Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1427 results about "Oil emulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of 'oil-in-water emulsion'. oil-in-water emulsion in the Pharmaceutical Industry. An oil-in-water emulsion is a mixture in which an oily medicine is dispersed in water or other liquid. Small droplets of oil are dispersed in water to create this oil-in-water emulsion.

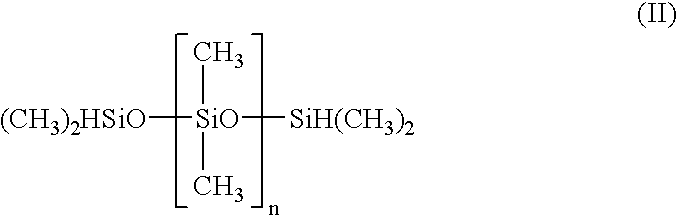

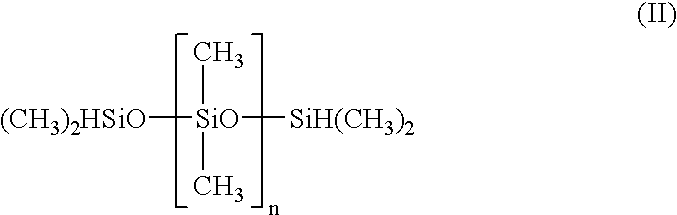

Resilient personal care composition comprising polyalkyl ether containing siloxane elastomers

InactiveUS20100092408A1Improve stabilityGood flexibilityCosmetic preparationsToilet preparationsPersonal careEther

A stable personal care composition in the form of a water-in-oil emulsion may comprise a silicone elastomer comprising a polyalkyl ether pendant or a polyalkyl ether crosslink, wherein the alkyl group contains three or more carbon atoms; a non-emulsifying silicone elastomer; an emulsifier; a polar oil; and water. The personal care composition allows for previously unattainable levels of polar oils and / or aqueous phase within a water-in-oil emulsion.

Owner:THE PROCTER & GAMBLE COMPANY

Hydroxy acids based delivery systems for skin resurfacing and anti-aging compositions

This invention relates to in-situ preparation of the derivatives of various hydroxy acids (HA), such as alpha-(Alpha) Hydroxy Acids (AHA), beta-(Beta) Hydroxy Acids (BHA), and Poly-Hydroxy Acids (PHA) with certain skin beneficial organic hetero-atom bases and their application in skin resurfacing (exfoliation), and in the synergistic treatment and regulation of topical disorders of skin such as skin aging, wrinkles, acne, rosacea, age-spots, canker sores, striae distensae (stretch marks), pimples, skin redness, and dry skin conditions of cracking, flaking, and scaling. Most HA derivatives produced by the in-situ method do not cause skin irritation and skin redness effects that are commonly experienced with AHA and BHA, yet there is no loss of their skin beneficial effects. These compositions can be traditional water and oil emulsions, liposomes, suspensions, colloids, solutions, masks, muds, serums, sprays, gels, lotions, creams, cleansers, and anhydrous systems, thus offering a wide choice of formulations to meet their consumer appeal and acceptance requirements.

Owner:GUPTA SHYAM K

Composition in the form of an oil-in water emulsion containing a silicone copolymer and showing a liquid crystalline phase and uses thereof

InactiveUS7087650B2Good cosmetic effectGood flexibilityCosmetic preparationsHair cosmeticsLiquid crystallineSURFACTANT BLEND

A composition in the form of an oil-in-water emulsion containing, in a physiologically acceptable medium, an oily phase dispersed in an aqueous phase, the aqueous phase containing particles of a noncrosslinked silicone copolymer and at least one amphiphilic surfactant capable of forming liquid crystals.

Owner:LOREAL SA

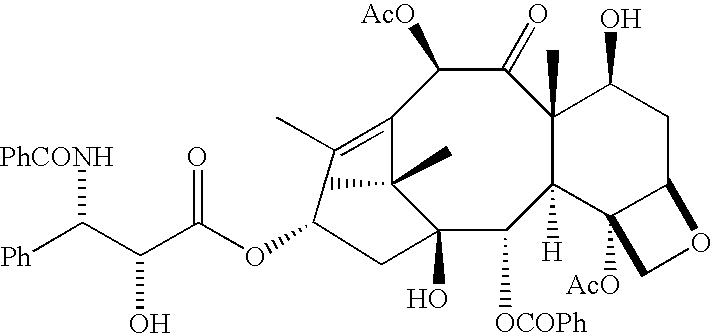

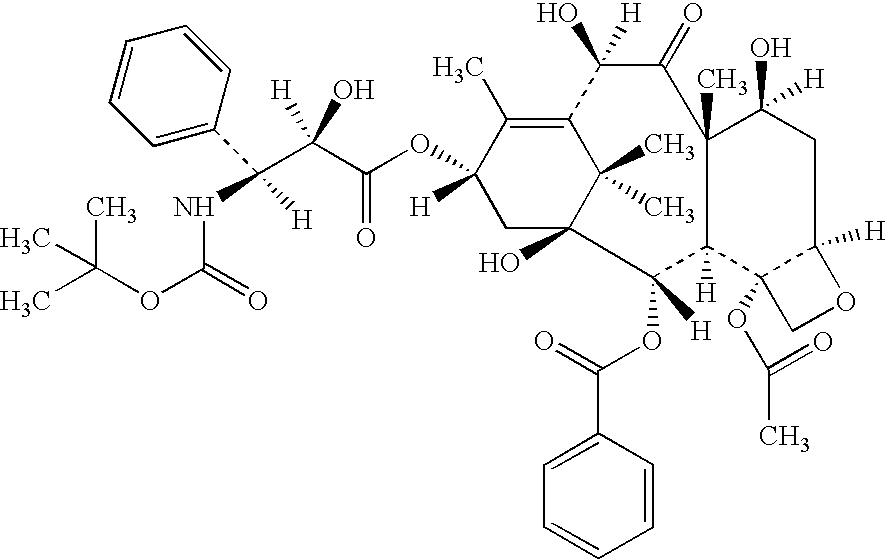

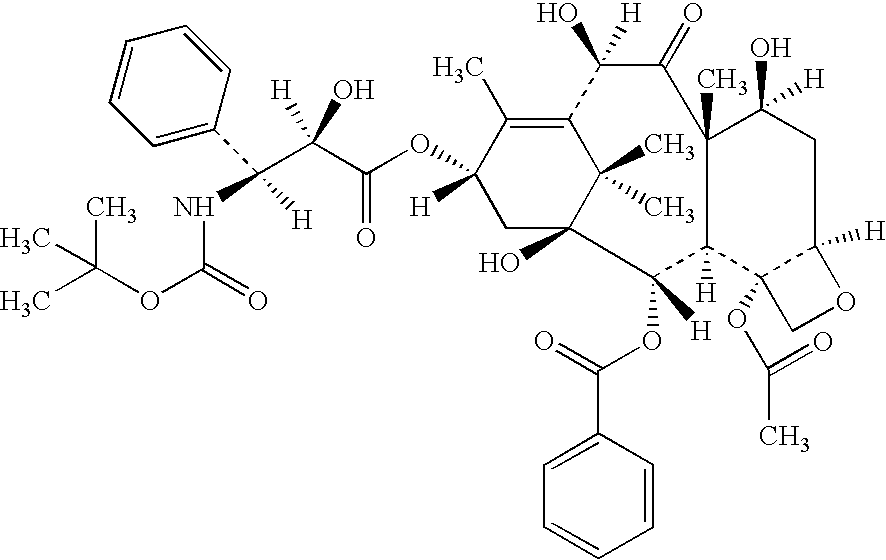

Low oil emulsion compositions for delivering taxoids and other insoluble drugs

ActiveUS20060067952A1Reduce oil contentNot hyperallergenicOrganic active ingredientsBiocideOil emulsionWater insoluble

The present invention provides injectable oil-in-water emulsions of taxoid drugs or other water insoluble drugs. The present invention also provides methods for preparing and using such oil-in-water emulsions.

Owner:CHEN ANDREW XIAN

Oil and oil invert emulsion drilling fluids with improved anti-settling properties

InactiveUS6339048B1Dc level restoring means or bias distort correctionTelephonic communicationEmulsionOrganoclay

This invention is of a drilling fluid composition containing a liquid thixotrope, which thixotrope is free of solvents or any other diluent, and is in easily usable, liquid form, pourable at ambient temperatures, and which provides effective and efficient rheological properties when used at low levels in such compositions. In a specific aspect, the invention provides an oil or oil invert emulsion drilling fluid composition containing one or more organoclays, and in addition contains a additive which comprises the reaction product of an alkoxylated nitrogen containing compound or a diamine, and one or more polycarboxylic acids in a specified equivalent ratio.

Owner:ELEMENTIS SPECIALTIES INC

Method of using water-in-oil emulsion to remove oil base or synthetic oil base filter cake

ActiveUS7481273B2Improve breathabilityHighly efficient in breakingCleaning apparatusScale removal and water softeningParticulatesParaffin wax

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

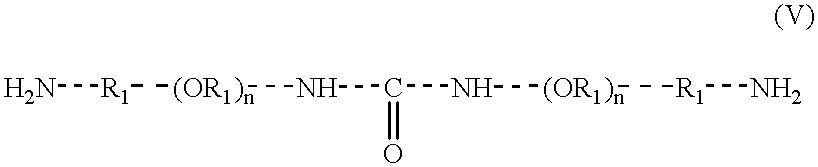

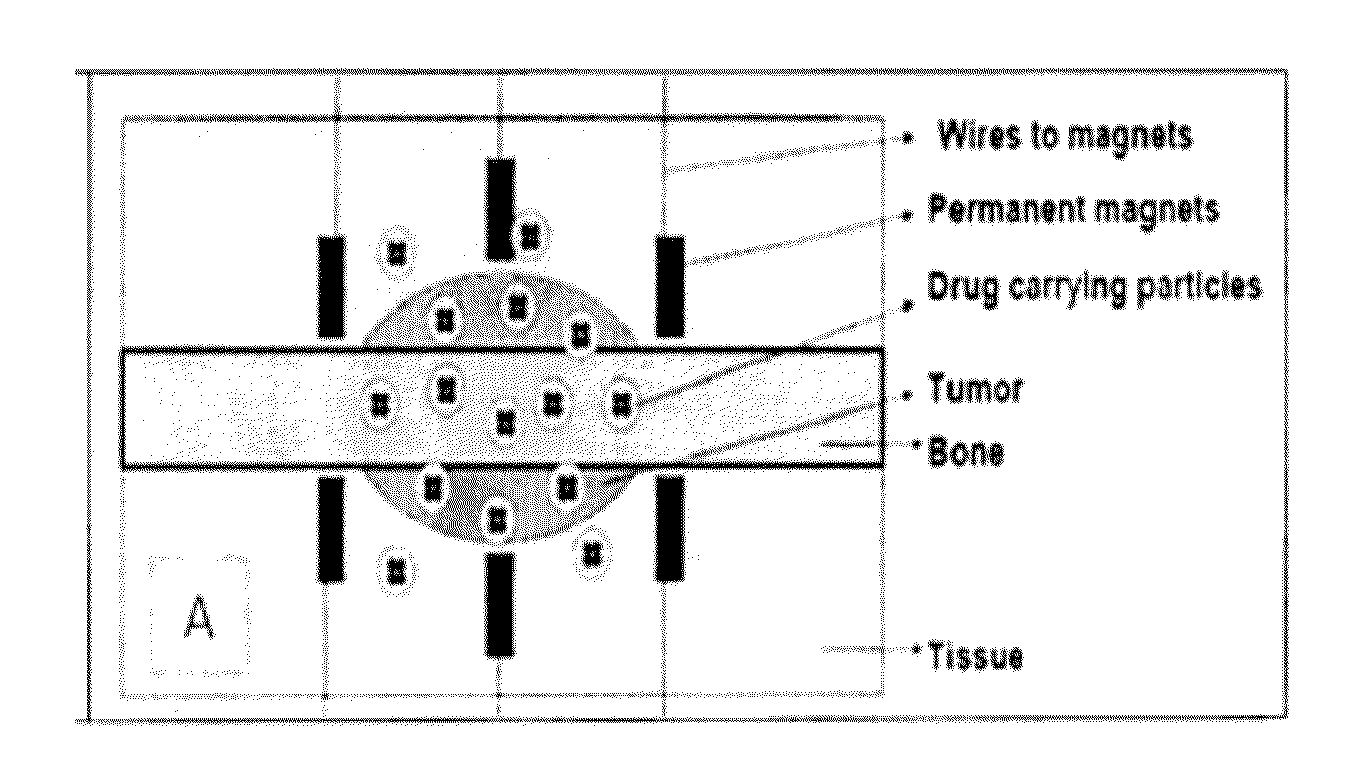

Composite magnetic nanoparticle drug delivery system

ActiveUS20120265001A1Accurate placementLimit deliveryBiocideHeavy metal active ingredientsDiseaseOil emulsion

A composite magnetic nanoparticle drug delivery system provides targeted controlled release chemotherapies for cancerous tumors and inflammatory diseases. The magnetic nanoparticle includes a biocompatible and biodegradable polymer, a magnetic nanoparticle, the biological targeting agent human serum albumin, and a therapeutic pharmaceutical composition. The composite nanoparticles are prepared by oil-in-oil emulsion / solvent evaporation and high shear mixing. An externally applied magnetic field draws the magnetic nanoparticles to affected areas. The biological targeting agent draws the nanoparticles into the affected tissues. Polymer degradation provides controlled time release delivery of the pharmaceutical agent.

Owner:WICHITA STATE UNIVERSITY

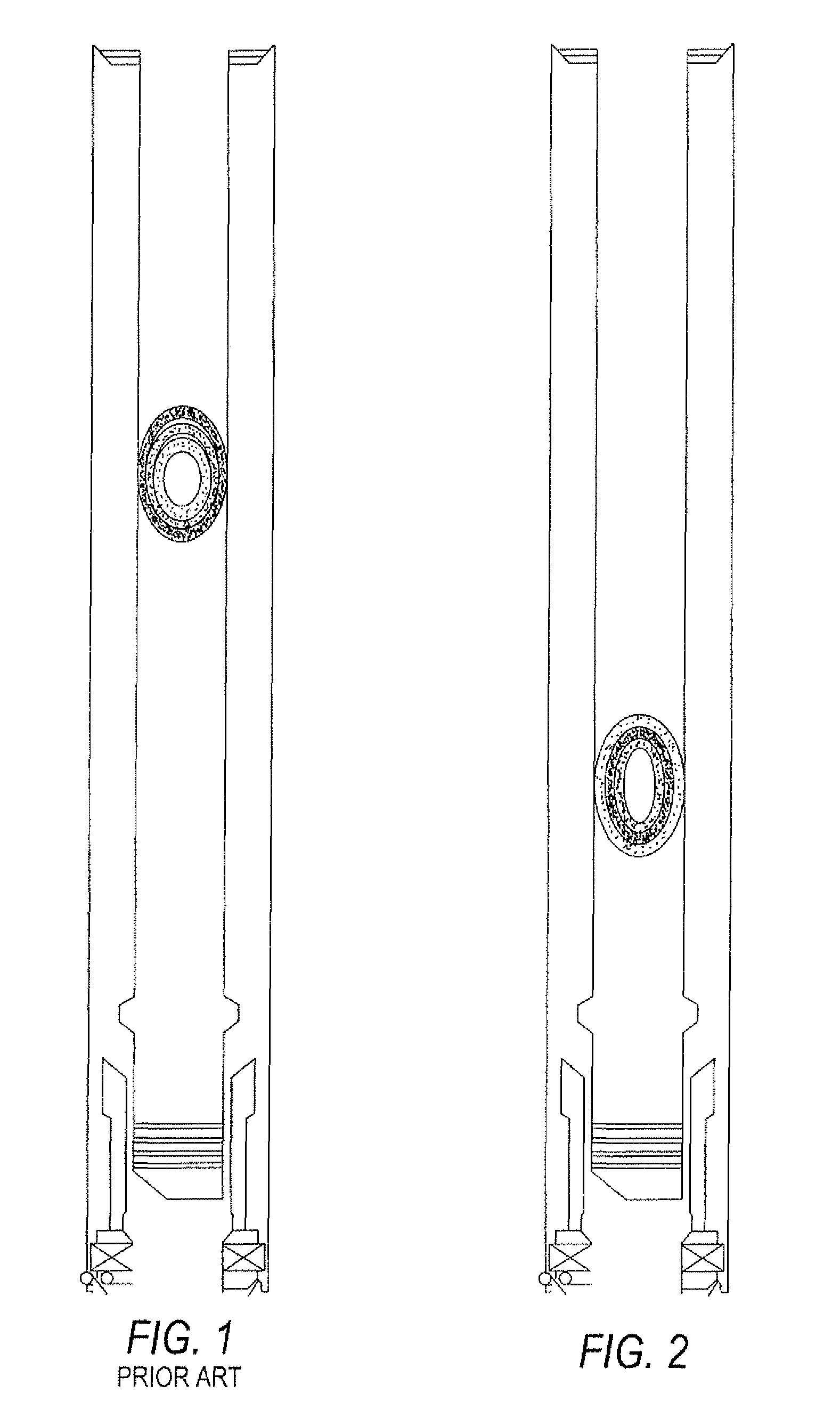

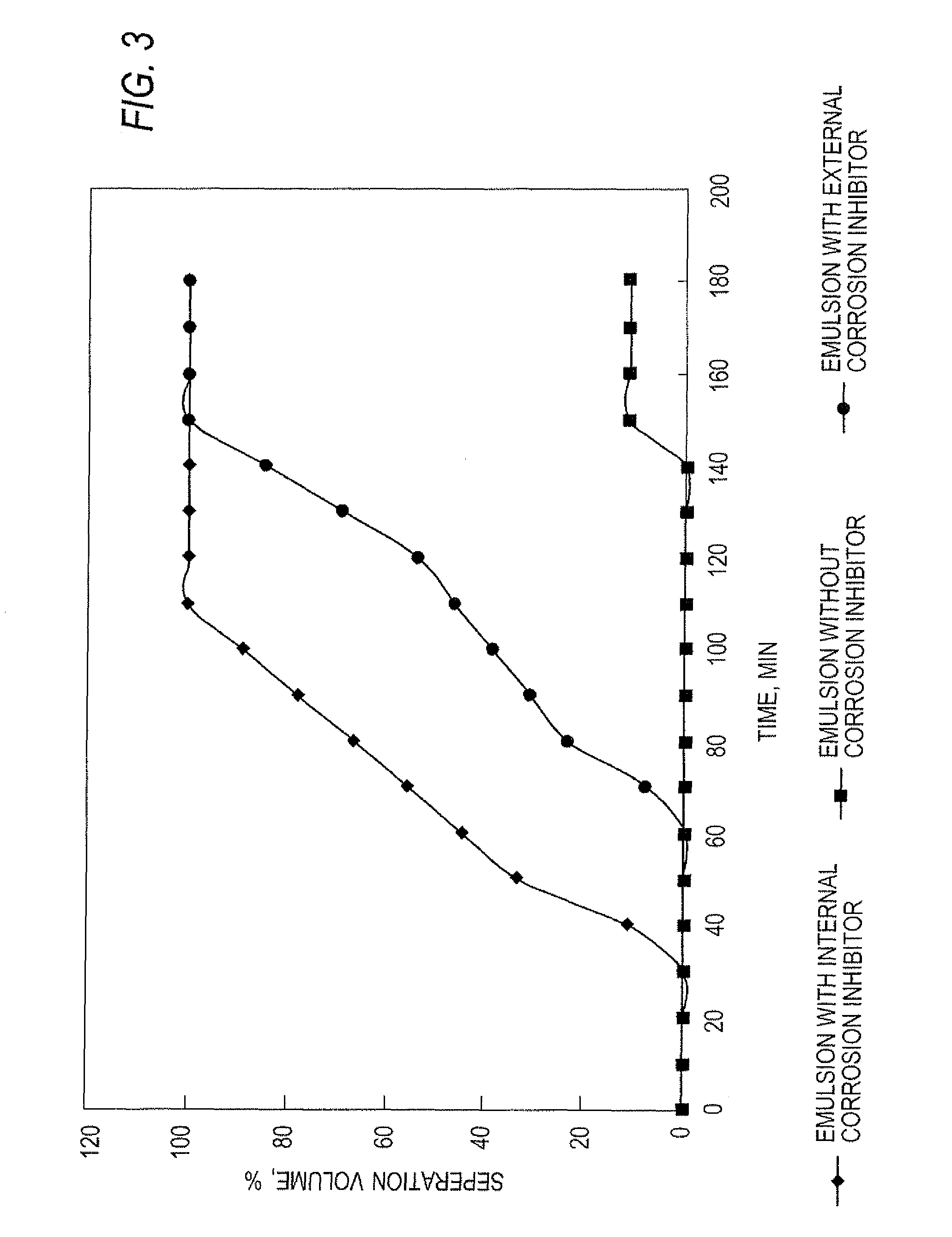

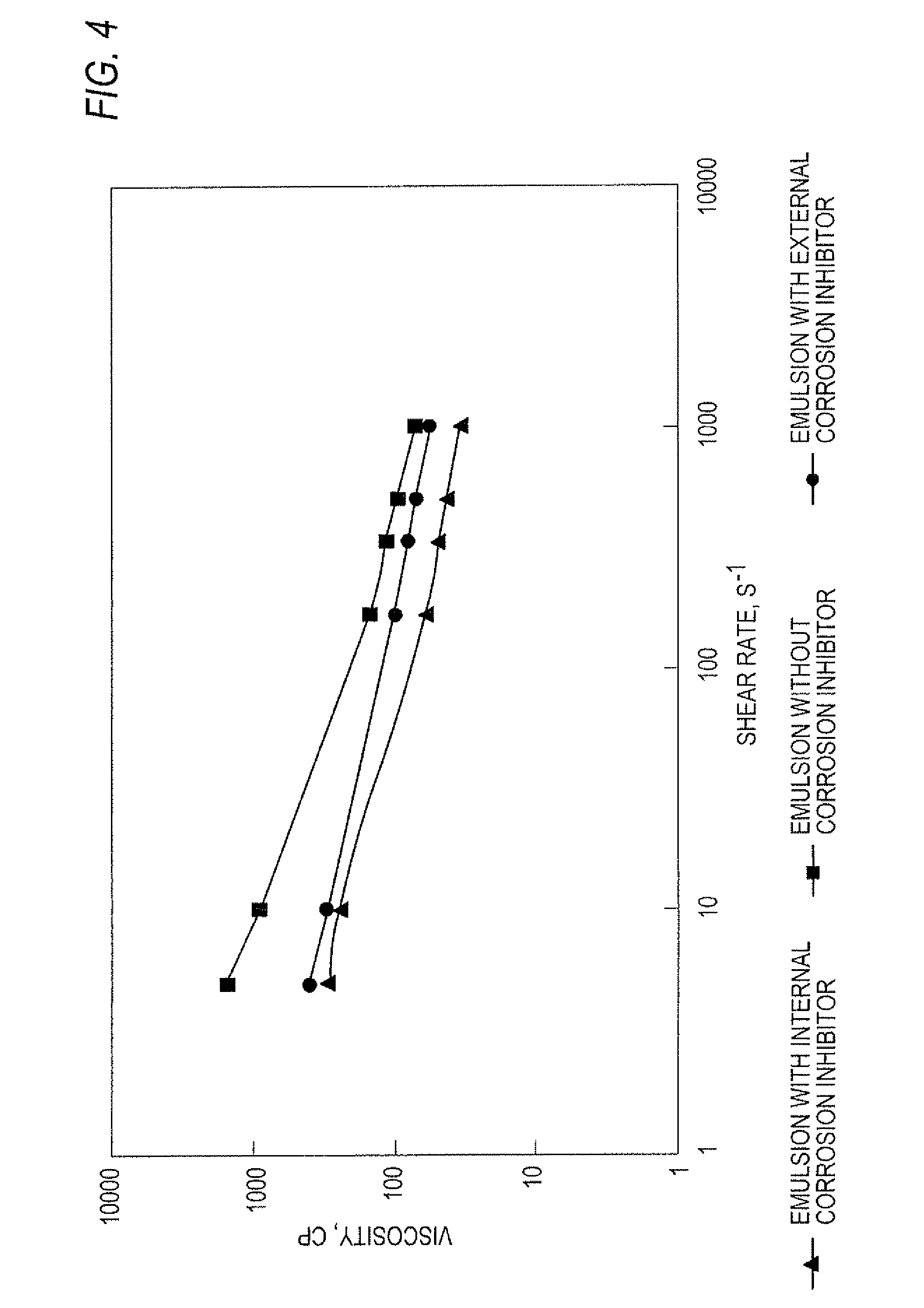

Method of mixing a corrosion inhibitor in an acid-in-oil emulsion

ActiveUS8039422B1Avoid corrosionPromote recoveryOther chemical processesMixing methodsOil emulsionWater in oil emulsion

An acid-in-oil emulsion having a corrosion inhibitor as the external phase has been found to prevent downhole corrosion when acidizing carbonate formations to enhance hydrocarbon recovery.

Owner:SAUDI ARABIAN OIL CO

Cationic oil-in-water emulsions

ActiveUS20120156251A1Promote particle formationImprove skin toneAntibacterial agentsOrganic active ingredientsAntigenOil emulsion

This invention generally relates to cationic oil-in-water emulsions that can be used to deliver negatively charged molecules, such as an RNA molecule. The emulsion particles comprise an oil core and a cationic lipid. The cationic lipid can interact with the negatively charged molecule thereby anchoring the molecule to the emulsion particles. The cationic emulsions described herein are particularly suitable for delivering nucleic acid molecules (such as an RNA molecule encoding an antigen) to cells and formulating nucleic acid-based vaccines.

Owner:GLAXOSMITHKLINE BIOLOGICALS SA

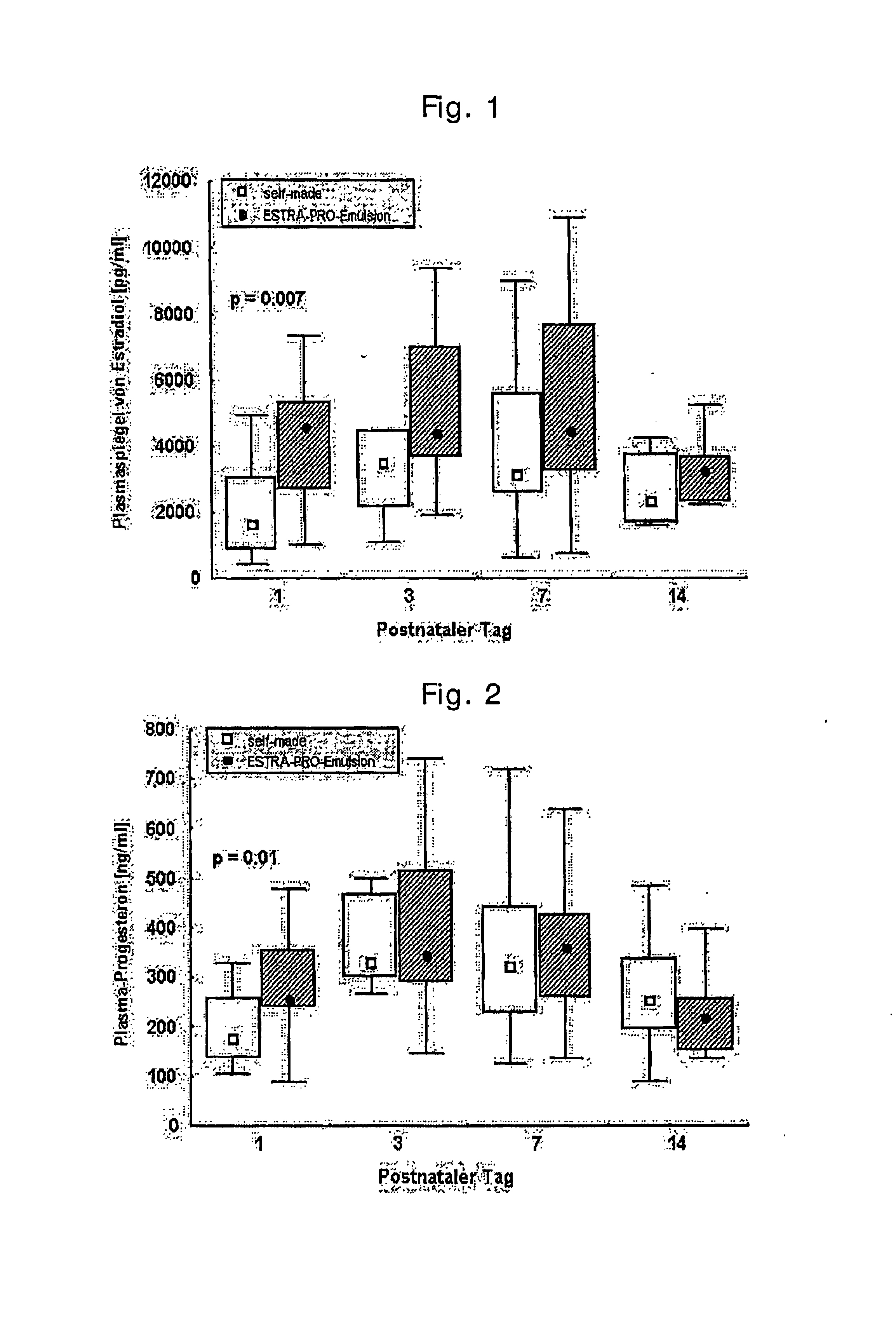

Oil emulsion for postnatal hormone substitution

InactiveUS20070071777A1High serum levelImprove usabilityBiocideOrganic active ingredientsLipid formationVein

The invention relates to a process for the preparation of hormone-containing oil emulsions (lipid emulsions), an isotonic oil emulsion obtainable by such process, and the use of the emulsion according to the invention for the preparation of a medicament for intravenous administration, especially for postnatal hormone substitution in premature babies and for the treatment of neurological damage after strokes.

Owner:B BRAUN MELSUNGEN AG

Stability enhanced water-in-oil emulsion and method for using same

InactiveUS7186673B2Improve stabilityImprove emulsion stabilityOther chemical processesMixing methodsWater in oil emulsionPre treatment

A method for enhancing the stability of a water-in-oil emulsion pretreating at least a portion of the oil prior to emulsification. The pretreatment step may consist of adding polymers to the oil, biotreating the oil, photochemically treating the oil, or combinations thereof. The emulsion may be used in various enhanced oil recovery methods including using the emulsion as a flooding agent to displace hydrocarbons in a subterranean formation, and using the emulsion as a barrier fluid for diverting flow of fluids in the formation.

Owner:EXXONMOBIL UPSTREAM RES CO

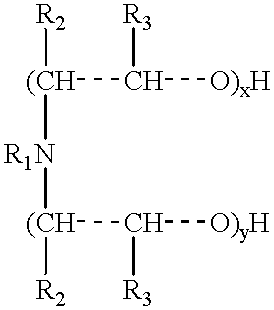

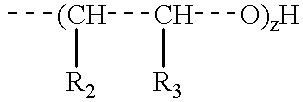

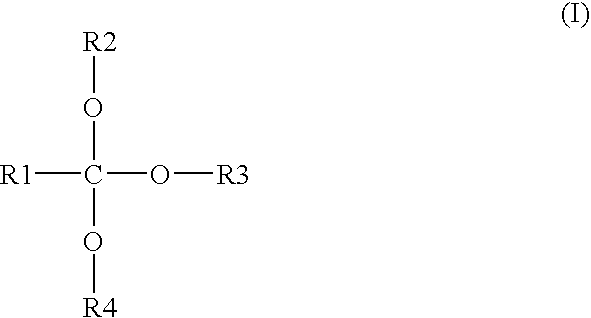

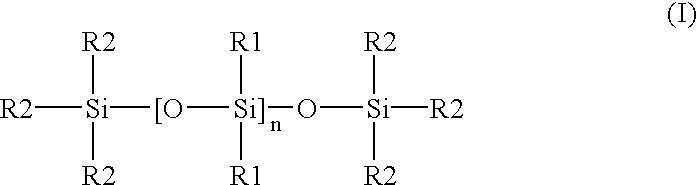

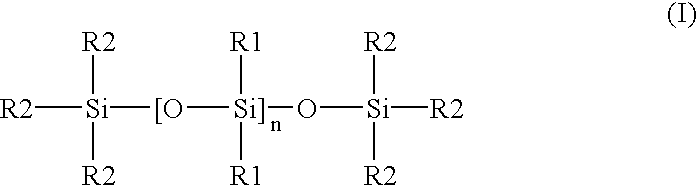

Environmentally-friendly oil/water demulsifiers

ActiveUS20090209666A1Cosmetic preparationsDewatering/demulsification with chemical meansDemulsifierHydrogen

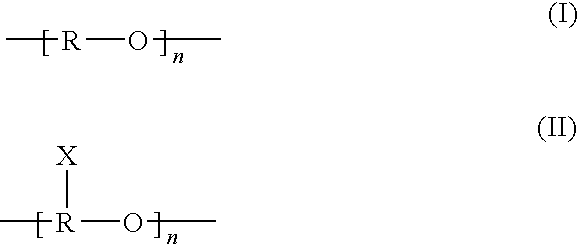

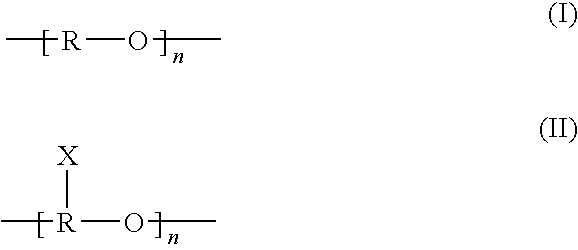

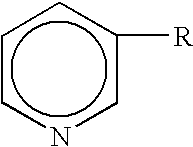

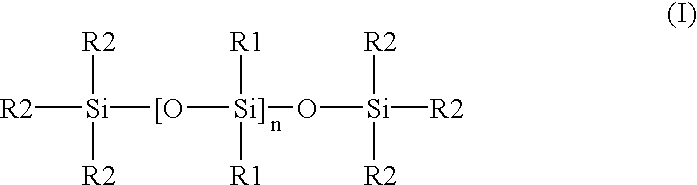

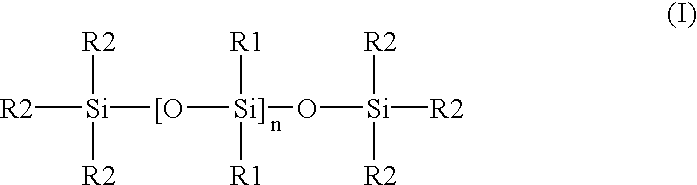

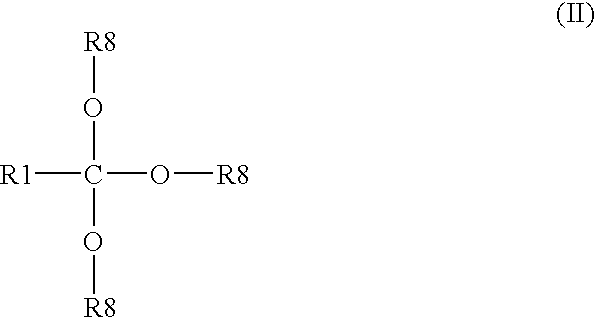

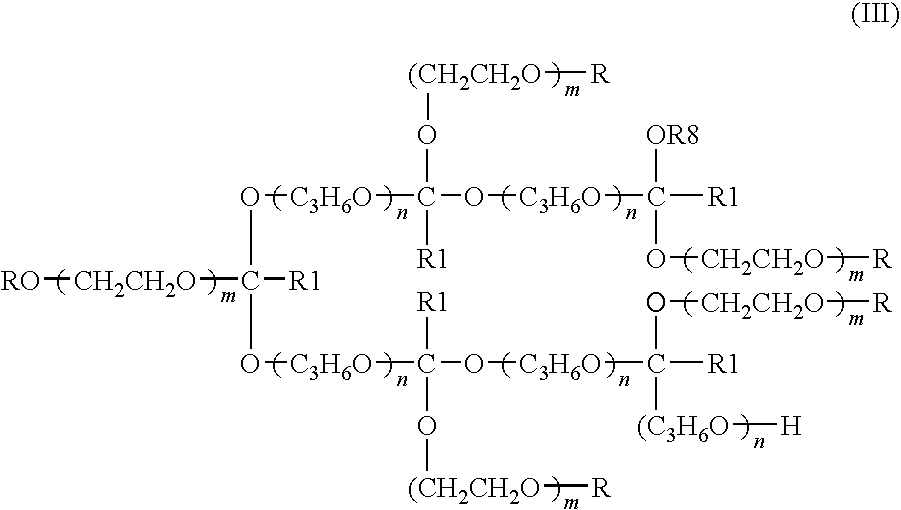

The invention relates to particular orthoester based polymers as well as the use of specific orthoester based polymers as a demulsifier for water / oil emulsions. Products suitable for use according to the invention have the formula (I), wherein R1 is hydrogen or a hydrocarbyl group with 1-4 carbon atoms, R2, R3, and R4 are, independently, a group comprising C3-C4 alkyleneoxy groups and / or ethyleneoxy groups in any order, and an end group Y, which is, independently, hydrogen, a hydrocarbyl group with 1-30 carbon atoms, a group —(CH2)zNR5R6 or —(CH2)zN+R5R6R7, wherein each of R5, R6, and R7 is, independently, an alkyl group with 1-22 carbon atoms or —CH2CH2OH, and z is 2 or 3, provided that at least one of the groups R2, R3, and R4 comprises at least one block of at least on then average 4 alkyleneoxy groups with 3 and / or 4 carbon atoms, and provided that if Y is hydrogen, then at least one of n and m is a number of 1-100, or a di- or polycondensate of the polymer via free hydroxyl groups in R2, R3 or R4.

Owner:AKZO NOBEL CHEM INT BV

Inspissated oil emulsion viscidity reducer

ActiveCN1778862AStrong resistance to mineral saltHigh emulsifying colloidDrilling compositionPhosphateOil emulsion

A thickened oil emulsifying viscosity reducer consists of anion surface activator, non-ionic-anion surface activator, demulsifier and water in proportion by 1:0.1-50:0.01-20 and water content is 0.2-5000 times of the sum of a, b and c. Anion surface activator comprises sodium salt and calcium salt of petroleum sulfoacid salt methyl condensate and sulfonated lignin; non-ionic-anion surface activator is chosen organic phosphate salt, sulfuric ester salt , carboxylate and sulfosalt of alkylphenol or fatty alcohol-polyoxyethylene ether; demulsifier is copolymer of alkyl ammonium halide cation demulsifier, polyethylene glycol polyoxytrimethylene polylol ether non-ionic demulsifier or polyethylene glycol polyoxytrimethylene polyethylene polyamines block. It has strong emulsifying ability and low thickened oil viscosity,

Owner:CHINA PETROLEUM & CHEM CORP +1

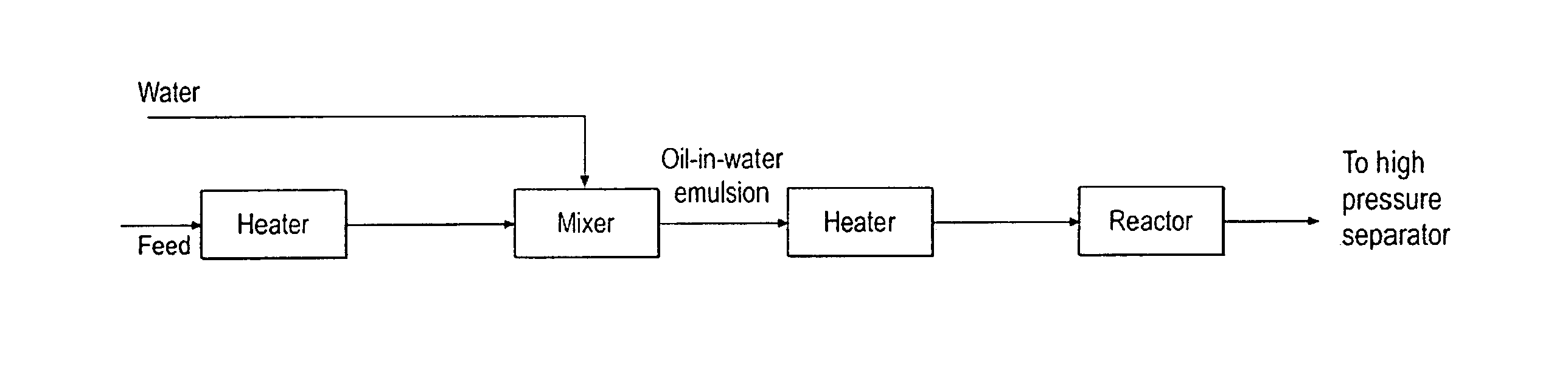

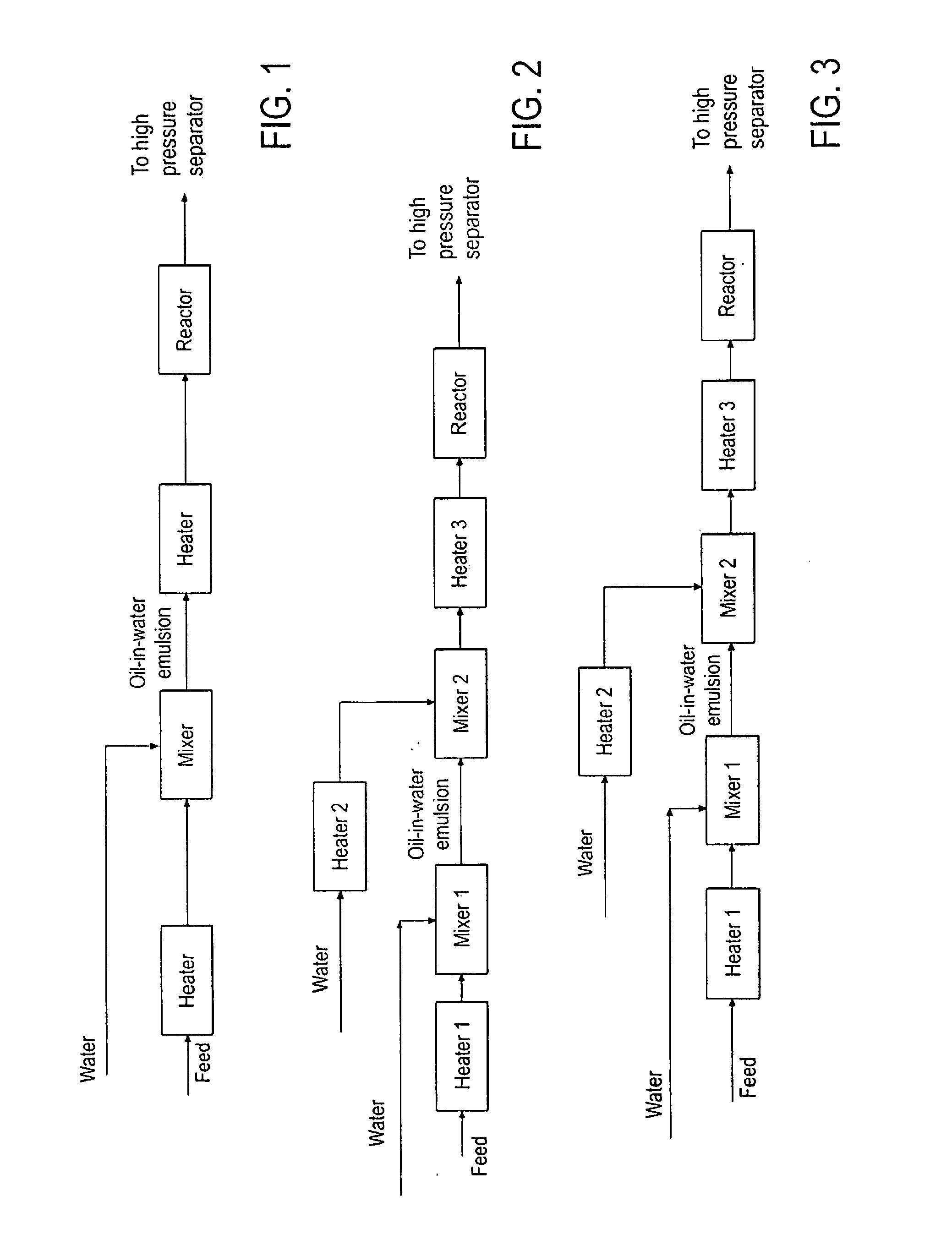

Upgrading heavy hydrocarbon oils

A process using supercritical water-oil emulsion to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is disclosed. The process does not require external supply of hydrogen nor does it use externally supplied catalysts.

Owner:CHEVROU USA INC

Method for displacing oil base drilling muds and/or residues from oil base drilling mud using water-in-oil emulsion

ActiveUS7188676B2Improve breathabilityEfficacious in displacingCleaning apparatusFluid removalParticulatesParaffin wax

Fluid producing wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted solid particulates, including pipe dope, asphaltenes and paraffins. Such emulsions are of particular applicability in the displacement of oil base drilling muds and / or residues from such muds from producing wells. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

Paper softening compositions containing low levels of high molecular weight polymers and soft tissue paper products comprising said compositions

Disclosed is a composition suitable for atomizing without excessive aerosolization in the form of an oil-in-water emulsion comprising: a) a continuous aqueous phase, and b) a discontinuous oil phase wherein the rheology of the aqueous phase is modified by the addition of a water-in-oil emulsion comprising: i) a high molecular weight polymer in a discontinuous aqueous phase, and ii) a continuous organic solvent phase. Preferred embodiments of the present invention relate to compositions for softening an absorbent paper tissue comprising a) a quaternary ammonium softening active ingredient; b) an electrolyte; c) a high molecular weight polymer emulsion comprising: i) from about 20% to about 40% by weight of the premix of a high molecular weight polymer; ii) from about 40% to about 60% of water; and iii) from about 20% to about 40% of an organic solvent; and d) a vehicle in which said softening active ingredient is dispersed.

Owner:THE PROCTER & GAMBLE COMPANY

Composition in the form of an oil-in water emulsion containing a silicone copolymer and showing a liquid crystalline phase and uses thereof

InactiveUS20030105169A1Texture applicationGood cosmetic effectCosmetic preparationsHair cosmeticsLiquid crystallineSURFACTANT BLEND

A composition in the form of an oil-in-water emulsion containing, in a physiologically acceptable medium, an oily phase dispersed in an aqueous phase, the aqueous phase containing particles of a noncrosslinked silicone copolymer and at least one amphiphilic surfactant capable of forming liquid crystals.

Owner:LOREAL SA

Oil emulsion

[Object] To provide an oil emulsion which can be readily ignited using a conventional, commercially available burner without need of a specific type of device and which has a high ratio of water to an oil and is inexpensive.[Solving Means] An oil emulsion is obtained by mixing under agitation an oil, an emulsifier and a specific type of water obtained by initially passing water through an ion exchange resin, passing either tourmaline or a silicon dioxide-rich rock selected among igneous rocks and further passing the other. The oil emulsion obtained by mixing the oil, the emulsifier and the water is inexpensive and is able to maintain a stable emulsified state.

Owner:FUKAI TOSHIHARU

Acid-in-oil emulsion compositions and methods for treating hydrocarbon-bearing formations

Disclosed herein is an acid-in-oil emulsion composition comprising an emulsifying agent; a dispersion agent; a base oil; and an acid, wherein the acid-in-oil emulsion composition is substantially devoid of priority pollutants. Disclosed herein too is a method for treating a hydrocarbon-bearing formation comprising blending an emulsifying agent, a base oil and an acid to produce an acid-in-oil emulsion, the acid-in-oil emulsion being substantially devoid of priority pollutants; and discharging the acid-in-oil emulsion into a downhole hydrocarbon-bearing well formation, where the acid-in-oil emulsion is operative to stimulate hydrocarbon production.

Owner:BAKER HUGHES INC

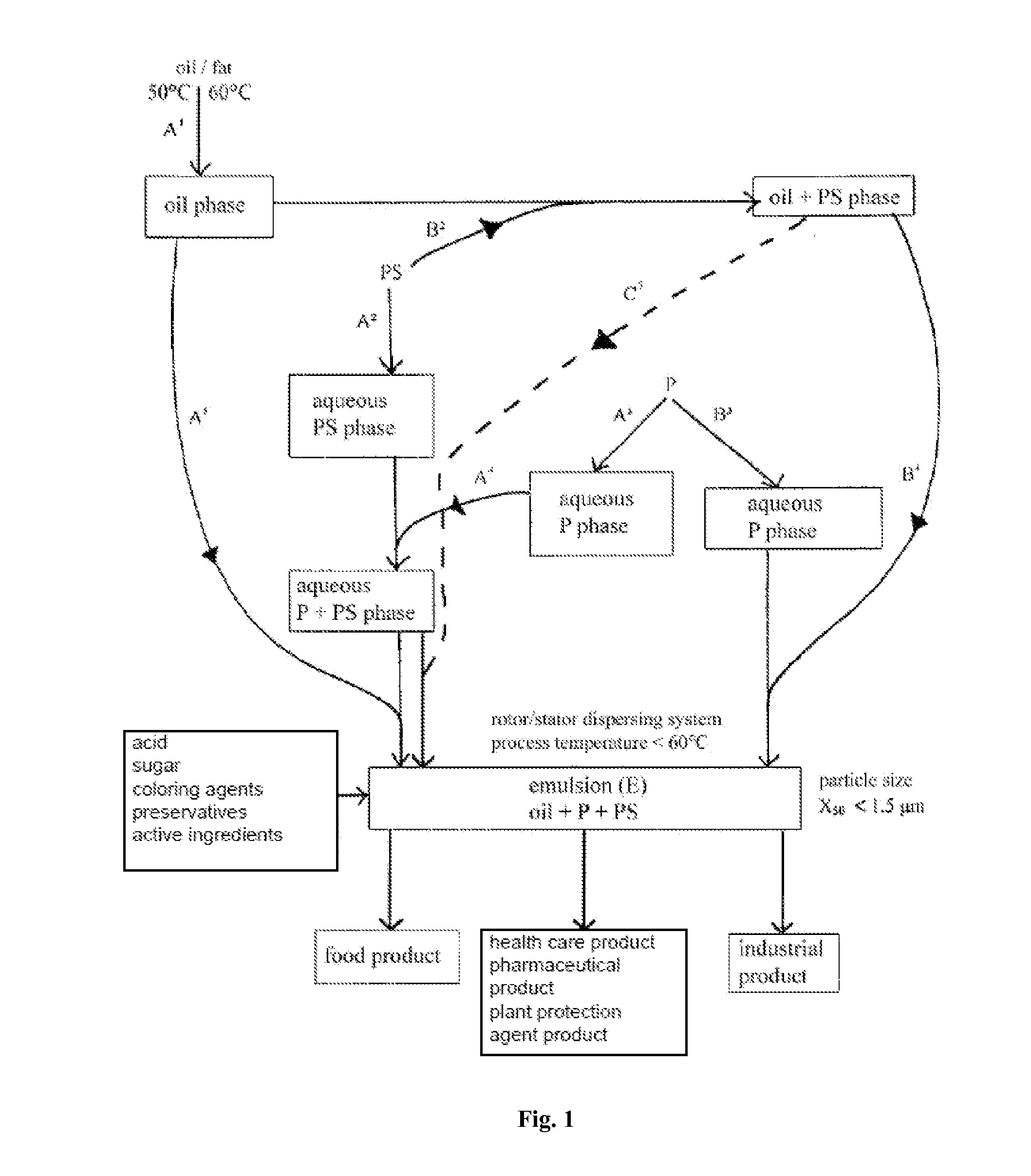

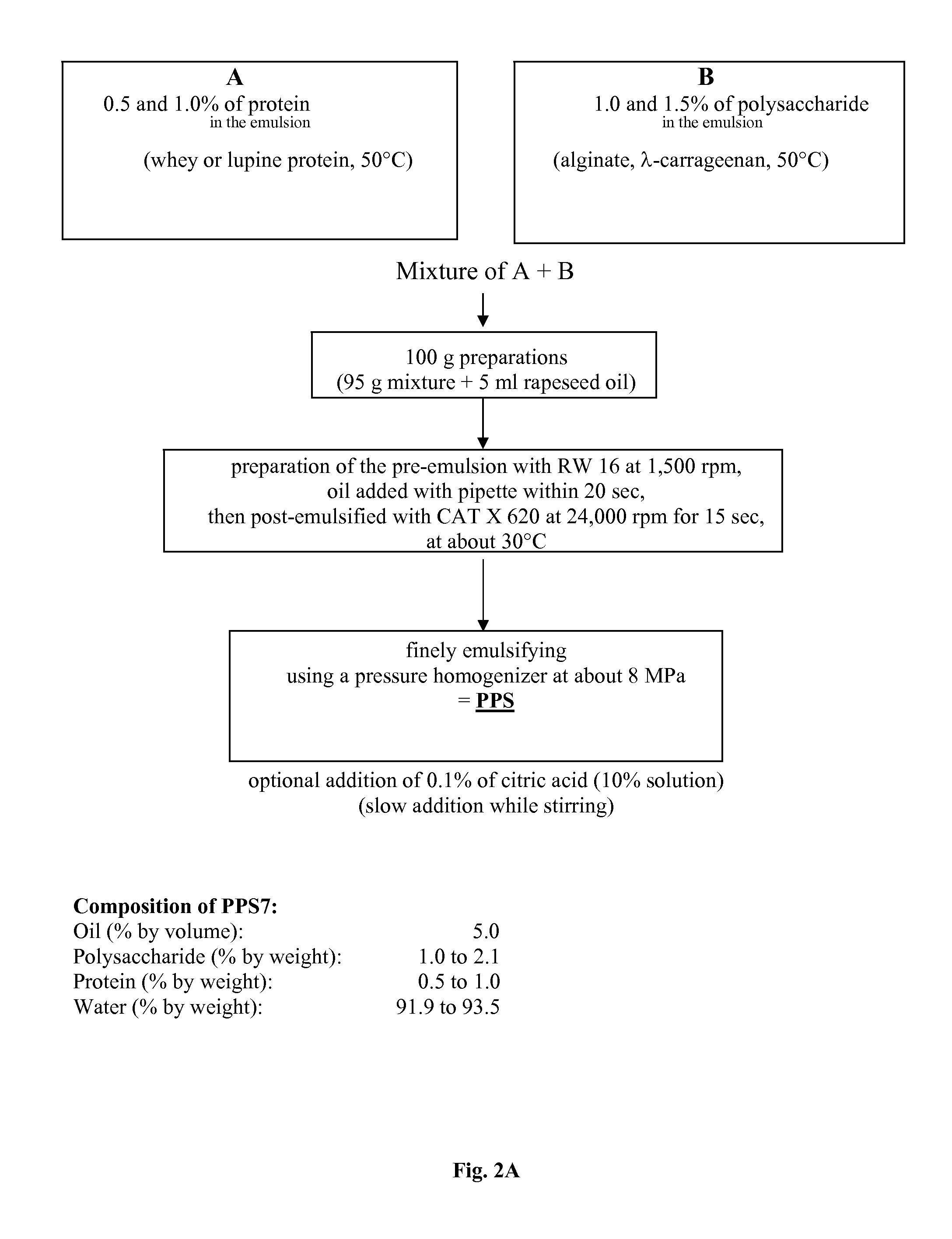

Concentrated, creamy to solid and dry compositions of an oil-in-water emulsion, method for the production thereof and use thereof for producing improved foods in terms of sensory aspects and nutrition physiology

InactiveUS20120135125A1Improve featuresEdible oils/fats ingredientsCosmetic preparationsFood additiveNutrition physiology

The invention relates to an oil-in-water emulsion, substantially comprising protein, polysaccharide and oil or fat having unique stabilizing properties, which is suited for use as a thickener, suspending agent, coating material and as an additive to food in the production of a plurality of products. Furthermore, foods are provided which have improved properties in terms of sensory aspects and nutrition physiology compared to conventionally produced products, and a method for the production thereof is provided. In addition, the emulsion and products produced according to the invention can be dried and subsequently rehydrated in order to obtain compositions that have substantially the same properties as the non-dried compositions.

Owner:OPTISENS

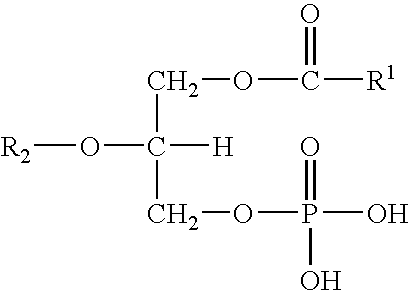

Oil-in-oil emulsions

ActiveUS20070189998A1More predictable behaviorLow settling rateBiocideCosmetic preparationsPhosphateOil emulsion

An stable oil-in-oil emulsion is disclosed containing a first oil phase dispersed as droplets in a continuous second oil phase, which droplets have a number median diameter of 10 nm to 1000 nm, wherein the first oil phase is substantially immiscible in the second oil phase and wherein the first oil phase comprises a liquid organic phosphate compound. In one preferred embodiment, the first oil phase comprises colorants, polymers, and / or other additives, depending on the particular use of the emulsion.

Owner:EASTMAN KODAK CO

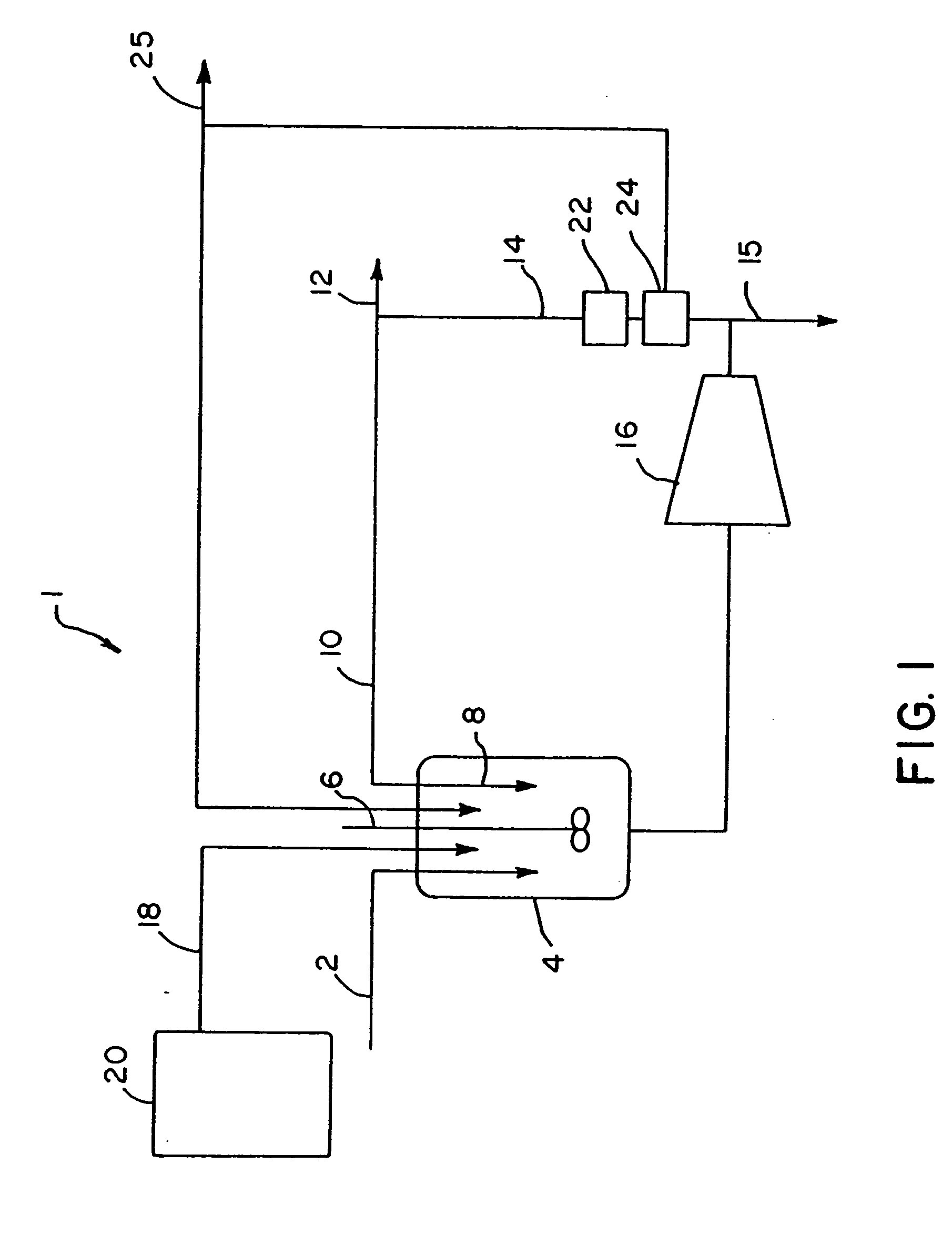

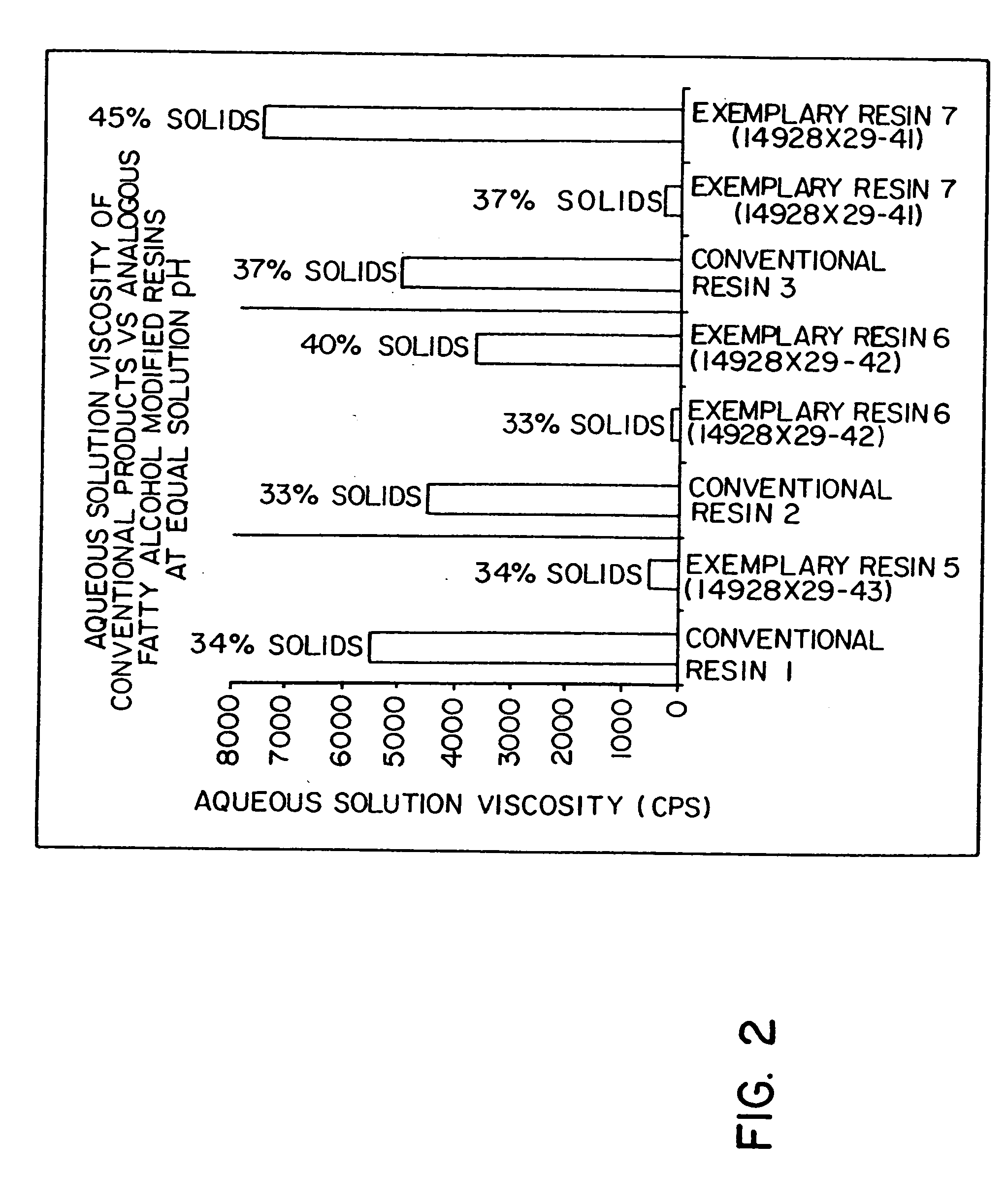

Continuous bulk polymerization and esterification process and compositions

InactiveUS20050059782A1High viscosityWater-repelling agents additionTransportation and packagingPolymeric surfacePolymer science

A continuous bulk polymerization and esterification process includes continuously charging into a reaction zone at least one ethylenically unsaturated acid-functional monomer and at least one linear or branched chain alkanol having greater than 11 carbon atoms. The process includes maintaining a flow rate through the reaction zone sufficient to provide an average residence time of less than 60 minutes and maintaining a temperature in the reaction zone sufficient to produce a polymeric product incorporating at least some of the alkanol as an ester of the polymerized ethylenically unsaturated acid-functional monomer. The polymeric product is used in various processes to produce water-based compositions including emulsions and dispersions such as oil emulsions, wax dispersions, pigment dispersions, surfactants and coatings which contain the polymeric product. A polymeric surfactant includes at least one ethylenically unsaturated acid-functional monomer which has been radically incorporated into the polymeric surfactant and at least one ester of the incorporated ethylenically unsaturated acid-functional monomer which has a linear or branched chain alkyl group with greater than 11 carbon atoms. The molar critical micelle concentration of the polymeric surfactant is less than 1.0×10−2 moles / liter. Aqueous 2 percent solutions of certain polymeric surfactants have a surface tension of less than 45 mN / m at 30° C. and exhibit a decrease in surface tension of at least 5 mN / m as the temperature warms from 30° C. to 50° C.

Owner:BASF CORP

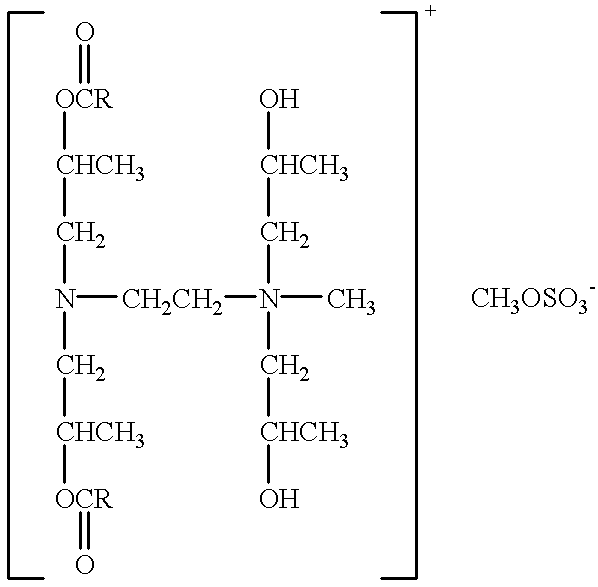

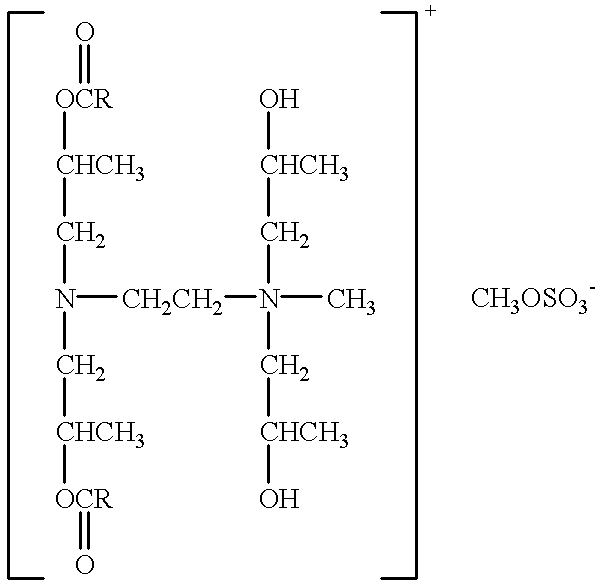

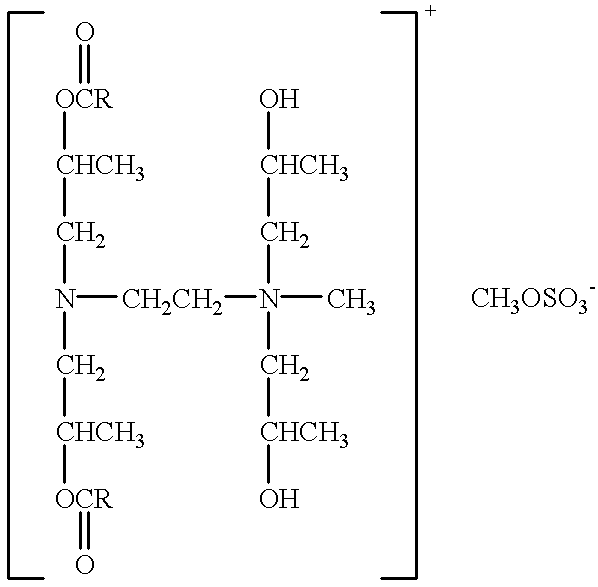

Cold-mix water-in-oil emulsions comprising quaternary ammonium compounds and process for producing same

The present invention relates to stable cold-mix water-in-oil emulsions and methods for preparing such emulsions. The cold-mix water-in-oil emulsions comprise oil (i.e., an emollient), water and an emulsification system comprising a quaternary ammonium-based low HLB emulsifier and optional co-emulsifiers. The emulsions are useful in preparing finished cosmetic compositions in the form of lotions, gels, or sprays, which provide improved moisturization, skin feel, skin care, and / or appearance benefits and / or reduced greasiness, with excellent rub-in and absorption characteristics. Also disclosed are cold-mix water-in-oil sunscreen emulsions and methods for preparing such sunscreen emulsions. The emulsions of the instant invention are generally capable of being substantially completely emulsified and stable at about 25° C.

Owner:STEPAN COMPANY

Nano oil in glycerin emulsion

The invention provides a cosmetic or pharmaceutical composition in the form of an oil-in-glycerin emulsion, with mean droplet size below one micron, comprising a continuous glycerin phase, at least one vegetable oil comprising an internal phase, at least one emulsifying stabilizer, and at least one bioactive compount comprising at least one hydrophobic, moiety within its structure, wherein the composition facilitates stratum-corneum penetration and dermal penetration of said bioactive compound.

Owner:J P M E D

Method of Using Water-in-Oil Emulsion to Remove Oil Base or Synthetic Oil Base Filter Cake

InactiveUS20090114394A1Improve permeabilityImprove effectivenessCleaning apparatusFluid removalParaffin waxOil emulsion

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES HLDG LLC

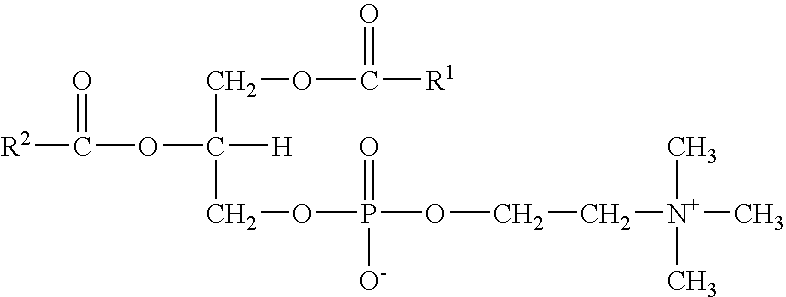

Cosmetic or pharmaceutical, low-viscosity oil-in-water emulsions containing phospholipids

InactiveUS20050124705A1Good lookingImprove combabilityCosmetic preparationsHair removalPhospholipidViscosity

The invention is a low viscosity oil-in-water emulsion that is readily atomizable for use in cosmetic and dermatological applications and particularly for spray or aerosol applications. The oil-in-water emulsion includes at least one phospholipid and at least one oil-in water emulsifier. In some embodiments, the emulsion may also include a water-in-oil emulsifier. The invention also includes a process for preparing the emulsion.

Owner:BEIERSDORF AG

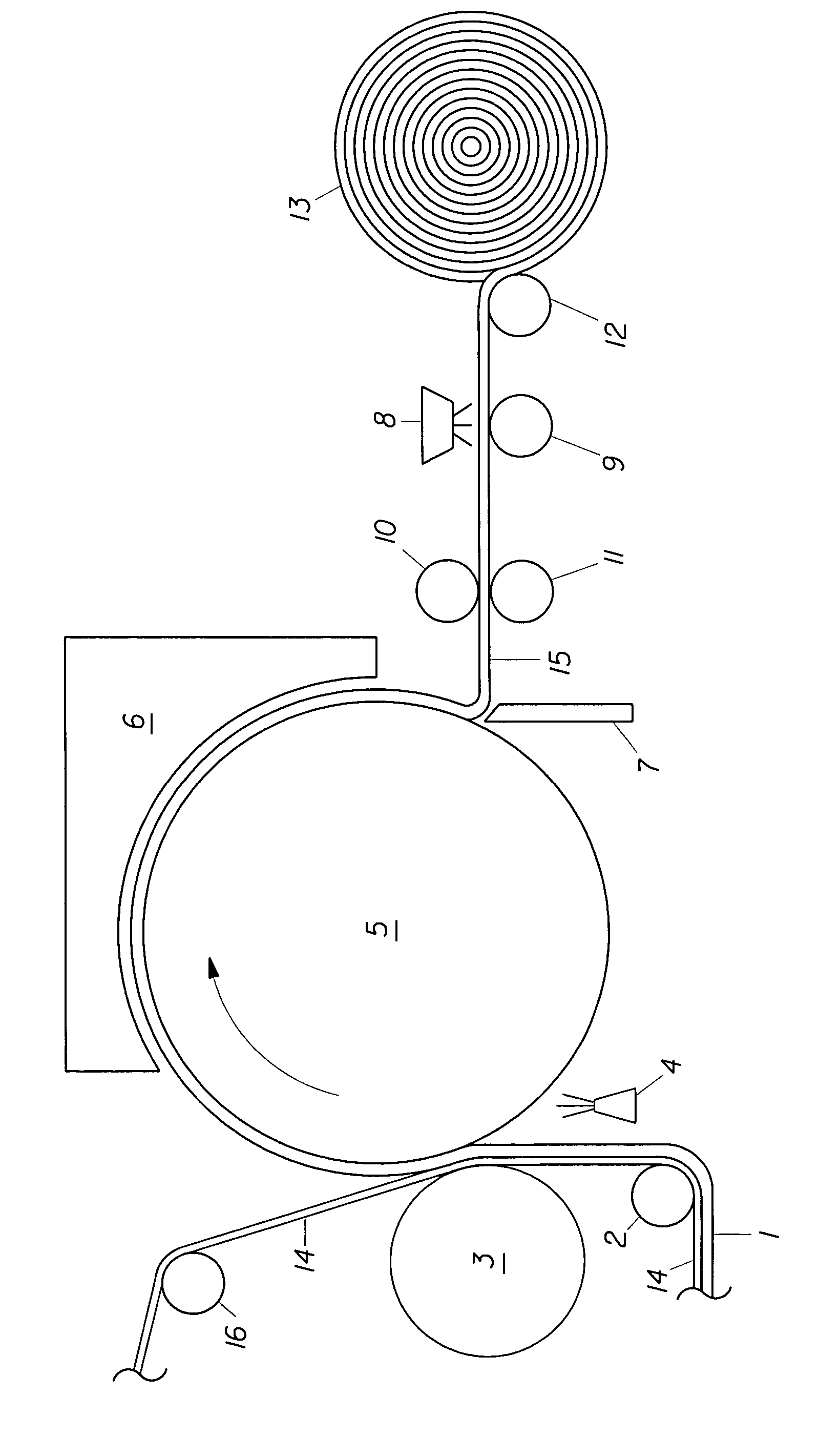

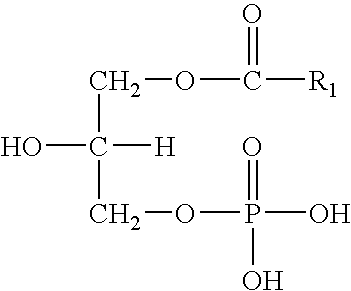

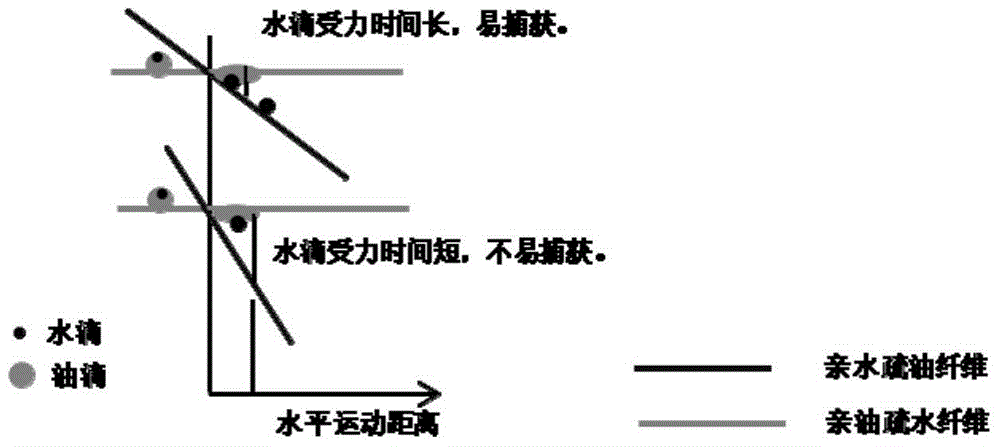

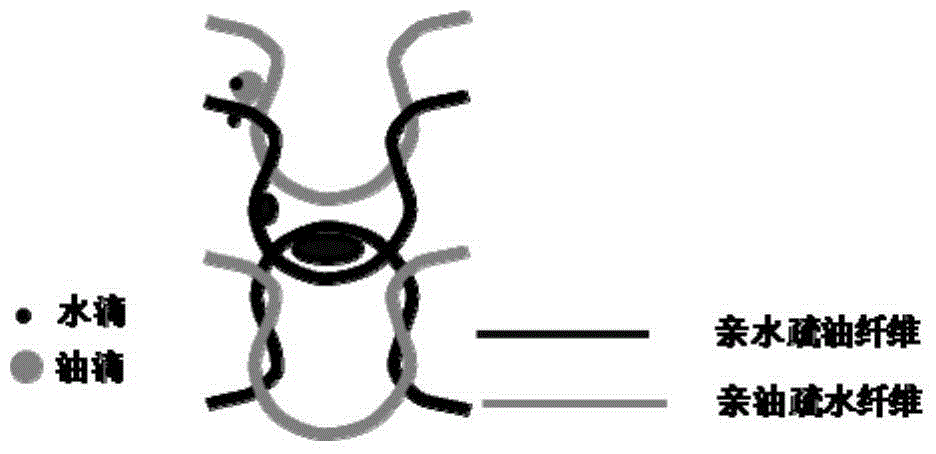

Deep dehydrating method and device for oil product

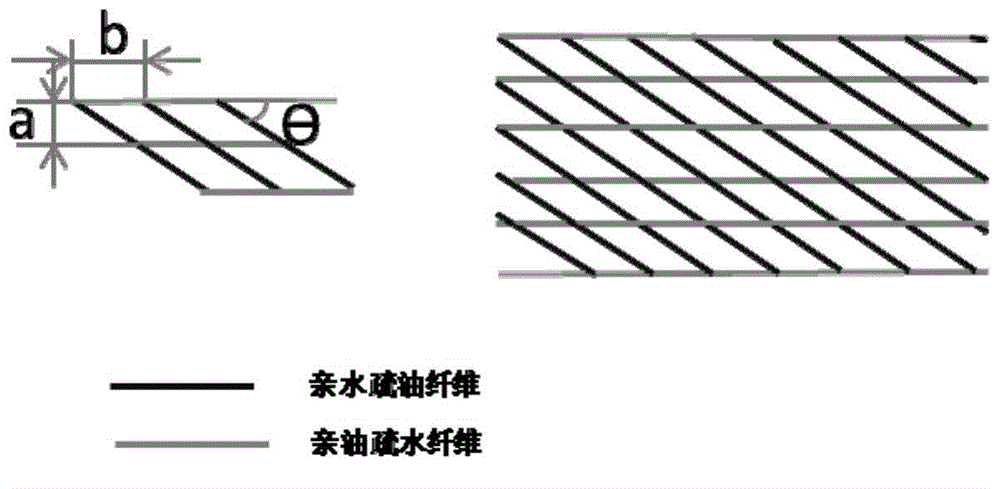

ActiveCN103980934APlay a role in demulsificationPlay a role in coalescenceFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiberMicrowave

The invention relates to a deep dehydrating method and device for an oil product. The deep dehydrating method for the oil product comprises the steps of firstly, enabling the oil product with trace water to pass through a rectifier to ensure that a fluid is uniform; secondly, realizing the capture, agglomeration and growth of trace water drops and demulsification and separation of a trace water-in-oil emulsion through one or more segments of X-shaped oleophylic / lyophobic and hydrophilic / oleophobic fiber braid layers; next, realizing the rapid agglomeration, growth and separation of the water drops through microwave-forced settlement separation; finally, realizing the capture and separation of the extremely trace water drops in the oil product through one segment of omega-shaped oleophylic / lyophobic and hydrophilic / oleophobic fiber braid layer, thereby realizing the deep dehydration of the oil product. The invention also provides a set of device for realizing the method. The device comprises a shell, a feeding pipe, a rectifier, a fiber agglomeration layer, a microwave forced separation layer, a liquid level meter and other parts. The method is high in separation efficiency, low in energy consumption and long in continuous operation period, and can be widely applied to the deep dehydrating processes of all oil products with trace water.

Owner:EAST CHINA UNIV OF SCI & TECH

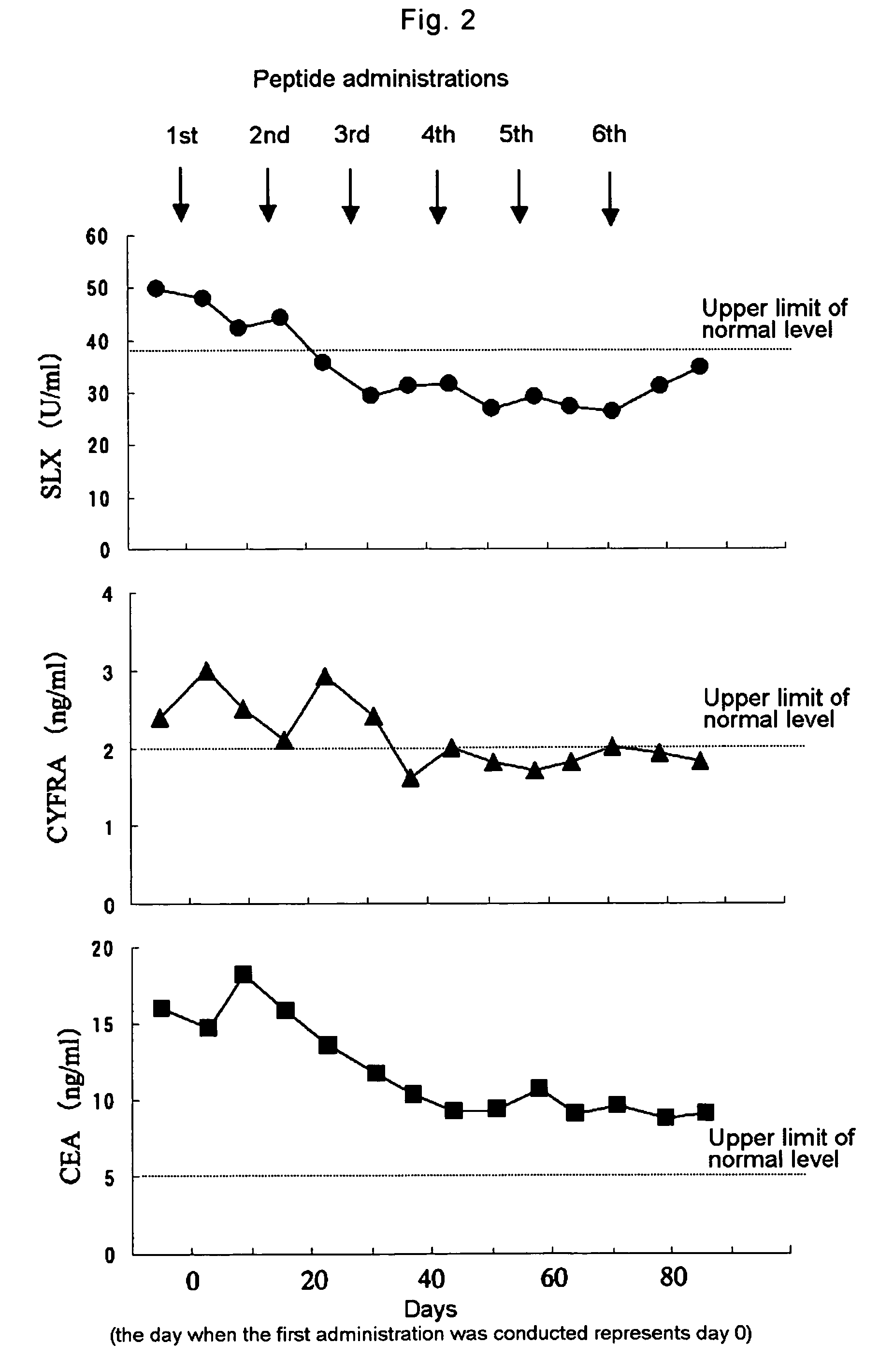

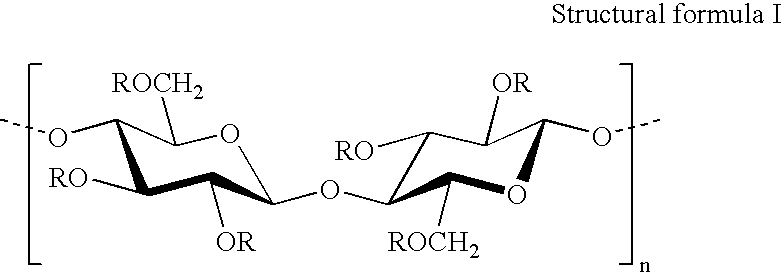

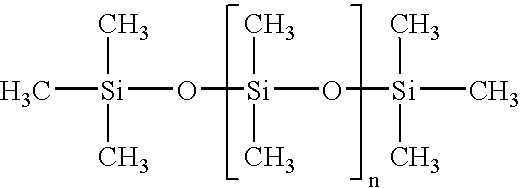

Cancer antigen peptide formulations

Cancer antigen peptides derived from WT1 which have an in vivo efficacy, particularly a clinical usefulness, and cancer vaccines as dosage forms suitable for said cancer antigen peptides, are provided.The invention relates to water-in-oil emulsions which comprise as an effective ingredient either one or both of peptides selected from the group consisting of a peptide having an amino acid sequence of Cys Met Thr Trp Asn Gln Met Asn Leu (SEQ ID NO: 2), and a peptide having an amino acid sequence of Cys Tyr Thr Trp Asn Gln Met Asn Leu (SEQ ID NO: 3), as well as processes for preparation of said emulsion.

Owner:INT INST OF CANCER IMMUNOLOGY INC

Low-viscosity cosmetic or dermatological preparations

InactiveUS20050266055A1Low viscosityEfficient and skin-friendly cleansing and careCosmetic preparationsToilet preparationsWater in oil emulsionOil phase

A low-viscosity Pickering water-in-oil emulsion having a viscosity of less than 3000 mPa·s, comprising (1) an oil phase, (2) a water phase, (3) at least one type of microfine, inorganic metal oxide particles a) having an average particle size of less than 200 nm, b) exhibiting both hydrophilic and also lipophilic properties, c) dispersible both in lipophilic and also in hydrophilic liquids and d) optionally surface-coated, (4) 0.01 to 5% by weight of at least one polymeric nonionic and / or cationic thickener and (5) at most 0.5% by weight of one or more emulsifiers.

Owner:BEIERSDORF AG

Composition in the form of a water-in-oil emulsion stabilized with a 2-acrylamido-2-methylpropanesulphonic acid (CO) polymer containing hydrophobic grafts

A composition, in the form of a water-in-oil emulsion, is characterized in that it contains at least one amphiphilic polymer or copolymer of 2-acrylamido-2-methylpropanesulphonic acid bearing hydrophobic grafts chosen from hydrocarbon-based radicals containing from 6 to 30 carbon atoms, oxyalkylenated hydrocarbon-based radicals comprising a hydrocarbon-based group containing from 6 to 30 carbon atoms and at least one oxyalkylene unit, and mixtures thereof.

Owner:LOREAL SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com