Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

530 results about "Municipal solid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Municipal solid waste (MSW), commonly known as trash or garbage in the United States and rubbish in Britain, is a waste type consisting of everyday items that are discarded by the public. "Garbage" can also refer specifically to food waste, as in a garbage disposal; the two are sometimes collected separately. In the European Union, the semantic definition is 'mixed municipal waste,' given waste code 20 03 01 in the European Waste Catalog. Although the waste may originate from a number of sources that has nothing to do with a municipality, the traditional role of municipalities in collecting and managing these kinds of waste have produced the particular etymology 'municipal.'

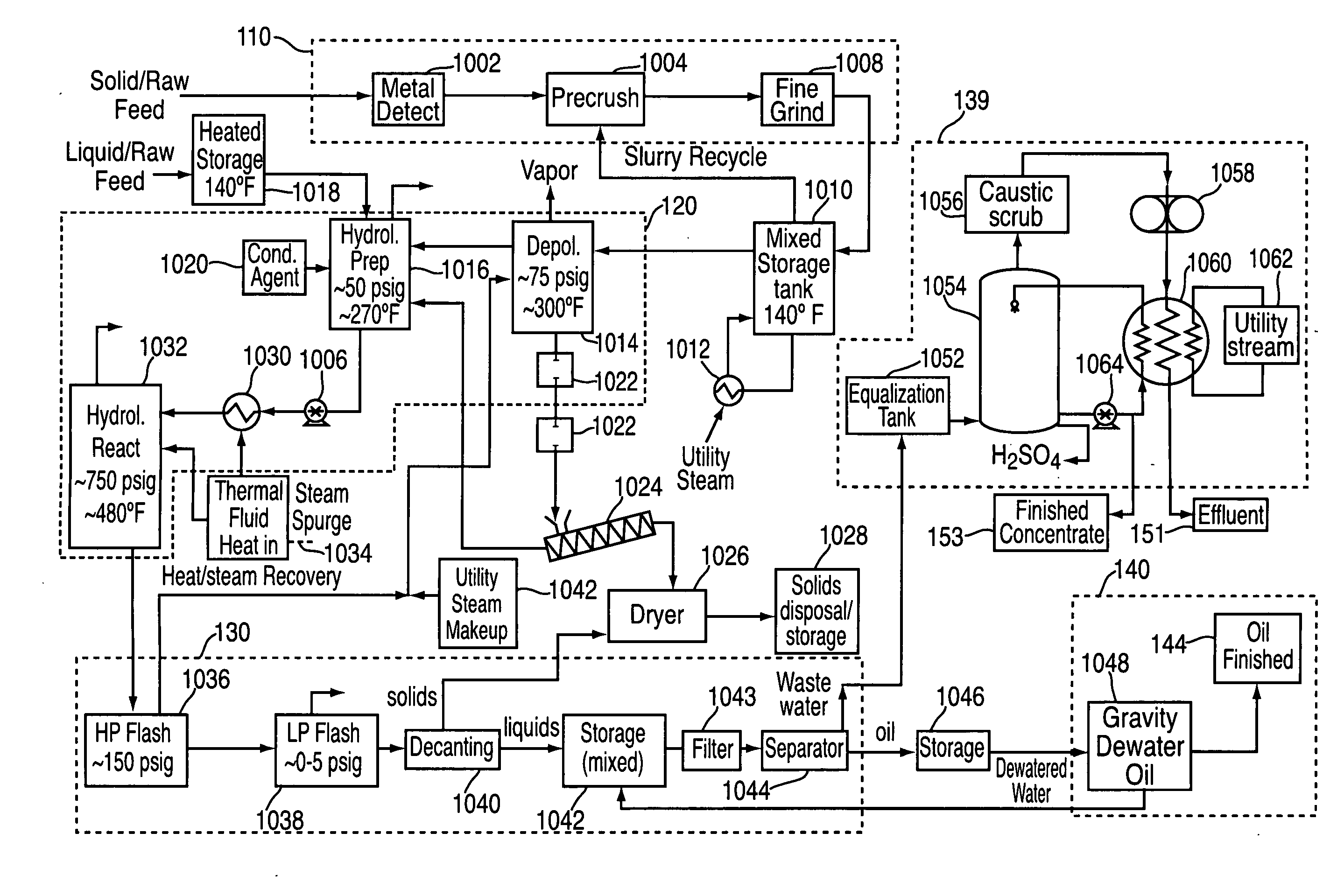

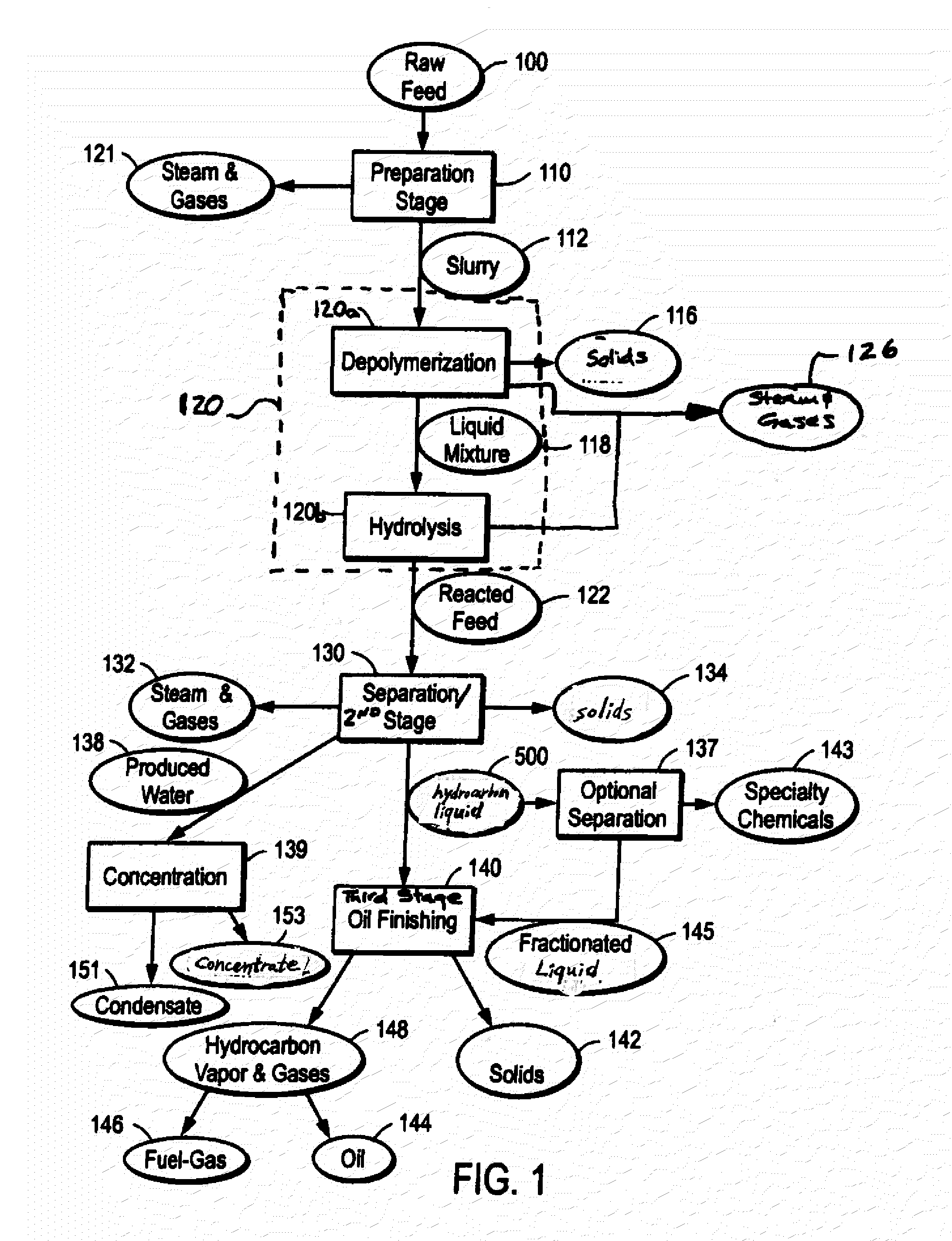

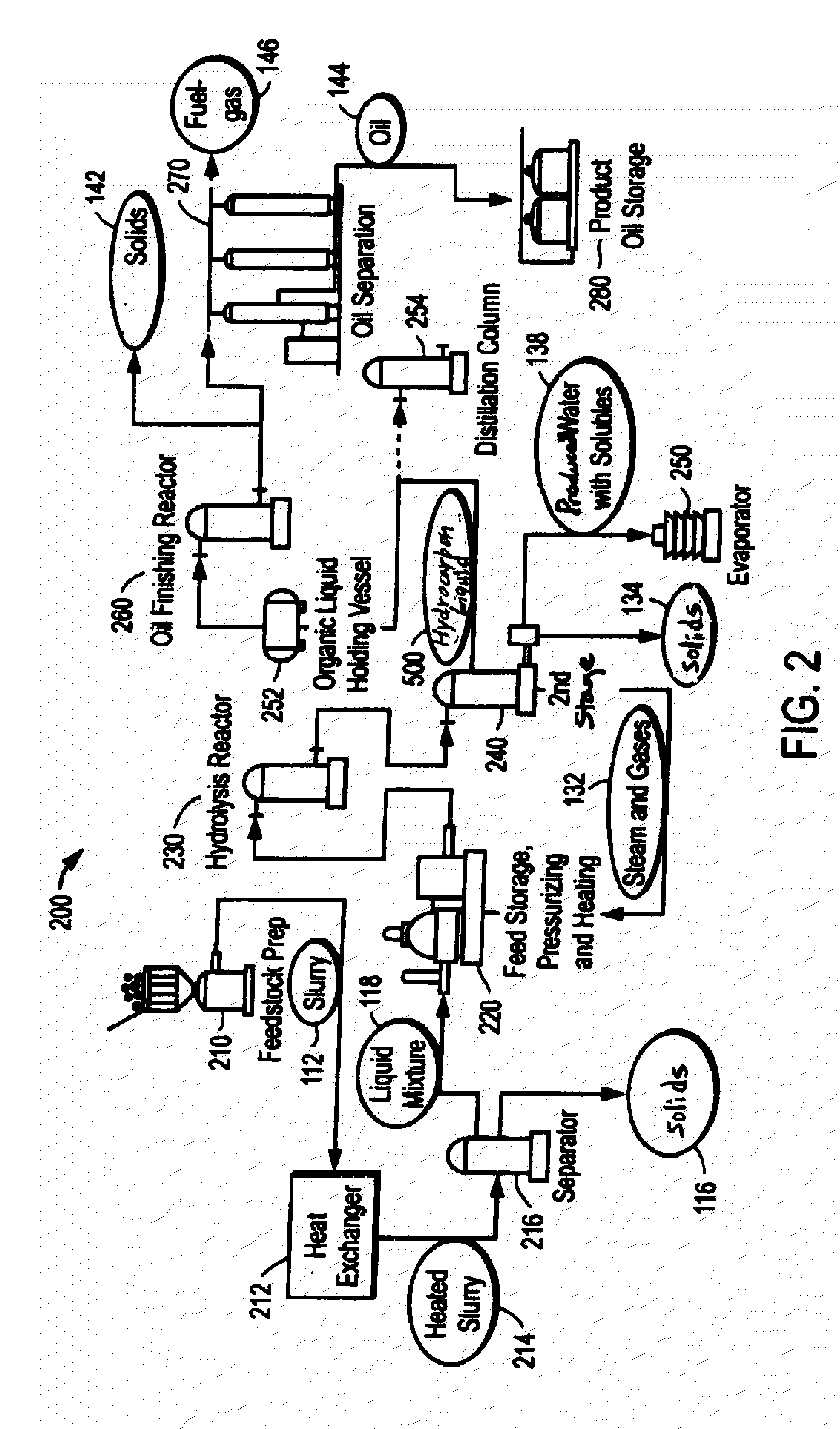

Methods and apparatus for converting waste materials into fuels and other useful products

ActiveUS20090062581A1Effectively handle problematic wasteFree of contaminantsTransportation and packagingSolid waste disposalSpeciality chemicalsBiological waste

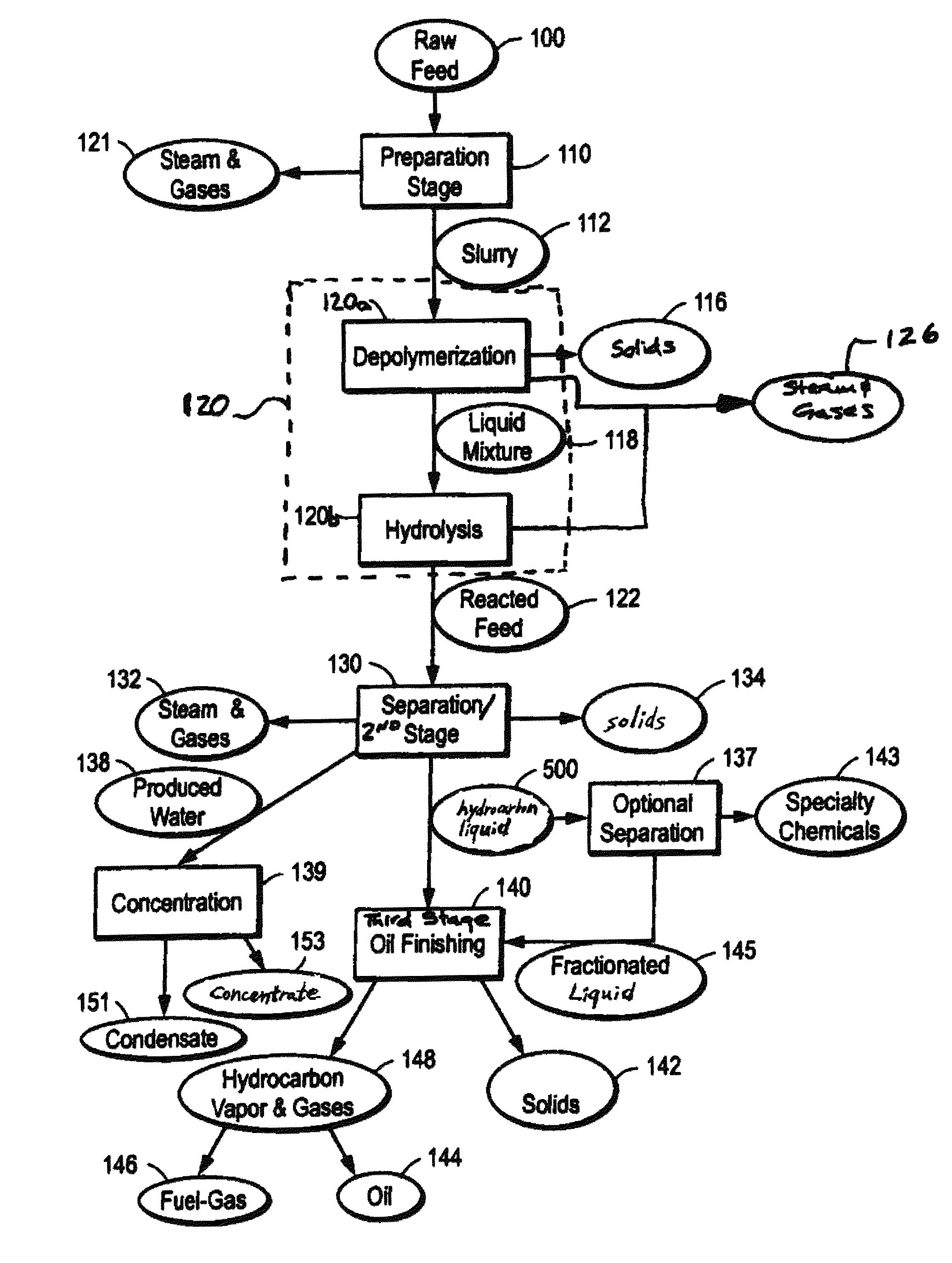

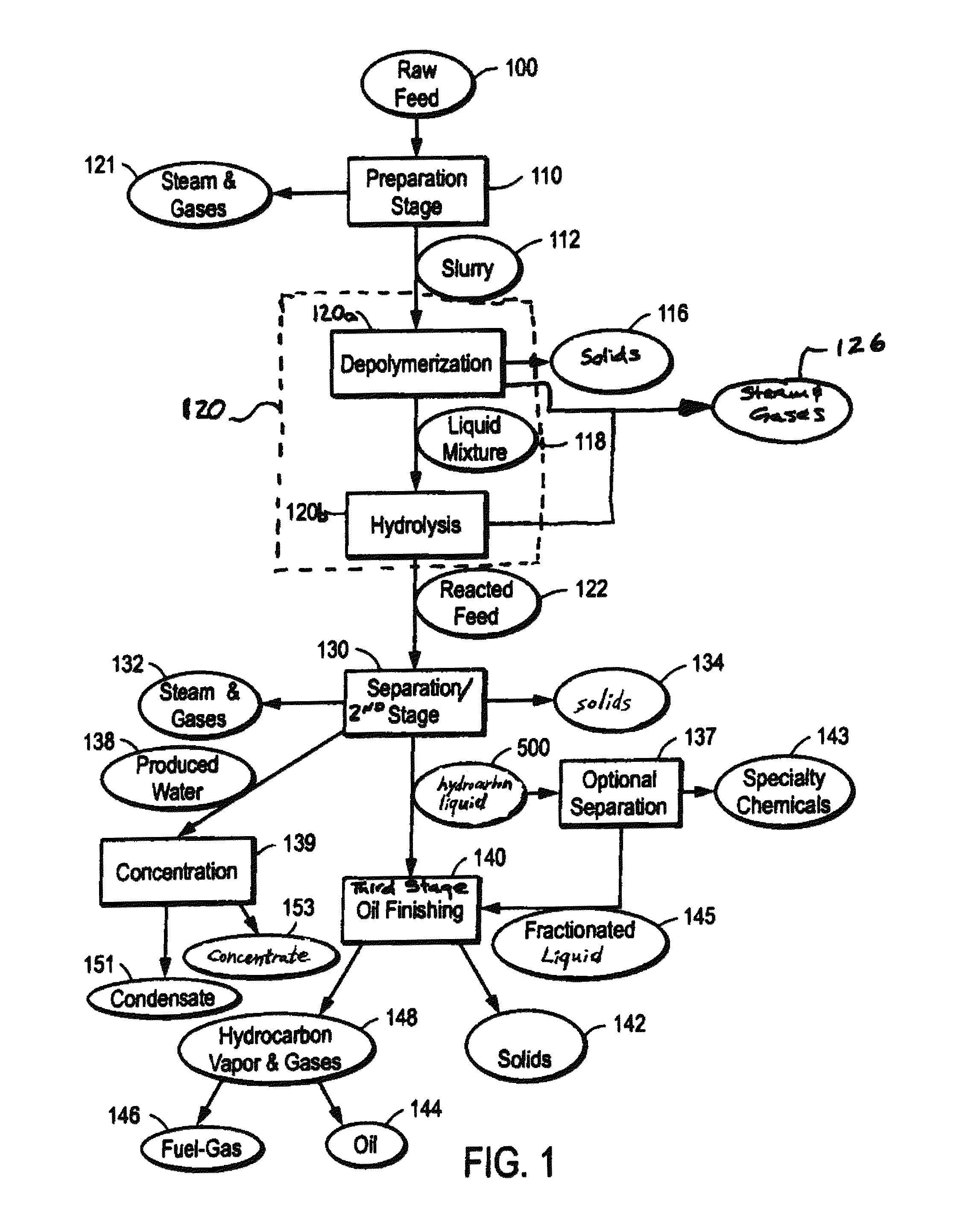

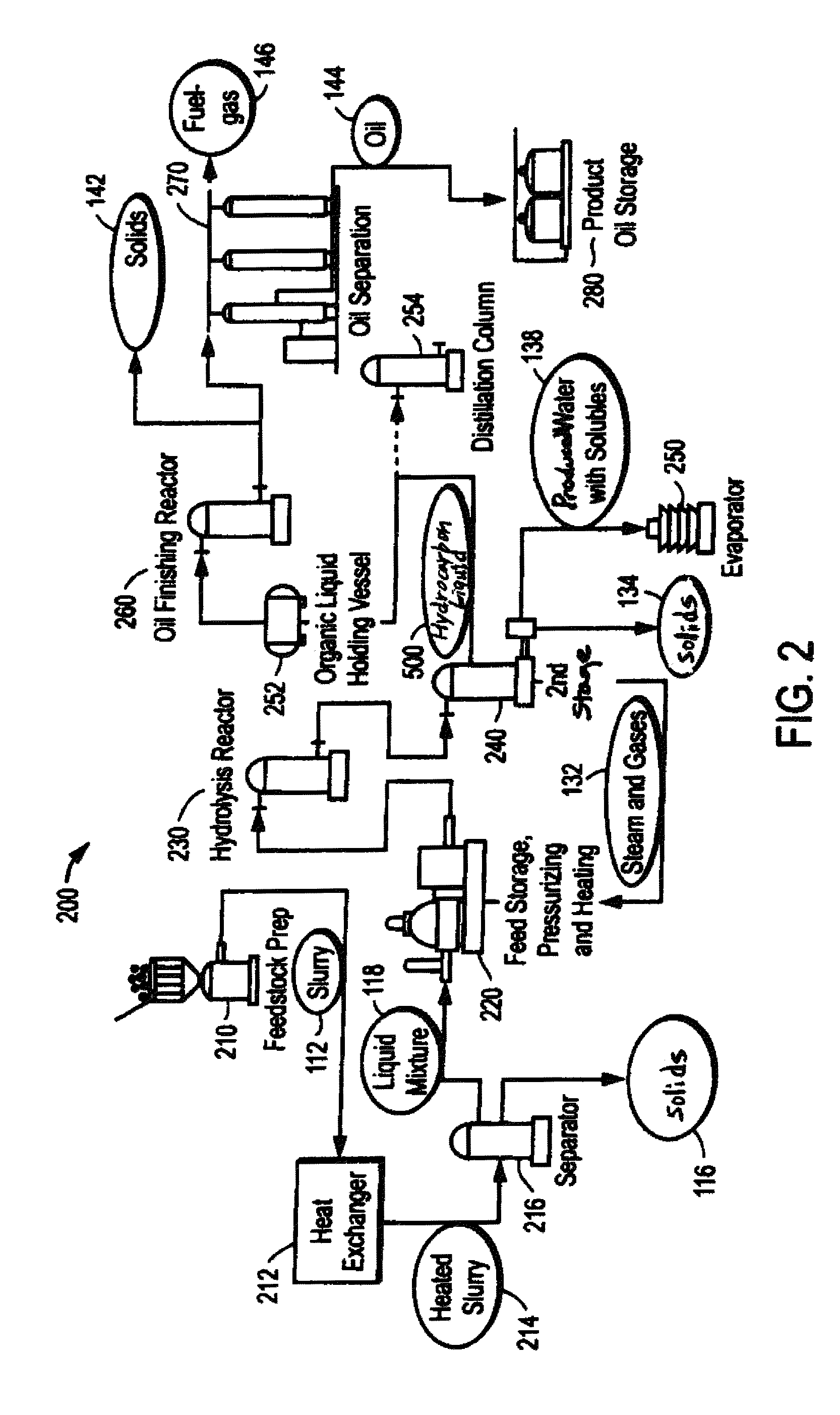

Conversion of waste and other organic feedstock into sustainable energy, feed, fertilizer, and other useful products of reliable purities is accomplished using water, heat, and pressure. More specifically, the invention provides methods and apparatus that handle mixed streams of various feedstocks, e.g. agricultural waste, biological waste, municipal solid waste, municipal sewage sludge, and shredder residue, to yield gas, oil, specialty chemicals, and carbon solids that can be used as is or are further processed. Useful products can be diverted at various points of the process or internalized to enhance the efficiency of the system.

Owner:SYNPET TEKNOLOJI GELISTIRME

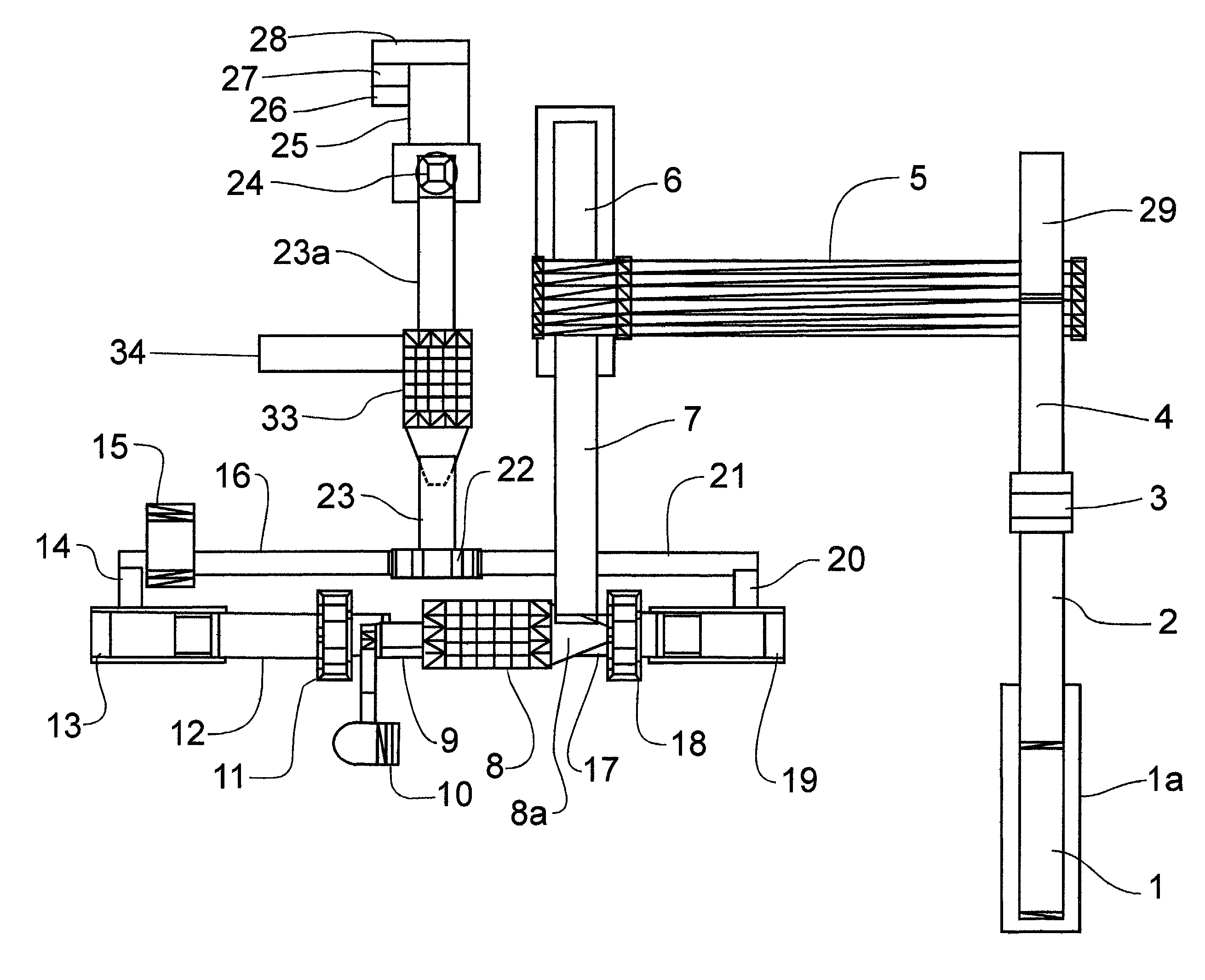

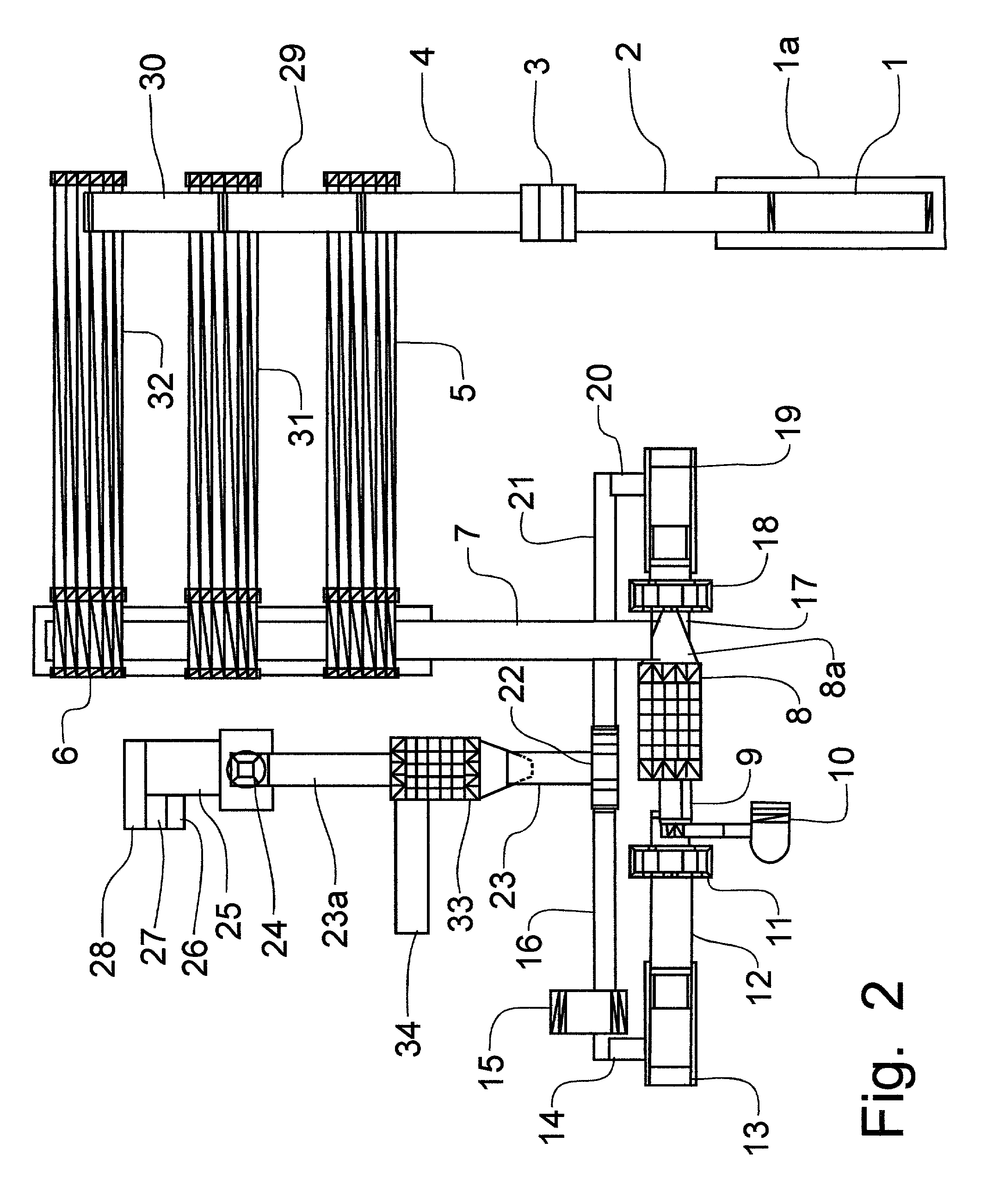

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

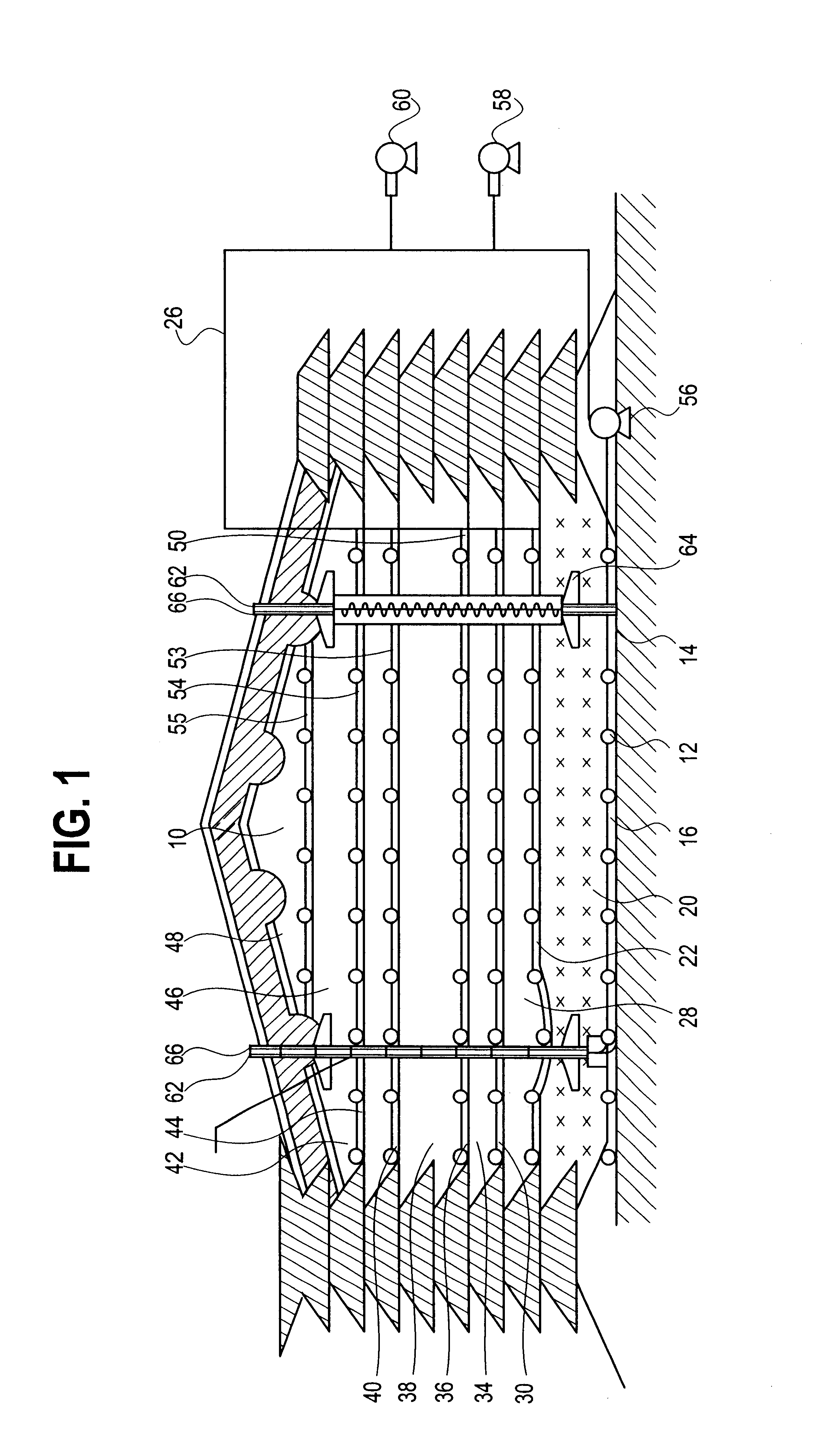

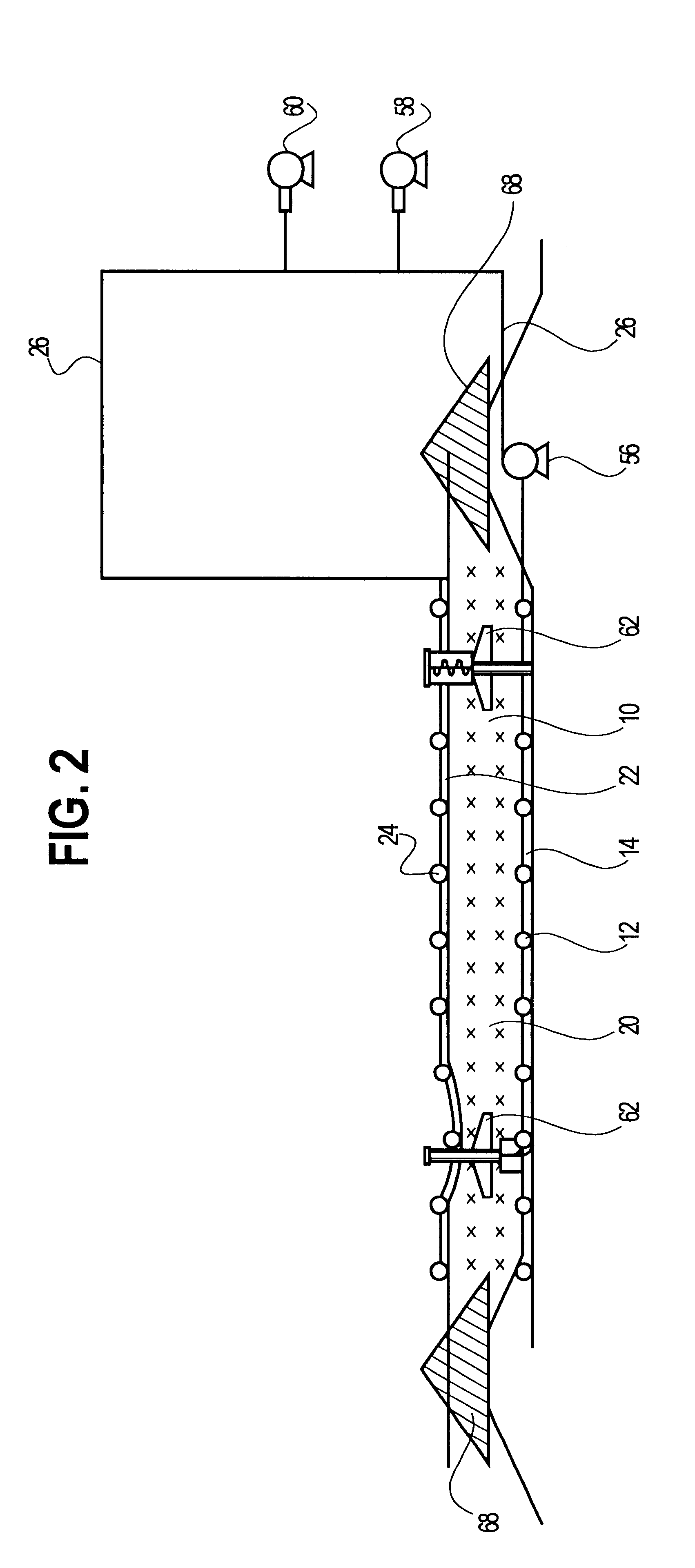

Sequential aerobic/anaerobic solid waste landfill operation

InactiveUS6283676B1Promote degradationQuality improvementSolid waste disposalContaminated soil reclamationOxygenMunicipal solid waste

Landfills including multiple lifts having horizontal piping layers and methods for their use to accelerate anaerobic and / or aerobic degradation of municipal solid waste to increase landfill capacity.

Owner:WM INTPROP HLDG L L C

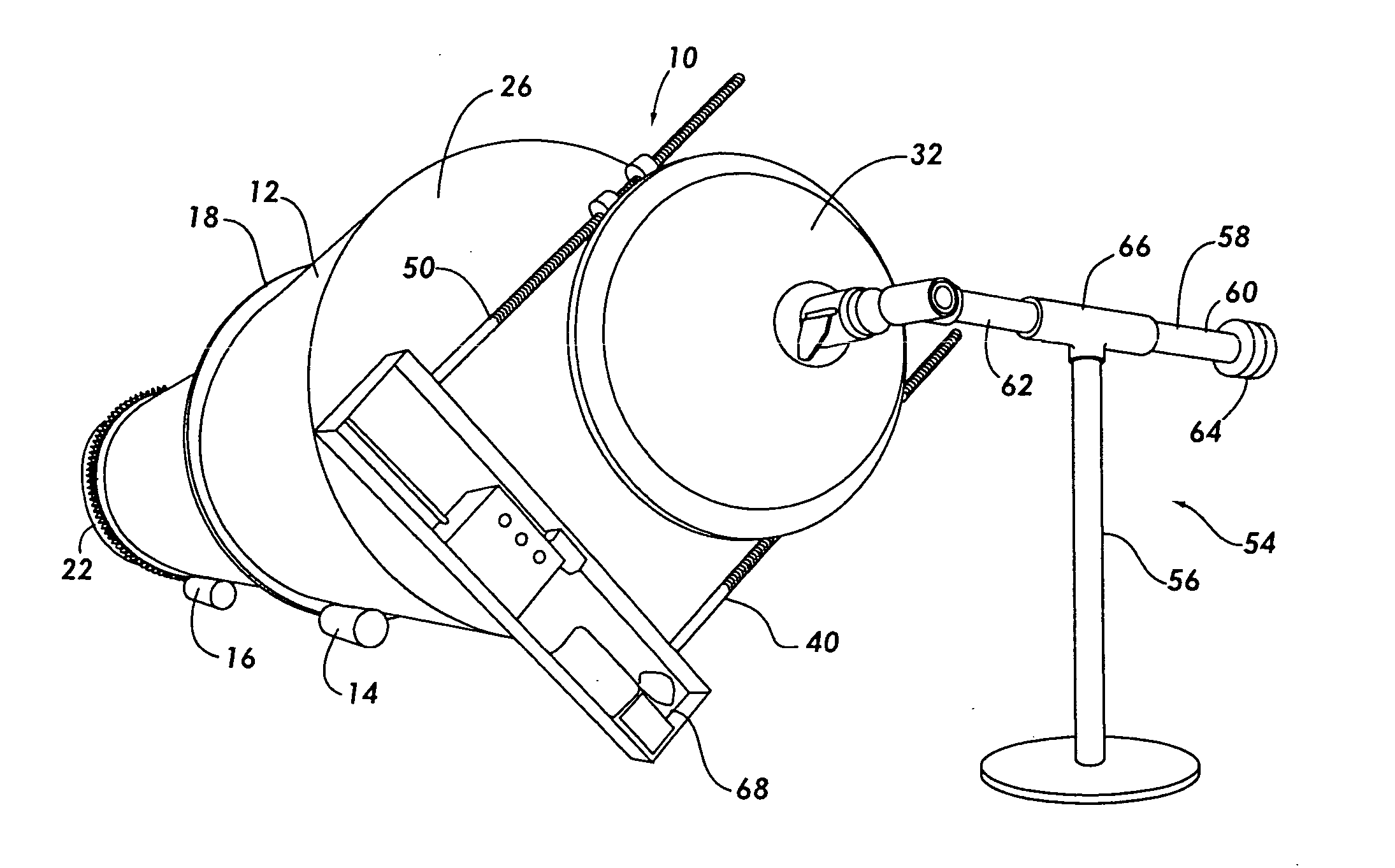

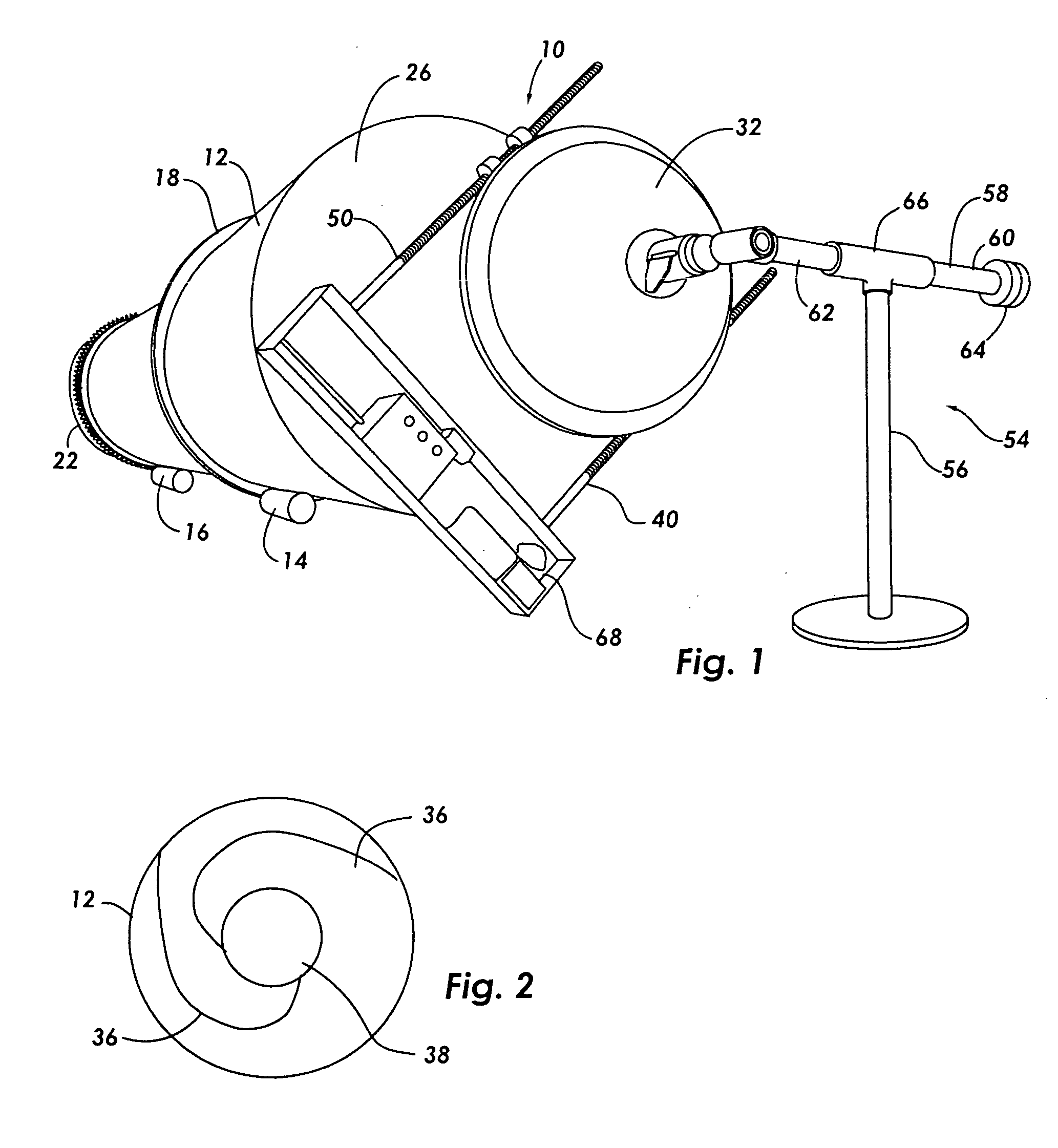

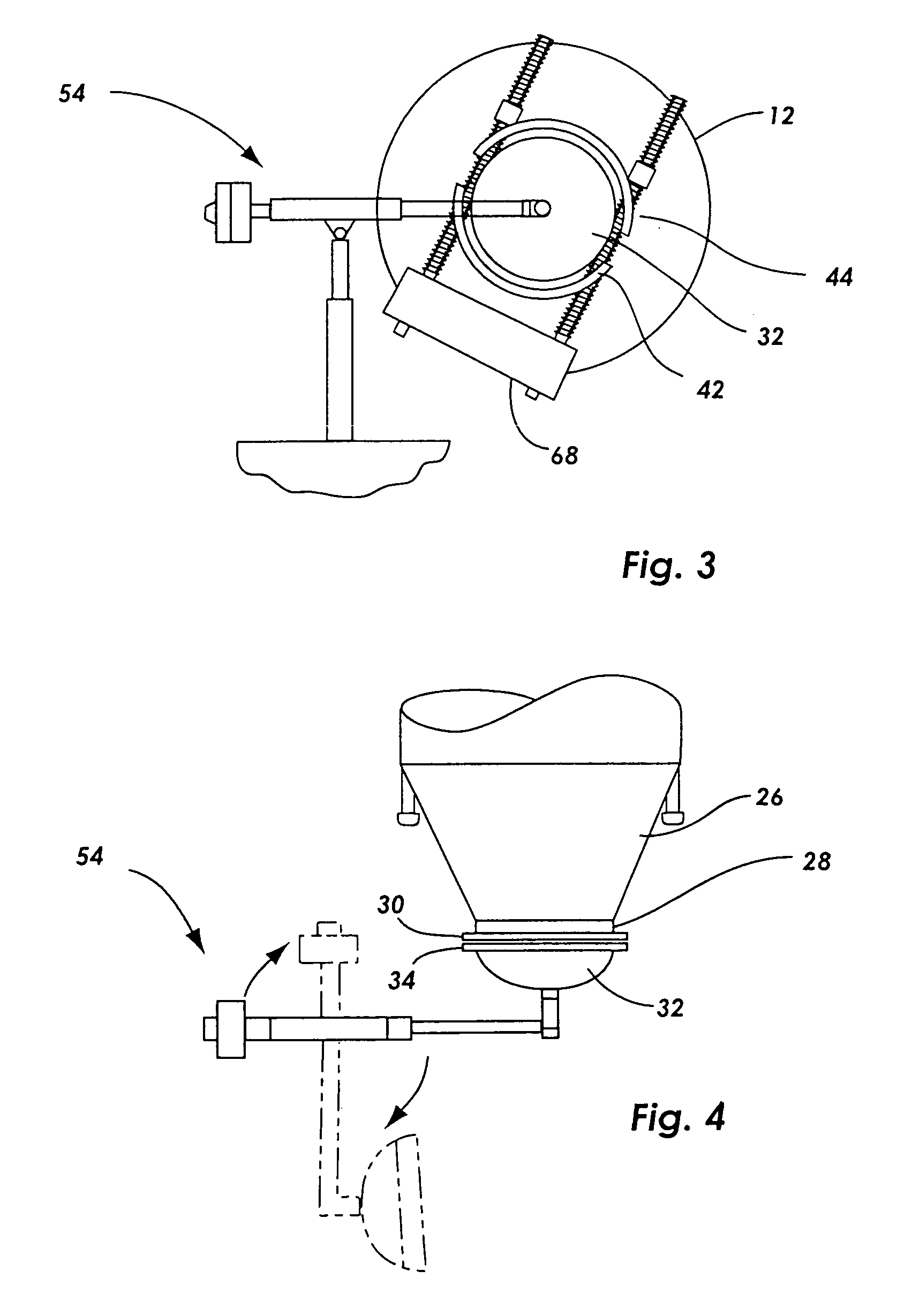

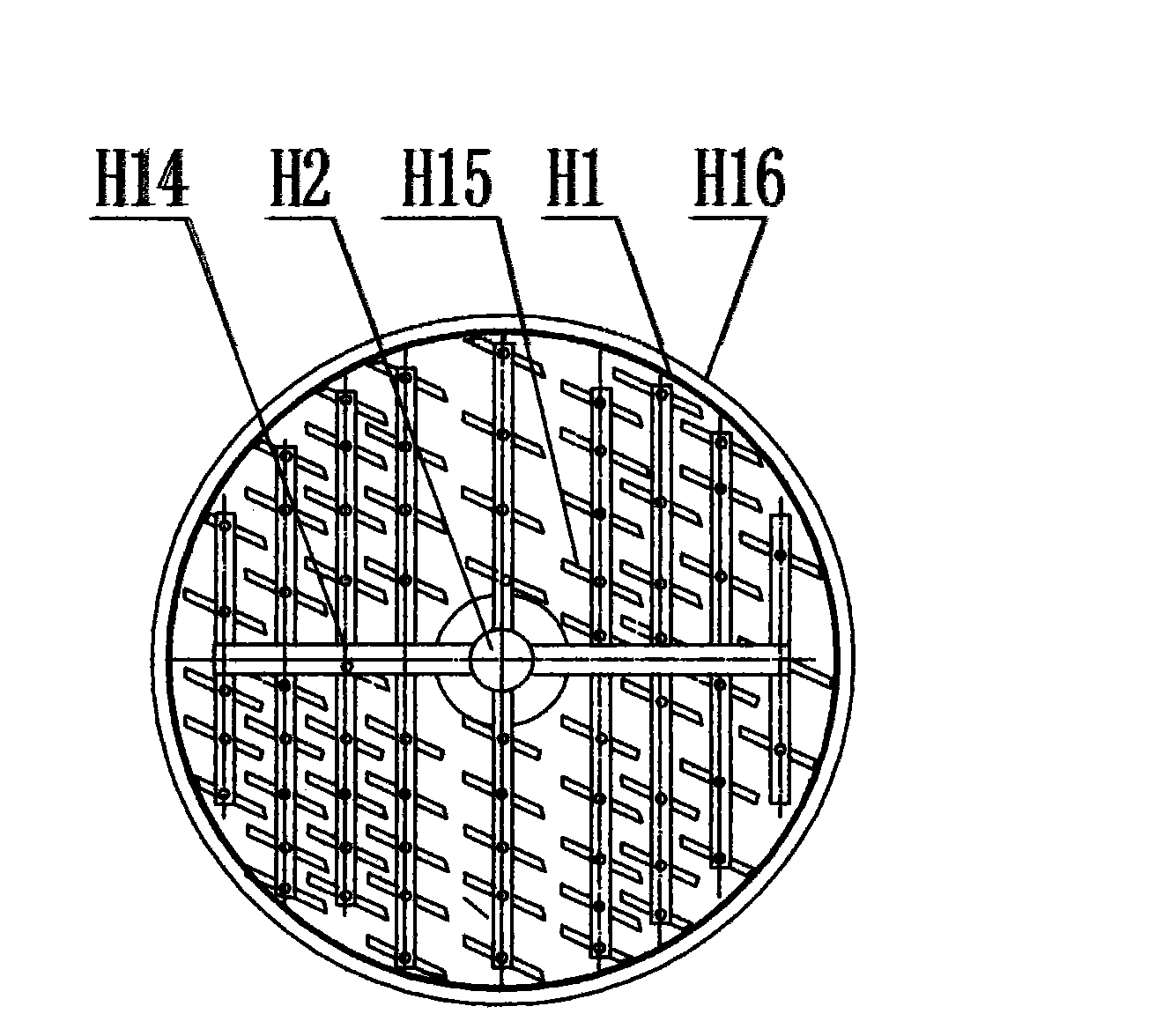

MSW processing vessel

InactiveUS20050166812A1Improve automationCremation furnacesIncinerator apparatusMunicipal solid waste

The present invention is an apparatus and a process for treating municipal solid waste (MSW). The apparatus includes a reaction vessel with helically arranged internal flights, a self-aligning door closure, and a swing-away door assembly. It also includes a novel structure for shredding MSW attached to the edges of the flights. This structure is number of projecting tooth like points.

Owner:NOLL ANTHONY P

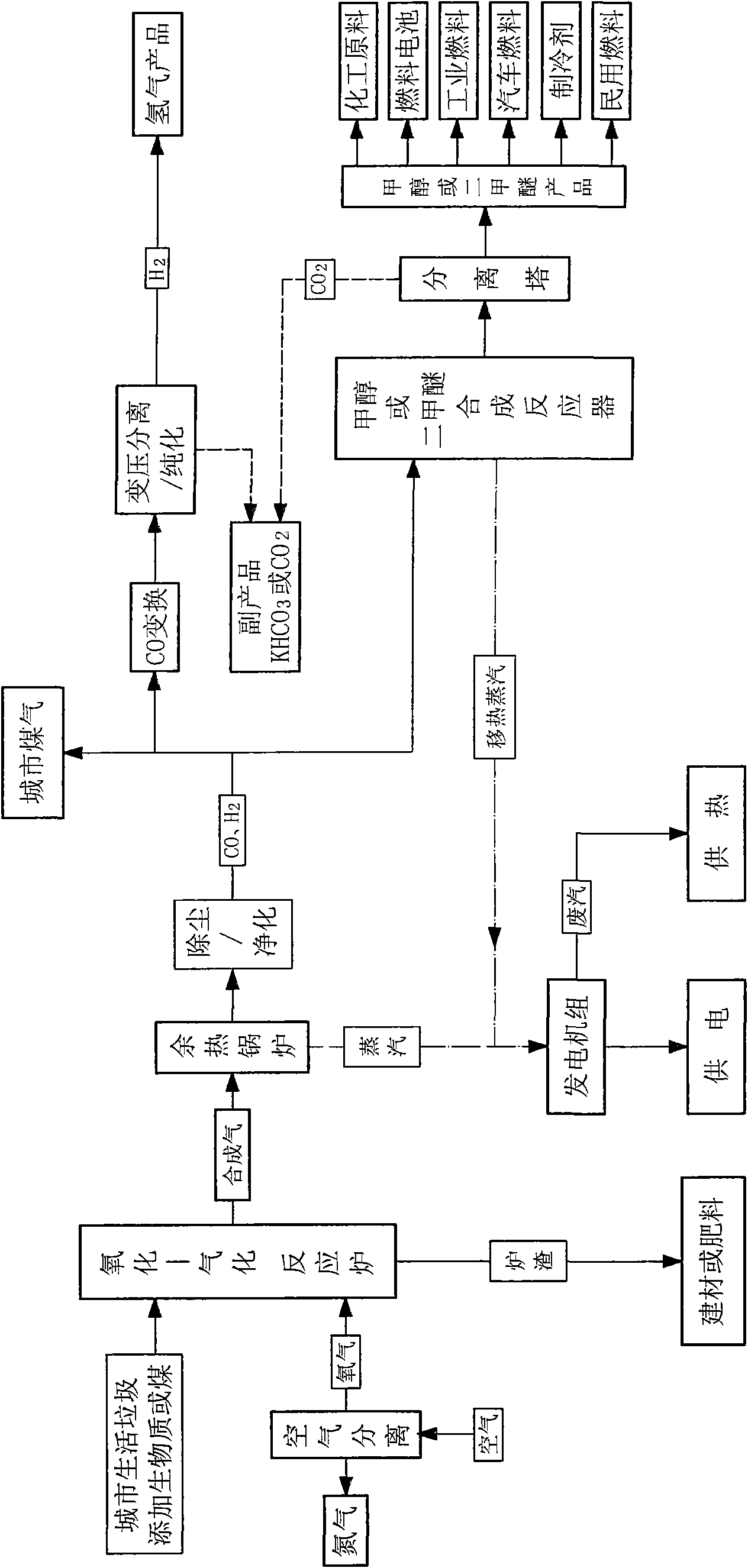

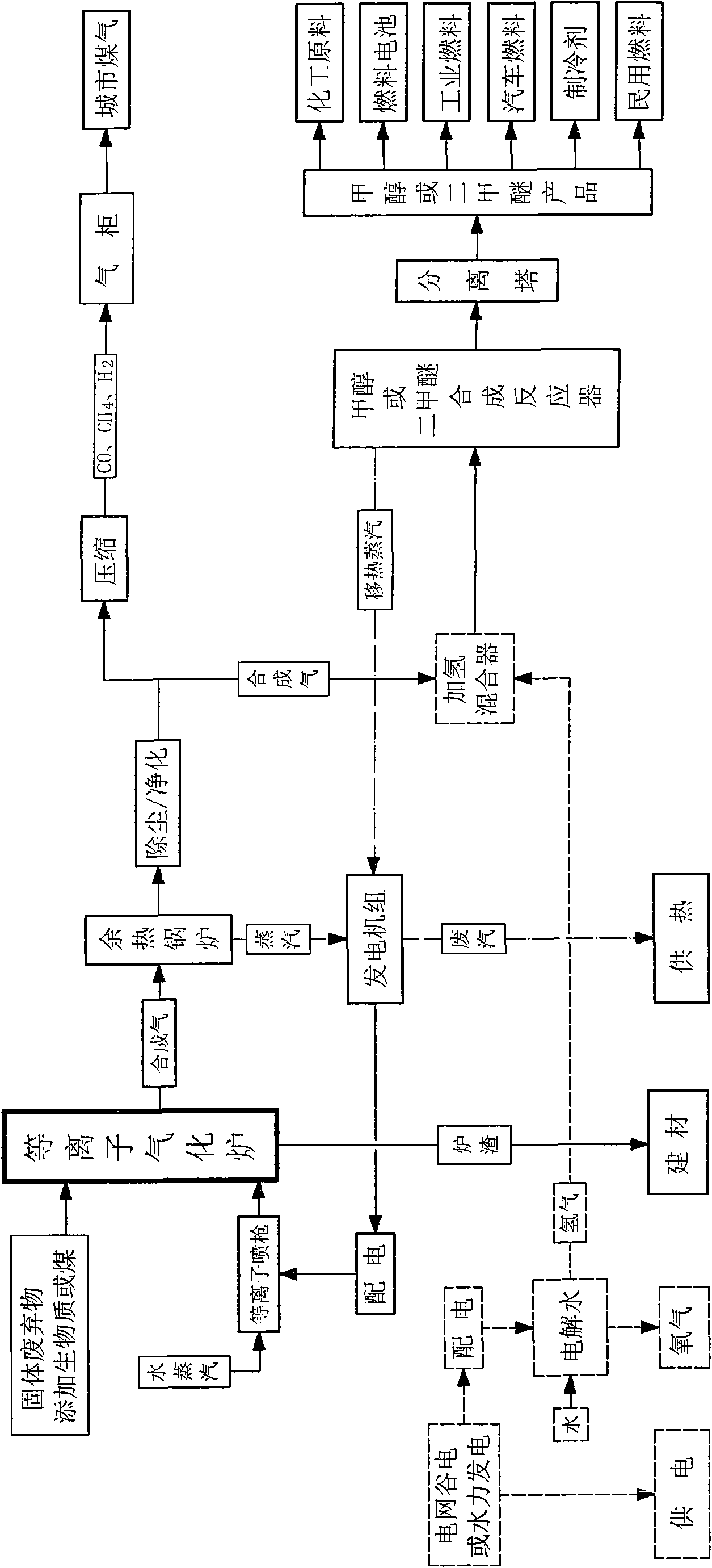

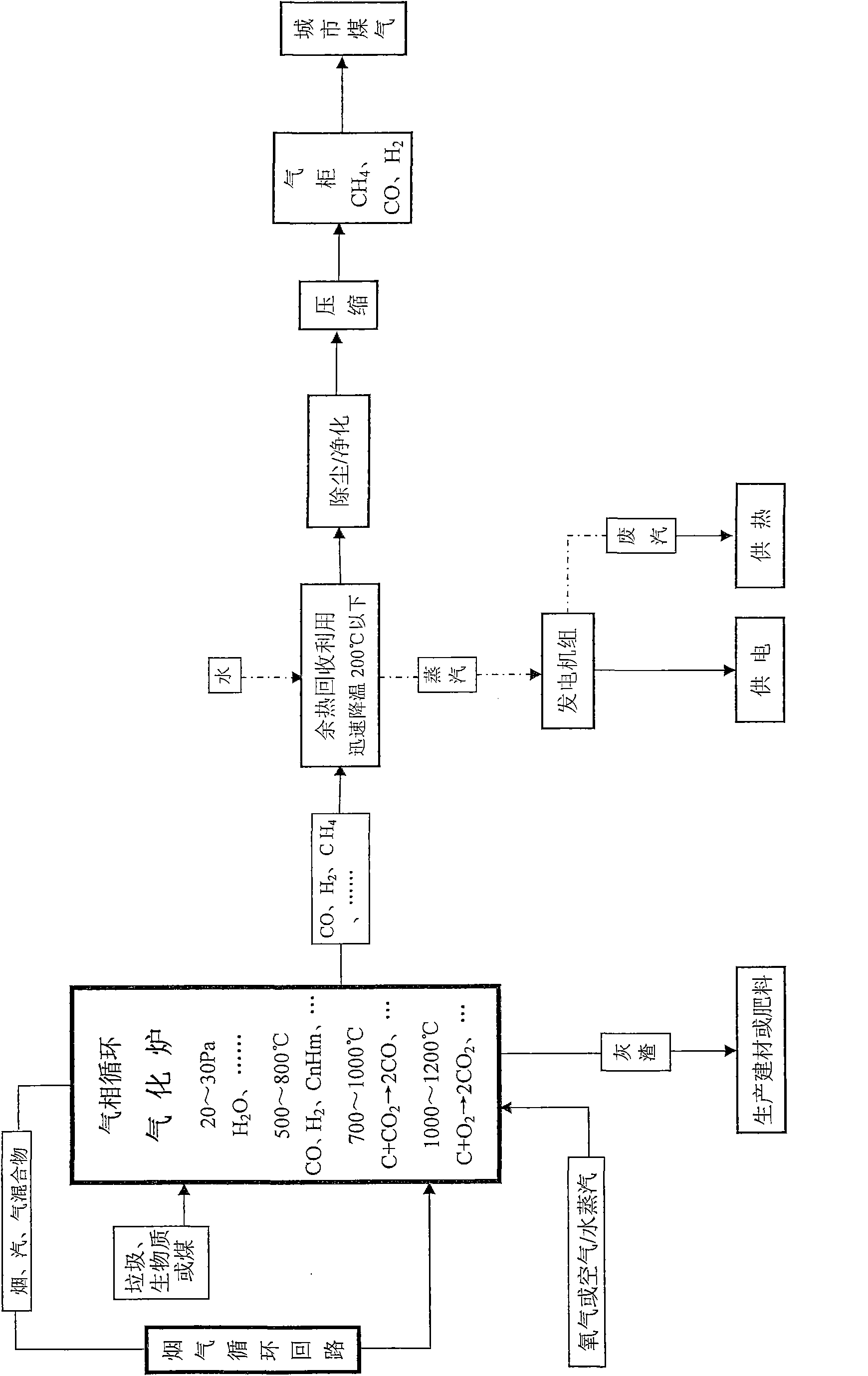

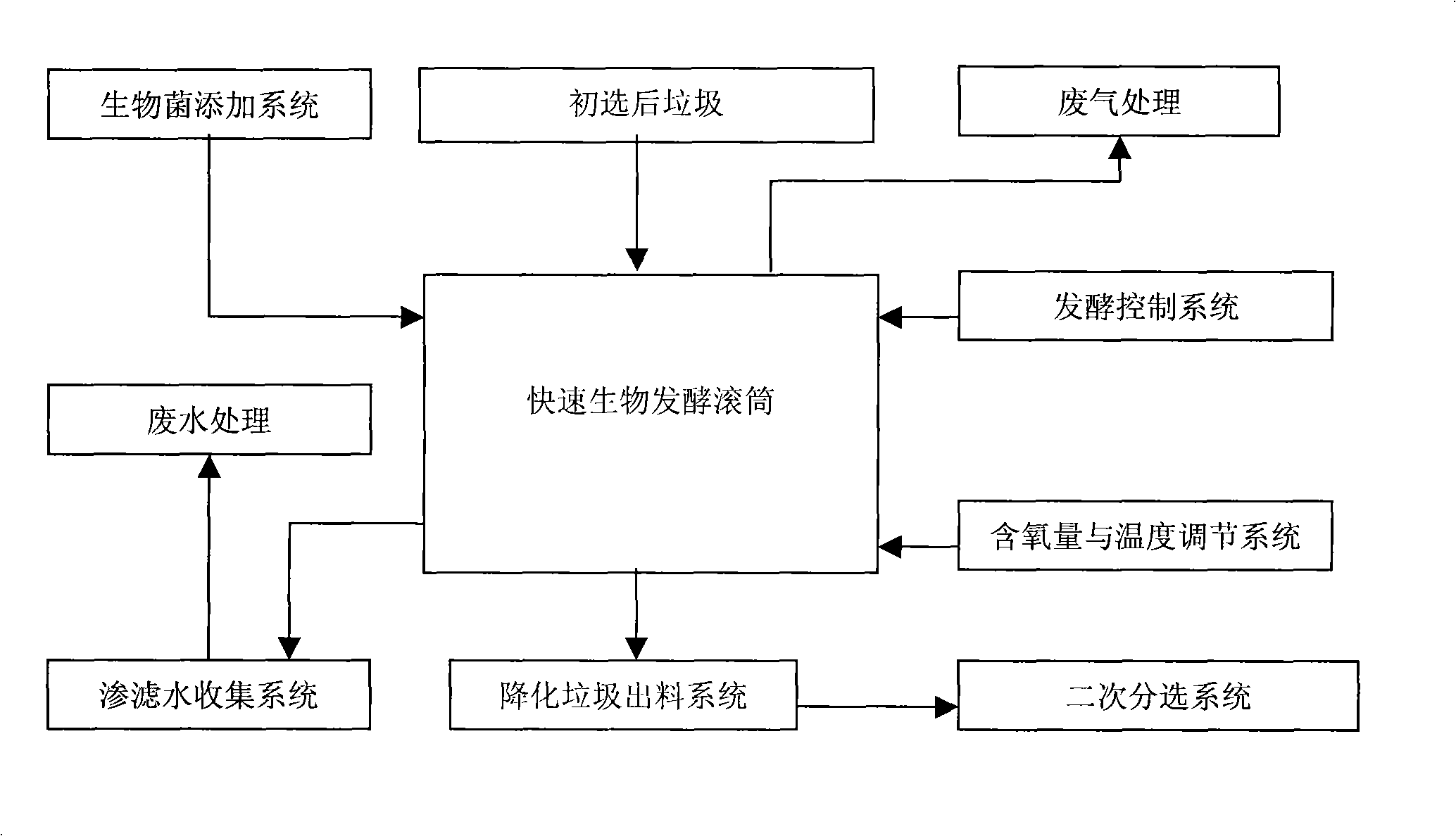

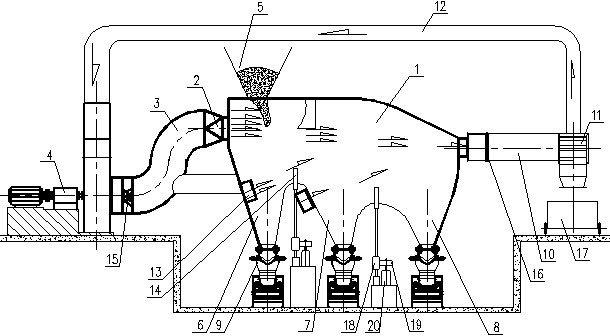

Process, system and device for waste biomass multi-production processing

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

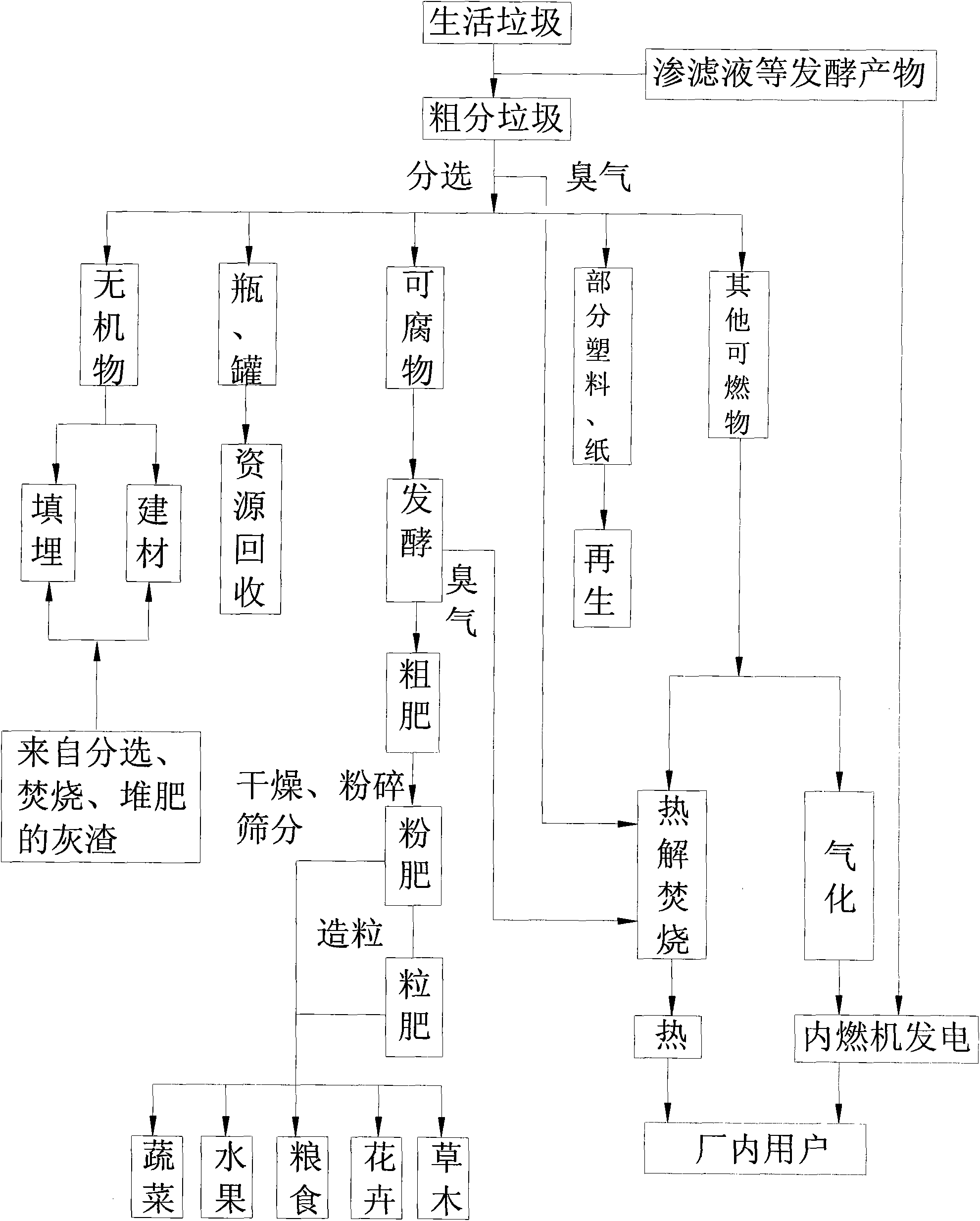

Method for comprehensively treating municipal solid waste

The invention relates to a method for comprehensively treating municipal solid waste. The method comprises mechanical treatment steps of manual sorting, bag breaking, magnetic separation, screening with a roller, winnowing and pulpifying and biological treatment steps of anaerobic digestion and aerobic composting. By combining all the steps for use, different components in the municipal solid waste are classified according to physicochemical properties of the components and then are treated; magnetic metal, plastic paper and the like which are obtained through sorting are recycled; organic waste obtained through sorting is crushed and pulpified and then is subjected to anaerobic digestion so as to produce methane; sludge is subjected to aerobic composting so as to produce organic fertilizer; the residual inorganic substances which cannot be treated or recycled can be subjected to sanitary landfill; and odor which is produced in the waste treatment process is treated in a centralized way, and then is discharged after reaching the standard. The method has great significance for treating the increasing municipal solid waste.

Owner:北京昊业怡生科技有限公司

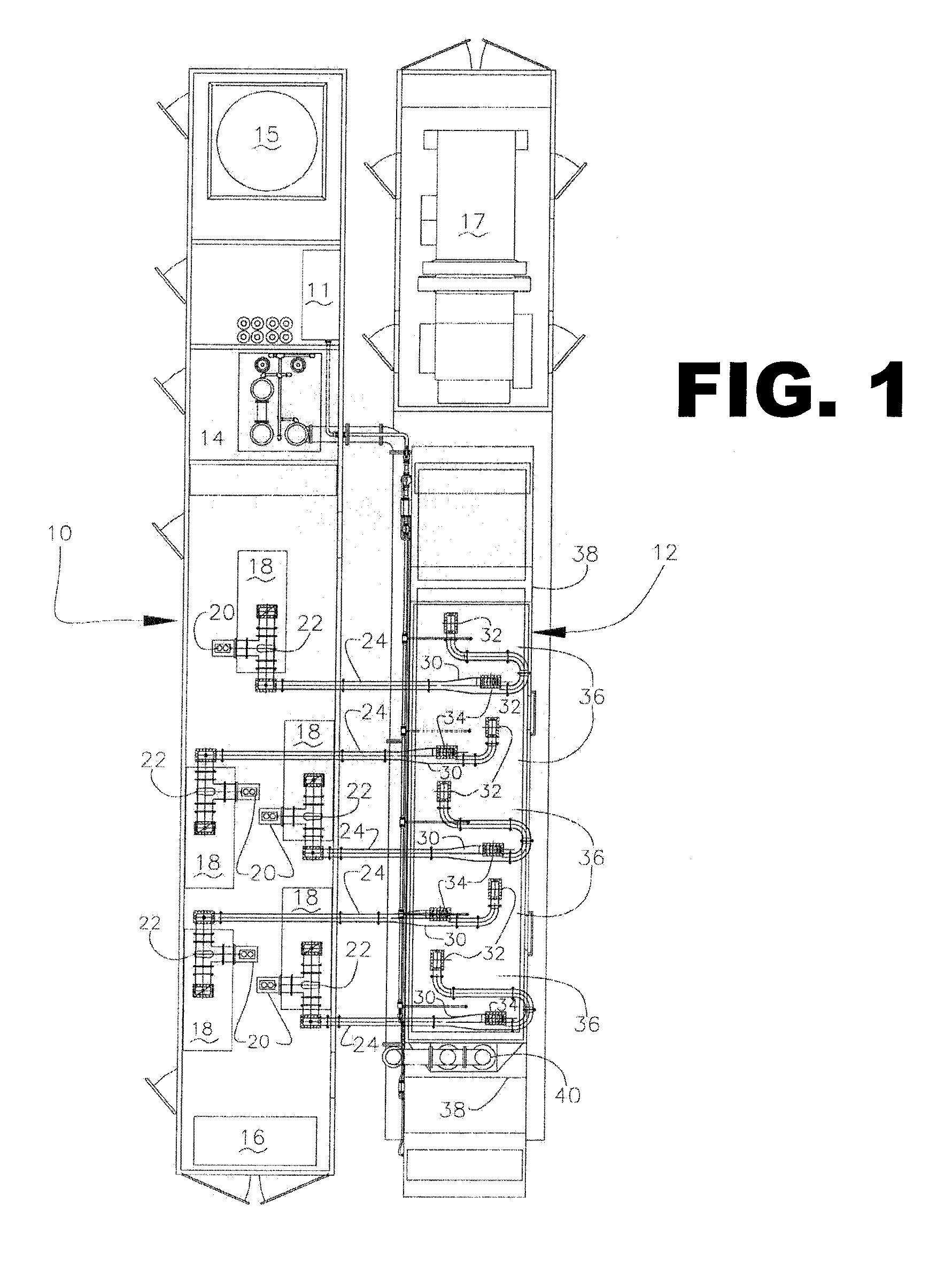

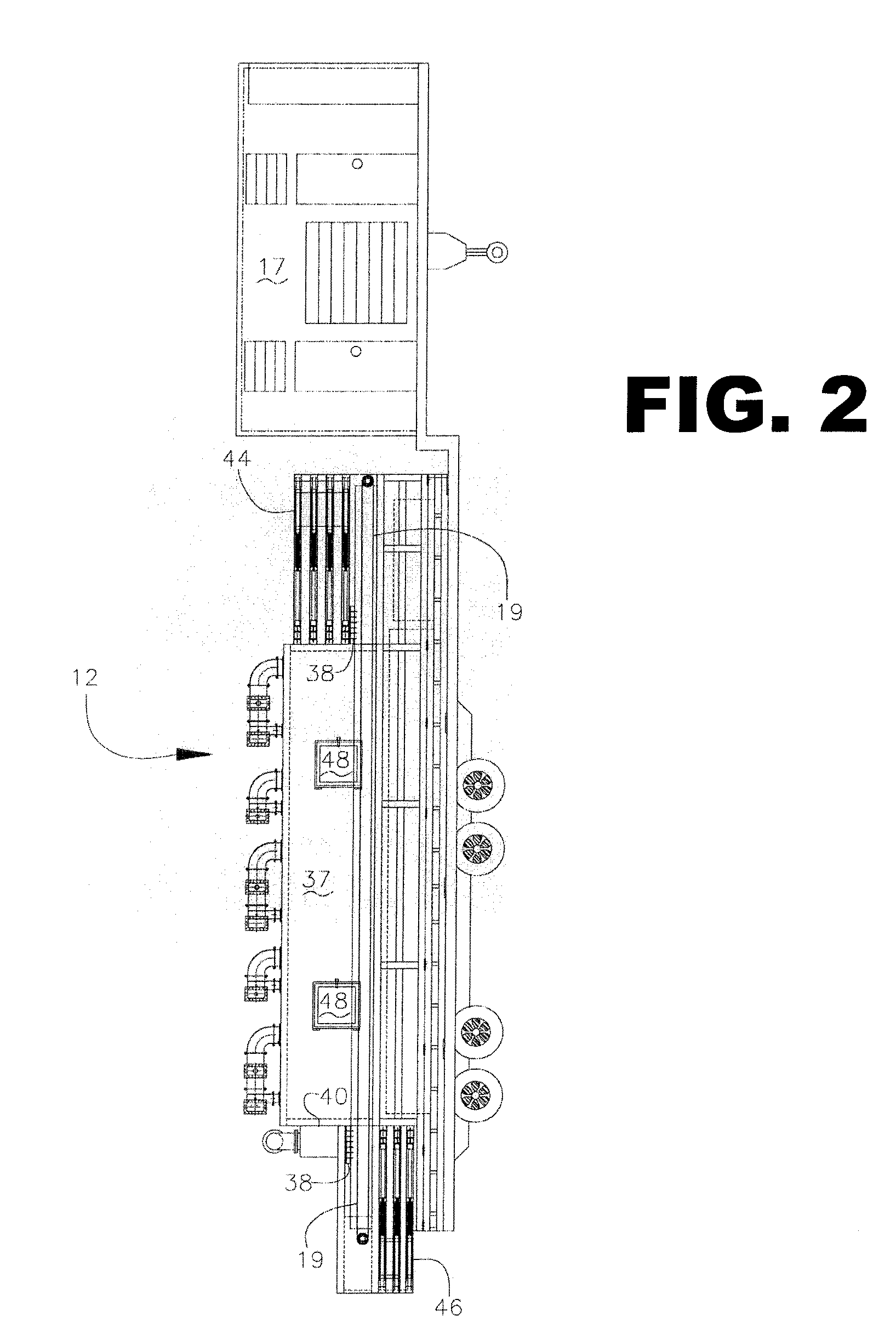

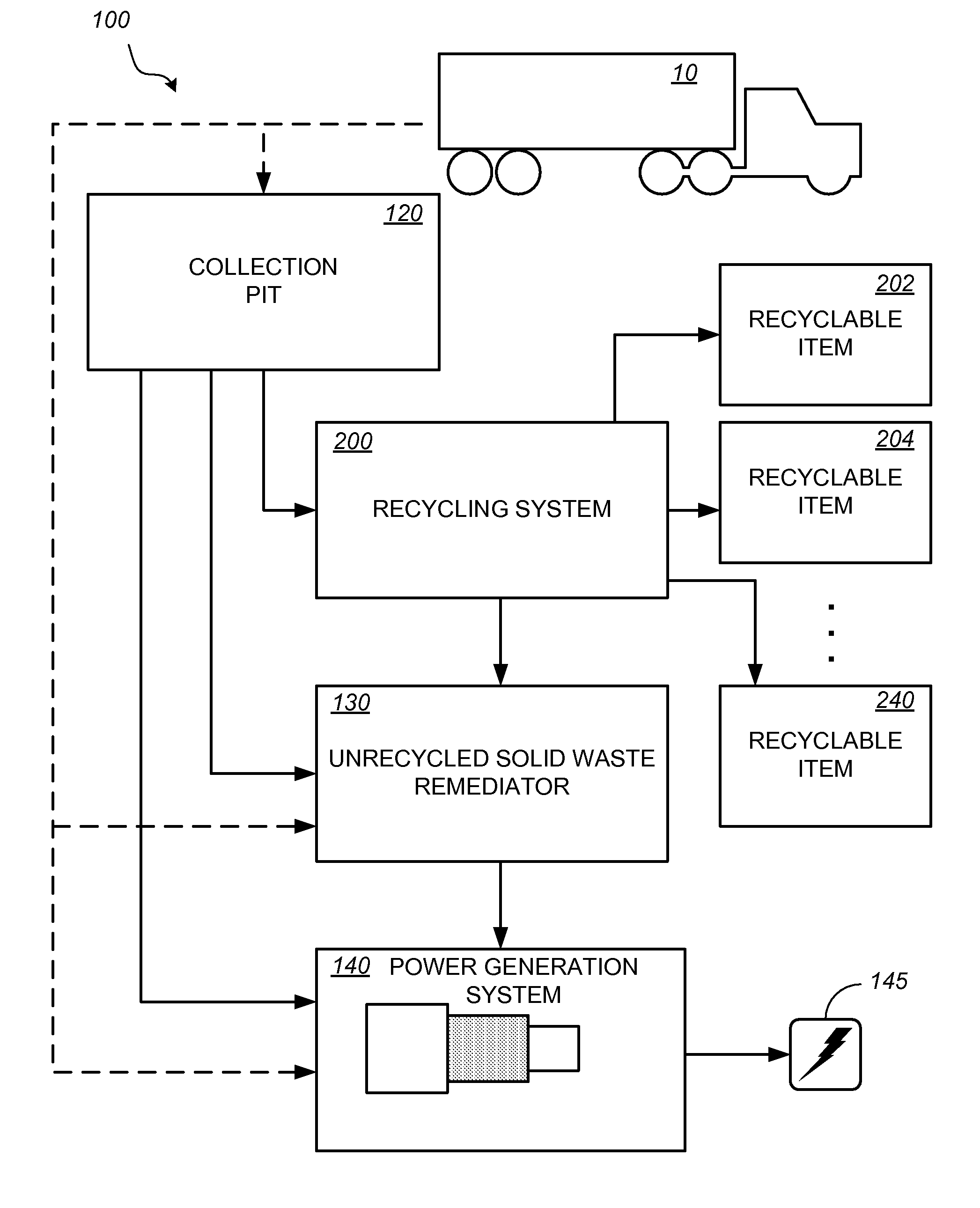

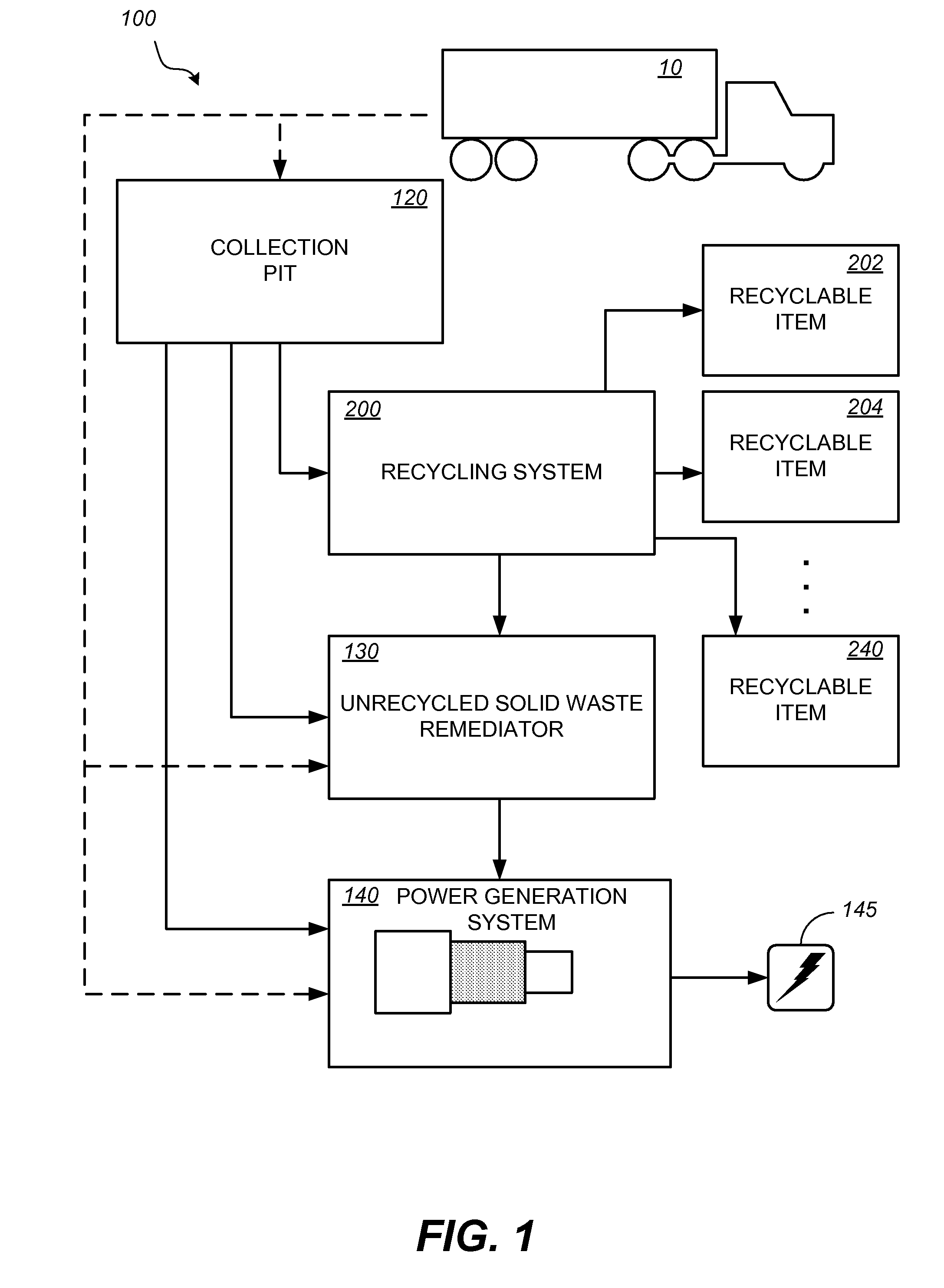

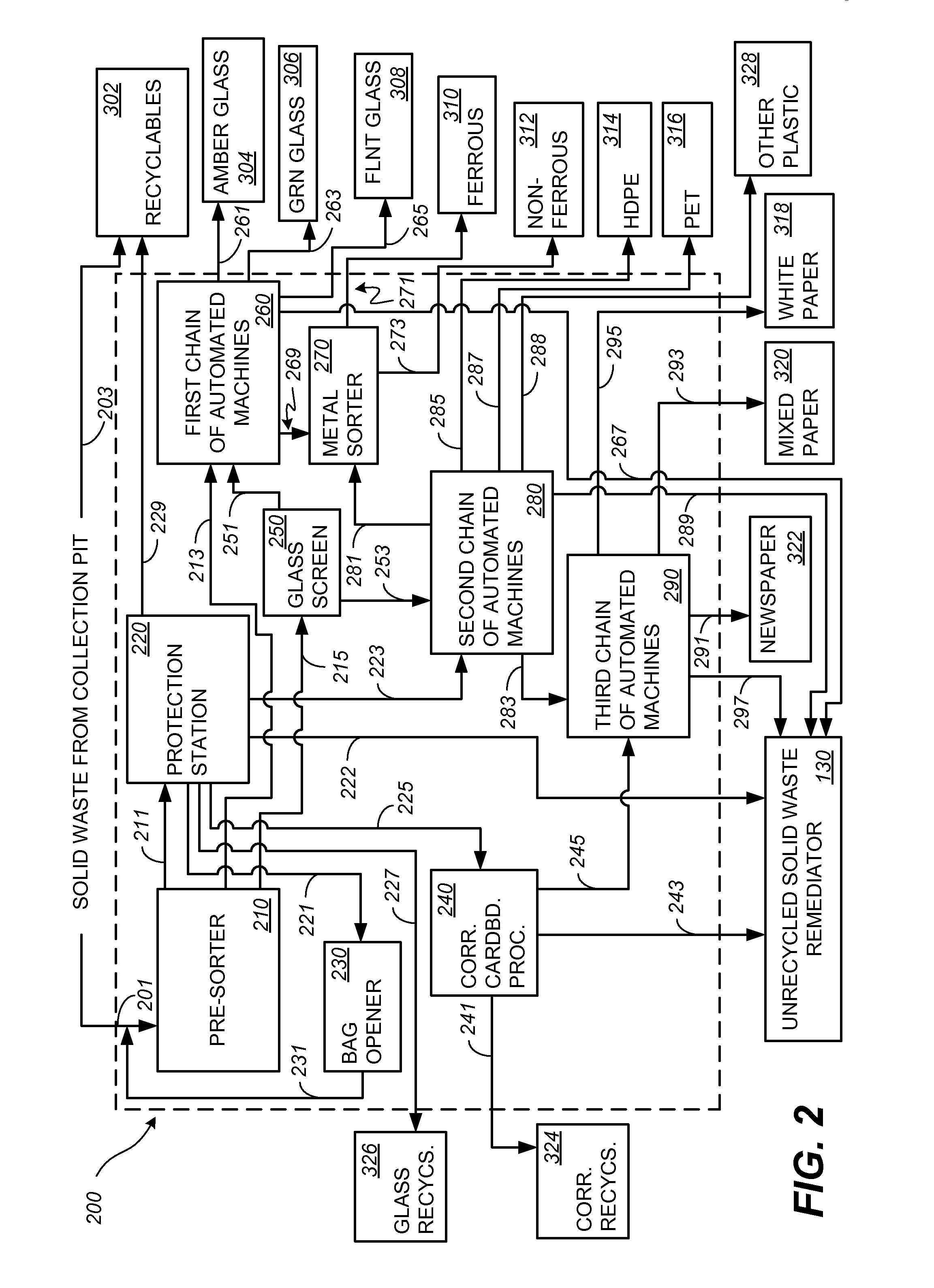

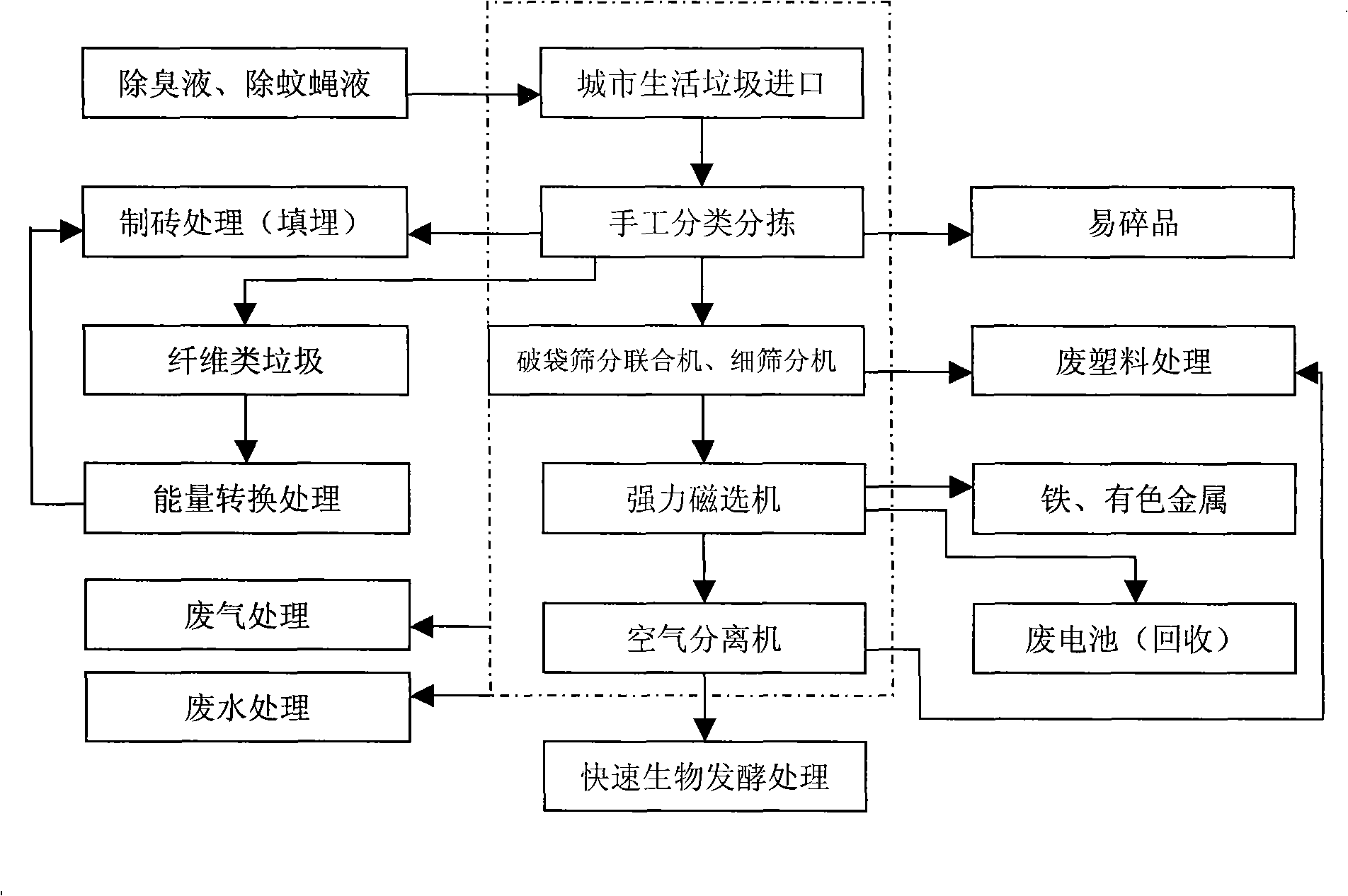

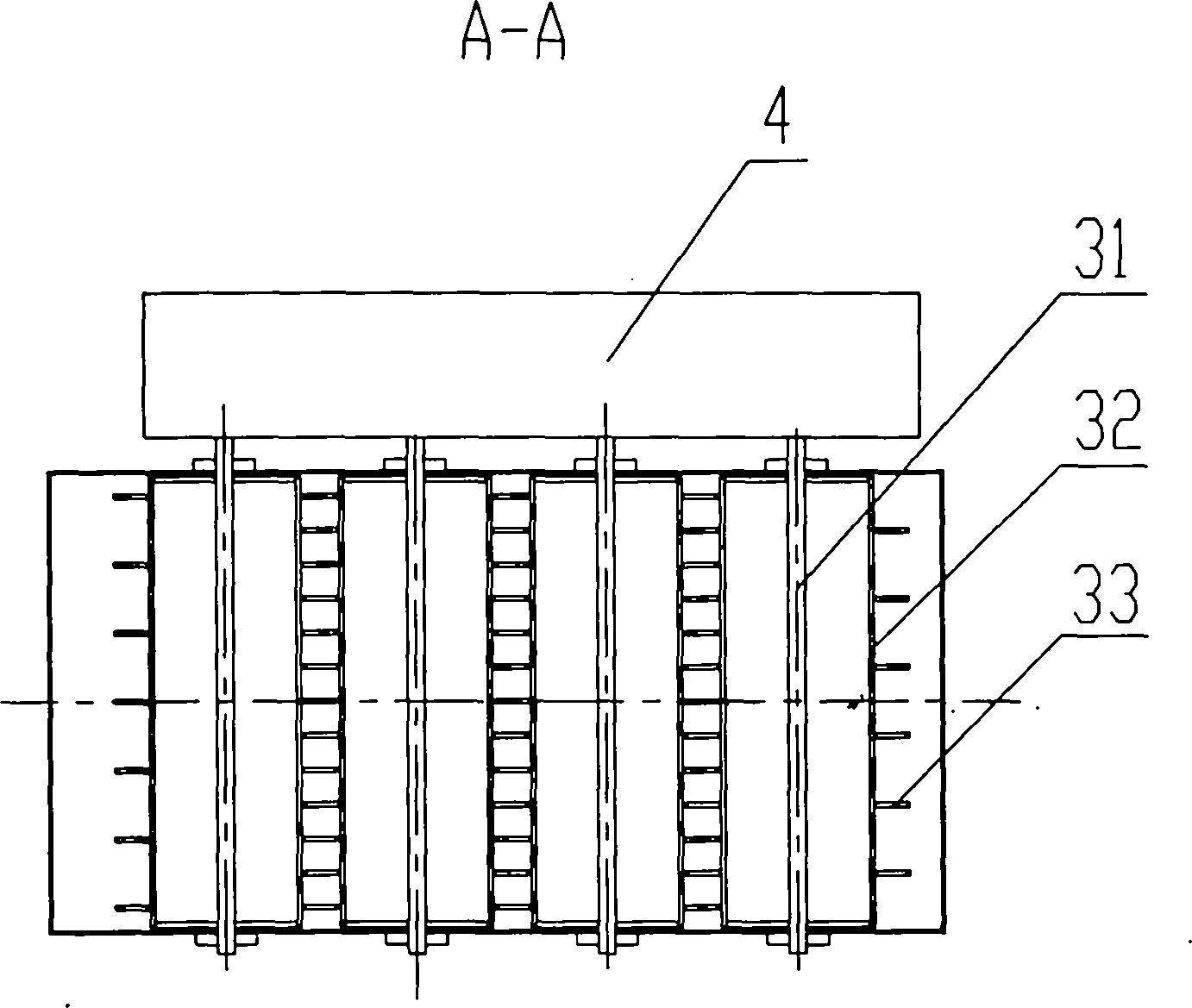

Systems and Methods for Processing Municipal Solid Waste

A pre-sorter forwards items from solid waste to designated processing paths in response to their size. Large items are manually processed to remove non-recyclables, to fuel a generator, to be returned to the pre-sorter after removal from a container, or forwarded to processing streams. The smallest items are forwarded to a first chain of machines that remove metal and glass from the items. Intermediate sized items are forwarded to an assembly that separates small, relatively dense, items from larger lightweight items. The former items are mixed and processed by a first chain of machines. The latter items are forwarded to a second chain of machines that separate and remove paper and other containers from recyclable metal and plastic. Multiple paper types are identified and removed by a third chain of machines. A remediator receives residual items from each of the first, second and third chains of machines.

Owner:ENVIRONMENTAL EQUIP MFG CONSOL

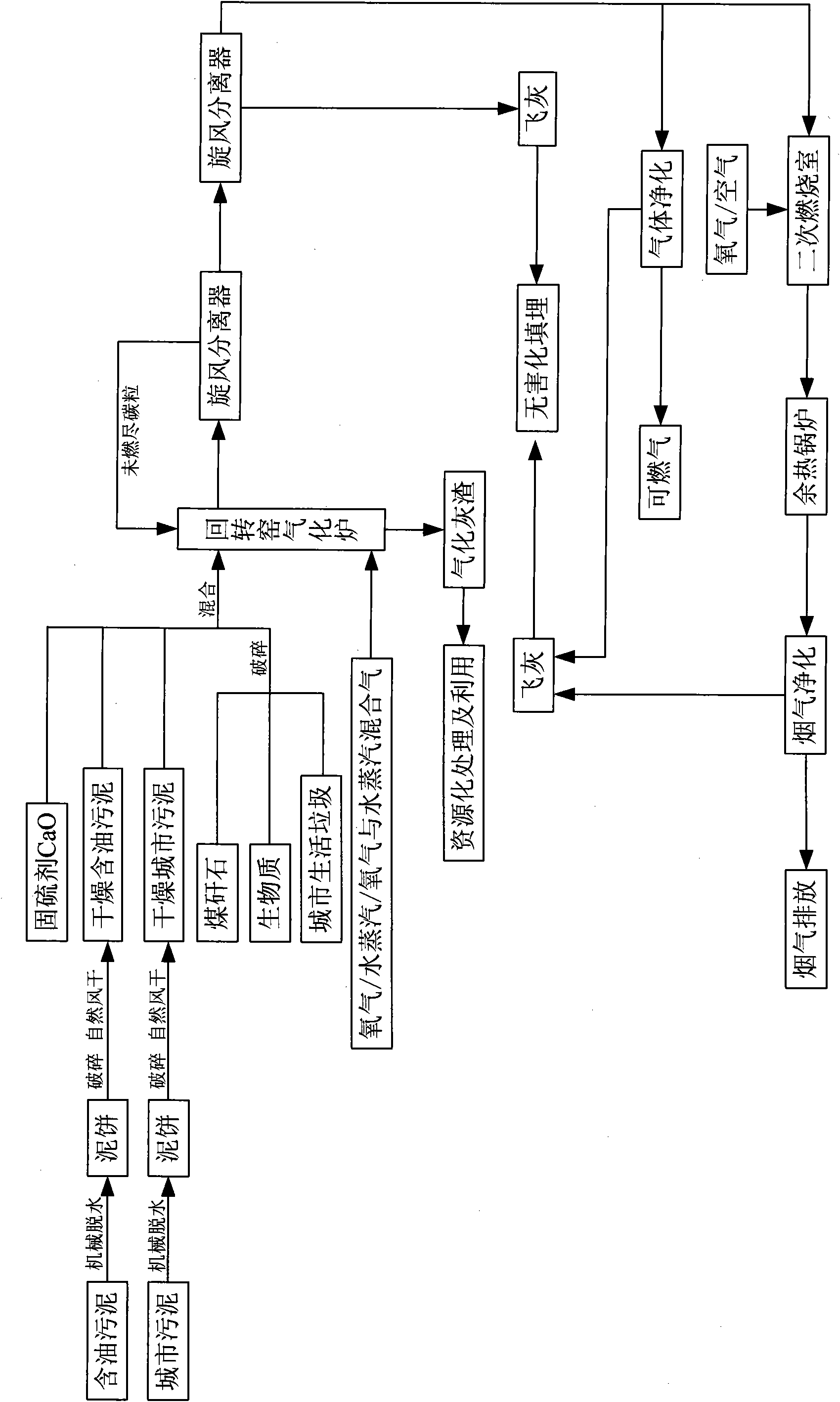

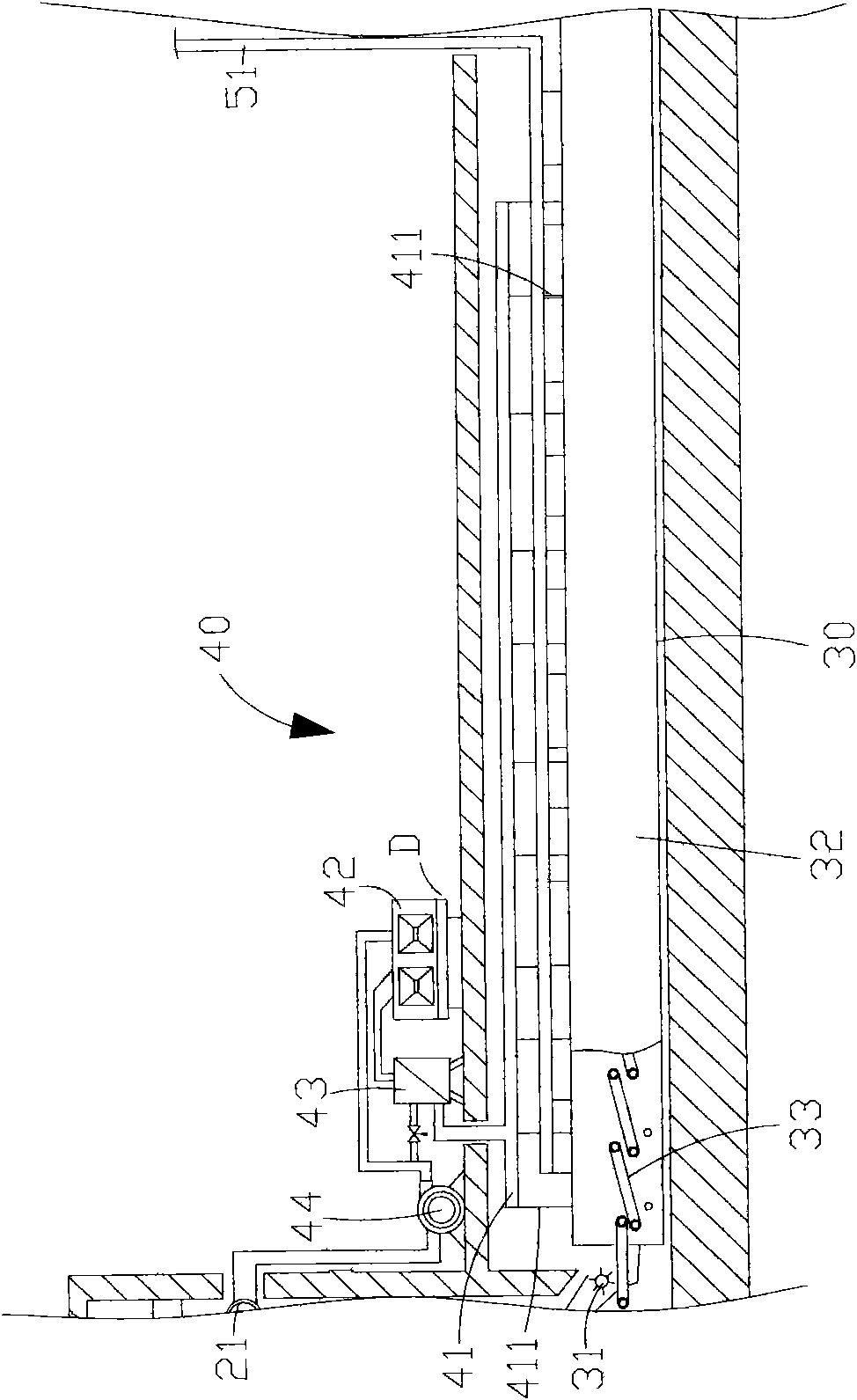

Method for gasifying and incinerating combustible solid wastes by utilizing rotary kiln

The invention discloses a process for the combined gasification and incineration of oily sludge, municipal sludge, coal refuse, municipal solid wastes and biomasses by utilizing a rotary kiln, which comprises the following steps of: dehydrating the oily sludge and the municipal sludge respectively, and at the same time, crushing the coal refuse, the municipal solid wastes and the biomasses into particles of a certain particle size; mixing the oily sludge and the municipal sludge which are hydrated, and the coal refuse, the municipal solid wastes and the biomasses which are rushed in a certain proportion; delivering the mixture into a gasification furnace of the rotary kiln by using a spiral feeder and also delivering a gasification medium into the rotary kiln; performing pyrolysis and gasification reaction on the mixture of the various combustible solid wastes at the high temperature of 1,000 to 1,200 DEG C to generate a crude gas rich in H2 and CO; and under the co-action of the high-temperature rotary kiln and subsequent treatment facility, recycling energy in the combustible solid wastes and rationally treating most of pollutants.

Owner:KUNMING UNIV OF SCI & TECH

Pretreatment method before power generating by incinerating municipal solid waste

InactiveCN101561143AReduce pollutionReduce inconvenienceIncinerator apparatusCombined combustion mitigationPretreatment methodEnvironmental engineering

A pretreatment method before power generating by incinerating municipal solid waste is used for processing the municipal solid waste into nontoxic incinerating matter and comprises the following steps of: firstly crushing and dehydrating the municipal solid waste, subsequently drying the municipal solid waste and treating the tail gas, and finally preparing a nontoxic incinerating matter by mixing the municipal solid waste with a certain proportion. After the pretreatment method is adopted, a large amount of municipal solid waste can be treated as nontoxic incinerating matter, the pollution of the municipal solid waste to the environment is reduced, the inconvenience of daily municipal solid waste treatment is also reduced, the space needed when the municipal solid waste is treated is reduced further and the defect that the piling of municipal solid waste causes pollution to the environment is solved excellently; furthermore, the pollution of the municipal solid waste to the environment is reduced, simultaneously, the municipal solid waste is prepared to the combustibles used for incineration power generation and the consumption of the resource is saved.

Owner:深圳恒信华天环保科技有限公司

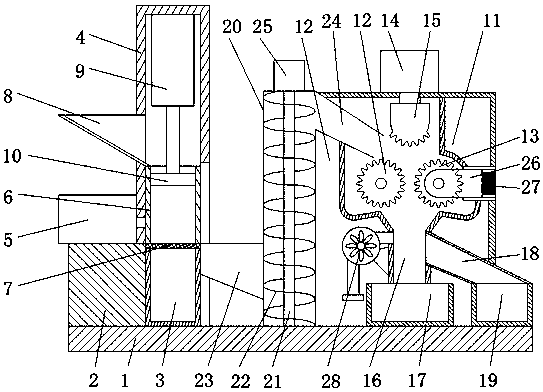

Municipal domestic waste squeezing, crushing and winnowing device and working method thereof

InactiveCN107627654AEfficient removalRealize automatic separationGrain treatmentsPressesHydraulic cylinderFixed frame

The invention discloses a municipal domestic waste squeezing, crushing and winnowing device and a working method thereof. The device comprises a bottom seat, a squeezing unit positioned at the left end of the top face of the bottom seat and a crushing unit positioned at the right end of the top face of the bottom seat, and a material lifting unit is arranged between the squeezing unit and the crushing unit; the squeezing unit comprises a base fixed on the top face of the bottom seat and a liquid storage barrel positioned on the right side of the base, a fixing frame is fixed to the top of thebase, an air cylinder is installed on the left side face of the fixing frame, and a squeezing barrel is arranged on the right side of the fixing frame; the left side face of the squeezing barrel is fixedly connected with the output end of the air cylinder, and a filtering plate is arranged at the top of the liquid storage barrel; and a feeding hole is formed in the side face of the fixing frame, the top of the fixing frame is provided with a squeezing hydraulic cylinder, and the output end of the bottom of the squeezing hydraulic cylinder is connected with a pressing plate. According to the device, squeezing, crushing and winnowing are continuously and automatically carried out; and the device is simple and reasonable in structure, convenient to use, practical and efficient.

Owner:陈彬

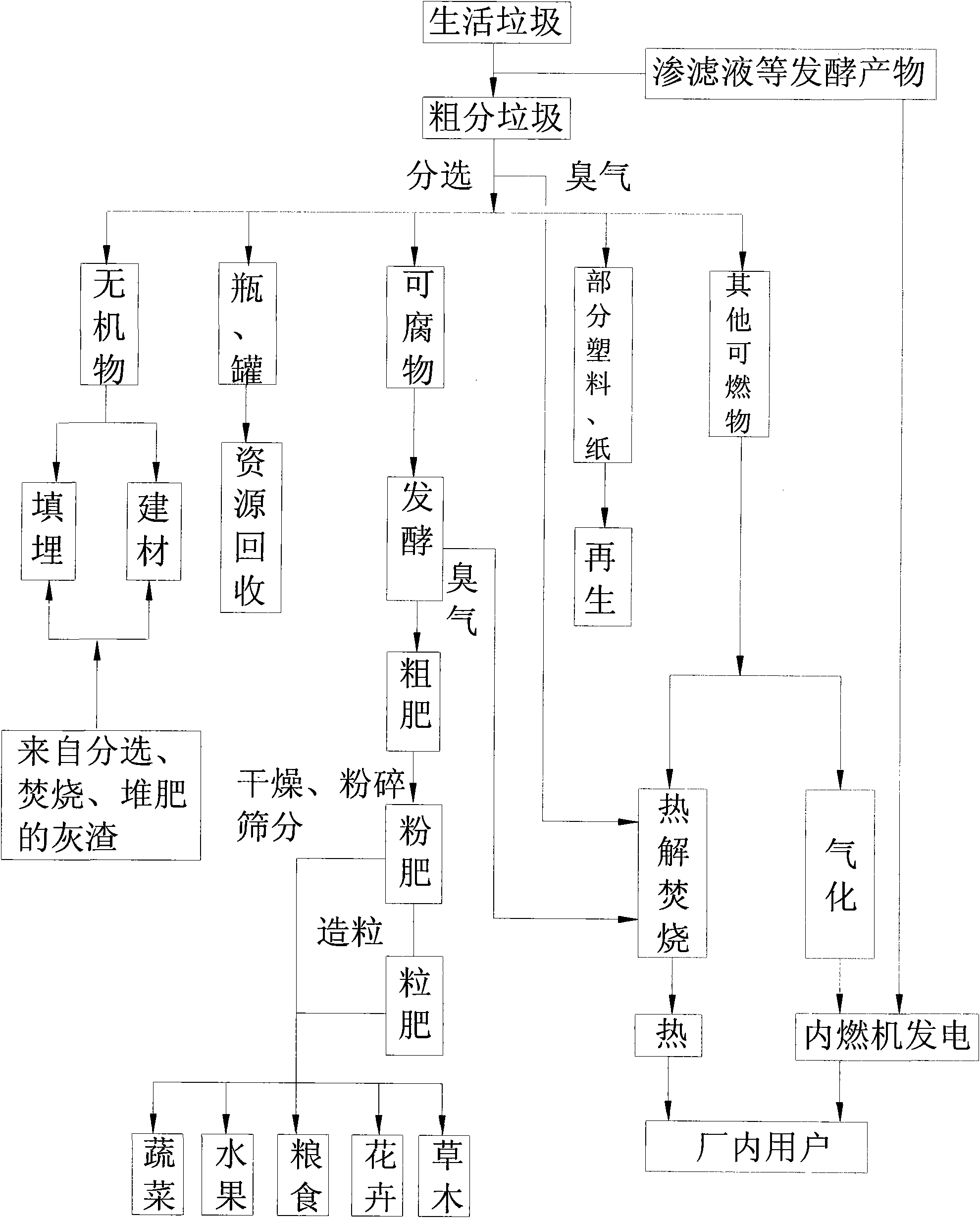

Novel treating method of resource recycling of wastes

InactiveCN101829667ASolve highSolve the entanglementBio-organic fraction processingSolid waste disposalResource utilizationOxygen

The invention discloses a treating method of resource recycling of wastes, comprising the following steps of: (1) coarse classification of wastes; (2) pretreatment and gasification of combustible components; (3) an overall process of resource classification, treatment and utilization of the wastes; and (4) combustion power generation of combustible gases, comprising thermal gases generated in the step (2) and the step (3) and combustion power generation of methane introduced into an internal combustion engine. In aspect of municipal solid waste aerobic-anaerobic highly-efficient fermentation technology, the invention solves the difficult problems of slow fermentation starting, long period, difficult bacteria culture and circulation and easy acidosis of municipal solid wastes and simultaneously develops an organic fertilizer production technology aiming at resource utilization of corrodible organic matters; under the same scale, by adopting the treating method, the landfill site is greatly saved and the capitalized cost is only 30 to 50 percent of incineration power generation, which is equivalent to sanitary landfill; and the waste treatment and operation cost does not reach one half of incineration and is close to the cost of the sanitary landfill.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

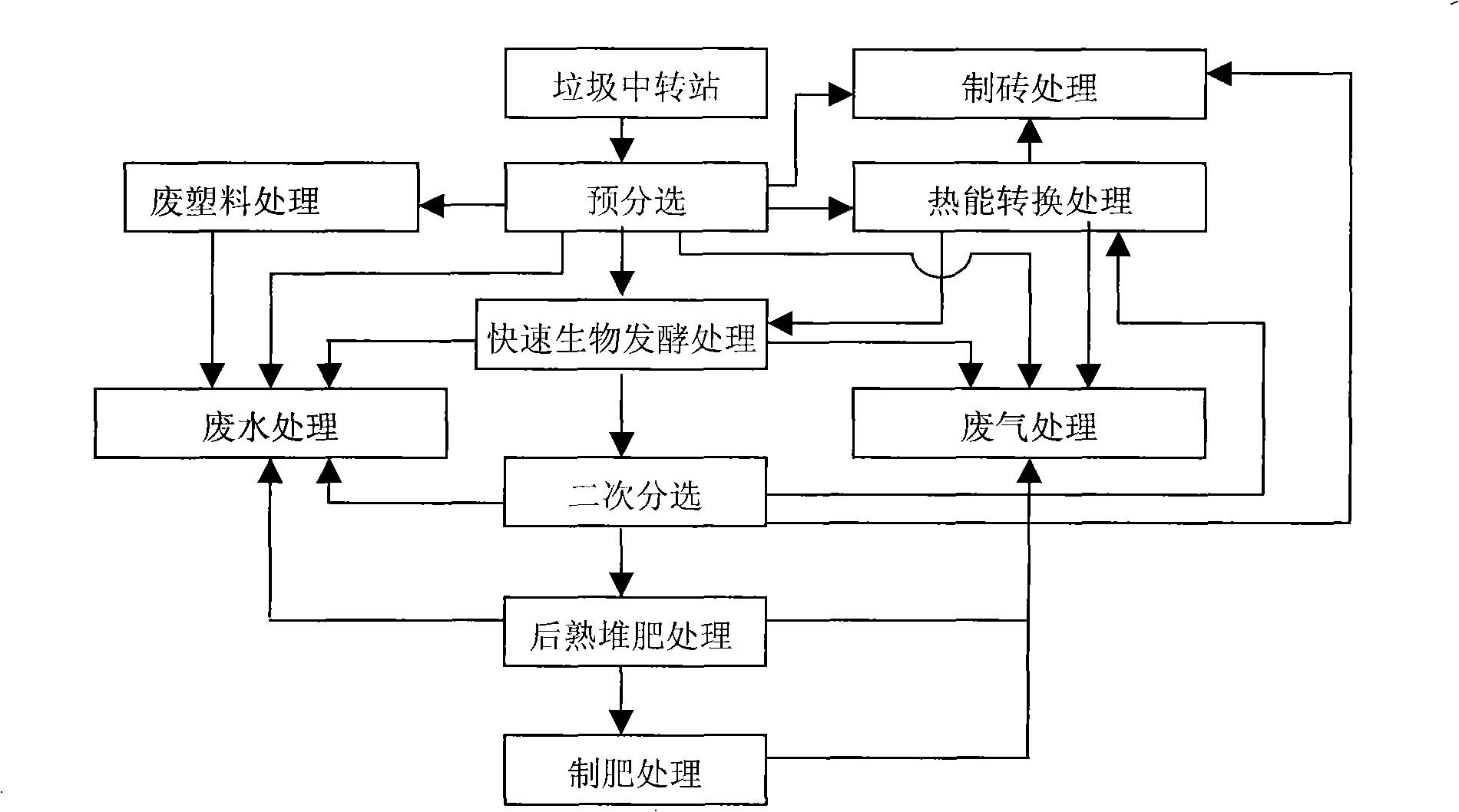

Integral treatment method for city household refuse

InactiveCN101289336ANo secondary pollutionHigh degree of harmlessnessSolid waste disposalClimate change adaptationFiberBrick

Owner:ZHEJIANG UNIV

Method and apparatus for processing municipal waste

InactiveUS6945484B1Lower the volumeSpeed up the extraction processBio-organic fraction processingProductsThermal energySteam pressure

A method for processing municipal waste substantially reduces the volume of material to be disposed into a landfill by increasing the volume of materials of value collected from the municipal waste and by composting the remaining materials to create a salable product. The process includes the removal of materials of value by magnetic devices to extract ferrous materials, by an air classifier to extract light plastic materials, by an eddy current mechanism to extract aluminum materials, and by a plastic sort mechanism to extract large plastic materials. Composting can be accomplished with a composting vessel that is located in the process either before the materials of value are removed or afterward. A grinding of the materials before a final screening allows the commercial grade compost to be separated from the materials that are to be sent to the landfill for final disposal. An alternative embodiment of the process utilizes a steam pressure vessel to disintegrate the waste material and to destroy any pathogens before materials of value are removed and the small and fine materials are composted. Large materials can be gasified to create heat energy for use in the steam pressure vessel.

Owner:TERZINI ROBERT +1

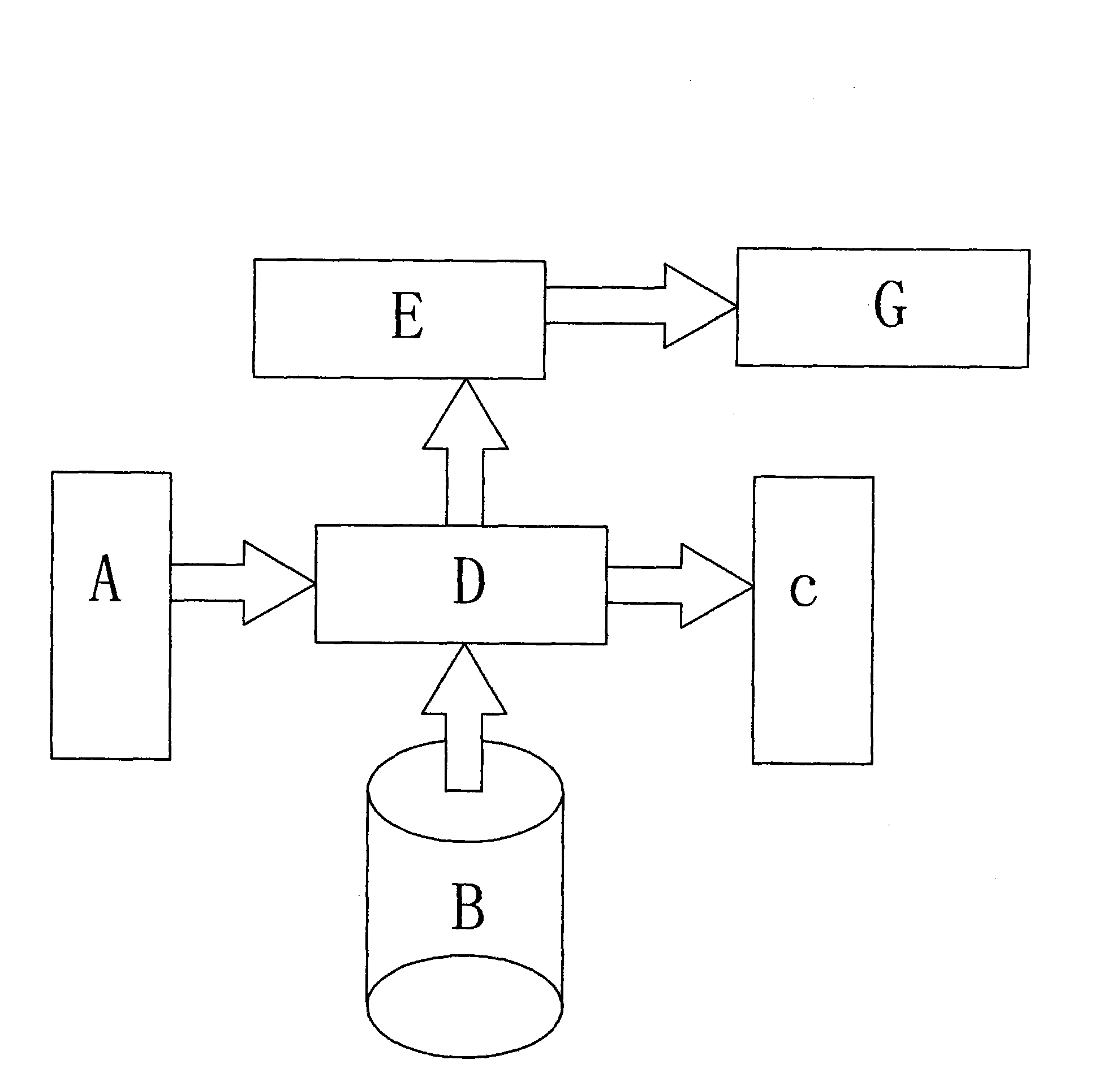

Garbage microwave pyrolysis comprehensive treatment system and method and equipment used by same

InactiveCN101797578AReduce oxygen contentLower operating temperatureSolid waste disposalHydrocarbon distillationLiquid productFuel oil

The invention discloses a garbage microwave pyrolysis comprehensive treatment system and a method and equipment used by the same, aiming to solve the problems of microwave pyrolysis treatment, and the method and equipment used by the system. The comprehensive treatment system comprises a municipal solid waste (MSW) preprocessing system A, a vertical garbage continuous microwave heating low temperature cracking furnace B, a solid product activated carbon production system C, a pyrolysis gas preparation fuel gas system D, a liquid product distilled extraction light oil and fuel oil system F and a matched sewage treatment system G, wherein the MSW preprocessing system A, the solid product activated carbon production system C and the pyrolysis gas preparation fuel gas system D are respectively connected with the vertical garbage continuous microwave heating low temperature cracking furnace B; and the liquid product distilled extraction light oil and fuel oil system F is connected with the oil recovery pipeline of the pyrolysis gas preparation fuel gas system D. The invention has the advantage that: low carbon emission is realized in the treatment process under the reducing atmosphere, fixed carbon in the garbage is emitted without violent toxicity like dioxin and heavy metal solid powder, the treated wastewater can be recycled and max garbage resource recycling is realized.

Owner:深圳市兖能环保科技有限公司

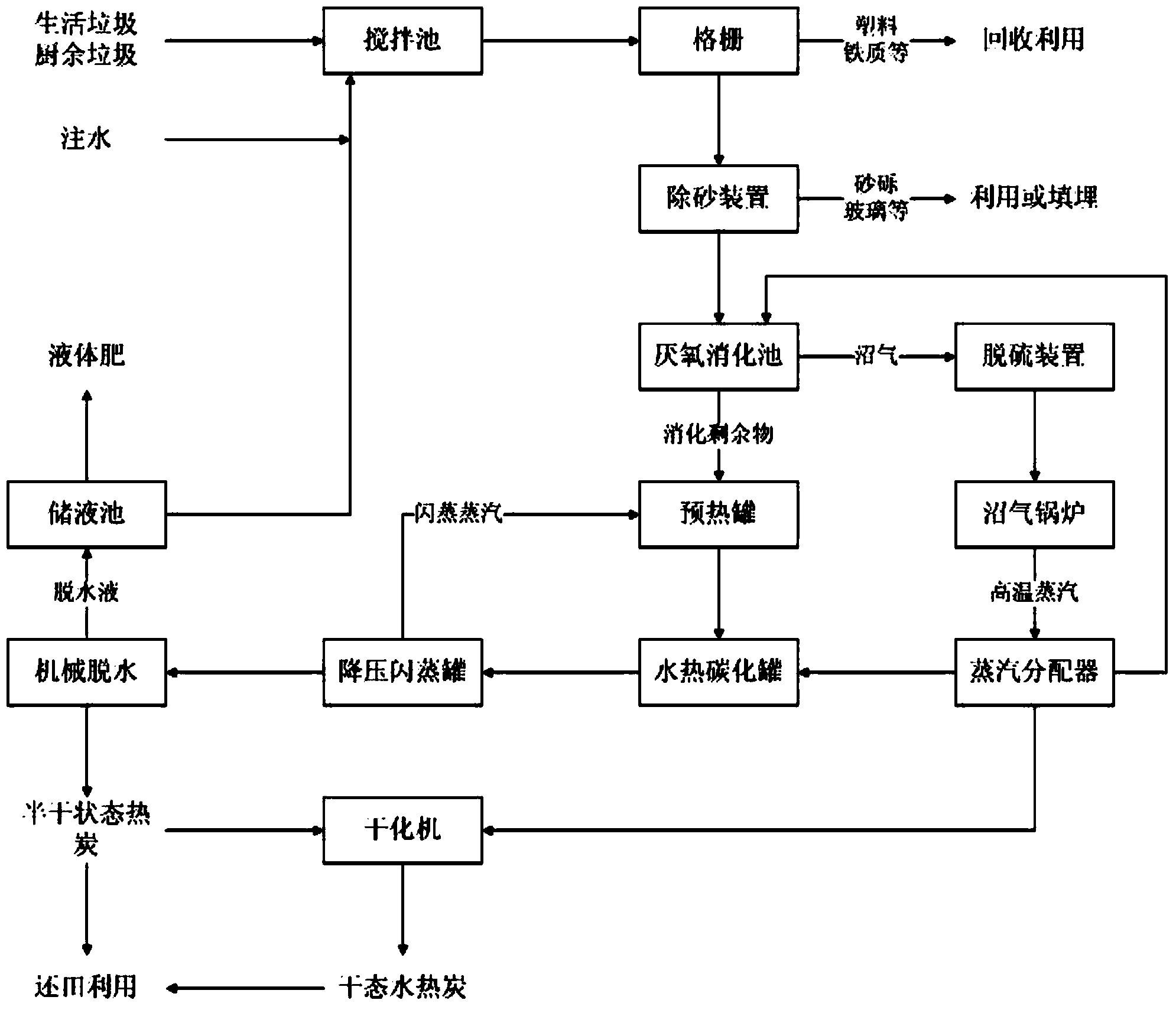

Domestic waste comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization

ActiveCN103722002AIncrease energy densityHigh agronomic valueBio-organic fraction processingSolid waste disposalResource recoveryEnergy regeneration

The invention relates to a municipal solid waste reduction, energy regeneration and recycling method, and discloses a domestic waste comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization. The domestic waste comprehensive treatment method comprises the following steps: slurry treatment, anaerobic digestion, hydrothermal carbonization, dewatering and drying. The domestic waste and kitchen waste are subjected to reduction, energy regeneration and recycling treatment, so that the domestic waste comprehensive treatment method is high in resource recycling degree, low in operation cost, clean and environment-friendly, and can ensure that pathogenic microorganisms in the wastes are completely killed, so that repugnant substances are converted and decomposed, and the domestic waste comprehensive treatment method has good economic value and social value.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

Fruit-tree-yield-increasing fertilizer and preparation method thereof

The invention discloses a fruit-tree-yield-increasing fertilizer prepared from the raw materials of, by weight: 300-340 parts of municipal solid waste, 300-340 parts of cattle and sheep dung, 200-230 parts of crop stalk, 200-230 parts of vine seedling, 50-60 parts of sawdust, 40-50 parts of corncob, 20-30 parts of coal gangue, 30-35 parts of urea, 40-45 parts of monoammonium phosphate, 50-55 parts of calcium magnesium phosphate, 12-15 parts of potassium chloride, 3-4 parts of borax, 3-5 parts of zinc sulfate, 3-5 parts of manganese sulfate, 2-4 parts of ferrous sulfate, 6-9 parts of an EM inoculant, 10-15 parts of a soil conditioner, and proper amount of water. According to the fertilizer used for increasing fruit tree yield, domestic wastes such as municipal solid waste, cattle and sheep dung, crop stalk, vine seedling, and the like are adopted as main raw materials. The fertilizer is suitable for various fruit trees, and has low production cost. The fertilizer comprises probiotics beneficial for fruit tree growth, and assists in improving fruit tree growth environment. Also, with the added other components, soil can be improved, fruit yield and quality can be improved, and fruit tree growth and reproduction can be promoted.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

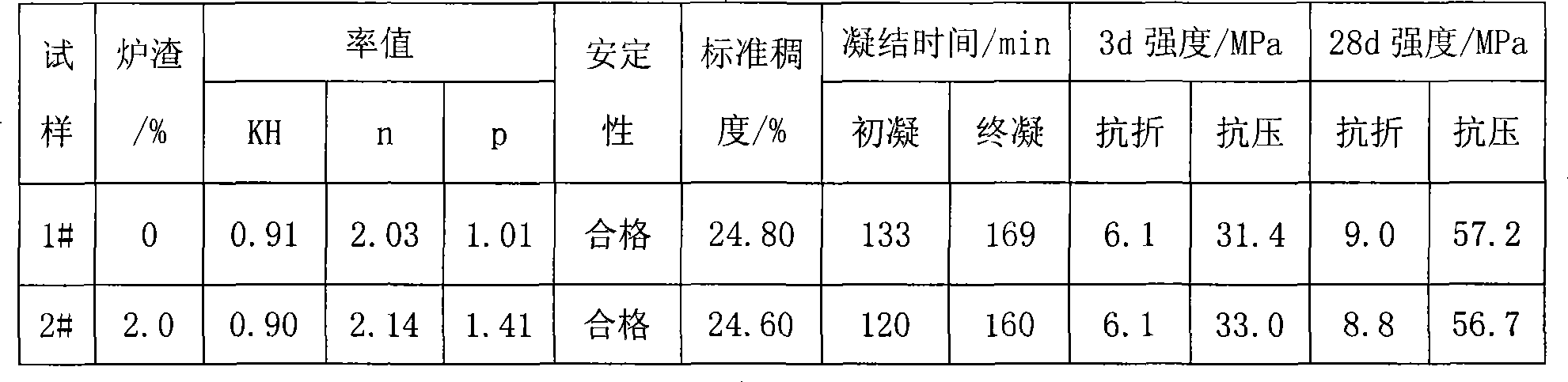

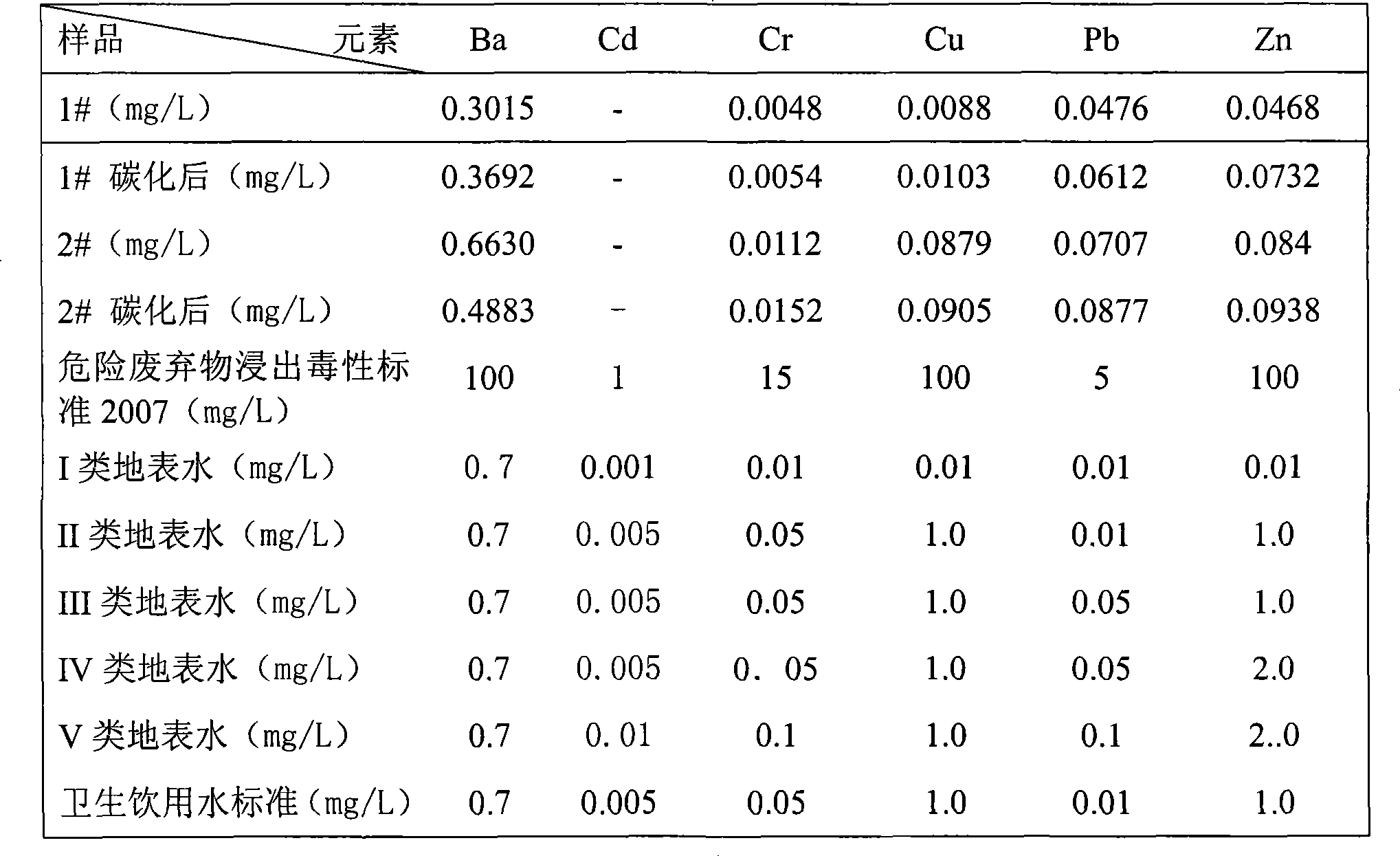

Method for producing portland cement clinker using domestic waste incineration residue

InactiveCN101386480APromote sustainable developmentReduce consumptionCement productionSlagCement kiln

The invention discloses a method for producing Portland cement clinker with incineration slag of municipal solid waste. The method is to mount a by-way air exhaust device on the prior novel cement kiln so as to solve the problem of crust and blockage caused by chlorine brought into the kiln by the slag. For a kiln system with a kiln row and a furnace row which are independent from each other, the by-way air exhaust device is arranged in an uptake of a kiln end gas chamber in the kiln row close to a five-stage cylinder; while for common industrial kiln, the air exhaust device is arranged between an outlet of decomposing furnace and an inlet of the five-stage cylinder or arranged at an uptake of an outlet of the five-stage cylinder. The use frequency of the by-way air exhaust device is between once per eight hours and once per three days, the temperature of the air entering the by-way air exhaust device is controlled to be more than 950 DEG C. The method is simple in process, low in treatment cost, and complete in toxicity removal due to the fact that heavy metals in the slag are solidified in the Portland cement clinker and are solidified in hydrates during the hydration of the mineral compositions of the Portland cement clinker. The method contributes to the development of cyclic economy and reduces the consumption of natural resources and energy of the cement industry.

Owner:SOUTH CHINA UNIV OF TECH

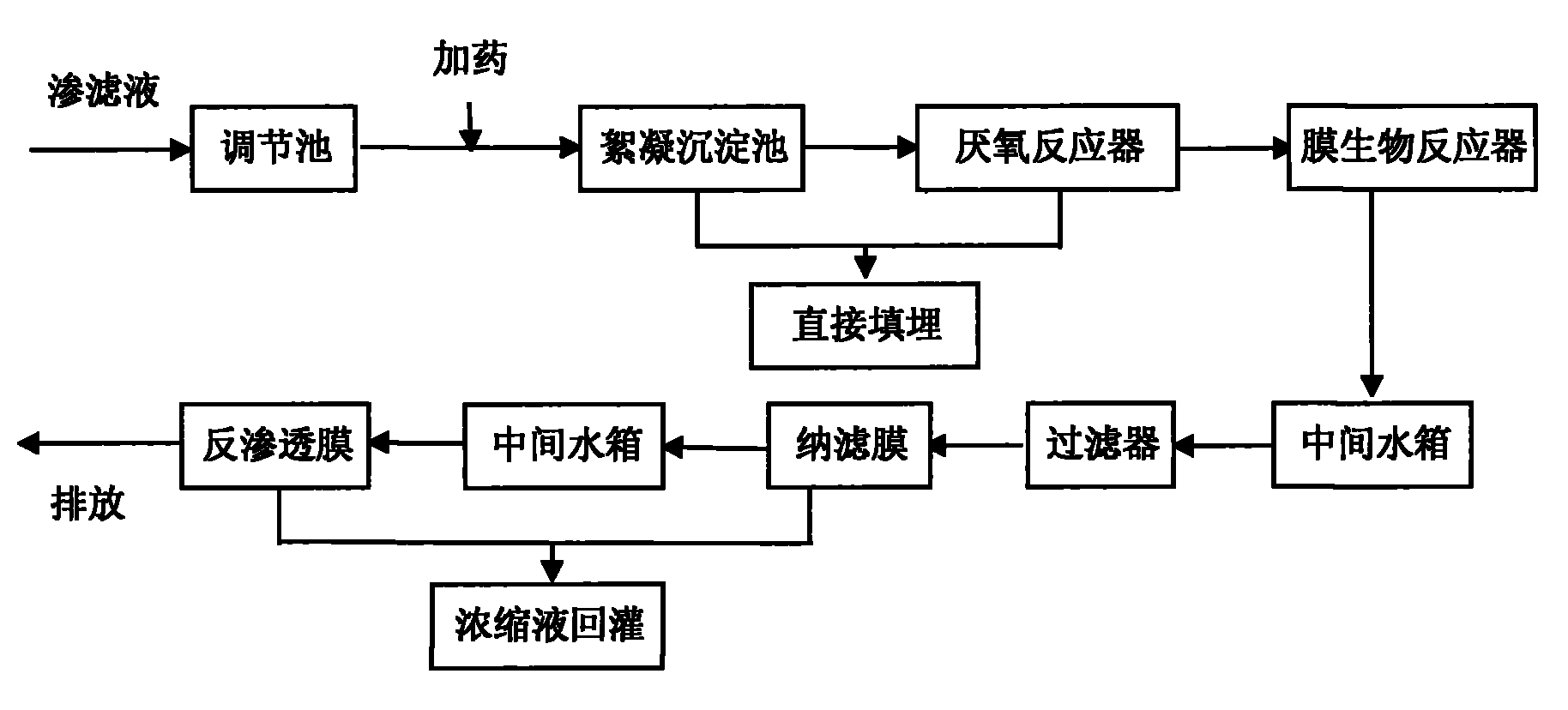

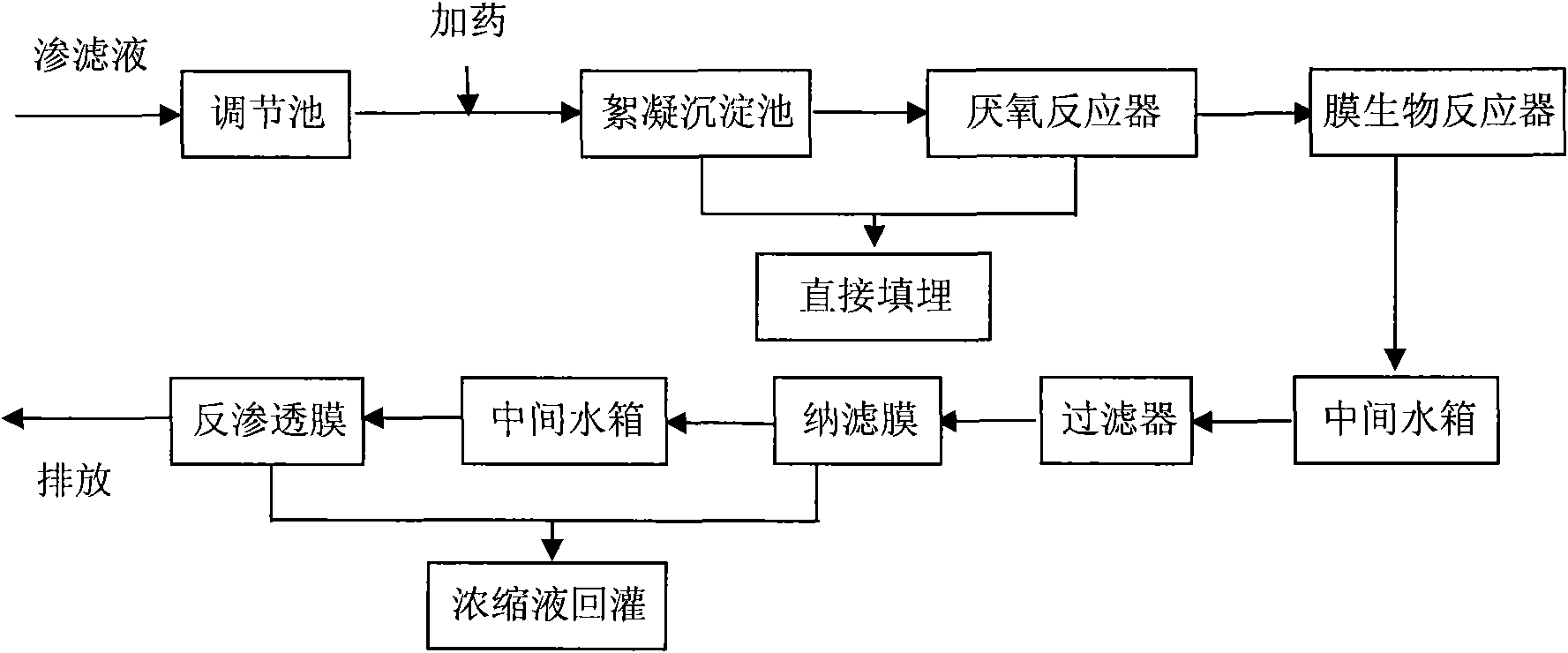

Method for treating leachate

InactiveCN101811796AHigh removal rateReduce occupancyMultistage water/sewage treatmentHigh concentrationReverse osmosis

The invention relates to a method for treating leachate, which is mainly used for treating town refuse landfill leachate and high-concentration industrial wastewater, and belongs to the technical field of environmental protection. A device for realizing the method comprises a regulating reservoir, a flocculation settling pond, an anaerobic reactor, a membrane bioreactor, a nanofiltration membrane and a reverse osmosis membrane, wherein the anaerobic reactor is an up-flow anaerobic sludge blanket (UASB) or an up-flow sludge blanket filter (UBF); and the membrane bioreactor comprises an anoxic zone and an aerobic zone. The method has high removing rate of CODcr, BOD5, suspended matters (SS) and ammonia nitrogen in the leachate; the device has the advantages of compact structure to reduce occupied land, convenient assembly, quick startup and reduction in debugging time; various membrane modules adopt a modular mode so as to contribute to maintenance and replacement; effluent meets the index requirements of 'Standard for Pollution Control on the Landfill Site of Municipal Solid Waste' (GB 16889-2008); and the effluent can be collected for recycling on occasions having low requirements on water quality.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

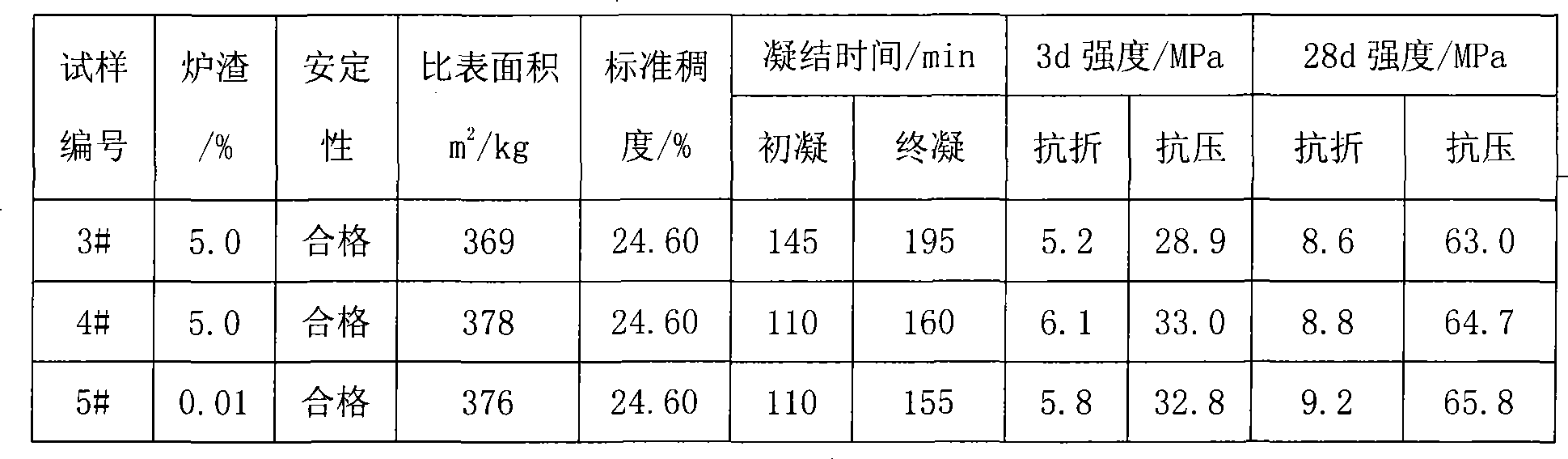

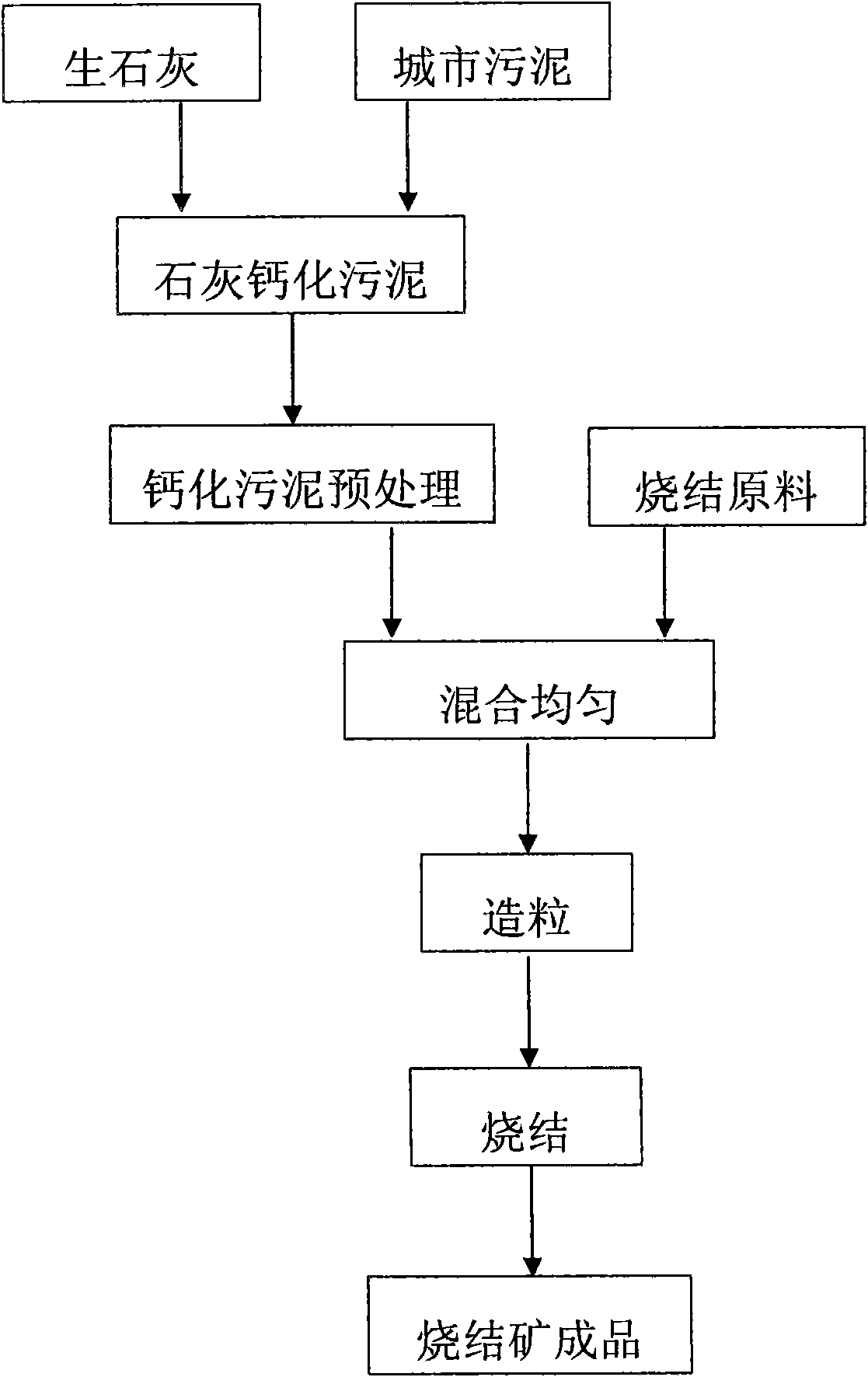

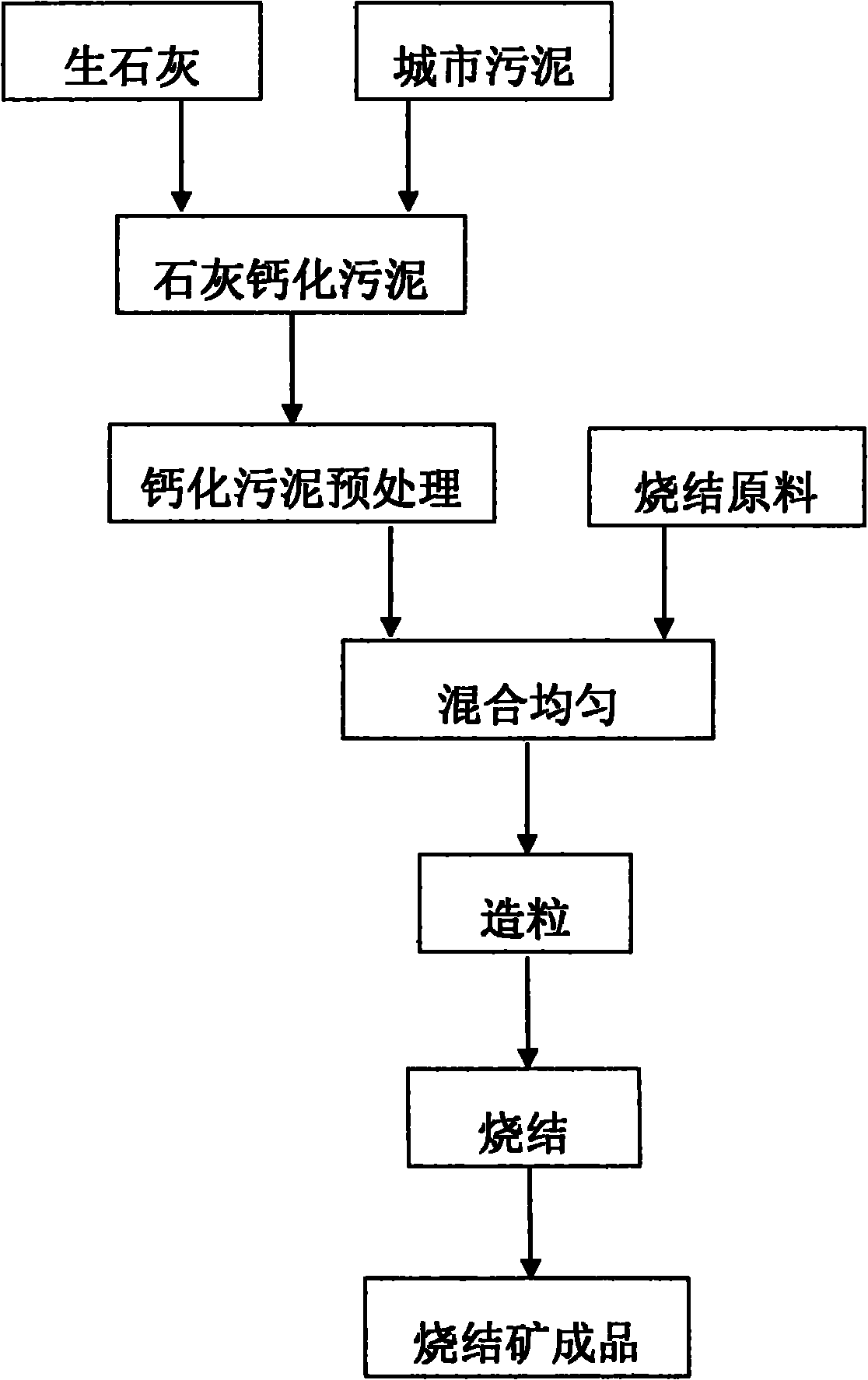

Method for utilizing municipal sludge as raw material of steel industrial sintering ore

ActiveCN102030450AAchieve recyclingAchieving processing powerSludge treatment by de-watering/drying/thickeningProcess efficiency improvementSludgeIron industry

The invention relates to a method for utilizing municipal sludge as a raw material of a steel industrial sintering ore and belongs to the technical fields of harmless treatment and high-additional-value utilization of municipal solid waste. The method comprises the following steps of: mixing the municipal sludge and quicklime according to a ratio; drying and dehydrating the mixture to obtain calcified sludge; adding the calcified sludge into sintering raw materials with correspondingly adjusted components according to a certain ratio and a certain mode, and allowing the mixture to enter the sintering process with other sintering raw materials; and producing the sintering core products serving as iron-making raw materials. The method has the advantages that: the lime calcified municipal sludge is added, so the sludge treatment cost is reduced and the secondary pollution problem during the sludge treatment is solved; the harmless treatment and the recycling utilization of municipal solid waste are realized; and the calcified sludge is added, so that the vertical sintering speed, the finished product ratio and the utilization coefficient can be effectively increased in the process of sintering the sintering core, the added amount of flux and fuel in the sintering raw materials is reduced, the raw material cost is reduced, and multiple purposes are fulfilled.

Owner:SHOUGANG ENVIRONMENTAL IND

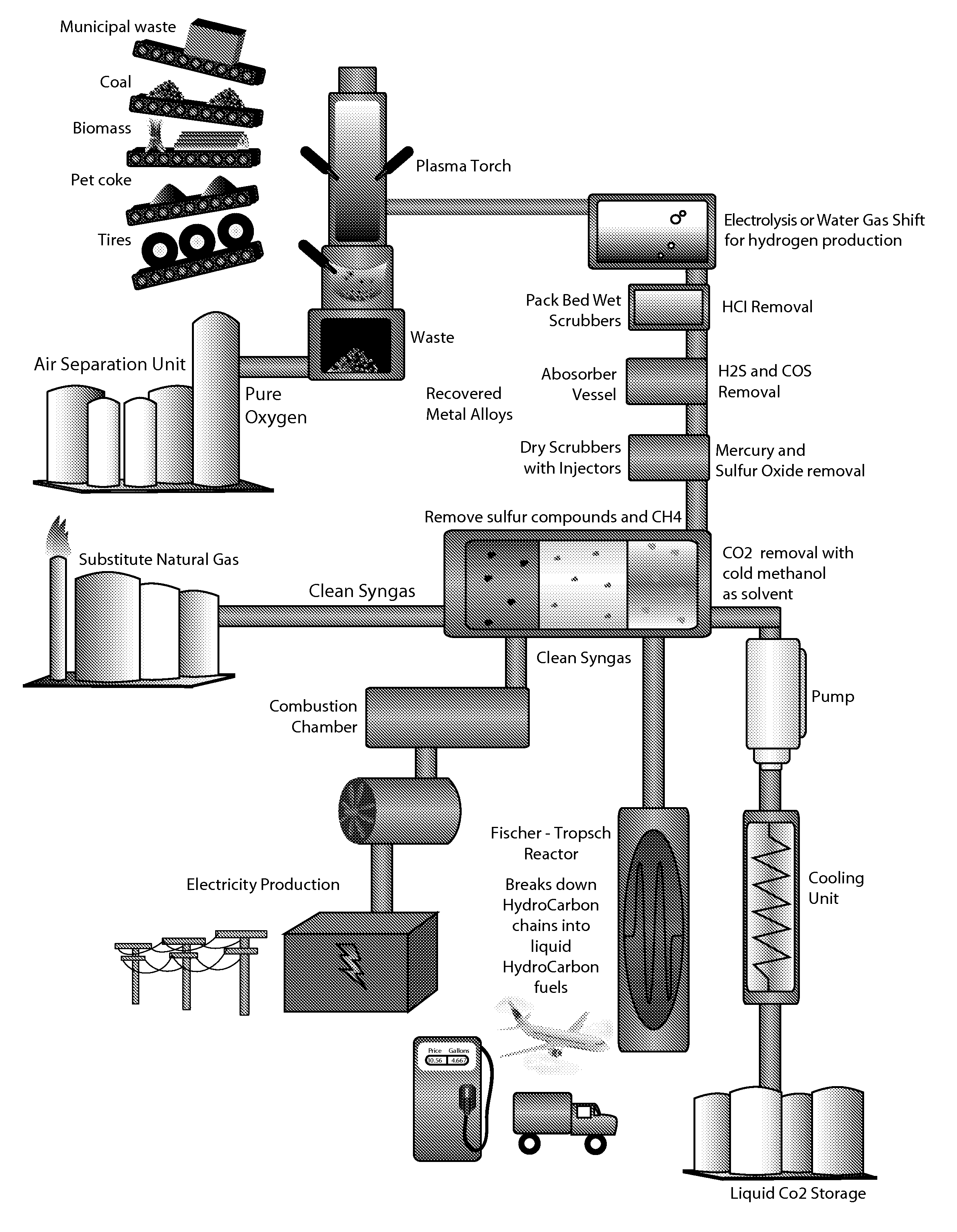

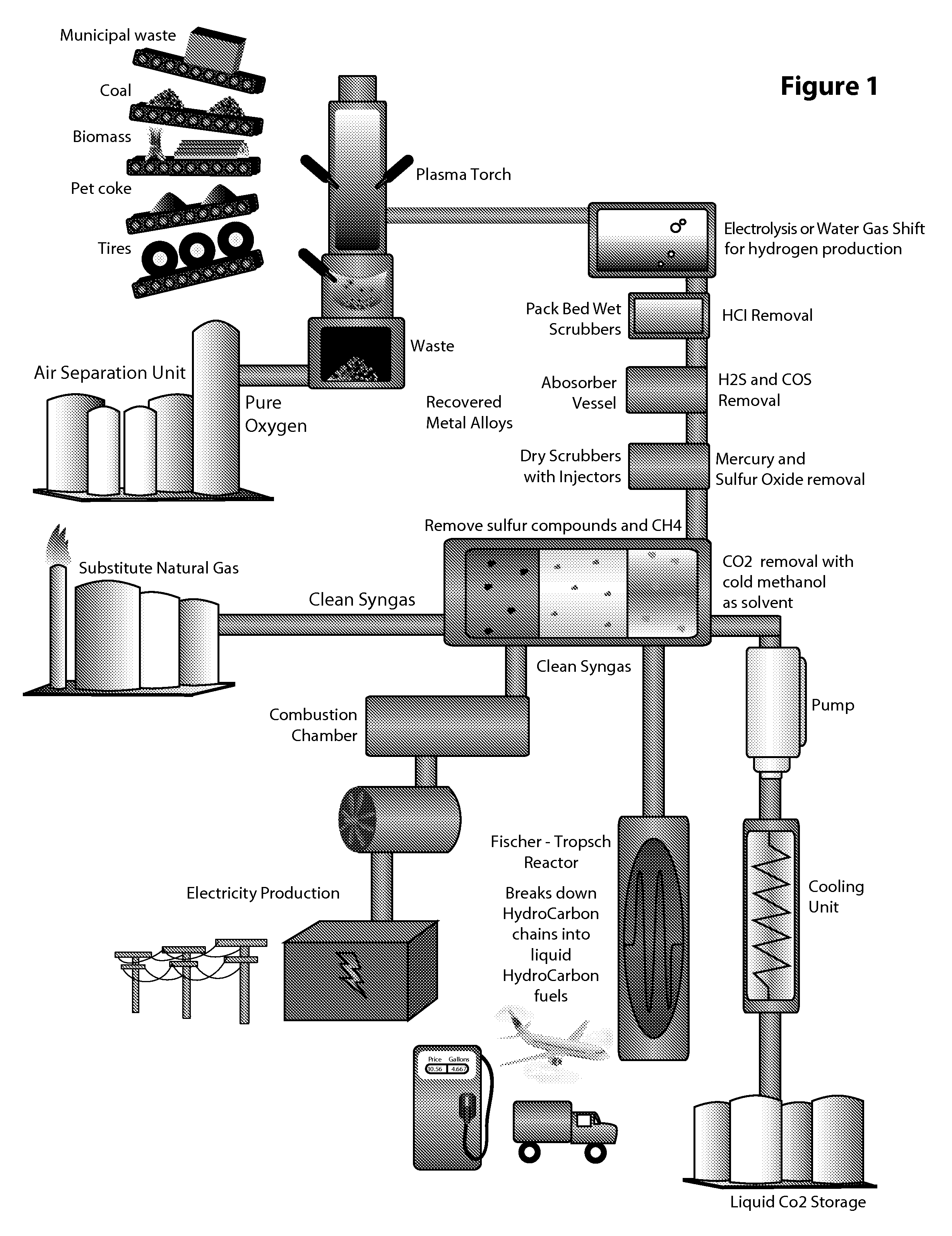

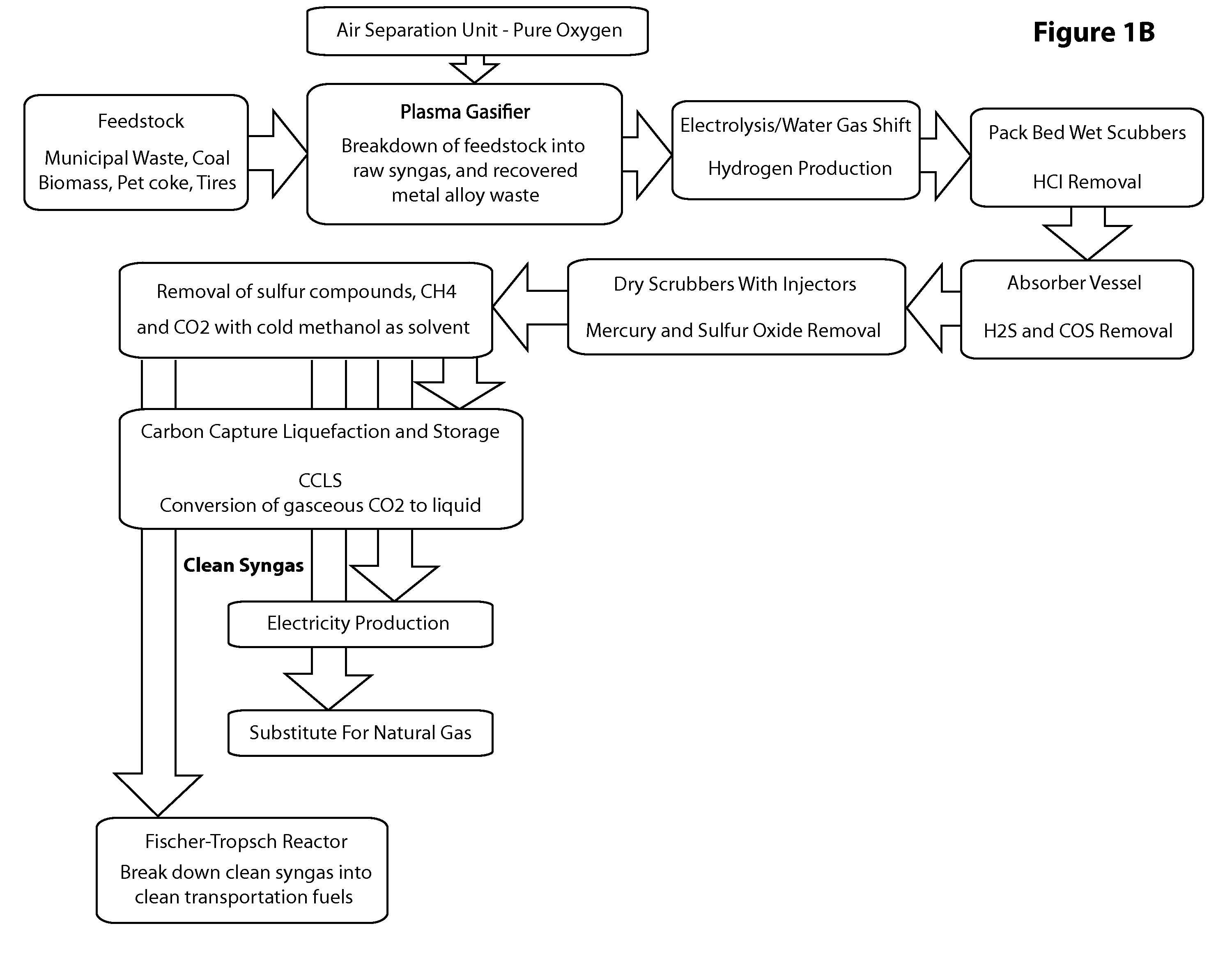

Waste Material, Coal, Used Tires and Biomass Conversion to Alternative Energy and Synthetic Fuels Solutions System with Carbon Capture and Liquefaction

ActiveUS20120032452A1Enhanced overall recoveryImprove powerCombustible gas catalytic treatmentBiofuelsEngineeringOxygen

The system contained within this application for non-provisional patent protection provides the ability to convert municipal solid waste materials, used tires, various biomass including wood chips and other agricultural waste, and the addition of coal into synthesis gas (syngas), with oxygen as plasma gas. The system will accommodate the possibility for variation in feedstock co-gasification of the various materials with plasma torches that will be embedded in a plasma gasification unit. One converted into synthesis gas (syngas), the syngas will be cleaned of acid gases and carbon dioxide (CO2). Carbon dioxide will be captured and converted for various industrial applications instead of being released into the atmosphere. Clean syngas generated by the system will become the gas fuel for various energy solutions including clean electricity, as substitute for natural gas, and ultra clean FT synthetic fuels.

Owner:KUKU LAI O

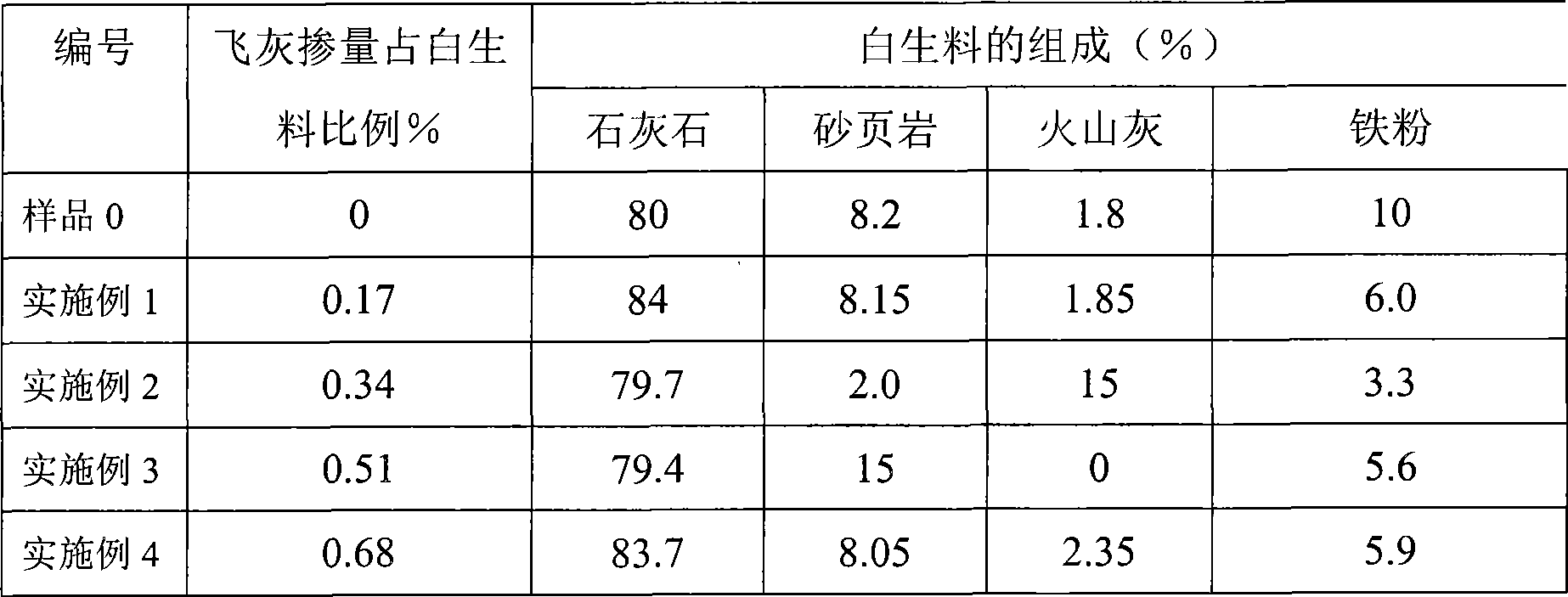

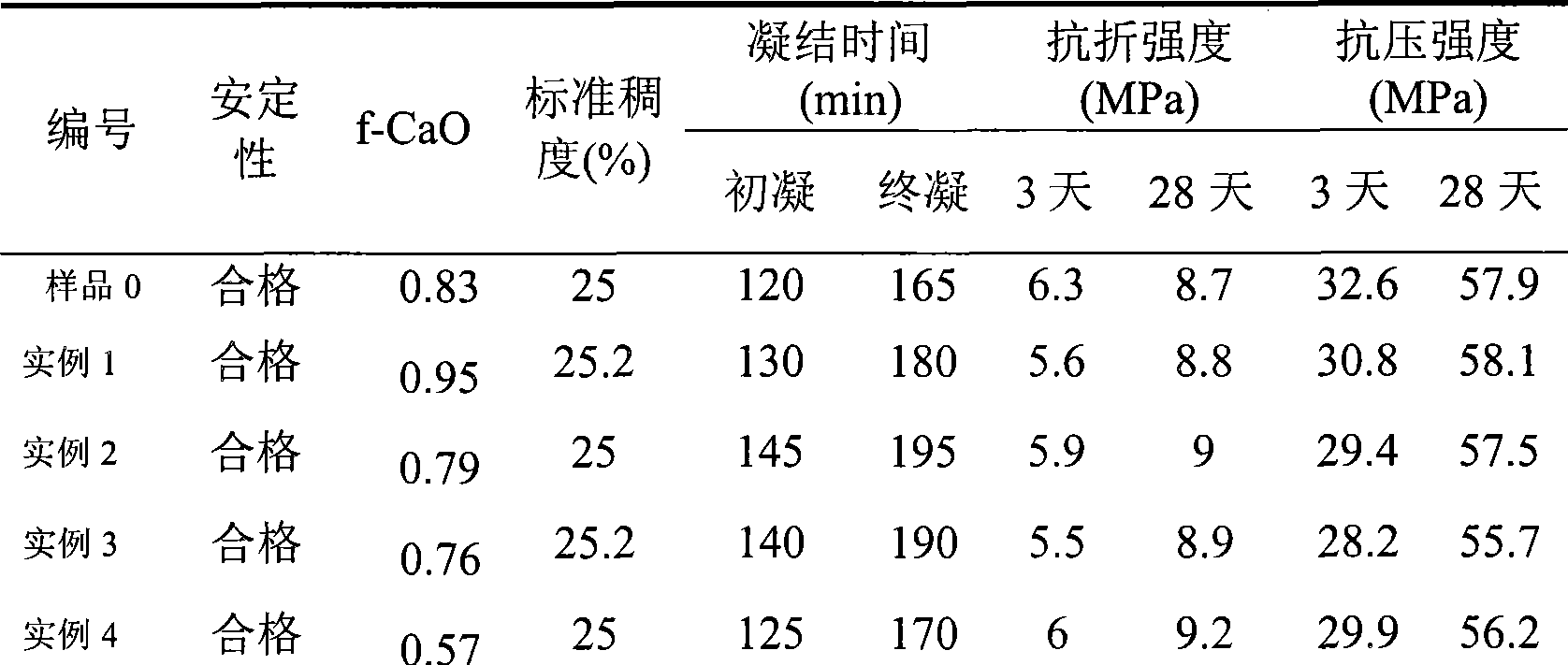

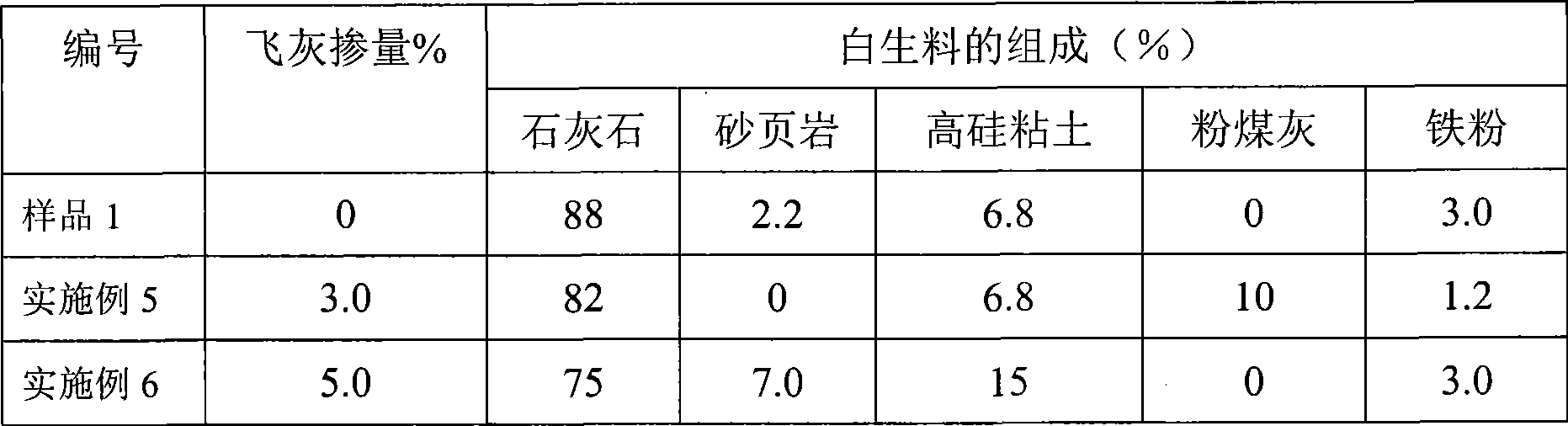

Method for producing portland cement clinker using domestic waste flying ash

The invention relates to a method for producing Portland cement clinker with incineration slag of municipal solid waste. The method solves the problem of crust and blockage caused by chlorine through the reconstruction of the prior kiln which is realized by mounting a by-way air exhaust device. For a kiln system with a kiln row and a furnace row which are independent from each other, the by-way air exhaust device is arranged in an uptake of a kiln end gas chamber in the kiln row close to a five-stage cylinder; while for common industrial kiln, the air exhaust device is arranged between an outlet of decomposing furnace and an inlet of the five-stage cylinder or arranged at an uptake of an outlet of the five-stage cylinder; the fly ash passes through a kiln head, the kiln end gas chamber, or the decomposing furnace and then is sprayed into the kiln. The use frequency of the by-way air exhaust device is between once per four hours and once per three days, the temperature of the air entering the by-way air exhaust device is controlled to be more than 950 DEG C. the method has the advantages of small reconstruction investment, low treatment cost, production of Portland cement clinker having wide application range and meeting JC / T853-1999 standards of Portland Cement Clinker, realization of reclamation, contribution to the development of cyclic economy, and reduction in consumption of natural resources and energy of the cement industry.

Owner:SOUTH CHINA UNIV OF TECH

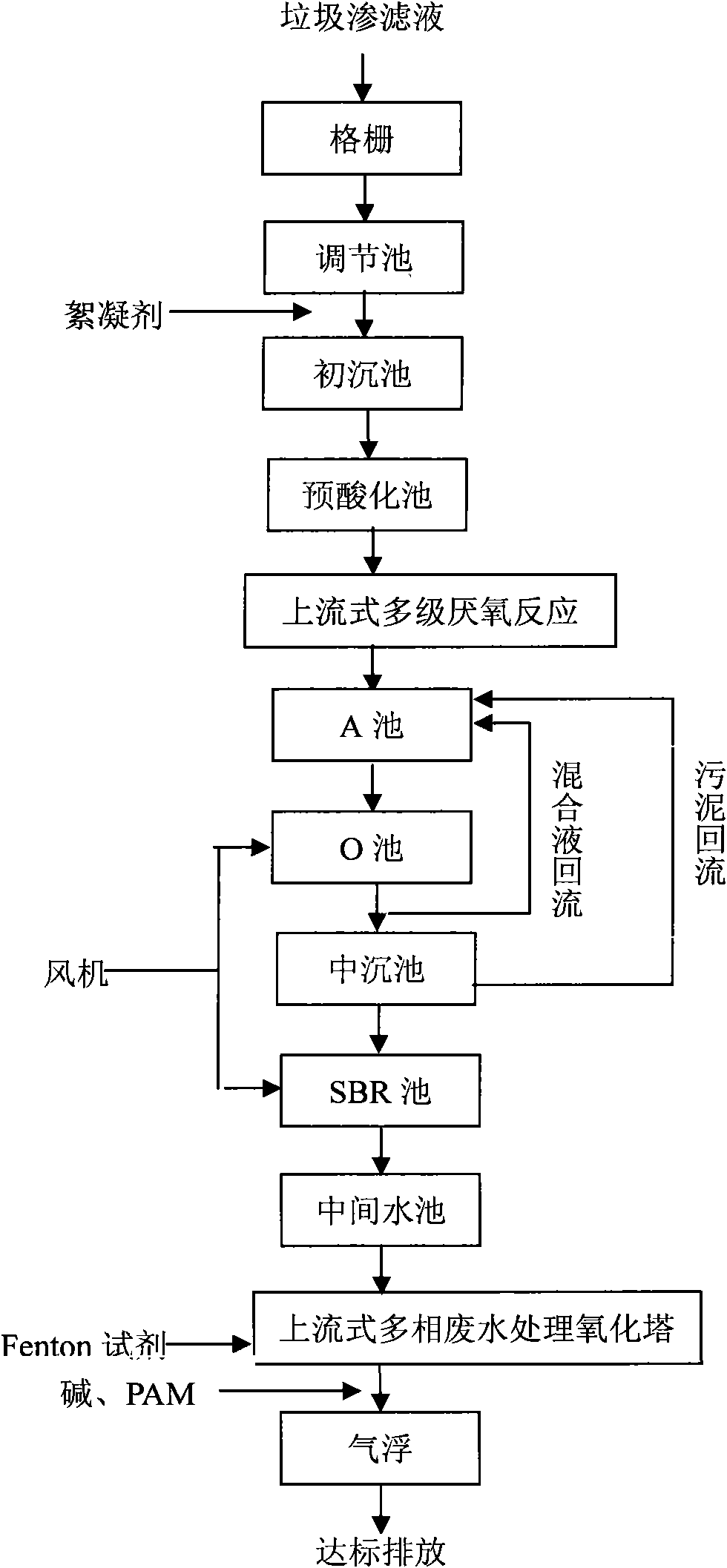

Method for treating garbage leachate

ActiveCN101767914ASimple and fast operationLow running costTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesTreatment effectCombined technique

The invention discloses a method for treating garbage leachate. The method treats the garbage leachate by using the combined technique of pretreatment, biochemical treatment and advanced treatment, wherein the pretreatment adopts a method of coagulating sedimentation, reduces the concentration of organic matters, ammonia nitrogen and metallics, and reduces the inhibiting effect on the subsequent biochemical treatment; the biochemical treatment uses an anaerobic process, an A / O process and SBR to biochemically degrade wastewater, thereby simultaneously removing the organic matters and achieving the goal of denitrification; and finally, Fenton advanced oxidation and air flotation are used for carrying out the advanced treatment, and the strong oxidizing property of hydroxyl free radicals is utilized to oxidize the organic matters, which are difficult to be biochemically degraded, in waste water, thereby ensuring that the outlet water is discharged after reaching the standard. The invention has the advantages of simple operation of the technique, low operating cost, good treatment effect, no secondary pollution and the like, and the advanced treatment can ensure that the outlet water is discharged after reaching the standard. The outlet water meets the standard for pollution control on the landfill site of municipal solid waste (GB 16889-2008).

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

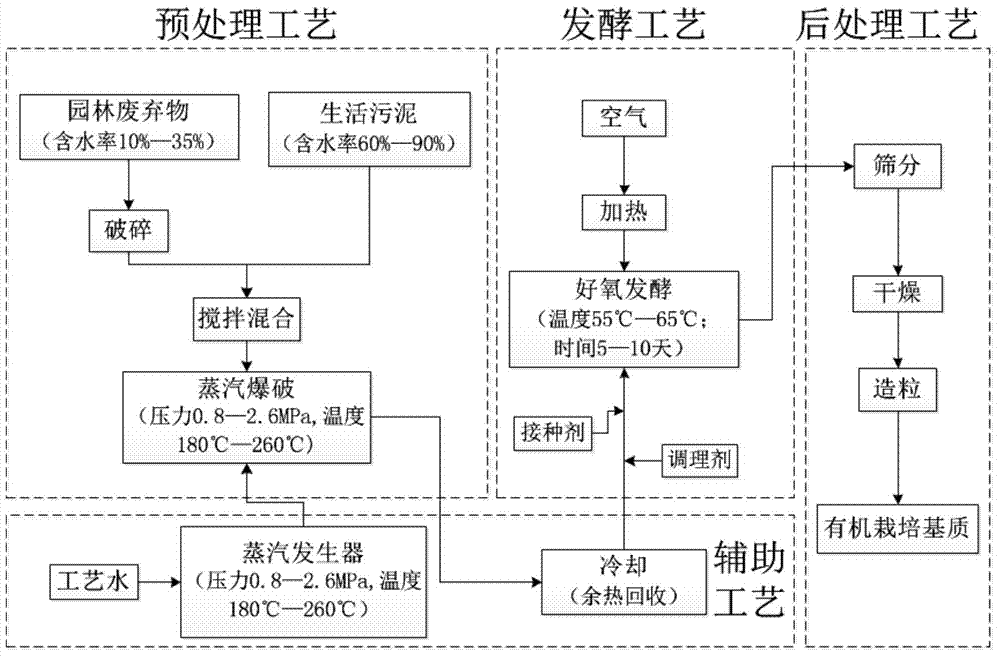

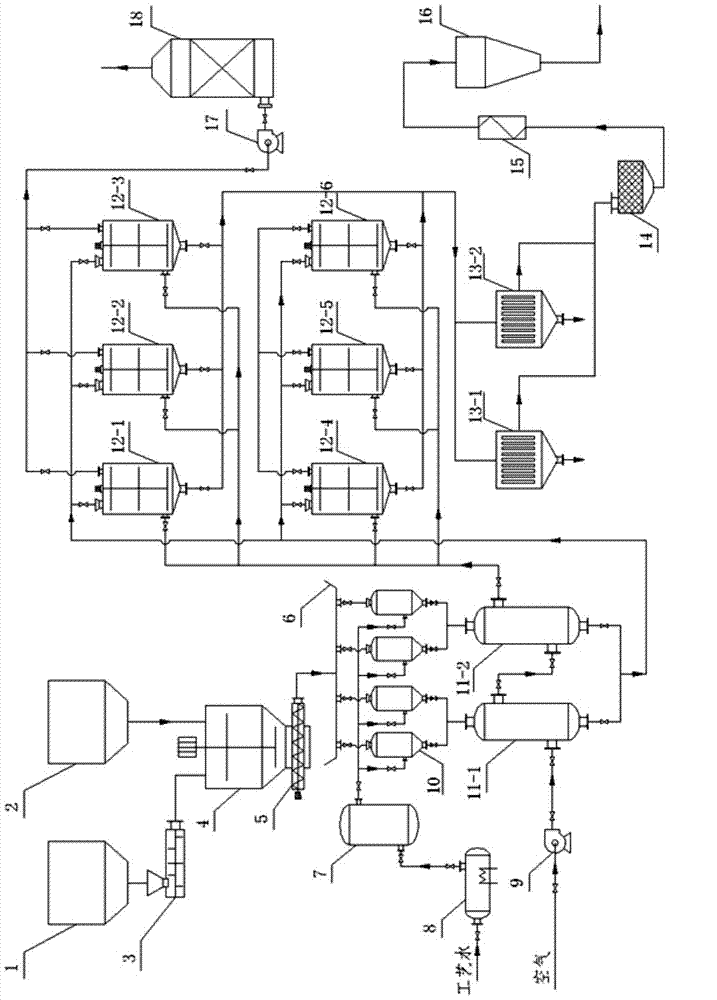

Method and device for preparing novel ecological culture medium from municipal waste

ActiveCN104744090AGuaranteed to be fully decomposedShorten the timeBio-organic fraction processingOrganic fertiliser preparationMunicipal sewageHigh pressure

The invention relates to a municipal waste recycling technology and aims to provide a method and a device for preparing a novel ecological culture medium from municipal waste. The method comprises the following steps: mixing garden waste with municipal sewage sludge to obtain a raw material mixture, wherein the moisture content of the dried municipal sewage sludge is 60%-90%; blasting the municipal sewage sludge with post steam, adding an inoculant into the processed material to perform aerobic fermentation; screening, drying and pelletizing the fermented material to obtain the ecological culture medium. The method has the beneficial effects that the time required for a fermentation process is short, the fermentation efficiency is high, the production process is energy-saving, and various pathogenic bacteria, parasitic ovum and the like in the raw material can be completely killed due to high-temperature high-process treatment, so that a harmless environment is realized, and continuous and automatic production can be realized. Moreover, secondary pollution can be prevented, the production efficiency is improved, and harmlessness, reduction and recycling of municipal sewage sludge and garden waste can be truly realized.

Owner:杨健

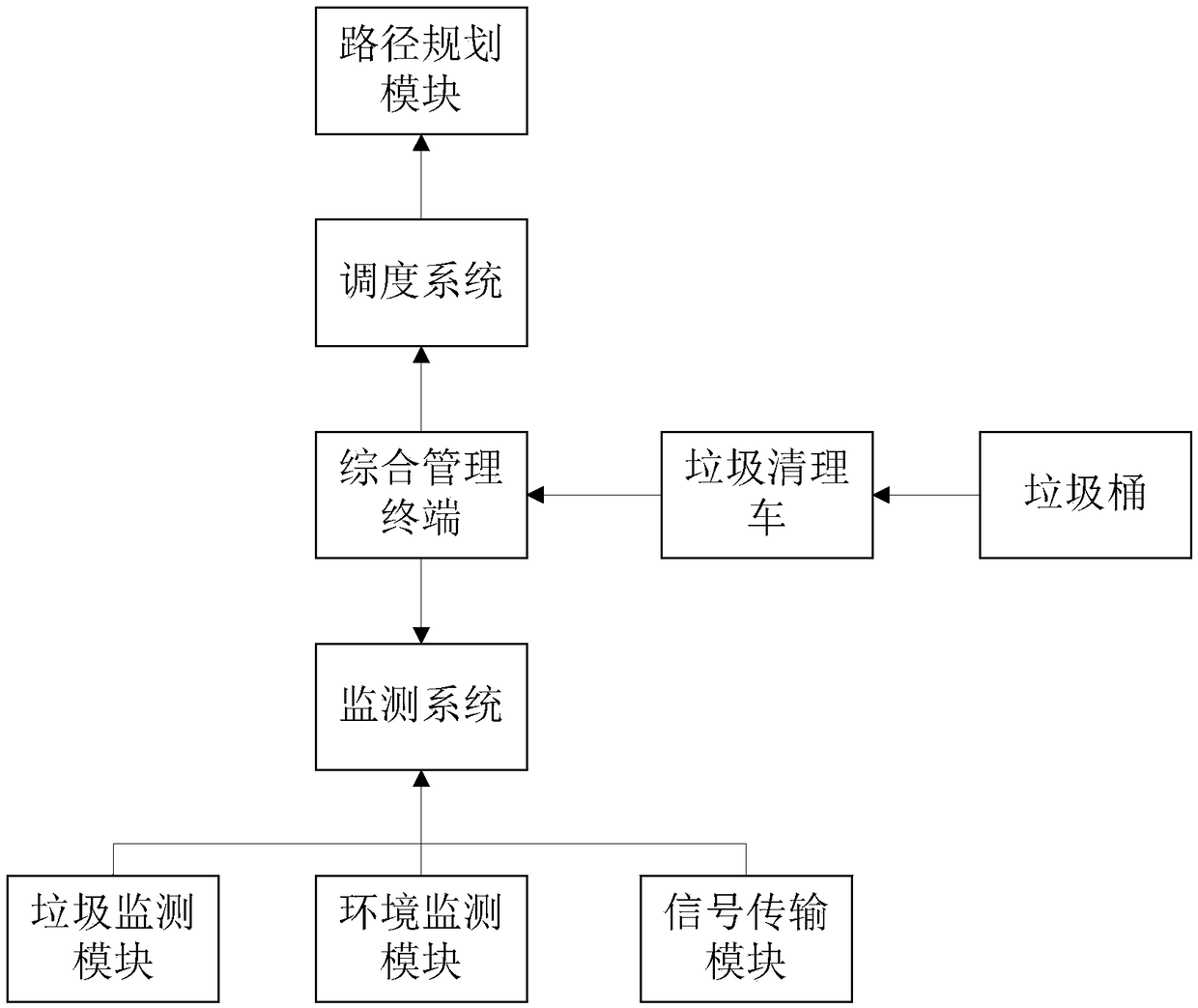

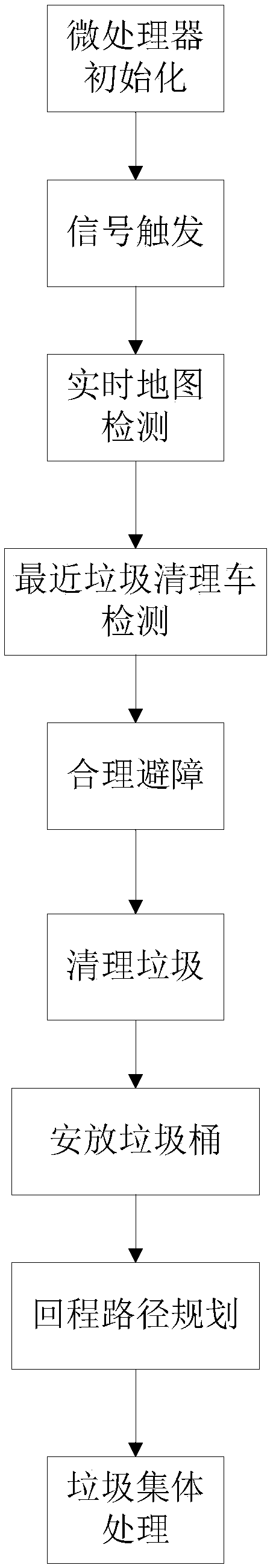

Municipal Solid Waste Cleaning and Transportation Dispatching System

PendingCN109345096AIncrease profitImprove cleaning efficiencyRefuse receptaclesSatellite radio beaconingRefuse collectionMonitoring system

the invention discloses a Municipal Solid Waste Cleaning and Transportation Dispatching System which includes an integrated management terminal, Monitoring system, dispatching system, A number of refuse bins and refuse collection vehicles, The monitoring system comprises a garbage monitoring module, environmental monitoring module and signal transmission module, A garbage monitoring module and anenvironment monitoring module are installed on the garbage bin, the scheduling system includes a path planning module, The garbage collection vehicle includes a garbage bin storage area, Garbage bin and garbage bin collection and placing mechanism, according to the information transmitted by the garbage monitoring module, The control path planning module drives the garbage collection vehicle for garbage collection, The integrated management terminal carries out analysis according to the crowd density monitored by the environmental monitoring module, and the integrated management terminal carries out analysis according to the crowd density monitored by the environmental monitoring module. The garbage can be allocated and managed by the integrated management terminal, so that the utilizationrate of the garbage can be high, the cleaning and transportation efficiency is high, the management is convenient, and the feedback is timely.

Owner:ZHEJIANG TONGMEI ENVIRONMENT TECH GRP CO LTD

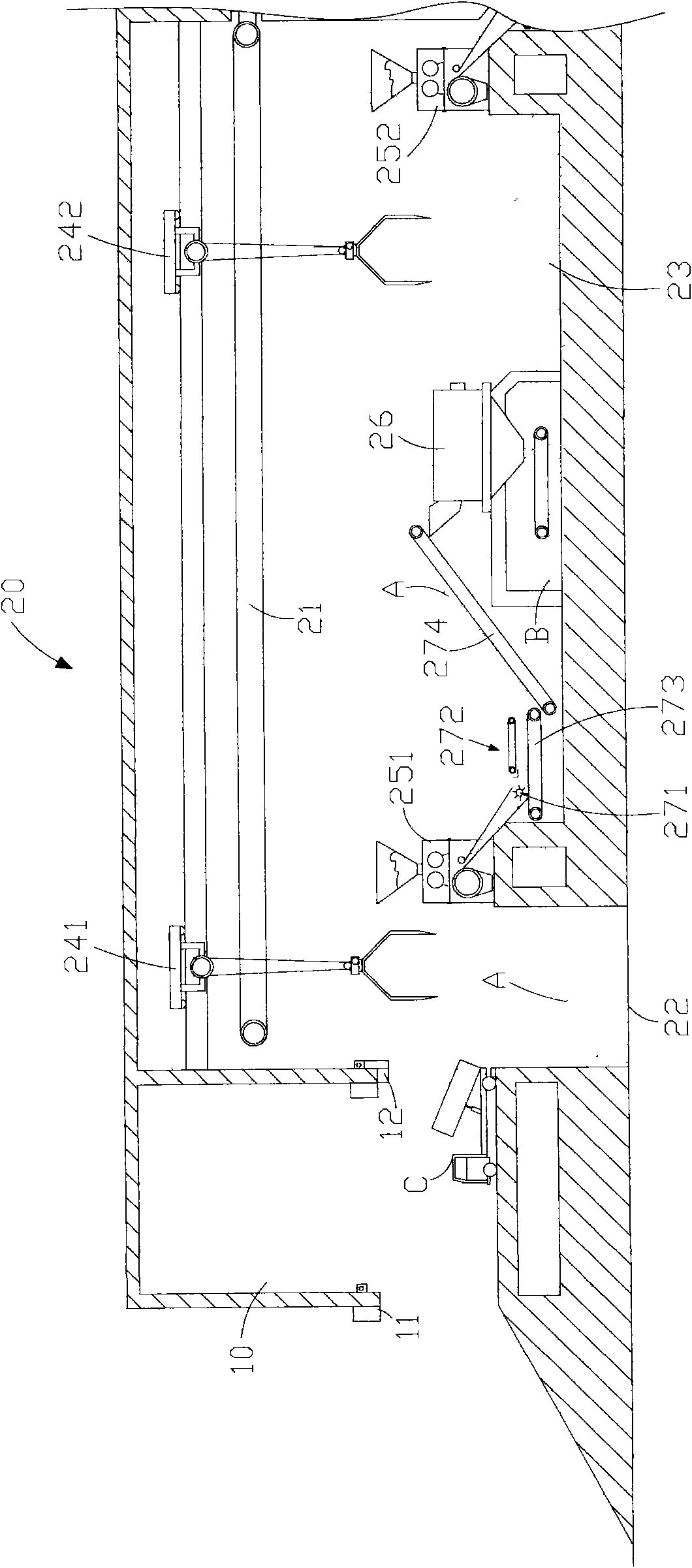

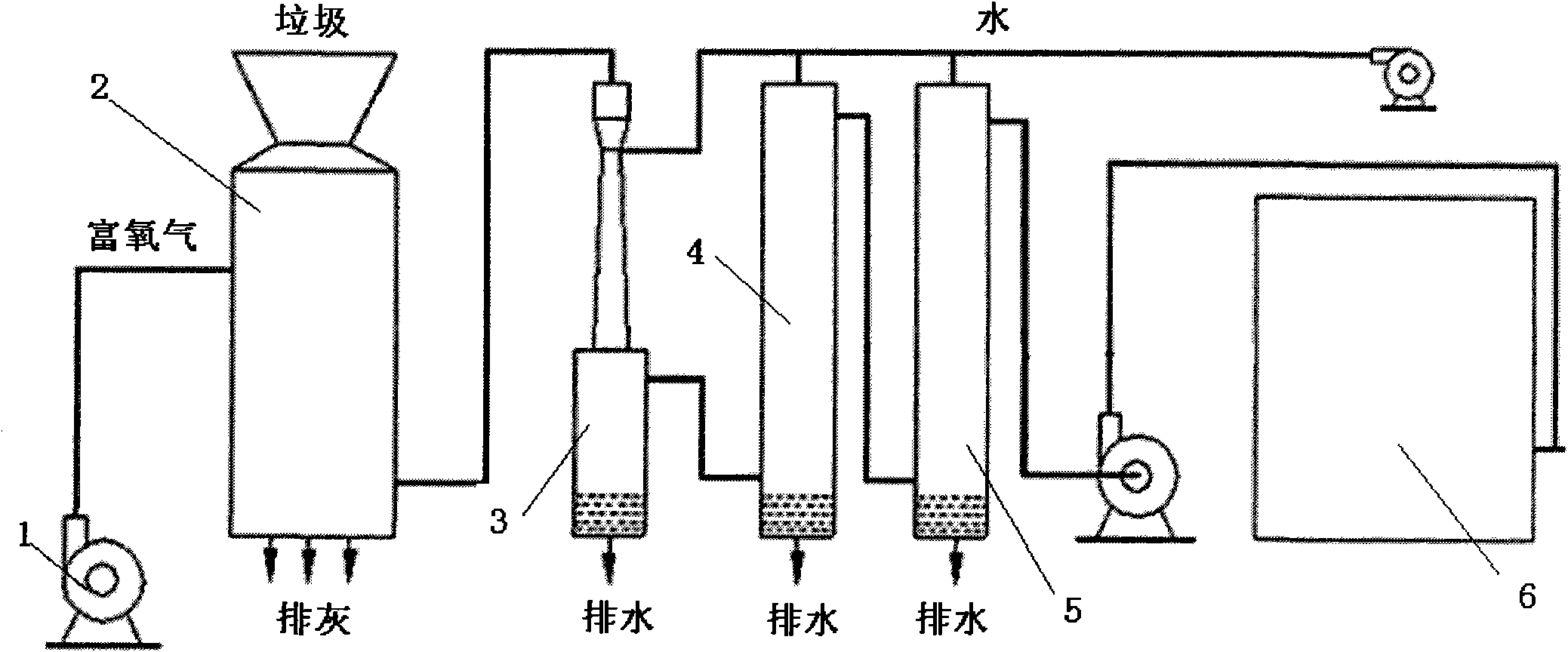

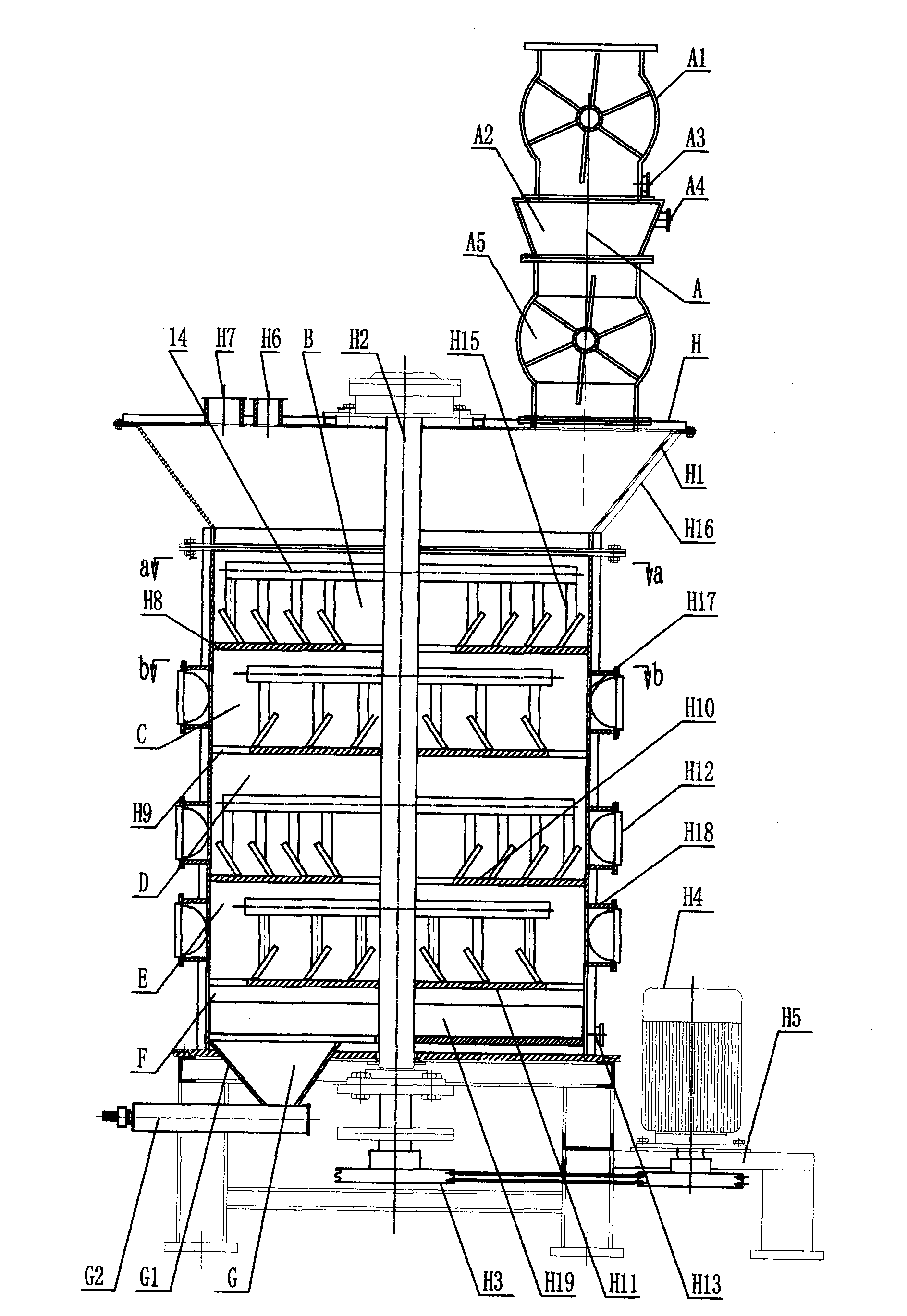

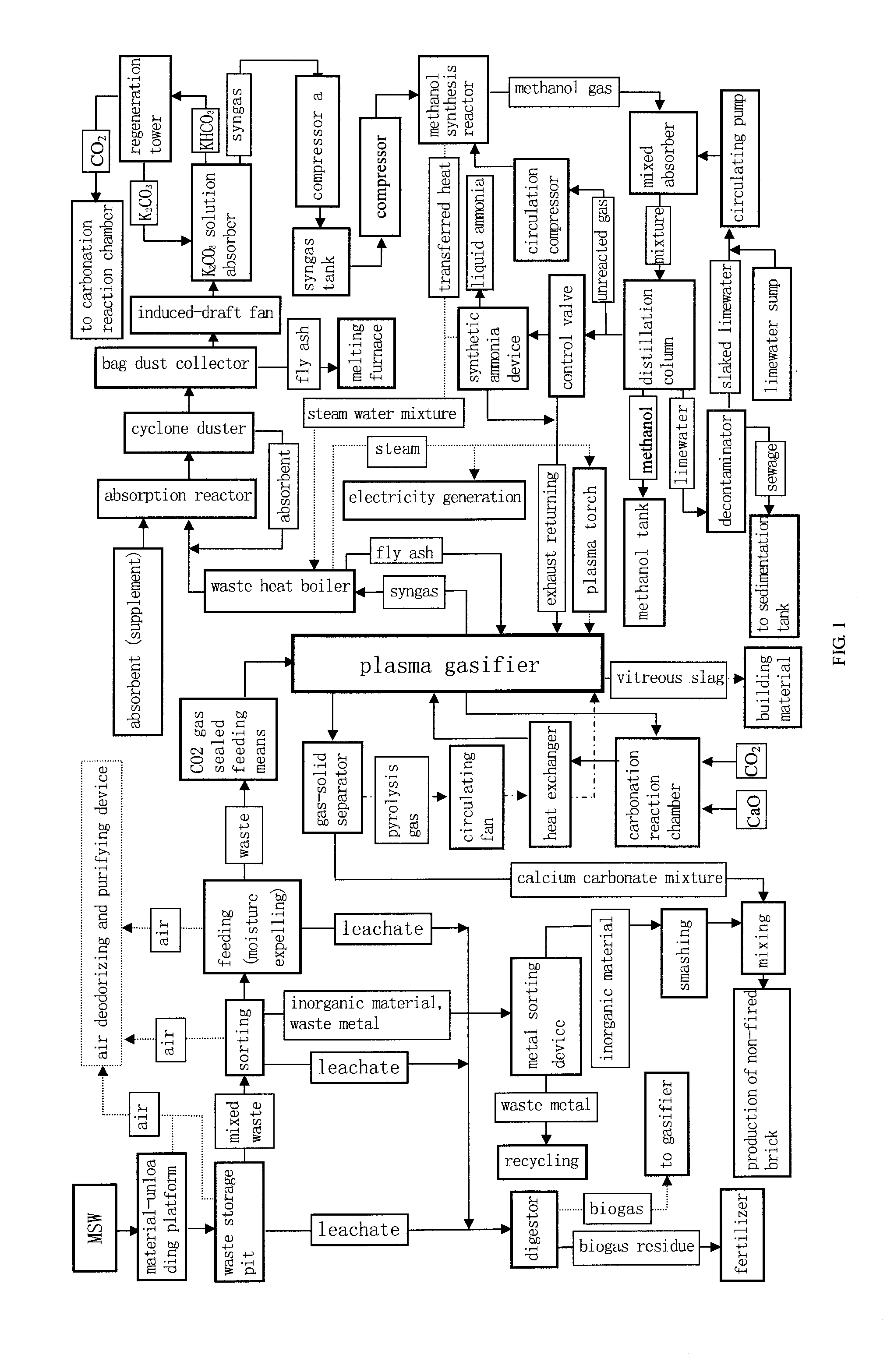

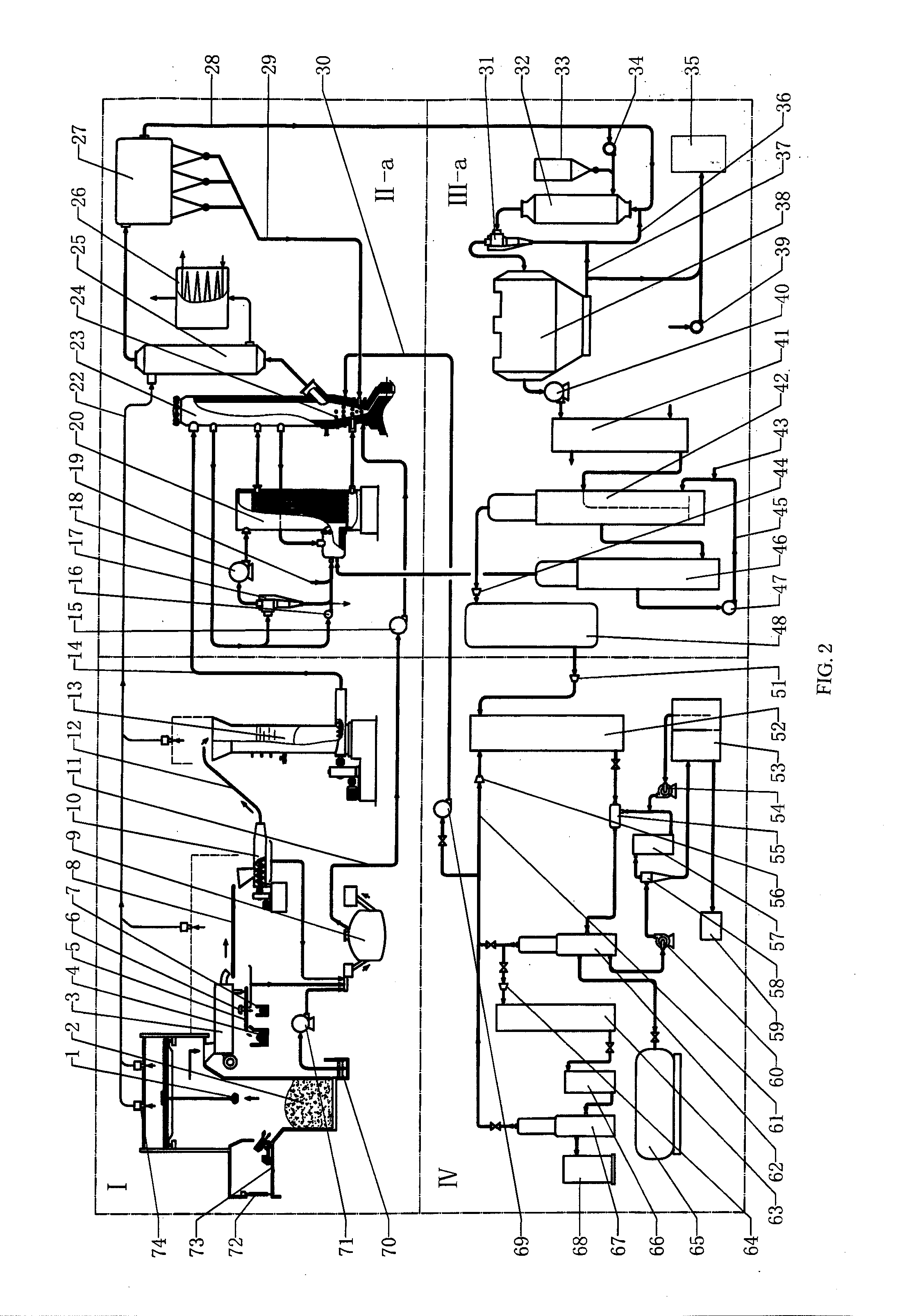

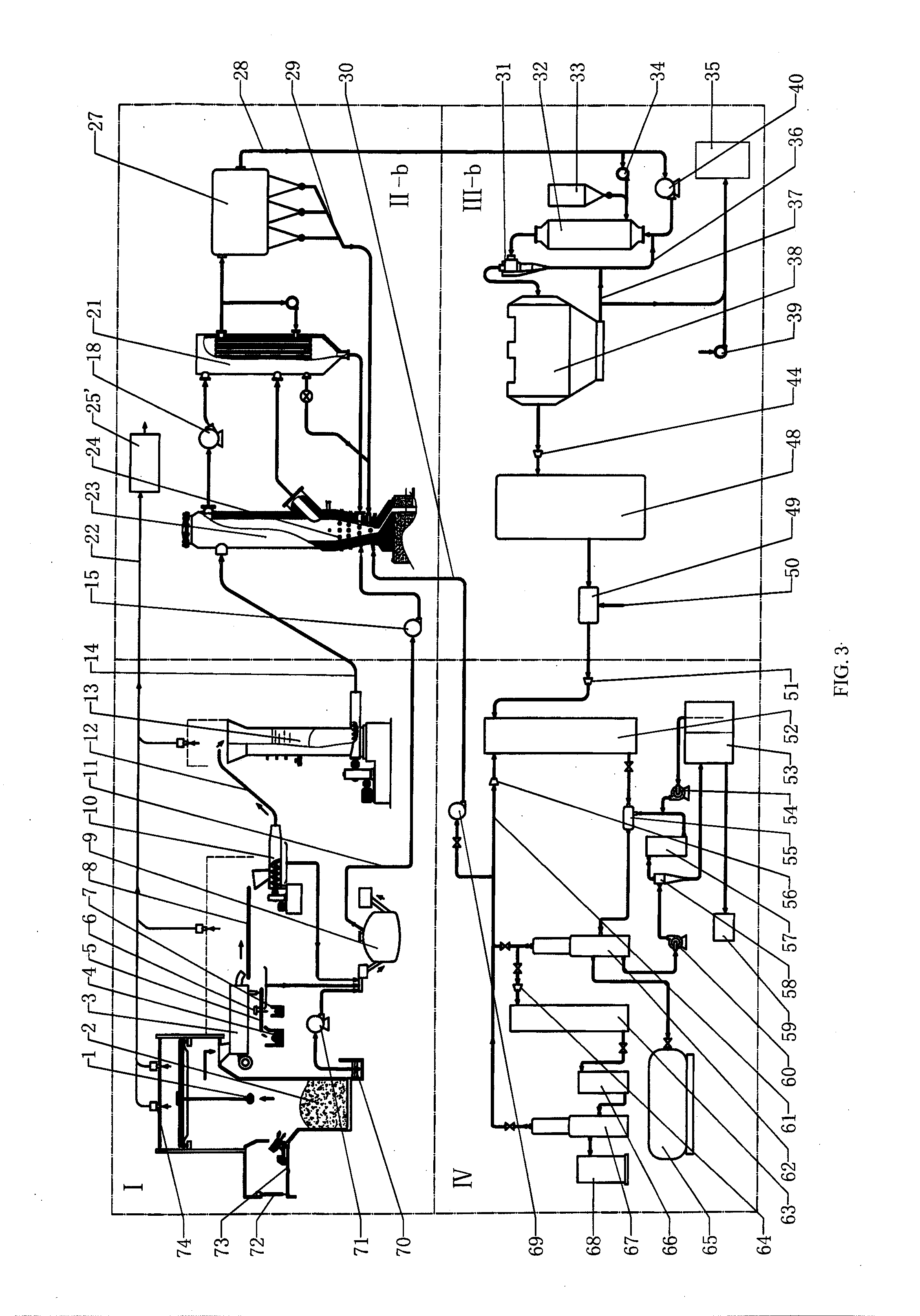

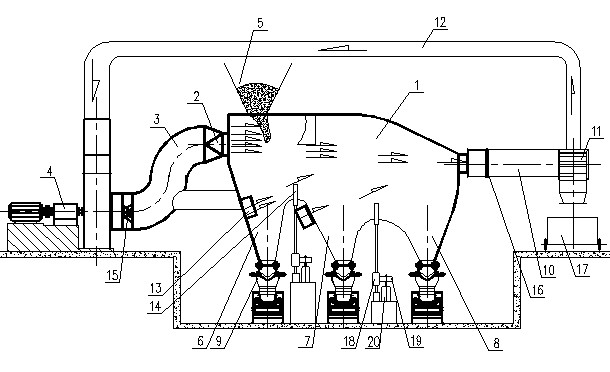

Method, system and equipment for gasification-liquefaction disposal of municipal solid waste

InactiveUS20130012605A1Zero emissionAvoid dioxin contaminationBio-organic fraction processingPreparation by oxidation reactionsHeat energyCarbonatation

A gasification-liquefaction disposal method, system and equipment for MSW are disclosed. The method involves the MSW pretreatment of dehydrating and separating, thus reducing water and inorganic substance content of the waste. Then, the MSW is introduced into a plasma gasifier (23) by a carbon dioxide air-sealed feeding device (13) and gasified therein to obtain hydrogen-rich syngas. The hydrogen-rich syngas is then cooled, deacidified, dedusted and separated to obtain carbon dioxide. Then, the hydrogen-rich syngas is catalyzed to produce methanol product in a methanol synthesis reactor (52). The separated carbon dioxide is sent back to a carbonation reaction chamber (2007) of a gasification system to perform carbonation reaction with calcium oxide, thereby releasing heat to provide assistant heat energy for gasification and avoiding greenhouse gas from being discharged into environment. Exhaust gas is returned to the plasma gasifier (23) for remelting treatment, thus forming a closed-loop circulation production system and realizing the disposal of the MSW with zero discharge and no pollution, thereby avoiding dioxin pollution and converting the MSW to chemical raw materials and fuel needed by mankind The method, system and equipment are suitable for harmless and recycling disposal of MSW, industrial high polymer waste, composting waste and waste in waste sorting sites.

Owner:QUZHOU CITY GUANGYUAN DOMESTIC GARBAGE LIQUEFY TECH INST

Wind power sorting system for municipal domestic waste

InactiveCN102601049AFall into exactlyFall into realizationGas current separationEngineeringVolumetric Mass Density

The invention discloses a wind power sorting system for municipal domestic waste, which comprises a box body, a tuyere, a fan, a waste inlet and more than two sorting cabins, wherein the fan is arranged at the upper part of the front end of the box body, the fan is connected with the tuyere through an inlet air duct, the waste inlet is arranged at the front part of the box body, and the more thantwo sorting cabins are arranged at the lower part of the box body. The wind power sorting system is characterized in that the heights of the openings of all sorting cabins decrease sequentially from front to back, and the openings of all sorting cabins increase sequentially from front to back. Buffering air locking devices are arranged at the lower parts of the sorting cabins. An exhaust pipe is arranged at the rear end of the box body, and the exhaust pipe is provided with a filter screen. The wind power sorting system of the municipal domestic waste can effectively sort various wastes in different densities and has the advantages of high efficiency, accurate sorting, automation, energy conservation and consumption reduction and strong adaptability and the like.

Owner:SICHUAN SANTA HEAVY IND MACHINERY

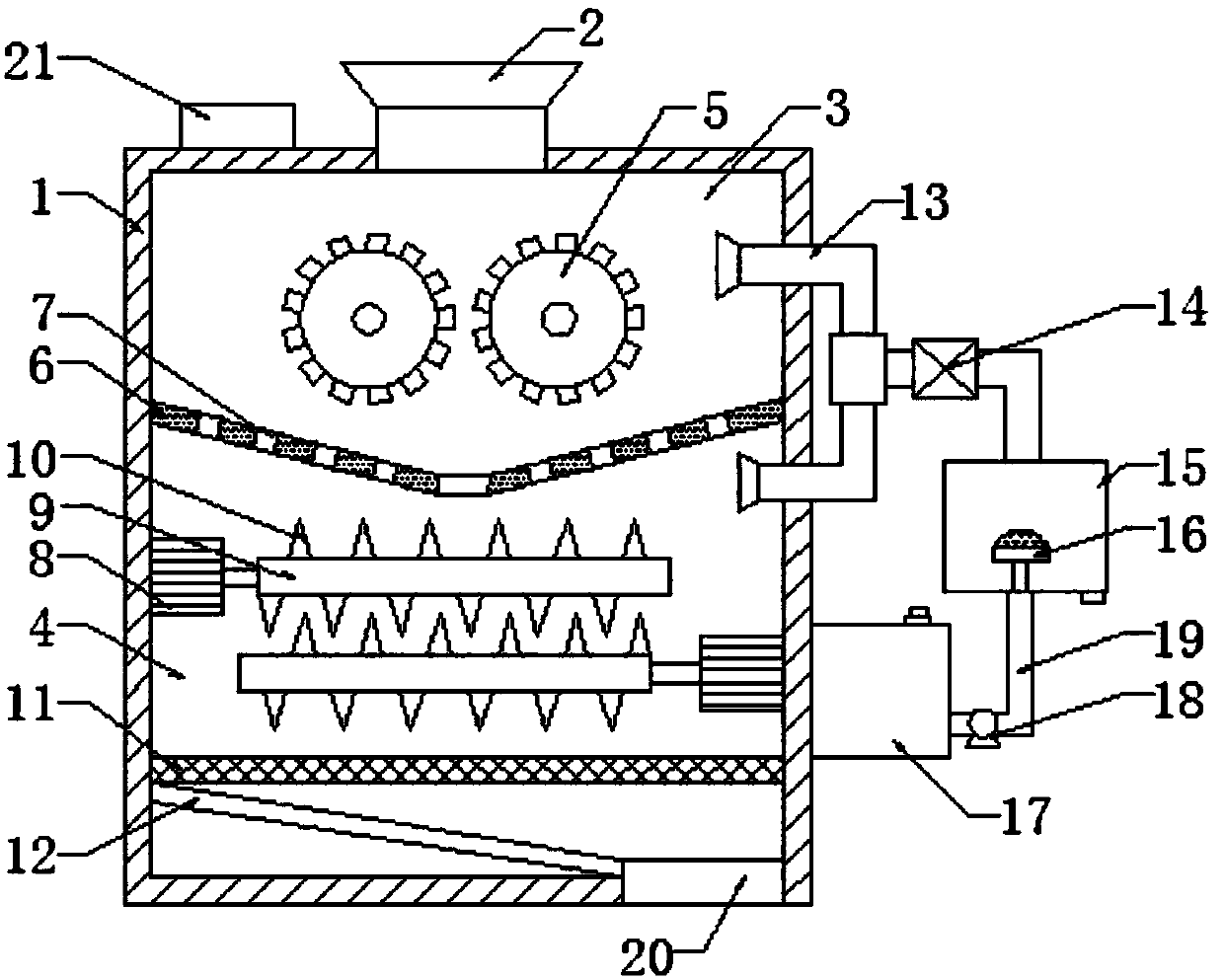

Municipal building waste crushing device with dust removal function

InactiveCN109926145AComplete and compact structural designConvenient whereaboutsUsing liquid separation agentDirt cleaningEngineeringMotor shaft

The invention discloses a municipal building waste crushing device with a dust removal function. The municipal building waste crushing device comprises a crushing box, a coarse smashing chamber, a fine smashing chamber, two servo motors, crushing knives and a dust removal box, the crushing box is internally provided with the coarse smashing chamber and the fine smashing chamber, a feeding inlet isformed in the top of the crushing box, a controller is arranged on one side of the feeding inlet, two crushing rollers are arranged in the coarse smashing chamber in parallel, the coarse smashing chamber and the fine smashing chamber are partitioned by a sieving plate, the sieving plate is evenly provided with a plurality of through holes, the two servo motors are mounted in the fine smashing chamber, motor shafts of the two servo motors are axially connected with two rotating shafts correspondingly, the crushing knives are arranged on the two sides of the two rotating shafts, the directionsof the two rotating shafts are opposite, by arranging the crushing rollers, building waste is preliminarily smashed firstly, coarsely smashed and then smashed by the crushing knives, smashing is morethorough, through mutual action of a water pump, an atomizing nozzle, the dust removal box and a suction ventilator, dust generated in the crushing process is absorbed through water mist, and the effect is good.

Owner:XIAN DONGJIA TRADE CO LTD

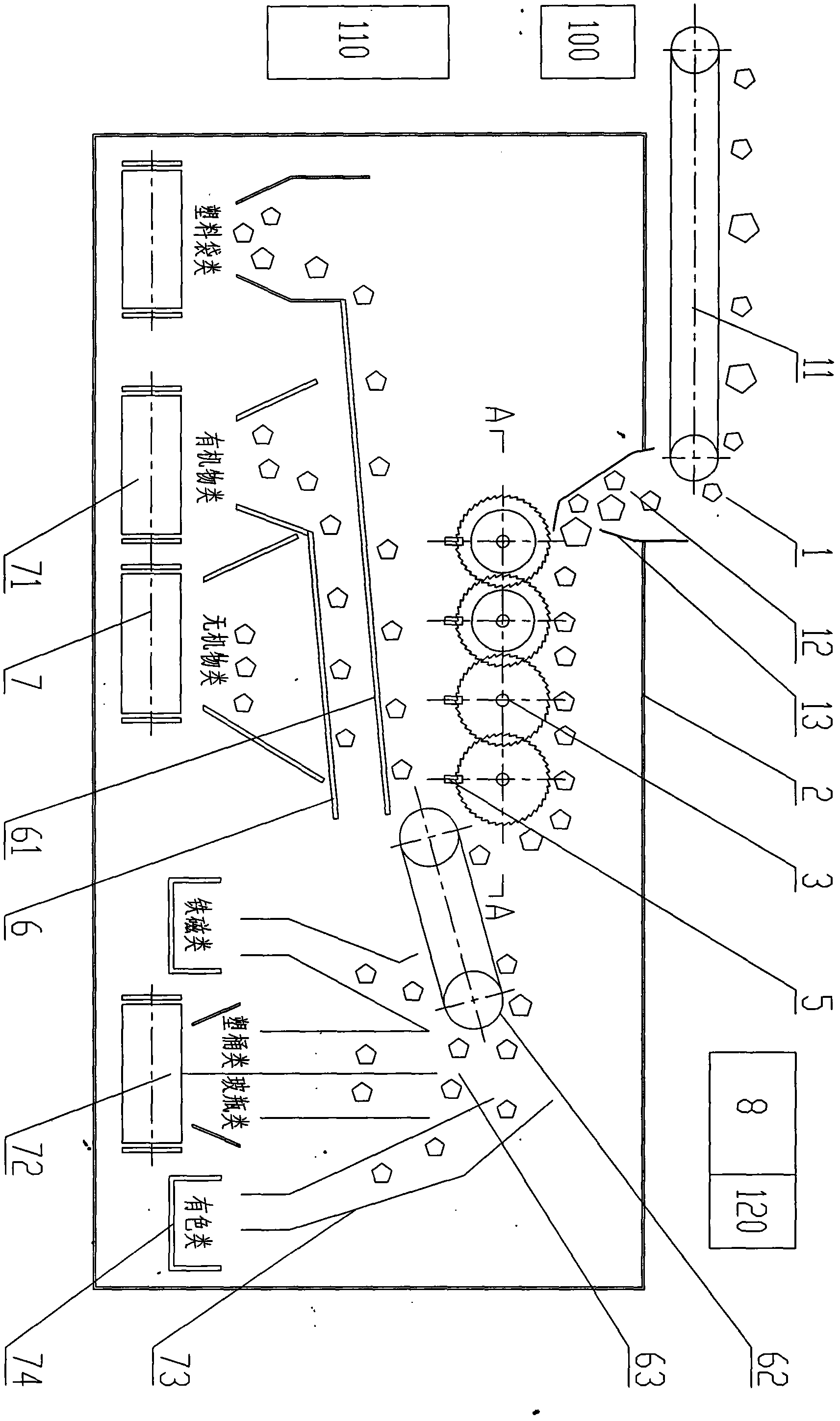

Bag-breaking and sorting integrated equipment for municipal domestic waste

The invention discloses bag-breaking and sorting integrated equipment for municipal domestic waste. The equipment mainly comprises a bag breaking and crushing device, a drive device, a material cleaning device, a composite sorting device, a discharging device and the like. Serrated knives on a roller row in the bag breaking and crushing device perform effective bag breaking on bagged and mixed municipal domestic waste and full crush on organisms; material cleaning mechanisms of rollers and the serrated knives can ensure the winding-free continuous operation of garbage bag breaking; and the equipment does not perform forced crushing on articles which are difficult to crush so as to avoid adverse effects of crushed brick and stone slag on the composting of the organisms, and the harm of crushed waste batteries and the like. The cost of the equipment can be reduced; and the abrasion of blades and the operation cost of the crushing energy consumption and the like are reduced. By adopting an advanced integrated sorting technology, the composite sorting device is used for thoroughly sorting the garbage subjected to bag breaking, and sorting high-purity components such as plastic bags, organisms, inorganic matters, plastic containers, soft packages, glass bottles, waste metal, batteries and the like, thereby contributing to the recycling of various resources.

Owner:朱海生 +1

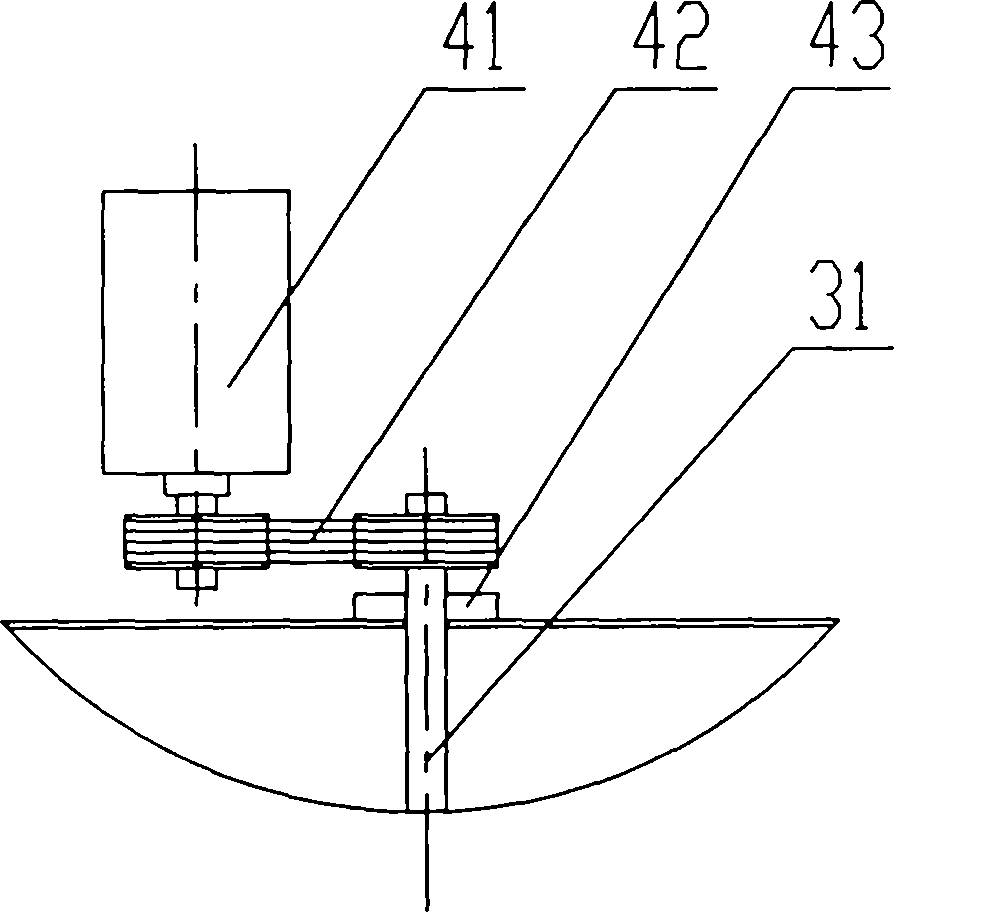

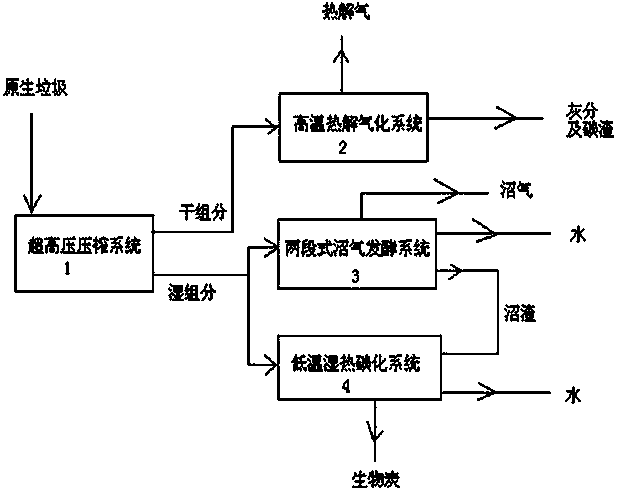

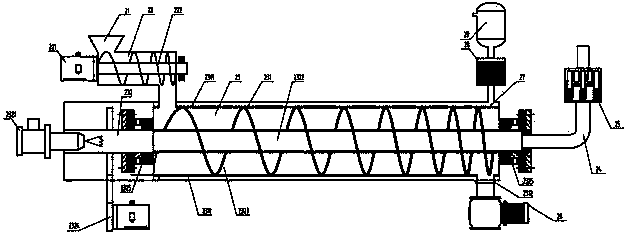

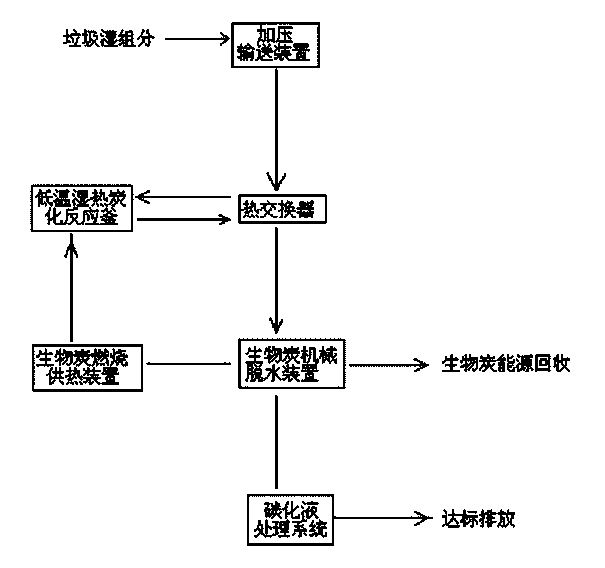

Municipal solid waste extreme decrement and highly resourceful treatment process and municipal solid waste extreme decrement and highly resourceful treatment device

The invention discloses a municipal solid waste extreme decrement and highly resourceful treatment process and a municipal solid waste extreme decrement and highly resourceful treatment device. In the treatment process, the municipal solid waste is classified into dry component with very low water content and wet component mainly formed by biomass waste pulp once under the ultrahigh pressure squeezing action of an ultrahigh pressure squeezer. The dry component is efficiently converted into pyrolysis gas with very high calorific value, a small amount of carbon residue and inert ash in a high-temperature pyrolysis gasification system which is specially designed. The pyrolysis gas can be also taken as fuel to be used in other industrial processes besides being taken as energy of the pyrolysis process. The wet component is converted into marsh gas or biochar with very high calorific value by virtue of a biogas fermentation system or a low-temperature dampness-heat carbonization system which is specially designed. Most of the rest biochar can be used for providing energy for other industrial production processes except that a small part of the biochar is taken as energy of the low-temperature dampness-heat carbonization process.

Owner:深圳龙澄高科技环保股份有限公司

Methods and apparatus for converting waste materials into fuels and other useful products

ActiveUS8877992B2Effectively handle problematic wasteFree of contaminantsHydrocarbon from carbon oxidesTransportation and packagingSpeciality chemicalsBiological waste

Conversion of waste and other organic feedstock into sustainable energy, feed, fertilizer, and other useful products of reliable purities is accomplished using water, heat, and pressure. More specifically, the invention provides methods and apparatus that handle mixed streams of various feedstocks, e.g. agricultural waste, biological waste, municipal solid waste, municipal sewage sludge, and shredder residue, to yield gas, oil, specialty chemicals, and carbon solids that can be used as is or are further processed. Useful products can be diverted at various points of the process or internalized to enhance the efficiency of the system.

Owner:SYNPET TEKNOLOJI GELISTIRME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com