Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2017 results about "Pure oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

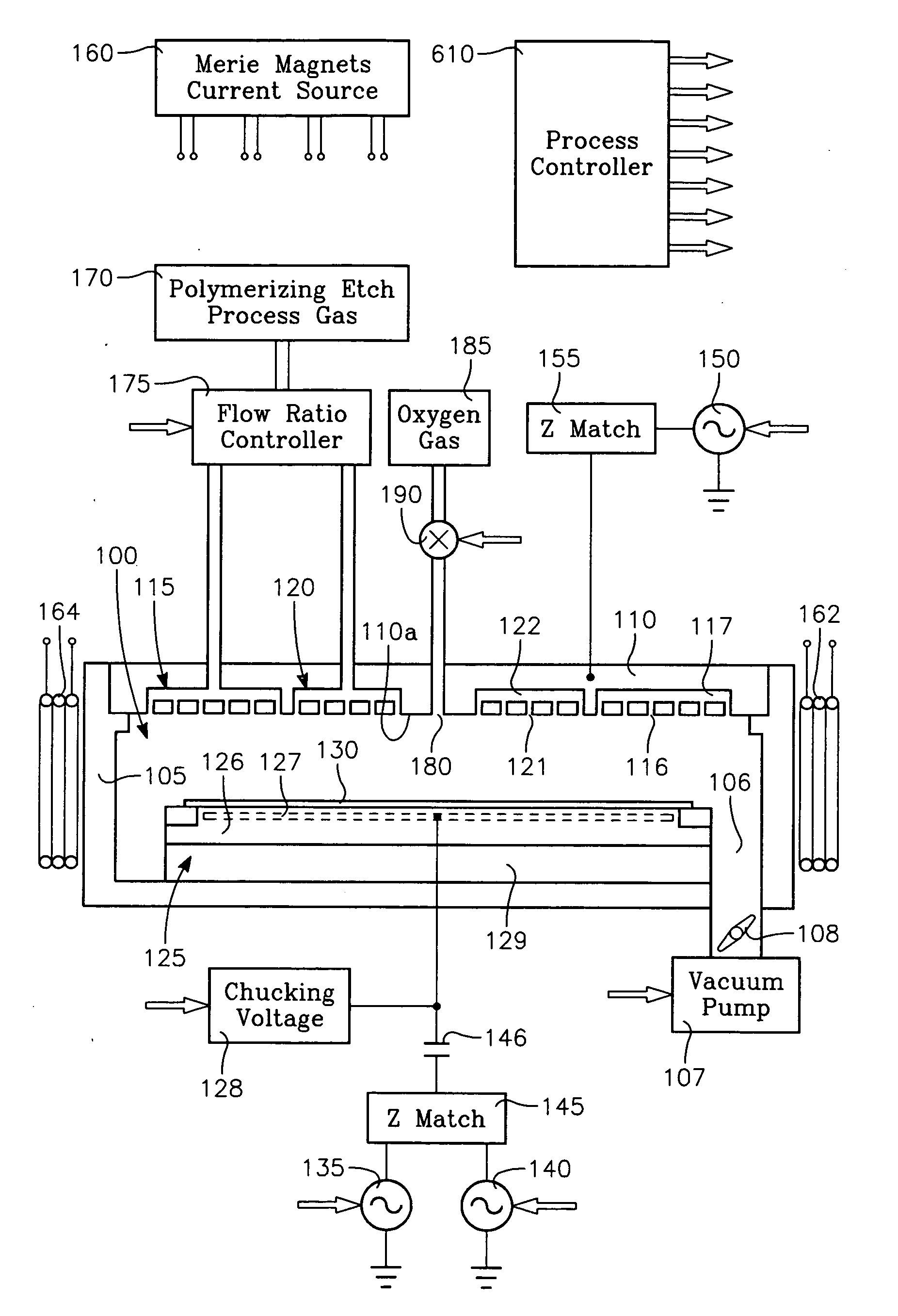

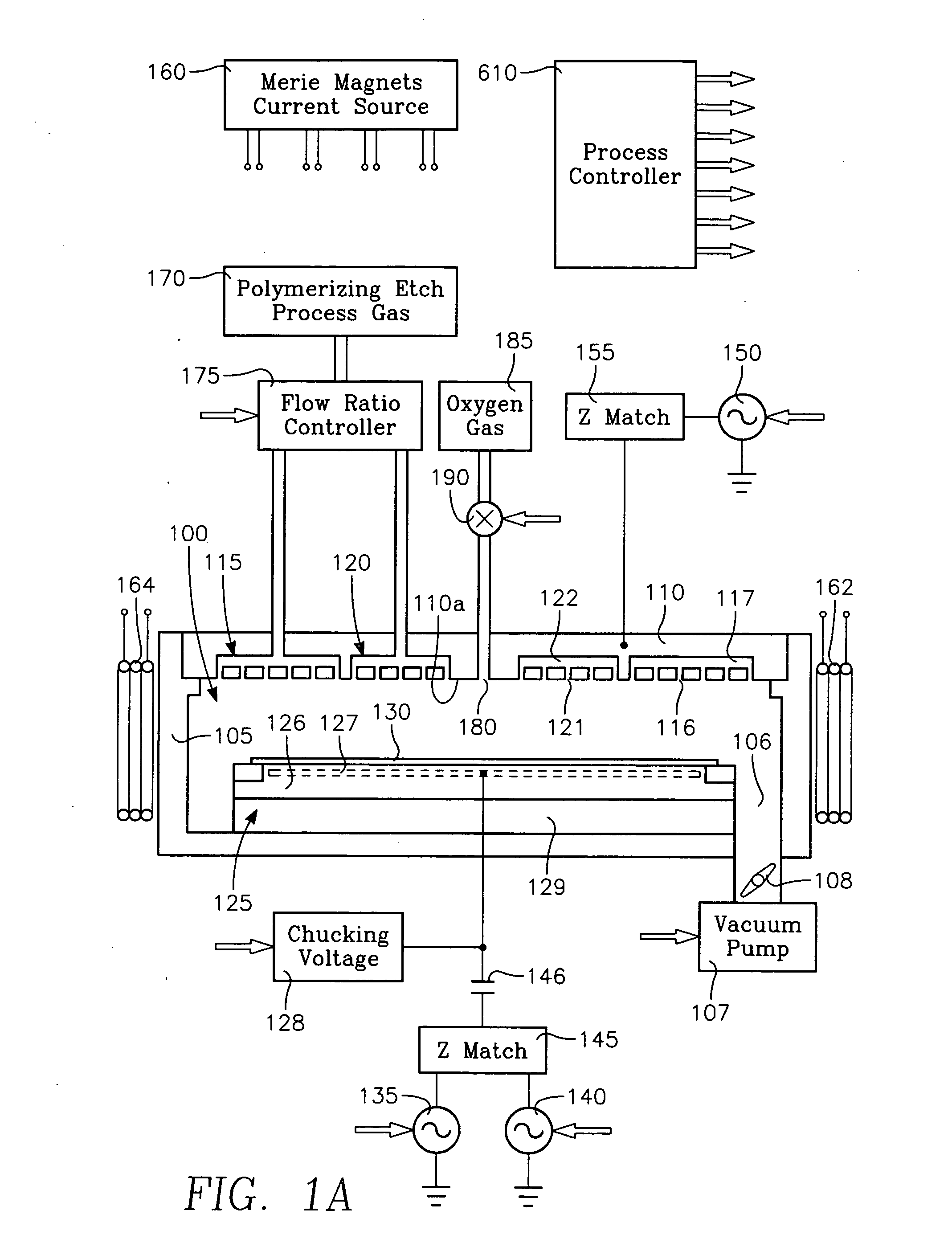

Plasma etch reactor with distribution of etch gases across a wafer surface and a polymer oxidizing gas in an independently fed center gas zone

A plasma etch reactor for plasma enhanced etching of a workpiece such as a semiconductor wafer includes a housing defining a process chamber, a workpiece support configured to support a workpiece within the chamber during processing and comprising a plasma bias power electrode. The reactor further includes a first process gas inlet coupled to receive predominantly or pure oxygen gas and a second process gas inlet coupled to receive a polymerizing etch process gas. The reactor has a ceiling plasma source power electrode including a center circular gas disperser configured to receive a process gas from the first process gas inlet and to distribute the process gas into the chamber over the workpiece, and an inner annular gas disperser centered around the center gas disperser configured to receive the process gas from the second process gas inlet and to distribute the process gas into the chamber over the workpiece through an inner plurality of injection ports.

Owner:APPLIED MATERIALS INC

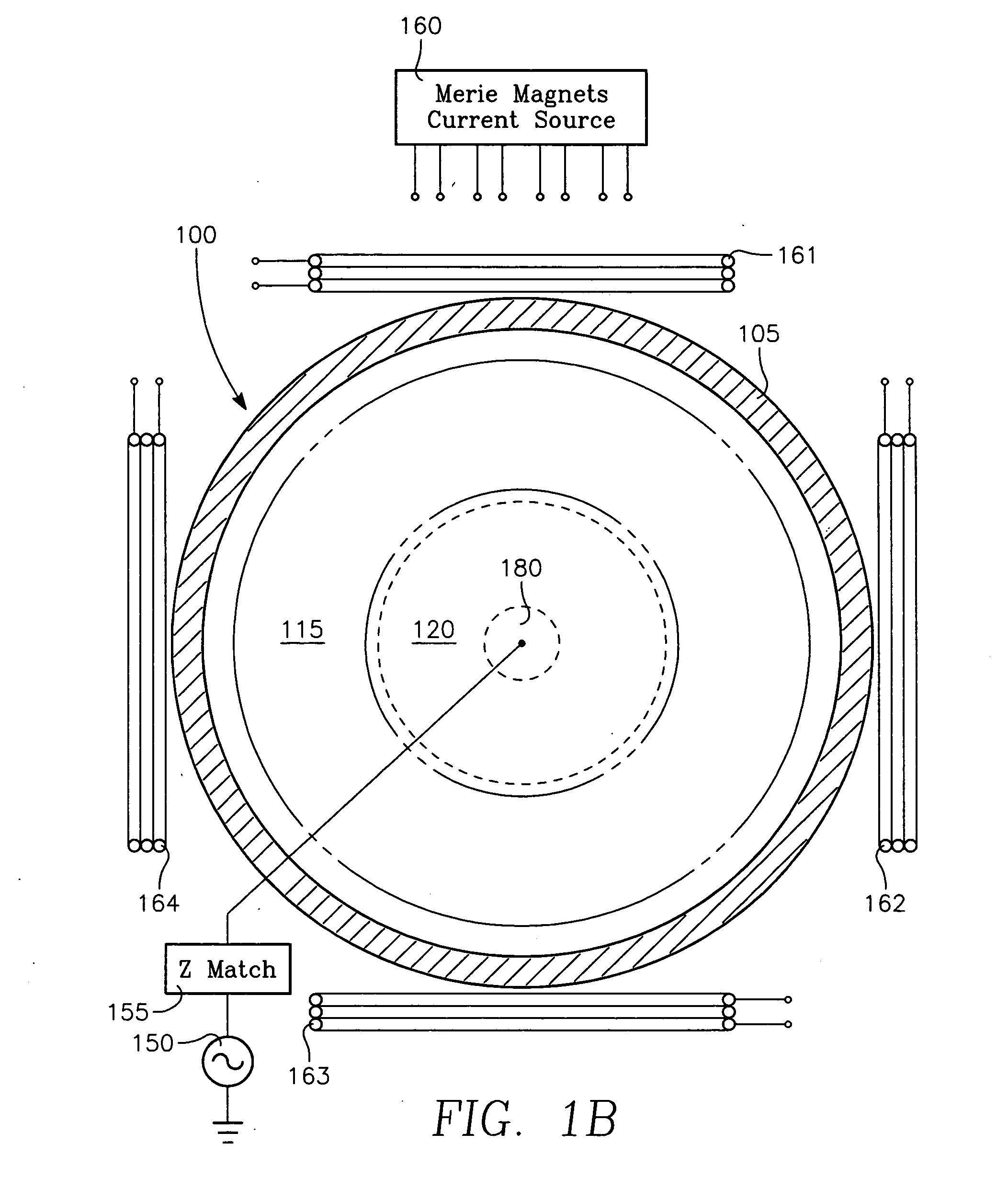

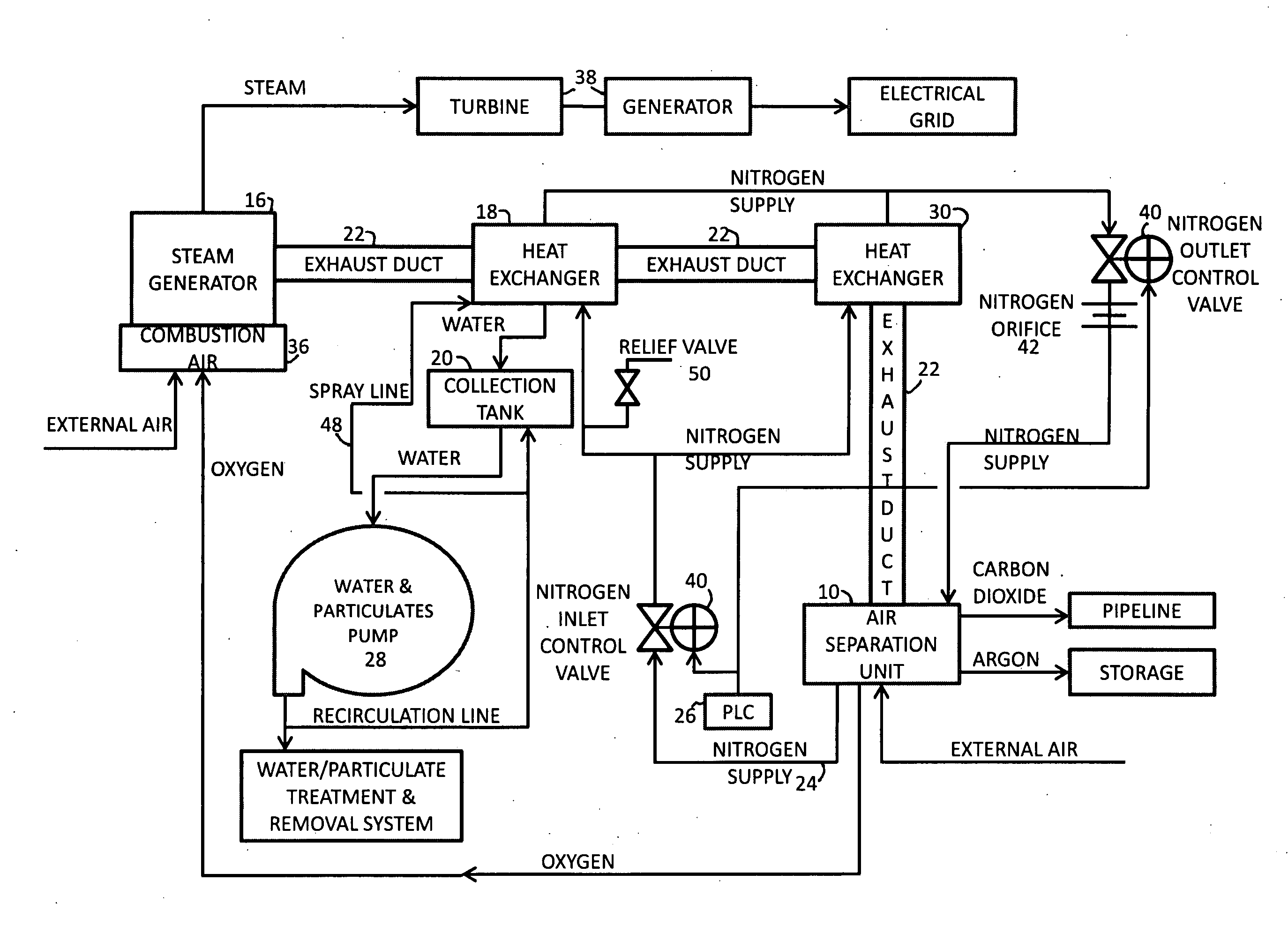

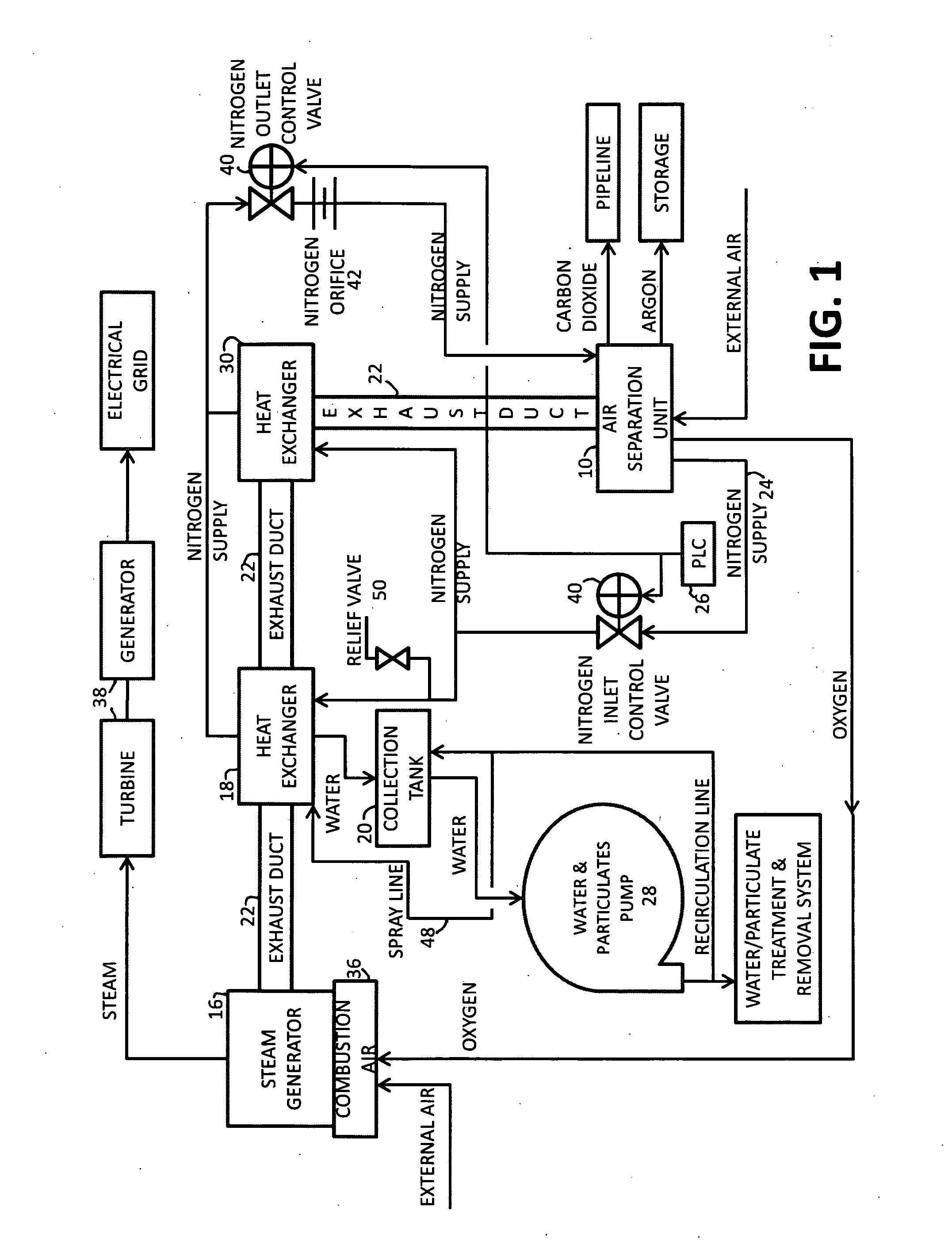

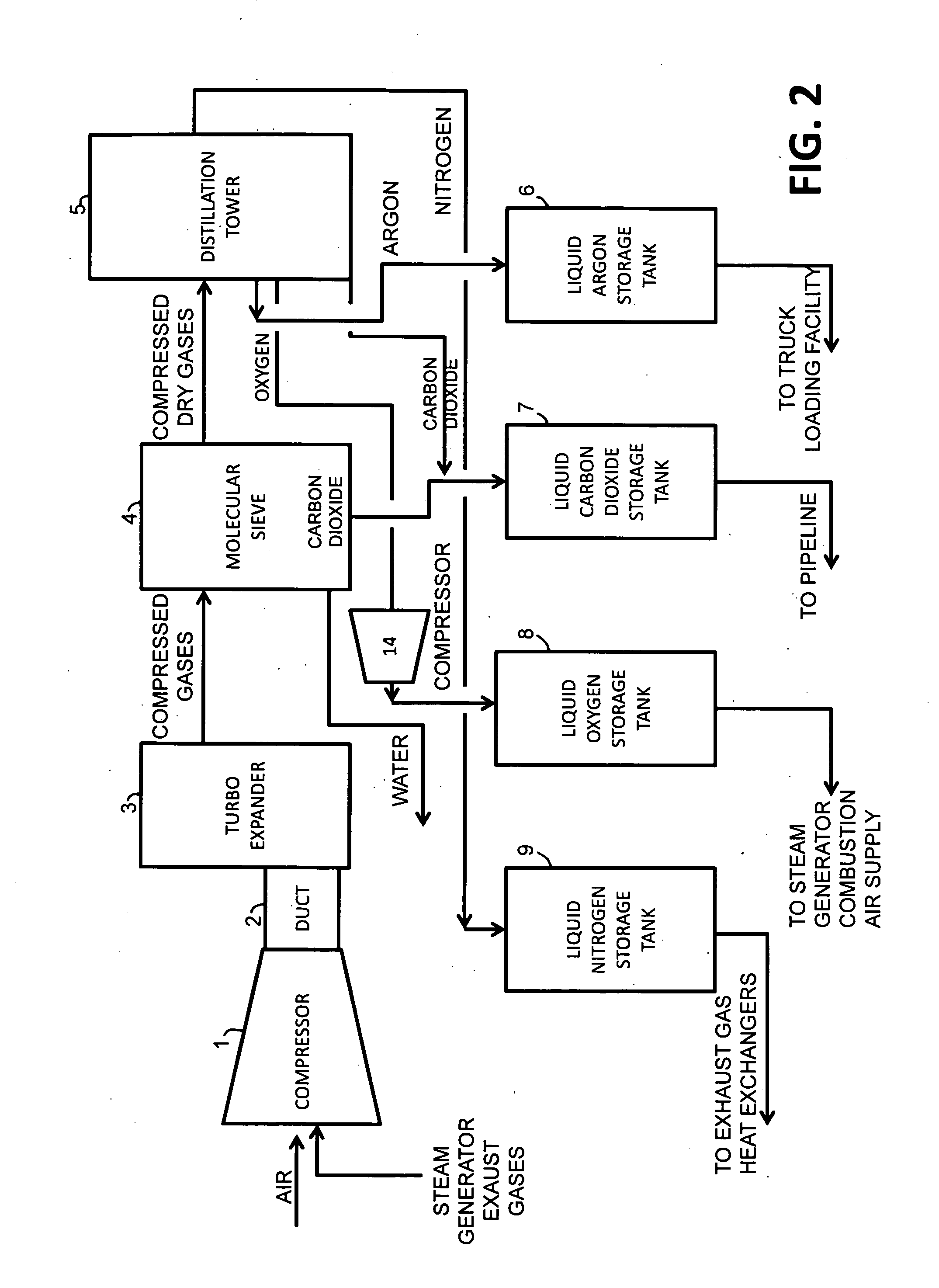

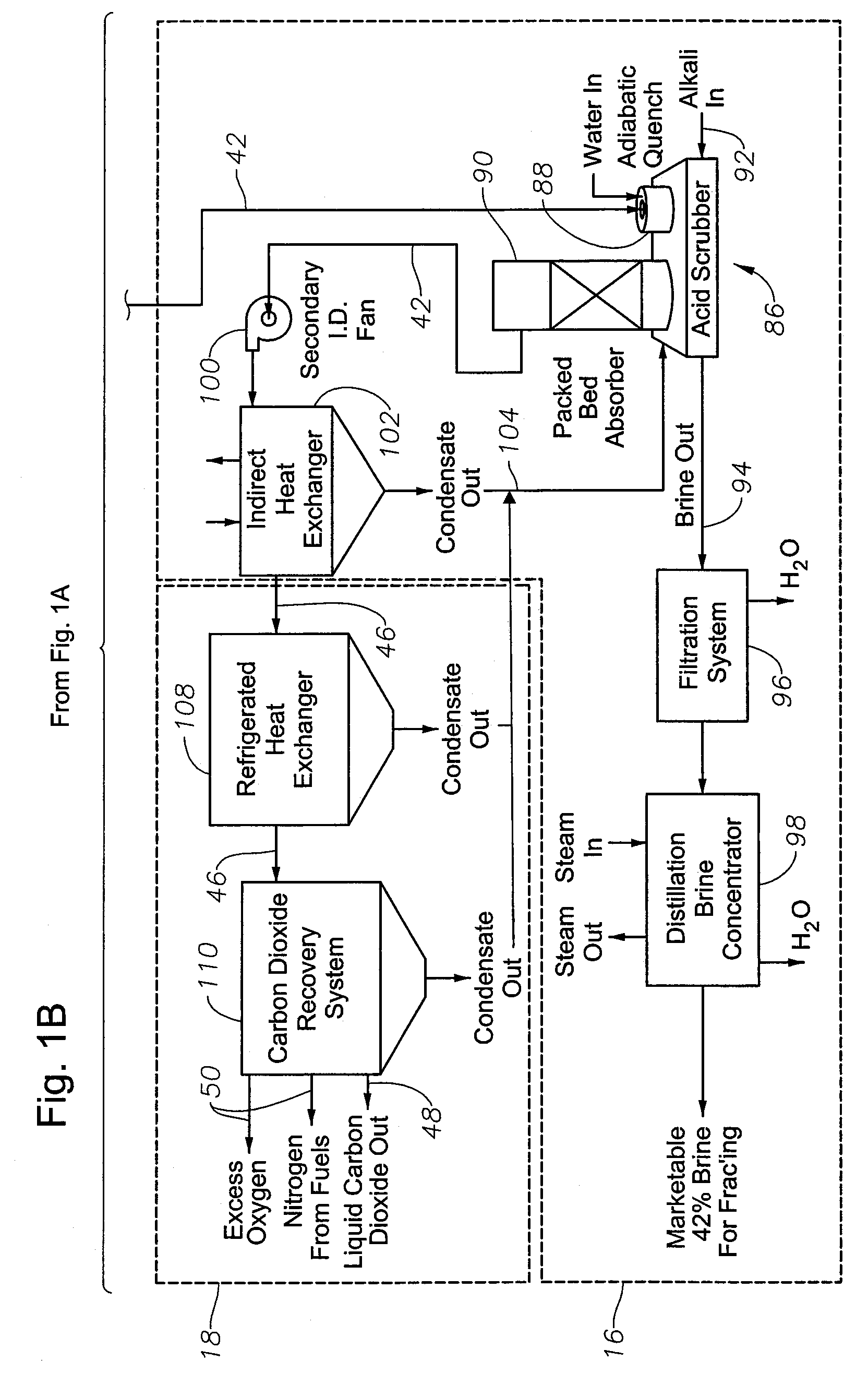

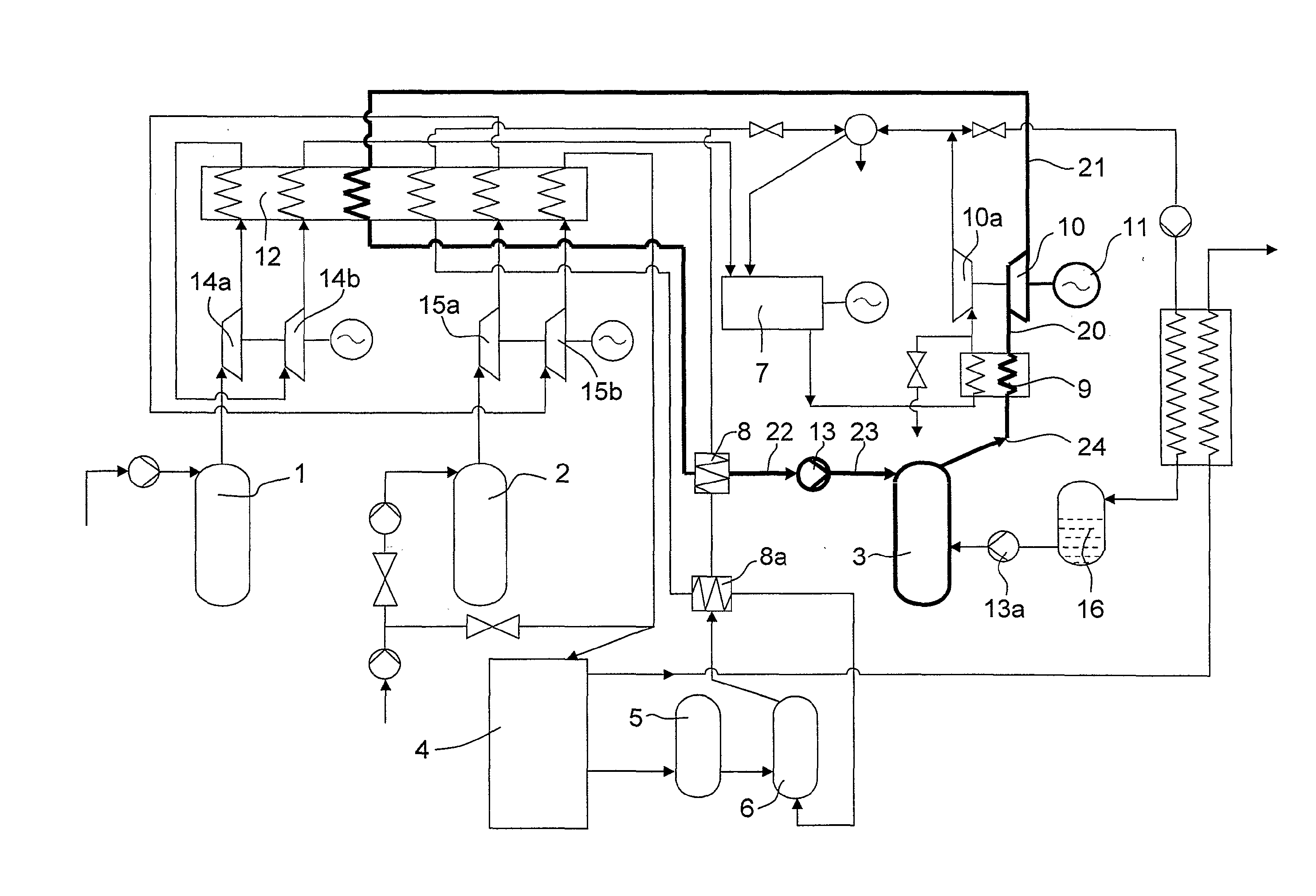

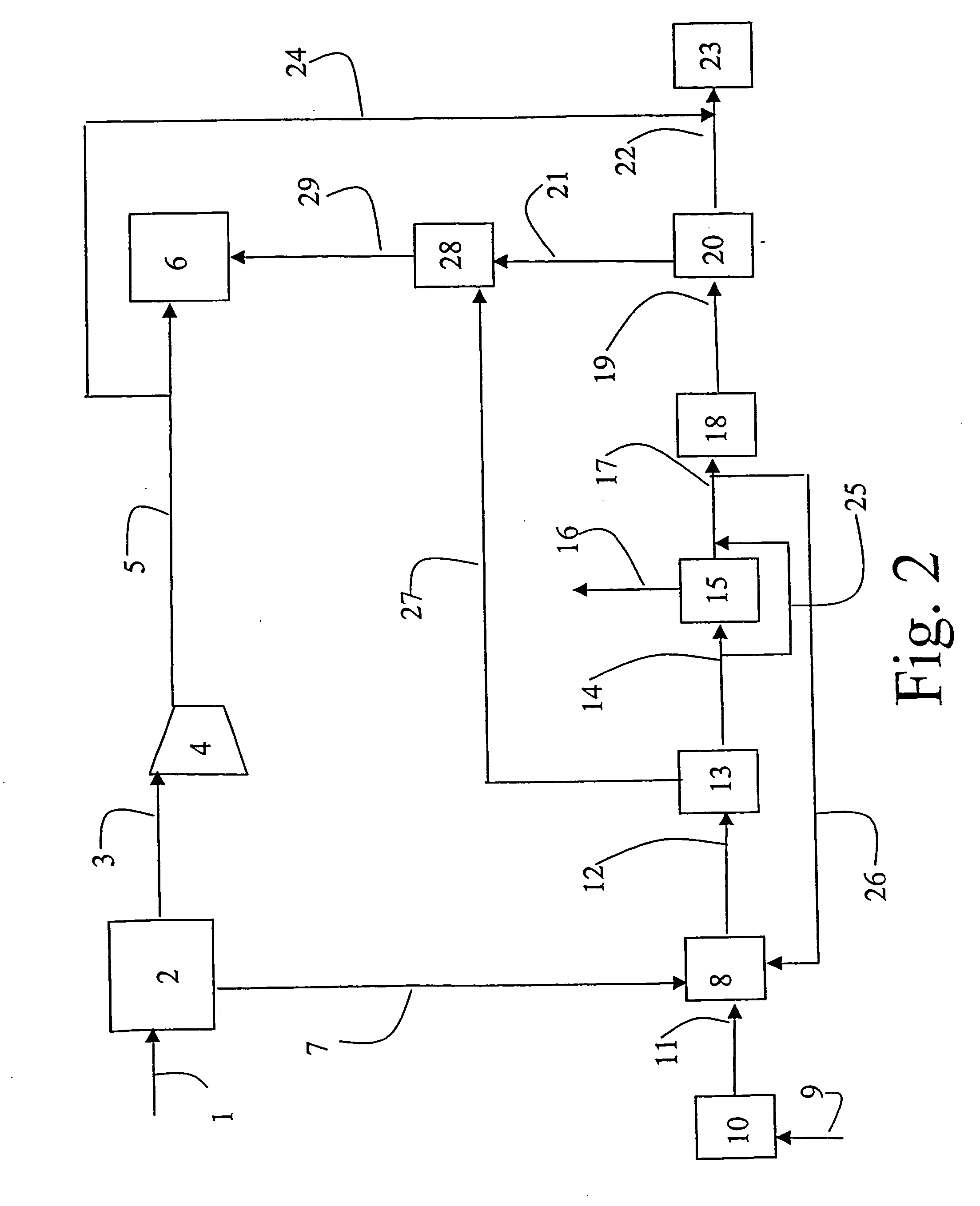

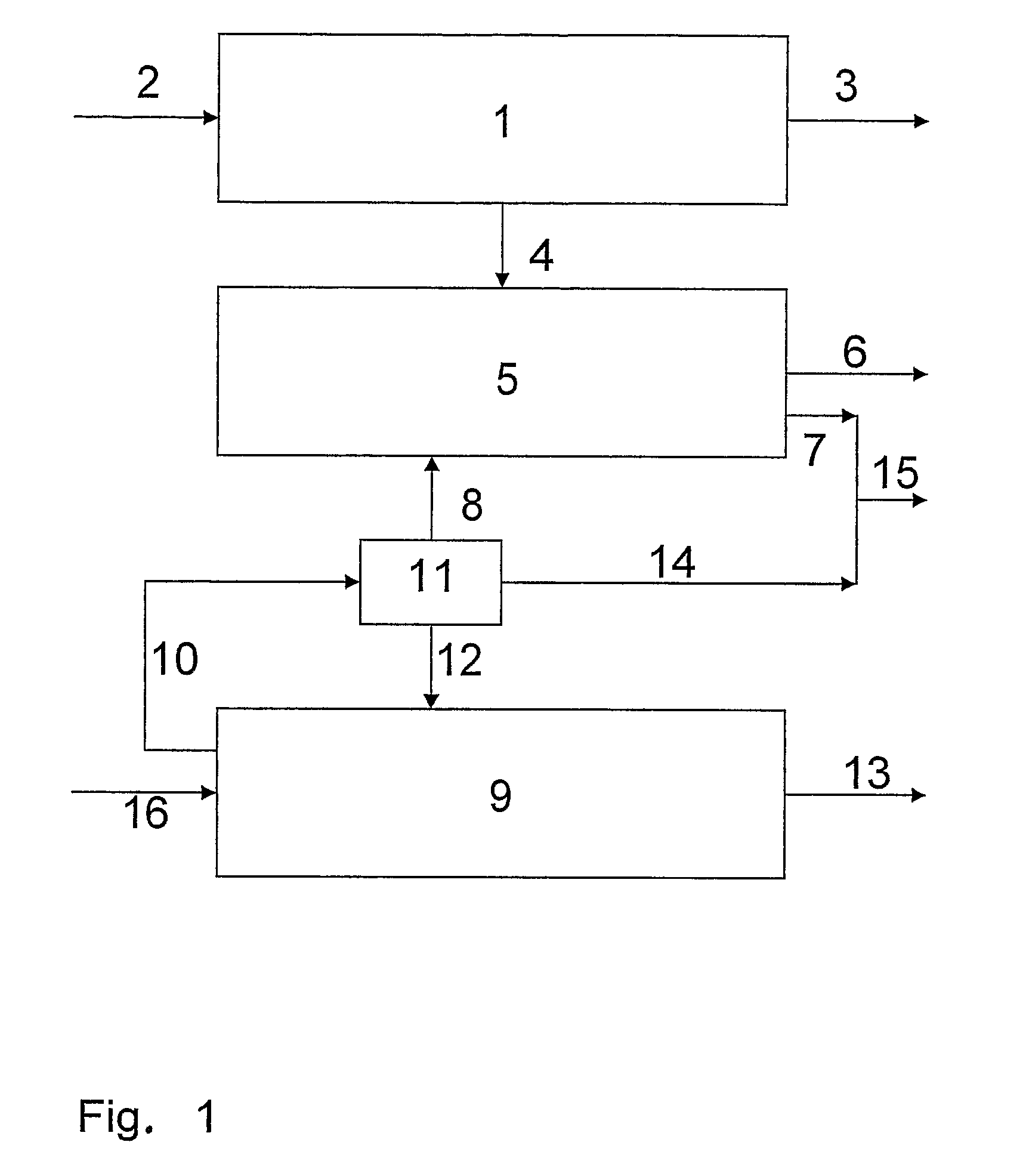

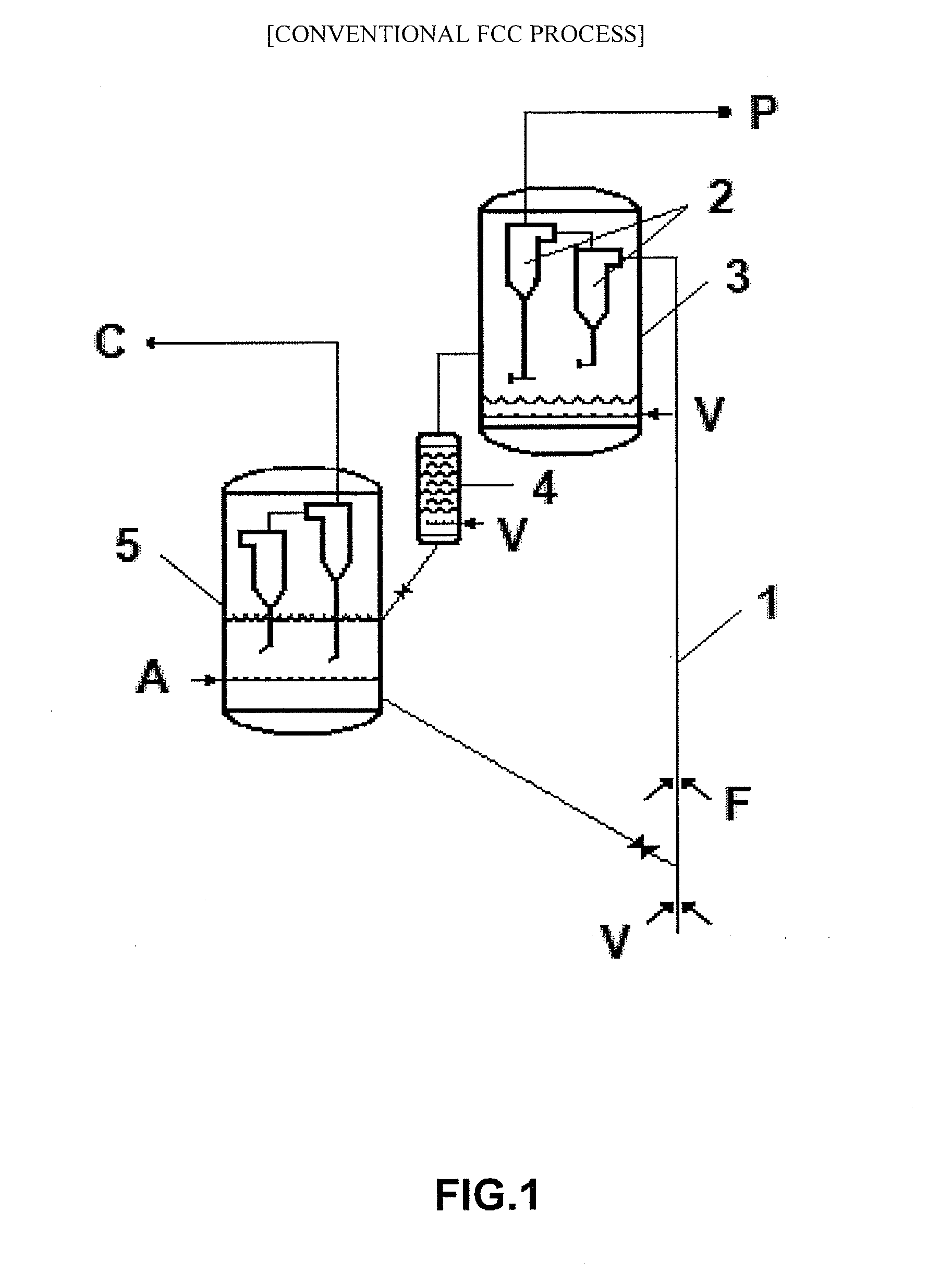

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

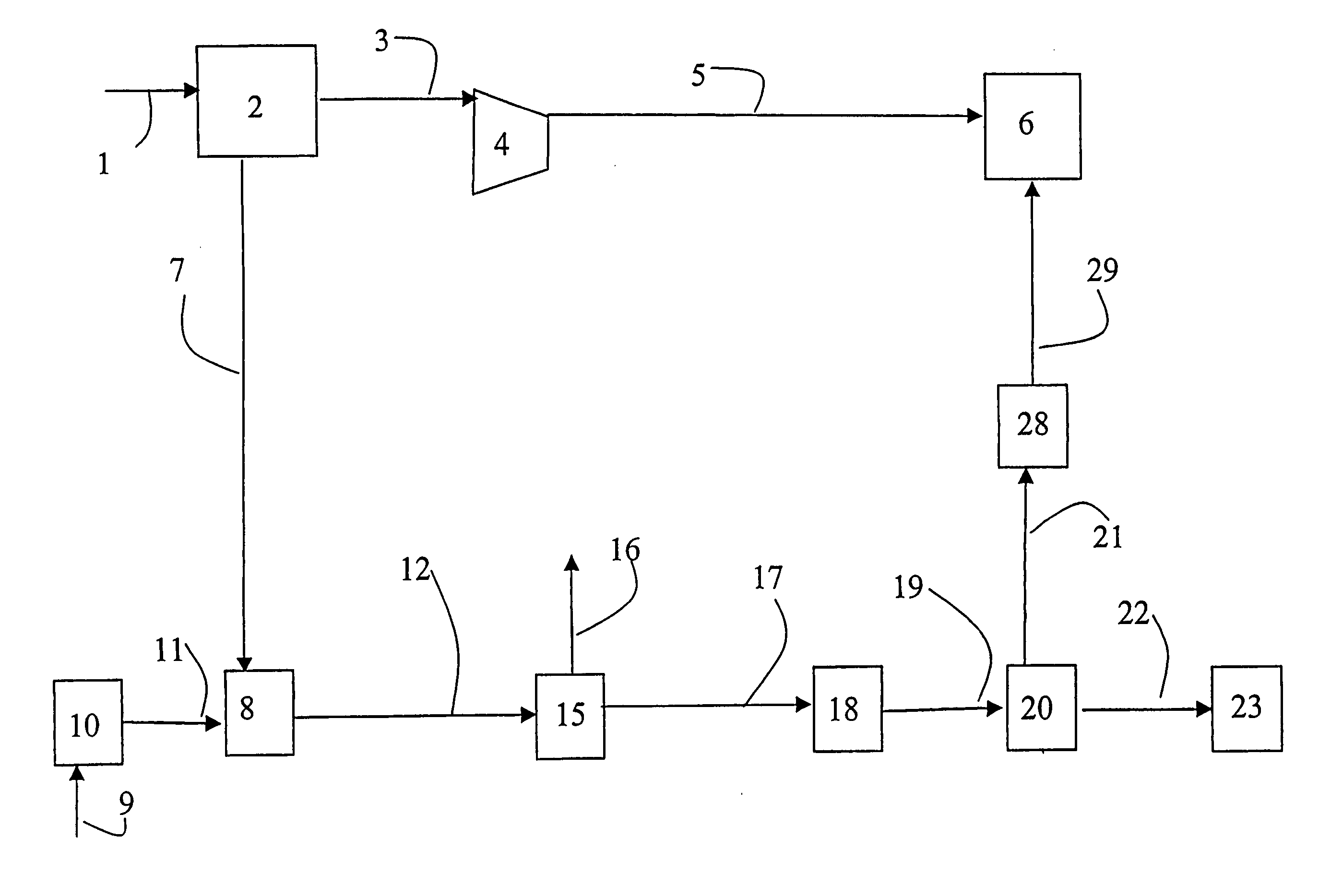

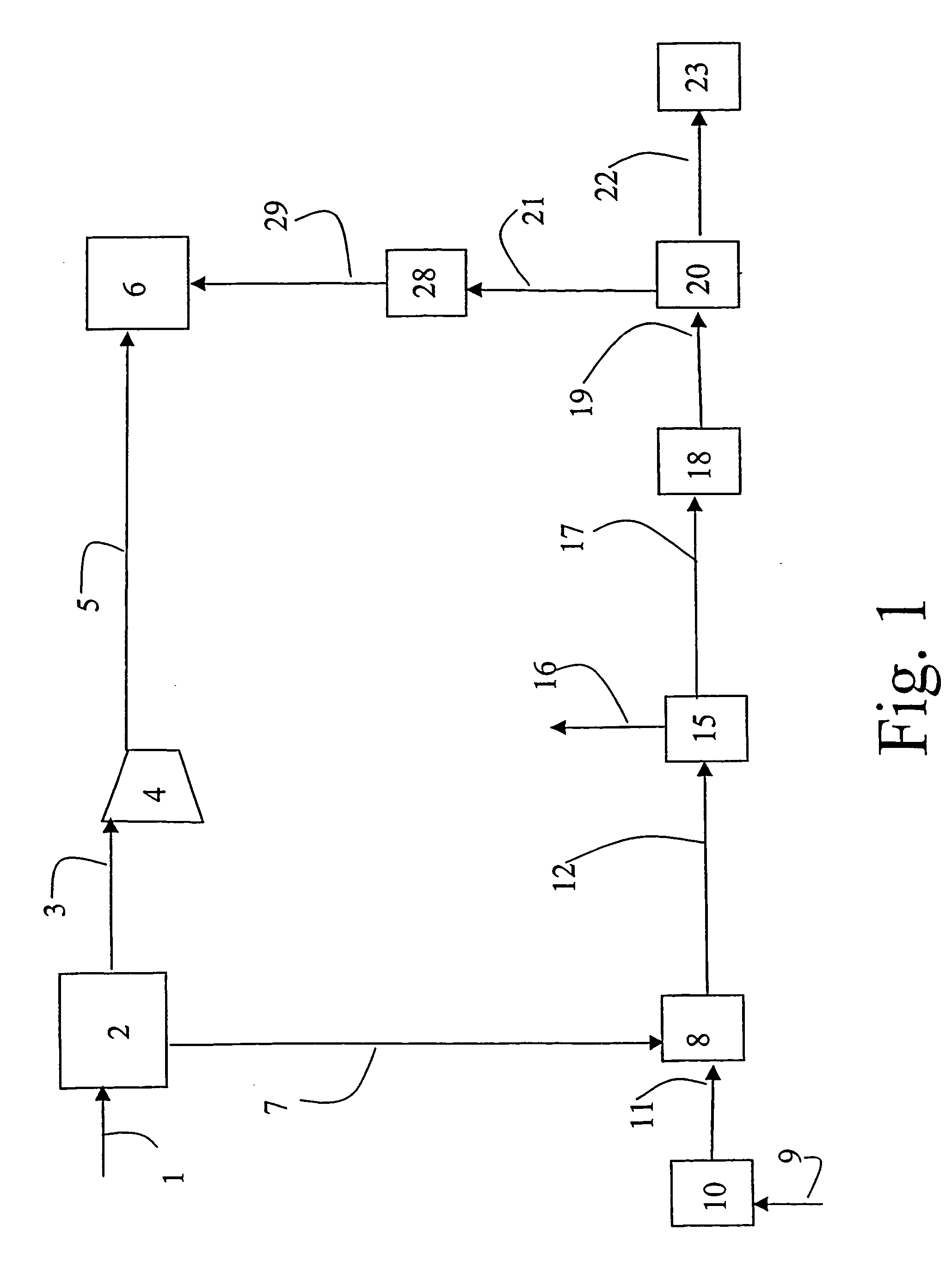

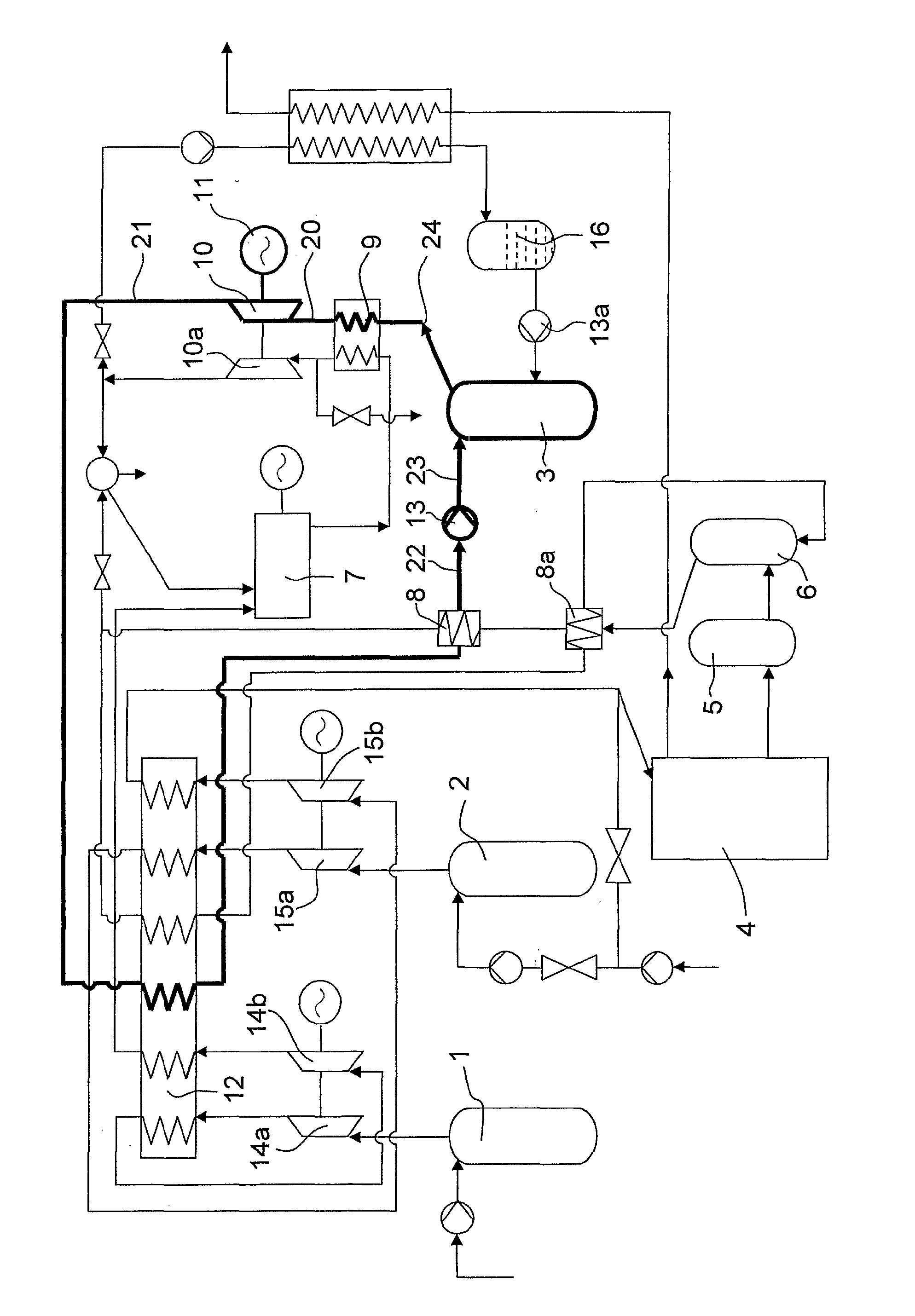

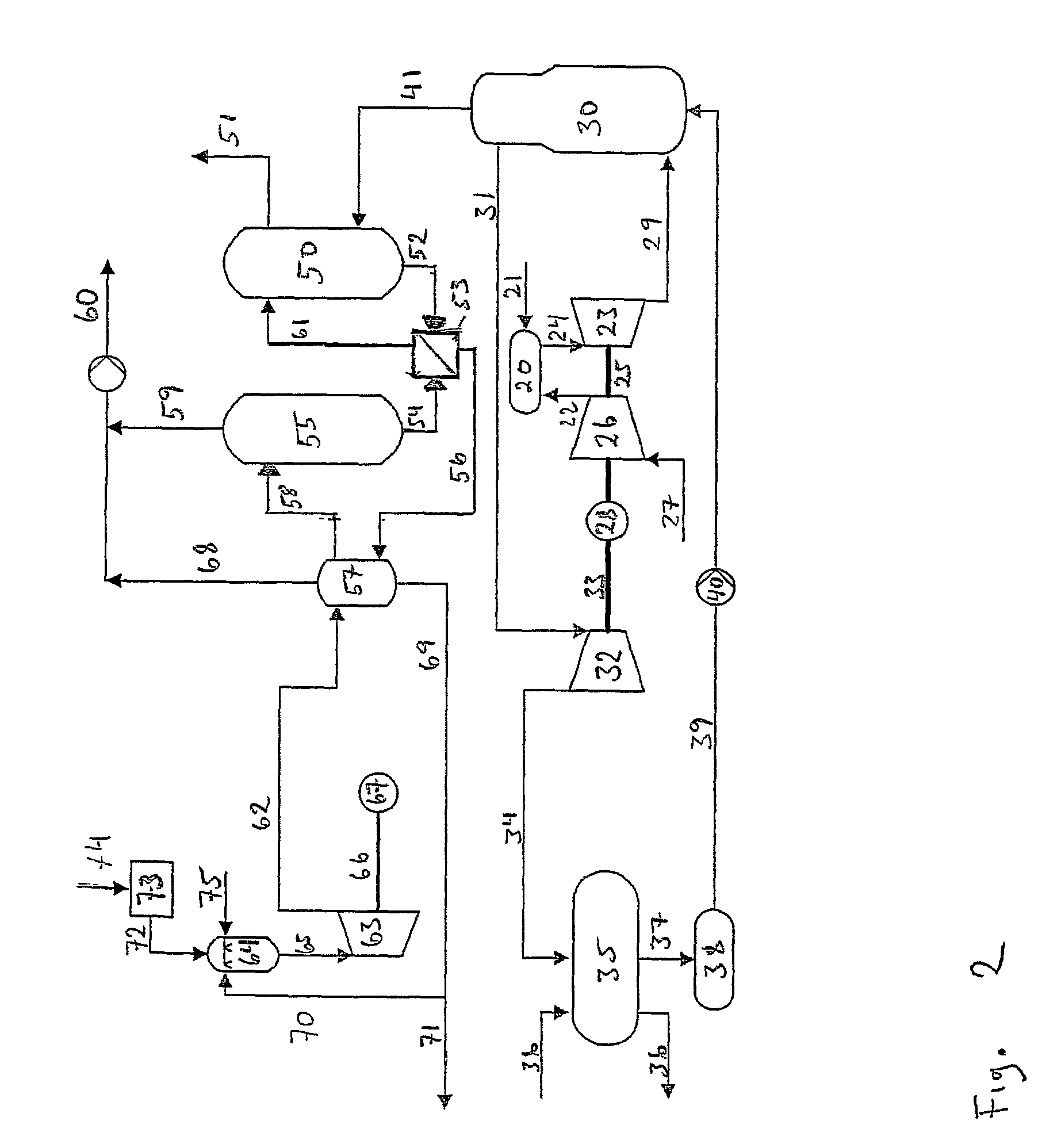

Method and plant or increasing oil recovery by gas injection

A method and a plant for simultaneous production of a gas for injection into an oil field and production of methanol, dimethyl ether and / or other oxygenated hydrocarbons or production of higher hydrocarbons from natural gas is disclosed. An air separation unit (ATR) for production of pure nitrogen for injection and pure oxygen for production of synthesis gas (“syngas”) by authermal reformation of a natural gas is an essential part of the method and plant.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Method of and power plant for generating power by oxyfuel combustion

InactiveUS7874140B2Costs lossesLosses of powerGas turbine plantsHeat recoveryPower stationCombustion

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

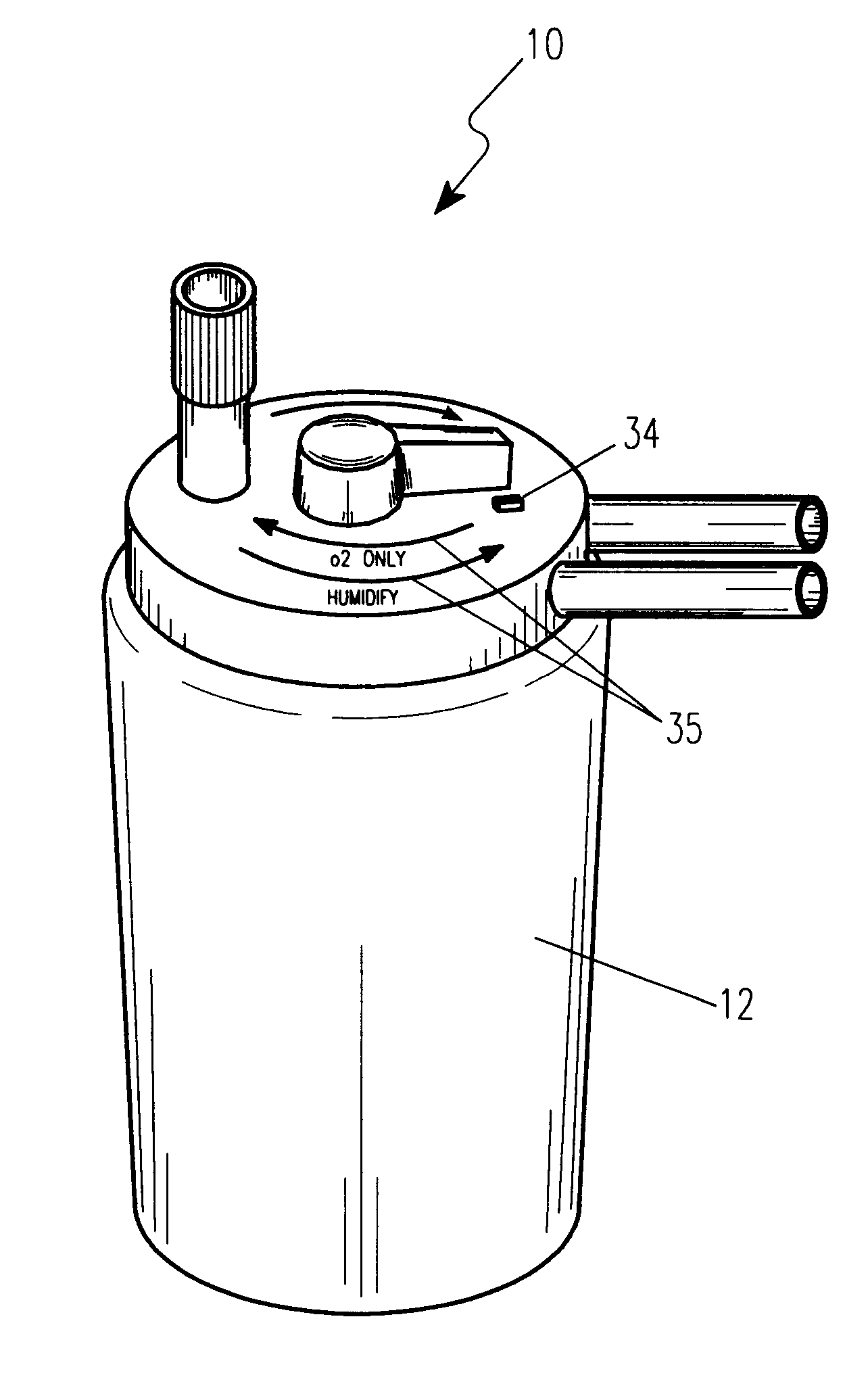

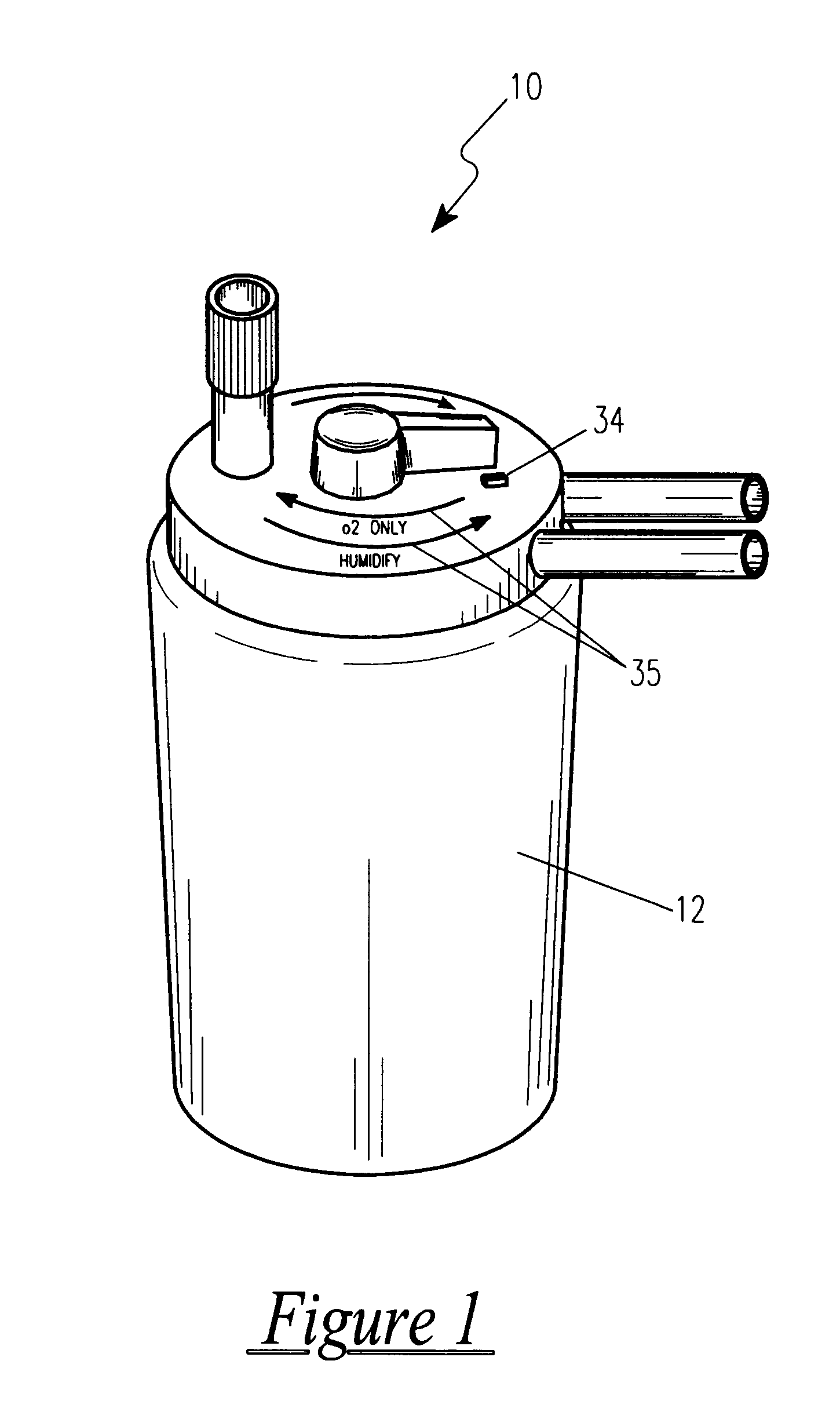

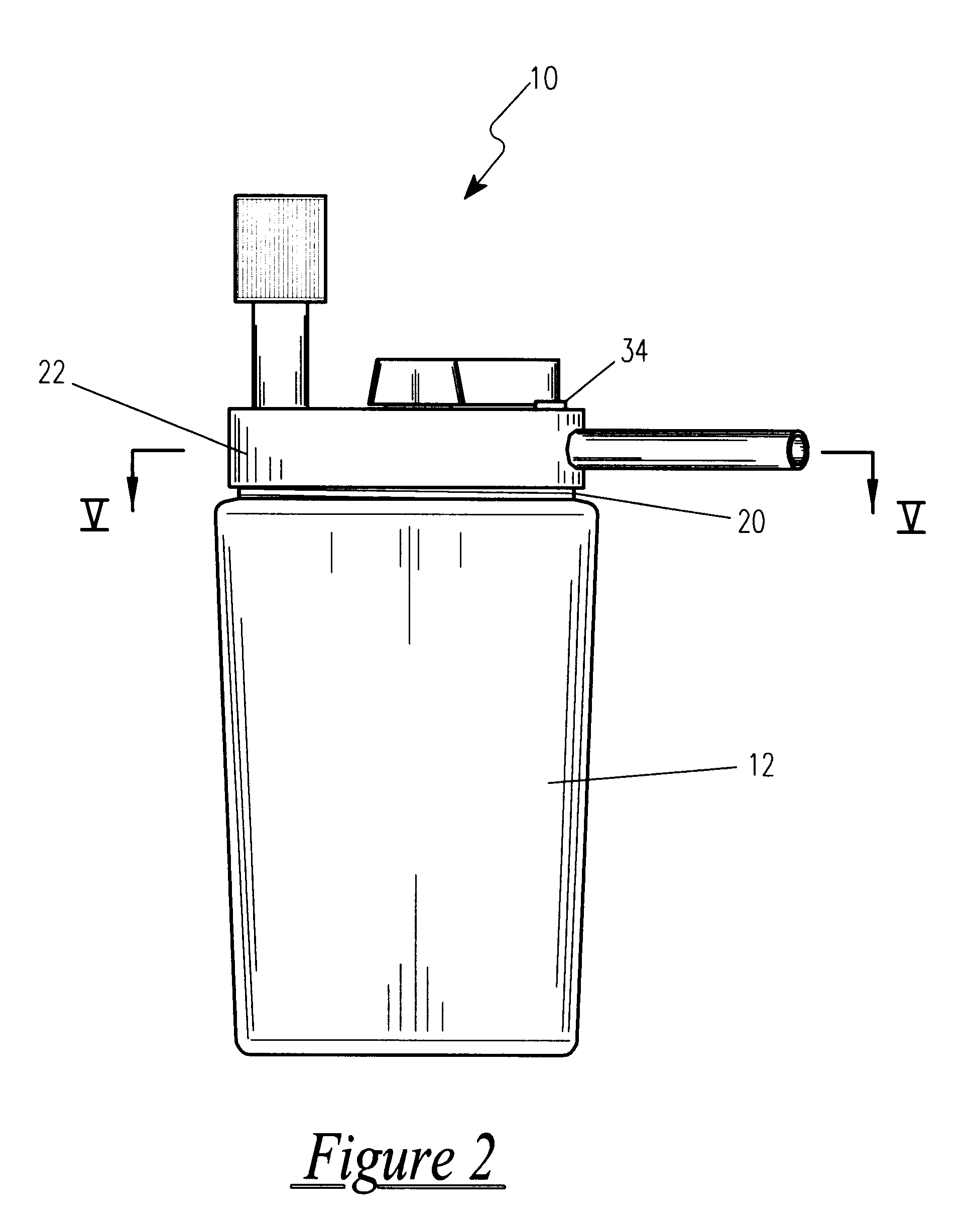

Dual port medical oxygen humidifier

InactiveUS6189870B1Easy to switchReduces and eliminates possibilityLighting and heating apparatusTransportation and packagingEngineeringMoisture

An improved disposable bubble oxygen humidifier is provided having a humidifying chamber included for the blending of oxygen and moisture. A slide switch on the top of the humidifier directs pure oxygen to the patient, or alternately, routes the oxygen through the humidifier and on to the patient. Hoses are attached at an inlet supply port and an outlet discharge port.

Owner:WITHALL GORDON

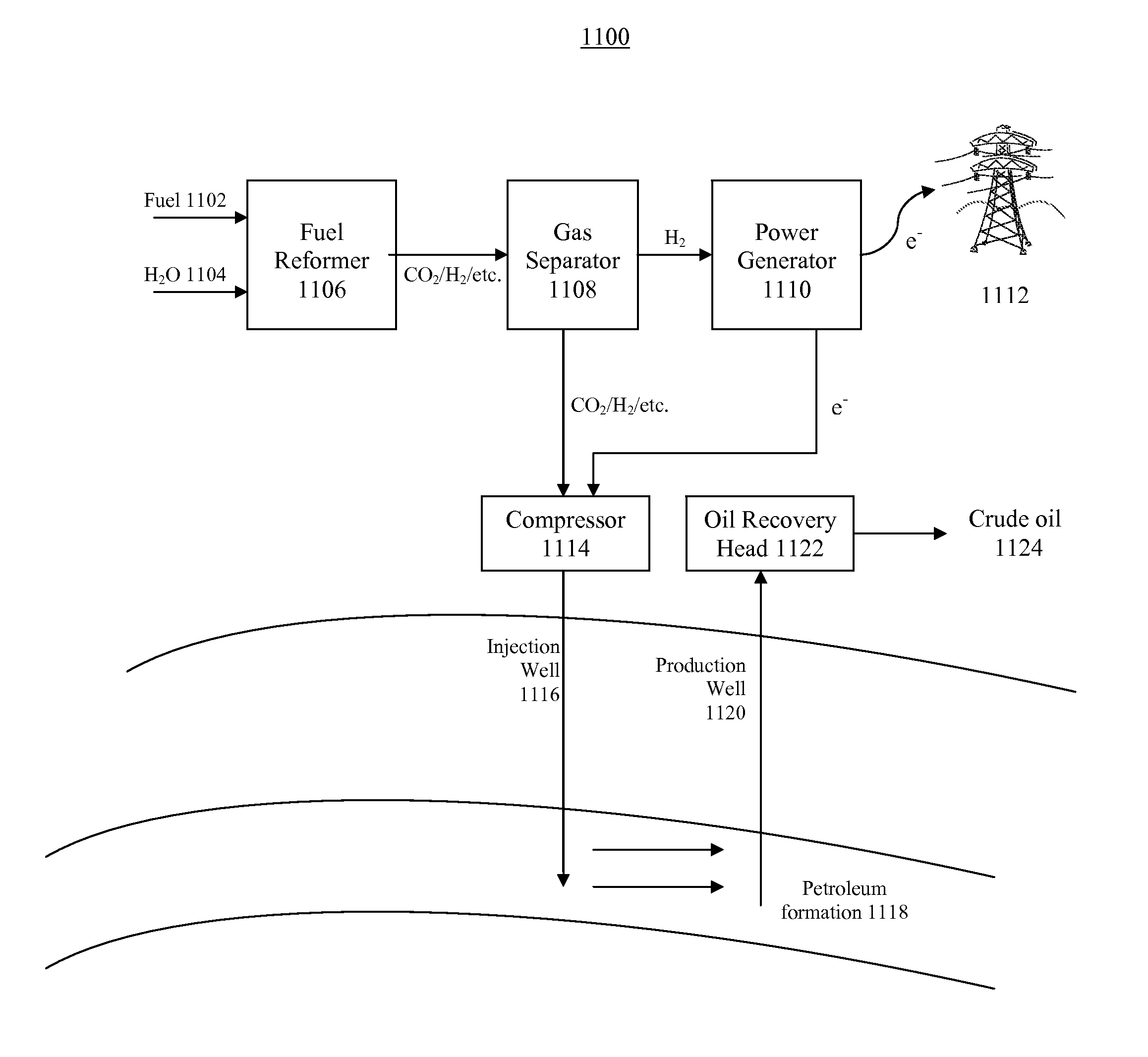

Systems and methods for generating in-situ carbon dioxide driver gas for use in enhanced oil recovery

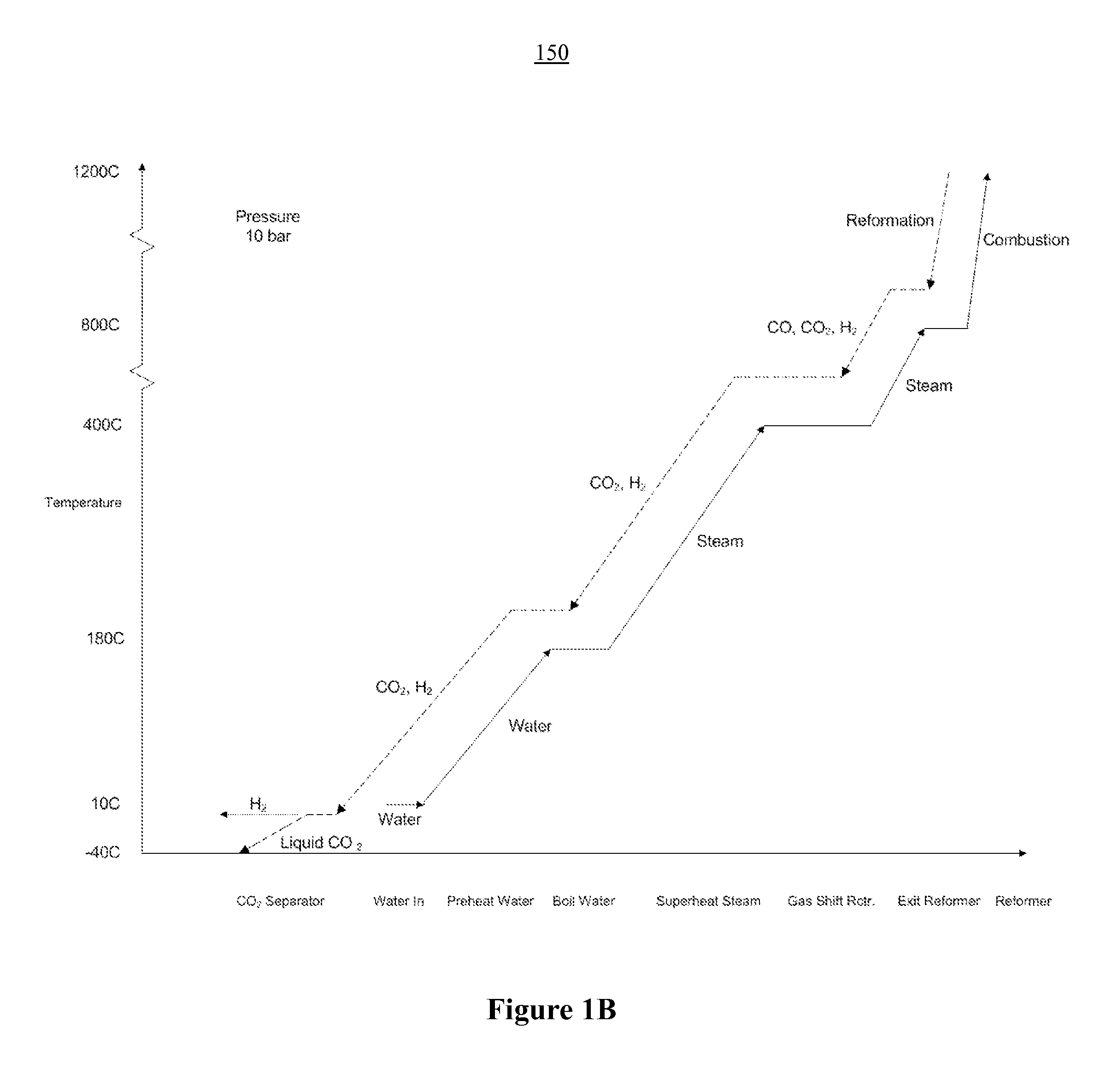

InactiveUS8616294B2Drilling rodsOther gas emission reduction technologiesSteam reformingSuperheated steam

The present invention is an in-situ apparatus for generating carbon dioxide gas at an oil site for use in enhanced oil recovery (EOR). The apparatus includes a steam generator adapted to boil and superheat water to generate a source of superheated steam, as well as a source of essentially pure oxygen. The apparatus also includes a steam reformer adapted to react a carbonaceous material with the superheated steam and the pure oxygen, in an absence of air, to generate a driver gas comprising primarily carbon dioxide gas and hydrogen gas. A separator is adapted to separate at least a portion of the carbon dioxide gas from the rest of the driver gas to generate a carbon dioxide-rich driver gas and a hydrogen-rich fuel gas. A compressor is used for compressing the carbon dioxide-rich driver gas for use in enhanced oil recovery, and the compressed carbon dioxide-rich driver gas, with substantially no oxygen, is injected to a predetermined depth in order to enhance oil recovery at the oil site. Unlike traditional CO2-EOR, which requires large power plants stationed near metropolitan areas and expensive pipeline networks, the in-situ apparatus can be placed or constructed at the site of the oil field, while a portion of the carbonaceous material may be obtained from a site outside the oil field.

Owner:PIONEER ENERGY

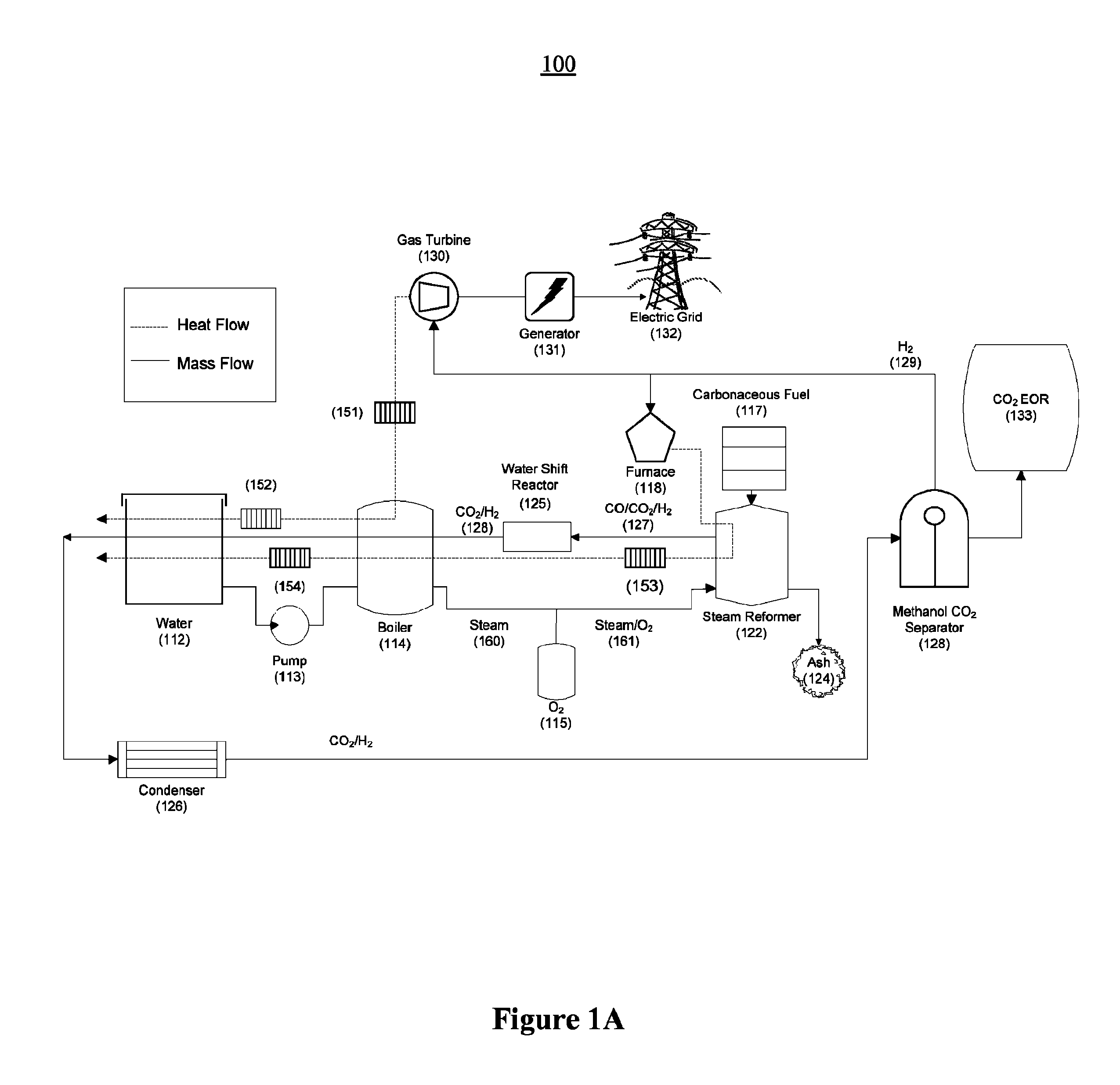

Reduced-emission gasification and oxidation of hydrocarbon materials for liquid fuel production

InactiveUS8038746B2Reduce system sizeHigh heat transfer rateHydrogenGas modification by gas mixingLiquid hydrocarbonsLiquid fuel

Owner:CLARK STEVE L

Method for leaching anode and cathode mixed material of waste lithium nickel manganese cobalt battery

InactiveCN101619394AAvoid it happening againSave pollution control costsProcess efficiency improvementLithiumManganese

The invention relates to a method for leaching an anode and cathode mixed material of a waste lithium nickel manganese cobalt battery, which comprises the following steps: putting an anode and cathode mixed material separated out of a waste lithium nickel manganese cobalt battery in a container which is resistant to pressure and the corrosion of sulphuric acid and nitric acid; then sealing the container and pumping the sulphuric acid and the nitric acid into the container; and leading industrial pure oxygen into the container to leach out the anode and cathode mixed material of the waste lithium nickel manganese cobalt battery, wherein leaching temperature is 20-100 DEG C; leaching pressure is 0.05-0.5MPa; the initial concentration of the leaching sulphuric acid is 1-5mol / L; the initial concentration of the nitric acid is 5-20g / L; reaction time is 1-5 hours; stirring is carried out in a reaction process, and stirring speed is 30-100r / min; and the addition of the sulphuric acid is 101-200 percent of the theoretical sulphuric acid consumption of all leached metal in the anode and cathode mixed material added into the container.

Owner:SICHUAN NORMAL UNIVERSITY

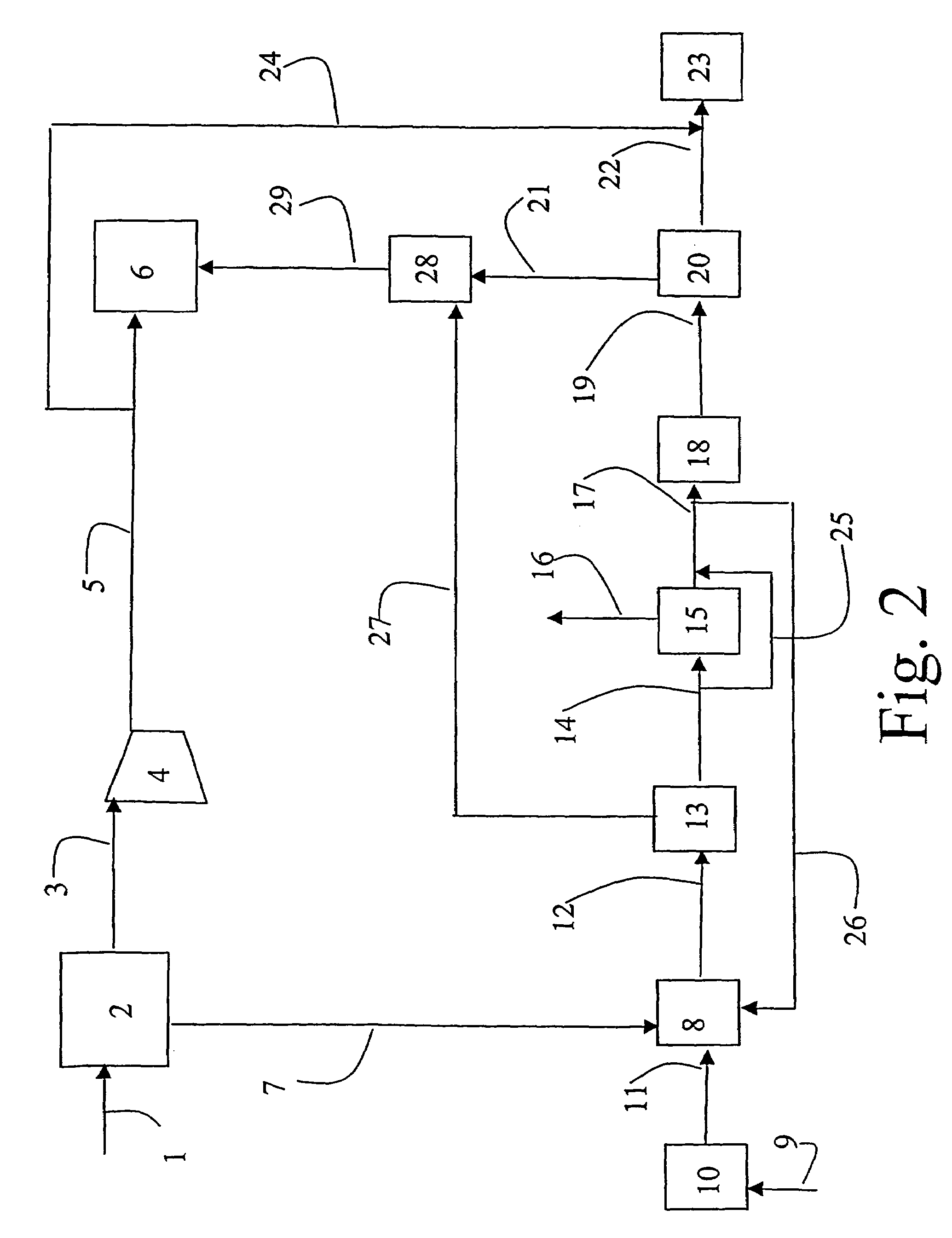

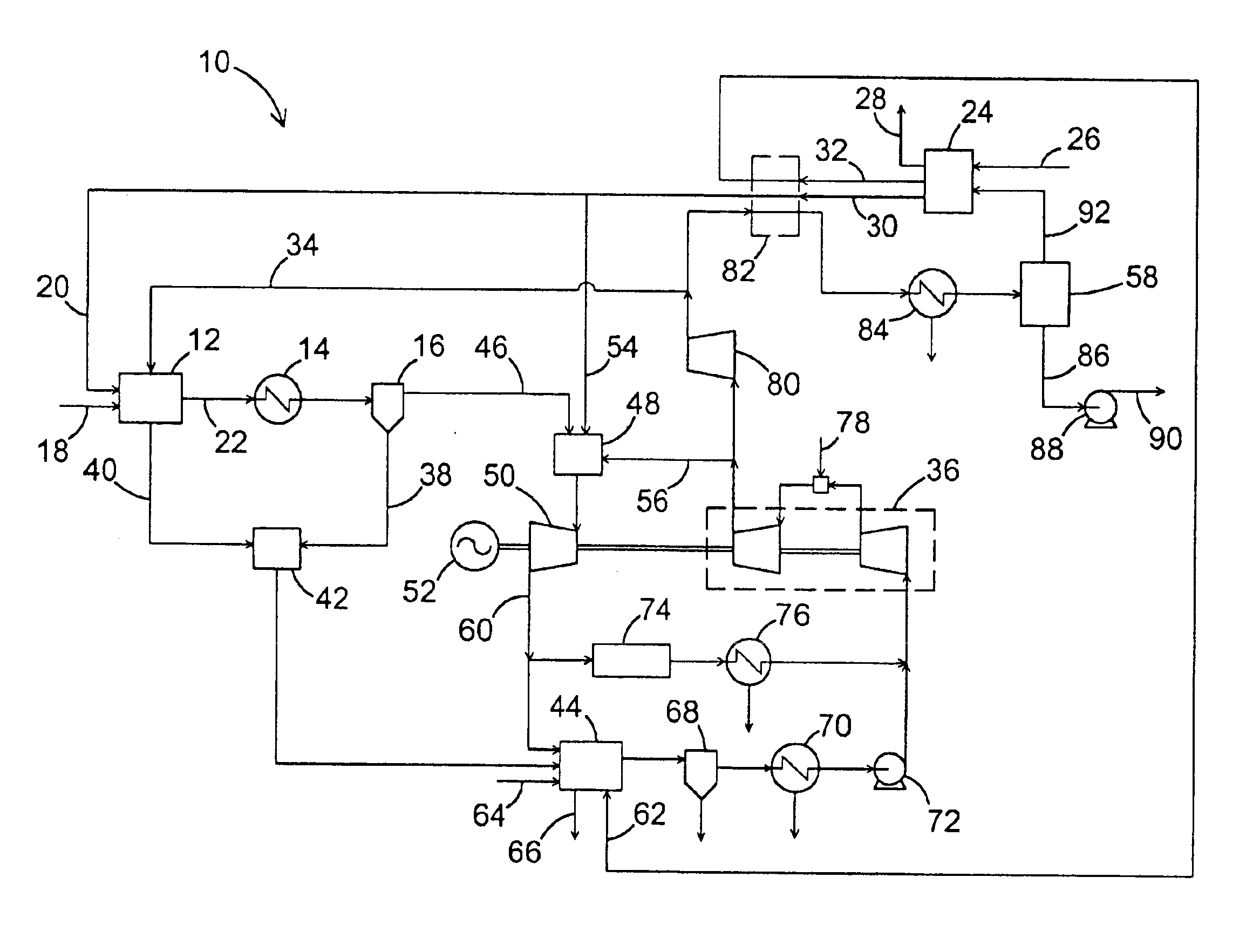

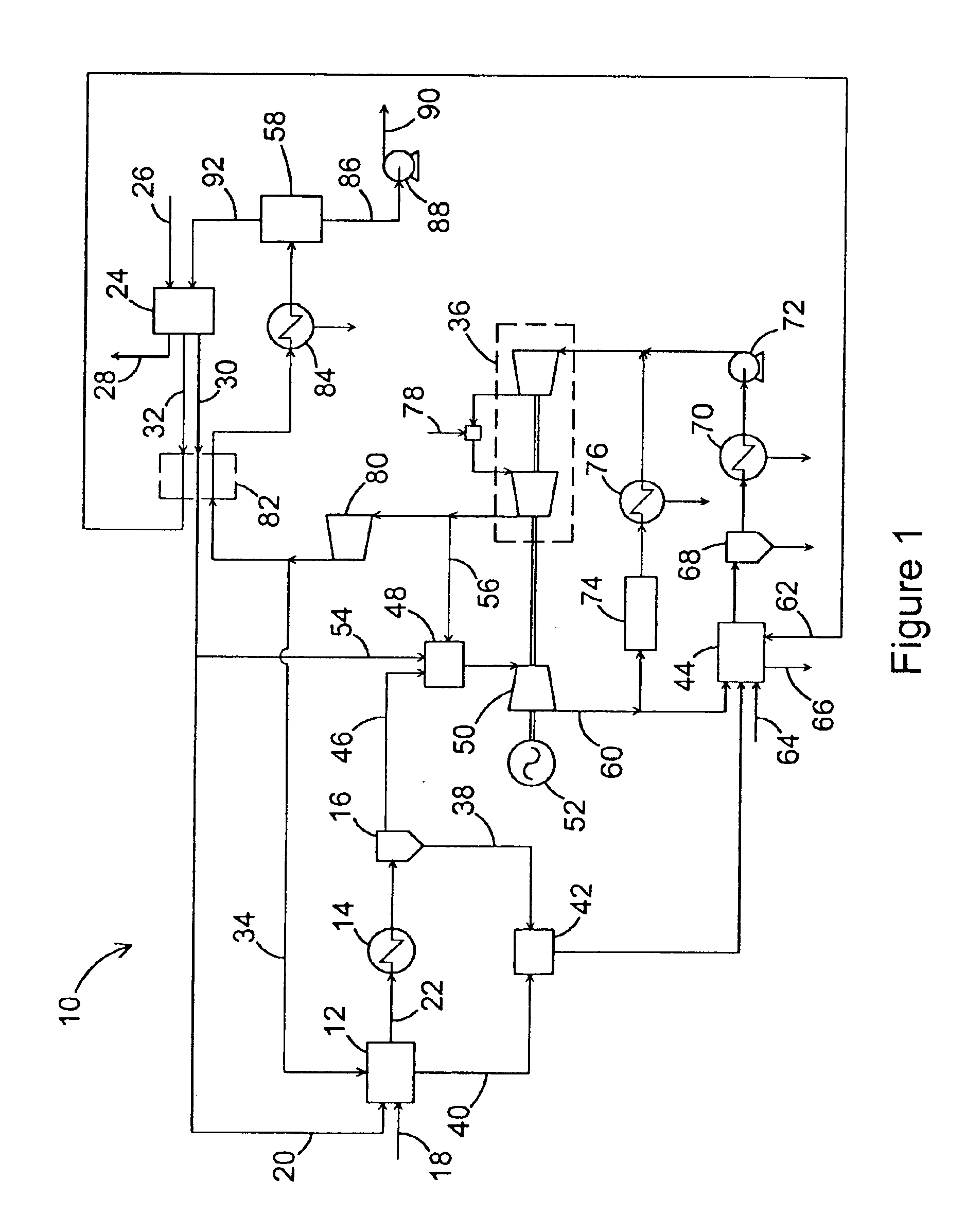

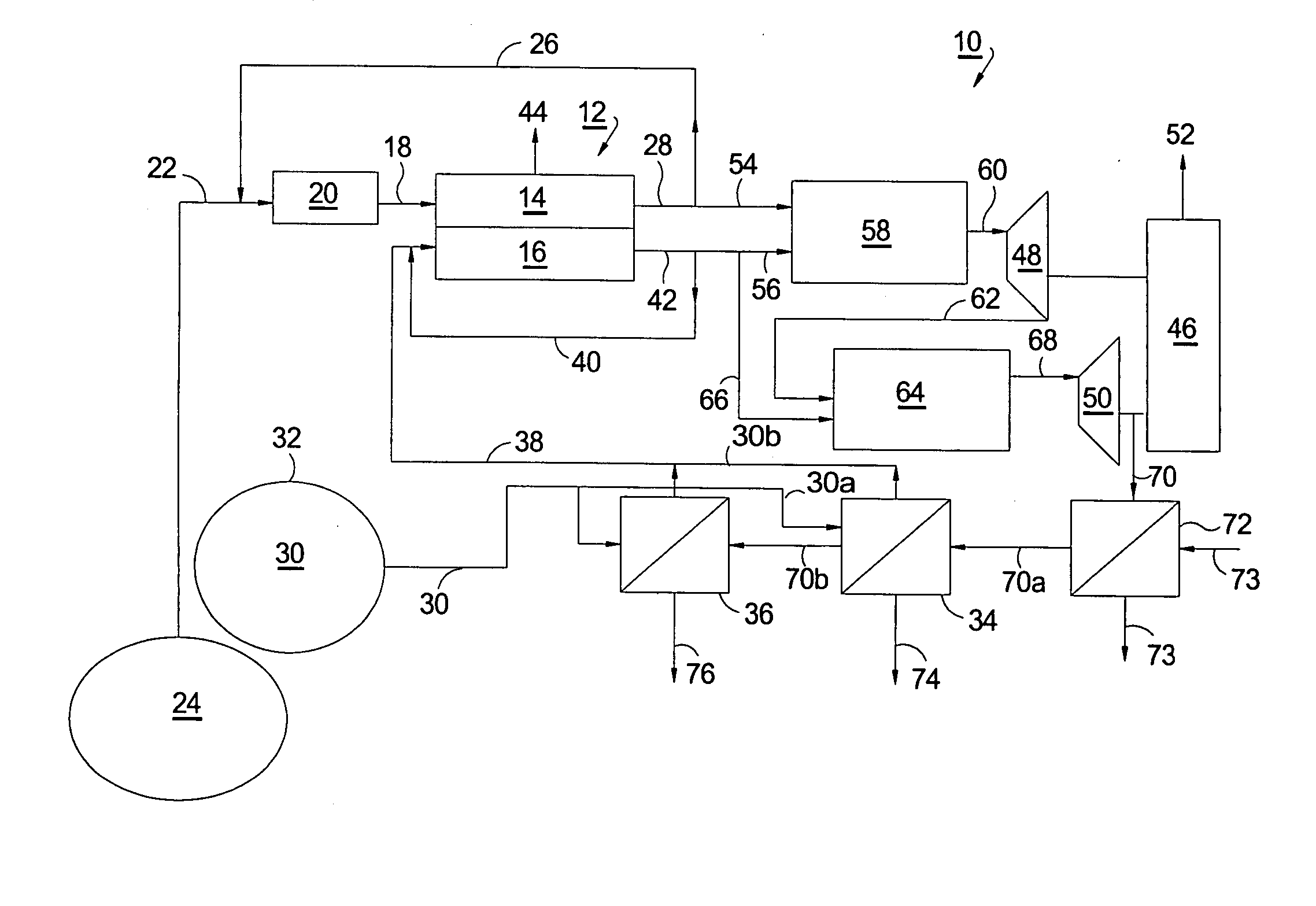

Advanced hybrid coal gasification cycle utilizing a recycled working fluid

InactiveUS6877322B2Generate efficientlyEliminate and reduce carbon dioxide emissionSolidificationLiquefactionSyngasCombustor

A power generating system having a hybrid gasification cycle, in which CO2 is recycled to a gasifier to be used as a gasification reactant and working fluid. The power generating system includes a source of fresh, pure oxygen, a gasifier, a particle separator arranged in flow connection with the gasifier, a syngas combustor, a gas turbine arranged in flow connection with the syngas combustor, a steam generator arranged in flow connection with the outlet of the gas turbine, and a gas compressor system which discharges a stream of compressed exhaust gas. A first portion of the stream of compressed exhaust gas is conducted to the gasifier to control the temperature in the gasifier, to provide CO2 and steam for gasification, and to decrease the demand for fresh, pure oxygen therein.

Owner:FOSTER WHEELER ENERGY CORP

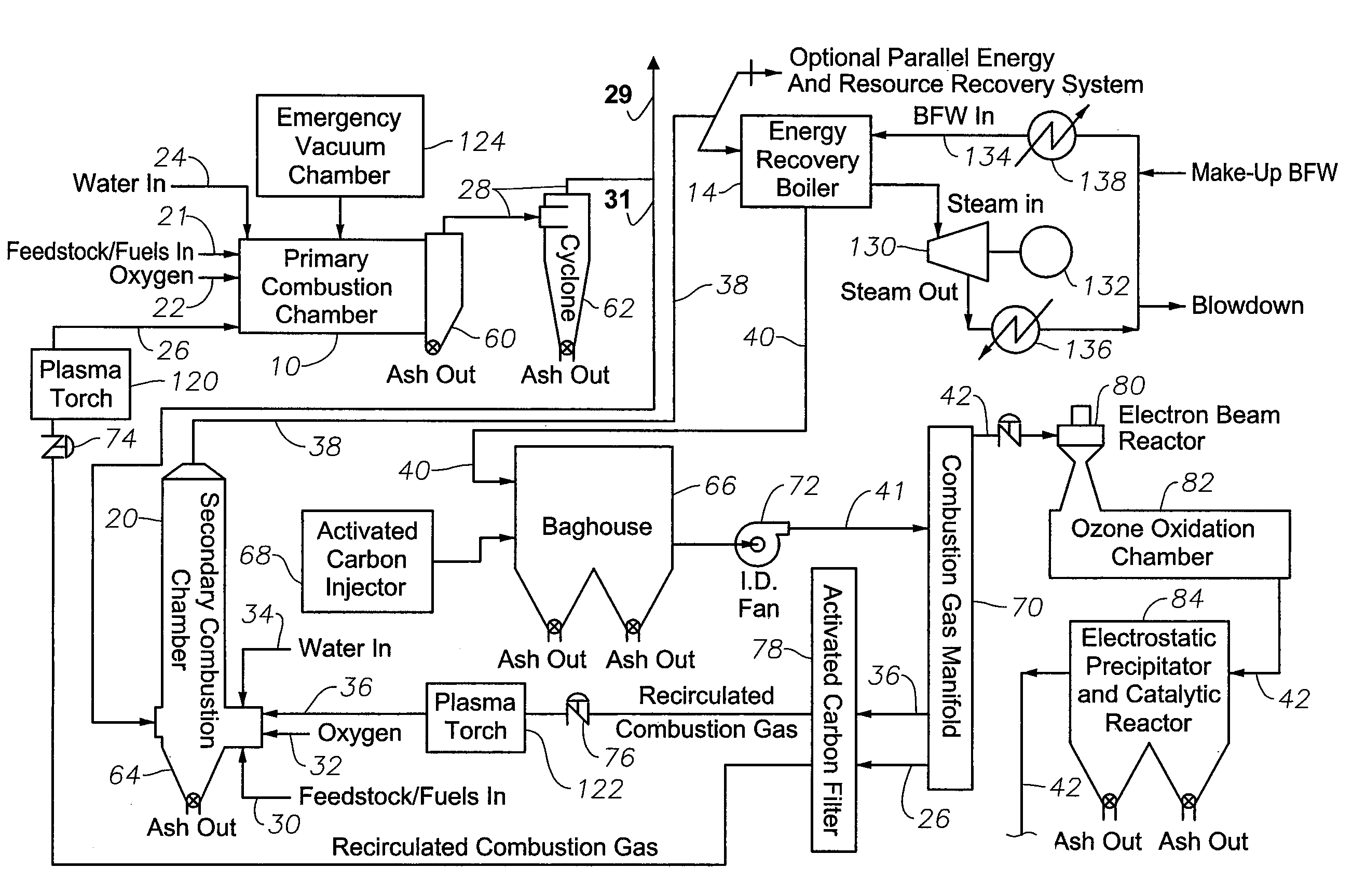

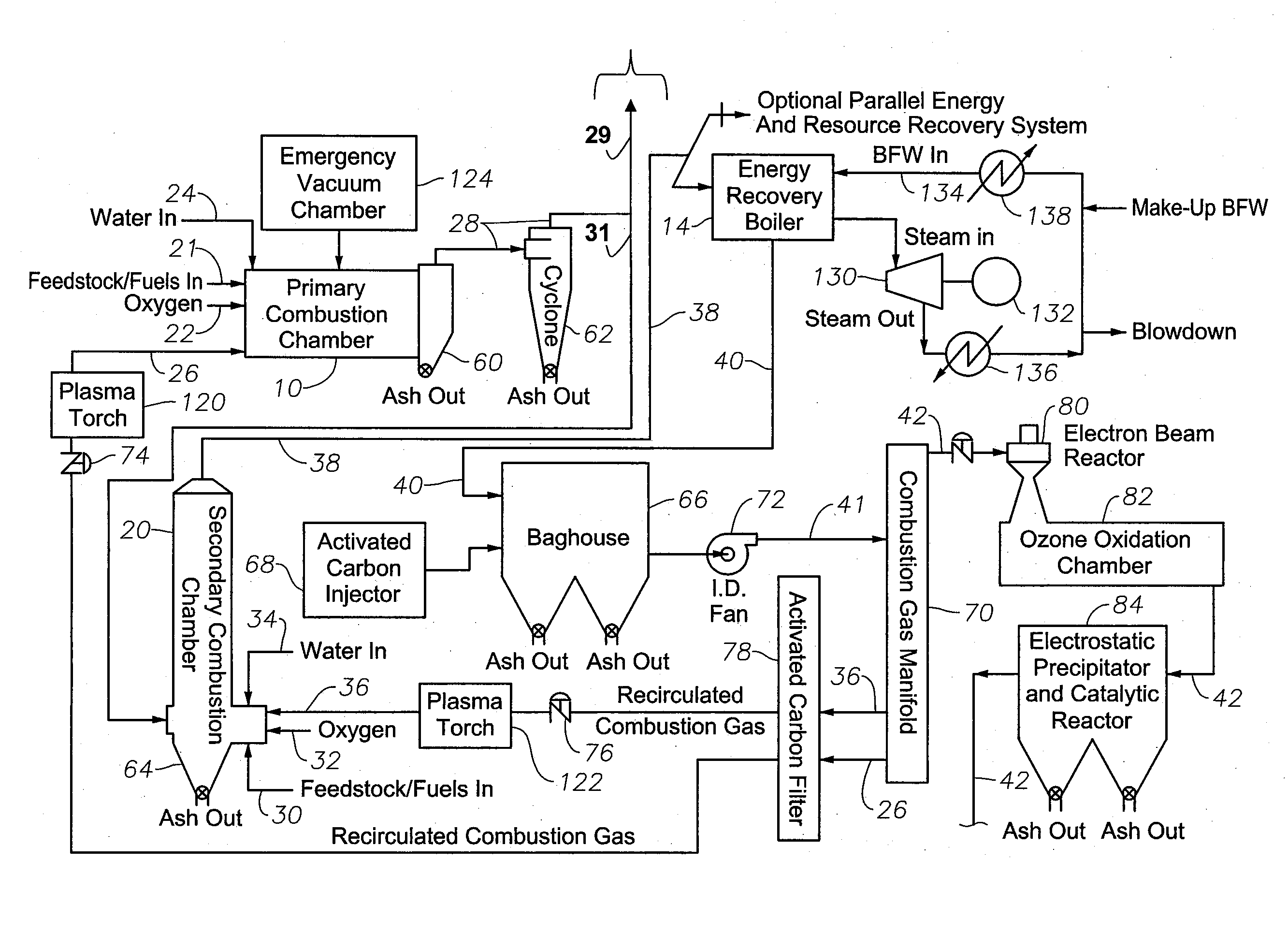

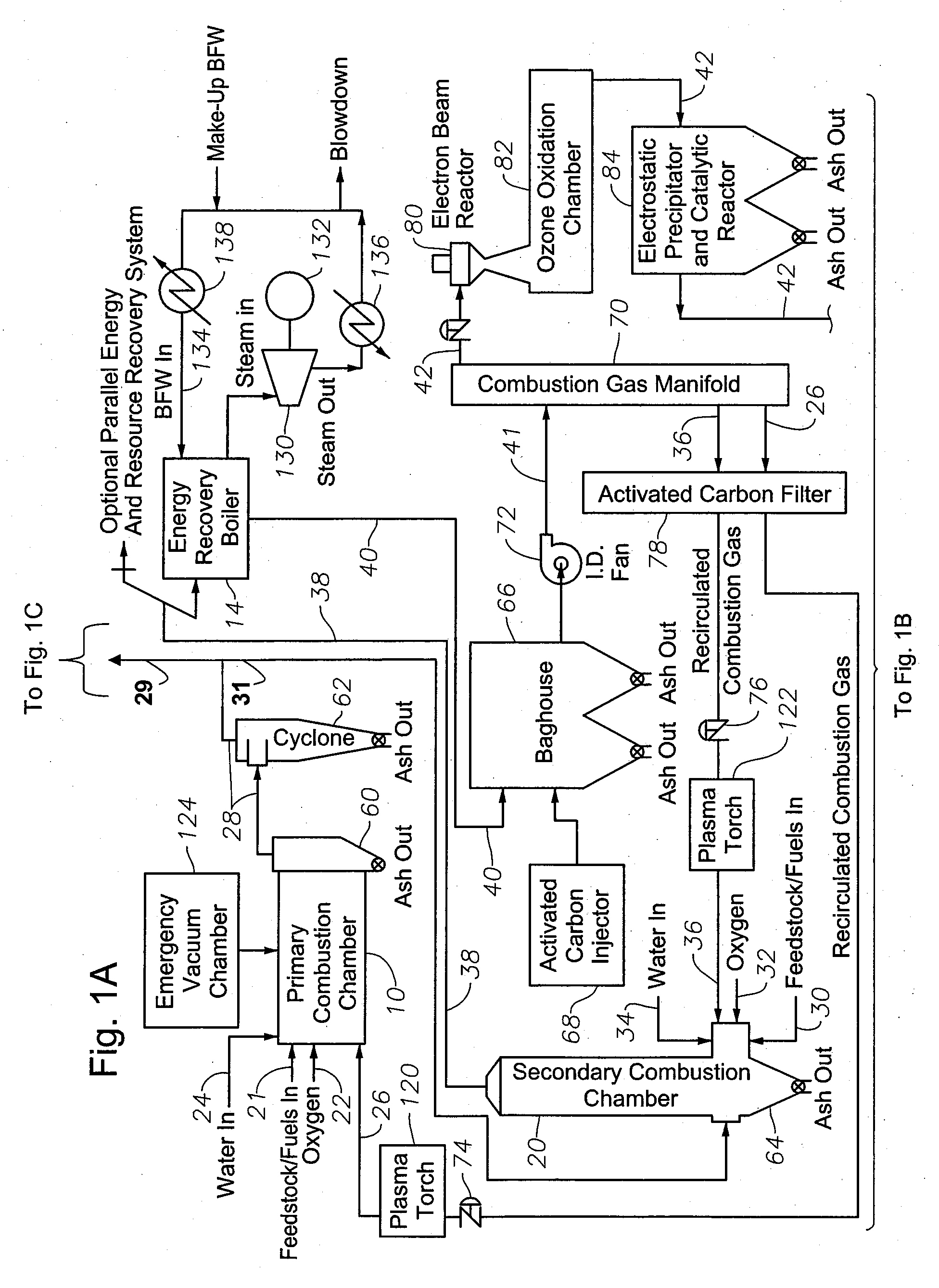

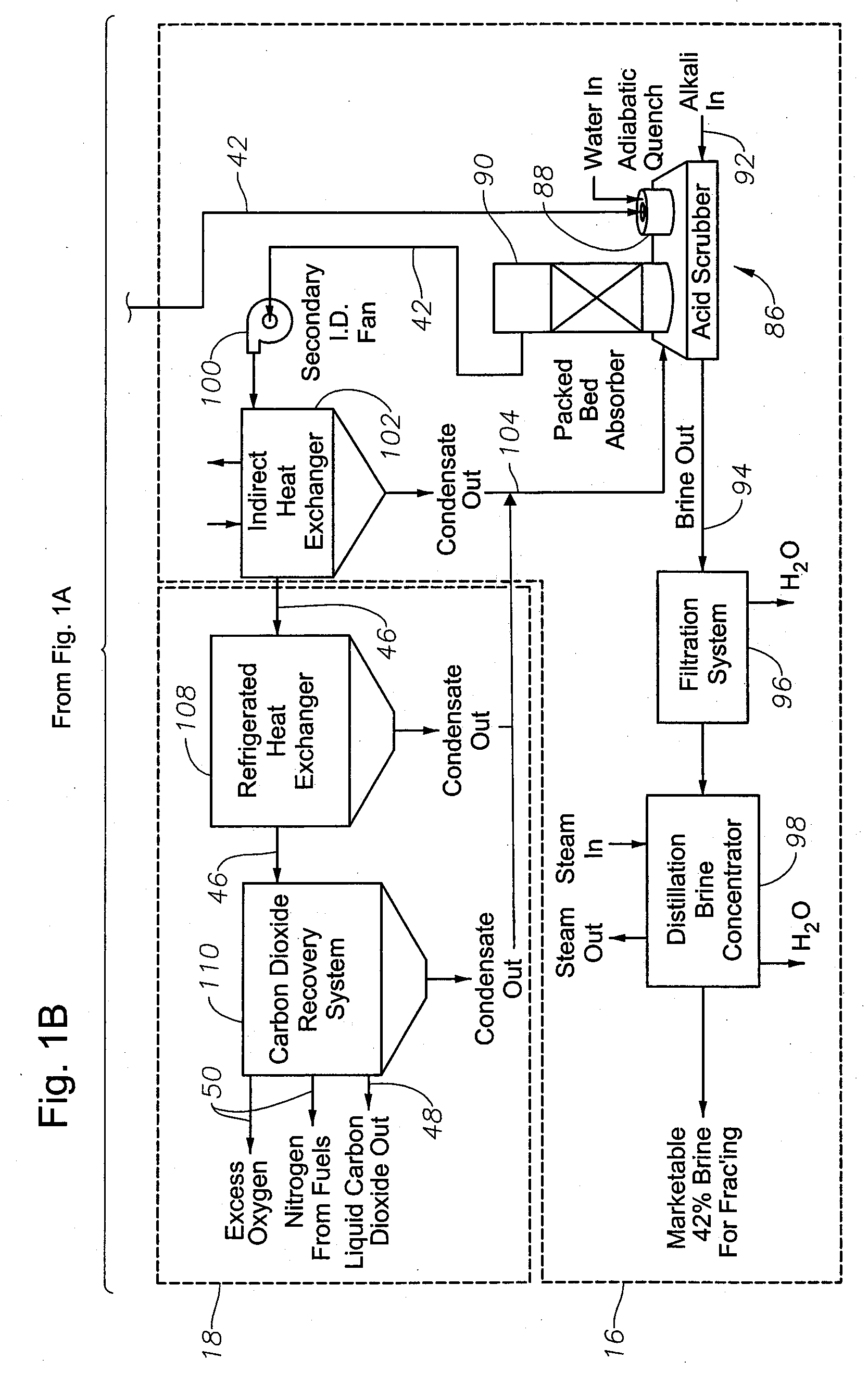

Reduced-Emission Gasification and Oxidation of Hydrocarbon Materials for Liquid Fuel Production

InactiveUS20080275278A1Reduce system sizeRaise the combustion temperatureGas modification by gas mixingLiquid hydrocarbon mixture productionThermal energyLiquid hydrocarbons

A system and process are disclosed for the controlled combustion of a wide variety of hydrocarbon feedstocks to produce thermal energy, liquid fuels, and other valuable products with little or no emissions. The hydrocarbon feeds, such as coal and biomass, are first gasified and then oxidized in a two-chamber system / process using pure oxygen rather than ambient air. A portion of the intermediate gases generated in the system / process are sent to a Fischer-Tropsch synthesis process for conversion into diesel fuel and other desired liquid hydrocarbons. The remaining intermediate gases are circulated and recycled through each of the gasification / oxidation chambers in order to maximize energy production. The energy produced through the system / process is used to generate steam and produce power through conventional steam turbine technology. In addition to the release of heat energy, the hydrocarbon fuels are oxidized to the pure product compounds of water and carbon dioxide, which are subsequently purified and marketed. The system / process minimizes environmental emissions.

Owner:CLARK STEVE L

Process for a high efficiency and low emission operation of power stations as well as for storage and conversion of energy

InactiveUS20100101231A1Improve overall utilizationReduce carbon dioxide emissionsSolidificationLiquefactionMass storageWorking fluid

The invention relates to a process and a device for process realizing to increase the efficiency of power stations by improvement of the efficiency of using the heat potentials for an electric power production by using of supercritical carbon dioxide as a working fluid and heat transfer medium as well as for the improvement of the ecological balance of power stations by minimization of the carbon dioxide emission and the total avoidance of NOx-emissions by using of pure oxygen for the burning process. Additionally the process allows the buffering of electric overcapacity energy producing mass storages for natural gas, pressed air and carbon dioxide and their effective using as well as in the continuous operation and for peak load supply of power stations.

Owner:TECHNIKUM CORP

Method and plant or increasing oil recovery by gas injection

A method and a plant for simultaneous production of a gas for injection into an oil field and production of methanol, dimethyl ether and / or other oxygenated hydrocarbons or production of higher hydrocarbons from natural gas is disclosed. An air separation unit (ATR) for production of pure nitrogen for injection and pure oxygen for production of synthesis gas ("syngas") by authermal reformation of a natural gas is an essential part of the method and plant.

Owner:DEN NORSKE STATS OLJESELSKAP AS

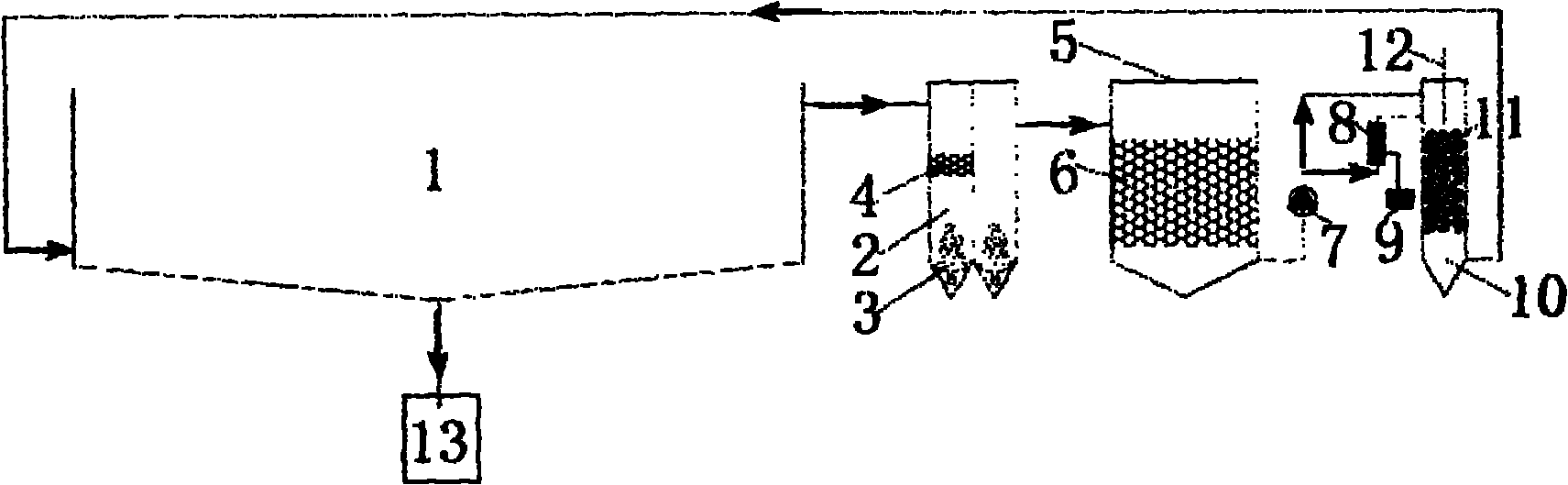

Industrialization ecological treatment circulation utilization system for fish culture waste water

InactiveCN101215069AImprove processing efficiencyReduce energy consumptionMultistage water/sewage treatmentSustainable biological treatmentAxial-flow pumpConstructed wetland

Disclosed is an ecological treatment and recycling system for factory fish-farming wastewater, which belongs to the field of fishery cultivation. The system comprises facilities and devices for treating recycle water like a fish pond, an ultra-low axial flow pump, a jet aeration oxygenation facility, a foam separating facility, a pure oxygen supplying device, a temperature control device, artificial wetland and the like, using an open type high-volume feed canal and a backwater canal to replace sealed pipes, using the foam separating facility to replace a protein separator, using the temperature control device of deep well to replace a heating-up and cool-down device, using the jet aeration oxygenation facility to replace an automatic aerator, a gas relay rock and an air pipe, using water plants of the artificial wetland and economic filtering materials to replace purifying filtration devices like a solid-liquid separation device and the like. The invention achieves functions like water lift, aeration, oxygenation, defoaming, temperature control and the like. The invention optimizes and combines a facility engineering technique and a biologic technology to replace expensive and complex water-treating equipment, and has the advantages of safety and dependability, simple management, energy-saving and environment protection, high yield and high grade and the like.

Owner:宜都天峡特种渔业有限公司

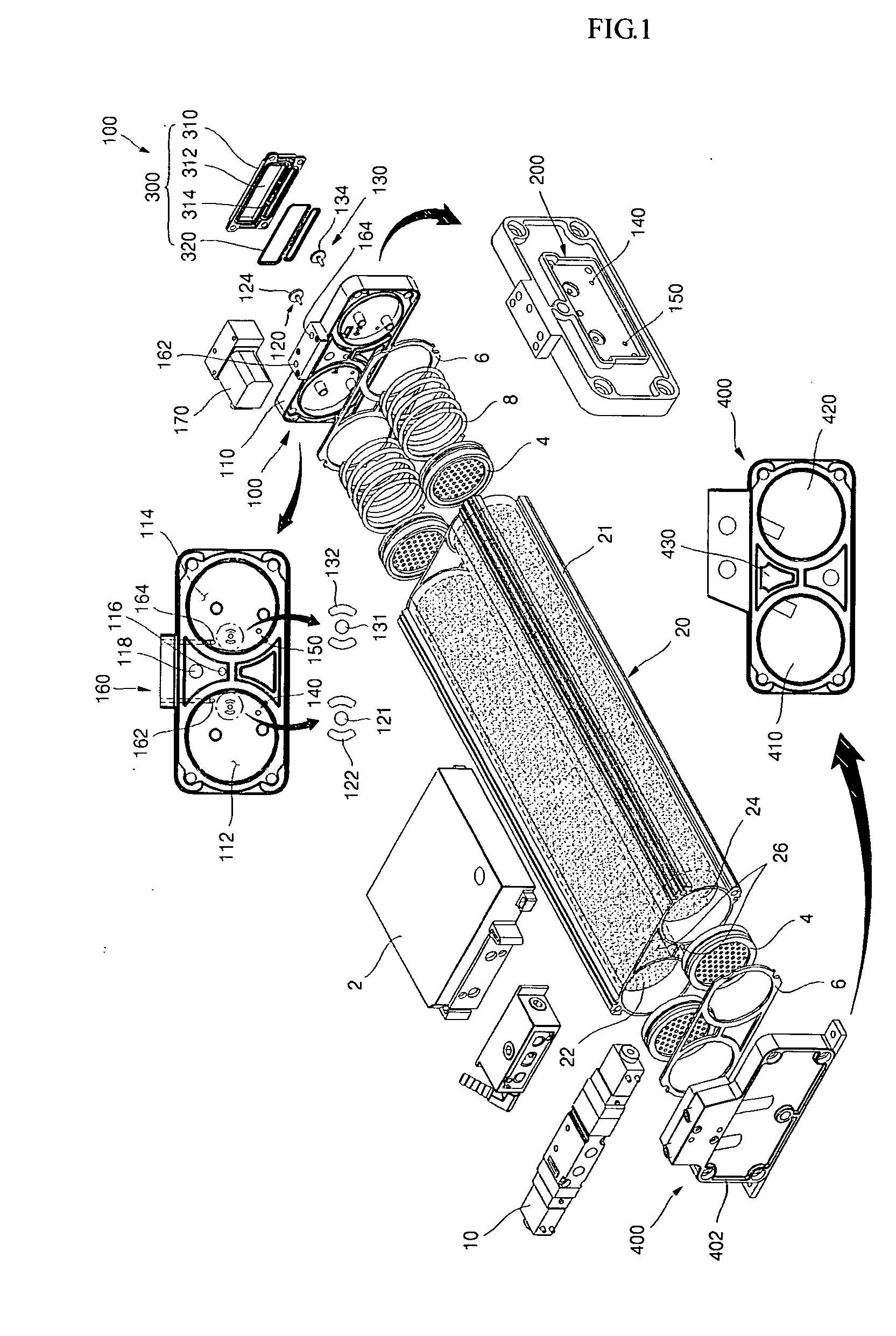

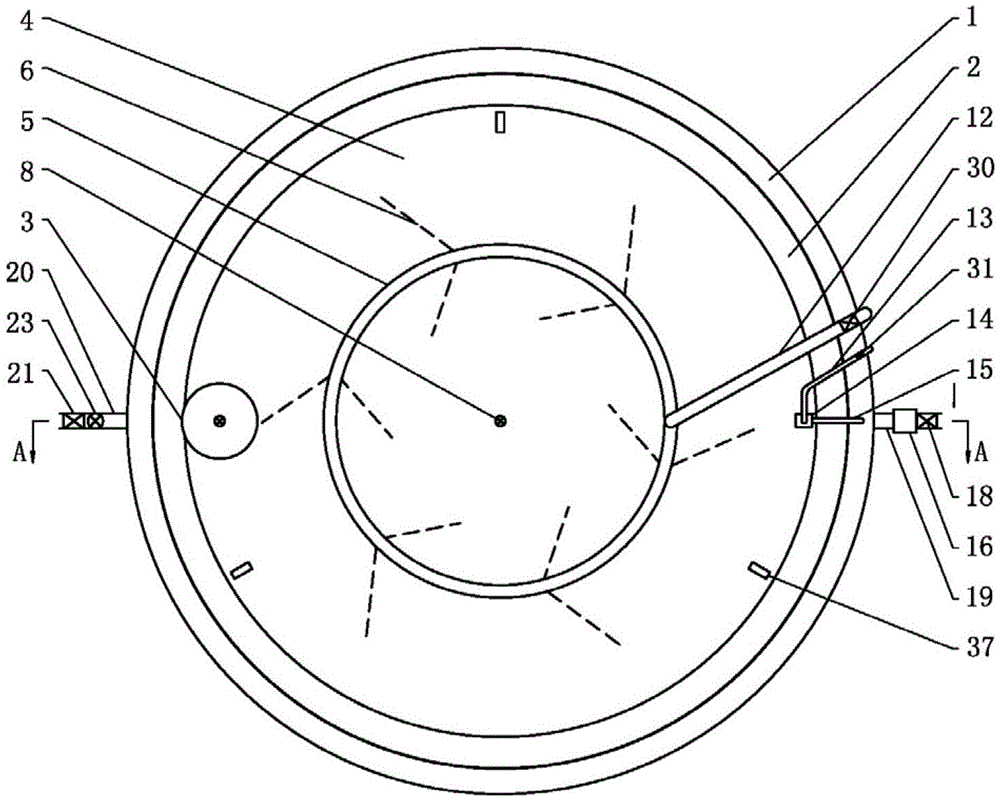

Apparatus of oxygen concentration system and method thereof

ActiveUS20070169623A1Reduce consumptionHigh purityGas treatmentBreathing filtersElectricityMechanical energy

The present invention relates to an apparatus and process of oxygen concentration system to make it possible to produce a highly purified concentrated oxygen,with modifying the structure of the adsorption bed and it achieves evenness of the first and second upper portions and controls to make simultaneous evenness of the first and second upper / lower portions together and thus increases purity of the oxygen produced and reduces mechanical energy and consumption of electricity of the air compressor, then it is about the oxygen concentration apparatus to make it possible to promote pure oxygen enrichment and its recovery rate and the oxygen concentration method to use it.

Owner:OXUS CO LTD

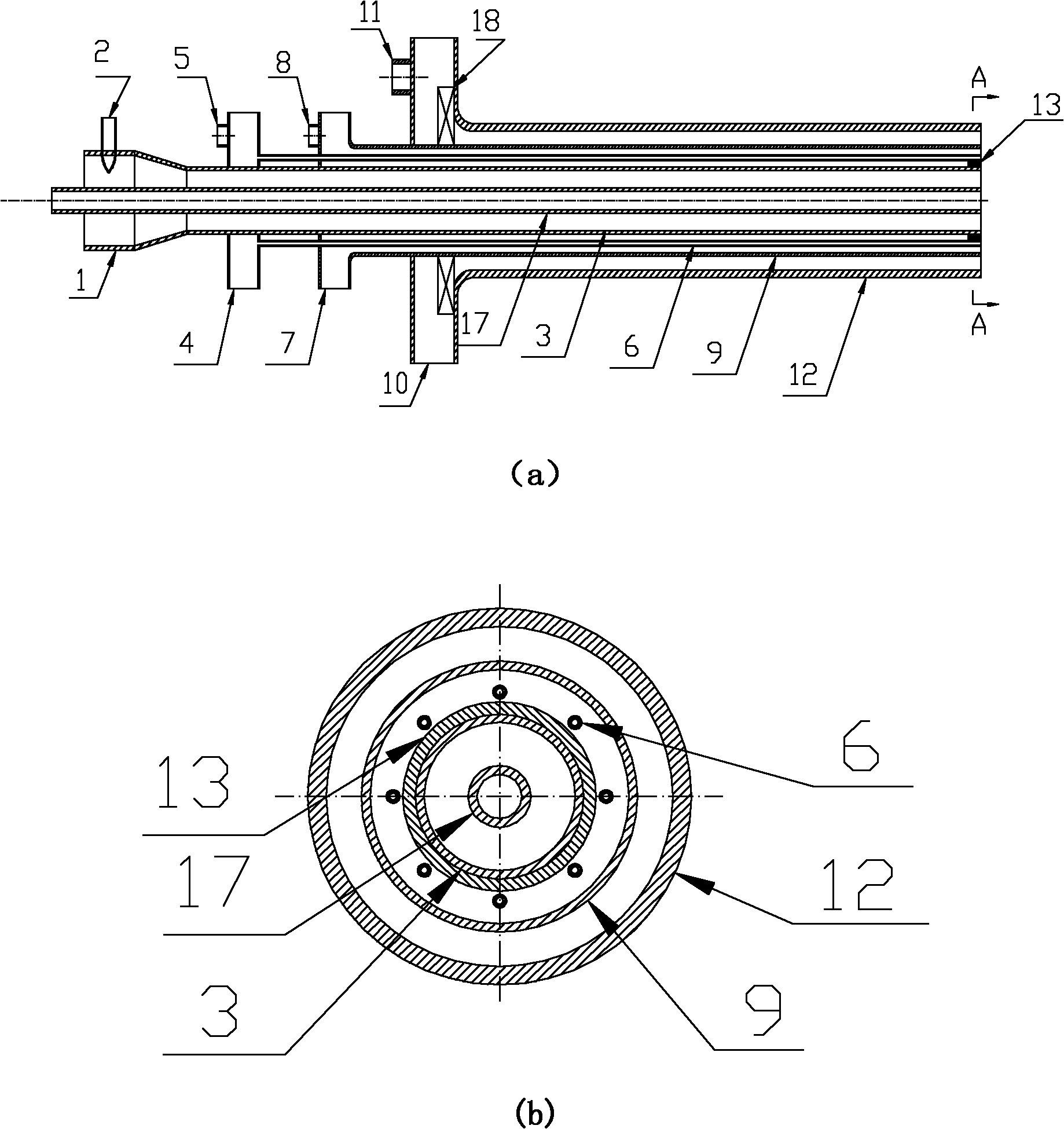

Oxygen-rich combustor

ActiveCN101825278AStable combustionSimple technologyPulverulent fuel combustion burnersDirect carbon-dioxide mitigationCombustorJet flow

The invention discloses an oxygen-rich combustor, which comprises an oil gun barrel, a primary air swirl generator, an inner secondary air generator and an outer secondary air swirl generator arranged coaxially, wherein an oxygen injector is positioned between the primary air swirl generator and the inner secondary air generator and comprises an oxygen chamber, an oxygen inlet pipe and oxygen pipes, the oxygen inlet pipe is positioned at one end of the oxygen chamber, and the oxygen pipes are connected with the other end of the oxygen chamber; and the oxygen pipes are uniformly distributed along the circumference around the axial direction. The air or a circulating flue gas is used as primary air for conveying coal powder; the oxygen injector conveys the air or pure oxygen; the inner secondary air and the outer secondary air mainly are the air or the pure oxygen / the circulating flue gas; the swirling number adjustability of the outer secondary air swirl generator, the action of high-speed oxygen jet flows and the oxygen mixed mode ensure that primary and secondary wind momentums are adjustable, and are favorable for sufficient combustion, low pollutant emission and heat and mass transfer.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and plant for removing carbon dioxide from flue gas

InactiveUS8043588B2Reduce energy costsEasy to modifyCombination devicesLiquid degasificationThermal energyDesorption

Owner:CO2 NORWAY +1

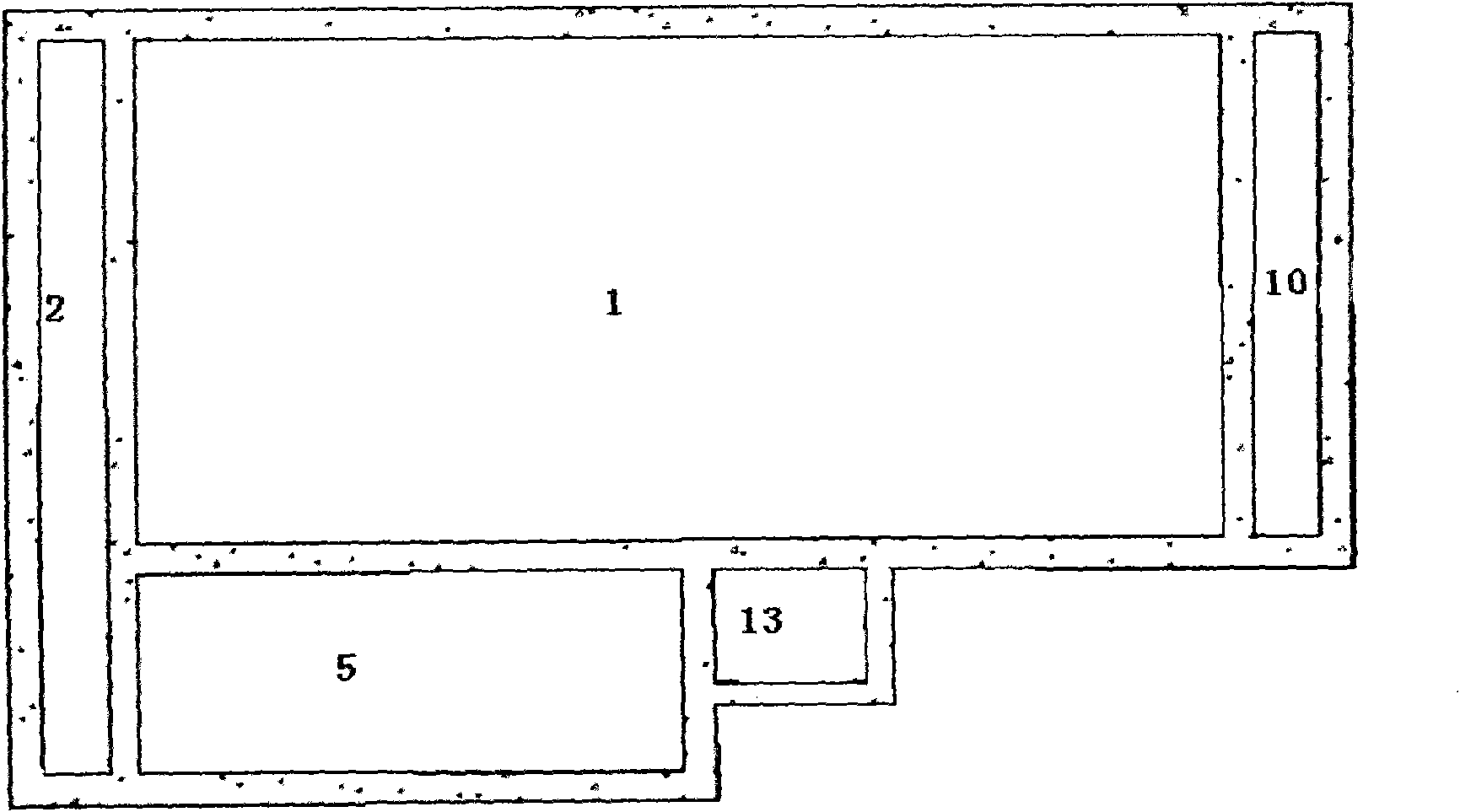

Integrated circulating water culture system

ActiveCN102754613AQuick removalEfficient removalMultistage water/sewage treatmentPisciculture and aquariaSuspended particlesParticulates

The invention discloses an integrated circulating water culture system which comprises a culture water tank, a foam separation and degassing chamber, a biological active carbon nitration reaction chamber and a low-pressure gas dissolution chamber, and is characterized in that: one part of water from a water drainage structure of the culture water tank is discharged and led into a biological flocculating constituent culture pool from the bottom of the culture water tank, and the other part flows into the foam separation and degassing chamber through an overflow hole at the upper part of the culture water tank; the suspended particles in the culture water are adsorbed by the micro bubbles of the foam separation and degassing chamber and rise to the top of the foam separation and degassing chamber to be discharged out; the culture water flows into the biological active carbon nitration reaction chamber through the foam separation and degassing chamber and is purified by a nitration biomembrane of the biological active carbon nitration reaction chamber and drawn out from the bottom of the biological active carbon nitration reaction chamber; 90% of the culture water drawn out is directly fed into the low-pressure gas dissolution chamber, and 10% of the culture water is fed into a pipeline mixer to mix pure oxygen and ozone and then fed into the low-pressure gas dissolution chamber; and the processed culture water flows back to the culture water tank from a drainage hole at the bottom of the low-pressure gas dissolution chamber.

Owner:SHANGHAI OCEAN UNIV

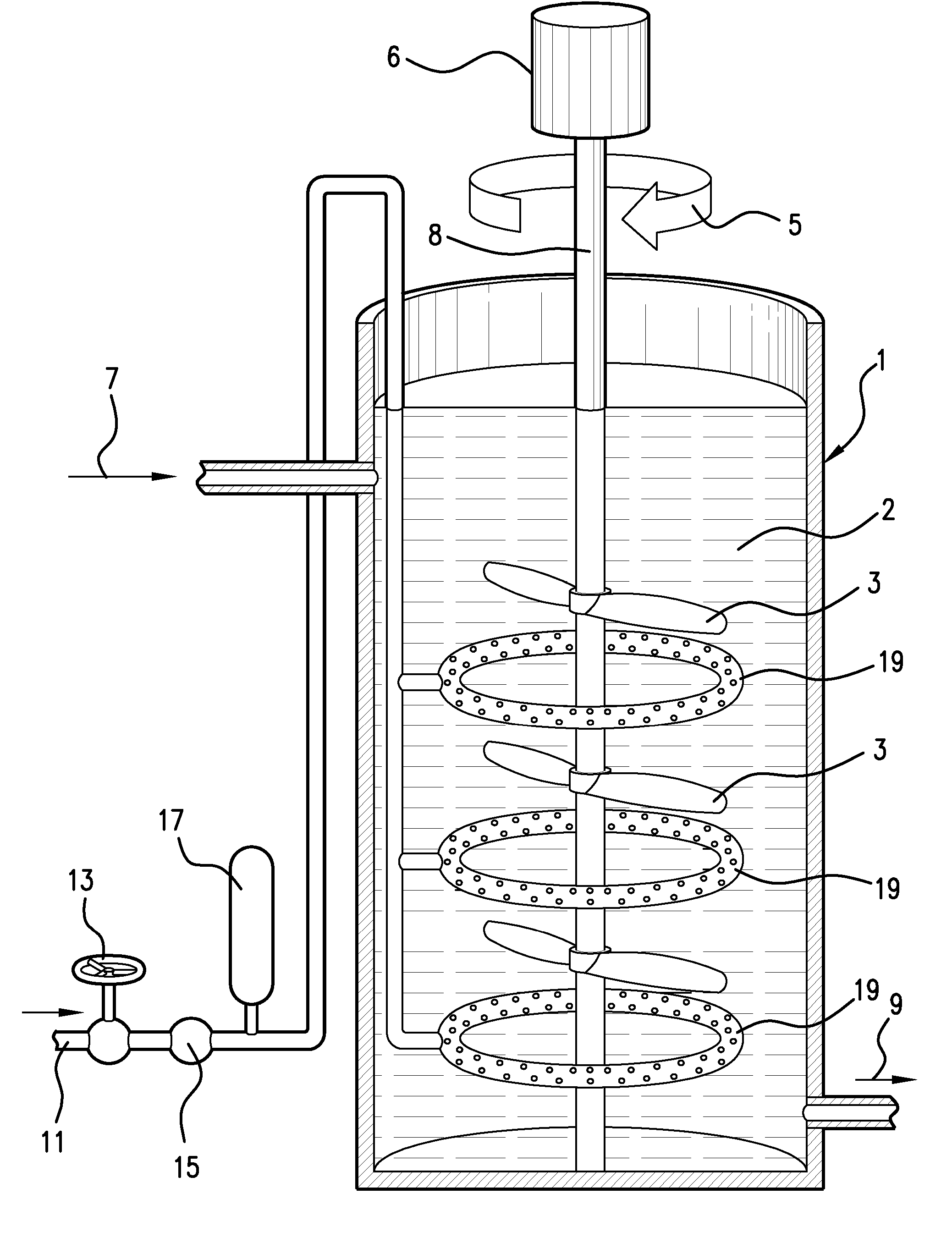

Use of pure oxygen in viscous fermentation processes

InactiveUS20070065927A1Guaranteed economical operationOptimize allocationTransportation and packagingRotary stirring mixersImpellerXanthan gum

A fermentation process uses substantially pure oxygen as the sole gas introduced into a fermentation vessel while fermentation reactions are active. The oxygen is introduced at multiple locations along the height of the vessel, and is preferably introduced in the vicinity of the blades of an impeller. The invention enhances the rate at which oxygen can be transferred to the fermentation medium, and is especially useful for fermentation media which become very viscous as the process continues. The invention can be used in the manufacture of viscous products such as xanthan gum, or other products having viscosities greater than about 100 cp.

Owner:AIR LIQUIDE AMERICA INC

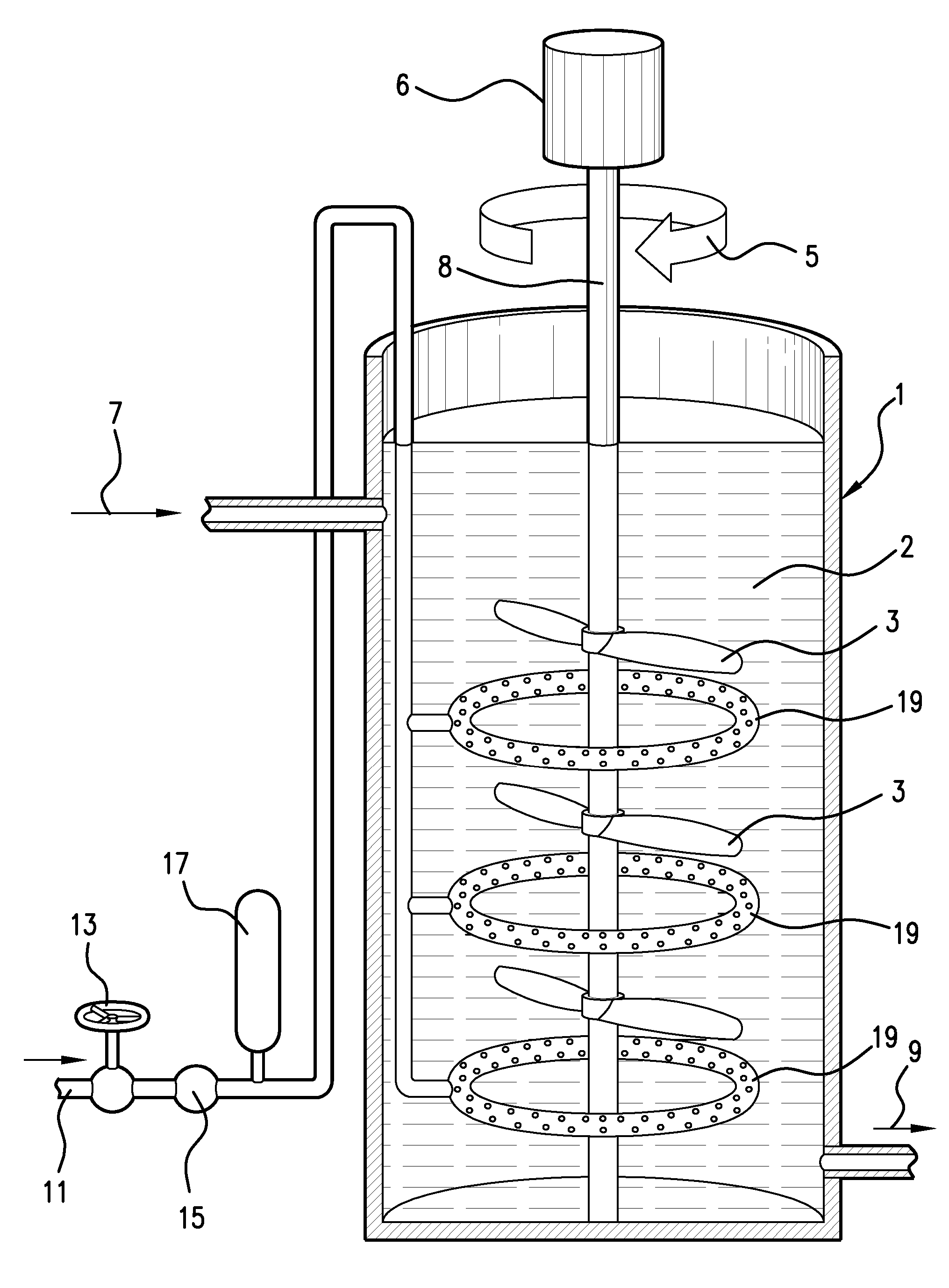

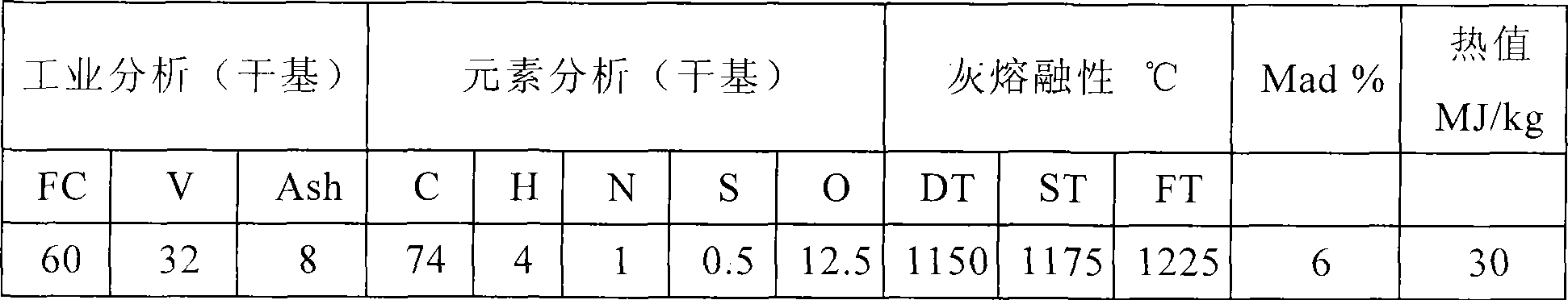

Method for producing spongy iron by direct reduction of dry coal powder gasification and hot coal gas fine ore fluidized bed

InactiveCN101397597AOvercoming gasification link limitationsGas emission reductionIron powderFluidized bed

The invention discloses a method for reducing and producing sponge iron directly by a dry coal dust gasified hot coal gas fineore fluidized bed, which comprises the following steps of: a) grinding and drying the feed coal; b) spraying the dry coal dust and pure oxygen into a pressured gasification furnace; c) chilling the hot coal gas at the top of a gasification furnace to be 900 DEG C to 950 DEG C by the cooled coal gas of 30 DEG C to 80 DEG C, then removing dust, and after washing and cooling part of the coal gas to be 30 DEG C to 80 DEG C, which then returns to the top of the gasification furnace, chilling the high-temperature coal gas; d) desulfurizing the remaining coal gas which is taken as reducing gas for entering a fluidized bed reactor; and e) introducing the hot coal gas into the last level of the multilevel fluidized bed; and then the coal gas flows in the opposite direction of the iron-containing powder lot; the coal gas flows through all levels of the fluidized bed in the reverse direction and the iron-containing powder lot flows through all levels of the fluidized bed in the forward direction, and then the iron-containing powder lot and the reduced gas countercurrent contact with each other, therefore, the sponge iron is obtained by progressive reduction and carburization. The reduced gas is produced by adopting the technology of gas generation; the energy utilization rate is improved by using the sensible heat of the hot coal gas to provide the energy which is necessary in the hematite reduction; and the generated sponge iron can be used for the electrosmelting of steel directly.

Owner:BAOSHAN IRON & STEEL CO LTD

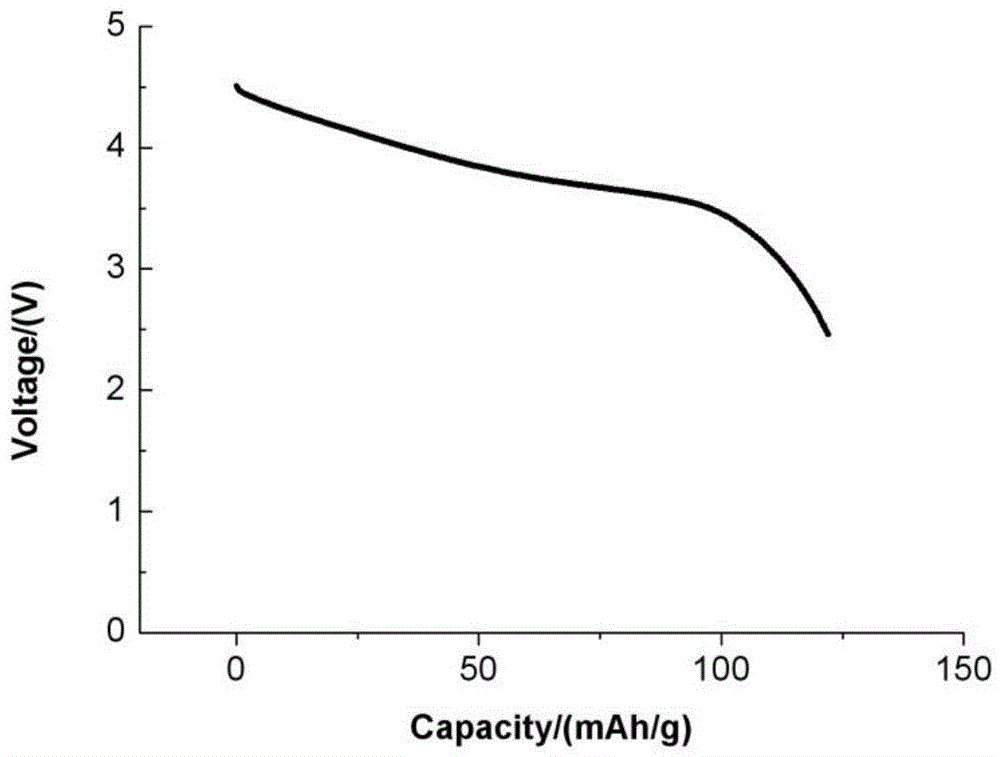

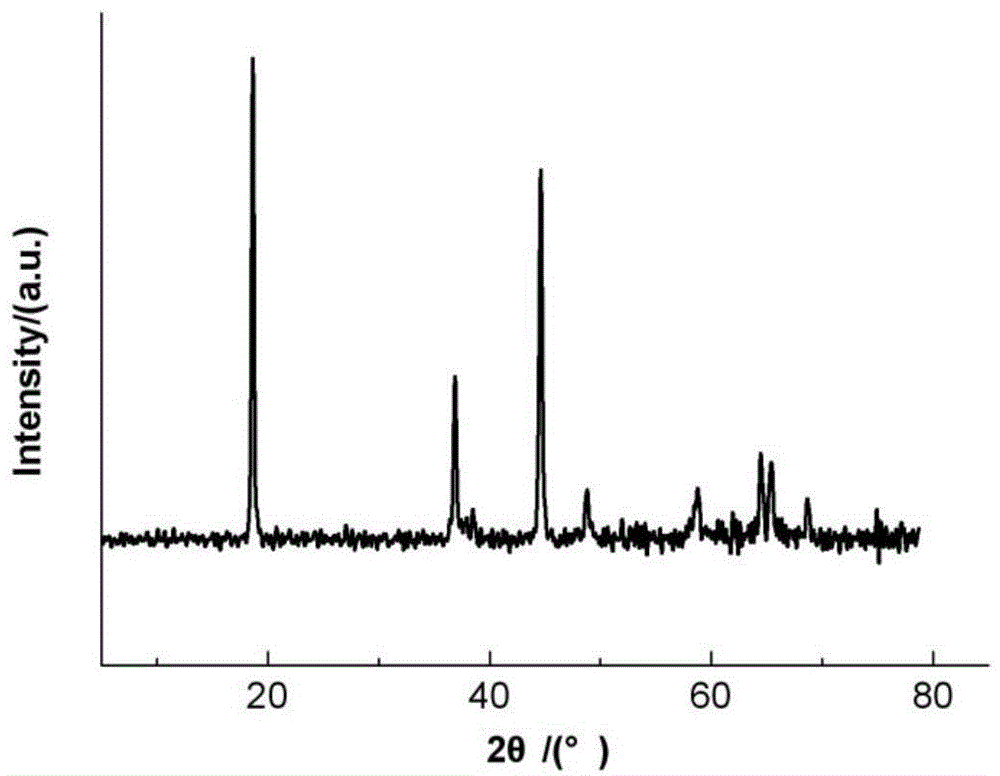

Method for preparing lithium-rich solid solution cathode material through reduction co-precipitation

ActiveCN102881876ALow costWide variety of sourcesHybrid capacitor electrodesCell electrodesManganeseLithium compound

The invention relates to a method for preparing a lithium-rich solid solution cathode material through reduction co-precipitation. The method comprises the following steps of: weighing lithium, nickel, manganese, cobalt and a reducing agent in a molar ratio of (1+x):(1-x).y:(x+z-x.z):(1-x).k:q; and mixing a measured wet grinding medium, the nickel, the manganese and the cobalt, adding the reducing agent, stirring, mixing, adding alkali liquor, performing wet grinding, aging, filtering, washing, adding the wet grinding medium and a lithium compound, performing wet grinding, drying to prepare a precursor, putting the precursor in air, oxygen-rich gas or pure oxygen atmosphere, and sintering to prepare the lithium-rich solid solution cathode material. The electrode material prepared by the method has uniform composition, high discharge performance, and high discharge cycle performance particularly under the high-current condition.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

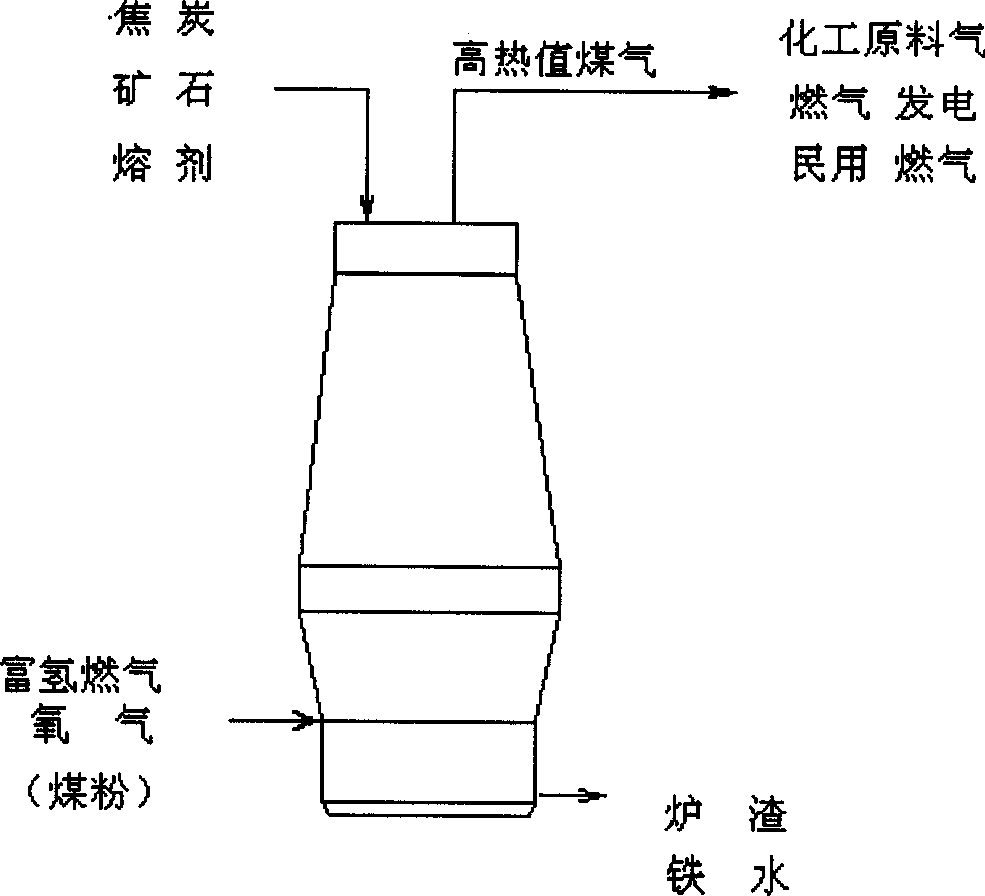

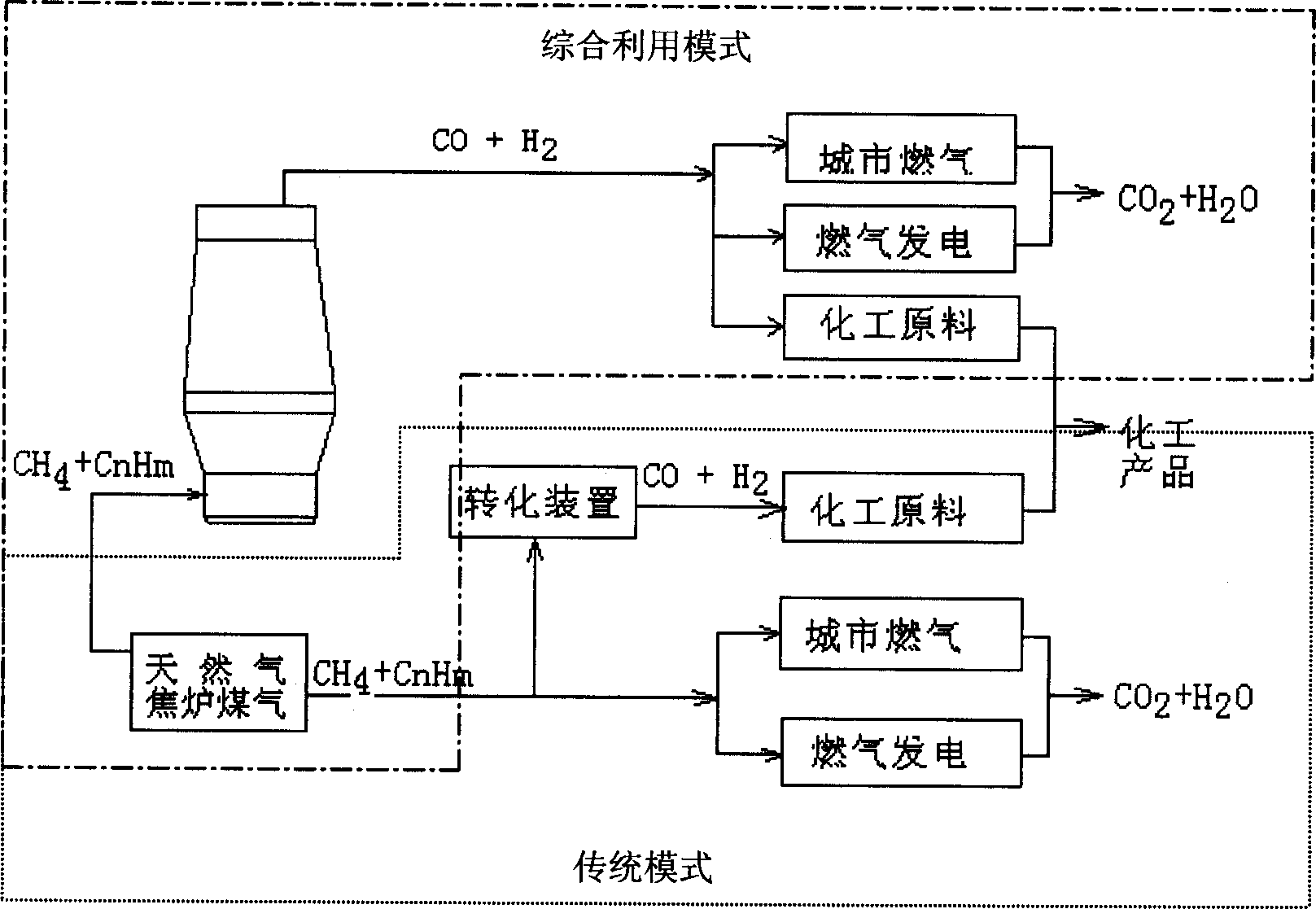

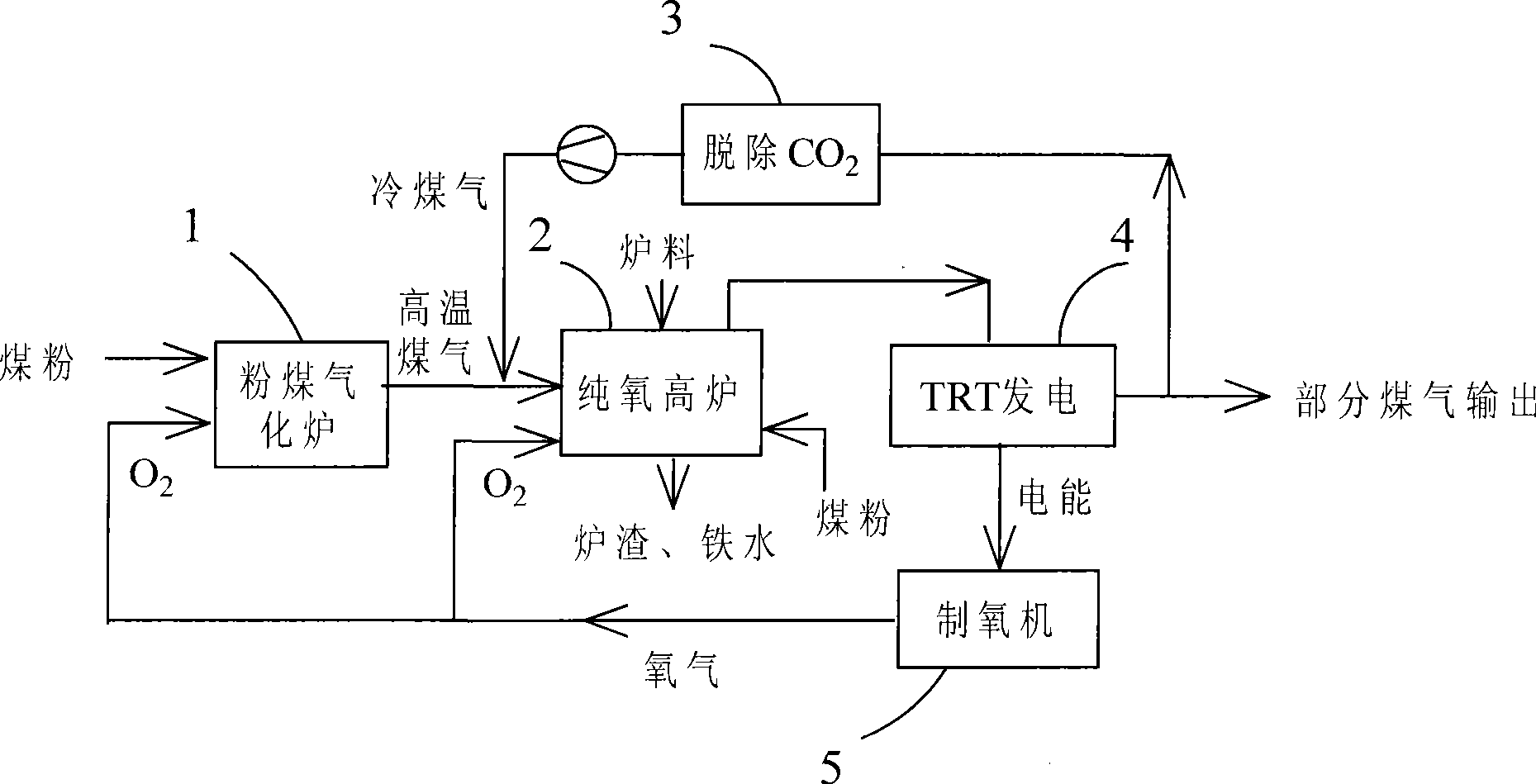

Blast furnace iron-making technique with hydrogen-rich fuel gas, pure oxygen and thus high efficiency and low CO2 exhaust

InactiveCN1487097AReduce focal ratioSolving the Contradiction of Insufficient Heat in the Upper Part of the Blast Furnace due to Less Blast Furnace GasBlast furnace detailsHydrogenCoke oven

The blast furnace iron-making technique includes blowing hydrogen-rich fuel gas in the blast hole of blast furnace of amount 500-1000 cu m / ton iron; normal temperature pure oxygen blasting while eliminating traditional hot blast furnace; gas in bosh containing H2 in 30-60 % except CO; gas in hearth top connecting CO+H2 in 85-95 %; and controlling the theoretic combustion temperature in 1800-2200 deg.c. The blast furnace iron-making technique can lower the blast furnace in 1800-2200 deg.c. The blast furnace iron-making technique can lower the blast furnace coke ratio to below 250 Kg / ton iron, lower CO2 exhaust by 400-600 Kg / ton iron and produce high heat value gas capable of being used as secondary energy source.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

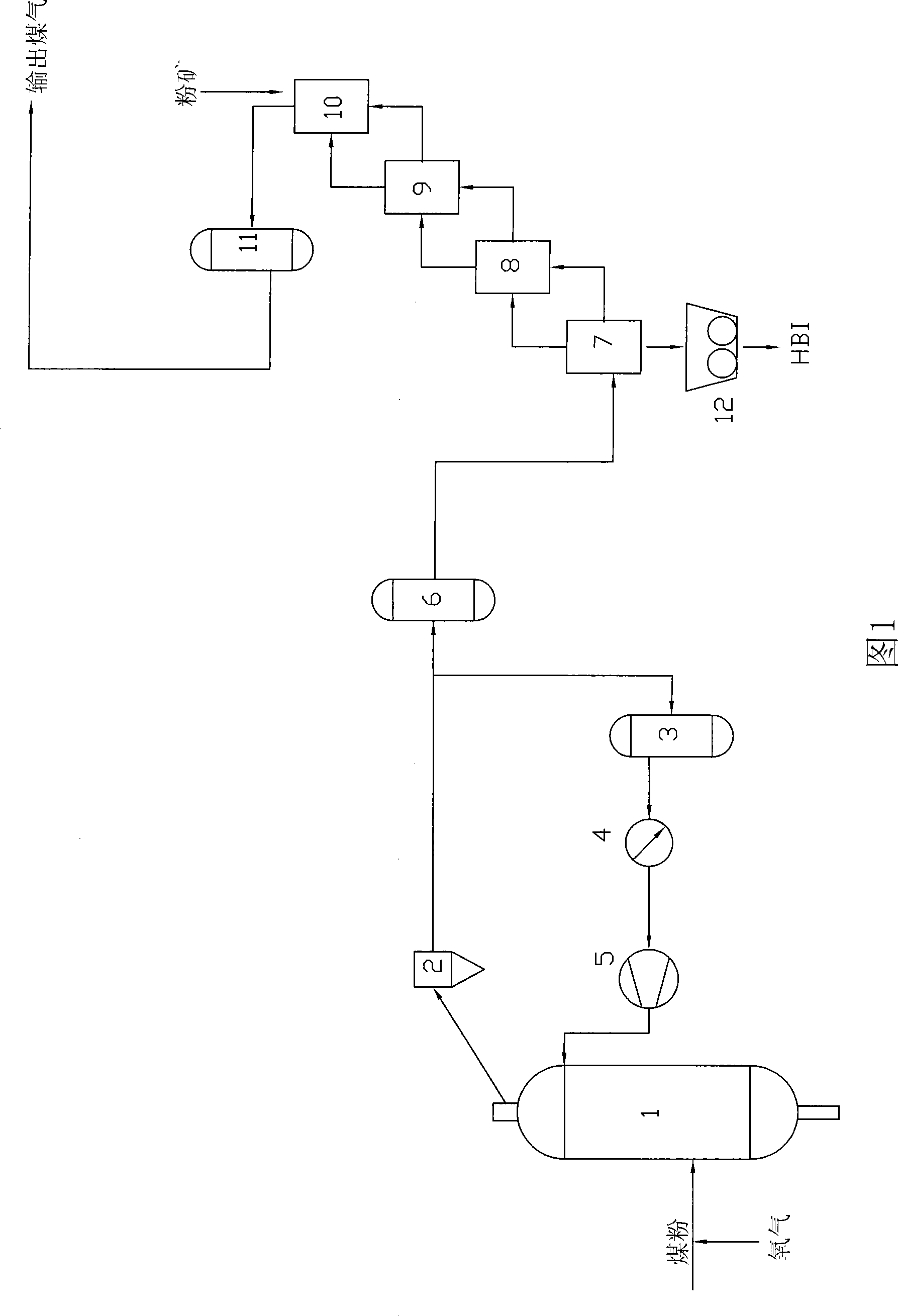

Low-coke-ratio blast furnace ironmaking technique

ActiveCN101519703AReduce energy lossAvoid heating carbon precipitation reaction failureBlast furnace detailsProduction ratePollutant emissions

The invention relates to a low-coke-ratio blast furnace ironmaking technique. Dry coal powder is pressurized and gasified in a separate gasification furnace, the dry coal powder is injected into the gasification furnace to be sufficiently mixed with pure oxygen, burnt and gasified to produce high-temperature coal gas, the pressure in the gasification furnace is 0.3MPa to 0.6MPa, and the temperature of the coal gas at the outlet is 1300 DEG C to 1550 DEG C; the coal gas at the outlet of the gasification furnace is mixed with the purified cold coal gas at the blast furnace top, and the temperature is controlled at 900 DEG C to 1050 DEG C; the high-temperature high-reducibility hot coal gas is then injected into the lower part of the body of the blast furnace, that is, the area above the root of a cohesive zone, so that the metallization ratio of charging can reach 85 percent to 95 percent when reaching the cohesive zone; and part of the coal powder is injected from the tuyere of the blast furnace to be subjected to pure oxygen combustion. The invention, which is a novel blast furnace ironmaking technique taking dead coal and oxygen as main energy sources, can reduce the coke ratio of the blast furnace to be less than 200kg, greatly increase the productivity of the blast furnace and reduce the emission of coke-making pollutant, thus enhancing the competitiveness of the blast furnace ironmaking technique.

Owner:XINJIANG BAYI IRON & STEEL

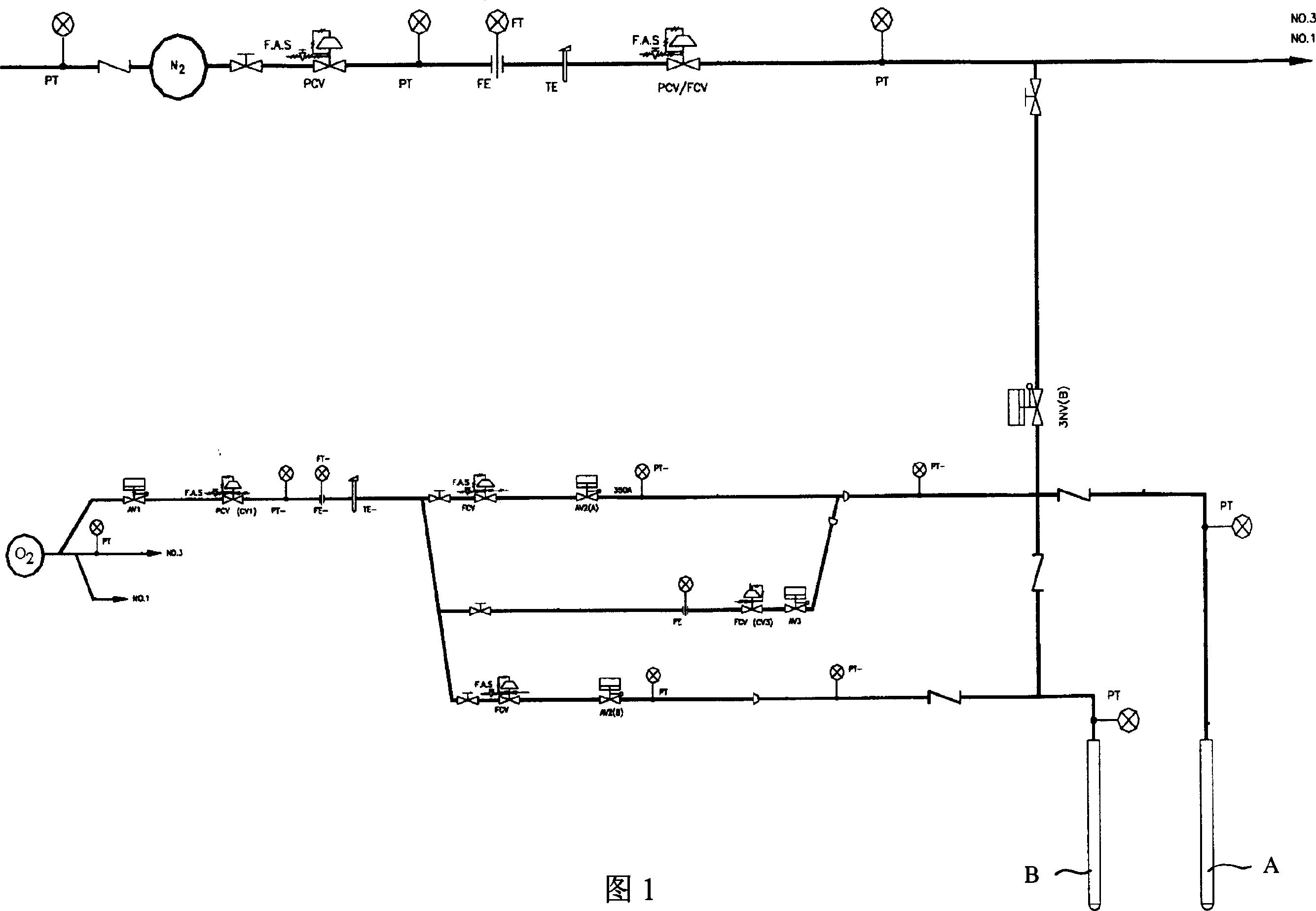

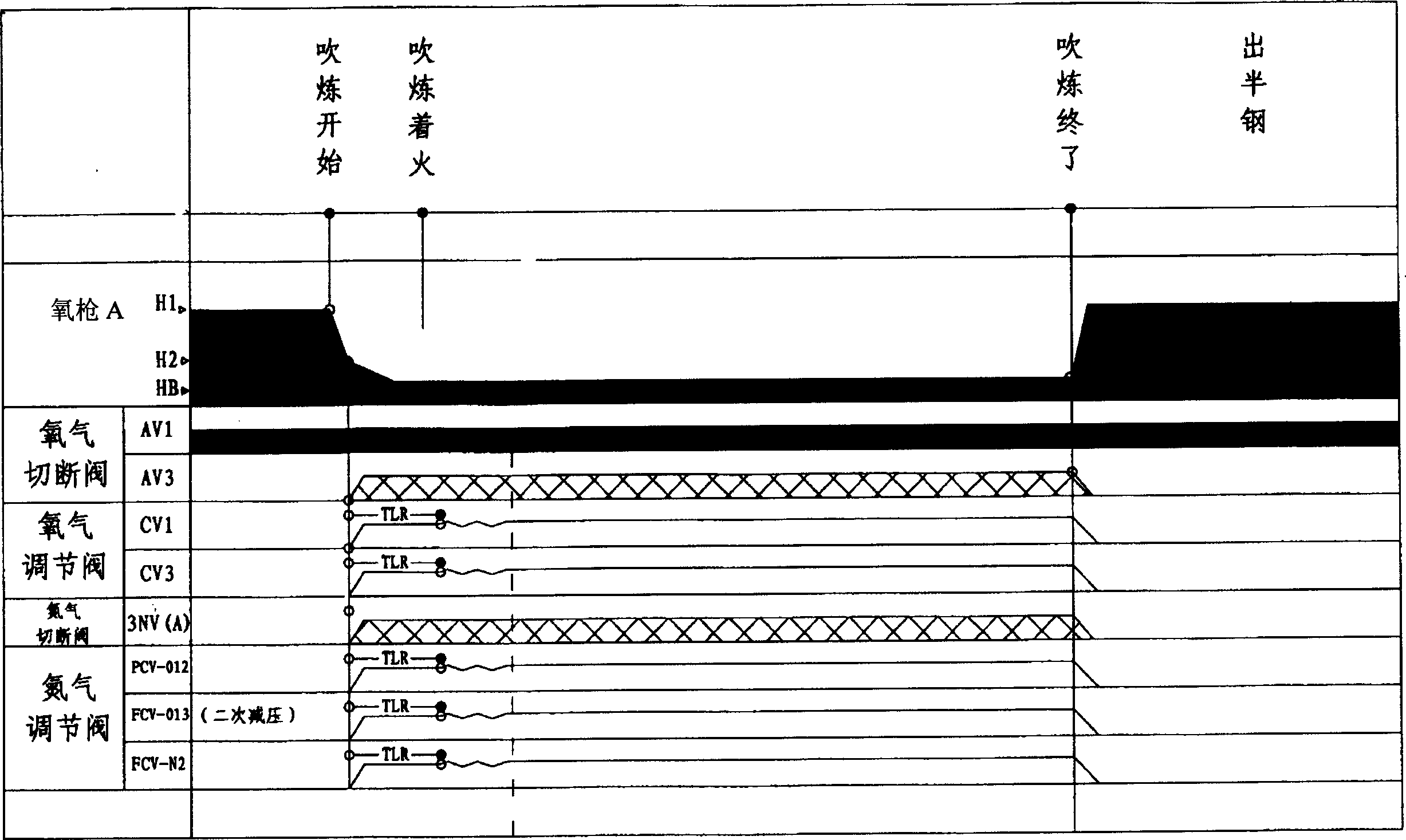

Converter oxide and nitrogen top-blown dephosphorizing method

InactiveCN1552919AHigh carbon contentInhibition of decarburization reactionsManufacturing convertersSputteringSlag

An oxygen-nitrogen top blowing converter process for desulfurization is carried out by blowing oxygen-nitrogen at its top while blowing nitrogen or inertial gases at its bottom to desulfurise. Its top blowpipe controls oxygen blowing to desulfurise in two modes, with mixed gases at some ratio or with pure oxygen switched with pure nitrogen, in order to inhibit sputtering and to enhance stirring in smelting pool when sputter occurs by excessive oxidation, so that balance of (P) / [P] in dynamics is improved. It desulfurises better when bottom blowing is weak, can inhibit decarbonise reaction effectively with >70% recovery of Mn in molten iron, also, strengthen blowing at top to stir strongly and shorten pre-treat time, increase rate of desulfurization, control slag elimination in procedure effectively to prevent sputtering, and increase stability and security.

Owner:BAOSHAN IRON & STEEL CO LTD

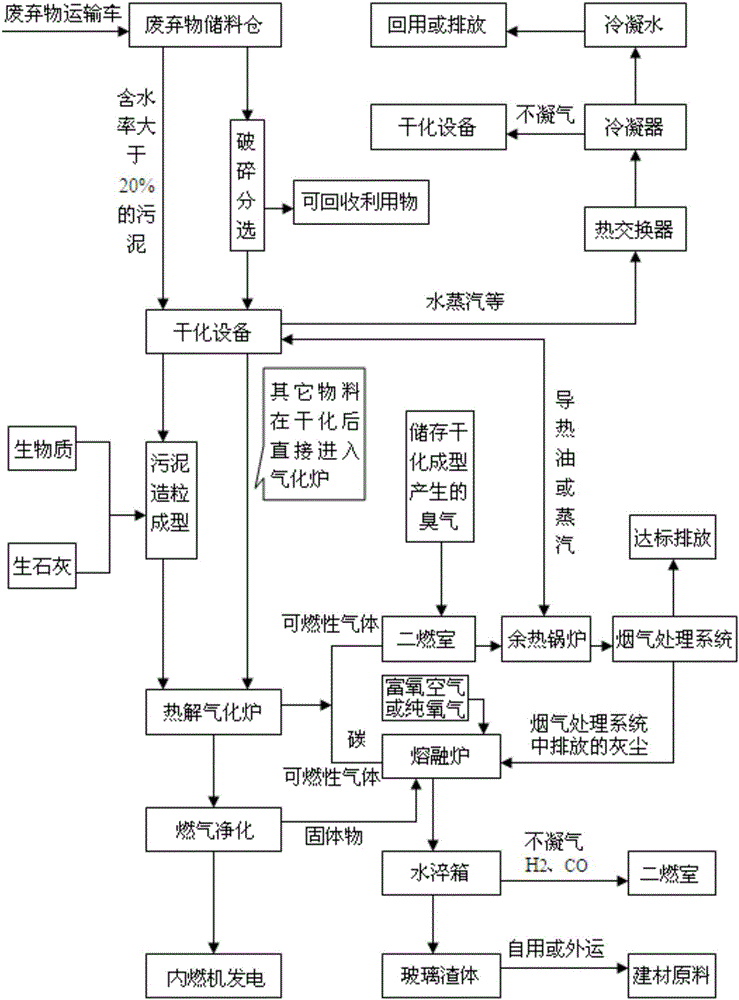

Solid organic waste gasification and melting cycle-treatment process

InactiveCN106493148AImprove resource utilizationSolid waste disposalTransportation and packagingCombustion chamberSludge

The invention relates to a solid organic waste gasification and melting cycle-treatment process, which comprises steps of crushing, anhydration, moulding, gasification and melting. A gasification product is mainly combustible gas and pyrolytic carbon, and the pyrolytic carbon undergoes melting treatment. The use of the combustible gas is mainly divided into two parts: most of the combustible gas is conveyed into a secondary combustion chamber to be combusted to heat an anhydration medium so as to provide energy for the anhydration phase or power an internal combustion engine; and part of the combustible gas is sent into a melting furnace and oxygen-enriched air or pure oxygen is added to melt the pyrolytic carbon, and generated flue gas is sent into the secondary combustion chamber. Tail gas generated during the phases of organic waste storage, crushing, anhydration and moulding is also sent into the secondary combustion chamber to be used as combustion air for high-temperature combustion treatment. By the technology for treatment of various solid organic wastes such as municipal domestic waste, industrial refuse, various livestock residues, sludge, straw and the like, quantitative reduction is obvious, and the technology has characteristics of energy conservation and emission reduction, low-carbon and environmental protection, less secondary pollution, high harmless degree, low operation cost and remarkable environmental benefit and the like.

Owner:上海蓝州环保科技有限公司

Oxy-combustion coal fired boiler and method of transitioning between air and oxygen firing

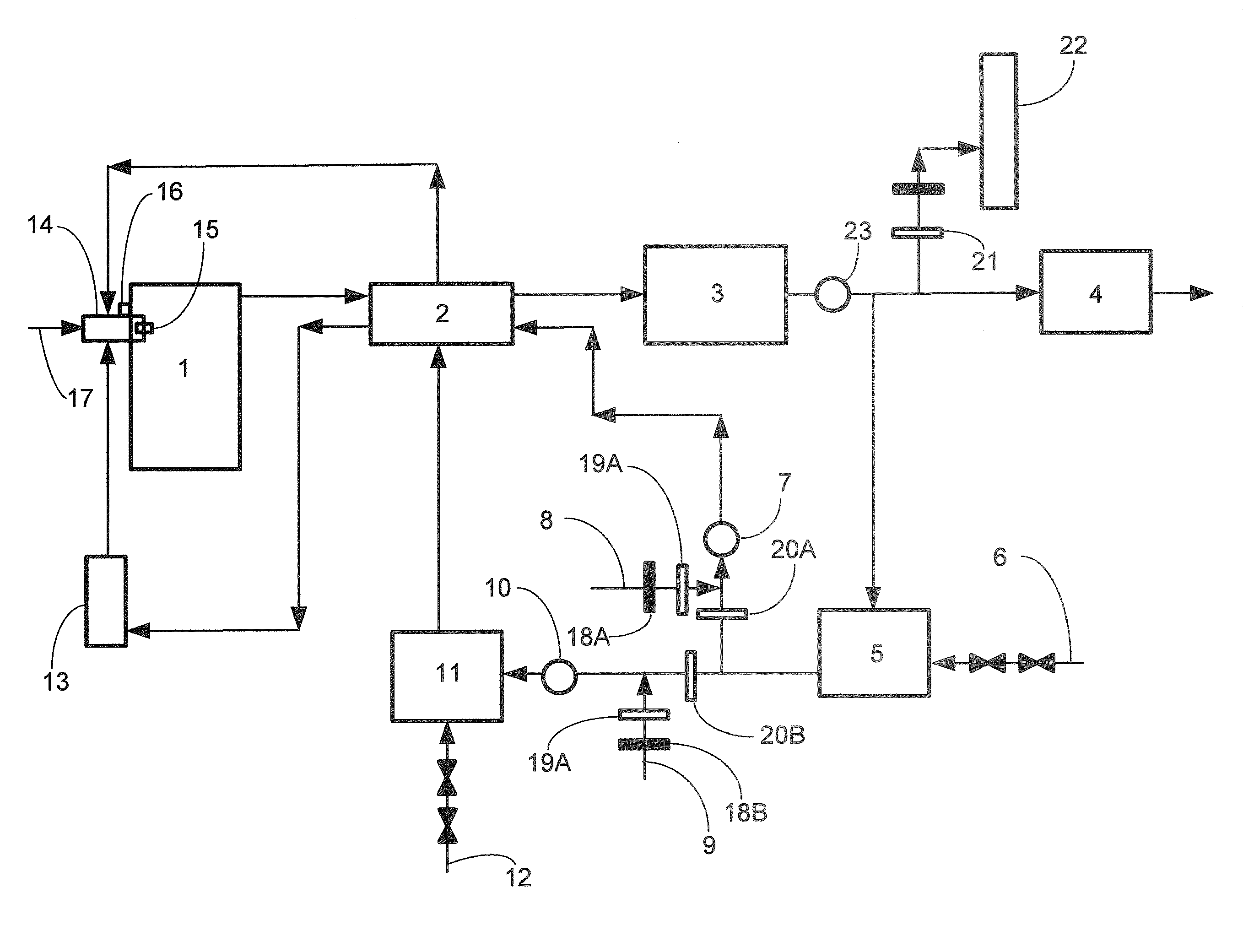

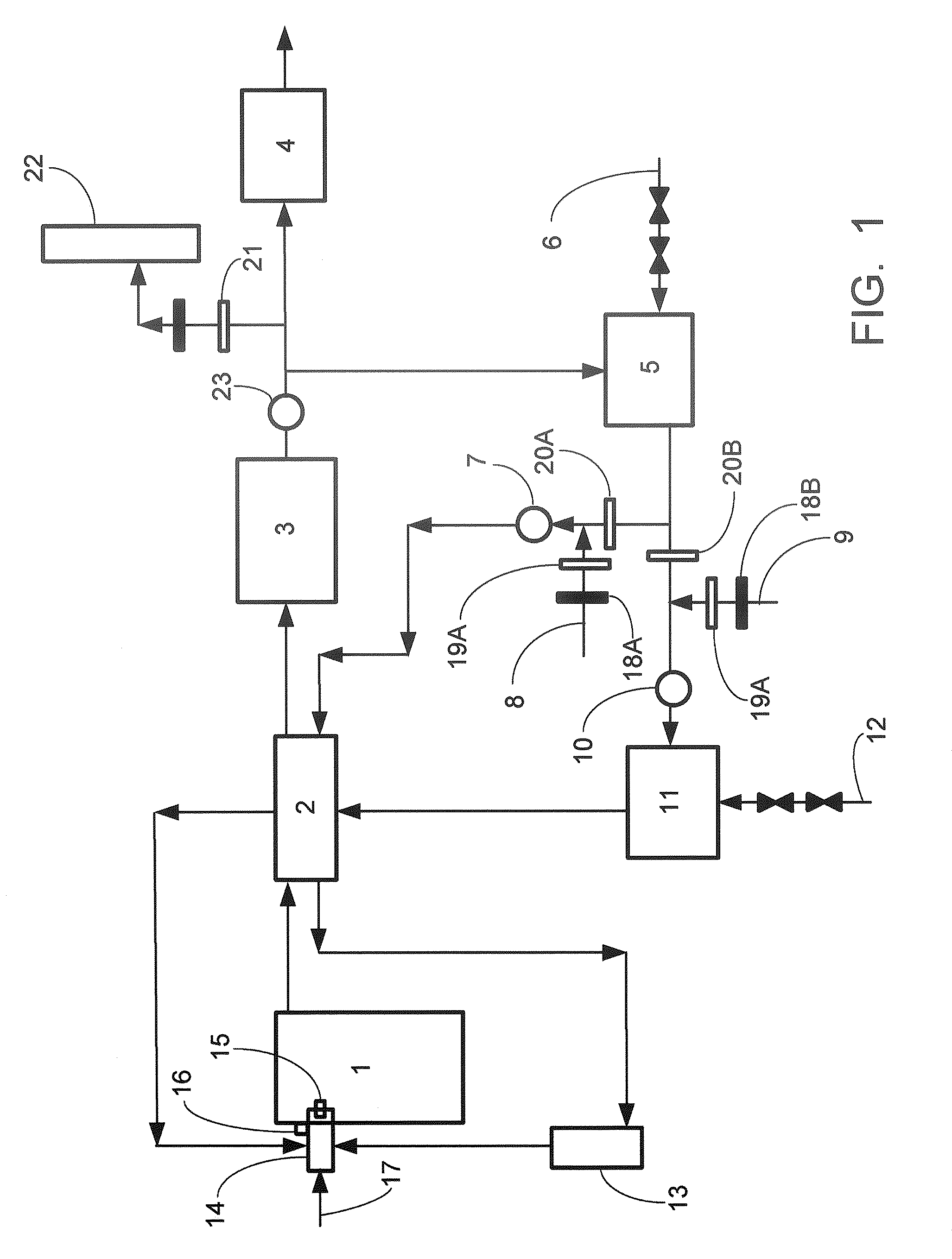

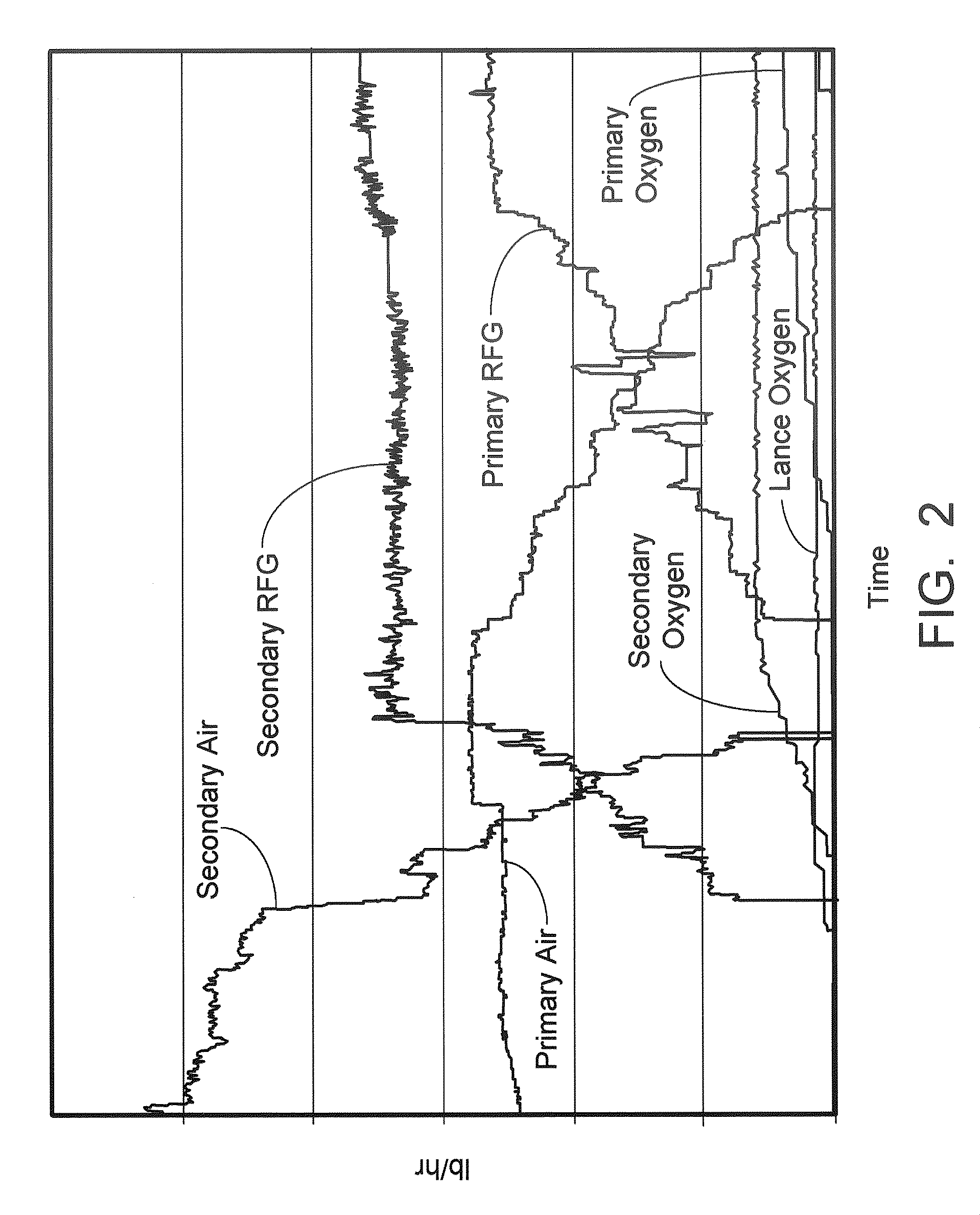

ActiveUS20090255450A1Easy to controlMinimize infiltrationLiquid carbonaceous fuelsPulverulent fuel combustion burnersBoiler furnaceCombustor

A new and unique boiler and method of transition between air and Oxy-combustion in a coal fired combustion process wherein near pure oxygen may be introduced to the boiler furnace in several locations including directly into the flame through the burner and / or directly into the furnace as nearly pure oxygen, and / or into the recycle flue gas streams to the burners, including both primary and secondary streams.

Owner:THE BABCOCK & WILCOX CO +1

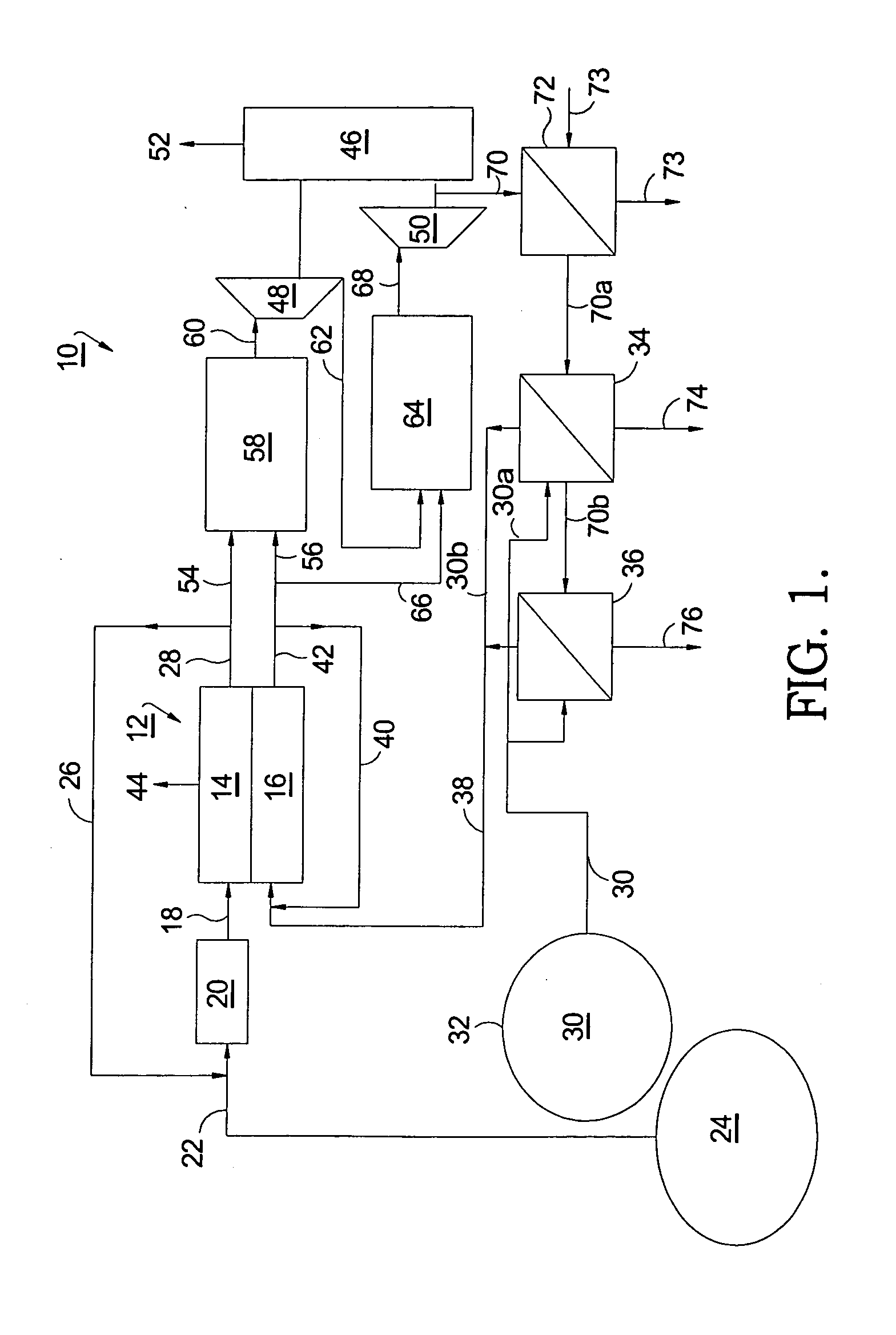

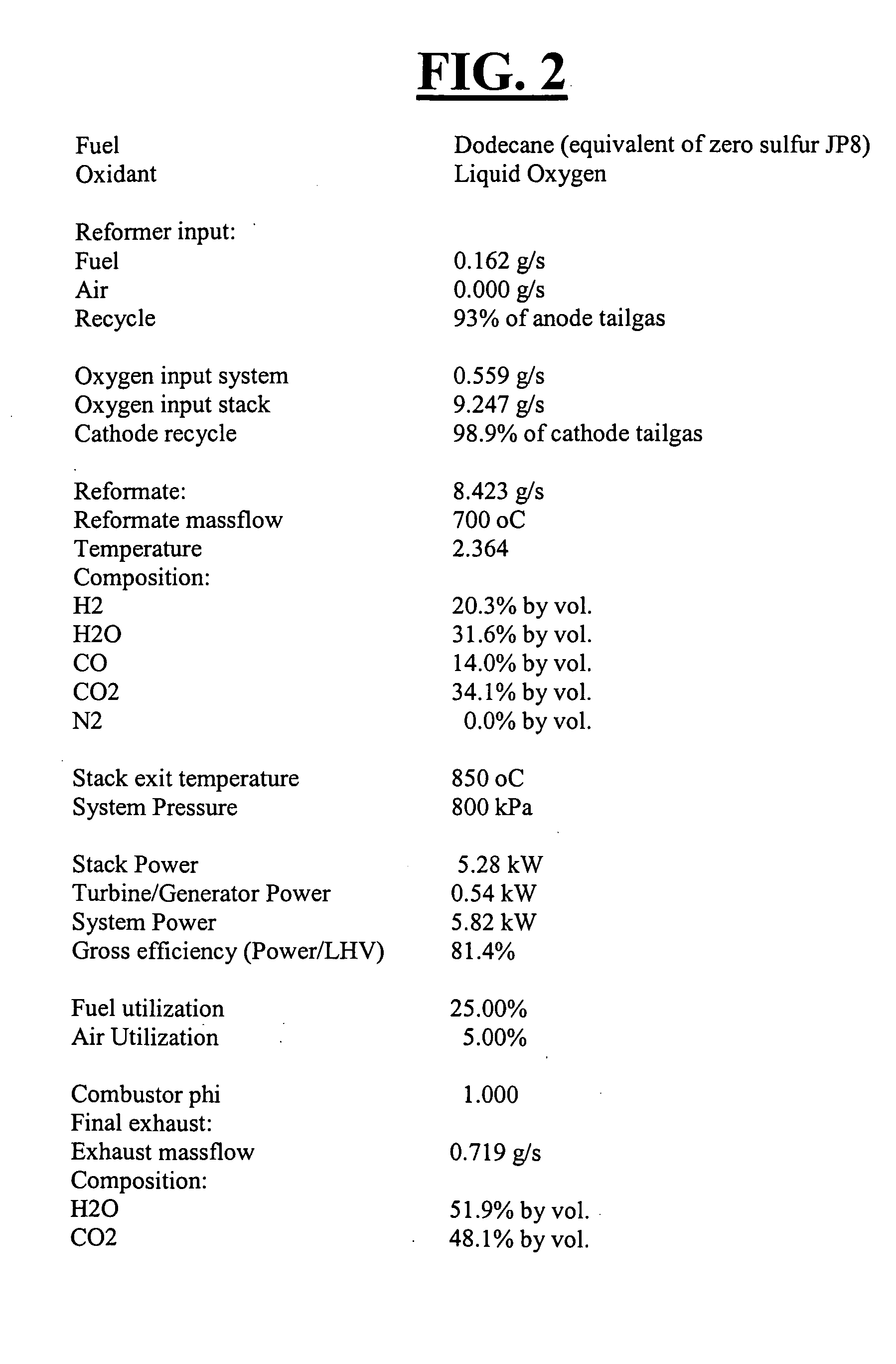

Hybrid solid oxide fuel cell and gas turbine electric generating system using liquid oxygen

InactiveUS20070163822A1Increasing oxygen pressureImprove efficiencyHybrid vehiclesAuxillary drivesHydrocotyle bowlesioidesElectric generator

A hybrid SOFC / gas turbine electric generating system comprising an SOFC stack, a hydrocarbon reformer, a first anode tailgas hydrogen-rich combustor to drive a first gas turbine stage, and a second stoichiometric combustor to drive a second gas turbine stage to drive a generator. Anode tailgas is also recycled into the reformer for substantially endothermic reforming of hydrocarbon fuel. Oxidant is provided as pure oxygen—which may be stored as liquid oxygen. All nitrogen may be excluded. Cathode exhaust is passed to the first combustor, to the second combustor, and is recycled into the cathodes. The turbine exhaust is passed through successive heat exchangers cooled by liquid oxygen being vaporized, precipitating water and solid CO2. The system is operated at about 800 kPa (about 8 atmospheres), thereby increasing the power output of the stack. The system may be operated with no gaseous exhaust or with by-products of water and CO2.

Owner:DELPHI TECH INC

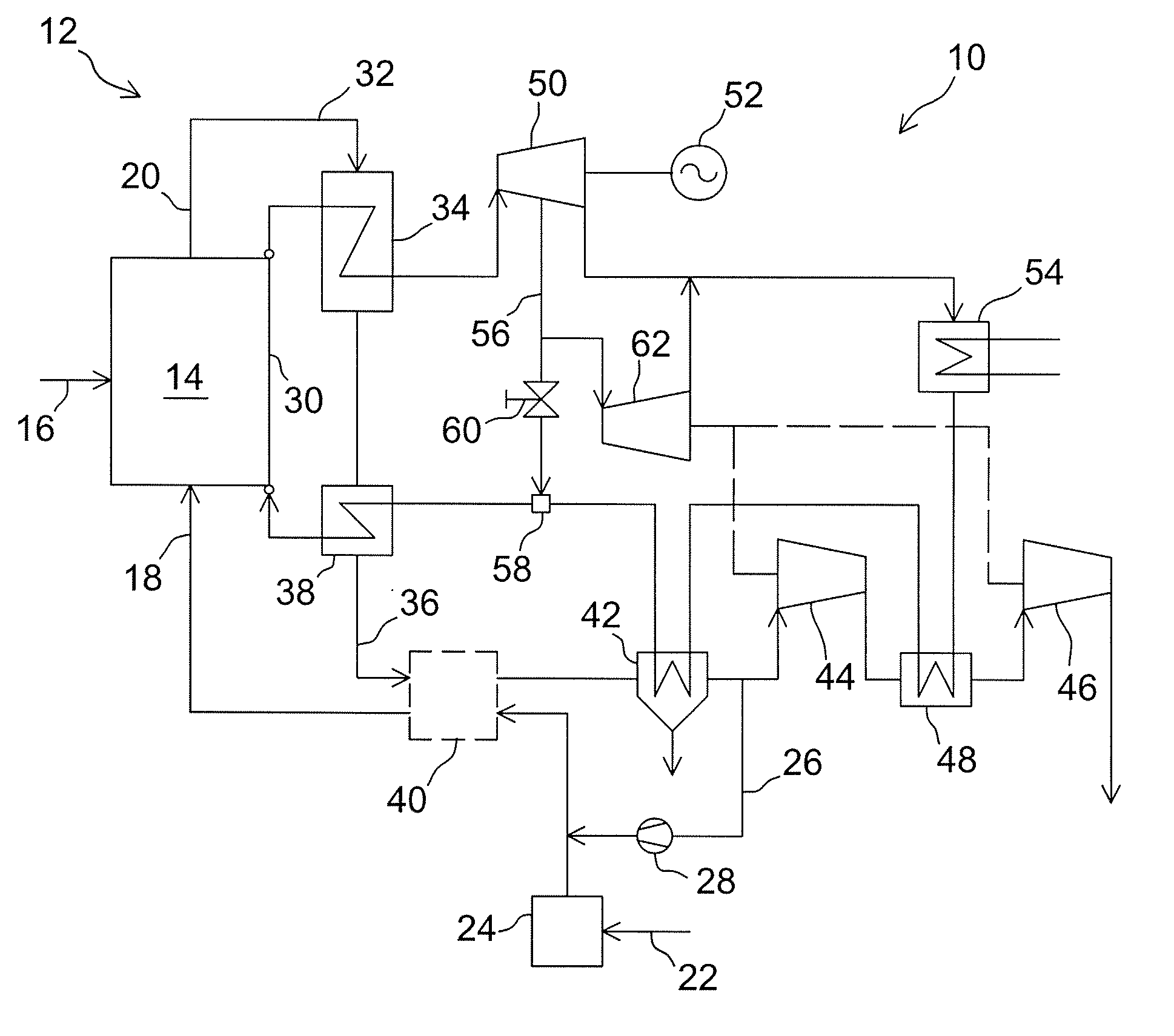

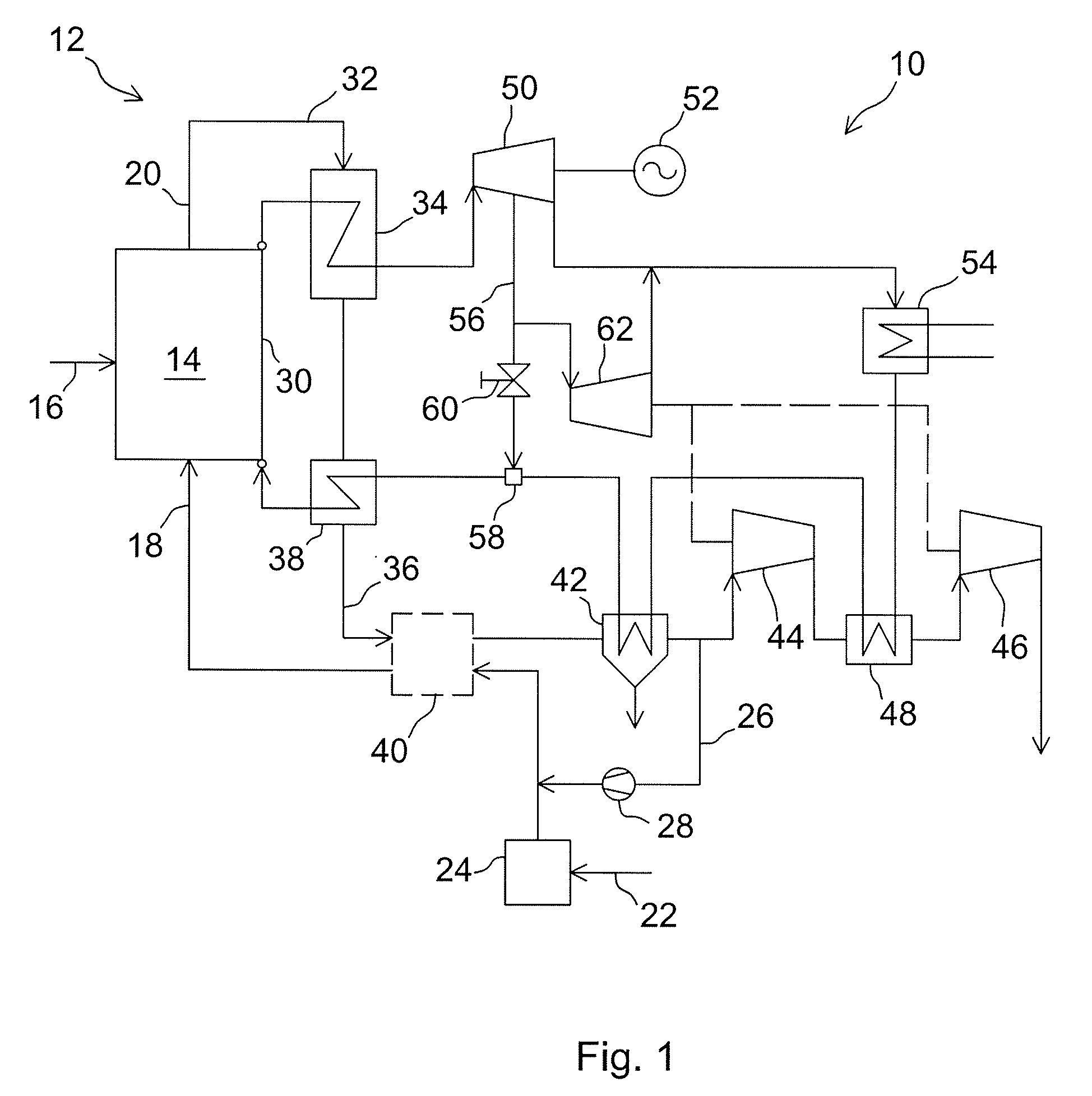

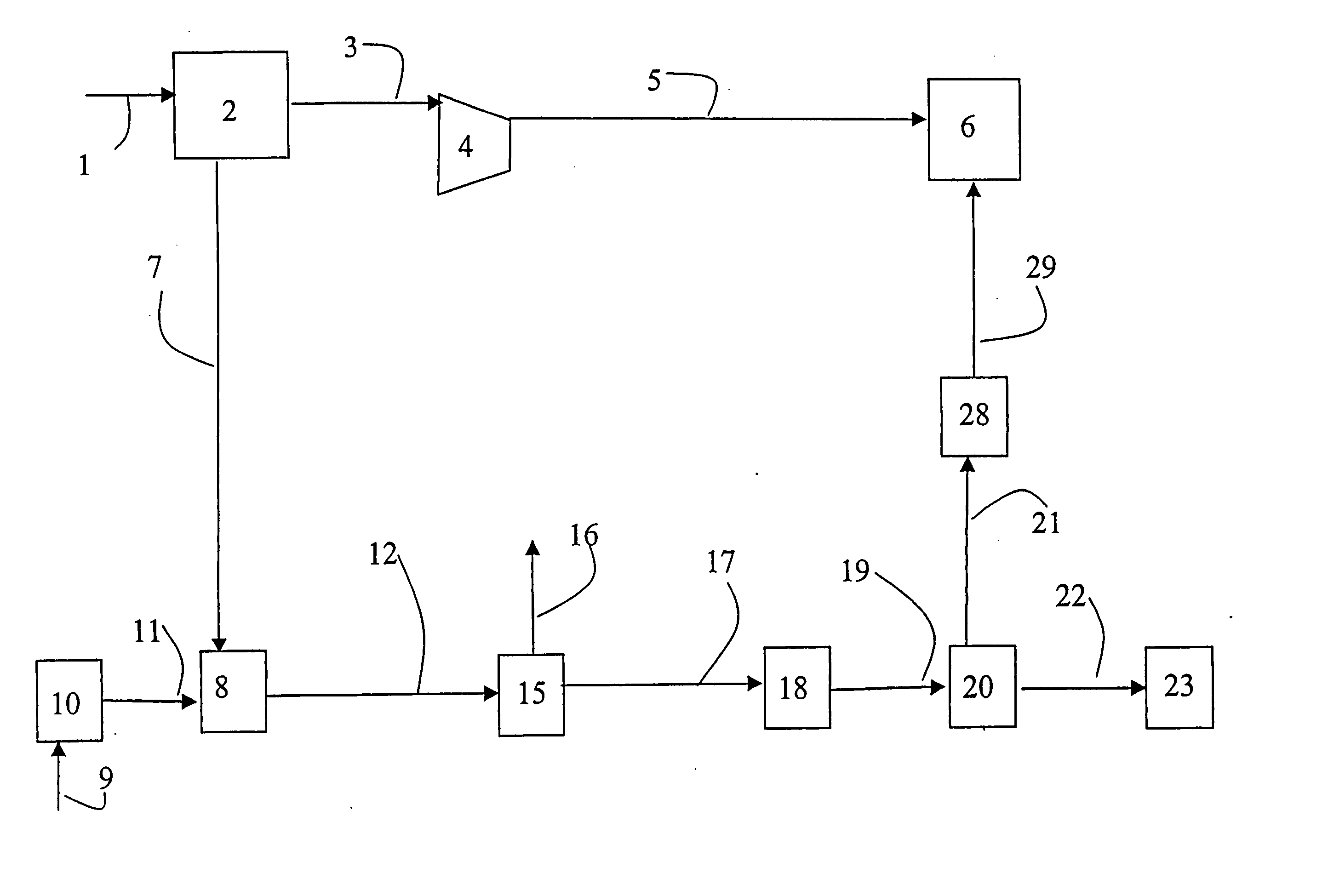

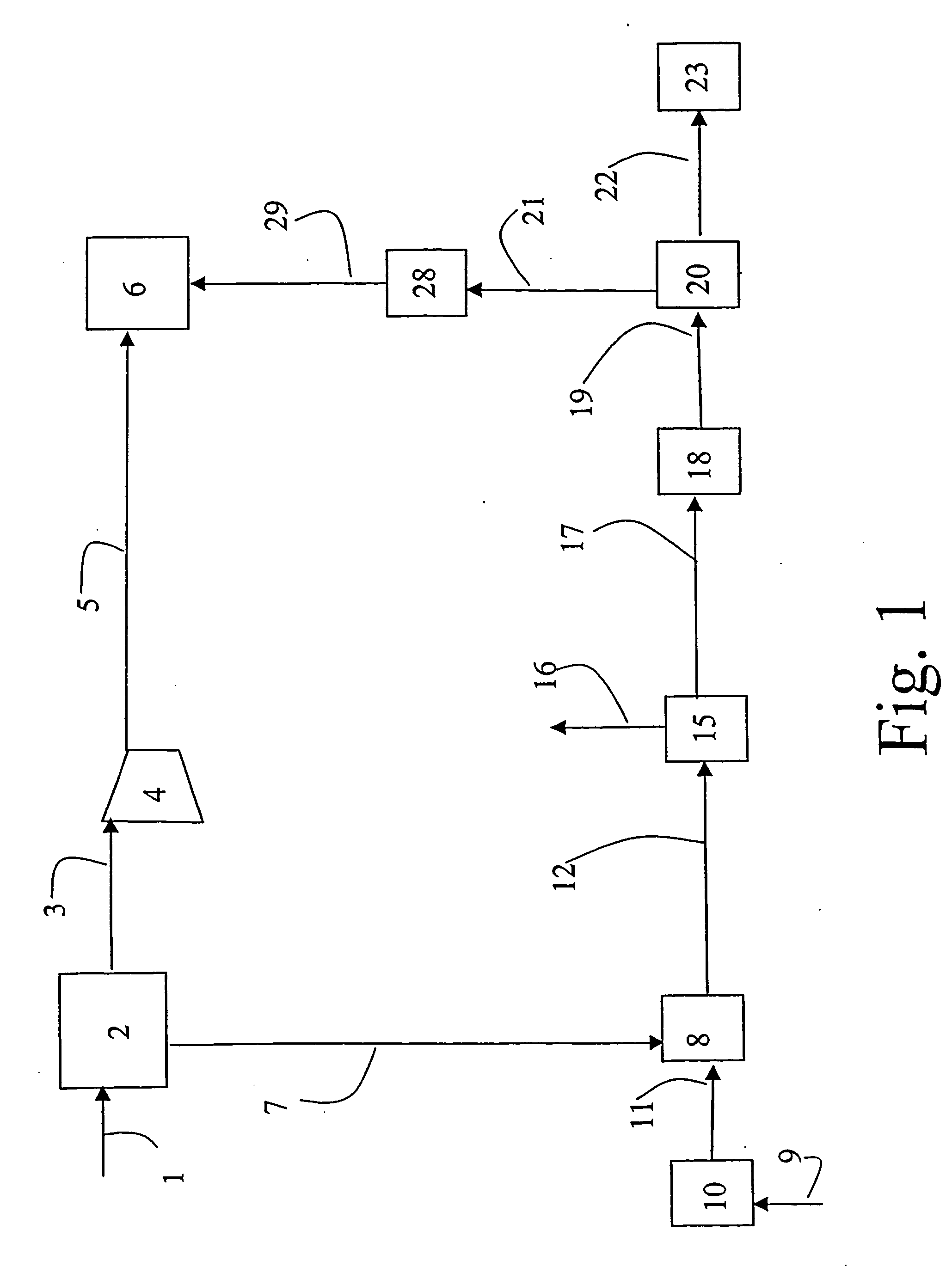

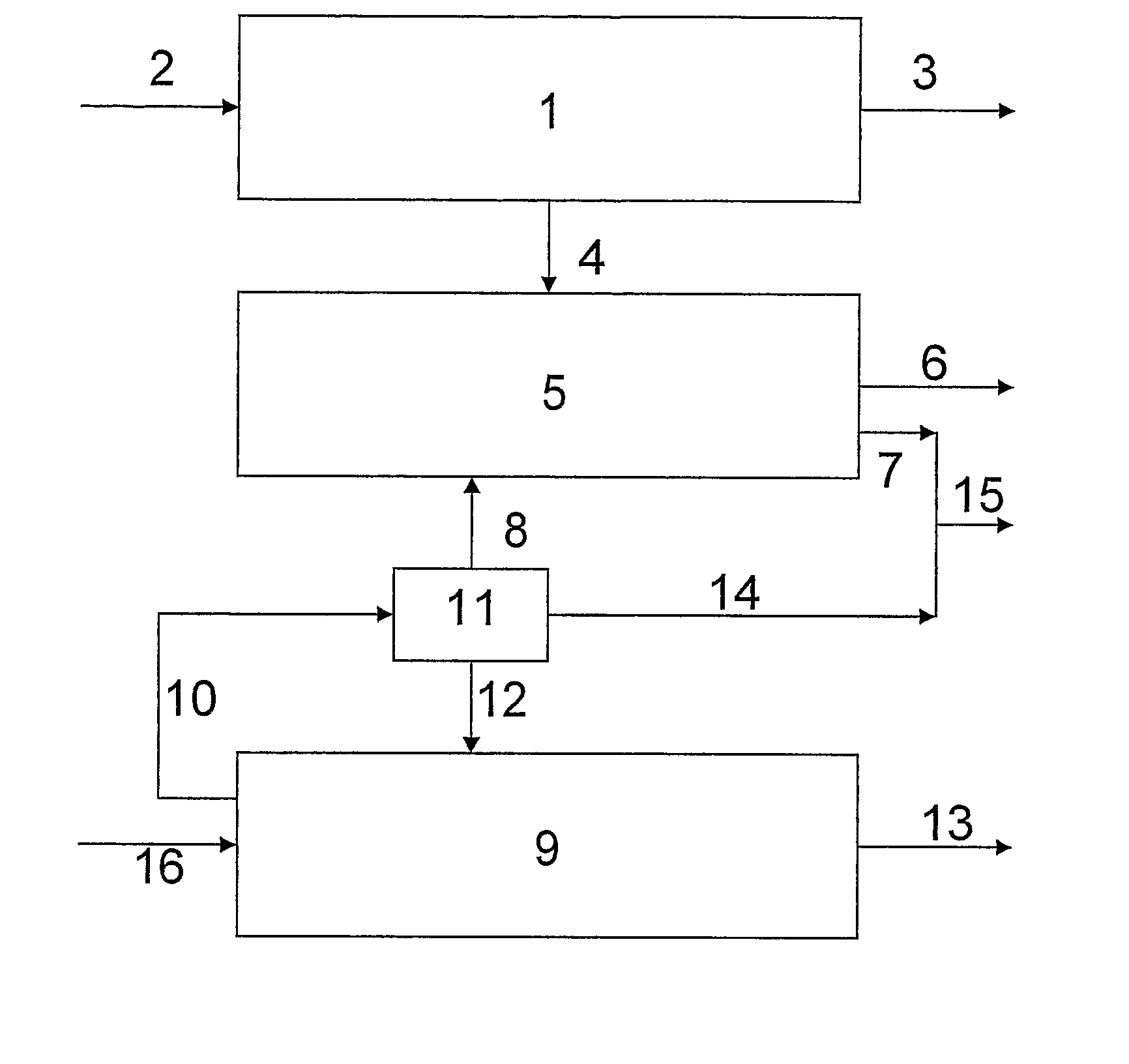

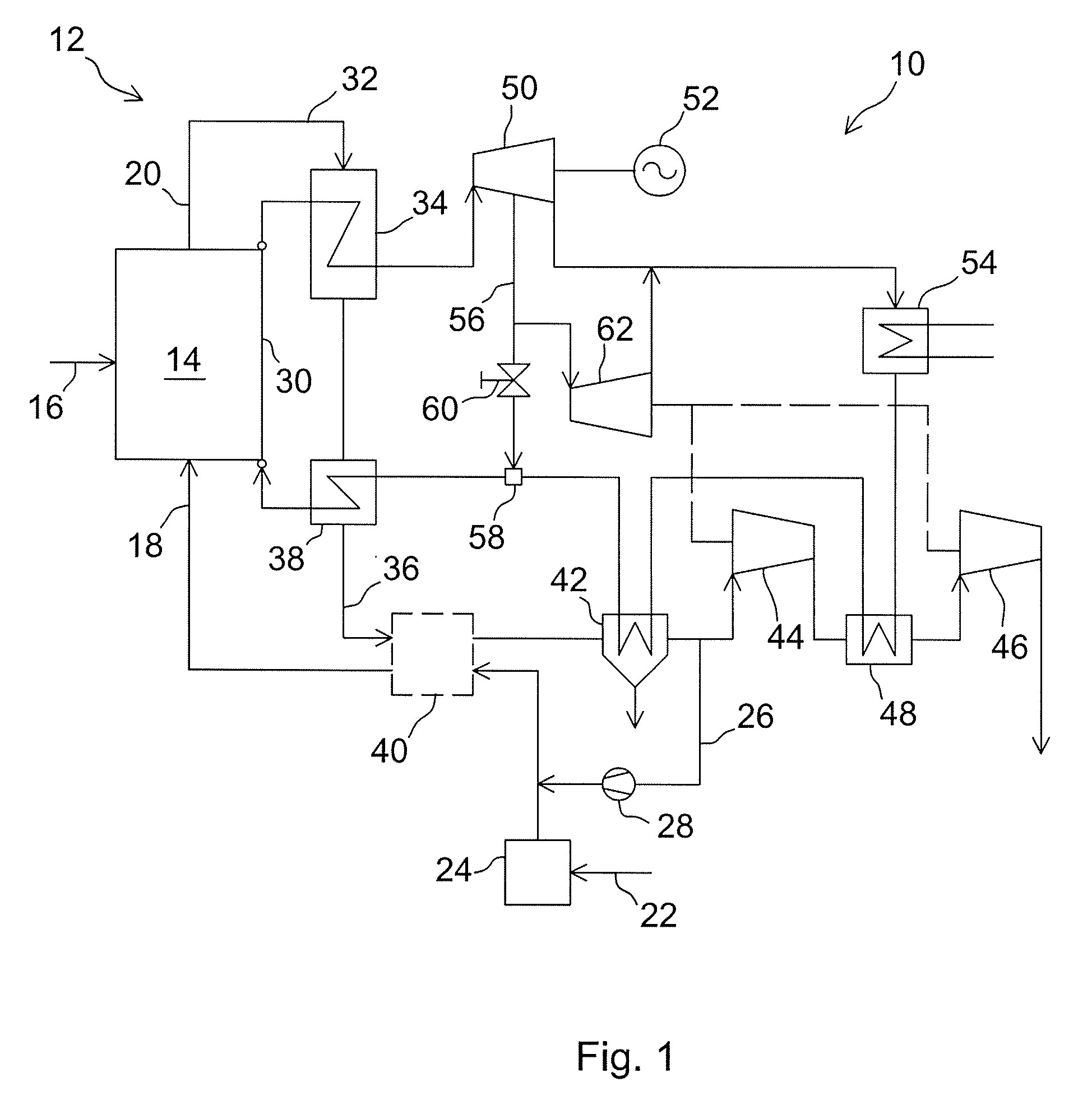

Method of and power plant for generating power by oxyfuel combustion

InactiveUS20080302107A1Costs lossesLosses of powerGas turbine plantsHeat recoveryCombustionPower station

A method of and a power plant for generating power by combusting carbonaceous fuel with substantially pure oxygen, and a method of modifying a process of generating power by combusting carbonaceous fuel from combusting the fuel with air to combusting the fuel with substantially pure oxygen. The methods include feeding substantially pure oxygen into a furnace for combusting fuel with the oxygen to produce exhaust gas including mainly carbon dioxide and water, recovering low-grade heat from the exhaust gas by using multiple exhaust gas coolers arranged in a downstream portion of the exhaust gas channel, wherein a first portion of the recovered low-grade heat is used for preheating feedwater; pressurizing a first portion of the exhaust gas in multiple exhaust gas compressors so as to produce liquid carbon dioxide, recycling a second portion of the exhaust gas to the furnace via an exhaust gas recycling channel, using a first portion of steam extracted from a steam turbine system to preheat feedwater, wherein the first portion of the recovered low-grade heat is more than 50% of the total amount of recovered low-grade heat, or larger than the first portion of the recovered low-grade heat in the air-fired process, allowing minimizing of the first portion of the extracted steam, and the expanding of a second portion of the extracted steam in at least one auxiliary steam turbine for driving at least one compressor or at least one pump of the power plant.

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

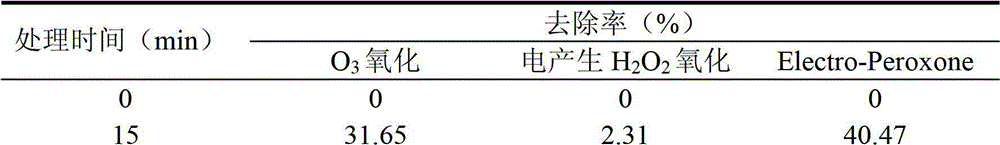

Wastewater treatment device and method for in-situ electric generation of H2O2 cooperating with O3 oxidation

InactiveCN102976451AReduce processing costsImprove securityWater treatment compoundsWater/sewage treatment by electrochemical methodsOzone generatorPersistent organic pollutant

The invention discloses a wastewater treatment device and method for in-situ electric generation of H2O2 cooperating with O3 oxidation. The device comprises a reaction container, wherein a magnetic stirrer is arranged at the bottom of the reaction container; a stirring magneton is arranged in the reaction container; a stainless steel microporous aeration head, an inert anode and a gas dispersing cathode are arranged in the reaction container; the inert anode and the gas dispersing cathode are vertically opposite to each other; the reaction container is also provided with a pipeline for introducing O3; and the inert anode and the gas dispersing cathode adopt a DC (direct current) power supply. The method comprises the following steps of: firstly inserting the inert anode and the gas dispersing cathode into the treated wastewater solution, and connecting with the DC power supply; then connecting pure oxygen with an ozone generator by a polytetrafluoroethylene tube; connecting the stainless steel microporous aeration head at a gas outlet of the ozone generator, and inserting into the bottom of the wastewater solution; and finally, switching on the DC power supply to treat the wastewater solution. Through the invention, H2O2 is continuously and efficiently generated and can quickly react with O3 to generate.OH so as to efficiently remove persistent organic pollutants in the water body.

Owner:TSINGHUA UNIV

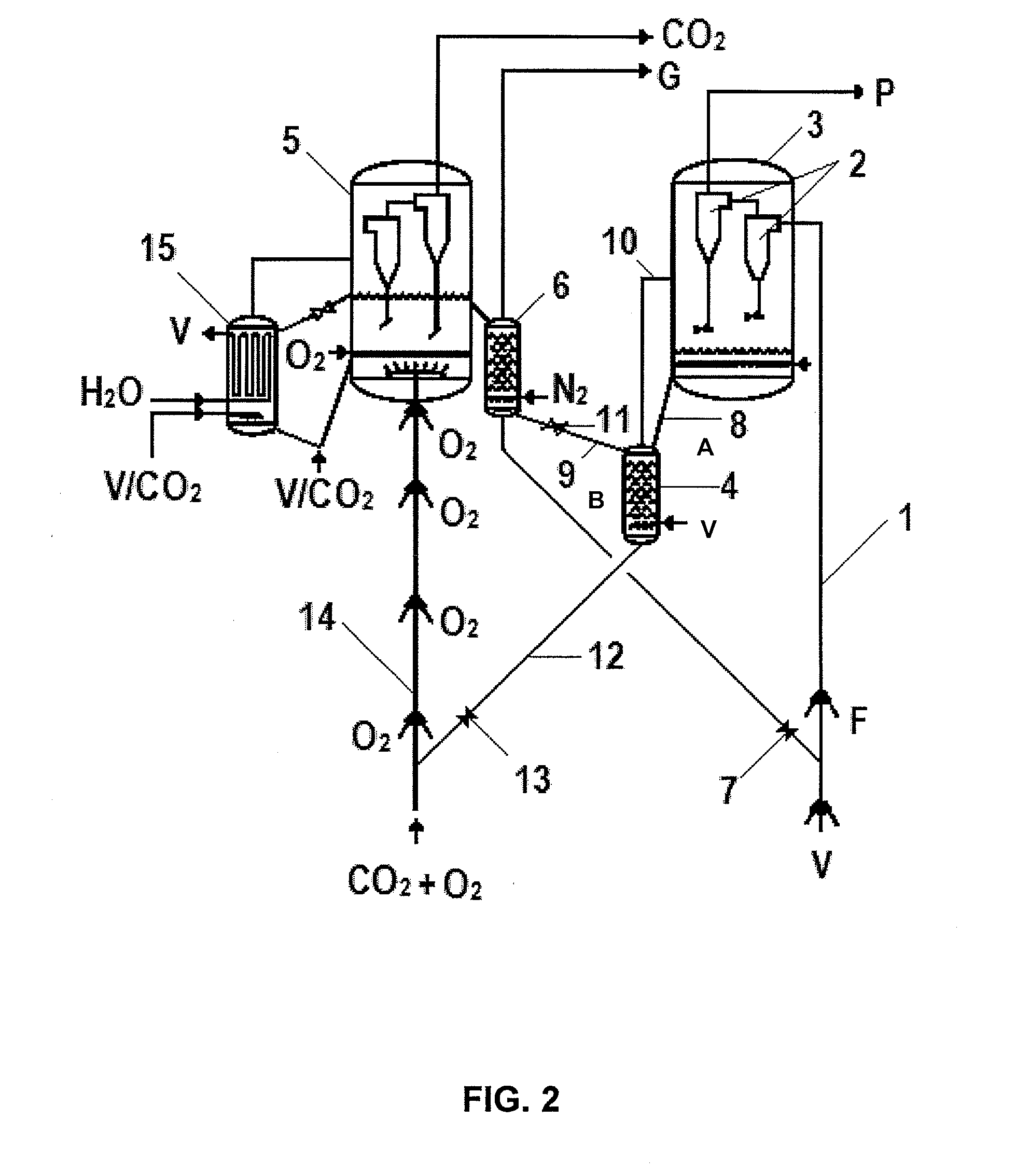

Fluid catalytic cracking process with reduced carbon dioxide emission

InactiveUS20110155642A1Simple processAvoid emissionsCatalytic crackingEthylene productionNitrogenNitrogen gas

This invention concerns a fluid catalytic cracking (FCC) process with reduced carbon monoxide emission which modifies the regeneration phase of the spent catalyst by using pure oxygen without the need for dilution when burning coke adhering to the catalyst. In addition, this invention improves the reconditioning stage of the catalyst, incorporating a reconditioner supplementary to a conventional reconditioner which employs nitrogen as a carrier gas in the reconditioning of the already regenerated catalyst.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

High-density fish culturing method

InactiveCN104872005ASmall amount of exchangeReduce consumptionClimate change adaptationPisciculture and aquariaHigh densityHigh energy

The invention relates to a high-density fish culturing method. The high-density fish culturing method includes the steps of 1), throwing fish fries in a fishpond; 2), sealing the fishpond; 3), regulating water flow; 4), feeding feed; 5), draining water and sewage; 6), fishing. According to the step 2) of fishpond sealing, sealing cover seats are arranged on the inner wall of the fishpond, a sealing cover of an arched structure is arranged on the sealing cover seats, a vent valve is arranged at the top of the sealing cover, and an oxygenation pipe is arranged in the fishpond; after the vent valve is opened, water is injected into the fishpond until the water level exceeds the sealing cover seats, and then the vent valve is closed; oxygen is fed into the fishpond, and a sealed pure-oxygen space is formed between the water surface and the position below the arched sealing cover by undissolved oxygen. The high-density fish culturing method solves the problems of difficulty in further improvement on culturing density, oxygenation equipment complexity, high energy consumption, low pure oxygen utilization ratio and inconvenience in culturing and operation in existing industrial fish culturing.

Owner:黄山四洋渔业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com