Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1108results about "Secondary cellulose fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

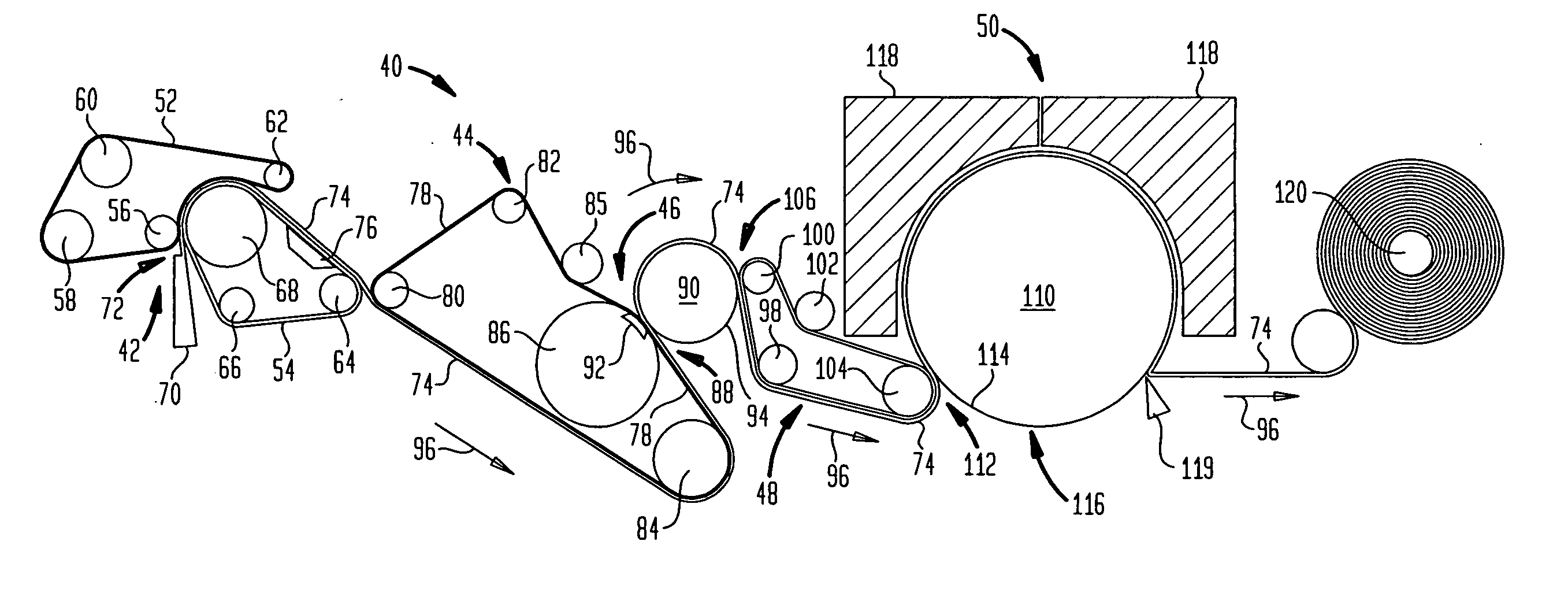

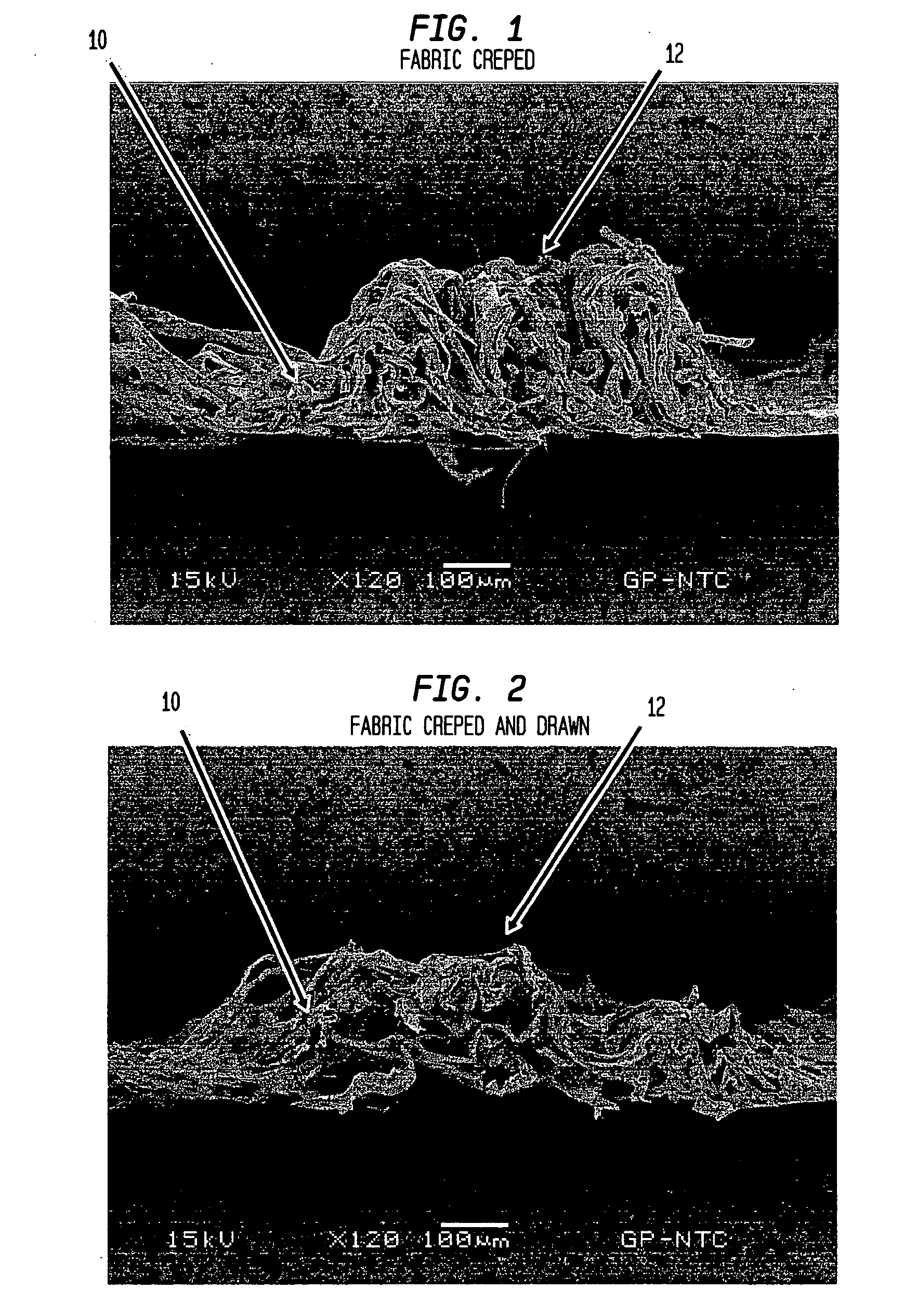

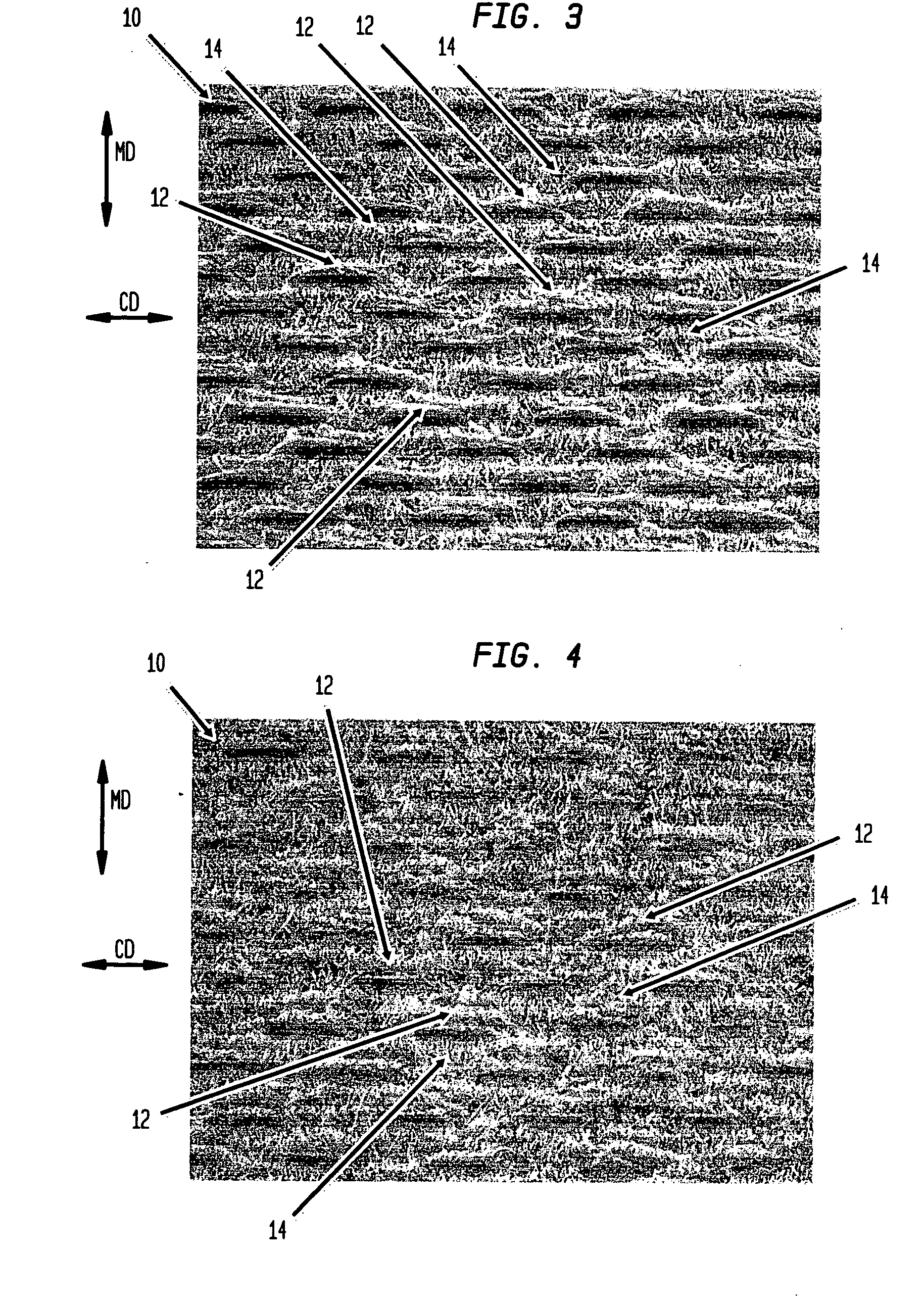

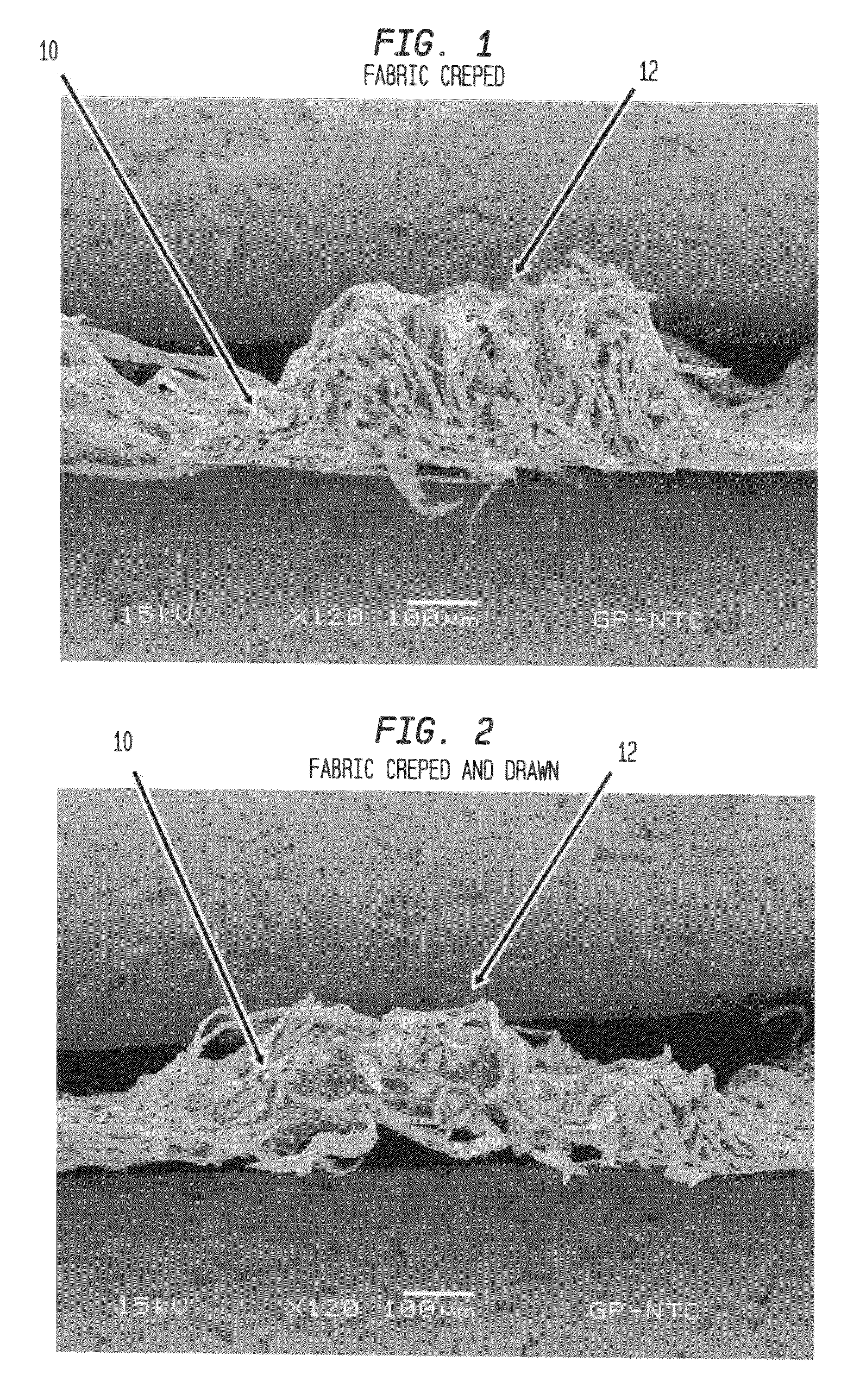

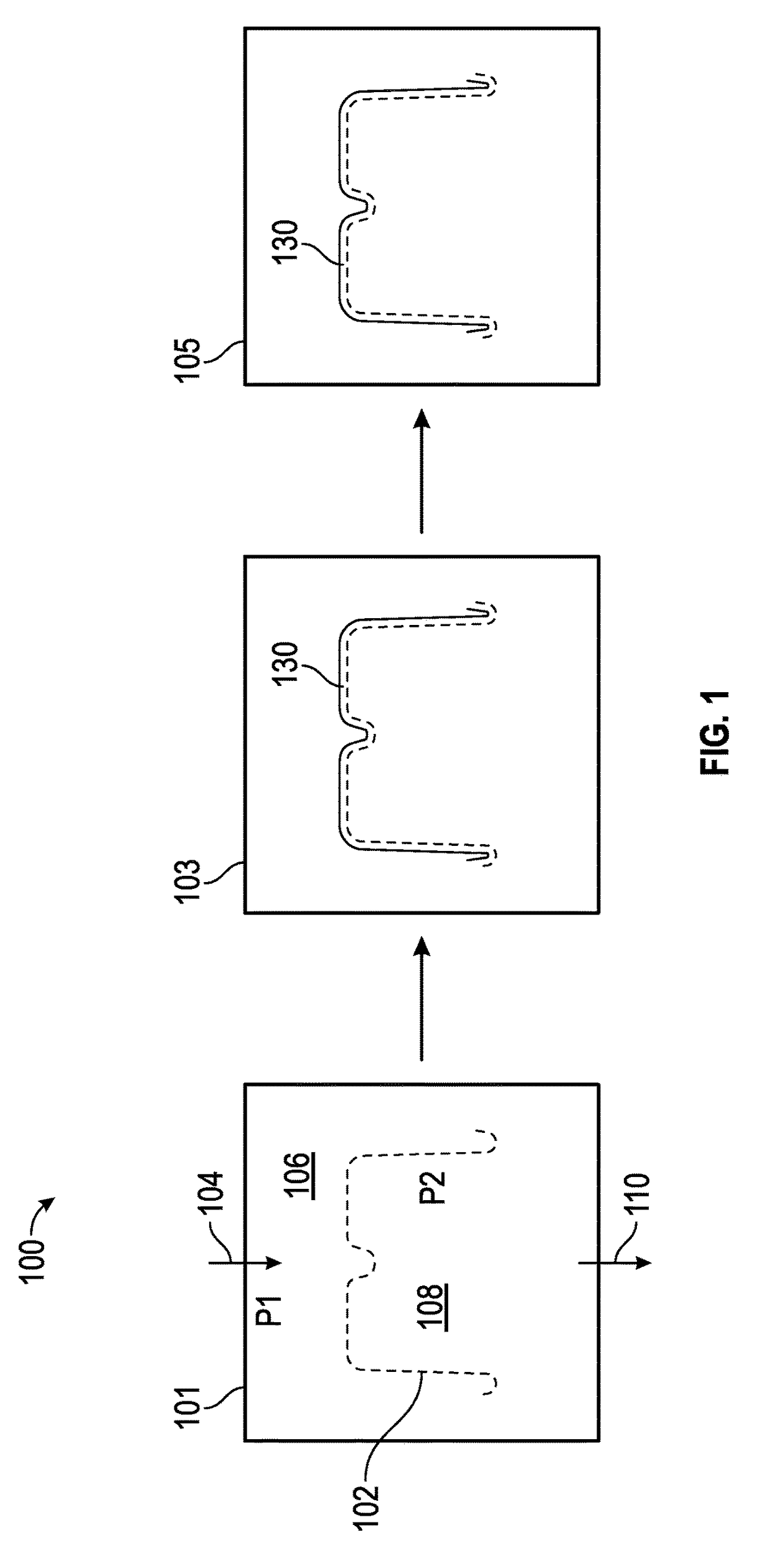

Fabric crepe/draw process for producing absorbent sheet

ActiveUS20050217814A1Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingFiberPapermaking

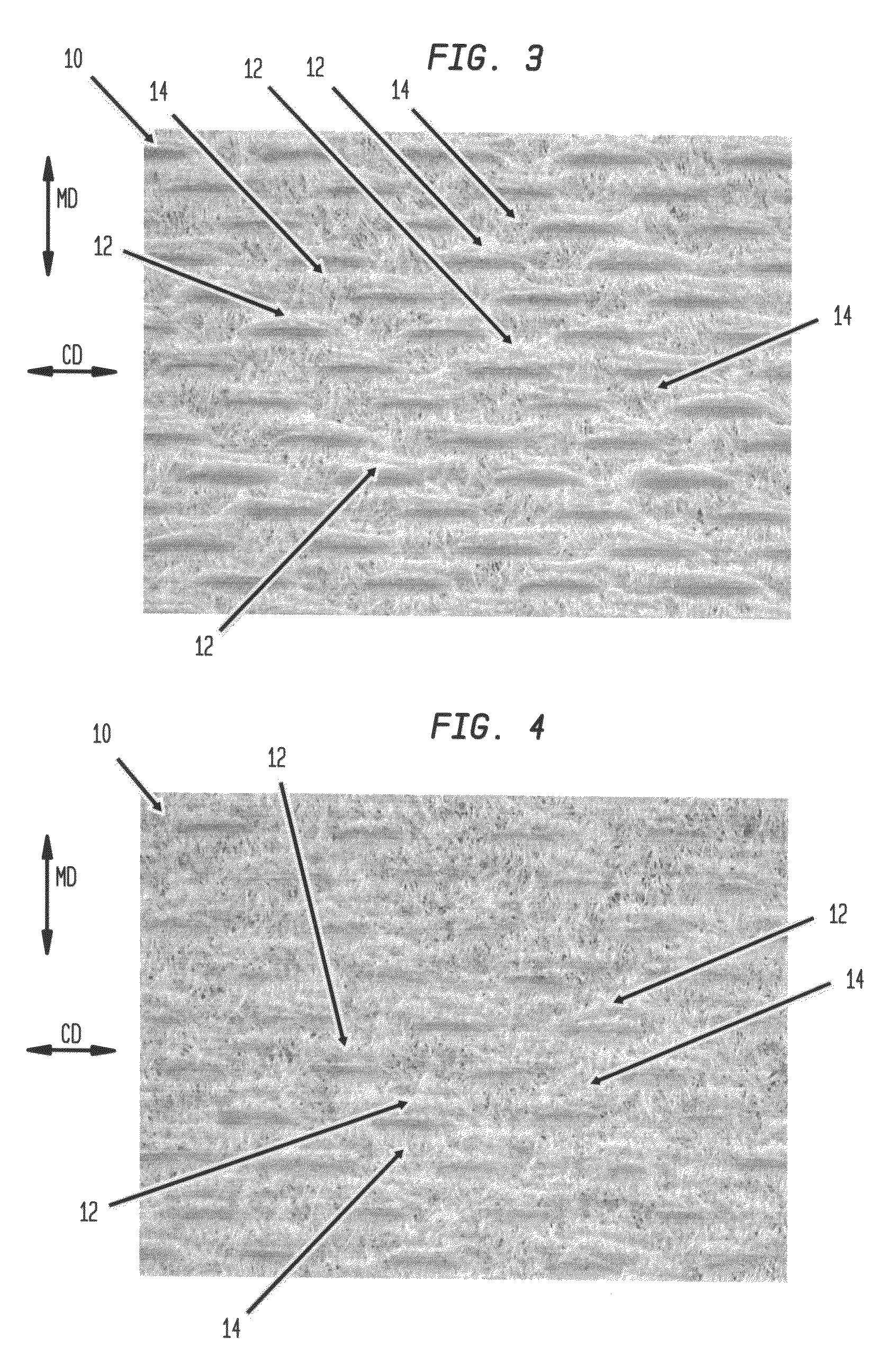

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

Fabric crepe/draw process for producing absorbent sheet

ActiveUS7789995B2Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingCelluloseFiber

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

Fabric-creped sheet for dispensers

ActiveUS7585388B2More MD stretchMore lengthMechanical working/deformationSpecial paperBiomedical engineeringSheet material

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

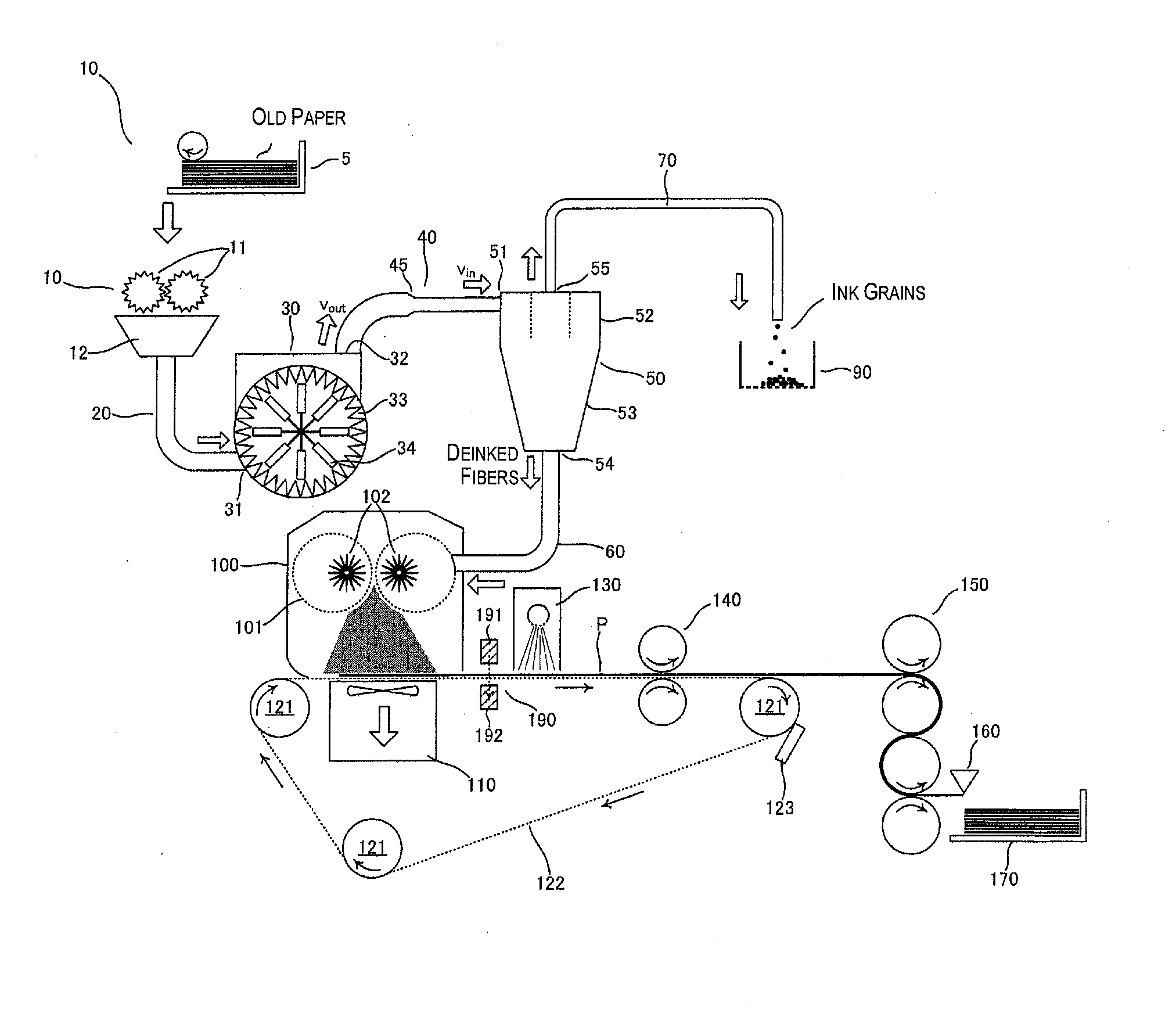

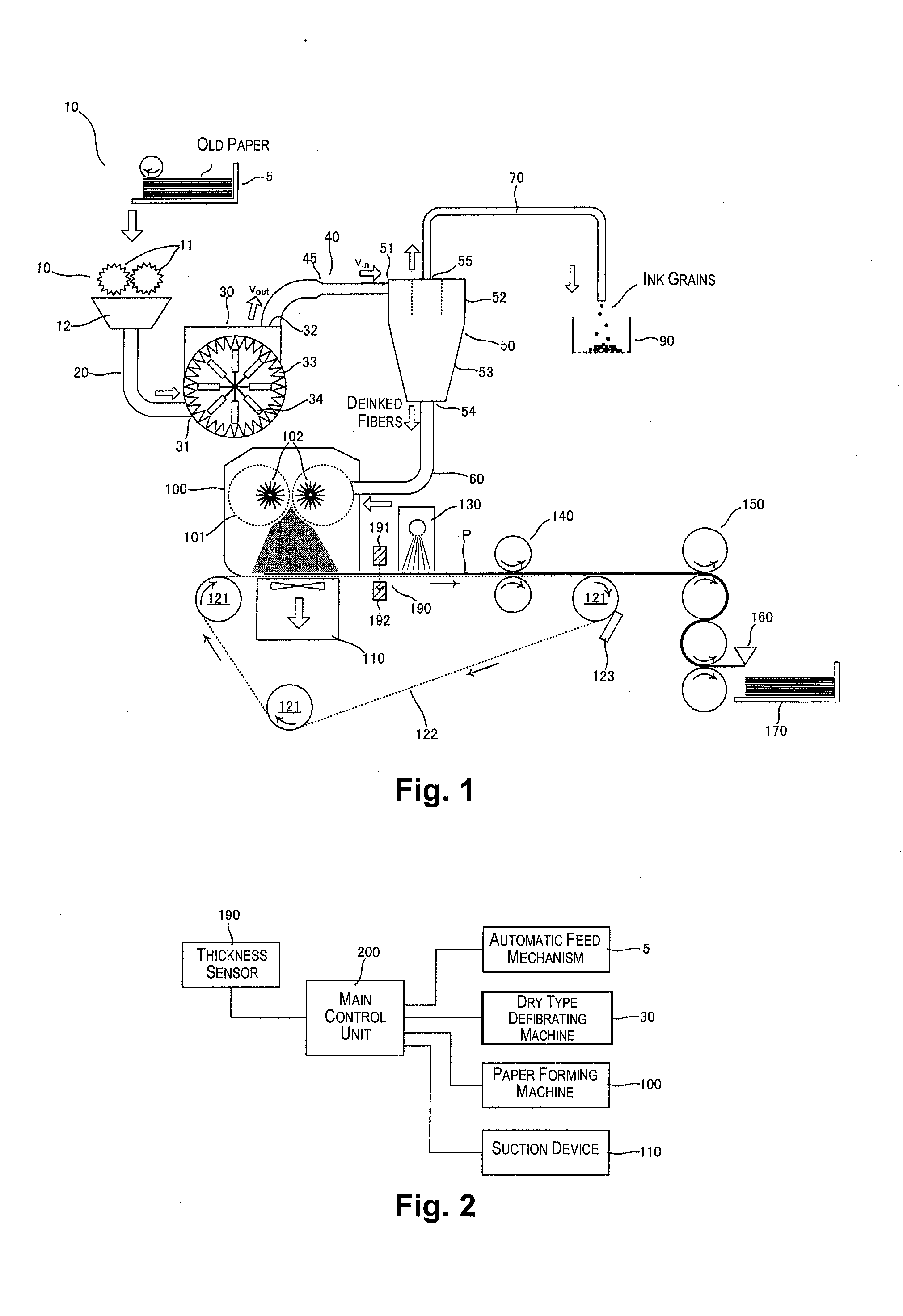

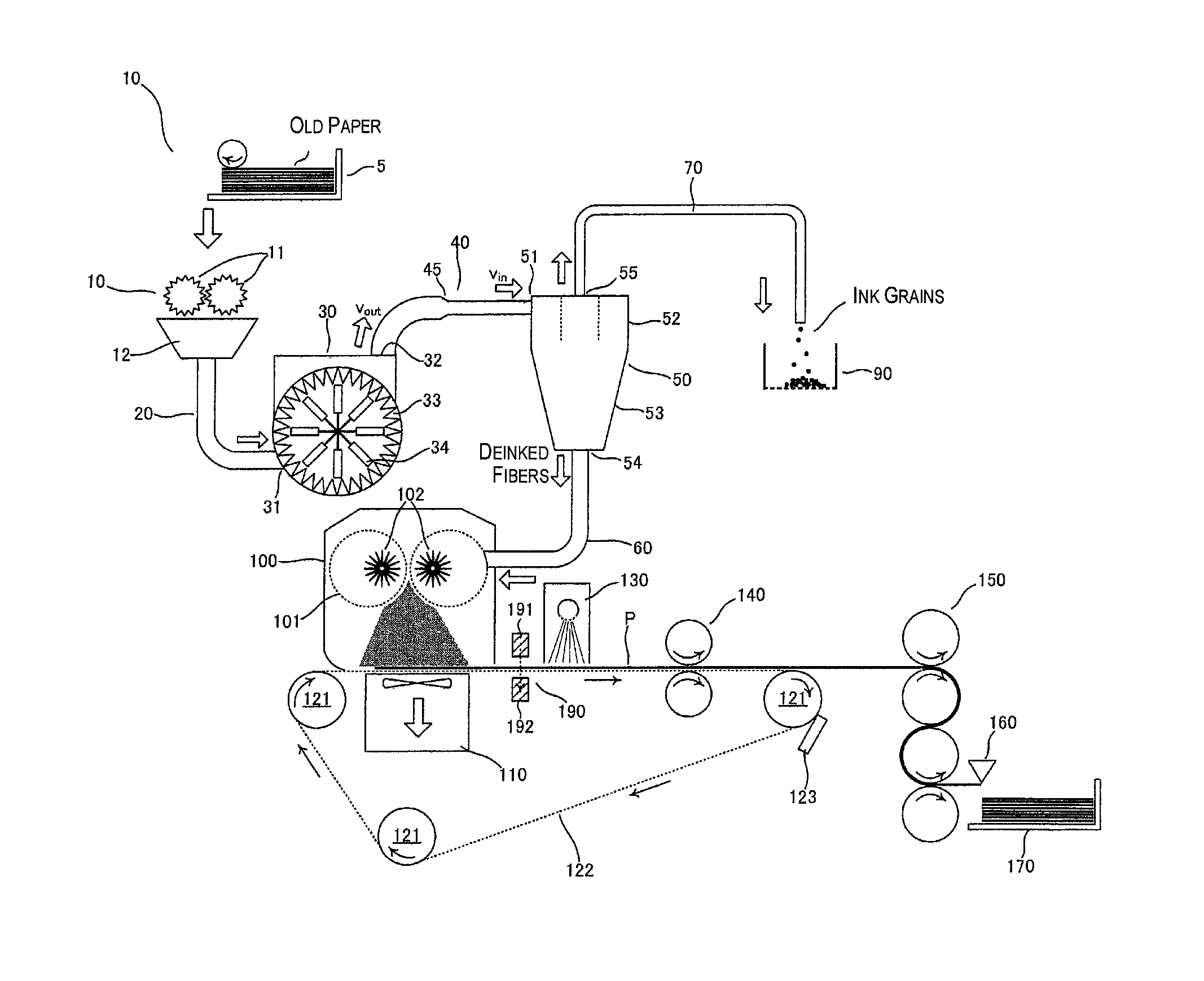

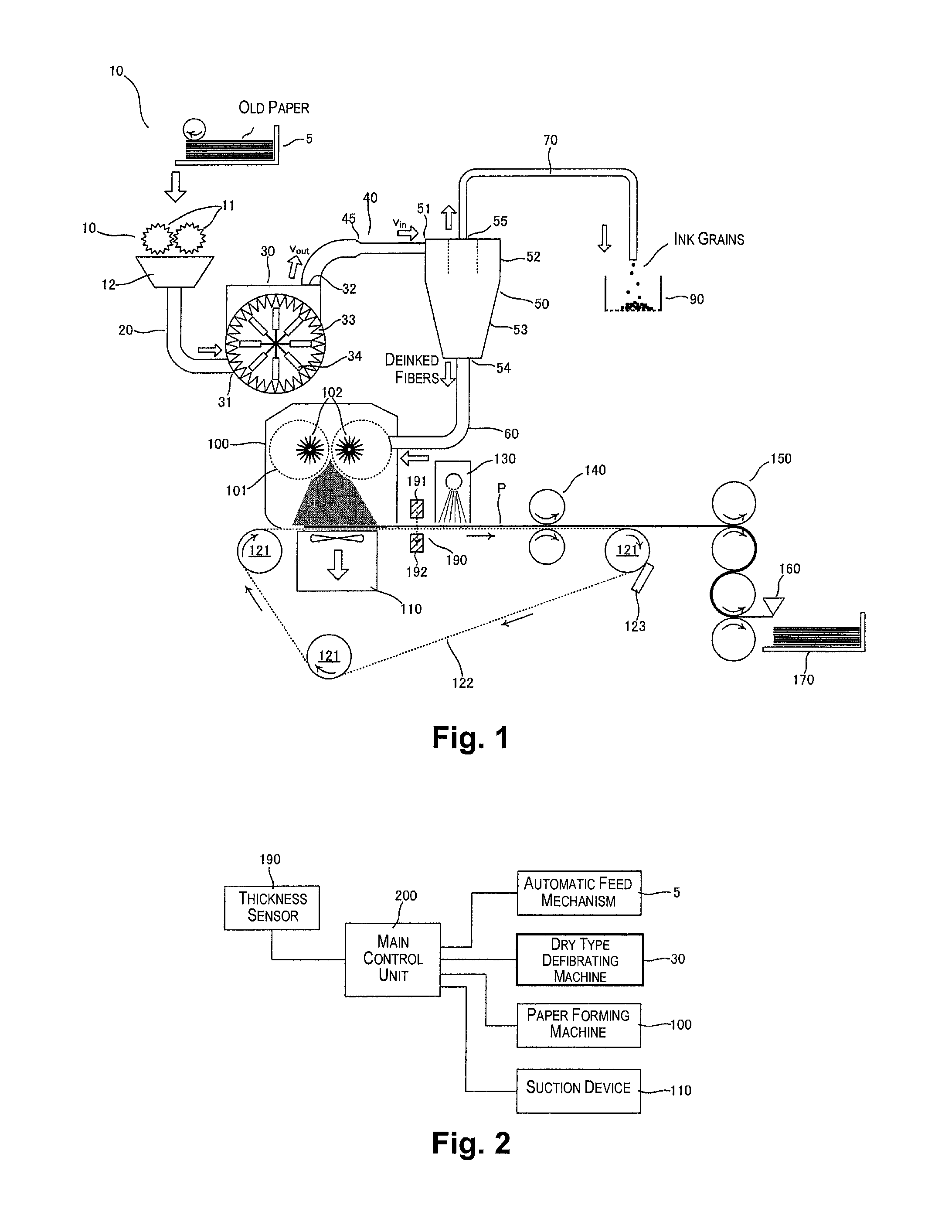

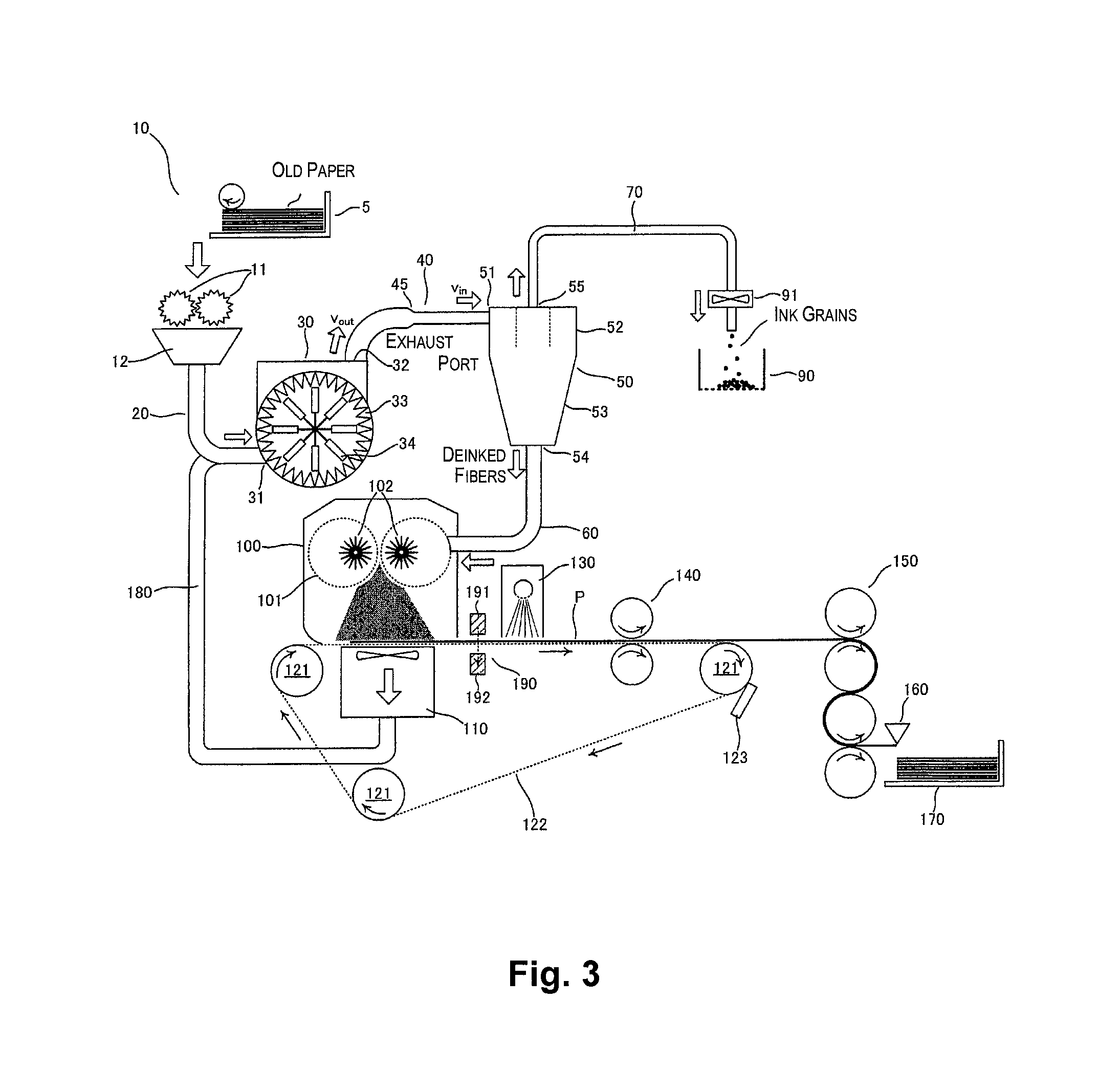

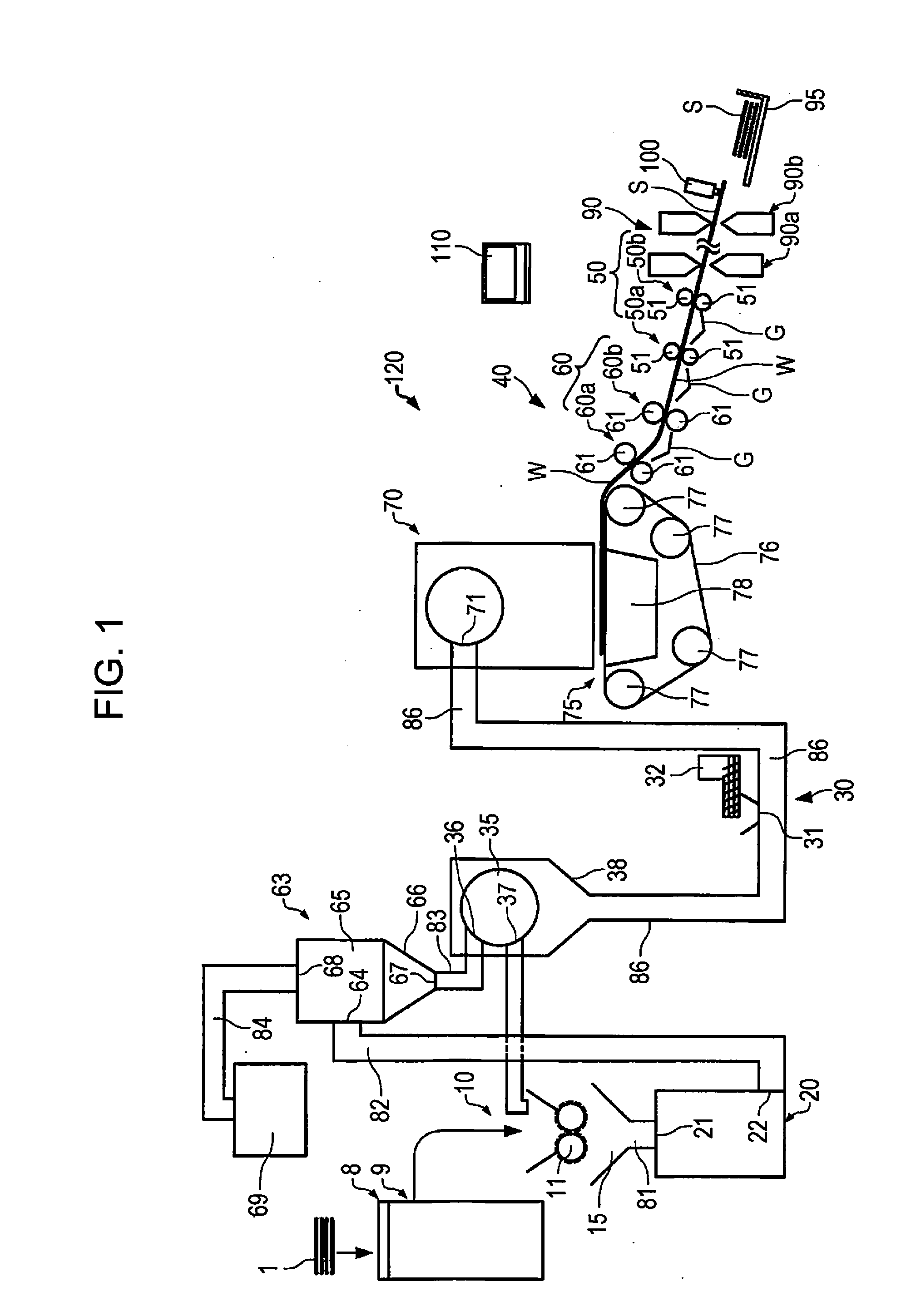

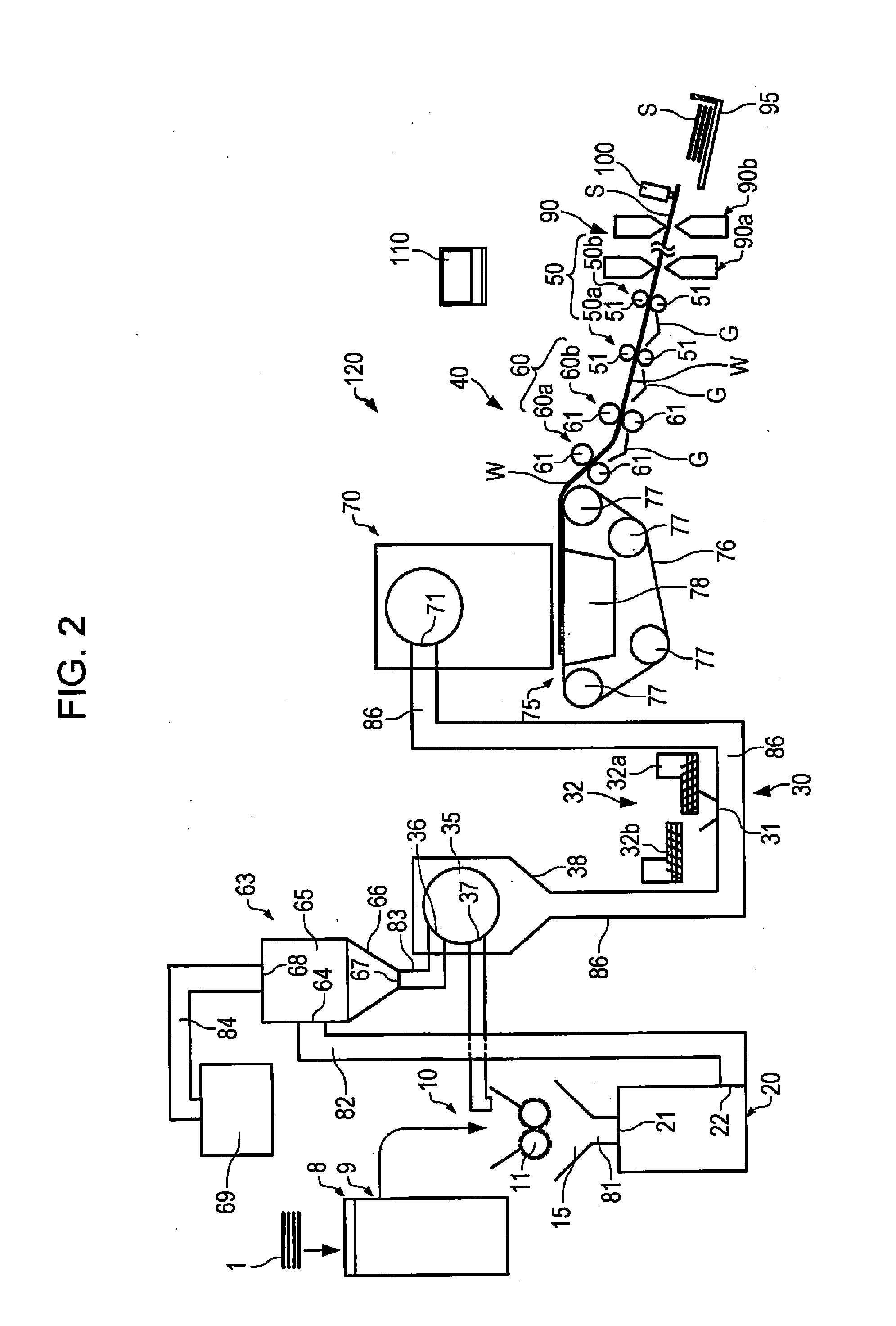

Paper recycling system and paper recycling method

InactiveUS20140027075A1Improve the level ofHigh whitenessPaper recyclingFlat articlesPaper recyclingPulp and paper industry

To provide a paper recycling device capable of recycling paper of increased whiteness level that can be widely used for applications other than paper for newspapers, the paper recycling device of the present invention has a dry type defibrator for crushing and defibrating paper, a first transport pipe for transporting defibrated material that was defibrated by the dry type defibrator, a cyclone for air classifying and deinking the defibrated material transported by the first transport pipe, a second transport pipe for transporting the defibrated material that was deinked by the cyclone, and a paper forming machine for forming paper with the defibrated material transported by the second transport pipe.

Owner:SEIKO EPSON CORP

Process for making abrasion resistant paper and paper and paper products made by the process

InactiveUS20050155731A1Improve optical brightnessLow friction surfacePaper after-treatmentPaper coatingPapermakingPaper sheet

In this papermaking process, a first strength agent is added to a stock suspension containing pulp and optionally other additives prior to its being formed into a web at the wet end of a papermaking machine. The web is then formed and processed into paper. A second strength agent is then applied to the surface of the paper. The strength agents may be selected to have opposite charge.

Owner:NAT GYPSUM PROPERTIES

Paper recycling system and paper recycling method

Owner:SEIKO EPSON CORP

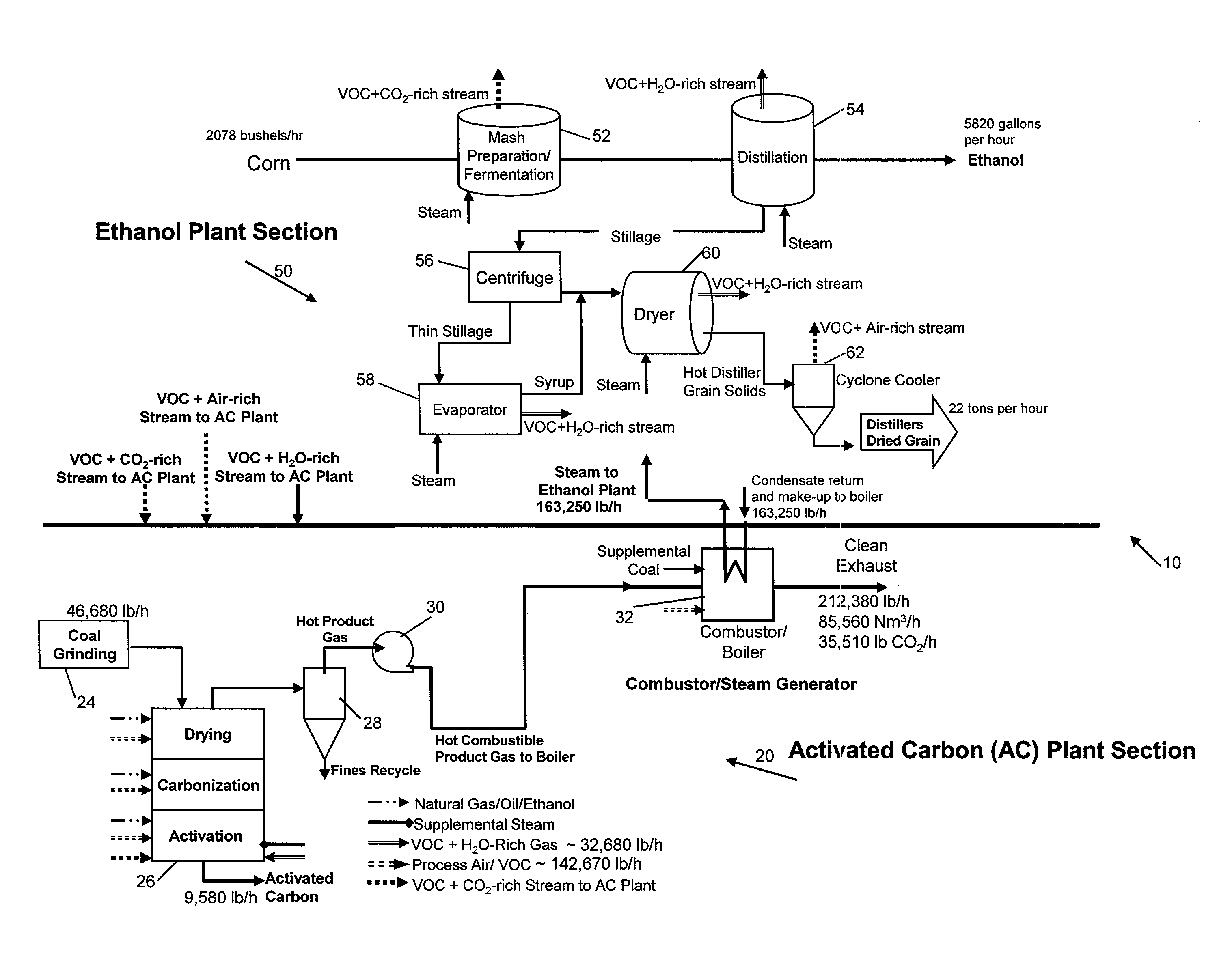

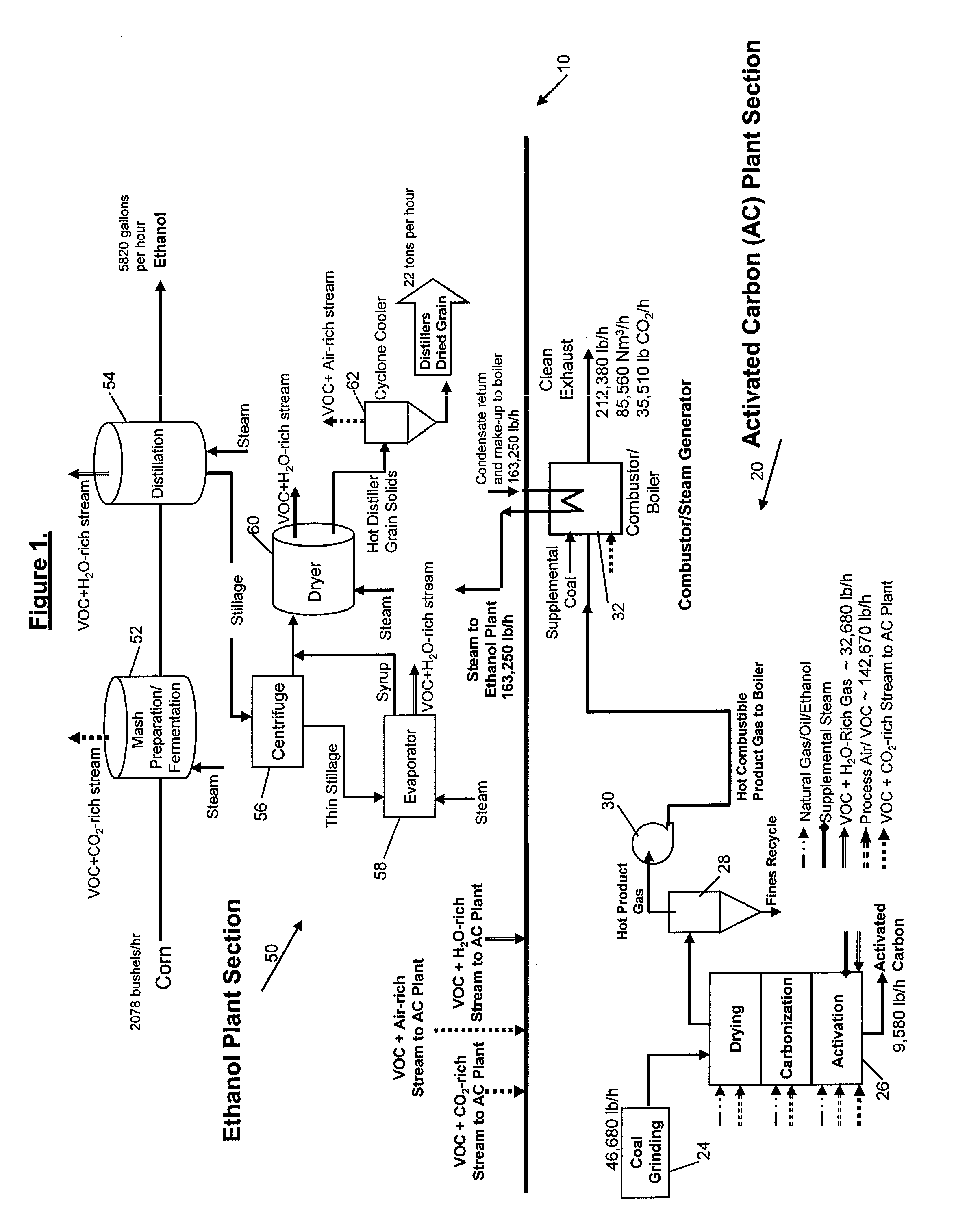

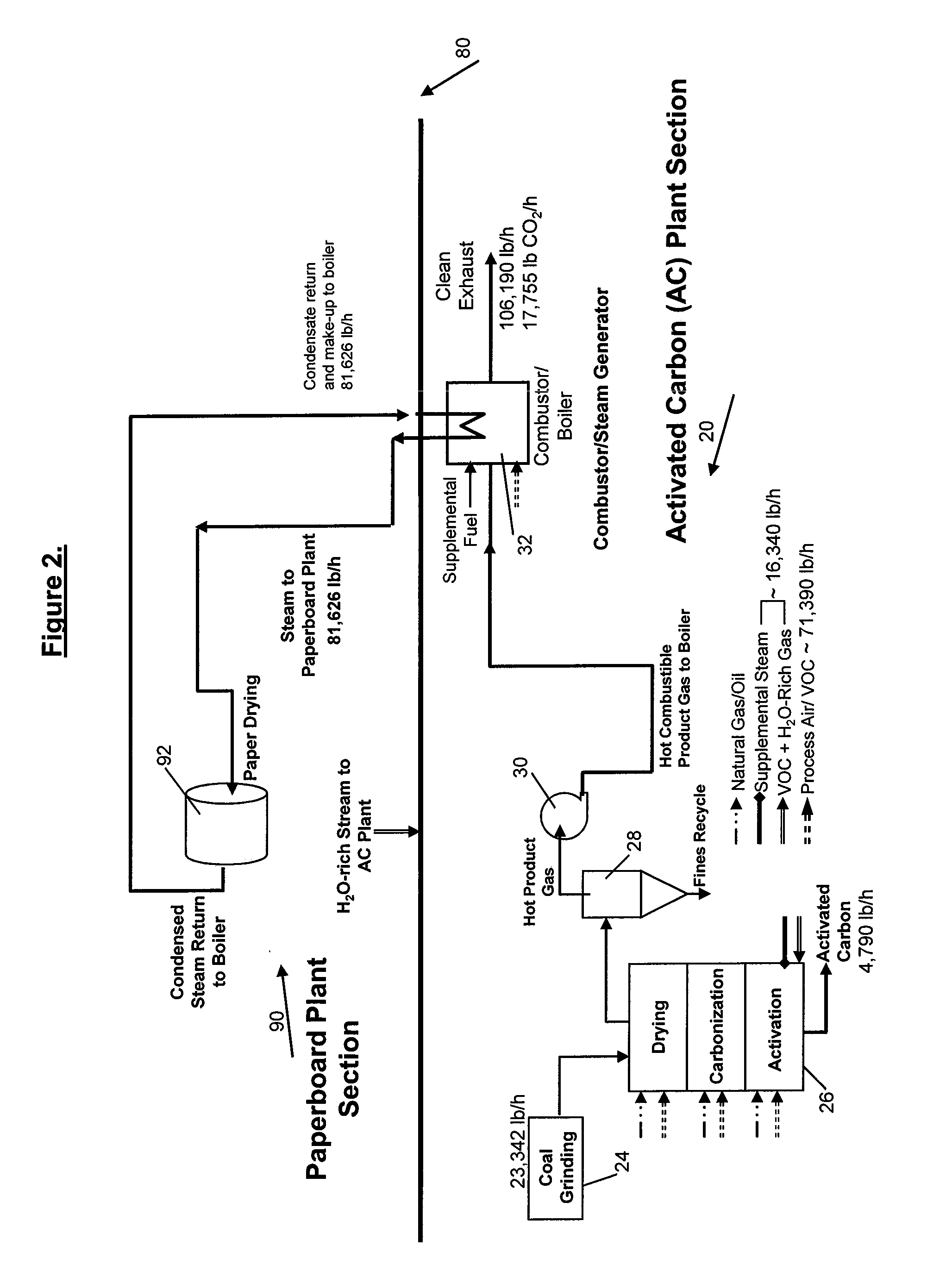

Method of Manufacturing Carbon-Rich Product and Co-Products

ActiveUS20100178624A1Simple and cost-effectiveImprove efficiencyBioreactor/fermenter combinationsGaseous fuel feeder/distributionWater vaporHigh carbon

A method in which a parent hydrocarbon-rich material is processed so as to produce both a carbon-rich solid material that has a higher carbon to hydrogen ratio than that of the parent material and a carbon-deficient combustible gas that has a lower carbon to hydrogen ratio than the parent material. In the process, the material is activated by exposing it to a hot gas stream having elevated levels of one or both of carbon dioxide and water vapor. The combustible gas is combusted to produce heat. At least about 80% of the heat is used in one or more endothermic steps that include drying coal or biomass.

Owner:SRINIVASACHAR SRIVATS

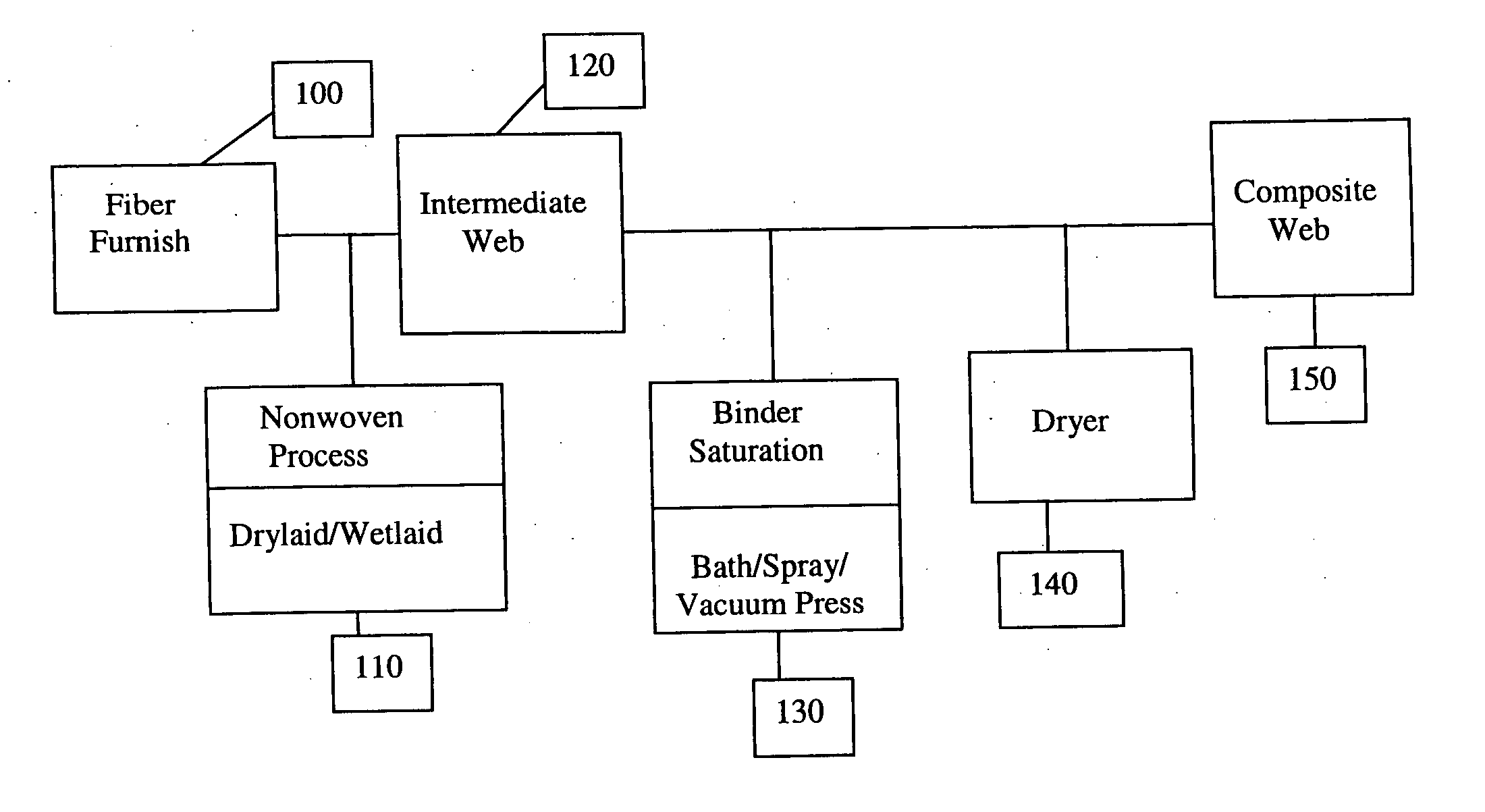

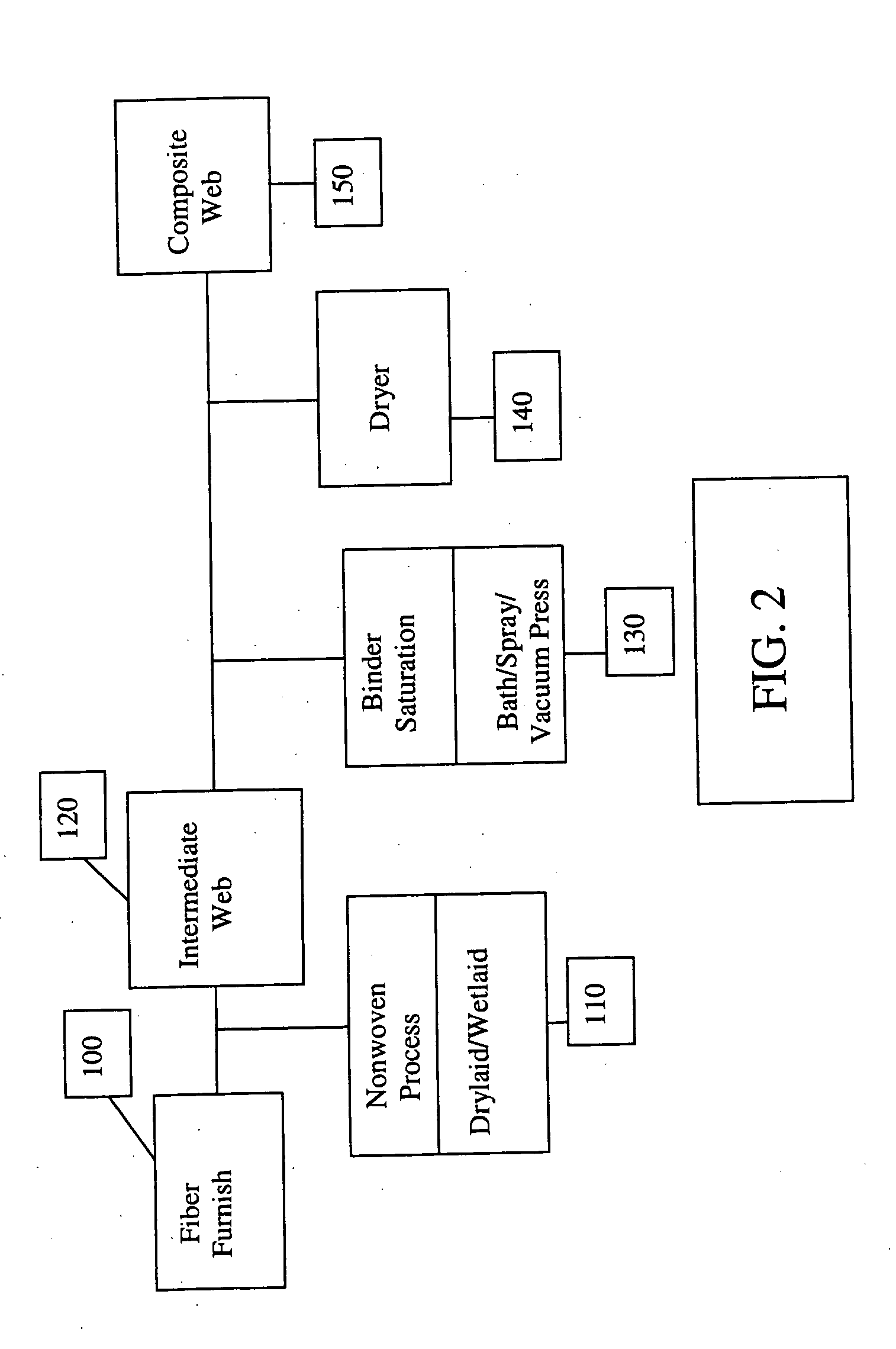

Composite web and process for manufacture from post-industrial scrap

A composite web and process for manufacture from post-industrial scrap wherein the fibers are pre-opened and cut to an average fiber length of about 4 mm. A scrap fiber component and a cellulosic component of such fibers are blended into a fiber furnish. The scrap fiber component includes at least 15% synthetic fibers and may include a blend of natural fibers, high melting point synthetic fibers, and low melting point synthetic fibers. The cellulosic component may include post-industrial cotton fibers which may be refined before blending with the scrap fiber component. The fiber furnish is processed into an intermediate web such as by a drylaid or a wetlaid nonwoven process. The intermediate web is saturated with a latex binding agent and pressed and / or dried to form a composite web capable of further processing into molded or formed consumer or industrial products. The process is capable of producing a high basis weight composite web.

Owner:SSI TECH INC

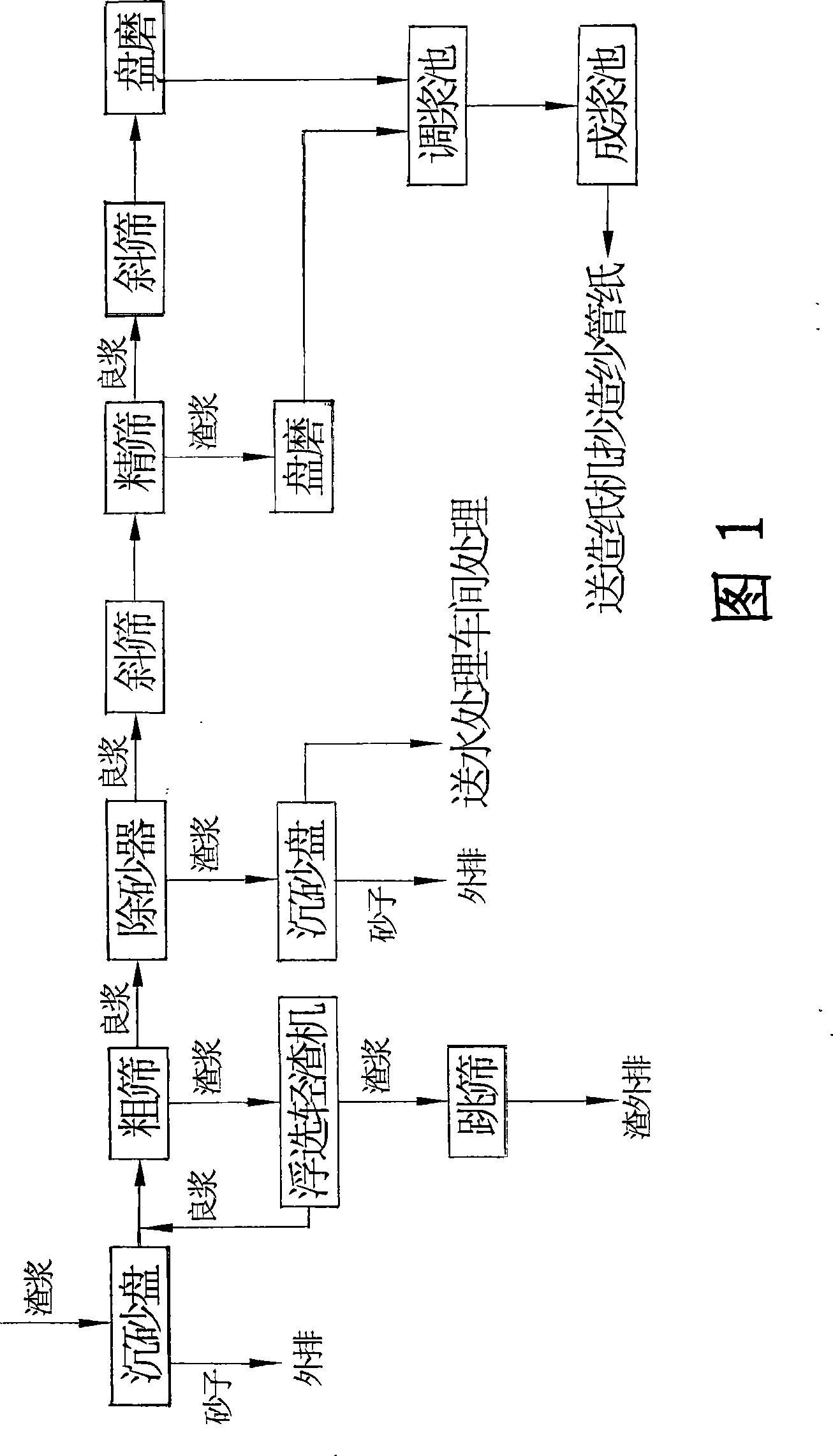

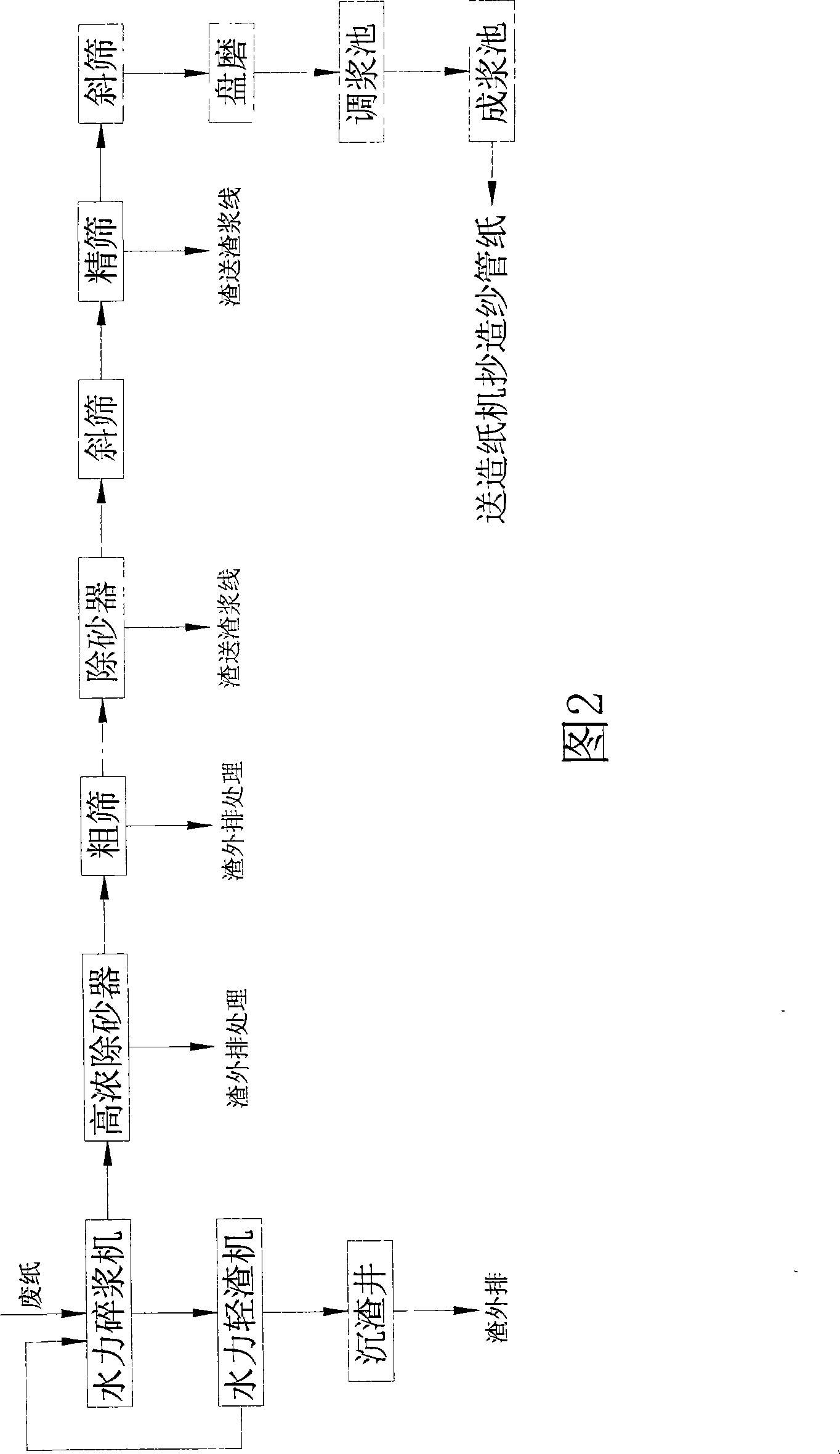

Method for producing recuperated yarn tube base paper by using waste slag and product thereof

ActiveCN101435171ASave resourcesAvoid churnWater-repelling agents additionPaper recyclingYarnProcess engineering

The invention relates to a manufacturing method which utilizes waste residue to produce regenerated yarn cop base paper and an obtained product thereof. The method comprises the following steps: the full stuff of processed waste slurry residue and the full stuff of processed waste paper are mixed according to proportion to carry out sand paper tube forming and then the regenerated yarn cop base paper is obtained. By adopting the method, waste paper resources can be saved, waste water treatment can be reduced, and the obtained regenerated yarn cop base paper has the advantages of low ration, good quality and the like.

Owner:JIAN GRP

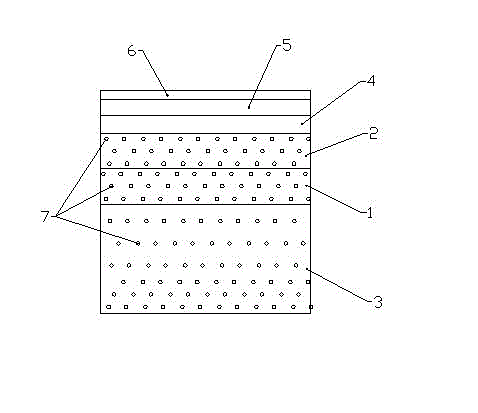

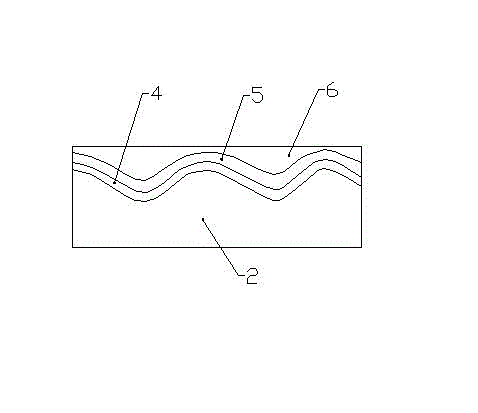

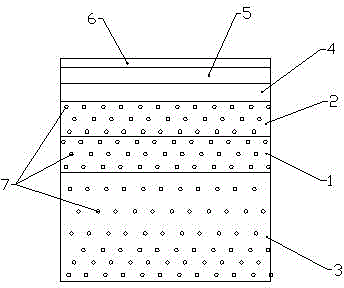

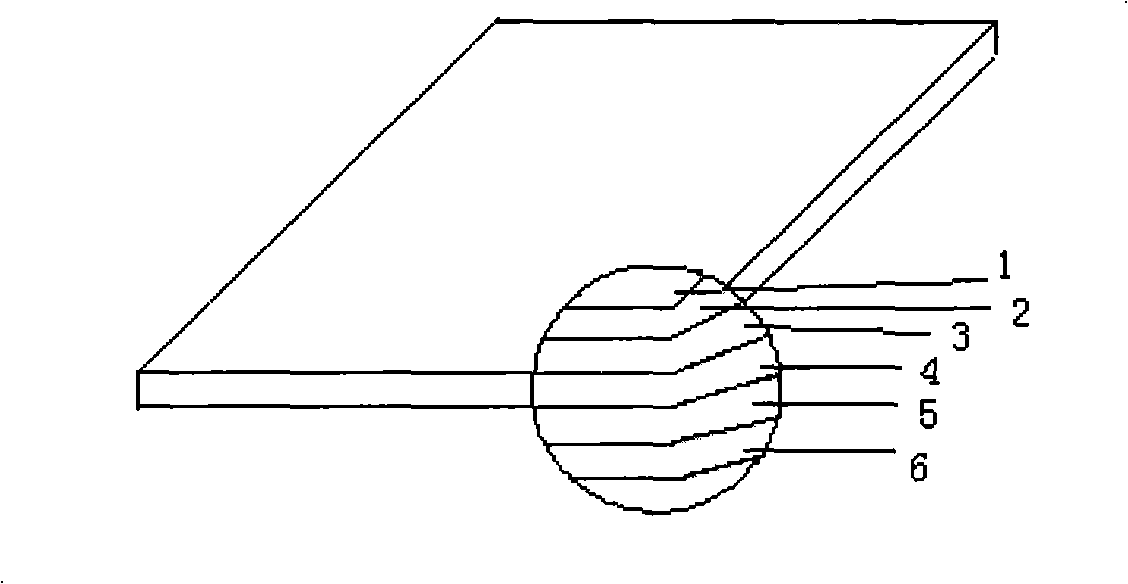

White-surface coated craft paper and production method thereof

ActiveCN102912689AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentRegenerating fibers

The invention discloses white-surface coated craft paper and a production method thereof. The white-surface coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer of the white-surface coated craft paper are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: mixing the bleached hardwood pulp, bleached softwood pulp and bleached regenerated fiber pulp DIP at any proportion, and manufacturing paper through a paper layer to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the white-surface coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

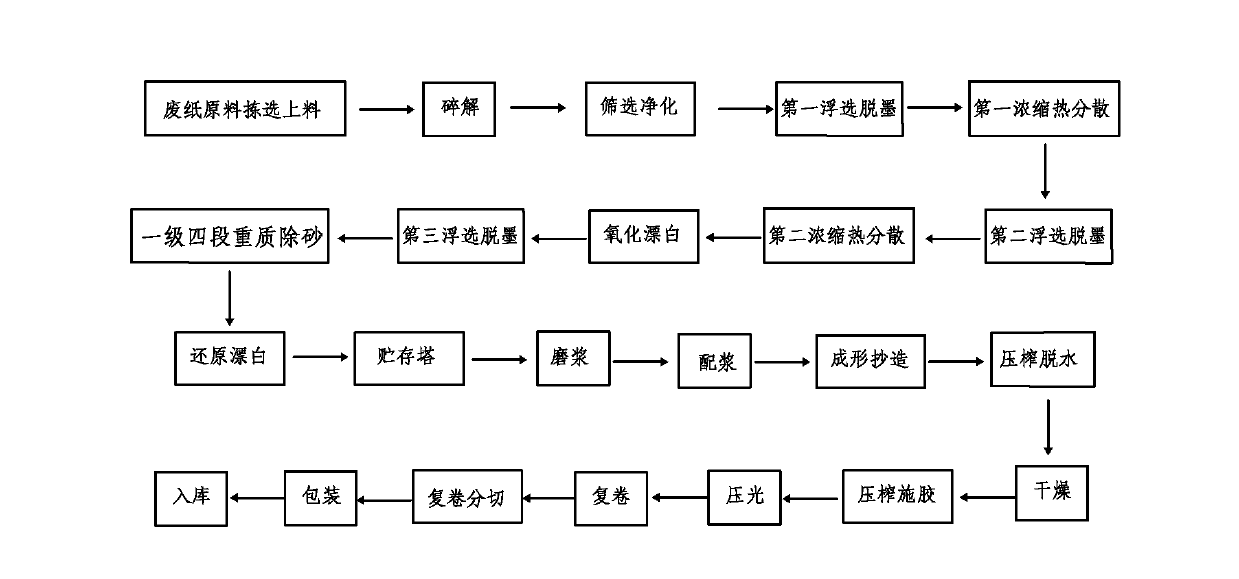

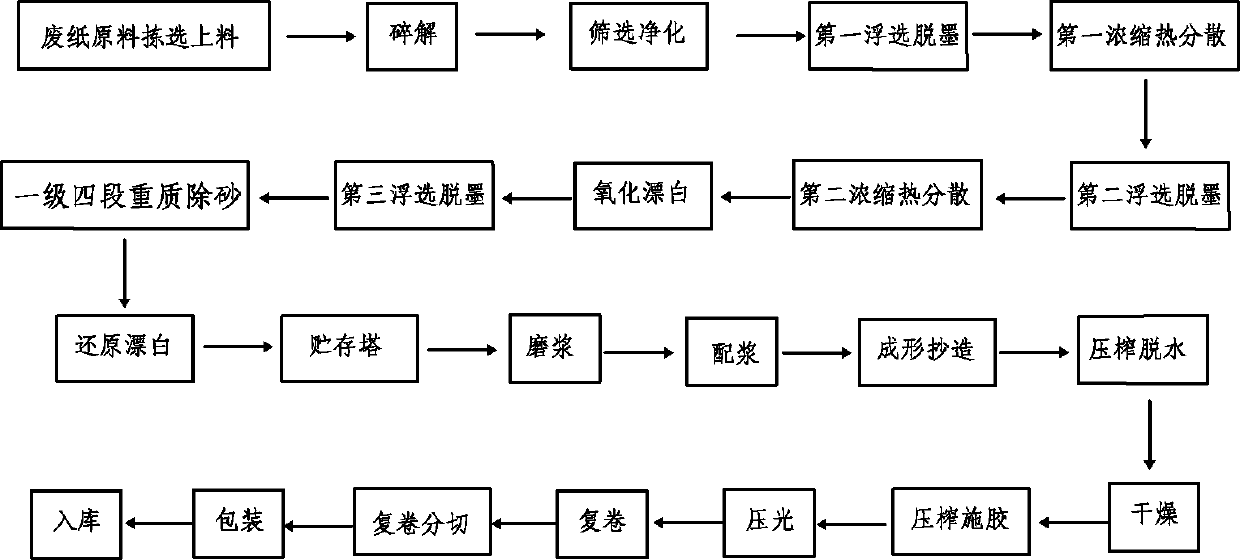

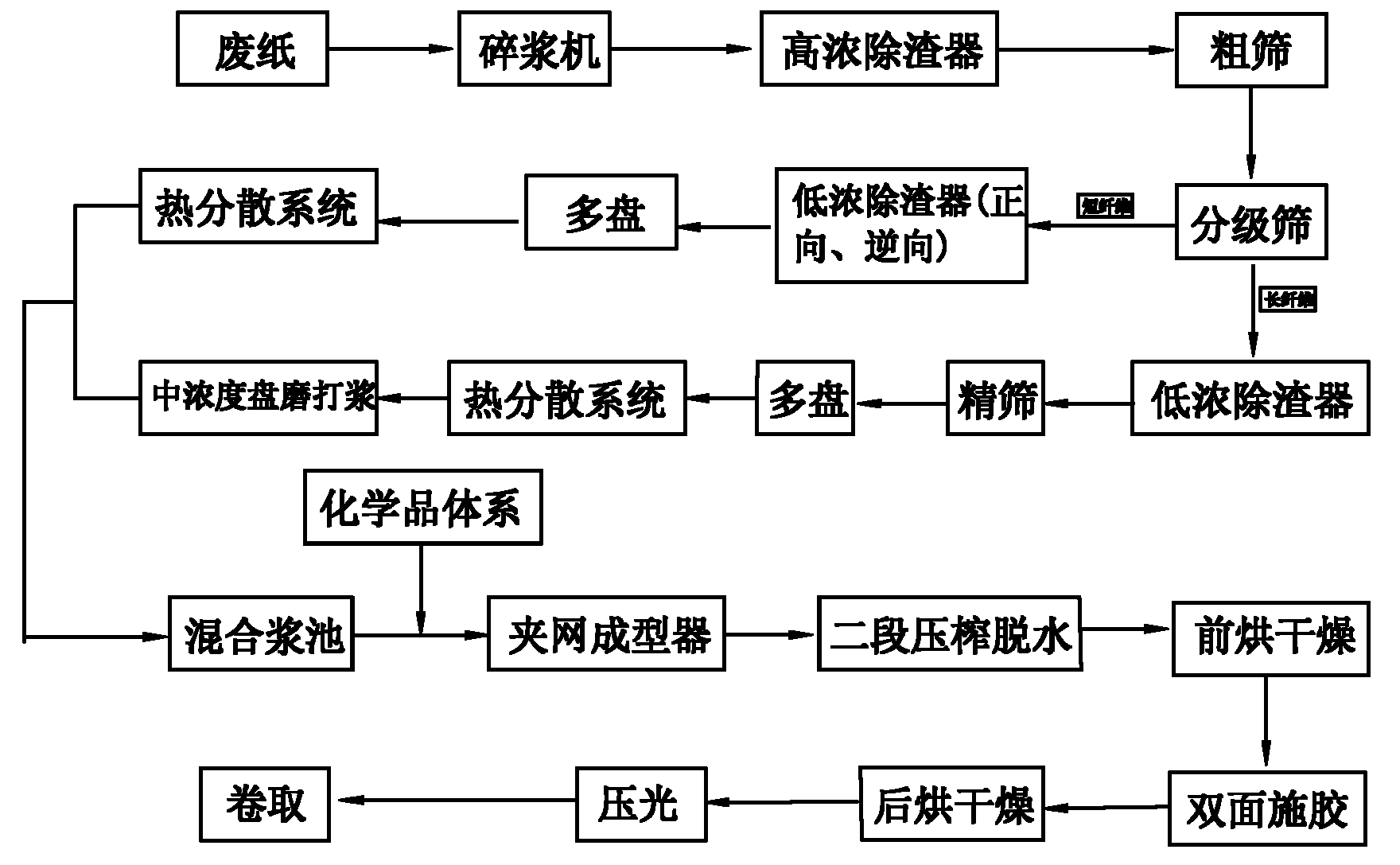

Process for preparing cultural paper by utilizing full-recovered pulp

InactiveCN102677532AQuality improvementImprove cleanlinessPaper recyclingLuminescent/fluorescent substance additionPapermakingSizing

The invention belongs to the technical field of a papermaking process and particularly relates to a process for preparing cultural paper by utilizing full-recovered pulp. The process for preparing the cultural paper by utilizing the full-recovered pulp comprises the following preparation steps of: a step A of sorting and loading waste paper raw materials; a step B of beating; a step C of screening and purifying; a step D of carrying out primary floatation deinking; a step E of carrying out primary concentration and heat dispersion; a step F of carrying out secondary floatation deinking; a step G of carrying out secondary concentration and heat dispersion; a step H of carrying out oxidation bleaching; a step I of carrying out reduction bleaching; a step J of storing in a tower; a step K of milling pulp; a step L of preparing the pulp; a step M of forming and manufacturing the paper with the pulp; a step N of squeezing and dehydrating; a step O of drying; a step P of squeezing and sizing; and a step Q of carrying out press polishing and then completing processing of a finished product by the working sections of reeling, rewinding, packaging and warehousing. According to the process disclosed by the invention, the high-quality cultural paper of which the appearance quality and the physical indexes all reach the domestic and overseas standards is produced by utilizing the low-price waste paper raw materials; the production cost is reduced; the production environment is clean and environmental-friendly; and the production efficiency is high.

Owner:DONGGUAN NINE DRAGONS PAPER IND

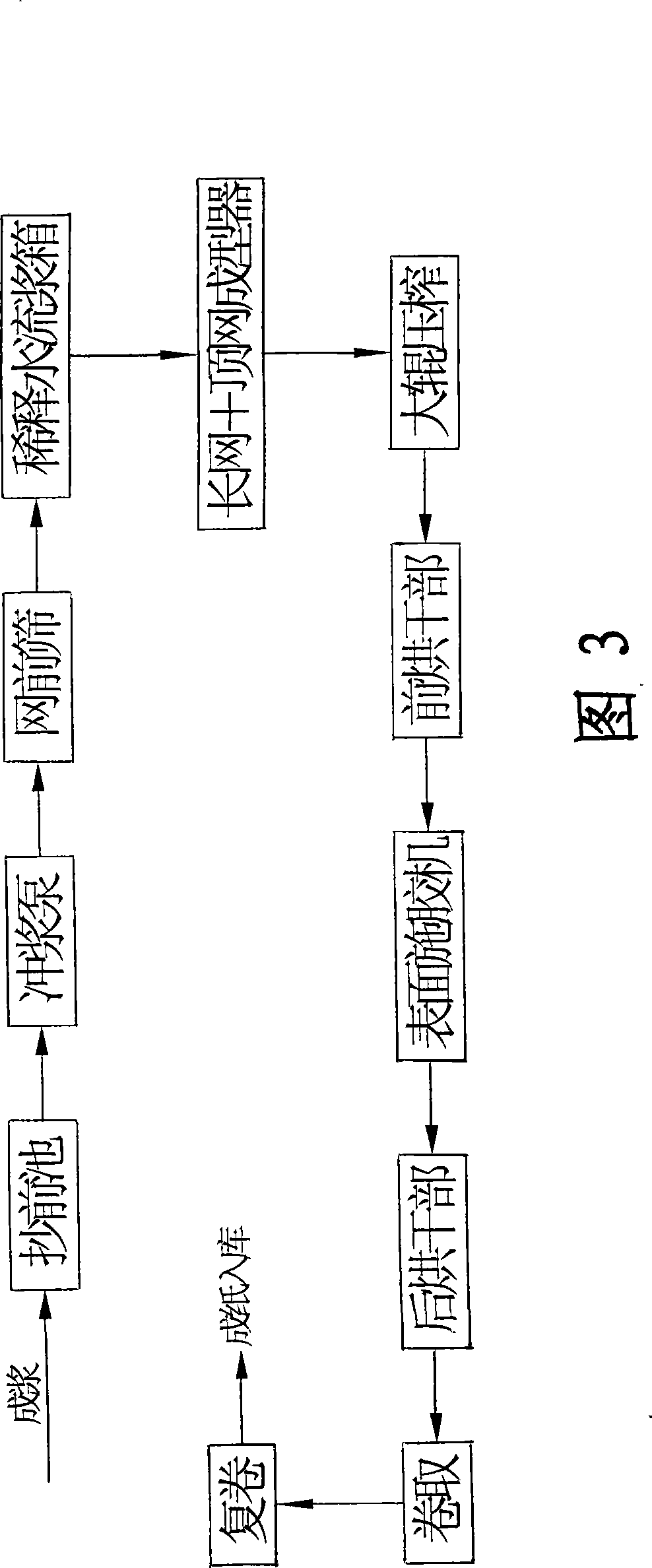

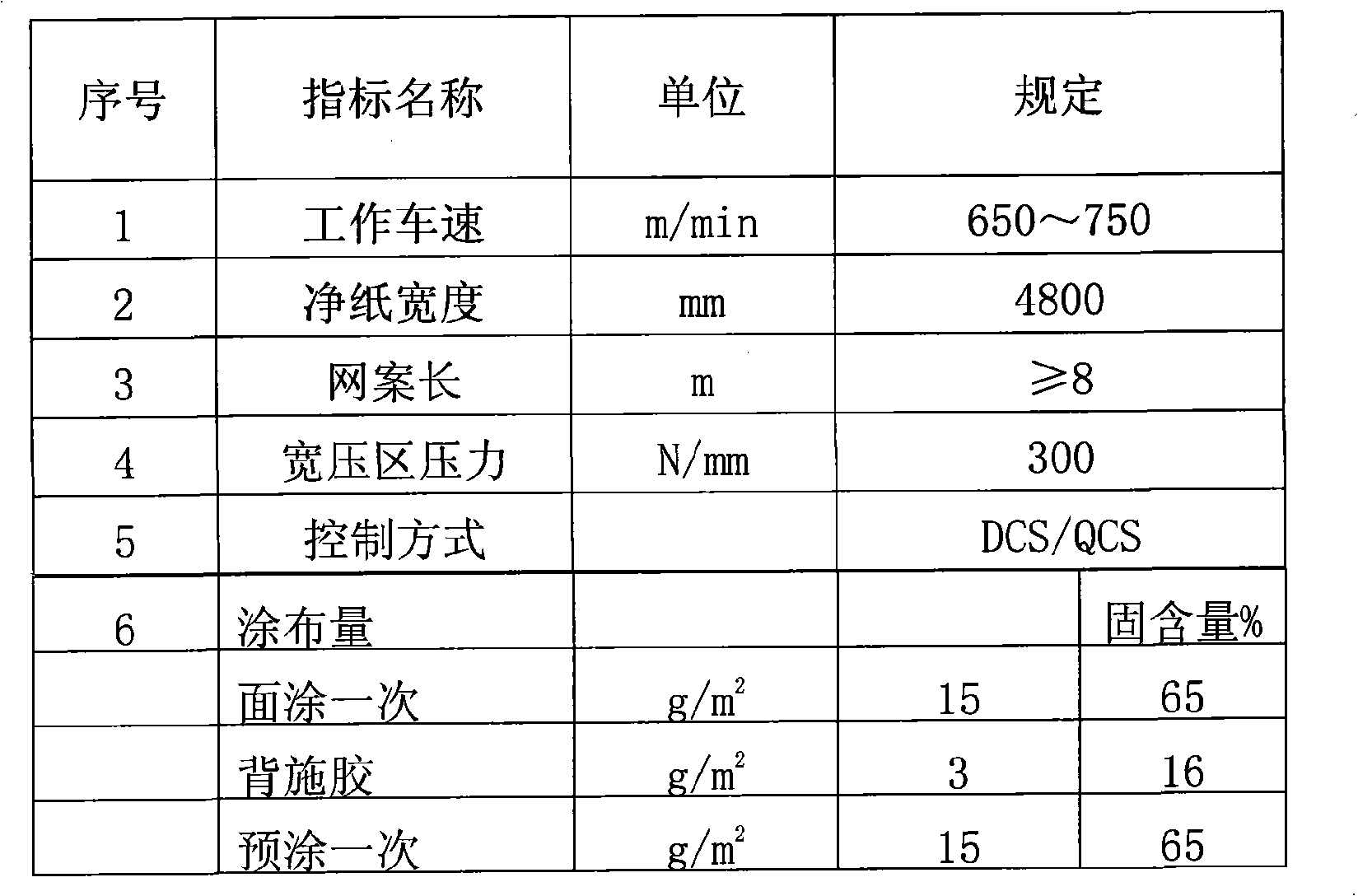

Method for producing coated kraft card board by home-made paper machine

The invention relates to technical field of coated kraft liner producing method. The producing method comprises feeding surface pulp, lining pulp, core pulp and bottom pulp pumped from machine chest of pulping workshop into respective machine chest; slushing and pressure screening the lining pulp, the core pulp and the bottom pulp by offline back water bank, then slushing and pressure screening the surface pulp by the offline back water bank after removing impurities in the surface pulp in a low concentration sand remover, finally all the pulp entering into a flow box to flow onto wire; after the pulp flowing onto wire, feeding the pulp into a coating system after forming by a four-long net forming machine, second shoe pressing, drying, glue blending, redrying, and press polishing by a two-roller hot pressing machine; feeding the coated paper into a state-regulating cylinder and a soft calendar to finish, then reeling by a horizontal paper reeling machine. The coated kraft liner producing method disclosed by the invention can greatly reduce use cost of the coated kraft liner to make the domestic market not dependent on import any longer.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

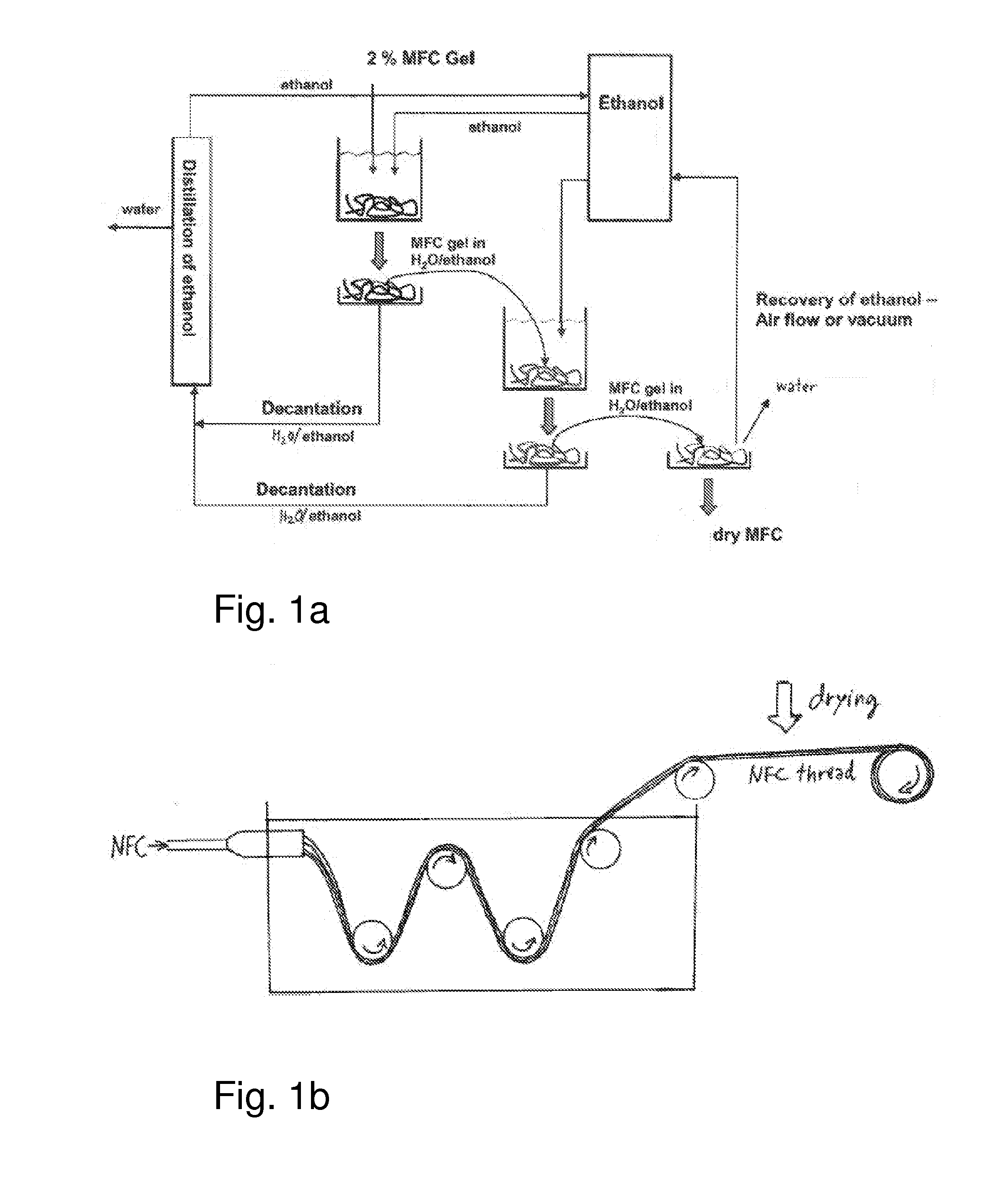

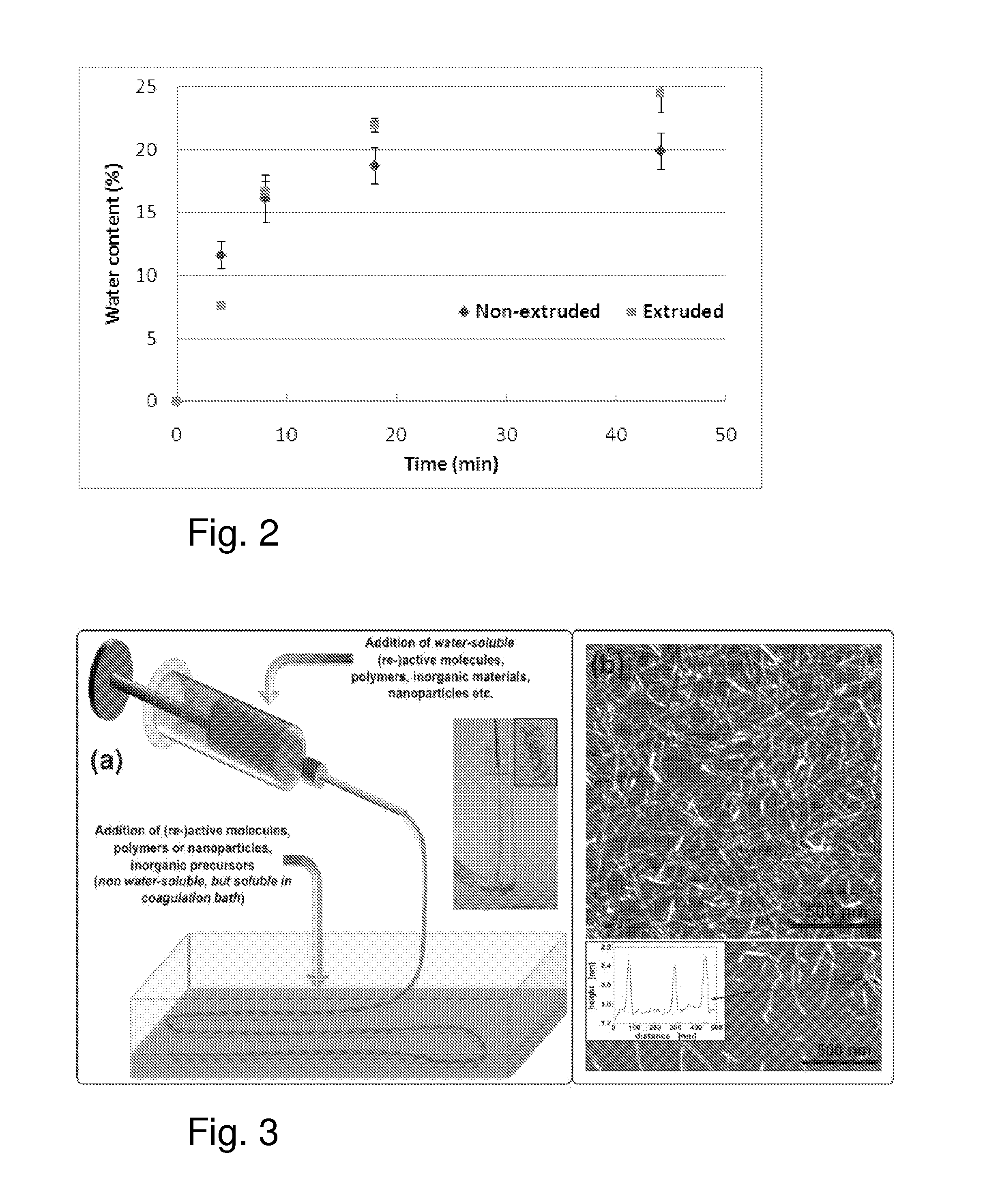

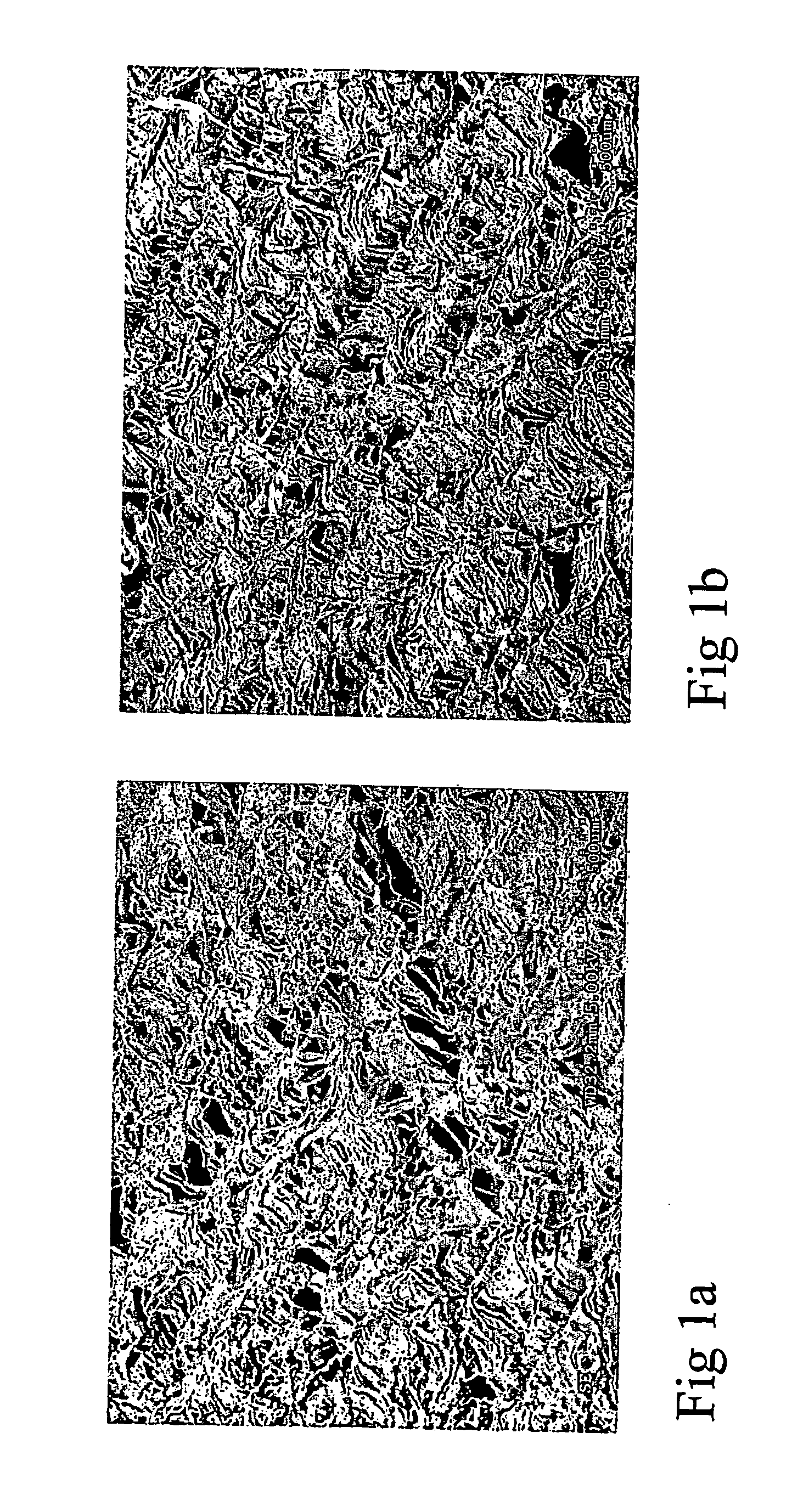

Method for fabricating fiber products and composites

ActiveUS20140058077A1Applicable at industrial scaleImprove mechanical propertiesMaterial nanotechnologyMonocomponent cellulose artificial filamentCelluloseFiber

Method for fabricating fiber and film products and composites includes: introducing an aqueous gel of nanofibrillar cellulose into a volume of organic extraction agent miscible with water so that the aqueous gel is kept as a separate phase and forms one or several discrete physical entities containing the nanofibrillar cellulose within the phase; changing water with the organic extraction agent in said one or several discrete physical entities of nanofibrillar cellulose; and drying the nanofibrillar cellulose by removing the organic extraction agent from the one or several discrete physical entities of nanofibrillar cellulose. In the method the aqueous gel of nanofibrillar cellulose is introduced into the volume of organic extraction agent in the form of one or several elongated elements which form a fiber-like or ribbon-like or film-like product after drying.

Owner:UPM-KYMMENE OYJ

Cardboard having great reigidity

InactiveUS6221212B1Low densityHigh tensile stiffness indexNon-fibrous pulp additionWrappersCardboardVolumetric Mass Density

Owner:STORA ENSO AB

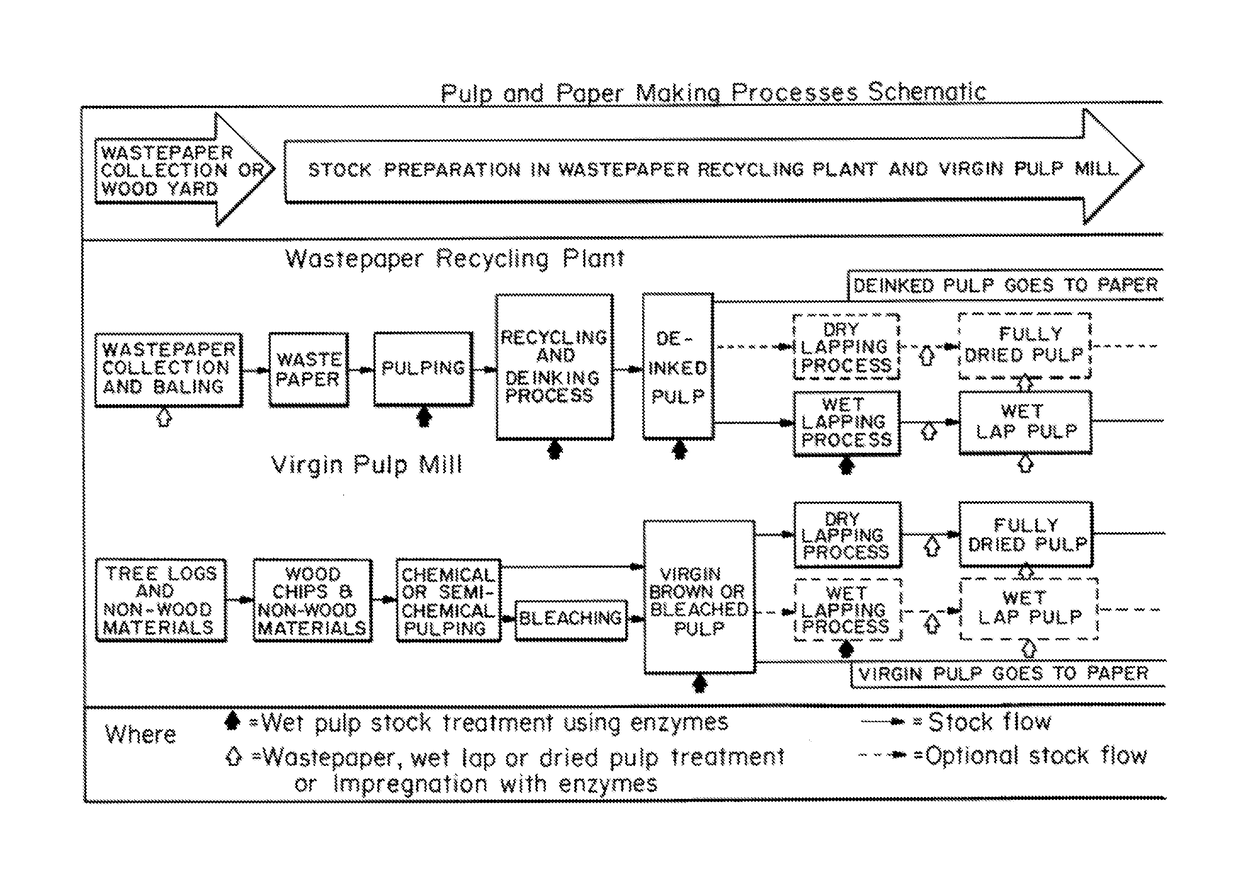

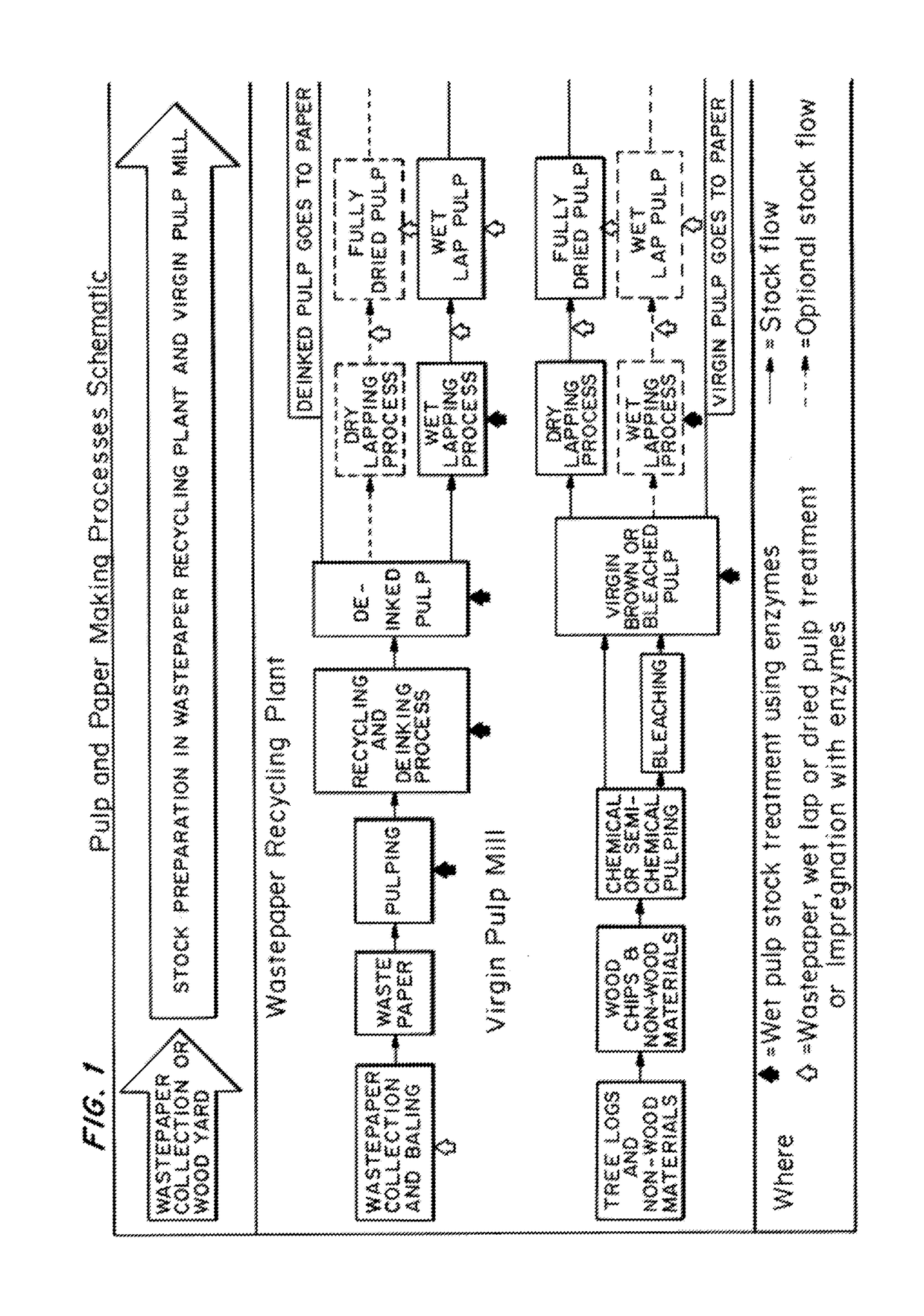

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20170328006A1Increasing pulp drainage and strength propertyQuality improvementMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Owner:ENZYMATIC DEINKING TECH LLC

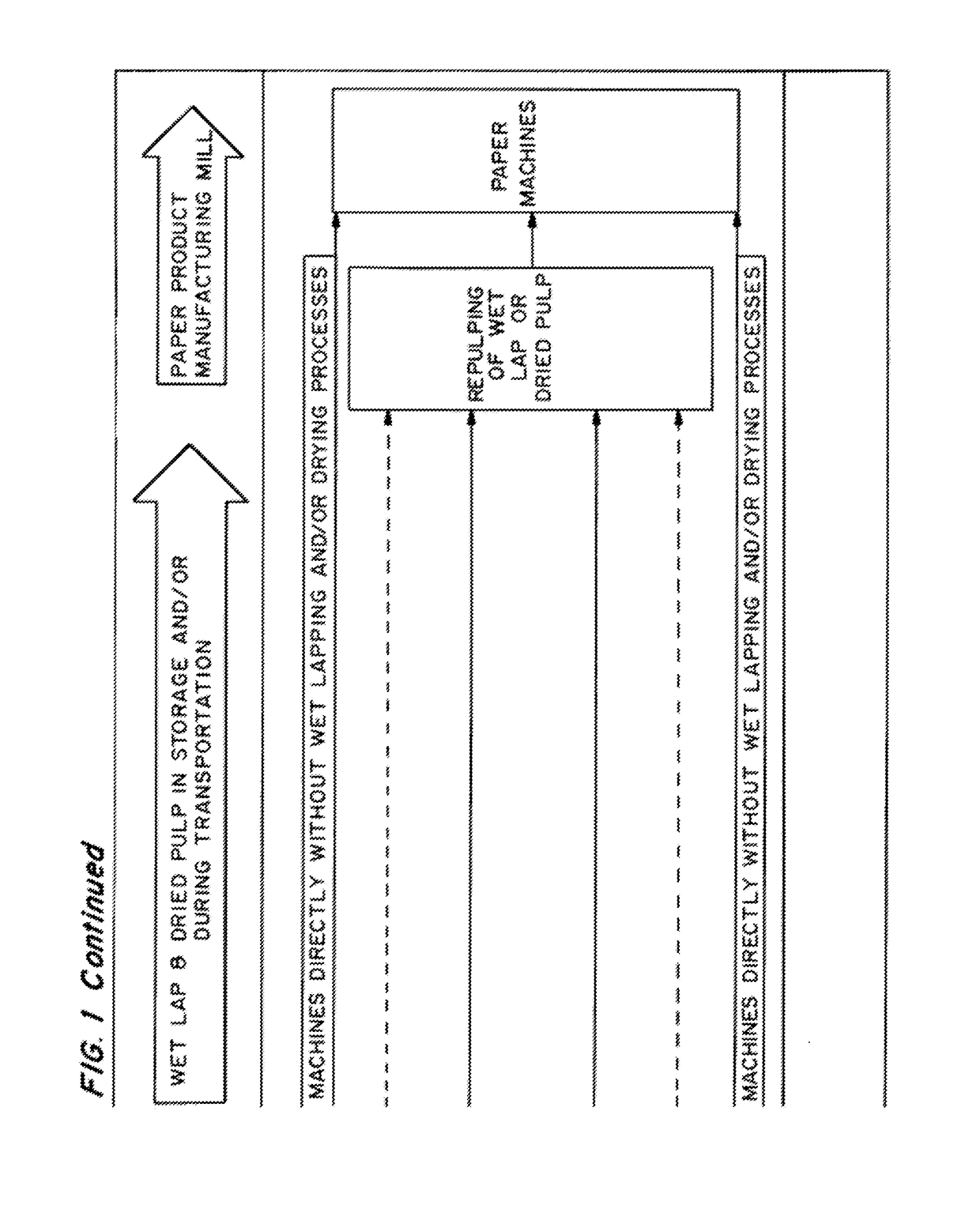

Foam assisted application of strength additives to paper products

A foaming formulation is provided herein. The foaming formulation includes at least one foaming agent in an amount of from about 0.001% to about 10% by weight based on a total weight of the foaming solution. The foaming formulation further includes a synthetic strength additive having a cationic functional group in an amount from about 0.01% to about 50% by weight based on a total weight of the foaming solution. The foaming formulation further includes water.

Owner:SOLENIS TECH CAYMAN

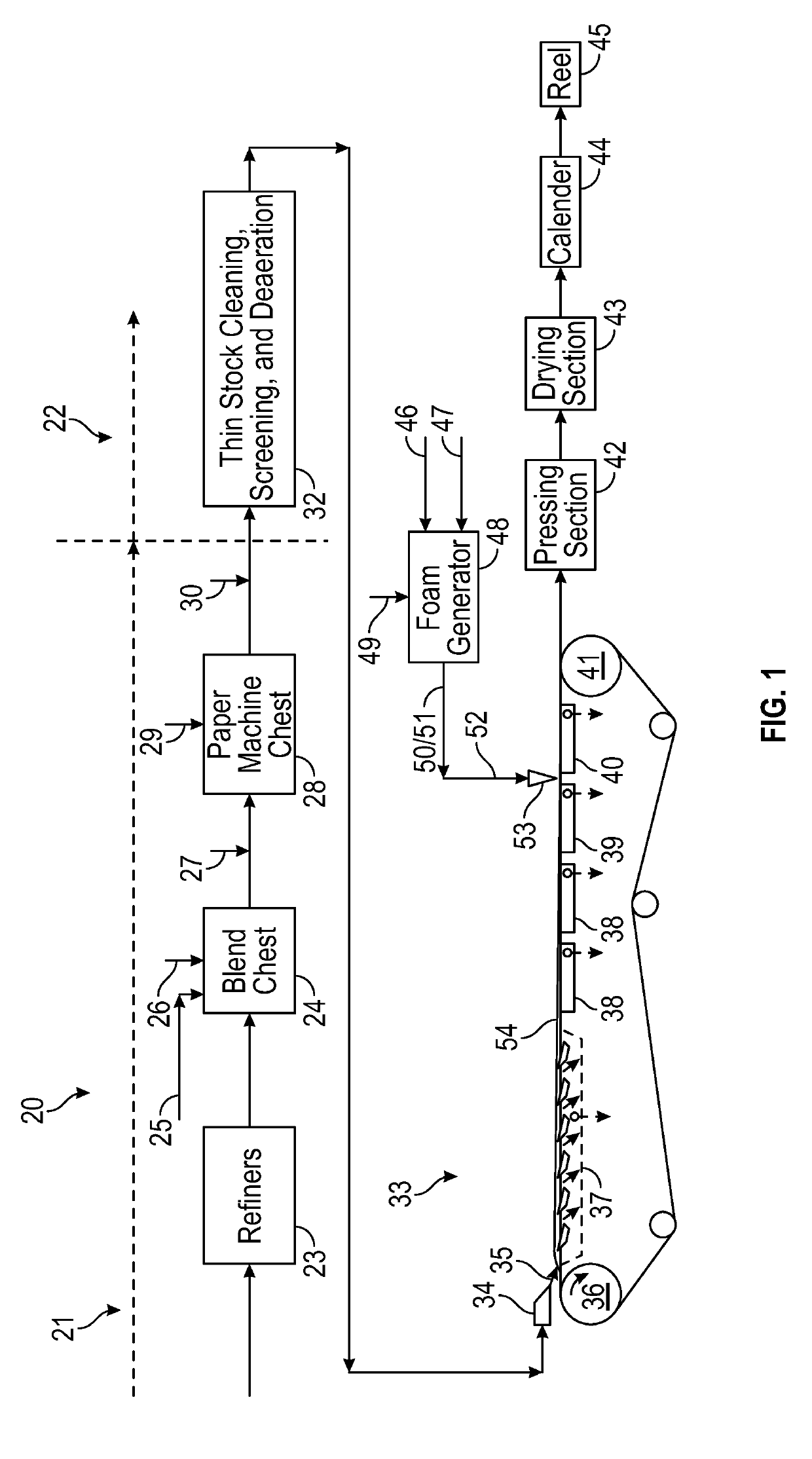

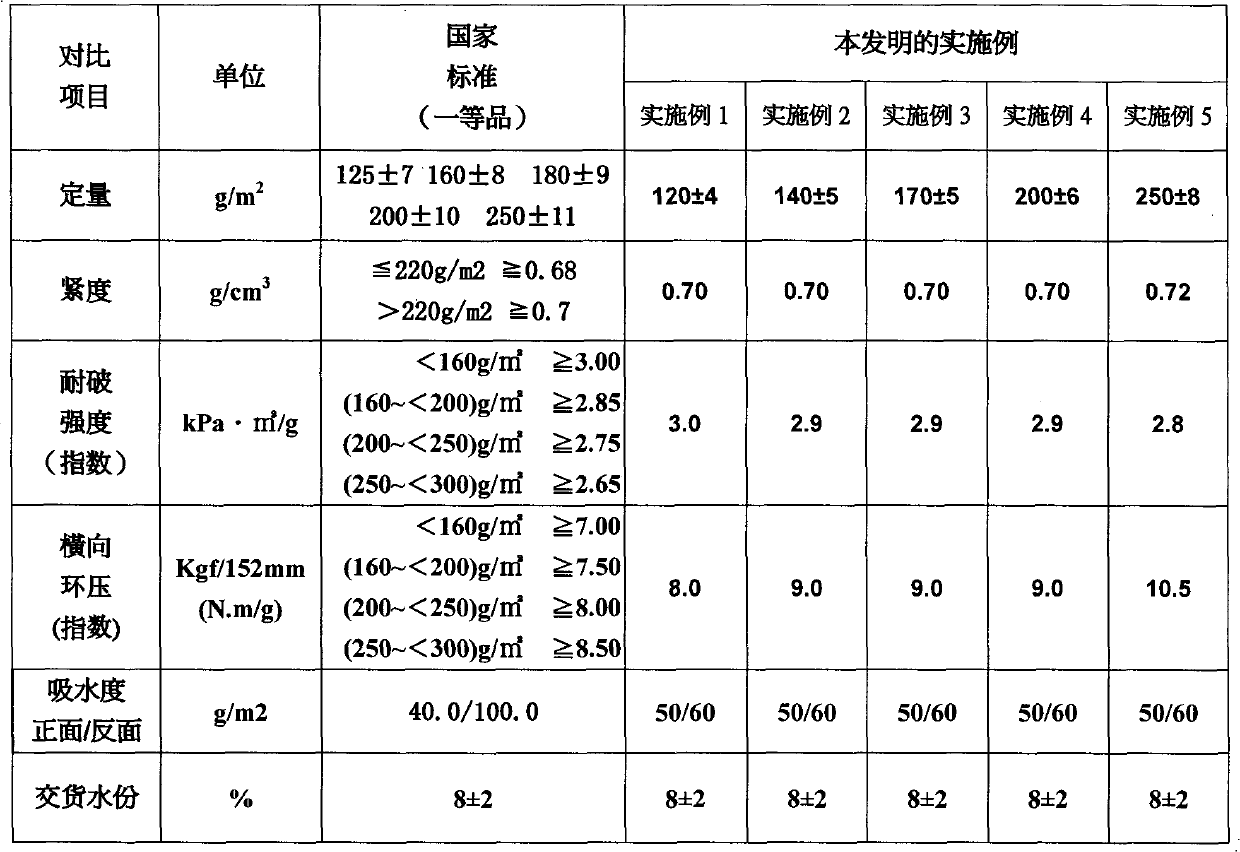

Production method of kraft cardboard with ultra low gram weight

ActiveCN102493261AHigh strengthReduce dosagePaper recyclingSecondary cellulose fibresCardboardViscose

The invention relates to the technical field of papermaking methods, especially to a production method of a kraft cardboard with an ultra low gram weight. The method comprises the following technological steps of: conducting batching; adding water for disintegrating so as to obtain a slurry; carrying out combined purification treatment to the slurry; performing moderate concentration beating; adding a chemical system into the combined slurry; papermaking; molding filtration water for papermaking; implementing two-stage squeezing dewatering; conducting primary baking for drying; carrying out sizing; performing further baking for drying; implementing calendering; and conducting coiling. The invention effectively solves the problems of low grade, poor strength, high pollution load of discharged sewage, large gram weight, incomplete treatment to viscose materials and hot melt materials in waste paper, large process investment and other problems in existing kraft cardboards. The production method of a kraft cardboard with an ultra low gram weight in the invention makes use of a combined technology of pulping and papermaking, and fully utilizes secondary fibers to prepare a kraft cardboard with an ultra low gram weight through papermaking, so that the fiber consumption is reduced. And the prepared kraft cardboard has high strength and a gram weight of 90g / m<2>. The method provided in the invention has high vehicle operation speed, reduces production cost and energy consumption, decreases pollutant discharge, and enhances economic benefits.

Owner:DONGGUAN NINE DRAGONS PAPER IND

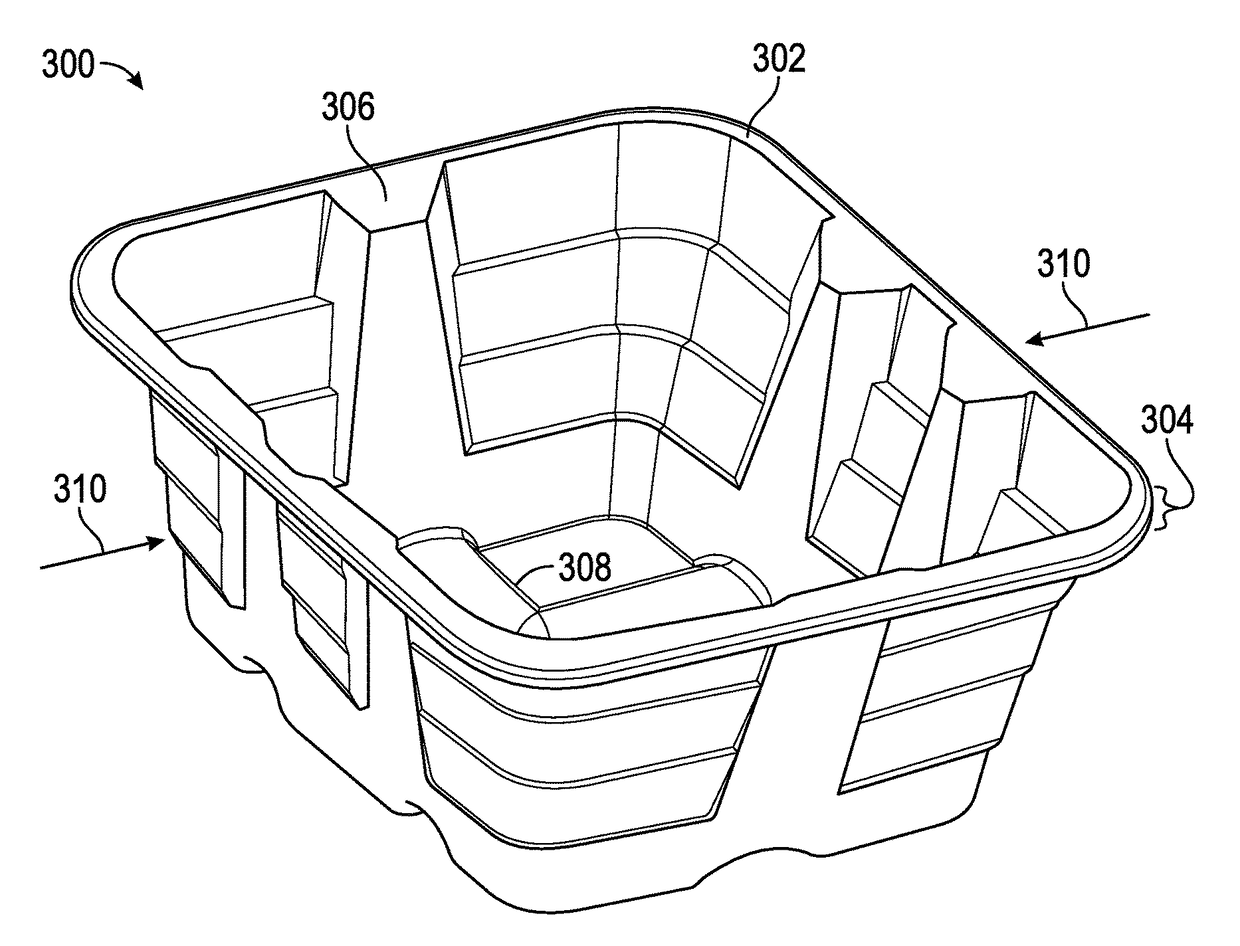

Method for manufacturing fiber-based produced containers

ActiveUS9856608B1Increase in sizeImprove structural rigidityWrappersWater-repelling agents additionFiberSlurry

Owner:FOOTPRINT INT LLC

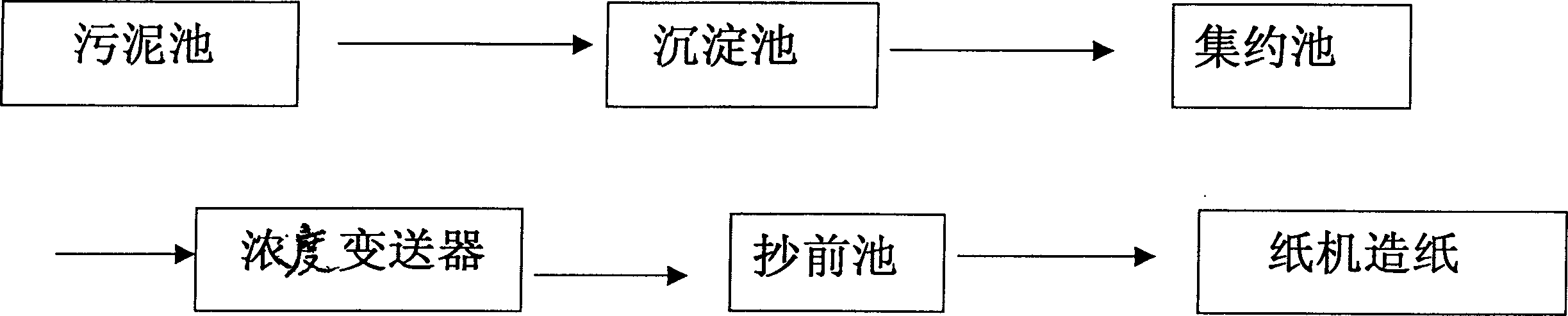

Recovering and reutilizing process for papermaking sludge

InactiveCN1614142AReduce consumptionZero emissionSecondary cellulose fibresCellulose material pulpingSludgeSewage

A process for reclaiming the paper-making sludge includes such steps as directly pumping the sludge from sewage treating pool into depositing pool, depositing, filling clean water to become usable pulp, pumping it into intensity pool, regulating its concentration, mixing it with normal pulp, and making paper.

Owner:喻宏雪

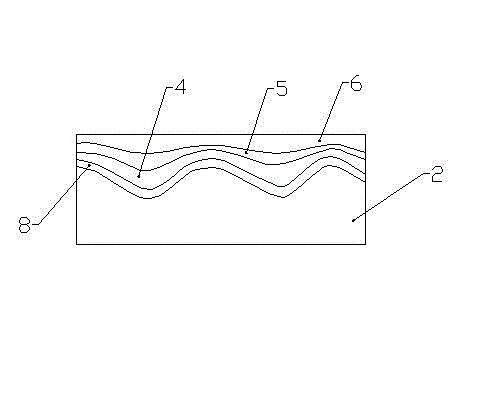

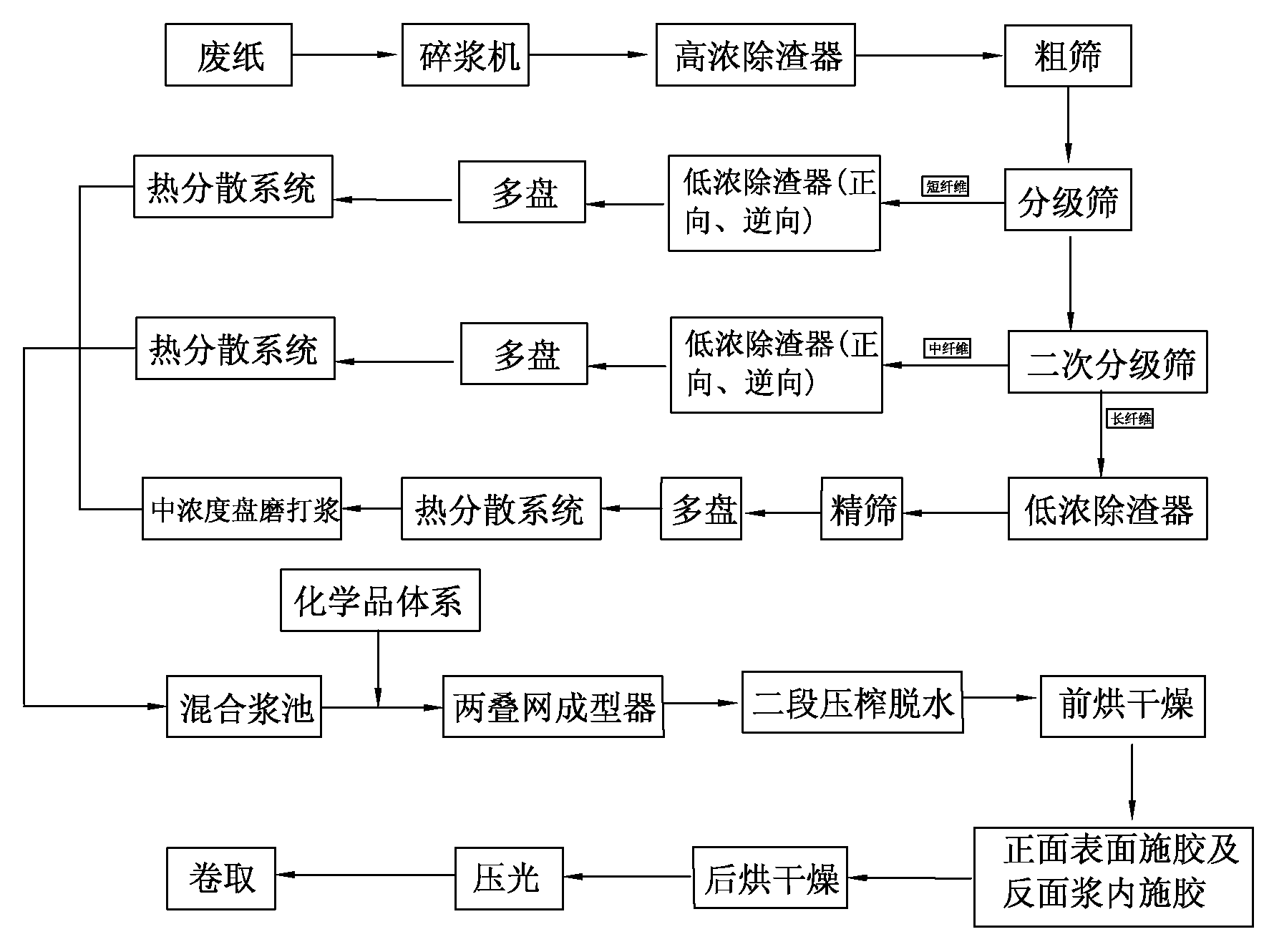

Coated craft paper and production method thereof

ActiveCN102912691AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentPulp and paper industry

The invention discloses coated craft paper and a production method thereof. The coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: manufacturing paper through a paper layer by taking the UKP pulp, the non-deinked waste paper pulp or the mixture of the UKP pulp and the non-deinked waste paper pulp as the pulp to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

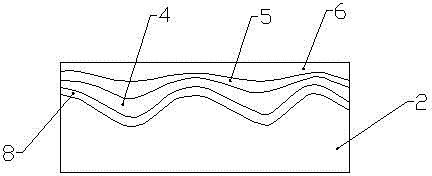

Kraft liner cardboard paper and manufacturing method thereof

ActiveCN101768891AReduce usageSave resourcesSecondary cellulose fibresPulp material addition processesCardboardEcological environment

The invention relates to kraft liner cardboard paper and a manufacturing method thereof, belonging to the technical field of packaging materials. The kraft liner cardboard paper is formed by the following raw materials in parts by weight: 30-40 parts of USA No.11 waste paper, 25-35 parts of European waste paper, 30-40 parts of Chinese domestic high-level carton paper and 2-4 parts of wood pulp. The technical scheme of the invention uses recovered waste paper imported from foreign countries and domestic waste cartons as main raw materials, so the amount of the used wood pulp is decreased by more than ten times when being compared with the prior art, and the precious timber resources are saved and the ecological environment is protected. The technological requirement of the method is not harsh, and the method is suitable for industrial production and can ensure that the technical effect of the kraft liner cardboard paper is reflected.

Owner:JIANGSU LEE & MAN PAPER MFG

Novel energy-conserving environment-protecting complete-regeneration coating white cardboard and method for preparing same

The invention relates to a coated white card board as well as the production method technique field. The novel energy-saving and environment-friendly complete regeneration coated white card board fully adopts reclaimed pulps. The coated white card board rationally uses imported waste paper and domestic waste paper to increase the resource utilization rate, and upgrades the technique in the coated white board industry so as to conform the industrial structure adjustment to the policy orientation. The coated white card board takes high quality waste paper which substitutes for chemical wood pulps and mechanical wood pulps as a raw material for production through treatments of sorting, pulping, deinking, screening and desanding and then mesh building, molding, calendering, coating, etc., and the produced coated white card board can save timber resources and reduce pulping pollution, as well as greatly reducing the consumption of water, steam and chemical raw materials.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

Crepe facilitating composition

InactiveUS20070000630A1Improve stress distributionGood flexibilityMechanical working/deformationSpecial paperFiberWater insoluble

The invention relates to a crepe facilitating aqueous composition comprising at least one water-insoluble, non-surface active thermoplastic material having a softening or melting point within the range of from 40° C. to 100° C., and at least one water-soluble polymer, preferably a cationic water-soluble polymer. As the composition is comprised in a wet fibre web during creping thereof, a more uniform creping is obtained while the integrity of the web is preserved and dust formation is reduced, and a tissue product having improved properties is provided.

Owner:BIM KEMI

Processing method for regenerative semi-chemical corrugated paper

InactiveCN1525004AImprove bindingReduce dosageReinforcing agents additionSecondary cellulose fibresHigh concentrationFiber

The invention is a regenerated corrugated raw paper manufacturing method, its main technical flows: mix import waste paper with internal waste paper, pulp by pulping engine, desand by high concentration desander, screen by fiber separator, desand by high concentration desander, screen by low concentration pressure sieve, desand by low concentration desander, condense by condenser, mill and pulp by medium concentration hydraulic disc, screen by pressure sieve, make by paper machine and spray papermaking chemical assistant when molding and cut by winder. The added quantity of import waste paper is 40-55% of total weight of the mixed waste paper. It changes traditional low concentration pulping technique. The technique is designed reasonably, and can effectively heighten the physical strength of the regenerated corrugated raw paper, reduce the raw material cost and be applied to medium-scale production.

Owner:ZHEJIANG BLUESTAR HLDG GRP

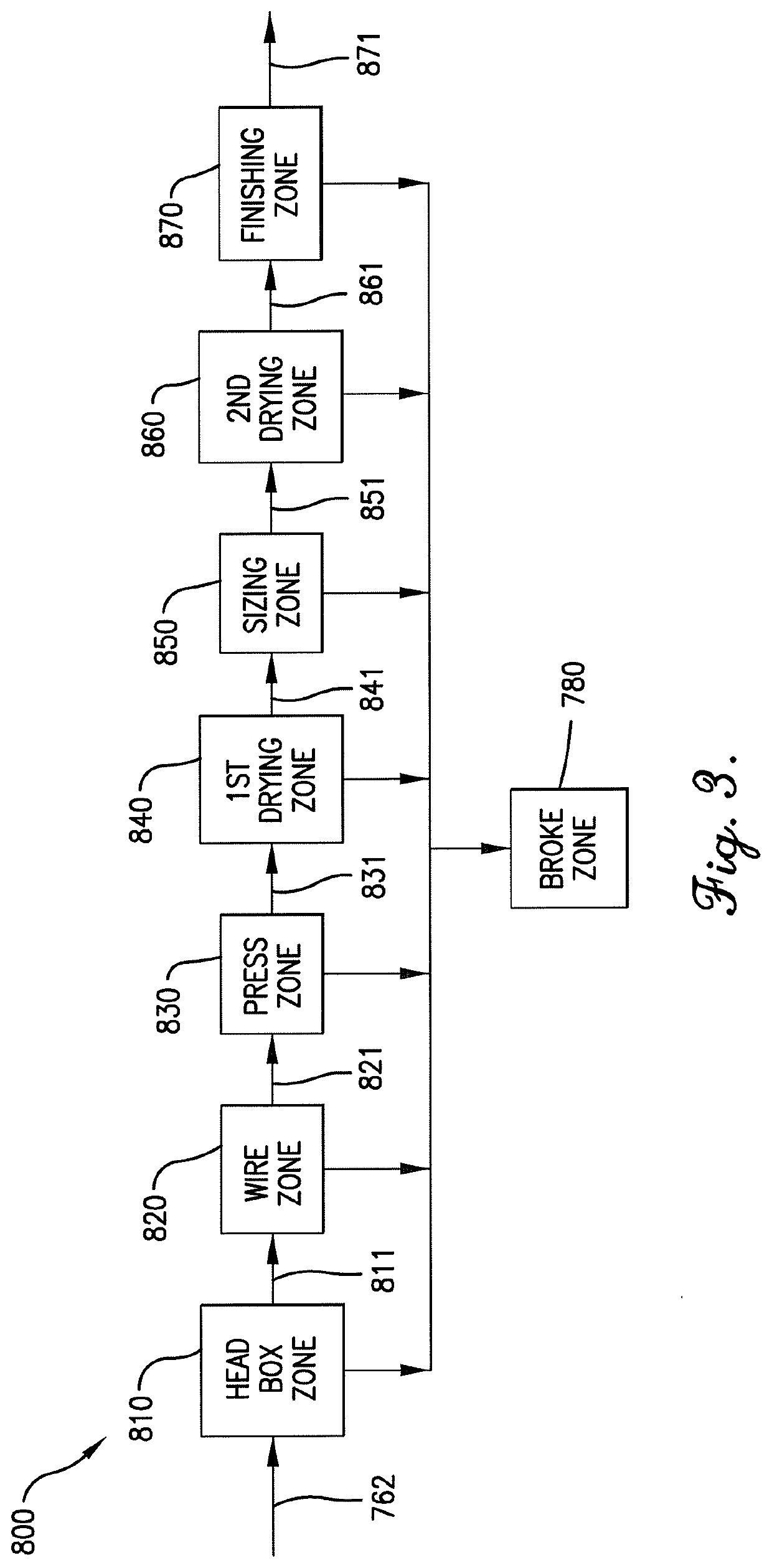

Compostable wet-laid articles comprising cellulose and cellulose esters

InactiveUS20200063365A1Reduce consistencyLow variabilityFlexible coversWrappersPolymer scienceCellulose fiber

Wet laid products including packaging is obtained from co-refined cellulose fibers and synthetic fibers are made biodegradable, and can also be compostable and soil biodegradable. The synthetic fibers include staple cellulose ester fibers. Desirably, such staple cellulose ester fibers have a denier per filament of 3 or less, a cut length of 6 mm or less, are crimped, or are non-round and crimped, and have a degree of substitution of 2.5 or less.

Owner:EASTMAN CHEM CO

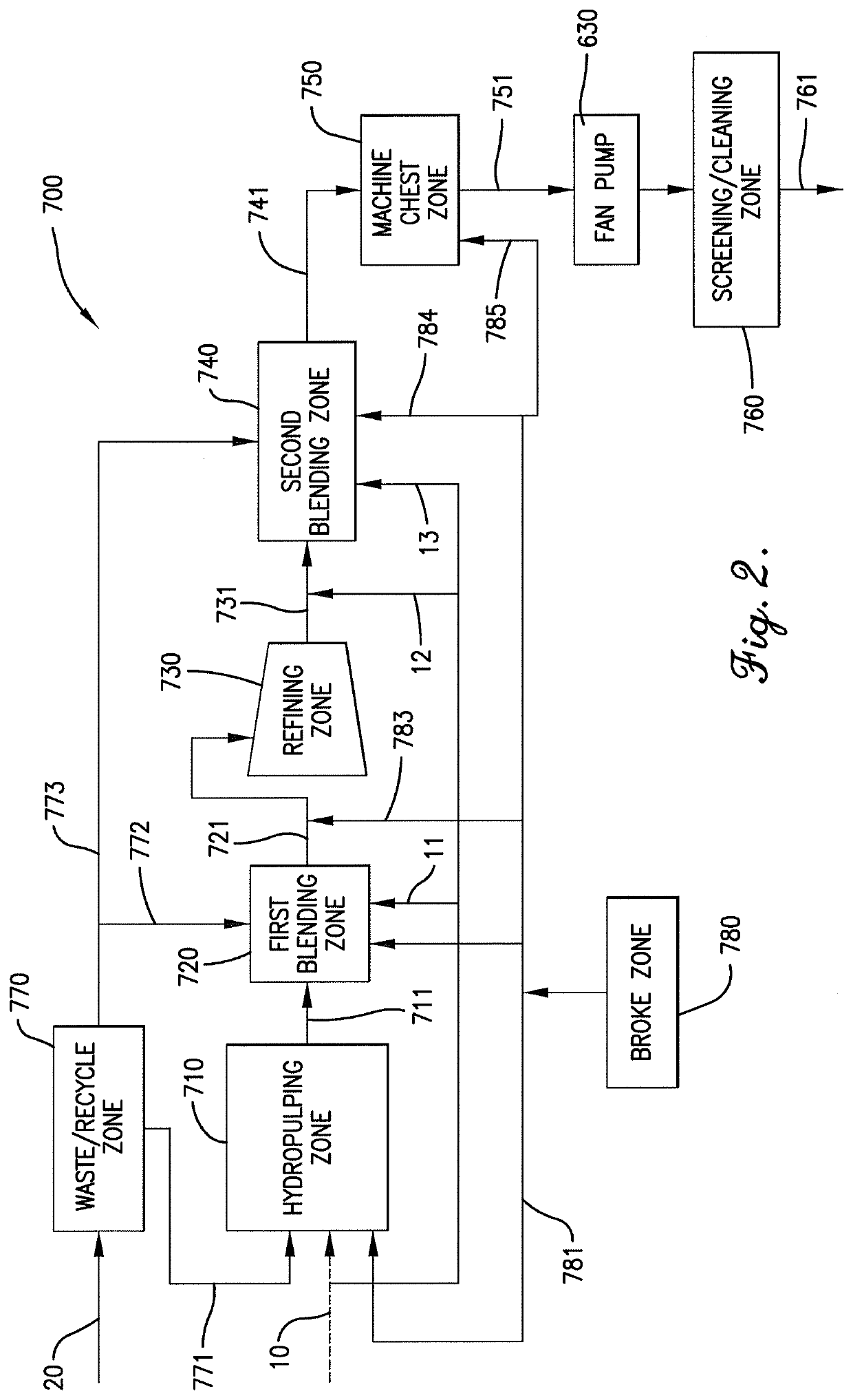

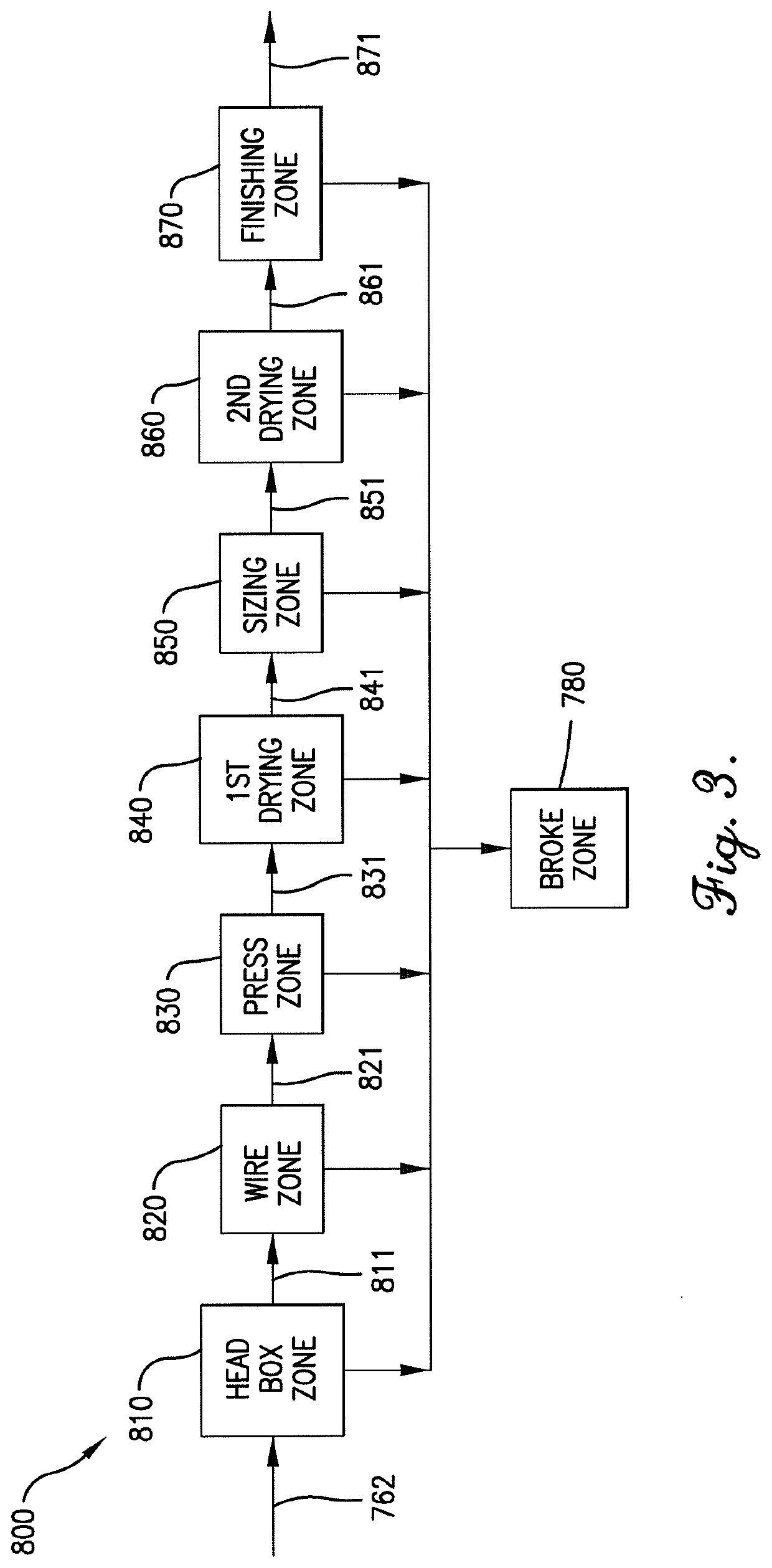

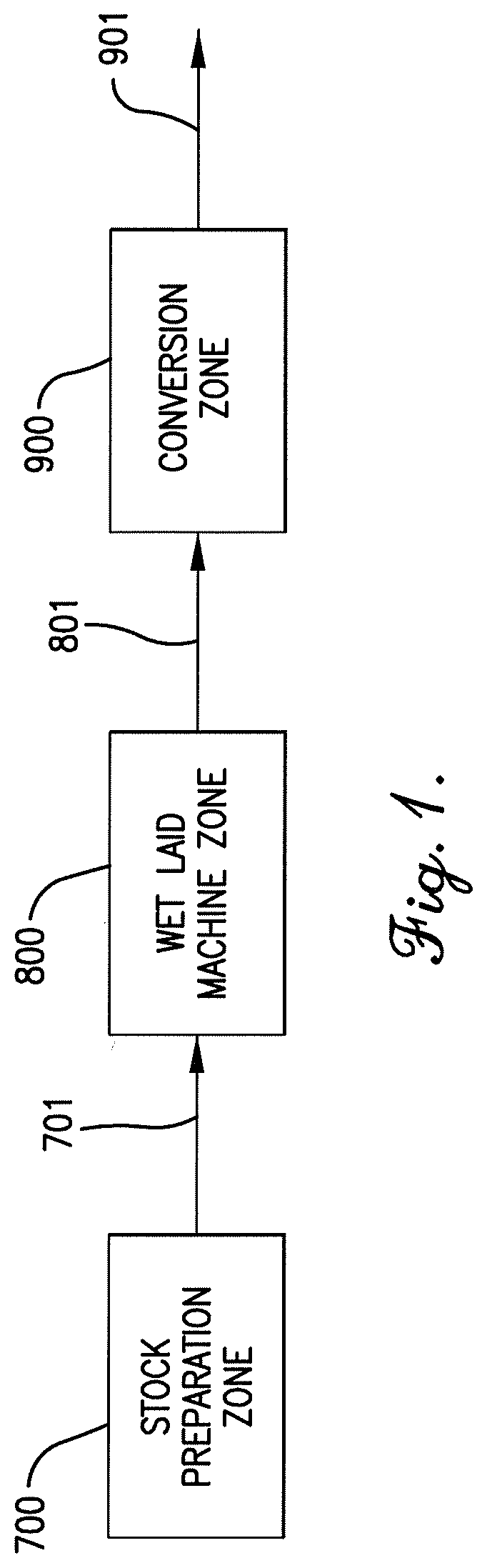

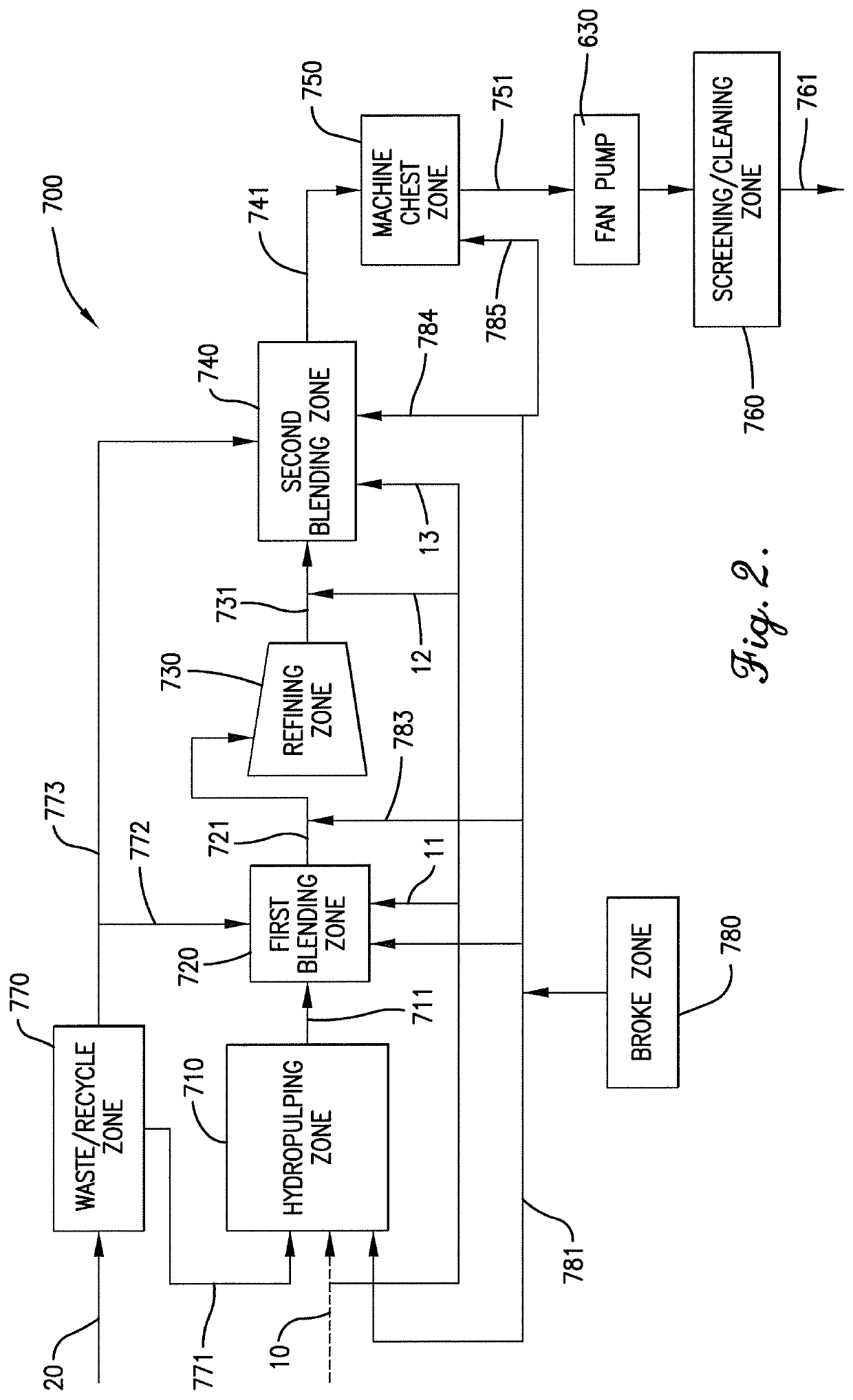

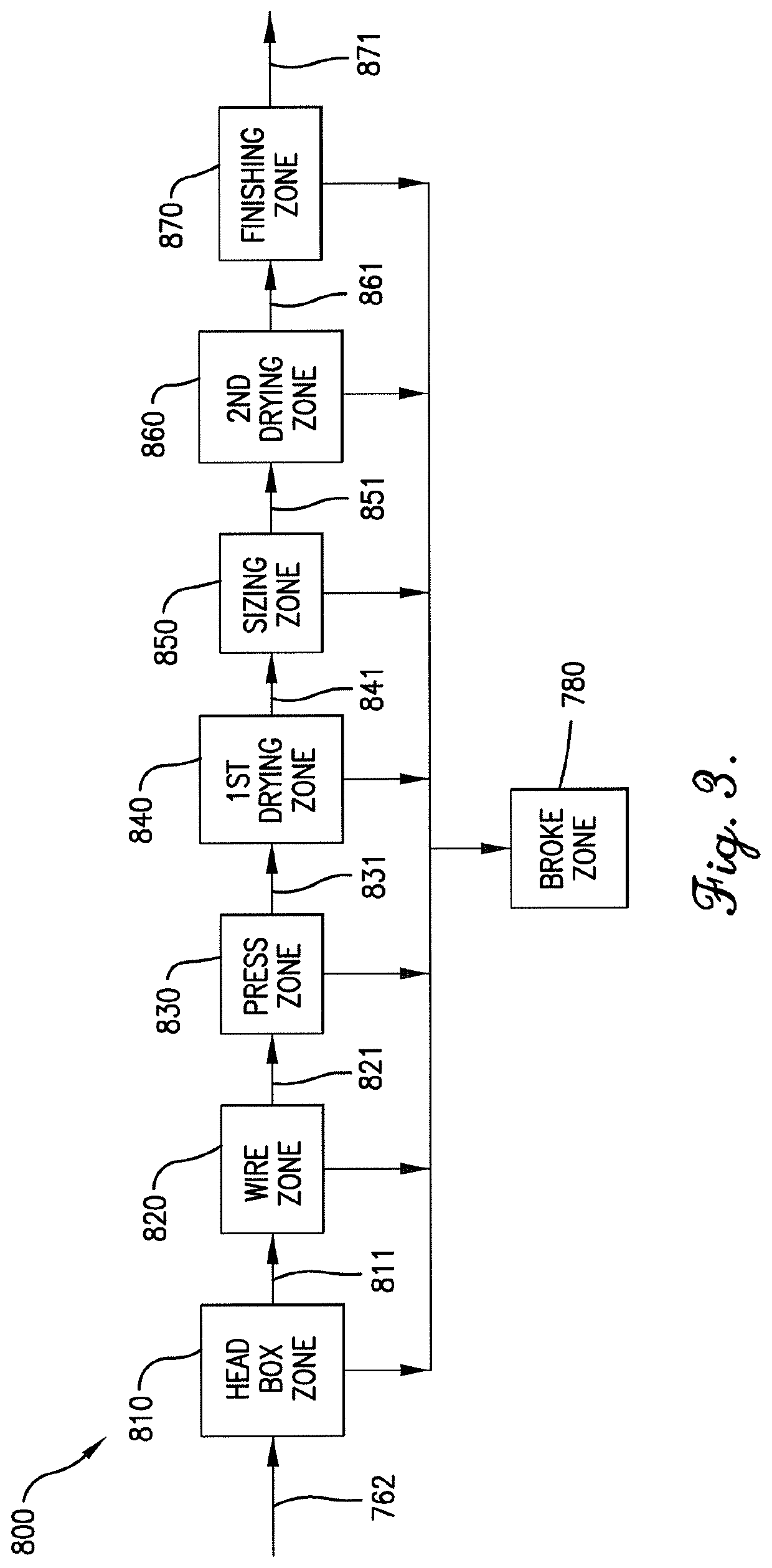

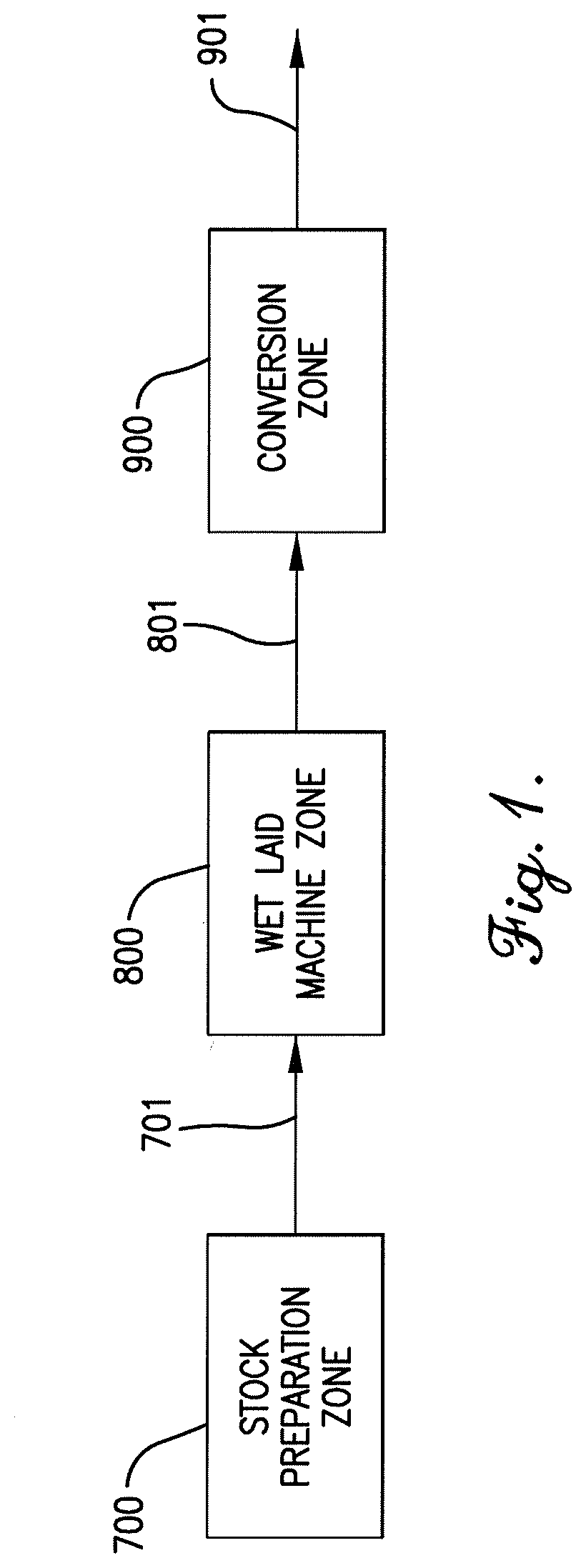

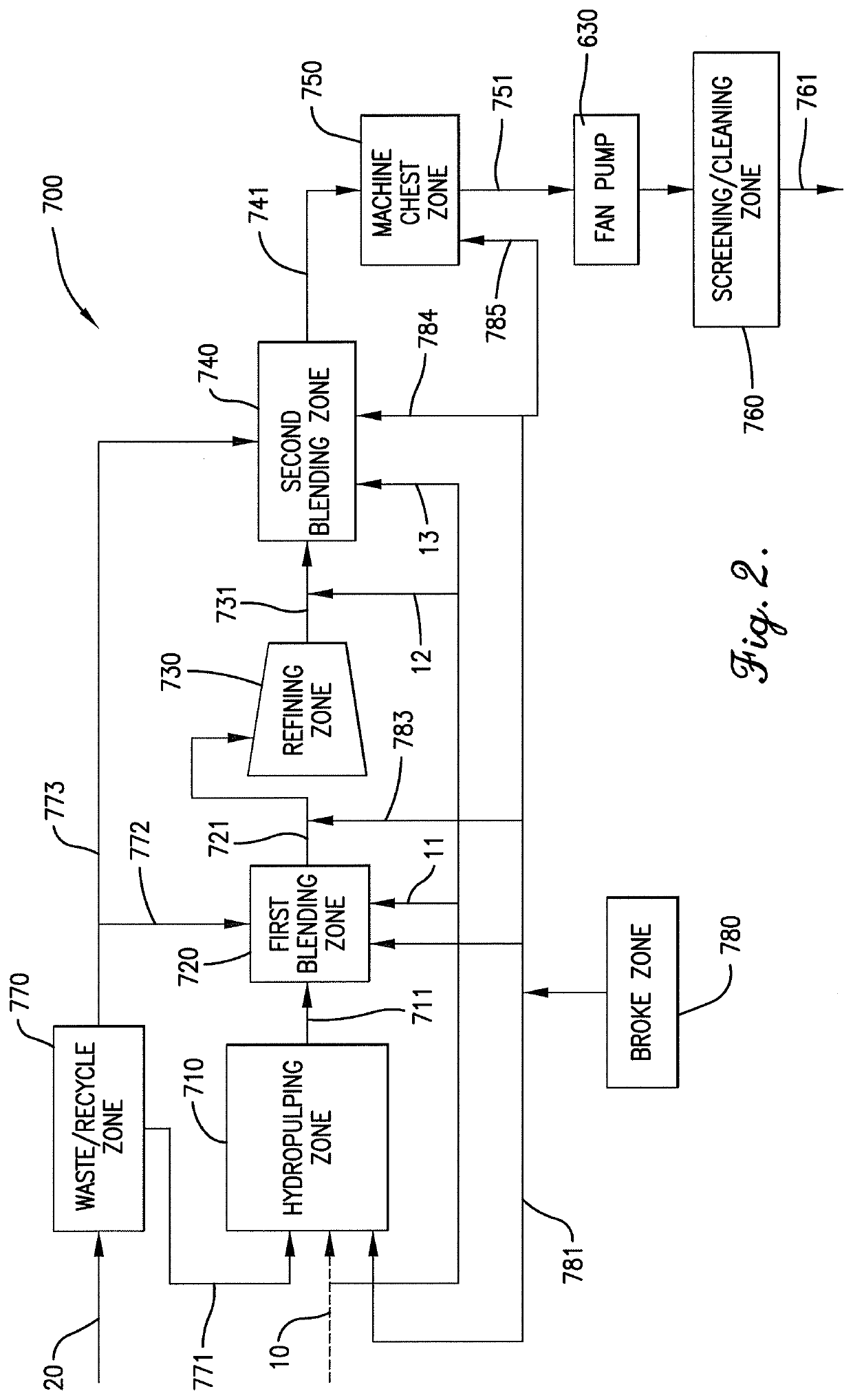

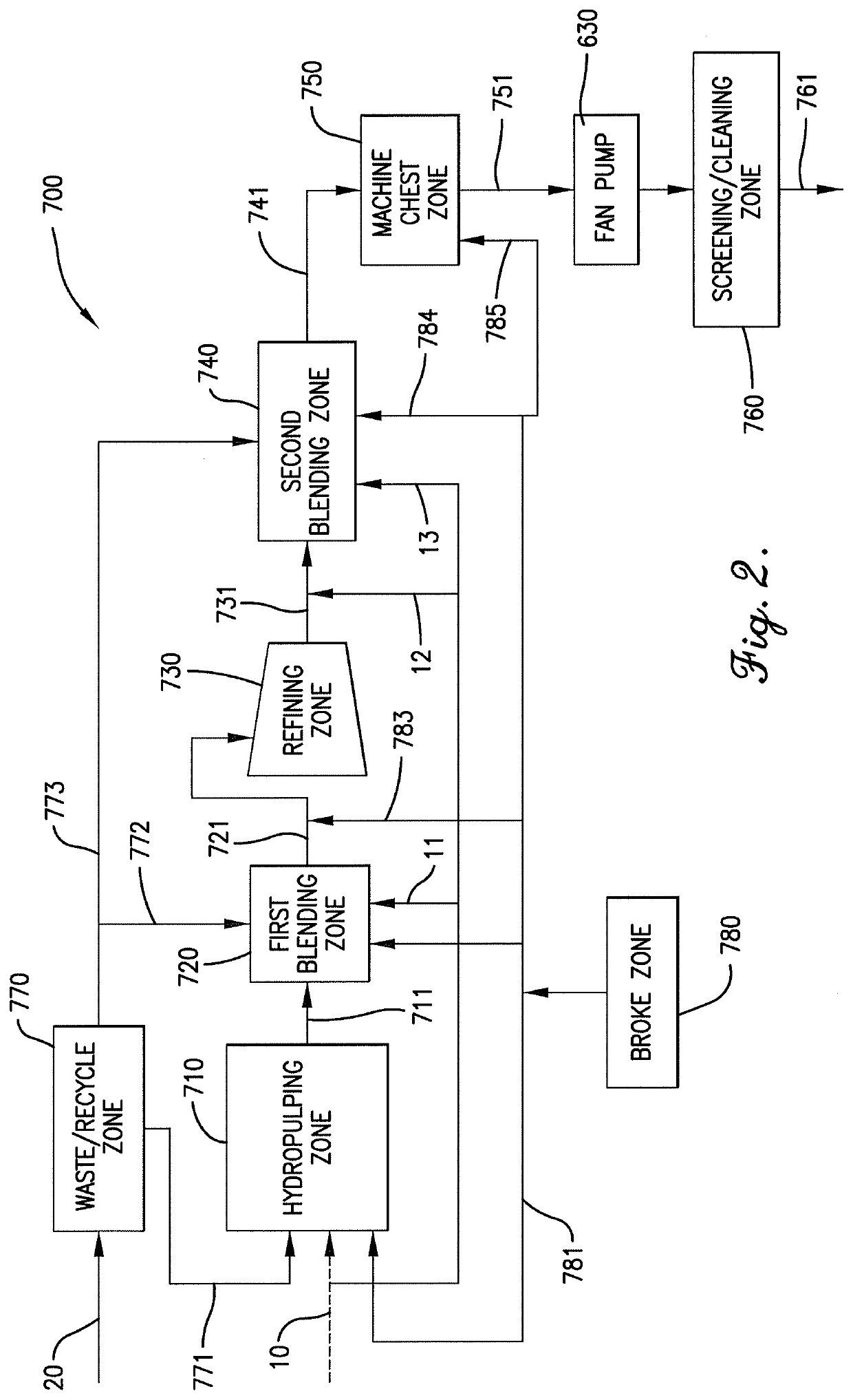

Composition of matter in a post-refiner blend zone

ActiveUS20200063358A1Reduce consistencyLow variabilityWater-repelling agents additionReinforcing agents additionPolymer scienceCellulose fiber

After cellulose fibers and cellulose ester fibers are co-refined, they are fed to a blend tank continuously feeds a wet laid process. The composition in the blend tank includes co-refined cellulose fibers and cellulose ester fibers and one or more additives, and the cellulose ester fibers have a denier per filament (DPF) of less than 3, a cut length of less than 6 mm, crimped, or non-round with a DPF of less than 3.

Owner:EASTMAN CHEM CO

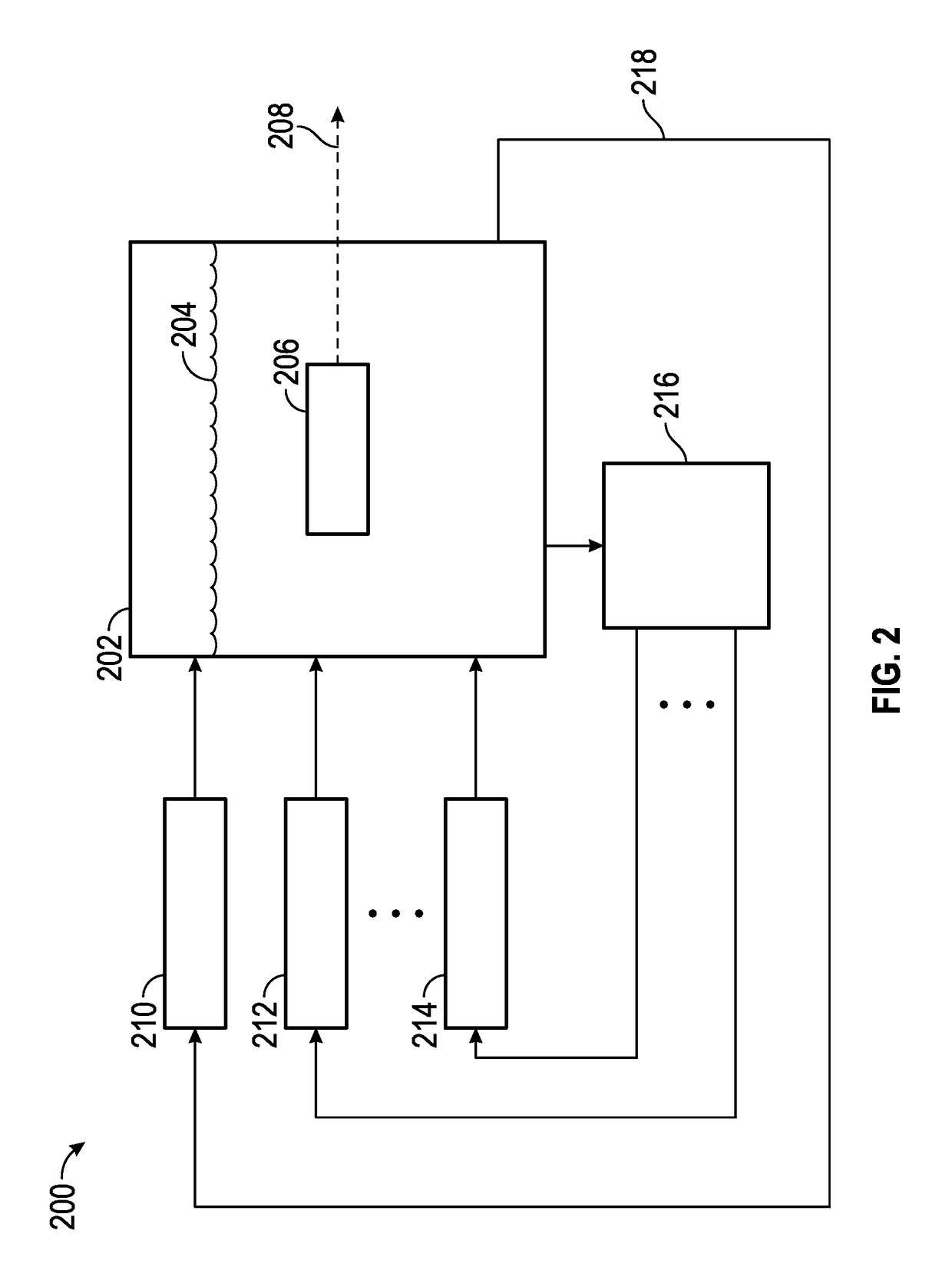

Sheet manufacturing apparatus and sheet manufacturing method

A sheet manufacturing apparatus includes: a defibrating unit which defibrates a raw material including at least fibers; an addition unit which adds an additive agent to a defibrated material which is defibrated in the defibrating unit; and a sheet forming unit which forms a sheet by bonding the plurality of fibers to each other via the additive agent. According to a history of the raw material, an amount of the additive agent which is fed by the addition unit varies. In addition, there is provided a sheet manufacturing method, including: defibrating the raw material which includes at least fibers; adding the additive agent to the defibrated material; and bonding the plurality of fibers to each other via the additive agent. According to the history of the raw material, a feed amount of the additive agent with respect to the raw material varies.

Owner:SEIKO EPSON CORP

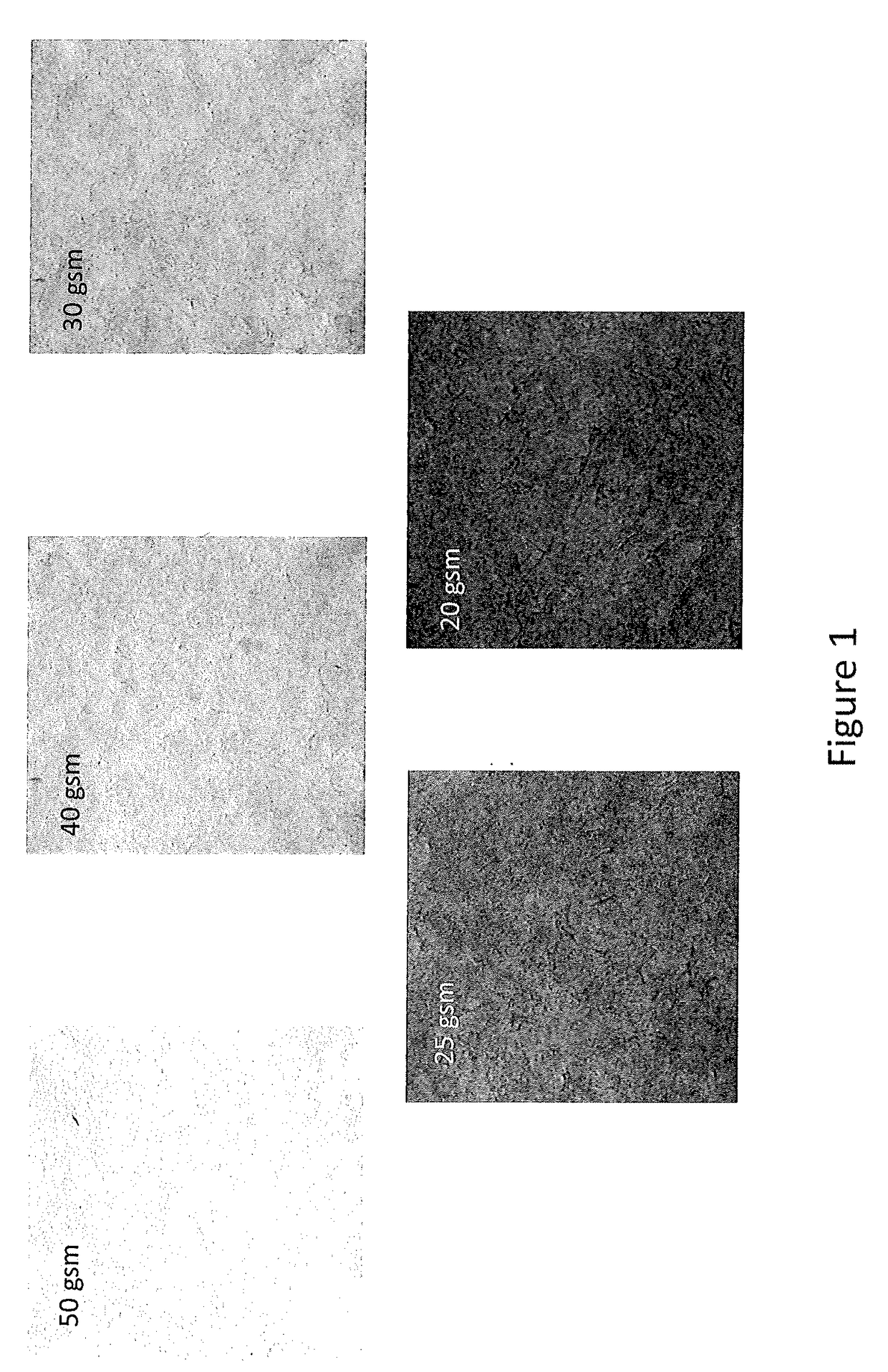

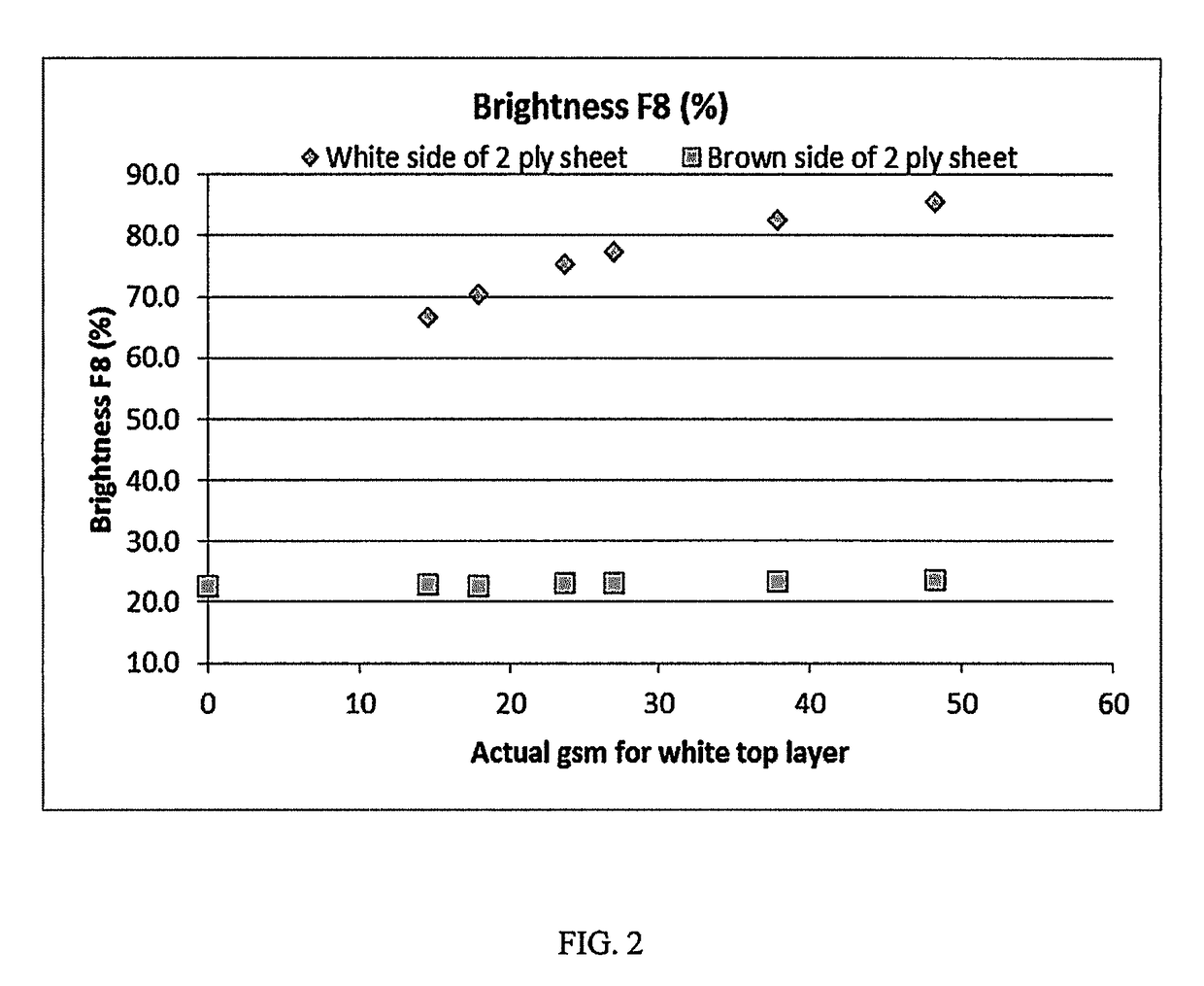

Paper and paperboard products

The present invention is directed to products, such as paper and paperboard products, comprising a substrate containing cellulose and top ply comprising microfibrillated cellulose and inorganic particulate, to methods of making such paper and paperboard products, and associated uses of such paper and paperboard products. The microfibrillated cellulose and inorganic particulate material are applied at the stage when the wet substrate is in the process of being formed on the wire of a papermaking machine, thereby avoiding the additional cost of more extensive equipment and machinery as well as in separate drying of a coating. The microfibrillated cellulose facilitates the application of inorganic particulate onto the surface of a wet paper or paperboard substrate when applied thusly, by trapping the inorganic particulate on the surface of the substrate and by giving the composite sufficient strength and a suitable pore structure to make it suitable for printing and other end-use demands.

Owner:FIBERLEAN TECH LTD

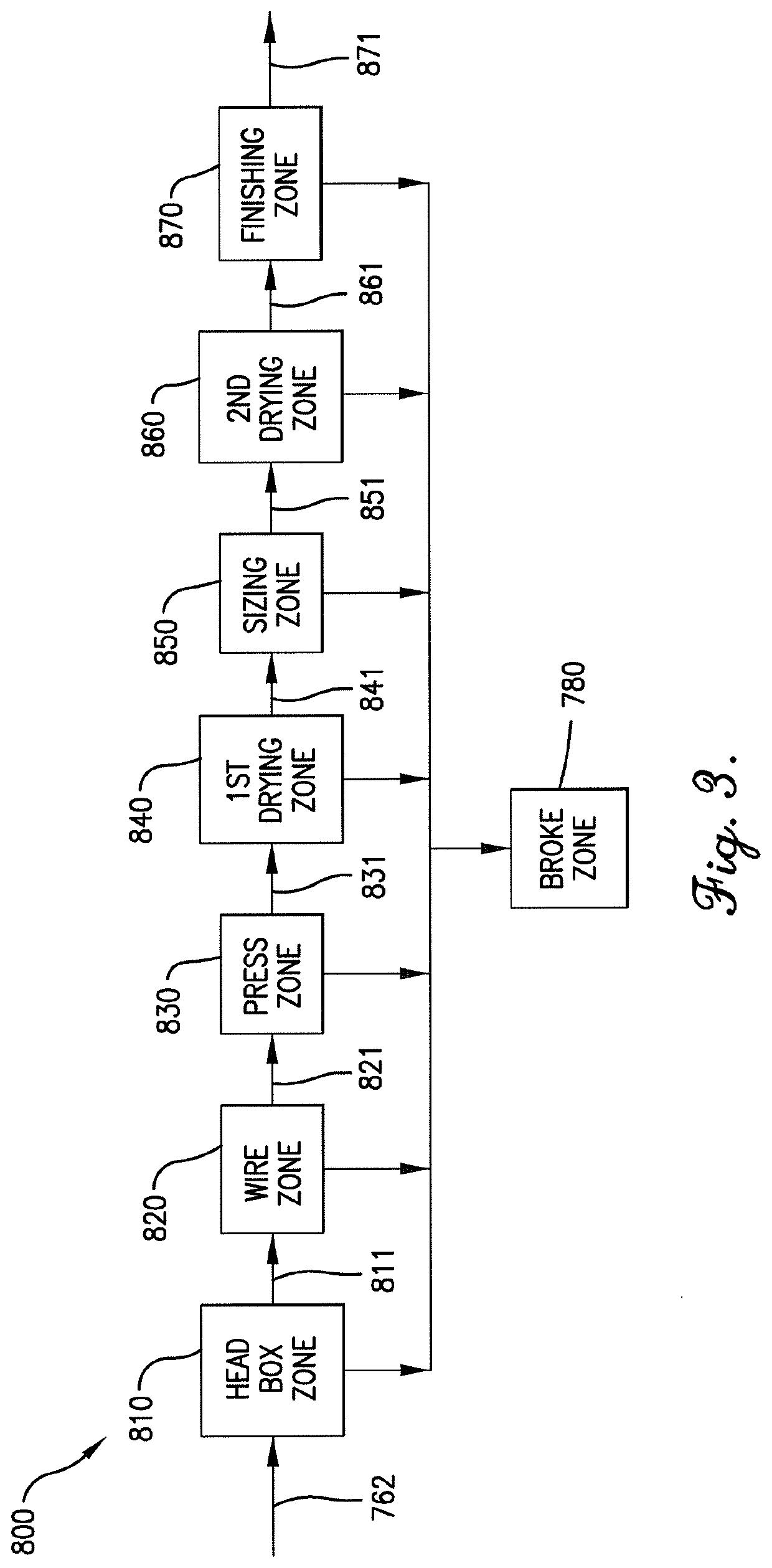

Composition of matter feed to a head box

ActiveUS20200063359A1Reduce consistencyLow variabilityWater-repelling agents additionWashing/displacing pulp-treating liquorsProcess engineeringCellulose fiber

A wet laid process includes a method for making paper in which a composition containing co-refined cellulose fibers and cellulose ester fibers made into a thick stock composition in a machine chest, the thick stock is fed to a cleaning / screening zone through a device that regulates the flow rate of thick stock, the consistency of the thick stock fed to the screening / cleaning zone is reduced to form a thin stock composition; the thin stock composition is subjected to a process for cleaning the thin stock and feeding the cleaned thin stock through screens to form a cleaned and screened thin stock composition, and the cleaned and screened thin stock composition is fed to a headbox.

Owner:EASTMAN CHEM CO

Elongated tubular articles from wet-laid webs

ActiveUS20200063349A1Reduce consistencyLow variabilitySpecial paperWater-repelling agents additionPolymer scienceCellulose fiber

Embodiments of the present invention relate to elongated tubular members that include at least one layer comprising a cellulose ester. In some cases, the cellulose ester may be in the form of staple fibers. The layer may be formed via a wet-laid fiber web that may also include cellulose fibers. The elongated tubular members may be suitable for use with food and / or beverage items as, for example, drinking straws or other similar items.

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com