Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1405results about How to "Reduce pressure on environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

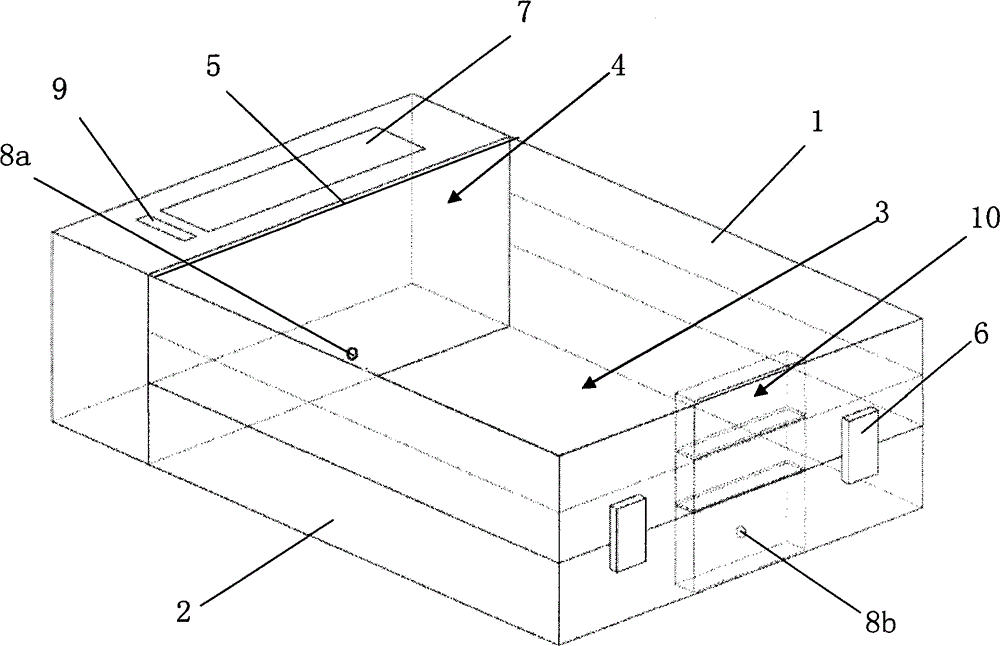

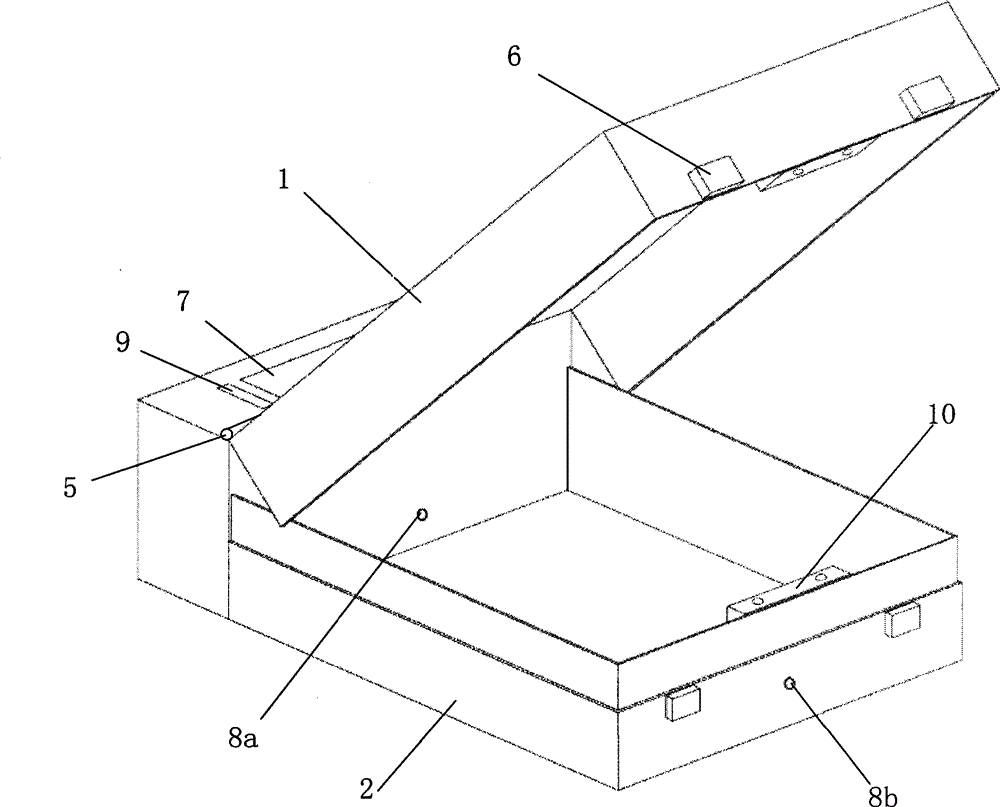

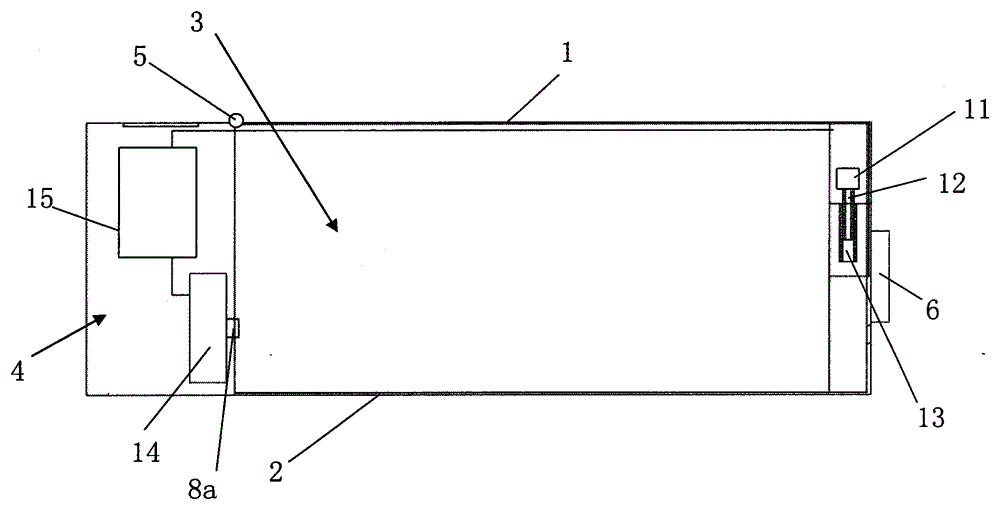

Internet-of-thing anti-counterfeiting and anti-theft package box and application method thereof

ActiveCN104129562AAvoid malicious openingAvoid package lossProgramme total factory controlLocking devicesAnti theftInternet of Things

The invention discloses an Internet-of-thing anti-counterfeiting and anti-theft package box and an application method thereof. A control device, an information acquisition device and a locking device are arranged in the package box. The control device is connected with a long-range monitoring center through a network, the monitoring center receives an operating request of a user with respect to the package box, and after the identity of the user is verified, a locking or unlocking instruction can be sent to the locking device through the control device. The information acquisition device sends the parameter information of the package box and goods in the package box to the monitoring center through the control device, and the monitoring center records the relevant information of the package box when an abnormal condition happens. Due to the fact that the package box is unlocked and locked through the far-end monitoring center, the unlocking or locking request has to be authenticated through the monitoring center, the probability that the goods can be maliciously opened in the transporting process is lowered, real-time tracking and monitoring can be achieved on the transported goods through the package information acquired by the information acquisition device, and the problem that packages are lost can be solved.

Owner:矩众合能(天津)科技发展有限公司

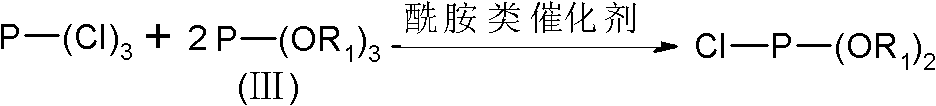

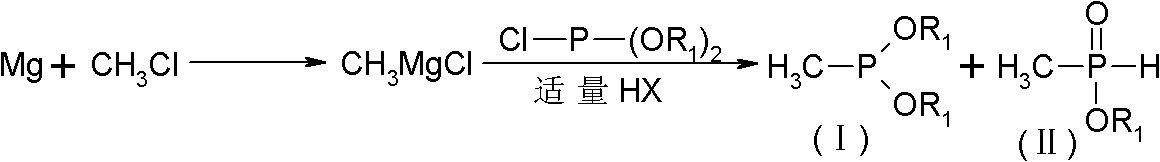

Improved synthesis method for glufosinate and analogue thereof

InactiveCN102399240AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateHydrogen halide

The invention discloses a comprehensive method for synthesizing glufosinate and analogue thereof by using phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials. The method comprises the following steps of: performing Grignard, disproportionation and coupling; introducing a proper amount of hydrogen halide; and synthesizing to obtain two intermediates, namely methyl diethyl phosphate (intermediate I) and methyl phosphinate (intermediate II), wherein the two intermediates can synthesize the glufosinate and the analogue thereof. By the method, the glufosinate and the analogue thereof are synthesized by completely utilizing the methyl diethyl phosphate and the methyl phosphinate synthesized by a Grignard route; yield is increased; production cost is reduced; and three wastes are reduced.

Owner:JIANGSU YOUTH CHEM +1

Method for preparing ternary cathode material precursor by recycling lithium-ion battery material

InactiveCN105633500AHigh purityLow costWaste accumulators reclaimingBattery recyclingManganeseLithium-ion battery

The invention relates to a method for preparing a ternary cathode material precursor by recycling a lithium-ion battery material. The method comprises the following steps: recycling a lithium-ion battery cathode material with sulfuric acid and hydrogen peroxide to obtain a first solution; adjusting the pH value of the first solution to be 5-6.5, adding a filter aid and filtering out impurities to obtain a second solution; adding nickel sulfate, cobalt sulfate and / or manganese sulfate to the second solution, adjusting the molar ratio of nickel to cobalt to manganese to be (0.4-0.6) to (0.1-0.3) to (0.2-0.4) to obtain a third solution; adding a complex precipitant to the third solution, adjusting the pH value of the third solution to be 7-9, and reacting to obtain a nickel-cobalt-manganese ternary material precursor sediment; and washing and drying the nickel-cobalt-manganese ternary material precursor sediment to obtain the ternary cathode material precursor. The method is high in recovery rate; the recycling process is simple; and the prepared ternary cathode material precursor is high in purity, small in particle size, narrow in distribution and even to mix.

Owner:TIANQI LITHIUM CORP

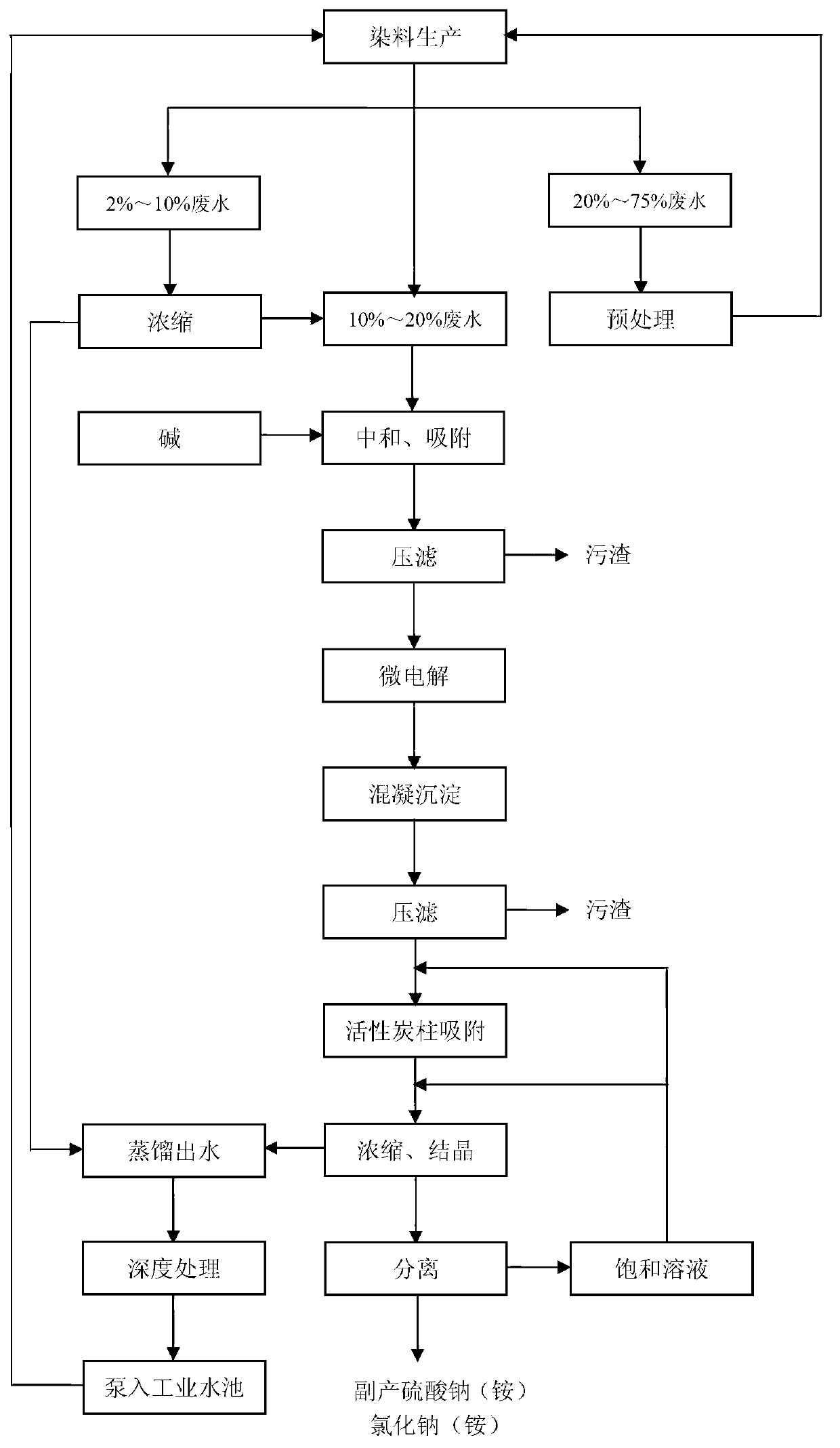

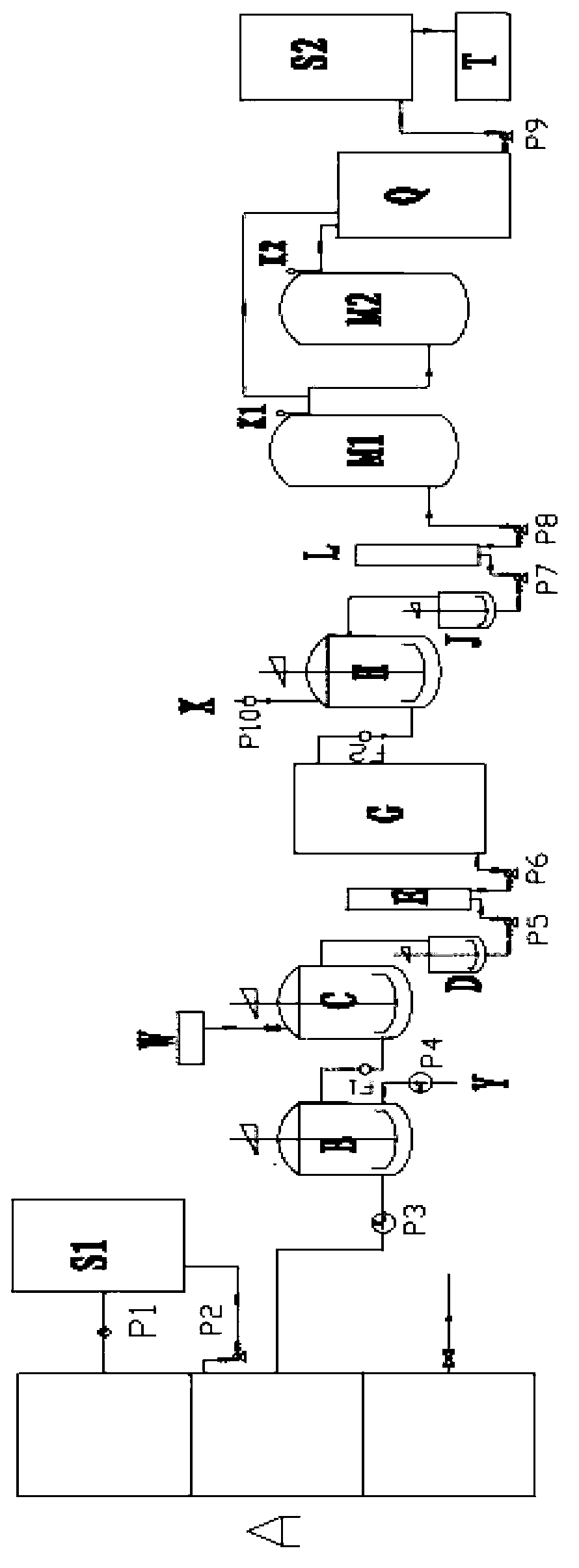

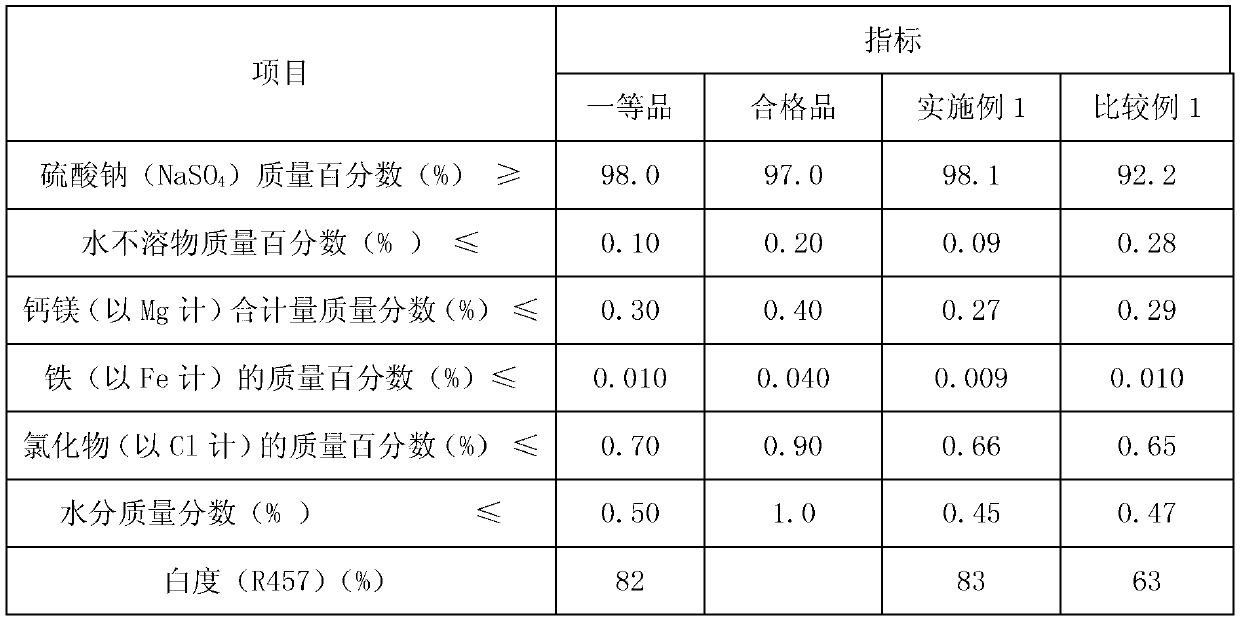

Dye acidic waste water treatment method and device

ActiveCN103130370AWide pH rangeLow costAmmonium sulfatesMultistage water/sewage treatmentAutomatic controlWater discharge

The invention relates to a dye acidic waste water treatment method and device. The method comprises steps as follows: separately collected dye waste acid is subjected to distilling concentration, neutralization, adsorption, micro-electrolysis, coagulative precipitation, activated carbon column adsorption, concentrating crystallization and separation through an automatic control system to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride; and the distilled water is subjected to advanced treatment to reach the industrial reuse water standard, enters an industrial water storage tank, and is circulated to the dye production procedure. The method and device are especially suitable for industries generating abundant waste sulfuric acid and waste hydrochloric acid, such as production of dyes, titanium white and the like. The abundant waste sulfuric acid and waste hydrochloric acid generated in the production process can be utilized to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride, thereby recycling acidic waste water, and changing wastes into valuable substances; and meanwhile, the distilled water can be circulated into industrial production after advanced treatment, thereby reducing the waste water discharge.

Owner:ZHEJIANG DIBANG CHEM

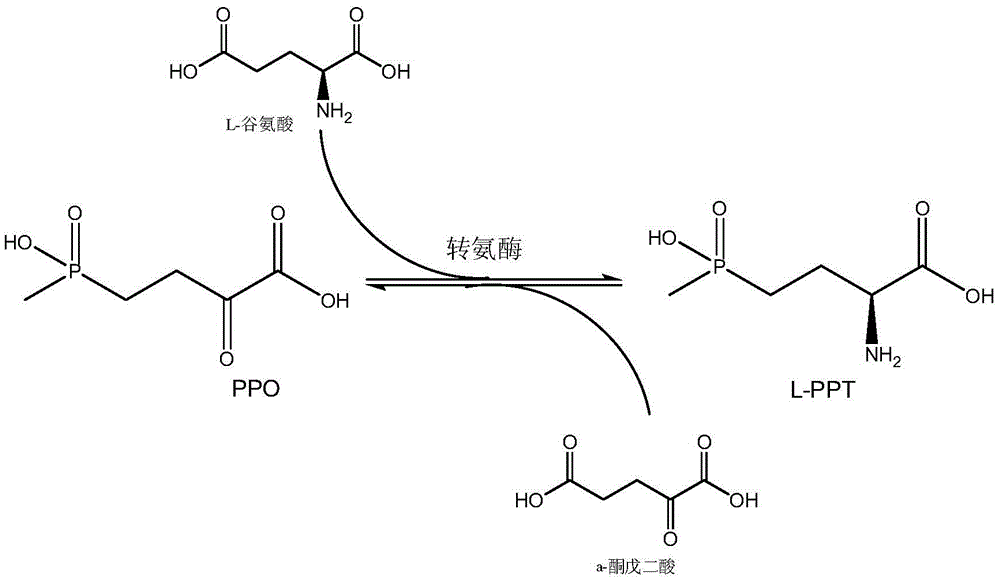

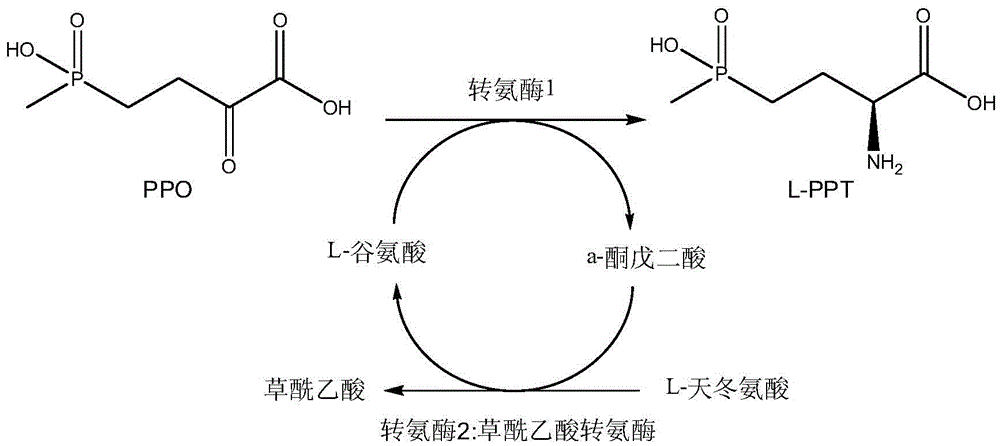

Production method of L-glufosinate

ActiveCN105603015AImprove conversion rateSimple separation processTransferasesMicroorganism based processesButyric acidHydroxy compound

The invention discloses a production method of L-glufosinate. The method includes the steps that with 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid and salt thereof being a substrate, isolated transaminase or a cell catalysis substrate of in-vitro expression transaminase reacts with an amino donor under the condition that the amino donor exists, so that L-glufosinate is obtained, wherein the amino donor is alanine, and the amino acid sequence of transaminase is shown in SEQ ID NO.1-3. With 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid and salt thereof being the substrate and alanine being the amino donor, the transamination reaction occurs through the specific transaminase catalysis substrate, the substrate can be completely converted into L-glufosinate, and the conversion rate of raw materials is high and can reach 100%.

Owner:ZHEJIANG UNIV

Steelmaking and slagging method

The invention provides a steelmaking and slagging method. The method comprises the following steps of: adding semisteel from which vanadium is extracted into a steel refining furnace; blowing oxygen into the steel refining furnace and blowing; in two minutes after the blowing is started, adding 9 to 11kg of lime, 9 to 11kg of high-magnesium lime, 3 to 8kg of fluxing agent, and 11 to 14kg of acid composite slag into the steel refining furnace based on one ton of semisteel from which vanadium is extracted; and in 9 minutes after the first slag is formed and blowing is started, adding 9 to 11kg of lime and 9 to 11kg of high-magnesium lime into the steel refining furnace based on one ton of semisteel from which vanadium is extracted, and continuously blowing to obtain molten steel and final slag. The fluxing agent is refined steel slag. Slagging is performed by the method, the slag can be formed quickly, the consumption of an iron and steel material is reduced, smelting time is shortened and steelmaking cost is saved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

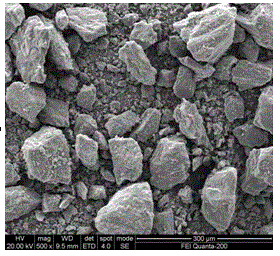

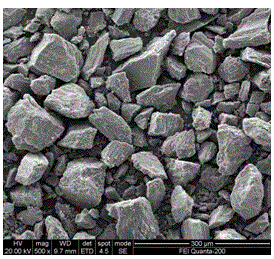

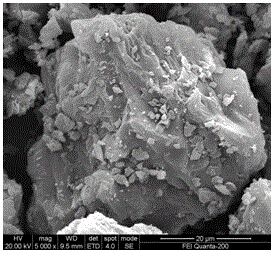

Method for recycling carbon and electrolytes from waste cathode carbon block of aluminum electrolytic cell

InactiveCN105821445AReduce dosageReduced dosage of chemicals (reduced amount of collectorElectrolysis componentsCalcium/strontium/barium fluoridesKeroseneFuel oil

The invention discloses a method for recycling carbon and electrolytes from a waste cathode carbon block of an aluminum electrolytic cell. The method comprises the following steps that 1, the cathode carbon block is crushed and grinded; 2, cathode carbon powder obtained from the cathode carbon block subjected to crushing and grinding in the step 1 is stirred and leached in alkali liquor and then filtered, so that a filter cake A1 and filtrate B1 are obtained; and a precipitating agent is added into the filtrate B1, so that a filter cake A2 and filtrate B2 are obtained after filtering is conducted; and 3, the filter cake A1, the filter cake A2, a flotation medium and flotation reagents are subjected to mixing and pulp conditioning, and thus the carbon and electrolytes are obtained through flotation and separation; the flotation reagents comprises the collecting agents, the foaming agents and the conditioning agents; the collecting agents are composed of the collecting agent C1 and the collecting agent C2 at the mass ratio of 0.65-0.75:0.25-0.35; the collecting agent C1 is selected from at least one of coal tar, heavy oil, kerosene and diesel oil; and the collecting agent C2 is selected from at least one of dodecylamine, sodium dodecyl benzene sulfonate, sodium oleate and sodium dodecyl sulfate. According to the method for recycling the carbon and the electrolytes from the waste cathode carbon block of the aluminum electrolytic cell, the carbon powder and the electrolytes are effectively separated and recycled from the waste cathode carbon block.

Owner:CENT SOUTH UNIV

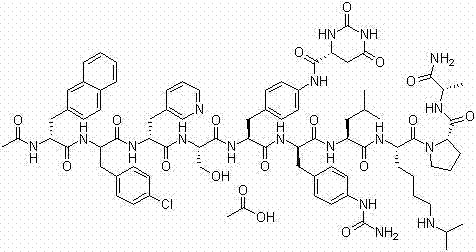

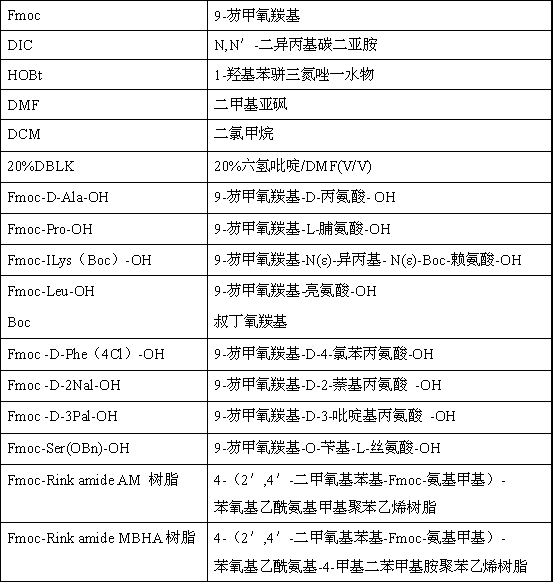

Solid-phase synthetic process for degarelix

ActiveCN102329373AAdvantages of solid phase synthesis processReduce usagePeptide preparation methodsBulk chemical productionAcetic anhydrideSide chain

The invention relates to a solid-phase synthetic method for degarelix. The method comprises the following steps of: 1) reacting resin with Fmoc-D-Ala-OH to obtain Fmoc-D-Ala-resin, wherein the resin is amino resin; 2) sequentially connecting according to the amino acid sequence of the degarelix by adopting an Fmoc solid-phase synthetic strategy; 3) removing Fmoc from a N terminal, and acetylating by using acetic anhydride and pyridine; 4) removing a protective group X on the 6th amino acid residue -4Aph(X) from a C terminal; 5) connecting L-4,5-dihydrooroticacid to a side-chain amino group of the 6th amino acid residue -4Aph at the C terminal; 6) cutting peptide resin by using a cracking reagent, precipitating by using anhydrous ether, and centrifuging to obtain crude peptide; and 7) purifying and separating to obtain the degarelix. The method is easy to operate and slightly damages human bodies and environments; and by the process, the content of impurities is effectively reduced, and the large-scale production can be performed.

Owner:HYBIO PHARMA

Preparation method of activated carbon by utilizing corncob hydrolysis residue

InactiveCN101837973ASolve the problem of effective transformation and utilizationTake advantage ofFermentationCelluloseCarbonization

The invention discloses a preparation method of activated carbon by utilizing corncob hydrolysis residue, which belongs to the technical field of functional sugar production. The process comprises four steps of removing cellulose, carbonization-activation, washing and drying and grinding. The preparation process utilizes the corncob hydrolysis residue after enzymolysis by cellulase to prepare the activated carbon for producing xylose (or xylitol), which can not only meet the demands of self-production and reduce the production cost but also be sold as a commodity to acquire economic benefits directly, thus realizing a great leap from high residue discharge amount to zero discharge in the xylitol production, reducing the environmental protection pressure, creating economic benefits and meeting the national requirements of energy saving, emission reduction and sustainable development.

Owner:FUTASTE PHARM CO LTD

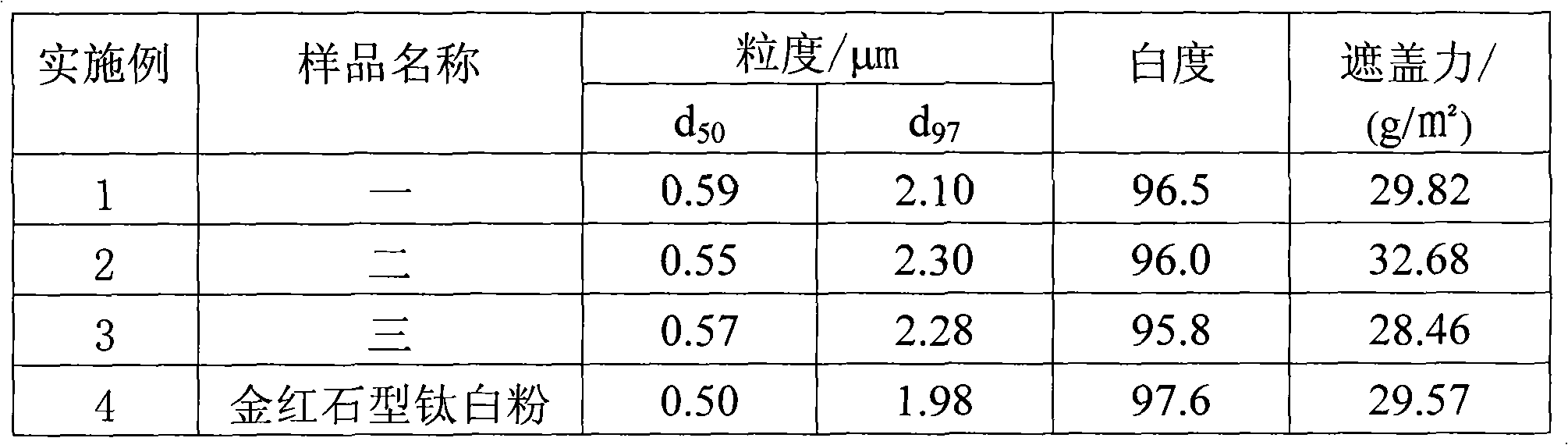

Preparation method of inorganic composite white pigment with high covering power

InactiveCN101775239AEfficient use ofReduce manufacturing costPigment physical treatmentColored whiteWhite powder

The invention relates to a preparation method of an inorganic composite white pigment with high covering power. The method comprises the steps of: taking titanium white powder and white mineral powder or composite white mineral powder as raw materials; taking a wet ultrafine stirring grinder or a sand miller as a compound device; performing segmented wet ultrafine grinding and compounding to the titanium white powder and the white mineral powder by adding a certain quantity of pH adjusting agent and dispersing agent; and drying and mechanically dispersing and depolymerizing size after ultrafine grinding and compounding to prepare the inorganic composite white pigment which can be used by replacing the titanium white powder, wherein the performance indexes such as the granularity, the whiteness and the covering power, and the like, of the inorganic composite white pigment are as the same as or similar with the granularity, the whiteness and the covering power of the titanium white powder. The method has simple preparation technology, lower preparation cost and cleaning preparation process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

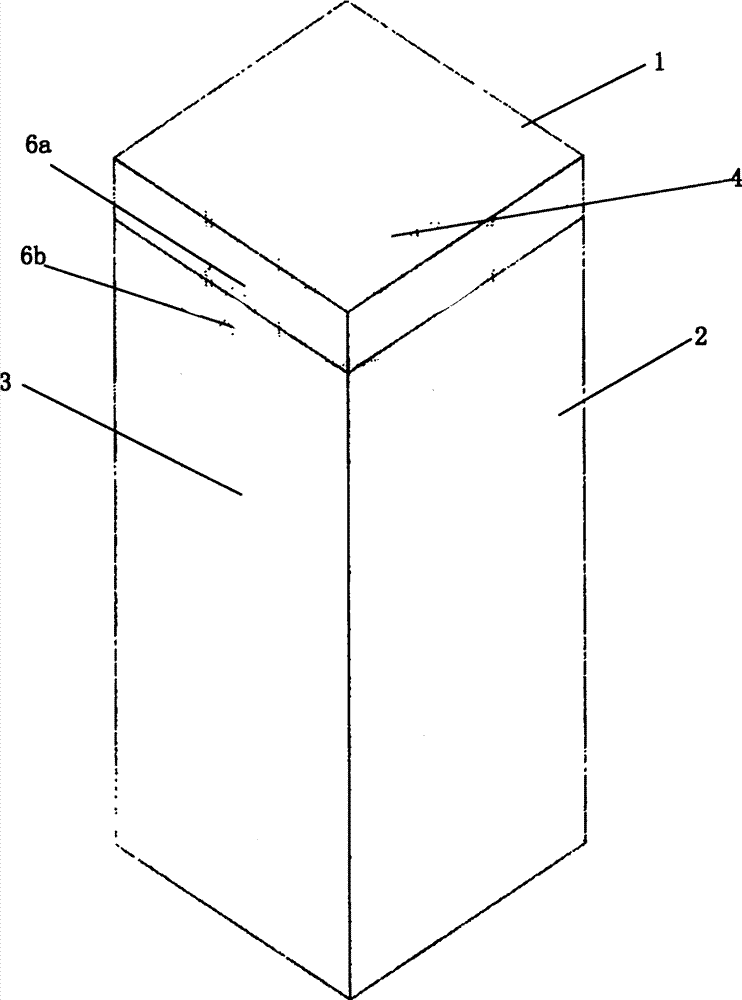

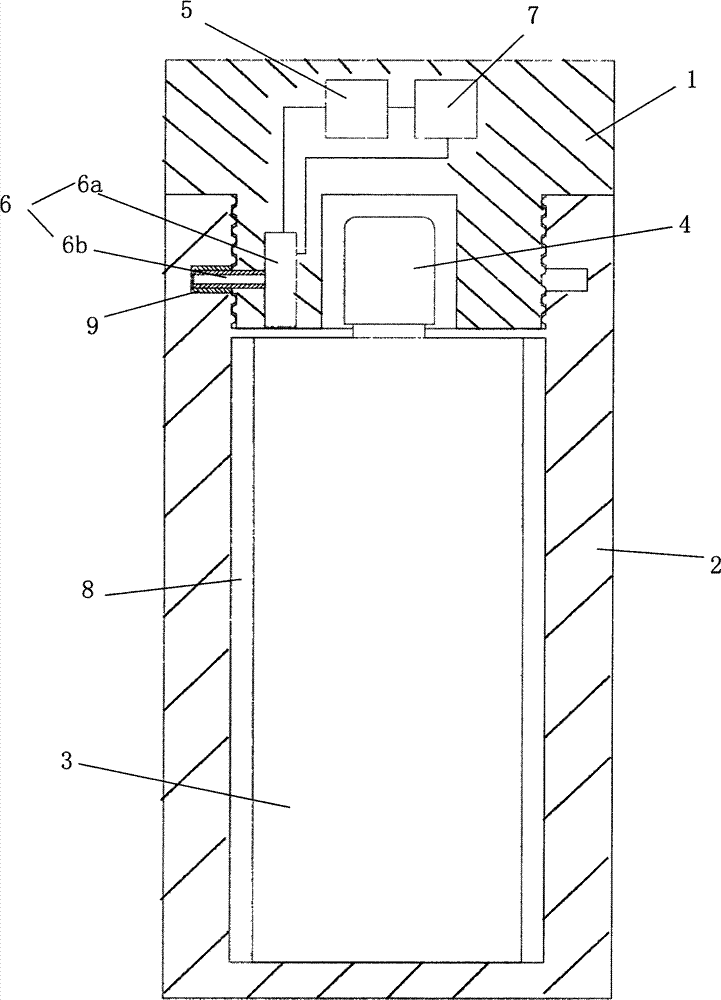

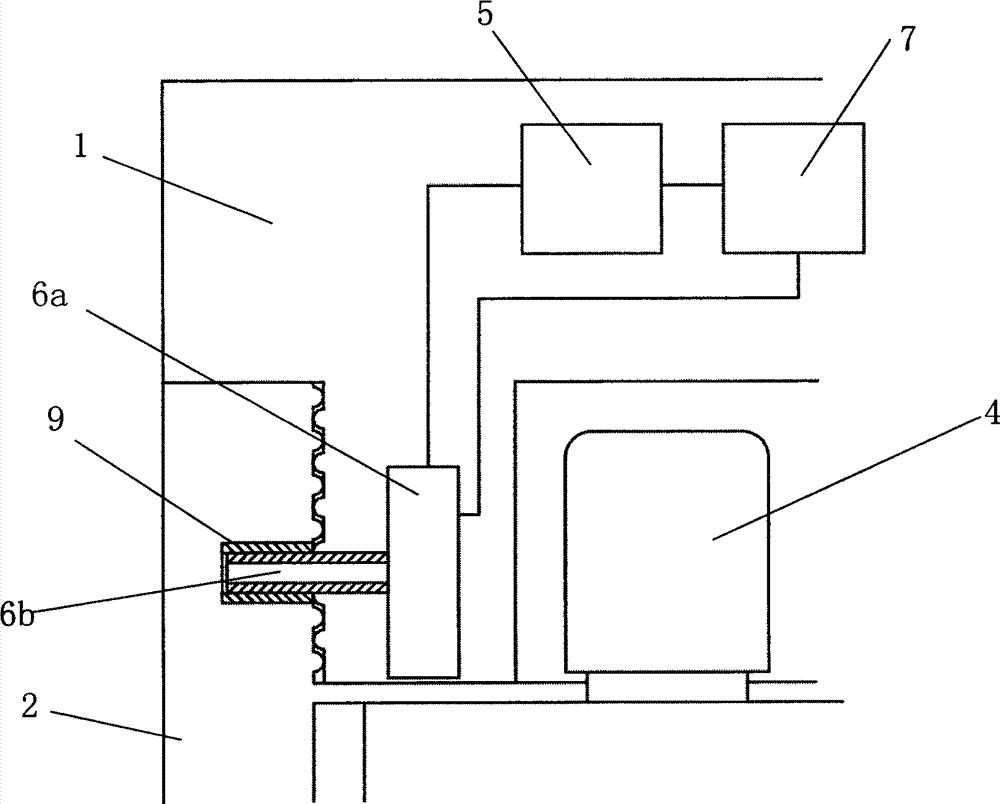

IOT anti-counterfeiting wine bottle and using method thereof

InactiveCN103771018AReduce pressure on environmental protectionReduce packaging costsLocking devicesWine bottleEngineering

An IOT anti-counterfeiting wine bottle comprises a wine bottle body which comprises an upper bottle body and a lower bottle body, wherein the upper bottle body and the lower bottle body are combined with each other. The upper bottle body and the lower bottle body form an outer shell of the wine bottle body, an inner container with a sealed cover is arranged in the outer shell, and meanwhile a control device, a locking device and a battery are further arranged in the outer shell. The control device is connected with a host of a far-end authentication center through a network, the control device sends a control instruction to the locking device, and the locking device enables the upper bottle body and the lower bottle body to be fixed. According to a using method of the IOT anti-counterfeiting wine bottle, networking certification is conducted on the wine bottle to confirm the authenticity, the wine bottle is opened through the fact that the authentication center sends an instruction in a long distance mode, fake products which are produced in an original imitation mode or in a mode of purchasing the wine bottle by counterfeiters can not be authenticated by the authentication center, and finally faking can not be implemented.

Owner:矩众合能(天津)科技发展有限公司

Preparation method of highly methyl etherified amino resin

The invention discloses a preparation method of highly methyl etherified amino resin, and relates to a synthetic preparation method of a liquid coating cross-linking agent-amino resin. The method comprises the following steps of: putting methanol and hexamethylolmelamine in a reaction kettle, wherein the weight ratio of the methanol and hexamethylolmelamine is 1:1-10, adding acid to adjust pH value to acidity, raising temperature to 20-50 DEG C for the first time, maintaining the temperature for 15min to 2h, raising temperature to 50-80 DEG C for the second time, then maintaining the temperature for 15min to 2h, then adding alkali to neutralize, adjusting the pH value to 7-10, raising the temperature by steam, dealcoholizing at constant pressure, then depressurizing, further removing the low-boiling-point substances at a pressure lower than -0.09MPa to obtain the highly methyl etherified amino resin product. The invention solves the problem of complex manufacturing processes, combines the two steps into one step, is simple and convenient to operate and control with period of time shortened from original 18h / kettle to about 9h / kettle and enhances the yield obviously, lowers the cost, reduces the energy consumption by 2 / 3, reduces the content of free formaldehyde and improves the environmental performance.

Owner:奥仕集团有限公司

Soft soil curing agent prepared by means of industrial residues

InactiveCN105236908AReduce pressure on environmental protectionSolve the shortage of resourcesSolid waste managementPortland cementSlag

The invention discloses a soft soil curing agent prepared by means of industrial residues. The curing agent is prepared from, by weight, 35-65% of steel slag, 30-50% of mineral waste residues, 10-30% of desulfurization gypsum, 2-6% of sulphoaluminate cement clinker, 2-4% of ordinary portland cement clinker, 2-5% of aluminum dregs and 0-5% of cement. The sum of the weight percentages of all the components is 100%. The soft soil curing agent is prepared by fully utilizing industrial residues of heat-engine plants, steel works and aluminum electrolysis enterprises, unconfined compression strength is high during soft soil foundation reinforcement, waste is recycled, and economic benefits and environmental protection benefits are high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

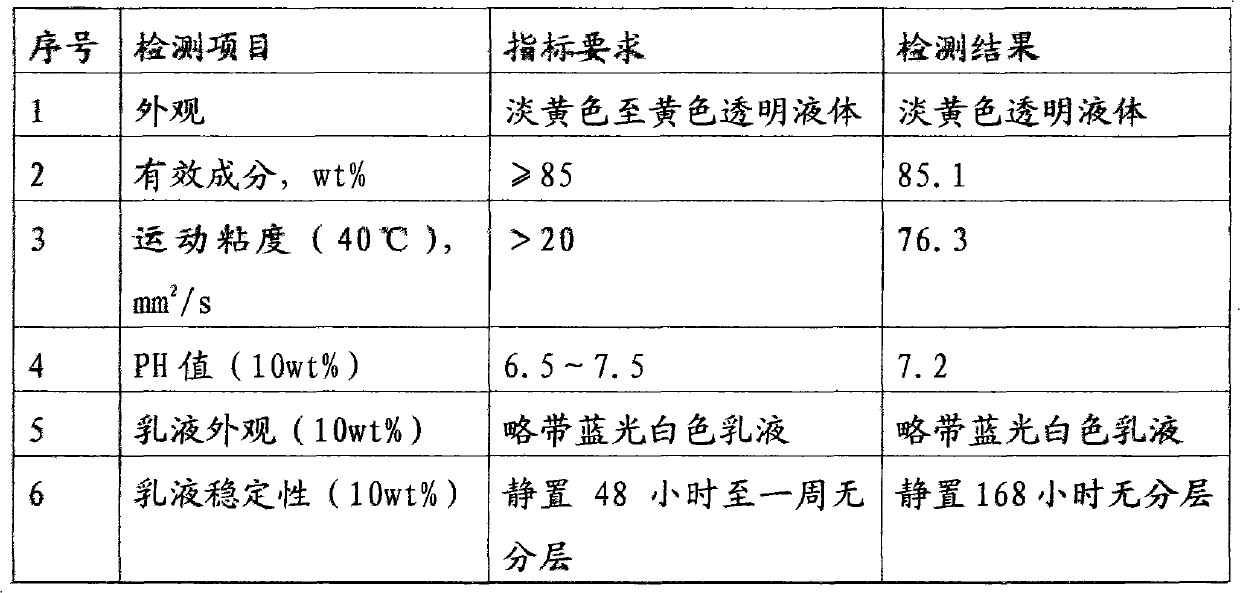

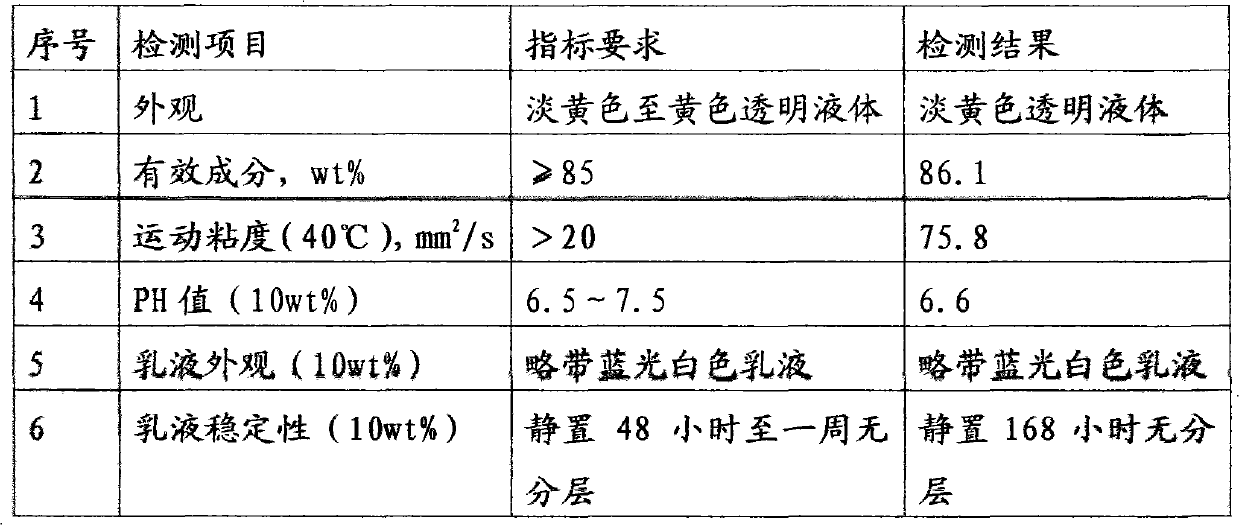

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

Method for synthesizing degarelix

InactiveCN102952174AReduce usageAvoid pollutionPeptide preparation methodsBulk chemical productionCombinatorial chemistryPhenylalanine

The invention discloses a method for synthesizing degarelix, wherein an amino resin protected with Fmoc is used as a raw material; according to a solid-phase synthesis method, DIC / HOBt (N,N'-diisopropylcarbodiimide / 1-hydroxybenzotrizole) is used as a coupling agent for transpeptidase reaction; 4-serine uses tert-butyl dimethyl to replace tertiary butyl for protection protecting hydroxyl; a hydroorotic acid fragment connected with 4-amino of 5-phenylalanine benzene ring is protected with triphenylmethyl at first, and then introduced, so that the rearrangement side reaction is prevented; and since D-4Aph (Cbm) is used for replacing D-4Aph (Cbm-tBu), a t-Bu removal difficulty is prevented and the occurrence of the side reaction is reduced. A synthesis technology of the method for synthesizing degarelix is simple in steps, easy to control, small in environment pollution and high in yield, thereby being applicable for industrial production.

Owner:济南环肽医药科技有限公司

Method for recycling bismuth in bullion lead

ActiveCN104141057AImprove direct yieldSave capacityPhotography auxillary processesProcess efficiency improvementElectrolysisAdditive ingredient

The invention relates to a method for recycling bismuth in bullion lead, and belongs to the field of the metallurgical technology combining a pyrogenic process with a wet process. The bullion lead is placed in a vacuum furnace first, vacuum distillation is carried out to separate lead, antimony, bismuth and copper, primary high bismuth lead and silver are produced, the produced primary high bismuth lead is placed in the vacuum furnace, vacuum distillation is conducted again to separate lead, antimony, bismuth and copper under control of the previous condition, and secondary high bismuth lead and residual silver are produced; the obtained secondary high bismuth lead and lead bullion ingredients are thrown into an anode pot to be cast into a bismuth anode plate, the bismuth anode plate is put into an electrolytic bath, mixed electrolytic refining is conducted on the bismuth anode plate together with the main process of lead electrolysis, and dissolved-out lead and washed high bismuth anode slime are obtained; the obtained high bismuth anode slime is subjected to reduction smelting and converting to produce crude bismuth; fire refining is carried out on the obtained crude bismuth, sulphur is added to the crude bismuth to remove copper, the crude bismuth is oxidized to remove arsenic and antimony, chlorine gas is led to the crude bismuth to remove lead, zinc is added to the crude bismuth to remove silver, finally caustic soda and saltpeter are added for refining, and a bismuth ingot product meeting national standards is produced. The technological process of the method is refined and simple.

Owner:蒙自矿冶有限责任公司

Preparation method of L-tyrosine or L-tyrosine derivative employing enzyme conversion

ActiveCN103343149AImprove conversion efficiencyEliminate separation and purificationMicroorganism based processesFermentationTyrosinePerylene derivatives

The invention belongs to the technical field of organisms, and particularly relates to a preparation method of L-tyrosine or L-tyrosine derivative (L-3-hydroxy tyrosine) employing enzyme conversion. The preparation method comprises the steps of: adopting feed liquid containing pyruvic acid as a substrate; adding bacterial cells with tyrosine phenol lyase activity, or crude enzyme, ammonia water, phenol or pyrocatechol; carrying out enzymatic reaction under the conditions that the temperature is 25-55 DEG C and the pH is 7-11; and separately preparing a converted product L-tyrosine or L-dioxyphenylalanine by using an isoelectric point crystallization method. By adopting the method, the L-tyrosine or L-dioxyphenylalanine with high additional value is synthetized by using cheap pyruvic acid liquid as the substrate by an enzymic method; the preparation method has the advantages of being wide in material source, high in enzymatic conversion efficiency, simple and convenient to operate, low in production cost and the like.

Owner:NANJING UNIV

Method for improving physical and mechanical properties of oxidation-degummed ramie

ActiveCN103215655AImprove applicabilityImprove performanceFibre treatment to obtain bast fibreFiberColloid

The invention provides a method for improving the physical and mechanical properties of oxidation-degummed ramie. The method comprises the following steps of: preparing a degumming solution by using caustic soda, an oxidant, a surfactant, a fiber expanding agent, an oxidant stabilizer and water; mixing raw ramie and the degumming solution, heating, and boiling off to sufficiently remove colloid; and then cooling, adding a reduction softener, maintaining the temperature, oiling and drying after washing with clear water, and opening and carding to obtain textile ramie fiber subjected to reduction modification. According to the method disclosed by the invention, the defects of the prior art are overcome; and the reduction softener is added to raffinate obtained after oxidation-degumming, oxycellulose produced in the degumming process is reduced and softened, so that the physical and mechanical properties, such as strength, length, elongation and softness of the fiber are improved, the working procedures are simplified, and pollution and environmental pressure are lightened.

Owner:DONGHUA UNIV

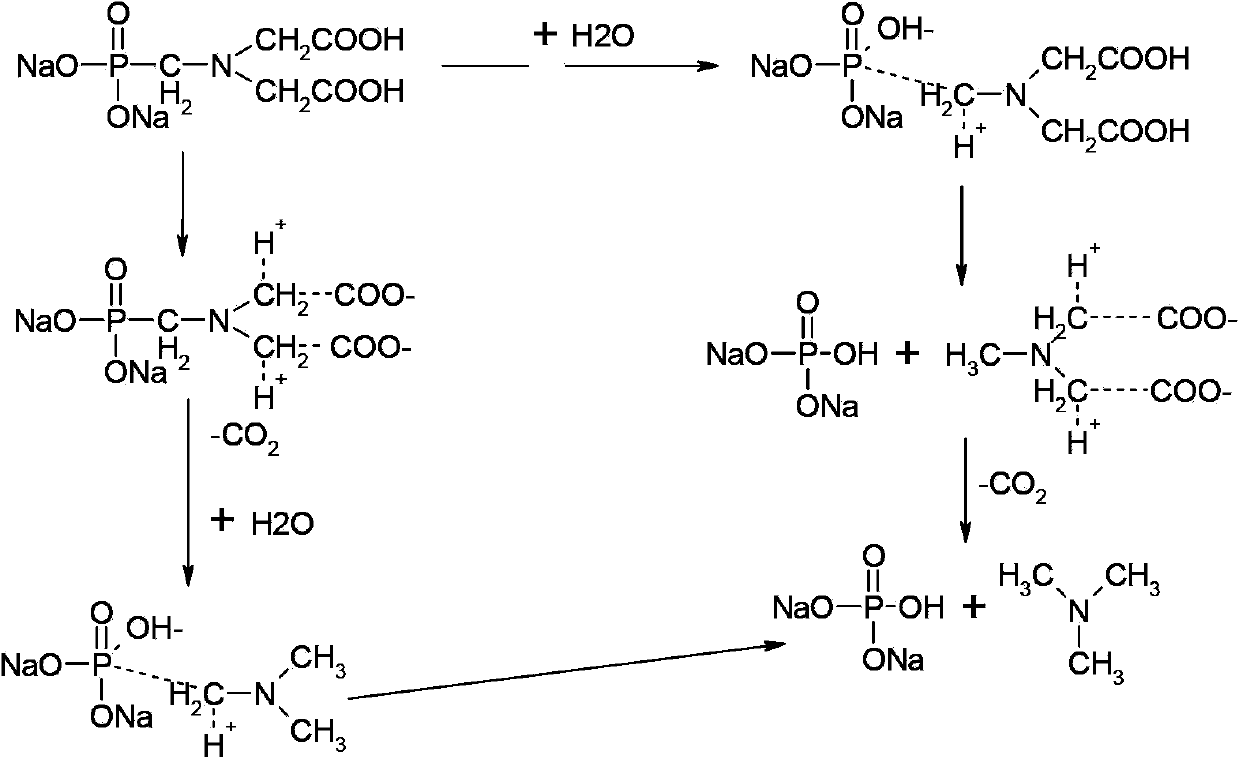

Comprehensive treatment and resource utilization method for industrial organic phosphorus waste liquid

ActiveCN103964622AFully recycleReduce generationMultistage water/sewage treatmentWater/sewage treatment by neutralisationResource utilizationEvaporation

The invention discloses a comprehensive treatment and resource utilization method for an industrial organic phosphorus waste liquid. The technology includes firstly the industrial organic phosphorus waste liquid allows organic phosphorus to be oxidized into inorganic phosphorus by a catalytic wet oxidation method, then the inorganic phosphorus material is subjected to evaporation, concentration and desalination, small-molecule organic matters generated from oxidation are removed, the material after concentration is subjected to high temperature treatment, and a solid product is recycled. Through the method of the invention, the waste liquid can be avoided from being directly subjected to a high temperature contact oxidation process to possibly generate nitrogen oxides, dioxin, smoke dust and other air pollution factors difficult to deal with, and secondary pollution cannot be generated. The waste liquid after treatment is appropriately blended to be transformed into pyrophosphate, polyphosphate, metaphosphate, orthophosphate and other substances according to needs, so that recycling and reutilization of phosphorus is achieved.

Owner:JIANGSU YOUTH CHEM +1

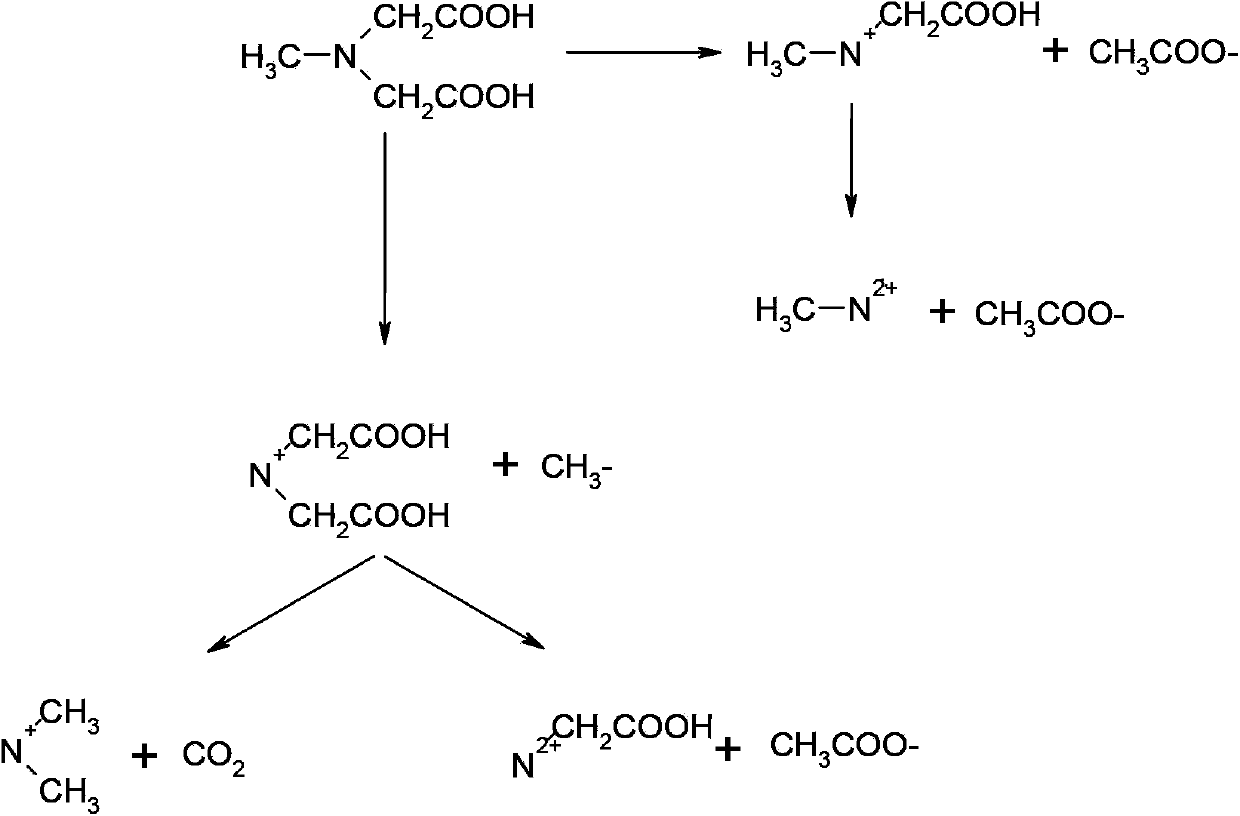

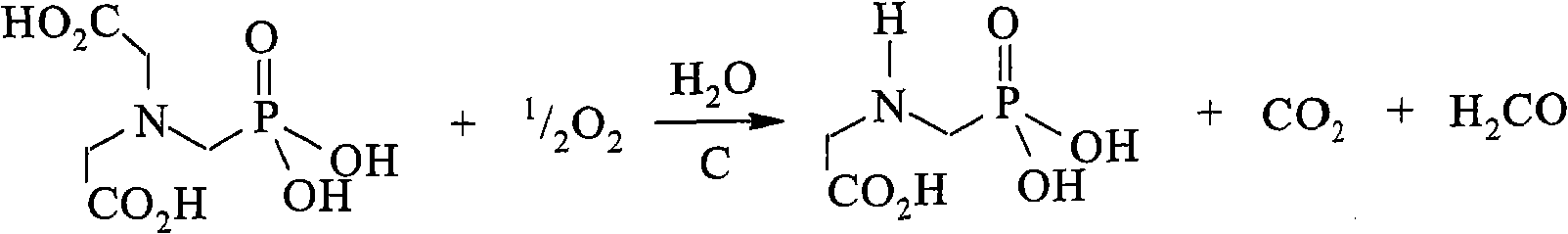

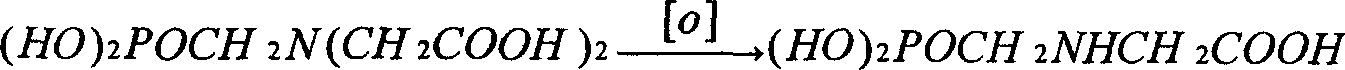

Comprehensive treatment method for glyphosate mother liquid

The invention relates to a comprehensive treatment method for mother liquid synthesized by oxidizing glyphosate by N-(Phosphonomethyl) iminodiacetic acid with an IDA (Iminodiacetic Acid) method. The mother liquid is treated by a condensed system to obtain condensed liquid and thin liquid, wherein the condensed liquid subjected to formaldehyde removal is used for preparing a gyphosate solution with high content or carrying out oxidation treatment, the treated thin liquid can be used for gyphosate production or biochemical treatment. The comprehensive treatment method not only recovers gyphosate, but also reduces the pollution to the environment.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Petroleum coke desulfurizing method

InactiveCN104611087AReduce sulfur contentReduce pressure on environmental protectionSolid fuelsThermal energyCarbon product

The invention discloses a petroleum coke desulfurizing method. The petroleum coke desulfurizing method comprises the following steps: heating petroleum coke to 400-700 DEG C for precalcining for a certain time first, and then in an ammonia gas atmosphere, heating green petroleum coke to 700-1000 DEG C and preserving heat for a certain time so as to achieve a desulfurizing aim. By the petroleum coke desulfurizing method, most of sulfur in the petroleum coke is removed under the conditions that more heat is not consumed and the microstructure and physical and chemical properties of the petroleum coke are not affected, so that the sulfur content of the petroleum coke is greatly reduced, the quality of the petroleum coke is improved, and the environmental pressure of a carbon product industry with the petroleum coke as a raw material is greatly reduced; therefore, the petroleum coke desulfurizing method is wide in application prospect.

Owner:CENT SOUTH UNIV

Glyphosate preparation and method for preparing same

ActiveCN1631894AReduce investmentReduce generationBiocideGroup 5/15 element organic compoundsWastewaterTechnical grade

Disclosed are a glyphosate and its preparing method oxidate oxidate to acquire mixed liquid of glyphosat; bifter hydration, add into glyphosate agent glyphosate preparation to change it into salt, then add surface active agent as assistant into the mixed liquid of salt and the surface active agent is one or several ones from nonion surface active agent or amphoteric surface active agent or organic silicon surface active agent, mix them to be average, acquiring the . In the course, there is no need to separate glyphosate technical grade, while preparation the with the glyphosate technical gradedirectly, which has decreased the amounts of equipment and worker, without drainage of glyphosate mother liquid, it completely makes use of glyphosate technical grade, as well as reduces waste water, benefiting for environmental protection.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Method for producing degradable material with manioc waste and wine stillage

InactiveCN101302734AWith foldableCompressive and folding resistantNatural cellulose pulp/paperReinforcing agents additionCartonPaperboard

The invention discloses a method for producing a novel degradable material by manioc dreg and pot ale and comprises the following steps: the manioc dreg or the pot ale is purified, ground, cleaned, drained and mixed with dry paper pulp according to the weight proportion of a to b; wherein, the a lies between 2 and 5, and the b lies between 5 and 8; a papermaking addition agent is added, and the mixture is molded and parched, thus obtaining the degradable material product. Paper pulps of vegetable fiber such as waste newspapers, carton paper, paperboards and other paper pulps of vegetable fiber materials can be taken as the dry paper pulp. The method for producing the novel degradable material by the manioc dreg and the pot ale adequately utilizes wastes of manioc resources such as the manioc dreg, the pot ale to produce the novel industrial degradable material with good quality and low cost, replaces degradable materials of cellular plastics, and not only solves the difficult processing problem of wastes and changes wastes into valuable, but also effectively generates the actions of controlling and eliminating the white pollution; furthermore, the method for producing the novel degradable material by the manioc waste and the pot ale has uncomplicated technique, short production period, low cost, low energy consumption, simple and convenient operation, high product stability and good economic, social and environment-protective benefits.

Owner:广西农垦明阳生化有限公司

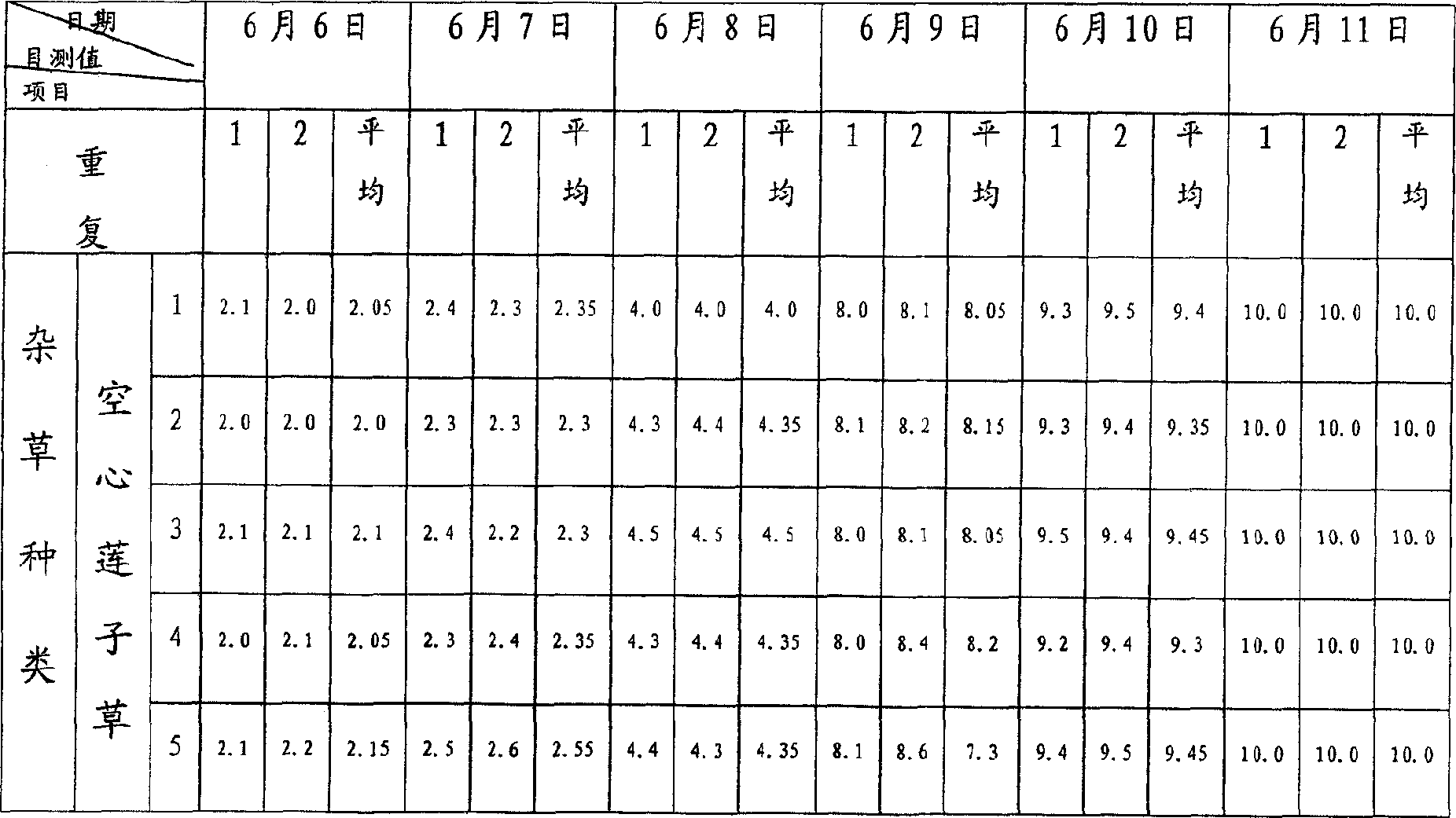

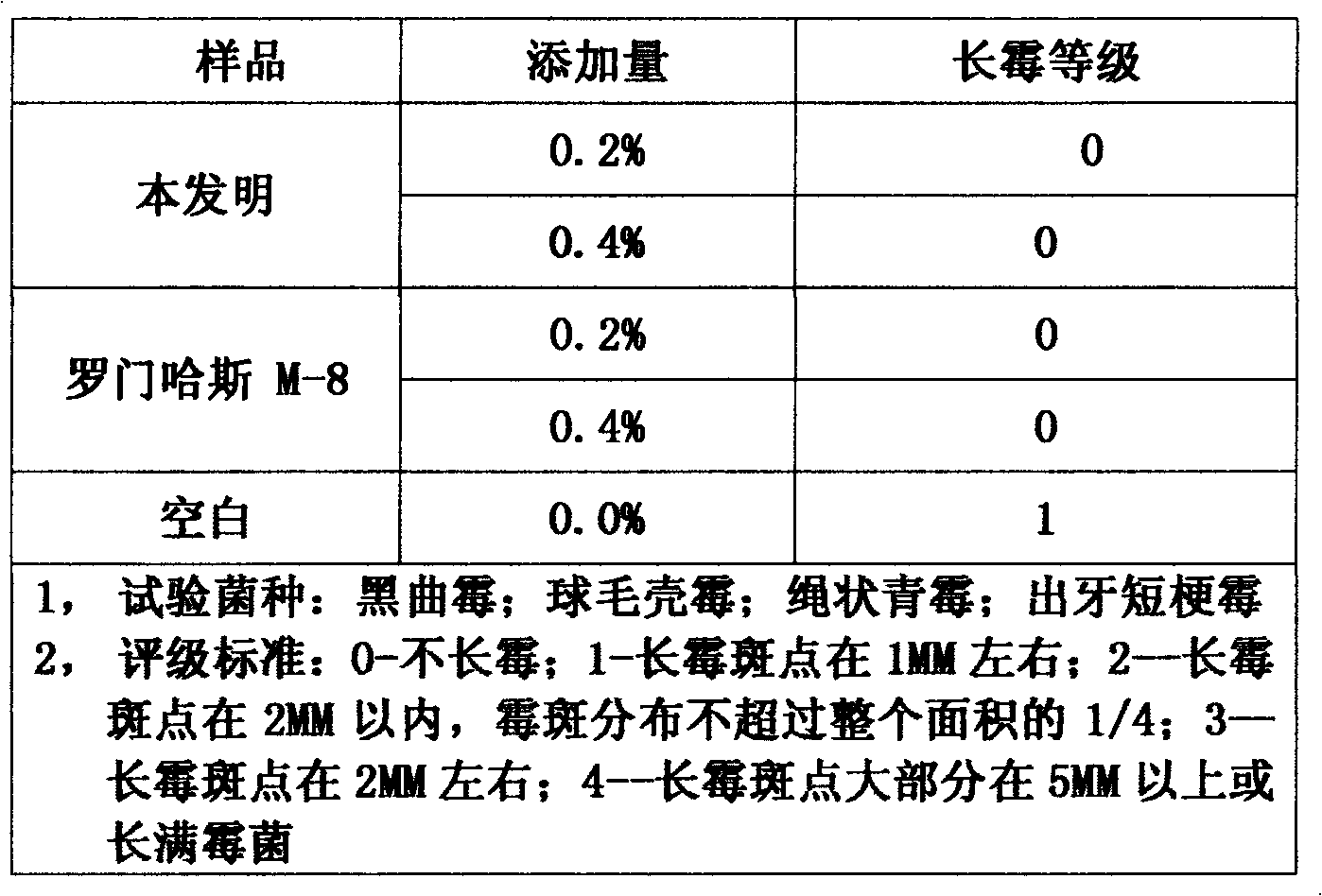

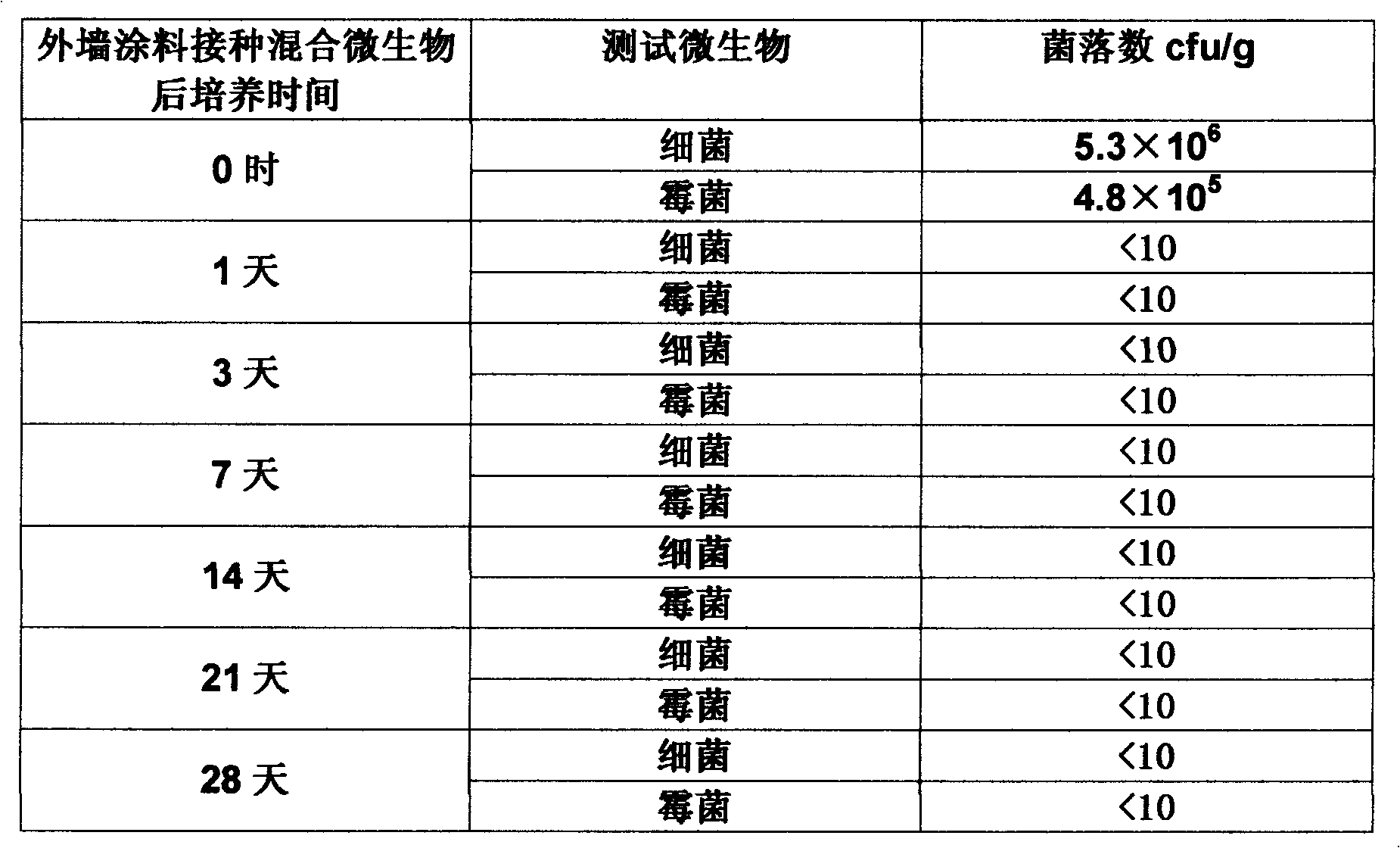

In-tank antiseptic antimildew agent composition integrated with dry film for paint

ActiveCN102702839AReduce dosageLow toxicityBiocidePaints with biocidesWater basedMicrobial challenge

The invention relates to an in-tank antiseptic antimildew agent composition integrated with a dry film for paint. The composition is prepared from a water-based paint in-tank antiseptic bactericide, a dry film antimildew agent, a solvent, an aid, a stabilizing agent and water. The in-tank antiseptic antimildew agent composition integrated with a dry film for paint has the advantages of reasonable formula, advanced process, good corrosion and mildew prevention effects, good stability, and the like. When the in-tank antiseptic antimildew agent composition integrated with a dry film for paint is used for paint, salt cluster phenomena can be avoided, an in-tank antiseptic effect can pass a microorganism challenge test, and the dry film mildew-growing grade is a zero grade.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

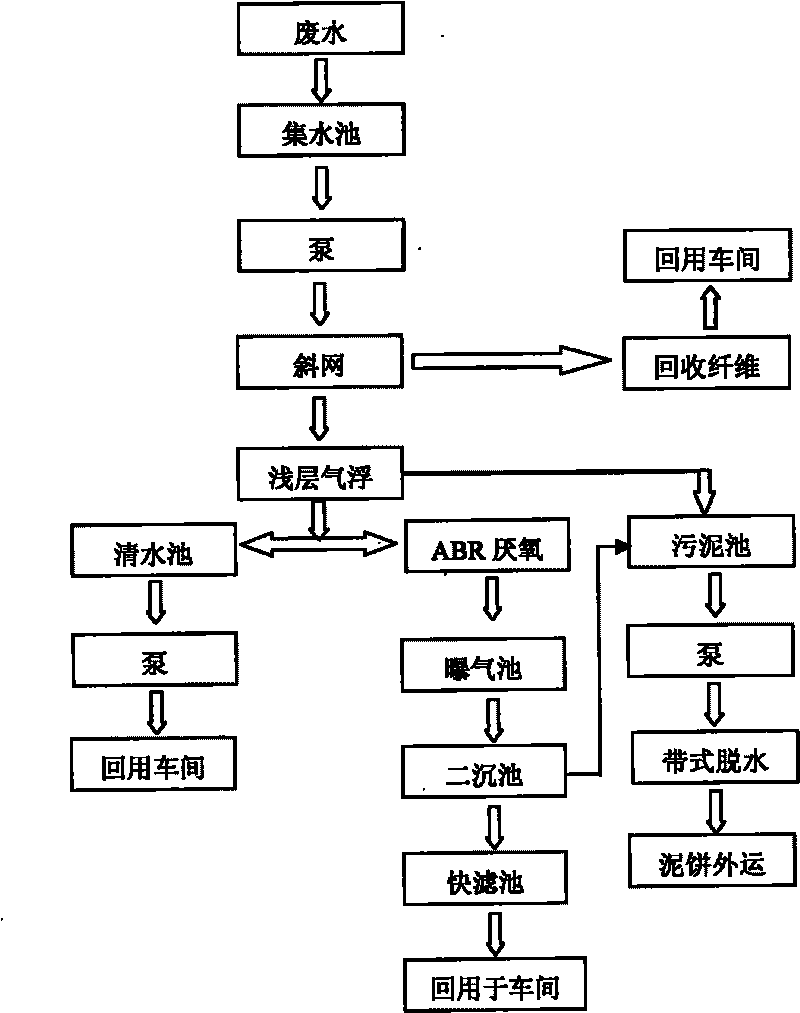

Closed circulation and zero emission processes for papermaking wastewater

InactiveCN101708916AReduce processing burdenGuaranteed treatment effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentZero emissionTreatment effect

The invention discloses closed circulation and zero emission processes for papermaking wastewater, which adopts the process flows of a super-efficient air floating device plus anaerobic biochemical treatment plus aerobic biochemical treatment, wherein the CODCr of effluent water, the BOD5, the concentration of suspended substances (SS) and the average value of the turbidity (10d) are 65.9mg / L, 26.7mg / L, 38.7mg / L and 23NTU respectively, and fully meet the national standard for recycling or discharge. The processes not only can effectively reduce the burden of wastewater treatment, ensure the treatment effect of the wastewater, but also can effectively reduce the fiber loss, reduce production cost, and can bring huge environmental and economic benefits to enterprises.

Owner:SHAANXI UNIV OF SCI & TECH

Process for preparing sodium dichromate

InactiveCN101693556AReduce Chloride ContentReduce Sulfate LevelsChromates/bichromatesCarbonizationSodium dichromate

The invention provides a process for preparing sodium dichromate, namely producing the sodium dichromate through a carbonization method comprising: converting sodium chromate into the sodium dichromate via carbon dioxide under pressurizing condition; delivering sodium chromate neutral liquor with impurities removed to a carbonization tower after a cascade reaction of more than three continuous towers; obtaining carbonizing liquor by controlling different gradient parameters (concentration and temperature of the carbonizing liquor, partial pressure of the carbon dioxide, carbonizing time and the like), continuously carbonizing and separating under pressure; obtaining sodium dichromate finished products through concentrating, filtering, evaporating, crystallizing and centrifugal dehydrating.

Owner:SICHUAN YINHE CHEM

Hot-soda washing desulfurization method

ActiveCN101319150AHigh operating temperatureEasy to operateGaseous mixture working upComing outSulfur

The present invention discloses a method for desulfurating by thermokalite washing, belonging to the desulfuration technical field. In order to solve the problems that the prior art is inconspicuous in desulfuration effect, not good in separation effect of liquid hydrocarbon and alkali liquor, low regeneration efficiency of alkali liquor, large in environment protection pressure, etc., a liquid-liquid converse thermokalite washing tower is adopted for removing the sulfur in liquefied gas by thermokalite at a higher temperature, an alkali liquor sedimentation tower is adopted for separating the alkali liquor and the liquefied gas, and then related equipment such as an alkali liquor regeneration tower, etc. is adopted for removing sulfide from a system. The method improves the operating temperature of the alkaline tower, quickens the conversion rate of sulfur in various forms, and can convert the sulfur in various forms in the liquid hydrocarbon into sulfide or disulphide, etc.; The titanium, cyanine and cobalt catalysts are omitted, and thus the cost of the catalyst is economized; the liquid hydrocarbon come out from the alkaline tower enters an alkali liquor knockout tower, the staying time is increased, and thus the effect of separation of the liquefied gas from the alkali liquor is better.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing corrugated paper and textile spool paper by manioc slag and wine stillage slag

InactiveCN101413225ASufficient raw materialsQuality improvementNon-fibrous pulp additionSecondary cellulose fibresSocial benefitsBobbin

The invention discloses a method for producing corrugated paper and bobbin paper by manioc waste and lees. The manioc waste and the lees are purified, ground, washed, and dehydrated respectively; impurities are removed; plant fiber is retained; the mixture of treated manioc waste and lees is mixed with waste paper stock according to the proportion of 1-7 to 3-9; and a paper-making additive is properly added to produce the corrugated paper and the bobbin paper. The method fully utilizes production wastes, namely the manioc waste and the lees to produce good and cheap corrugated paper and bobbin paper. The methd has the advantages of adequate production raw materials, low cost, simple and convenient operation, good product stability, large market potential, and high product profit, prolongs industrial chains of the manioc waste and the lees, solves the waste utilization problem of the prior manioc waste and lees, also reduces the environmental protection pressure of enterprises, improves the economical benefit of the enterprises, drives surrounding villages to be commonly prosperous, and has good social benefit and environmental protection benefit.

Owner:GUANGXI MINGYANG ENVIRONMENTAL PAPER PRODS

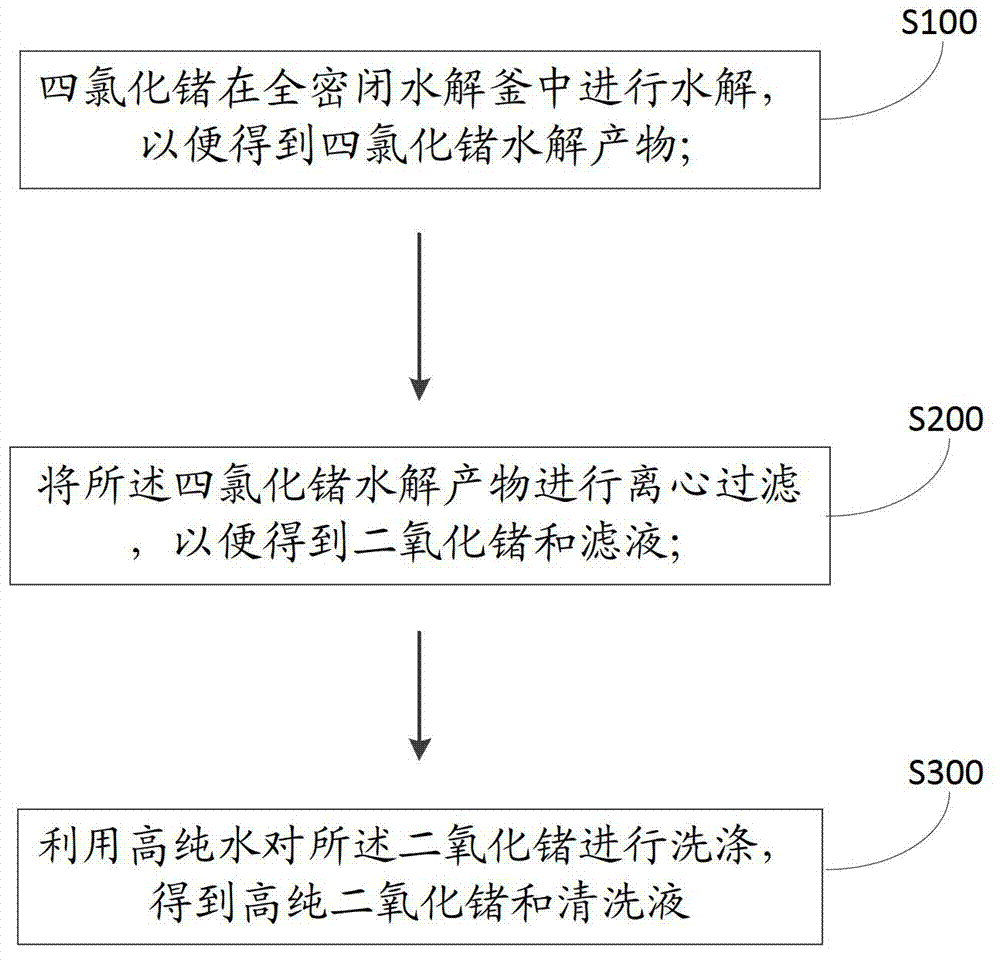

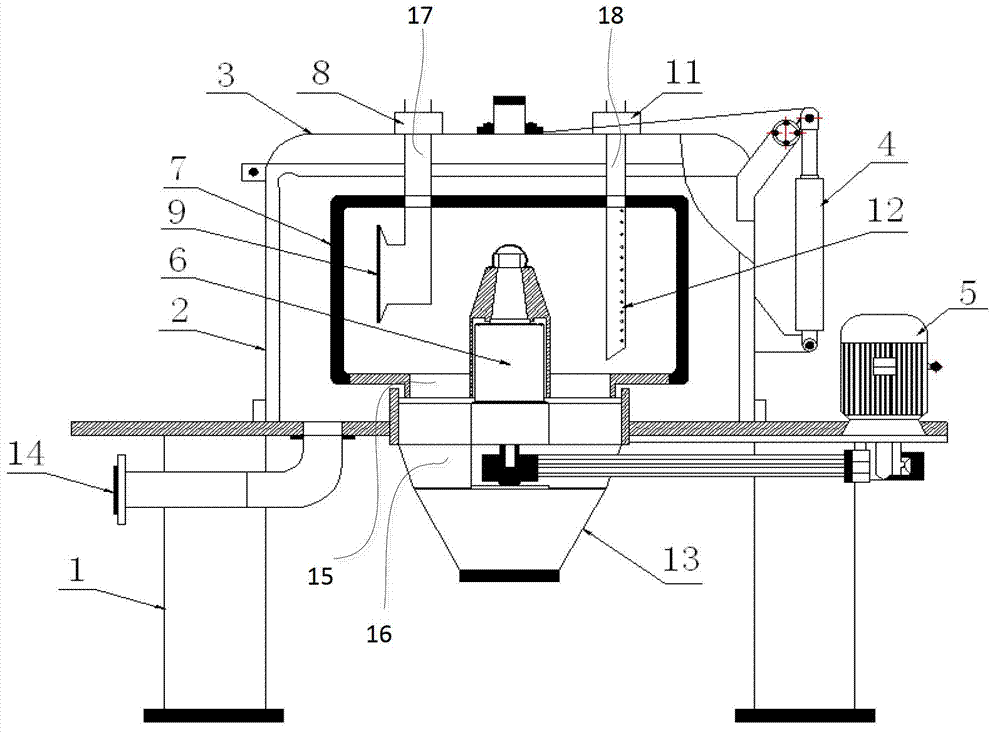

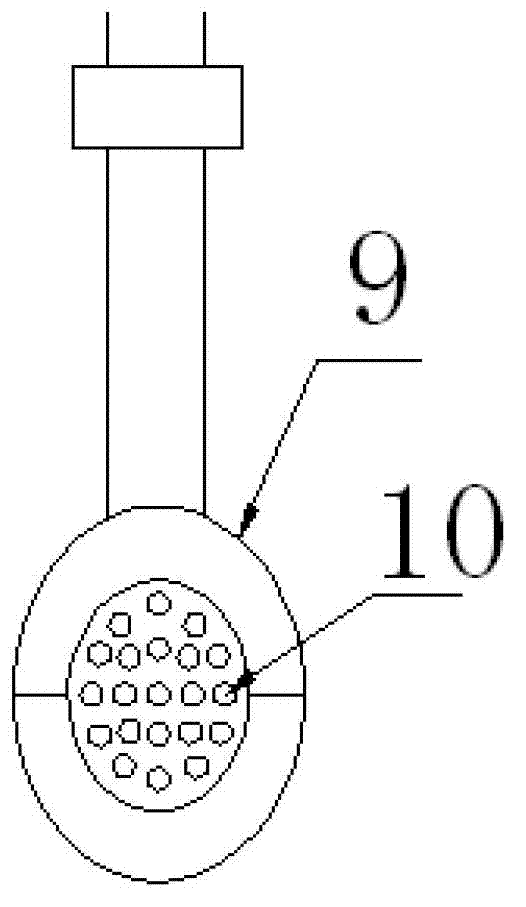

Novel process for preparing germanium dioxide (GeO2)

ActiveCN102774877AReduce lossesHigh degree of automationGermanium dioxideGermanium dioxideHydrolysis

The invention provides a method for preparing germanium dioxide (GeO2). According to the embodiment of the invention, the method comprises the following steps: hydrolyzing the germanium tetrachloride(GeCl4) in a fully-closed hydrolysis reactor to obtain the hydrolysis product of the GeCl4, centrifuging and filtering the hydrolysis product of the GeCl4 to obtain the GeO2 and the filtrate, and cleaning the GeO2 by high-purity water to obtain the high-purity GeO2 and the cleaning solution. According to the embodiment of the invention, the GeO2 hydrolyzing, filtrating and washing method and device have the advantages of high degree of automation, high GeO2 hydrolysis yield, good solid-liquid centrifugal separation effect, low production costs, less metal loss and environment friendliness.

Owner:云南驰宏国际锗业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com