Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70419results about "Metal/metal-oxides/metal-hydroxide catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

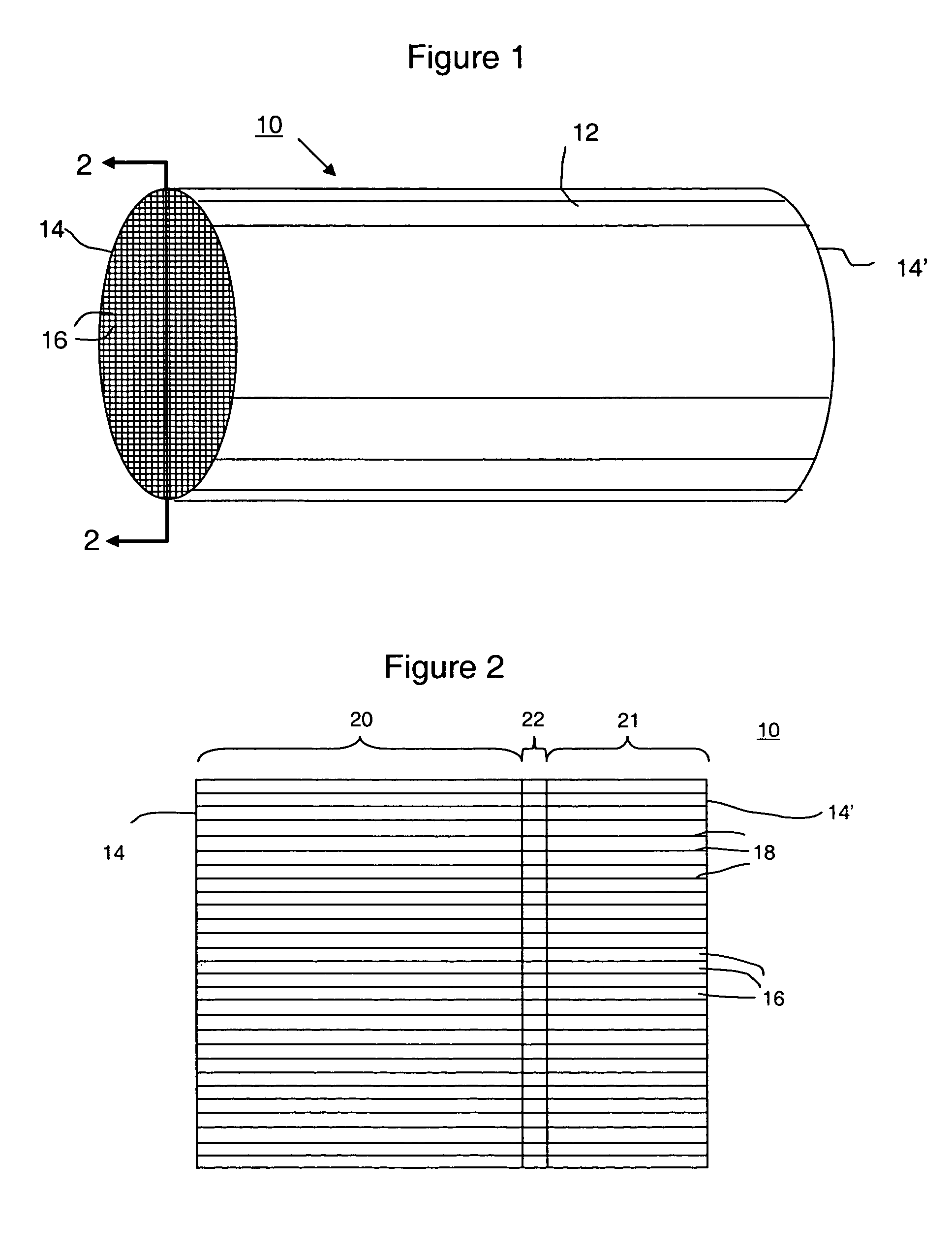

Doped elongated semiconductors, growing such semiconductors, devices including such semiconductors and fabricating such devices

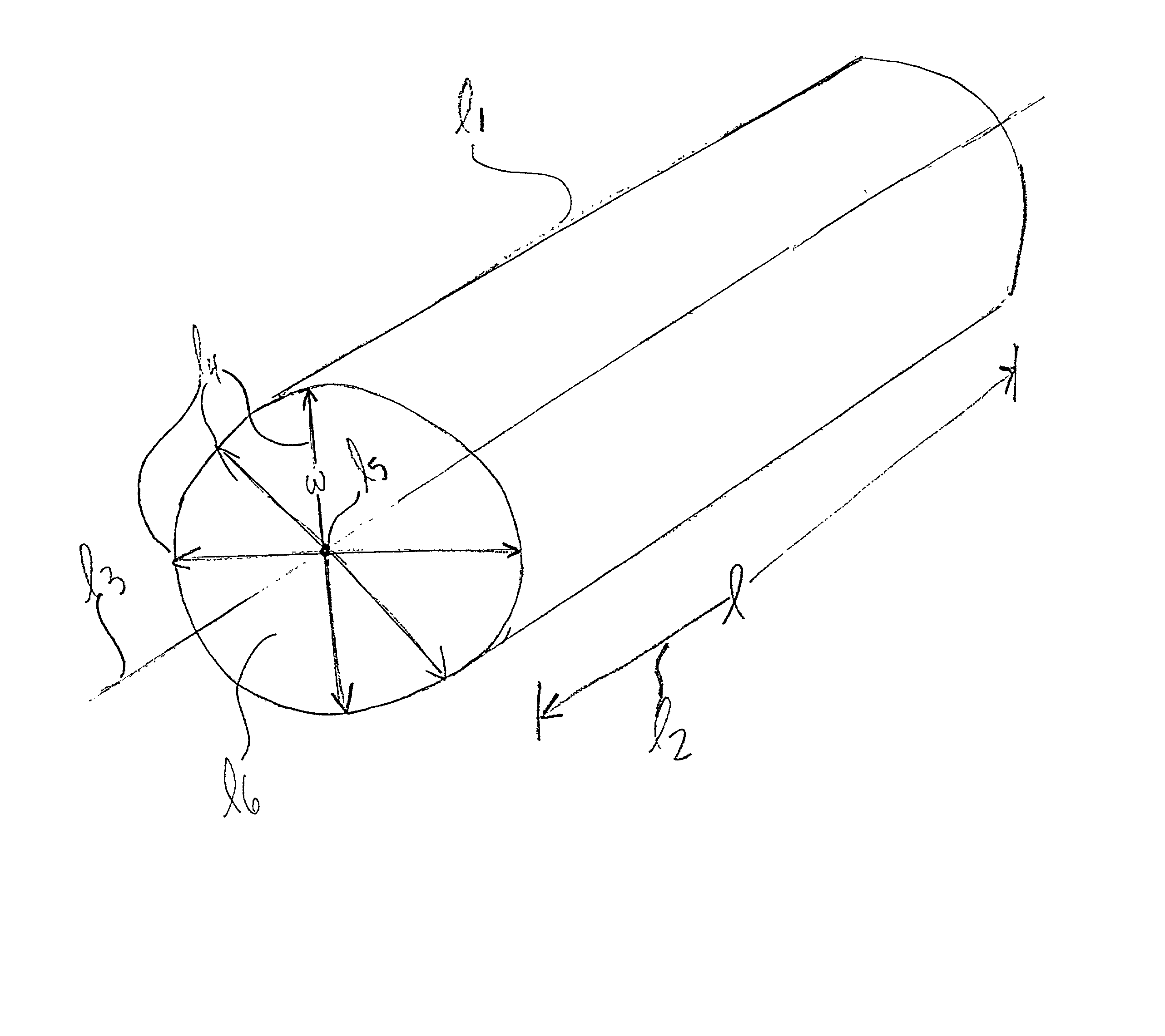

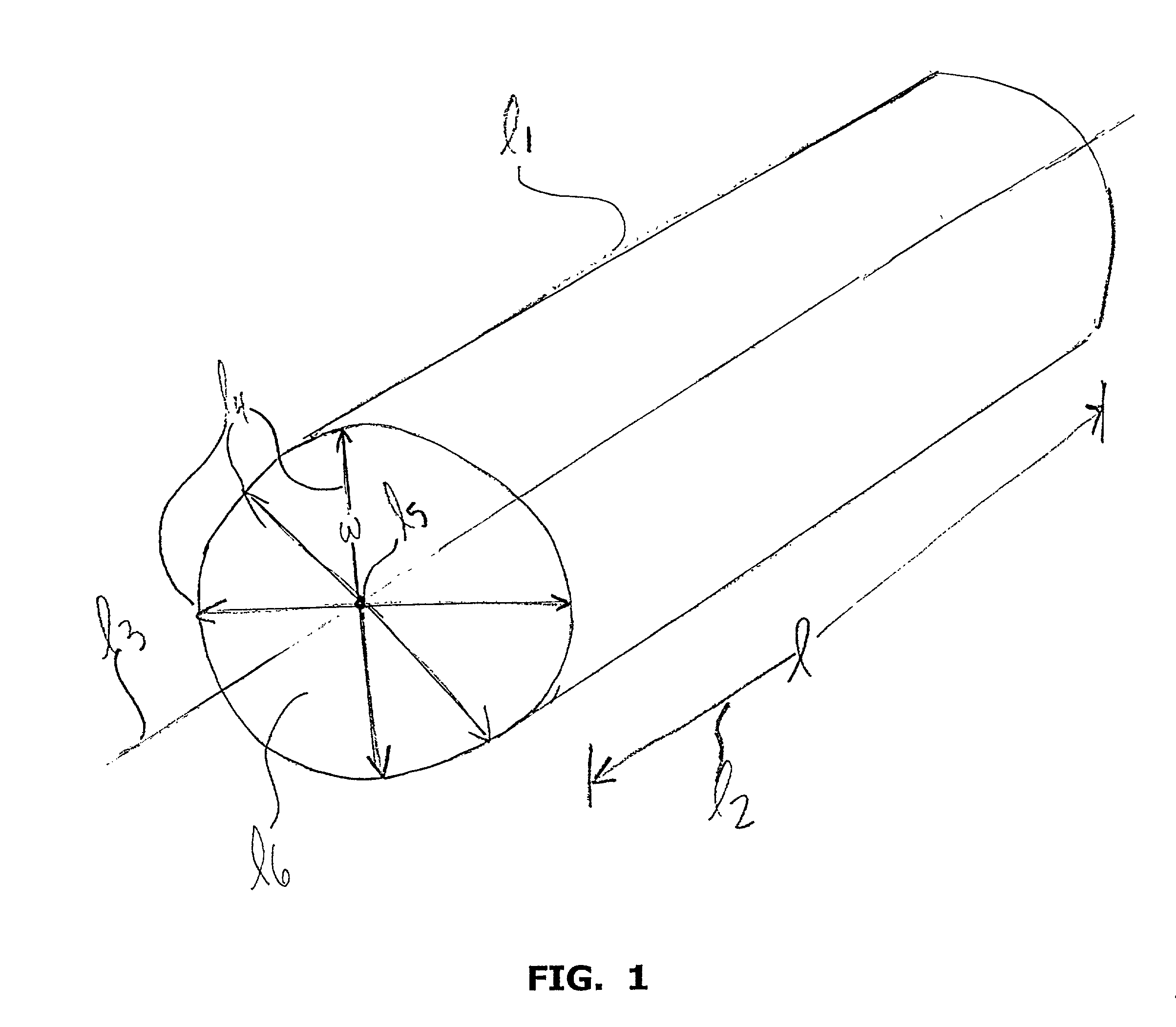

A bulk-doped semiconductor that is at least one of the following: a single crystal, an elongated and bulk-doped semiconductor that, at any point along its longitudinal axis, has a largest cross-sectional dimension less than 500 nanometers, and a free-standing and bulk-doped semiconductor with at least one portion having a smallest width of less than 500 nanometers. Such a semiconductor may comprise an interior core comprising a first semiconductor; and an exterior shell comprising a different material than the first semiconductor. Such a semiconductor may be elongated and my have, at any point along a longitudinal section of such a semiconductor, a ratio of the length of the section to a longest width is greater than 4:1, or greater than 10:1, or greater than 100:1, or even greater than 1000:1. At least one portion of such a semiconductor may a smallest width of less than 200 nanometers, or less than 150 nanometers, or less than 100 nanometers, or less than 80 nanometers, or less than 70 nanometers, or less than 60 nanometers, or less than 40 nanometers, or less than 20 nanometers, or less than 10 nanometers, or even less than 5 nanometers. Such a semiconductor may be a single crystal and may be free-standing. Such a semiconductor may be either lightly n-doped, heavily n-doped, lightly p-doped or heavily p-doped. Such a semiconductor may be doped during growth. Such a semiconductor may be part of a device, which may include any of a variety of devices and combinations thereof, and, and a variety of assembling techniques may be used to fabricate devices from such a semiconductor. Two or more of such a semiconductors, including an array of such semiconductors, may be combined to form devices, for example, to form a crossed p-n junction of a device. Such devices at certain sizes may exhibit quantum confinement and other quantum phenomena, and the wavelength of light emitted from one or more of such semiconductors may be controlled by selecting a width of such semiconductors. Such semiconductors and device made therefrom may be used for a variety of applications.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

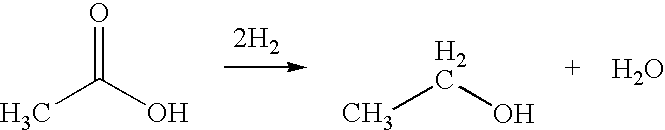

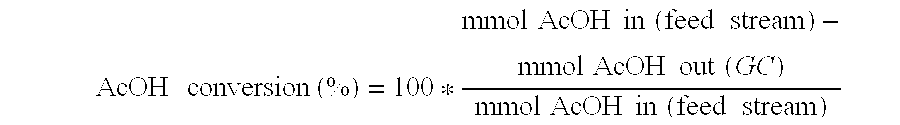

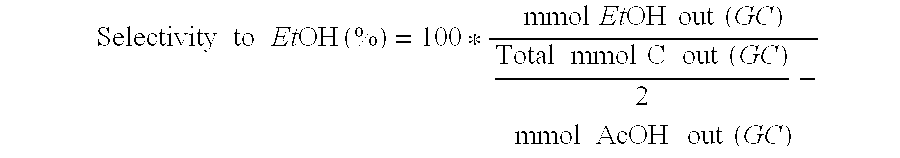

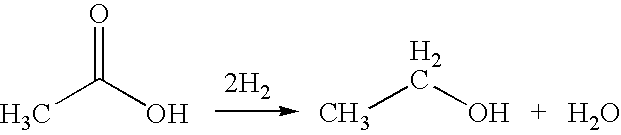

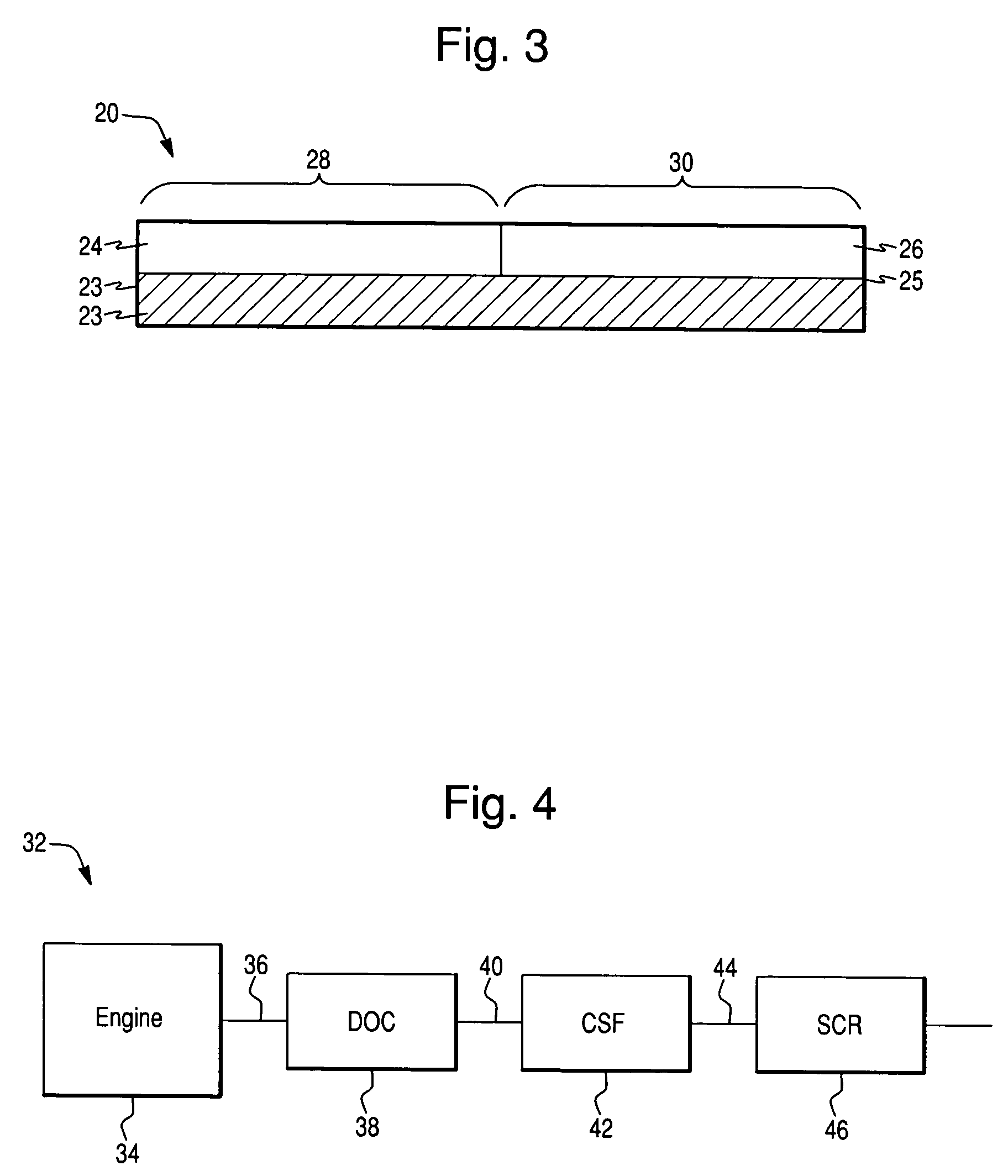

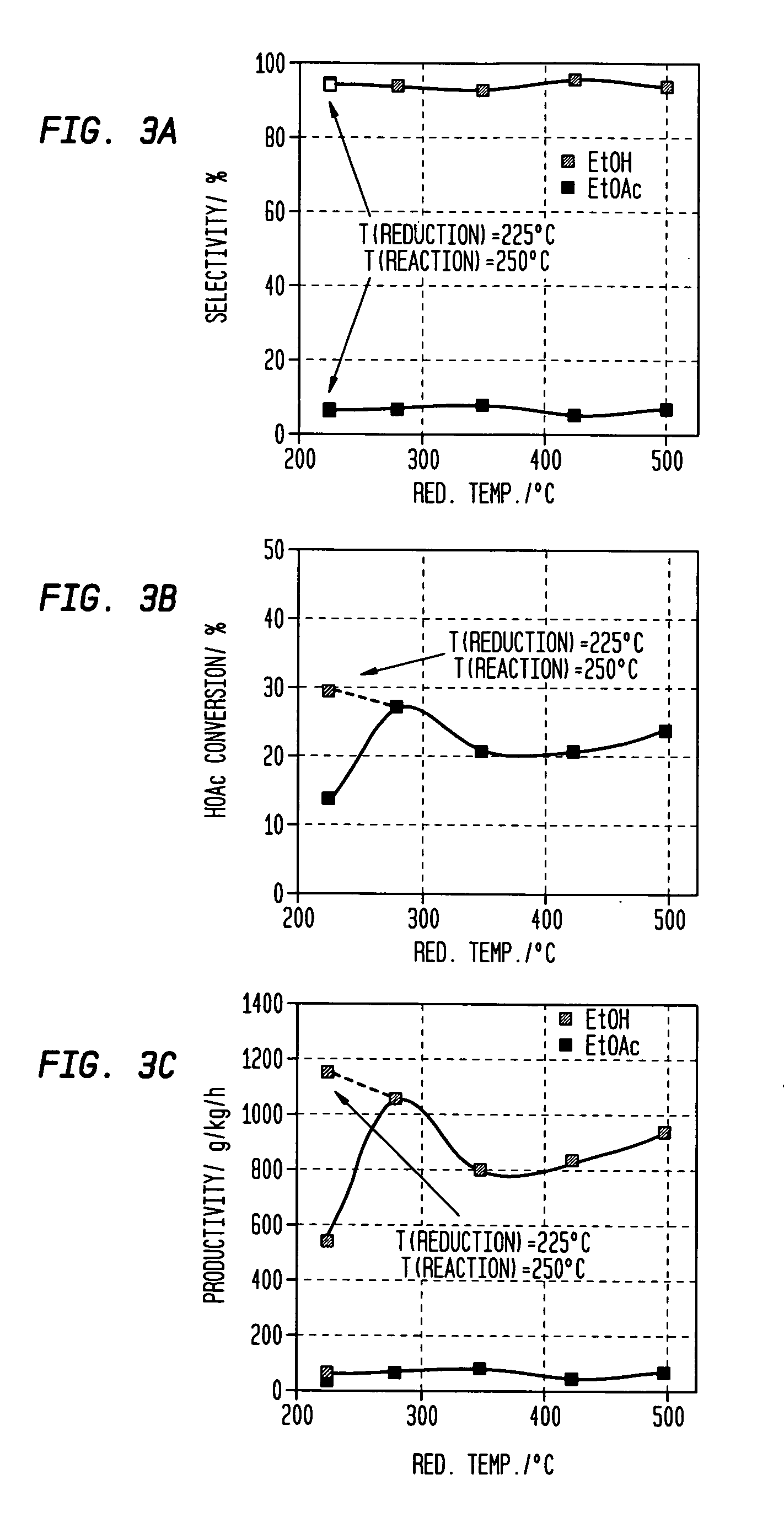

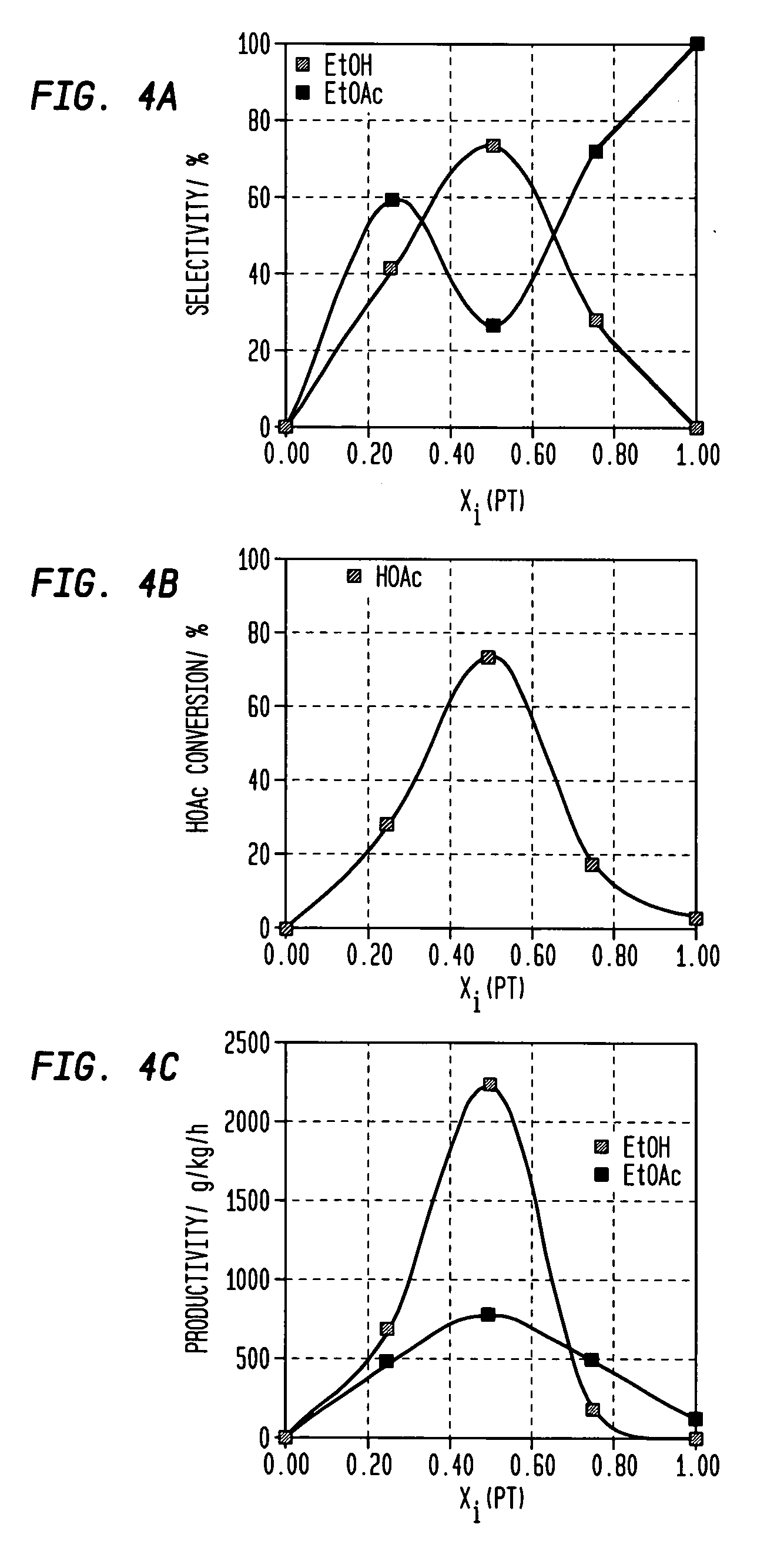

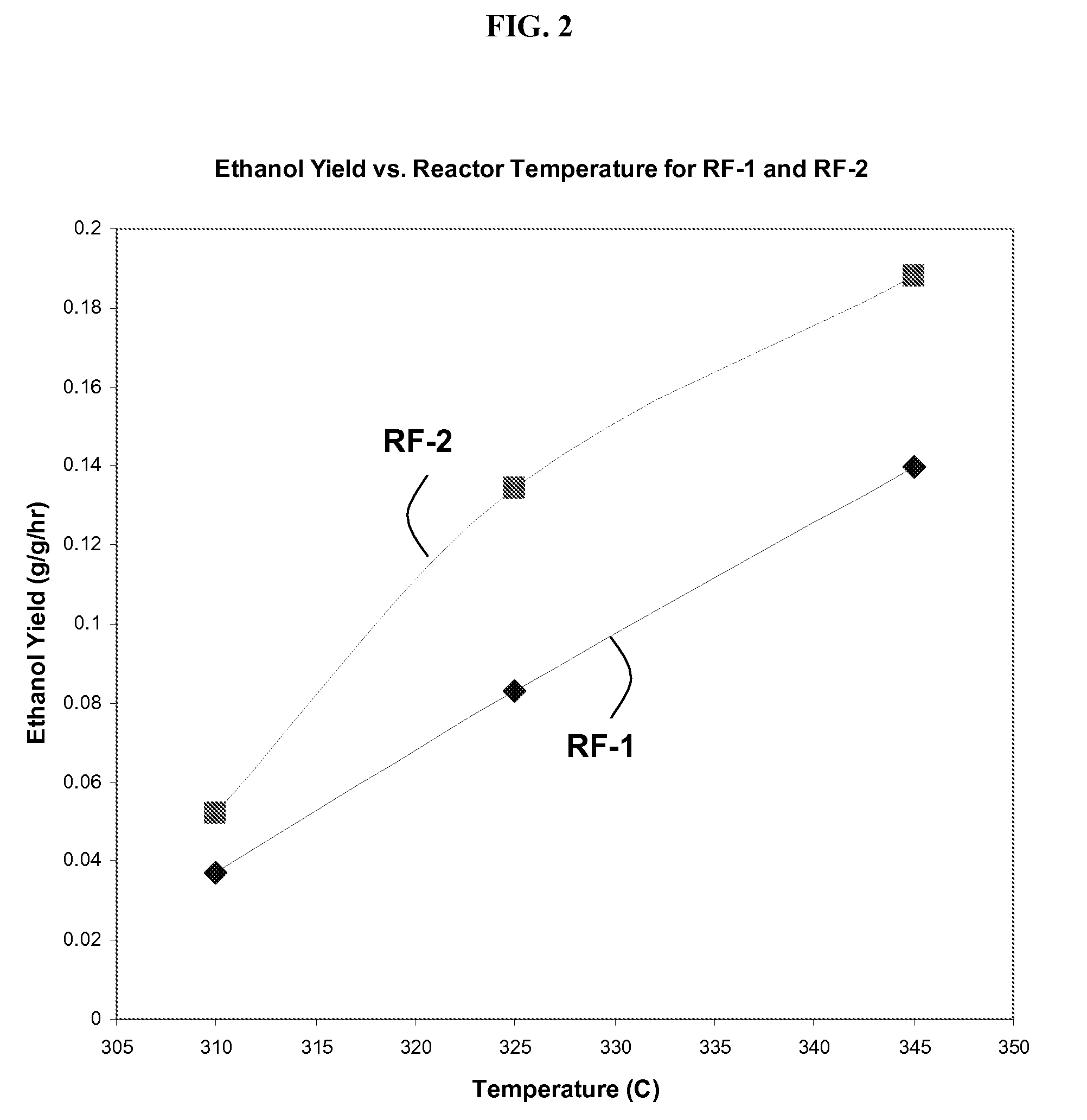

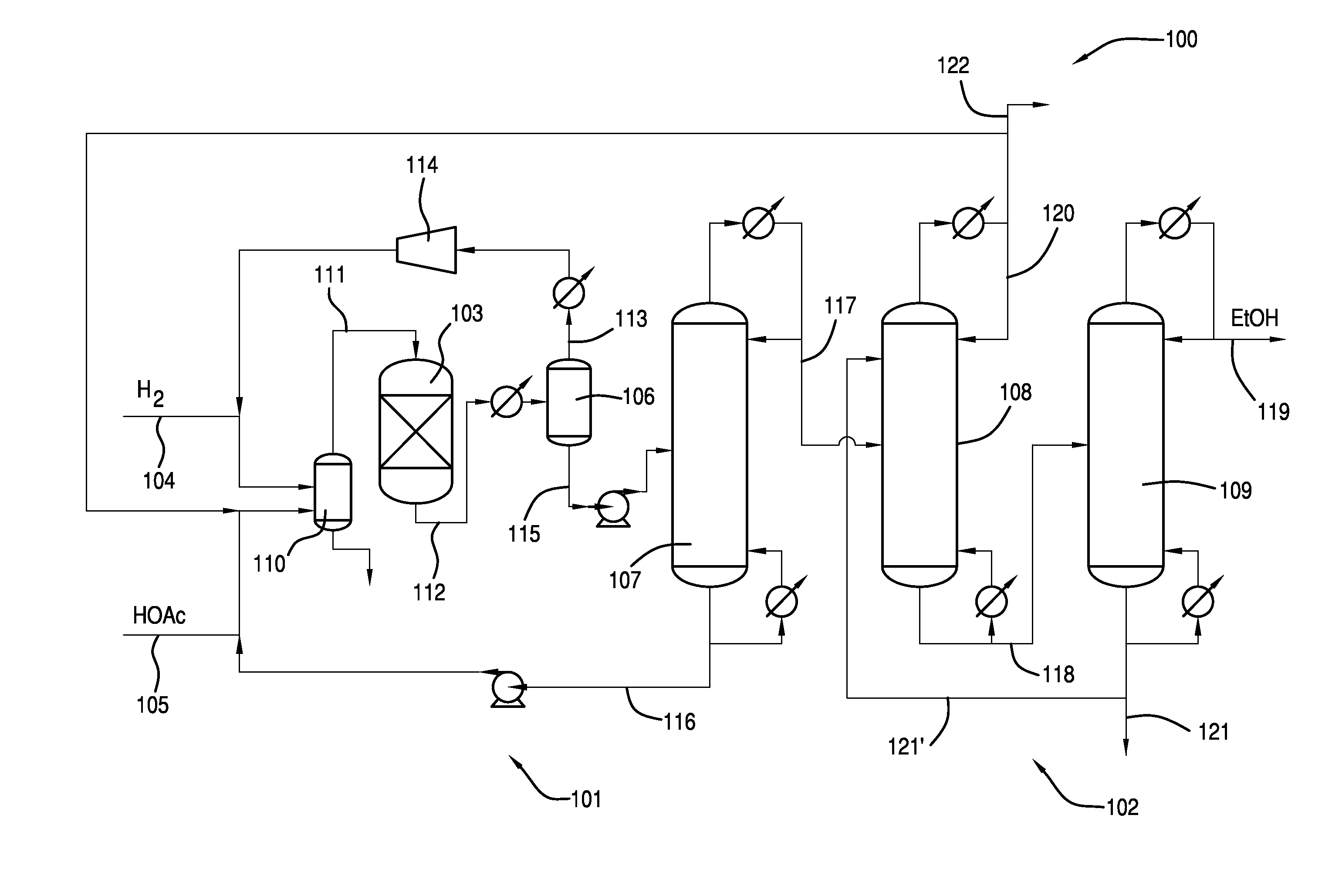

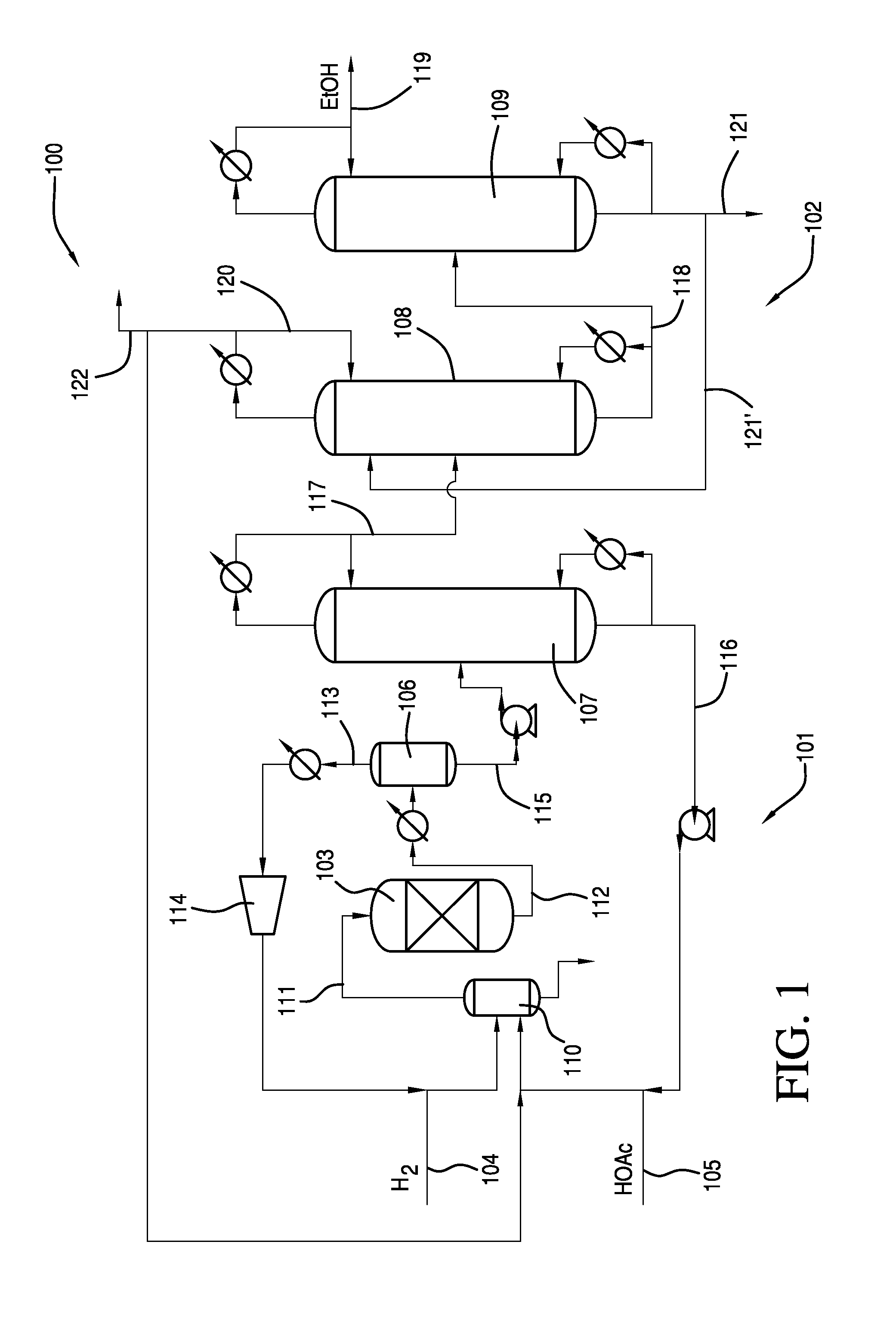

Ethanol production from acetic acid utilizing a cobalt catalyst

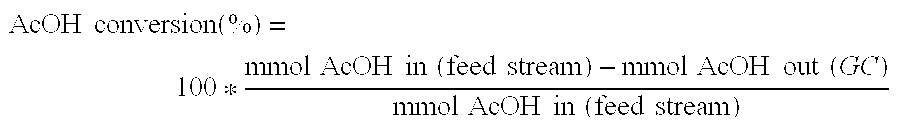

InactiveUS7608744B1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionAcetic acidPlatinum

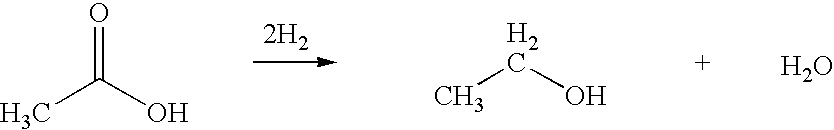

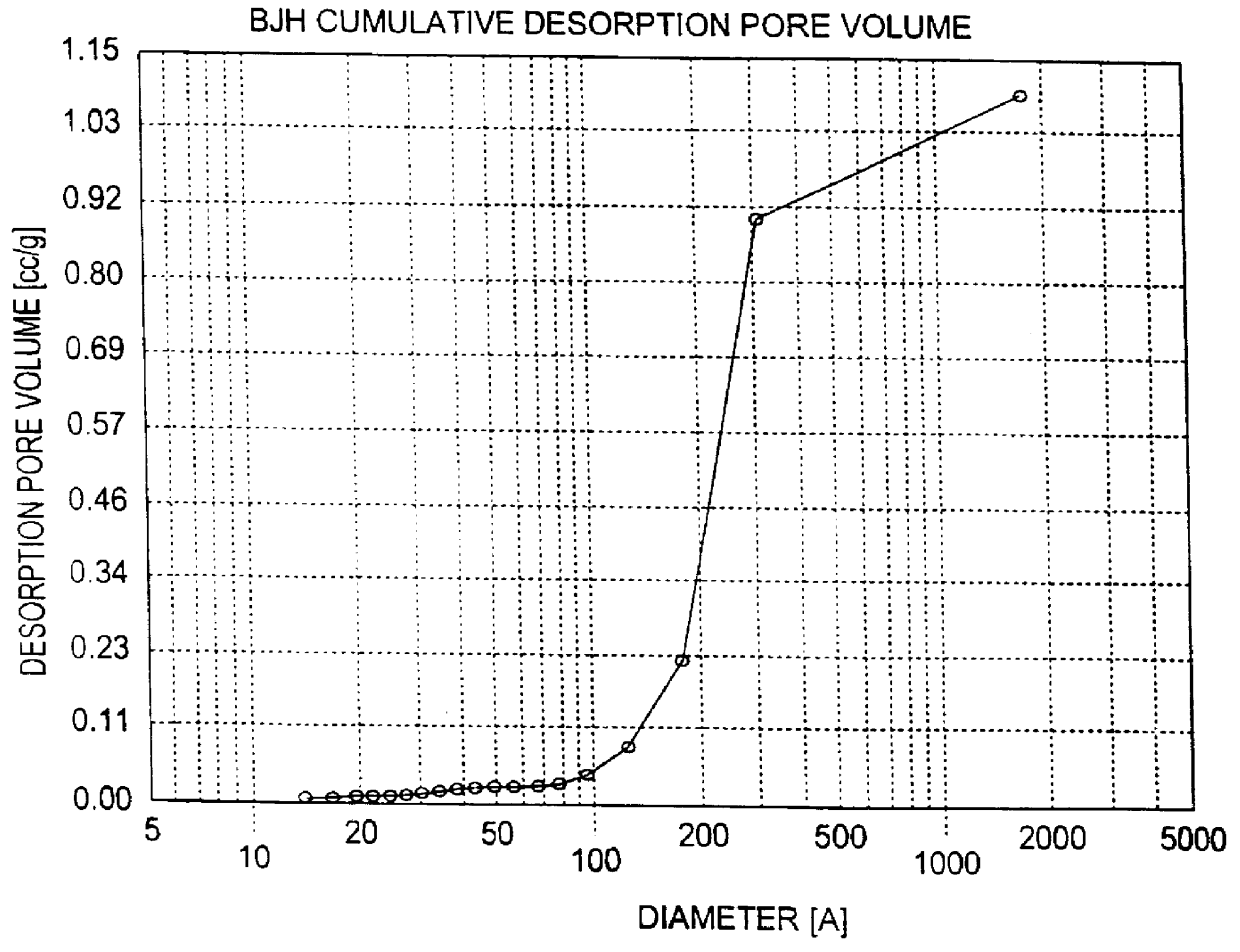

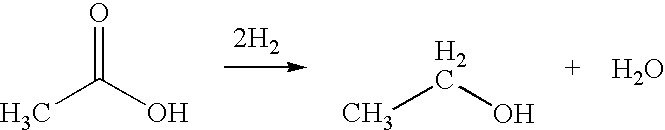

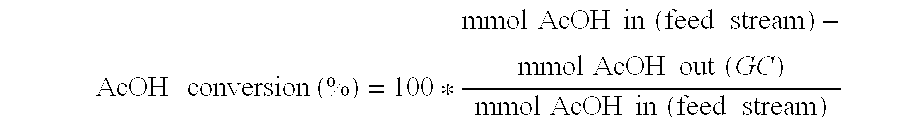

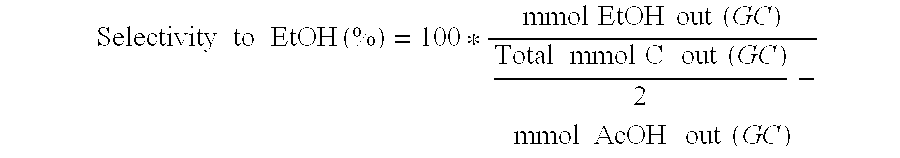

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either cobalt and palladium supported on graphite or cobalt and platinum supported on silica selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

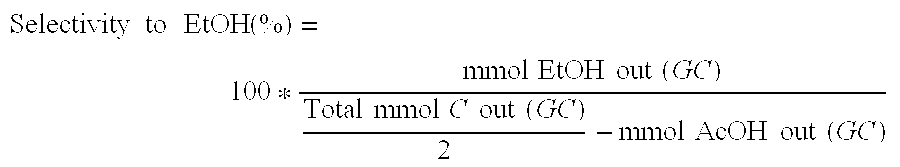

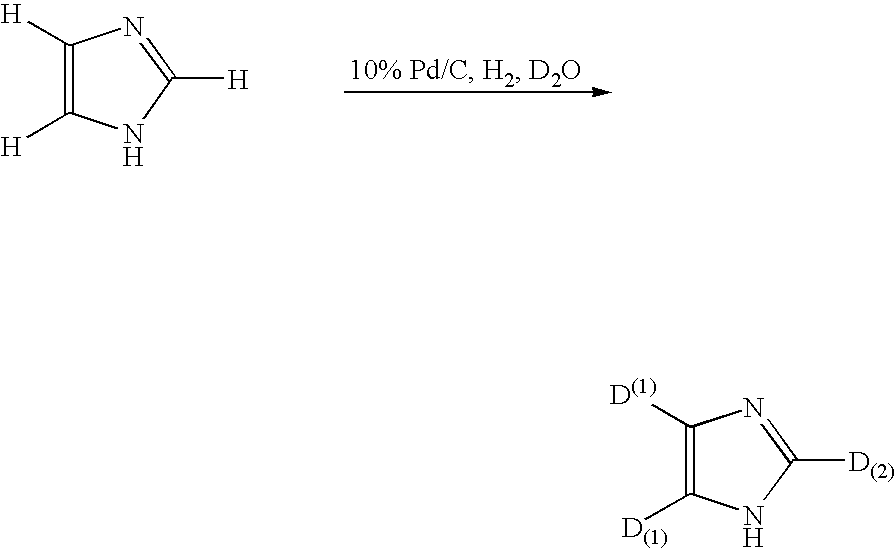

Method for deuteration of a heterocyclic ring

ActiveUS7517990B2Isotope introduction to heterocyclic compoundsSugar derivativesNickel catalystHydrogen atom

The present invention relates to a method for deuteration of a heterocyclic ring, which comprises subjecting a compound having a heterocyclic ring to sealed refluxing state in a deuterated solvent in the presence of an activated catalyst selected form a palladium catalyst, a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst. In accordance with a method of the present invention, a hydrogen atom belonging to a heterocyclic ring of a compound having a heterocyclic ring can be very efficiently deuterated because temperature of deuteration reaction can be maintained at higher than boiling point of the solvent.Further, a method for deuteration of the present invention can be applied widely to deuteration of various compounds having a heterocyclic ring which are liable to decomposition under supercritical conditions or acidic conditions, leading to industrial and efficient deuteration of a compound having a heterocyclic ring.

Owner:FUJIFILM WAKO PURE CHEM CORP

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS7863489B2High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicateAcetic acid

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

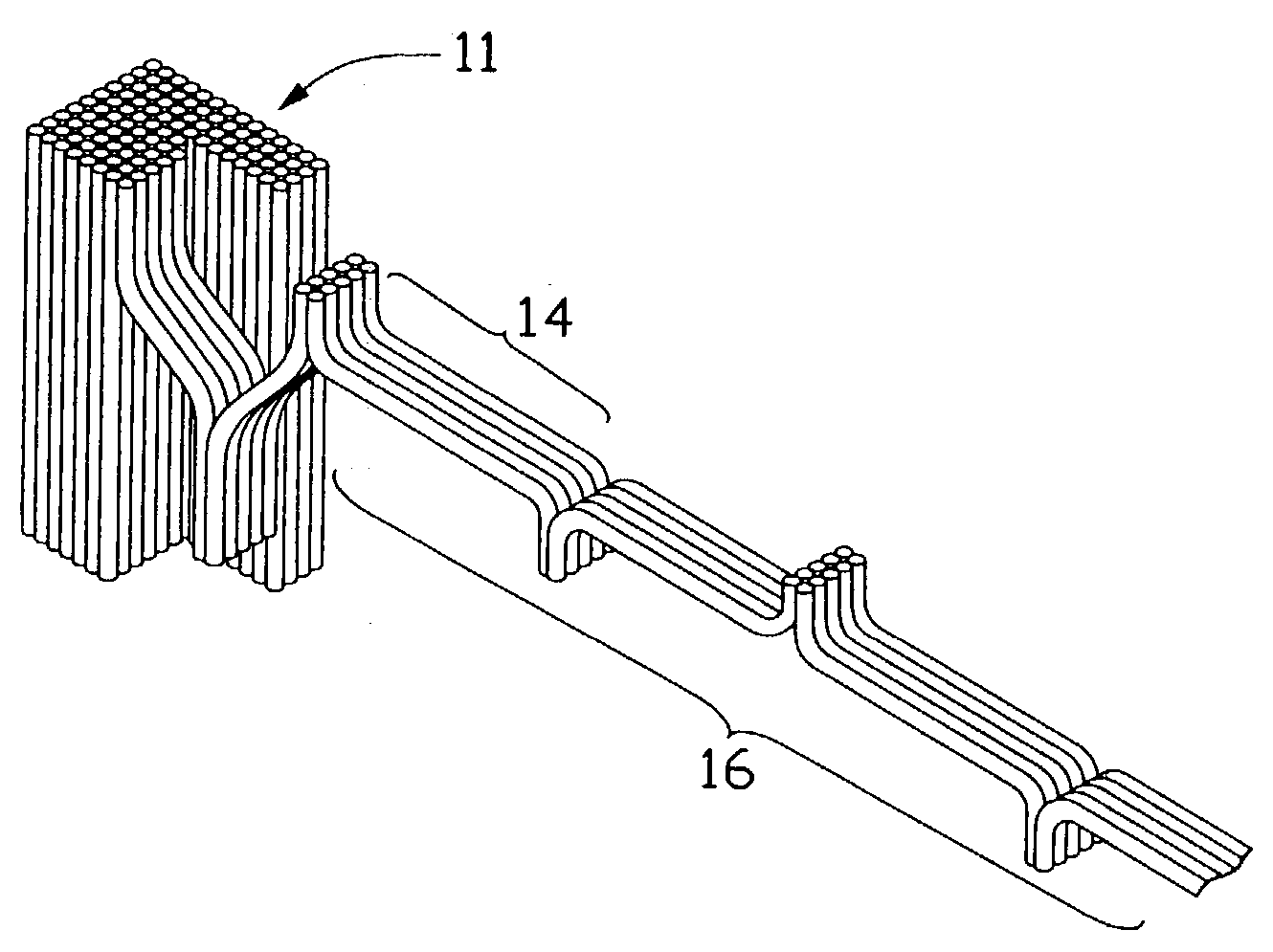

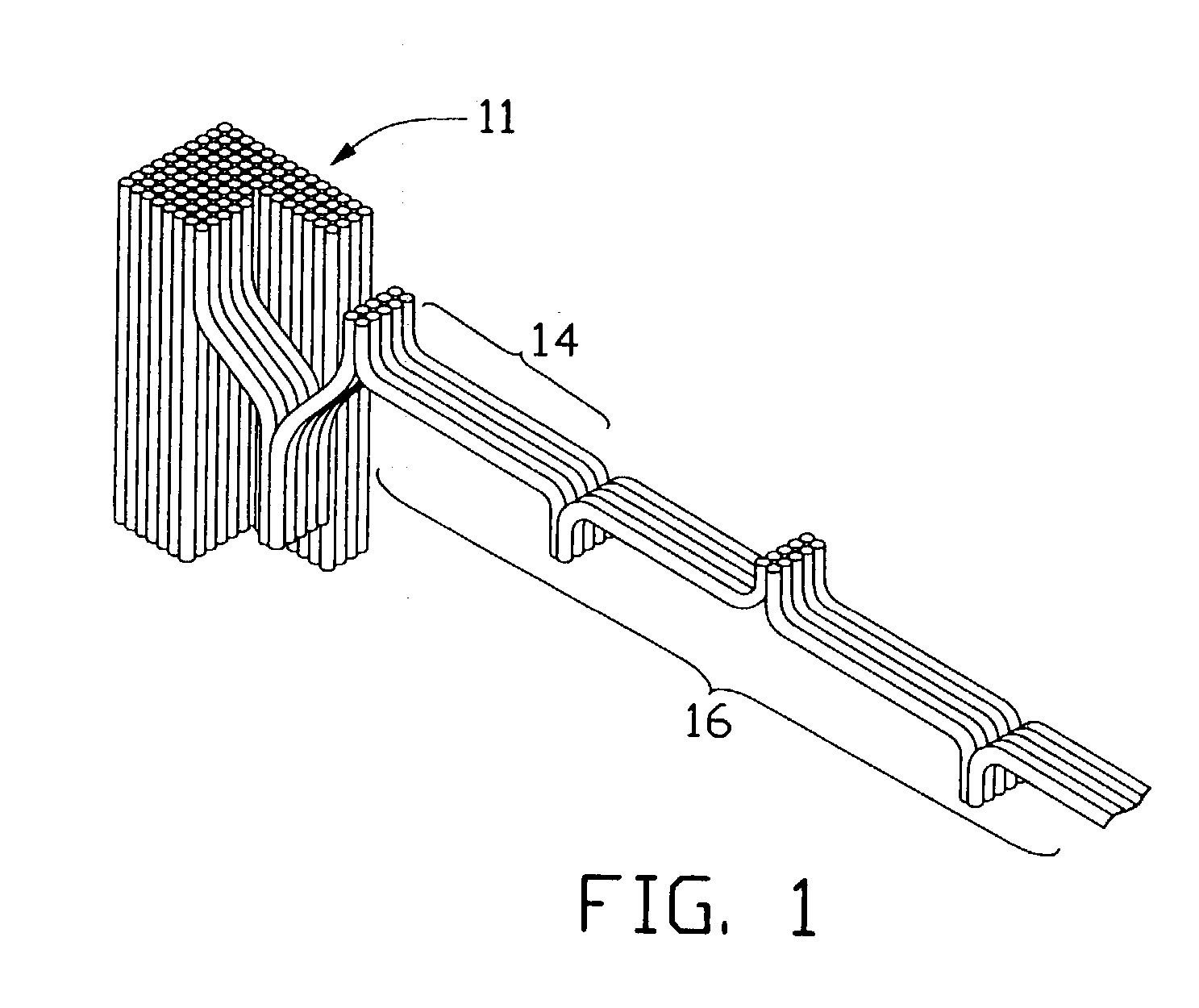

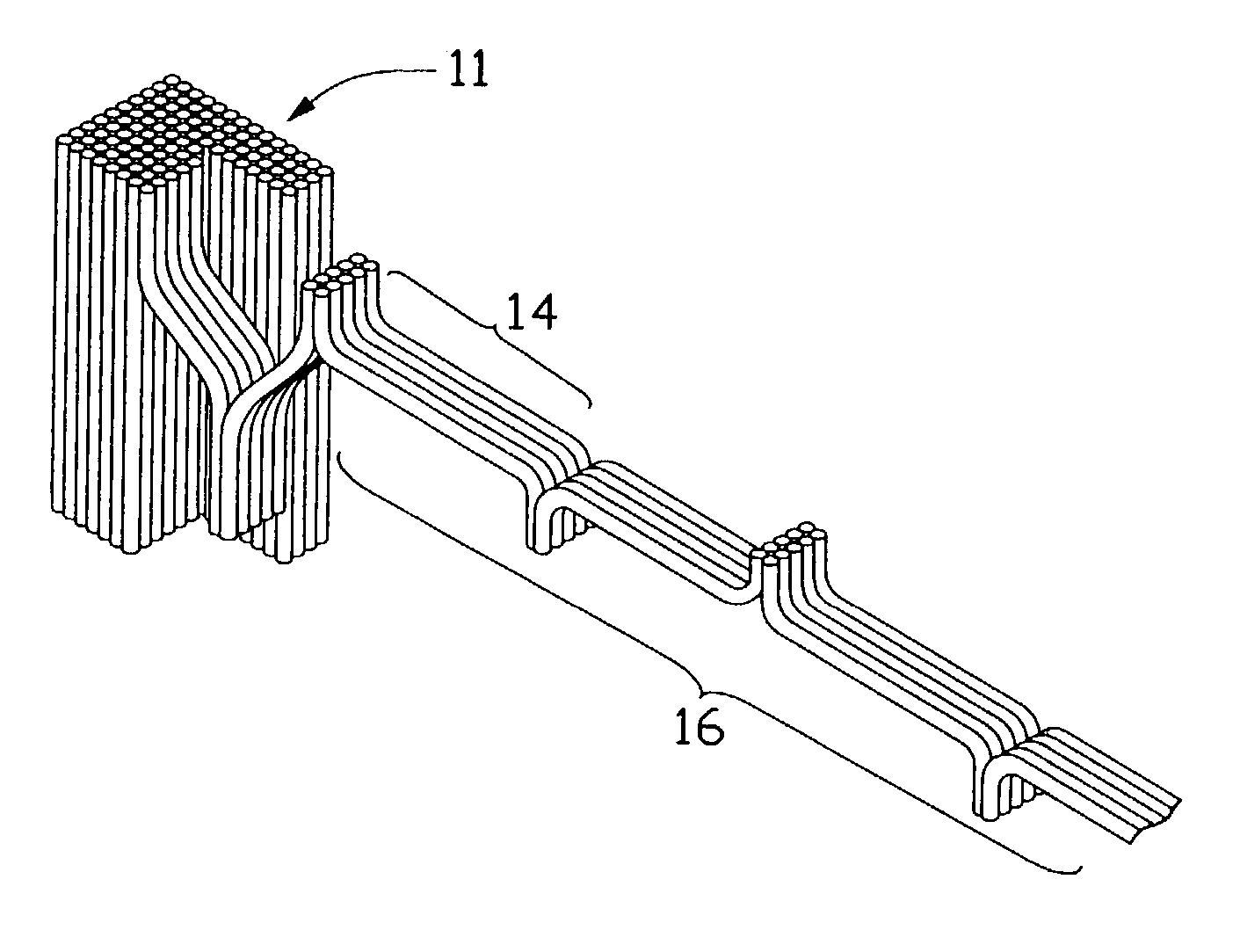

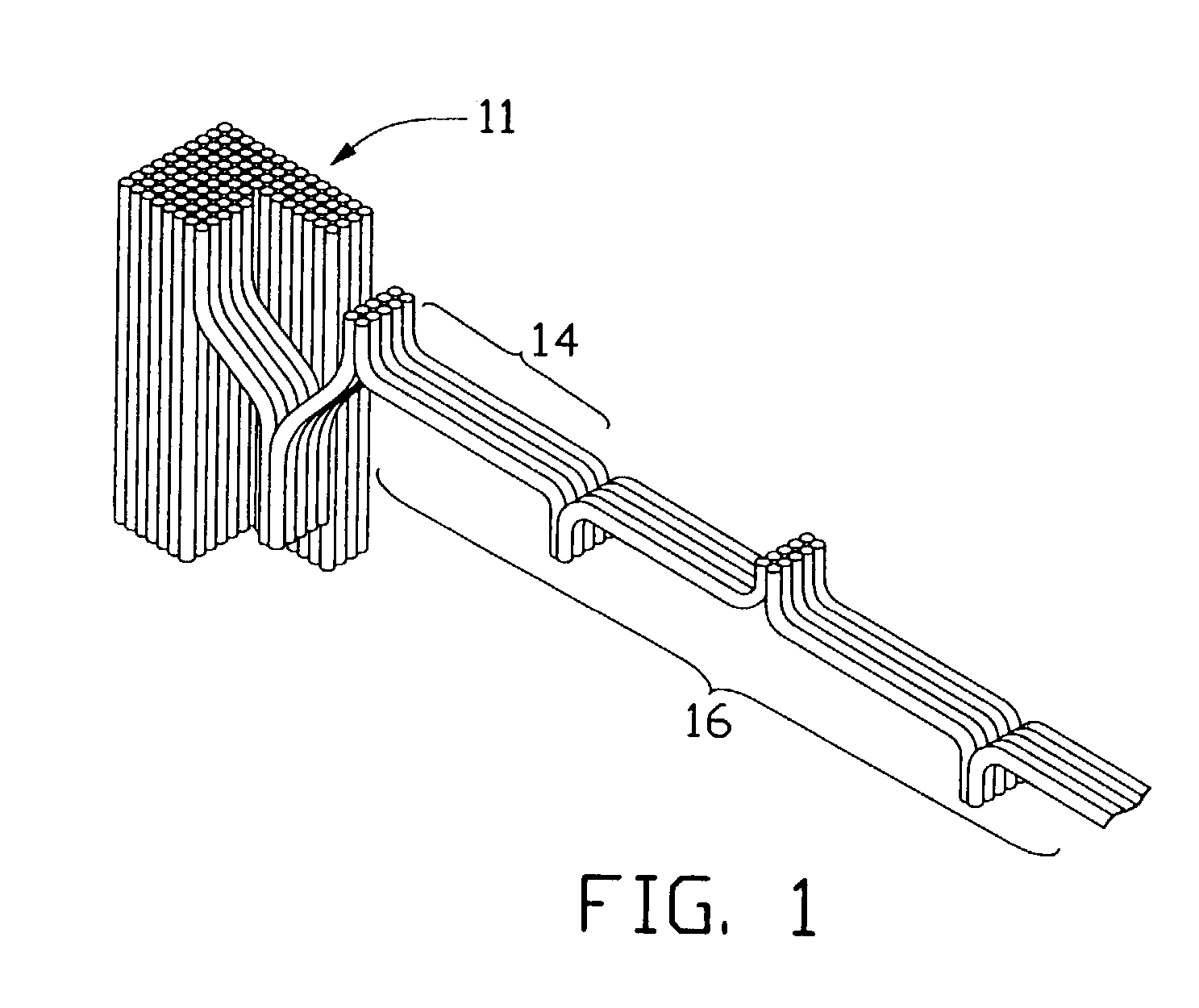

Method for fabricating carbon nanotube yarn

ActiveUS20040053780A1Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

Method for fabricating carbon nanotube yarn

ActiveUS7045108B2Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

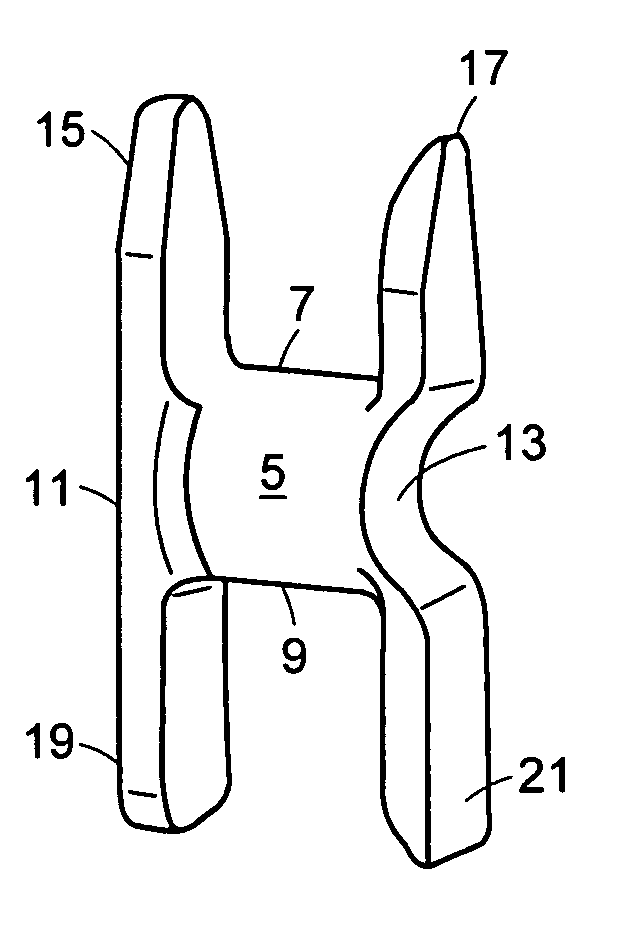

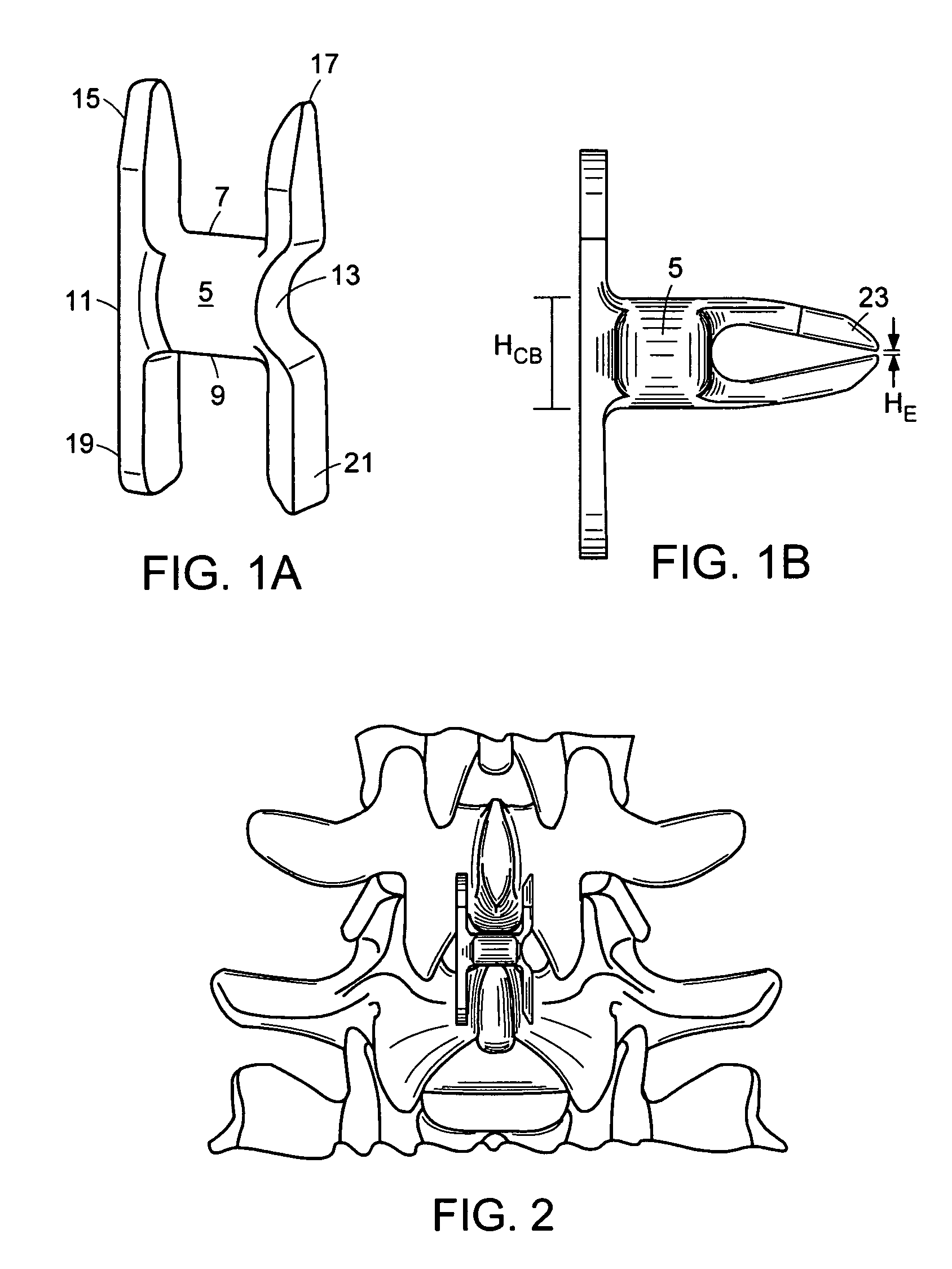

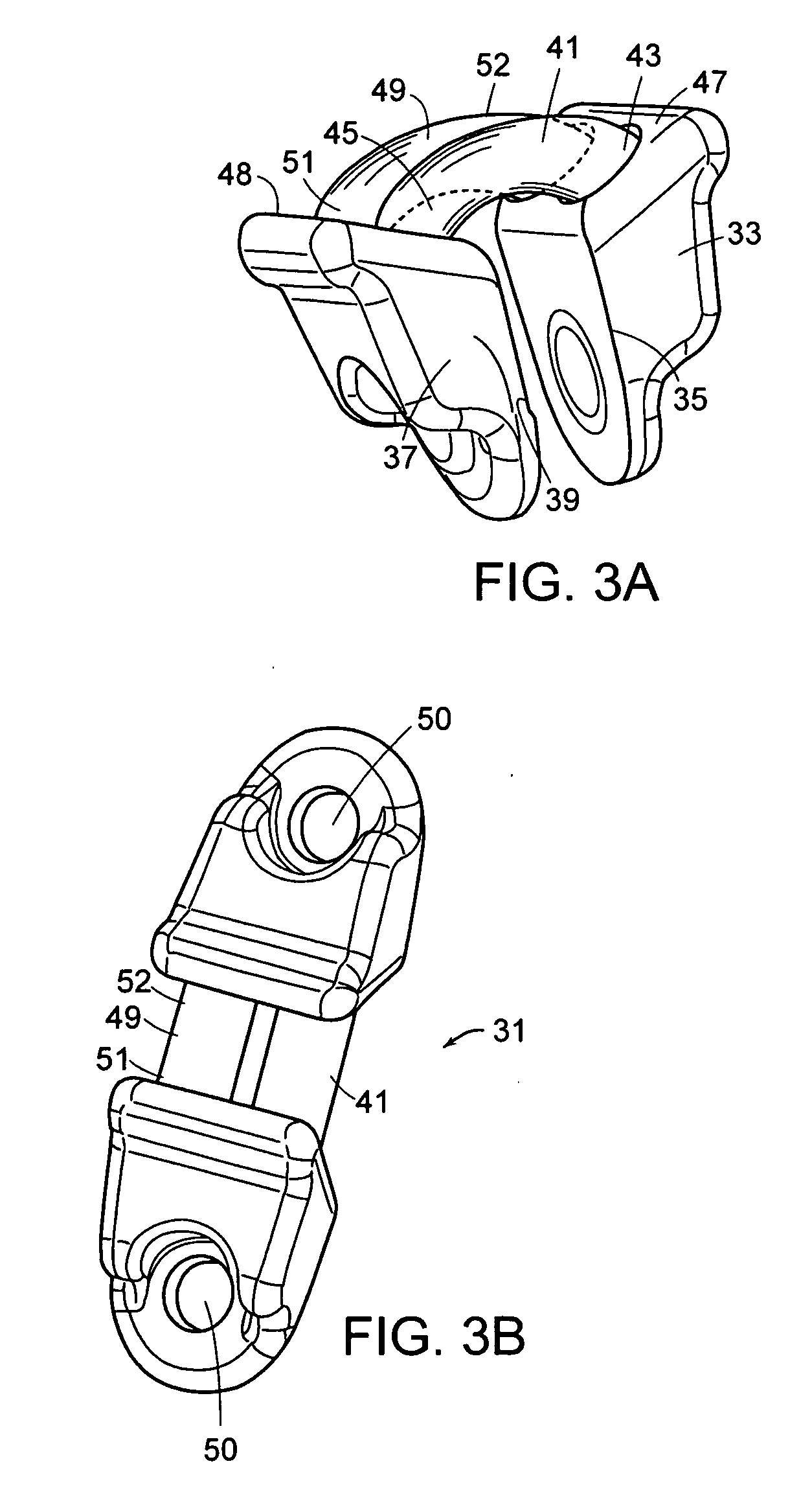

Posterior process dynamic spacer

ActiveUS20050203512A1Gently limiting excessive extensionOrganic chemistryInternal osteosythesisProcess dynamicsMedicine

Owner:DEPUY SPINE INC (US)

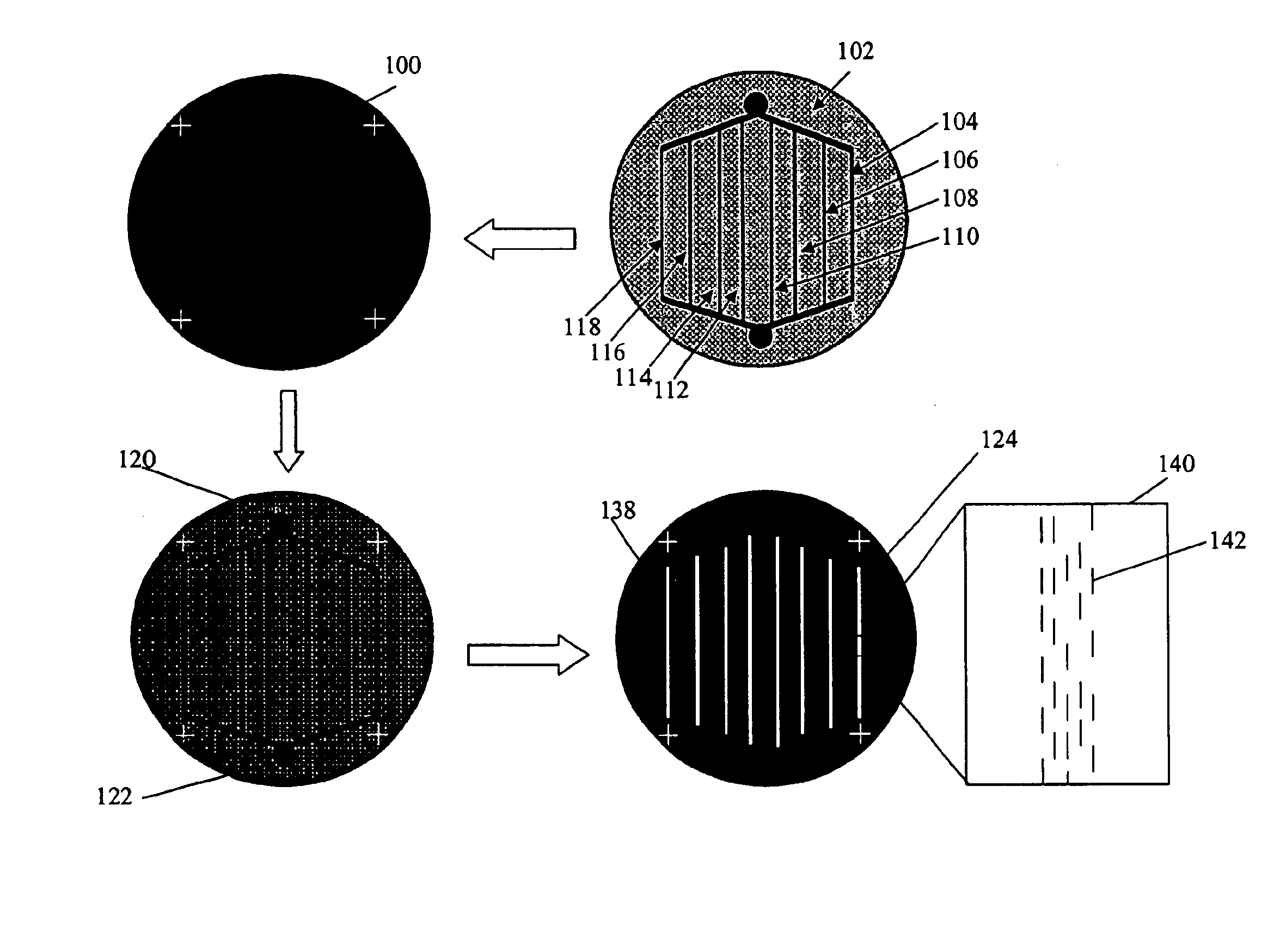

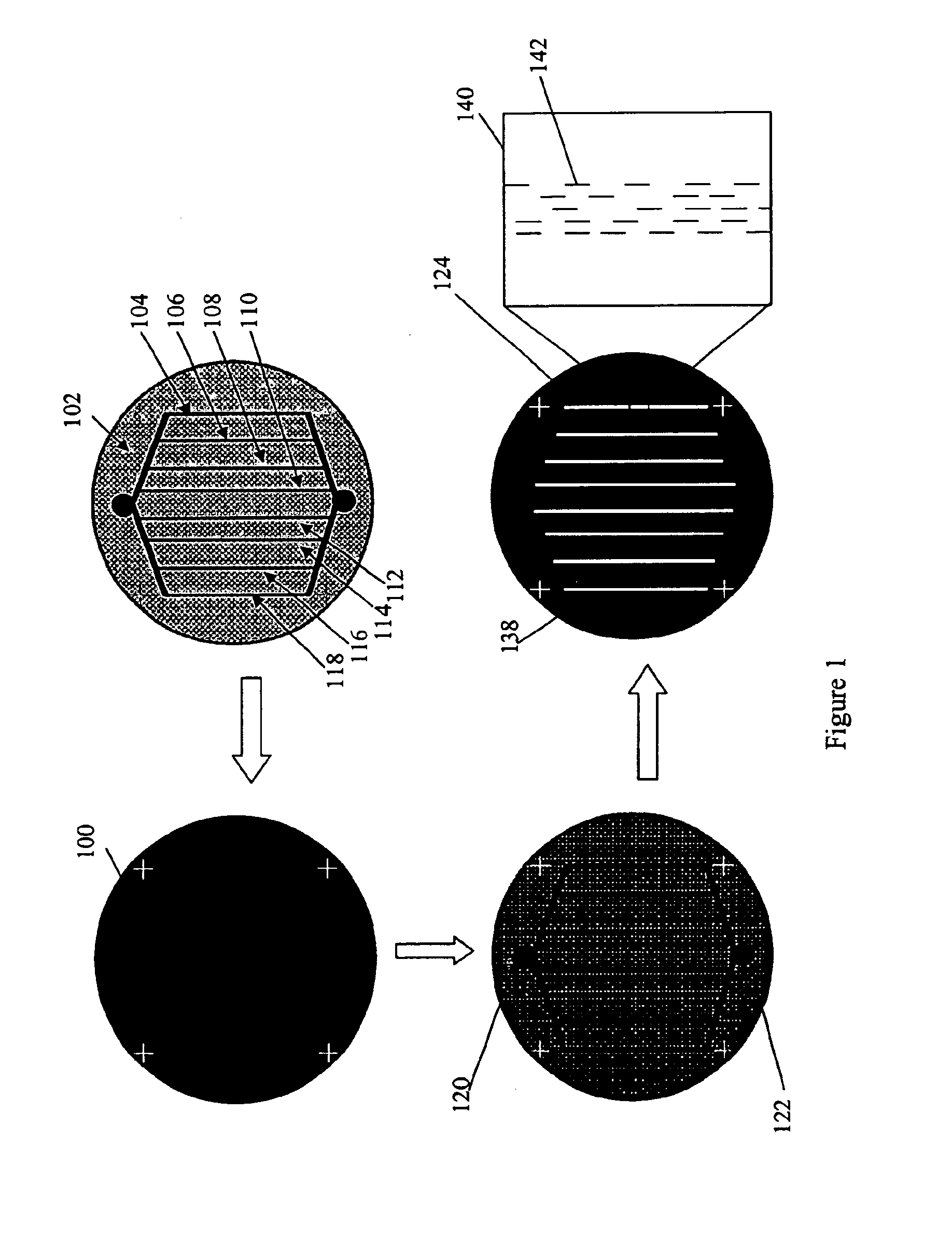

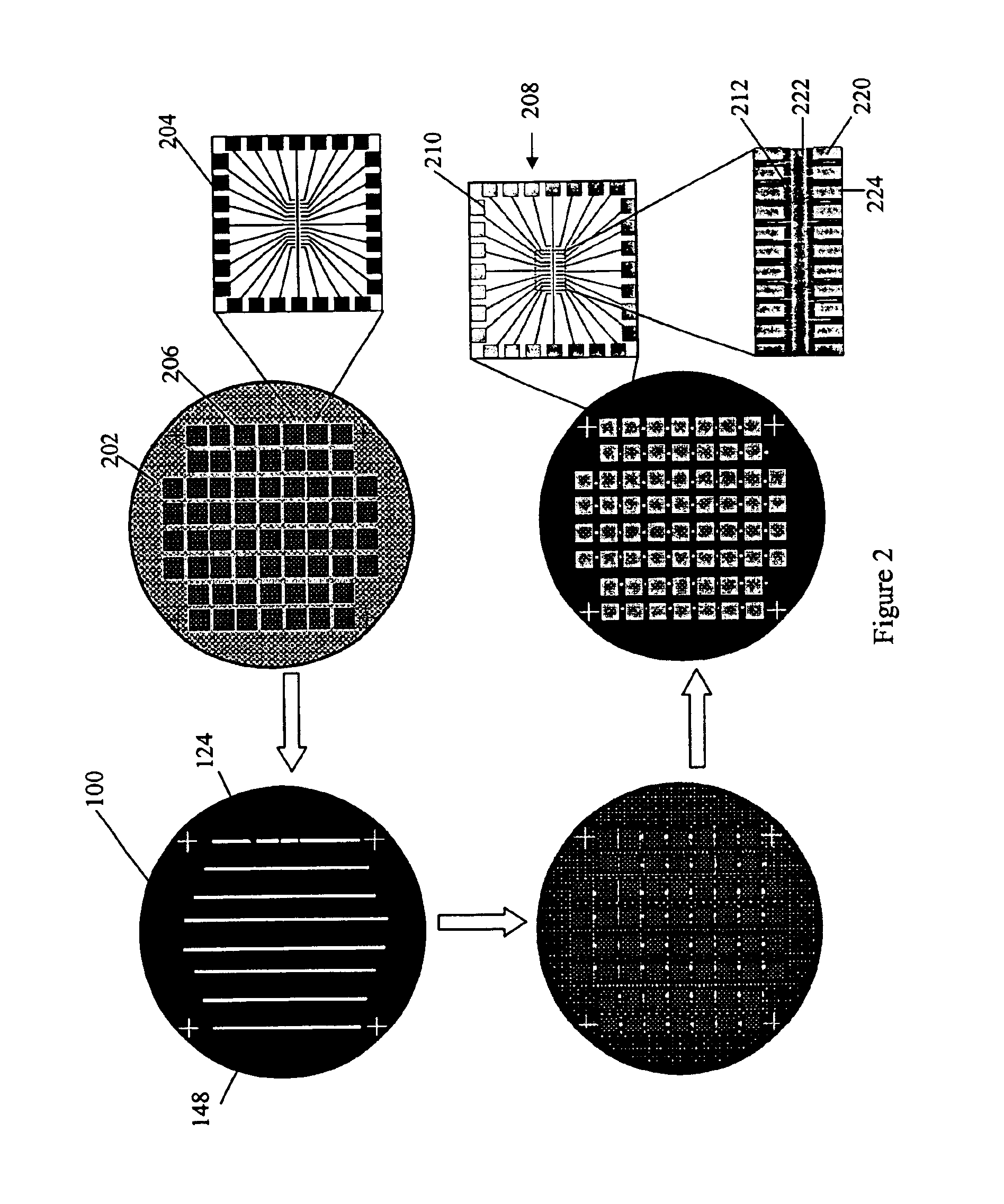

Methods of positioning and/or orienting nanostructures

Methods of positioning and orienting nanostructures, and particularly nanowires, on surfaces for subsequent use or integration. The methods utilize mask based processes alone or in combination with flow based alignment of the nanostructures to provide oriented and positioned nanostructures on surfaces. Also provided are populations of positioned and / or oriented nanostructures, devices that include populations of positioned and / or oriented nanostructures, systems for positioning and / or orienting nanostructures, and related devices, systems and methods.

Owner:ONED MATERIAL INC

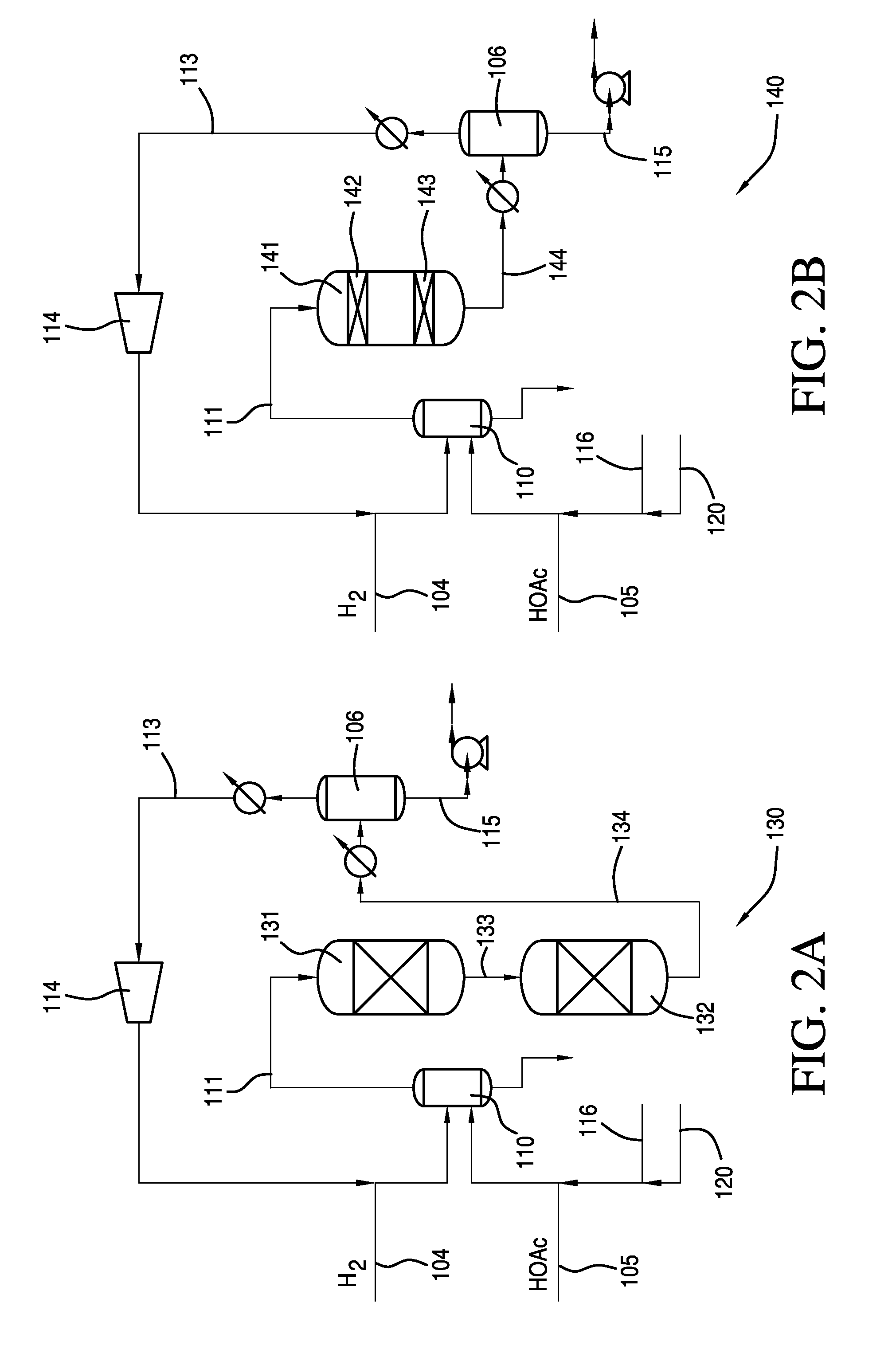

Ethylene production from acetic acid utilizing dual reaction zone process

A process for selective formation of ethylene from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with a first catalytic composition including a suitable hydrogenating catalyst in a first reaction zone to form an intermediate mixture including ethanol and ethyl acetate; and subsequently reacting the intermediate mixture over a suitable dehydrating and / or cracking catalyst in a second reaction zone to form ethylene. Selectivities of ethylene of over 80% are achieved.

Owner:CELANESE INT CORP

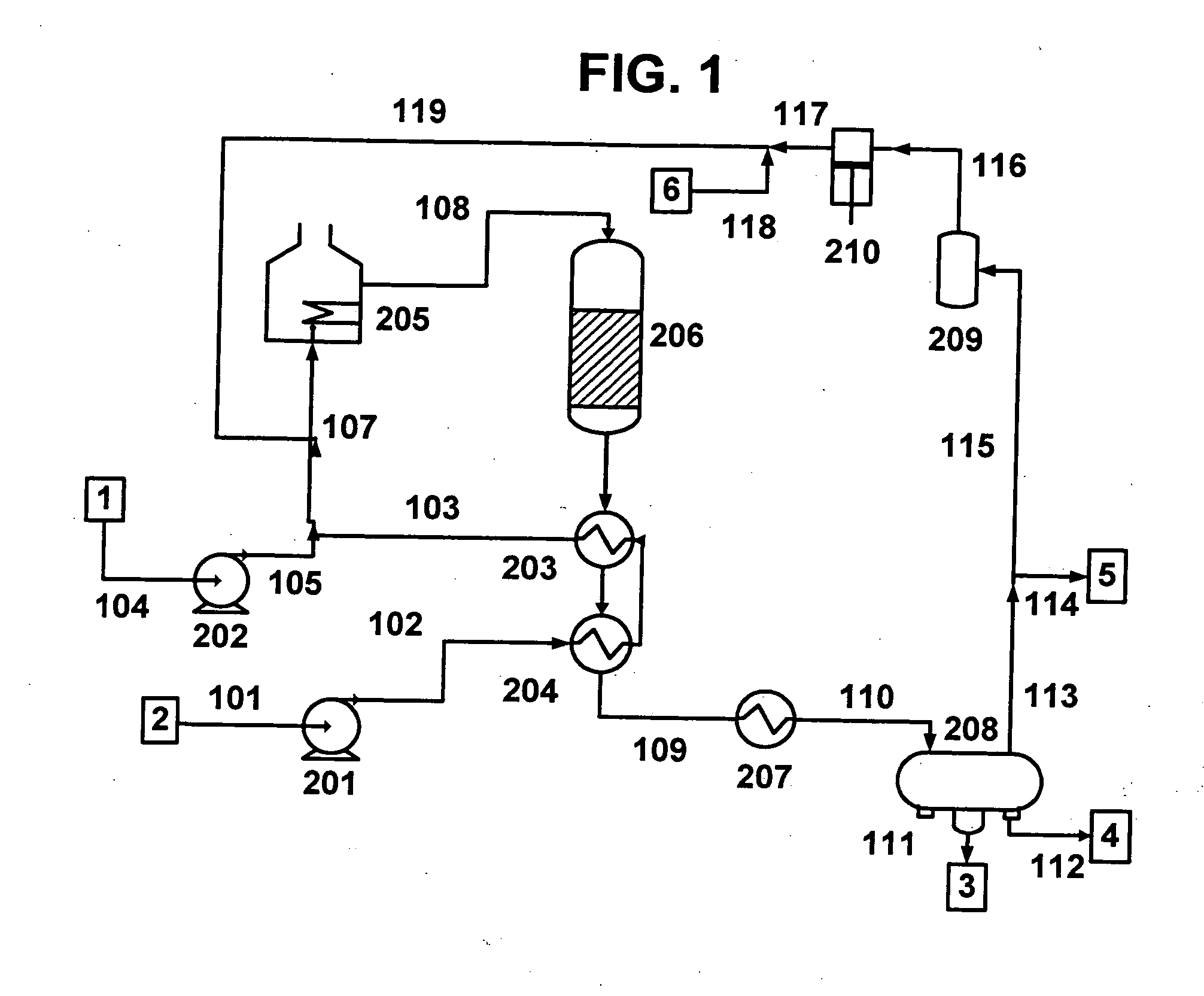

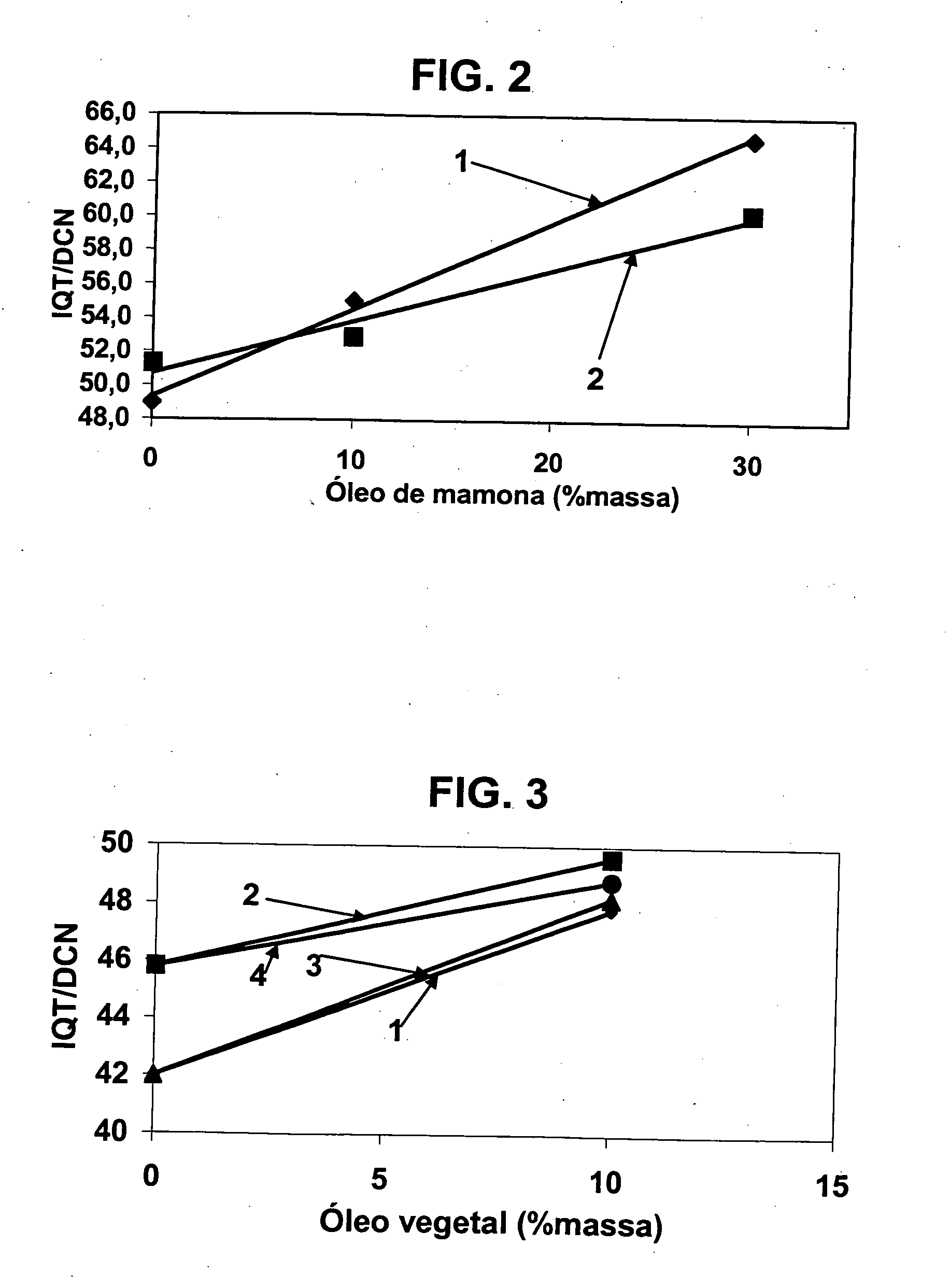

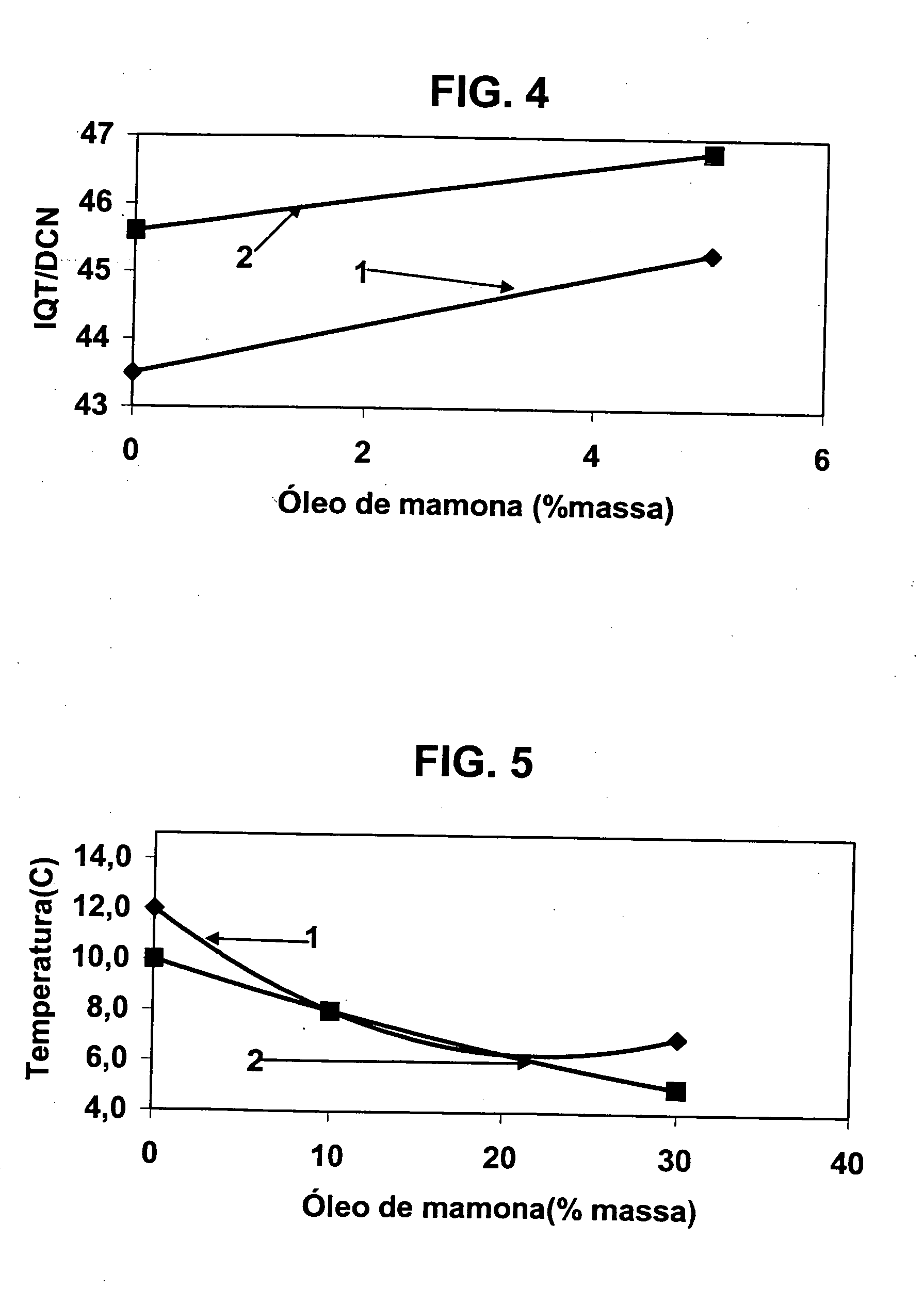

Vegetable oil hydroconversion process

InactiveUS20060186020A1Improved cetane indexAvoid excessive densityMolecular sieve catalystsBiofuelsVegetable oilHydrogen

A vegetable oil hydroconversion process is described for hydroconverting a mixture between 1 to 75% in mass of oil or natural fat (1) and the rest mineral oil (2), hydroconverted in a reactor (205) under conditions of pressure, temperature, hydrogen (flow 119) and sulfide catalyst of Groups VIII and VIB, obtaining, after sour water separation (flow 111) and rectification (flow 112), a specified diesel product (4). The product (4) has an ITQ / DCN (cetane number) higher than a product obtained from a pure mineral based oil would have, lower density than from a base oil and a plugging point depending on the mineral oil flow, as well as greater oxidation stability than the base oil.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

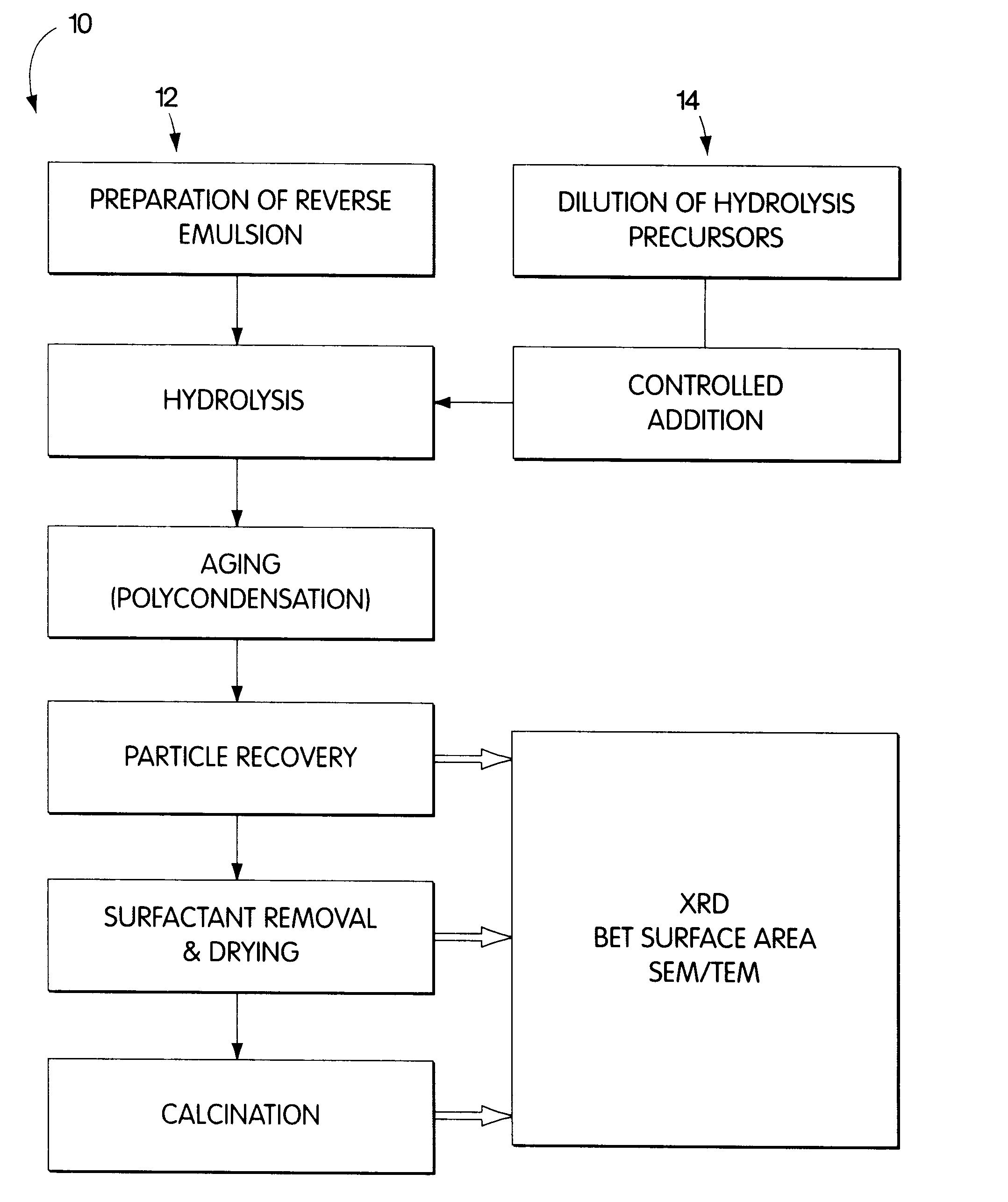

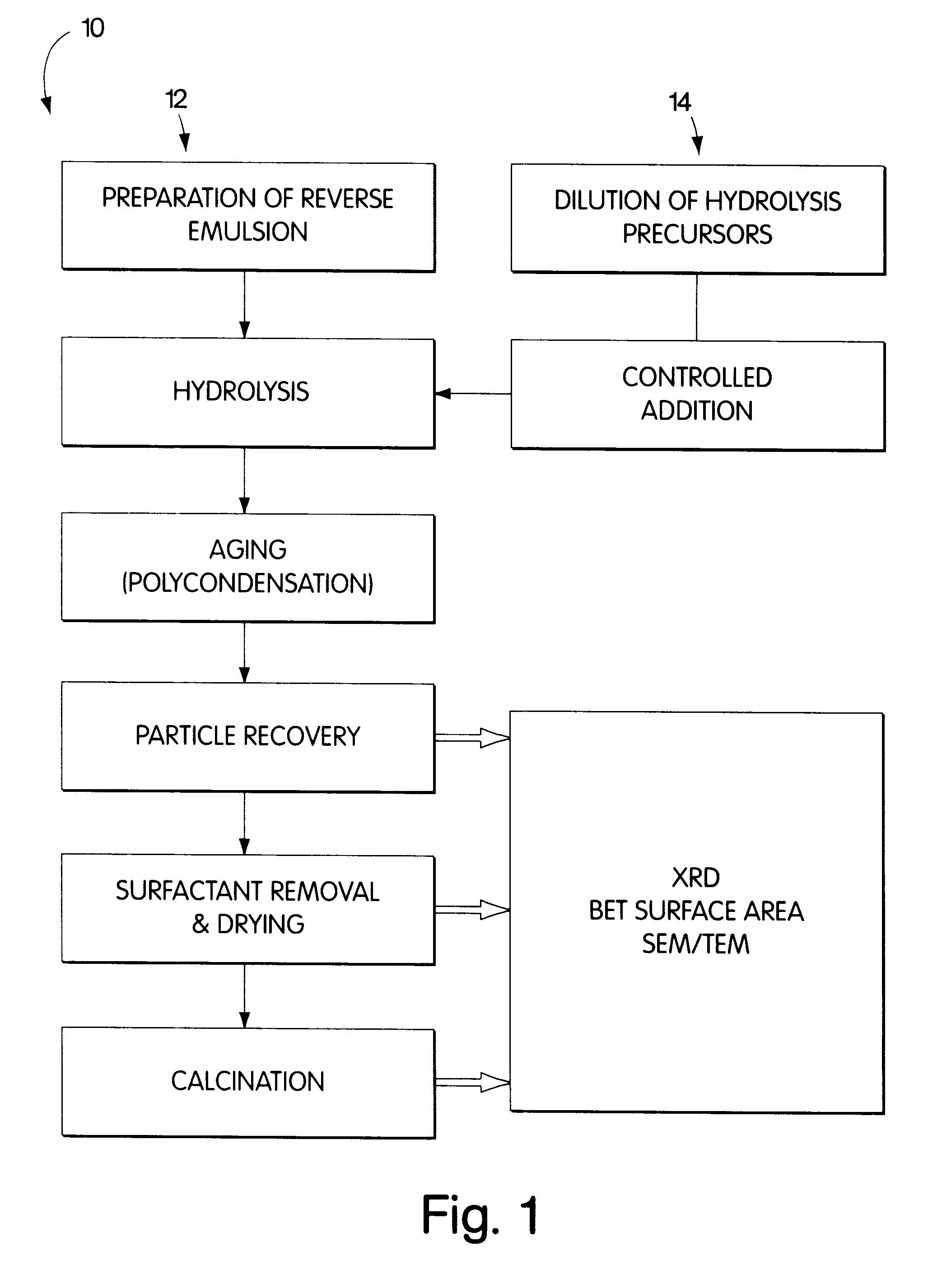

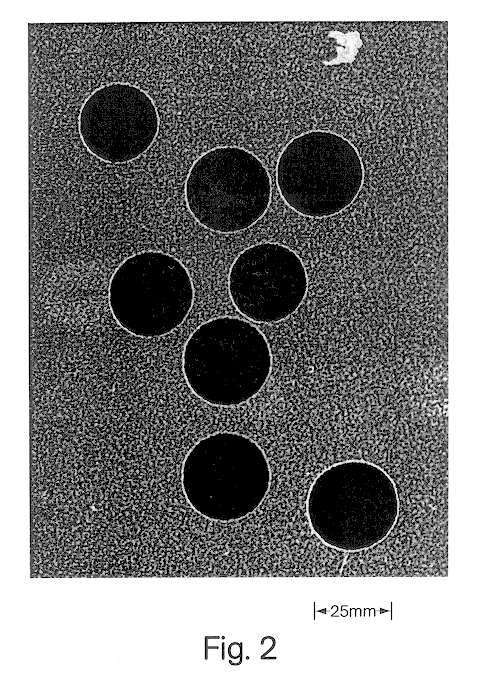

Synthesis of nanometer-sized particles by reverse micelle mediated techniques

The present invention relates to a method of producing particles having a particle size of less than 100 nm and surface areas of at least 20 m2 / g where the particles are free from agglomeration. The method involves synthesizing the particles within an emulsion having a 1-40% water content to form reverse micelles. In particular, the particles formed are metal oxide particles. The particles can be used to oxidize hydrocarbons, particularly methane.

Owner:MASSACHUSETTS INST OF TECH

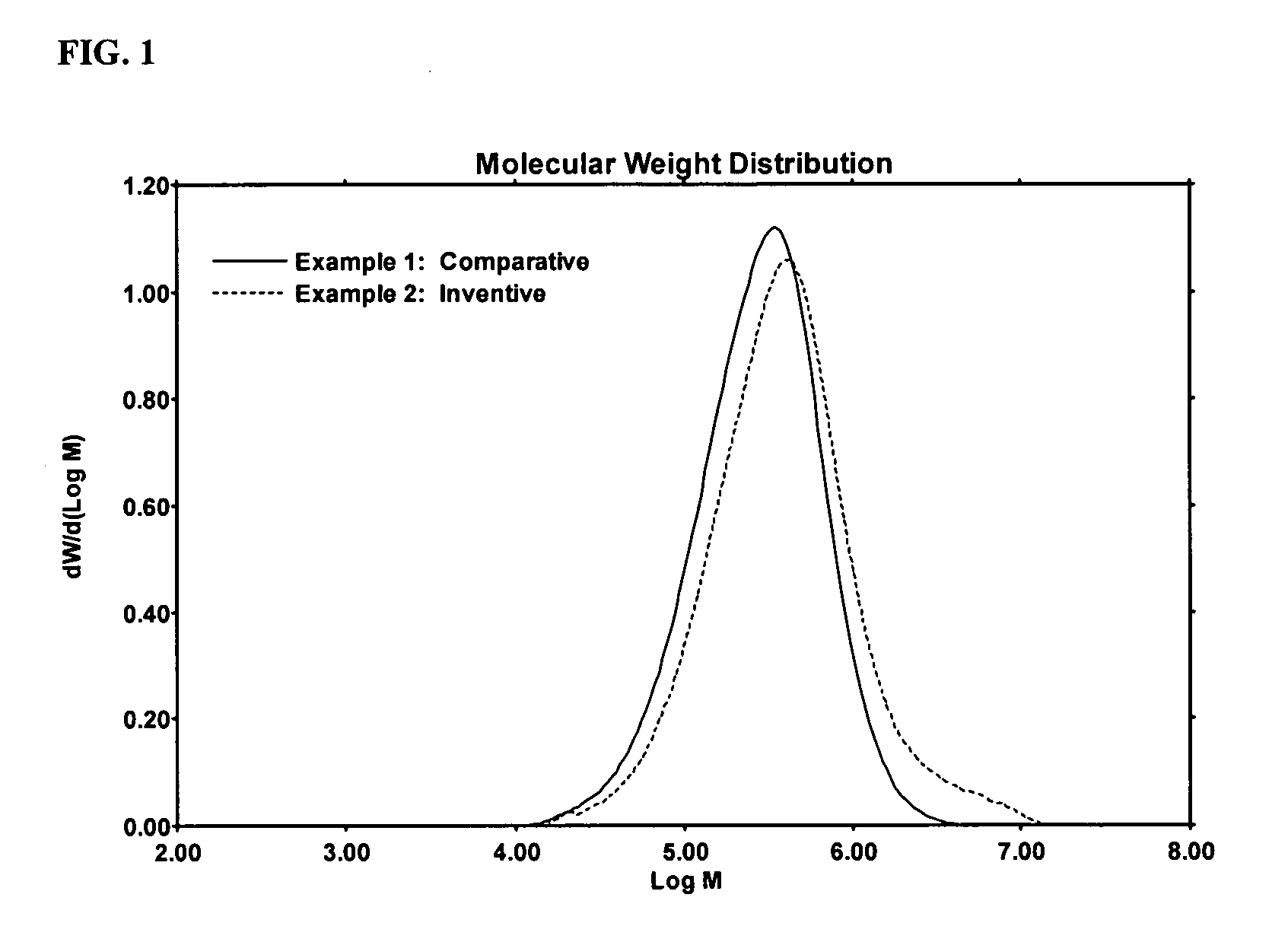

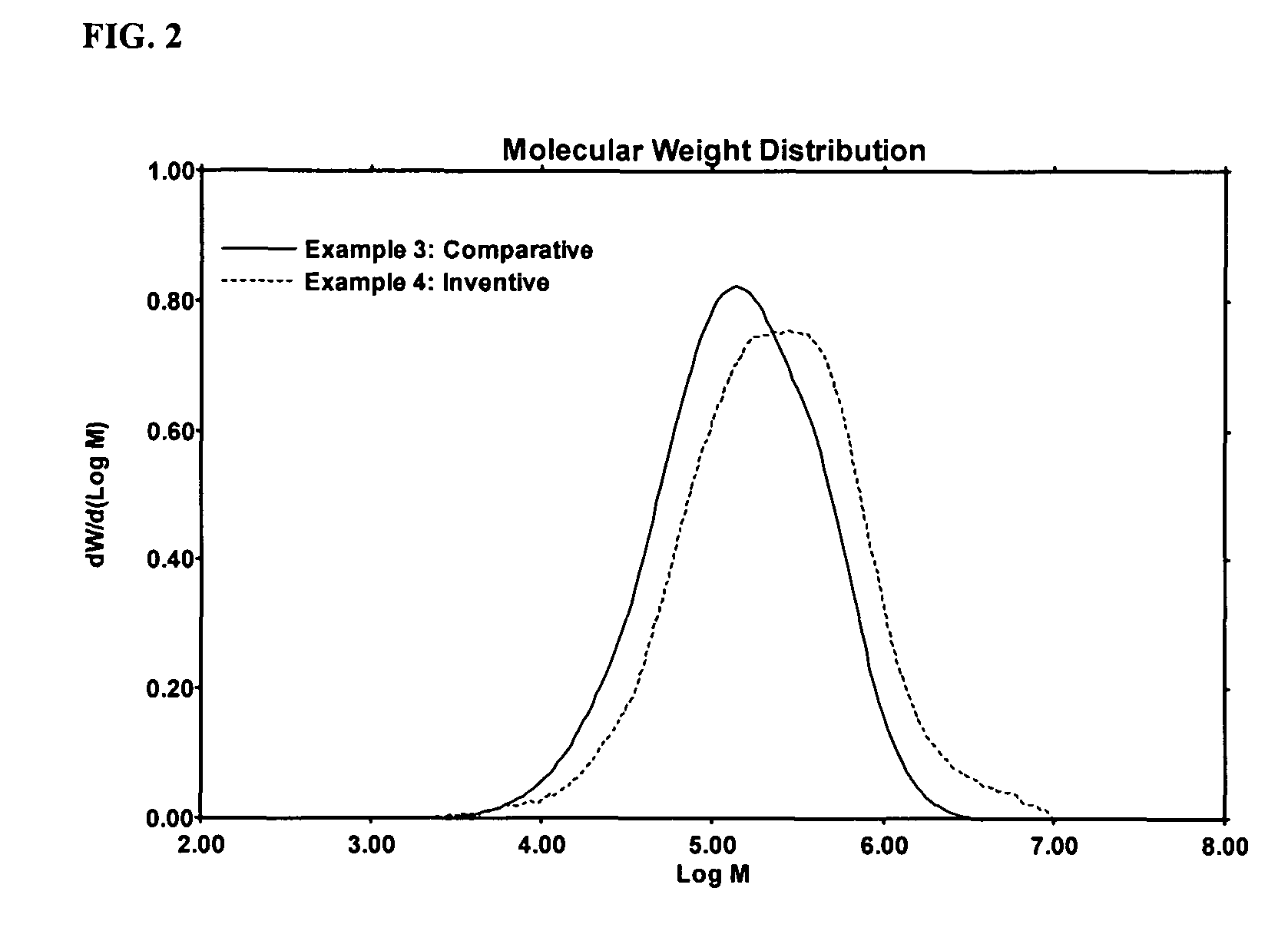

Methods for producing metal-containing sulfated activator-supports

ActiveUS8309485B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationPolymerization catalysts

The present invention provides metal-containing sulfated activator-supports, and polymerization catalyst compositions employing these activator-supports. Methods for making these metal-containing sulfated activator-supports and for using such components in catalyst compositions for the polymerization of olefins are also provided.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Method of preparing catalyst for manufacturing carbon nanotubes

InactiveUS20070020167A1Improve uniformityMinimize agglomerationMaterial nanotechnologyNanostructure manufactureFreeze-dryingCarbon nanotube

A novel method of forming catalyst particles, on which carbon nanotubes grow based, on a substrate with increased uniformity, and a method of synthesizing carbon nanotubes having improved uniformity are provided. A catalytic metal precursor solution is applied to a substrate. The applied catalytic metal precursor solution is freeze-dried, and then reduced to catalytic metal. The method of forming catalyst particles can minimize agglomeration and / or recrystallization of catalyst particles when forming the catalyst particles by freeze-drying the catalyst metal precursor solution. The catalyst particles formed by the method has a very uniform particle size and are very uniformly distributed on the substrate.

Owner:SAMSUNG SDI CO LTD

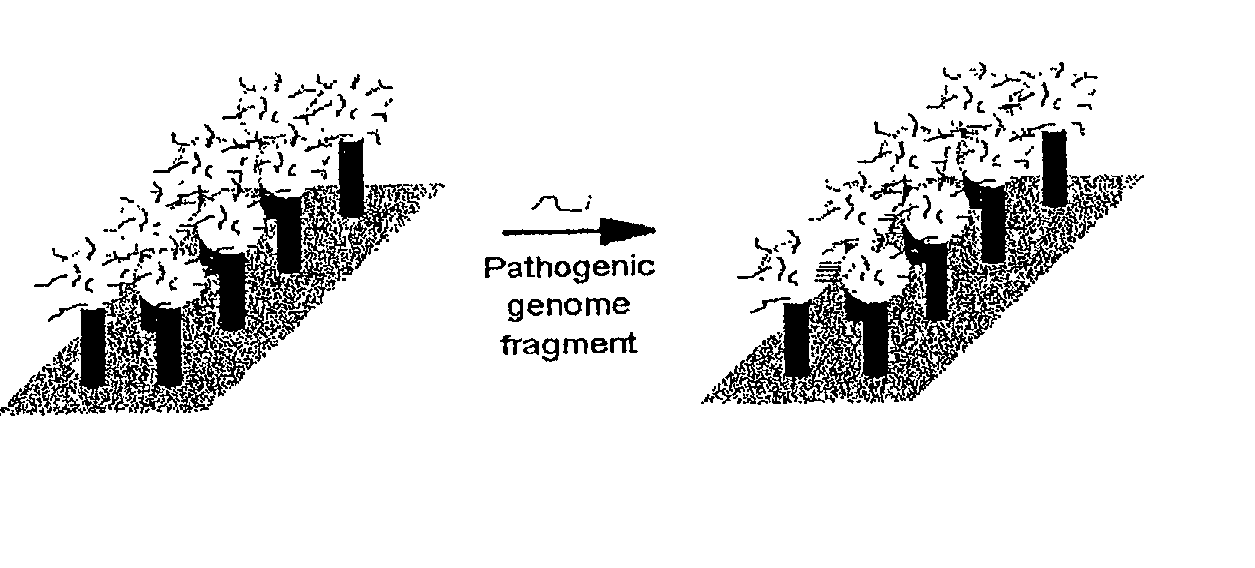

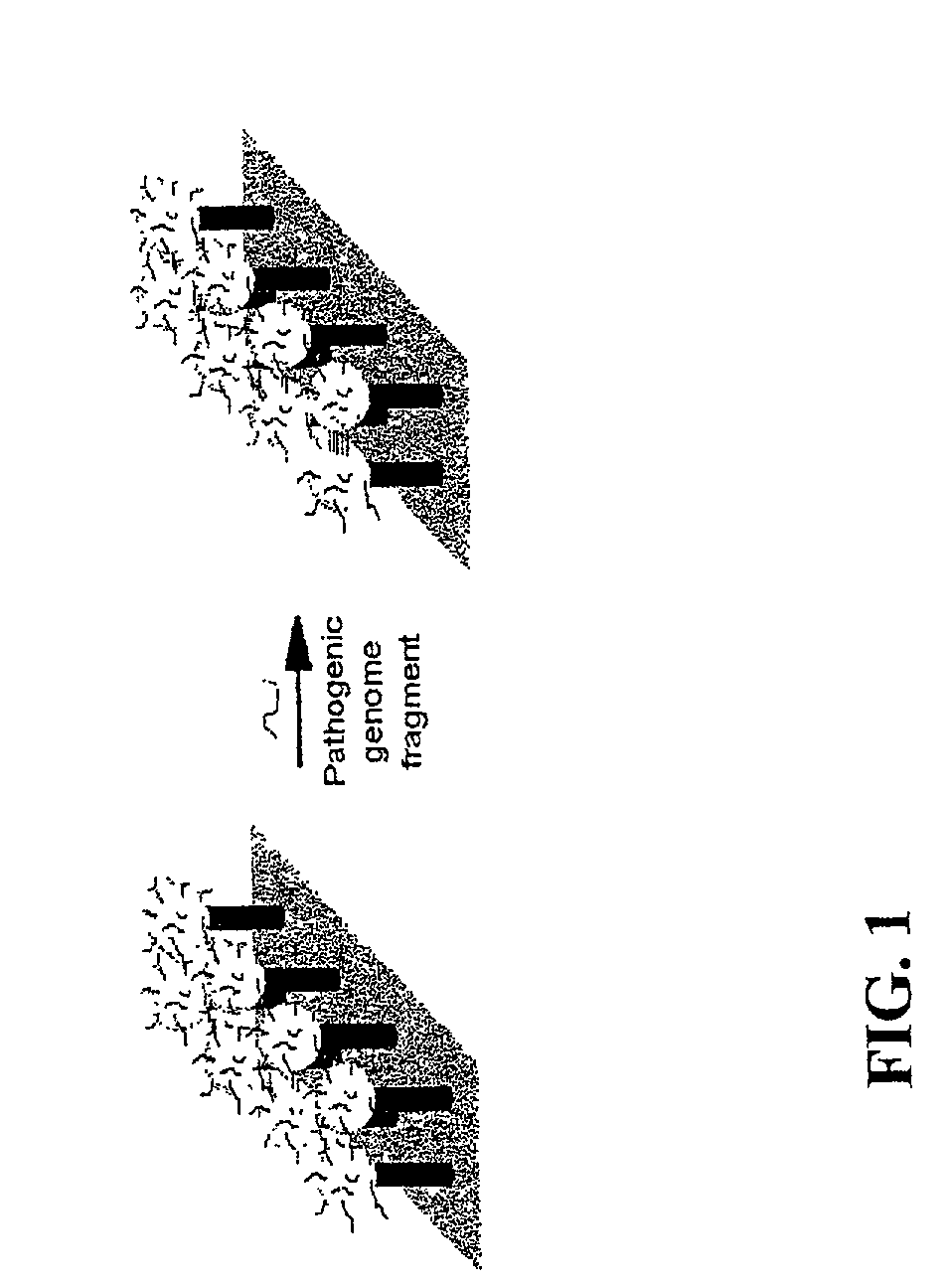

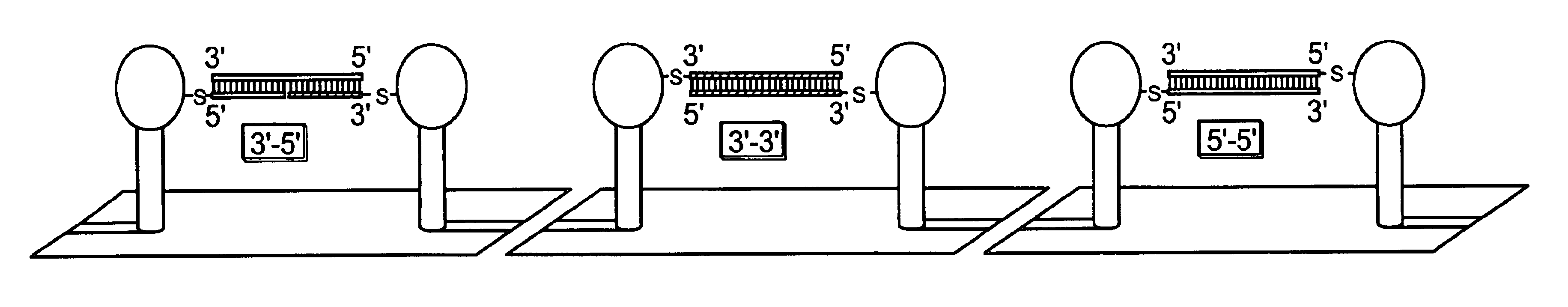

DNA-bridged carbon nanotube arrays

InactiveUS20020172963A1High precisionHigh sensitivityBioreactor/fermenter combinationsMaterial nanotechnologyChemical ligationElectron transfer reactions

A class of biological sensing devices that include a substrate comprising an array of carbon nanotubes (CNTs) to which are chemically attached biological molecules is disclosed. The attached biological molecules are capable of electrical conductivity that is responsive to chemical changes occurring as a result of their interaction with target species. A means for means for using DNA as a material of potential in molecular electronic sensor devices, being primarily based on molecular electron-transfer reaction processes between DNA-binding donors and acceptors is also disclosed, including composition, method of manufacture and their use are described.

Owner:TRUSTEES OF BOSTON COLLEGE THE

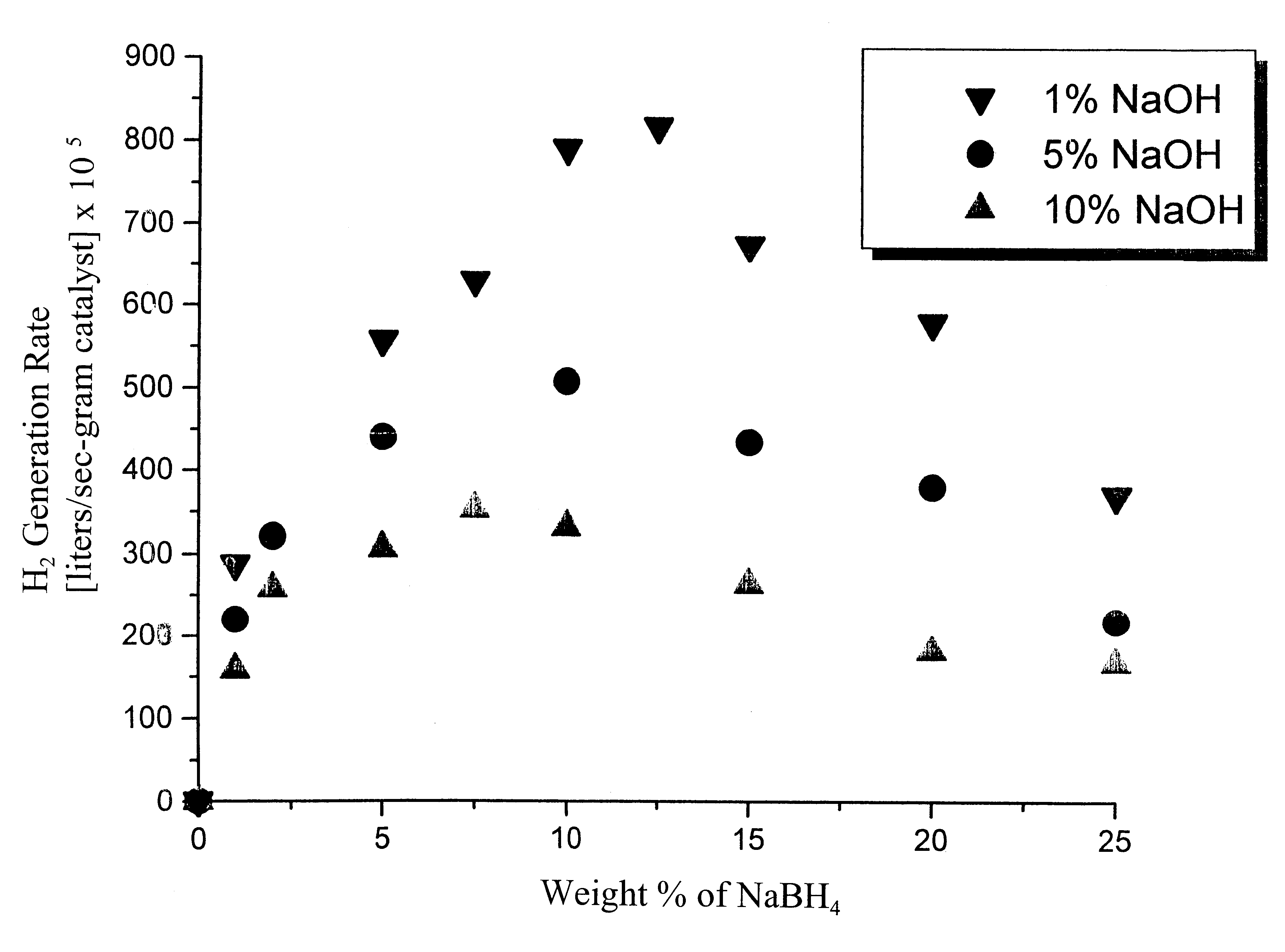

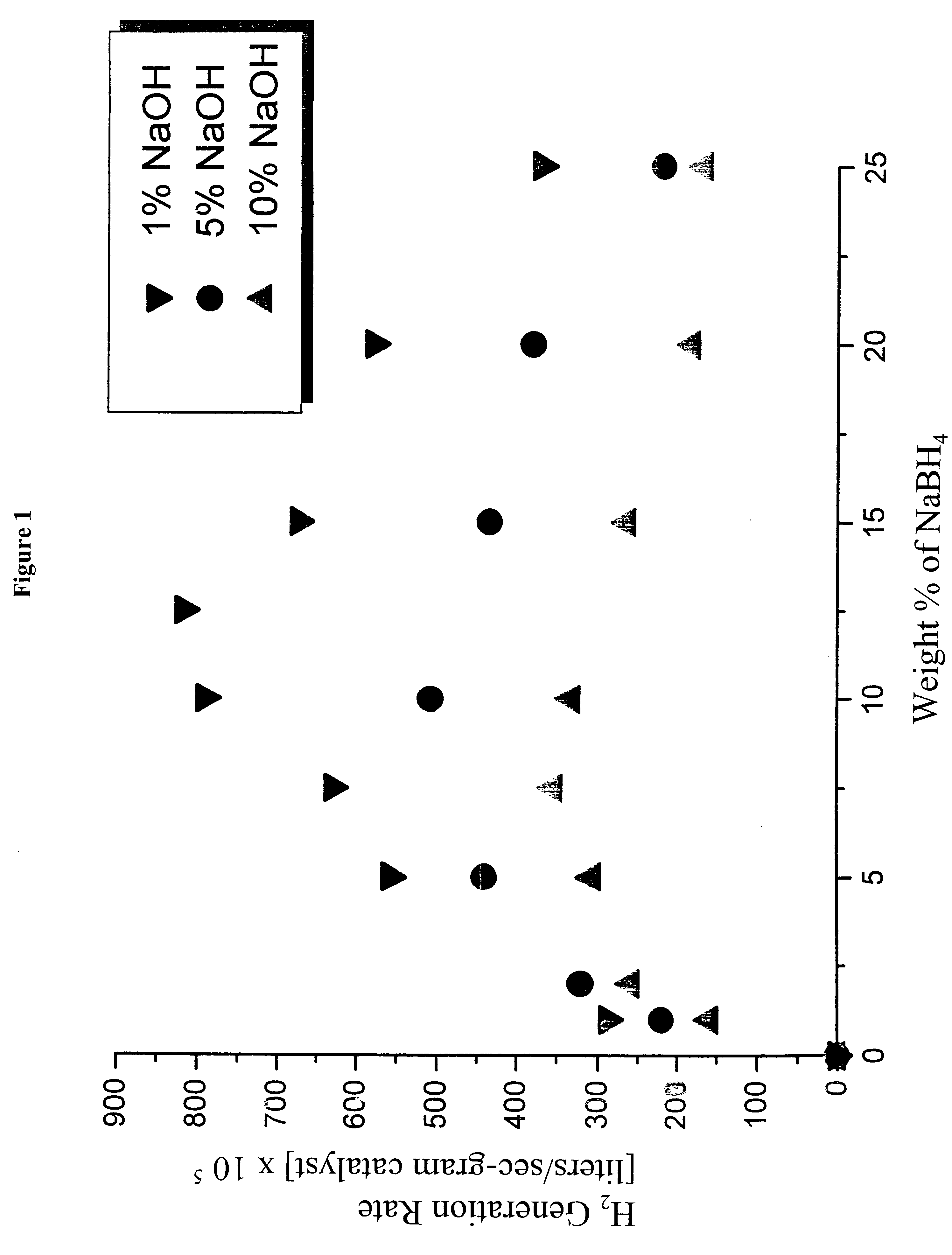

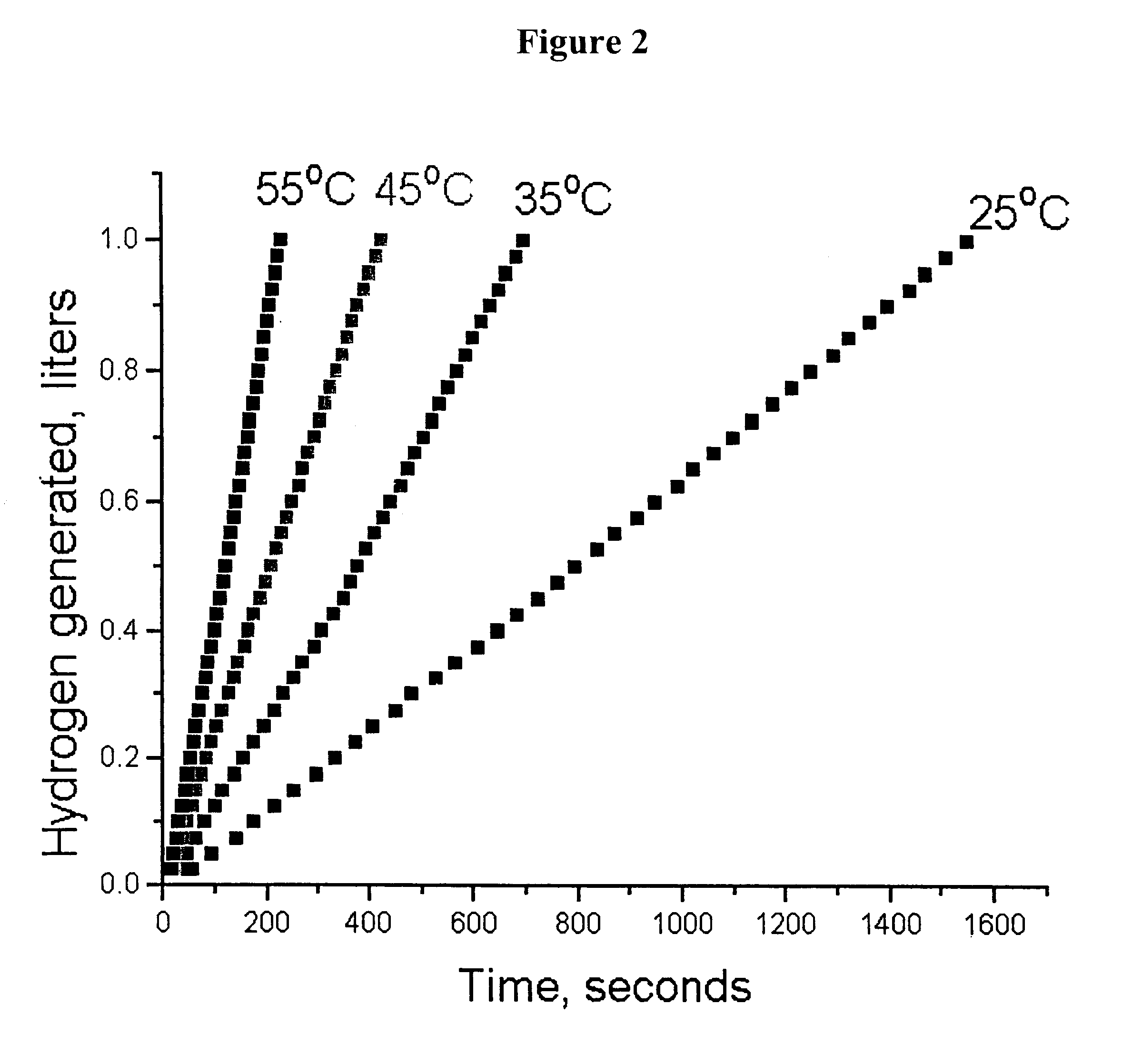

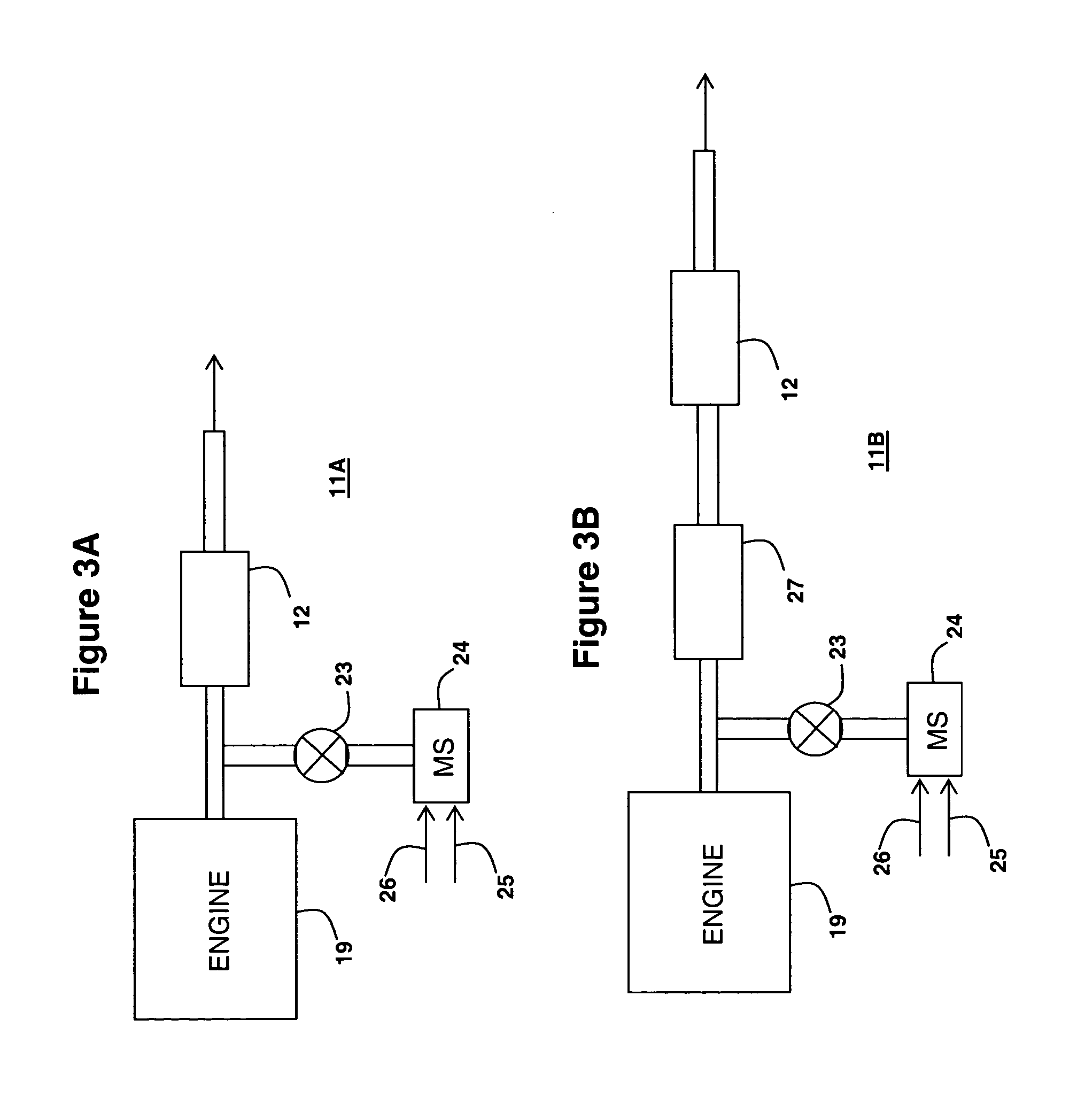

System for hydrogen generation

InactiveUS6534033B1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationControlled releaseBorohydride

The present invention relates to a composition and method for storage and controlled release of hydrogen. In particular, the present invention relates to the use of borohydride based solutions as a hydrogen storage source and a catalyst system to release hydrogen therefrom.

Owner:SILICON VALLEY BANK +1

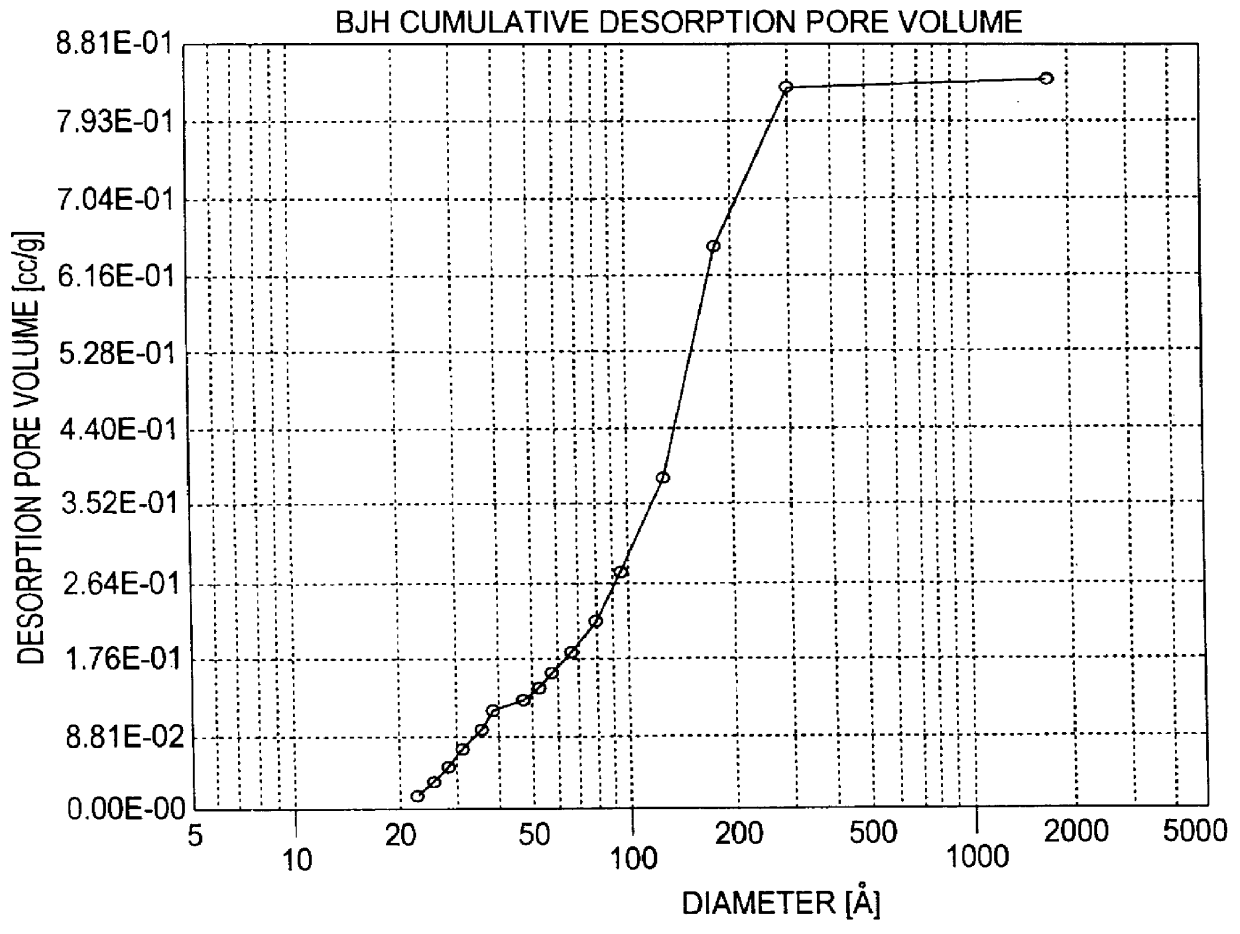

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

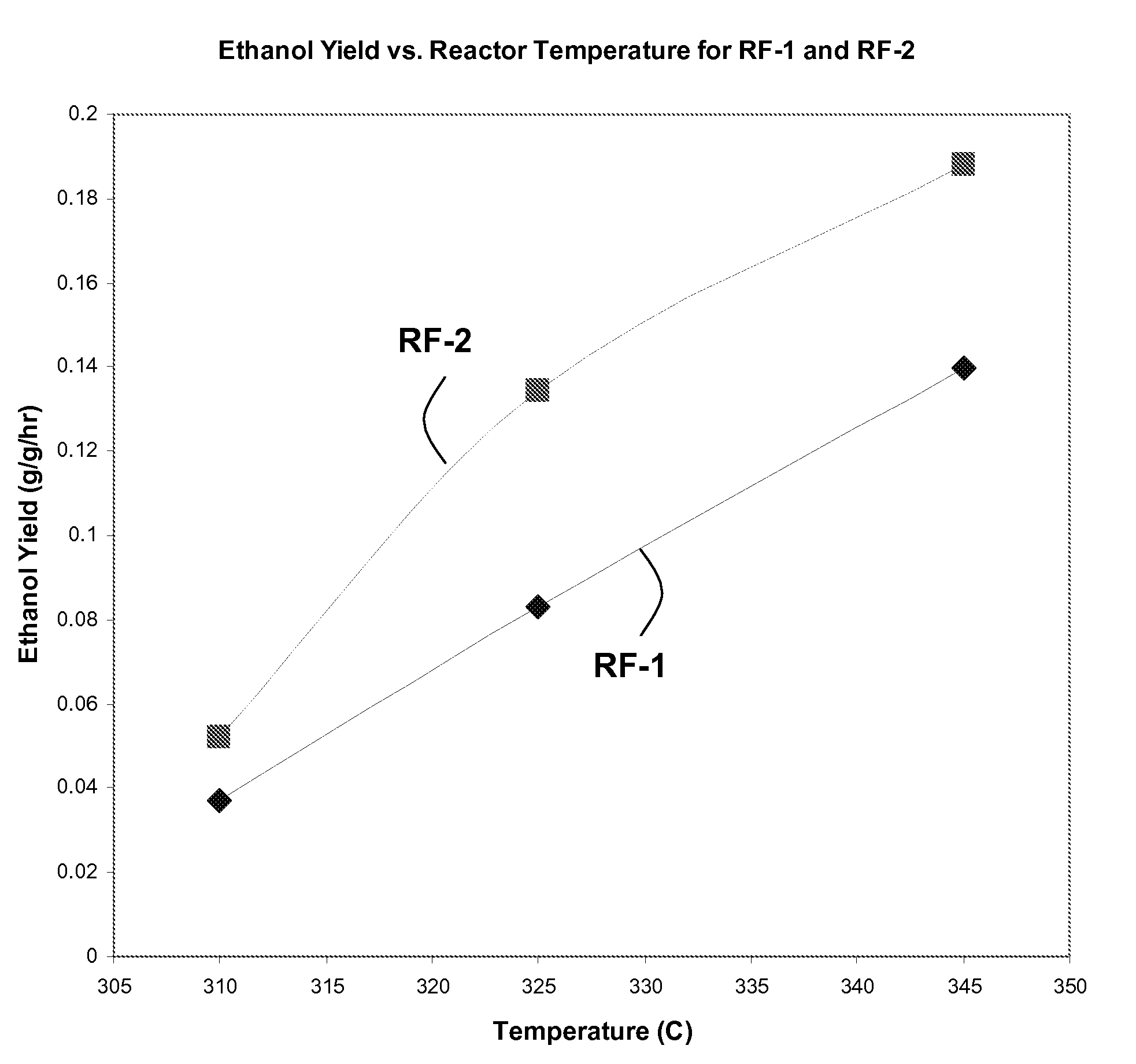

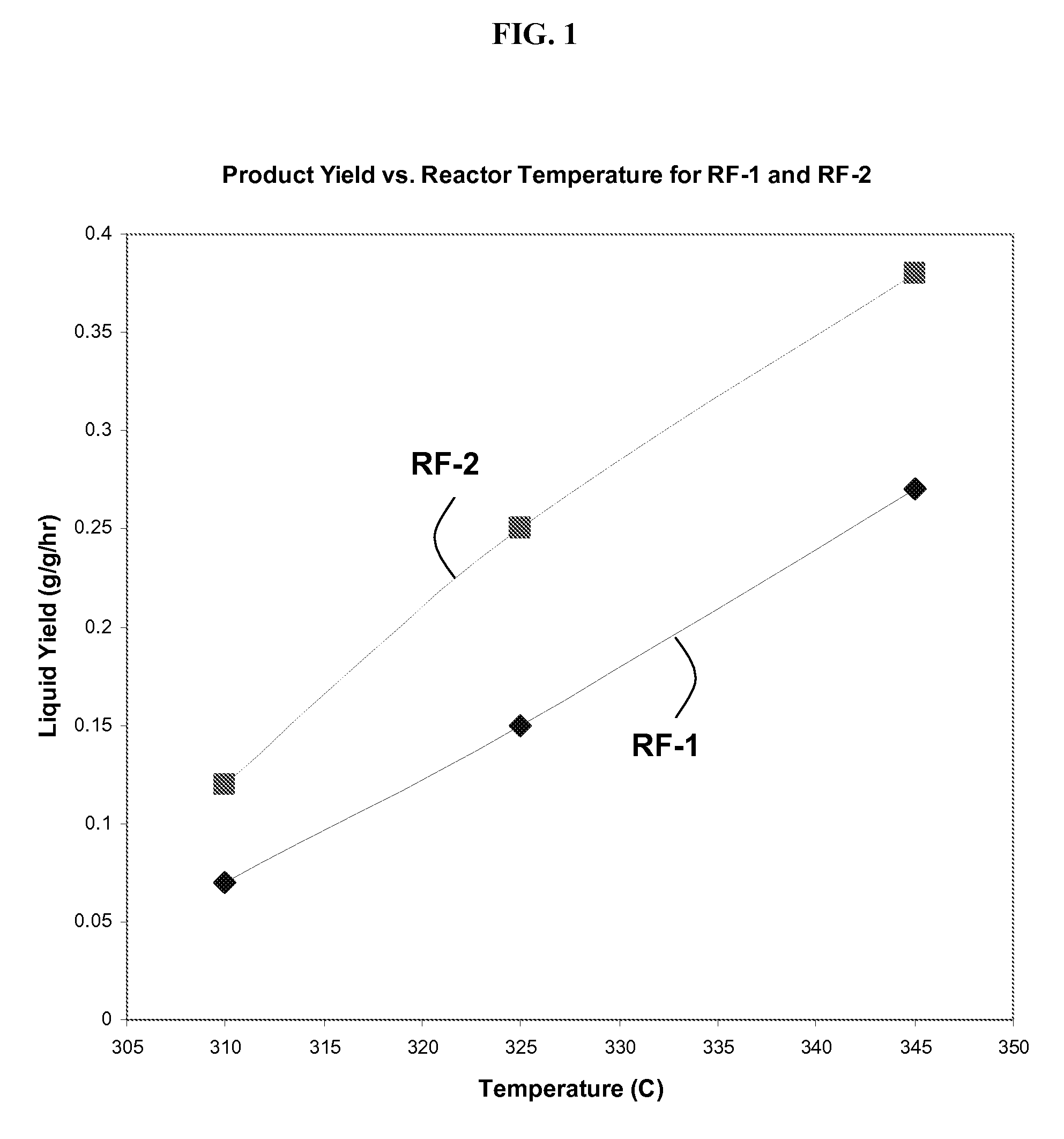

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS20100029995A1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicatePlatinum

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS20080045405A1Nitrous oxide captureMolecular sieve catalystsExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

Tunable catalyst gas phase hydrogenation of carboxylic acids

InactiveUS20100121114A1High selectivityExcessive loss of activityOrganic compound preparationHeterogenous catalyst chemical elementsPlatinumAcetic acid

A process for selective formation of ethanol from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with catalyst comprising platinum and tin on a high surface area silica promoted with calcium metasilicate. Selectivities to ethanol of over 85% are achieved at 280° C. with catalyst life in the hundreds of hours.

Owner:CELANESE INT CORP

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

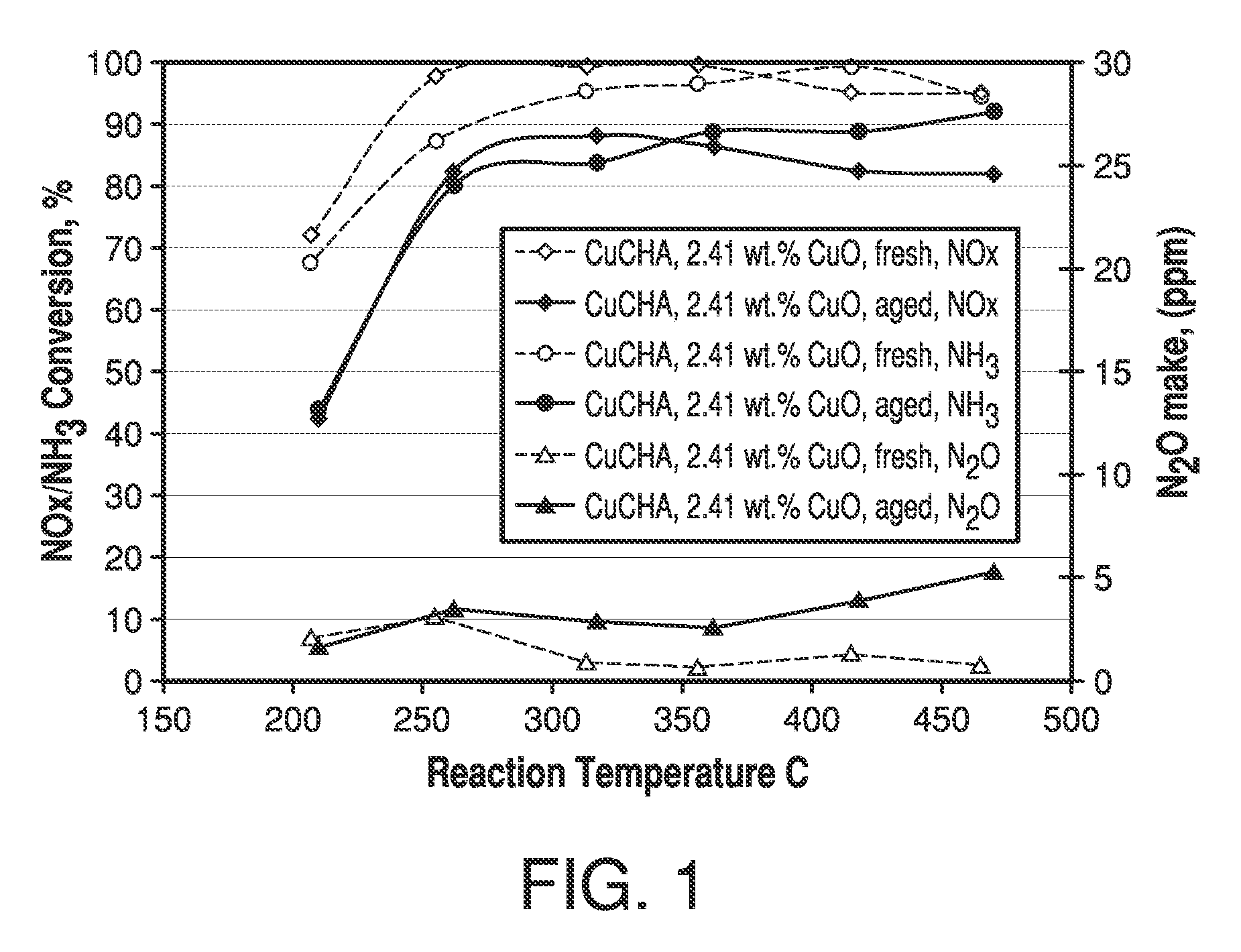

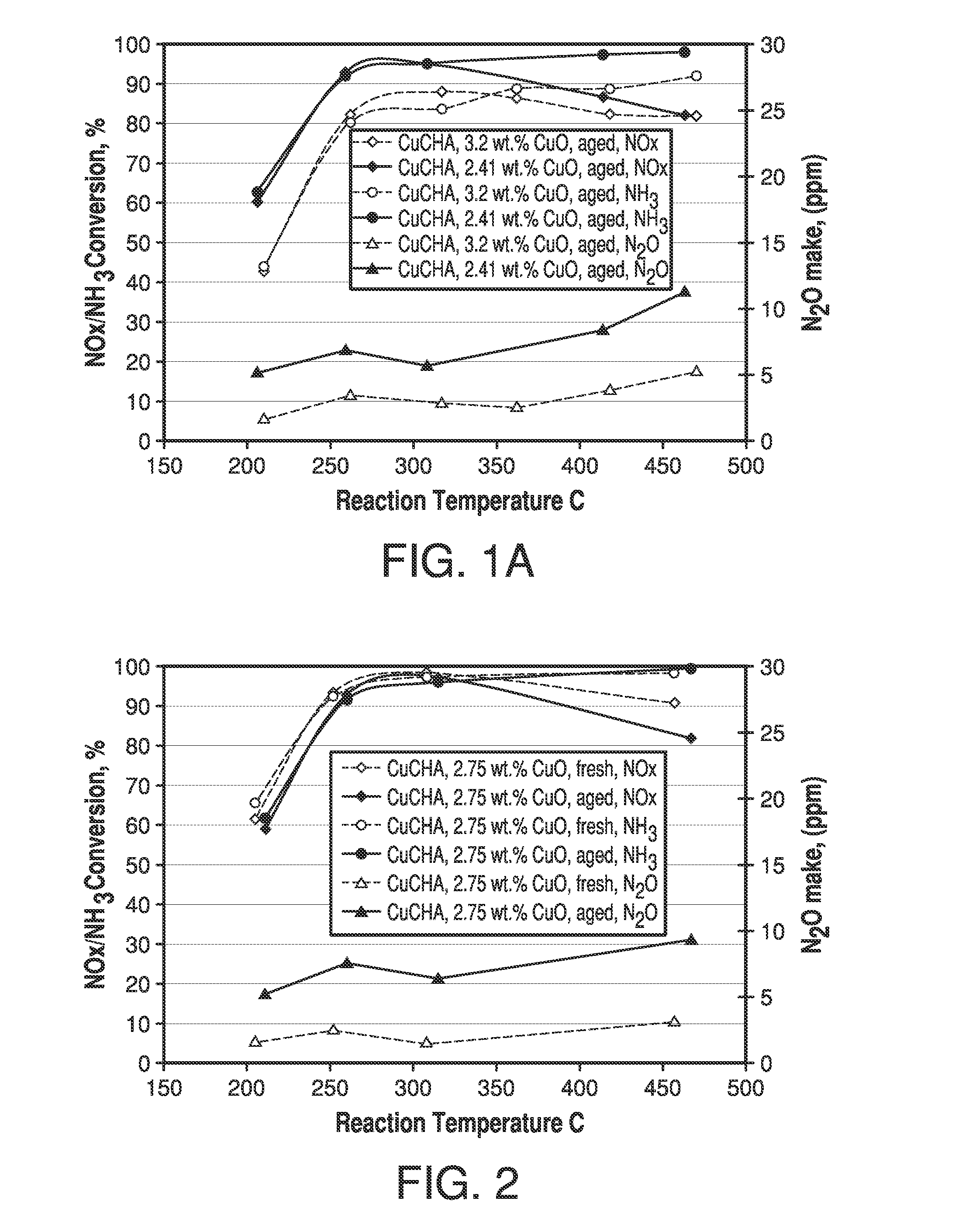

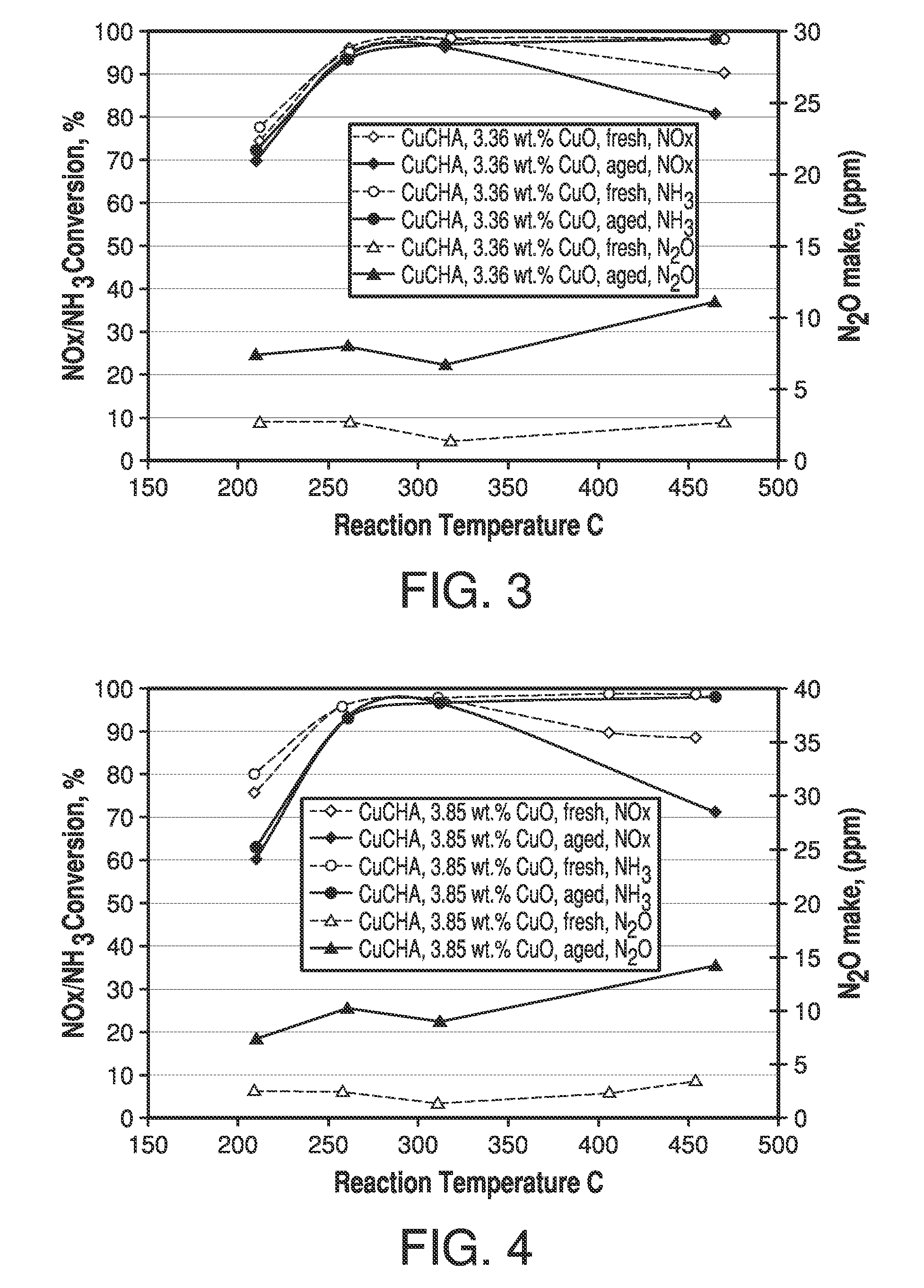

Copper CHA zeolite catalysts

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

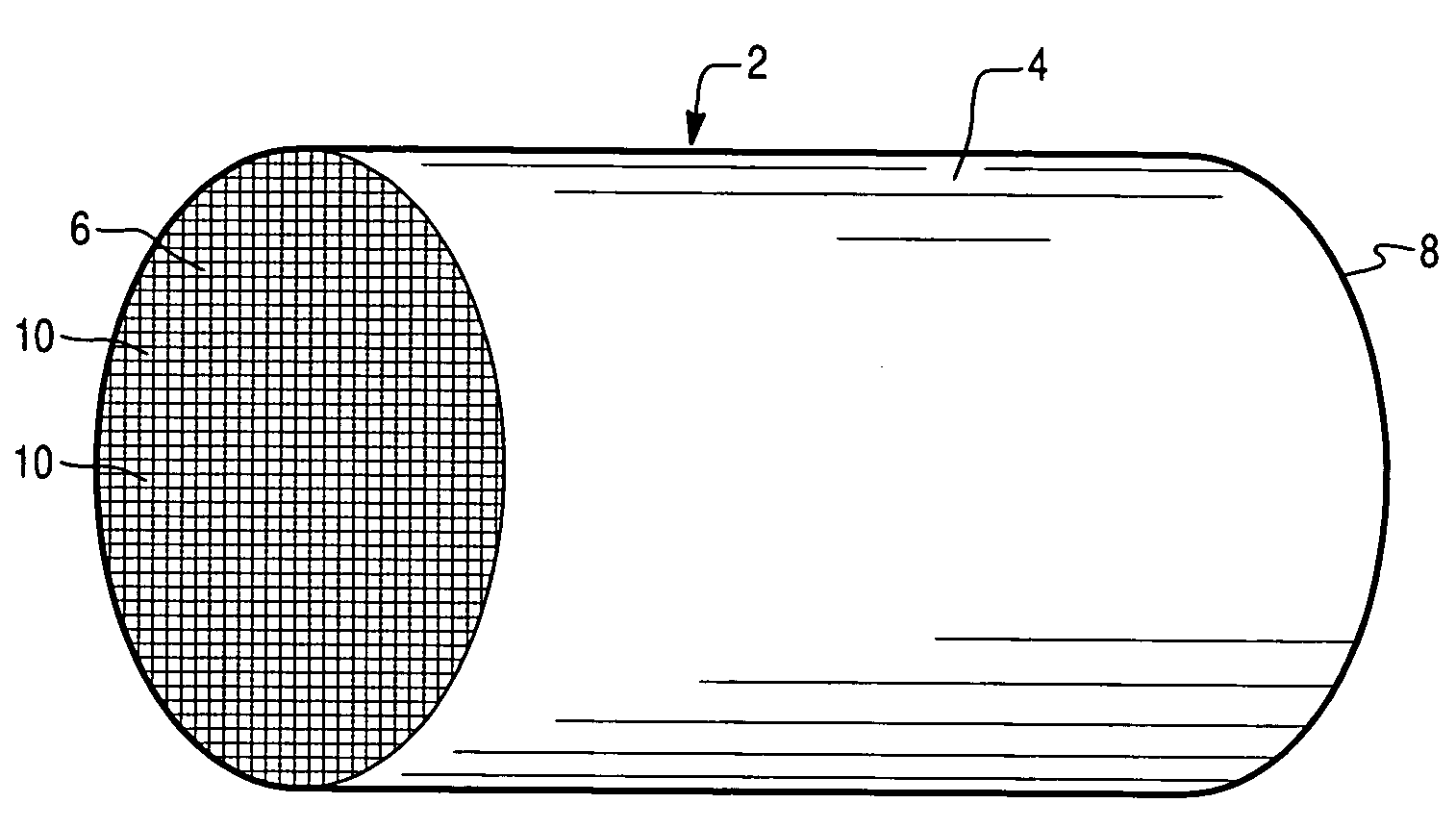

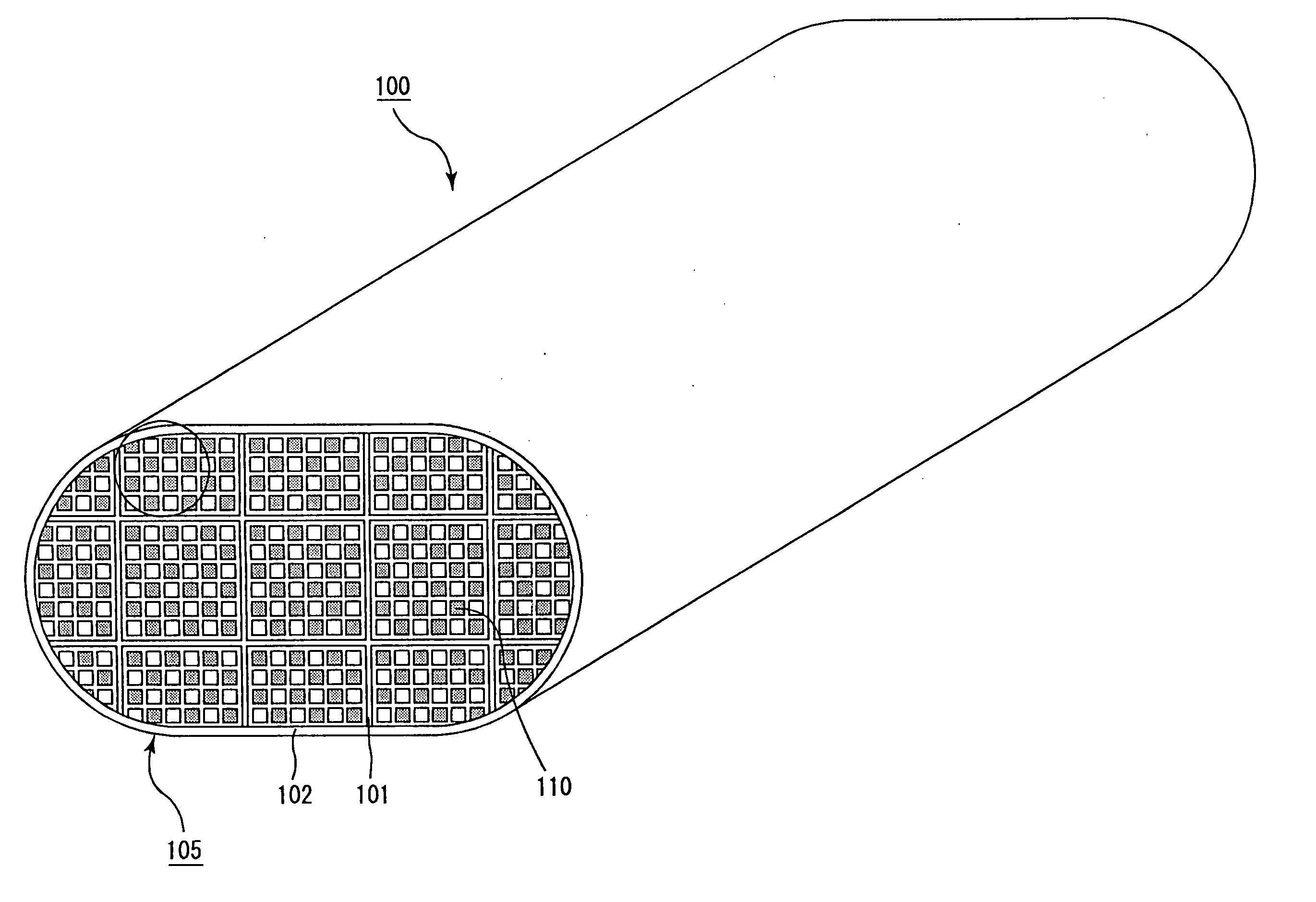

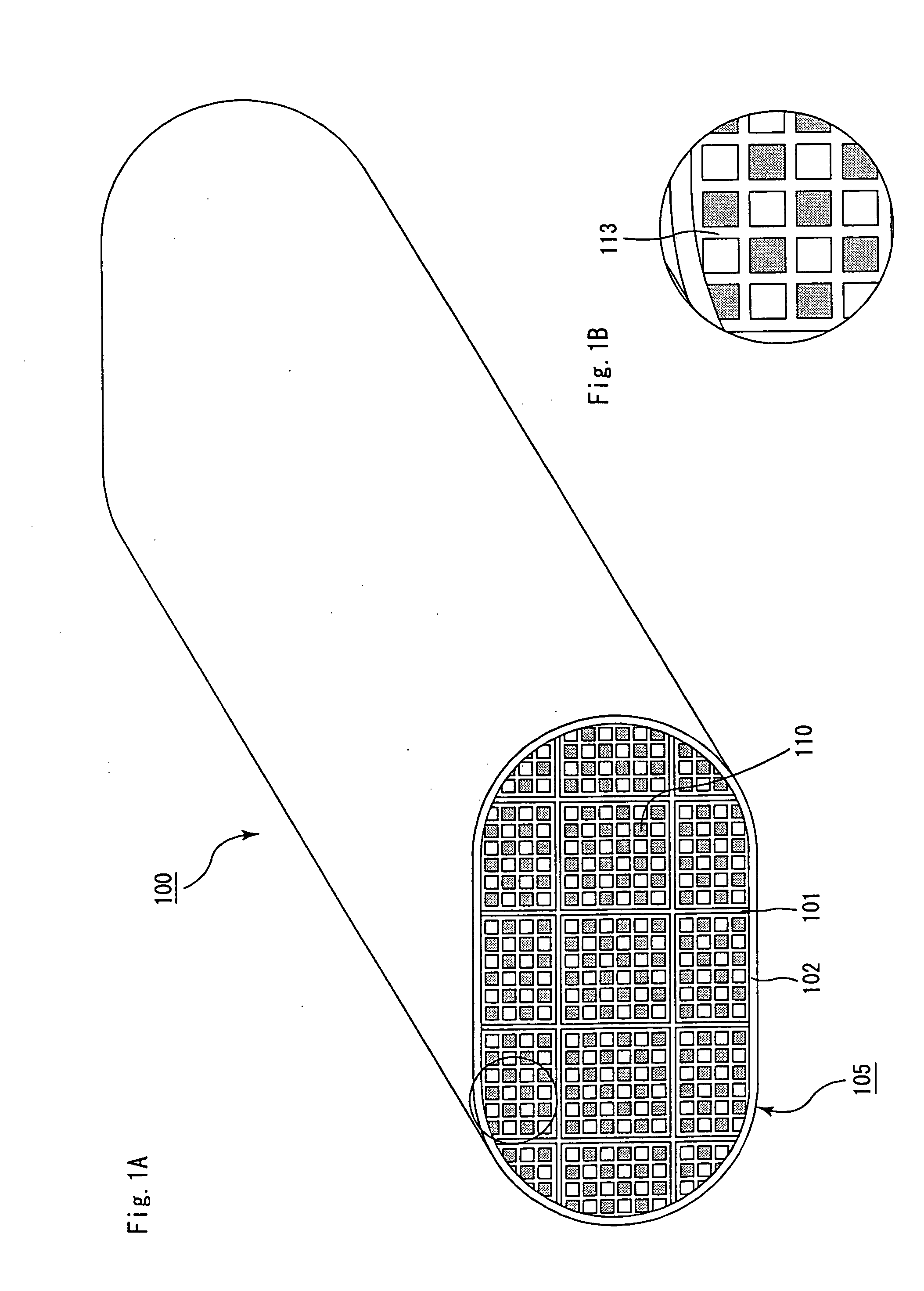

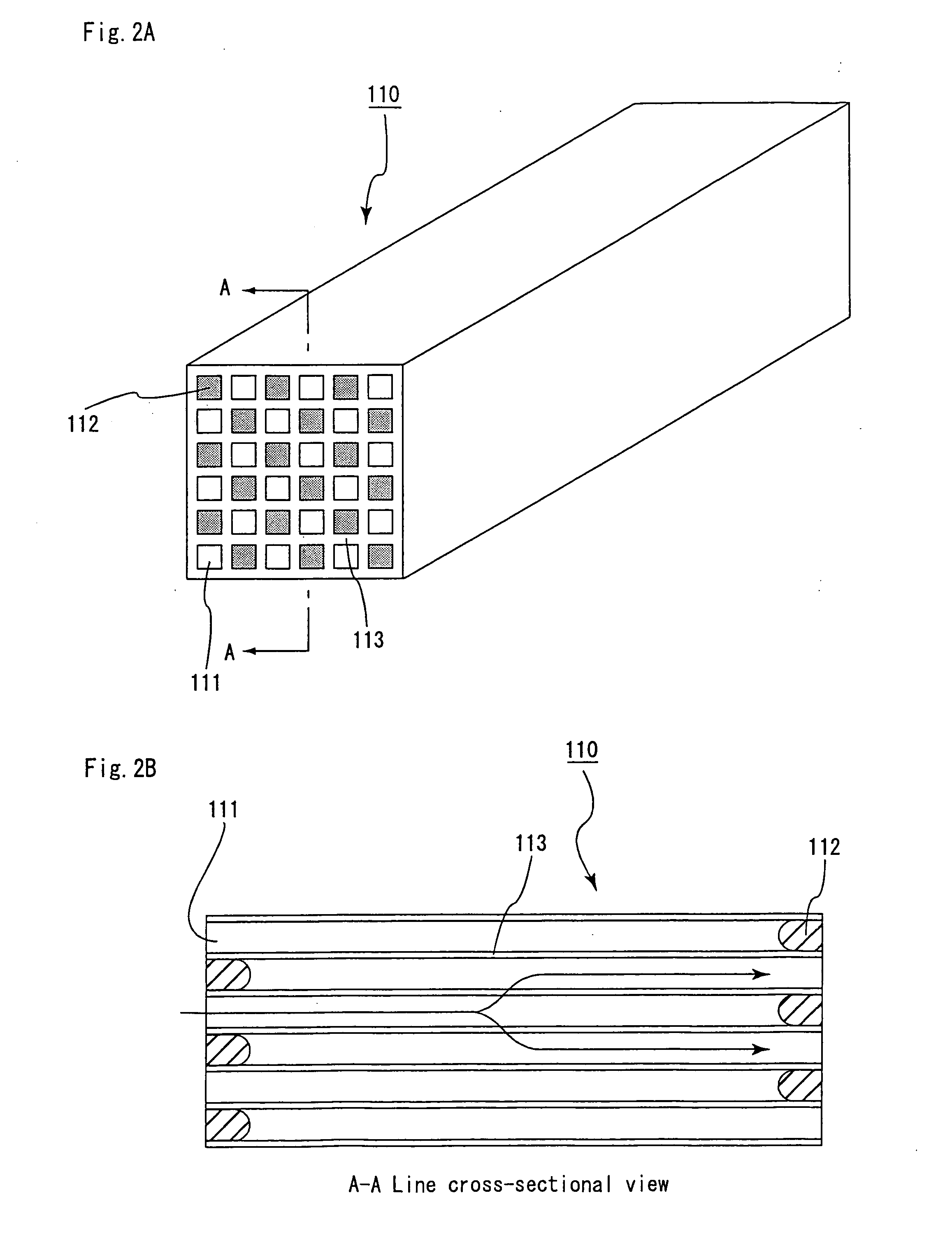

Honeycomb structural body and manufacturing method thereof

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

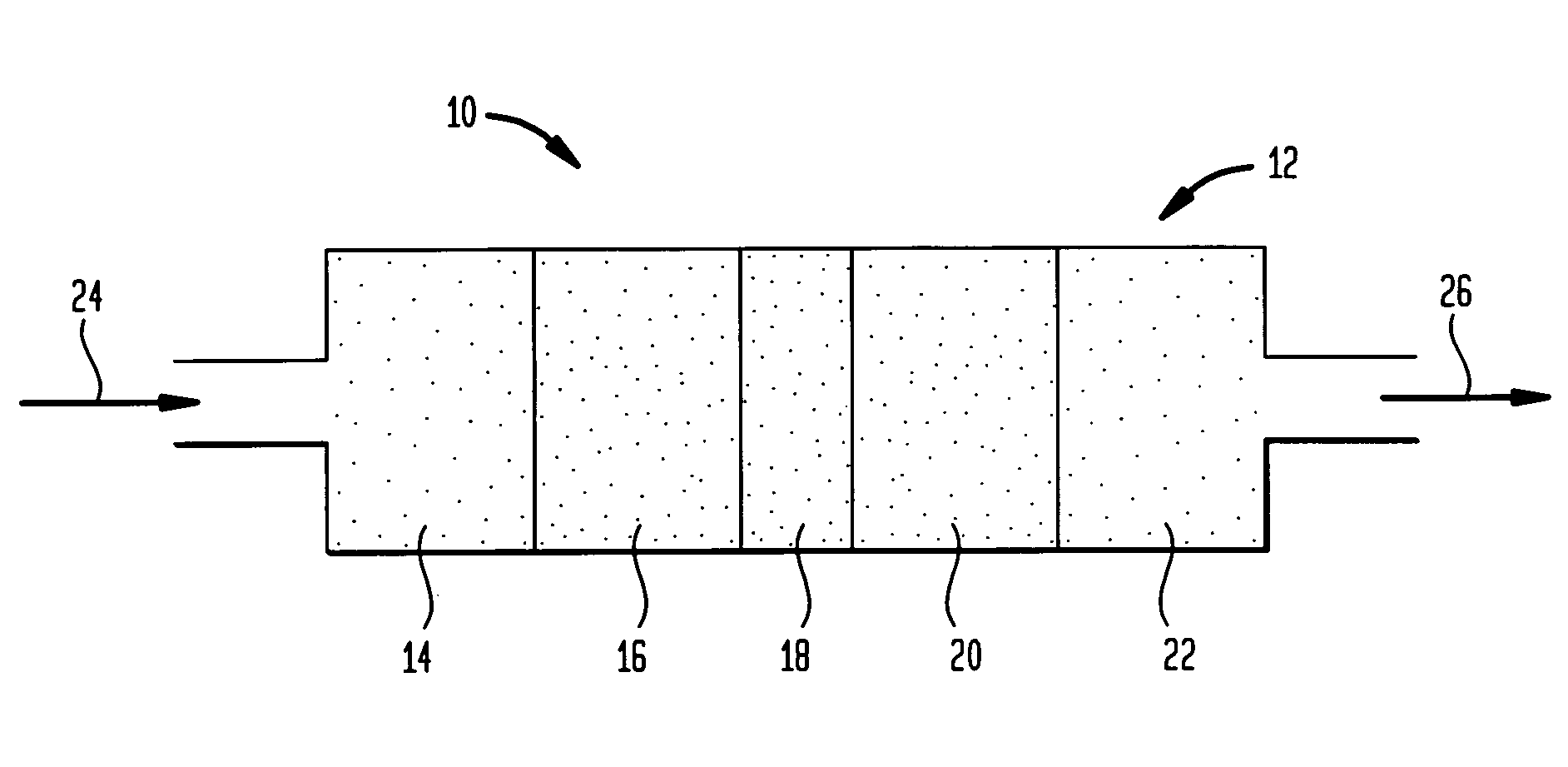

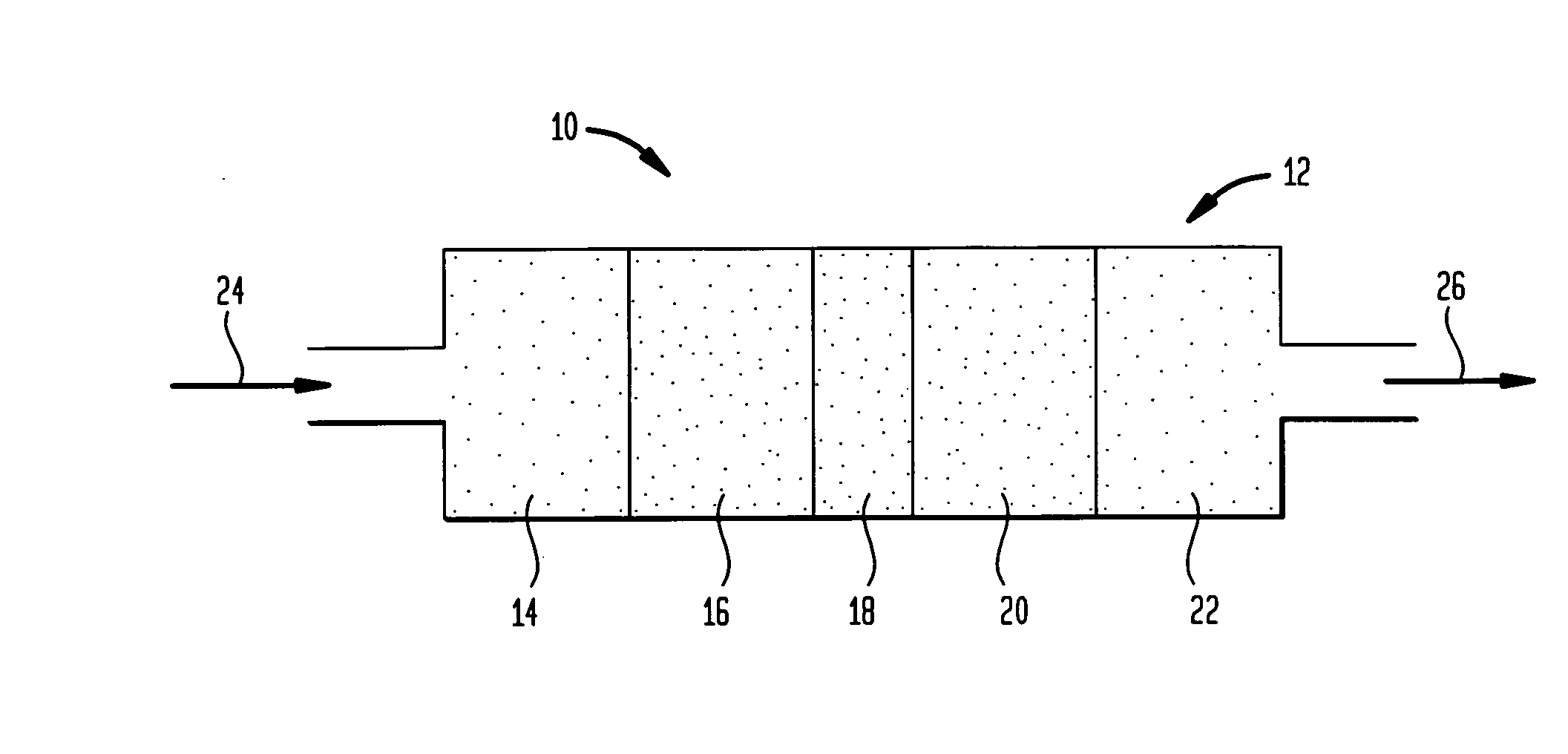

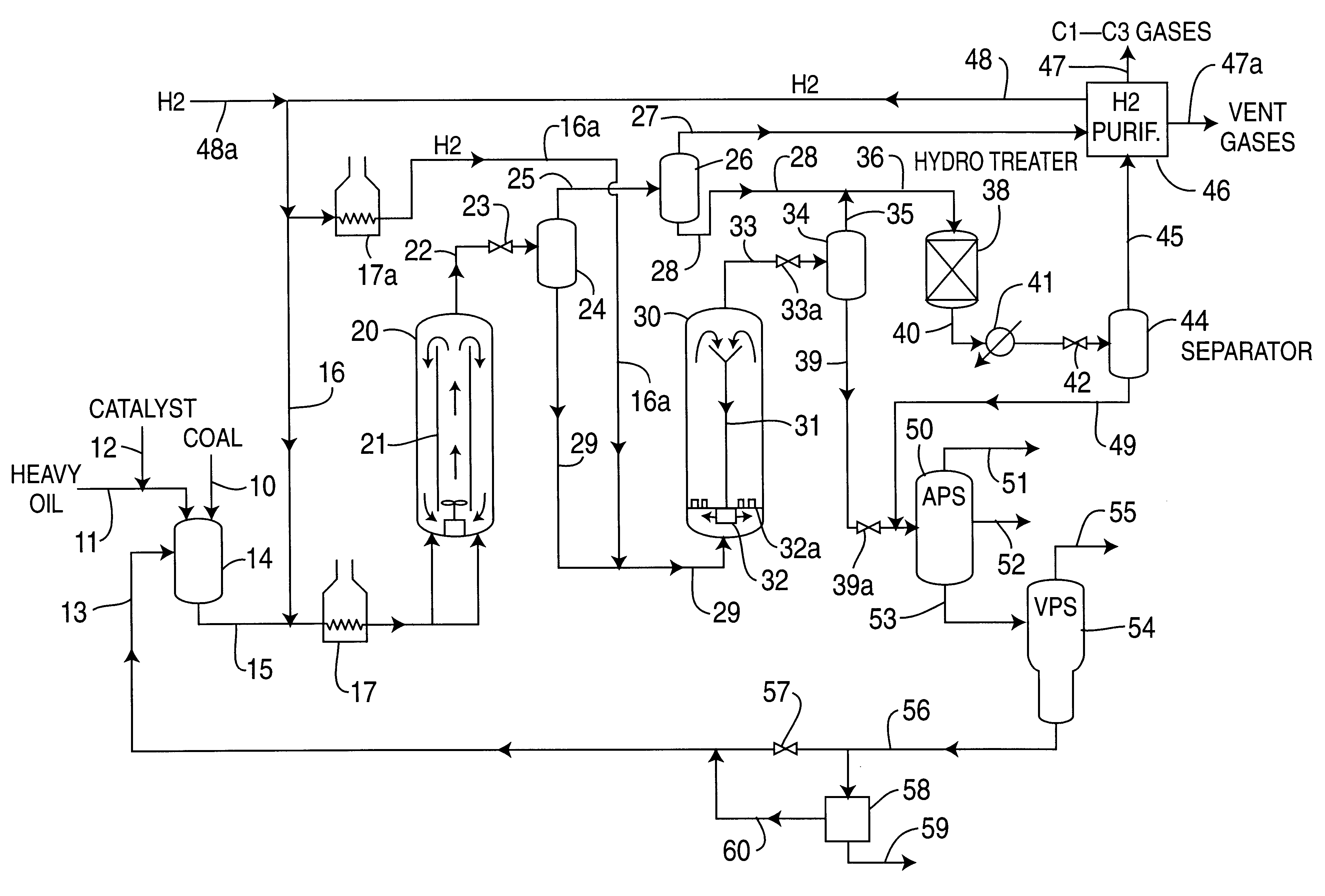

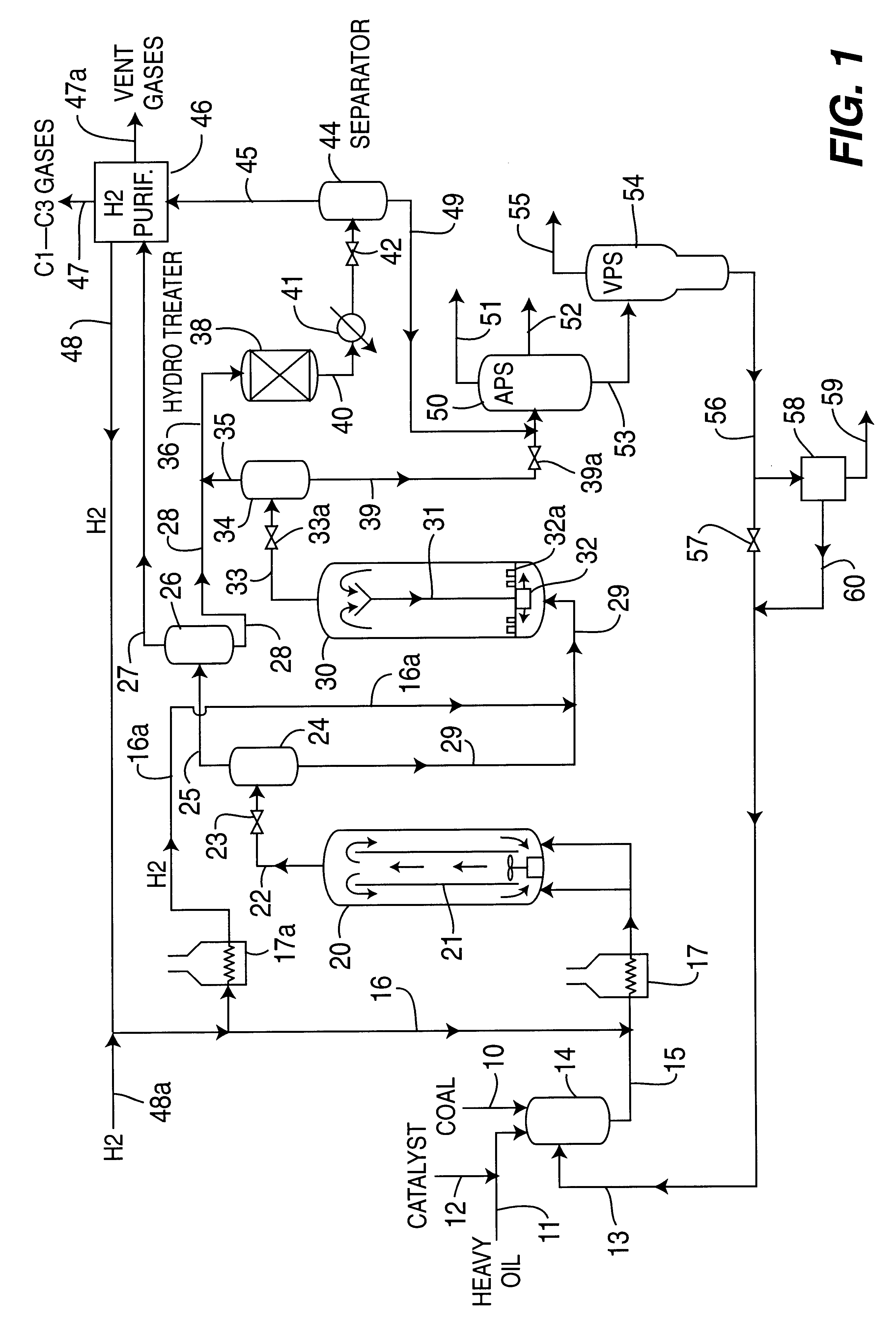

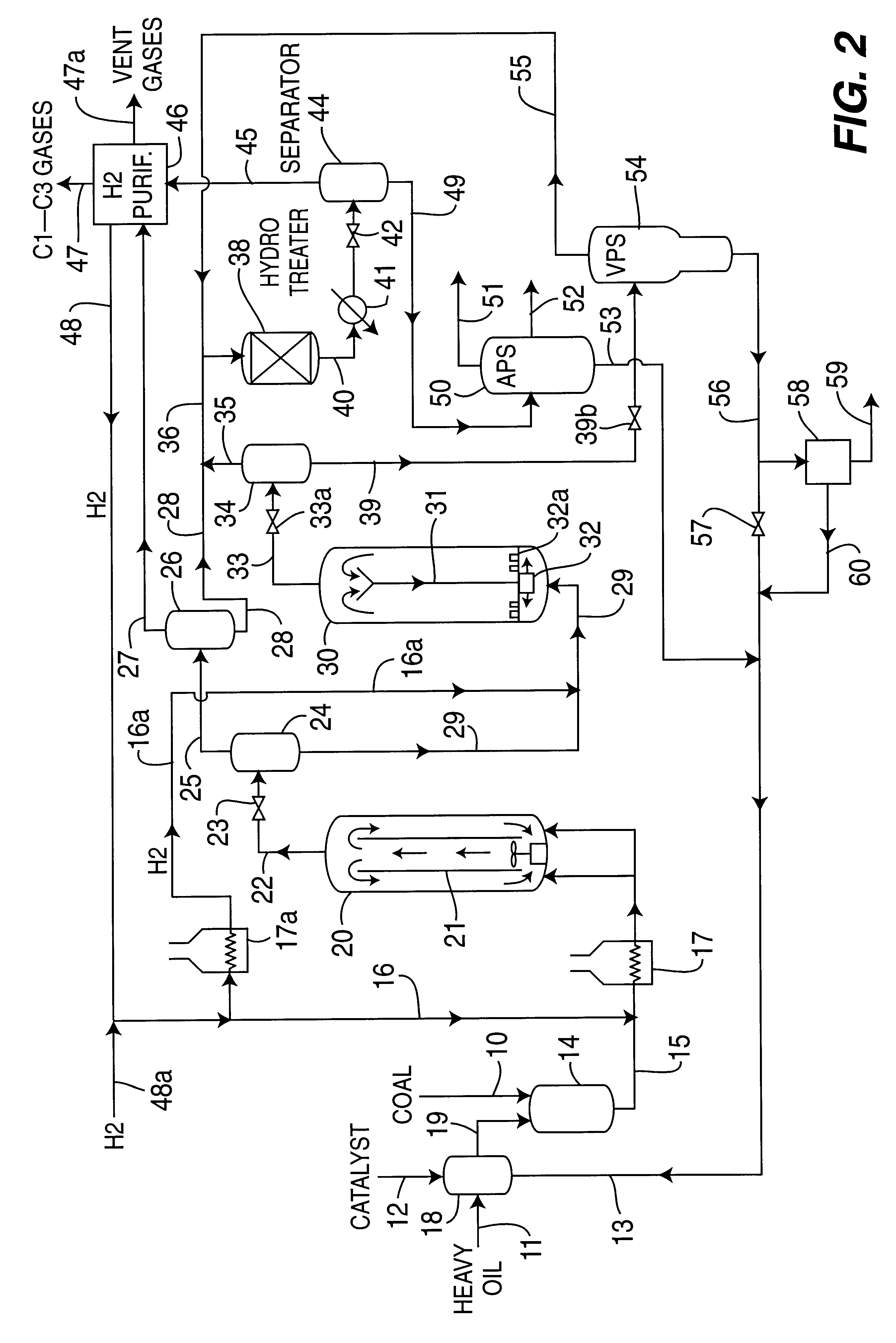

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

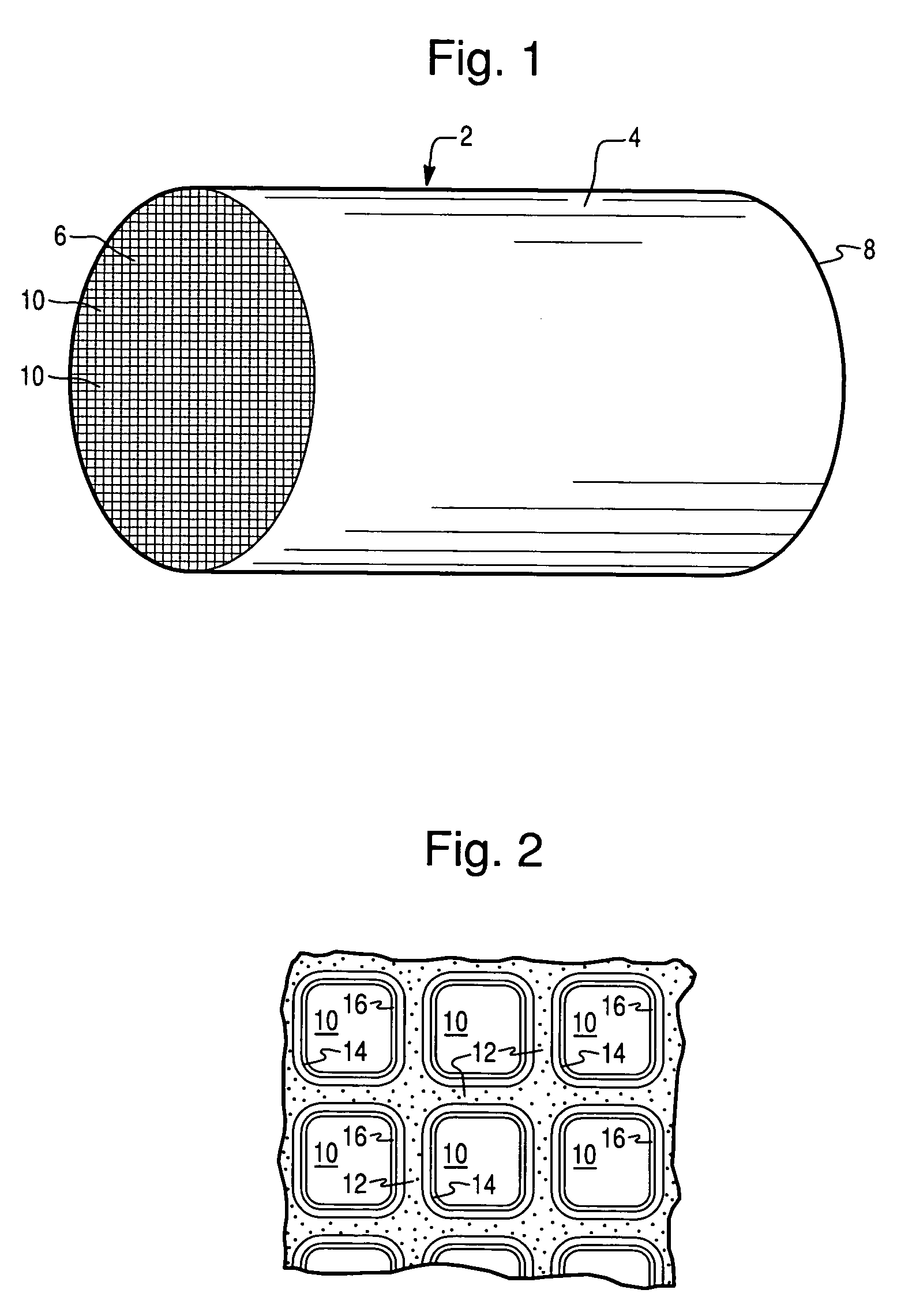

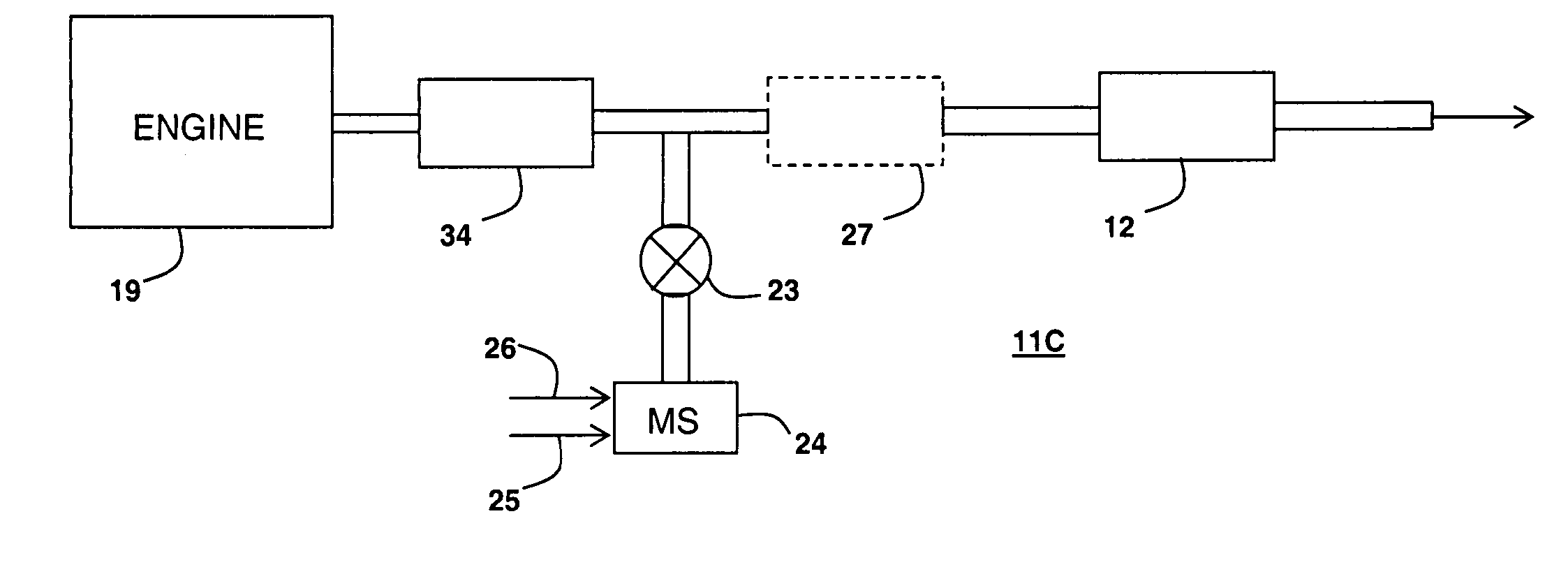

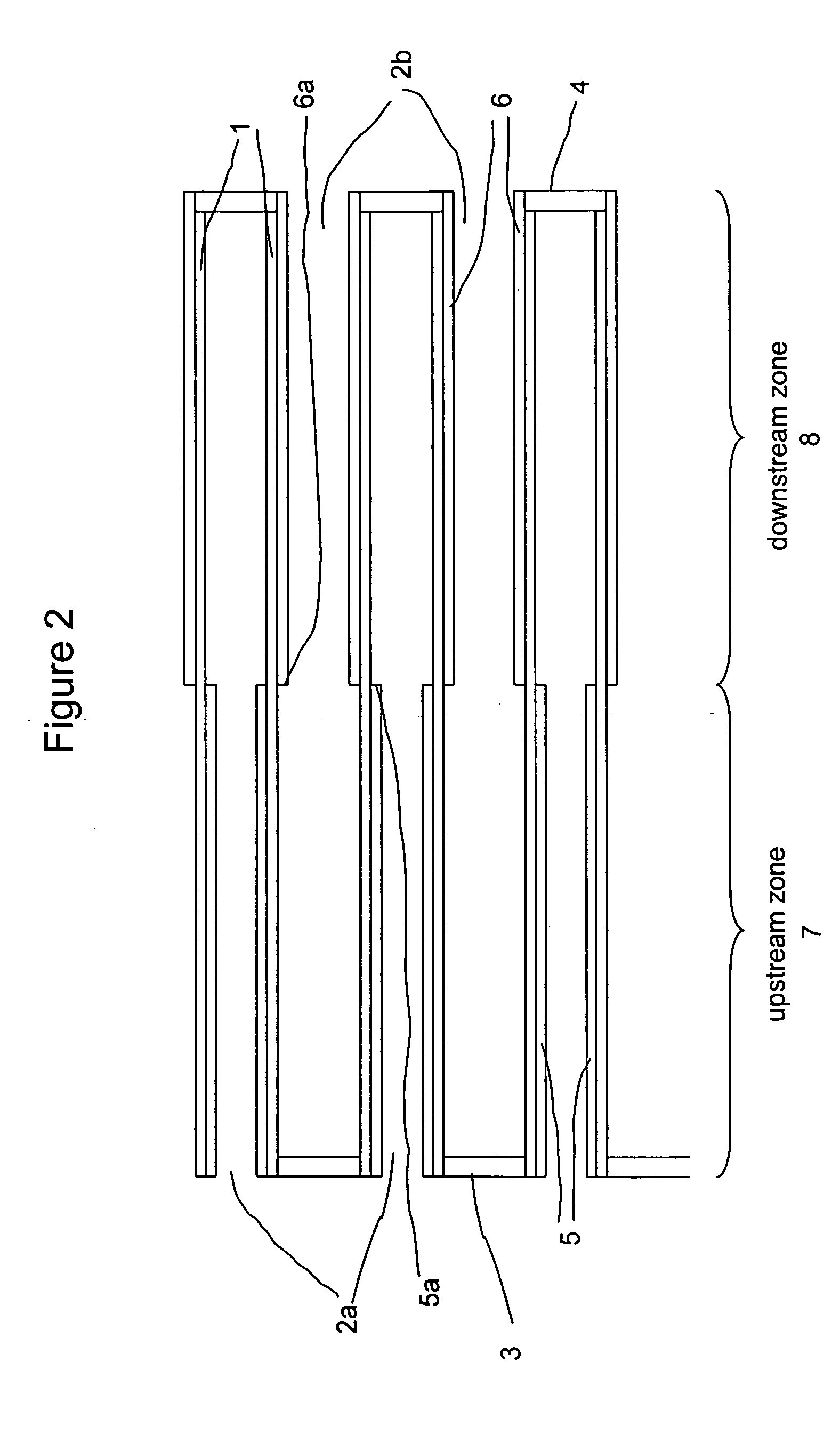

Zone coated catalyst to simultaneously reduce NOx and unreacted ammonia

ActiveUS20060039843A1Efficient conversionReduce riskCombination devicesNitrogen compoundsEngineeringInternal combustion engine

Provided is an emissions treatment system and method for reducing NOx emissions in the exhaust stream produced from an internal combustion engine. The system has an injector for periodically metering ammonia or an ammonia precursor into an exhaust stream; and a first substrate with a first SCR catalyst composition, downstream of the injector. The first substrate has an inlet end, an outlet end, a length extending between the inlet end to the outlet end, wall elements and a plurality of passages defined by the wall elements. The first SCR catalyst composition is disposed on the wall elements from the inlet end toward the outlet end to a length that is less than the substrate's axial length to form an inlet zone. The first substrate also has an NH3 destruction catalyst composition with a platinum group metal component dispersed on a refractory metal oxide. The NH3 destruction catalyst is disposed on the wall elements from the outlet end toward the inlet end to a length that is less than the substrate's axial length to form an outlet zone. Generally, there is from 0.1 to 10 g / ft3 of platinum group metal component in the outlet zone.

Owner:BASF CATALYSTS LLC

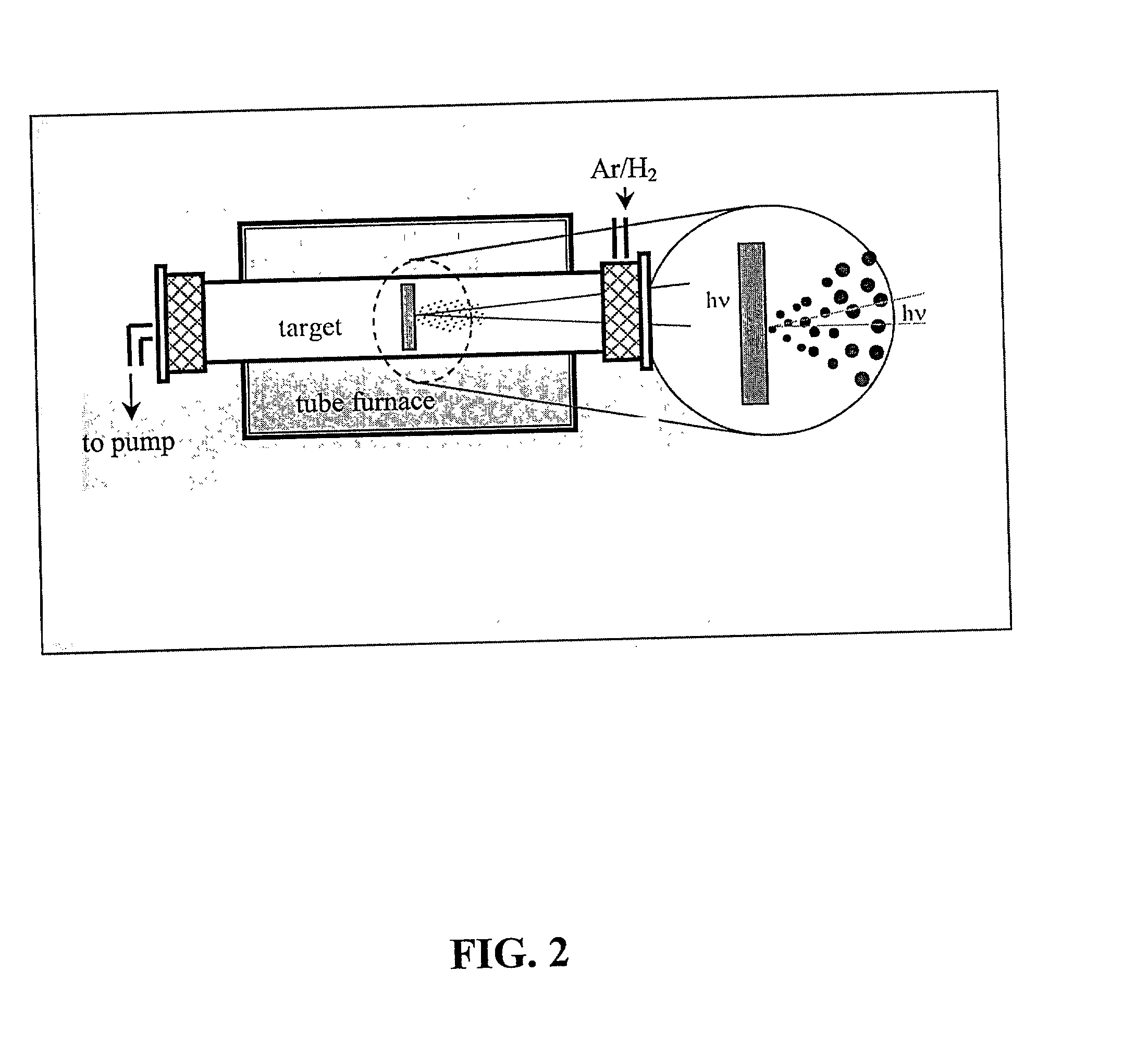

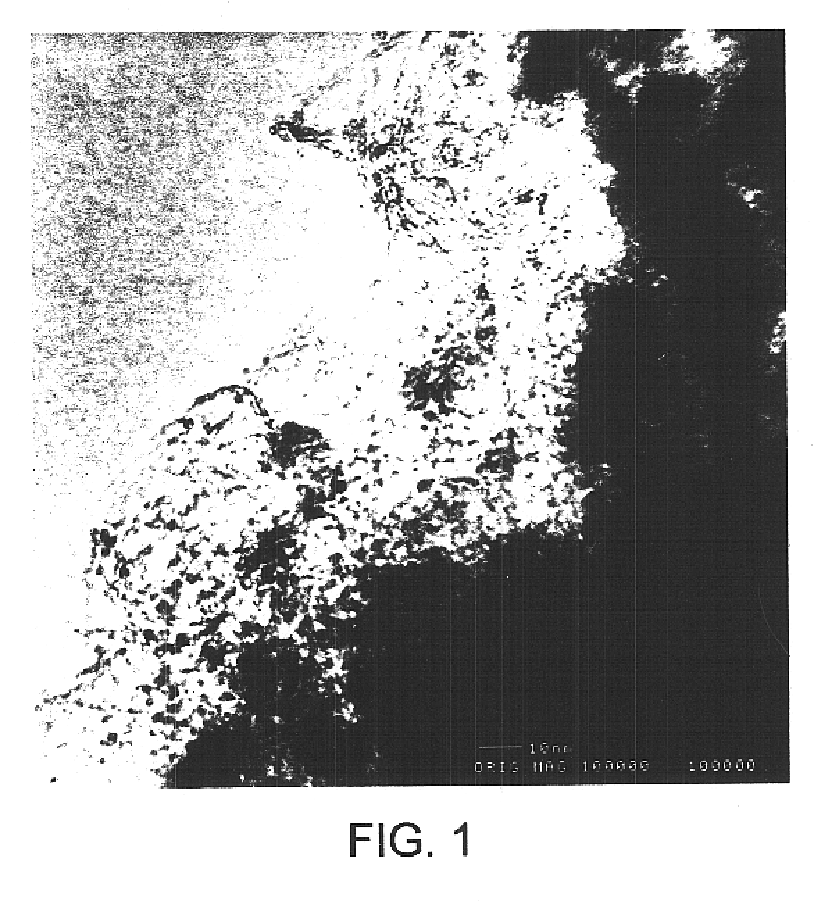

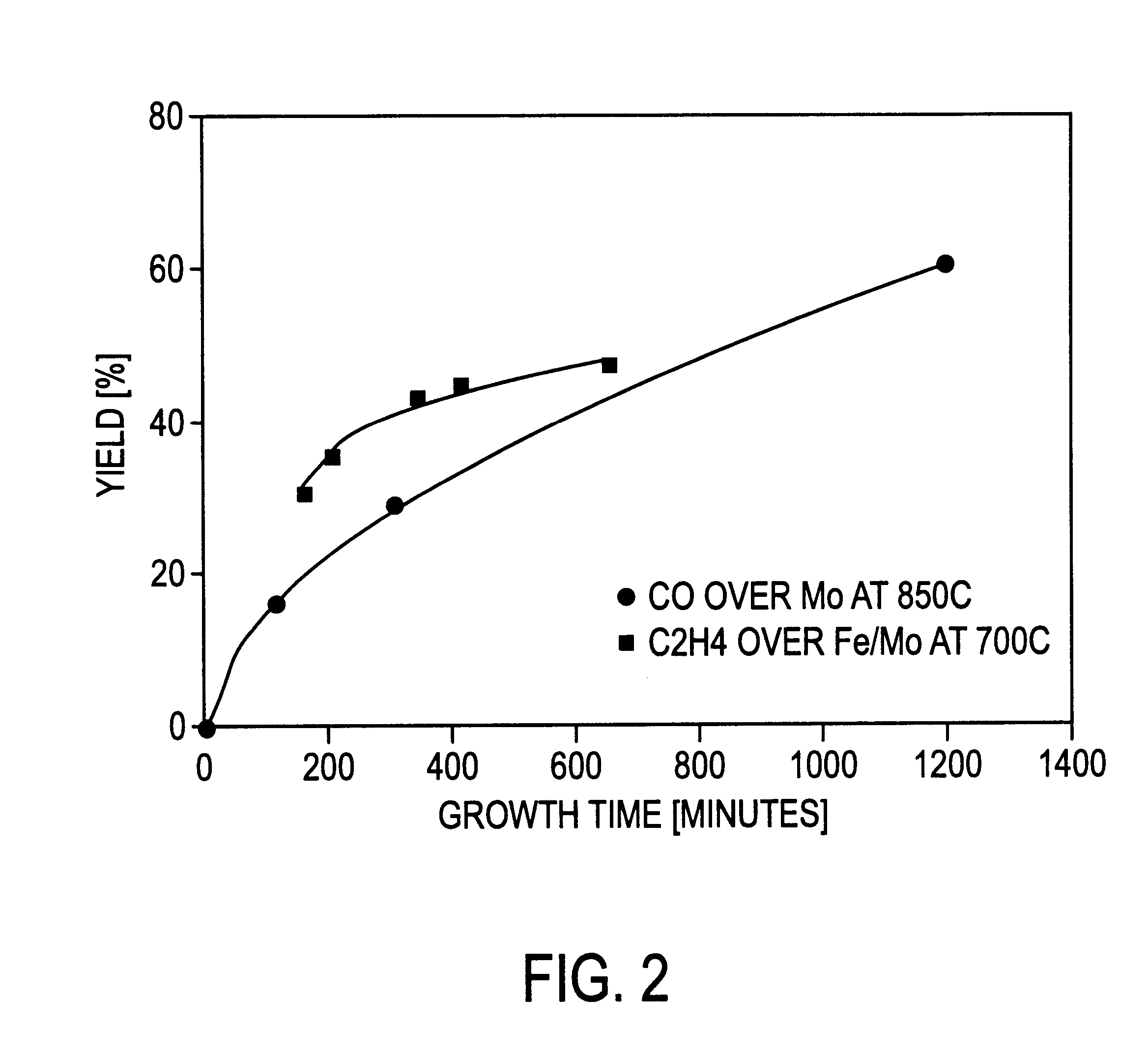

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

Pressure-balanced, catalyzed soot filter

ActiveUS20060057046A1Minimal overall platinum group metal component material costSpeed up the conversion processCombination devicesMolecular sieve catalystsParticulatesCatalytic function

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

DNA-bridged carbon nanotube arrays

InactiveUS6958216B2High sensitivityImprove portabilityImmobilised enzymesBioreactor/fermenter combinationsChemical ligationElectron transfer reactions

A class of biological sensing devices that include a substrate comprising an array of carbon nanotubes (CNTs) to which are chemically attached biological molecules is disclosed. The attached biological molecules are capable of electrical conductivity that is responsive to chemical changes occurring as a result of their interaction with target species. A means for means for using DNA as a material of potential in molecular electronic sensor devices, being primarily based on molecular electron-transfer reaction processes between DNA-binding donors and acceptors is also disclosed, including composition, method of manufacture and their use are described.

Owner:TRUSTEES OF BOSTON COLLEGE THE

Process for Making Ethanol From Acetic Acid Using Acidic Catalysts

InactiveUS20110082322A1Organic compound preparationCarboxylic acid esters preparationAcetic acidMetal

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of a catalyst comprises a first metal on an acidic support. The acidic support may comprise an acidic support material or may comprise an support having an acidic support modifier. The catalyst may be used alone to produced ethanol via hydrogenation or in combination with another catalyst. In addition, the crude ethanol product is separated to obtain ethanol.

Owner:CELANESE INT CORP

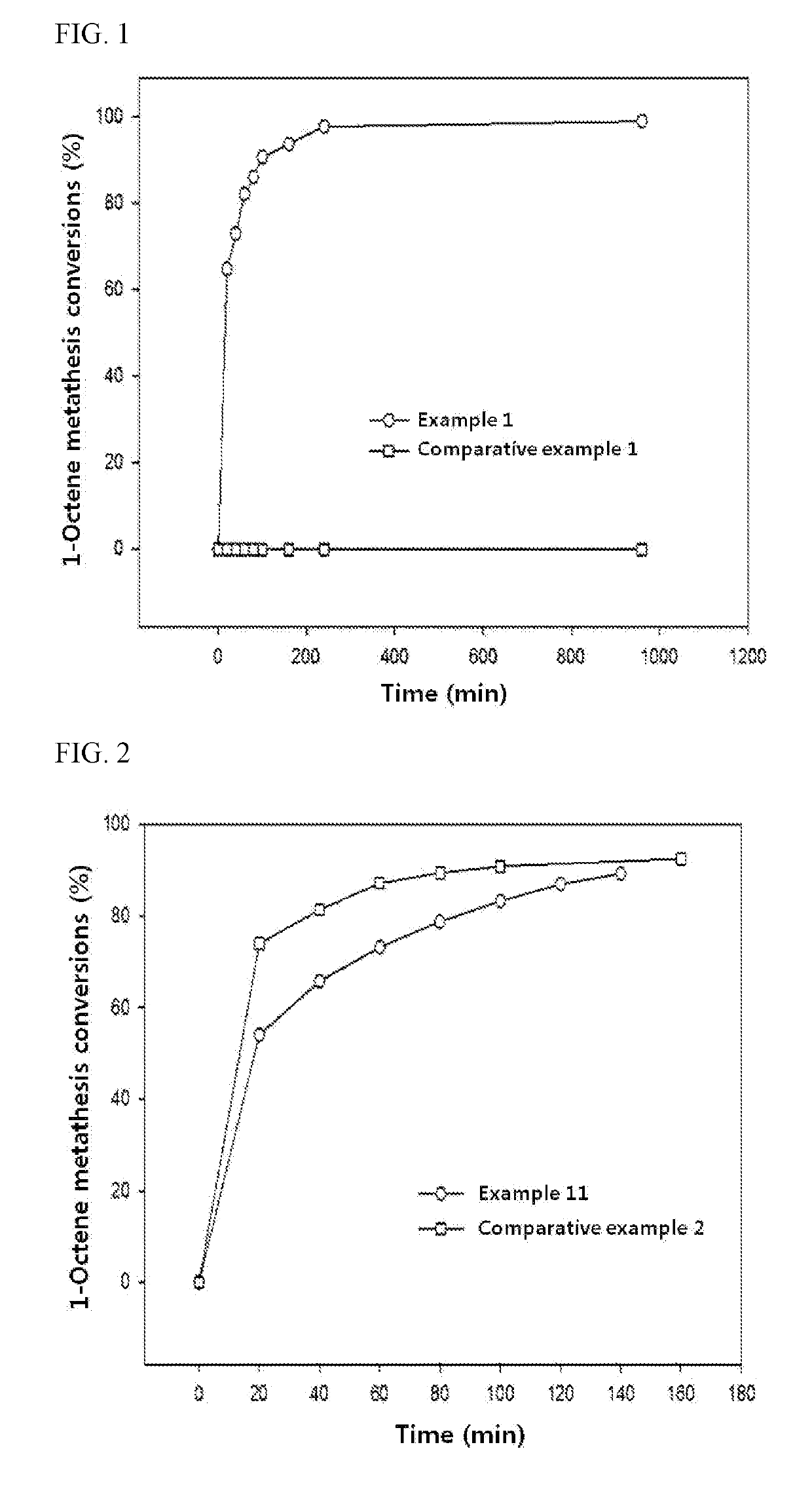

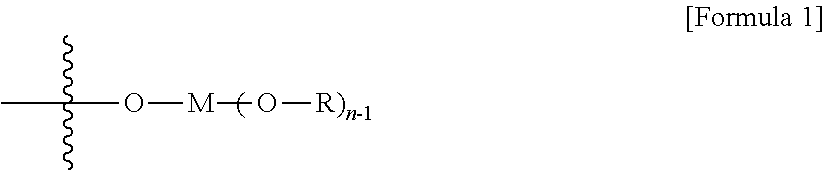

Olefin metathesis reaction catalyst and preparation method therefor

ActiveUS20190217277A1Separated/recovered readilyEasy to useMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumUnsaturated hydrocarbon

The present invention relates to an olefin metathesis reaction catalyst where rhenium (Re) oxide or molybdenum (Mo) oxide is supported, as a catalyst main component, on a surface-modified mesoporous silica or mesoporous alumina support, and a preparation method therefor. The olefin metathesis reaction catalyst of the present invention allows highly efficient metathesis of long-chain unsaturated hydrocarbons having at least eight carbons at a low temperature of 150° C. or lower. The catalyst can be separated readily from reaction solution, regenerated at a low temperature of 400° C. or lower by removing toxins accumulated on it during the metathesis reaction, and used repeatedly in metathesis reaction many times, thereby being made good use in commercial olefin metathesis processes.

Owner:KOREA RES INST OF CHEM TECH

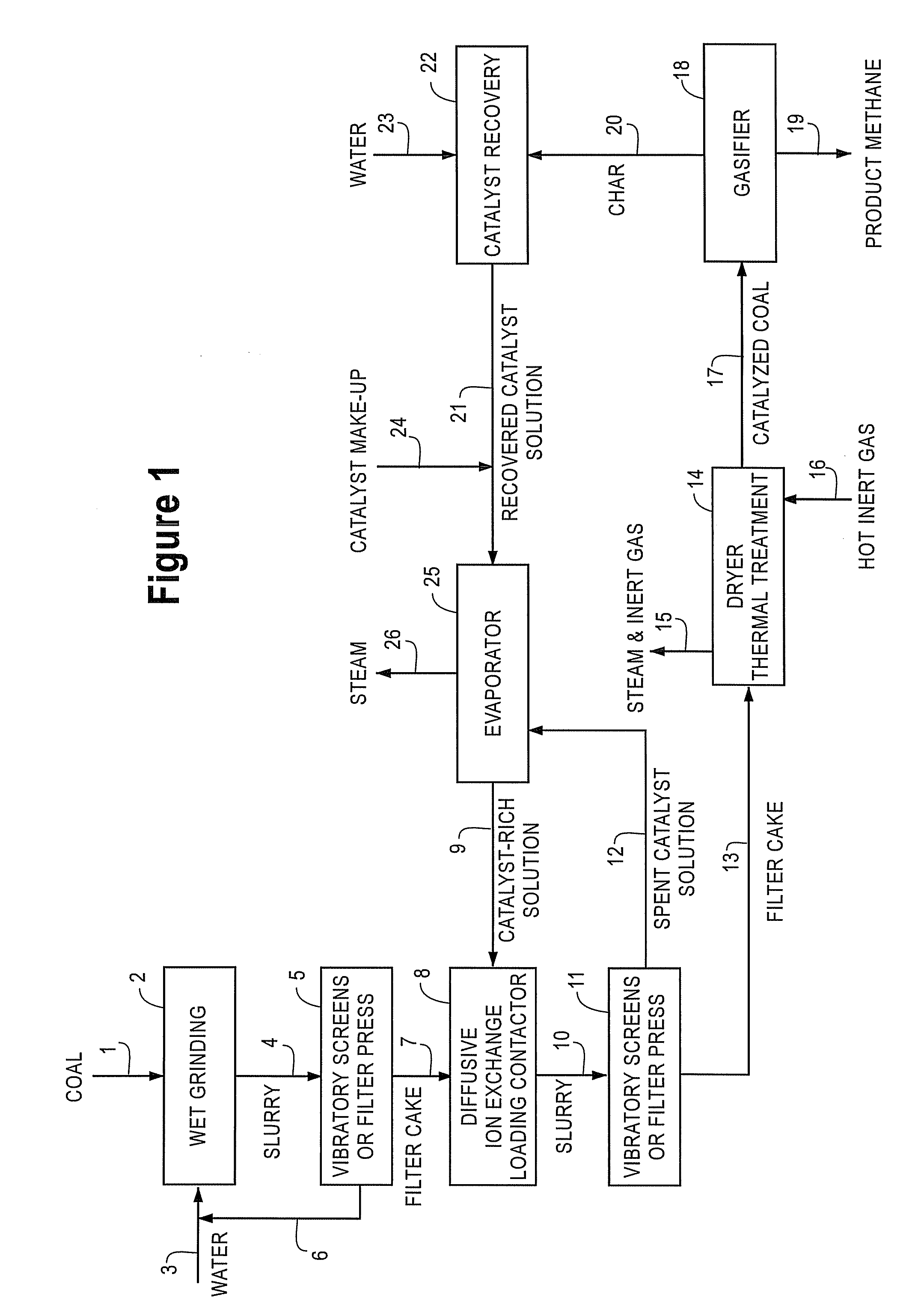

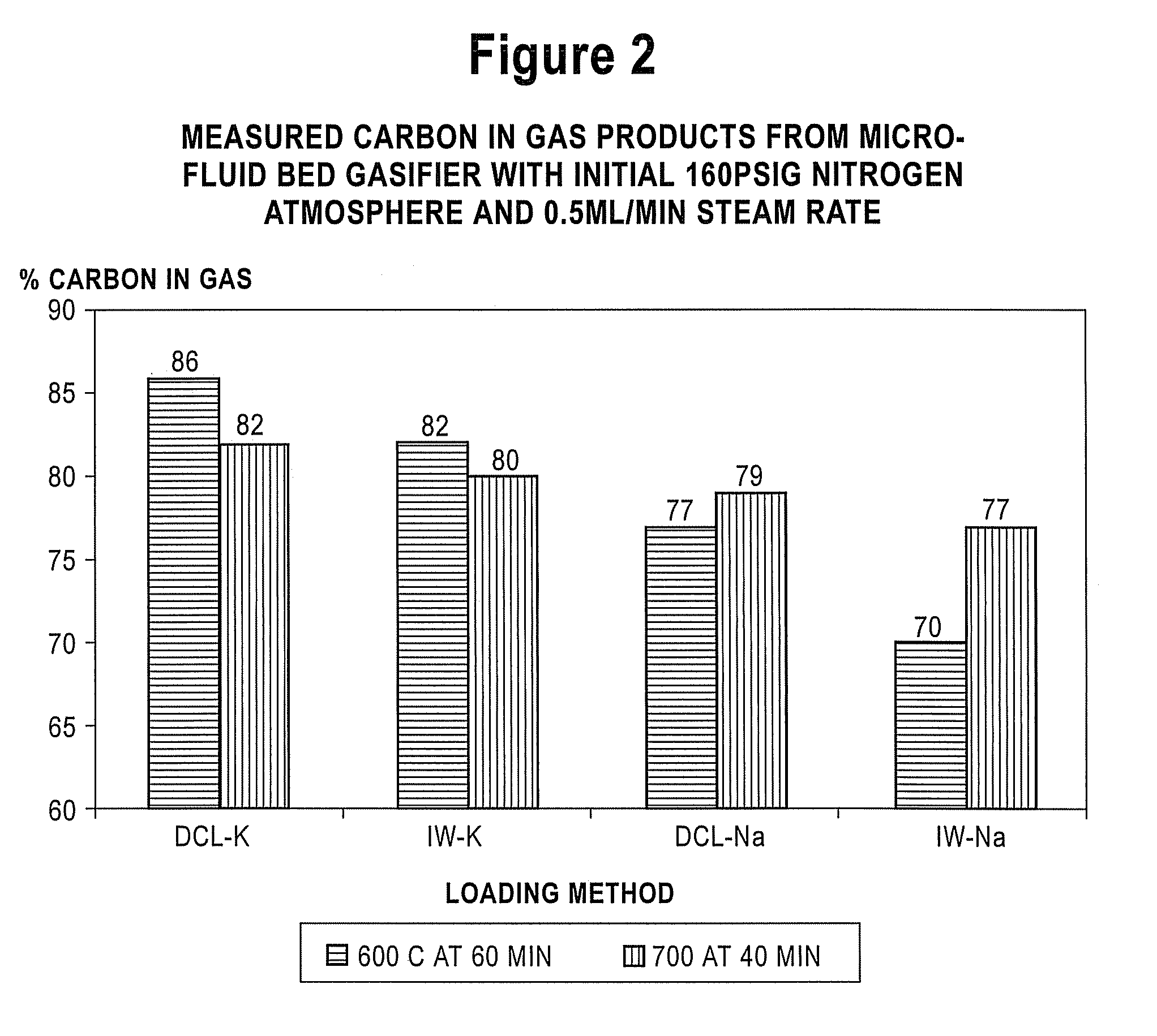

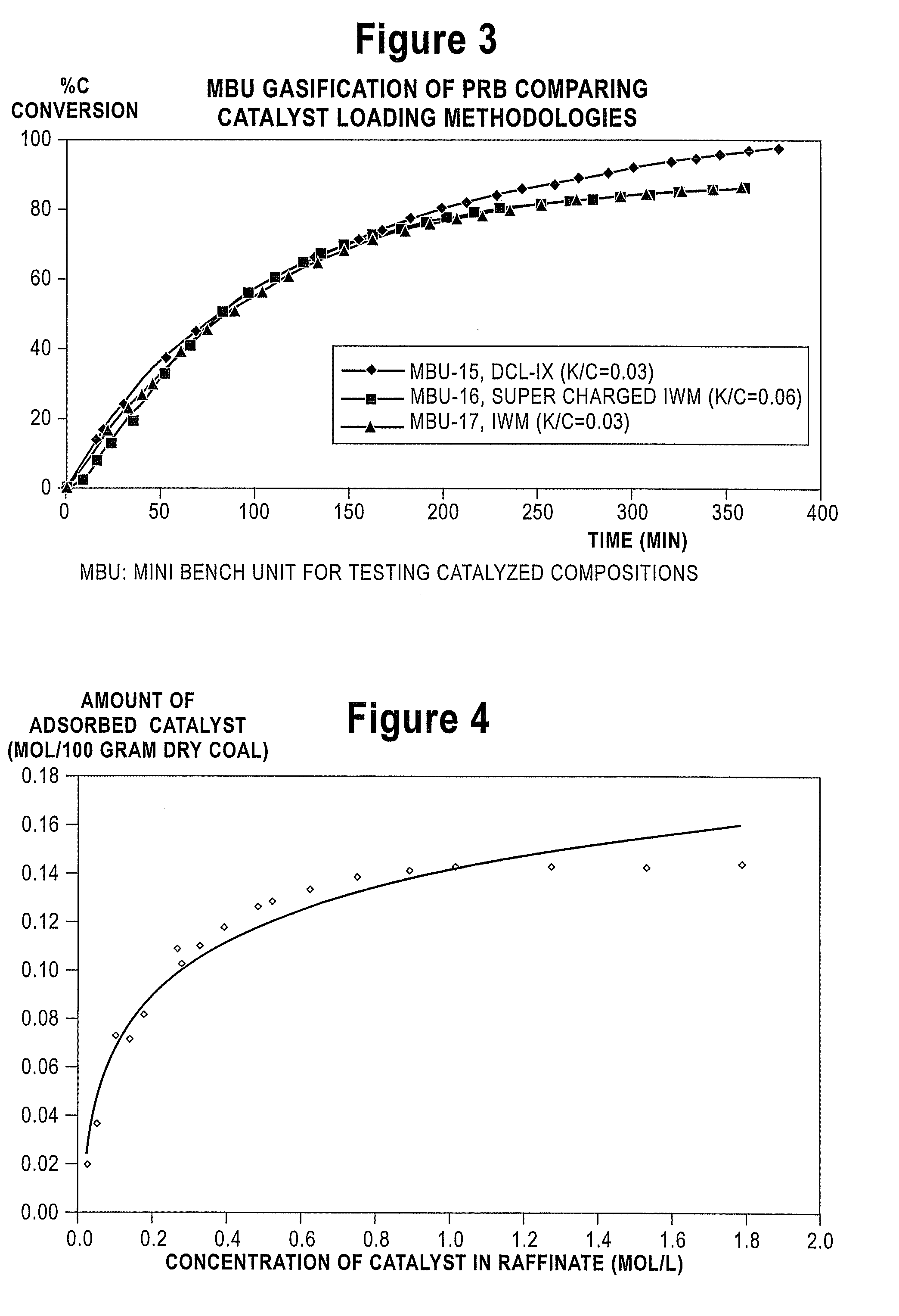

Catalyst-Loaded Coal Compositions, Methods of Making and Use

ActiveUS20090048476A1Efficient and high-yielding gasificationHigh yield productionCatalyst regeneration/reactivationSolid fuelsPtru catalystCoal matrix

The present invention relates to catalyst-loaded coal compositions having a moisture content of less than about 6 wt %, a process for the preparation of catalyst-loaded coal compositions, and an integrated process for the gasification of the catalyst-loaded coal compositions. The catalyst-loaded coal compositions can be prepared by a diffusive catalyst loading process that provides for a highly dispersed catalyst that is predominantly associated with the coal matrix, such as by ion-exchange.

Owner:SURE CHAMPION INVESTMENT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com