Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

26750 results about "Reaction product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Products are the species formed from chemical reactions. During a chemical reaction reactants are transformed into products after passing through a high energy transition state. ... The products of a chemical reaction influence several aspects of the reaction. If the products are lower in energy than the reactants, then the reaction will give off excess energy making it an exergonic reaction.

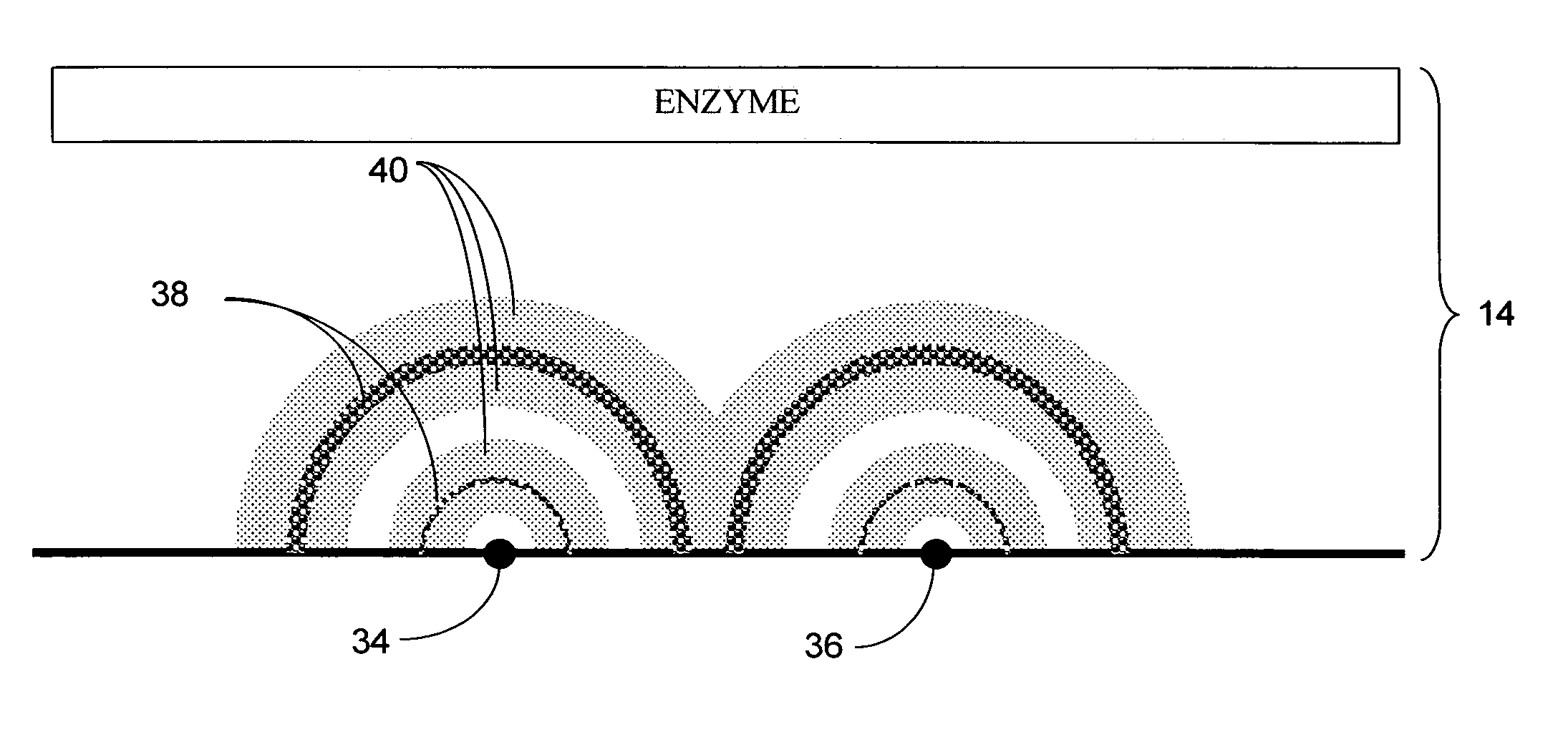

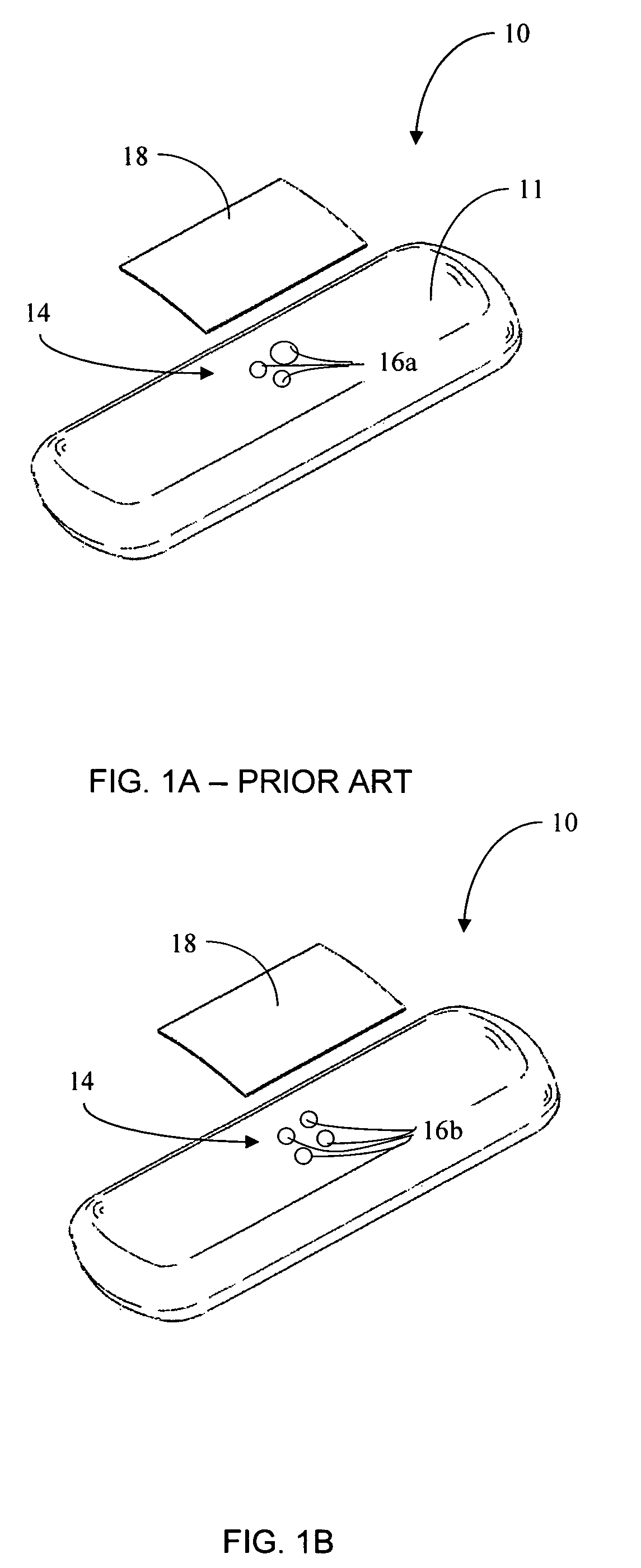

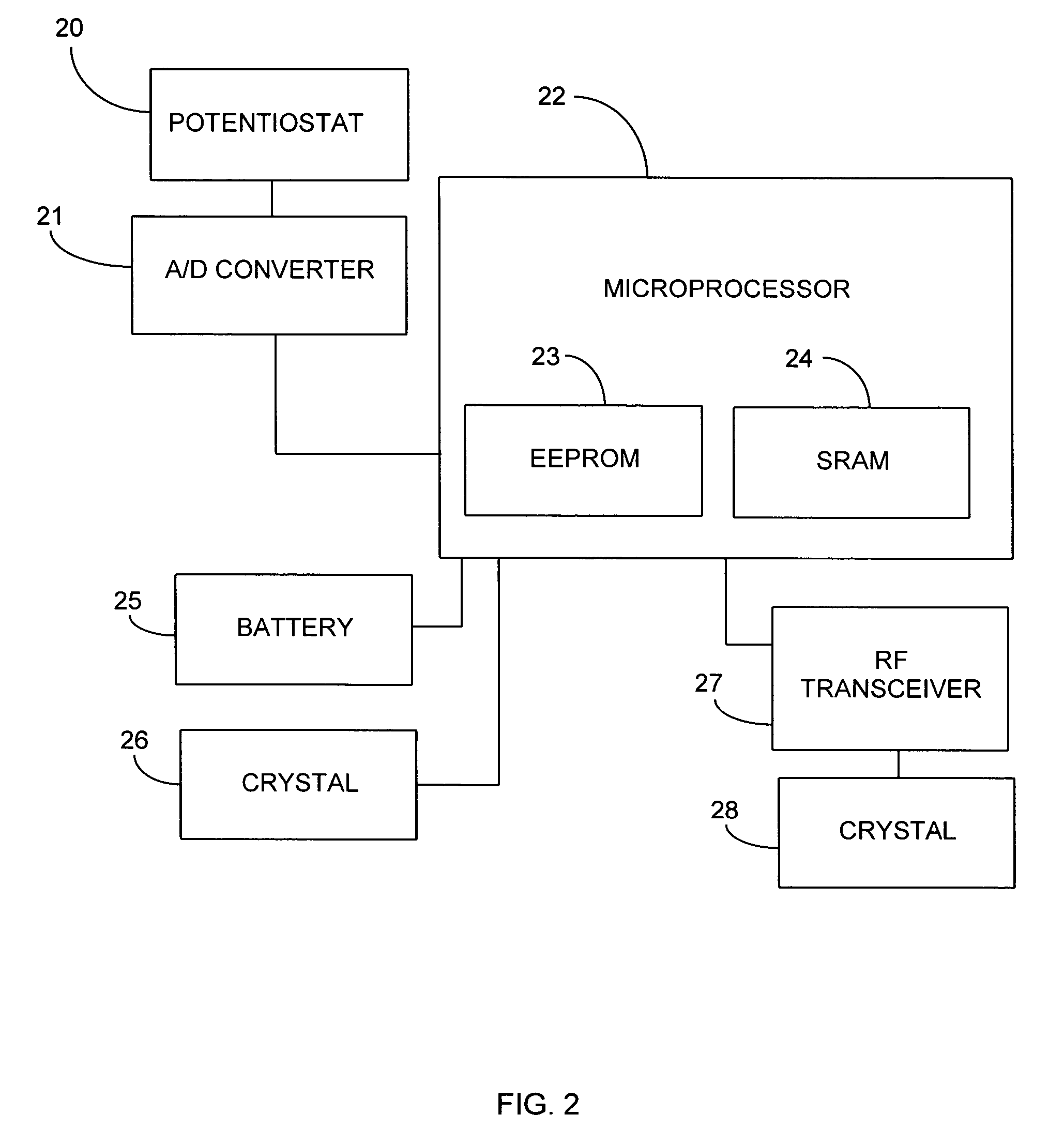

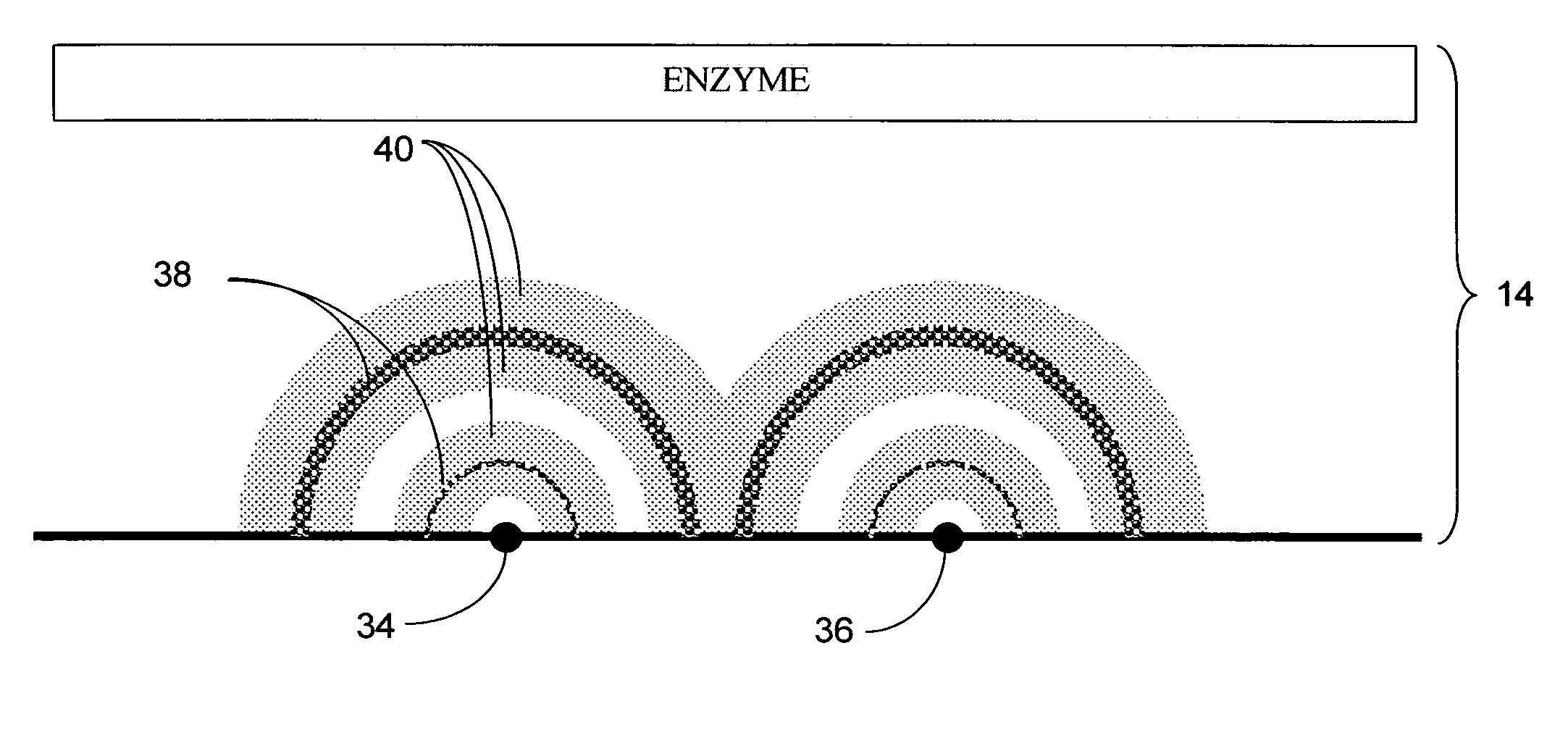

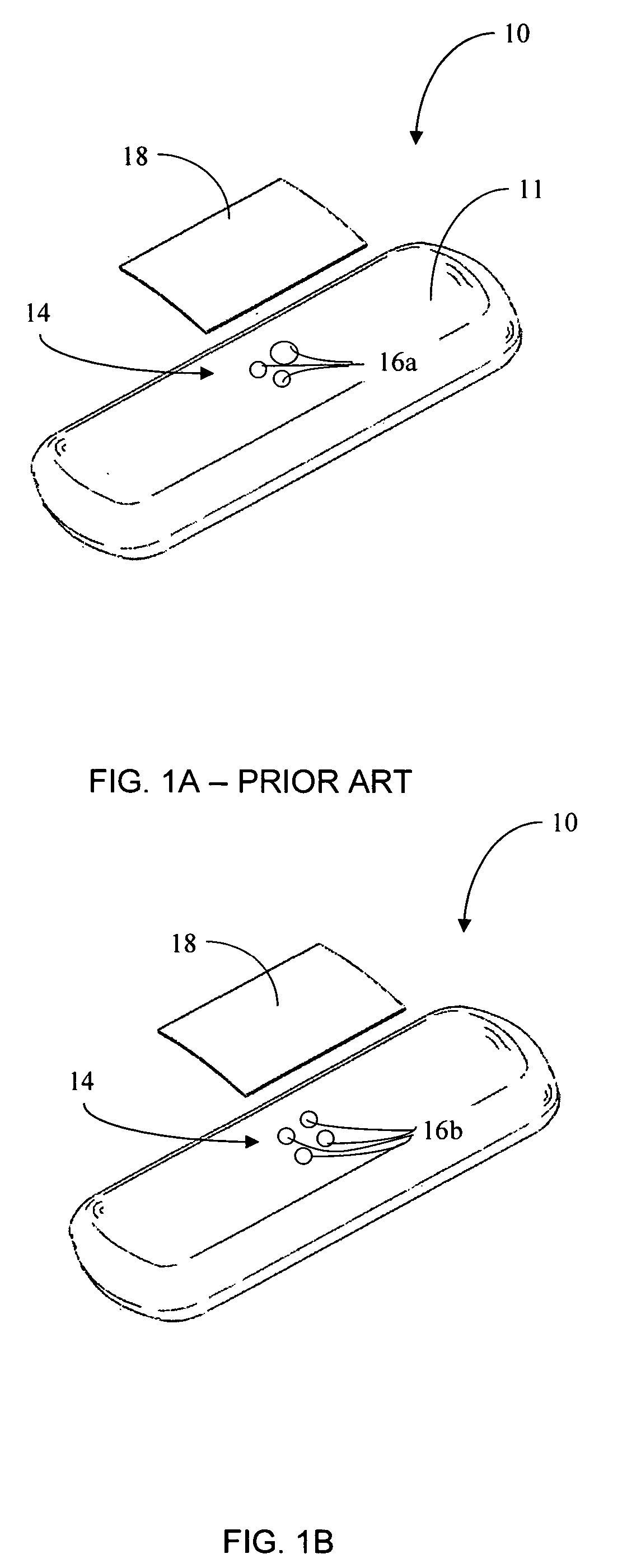

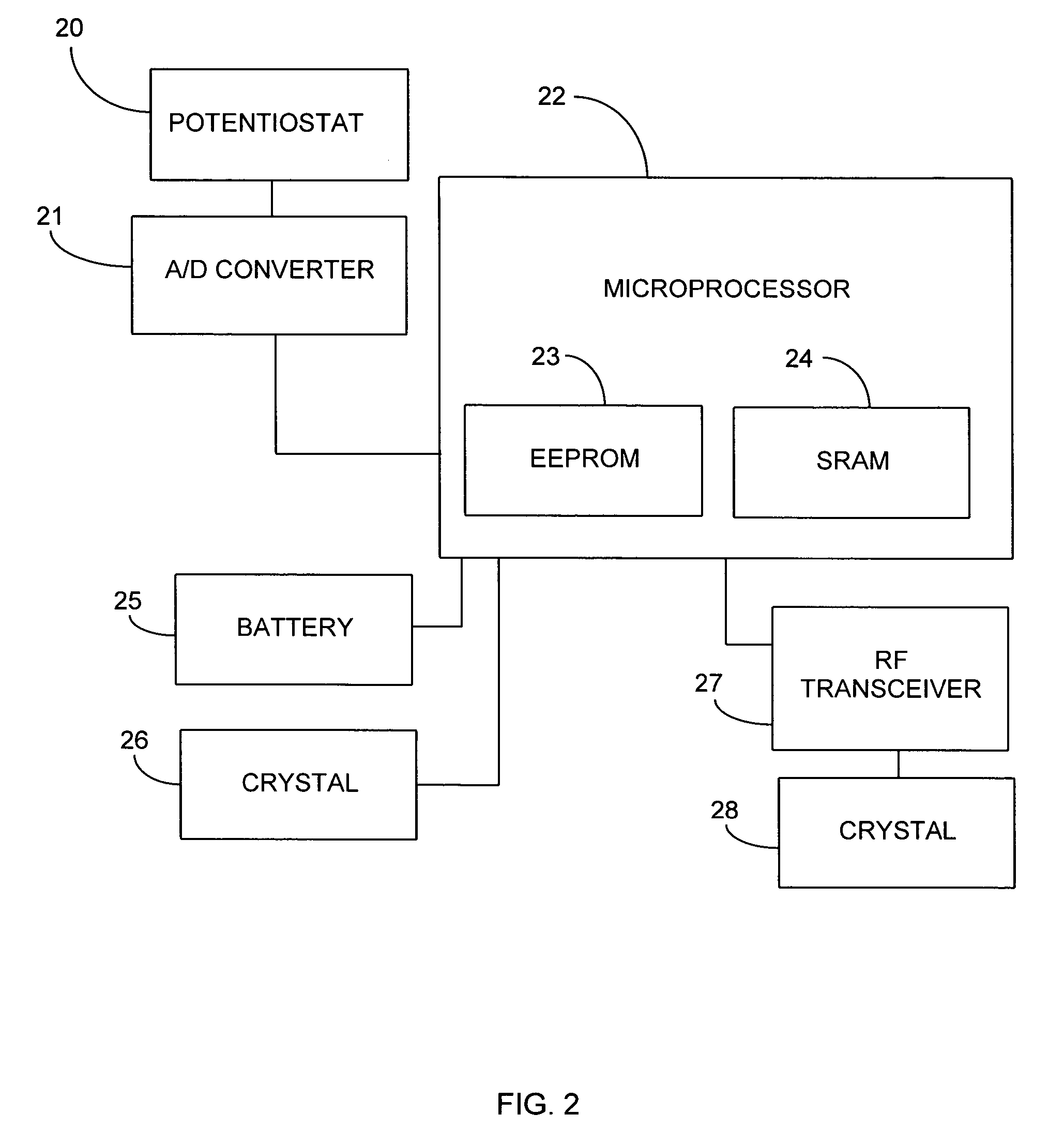

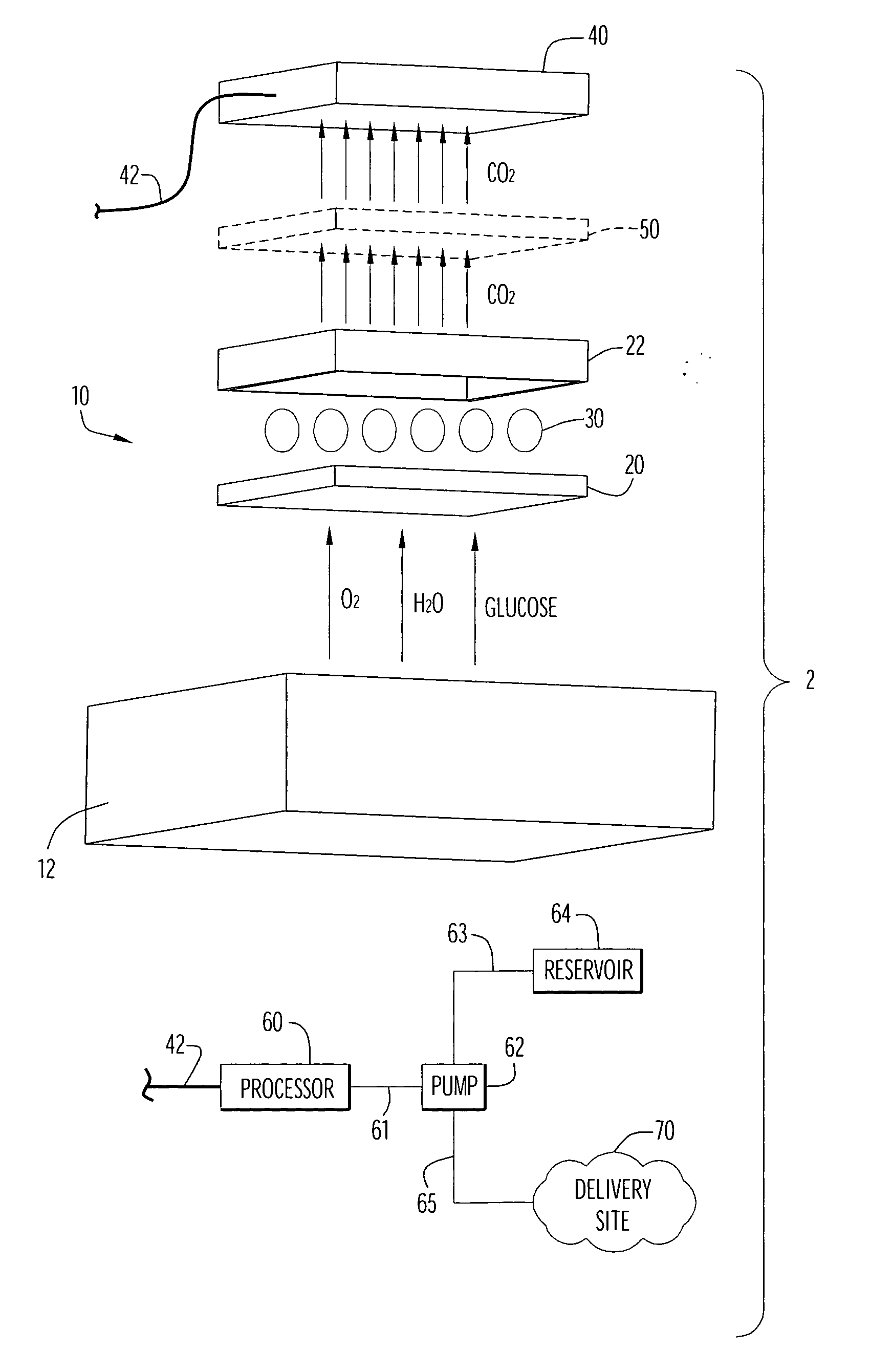

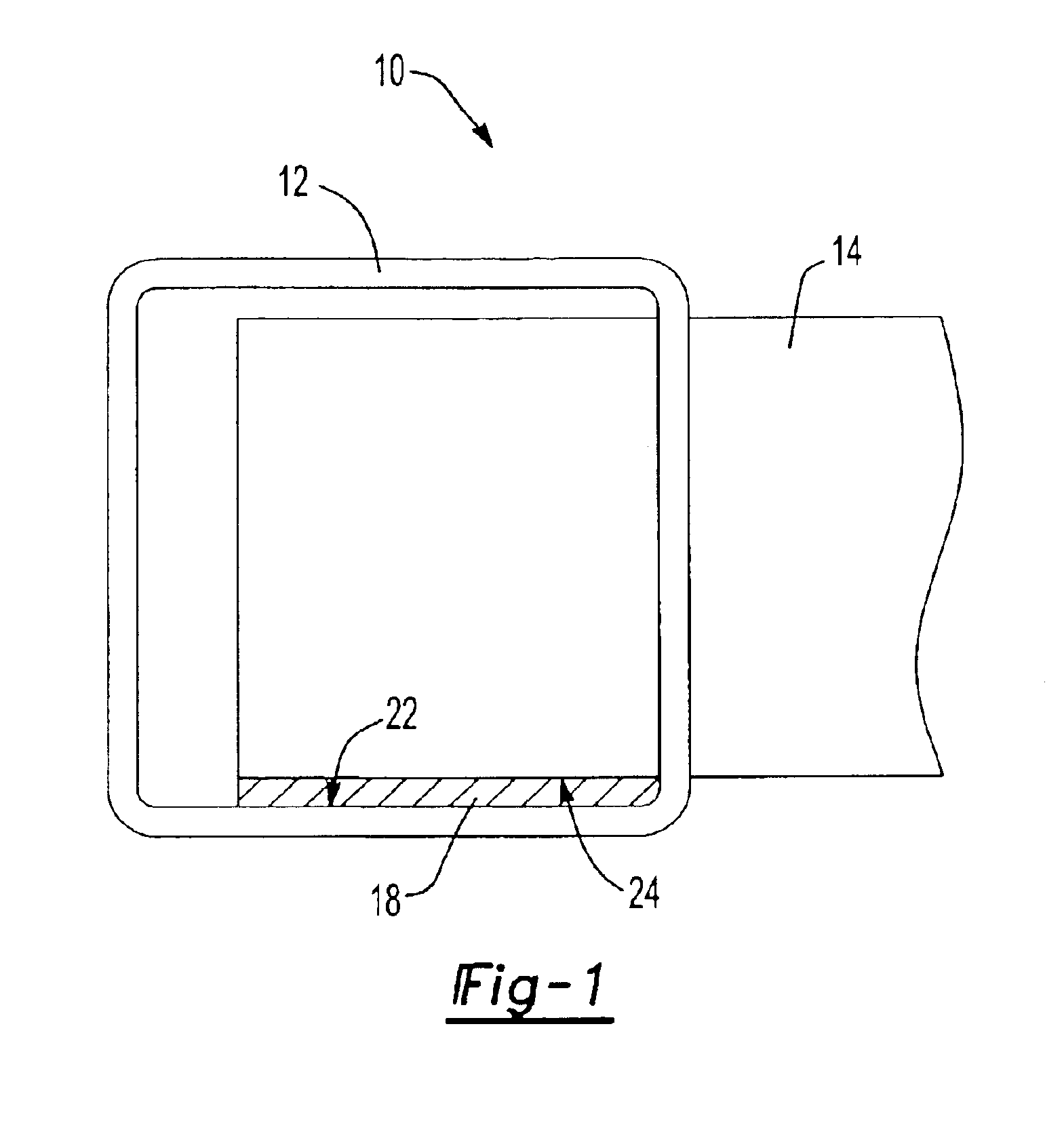

Electrochemical sensors including electrode systems with increased oxygen generation

ActiveUS7108778B2Immobilised enzymesBioreactor/fermenter combinationsAnalyteElectrochemical gas sensor

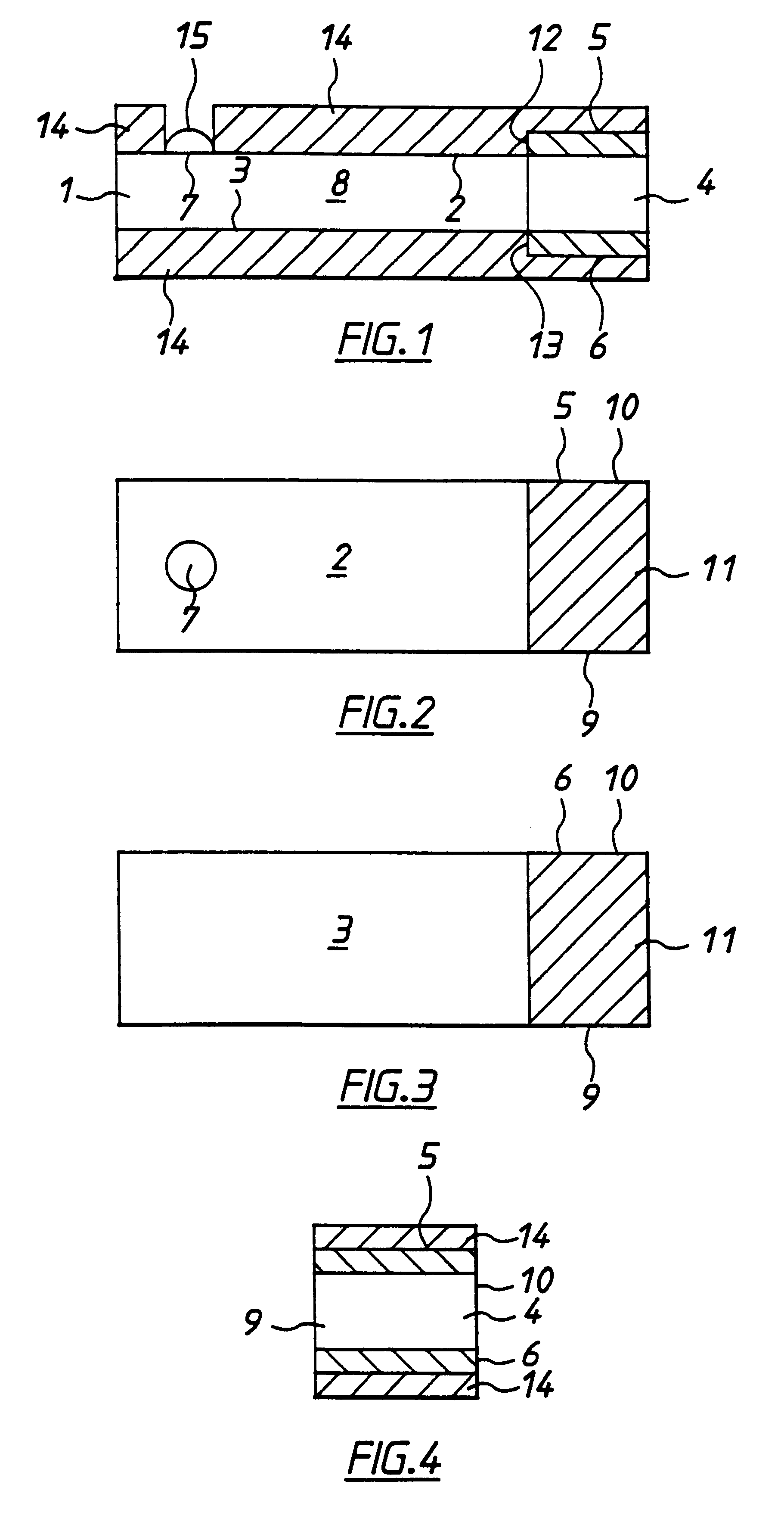

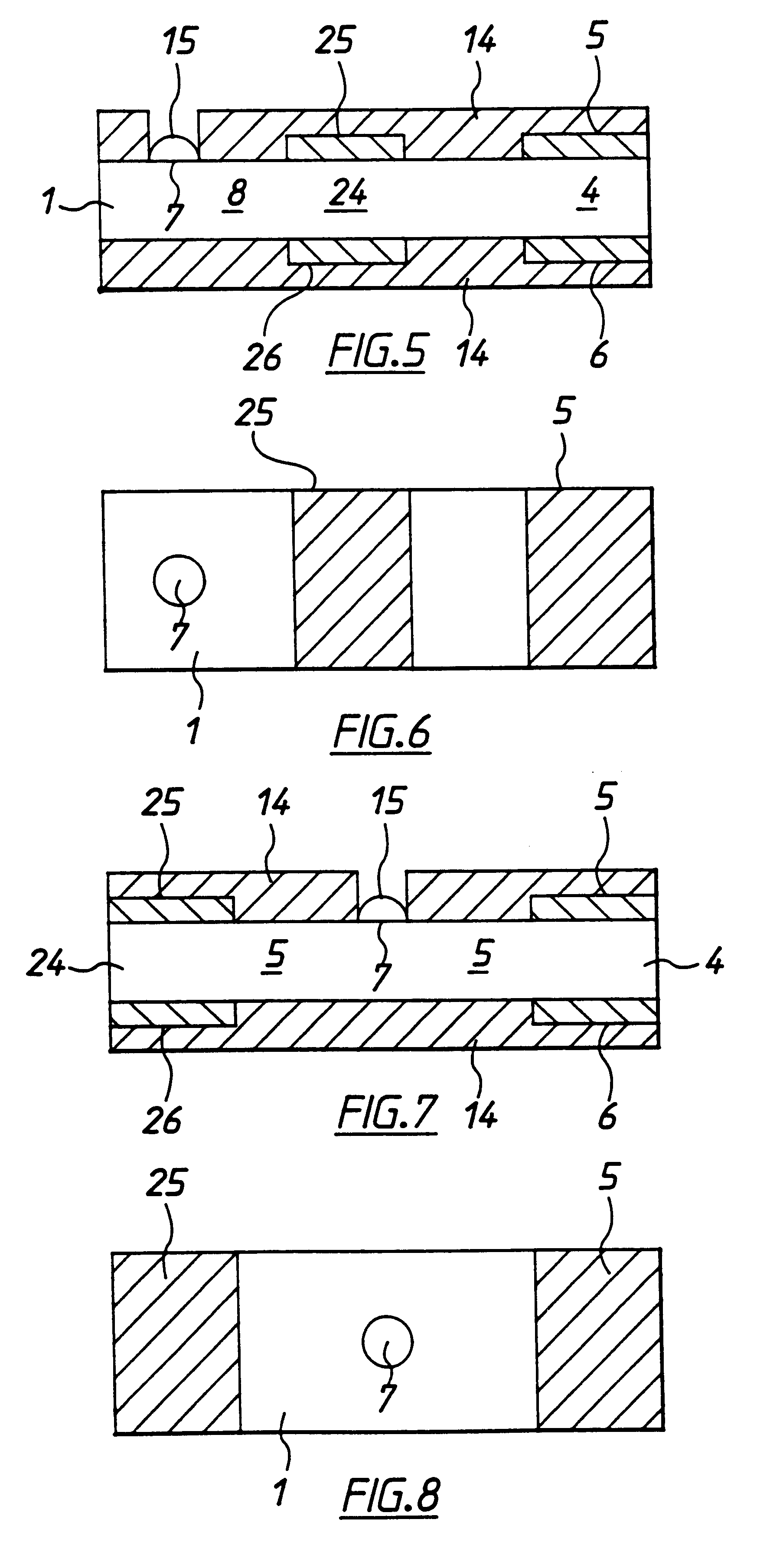

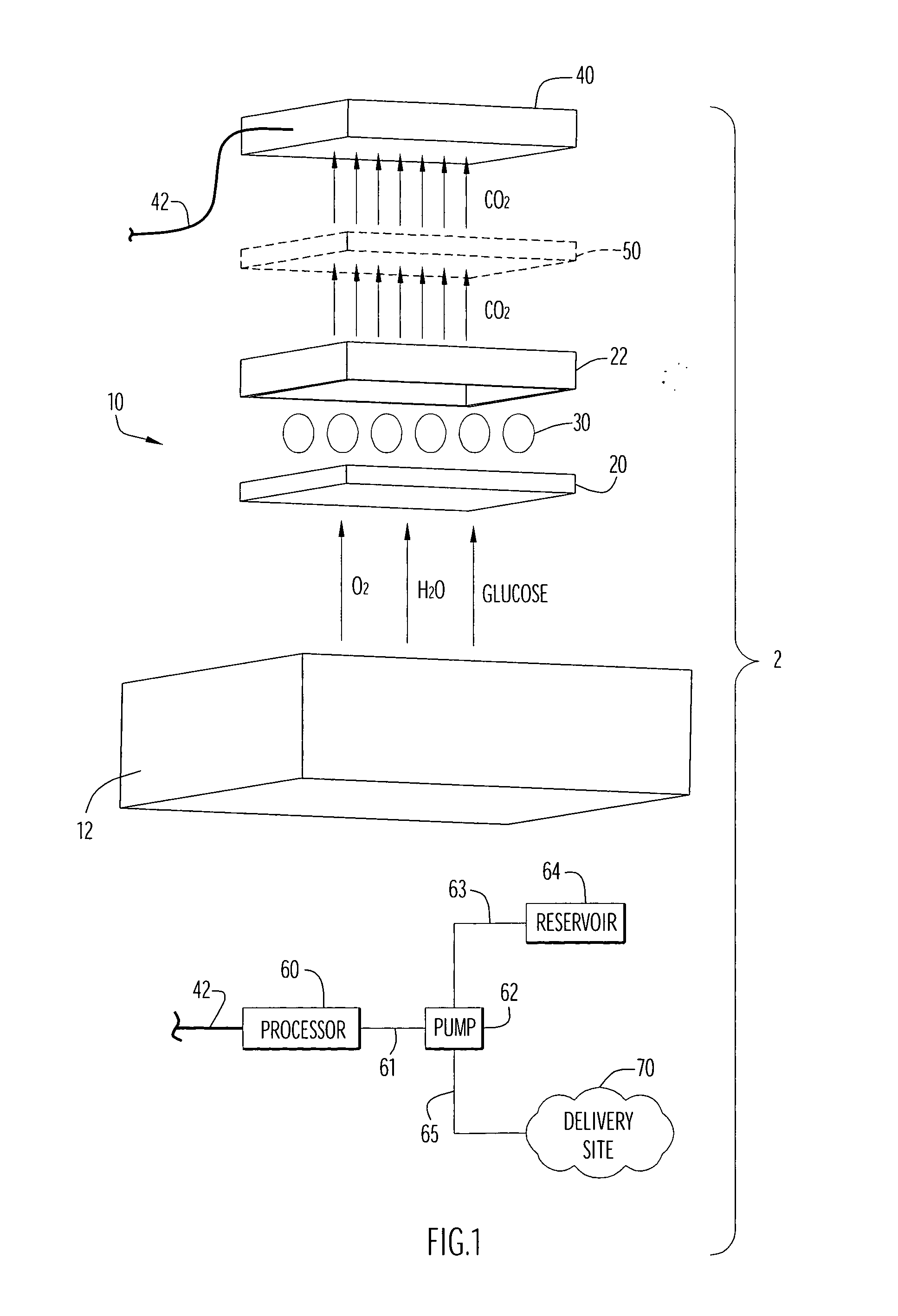

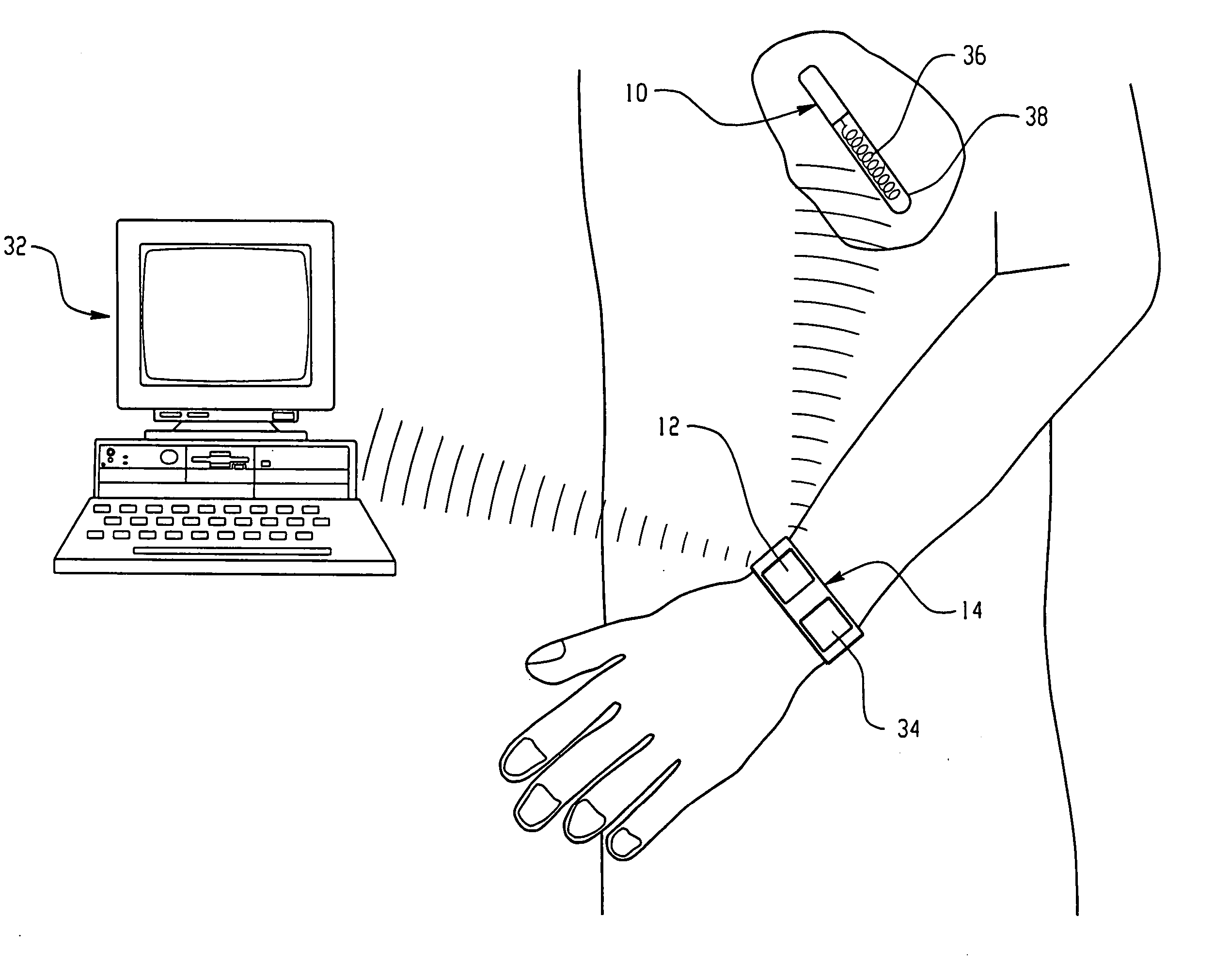

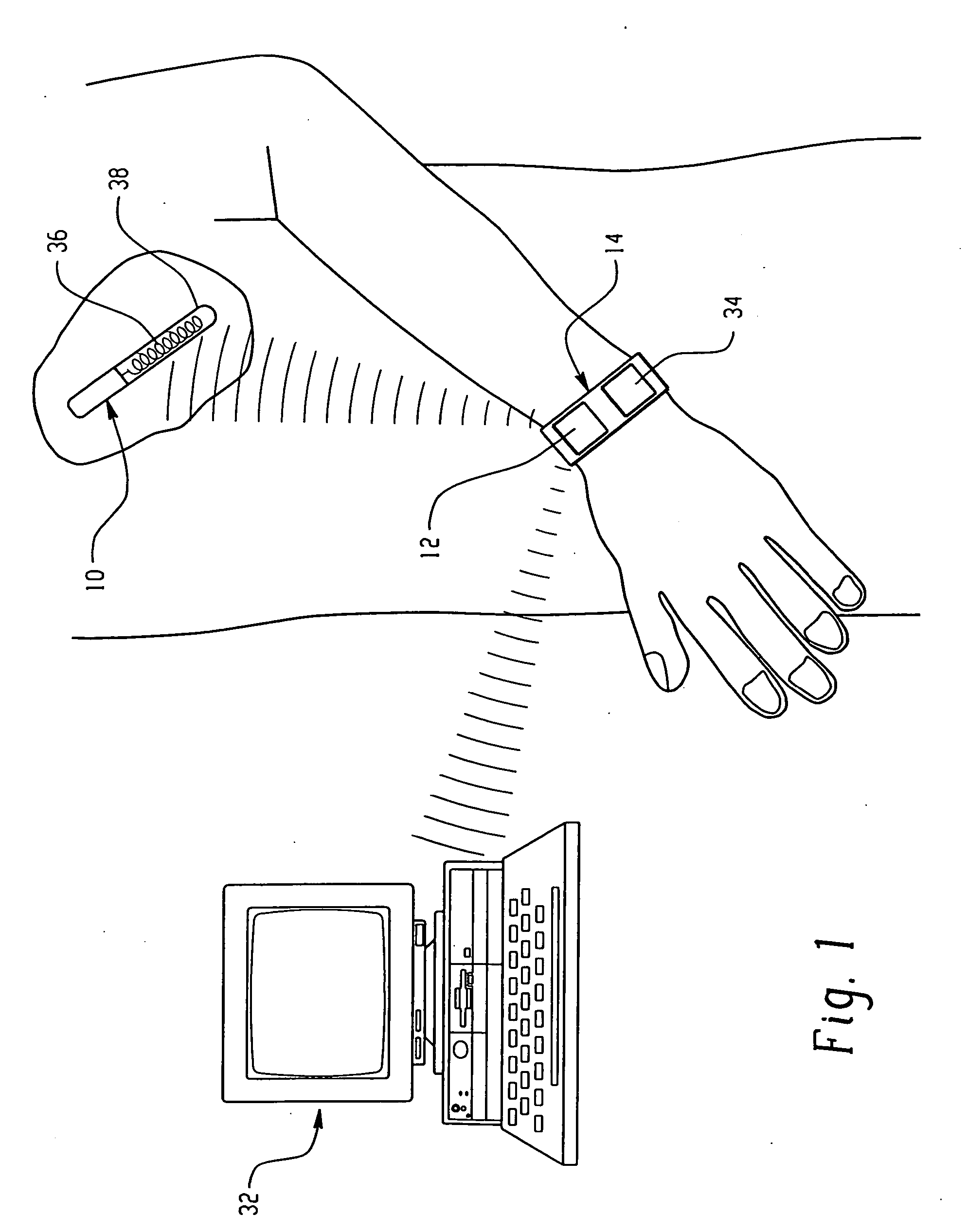

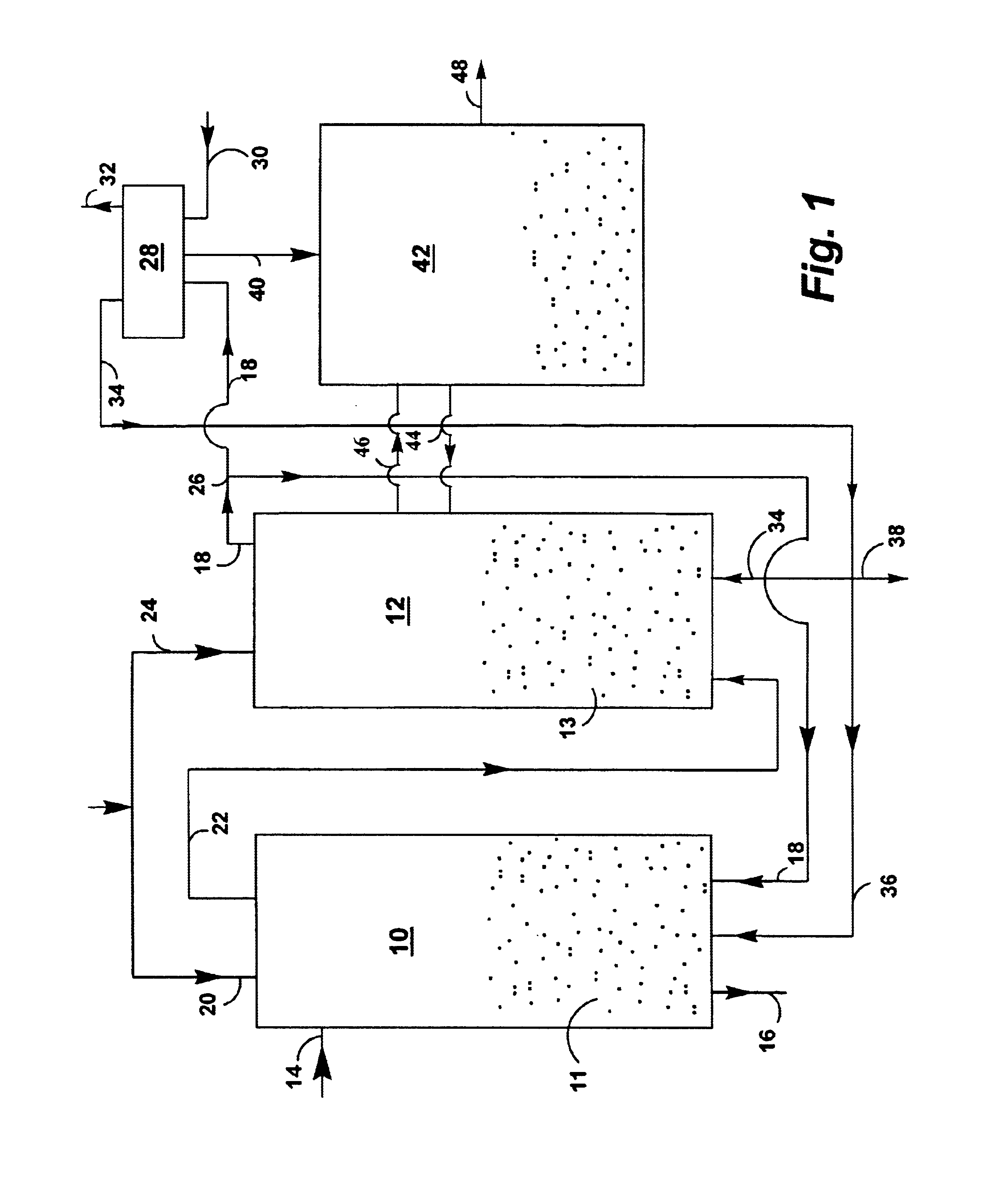

The present invention relates generally to systems and methods for increasing oxygen generation in electrochemical sensors in order to overcome the oxygen limitations. The preferred embodiments employ electrode systems with at least two electrodes in relatively close proximity to each other; wherein at least one electrode is configured to generate oxygen and at least one other electrode is configured to sense an analyte or a product of a reaction indicative of the concentration of analyte. The oxygen generated by the oxygen-generating electrode is available to the catalyst within a membrane system and / or the counter electrode, thereby enabling the electrochemical sensors of the preferred embodiments to function even during ischemic conditions.

Owner:DEXCOM INC

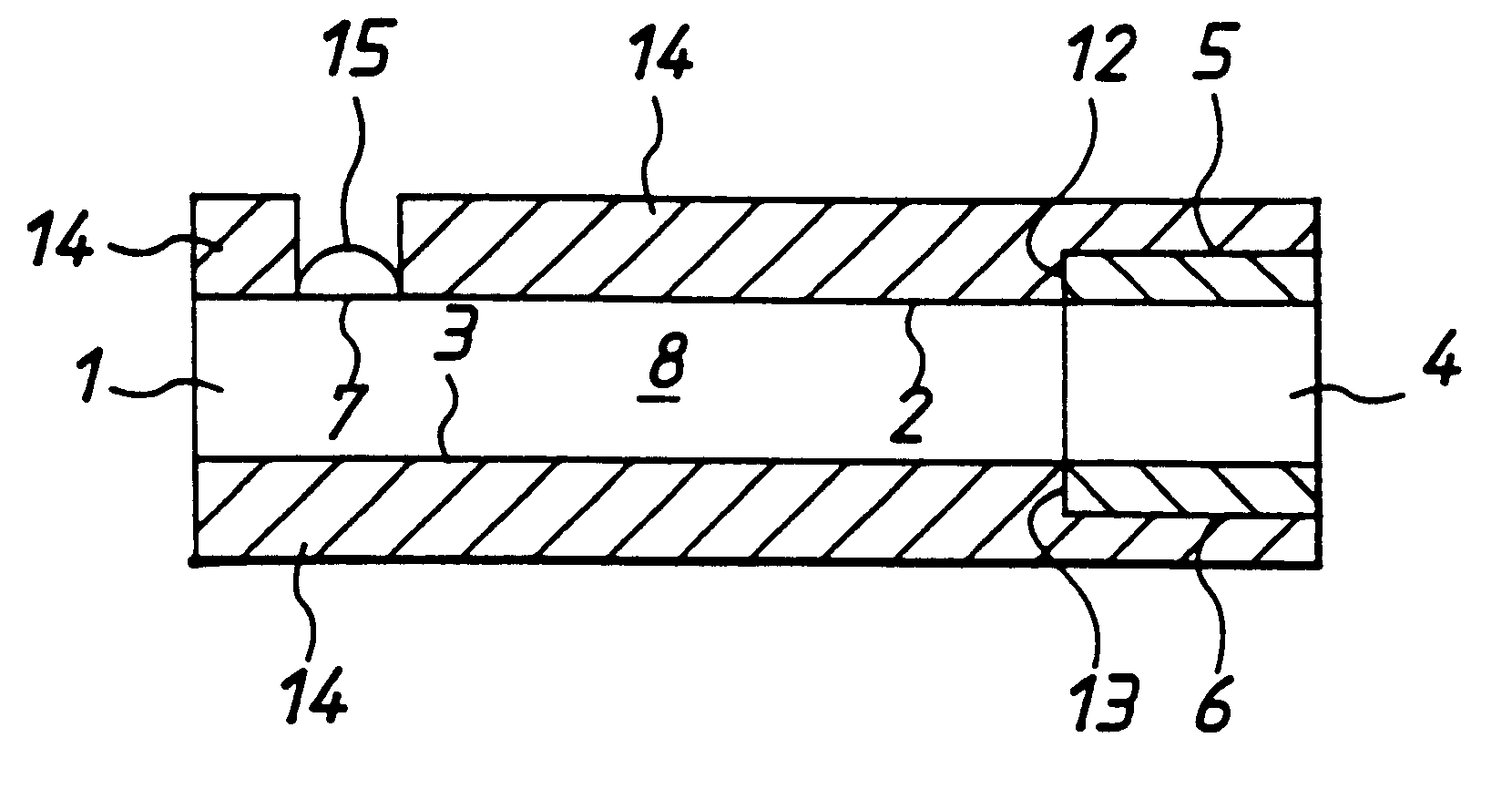

Electrochemical cell

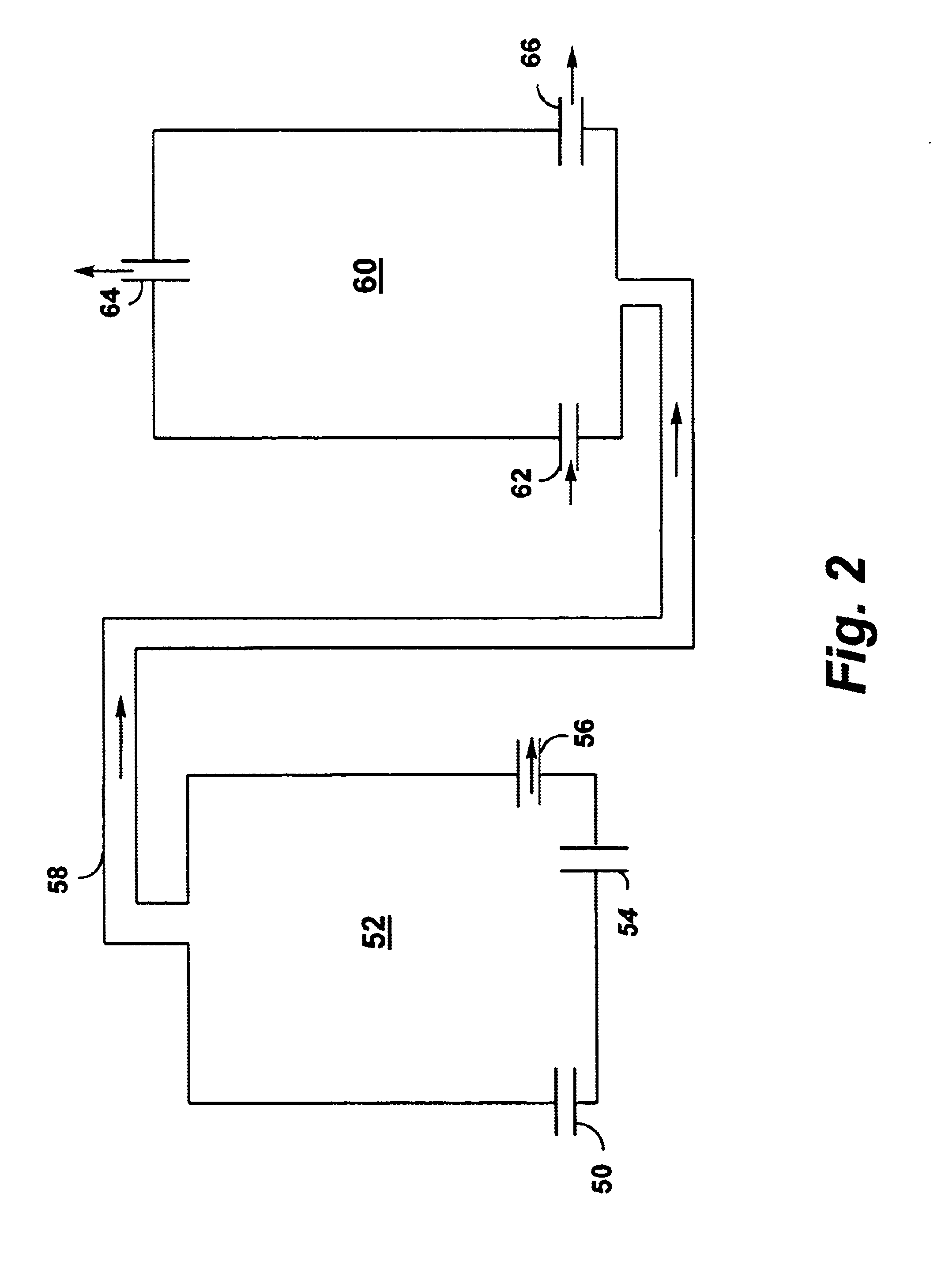

InactiveUS6284125B1Improve accuracyImprove reliabilityImmobilised enzymesBioreactor/fermenter combinationsElectricityDiffusion

A method for determining the concentration of a reduced (or oxidised) form of a redox species in an electrochemical cell of the kind comprising a working electrode and a counter electrode spaced from the working electrode by a predetermined distance, said method comprising the steps of: (1) applying an electric potential difference between the electrodes; (2) selecting the potential of the working electrode such that the rate of electro-oxidation of the reduced form (or electro-reduction of the oxidised form) of the species is diffusion controlled, (3) selecting the spacing between the working electrode and the counter electrode so that reaction products from the counter electrode arrive at the working electrode; (4) determining current as a function of time after application of the potential and prior to achievement of a steady state; (5) estimating the magnitude of the steady state current, and (6) obtaining from the change in current with time and the magnitude of the steady state current, a value indicative of the diffusion coefficient and / or of the concentration of the reduced form (or the oxidised form) of the species. Also disclosed is an apparatus for determining the concentration of a redox species in an electrochemical cell comprising: an electrochemical cell having a working electrode and a counter (or counter / reference) electrode, means for applying and electric potential difference between said electrodes, means for measuring the change in current with time, and characterised in that the working electrode is spaced from the counter electrode by less than 500 mum.

Owner:LIFESCAN INC

Process for producing acetic acid

ActiveUS7208624B2Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

Electrochemical sensors including electrode systems with increased oxygen generation

The present invention relates generally to systems and methods for increasing oxygen generation in electrochemical sensors in order to overcome the oxygen limitations. The preferred embodiments employ electrode systems with at least two electrodes in relatively close proximity to each other; wherein at least one electrode is configured to generate oxygen and at least one other electrode is configured to sense an analyte or a product of a reaction indicative of the concentration of analyte. The oxygen generated by the oxygen-generating electrode is available to the catalyst within a membrane system and / or the counter electrode, thereby enabling the electrochemical sensors of the preferred embodiments to function even during ischemic conditions.

Owner:DEXCOM

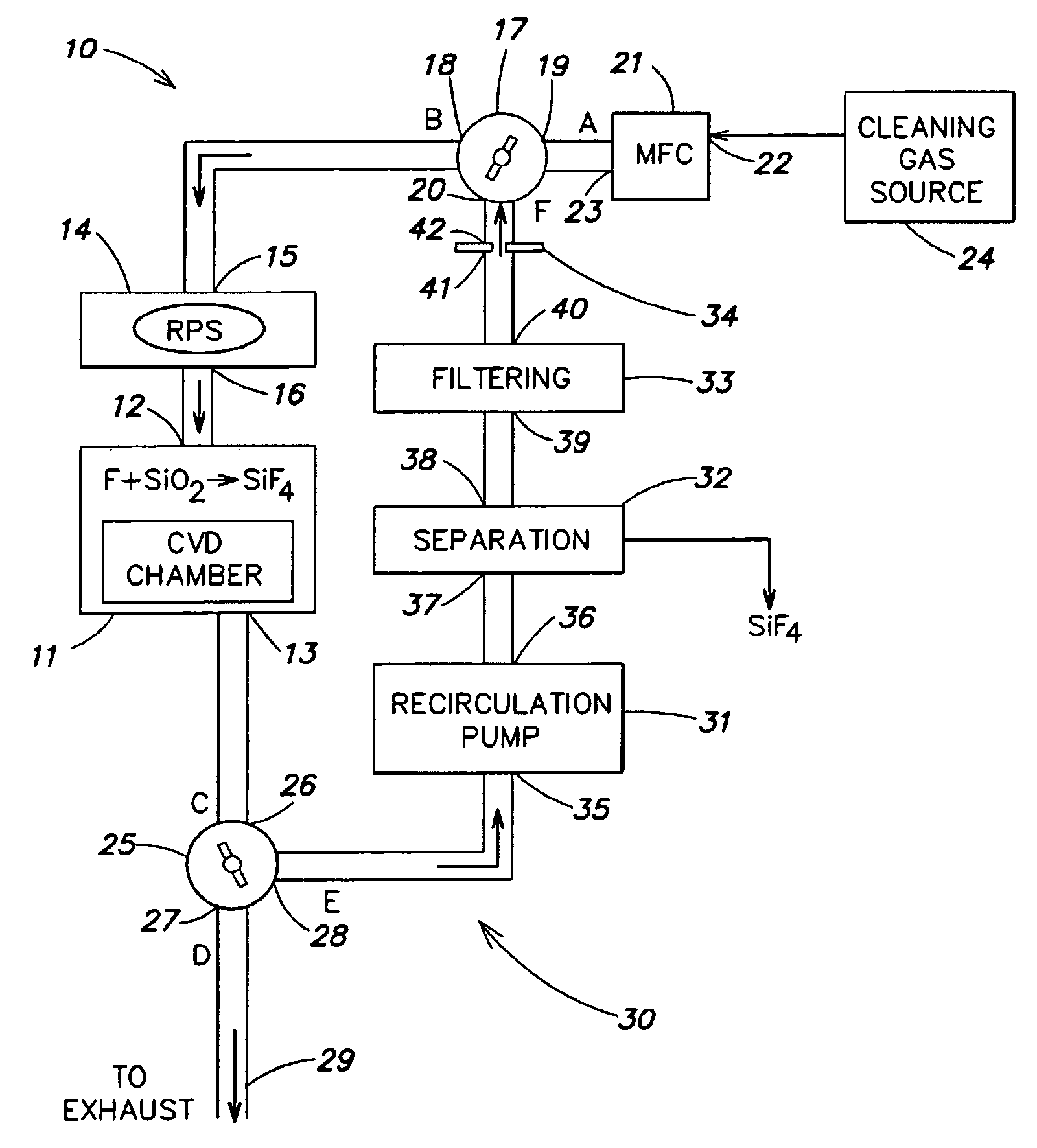

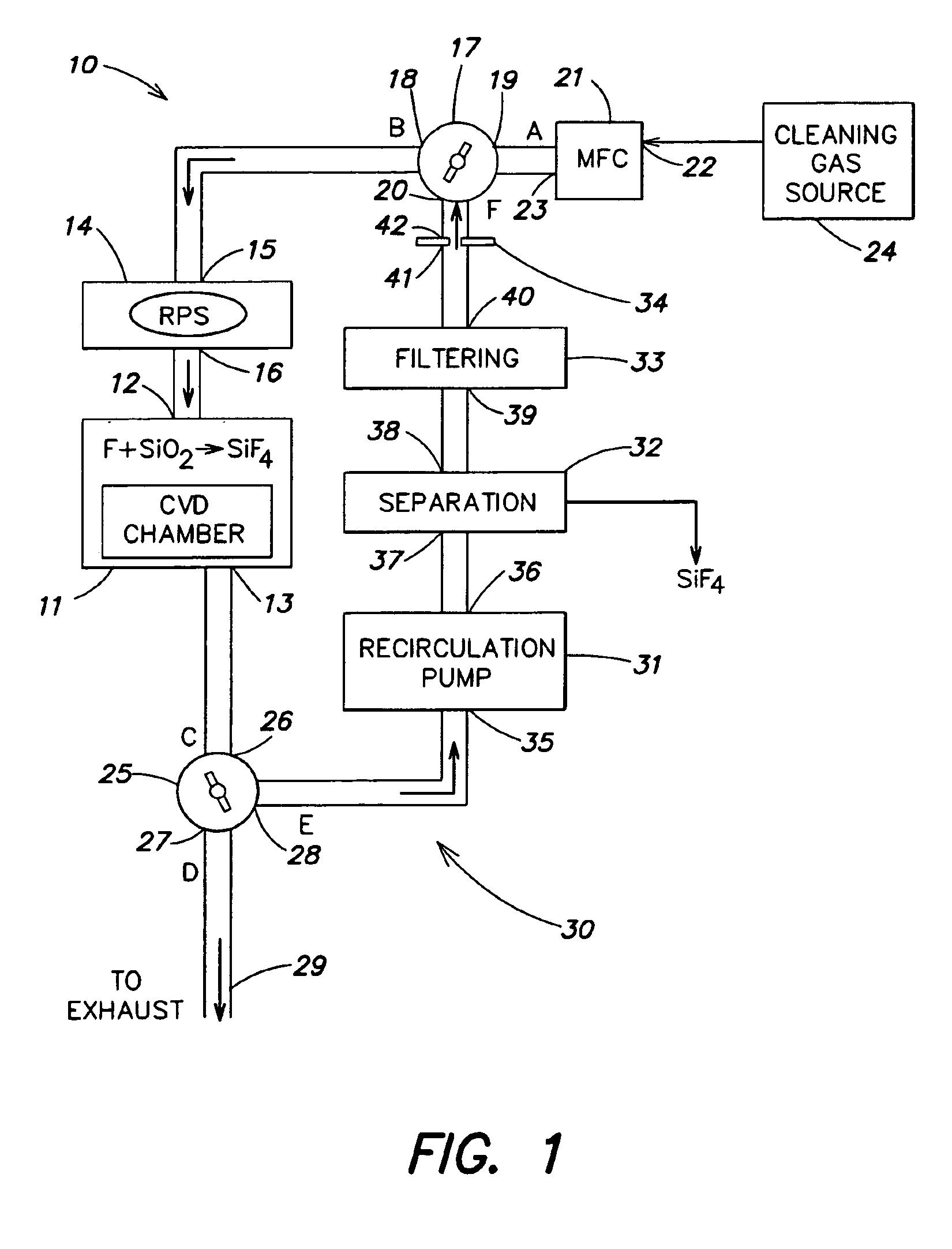

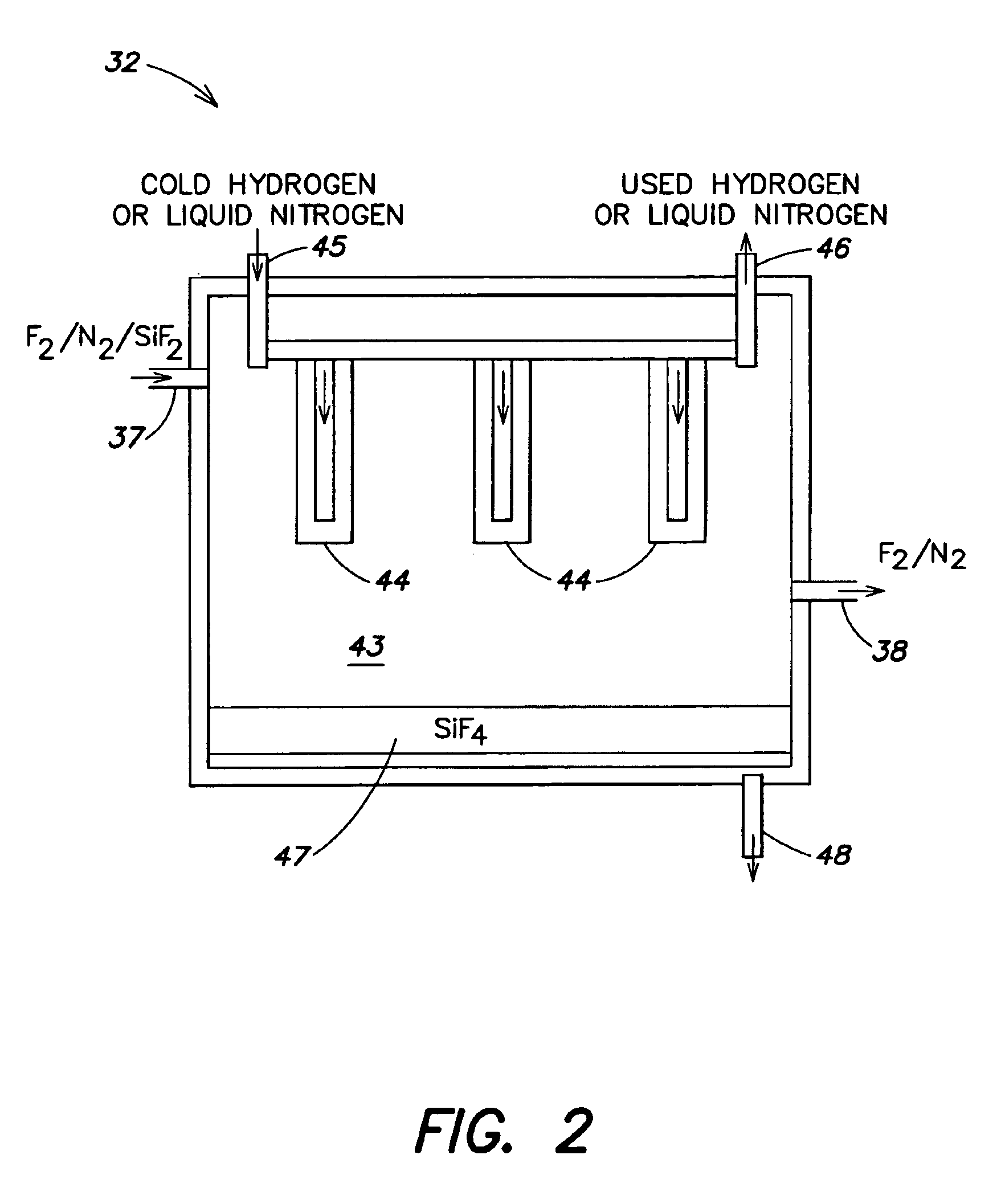

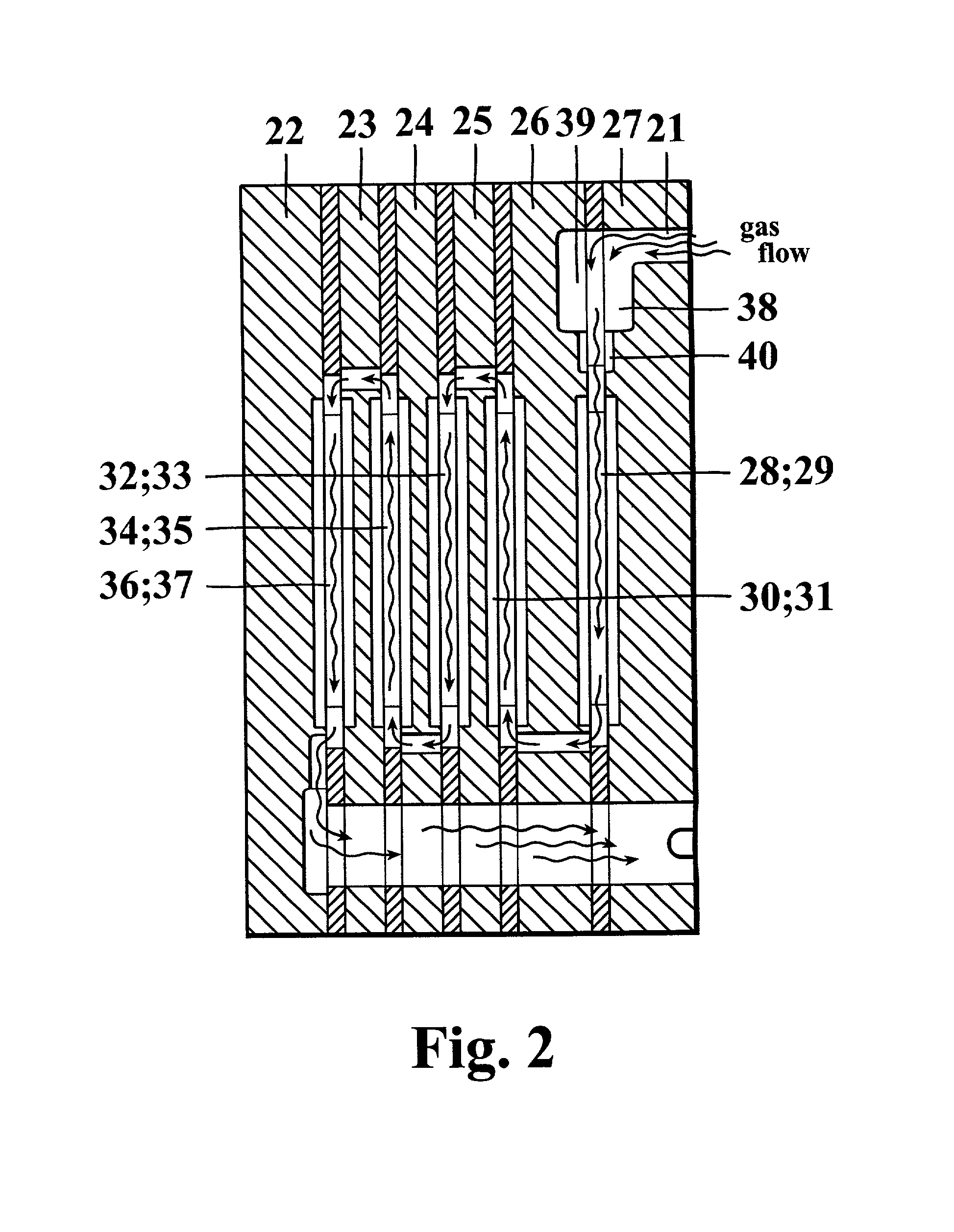

Semiconductor device fabrication chamber cleaning method and apparatus with recirculation of cleaning gas

InactiveUS6863019B2Low costReduce consumptionElectric discharge tubesElectrostatic cleaningNuclear engineeringProduct gas

A method of cleaning a semiconductor fabrication processing chamber involves recirculation of cleaning gas components. Consequently, input cleaning gas is utilized efficiently, and undesirable emissions are reduced. The method includes flowing a cleaning gas to an inlet of a processing chamber, and exposing surfaces of the processing chamber to the cleaning gas to clean the surfaces, thereby producing a reaction product. The method further includes removing an outlet gas including the reaction product from an outlet of the processing chamber, separating at least a portion of the reaction product from the outlet gas, and recirculating a portion of the outlet gas to the inlet of the processing chamber.

Owner:APPLIED MATERIALS INC

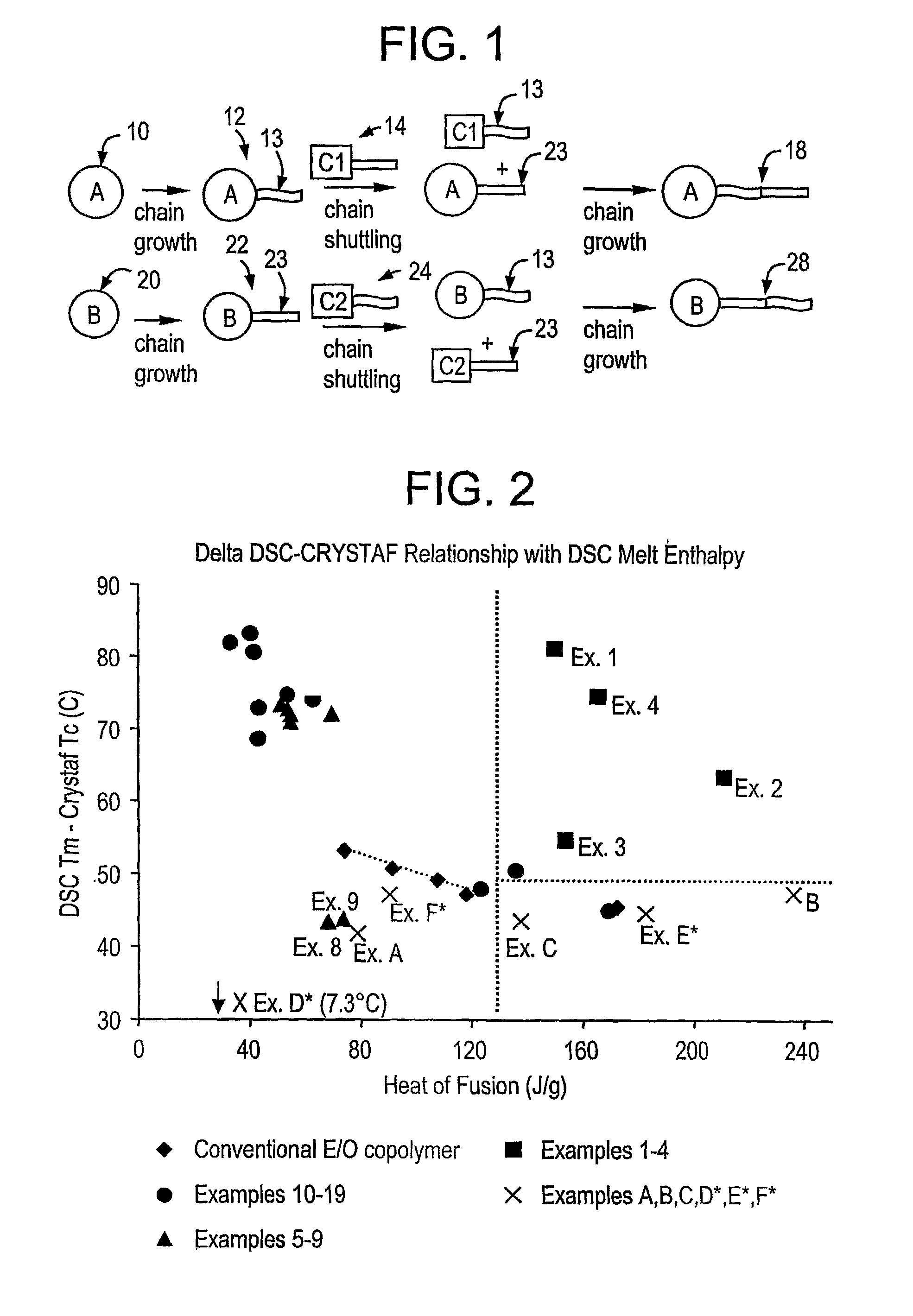

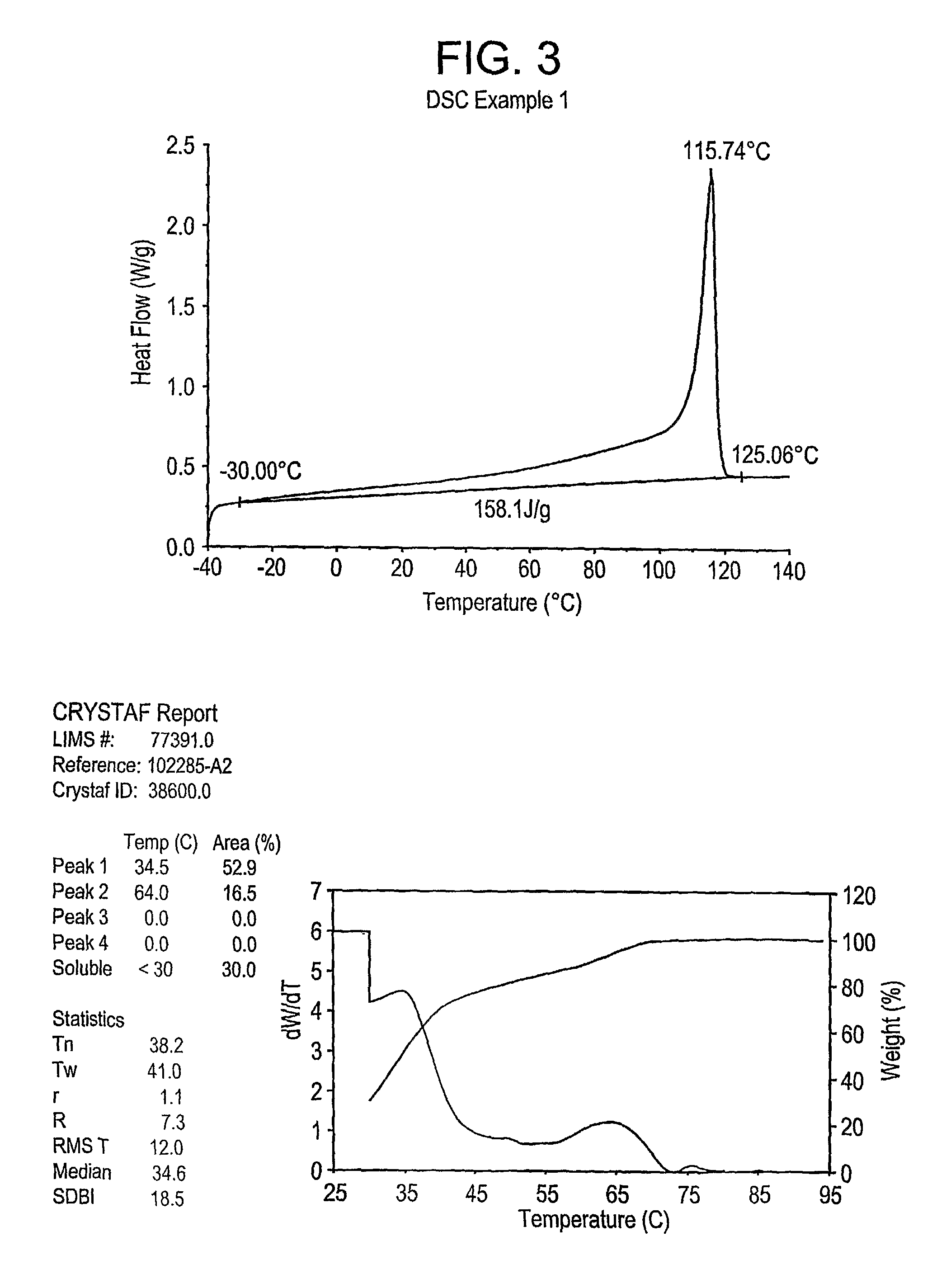

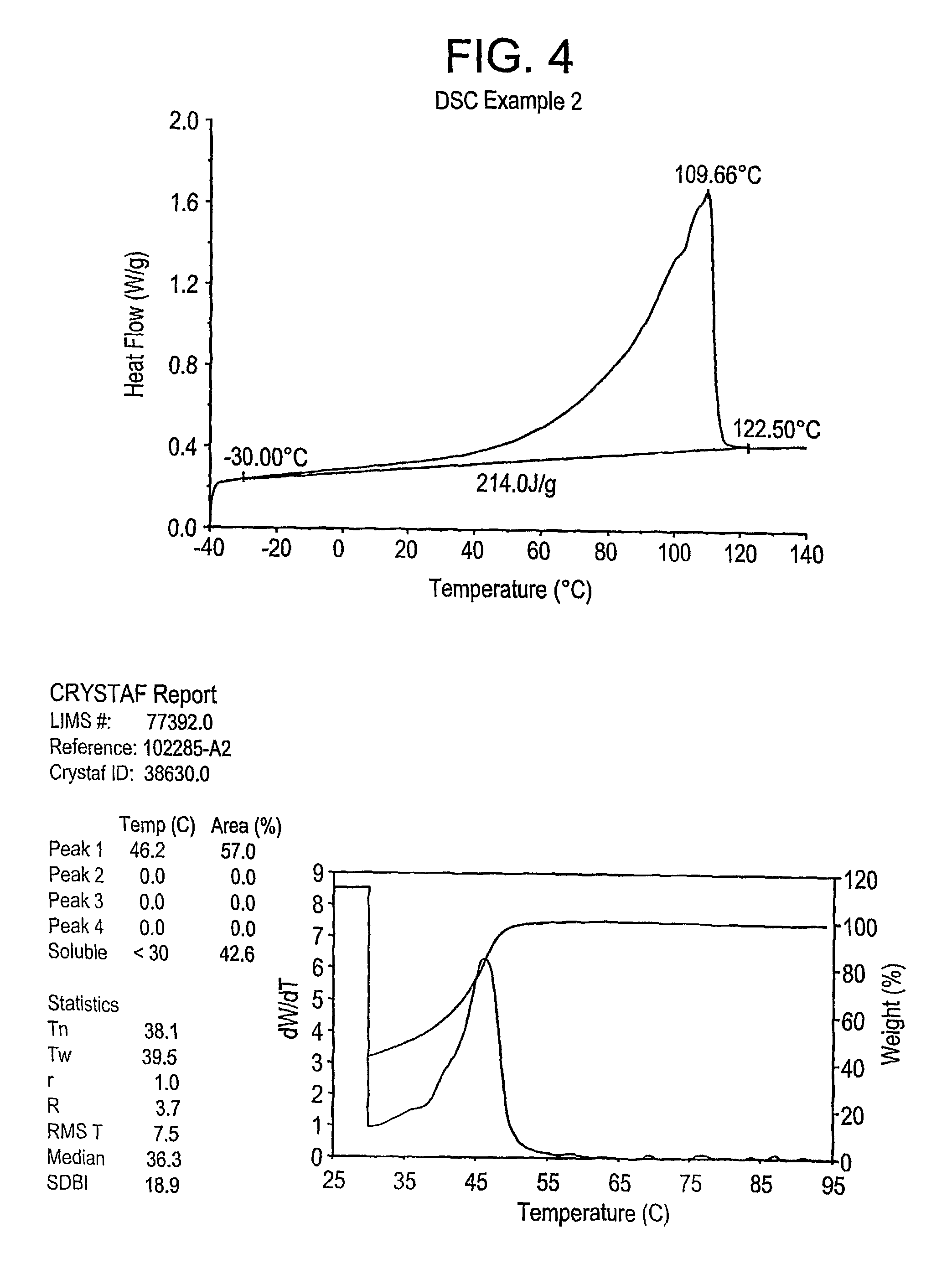

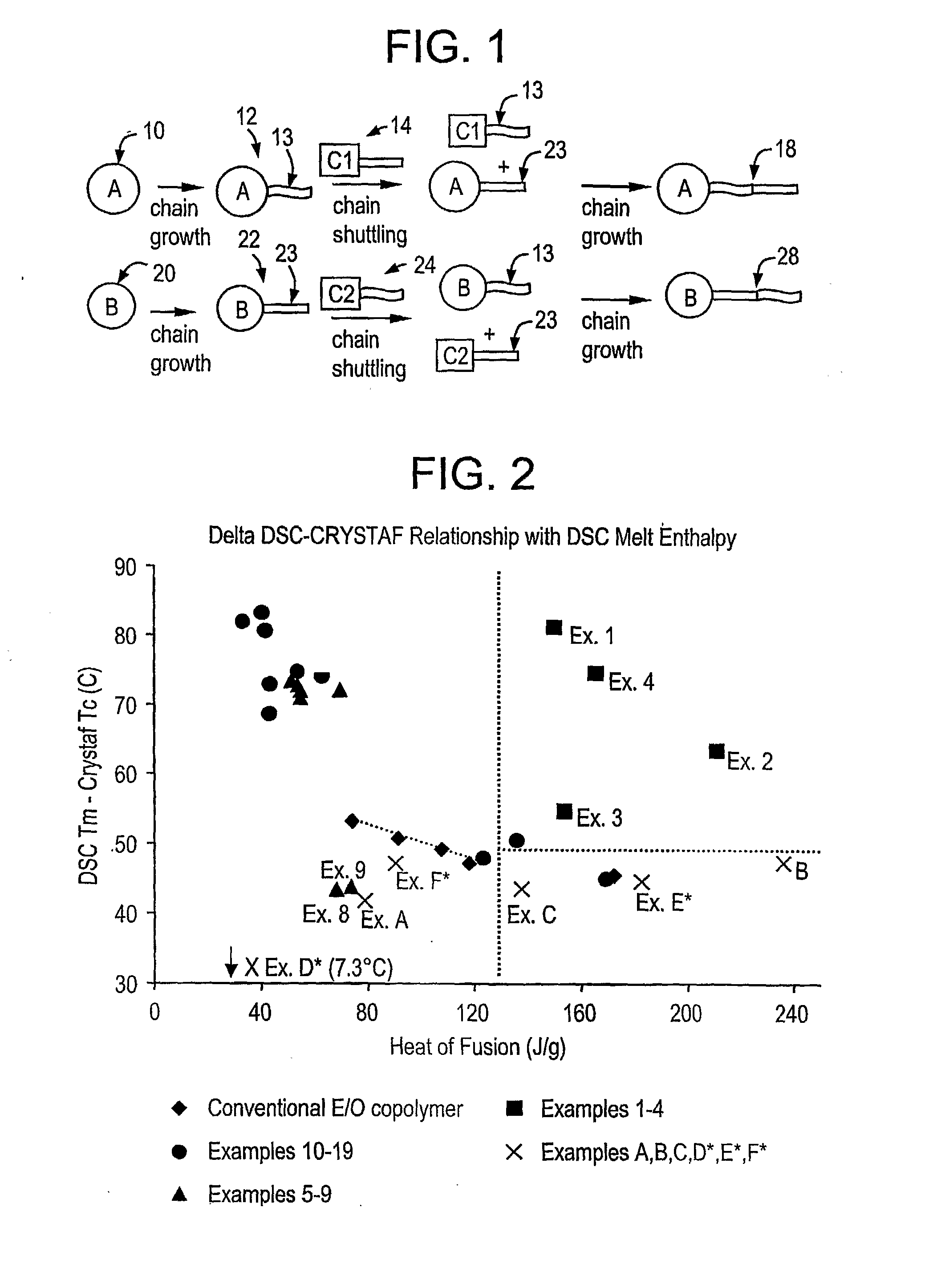

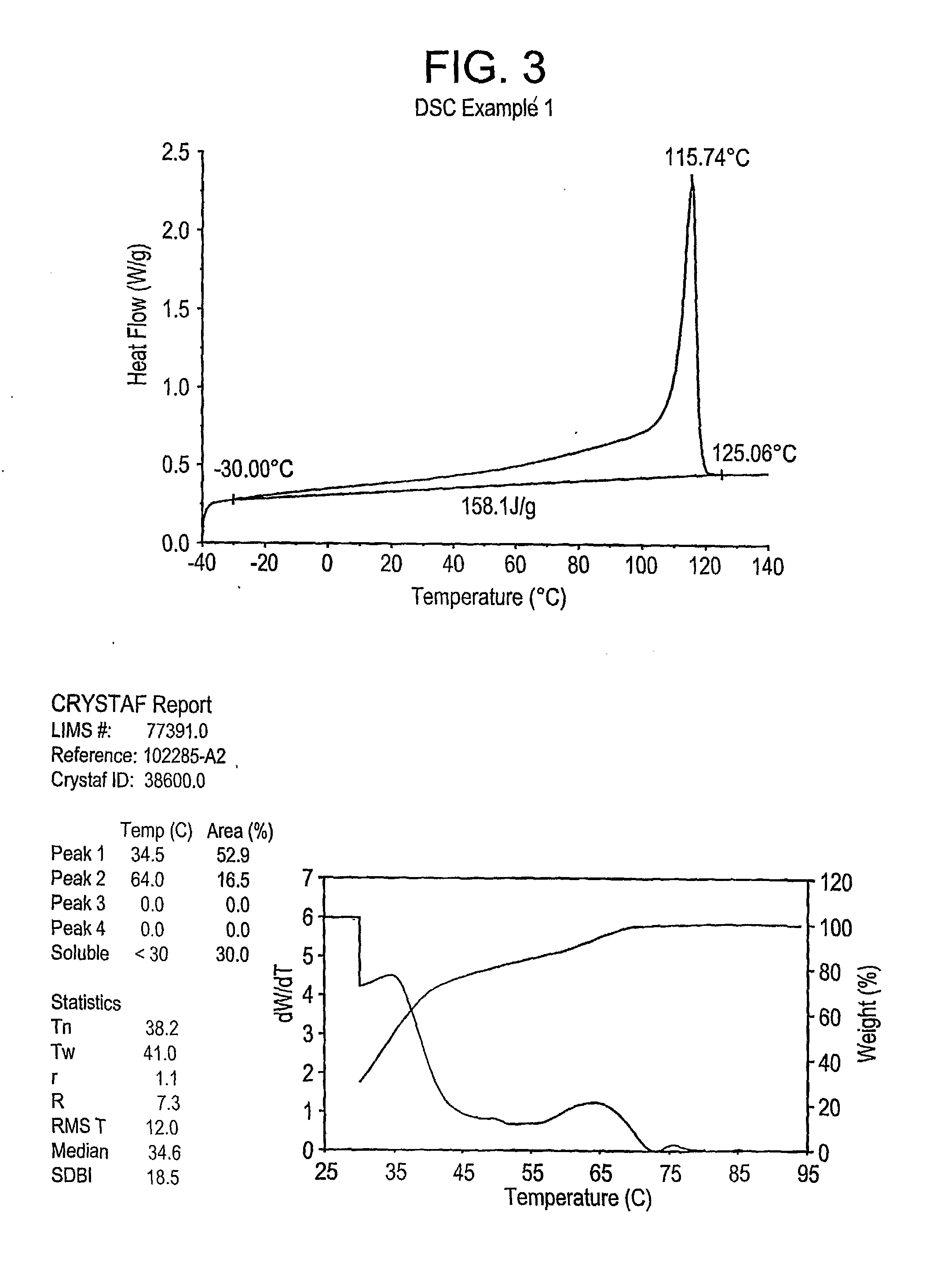

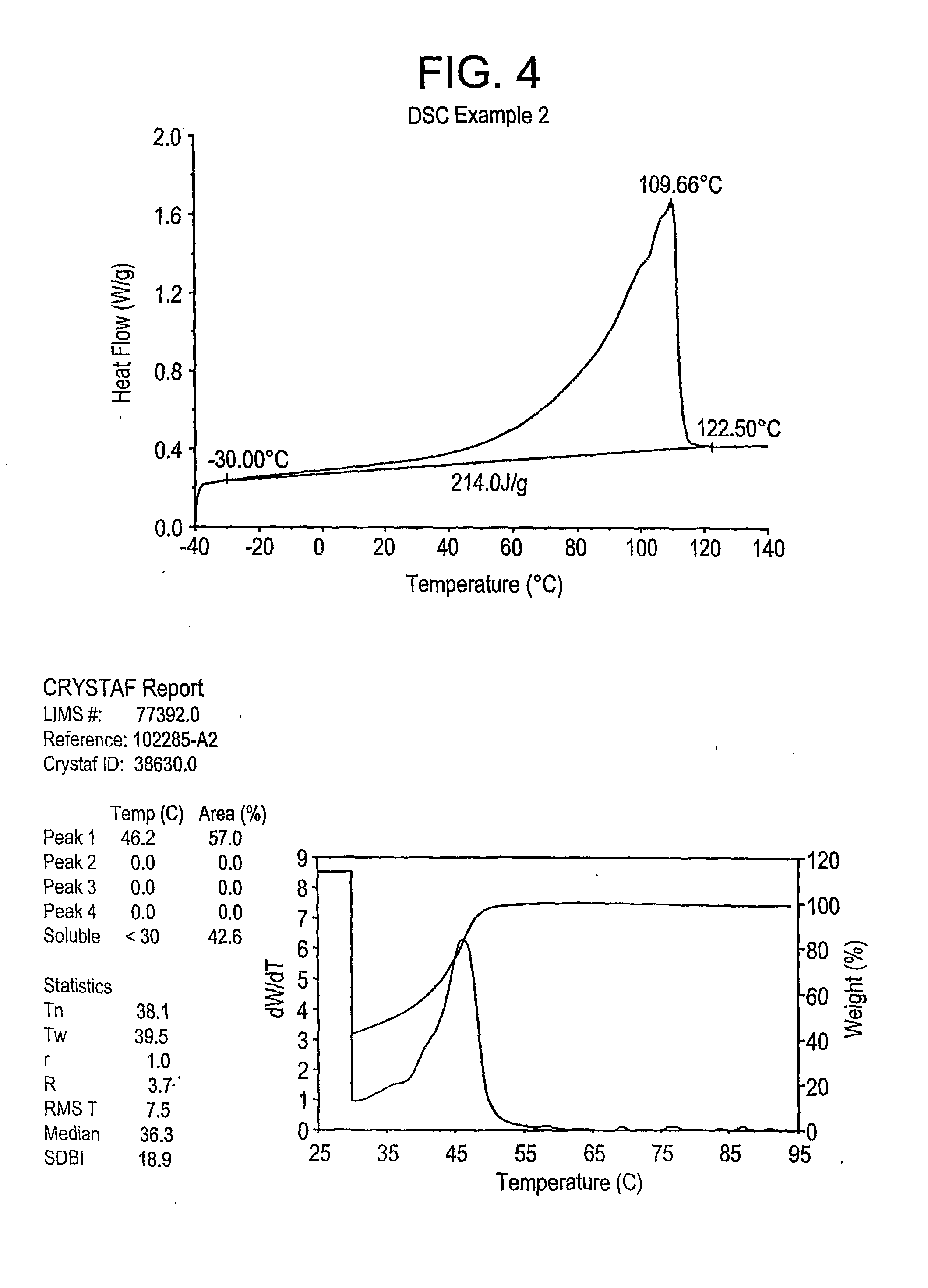

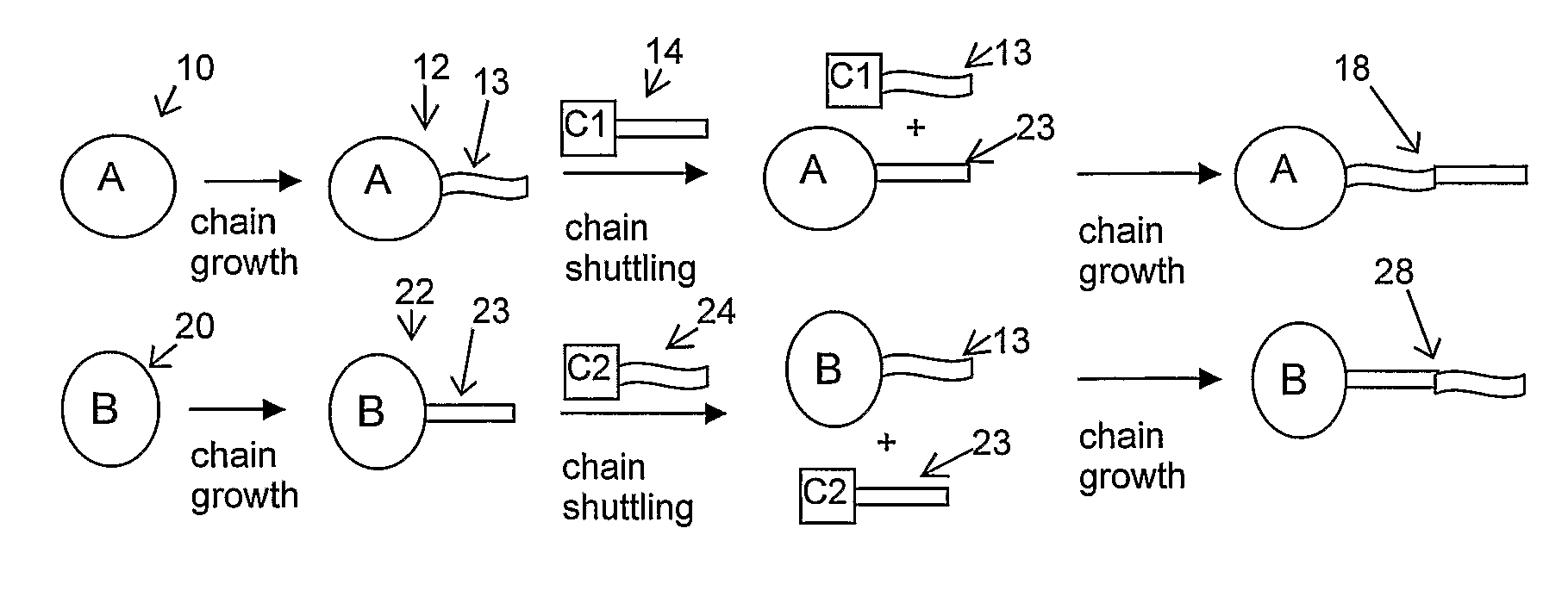

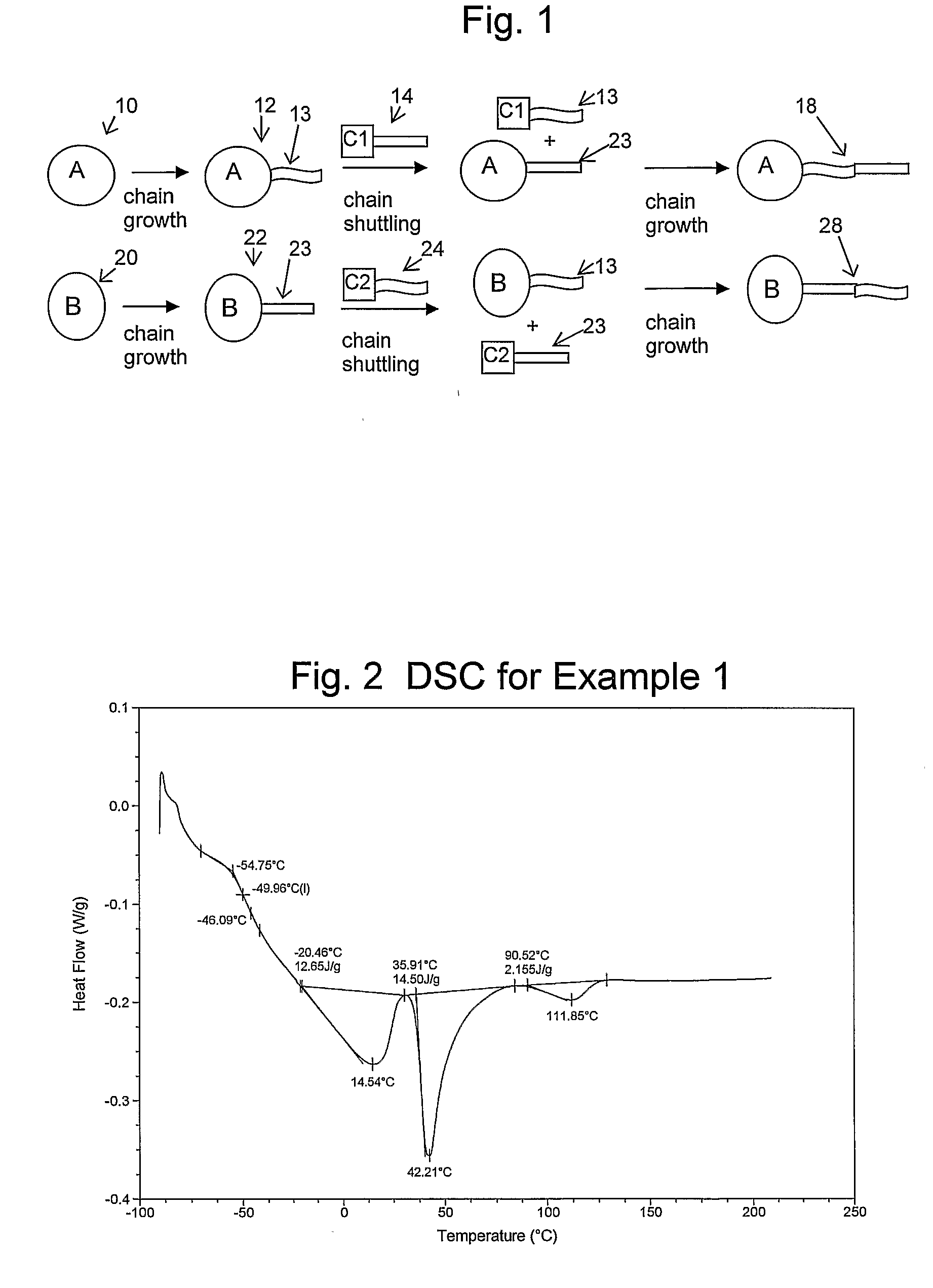

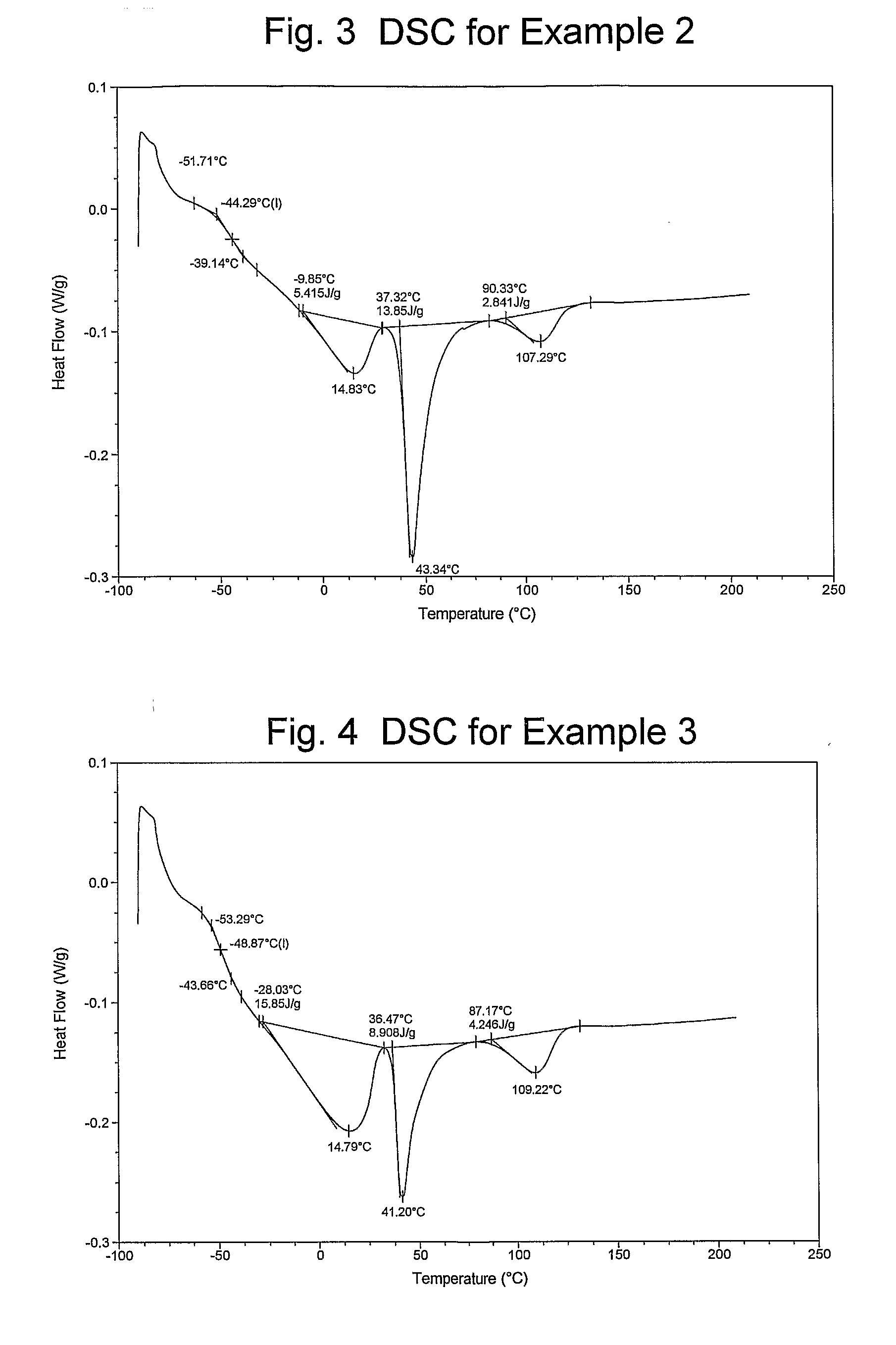

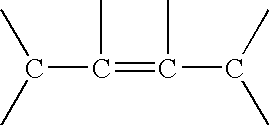

Catalyst composition comprising shuttling agent for ethylene multi-block copolymer formation

ActiveUS7858706B2Improve efficiencySynthetic resin layered productsThin material handlingOlefin polymerizationPolymerization catalysts

A composition for use in forming a multi-block copolymer, said copolymer containing therein two or more segments or blocks differing in chemical or physical properties, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

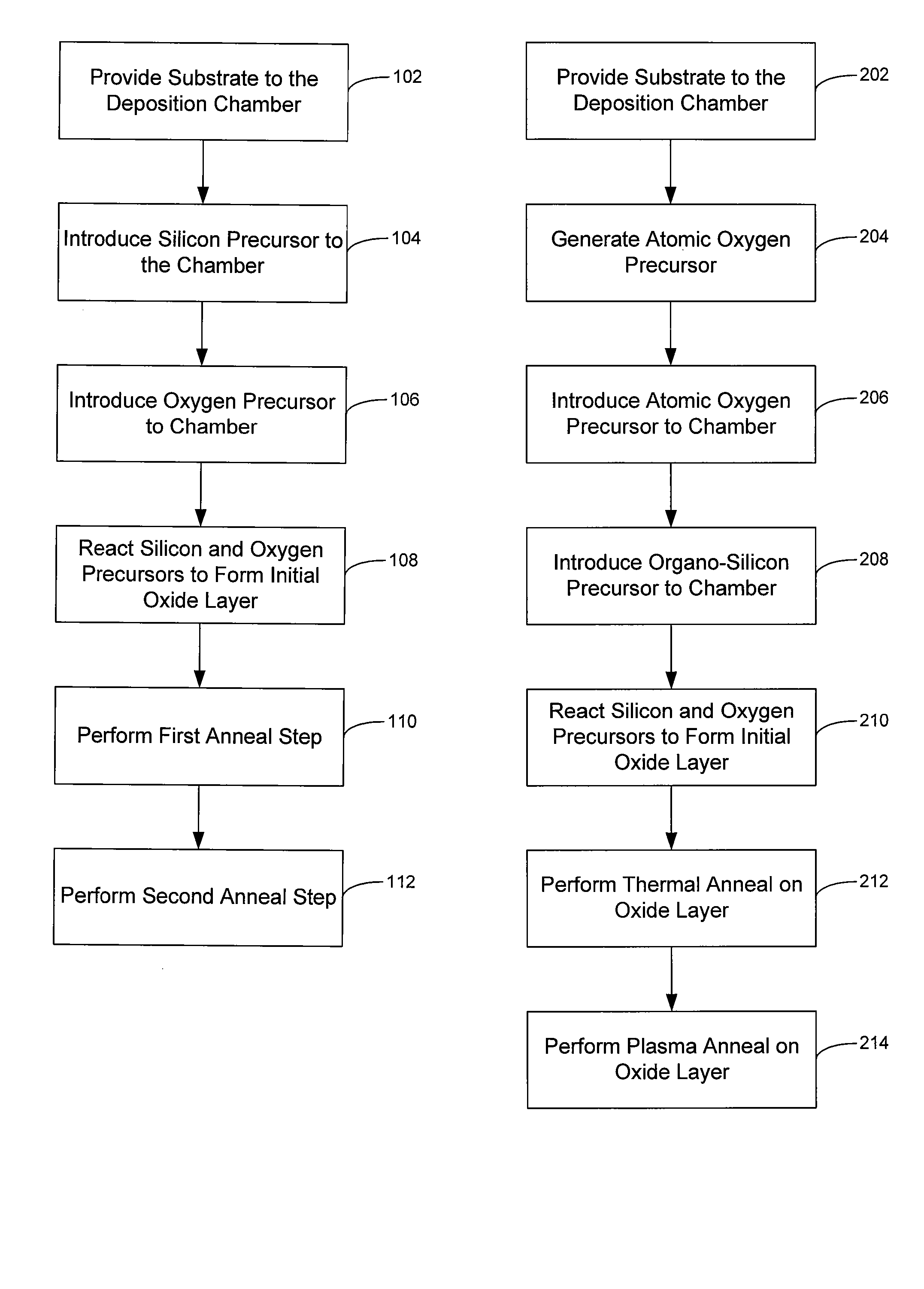

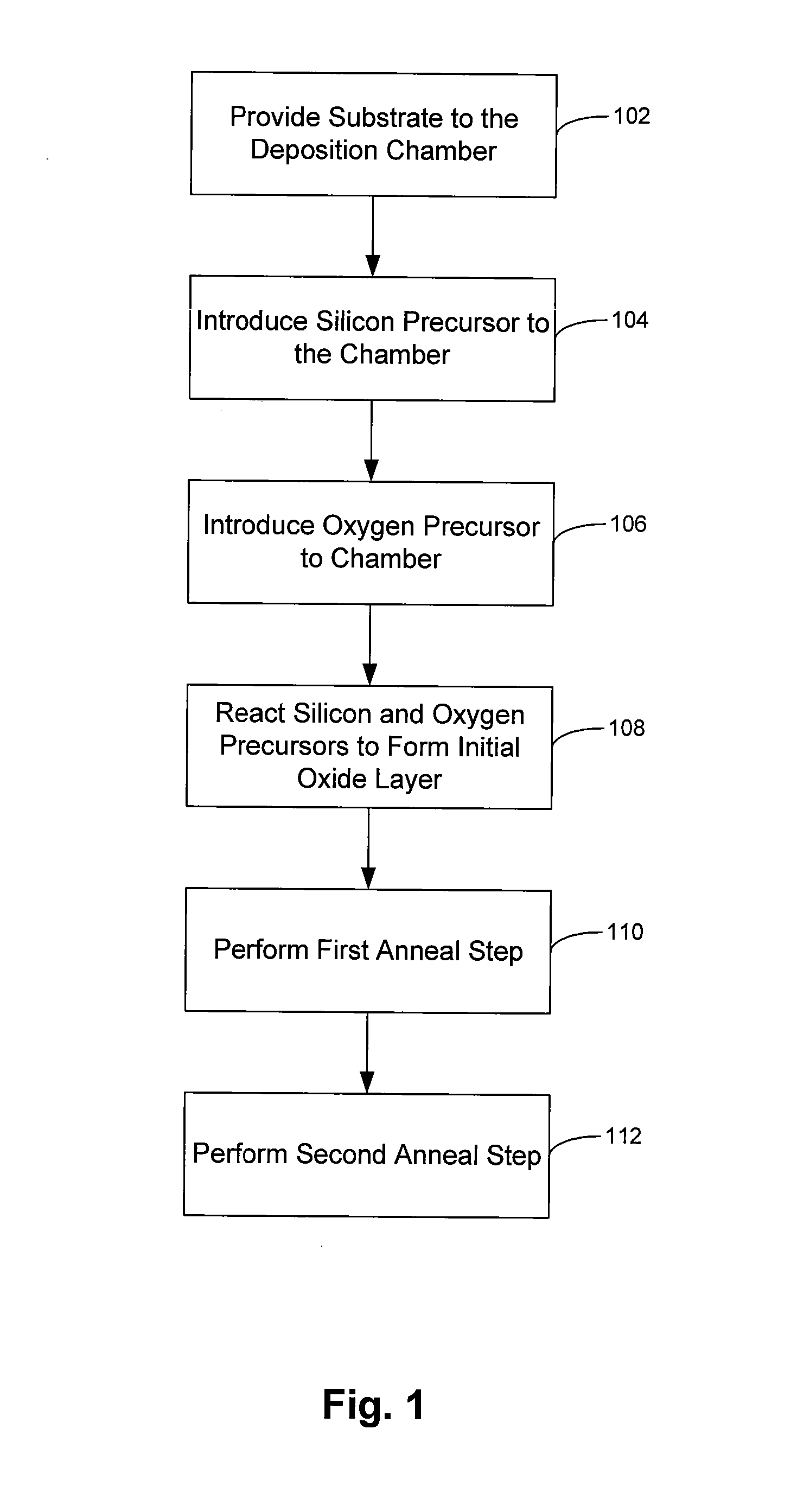

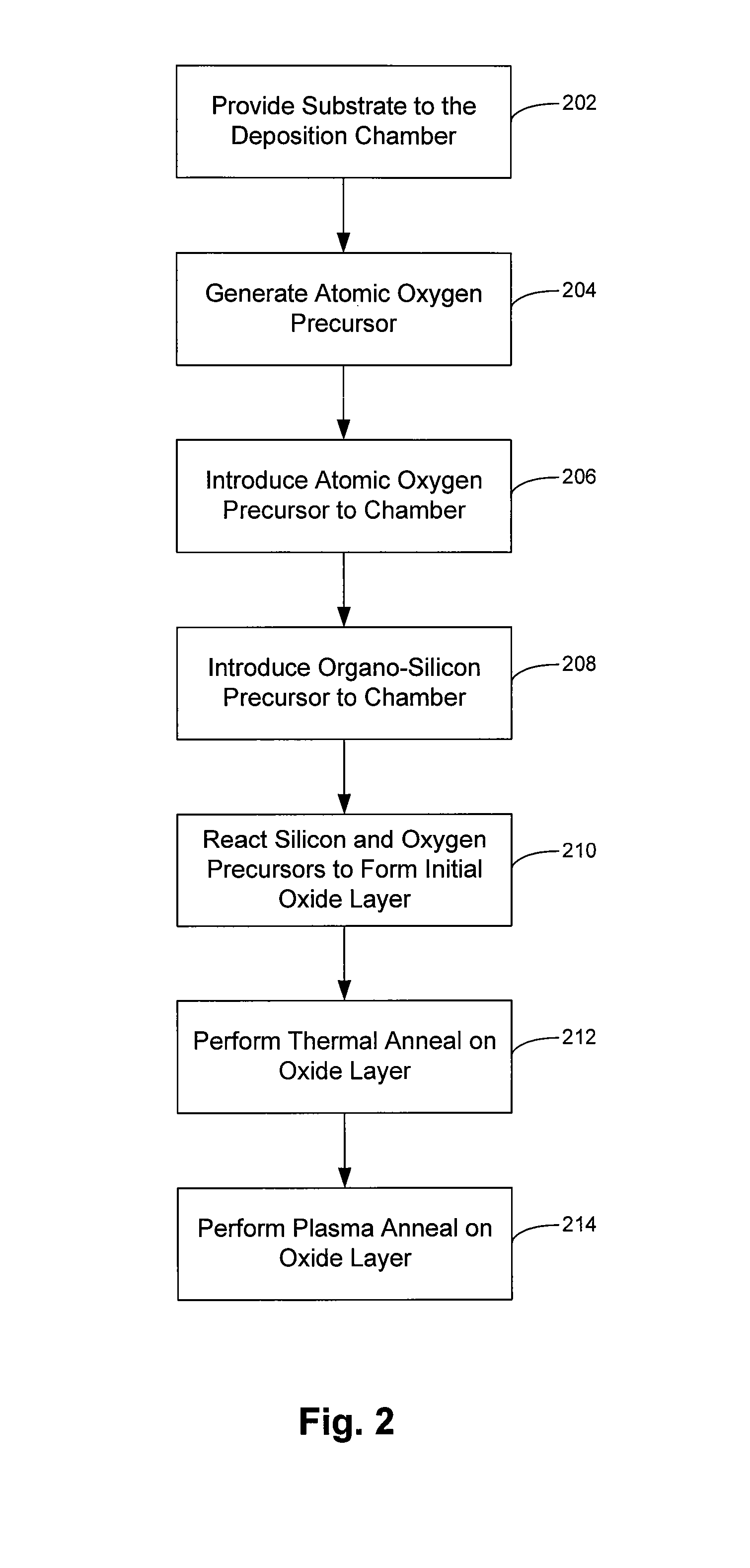

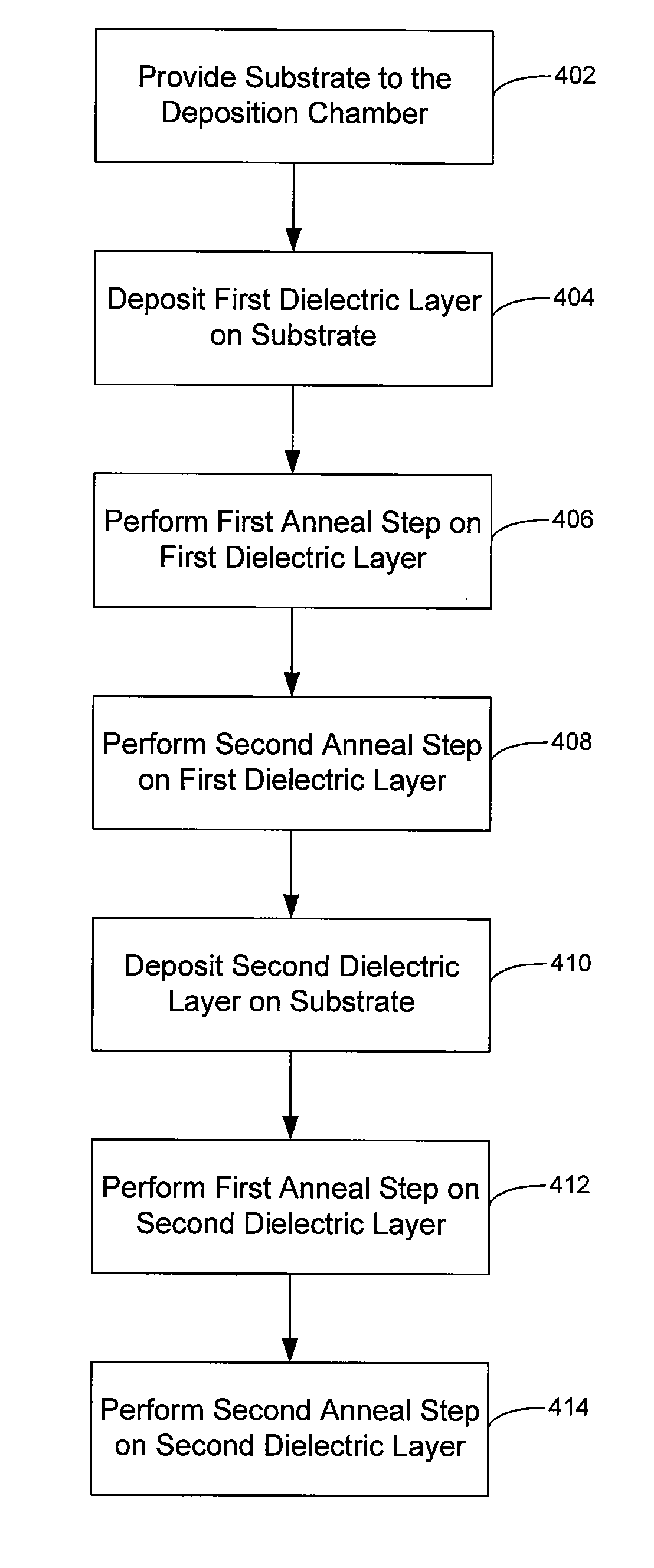

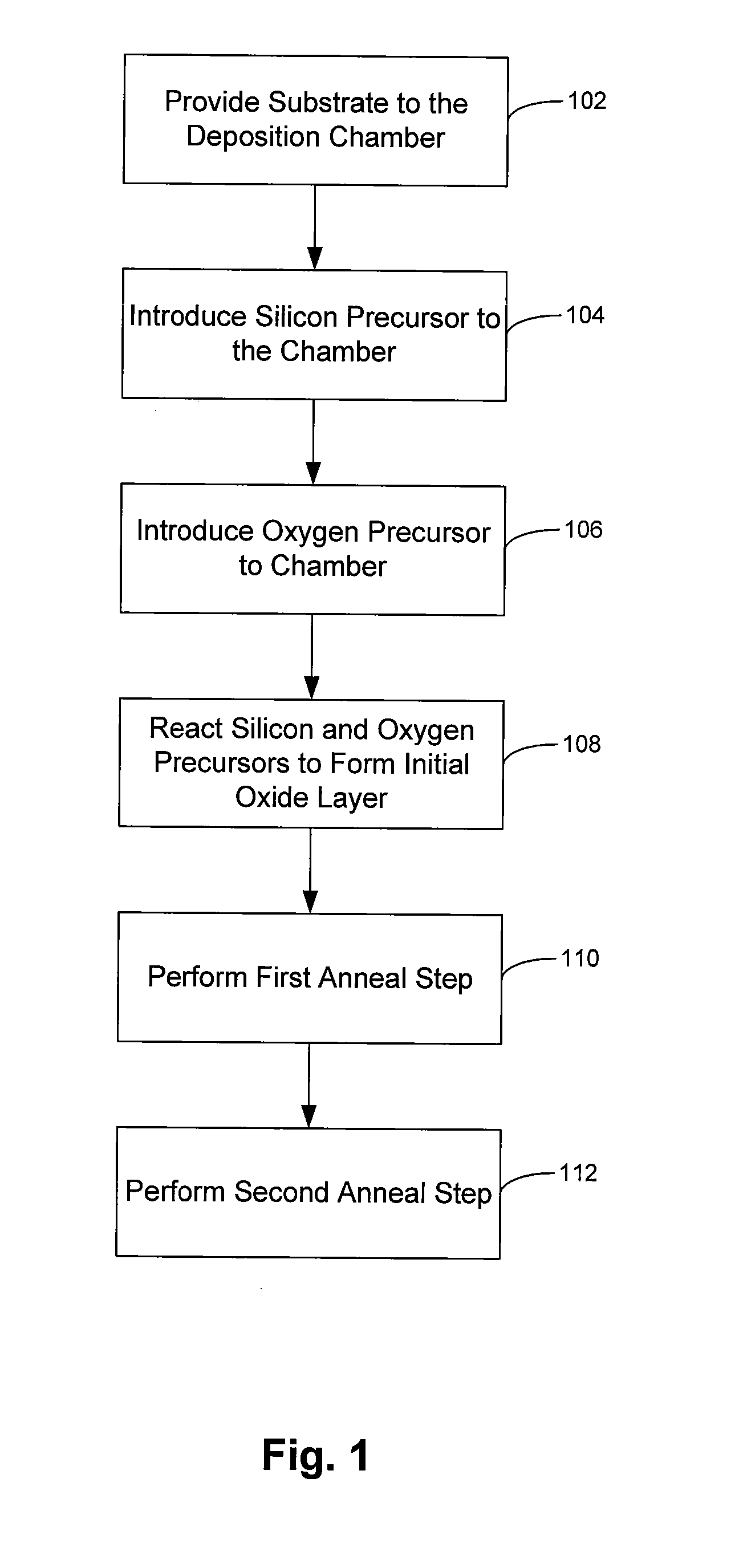

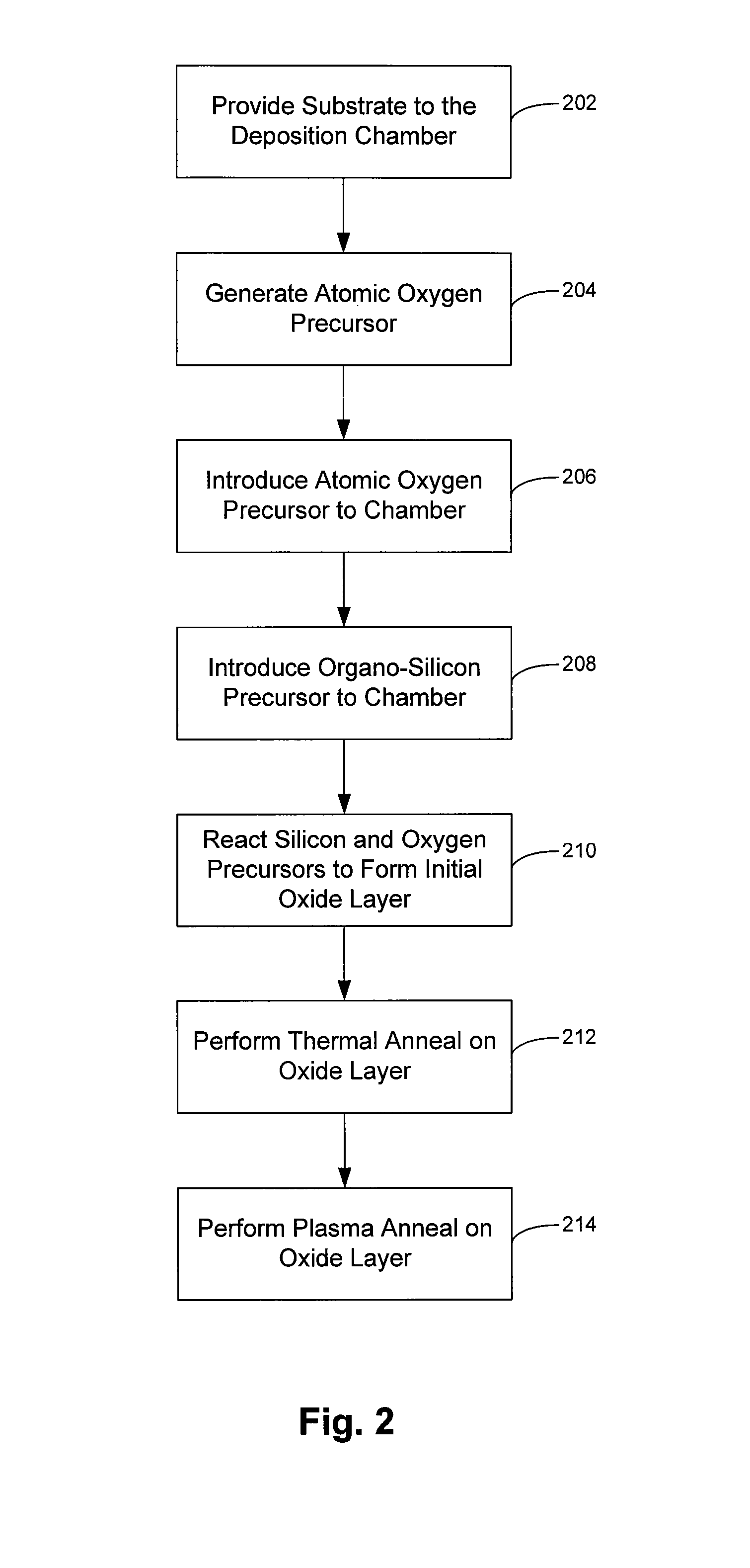

Method for depositing and curing low-k films for gapfill and conformal film applications

ActiveUS20080026597A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideAtomic oxygen

Methods of making a silicon oxide layer on a substrate are described. The methods may include forming the silicon oxide layer on the substrate in a reaction chamber by reacting an atomic oxygen precursor and a silicon precursor and depositing reaction products on the substrate. The atomic oxygen precursor is generated outside the reaction chamber. The methods also include heating the silicon oxide layer at a temperature of about 600° C. or less, and exposing the silicon oxide layer to an induced coupled plasma. Additional methods are described where the deposited silicon oxide layer is cured by exposing the layer to ultra-violet light, and also exposing the layer to an induced coupled plasma.

Owner:APPLIED MATERIALS INC

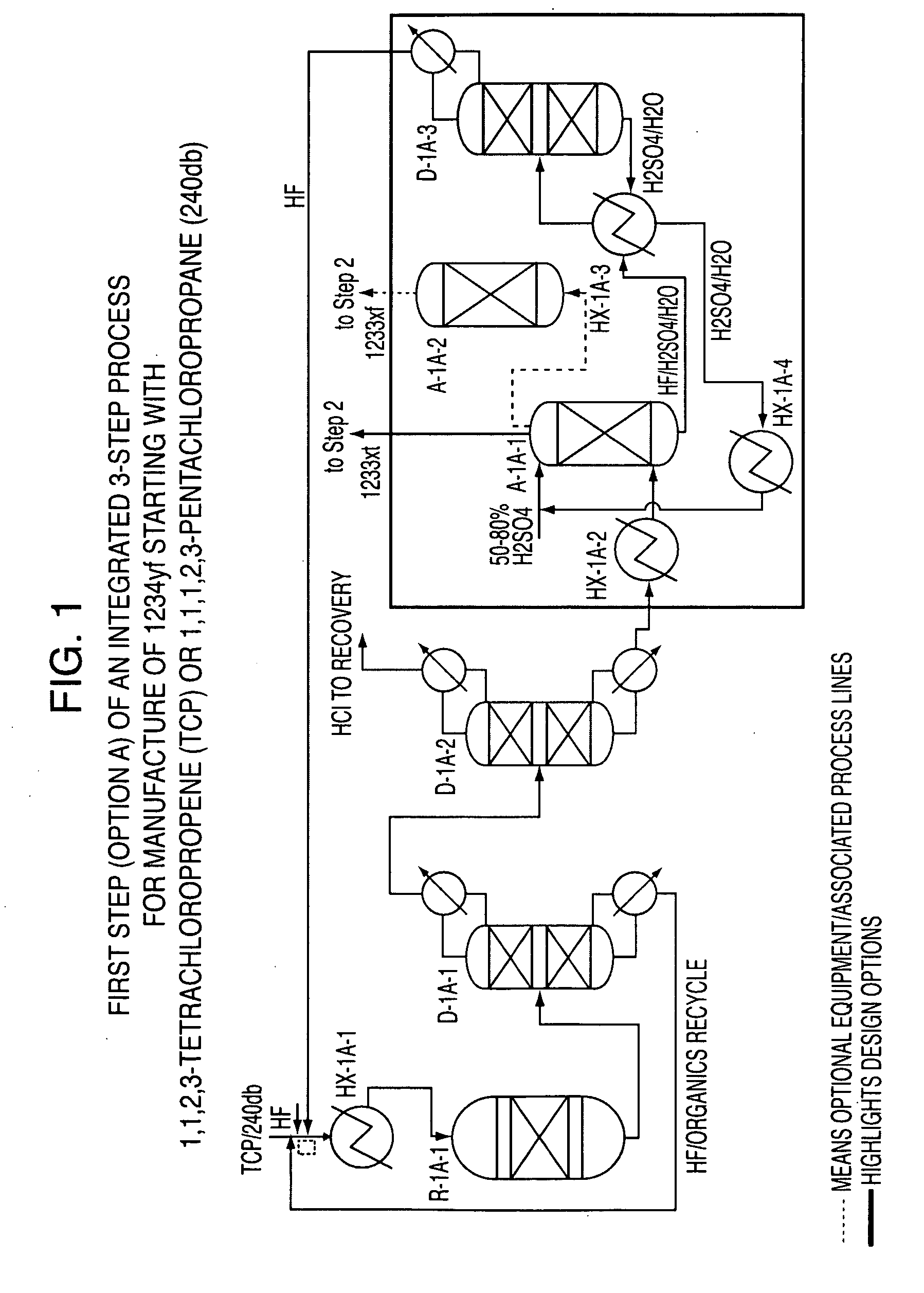

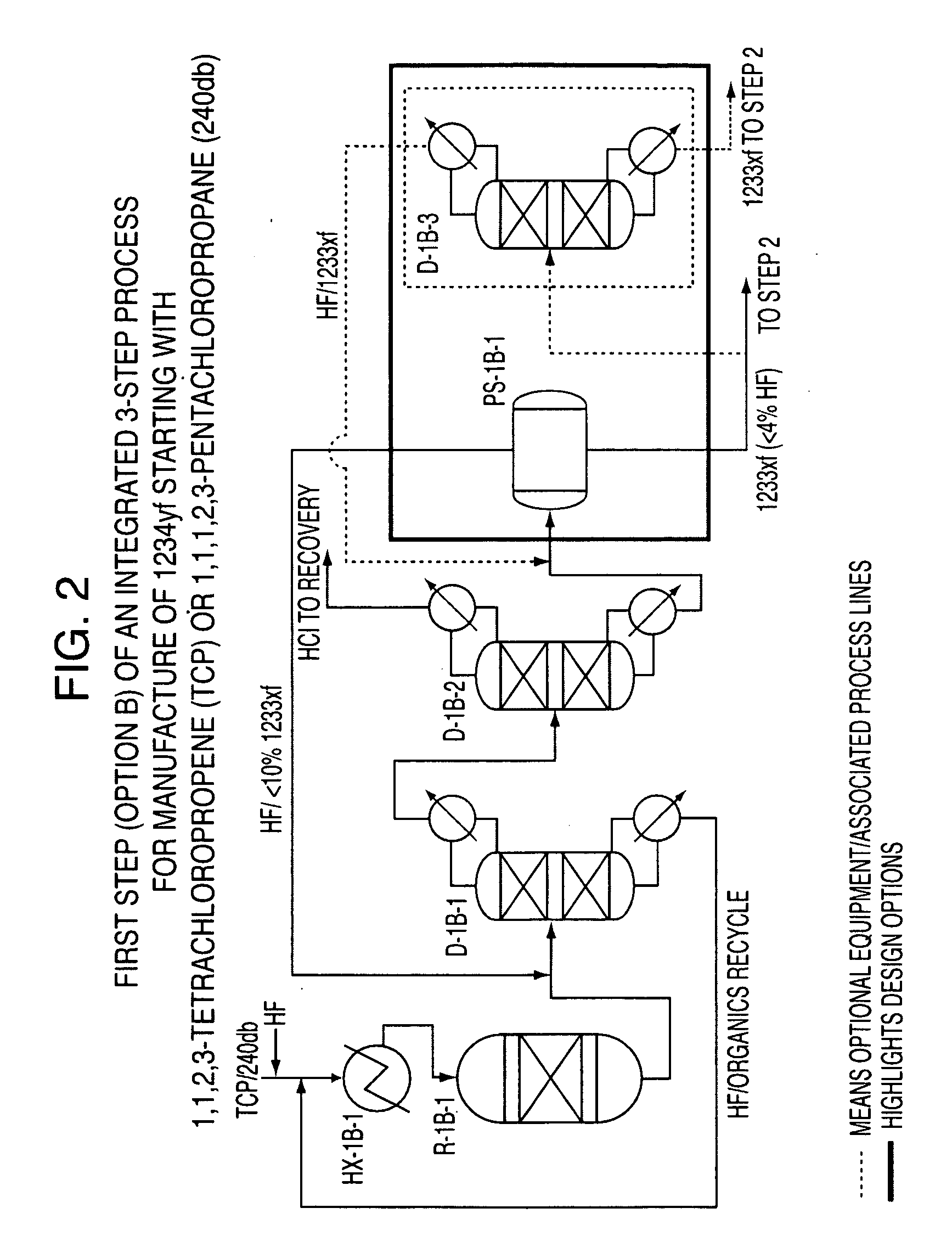

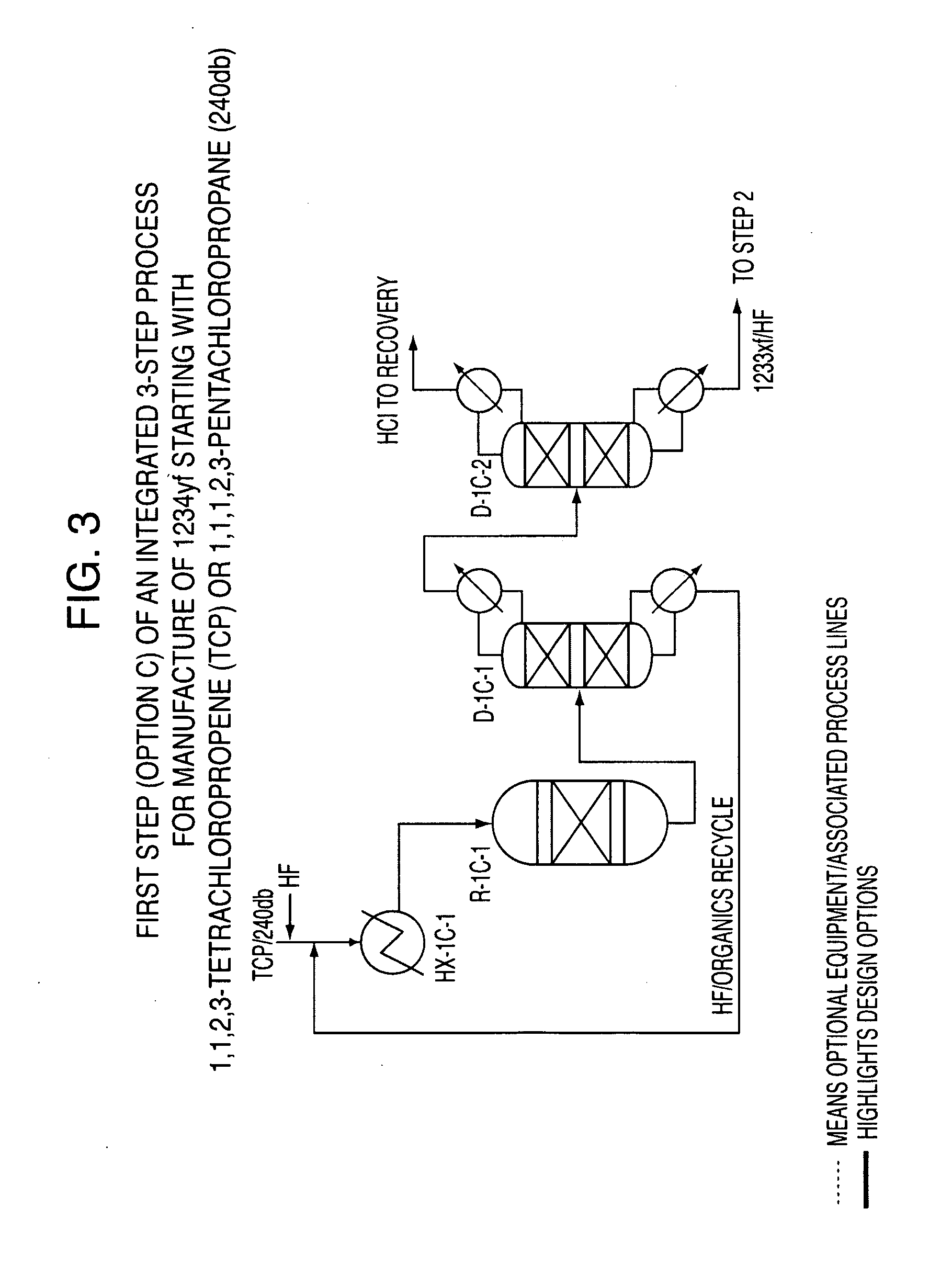

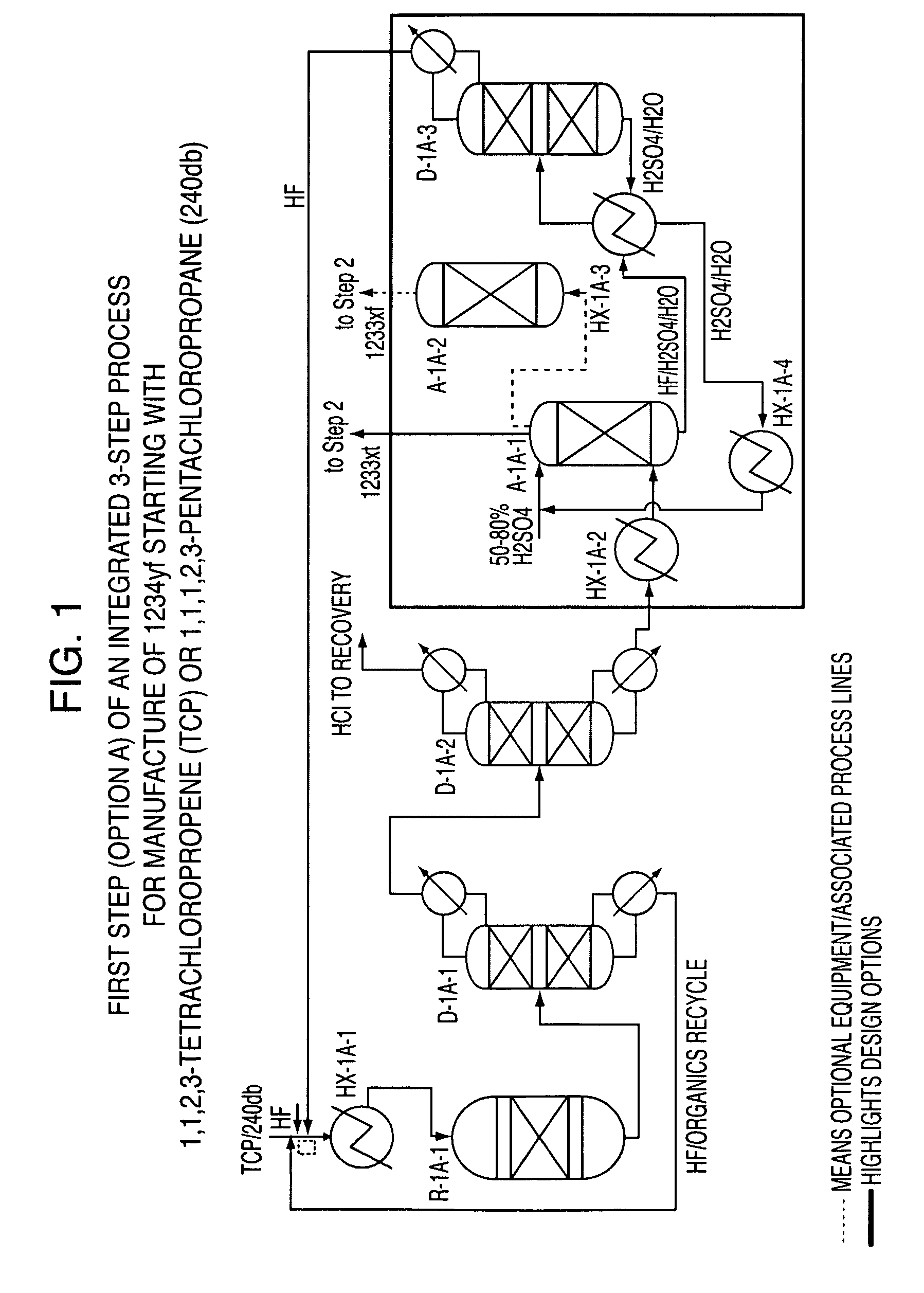

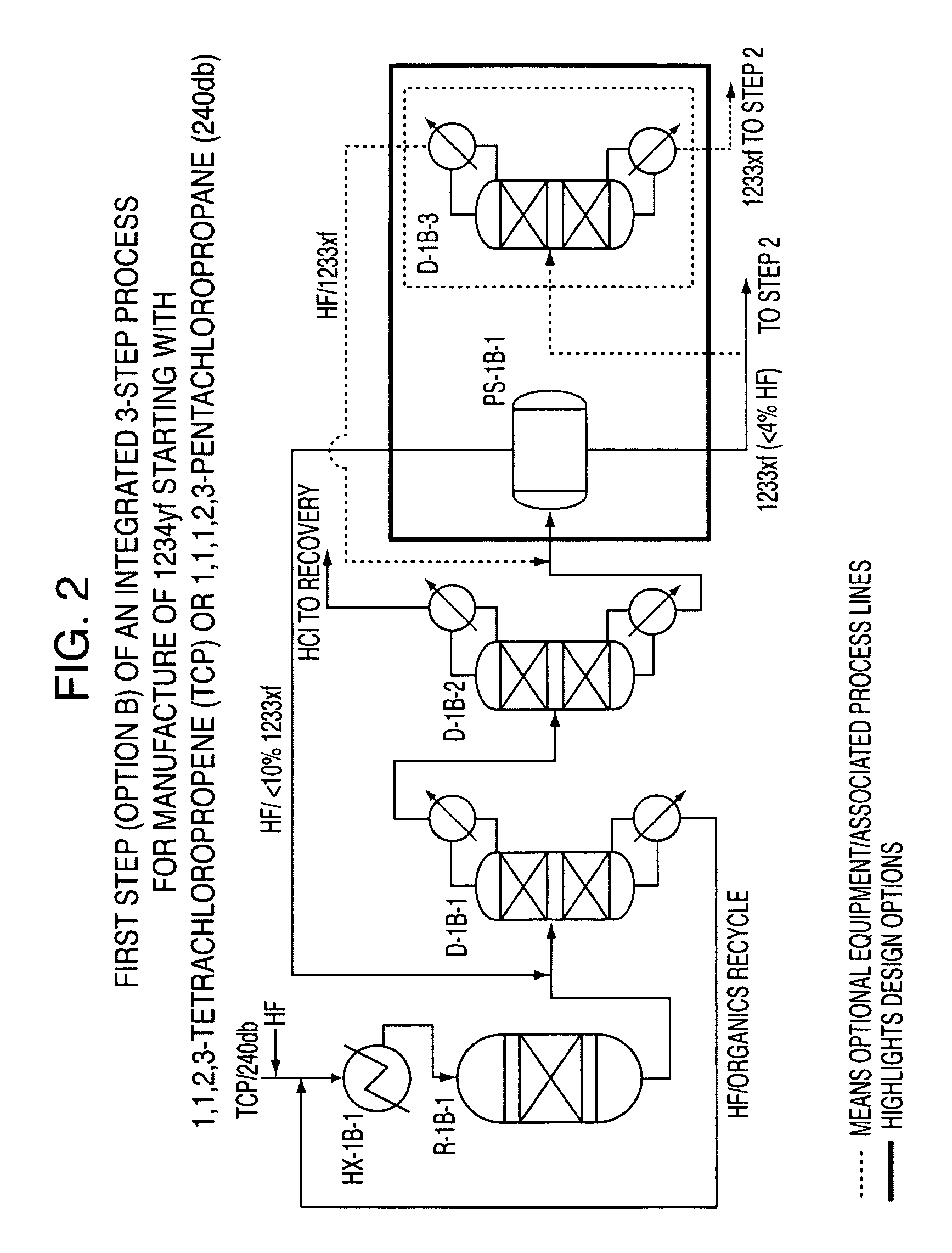

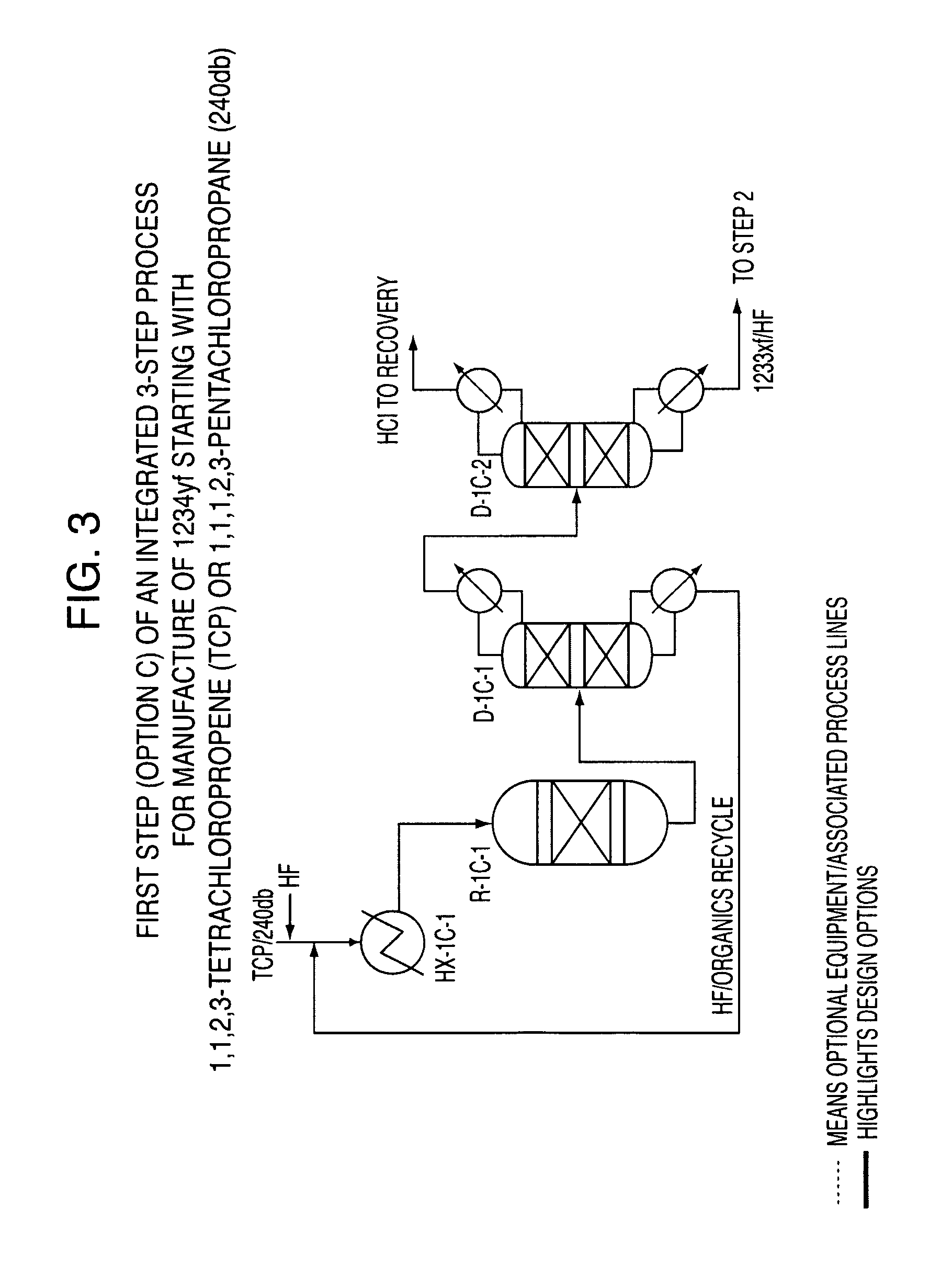

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS20090240090A1Maximize raw material utilizationMaximize product yieldPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

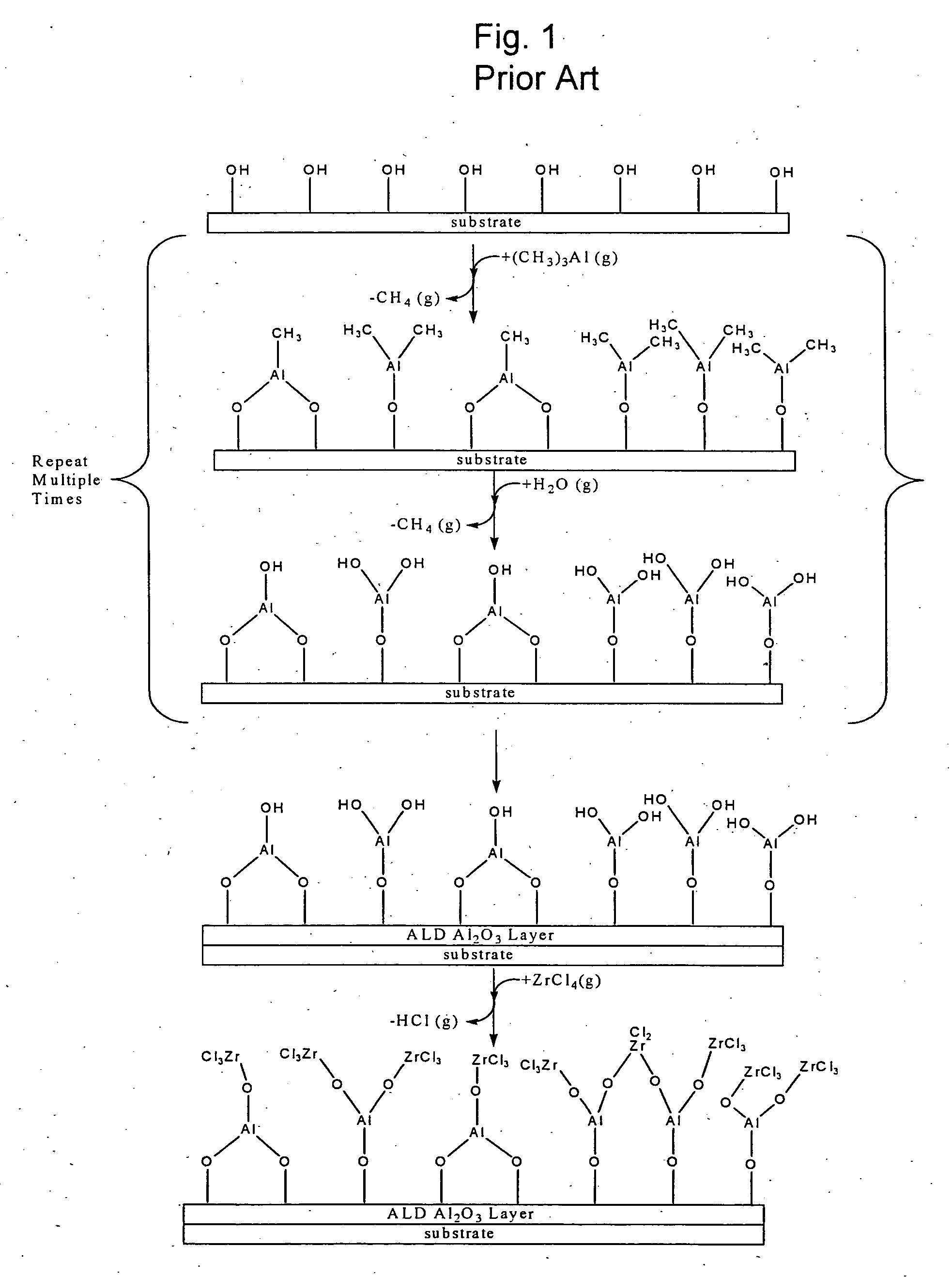

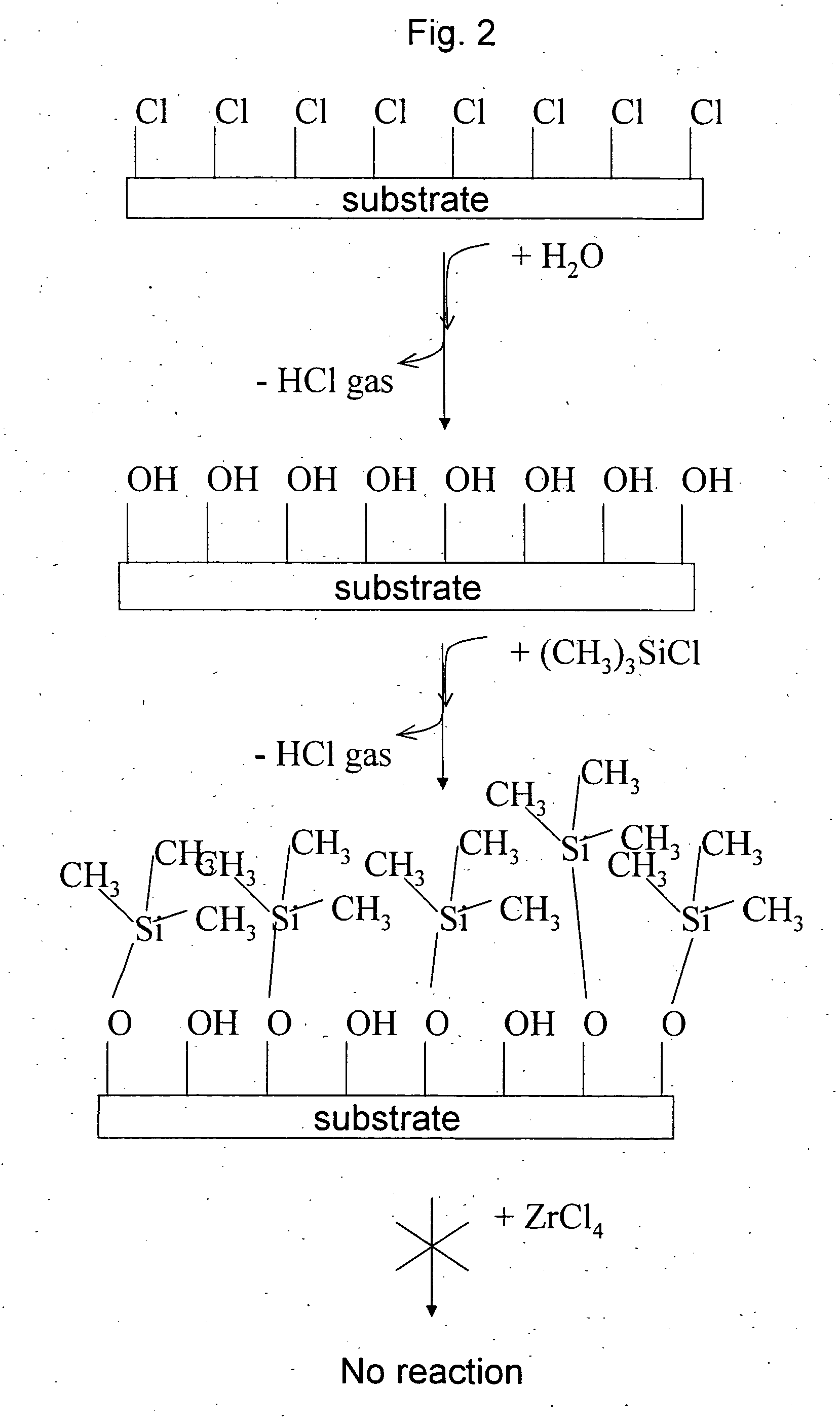

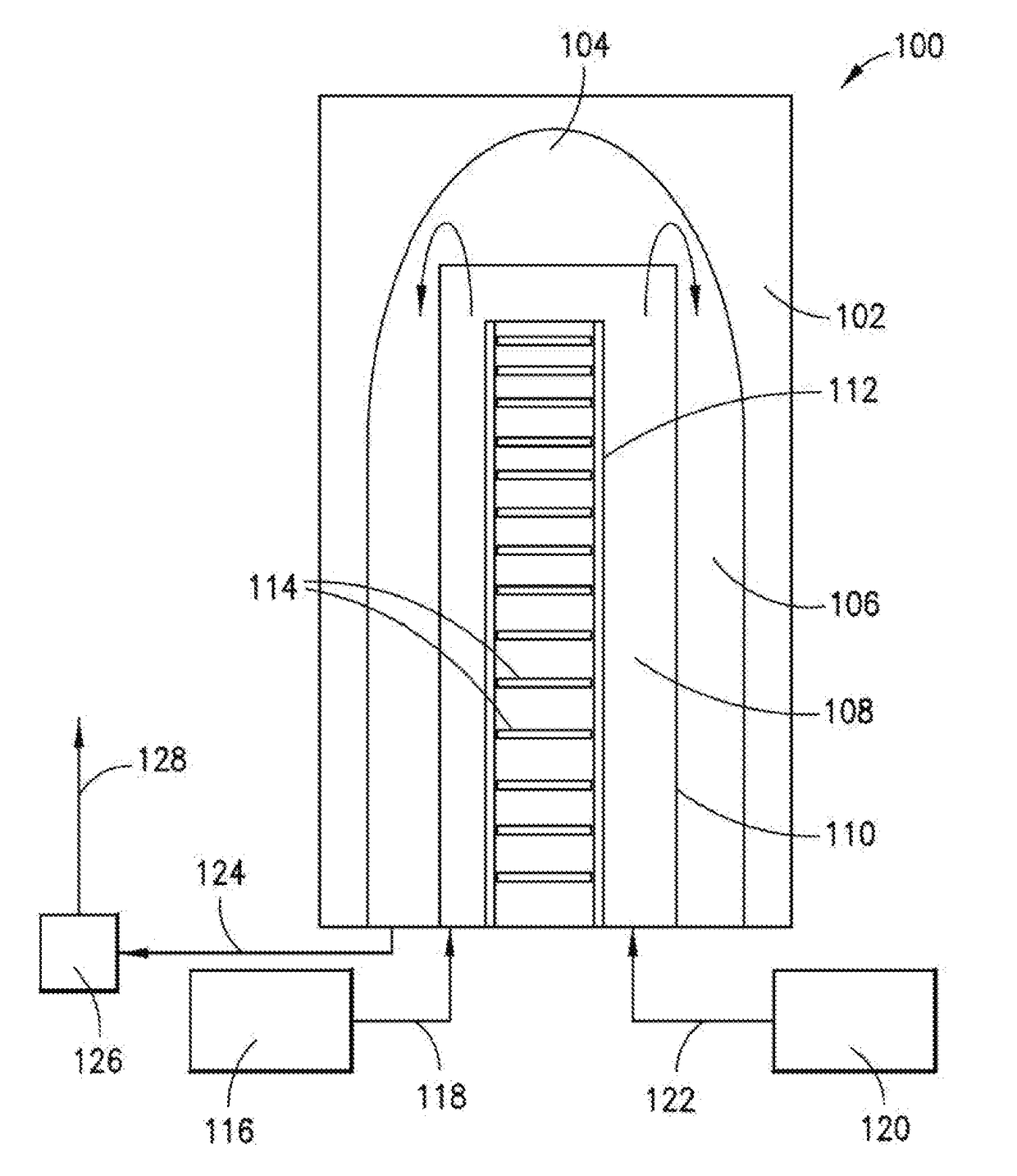

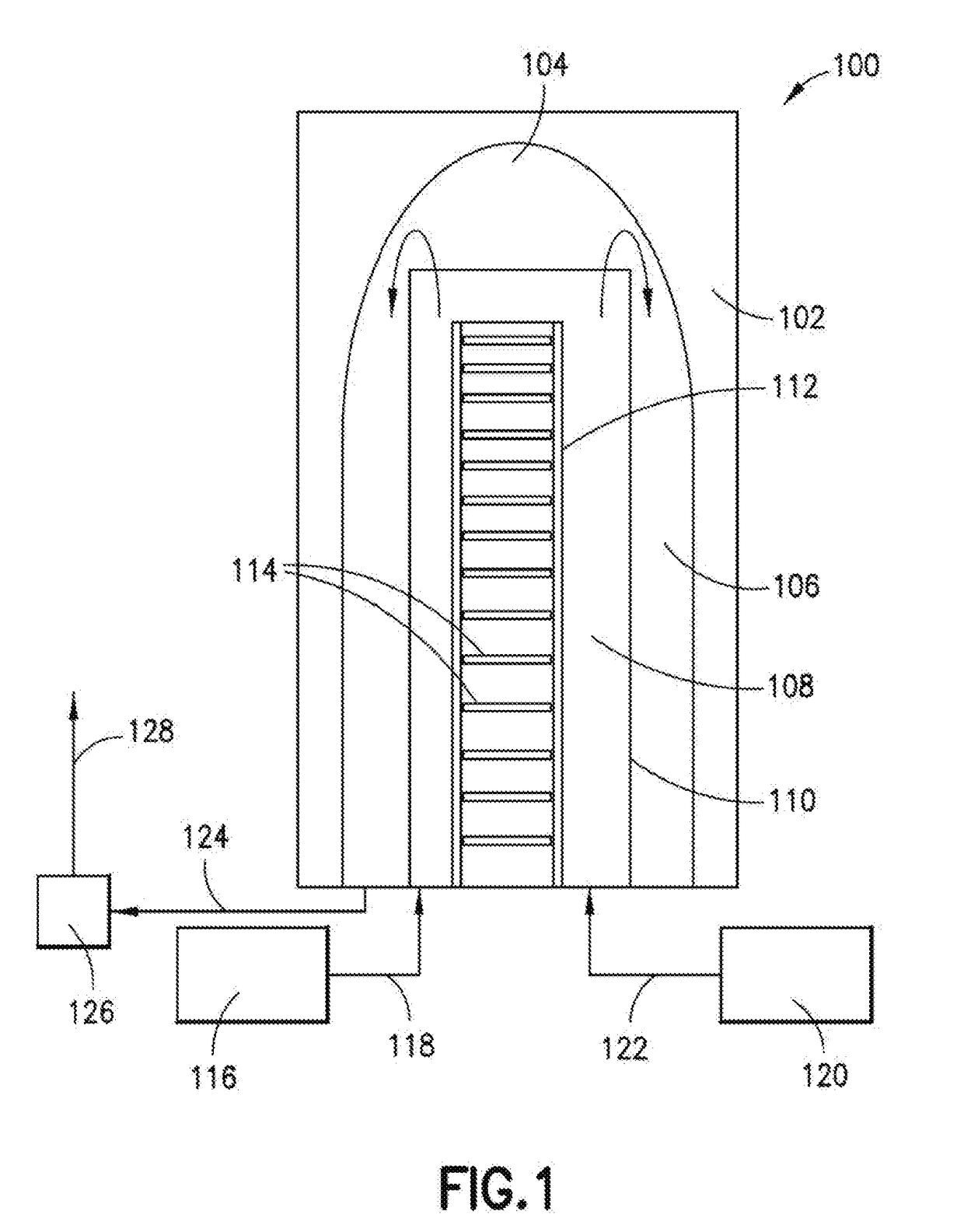

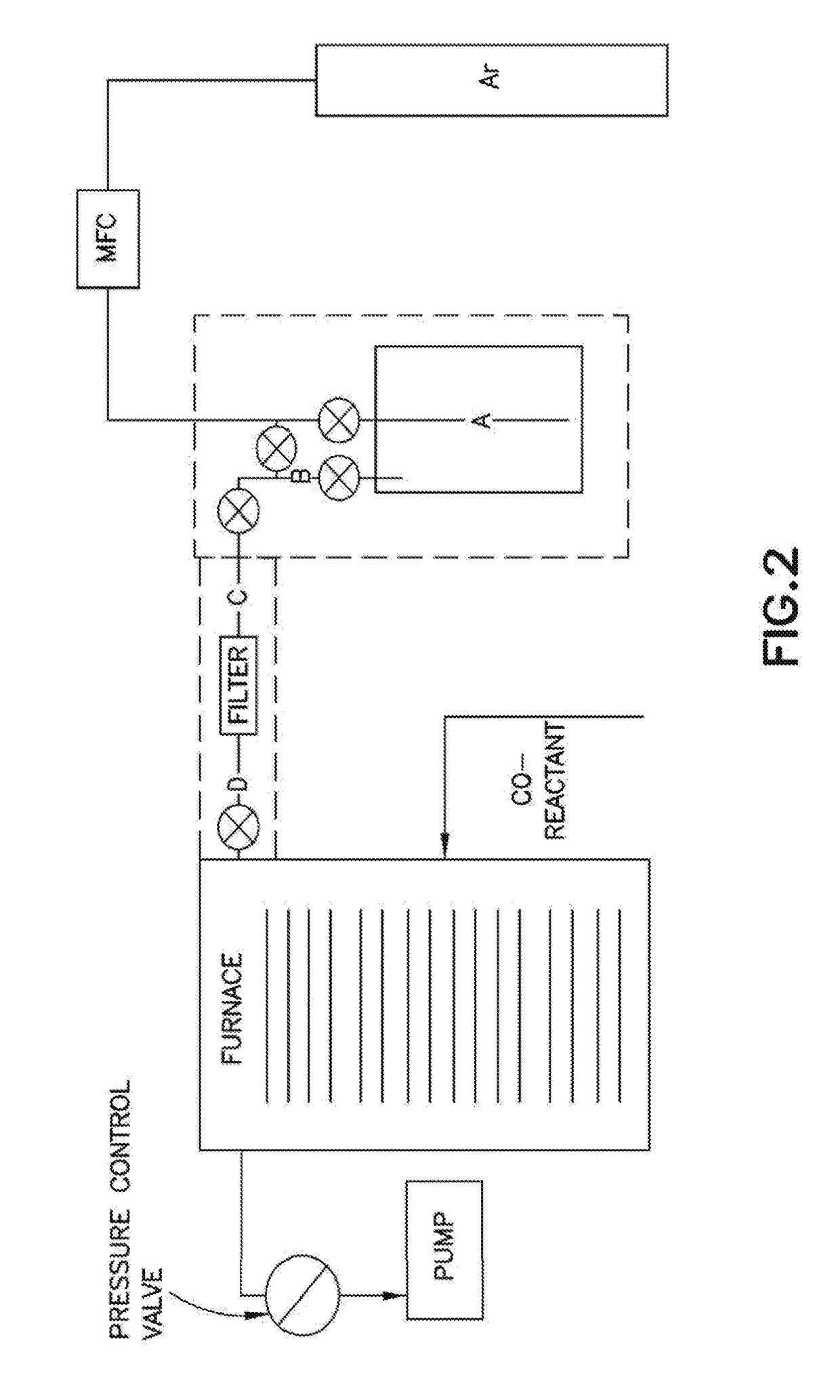

Passivating ALD reactor chamber internal surfaces to prevent residue buildup

InactiveUS20060040054A1Minimizing undesired chemisorptionReduce accumulationChemical vapor deposition coatingImproved methodDeposition process

This invention is directed to an improved method for preventing deposition residue buildup on the internal surfaces of an ALD reactor chamber. In an ALD deposition process, the surfaces of a substrate are treated with an initiating precursor generating a labile atom reactive with a deposition precursor. Excess initiating precursor is removed from the reactor and the substrate surface then is exposed to a deposition precursor reactive with the labile atom under conditions for generating a fugitive reaction product containing the labile atom and leaving a deposition product. The process is repeated generating alternate layers of initiation and deposition precursor reaction products. The improvement in the ALD process resides in passivating the internal surfaces of the reactor by removing labile atoms reactable with either the initiating or deposition precursors prior to effecting ALD deposition.

Owner:VERSUM MATERIALS US LLC

Catalyst composition comprising shuttling agent for ethylene multi-block copolymer formation

ActiveUS20070167578A1Improve efficiencySynthetic resin layered productsThin material handlingOlefin polymerizationPolymerization catalysts

A composition for use in forming a multi-block copolymer, said copolymer containing therein two or more segments or blocks differing in chemical or physical properties, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Catalyst Composition Comprising Shuttling Agent for Higher Olefin Multi-Block Copolymer Formation

ActiveUS20080311812A1Improve efficiencyHigh monomer conversion rateWoven fabricsNon-woven fabrics4-Methyl-1-penteneOlefin polymerization

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

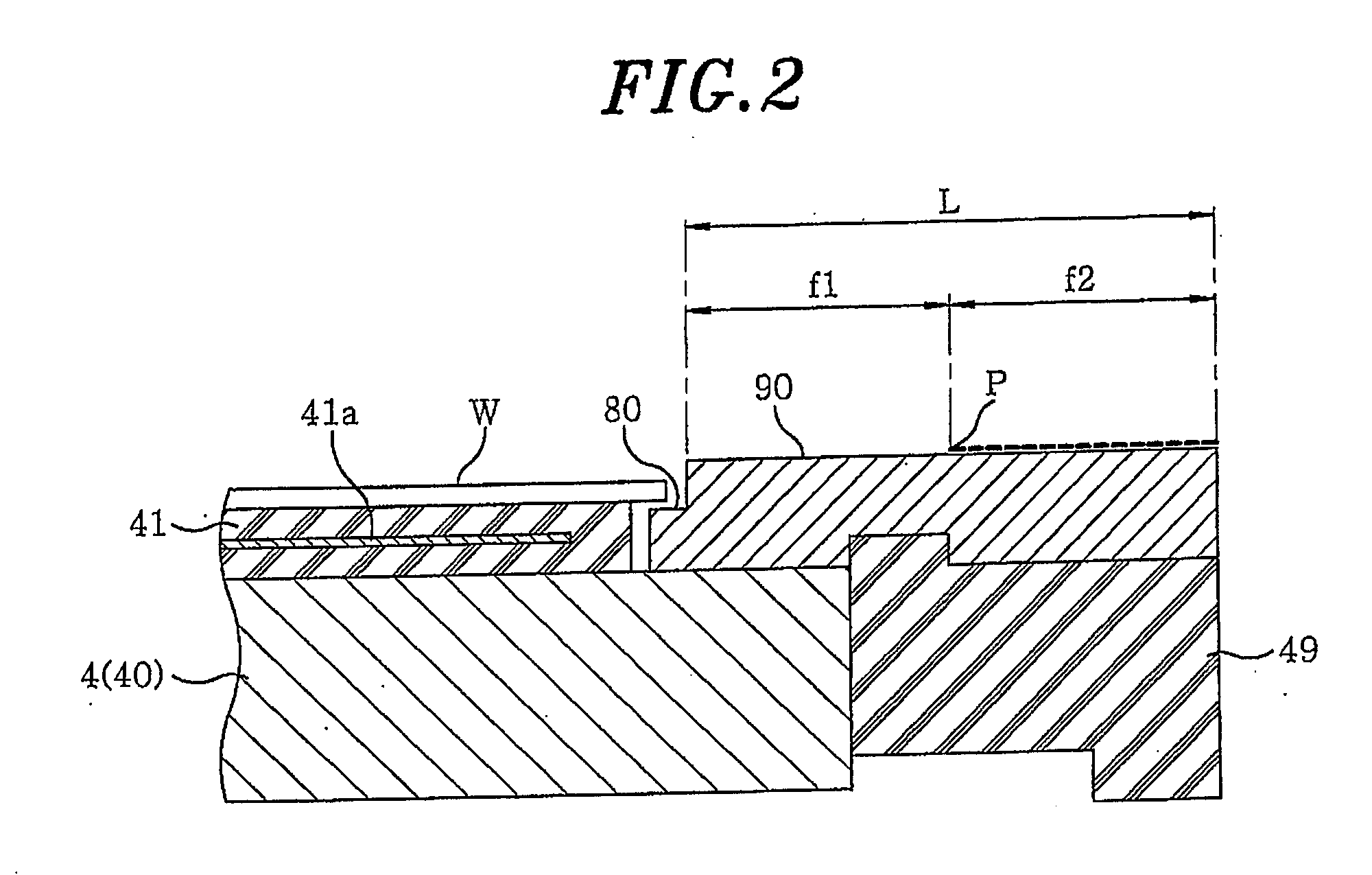

Composite thin-film glucose sensor

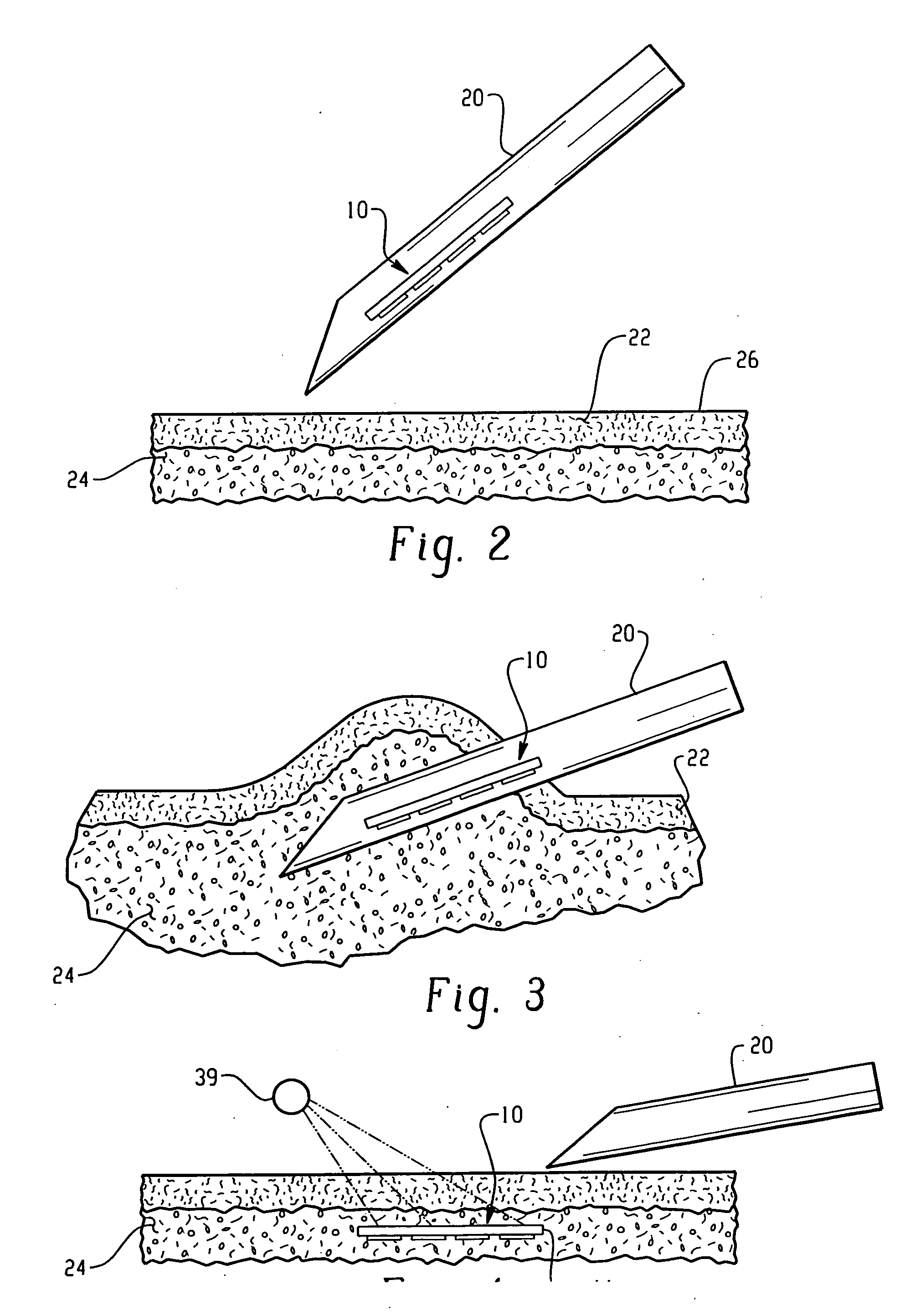

InactiveUS20050197554A1Easy and inexpensive to manufactureReduce deliveryMicrobiological testing/measurementCatheterGlucose sensorsAnalyte

A sensor system including a holder with at least one semi-permeable layer that forms a chamber, at least one reactant that reacts with at least one analyte, the at least one reactant being contained within the chamber, and a detector disposed proximate the at least one semi-permeable layer and configured to detect and measure a concentration of a reaction product from reaction of the at least one reactant with the at least one analyte. The at least one semi-permeable layer allows passage of the analyte into the chamber and allows passage of the reaction product to the detector. In a preferred embodiment, the analyte includes glucose, and the reaction product detected includes carbon dioxide.

Owner:POLCHA MICHAEL

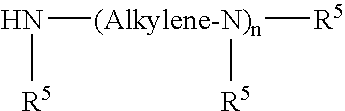

Wettable hydrogels comprising reactive, hydrophilic, polymeric internal wetting agents

The present invention relates to wettable silicone hydrogels comprising the reaction product of at least one siloxane containing component and at least one reactive, hydrophilic polymeric internal wetting agent. The present invention further relates to silicone hydrogel contact lenses comprising at least one oxygen permeable component, and an amount of reactive, hydrophilic polymeric internal wetting agent sufficient to impart wettability to said device.

Owner:JOHNSON & JOHNSON VISION CARE INC

Sensor system

ActiveUS20050221276A1Readily apparentBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyte(Hydroxyethyl)methacrylate

A sensor probe suited for implanting into the skin of a person includes a sensor body which may be formed from a polymer which includes 2-hydroxyethyl methacrylate (HEMA). A sensing system is supported by the body. The sensing system exhibits a detectable change when the probe is exposed to the analyte in the fluid. The sensing system may include an enzyme capable of catalyzing a reaction of the analyte to form a reaction product and a dye system which absorbs in the infrared region of the spectrum in response to the reaction product.

Owner:CASE WESTERN RESERVE UNIV

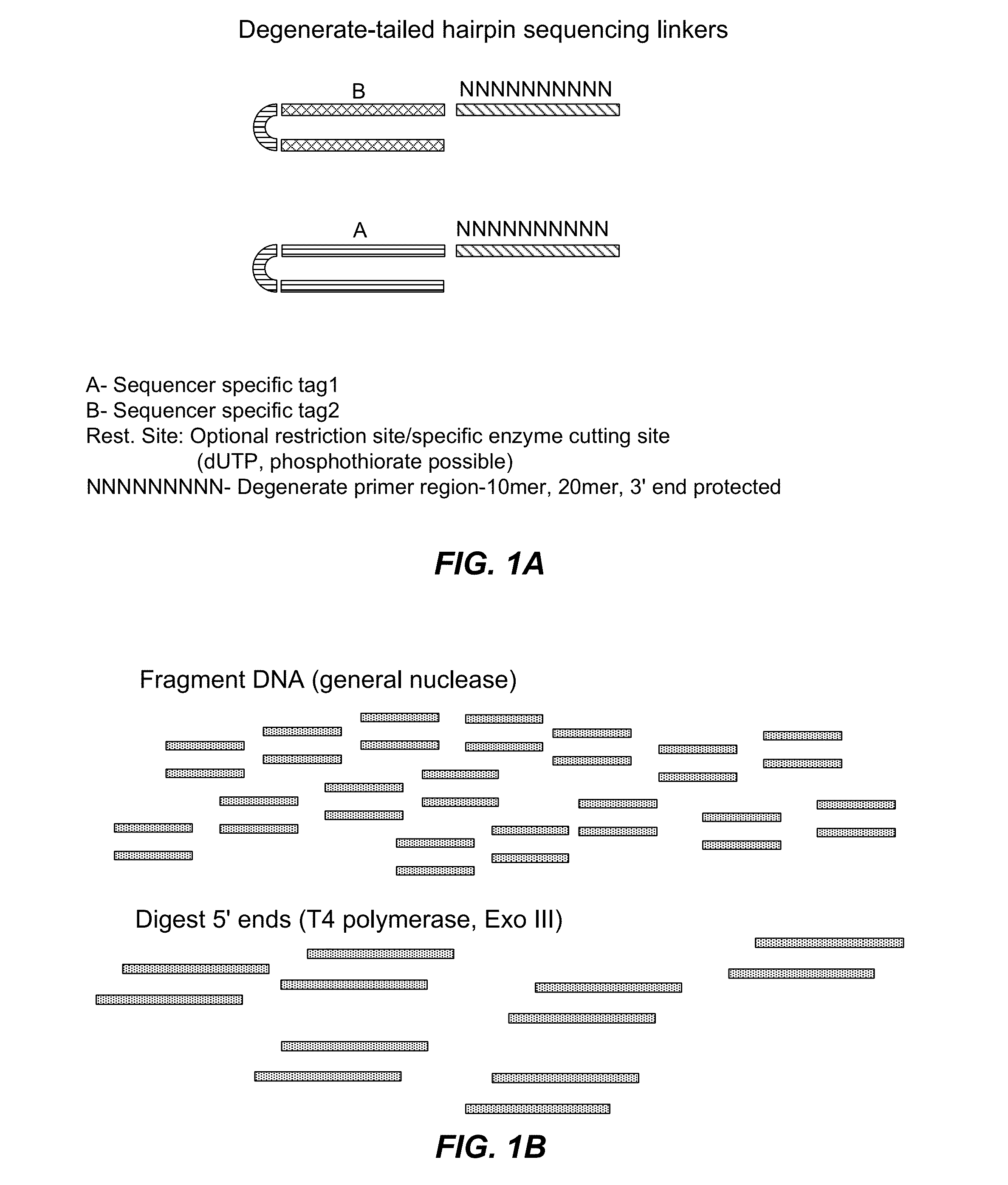

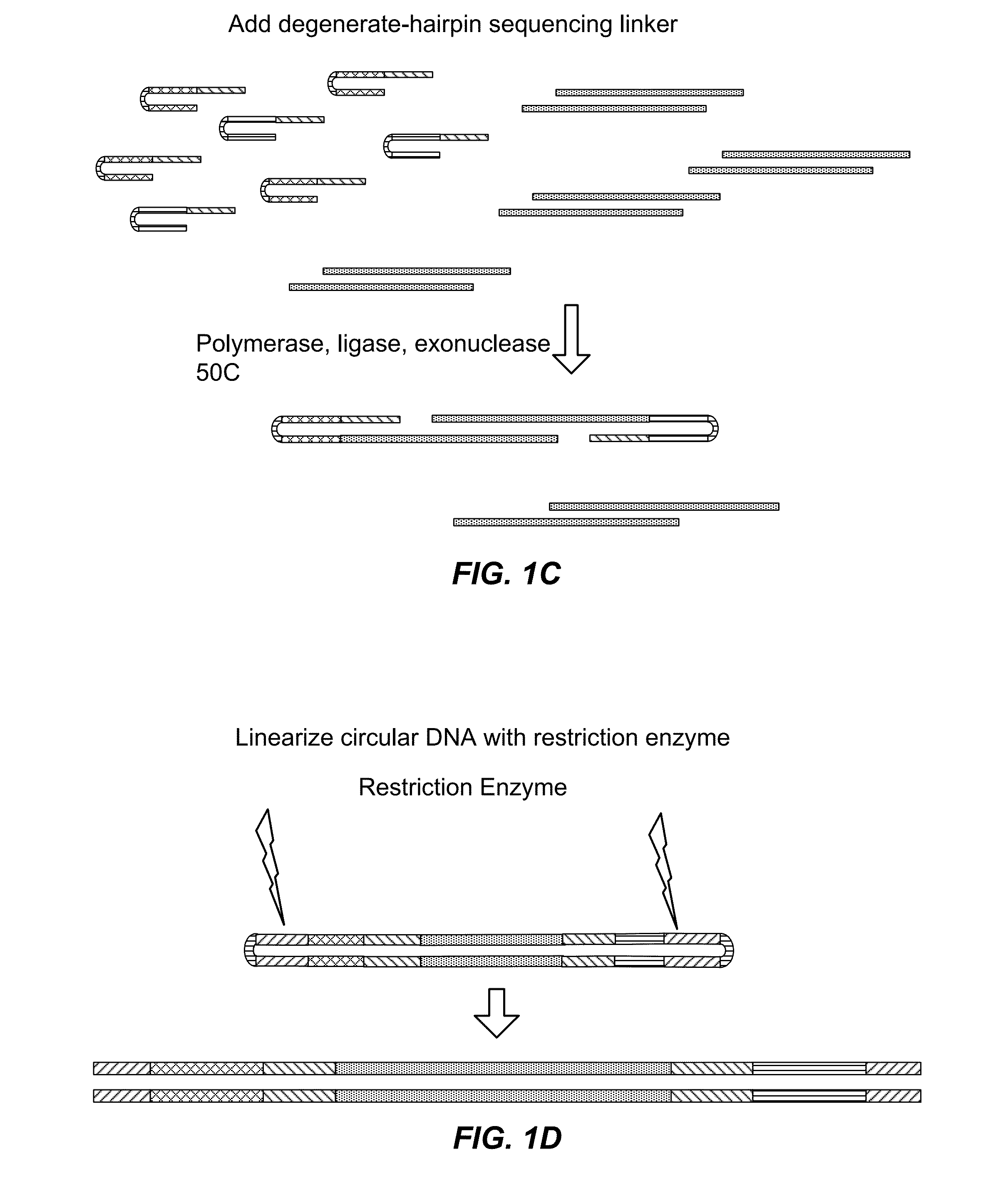

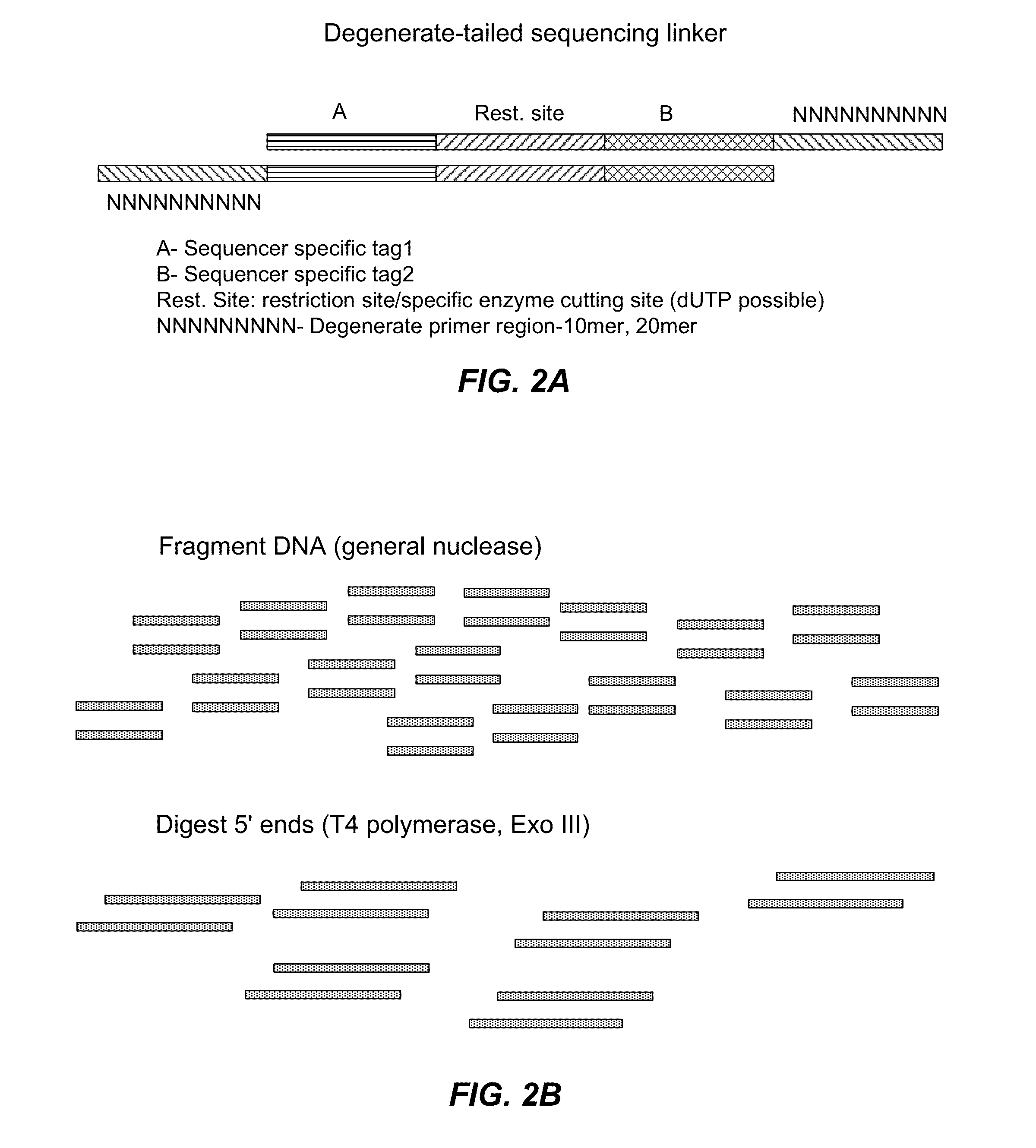

Nucleic acid encoding reactions

ActiveUS20130005585A1Avoid substantial annealingNucleotide librariesMicrobiological testing/measurementNucleotideBarcode

Described herein are methods useful for incorporating one or more adaptors and / or nucleotide tag(s) and / or barcode nucleotide sequence(s) one, or typically more, target nucleotide sequences. In particular embodiments, nucleic acid fragments having adaptors, e.g., suitable for use in high-throughput DNA sequencing are generated. In other embodiments, information about a reaction mixture is encoded into a reaction product. Also described herein are methods and kits useful for amplifying one or more target nucleic acids in preparation for applications such as bidirectional nucleic acid sequencing. In particular embodiments, methods of the invention entail additionally carrying out bidirectional DNA sequencing. Also described herein are methods for encoding and detecting and / or quantifying alleles by primer extension.

Owner:FLUIDIGM CORP

Method and apparatus of growing a thin film onto a substrate

InactiveUS20020108570A1Good film uniformitySimple and efficientPolycrystalline material growthSemiconductor/solid-state device manufacturingInlet channelGas phase

A method and an apparatus for growing a thin film onto a substrate by the ALD process. The apparatus comprises a reaction chamber into which the substrate can be disposed; a plurality of inlet channels communicating with said reaction chamber, said inlet channels being suited for feeding the reactants employed in a thin-film growth process in the form of vapor-phase pulses into said reaction chamber; at least one outlet channel communicating with said reaction chamber, said outlet channel being suited for the outflow of reaction products and excess amounts of reactants from said reaction space; and a pre-reaction chamber arranged immediately upstream of the reaction chamber, said pre-reaction chamber forming a first reaction zone, in which the reactants of successive vapor-phase pulses can be reacted with each other in the vapor phase to form a solid product, whereas said reaction chamber forming a second reaction zone can be operated under conditions conducive to ALD growth of a thin film.

Owner:ASM INTERNATIONAL

Nanoporous silicone resins having low dielectric constants

InactiveUS6541107B1Group 4/14 element organic compoundsDead plant preservationOrganic solventCarbon–carbon bond

Nanoporous silicone resins and silicone resin films having low dielectric constants and a method for preparing such nanoporous silicone resins. The silicone resin comprises the reaction product of a mixture comprising(A) 15-70 mol % of a tetraalkoxysilane described by formula where each R1 is an independently selected alkyl group comprising 1 to about 6 carbon atoms,(B) 12 to 60 mol % of a hydrosilane described by formula where each X is an independently selected hydrolyzable substituent,(C) 15 to 70 mole percent of an organotrialkoxysilane described by formula where R2 is a hydrocarbon group comprising about 8 to 24 carbon atoms or a substituted hydrocarbon group comprising a hydrocarbon chain having about 8 to 24 carbon atoms and each R3 is an independently selected alkyl group comprising 1 to about 6 carbon atoms; in the presence of(D) water,(E) hydrolysis catalyst, and(F) organic solvent for the reaction product.The silicone resin is cured and heated in an inert atmosphere at a temperature sufficient to effect thermolysis of carbon-carbon bonds of the R2 groups thereby forming a nanoporous silicone resin.

Owner:DOW CORNING CORP

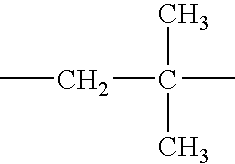

Quaternary Ammonium Salt of a Polyalkene-Substituted Amine Compound

InactiveUS20080113890A1Organic compound preparationTransportation and packagingCompound aQuaternary ammonium cation

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) polyalkene-substituted amine having at least one tertiary amino group; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

Coatings for enhancement of properties and performance of substrate articles and apparatus

PendingUS20180044800A1Avoid reactionGood semiconductor performanceSemi-permeable membranesVacuum evaporation coatingCoated surfaceReactive gas

Coatings applicable to a variety of substrate articles, structures, materials, and equipment are described. In various applications, the substrate includes metal surface susceptible to formation of oxide, nitride, fluoride, or chloride of such metal thereon, wherein the metal surface is configured to be contacted in use with gas, solid, or liquid that is reactive therewith to form a reaction product that is deleterious to the substrate article, structure, material, or equipment. The metal surface is coated with a protective coating preventing reaction of the coated surface with the reactive gas, and / or otherwise improving the electrical, chemical, thermal, or structural properties of the substrate article or equipment. Various methods of coating the metal surface are described, and for selecting the coating material that is utilized.

Owner:ENTEGRIS INC

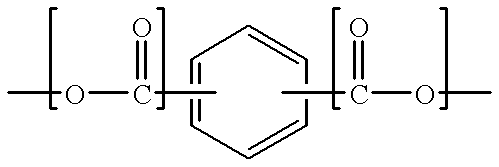

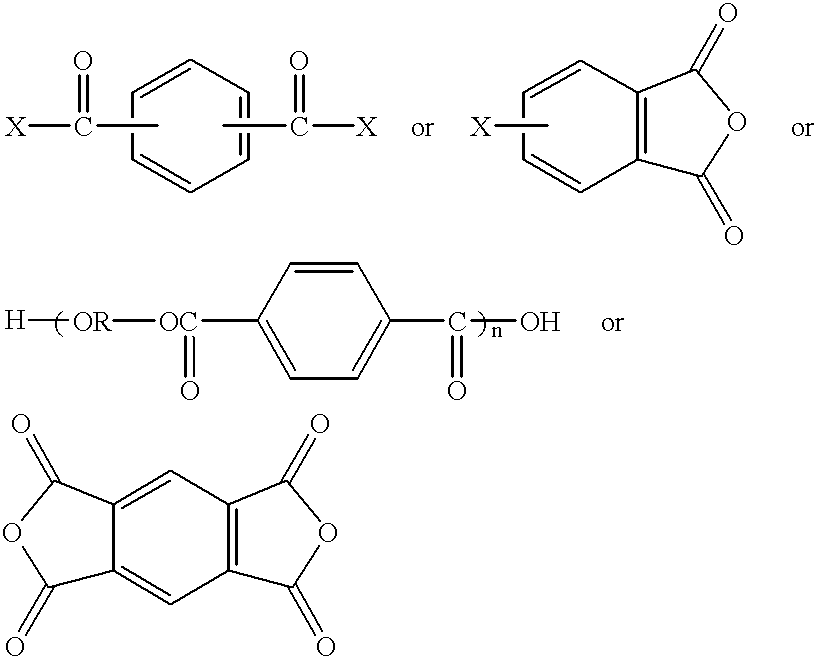

Pentane compatible polyester polyols

InactiveUS6359022B1Increase valueImprove flame retardant performanceOther chemical processesPolyesterDolichol

Disclosed are aromatic polyester polyols, polyol based resin blends, and rigid closed-cell polyisocyanate-based foams made using the polyol based resin blends. The resin blends generally comprise:(a) an aromatic polyester polyol reaction product formed by inter-esterification of a phthalic acid based material; a hydroxylated material having a functionality of at least 2; and a hydrophobic material; and(b) a C4-C7 hydrocarbon blowing agent. Also disclosed is a method for preparing rigid closed-cell polyisocyanate-based foams comprising reacting a polyisocyanate and a polyol based resin blend.

Owner:STEPAN COMPANY

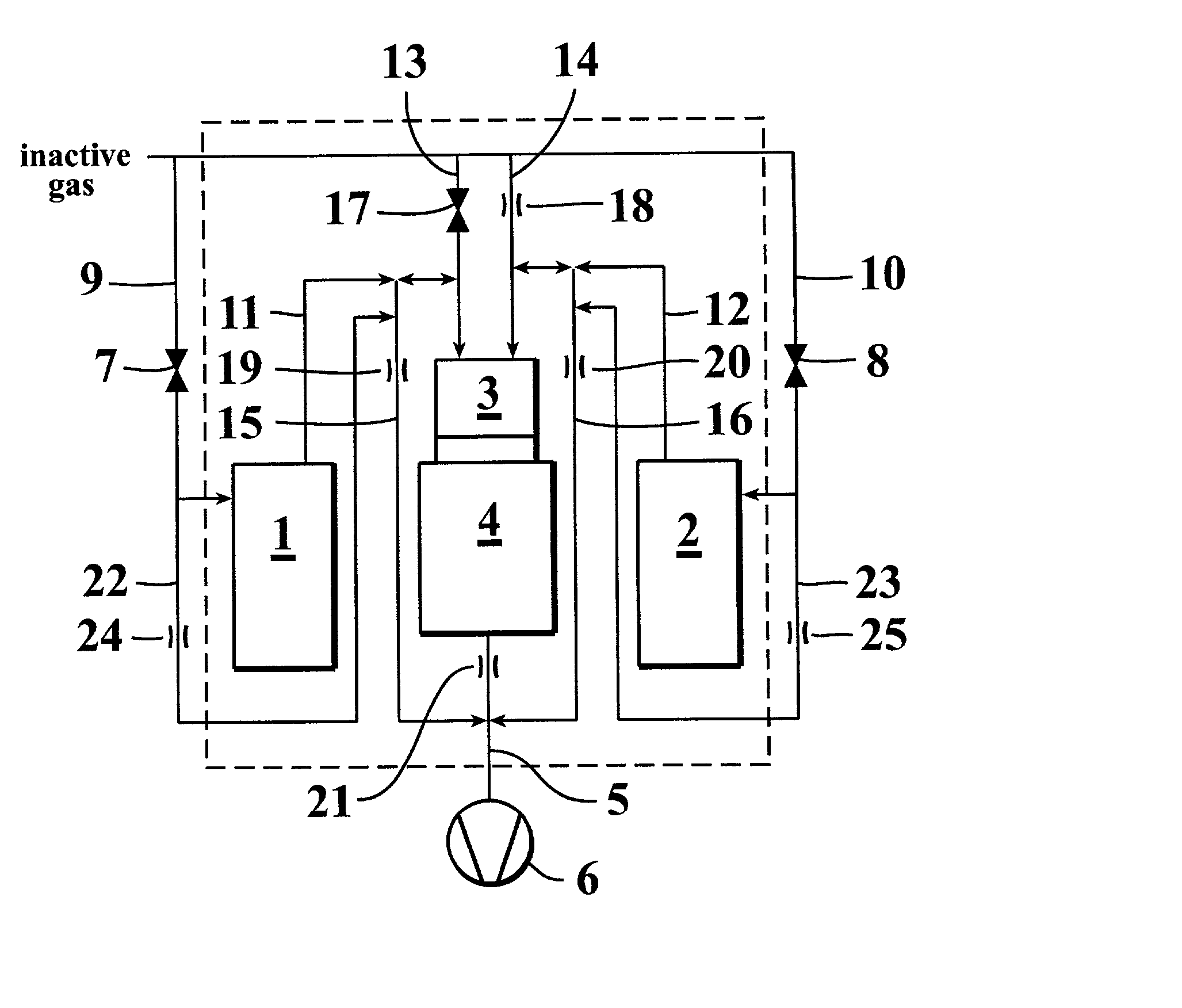

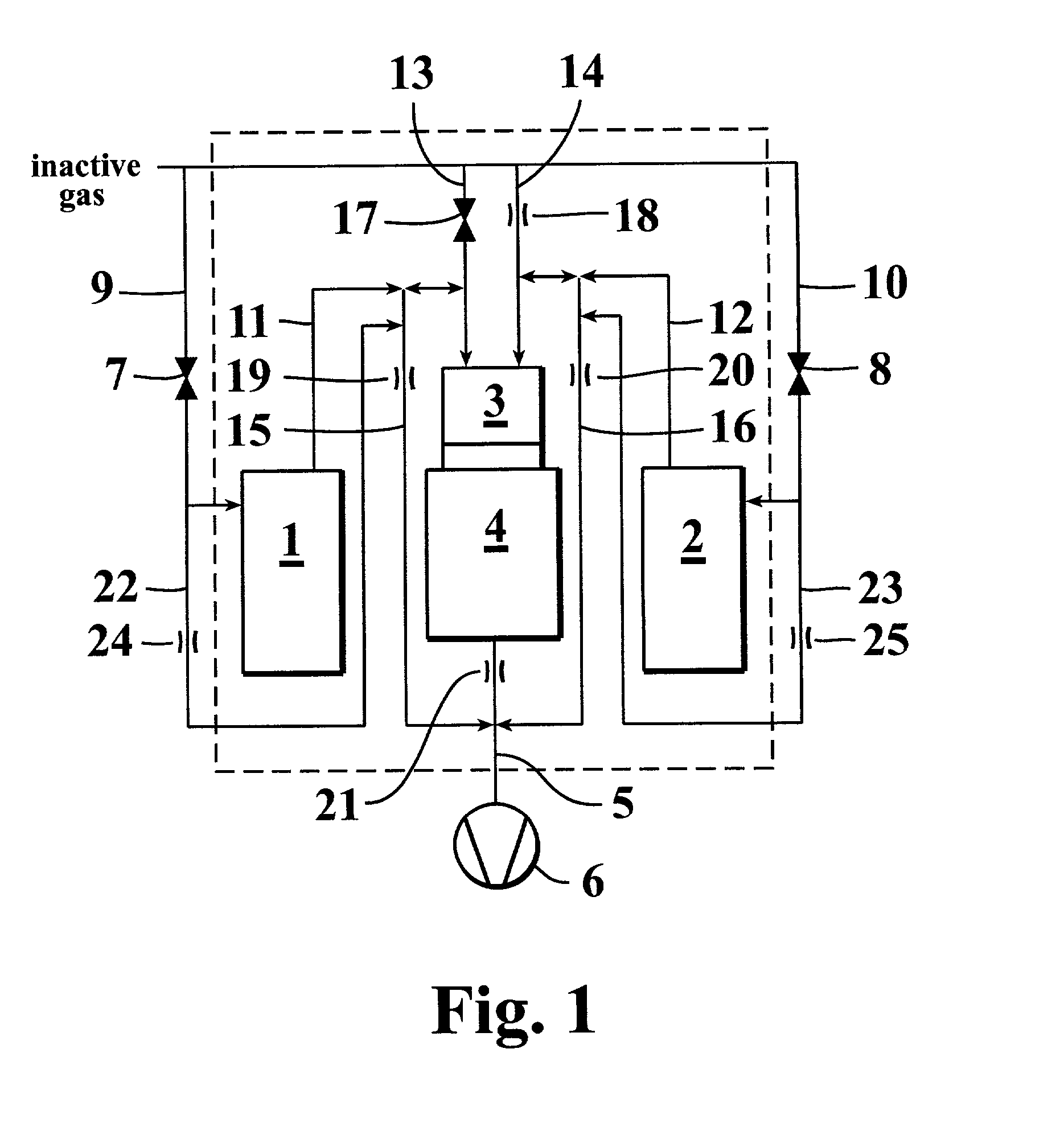

Method and apparatus for removing substances from gases

InactiveUS7799300B2Simple and reliable technicalEliminate the problemAuxillary pretreatmentEnergy based chemical/physical/physico-chemical processesSurface reactionGas phase

The present invention concerns a method and an apparatus for removing substances from gases discharged from gas phase reactors. In particular, the invention provides a method for removing substances contained in gases discharged from an ALD reaction process, comprising contacting the gases with a “sacrificial” material having a high surface area kept at essentially the same conditions as those prevailing during the gas phase reaction process. The sacrificial material is thus subjected to surface reactions with the substances contained in the gases to form a reaction product on the surface of the sacrificial material and to remove the substances from the gases. The present invention diminishes the amount of waste produced in the gas phase process and reduces wear on the equipment.

Owner:ASM INTERNATIONAL

Process for applying a streamable epoxy adhesive

InactiveUS20050070634A1Low viscosityHigh strength bondAdhesive processes with adhesive heatingEpoxy resin adhesivesBENZYL ALCOHOL/WATERViscosity

The invention is a composition comprising applying to a substrate a stream of an adhesive comprising: one or more epoxy resins; one or more rubber modified epoxy resins; one or more toughening compositions comprising the reaction product of one or more isocyanate terminated prepolymers and one or more capping compounds having one or more phenolic, benzyl alcohol, aminophenyl, or, benzylamino groups wherein the reaction product is terminated with the capping compounds; one or more curing agents for epoxy resins and one or more catalysts which initiate cure at a temperature of about 100° C. or greater; and optionally; fillers adhesion promoters, wetting agents or rheological additives useful in epoxy adhesive compositions; wherein the adhesive composition has a viscosity at 45° C. of about 20 Pa.s to about 400 Pa.s. The composition can be used as an adhesive and applied as a stream using a high speed streaming process.

Owner:DOW GLOBAL TECH LLC

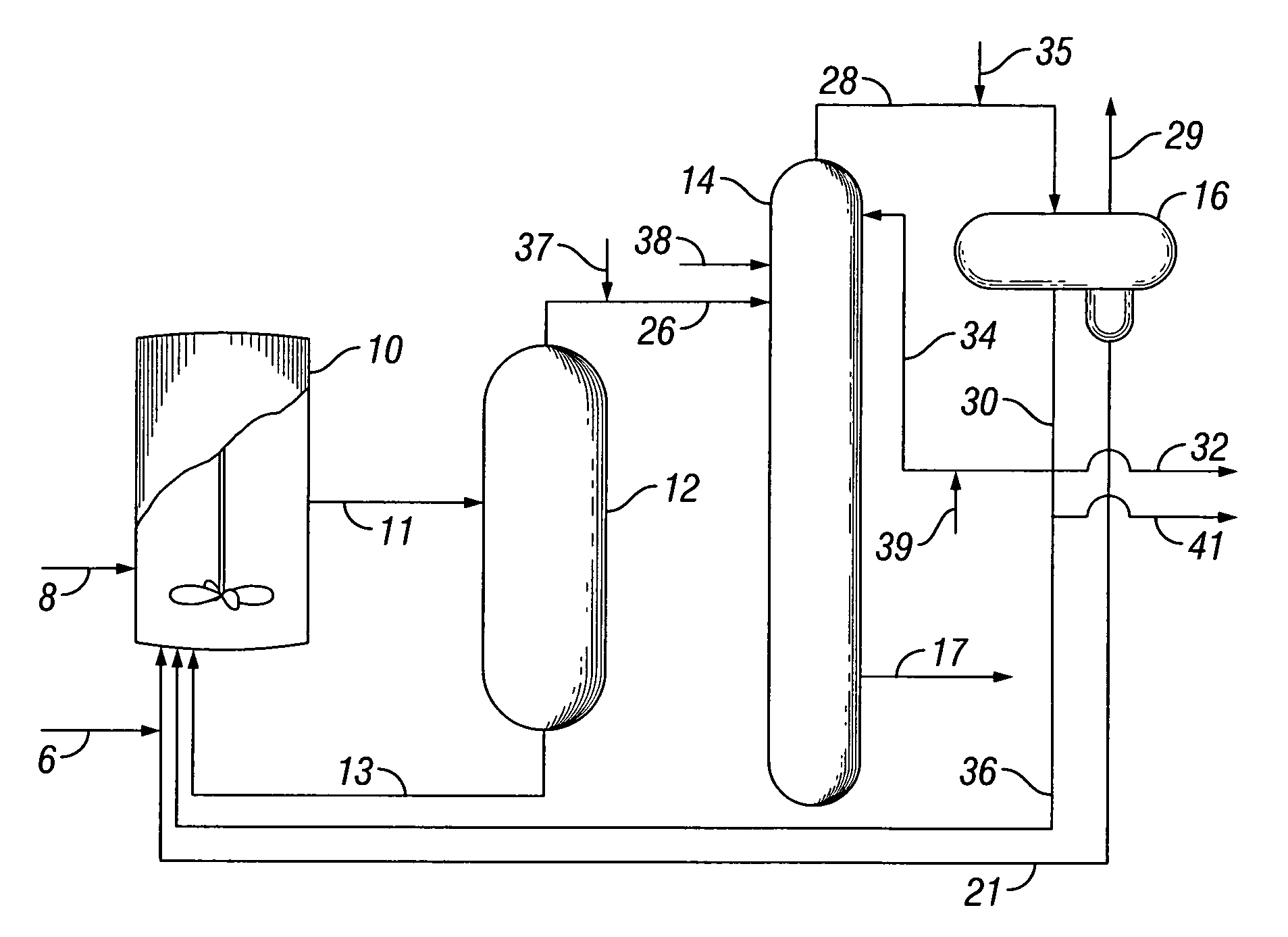

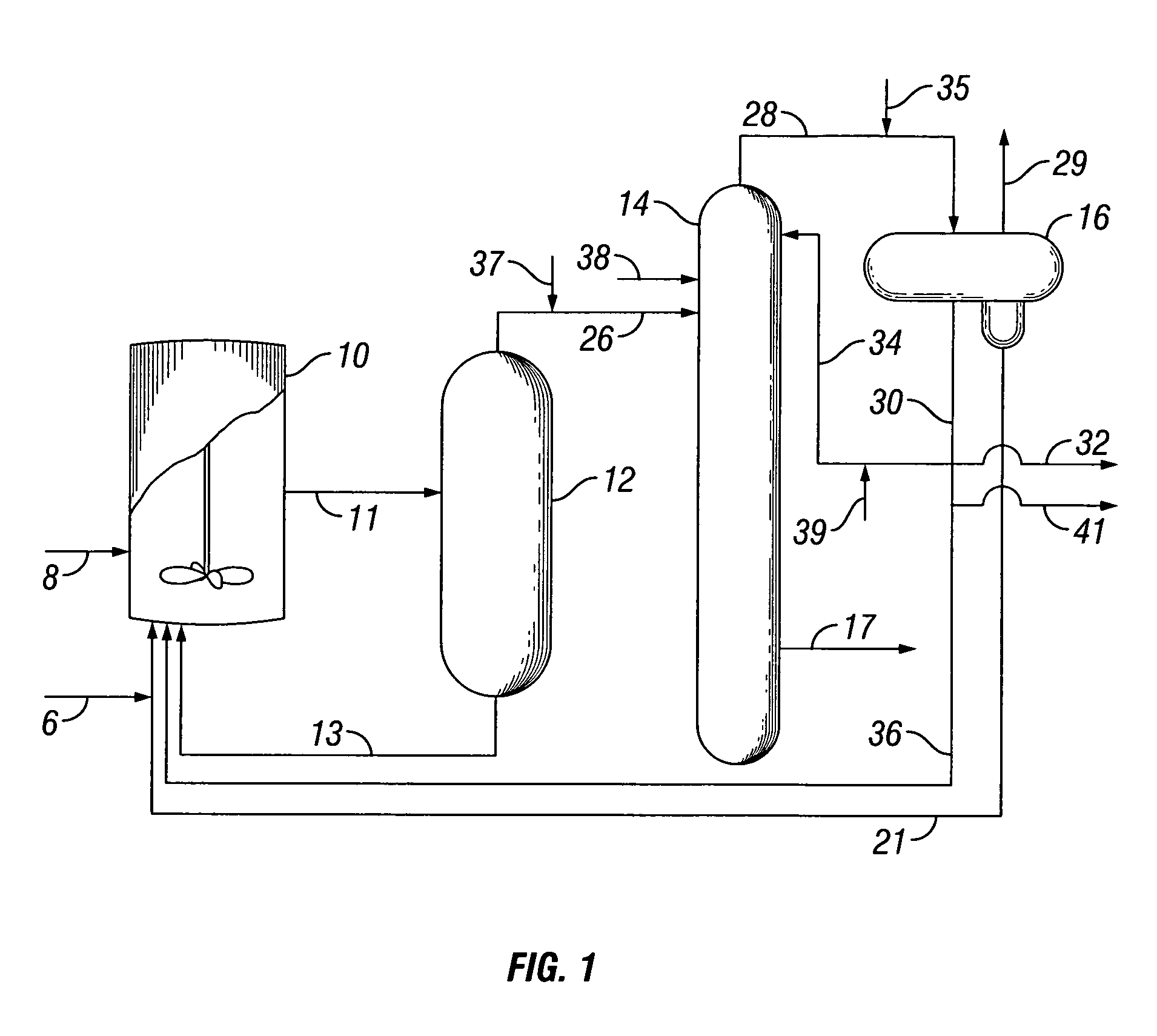

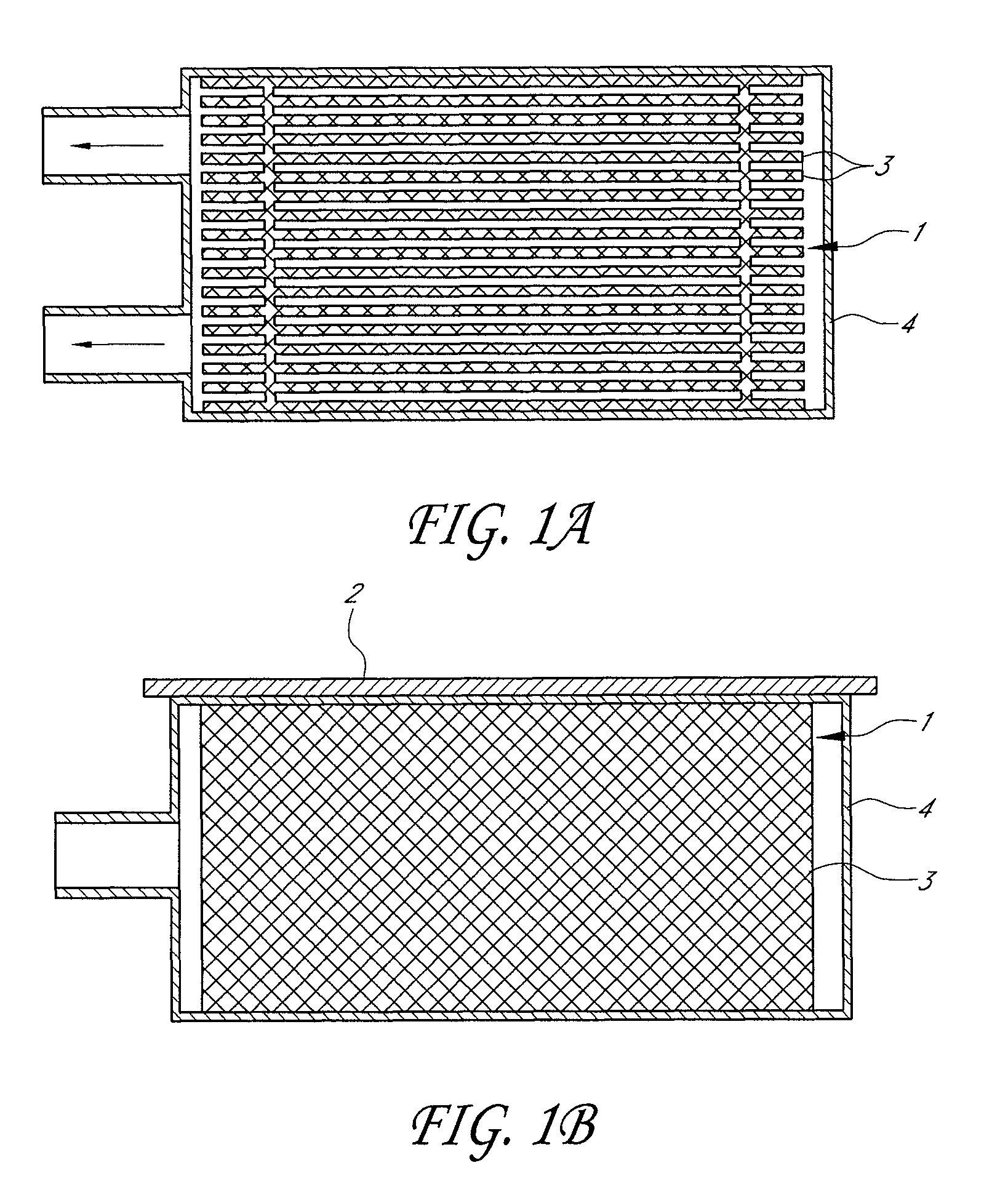

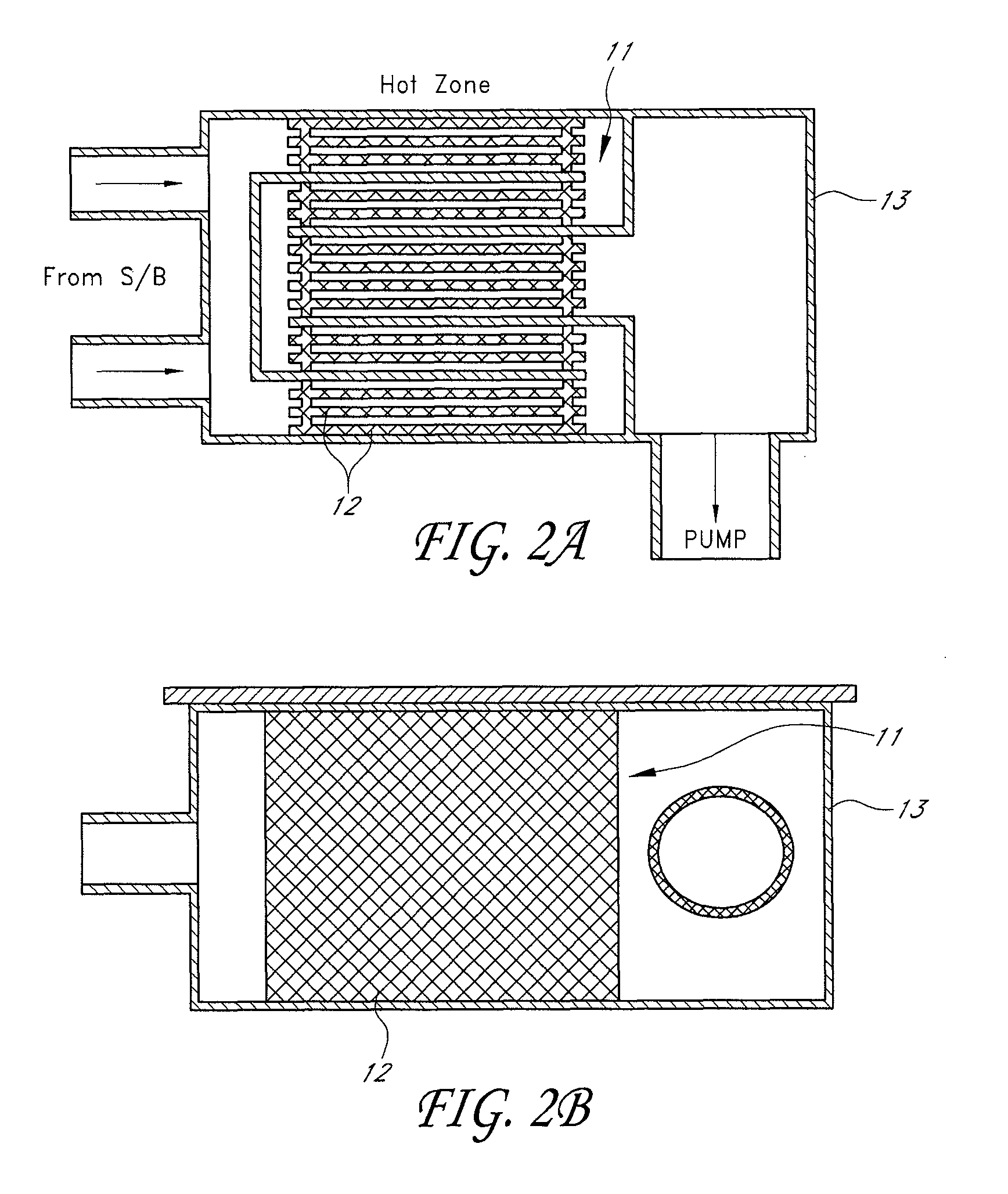

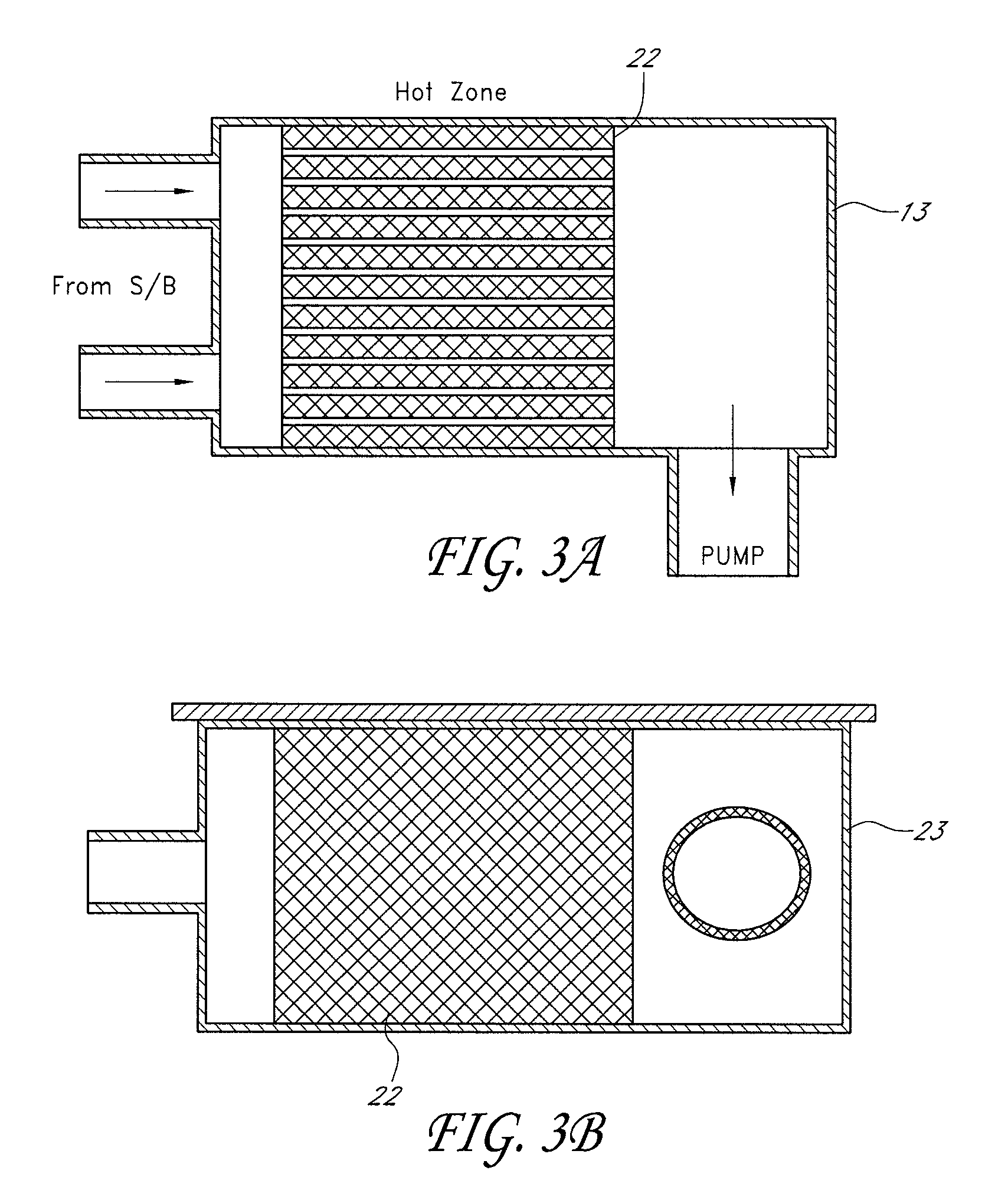

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS8058486B2Maximize utilizationYield maximizationPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

Lanthanide-based catalyst composition for producing cis-1,4-polydienes

InactiveUS7008899B2Easy to processHigh viscosityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPtru catalystLanthanide

A catalyst composition that is the combination of or the reaction product of ingredients comprising (a) a lanthanide compound, (b) an organoaluminum hydride, and (c) a tin halide compound.

Owner:BRIDGESTONE CORP

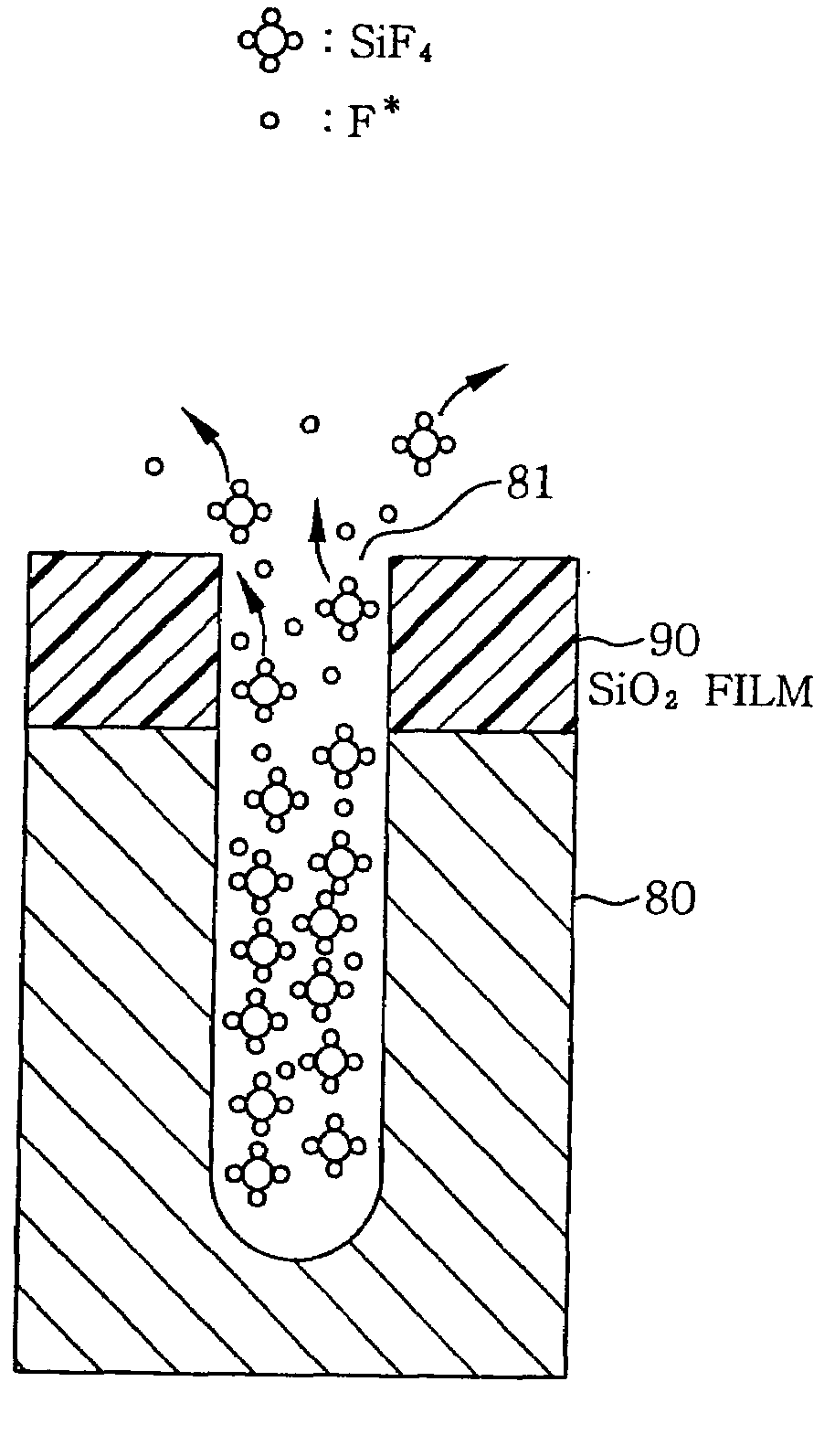

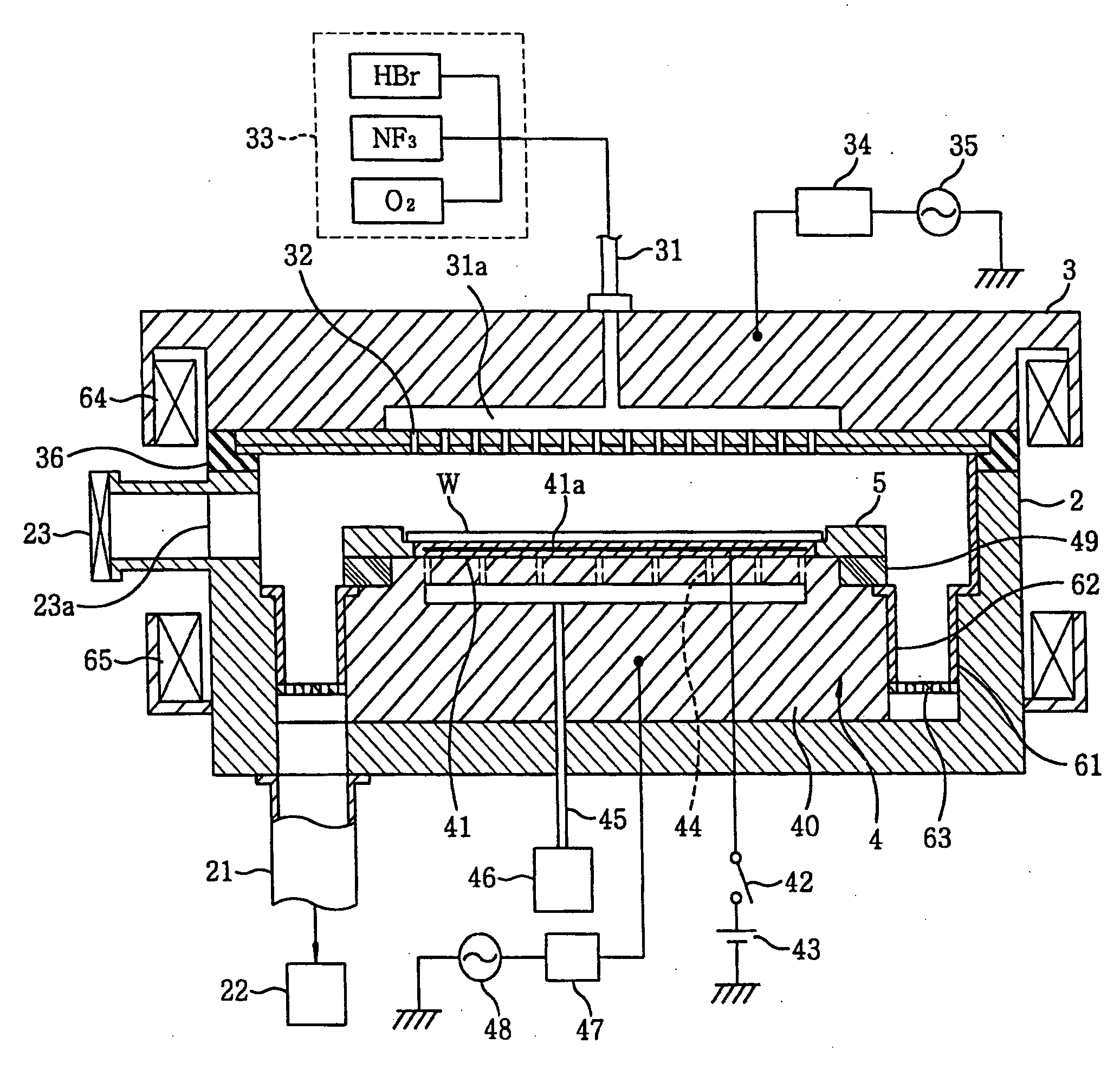

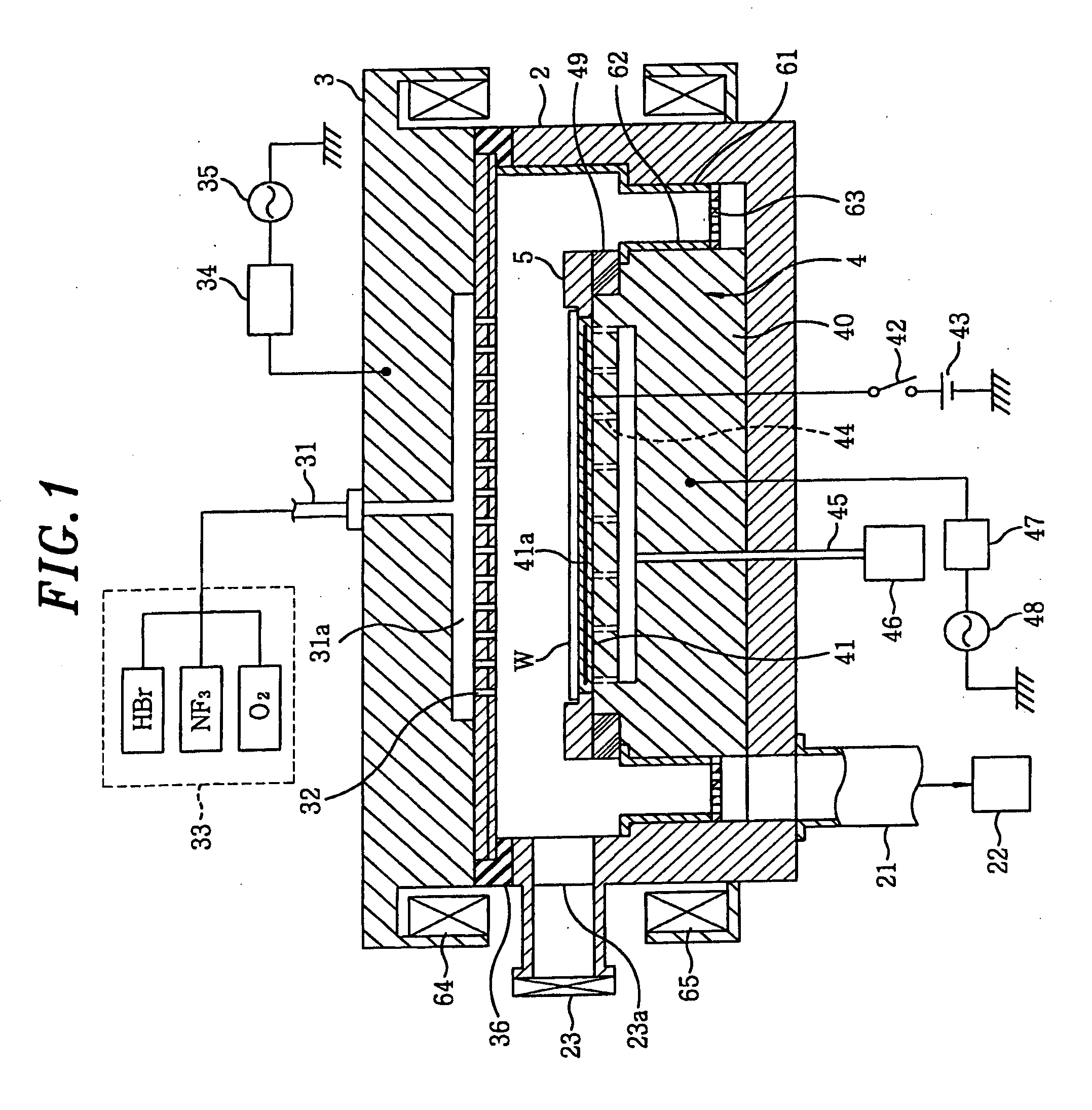

Plasma etching method and apparatus therefor

InactiveUS20090045167A1Increase chanceIncrease etch rateElectric discharge tubesVacuum gauge using ionisation effectsPeak intensityFluorine containing

A fluorine-containing compound gas, e.g., SF6 gas, is converted into a plasma and a silicon portion of an object to be processed is etched by the plasma. At the same time, using a light source having a peak intensity of light in a wavelength range of light absorption of a reaction product, e.g., SiF4, for which, to be more precise, ranges from 9 μm to 10 μm, the light is irradiated onto a surface of an object to be processed from the light source. The SiF4 molecules absorb the light, become activated and gain kinetic energy to be used in gaining an easy escape from a hole. As a consequence, an amount (a partial pressure) of fluorine radicals (F*) used as an etchant is increased and an etching rate of a silicon is increased.

Owner:TOKYO ELECTRON LTD

Focus ring, plasma etching apparatus and plasma etching method

ActiveUS20090255902A1Improve etching effectAccurate storageElectric discharge tubesDecorative surface effectsSusceptorSurface roughness

In a plasma etching apparatus for performing a plasma etching on a surface of a substrate mounted on a susceptor in a processing vessel, a focus ring is installed to surround the substrate and has a first region at an inner side on a surface thereof, in which an average surface roughness is small such that a reaction product produced during an etching processing is not captured to be deposited, and a second region at an outer side from the first region, in which an average surface roughness is large such that a reaction product produced during the etching process is captured to be deposited. A boundary between the first and the second region is a part where an etching amount is relatively significantly changed compared to other parts while the focus ring is equipped in the plasma etching apparatus and the plasma etching is performed on the substrate.

Owner:TOKYO ELECTRON LTD

Method for depositing and curing low-k films for gapfill and conformal film applications

ActiveUS7790634B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideAtomic oxygen

Methods of making a silicon oxide layer on a substrate are described. The methods may include forming the silicon oxide layer on the substrate in a reaction chamber by reacting an atomic oxygen precursor and a silicon precursor and depositing reaction products on the substrate. The atomic oxygen precursor is generated outside the reaction chamber. The methods also include heating the silicon oxide layer at a temperature of about 600° C. or less, and exposing the silicon oxide layer to an induced coupled plasma. Additional methods are described where the deposited silicon oxide layer is cured by exposing the layer to ultra-violet light, and also exposing the layer to an induced coupled plasma.

Owner:APPLIED MATERIALS INC

System and process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether

ActiveCN101823929AHigh yieldHigh selectivityHydrogen separation using liquid contactHydrocarbon from oxygen organic compoundsAromatizationAromatic hydrocarbon

The invention relates to a system and a process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether and belongs to the technical field of aromatic hydrocarbon production. The methanol or the dimethyl ether serving as a raw material firstly reacts in an aromatization reactor; a reaction product is separated; H2, methane, mixed C8 aromatic hydrocarbon and partial C9s + hydrocarbons serving as products are output from the system; and C2+ non-aromatic hydrocarbon and aromatic hydrocarbons except the mixed C8 aromatic hydrocarbon and the partial C9s + hydrocarbons are take as a circular material flow and return to corresponding reactors for further aromatization reaction. By separating and recycling the product obtained in the process of aromizing the methanol or the dimethyl ether, the system and the process improve the yield and selectivity of the aromatic hydrocarbon; and moreover, the process is flexible, and target products can be changed according to market demands.

Owner:TSINGHUA UNIV

Activatable material

InactiveUS6846559B2Assist in flow controlPreventing fatigue crack growthSynthetic resin layered productsRecord information storageEpoxyElastomer

An activatable (e.g., heat expandable) material and articles incorporating the same is disclosed. The material includes an epoxy resin; an epoxy / elastomer hybrid or reaction product; a blowing agent; a curing agent; and optionally, a filler. In preferred embodiments, the material includes aramid fiber, nanoclay or both.

Owner:ZEPHYROS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com