Pretreatment method before power generating by incinerating municipal solid waste

A technology for domestic waste incineration and domestic waste, applied in the field of pretreatment before domestic waste incineration for power generation, can solve problems such as air pollution, groundwater quality deterioration, dioxin pollution, etc., and achieve the effects of reducing inconvenience, reducing space, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

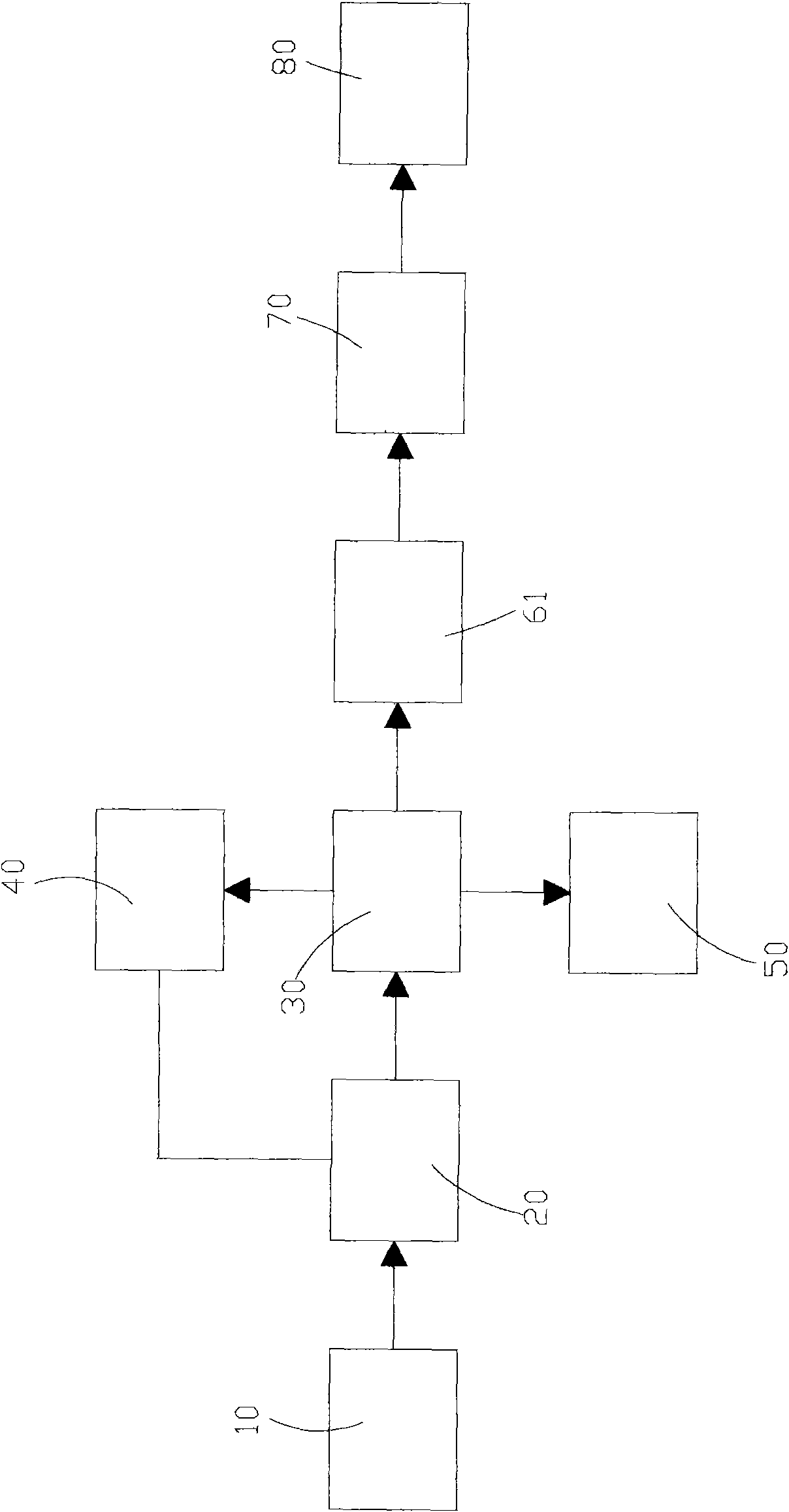

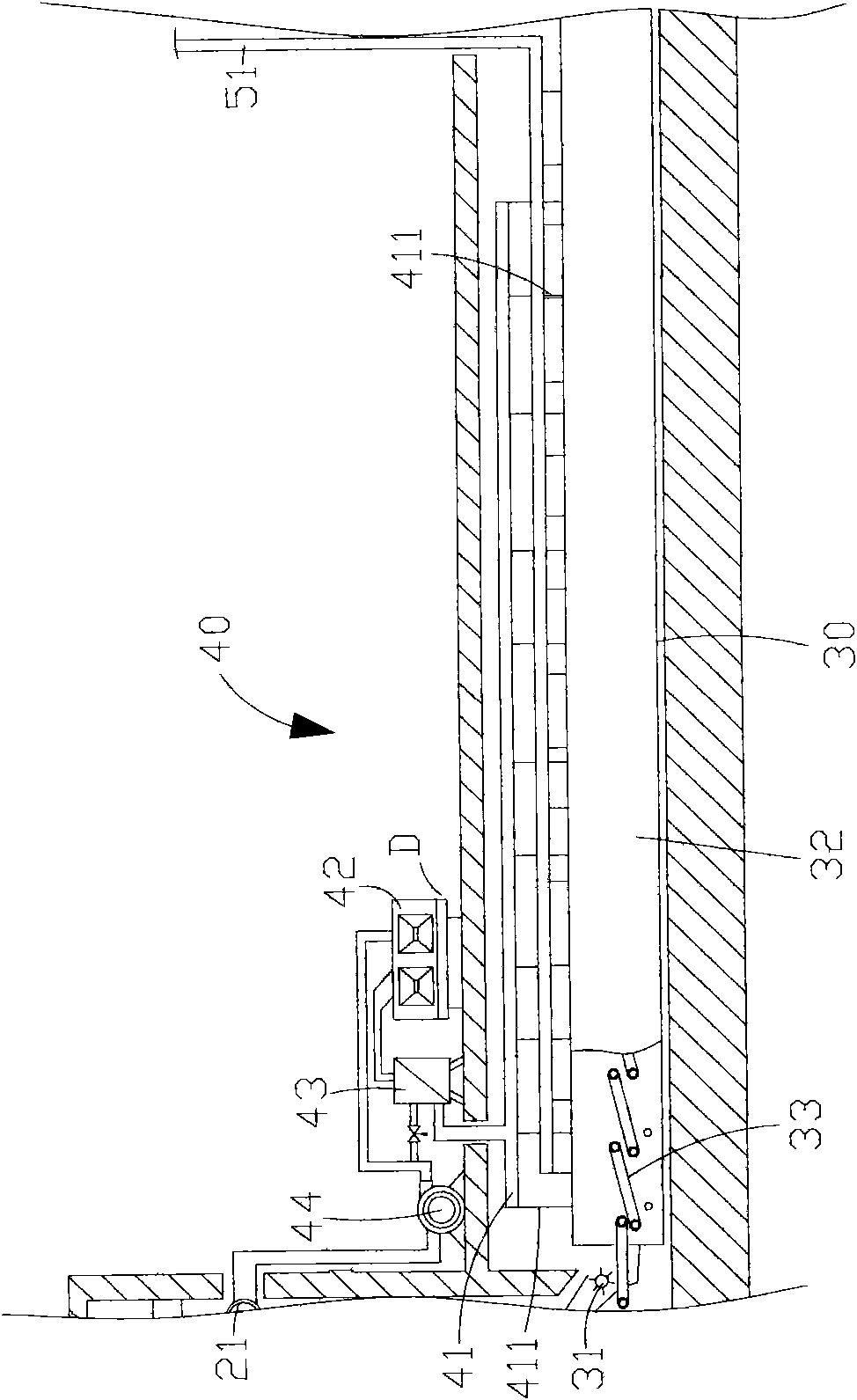

[0042] Such as Figures 1 to 5 Shown: a pretreatment method before domestic waste incineration for power generation, which includes the following steps:

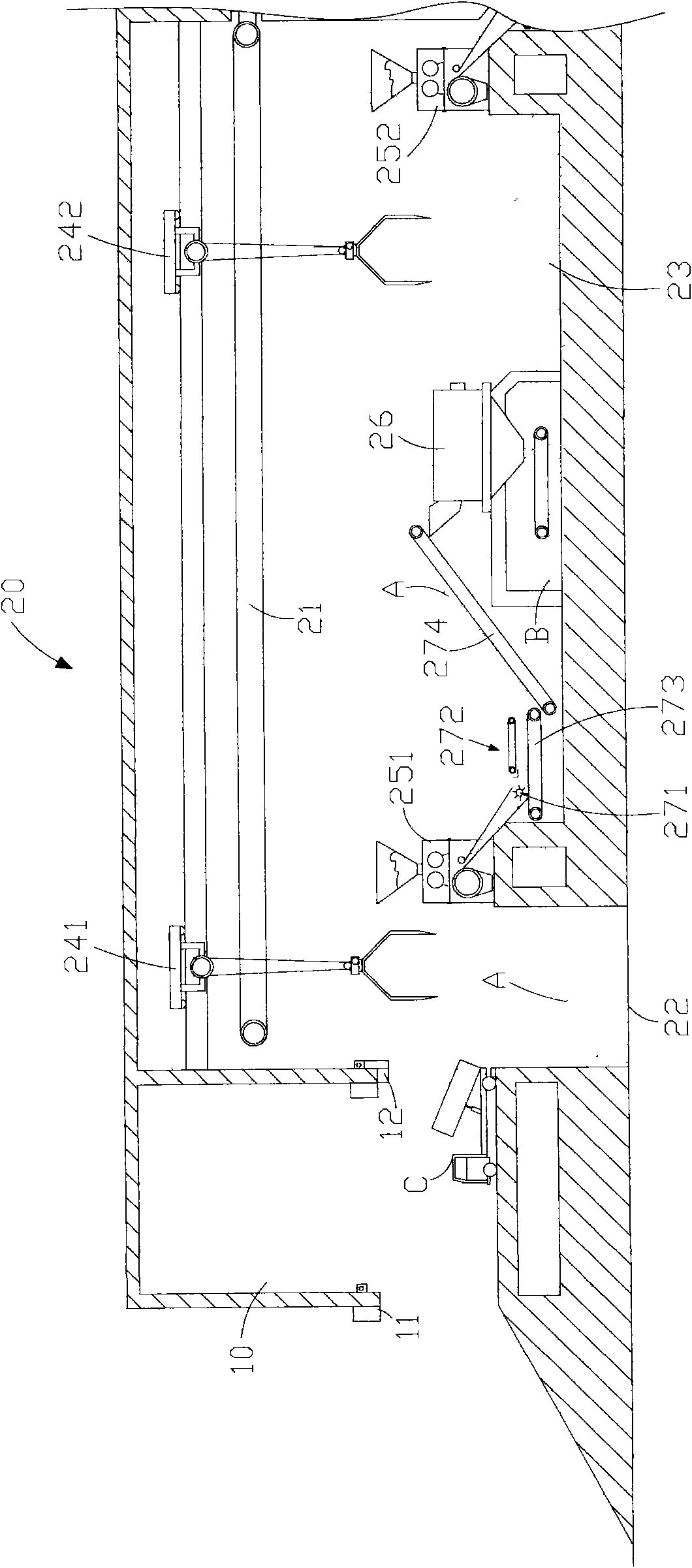

[0043] Such as figure 1 , 2 Shown: the first step, the domestic waste crushing and dehydration stage;

[0044] First, the domestic garbage A is transported to the unloading hall 10 by the garbage truck C, then the domestic garbage A is dumped into the garbage treatment workshop 20, and the domestic garbage A is crushed and magnetized in the garbage treatment workshop 20. selection and dehydration.

[0045] Wherein, the entrance of this unloading hall 10 is provided with damper 11, and this damper 11 works and produces wind wall, and then the smell in this unloading hall 10 can not be distributed to this unloading hall 10 outside, this unloading hall 10 and The garbage processing workshop 20 is connected, and between the unloading hall 10 and the garbage processing workshop 20, a discharge hall curtain sealing machine 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com