Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6610results about "Non-fibrous pulp addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

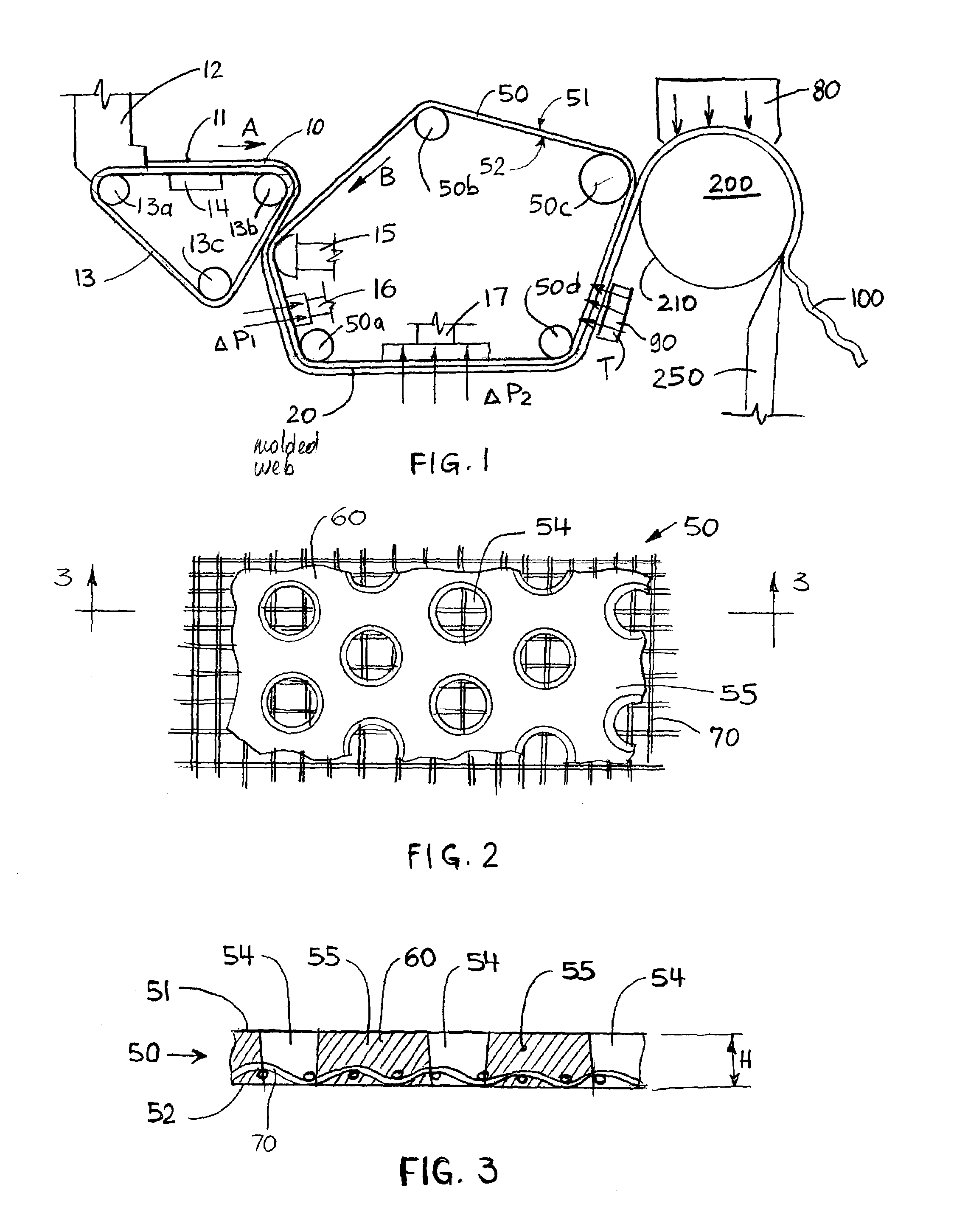

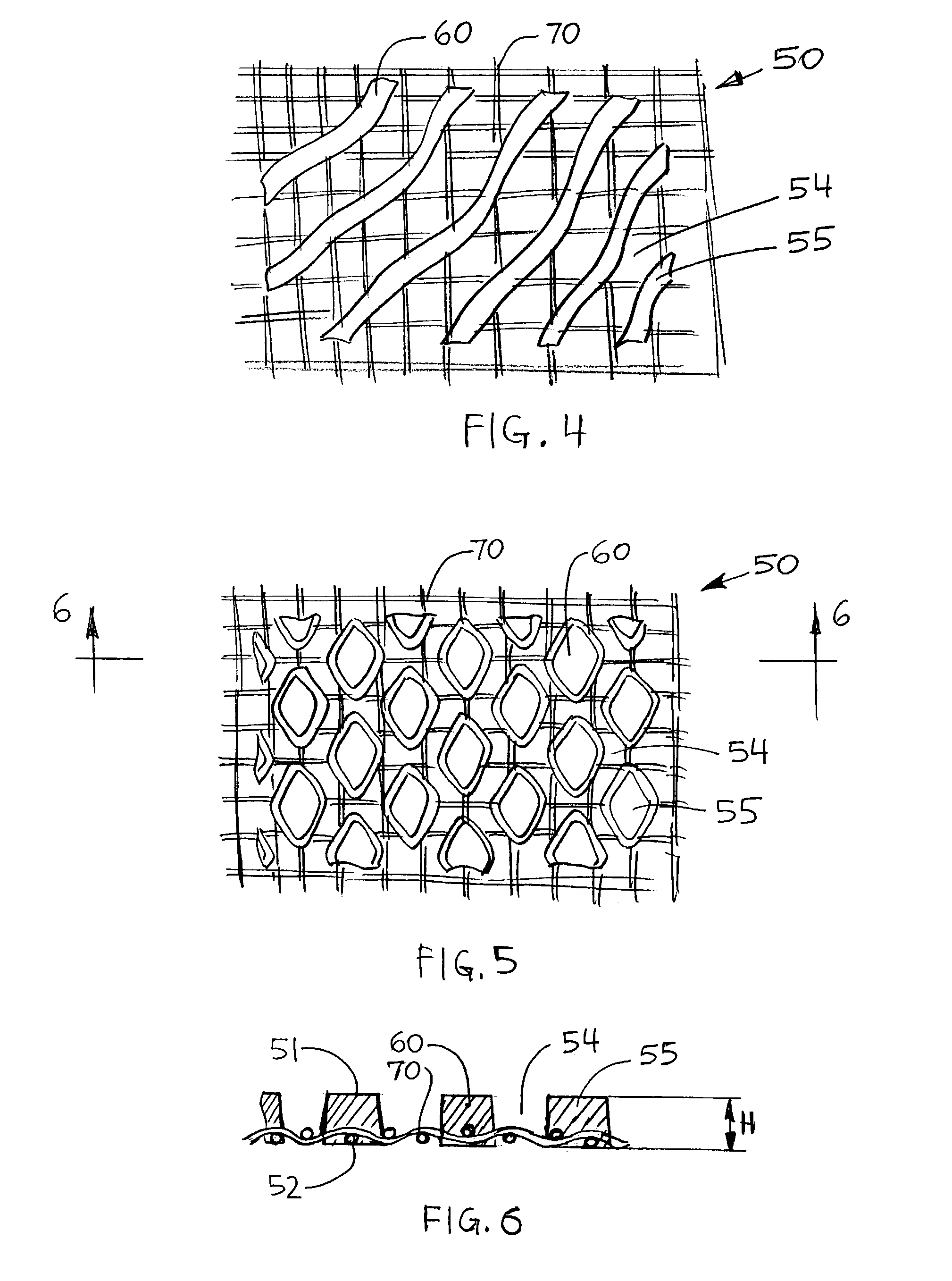

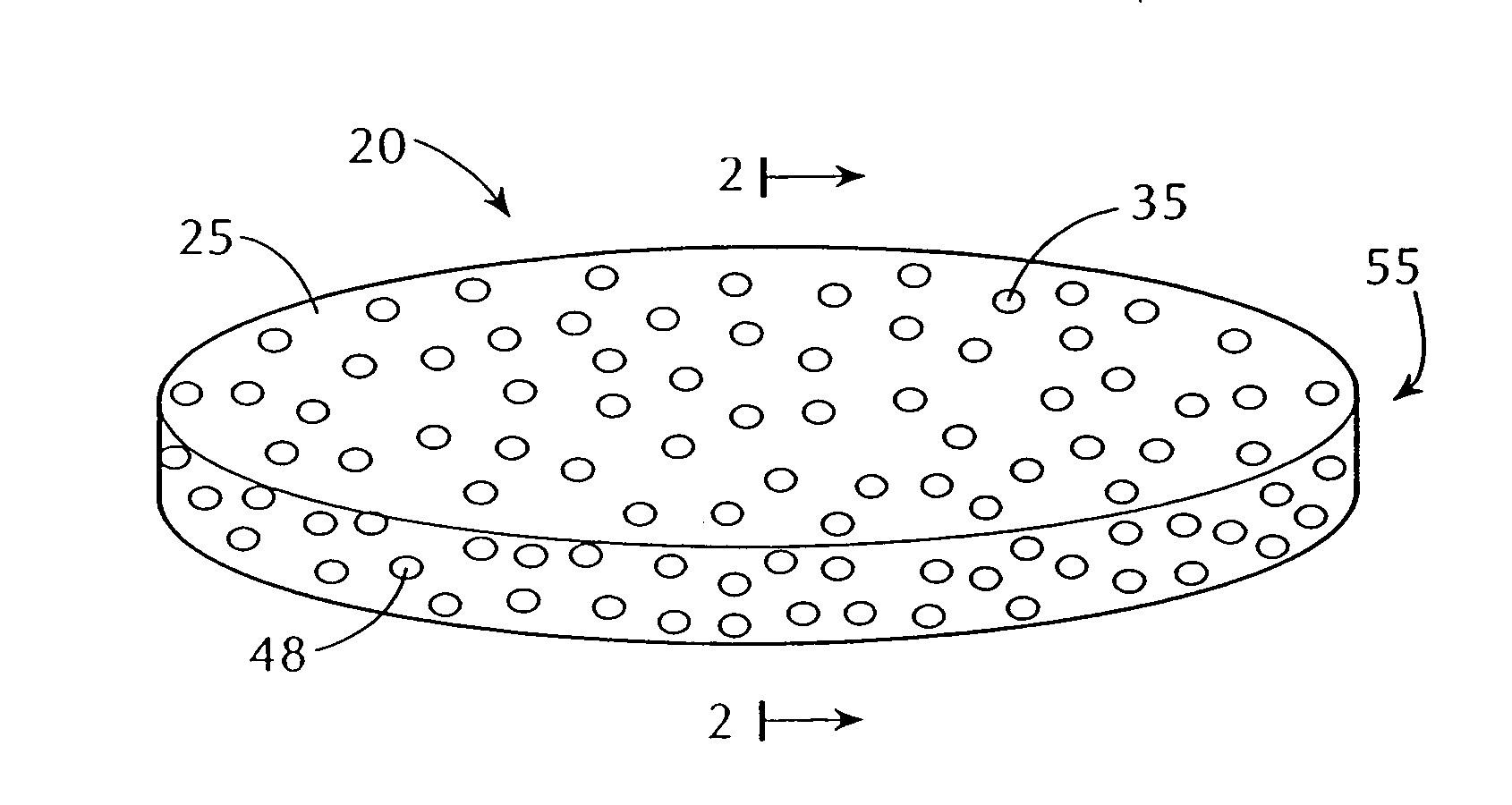

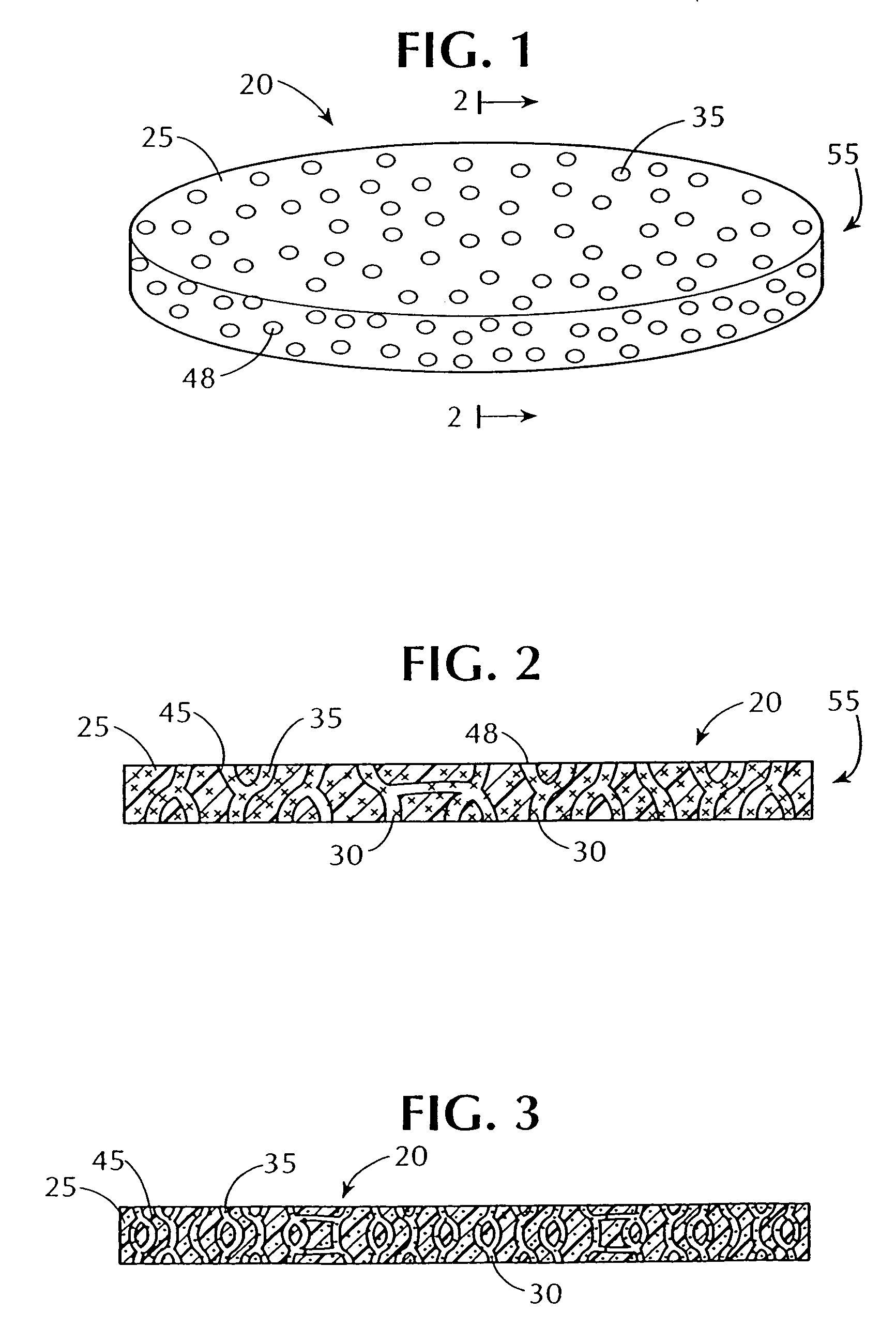

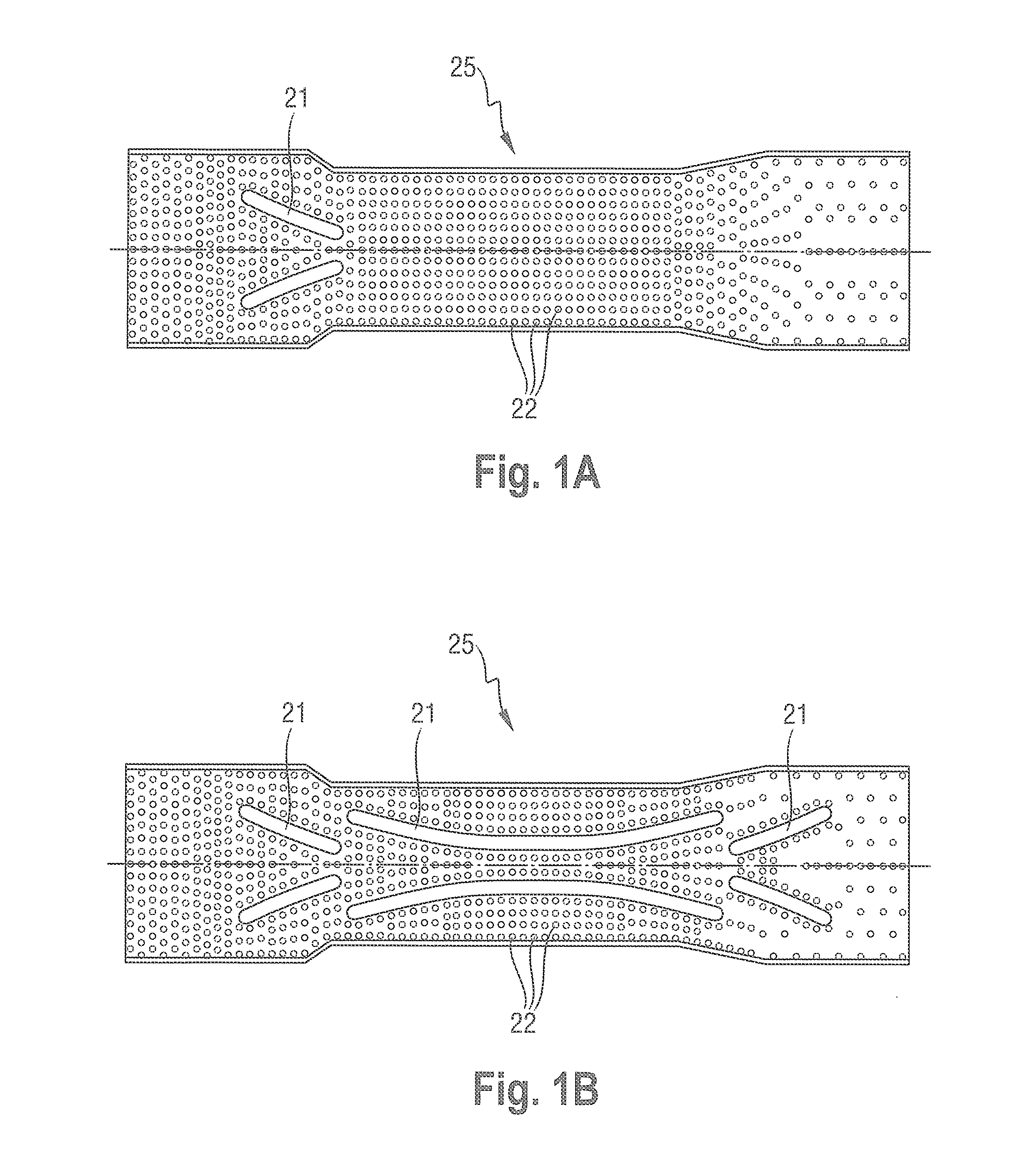

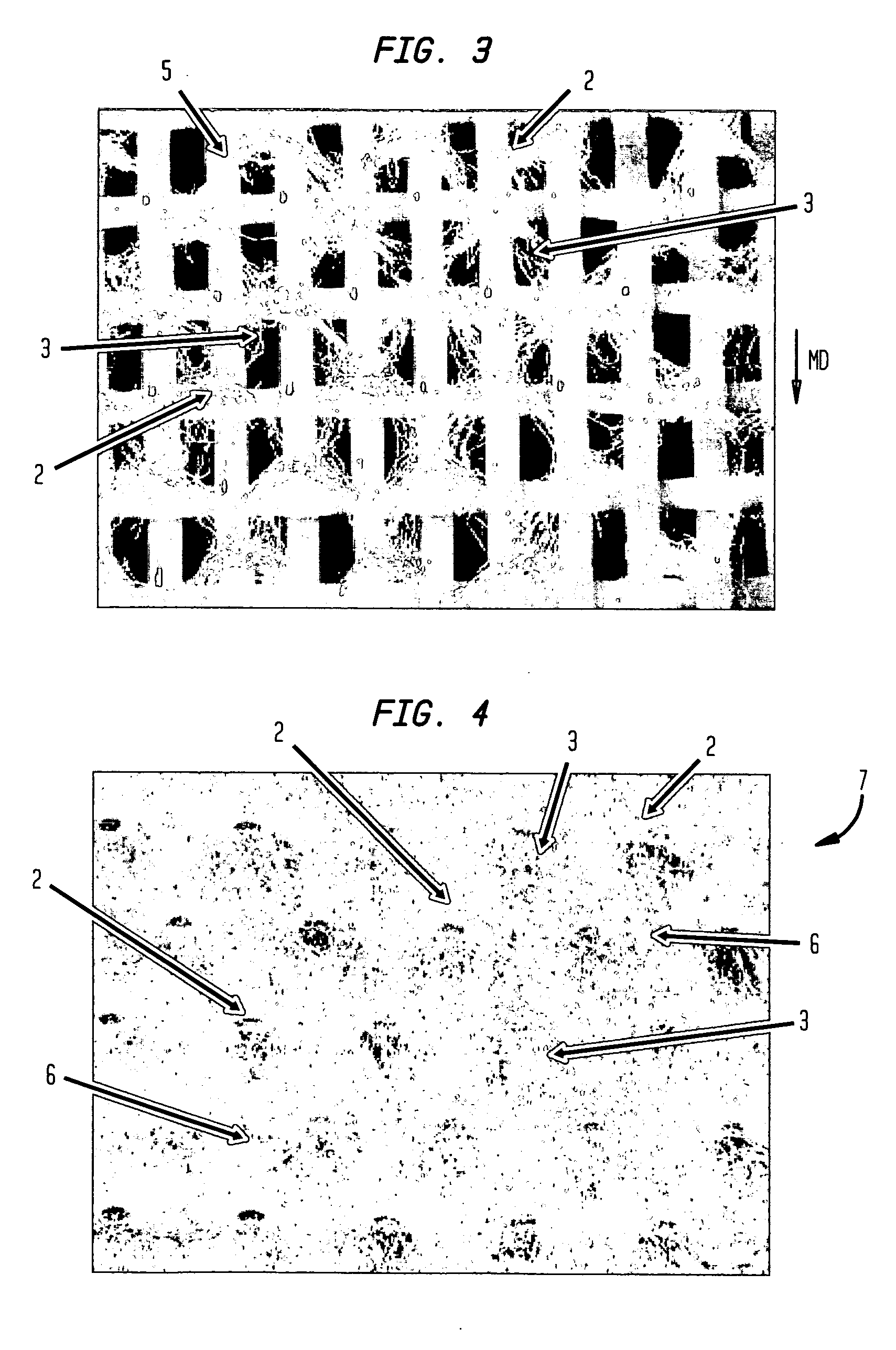

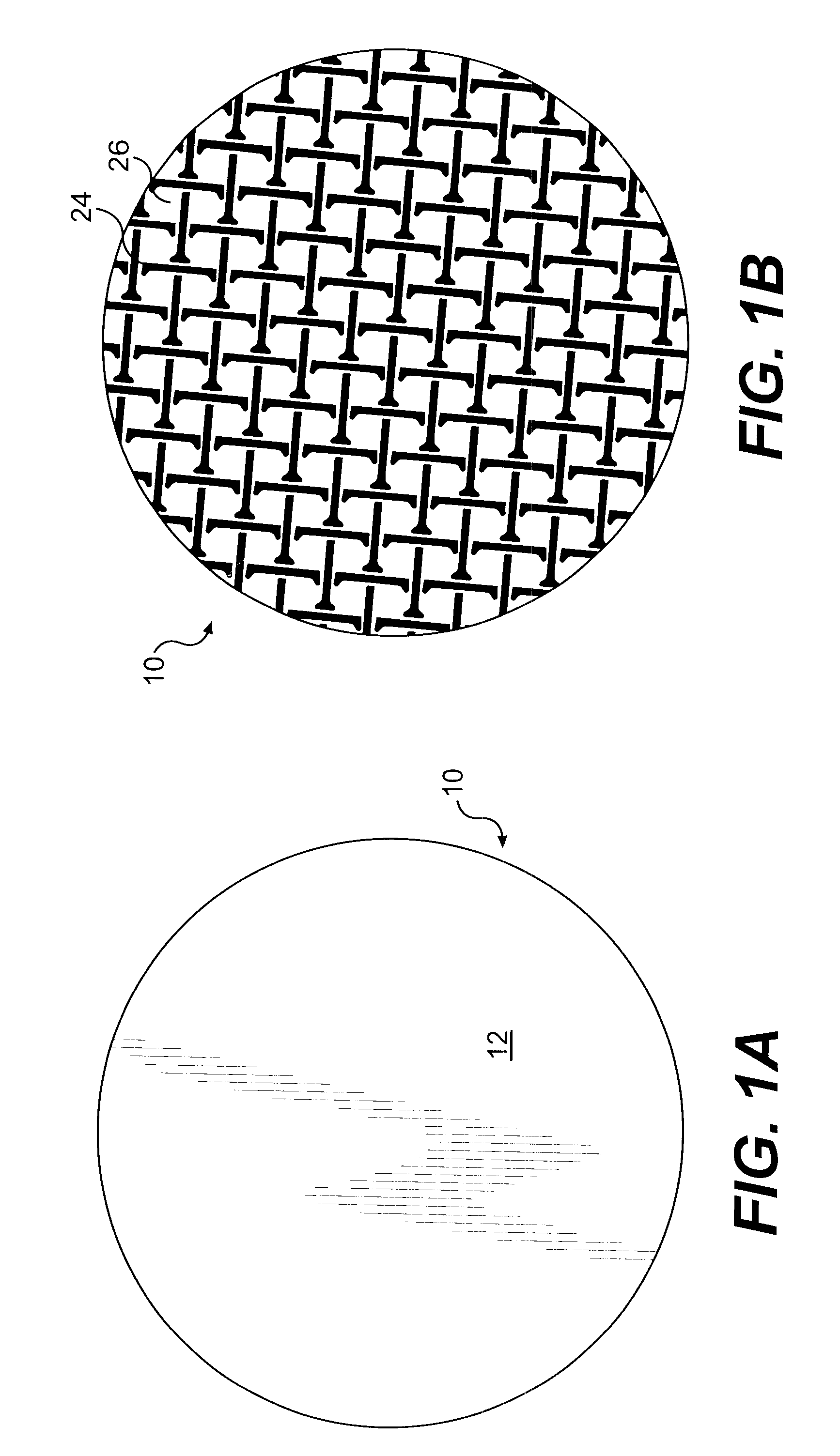

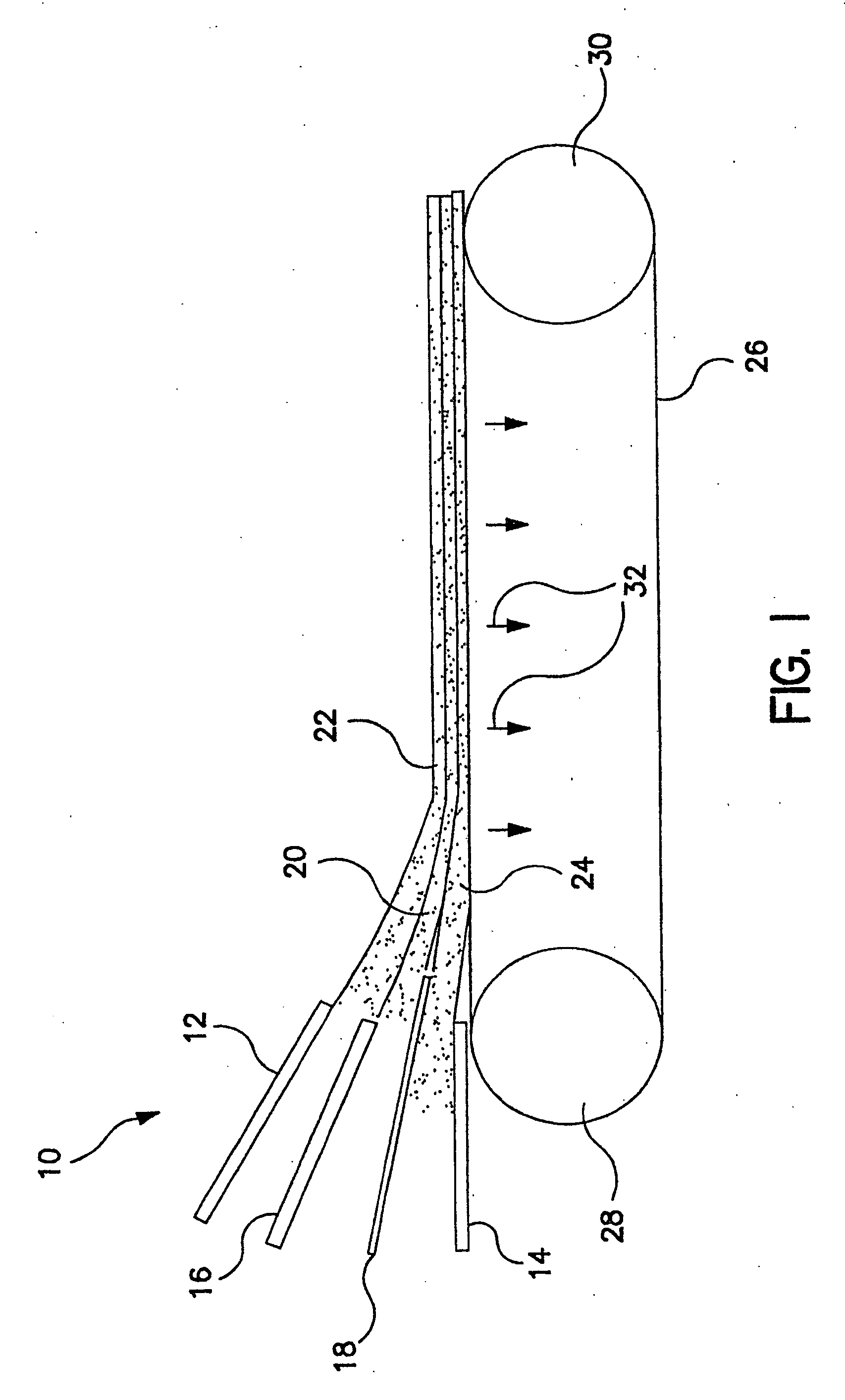

Process for making unitary fibrous structure comprising randomly distributed cellulosic fibers and non-randomly distributed synthetic fibers

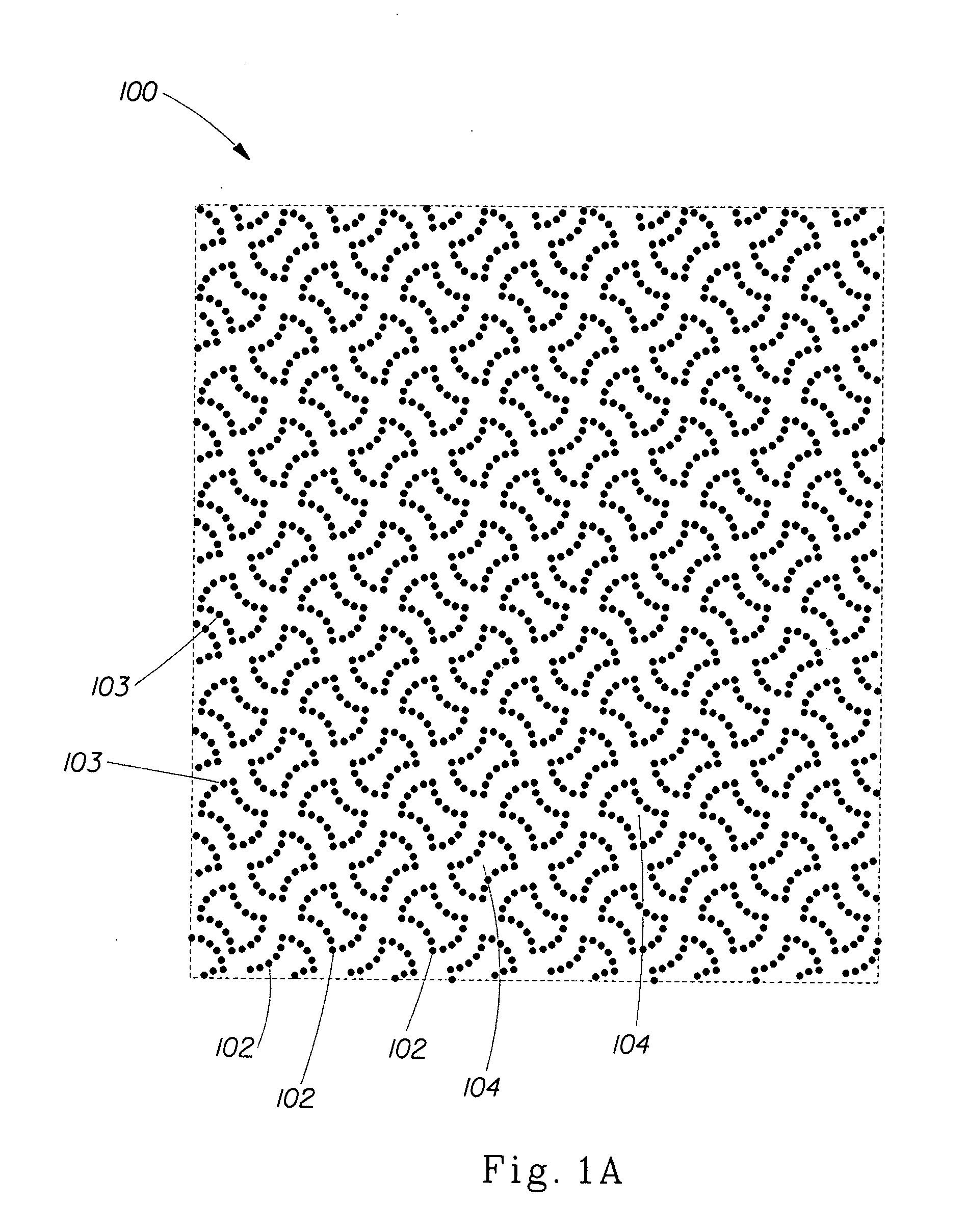

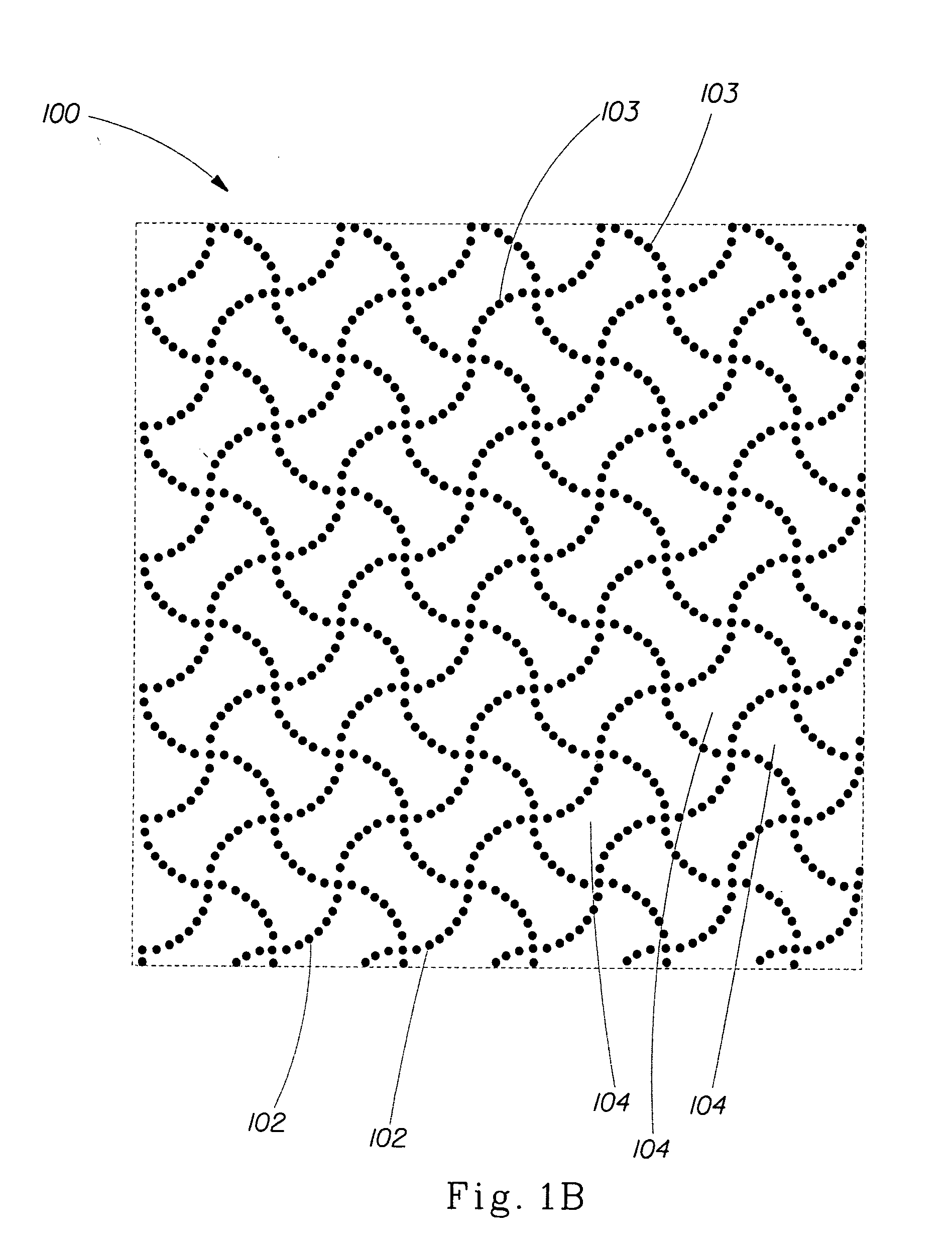

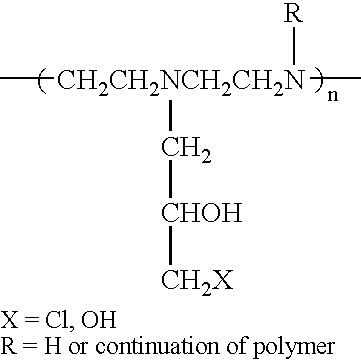

InactiveUS7067038B2High densityNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceRepeat pattern

Owner:THE PROCTER & GAMBLE COMPANY

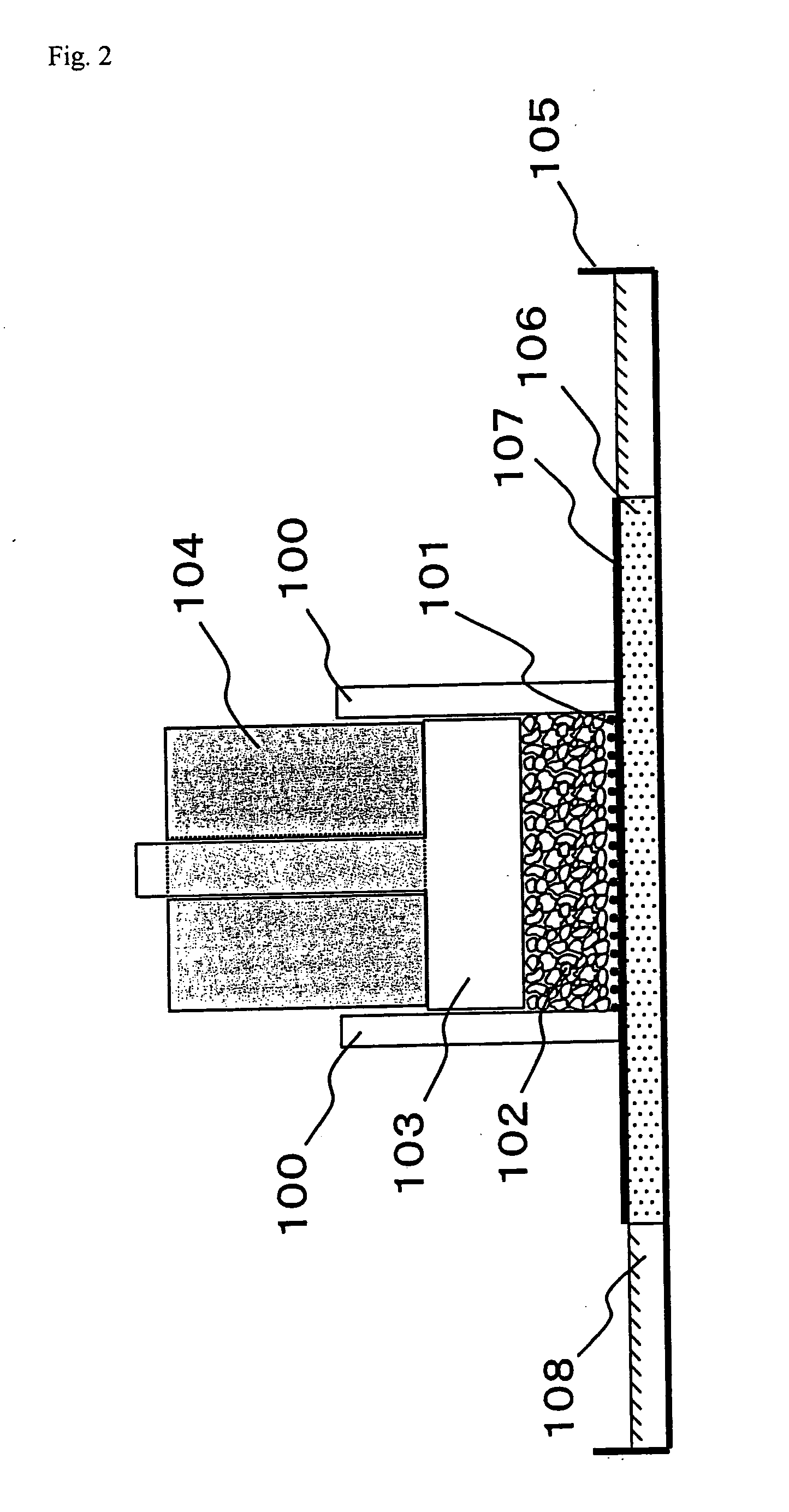

Vater-absorbent resin composition and its production process

ActiveUS20060073969A1Little gel-blockingGood liquid permeabilityNon-fibrous pulp additionOther chemical processesLiquid diffusionCompound (substance)

There are disclosed a water-absorbent resin composition and its production process, wherein the water-absorbent resin composition causes little gel-blocking and is excellent in the liquid permeability and liquid diffusibility and is high also in the absorption performances and further is strong also against the physical damage; and there are further disclosed a water-absorbent resin composition and its production process, wherein the water-absorbent resin composition has the following further advantages, in addition to the above, of involving little segregation of the metal compound and further having a dust prevention effect. One of water-absorbent resin compositions according to the present invention is a water-absorbent resin composition comprising water-absorbent resin particles obtained by polymerizing a monomer including acrylic acid and / or its salt, with the composition having a mass-average particle diameter of 100 to 600 μm and comprising water-soluble polyvalent metal salt particles and the water-absorbent resin particles that have been surface-crosslinked.

Owner:NIPPON SHOKUBAI CO LTD

Desiccant entrained polymer

The present invention includes a composition having a co-continuous interconnecting channel morphology. These co-continuous interconnecting channels are predominately occupied with a polymer and particles that control the percolation through the composition. The particles are composed of a material such as an absorbing agent, releasing agent and / or activation agent. The polymer composition may be used to form a desired shaped article such as plug type inserts and liners for closed containers, or it may be formed into a film, sheet, bead or pellet.

Owner:CSP TECH NORTH AMERICA

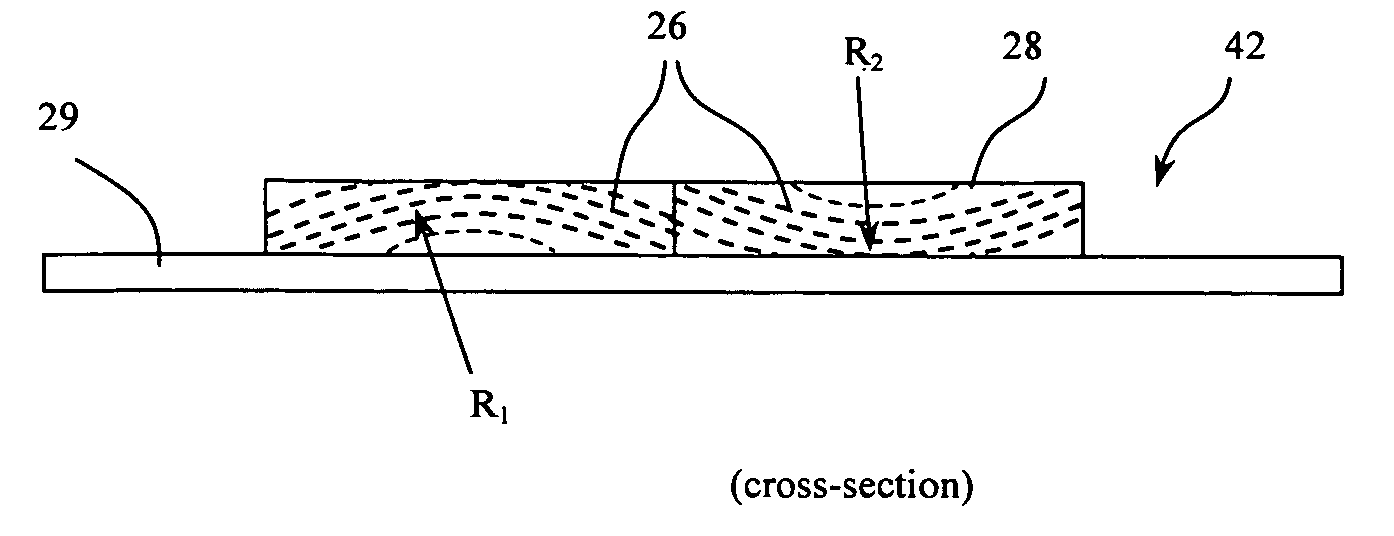

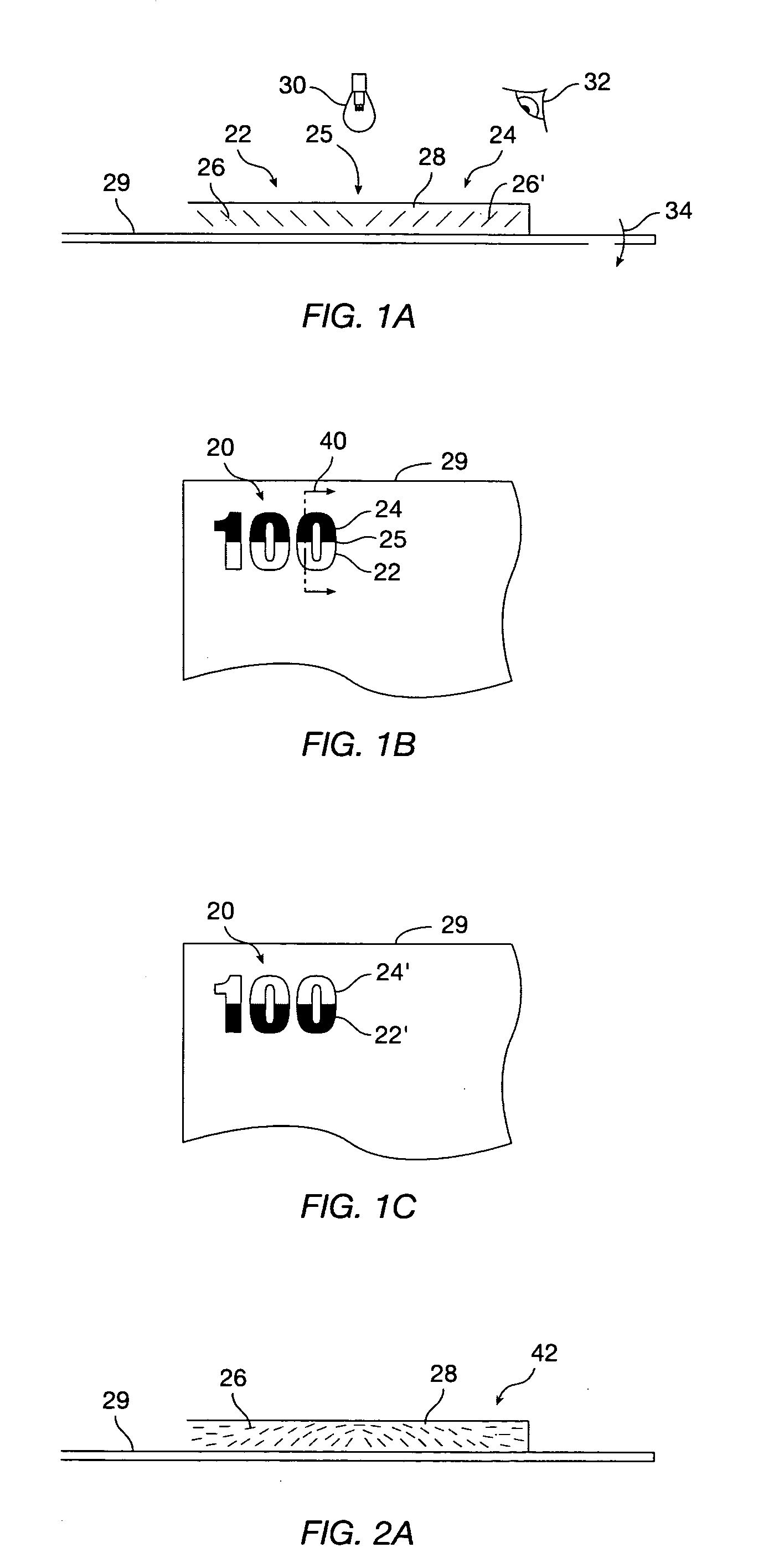

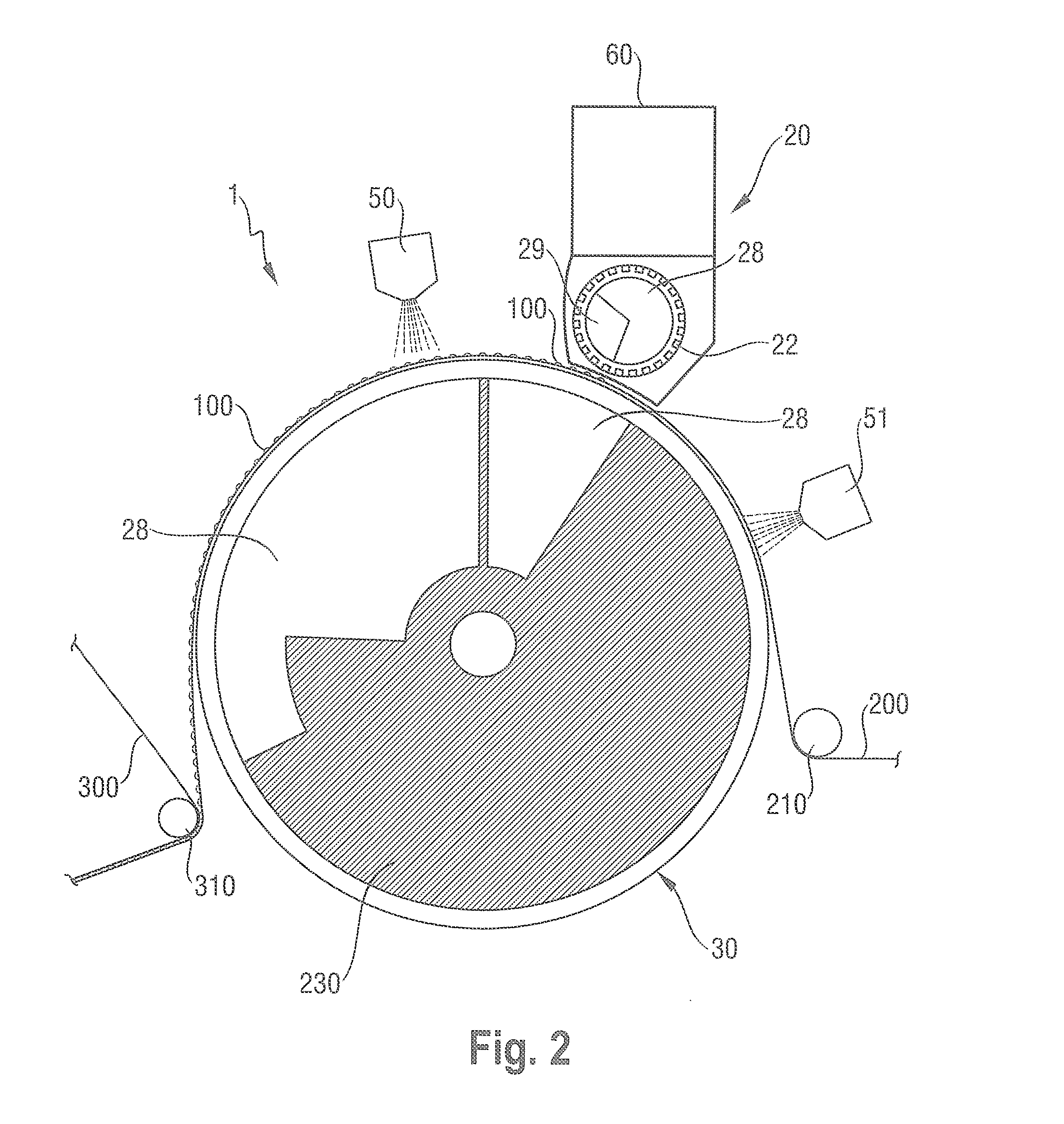

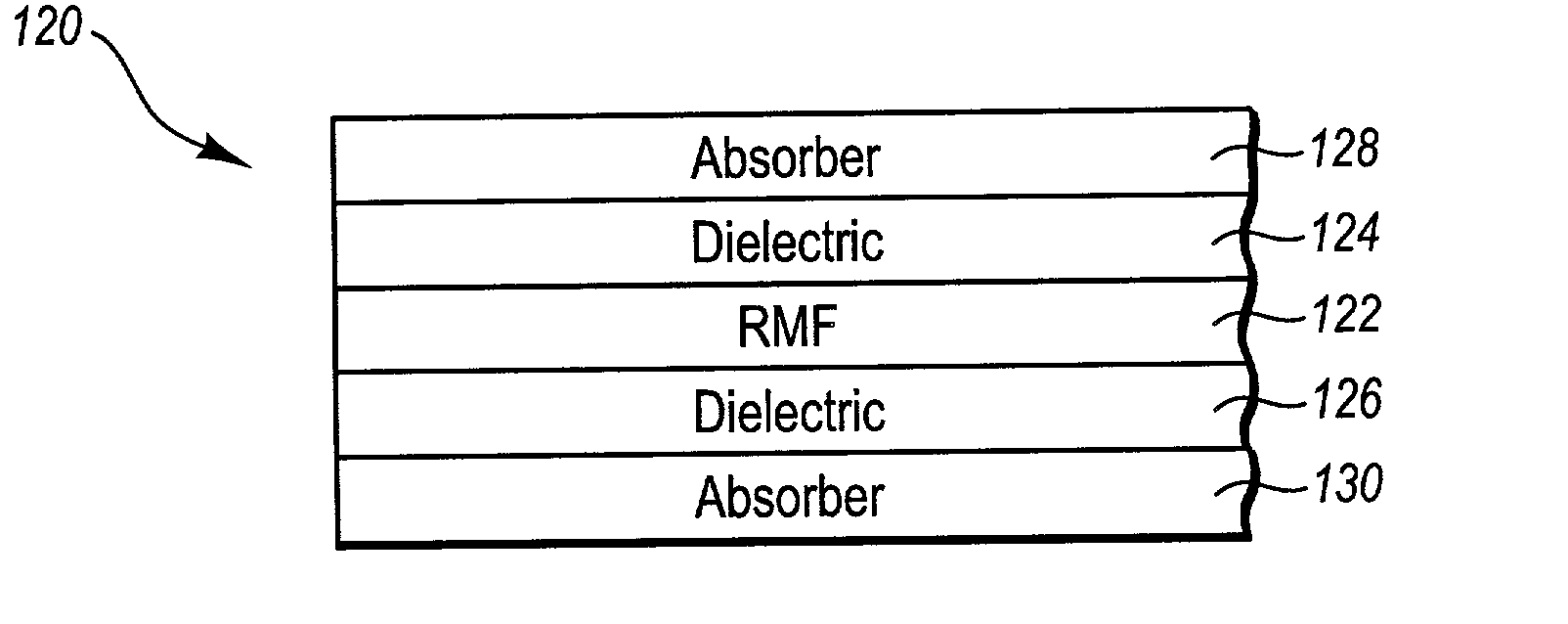

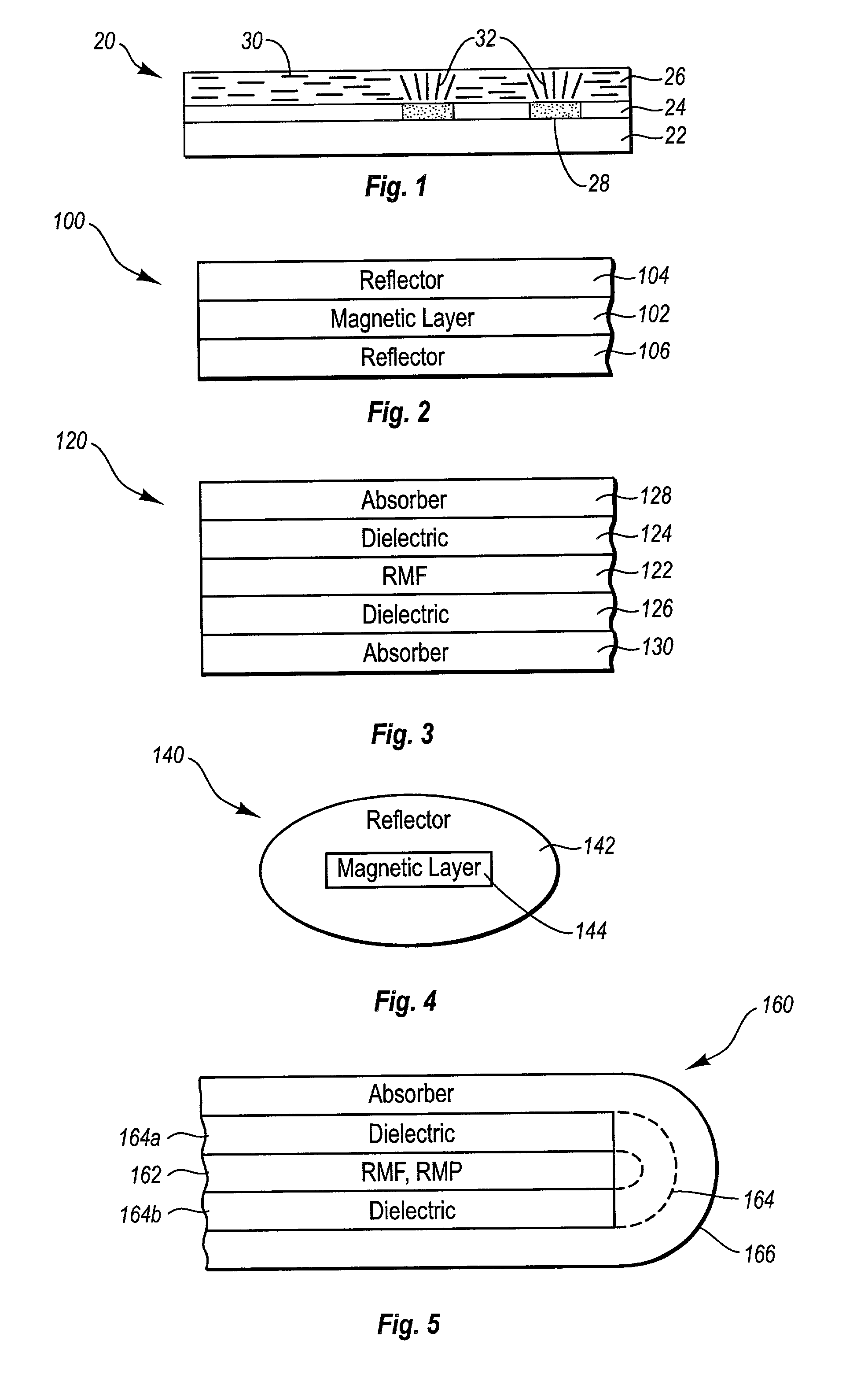

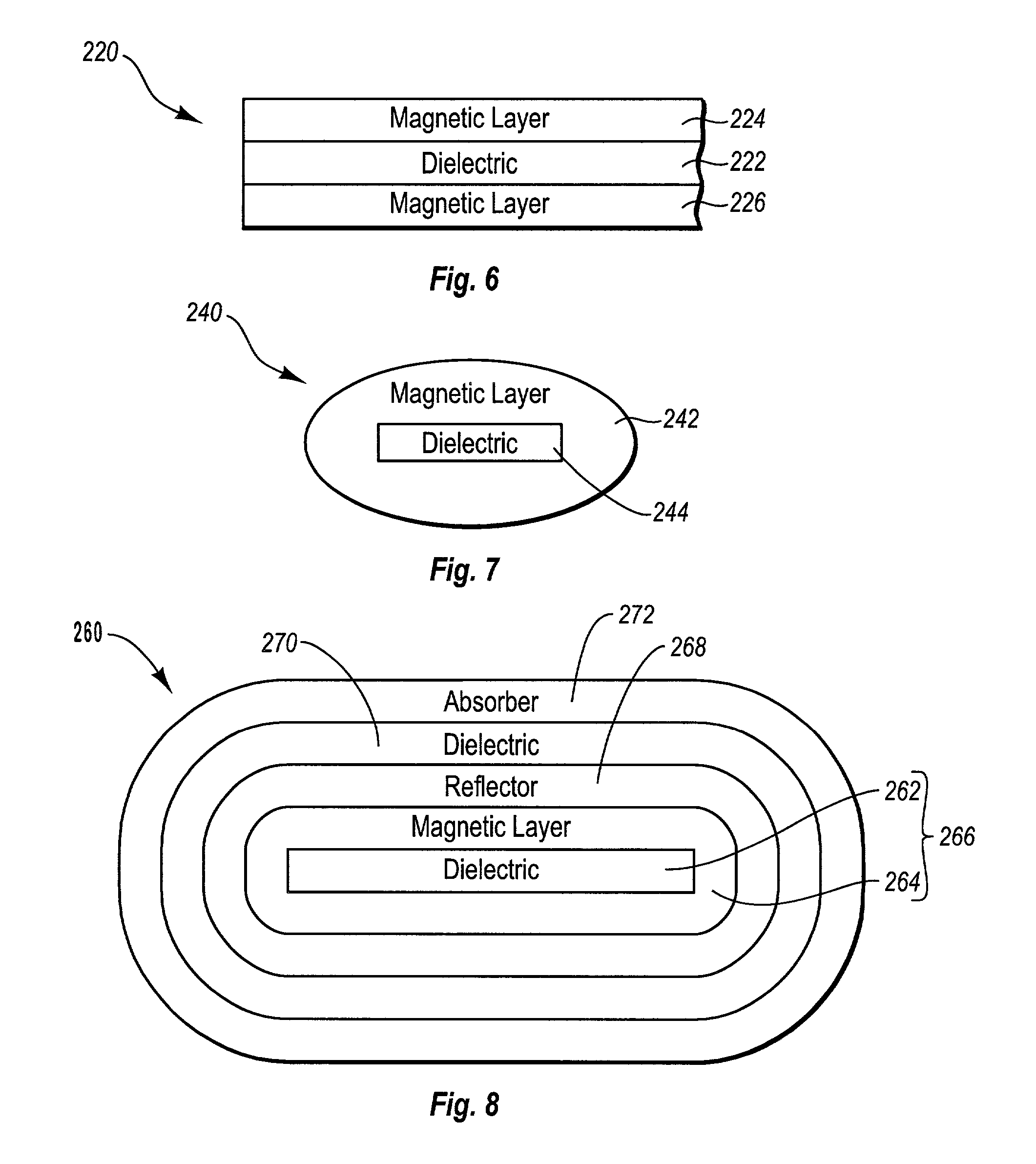

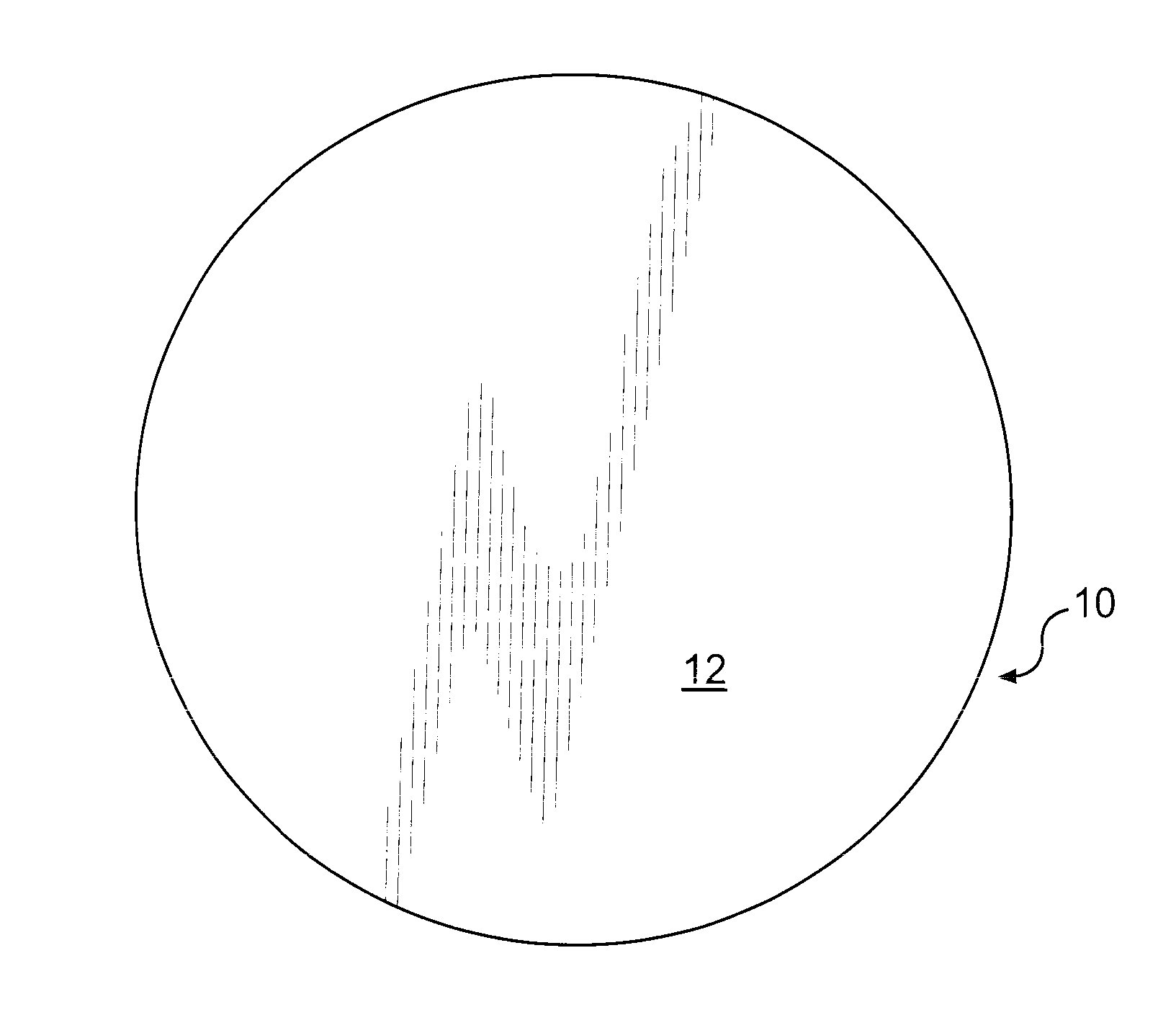

Method and apparatus for orienting magnetic flakes

InactiveUS20050106367A1Non-fibrous pulp additionDecorative surface effectsPaper documentDocument preparation

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

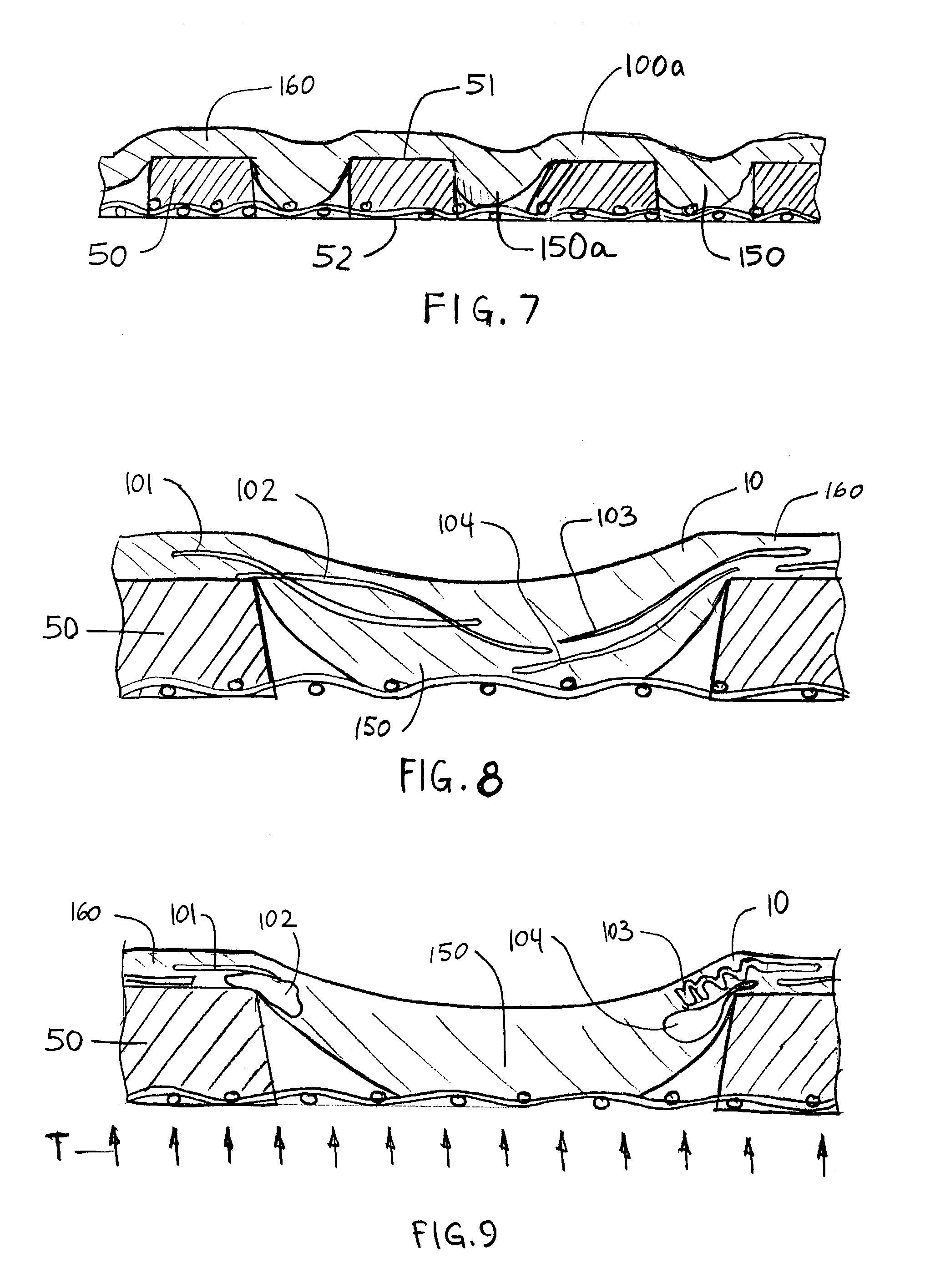

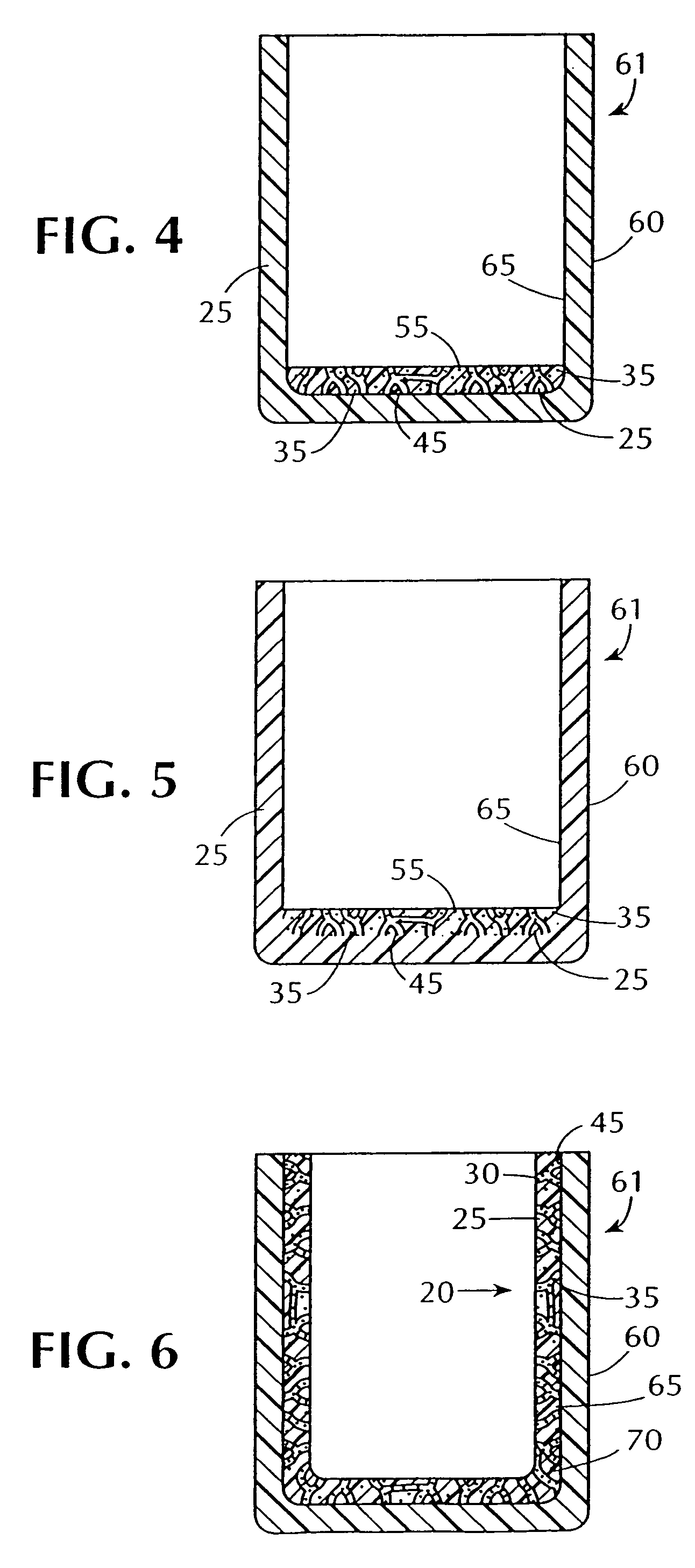

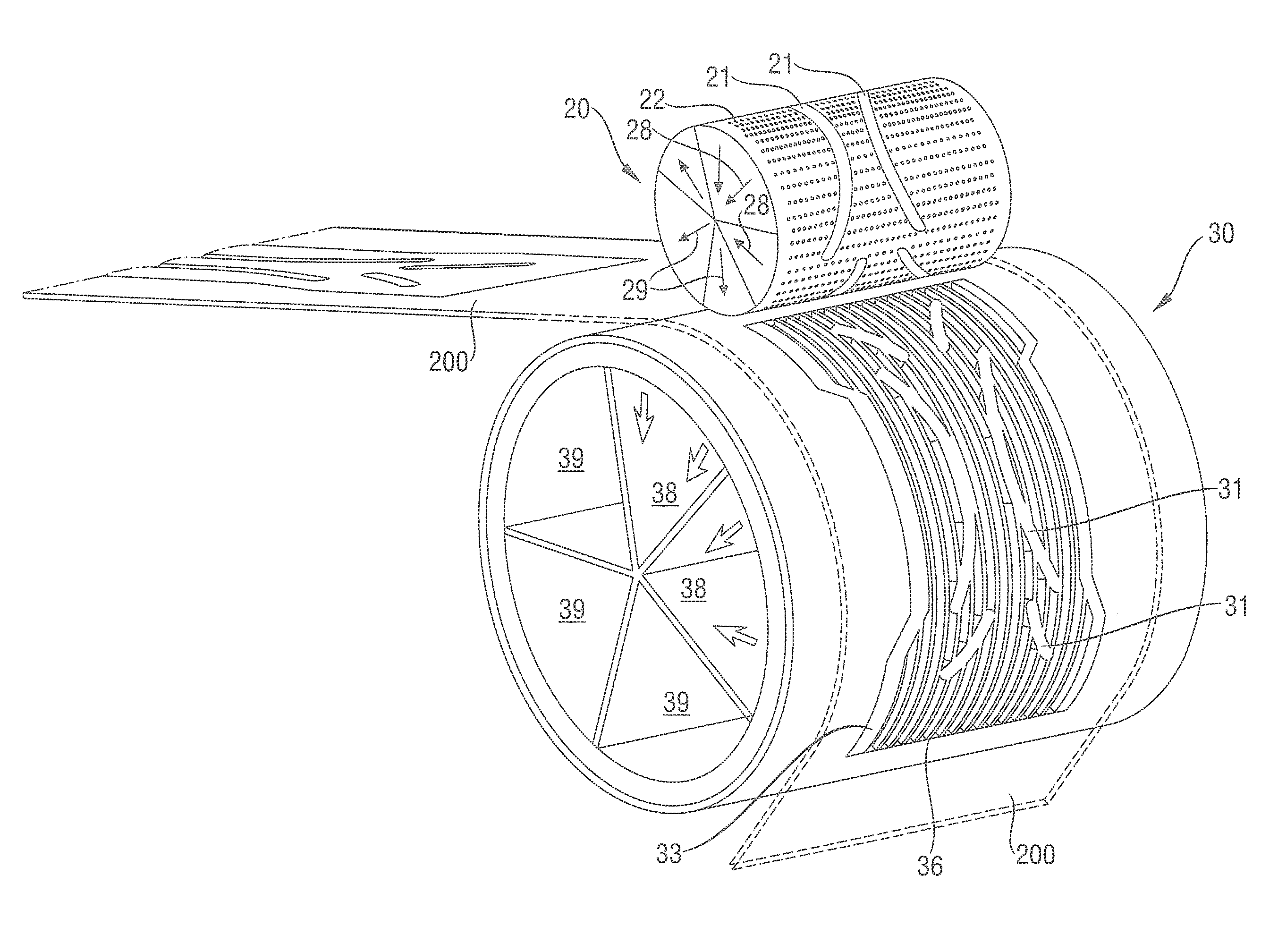

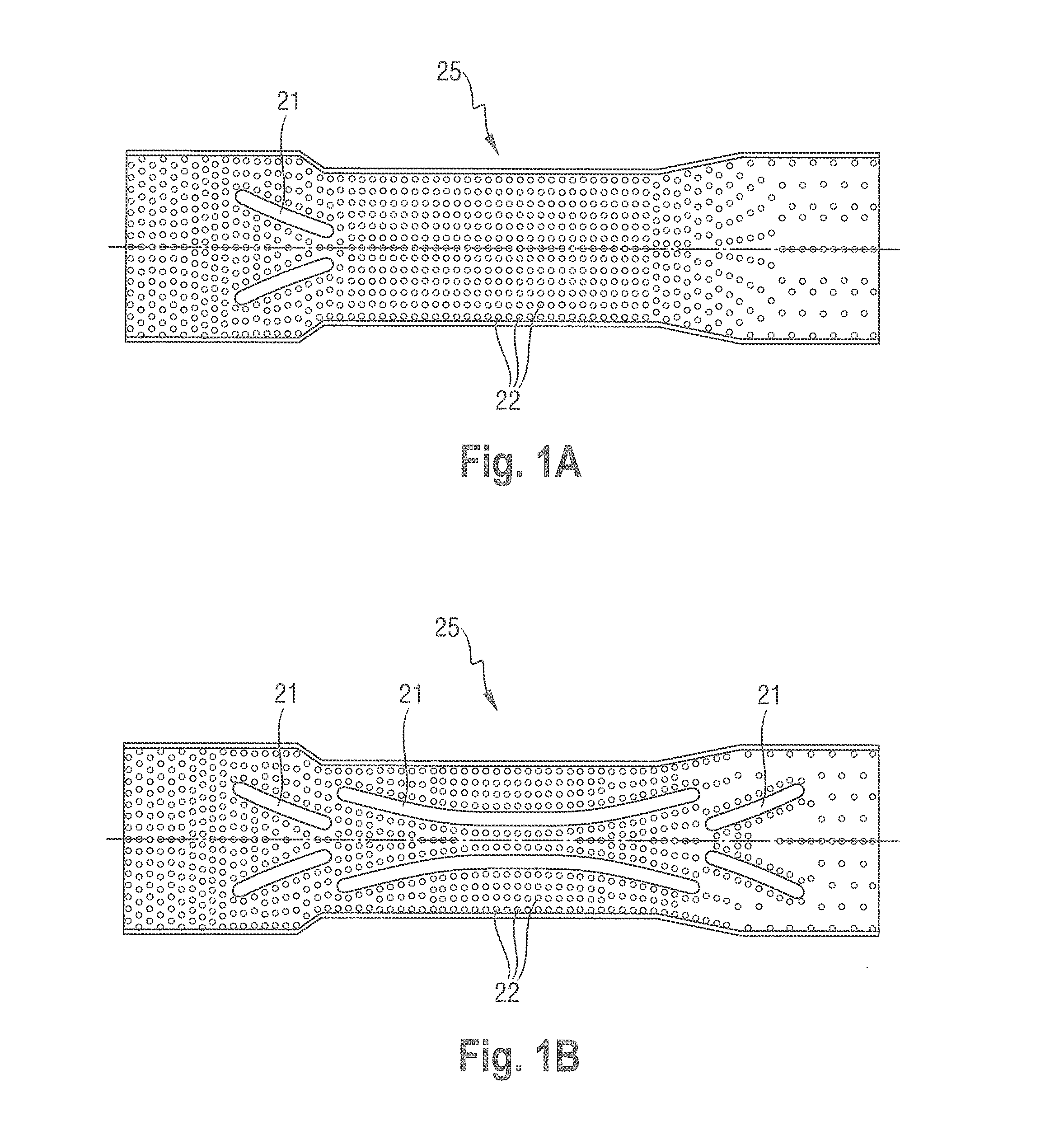

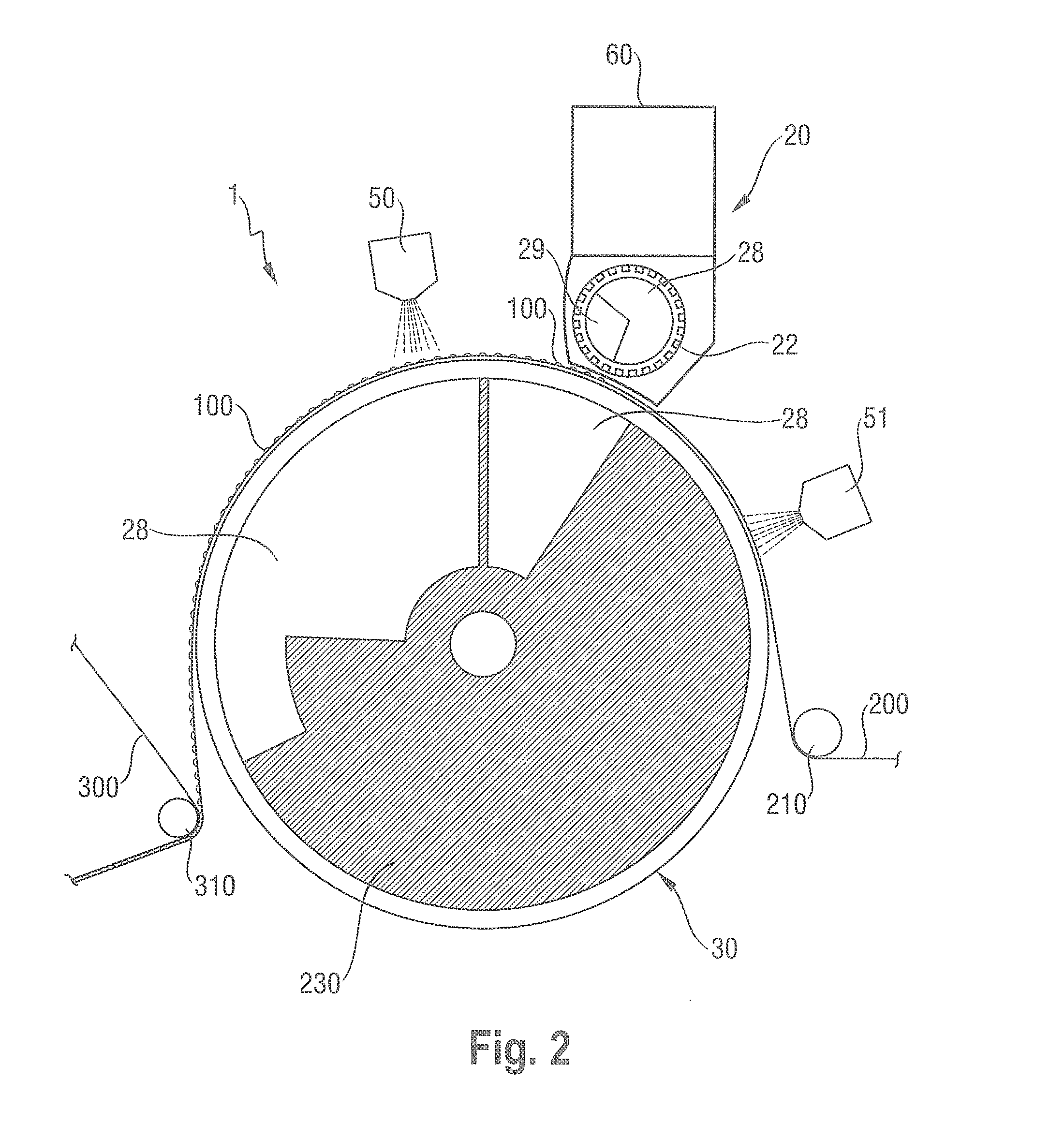

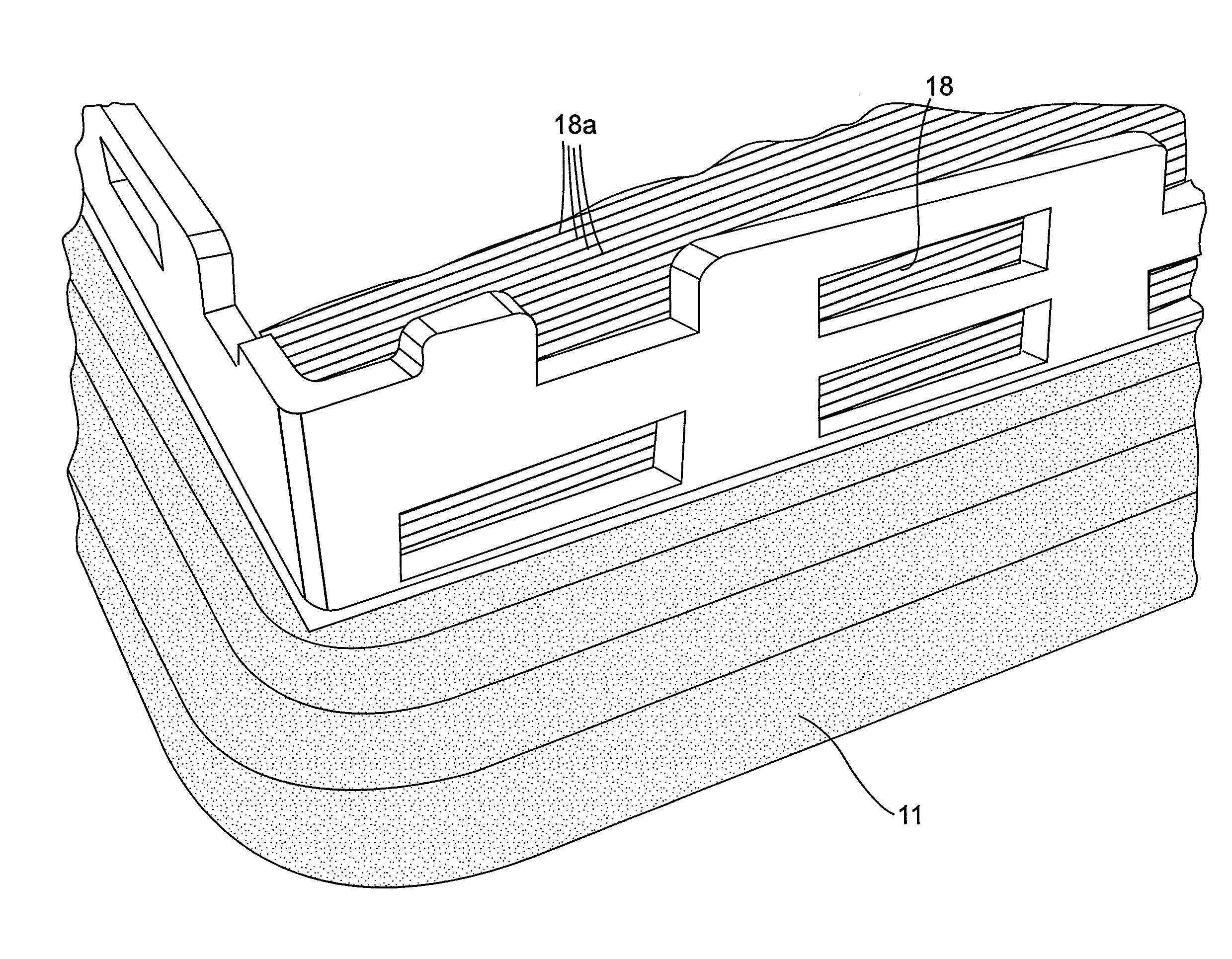

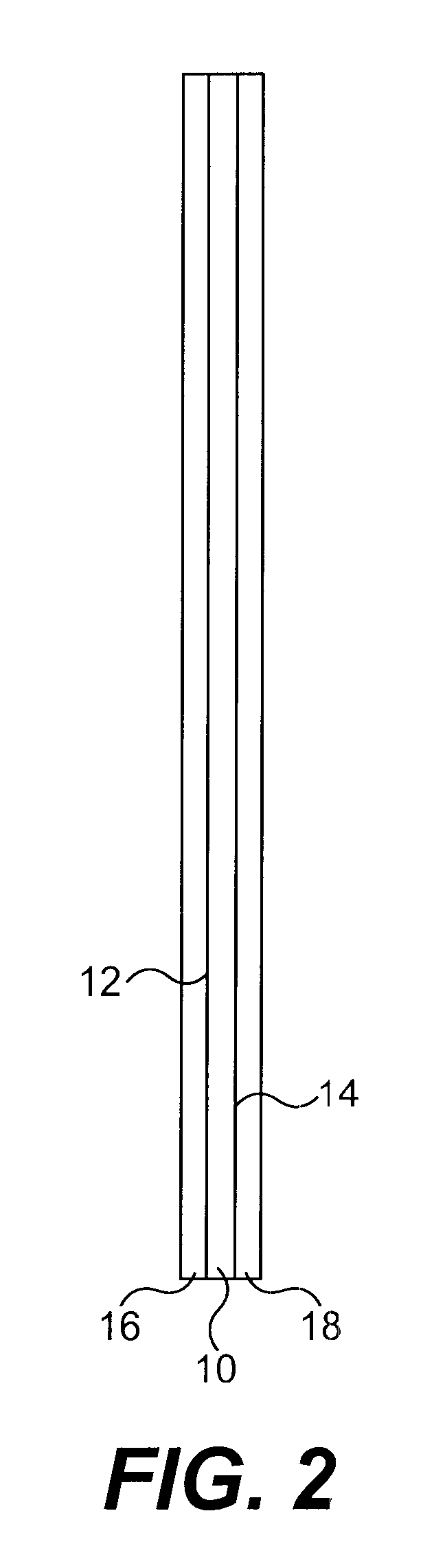

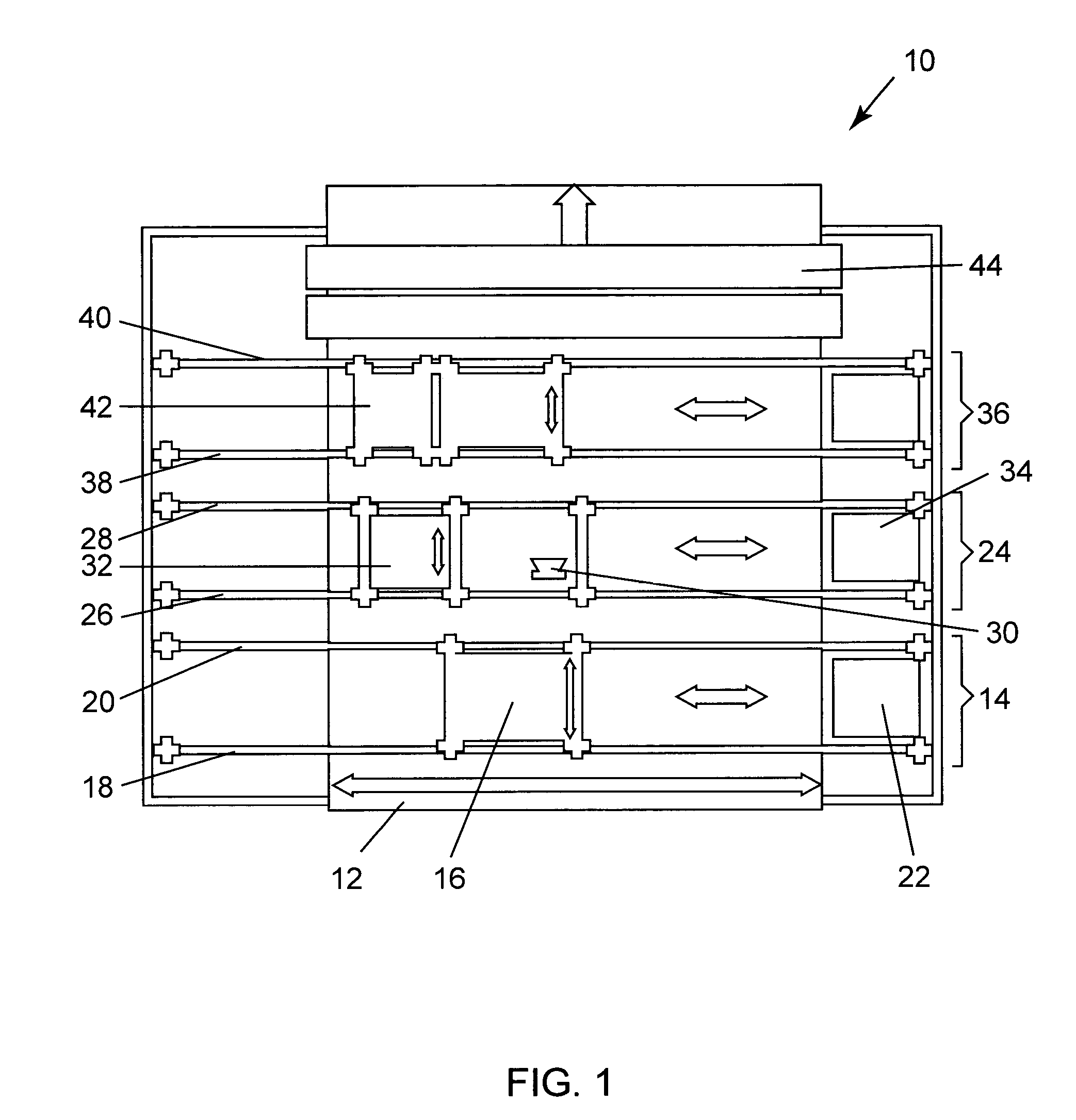

Method and Apparatus for Making Absorbent Structures with Absorbent Material

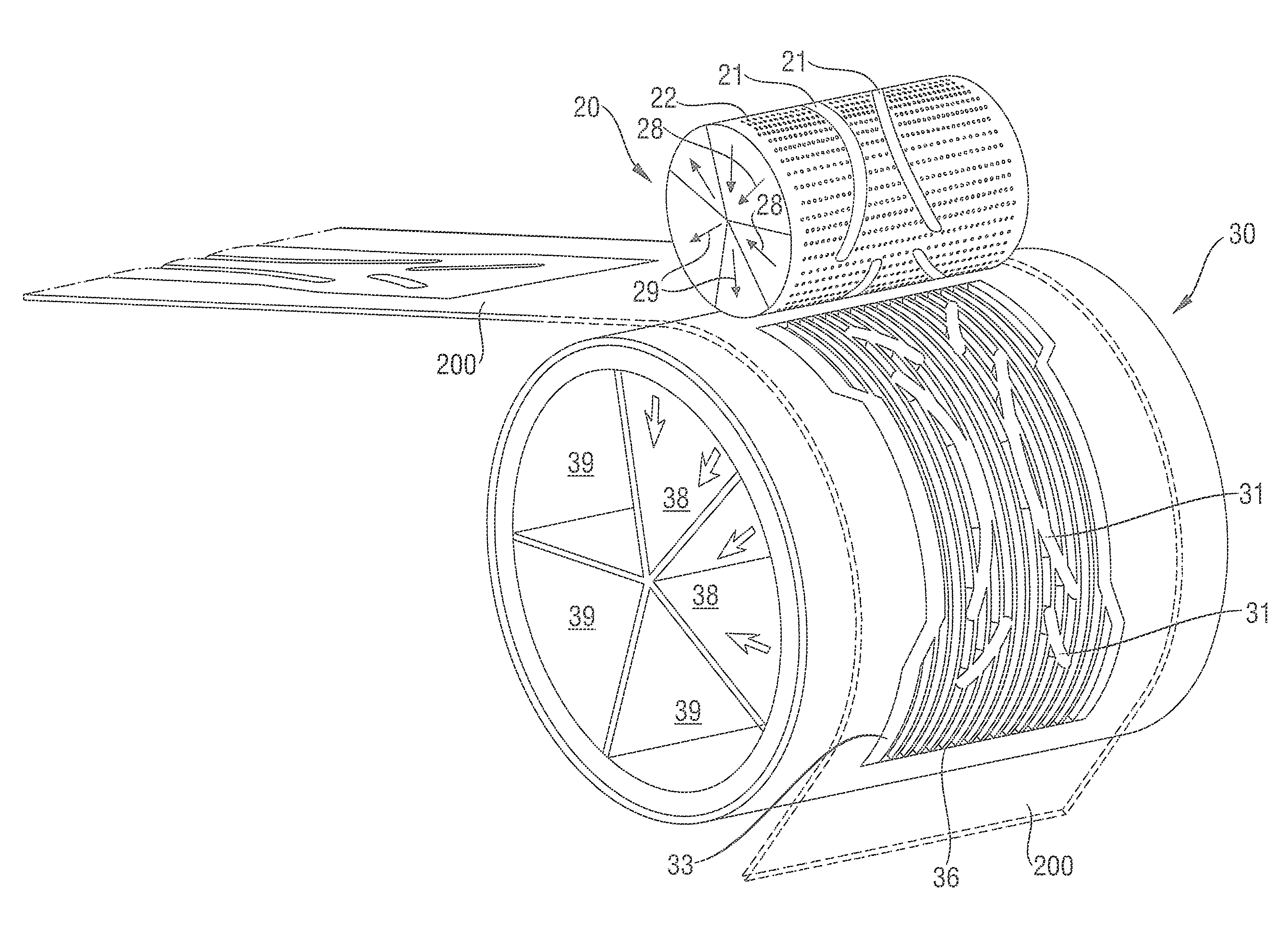

Apparatus and method for producing absorbent structures with absorbent layers with channel(s) without absorbent material, using a first moving endless surface with specific raised strip(s) and a second moving endless surface with specific mating strip(s).

Owner:THE PROCTER & GAMBLE COMPANY

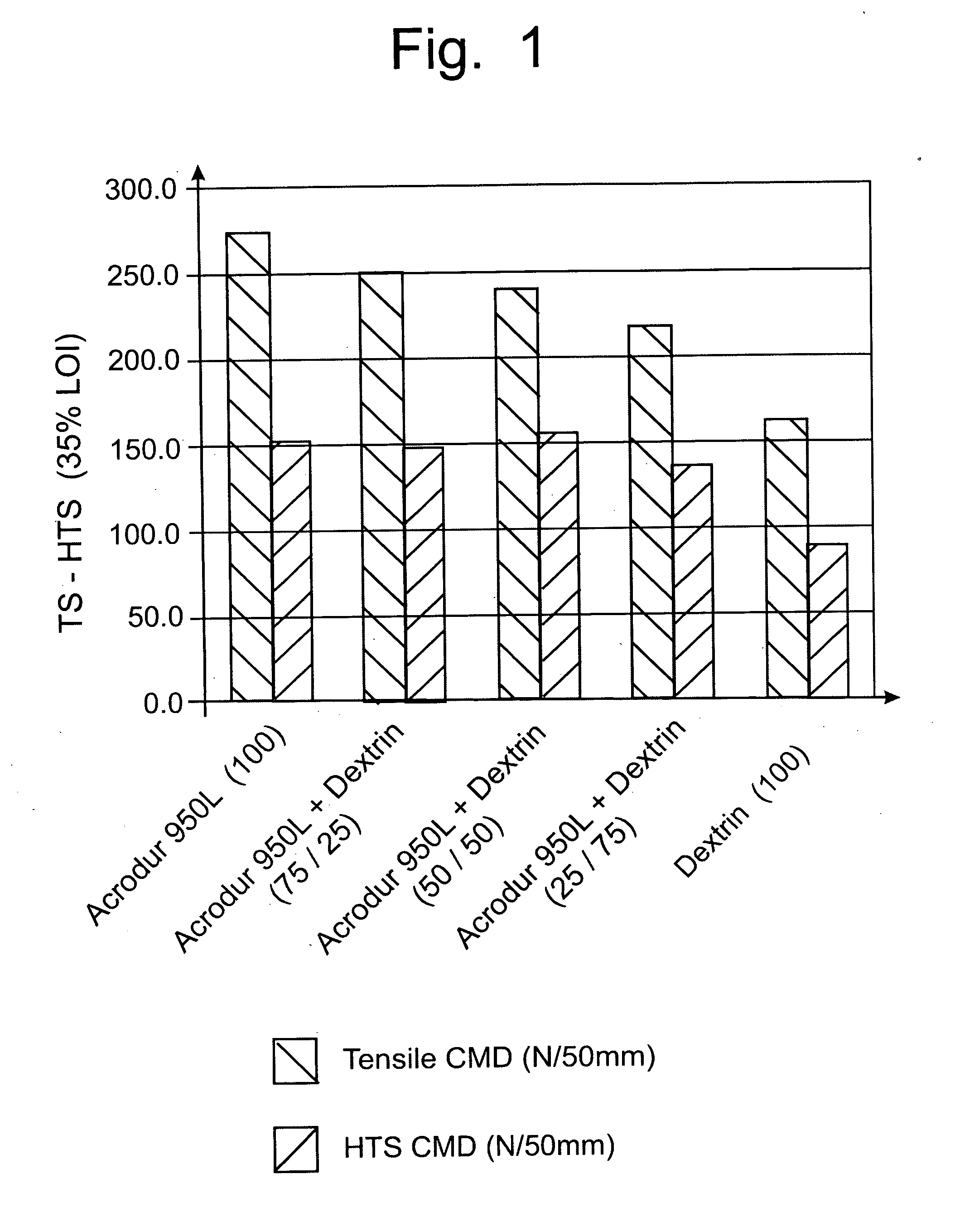

Dextrin binder composition for heat resistant non-wovens

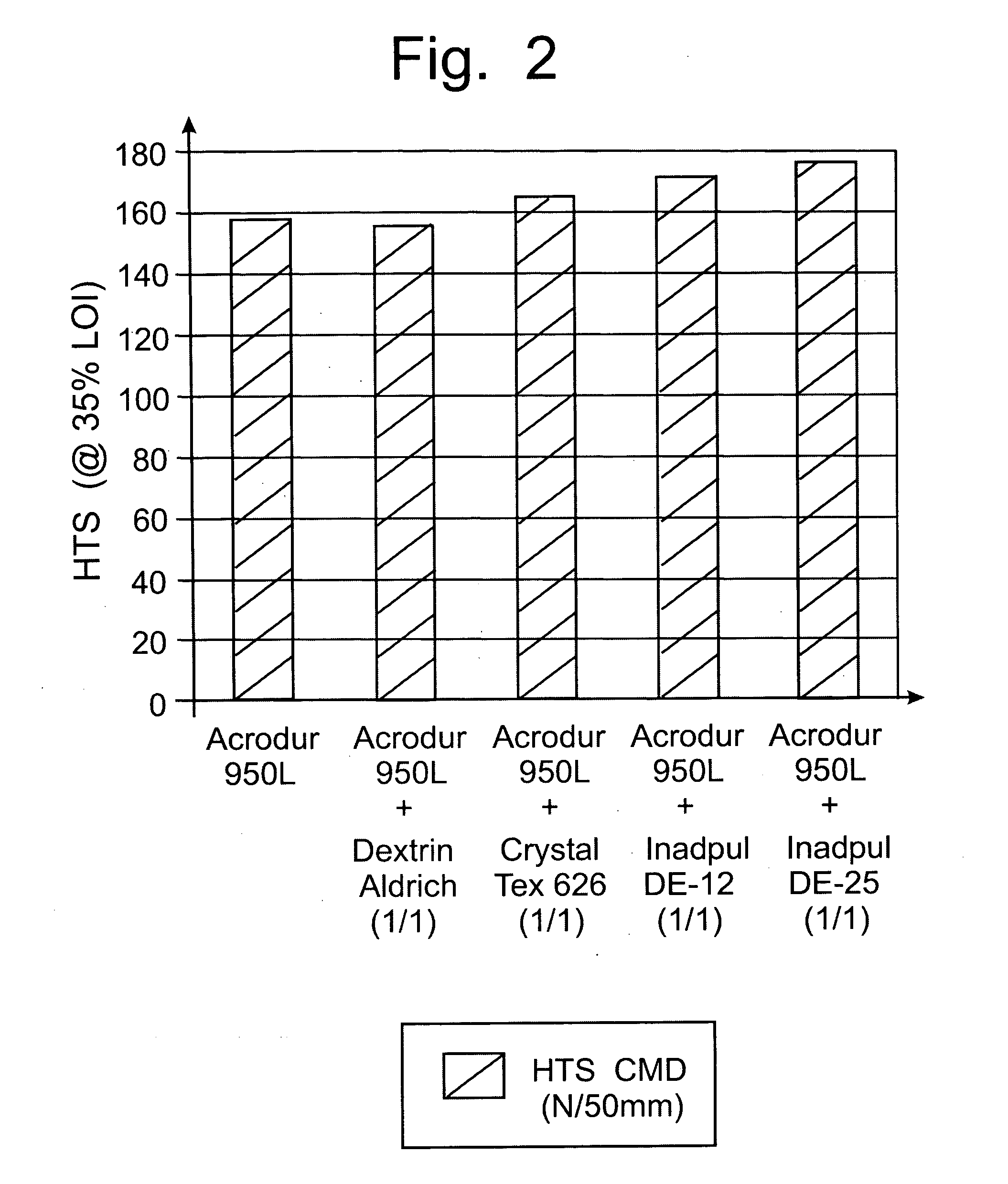

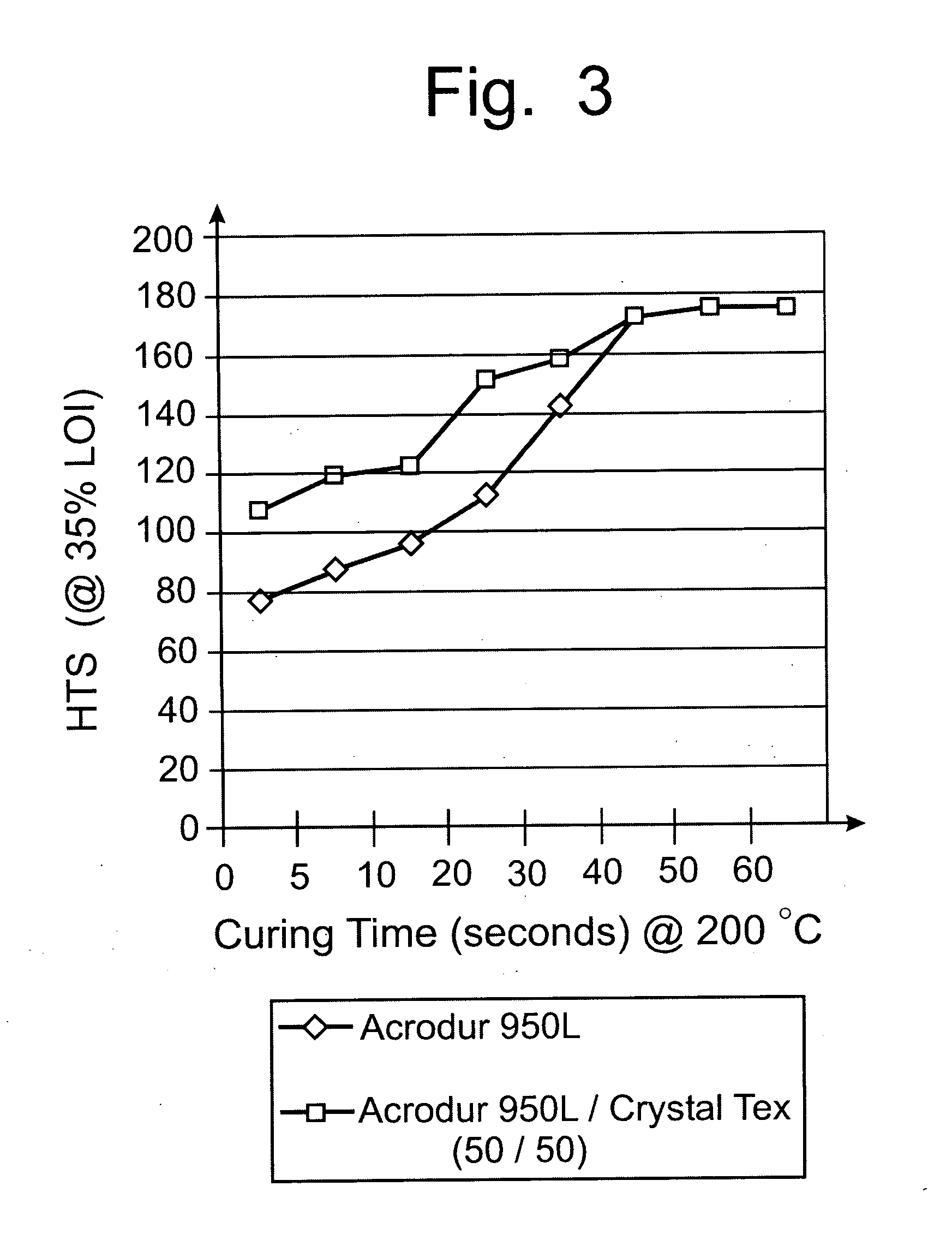

InactiveUS20050215153A1Maintain strengthHigh hot tensile strengthNon-fibrous pulp additionStarch adhesivesPolyolCarboxylic acid

A polycarboxy binder composition that contains a dextrin as a co-binder is provided. The dextrin co-binder may be a dextrin, a modified dextrin, a maltodextrin, or combinations thereof. The dextrin may be chemically modified. A pre-binder composition is formed that contains a polycarboxy polymer, a crosslinking agent, and optionally a catalyst. The polycarboxy polymer may be a homopolymer or copolymer prepared from unsaturated carboxylic acids and may be modified to contain one or more vinyl compounds. The crosslinking agent may be a polyol that contains at least two hydroxyl groups. The pre-binder composition may be formed by admixing the polycarboxy polymer, the crosslinking agent, and optionally, the catalyst, in a mixing device. Dextrin may be added to the pre-binder composition in an amount of from 10-75% of the total binder composition. The dextrin binder composition may have a ratio of from approximately 90:10 to 25:75 pre-binder:dextrin co-binder.

Owner:OWNS CORNING COMPOSITES

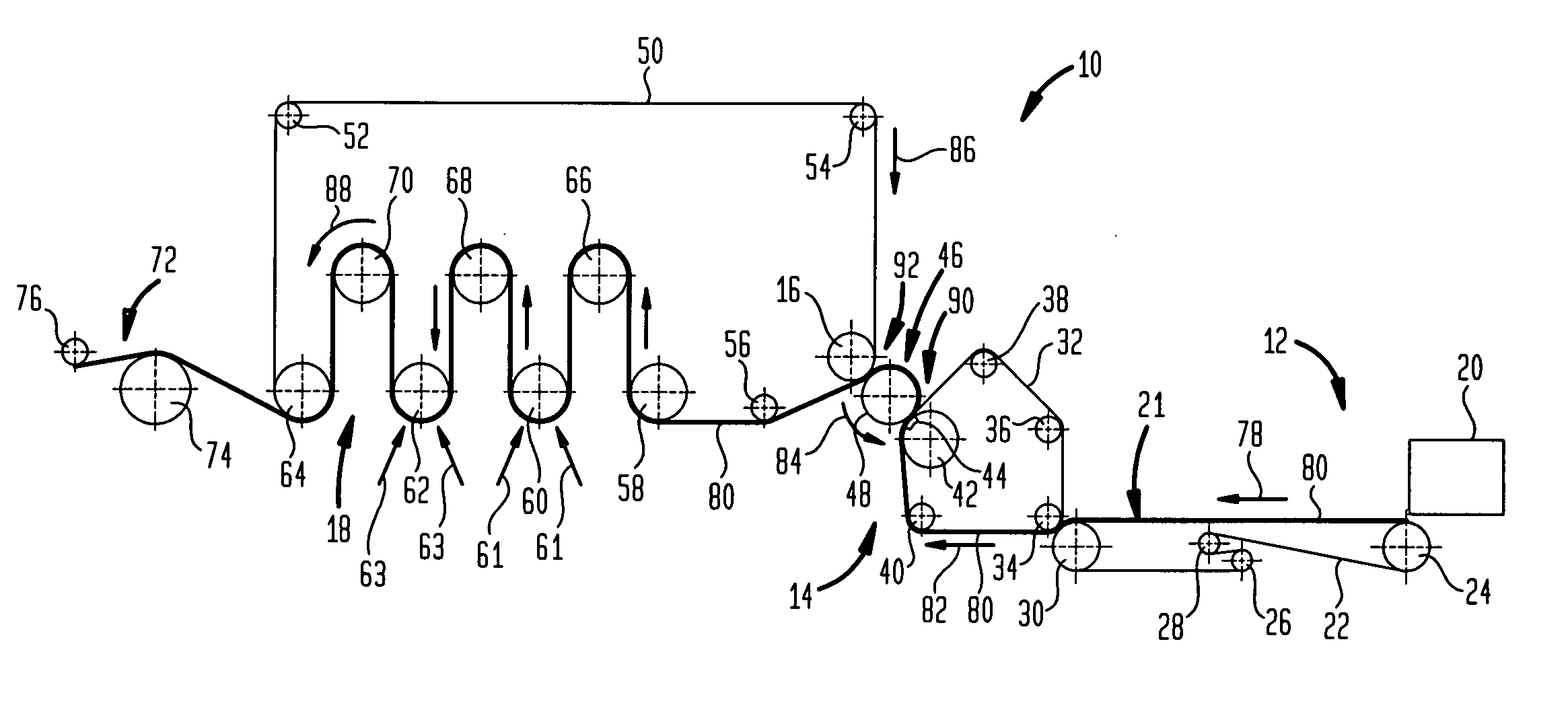

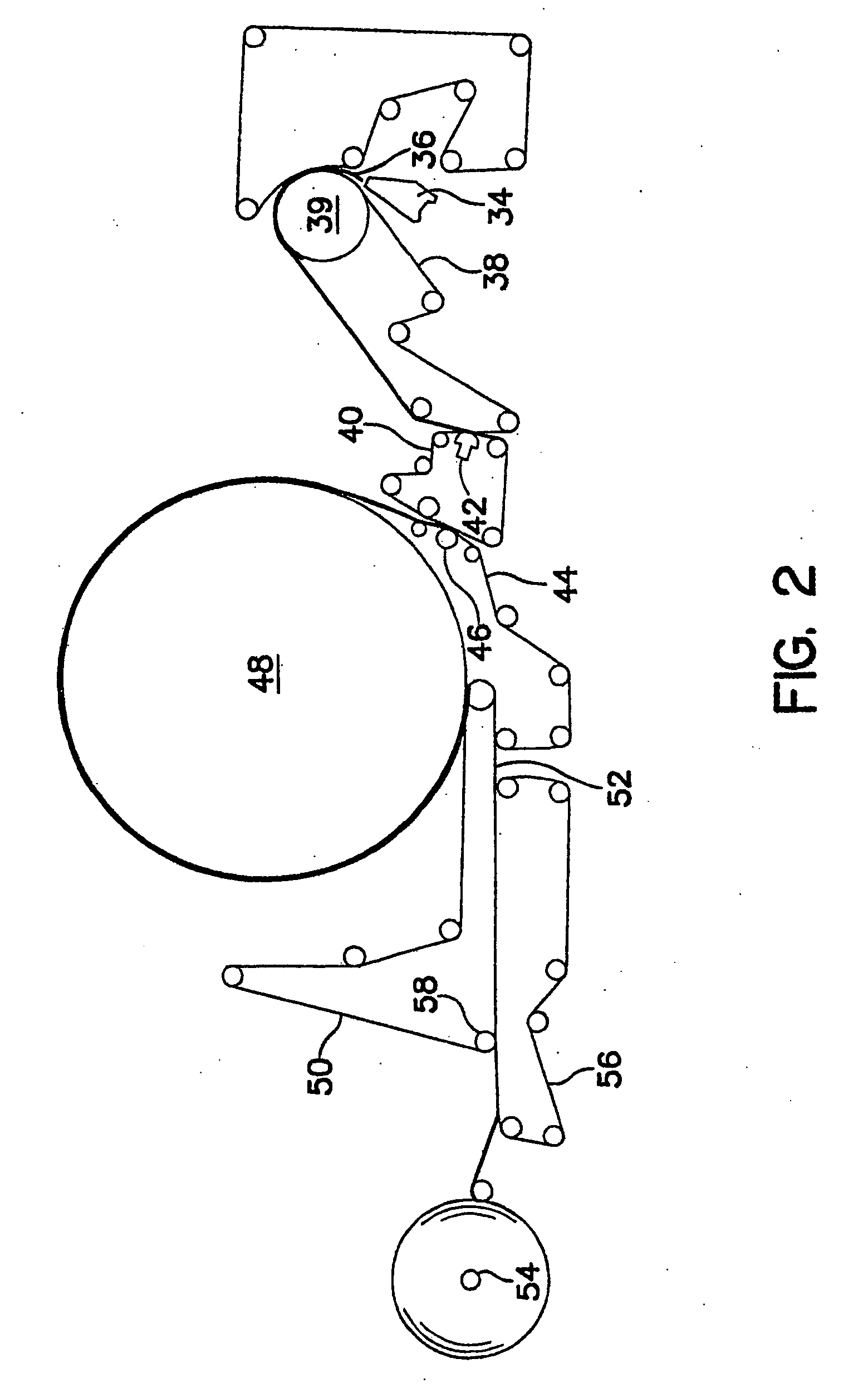

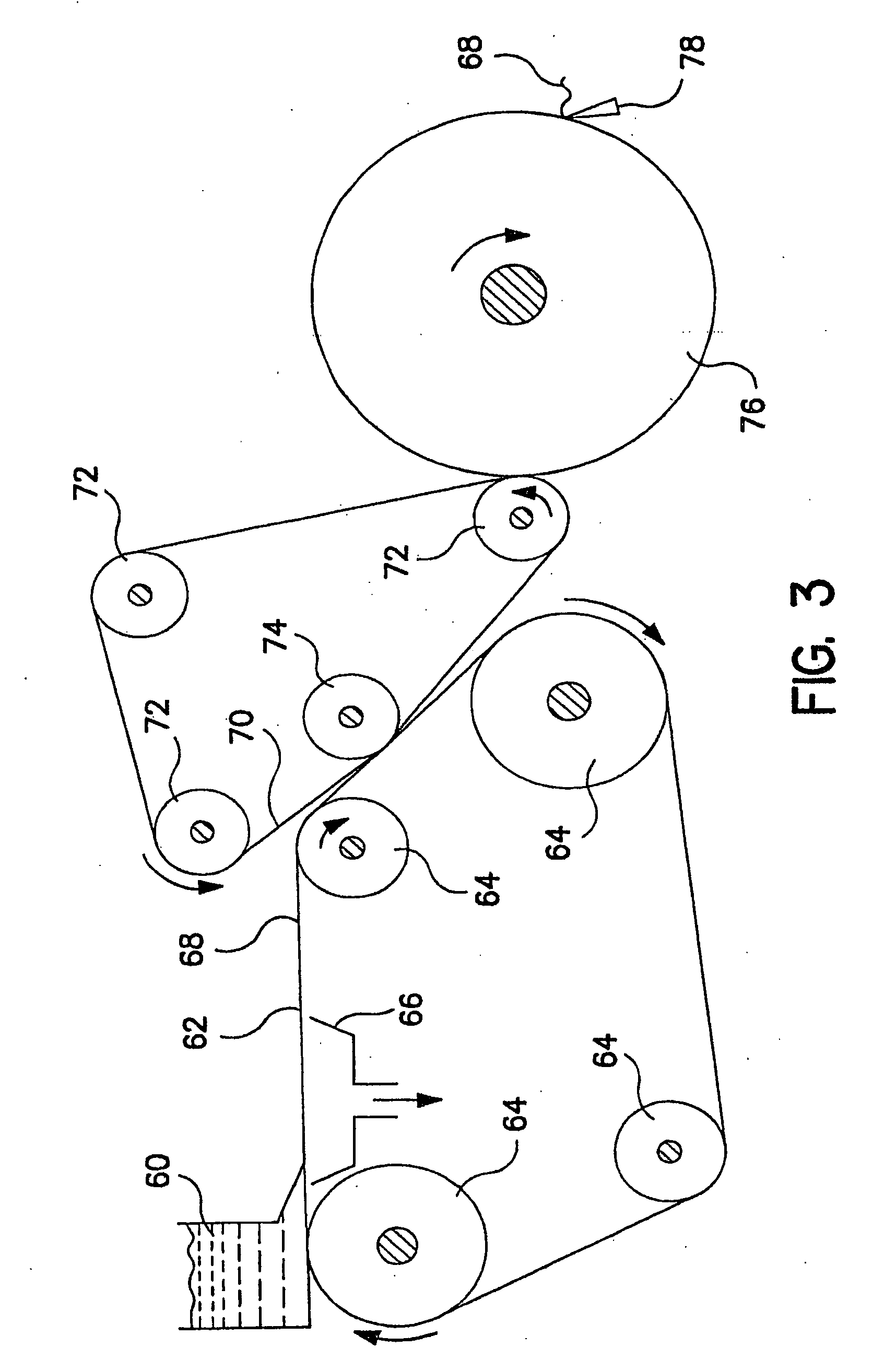

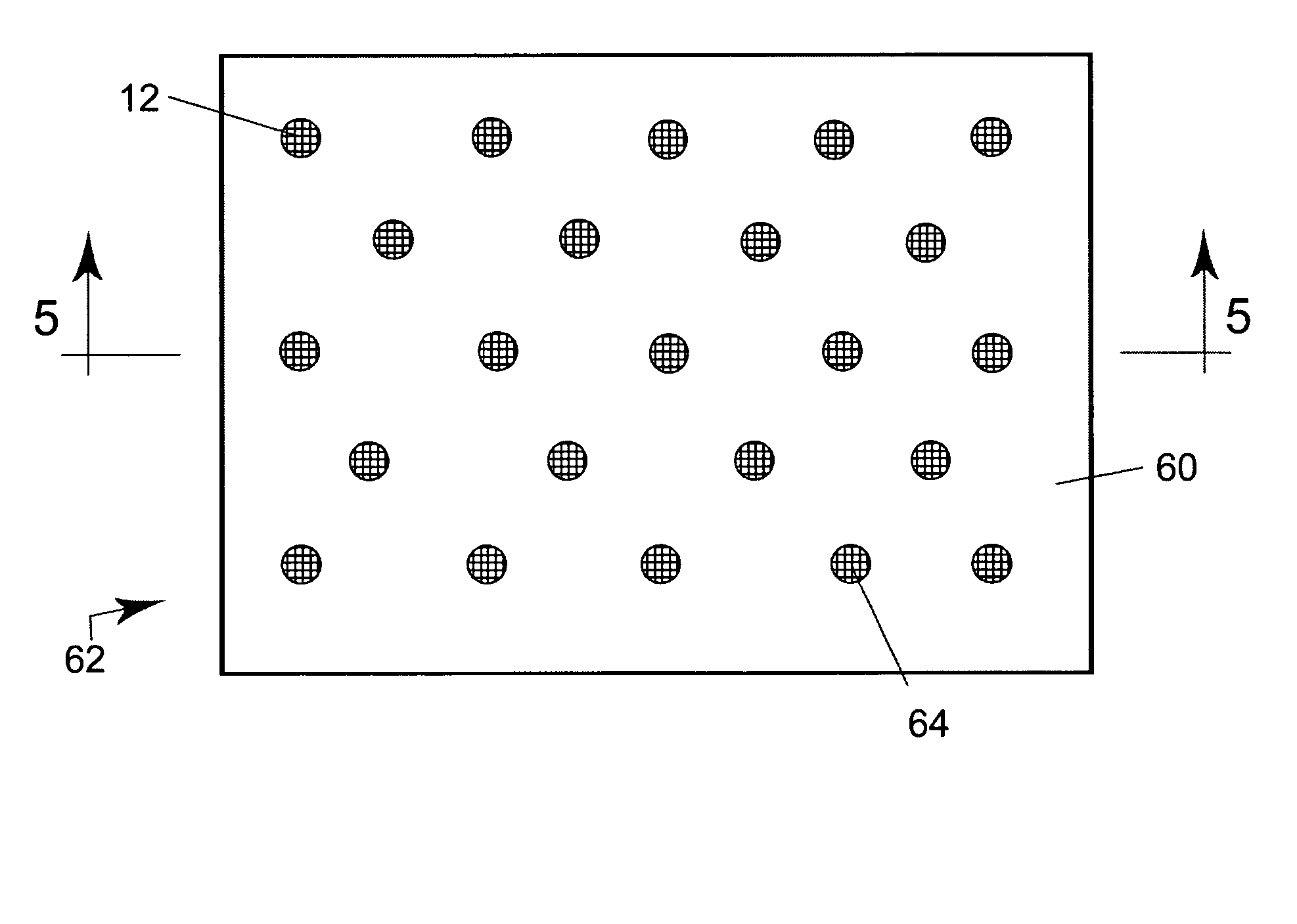

Materials, equipment and methods for manufacturing cigarettes

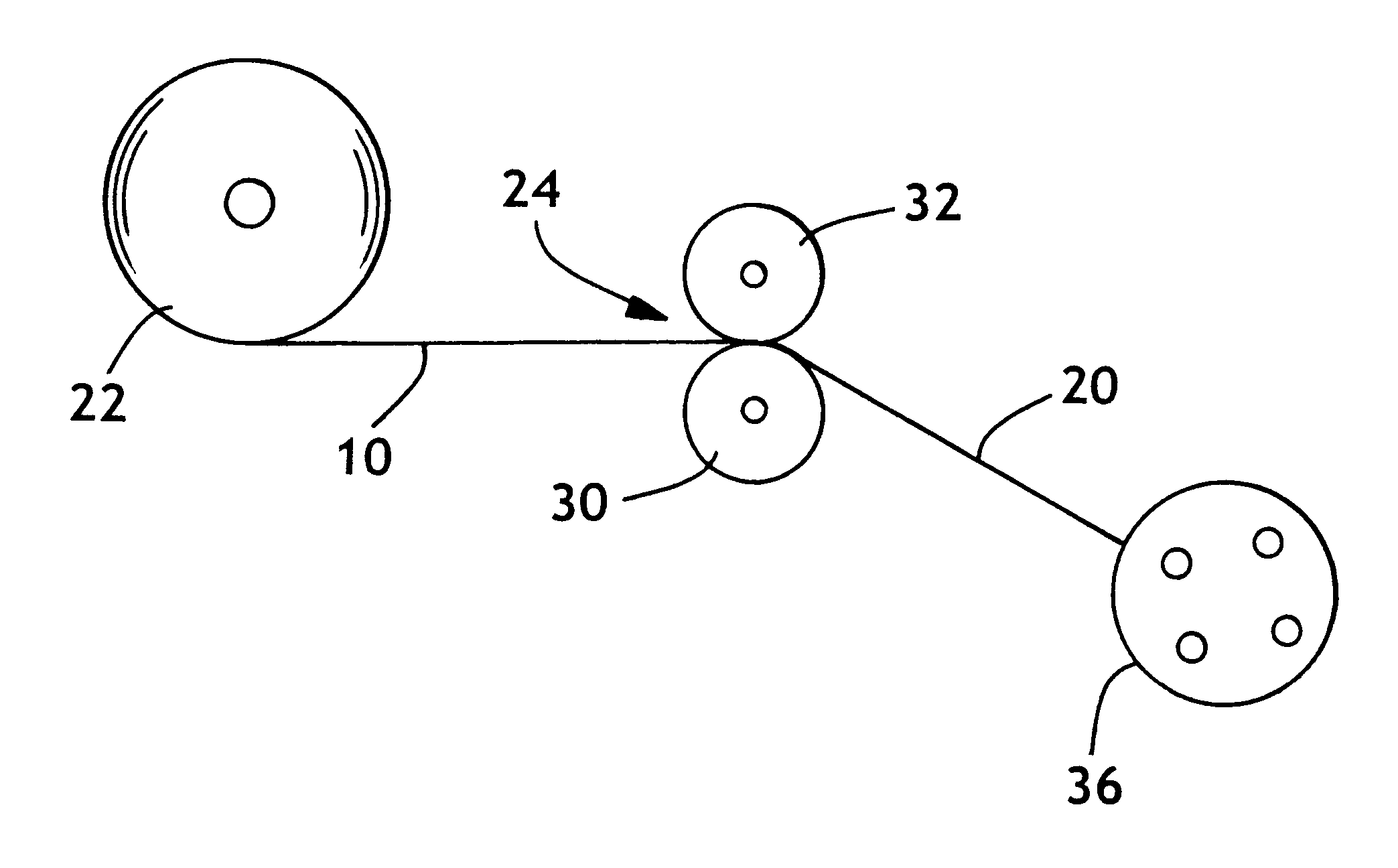

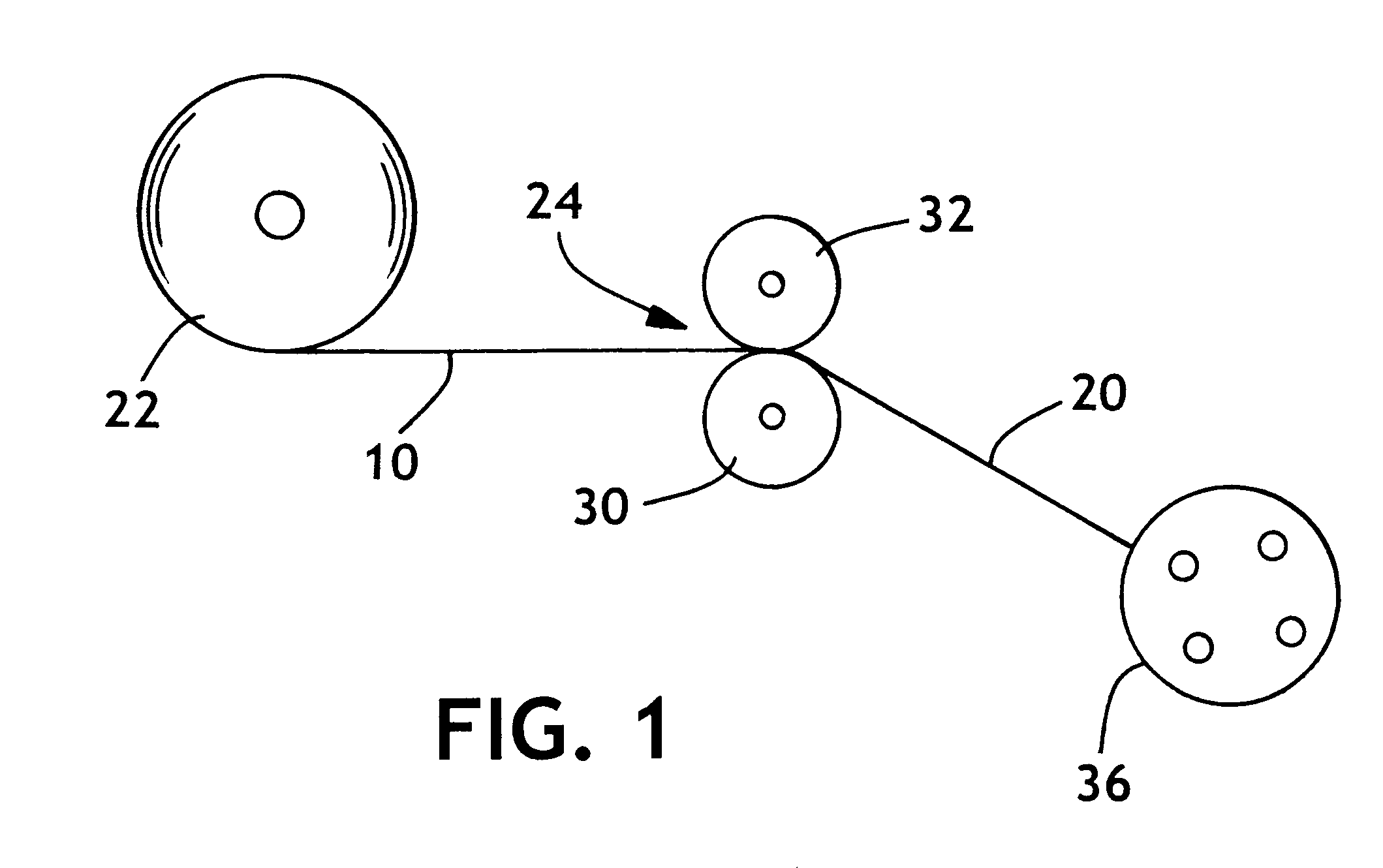

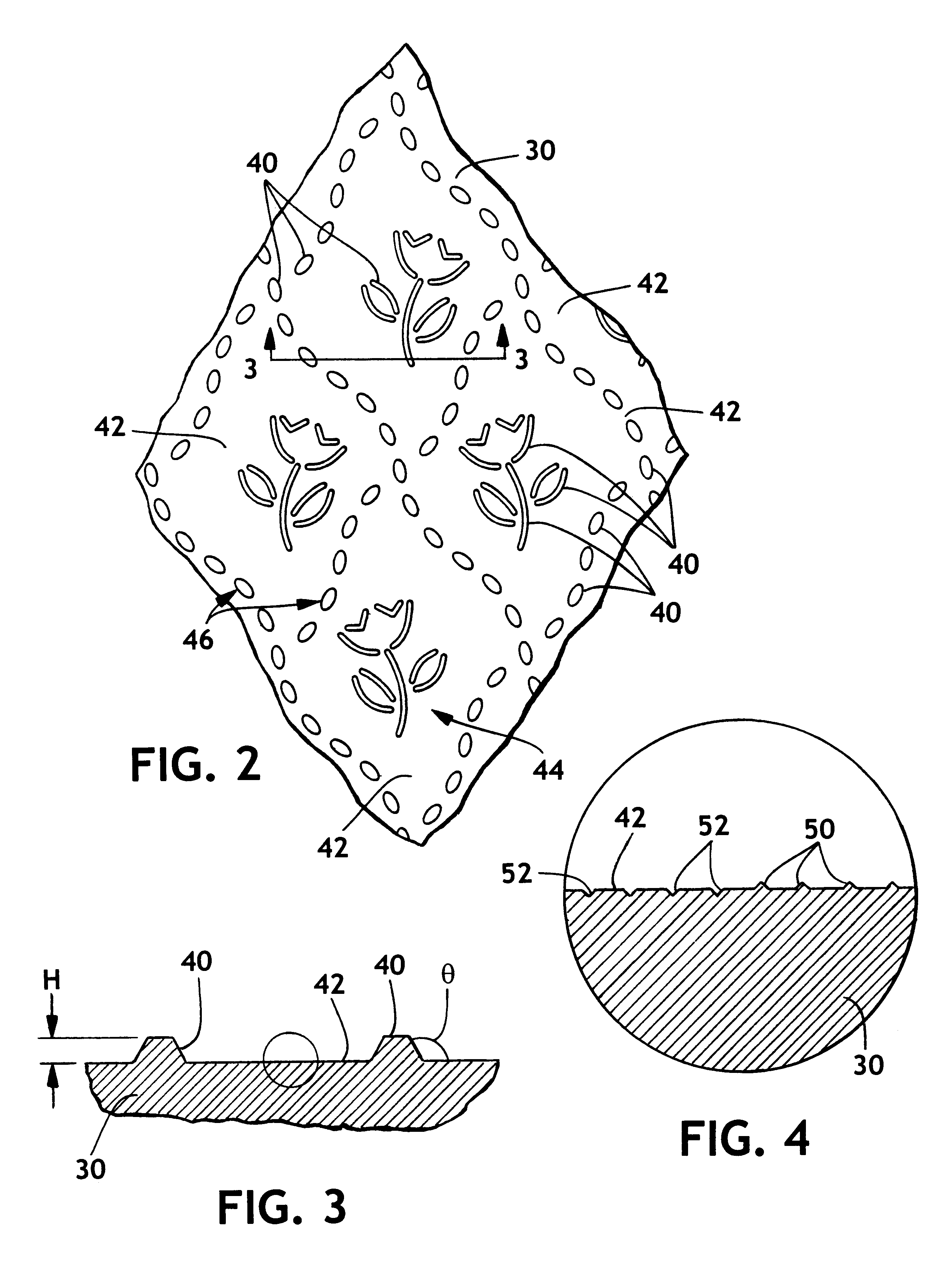

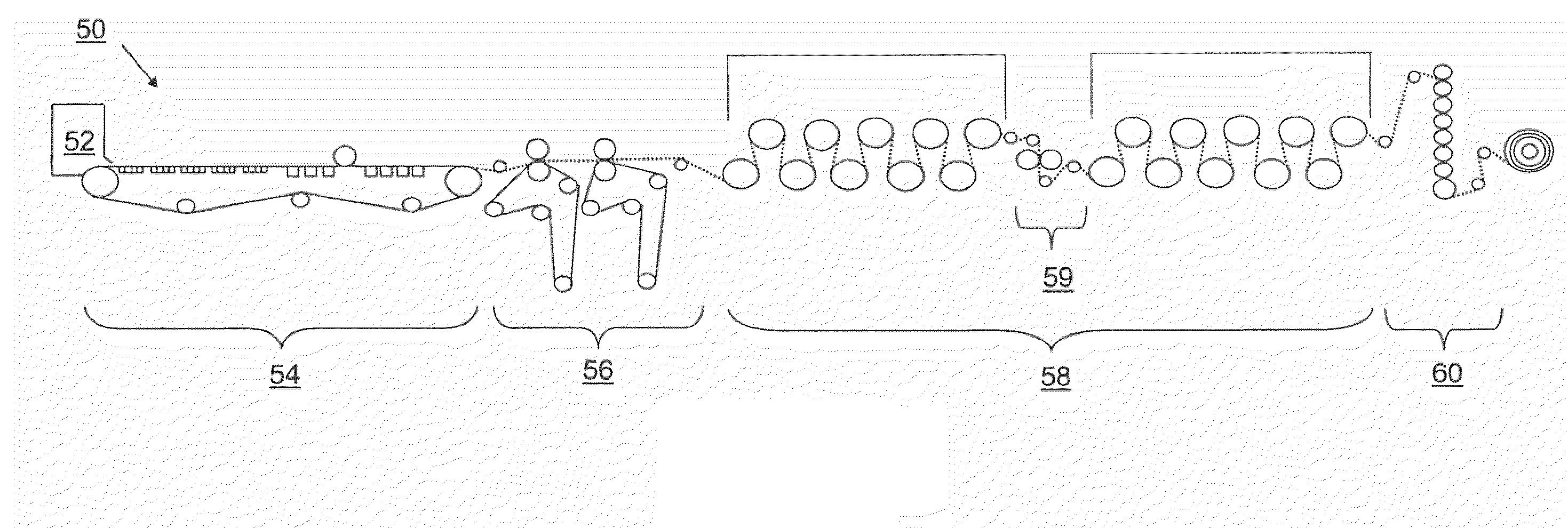

ActiveUS20050076929A1Minimize and avoid and prevent transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinAssembly systems

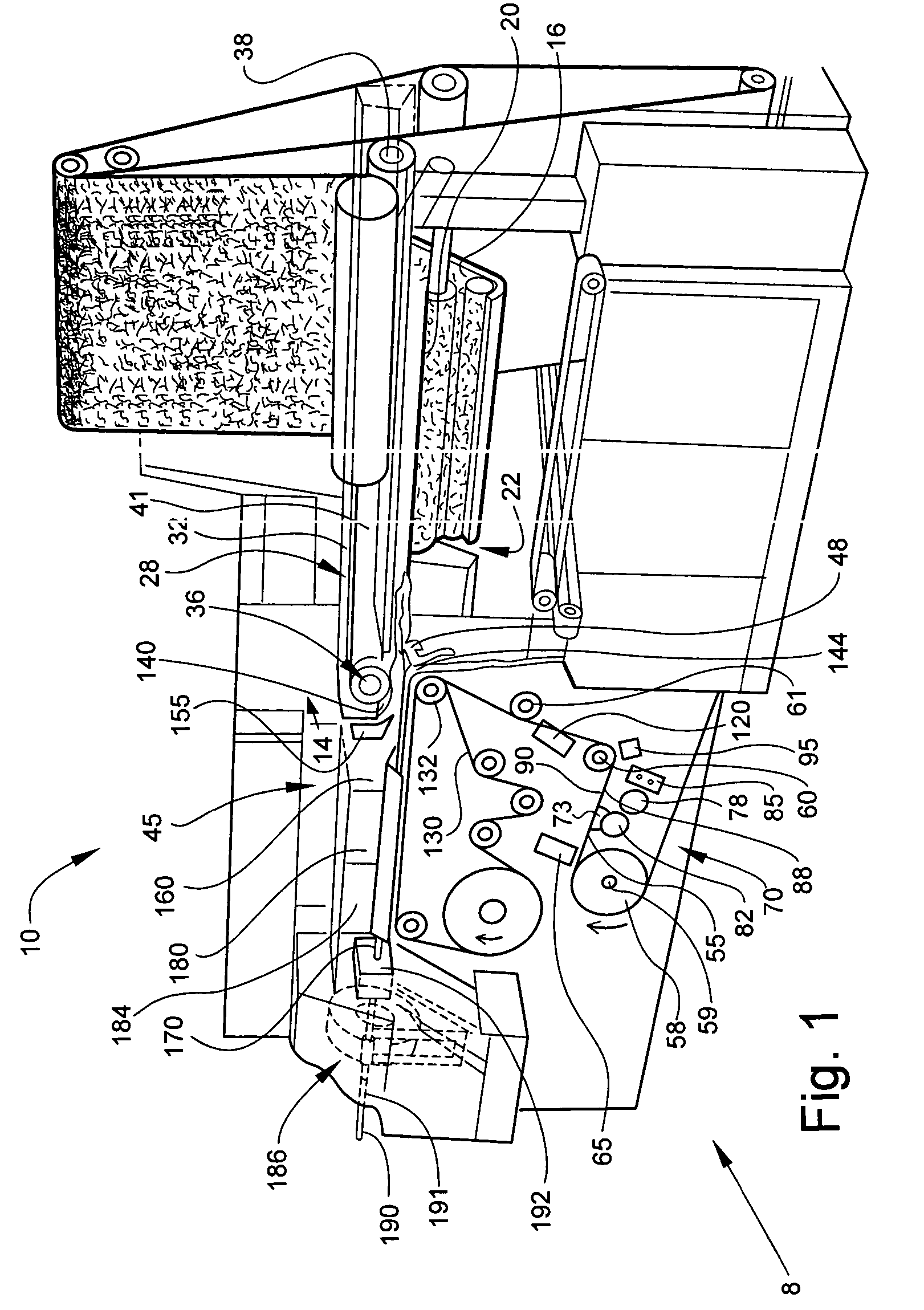

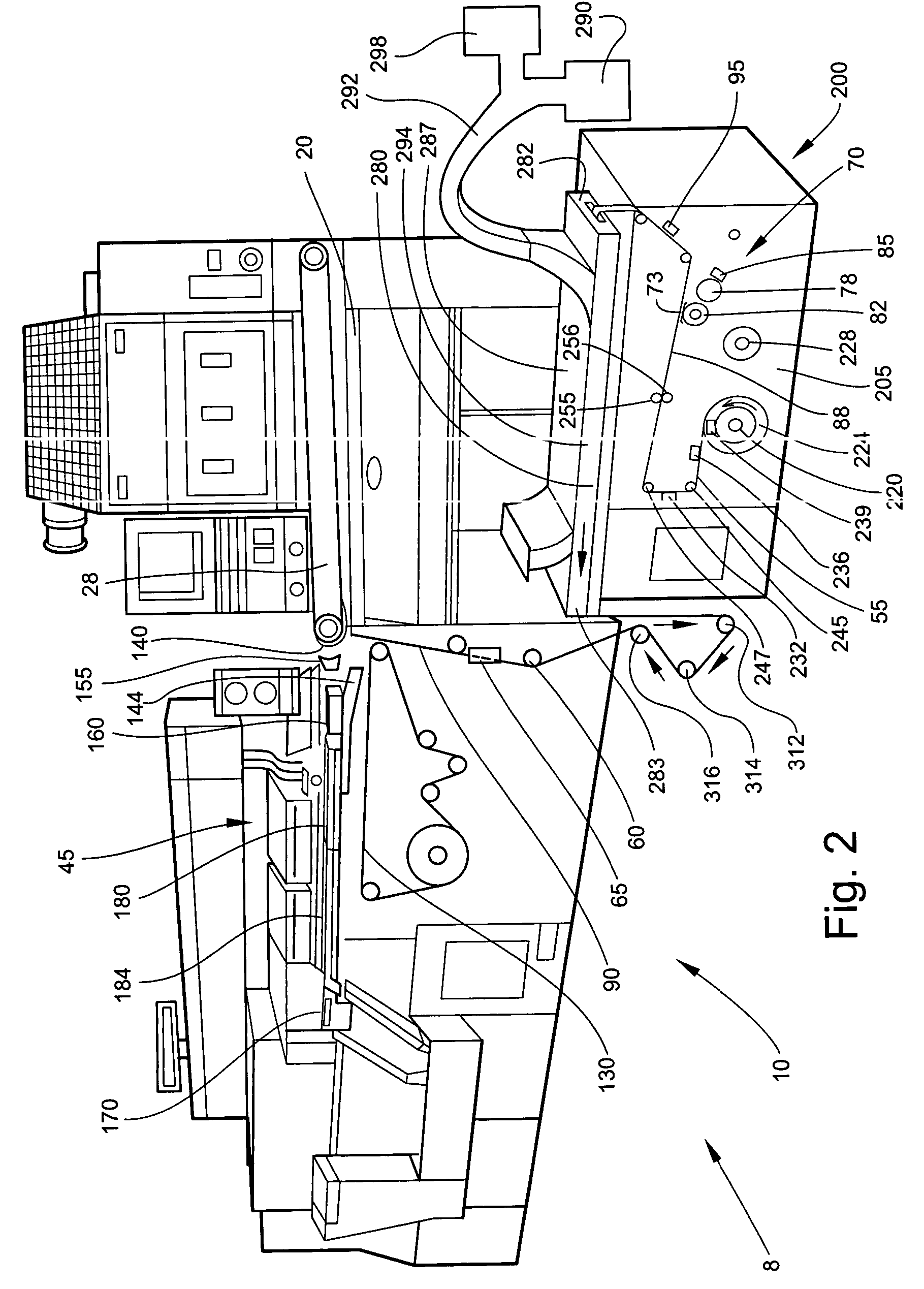

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers a series of roller. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. An alternate assembly system provides a source of paper web, applies additive material to that web in a pattern, dries the paper web, and winds the treated paper web on to a bobbin; and that bobbin is later used to provide a source of paper web on a cigarette making machine unrolls that bobbin, receives the treated paper web from that bobbin, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

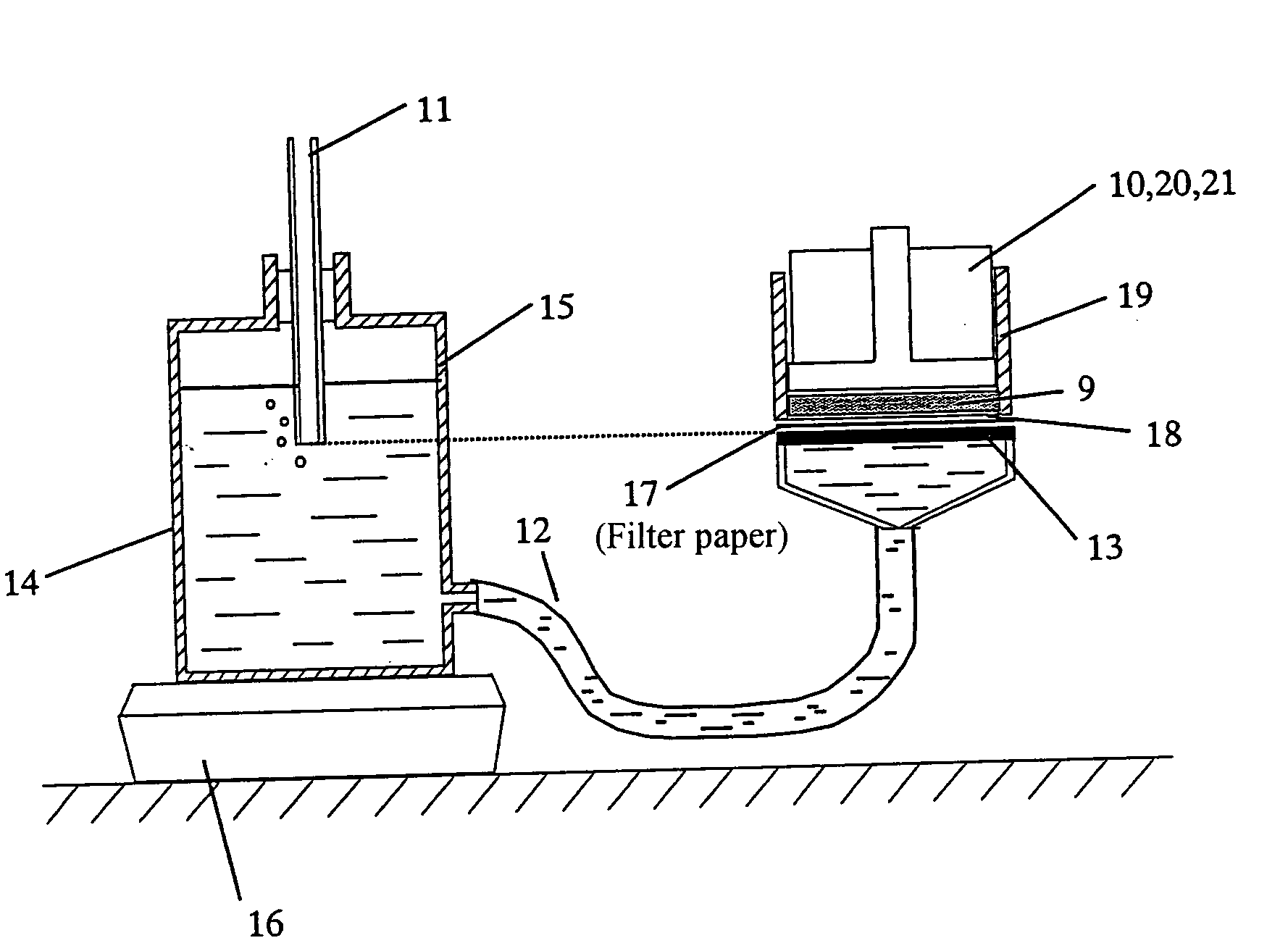

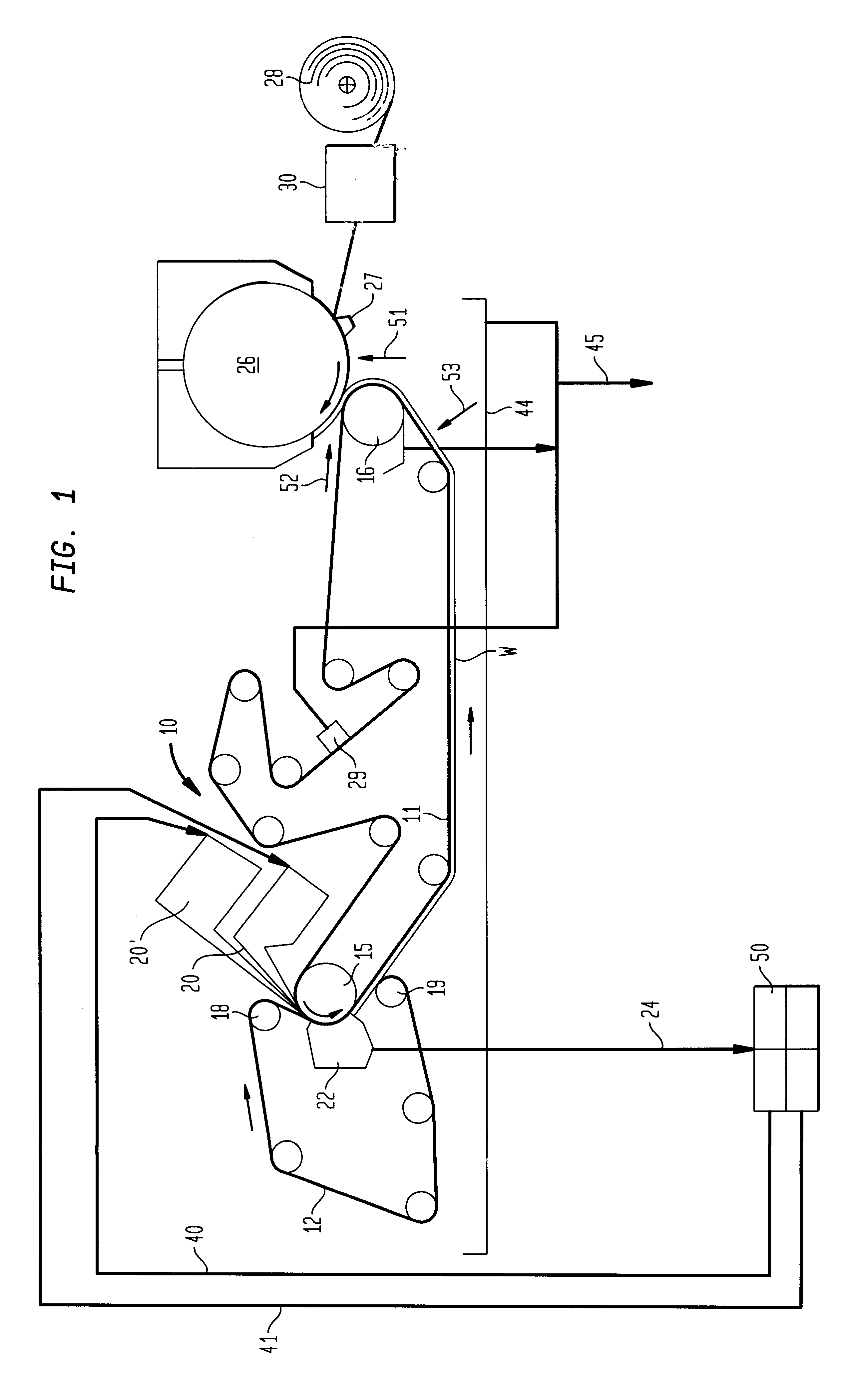

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

Paper tissue having enhanced softness

InactiveUS6344111B1Increase softnessMaintain tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

A novel paper article, a method of making a paper product, and an embossing roll are disclosed for providing a paper surface region having a minority of fiber to fiber bonds broken in the paper surface region to a depth less than about 0.02 mm from the paper surface. In one aspect, the roughened embossing roll includes protuberances or depressions sized at less than about 0.1 mm. In one aspect, the roughened embossing roll includes protuberances or depressions adapted to produce paper product surface deformations in the paper surface, wherein the paper product surface deformations are invisible to an unaided human eye. The present invention provides a paper product having higher perceived softness while maintaining tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method and apparatus for making absorbent structures with absorbent material

Owner:PROCTER & GAMBLE CO

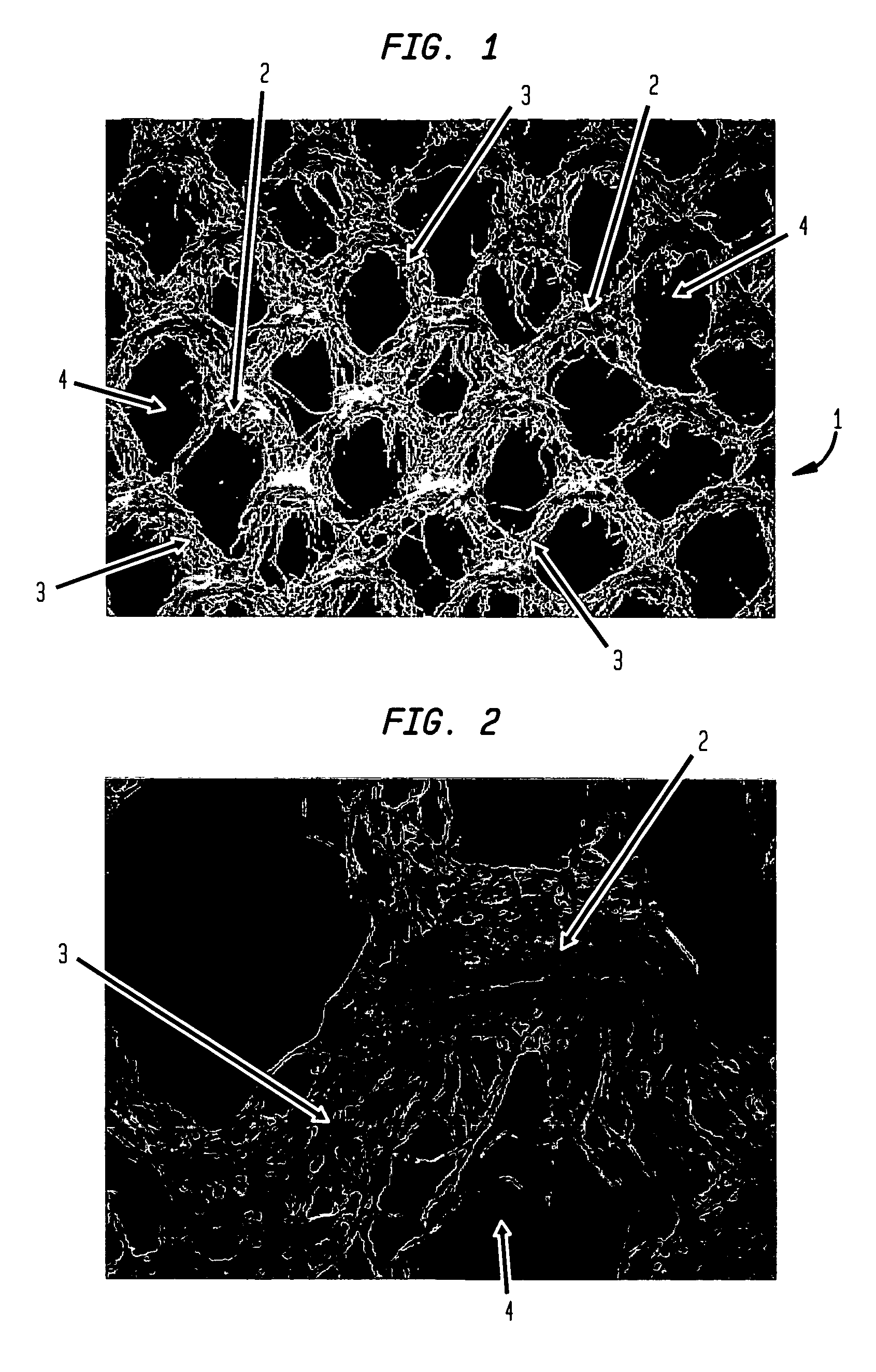

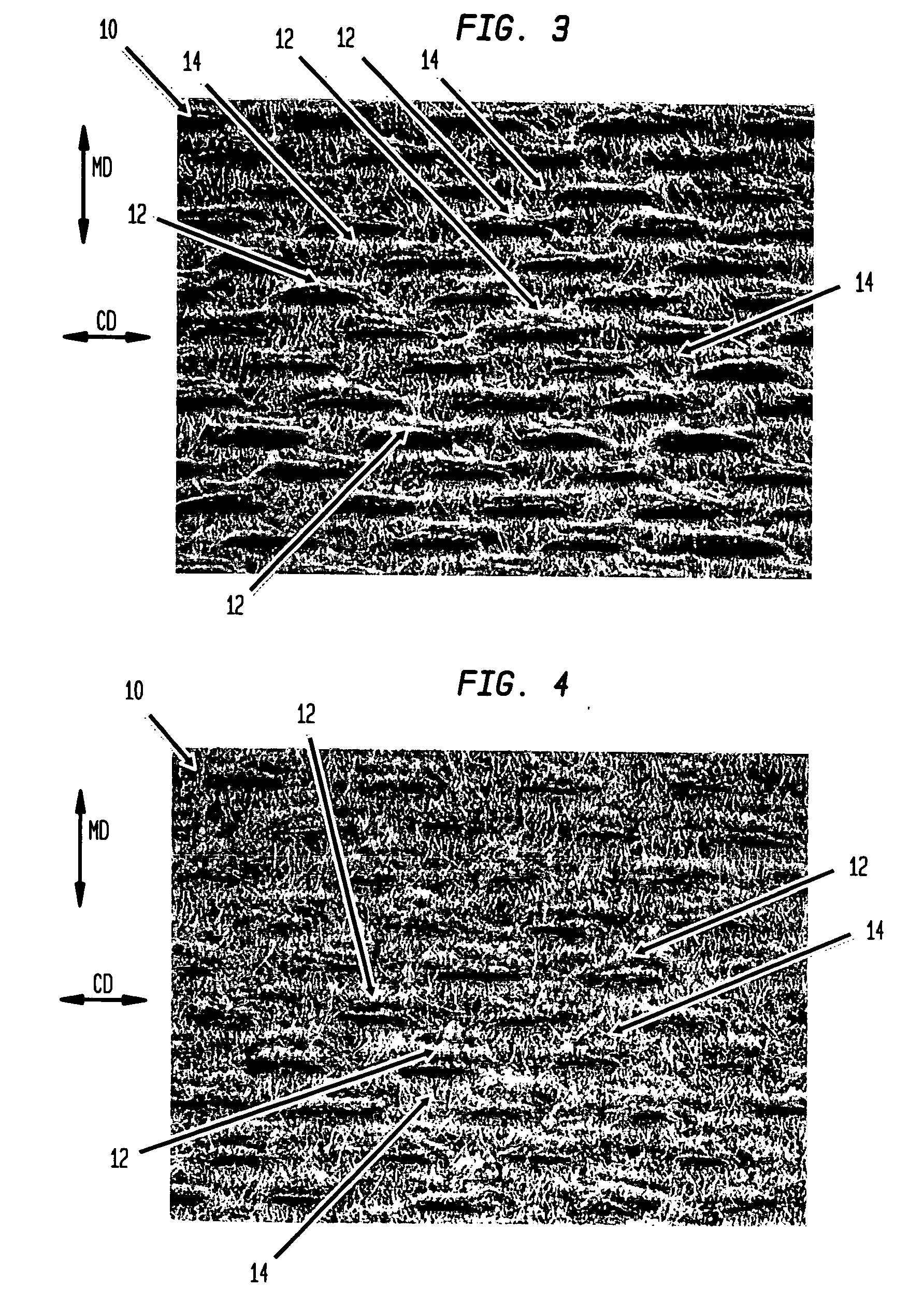

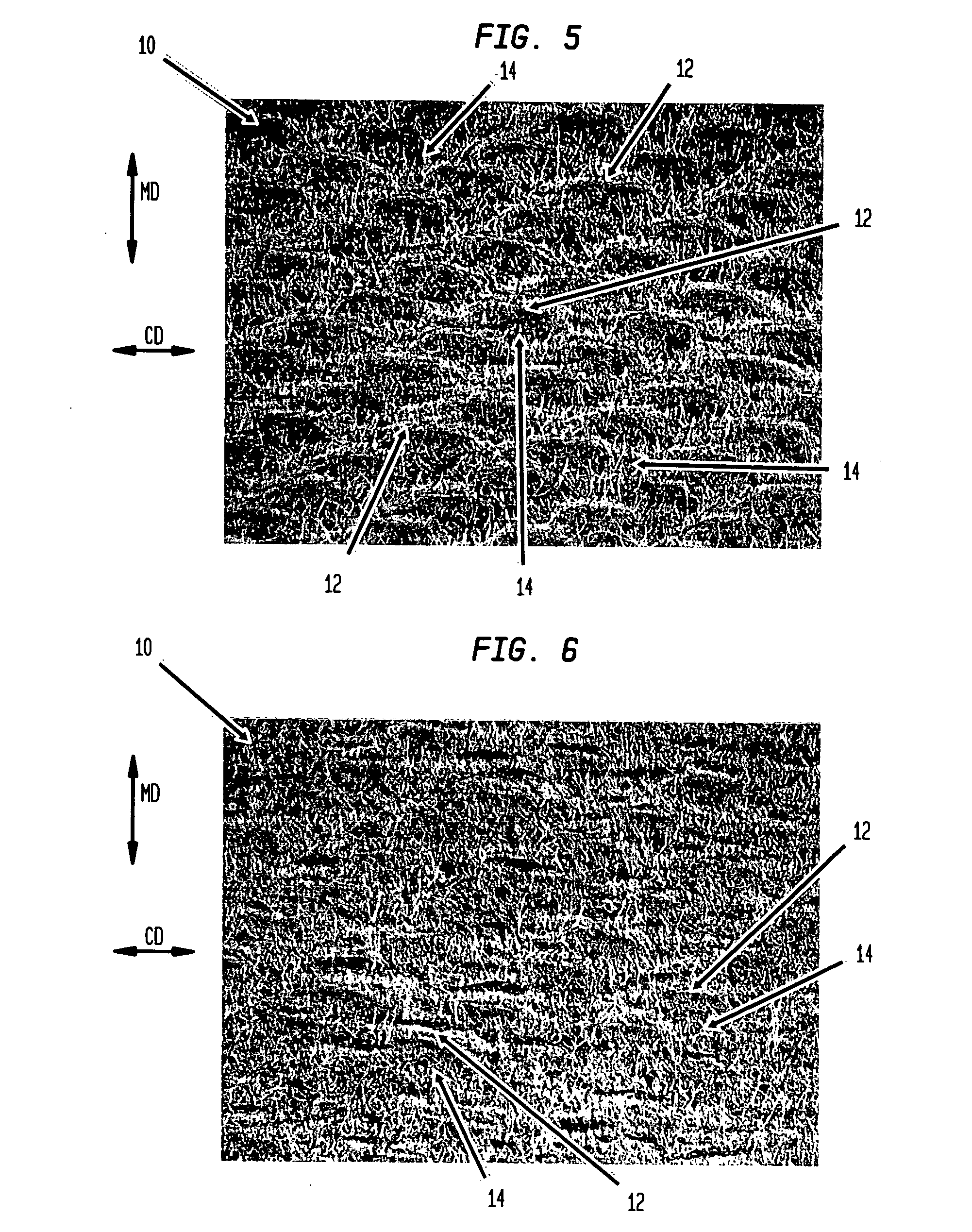

Multi-ply paper towel with absorbent core

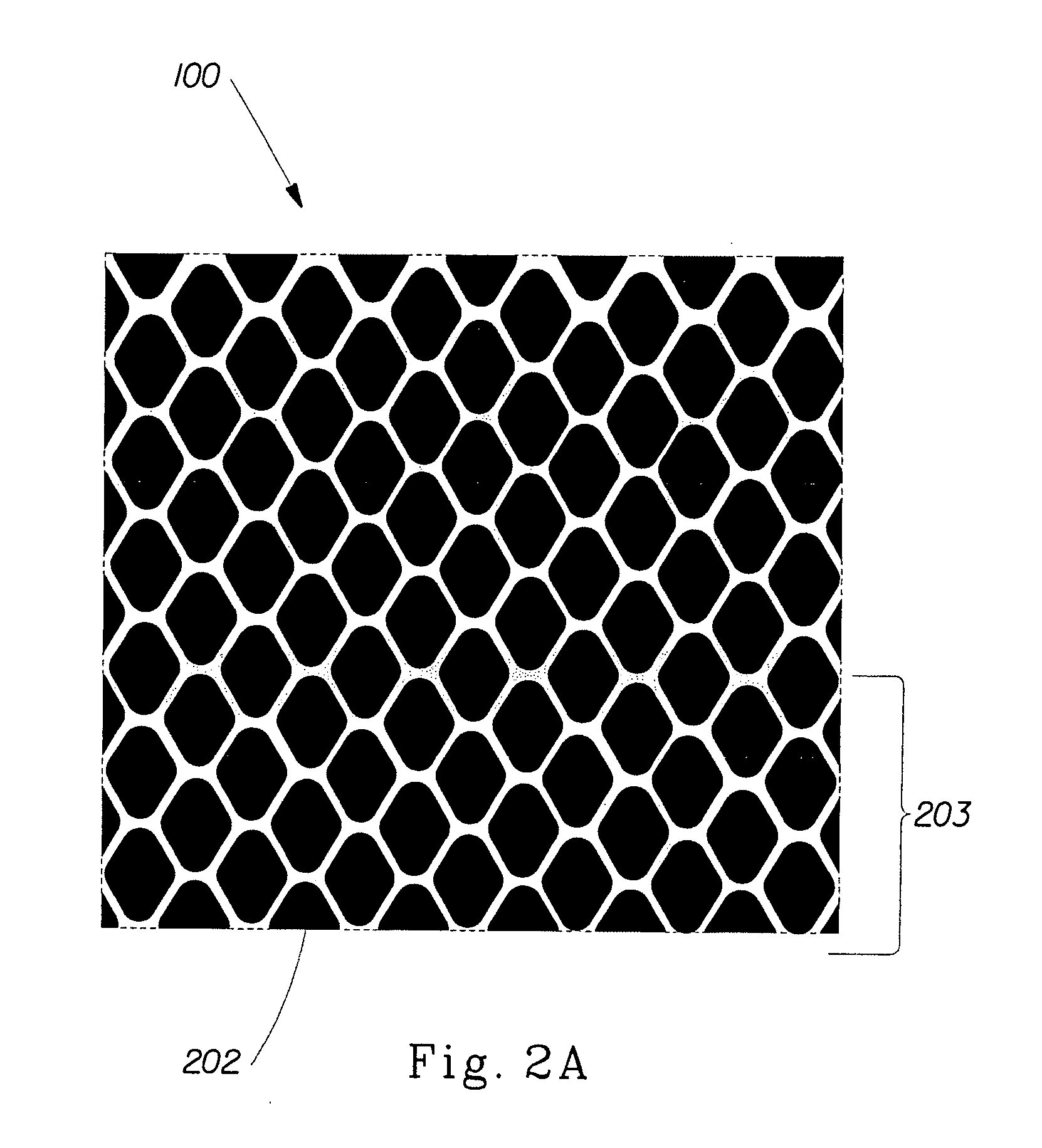

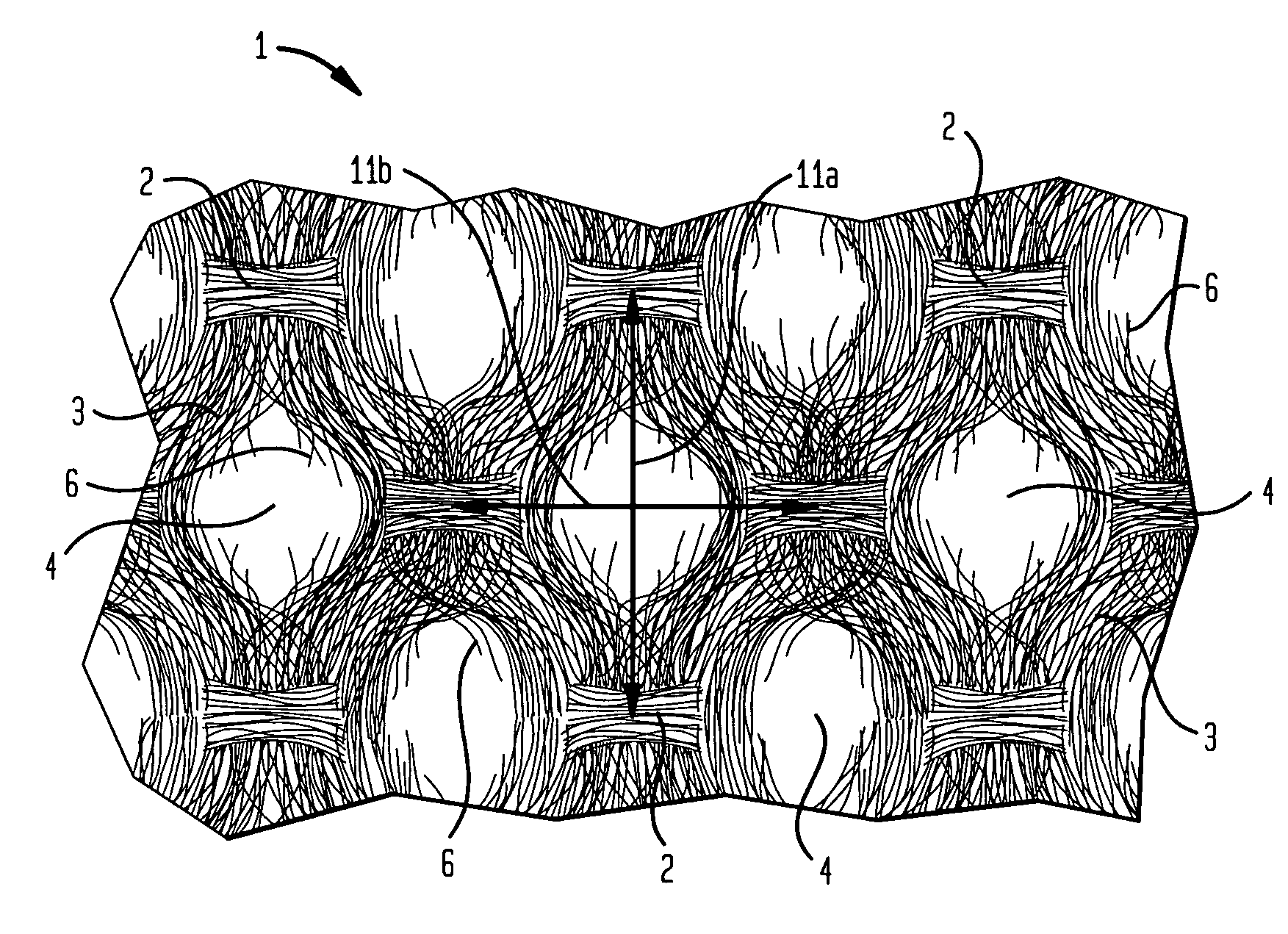

ActiveUS20060237154A1High performance absorbencyVariationNon-fibrous pulp additionNatural cellulose pulp/paperFiber networkEngineering

A multi-ply absorbent sheet of cellulosic fiber with continuous outer surfaces is provided an absorbent core between the outer surfaces. The absorbent core includes a non-woven fiber network having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the direction between pileated regions interconnected thereby, and (iii) a plurality of fiber-deprived cellules between the fiber enriched and linking regions, also being characterized by a local basis weight lower than the fiber enriched regions. The cellules provide a sponge-like internal structure of low fiber density regions.

Owner:GPCP IP HLDG LLC

Nonwovens produced from multicomponent fibers

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

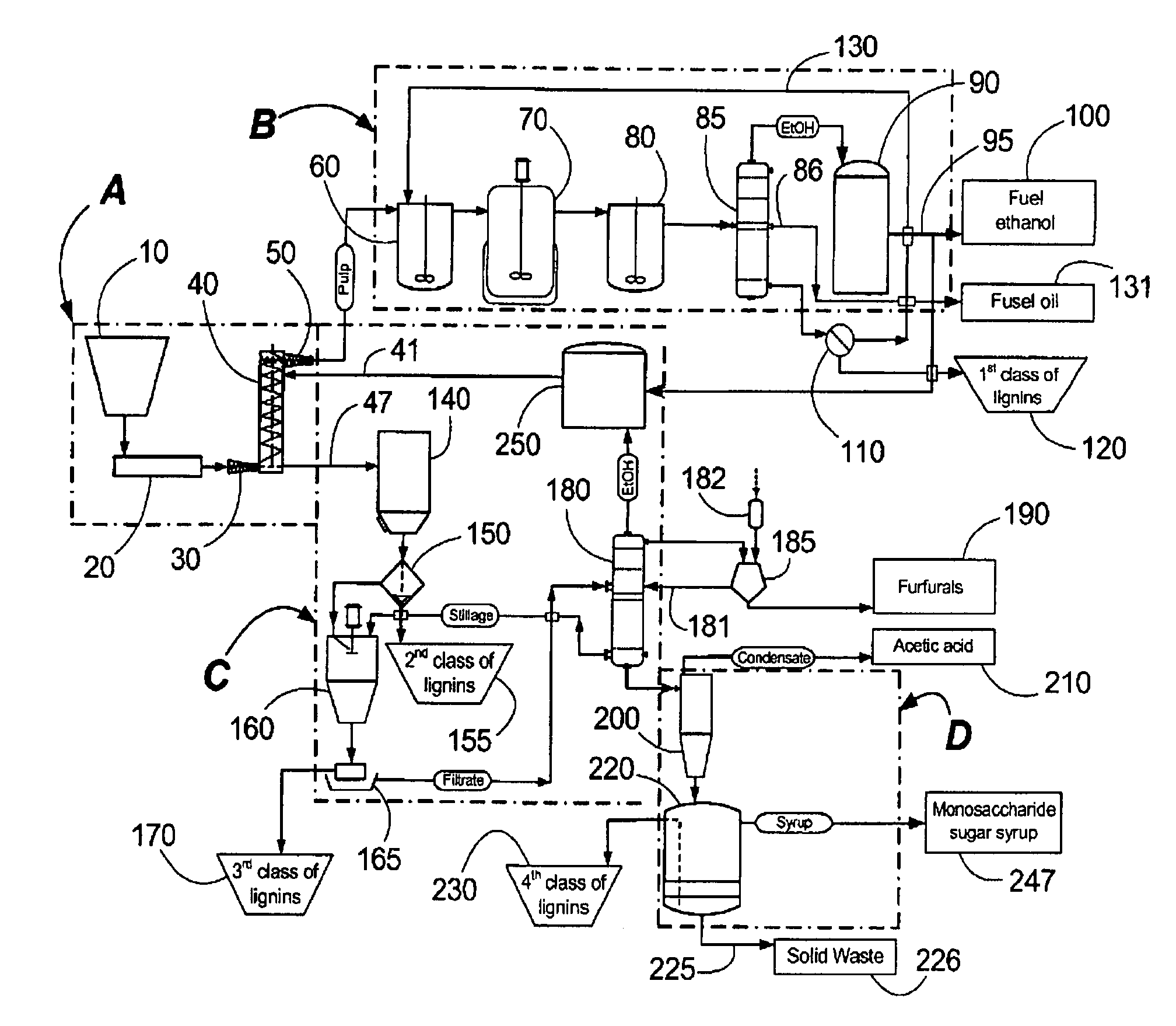

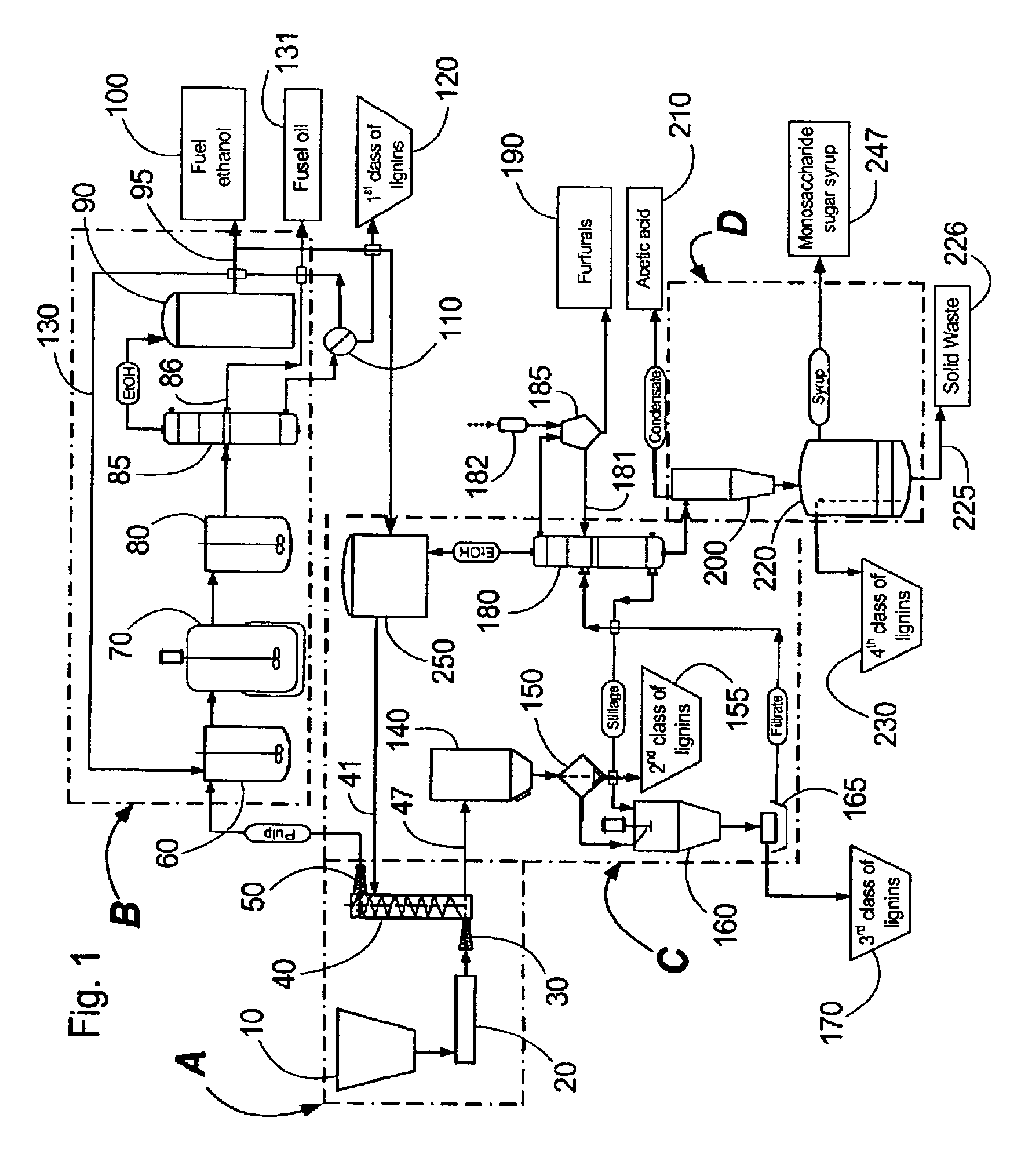

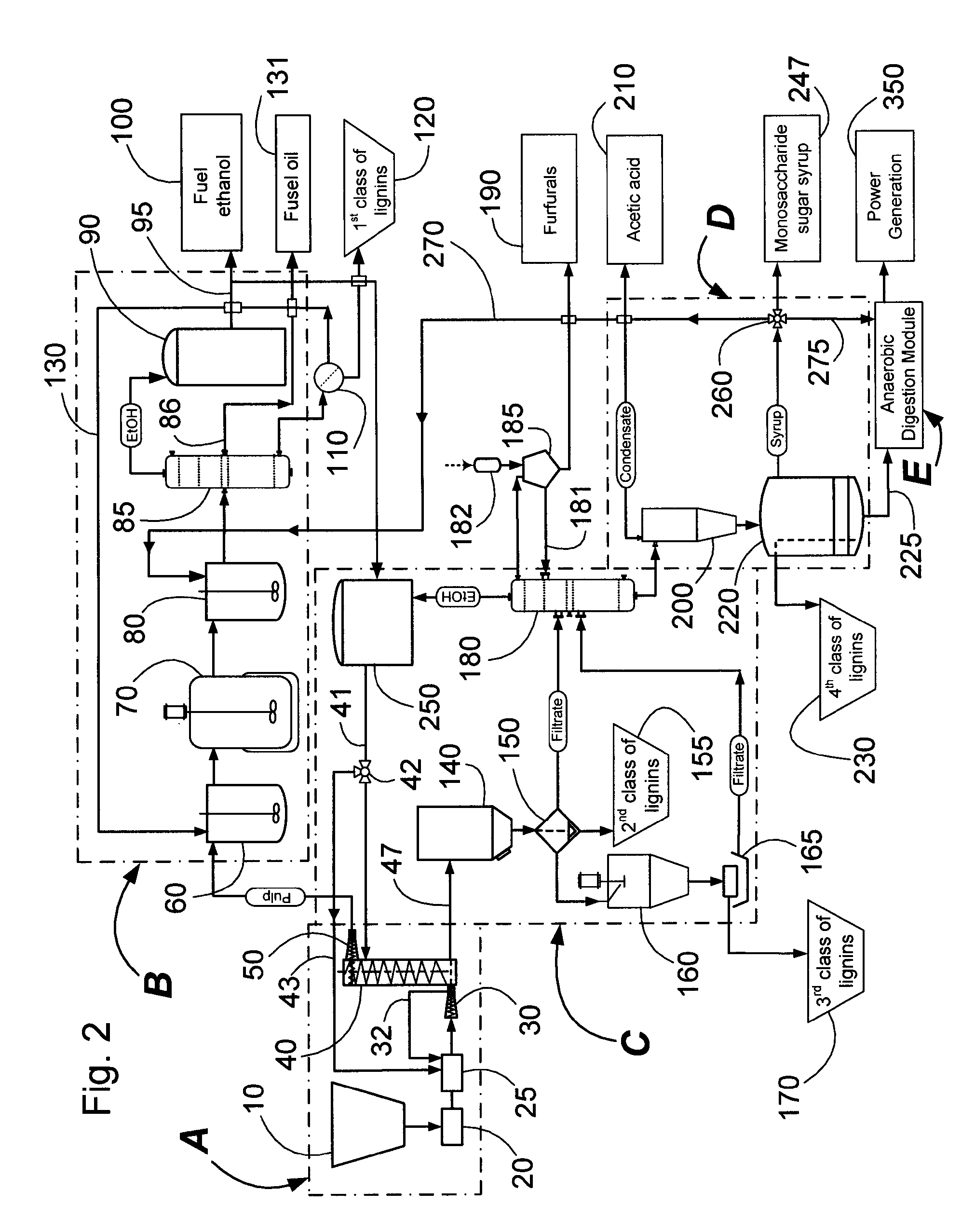

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

Embossed multi-ply fibrous structure product

A multi-ply fibrous structure product having two or more plies of fibrous structure where at least one of the plies has a plurality of domes formed during the papermaking process and there are from about 10 to about 1000 domes per square inch of the product. At least one of the plies of the multi-ply fibrous structure has a plurality of embossments thereon with a total embossment area of from about 3% to about 15%. The embossments may be arranged such that they define non-geometric foreground patterns of unembossed cells.

Owner:THE PROCTER & GAMBLE COMPANY

Hydraulically-Formed Nonwoven Sheet with Microfibers

InactiveUS20100272938A1Non-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricMedical device

In a first embodiment, a hydraulically-formed nonwoven sheet, a package comprising such sheet, a method of packaging a medical device using a package with such sheet and a method of manufacturing such sheet are provided. This nonwoven sheet comprises first and second non-cellulosic polymeric fibers. The first non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000; the second non-cellulosic polymeric fibers have an average diameter greater than about 3.5 micron and an average aspect ratio of about 400 to about 1000. In a second embodiment, a hydraulically-formed nonwoven sheet is provided. This nonwoven sheet comprises binding material, non-cellulosic polymeric fibers and cellulosic based materials. The non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000. The second nonwoven sheet has a bacterial filtration efficiency of at least about 98%.

Owner:BEMIS COMPANY INC

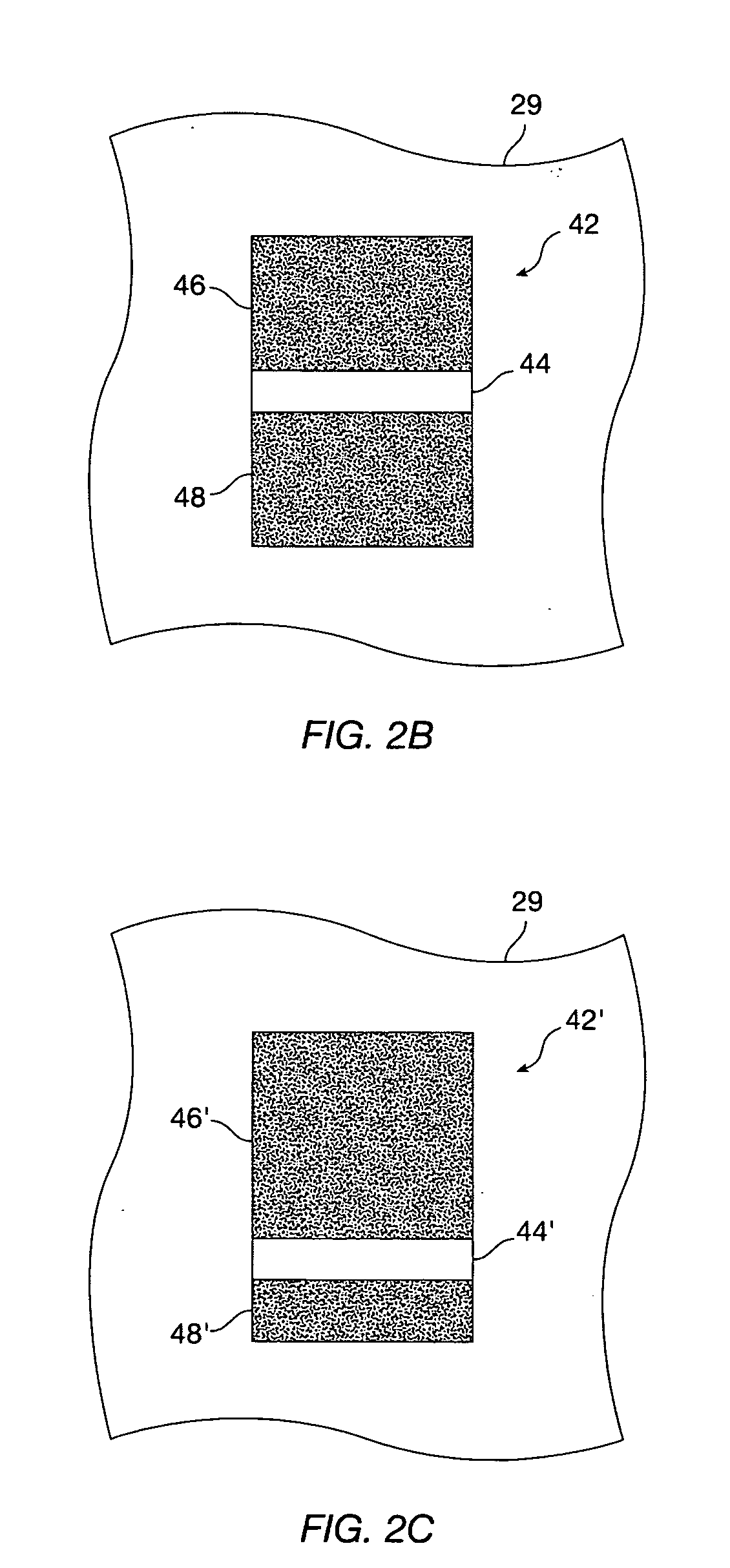

Methods for producing imaged coated articles by using magnetic pigments

InactiveUS20020182383A1Good colorGood optical performancePigmenting treatmentNon-fibrous pulp additionPigmentMagnetic field

Methods and devices for producing images on coated articles are provided. The methods generally comprise applying a layer of magnetizable pigment coating in liquid form on a substrate, with the magnetizable pigment coating containing a plurality of magnetic non-spherical particles or flakes. A magnetic field is then applied to selected regions of the pigment coating while the coating is in liquid form, with the magnetic field altering the orientation of selected magnetic particles or flakes. Finally, the pigment coating is solidified, affixing the reoriented particles or flakes in a non-parallel position to the surface of the pigment coating to produce an image such as a three dimensional-like image on the surface of the coating. The pigment coating can contain various interference or non-interference magnetic particles or flakes, such as magnetic color shifting pigments.

Owner:VIAVI SOLUTIONS INC

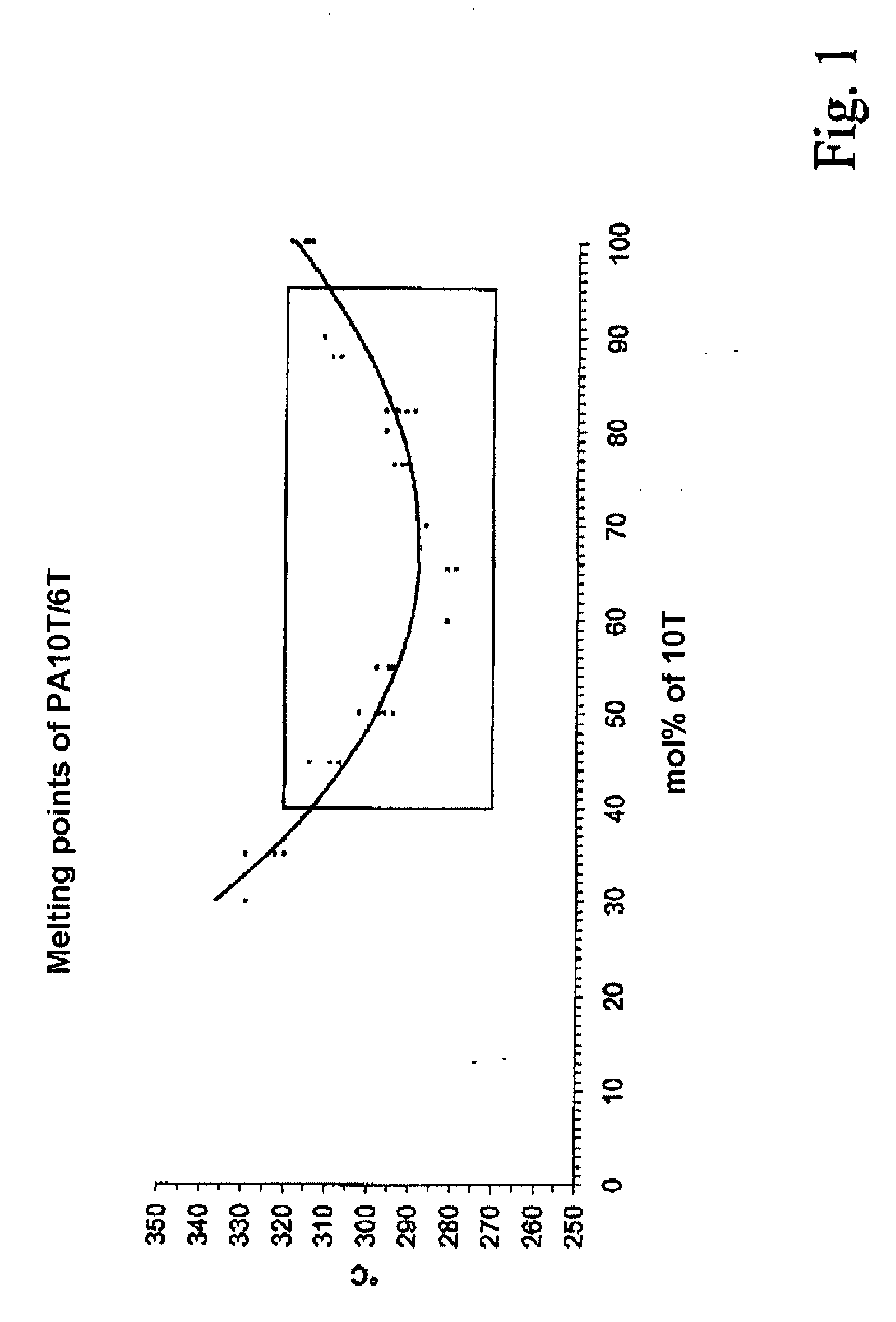

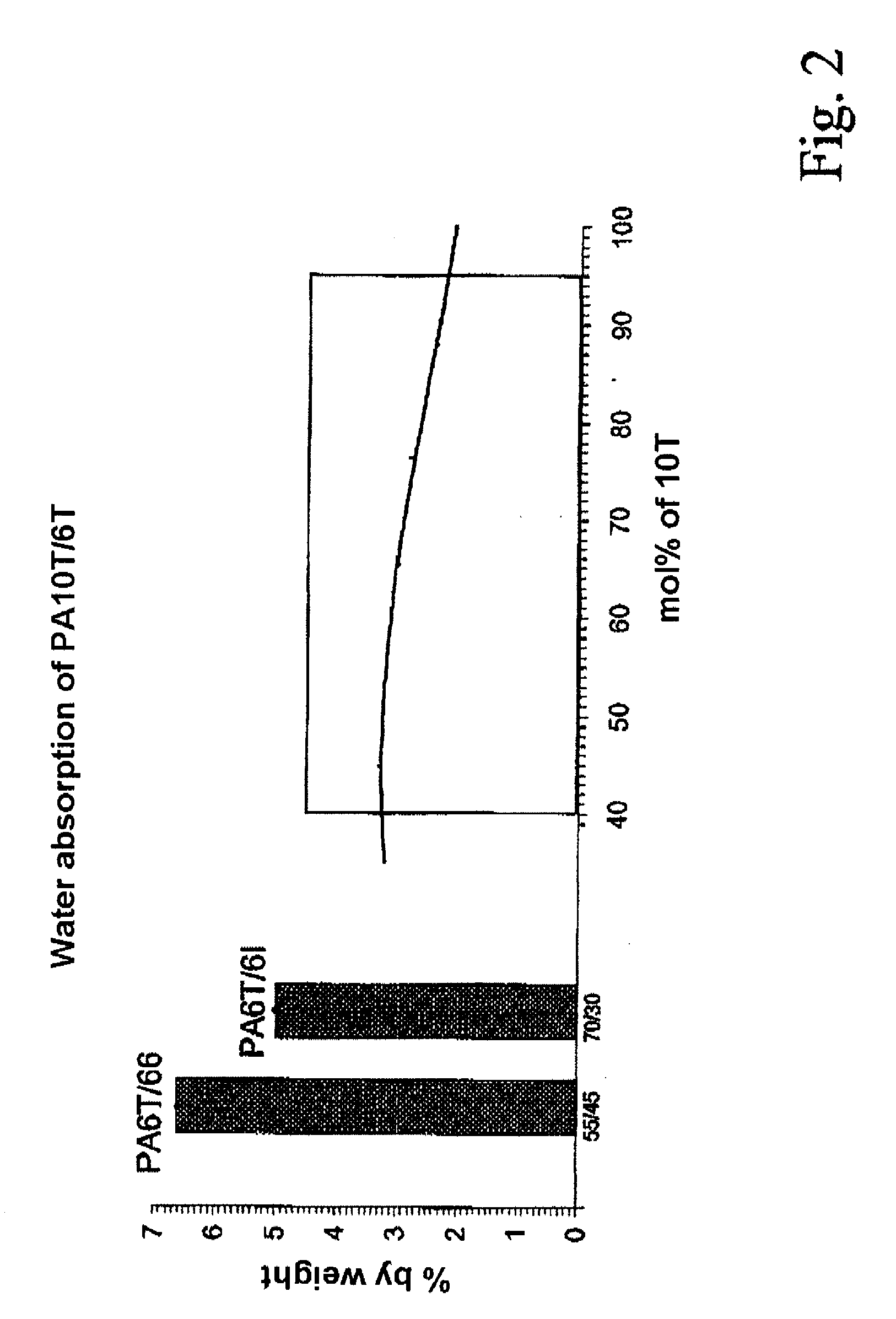

Semiaromatic polyamide molding compositions and their use

ActiveUS20080274355A1High strengthLow water absorptionPigmenting treatmentNon-fibrous pulp additionHexamethylenediamineAramides

A polyamide molding composition with the following constitution is described:(A) from 30 to 100% by weight of at least one 10T / 6T copolyamide, where this is composed of(A1) from 40 to 95 mol % of 10T units, formed from the monomers 1,10-decanediamine and terephthalic acid(A2) from 5 to 60 mol % of 6T units, formed from the monomers 1,6-hexanediamine and terephthalic acid(B) from 0 to 70% by weight of reinforcing materials and / or fillers(C) from 0 to 50% by weight of additives and / or further polymerswhere the entirety of components A to C is 100%, with the proviso that in component (A) up to 30 mol %, based on the entirety of the dicarboxylic acids, of the terephthalic acid can have been replaced by other aromatic, aliphatic, or cycloaliphatic dicarboxylic acids, and with the proviso that in component (A) up to 30 mol % of 1,10-decanediamine and respectively 1,6-hexanediamine, based on the entirety of the diamines, can have been replaced by other diamines, and with the proviso that not more than 30 mol % in component (A), based on the entirety of the monomers, can have been formed via lactams or amino acids. Uses of this polyamide molding composition are moreover described, as also are processes for the preparation of these polyamide molding compositions.

Owner:EMS PATENT AG

Extracts from plant and non-plant biomass and uses thereof

Novel oil extracts from Angiosperm and Gymnosperm plants and other-plant biomass from human, veterinary, birds, aquatic species, microbial and mycological sources useful in human, veterinary and agricultural, mycological and microbiological applications are described. Methods of preparation of these extracts in oil and methods of application and administration are also described.

Owner:KANE SHANTARAM GOVIND

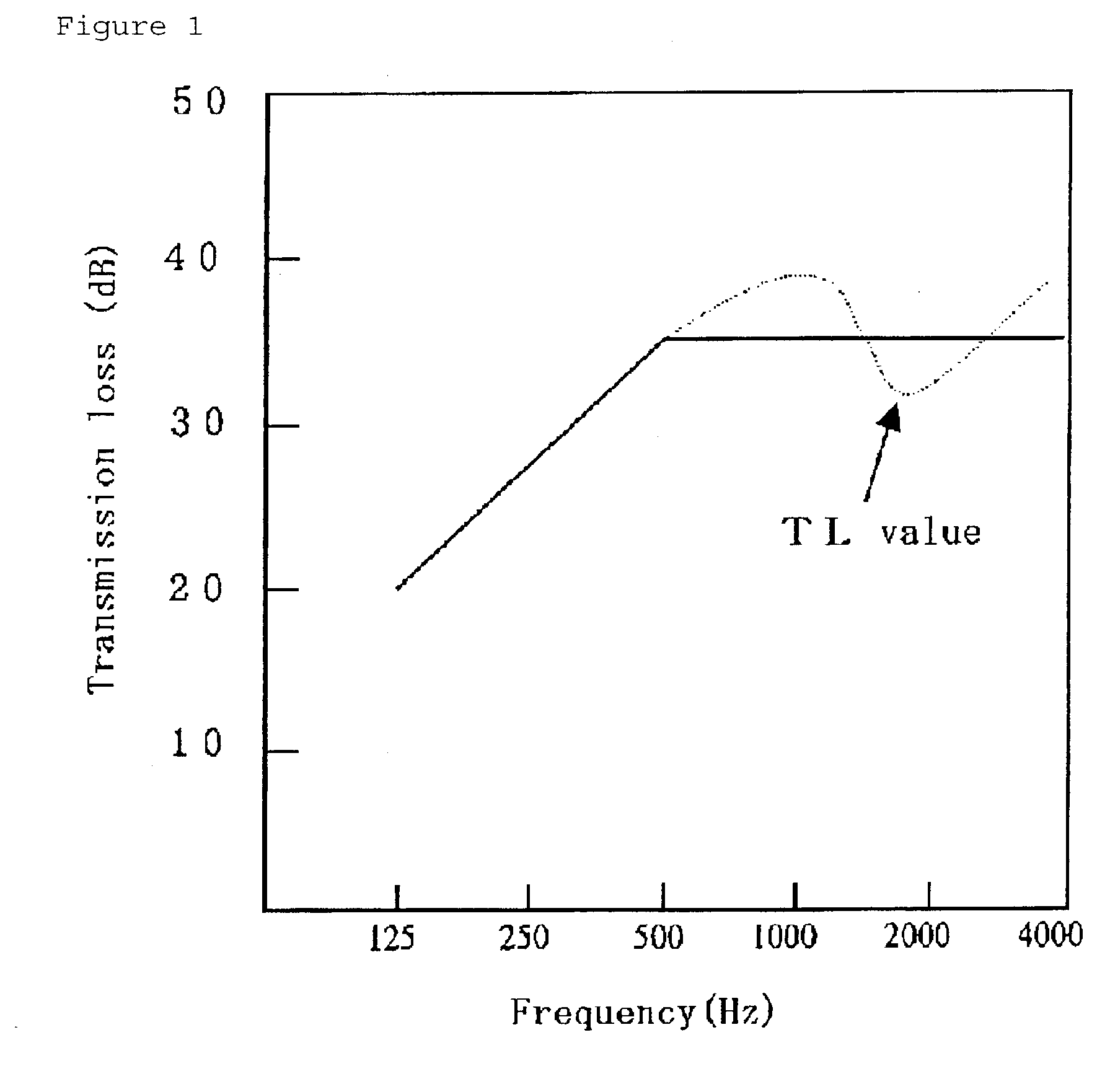

Interlayer film for laminated glass and laminated glass

InactiveUS20030139520A1Improve adhesionHigh transparencyNon-fibrous pulp additionFibre treatmentChemistryUltrasound attenuation

The invention provides an interlayer film for a laminated glass and a laminated glass, which are protected against a slump in TL value through attenuation of said coincidence effect and adapted to display an outstanding sound insulation performance over a broad temperature range. An interlayer film for a laminated glass comprising a plasticizer and a polyacetal resin, which is a blend of a polyacetal resin having an average polymerization degree of 1,000 to 3,000 and a polyacetal resin having an average polymerization degree of 3,000 to 5,000, and which has an acetalization degree of 60 to 85 mol % and an acetyl group content of 8 to 30 mol %. An interlayer film for a laminated glass which shows a temperature dependence of loss tangent in which the lowest-temperature side maximum of loss tangent appears at 30° C. or lower when examined for dynamic viscoelasticity.

Owner:SEKISUI CHEM CO LTD

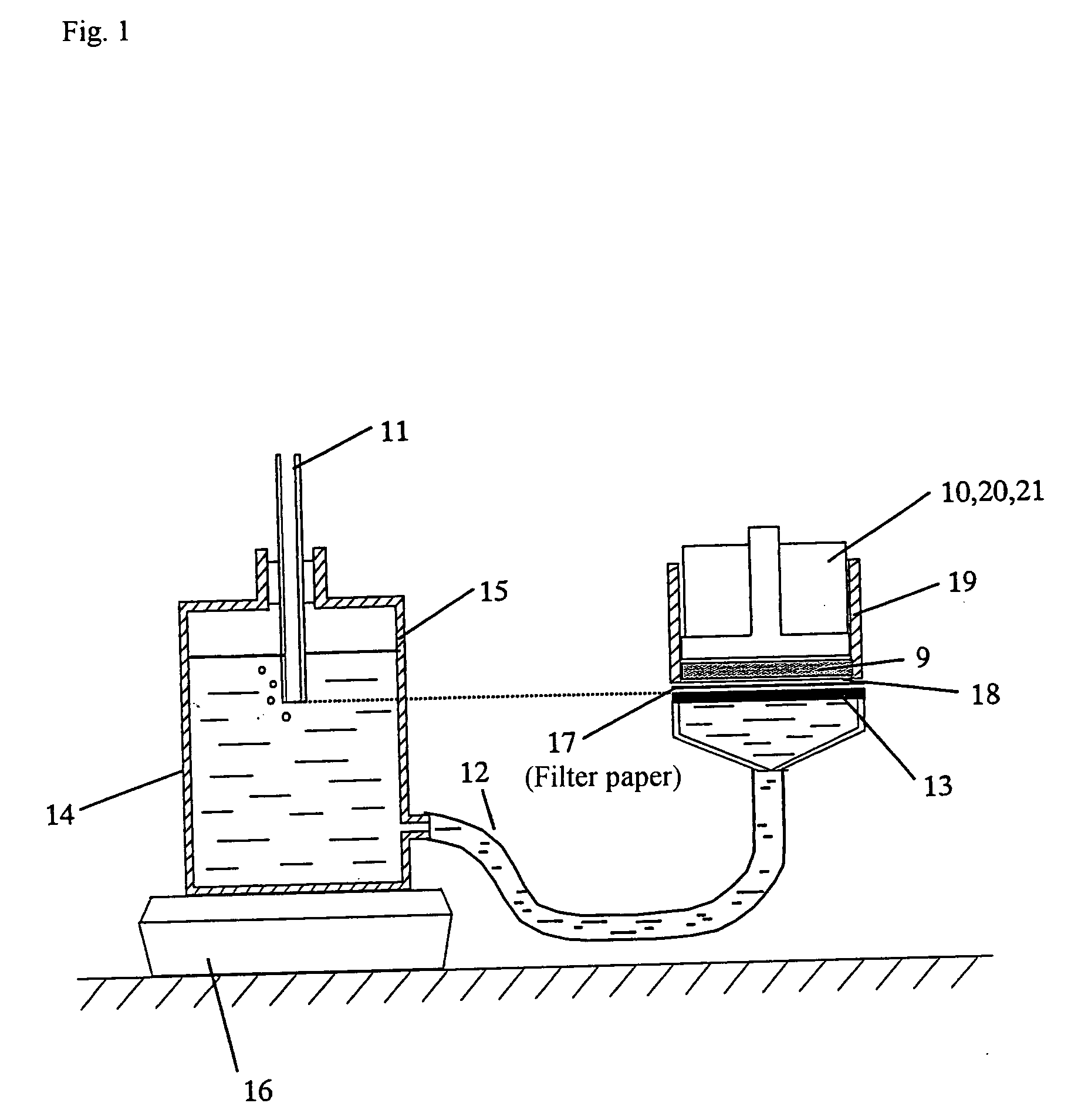

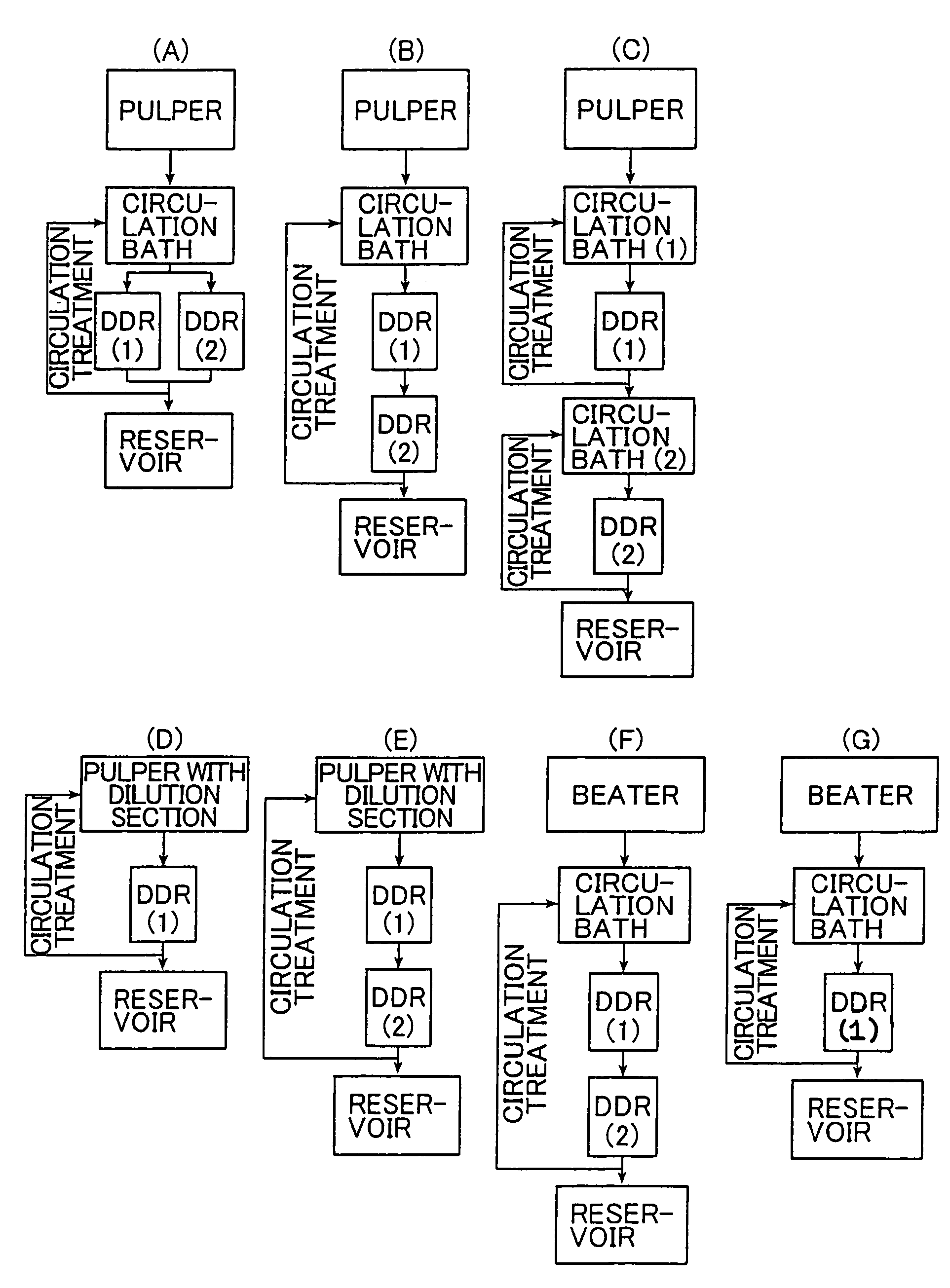

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS7381294B2Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

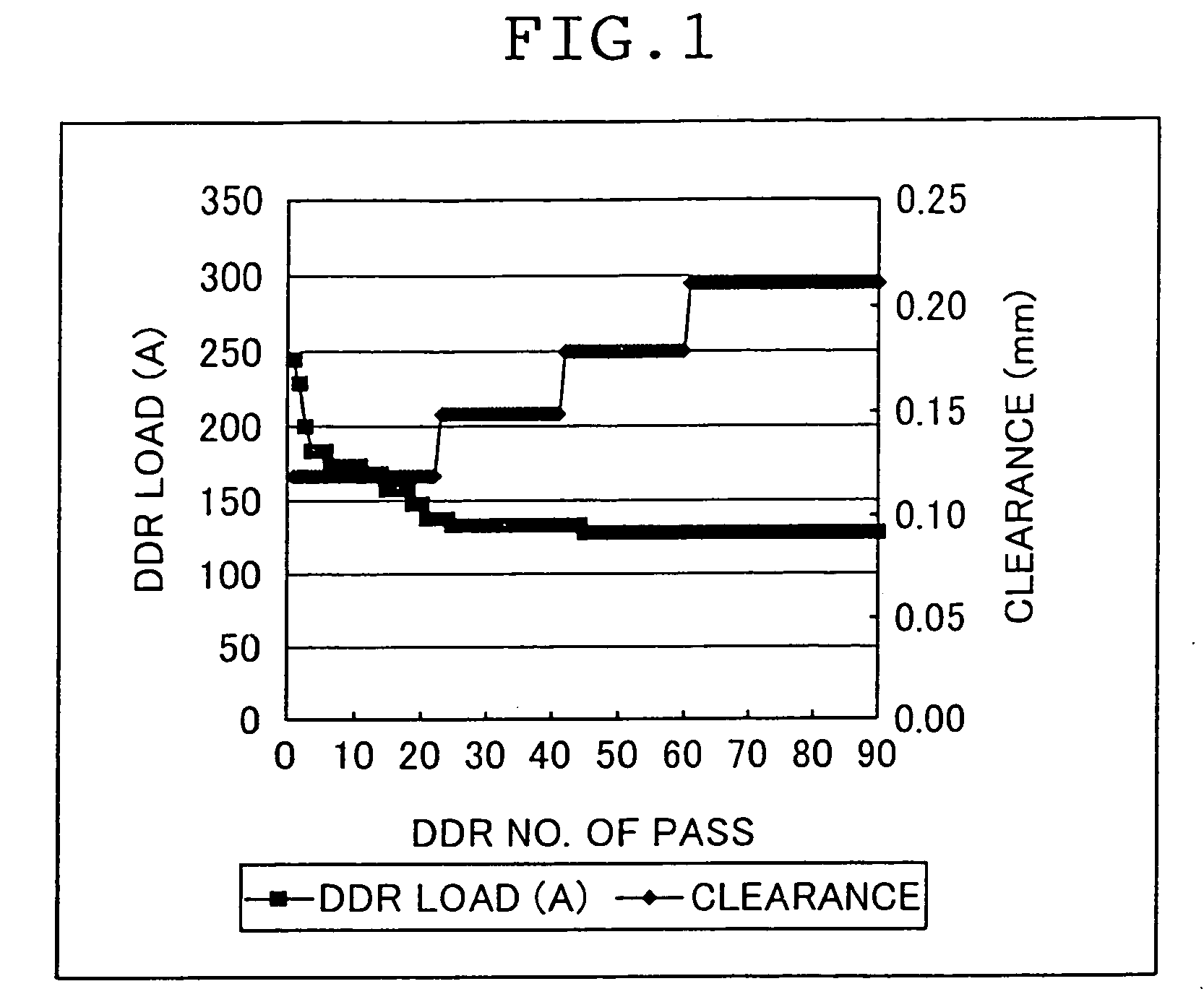

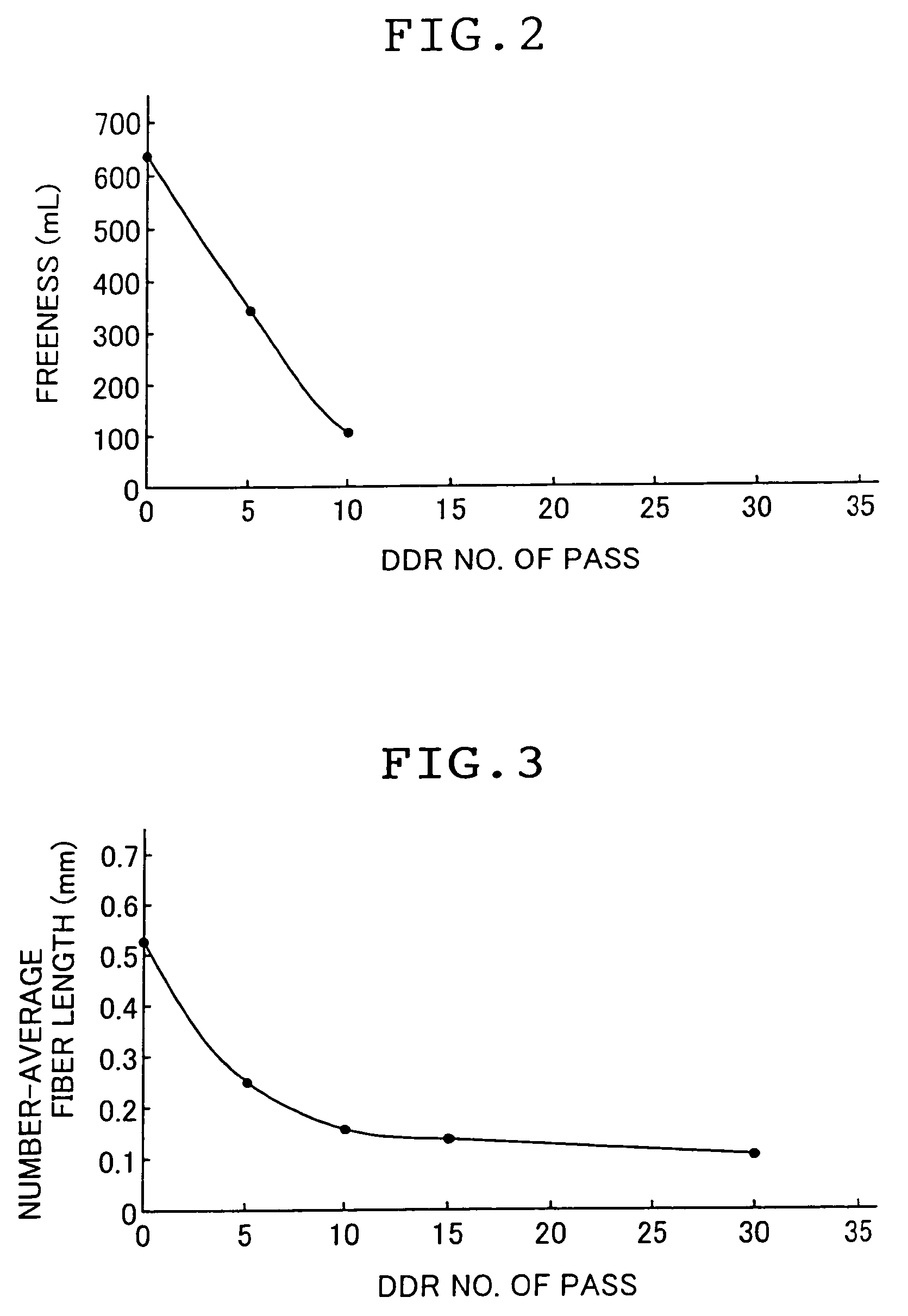

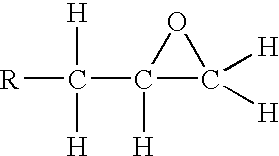

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

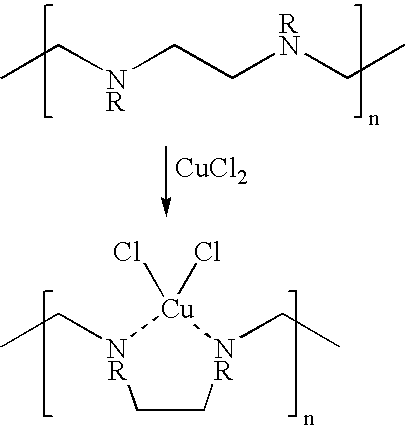

Method for reducing odor using coordinated polydentate compounds

InactiveUS20050084474A1Facilitate typeFacilitate cross-linkingHeavy metal active ingredientsBiocideCompound aCompound (substance)

A method for reducing odor is provided. The method comprises forming a coordination complex between a transition metal and a polydentate compound, and contacting the coordinated complex with an odorous compound. The transition metal provides one or more active sites for capturing the odorous compound. In some embodiments, the polydentate compound may be a polyalkylimine, such as polyethyleneimine, polypropyleneimine, or a dendrimer thereof.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Multi-ply paper towel with absorbent core

ActiveUS7662257B2VariationImprove performanceNon-fibrous pulp additionNatural cellulose pulp/paperCellulosePaper towel

A multi-ply absorbent sheet of cellulosic fiber with continuous outer surfaces is provided an absorbent core between the outer surfaces. The absorbent core includes a non-woven fiber network having: (i) a plurality of pileated fiber enriched of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking whose fiber orientation is biased along the direction between pileated interconnected thereby, and (iii) a plurality of fiber-deprived cellules between the fiber enriched and linking regions, also being characterized by a local basis weight lower than the fiber enriched regions. The cellules provide a sponge-like internal structure of low fiber density regions.

Owner:GPCP IP HLDG LLC

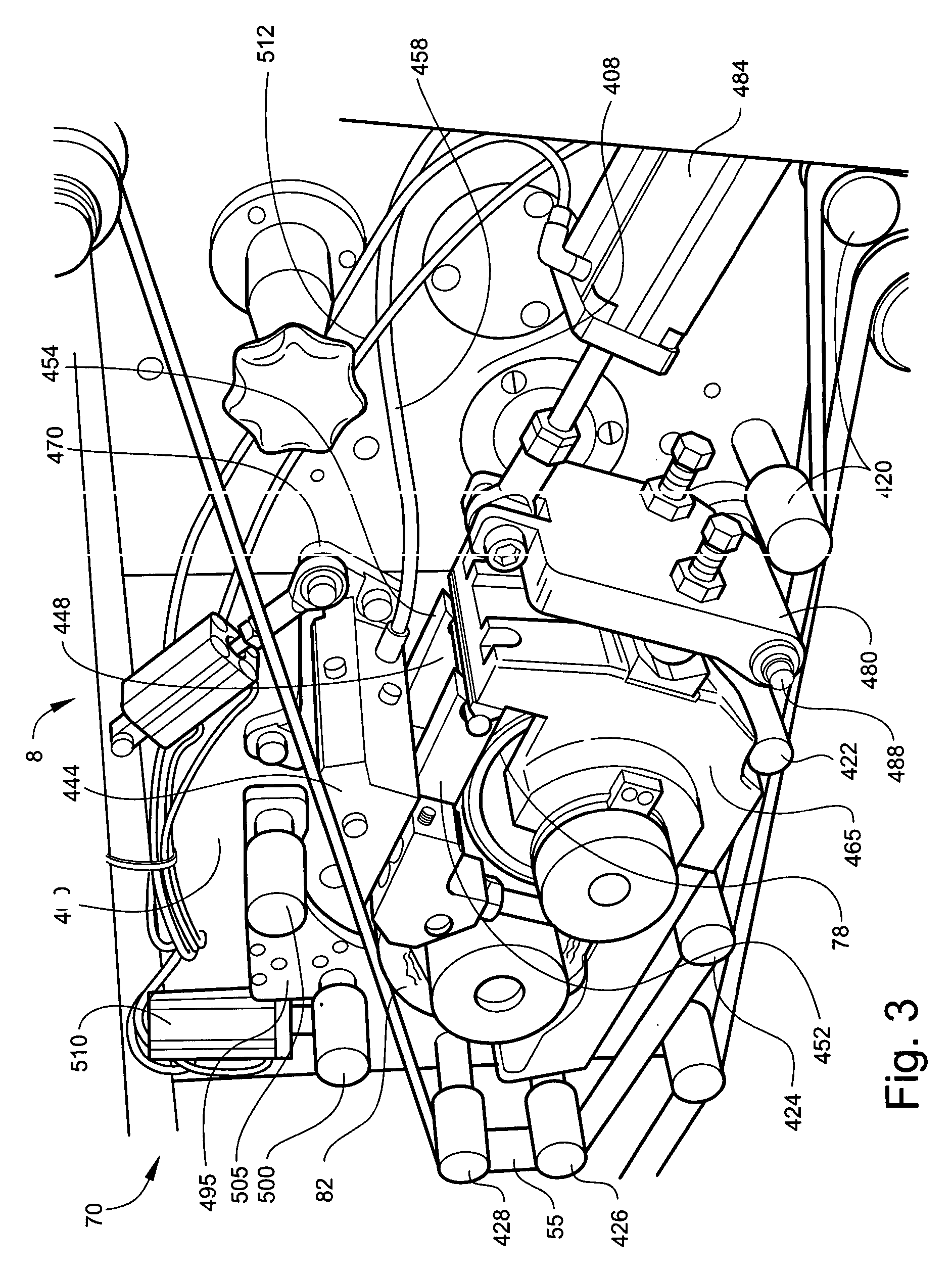

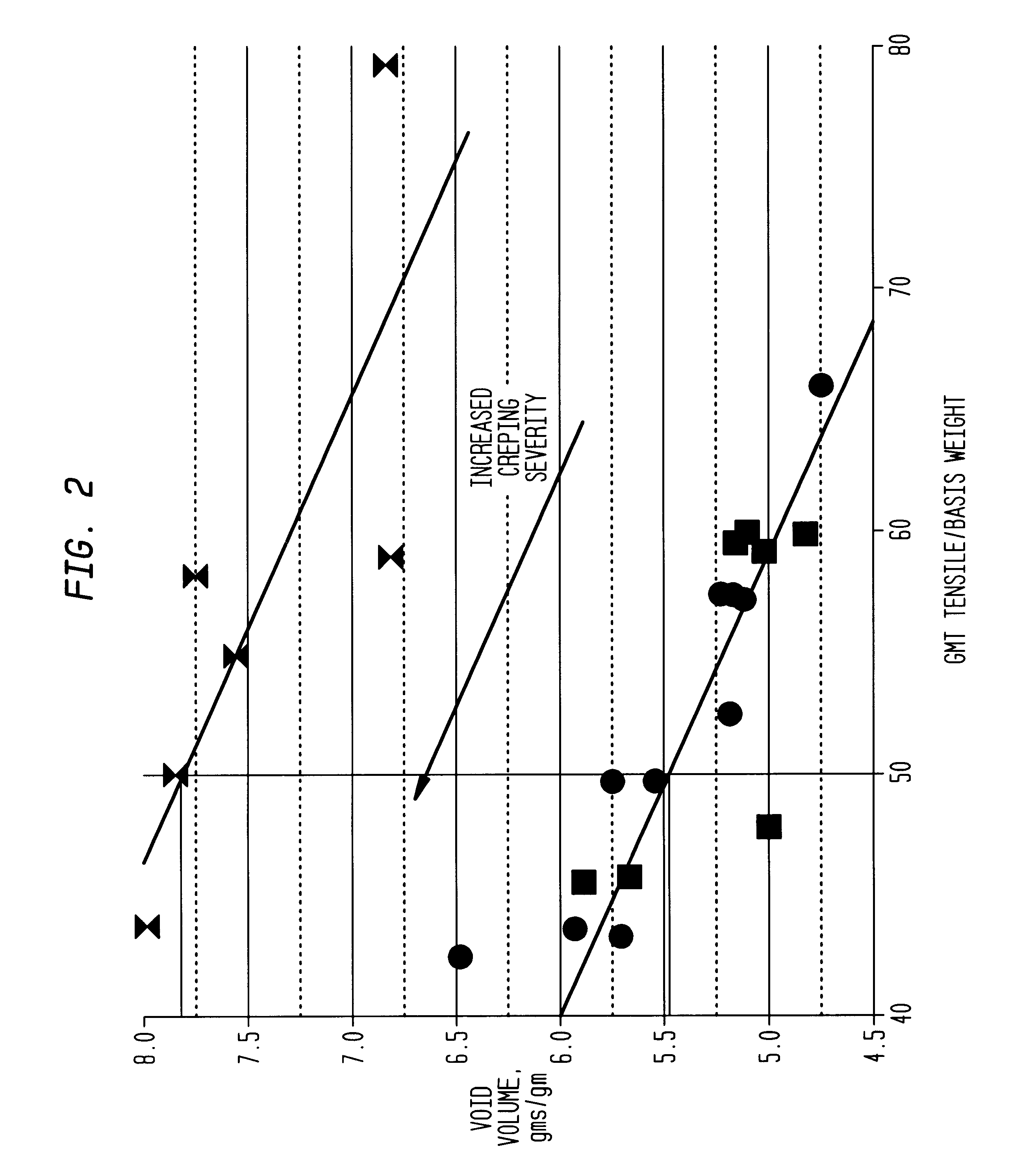

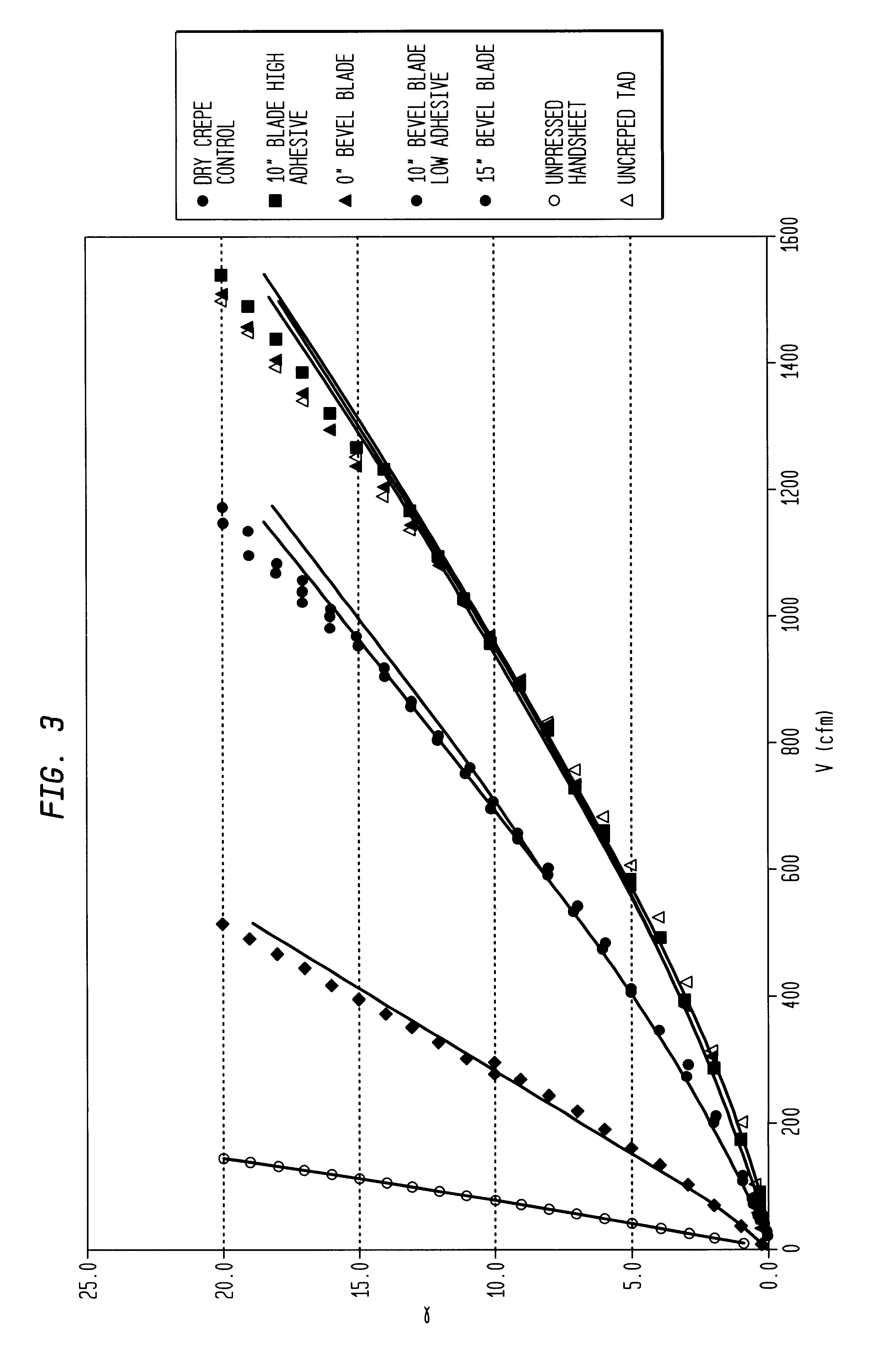

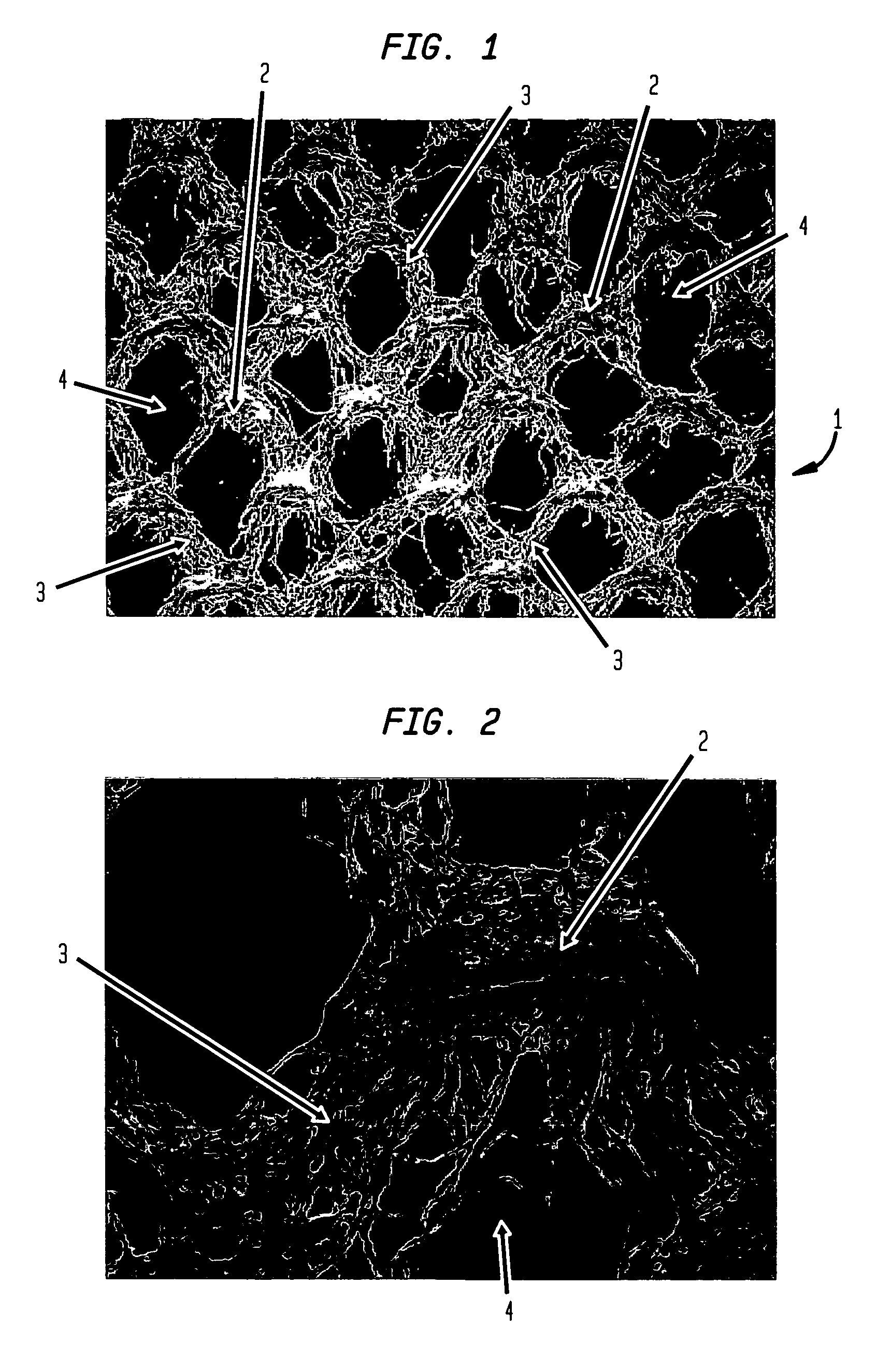

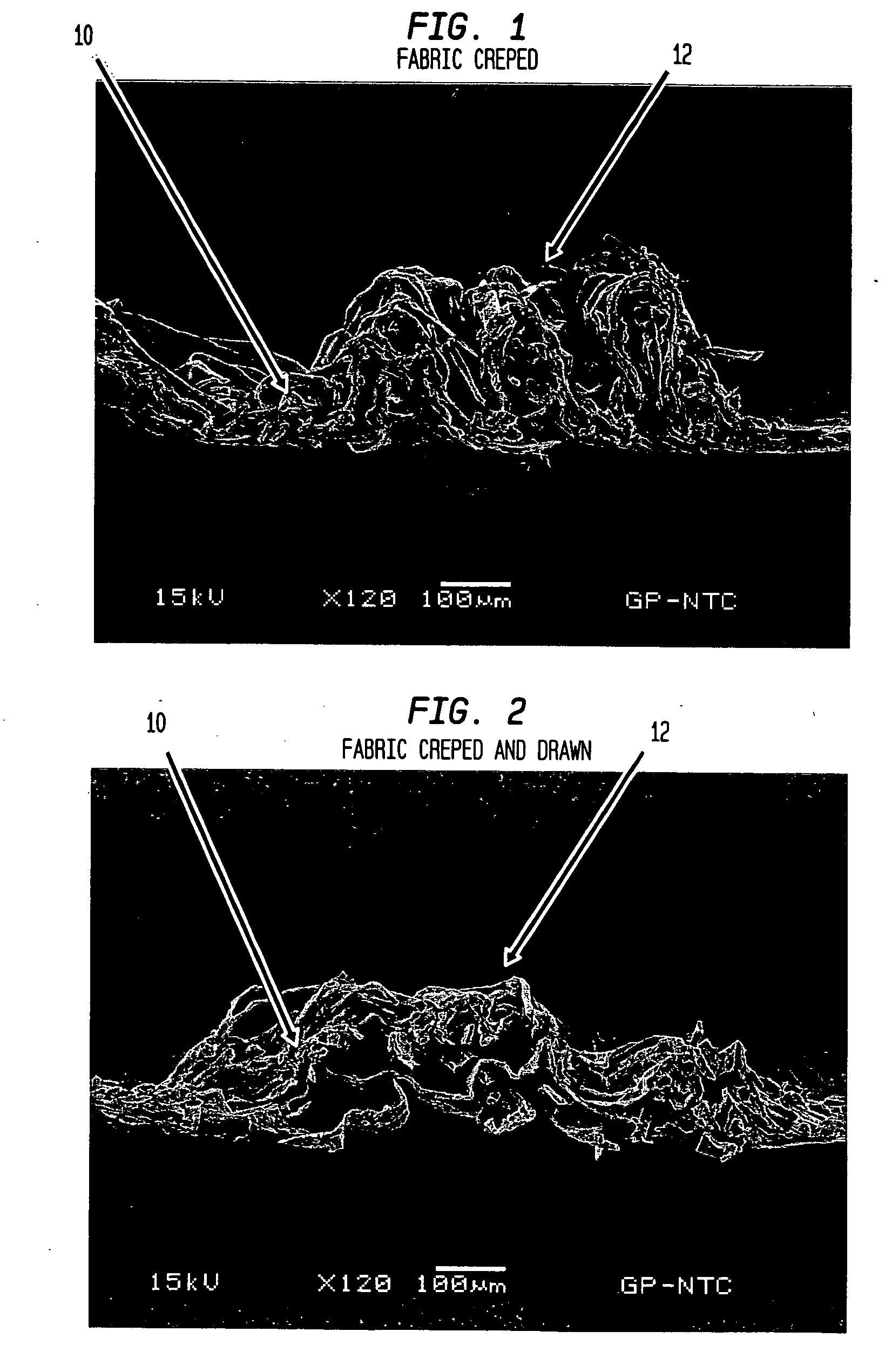

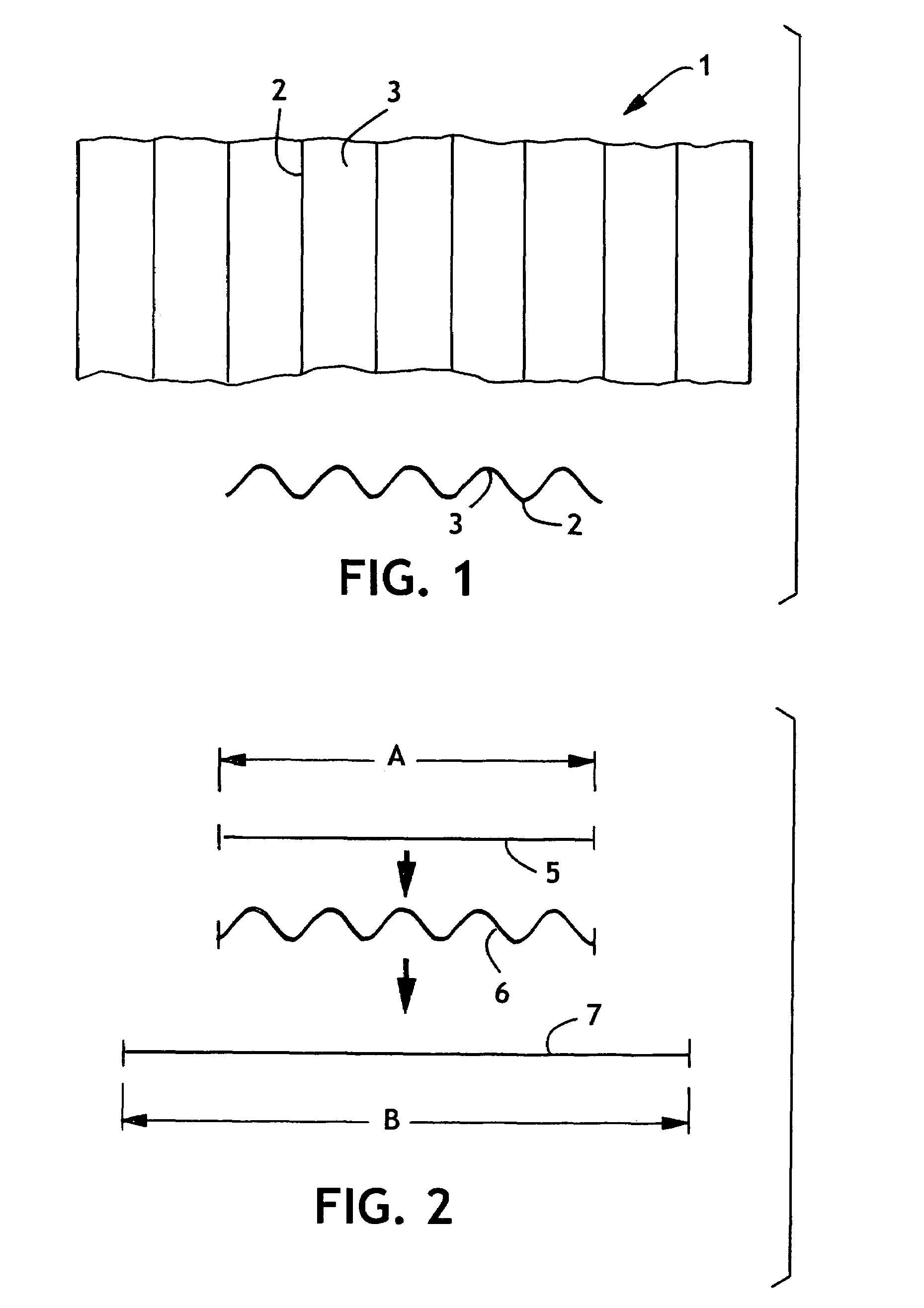

Fabric crepe and in fabric drying process for producing absorbent sheet

ActiveUS20050241787A1Decrease sidednessReduced areaNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberPulp and paper industry

A method of making a cellulosic web includes: forming a nascent web from a papermaking furnish, the nascent web having a generally random distribution of papermaking fiber; b) transferring the web having a generally random distribution of papermaking fiber to a translating transfer surface moving at a first speed; drying the web to a consistency of from about 30 to about 60 percent including compactively dewatering the web prior to or concurrently with transfer to the transfer surface; fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a creping fabric with a patterned creping surface, the fabric creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric such that the web has a plurality of fiber-enriched regions arranged in a pattern corresponding to the patterned creping surface of the fabric, optionally drying the wet web while it is held in the creping fabric. Preferably, the formed web is characterized in that its void volume increases upon drawing.

Owner:GPCP IP HLDG LLC

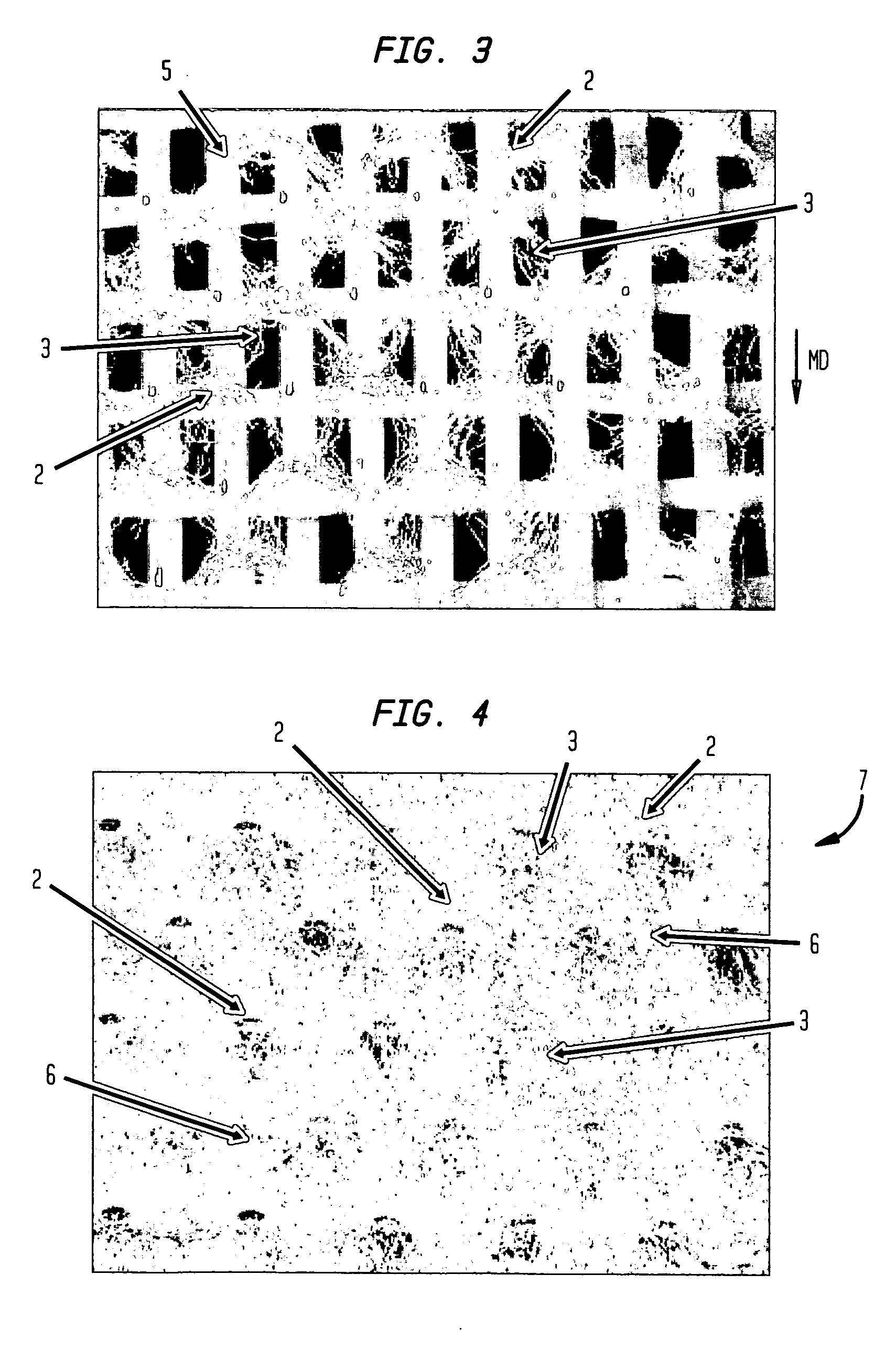

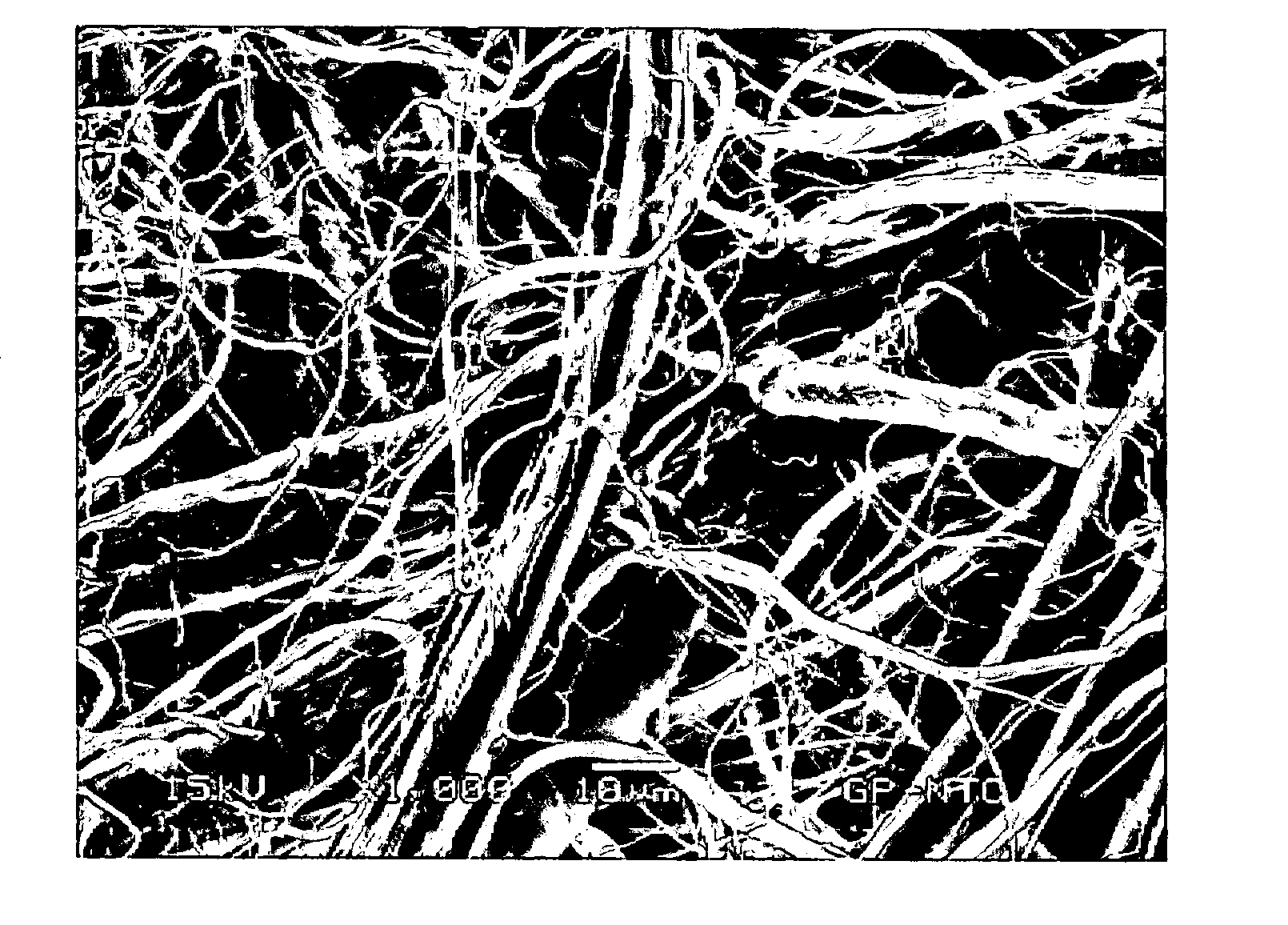

Absorbent sheet having regenerated cellulose microfiber network

ActiveUS20070224419A1High wet/dry tensile ratioImprove consistencyNon-fibrous pulp additionPaper after-treatmentPolymer sciencePapermaking

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

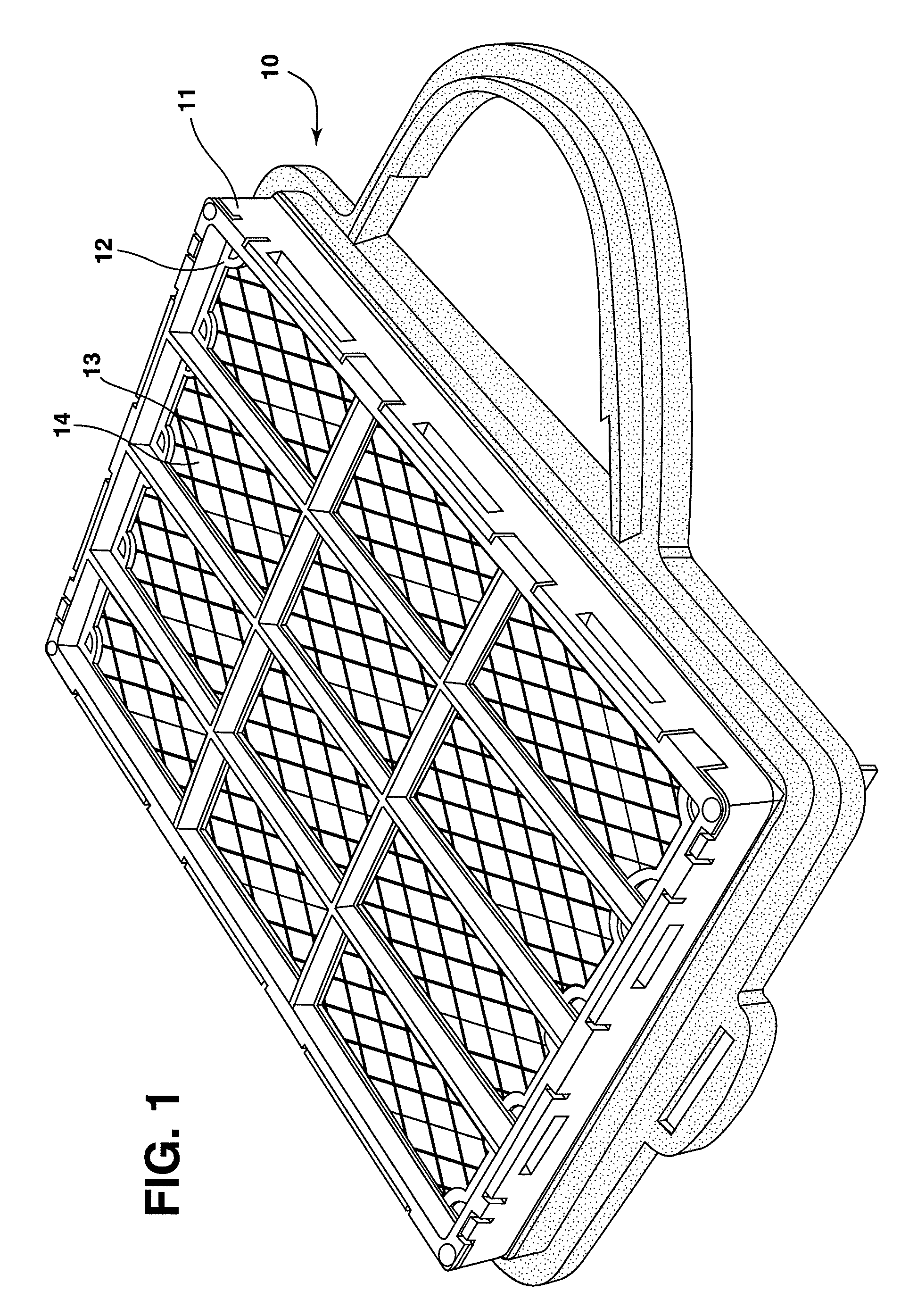

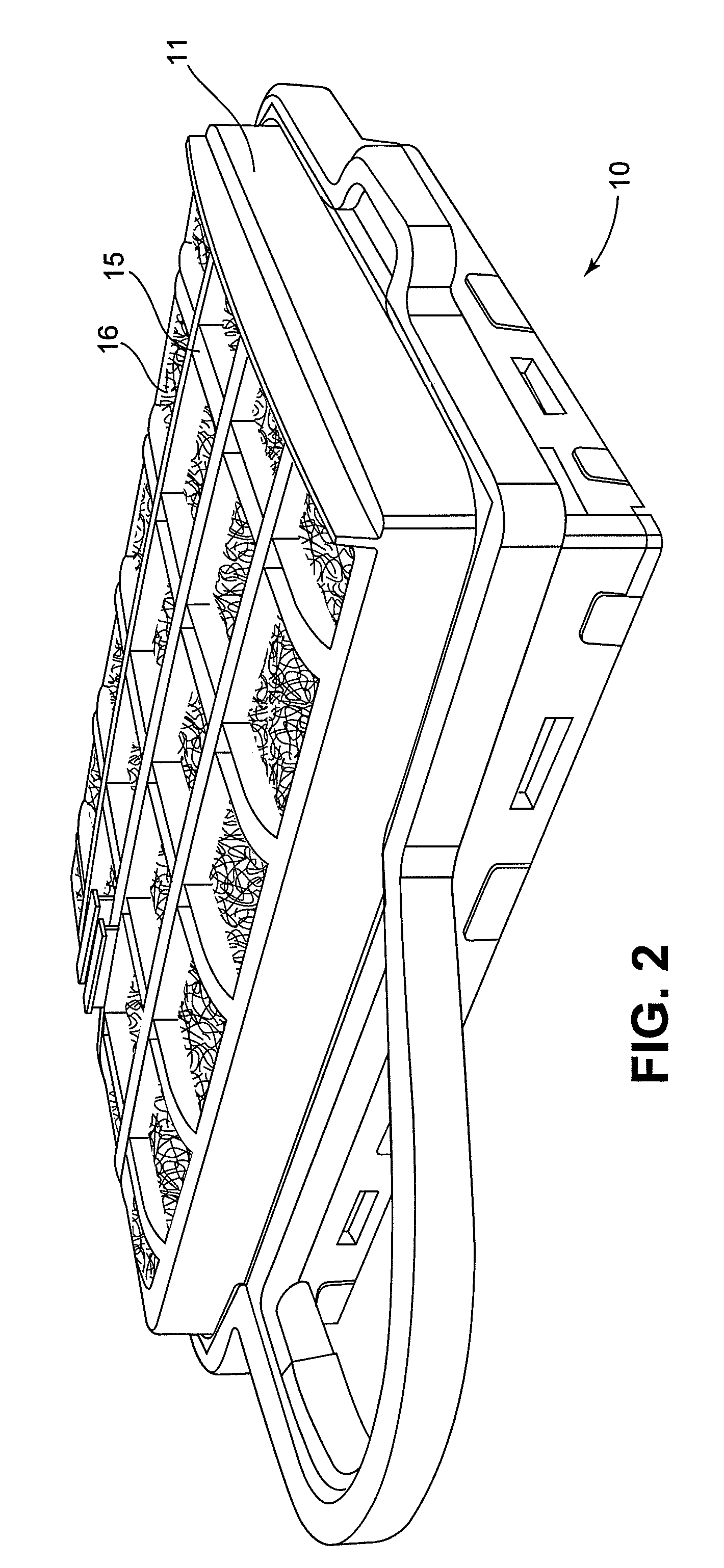

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

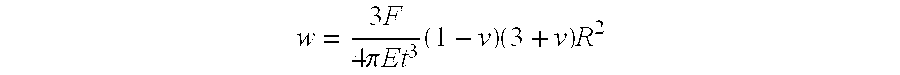

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS6919111B2Quality improvementImprove insulation performanceNon-fibrous pulp additionWrappersPaperboardEngineering

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. per 3000 square feet and, at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inches, has a GM Taber stiffness of at least about 0.00246 w2.63 grams-centimeter / fiber mat density1.63, and a GM tensile stiffness of at least about 615+13.18 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

Paper manufacturing process

ActiveUS7419569B2High strengthNon-fibrous pulp additionNatural cellulose pulp/paperPre-conditionPre conditioning

A method of making soft, strong, high bulk tissue is disclosed. The method includes pre-conditioning a wet web by straining the wet web in the cross-machine direction prior to transferring the wet web to a throughdrying fabric. The pre-conditioned web provides improved sheet softness and conforms more readily to the surface contour of the throughdrying fabric, thereby creating greater caliper (bulk) in the resulting dried sheet. The bulk is maintained during a subsequent creping step by maintaining the dried sheet in registration with the throughdrying fabric when the dried sheet is applied to the surface of the creping cylinder.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Embossed tissue products

InactiveUS20070137813A1Preserve strengthHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. After the additive composition is applied to the web or otherwise incorporated into the tissue web, the tissue web is embossed. During embossing, the additive composition forms well defined embossments in the web that are water resistant. In one embodiment, the additive composition may also be used to bond multiple tissue webs together to form a multiple ply product during the embossing operation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of fabricating a belt and a belt used to make bulk tissue and towel, and nonwoven articles and fabrics

A method for manufacturing a belt and a belt for use in the production of bulk tissue and towel, and of nonwoven articles and fabrics, requires the application of a sacrificial material onto a base substrate in a predetermined pattern which is to be imparted onto products manufactured with the belt. The sacrificial material is deposited in droplets in a controlled manner so as to control the x, y, z dimension of the material deposited and preferably has having an average diameter of 10μ (10 microns) or more. A polymeric resin material is then deposited on the base substrate in all areas except those on which the sacrificial material has previously been applied. The polymeric resin material is then set by means appropriate to its composition, and the sacrificial material removed. Optionally, the polymeric resin material may then be abraded to provide the belt with a uniform thickness, and a smooth, macroscopically monoplanar surface.

Owner:ALBANY INT CORP

Security paper

InactiveUS6159585AAvoid the needLow compositionNon-fibrous pulp additionNatural cellulose pulp/paperOrganic solventChemical separation

A security paper indicates exposure to a solvent by a solvent resistant color signal. A metal mordant dye first co-reactant and a mordant dye second co-reactant form an organic solvent-insoluble colored reaction product when the paper is washed with an organic solvent. The metal mordant dye first co-reactant and a mordant dye second co-reactant are chemically isolated from each other so as to prevent the coordinate covalent bond from forming until the paper is washed with an organic solvent. The chemical isolation can be effected by encapsulation or other physical separation of the co-reactants. The organic solvent-insoluble colored reaction product, once formed, remains entrapped in the web when the paper is washed with an organic solvent. The chemical isolation prevents the organic solvent-insoluble colored reaction product from forming upon the application of pressure alone to the paper.

Owner:DOMTAR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com