Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

463 results about "Selective catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing fluorinated organic compounds

ActiveUS20070197842A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystDistillation

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

Method for producing fluorinated organic compounds

ActiveUS8084653B2Preparation by hydrogen halide split-offPreparation by halogen replacementActivated carbonGas phase

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

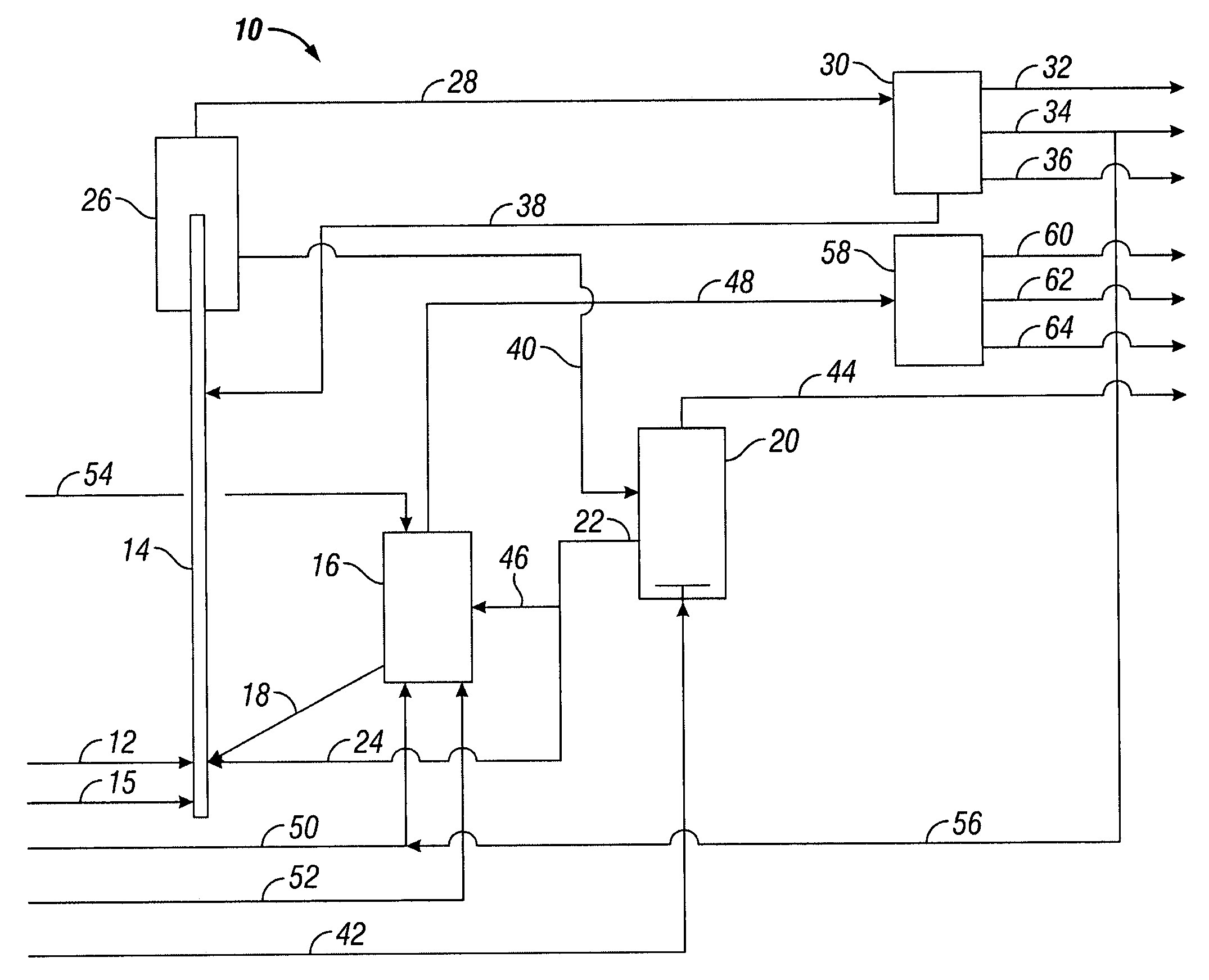

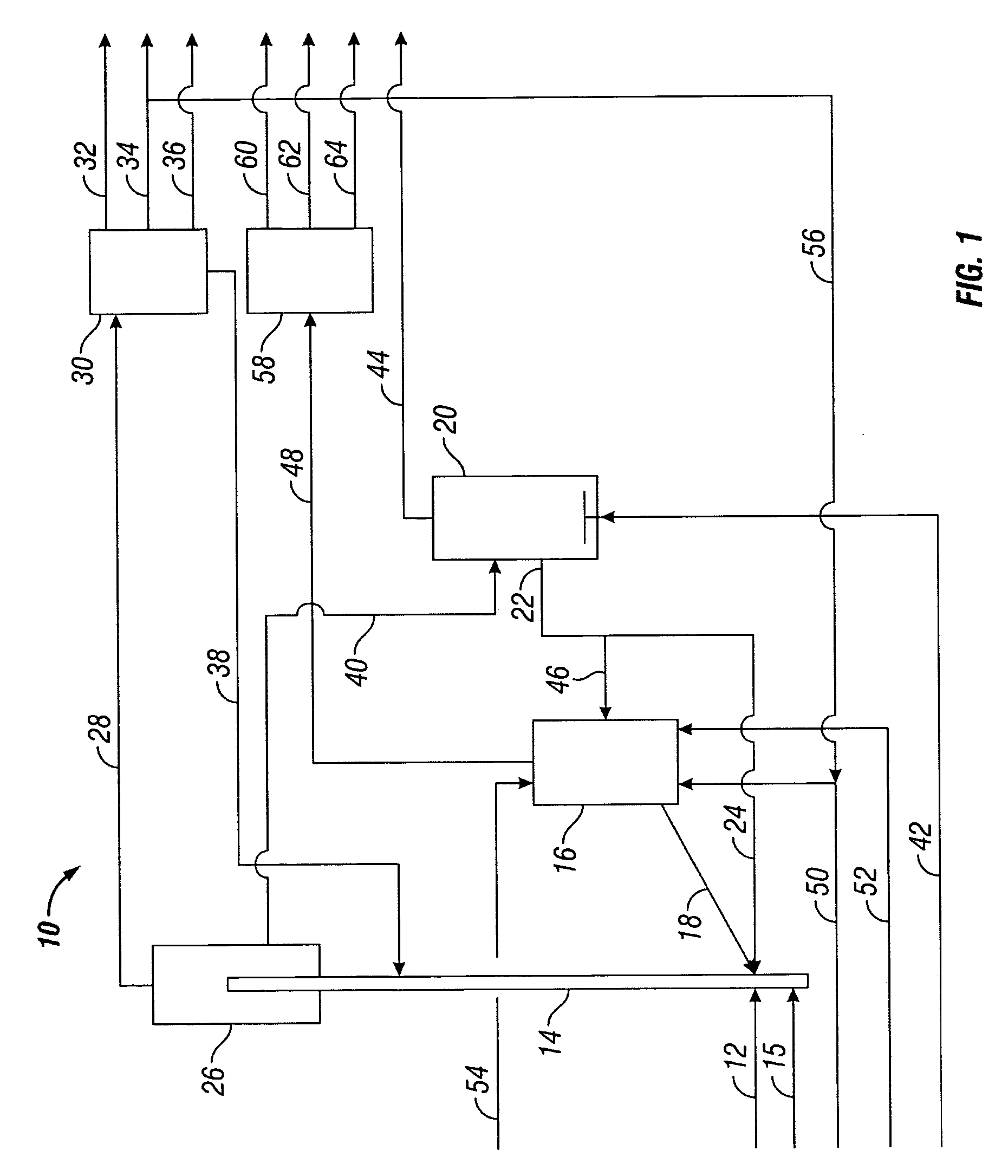

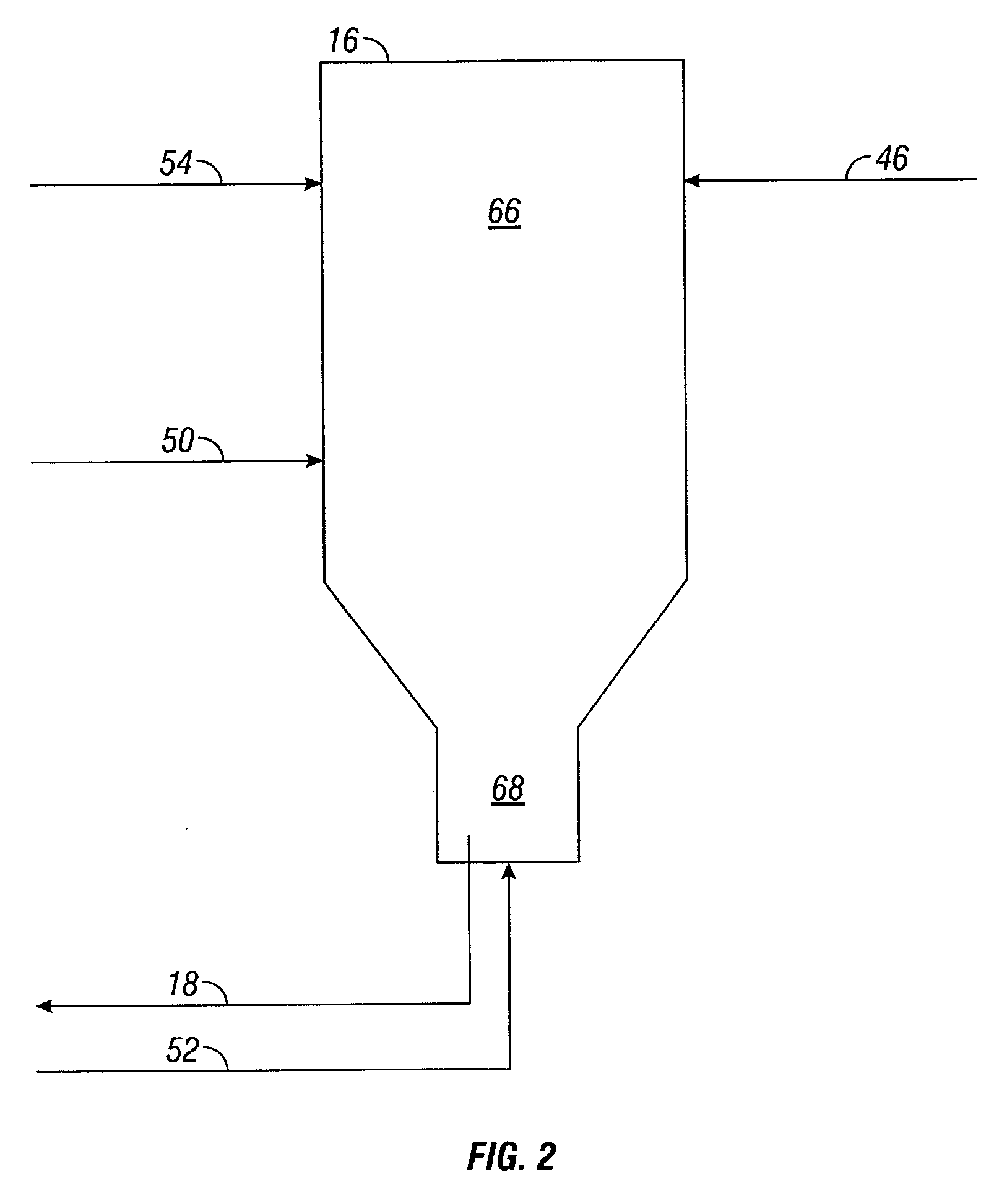

Method and apparatus for making a middle distillate product and lower olefins from a hydrocarbon feedstock

ActiveUS20060178546A1Yield maximizationCatalytic crackingCatalytic naphtha reformingPetroleum productGasoline

Disclosed is a process for making middle distillate and lower olefins. The process includes catalytically cracking a gas oil feedstock within a riser reactor zone by contacting under suitable catalytic cracking conditions within the riser reactor zone the gas oil feedstock with a middle distillate selective cracking catalyst that comprises amorphous silica alumina and a zeolite to yield a cracked gas oil product and a spent cracking catalyst. The spent cracking catalyst is regenerated to yield a regenerated cracking catalyst. Within an intermediate cracking reactor such as a dense bed reactor zone and under suitable high severity cracking conditions a gasoline feedstock is contacted with the regenerated cracking catalyst to yield a cracked gasoline product and a used regenerated cracking catalyst. The used regenerated cracking catalyst is utilized as the middle distillate selective catalyst.

Owner:SHELL USA INC

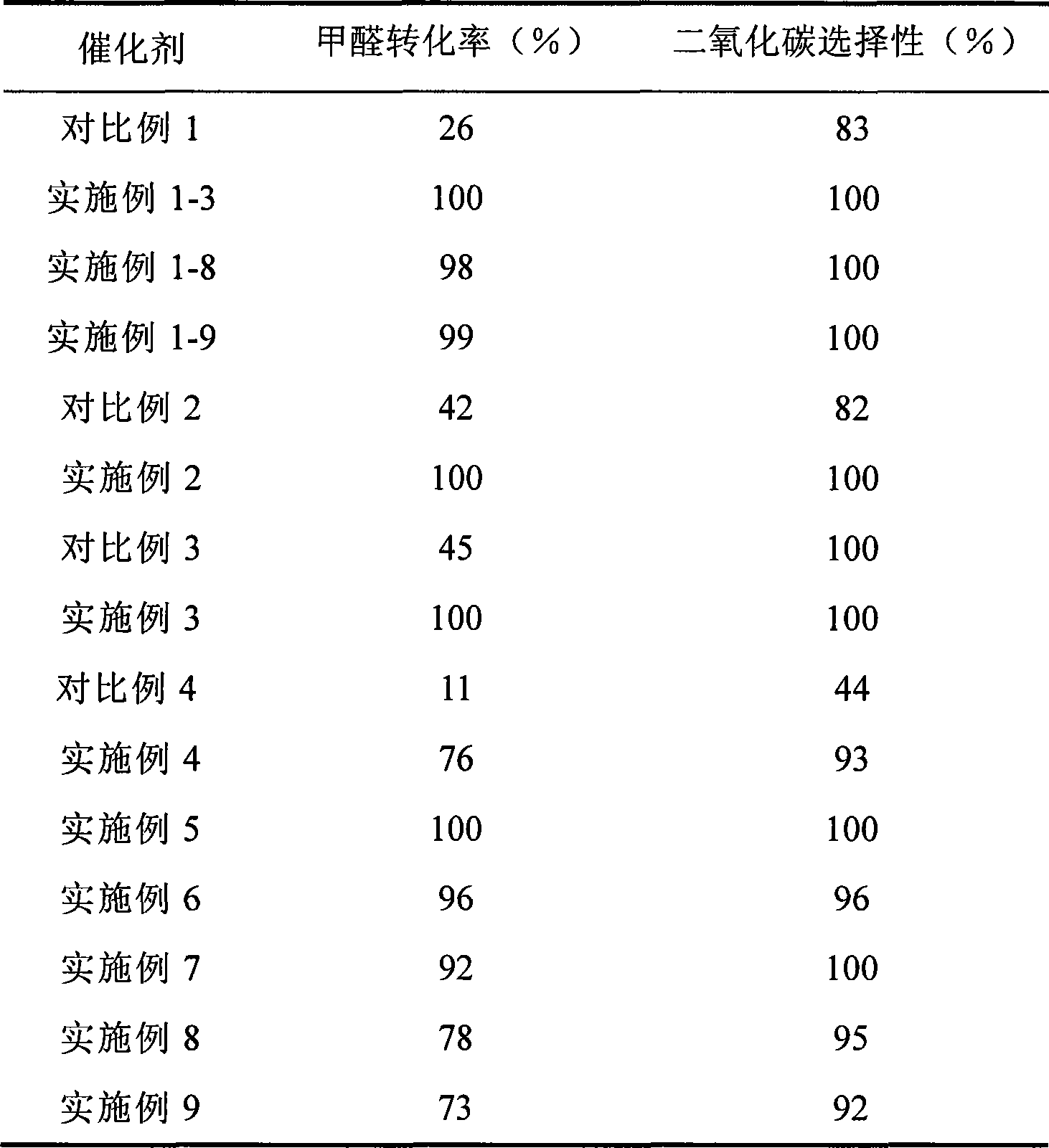

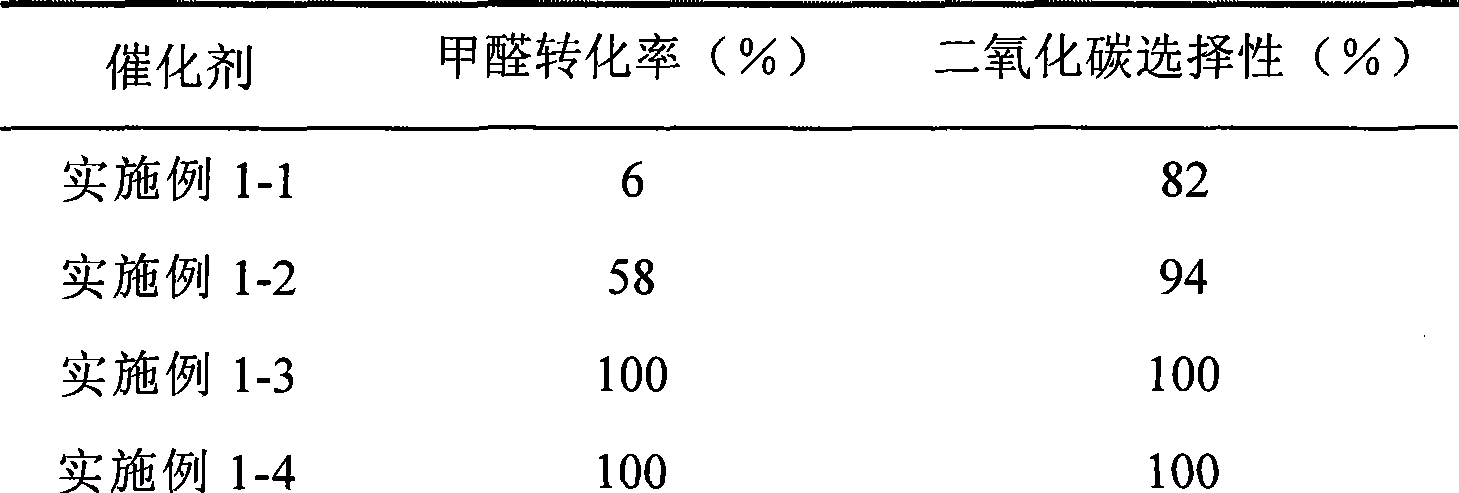

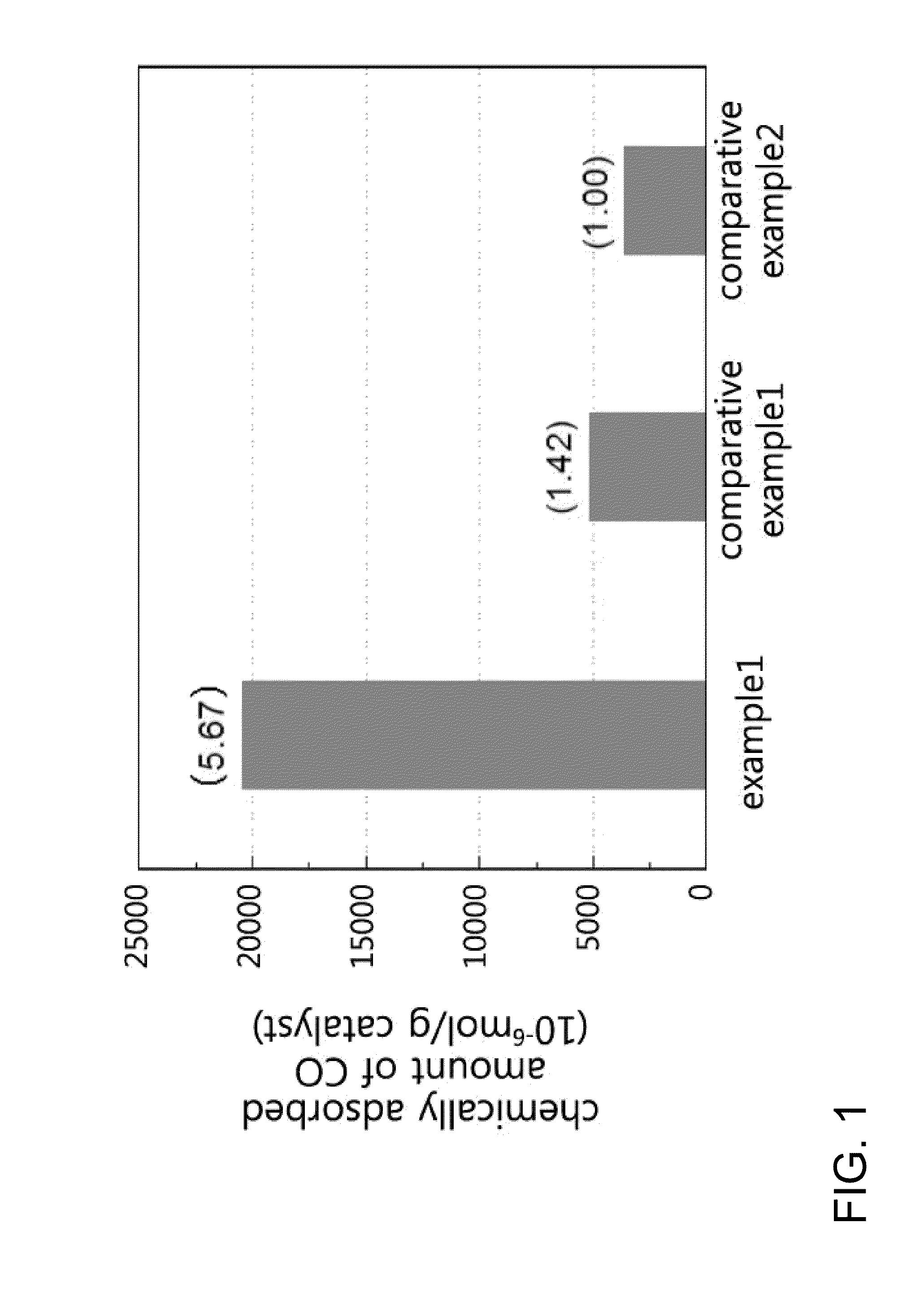

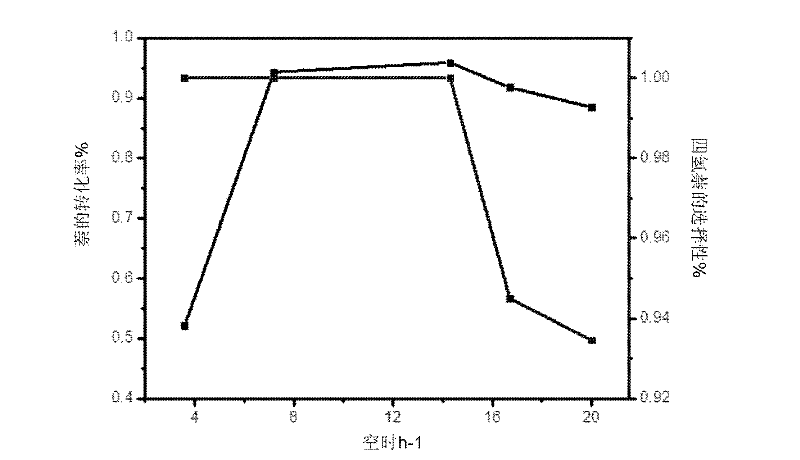

Catalyst for complete oxidation of formaldehyde at room temperature

ActiveCN101380574AEasy to makeEasy to operateDeodrantsMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

The invention provides a high selectivity catalyst used for catalyzing and completely oxidizing formaldehyde with low concentration at room temperature. The catalyst can catalyze formaldehyde completely so as to lead the formaldehyde to be converted into carbon dioxide and water at room temperature. In addition, the conversion rate of formaldehyde remains 100% within a long period of time, without complex auxiliary facilities such as light source, a heating oven and the like, and external conditions. The catalyst comprises three parts which are inorganic oxide carrier, noble metal component and auxiliary ingredient. Porous inorganic oxide carrier is one of cerium dioxide, zirconium dioxide, titanium dioxide, aluminium sesquioxide, tin dioxide, silicon dioxide, lanthanum sesquioxide, magnesium oxide and zinc oxide or the mixture thereof or composite oxide thereof, zeolite, sepiolite and porous carbon materials. The noble metal component of the catalyst is at least one of platinum, rhodium, palladium, gold and silver. The auxiliary ingredient is at least one of the alkali metals of lithium, sodium, kalium, rubidium and cesium. The loading of the noble metal component used in the catalyst of the invention is 0.1 to 10% according to weight converter of metal elements and the selective preference is 0.3 to 2%. The loading of the auxiliary ingredient is 0.2 to 30% according to weight converter of metal elements and the selective preference is 1 to 10%. When the loading of the auxiliary ingredient is lower than 0.2% or higher than 30%, the activity of the catalyst for catalyzing and oxidizing formaldehyde at room temperature is decreased remarkably.

Owner:广东顺德中科鸿图环境材料有限公司

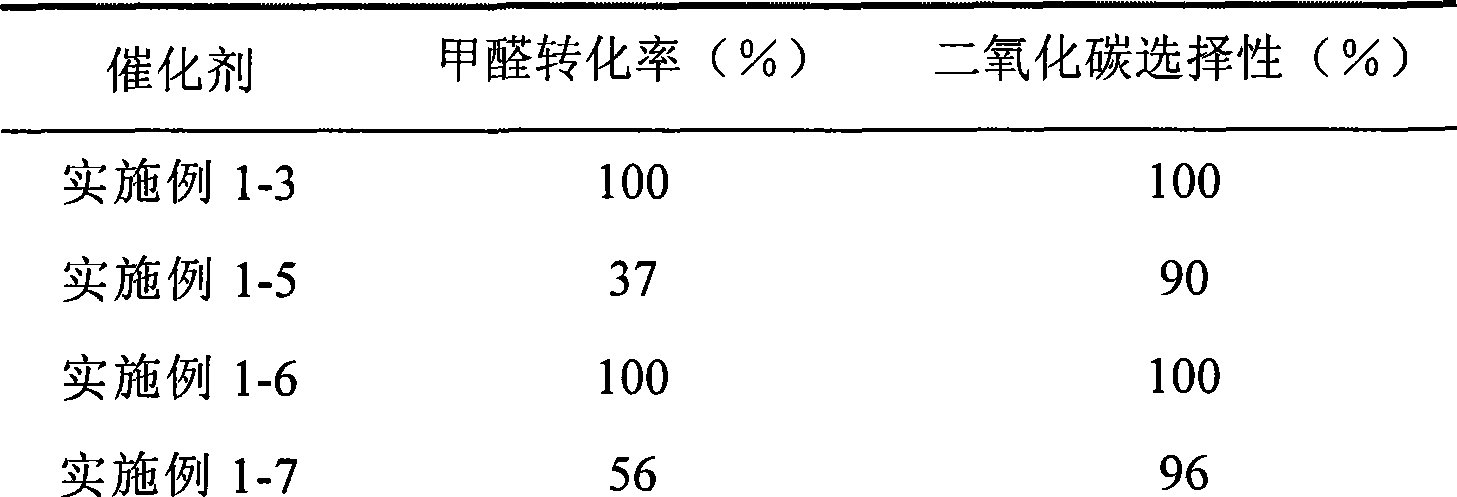

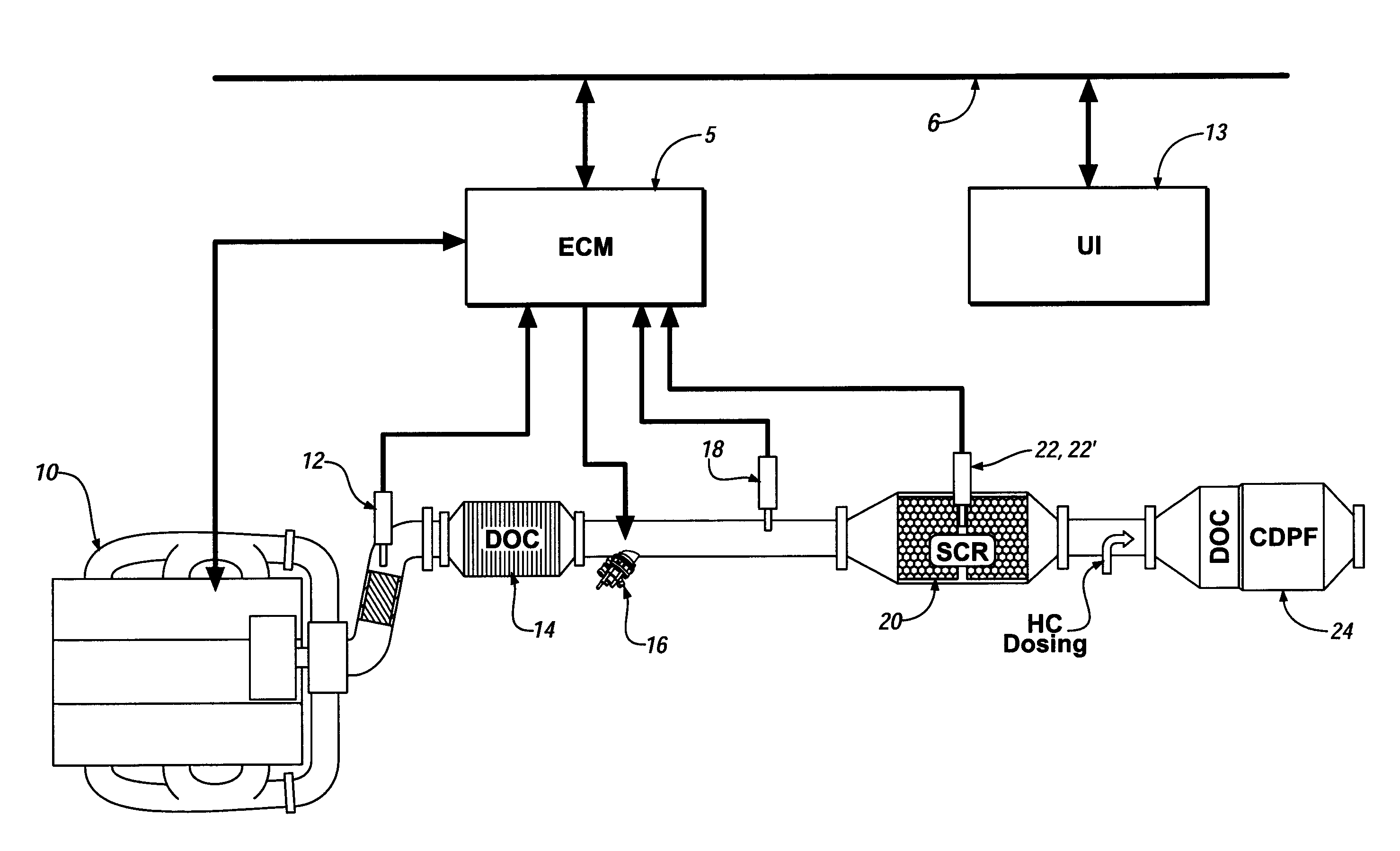

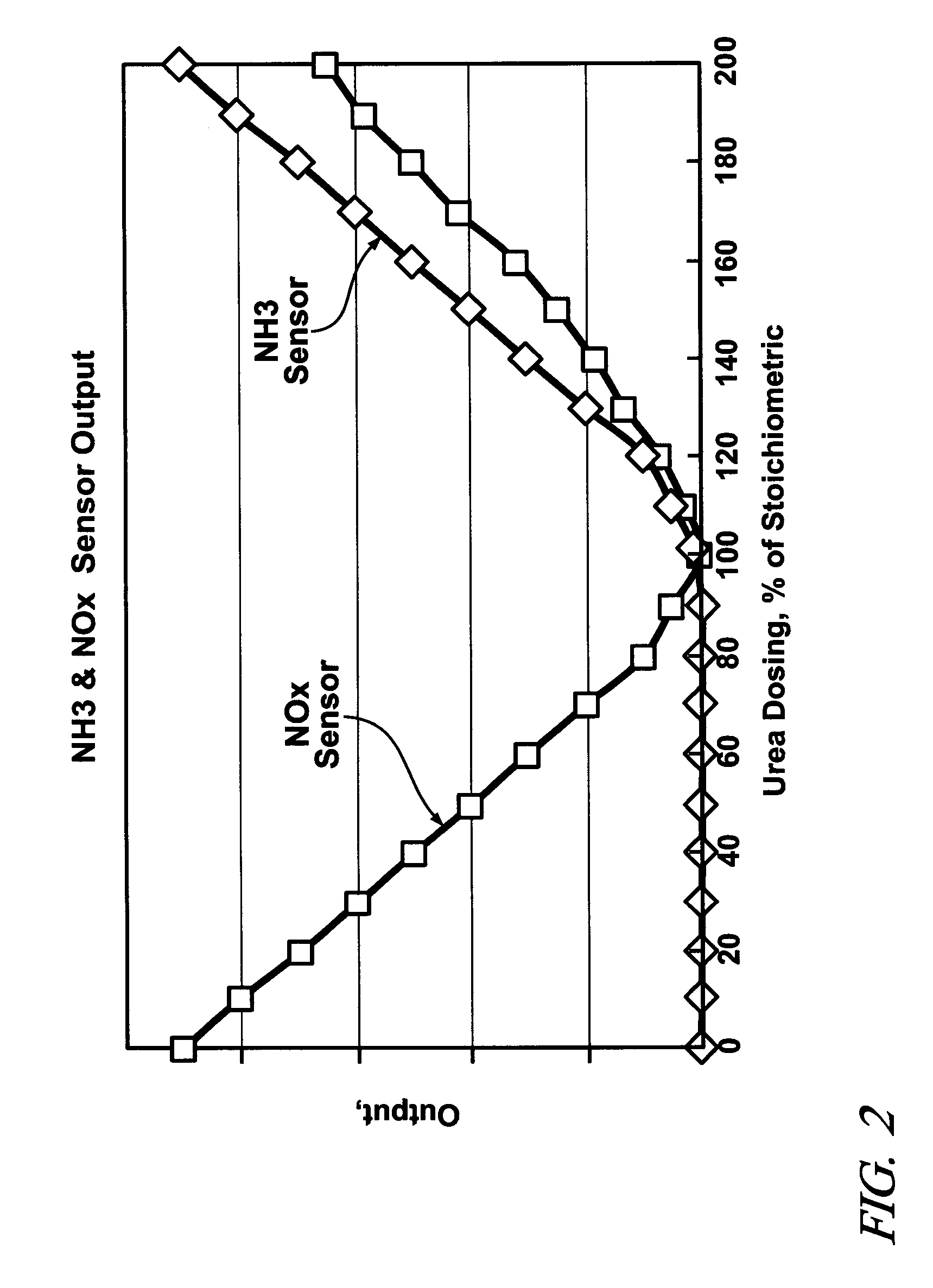

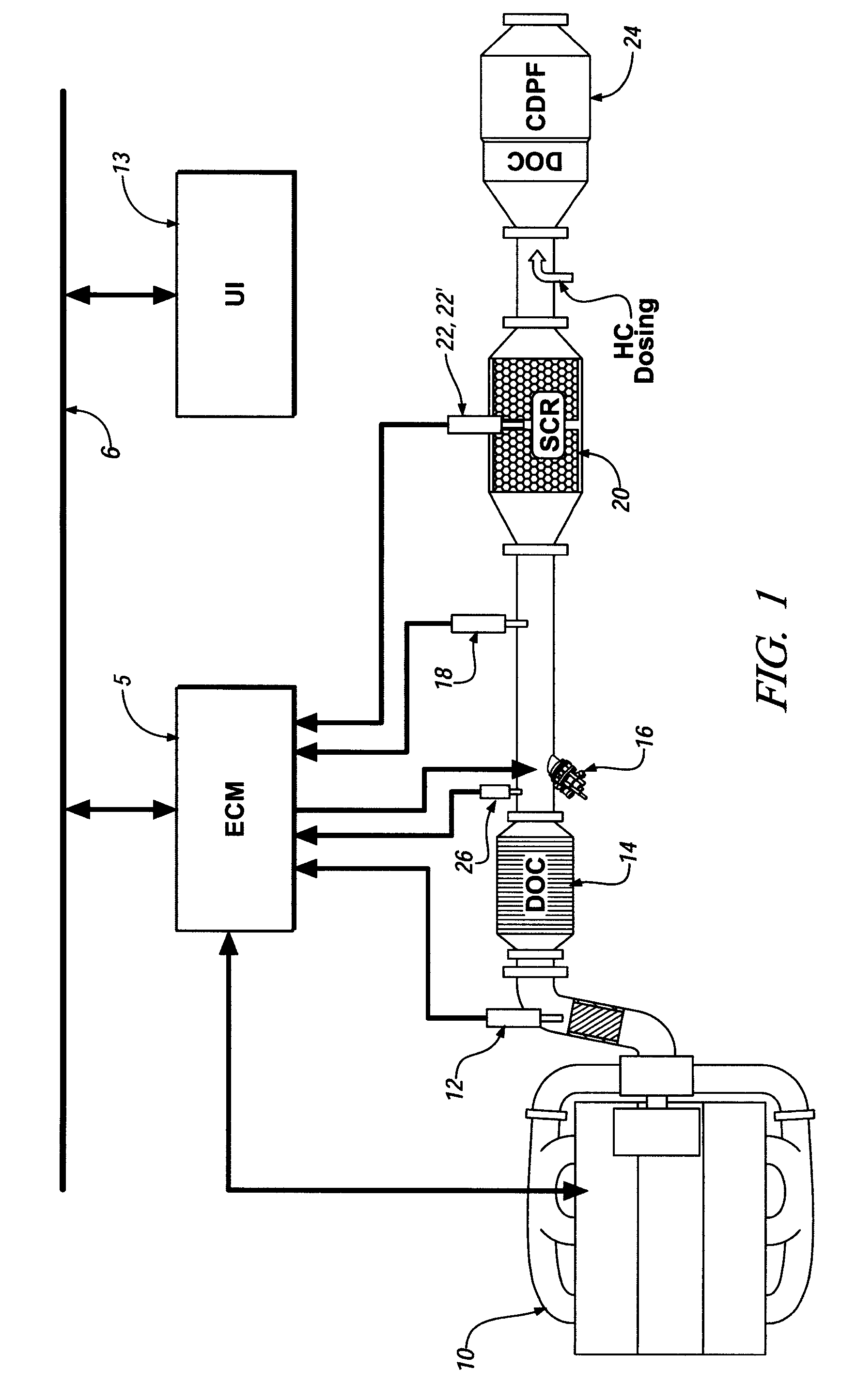

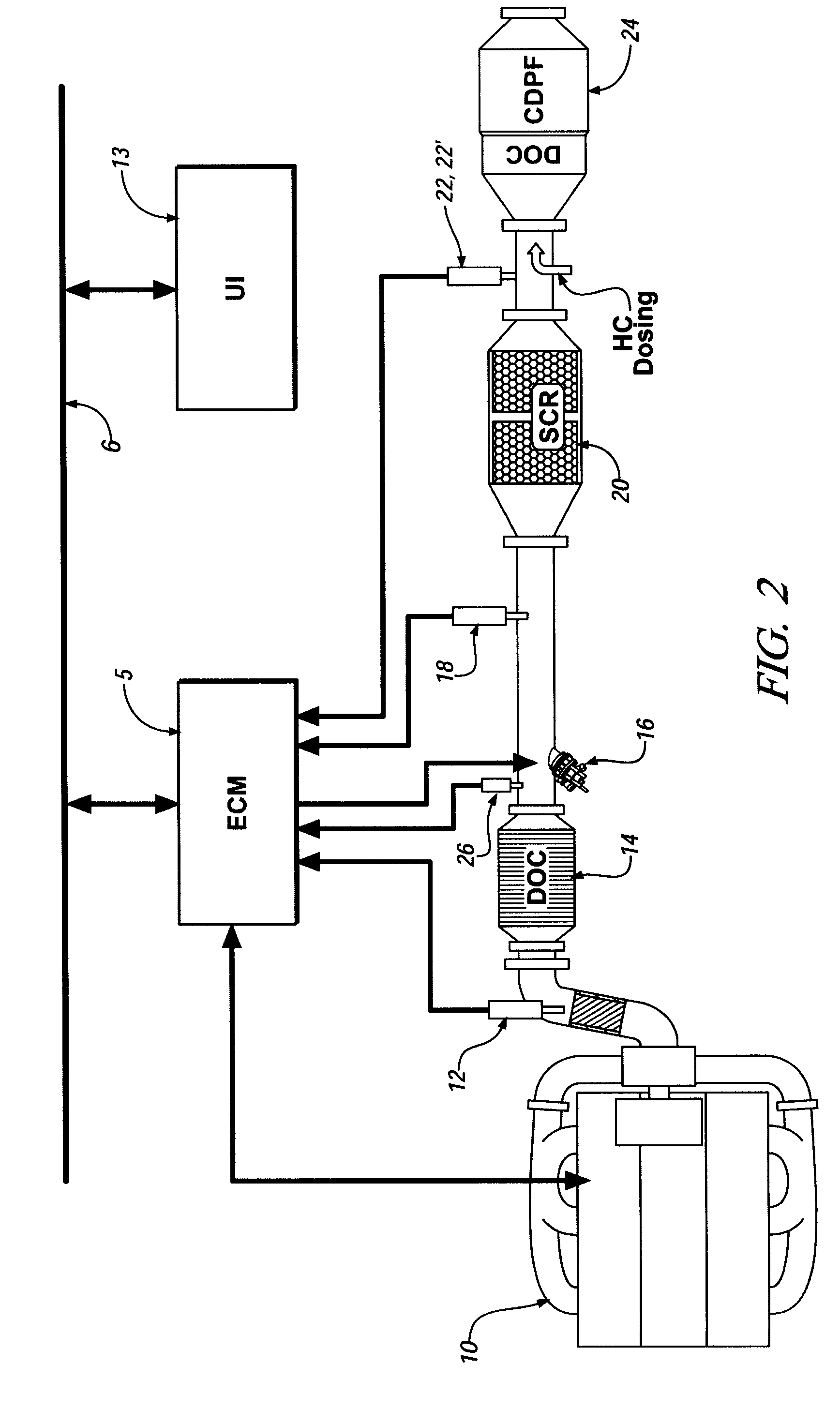

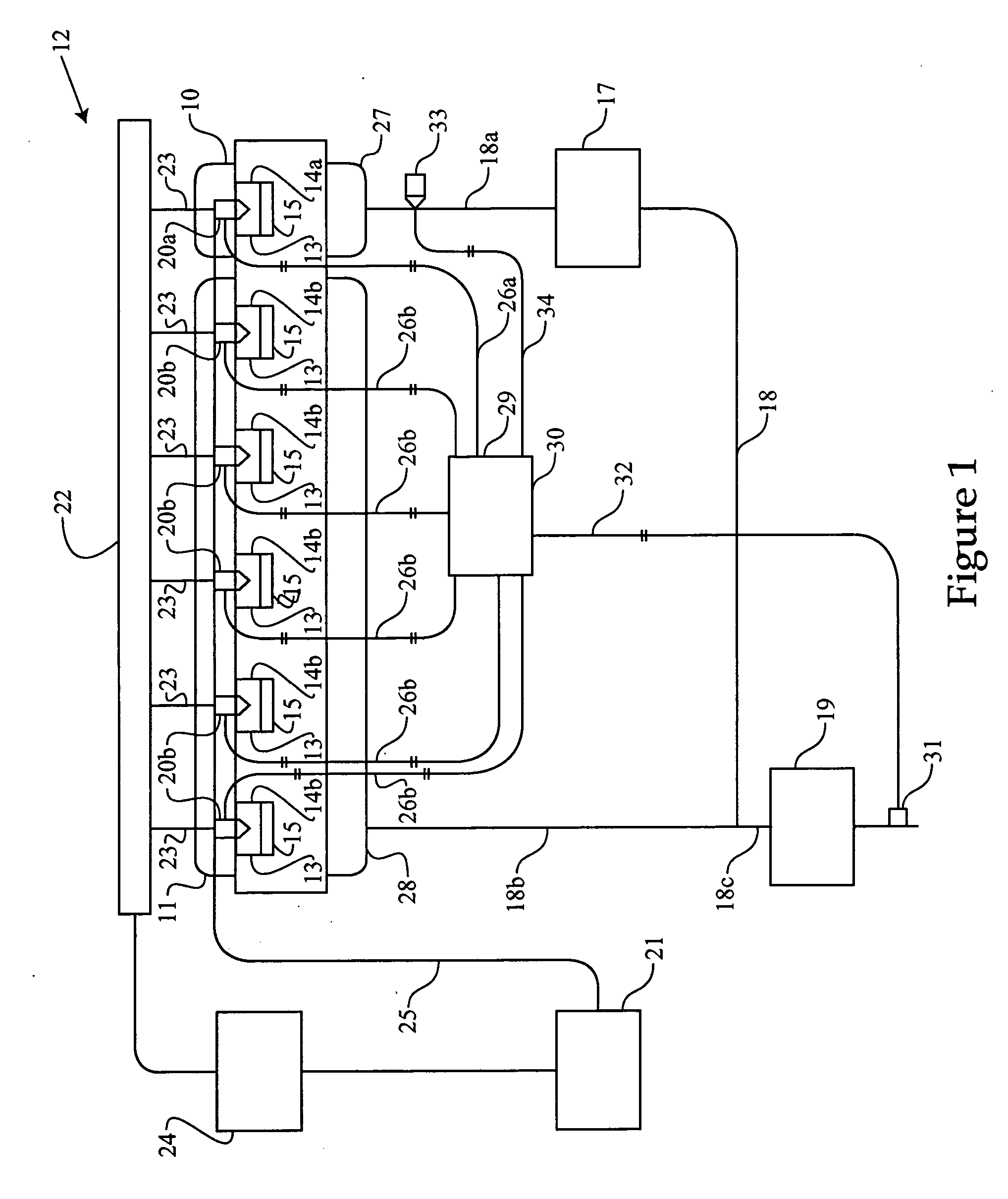

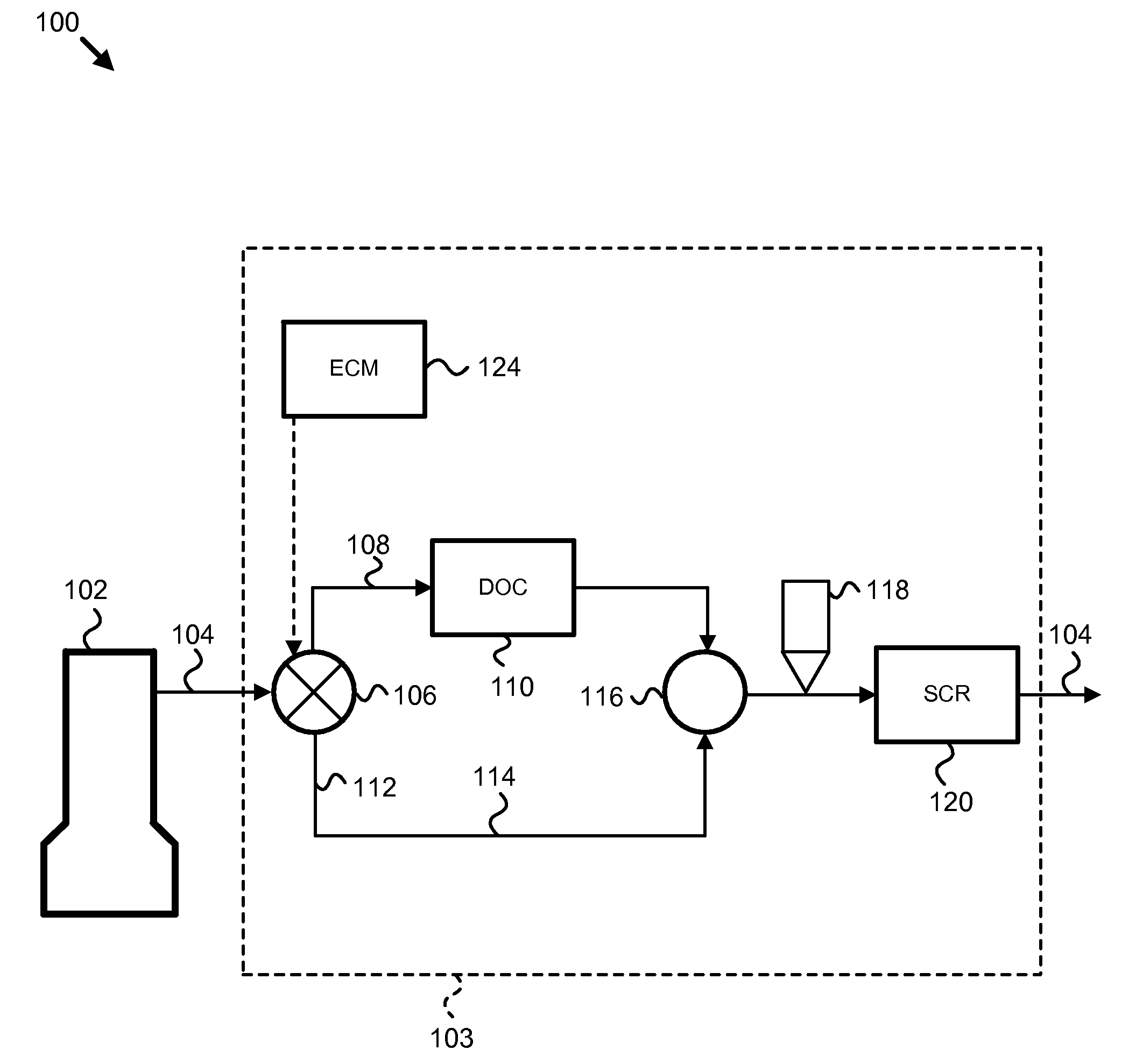

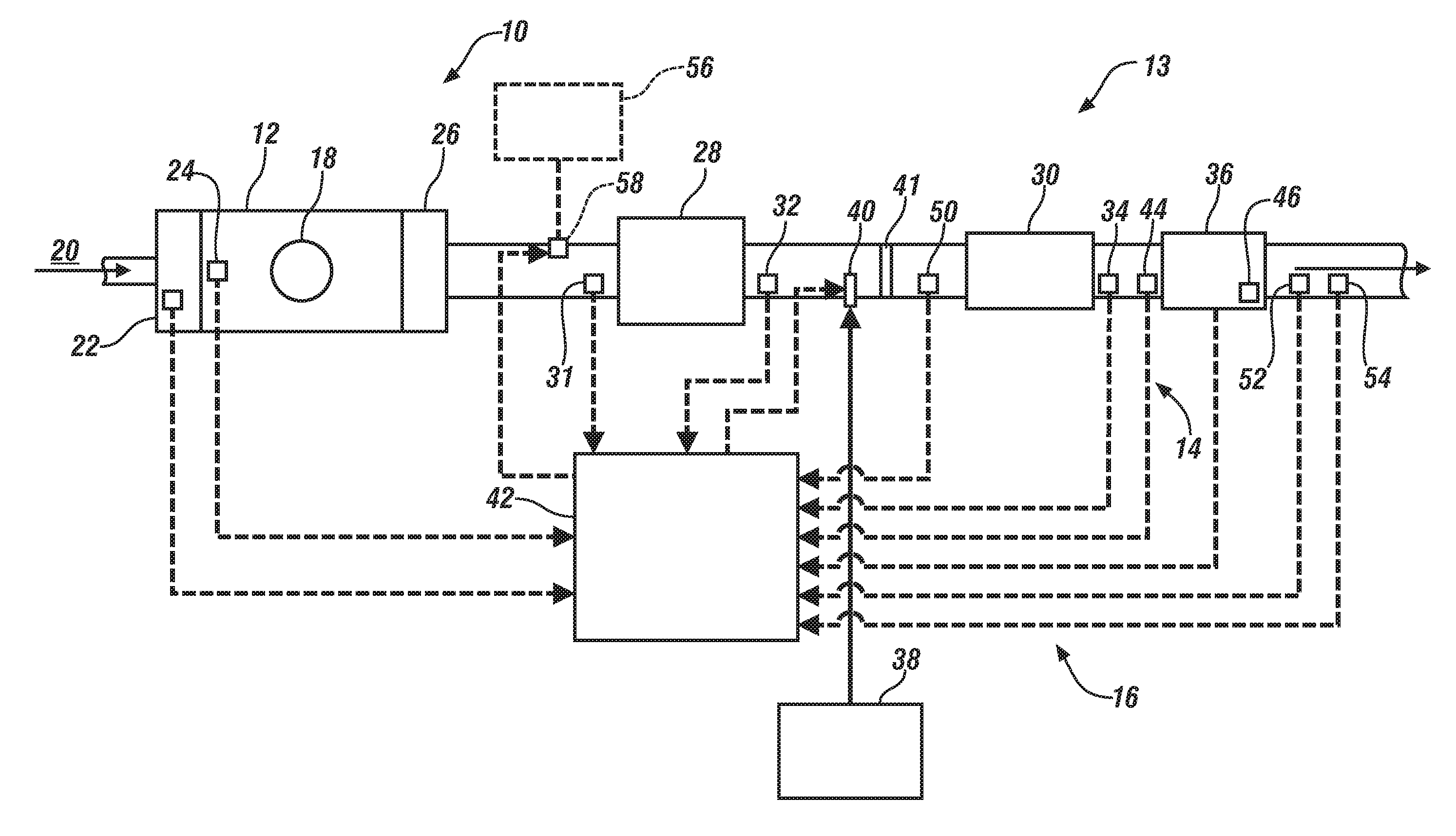

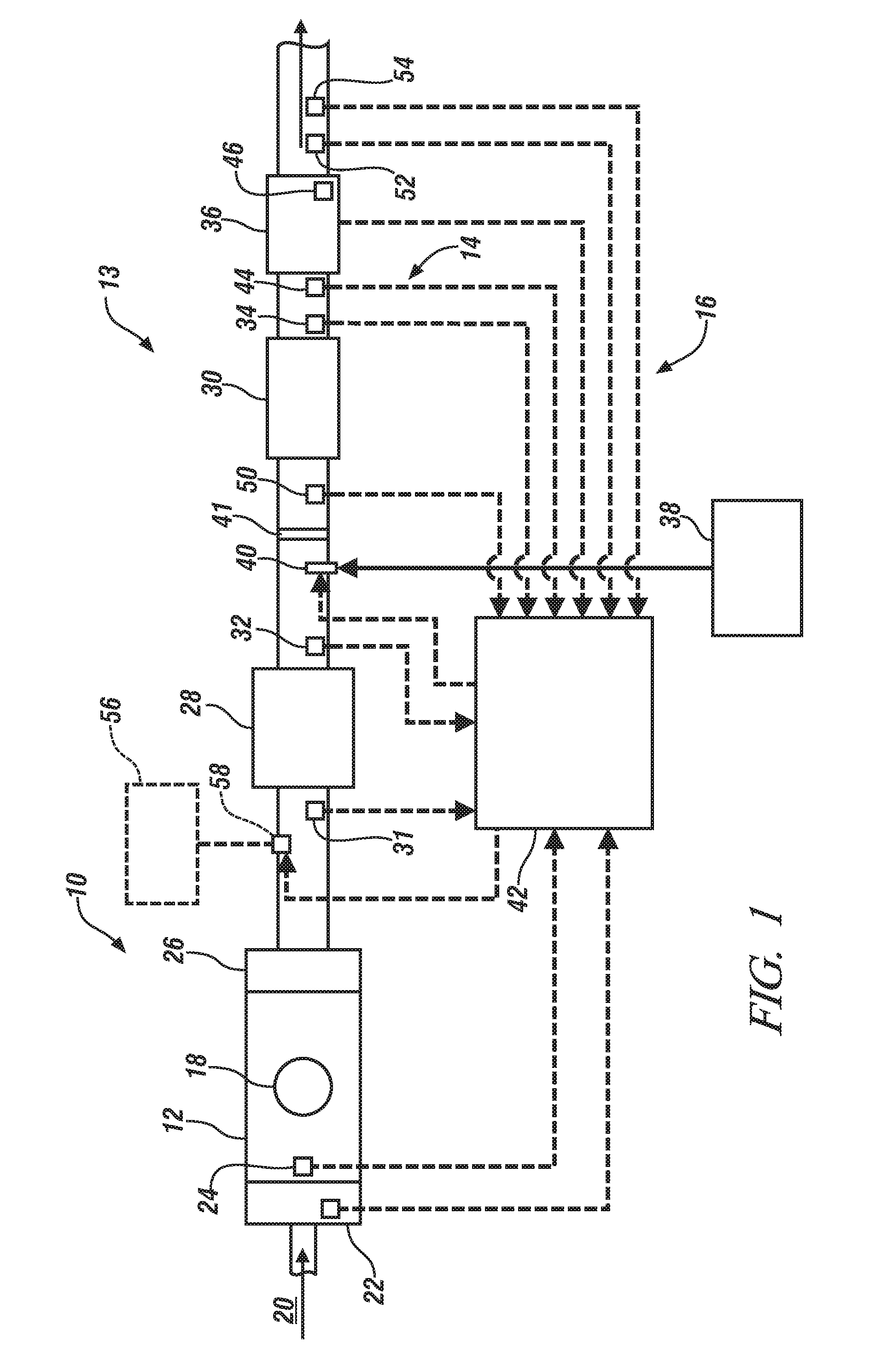

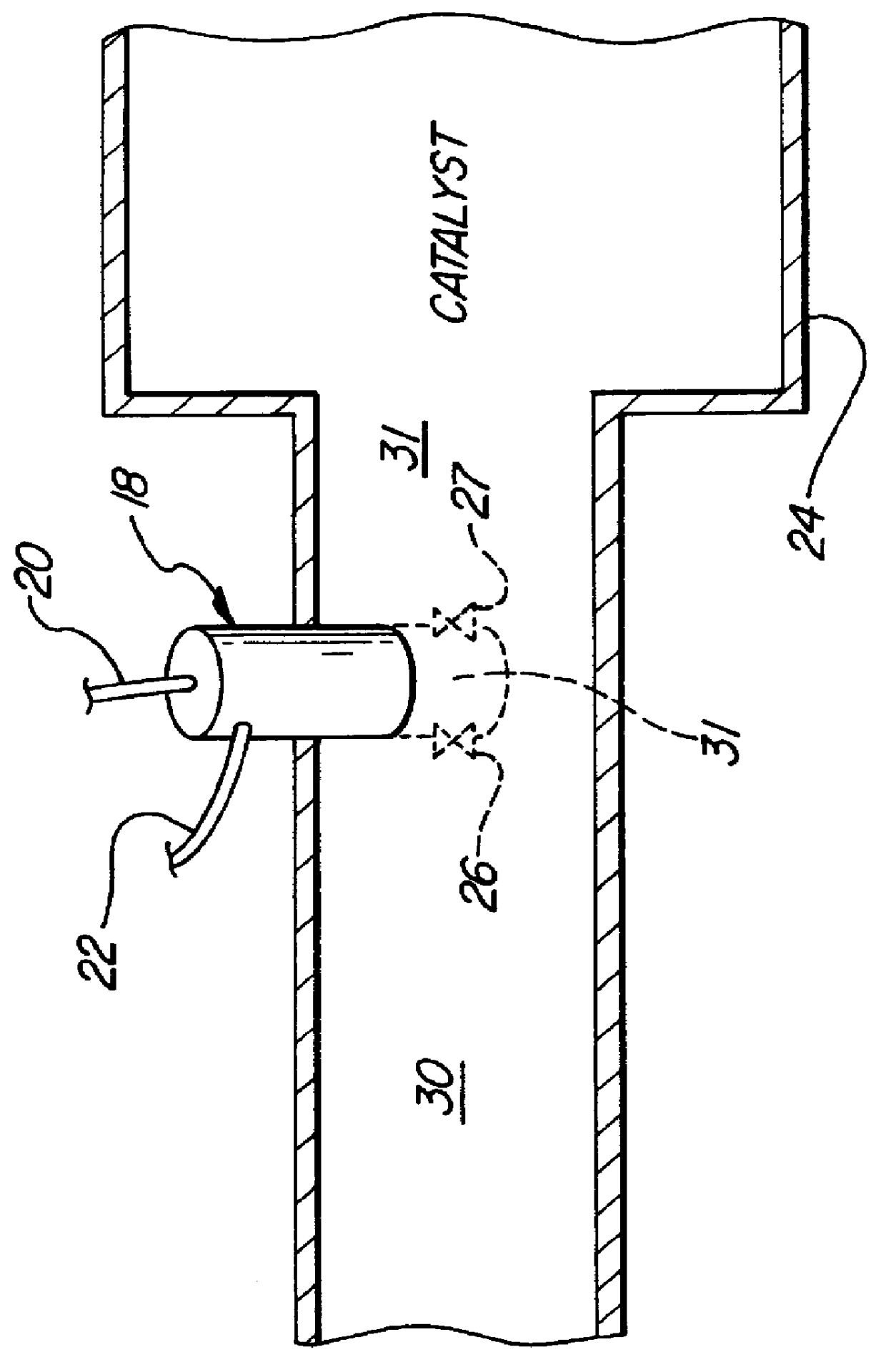

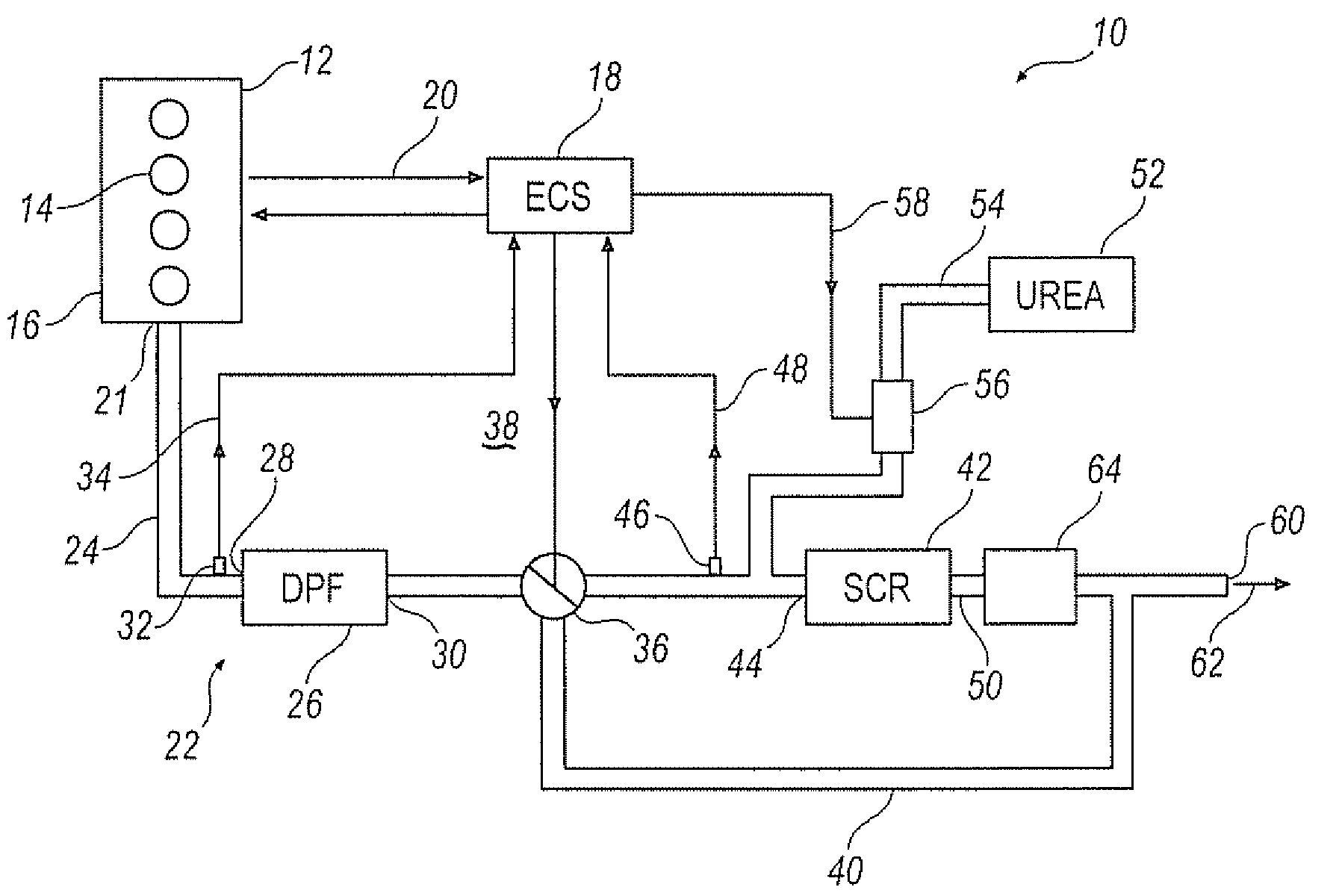

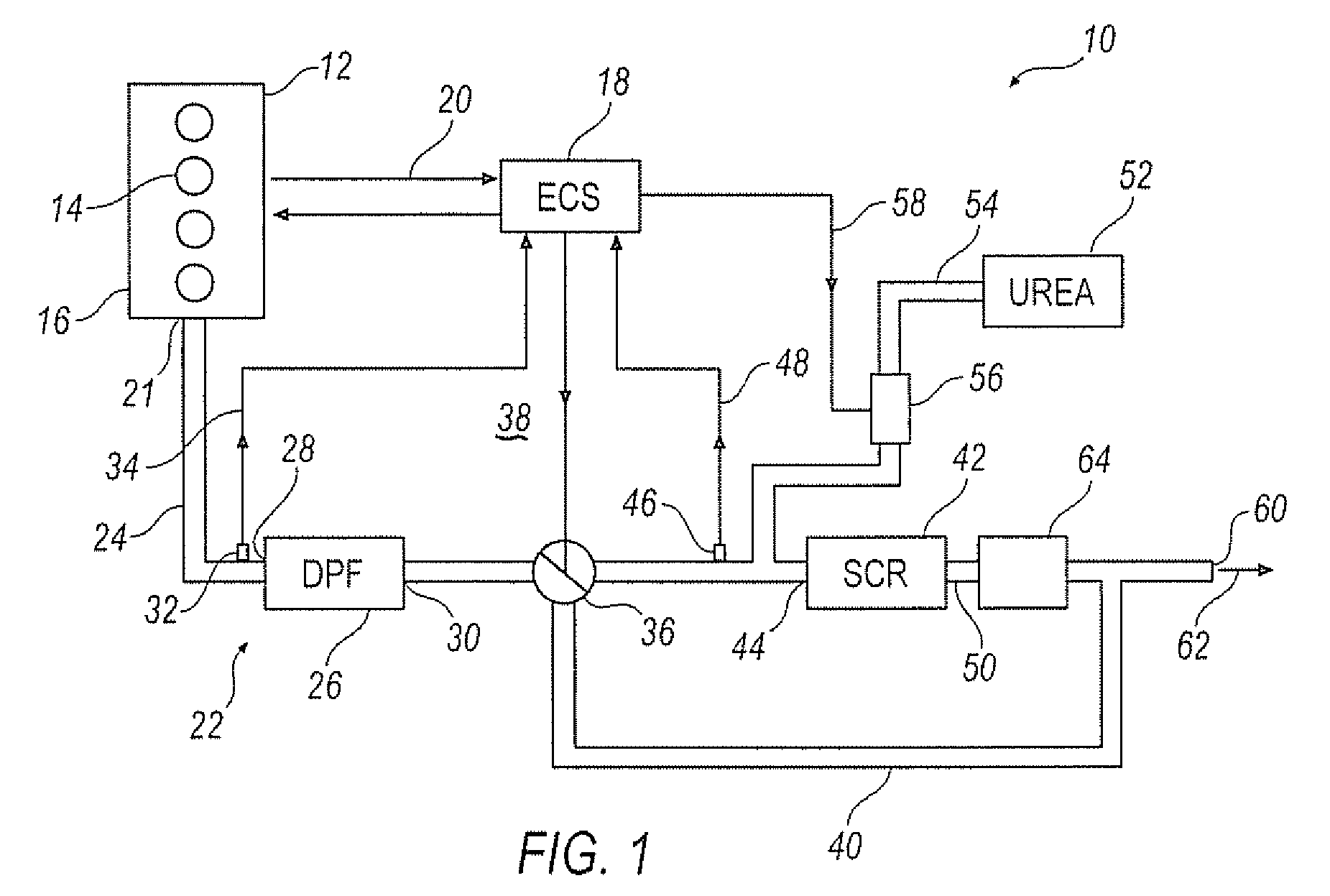

Method and Apparatus for Urea Injection in an Exhaust Aftertreatment System

An exhaust aftertreatment system and control system is provided, including a urea injecting device, a selective catalyst reduction device, and, a sensing device operative to monitor a forward portion of the selective catalyst reduction device. The sensing device can comprise a NOx sensor, and alternatively, an ammonia sensor. A control module adapted to monitor signal inputs from the engine, the NOx sensing system, the temperature sensing system, and the sensing device operative to monitor a forward portion of the selective catalyst reduction device; and, adapted to control operation of the urea injecting device.

Owner:GM GLOBAL TECH OPERATIONS LLC

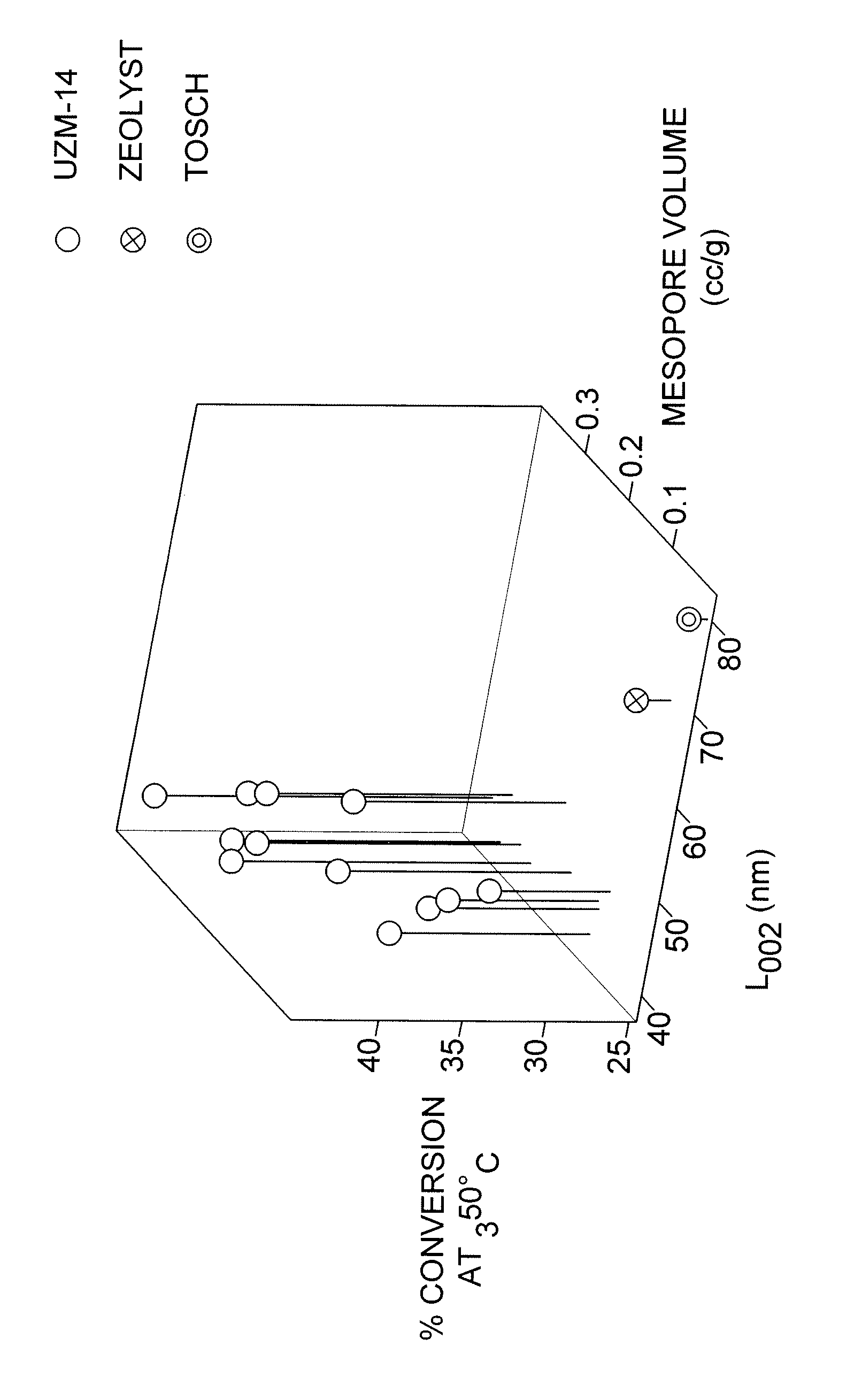

Selective catalyst for aromatics conversion

The subject invention comprises a novel UZM-14 catalytic material comprising globular aggregates of crystallites having a MOR framework type with a mean crystallite length parallel to the direction of 12-ring channels of about 60 nm or less and a mesopore volume of at least about 0.10 cc / gram. Catalysts formed from the novel material are particularly effective for the transalkylation of aromatics.

Owner:UOP LLC

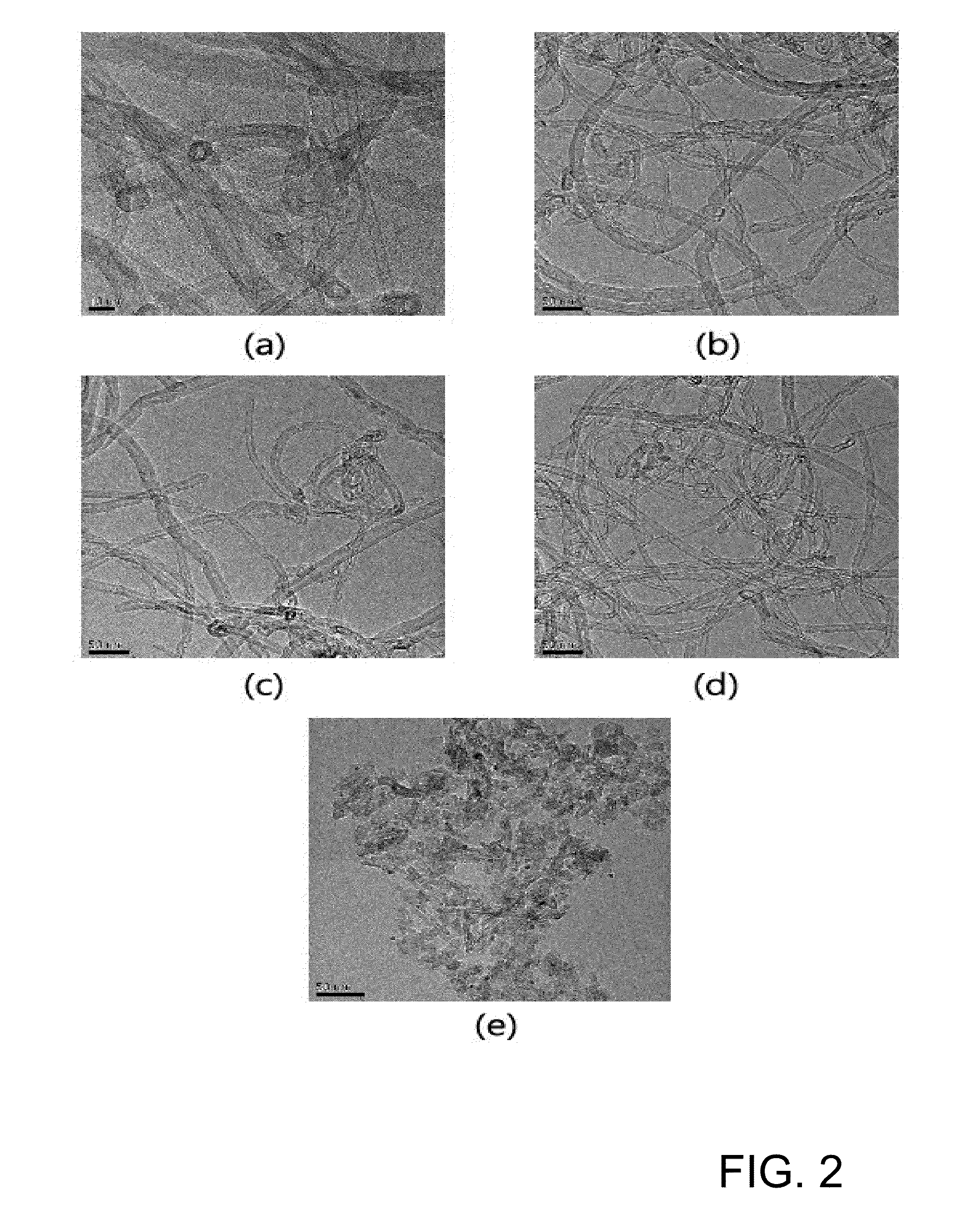

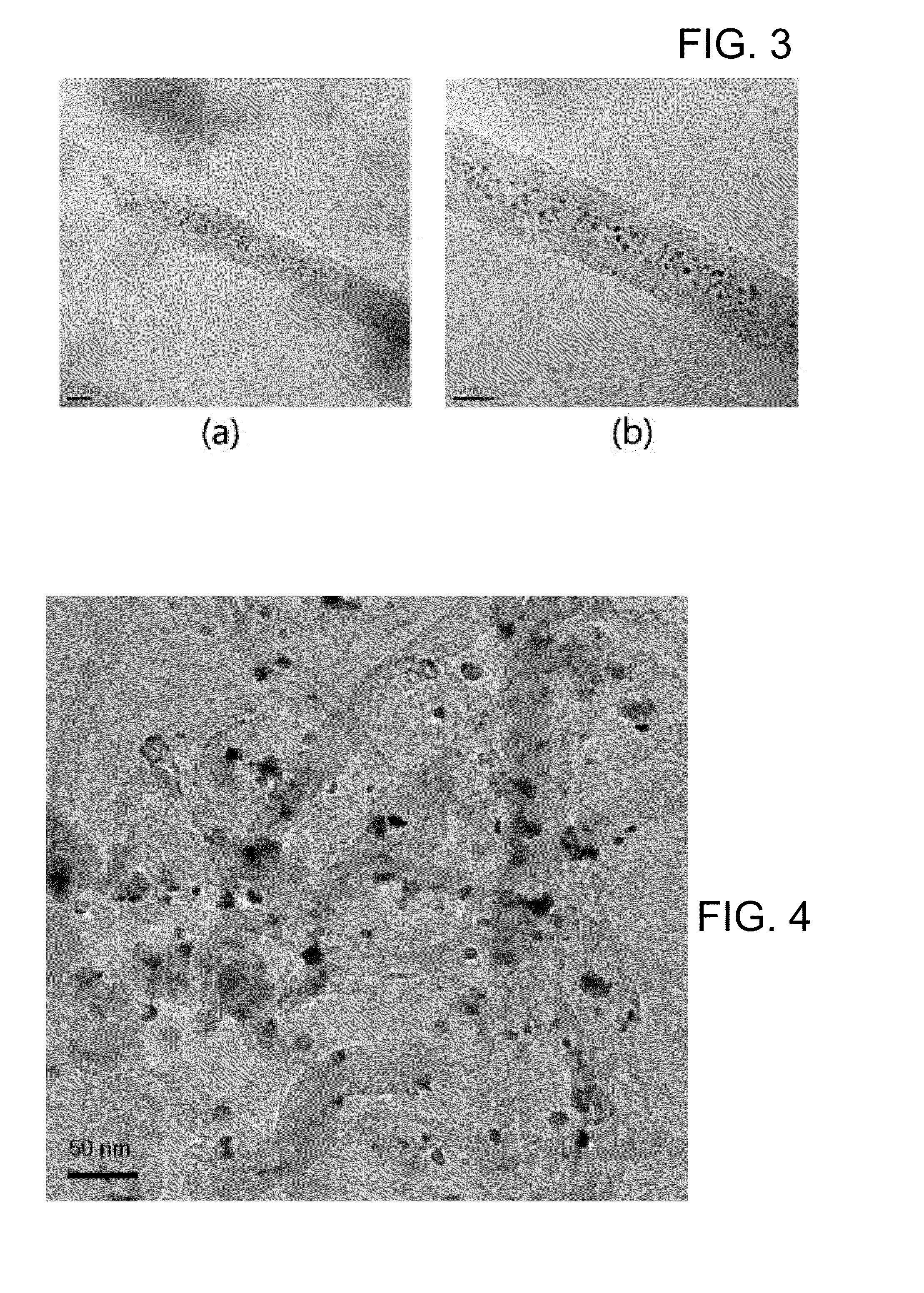

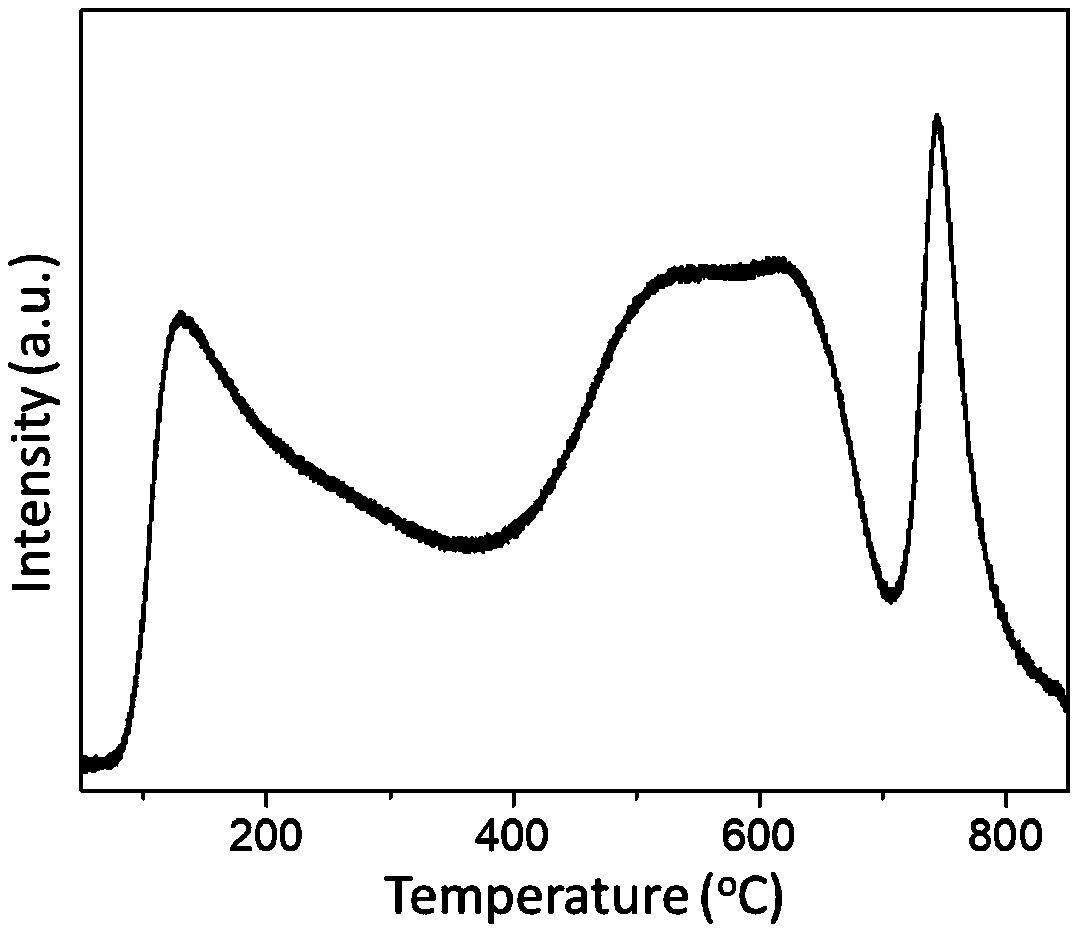

Carbon nanotube catalysts having metal catalyst nano-particles supported on inner channel of carbon nanotube and preparation method thereof

InactiveUS20100298125A1High activityIncreased durabilityMaterial nanotechnologyIndividual molecule manipulationNanoparticleGas phase

A carbon nanotube catalyst wherein metal catalyst nanoparticles are selectively supported only on the inner channel surface of the carbon nanotube, and a method for preparing the same are provided. Specifically, provided are: a carbon nanotube catalyst with supported metal catalyst nanoparticles, having excellent selective catalyst activity and durability, wherein the carbon nanotube catalyst is prepared by carrying out a specific pretreatment so as to form some defects on the inner surface of a carbon nanotube and then exposing the pretreated carbon nanotube to a flow of vapor phase metal precursors so that metal catalyst nanoparticles can be supported only on the inner channel surface of the carbon nanotube by CVD (Chemical Vapor Deposition) process; and a method for preparing the same.

Owner:KOREA INST OF ENERGY RES

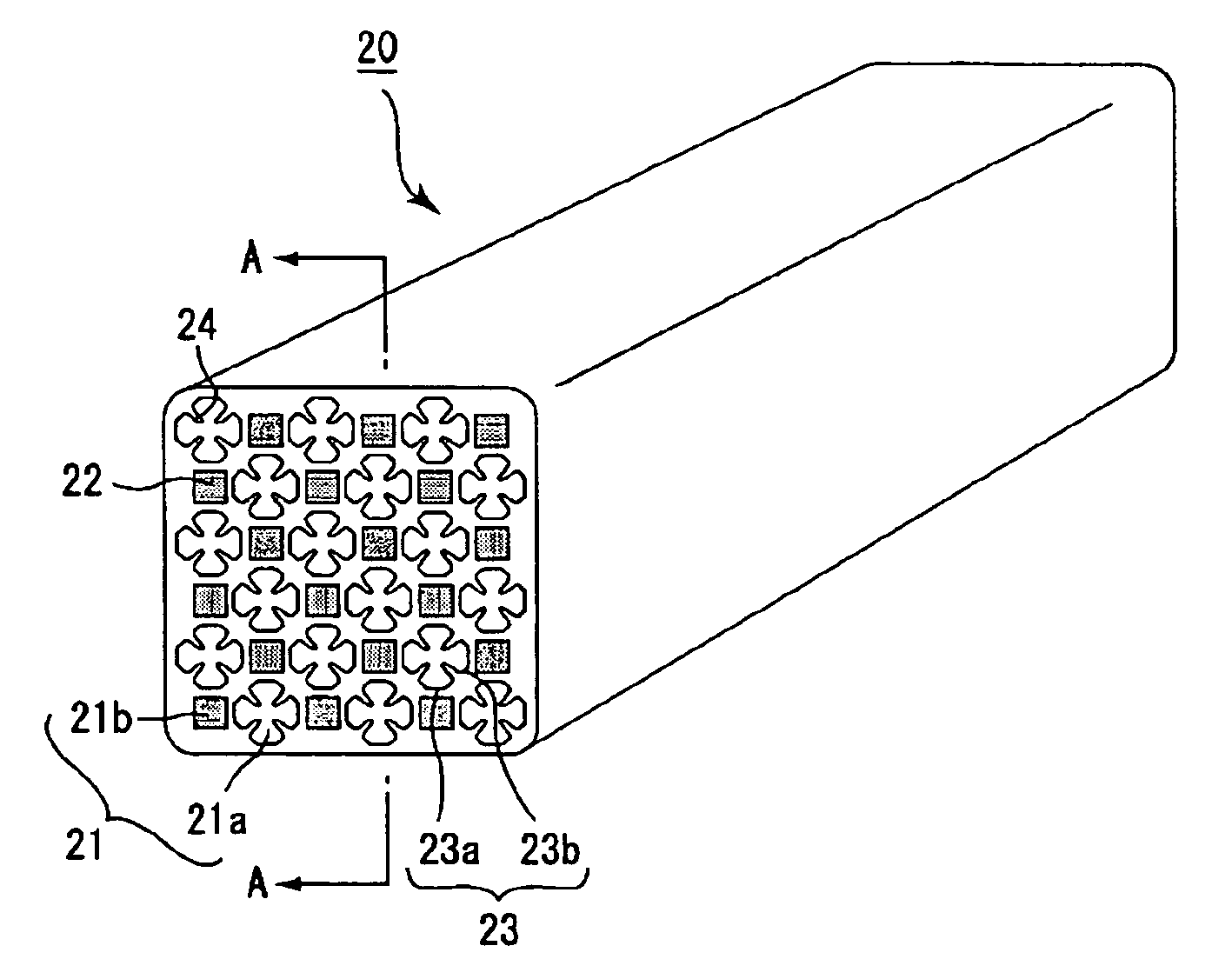

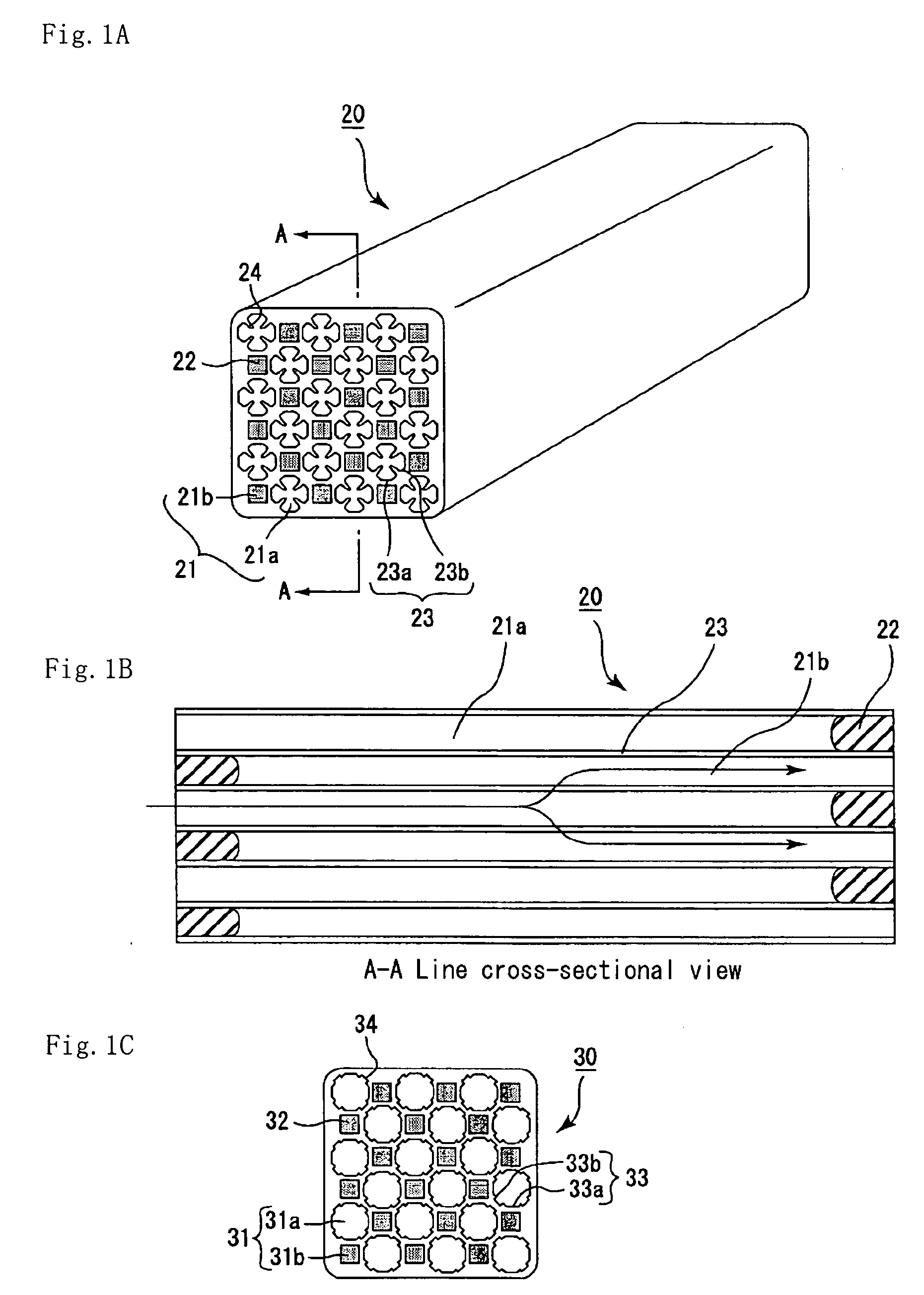

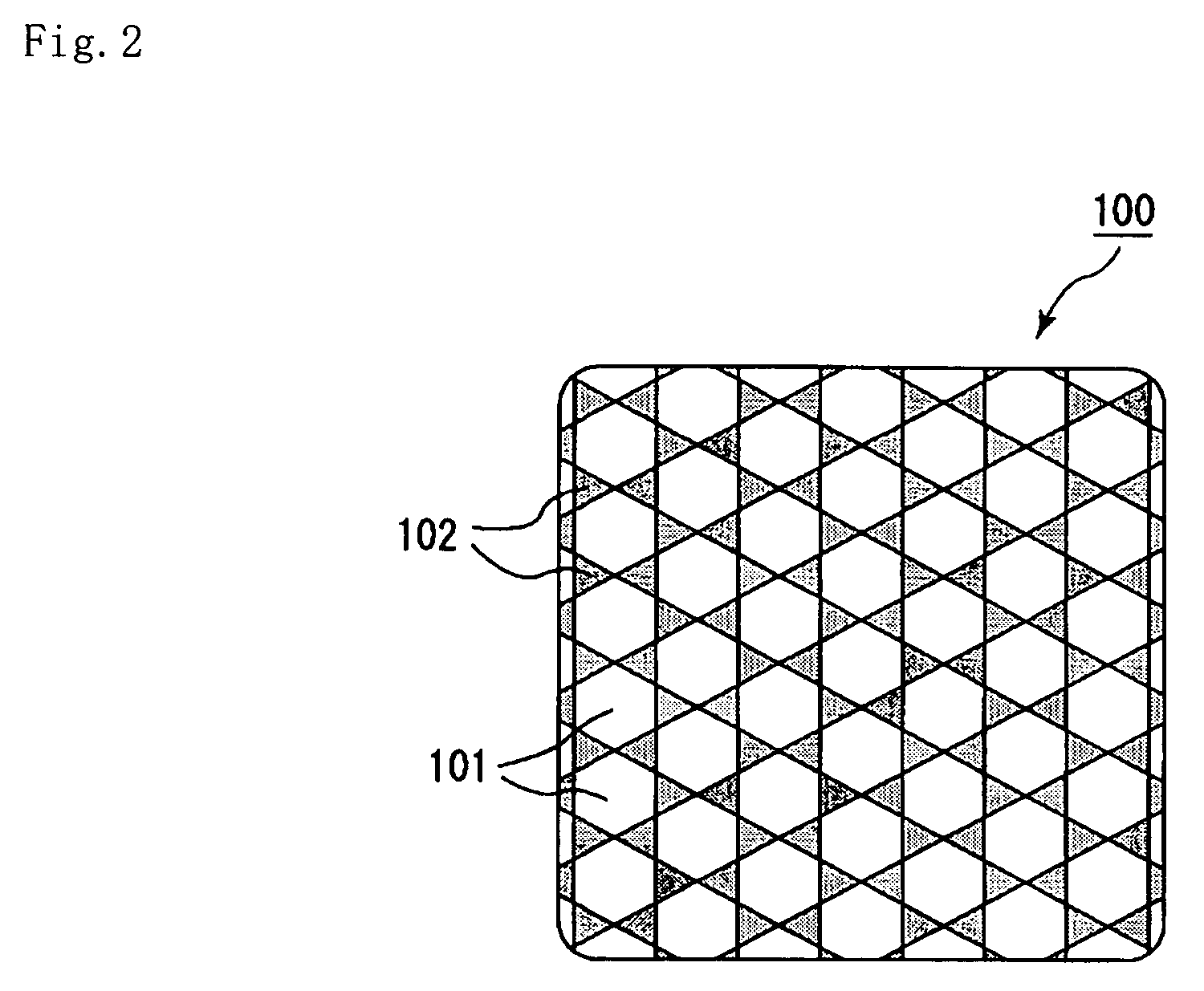

Honeycomb structured body

InactiveUS20060188415A1Combination devicesPhysical/chemical process catalystsEngineeringMechanical engineering

A honeycomb structured body of the present invention is a pillar-shaped honeycomb structured body comprising a large number of through holes that are longitudinally placed in parallel with one another with a partition wall therebetween, wherein the large number of through holes include a group of large-capacity through holes being sealed at one of end portions so that the sum of areas on a cross section perpendicular to the longitudinal direction is made relatively larger, and a group of small-capacity through holes being sealed at the other end portion so that the sum of areas on the cross section is made relatively smaller, and the partition wall that separates the adjacent through holes constituting the group of large-capacity through holes is provided with a selective catalyst supporting portion used for selectively supporting a catalyst.

Owner:IBIDEN CO LTD

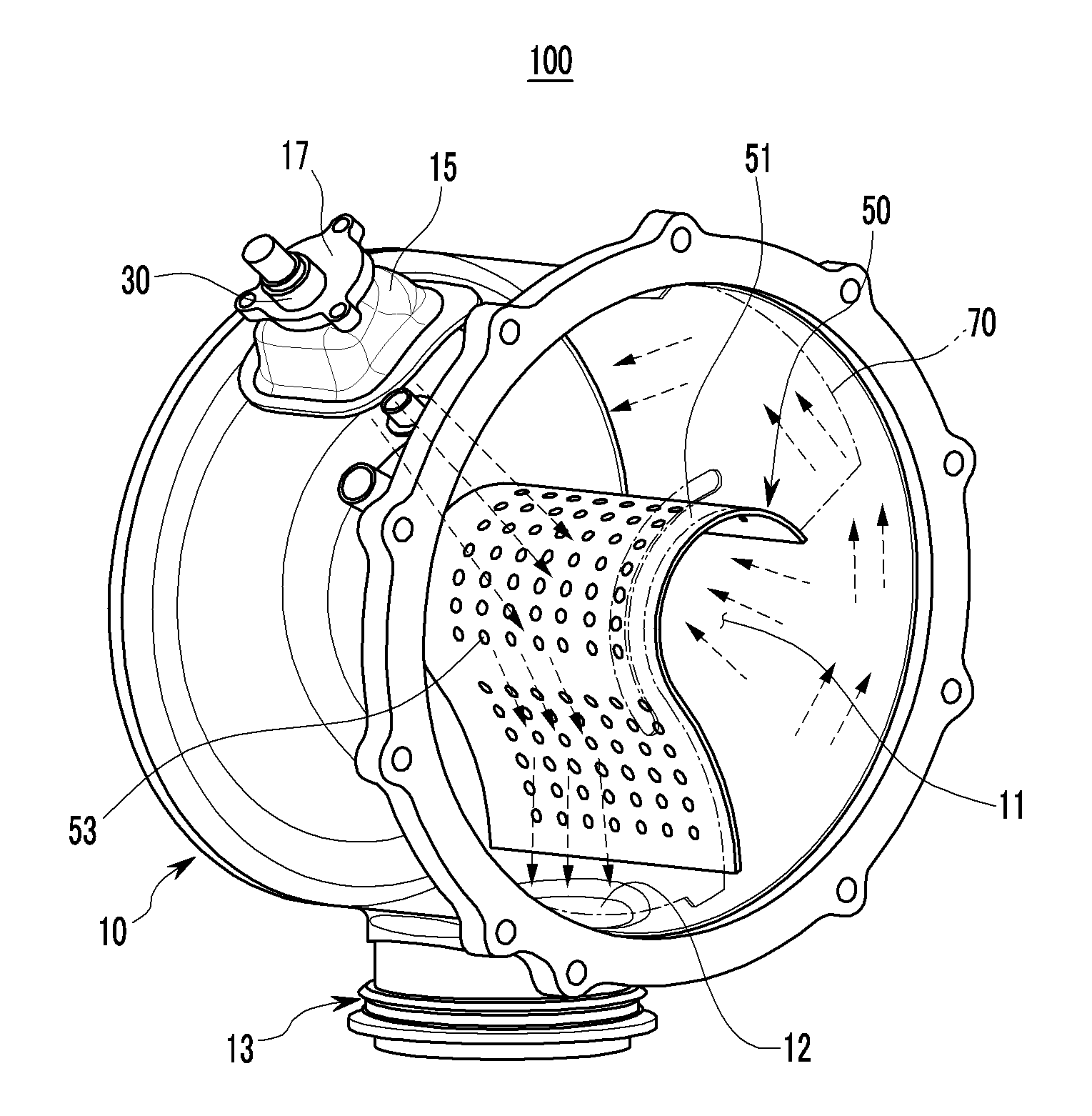

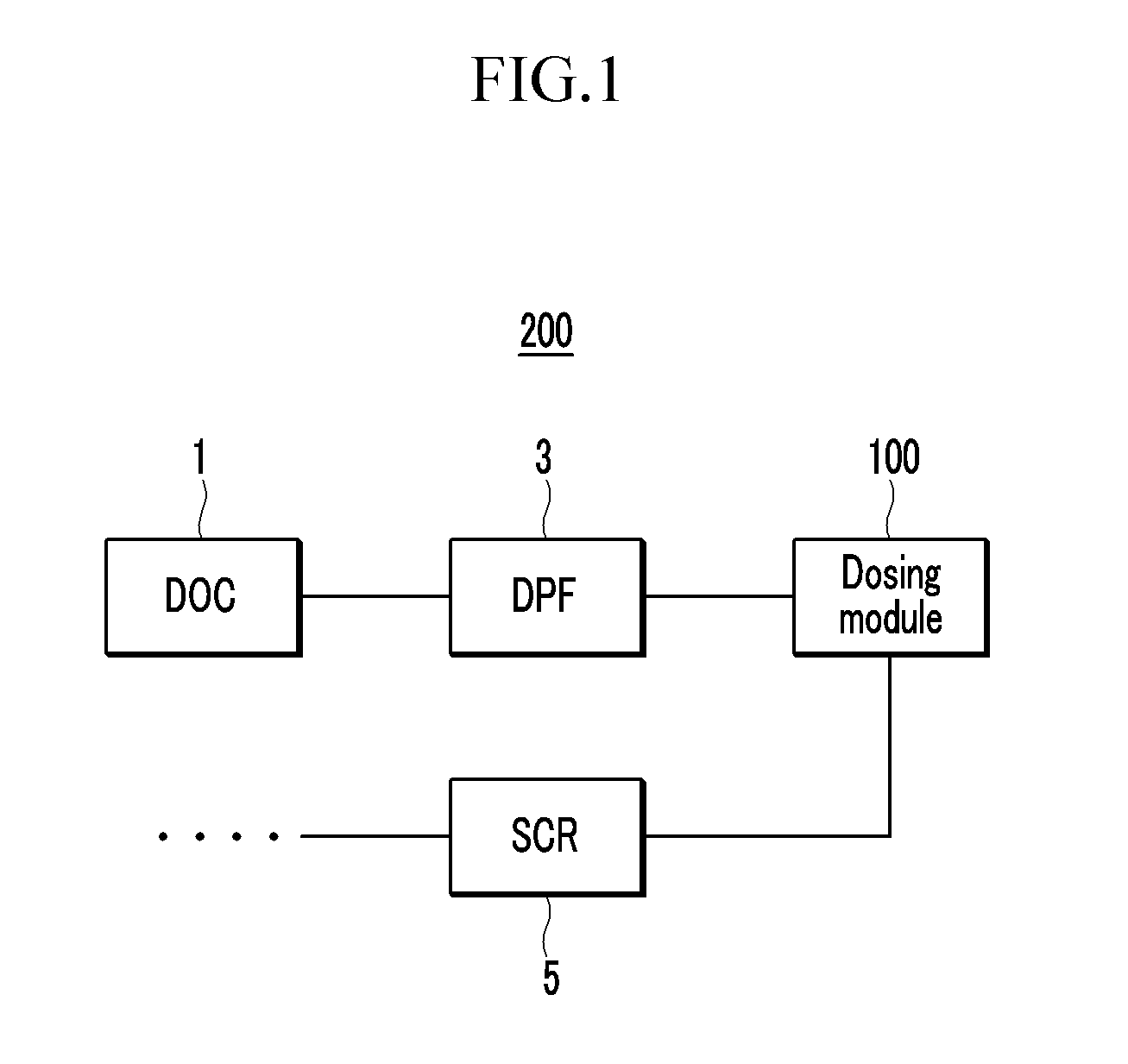

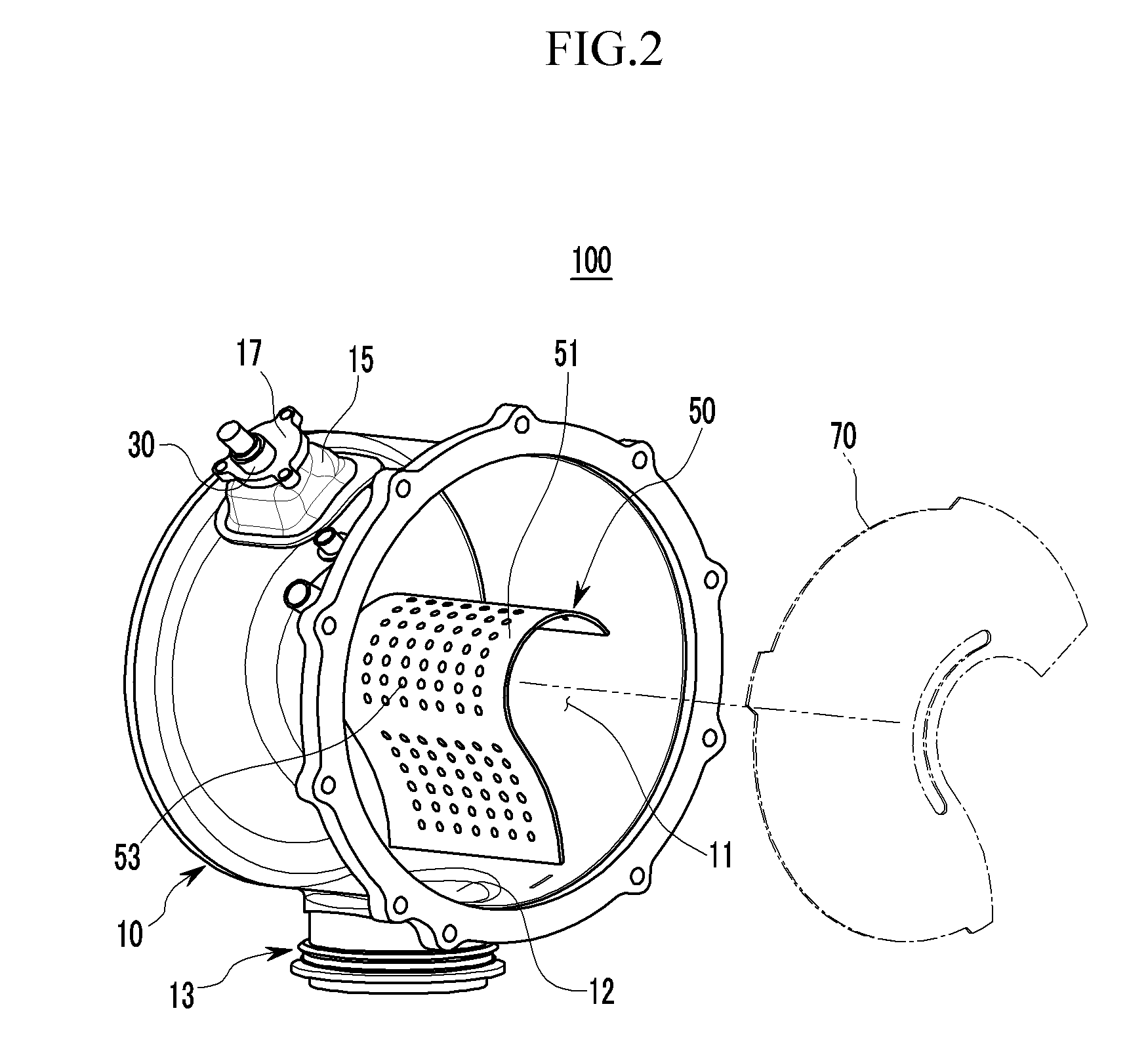

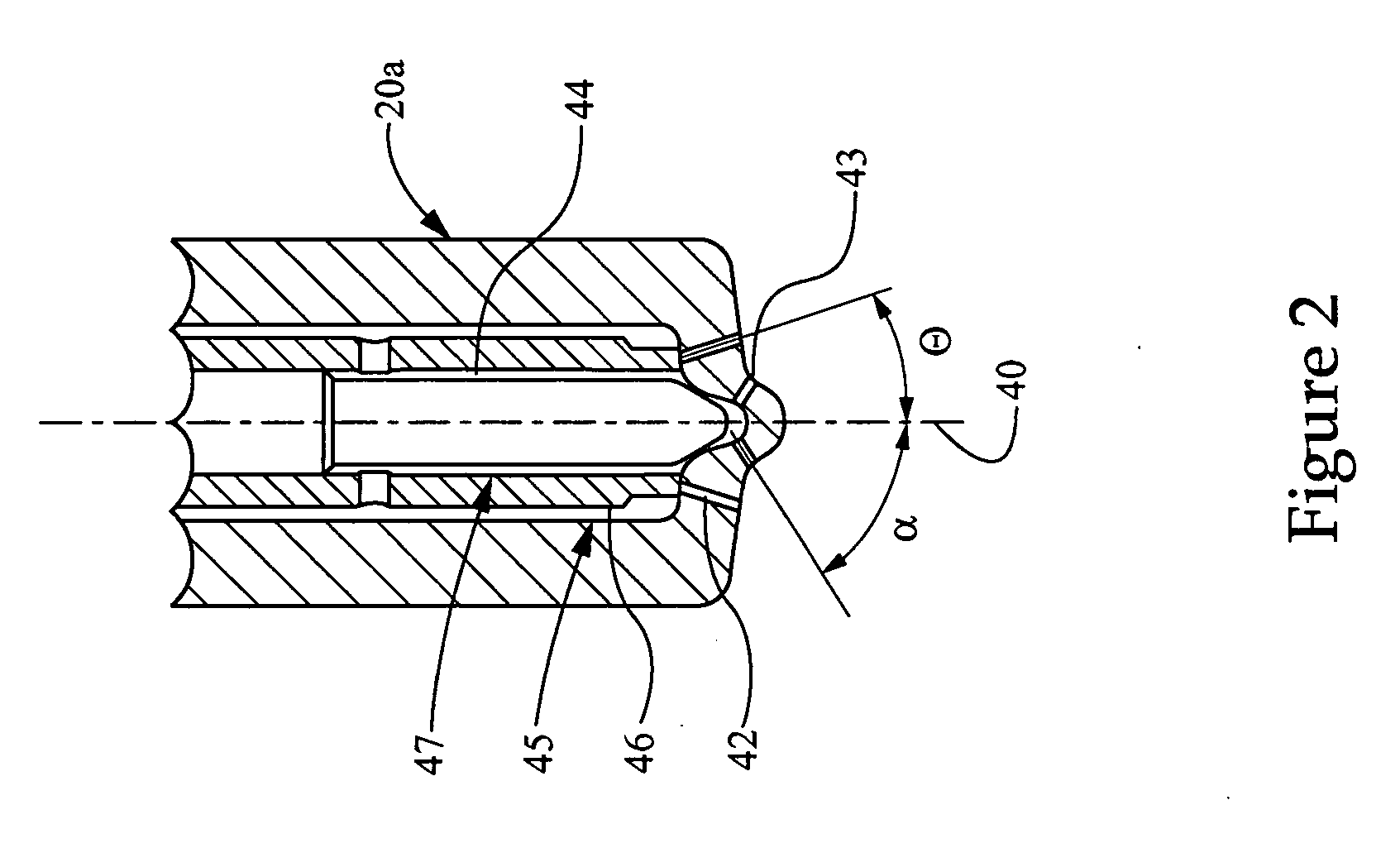

Dosing module for exhaust post treatment system of vehicle

InactiveUS20120144812A1Improve efficiencyUniformityInternal combustion piston enginesFlow mixersEnvironmental engineeringReducing agent

A dosing module for an exhaust gas post treatment system of a vehicle, which may be used to inject a reducing agent along a flow direction of exhaust gas at a front side of a selective catalyst reduction (SCR) unit, may include a dosing main body having a connection portion that may be connected to the SCR unit and an inflow portion into which the exhaust gas flows, an injector that may be disposed at a boss portion that may be mounted on the dosing main body to inject the reducing agent into the dosing main body, and a guide member that may be disposed inside the dosing main body to guide the exhaust gas flowing into the dosing main body along a predetermined route.

Owner:HYUNDAI MOTOR CO LTD +1

Method and apparatus for monitoring a urea injection system in an exhaust aftertreatment system

A monitoring system for an exhaust aftertreatment system is provided, comprising an injecting device operable to inject reductant into an exhaust gas feedstream upstream of a selective catalyst reduction device. The monitoring system comprises a control module, adapted to selectively intrusively control a rate of dosing from the injecting device and, monitor inputs from a sensing device. The sensing device can comprise an ammonia sensor, and, alternatively, a NOx sensor. The control module is adapted to discontinue the rate of dosing, and substantially increase and decrease the rate of dosing for a predetermined amount of time, and to identify a fault in the sensing device and the selective catalyst reduction device.

Owner:GM GLOBAL TECH OPERATIONS LLC

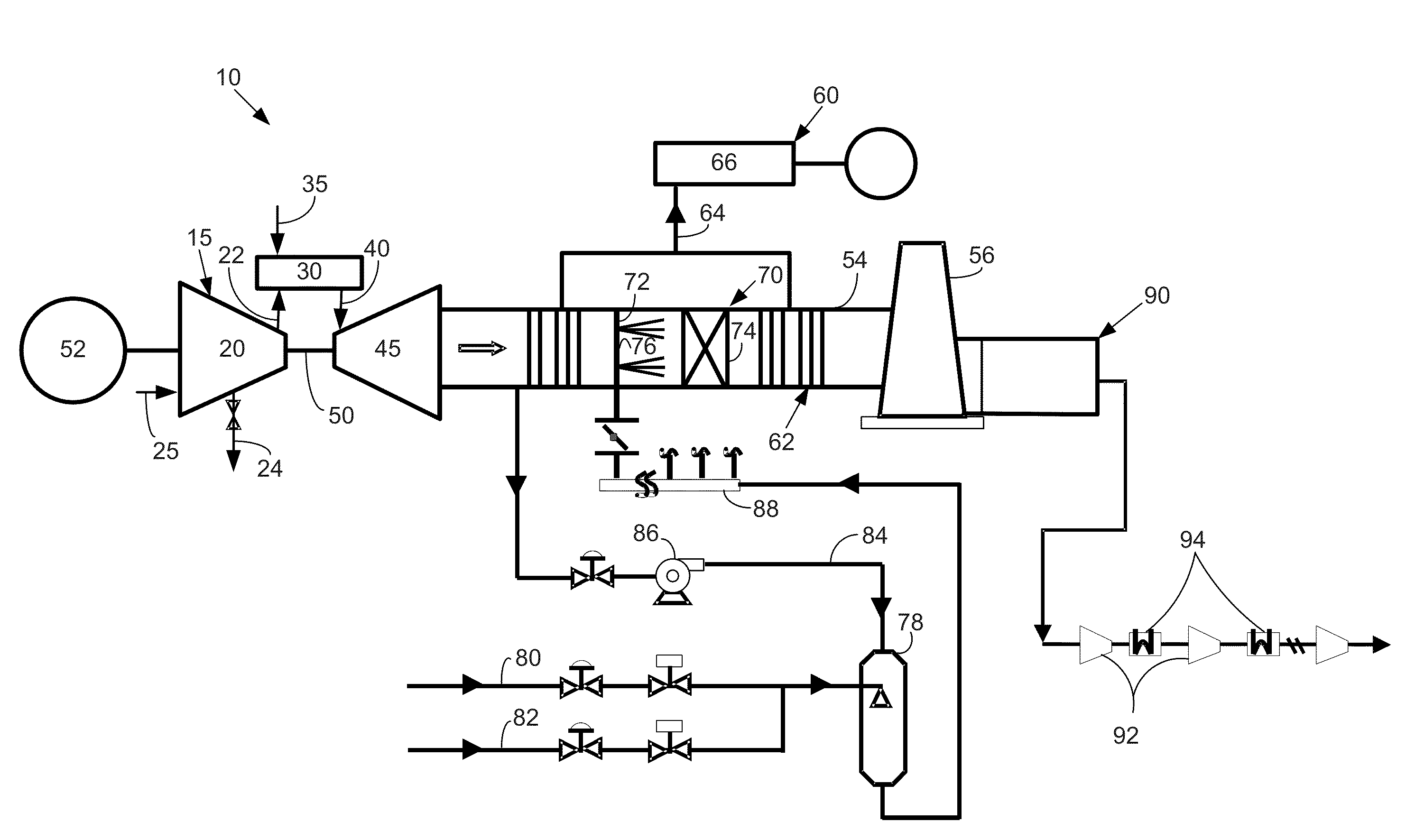

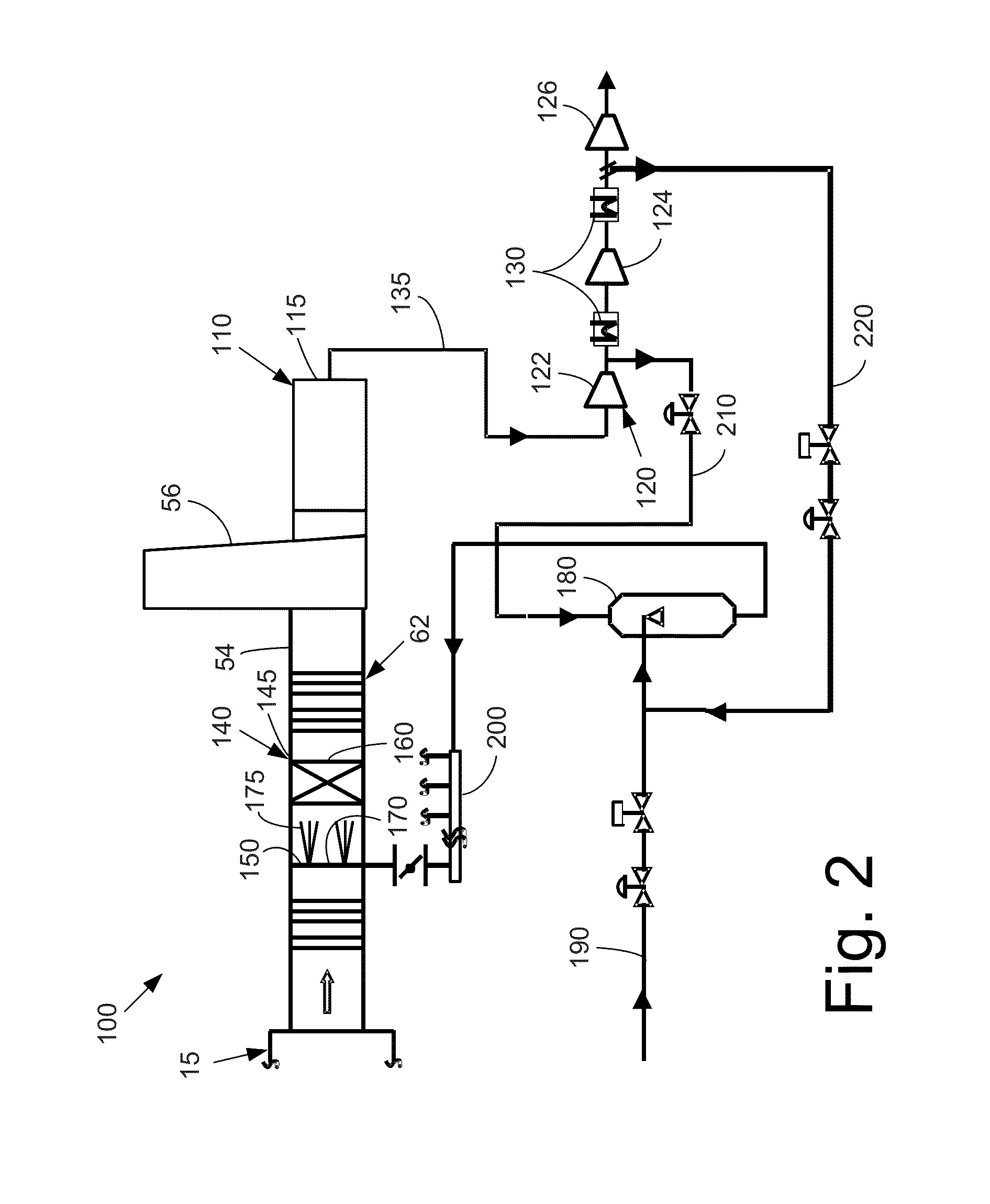

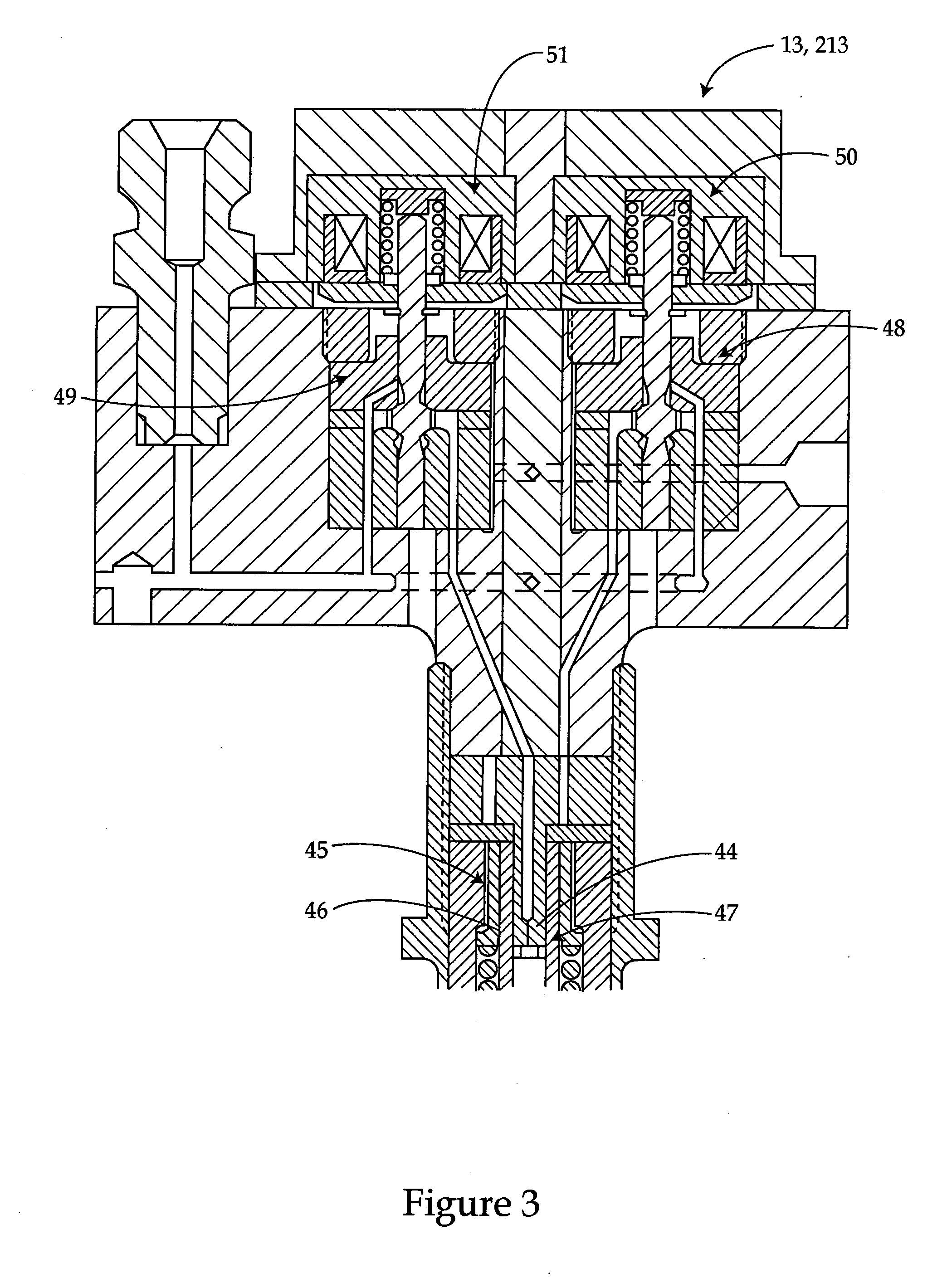

Efficient Selective Catalyst Reduction System

The present application provides a gas turbine engine system. The gas turbine engine system may include a gas turbine engine producing a flow of combustion gases, an emissions reduction system in communication with the gas turbine engine, a flow of ammonia to be injected into the flow of combustion gases, and a source of compressed gas to vaporize the flow of ammonia.

Owner:GENERAL ELECTRIC CO

On-board ammonia generation and exhaust after treatment system using same

InactiveUS20070092426A1Optimization orderElectrical controlExhaust apparatusCombustion chamberAfter treatment

Often NOx selective catalysts that use ammonia to reduce NOx within exhaust to a harmless gas require on-board storage of ammonia which can be hazardous and inconvenient. In order to generate ammonia in exhaust, the present disclosure increases a NOx concentration in exhaust from at least one combustion chamber, at least in part, by injecting fuel in a predetermined increased NOx generation sequence that includes a first injection during non-auto ignition conditions and a second injection during auto ignition conditions. At least a portion of the NOx is converted to ammonia by passing at least a portion of the exhaust with the increased NOx concentration over an ammonia-producing catalyst.

Owner:CATERPILLAR INC

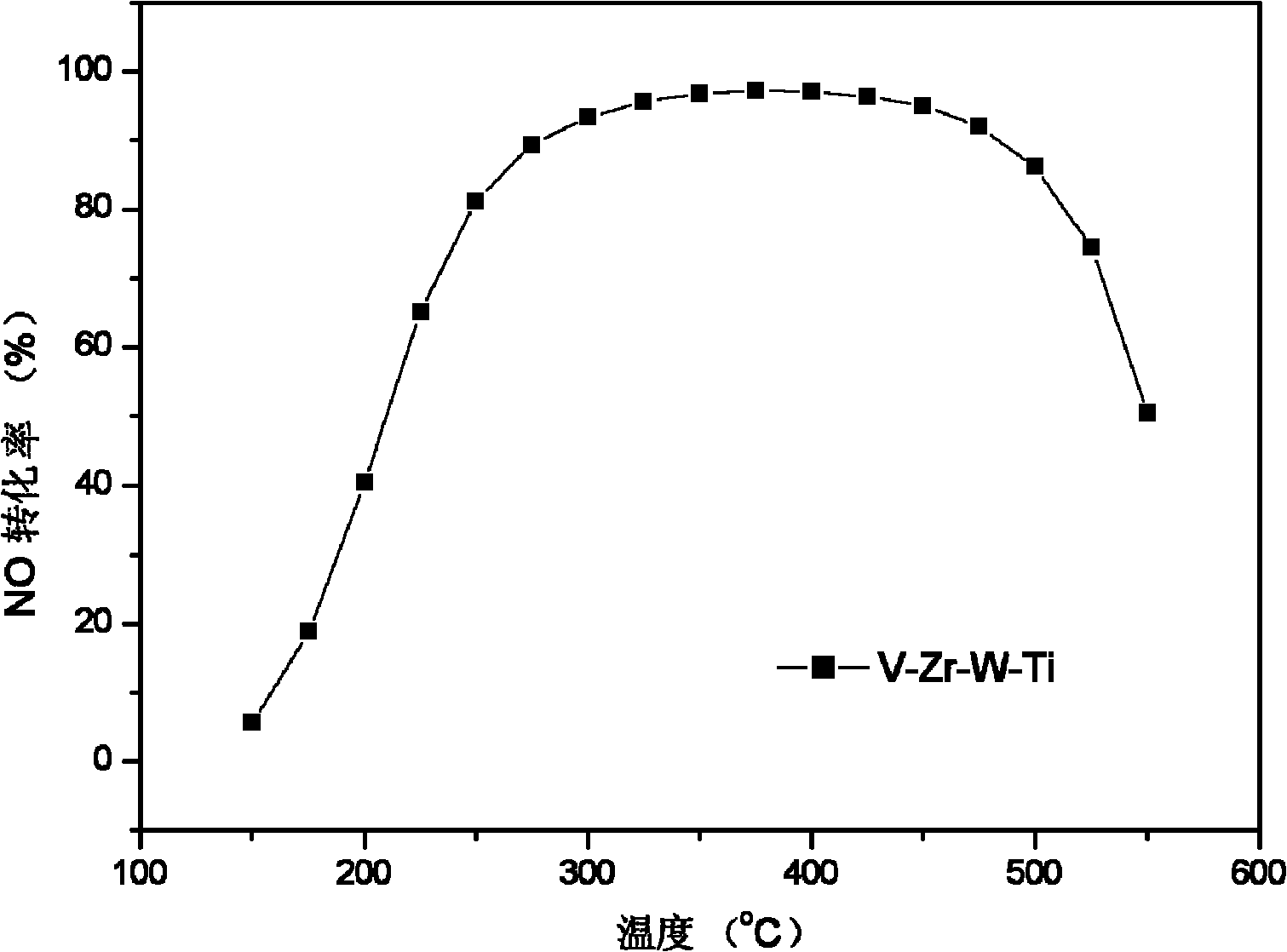

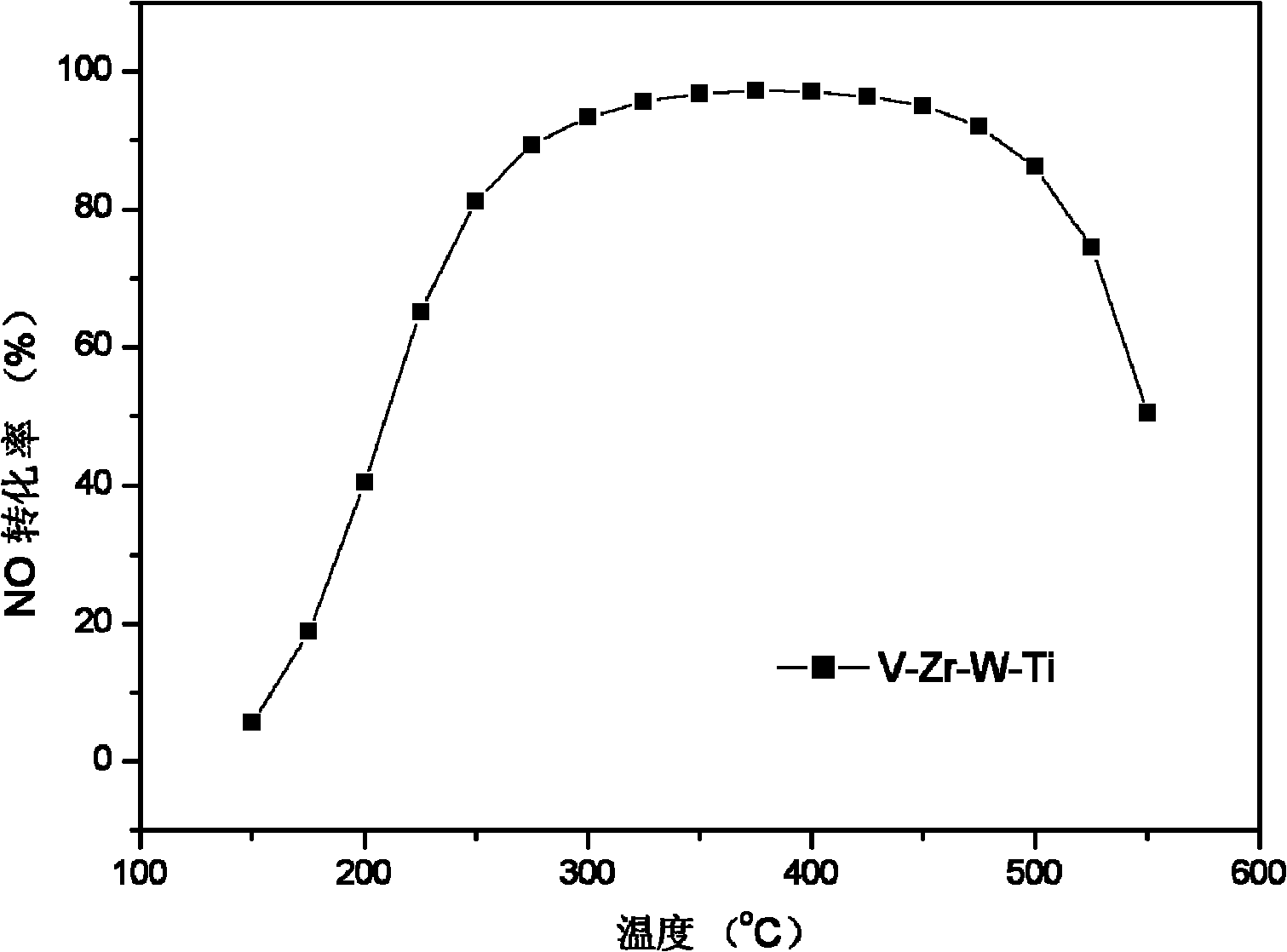

Selective catalyst for removing oxynitrides from tail gases of diesel vehicles and preparation method thereof

InactiveCN101912775AImprove smoothnessSatisfy and attain purifyingInternal combustion piston enginesDispersed particle separationWater vaporCordierite

The invention discloses a selective catalyst for removing oxynitrides from tail gases of diesel vehicles and a preparation method thereof. Cordierite honeycomb ceramic serves as a carrier, and the oxides of vanadium, zirconium, tungsten and titanium form a catalytic active site. The preparation method comprises the following steps of: sequentially dissolving vanadium pentoxide, a zircon salt, tungsten trioxide and titanium dioxide into the aqueous solution of oxalic acid, adding a bonder into the mixed solution to prepare pulp, impregnating the cordierite honeycomb ceramic in the pulp, drying the cordierite honeycomb ceramic for 1 to 3 hours at 100 to 150 DEG C, and roasting the cordierite honeycomb ceramic for 2 to 4 hours at 450 to 550 DEG C. In the invention, the preparation method is improved, and a powder catalyst is improved into a honeycomb selective catalytic reduction (SCR) catalyst applied to the removal of the oxynitrides from the tail gases of the diesel vehicles, so the high-efficiency catalytic removal of the oxynitrides can be realized at the temperature of 205 to 515 DEG C; and in the presence of steam or SO2, the activity of the catalyst is kept over 80 percent.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

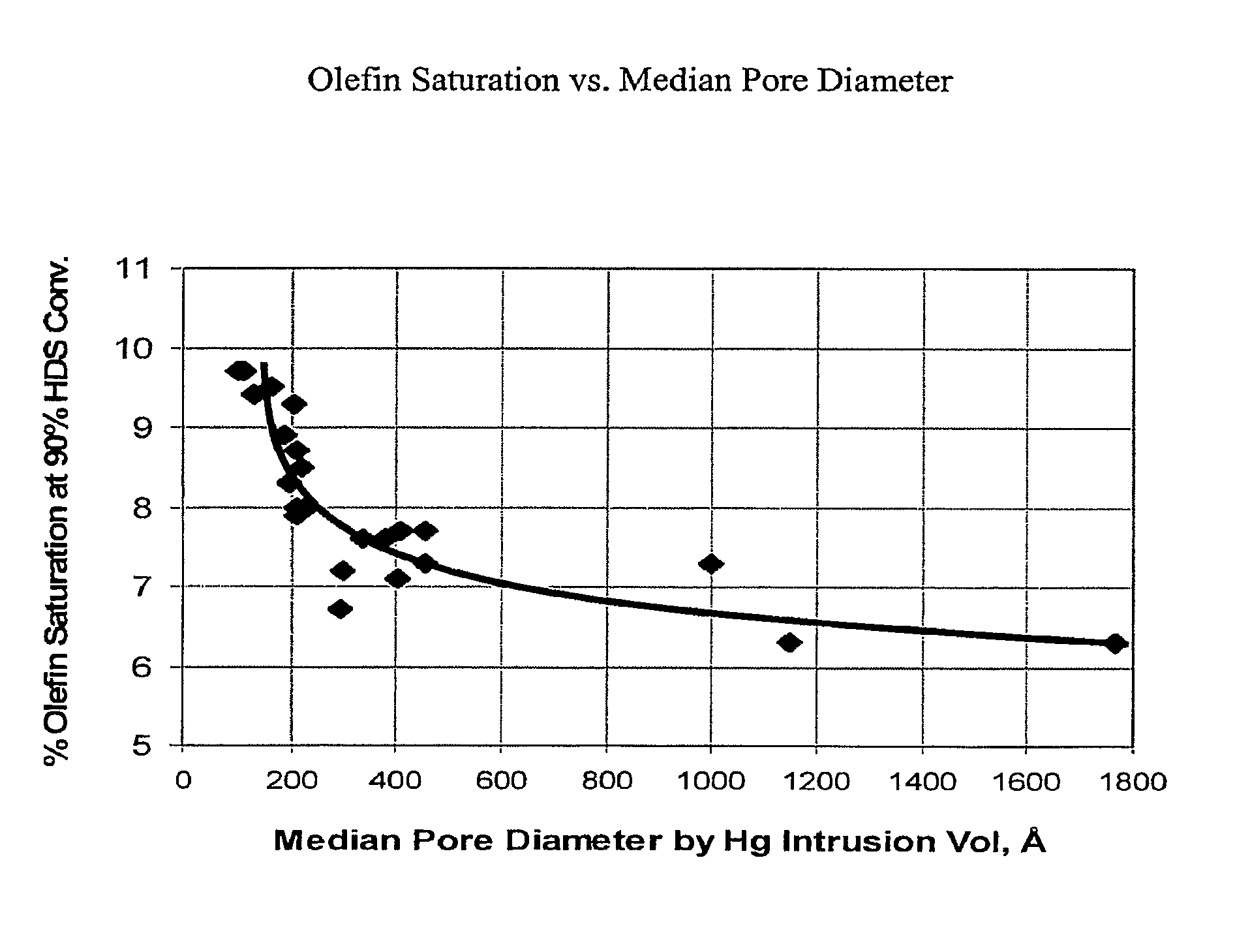

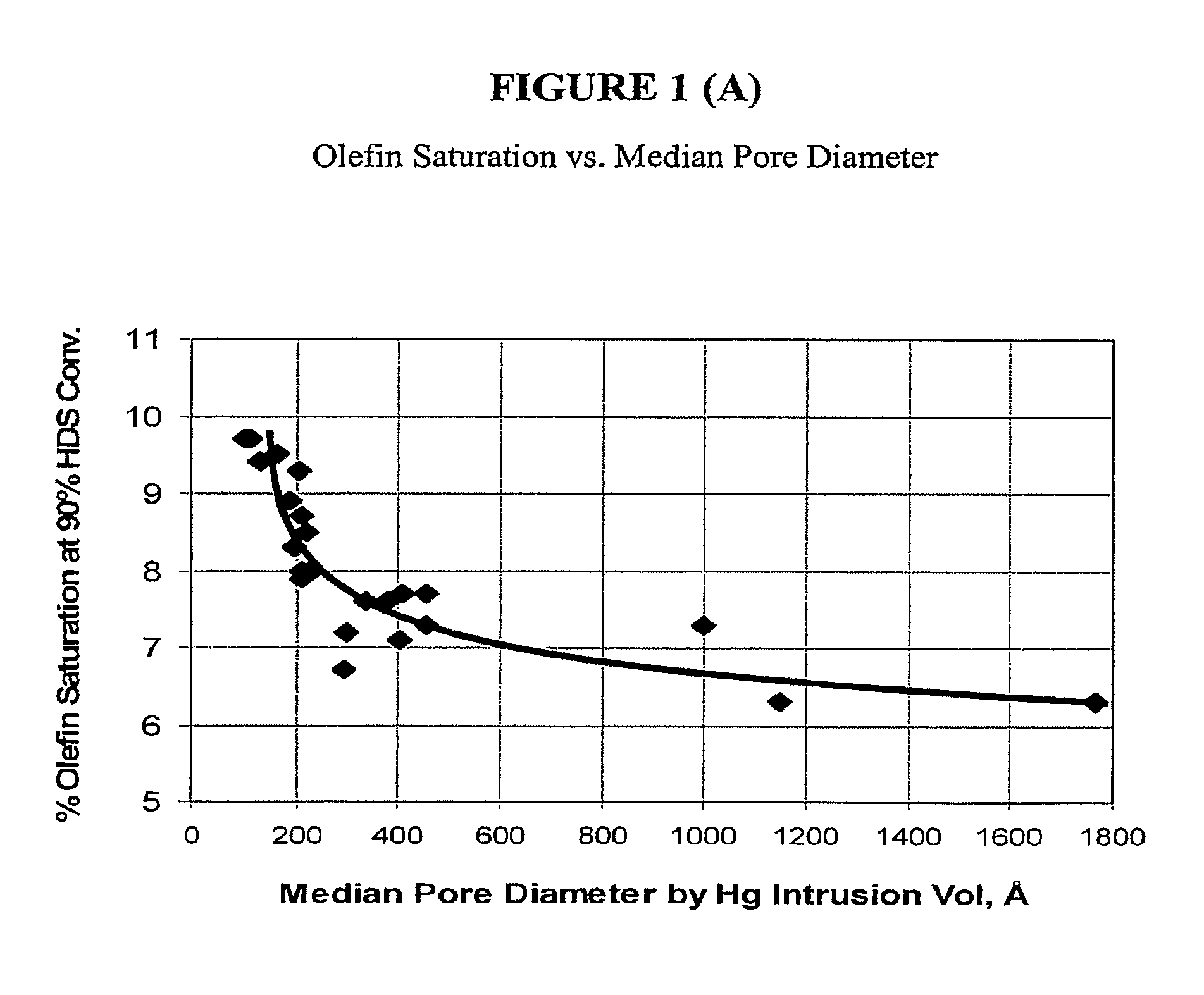

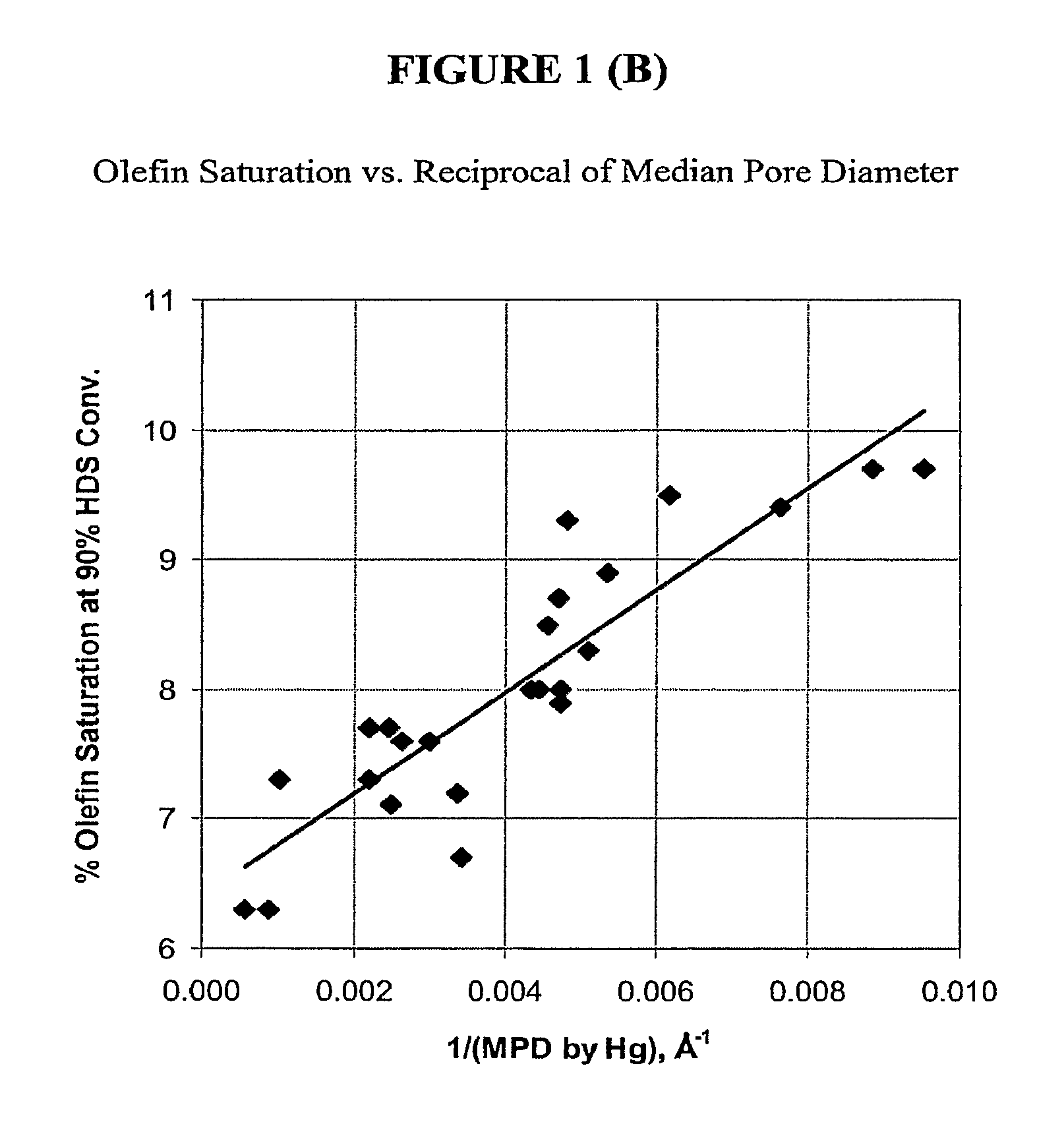

Selective catalysts having silica supports for naphtha hydrodesulfurization

ActiveUS8216958B2High selectivityImprove the level ofOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationNaphthaPtru catalyst

Owner:EXXON RES & ENG CO

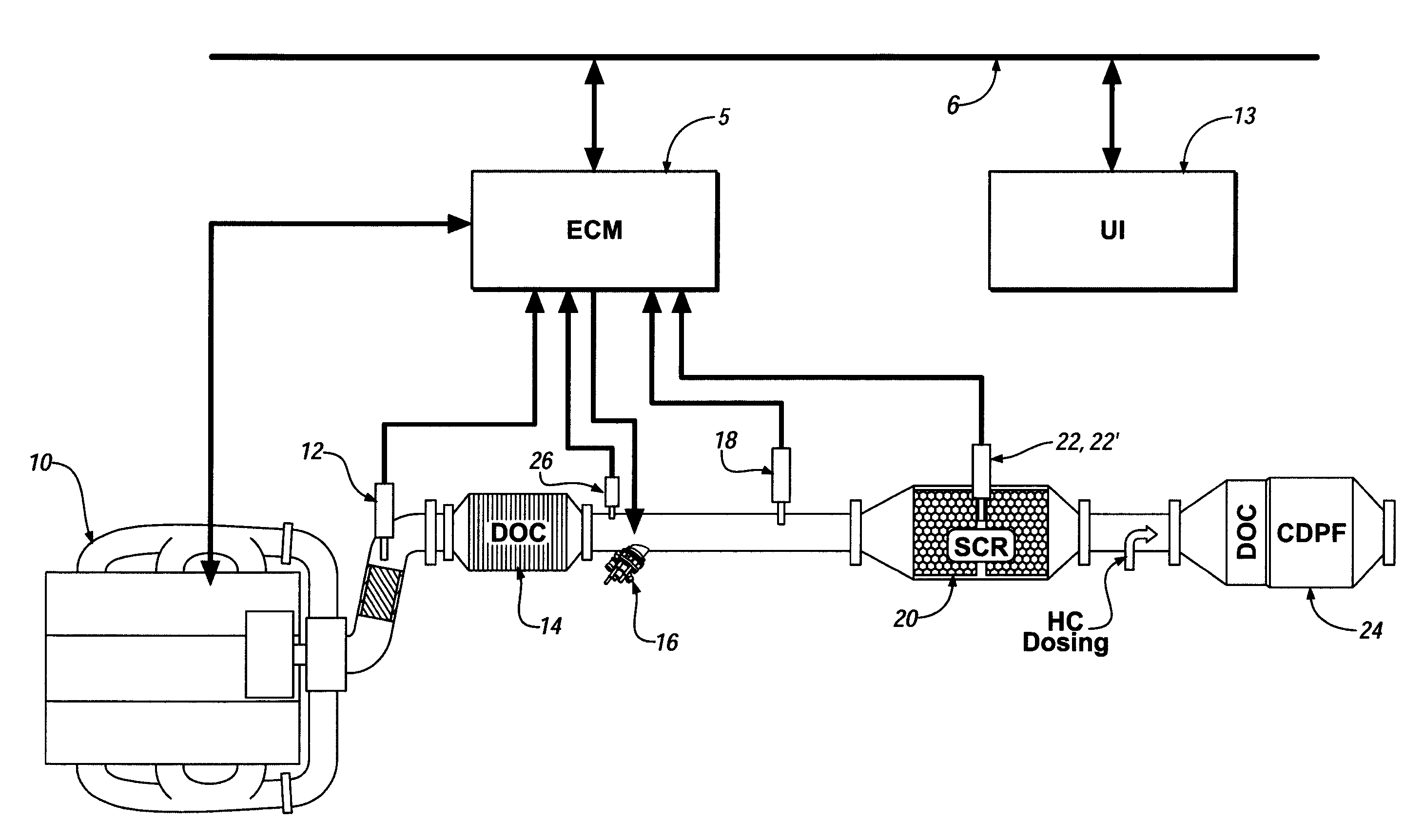

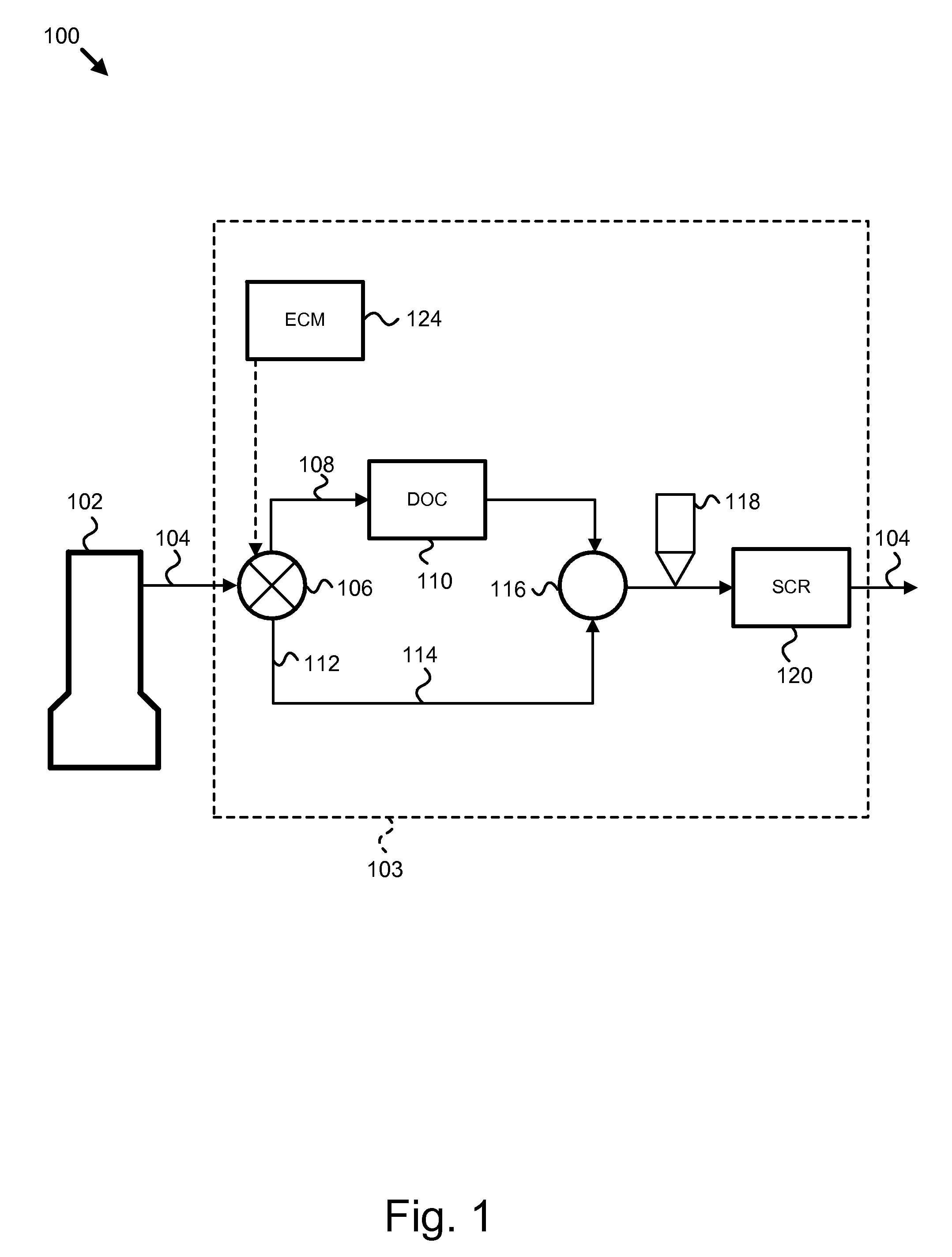

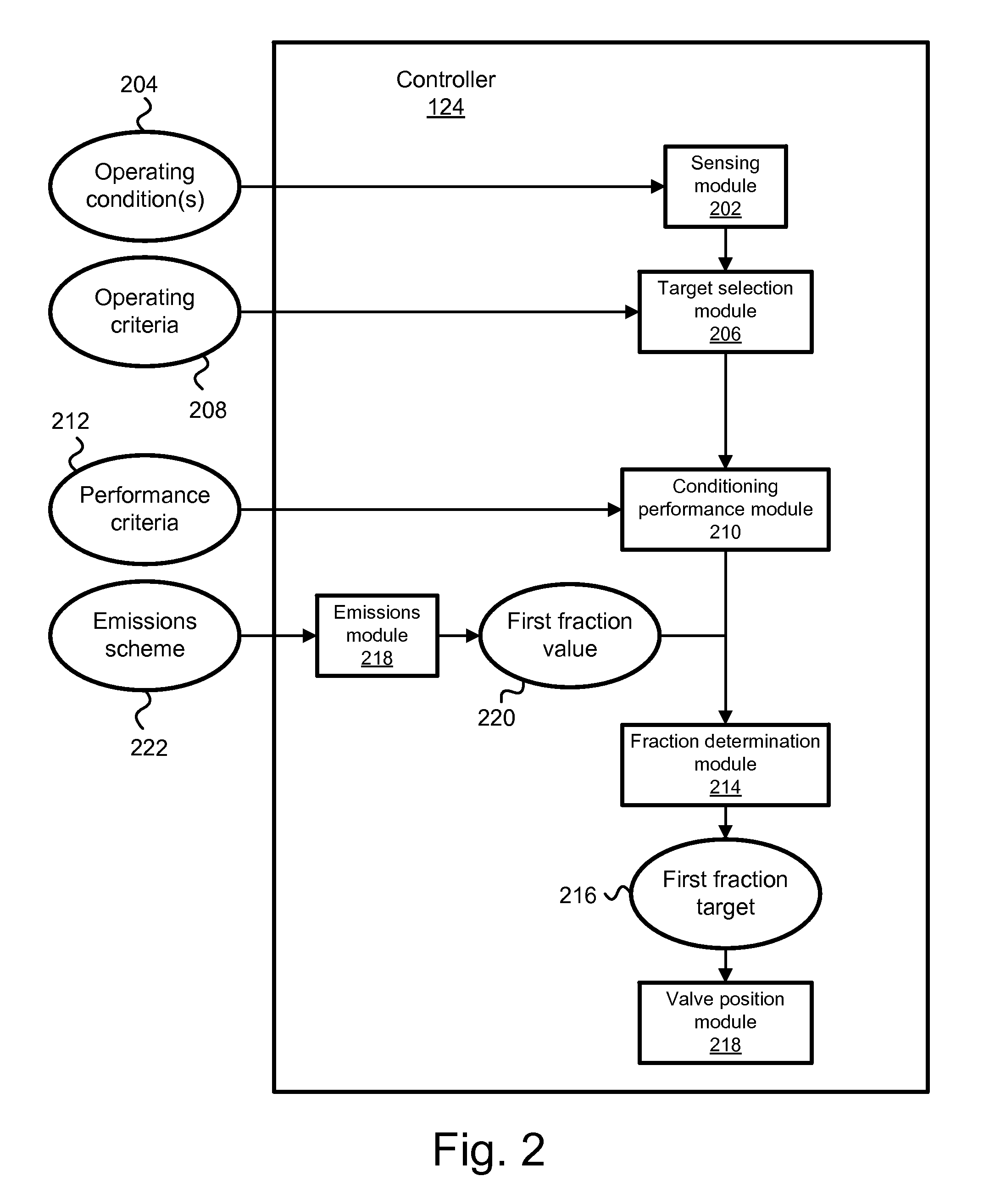

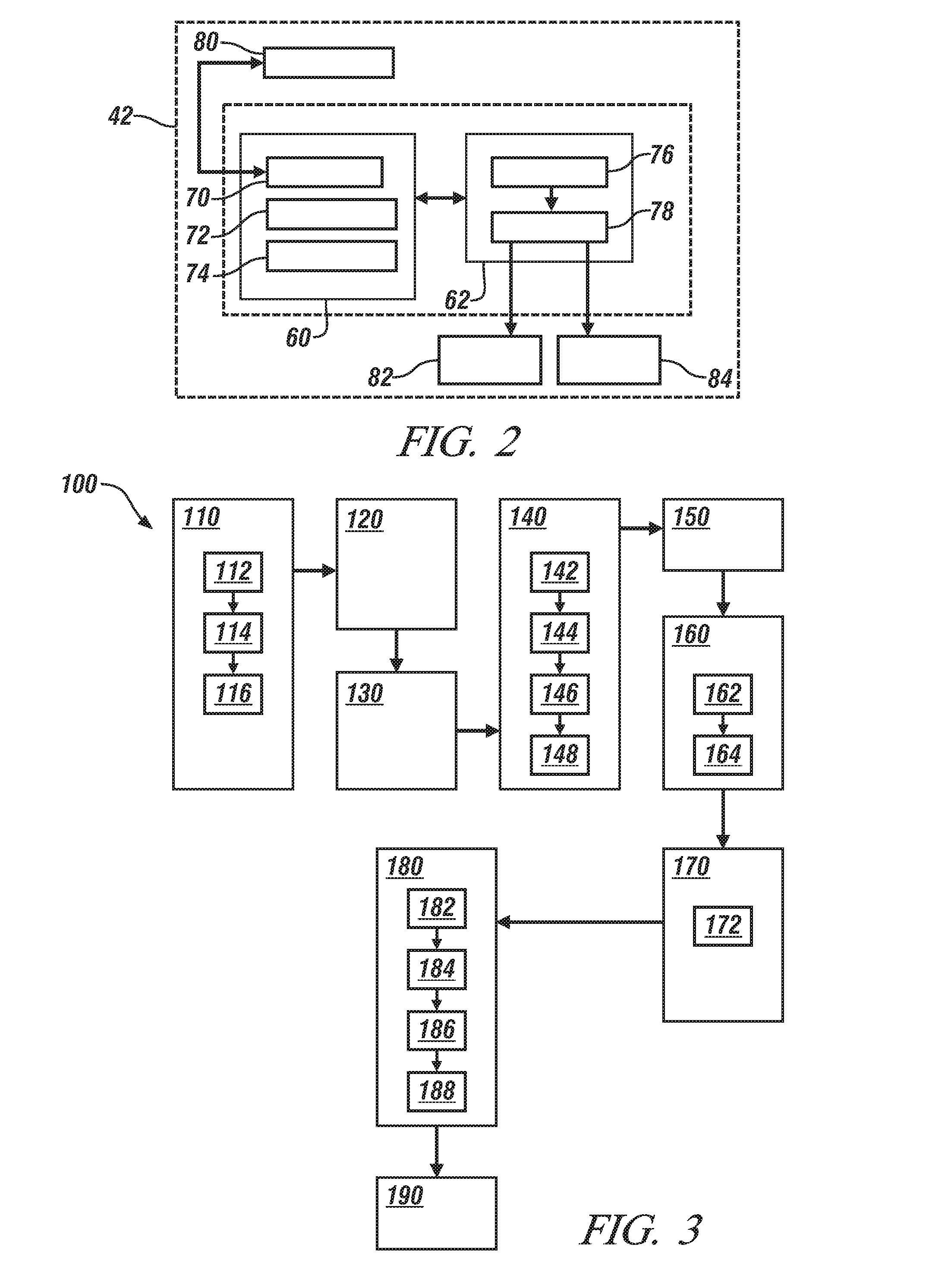

Apparatus, system, and method for exhaust aftertreatment efficiency enhancement

ActiveUS20080155968A1Improve efficiencySampled-variable control systemsInternal combustion piston enginesOperant conditioningBypass valve

An apparatus, system, and method are disclosed for enhancing the efficiency of an exhaust aftertreatment application. The method may include determining the current operating conditions of the application, the optimal operating conditions of a target component, and the performance criteria of a conditioning component relative to the optimal operating conditions. The method may include determining an optimal fraction of an exhaust flow to pass through the conditioning component to achieve the optimal operating conditions of the target component. The method may further include manipulating a bypass valve position based on the optimal fraction of exhaust flow to pass through the conditioning component. The target component may be a selective catalyst reduction (SCR) component that operates optimally at a designed NO2 / NOx mole ratio. The conditioning component may be a diesel oxidation catalyst (DOC) that affects the NO2 / NOx mole ratio. A method is thereby provided to operate an exhaust aftertreatment application more efficiently relative to an application without the invention.

Owner:CUMMINS FILTRATION IP INC

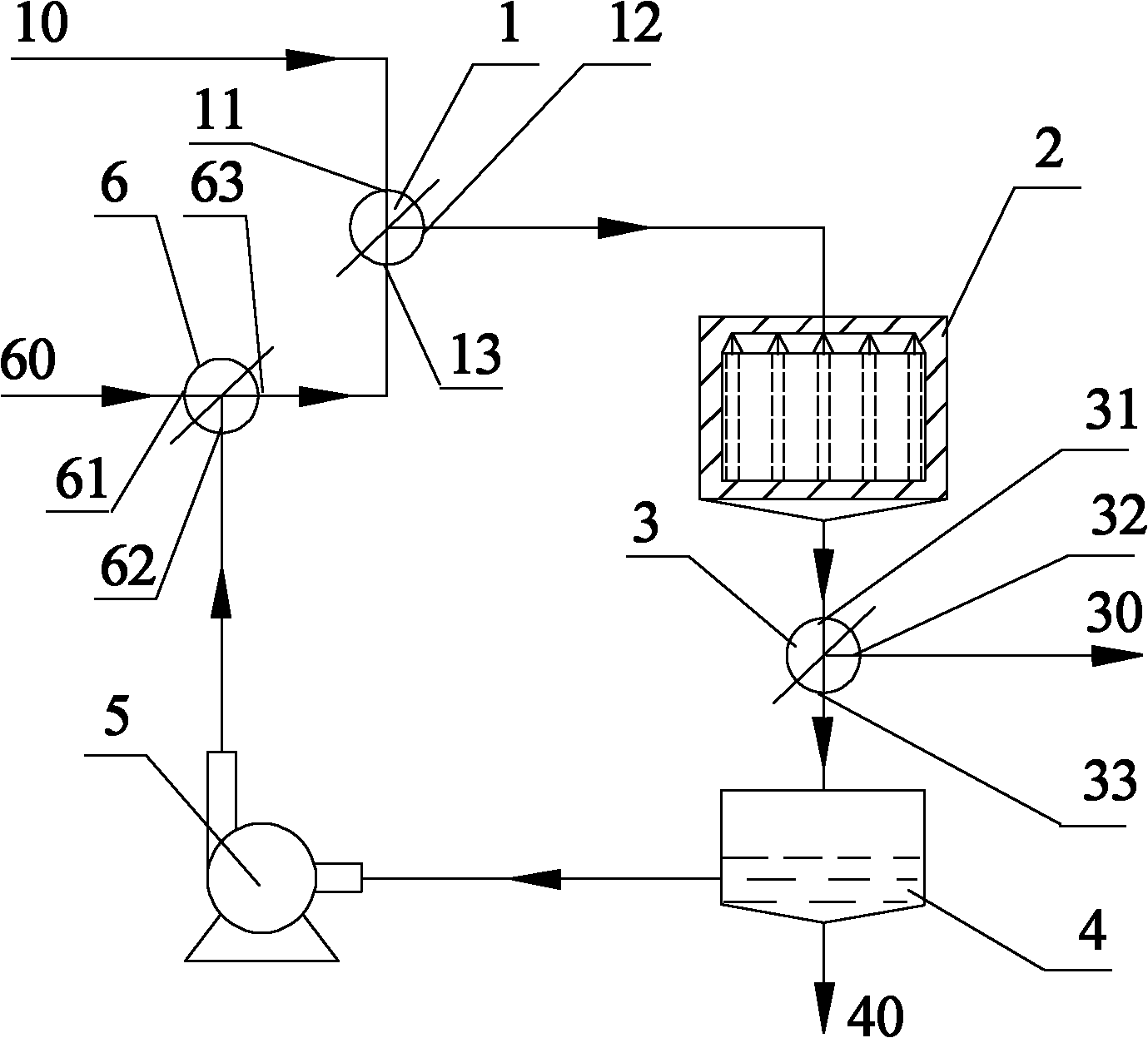

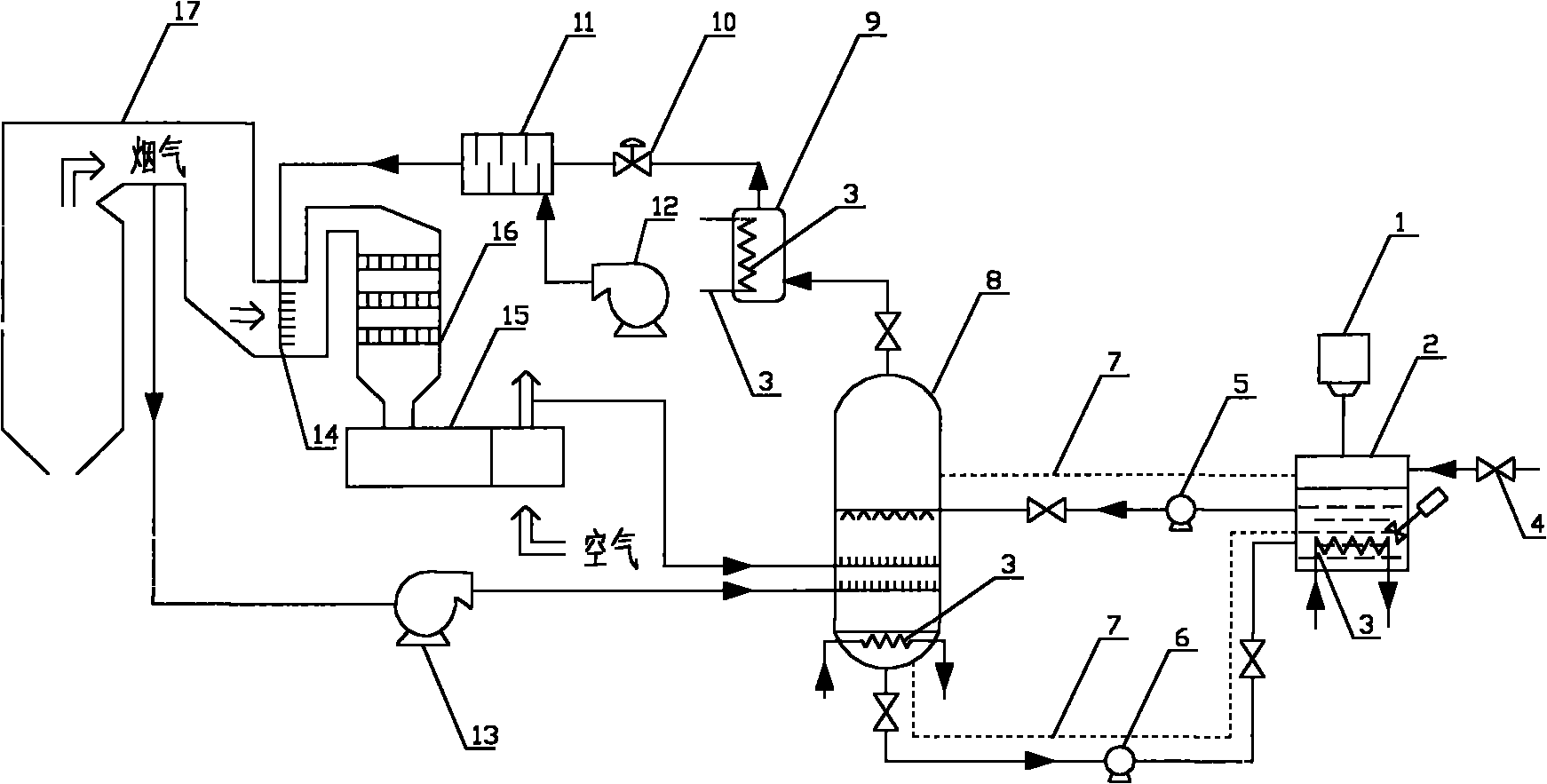

Device and process for realizing denitration reaction and regeneration of SCR catalyst

ActiveCN102114422AHigh activityAchieve emission standardsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasProcess engineering

The invention discloses a reactor device for realizing the denitration reaction and regeneration of a selective catalyst reduction (SCR) catalyst. The device comprises a reactor and a circulating pool, wherein a first three-way adapter valve which is connected with a flue gas input pipeline is arranged at an inlet of the reactor; a second three-way adapter valve is arranged between the reactor and the circulating pool; and through a circulating pump, the circulating pool is communicated with a third three-way adapter valve and then is communicated with the first three-way adapter valve. The invention also discloses a process for realizing the denitration reaction and regeneration of the SCR catalyst, wherein the denitration reaction of the SCR catalyst and the regeneration process of the SCR catalyst can be alternately performed in the same reaction device. A regeneration reaction device for the SCR catalyst and a denitration reaction device for the SCR catalyst are fused into one reaction device, the investment cost of equipment is effectively reduced, working procedures and expenses of the detachment and reinstallation of the SCR catalyst are avoided, and tim and labor are saved. Meanwhile, the process greatly reduces the using amount of acid solution and main agent supplement solution in regenerative raw materials.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

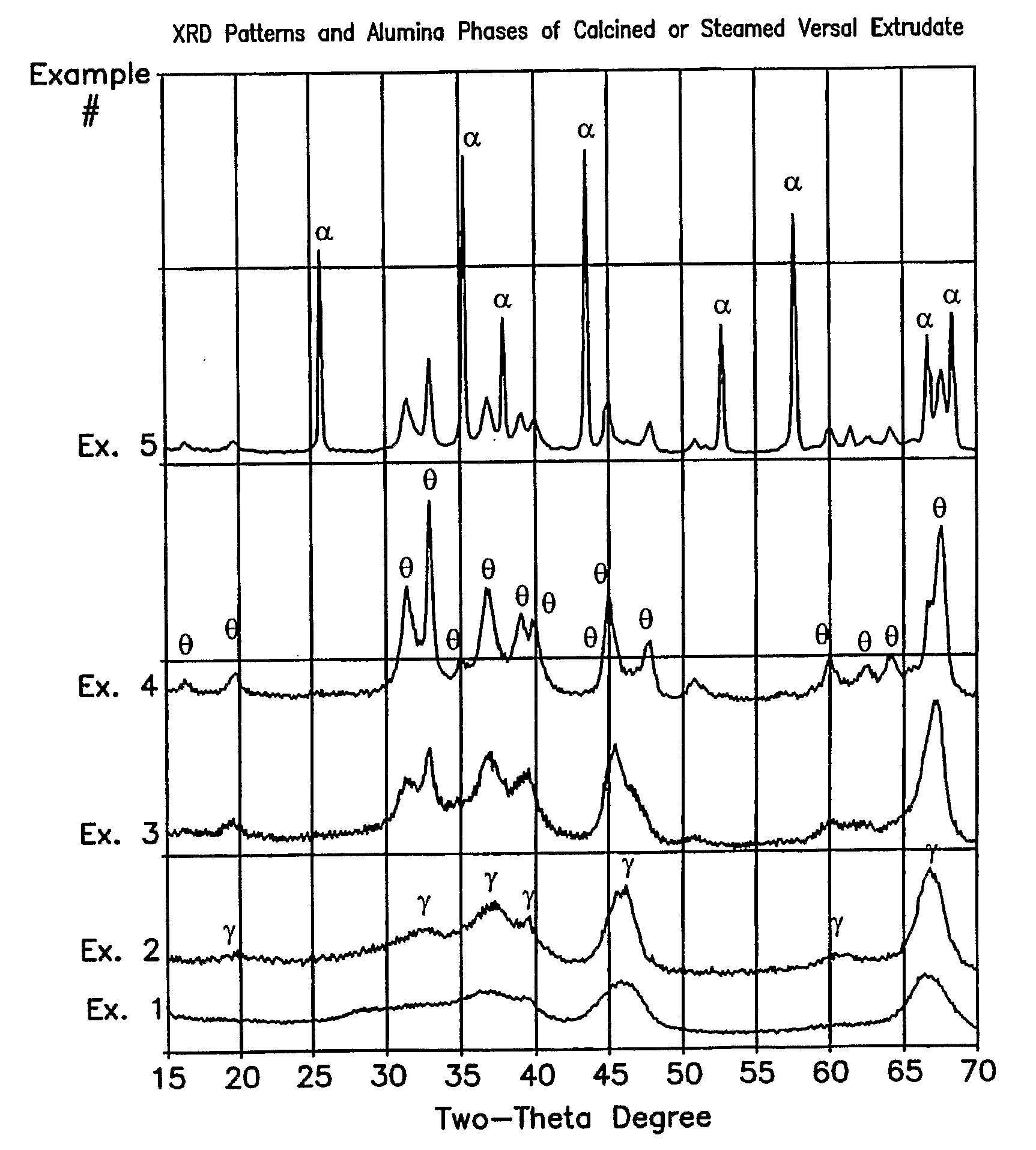

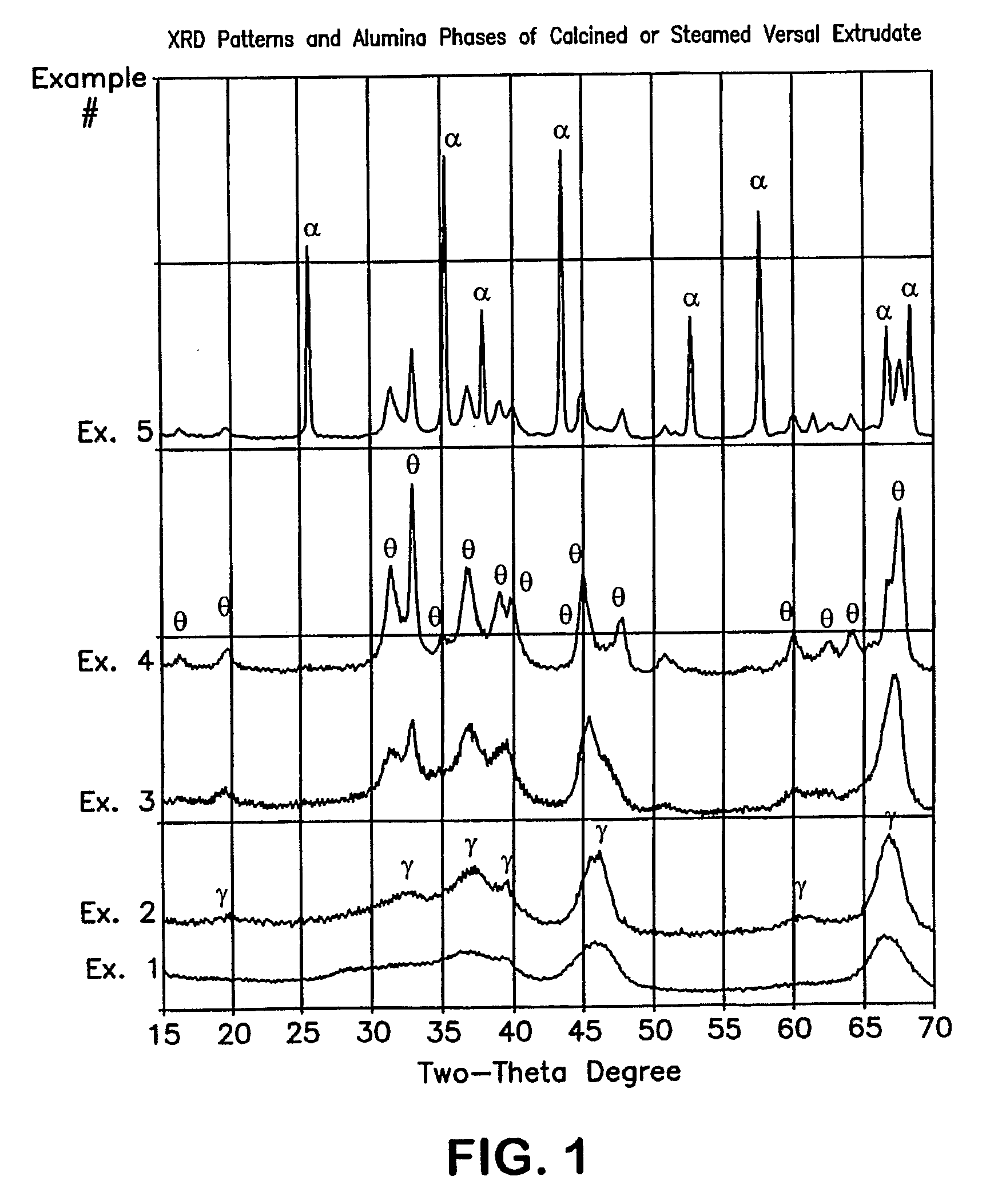

Selective Catalysts Having High Temperature Alumina Supports For Naphtha Hydrodesulfurization

InactiveUS20090321320A1High selectivityImprove the level ofOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationNaphthaPolymer science

This invention relates to a catalyst and method for hydrodesulfurizing naphtha. More particularly, a Co / Mo metal hydrogenation component is loaded on a high temperature alumina support in the presence of a dispersion aid to produce a catalyst that is then used for hydrodesulrurizing naphtha. The high temperature alumina support has a defined surface area that minimizes olefin saturation.

Owner:EXXON RES & ENG CO

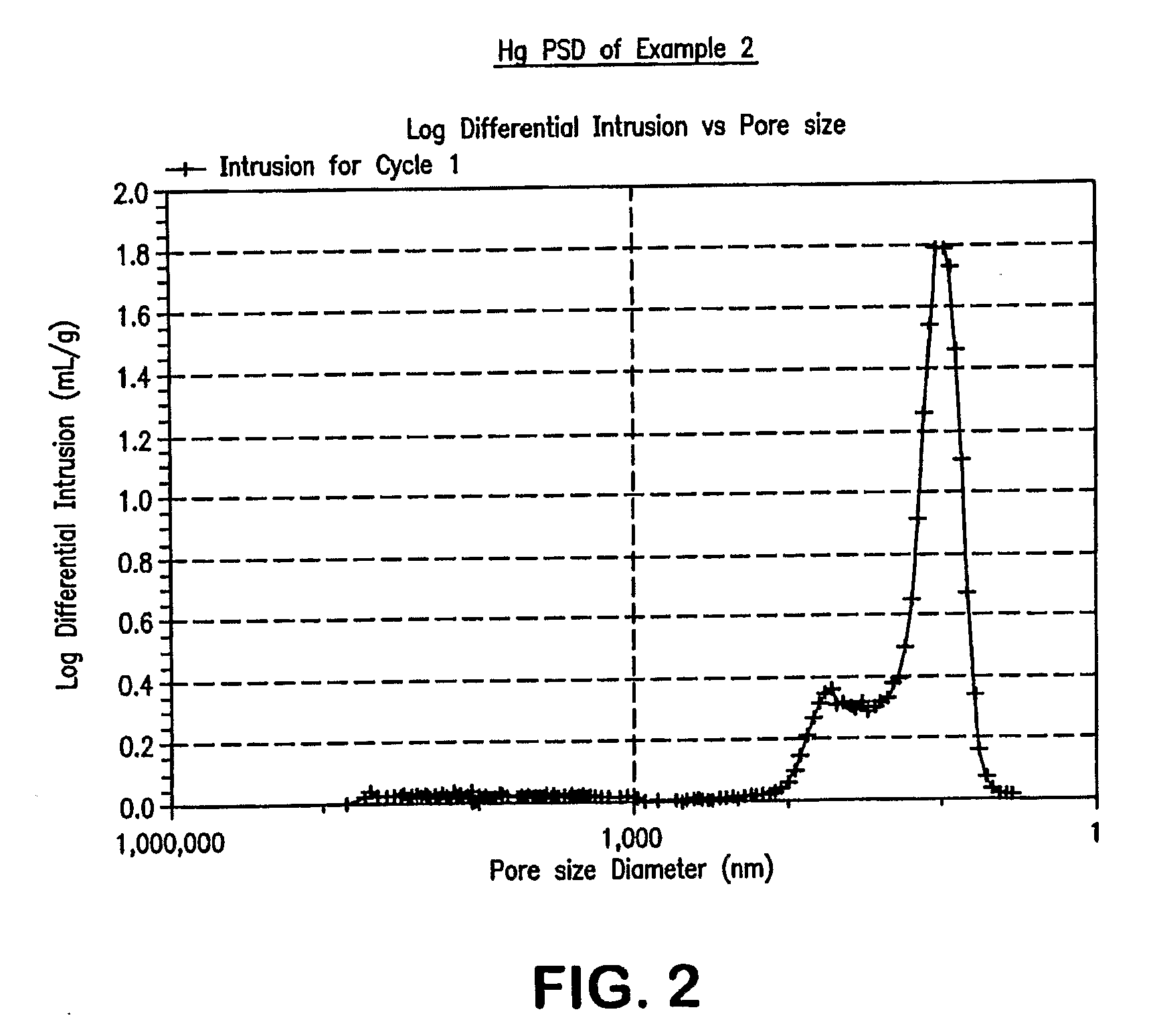

Selective Catalysts For Naphtha Hydrodesulfurization

ActiveUS20100133148A1High selectivityImprove the level ofMolecular sieve catalystsOther chemical processesNaphthaHydrodesulfurization

The invention relates to a catalyst for hydrodesulfurizing naphtha, to a method for preparing said catalyst and to a method for hydrodesulfurizing naphtha using said catalyst. More particularly, the catalyst comprises a Co / Mo metal hydrogenation component on a silica support having a defined pore size distribution and at least one organic additive. The catalyst has high dehydrosulphurisation activity and minimal olefin saturation when used to hydrodesulfurize FCC naphtha.

Owner:EXXON RES & ENG CO

System and method for controlling an exhaust system having a selective catalyst reduction component

InactiveUS20130263575A1Internal combustion piston enginesExhaust apparatusReliability engineeringApparent age

A method for controlling operation of an SCR component includes receiving a signal reflecting a sensed condition of an exhaust stream associated with the SCR component, estimating an apparent aging time of the SCR component based on the sensed condition of the exhaust stream, and setting an operating condition of the SCR component based on the apparent aging time of the SCR component.

Owner:GM GLOBAL TECH OPERATIONS LLC

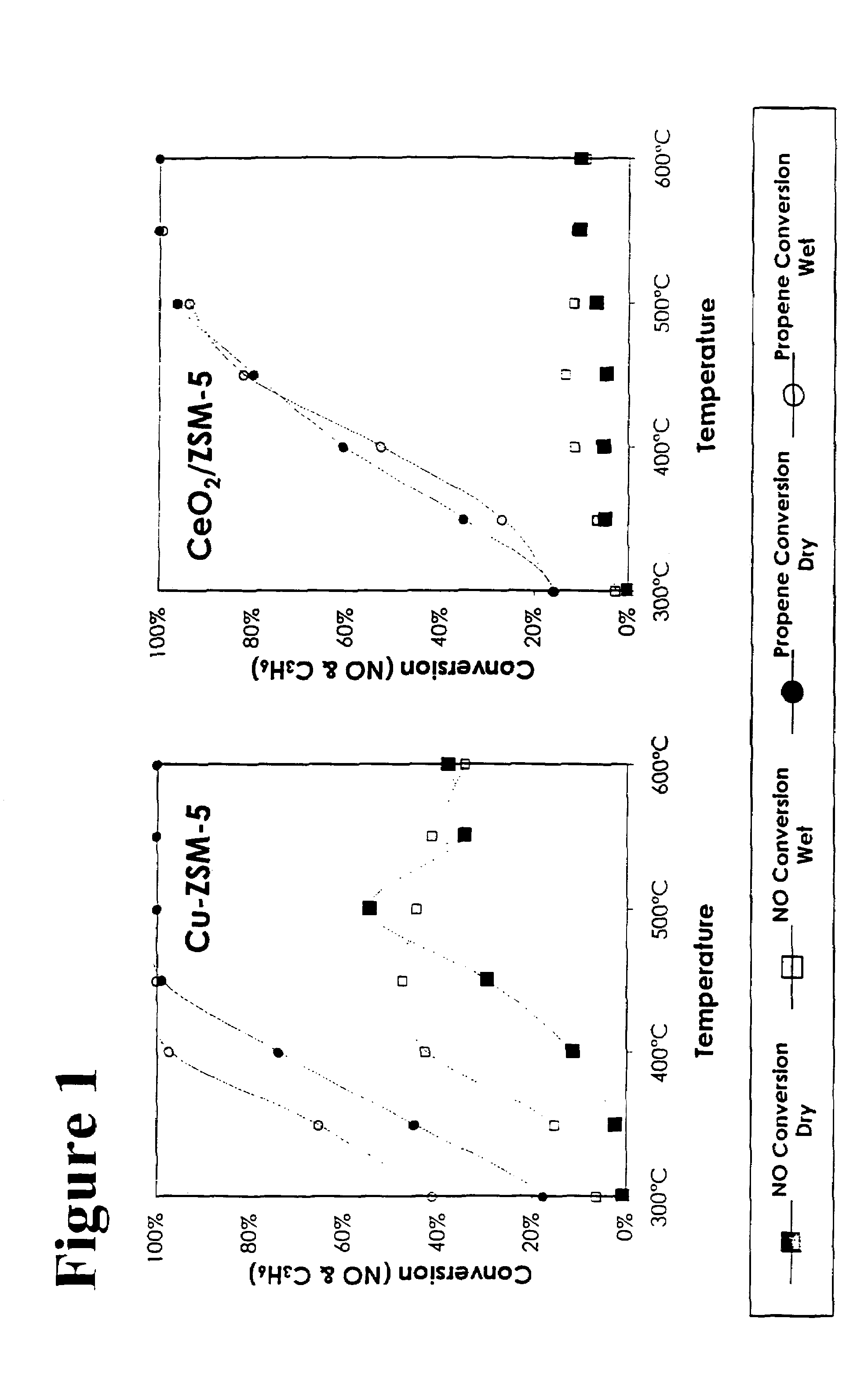

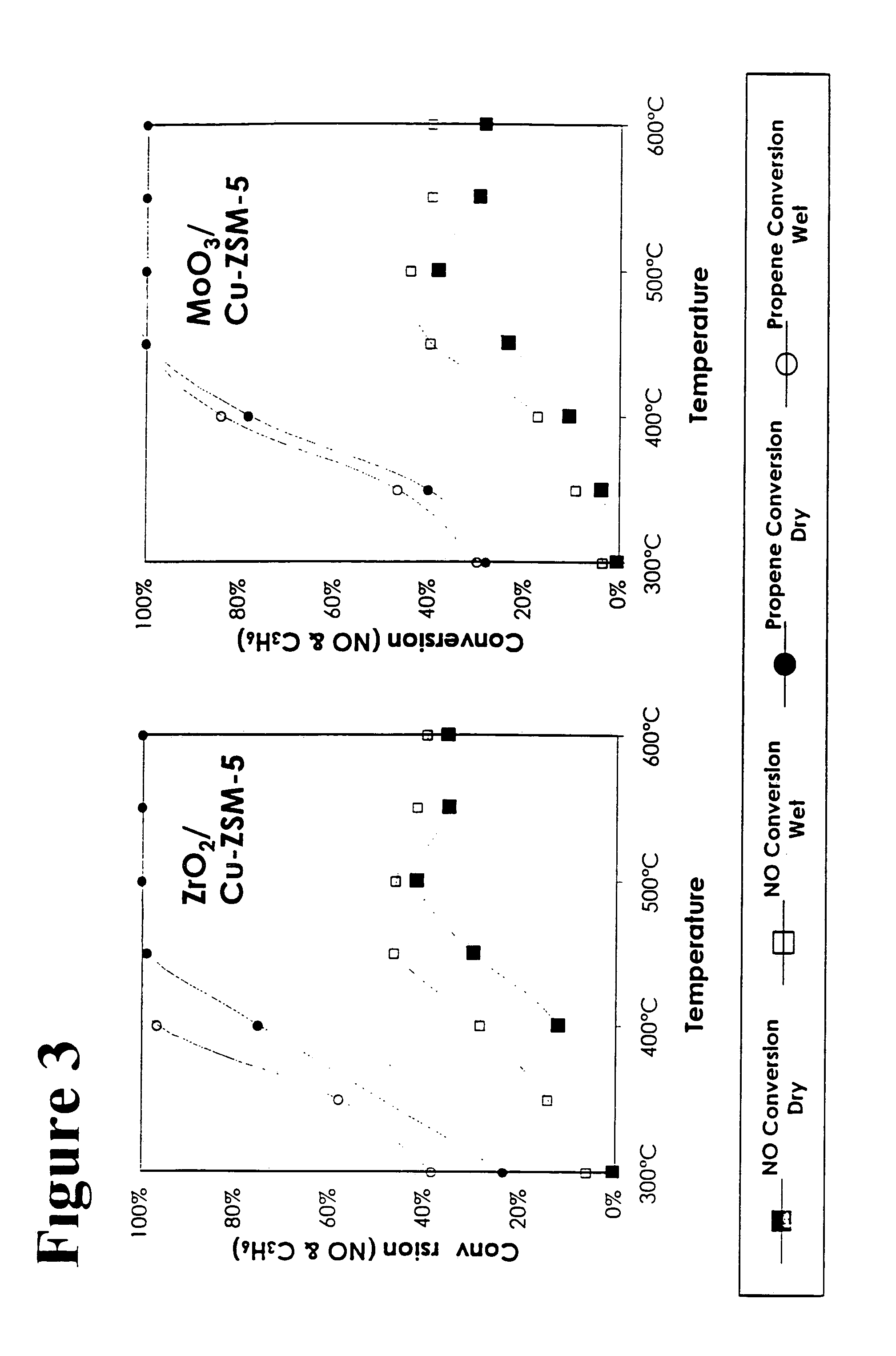

Catalyst for selective NOx reduction using hydrocarbons

Owner:CHICAGO UNIV OF THE +1

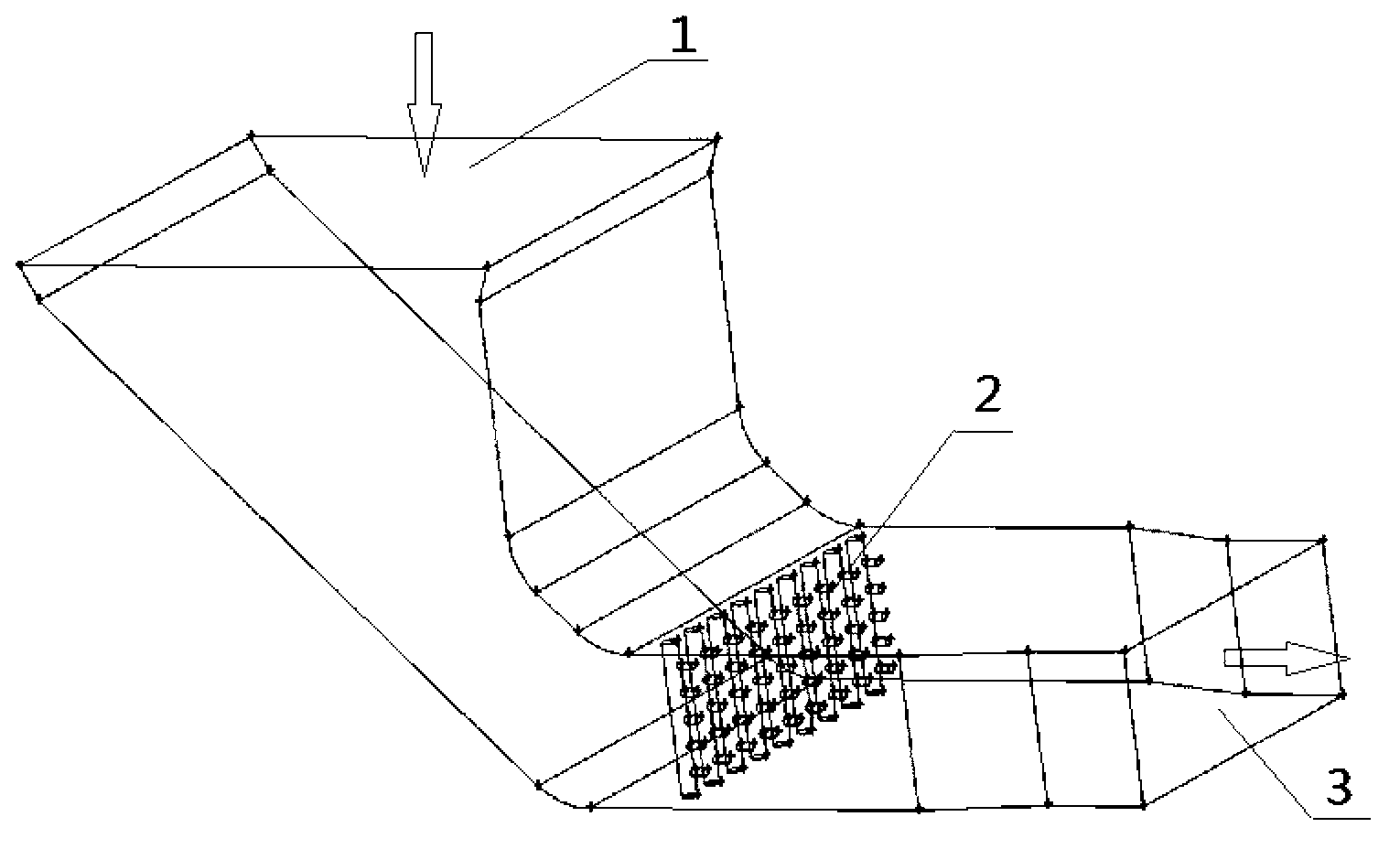

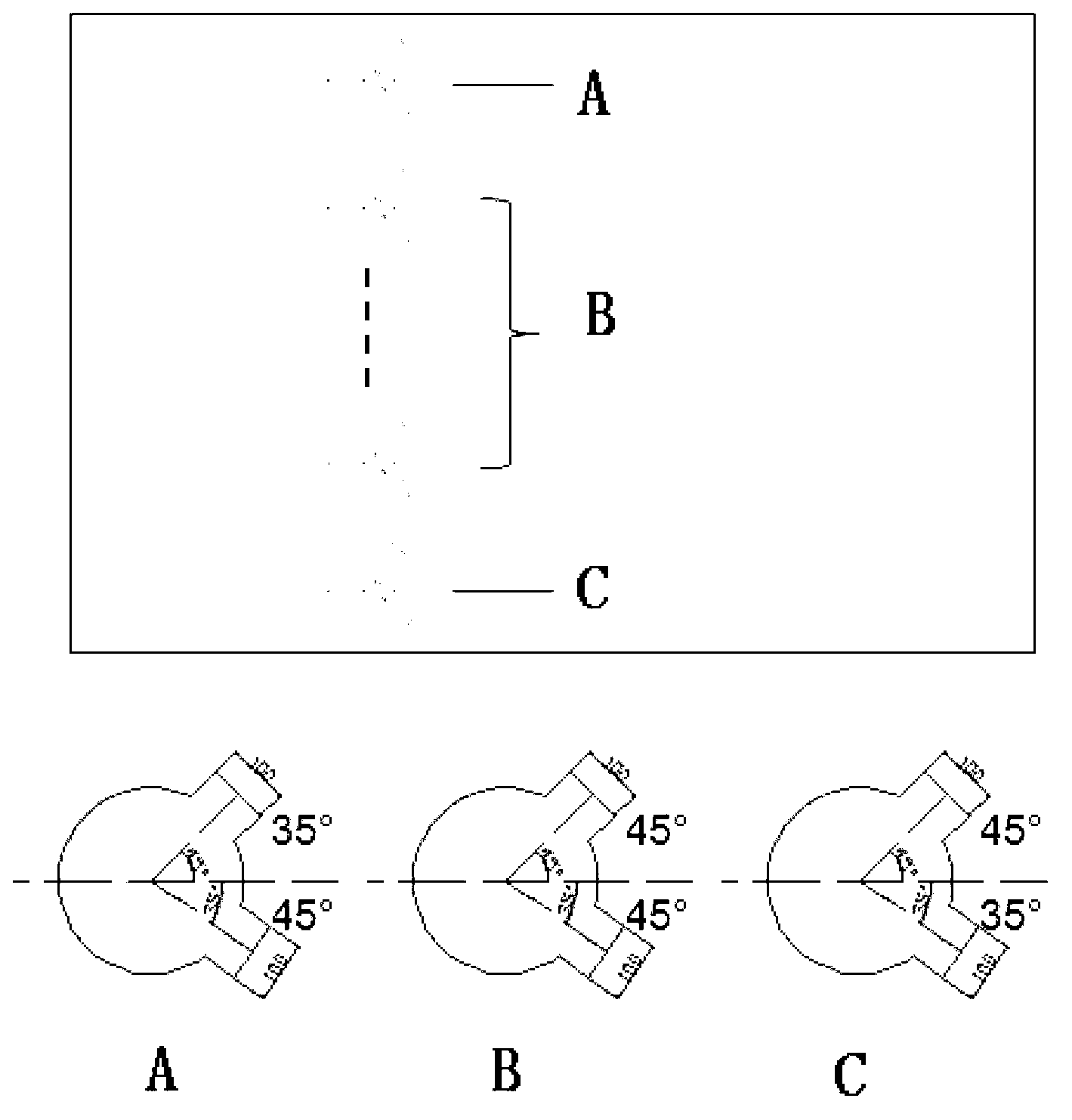

Device and process for effectively removing sulfur trioxide in smoke through natural alkali

InactiveCN103055684ASmall pressure lossReduce resistanceDispersed particle separationAir preheaterAlkalinity

The invention relates to a device and a process for effectively removing sulfur trioxide in smoke through a natural alkali. The device comprises a smoke inlet and a smoke outlet, wherein a bent transitional flue is arranged between the smoke inlet and the smoke outlet; a nozzle system is arranged on the bent transitional flue; a wear-proof plate is arranged on the smoke incoming direction of the nozzle system; and the nozzle system is connected with a natural alkali slurry preparation system. The smoke from the outlet of a selective catalyst reduction (SCR) reactor is sprayed and washed through the natural alkali slurry to completely absorb sulfur trioxide (SO3), and then enters an air preheater. The device for effectively removing sulfur trioxide in the smoke through the natural alkali disclosed by the invention, through the nozzle system on the flue between the tail part of the SCR reactor and the air preheater and by spraying the natural alkali slurry into the flue, can absorb and remove SO3 with a removal efficiency of 80-90% through the strong alkalinity of the natural alkali; through setting the position, quantity, angle and outlet flow velocity of the nozzle, uniform mixing of the absorbent and the smoke is guaranteed; and through the wear-proof plate, abrasion of the smoke on the nozzle is reduced, and optimization and adjustment are carried, so as to reduce the resistance of the flue to the greatest extent.

Owner:SHANDONG UNIV

Method for fully recovering silicon dioxide in waste SCR (Selective Catalyst Reduction) catalyst

The invention relates to the field of smoke denitration, in particular to a method for fully recovering silicon dioxide in a waste SCR (Selective Catalyst Reduction) catalyst. The method comprises the following steps: soaking the pulverized waste SCR catalyst with three to four times of water to remove impurities, leaching powder from which the impurities are removed with excessive thick alkaline solution with the concentration of 60-80wt%, filtering to obtain a Na2TiO3 solid, adding sulfuric acid into filtrate, regulating pH to 11.5-12.5 at a temperature of 70-90 DEG C, leaving the mixture to stand for 0.5-1h, filtering, and discarding filter cakes; adding sulfuric acid into the filtrate until the pH is regulated to 9-10 to obtain the silicate filter cakes, heating and stirring the silicate filter cakes in mixed acid of dilute sulfuric acid and oxalic acid at a temperature of 40-60 DEG C for 1-2h, filtering, washing the filter cakes with deionized water, washing off acid radical ions in the solid, and obtaining high-purity silicon dioxide through heating and decomposition. Therefore, the recovery of the silicon dioxide in the waste SCR catalyst can be realized without a roasting process.

Owner:沈阳远大固废处理有限公司

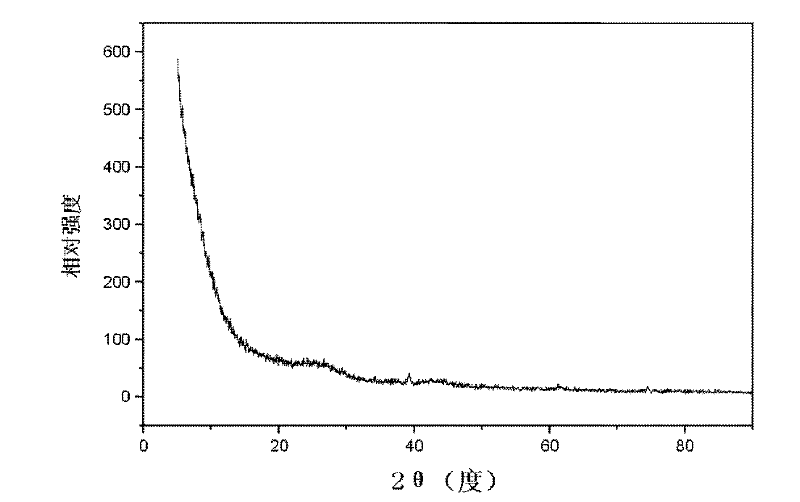

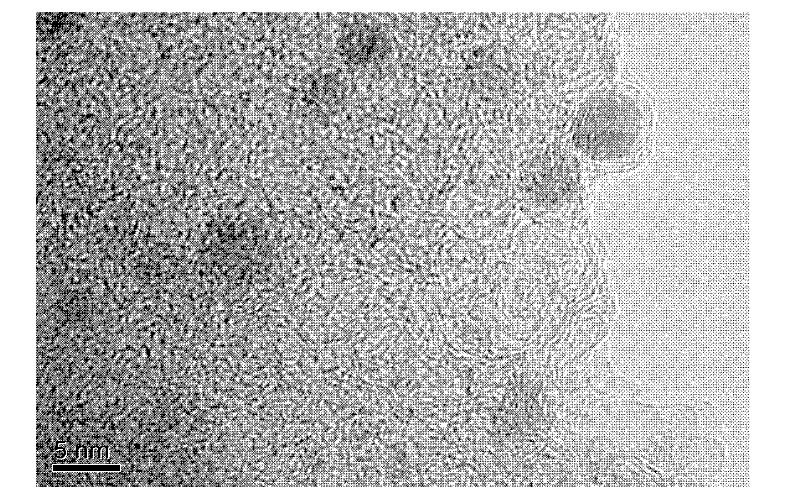

High-selectivity catalyst for naphthalene hydrogenation reaction for preparing tetrahydronaphthalene and preparation method thereof

InactiveCN102600877AHigh selectivityPrevent polymerization and sinteringMolecular sieve catalystsHydrocarbon by hydrogenationMicrowave pyrolysisHydrogenation reaction

The invention discloses high-selectivity carbide catalyst for naphthalene hydrogenation reaction for preparing tetrahydronaphthalene and a quick microwave preparation method thereof, belonging to the technical field of catalyst material application and preparation. The method comprises the steps of: fully grinding complex compounds containing relevant metals and carriers, or supporting the complex compounds containing the relevant metals onto the surfaces of carriers through a solution impregnation method and conducting microwave pyrolysis in inert gas to form the supported carbide catalyst. The invention provides the high-efficiency carbide catalyst with 100 percent selectivity aiming at the naphthalene hydrogenation reaction for preparing the tetrahydronaphthalene and a simple, convenient, quick, environmental-friendly and energy-saving preparation method thereof. The prepared carbide particles are evenly dispersed on the carriers, so that the situation of surface carbon deposition is avoided. The contradiction between high catalyst selectivity and high cost is successfully avoided, and therefore the high-selectivity carbide catalyst and the preparation method thereof have promising industrial application prospect.

Owner:DALIAN UNIV OF TECH

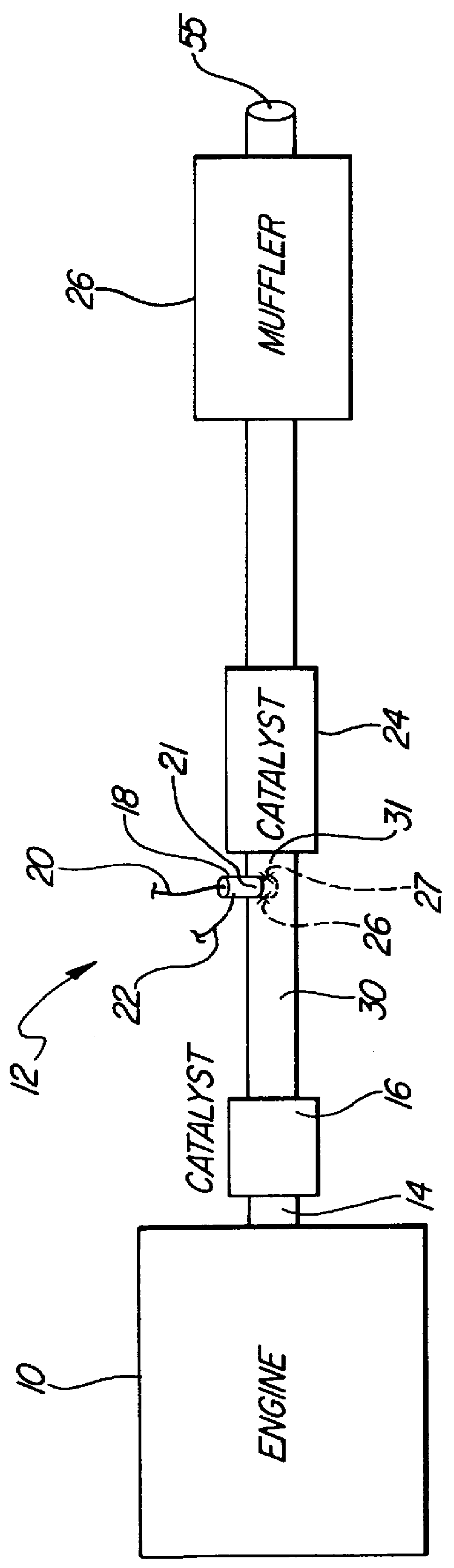

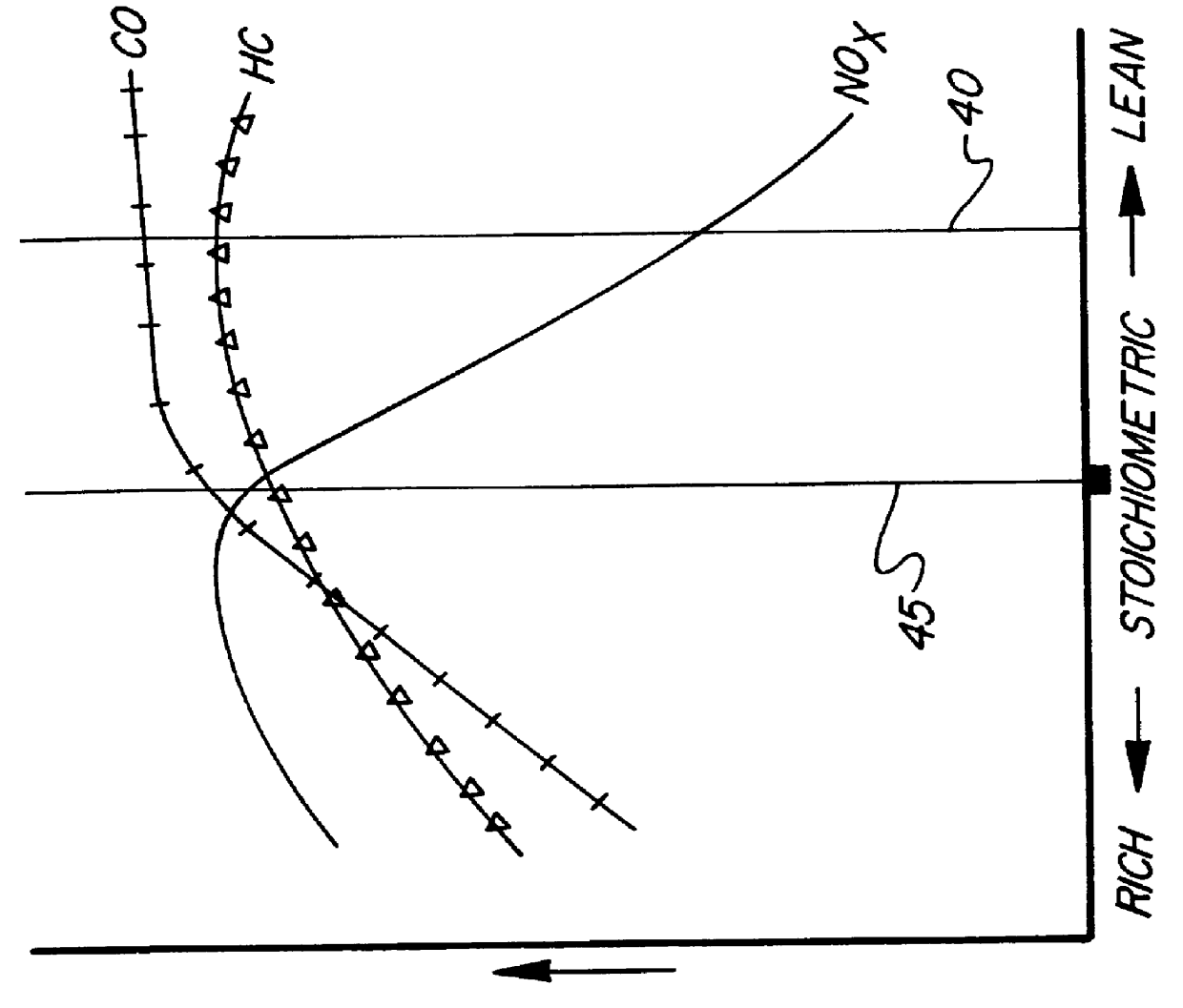

Selective catalyst reduction wit pox reactor for engine exhaust aftertreatment

An exhaust stream aftertreatment system that selectively reduces NOx emissions during lean-burn operation of an internal combustion engine is provided. The apparatus includes a partial oxidation reactor having a fuel source, an ignition device, and various values. The partial oxidation reactor is disposed in the exhaust pipe of automobile between the engine and the threeway catalyst. A light-off catalyst is provided adjacent to the engine, upstream from the partial oxidation reactor. The three-way catalyst and the light-off catalyst are typical automotive catalysts having a substrate plated with a precious metal to facilitate the oxidation of hydrocarbons (HC) and carbon monoxide (CO) as well as the reduction of nitrogen monoxide and nitrogen dioxide (NOx). The partial oxidation reactor is adapted to operate while the internal combustion engine is producing high levels of NOx or while the engine is operating in a lean burn regime.

Owner:FCA US

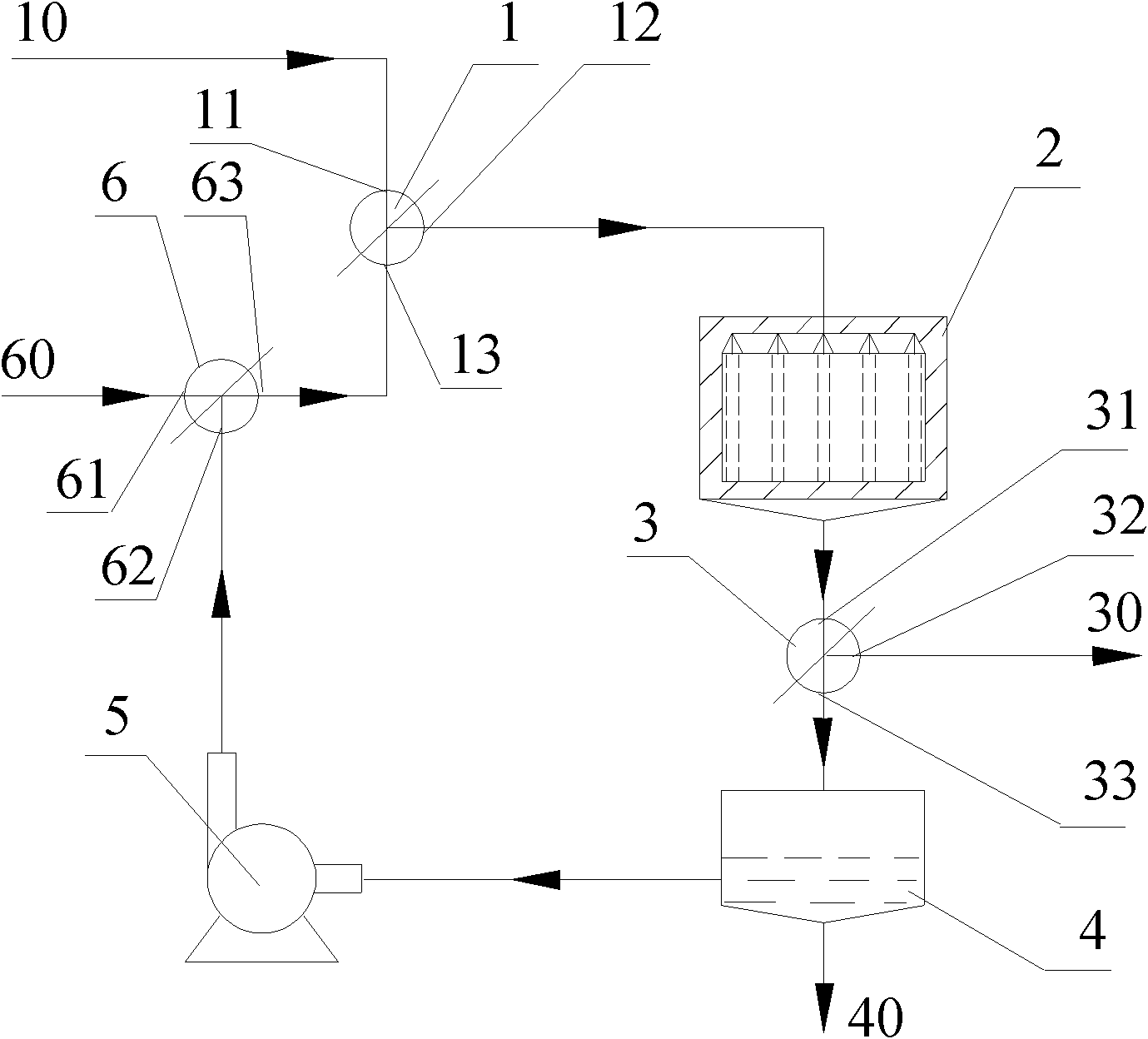

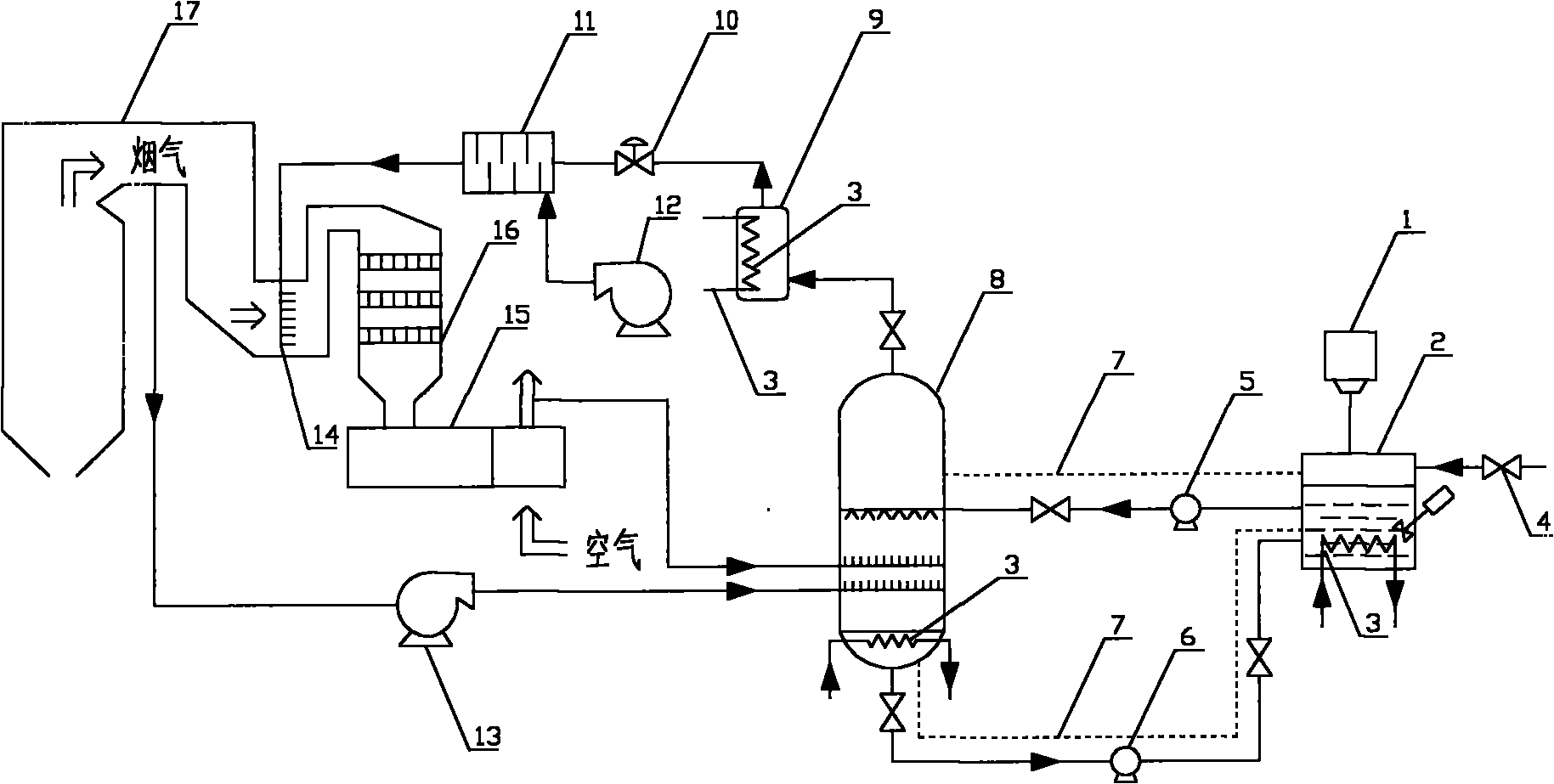

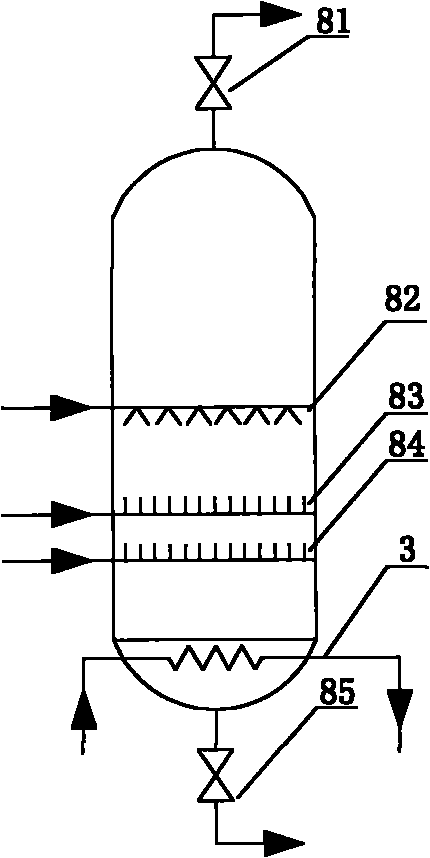

Process and system for preparing ammonia from ammonium bicarbonate by using wet process for flue gas denitration

ActiveCN101829486AAvoid safety hazardsTransport and storage safetyDispersed particle separationSodium bicarbonateGrating

The invention discloses a process and a system for preparing ammonia from ammonium bicarbonate by using a wet process for flue gas denitration, belonging to the technical field of flue gas denitration in a thermal power plant. In the process, an ammonium bicarbonate solution at 90 DEG C is boosted and then enters an atomizing nozzle of a pyrolyzing furnace for backflow ejection, fogdrop of the ammonium bicarbonate decompose out ammonia gas under the heating action of high-temperature flue gas flowing from bottom to top, and the residual ammonium bicarbonate solution converges at the bottom of the pyrolyzing furnace and then returns to a dissolution pool through a circulating pump for recycling; and the ammonia gas flows to a buffer tank together with air, enters an ammonia gas-air mixer and then enters an SCR (Selective Catalyst Reduction) reactor through an ammonia-spraying grating after being diluted to certain concentration, and in the presence of a catalyst, the ammonia gas reduces NOX into N2. The ammonium bicarbonate is a reducing agent which is convenient and safe to transport and store, has better economy than urea and avoids the potential safety hazard of the reducing agents of liquid ammonia, ammonia water and the like in the aspects of transportation and storage. By adopting the ammonium bicarbonate as the reducing agent to pyrolyze for preparing the ammonia with the wet process, the whole system has the advantages of easy dosage control of the ammonium bicarbonate, stable ammonia gas generation, simplicity and high efficiency.

Owner:ZHEJIANG GUANGHAN ENVIRONMENTAL PROTECTION TECH

Rare-earth oxide modified high-selectivity catalyst for adiponitrile hydrogenation and hexylenediamine production, preparation method and application thereof

InactiveCN109647419AHigh mechanical strengthReduce pollutionOrganic compound preparationAmino compound preparationRare earthSolvent

The invention discloses a rare-earth oxide modified high-selectivity catalyst for adiponitrile hydrogenation and hexylenediamine production, a preparation method and application thereof. An alumina-supported nickel-based catalyst is used as an active component, and at 25-90 DEG C and through a parallel flow precipitation process, a low-content rare-earth oxide is used for the modification. A tankreactor is adopted at the low temperature and without an alkaline reagent to carry out a reaction at the pressure of 1-9 MPa for 1-6 h so as to achieve adiponitrile catalytic conversion for high-selectivity preparation of hexylenediamine. No alkaline reagent or NH3 is added during the reaction process to inhibit side reaction of cyclization. The environmental pollution is reduced; and the catalysthas high mechanical strength, the reaction post-treatment is simple and the reaction condition is relatively mild. According to the method and in part of the embodiments, the conversion rate of adiponitrile reaches up to 100% according to set reaction parameters, and selectivity of the product hexylenediamine can reach up to 90%. The invention has good economic benefit and industrial applicationprospects.

Owner:DALIAN UNIV OF TECH

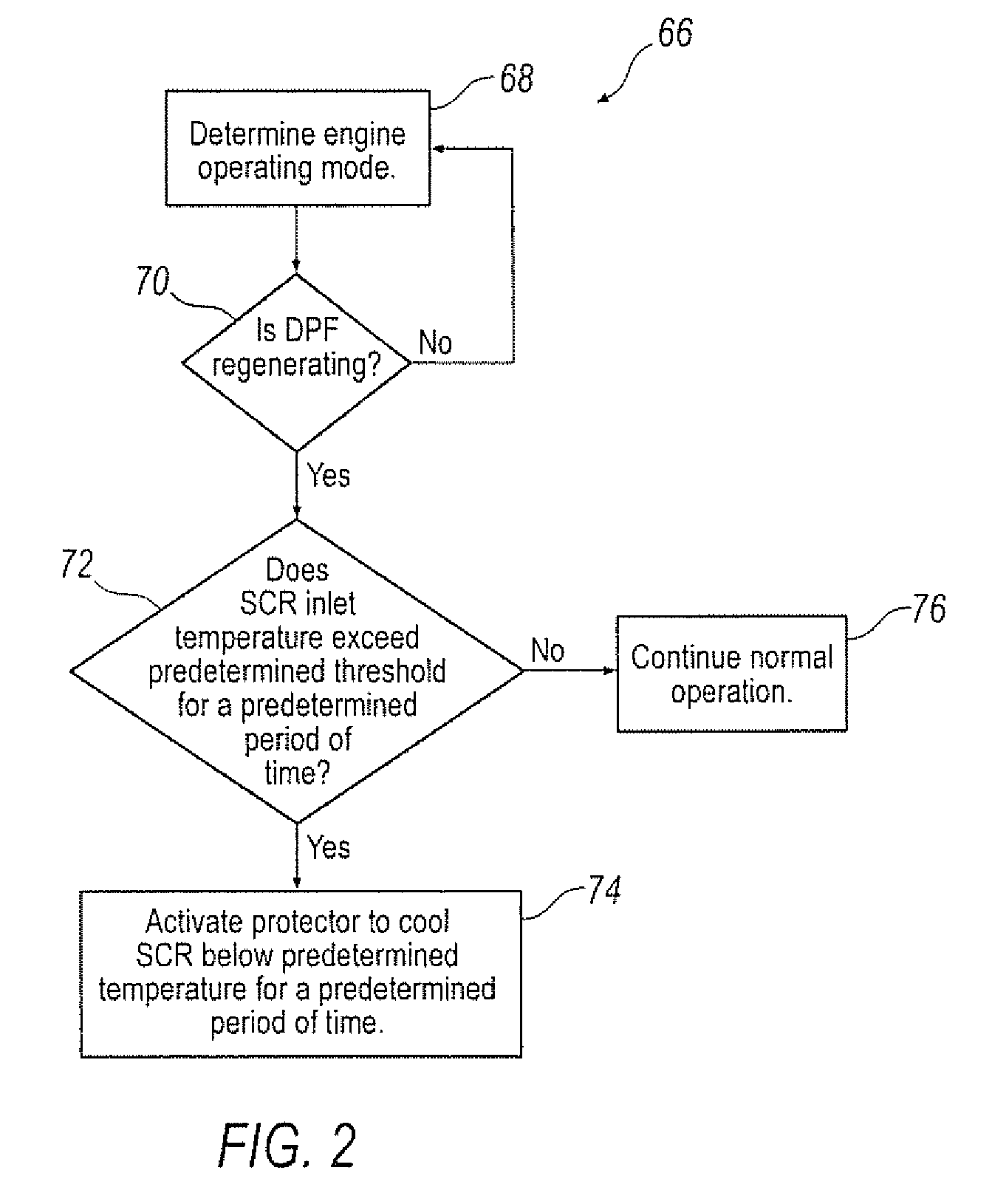

Methods to protect selective catalyst reducer aftertreatment devices during uncontrolled diesel particulate filter regeneration

InactiveUS20090199537A1Promote resultsAvoid overall overheatingElectrical controlInternal combustion piston enginesPremature agingEngineering

The present invention is directed to a method to operate an electronically controlled internal combustion engine with an exhaust system equipped with a diesel particulate filter upstream of a selective catalyst reducer to protect the selective catalyst reducer from premature aging and failure caused by exhaust temperature heat generated during uncontrolled regeneration of the diesel particulate filter.

Owner:DETROIT DIESEL CORP

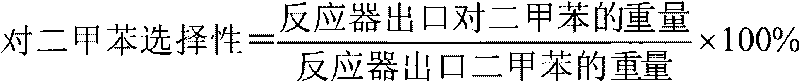

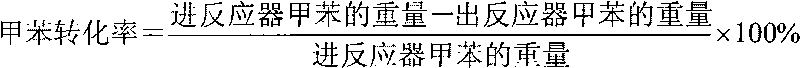

Catalyst with shape selecting function

The invention relates to a catalyst with shape selecting function, which mainly solves the problems that the shape selecting function of the conventional shape selective catalyst is difficult to realize, the molecular sieve has the shape selecting function after modifying and the modified catalyst has lower activity. The catalyst with the shape selecting function comprises the following components in part by weight: a) 5 to 95 parts of core-shell molecular sieve material and b) 5 to 95 parts of adhesive, wherein the core phase of the core-shell molecular sieve is selected from ZSM-5, ZSM-11, ZSM-35, ZSM-48, beta, mordenite, MCM-22 and phosphorus-aluminum molecular sieve; and the technical scheme that the core-shell molecular sieve is continuous and compact ZSM-5 crystalline grains well solves the problems. The catalyst can be used in industrial production of methylbenzene selective disproportionation and methylbenzene methylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

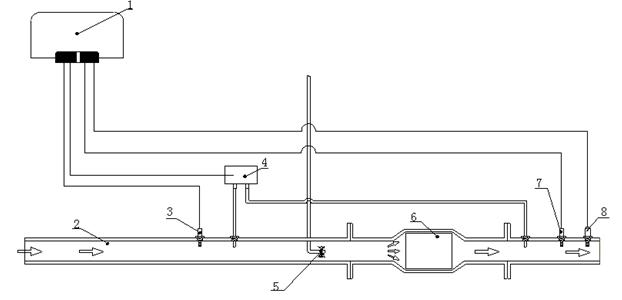

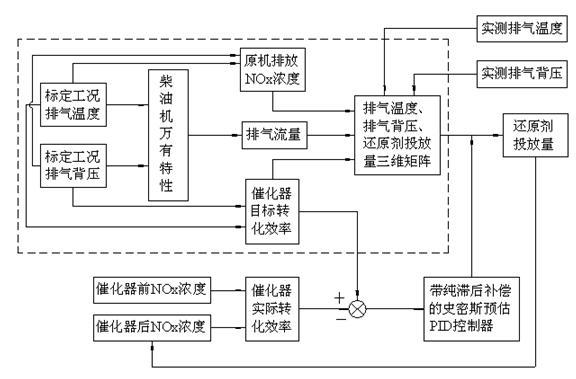

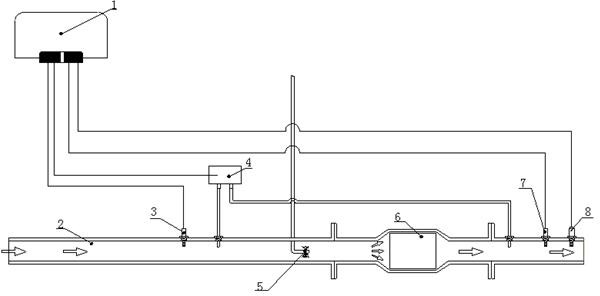

Closed loop control method for SCR (Selective Catalyst Reduction) system of all-working-condition diesel engine

InactiveCN102493860AEasy to controlInternal combustion piston enginesExhaust apparatusProportion integration differentiationClosed loop

The invention discloses a closed loop control method for an SCR (Selective Catalyst Reduction) system of an all-working-condition diesel engine. The method is carried out according to the following steps of: (1) establishing a novel three-dimensional matrix of the adding amount of reducing agent for the SCR system based on exhaust temperature and exhaust backpressure of the all-working-condition diesel engine; and (2) forming a precise control mode of a closed loop of the SCR system of the all-working-condition diesel engine by utilizing a nitrogen oxide sensor and a PID (Proportion Integration Differentiation) controller. By using the closed loop control method for the SCR system of the all-working-condition diesel engine in the invention, the acquisition of working-condition parameters of the diesel engine can not depend on an electronic control unit (ECU) of the diesel engine, the technical obstacle that the current home and abroad SCR systems are only suitable for electrically controlling the diesel engine is broken through, and an approach for reducing the discharging amount of NOx is provided for vehicles assembled with light, middle and heavy non-electric control diesel engines.

Owner:MILITARY TRANSPORTATION UNIV PLA

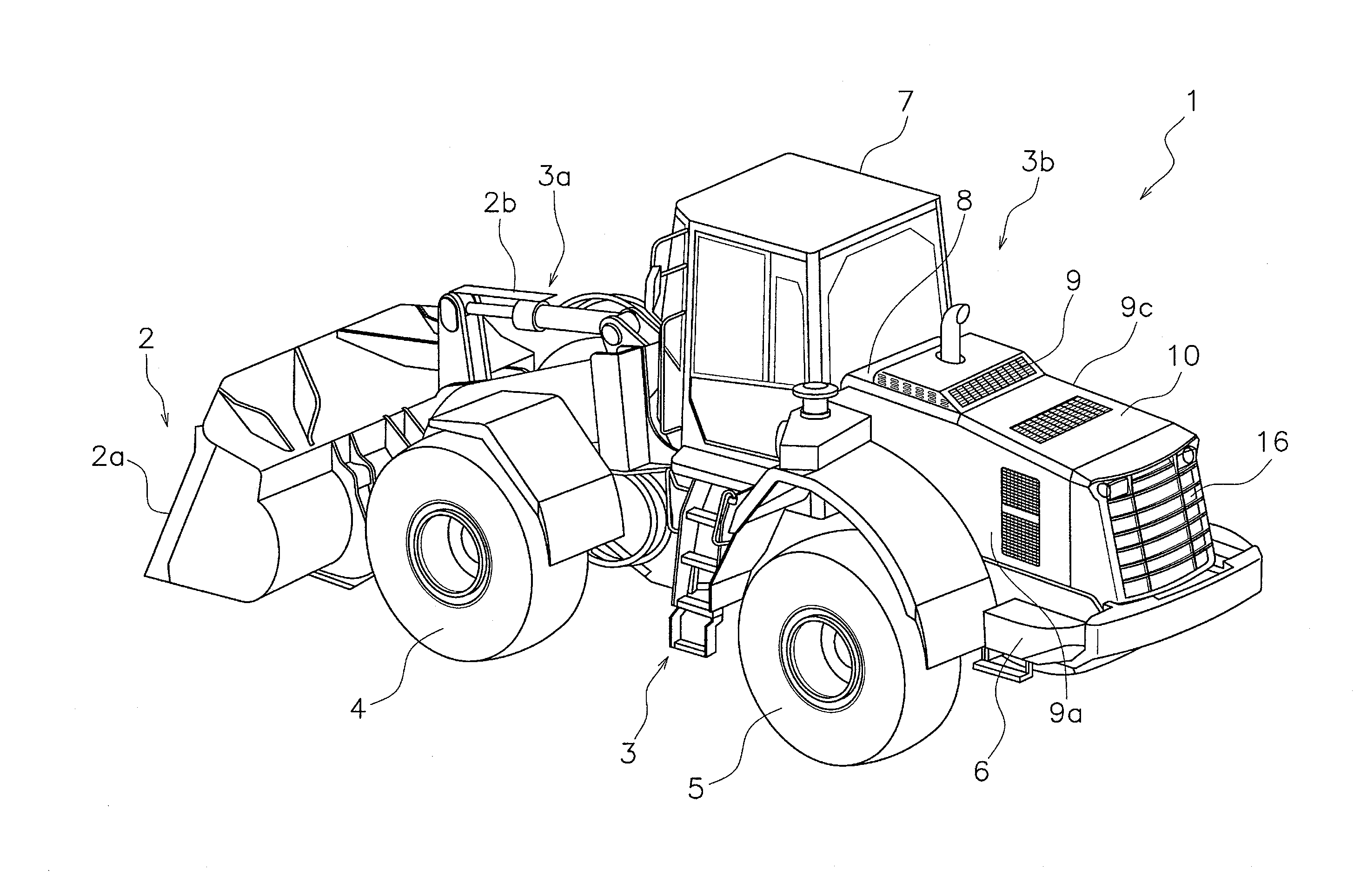

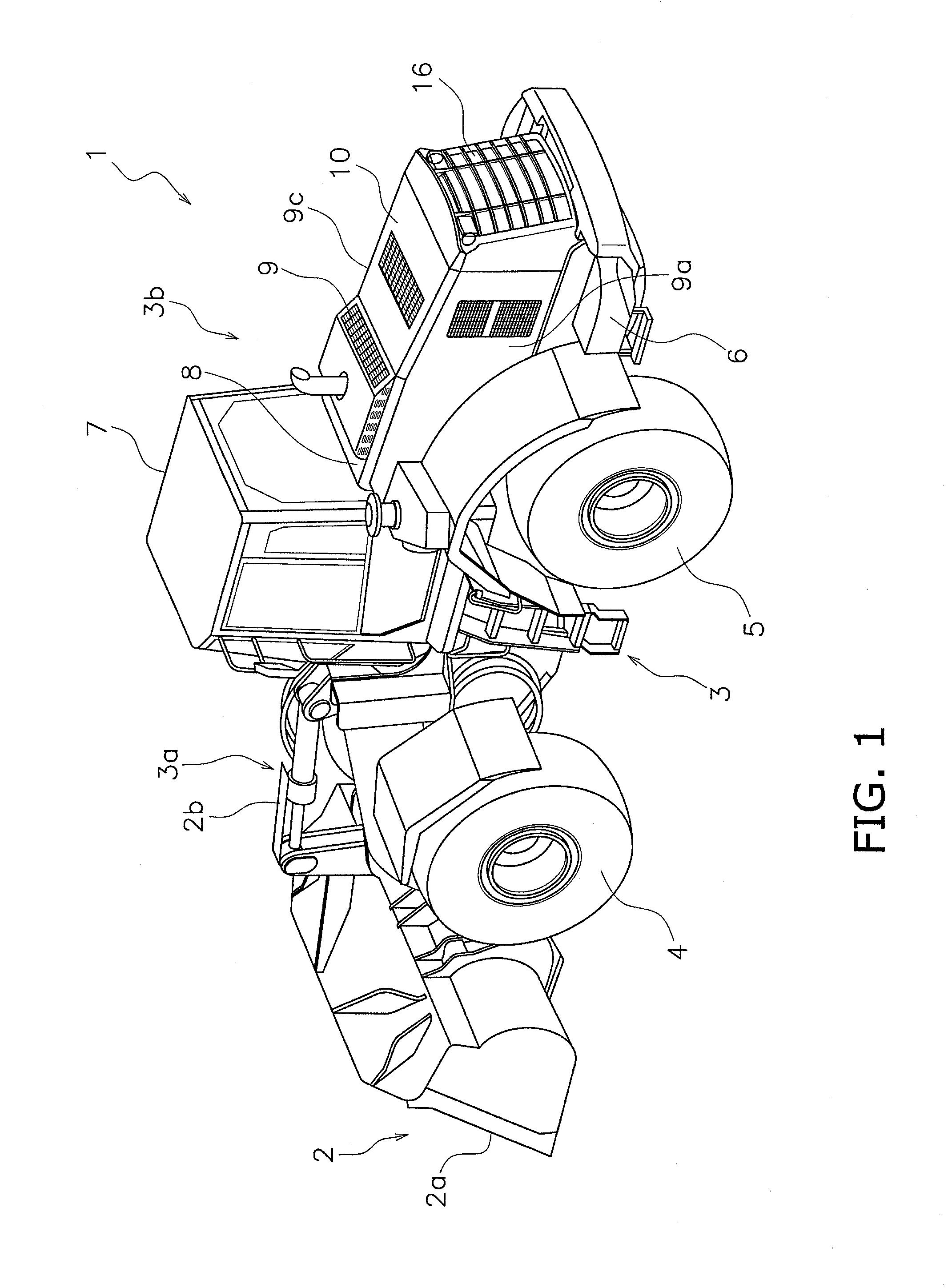

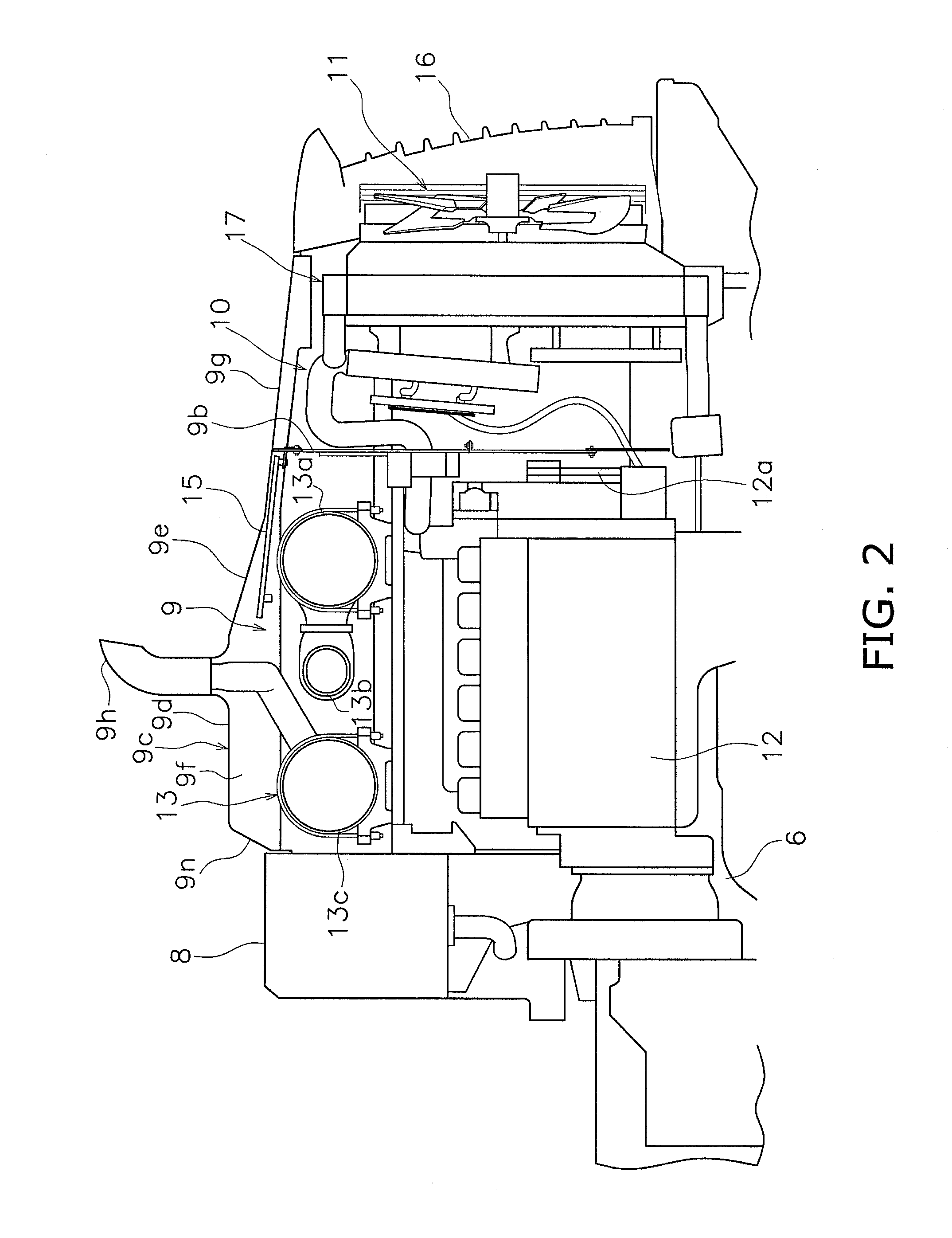

Wheel loader

InactiveUS20140238767A1Speed up the flowIncrease temperatureInternal combustion piston enginesExhaust apparatusEngineeringDiesel particulate filter

A wheel loader comprises an engine, an exhaust gas post-processing device, an engine room, a top plate, a cooling room, a partition wall, and a drainage mechanism. The exhaust gas post-processing device is disposed above the engine in the engine room and includes a diesel particulate filtering device and a selective catalyst reduction catalyst device. The top plate has a sloping part with a height that decreases toward the rear, and a first ventilation part that includes a plurality of through-holes formed in the sloping part. The top plate defines an upper plane of the engine room. The cooling room accommodates a cooling unit and is disposed to the rear of the engine room, separated by the partition wall. The drainage mechanism is disposed below the first ventilation part, and configured to drain water entering the engine room from the first ventilation part to the outside of the engine room.

Owner:KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com