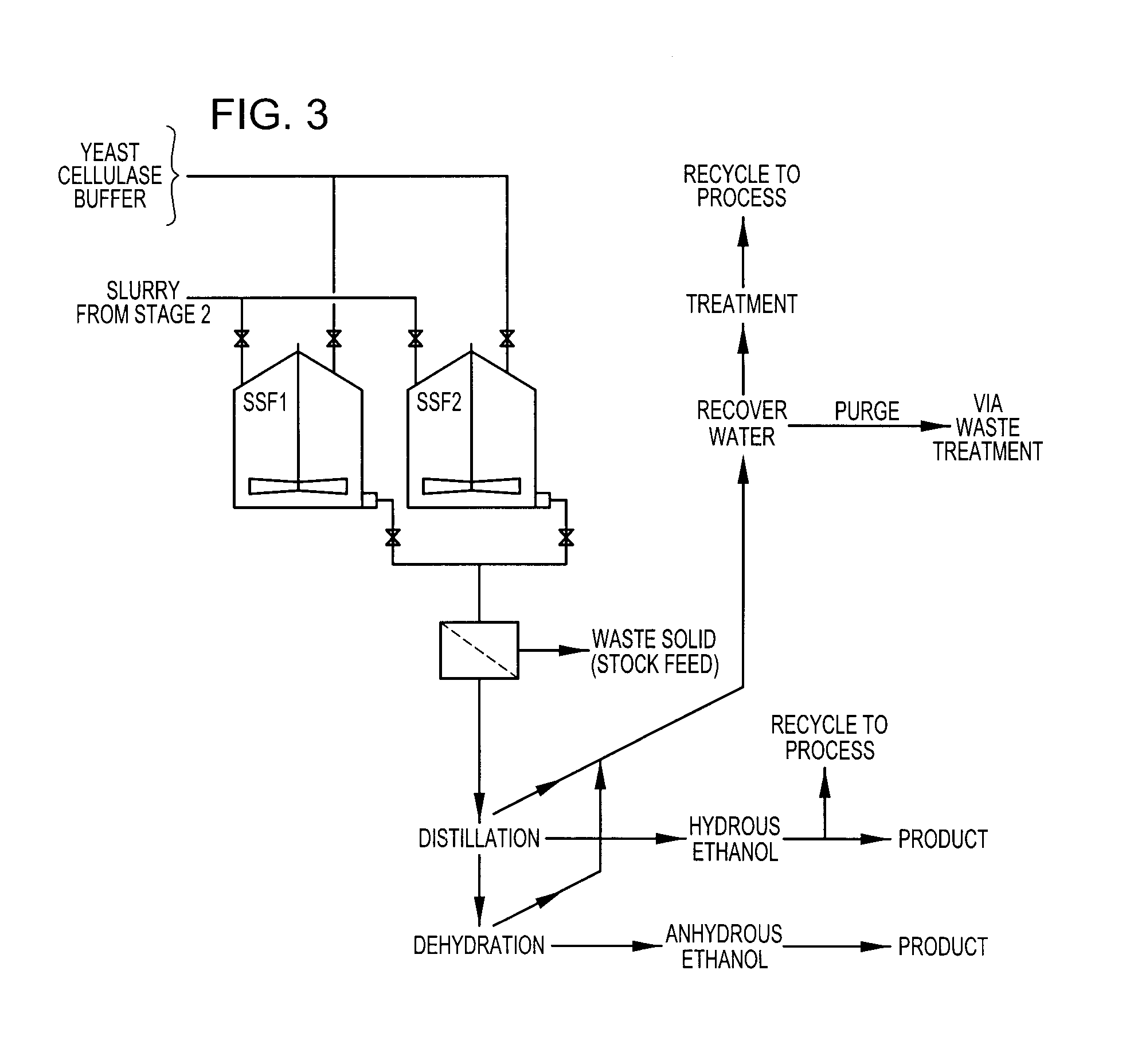

Process for the production of biofuel from plant materials

InactiveUS20070259412A1Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseBiofuel

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com