Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

578results about How to "Yield maximization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

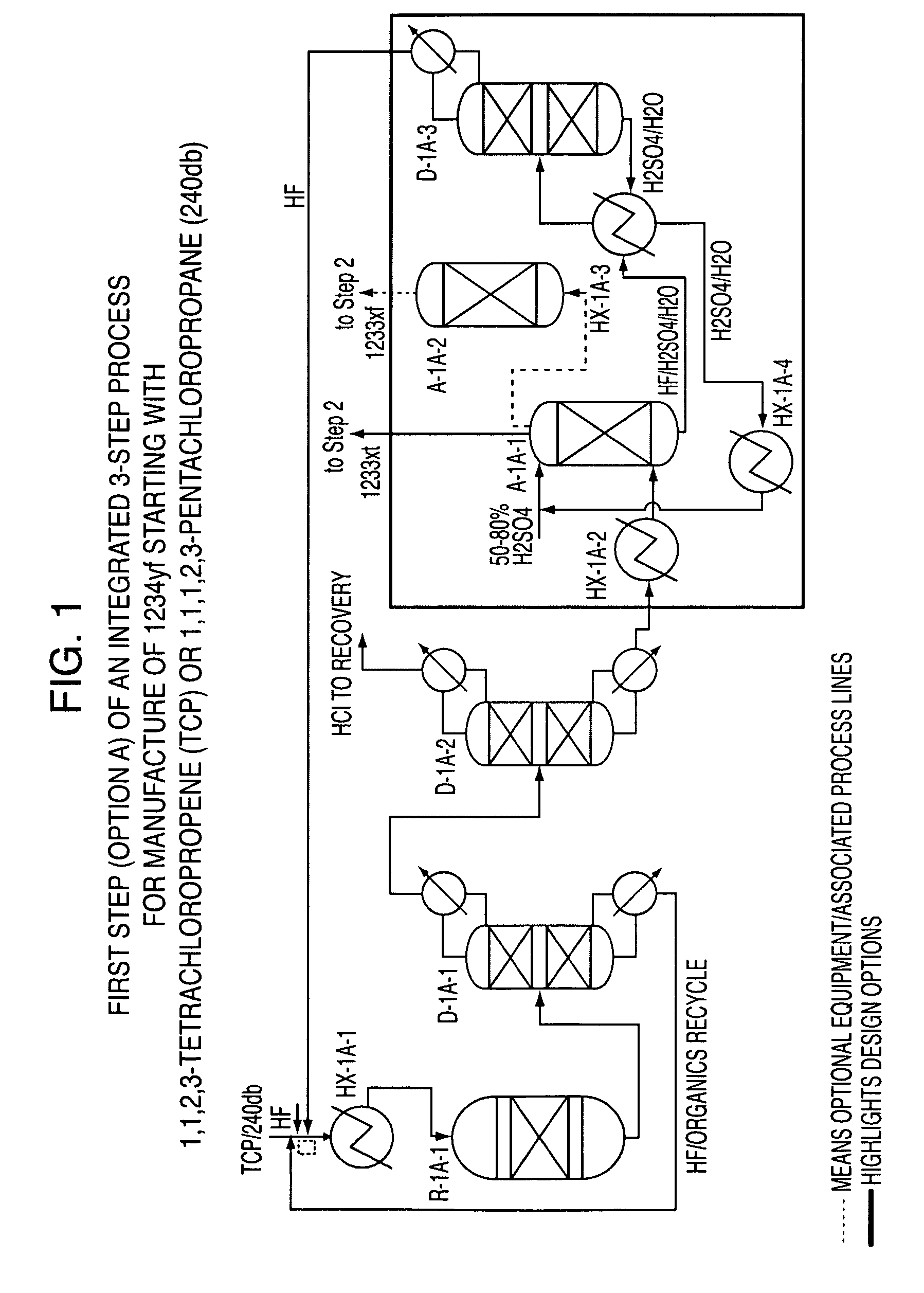

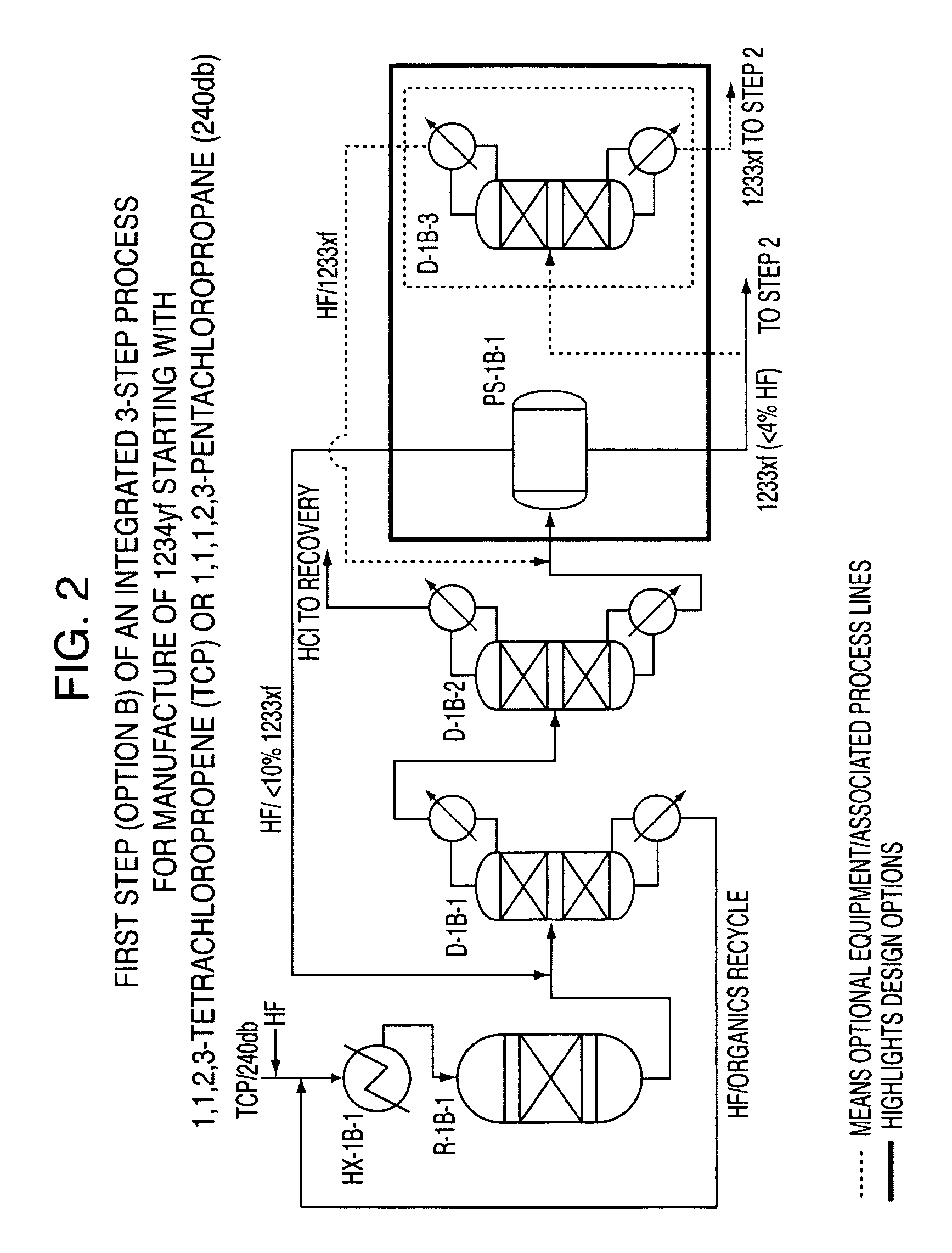

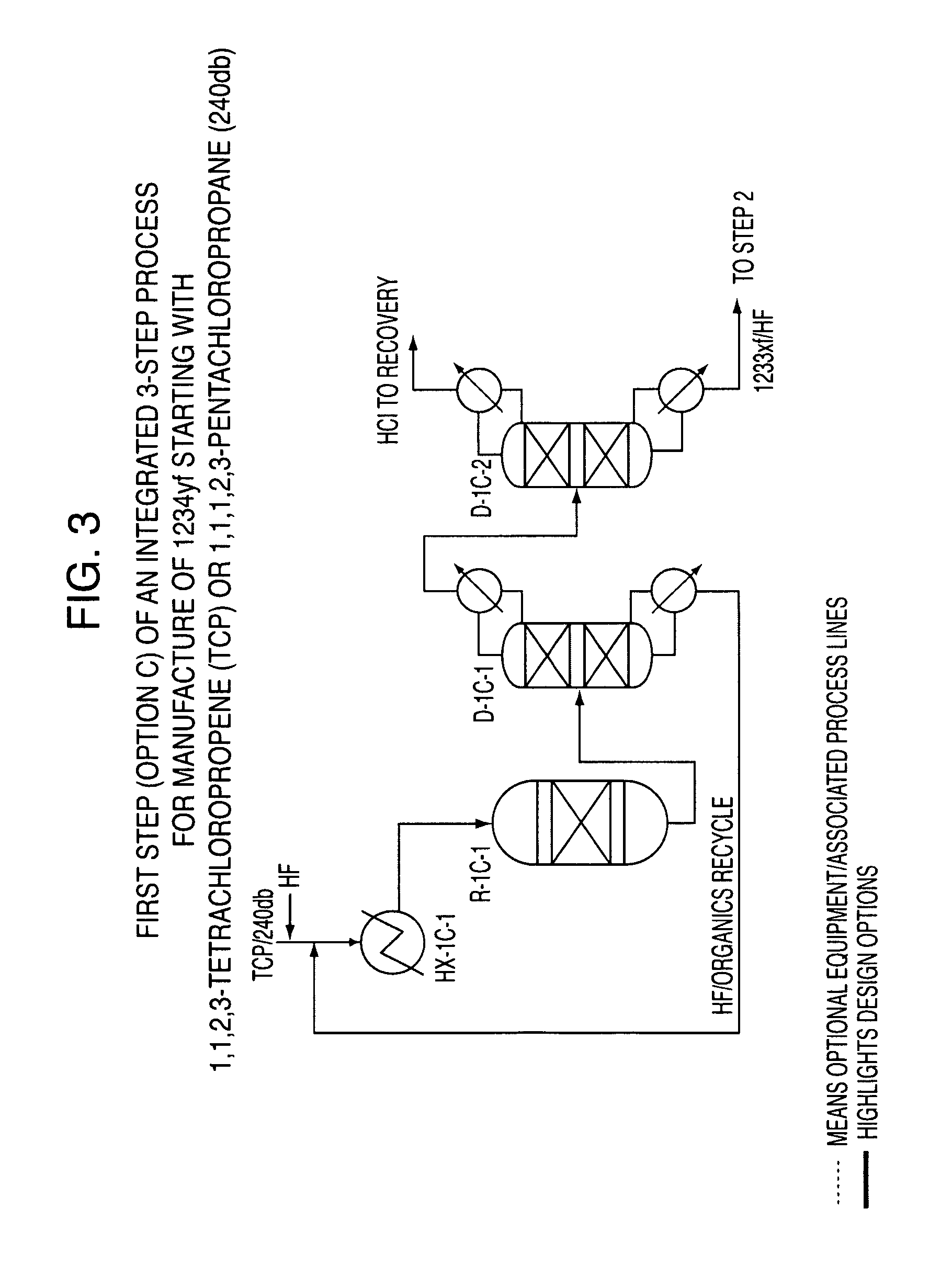

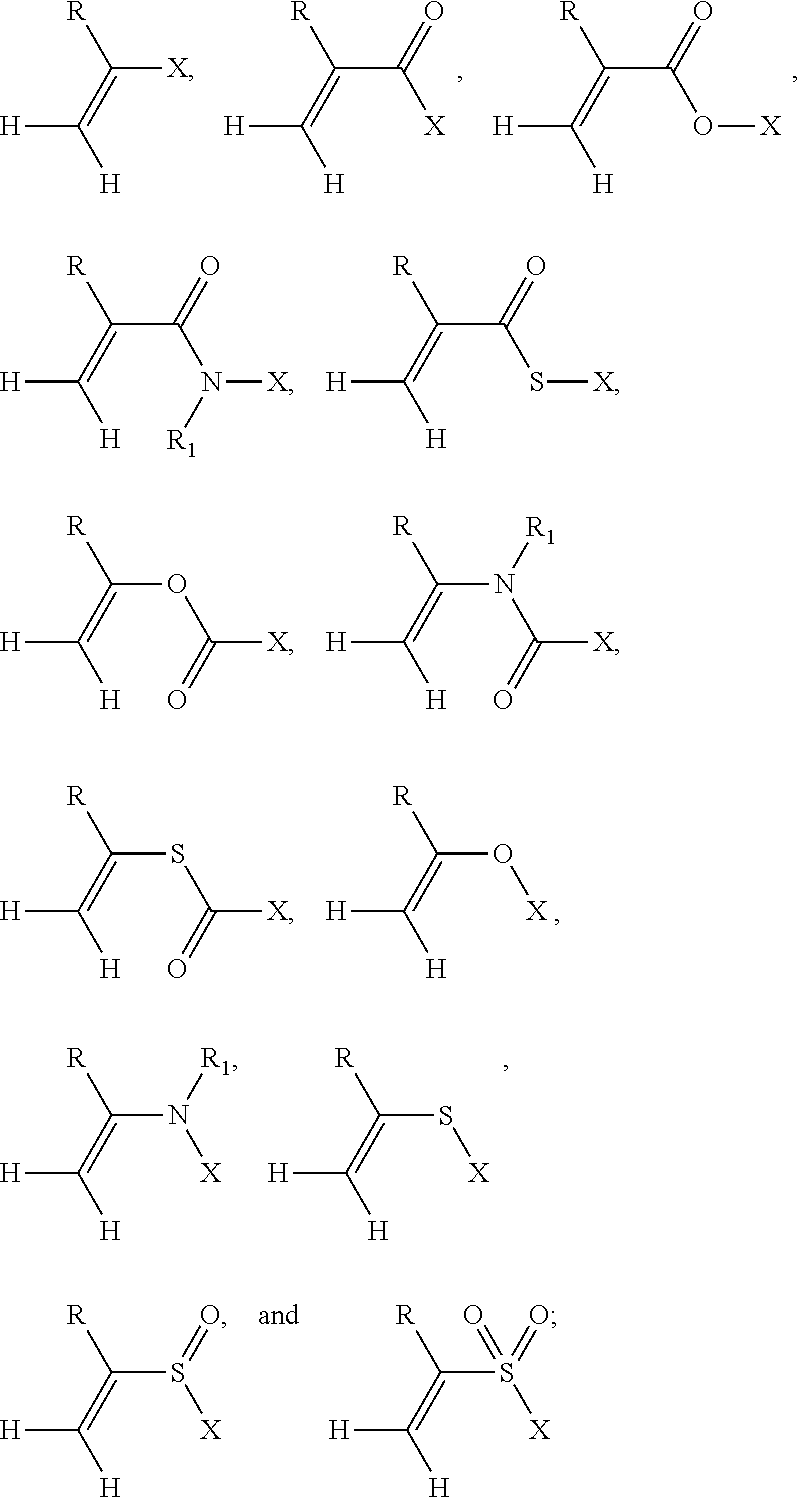

Integrated process to produce 2,3,3,3-tetrafluoropropene

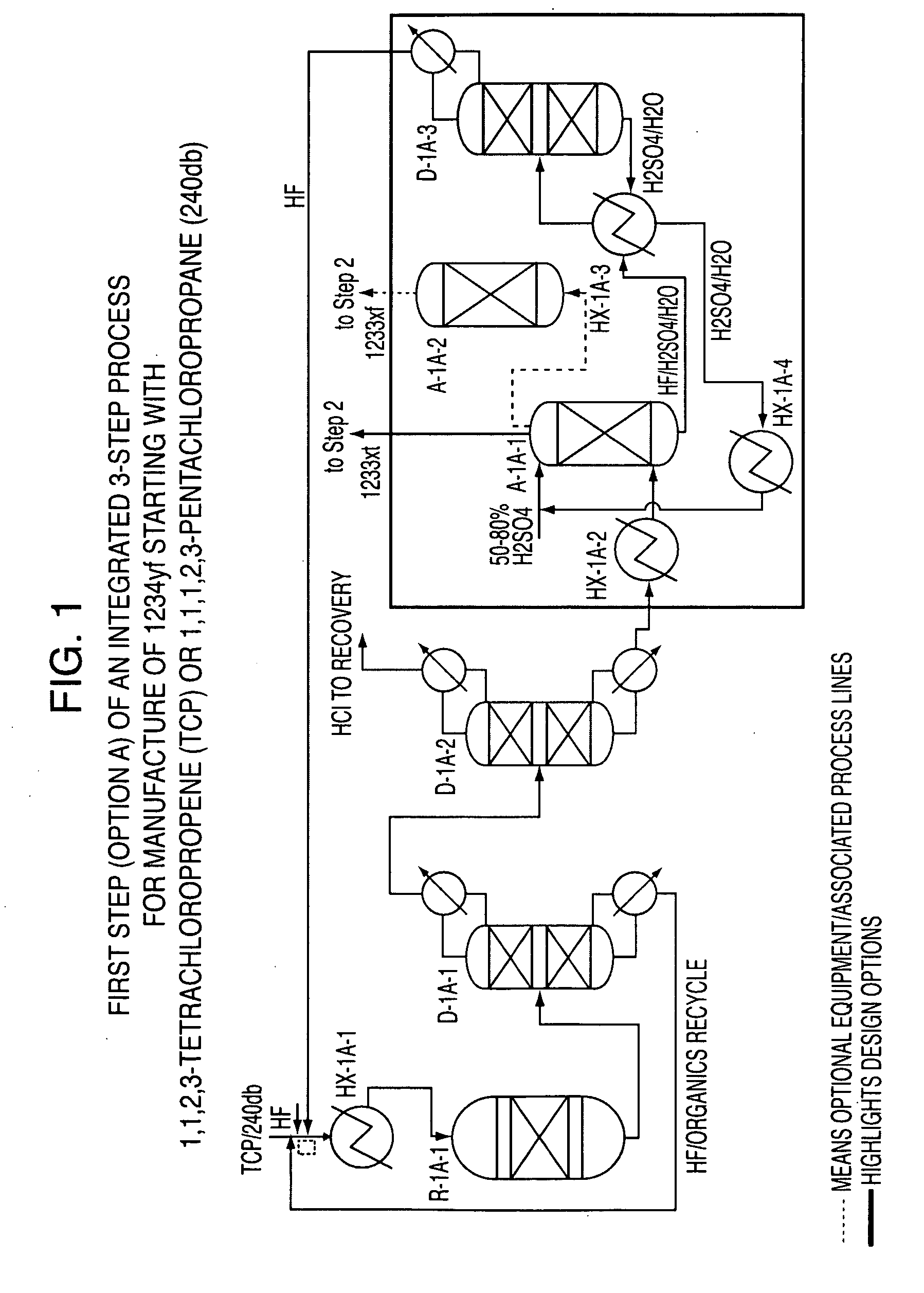

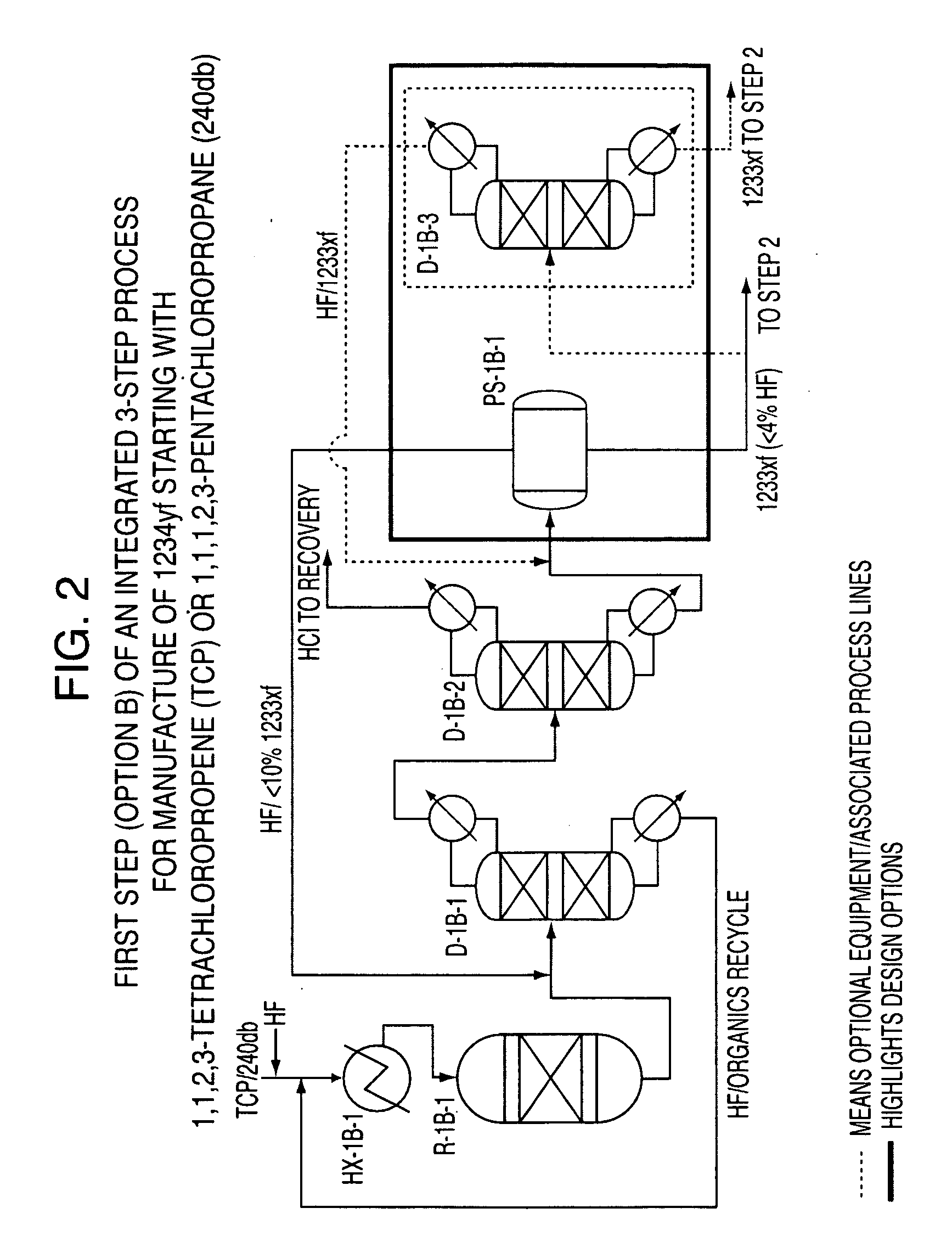

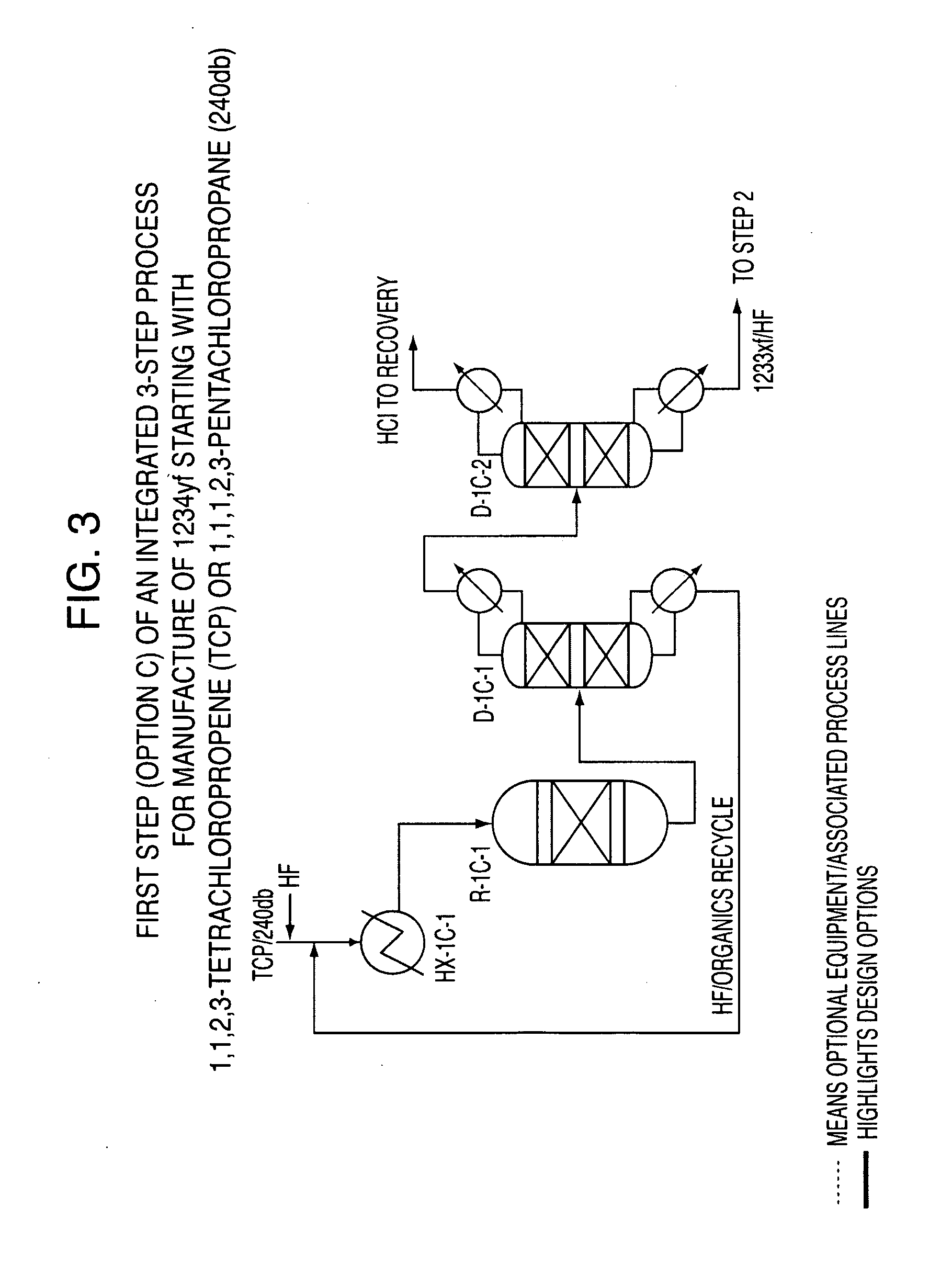

ActiveUS20090240090A1Maximize raw material utilizationMaximize product yieldPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

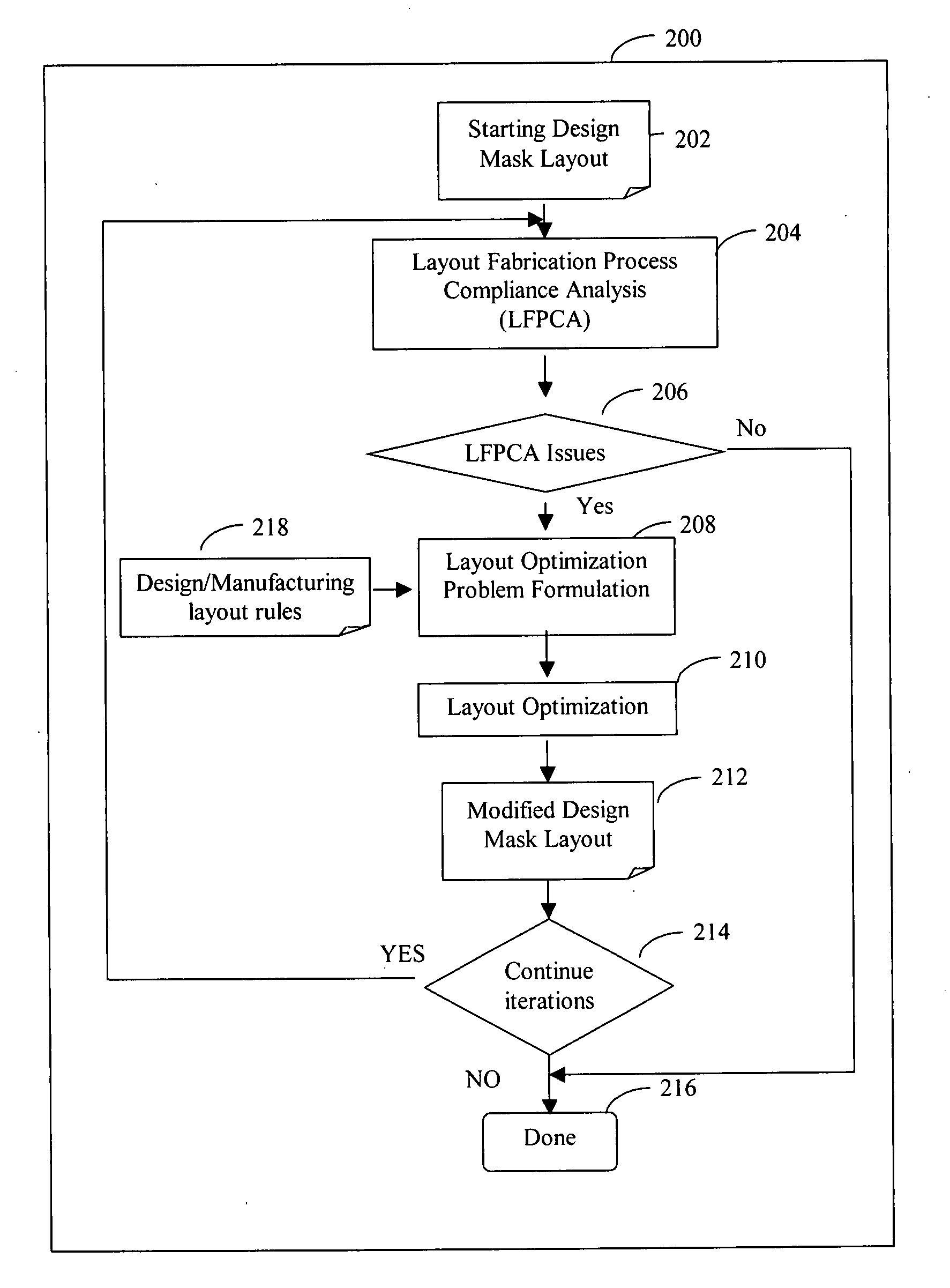

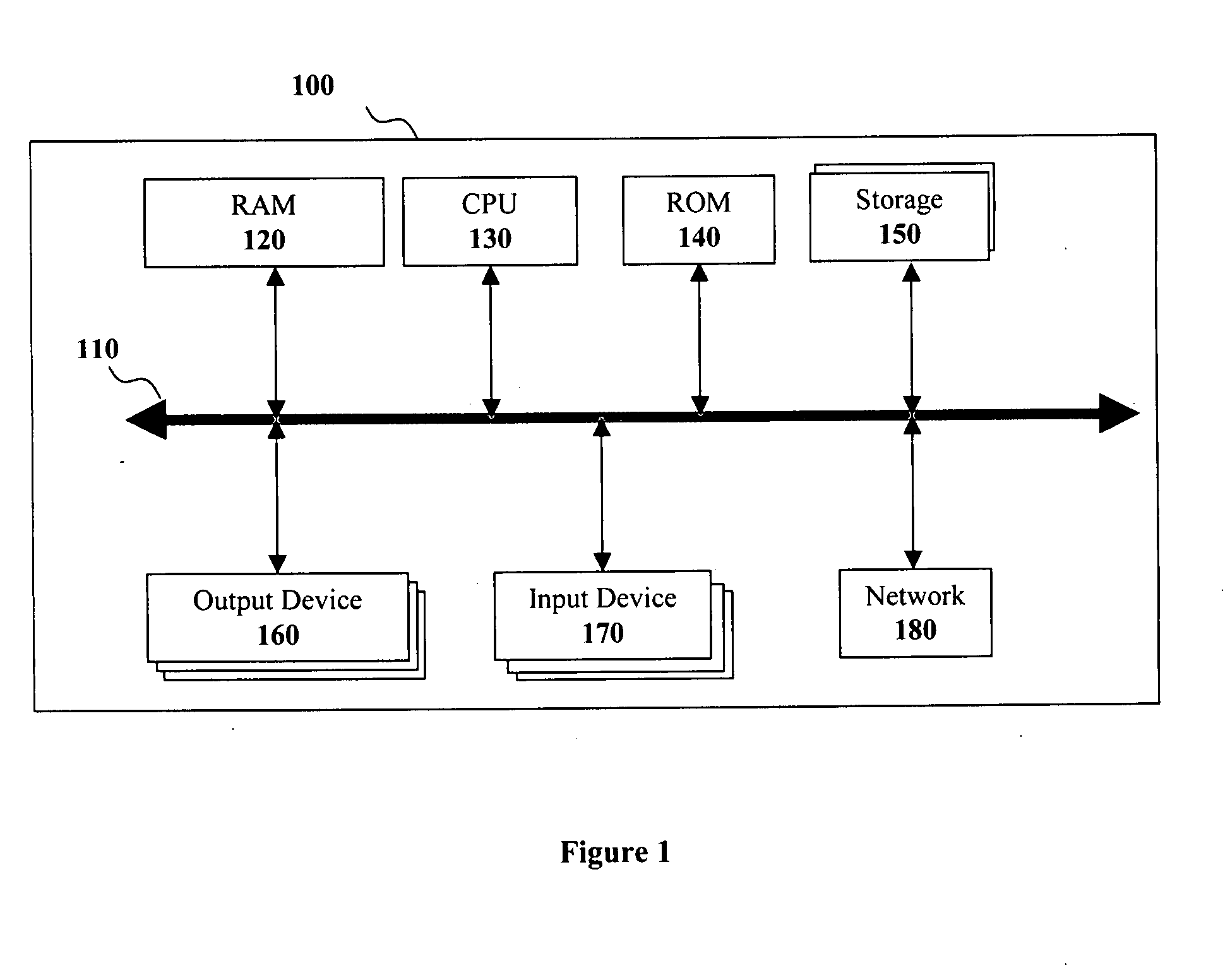

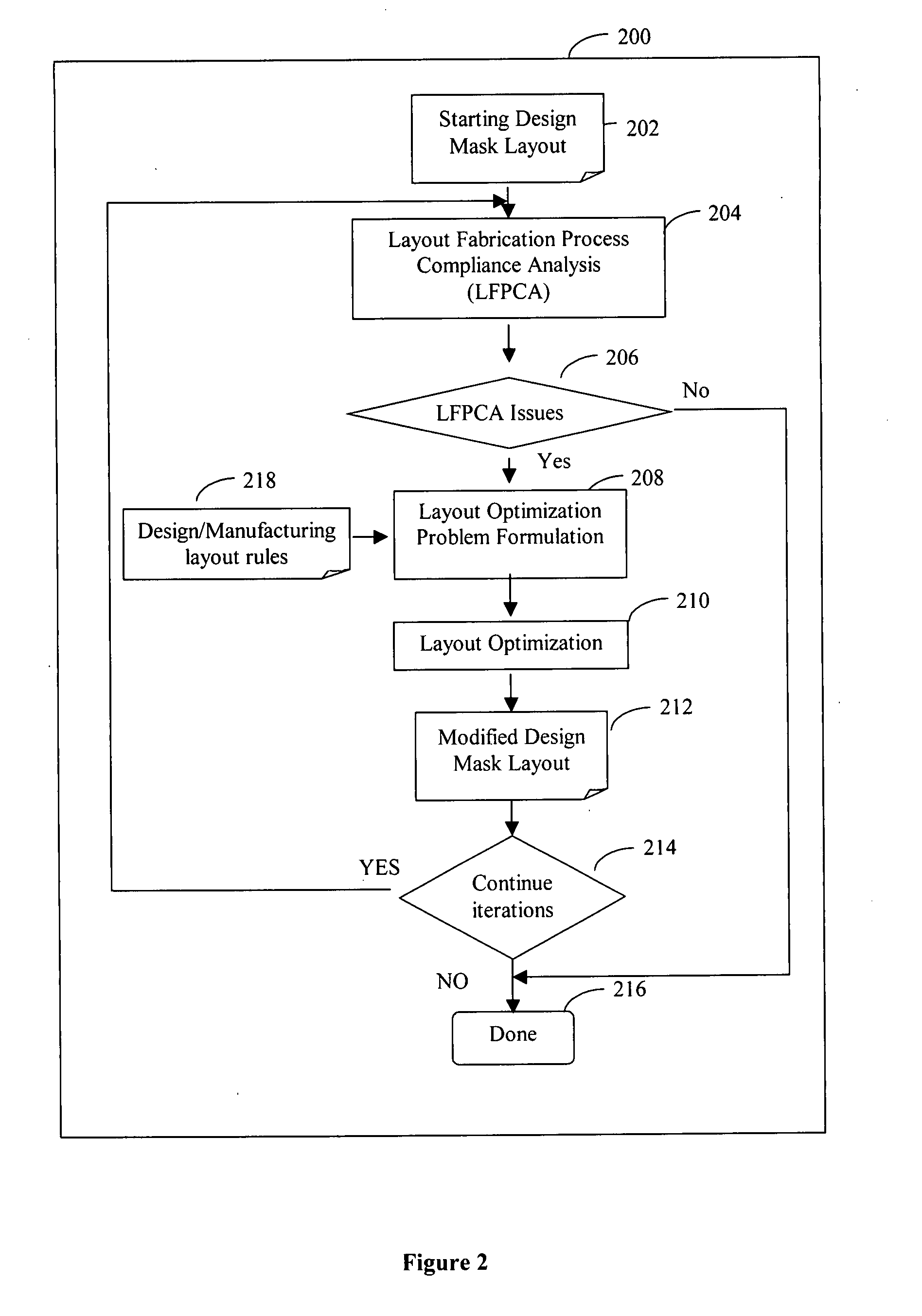

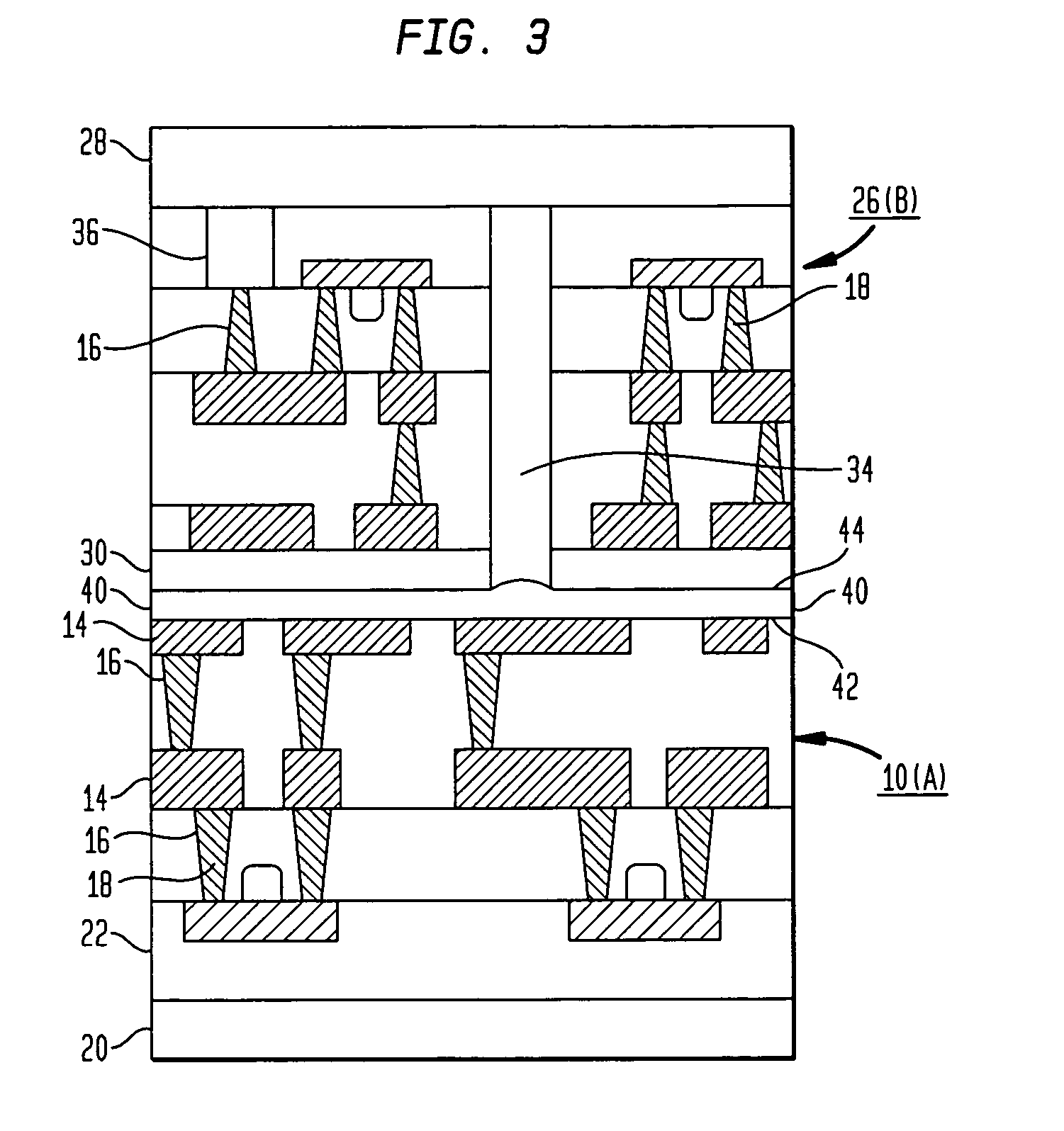

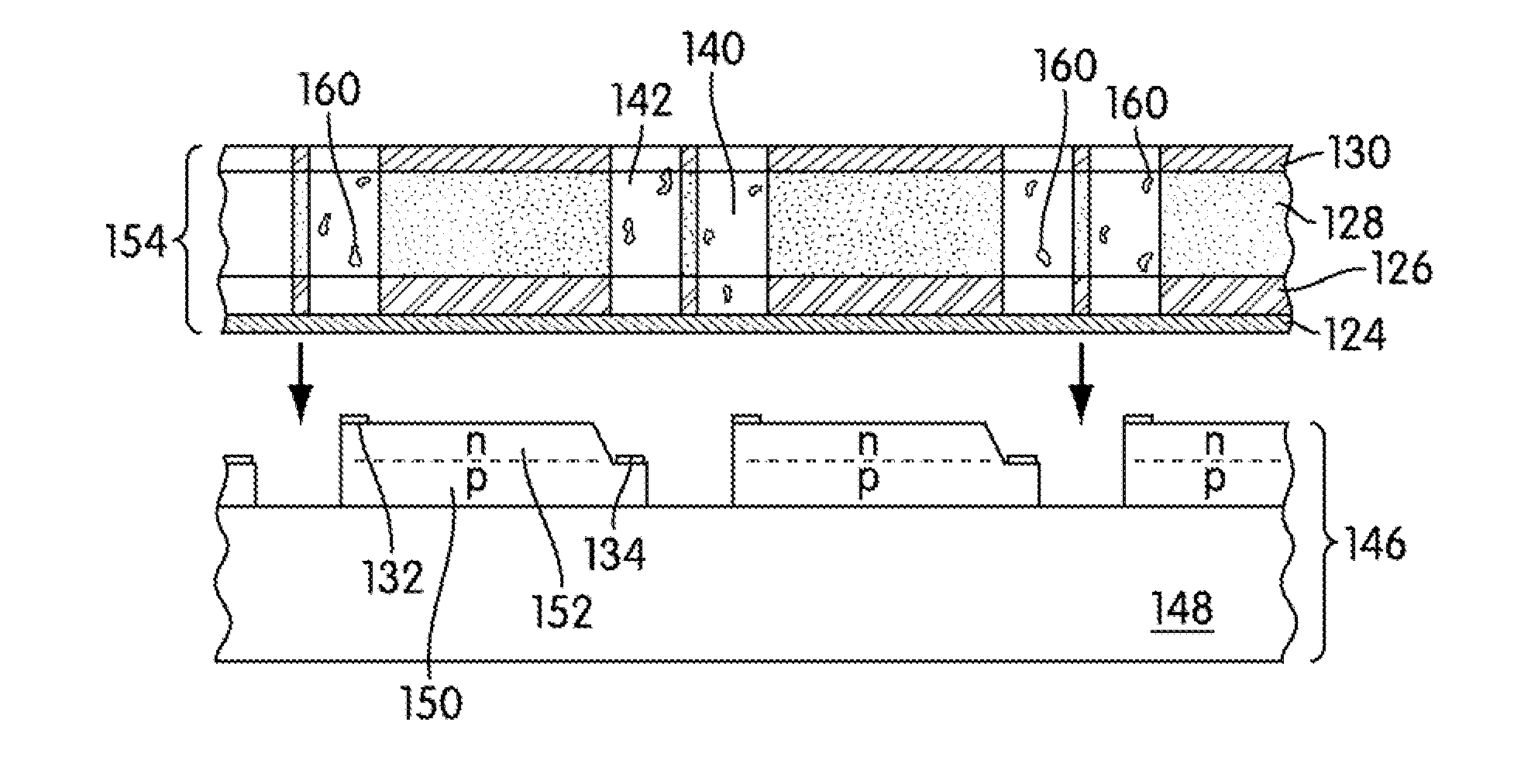

System and method of maximizing integrated circuit manufacturing yield with fabrication process simulation driven layout optimization

InactiveUS20080046846A1Maximizing manufacturing yieldYield maximizationCAD circuit designSoftware simulation/interpretation/emulationIntegrated circuit manufacturingEngineering

A system and a method of maximizing the manufacturing yield of integrated circuit (“IC”) design using IC fabrication process simulation driven layout optimization is described. An IC design layout is automatically modified through formulation of a layout optimization problem utilizing the results of layout fabrication process compliance analysis tools. The modification of layout is performed adaptively and iteratively to make an IC layout less susceptible to yield issues while maintaining design rule correctness and minimal circuit performance impact.

Owner:CHEW MARKO P +1

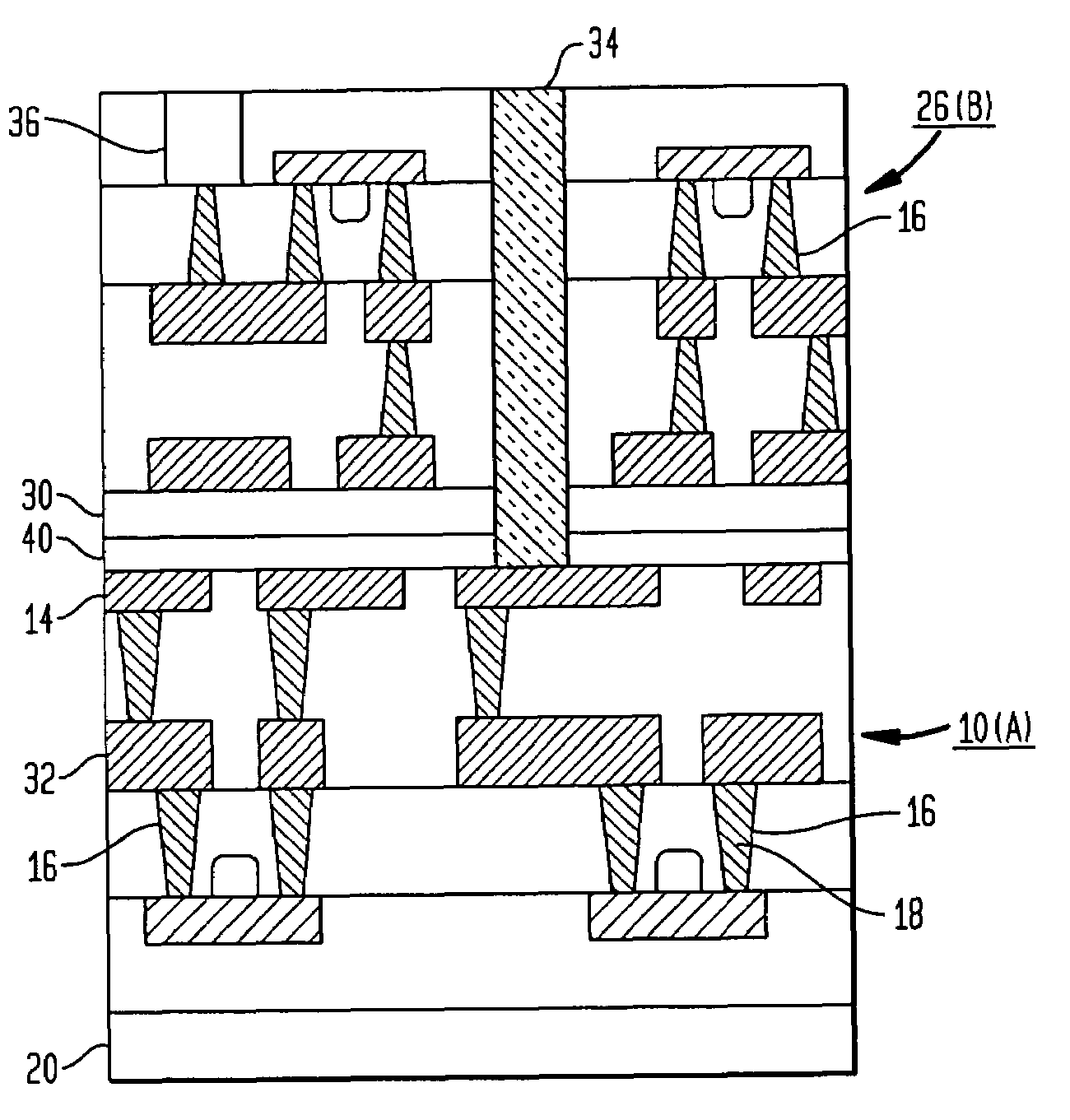

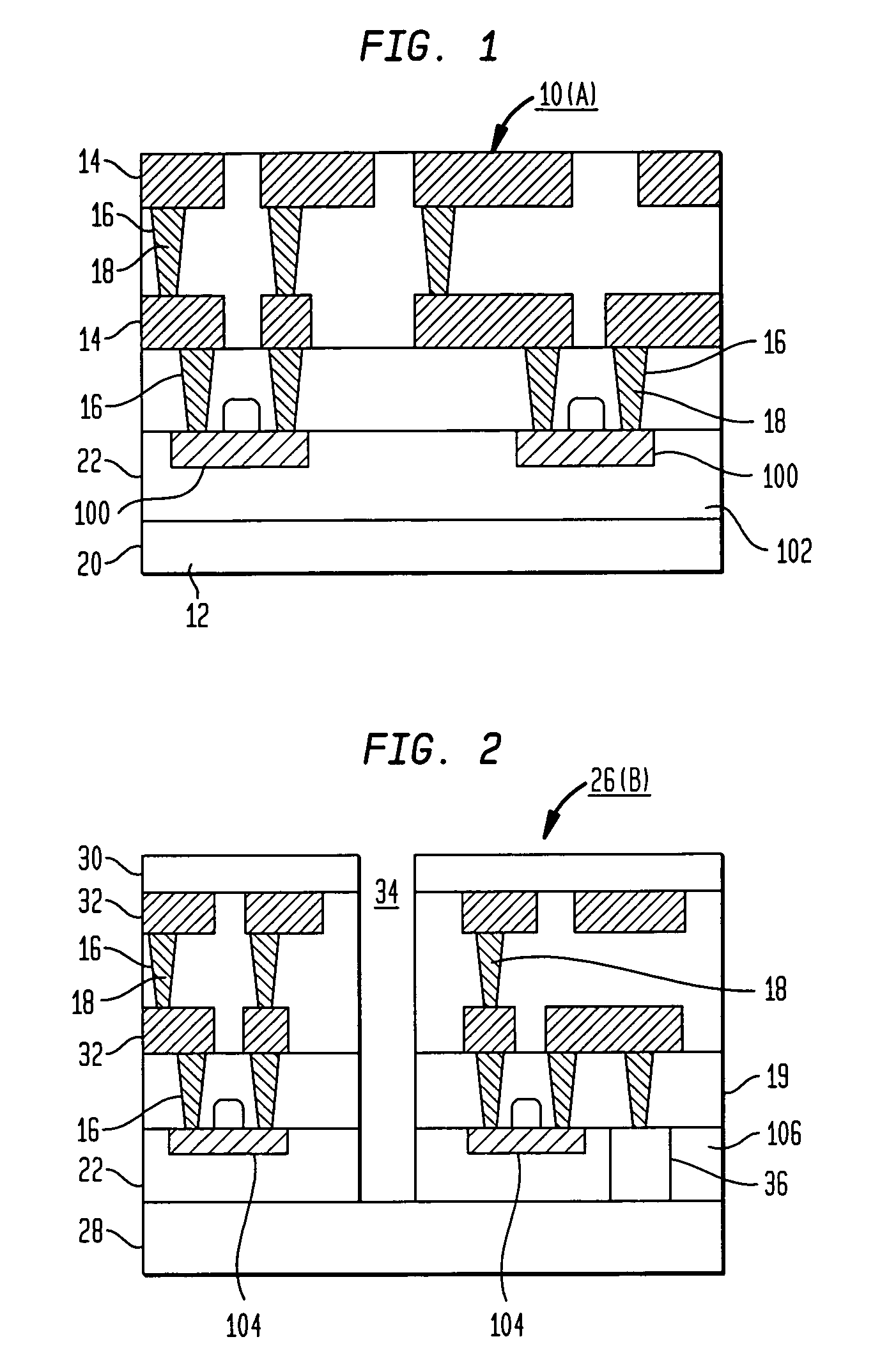

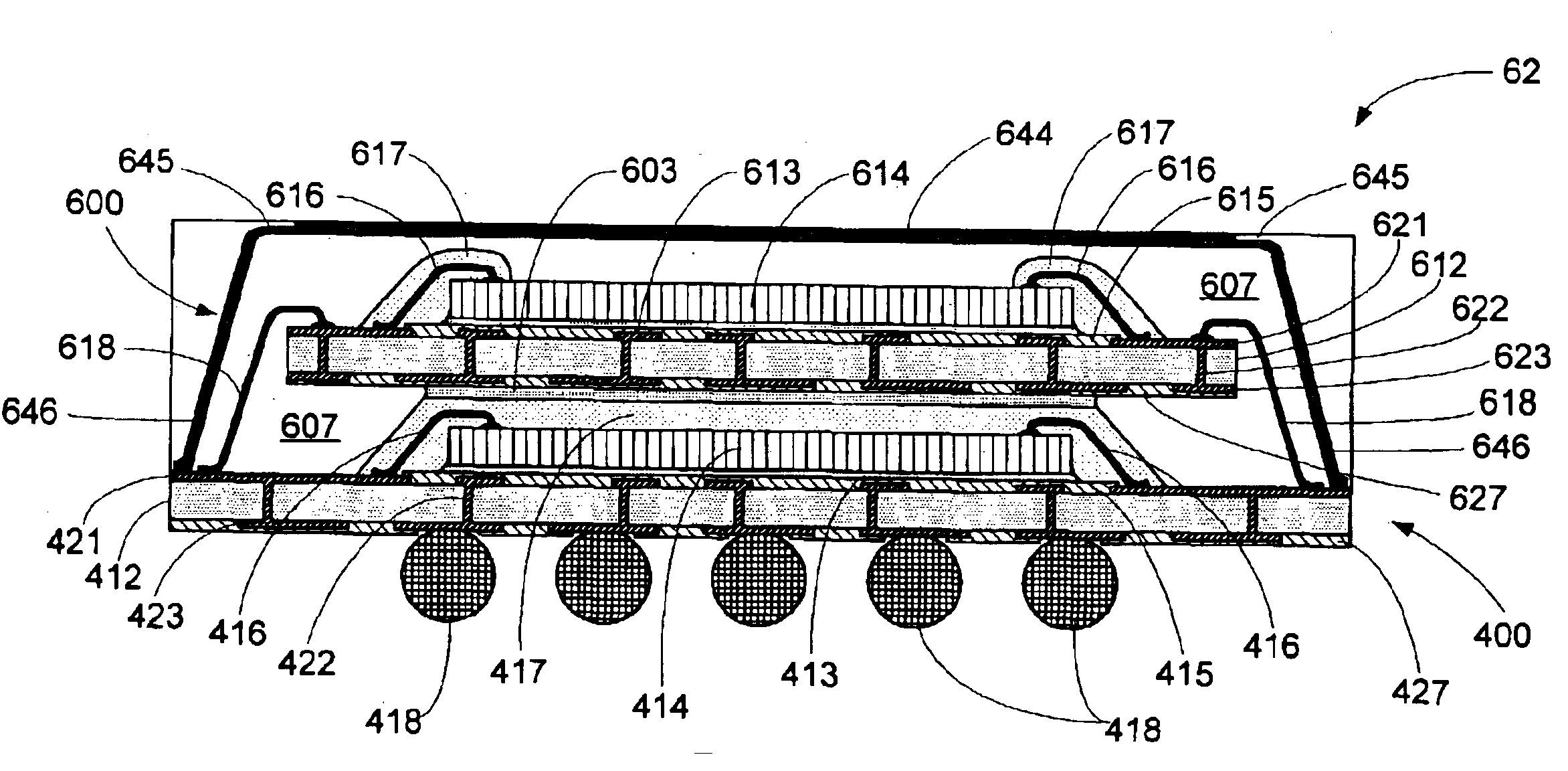

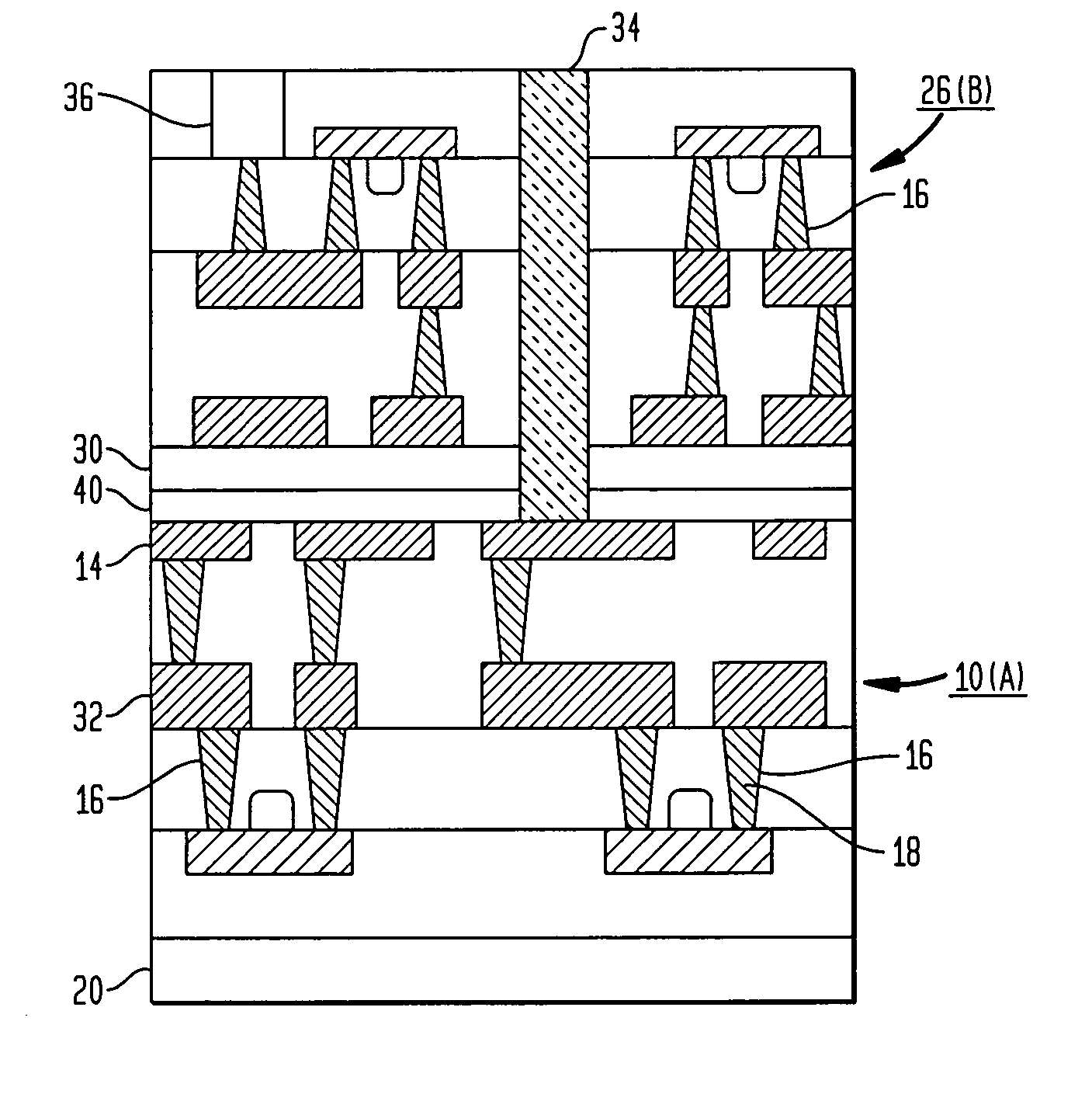

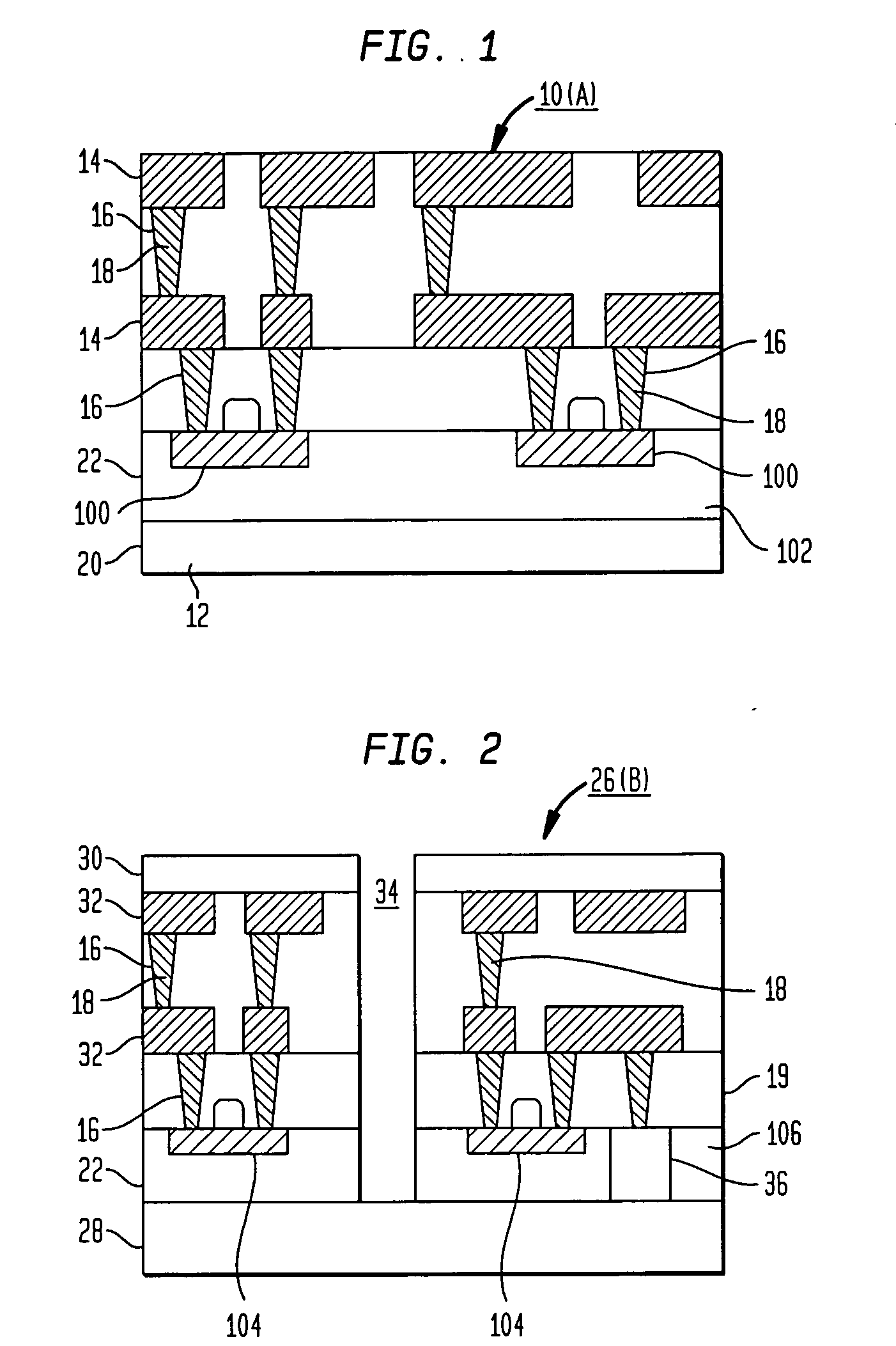

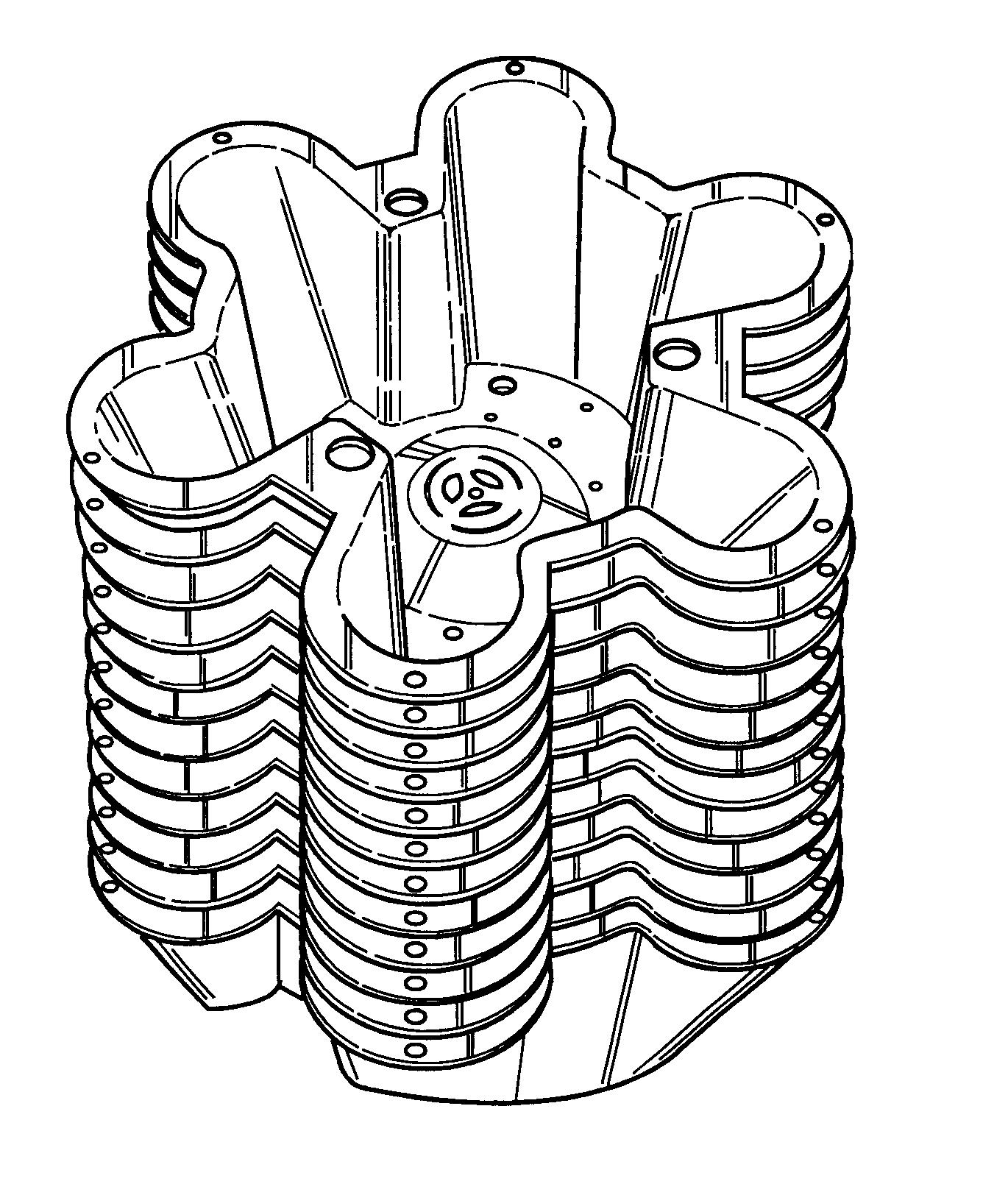

Accessible chip stack and process of manufacturing thereof

InactiveUS7528494B2Readily capable being thinnedYield maximizationSemiconductor/solid-state device detailsSolid-state devicesEngineeringThree-dimensional integrated circuit

A process of manufacturing a three-dimensional integrated circuit chip or wafer assembly and, more particularly, a processing of chips while arranged on a wafer prior to orienting the chips into stacks. Also disclosed is the manufacture of the three-dimensional integrated circuit wherein the chip density can be very high and processed while the wafers are still intact and generally of planar constructions.

Owner:ALSEPHINA INNOVATIONS INC

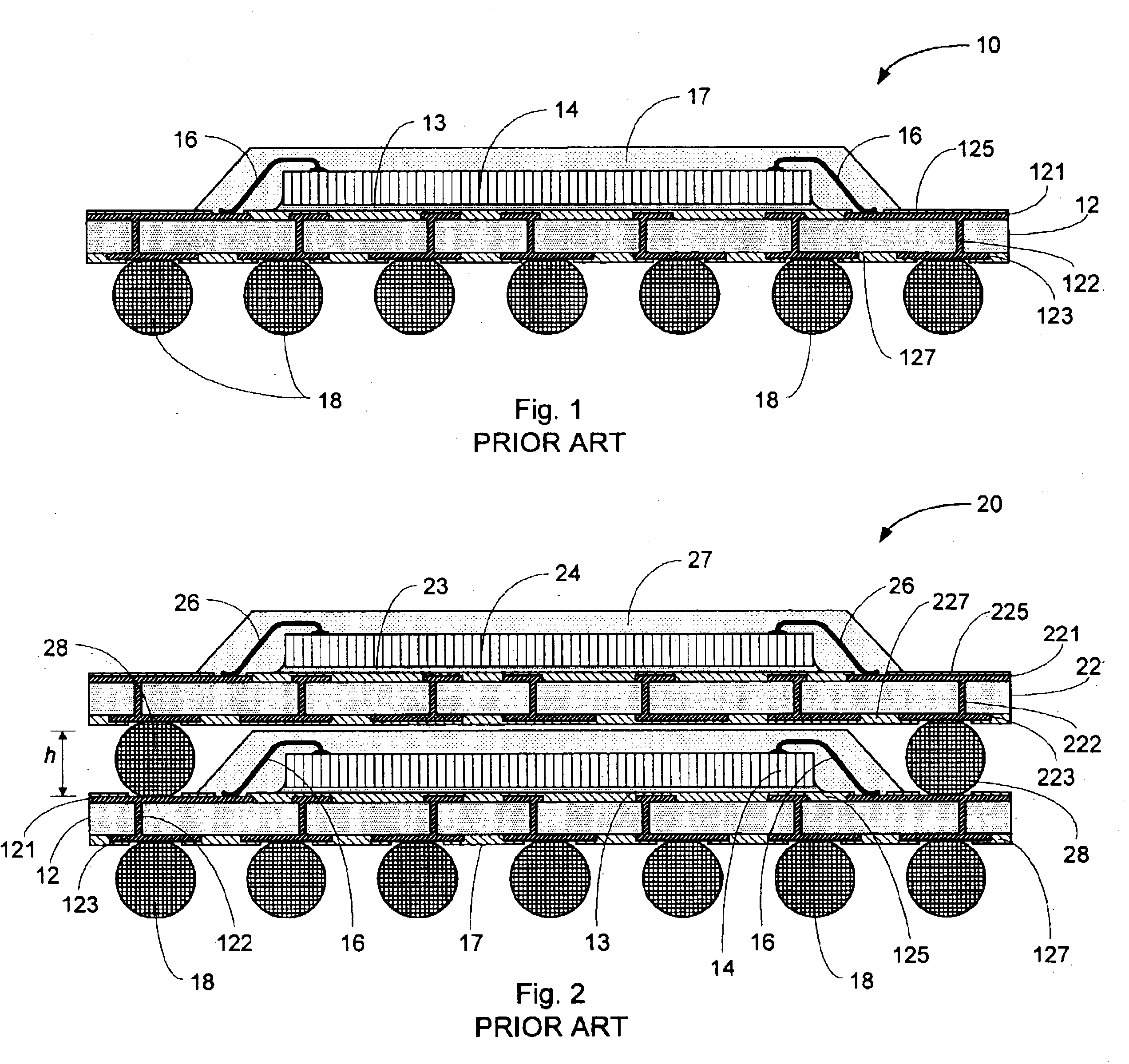

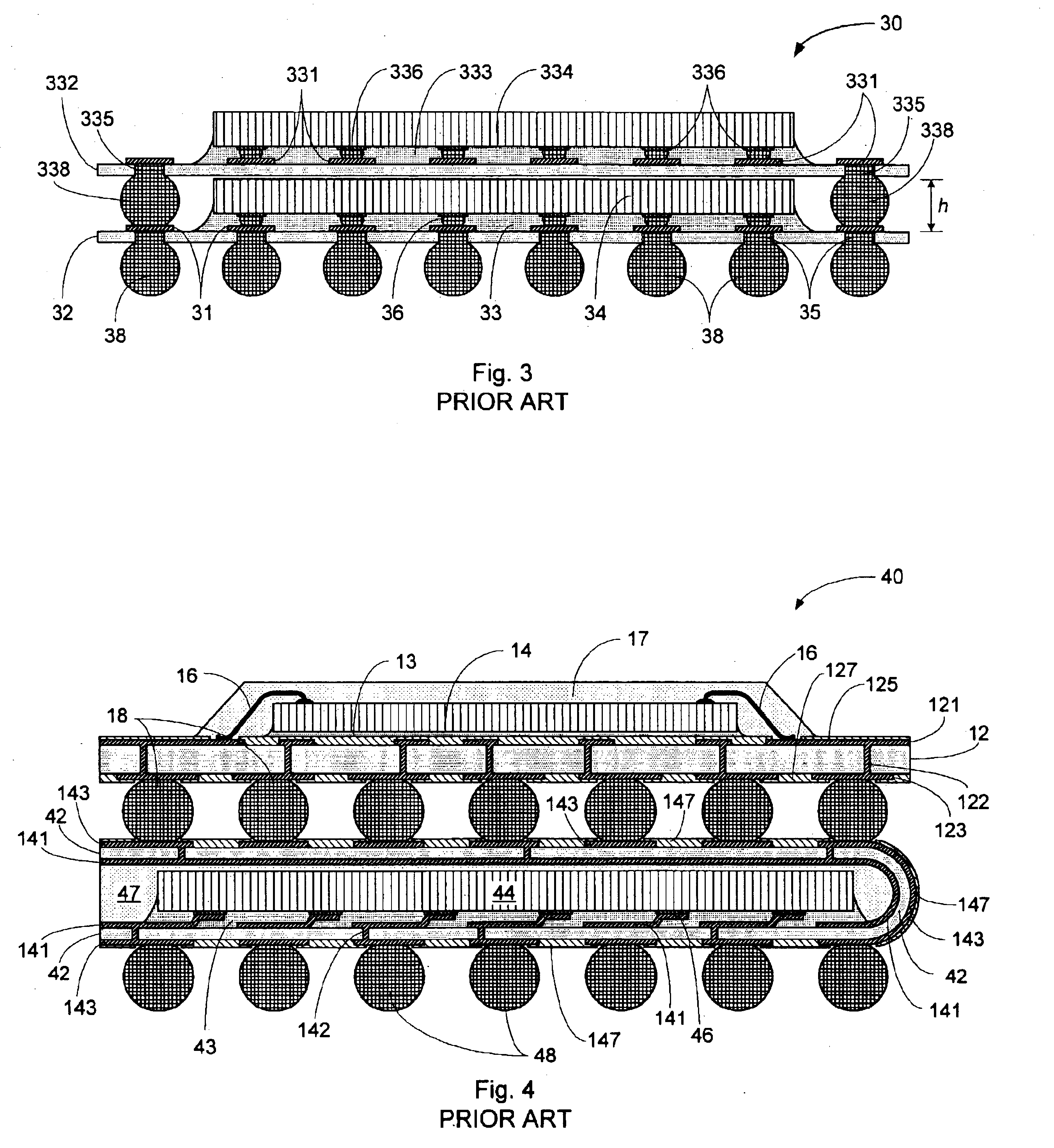

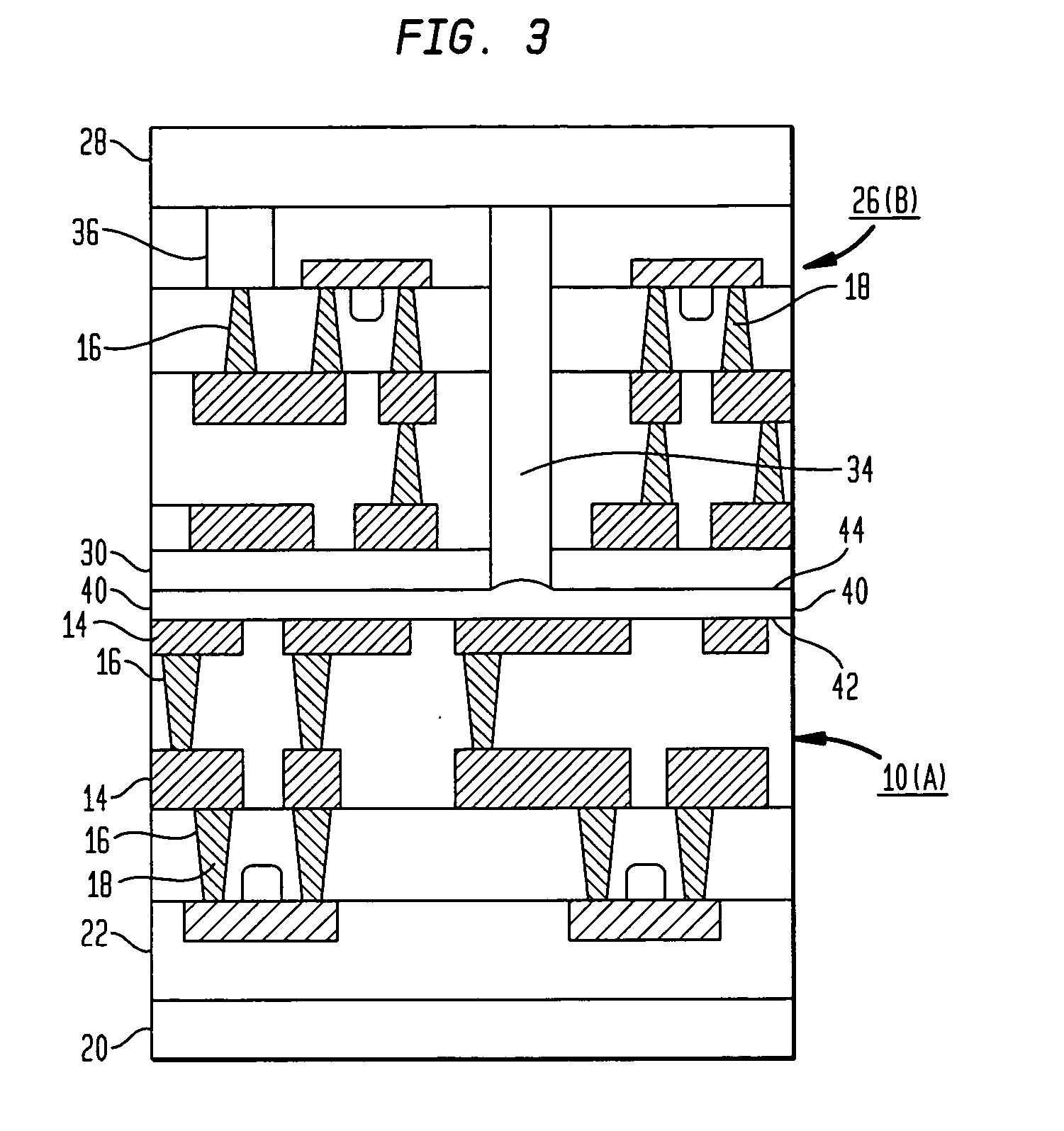

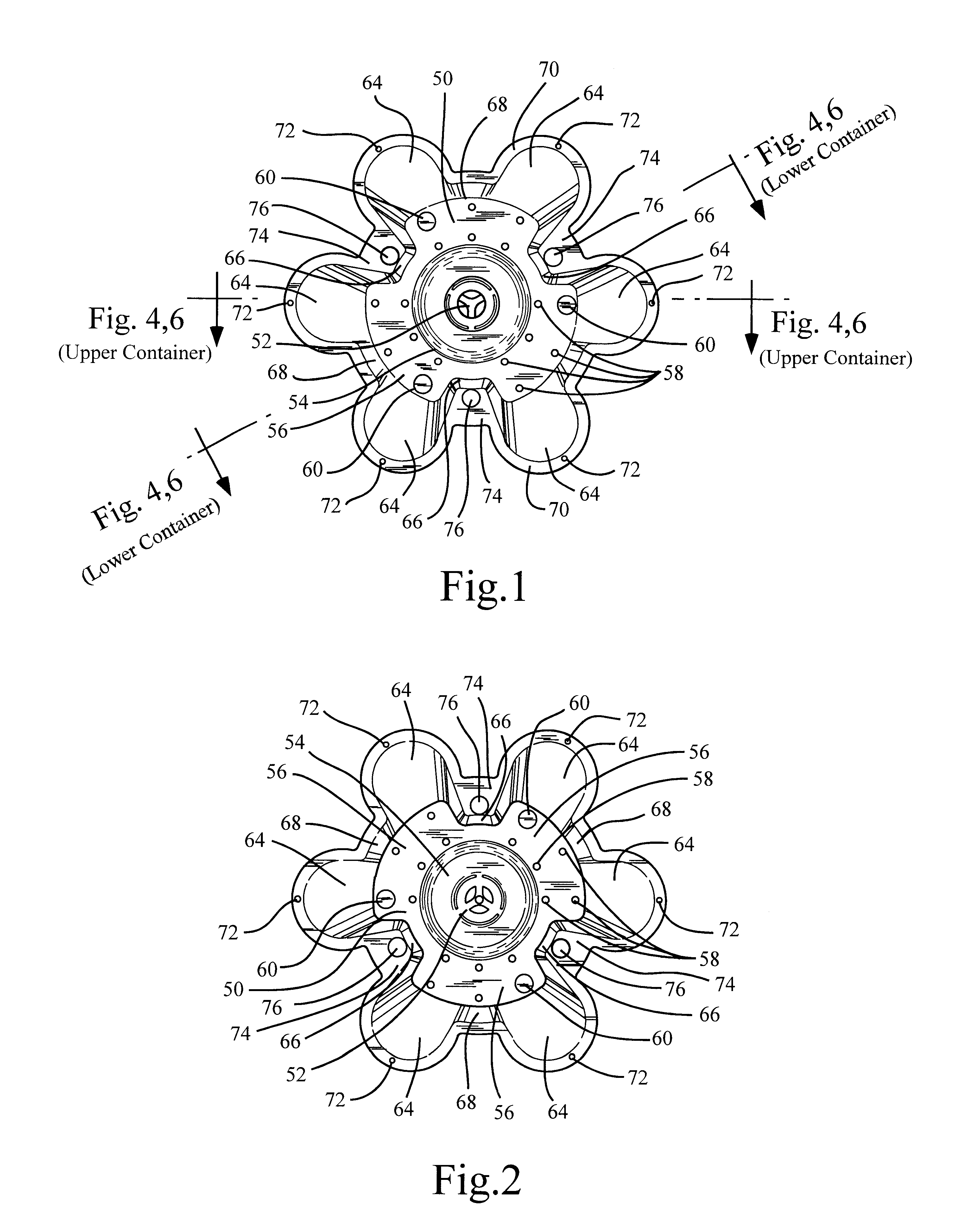

Semiconductor multi-package module having wire bond interconnect between stacked packages and having electrical shield

ActiveUS6838761B2Low production costOverall design flexibilitySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

A semiconductor multi-package module having stacked lower and upper packages, each package including a die attached to a substrate, in which the upper and lower substrates are interconnected by wire bonding. Also, a method for making a semiconductor multi-package module, by providing a lower molded package including a lower substrate and a die, affixing an upper molded package including an upper substrate onto the upper surface of the lower package, and forming wire bond z-interconnects between the upper and lower substrates.

Owner:STATS CHIPPAC LTD

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS8058486B2Maximize utilizationYield maximizationPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

Accessible chip stack and process of manufacturing thereof

InactiveUS20070096263A1Maximize yieldIncrease outputSemiconductor/solid-state device detailsSolid-state devicesThree-dimensional integrated circuitVolumetric Mass Density

A process of manufacturing a three-dimensional integrated circuit chip or wafer assembly and, more particularly, a processing of chips while arranged on a wafer prior to orienting the chips into stacks. Also disclosed is the manufacture of the three-dimensional integrated circuit wherein the chip density can be very high and processed while the wafers are still intact and generally of planar constructions.

Owner:ALSEPHINA INNOVATIONS INC

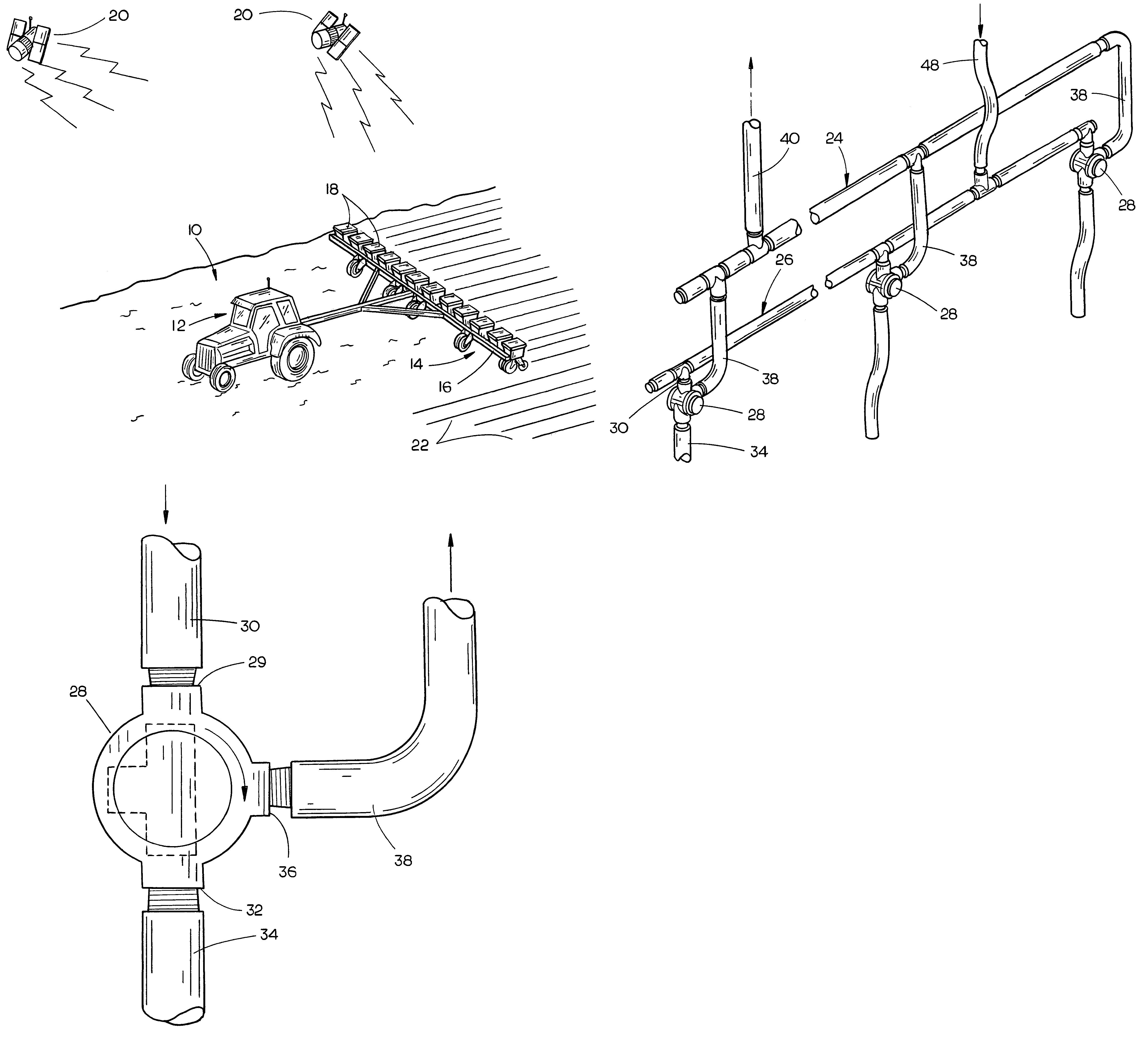

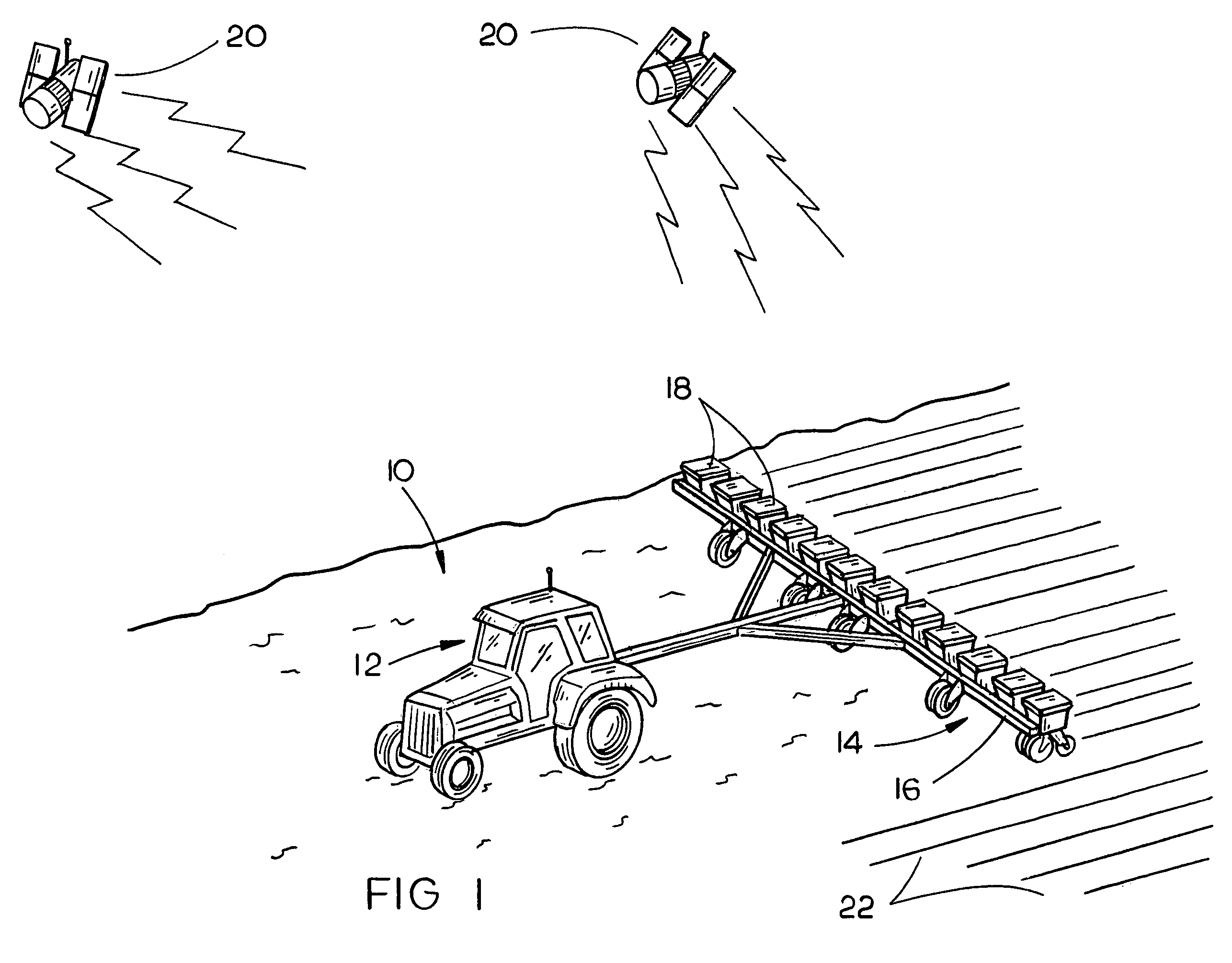

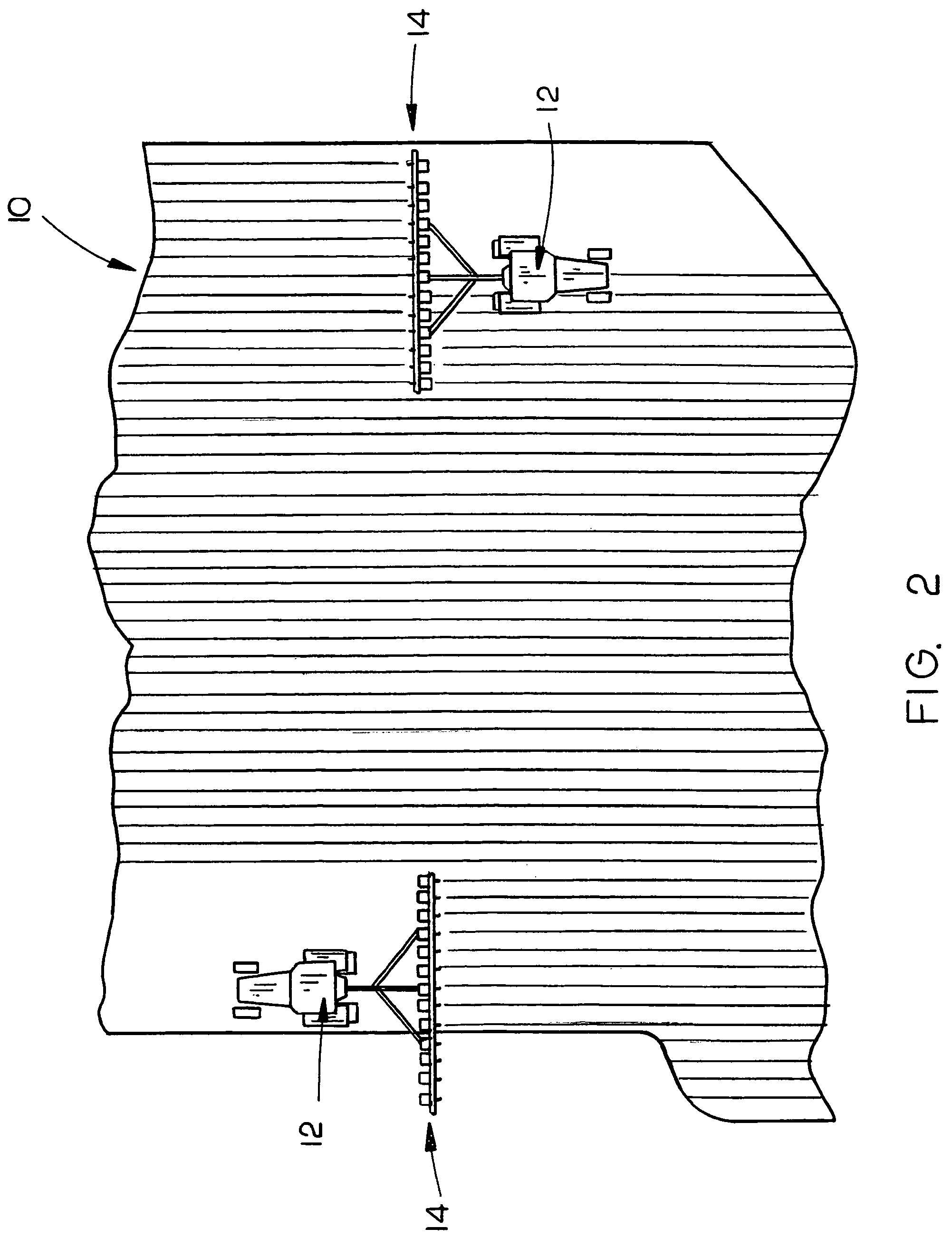

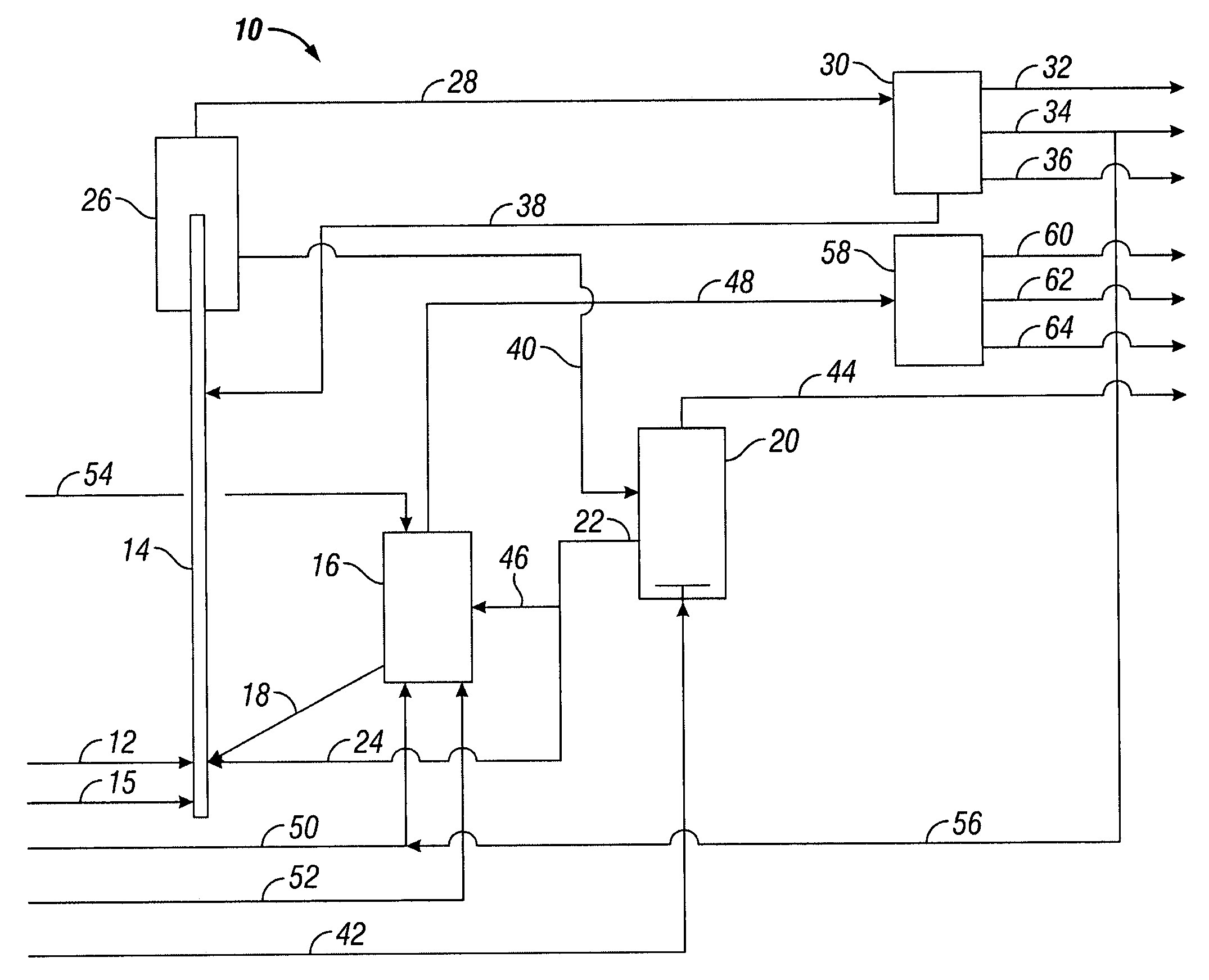

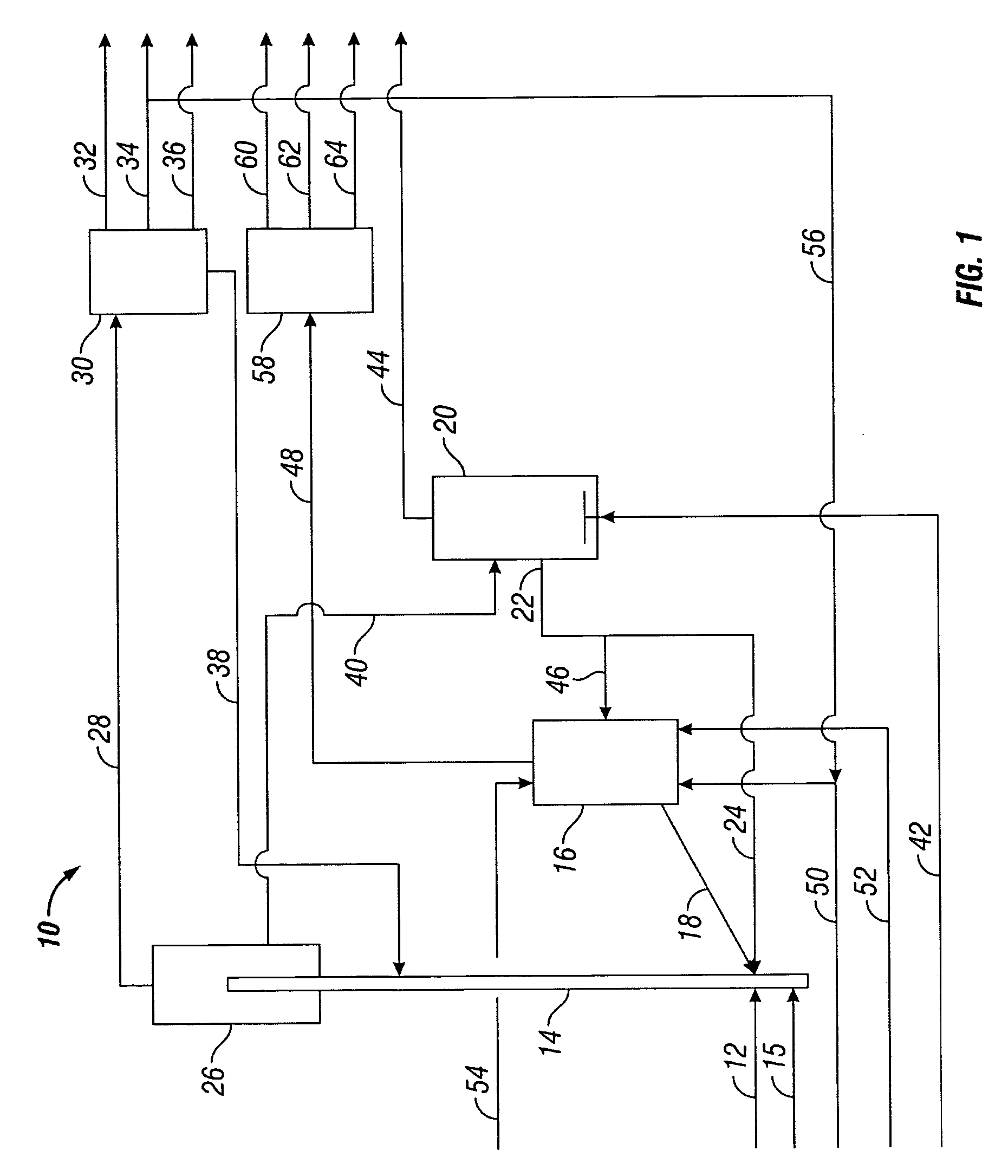

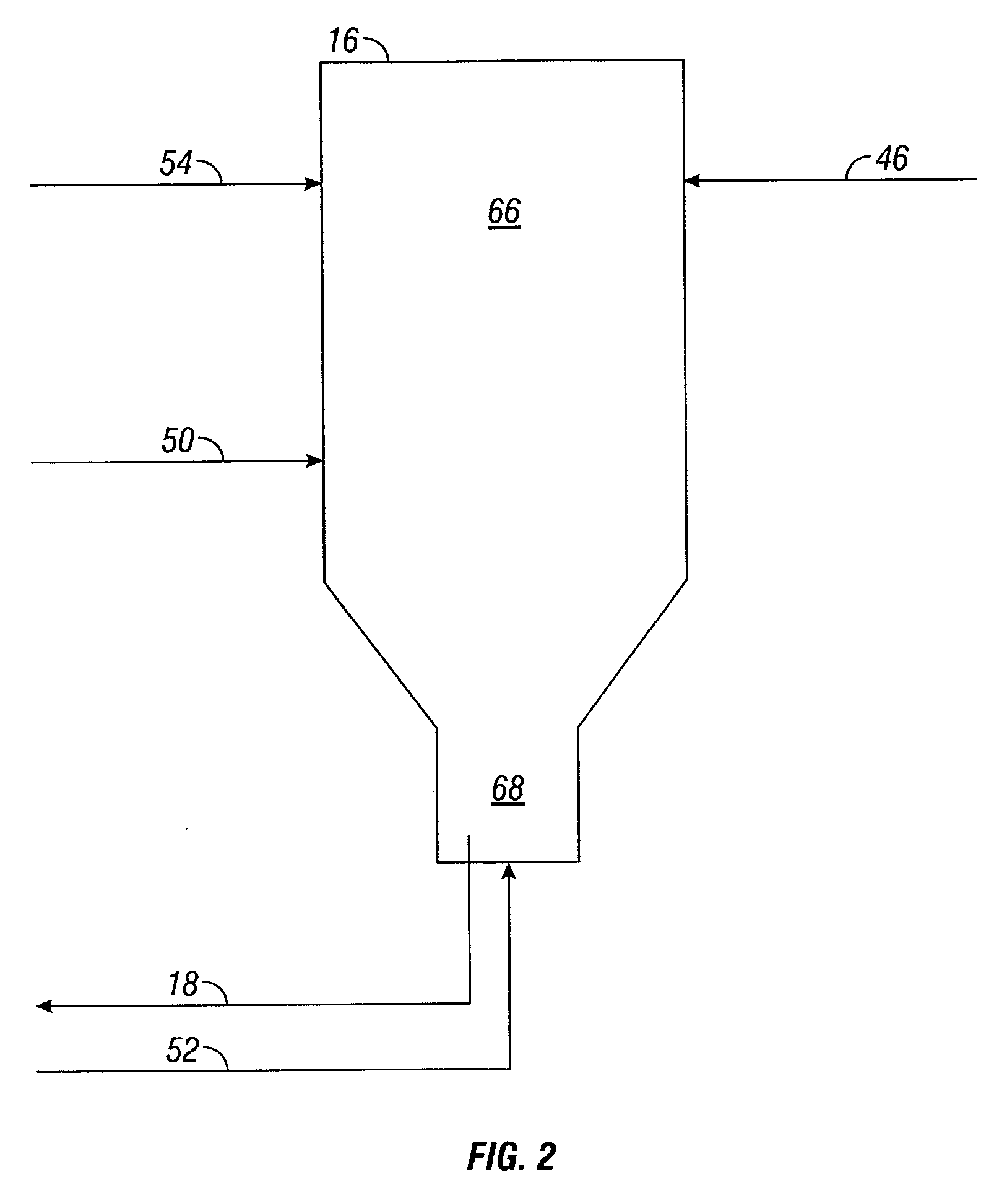

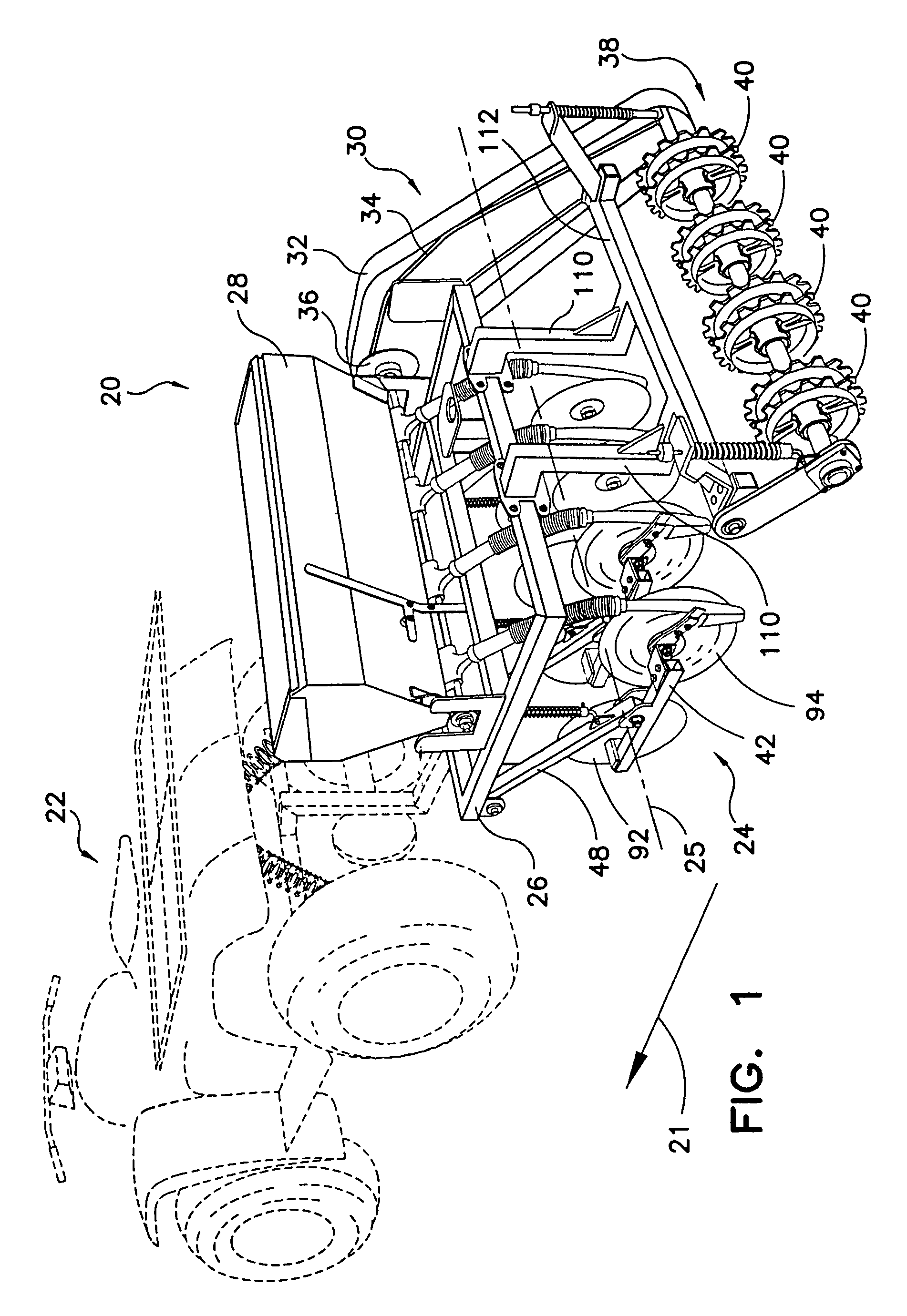

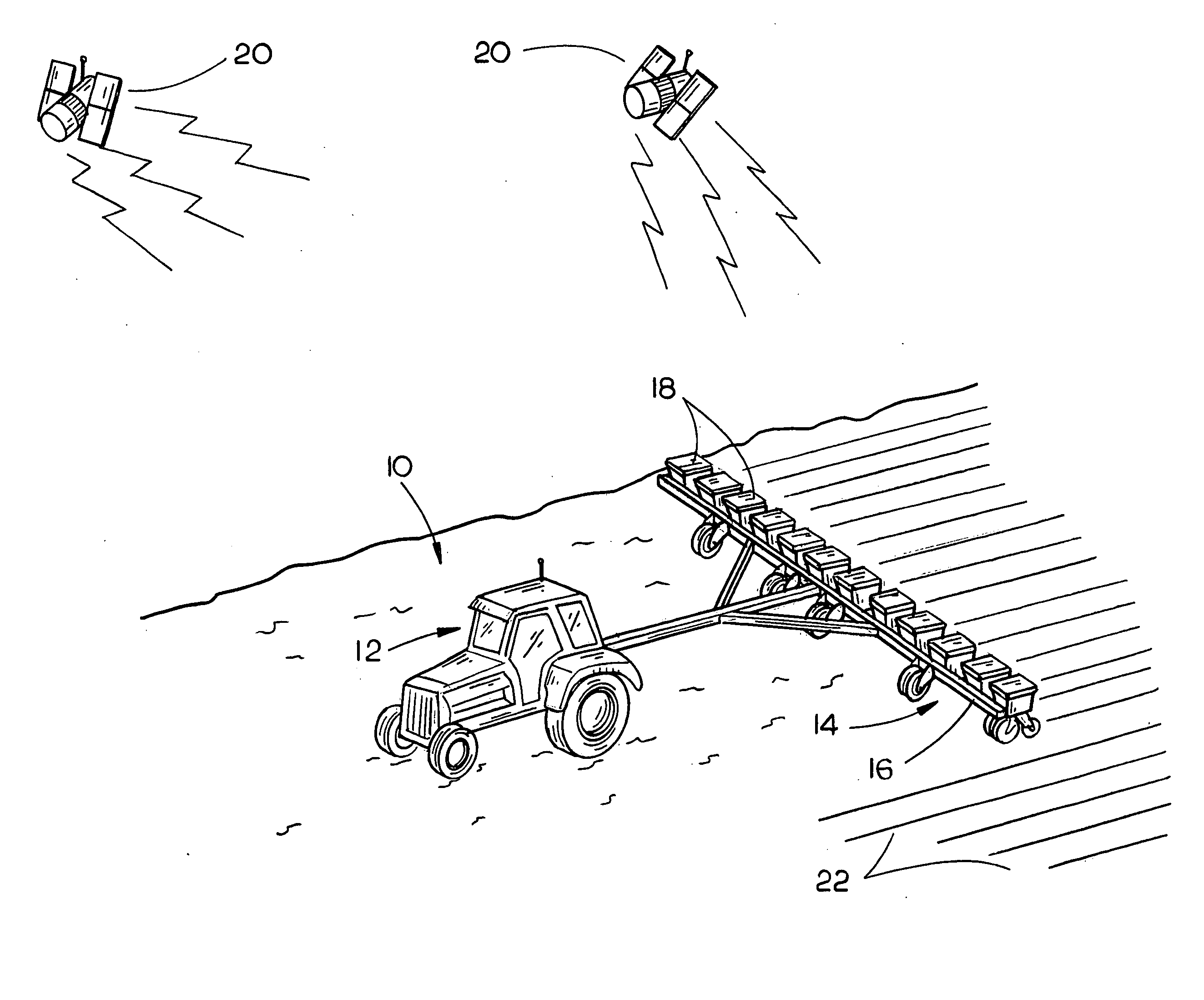

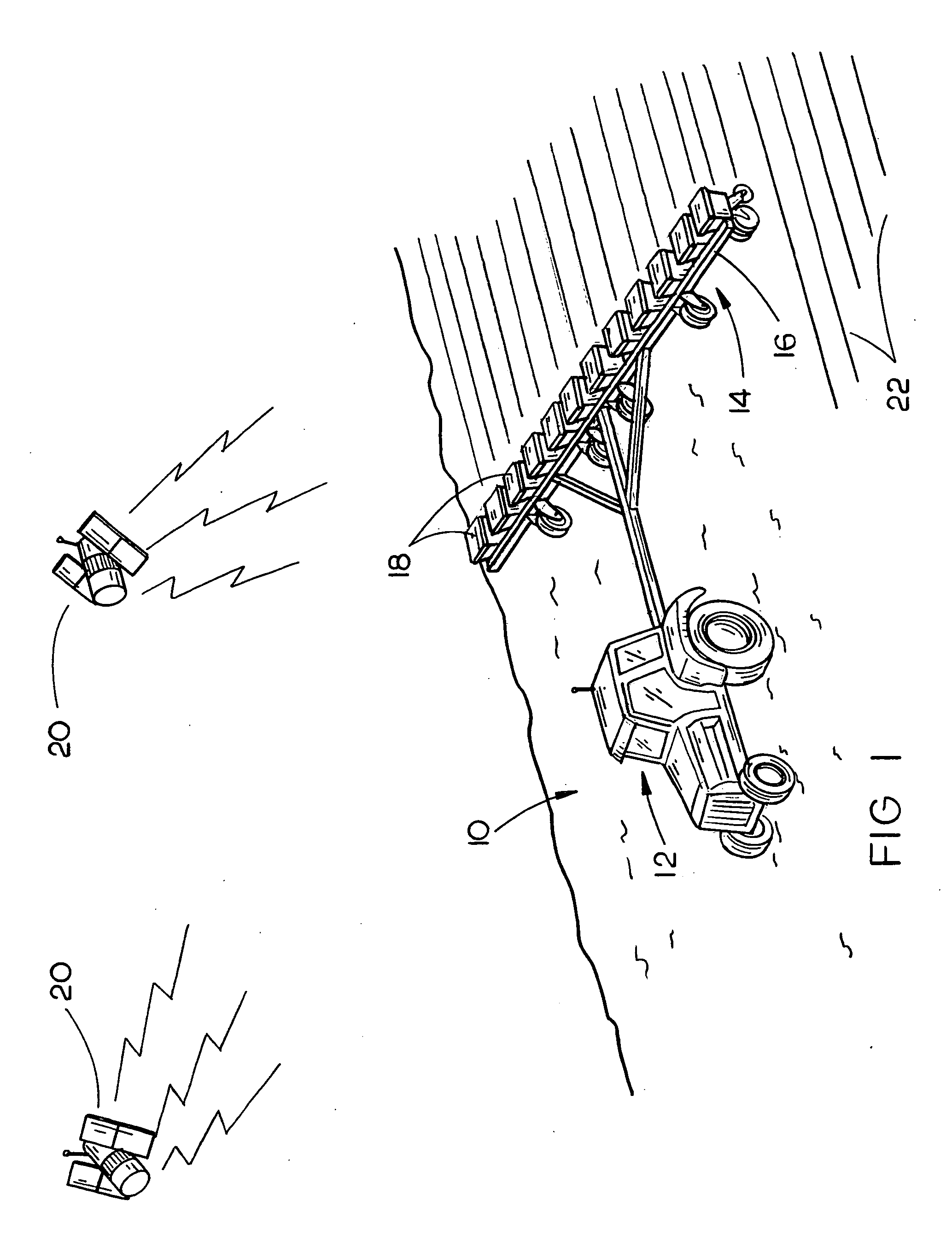

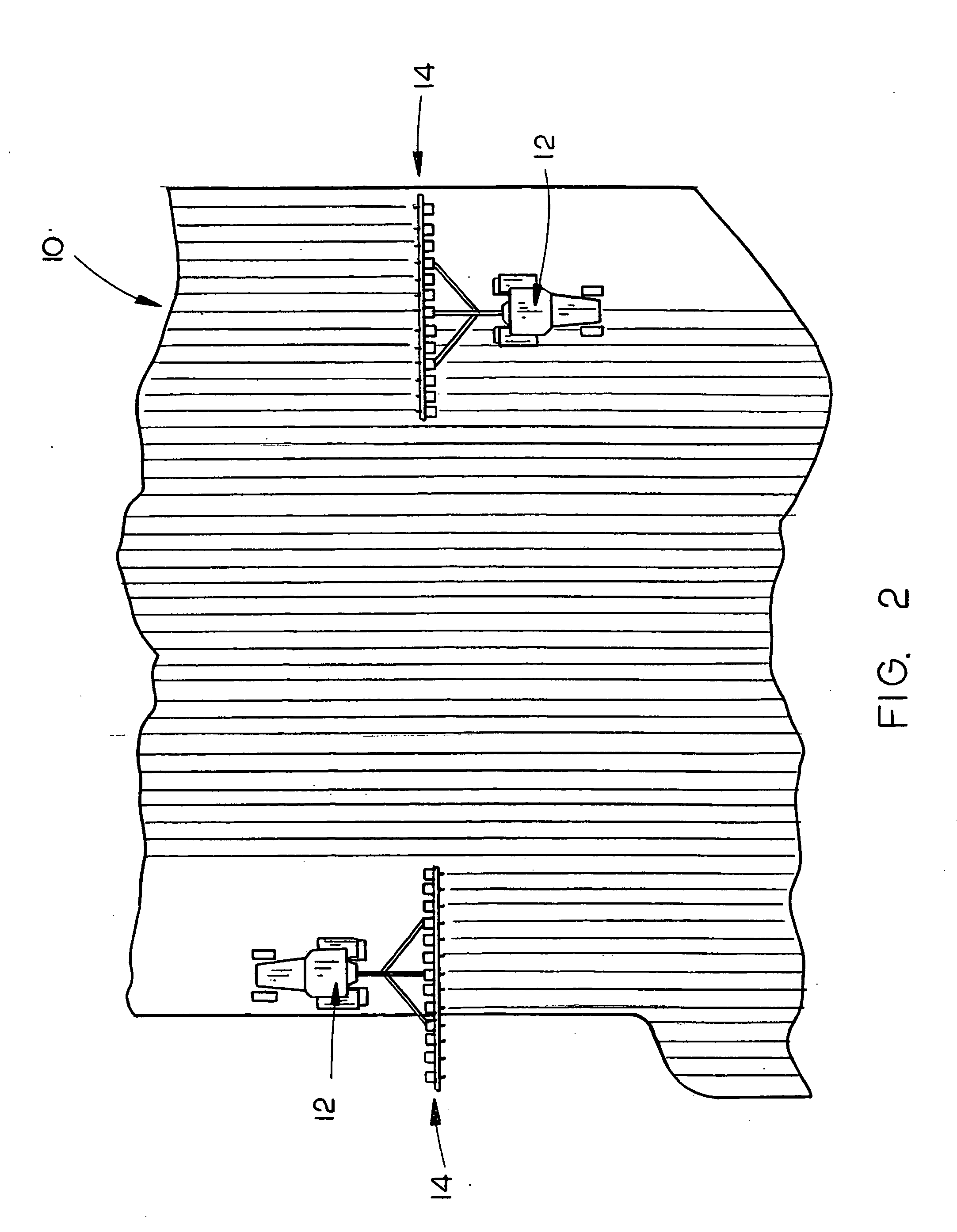

Individual row rate control of farm implements to adjust the volume of crop inputs across wide implements in irregularly shaped or contour areas of chemical application, planting or seeding

InactiveUS7395769B2Optimize input application rate per acreYield maximizationAnalogue computers for trafficLiquid fertiliser distributionAutomatic controlEngineering

Owner:UNVERFERTH MFG

Method and apparatus for making a middle distillate product and lower olefins from a hydrocarbon feedstock

ActiveUS20060178546A1Yield maximizationCatalytic crackingCatalytic naphtha reformingPetroleum productGasoline

Disclosed is a process for making middle distillate and lower olefins. The process includes catalytically cracking a gas oil feedstock within a riser reactor zone by contacting under suitable catalytic cracking conditions within the riser reactor zone the gas oil feedstock with a middle distillate selective cracking catalyst that comprises amorphous silica alumina and a zeolite to yield a cracked gas oil product and a spent cracking catalyst. The spent cracking catalyst is regenerated to yield a regenerated cracking catalyst. Within an intermediate cracking reactor such as a dense bed reactor zone and under suitable high severity cracking conditions a gasoline feedstock is contacted with the regenerated cracking catalyst to yield a cracked gasoline product and a used regenerated cracking catalyst. The used regenerated cracking catalyst is utilized as the middle distillate selective catalyst.

Owner:SHELL USA INC

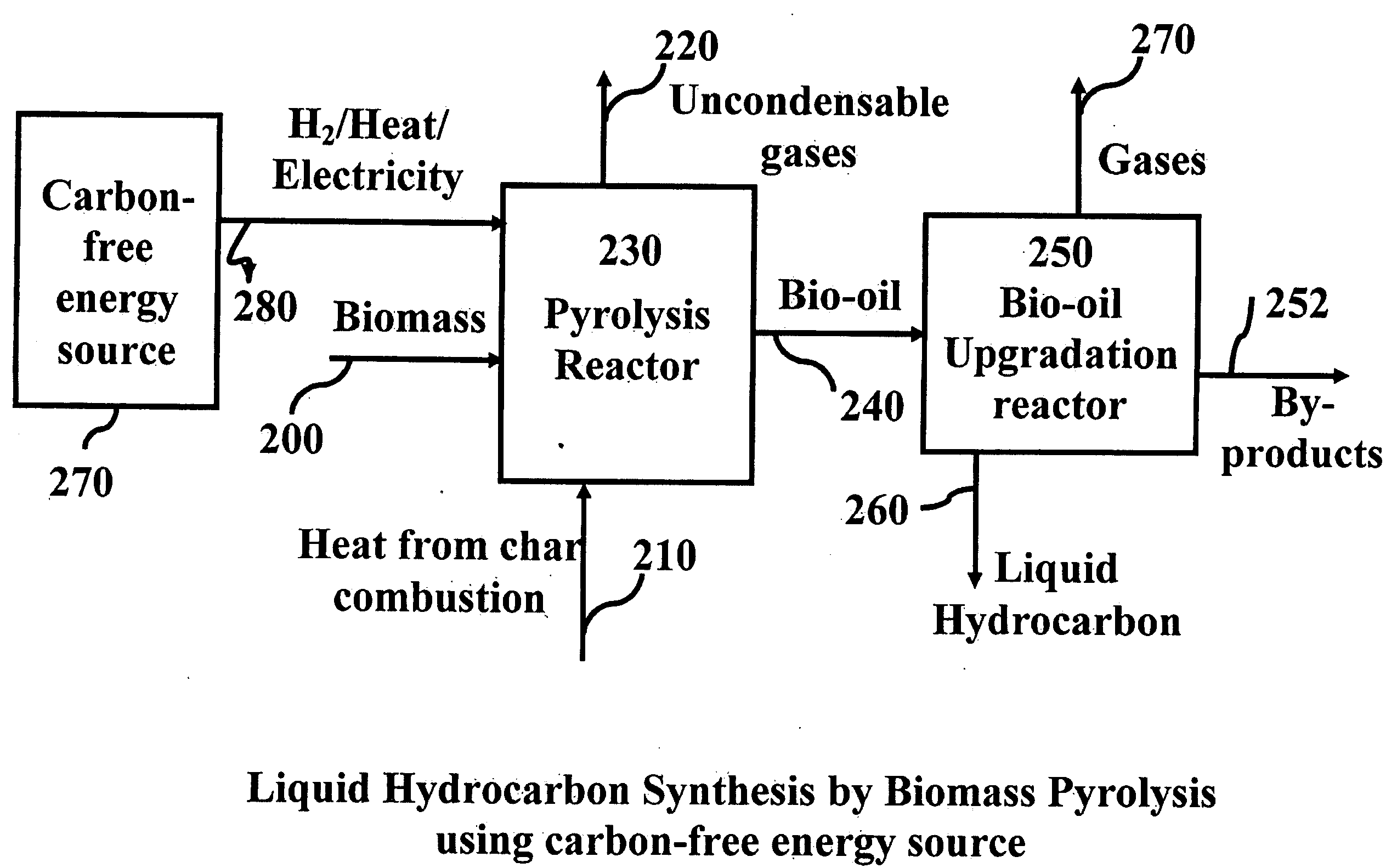

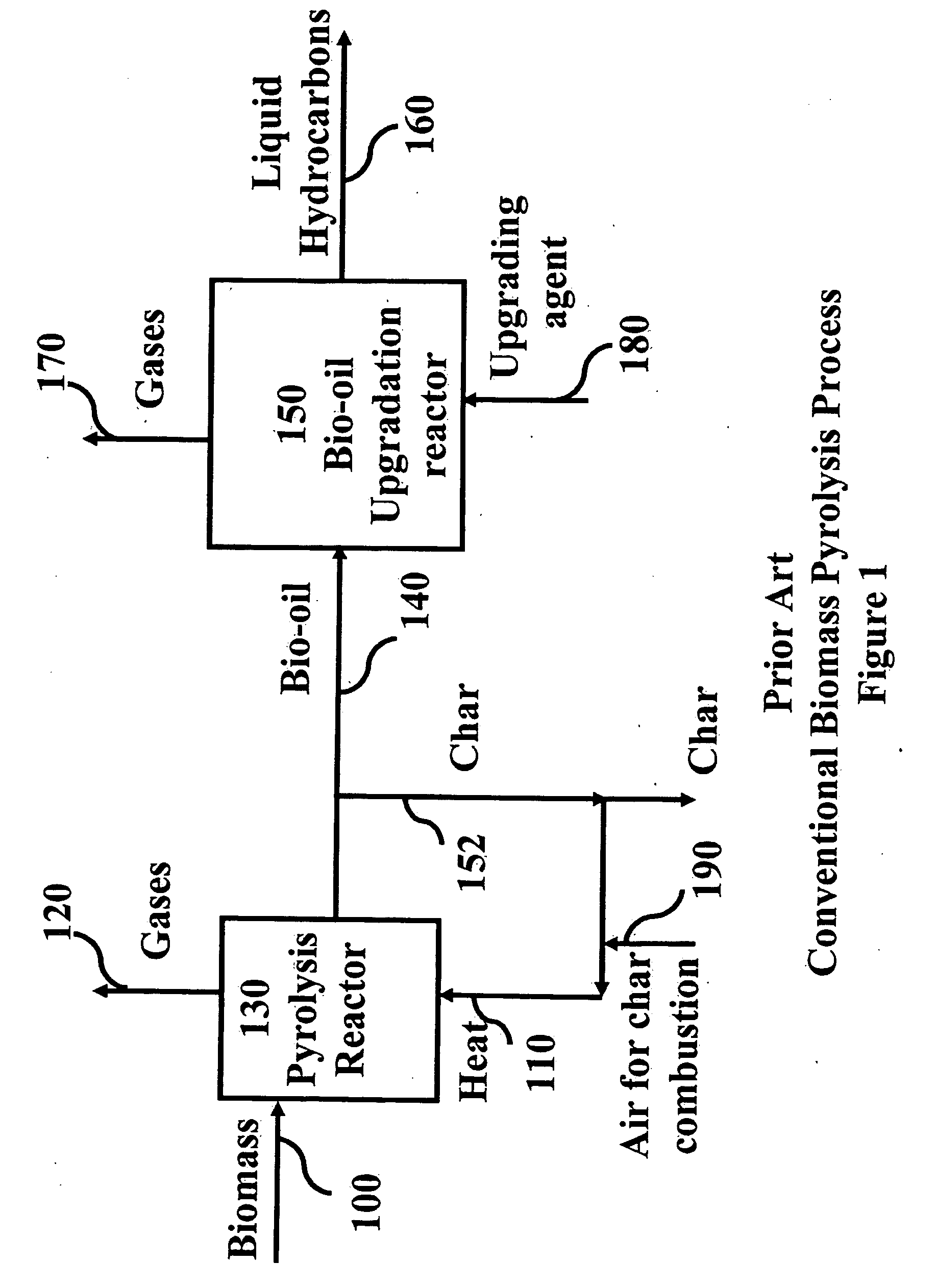

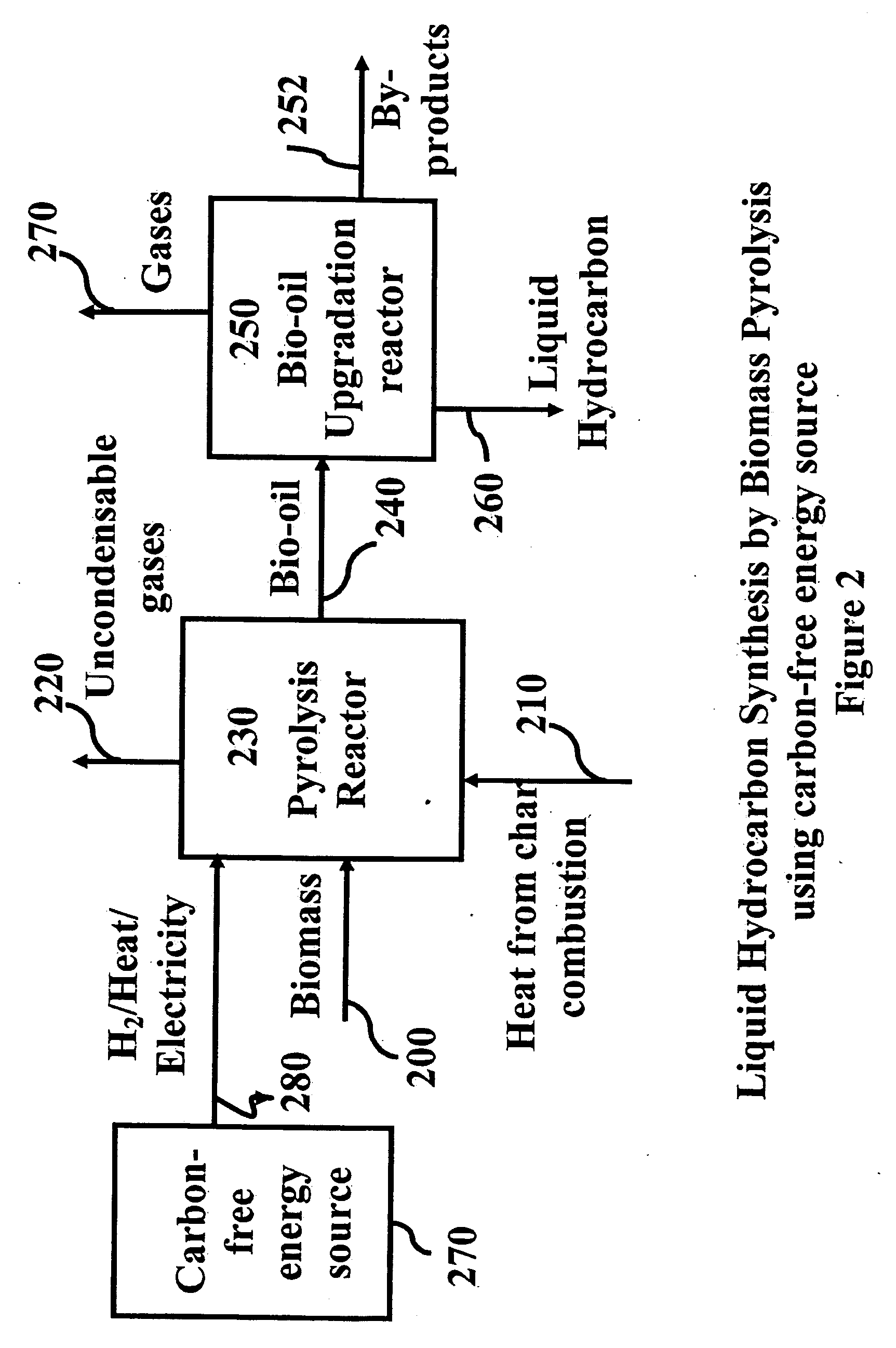

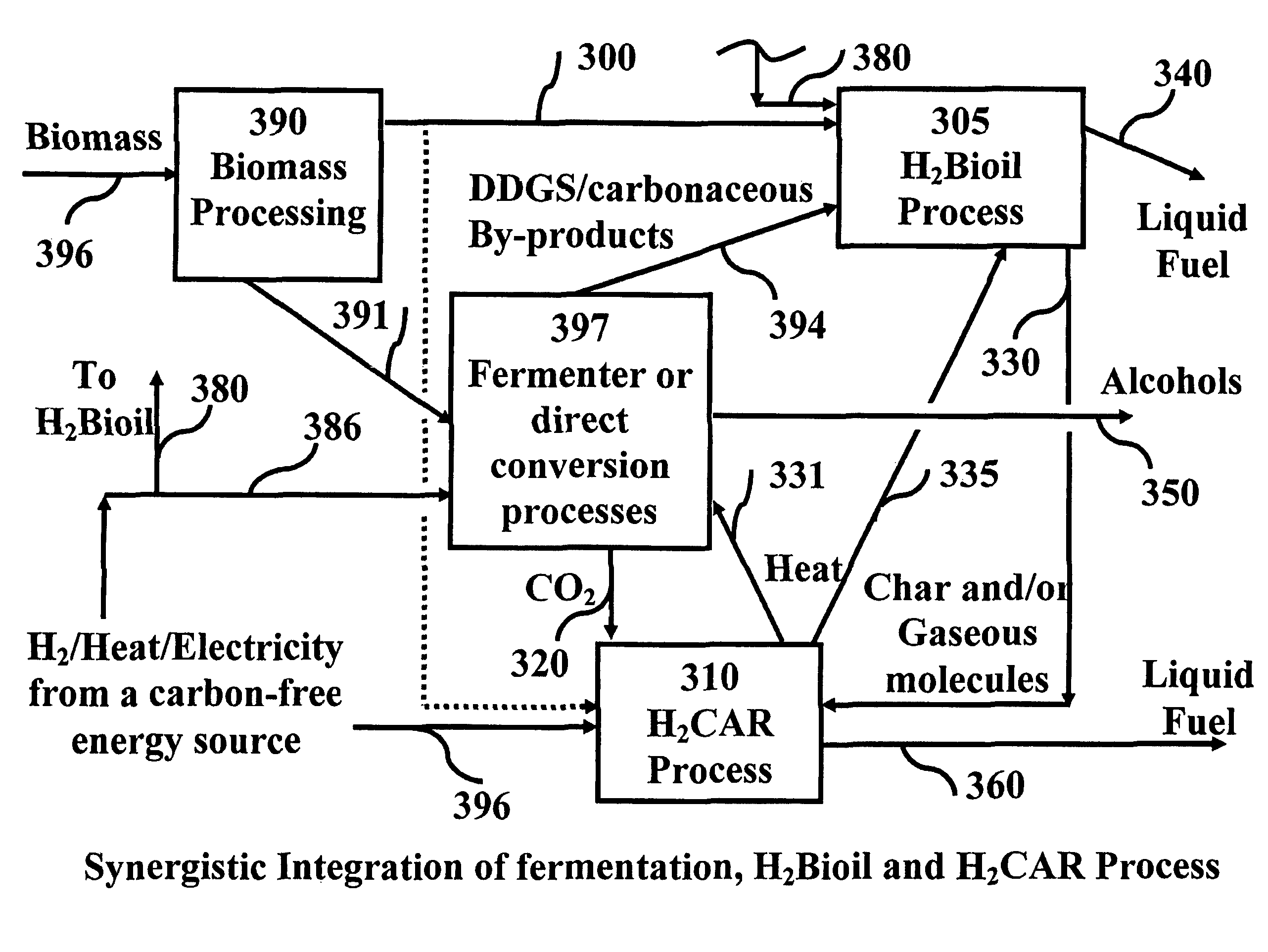

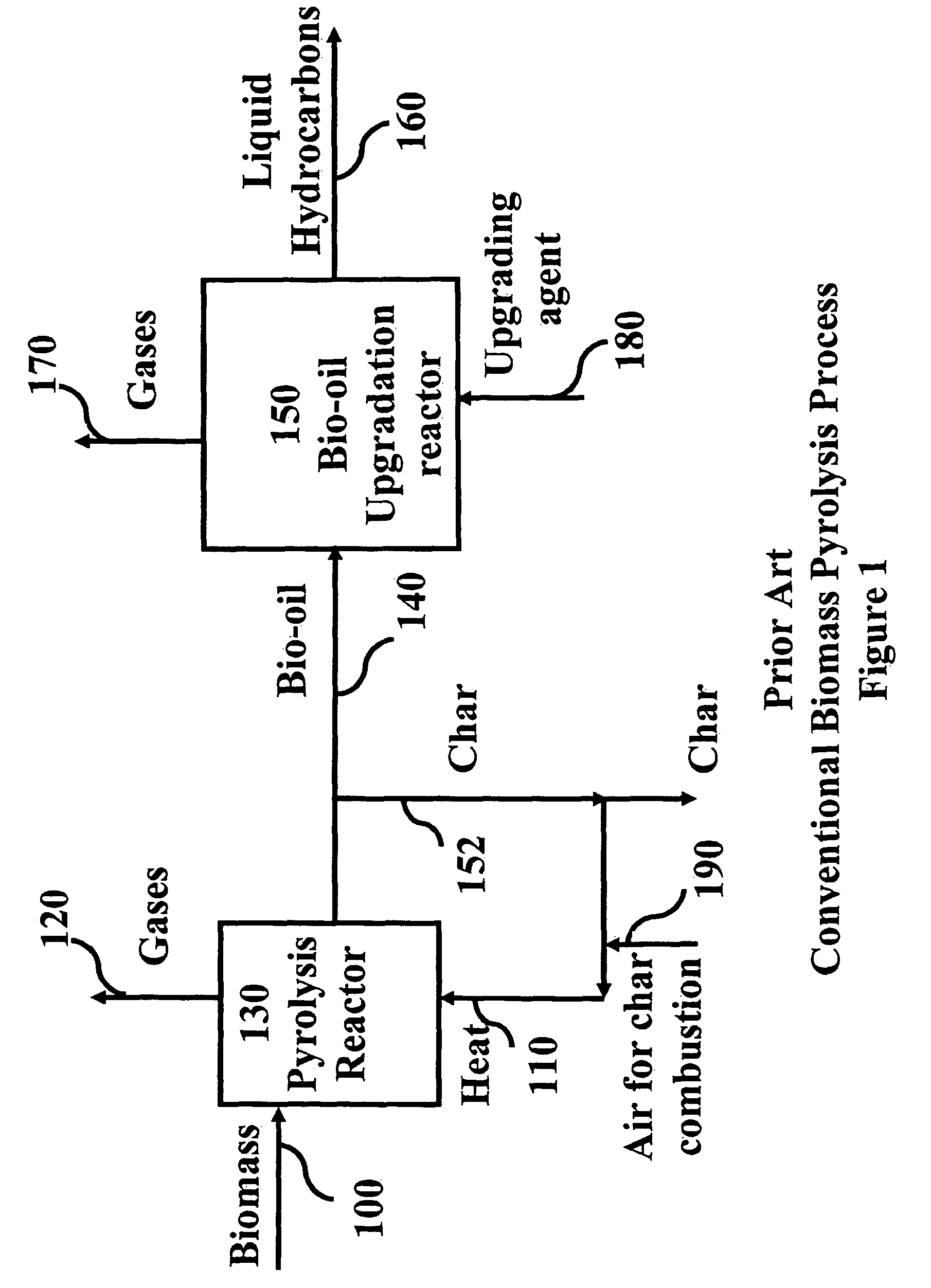

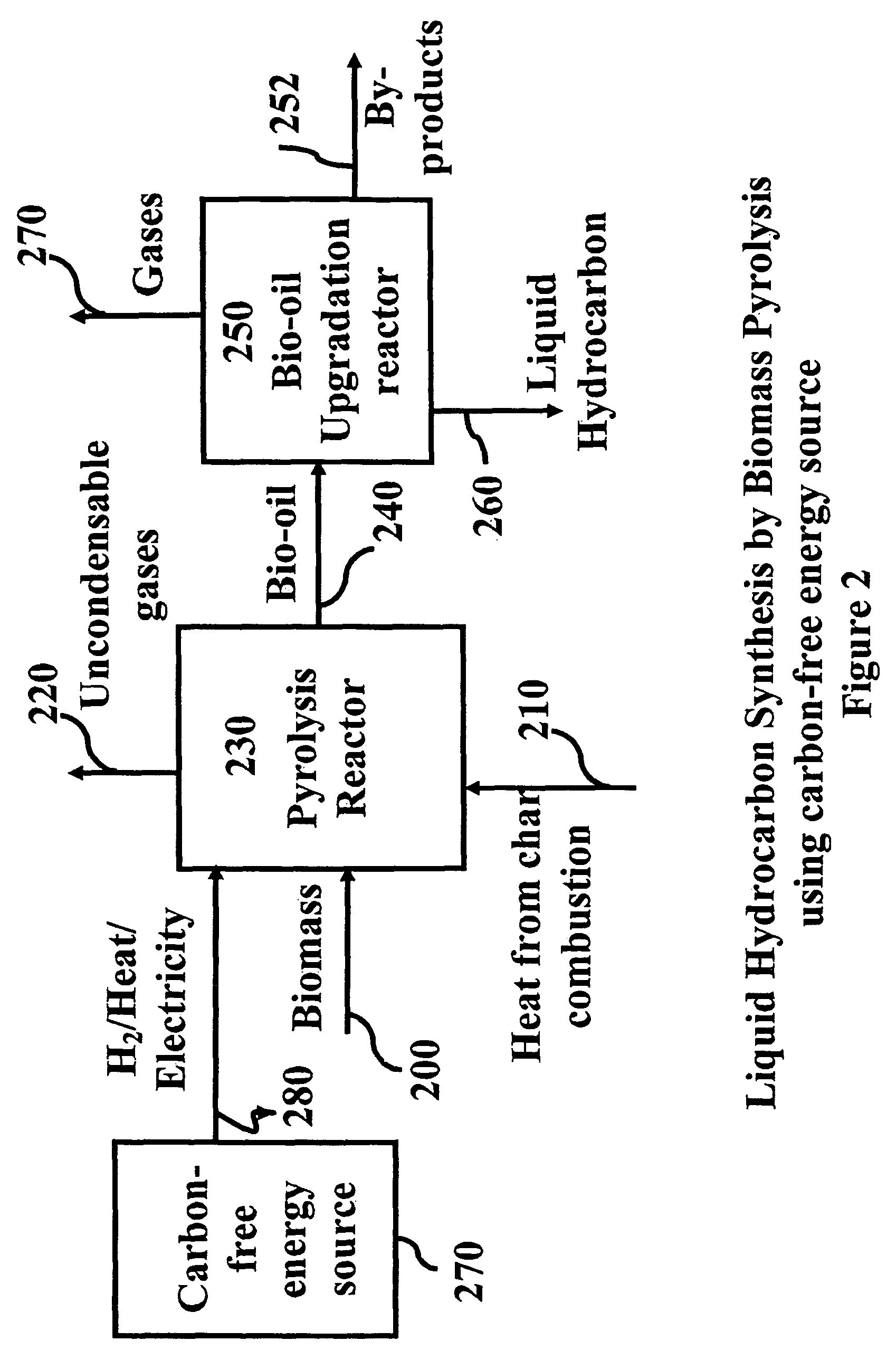

Novel process for producing liquid hydrocarbon by pyrolysis of biomass in presence of hydrogen from a carbon-free energy source

ActiveUS20090082604A1Process stabilityIncrease energy contentBioreactor/fermenter combinationsBiological substance pretreatmentsAlkaneHydrogen

In at least one embodiment of the present invention, a method for producing liquid hydrocarbons from biomass is provided. The method comprises pyrolizing the biomass with hydrogen (H2) to form bio-oil. The bio-oil comprises alkanes, alkenes, alcohols, aldehydes, ketones, aromatics, hydrocarbons or mixtures thereof. The H2 is formed from a carbon-free energy source.

Owner:PURDUE RES FOUND INC

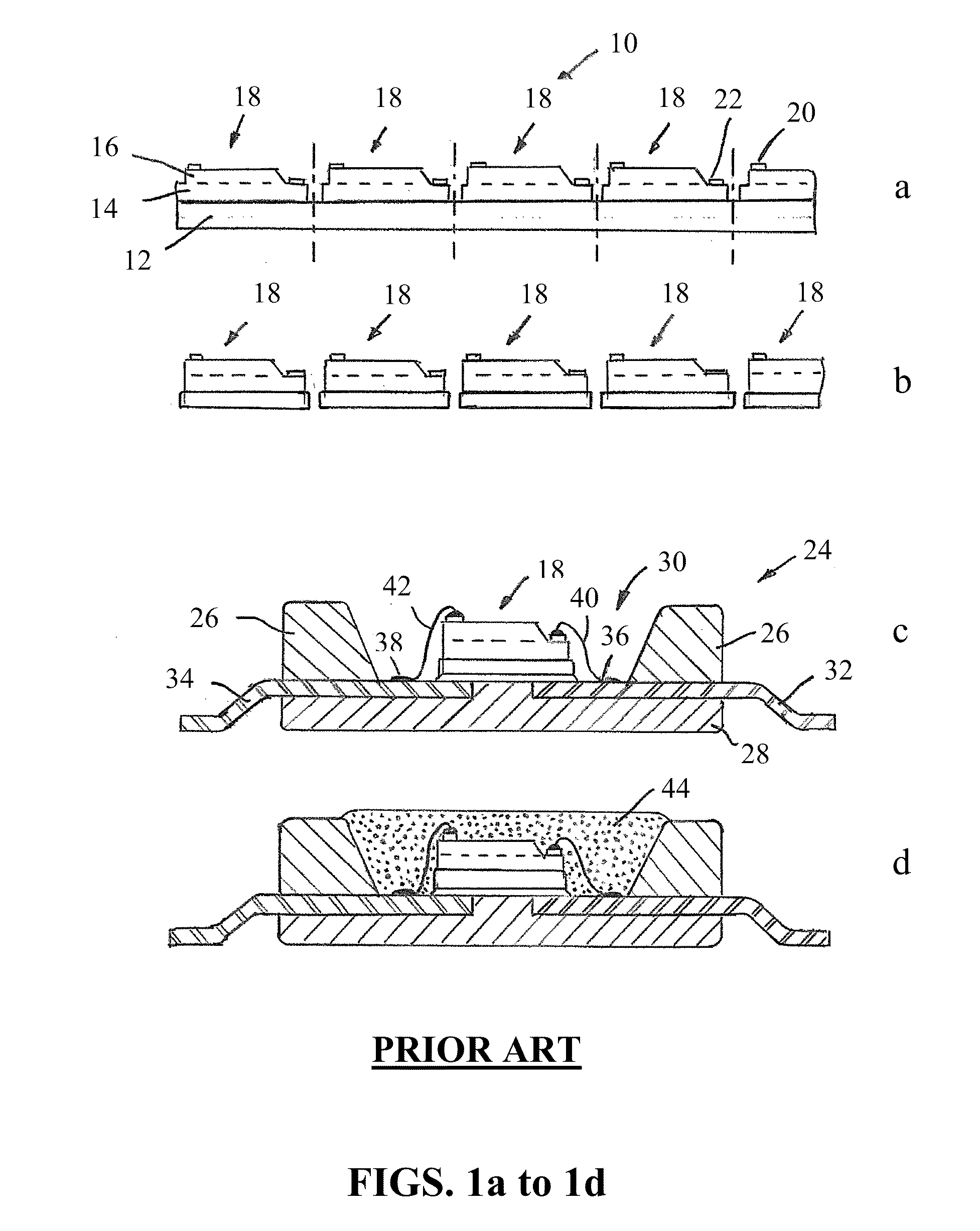

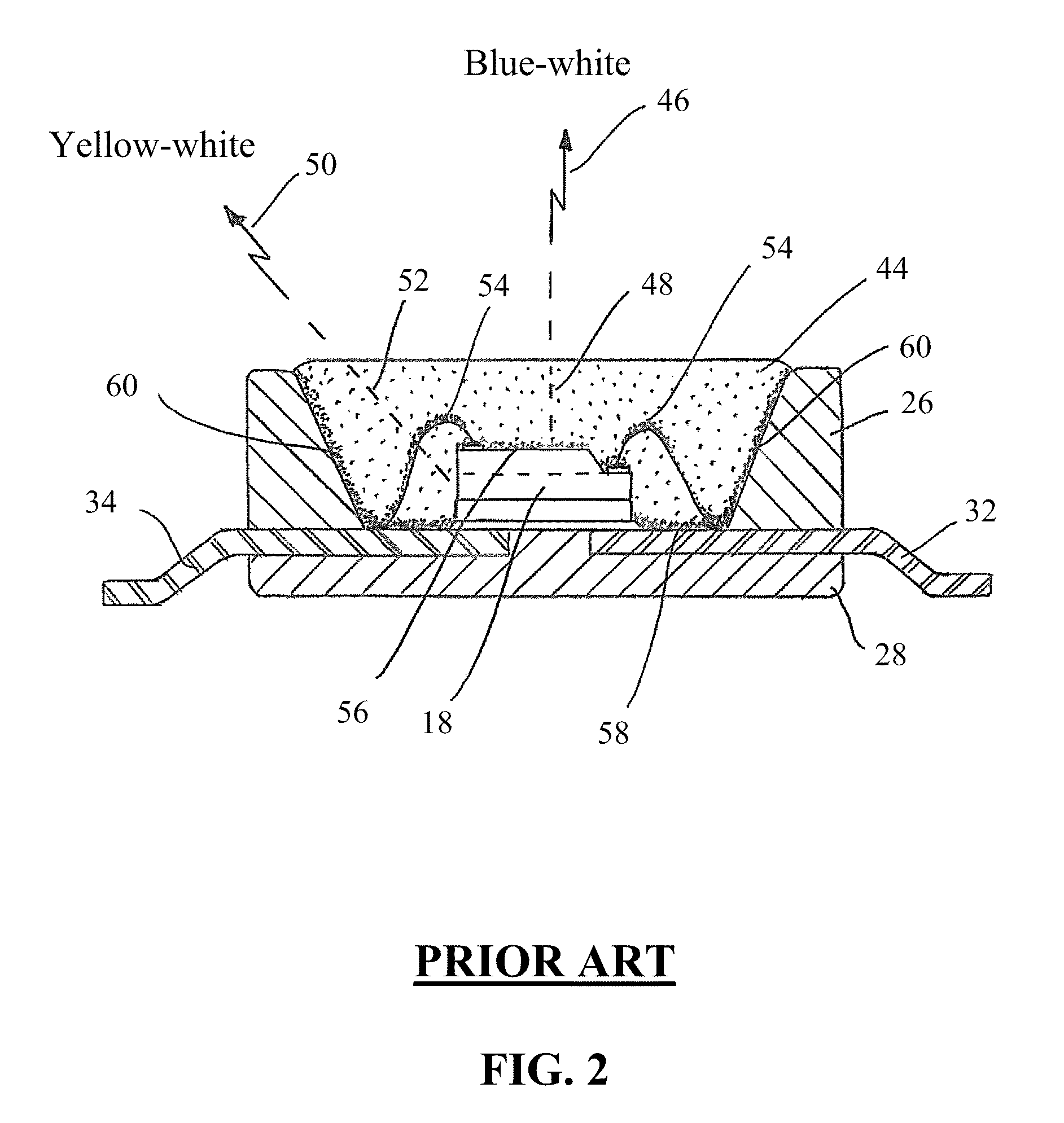

Manufacture of light emitting devices with phosphor wavelength conversion

InactiveUS20100295077A1Reduce and even eliminate needYield maximizationSolid-state devicesSemiconductor/solid-state device manufacturingPolymerElectrode Contact

A method of manufacturing a light emitting device: an LED wafer having an array of LEDs formed on a surface thereof, the method comprises: a) fabricating a sheet of phosphor / polymer material comprising a light transmissive polymer material having at least one phosphor material distributed throughout its volume and in which the polymer material is transmissive to light generated by the LEDs and to light generated by the at least one phosphor material; b) selectively making apertures through the phosphor / polymer sheet at positions corresponding to electrode contact pads of the LEDs of the LED wafer; c) attaching the sheet of phosphor / polymer material to the surface of the LED wafer such that each aperture overlies a respective electrode contact pad; and d) dividing the wafer into individual light emitting devices. The method can further comprise, prior to dividing the LED wafer, cutting slots through the phosphor / polymer material that are configured to pass between individual LEDs.

Owner:INTEMATIX

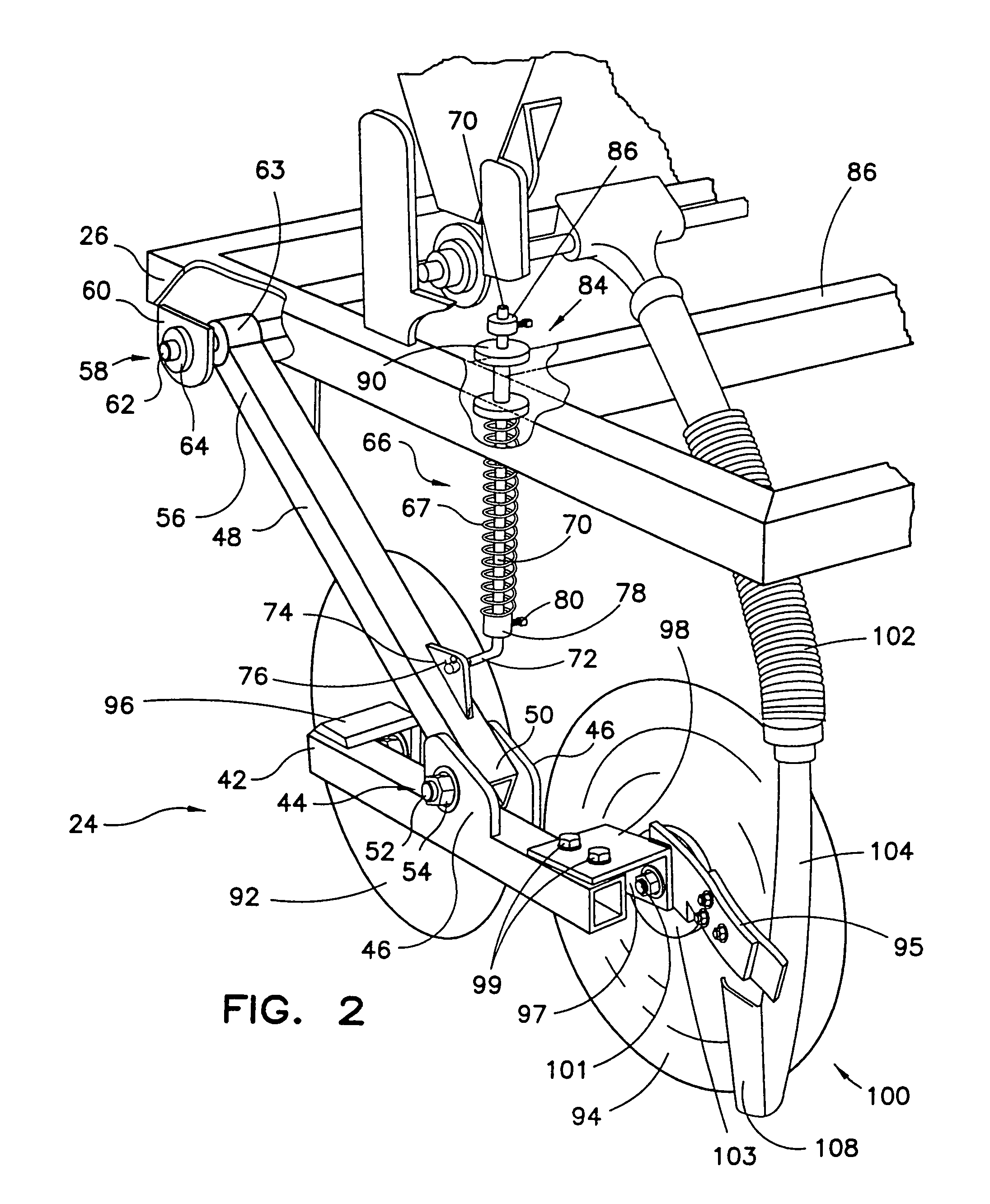

Seed drill with walking beam assembly

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

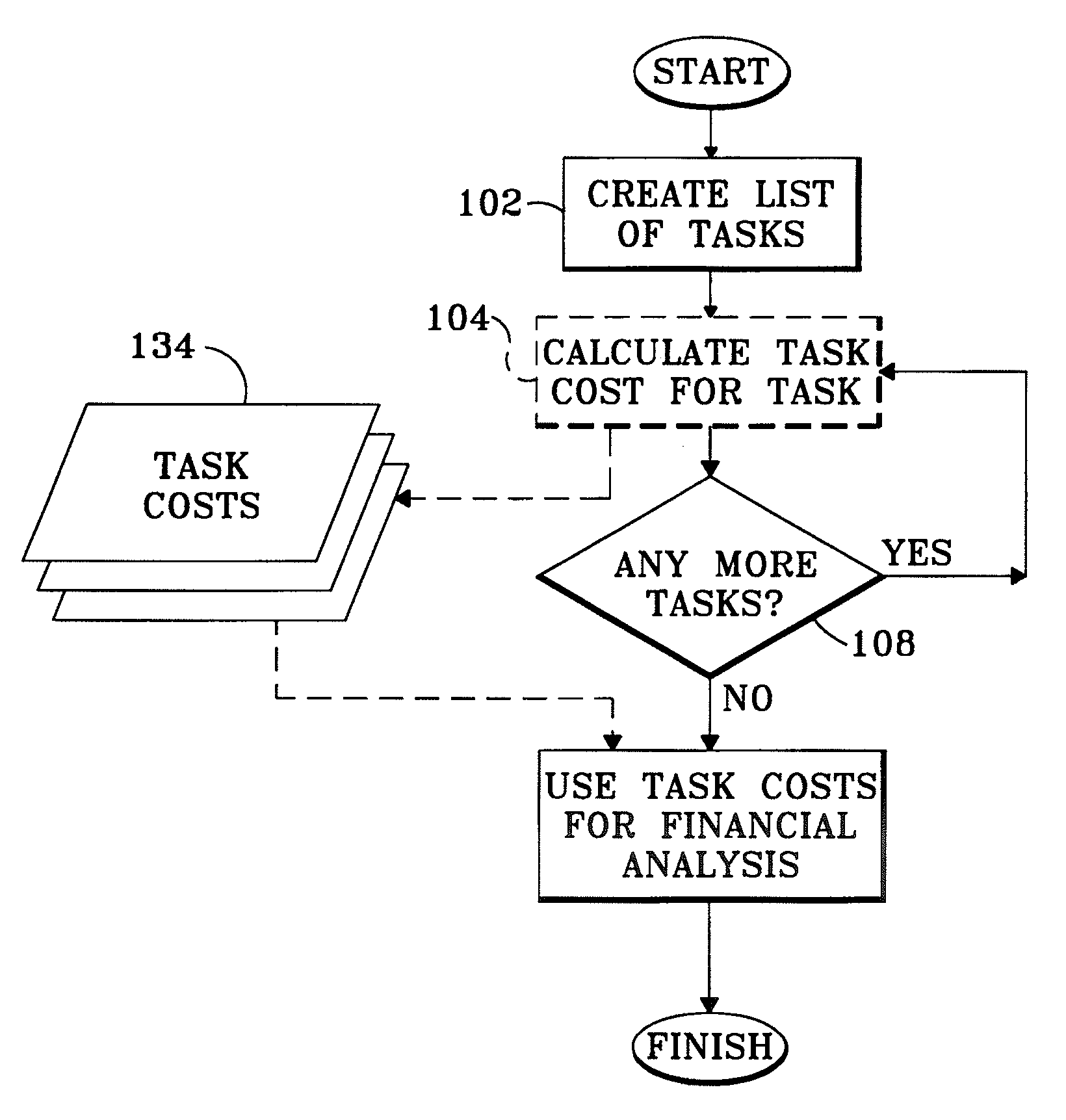

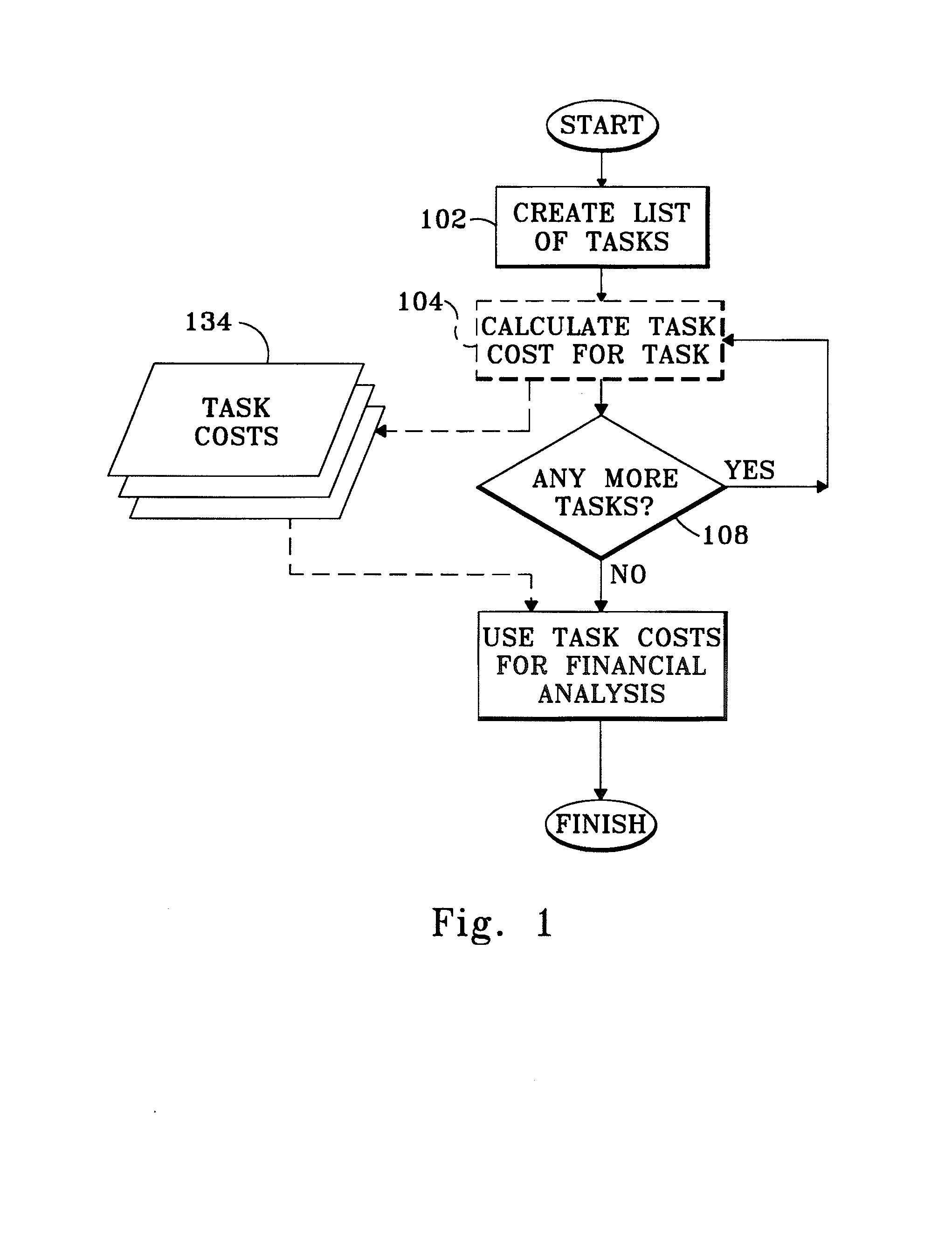

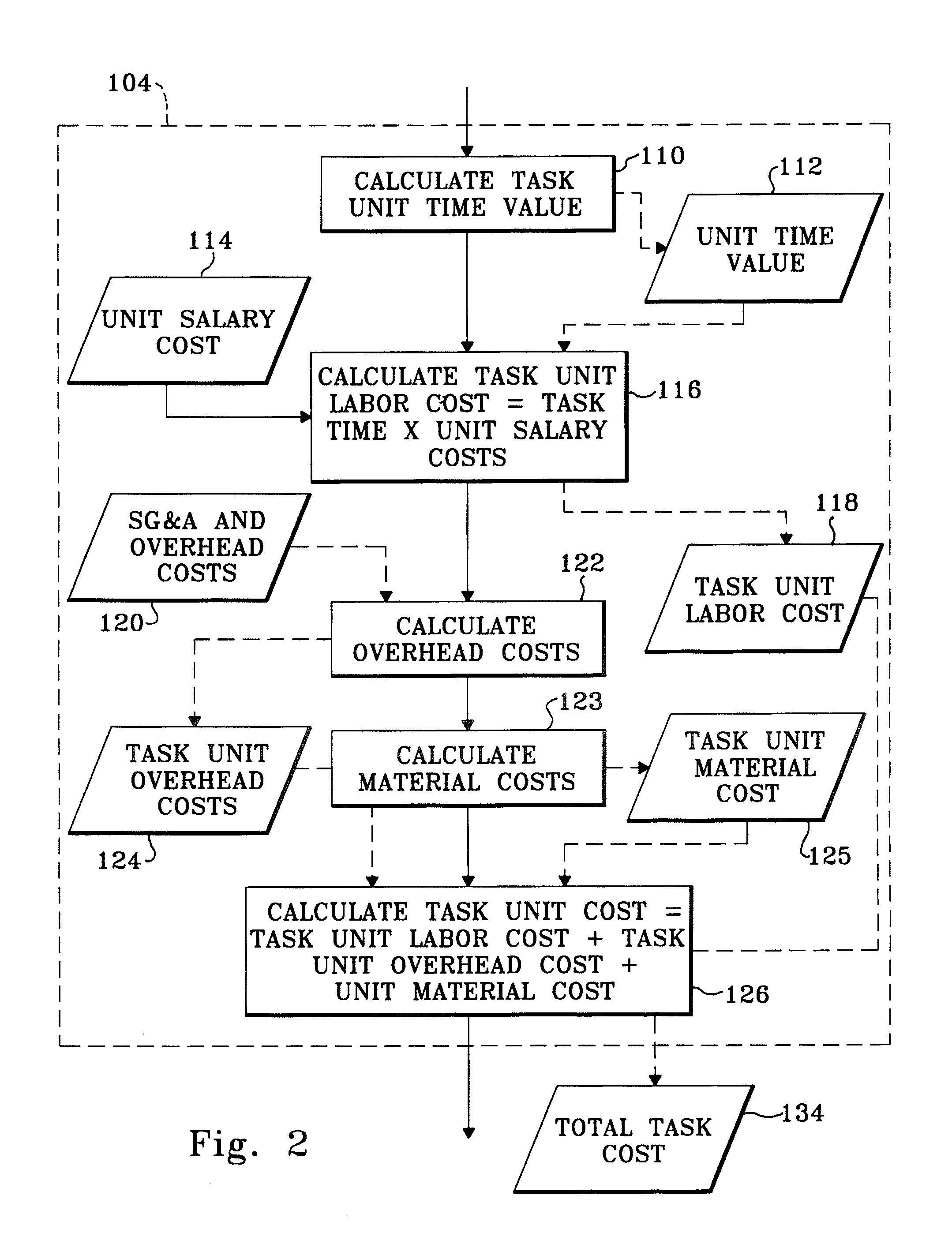

Method of determining task costs for activity based costing models

InactiveUS7149700B1Accurate analysisEstablish profileMultiprogramming arrangementsOffice automationPaymentBusiness process

A method of carrying out activity based costing in a professional practice, such as a healthcare practice or hospital is provided. The costs of activities involving an operator are calculated based on the time the operators should be expected to spend on a task, and the cost overhead, particularly the payment, of the operator. This is achieved using a Pre-Determined Motion Time System such as the MOST® system. This allows the inherent profitability of a business operation to be established independent of the current employees, so that the profitability of the business processes themselves can be ascertained.

Owner:WHITTIER GROUP

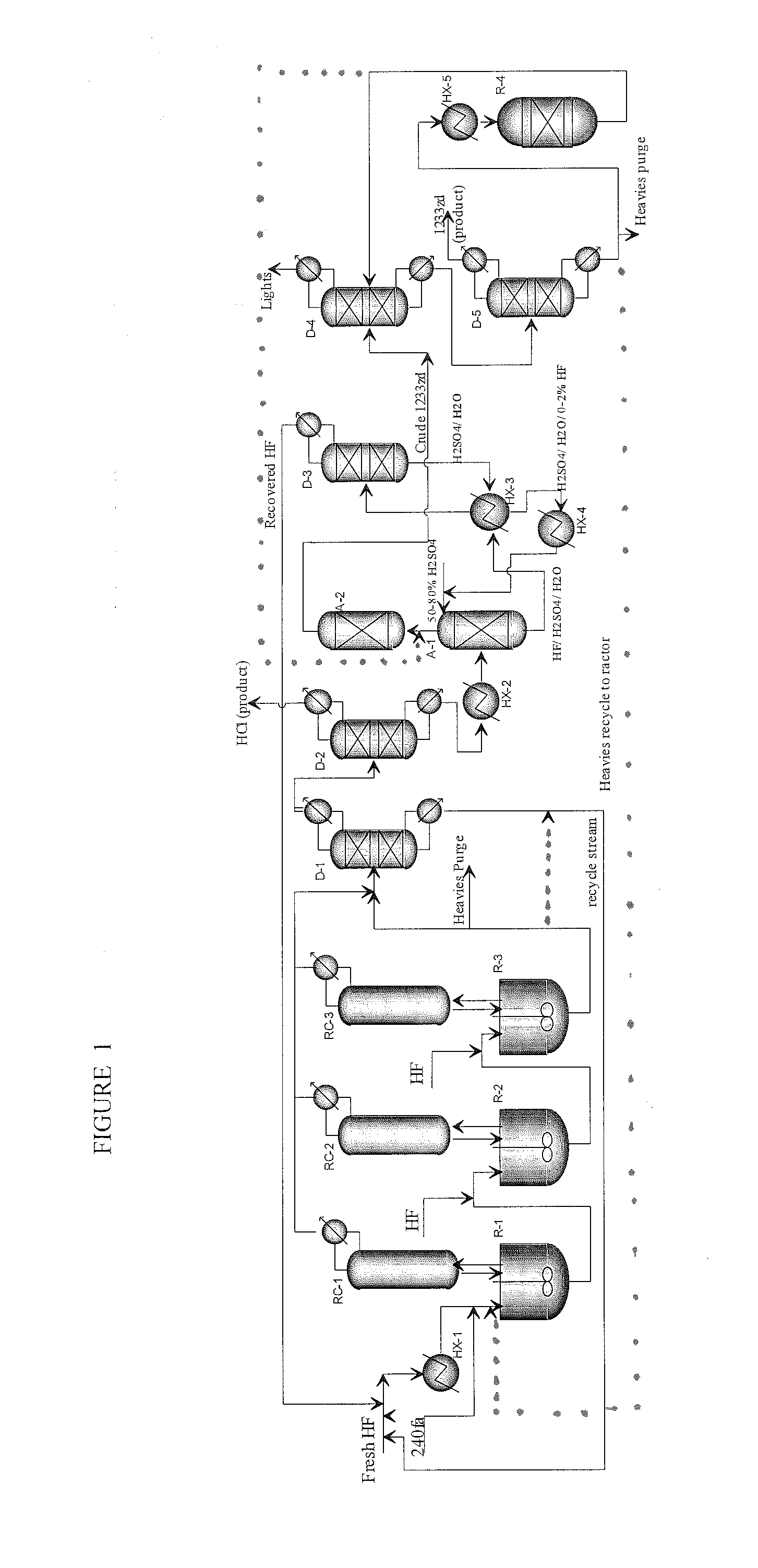

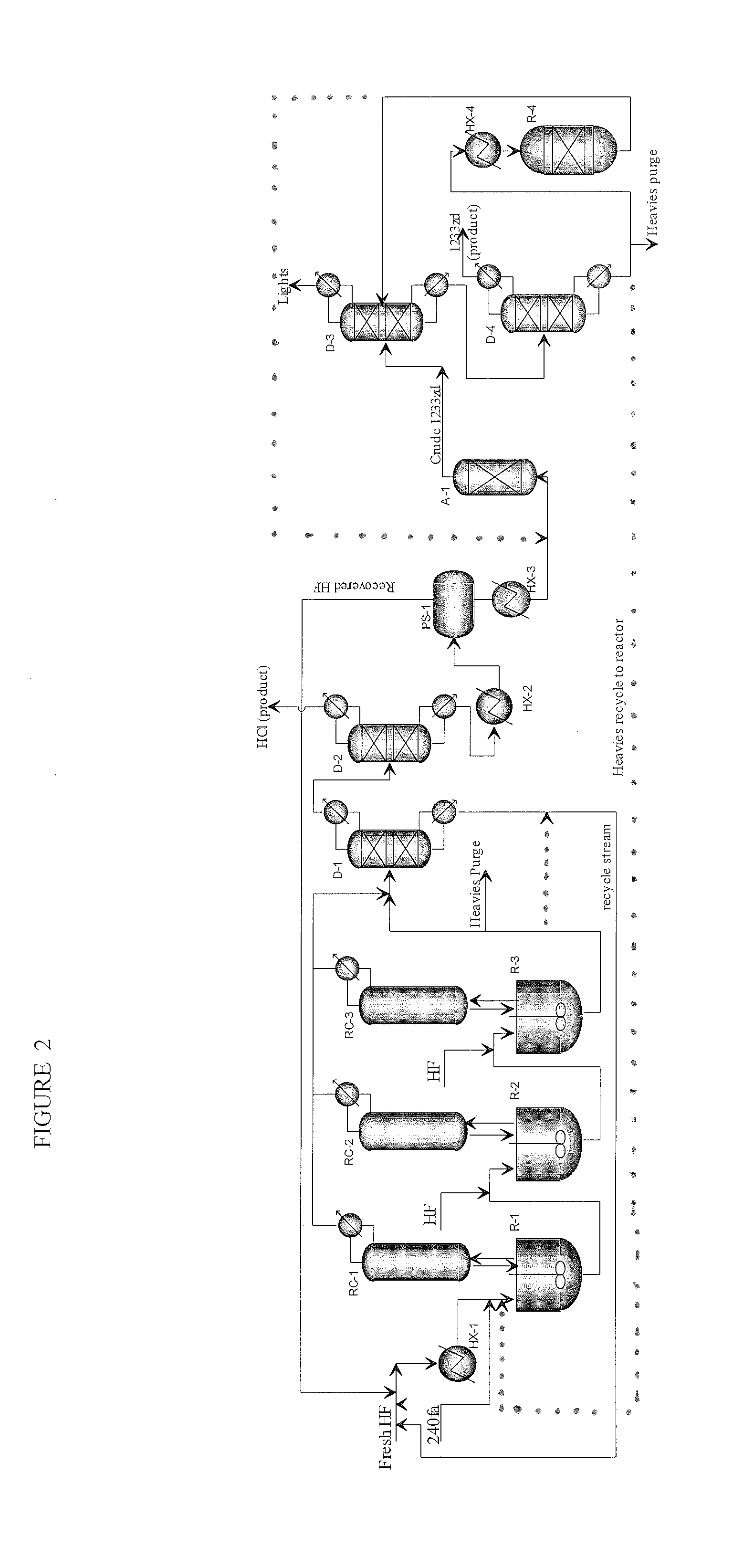

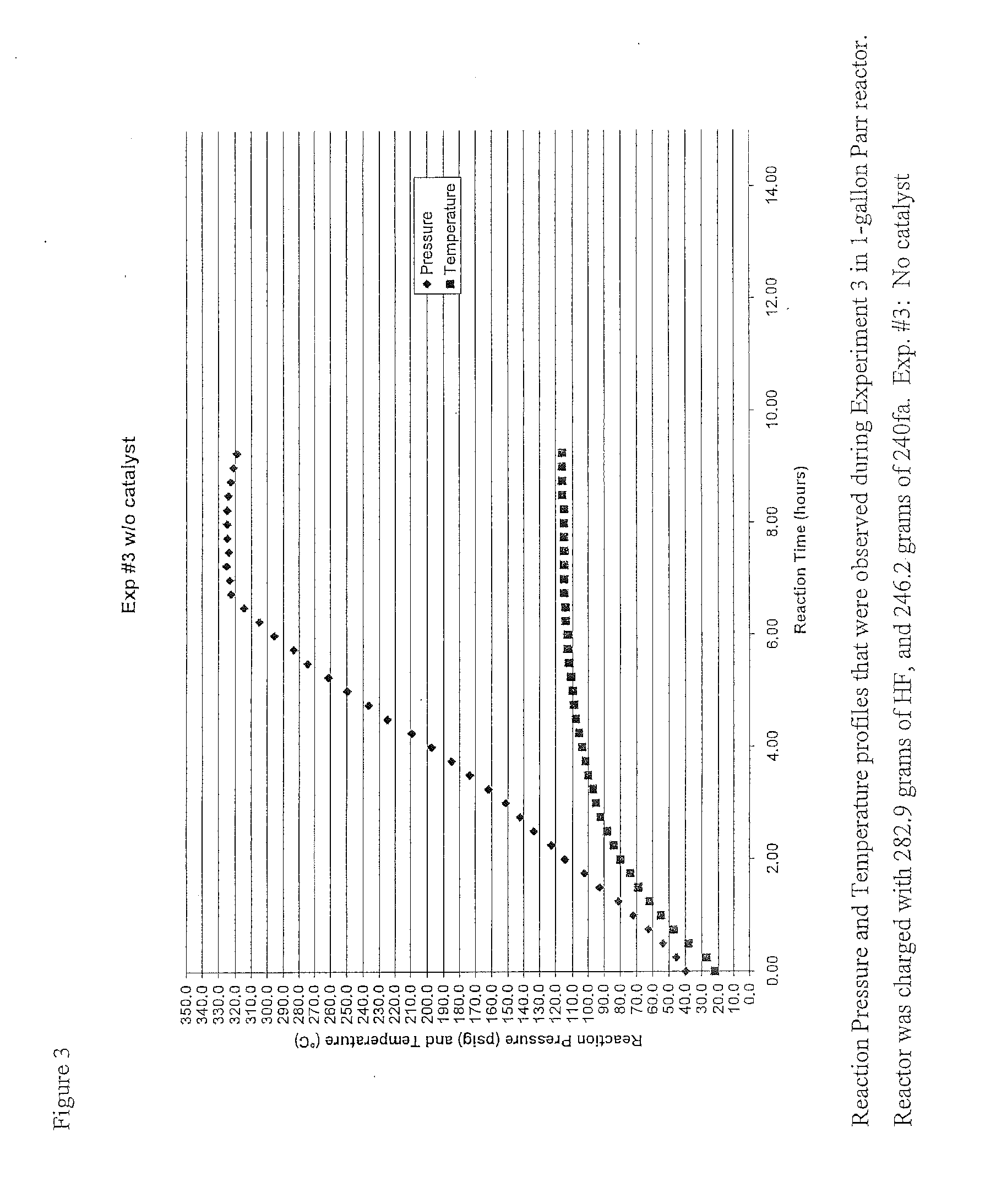

Continuous low-temperature process to produce trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20120059199A1Slow reaction rateYield maximizationChlorine/hydrogen-chloridePreparation by hydrogen halide split-offIsomerizationUnit operation

Disclosed is process for the production of (E) 1-chloro-3,3,3-trifluoropropene (HCFO-1233zd(E)) by conducting a continuous reaction without the use of a catalyst. Also disclosed is an integrated system for producing hydrofluoro olefins, particularly 1233zd(E). The manufacturing process includes six major unit operations: (1) a fluorination reaction of HCC-240fa (in continuous or semi-batch mode) using HF with simultaneous removal of by-product HCl and the product 1233zd(E); (2) recycle of unreacted HCC-240fa and HF together with under-fluorinated by-products back to (1); (3) separation and purification of by-product HCl; (4) separation of excess HF back to (1); (5) purification of final product, 1233zd(E); and (6) isomerization of by-product 1233zd(Z) to 1233zd(E) to maximize the process yield.

Owner:HONEYWELL INT INC

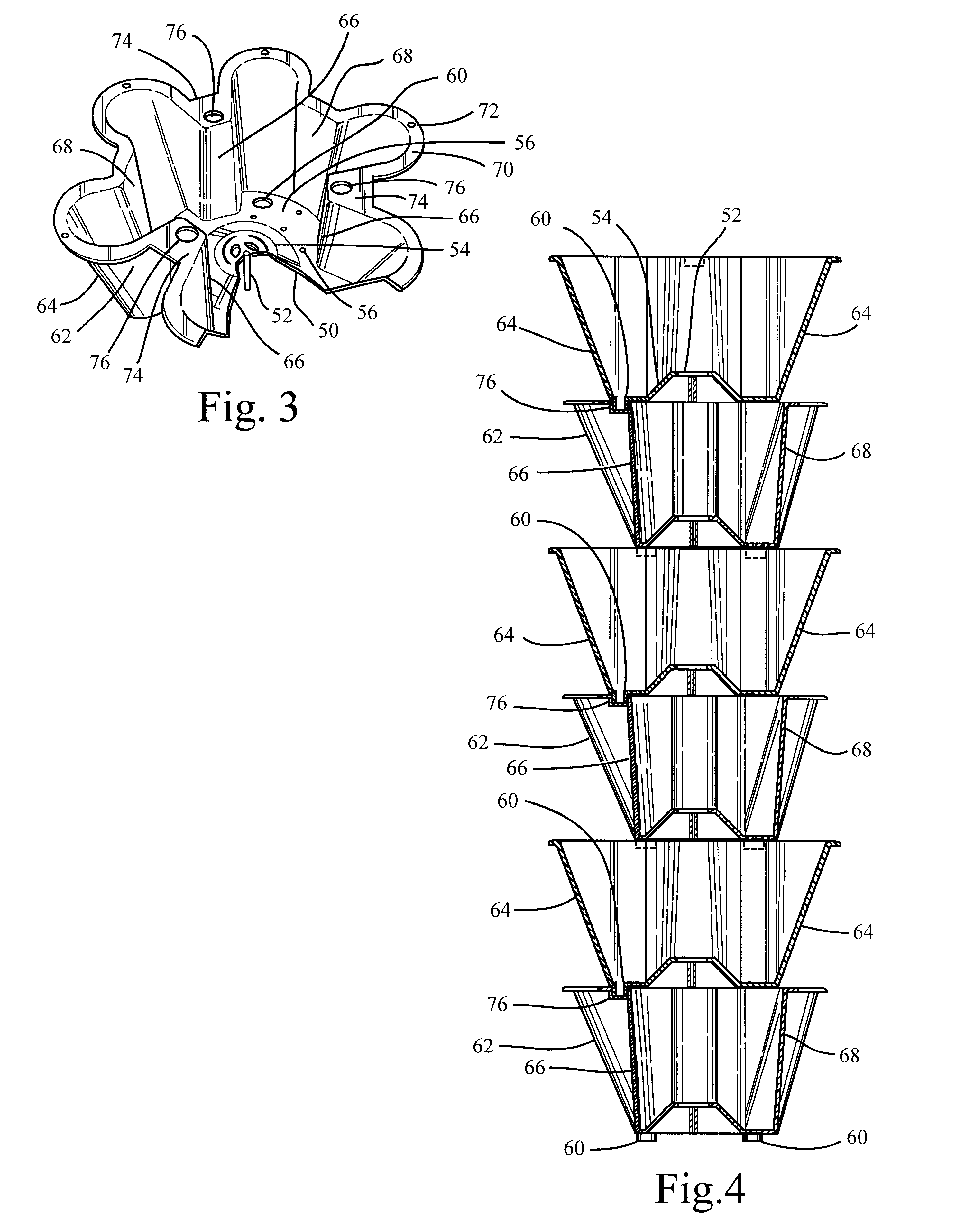

Intensive plant growing stacking container system

InactiveUS6612073B1Quickly and easily repeatedSmall sizeWatering devicesCultivating equipmentsEngineeringVertical array

A molded plant growing container system is easily stacked in a vertical array providing a self-supporting apparatus for intense horticulture. This apparatus increases crop yields over conventional growing methods. The containers nest within each other for ease of transport, are quickly and easily assembled, provide efficiency in installation and use of growing medium, increased numbers of plants in a given space, and are adaptable to a variety of irrigation methods.

Owner:MARKS & NOVA BALL MARKS TRUSTEES OR SUCCESSORTRUSTEE OF THE MARKS FAMILY TRUST UAD 5 13 05 ROBIN

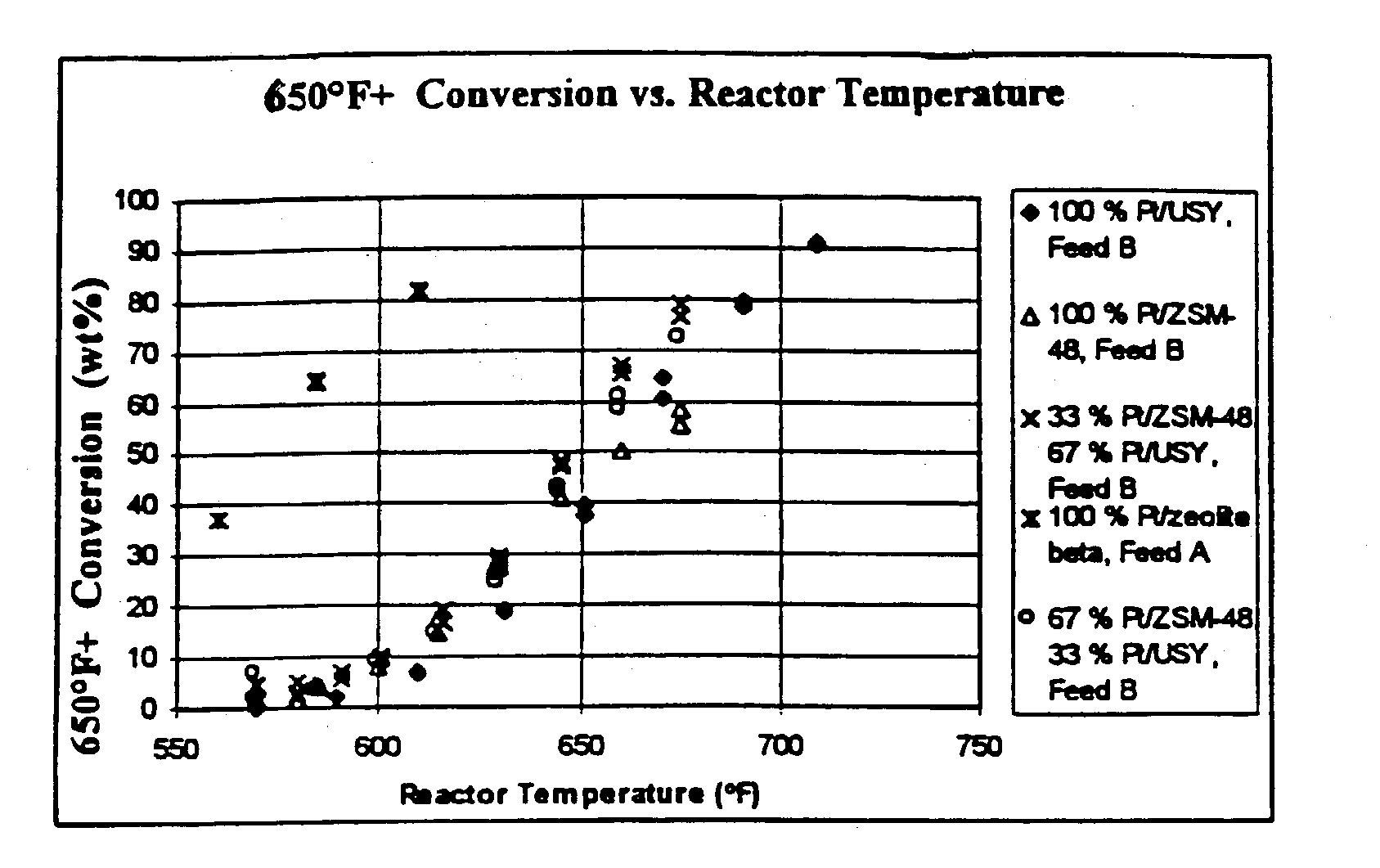

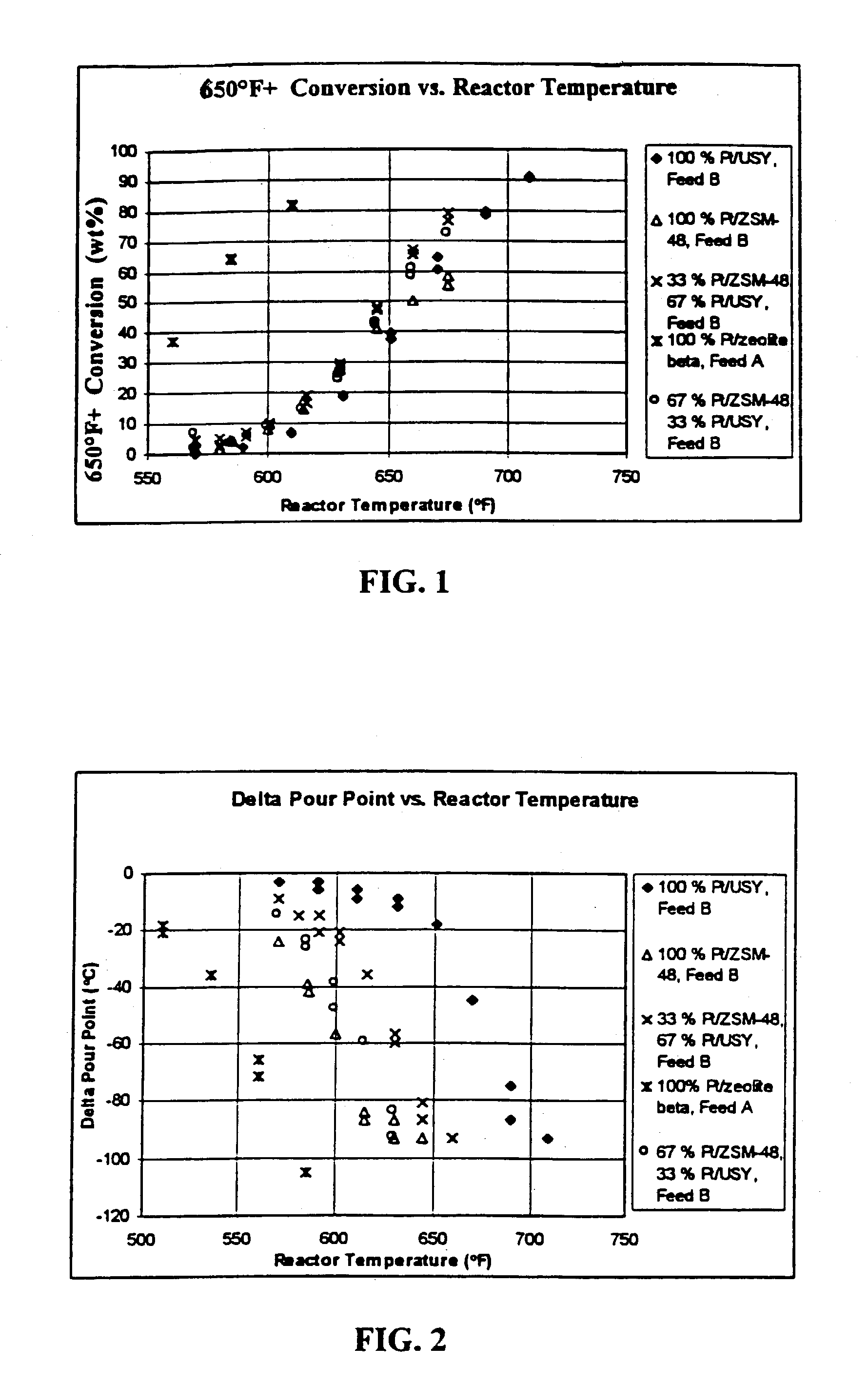

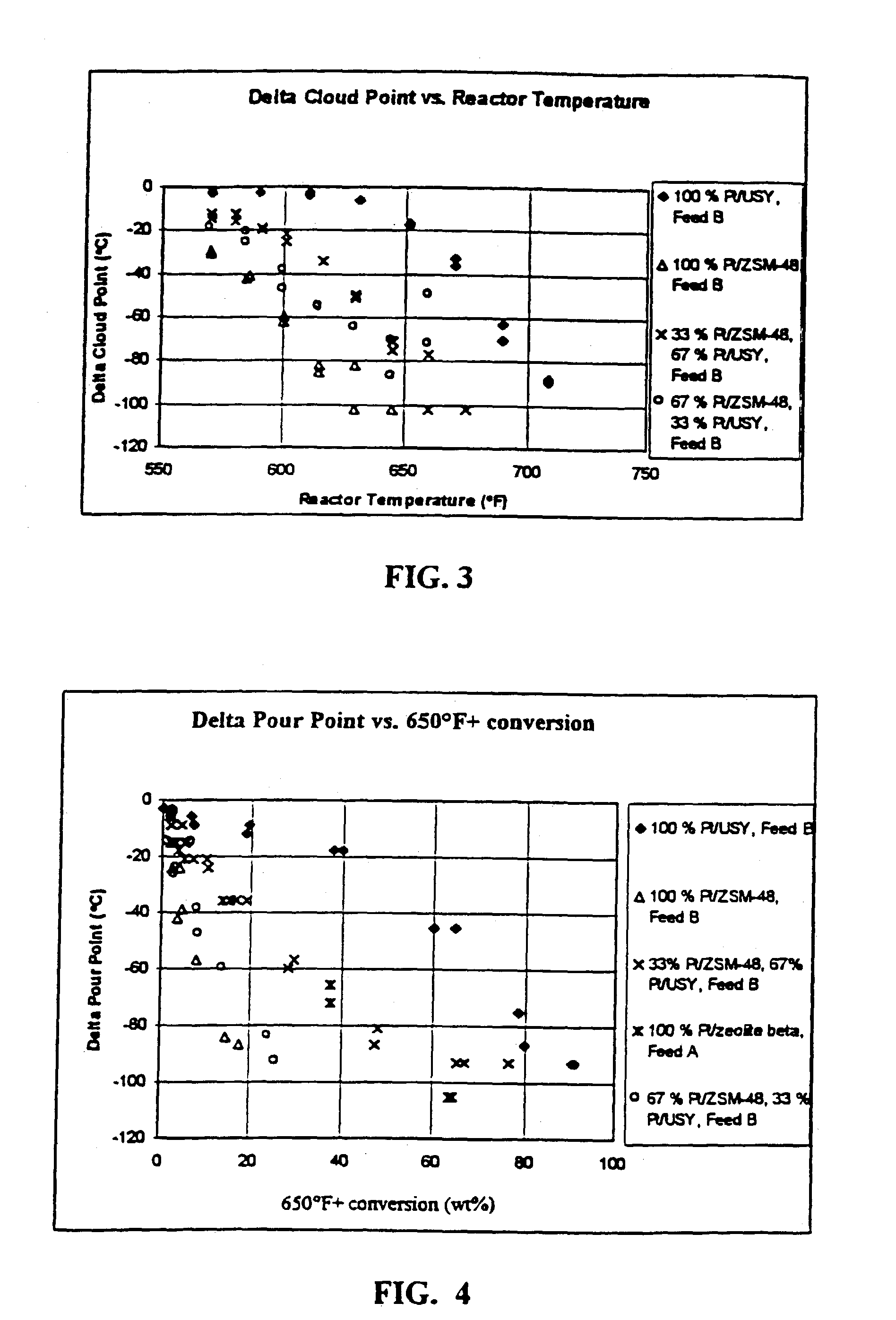

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS20030168379A1Yield maximizationReduce pointsMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

Coatings for Electrowetting and Electrofluidic Devices

ActiveUS20130171546A1Low surface energy polymersHigh dielectric strengthElectrostatic separatorsSludge treatmentGas phaseUltimate tensile strength

Electrowetting devices coated with one or more polymeric layers and methods of making and using thereof are described herein. The coatings may be formed in a single layer or as multiple layers. In one embodiment the first layer deposited serves as an insulating layer of high dielectric strength while the second layer deposited serves as a hydrophobic layer of low surface energy. These materials may themselves be deposited as multiple layers to eliminate pinhole defects and maximize device yield. In one embodiment the insulating layer would be a vapor deposited silicone polymeric material including, but not limited to, polytrivinyltrimethylcyclotrisiloxane or polyHVDS. In another embodiment the insulating layer may be a vapor deposited ceramic such as SiO2 with very little carbon content. In a further embodiment the insulating layer may be composed of alternating layers of a siloxane material and a ceramic material.

Owner:GVD CORP

Process for producing a renewable fuel in the gasoline or jet fuel range

ActiveUS7928273B2Yield maximizationFatty acid isomerisationFatty acid oxidationVegetable oilGasoline

Processes for producing hydrocarbons in the gasoline and jet fuel range. The processes involve the thermal decarboxylation of fatty acids, which can be derived from the hydrolysis of triglycerides, which triglycerides can be vegetable oils, animal fats, or combinations thereof. The resulting hydrocarbons can be hydrocracked, and, optionally, isomerized and / or hydrotreated, to yield hydrocarbons in the jet fuel or gasoline range. Where the resulting hydrocarbons include olefinic double bonds, they can alternatively be combined with low molecular weight olefins, and subjected to olefin metathesis to yield hydrocarbons in the jet fuel or gasoline range.

Owner:BRADIN DAVID

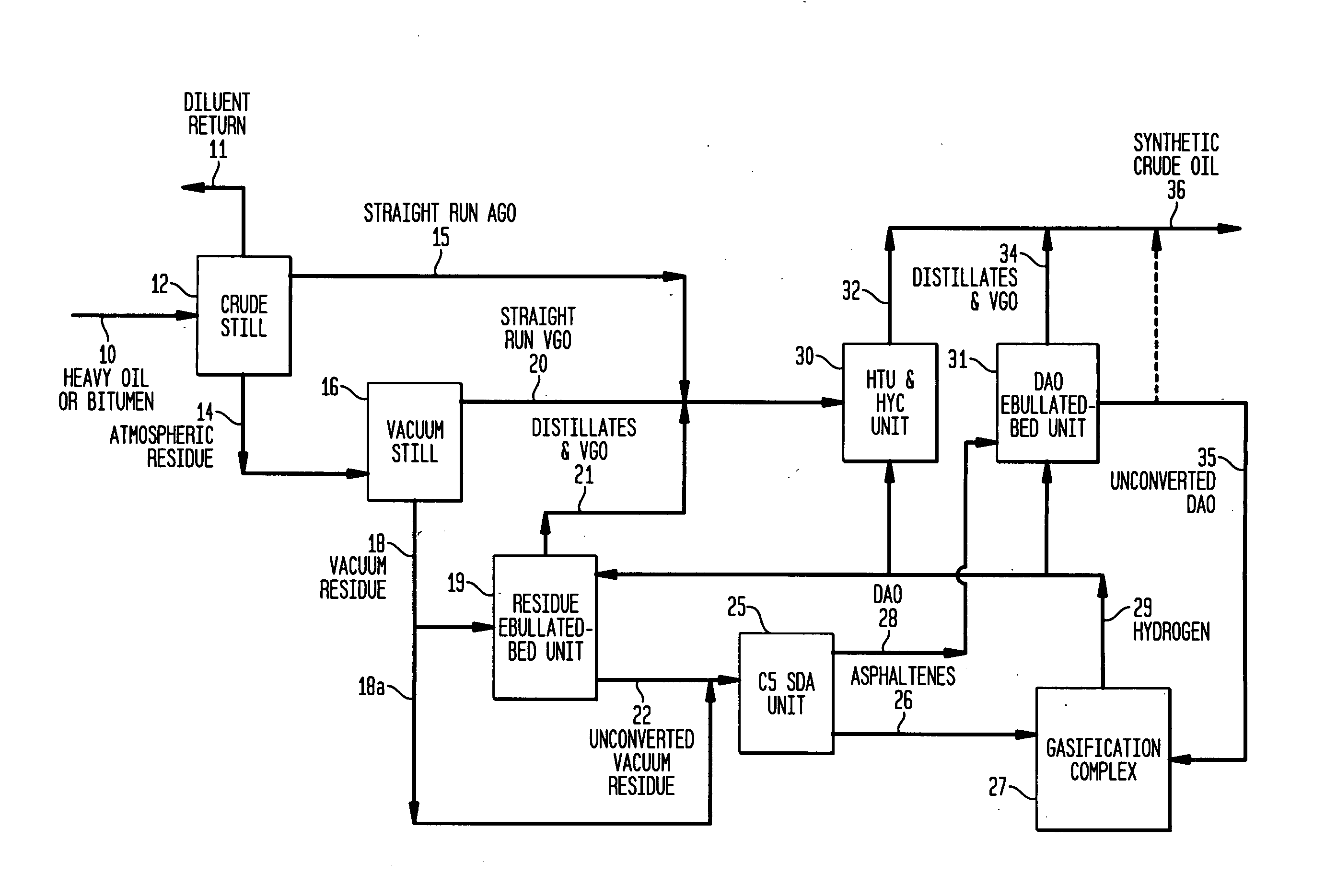

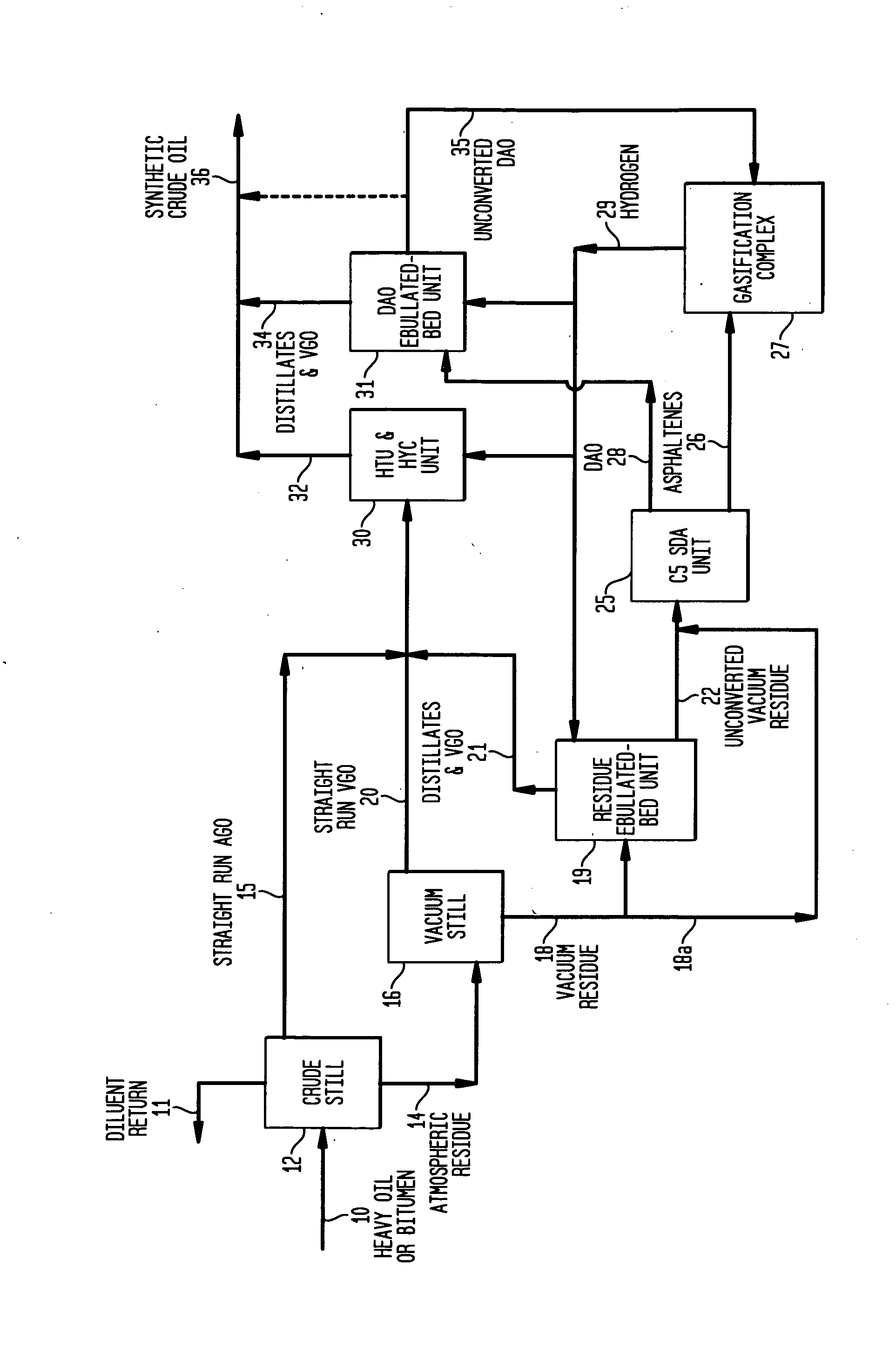

Innovative heavy crude conversion/upgrading process configuration

InactiveUS20110198265A1Maximizing liquid SCO yieldYield maximizationHydrocarbon oil crackingTreatment with hydrotreatment processesFuel oilProcess configuration

The described invention discloses an innovative solvent deasphalter and hydroconversion-processing configuration for converting bitumen or heavy oils to produce a transportable synthetic crude oil (SCO). The innovative processing scheme disclosed herein maximizes the synthetic crude oil yield at a minimal investment compared to currently known methods.

Owner:INST FR DU PETROLE

Process for catalytic dewaxing and catalytic cracking of hydrocarbon streams

InactiveUS7261805B2Reducing pour point pointReducing point cloud pointTreatment with plural serial cracking stages onlyCoke ovensWaxIsomerization

A process for upgrading a hydrocarbon feedstock containing waxy components and having an end boiling point exceeding 650° F., which includes contacting the feedstock at superatmospheric hydrogen partial pressure with an isomerization dewaxing catalyst that includes ZSM-48 and contacting the feedstock with a hydrocracking catalyst to produce an upgraded product with a reduced wax content. Each catalyst is present in an amount sufficient to reduce the cloud point and the pour point of the feedstock at a conversion of greater than about 10%, and an overall distillate yield of greater than about 10% results from the process.

Owner:EXXON RES & ENG CO

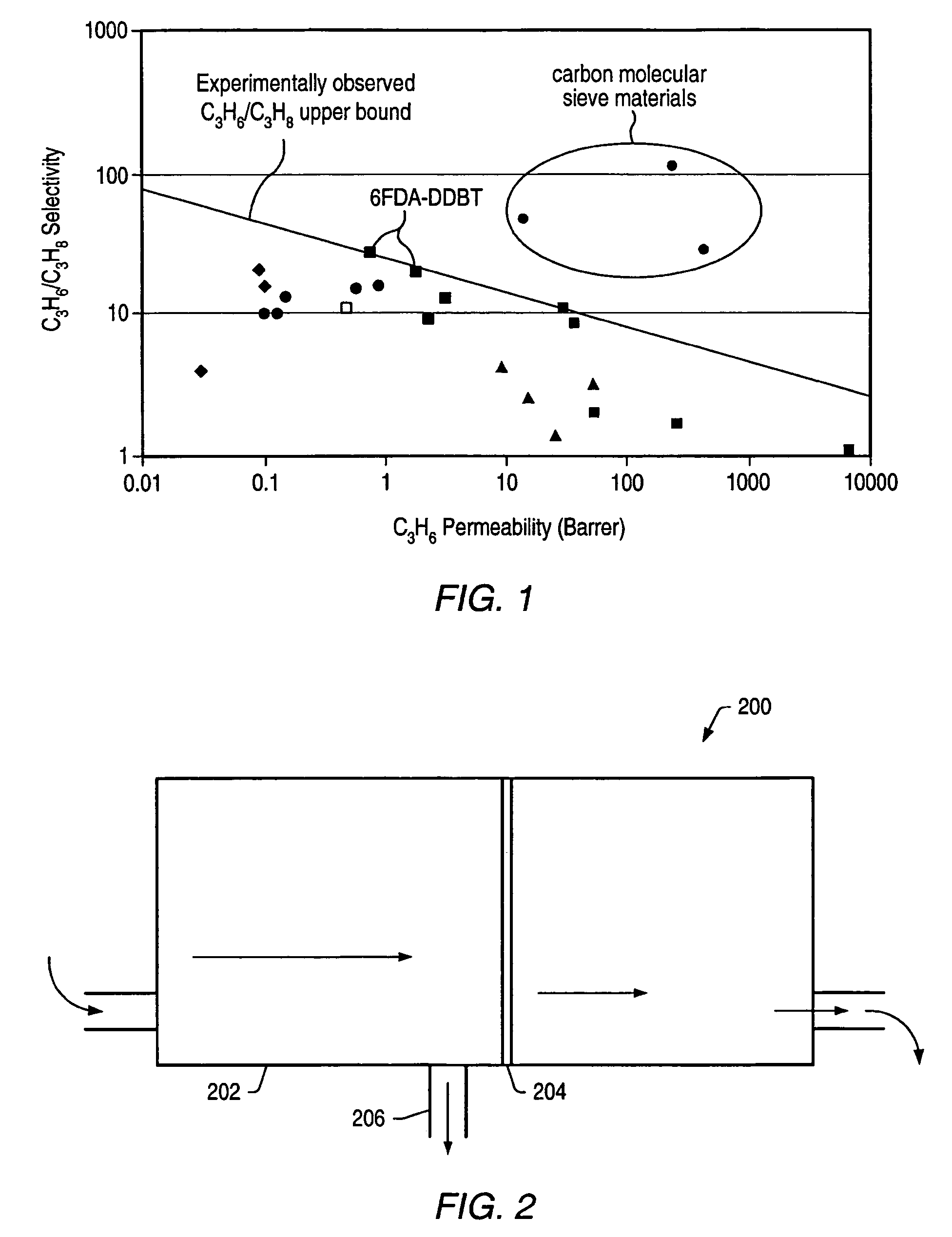

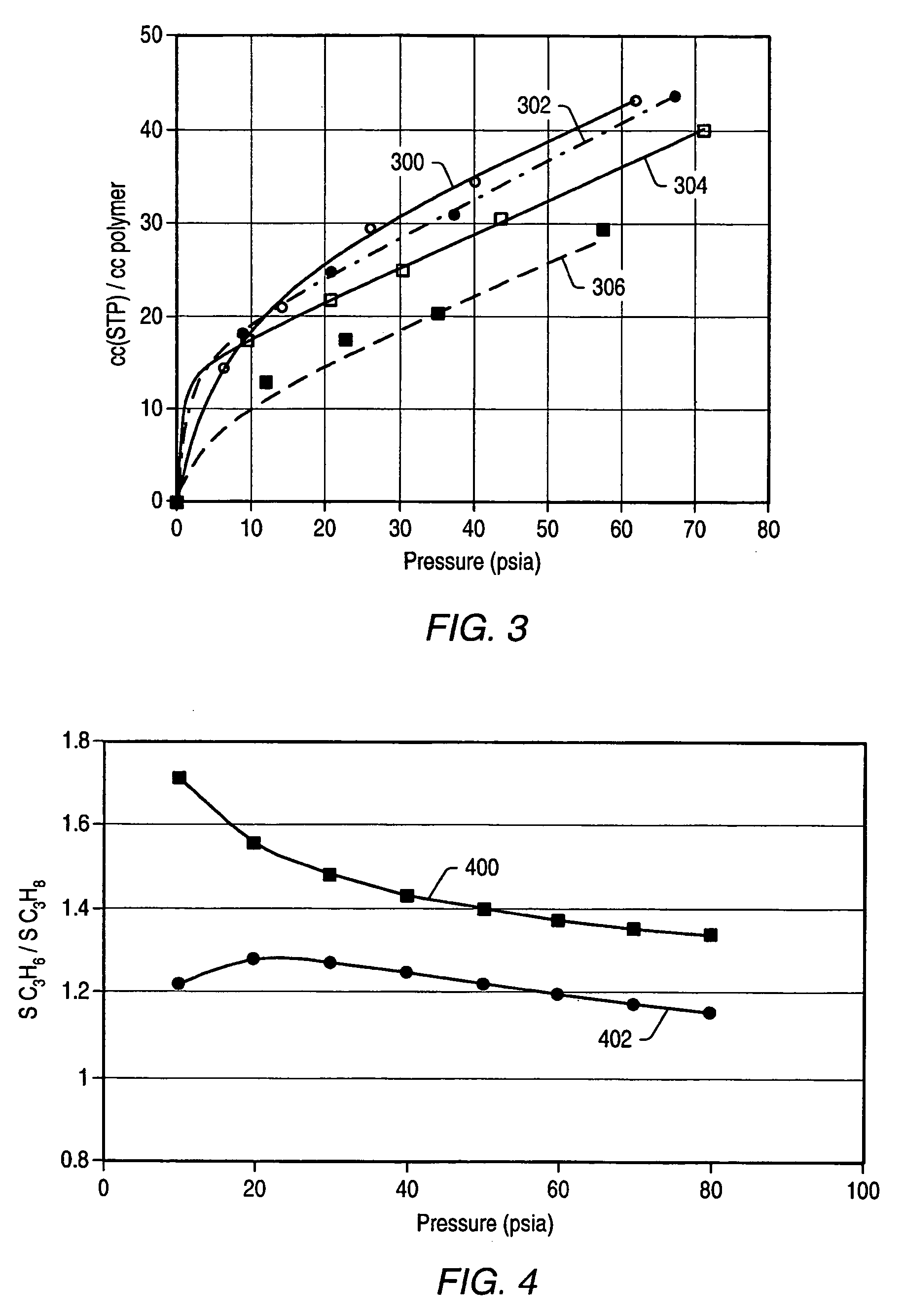

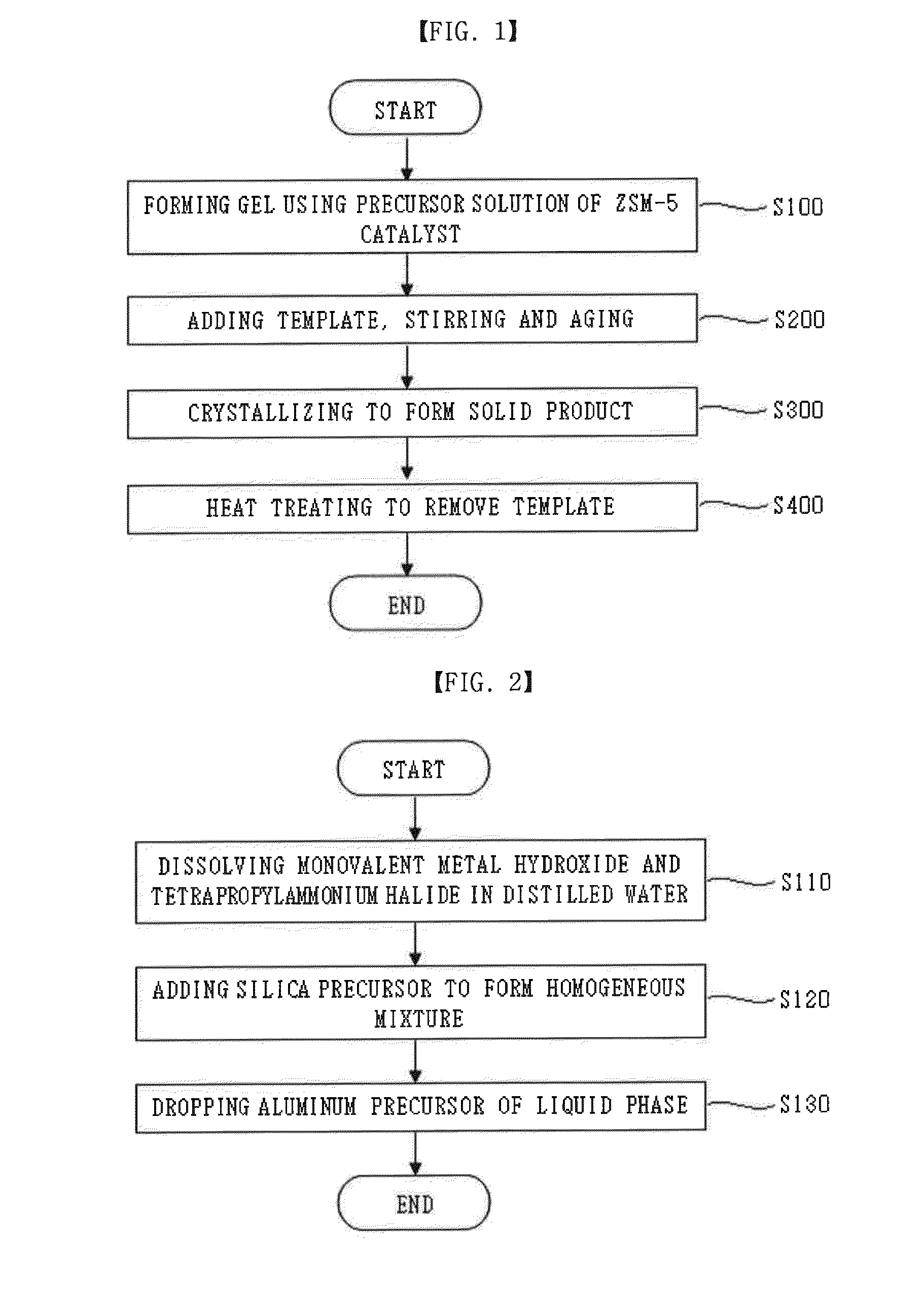

Dithiolene functionalized polymer membrane for olefin/paraffin separation

InactiveUS7160356B2Easy to separateYield maximizationSemi-permeable membranesMembranesImideSolubility

A polymeric composite may be used for forming fluid separation membranes. The membranes may be formed from polyimide, polyamide or poly (pyrrolone-imide) materials. Polyamides may be formed by the condensation of a tetraamine, a tetraacid, and a diamine. Polyimides and poly (pyrrolone-imides) may be formed by the cyclization of a polymer precursor. A polymeric composite may include a dithiolene or a mixture of dithiolenes. A polymer matrix incorporating dithiolenes may exhibit an olefin / paraffin solubility selectivity. A solubility selectivity may be between about 1.1 and about 2.0.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

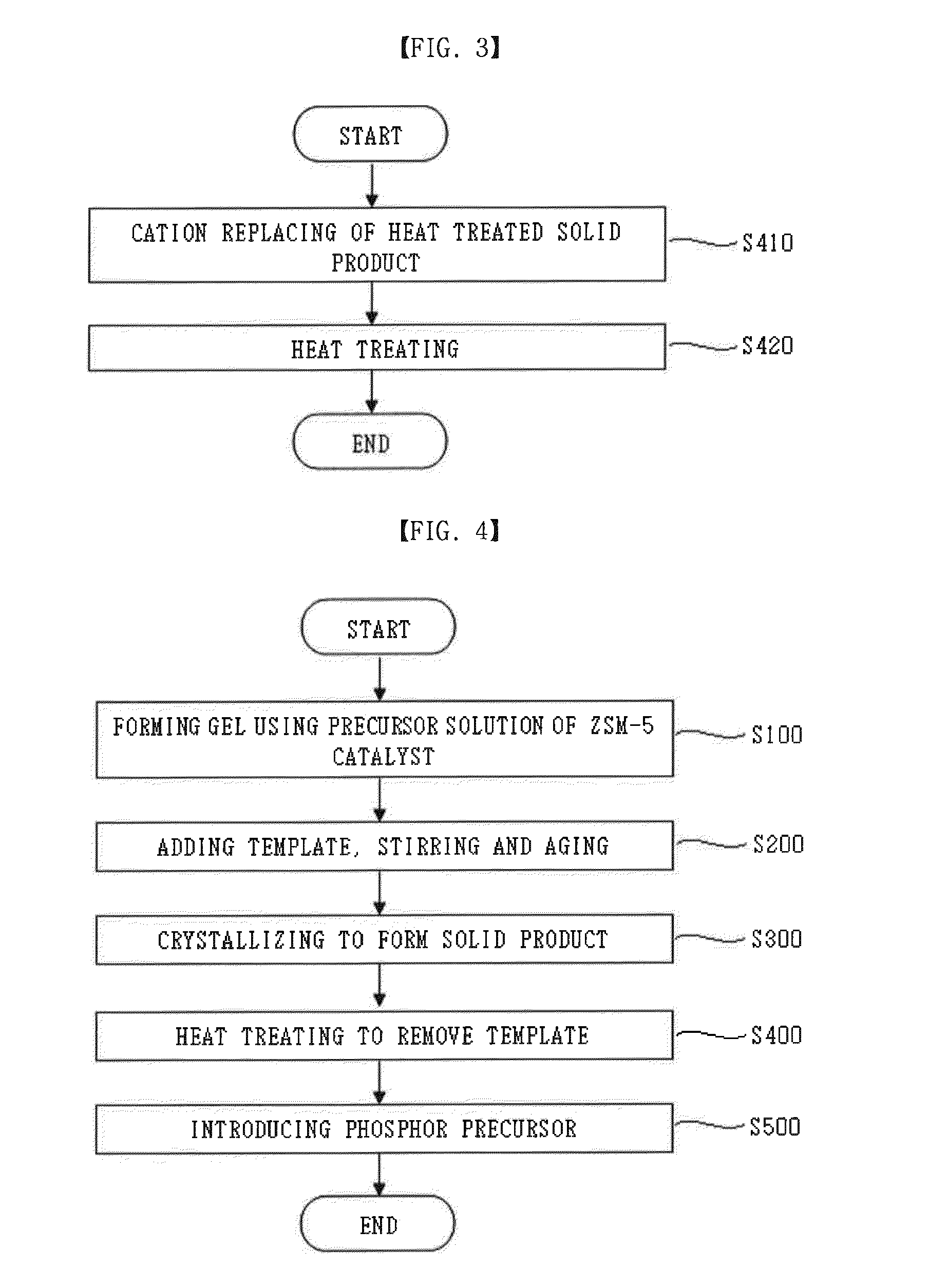

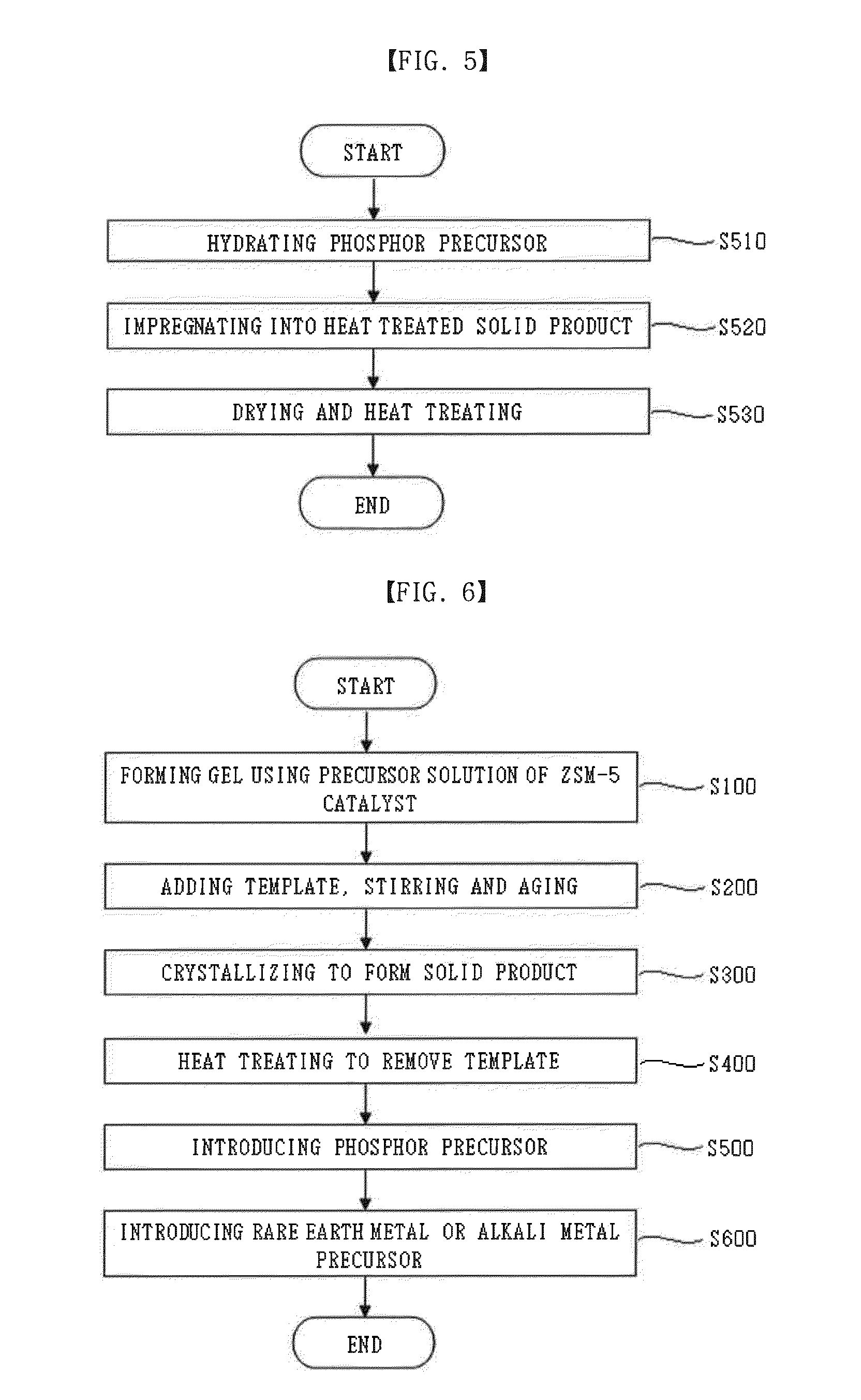

ZSM-5 catalyst with micropores and mesopores, preparation method thereof and production method of light olefins through catalytic cracking of hydrocarbons using the catalyst

InactiveUS20130085311A1Increase productionImprove featuresTreatment with plural serial cracking stages onlyCatalytic crackingHydrocarbon mixturesNaphtha

Provided is a method of preparing a ZSM-5 catalyst for preparing light olefins including ethylene and propylene through a catalytic cracking of a hydrocarbon mixture of C4 to C7 produced after a naphtha cracking. The method includes (a) forming a gel by aging a mixture solution including a silica precursor and an aluminum precursor; (b) adding a template possibly forming mesopores through a heat treatment, into the gel, stirring and then aging; (c) forming a solid product by crystallizing the aged mixture in step (b); and (d) heat treating the solid product to remove the template. The ZSM-5 catalyst may include micropores and mesopores and may have good physical and chemical properties along with a good pore property. The production yield of the light olefins may be increased.

Owner:HONAM PETROCHEM

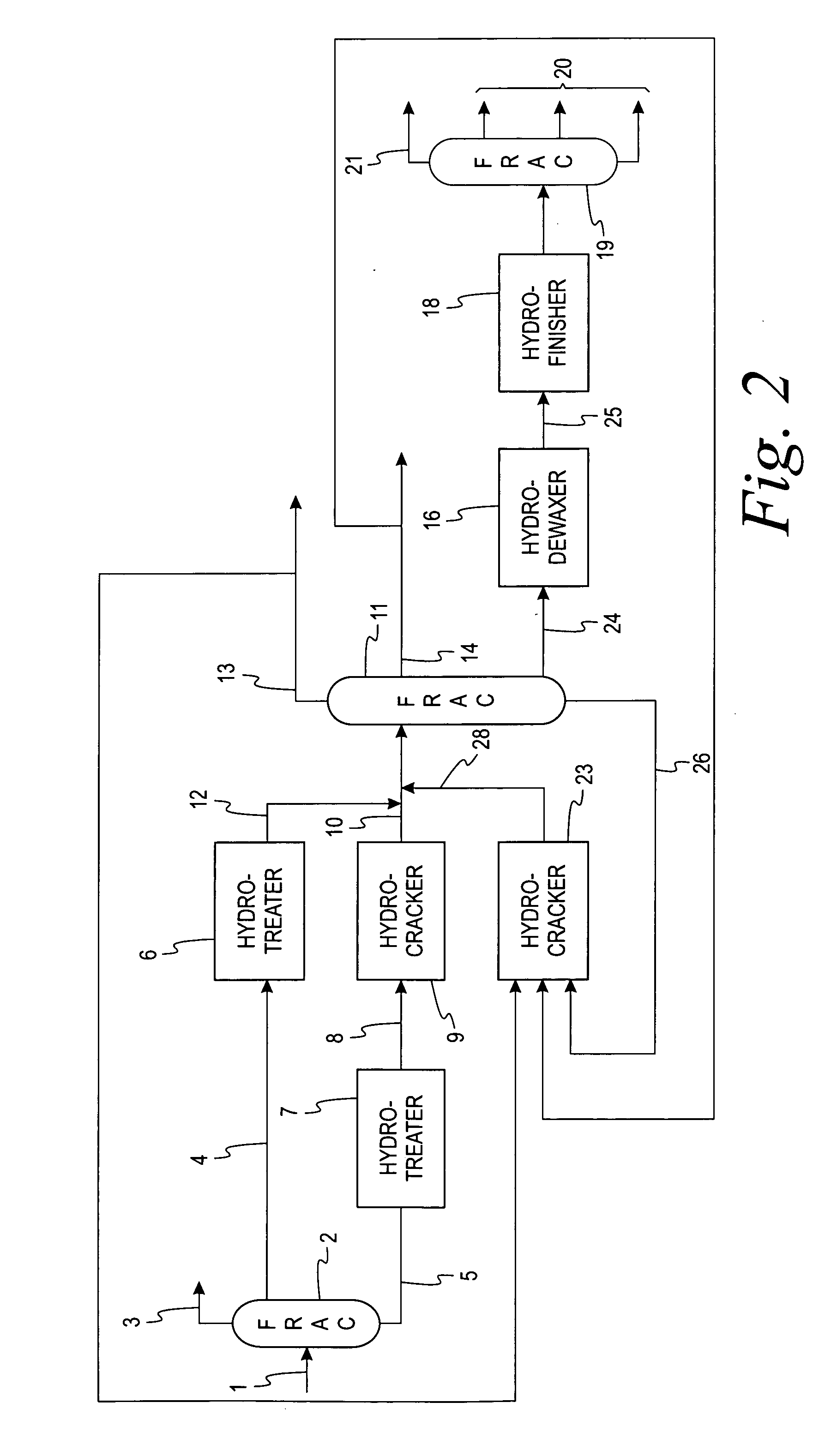

Process to produce synthetic fuels and lubricants

InactiveUS20050183988A1Yield maximizationEquipment cost can be minimizedThermal non-catalytic crackingCatalytic crackingBase oilPetroleum

A process utilizing a low severity hydrocracker prior to a high severity hydrocracker for the processing of petroleum based and synthetic hydrocarbon feedstocks into distillate fuels and high quality lubricant base oils. The process minimizes the size and conditions required by the high severity hydrocracker by closely matching such configuration with the desired product slate.

Owner:REG SYNTHETIC FUELS LLC

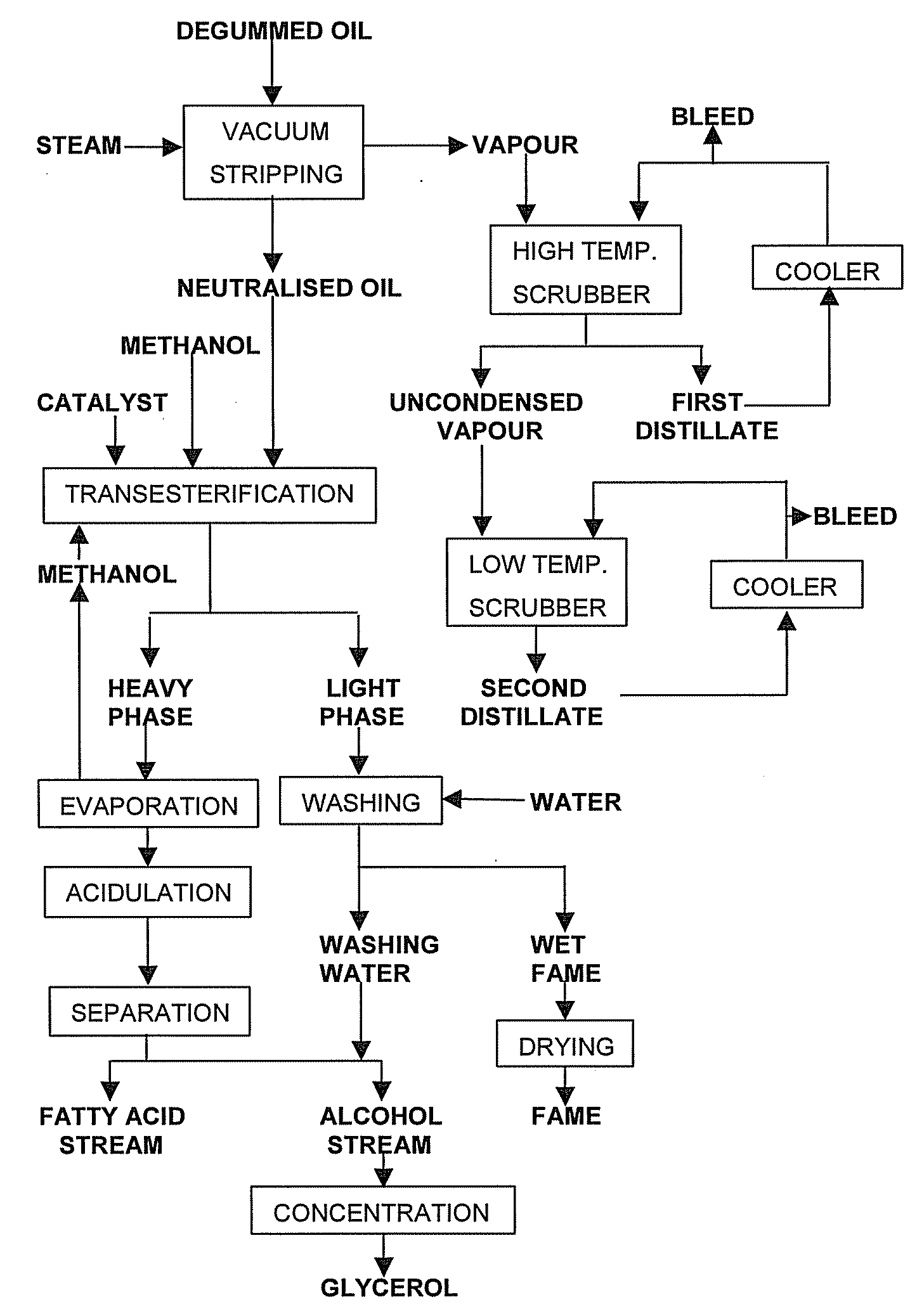

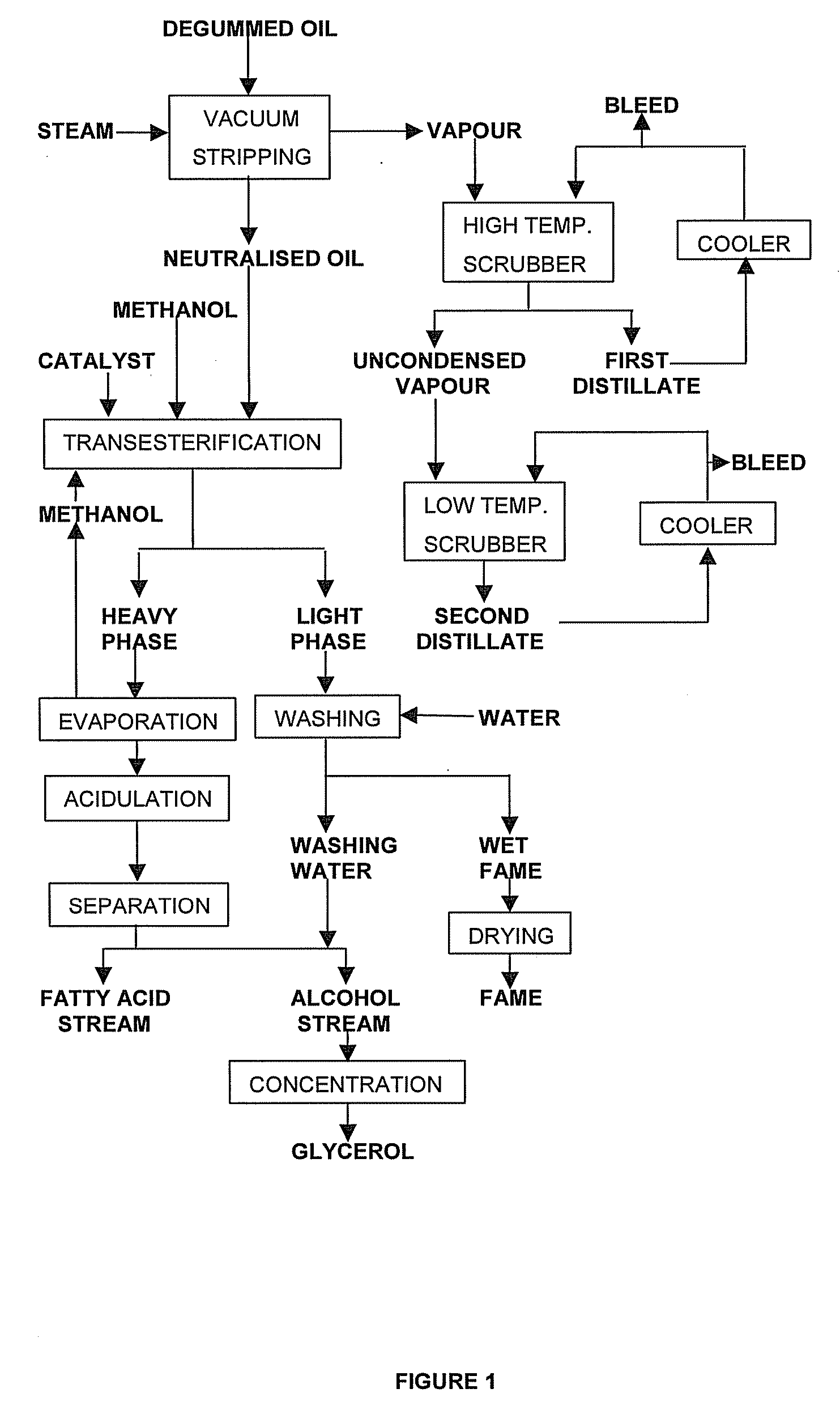

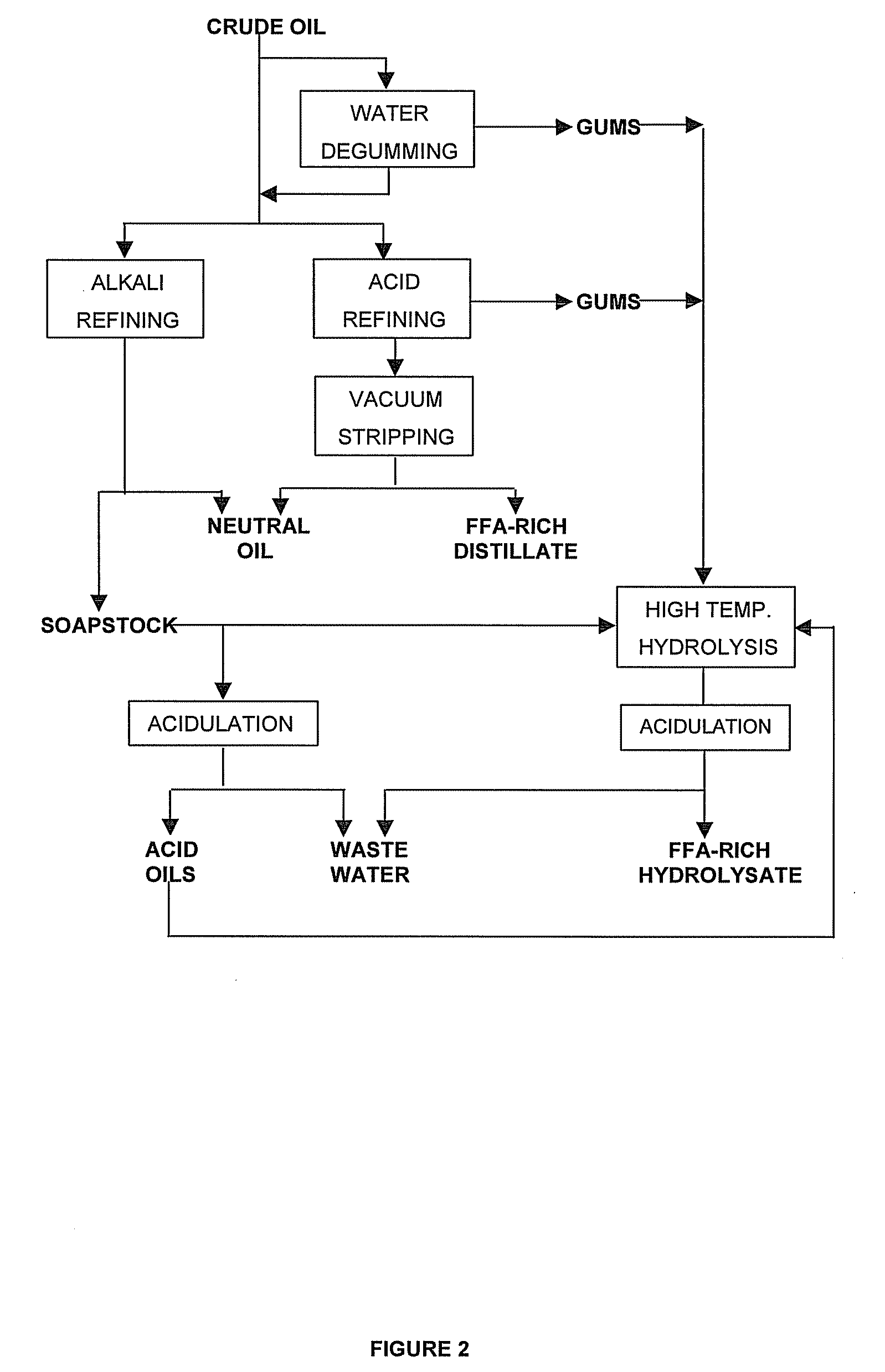

Production of esters of fatty acids and lower alcohols

InactiveUS20080051599A1Impurity can be harmfulBroad processingFatty acid esterificationFatty acids production/refiningTrans esterificationPtru catalyst

Process for the production of esters of fatty acids and C1-C5 alkyl alcohols comprising the steps of: (a) providing a fatty feed comprising a triglyceride oil or fat, partial glycerides and / or free fatty acids, (b) neutralising said fatty feed by vacuum stripping at a temperature from 200° C. to 280° C., thus providing a vapour stream and a residue, (c) collecting a distillate by scrubbing said vapour stream, (d) transesterifying said residue with a C1-C5 alkyl alcohol while using an alkaline catalyst, (e) separating the transesterification reaction mixture from step (d) into a fraction comprising C1-C5 alkyl esters of fatty acids and an alcoholic fraction (a) wherein at least part of free acids obtained as side products in step (a) and / or (c) and / or (e) are esterifyed with an alcohol using an acid catalyst, the product of this esterification being added to said fatty feed or said residue.

Owner:DESMET BALLESTRA OLEO

Process for producing liquid hydrocarbon by pyrolysis of biomass in presence of hydrogen from a carbon-free energy source

ActiveUS8217211B2Yield maximizationInhibition formationBioreactor/fermenter combinationsBiological substance pretreatmentsAlkaneHydrogen

In at least one embodiment of the present invention, a method for producing liquid hydrocarbons from biomass is provided. The method comprises pyrolizing the biomass with hydrogen (H2) to form bio-oil. The bio-oil comprises alkanes, alkenes, alcohols, aldehydes, ketones, aromatics, hydrocarbons or mixtures thereof. The H2 is formed from a carbon-free energy source.

Owner:PURDUE RES FOUND INC

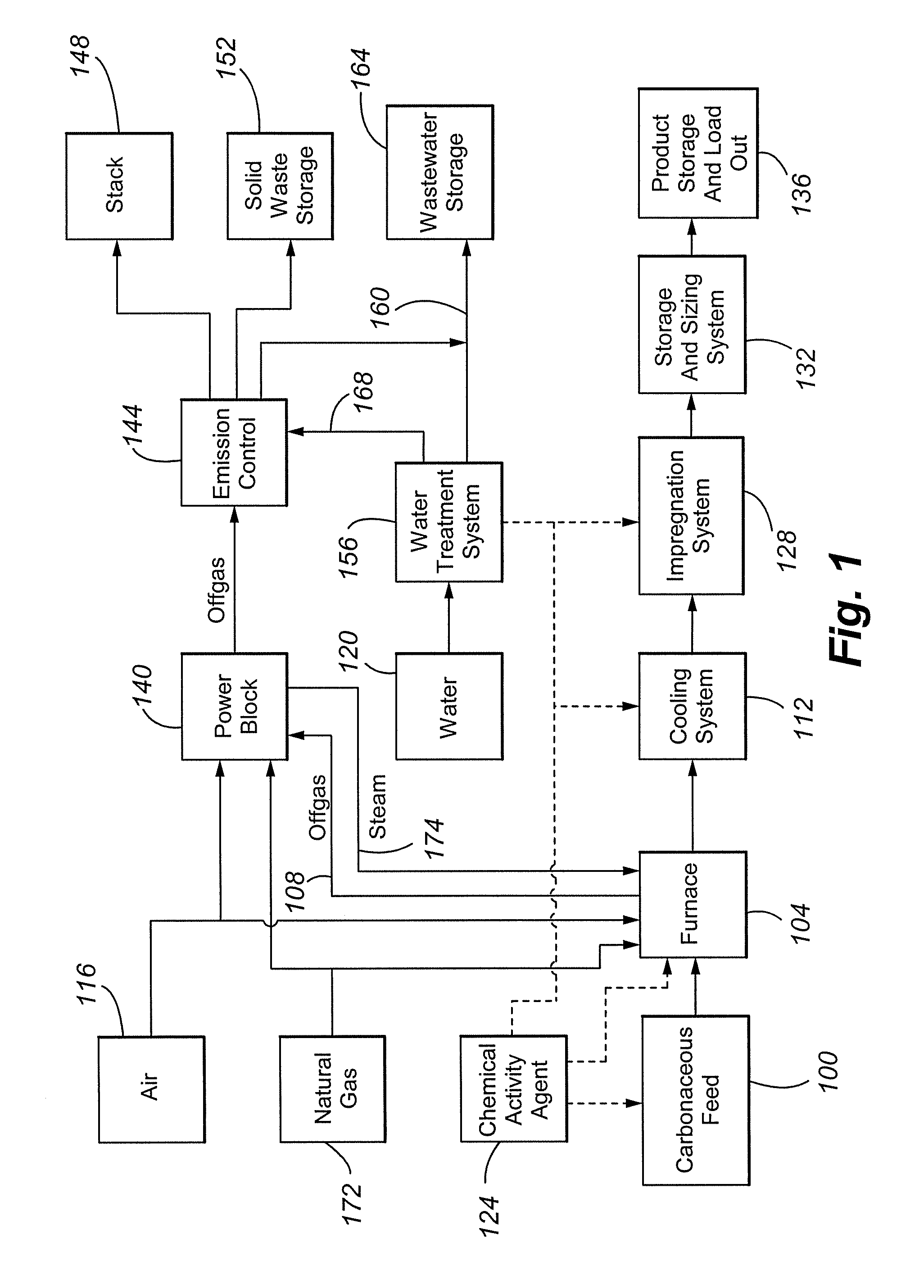

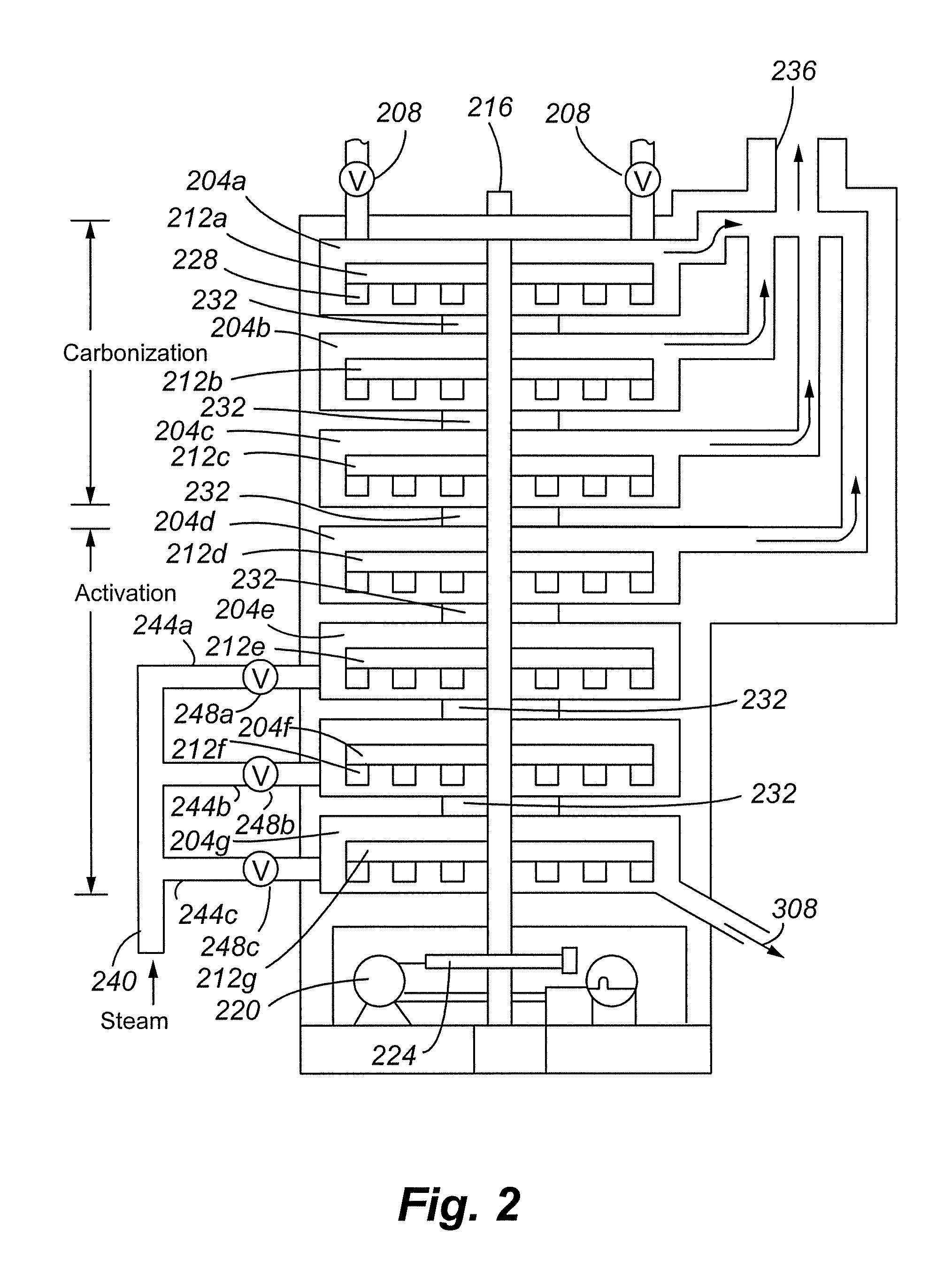

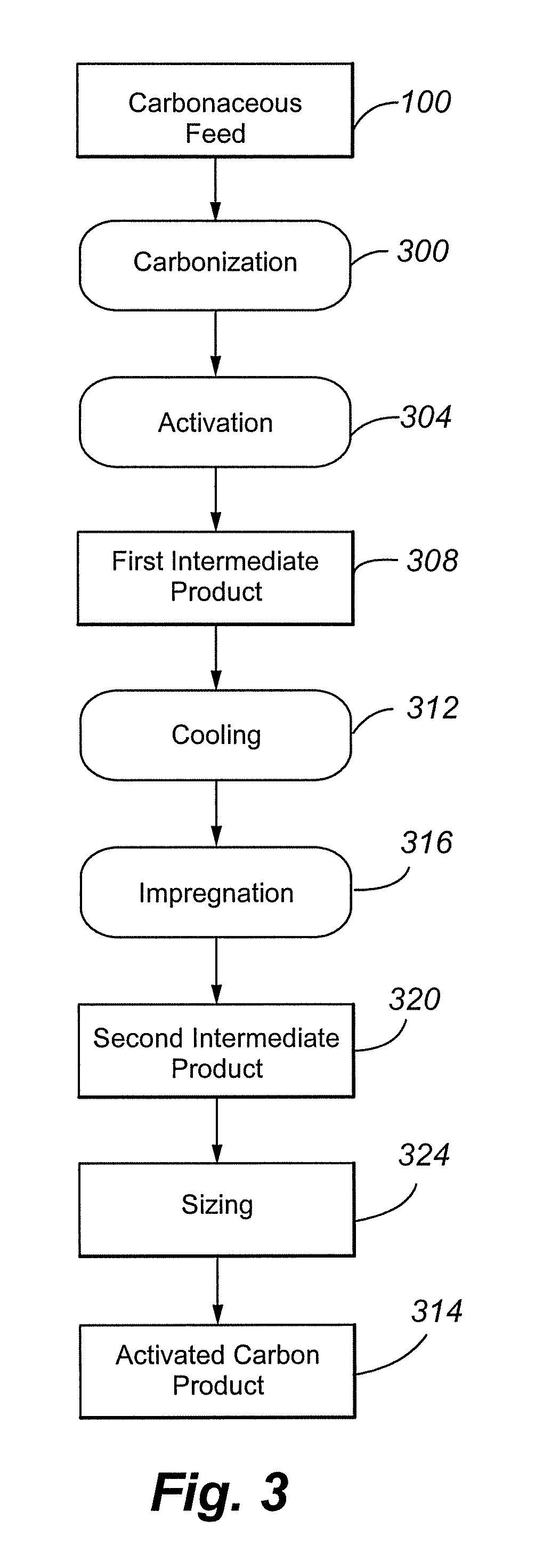

Process for the manufacture of carbonaceous mercury sorbent from coal

InactiveUS20070254807A1Large specific surface areaYield maximizationGas treatmentCarbon compoundsActivated carbonSorbent

The present invention is directed to a process for manufacturing a carbonaceous sorbent, particularly activated carbon, that uses lower average residence times and / or higher operating temperatures to produce activated carbon having favorable properties for mercury collection.

Owner:ADA CARBON SOLUTIONS

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS6652735B2Yield maximizationReduce pointsHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

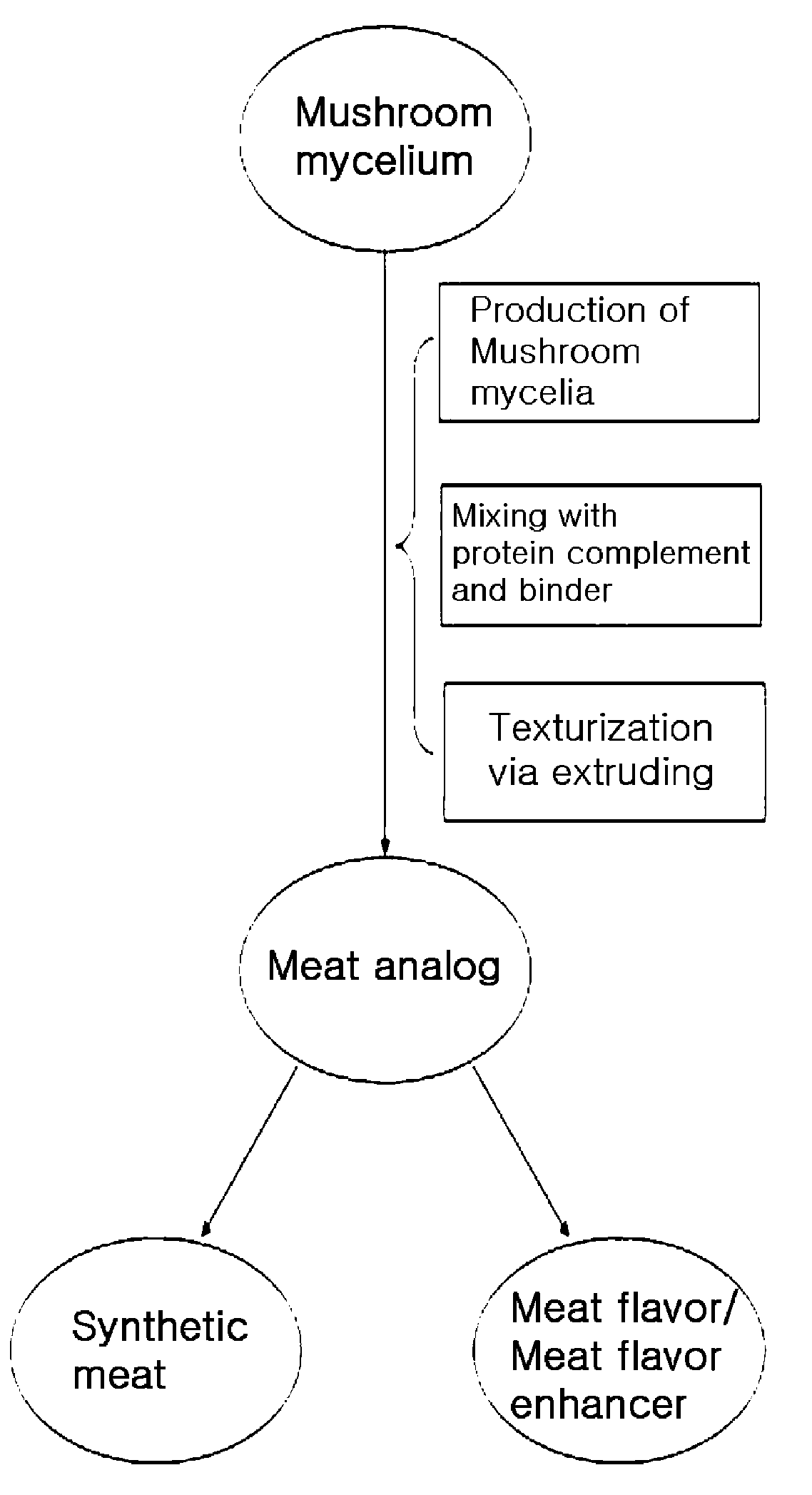

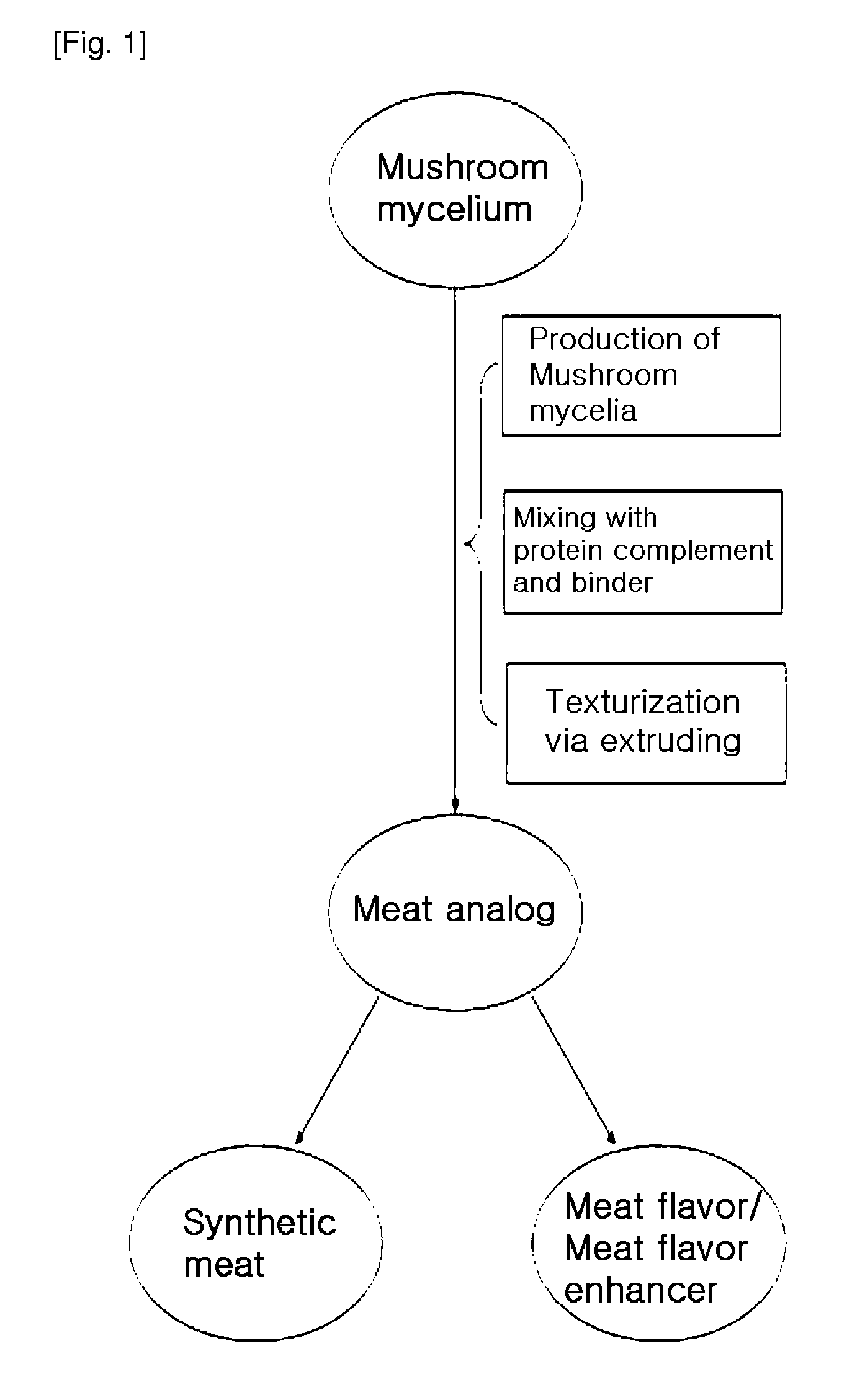

Method of producing mushroom mycelia based meat analog, meat analog produced thereby, low calorie synthetic meat, meat flavor and meat flavor enhancer comprising the meat analog

InactiveUS20090148558A1Yield maximizationMaximize economical efficiencyFungiAnimal feeding stuffLow calorieFood flavor

Provided is a method of producing mushroom mycelia-based meat analog, a meat analog produced using the method, a low-calorie synthetic meat and a meat flavor comprising the meat analog. The meat analog can be produced from mushroom mycelia within a short period of time in a cost and effort effective manner. A meat analog having improved meat-like texture and flavor compared to a conventional soy protein can be produced, and thus a low-calorie synthetic meat and a meat flavor can be produced using the meat analog.

Owner:CJ CORPORATION

Individual row rate control of farm implements to adjust the volume of crop inputs across wide implements in irregularly shaped or contour areas of chemical application, planting or seeding

InactiveUS20060086295A1Maximize yield potentialOptimize input application rate per acreAnalogue computers for trafficLiquid fertiliser distributionAutomatic controlEngineering

A farm implement for applying a product to a row crop or a row seeded field wherein the implement has a plurality of spaced-apart product dispensers mounted thereon, each of which is individually automatically controlled. The rate of product being dispensing from each of the product dispensers is automatically operated dependent upon the ground speed of the individual product dispensers or dependent on other criteria.

Owner:UNVERFERTH MFG

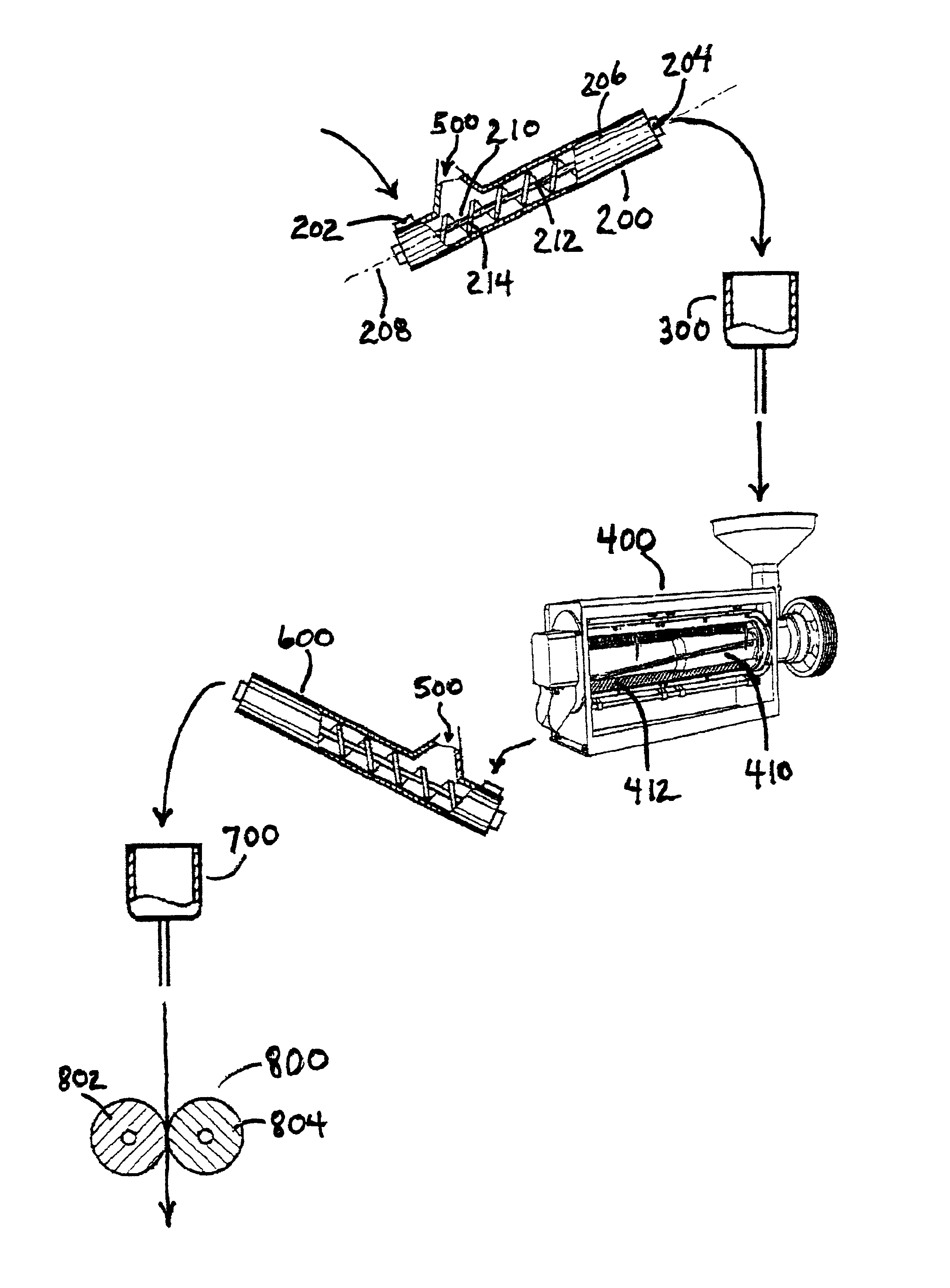

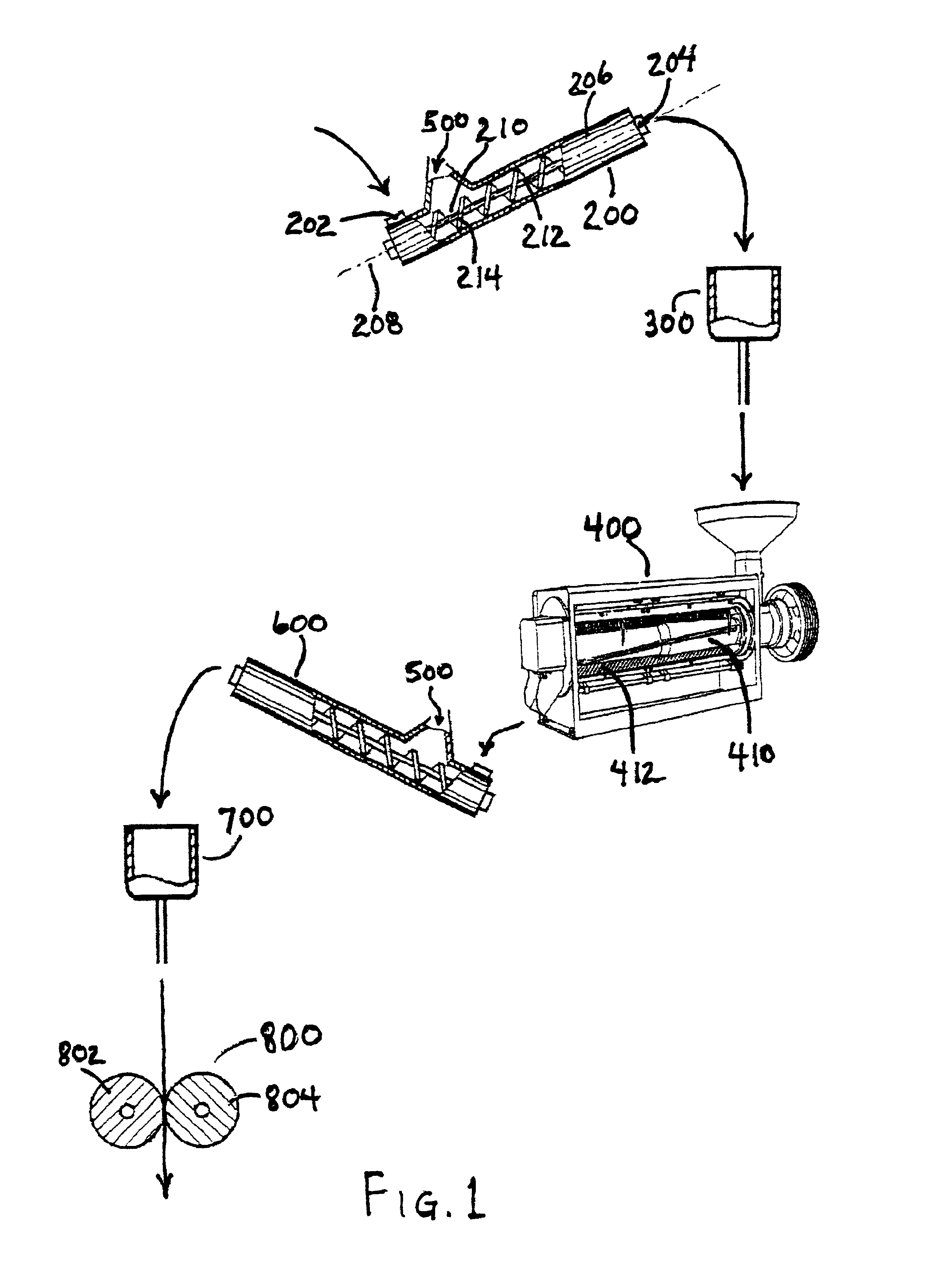

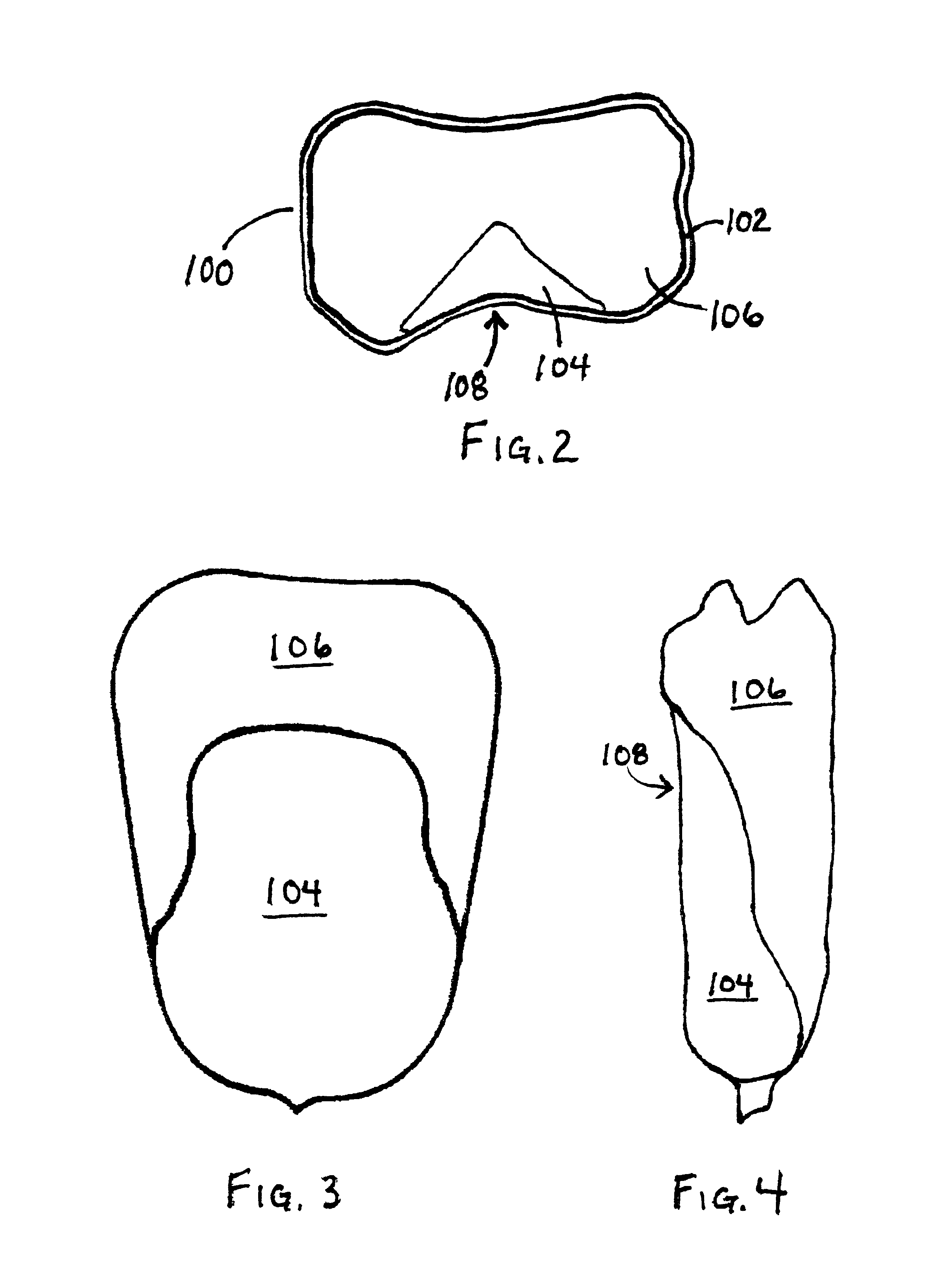

Corn degermination process

InactiveUS6936294B2Increase productionYield maximizationGrain huskingGrain polishingSurface velocityEngineering

Owner:SATAKE USA INC

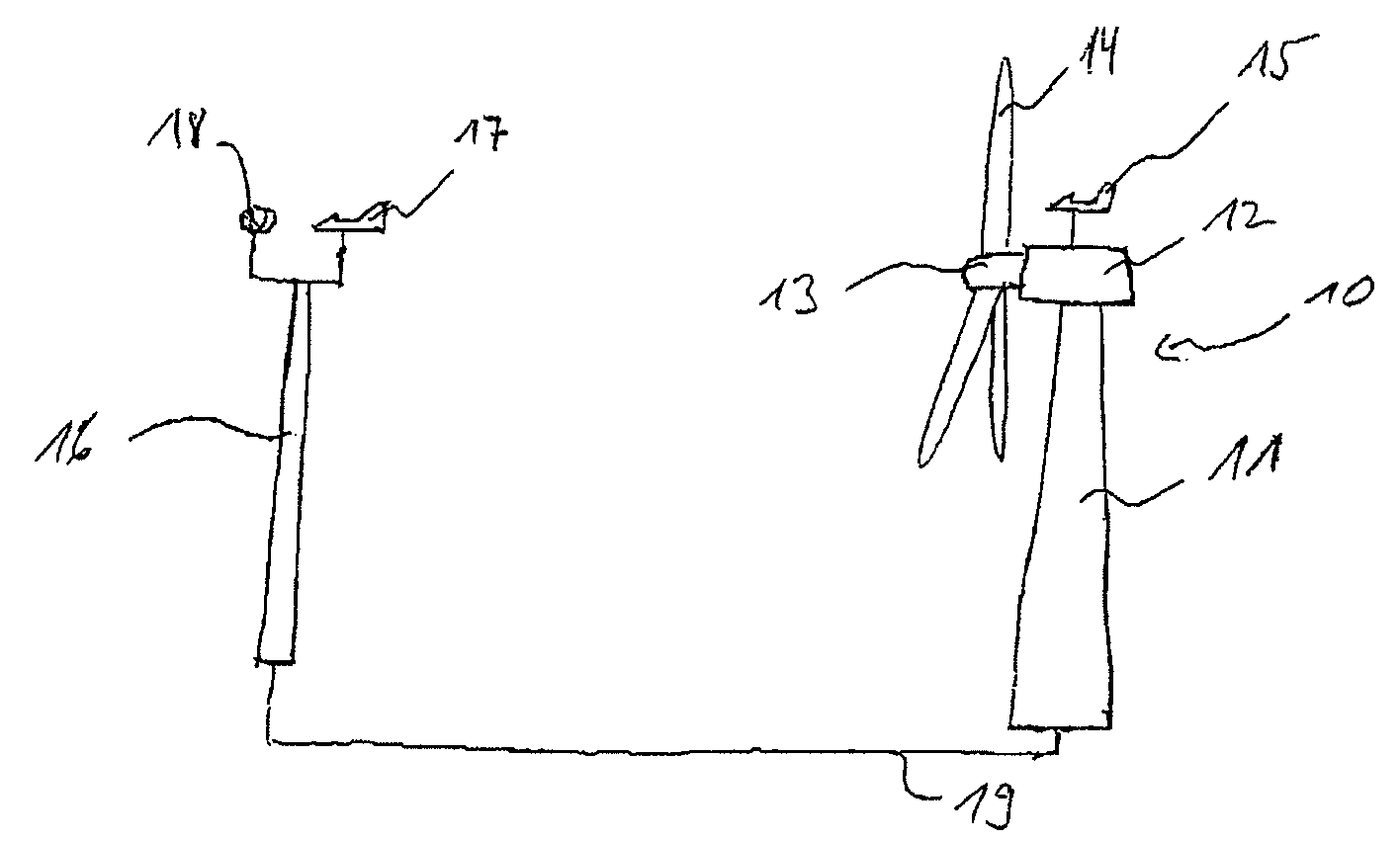

Method and system for operating a wind energy installation

ActiveUS20090261588A1Maximises energy yieldAccurate recordOptimise machine performancePropellersEngineeringAtmospheric sciences

A method for operating a wind energy installation and a system for implementing the method. An oblique incident flow value, which represents the difference between the wind direction and the direction of a rotor axis of the wind energy installation, and a load value, which represents the load state of the wind energy installation, are determined. A total load value is determined based on the load value and the oblique incident flow value. The rotor rotation speed is reduced when the total load value is above a first limit value. The wind energy installation is shut down when, in addition, a second limit value is exceeded. The method makes it possible to react objectively to oblique incident flows and can reduce a load on a wind energy installation without causing large yield losses.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com