Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

334 results about "Stillage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stillage is like a pallet or skid but with a cage or sides or some form of support specifically tailored to the material it is intended to carry. Some are designed to be stackable. Stillages are mainly used to transport goods without the need to load and unload the product being carried, which saves time and decreases the chance of damage. An example is the use of stillages in the glass industry, where they are shaped like an upright "A"; the glass leans inward and is strapped to the stillage ready for transport.

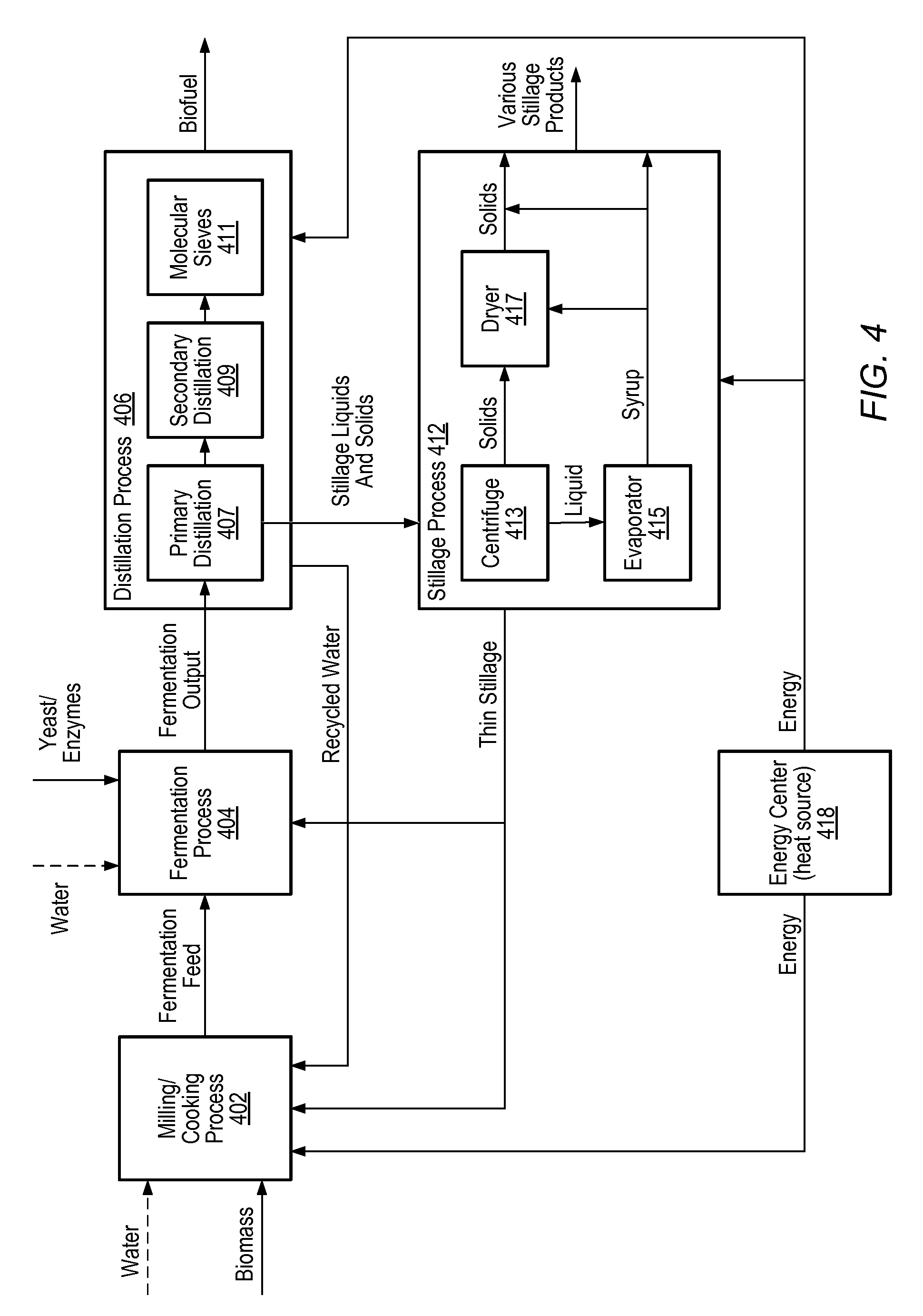

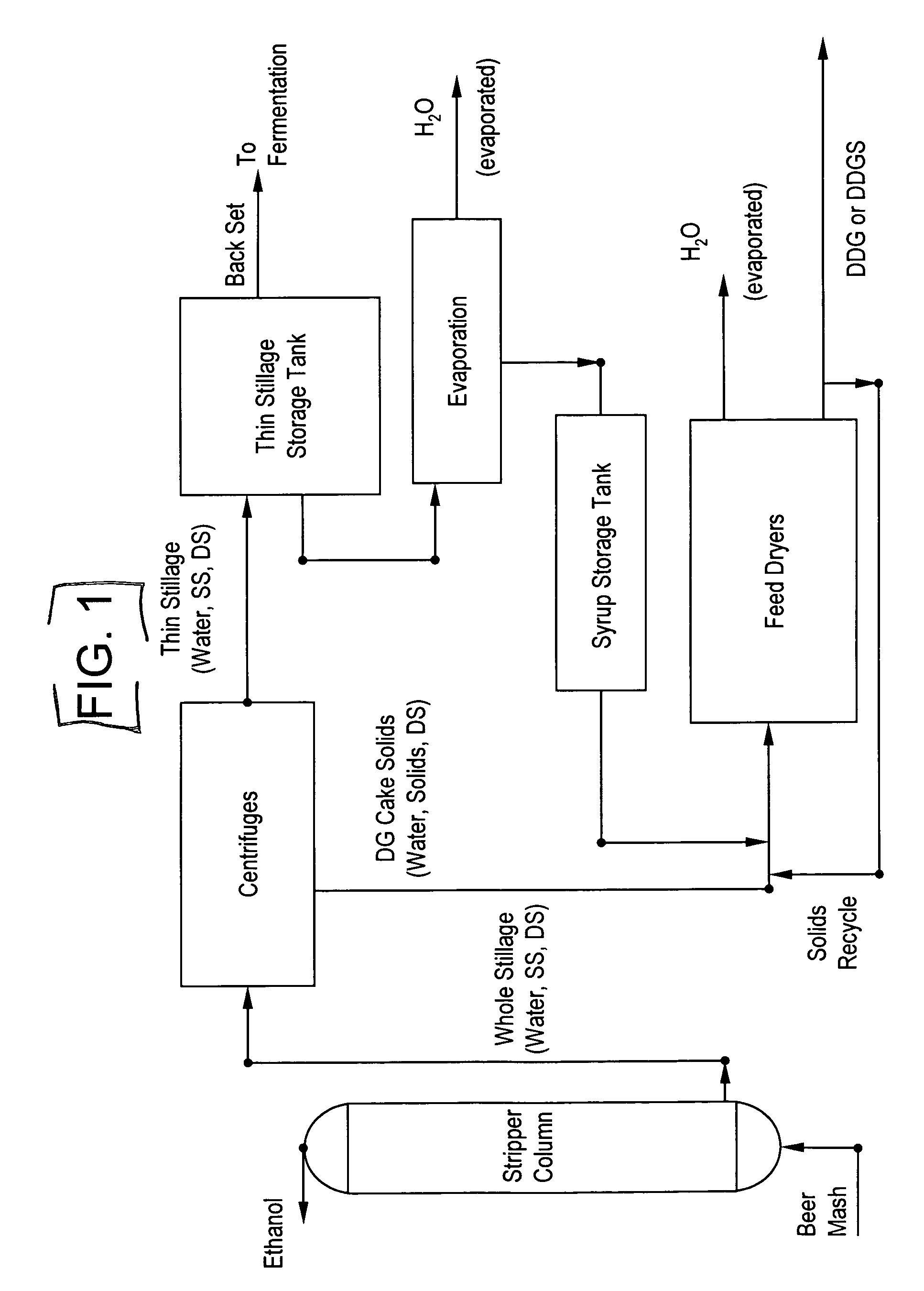

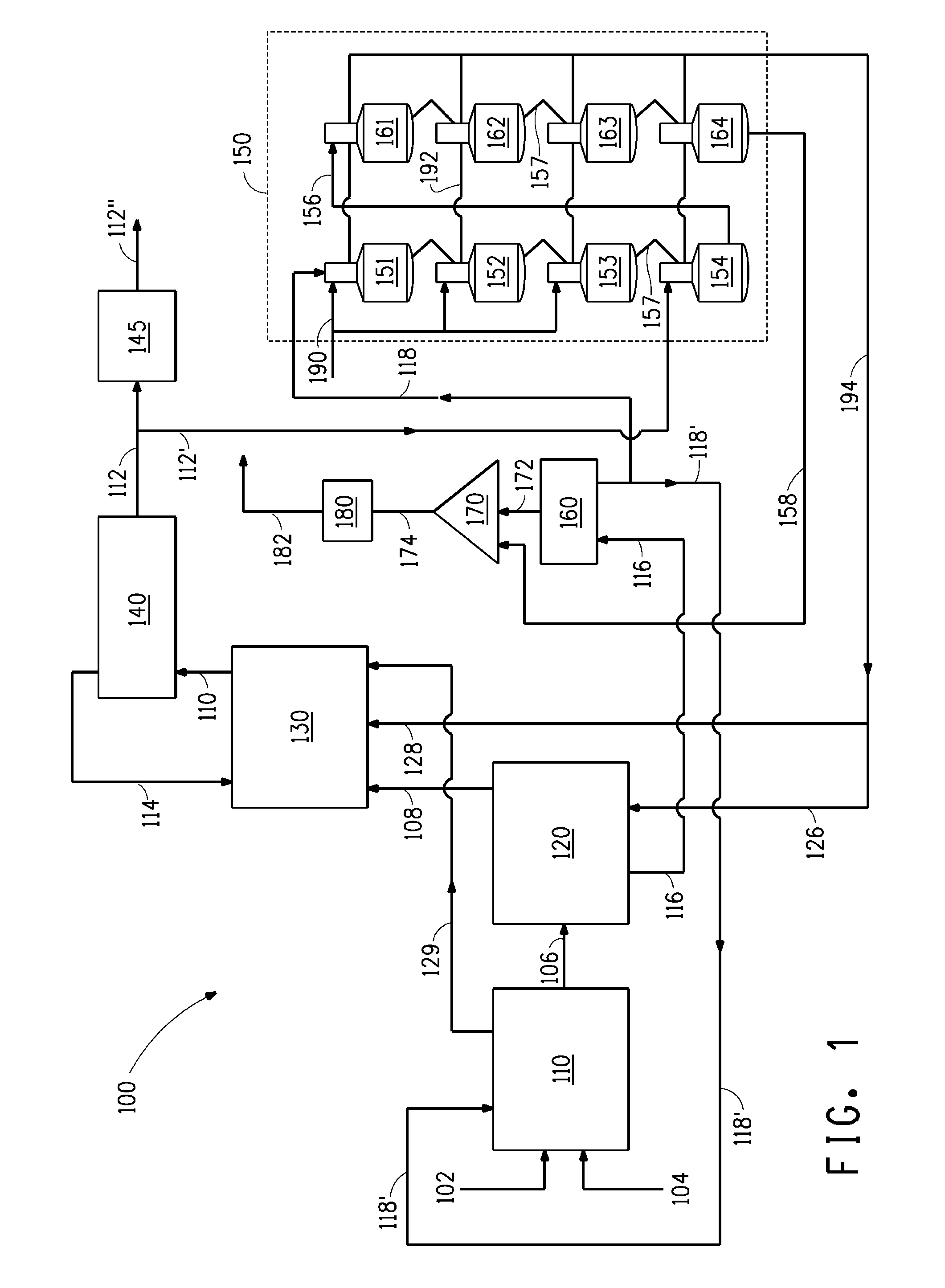

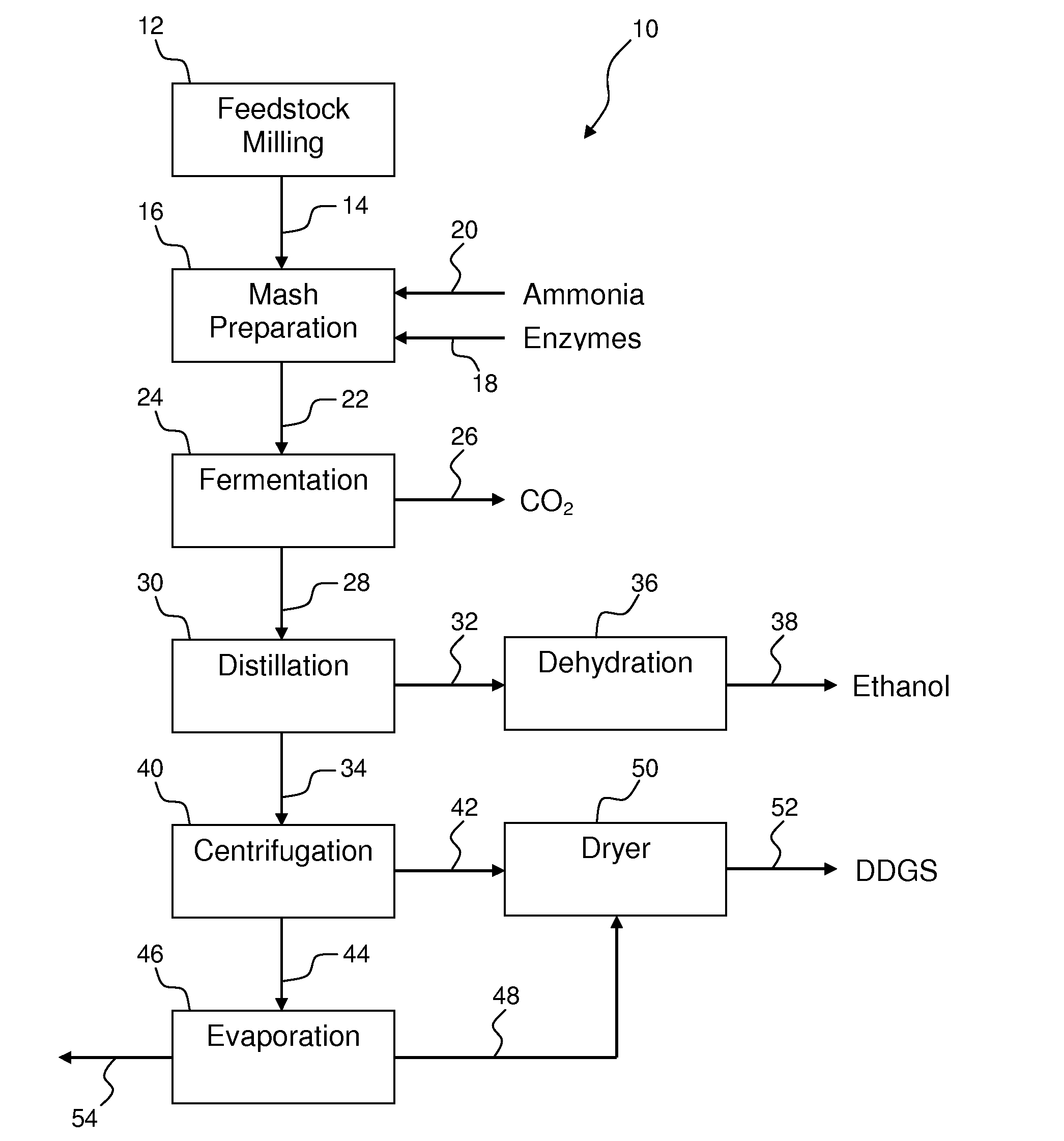

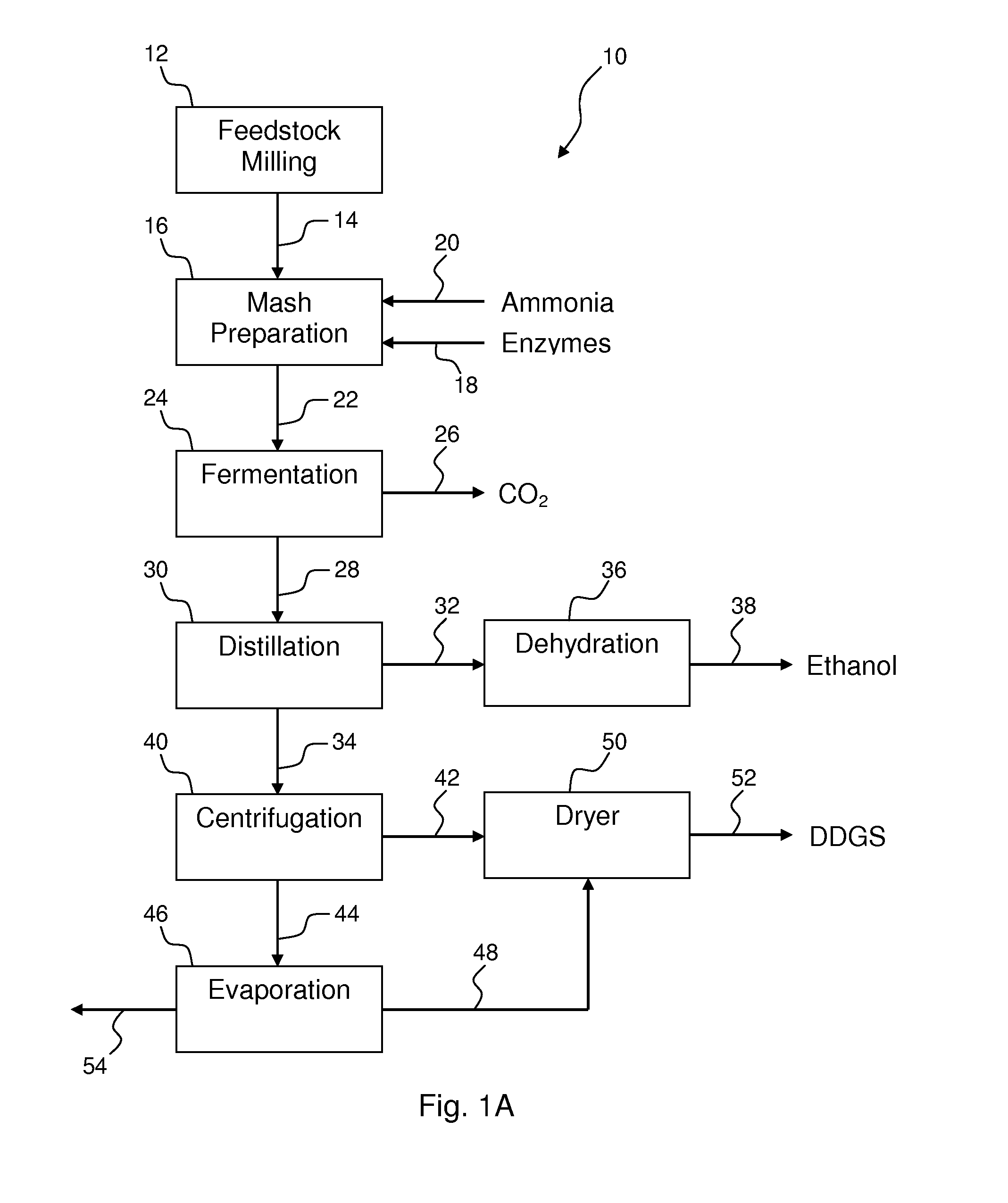

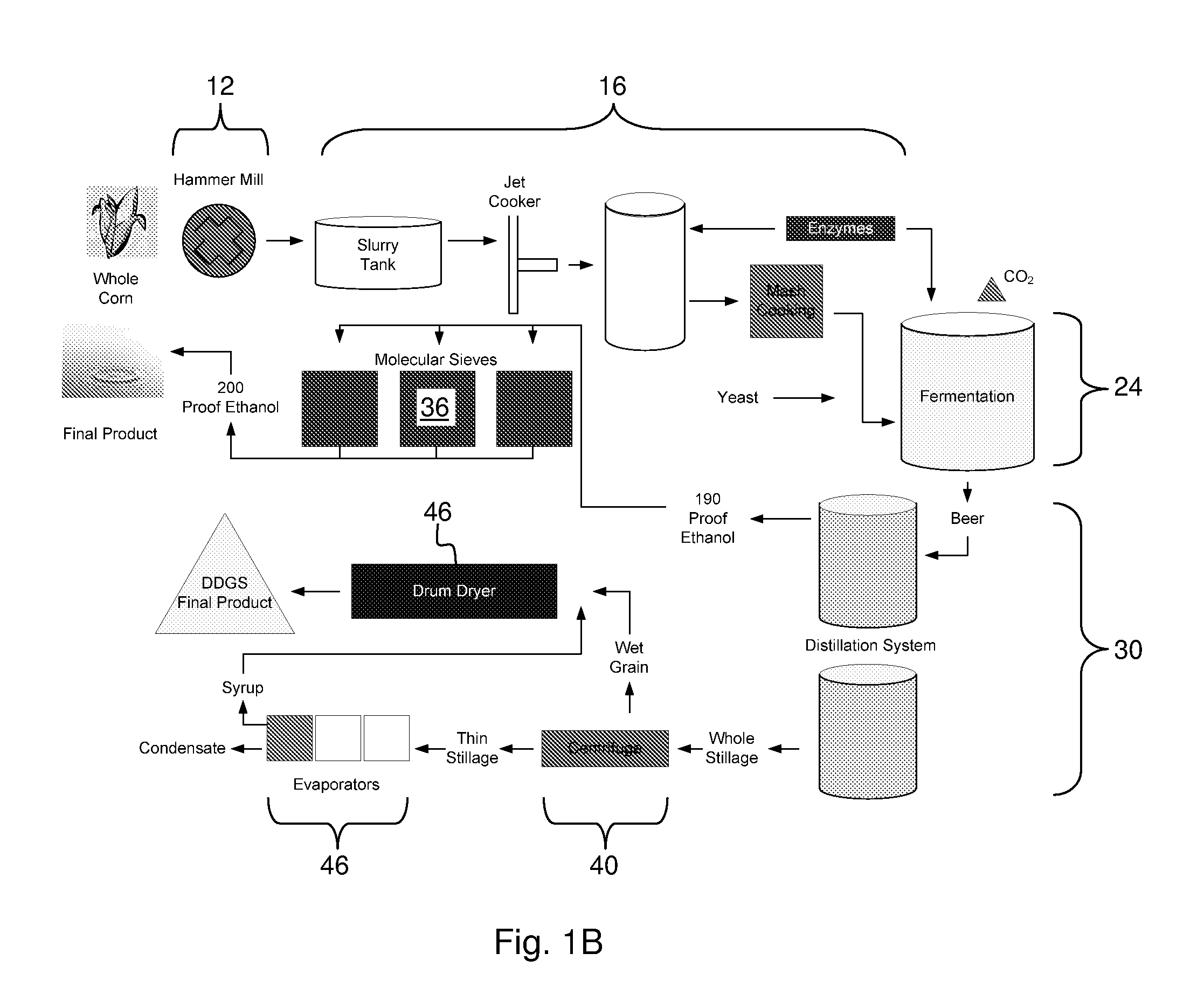

Ethanol distillation process

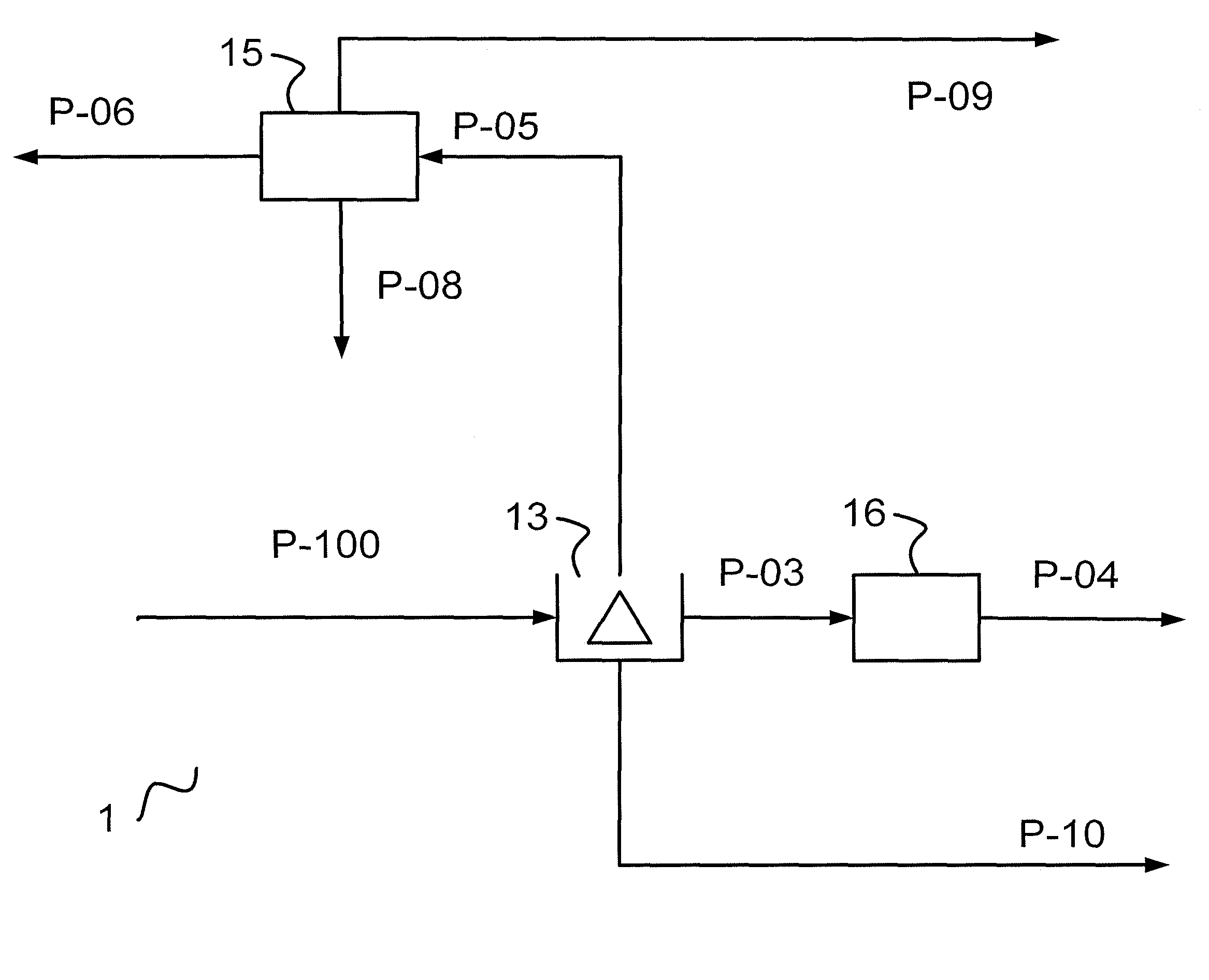

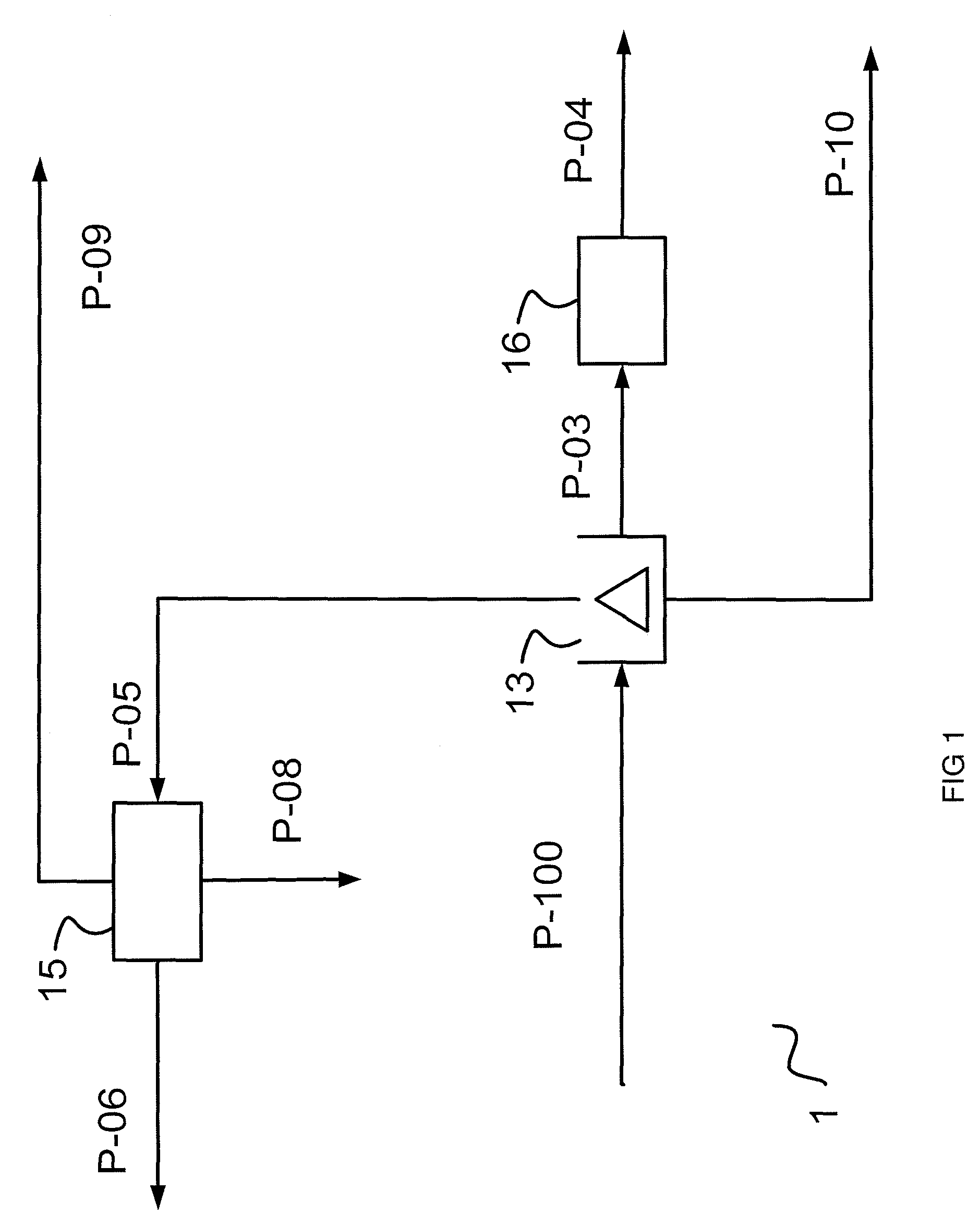

InactiveUS7297236B1Avoid insufficient heatingShorten the timeFermented solutions distillation/rectificationDistillation in boilers/stillsDistillationEvaporation

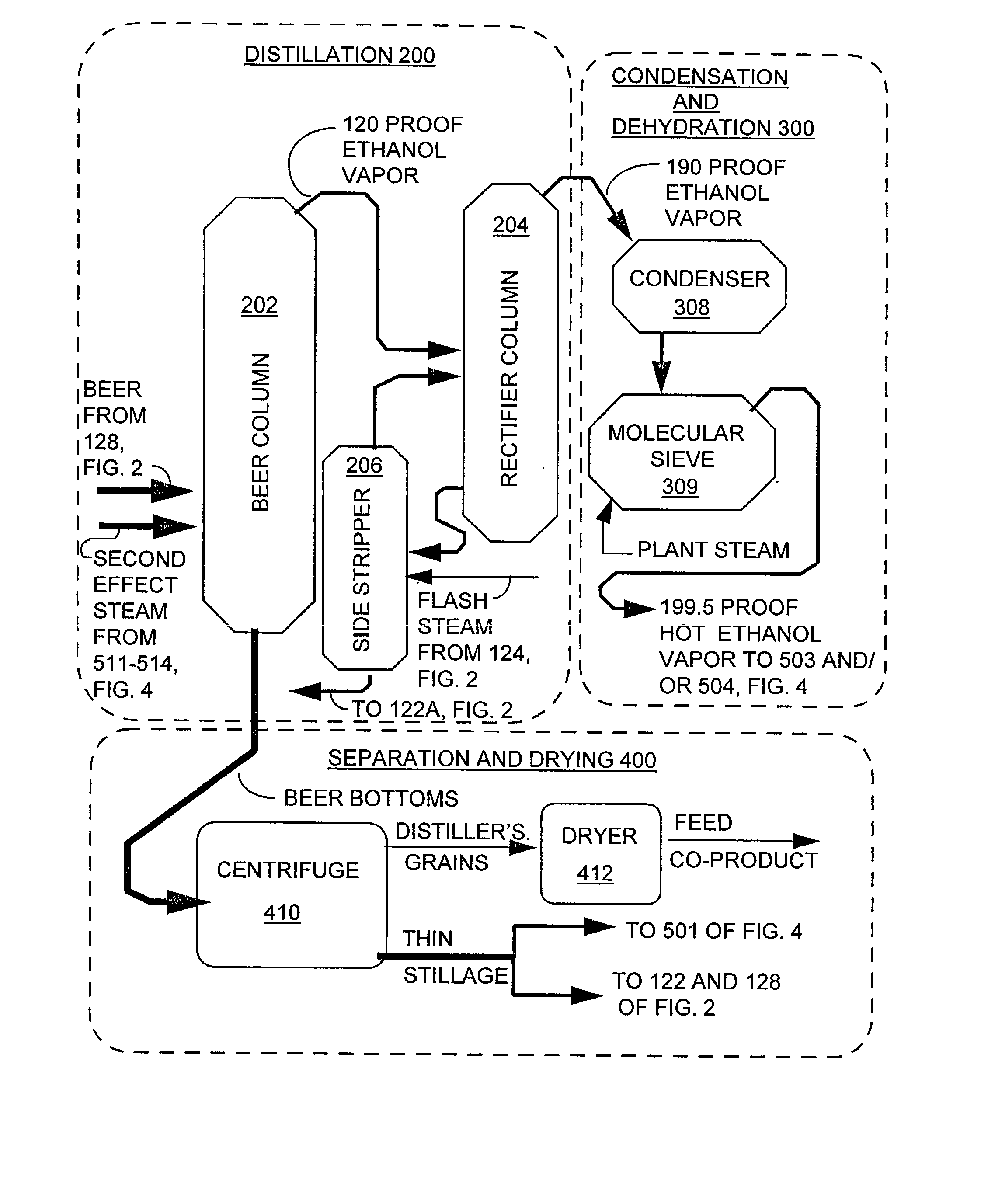

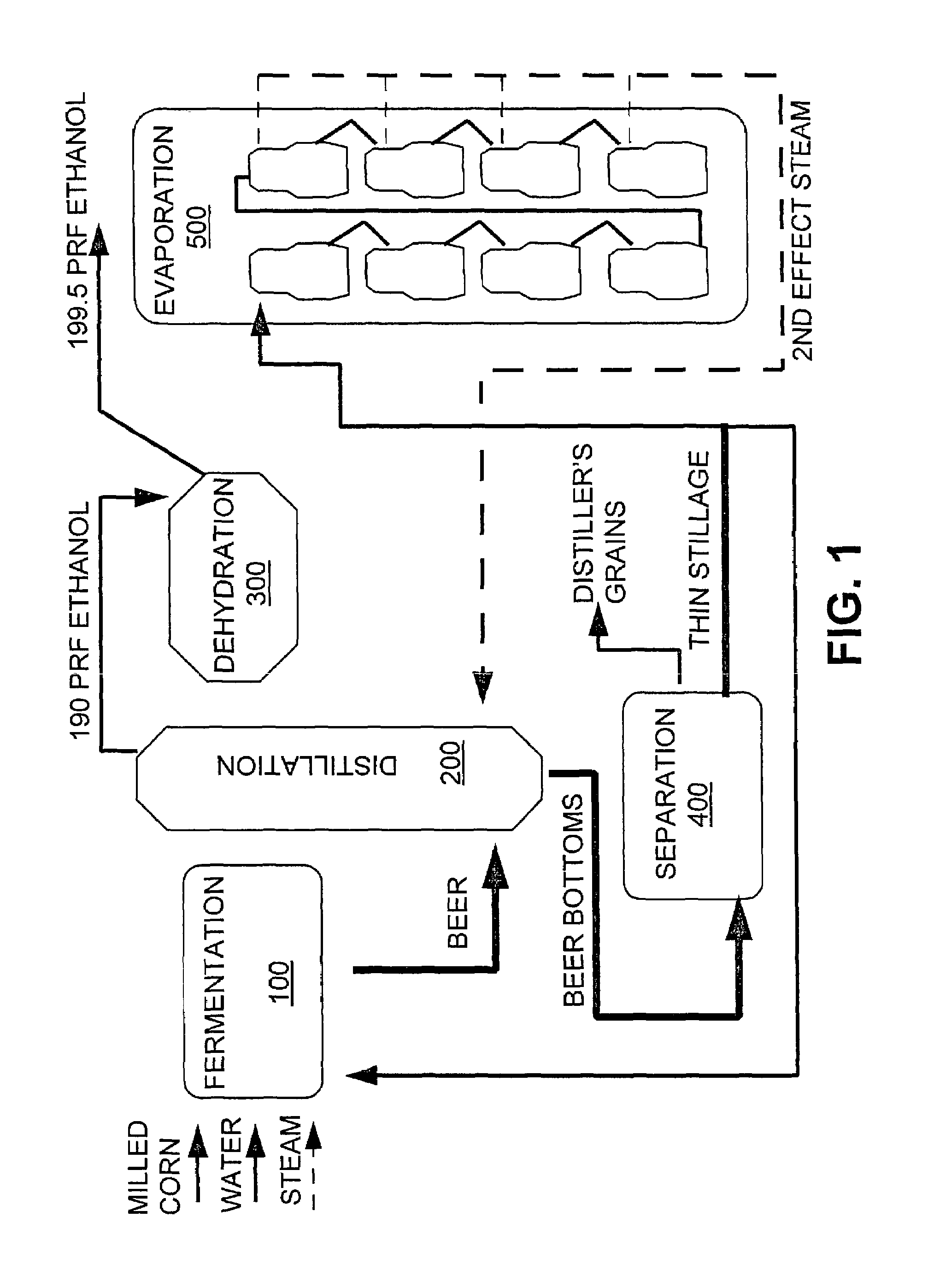

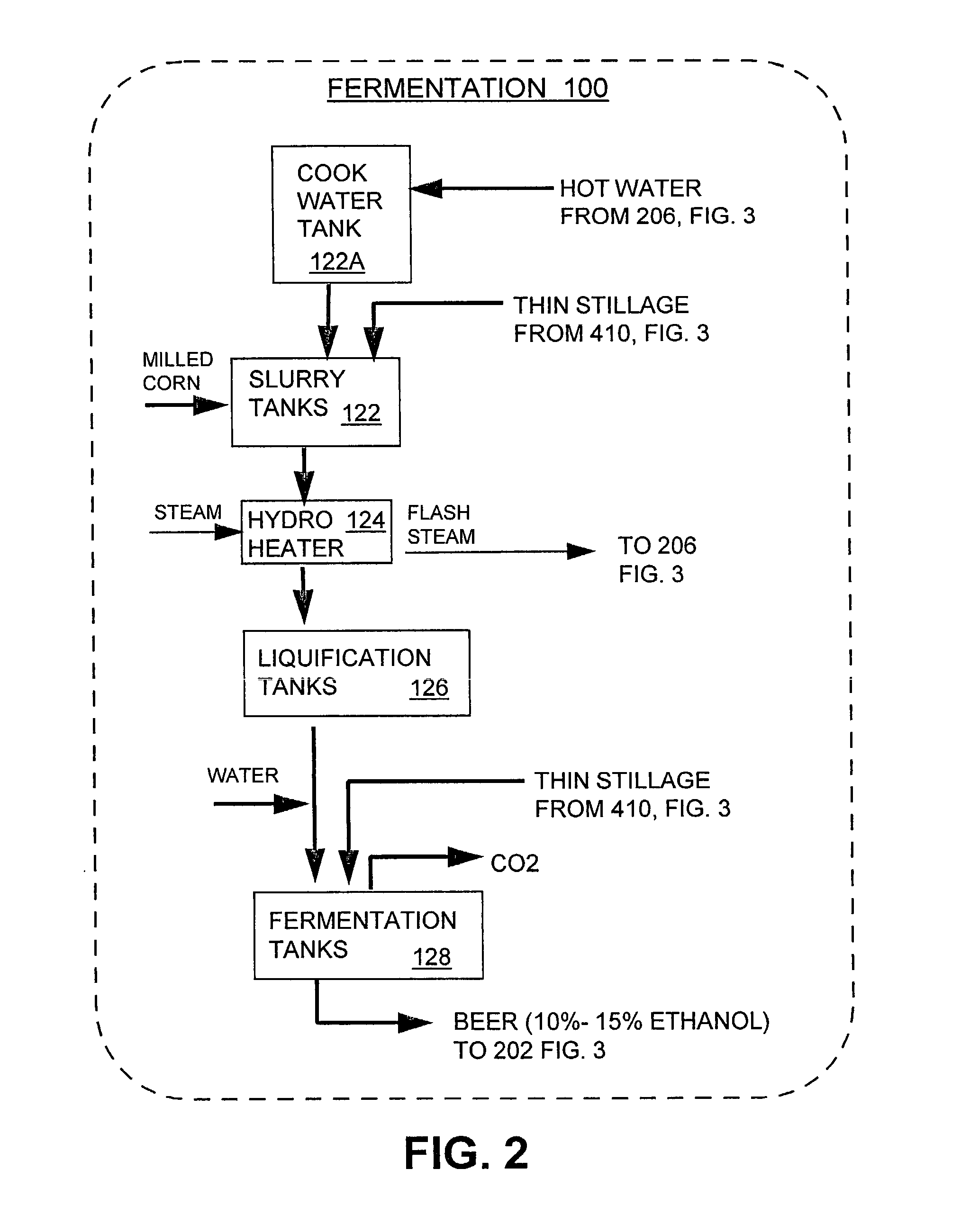

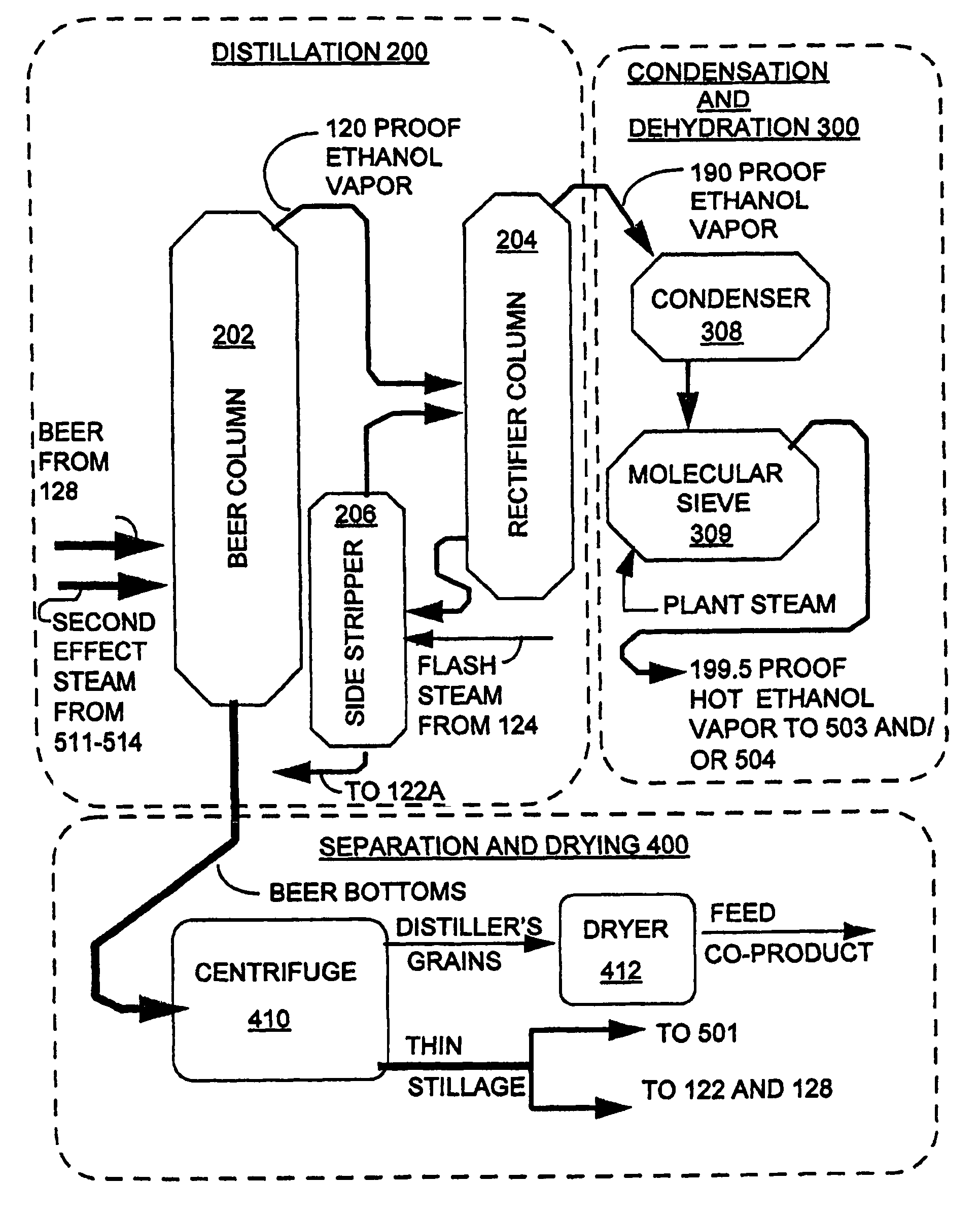

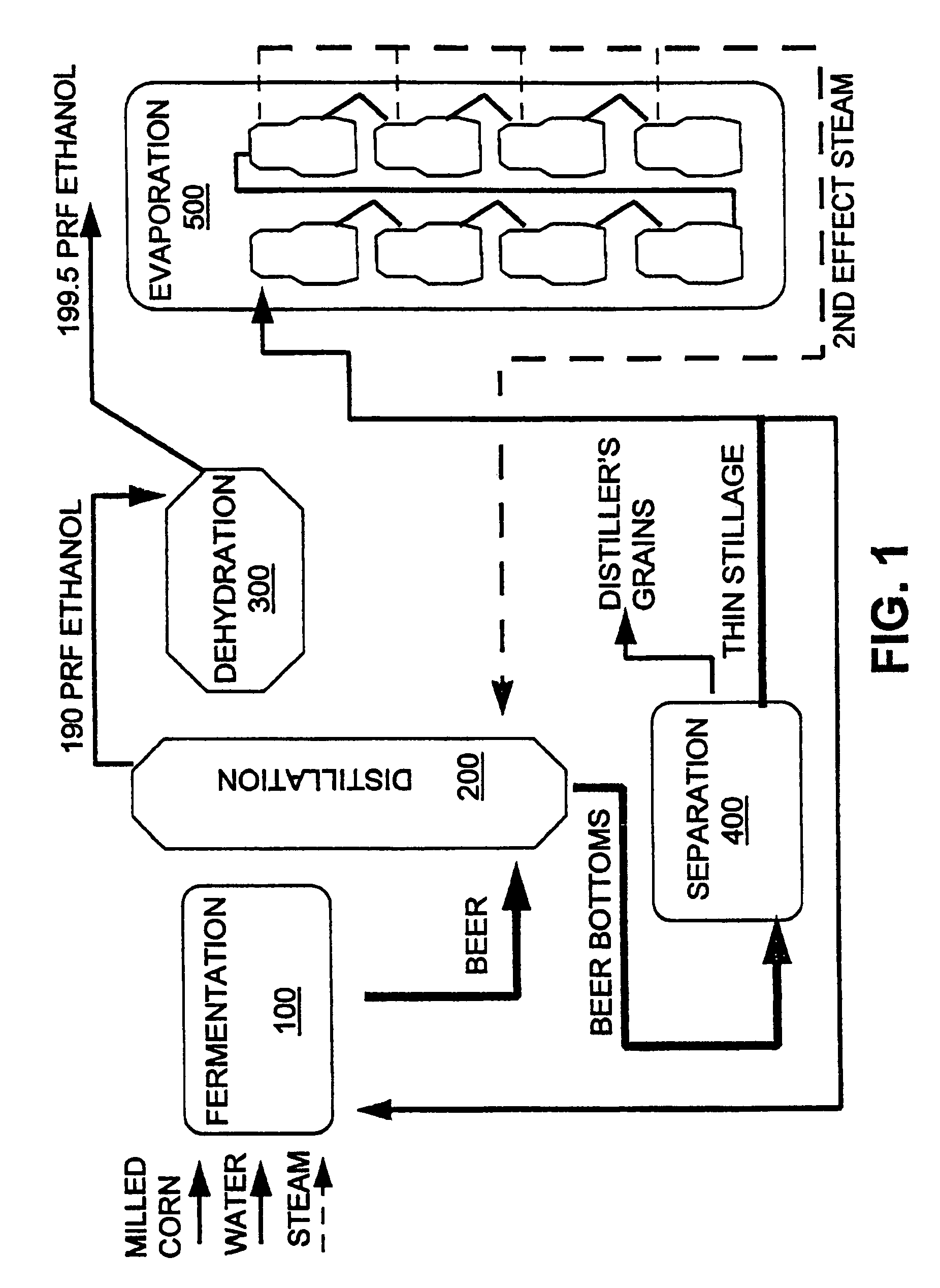

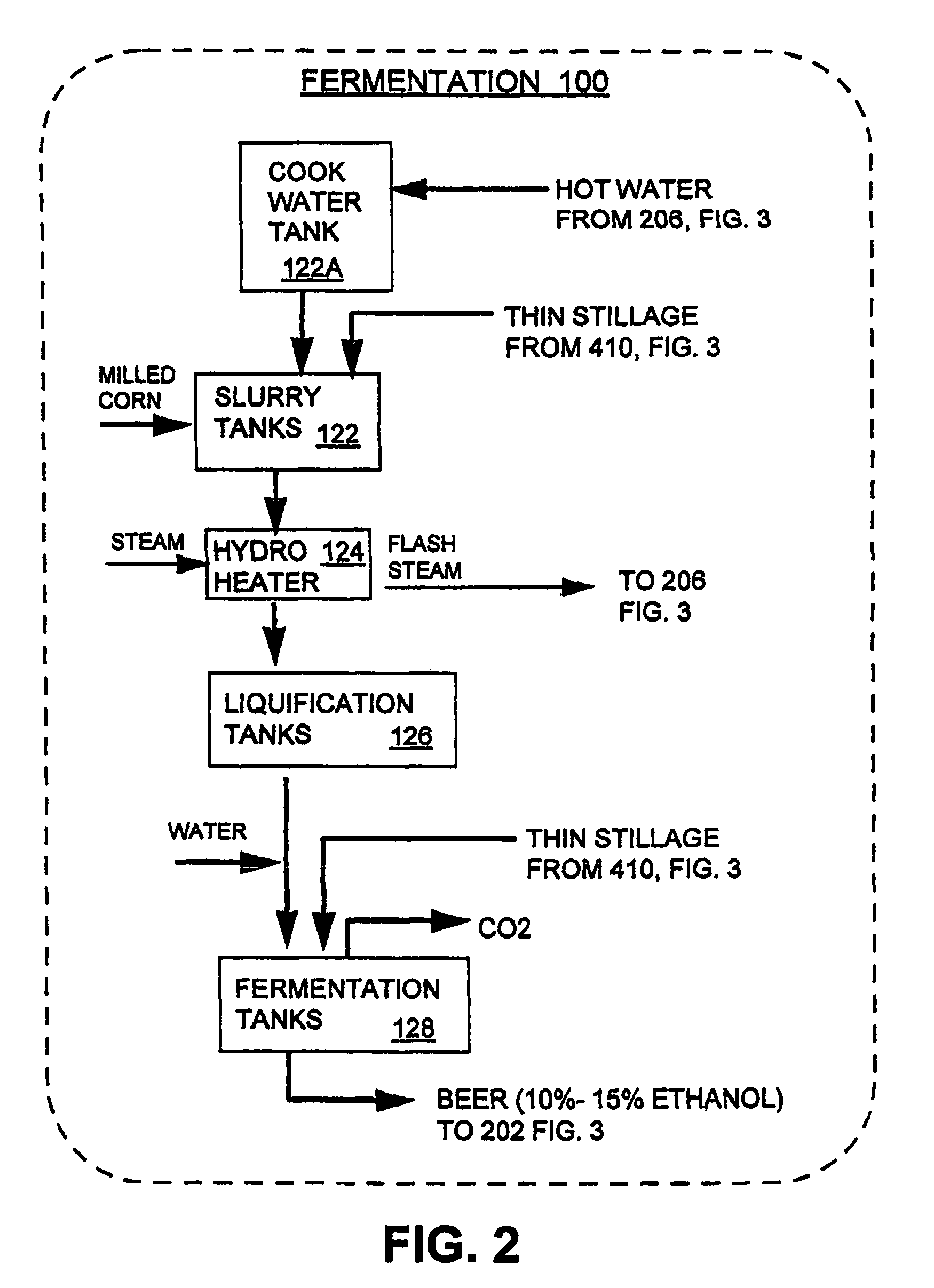

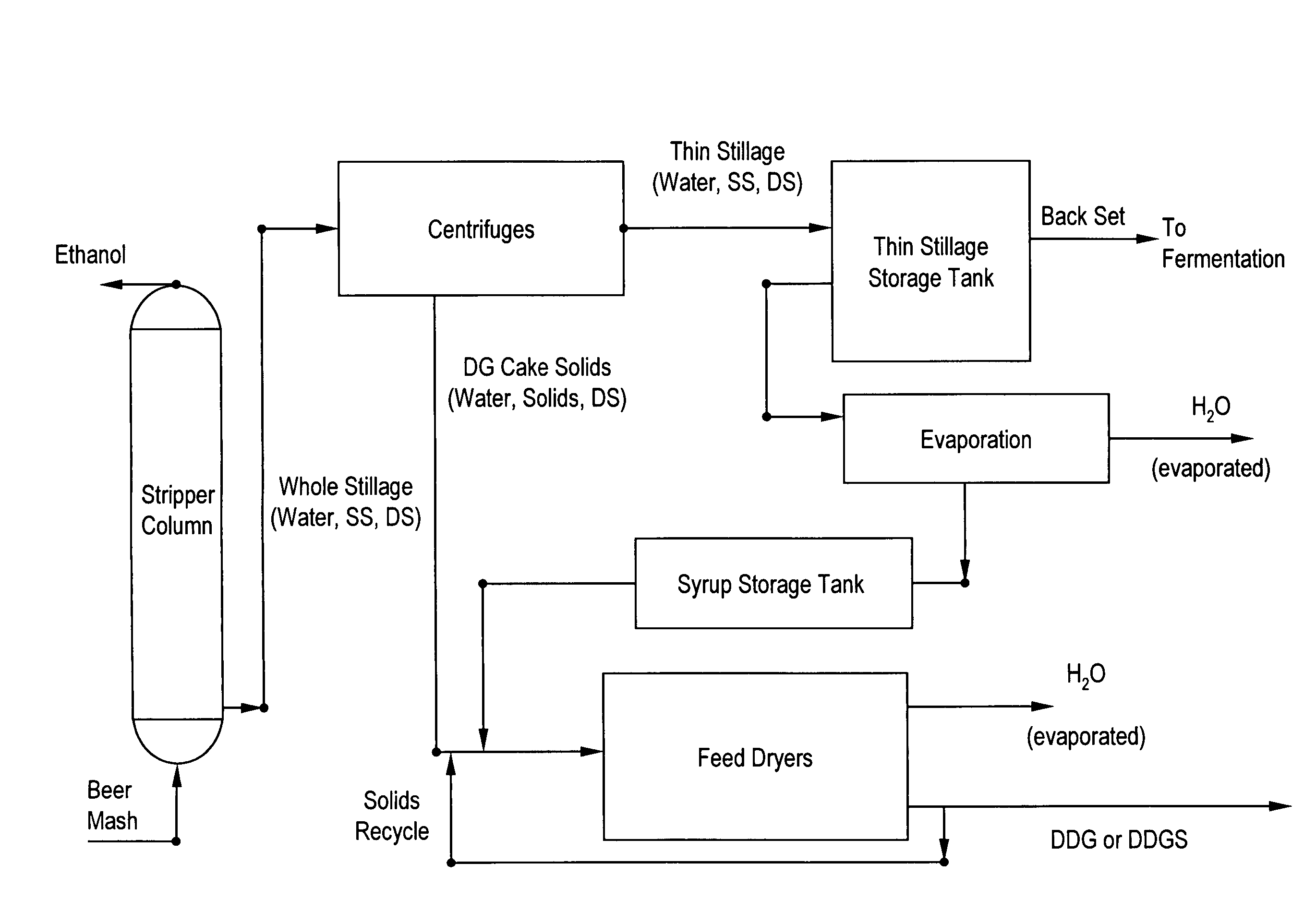

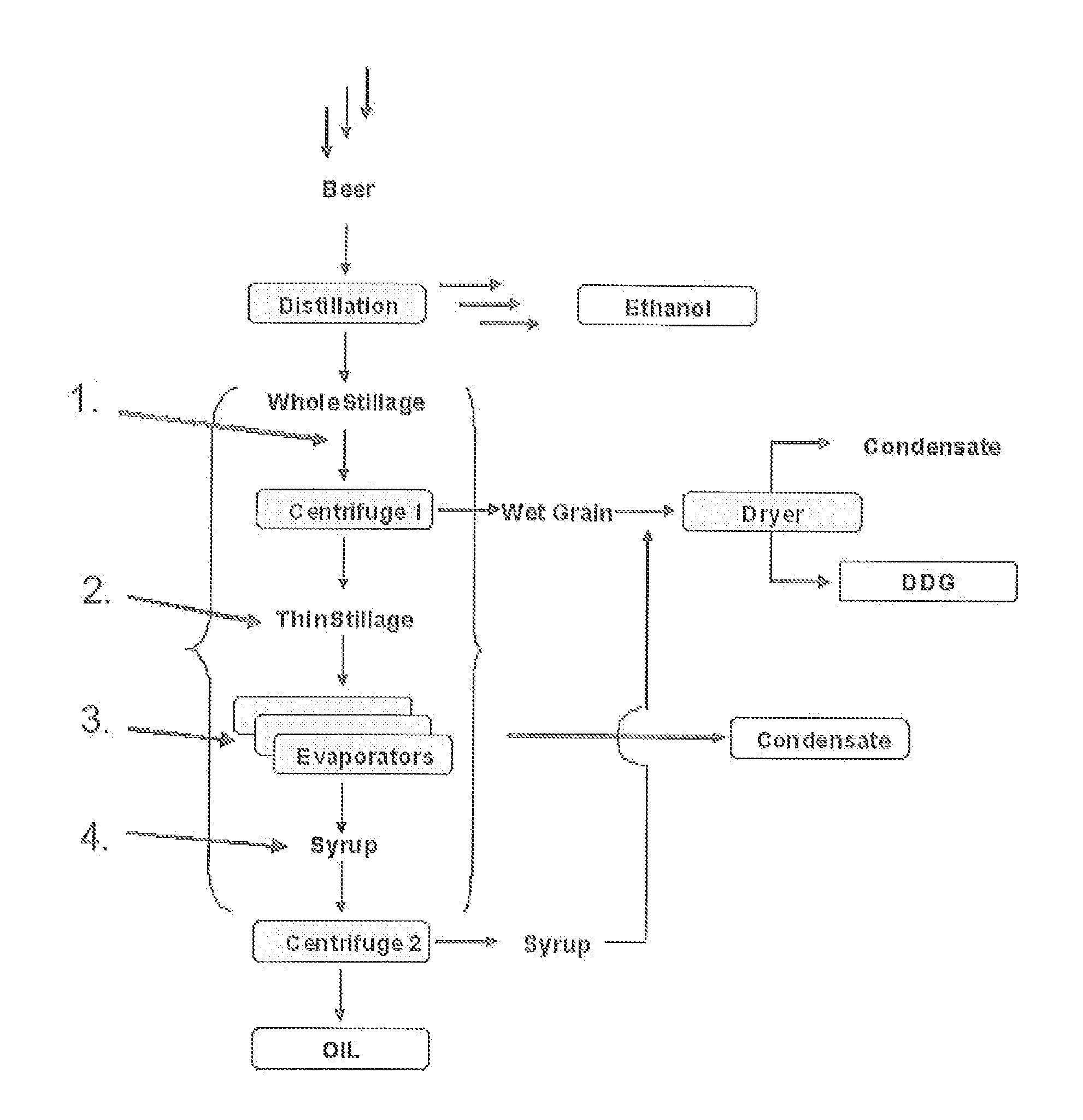

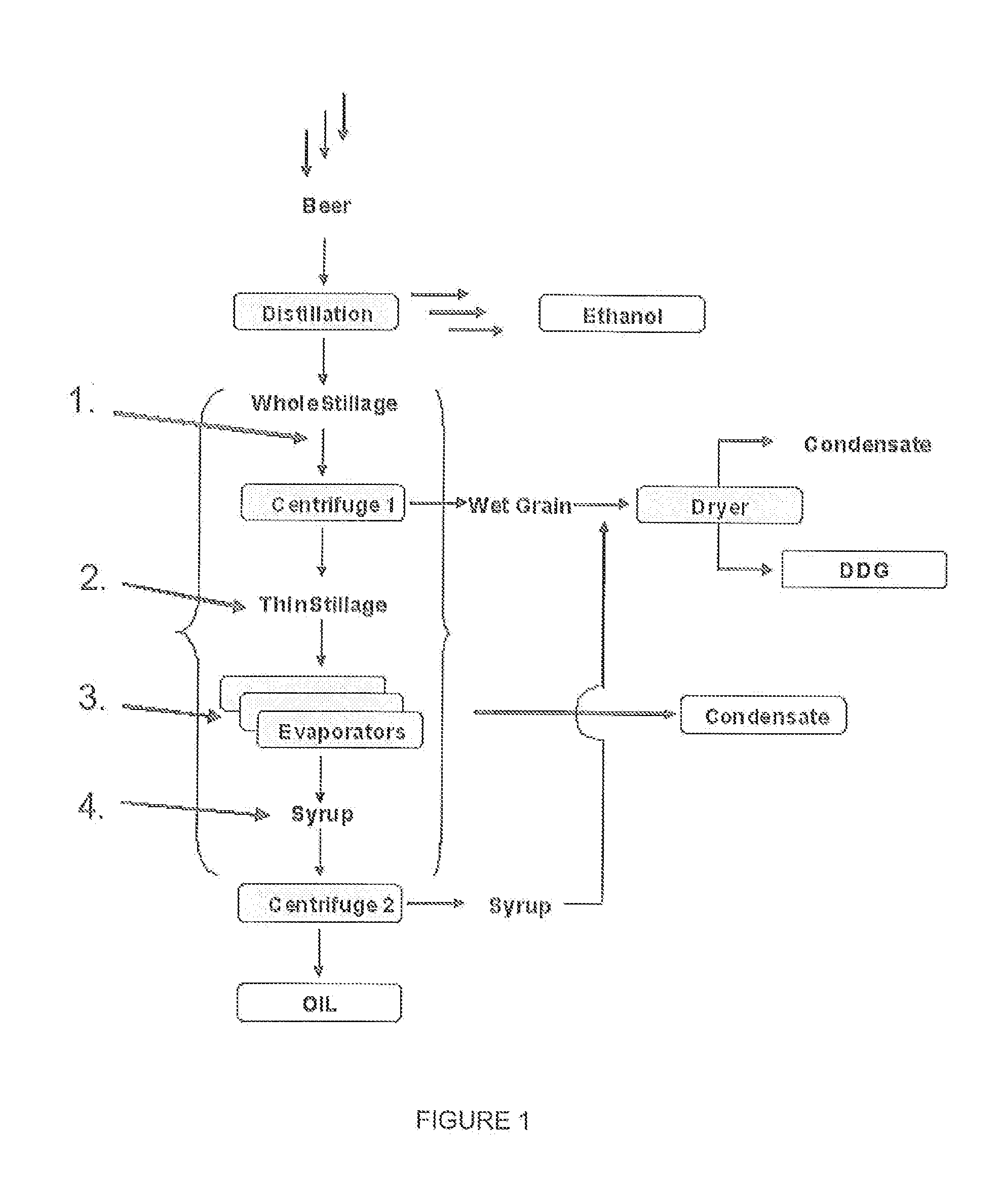

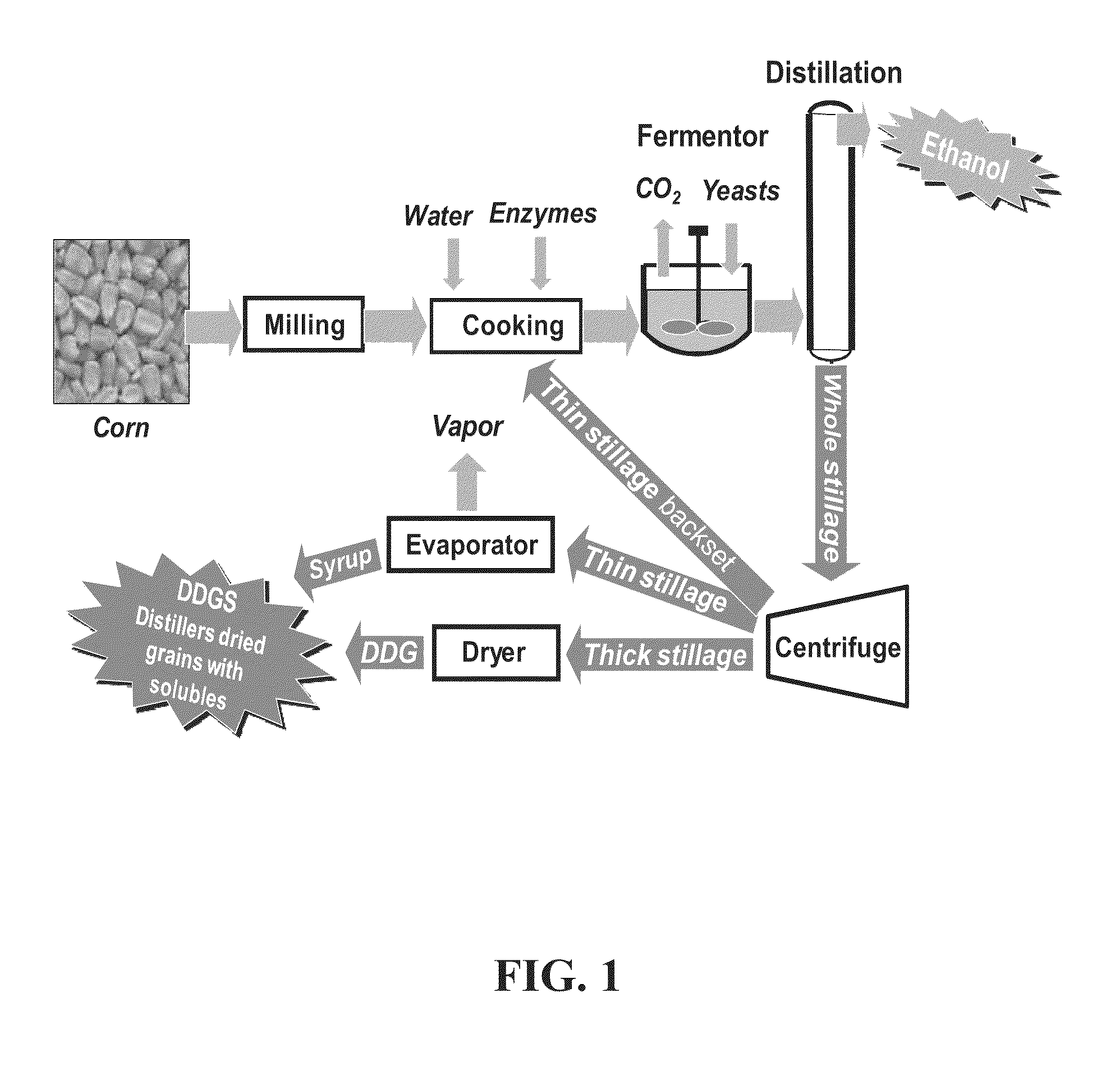

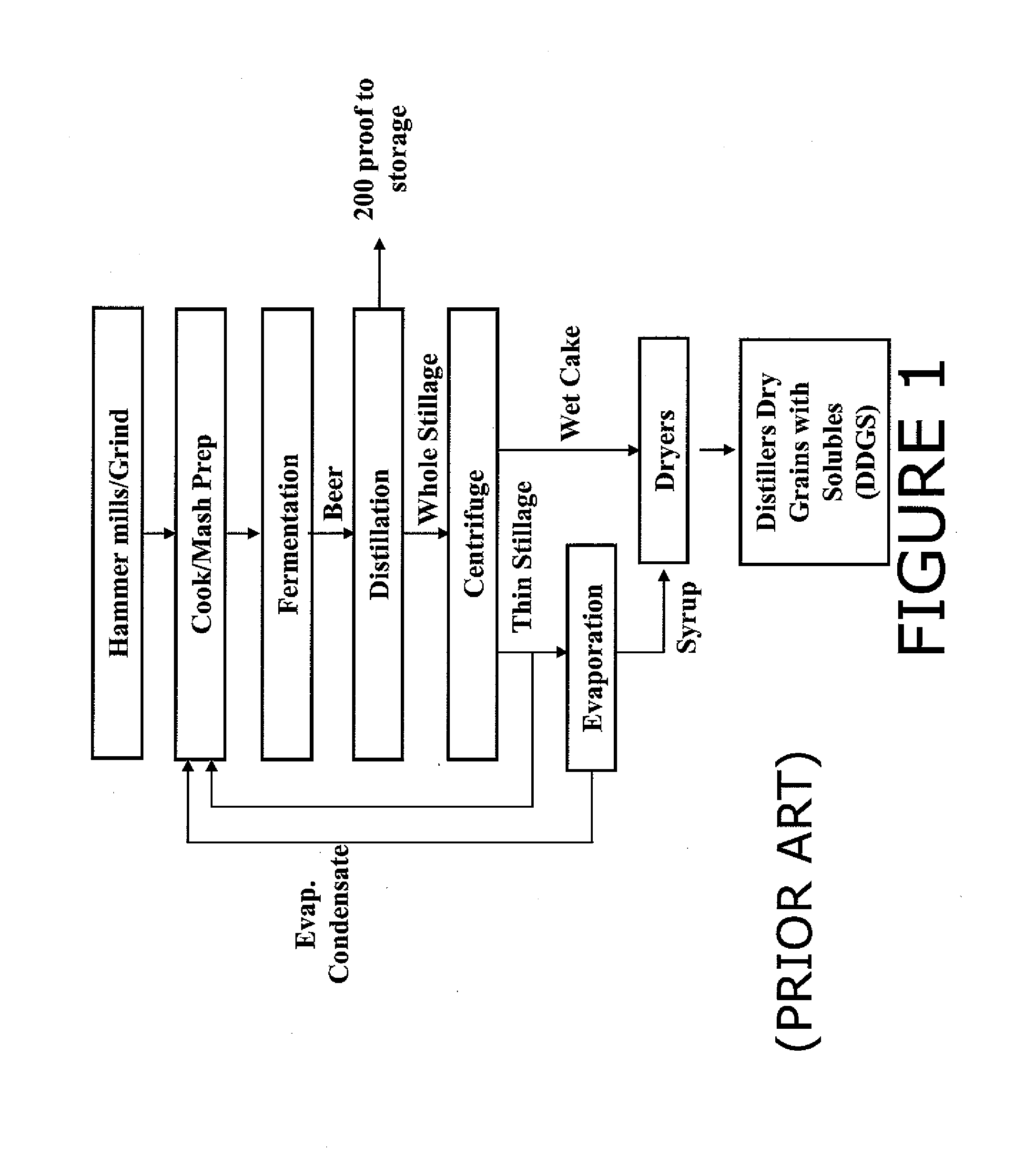

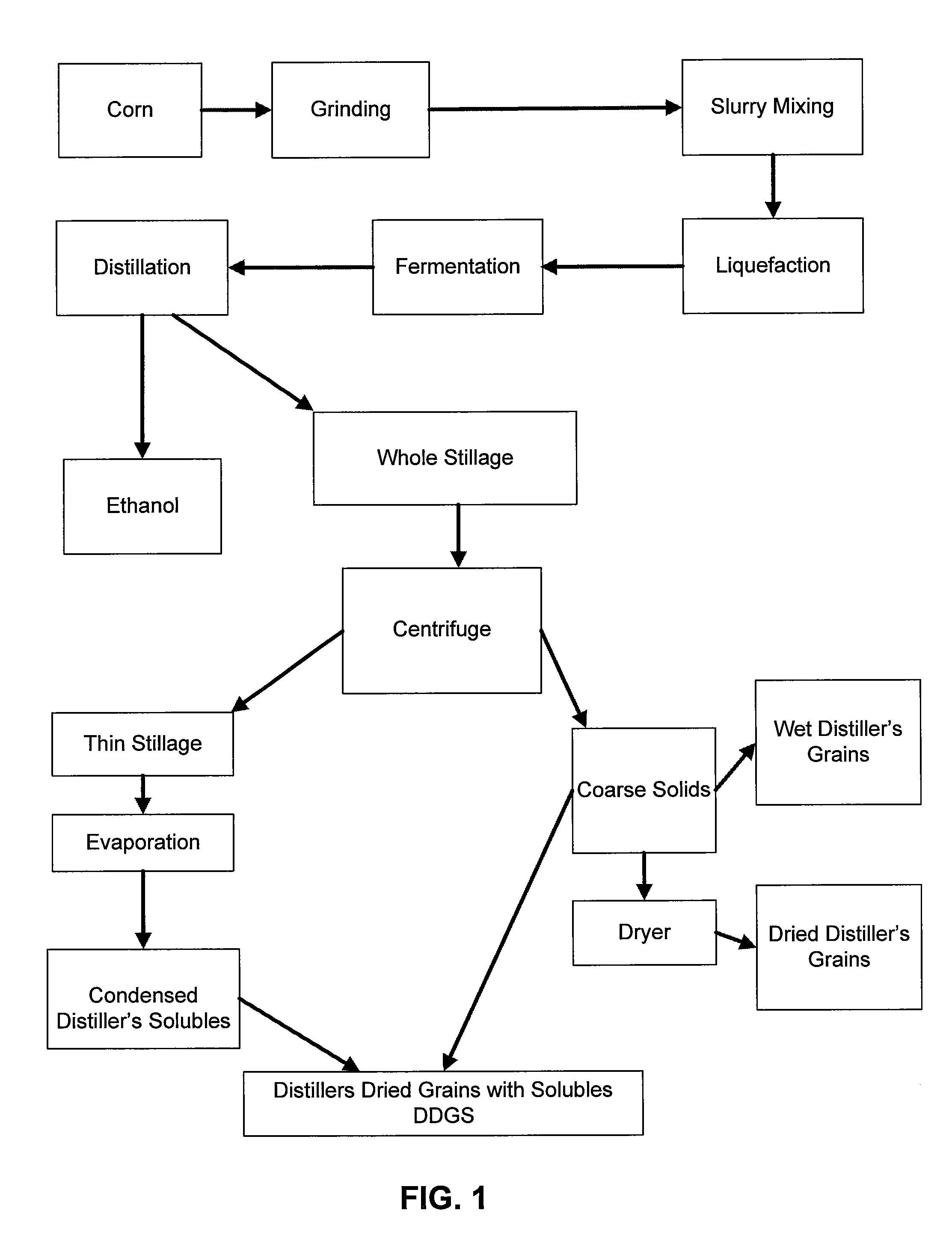

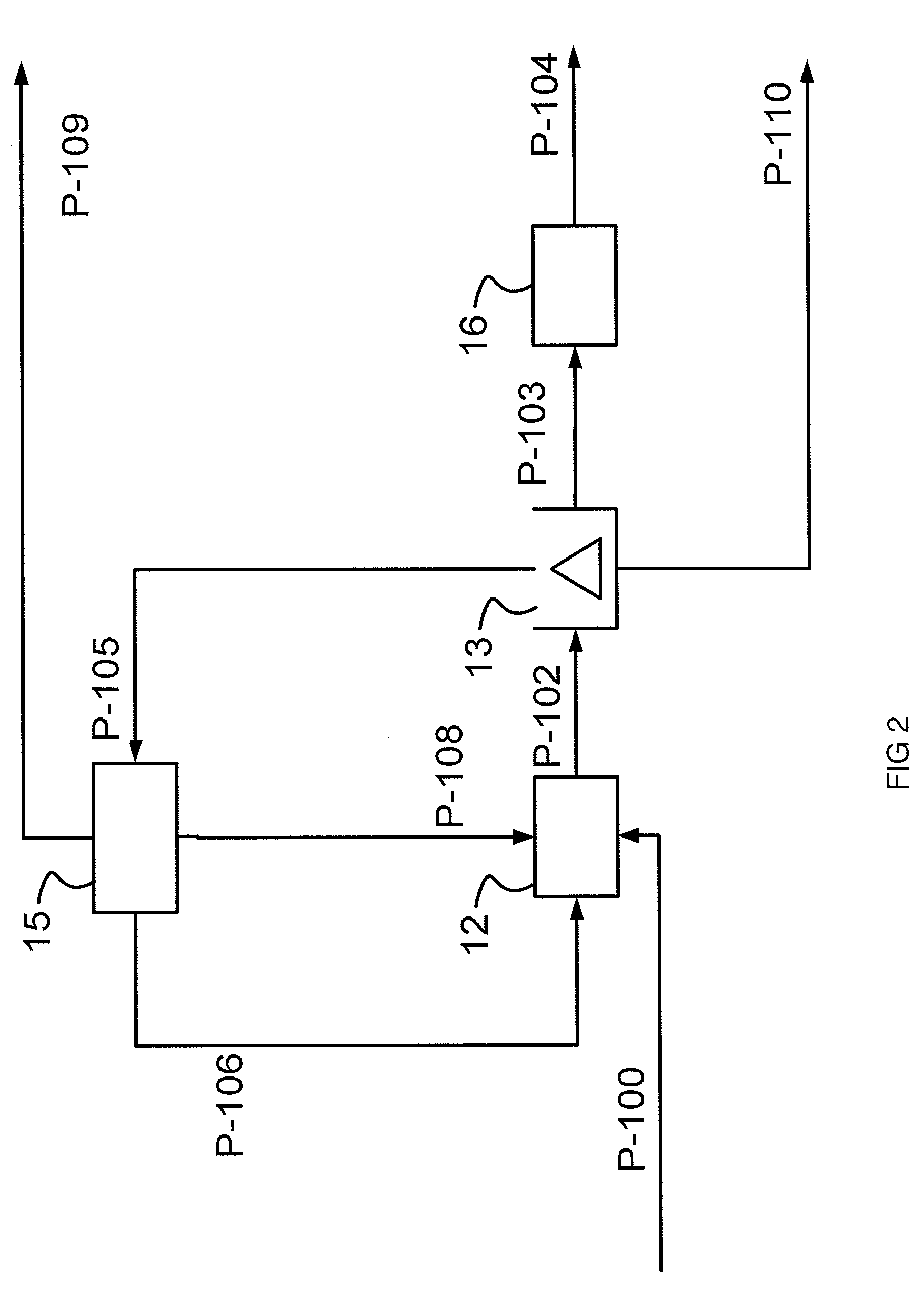

A process arrangement for distilling fuel grade ethanol includes a fermentation portion, a distillation portion, a condensation and dehydration portion, a separation and drying portion and an evaporation portion. The fermentation portion produces beer. The distillation portion, the condensation and dehydration portion and the separation and drying portion receives beer from the fermentation portion and produces hot ethanol vapor and thin stillage. In the evaporation portion, a set of first effect evaporators which are heated either by plant steam or hot ethanol vapor, concentrate thin stillage into mid stillage while producing first effect steam. The first effect steam from the first effect evaporators provides heat to a set of second effect evaporators which concentrate the mid stillage into a syrup for further drying. The second effect evaporators produce second effect steam which is used to heat the distillation portion of the process arrangement. The multiple evaporators of the first and second effects of the evaporation portion can be selectively taken off-line for maintenance while the evaporation portion and the remainder of the process arrangement continue to operate at full capacity.

Owner:ICM

Ethanol distillation process

InactiveUS7572353B1Shorten the timeLess rapidlyFermented solutions distillation/rectificationOrganic compound preparationDistillationEvaporation

Owner:ICM

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

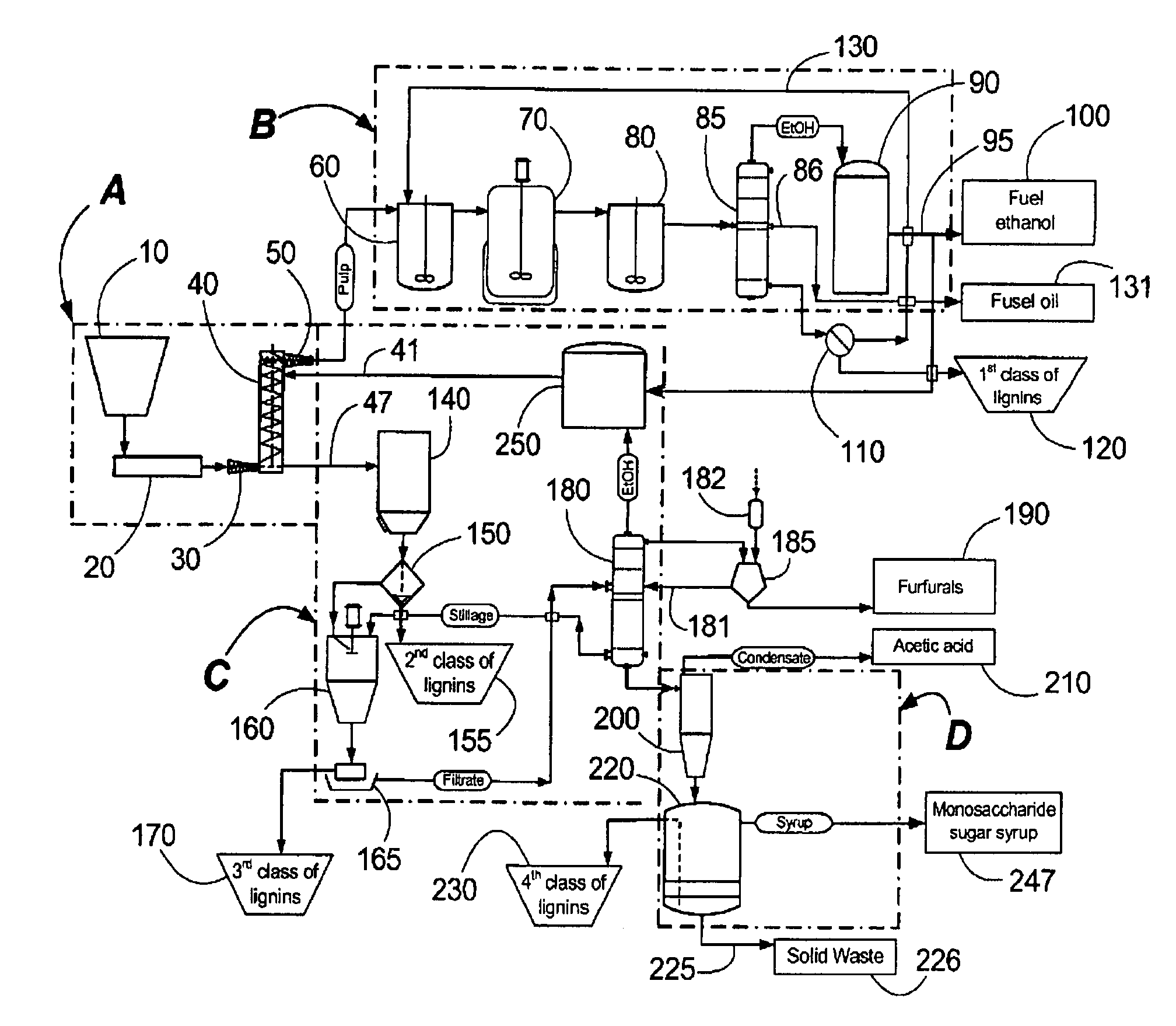

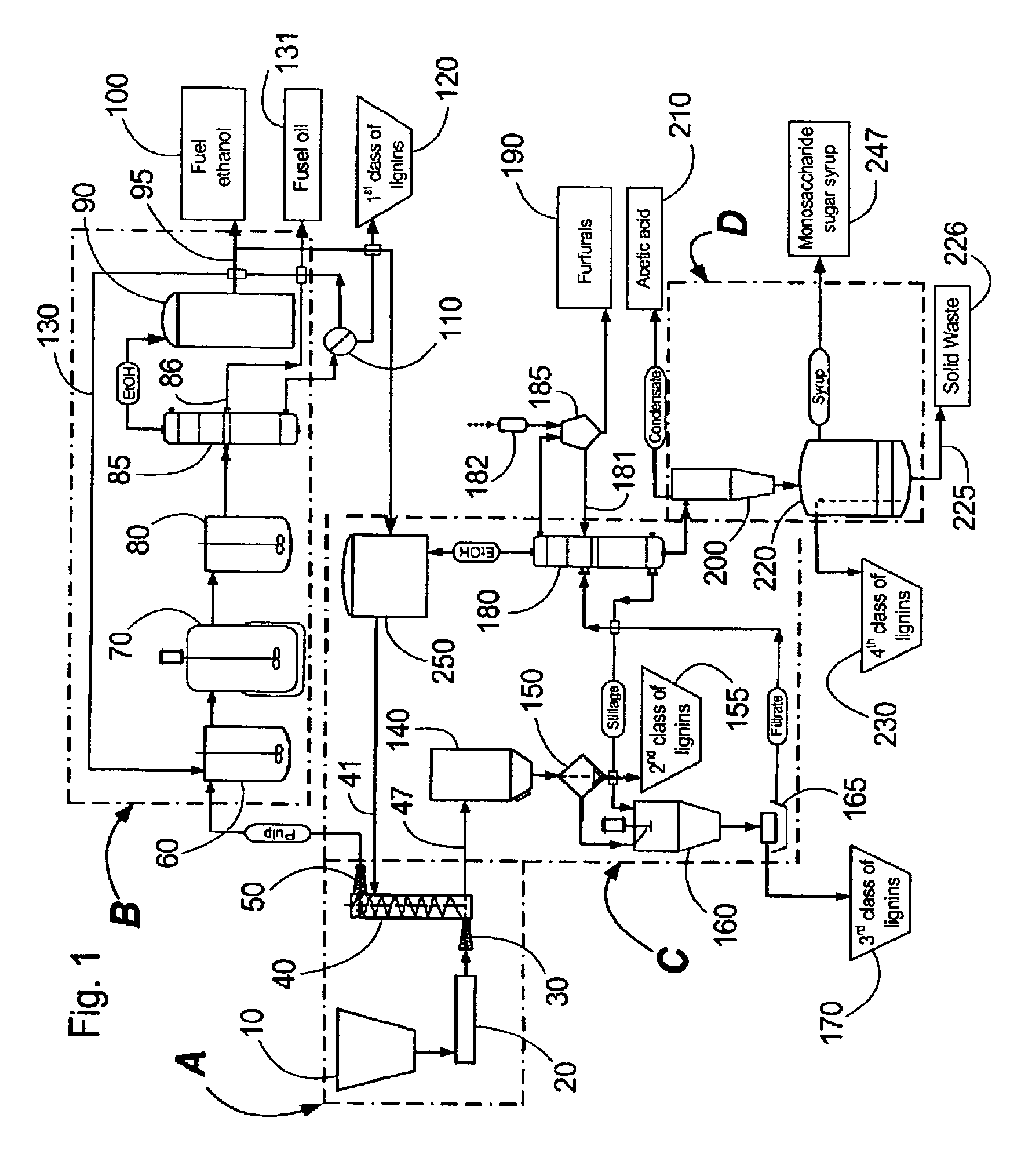

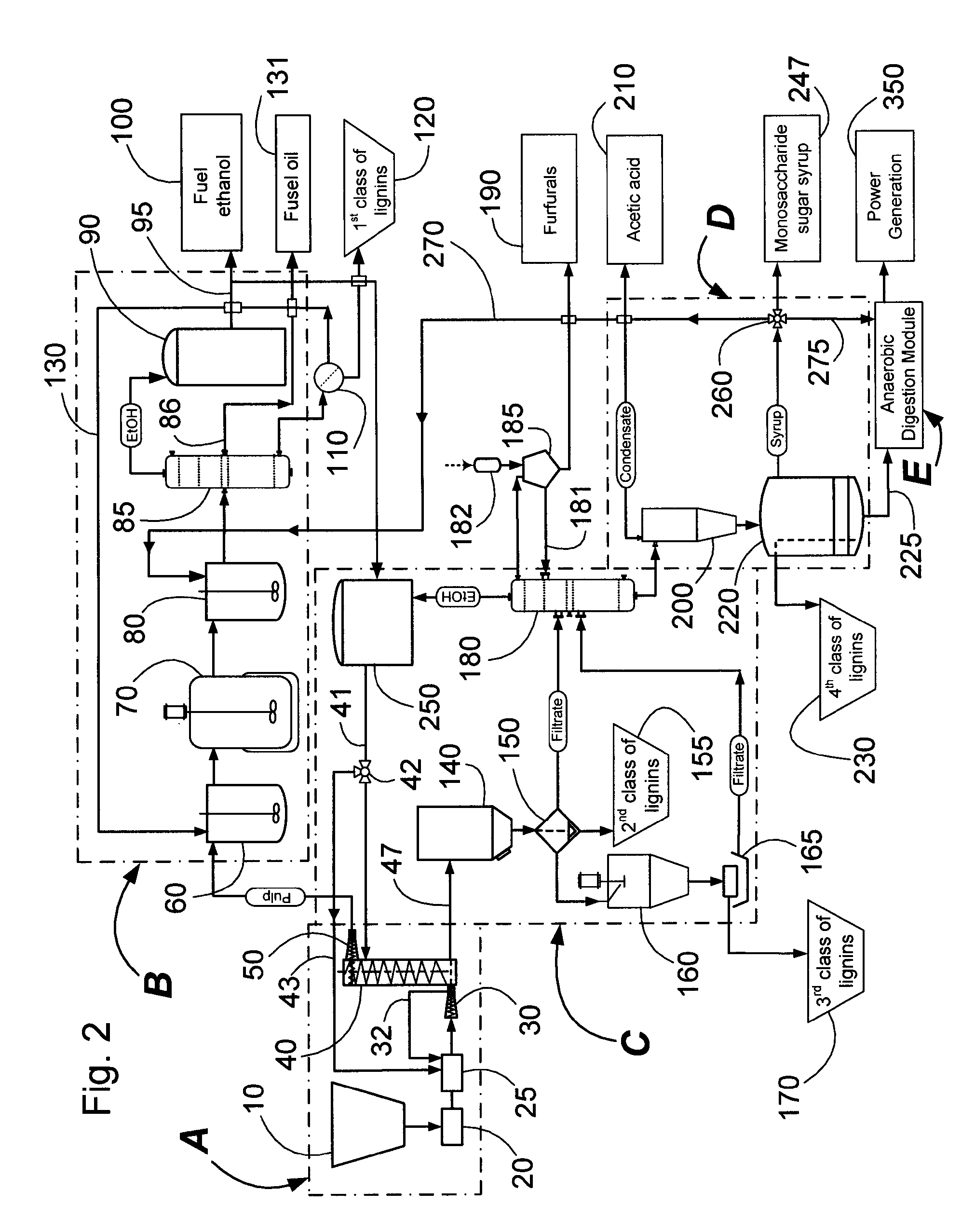

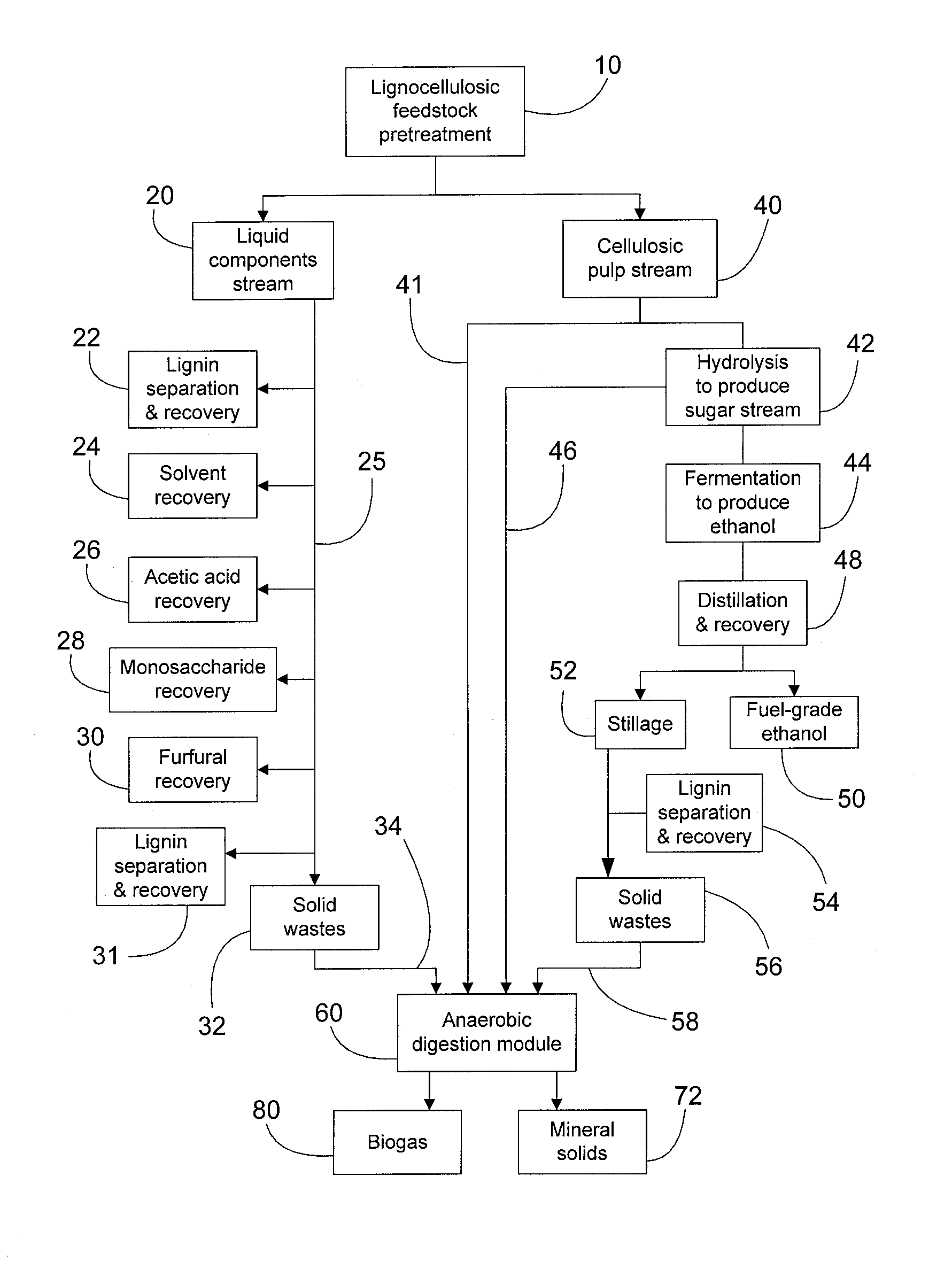

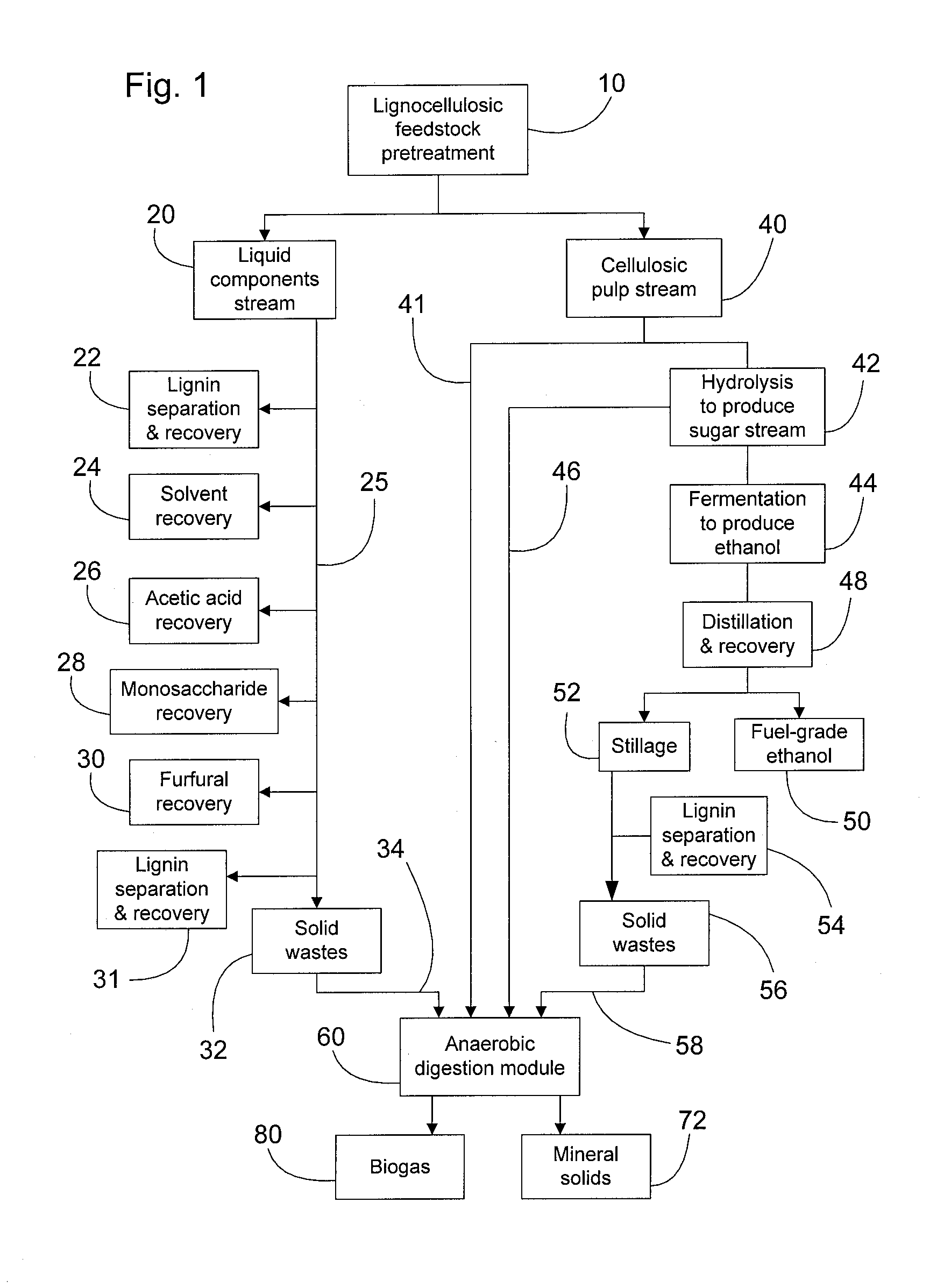

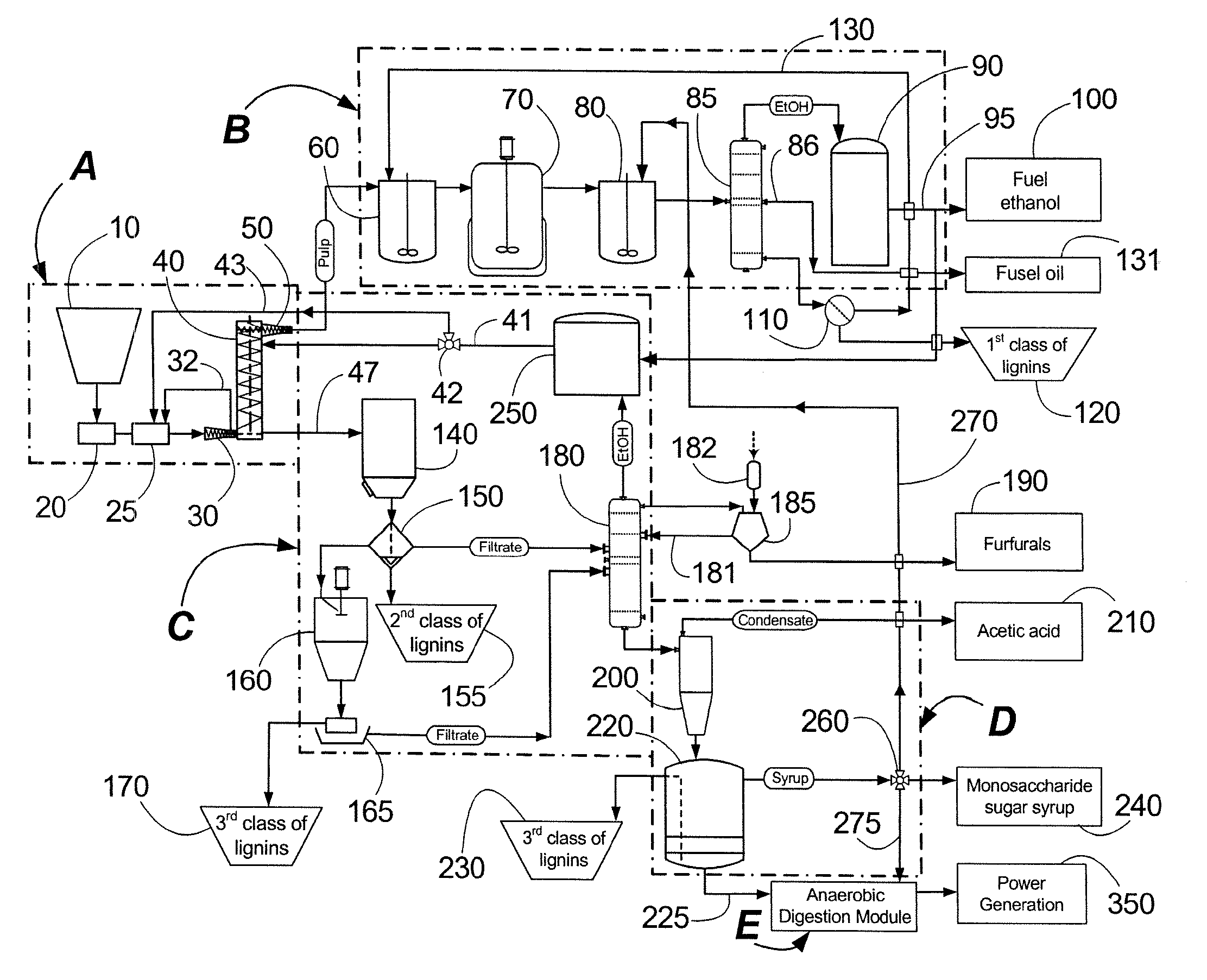

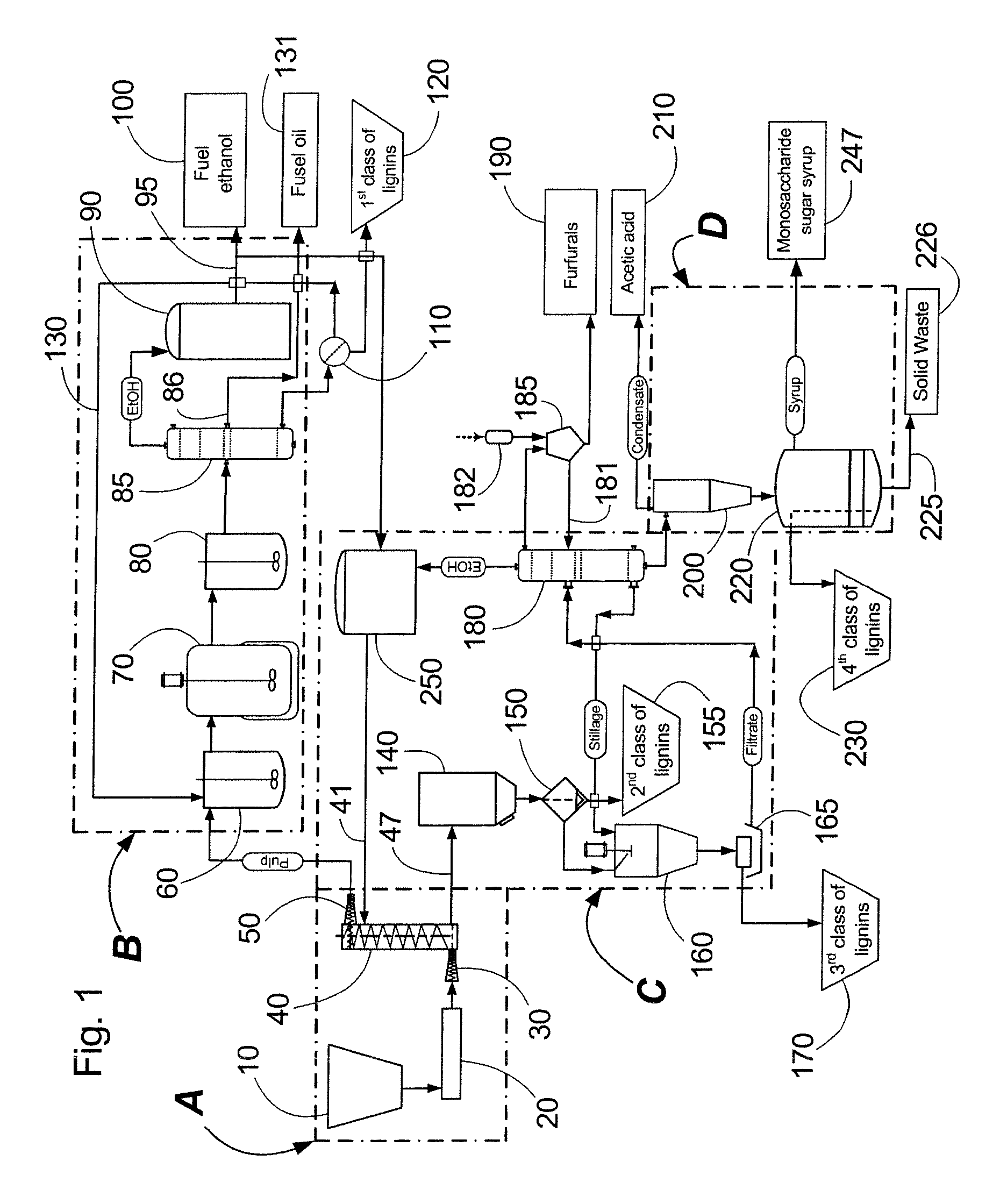

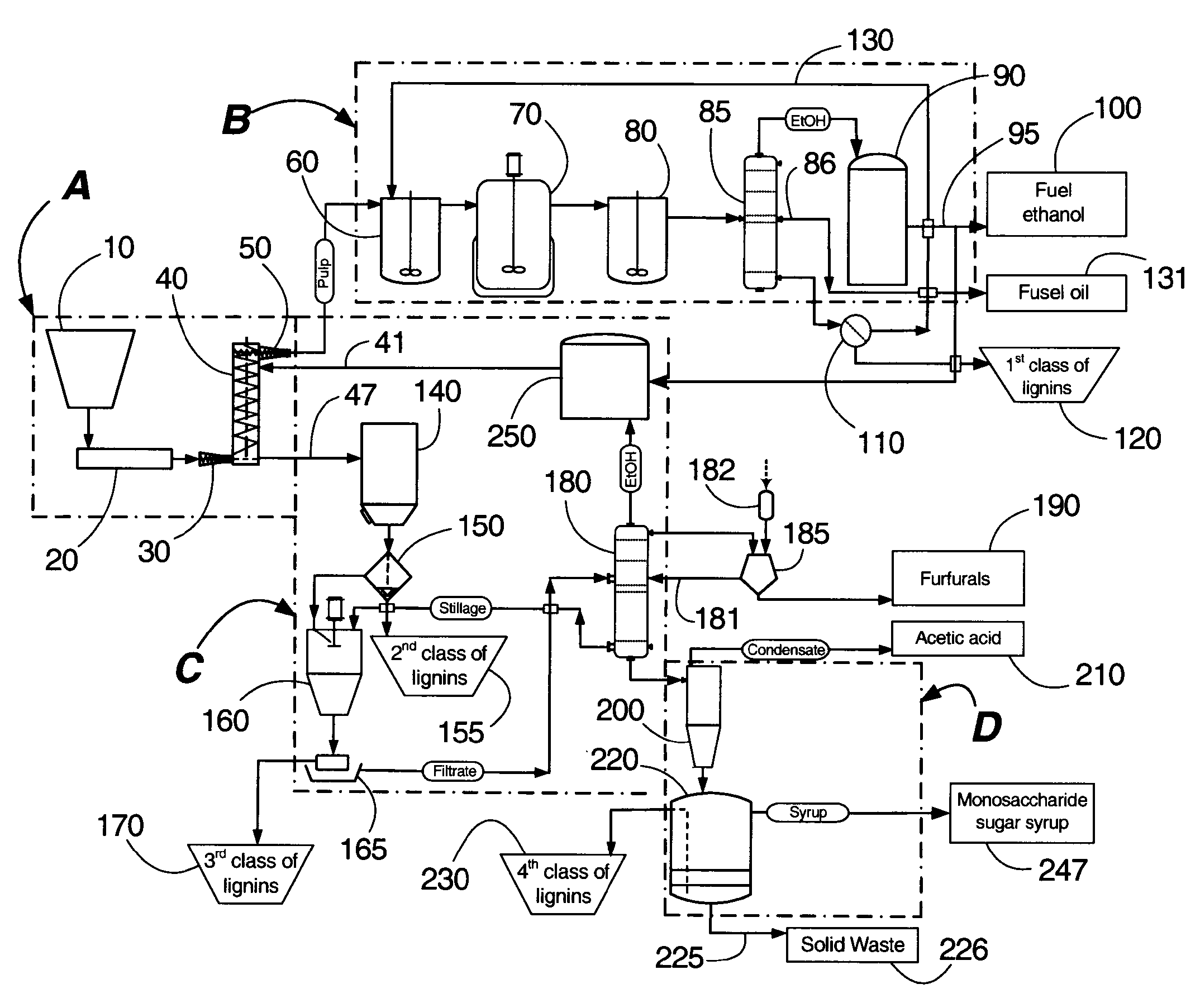

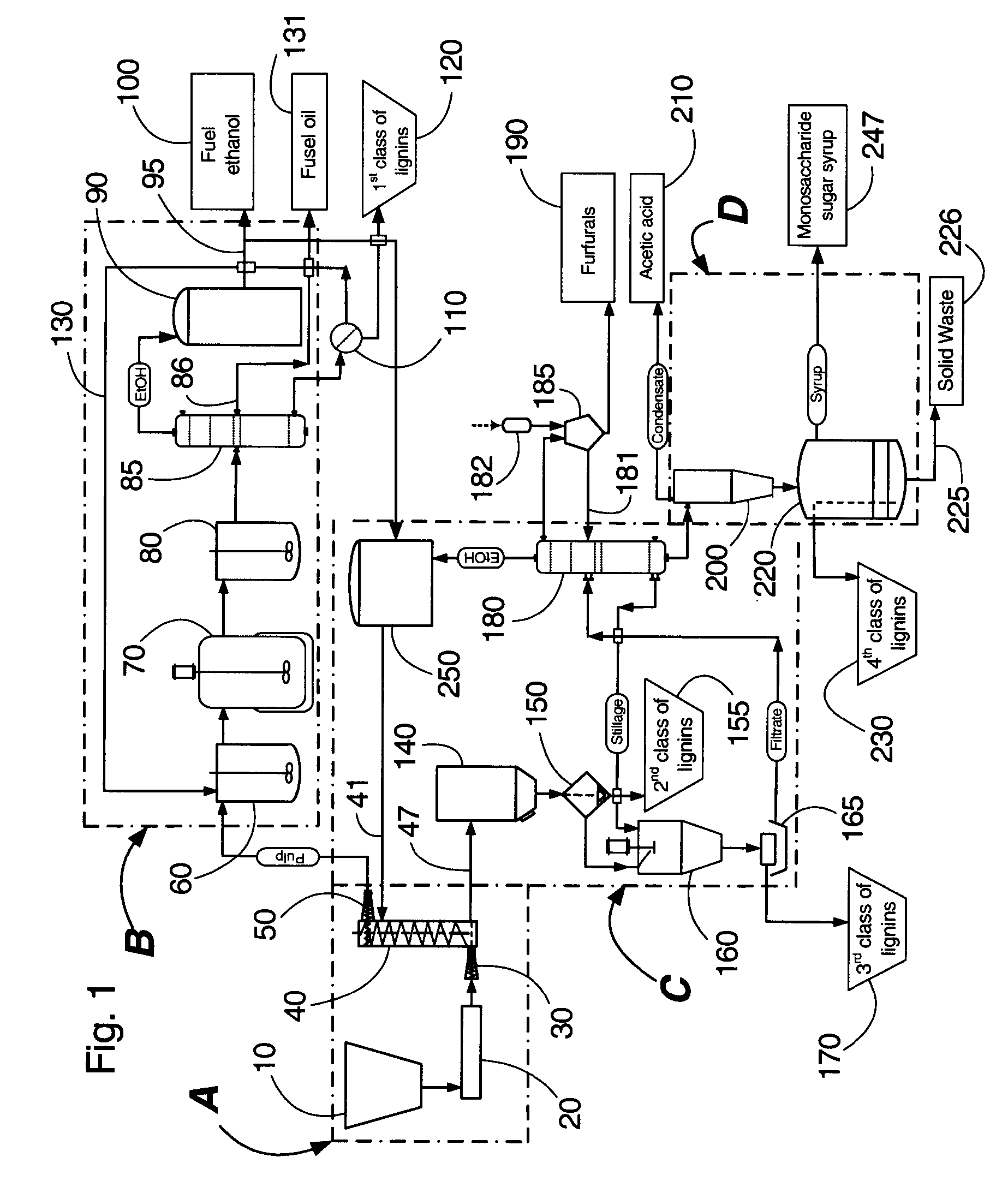

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

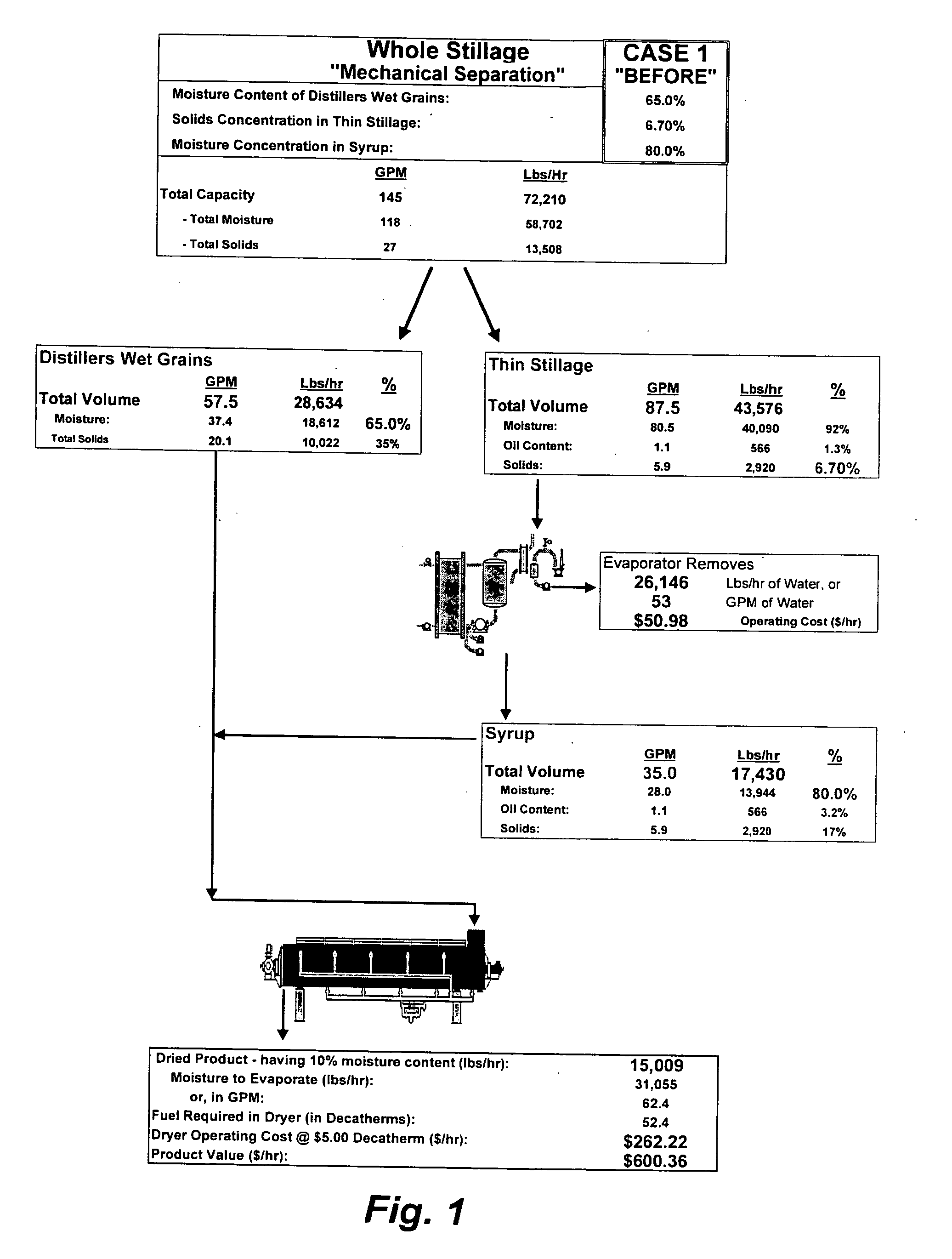

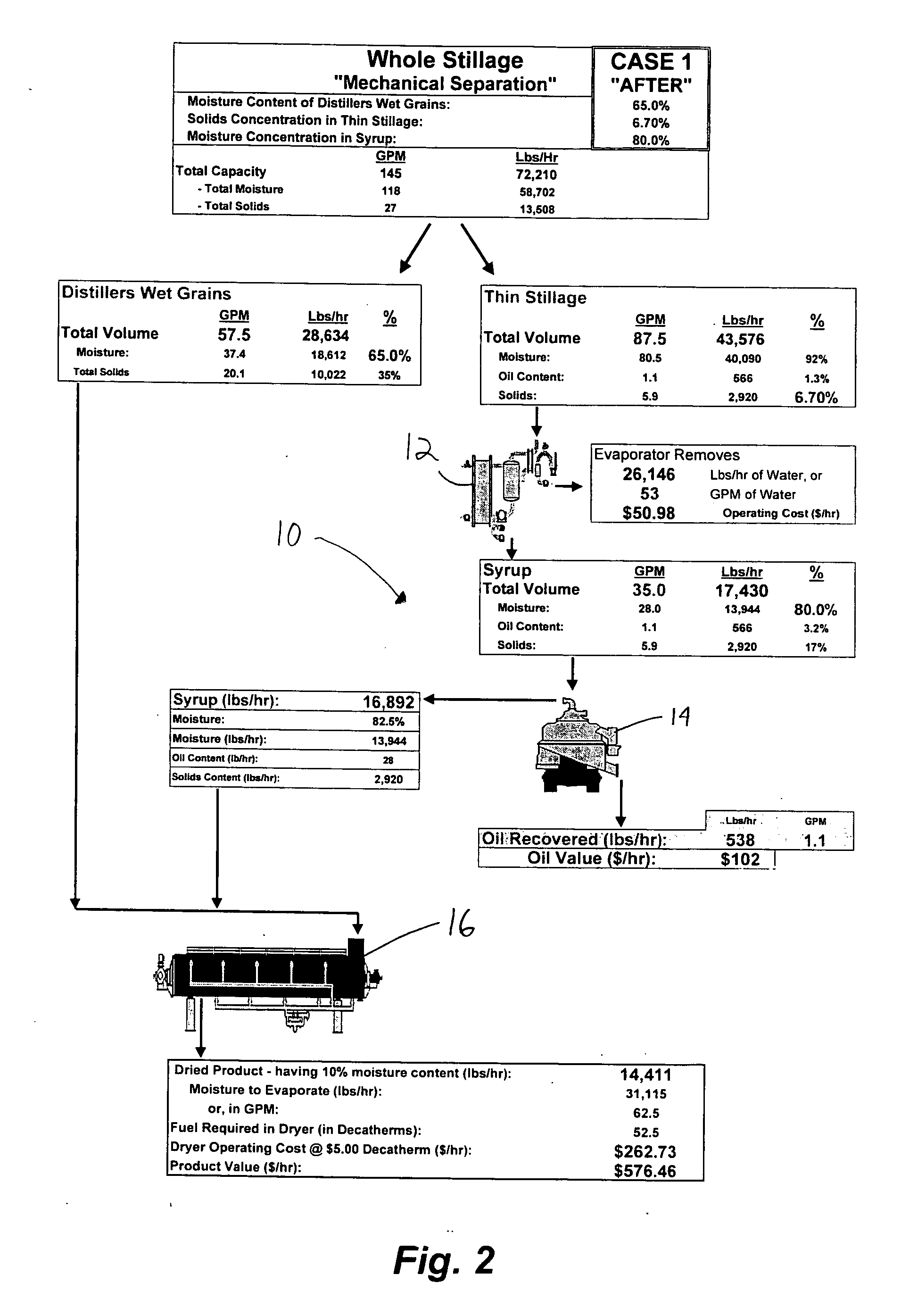

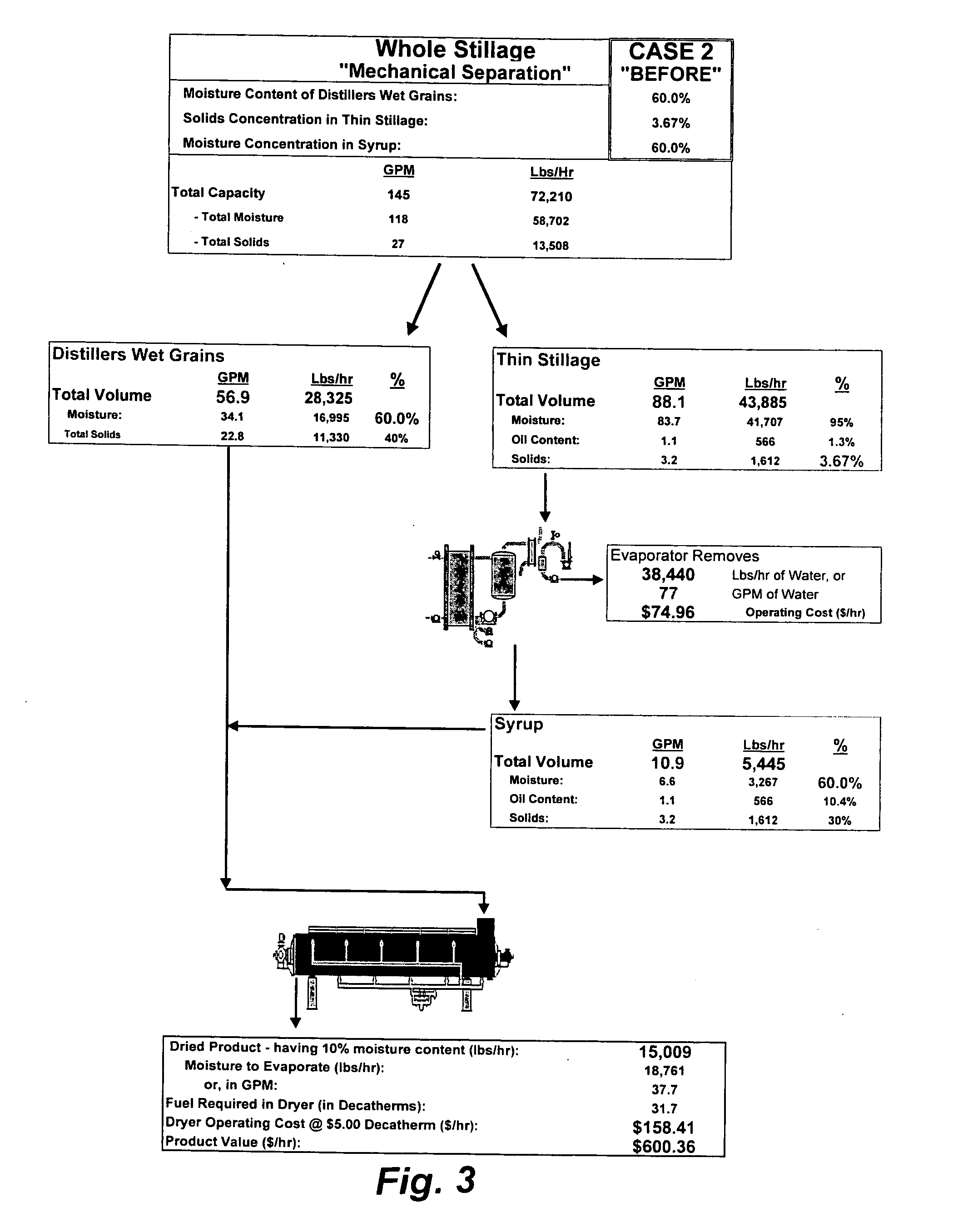

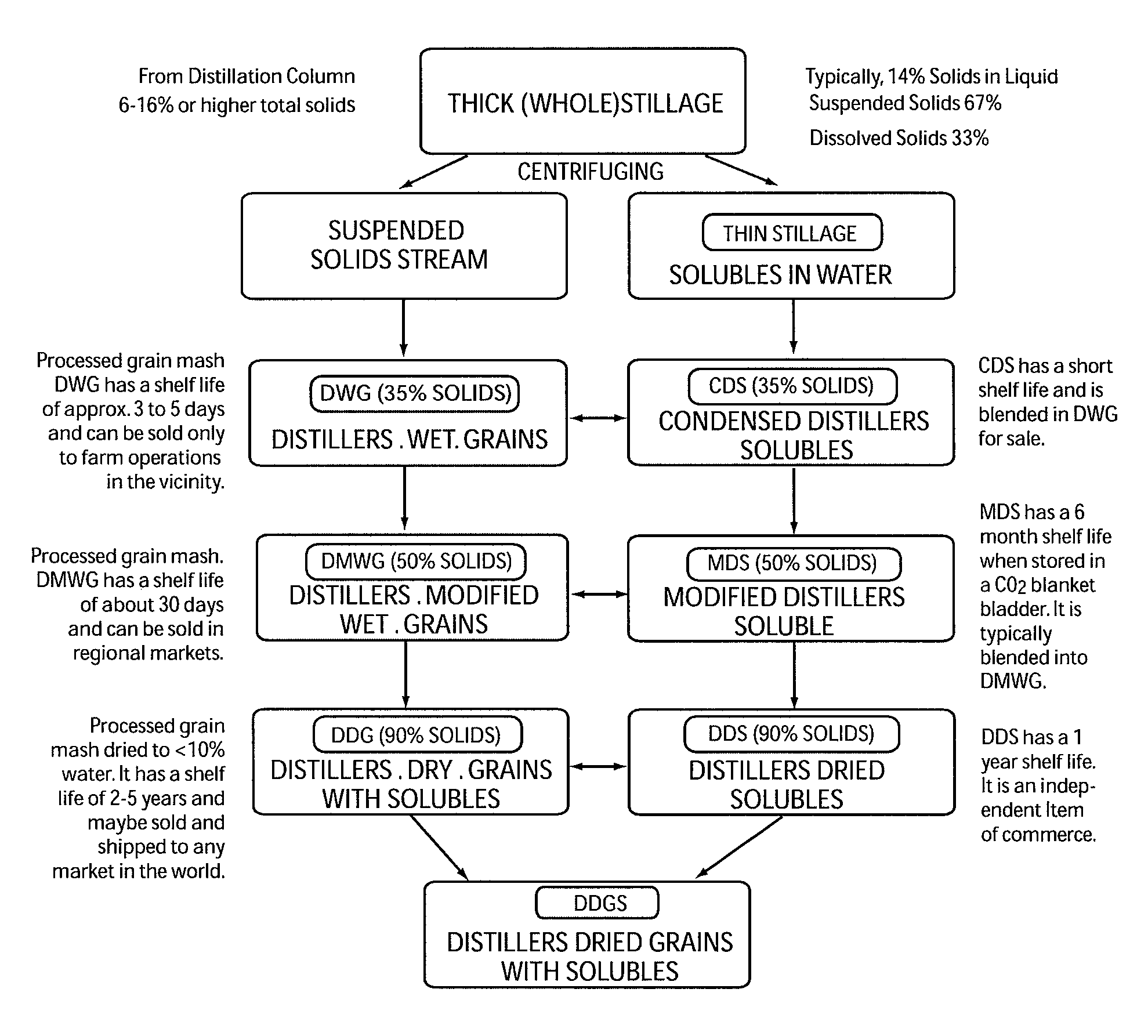

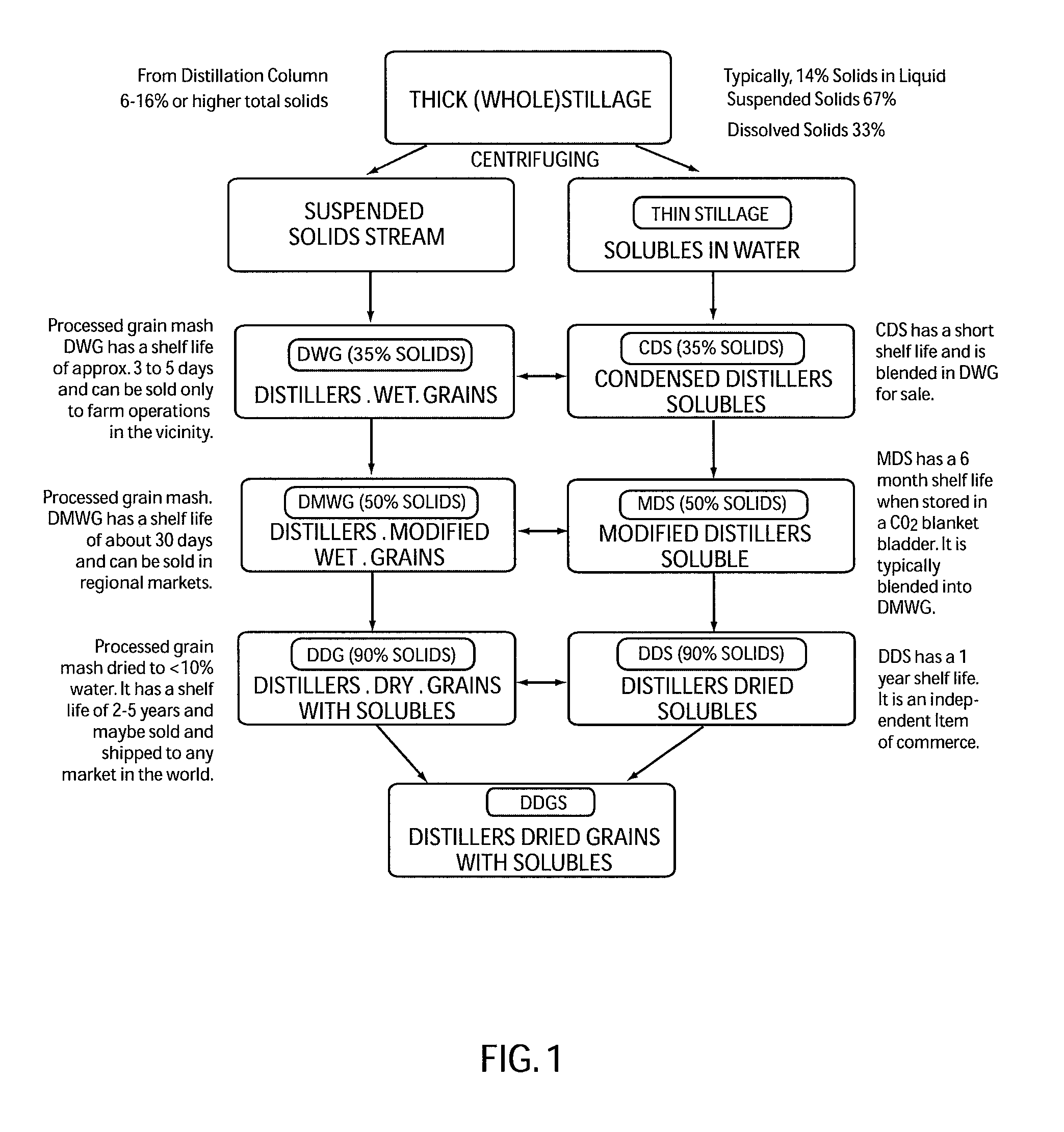

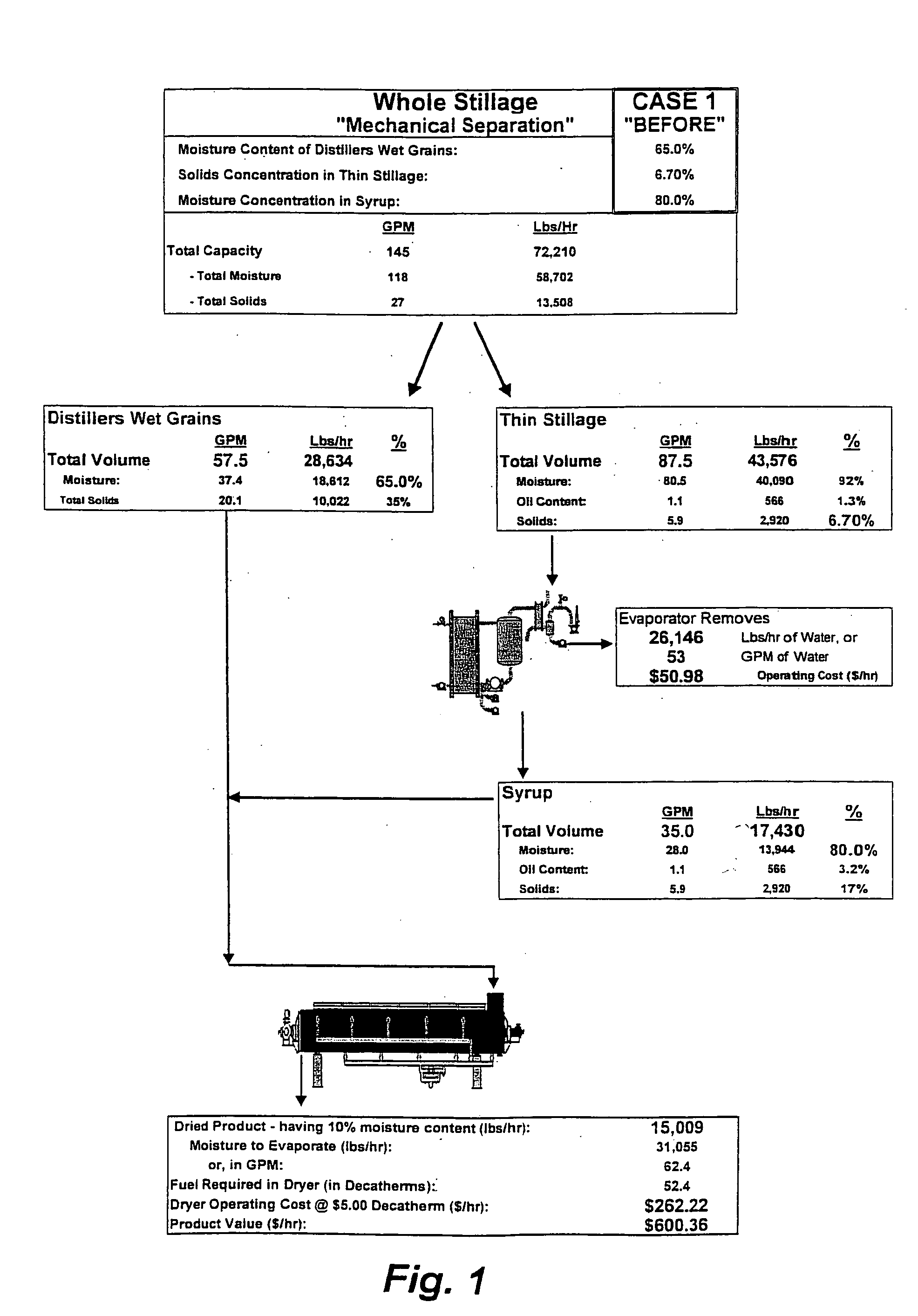

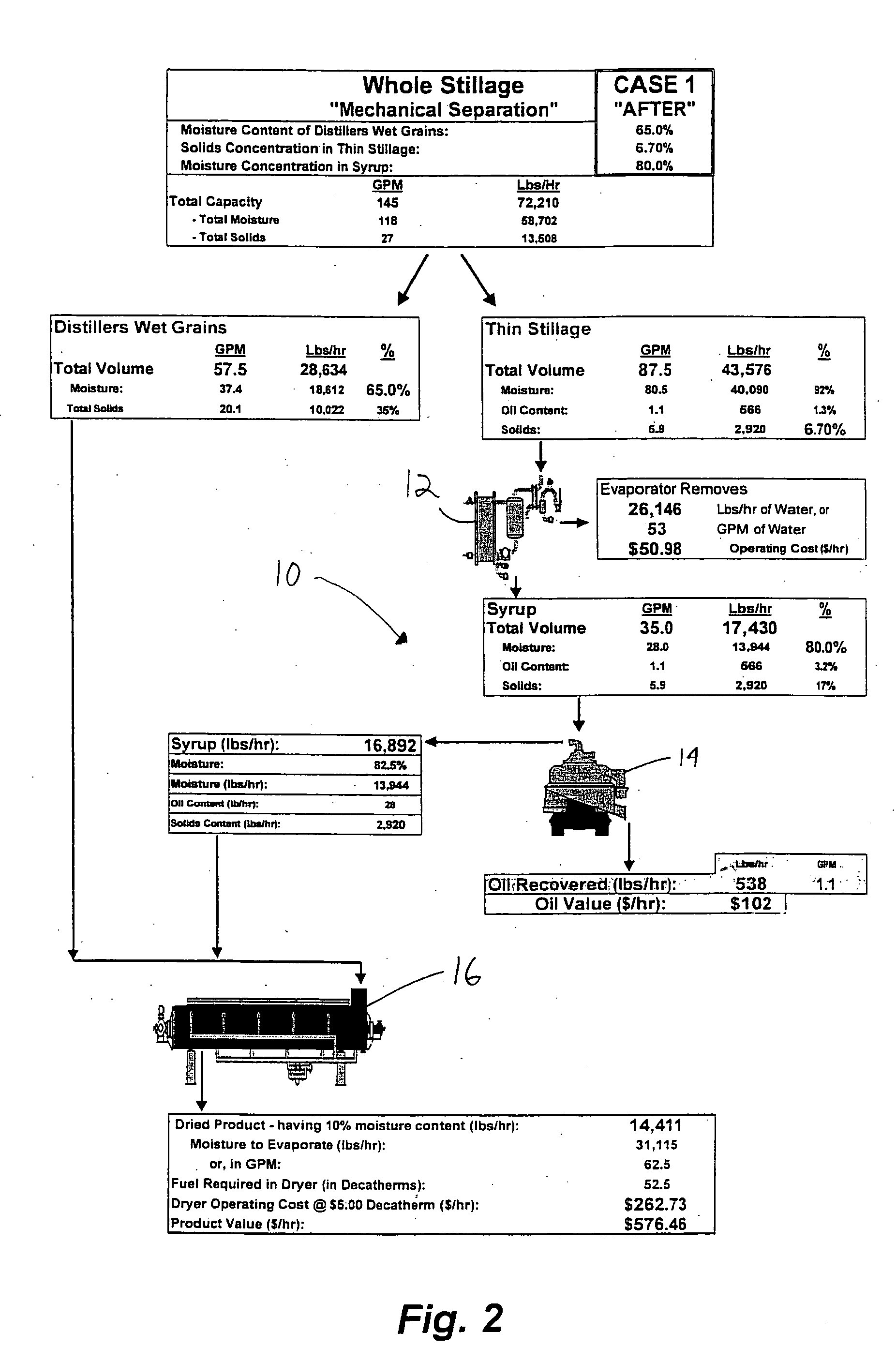

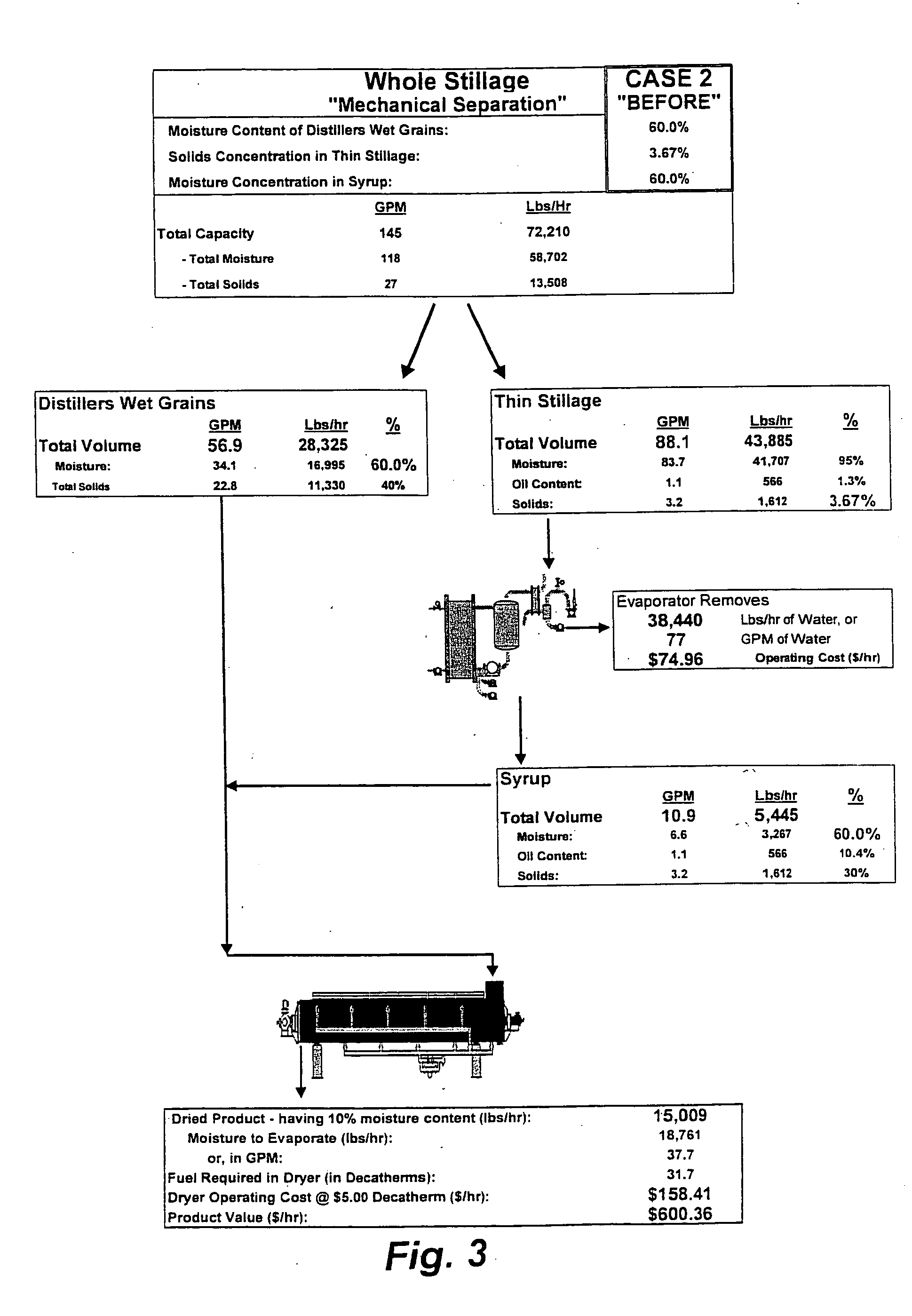

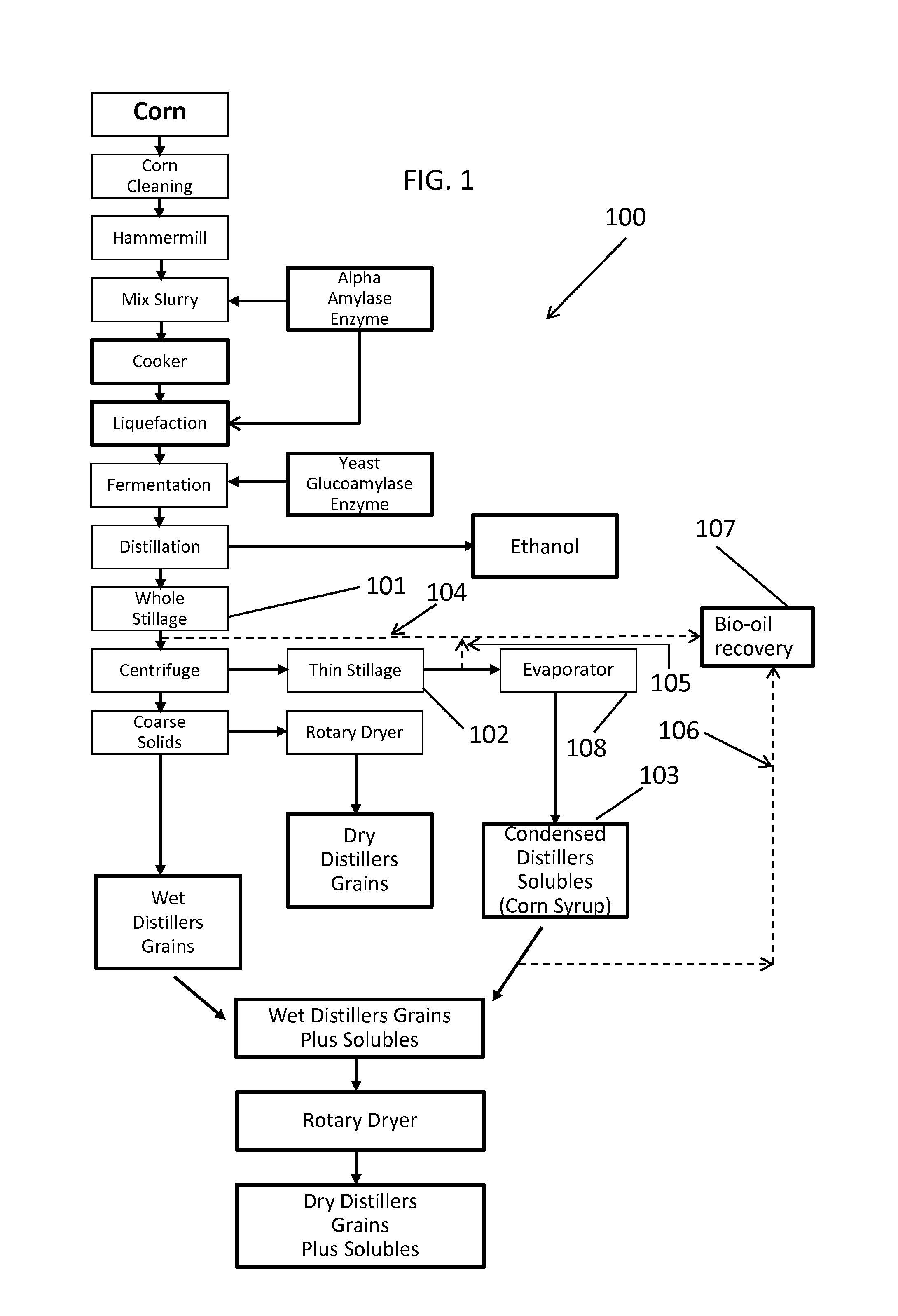

Method of processing ethanol byproducts and related subsystems

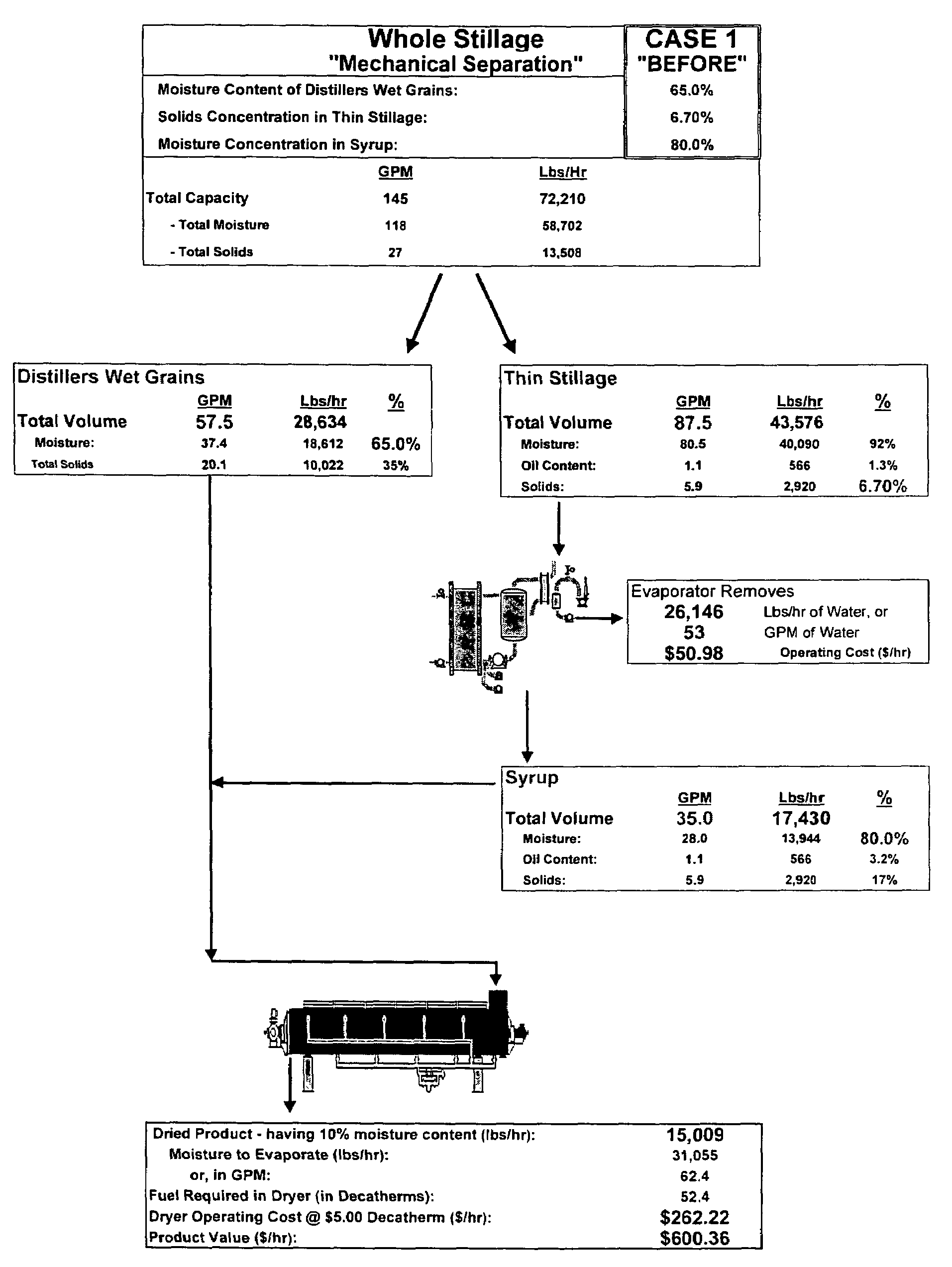

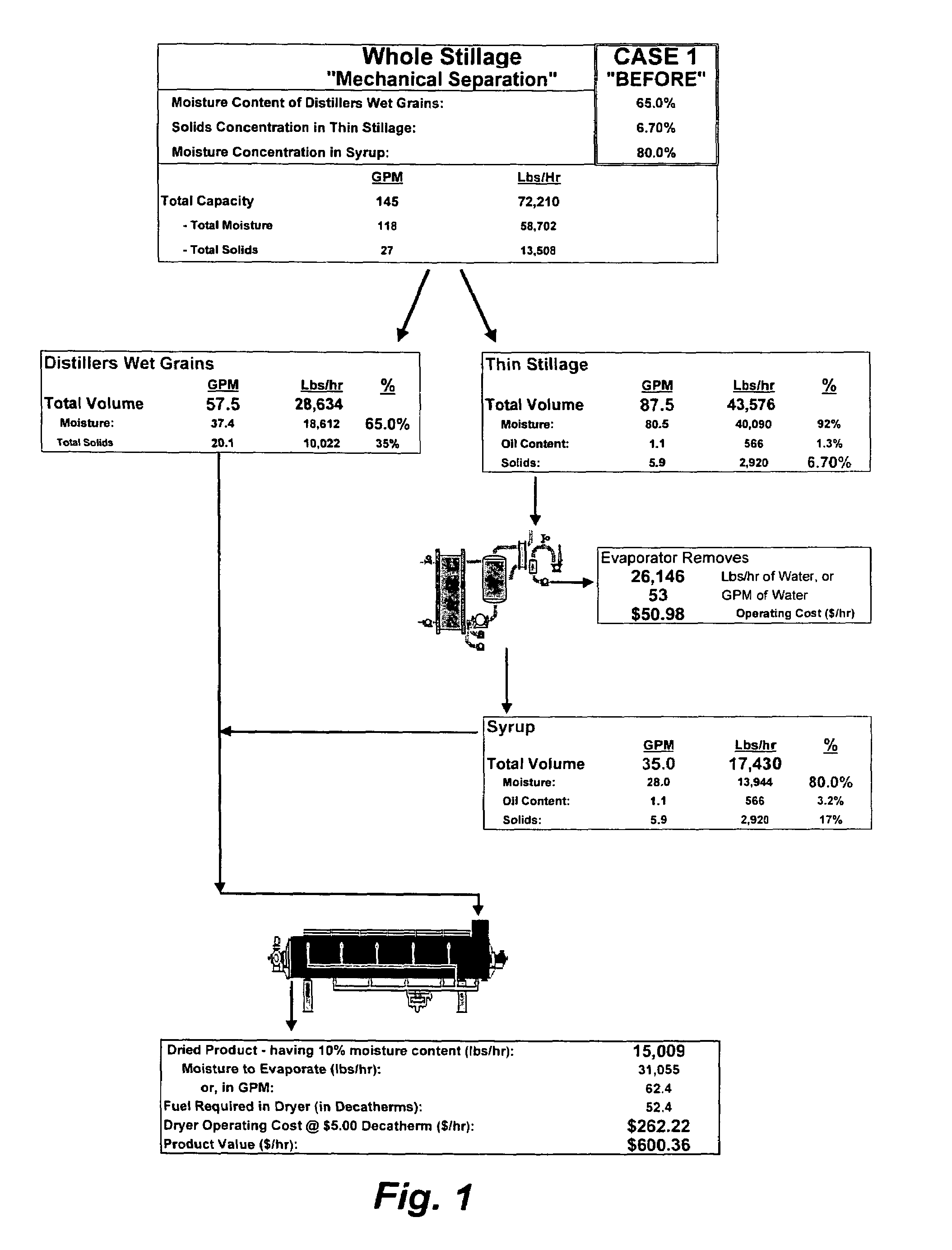

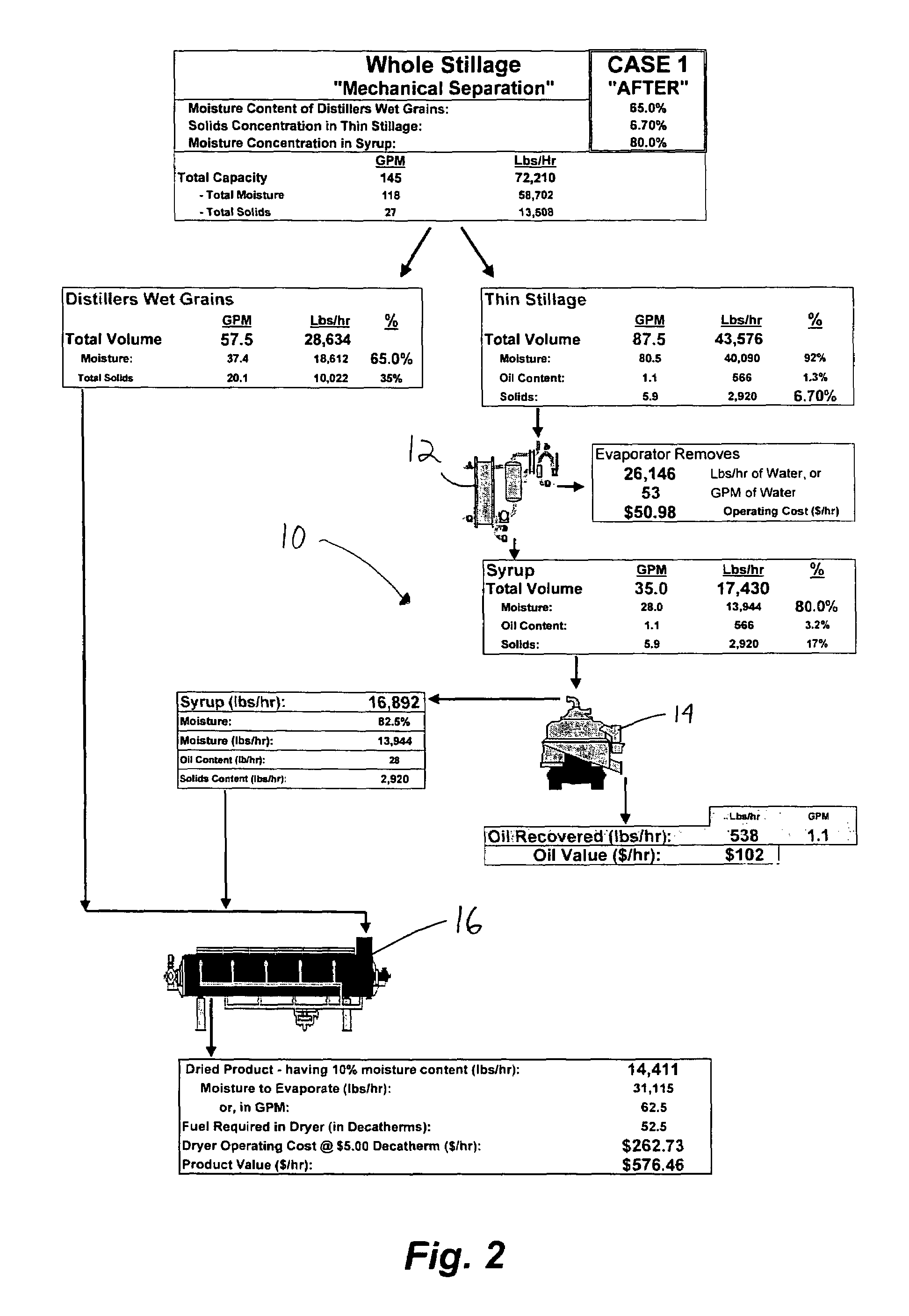

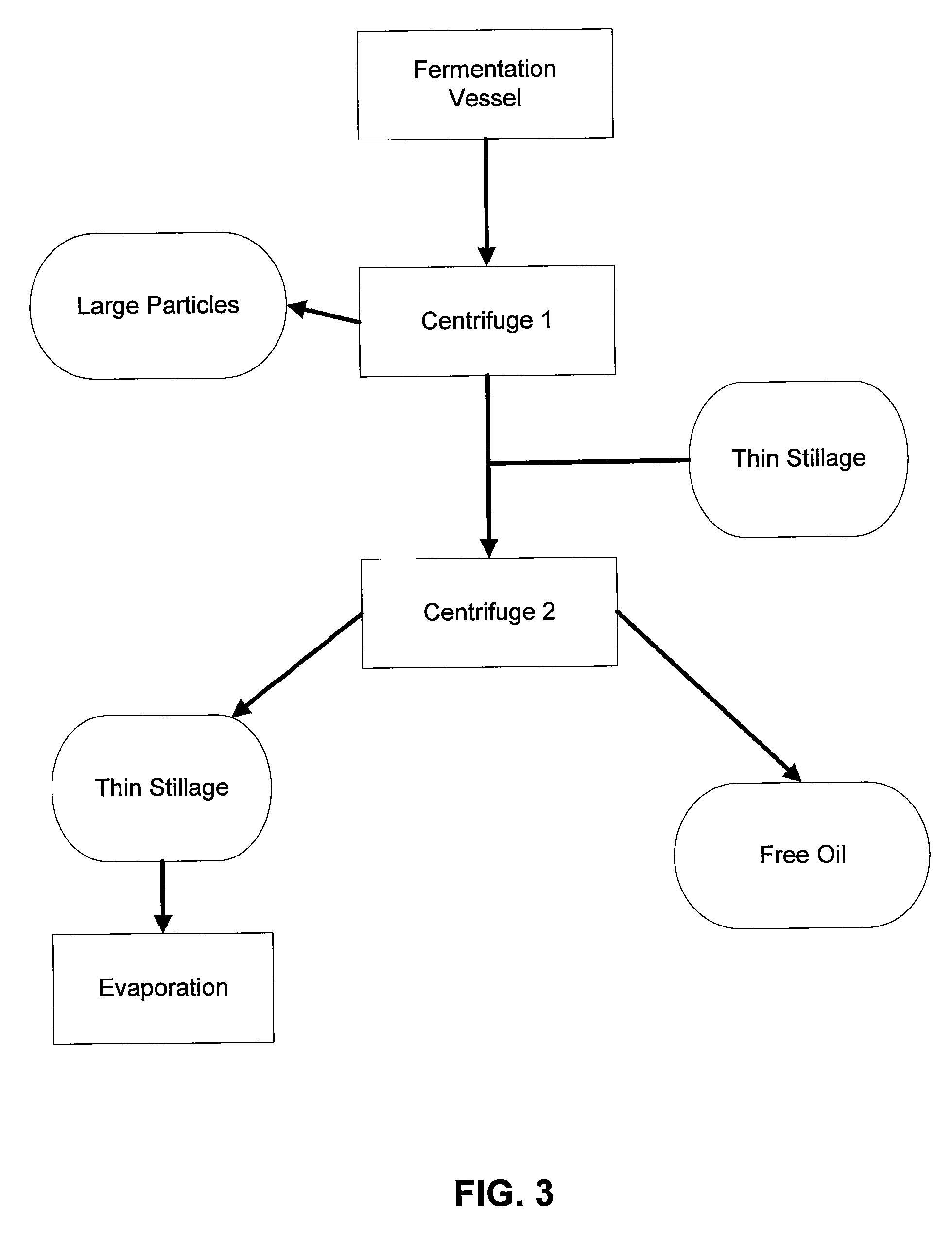

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

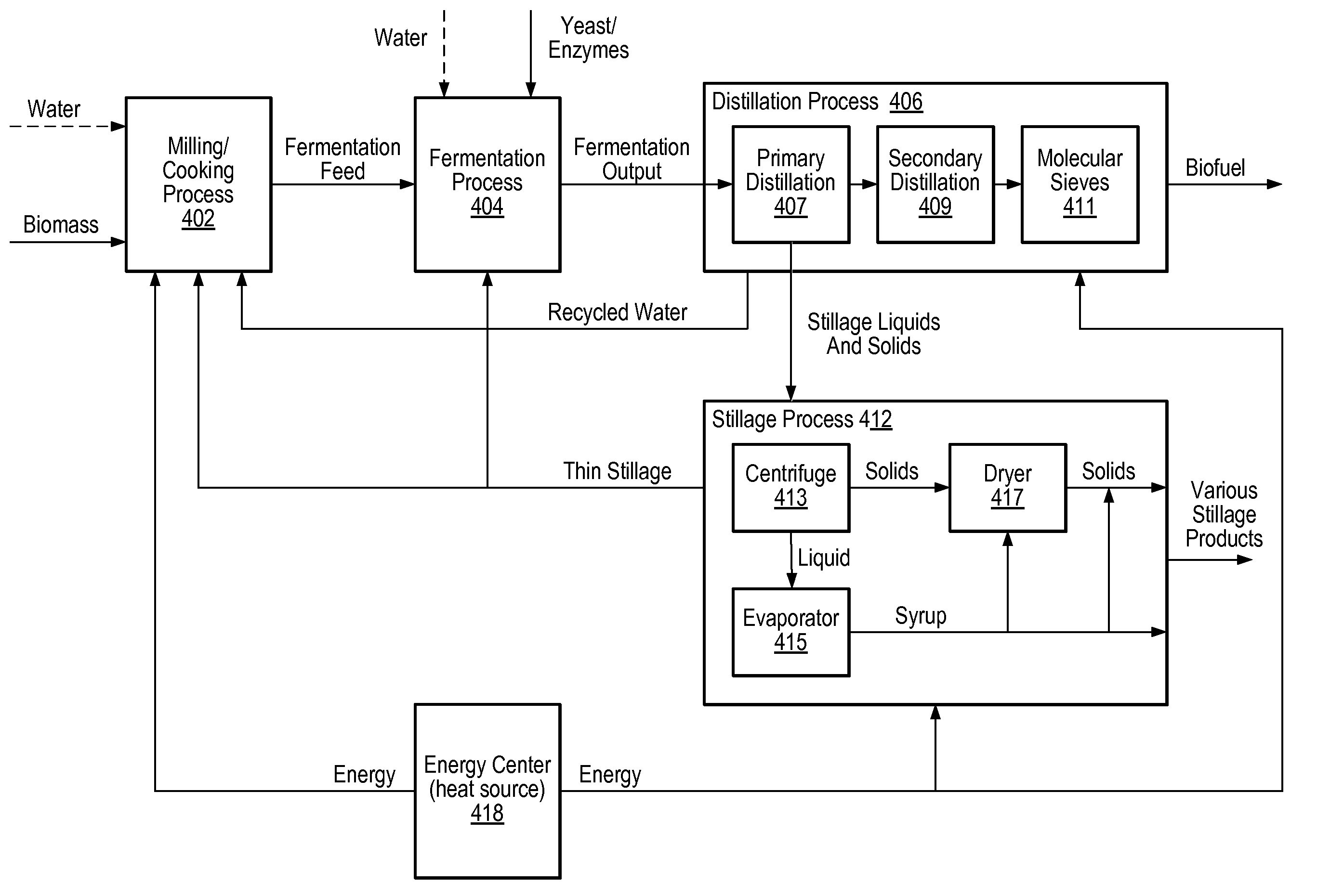

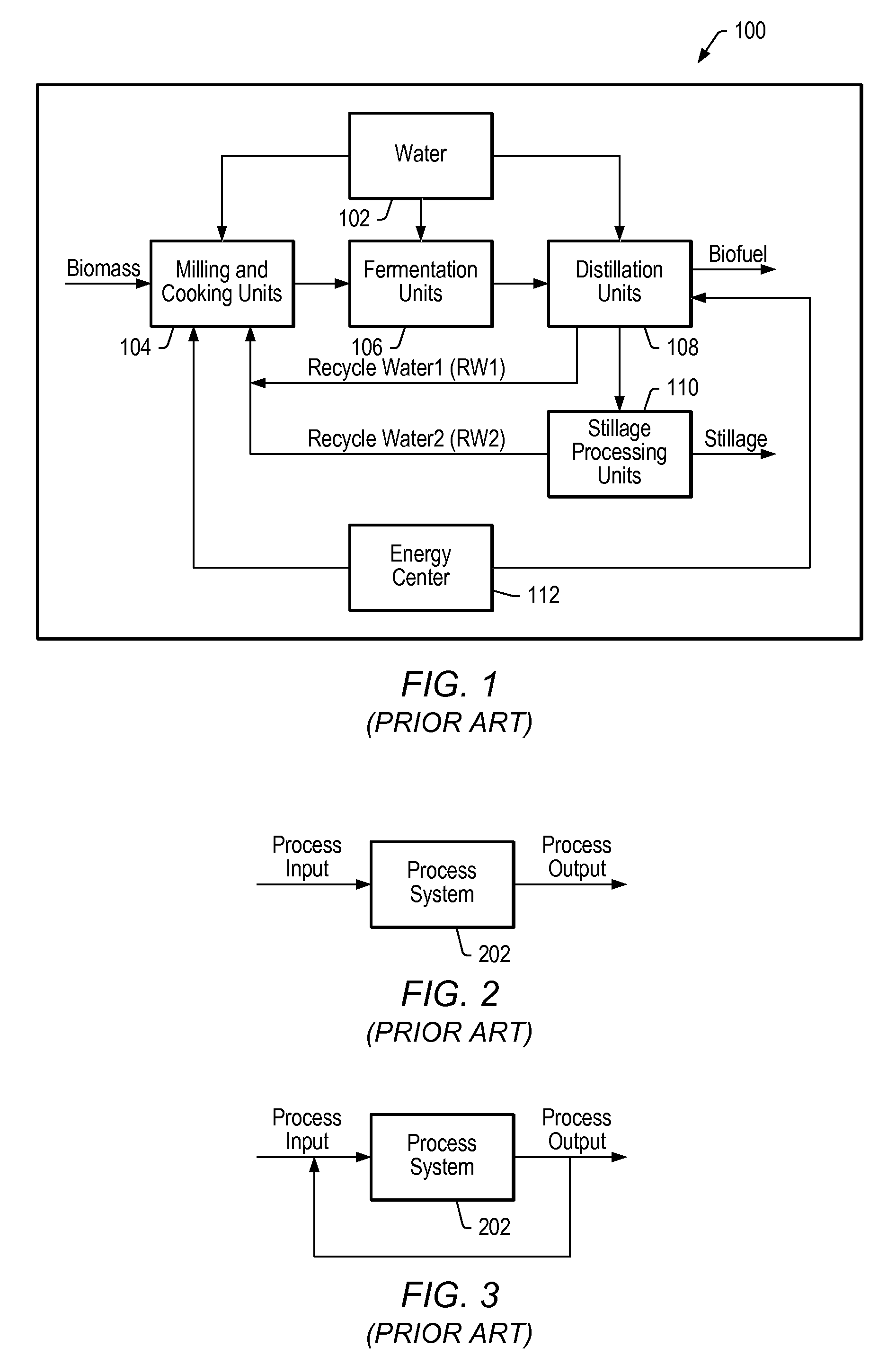

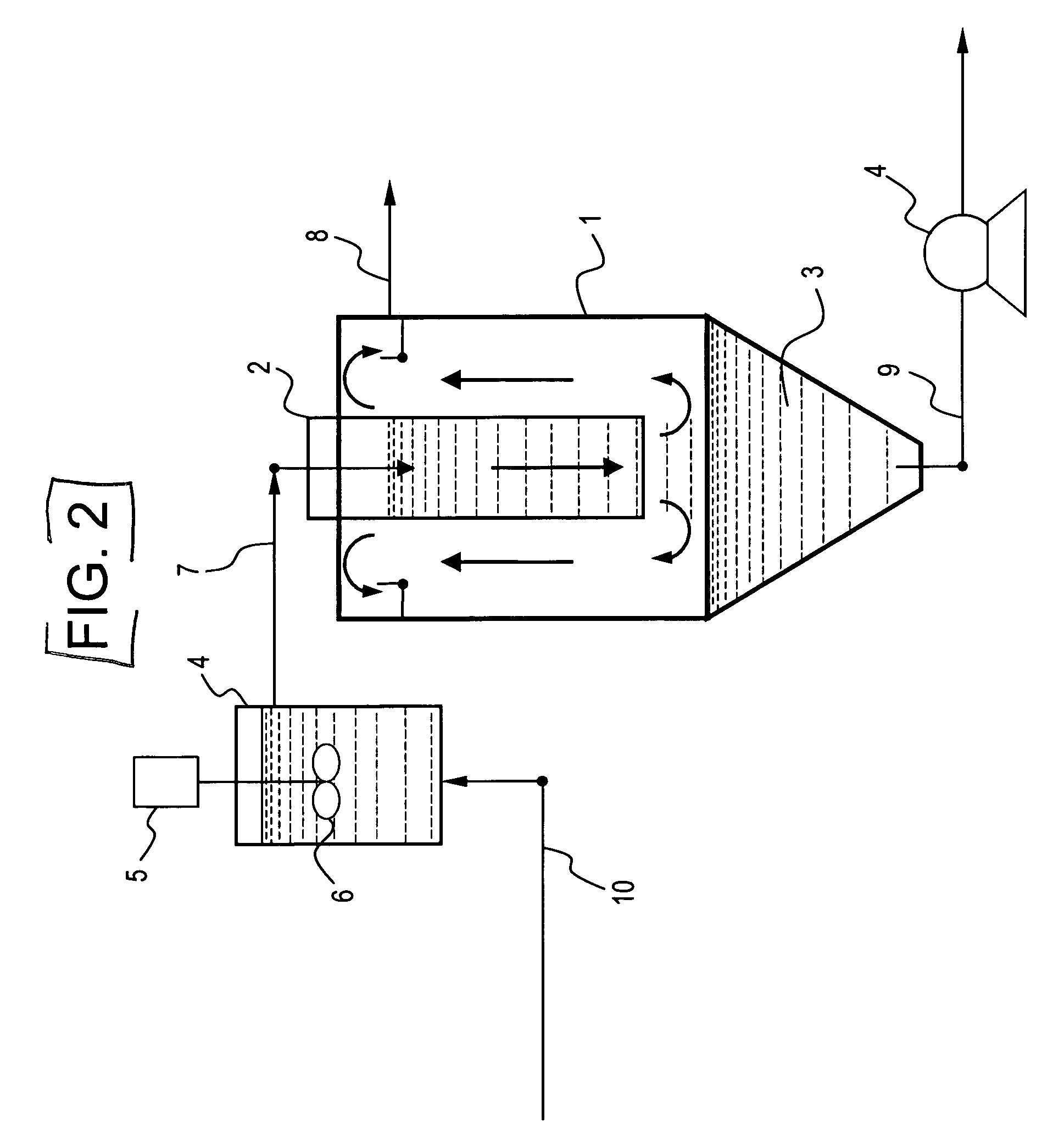

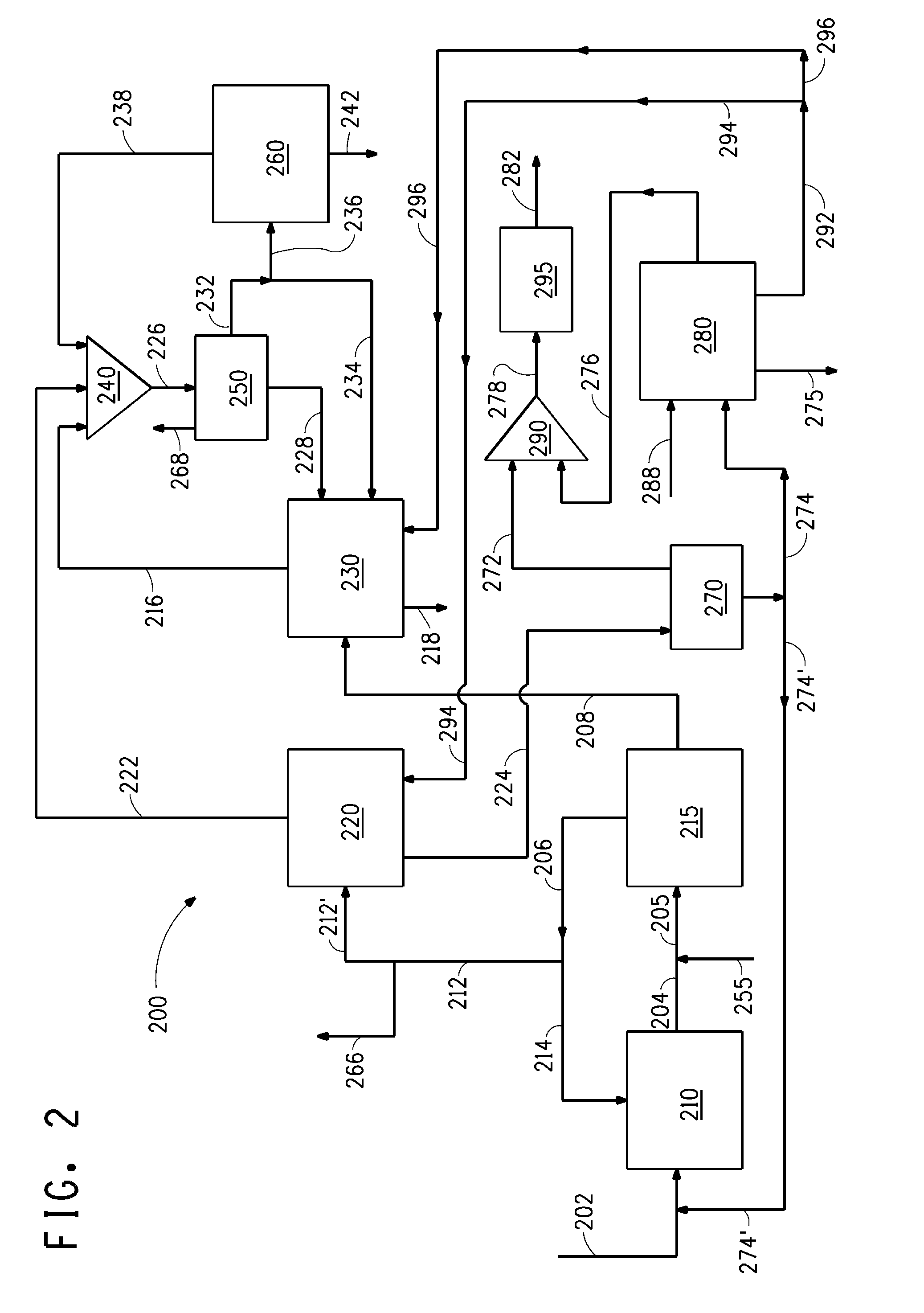

Model predictive control of a stillage sub-process in a biofuel production process

InactiveUS20080103747A1Analogue computers for chemical processesAdaptive controlProcess systemsTarget control

System and method for managing a biofuel stillage sub-process of a biofuel production process using a dynamic multivariate predictive model of the stillage sub-process. An objective for the stillage sub-process is received specifying target production of output of the stillage sub-process, including a target value for moisture content of one or more of: dry distillers grain, wet distillers grain, or evaporator syrup. Process information comprising stillage sub-process information is received from the biofuel production process. The dynamic multivariate predictive model is executed in accordance with the objective using the process information as input, to generate model output comprising target values for a plurality of manipulated variables related to the stillage sub-process, in accordance with the objective. The biofuel production process is controlled in accordance with the target values of the plurality of manipulated variables to control production of outputs or inputs of the stillage sub-process in accordance with the objective.

Owner:ROCKWELL AUTOMATION TECH

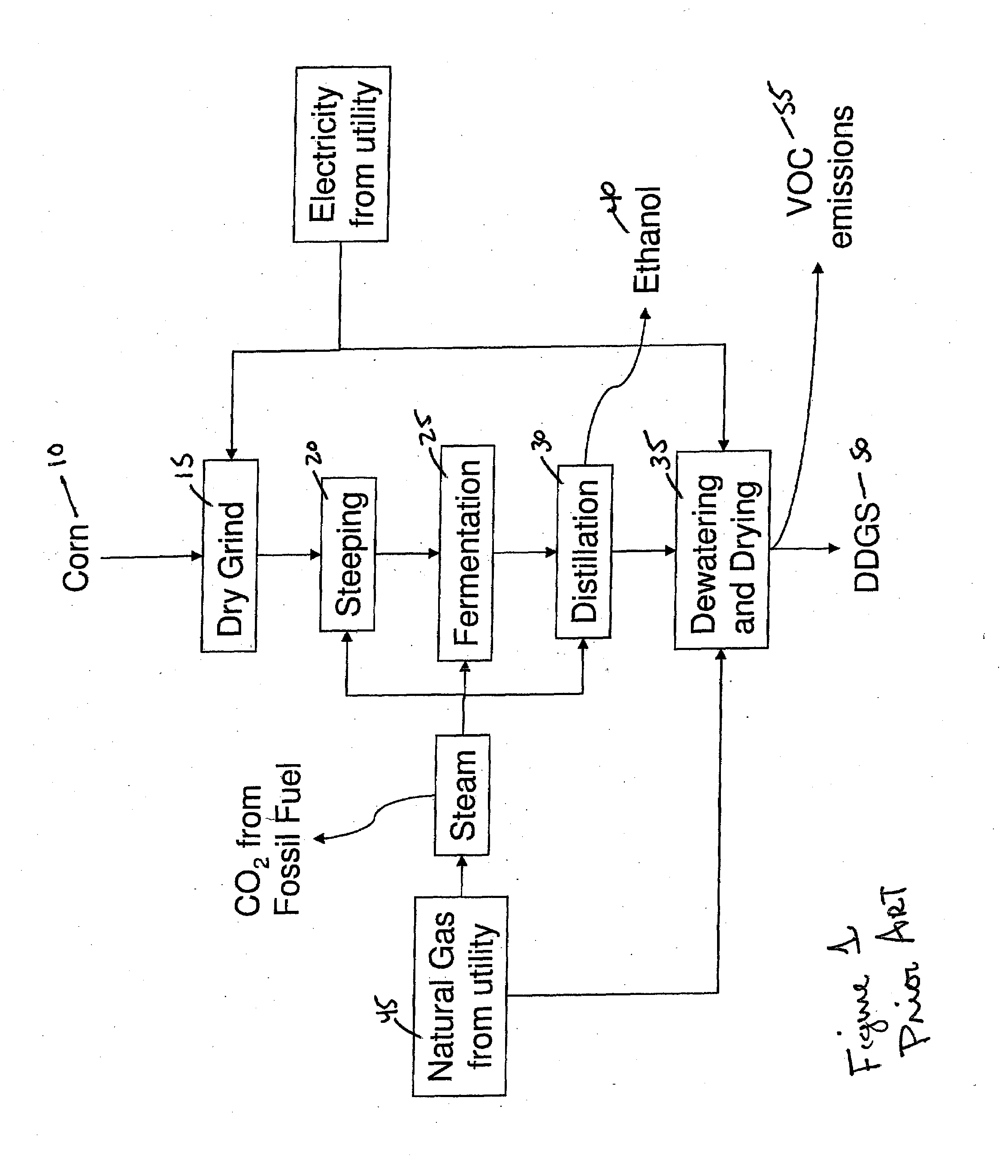

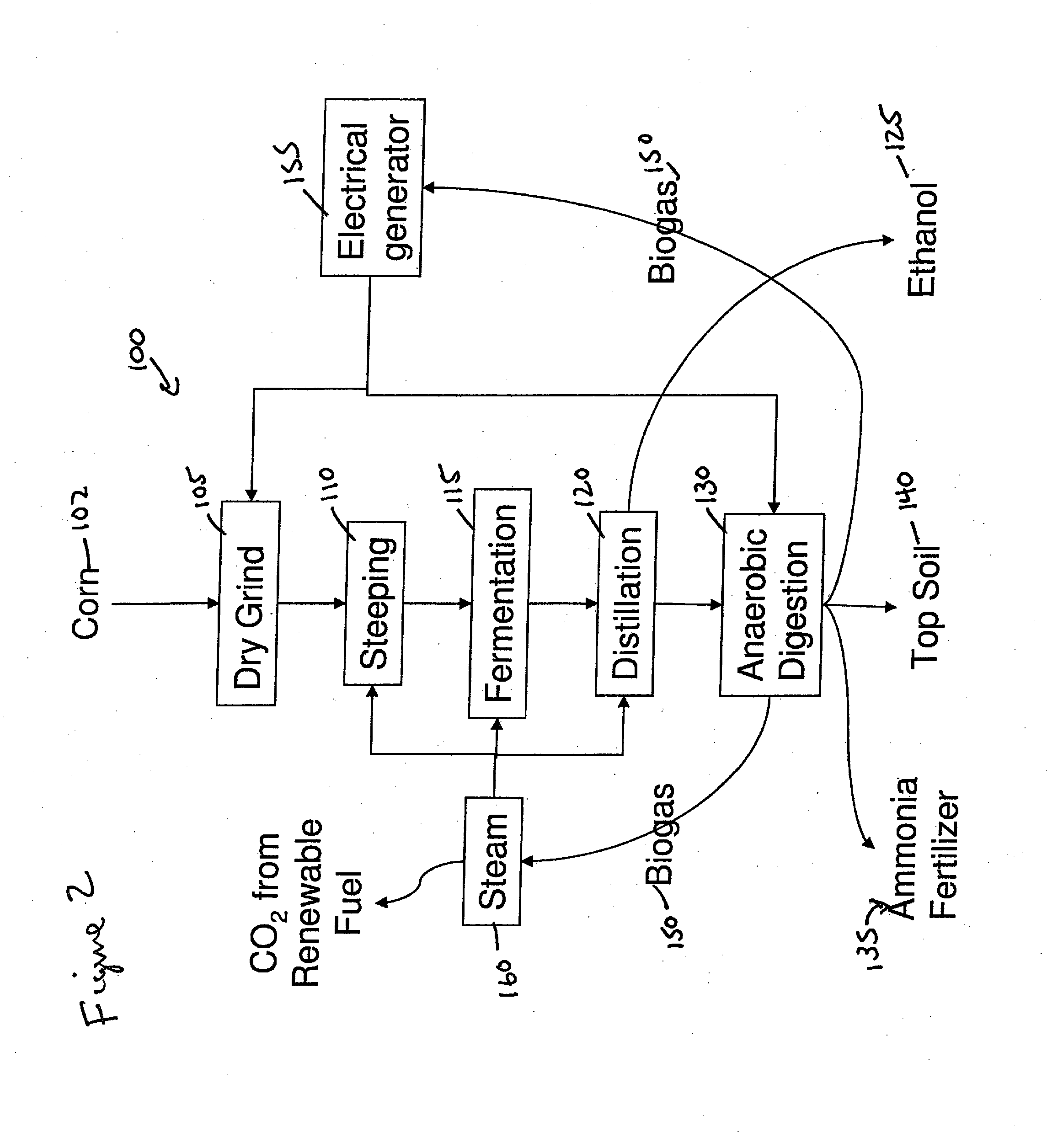

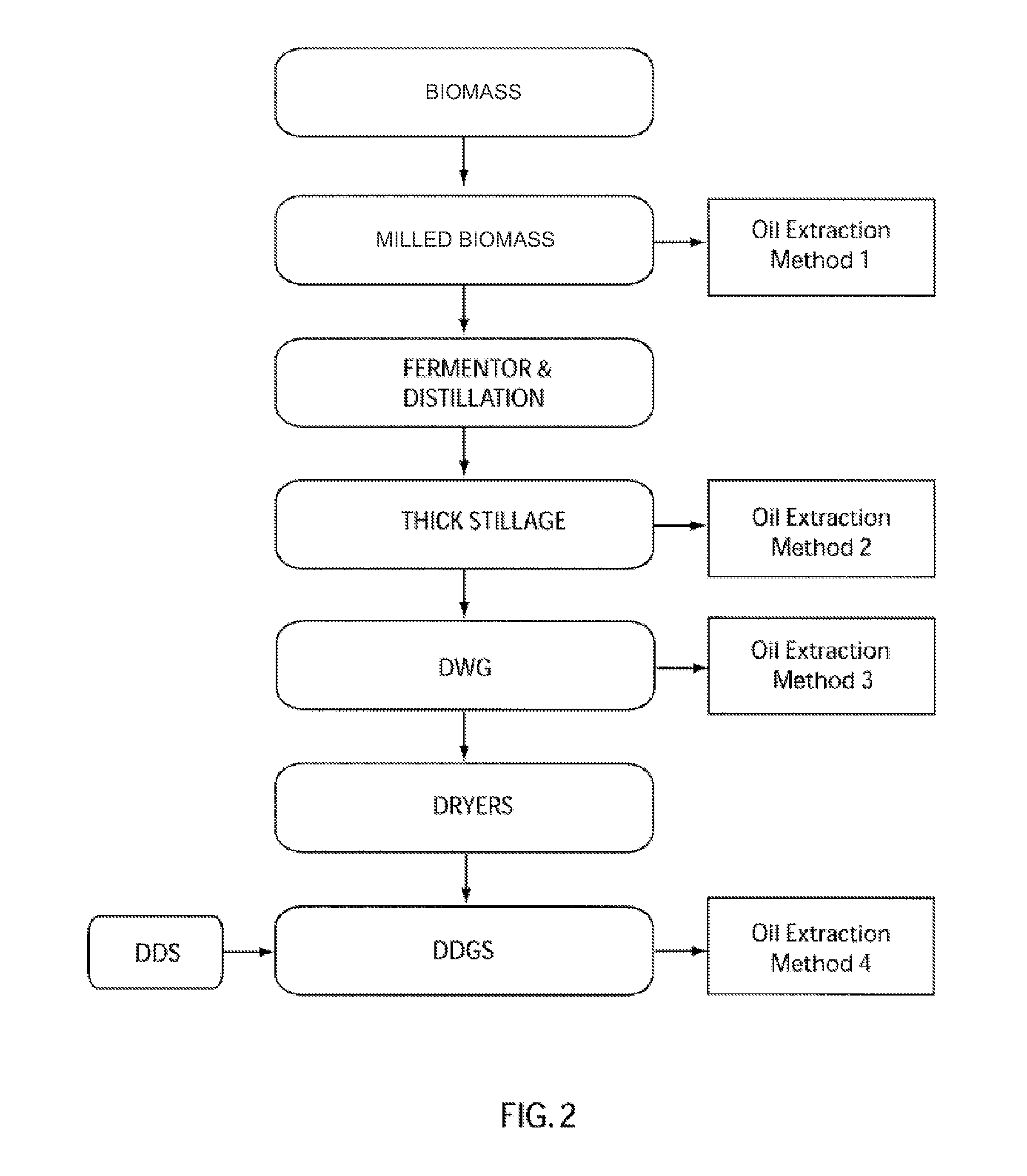

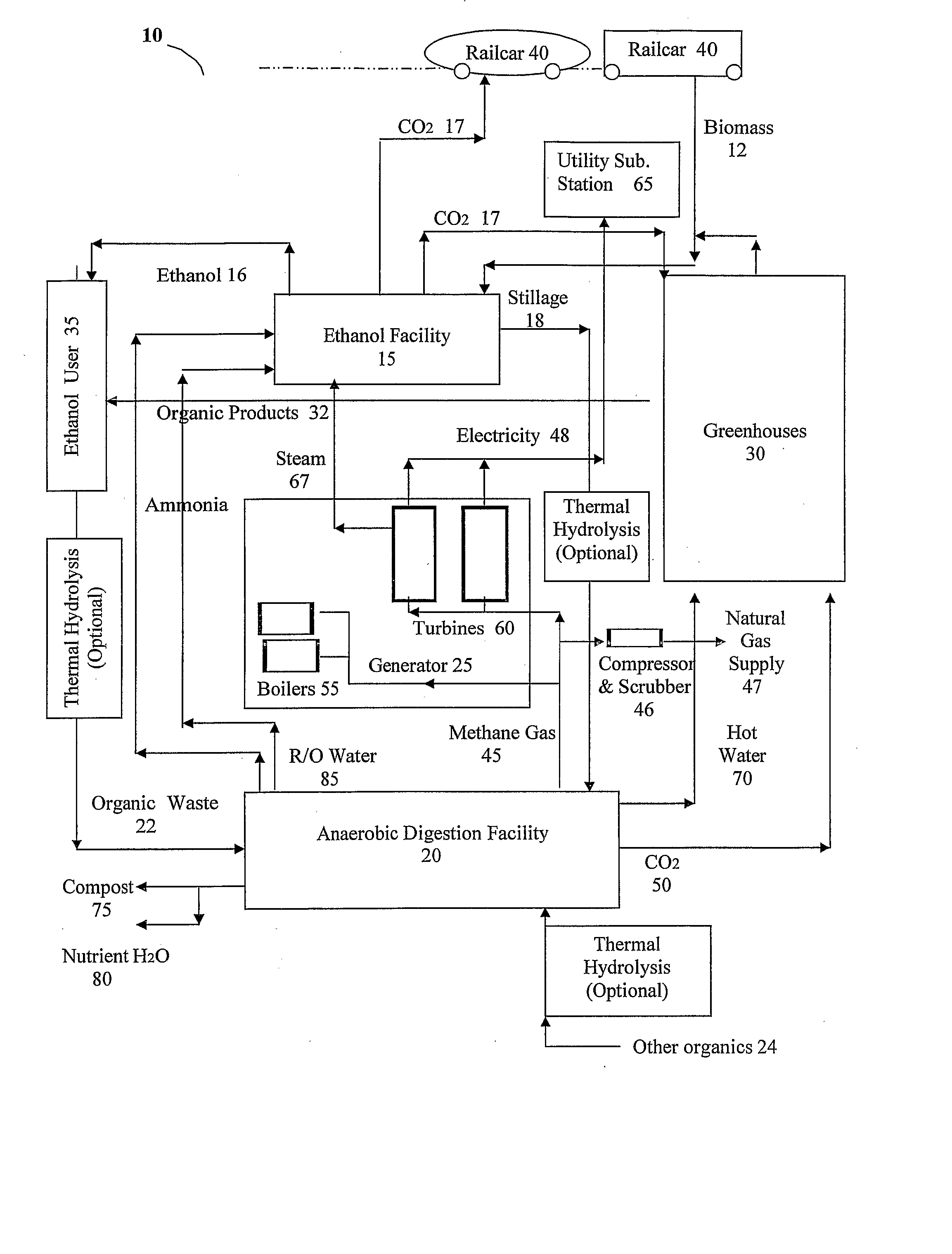

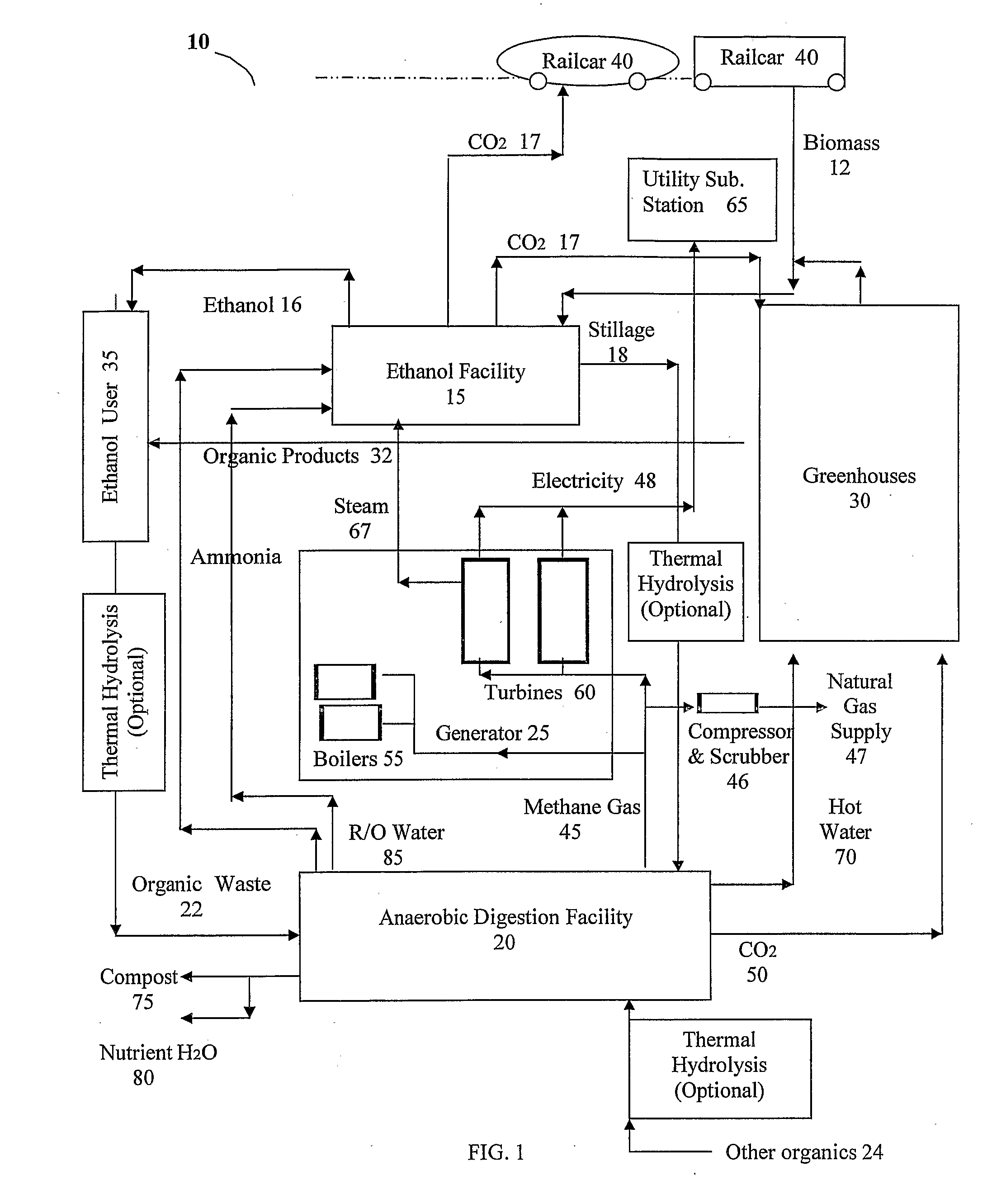

Process for producing ethanol and for energy recovery

InactiveUS20070141691A1Increasing net energy valueReducing the reliance of the ethanol industryBioreactor/fermenter combinationsBio-organic fraction processingElectricityDistillation

The present invention is directed to a process for the production of ethanol and energy. The process includes the steps of fermenting a corn mash in an aqueous medium to produce a beer. Next, the beer is distilled to produce ethanol and a whole stillage. The whole stillage is anaerobically digested to produce a biogas and a residue. The biogas is combusted to produce electricity and steam. The electricity and steam are used during the fermentation and distillation process. The residue may further be separated into a liquid fertilizer and top soil residue.

Owner:STANLEY CONSULTANTS

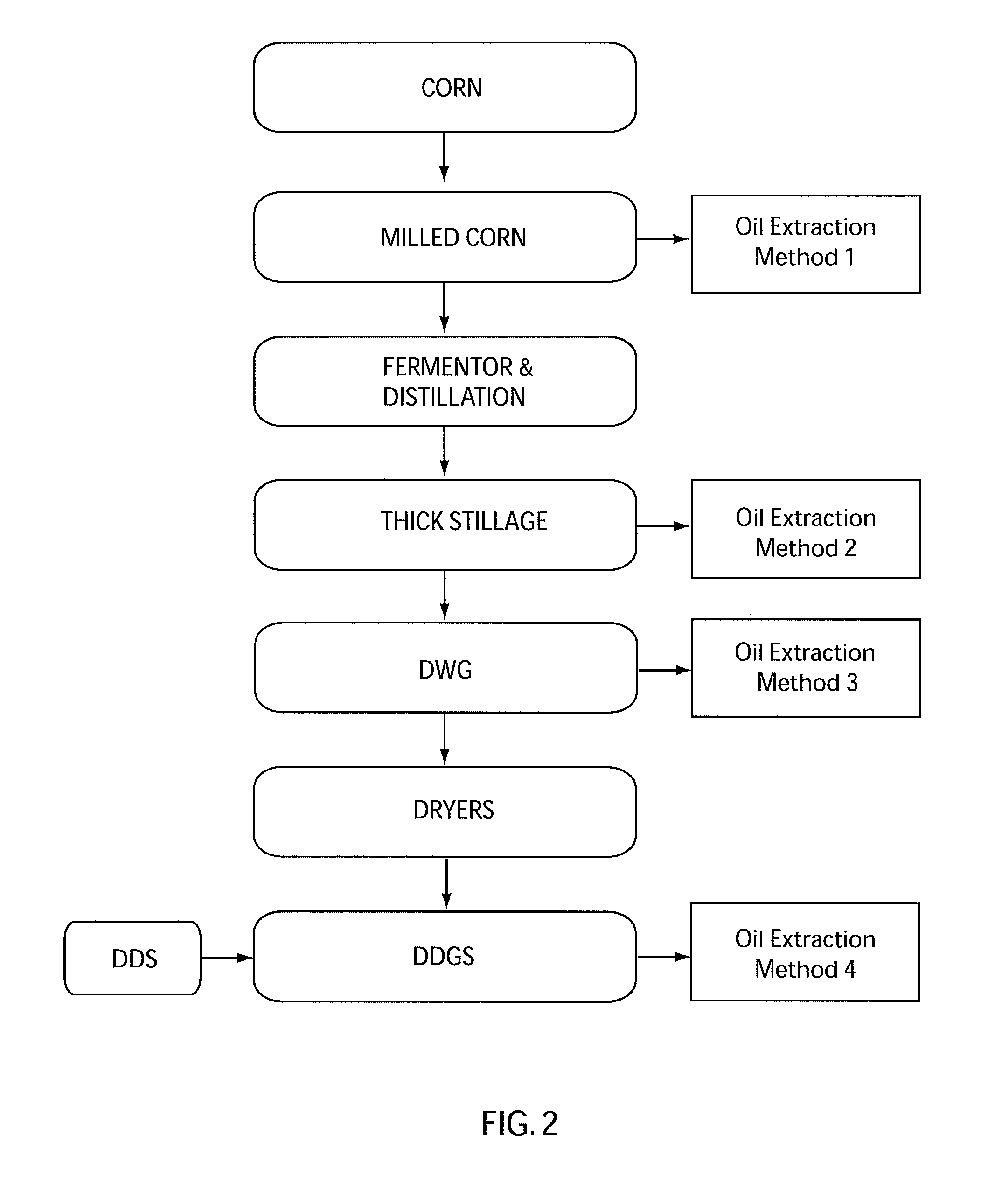

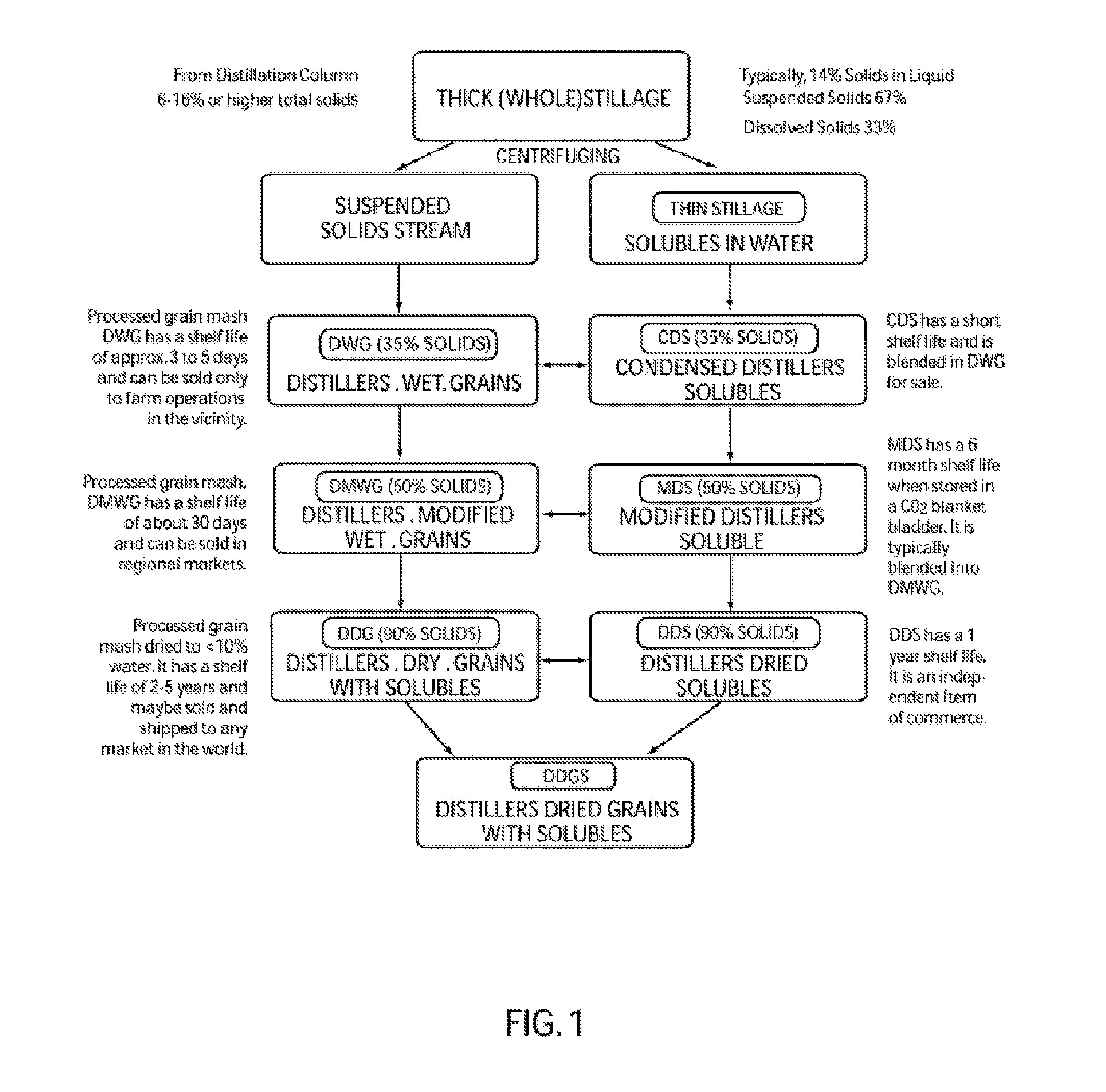

Oil recovery from dry corn milling ethanol production processes

A corn oil extraction process is disclosed. The process includes the recovery of corn oil and other co-products, including but not limited to steam, electric power and chemicals, from an ethanol production process and in particular, a process that involves dry corn milling methods. The process involves extraction of oil from milled corn and residues from the fermentation step, including thick stillage, distillers wet grain, distillers dry grain and distillers dry grains with solubles, by the application of an alkyl acetate, phase separation and recovery of the separated matter. A process of drying wet co-product using ethanol and carbon dioxide from the production facility is also disclosed.

Owner:GROWMARK

Process for the production of animal feed and ethanol and novel animal feed

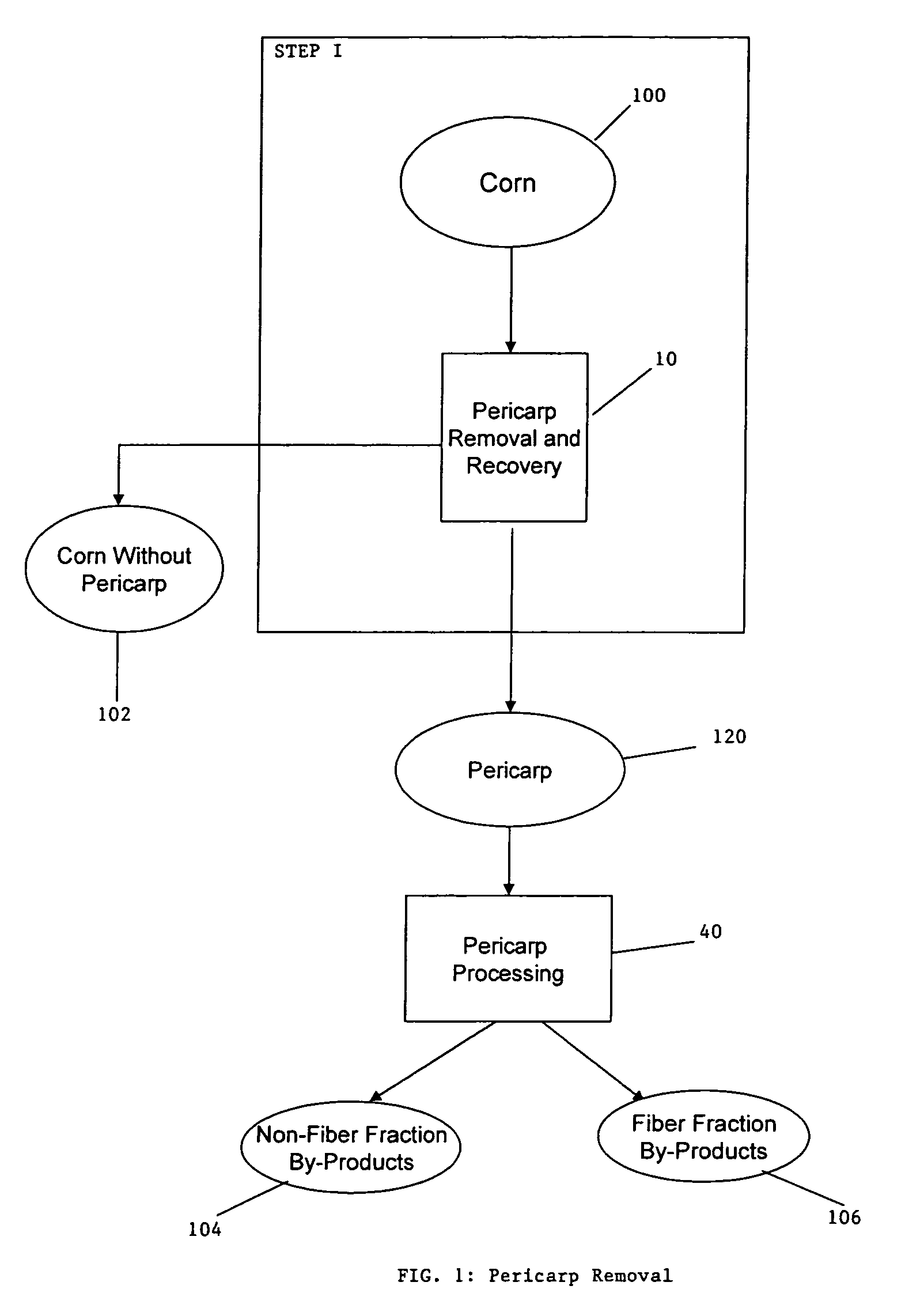

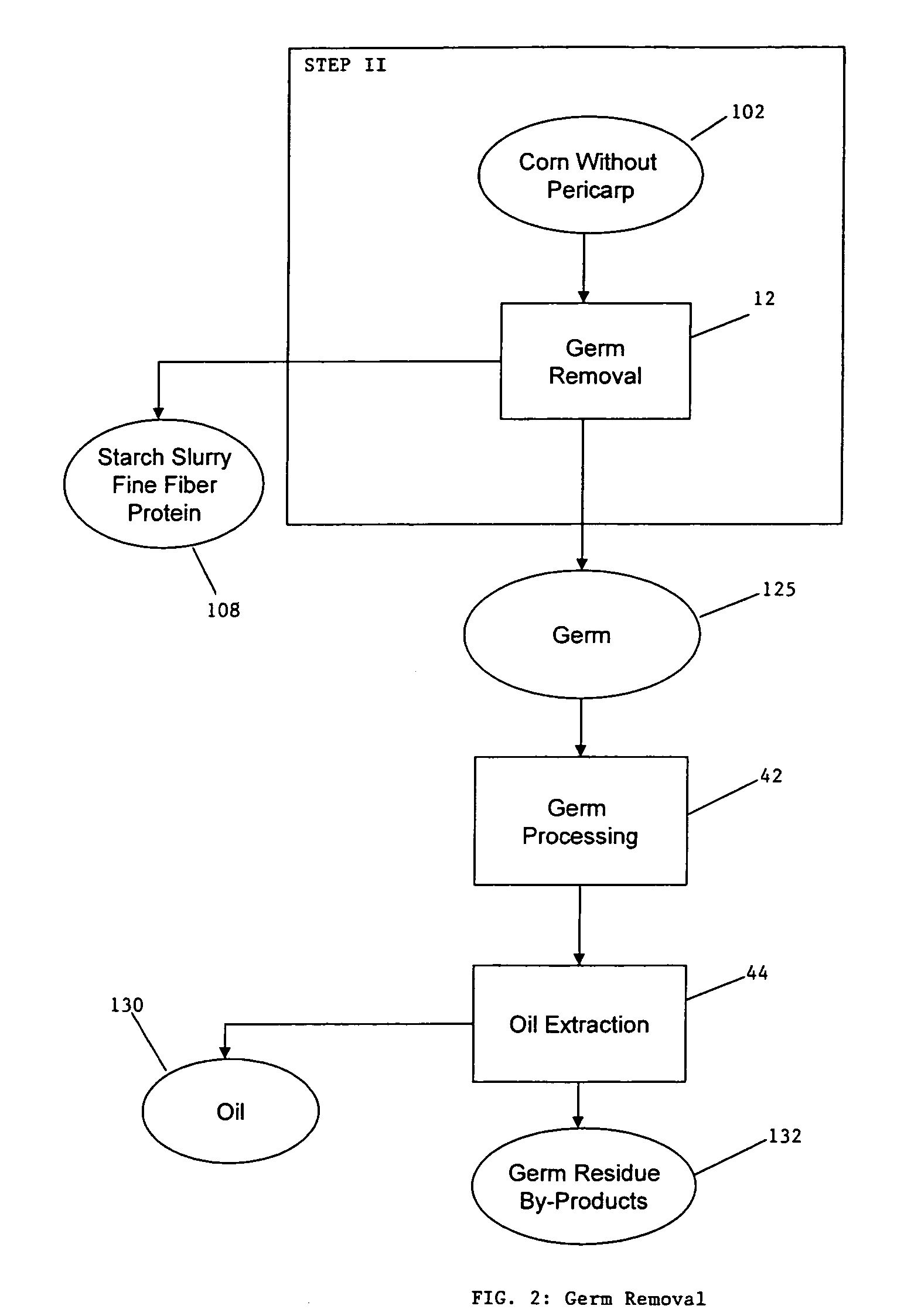

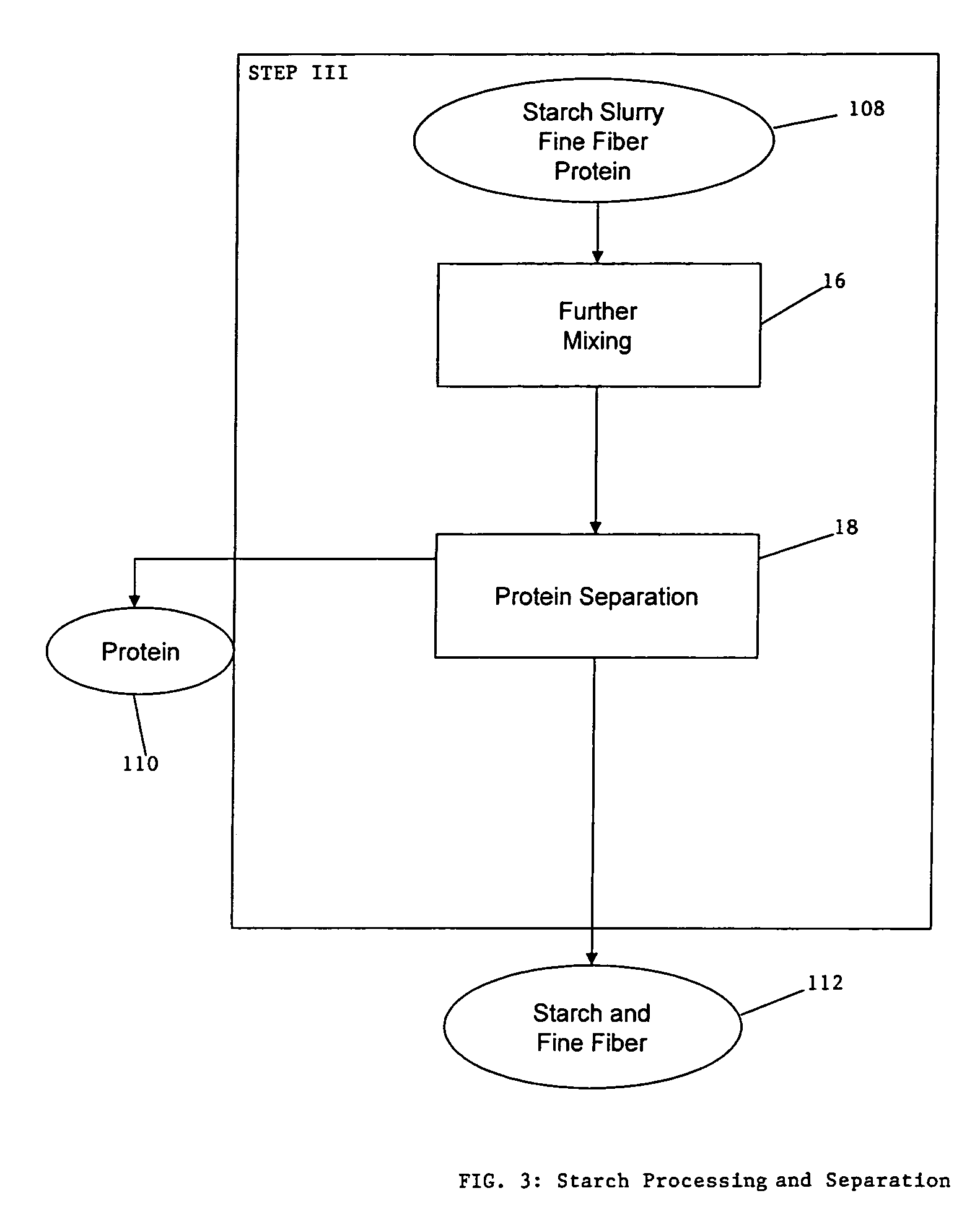

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

Method of dewatering thin stillage processing streams

InactiveUS20060006116A1Improve agglomerationAbility to withstandBy-product recoveryWater treatment parameter controlAcryditeSodium methacrylate

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:NALCO CO

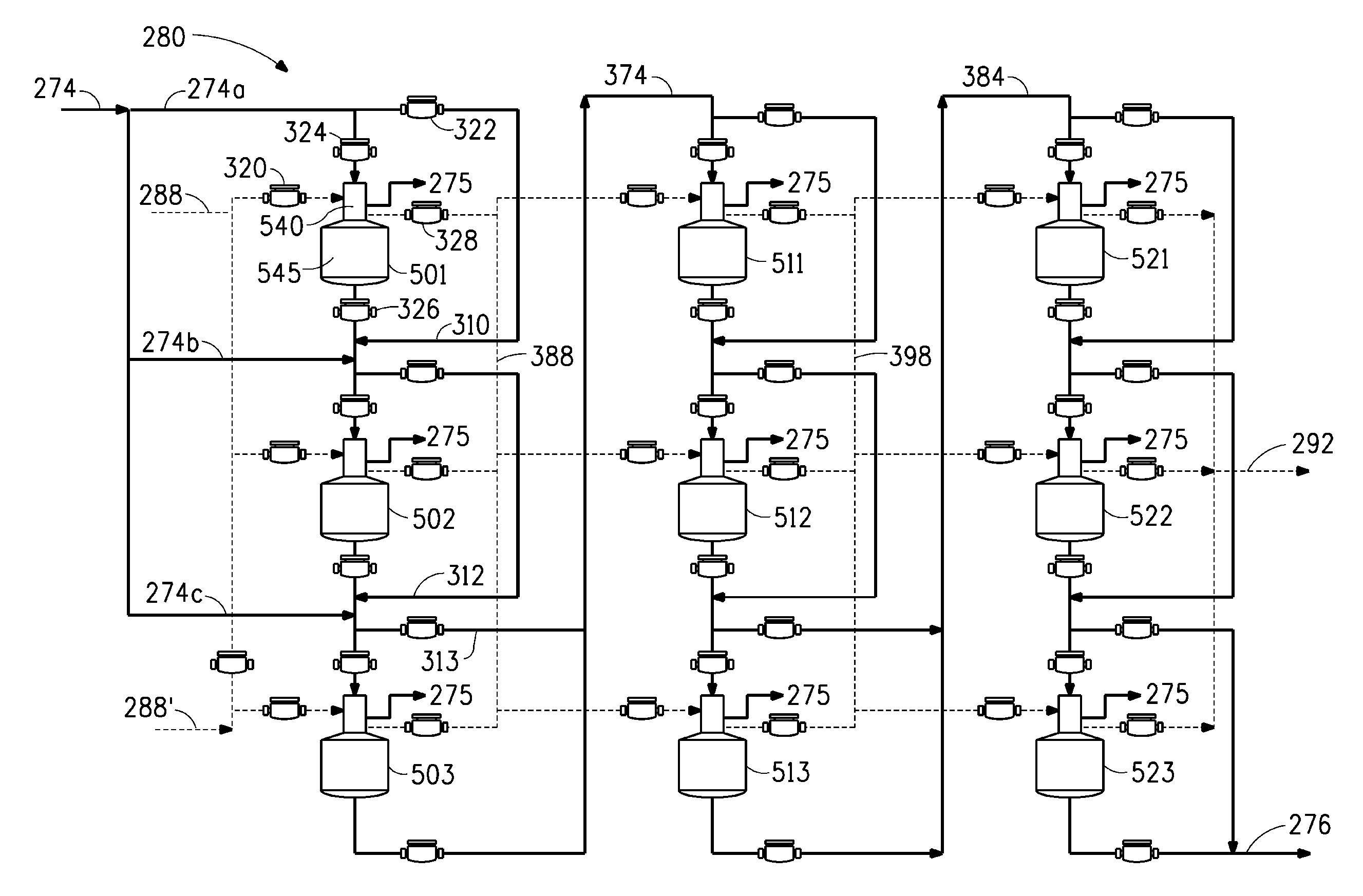

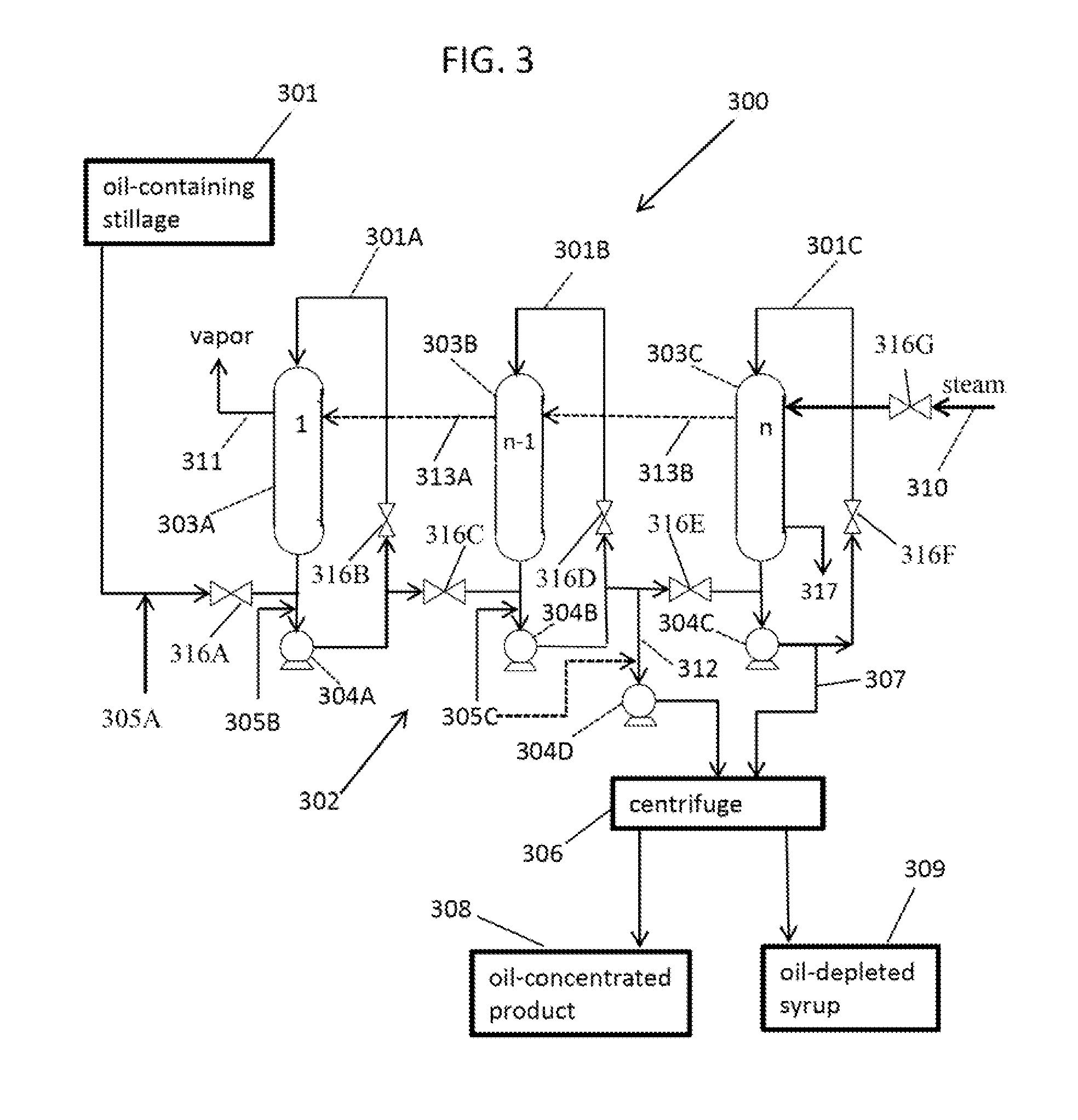

Systems and methods for alcohol recovery and concentration of stillage by-products

ActiveUS20110315541A1Efficient use ofHydrocarbon purification/separationHydroxy compound preparationAlcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

Process for improving the yield and efficiency of an ethanol fermentation plant

A process for improving the yield and efficiency of an ethanol fermentation plant that receives organic fermentable feedstock material, prepares the feedstock for fermentation, ferments the feedstock with yeast to produce ethanol, and produces stillage as a byproduct of ethanol fermentation. The process steps which can be operated independently or in combination, may include, but are not limited to, degrading fatty acids in the fermentable feedstock material prior to fermentation; degrading cellulose and hemicellulose present in the feedstock prior to fermentation; adding a surfactant to the fermentable feedstock; separating a liquid fraction from the stillage; recycling the liquid fraction to be combined with the fermentable feedstock; recovering a solid fraction from the stillage; and introducing at least a portion of the solid fraction to an anaerobic digester to produce methane.

Owner:WATER SOLUTIONS TECH LLC

Concurrent Anaerobic Digestion and Fermentation of Lignocellulosic Feedstocks

InactiveUS20110236946A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholSemi solid

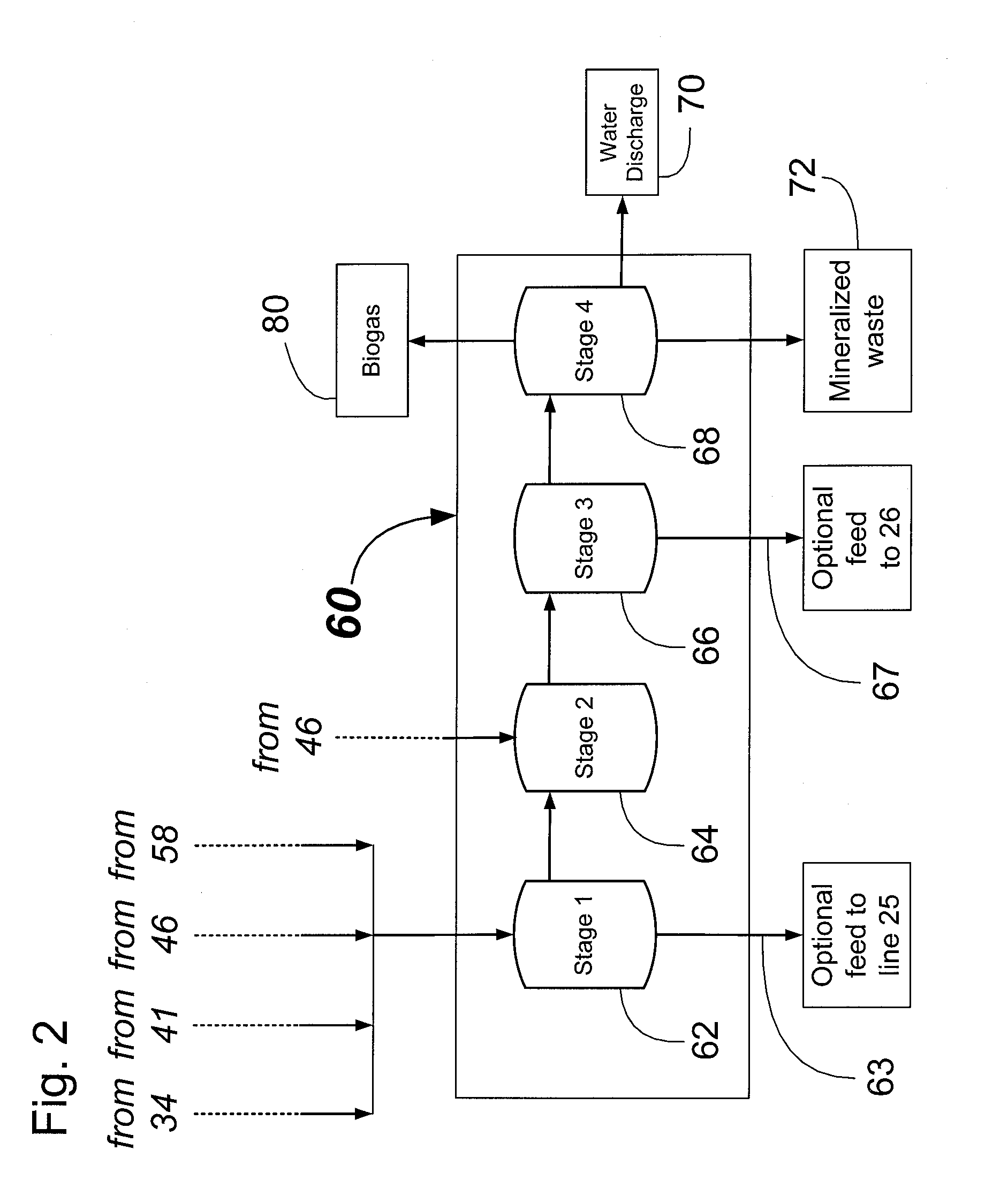

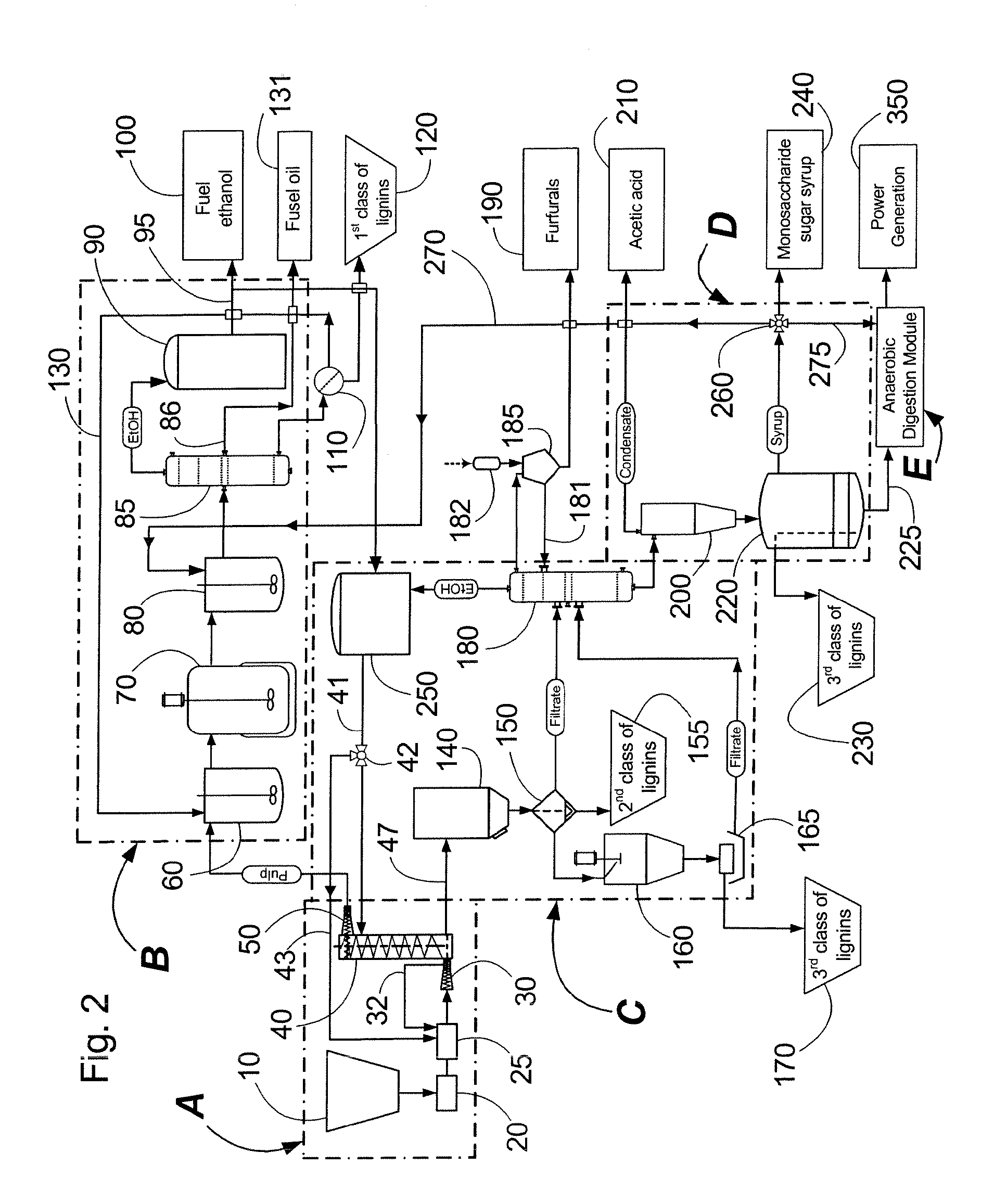

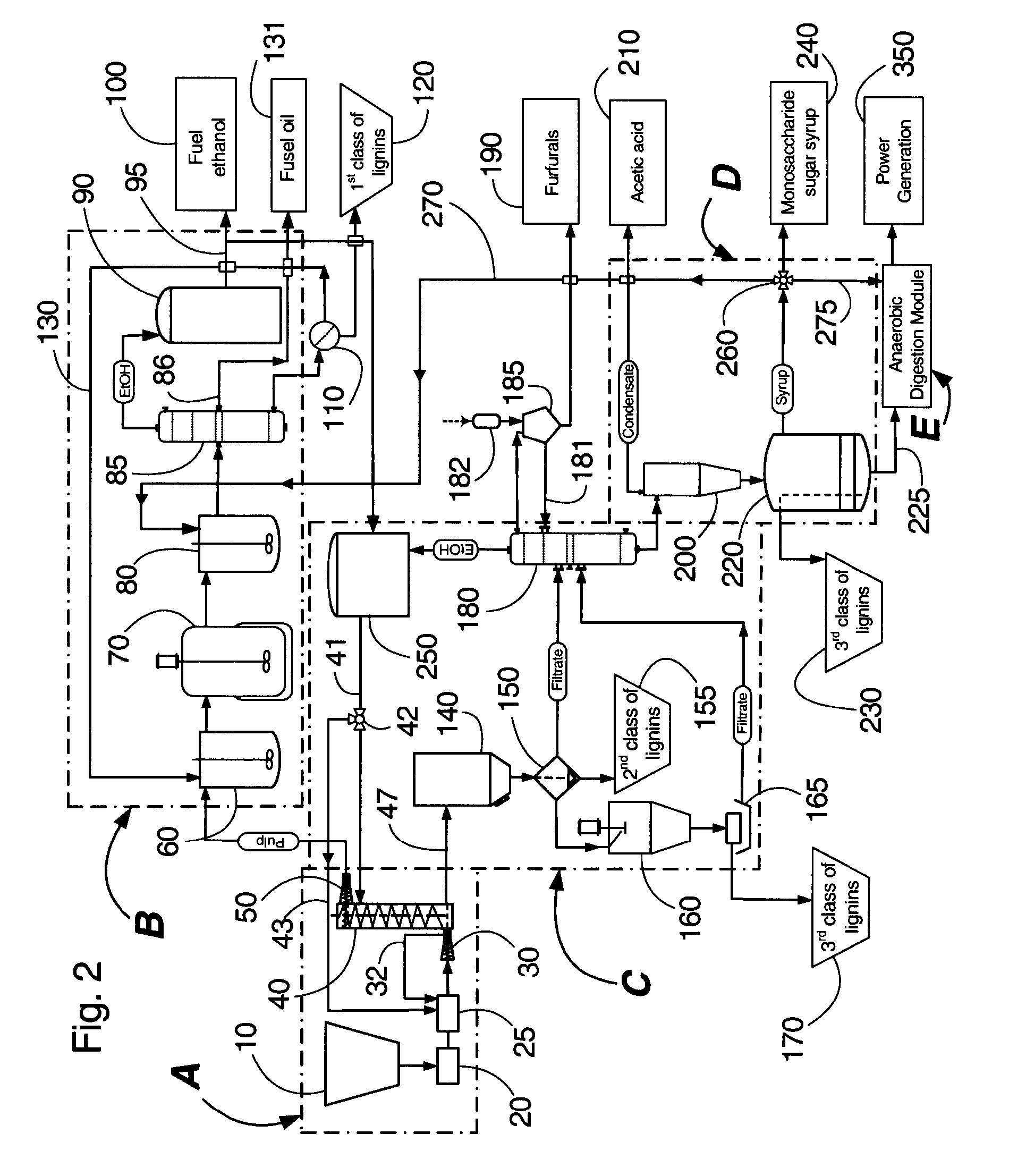

A process for concurrent production of lignins, fuel alcohol, and biogas from lignocellulosic feedstocks. The process comprises: (1) pretreating a lignocellulosic feedstock to produce a solubilised liquid components stream comprising lignins, lignin-derived compounds, and a cellulosic pulp stream, (2) separating the liquid stream from the cellulosic pulp stream, (3) processing the liquid stream to separate and recover at least lignins, lignin-derived compounds, and semi-solid waste material, (b) processing the cellulosic pulp stream to saccharify and ferment the cellulose pulp to produce a beer which is then separated into fuel-grade alcohol and a waste stillage material, (4) anaerobically digesting the semi-solid waste material from the liquid stream and the waste stillage material to produce a biogas. The rate of anaerobic digestion can be manipulated by controllably supplying a portion of the monosaccharides produced from the cellulosic pulp. The cellulosic pulp stream may also be anaerobically digested.

Owner:LIGNOL INNOVATIONS

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080299628A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateBioreactor/fermenter combinationsPressurized chemical processFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

Chemical additives and use thereof in stillage processing operations

ActiveUS20120245370A1Quality improvementReduced deposited materialFatty oils/acids recovery from wasteOrganic compound preparationStillageChemistry

Owner:SOLENIS TECH CAYMAN

Oil recovery and syngas production from biomass-based processes

InactiveUS20100331580A1Small sizeSolvent extractionCombustible gas catalytic treatmentSyngasCompound (substance)

A biomass-based oil extraction process is disclosed. The process includes the recovery of biomass-based oil and other co-products, including but not limited to steam, electric power and chemicals, from various biomass processes and in particular, a process that involves dry biomass milling methods. The process involves extraction of oil from milled biomass-based products and residues from the fermentation step, including thick stillage, distillers wet grain, distillers dry grain and distillers dry grains with solubles, by the application of an alkyl acetate, phase separation and recovery of the separated matter. A process of drying wet co-product using ethanol and carbon dioxide from the production facility is also disclosed. Also a process for the production of syngas from oil containing or deoiled biomass-based products in a pressurized gasifier is disclosed.

Owner:FS FINANCIAL SERVICES

Self-Sustaining and Continuous System and Method of Anaerobically Digesting Ethanol Stillage

A system and method of anaerobically digesting ethanol stillage and reintegrating substantially all by-products thereof back into the system is disclosed. The system includes an ethanol producing facility for producing ethanol and an anaerobic digestion facility for anaerobically digesting stillage from the ethanol producing facility to produce a plurality of by-products. A plurality of sub-systems utilize the plurality of by-products from anaerobic digestion to produce a plurality of end-products. At least one of the plurality of end-products from the various sub-systems is integrated back into the ethanol producing facility and into at least one of the sub-systems such that the system of anaerobically digesting stillage is a continuous and self-sustaining operation.

Owner:ENVIROPLUS

Method of dewatering thin stillage processing streams

ActiveUS7497955B2Improve agglomerationAbility to withstandWater treatment parameter controlWater treatment compoundsSodium methacrylateSodium salt

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and flocculated solids; and separating the water from the flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

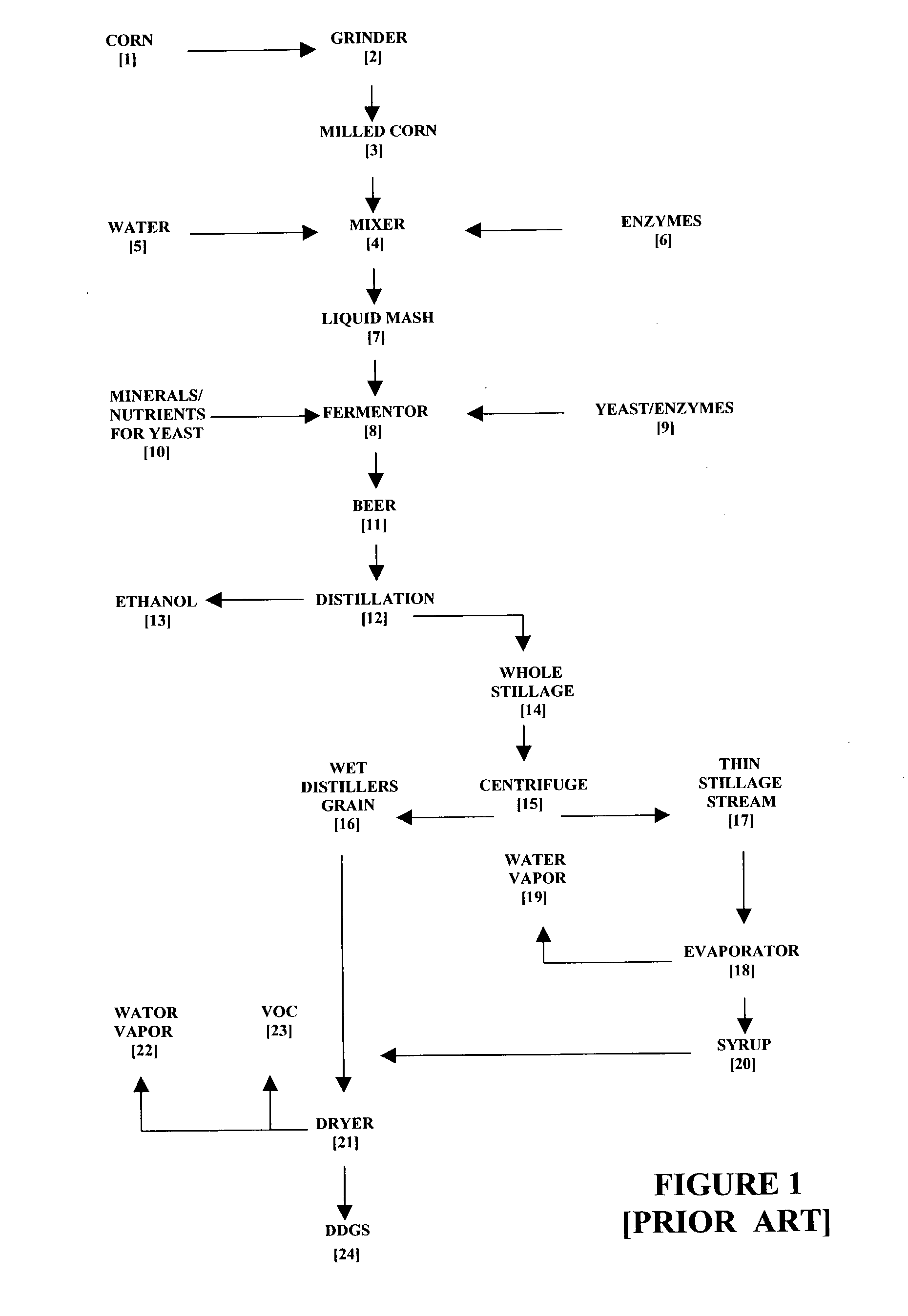

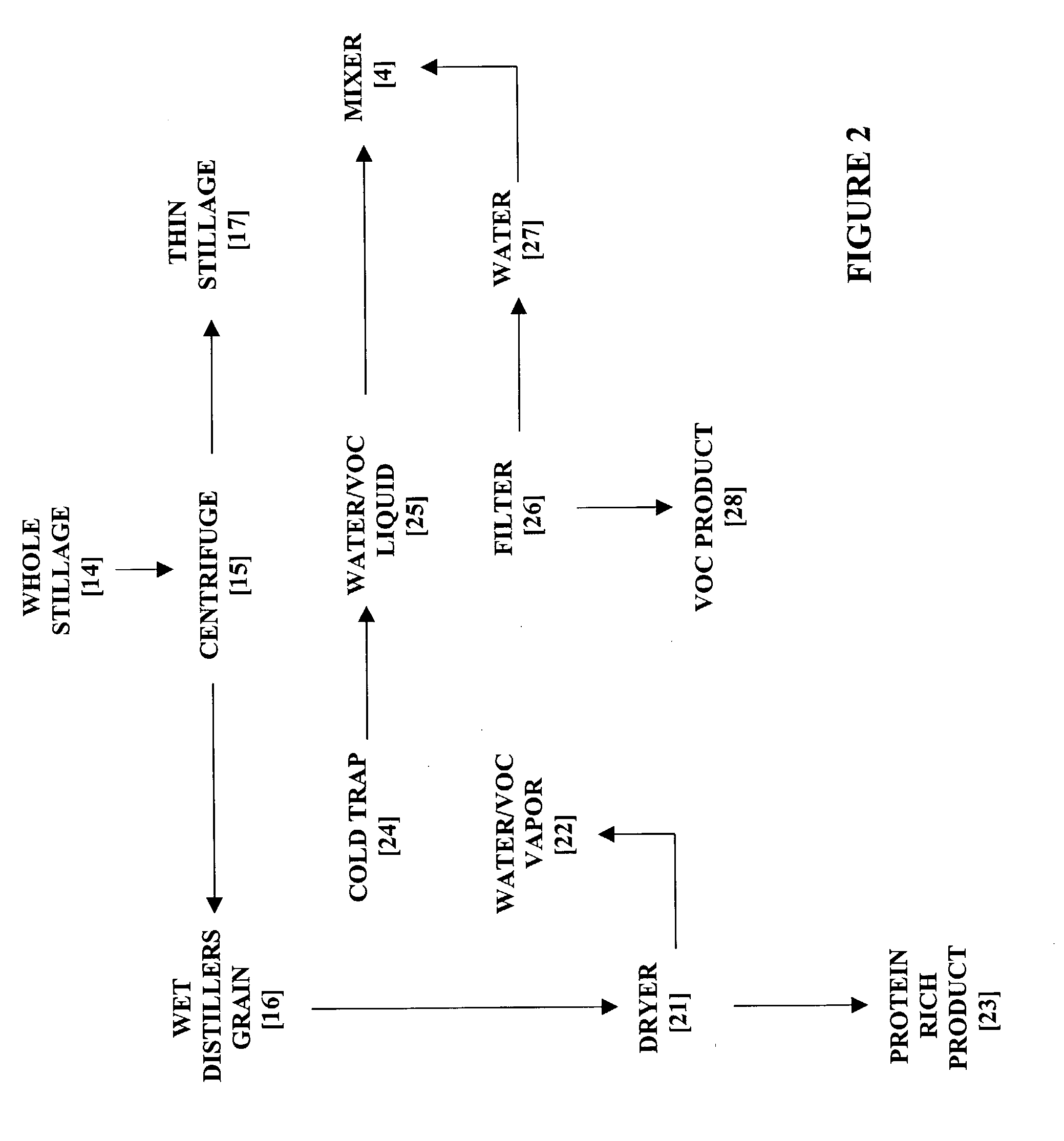

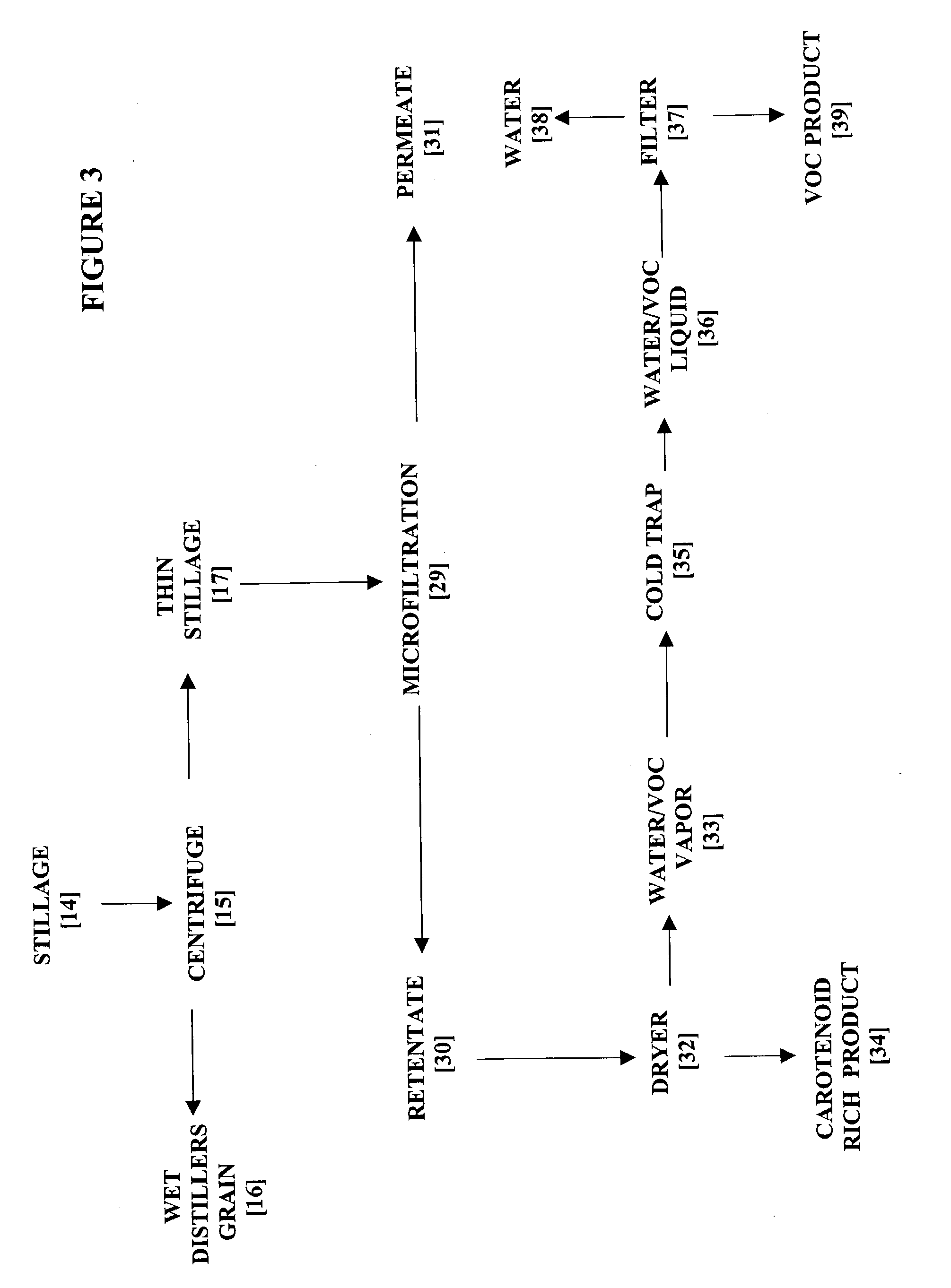

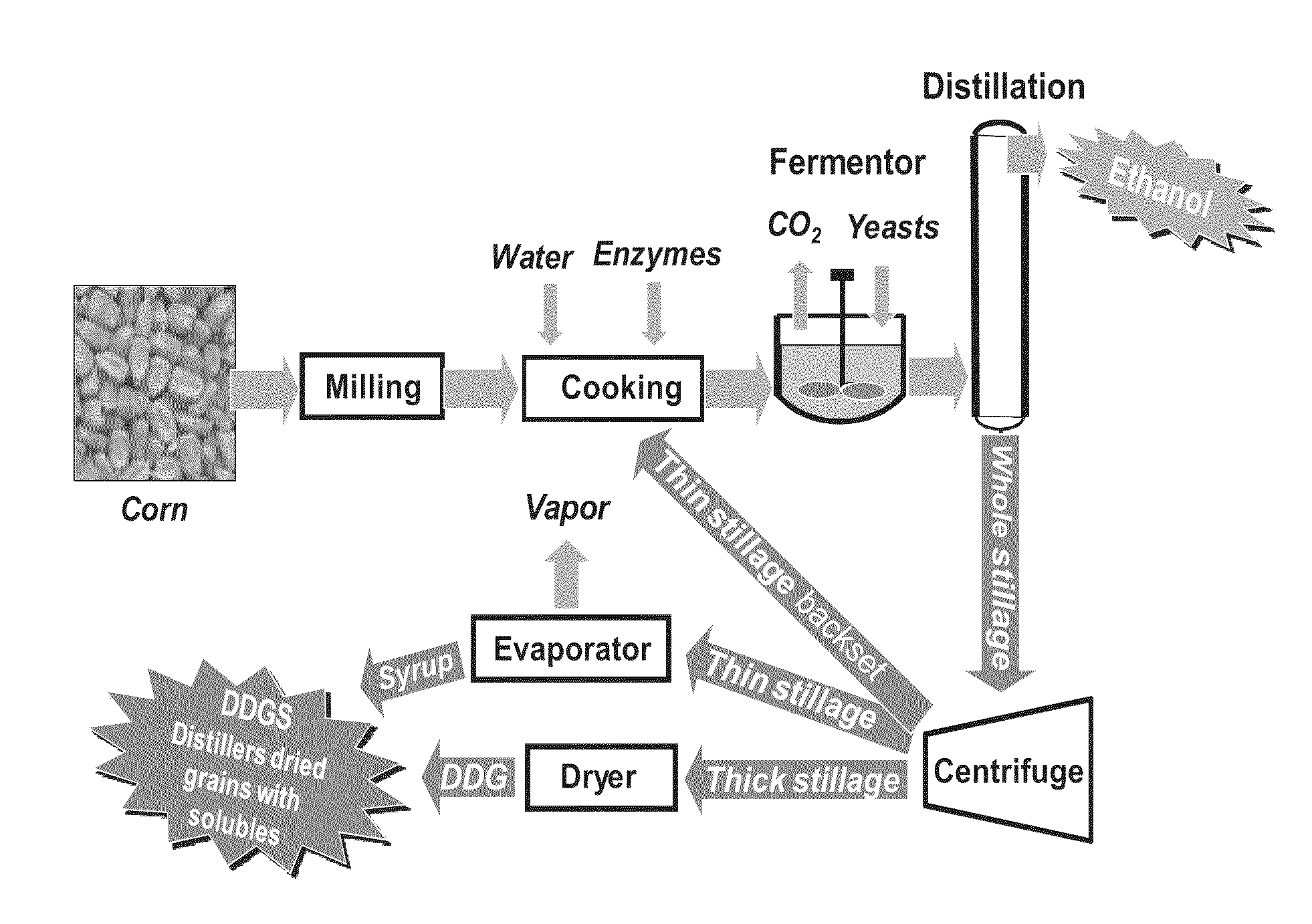

Ethanol production process

InactiveUS20060194296A1Quantity minimizationSpeed up the processBiofuelsFermentationValue added productChemistry

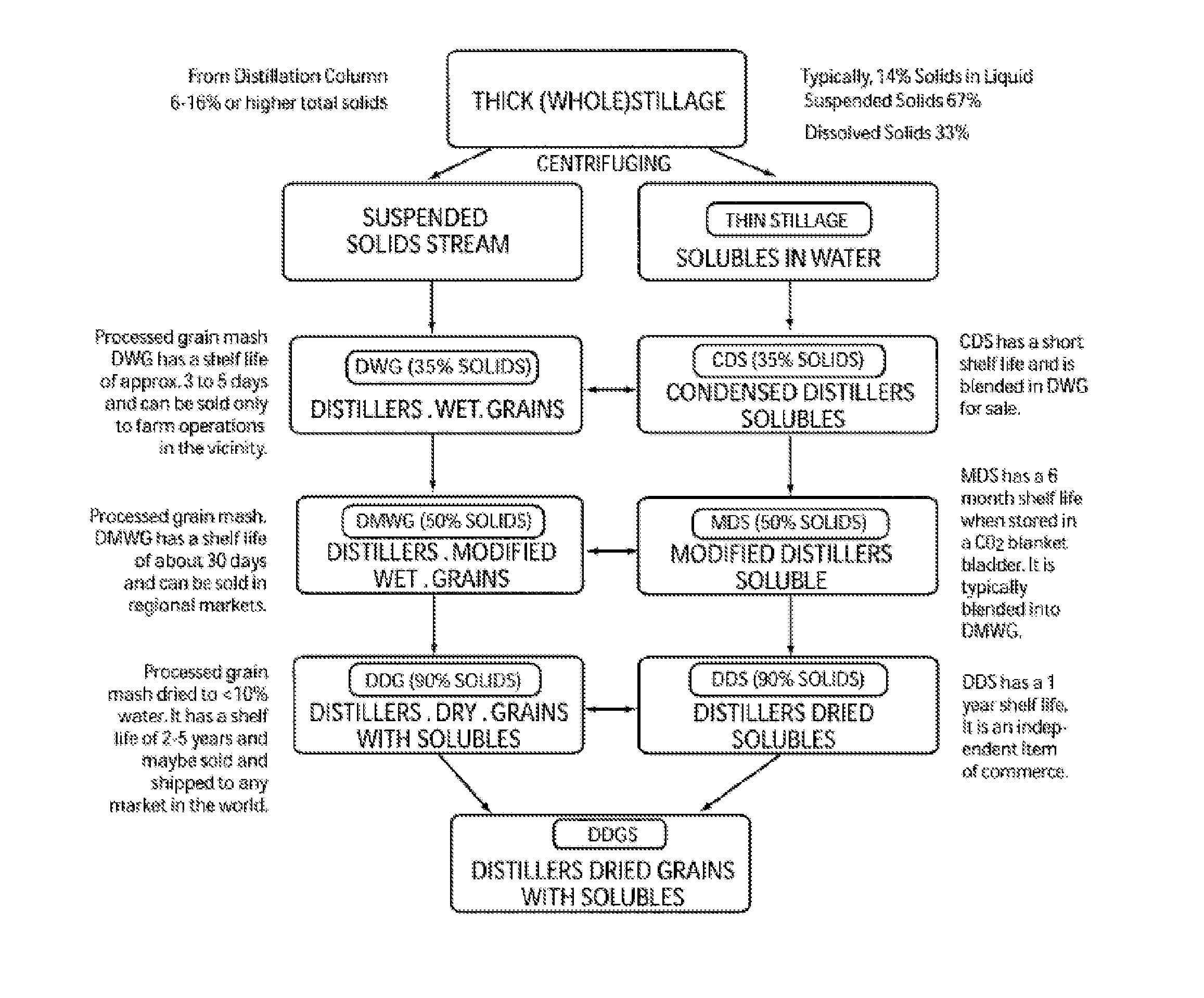

An improved ethanol production process providing novel stillage treatment is disclosed wherein the stillage is separated into four value added product streams that are subjected to drying conditions reducing or eliminating volatization of any VOC's in the product streams.

Owner:FARMERS FIRST GRP +1

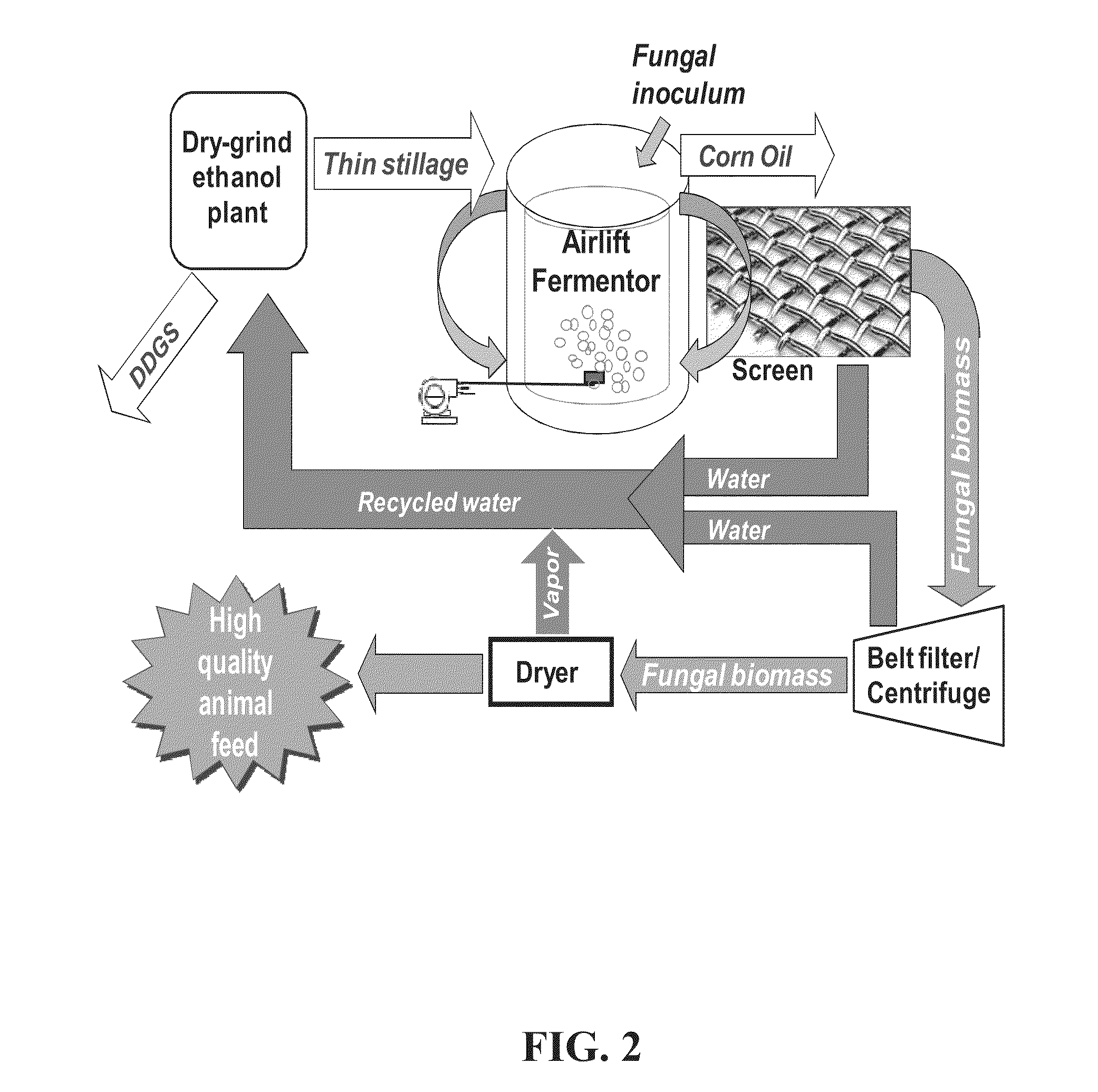

Fungi cultivation on alcohol fermentation stillage for useful products and energy savings

ActiveUS20100196994A1Easy to dehydrateEasy to shapeFungiEnergy based wastewater treatmentAirlift reactorGlycerol

A method of processing stillage from fermentation derived alcohol is disclosed, including dry-grind ethanol production from corn, by fermentation with filamentous fungi. This produces high-value fungal biomass that can be recovered by screening, is easily dewatered and used as an animal feed, human food or as a source of nutraceuticals. The methodology uses an airlift reactor to enhance the morphology of the fungi for easy harvesting and separation of water for recycling and reuse and to recover added enzymes and mineral acid with the water. The process also separates oil from the stillage. The fungal processing removes organic substances from the water that are otherwise inhibitory to the reuse prospects for the water, i.e. suspended and dissolved organic matter, including glycerol, lactic and acetic acids. The process also separates oil from the stillage by enmeshing the oil in the fungal biomass and can produce more oil through cultivation of oleaginous fungi. This approach generates revenue from low value thin stillage, while substantially reducing stillage processing costs, mainly by averting the need for evaporation of the thin stillage.

Owner:VAN LEEUWEN JOHANNES

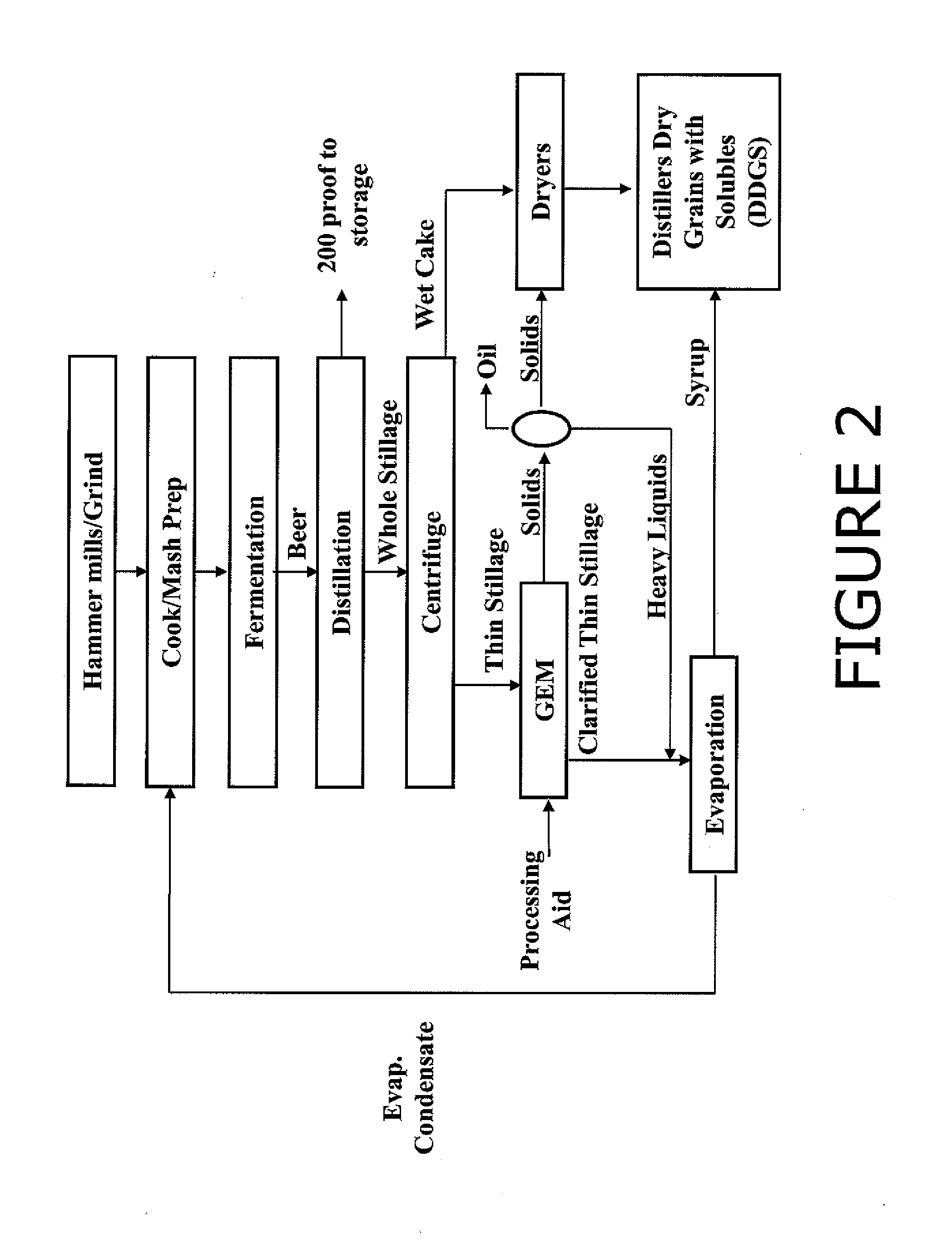

Method for conditioning and processing whole or thin stillage to aid in the separation of and recover protien and oil fractions

ActiveUS20120125859A1Lower energy requirementsFatty/oily/floating substances removal devicesSpecific water treatment objectivesProcedure AgentsProcess engineering

The invention provides a method and apparatus for reducing the energy needed to process stillage in an ethanol refining operation. The method involves adding to stillage an effective amount of at least one processing aid. The flocculant induces the separation of insoluble material that would otherwise remain suspended in water but which impose a high shear energy cost on the refining processes. This allows for the removal of insoluble material that would otherwise be overlooked but which increase energy costs. This allows for more efficient and effective separation and recovery of insoluble fractions of the concentrated thin stillage that would otherwise be overlooked and lost in the process. Loss of these valued fractions as a result of traditional processing techniques and those requiring extensive additional energy input results in the loss of high value co-products to low revenue process streams. This allows stillage to be processed more rapidly with a lower energy cost and improved co-product recovery economics.

Owner:ECOLAB USA INC

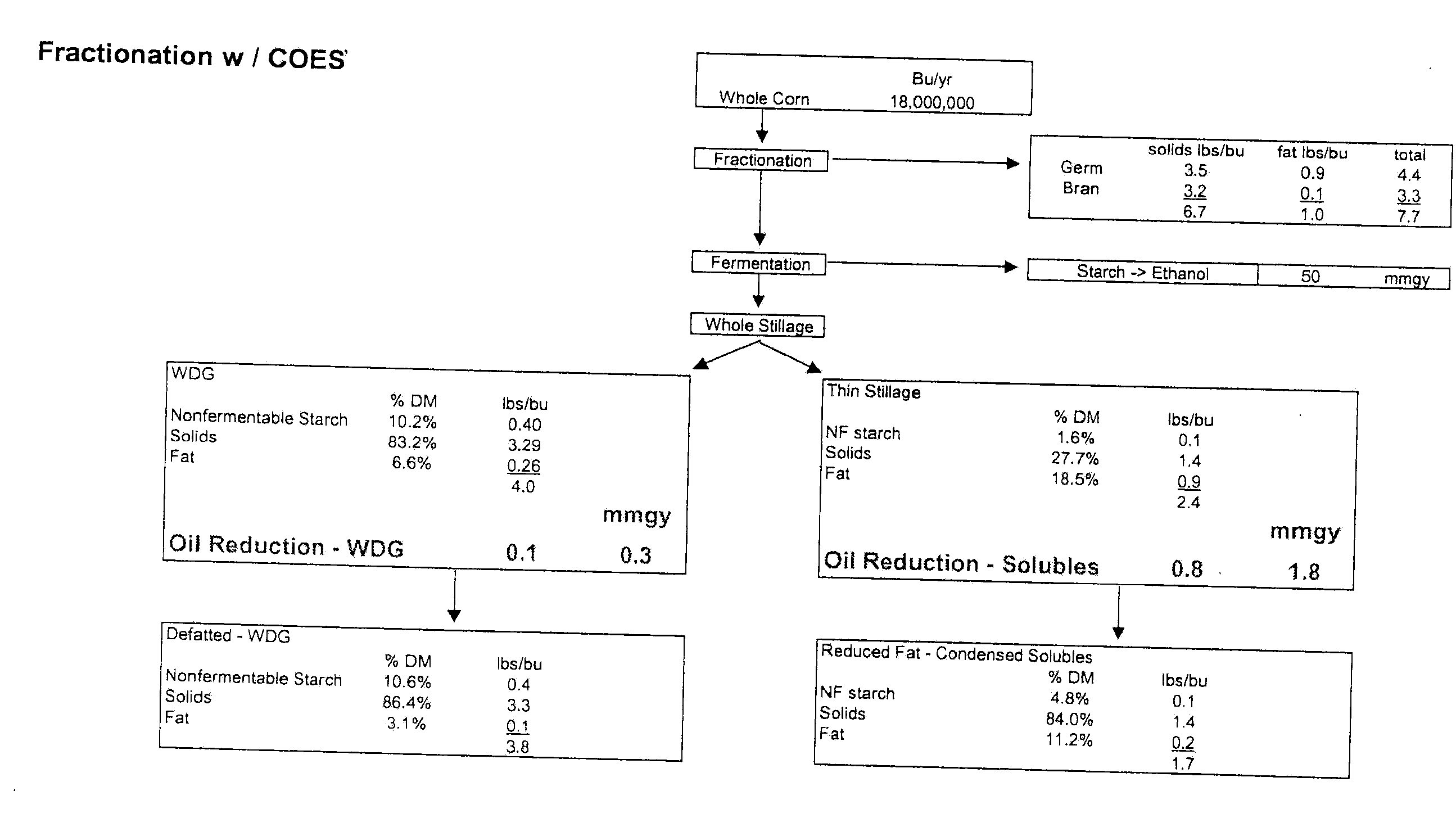

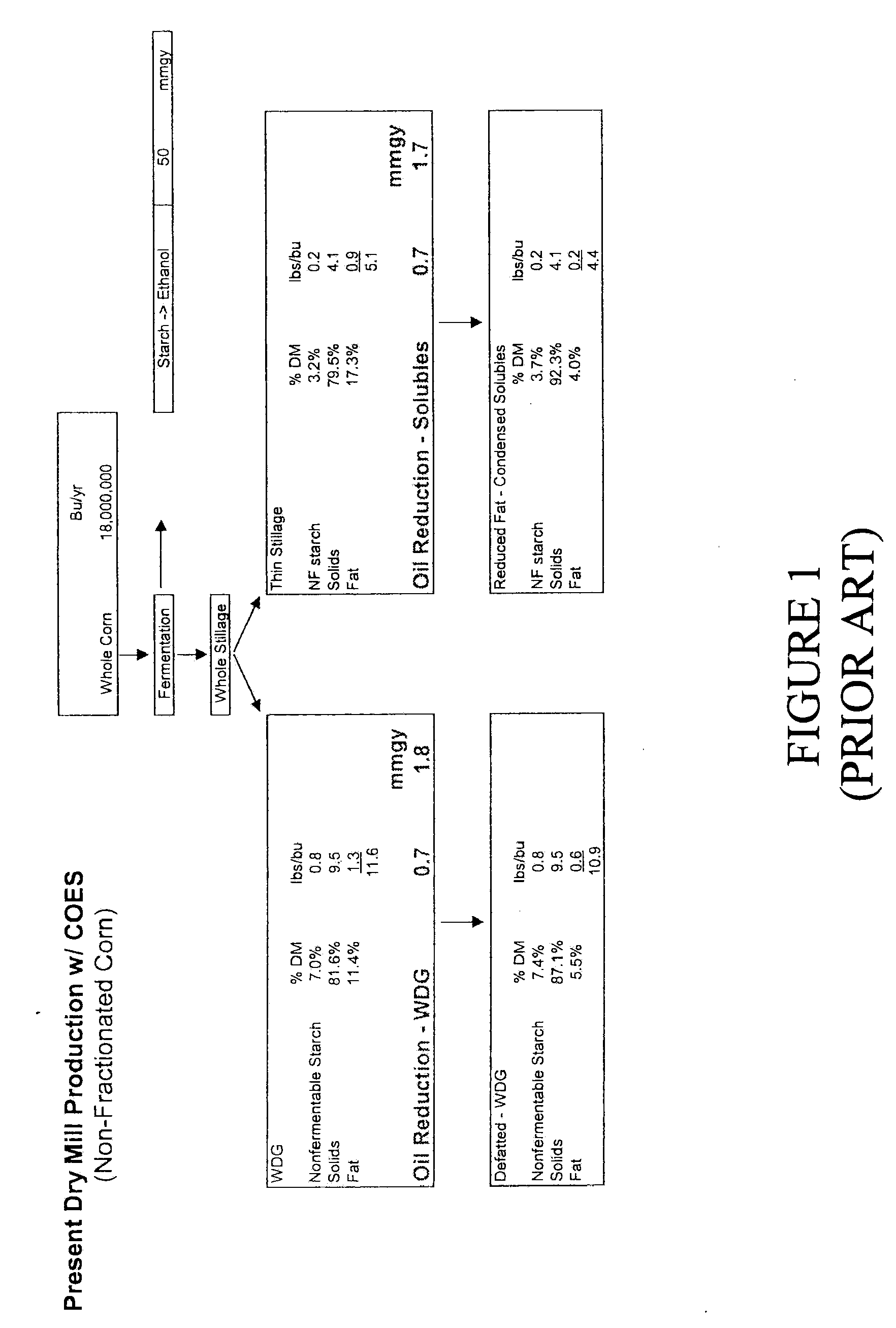

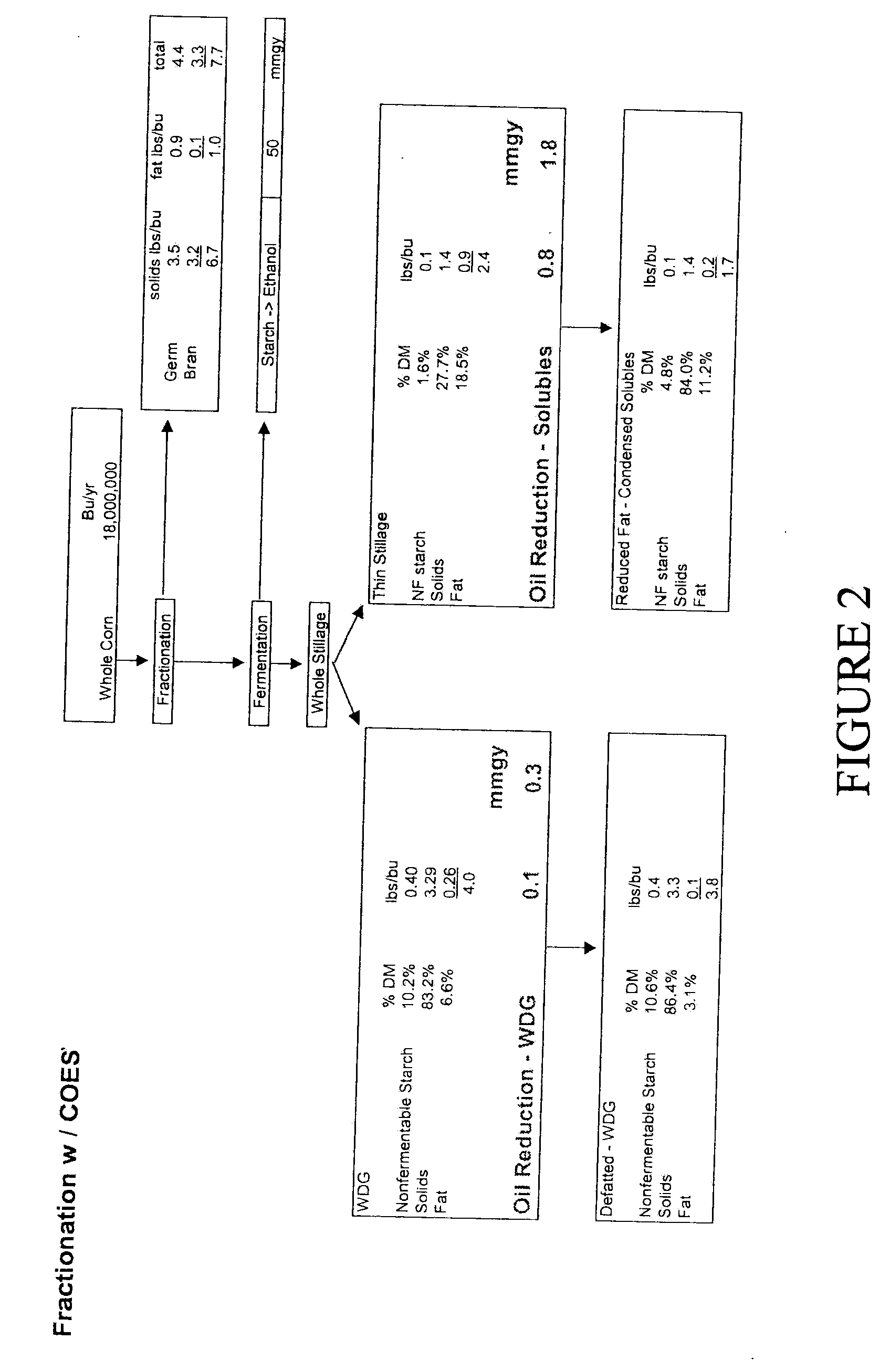

Methods for Recovering Oil from a Fractionated Dry Milling Process

InactiveUS20080299632A1Avoid boilingFatty oils/acids recovery from wasteOrganic compound preparationFractionationMaterials science

Processes for recovering oil from thin stillage produced during a fractionation-based dry milling process. The thin stillage can be heated or heated in combination with centrifuging to separate and recover oil from the thin stillage. Optionally, the thin stillage may be concentrated prior to recovering the oil.

Owner:GS CLEANTECH CORP

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080295980A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

Method of liberating bound oil present in stillage

InactiveUS20090227004A1Promote recoveryEfficient reductionFatty oils/acids recovery from wasteFatty acids production/refiningStillageChemistry

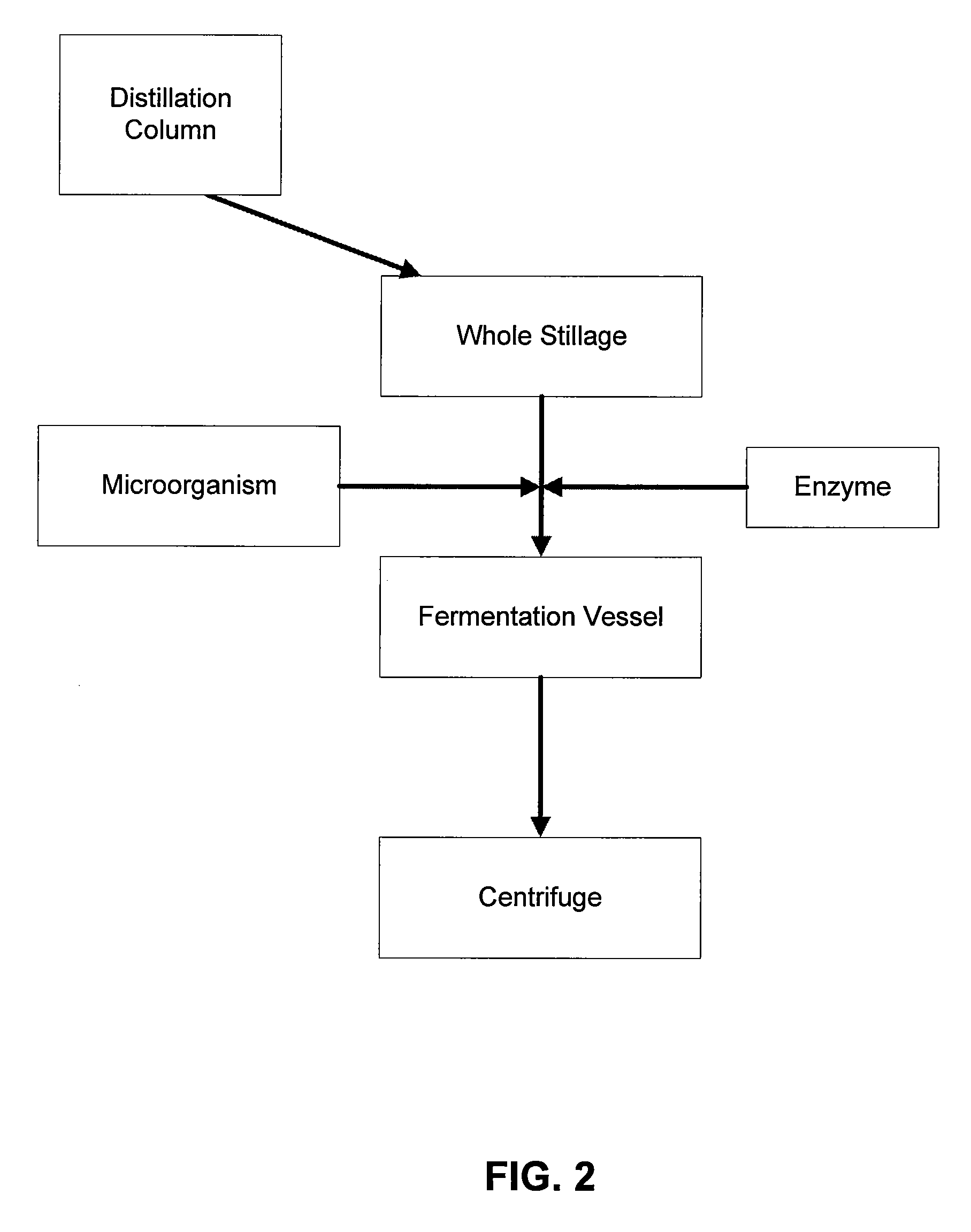

A method for processing of byproducts in an ethanol production process is provided. The method includes applying a mixture of a microorganism to a stillage stream, metabolizing gums in the stillage stream using the mixture to release oil in the gums carried by the stillage stream and recovering the oil. Methods of liberating or releasing bound oil present in stillage are also provided.

Owner:AG VENTURES ALLIANCE COOP

Method of dewatering grain stillage solids

ActiveUS20050079270A1Improve throughputShorten the timeBy-product recoveryFood processingAcryditeSodium methacrylate

A method of dewatering corn stillage solids comprising adding to the solids an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

Method of dewatering thin stillage processing streams

ActiveUS20070210007A1Improve agglomerationAbility to withstandWater treatment parameter controlWater treatment compoundsAcryditeSodium methacrylate

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and flocculated solids; and separating the water from the flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

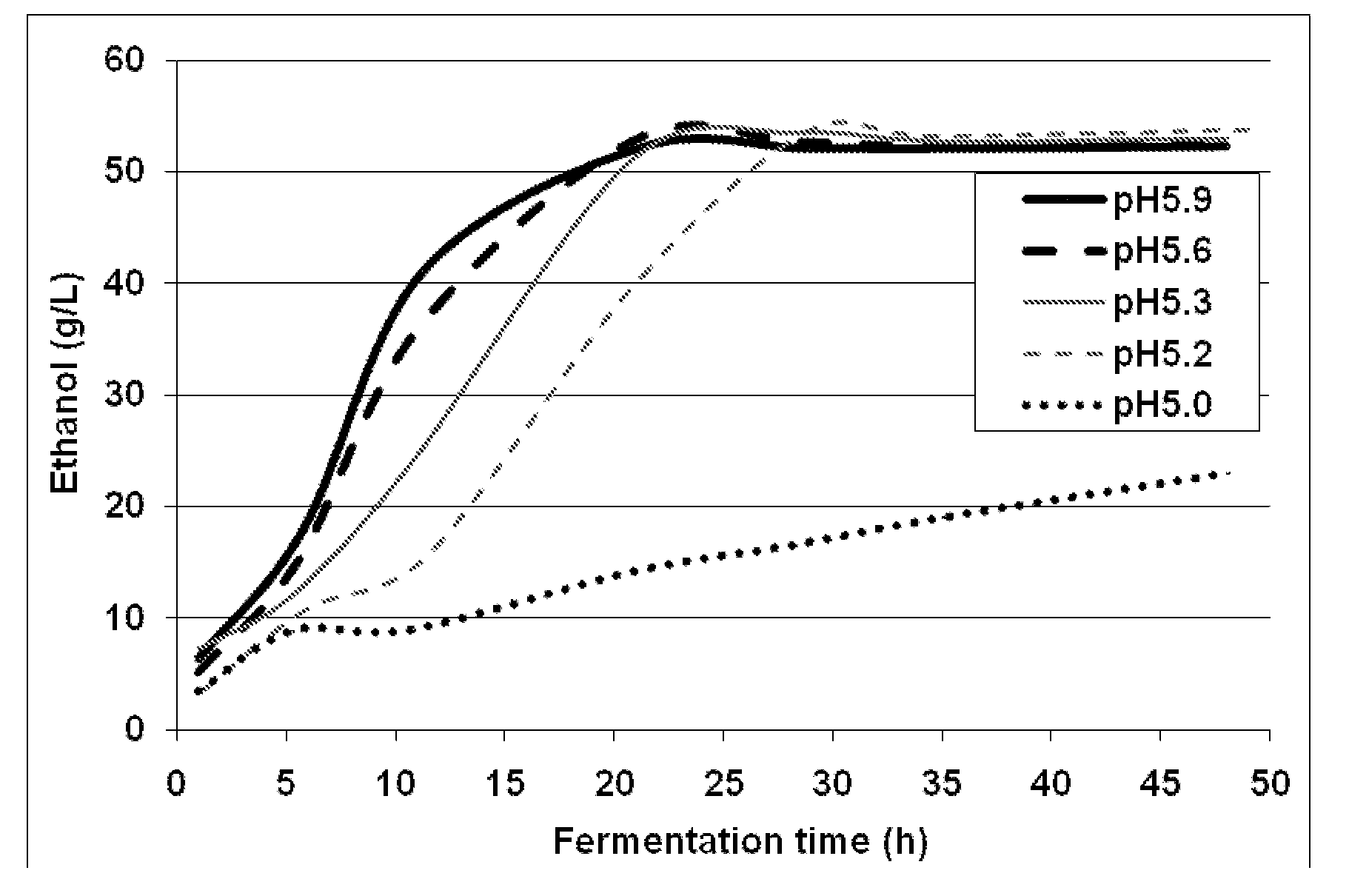

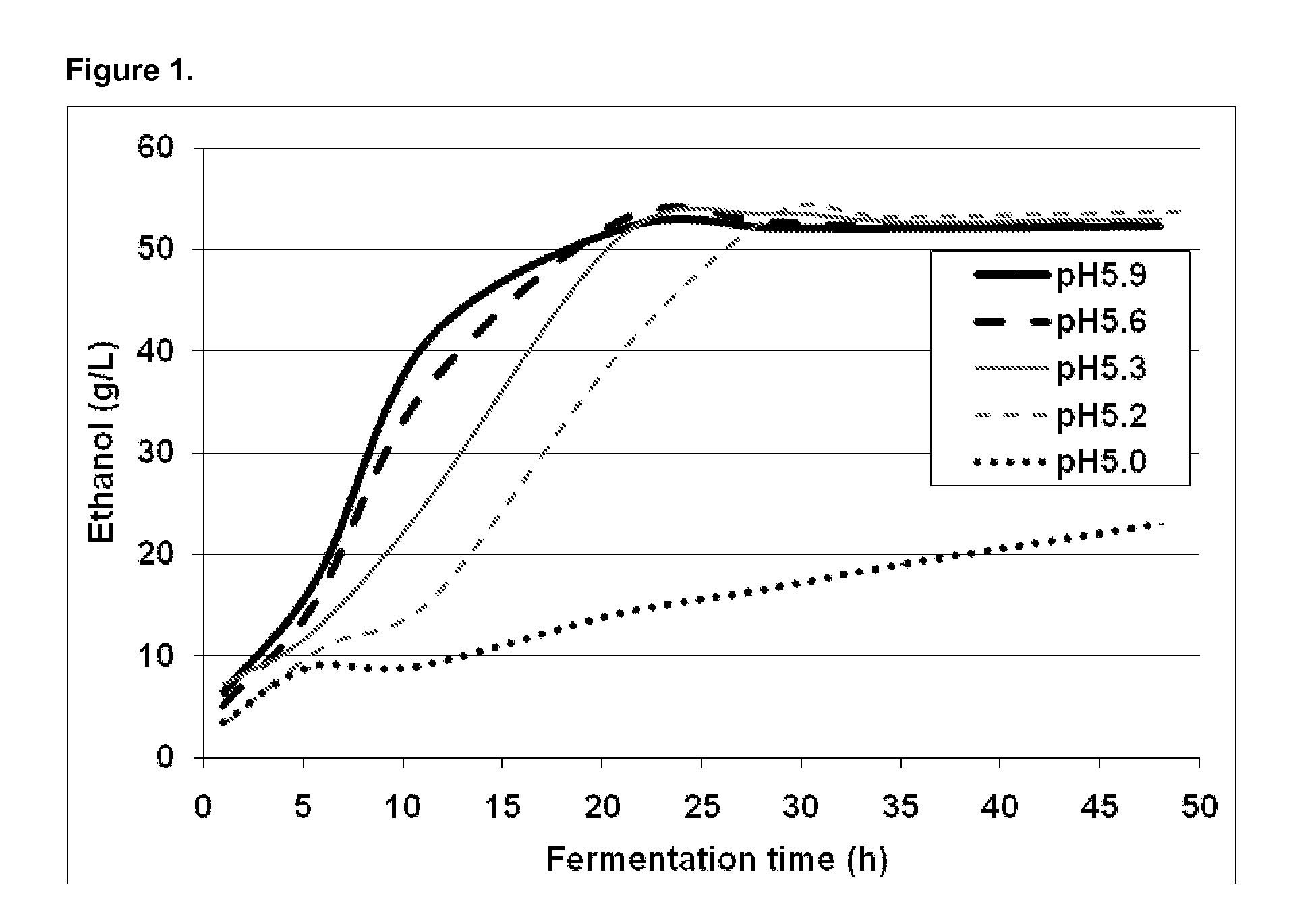

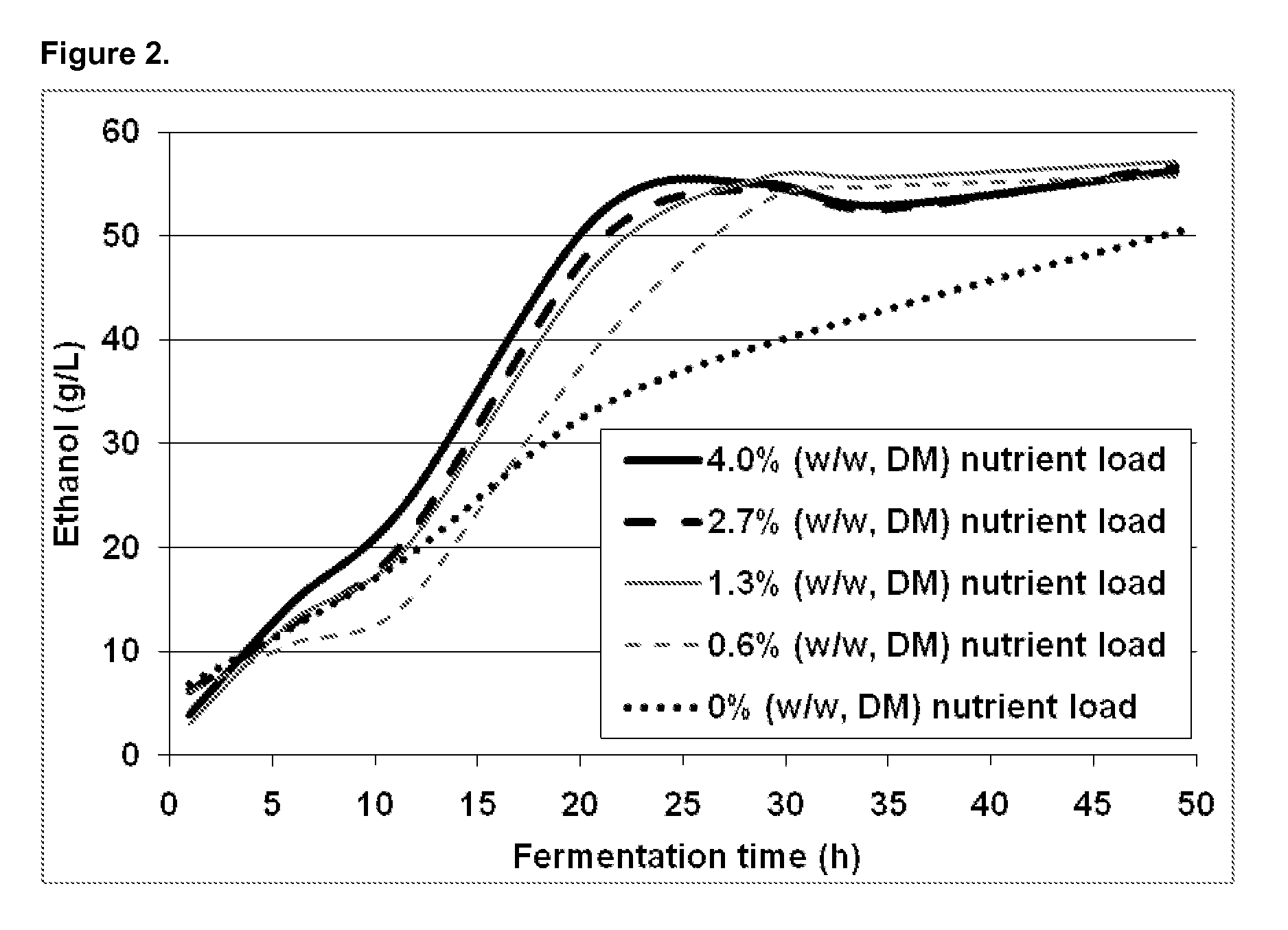

Process for alcoholic fermentation of lignocellulosic biomass

InactiveUS20100159552A1Lower cost of capitalReduce operating costsBiofuelsFermentationCelluloseHydrolysate

A process for the production of ethanol wherein a hydrolyzed lignocellulosic biomass is fermented in the presence of a stillage residue. The fermentation of cellulosic hydrolysates is improved by adding prior to and / or during fermentation a stillage residue side stream from a corn starch-to-ethanol process as a nutrient source for the yeast organisms used in the fermentation. Stillage residues from the grain dry mill ethanol producing process, including the whole stillage, wet cake, thin stillage, and / or syrup are added to assist as a nitrogen and nutrient source for the fermentive processes. The stillage residue is produced by any grain-to-ethanol process.

Owner:GREENFIELD SPECIALTY ALCOHOLS

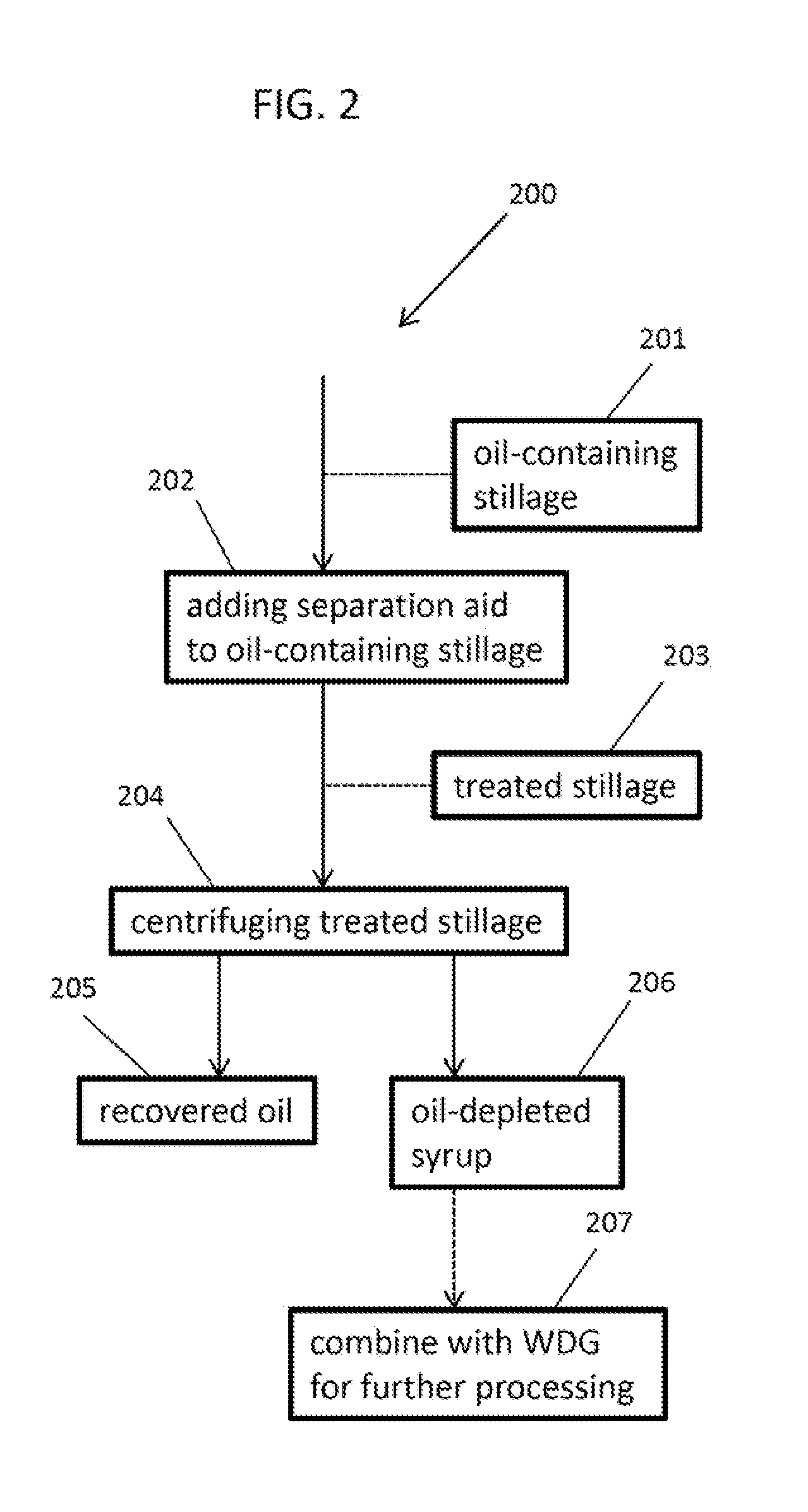

Methods And Systems For Bio-Oil Recovery And Separation Aids Therefor

ActiveUS20140171670A1Reduce surface tensionEffective recoveryFatty oils/acids recovery from wasteRotary centrifugesSURFACTANT BLENDCentrifuge

A method and system for bio-oil recovery from biomass are provided which includes adding at least one separation aid to stillage that contains oil to form a treated stillage prior to centrifuging the stillage, and centrifuging the treated stillage in at least one centrifuge to separate at least a portion of the oil from the treated stillage. The separation aid can contain at least one lecithin and at least one oil and optionally at least one surfactant having an HLB value of at least 6. Treated stillage products are also provided which can contain the indicated separation aid and recovered oil.

Owner:BUCKMAN LAB INT INC

Recovery of desired co-products from fermentation stillage streams

ActiveUS8236977B2Reduce pressureFatty oils/acids recovery from wasteWater/sewage treatment by centrifugal separationCo productChemistry

Processes and methods of recovering desired products from fermentation stillage are presented, including processes and methods of recovering lipids and aqueous materials.

Owner:EDENIQ INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com