Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10133results about "Hydroxy compound preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

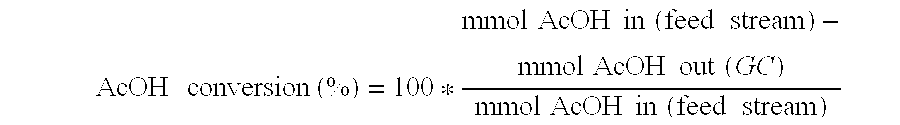

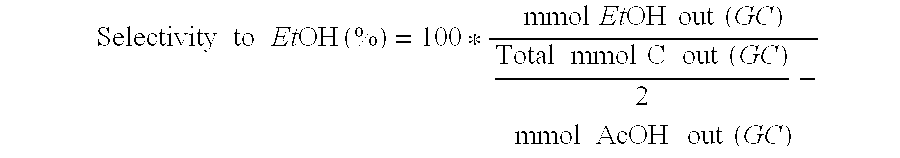

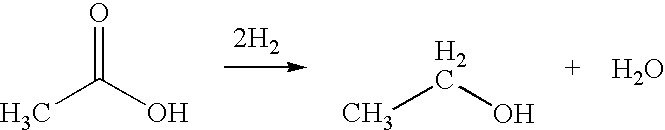

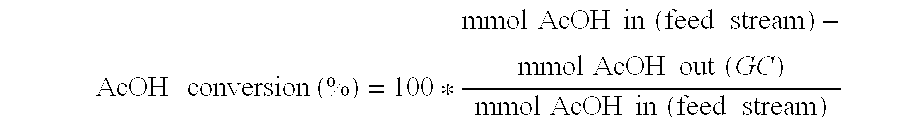

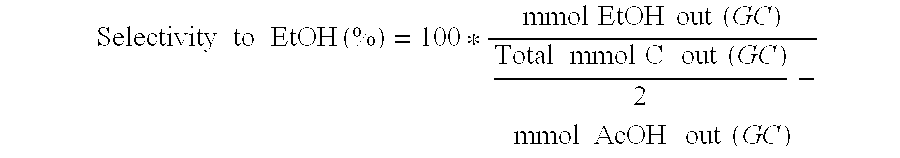

Ethanol production from acetic acid utilizing a cobalt catalyst

InactiveUS7608744B1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionAcetic acidPlatinum

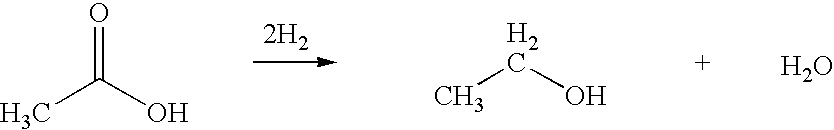

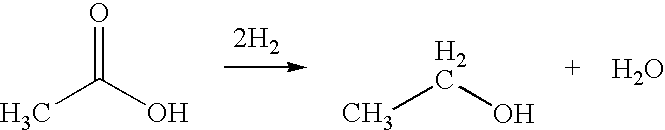

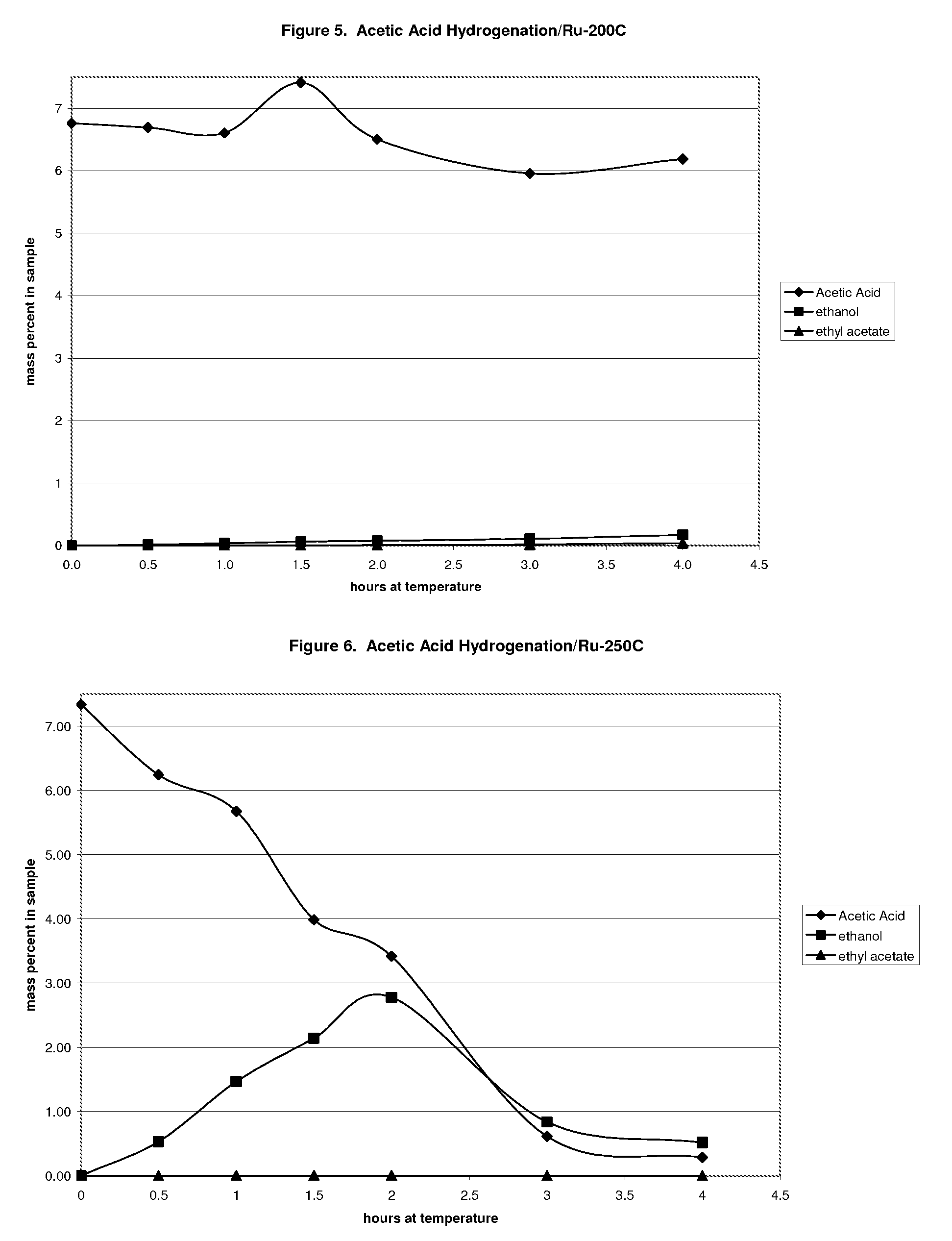

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either cobalt and palladium supported on graphite or cobalt and platinum supported on silica selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS7863489B2High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicateAcetic acid

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

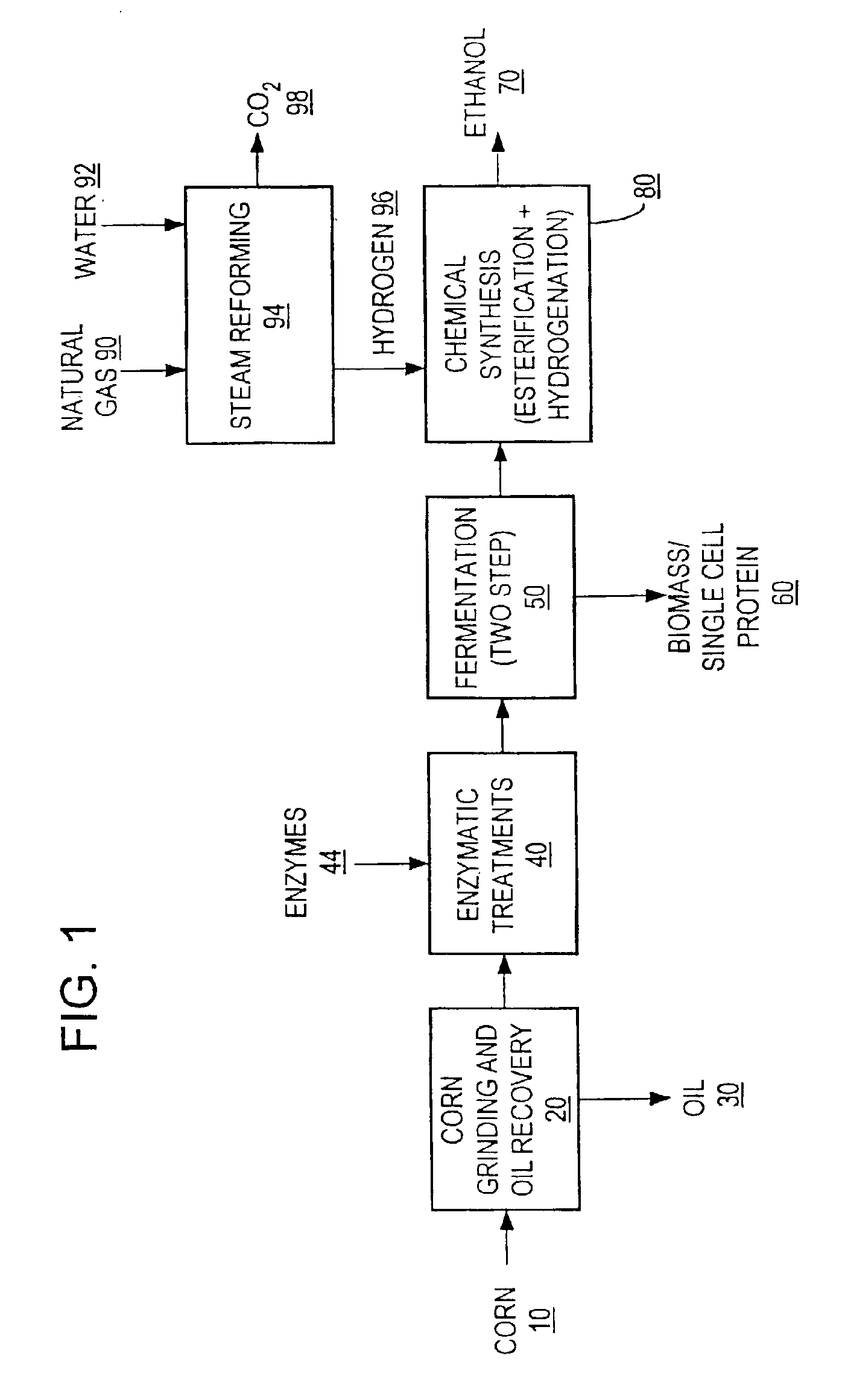

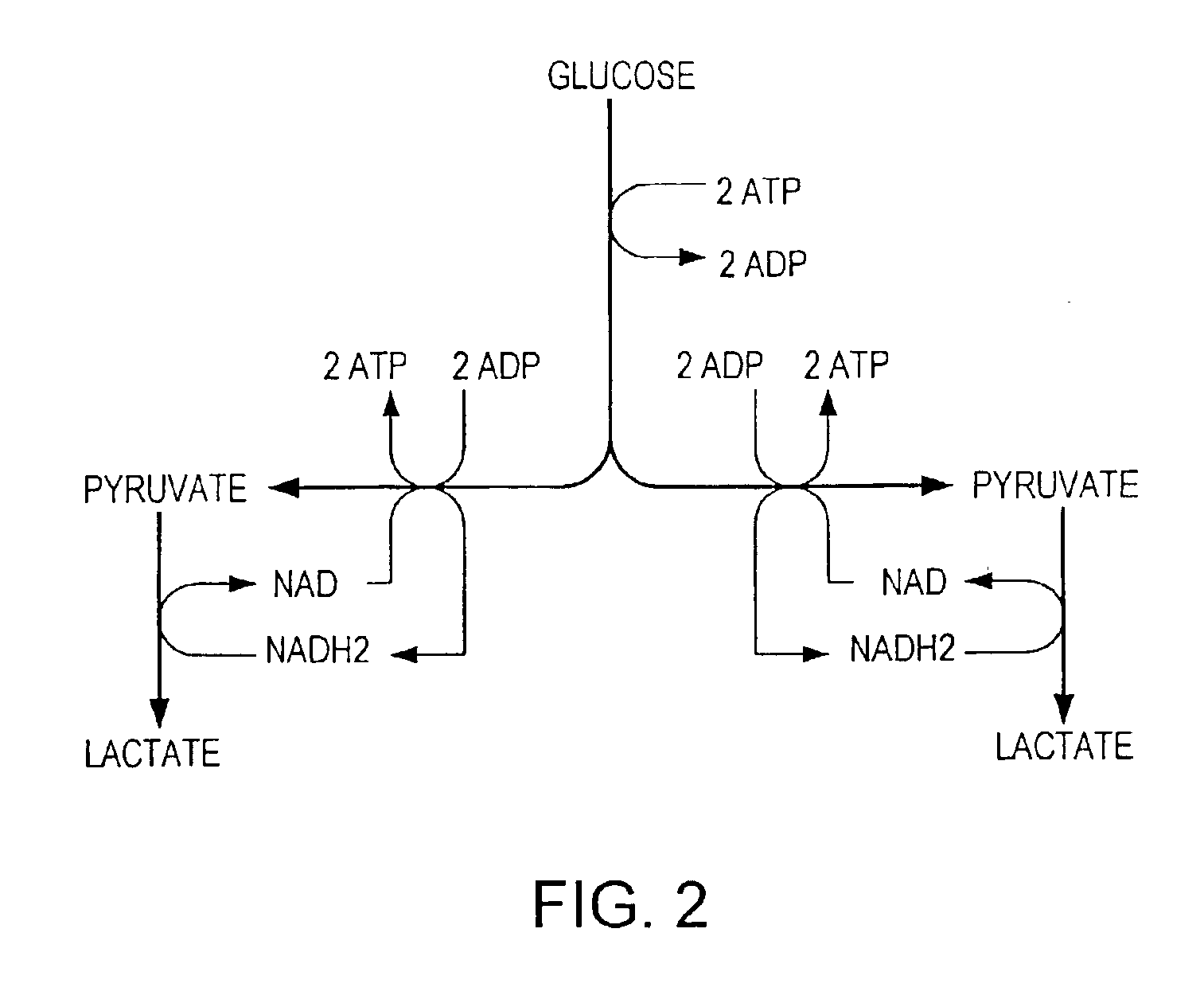

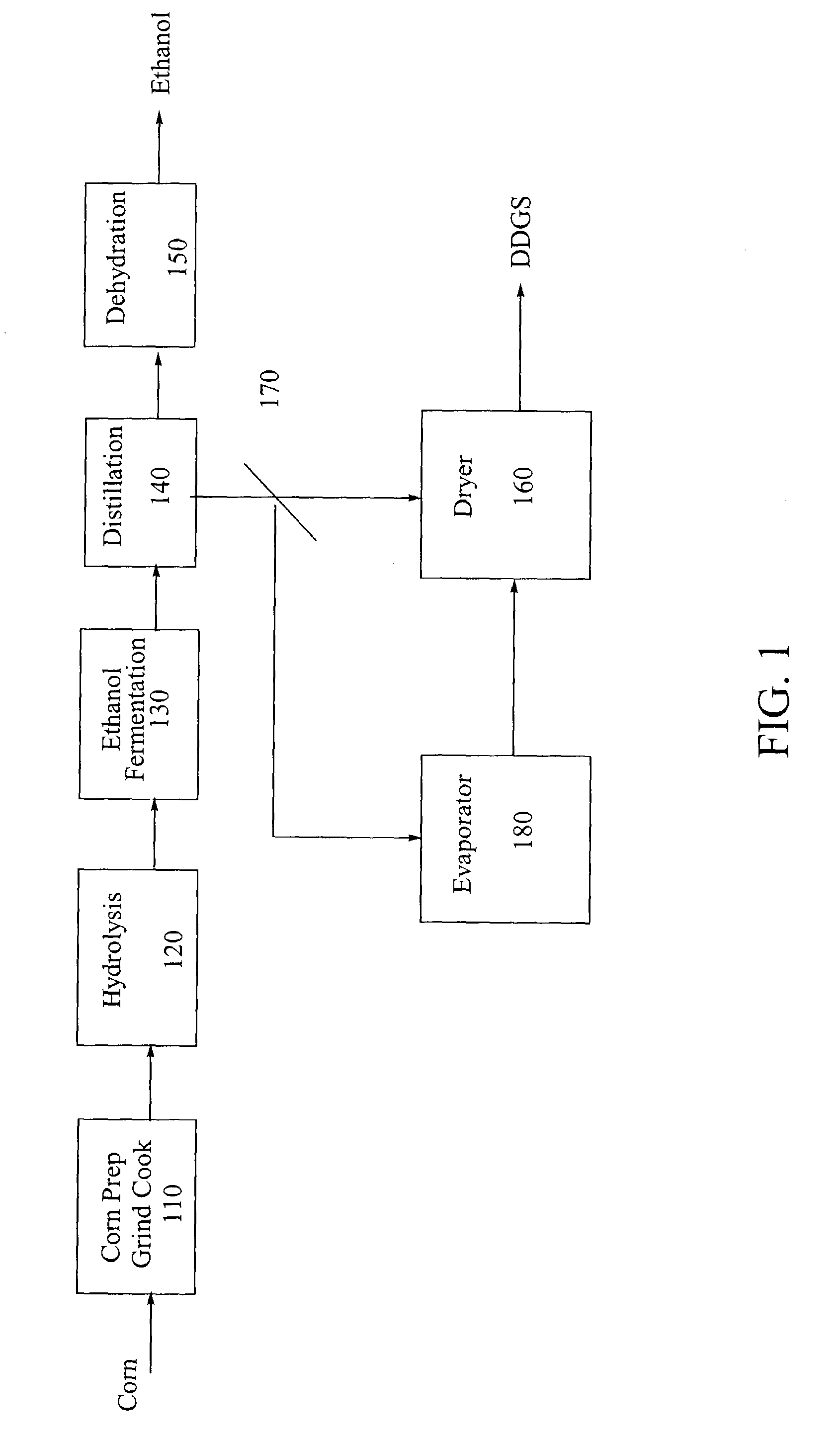

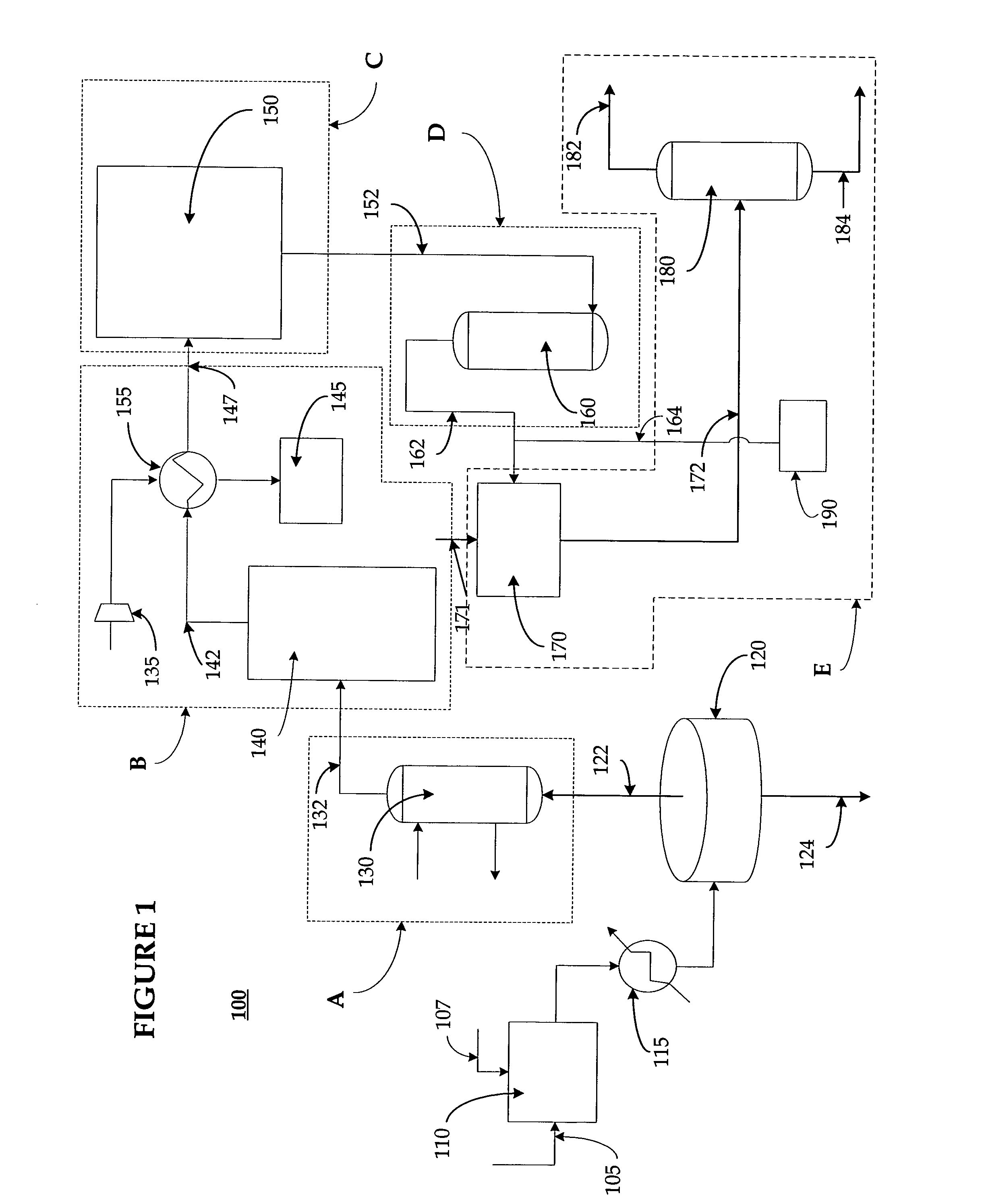

Process for producing ethanol

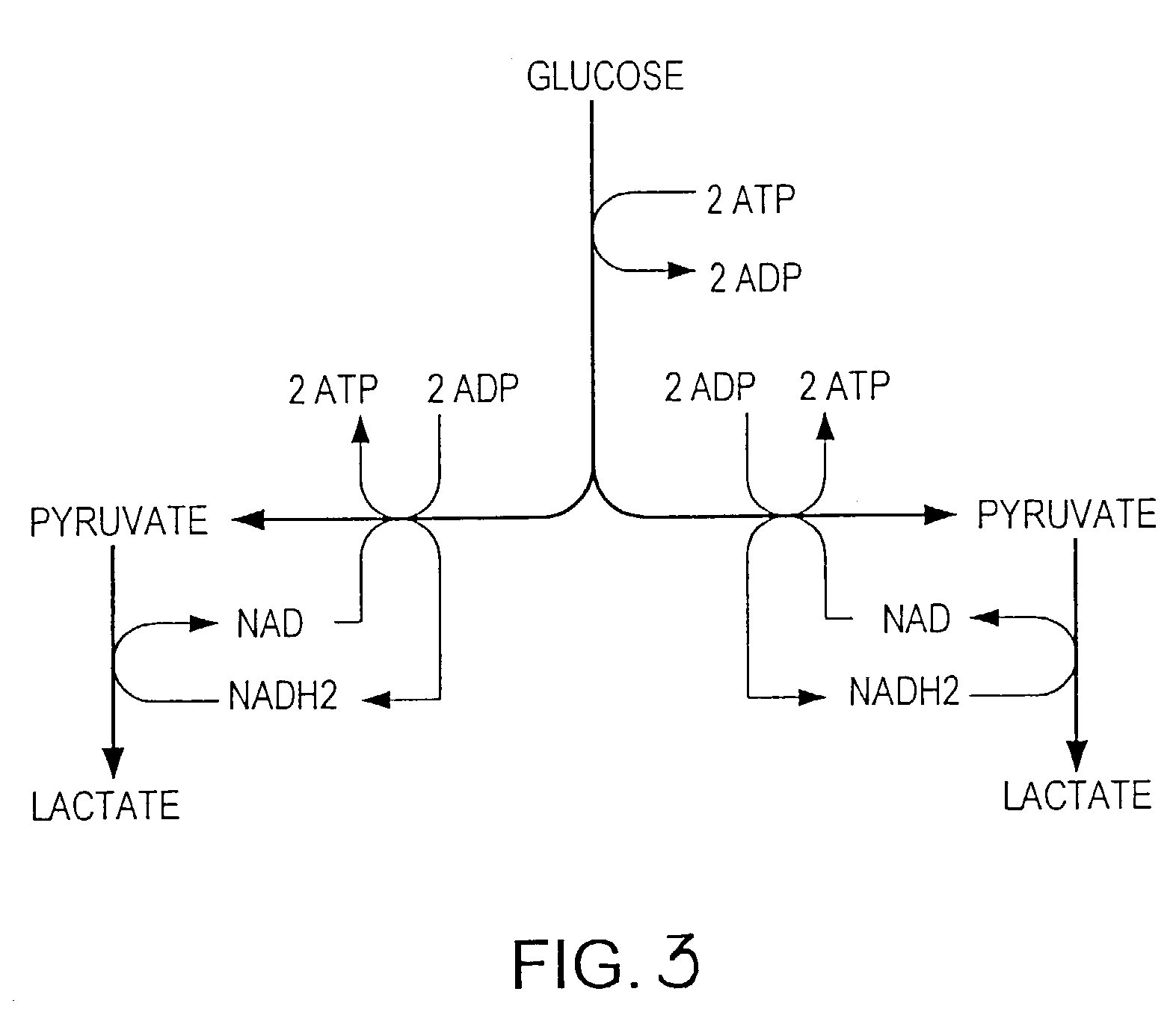

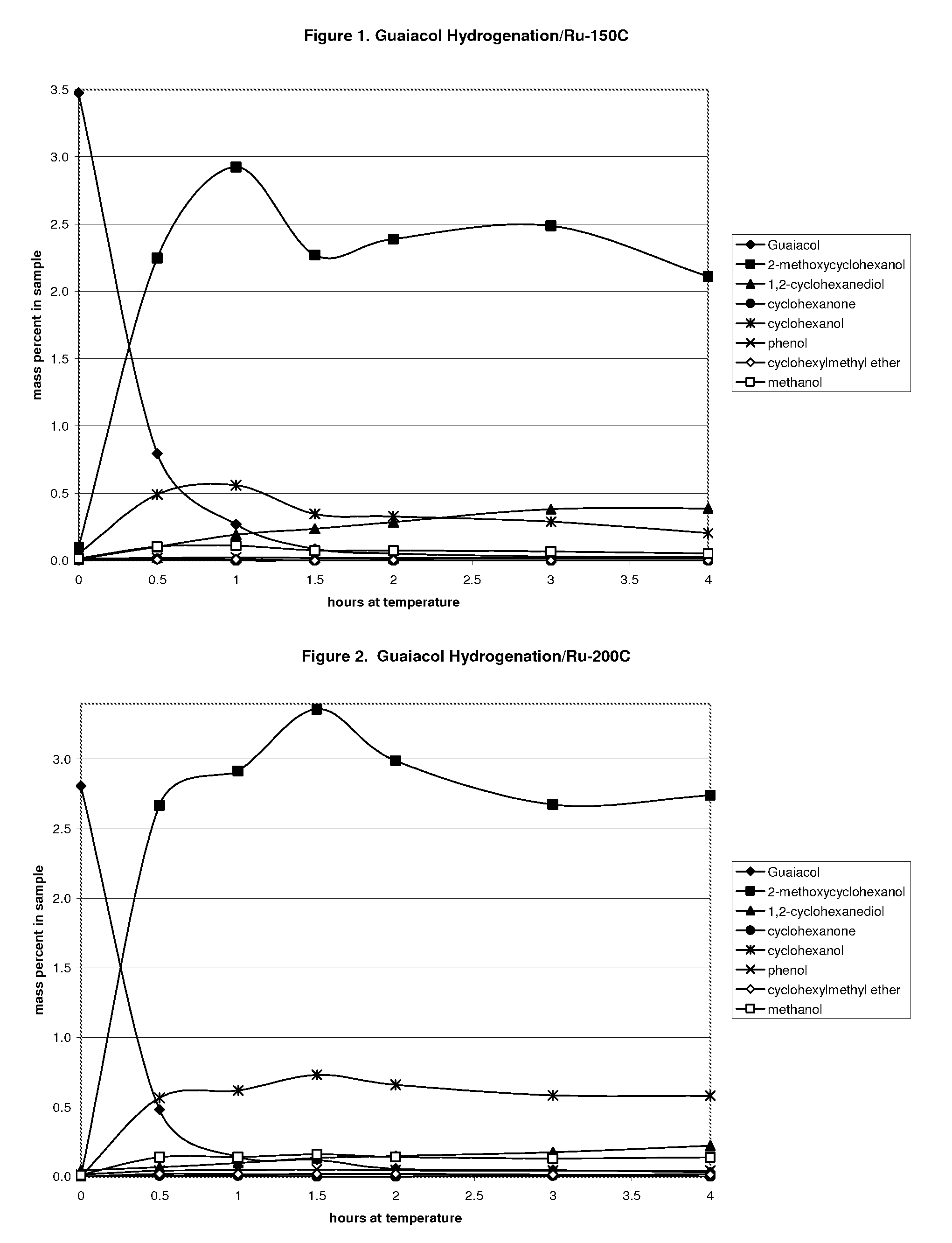

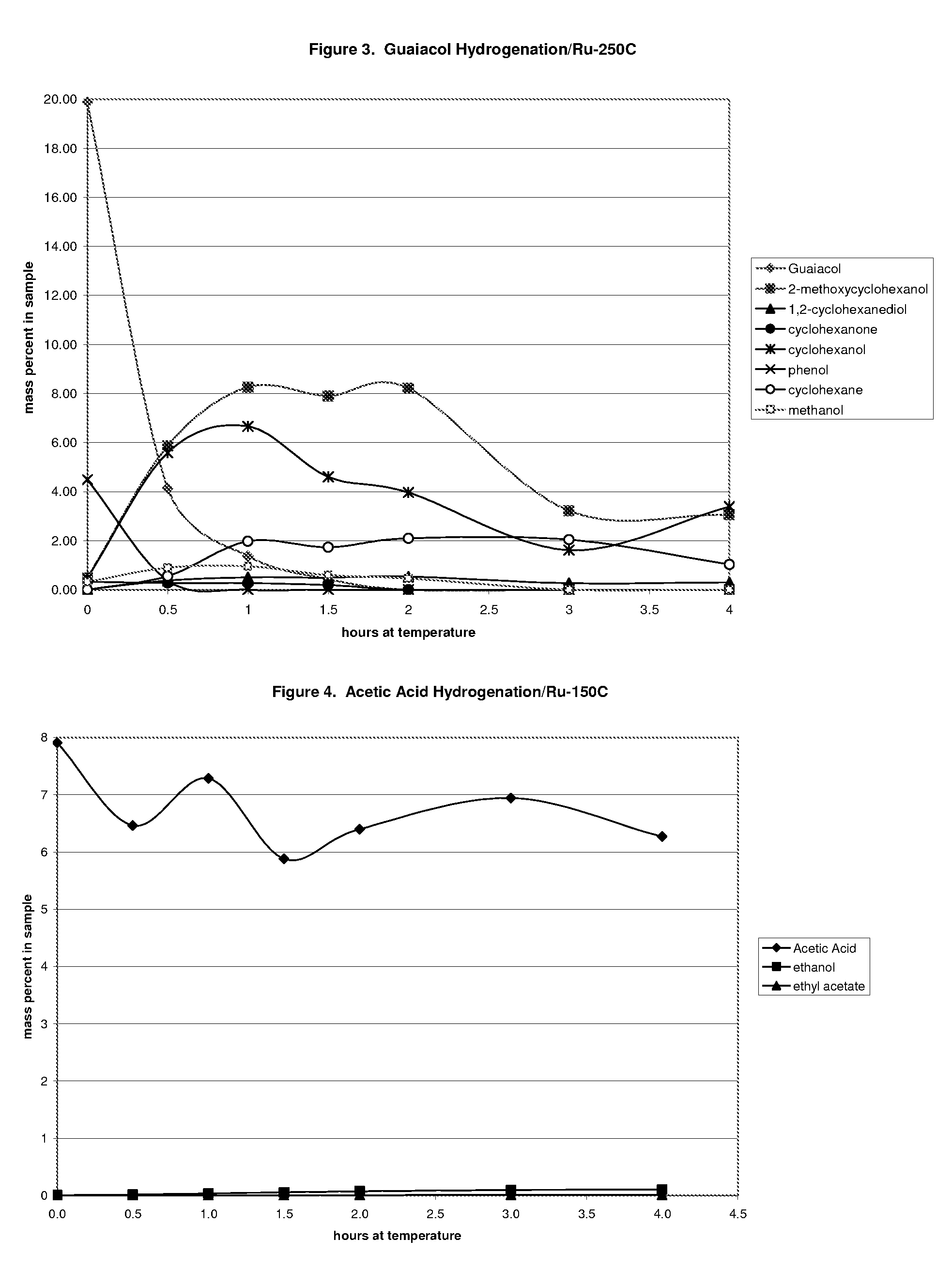

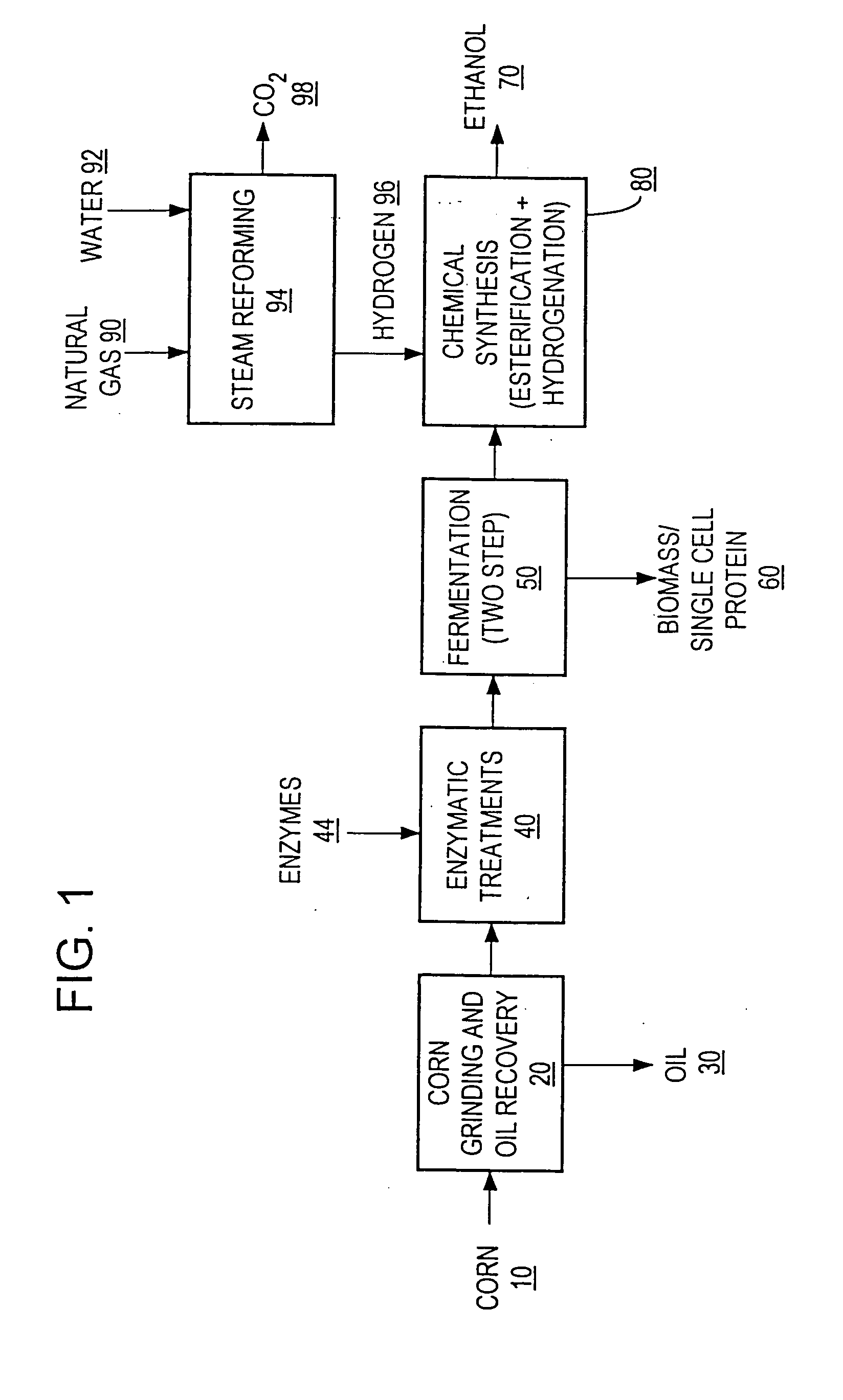

InactiveUS6927048B2High carbon yieldHigh protein concentrationOrganic compound preparationCarboxylic acid esters preparationAcetic acidHydrogenation reaction

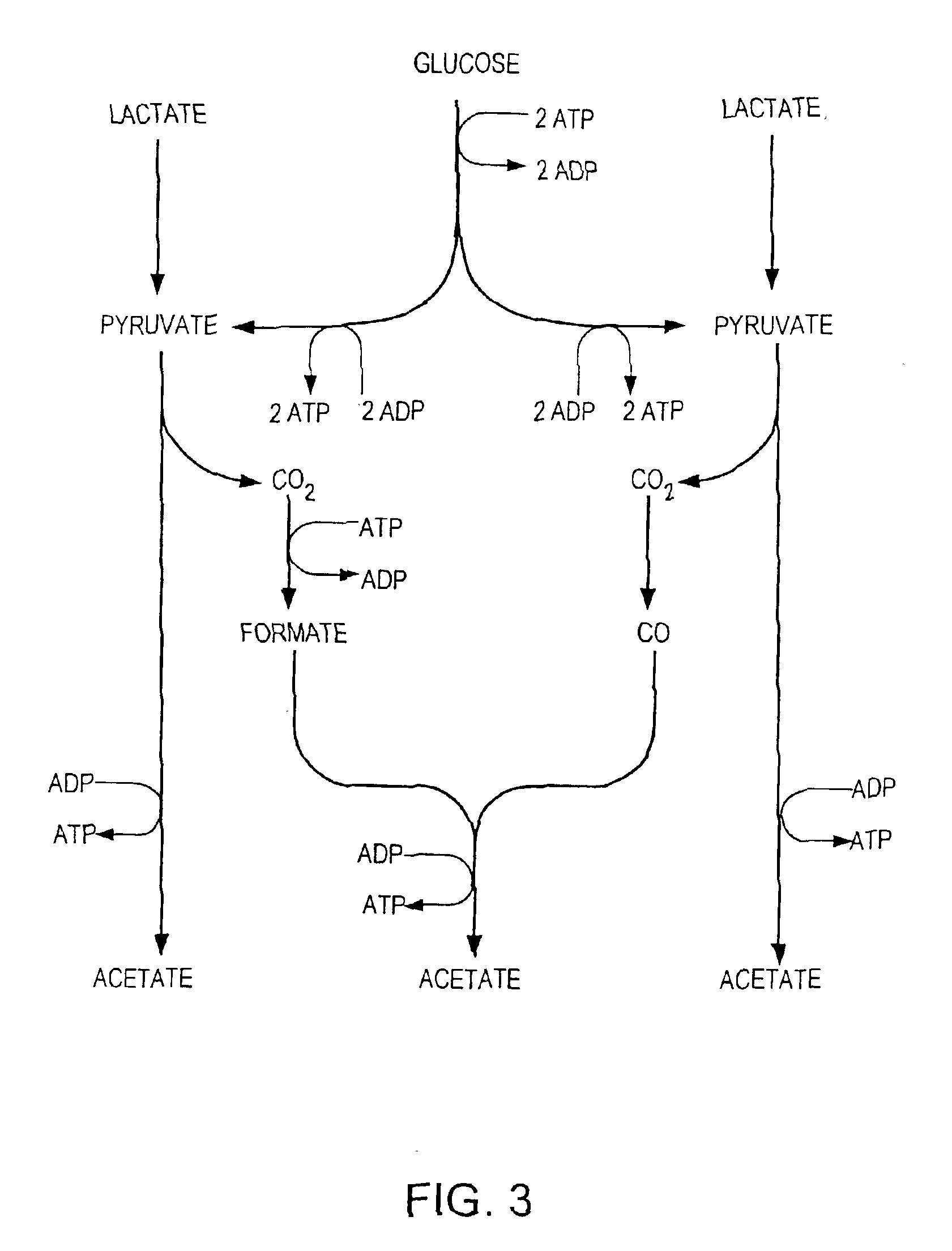

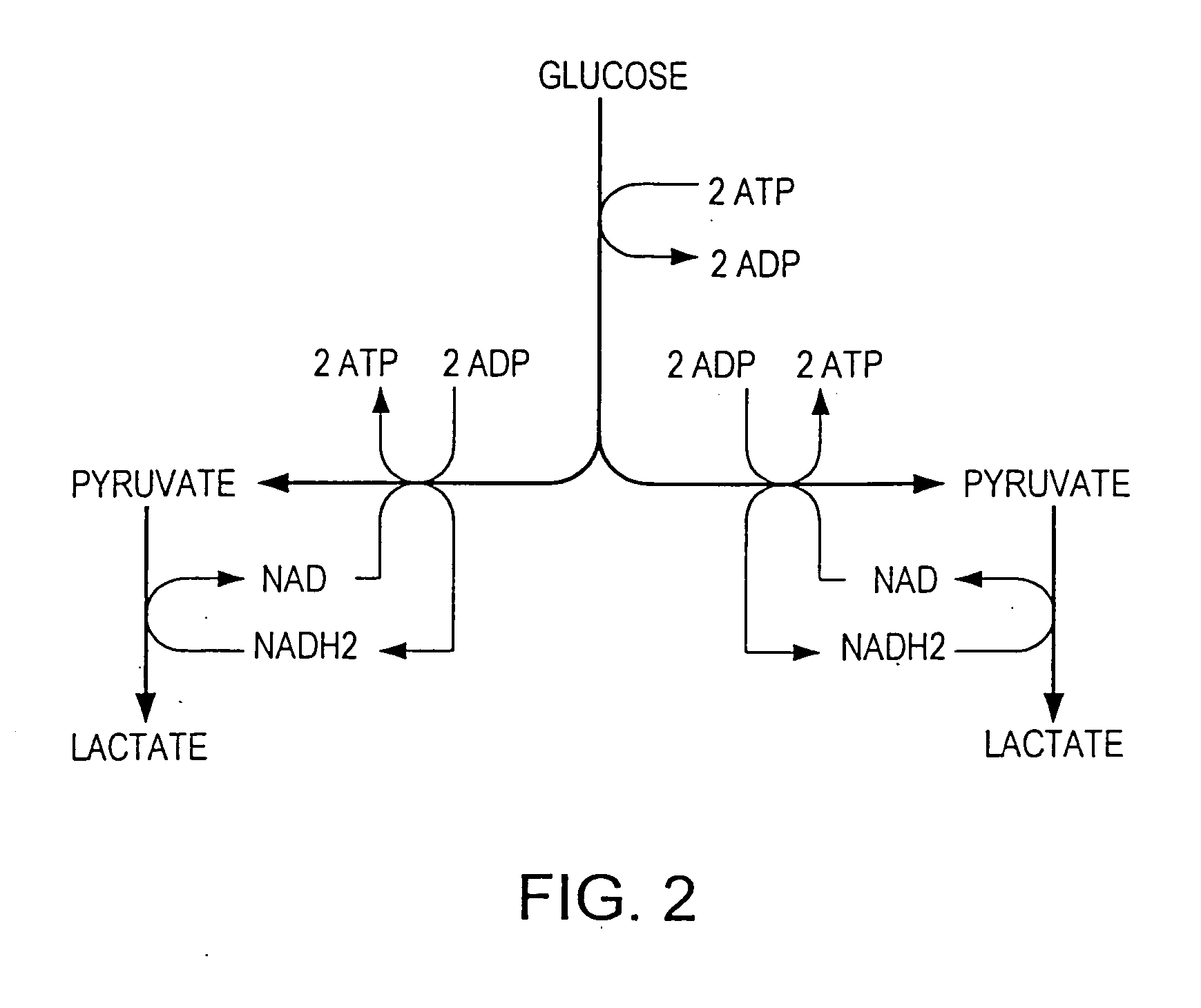

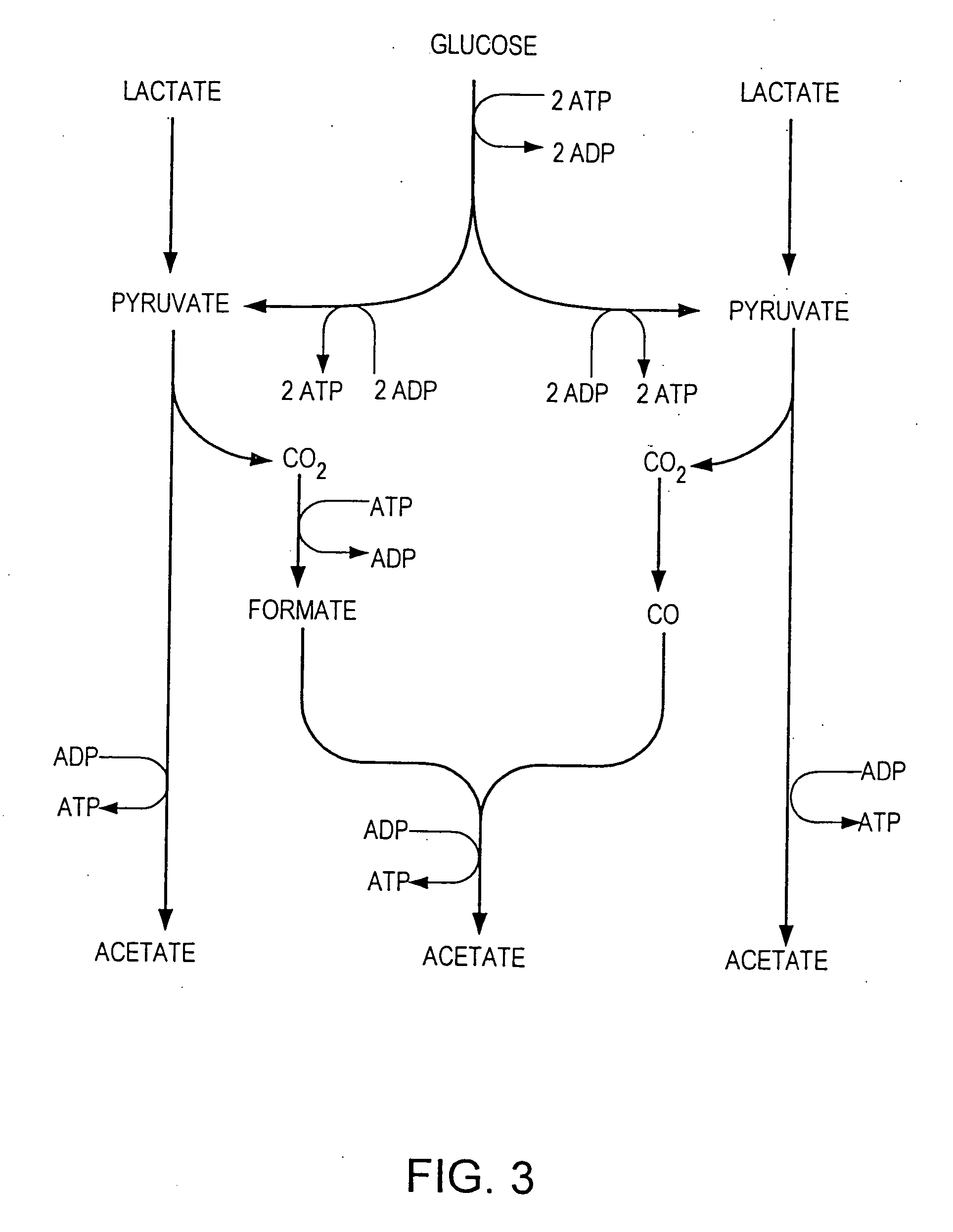

A process for producing ethanol including a combination of biochemical and synthetic conversions results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from carbohydrates, such as corn, using enzymatic milling and fermentation steps, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts can include corn oil, and high protein animal feed containing the biomass produced in the fermentation.

Owner:ZEACHEM

System for creating and maintaining a database of information utilizing user opinions

InactiveUS20040205065A1Easily and uniquely searchedInformed decision makingMetadata text retrievalOrganic compound preparationInternet basedHuman language

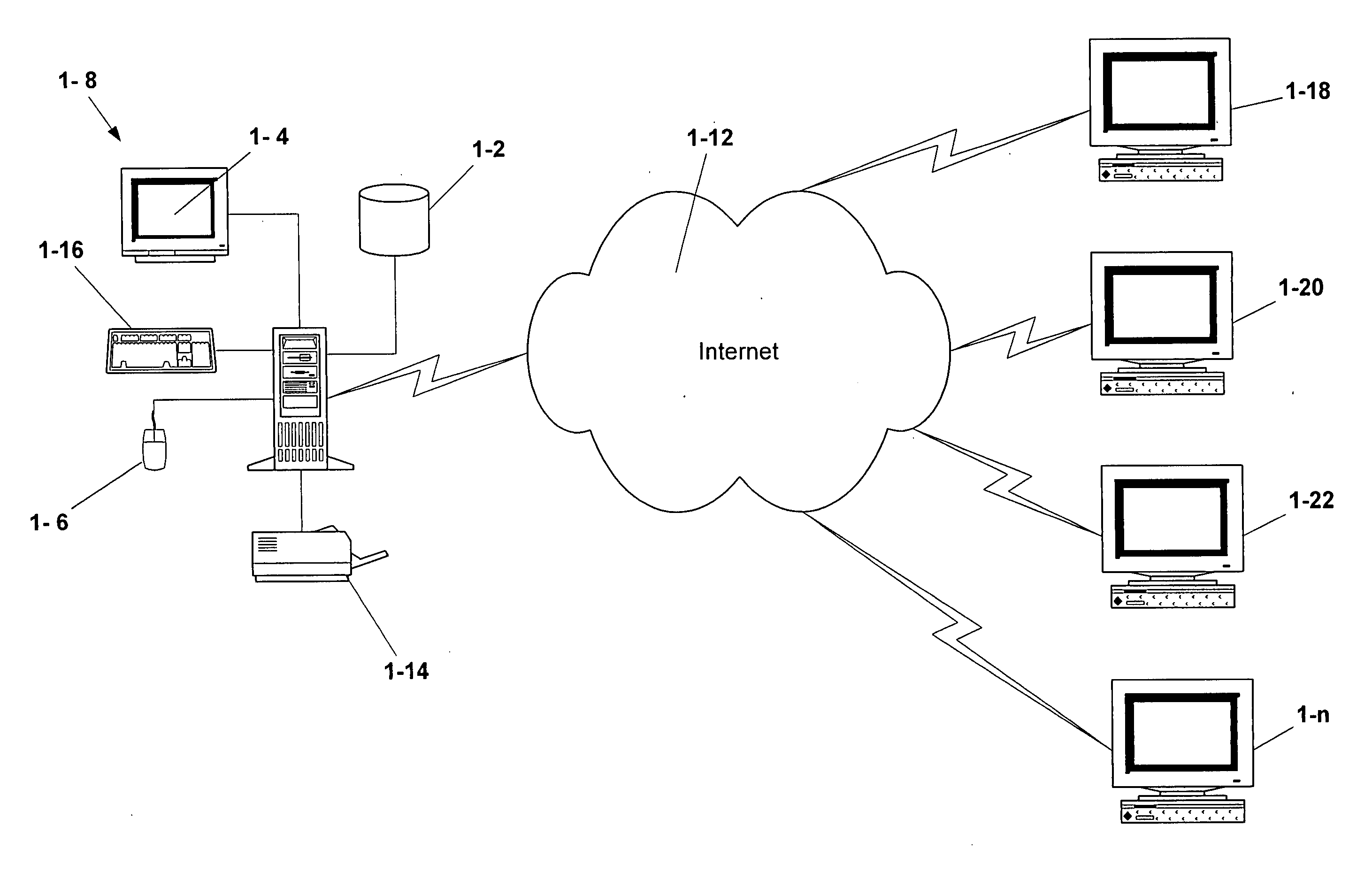

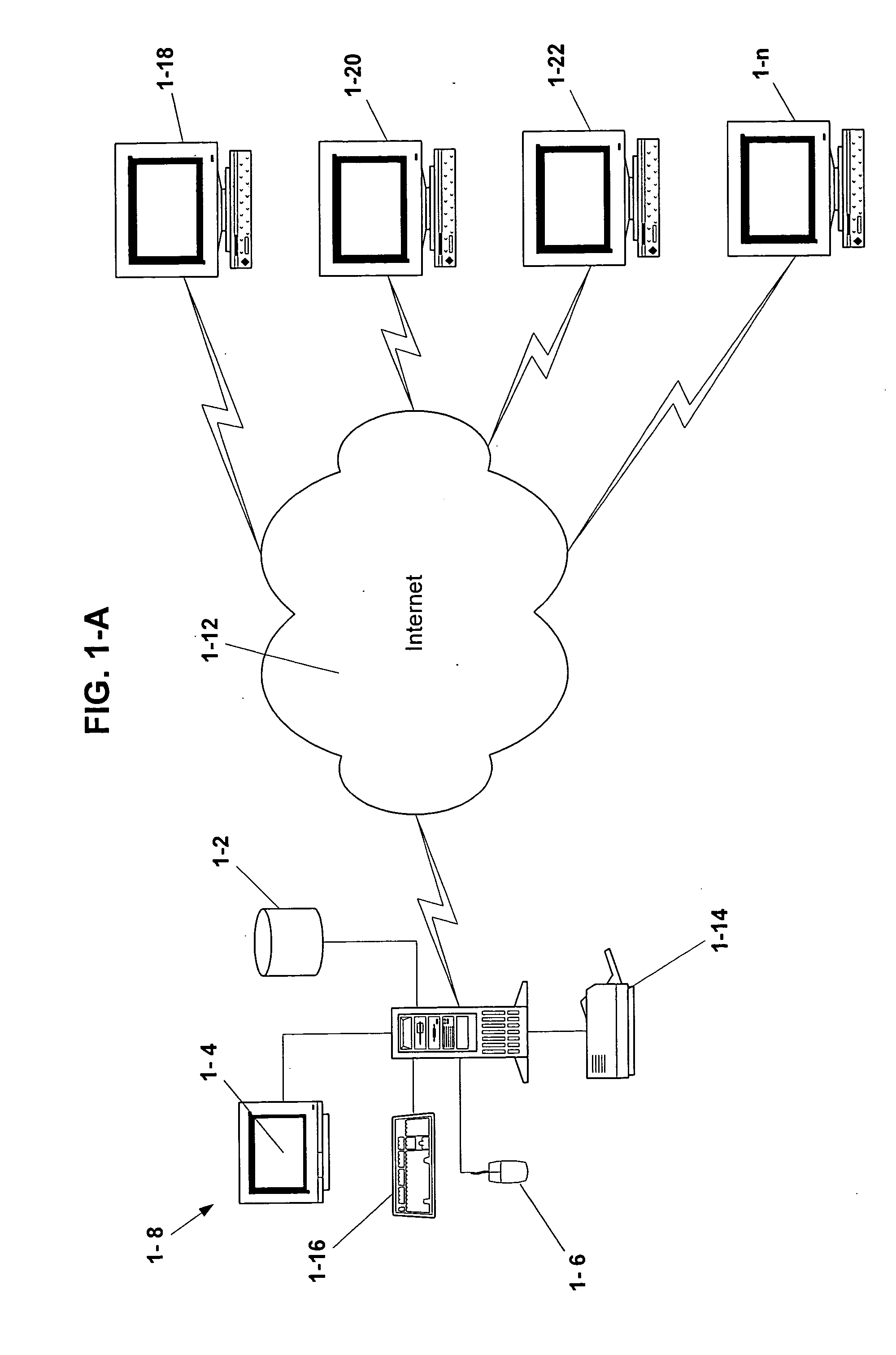

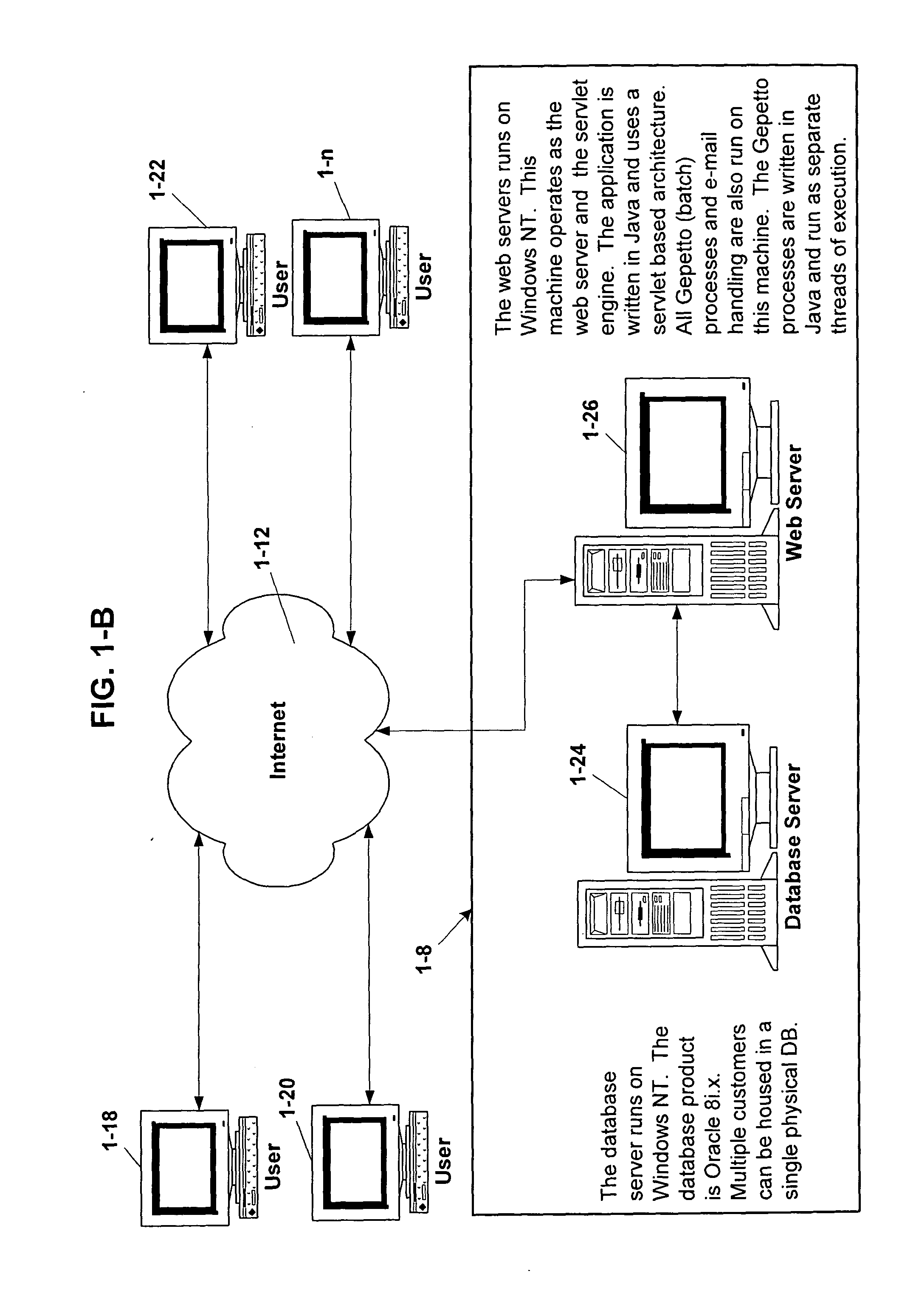

A system for automatically creating and maintaining a database of information utilizing user opinions about subjects, particularly exceptional experiences. Described is an Internet system assisting / motivating a population of users interested in information about certain categories of subjects to automatically maintain the database content and to improve the usefulness and quality of the database information without any substantial management by the website owner-manager. The user opinions are primarily in the form of both comments and ratings about which natural-language terms best describe a particular subject, enabling user searches of the subject database to be by way of preferred such descriptive natural-language terms, which terms are further preferred to be evaluative and approving. Also, a system for automatically creating and maintaining a database of information utilizing user knowledge about sales related subjects. Described is an Internet-based system for assisting / motivating a population of users interested in information about certain categories of sales related subjects to automatically maintain the database content and to improve the usefulness and quality of the database information without any substantial management by the website owner-manager. The user opinions are primarily in the form of both comments and ratings of which sales related subjects best provide assistance in completing a sale.

Owner:QUICK COMMENTS

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS20100029995A1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicatePlatinum

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

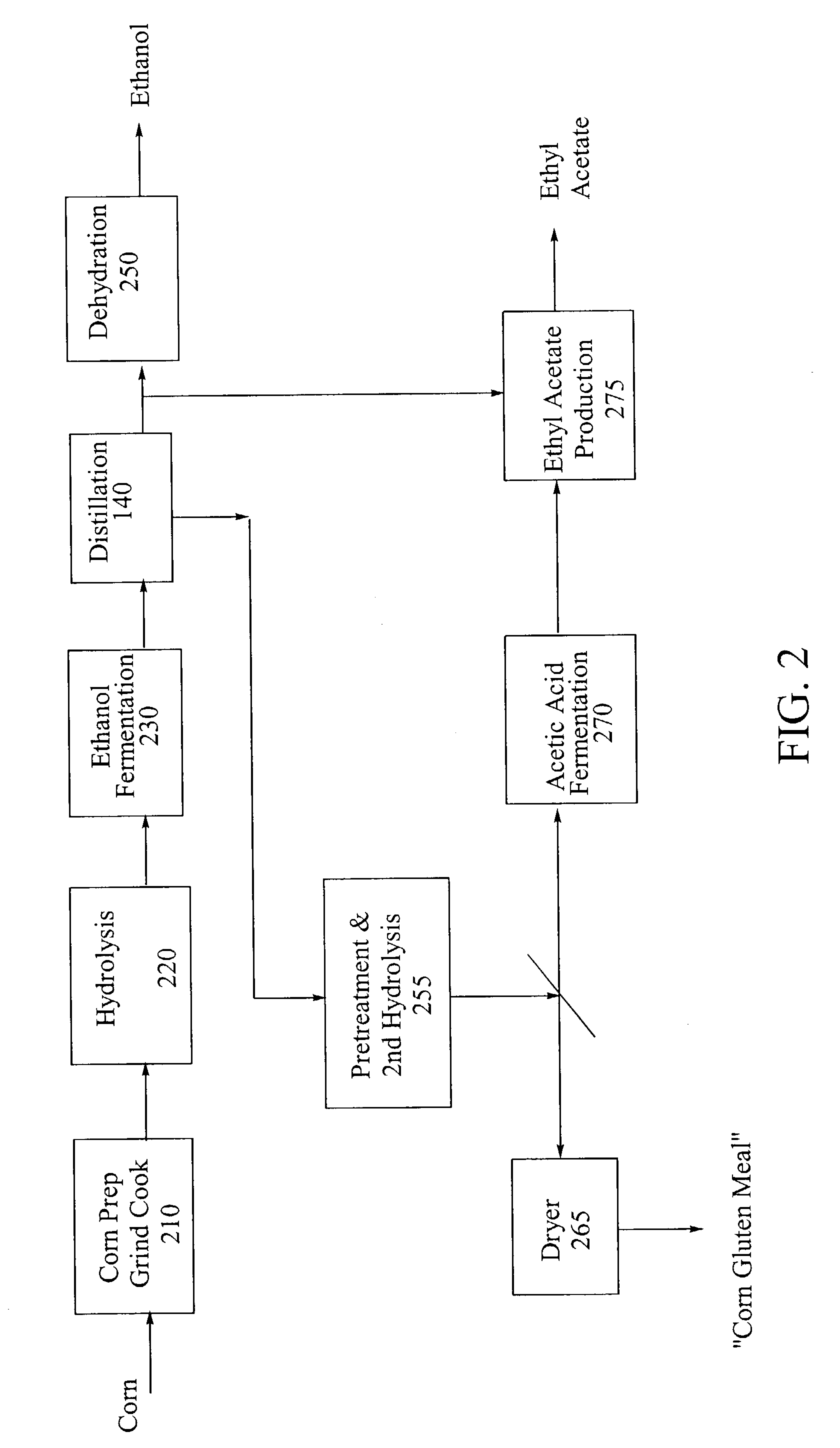

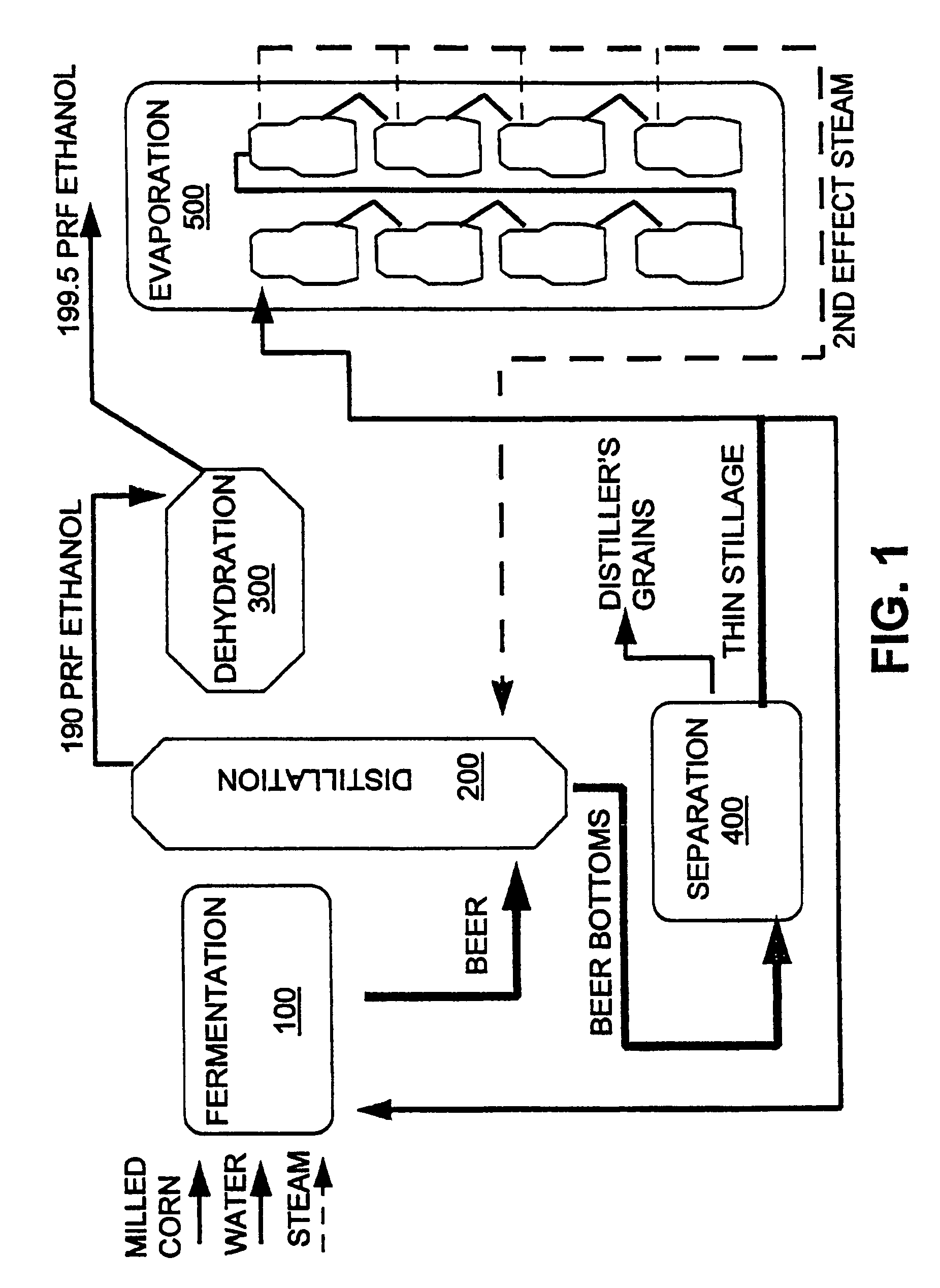

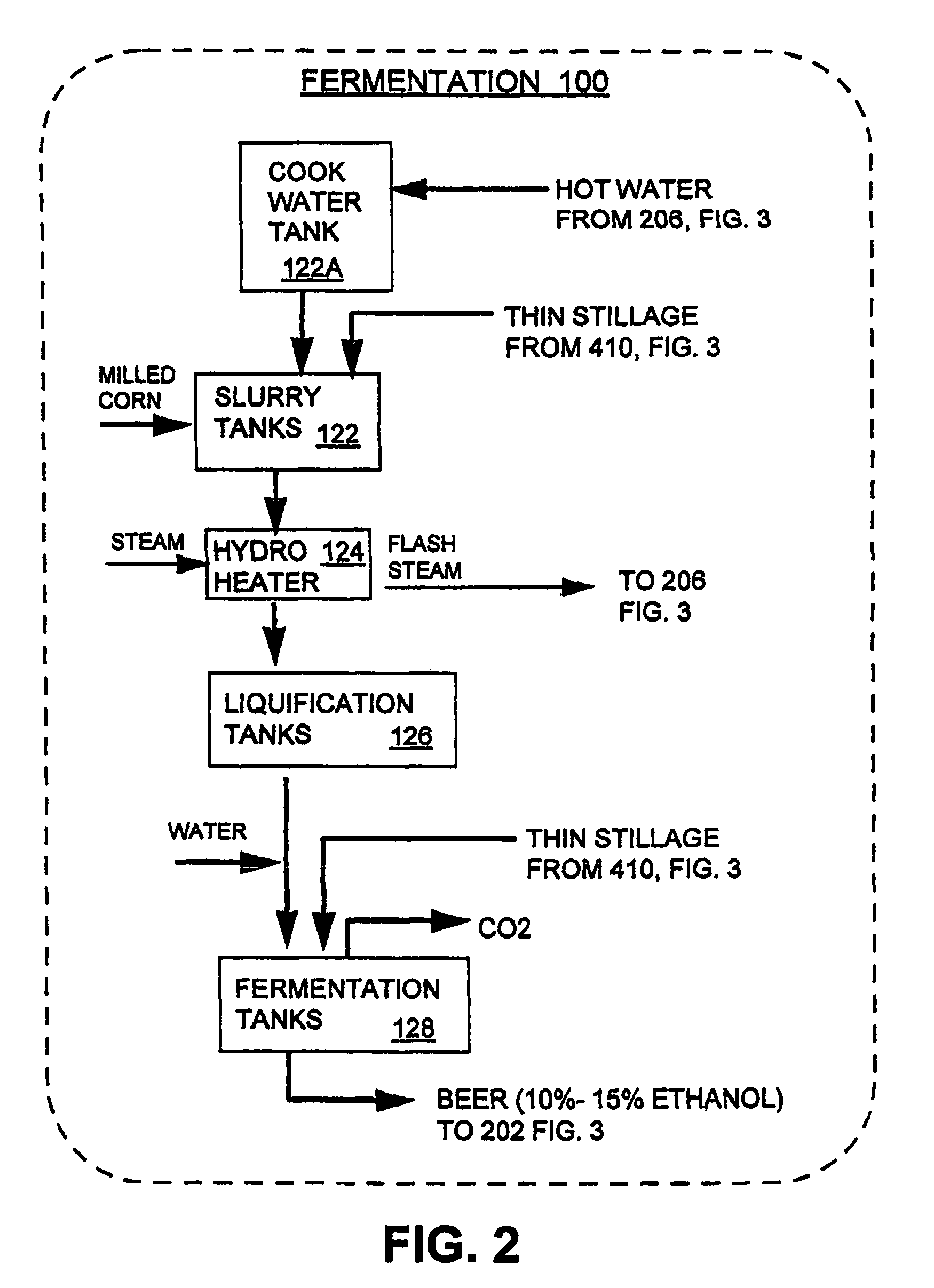

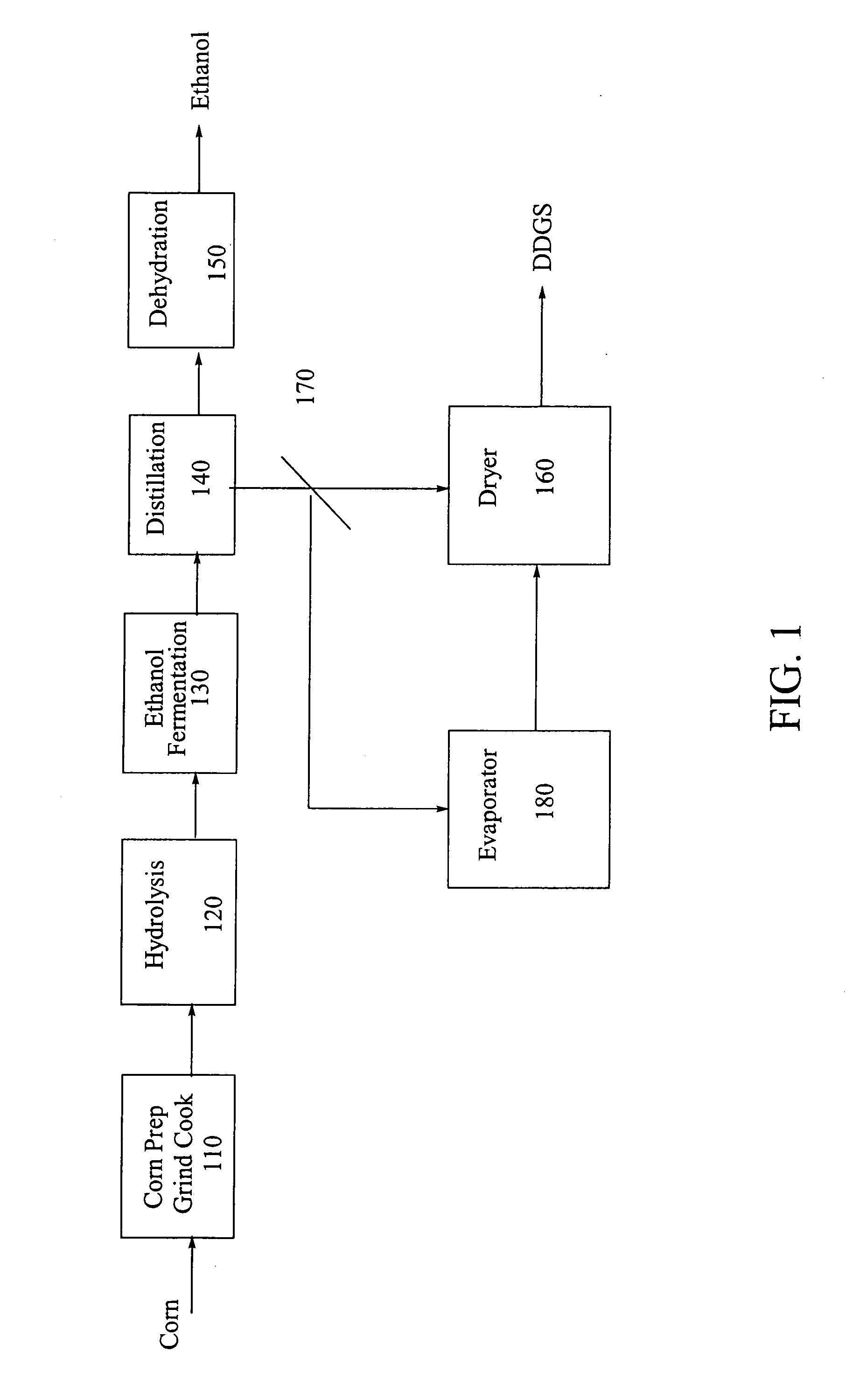

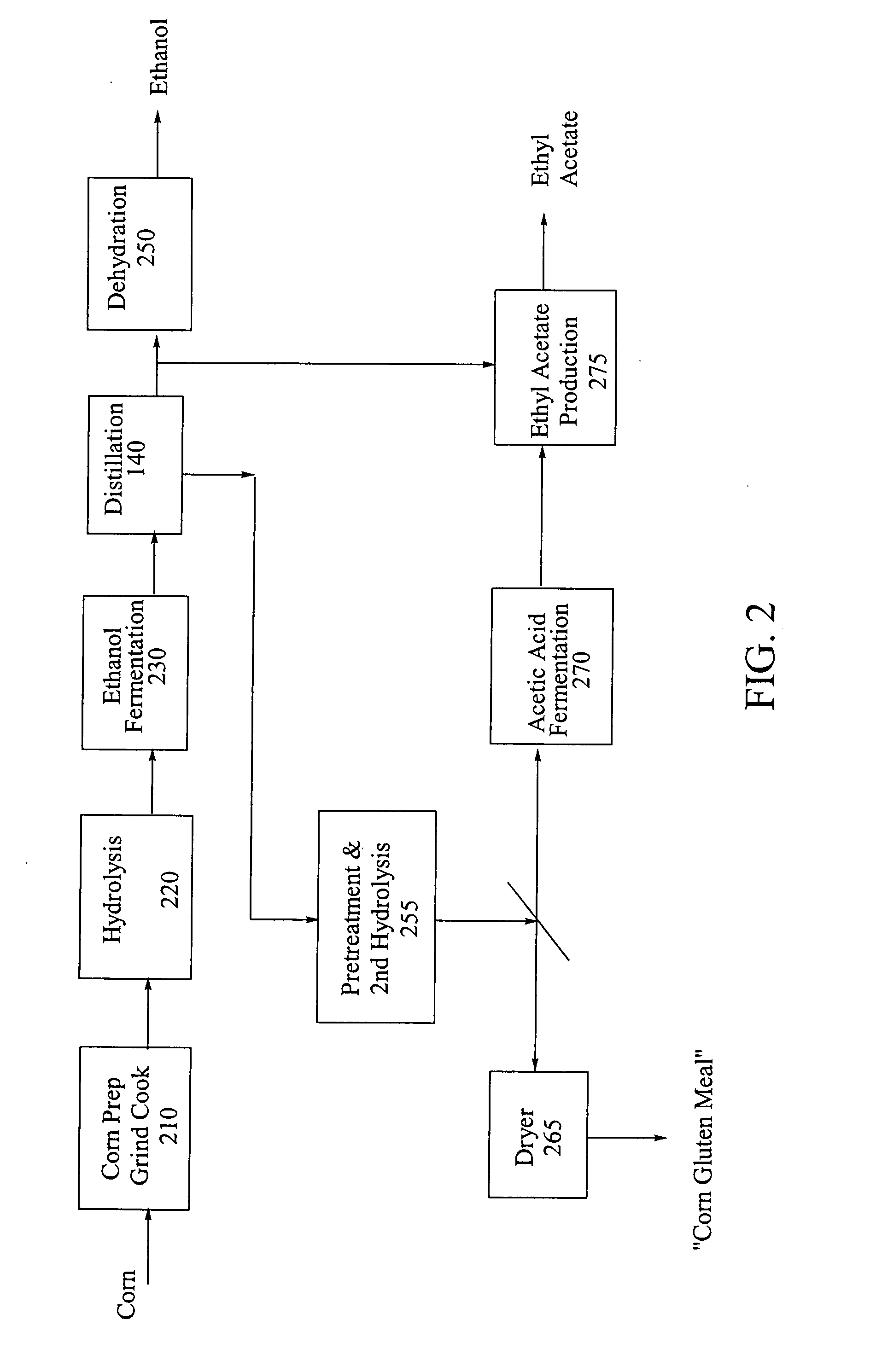

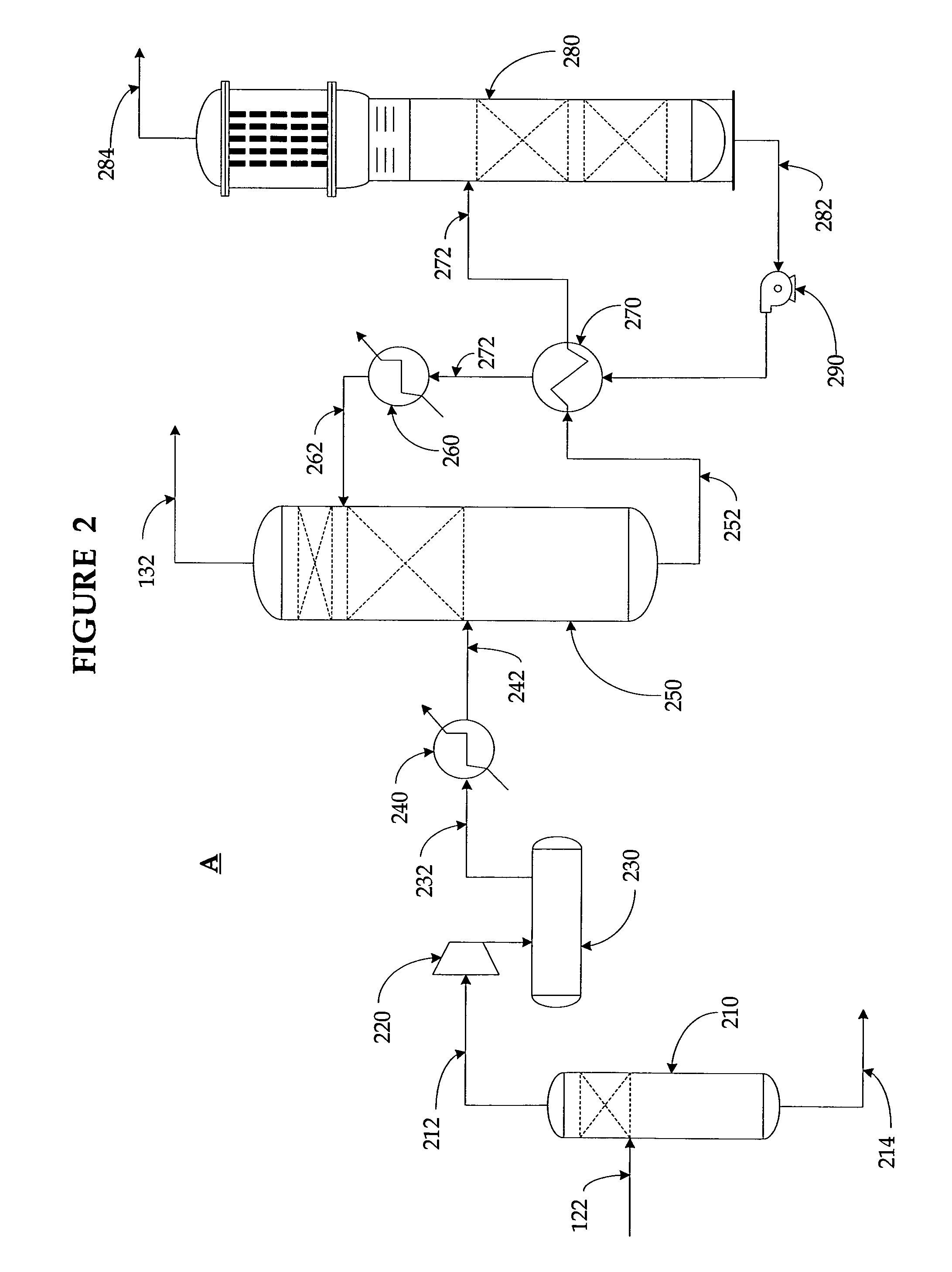

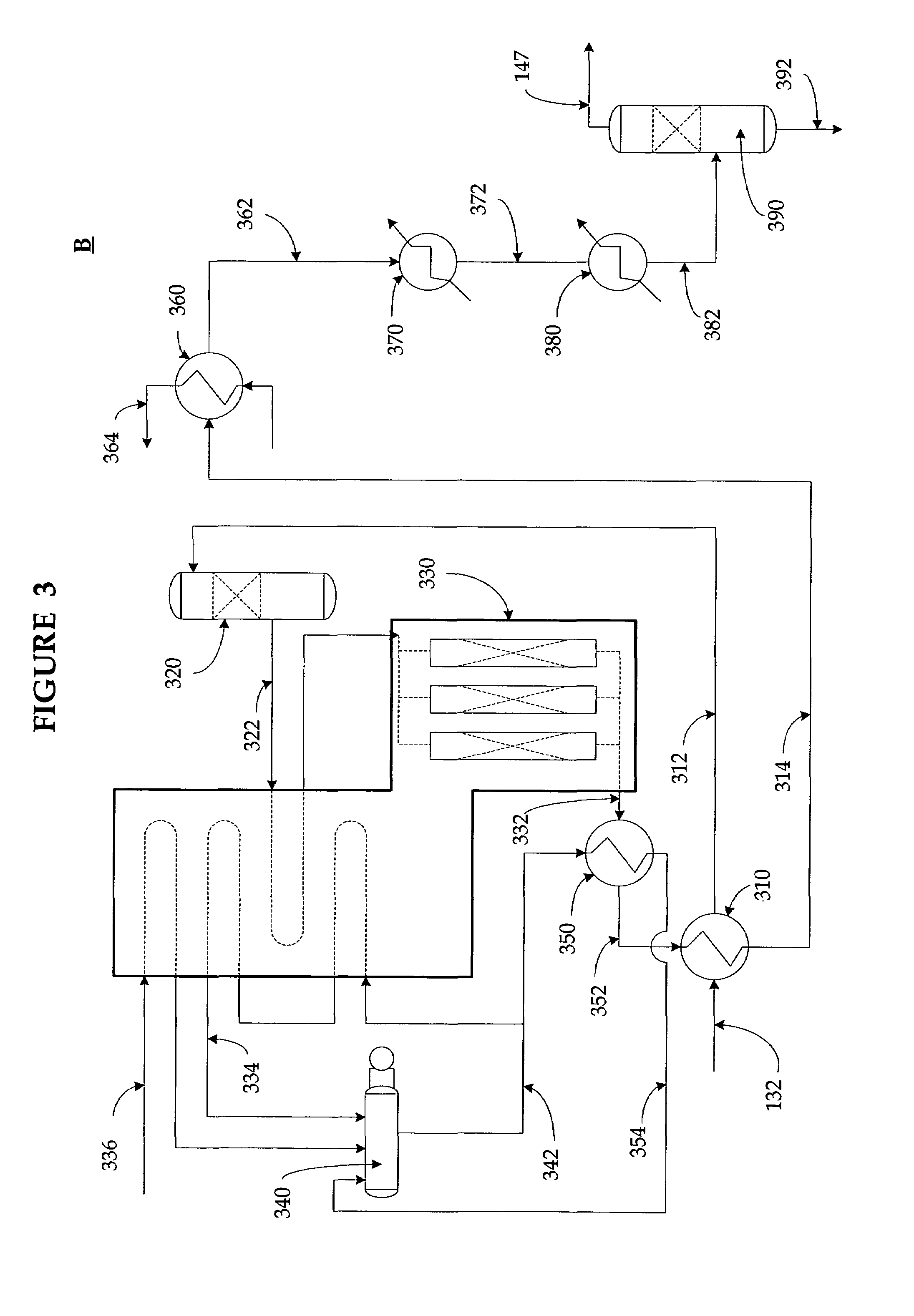

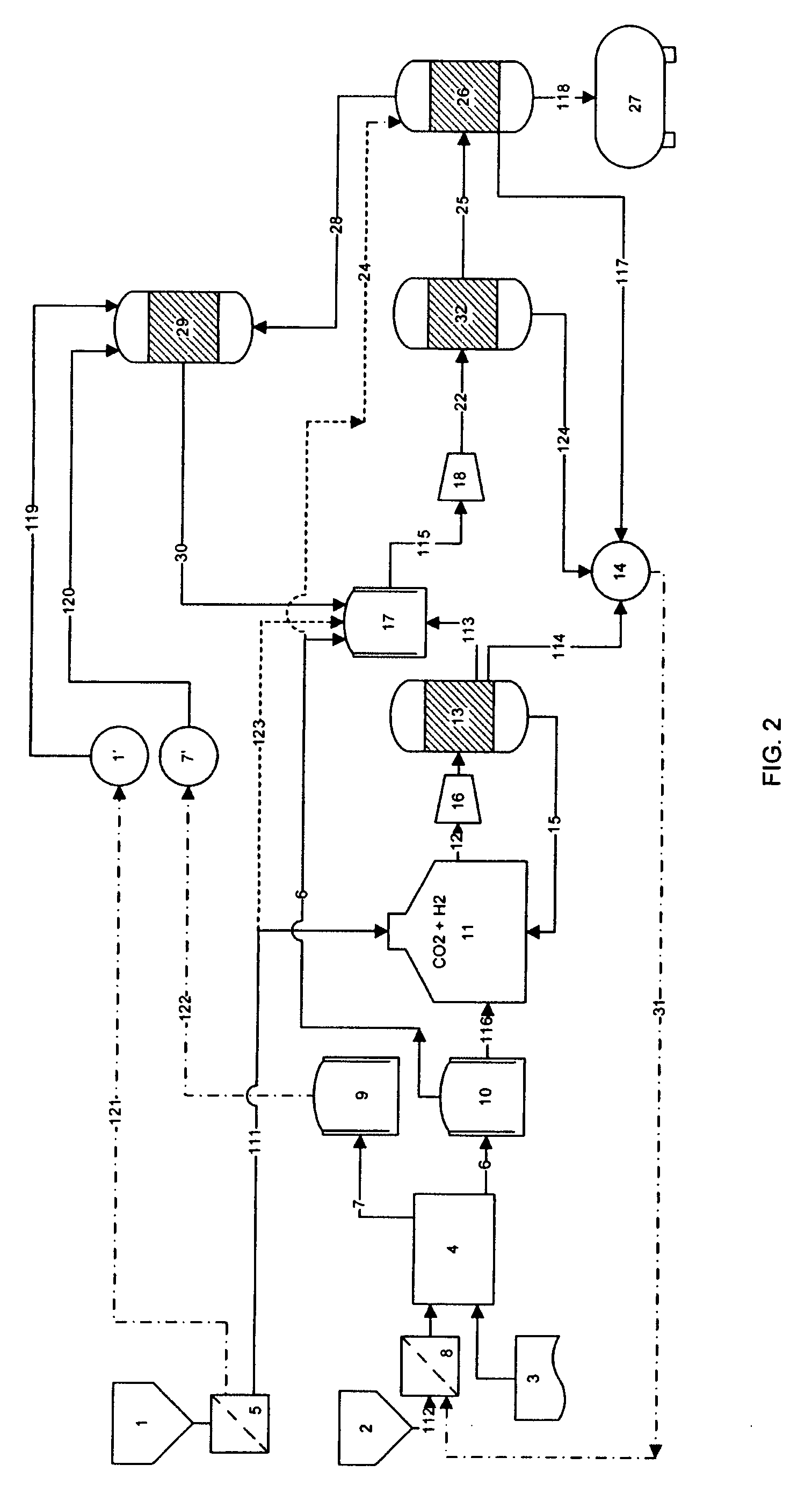

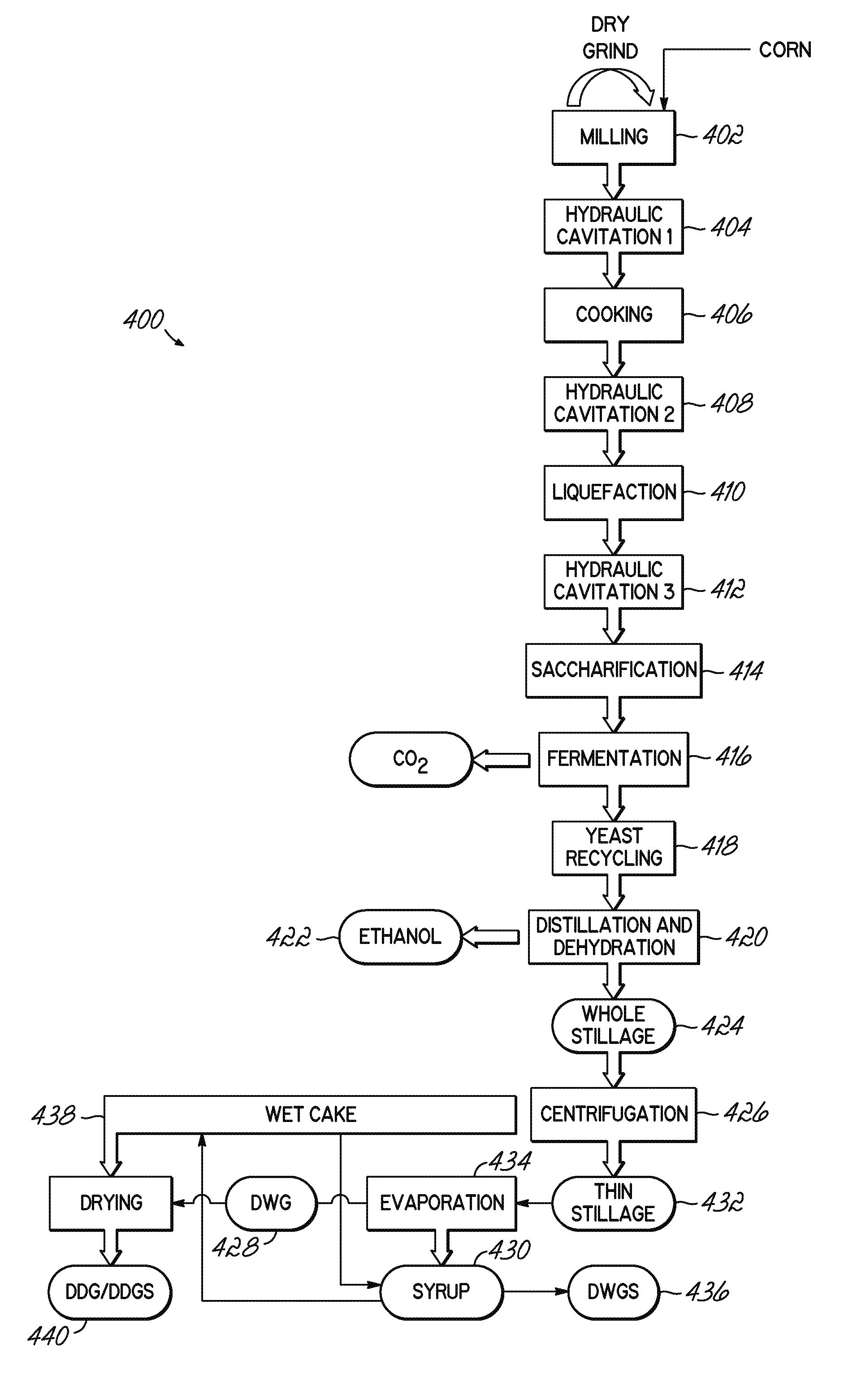

Process for producing ethanol from corn dry milling

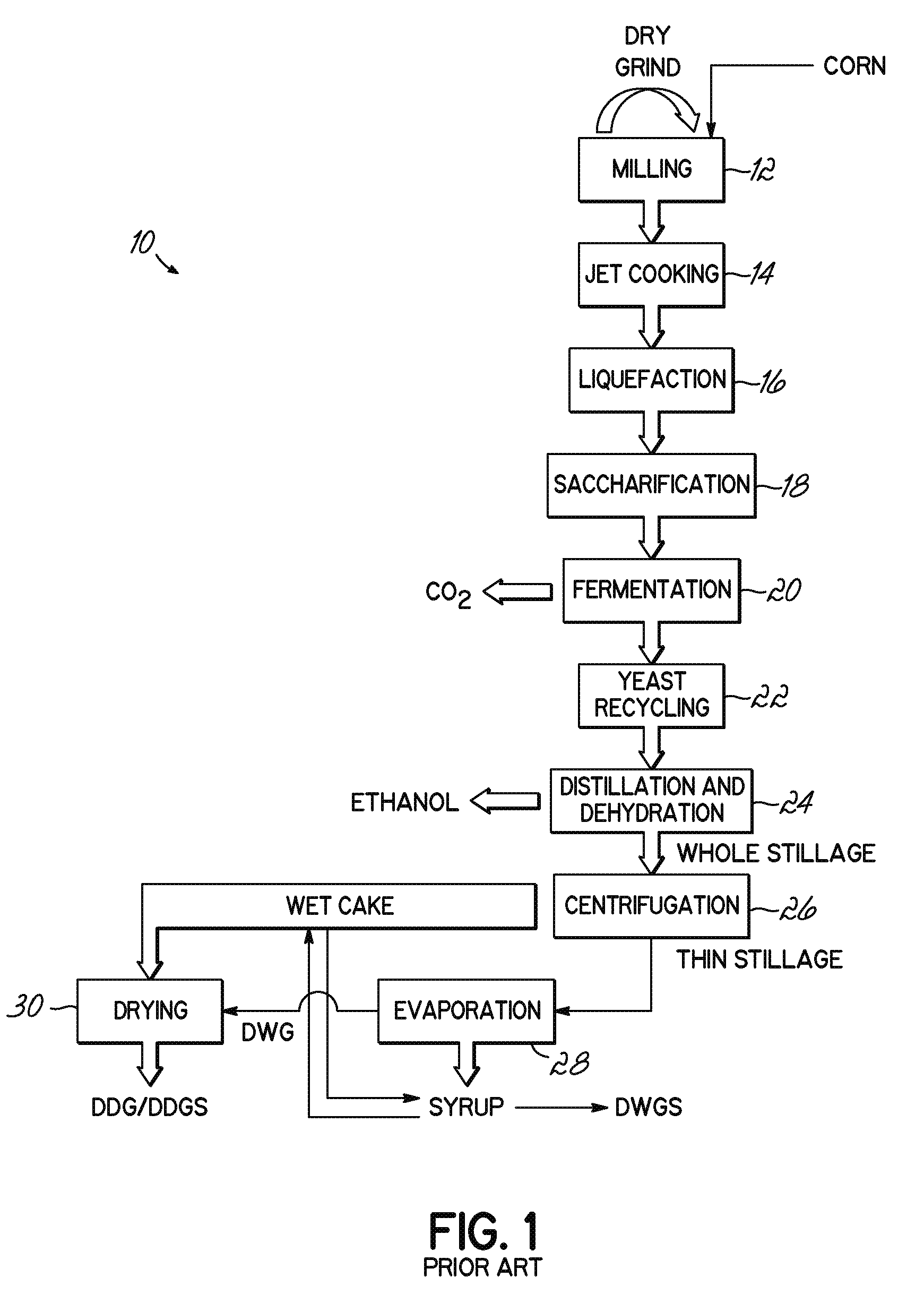

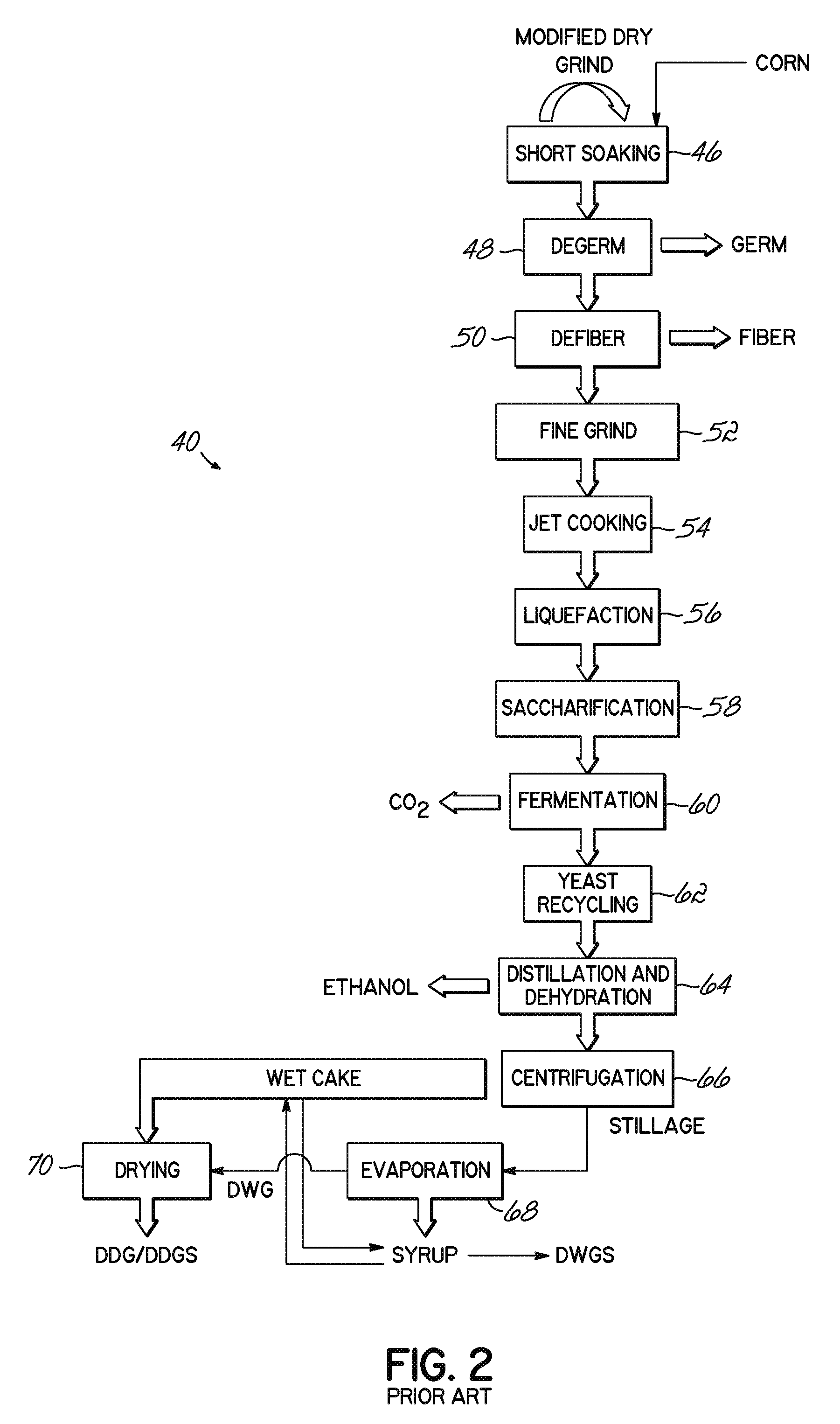

InactiveUS7074603B2Fermented solutions distillation/rectificationOrganic compound preparationAcetic acidHydrogenation reaction

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

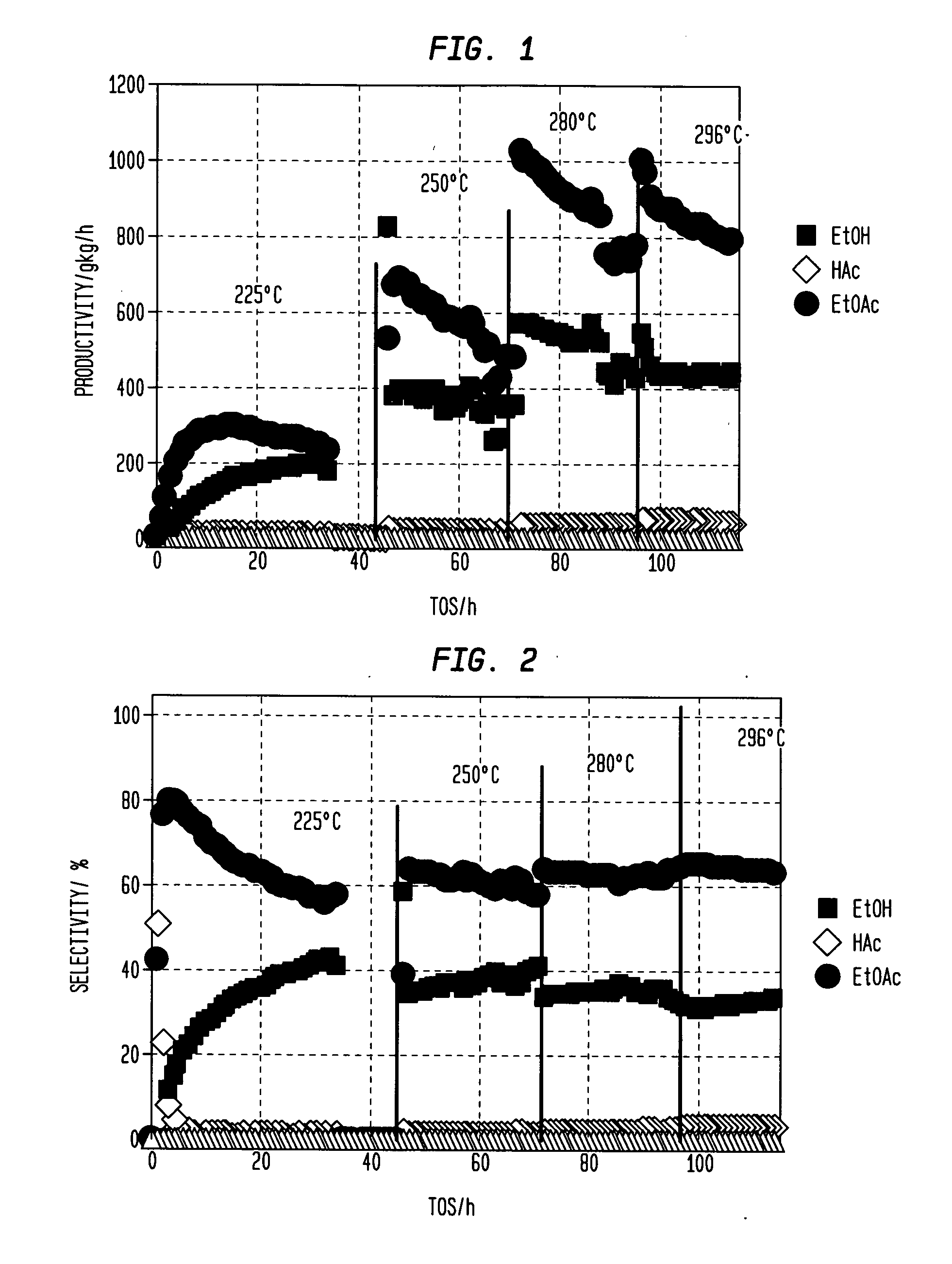

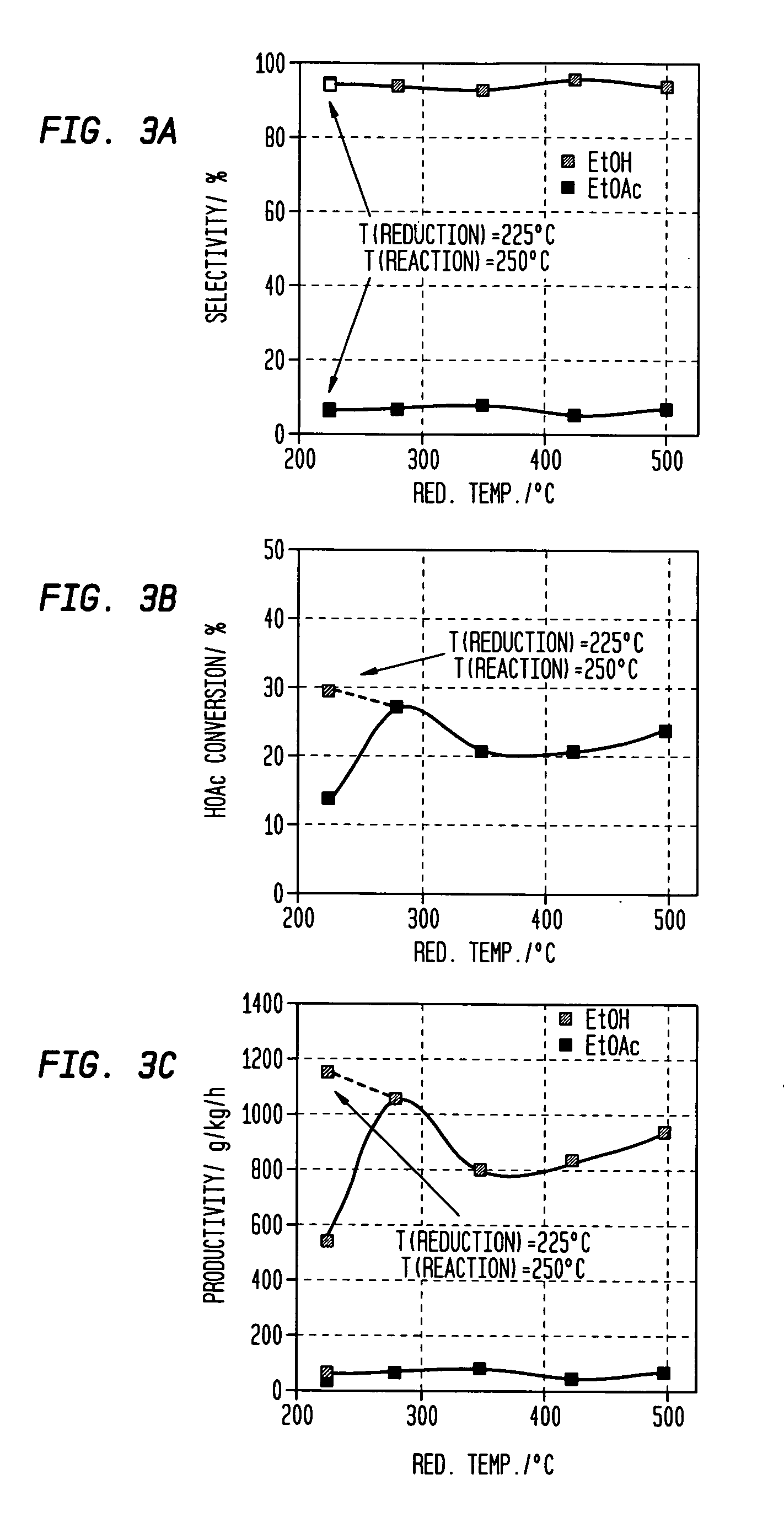

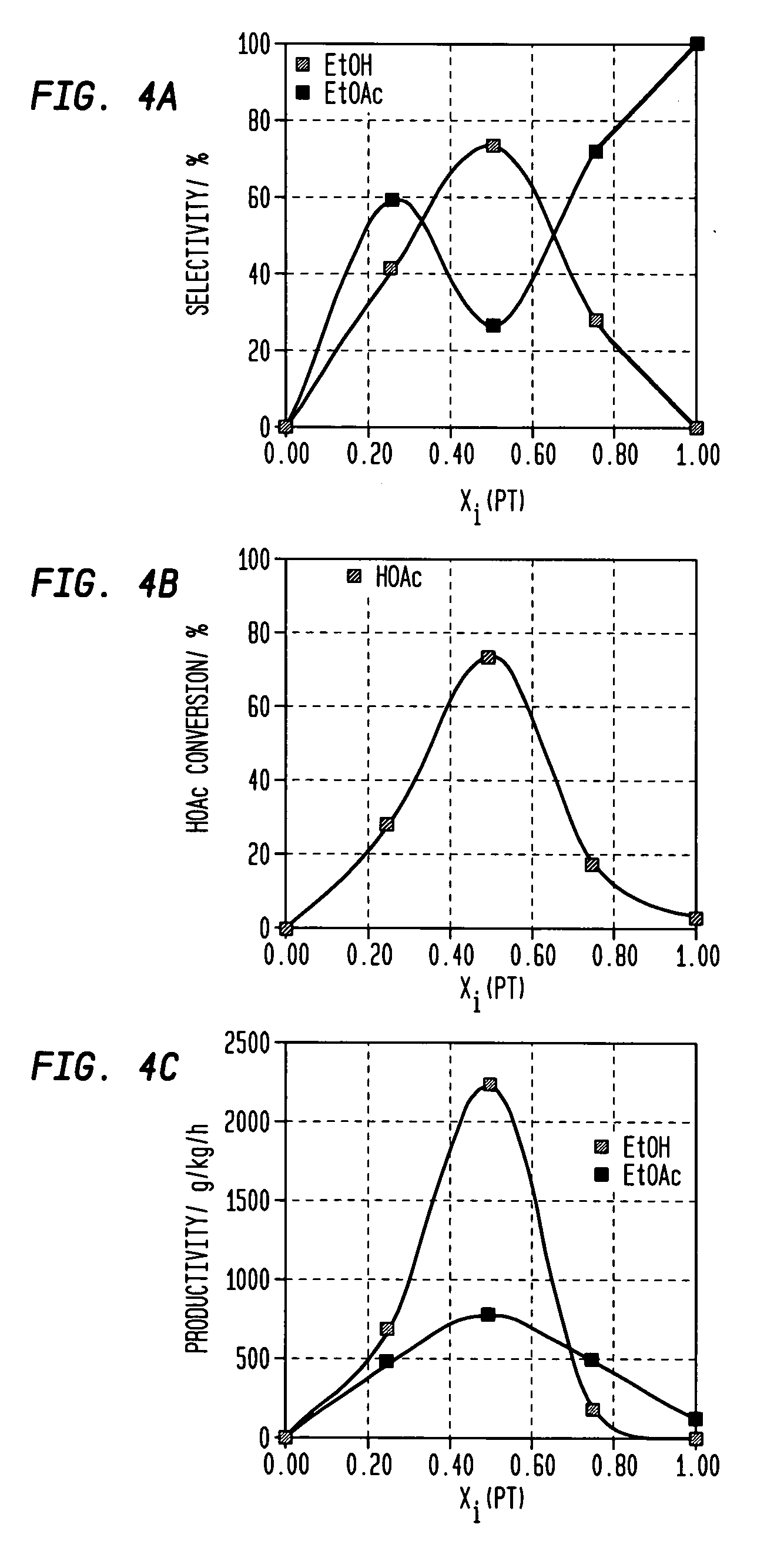

Tunable catalyst gas phase hydrogenation of carboxylic acids

InactiveUS20100121114A1High selectivityExcessive loss of activityOrganic compound preparationHeterogenous catalyst chemical elementsPlatinumAcetic acid

A process for selective formation of ethanol from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with catalyst comprising platinum and tin on a high surface area silica promoted with calcium metasilicate. Selectivities to ethanol of over 85% are achieved at 280° C. with catalyst life in the hundreds of hours.

Owner:CELANESE INT CORP

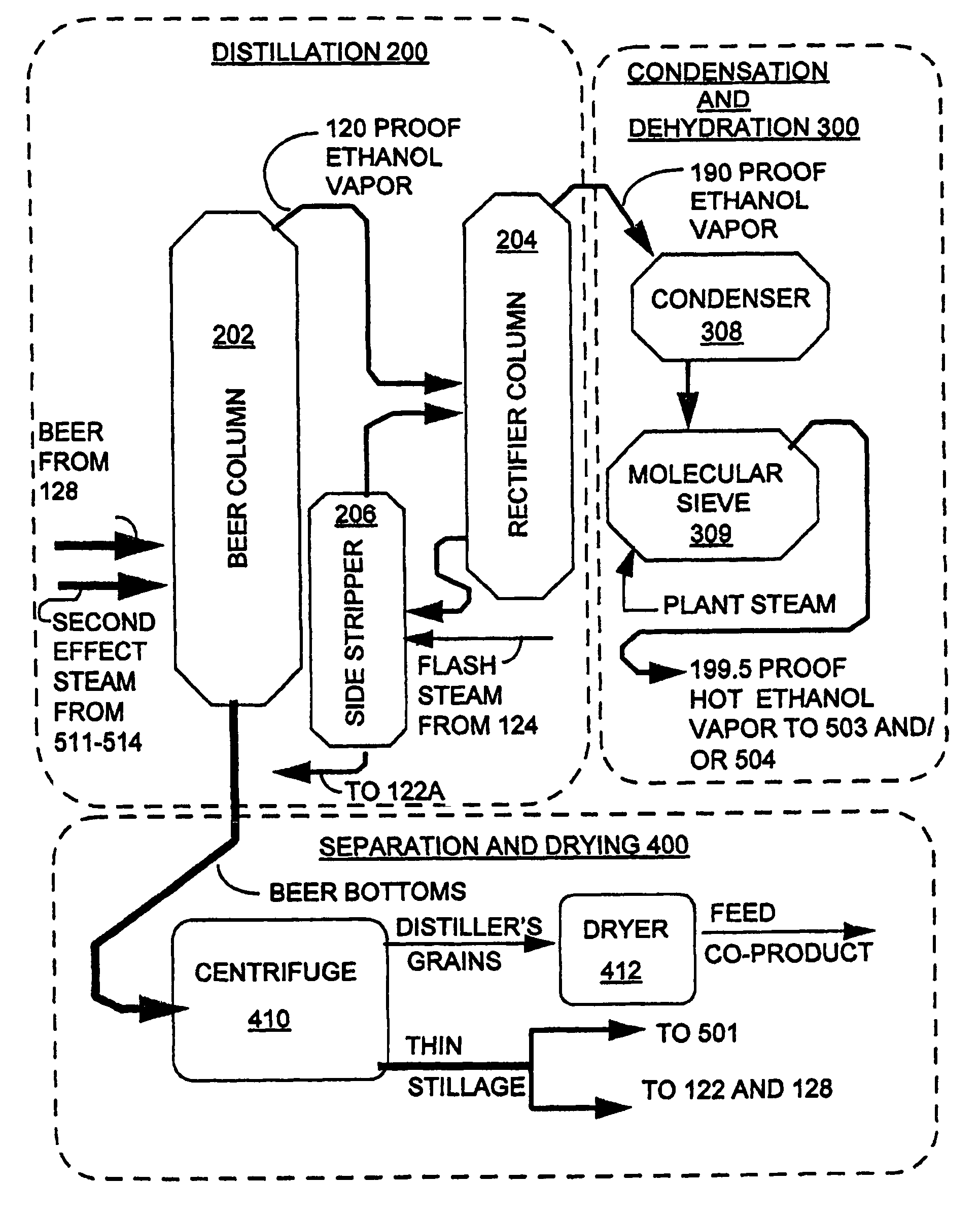

Ethanol distillation process

InactiveUS7572353B1Shorten the timeLess rapidlyFermented solutions distillation/rectificationOrganic compound preparationDistillationEvaporation

Owner:ICM

Process for producing ethanol

InactiveUS20060019360A1High carbon yieldHigh protein concentrationOrganic compound preparationChemical industryAcetic acidHydrogenation reaction

A process for producing ethanol including a combination of biochemical and synthetic conversions results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from carbohydrates, such as corn, using enzymatic milling and fermentation steps, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts can include corn oil, and high protein animal feed containing the biomass produced in the fermentation.

Owner:ZEACHEM

Process for producing ethanol from corn dry milling

InactiveUS20060127999A1Speed up the conversion processFermented solutions distillation/rectificationOrganic compound preparationAcetic acidDistillation

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

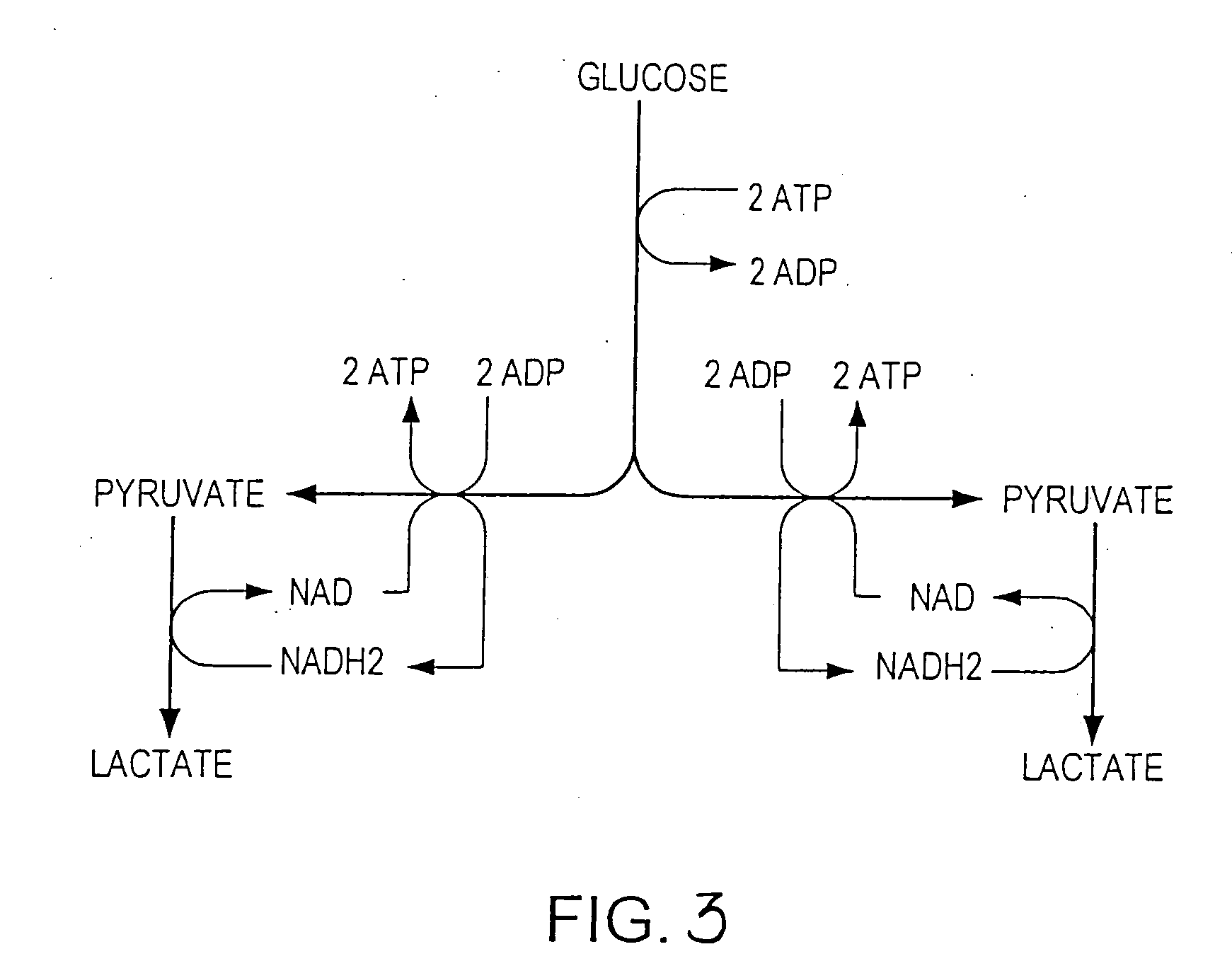

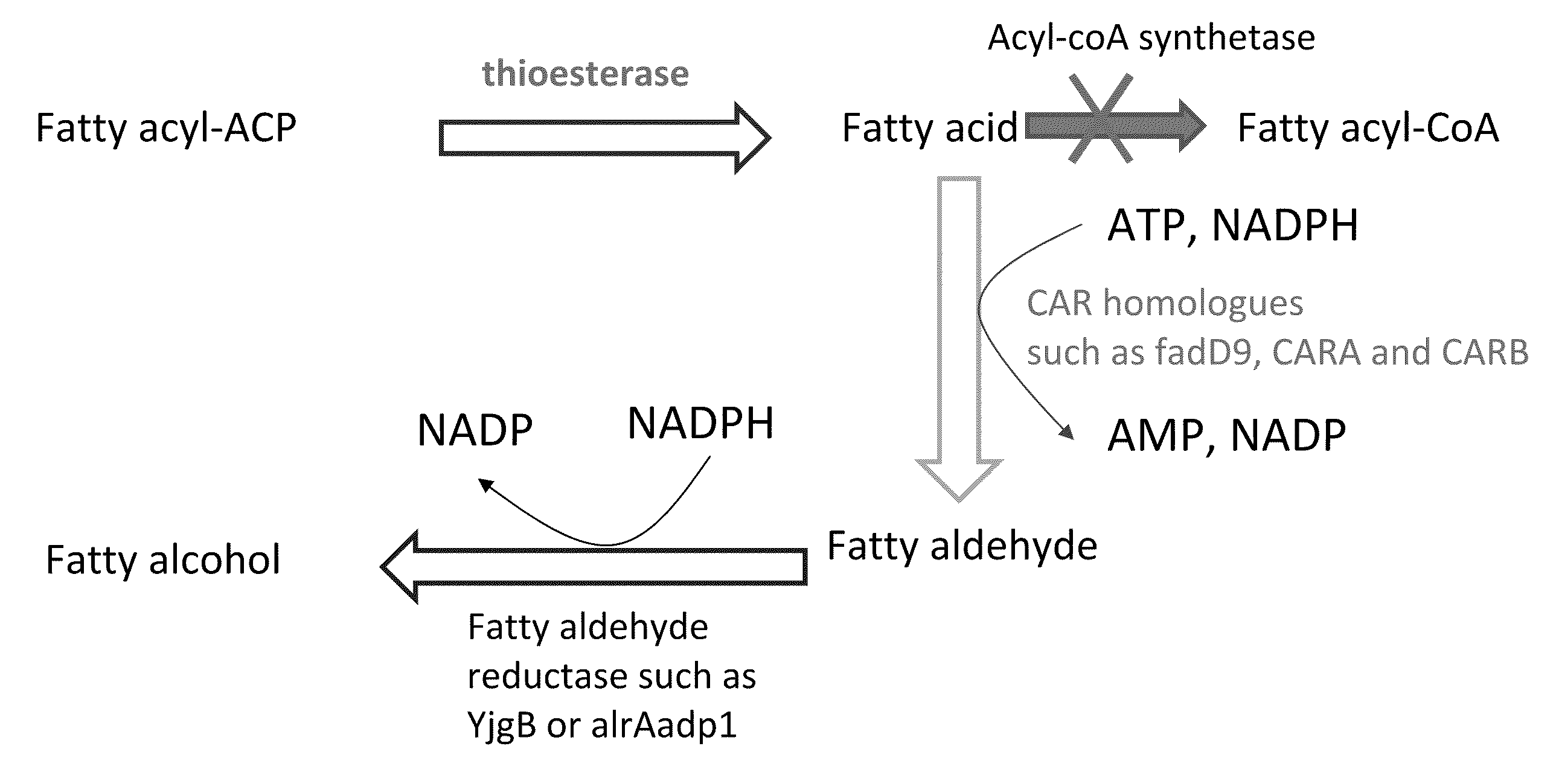

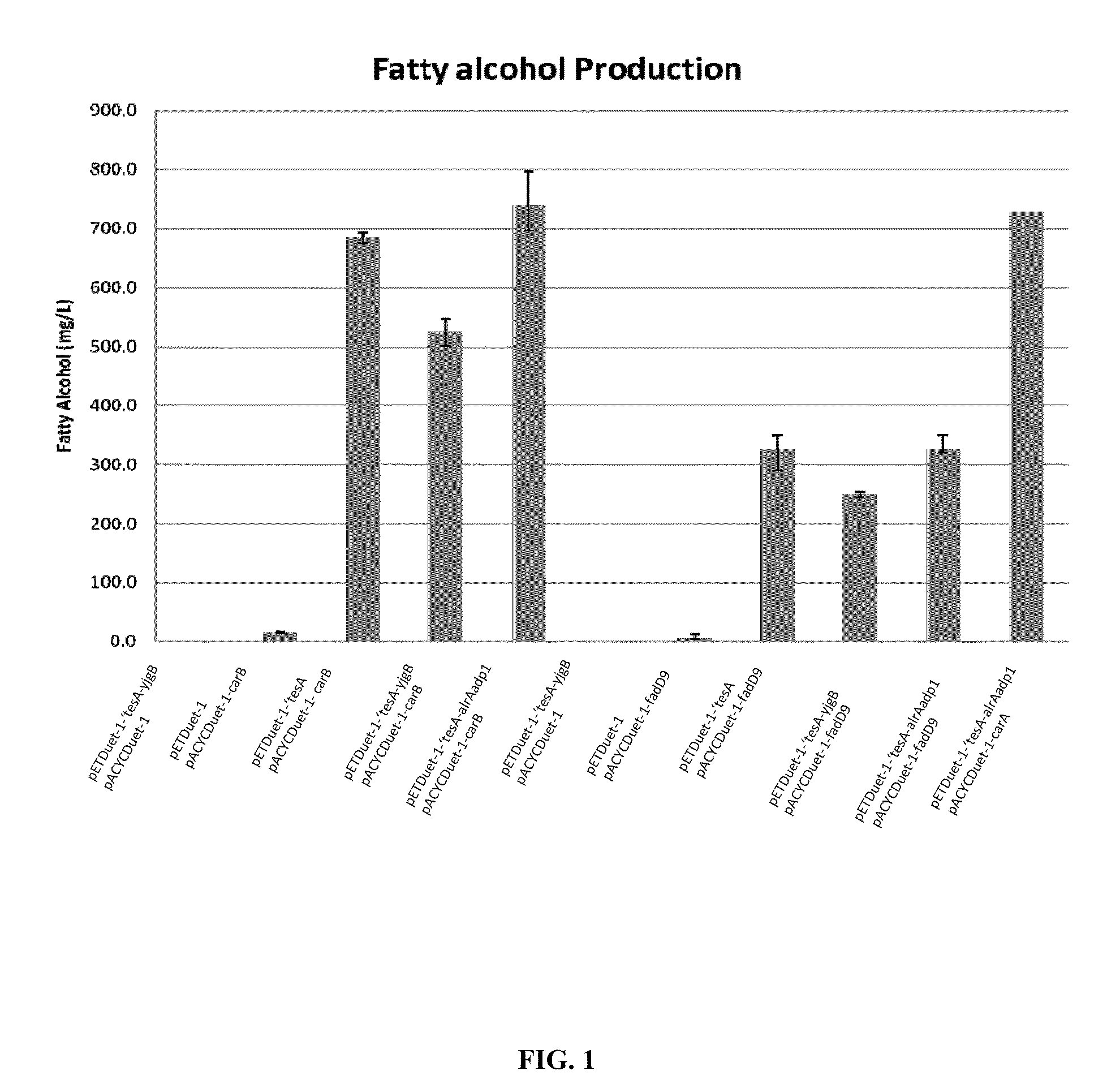

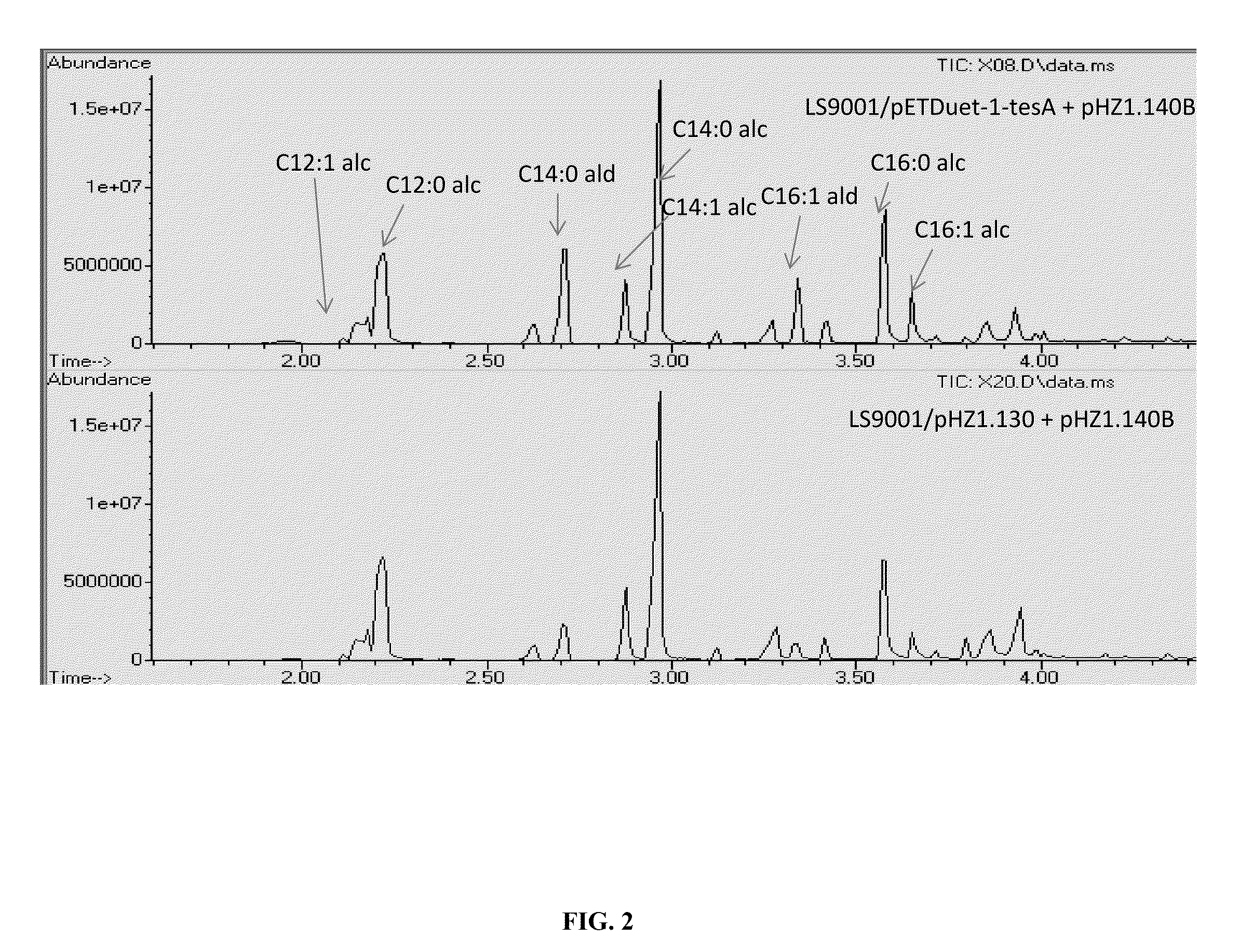

Methods and compositions for producing fatty alcohols

Methods and compositions, including nucleotide sequences, amino acid sequences, and host cells, for producing fatty alcohols are described.

Owner:LS9 INC +1

Catalyzer for the oxalic ester hydrogenation synthesizing of ethylene glycol and method of preparing the same

A catalyst for hydrogenated synthesis of glycol with oxalate and a preparation method for the catalyst belong to the glycol preparation technical field. The catalyst of the present invention uses the copper metal as the main active component, and zinc as the promoter, and is manufactured with the method of deposition. A carrier of the catalyst is the modified silica sol. The select content of the copper metal is 5 to 45 percent of the carrier weight, and the optimal content of the copper metal is 10 to 40 percent. The content of zinc metal is 0.1 to 15 percent of the carrier weight, and the optimal content of zinc metal is 1 to 8.0 percent. The select specific surface area of the carrier is 90-350m2 / g, and the optimal is 150-300m2 / g. Proven by experiments, the catalyst is provided with the very high reaction activity and glycollate selectivity in the reaction to synthesize glycollate with oxalate and hydrogen Moreover, the catalyst is provided with the long usable life and the stable reaction performance, and can be easily controlled.

Owner:TIANJIN UNIV +1

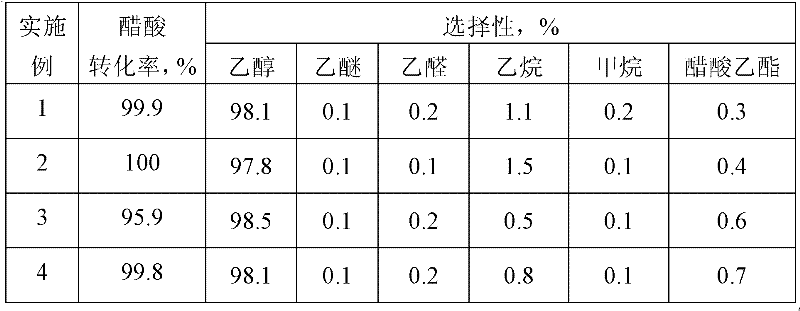

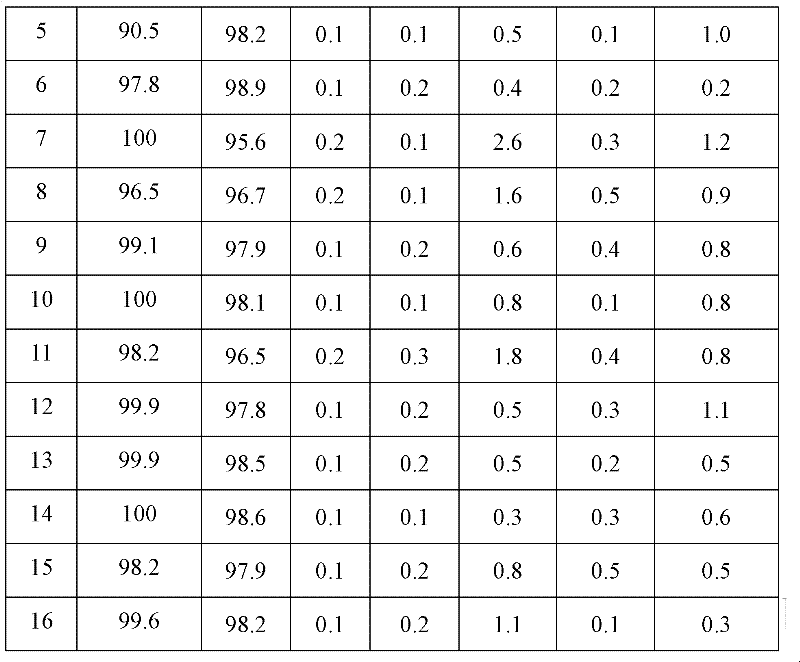

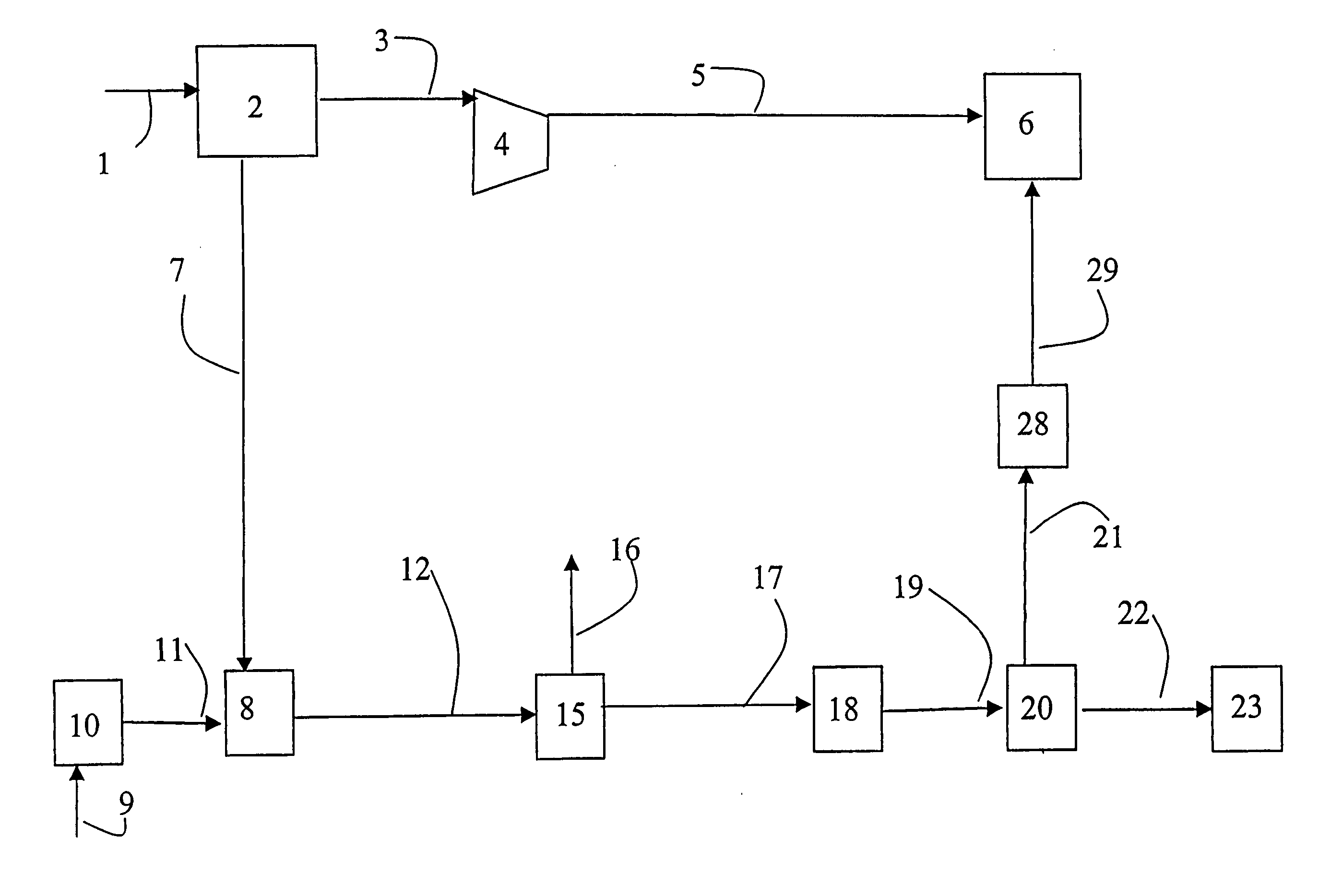

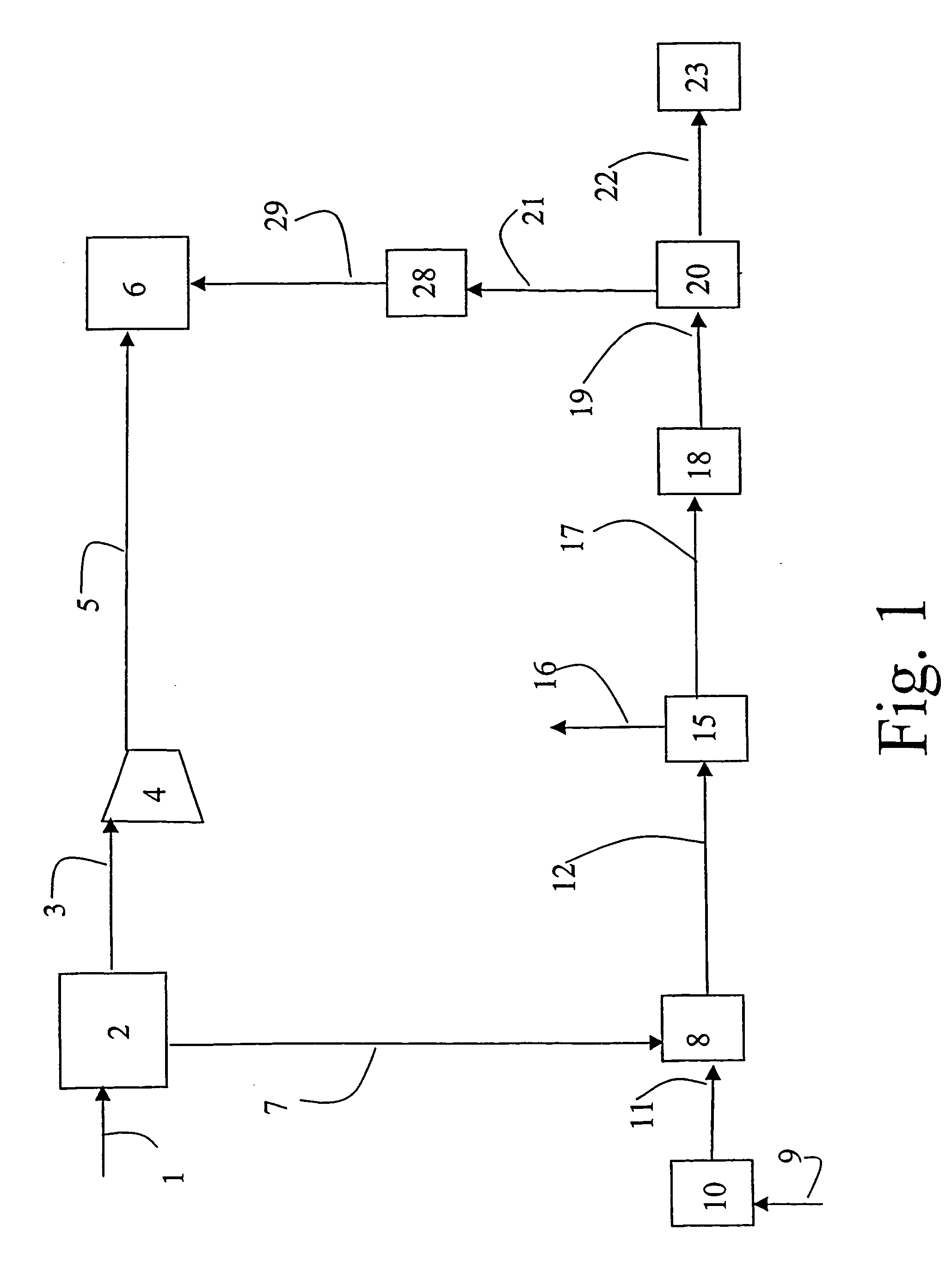

Method for preparing alcohol by acetic acid gas phase hydrogenation

ActiveCN102229520ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationHydroxy compound preparationACETIC ACID LIQUIDGas phase

The invention relates to a method for preparing alcohol by acetic acid gas phase hydrogenation. A reaction system comprises acetic acid, hydrogen and a catalyst; the reaction temperature is 120-300 DEG C; the reaction pressure is 1.0-20.0MPa; the space velocity of acetic acid liquid is 0.5-10.5h<-1>; the molar ratio of H2 to acetic acid is 1-250; the catalyst takes activated carbon as a carrier; and main active components comprise one or two of transitional metals such as W and Mo. The addition agent is one of or more of precious metals such as Pd, Re, Pt, Rh and Ru and the like; and the acetic acid and the hydrogen can be converted into alcohol with high activity and selectivity under the action of the catalyst.

Owner:JIANGSU SOPO CHEM +1

Catalyst for preparing alcohol by acetic ester hydrogenation as well as preparation method and application thereof

InactiveCN101934228AHigh reactivityLow investment costOrganic compound preparationHydroxy compound preparationManganeseCopper oxide

The invention discloses a catalyst for preparing alcohol by acetic ester hydrogenation as well as a preparation method and an application thereof, which is characterized in that the main catalyst of the catalyst is copper or copper oxide or a mixture of the copper and the copper oxide, and the cocatalyst can be also added, wherein the cocatalyst is one or more of oxides of zinc, manganese, chromium, calcium, barium, iron, nickel and magnesium; and the carrier is alumina or silica sol. The catalyst has high activity and high selectivity under the condition of low temperature and low pressure, thus greatly reducing the investment cost of permanent plants, lowering production energy consumption, being extremely beneficial for the industrial production, and having good stability and long service life. The catalyst of the invention is used to cause percent conversion of a reaction of converting the acetic ester into the alcohol is more than or equal to 80% and the selectivity of the alcohol is more than or equal to 95%.

Owner:江苏丹化煤制化学品工程技术有限公司

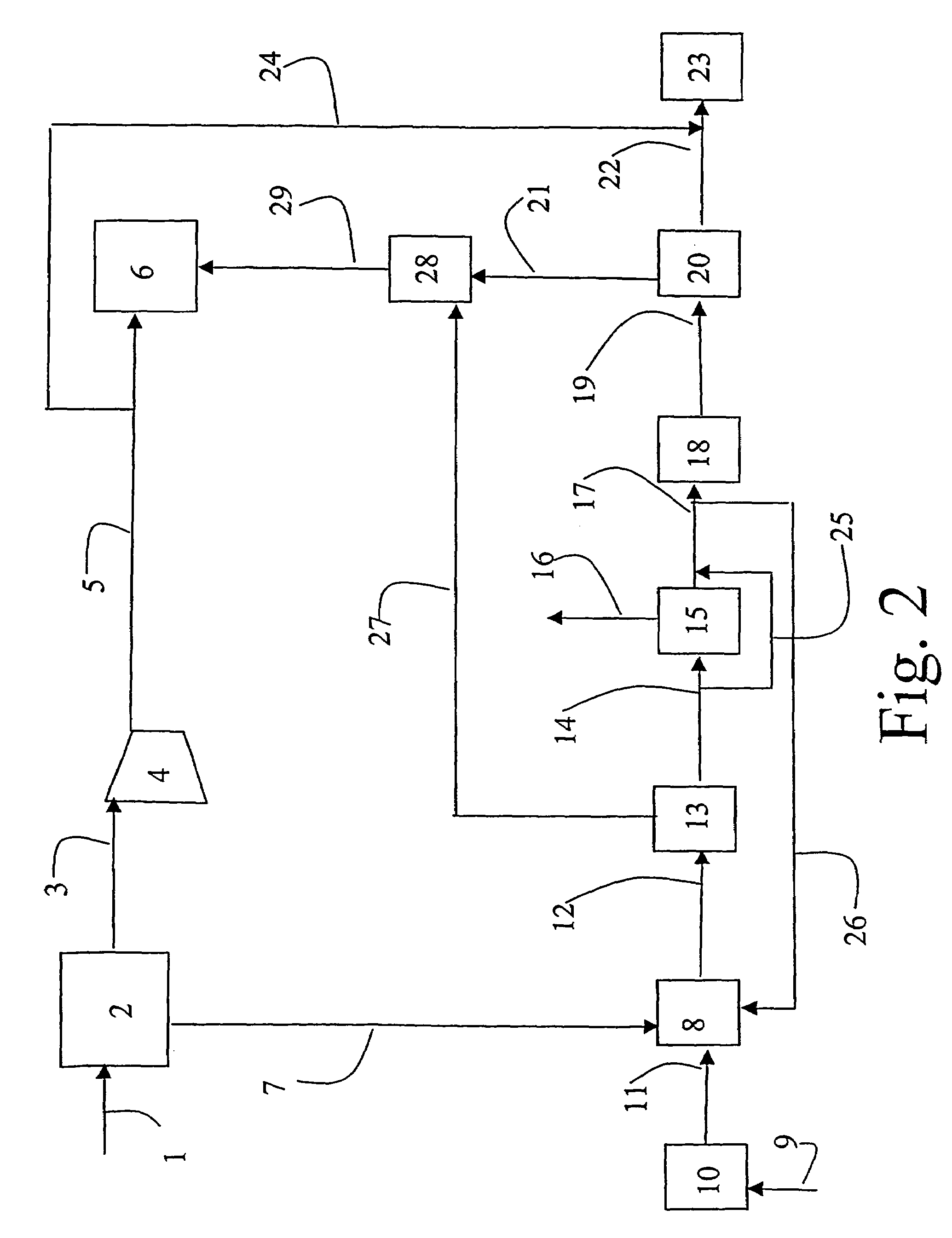

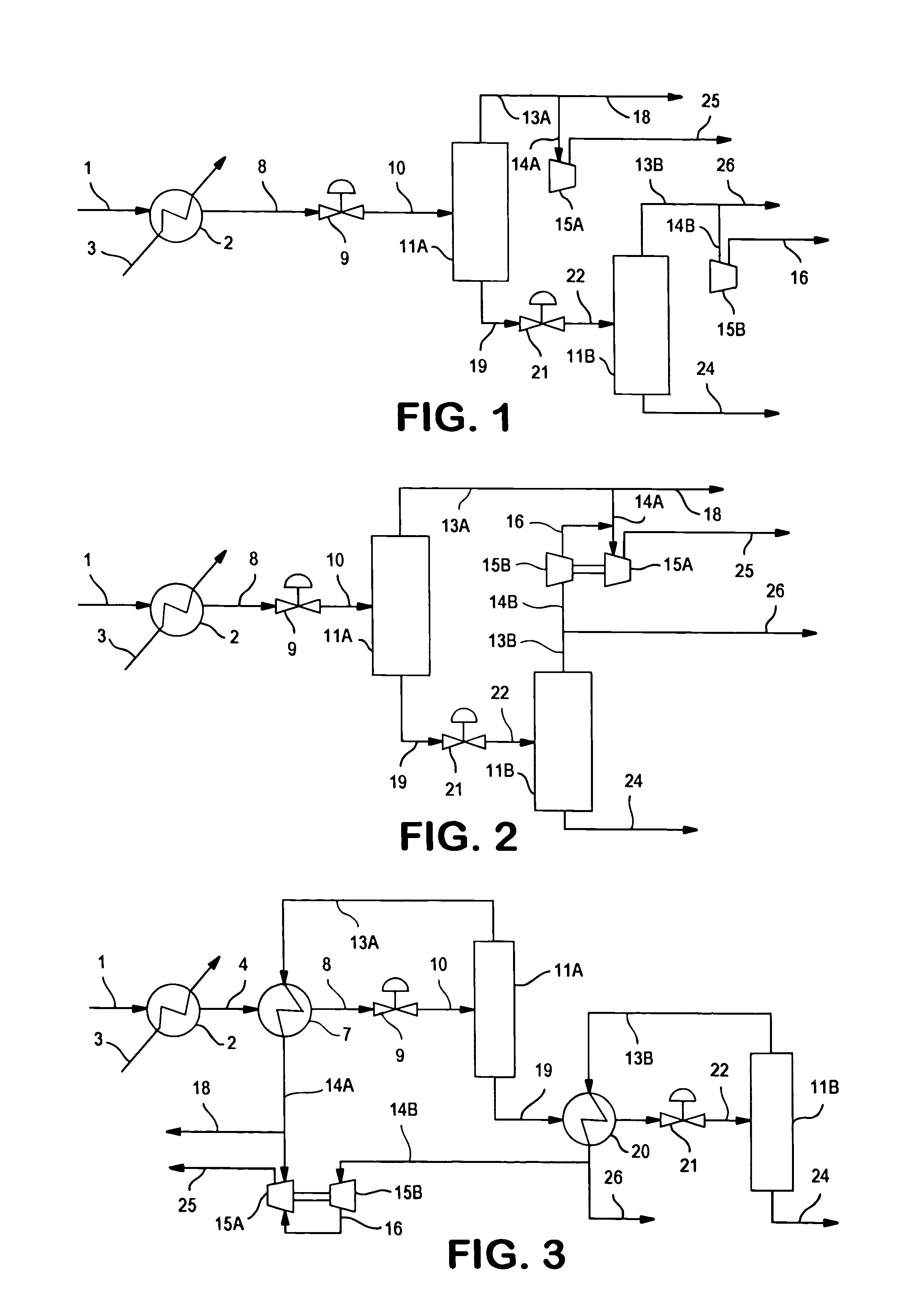

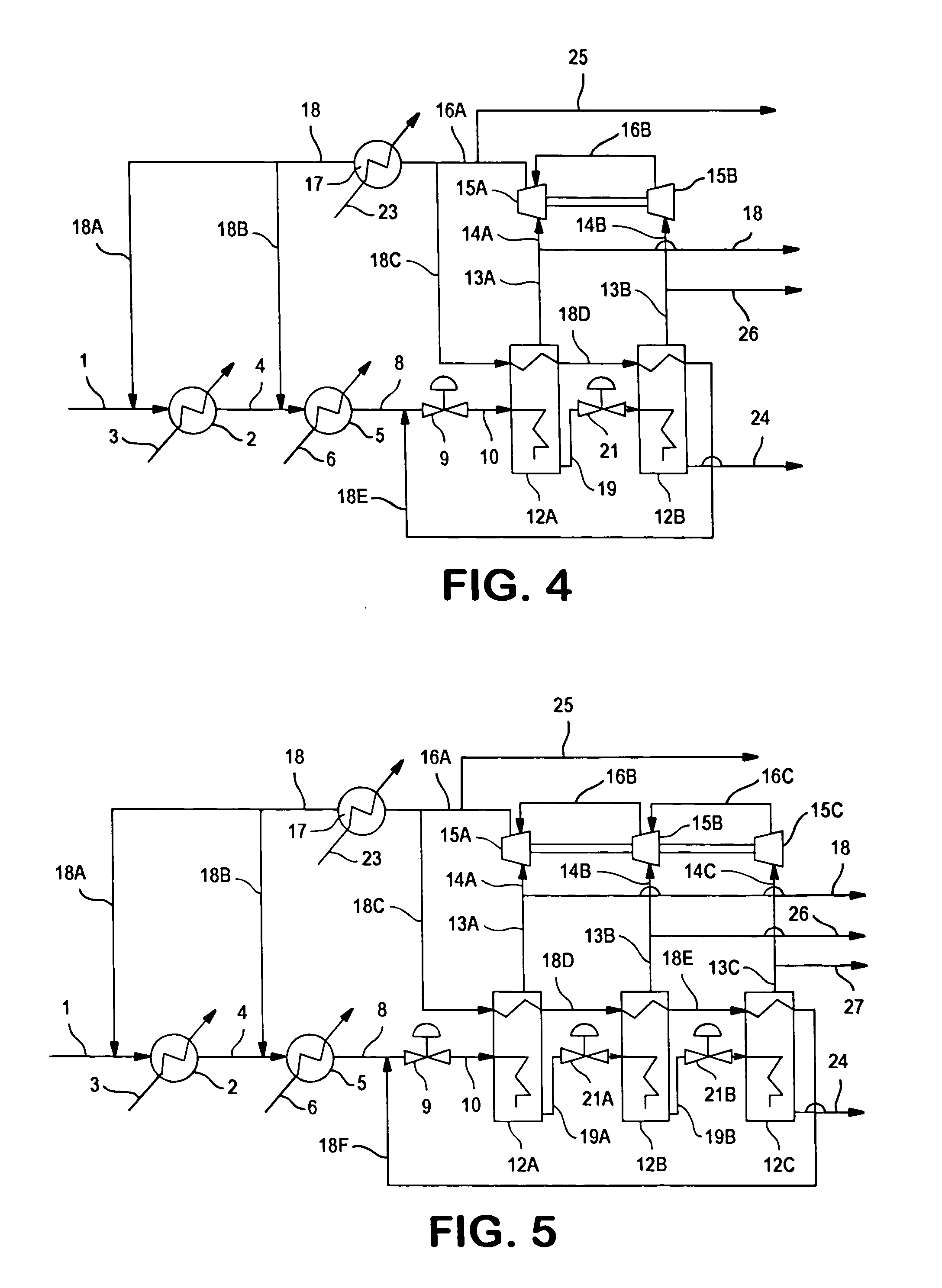

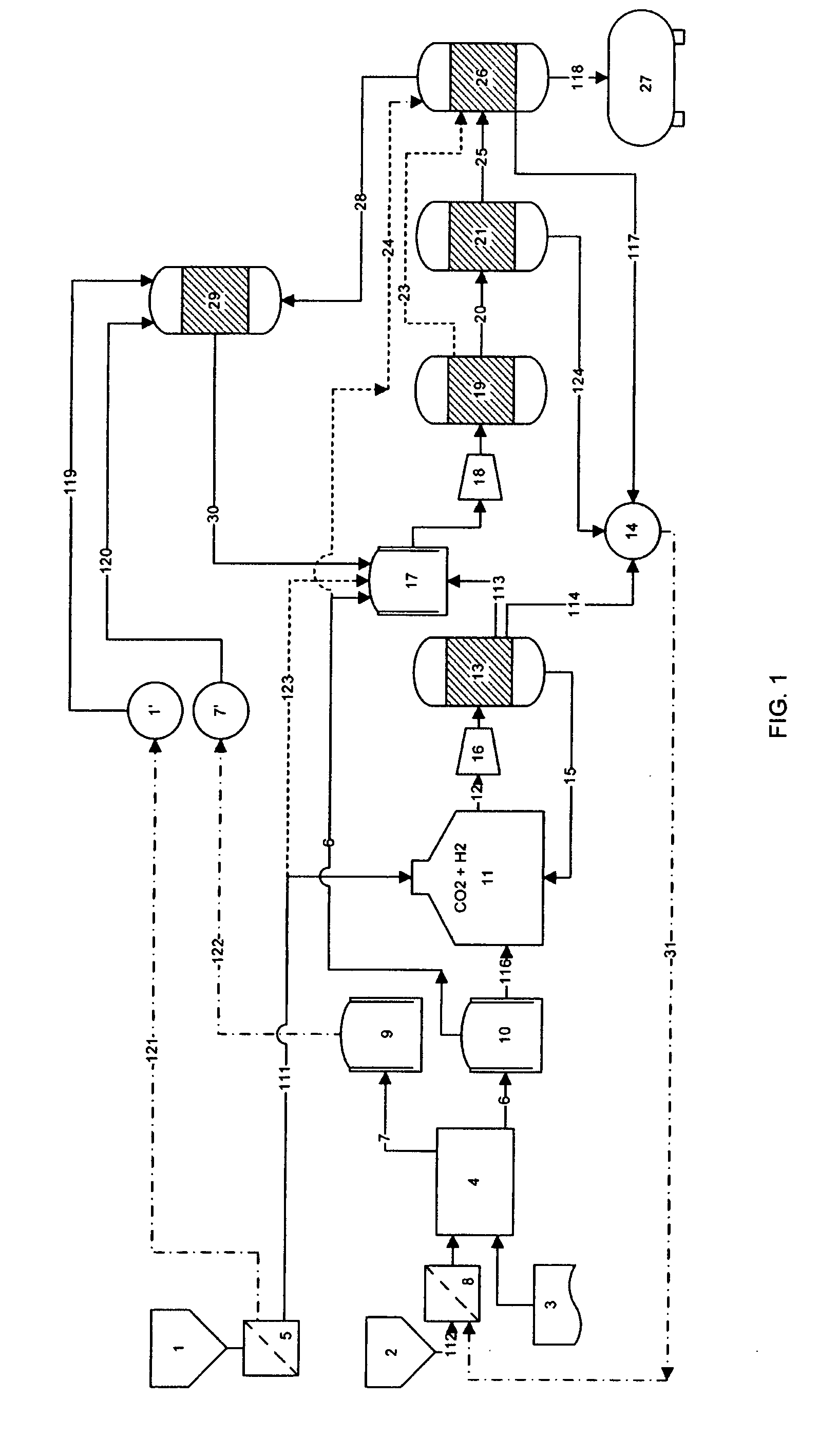

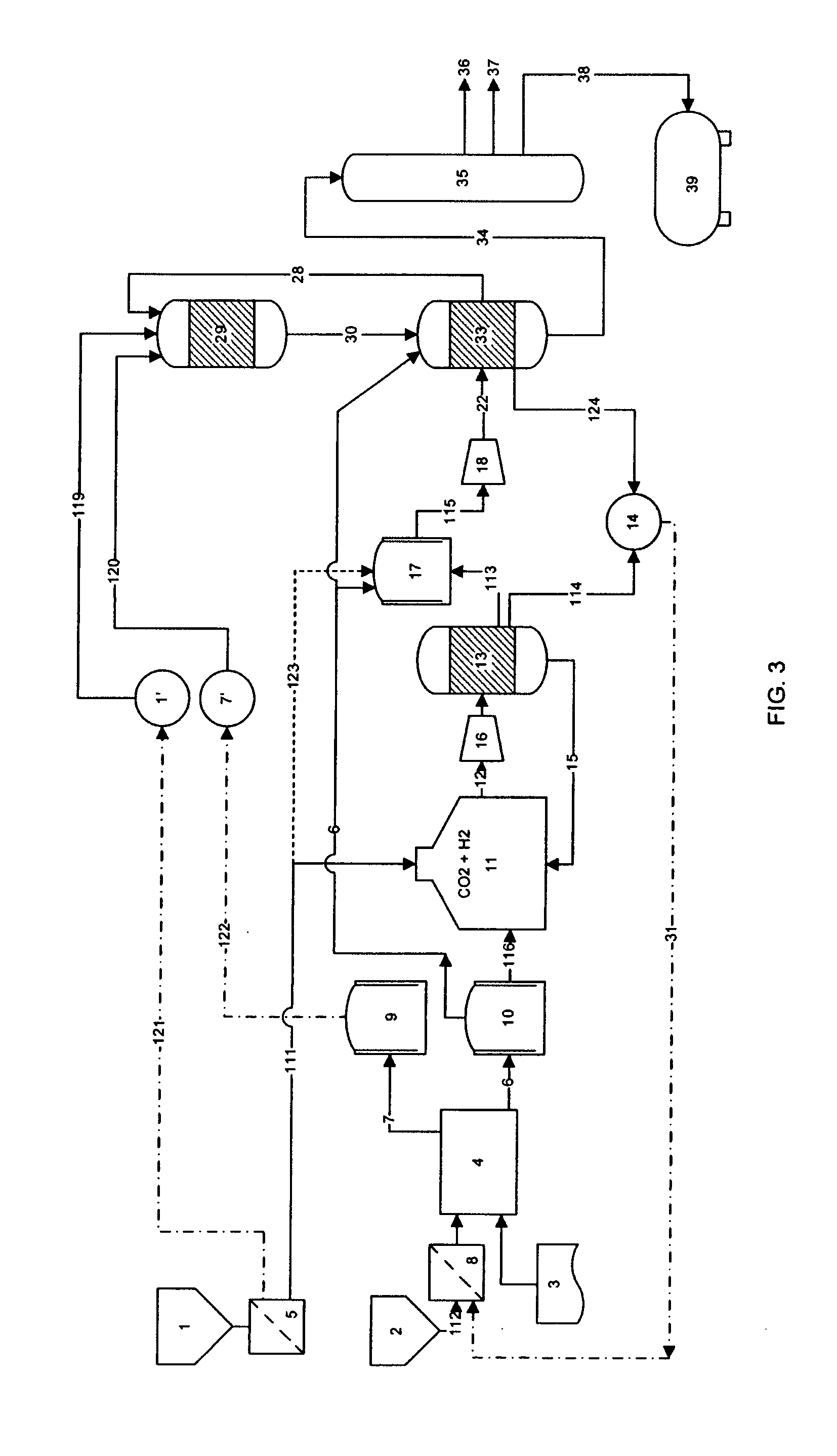

Method and plant or increasing oil recovery by gas injection

A method and a plant for simultaneous production of a gas for injection into an oil field and production of methanol, dimethyl ether and / or other oxygenated hydrocarbons or production of higher hydrocarbons from natural gas is disclosed. An air separation unit (ATR) for production of pure nitrogen for injection and pure oxygen for production of synthesis gas (“syngas”) by authermal reformation of a natural gas is an essential part of the method and plant.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Methods and apparatus for producing syngas and alcohols

The present invention features methods and apparatus for the pyrolysis or torrefaction of a carbon-containing feedstock before it is converted to syngas. In some embodiments, biomass is first pretreated by torrefaction and / or pyrolysis, followed by devolatilization and / or steam reforming to produce syngas. Various mixtures of such pretreated biomass, combined with fresh biomass, can be employed to produce syngas. The syngas can be converted to alcohols, such as ethanol, or to other products.

Owner:RANGE FUELS INC

System and method for extracting energy from agricultural waste

InactiveUS7169821B2Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

Owner:BEST BIOFUELS LLC

Olefin production via oxygenate conversion

InactiveUS20070155999A1Improved arrangementImproved processing schemeOrganic compound preparationHydroxy compound preparationSyngasOxygen compound

Improved processing for the production of light olefins via oxygenate conversion processing is provided. Synthesis gas conversion such as to produce an effluent including at least methanol can be integrated with oxygenate conversion processing such as to produce an oxygenate conversion reactor effluent including at least light olefins and dimethyl ether. At least a portion of the oxygenate conversion reactor effluent can be contacted with such produced methanol to effect recovery of dimethyl ether from the oxygenate conversion reactor effluent.

Owner:UOP LLC

Method for producing hydrocarbons and oxygen-containing compounds from biomass

InactiveUS20050112739A1Improve direct utilizationImprove utilizationOrganic compound preparationHydrocarbon by hydrogenationChemical industryChemical reaction

The present invention generally relates to biochemical and chemical industry, and more particularly to a method which can be used in fermenting carbohydrate substrates of plant origin for producing C1-C5 alcohols, and for synthesis of higher alcohols, other oxygen-containing compounds and hydrocarbons as well as for the production of motor fuel components from biomass. Since C6 and higher alcohols, ethers, acetals, and higher hydrocarbons are not obtainable by a direct biochemical route, it is proposed to synthesize these using known chemical reactions, wherein by-products of fermentation are as raw materials for said synthesis.

Owner:SWEDISH BIOFUELS AB

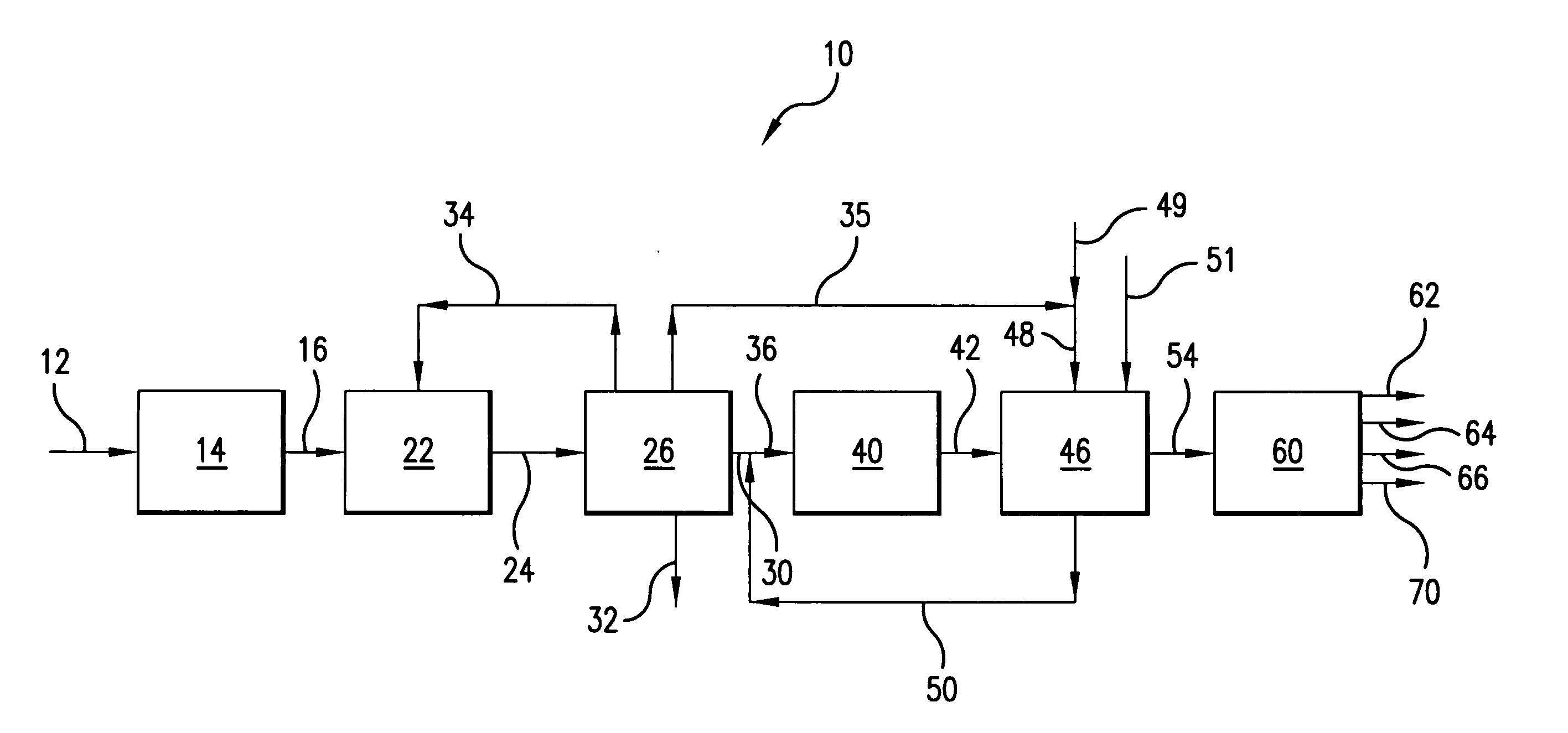

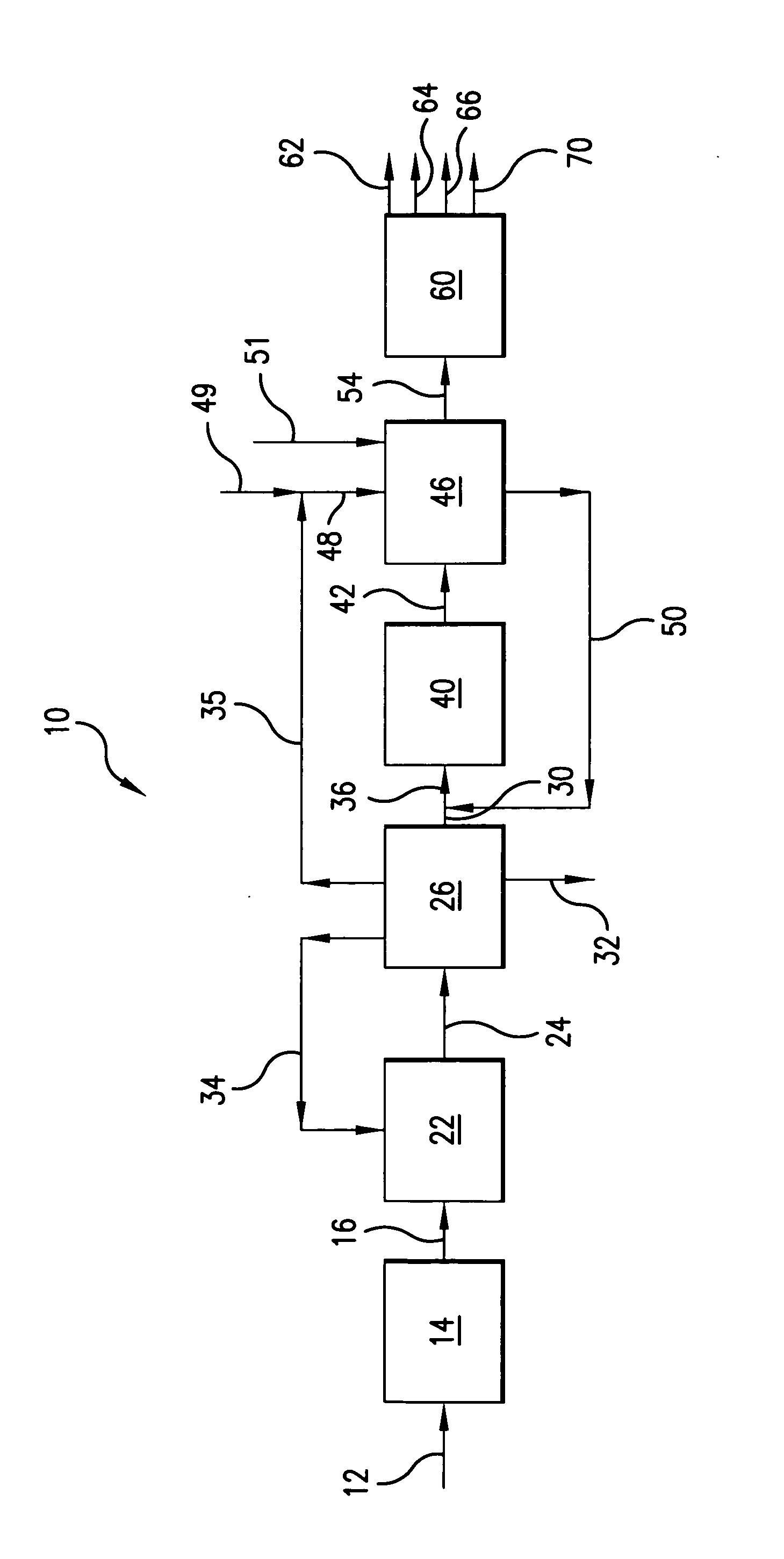

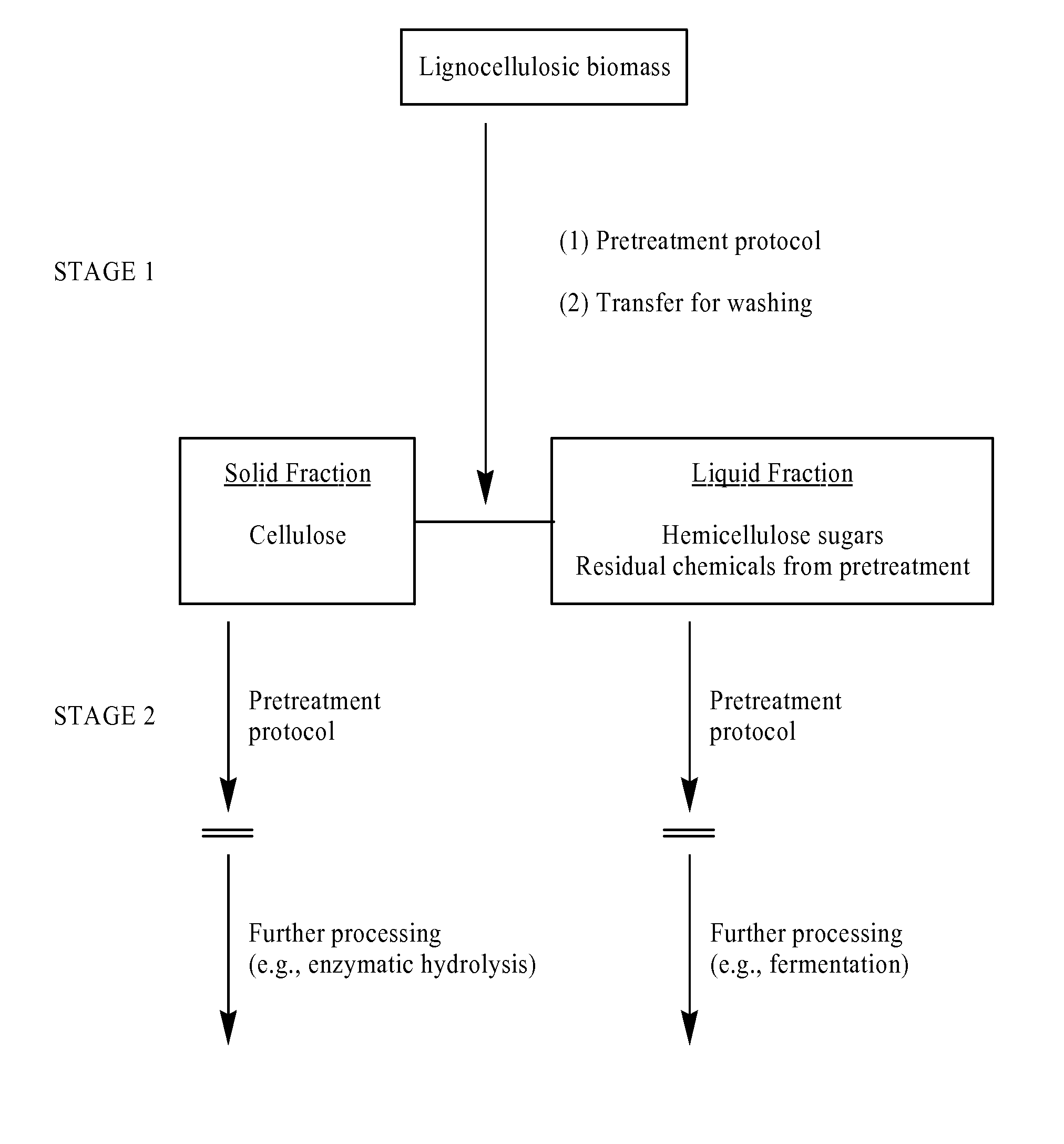

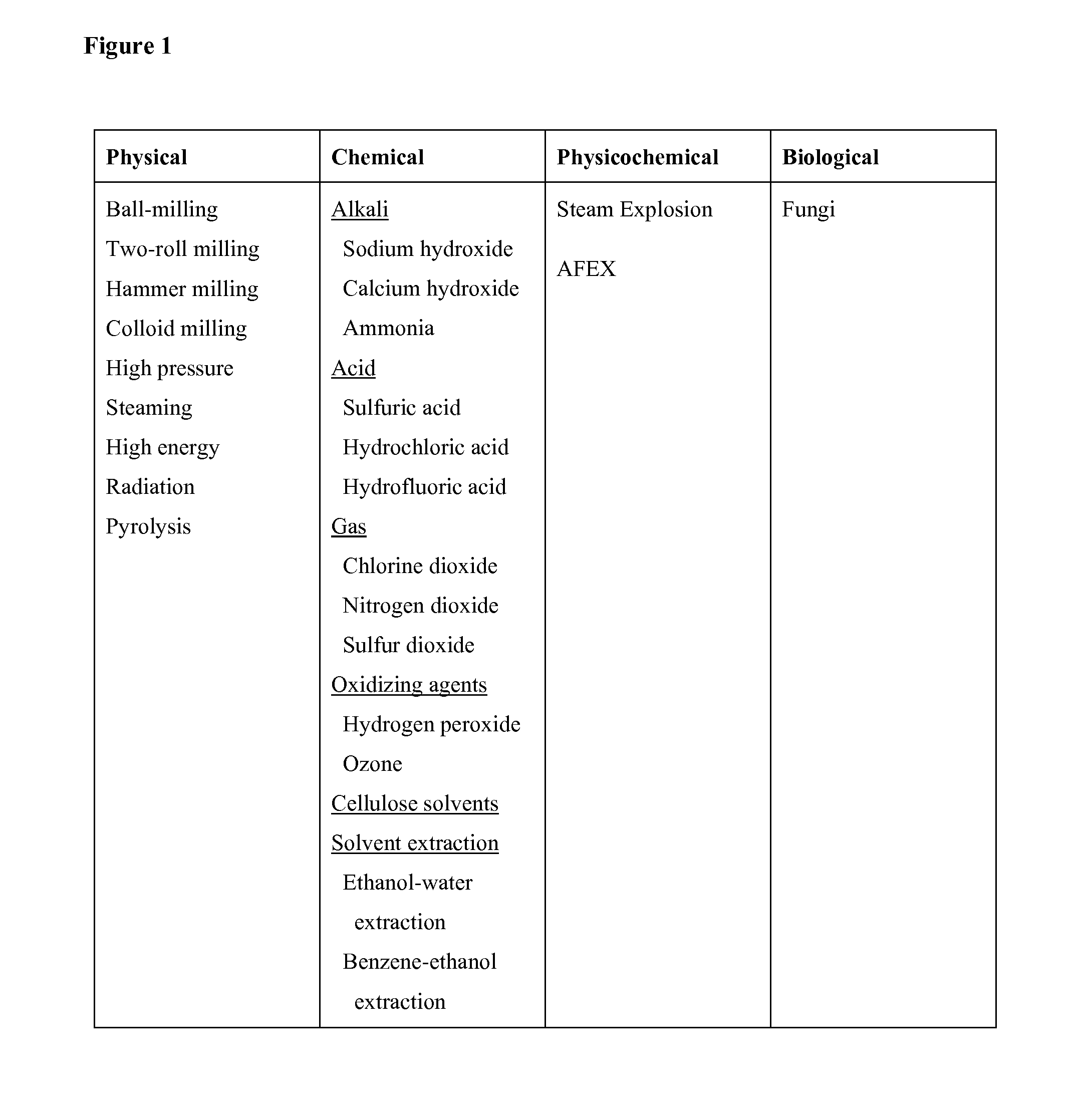

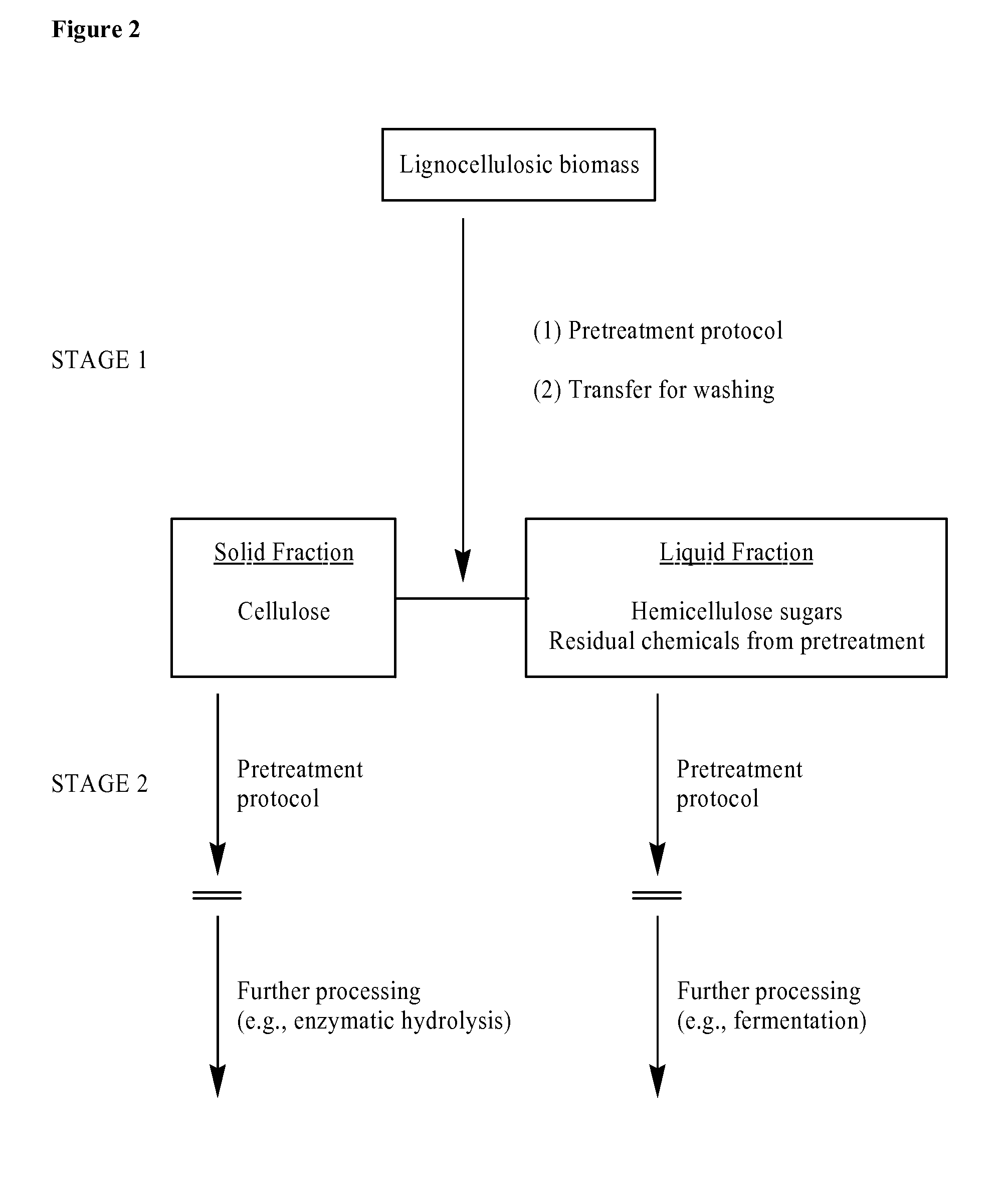

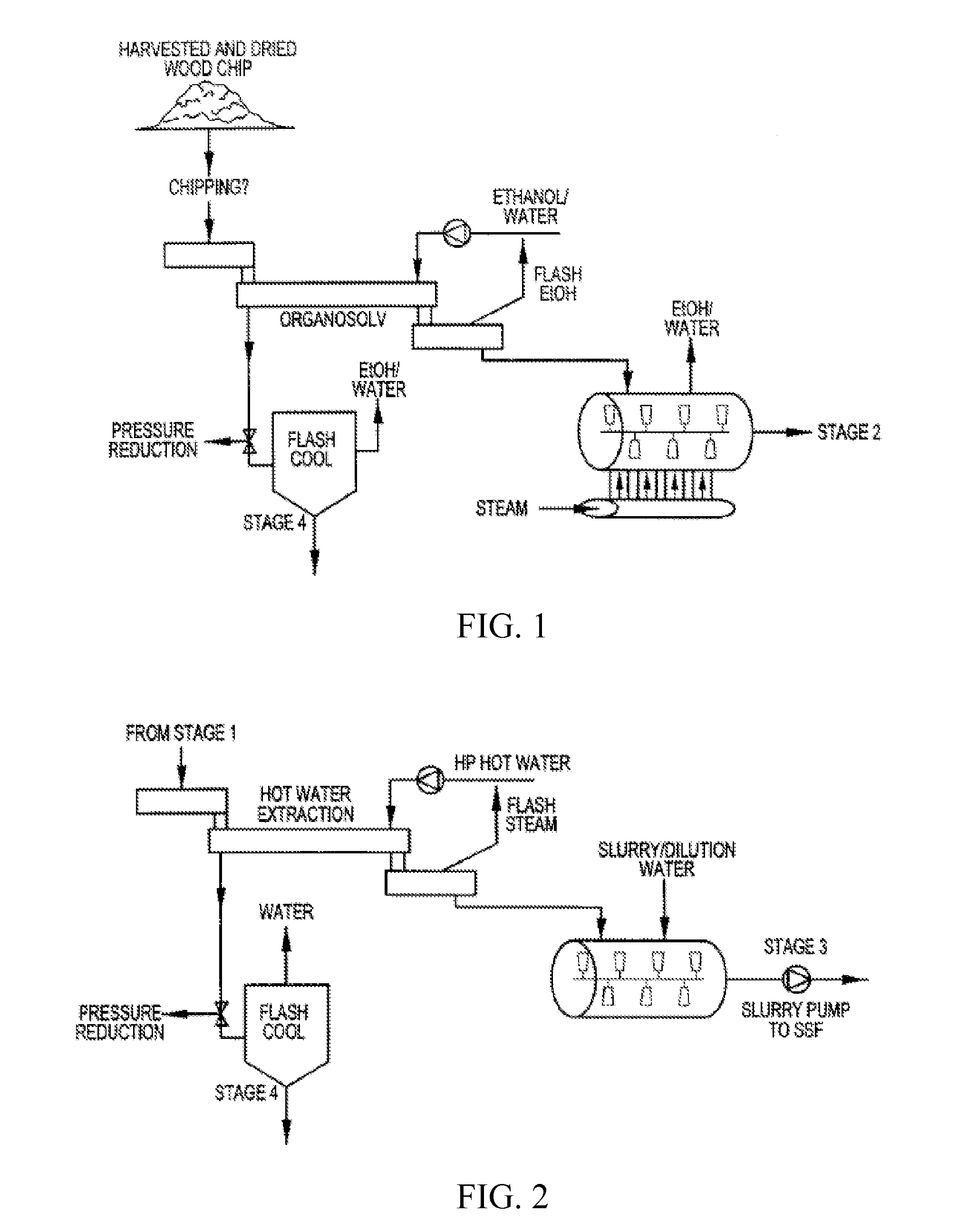

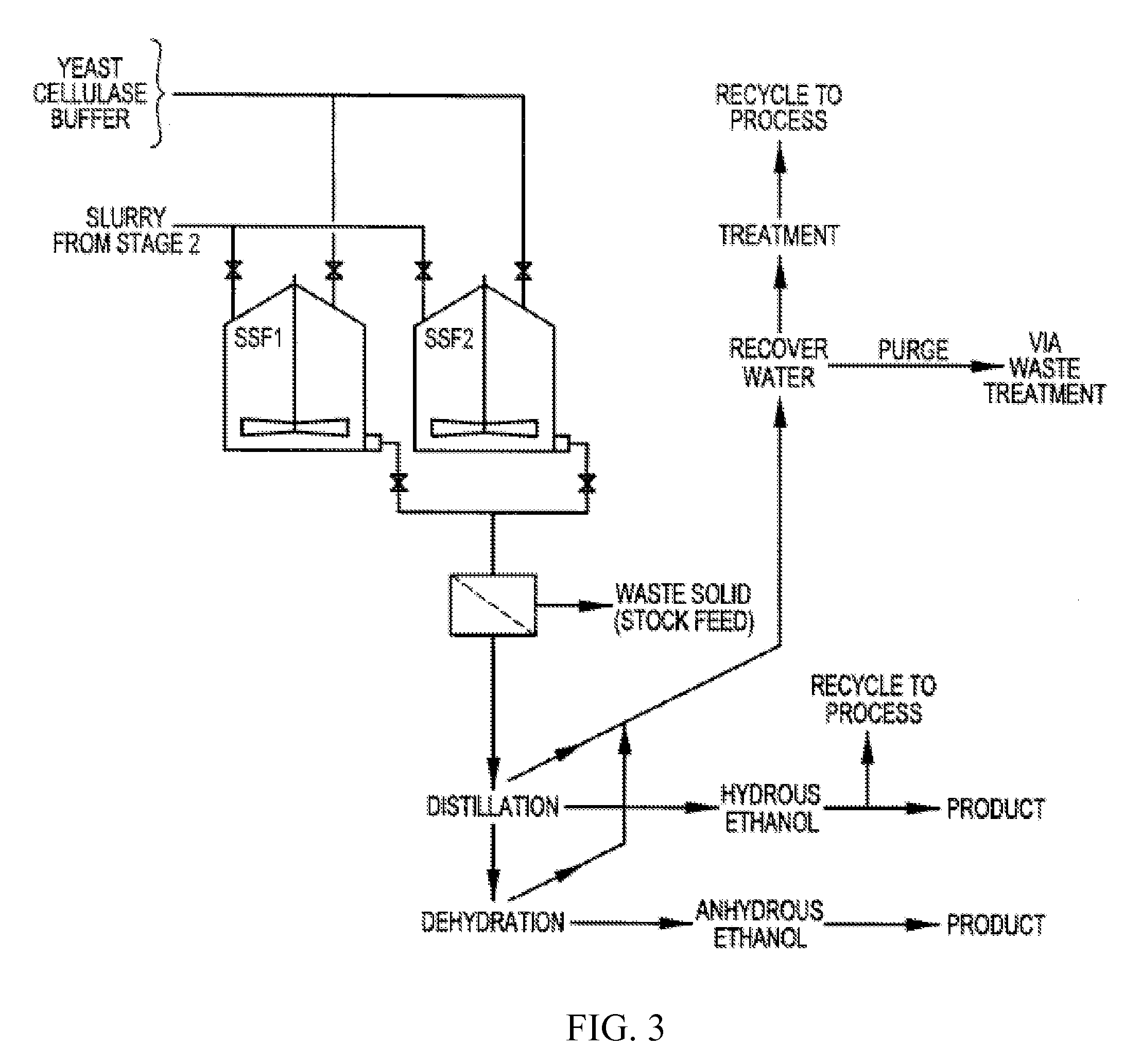

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090062516A1Good for healthImprove responseSugar derivativesOrganic compound preparationFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

Light olefin production via dimethyl ether

InactiveUS20070203380A1Improved arrangementImproved processing schemeOrganic compound preparationOxygen compounds preparation by reductionOlefin synthesisDimethyl ether

Improved processing for the production of light olefins is provided involving synthesis gas conversion to form an effluent including product dimethyl ether, subsequent separation of the product dimethyl ether and conversion thereof to the desired light olefins. The synthesis gas conversion effluent may also desirably include methanol and at least a portion of such methanol may be employed to effect the separation of the product dimethyl ether.

Owner:UOP LLC

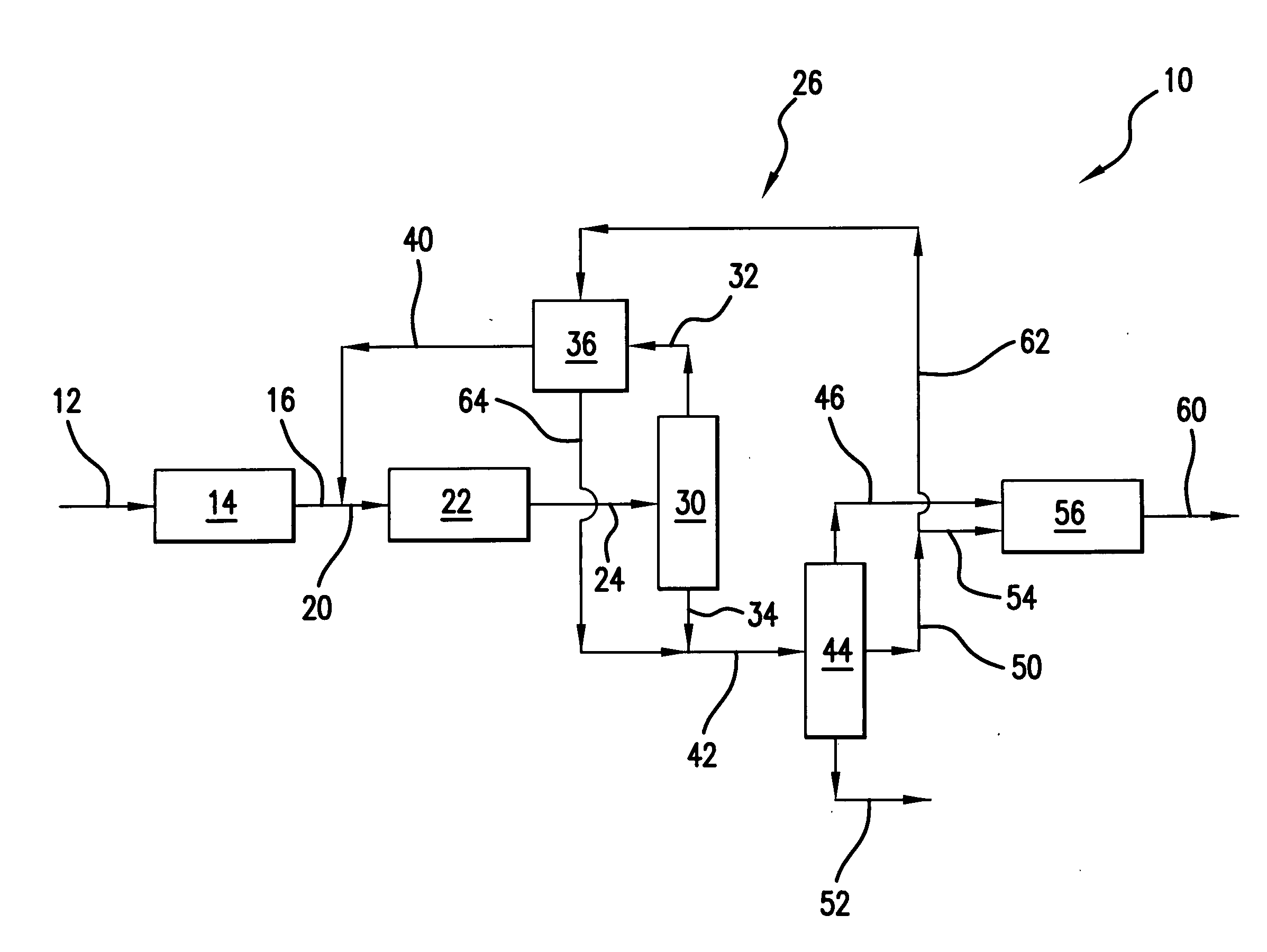

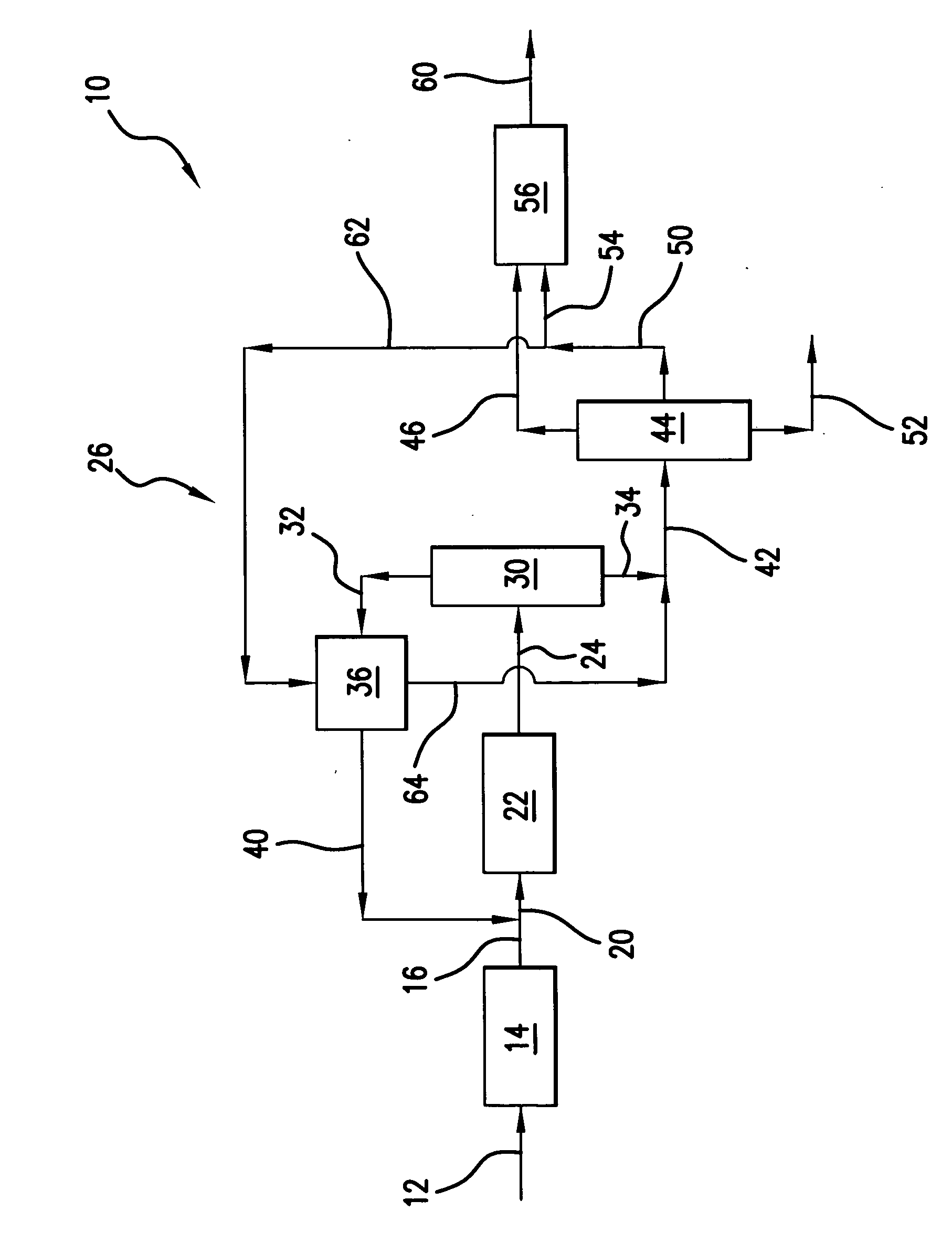

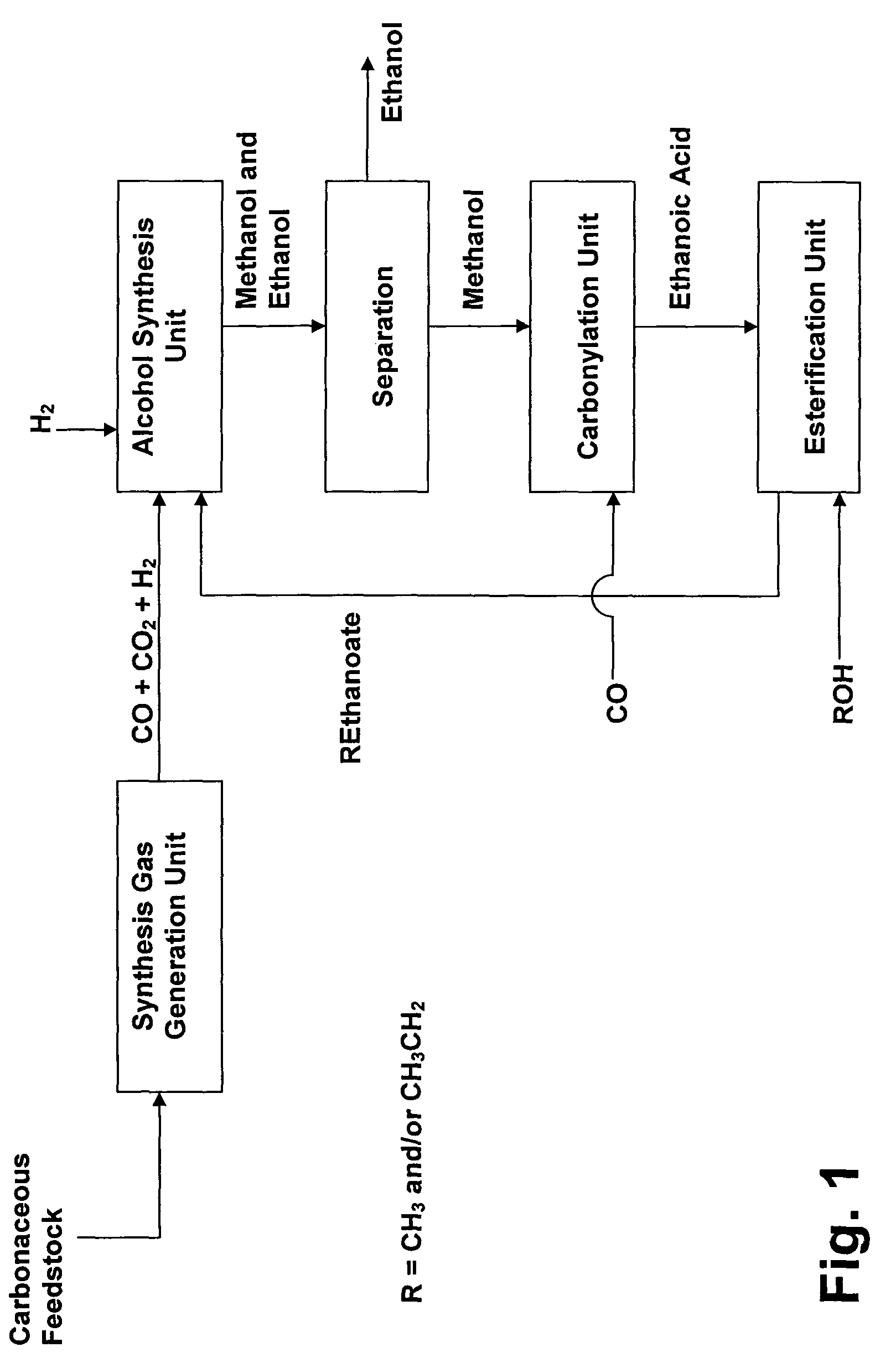

Process for the conversion of hydrocarbons into ethanol

ActiveUS7947746B2Increased formationIncreased purge stepOrganic compound preparationOxygen compounds preparation by reductionAcetic acidAlcohol

Process for converting synthesis gas to ethanol, including the steps of 1) introducing synthesis gas, together with methyl ethanoate and / or ethyl ethanoate, into an alcohol synthesis unit to produce methanol and ethanol, 2) separating the methanol from the ethanol of step 1, 3) introducing methanol, from step 2, together with CO, into a carbonylation unit in the presence of a methanol carbonylation catalyst, to produce ethanoic acid, and 4) introducing ethanoic acid, from step 3, together with methanol and / or ethanol, into an esterification unit to produce methyl ethanoate and / or ethyl ethanoate. In step 5), methyl ethanoate and / or ethyl ethanoate, produced in step 4, are fed into the alcohol synthesis unit of step 1, and in step 6) ethanol from step 2 is recovered.

Owner:INEOS ACETYLS UK LTD

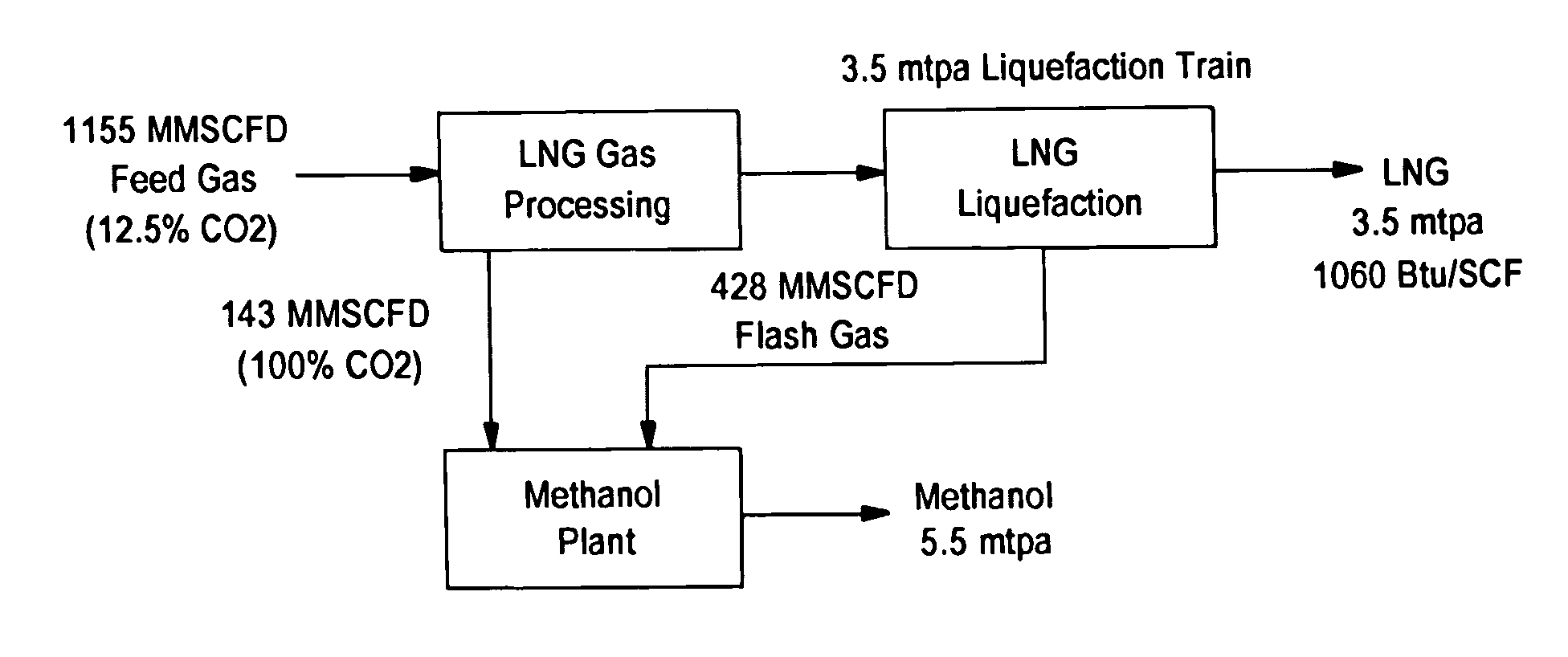

Integrated processing of natural gas into liquid products

ActiveUS7168265B2Effectively integrating the LNG and GTL phases and processing stepsHydrogenSolidificationLiquid productProcess engineering

An integrated process for producing LNG and GTL products is provided, wherein a CO2-containing natural gas feed to an LNG production zone is first pre-treated to separate at least a portion of the CO2 therefrom, and the resulting CO2 stream obtained thereby is then directed to a GTL production zone and utilized to make GTL products that include methanol and / or methanol derivatives.

Owner:BP CORP NORTH AMERICA INC

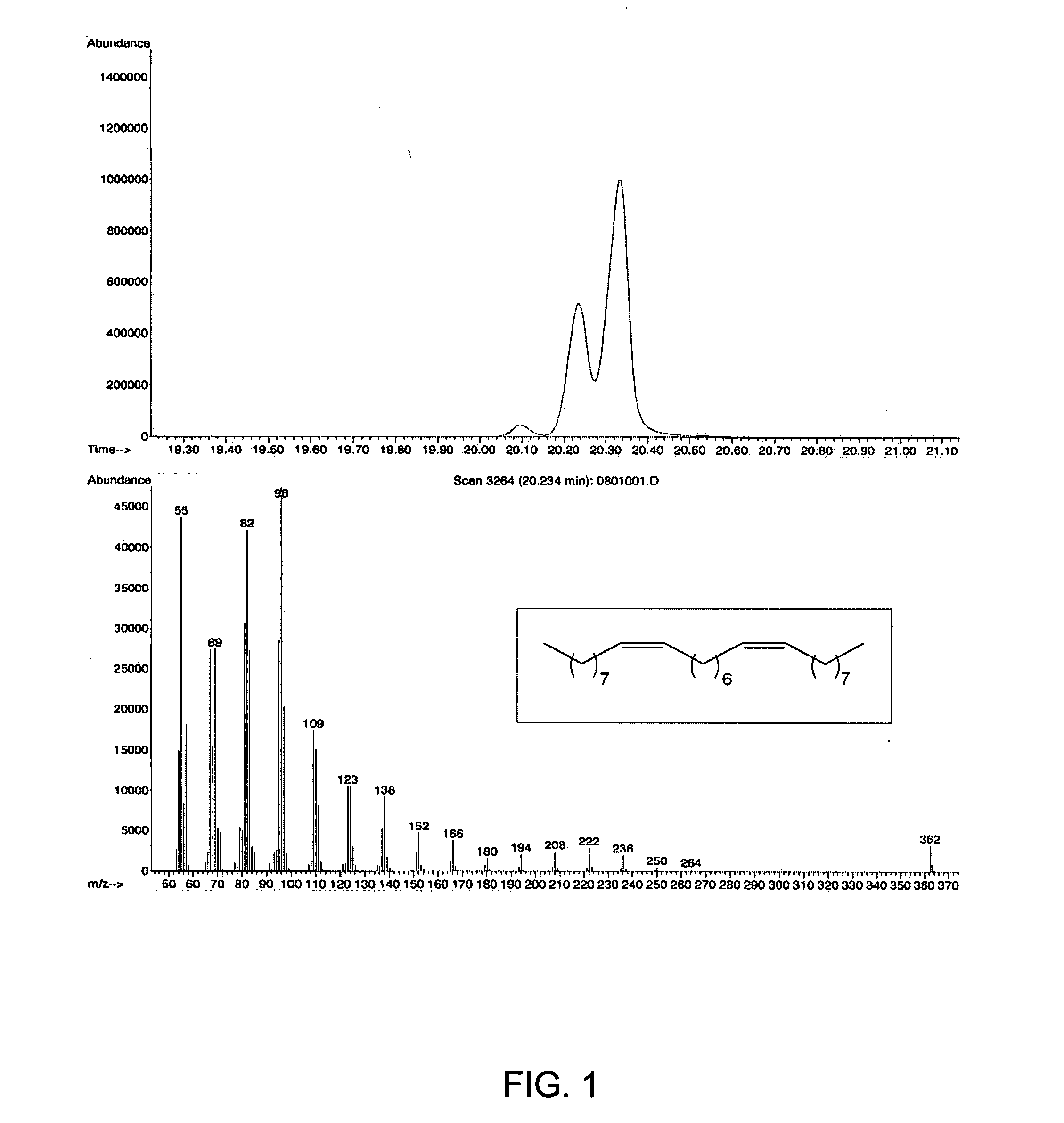

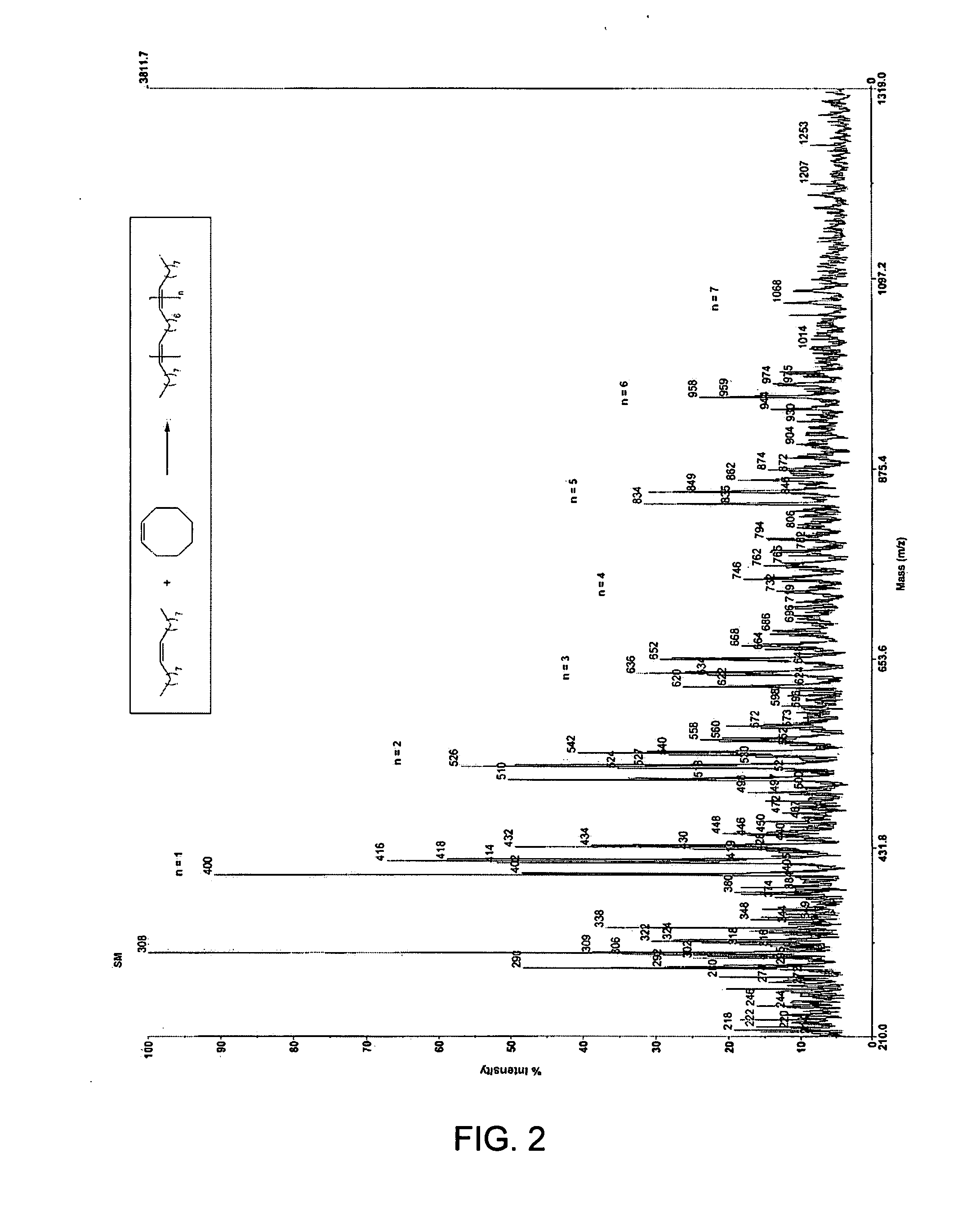

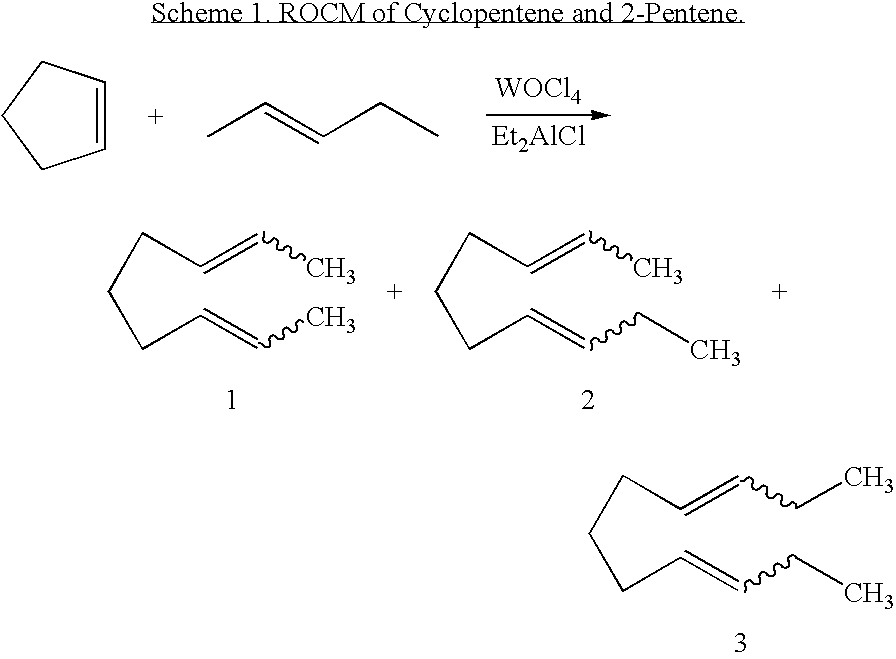

Ring opening cross-metathesis reaction of cyclic olefins with seed oils and the like

ActiveUS20080064891A1Fatty acid esterificationOrganic compound preparationOrganic synthesisRuthenium

This invention relates generally to olefin metathesis, and more particularly relates to the ring-opening, ring insertion cross-metathesis of cyclic olefins with internal olefins such as seed oils and the like. In one embodiment, a method is provided for carrying out a catalytic ring-opening cross-metathesis reaction, comprising contacting at least one olefinic substrate with at least one cyclic olefin as a cross metathesis partner, in the presence of a ruthenium alkylidene olefin metathesis catalyst under conditions effective to allow ring insertion cross metathesis whereby the cyclic olefin is simultaneously opened and inserted into the olefinic substrate. The invention has utility in the fields of catalysis, organic synthesis, and industrial chemistry.

Owner:WILMAR TRADING PTE LTD

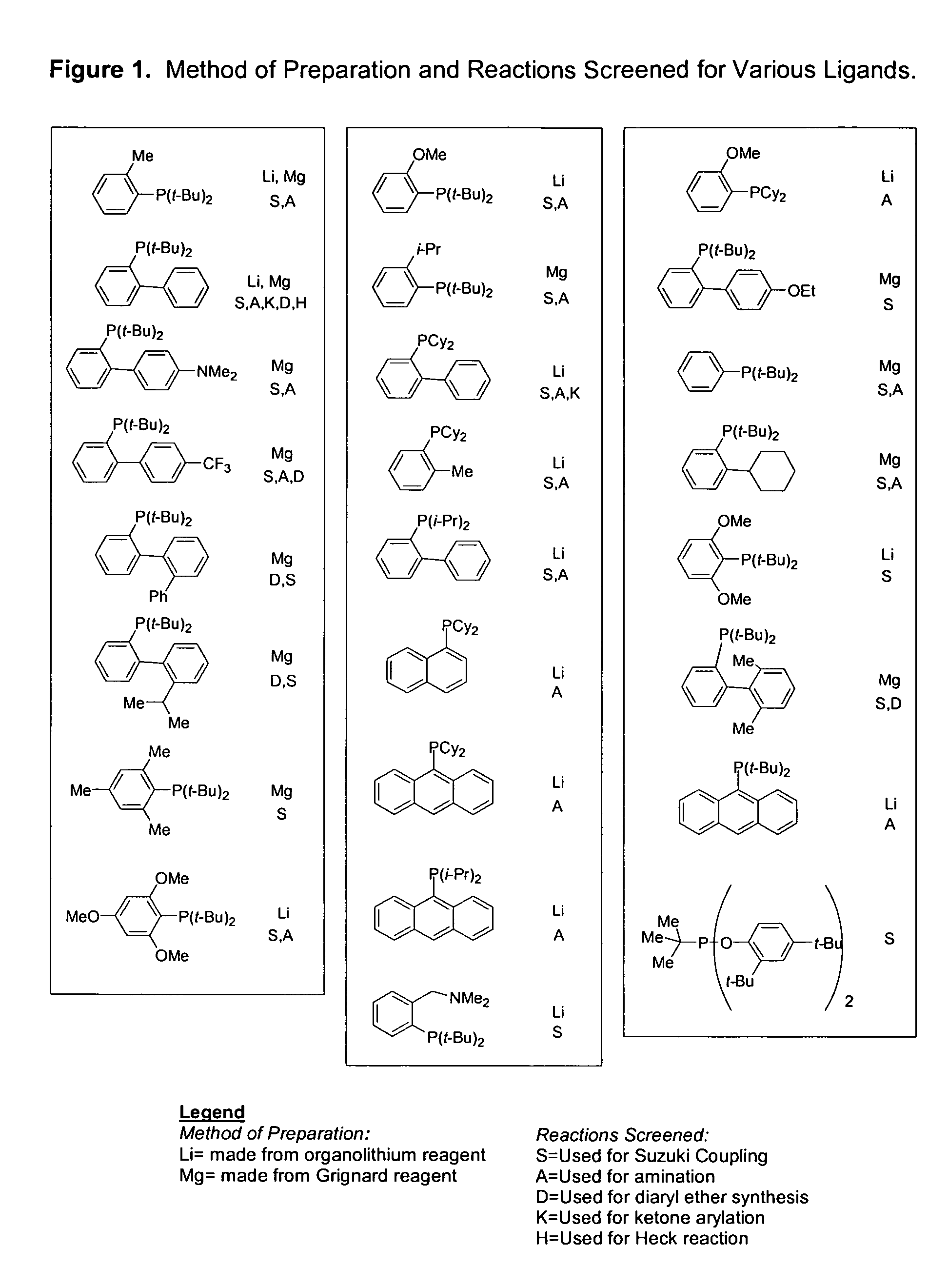

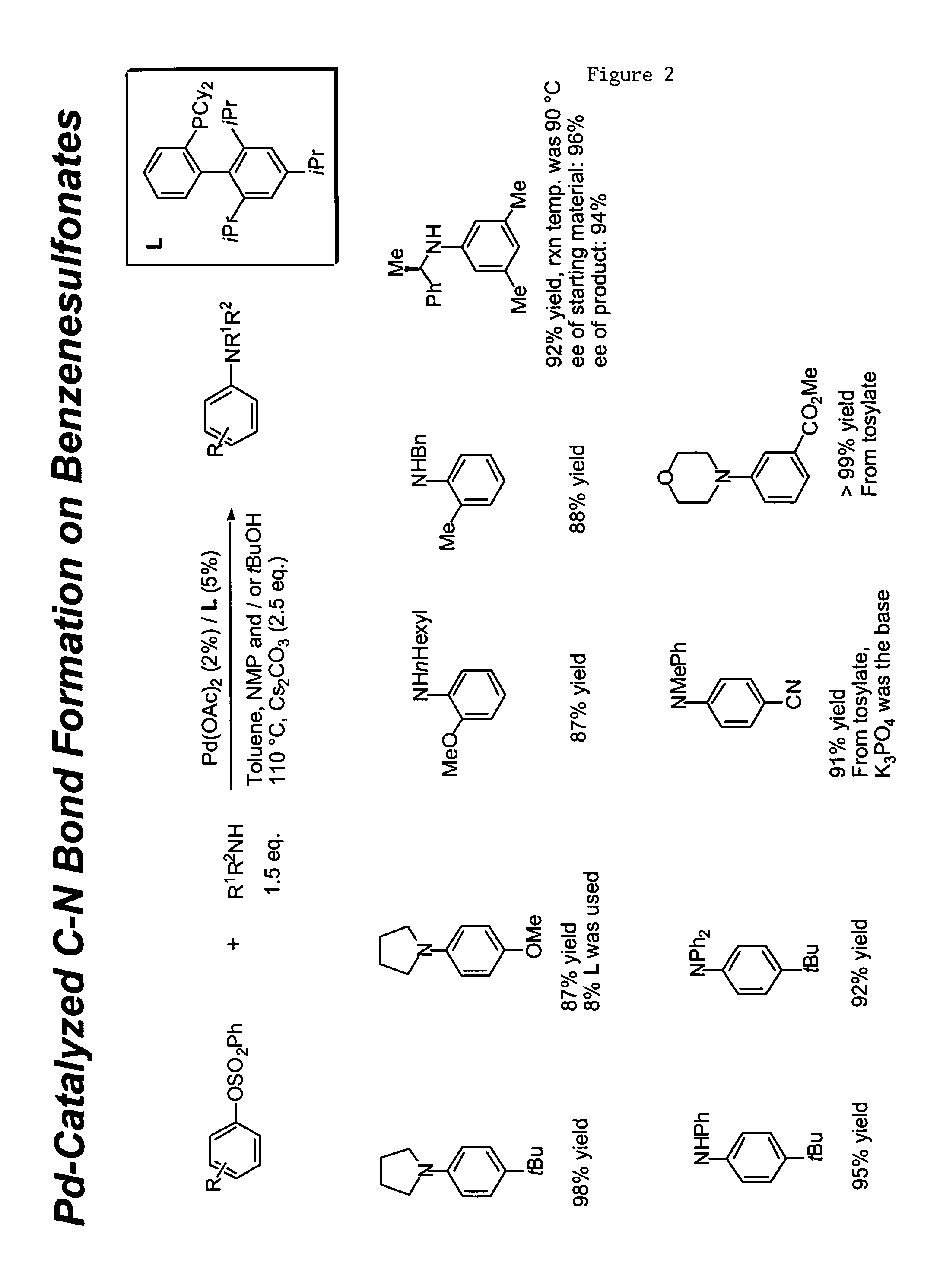

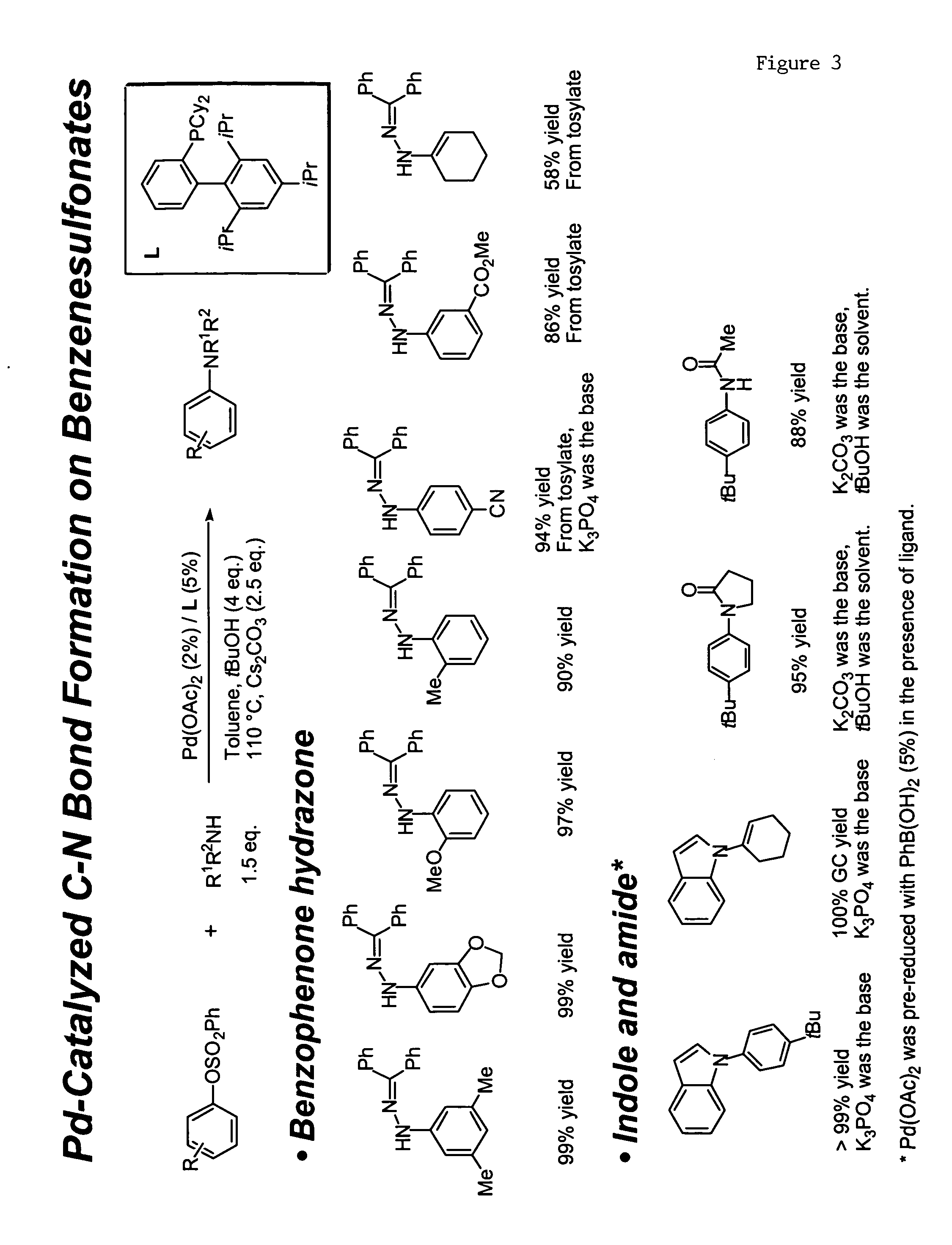

Ligands for metals and improved metal-catalyzed processes based thereon

InactiveUS7223879B2More featureEasy to useCarboxylic acid nitrile preparationCarboxylic acid esters preparationCarbon–carbon bondHeteroatom

One aspect of the present invention relates to ligands for transition metals. A second aspect of the present invention relates to the use of catalysts comprising these ligands in transition metal-catalyzed carbon-heteroatom and carbon-carbon bond-forming reactions. The subject methods provide improvements in many features of the transition metal-catalyzed reactions, including the range of suitable substrates, reaction conditions, and efficiency.

Owner:MASSACHUSETTS INST OF TECH

Process for producing liquid fuel from carbon dioxide and water

ActiveUS20070244208A1Combustible gas chemical modificationOrganic compounds purification/separation/stabilisationHydrocotyle bowlesioidesLiquid fuel

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

Alcohol production using hydraulic cavitation

InactiveUS20080277264A1Increase speedHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationLiquid medium

A system and method is provided which includes using a liquid treatment apparatus, which is equipped with cyclonettes, for example, to subject a liquid medium processing stream in an alcohol production process to hydraulic cavitation, i.e., to shear under vacuum, at one or more locations. The liquid treatment apparatus, in one embodiment, is directed to the formation of a central axial jet and a vacuum chamber that can be sealed by the exiting jet. Cavitation is generated by directing a high velocity jet of liquid medium processing stream through a volume of vapor under a vacuum created in the chamber through which the jet travels. This can reduce the production cost of alcohol, such as ethanol, by improving alcohol yield per bushel, among other benefits. In one embodiment, the alcohol production process is a dry grind process, a modified dry grind process, or a wet mill process. In one embodiment the alcohol production process utilizes grain as a starting material.

Owner:FLUID QUIP INC

Method for preparing ethanol by hydrogenation of acetic ester

ActiveCN102093162AHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationReaction temperatureBULK ACTIVE INGREDIENT

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Popular searches

Waste based fuel Metal/metal-oxides/metal-hydroxide catalysts Catalyst activation/preparation Fermentation Digital data processing details Distillation purification/separation Special data processing applications Text database browsing/visualisation Fractional distillation Hydrocarbon from oxygen organic compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com