Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1307 results about "Catalytic decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing single wall nanotubes using unsupported metal catalysts

InactiveUS6221330B1Continuous and efficient productionMaterial nanotechnologyFibre chemical featuresHydrogenGas phase

A process for producing hollow, single-walled carbon nanotubes by catalytic decomposition of one or more gaseous carbon compounds by first forming a gas phase mixture carbon feed stock gas comprising one or more gaseous carbon compounds, each having one to six carbon atoms and only H, O, N, S or Cl as hetero atoms, optionally admixed with hydrogen, and a gas phase metal containing compound which is unstable under reaction conditions for said decomposition, and which forms a metal containing catalyst which acts as a decomposition catalyst under reaction conditions; and then conducting said decomposition reaction under decomposition reaction conditions, thereby producing said nanotubes.

Owner:HYPERION CATALYSIS INT

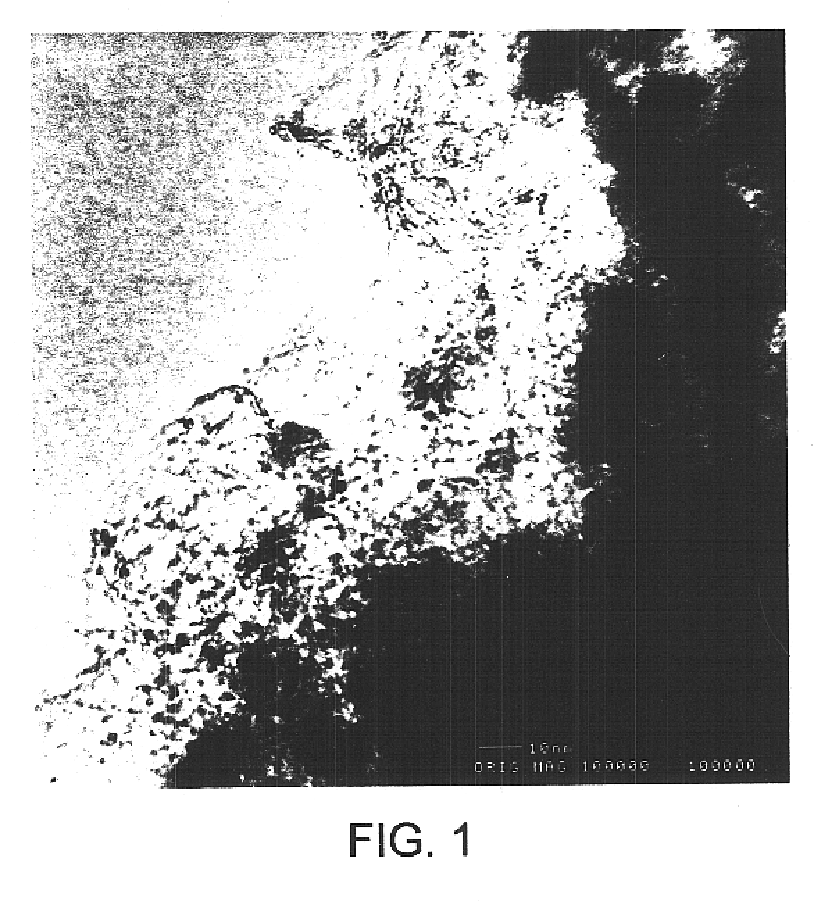

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

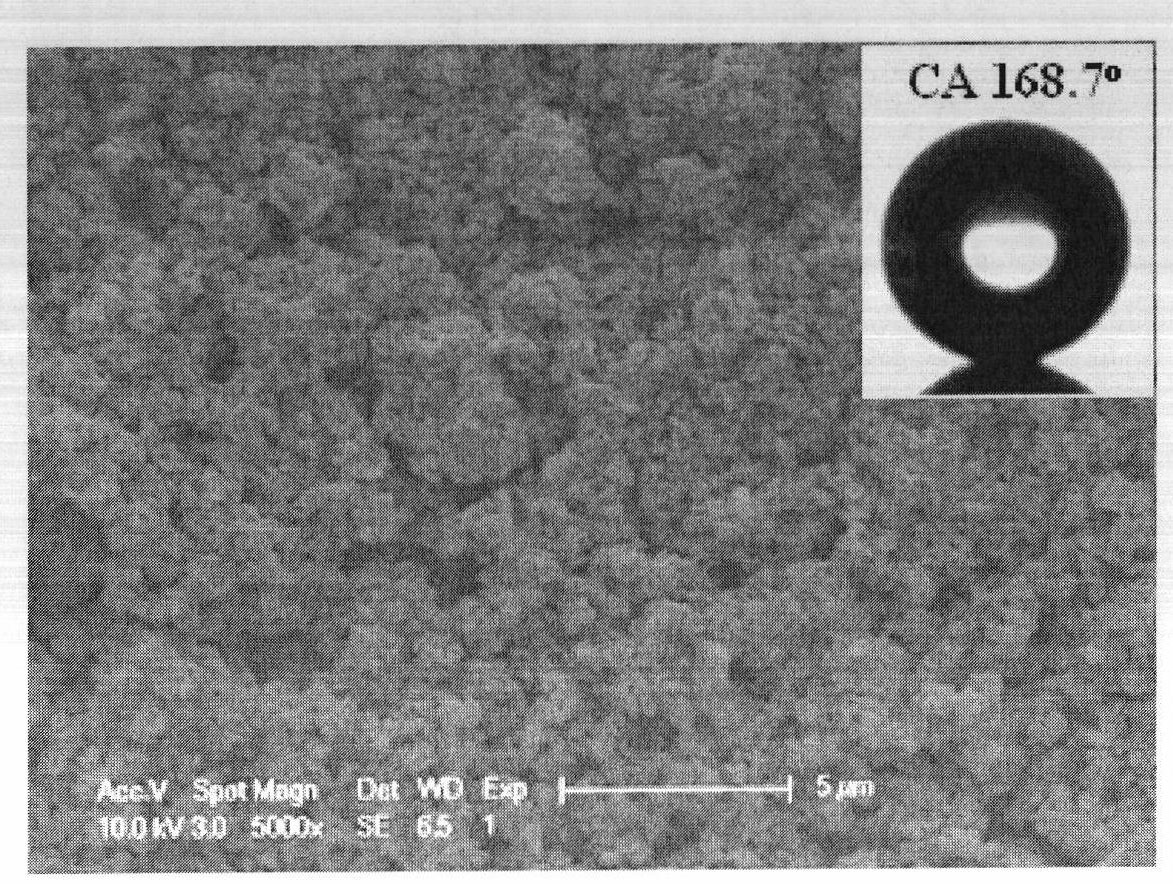

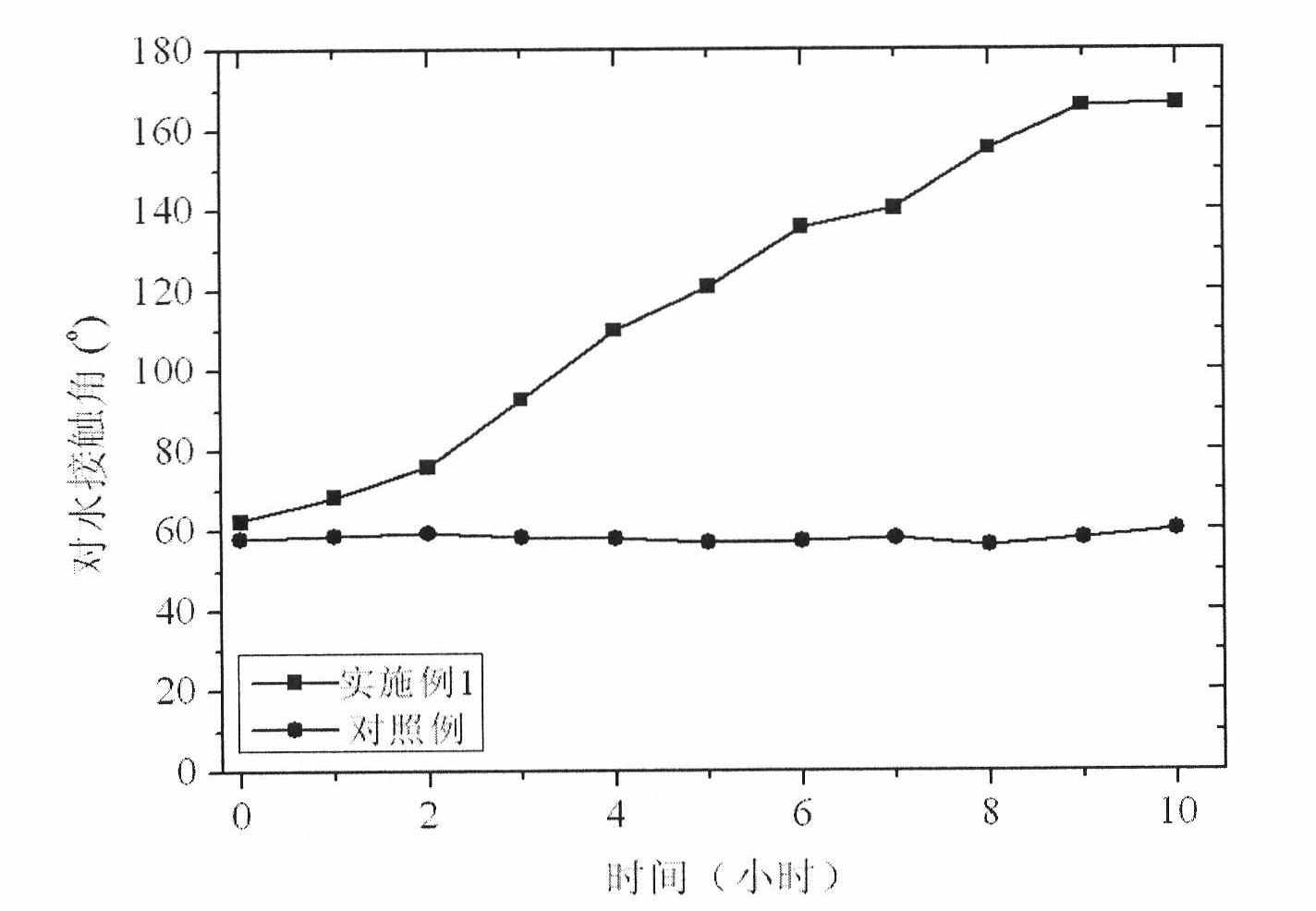

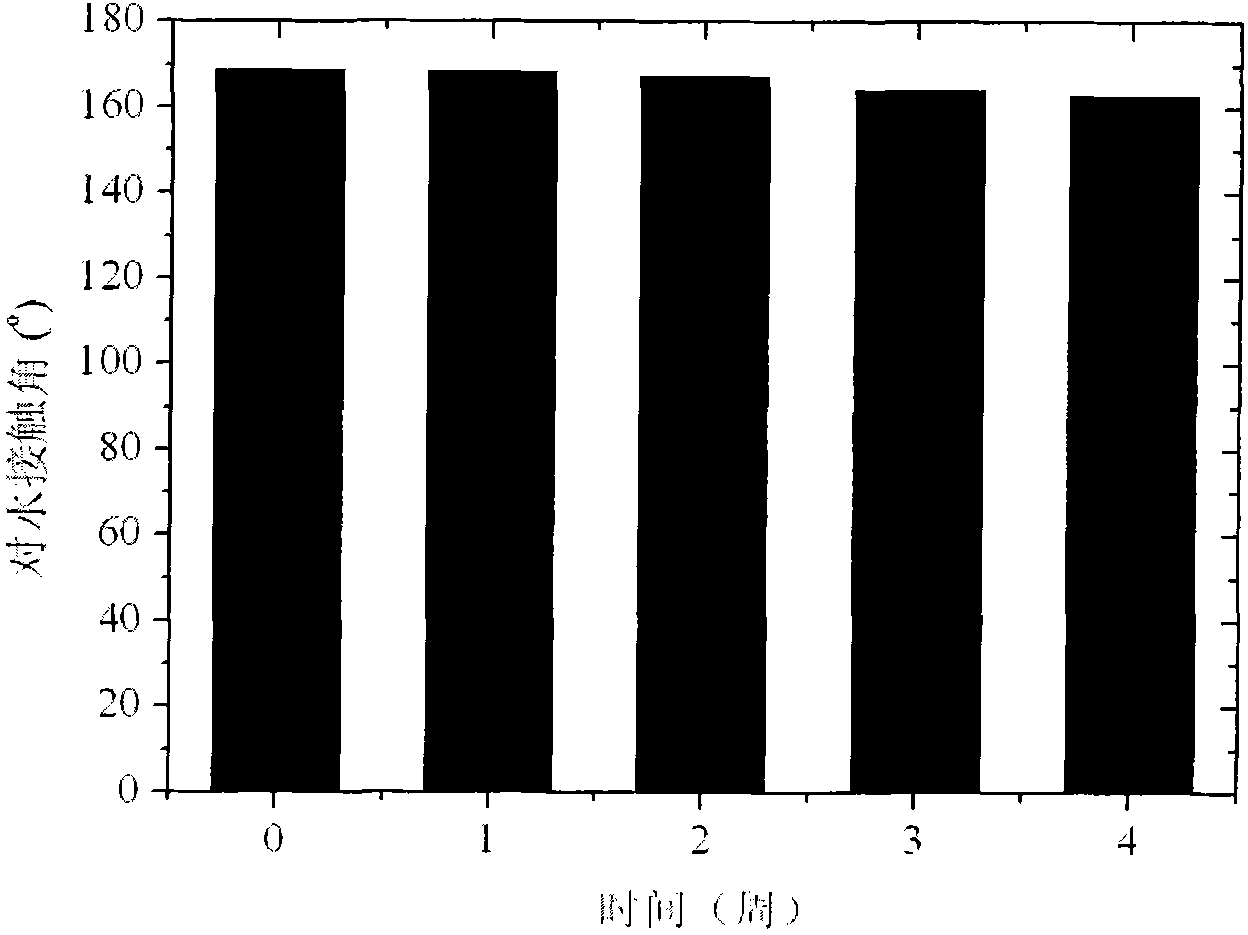

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

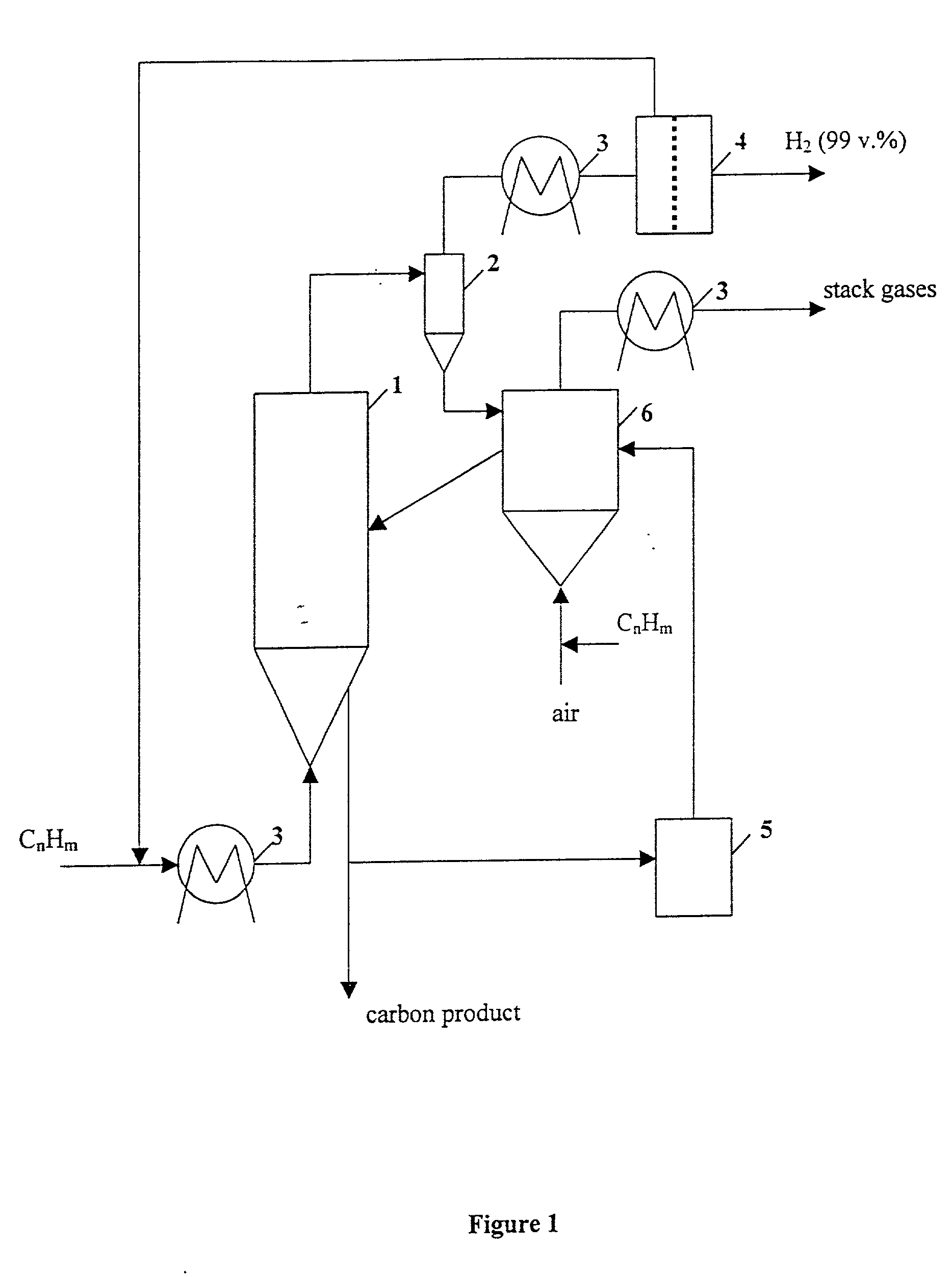

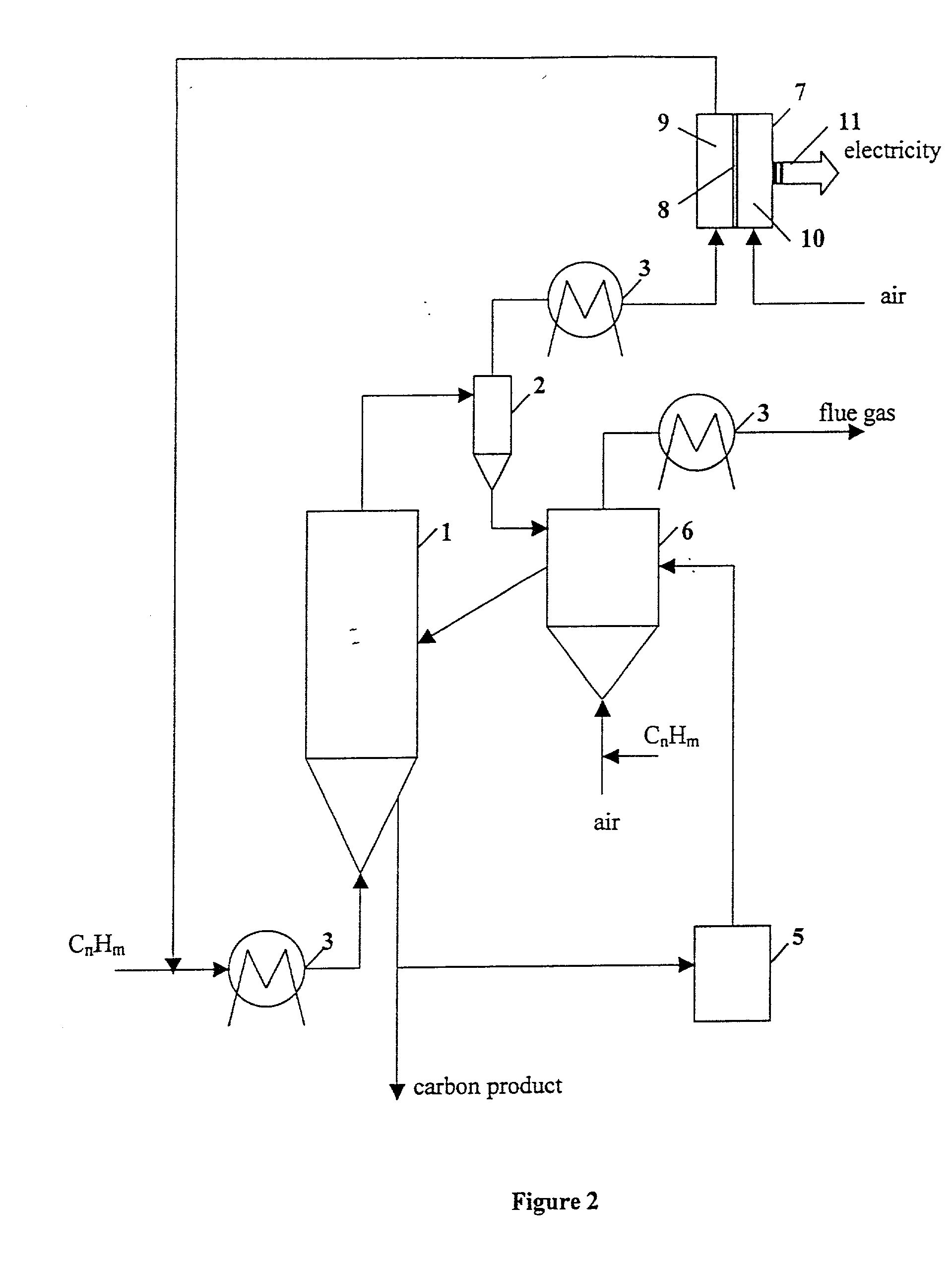

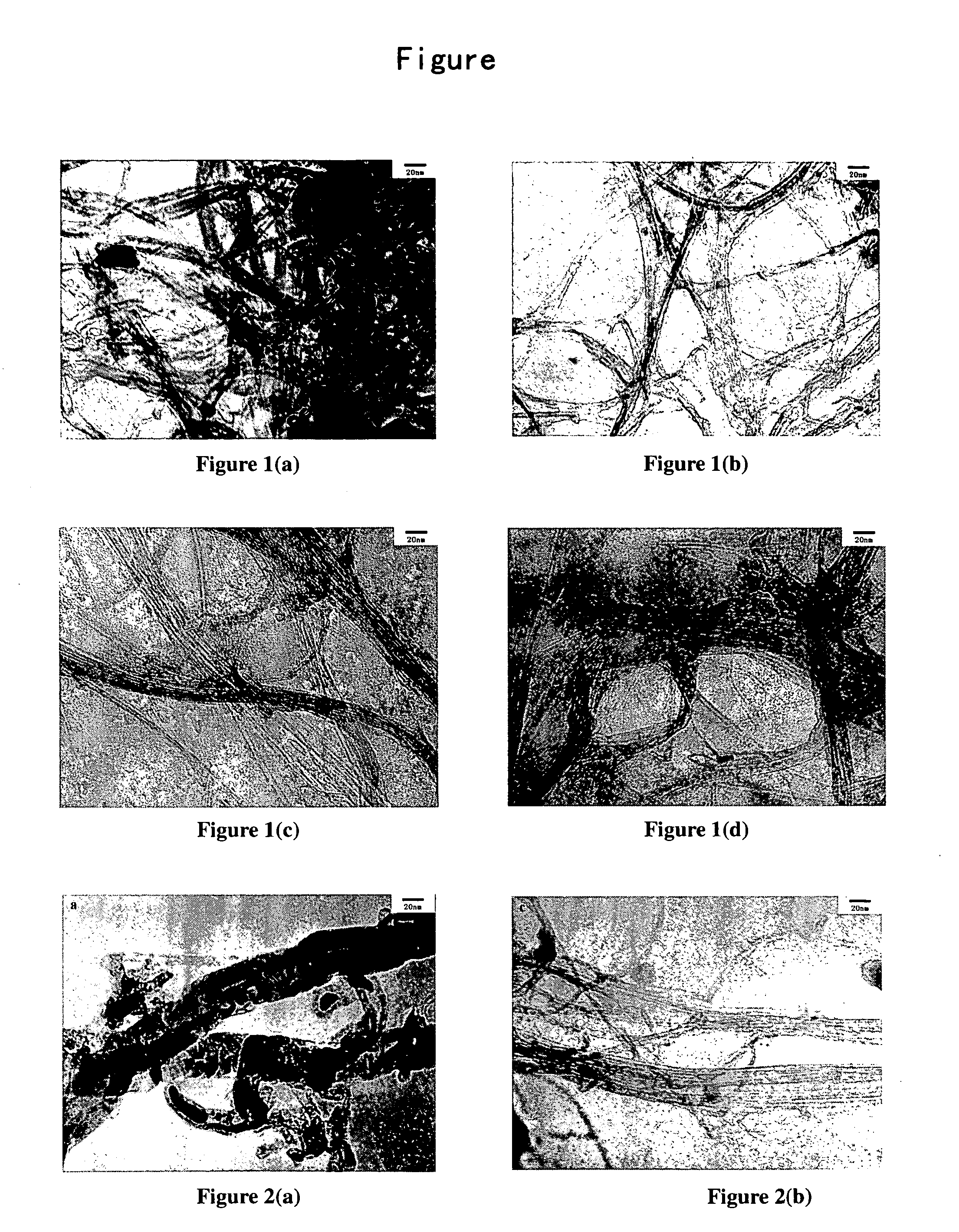

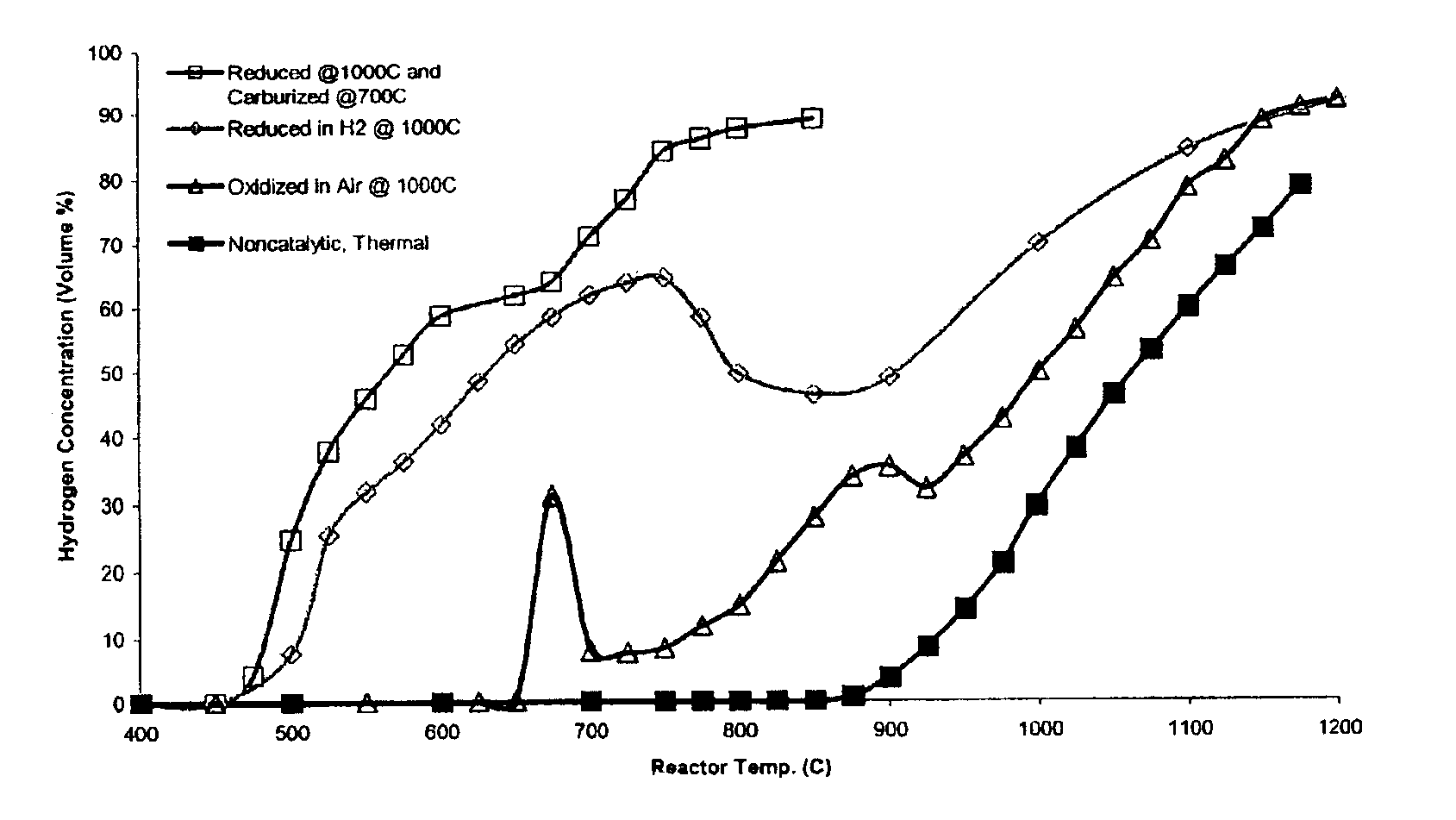

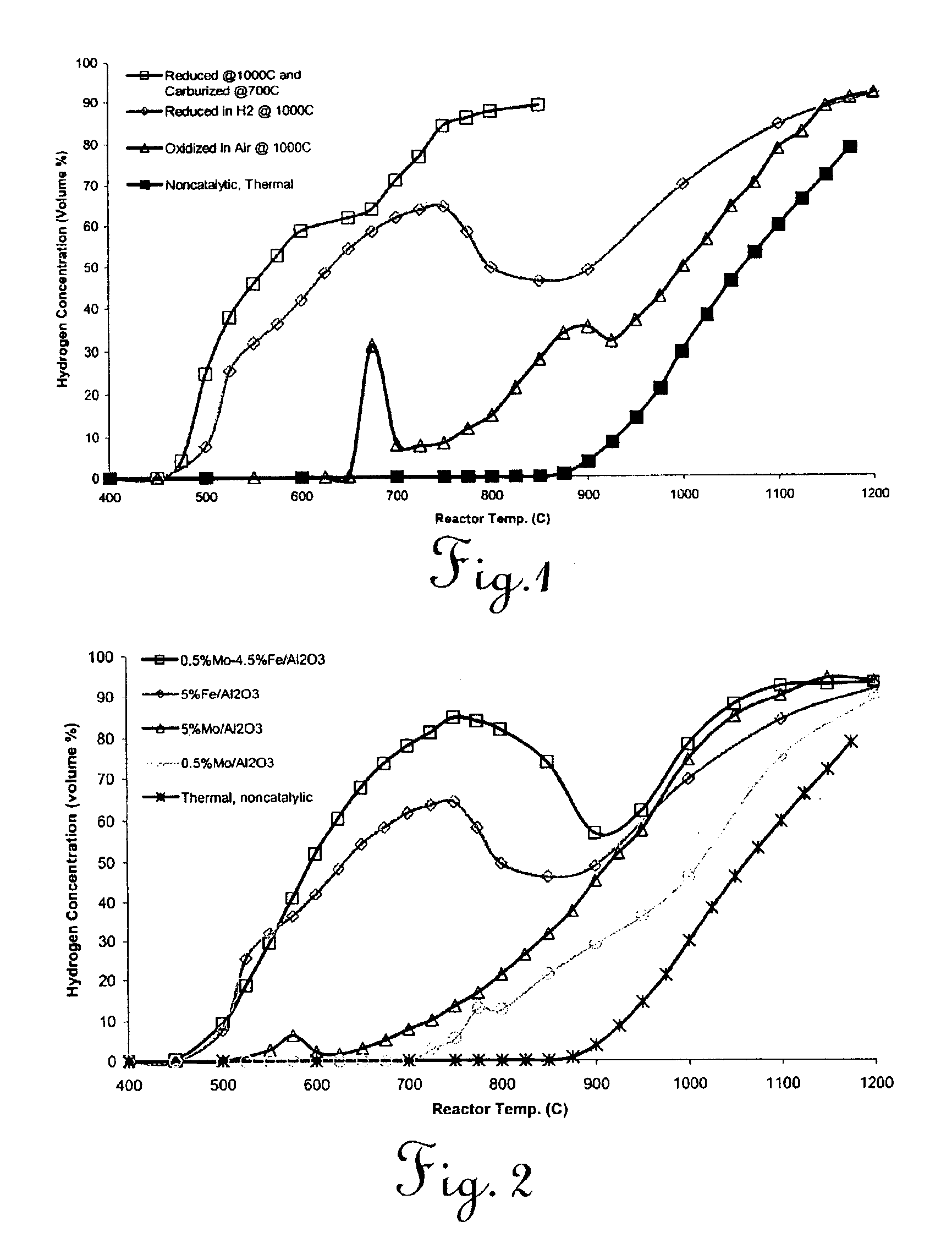

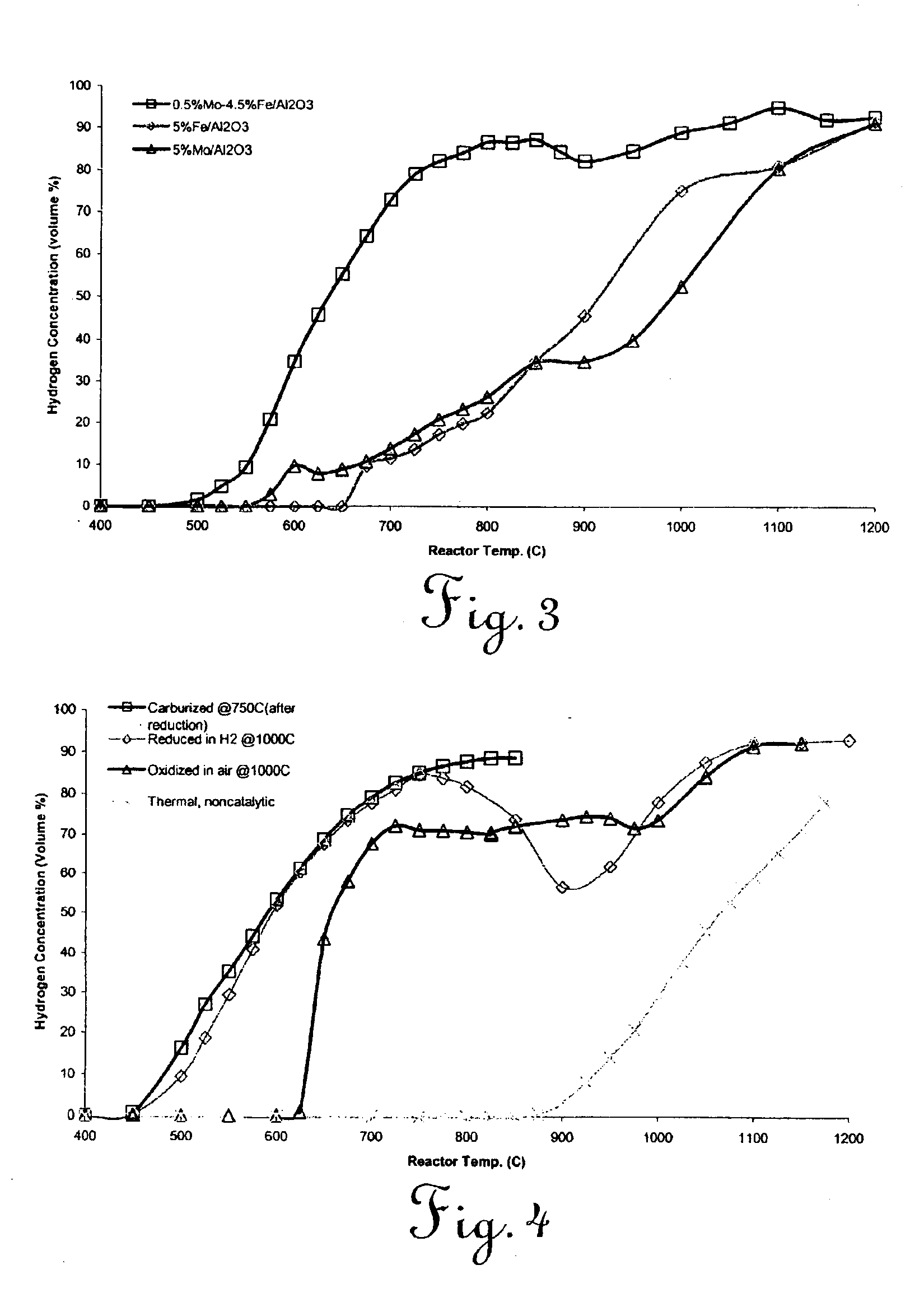

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

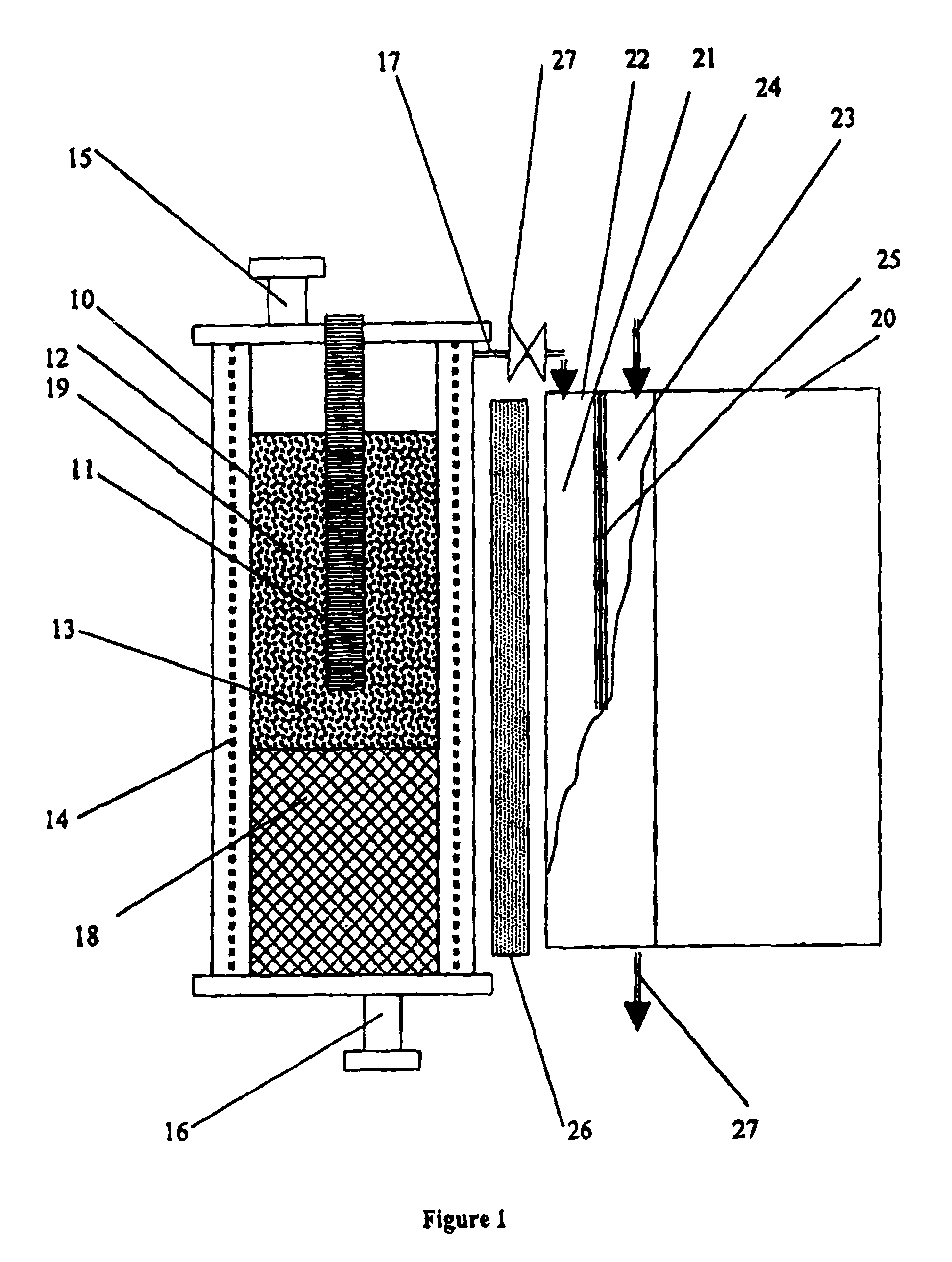

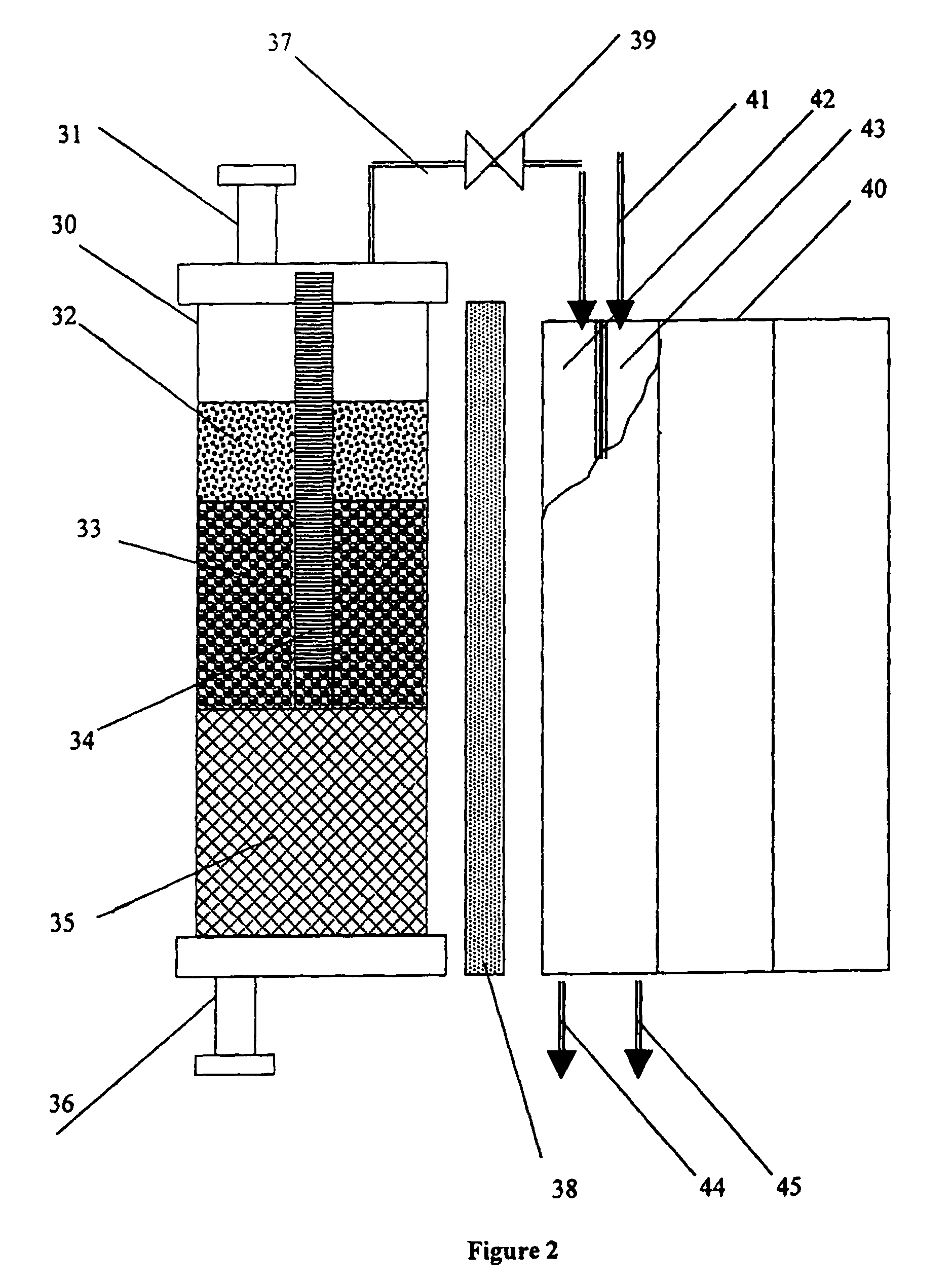

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

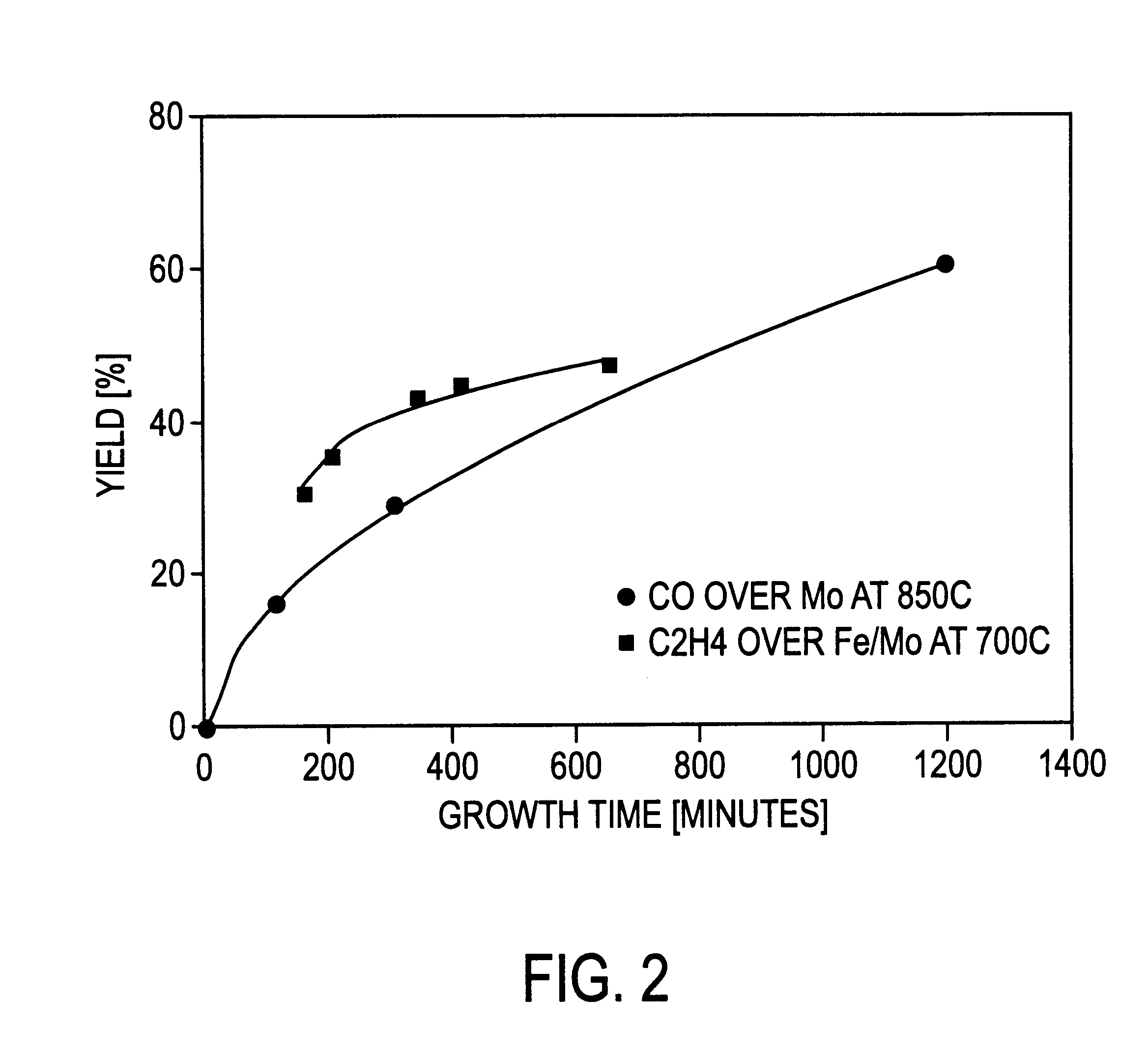

Catalytic growth of single- and double-wall carbon nanotubes from metal particles

InactiveUS7125534B1Improve productivityImprove scalabilityMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

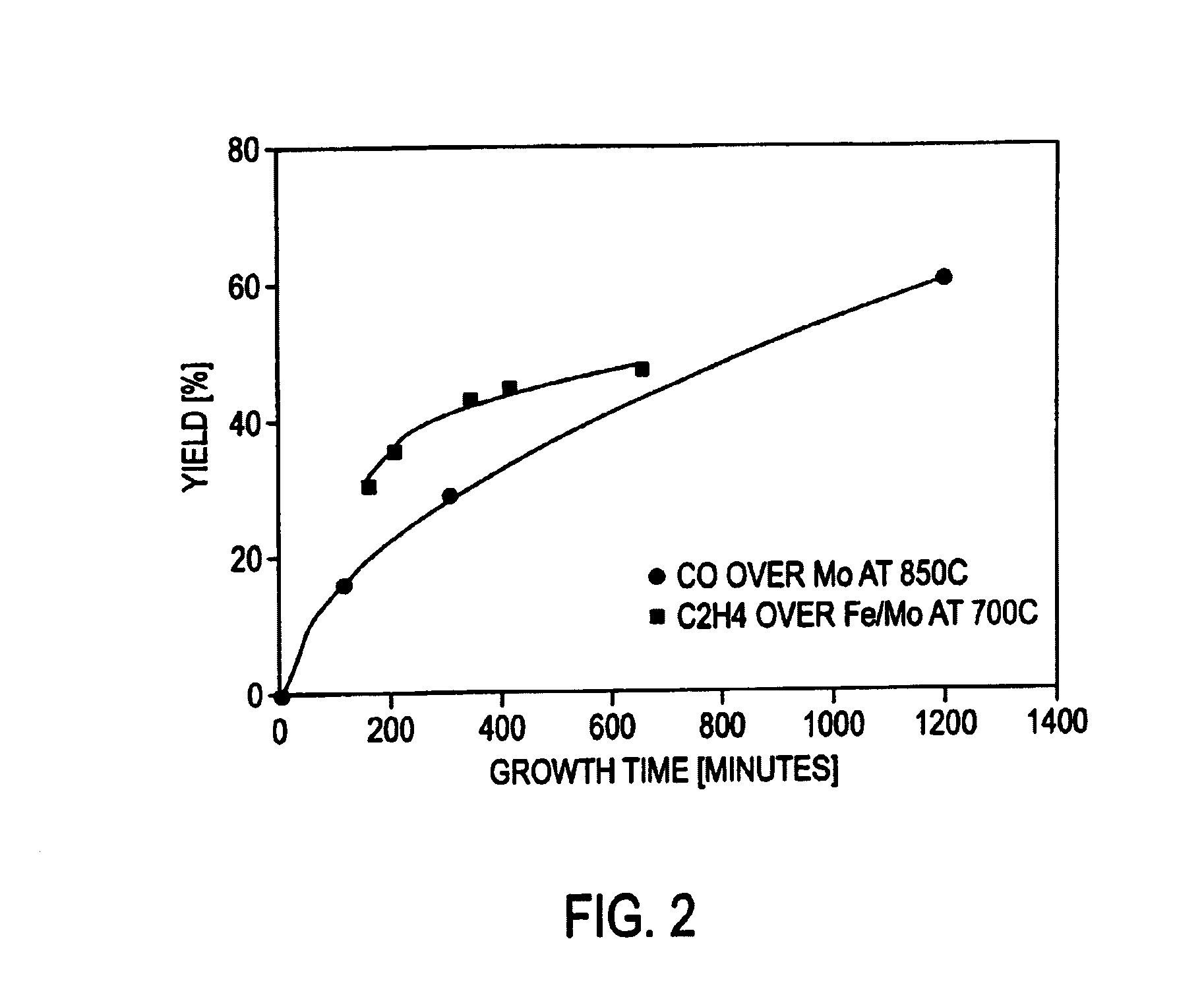

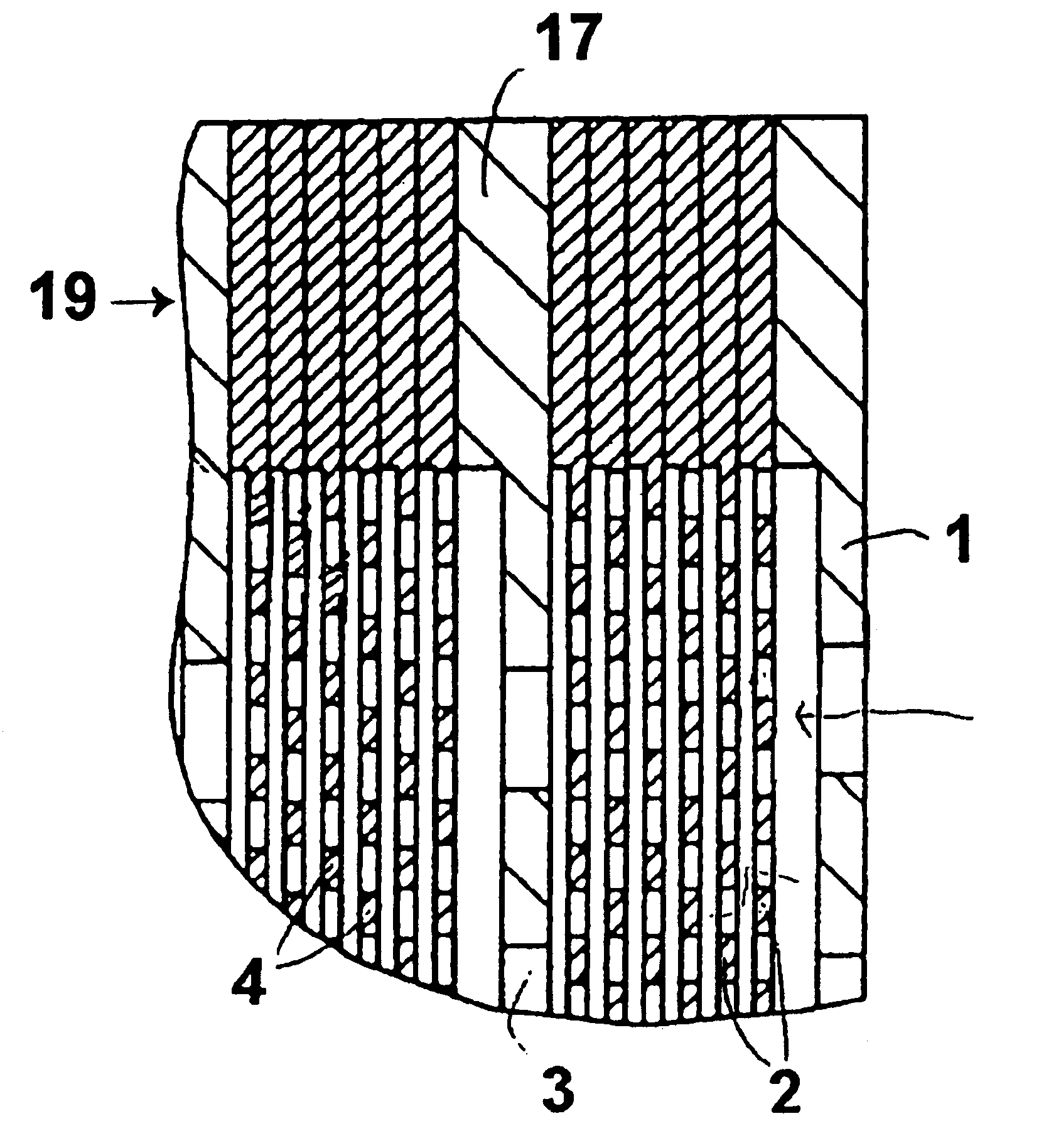

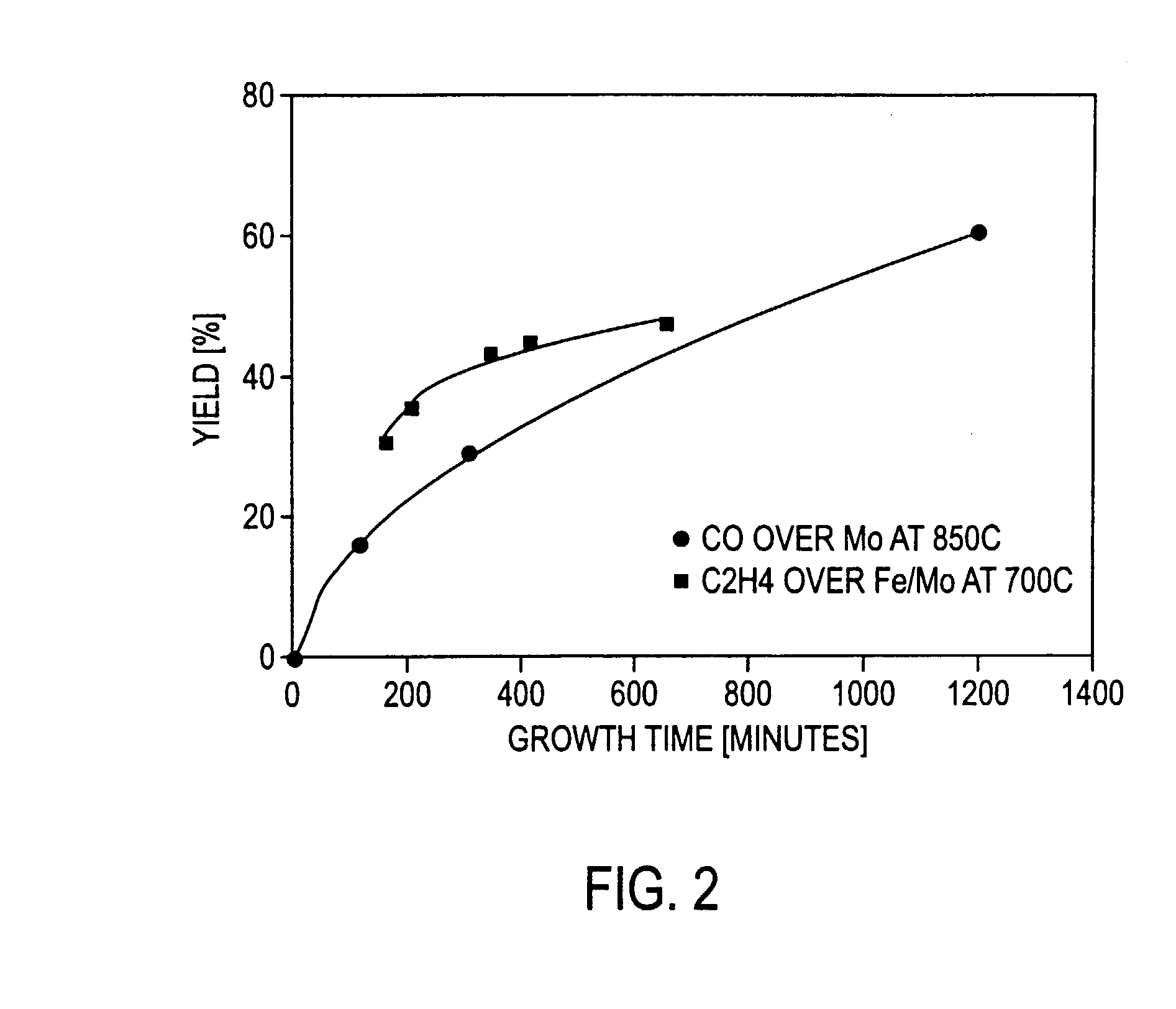

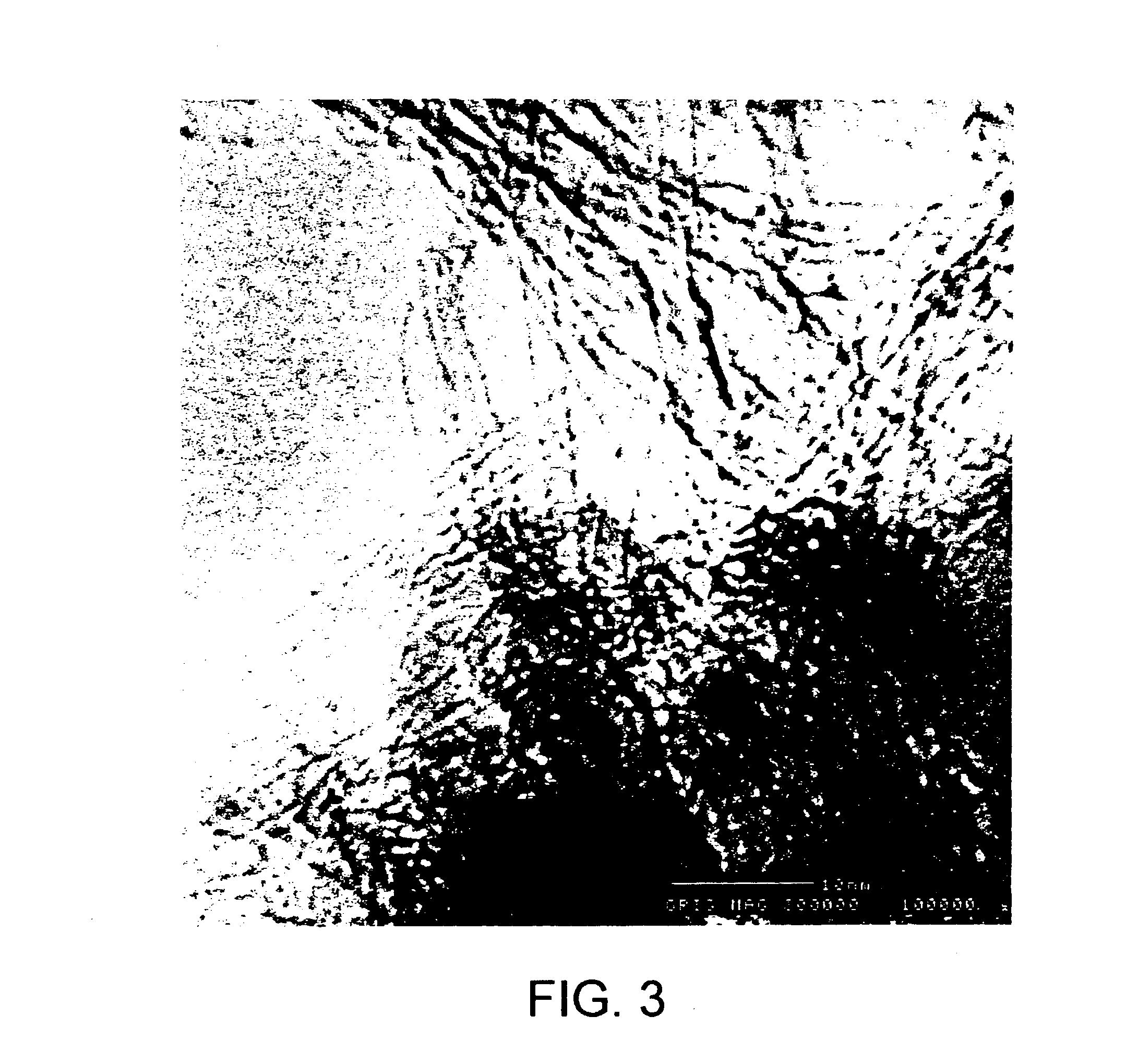

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst. The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

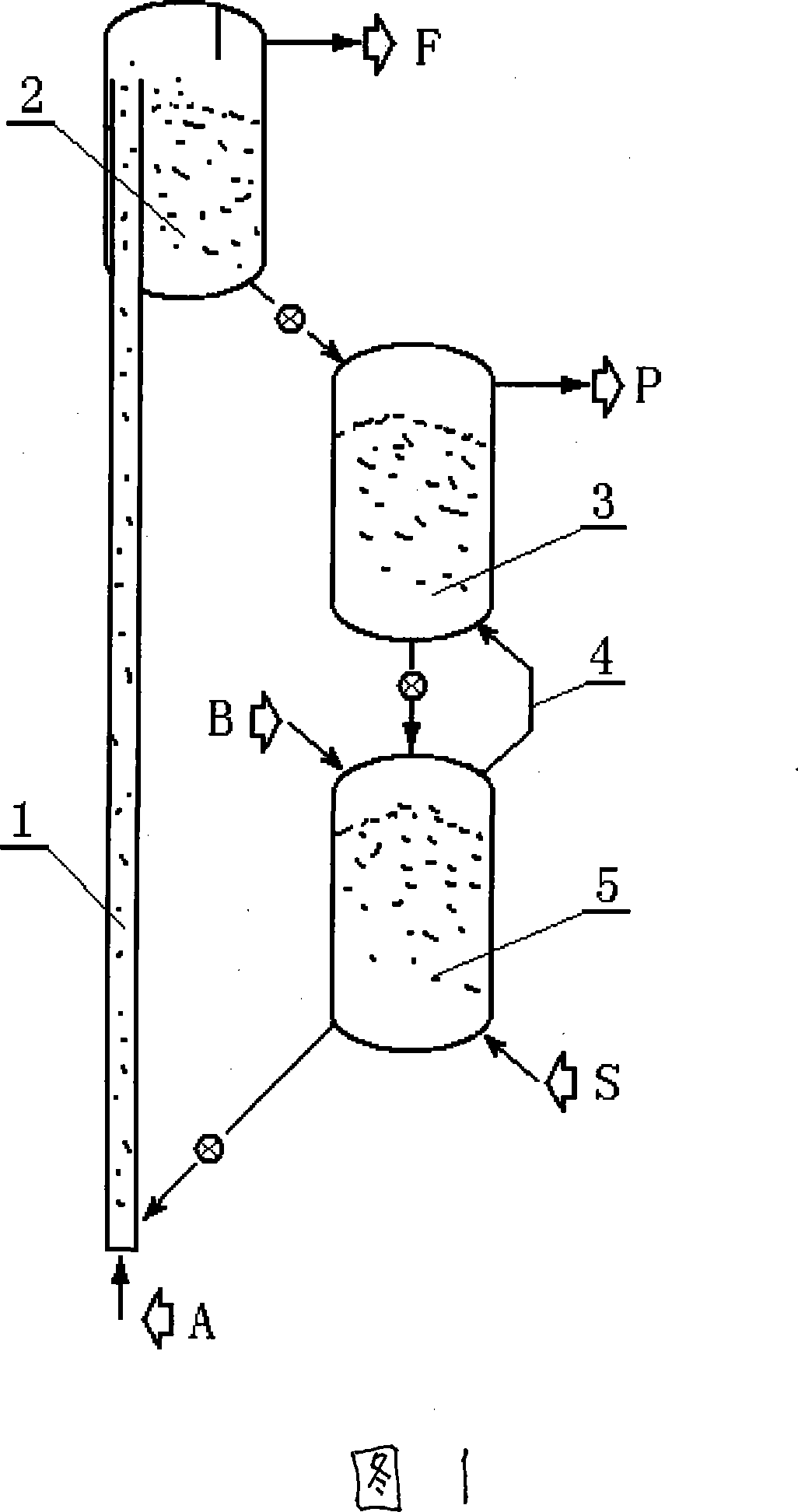

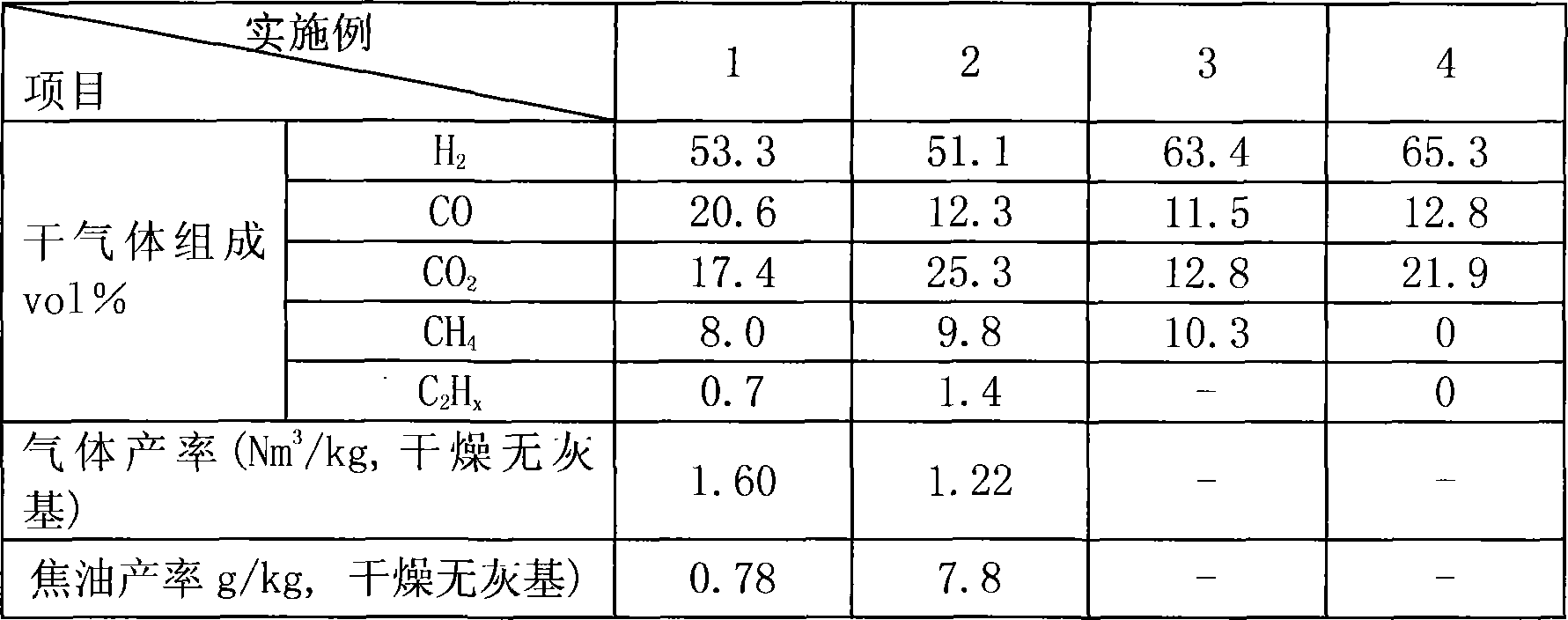

Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

InactiveCN101045524AReasonable temperature distributionReduce the temperatureDirect heating destructive distillationHydrogen productionCatalytic reformingHeat carrier

A process for preparing the H2-enriched gas by catalytic gasification of solid fuel features that the solid catalyst used also as the heat carrier is circulating through riser combustion reactor, solid catalyst storage tank, catalytic reforming reactor and pyrolyzing reactor. In said pyrolyzing reactor, the biomass or coal and the solid heat carrier (catalyst) take part in fast pyrolytic reaction. Its resultant and the water steam take part in catalytic decomposing and reforming reaction to generate H2-enriched gas or synthetic gas.

Owner:DALIAN UNIV OF TECH

Filamentous carbon particles for cleaning oil spills and method of production

InactiveUS7473466B1Increase specific energy and overall energy efficiencyHydrogen/synthetic gas productionGlass/slag layered productsFiberCarbon nanotube

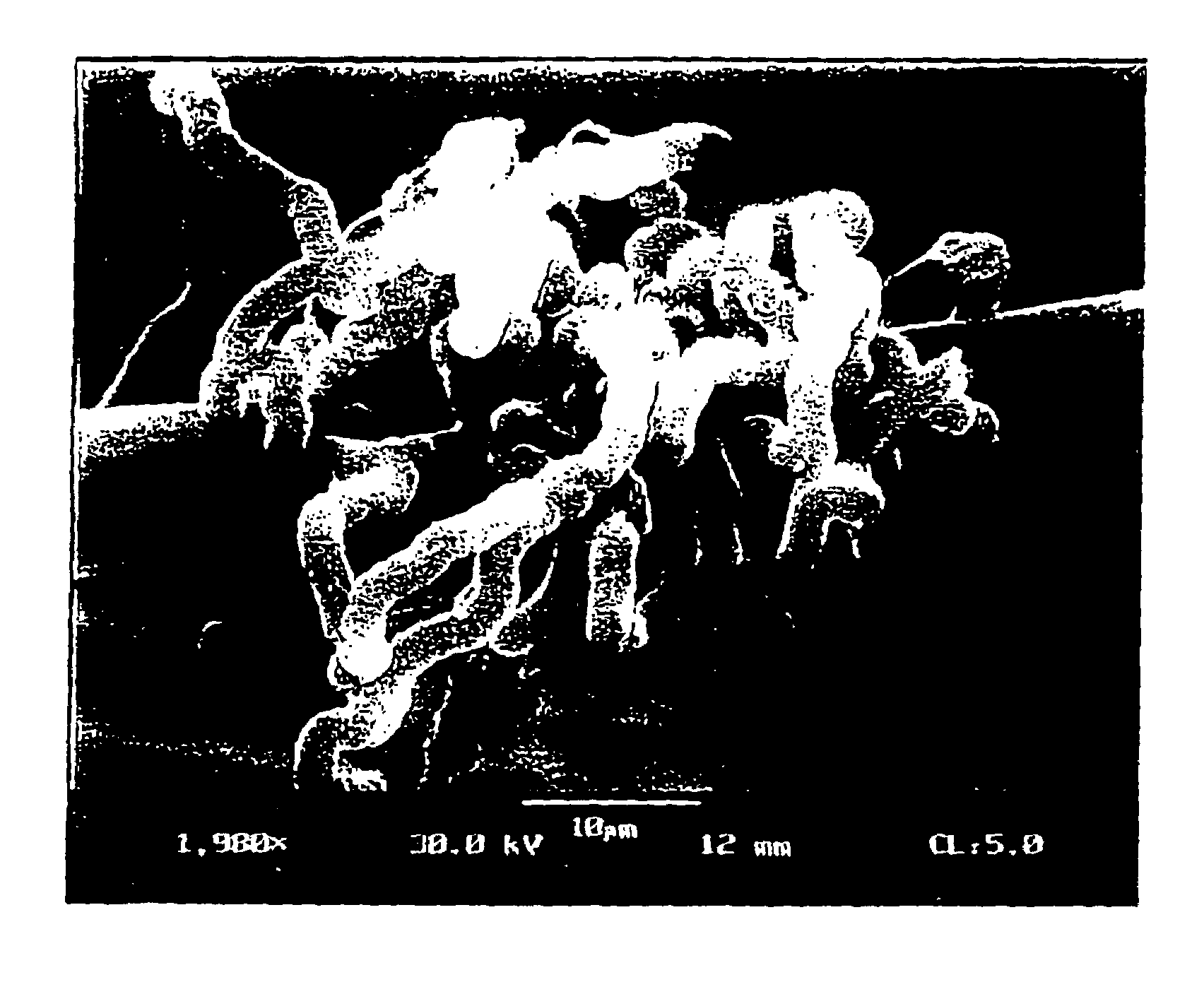

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. In the process of producing hydrogen for the generator via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in an oxidant-free environment, novel carbon products are produced with filamentary surfaces, “octopus”-like carbon filaments, single carbon nanotube fibers and the like. Two novel processes are disclosed for the production of carbon filaments and a novel filamentous carbon product useful in the clean-up of oil spills on the surface of water. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, and sulfurous fuels. The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it can be directly fed to any type of a fuel cell. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

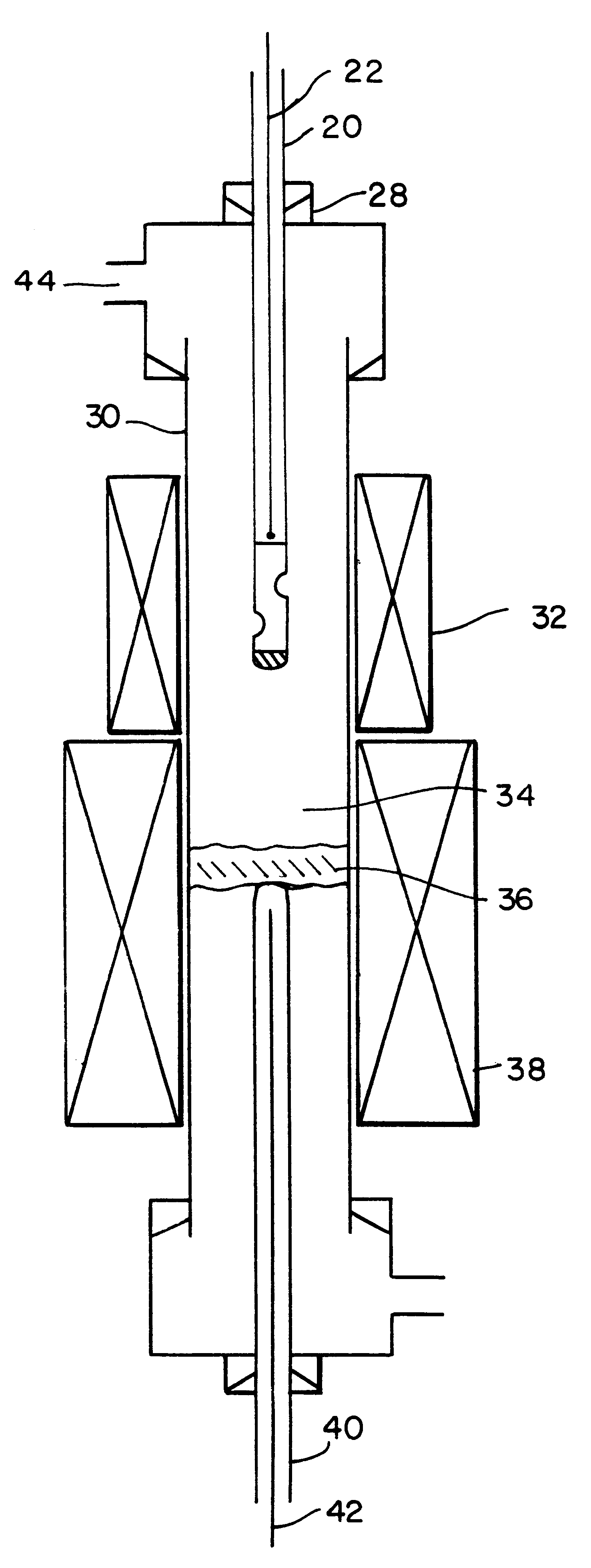

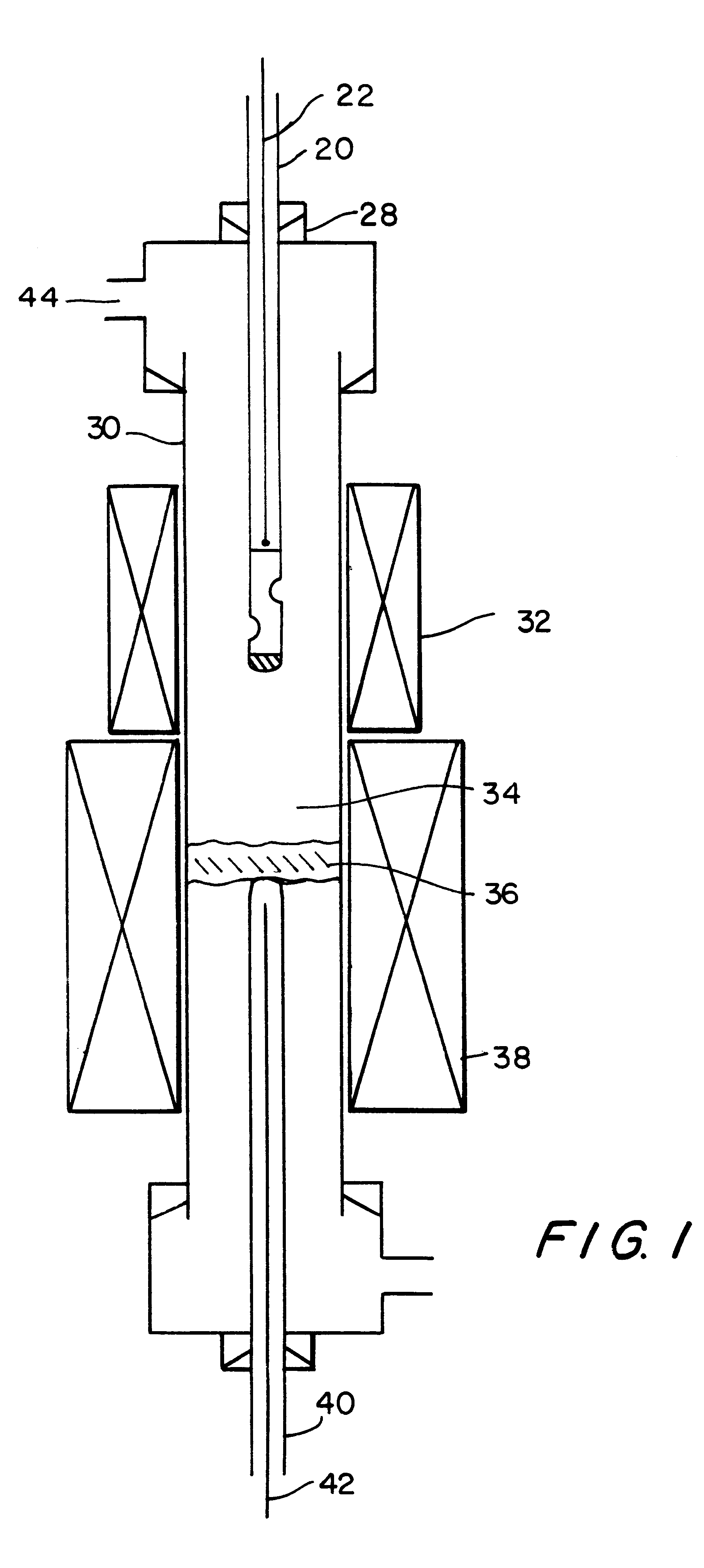

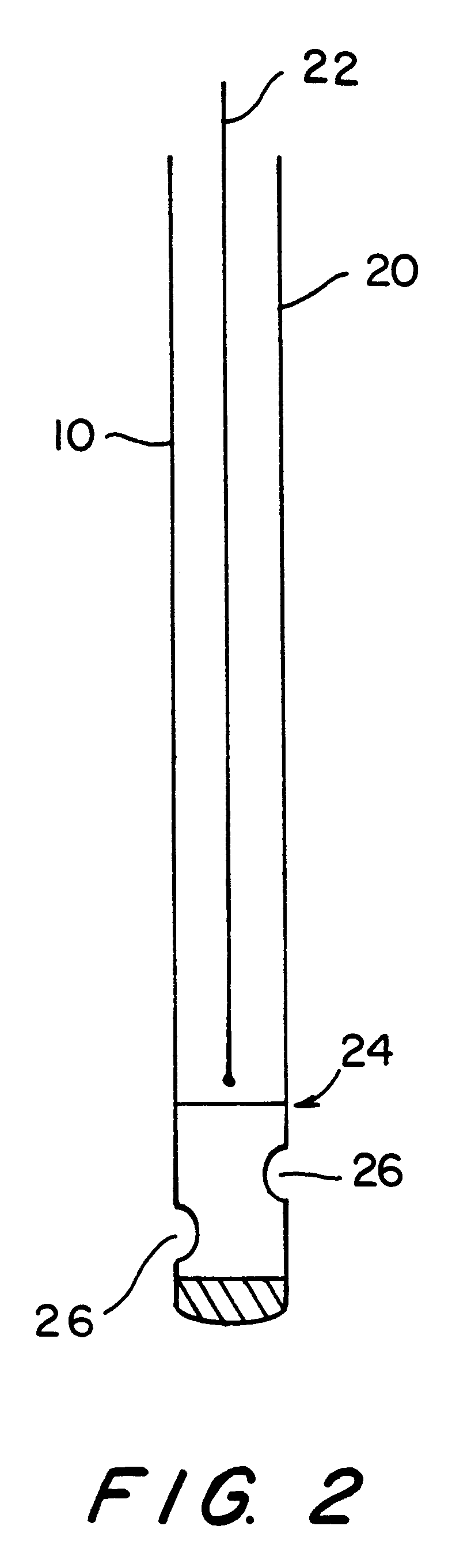

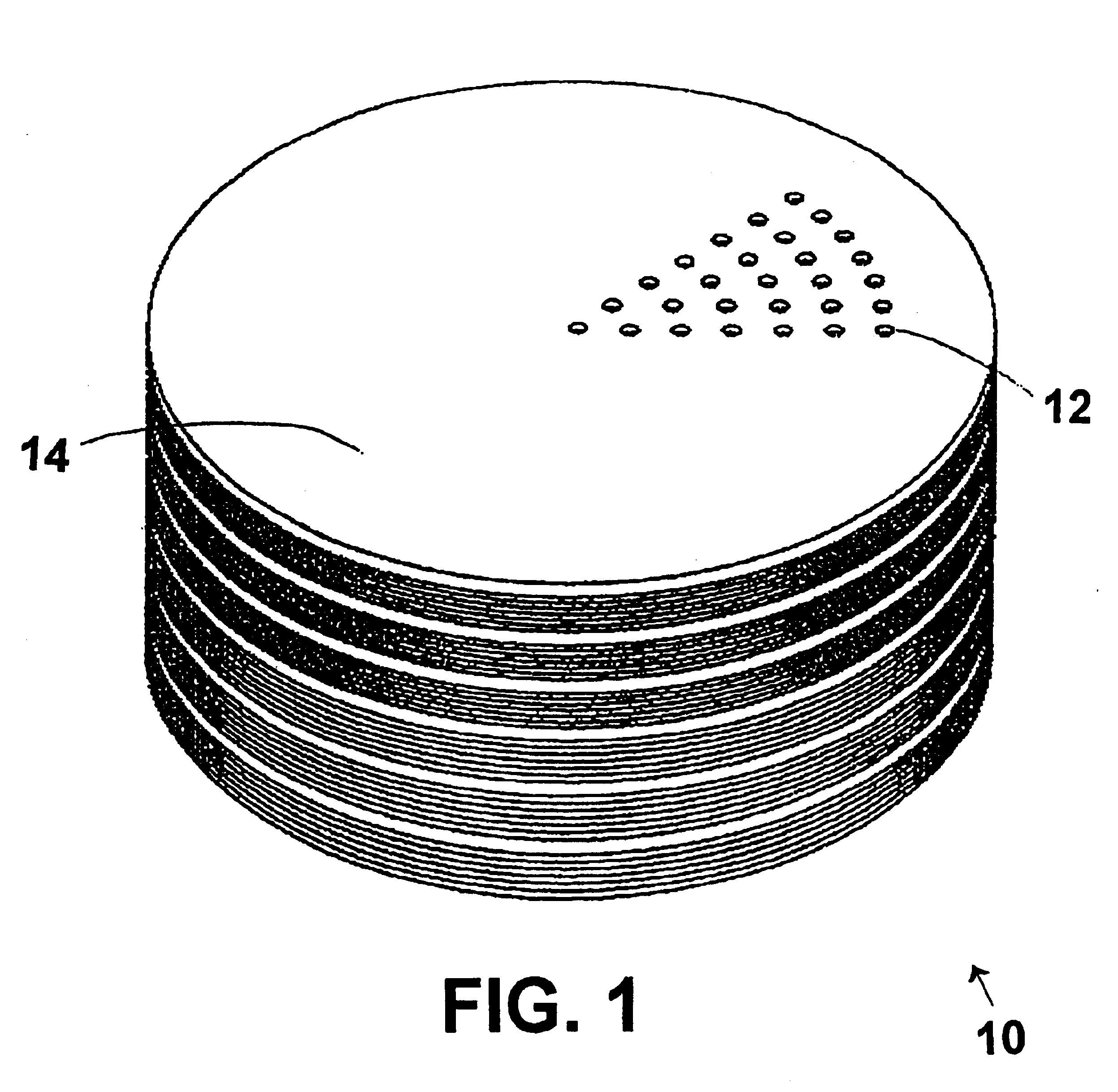

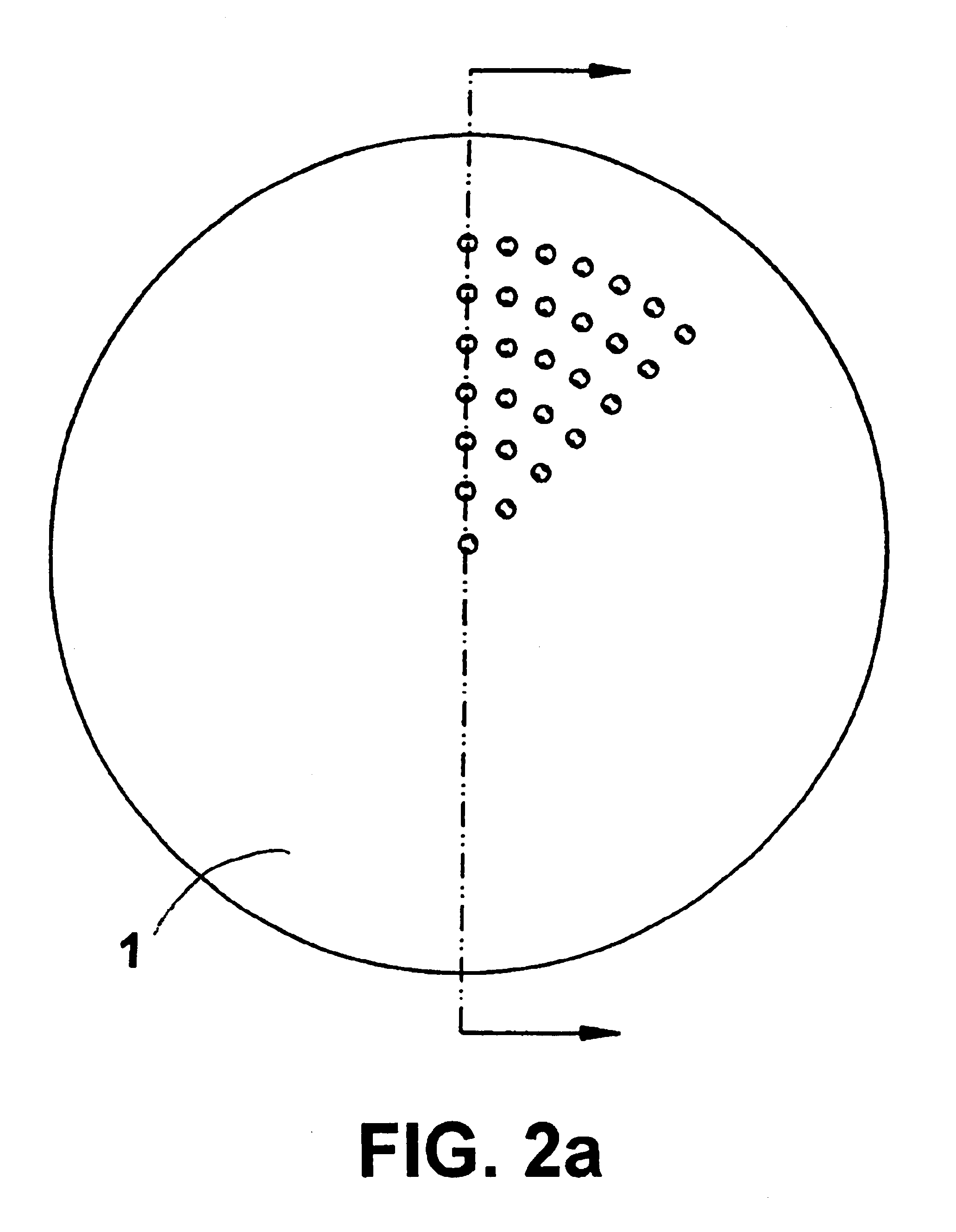

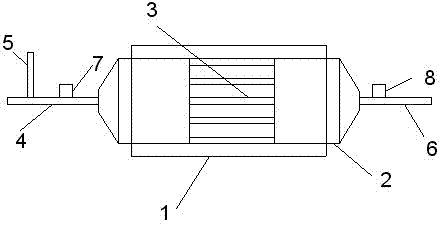

Axial flow catalyst pack

InactiveUS6746651B1Promote uniform mixingEffective contactHydrogen productionChemical/physical/physico-chemical stationary reactorsCatalytic decompositionEngineering

A stack of very thin metal plates provides high surface area for catalytic decomposition of a fluid flowing axially from upstream to downstream through the stack. Each plate has flow-through passages of selected size and location to promote uniform flow and good surface contact with a catalyst surface on the plates. The downstream surface of each plate is etched to provide gaps between plates for lateral fluid flow. The plates are divided into groups separated by metering plates that promote more uniform flow from group to group.

Owner:AEROJET ROCKETDYNE INC

Method of synthesizing single walled carbon nanotubes

InactiveUS20060245996A1High purityLow costMaterial nanotechnologySingle-walled nanotubesWater vaporCarbon nanotube

The present invention discloses a method of synthesizing single walled carbon nanotubes. Highly pure single walled carbon nanotubes is synthesized by the catalytic decomposition of carbon containing gases with Fe, Co, Ni, Mo and W catalysts in the presence of a small mount of water vapor, which can prohibit the generation of amorphous carbon and multi-walled carbon nanotubes on the surface of the catalysts and promote the generation of single-walled carbon nanotubes.

Owner:PEKING UNIV

Catalytic conversion of hydrocarbons to hydrogen and high-value carbon

The present invention provides novel catalysts for accomplishing catalytic decomposition of undiluted light hydrocarbons to a hydrogen product, and methods for preparing such catalysts. In one aspect, a method is provided for preparing a catalyst by admixing an aqueous solution of an iron salt, at least one additional catalyst metal salt, and a suitable oxide substrate support, and precipitating metal oxyhydroxides onto the substrate support. An incipient wetness method, comprising addition of aqueous solutions of metal salts to a dry oxide substrate support, extruding the resulting paste to pellet form, and calcining the pellets in air is also discloses. In yet another aspect, a process is provided for producing hydrogen from an undiluted light hydrocarbon reactant, comprising contacting the hydrocarbon reactant with a catalyst as described above in a reactor, and recovering a substantially carbon monoxide-free hydrogen product stream. In still yet another aspect, a process is provided for catalytic decomposition of an undiluted light hydrocarbon reactant to obtain hydrogen and a valuable multi-walled carbon nanotube coproduct.

Owner:KENTUCKY UNIV RES FOUND OF

Method for the Decomposition of N2O, Catalyst Therefor and Preparation of This Catalyst

ActiveUS20080044334A1Promote conversionImprove stabilityNitrous oxide captureNitrogen compoundsRheniumIridium

The invention relates to a method for the catalytic decomposition of N2O in a gas containing N2O in the presence of a catalyst, wherein the catalyst comprises a zeolite that has been loaded with a first metal selected from the group of noble metals consisting of ruthenium, rhodium, silver, rhenium, osmium, iridium, platinum and gold, and with a second metal selected from the group of transition metals consisting of chromium, manganese, iron cobalt, nickel and copper, and wherein the loading of the zeolite with metals has been obtained by first loading the zeolite with the noble metal and then with the transition metal, as well as a catalyst for this method and a method for the preparation of this catalyst.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Ammonia Decomposition Catalyst and Process for Decomposition of Ammonia Using the Catalyst

InactiveUS20090060809A1Improve decomposition abilitySuppress generationCyanogen compoundsMolecular sieve catalystsHigh concentrationCatalytic decomposition

Disclosed is a catalyst useful for catalytic decomposition of high concentration ammonia, and also disclosed is a process for decomposing ammonia using the catalyst. As the ammonia decomposion catalyst, a catalyst which supports a metallic element selected from Fe, Co, Ni and Cu by ion exchange method on porous silica alumina having an Si / Al atomic ratio of 1 to 90 and a specific surface area of 200 to 900 m2 / g and contains a noble metal selected from Ru, Rh, Pd, Ir and Pt in an amount of 10 to 500 ppm based on the total mass of the catalyst is useful.

Owner:SUD CHEM CATALYSTS JAPAN

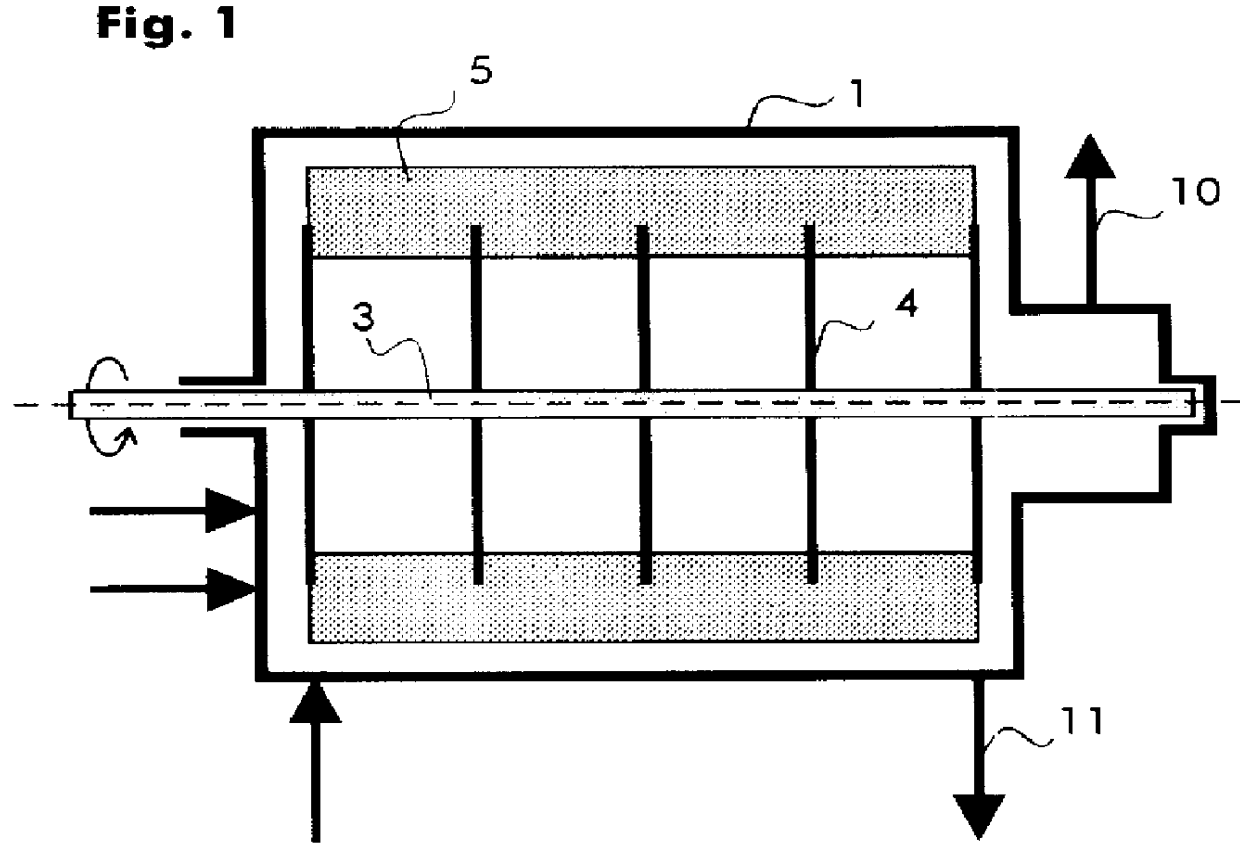

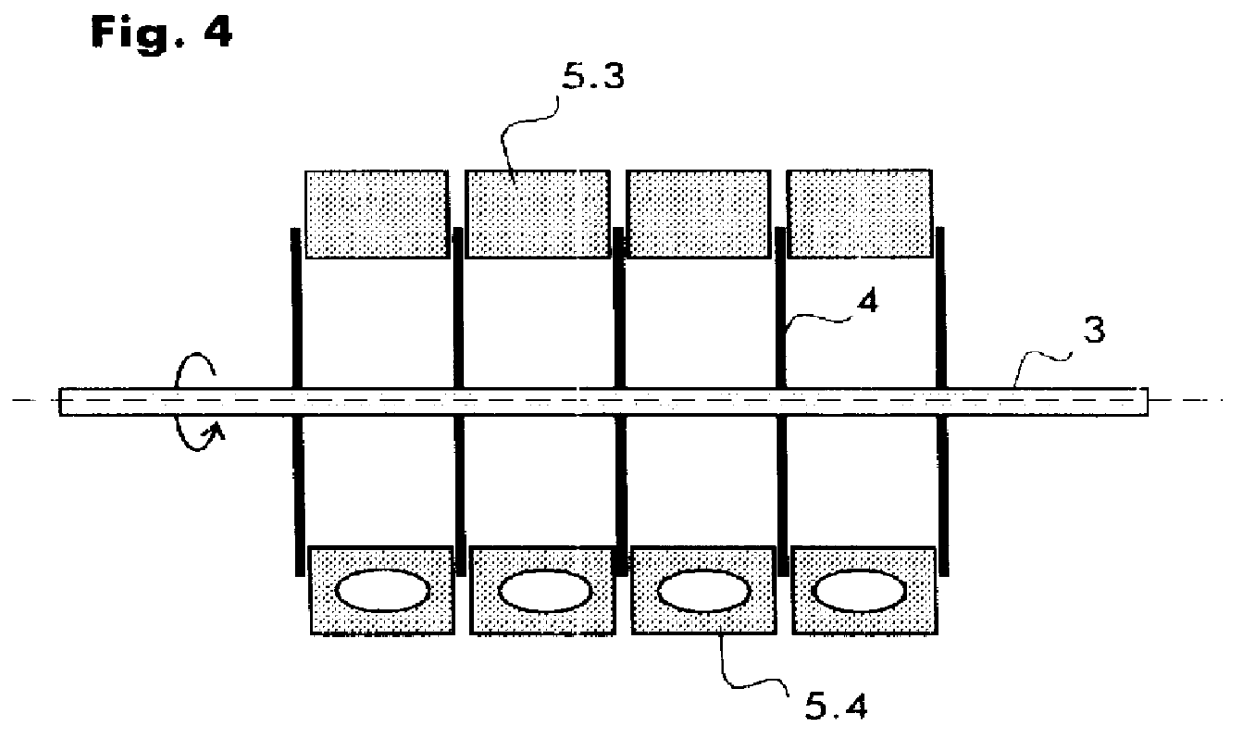

Process for thermal and/or catalytic decomposition and/or depolymerization of low-grade organic substances and device for carrying out the process

InactiveUS6165349AImprove economyEfficient processingCatalytic crackingSolid waste disposalDepolymerizationLower grade

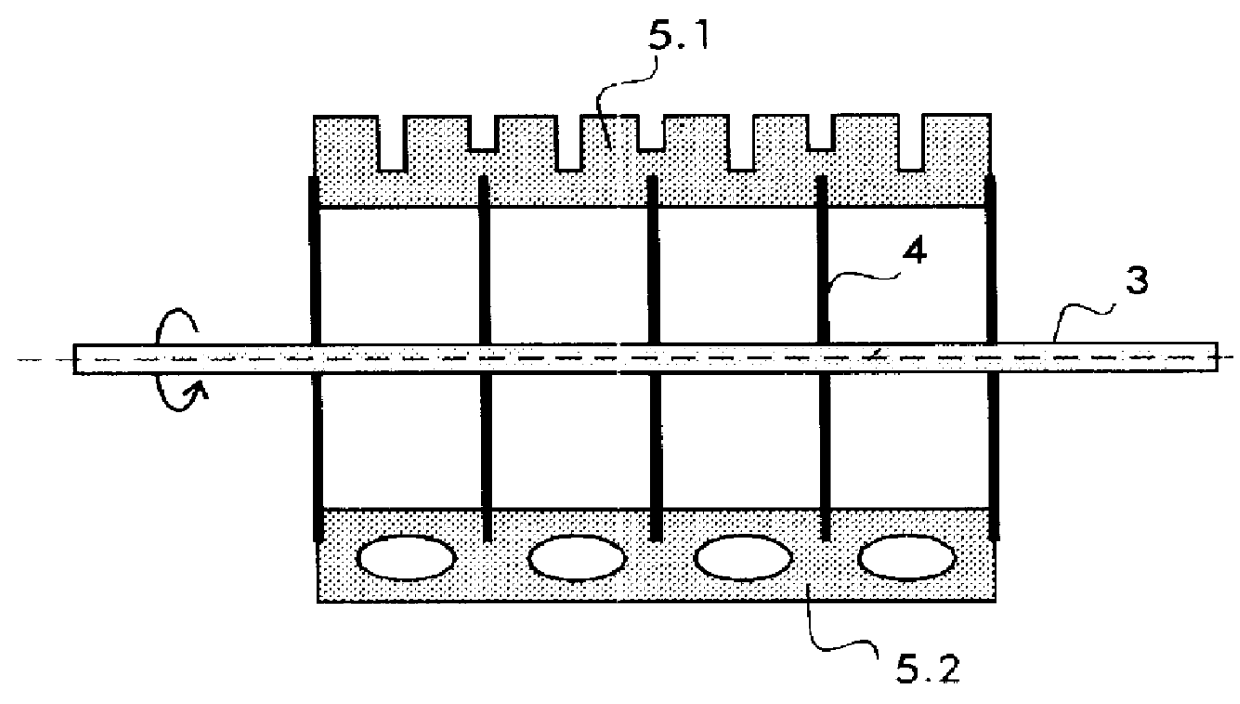

PCT No. PCT / SK97 / 00006 Sec. 371 Date Jun. 1, 1999 Sec. 102(e) Date Jun. 1, 1999 PCT Filed Jul. 4, 1997 PCT Pub. No. WO98 / 39368 PCT Pub. Date Sep. 11, 1998The nature of the process consists in that the low-grade organic substances are subject, at a temperature of 150 DEG C. to 700 DEG C. and at a pressure of 0.1 MPa to 2.5 MPa, to the action of a moving bed of solid particles of a substance which perform whirling motion, whereby the solid particles of a substance constituting the moving bed are set to whirling motion by intensive agitation. The device consists of a reaction chamber (1) with a rotation mechanism (2) which rotation mechanism (2), located rotably in the faces of the reaction chamber (1), consists of a shaft (3) to which vanes (5) are symetrically attached by means of driving discs (4). The vanes (5) may be arranged in 3 to 10 rows, and they may be provided with openings (5.1) or cut-outs (5.2) of various geometrical shapes, and they may be divided into individual segments (5.3). Also the driving discs (4) may be provided with openings (4.1) of various geometrical shapes.

Owner:MADAR IVAN

System and method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate

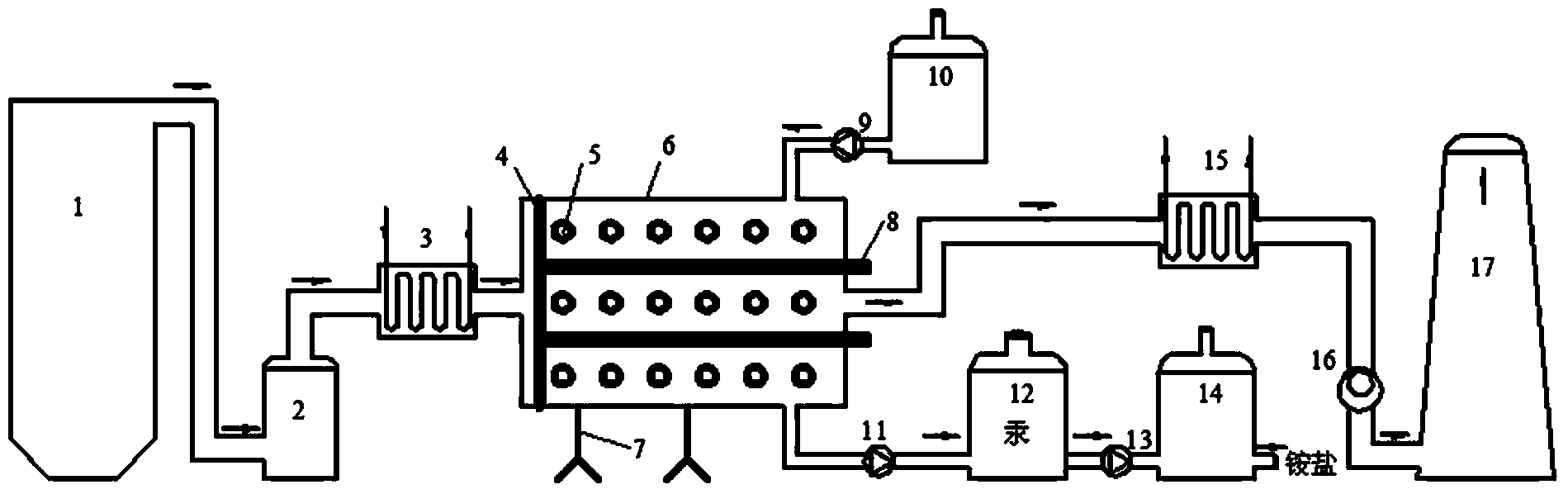

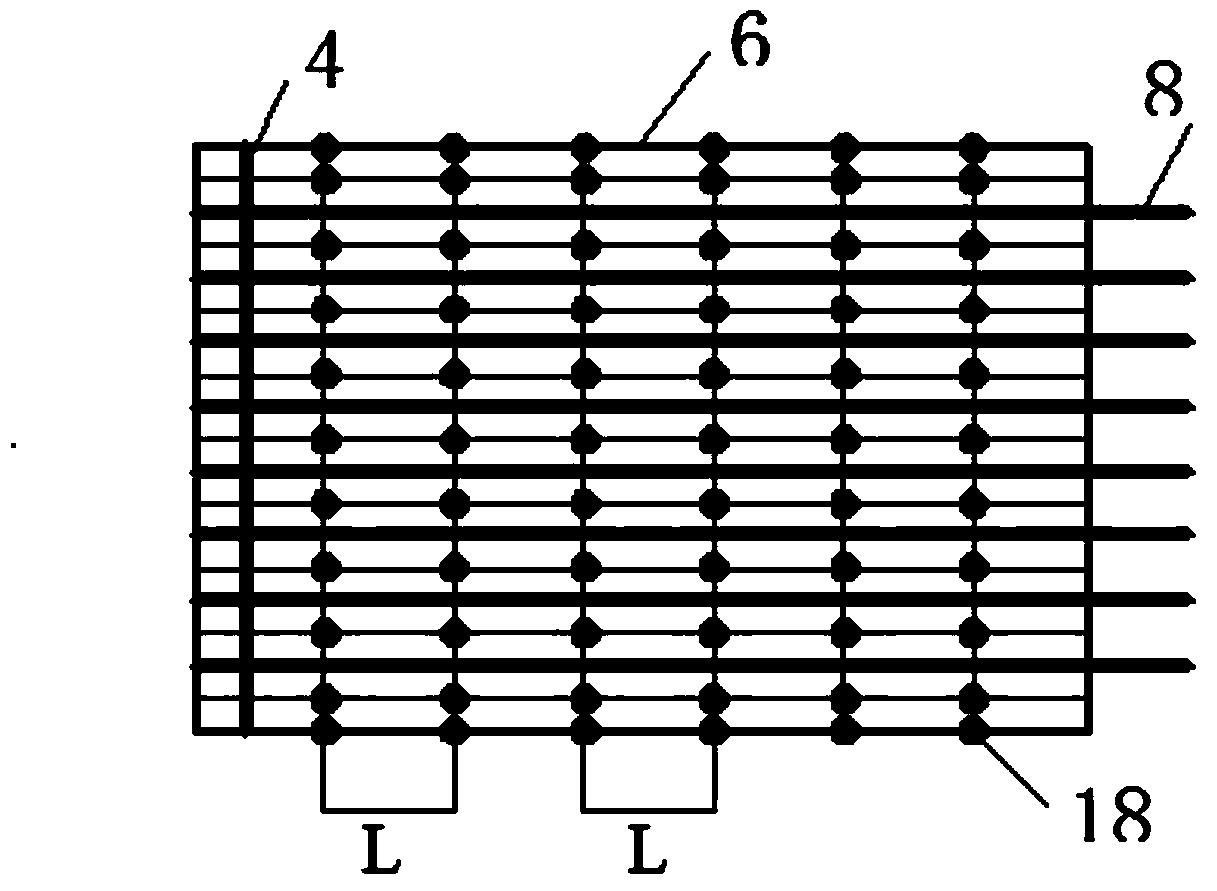

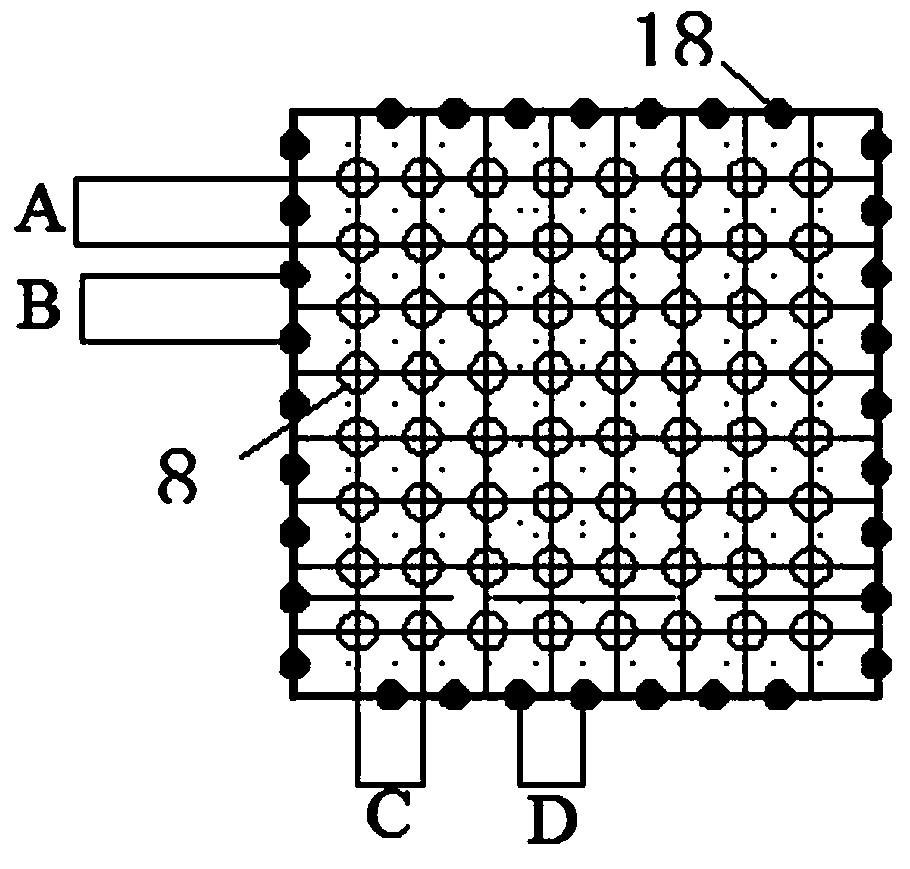

ActiveCN103638796ALow investment costLow running costDispersed particle separationAir quality improvementSulfate radicalsResource utilization

The invention discloses a system and a method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate. The system is mainly provided with a boiler or kiln, a deduster, a flue gas temperature regulator, a photochemistry reactor, a liquid spraying system as well as a byproduct post-processing system. Flue gas discharged from the boiler or kiln enters the photochemistry reactor arranged on a flue channel after being subjected to dedusting and temperature regulation, and an ammonium persulfate solution from the liquid spraying system is sprayed into the photochemistry reactor in a mist form; an UV (ultraviolet) lamp in the photochemistry reactor emits UV light to perform catalytic decomposition on ammonium persulfate, releases sulfate radical free radicals with high oxidizing property (SO4-.), and meanwhile oxidizes and removes SO2, NOx and mercury in the flue gas. Oxidized products are subjected to resource utilization after being processed by the byproduct post-processing system. The method has the prominent advantages that the method can be used for removing multiple pollutants in coal burned flue gas synchronously, has no secondary pollution during removing, and can be used for transforming aging units and the like, and the system is a novel flue gas purifying system with a wide application prospect.

Owner:JIANGSU UNIV

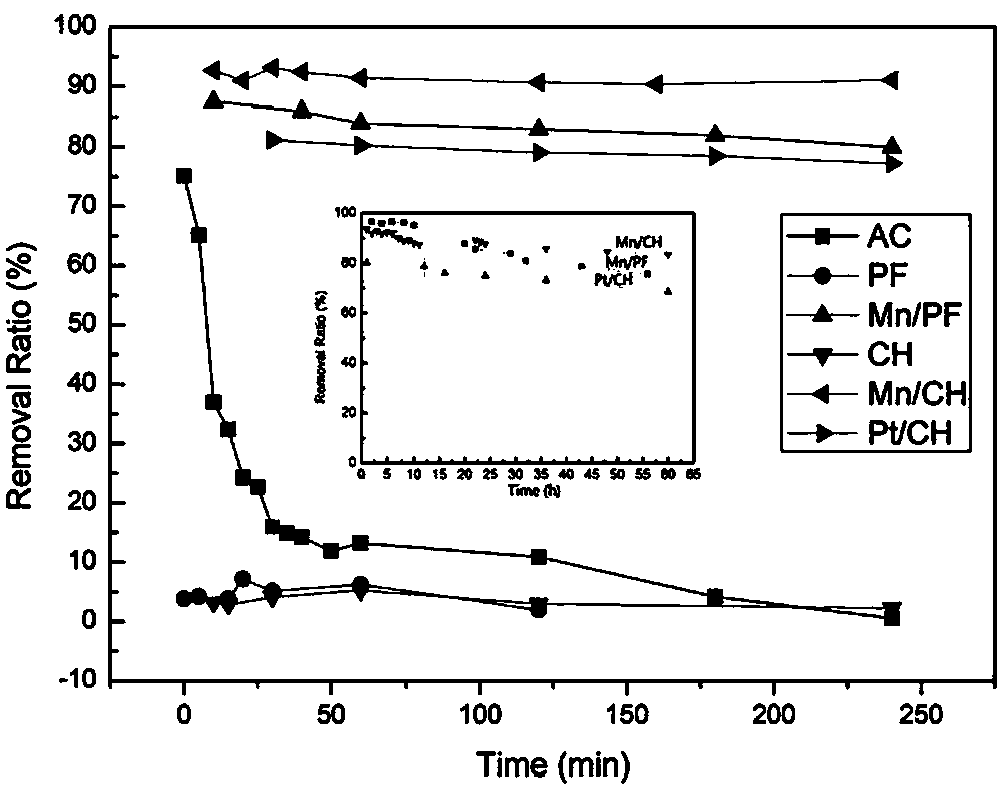

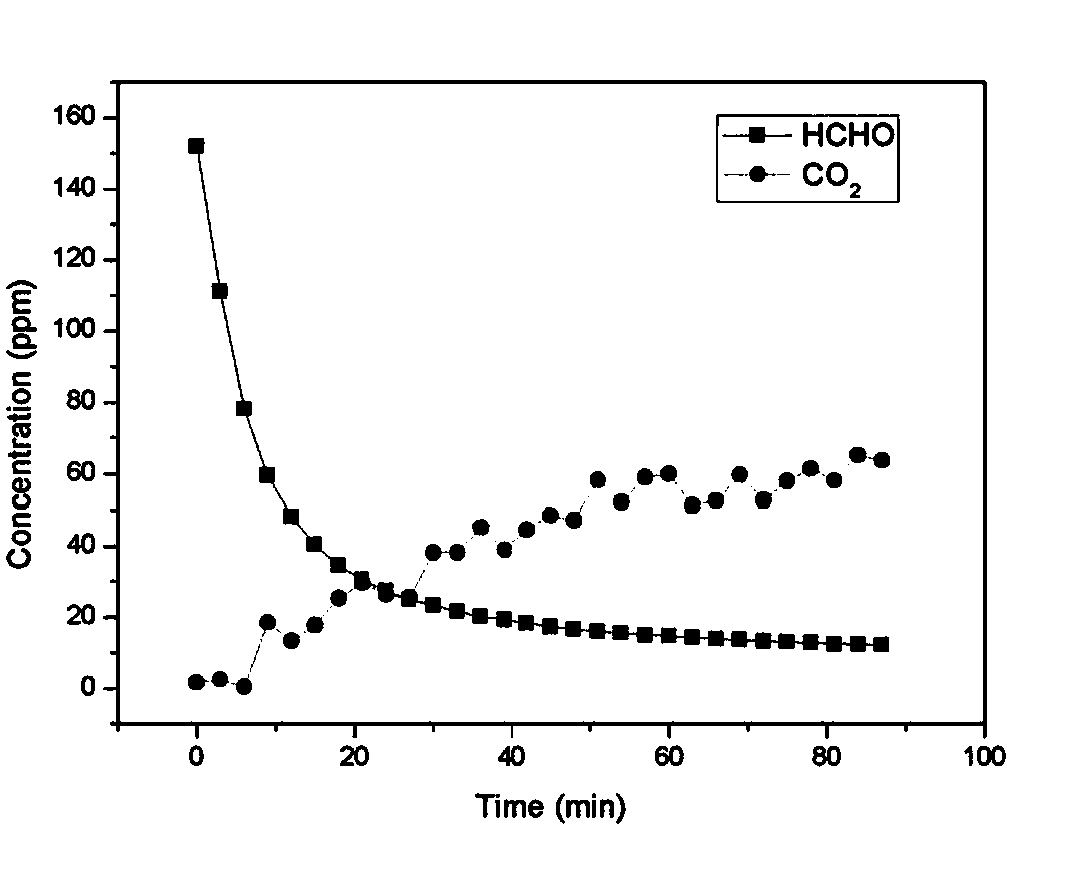

Air purification material and preparation method and application thereof

ActiveCN104190251AEfficient decompositionQuick removalDispersed particle separationFiberParticulates

The invention relates to an air purification material and a preparation method and application thereof, belonging to the technical field of chemical catalytic decomposition, in particular belonging to the technical field of decomposition of formaldehyde pollutants in environment air. The air purification material comprises a base material and manganese oxide, wherein the manganese oxide is supported on the base material, the base material is honeycomb ceramics or a fiber material with a particle filtering function, and the manganese oxide is birnessite manganese oxide prepared from permanganate and oxalate. The air purification material can effectively decompose formaldehyde pollutants in indoor air and can rapidly and constantly remove the formaldehyde pollutants in indoor air at room temperature. The air purification material can be regenerated through heating, so that the service life of the material is prolonged and the practical application is facilitated.

Owner:TSINGHUA UNIV

Air cleaning material, and preparation method and application thereof

ActiveCN103480267ASimple preparation processLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberParticulates

The invention relates to an air cleaning material, and a preparation method and an application thereof, and belongs to the technical field of chemical catalytic decomposition. The air cleaning material comprise a base material and a manganese oxide loaded on the base material; the manganese oxide is a birnessite type manganese oxide prepared by performing in-situ reduction on a permanganate and a reducing agent; and the base material is filter cotton, non-woven fabrics, cotton cloth, gauze, or fiber with particle filtering function. The preparation method comprises the following steps: step 1, dissolving a quaternary ammonium salt and the permanganate in water, adding the base material; step 2, adding the reducing agent into the solution obtained in the step 1, mixing uniformly; step 3, heating the solution obtained in the step 2 at a constant temperature; and step 4, taking out the base material and drying to obtain the finished product. According to the technical scheme, the manganese oxide is simple loaded on the fiber material base material such as filter cotton and the like, so that the obtained low-wind-resistance cleaning material is capable of continuously rapid degrading formaldehyde and ozone in the air at room temperature; and the preparation method of the air cleaning material is simple and low in cost, and no other pollutions are introduced.

Owner:TSINGHUA UNIV

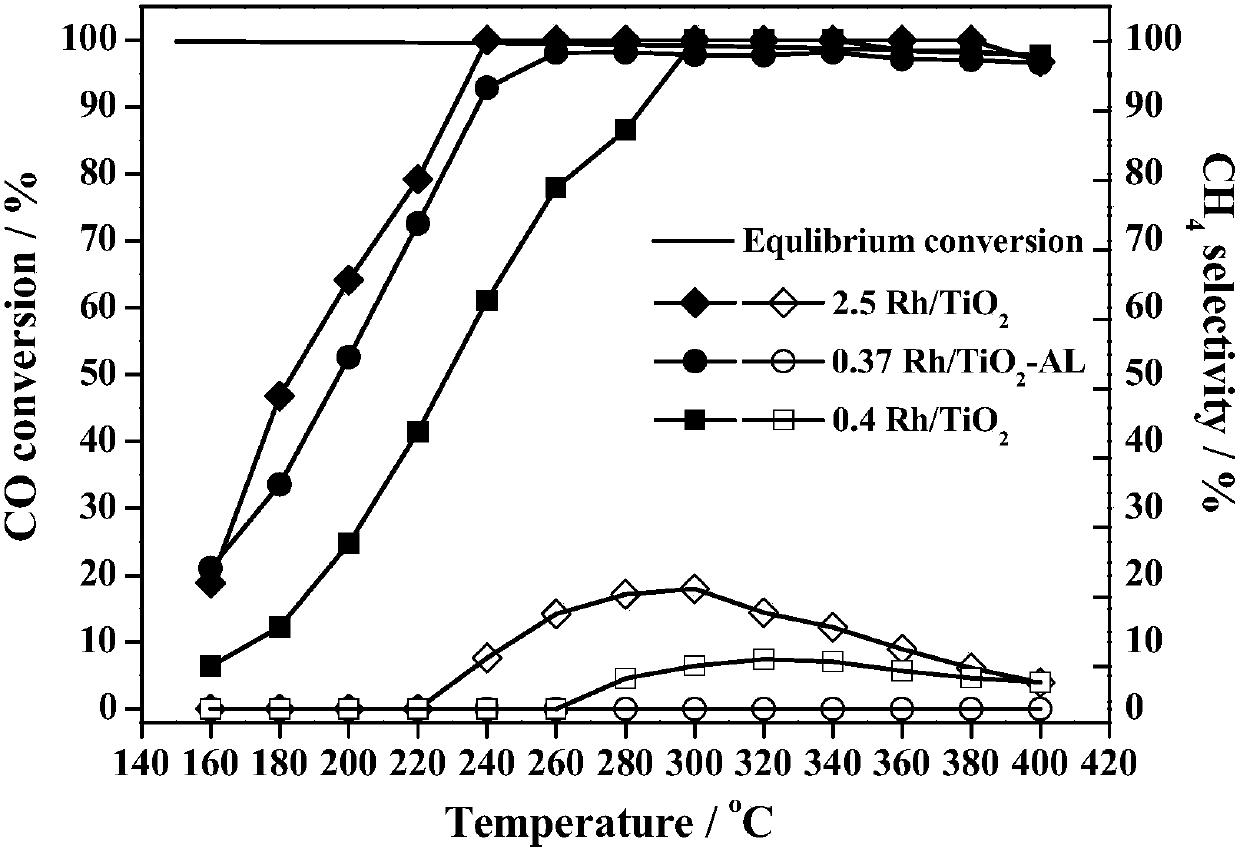

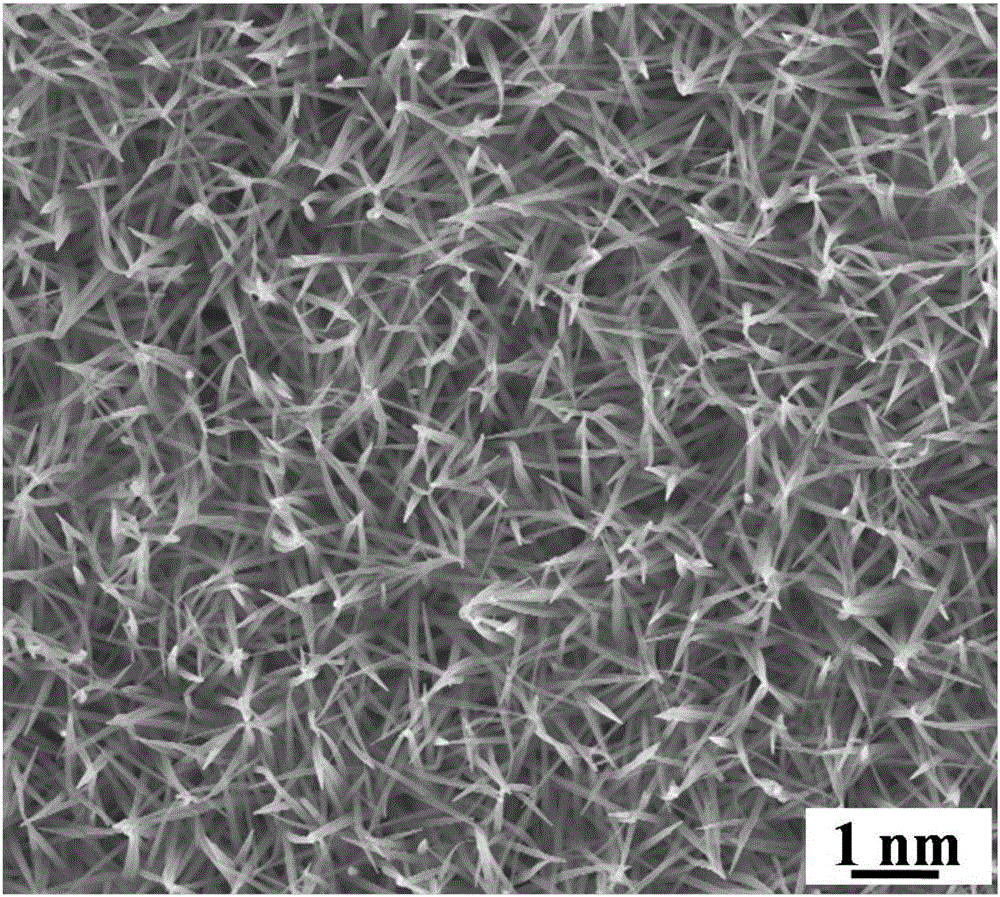

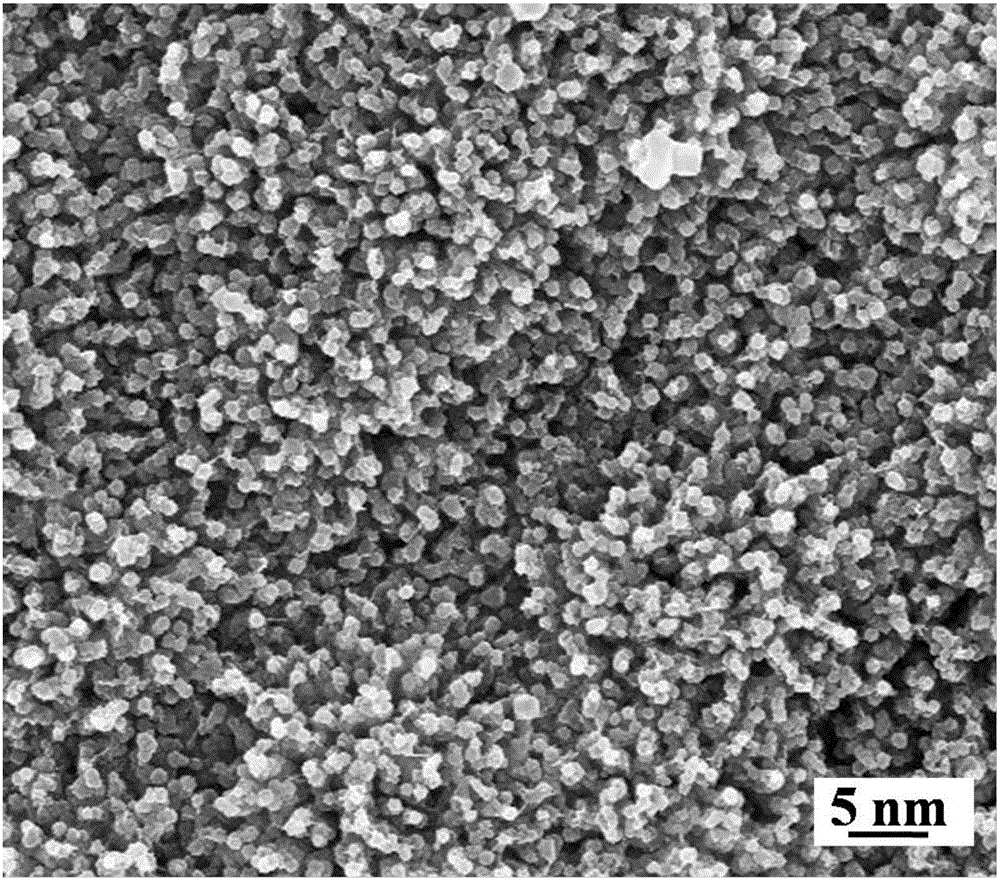

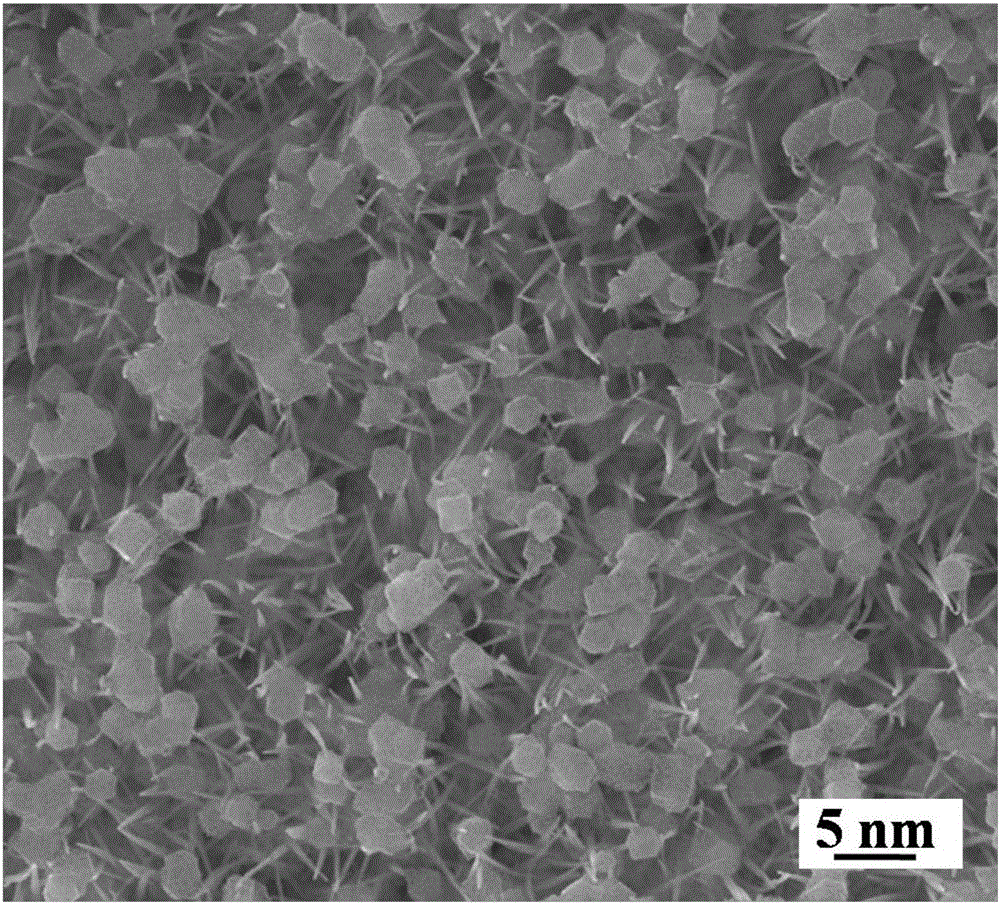

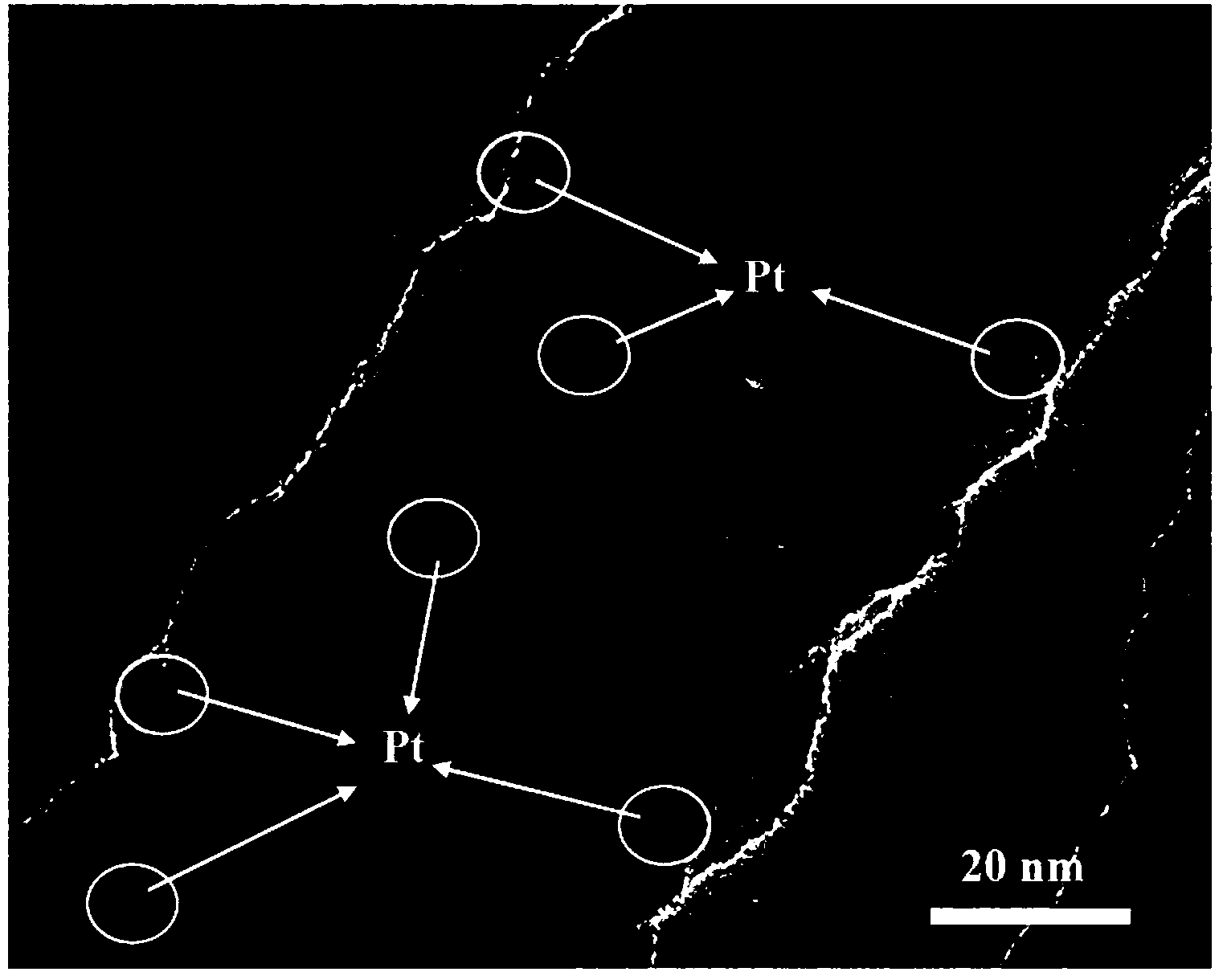

Monoatomic dispersed noble metal catalyst and application thereof

ActiveCN107649124AHave substantive characteristicsEnhance intrinsic reactivityHydrogenCatalyst activation/preparationIridiumMethanation

The invention relates to a monoatomic dispersed platinum group metal based catalyst with a higher loading capacity and an application of the catalyst. Specifically, the invention relates to a bicomponent catalyst of titanium oxide and one selected from metals rhodium (Rh), ruthenium (Ru), platinum (Pt), iridium (Ir) and palladium (Pd) as well as preparation and an application of the catalyst. Themetal is highly dispersed in the form of a single atom on the carrier titanium oxide, and the metal content is up to 0.4-2%. The catalyst provided by the invention is suitable for the CO water gas shift reaction, and can improve the CO conversion rate and inhibit a methanation side reaction; and meanwhile, the catalyst also has very good low-temperature activity and use stability on catalytic decomposition of the liquid single-component propellant level anhydrous hydrazine used in a satellite attitude control engine in the aerospace industry.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method for preparing Co3O4@CoP composite electrode based on MOF template

InactiveCN105977467AImprove performanceEasy to mass manufactureCell electrodesDecompositionNew energy

The invention provides a preparation method for preparing a Co3O4@CoP composite electrode based on an MOF template and belongs to the technical field of energy conversion. The preparation method comprises the following steps: uniformly growing Co(CO3)0.5OH 0.11H2O on a nickel plate substrate by virtue of simple hydrothermal reaction, and further growing favorable-appearance ZIF-67 in situ on the surface of Co(CO3)0.5OH 0.11H2O, thereby obtaining a Co(CO3)0.5OH 0.11H2O@ZIF-67 composite material; and furthermore, performing bonderizing so as to obtain Co3O4@CoP derivates. Compared with a single Co(CO3)0.5OH 0.11H2O electrode, the derivate electrode material has relatively low oxygen evolution potential and relatively high corresponding current density under same electric potential, and can be applied to the fields of hydrogen production based on electrocatalysis and decomposition of water and conversion of new energy resources such as fuel cells.

Owner:BEIJING UNIV OF TECH

Porous carbon adsorbing agent containing nano zinc oxide micropartical and its preparation process and application

InactiveCN1724138AImprove adsorption capacityAvoid breedingOther chemical processesSorbentPorous carbon

A porous charcoal adsorbent for cleaning environment is composed of porous charcoal as carrier and zinc oxide nano-particles as active component. Its preparing process includes such steps as reaction between zinc nitrate micro-emulsion and sodium hydroxide to obtain zinc oxide nano-particles, carrying them by porous charcoal and heat treating. Its advantages are high absorptive power and high photo-catalytic and antibacterial activities.

Owner:SUN YAT SEN UNIV

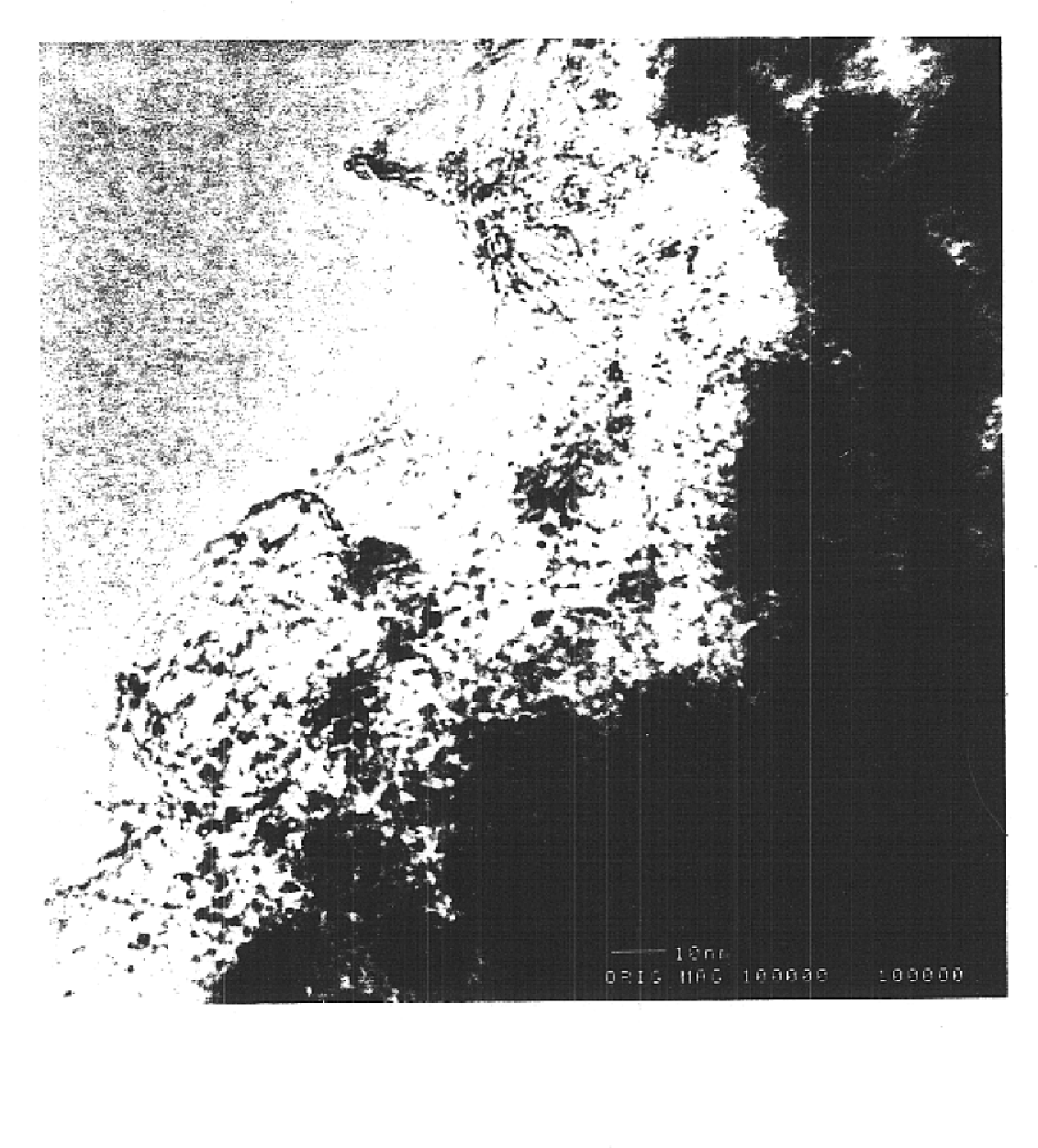

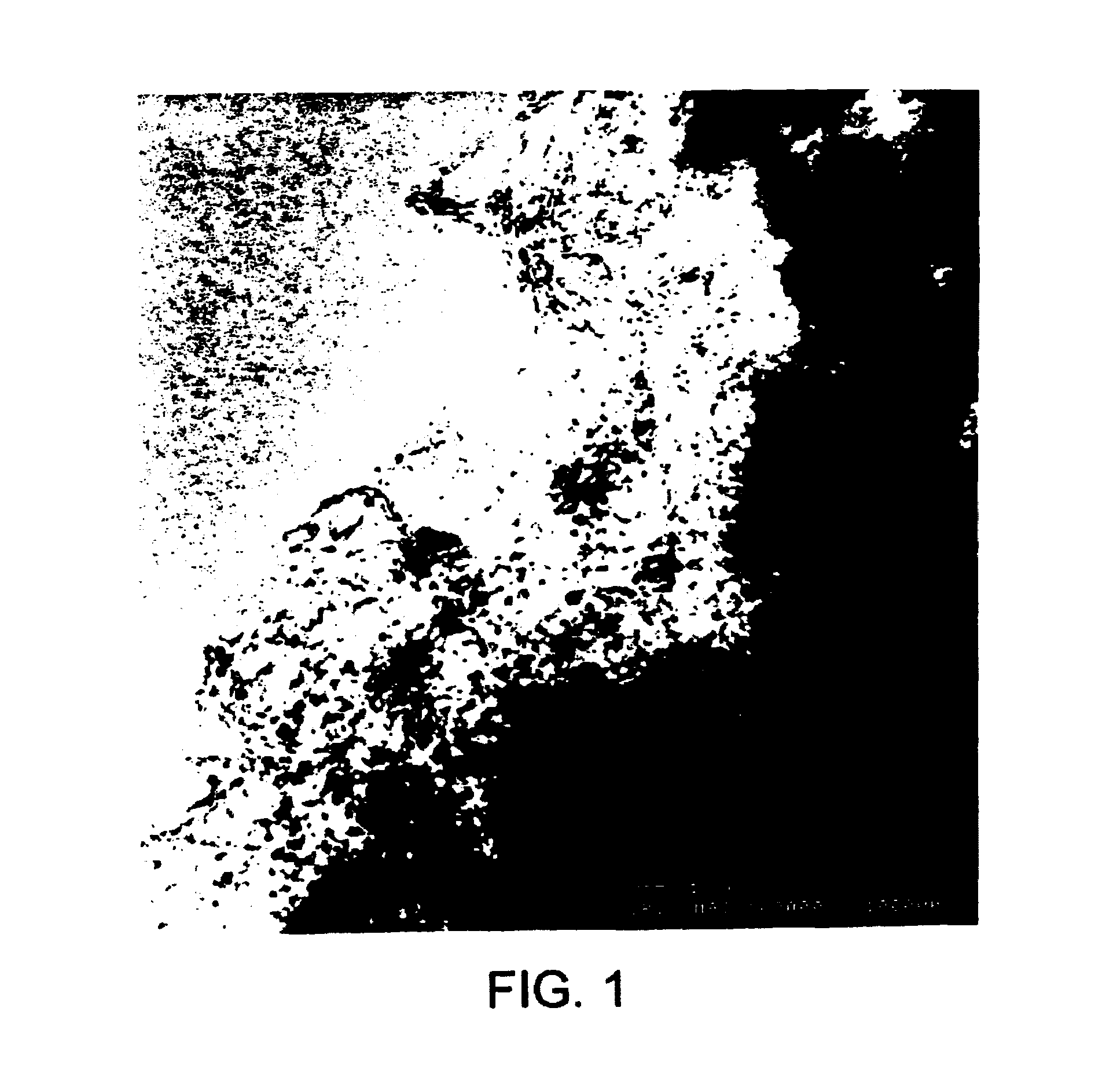

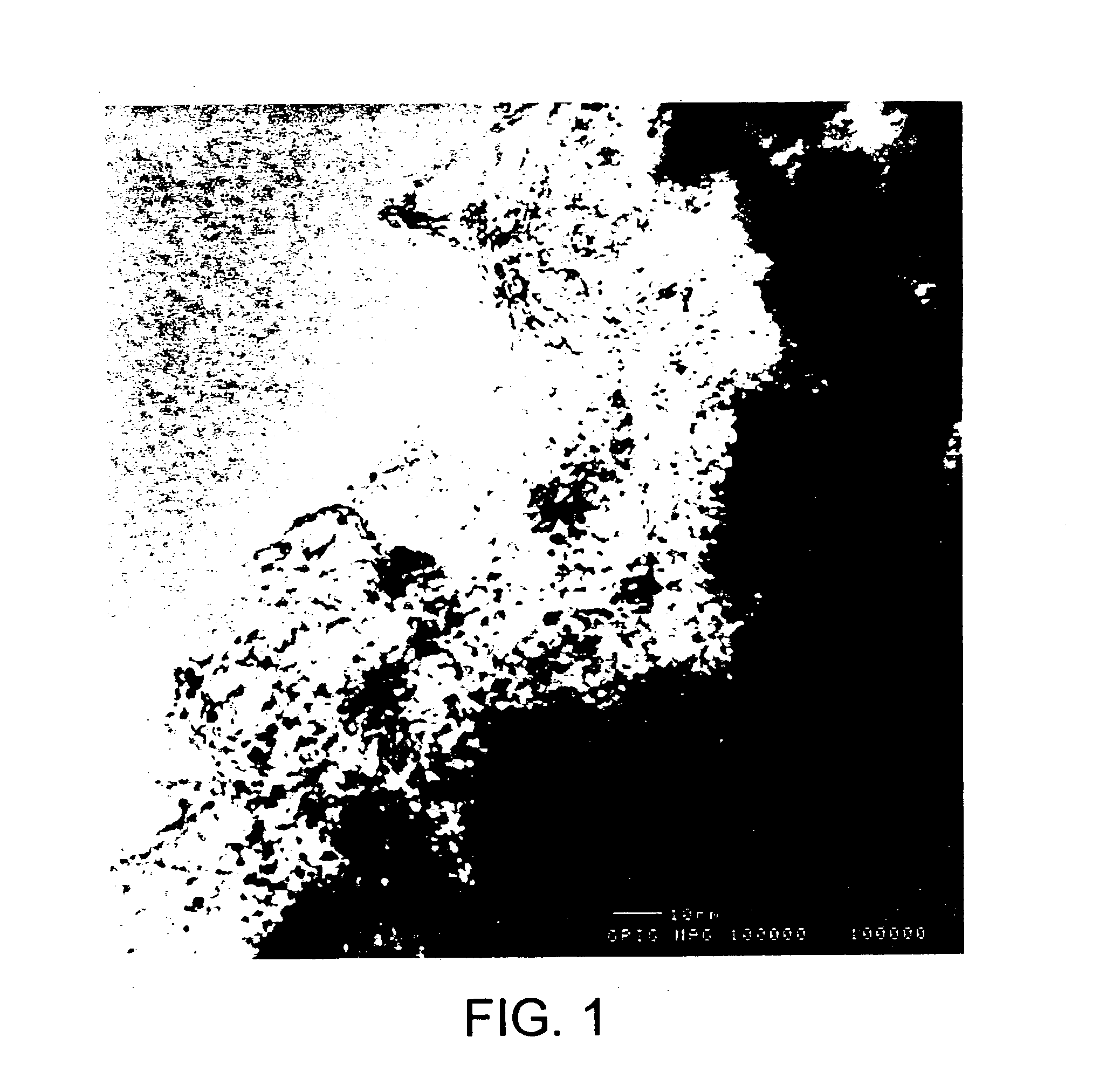

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS20030175200A1Less pollutionNarrow size distributionMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

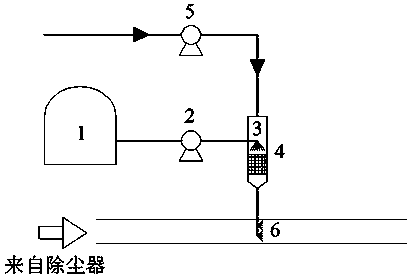

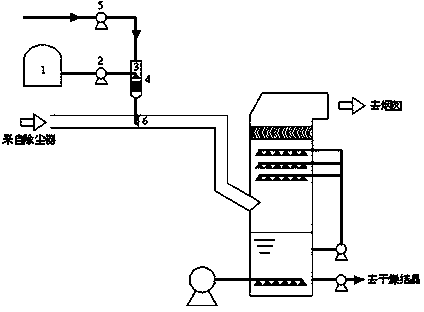

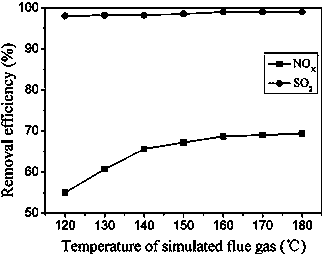

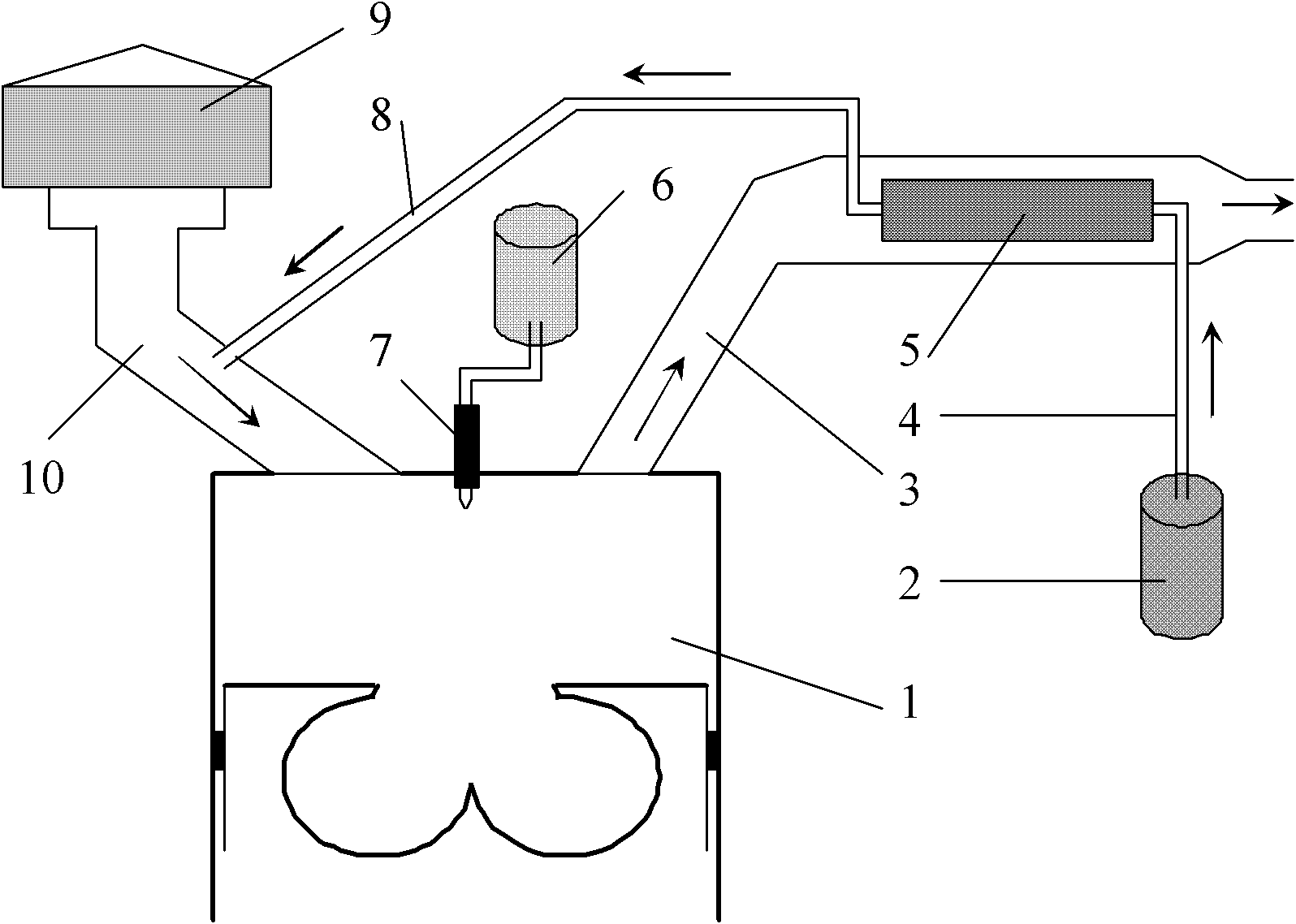

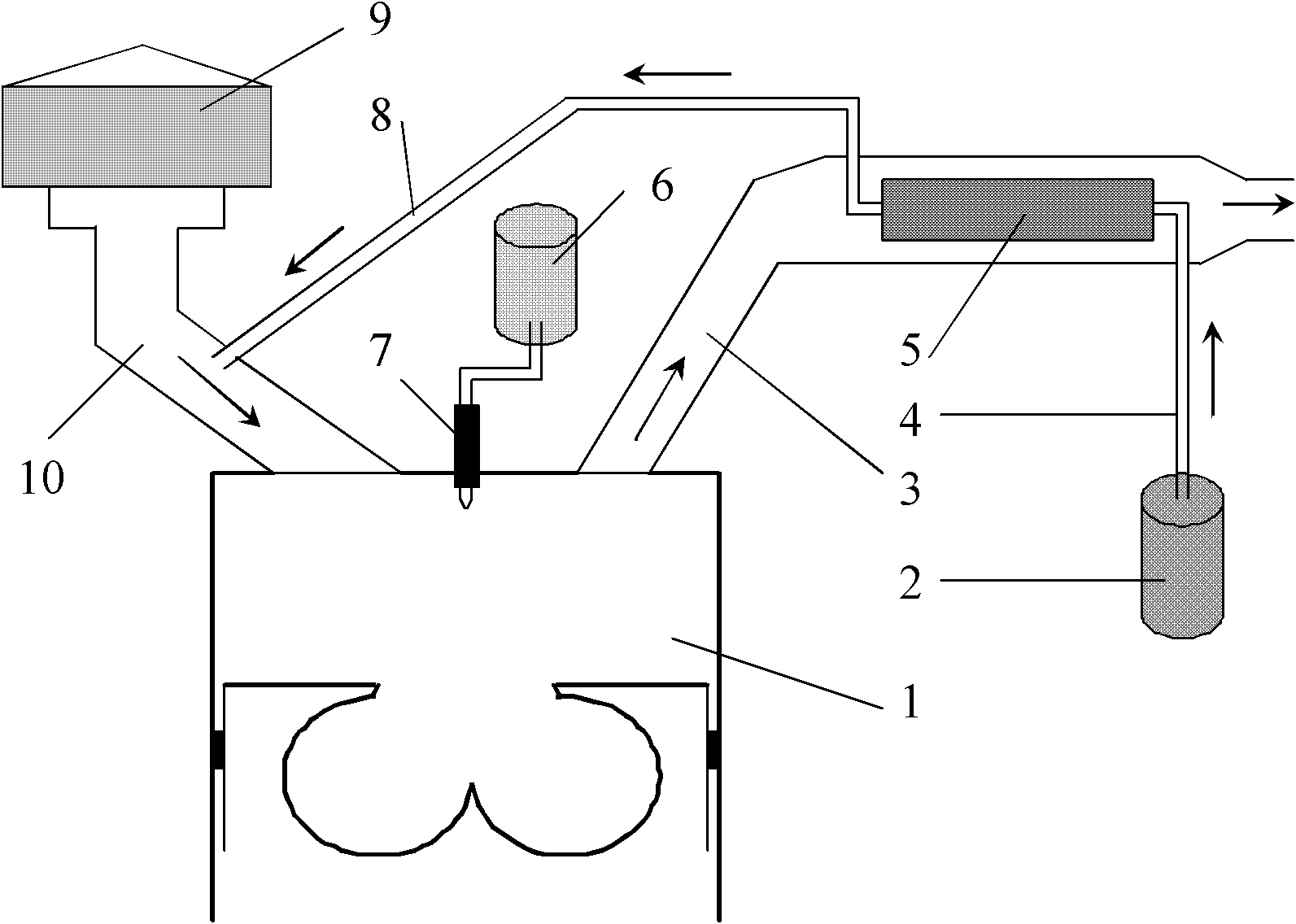

Device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation

ActiveCN103463978AHigh removal rateImprove oxidation efficiencyDispersed particle separationAir quality improvementPtru catalystCatalytic decomposition

The invention provides a device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation (H2O2). The H2O2 is sprayed into an H2O2 catalytic decomposition device through an injection pump and reacts with catalysts, a large amount of active matter is generated, the active matter is injected into a smoke channel along with a bypass air flow from an air blower in a blowing mode and reacts with sulfur dioxide (SO2) and oxynitride (NOX) in smoke to generate sulfuric acid and nitric acid. The sulfuric acid, the nitric acid and pollutants left in the smoke enter an ammonia absorption tower, and finally two kinds of important chemical fertilizer, namely ammonium sulfate and ammonium nitrate are generated. The device and method are suitable for smoke simultaneous desulfurization and denitrification in large, medium and small size boiler and reconstruction application of built combustion equipment, and the NOX and SO2 can be removed at the same time.

Owner:NANJING UNIV OF SCI & TECH

Method for catalytically decomposing carbon fiber-reinforced thermosetting epoxy resin composite material

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

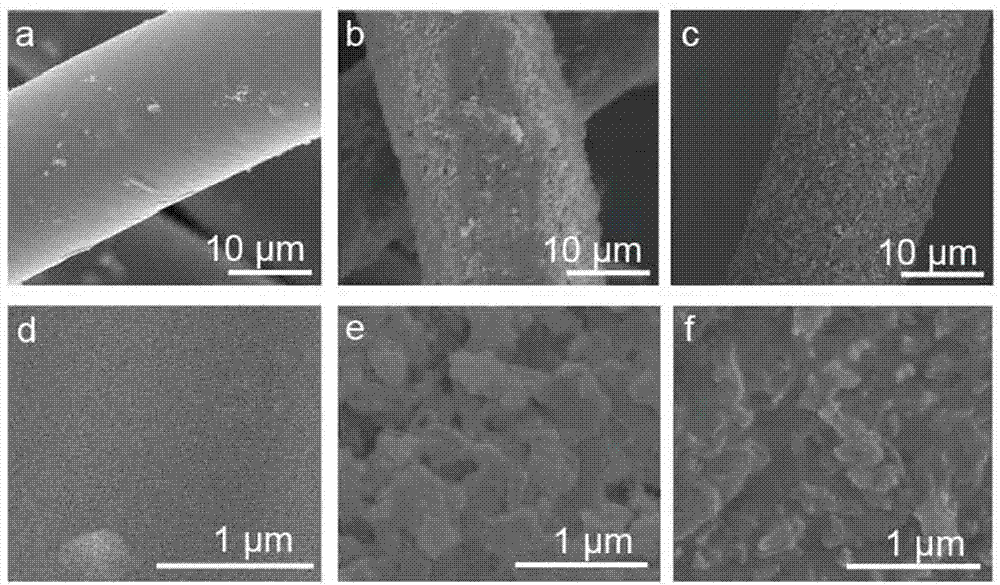

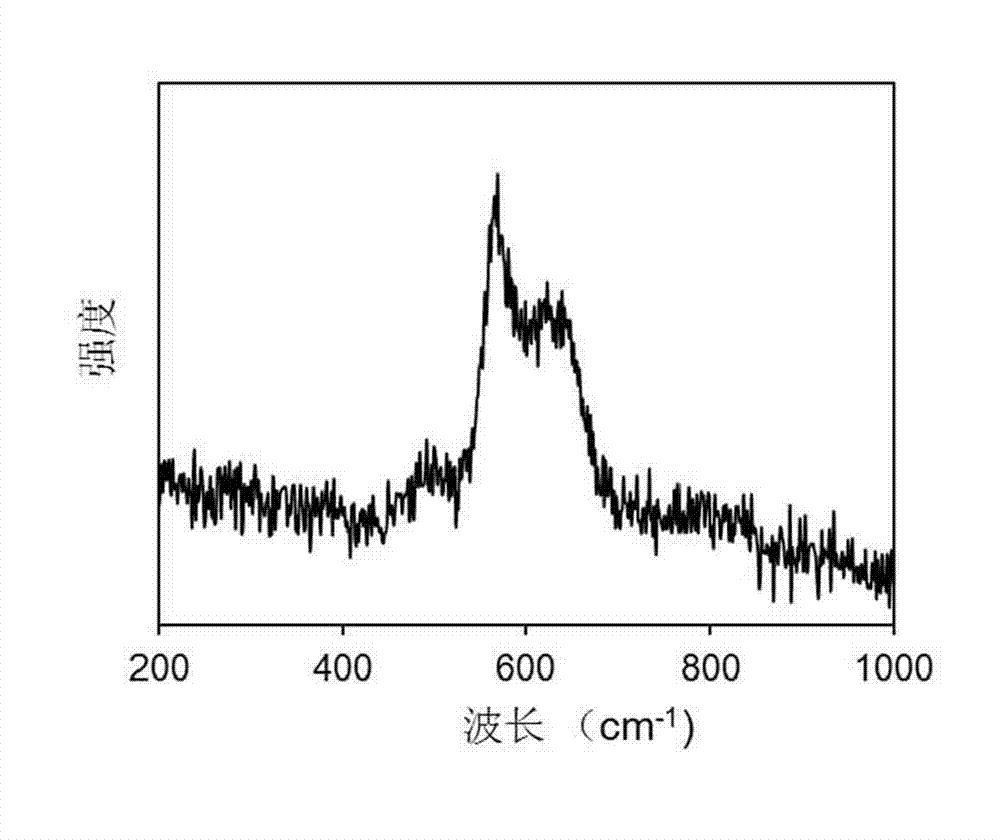

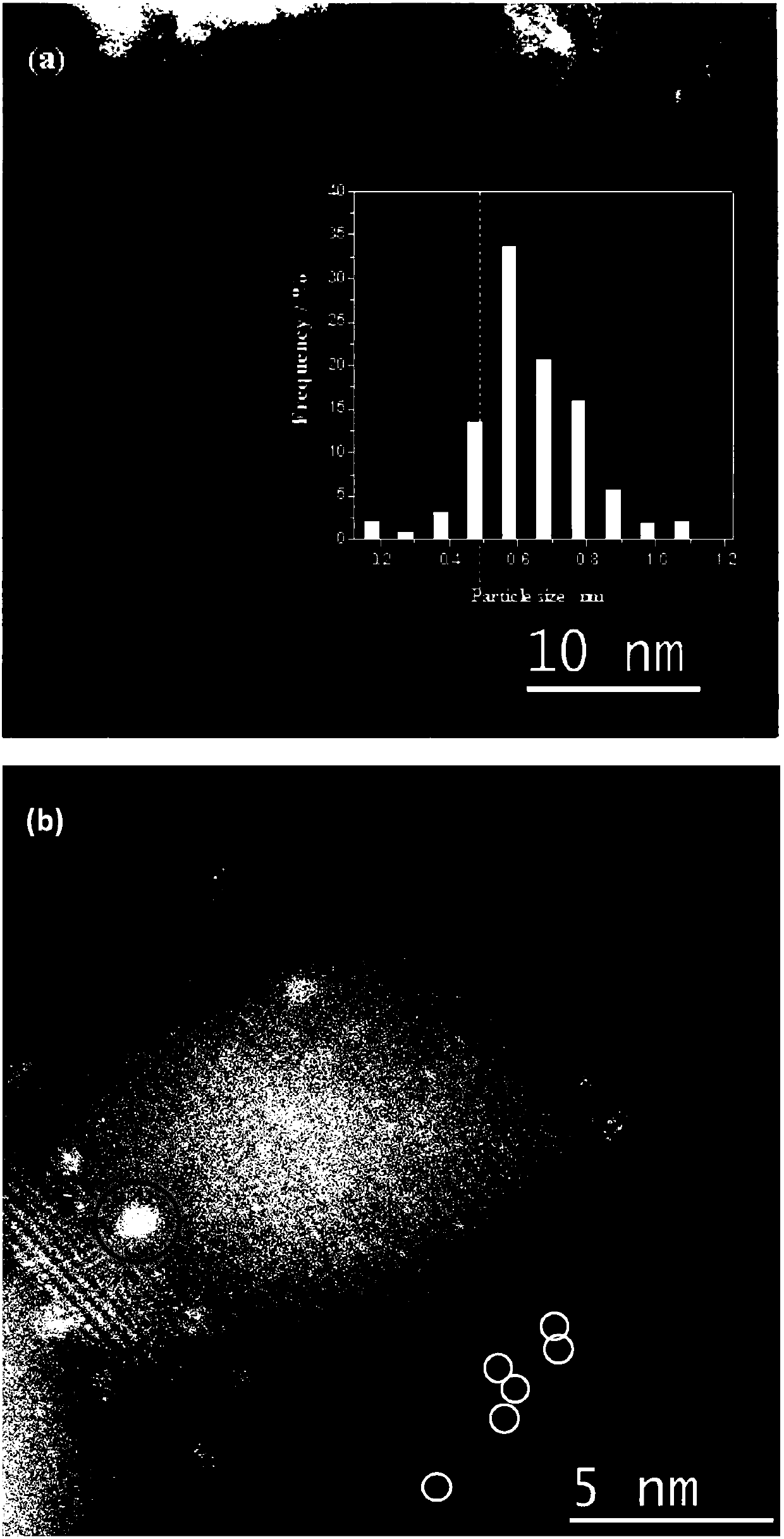

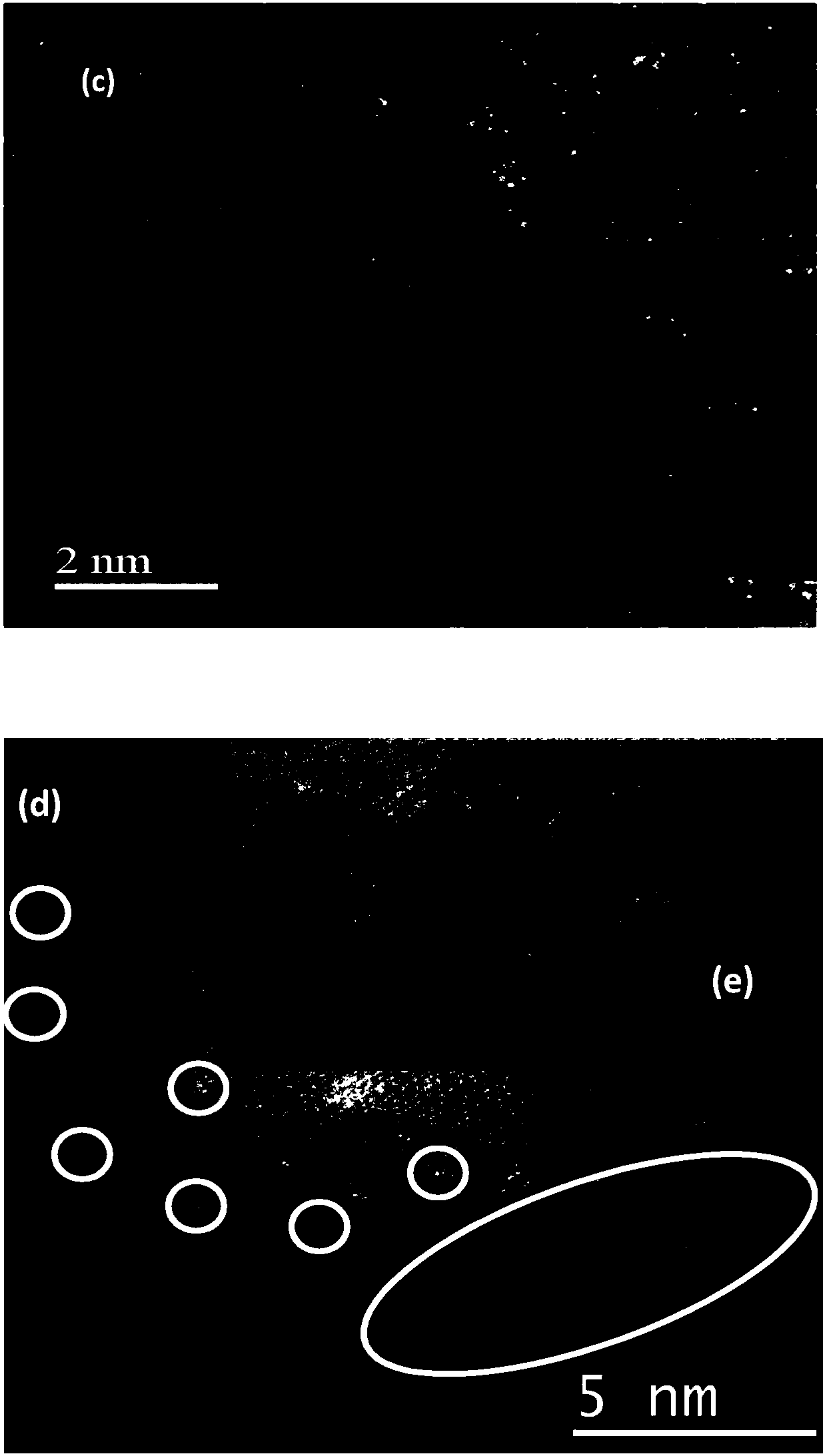

Porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst and preparation method thereof

ActiveCN103721705AHigh activityNot easy to fall offDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberActive component

The invention relates to a porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst and a preparation method thereof. The porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst comprises a porous TiO2 fiber carrier and noble metal active components which are dispersed in the carrier; the porous TiO2 fiber carrier is of a felt shape, and is formed by weaving the TiO2 fibers with the length of a plurality of microns; irregular pores with the pore diameter range of 2-1000nm are formed in the TiO2 fibers so as to form a graduation mesoporous-macroporous structure; and the noble metal exists in a zero valence form with the particle size range of 0.5-3nm. The porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst provided by the invention is of a graduation mesoporous-macroporous structure; the active component noble metal has good dispersibility in the carrier, has the particle size of 1-3nm, and is zero valence; and formaldehyde can be subjected to catalytic decomposition at room temperature, and the catalytic activity is good, and the using quantity is less.

Owner:WUHAN UNIV OF TECH

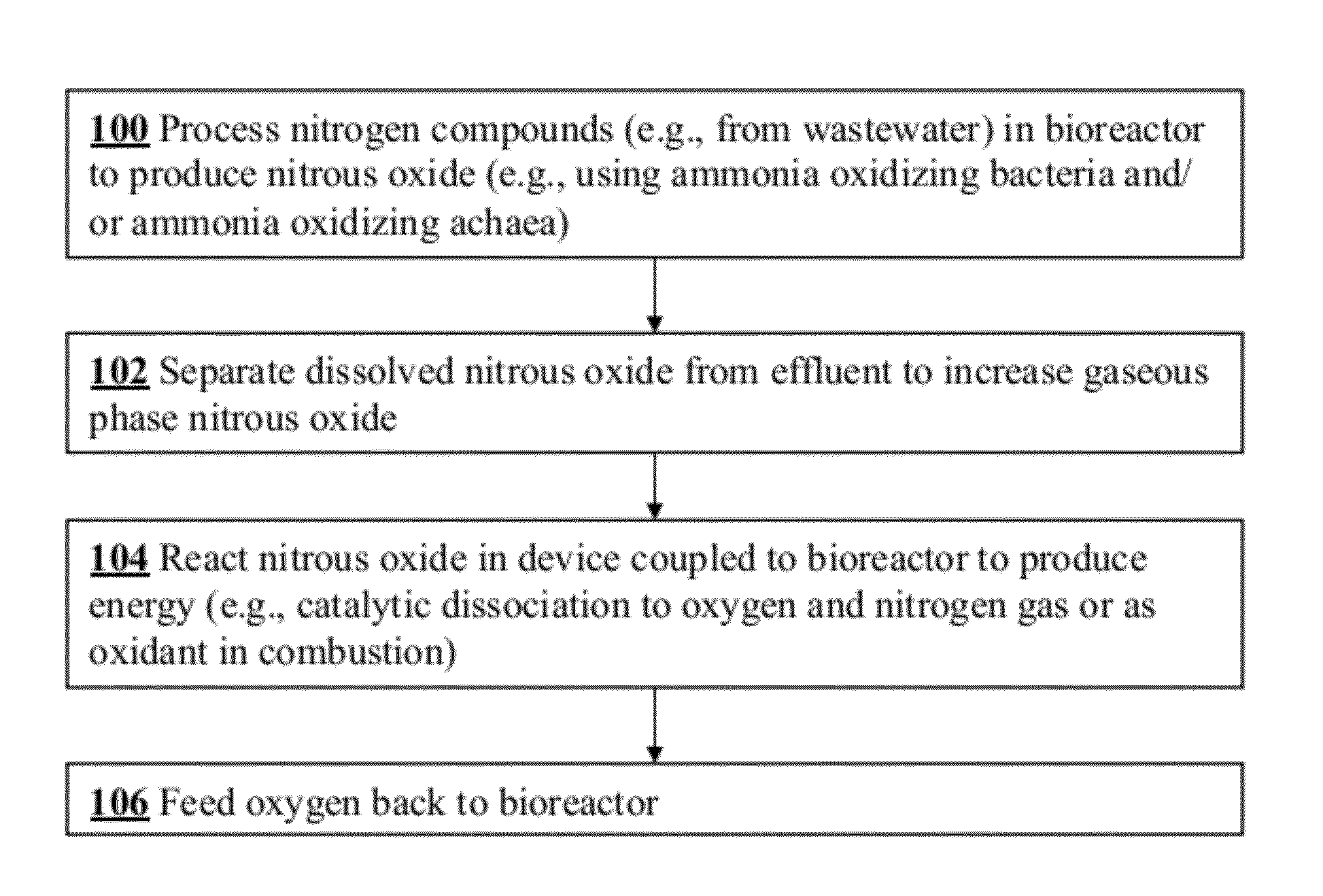

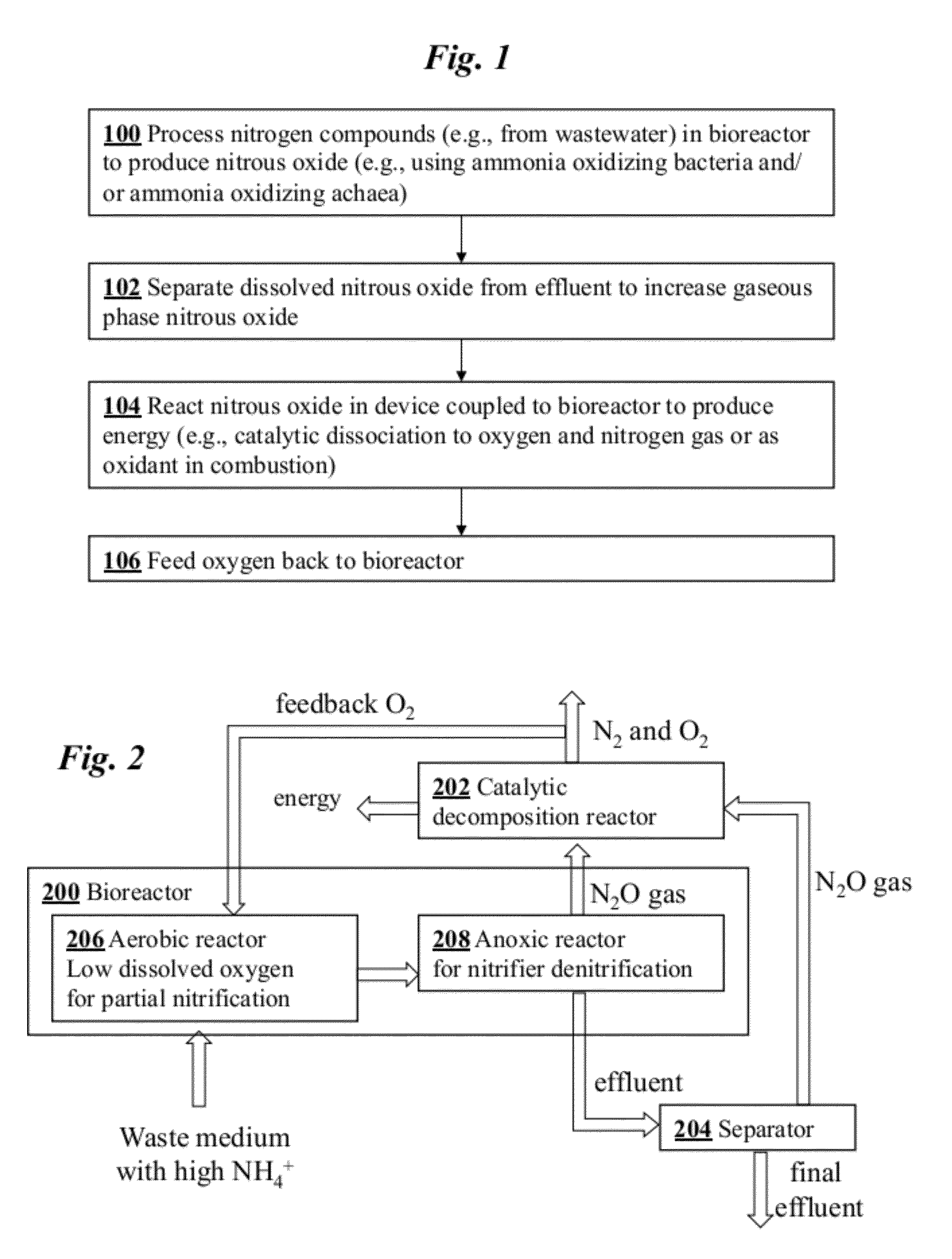

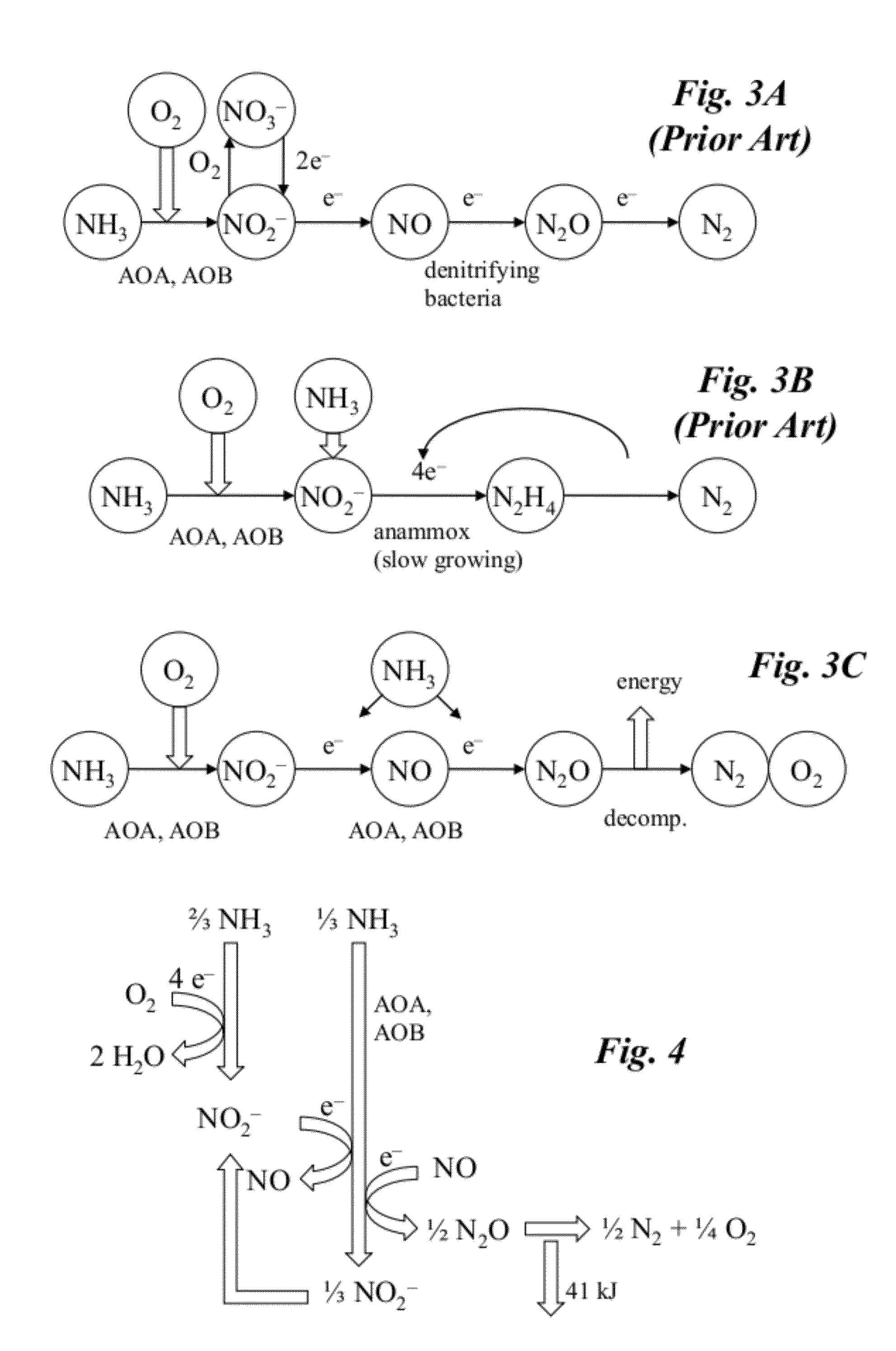

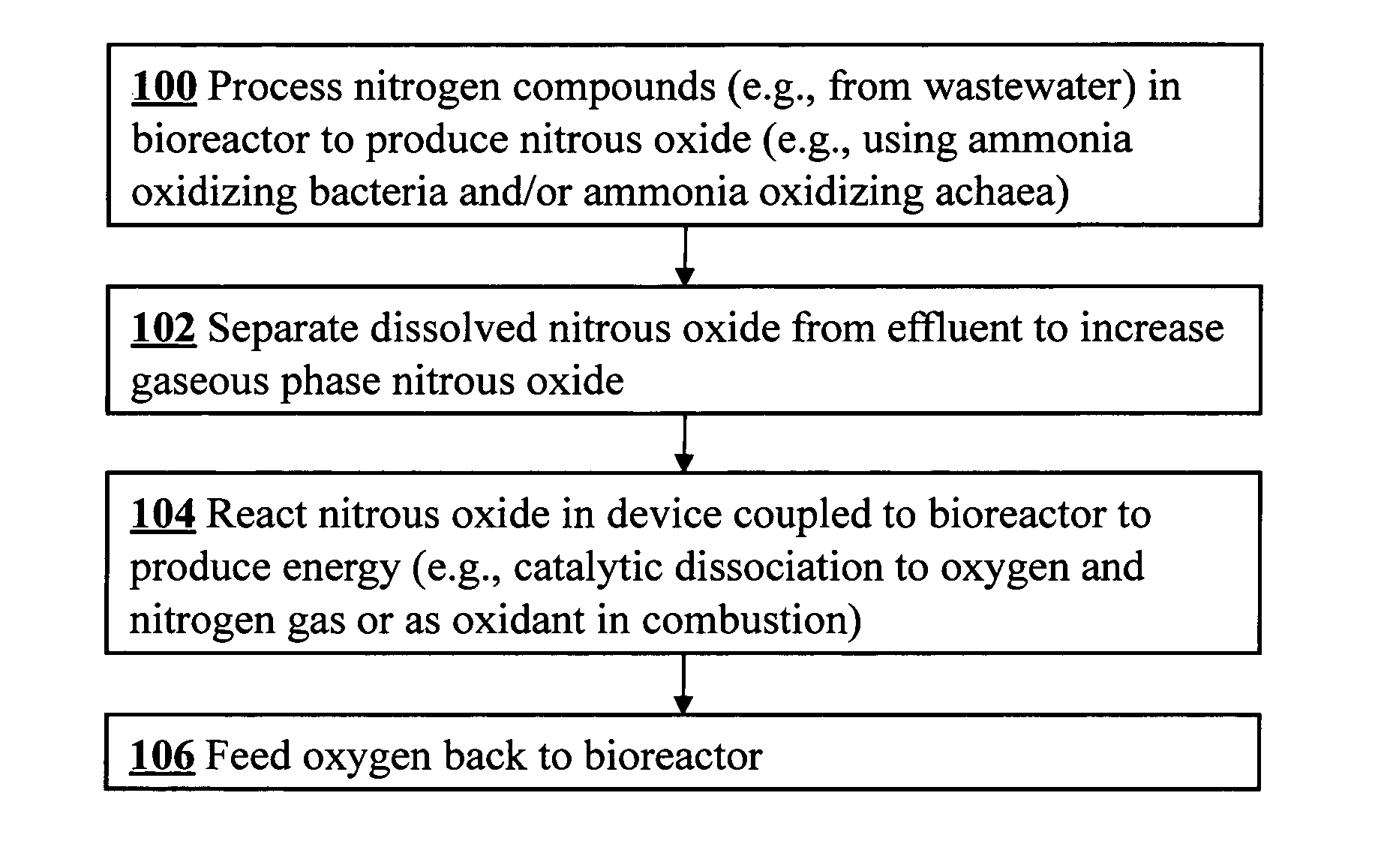

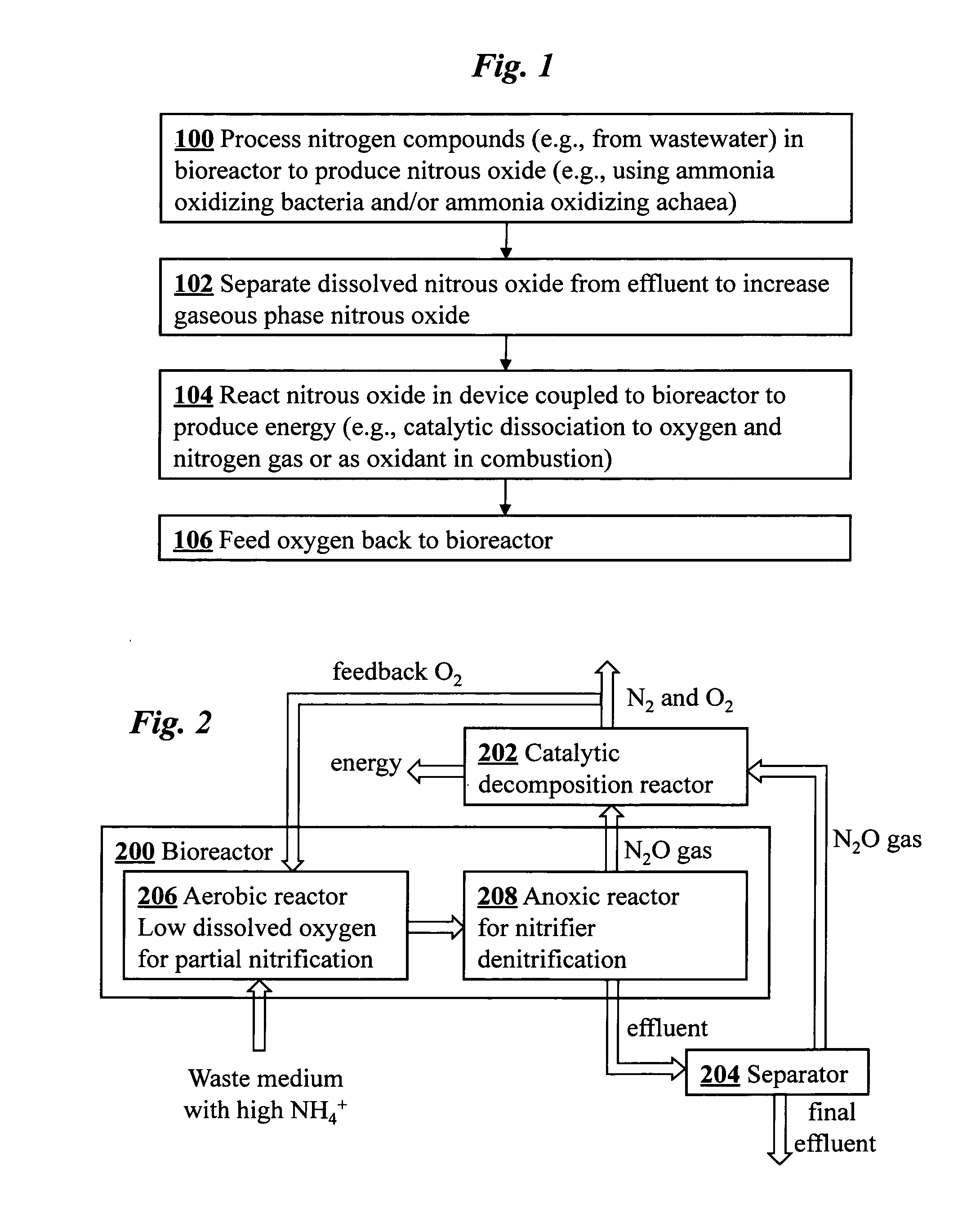

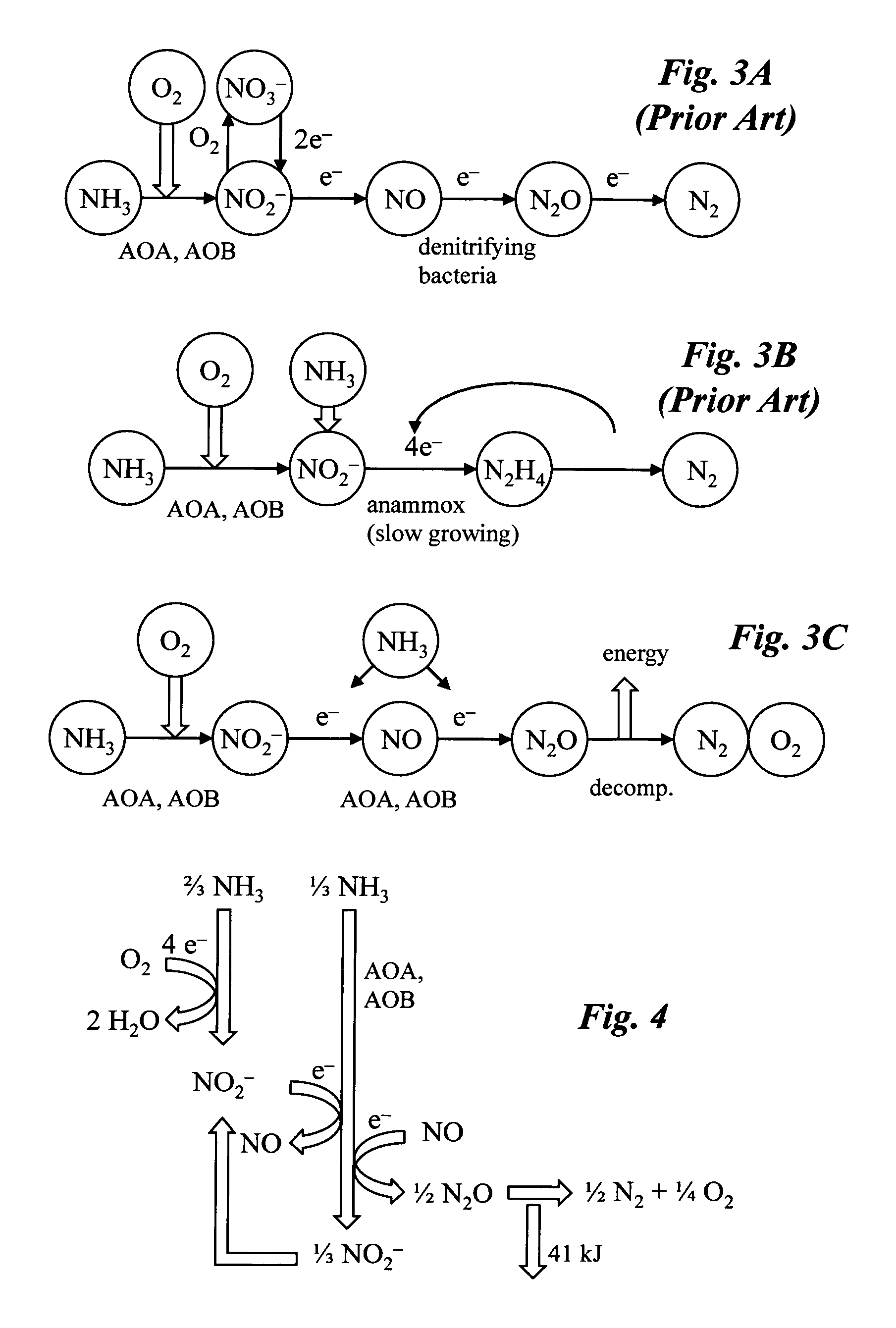

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide including phosphorus recovery and nitrite reduction to nitrous oxide

InactiveUS20120309071A1Minimize N2O productionProducer of clean energyWater treatment parameter controlOxygen/ozone/oxide/hydroxideChemical reactionGas phase

A method to produce N2O from organic nitrogen and / or reactive nitrogen in waste uses a bioreactor coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

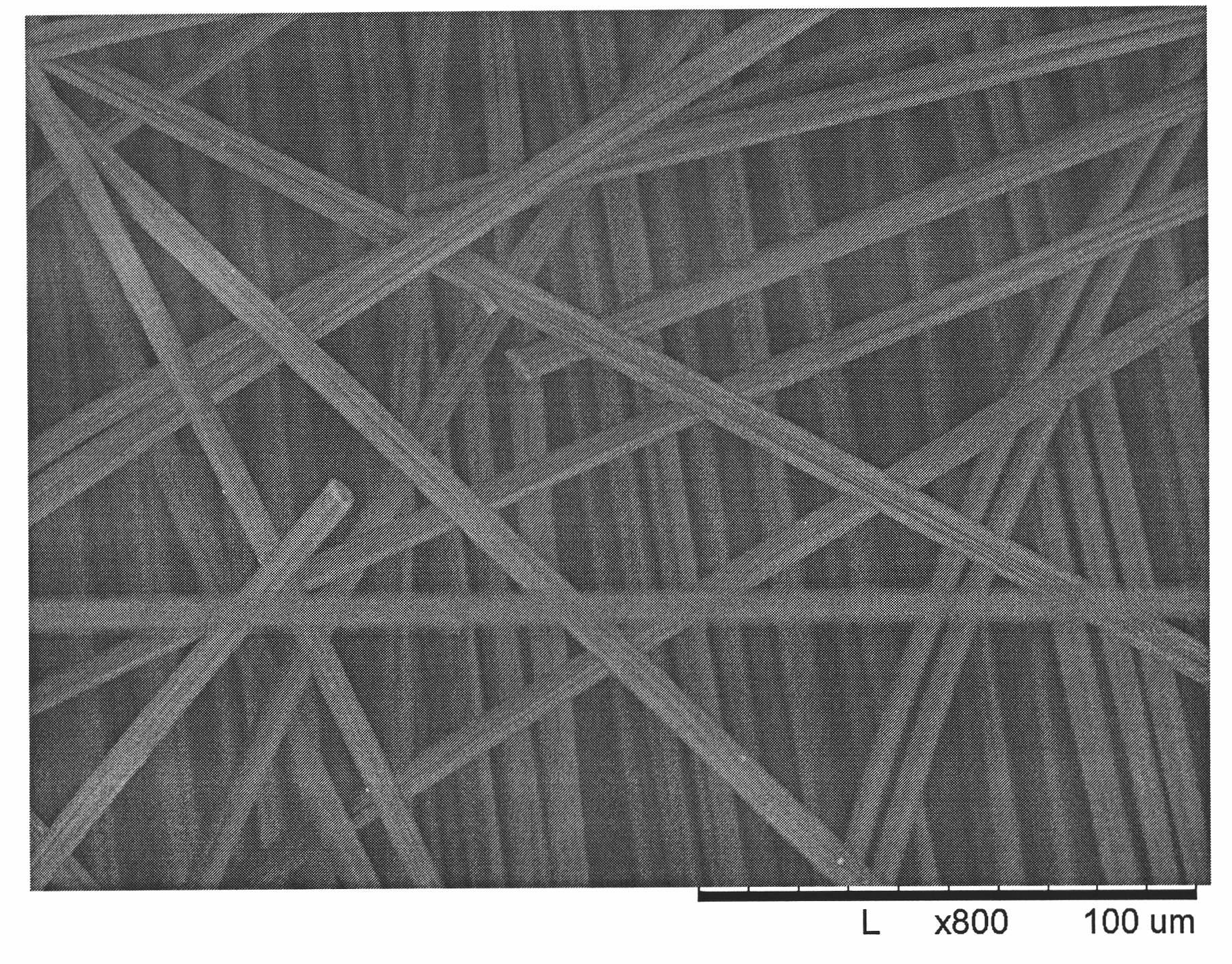

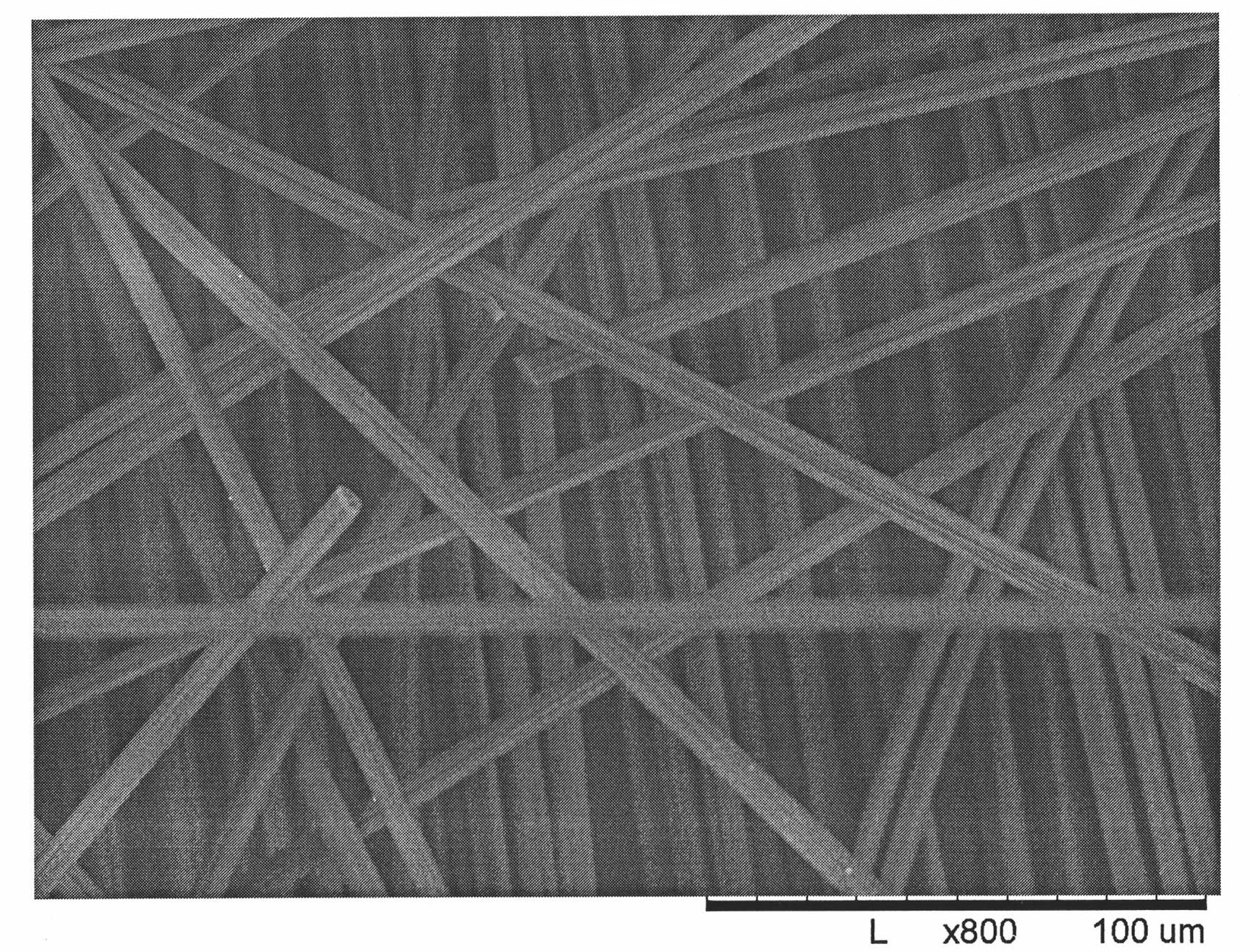

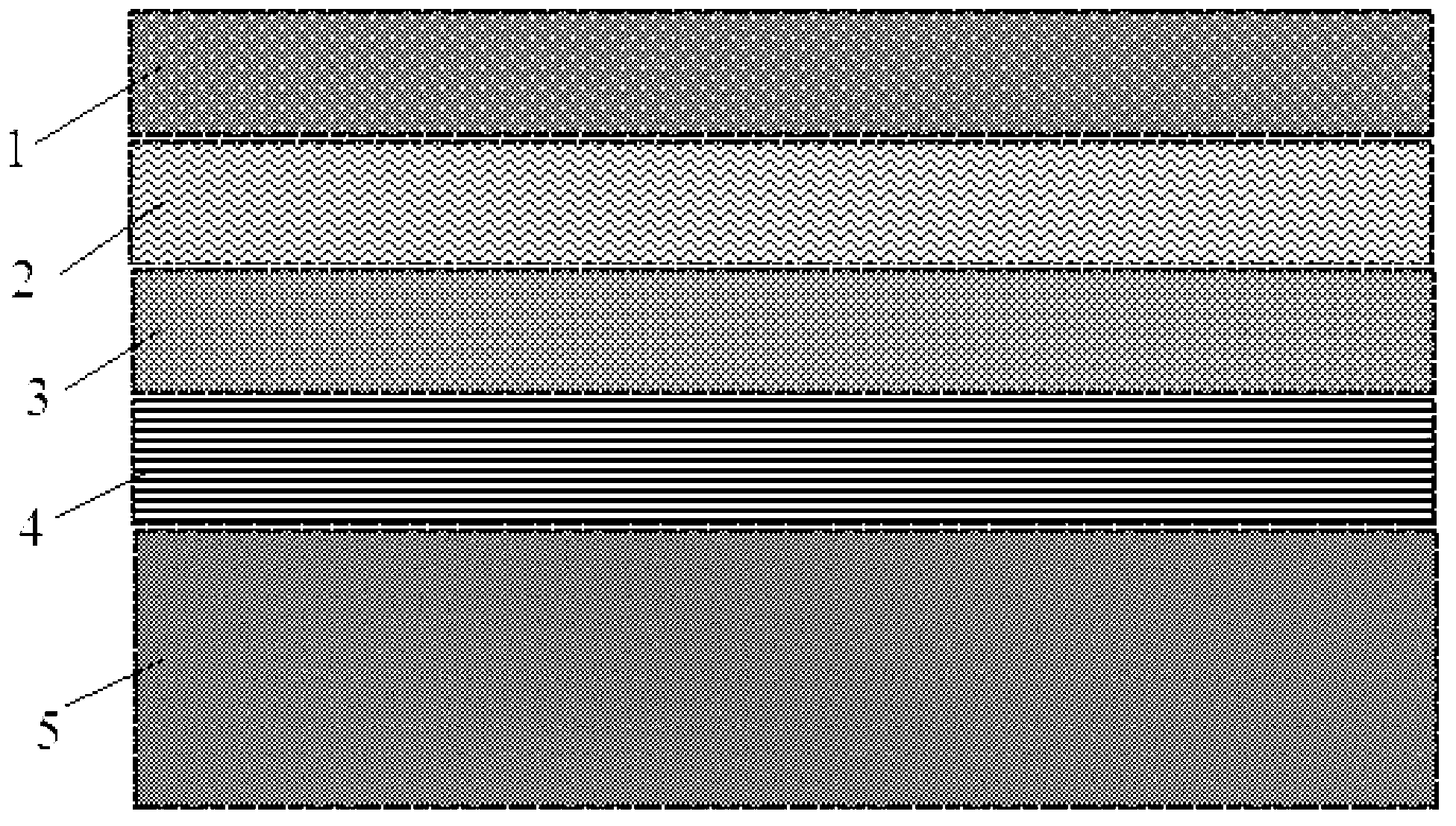

Dedusting and denitration integrated functional filter material and preparation method thereof

ActiveCN103252135AImprove capture abilityImprove efficiencyCombination devicesFiltration separationFiberPunching

The invention discloses a dedusting and denitration integrated functional filter material which comprises a dust facing layer, a buffer layer, a catalytic decomposition layer, a base cloth layer and a support layer, wherein the dust facing layer is prepared by blending polytetrafluoroethylene fiber and polyimide fiber; the buffer layer is prepared by blending polytetrafluoroethylene fiber and polyimide fiber; the catalytic decomposition layer is prepared from a polytetrafluoroethylene film containing a V2O5-WO3 / TiO2 denitration catalyst; the base cloth layer is prepared from polytetrafluoroethylene fiber; the support layer is prepared from polytetrafluoroethylene fiber; the base cloth layer is located on the support layer; the catalytic decomposition layer is located on the base cloth layer; the buffer layer is located on the catalytic decomposition layer; the dust facing layer is located on the buffer layer; the dust facing layer, the buffer layer and the catalytic decomposition layer are hooked on the base cloth layer through a needle punching method; and the support layer is arranged below the base cloth layer through a needle punching method. The dedusting and denitration integrated functional filter material disclosed by the invention has the advantages that high-temperature dedusting and denitration can be realized, and the denitration efficiency can be improved. The invention also discloses a preparation method of the filter material.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Petroleum hydrocarbon catalytic pyrolysis catalyst and its application

ActiveCN1955255AIncrease throughputHigh airspeedHydrocarbonsNaphtha reformingCatalytic pyrolysisAlkaline earth metal

This invention provides a petroleum hydrocarbon catalytic decomposition accelerant and its application. This accelerant includes following components: (1) lanthanide, its weight amount is 0.1-25%; (2) phosphorus or boron, its weight amount is 0.1-10%; (3) base metal, alkali metal and transition metal, their weight amount is 0.1-15%; (4) The others are ZSM-5,ZRP used as carrier. This accelerant used for production of low carbon alkenes by cracking heavy magnesium alkanes, with space velocity of gas 1-25hr-1, such as naphtha, diesel oil, educed pressure diesel and so on. The yield of ethylene, propylene, butylenes and butadiene will improve by 5%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ozone-assisted method for catalytic decomposition of volatile organic pollutants in high-temperature flue gas

ActiveCN102814108AHighly selective adsorptionHigh selectivityDispersed particle separationCarbon nanotubeCatalytic decomposition

The invention discloses an ozone-assisted method for catalytic decomposition of volatile organic pollutants in high-temperature flue gas. According to the invention, ozone gas is introduced into a fixed bed reactor of a catalytic reaction. According to the catalyst in the fixed bed reactor, carbon nano-tubes, activated carbon, titanium dioxide, silica, or a composition thereof is adopted as a carrier; and Mn2O3, MnO2, CeO2, CuO, Cu2O, V2O5, Fe2O3, FeO, or a composition thereof is adopted as an active component. The active component accounts for 1-50% of total mass of the catalyst. The concentration of the introduced ozone gas is in a range of 0.1-50mg / L. According to the invention, a strong oxidant ozone is introduced in a catalytic decomposition process, such that active oxygen in the system is increased, catalytic decomposition of pollutant molecules is promoted, catalytic decomposition efficiency of the catalyst upon the volatile organic pollutants is substantially improved, and carbon dioxide selectivity is greatly improved. Therefore, an optimal effect of volatile organic pollutant low-temperature catalytic decomposition is achieved.

Owner:ZHEJIANG UNIV

Method and device for reducing fuel consumption of diesel engine by catalytic decomposition of oxygen-containing fuel

InactiveCN102278240AEmission reductionReduce consumptionInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberExternal energy

A method and device for reducing fuel consumption of a diesel engine by catalytic decomposition of oxygen-containing fuel belong to the technical field of diesel engine combustion energy saving and emission reduction. In the present invention, the oxygen-containing fuel is fed into the catalytic reactor installed in the exhaust channel of the diesel engine, and the catalytic reactor is heated by the waste heat of the tail gas discharged from the combustion chamber, so that the oxygen-containing fuel is catalytically decomposed, and the generated hydrogen-rich and carbon monoxide-rich The decomposed gas enters the intake port, mixes with air, and enters the combustion chamber. At the same time, the emulsified oil is sprayed from the nozzle. The atomized emulsified oil evaporates, mixes, ignites and burns in the combustion chamber, and pushes the piston to do work. The system of the present invention makes full use of the waste heat of the exhaust gas of the diesel engine, and can realize the catalytic decomposition of the oxygen-containing fuel without providing energy from the outside. At the same time, combined with the use of emulsified oil, the comprehensive fuel saving rate of the diesel engine can reach 10-15%, and can be greatly improved. Reduce the emission of pollutants such as nitrogen compounds and soot, so as to achieve the purpose of energy saving and emission reduction.

Owner:TSINGHUA UNIV

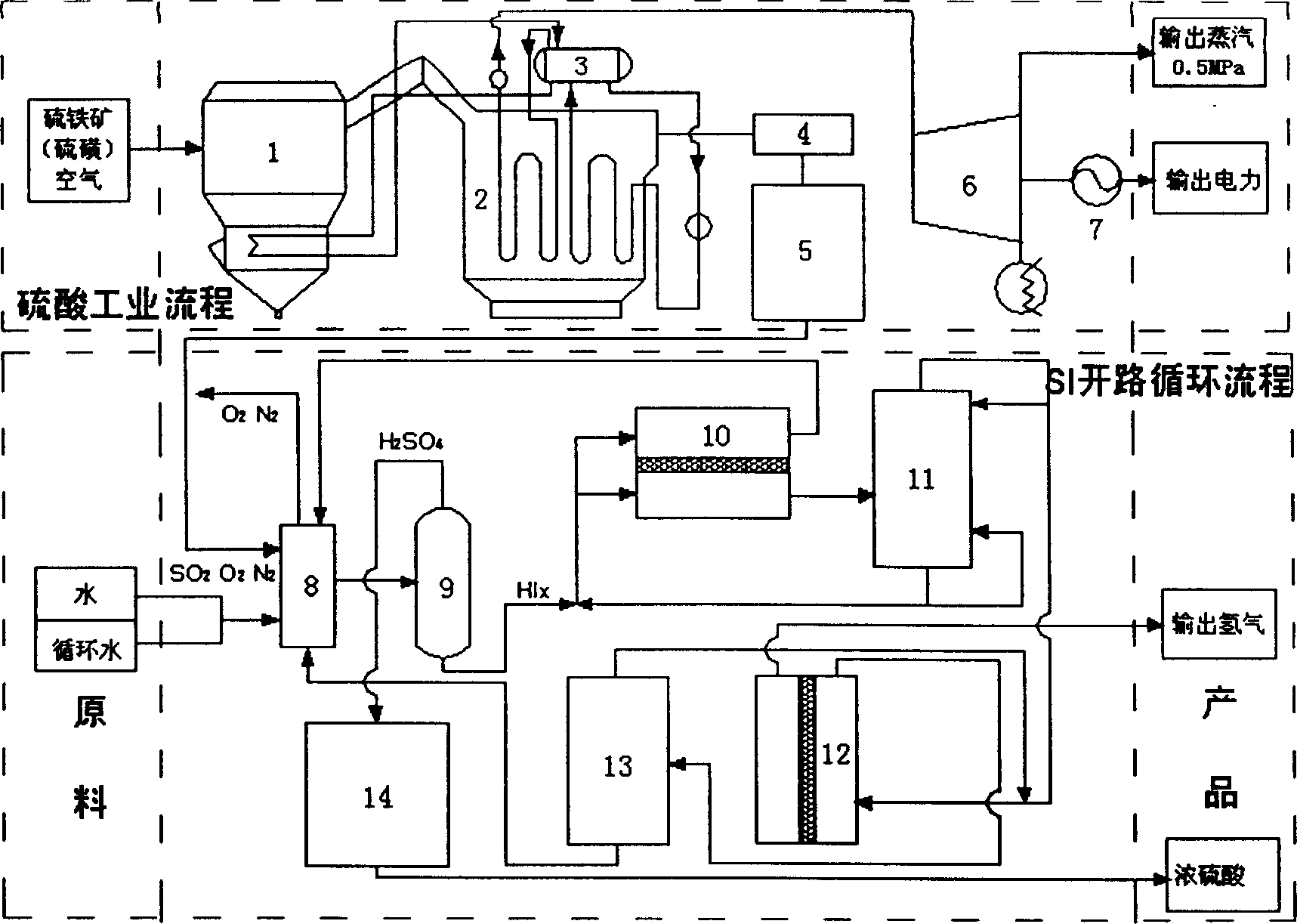

Technical method of sulfur iodine open circuit circulation hydrogen manufacture and its equipment

ActiveCN1785796AReduce the temperatureReduce energy consumptionIodine/hydrogen-iodideSulfur-trioxide/sulfuric-acidIt equipmentHydrogen

The present invention relates to a process for preparing hydrogen gas, and is aimed at providing a technological process capable of combining sulfur-iodine open-circuit circulation and sulfuric aid industry to simultaneously produce hydrogen gas and sulfuric acid and provide electric power and its equipment. Said method includes the following steps: roasting sulfur-bearing mineral, Bunsen reaction, separating HIx phase and H2SO4 phase solution, using electroosmose process to concentrate and purify HIx phase and utilizing HI membrane catalytic decomposition reactor to make decomposition to obtain I2 and find product H2.

Owner:ZHEJIANG UNIV

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide

InactiveUS20110207061A1Treatment with aerobic and anaerobic processesSustainable biological treatmentSequencing batch reactorFiber

A bioreactor designed to produce N2O from organic nitrogen and / or reactive nitrogen in waste is coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas.Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane. The bioreactor may have various designs including a two-stage bioreactor, a hollow-fiber membrane bioreactor, or a sequencing batch reactor. The bioreactor may involve Fe(II)-mediated reduction of nitrite to nitrous oxide.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com