Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

384 results about "Carbon product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon products are obtained by heating coal (to give coke), natural gas (to give blacks), or carbonaceous material of vegetable or animal origin, such as wood or bone (to give charcoal), at elevated temperatures in the presence of insufficient oxygen to allow combustion.

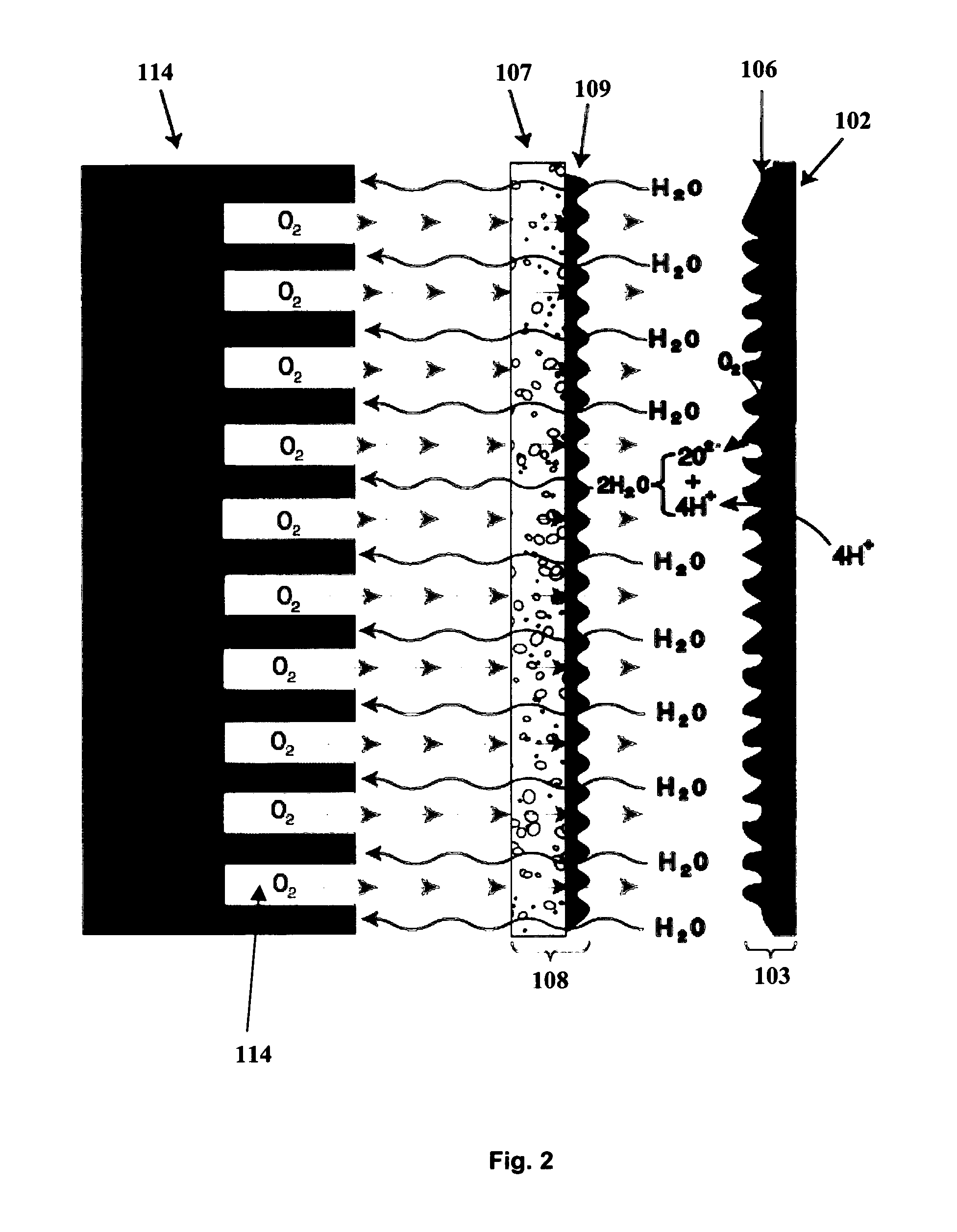

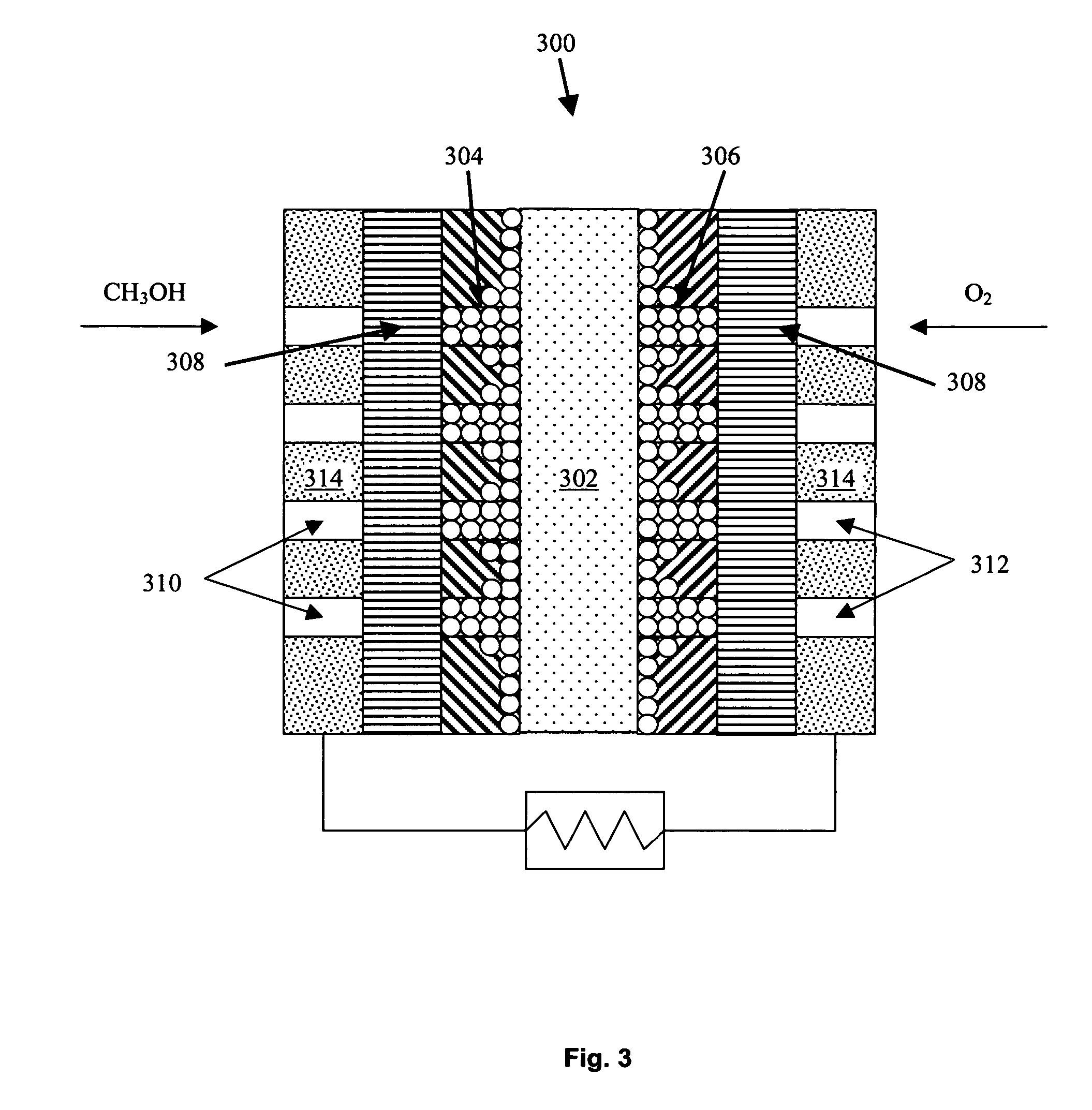

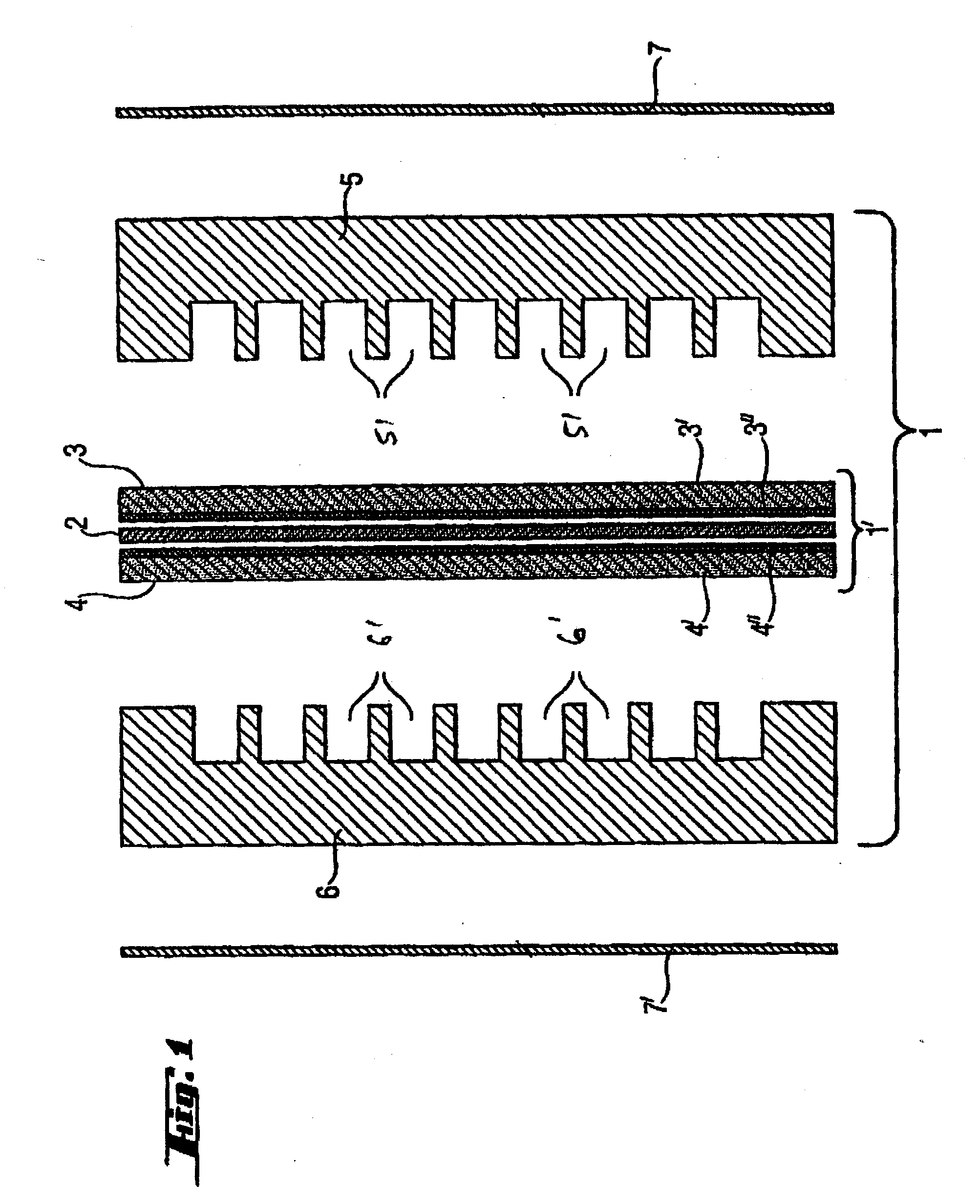

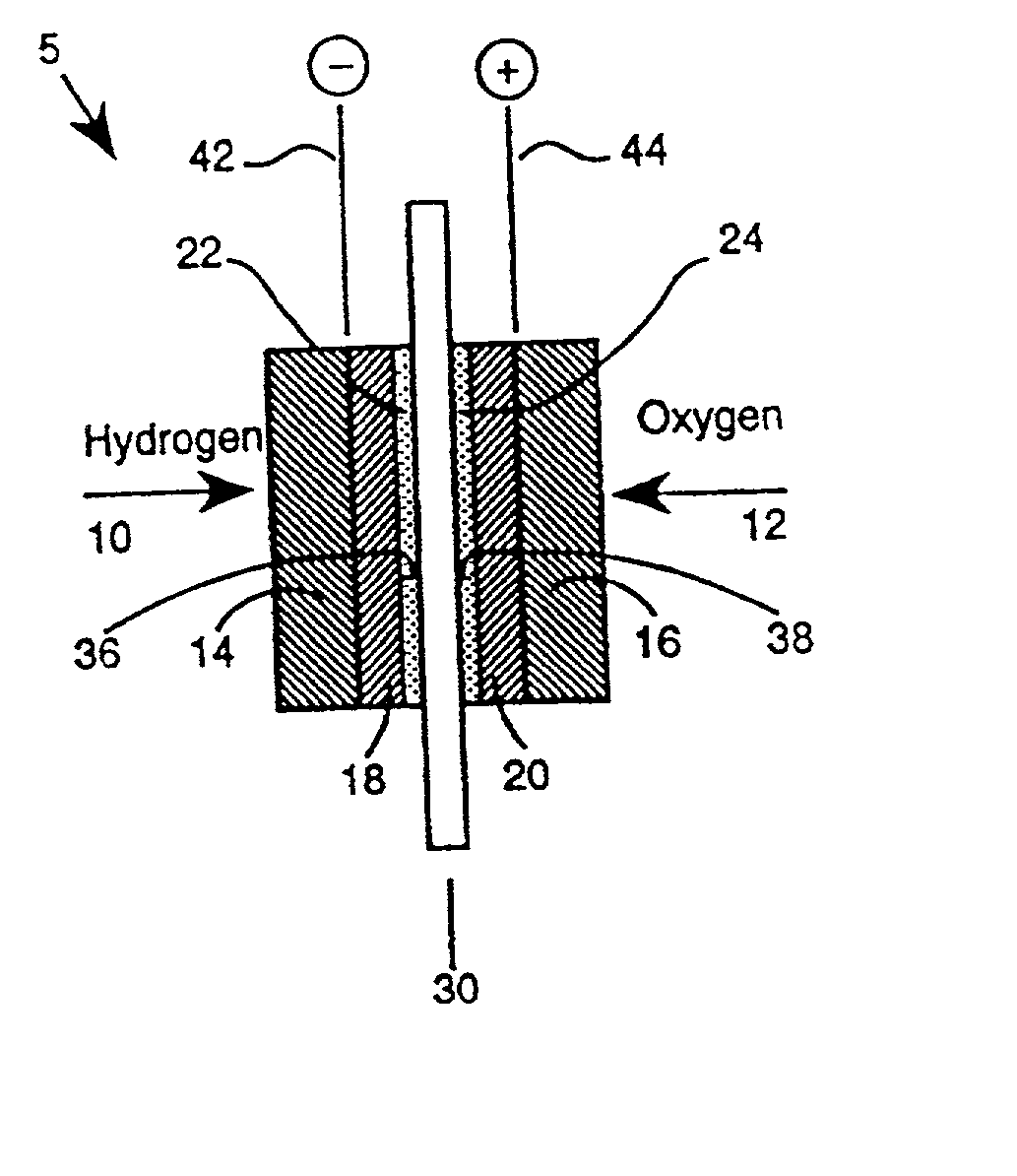

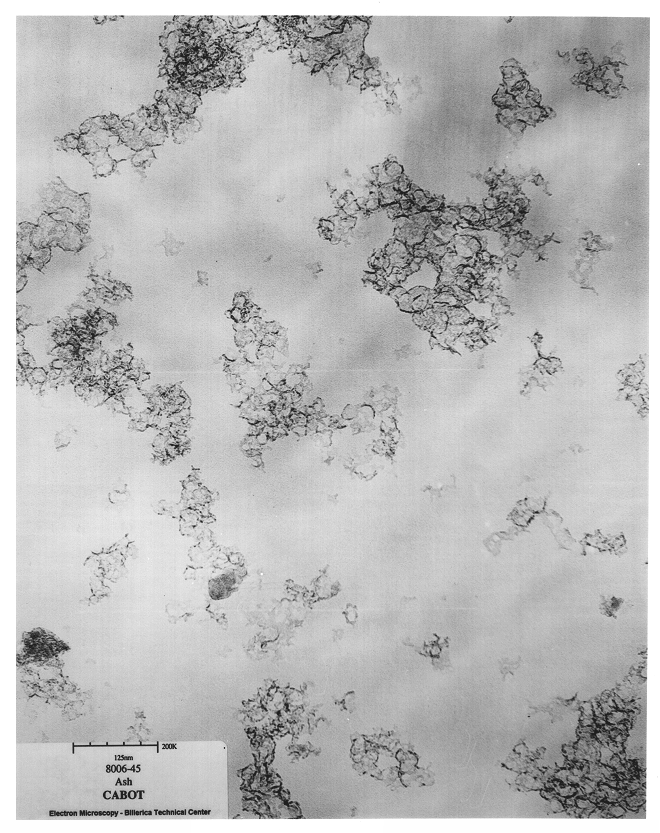

Fuel cells and other products containing modified carbon products

InactiveUS20030017379A1Decrease electrode performanceReduction of gas mass transport efficiencyOrganic diaphragmsAlkali metal halidesFuel cellsModified carbon

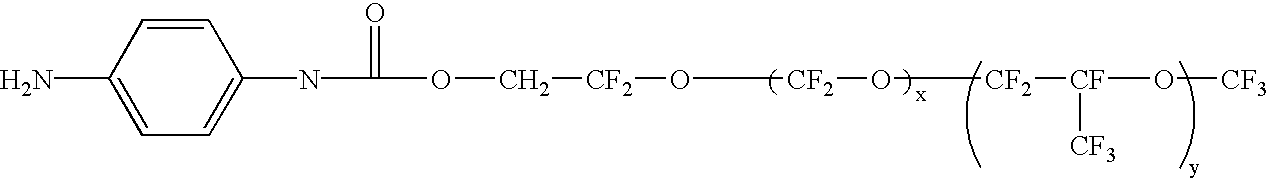

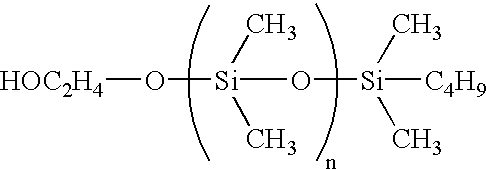

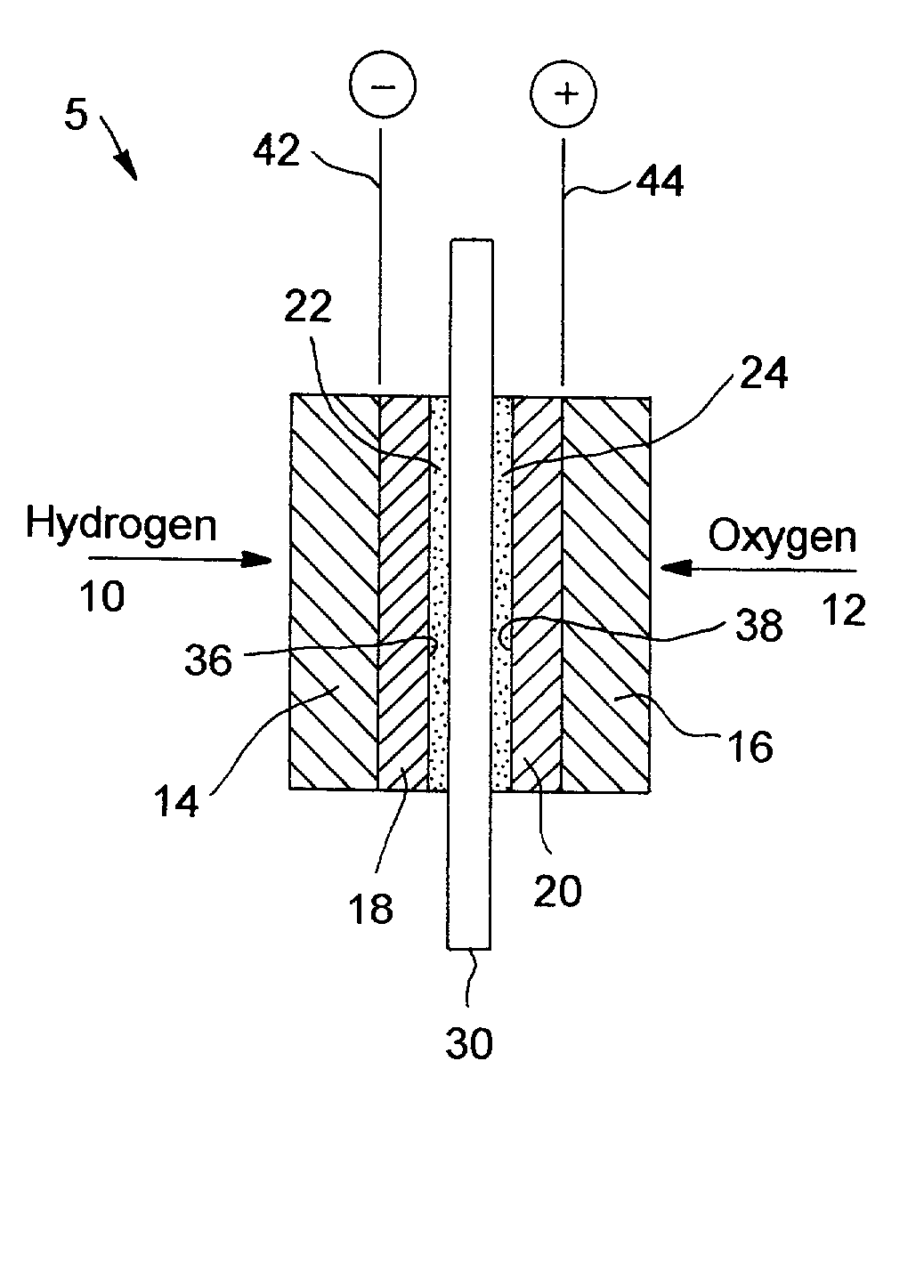

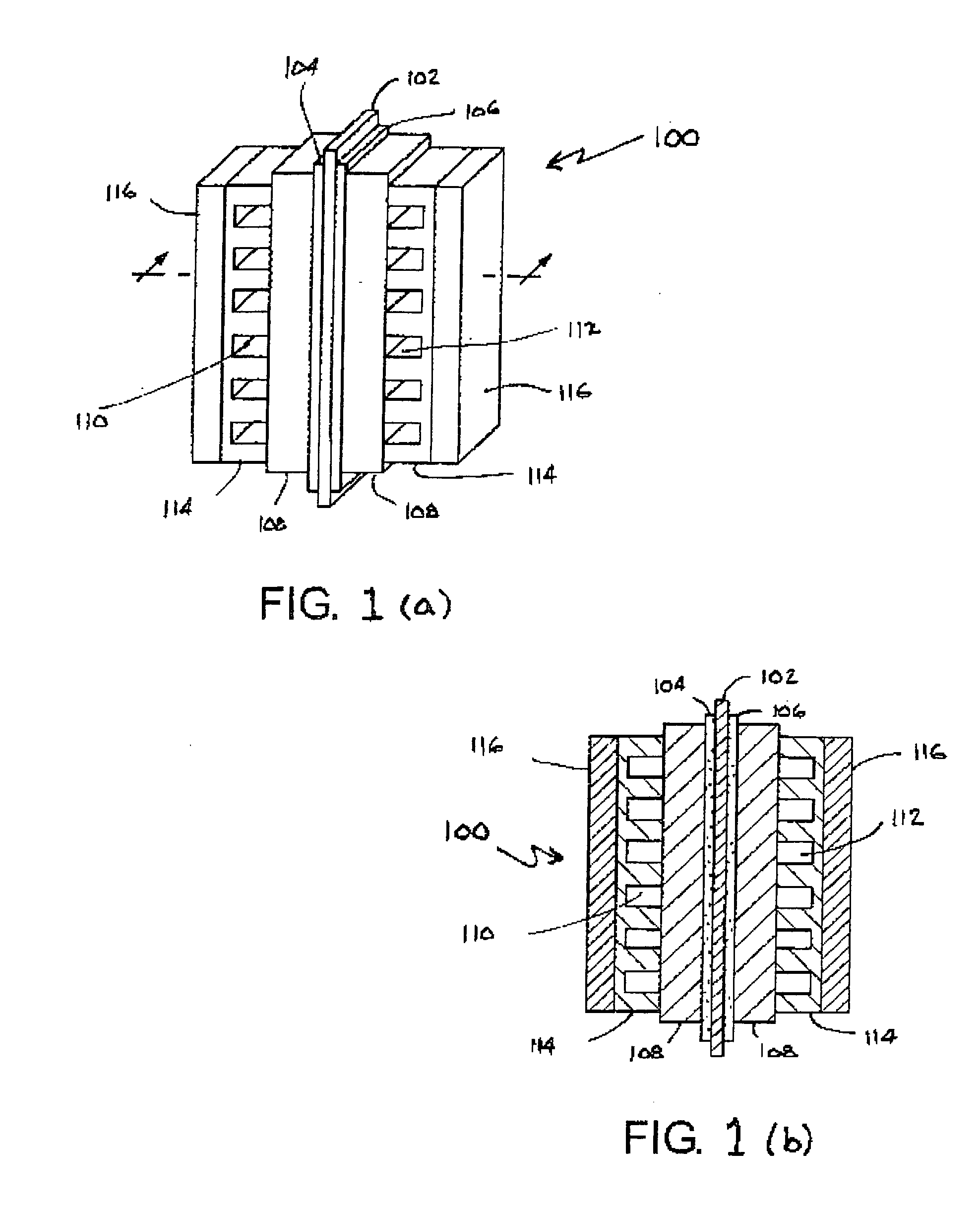

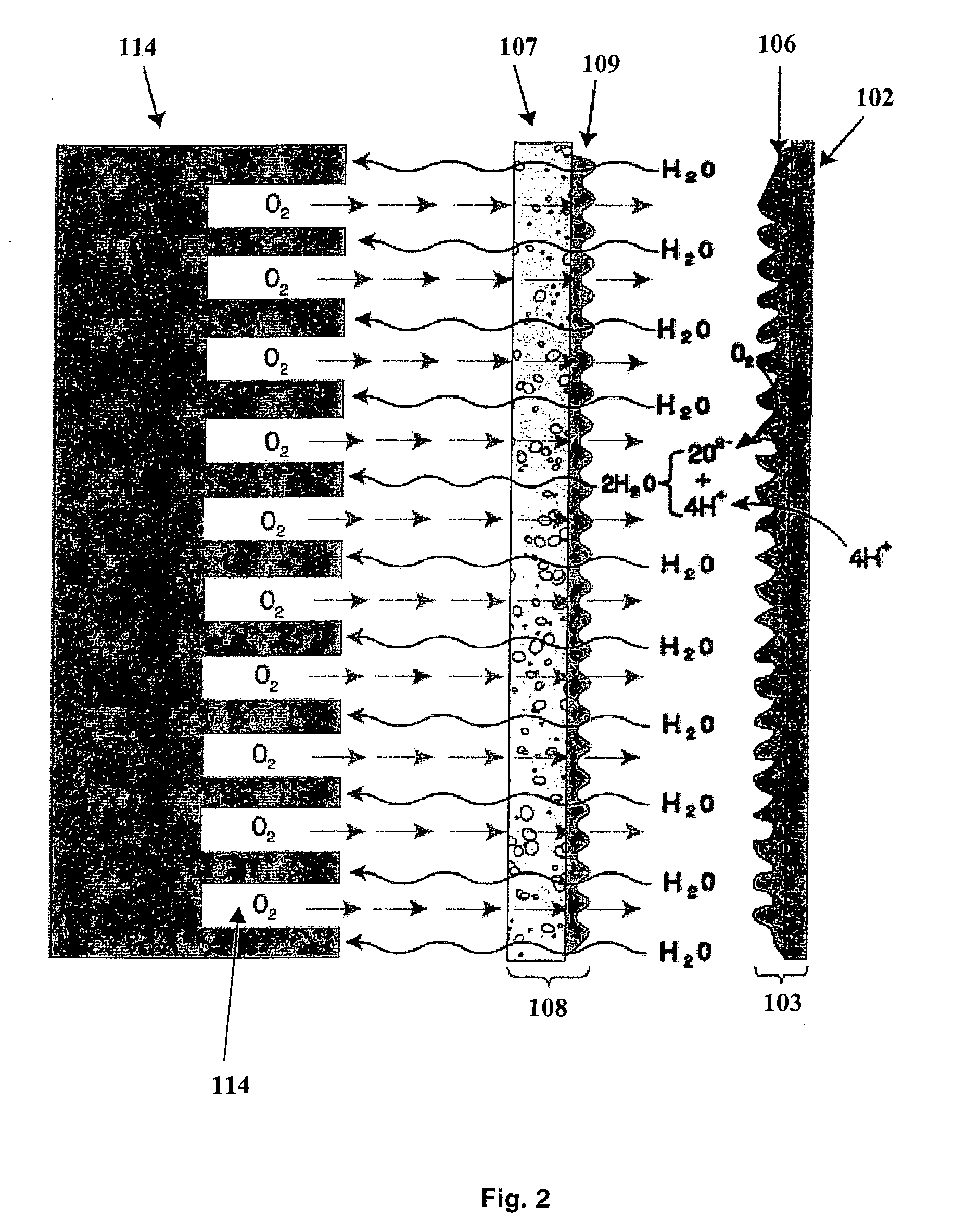

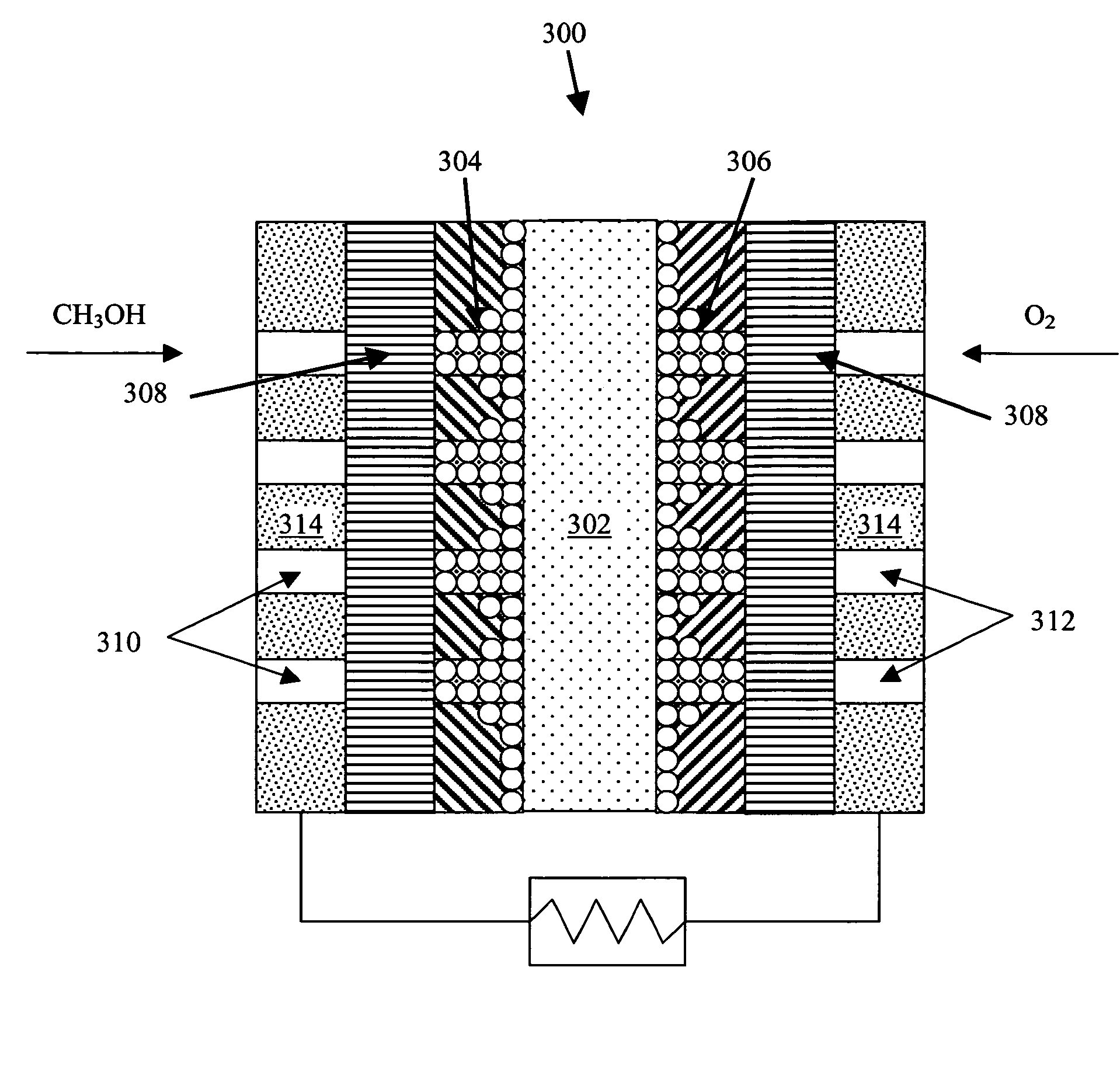

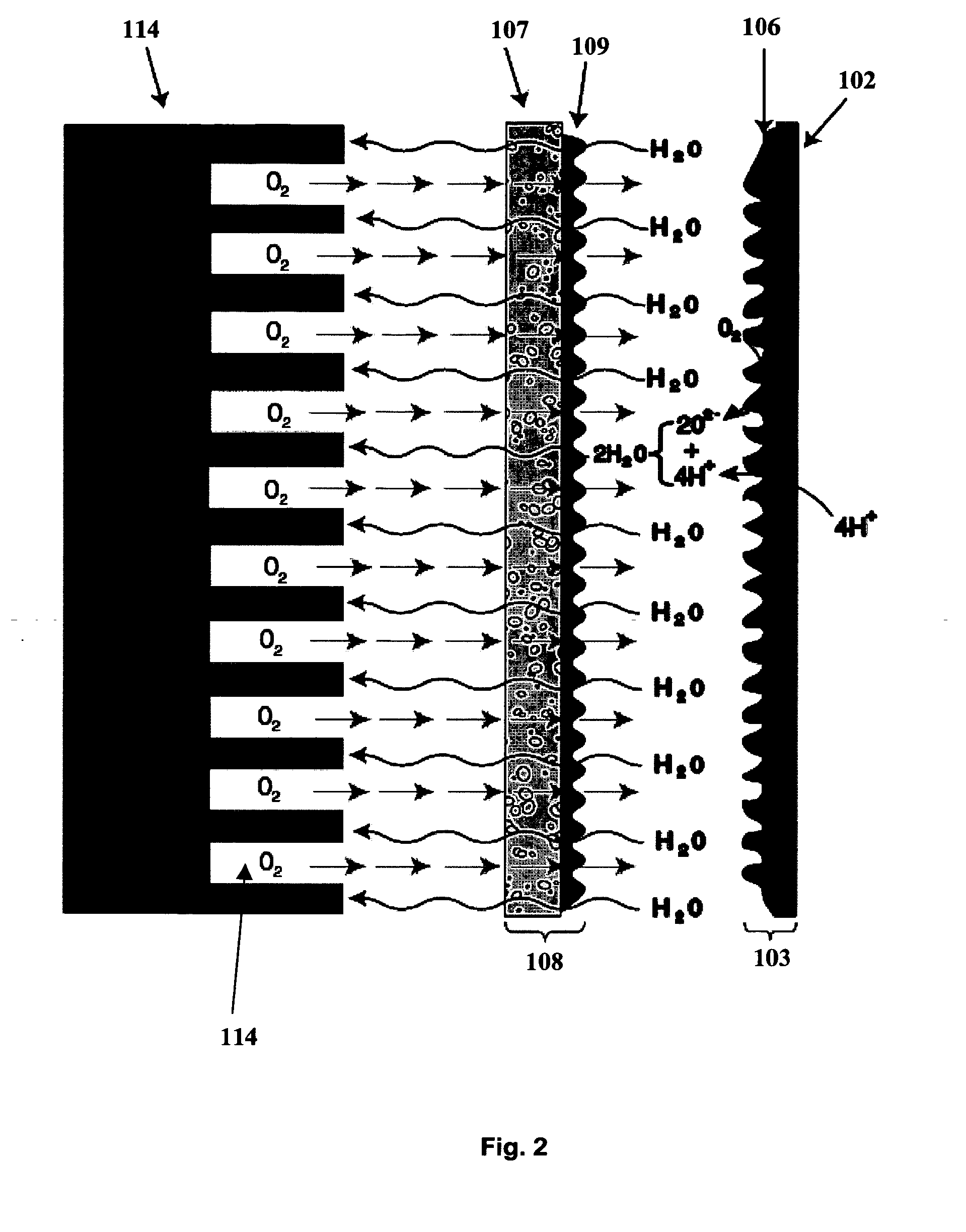

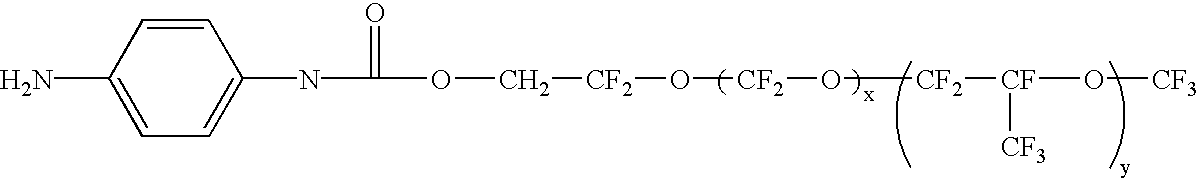

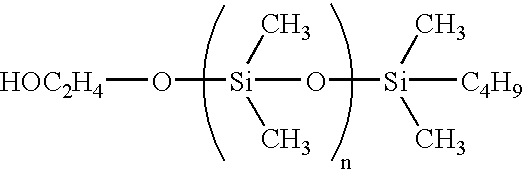

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

Modified carbon products, their use in electrocatalysts and electrode layers and similar devices and methods relating to the same

Electrodes and electrocatalyst layers incorporating modified carbon products. The modified carbon products may advantageously enhance the properties of an electrode or electrode layer, leading to more efficiency within the a fuel cell or similar device.

Owner:CABOT CORP

Modified carbon products, their use in fluid/gas diffusion layers and similar devices and methods relating to the same

Gas / Fluid diffusion layers incorporating modified carbon products. The modified carbon products advantageously enhance the properties of gas / fluid diffusion layers, leading to more efficiency within a fuel cell or similar device incorporating the gas / fluid diffusion layer.

Owner:CABOT CORP

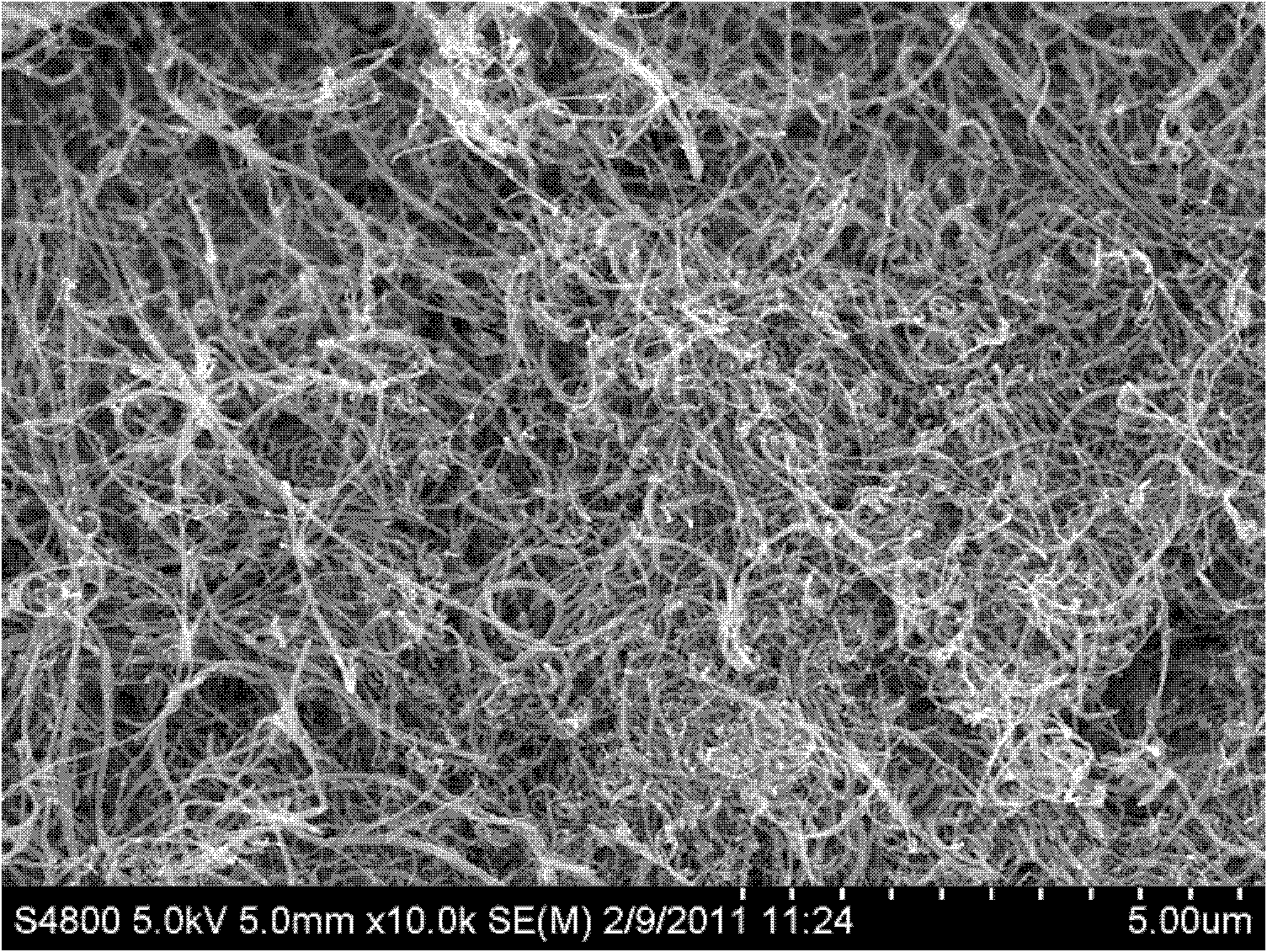

Filamentous carbon particles for cleaning oil spills and method of production

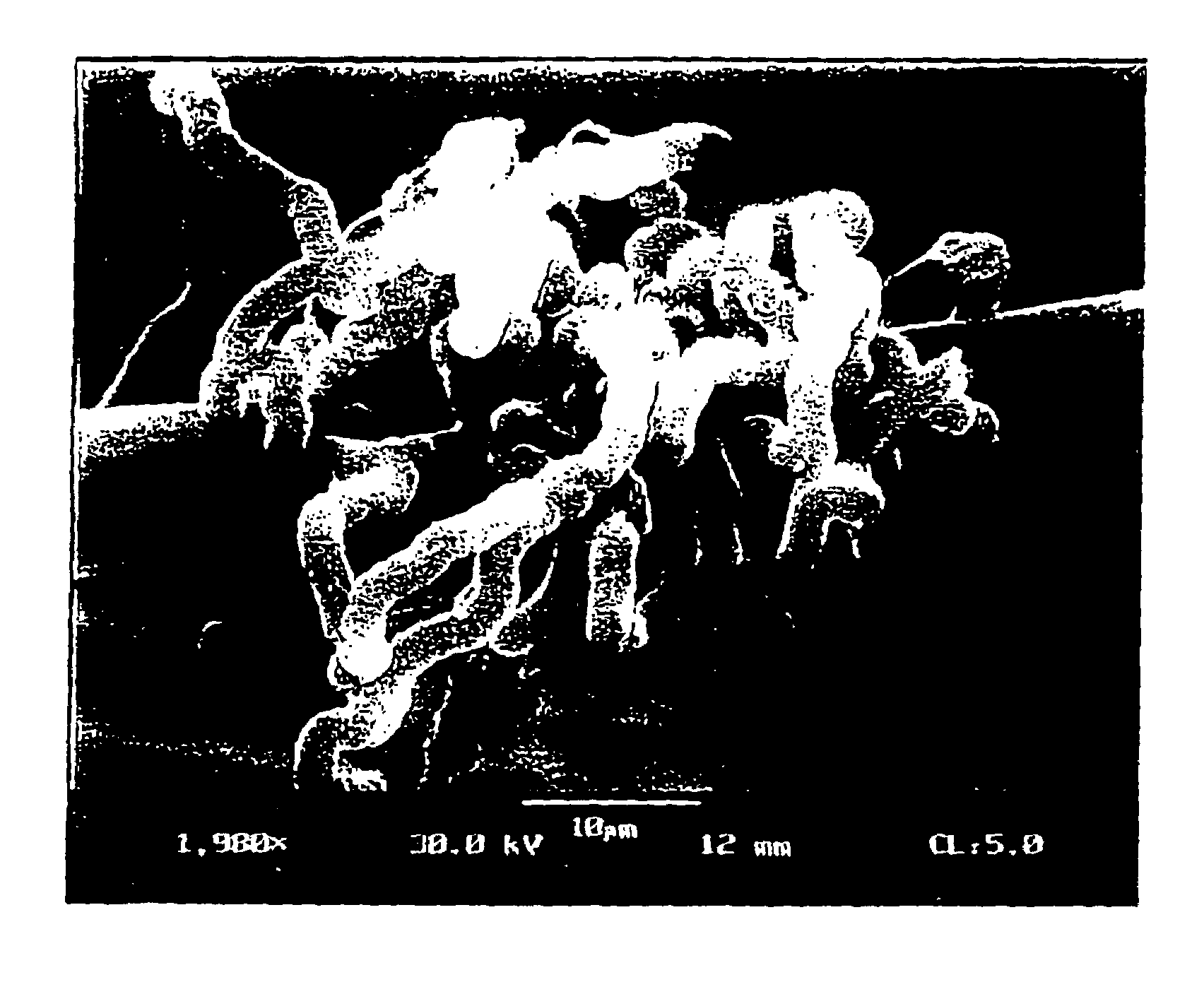

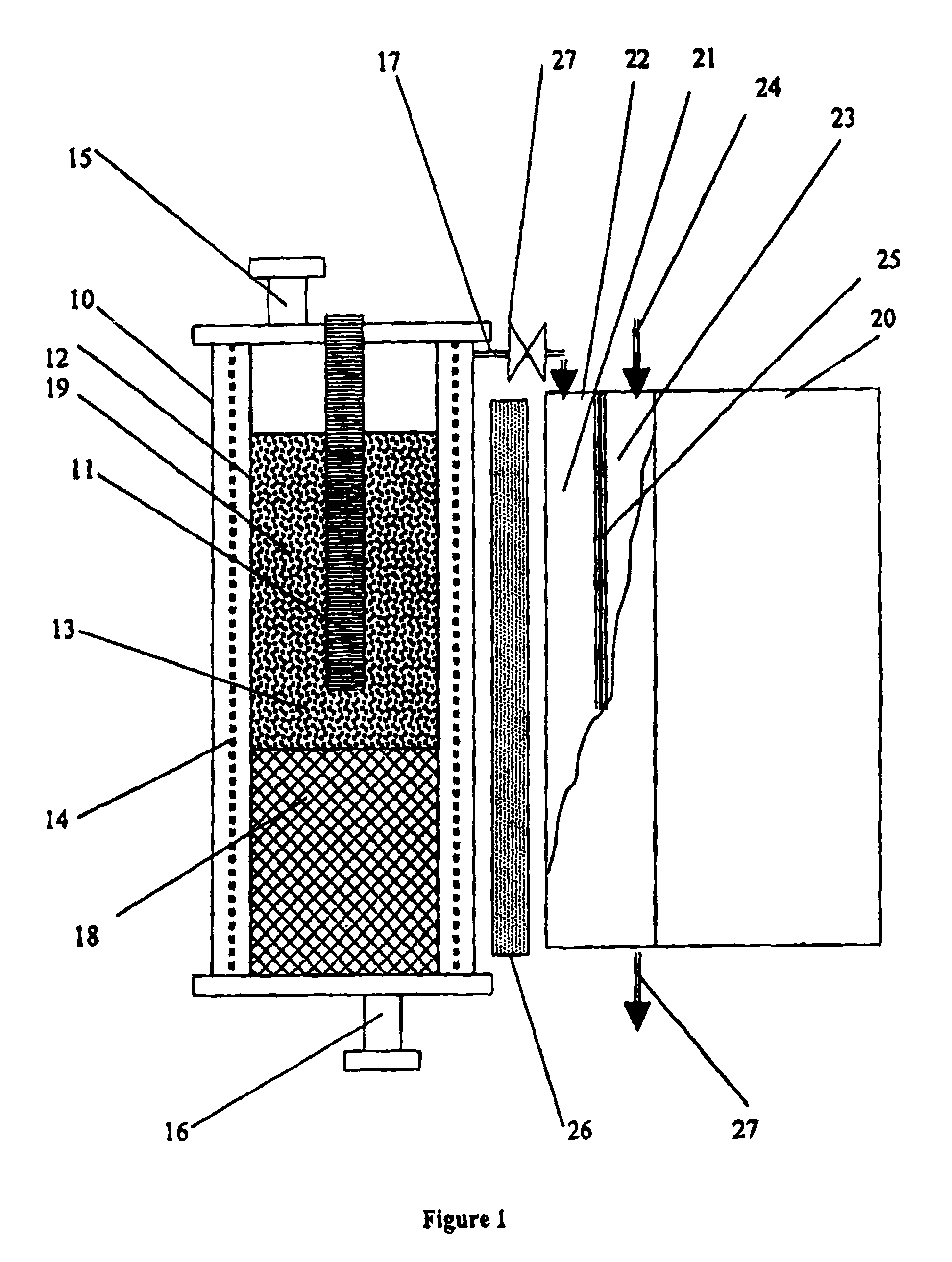

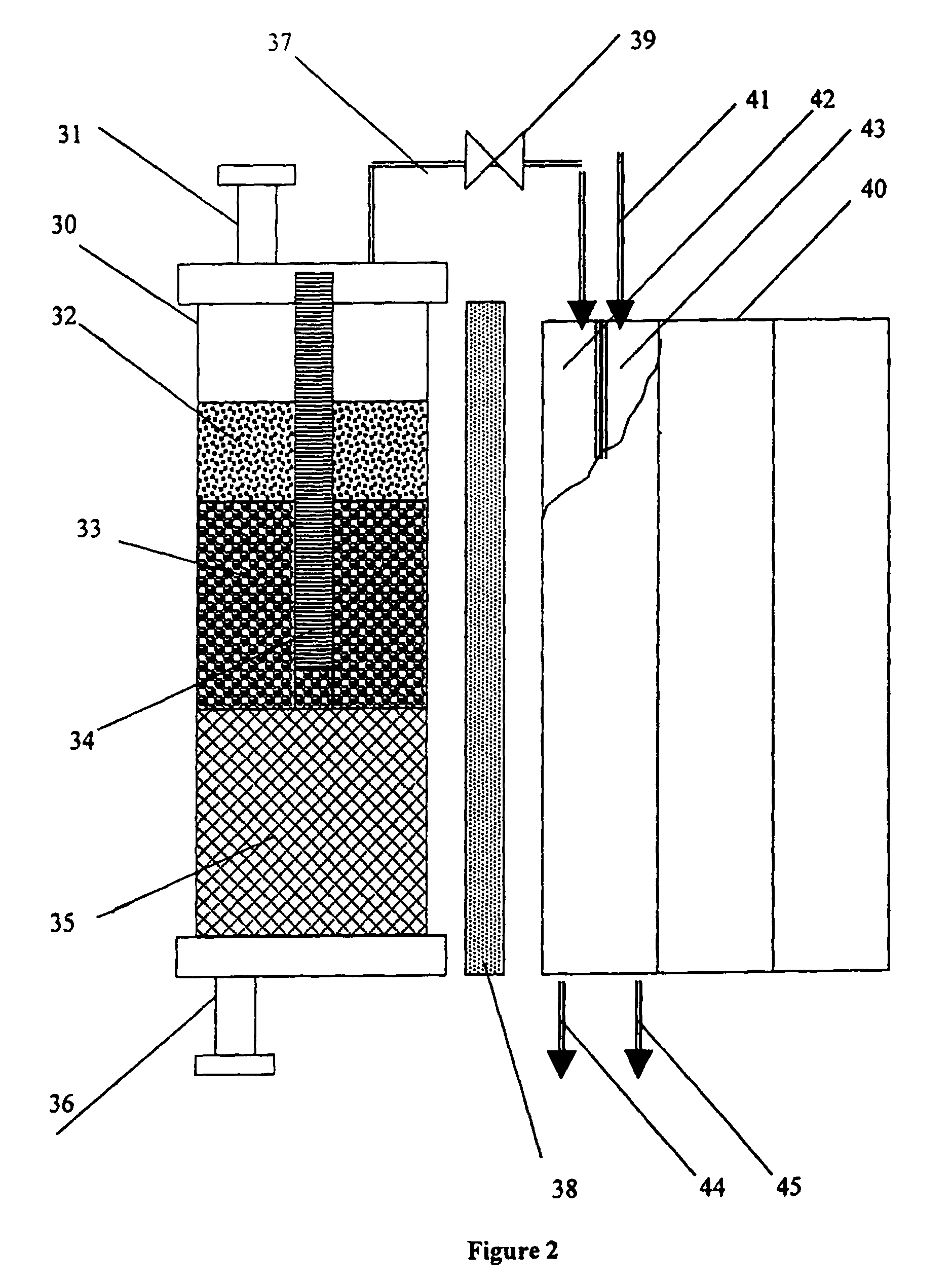

InactiveUS7473466B1Increase specific energy and overall energy efficiencyHydrogen/synthetic gas productionGlass/slag layered productsFiberCarbon nanotube

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. In the process of producing hydrogen for the generator via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in an oxidant-free environment, novel carbon products are produced with filamentary surfaces, “octopus”-like carbon filaments, single carbon nanotube fibers and the like. Two novel processes are disclosed for the production of carbon filaments and a novel filamentous carbon product useful in the clean-up of oil spills on the surface of water. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, and sulfurous fuels. The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it can be directly fed to any type of a fuel cell. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

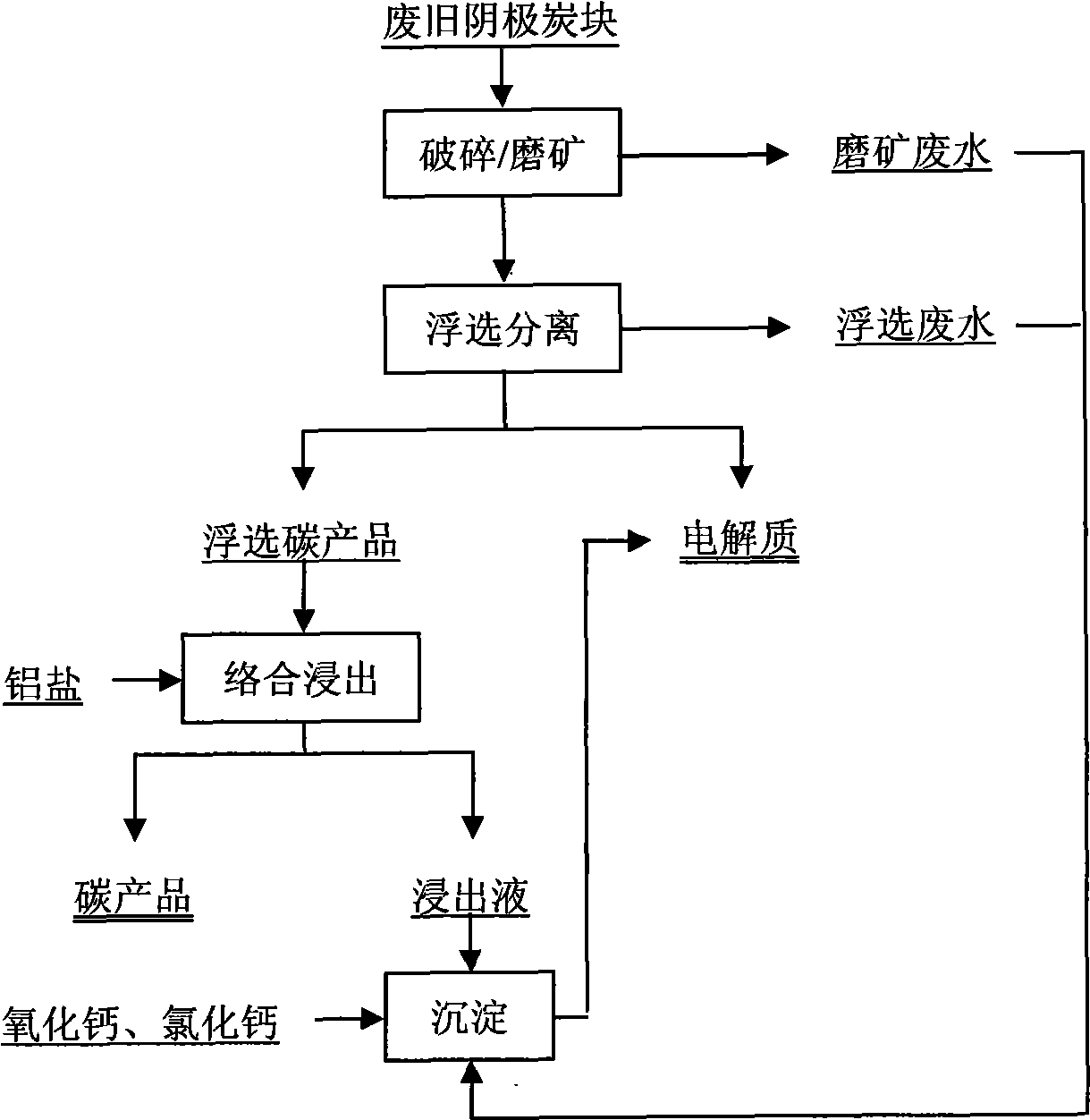

Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

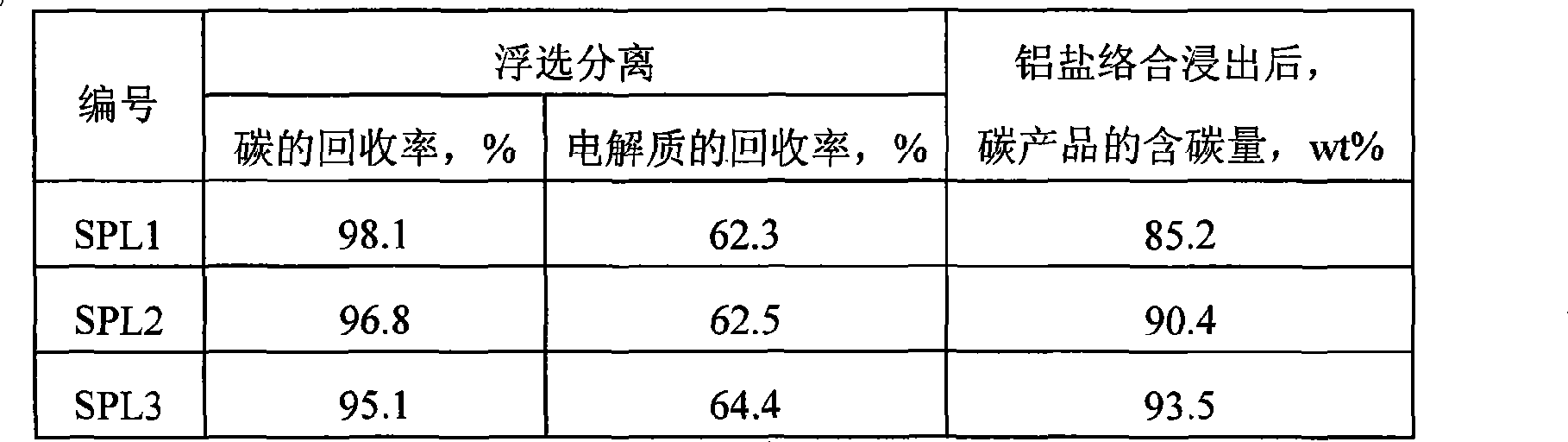

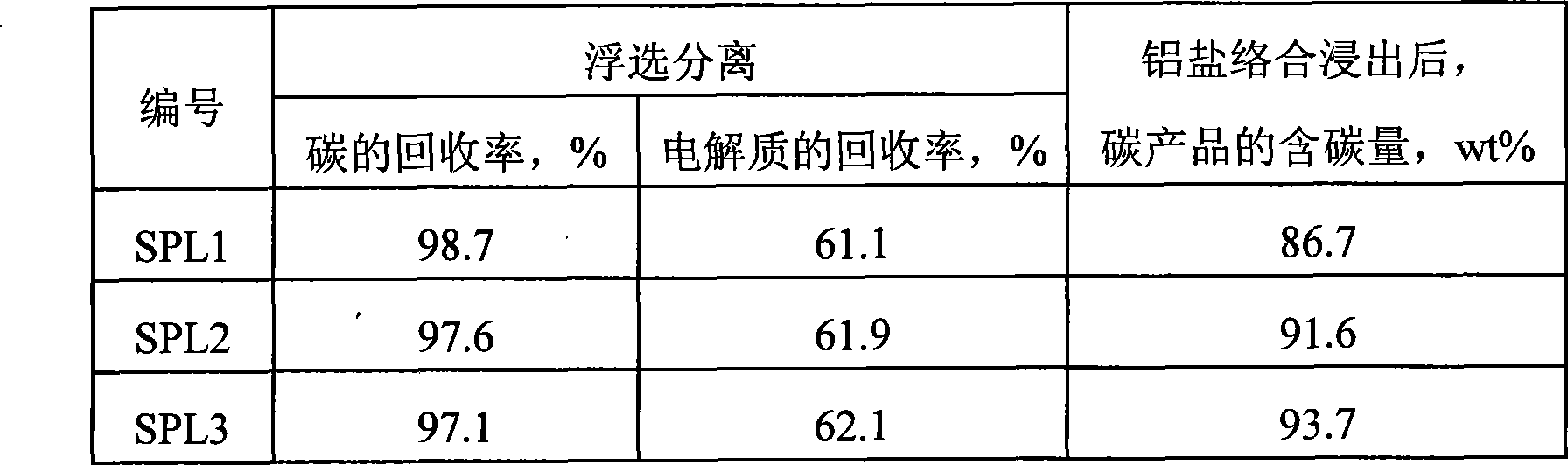

ActiveCN101480658ARealize flotation separationHigh carbon contentFluoride preparationWaste processingPregnant leach solutionHigh carbon

The invention relates to a method for comprehensively using aluminium to electrolyze a waste cathode carbon block, which belongs to the technical field of environment protection and comprises the following steps: crushing and grinding the waste cathode carbon block; adjusting the concentration and the PH value of ore slurry after the grinding, then using floatation equipment to carry out floatation treatment, and separating electrolyte and carbon which are contained in the waste cathode carbon block; using an aluminium salt solution to soak for extracting the electrolyte contained in a carbon product obtained from the floatation, and further improving the grade of a high-carbon product; mixing the grinding waste water, the floatation waste water and the soaking solution, and adding CaO and CaCl2 to precipitate and recover aluminium and fluothane in the mixture. The method for comprehensively using aluminium to electrolyze a waste cathode carbon block has simple operating condition, low energy consumption, high recovery ratio of valuable substances and good application prospect.

Owner:NORTHEASTERN UNIV

Modified carbon products, their use in bipolar plates and similar devices and methods relating to same

InactiveUS20050221139A1Improve hydrophobicityReduce hydrophobicityElectrolyte holding meansFuel cells groupingFuel cellsModified carbon

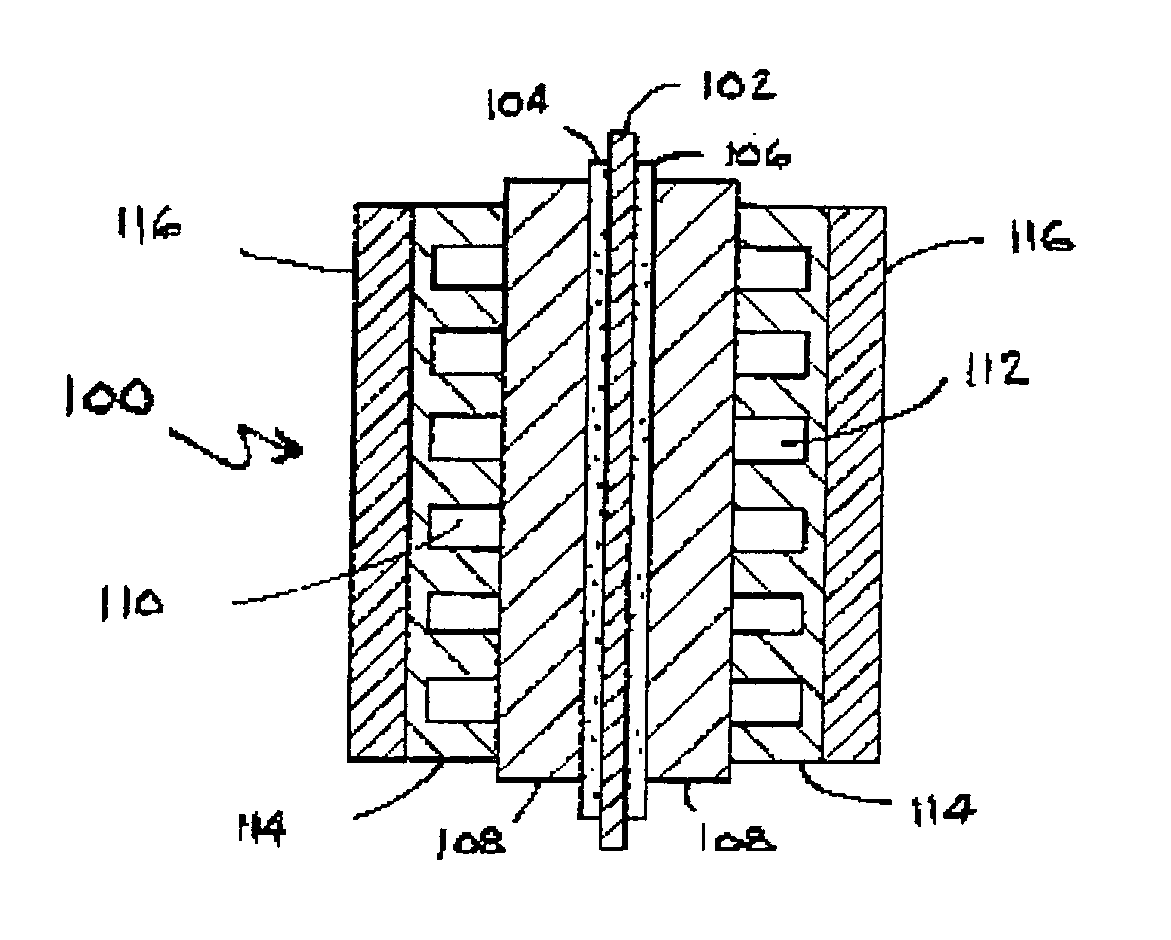

Bipolar plates incorporating modified carbon products. The modified carbon products advantageously enhance the properties of the bipolar plates, leading to more efficiency within a fuel cell or a similar device.

Owner:CABOT CORP

Carbon fiber electrode substrate for electrochemical cells

ActiveUS20030194557A1Improve conductivityContinuous processabilityNon-fibrous pulp additionNatural cellulose pulp/paperPorosityFiber

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

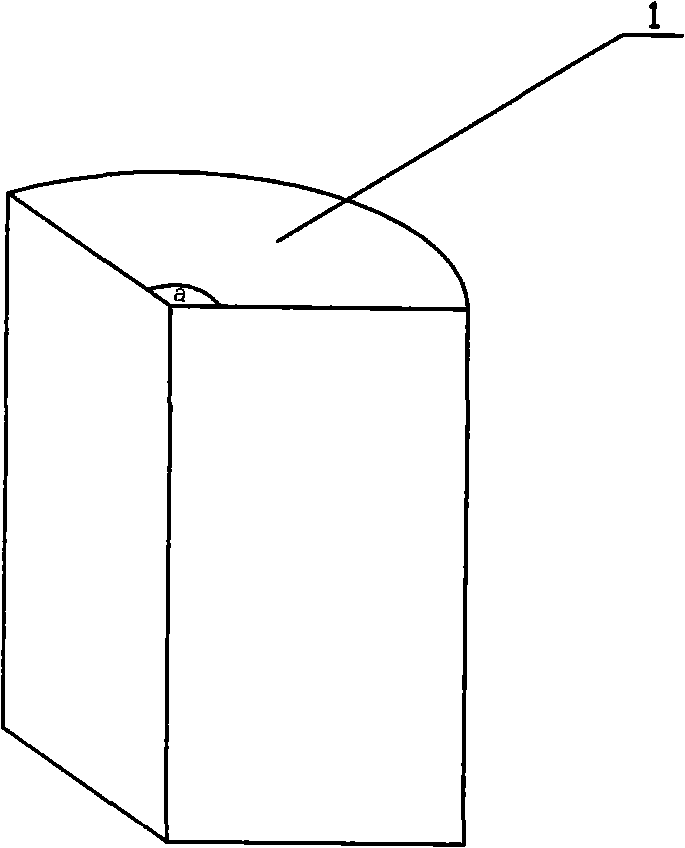

High pure graphitic profile and preparation technique thereof

The invention relates to a production process of a high-purity graphite section and a sectorial columnar graphite section prepared by the process. The process comprises the following steps: milling, mixing kneading, rolling, re-milling, compression molding, roasting, dipping, re-roasting and dipping to the selected materials; placing the roasted carbon products in a closed graphite purification furnace; sequentially inletting inert gas, chlorine, Freon and tetrafluoroethane inert gas under corresponding temperature for graphitization purification. The process has the advantages of short roasting and graphitization time, high production efficiency and low energy consumption. The graphite section prepared by the process is characterized by high purity, high density, high intensity, good thermal shock resistance, easy precision finishing and extremely wide application. Moreover, the prepared sectorial columnar graphite section, which is easy to be spliced into cylindrical graphite, can avoid the generation of cracks owing to excessive temperature differentials between the exterior and the core of large-scaled sections, prolongs the service life of the products and meets the needs of the market on large-size and high-standard cylindrical graphite section.

Owner:洛阳宜墨新材料有限公司

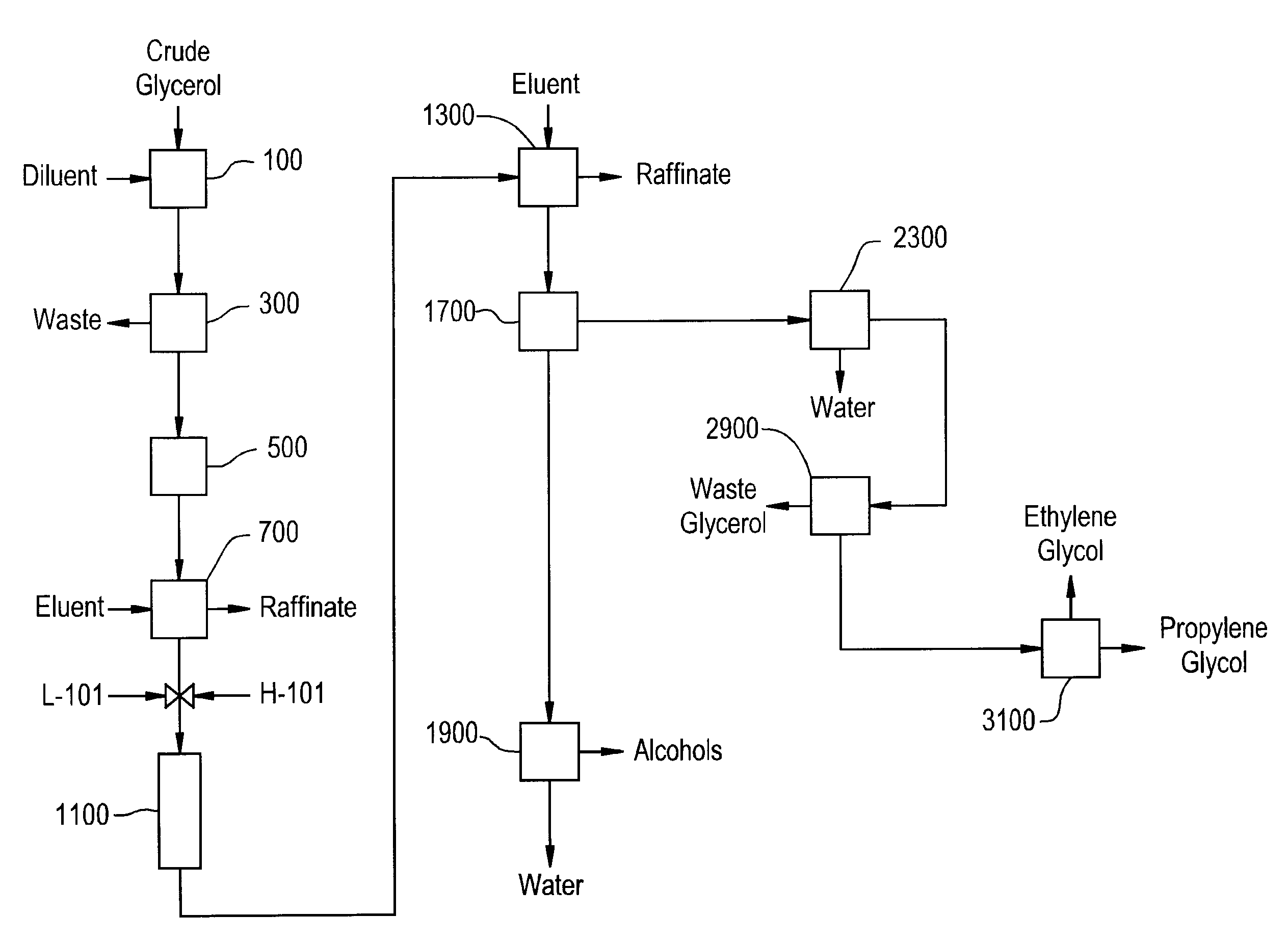

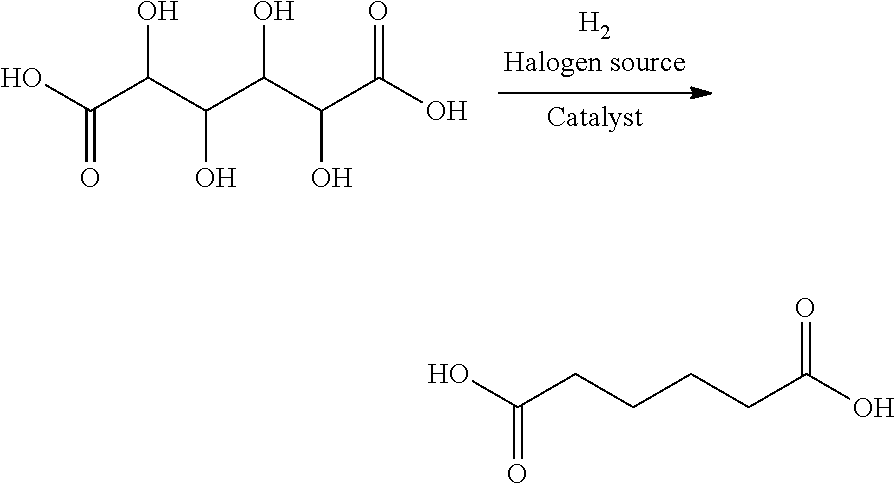

Preparation of Derivative of Polyhydric Alcohols

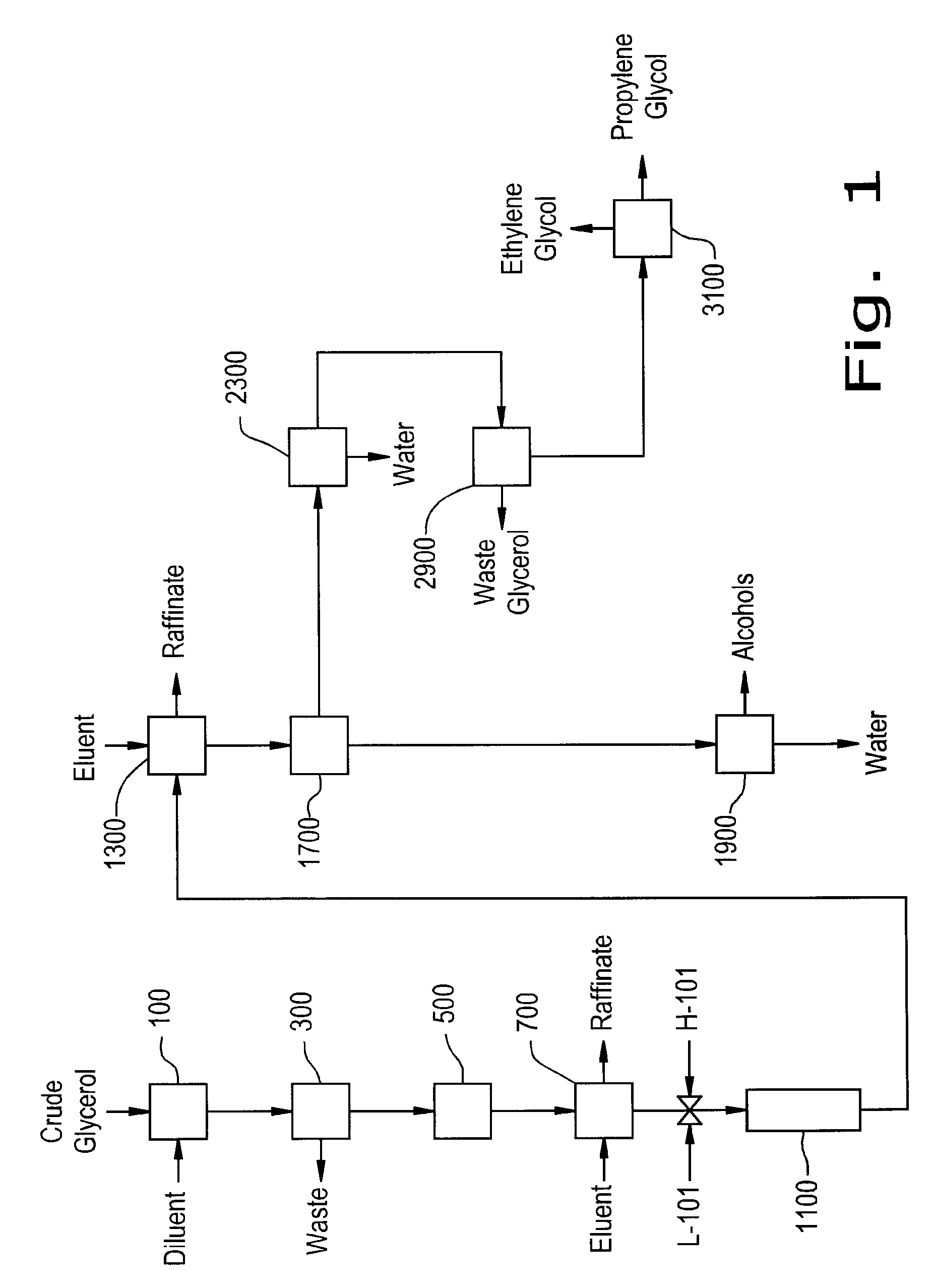

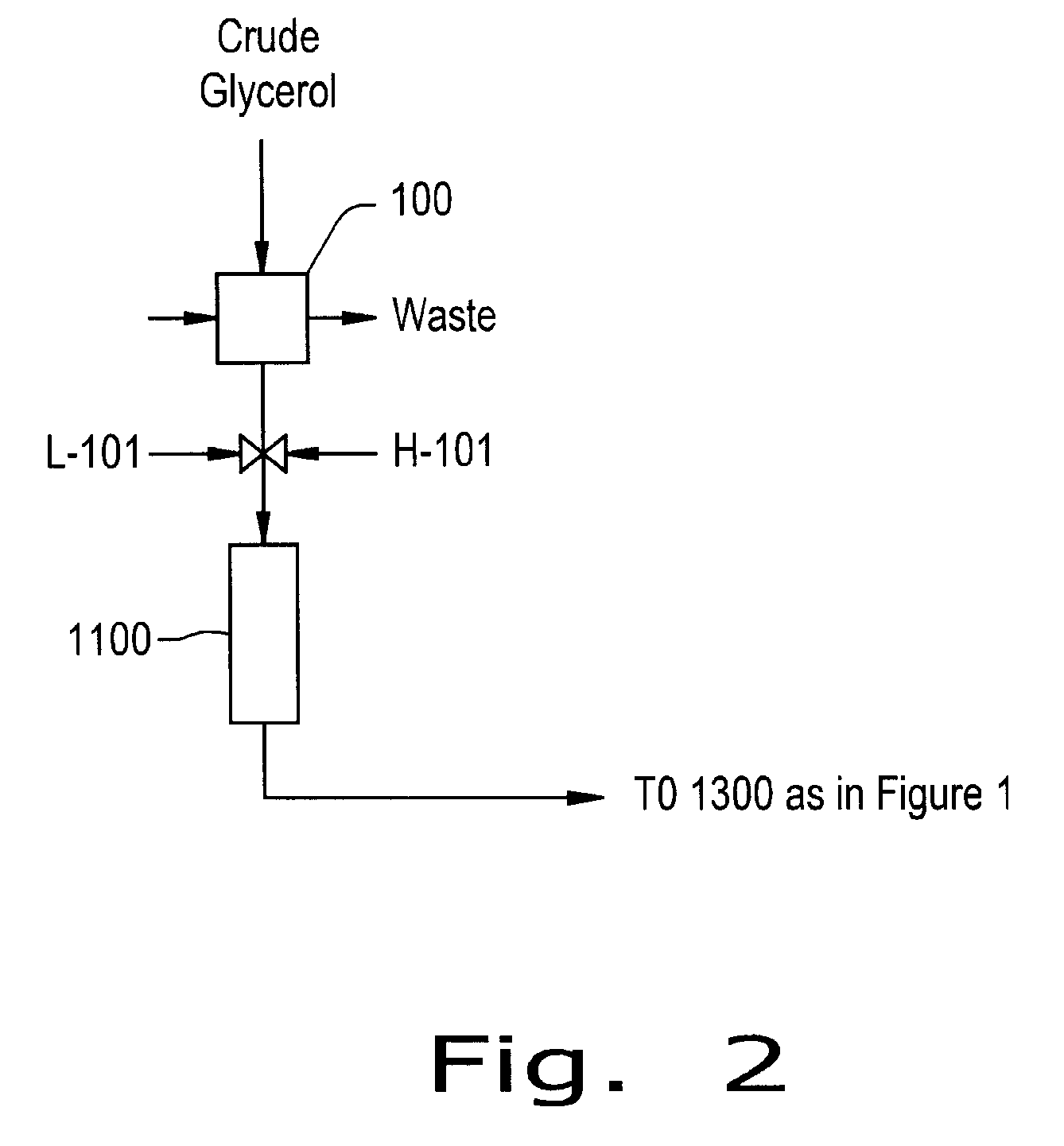

A method for converting a polyhydric alcohol into propylene glycol and butanediols is disclosed. Also disclosed are methods for converting polyhydric alcohols into three-carbon products and four-carbon products. Also disclosed are methods for maximizing conversion of polyhydric alcohols and minimizing formation of reaction products that are difficult to remove from the desired product. In other embodiments, methods are described to optimize use of reactants, including hydrogen, in hydrogenolysis of polyhydric alcohols.

Owner:ARCHER DANIELS MIDLAND CO

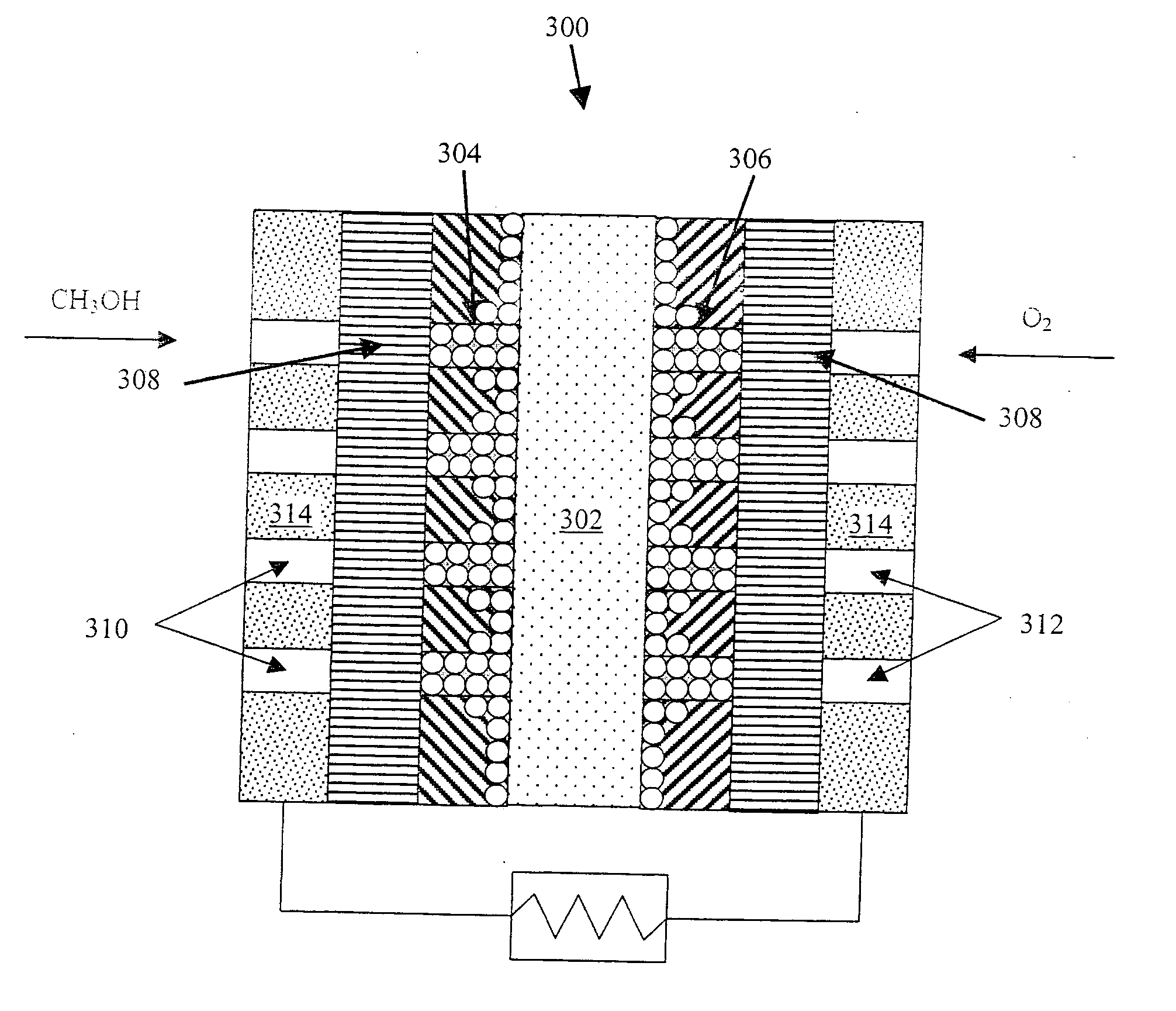

Fuel cells and other products containing modified carbon products

InactiveUS20030022055A1Improve propertiesLess-expensive to manufactureActive material electrodesSolid electrolyte fuel cellsFuel cellsModified carbon

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

Modified carbon products, their use in proton exchange membranes and similar devices and methods relating to the same

InactiveUS20050221141A1High mechanical strengthDecrease in proton conductivityElectrolyte holding meansIon-exchanger regenerationFuel cellsModified carbon

Proton exchange membranes incorporating modified carbon products. The modified carbon products advantageously enhance the properties of proton exchange membranes, leading to more efficiency within a fuel cell or similar device.

Owner:CABOT CORP

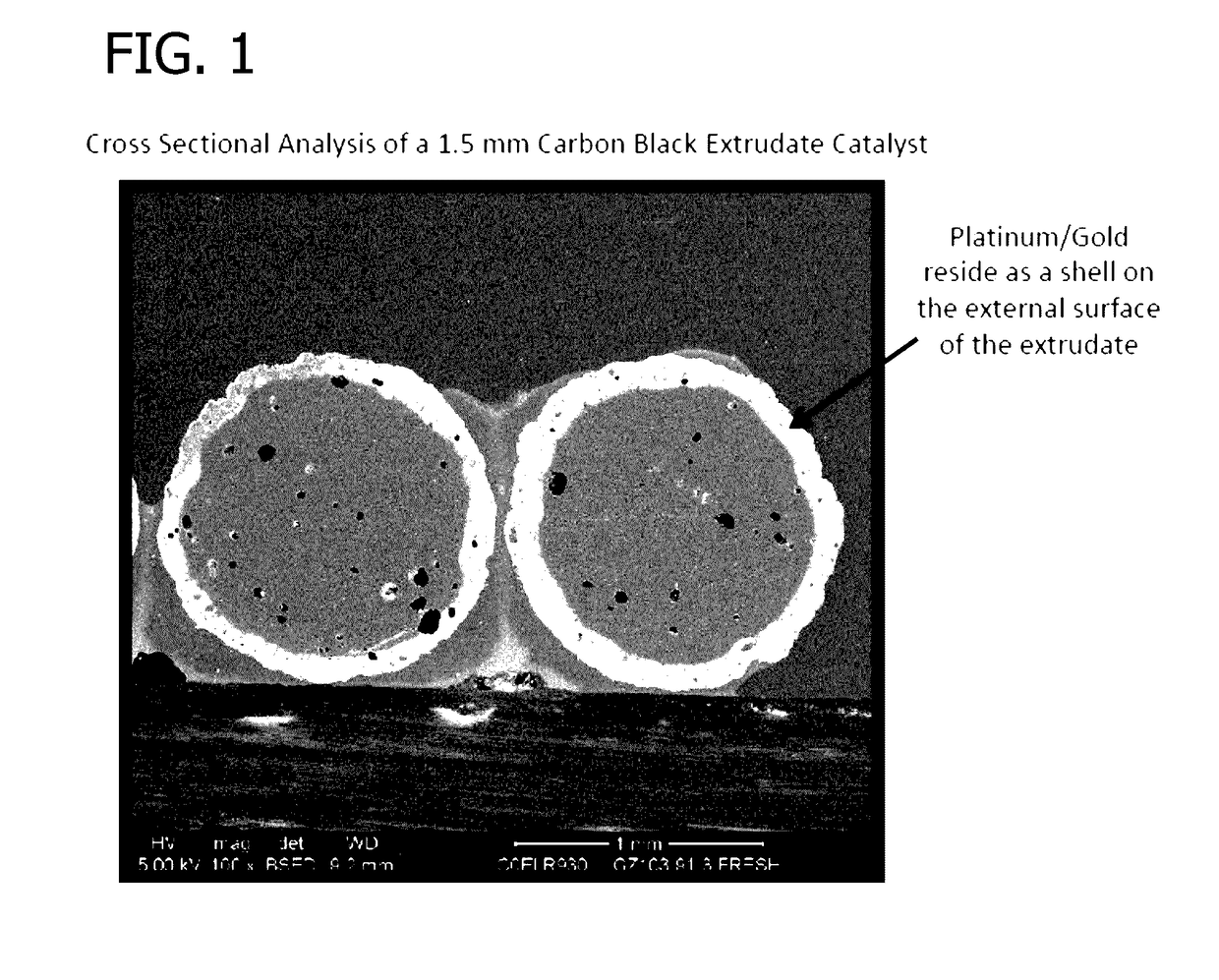

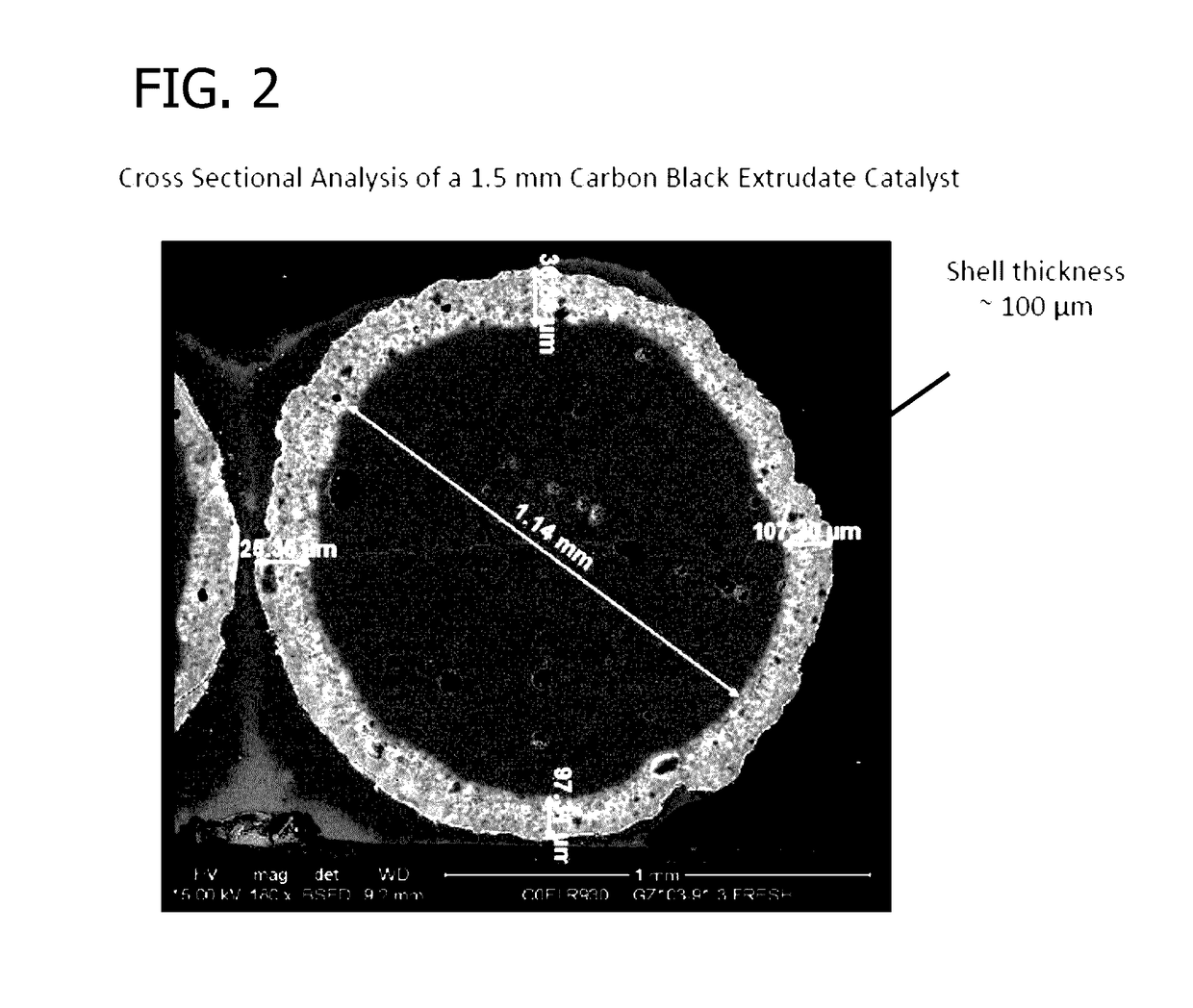

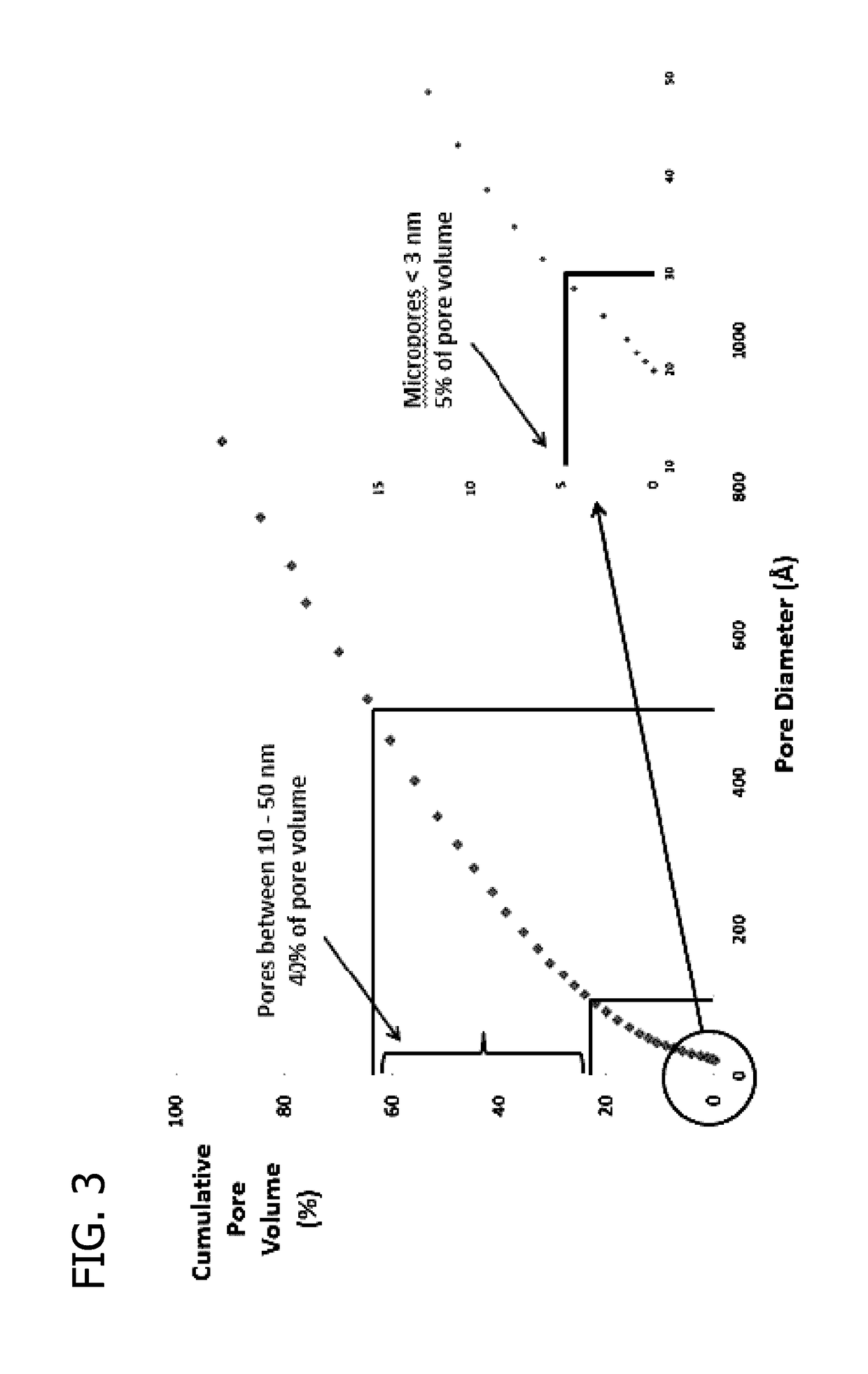

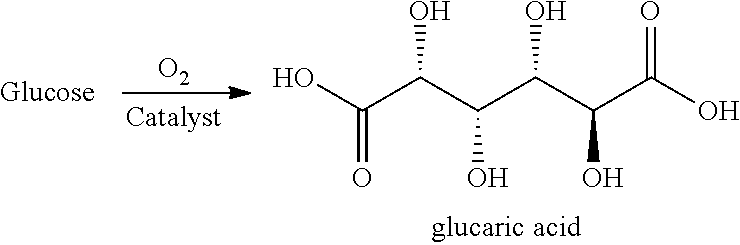

Porous shaped carbon products

ActiveUS20170120219A1Improve wettabilityPigmenting treatmentOrganic compound preparationPorous carbonSorbent

Shaped porous carbon products and processes for preparing these products are provided. The shaped porous carbon products can be used, for example, as catalyst supports and adsorbents. Catalyst compositions including these shaped porous carbon products, processes of preparing the catalyst compositions, and various processes of using the shaped porous carbon products and catalyst compositions are also provided.

Owner:ARCHER DANIELS MIDLAND CO

Purification and graphitization method of graphite material

ActiveCN102126721AImprove product qualityLow costChemical industryBromineElectrical energy consumption

The invention discloses a purification and graphitization method of a graphite material, aiming at solving the technical problems of improving the quality of the graphite material, saving energy and reducing cost. The method comprises the following steps: putting a graphite product or a carbon product in a graphite crucible in a furnace body; heating to 900-1700 DEG C, and then introducing nitrogen or argon; continuing to heat to 1000-1950 DEG C, introducing chlorine and then continuing to rising the temperature to 1400-2300 DEG C; simultaneously, introducing bromine or a fluorine-containing gas, heating to 1800-3300 DEG C and then stopping heating; introducing the chlorine until the temperature is reduced to below 1000-2000 DEG C; and feeding nitrogen or argon lasting for more than 0-15 hours. Compared with the prior art, the ash content of the obtained graphite product is less than 0.00011%; electrical energy consumption is reduced; and the method has the advantages that the processis simple, the cost is low, the quality of the graphite product is stable, and energy is saved.

Owner:BTR NEW MATERIAL GRP CO LTD

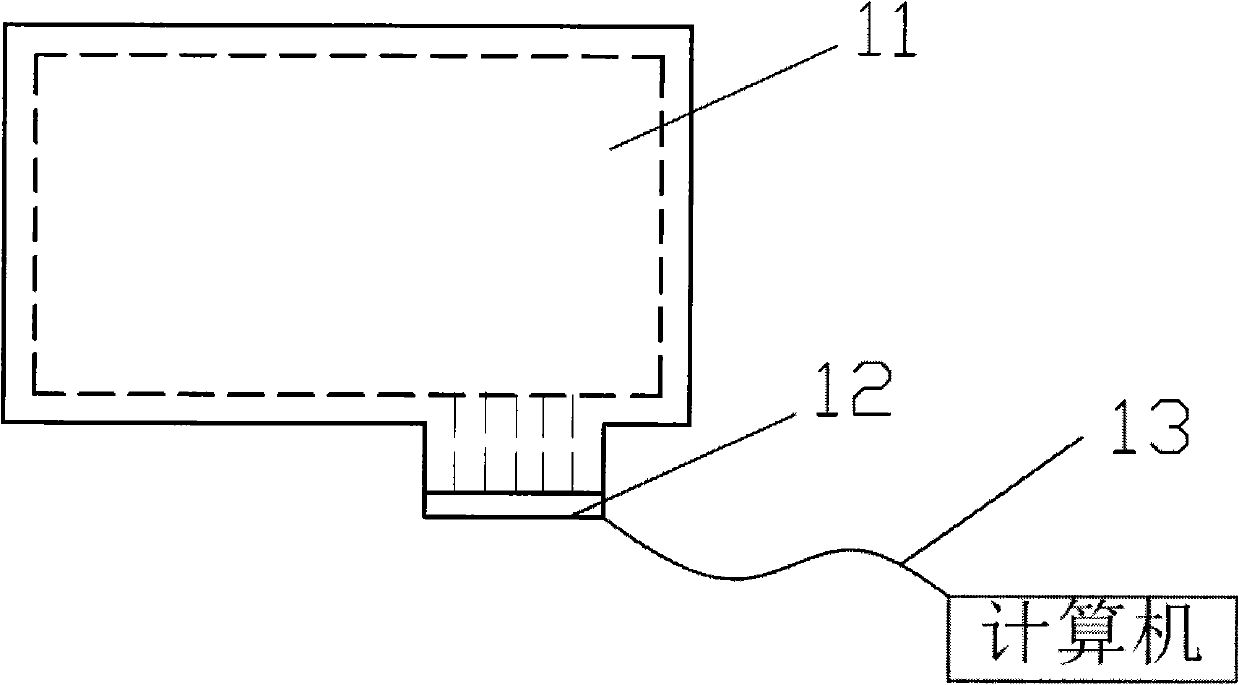

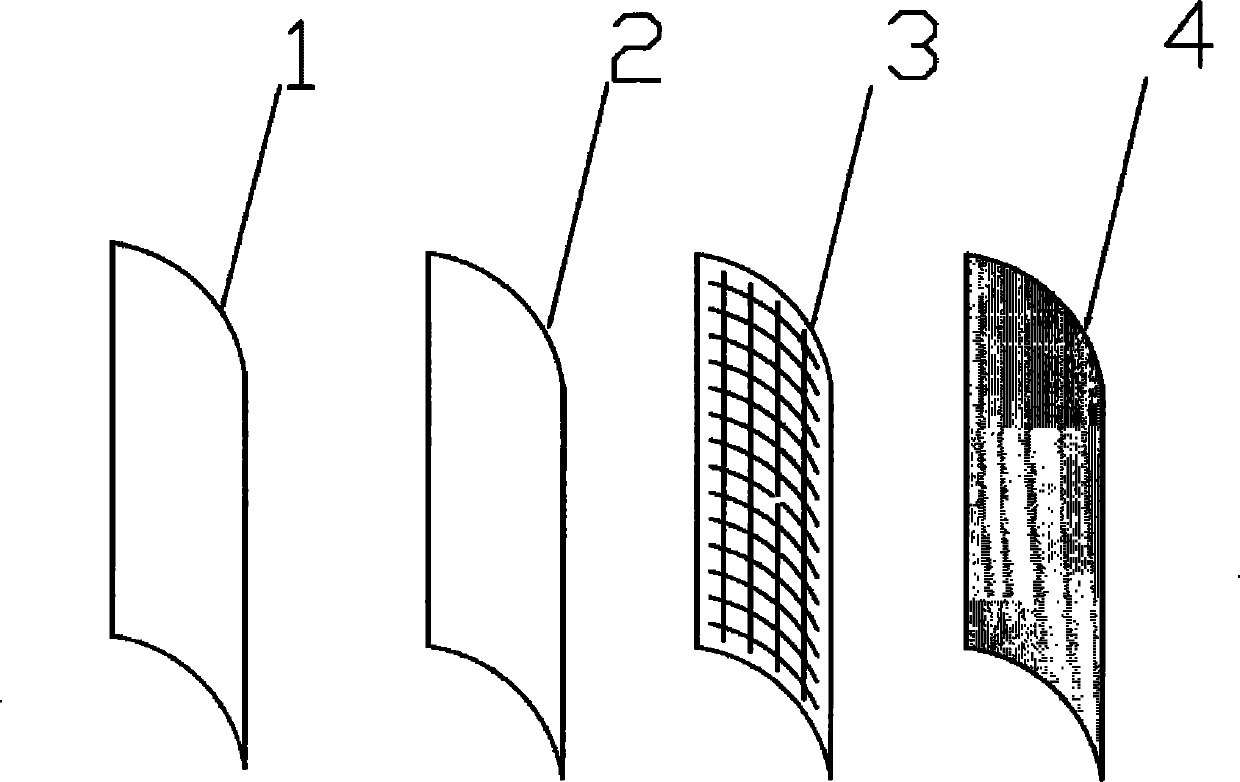

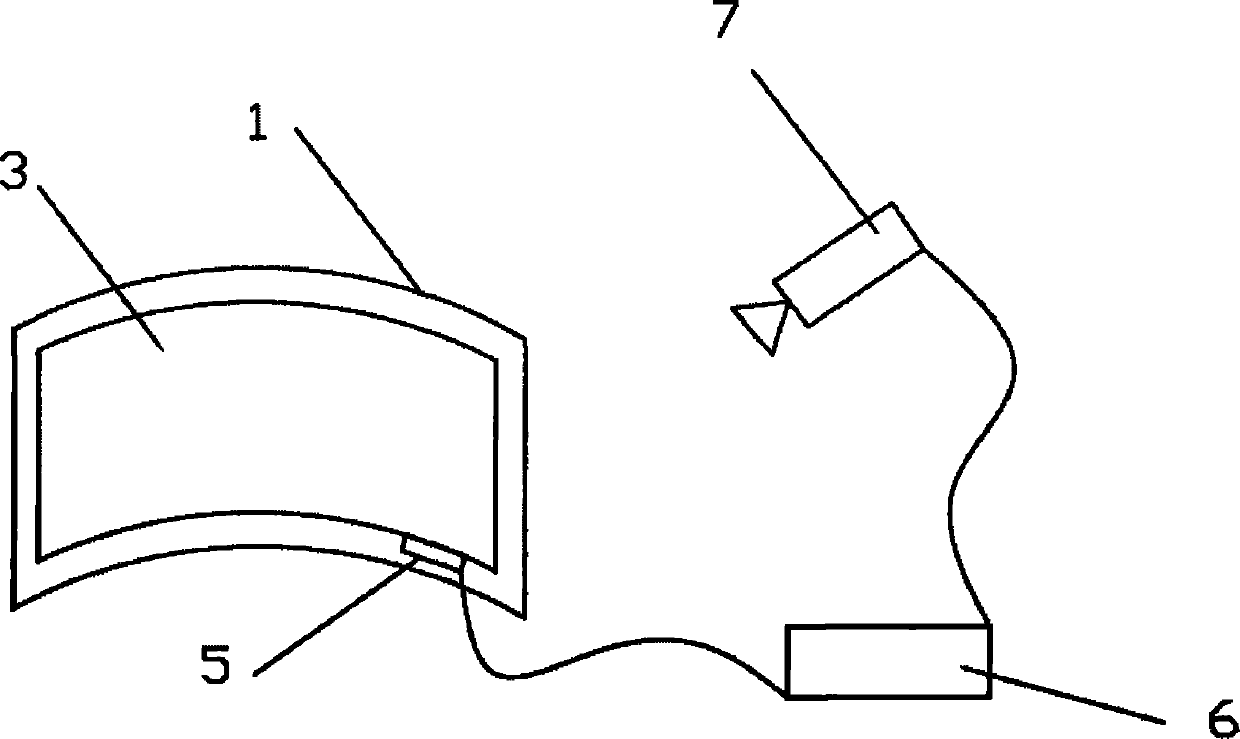

Curve screen based on nanometer touch-control membrane technique and manufacturing method thereof

ActiveCN102169388AImprove mechanical propertiesMalleableInput/output processes for data processingSystem integrationCarbon product

The invention discloses a curve screen based on nanometer touch-control membrane technique and a manufacturing method thereof. The curve screen comprises a curve substrate, wherein the curve substrate is an arc-shaped imaging device; the radian of the curve substrate is 0-180 degrees; the curve substrate is adhered to a nanometer touch-control membrane having flexibility; a sensing signal acquisition control integrated circuit is arranged on the nanometer touch-control membrane and is connected to a computer control unit through an interface; and the computer control unit is connected to the curve substrate in a wired or wireless communication manner. In the invention, the touch control technique is realized on the curved surface. The curve screen provided by the invention is suitable fordisplay devices in different sizes. The unit cost is low, the system integration is simple, and the operation is easy, thereby ensuring that the curve screen provided by the invention is a low energy-consumption and low-carbon product.

Owner:UC NANO TECH CO LTD

Method for conducting ultrasonic-assisted acid leaching treatment on aluminum electrolytic waste cathode carbon blocks

The invention relates to a method for conducting ultrasonic-assisted acid leaching treatment on aluminum electrolytic waste cathode carbon blocks and belongs to the technical field of aluminum electrolytic solid waste resource recovery. The method comprises the steps that the aluminum electrolytic waste cathode carbon blocks are crushed and added into acid liquor to be subjected to leaching, and powdered carbon and filtrate are obtained through filtration; acid leaching is carried out in an ultrasonic environment; and the pH value of the filtrate is adjusted to be neutral, crystals are separated out through evaporative crystallization, a cryolite and aluminum hydroxide mixture is obtained through filtration, and distilled water is utilized repeatedly. The method is simple in process, operating is convenient, the cyclic utilization rate of materials is high, environmental pollution is little, the reaction speed is increased through the synergistic effect of ultrasonic waves and acid leaching, and the purity of powdered carbon products is improved. The method is suitable for treatment of aluminum electrolytic waste cathode carbon blocks with the carbon content higher than 50%, and the purity of obtained powdered carbon can reach up to 98.47%.

Owner:CENT SOUTH UNIV

Methods for preparing silica-coated carbon products

Methods of making a silica-coated carbon product are described. In one method, an aqueous media or solution and a carbon product are contacted with a solution comprising a silicate substantially free of metal ions, for a sufficient time and temperature to form the silica-coated carbon product. A method of making a silica-coated product by contacting the aqueous media and a carbon product with a solution comprising monosilicic acid is also described as well as exchanging metal ions in a solution comprising metallic silicate for hydrogen ions and contacting an aqueous media and a carbon product with the solution to form silica-coated carbon products. Silica-coated carbon products resulting from these methods are also described and include a plurality of silica-coated products wherein each of the silica-coated products are substantially and uniformly coated with silica and in the substantial absence of free silica. Also, elastomeric compositions and the like containing the silica-coated carbon products are described.

Owner:CABOT CORP

Nano core-shell type copper-nickel bimetal powder body and preparing method and application thereof

ActiveCN101209493AOvercome the disadvantage of easy oxidationMeet the requirement of transparent appearanceCoatingsThioureaConductive materials

The invention relates to a bimetal powder of copper and nickel and a preparation method thereof. The invention solves the defect of easy oxidation of the simple substance nanometer copper powder and improves the use effect of the ordinary copper nickel composite powder. Referring to the prior art, the invention firstly prepares a nanometer copper powder, the copper powder is stirred and dispersed homogeneously in the water, and suspension liquid of the copper powder is prepared; the suspension liquid of the copper powder is blended with the nickel sulfate solution comprising macromolecule protective agent and special copper coordination agent thiourea so as to cause a replacement reaction between nickel ion and the copper; surfaces of the ultrafine copper particles are partly or all coated with the nickel, thus forming the core-shell copper-nickel bimetal nanometer powder. The bimetal powder can be taken as lubricant, lubricating grease extreme pressure-antiwear additives, additives in powder metallurgy, or as porous materials, antibacterial materials, antifouling coatings, conductive materials, magnetic materials, self-lubricating materials, antifriction materials, diamond tools, and raw materials or additives of electrical carbon products.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Flotation column process for separating carbon residue in fly ash

The invention offers a kind of craft for separating pillars in the coal powder. It includes three parts of mineral liquid preparation, pillar separate choosing, and product off water. It uses double liquid pillar and material and water-off equipment, and then makes the pillar-box press filter craft, taking off the carbon grains not fired in the coal powder. Put the high carbon coal and water into the mixing bucket, through mixing the mineral liquid is made, transfer it to the entrance of pillar, by the separating choosing, we get pure mineral and the mineral coal powder, through box press filter machine, we get the carbon product and coal powder product. The advantages of the invention are: simple craft, little cost, little energy, and repair little, operating cost little.

Owner:UNIV OF SCI & TECH BEIJING

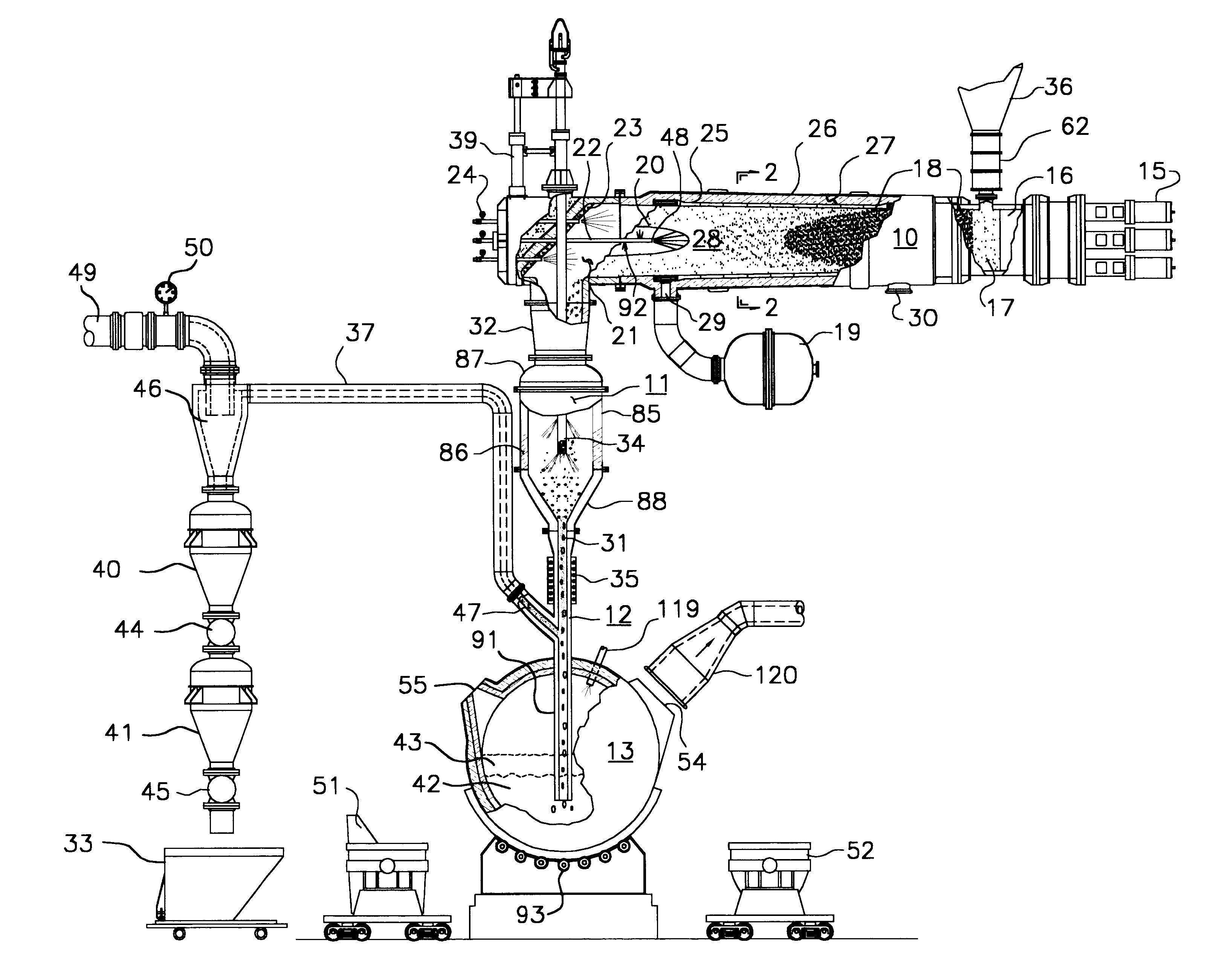

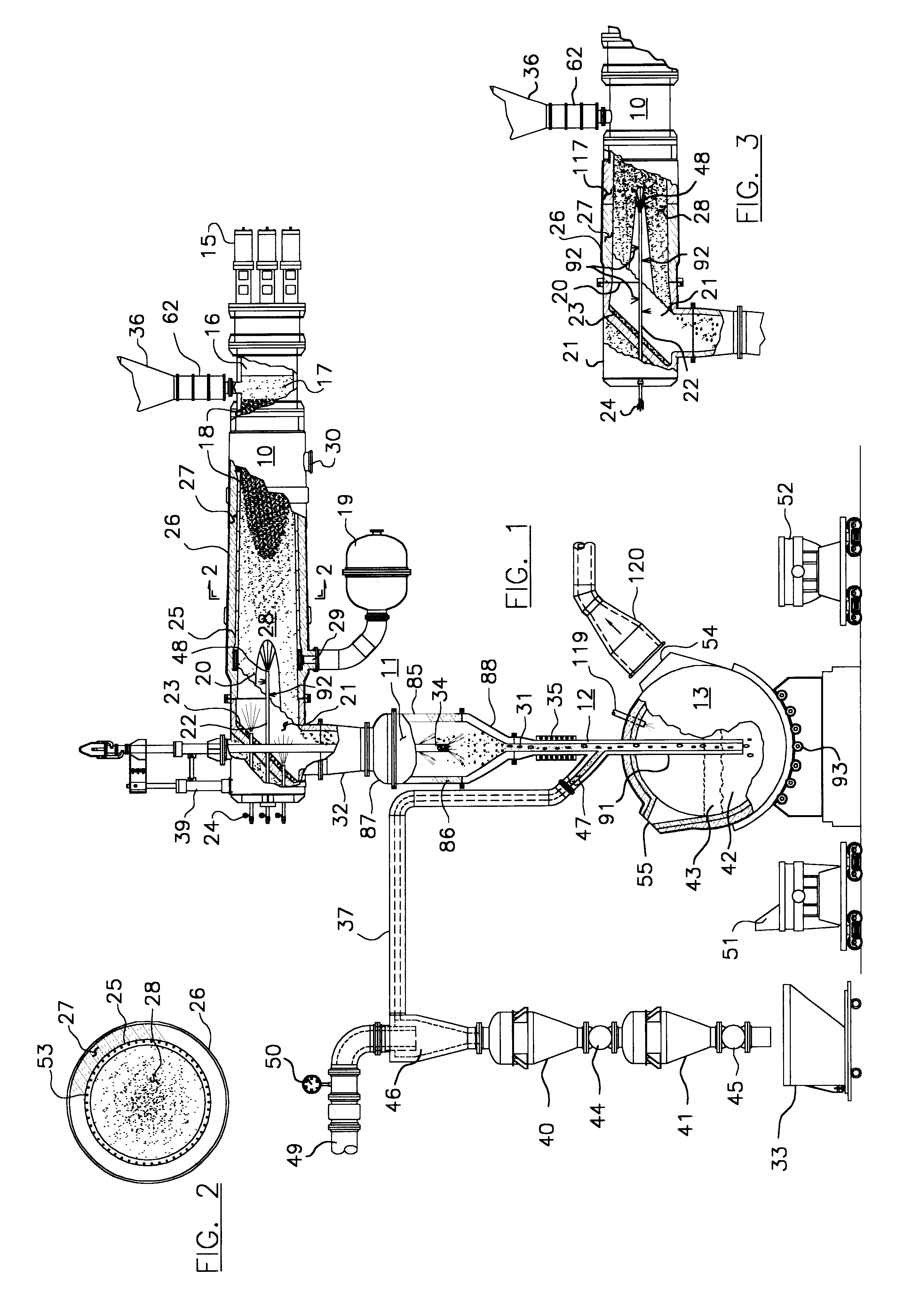

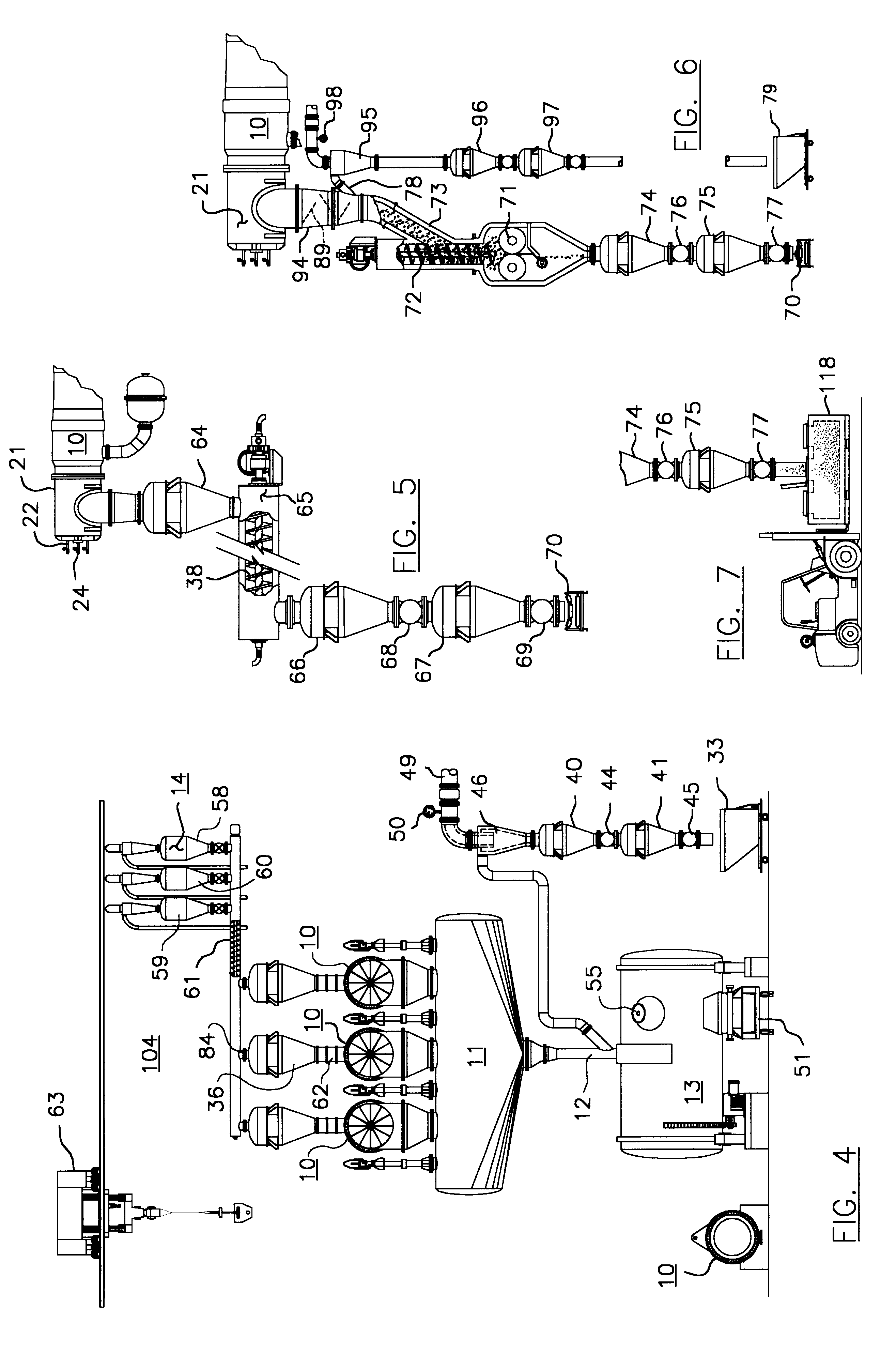

Method and apparatus for practicing carbonaceous-based metallurgy

InactiveUS6409790B1Low costReduce capital investmentMaintainance of heating chambersBlast furnace detailsThermal energyOperational costs

An energy efficient, coal-based method and apparatus that are environmentally friendly which produce under pressure metallized / carbon product and molten metal directly from abundant coal or other carbonaceous material, and low cost fines (or ore concentrate) wherein the metal is devoid of gangue material and possesses the inherent advantage of retaining the heat for subsequent processing. This method and apparatus which are modular and highly integrated significantly reduce capital and operating costs; they also provide the capability selective placement of the reductant for the delivery of high levels of thermal energy input which leads to ease of desulflurization and high productivity. The technology herein disclosed is entirely closed and is applicable to various ores including ferrous and non-ferrous.

Owner:CALDERON ENERGY OF BOWLING GREEN

Regeneration treatment method for waste cathode carbon blocks of aluminum electrolytic cell

The invention discloses a regeneration treatment method for waste cathode carbon blocks of an aluminum electrolytic cell and belongs to the technical field of solid waste treatment in the aluminum electrolysis industry. The main treatment process comprises the steps of crushing, screening, toxicity inhibition, batching and pressure-controlled heat treatment. After waste cathode carbon block materials of the aluminum electrolytic cell are crushed and screened, toxic inhibitors of hydrogen peroxide, potassium permanganate, hypochlorite and the like are added, then carbonaceous materials of anthracite, calcined petroleum coke, waste anode carbon blocks, anode scraps and the like are blended to serve as furnace-in raw materials, and the furnace-in raw materials are placed in a resistance furnace to be subjected to heat treatment at the ordinary pressure (1200-1800 DEG C) or the control pressure (1000-1600 DEG C and 0.01-0.5 atm). Fluoride volatilized from flue gas can be used for producingfluoride salt electrolytes after being cooled and crystallized, treated materials do not contain any contaminant, the carbon content is up to 99%, the conductivity is good, the specific surface areais large, the treated materials can be used for producing various carbon products, waste is turned into wealth, and environment-friendly resource application of overhaul of the waste cathode carbon blocks of the aluminum electrolytic cell is achieved.

Owner:UNIV OF SCI & TECH BEIJING

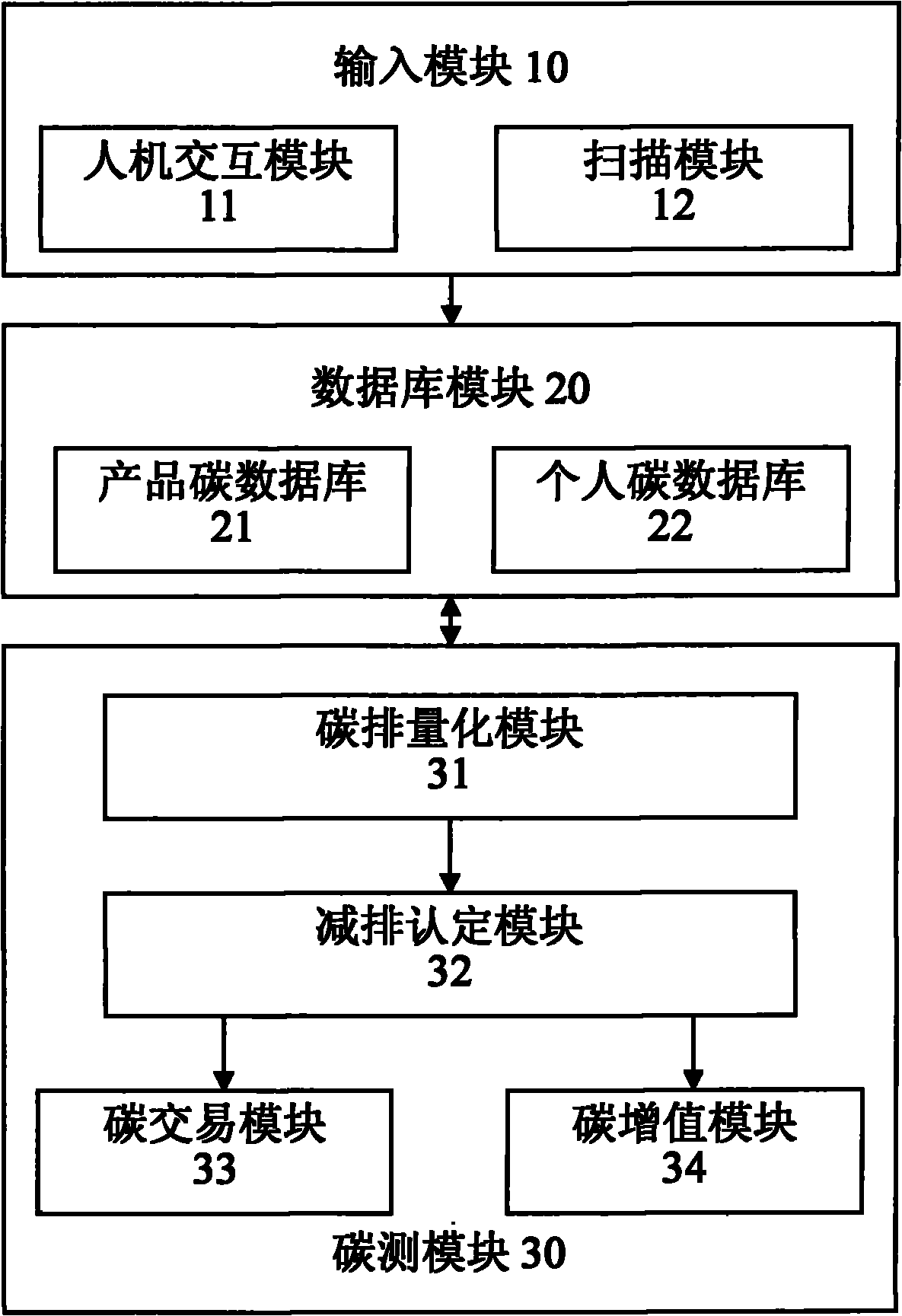

Personal-based carbon dioxide recording and tracing system platform

InactiveCN101832795ARealize detection and quantificationEasy to track and queryRecording measured valuesCarbon productCarbon exchange

The invention relates to a personal-based carbon dioxide recording and tracing system platform, which is characterized by comprising a carbon measuring module, wherein the carbon measuring module concretely and successively comprises a carbon discharge module and an emission reduction verification module used for detecting and verifying carbon dioxide discharge amount and emission reduction amount respectively. The invention calculates and obtains carbon dioxide emission reduction data by scanning input carbon dioxide discharge amount of a product, and regains the carbon dioxide discharge amount and emission reduction amount information of a user after the user scans and uploads the used low carbon product relative certificate thereof so as to realize detection quantization of carbon dioxide discharged in daily activities of the user, calculate the carbon emission reduction amount after low carbon lifestyle is changed, and record and store in a personal carbon database for tracing and querying conveniently. The user also can further participate in exchange activities which take the carbon dioxide emission reduction amount as a currency by a carbon exchange module and a carbon appreciation module.

Owner:SHANGHAI LINTAN ENERGY SAVING S&T

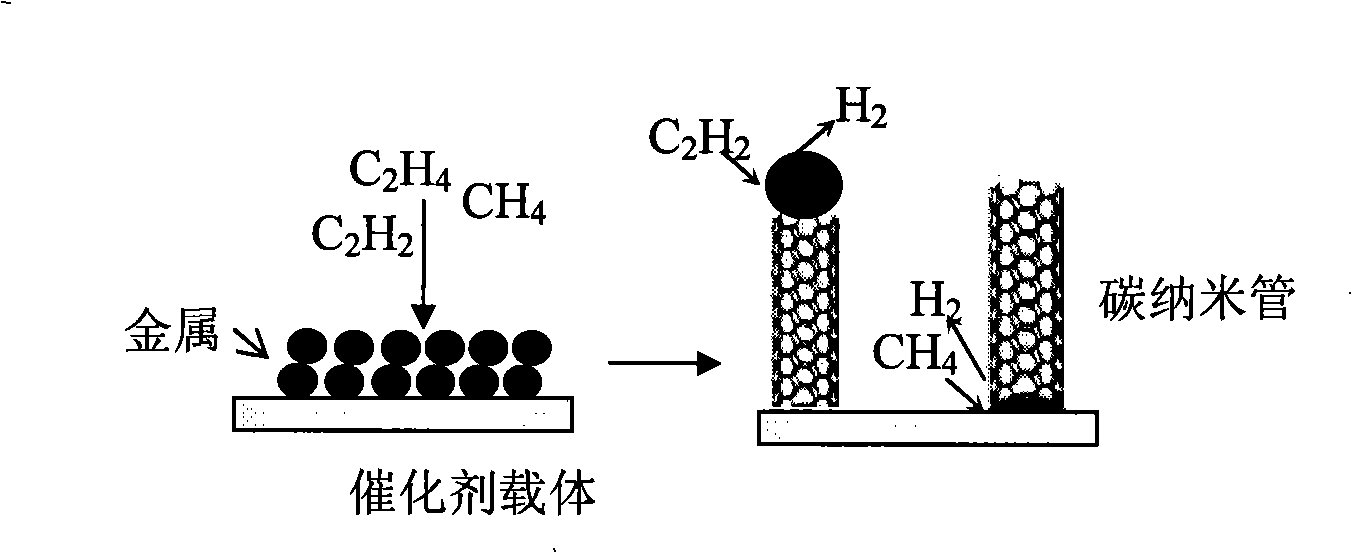

Process for preparing hydrogen gas and nanometer carbon by catalyzing and cracking methane at low temperature

A method for preparing hydrogen and nano carbon through the catalytic pyrolysis of methane at lower temperature belongs to the technical field of petroleum and natural gas chemical production. The method comprises the steps of putting a catalyst in a reactor, heating to 400-700 DEG C jointly, introducing hydrogen or CO into conduct catalyst reduction, and keeping the temperature and the reducing atmosphere; switching the gas to a hydrocarbon gas in heat release in pyrolysis, the volume ratio of the hydrocarbon gas to methane is 1:9 to 9:1; introducing a feed gas, methane, into the reactor at the temperature of 400-700 DEG C, under the absolute pressure of 0.05 to 0.2 MPa, and at the catalyst airspeed of 100-100 liter (hydro carbon) / g (catalyst) / hour; preparing and obtaining hydrogen when the feed gas passes through the bed layer of the catalyst; and depositing carbon on the catalyst. The catalyst is a nano metallic catalyst. The method has the advantages of low operation temperature, prolonged service life of the catalyst, high conversion rate, continuous operations in the forms of various reactors, reduced production cost, and high purity and controllable appearance of carbon products.

Owner:TSINGHUA UNIV

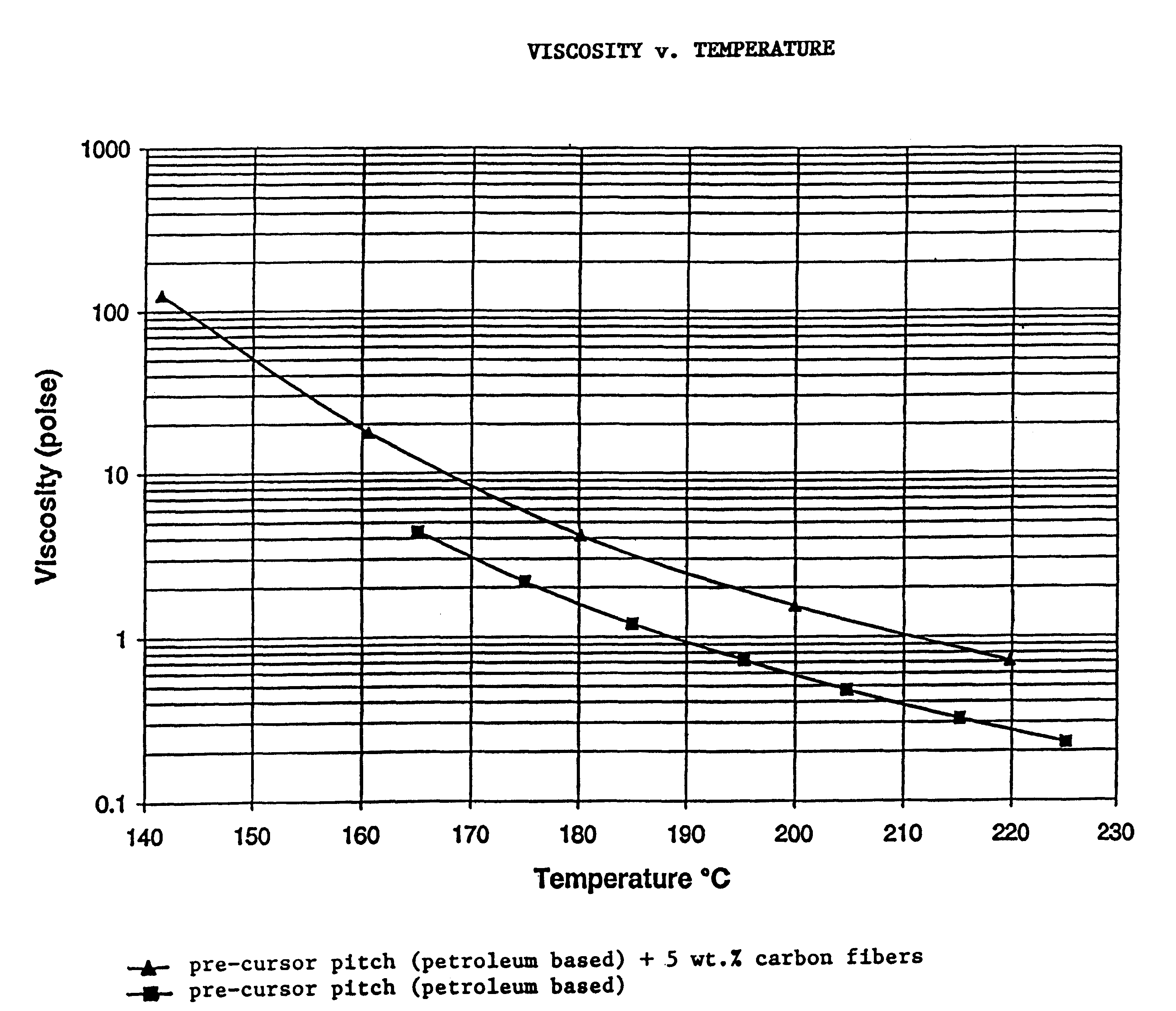

Carbon fiber binder pitch

InactiveUS6395220B1Minimal amountCoke ovensWorking-up pitch/asphalt/bitumen by chemical meansGraphite electrodeFiber bundle

Carbon fiber bundles may be dispersed into substantially single mono-filaments in pitch by stirring a mixture of fibers and pitch at a temperature at which the pitch has a viscosity of about 0.1 to about 5 poise. The resulting fiber pitch binder contains about 0.5 to about 10.0 wt. % carbon fibers substantially dispersed as substantially single mono-filaments which are randomly oriented which may then be used directly as a binder for producing carbon bodies, for example, graphite electrodes, pinstock or specialty graphite articles. This unique binder using an economical amount of carbon fibers has the capacity to increase the strength and reduce the coefficients of thermal expansion of the resulting carbon products in more than one direction due to the random orientation of the carbon fibers.

Owner:JPMORGAN CHASE BANK NA

Petroleum coke desulfurizing method

InactiveCN104611087AReduce sulfur contentReduce pressure on environmental protectionSolid fuelsThermal energyCarbon product

The invention discloses a petroleum coke desulfurizing method. The petroleum coke desulfurizing method comprises the following steps: heating petroleum coke to 400-700 DEG C for precalcining for a certain time first, and then in an ammonia gas atmosphere, heating green petroleum coke to 700-1000 DEG C and preserving heat for a certain time so as to achieve a desulfurizing aim. By the petroleum coke desulfurizing method, most of sulfur in the petroleum coke is removed under the conditions that more heat is not consumed and the microstructure and physical and chemical properties of the petroleum coke are not affected, so that the sulfur content of the petroleum coke is greatly reduced, the quality of the petroleum coke is improved, and the environmental pressure of a carbon product industry with the petroleum coke as a raw material is greatly reduced; therefore, the petroleum coke desulfurizing method is wide in application prospect.

Owner:CENT SOUTH UNIV

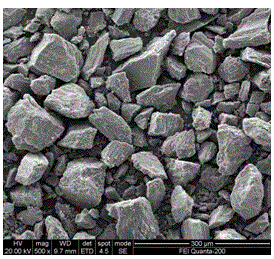

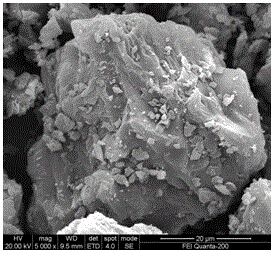

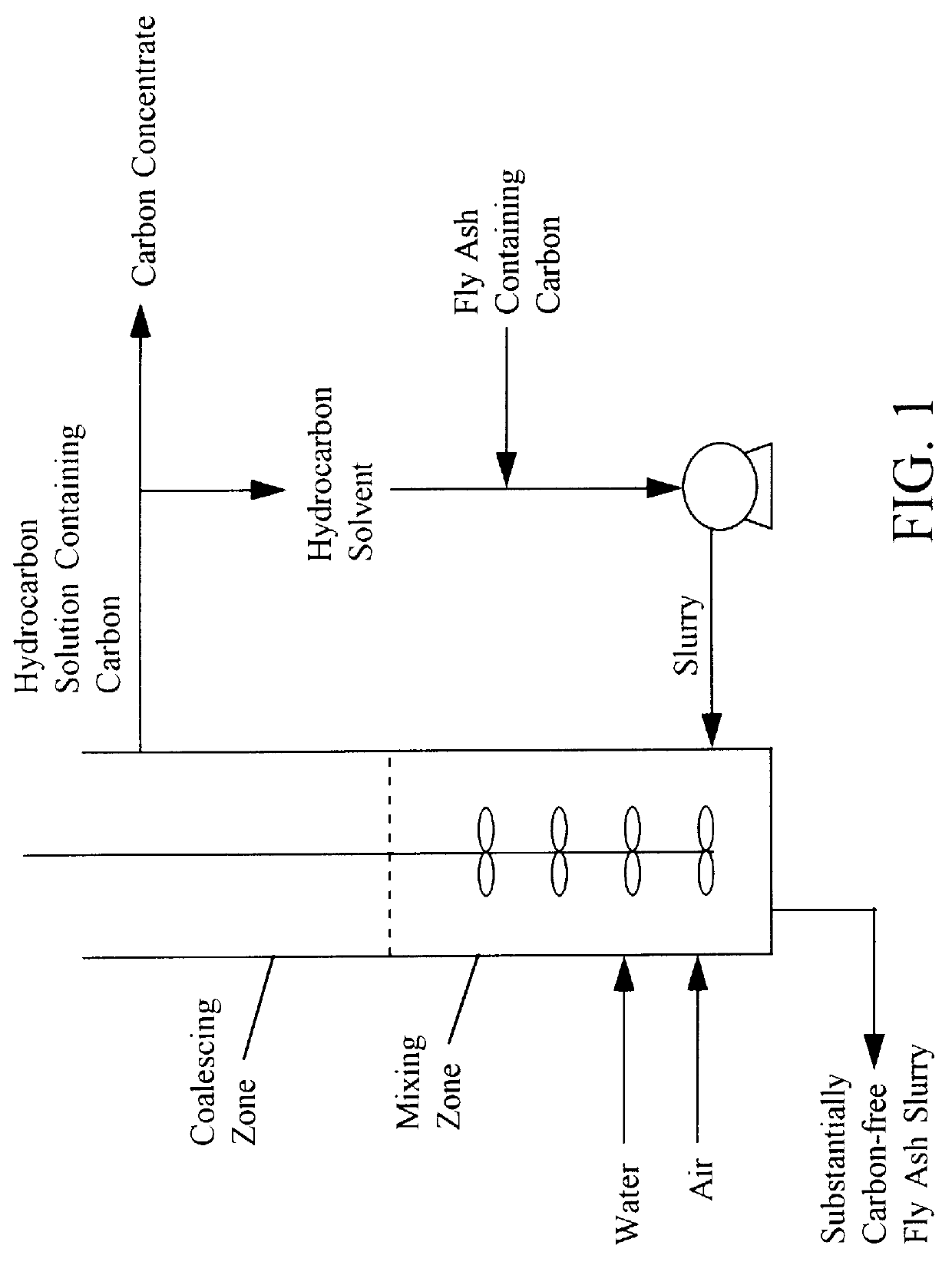

Continuous air agglomeration method for high carbon fly ash beneficiation

The carbon and mineral components of fly ash are effectively separated by a continuous air agglomeration method, resulting in a substantially carbon-free mineral stream and a highly concentrated carbon product. The method involves mixing the fly ash comprised of carbon and inorganic mineral matter with a liquid hydrocarbon to form a slurry, contacting the slurry with an aqueous solution, dispersing the hydrocarbon slurry into small droplets within the aqueous solution by mechanical mixing and / or aeration, concentrating the inorganic mineral matter in the aqueous solution, agglomerating the carbon and hydrocarbon in the form of droplets, collecting the droplets, separating the hydrocarbon from the concentrated carbon product, and recycling the hydrocarbon.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Porous shaped metal-carbon products

ActiveUS20170120223A1Pigmenting treatmentOrganic compound preparationCarbon productMaterials science

The present invention provides a porous metal-containing carbon-based material that is stable at high temperatures under aqueous conditions. The porous metal-containing carbon-based materials are particularly useful in catalytic applications. Also provided, are methods for making and using porous shaped metal-carbon products prepared from these materials.

Owner:ARCHER DANIELS MIDLAND CO

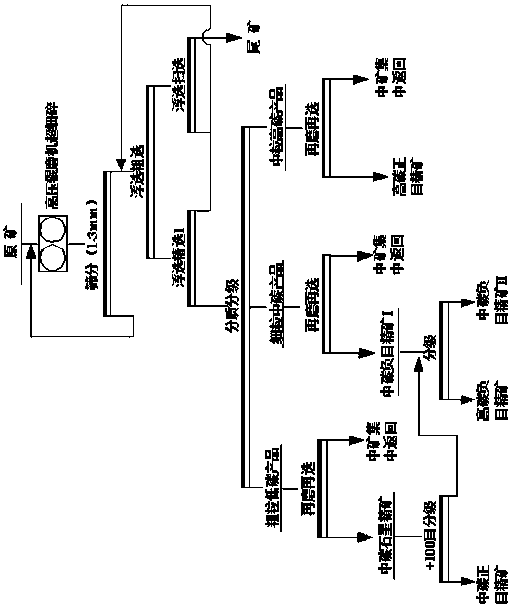

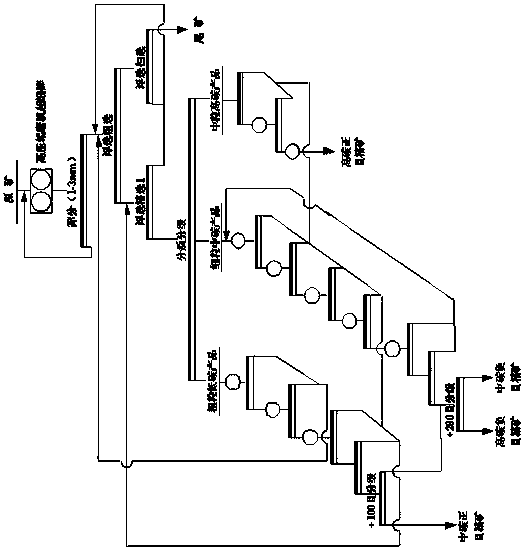

Grading and separating method for protecting crystalline graphite flakes

The invention provides a grading and separating method for protecting crystalline graphite flakes, and aims to solve the problem of high loss rate of the crystalline graphite flakes. The method comprises the following steps: (1) performing closed circuit grinding on raw ore with a high-pressure grinding roller; (2) grading and separating a ground product obtained in step (1) after 'primary rougherflotation, primary concentration and primary scavenging' flotation; (3) re-grinding and re-separating a coarse-grain low-carbon product to obtain medium-carbon graphite concentrate and middling, screening the medium-carbon graphite concentrate to obtain medium-carbon positive-mesh concentrate and medium-carbon negative-mesh concentrate I; re-grinding and re-separating a medium-grain high-carbon product to obtain high-carbon positive-mesh concentrate and middling; re-grinding and re-separating a fine-grain medium-carbon product to obtain medium-carbon negative-mesh concentrate I; grading the medium-carbon negative-mesh concentrate to obtain high-carbon negative-mech concentrate and medium-carbon negative mesh concentrate II. By adopting the method, differential separation of graphite is realized, and the added value of the graphite concentrate is increased.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

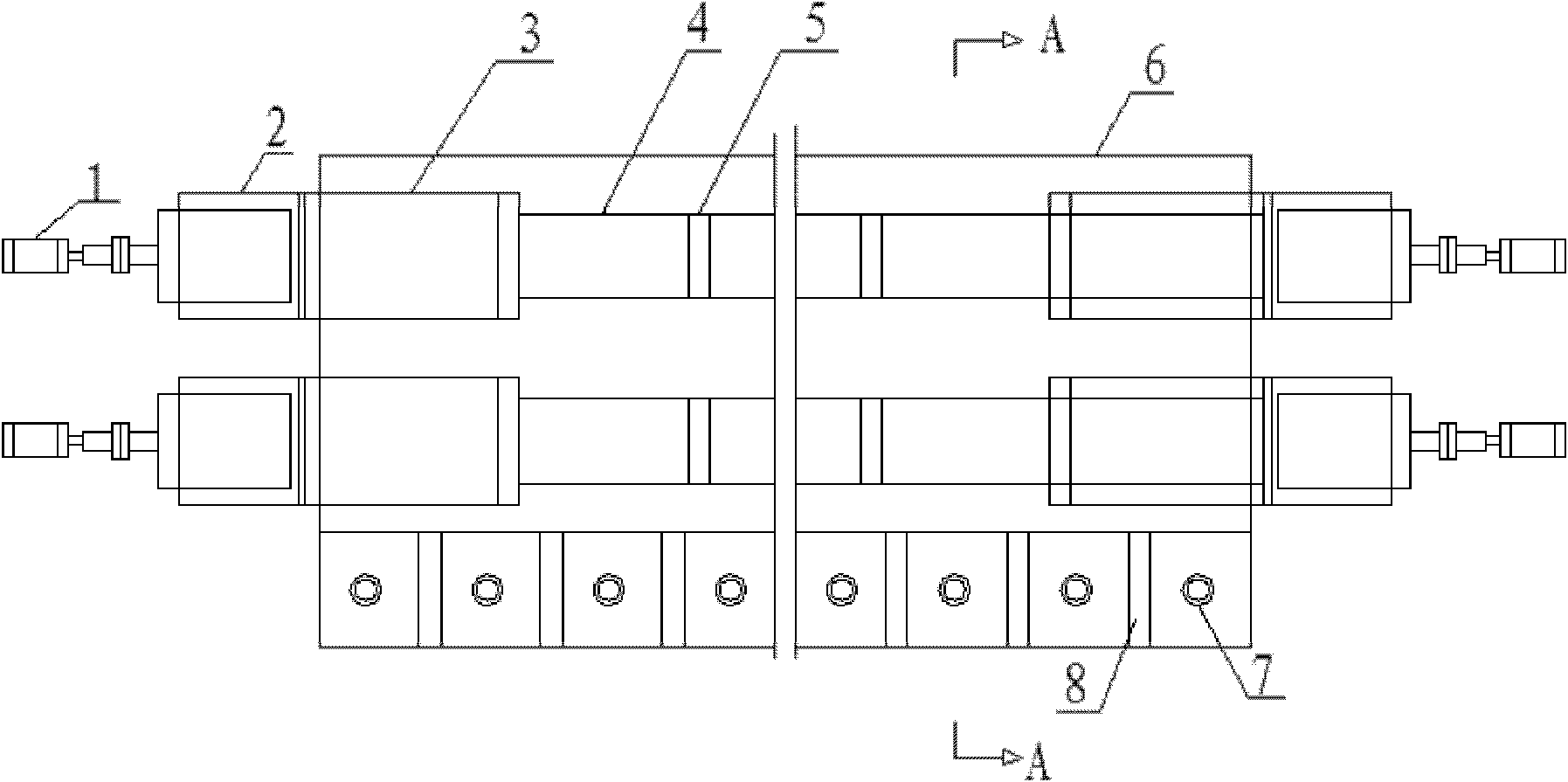

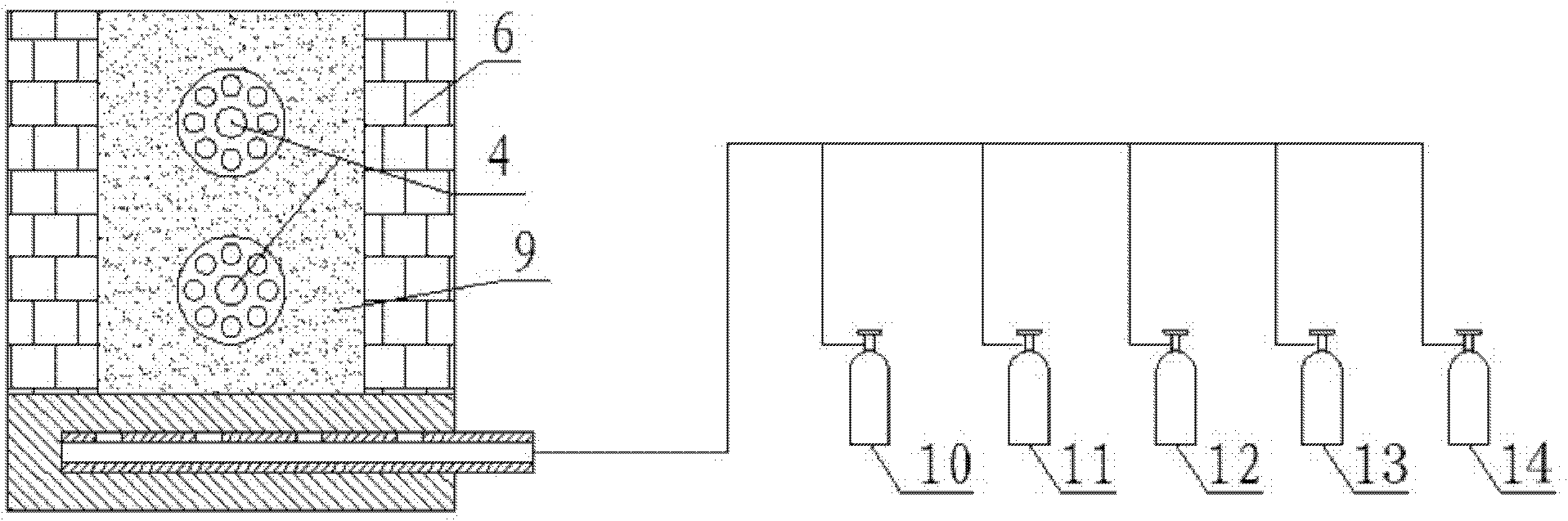

High-temperature continuous treatment system for disposing waste cathode of electrolytic aluminum

ActiveCN106185818ASimple structureEasy to operateFluoride preparationEnergy inputParticulatesResource utilization

The invention relates to the technical field of the treatment of solid waste substances, and particularly relates to a high-temperature continuous treatment system for disposing a waste cathode of electrolytic aluminum. The invention provides the high-temperature continuous treatment system for disposing the waste cathode of the electrolytic aluminum. The high-temperature continuous treatment system comprises a crushing system, a feed system, a roasting system, a fume treatment system and a solid particulate matter treatment system, wherein the crushing system is used for crushing a charcoal block of the waste cathode of the electrolytic aluminum to form particulate material and conveying the particulate material to the roasting system by the feed system; the roasting system comprises an electric calcining furnace, a gas discharge opening is formed in the upper end of the electric calcining furnace, and a solid discharge opening is formed in the lower end of the electric calcining furnace; the fume treatment system is connected with the gas discharge opening; the solid particulate matter treatment system is connected with the solid discharge opening. By the system, a fluoride salt and a carbon product which are high in quality and further have economic value added are obtained; further, the system is simple in structure, convenient to operate and low in energy consumption and cost, has innocent treatment, and improves the treatment efficiency and the resource utilization efficiency of the charcoal block of the waste cathode of the electrolytic aluminum.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

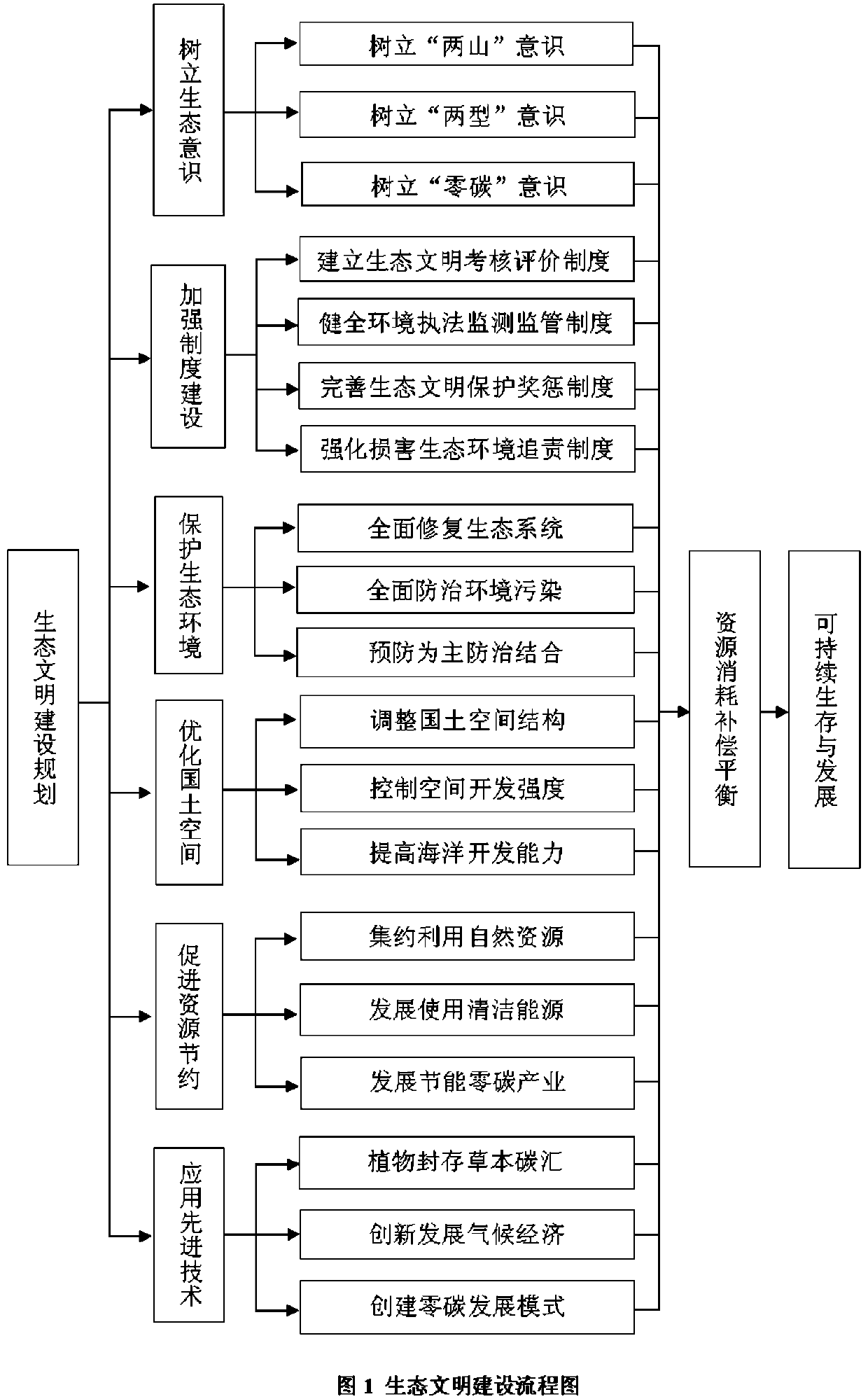

Dynamic carbon and static carbon mutual conversion method

PendingCN110012785ALarge biomassImprove the ability to convert into "static carbon"Nitrous oxide captureMethane captureMonsoon circulationClean energy

A dynamic carbon and static carbon mutual conversion method includes: planting rank vegetations, and repeatedly cutting and storing to convert 'dynamic carbon' in the atmosphere into 'static carbon' in the biosphere; controlling biomass oxidation quantity to balance the total quantity of 'dynamic carbon' in the atmosphere; intervening soil wind erosion, rock weathering, monsoon circulation and ocean current distribution regularities to restrain 'static carbon' in the biosphere, the hydrosphere and the lithosphere from transferring into the atmosphere; increasing biomass in coastal wetlands, continental shelf shallow areas, rivers and lakes to promote 'static carbon' in the hydrosphere to transfer into the lithosphere; replacing fossil fuels with clean energy to reduce incremental quantityof 'dynamic carbon' in the atmosphere; developing new climate economy to increase bio-carbon products and increase storage of 'static carbon' in the biosphere; clearing 'dynamic carbon' in the atmosphere according to physical and chemical methods so as to regulate the greenhouse effect, eliminate dust haze, slow down global climate change speed and prolong survival time of human on the earth.

Owner:雷学军

Preparation method of novel sludge carbon-based desulfurization and denitrification catalyst

InactiveCN105170131AHigh activityImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSludgeReactive site

The invention relates to the technical field of regenerating treatment and recycling utilization of sludge and particularly discloses a preparation method of a novel sludge carbon-based desulfurization and denitrification catalyst. The preparation method disclosed by the invention has the advantages that a carbon product obtained by utilizing a hydrothermal carbonization method has more active sites and stable C-O compounds, and the adsorbing capability is larger than that of high-temperature cracked carbon, and rare-soil metal is used as a catalyst; the novel sludge carbon-based desulfurization and denitrification catalyst has the characteristics of wide source and low price, and the obtained sludge carbon-based catalyst is high in activity and strong in stability; the processing steps are simple and feasible; the catalyst is environmental-friendly, is easy in promotion and application, has industrial application prospect and achieves the purpose of treating-waste-by-waste really.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com