Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

234results about "Liquid handling installations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

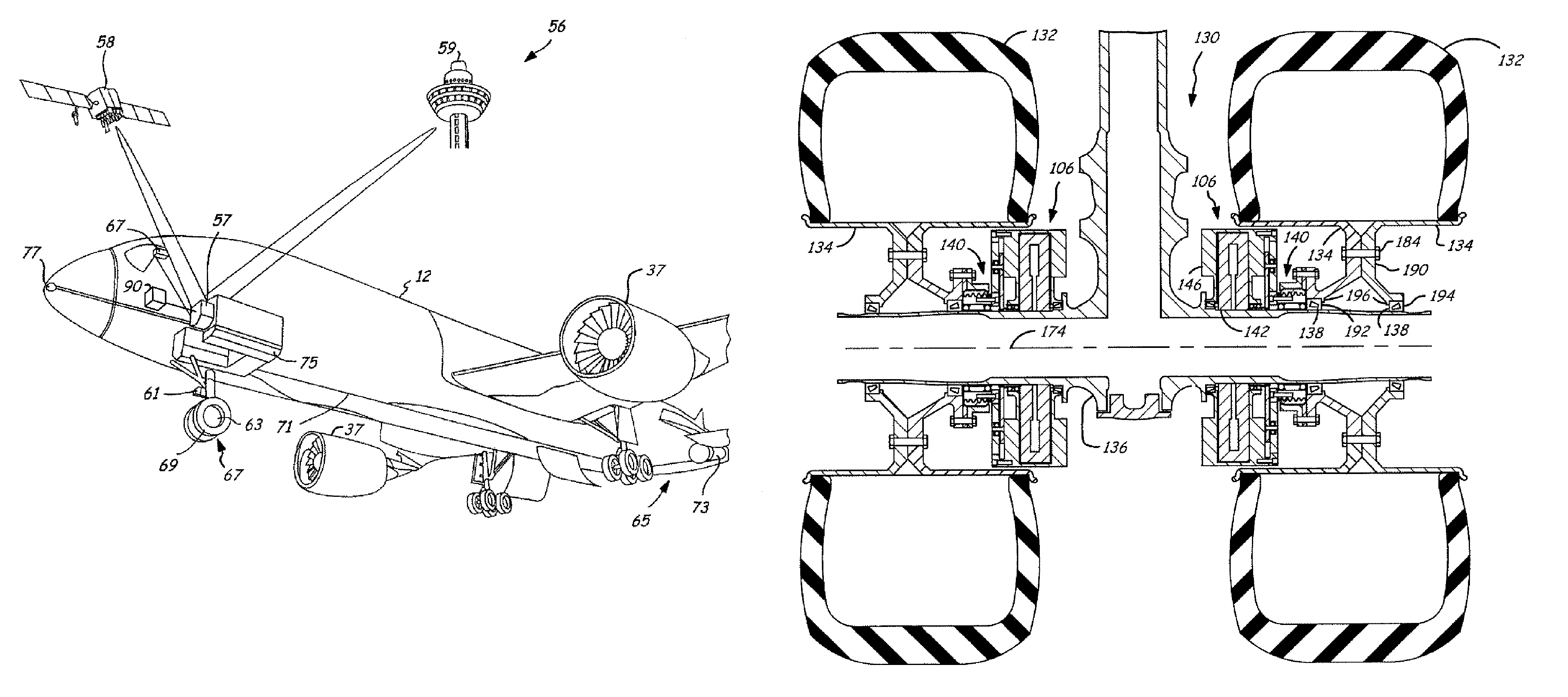

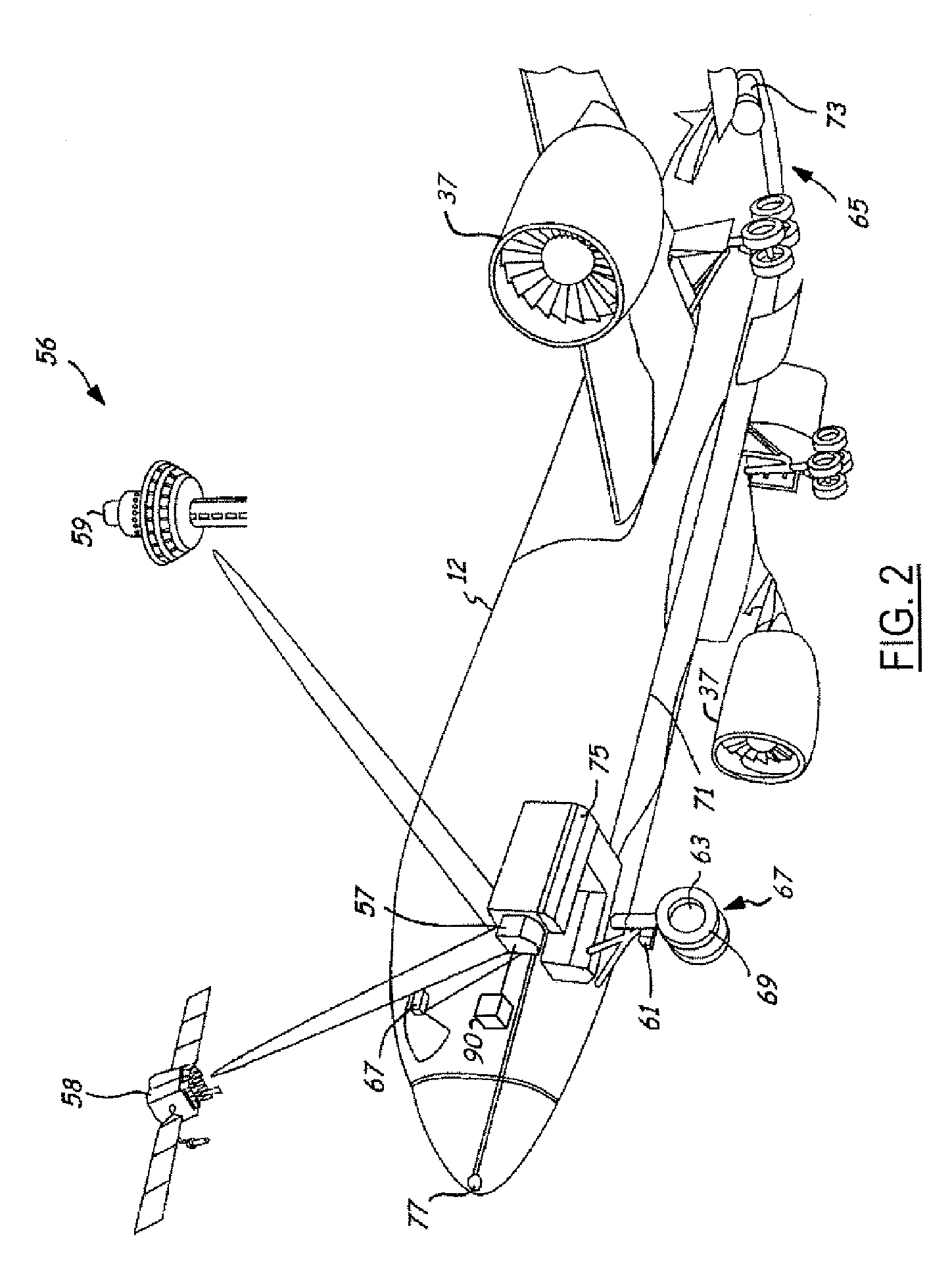

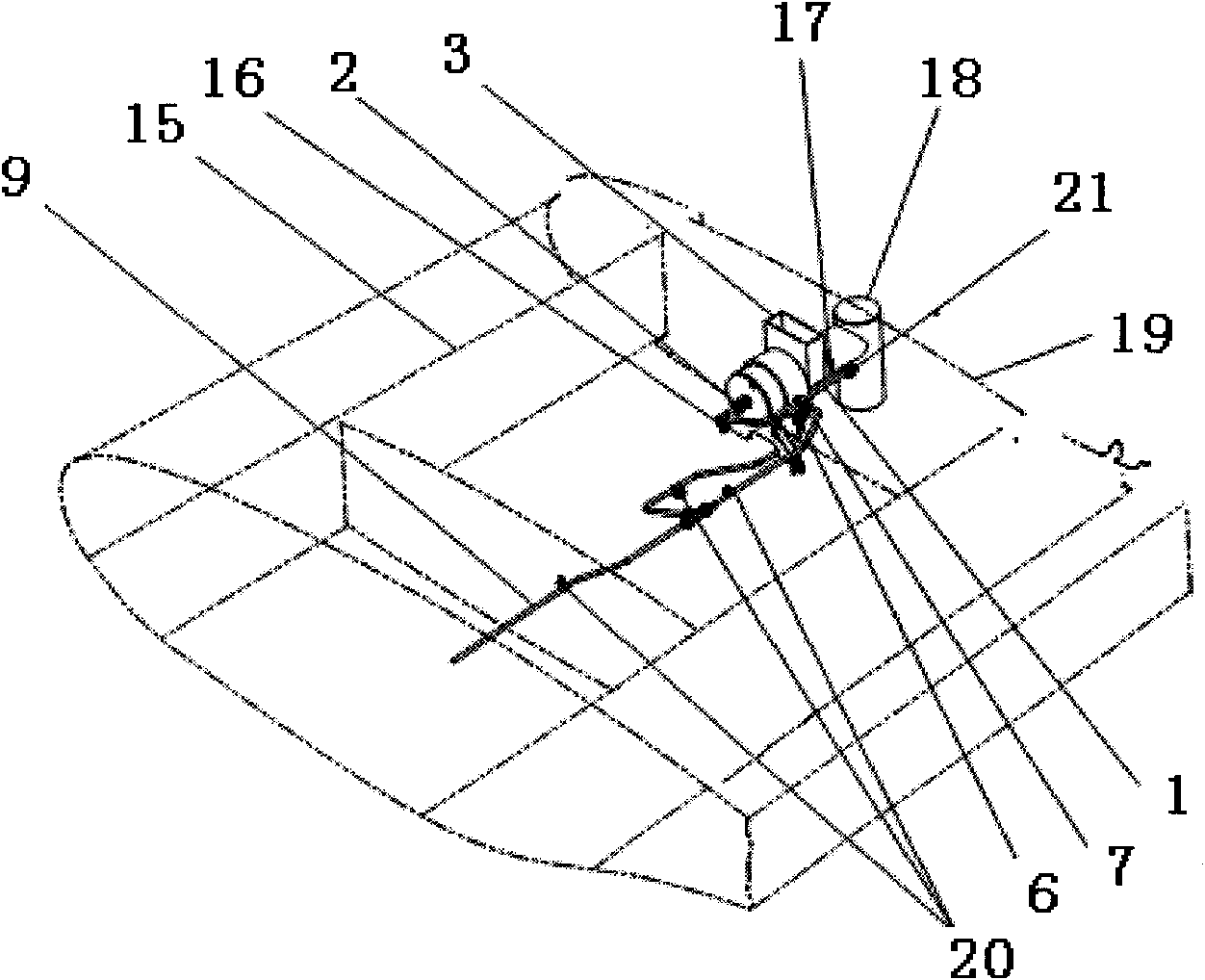

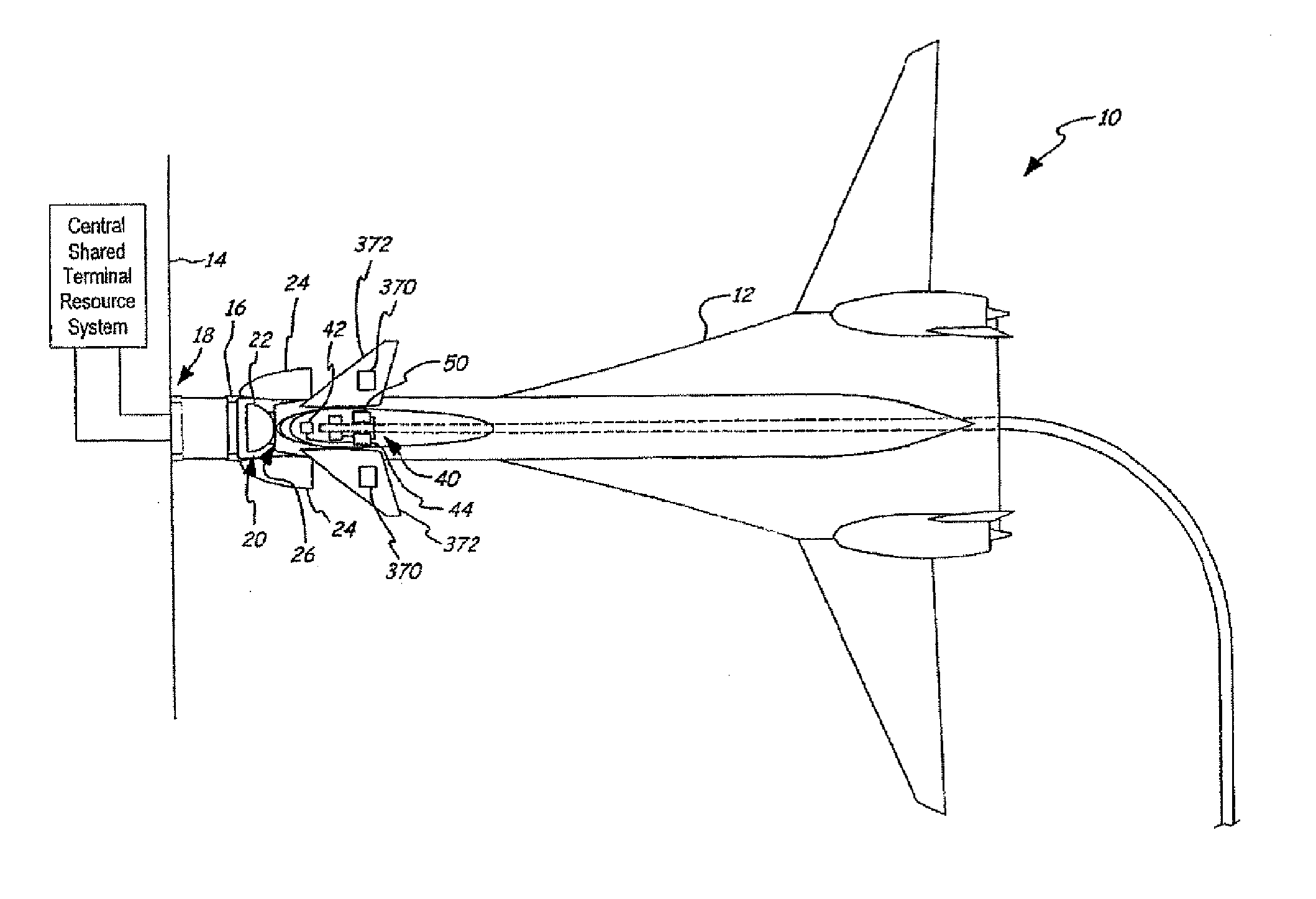

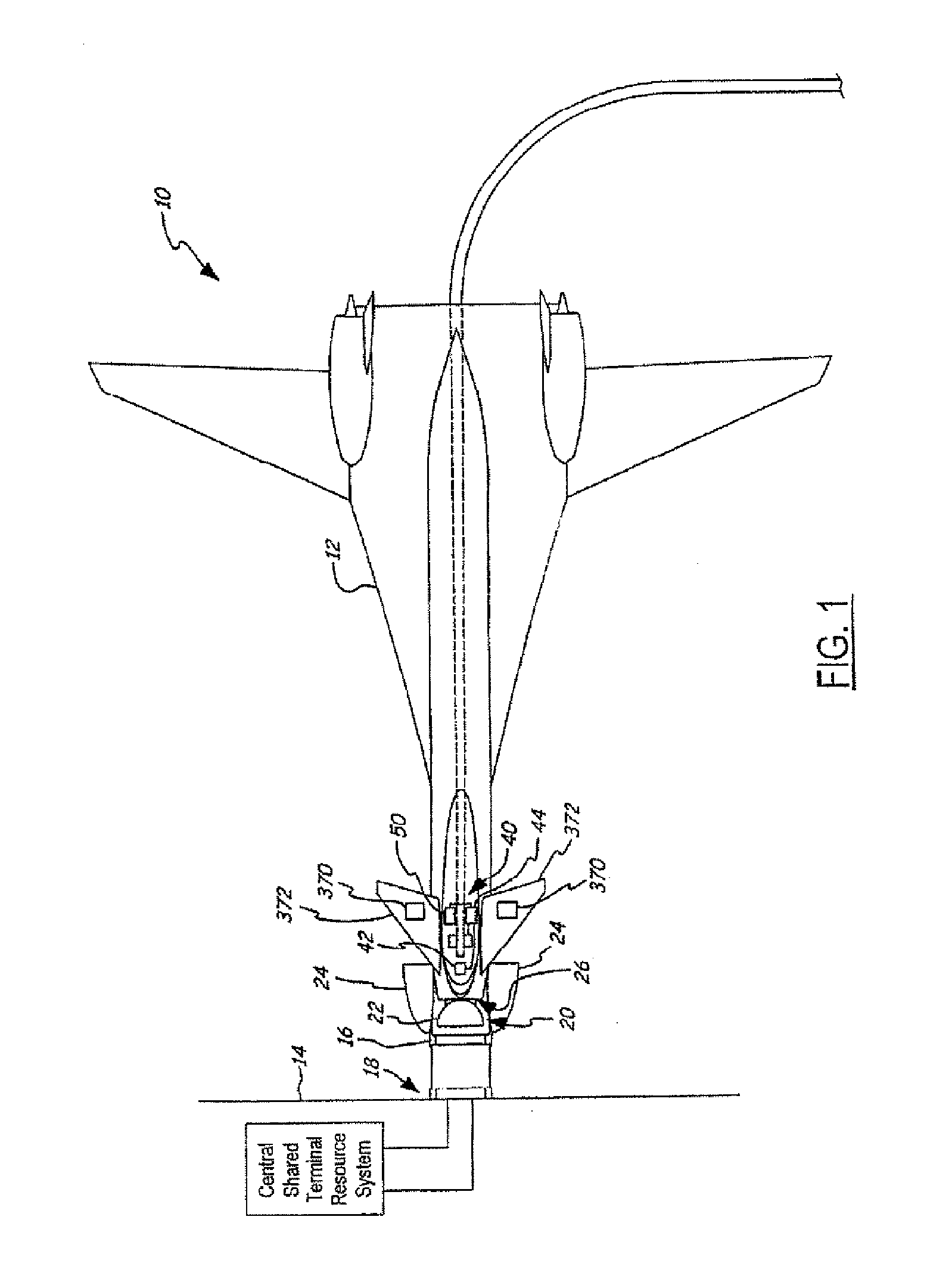

Powered nose aircraft wheel system

InactiveUS7445178B2Improves arrival and departure efficiency and productivityEasy to useLiquid handling installationsEnergy efficient operational measuresNoseAuxiliary power unit

A powered nose aircraft wheel system (130) for an aircraft (12) includes landing gear (104) that extends from the aircraft (12). A wheel axel (136) is coupled to the landing gear (104). A wheel (134) is coupled to the wheel axel (136). A wheel motor (106) is coupled to the wheel axel (136) and the wheel (134). A controller (120) is coupled to the wheel motor (106) and rotates the wheel (134). A method of taxiing an aircraft (12) includes permitting the wheel (134) of the aircraft (12) to freely spin during the landing of the aircraft (12). Power is transferred from an auxiliary power unit (73) of the aircraft (12) to the wheel motor (106). The wheel (134) is rotated via the wheel motor (106). The aircraft (12) is steered and the speed of the wheel (134) is controlled via one or more controllers selected from an onboard controller (18, 118, 120) and an offboard controller (45, 58, 59).

Owner:THE BOEING CO

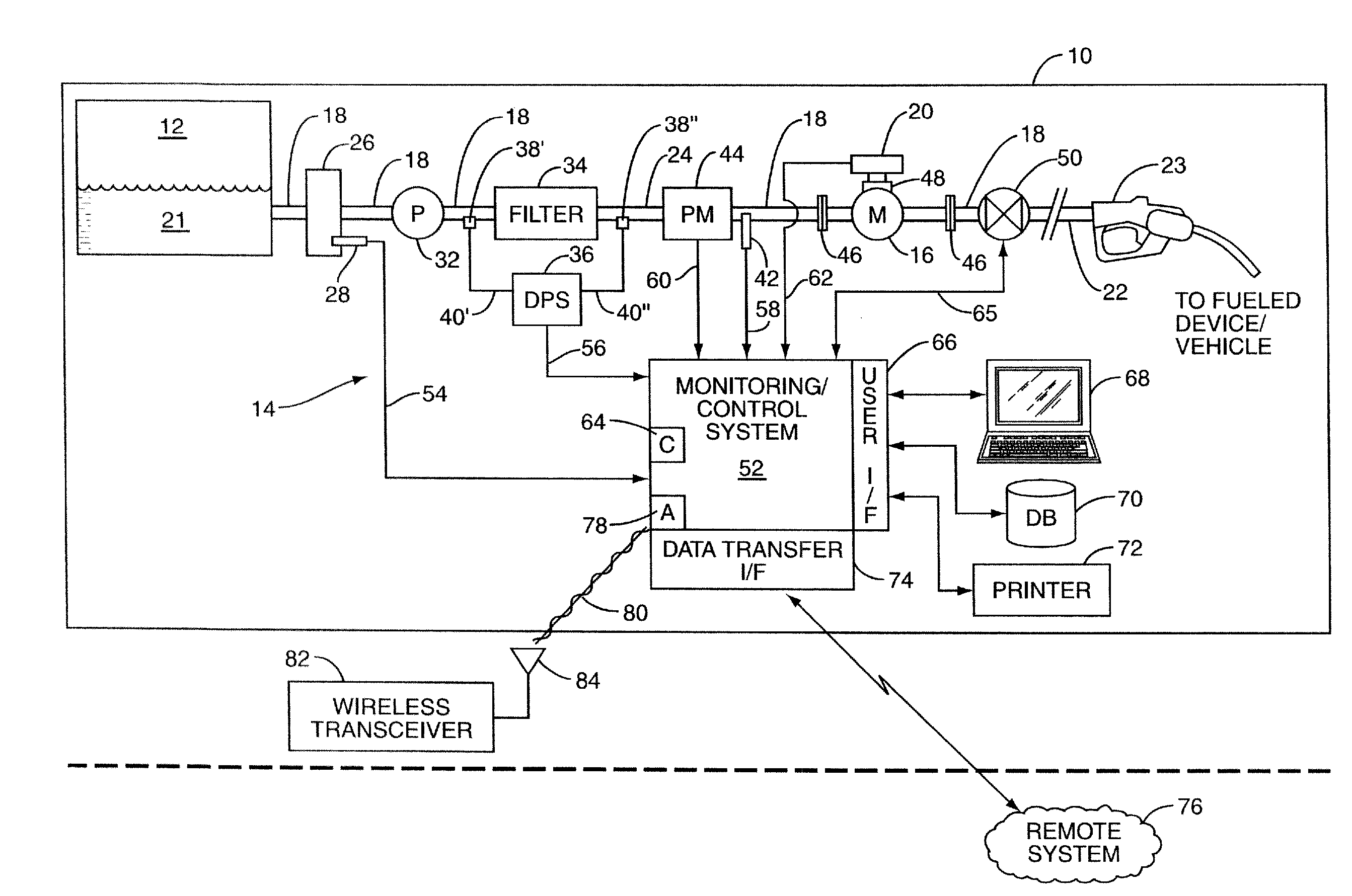

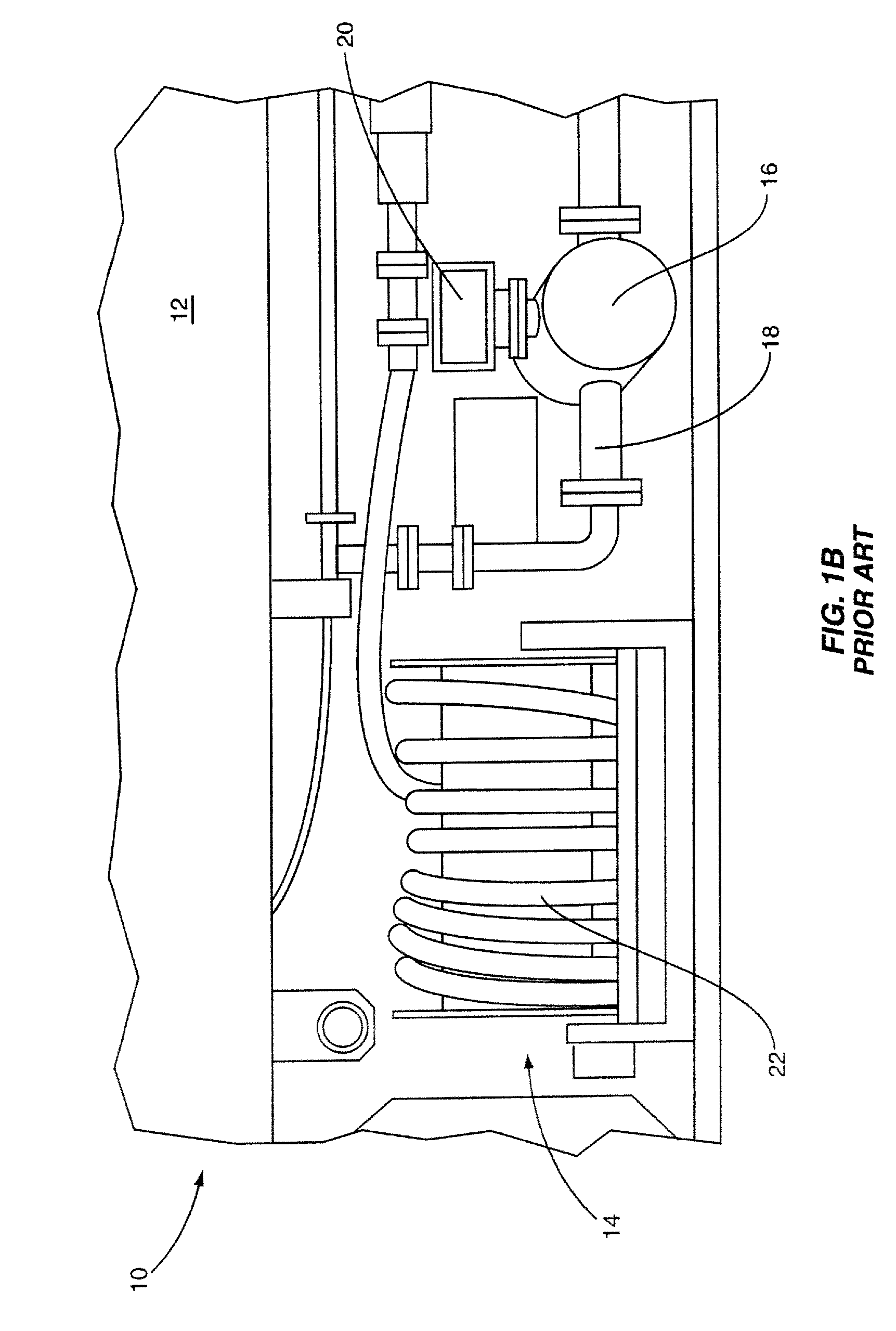

Automated Fuel Quality Detection and Dispenser Control System and Method, Particularly for Aviation Fueling Applications

ActiveUS20080230146A1Reduce riskAvoid refuelingLiquid handling installationsLevel indicatorsWater detectorAviation

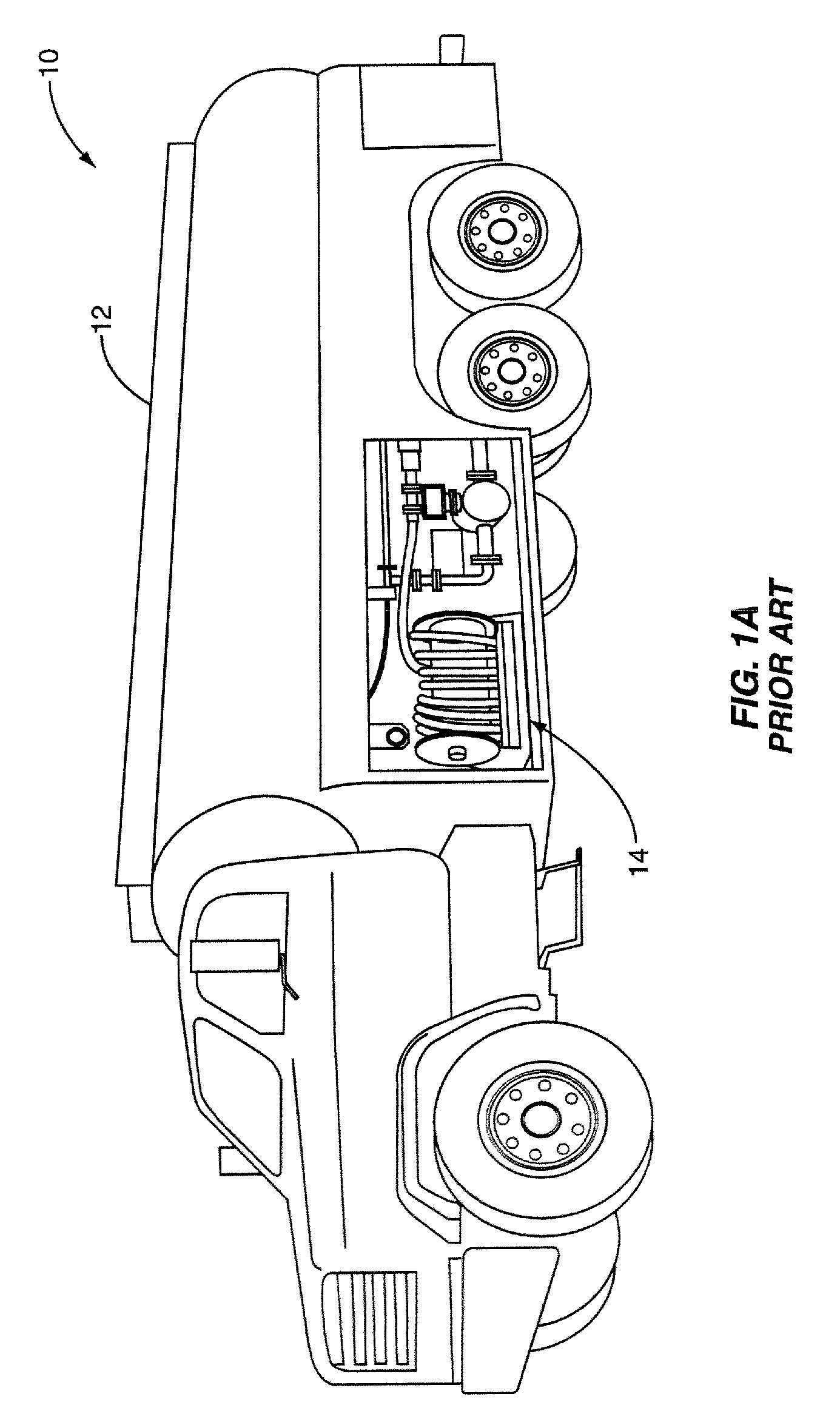

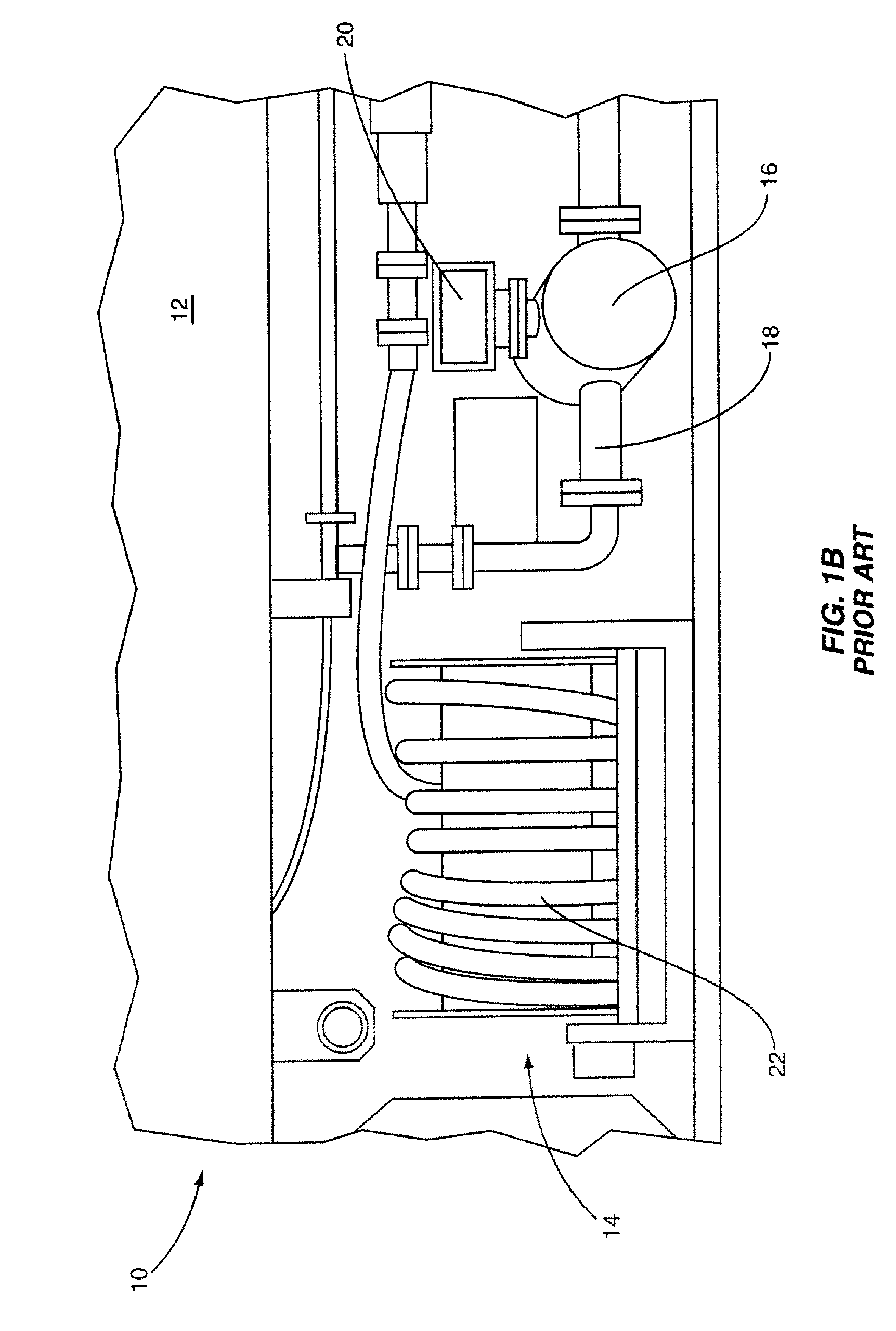

A fuel quality monitoring system and method to automatically and / or continuously monitor quality of fuel dispensed and control the operation of the fuel dispenser. The control system monitors fuel quality to prevent unsafe refuelings when the fuel quality is unacceptable. In one embodiment, a combination of a differential pressure sensor, a water detector, and / or a particle monitor is employed inline the fuel flow path of a fuel dispenser, and in particular an aviation refueling truck, to monitor the quality of the fuel. If fuel quality is at an acceptable level although not ideal, the control system can allow fueling with the generation of reports and alarms. If the fuel quality is unacceptable, fuel flow can be stopped. If the differential pressure across the filter indicates a high degree of debris and / or water retention, the control system can automatically lower the flow rate to reduce the risk of filter breakdown without completely preventing fueling until the filter can be replaced.

Owner:FUEL GUARD SYST +1

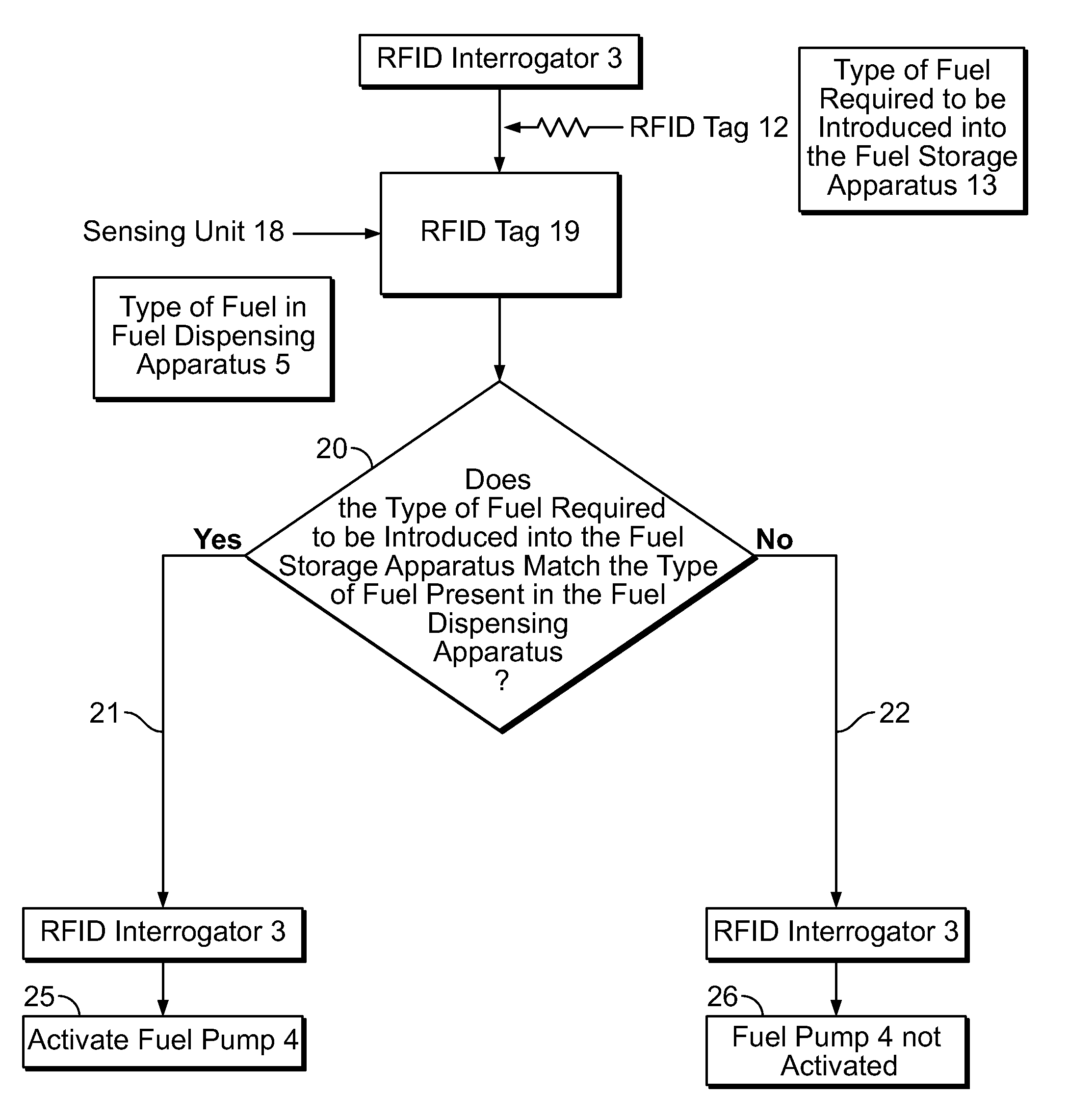

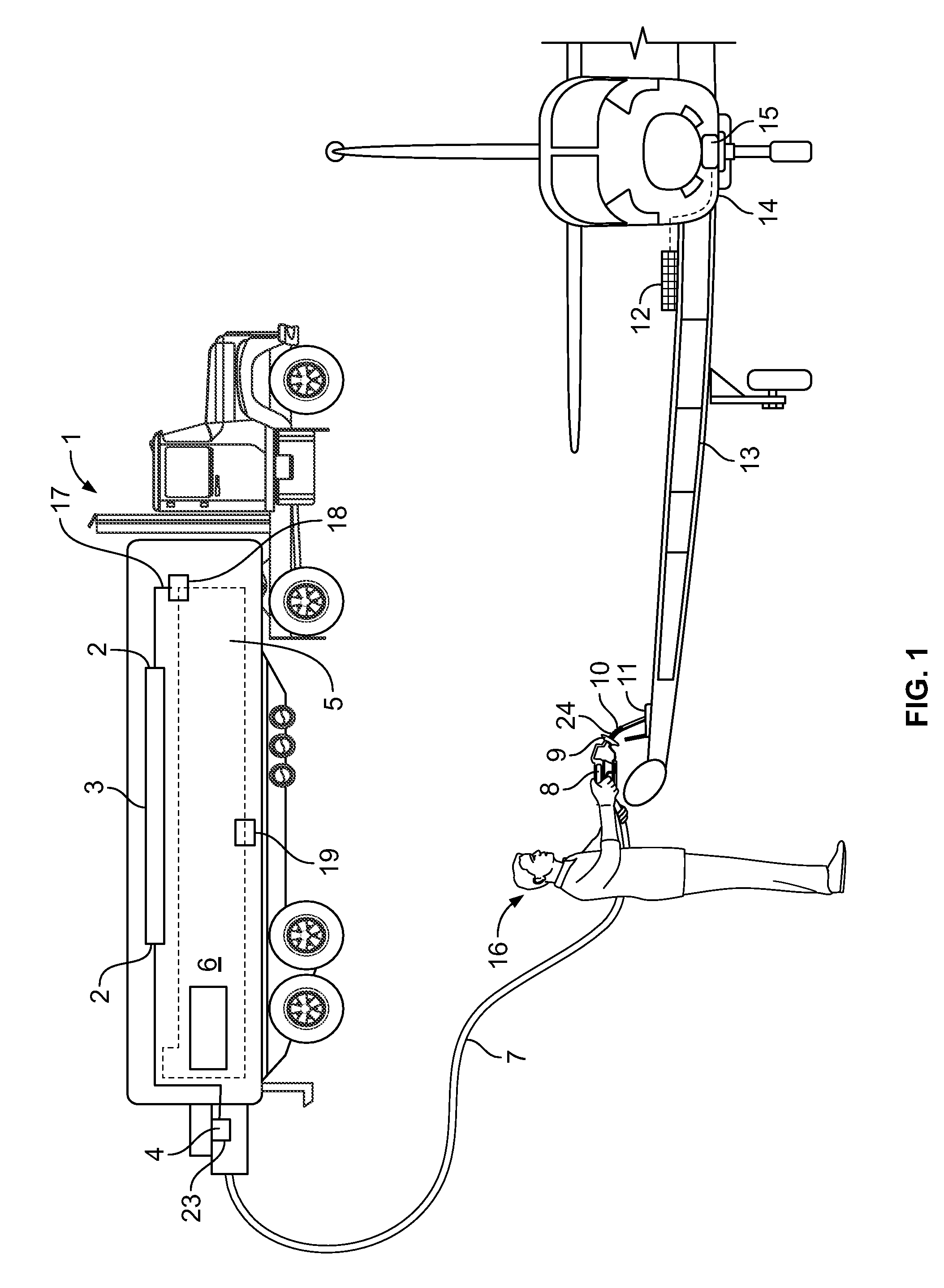

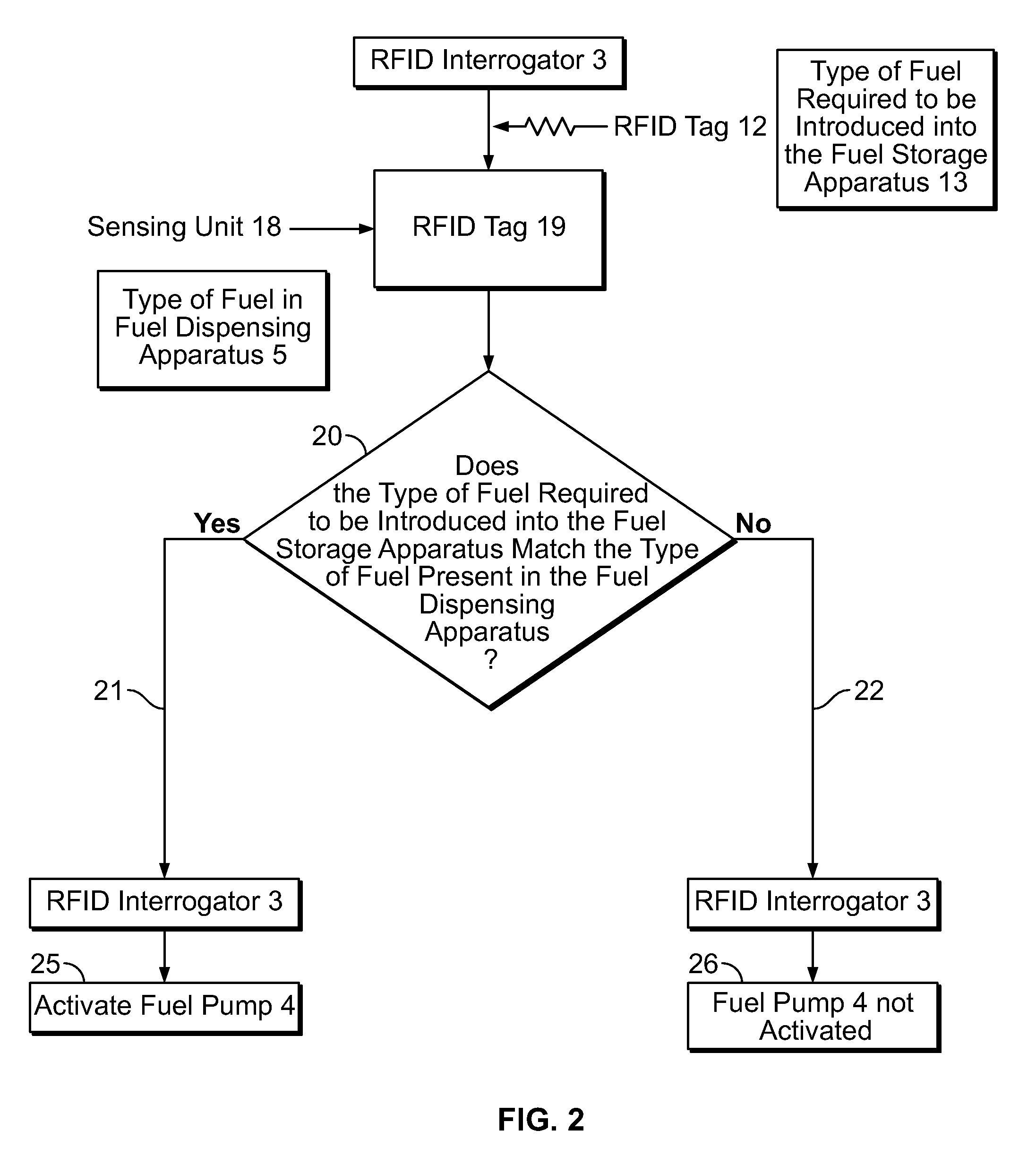

Method and System for Preventing Misfueling

InactiveUS20090315729A1Liquid handling installationsLiquid transferring devicesFuel typeFuel storage

The methods and system of the present invention provide for a means of preventing the introduction of incorrect fuel type into an engine. Data is transmitted wirelessly from a fuel storage apparatus to at least one receiver. In part, the selected data comprises the type of fuel that is required to be introduced into the fuel storage apparatus. Data is also transmitted wirelessly from a fuel dispensing apparatus to the receiver. In this case, the data comprises, in part, the type of fuel present in the fuel dispensing apparatus. The receiver determines whether the type of fuel required to be introduced into the fuel storage apparatus corresponds to the type of fuel present in the fuel dispensing apparatus. If the two types of fuel correspond, i.e., match, fuel is dispensed from the fuel dispensing apparatus into the fuel storage apparatus. If the two types of fuel do not match, the fuel dispensing apparatus is not activated. The receiving apparatus may also provide an indication that the fuel from the fuel dispensing apparatus does not match the type required to be introduced into the fuel storage apparatus. In another embodiment, if the two types of fuel do not match, a cut-off system is activated that stops dispensing of the fuel during the fueling process.

Owner:INHOFFER SCOTT

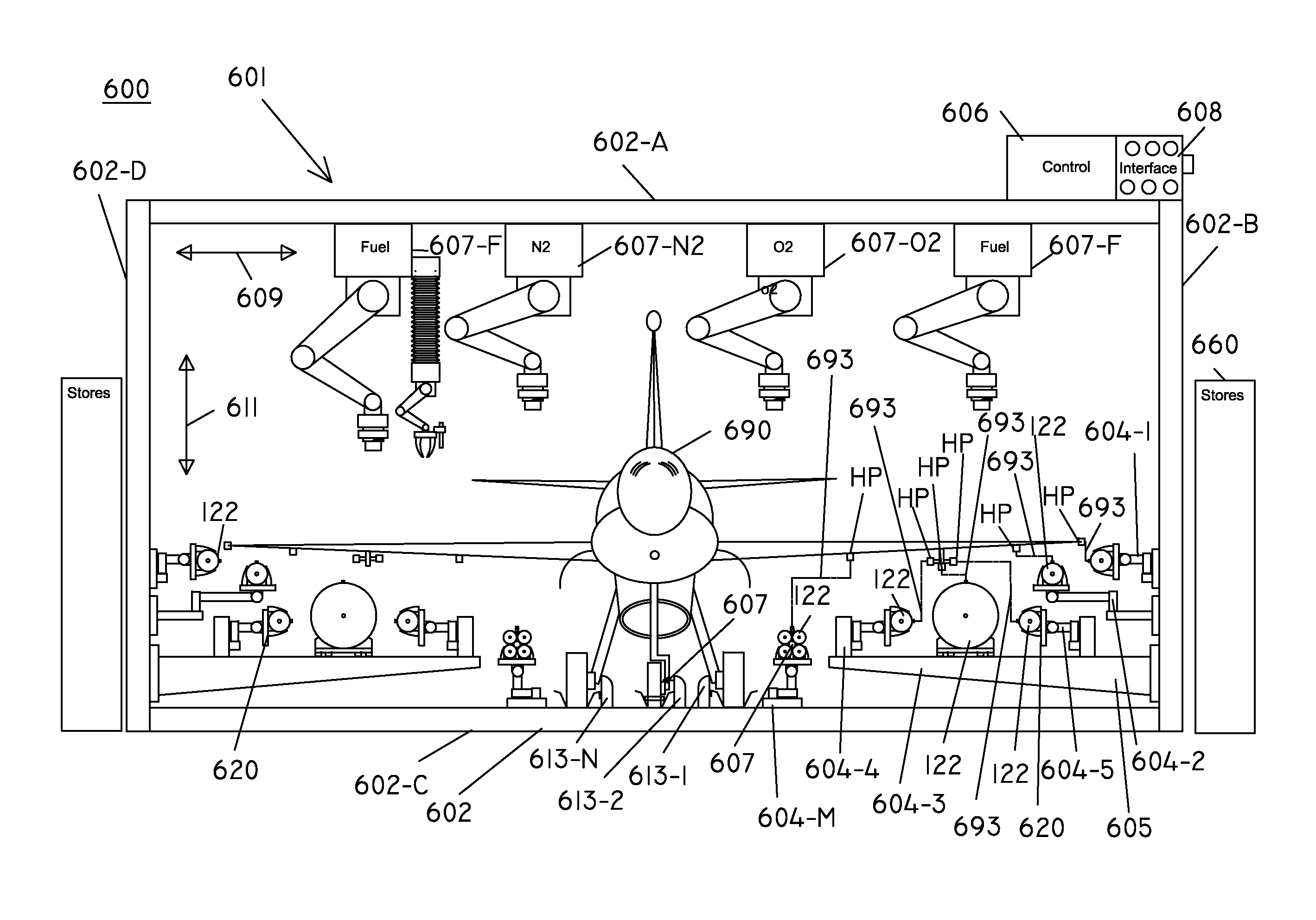

Rapid store load system for aircraft and method of operation thereof

Owner:GROSSMAN VICTOR A

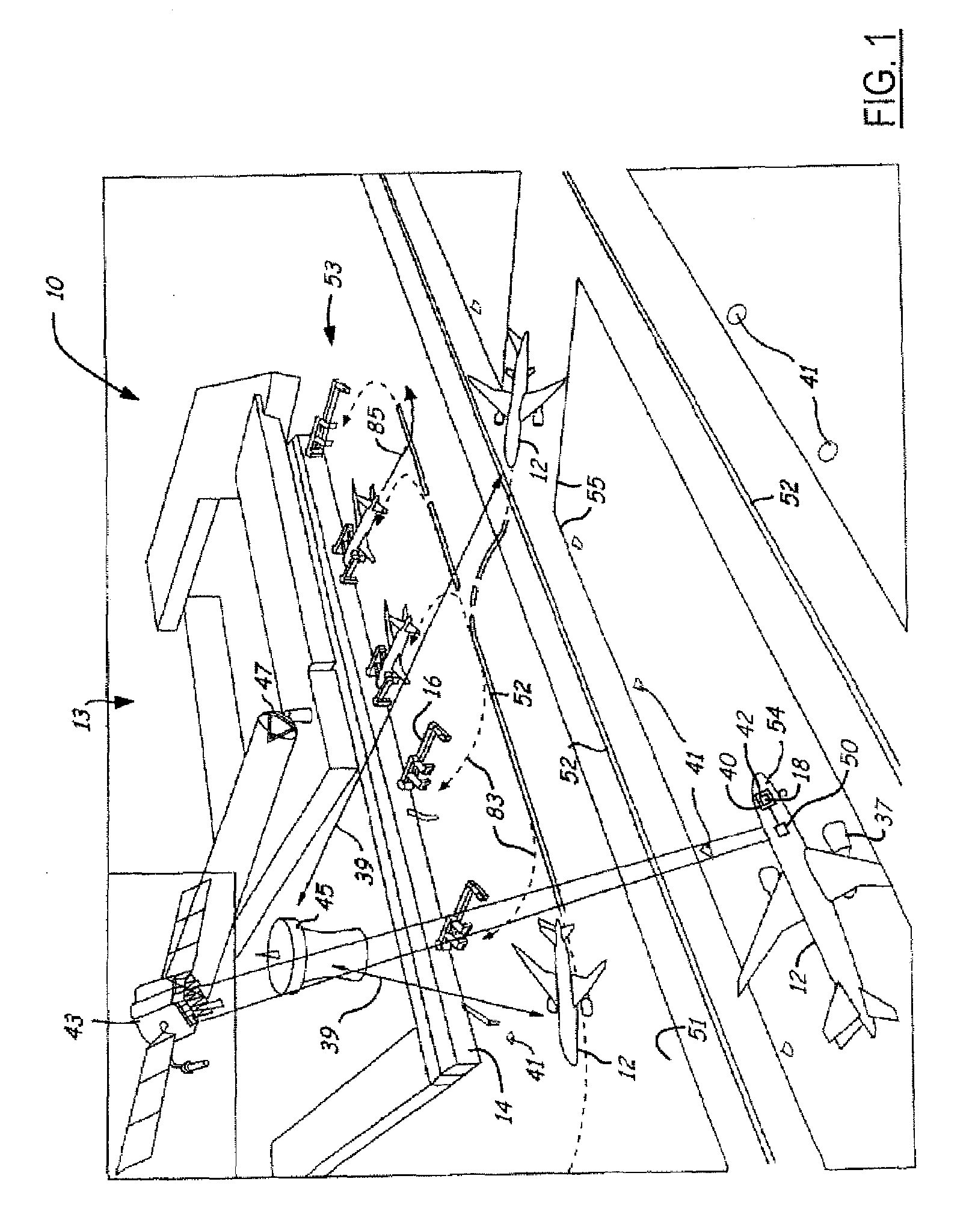

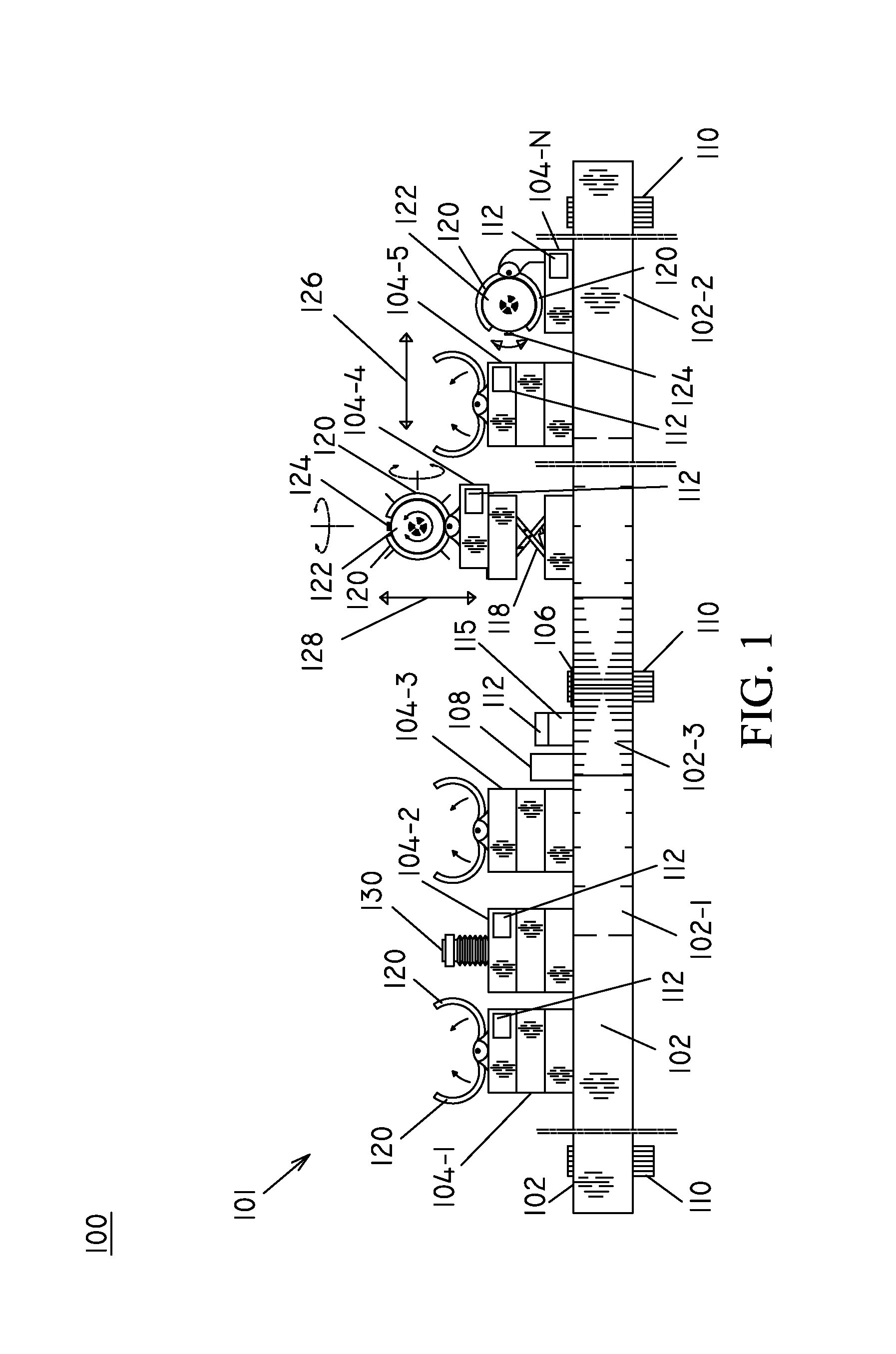

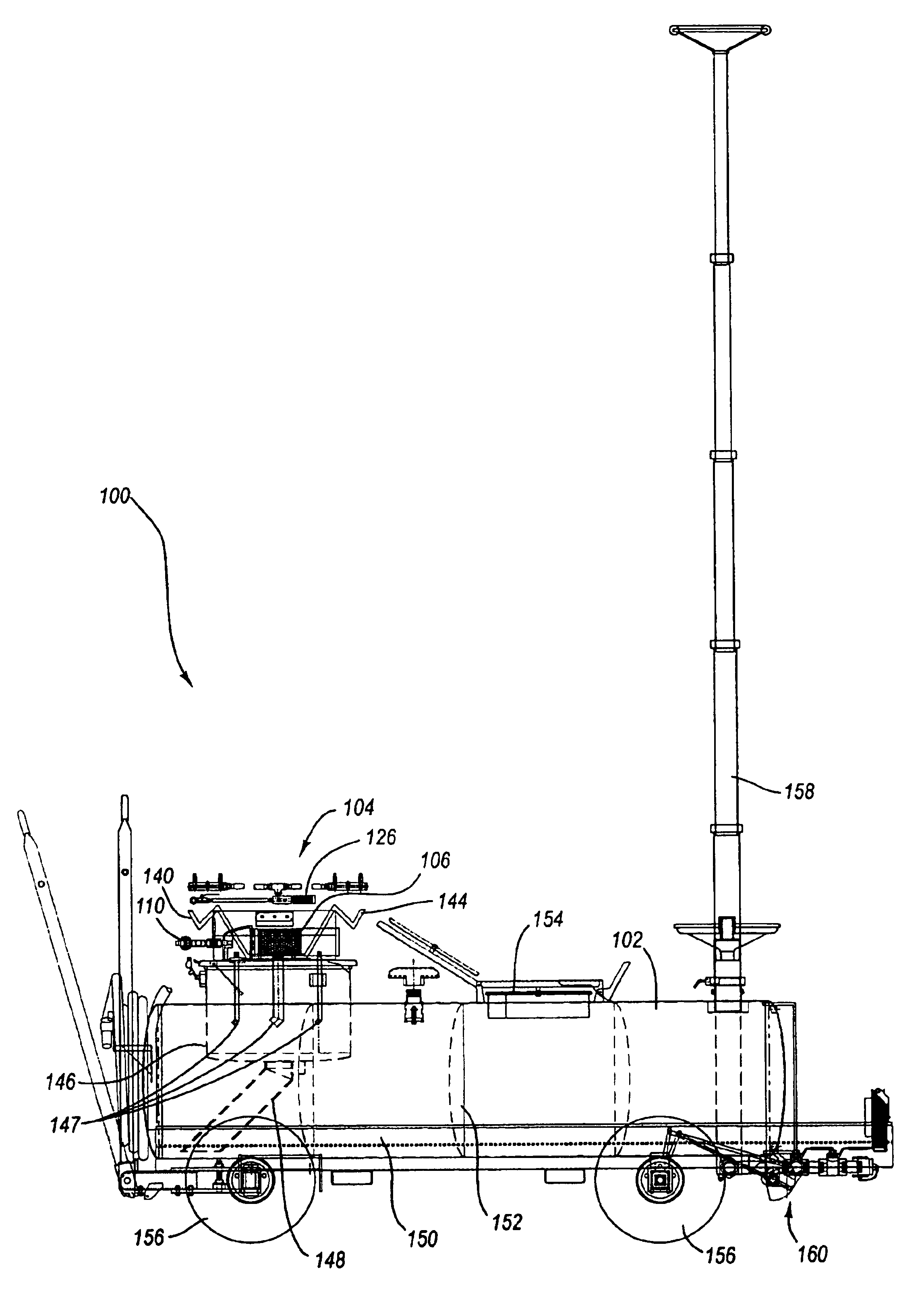

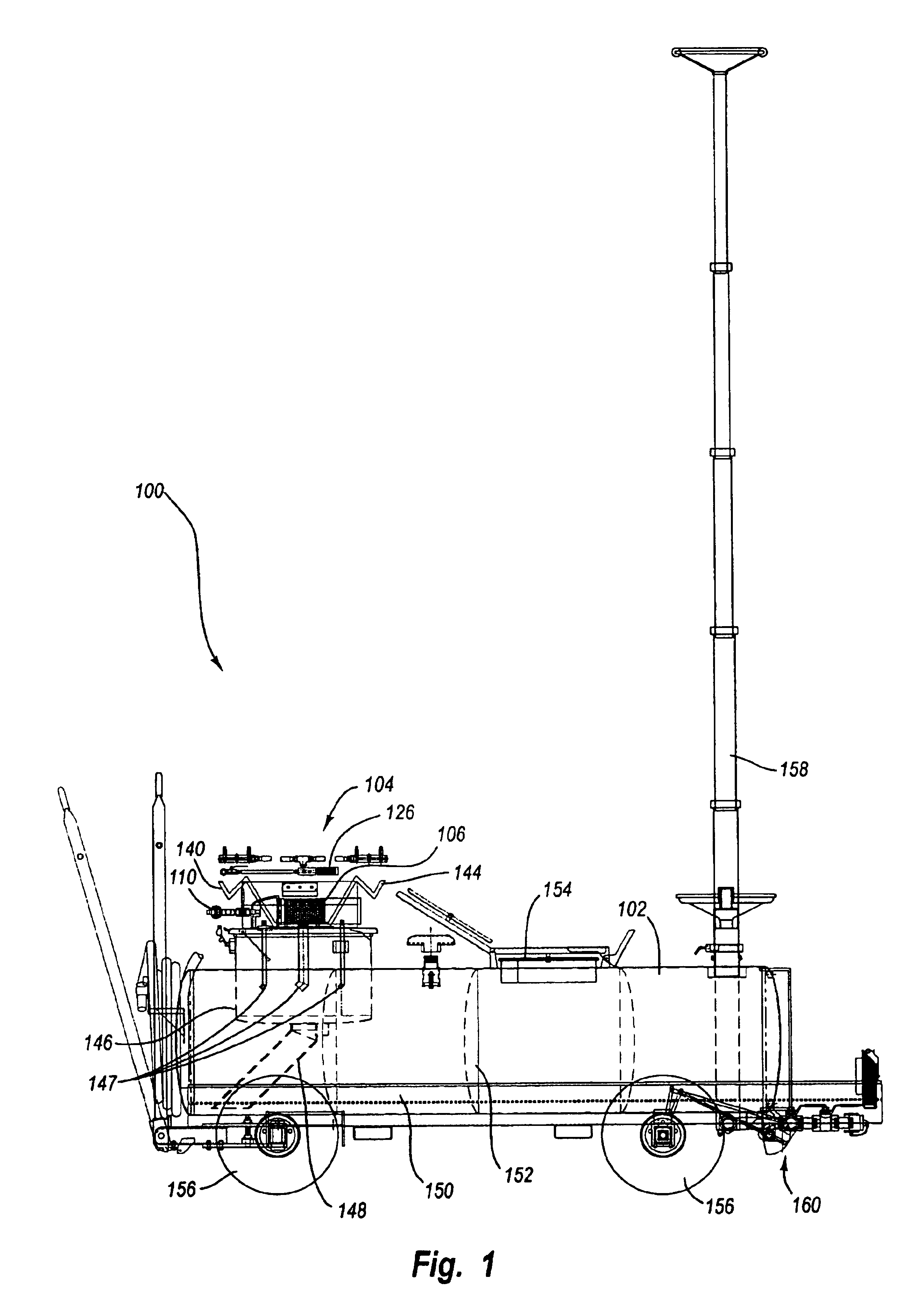

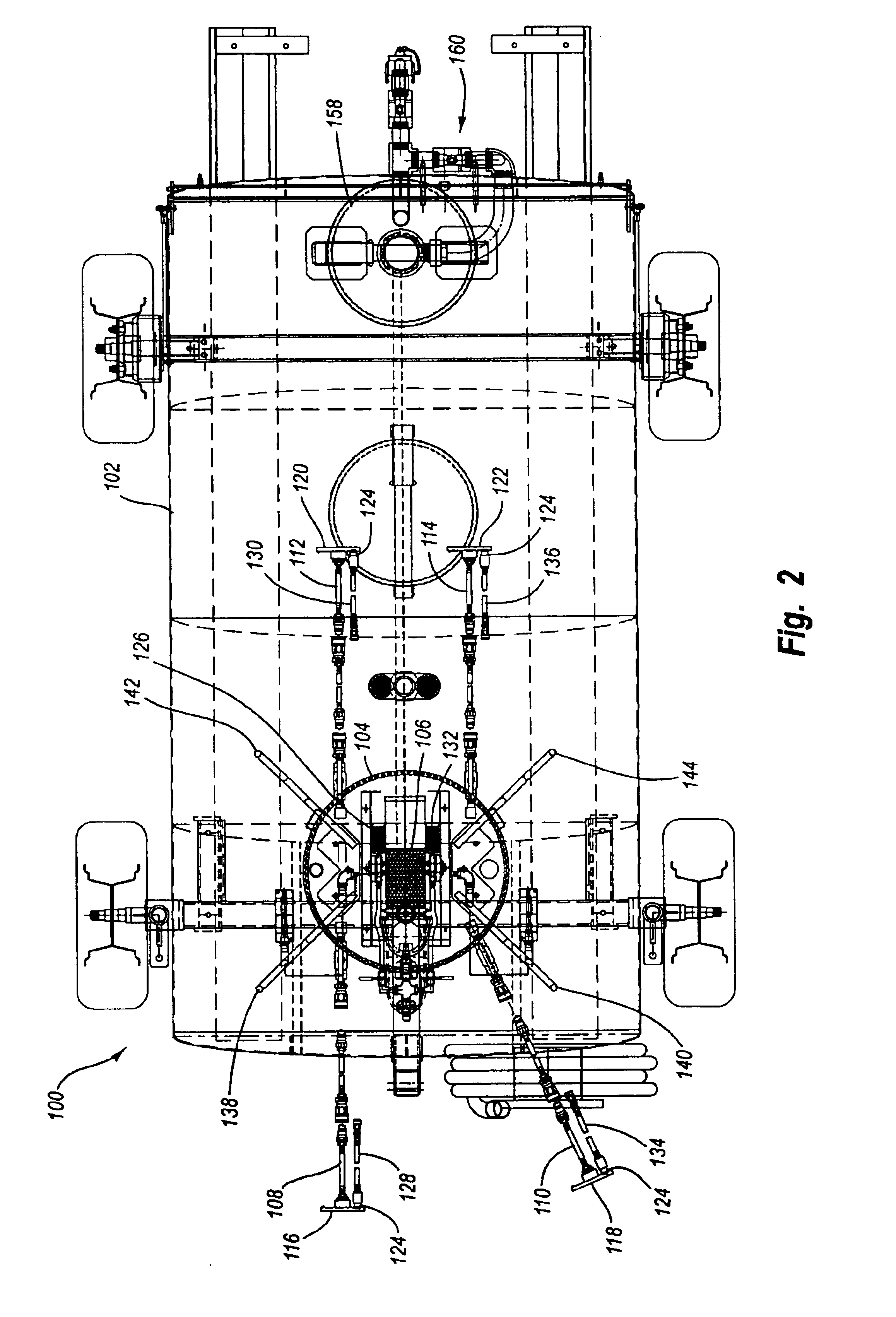

Operational ground support system having automated primary servicing

InactiveUS20070051852A1Minimal human interventionDecrease tarmac congestionLiquid handling installationsHelicopter landing platformAirplaneTarmac

An aircraft servicing system (10) includes a tarmac-servicing system (500). The tarmac-servicing system (500) includes an aircraft-mating element (510) that is mounted and extendible from within an area of a tarmac (502) to couple with an aircraft (504). The tarmac-servicing system (500) supplies primary services to the aircraft (504), such as fuel, air, electrical power, water, coolant, potable water, and gray water. A method of servicing the aircraft (504) includes aligning a primary servicing port (512) of the aircraft (504) over a primary servicing area of a tarmac (502). A tarmac-servicing element (510) is extended out from the tarmac (502) to the aircraft (504). The tarmac-servicing element (510) is aligned and connected to the primary servicing port (512). Primary services are supplied and removed to and from the aircraft (504) in response to the tarmac-servicing element connection with the primary servicing port (512).

Owner:THE BOEING CO

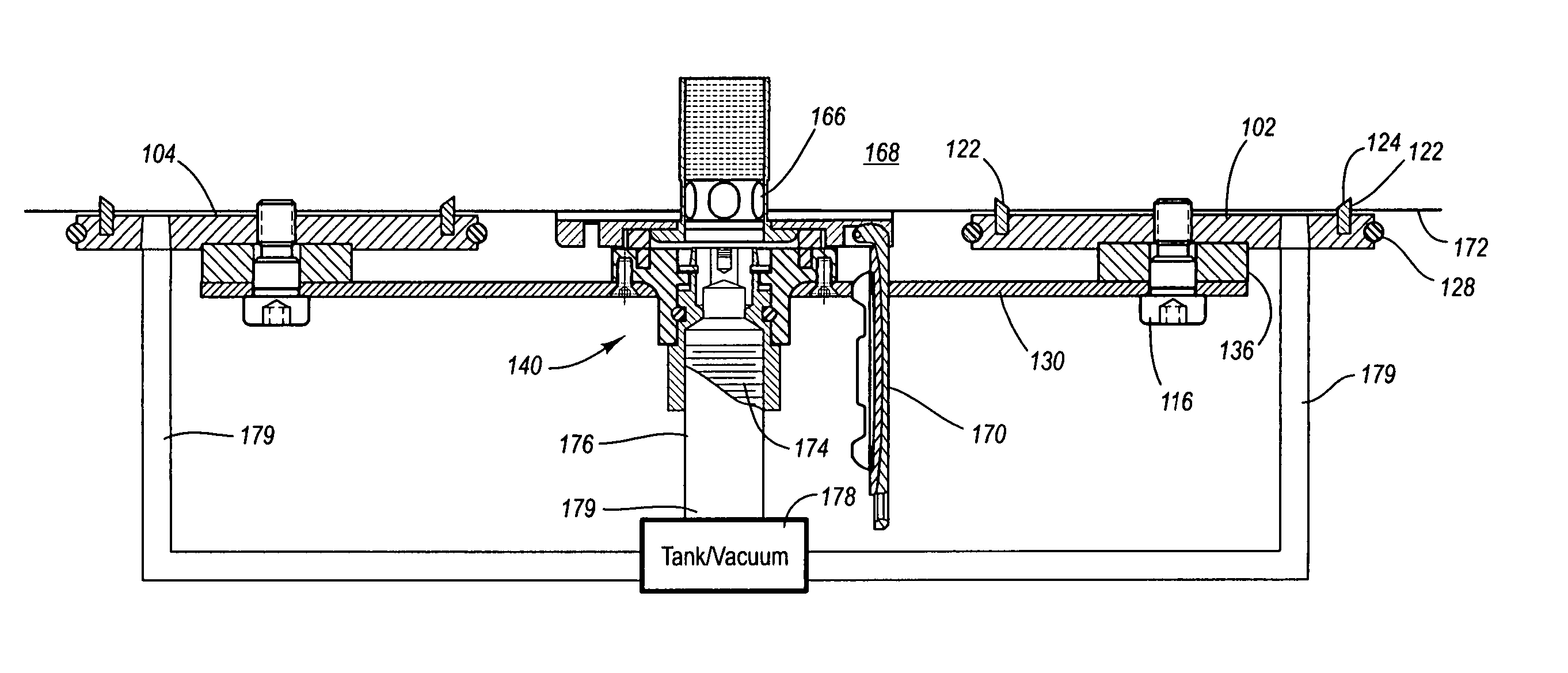

Aircraft defueling system

An apparatus and method for defueling and aircraft. The apparatus includes a vacuum fuel tank comprising a first vacuum generator, a defueling hose in fluid communication with the vacuum fuel tank, a first defueling fitting attached to the first defueling hose, and a second vacuum generator operatively connected to the first defueling fitting. By providing both a first and a second vacuum generator, the defueling fitting can be attached and detached from an aircraft independent of the suction used to withdraw fuel from an aircraft. According to some embodiments, there may be multiple defueling hoses and additional vacuum generators. Further, some embodiments include a telescoping funnel that can be selectively isolated from the vacuum fuel tank so that the tank can be held at vacuum pressure.

Owner:SPOKANE STAINLESS TECH INC

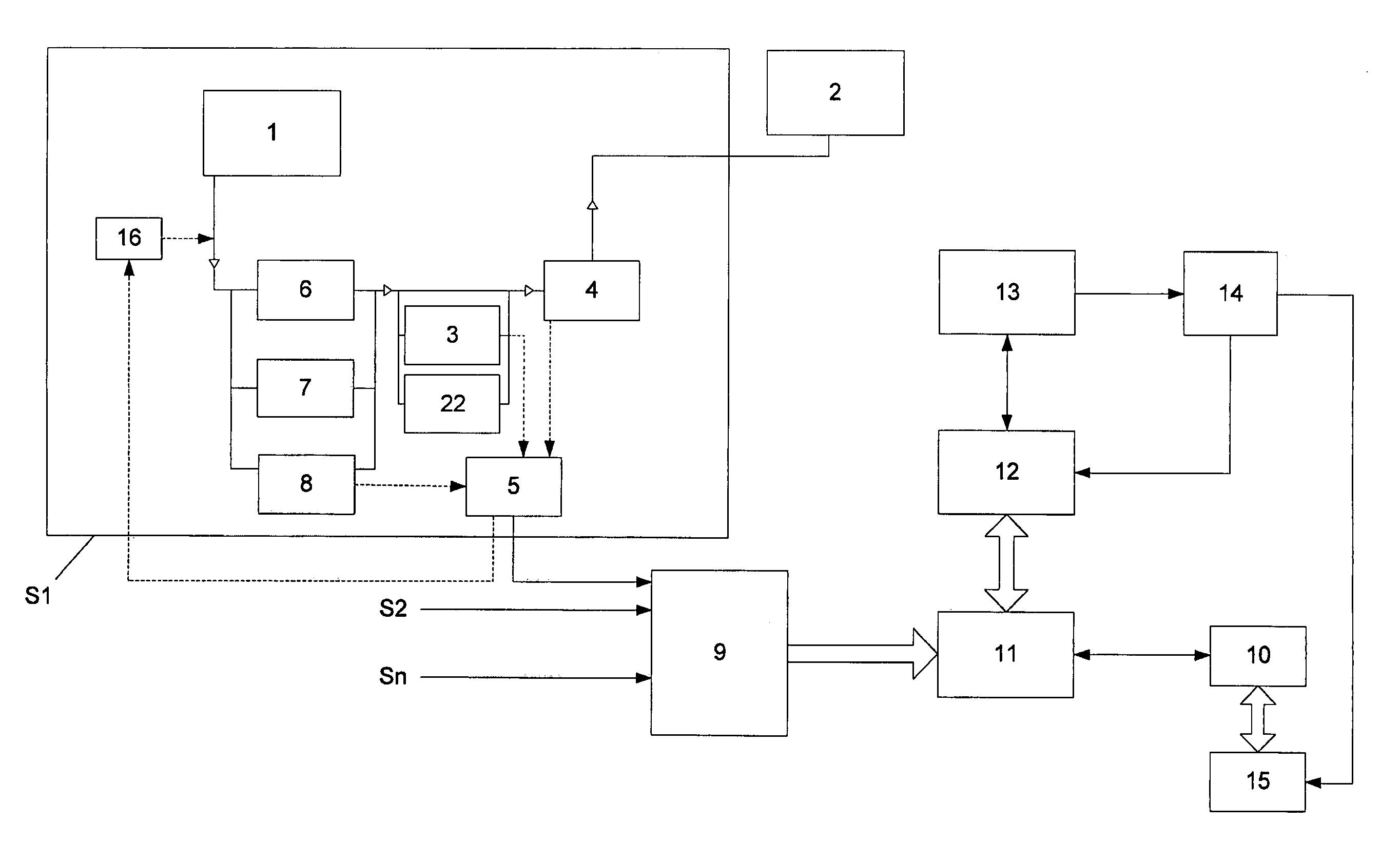

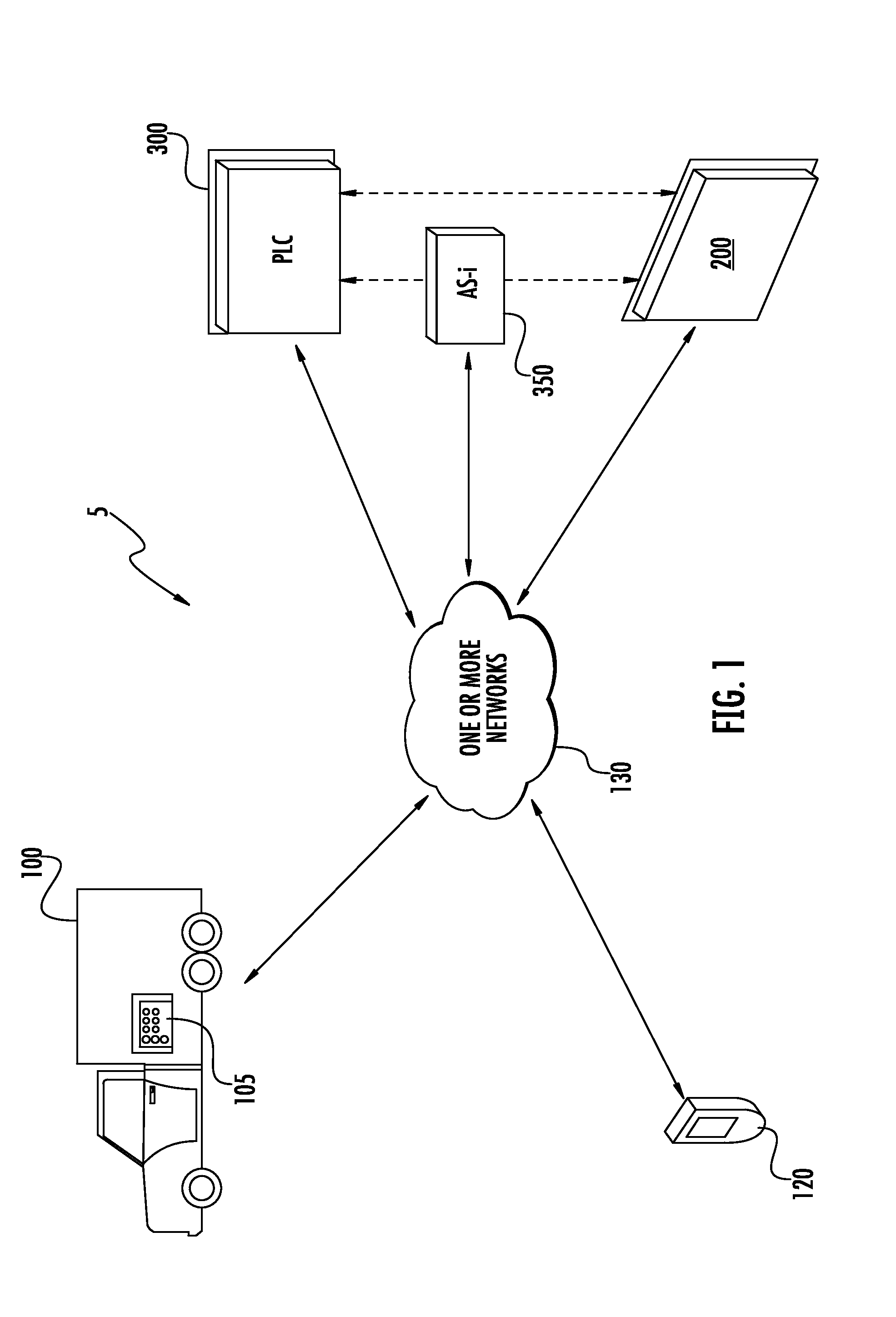

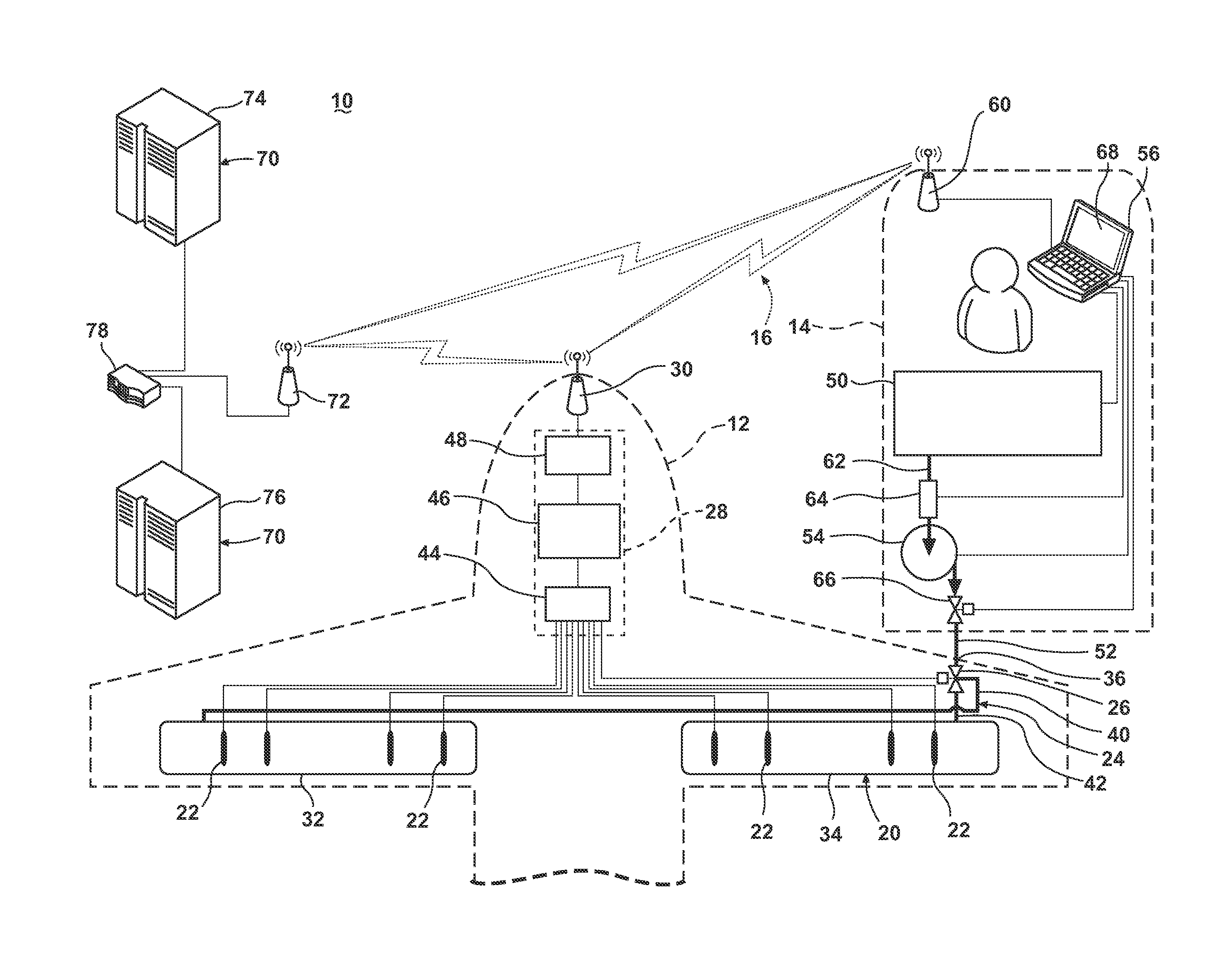

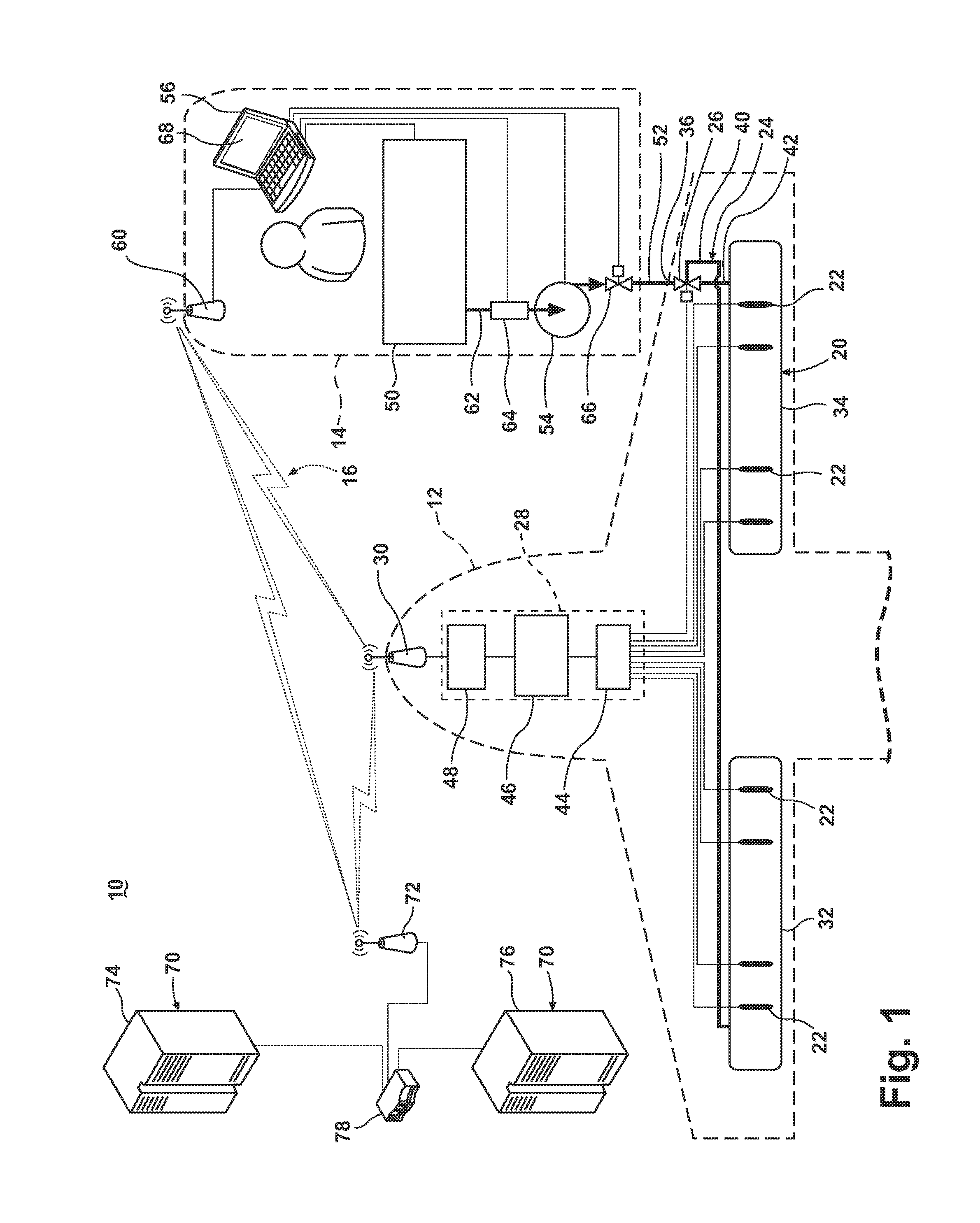

Fuel Quality Traceable and Remote System

ActiveUS20110130882A1Quality improvementPromote generationLiquid handling installationsEnergy efficient operational measuresRemote systemFuel quality

A fuel quality traceable and remote system for monitoring and controlling fuel characteristics during transport from a fuel supply to a supplied device is provided. The system includes one or more subsystems that include at least one sensor monitoring the characteristics of the fuel. The sensor operably sends the data relating to the characteristics to a data register-transmitter which sends the data to a base station that uploads the data to a remote server. The remote server is remotely accessible by a user. The system can also generate warning messages to warn a user when the characteristics are outside a tolerable range. Further, the system can automatically or manually interrupt fuel transport when the characteristics are outside a tolerable range.

Owner:PECOFACET OKLAHOMA

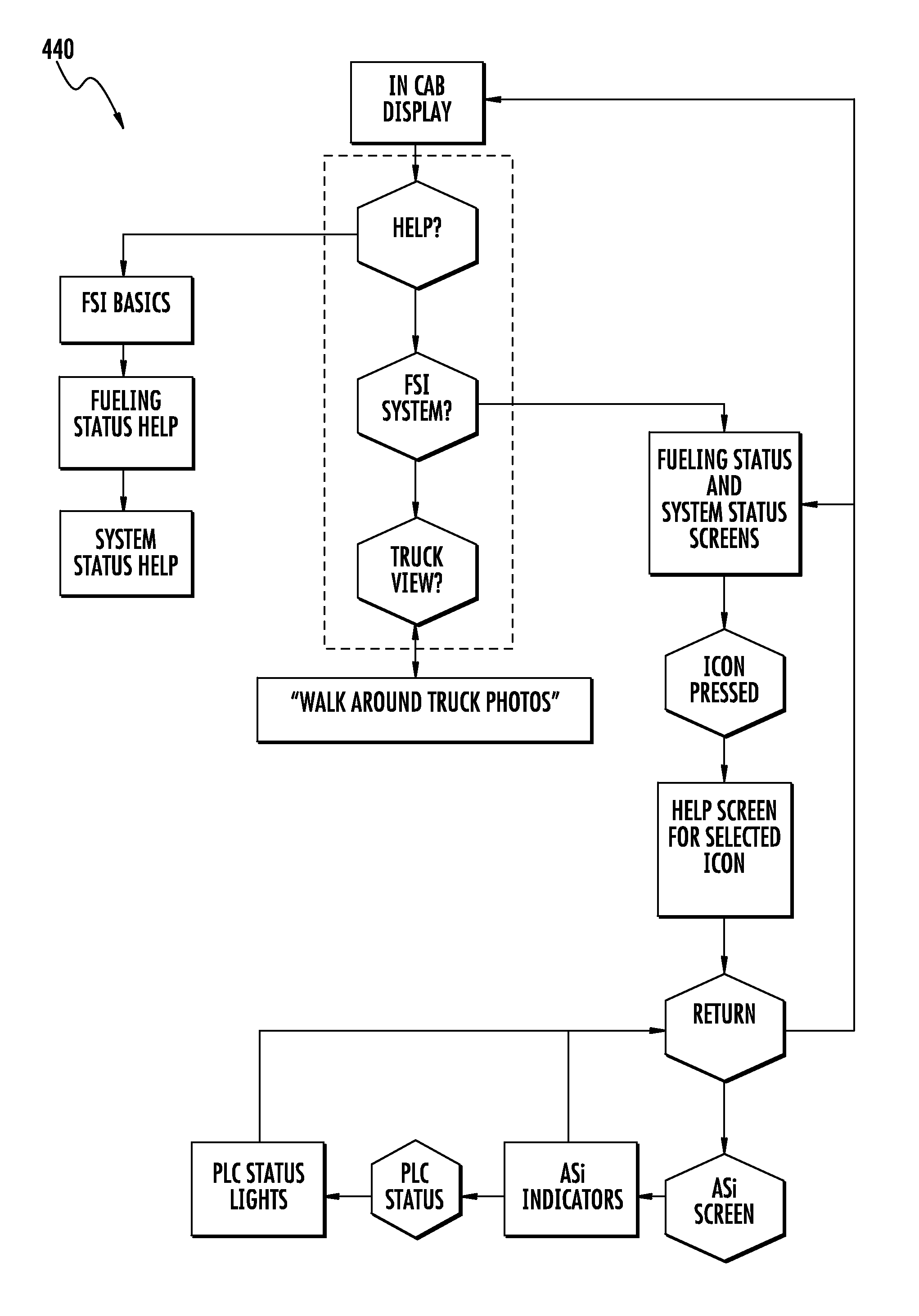

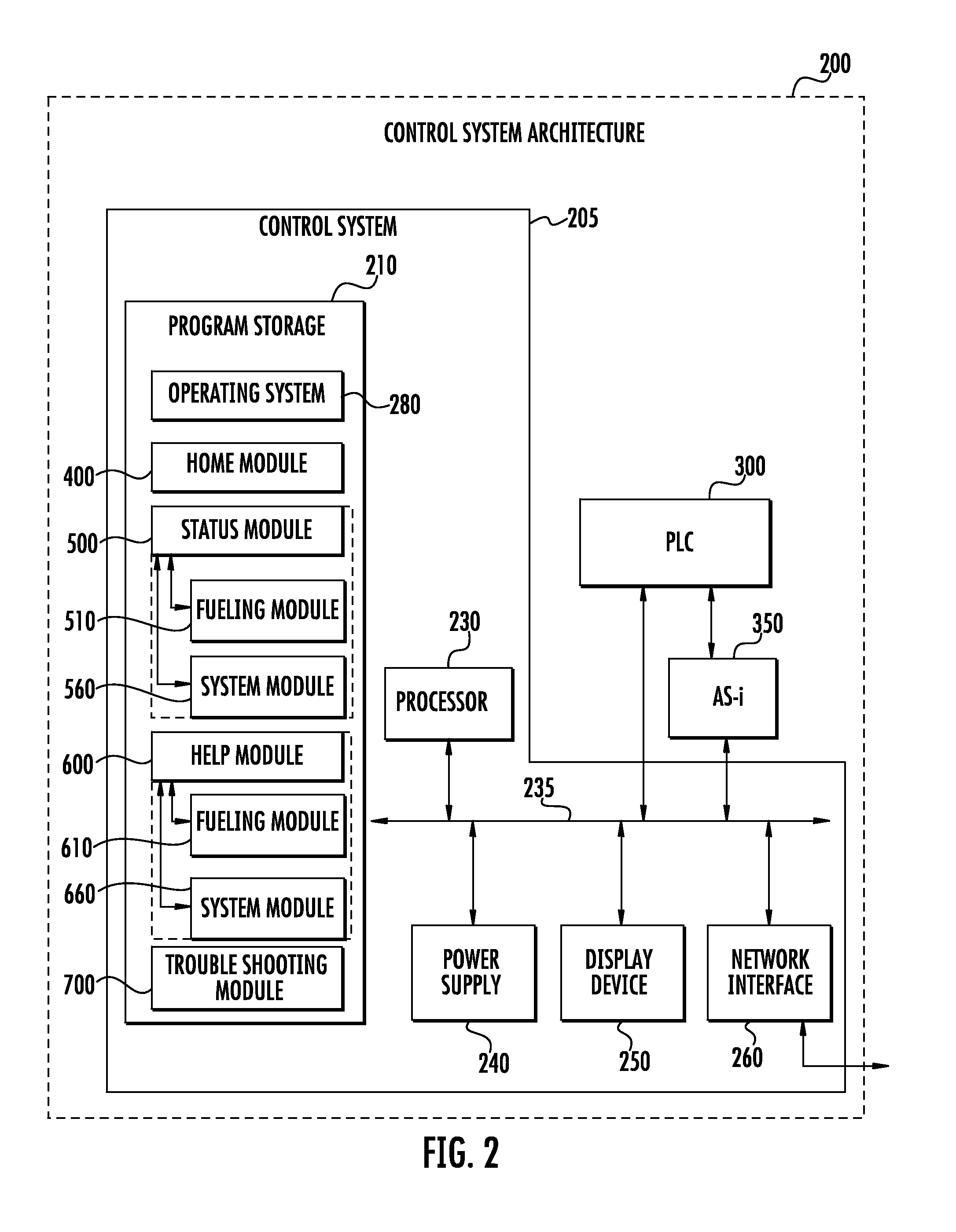

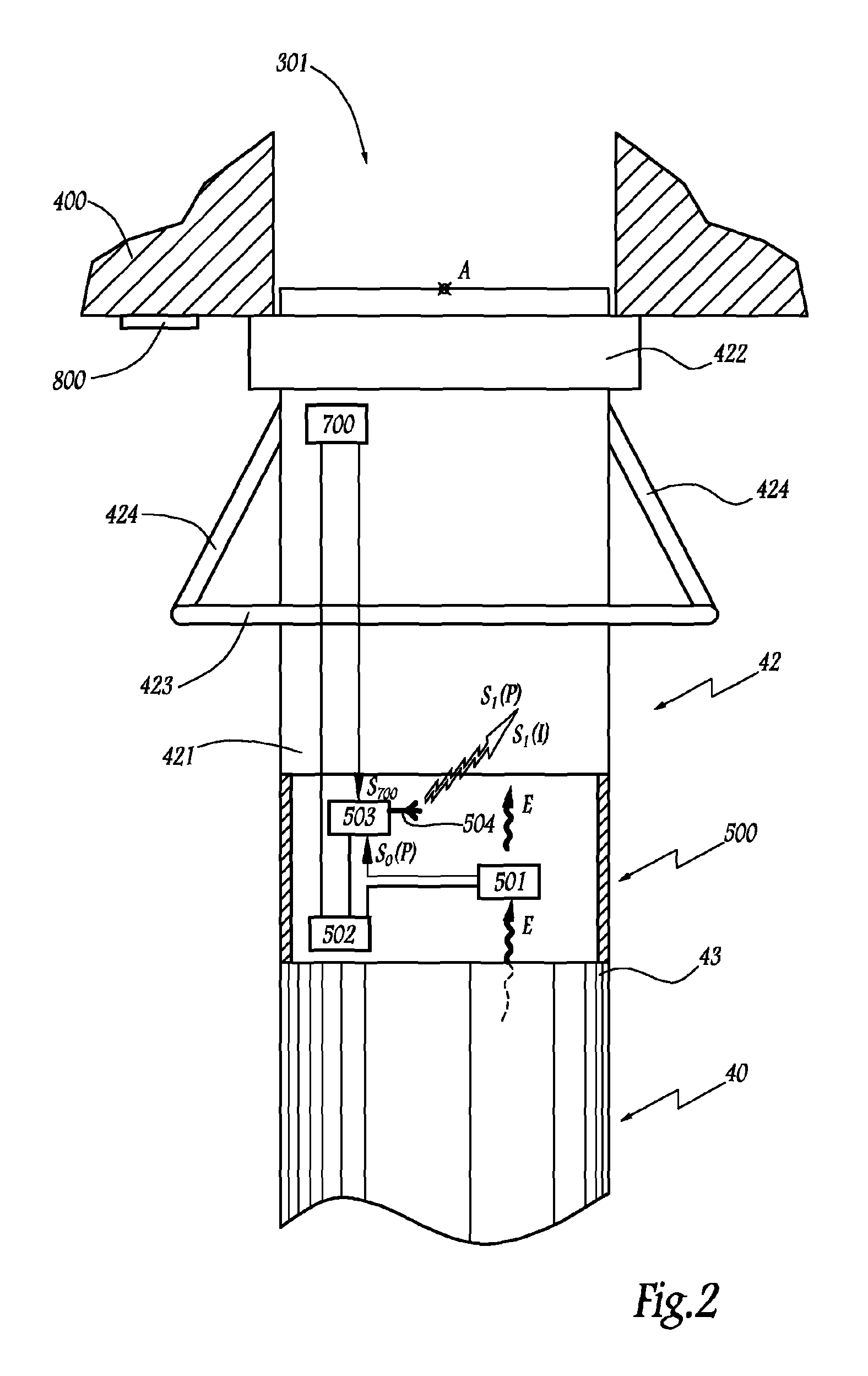

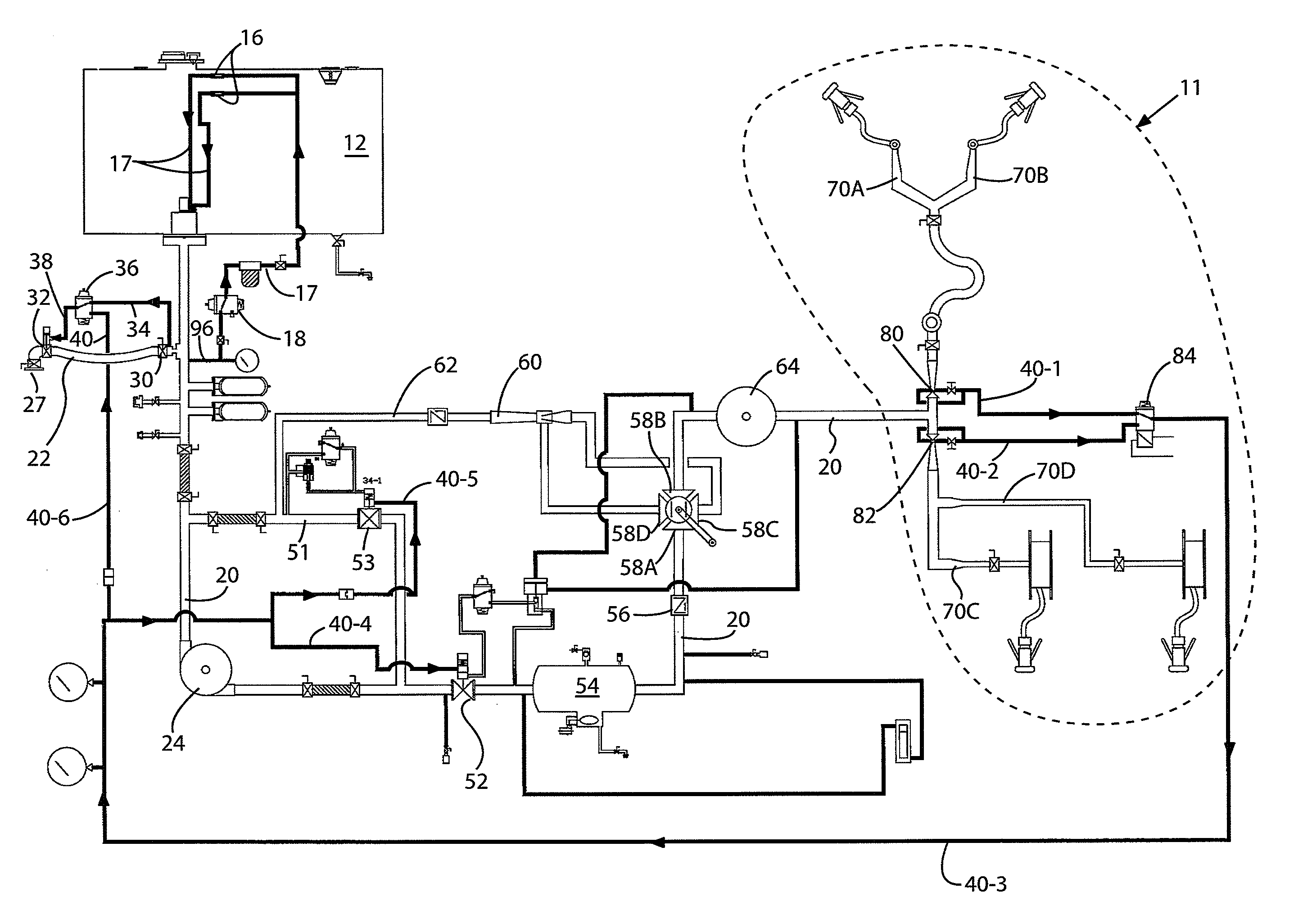

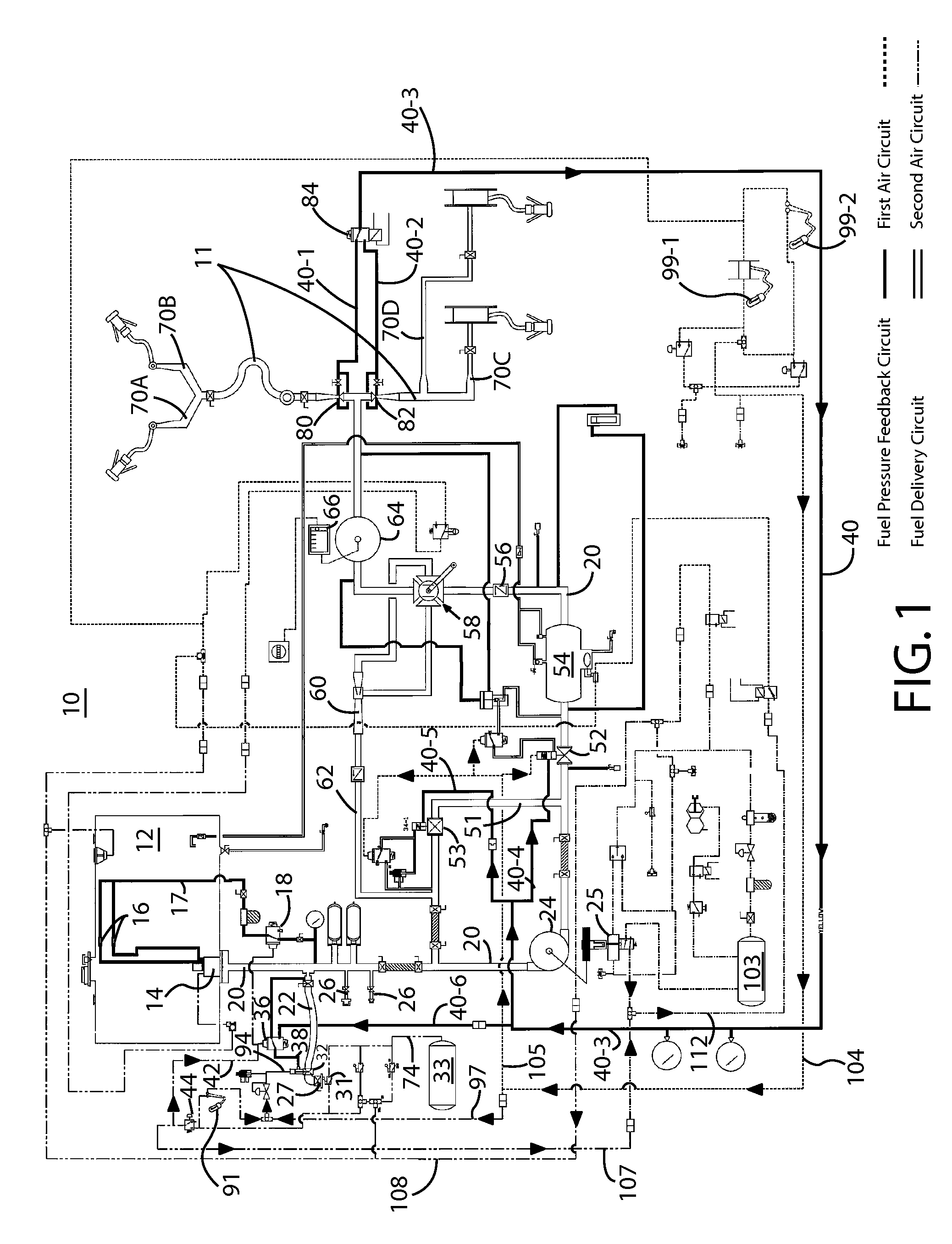

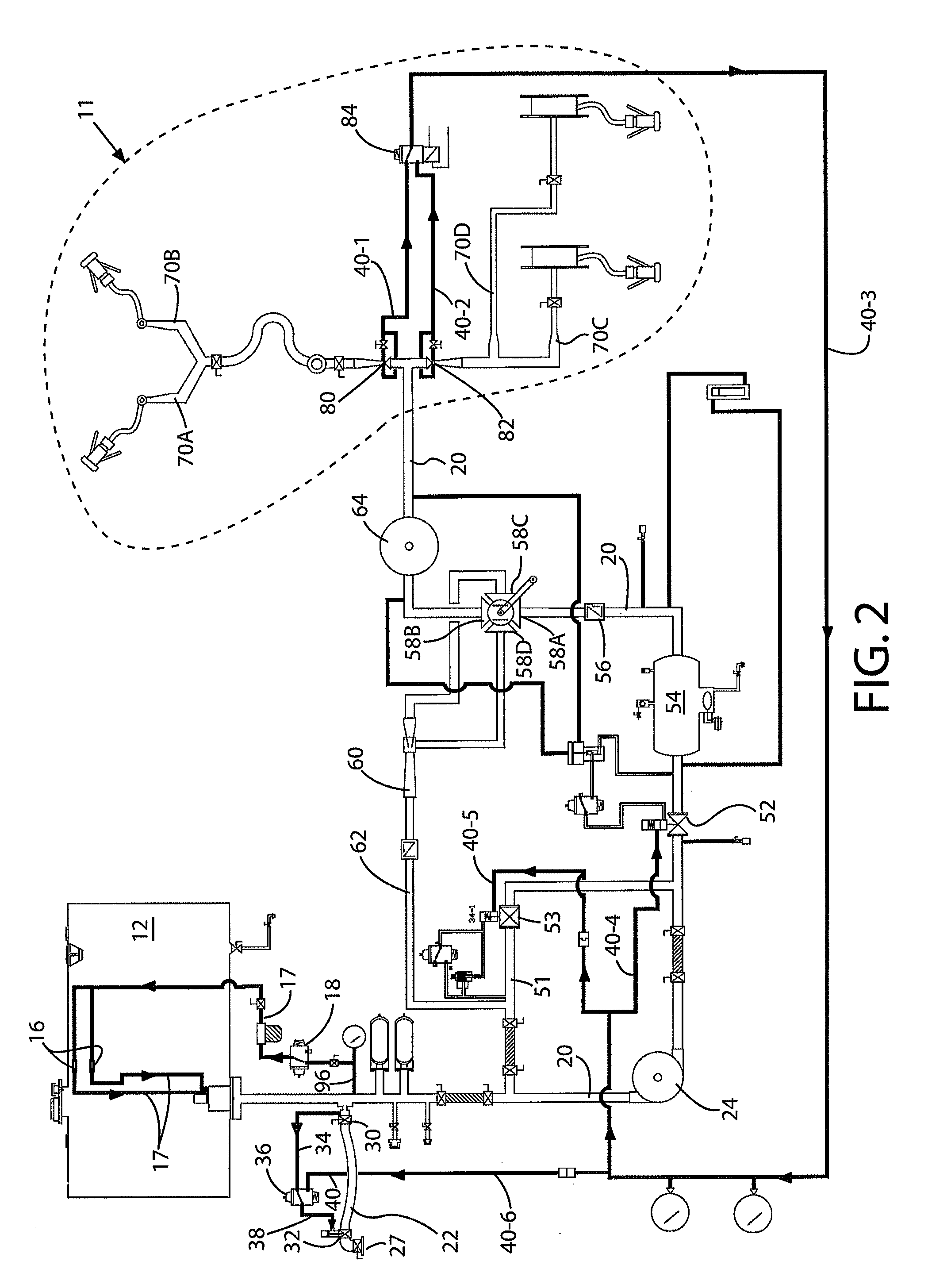

Systems and methods for providing a control system for aircraft refueling trucks

InactiveUS20130007650A1Easy to moveLiquid handling installationsInput/output processes for data processingAnalysis dataControl system

According to various embodiments, apparatuses and methods for providing a control system for aircraft refueling trucks is provided. The control system is configured for facilitating remote troubleshooting of one or more safety mechanisms associated with a flow of liquid fuel from a refueling vehicle to an aircraft, and analyzes data to determine whether one or more parameters associated with the one or more safety mechanisms have been satisfied. Once determined, the control system may generate a status for one or more selectable status indicators associated with the one or more safety mechanisms and display a visual representation of a particular safety mechanism associated with the selected status indicator The visual representation may include an image representing at least a physical location of the particular safety mechanism relative to the refueling truck so as to facilitate remote troubleshooting of the particular safety mechanism.

Owner:BETA FLUID SYST

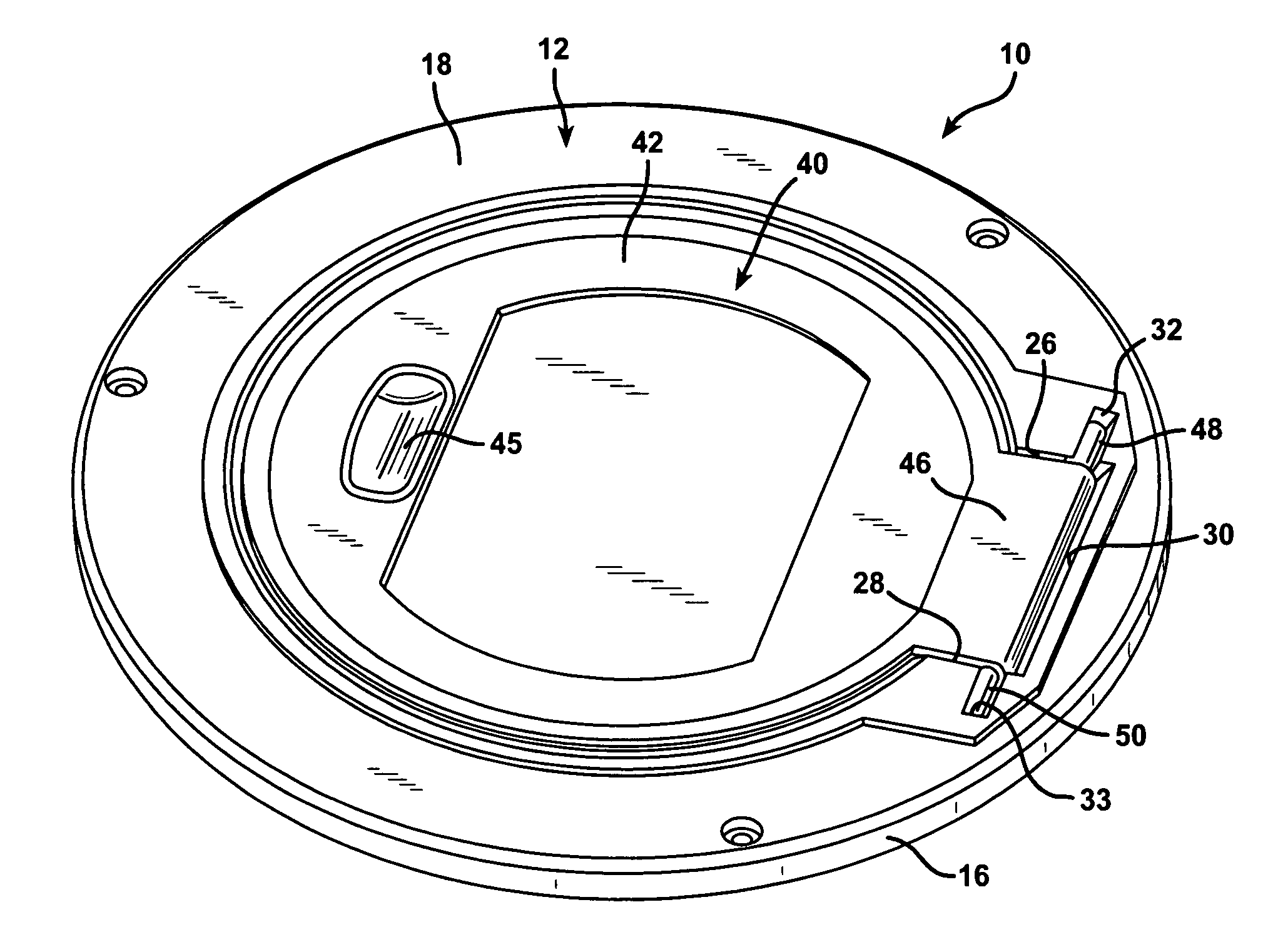

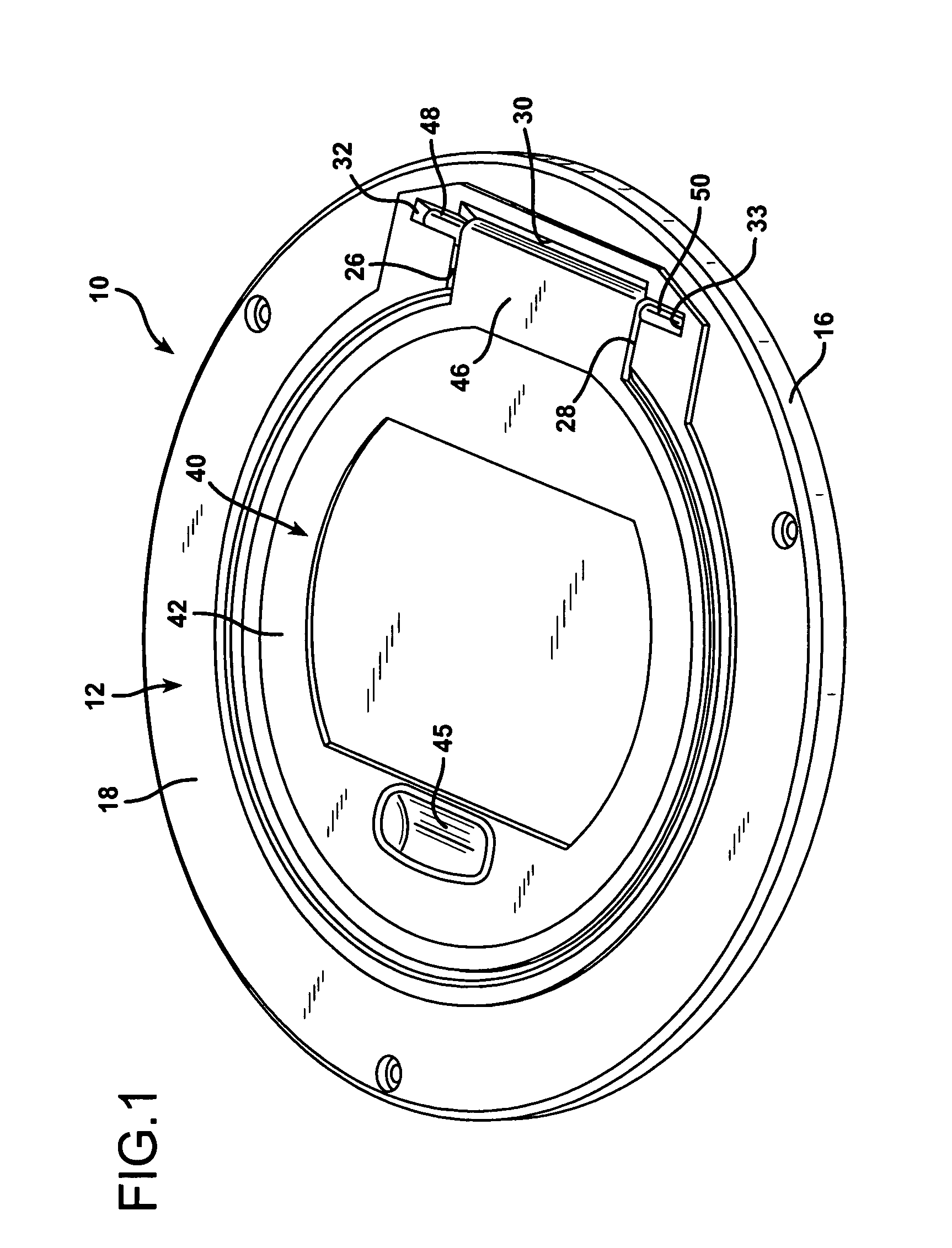

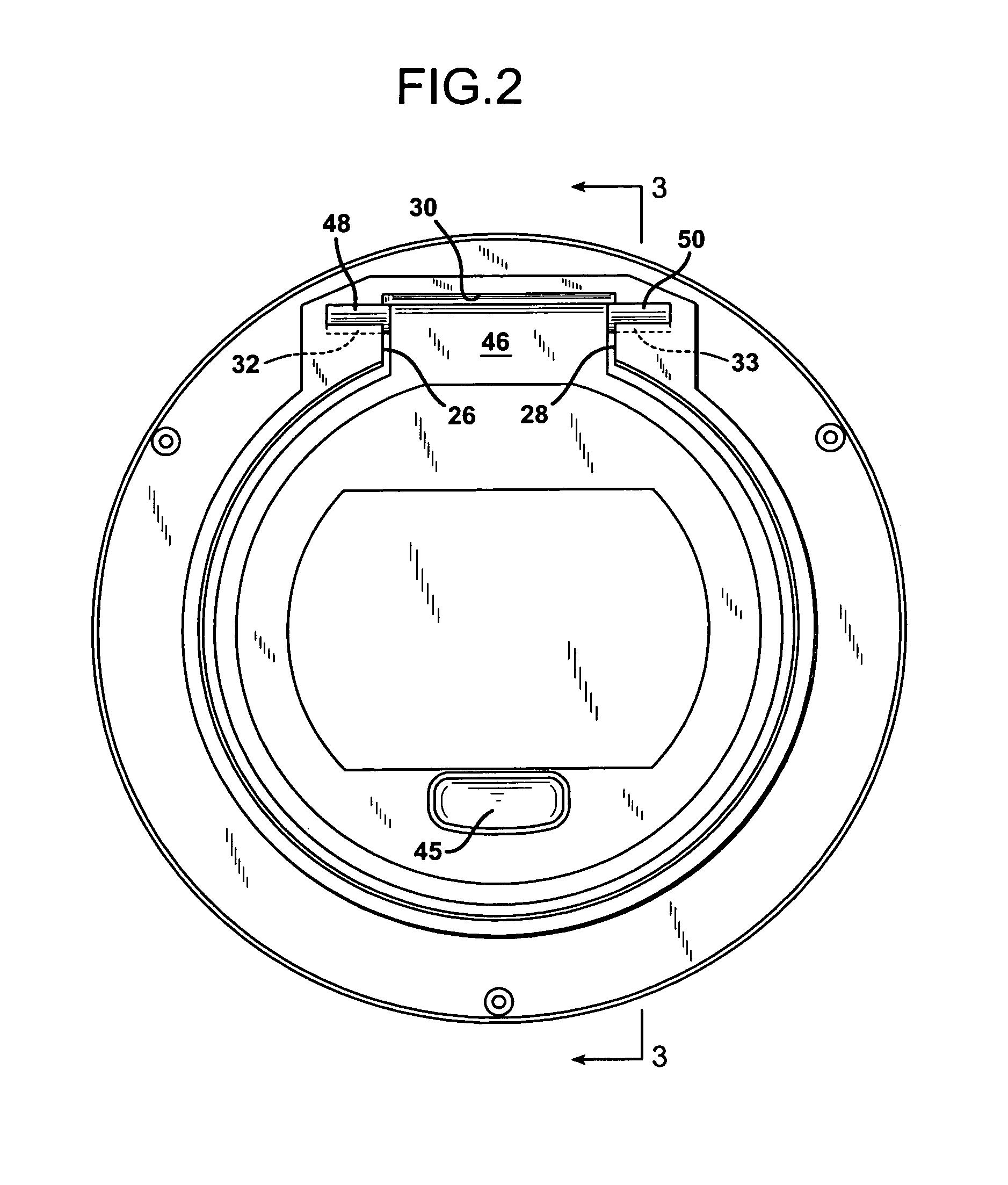

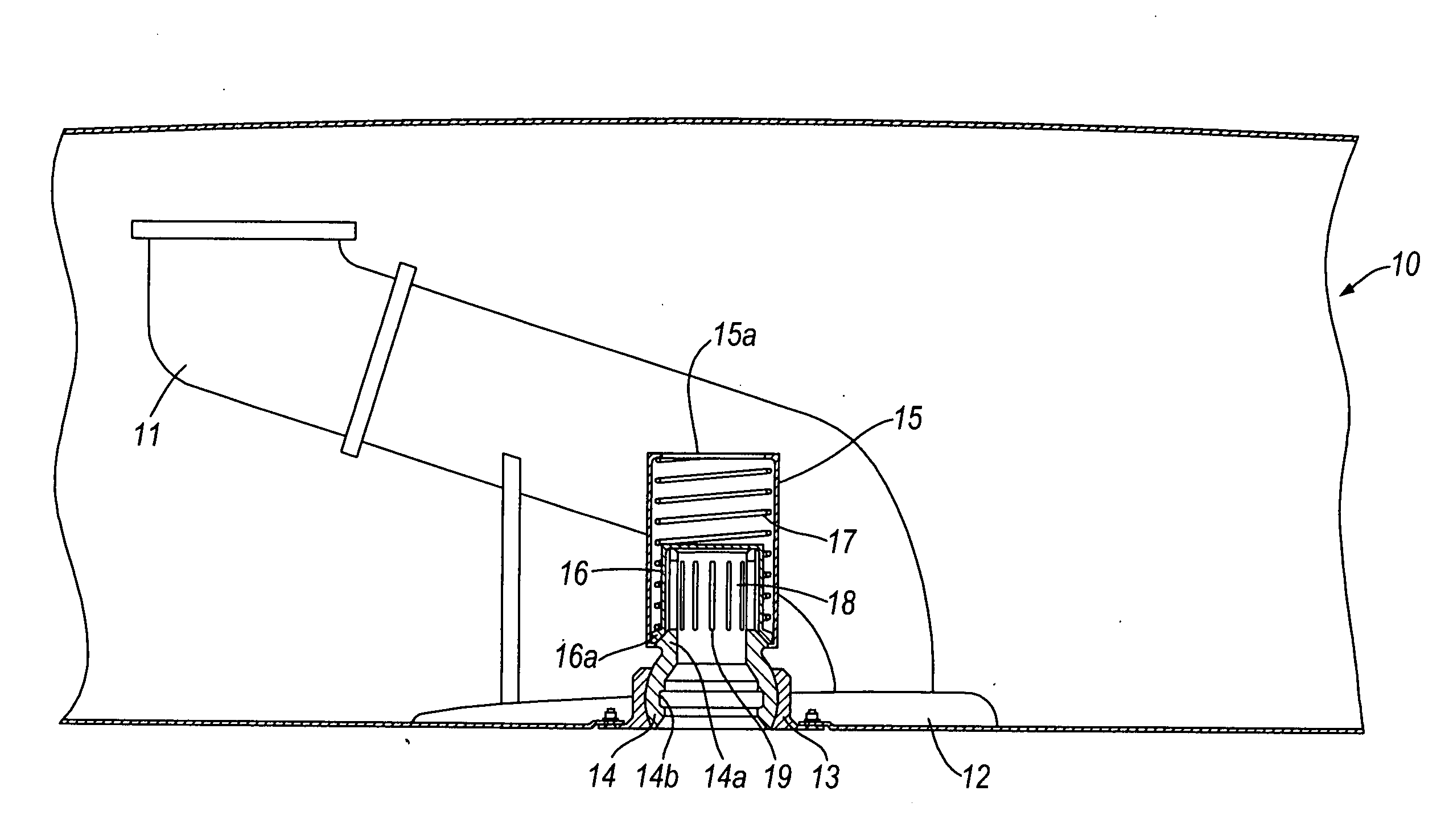

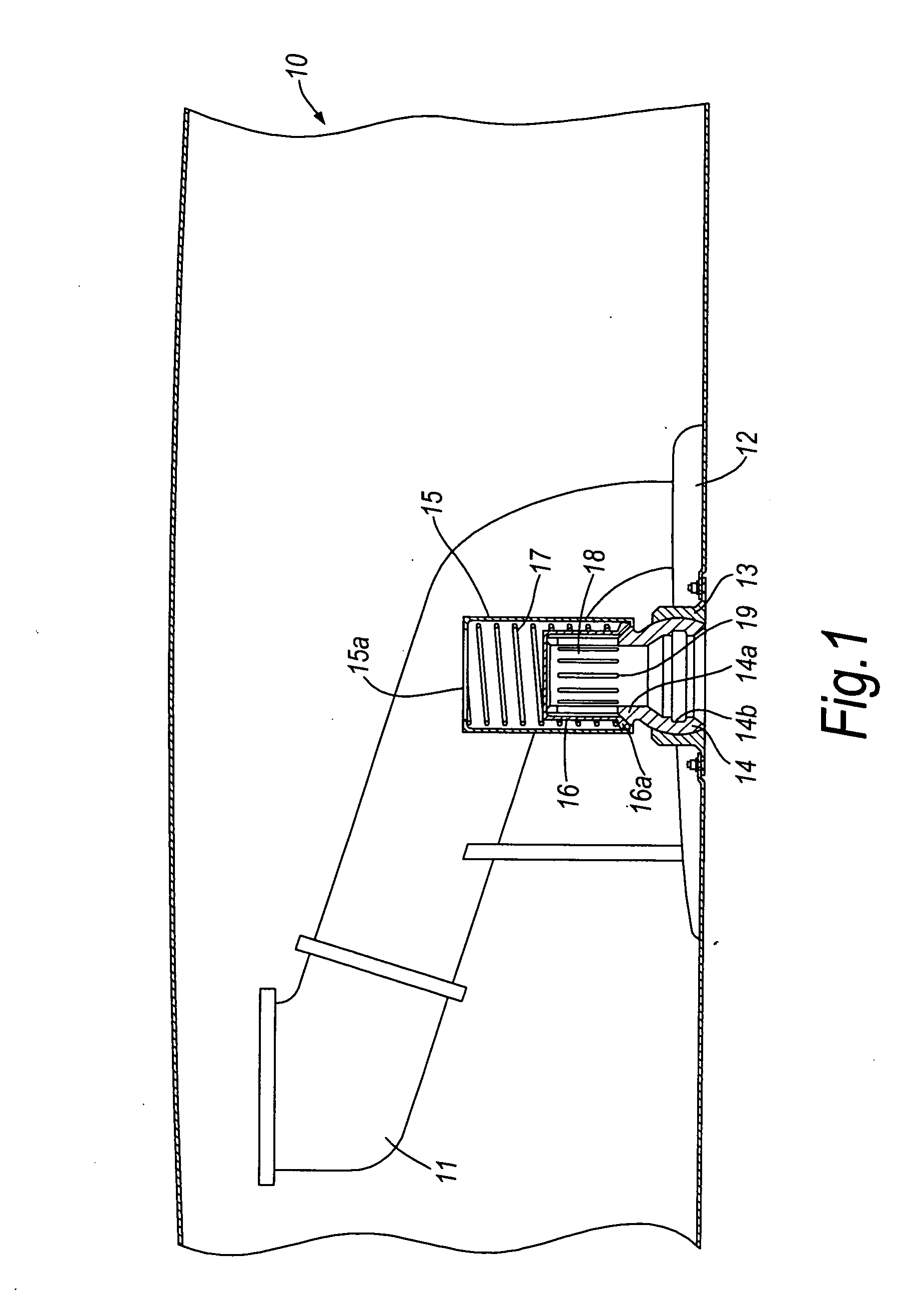

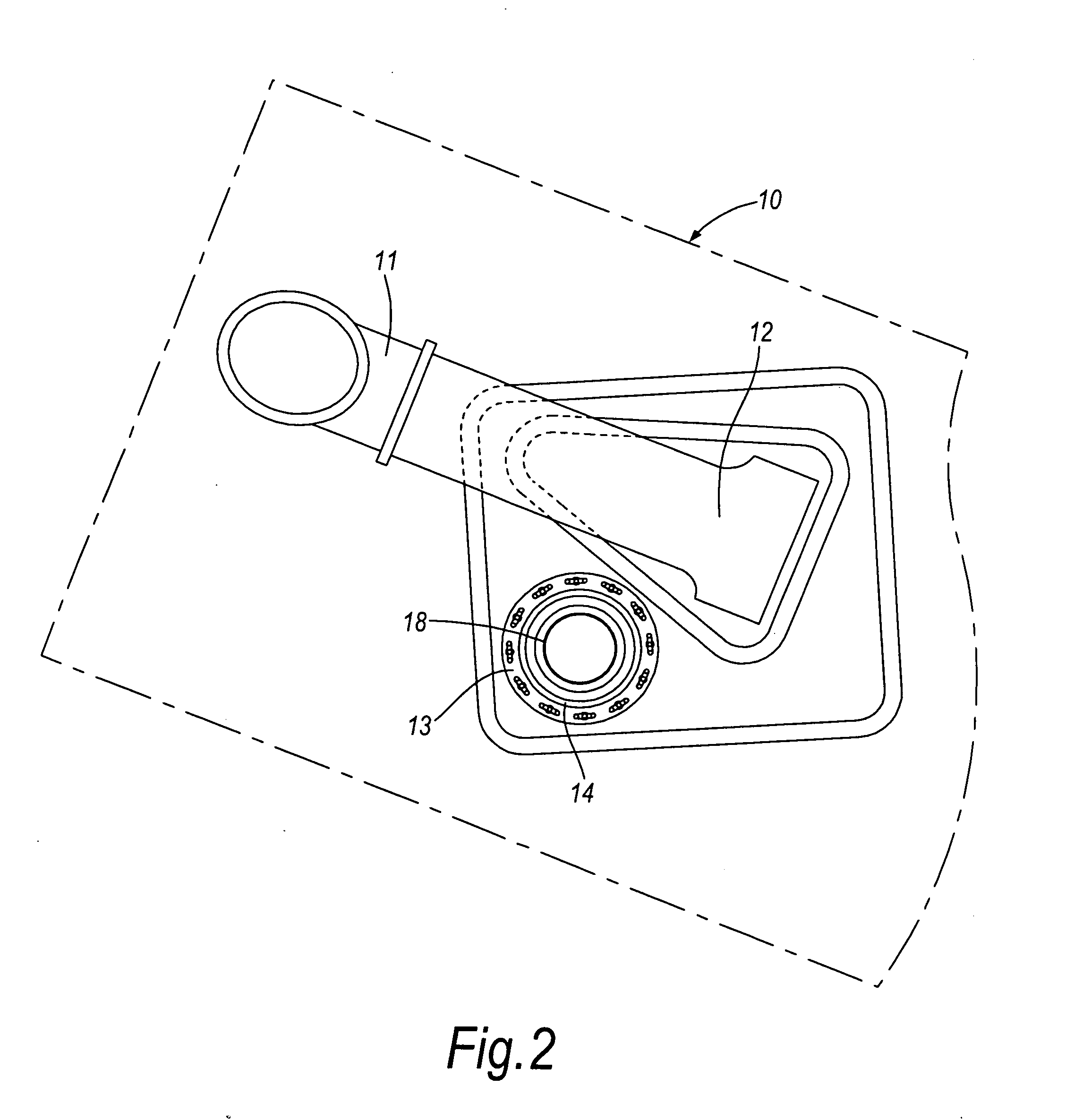

Removable aircraft servicing pit lid

InactiveUS6957927B1Avoid disadvantagesPromote lowerBuilding roofsLiquid handling installationsEngineeringAirplane

An aircraft servicing pit is provided that has a pit lid set within a supporting frame and hinged for rotation relative to a pit access opening. However, the pit lid is also completely detachable from the surrounding frame once it opened. The pit lid support has a flat deck surface with an access opening surrounded by a supporting rim located beneath the deck surface. A hinge pocket is defined in the structure of the pit lid support. A pair of hinge axle end slots are formed on the opposite sides of the pit lid support frame and are inclined upwardly and outwardly. The pit lid has a hinge leaf with a pair of hinge axle ends projecting transversely therefrom in opposite directions. The hinge axle ends engage the hinge axle end slots and are entrapped therein when the pit lid is closed. When the pit lid is open to the point where the pit lid is in generally coplanar relationship relative to the hinge axle end slots, the hinge axle ends can be easily withdrawn from the slots and the pit lid removed completely from its supporting frame. Complete detachment of the pit lid in this fashion eliminates obstructions otherwise presented by the pit lid and its hinge in drawing cables and hoses out of the pit enclosure.

Owner:CAVOTEC ACQUISITION US

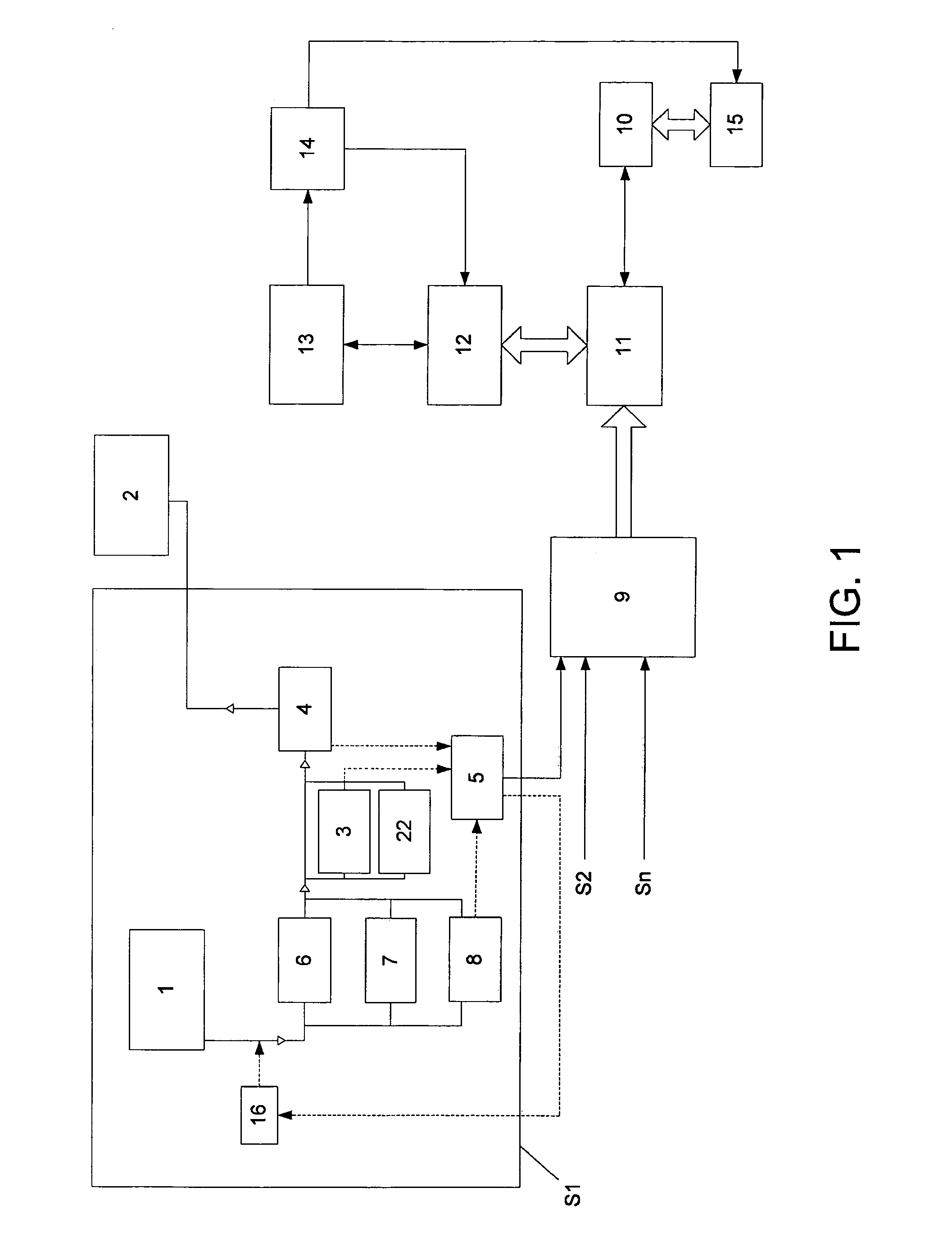

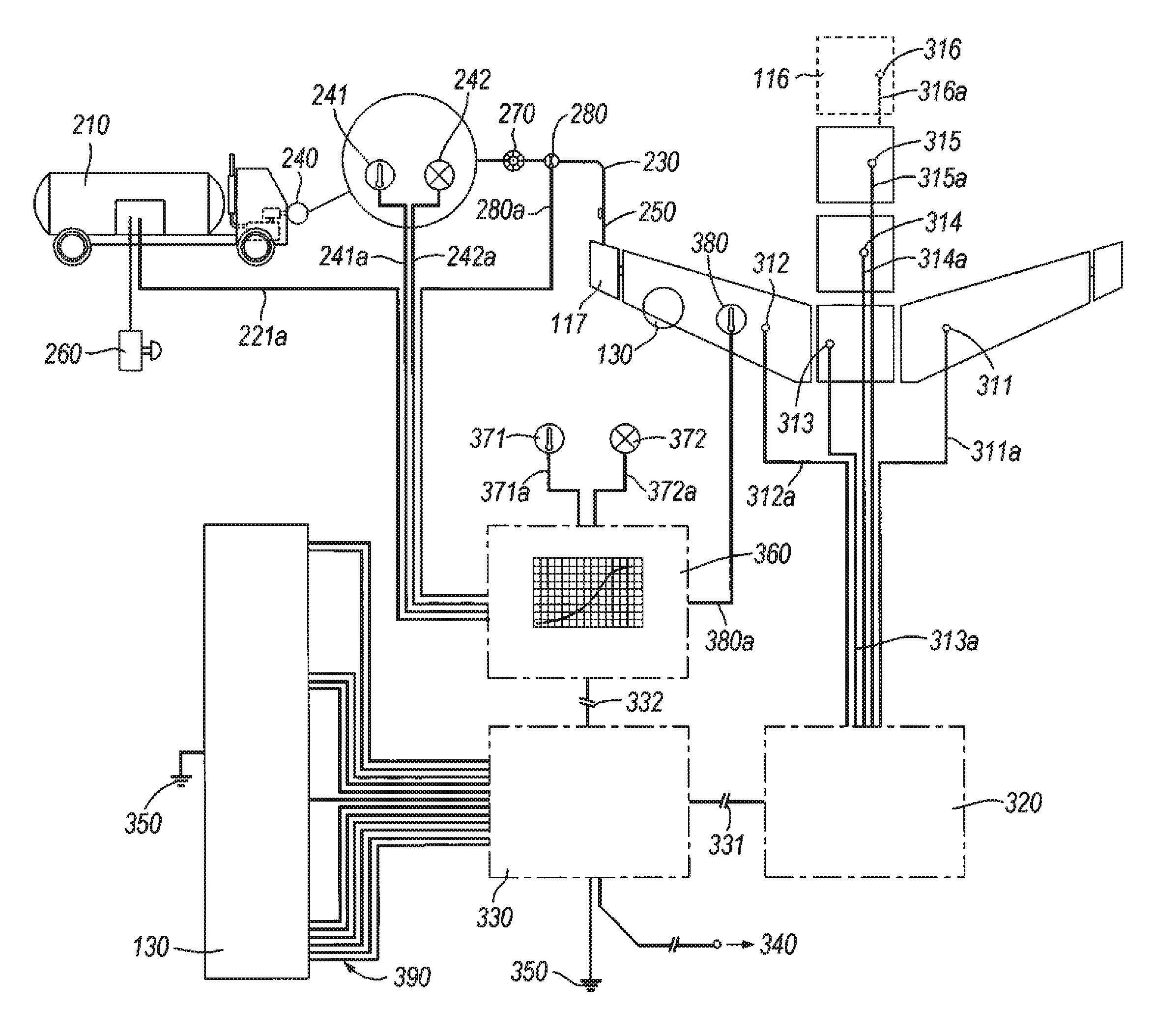

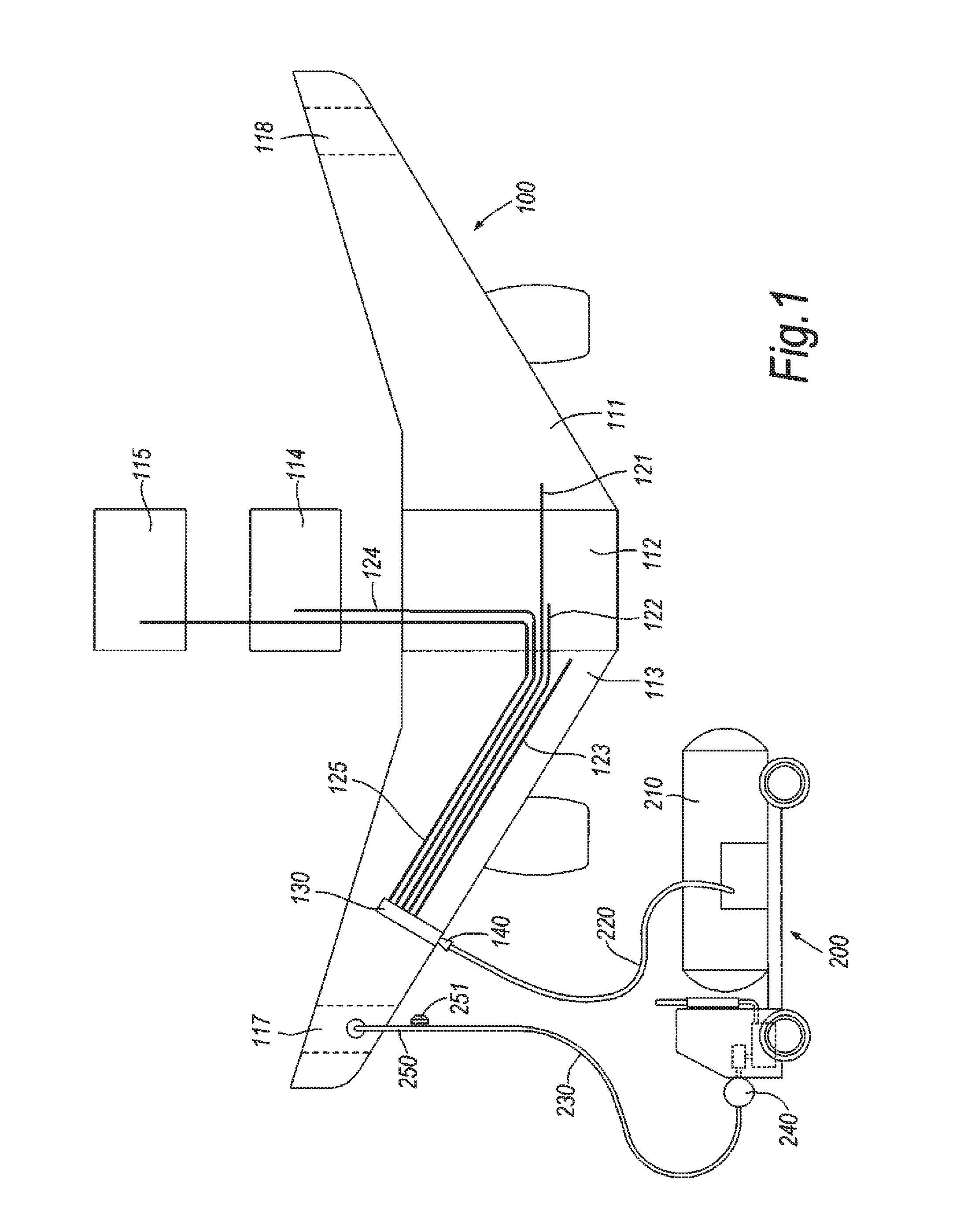

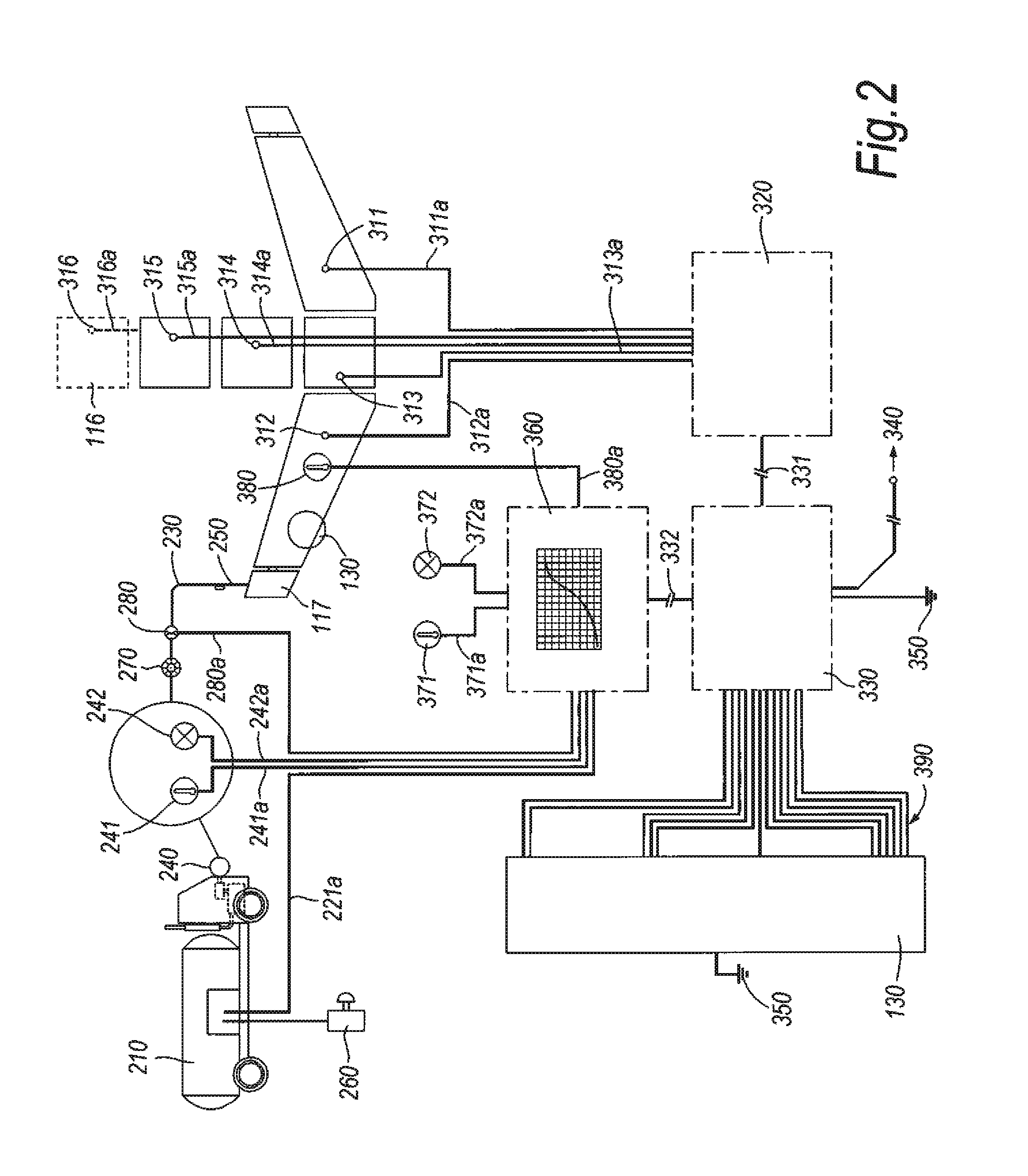

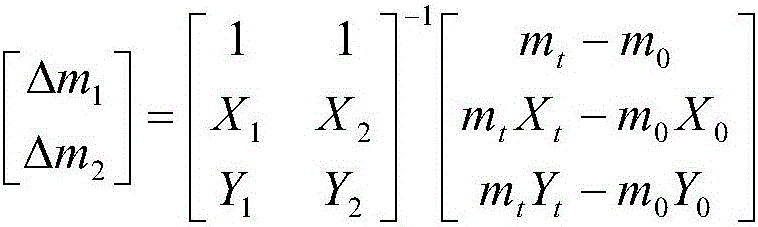

Refuel control system and method of refuelling

InactiveUS20130119202A1Minimizes surge pressureReduce refueling timesLiquid handling installationsPower plant fuel tanksAirplaneMonitoring data

The invention provides a refuel control system for controlling refuel of at least one tank (111,112,113, 14,115,116) onanaircraft 100,the refuel control system comprising monitoring apparatus (241, 242, 280, 371, 372, 380, 311, 312, 313, 314, 315, 316, 221) for monitoring data relevant to the refuel process, a control device (330) for receiving said data from the monitoring apparatus, and a refuel valve (130) for controlling flow of fuel to the tank wherein said refuel valve is controllable by the control device such that refuel of the tank can be controlled based on the monitored data. The invention also provides a method of refuelling at least one fuel tank on an aircraft.

Owner:AIRBUS OPERATIONS LTD

Pilot control overflowing system for airplane pressure fuel filling

InactiveCN101870365ANot affected by flight attitudeImprove securityLiquid handling installationsPressure controlled ventilationPressure control

The invention discloses a pilot control overflowing system for airplane pressure fuel filling. The pilot control overflowing system is characterized in that a manifold of an airplane pressure fuel filling joint passes through a tee joint and then is divided into two paths for transferring pressure, wherein one path is connected with an excess oil discharge control joint on an overflowing valve through a pressure control pipe and the other path is connected with a pressure control joint on the overflowing valve through a pressure control pipe; and a ventilation balanced joint on the overflowing valve is communicated with the atmosphere through a ventilation balanced pipe. Compared with the prior art, the invention has the advantages of automatic and simple control, favorable safety and reliability, light weight, no influence from the flying posture of the airplane and the like and is suitable for a pressure fuel filling system of a small-sized airplane.

Owner:HARBIN

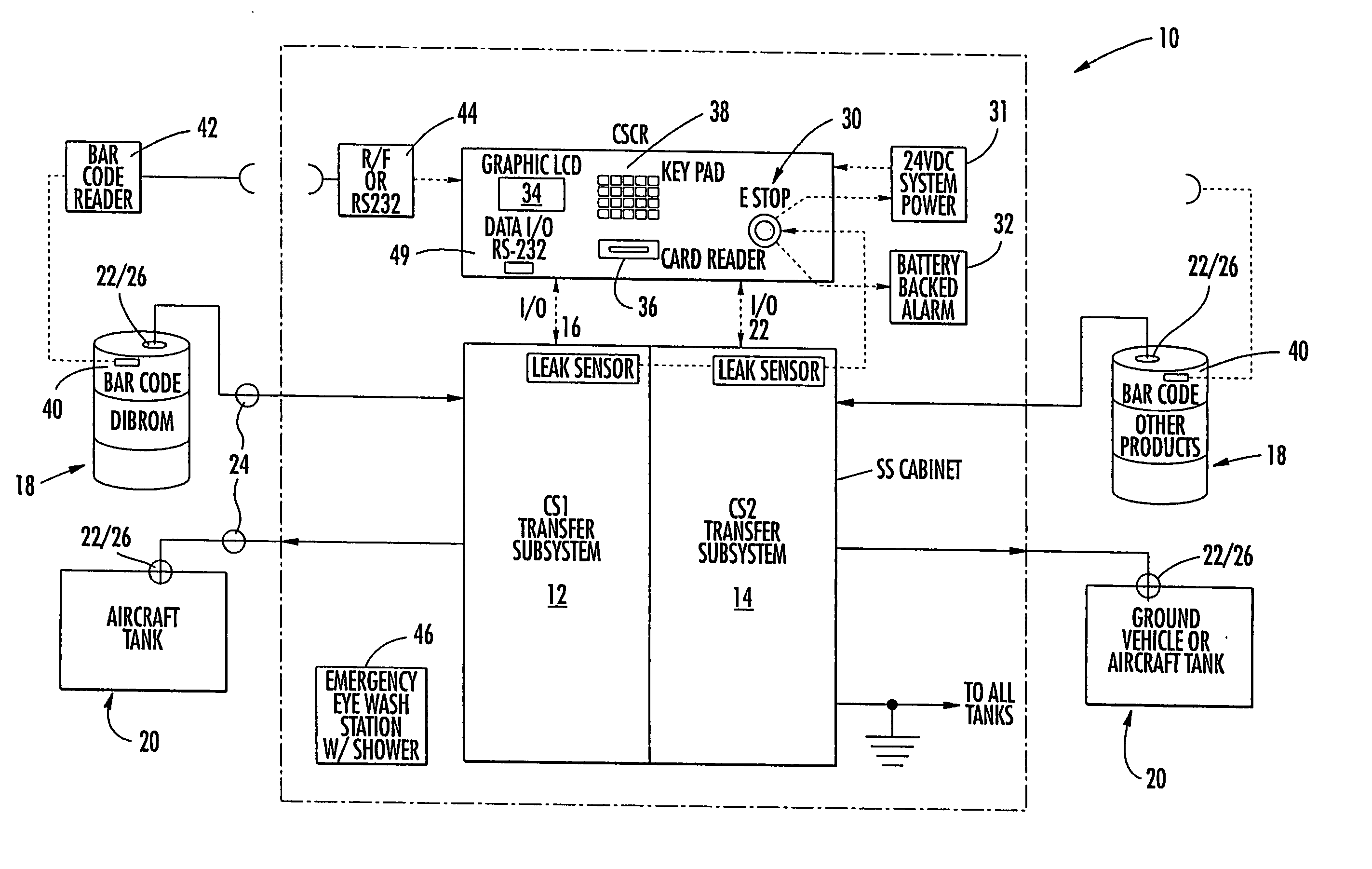

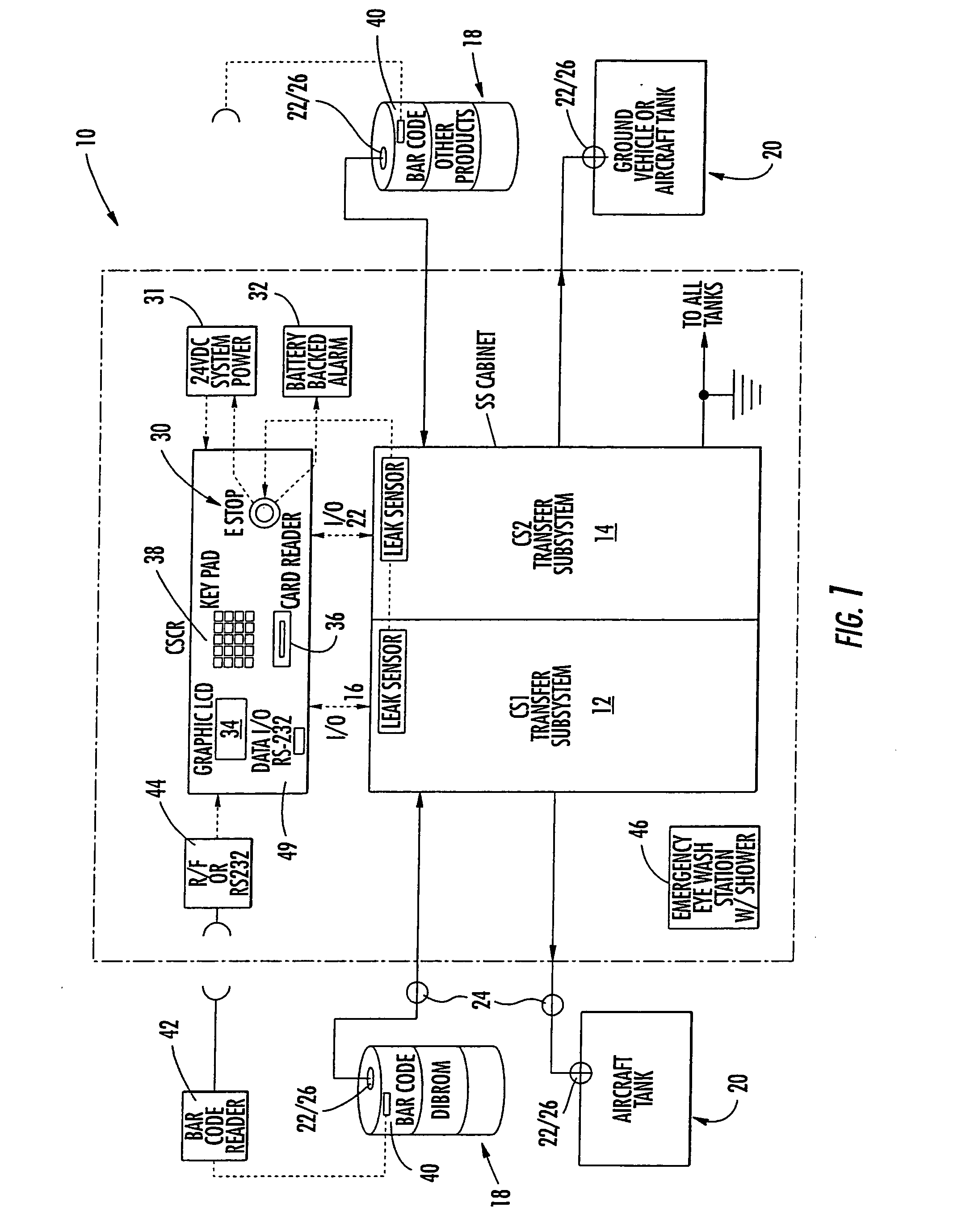

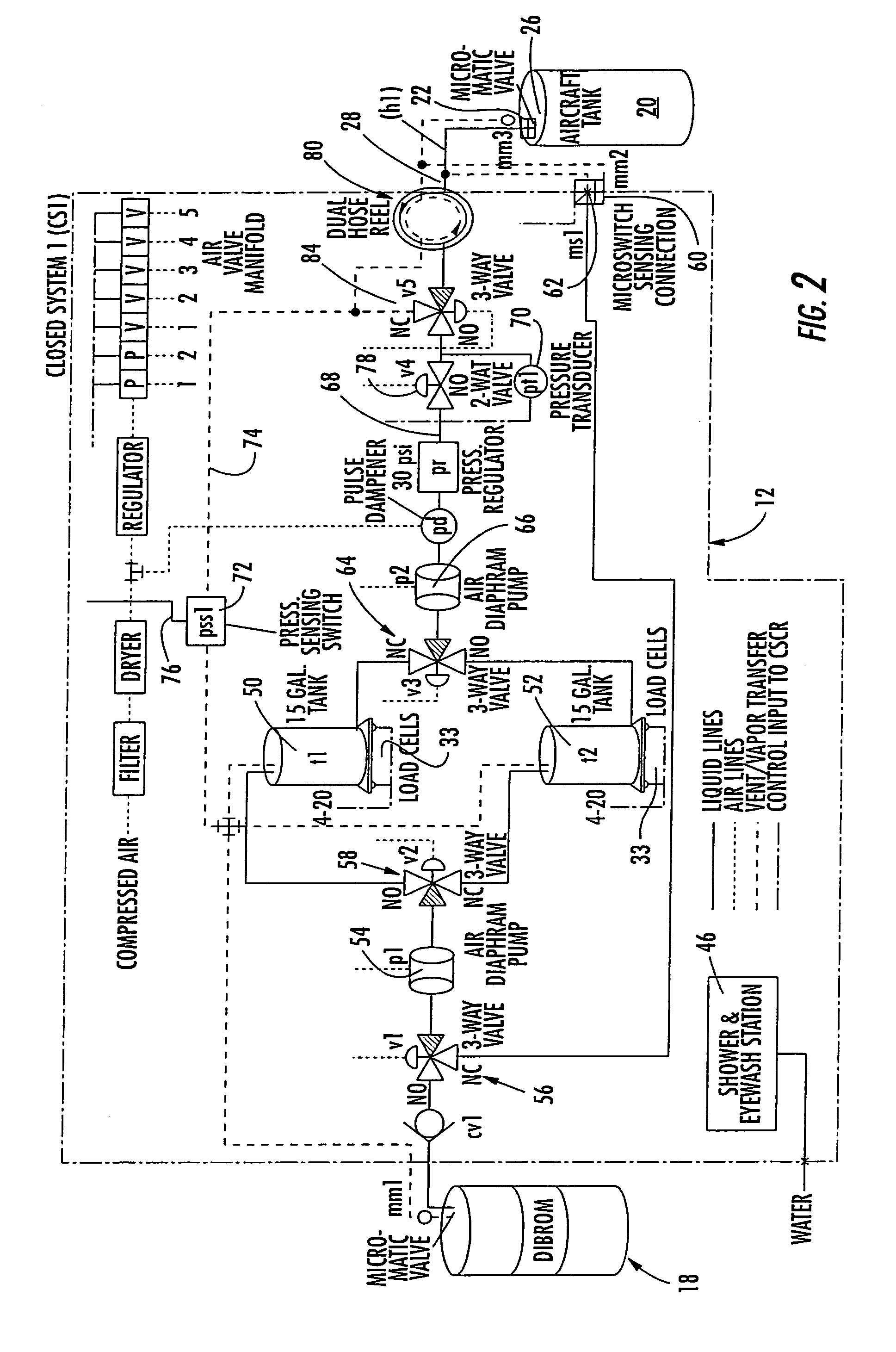

Hazardous fluids transfer system and method

InactiveUS20050189036A1Safe transferReduce exposureLiquid handling installationsLiquid fillingLiquid lineLine tubing

A hazardous fluid transfer system is automated for controlling transfer of hazardous fluid within a closed environment thus providing protection to an operator handling the transfer. The hazardous fluid is transferred from a source container to a target container using a processor controlled pump responsive to flow and pressure within a liquid line. A pre-programmed processor receives pressure and flow signals from transducers monitoring the liquid line. The processor actuates a valve within a vapor line between the source and target containers in response to pressure within the target container. The valve is opened for allowing vapor to accumulate within an accumulator during a filling of the target container and closed for causing the accumulator to force vapor stored in the accumulator into the source container, thus transferring the liquid from the source container to the target container while maintaining fluid transfer within the closed environment.

Owner:ADAPCO

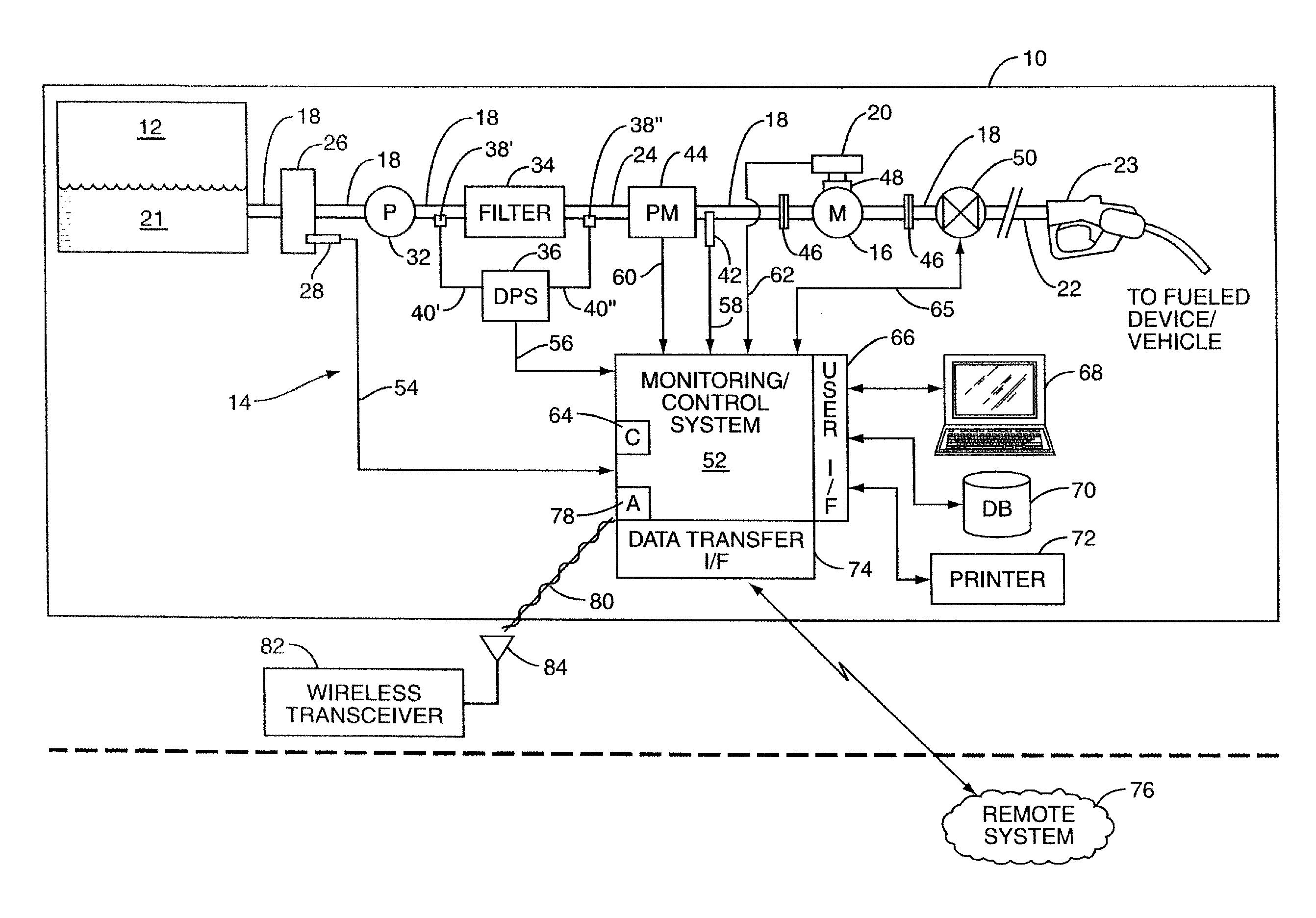

Automated fuel quality detection and dispenser control system and method, particularly for aviation fueling applications

ActiveUS8720499B2Reduce riskAvoid refuelingLiquid handling installationsLevel indicatorsWater detectorAviation

A fuel quality monitoring system and method to automatically and / or continuously monitor quality of fuel dispensed and control the operation of the fuel dispenser. The control system monitors fuel quality to prevent unsafe refuelings when the fuel quality is unacceptable. In one embodiment, a combination of a differential pressure sensor, a water detector, and / or a particle monitor is employed inline the fuel flow path of a fuel dispenser, and in particular an aviation refueling truck, to monitor the quality of the fuel. If fuel quality is at an acceptable level although not ideal, the control system can allow fueling with the generation of reports and alarms. If the fuel quality is unacceptable, fuel flow can be stopped. If the differential pressure across the filter indicates a high degree of debris and / or water retention, the control system can automatically lower the flow rate to reduce the risk of filter breakdown without completely preventing fueling until the filter can be replaced.

Owner:FUEL GUARD SYST +1

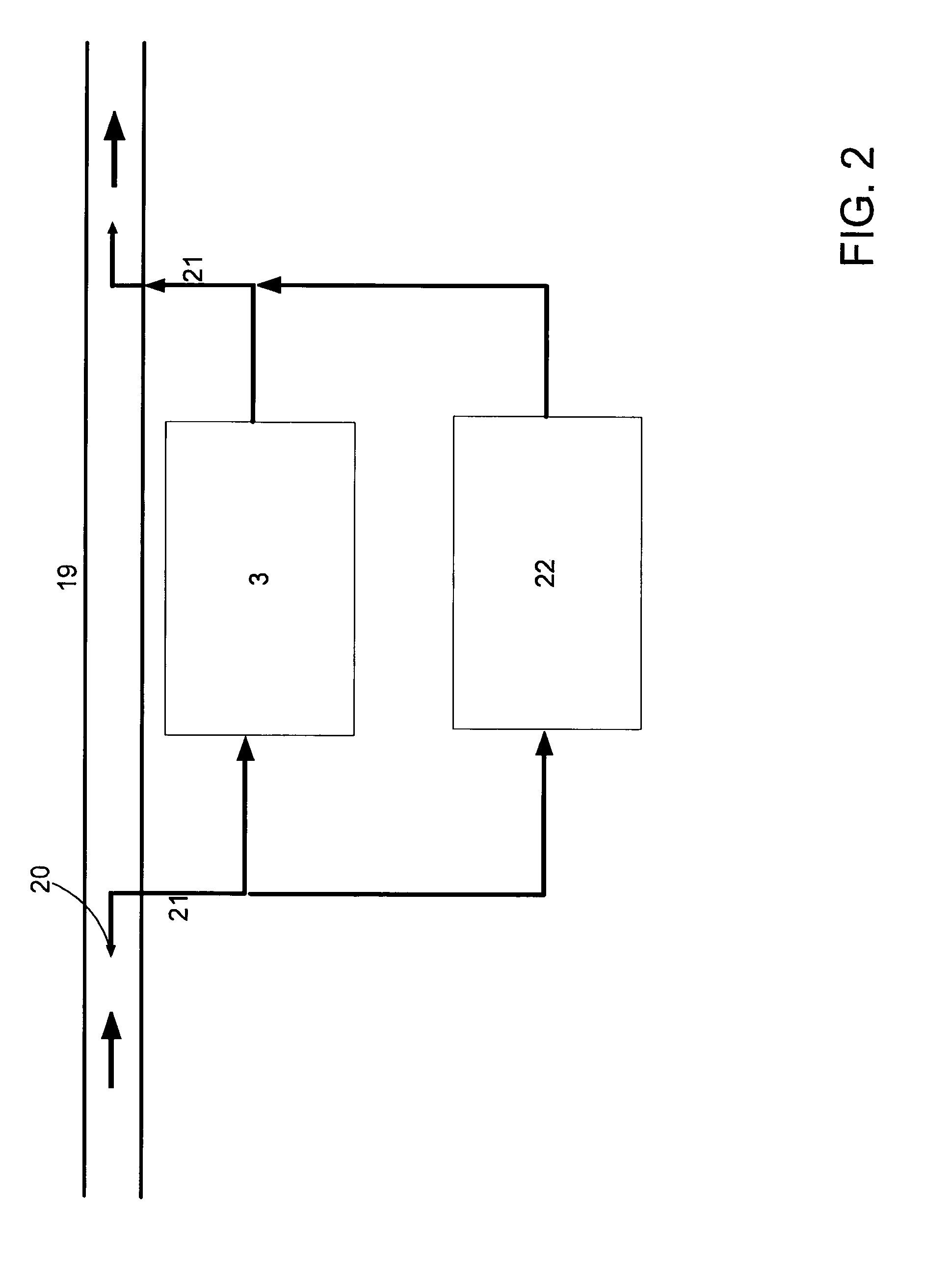

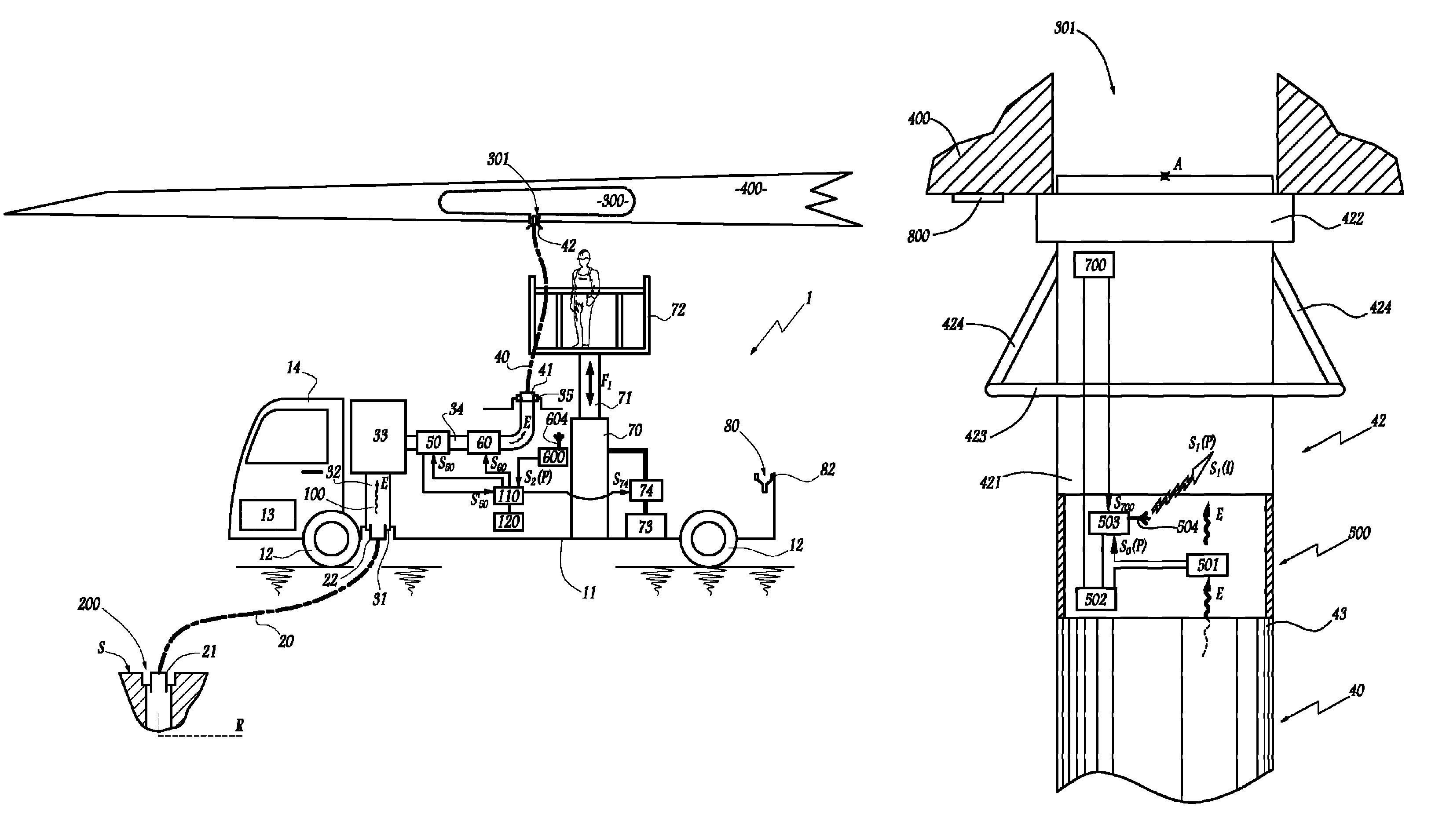

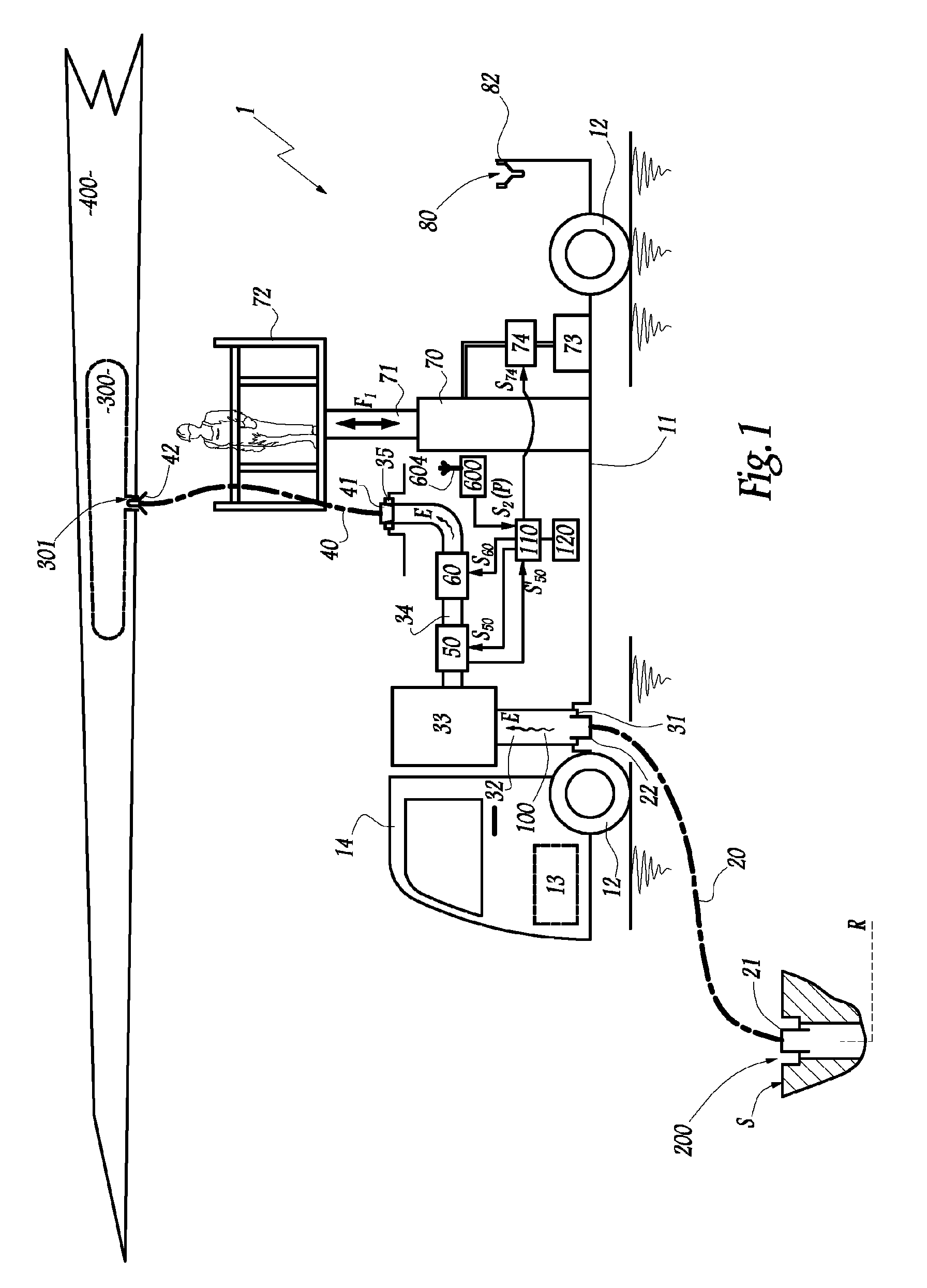

Refueling equipment, and method for refueling an aircraft using said equipment

The invention relates to equipment for refueling an aircraft, including a pipe (40) provided with means (42) for connecting onto an intake port (301) of the fuel tank of the aircraft (400) and, at or in the vicinity of the connection means (42), means (501) for determining the value of at least one parameter representative of a flow (E) of fuel passing through the connection means. Said equipment further includes at least one receiver onboard the refueling equipment (1), means (503, 504) for transmitting, to the receiver, a signal (Si(P)) representative of a parameter value predetermined by determination means (501) and an electronic unit capable of receiving, from the receiver, a signal representative of the parameter and of driving at least one flow control and monitoring device in accordance with the signal received from the receiver. The refueling method includes the steps of during a refueling operation, determining the value of at least one parameter representative of the flow (E) at or in the vicinity of the connection means (42), transmitting, to at least one receiver onboard the refueling apparatus, a signal (Si(P)) representative of a parameter value predetermined during the previous step, and automatically driving, in accordance with the signal received by the receiver, a flow control and monitoring device.

Owner:DESAUTEL

System for wireless refueling of an aircraft

A system for wirelessly refueling an aircraft includes an aircraft having a fuel tank, a control valve, a fuel sensor outputting a fuel signal indicative of the amount of fuel in the at least one fuel tank, and a controller controlling the control valve in response to the fuel signal, a refueling apparatus having a fuel supply, a pump and a controller in which is stored a fuel profile including fuel data indicative of the amount of fuel to be supplied to the at least one fuel tank, and wireless communication systems operably coupled to the controllers within the aircraft and refueling apparatus to control the operation of the control valve and the pump to fill the at least one fuel tank in accordance with the fuel profile and in response to the fuel signal.

Owner:GENERAL ELECTRIC CO

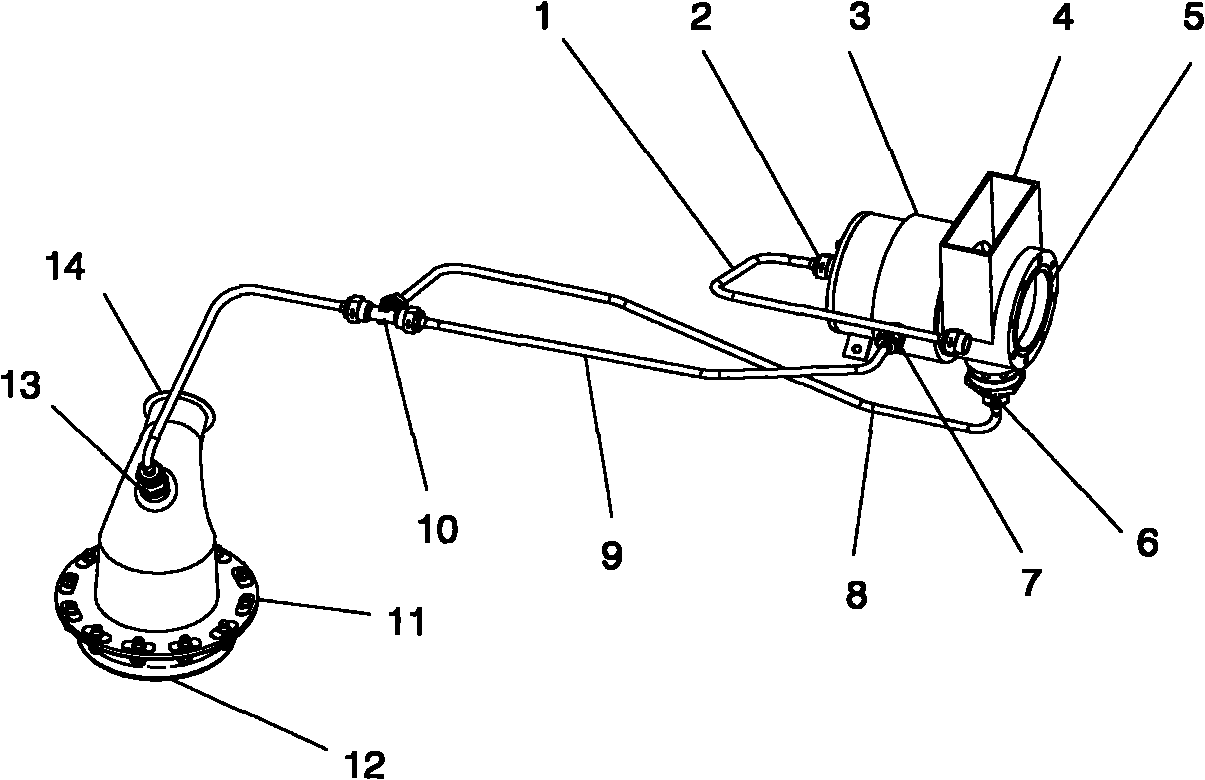

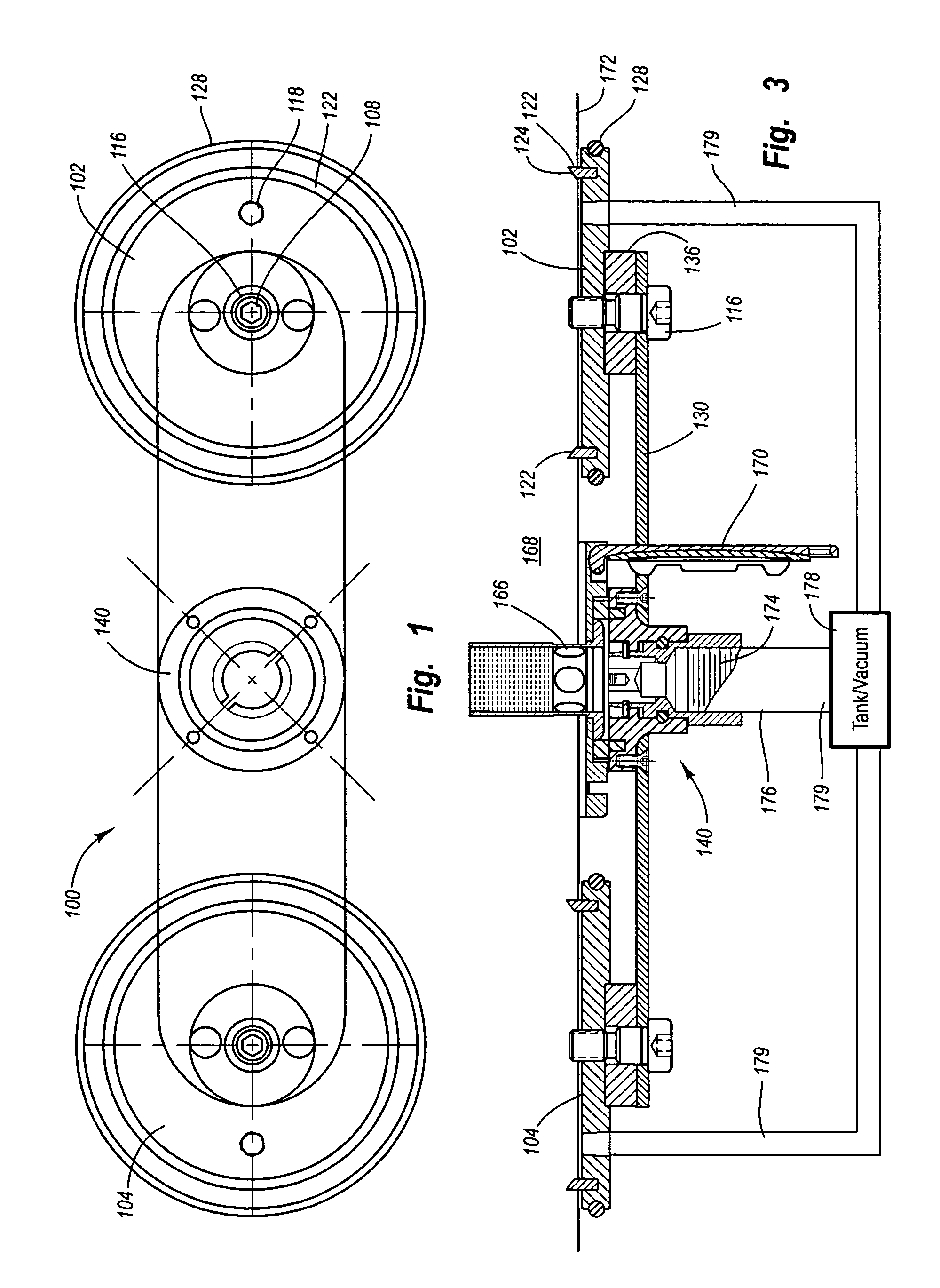

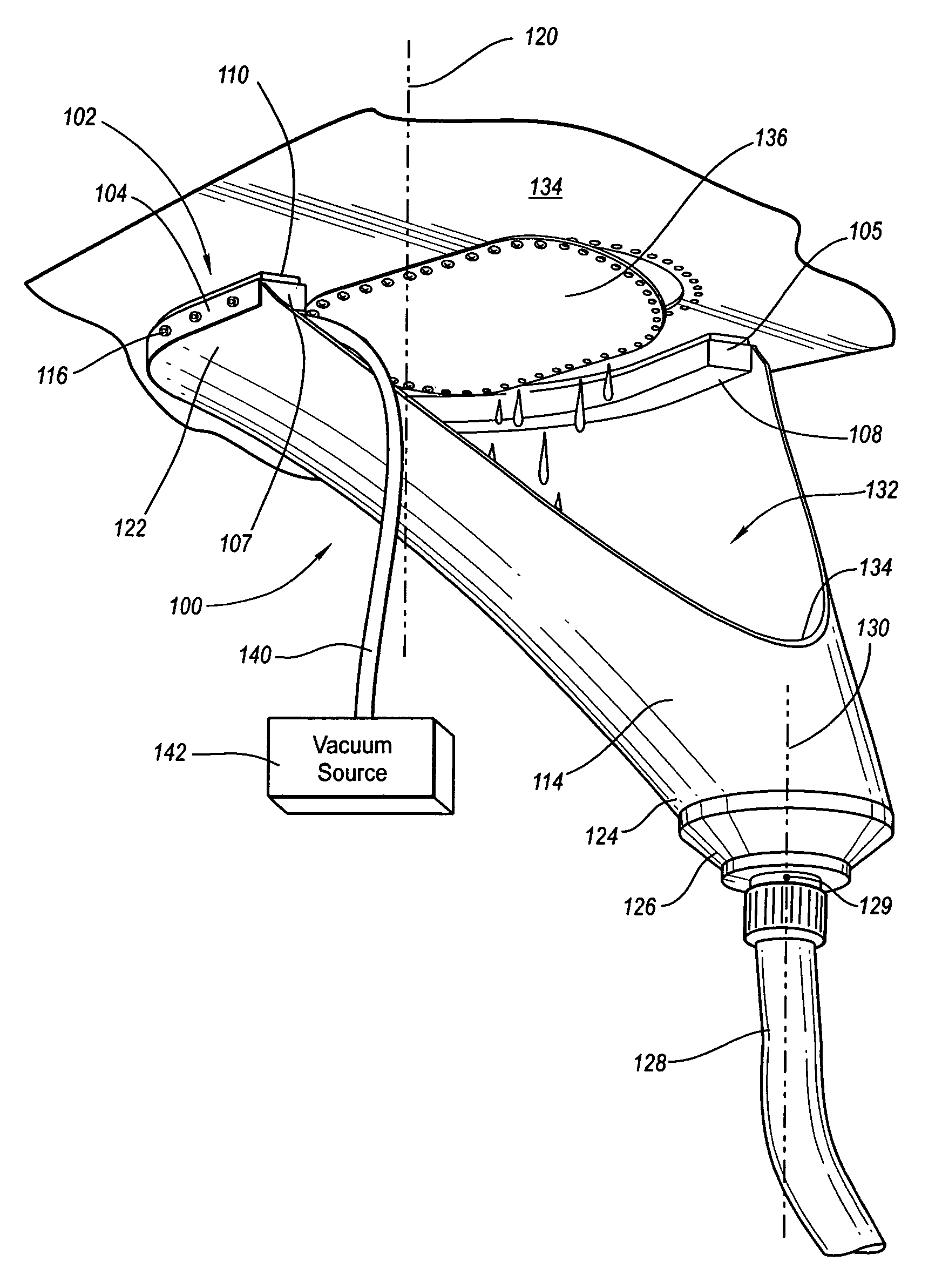

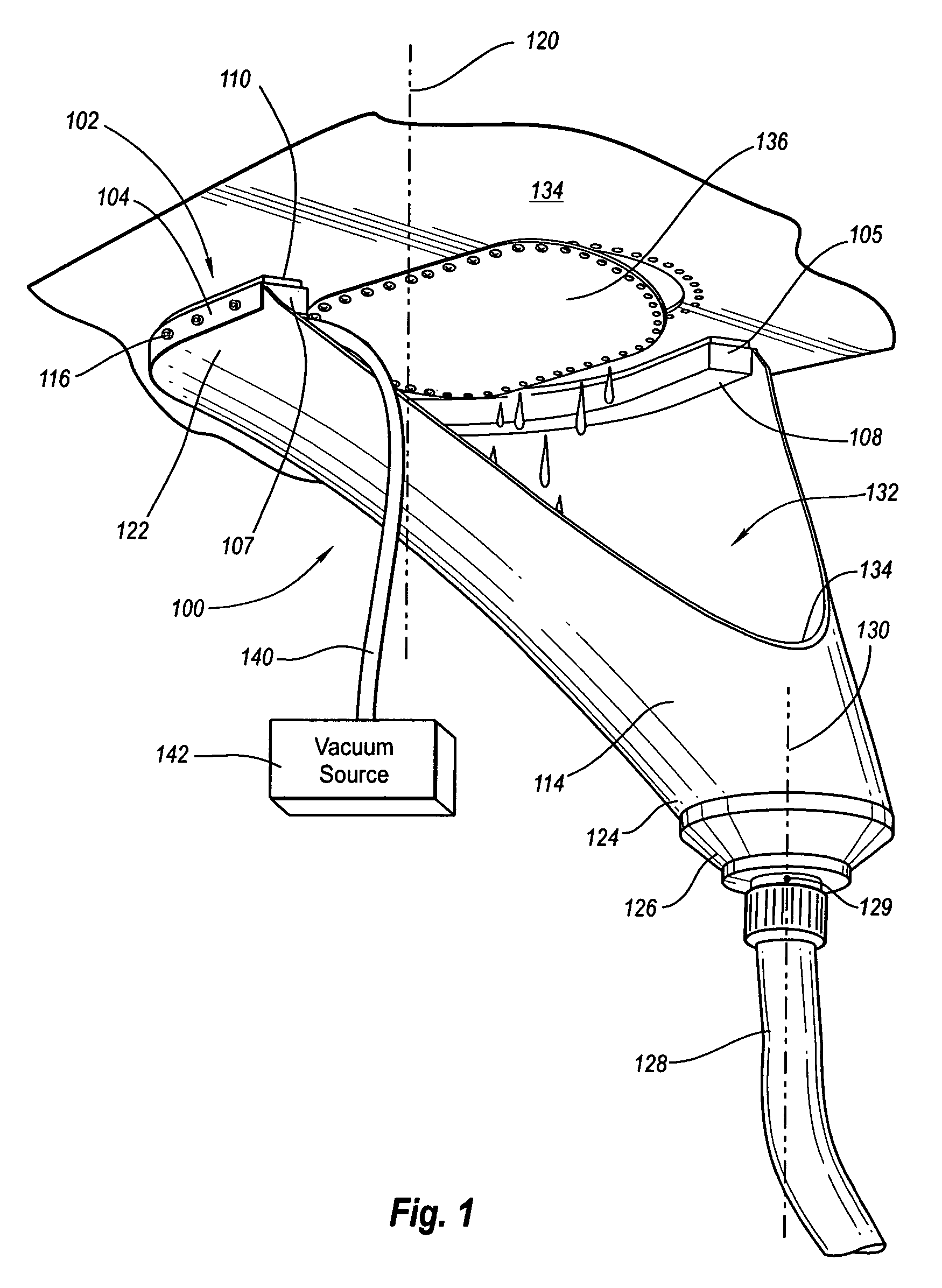

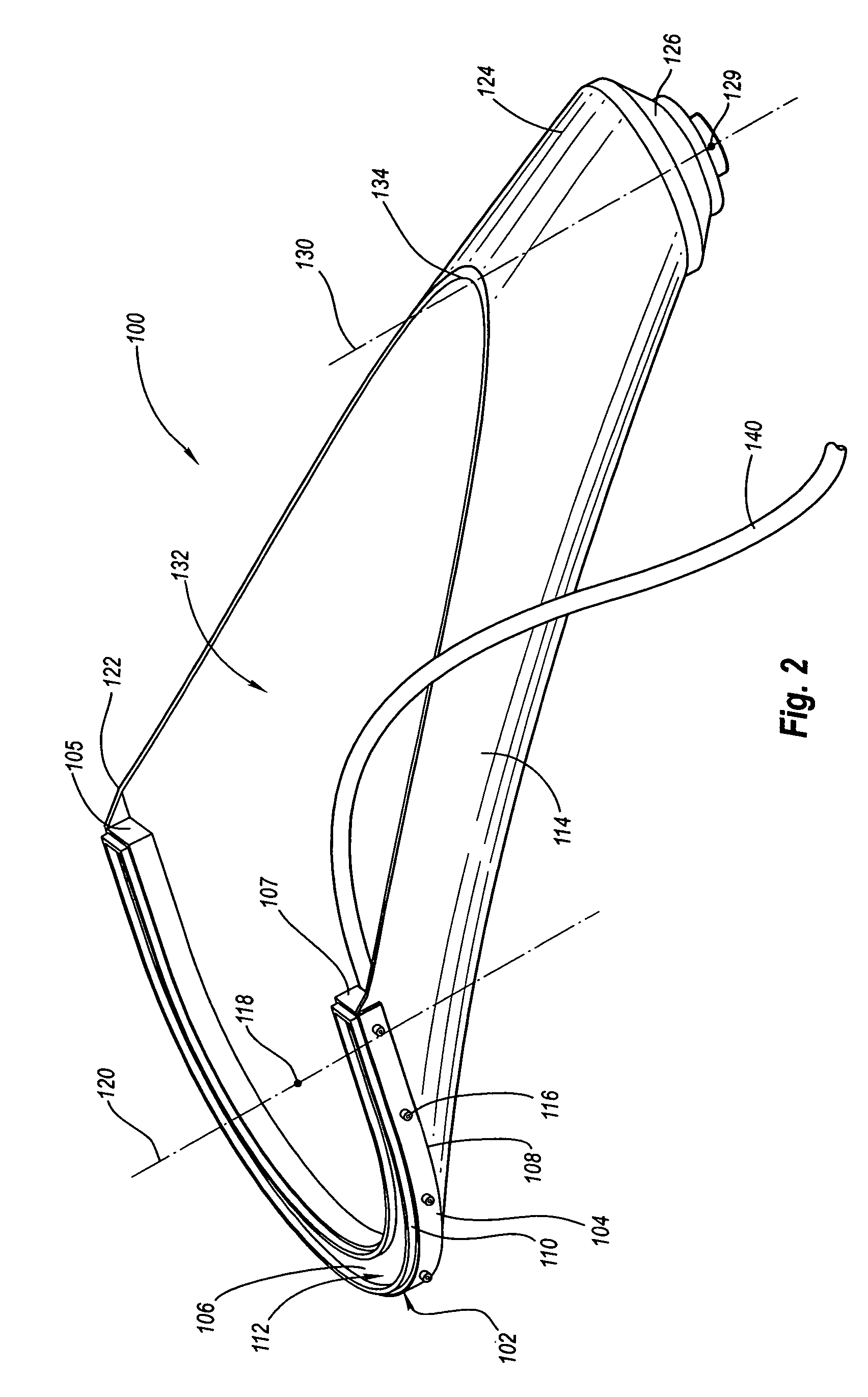

Aircraft defueling apparatus and method

ActiveUS20050081949A1Improve securityFacilitates convenient defuelingCrankshaftsLiquid handling installationsActuatorFuselage

A method and apparatus for defueling an aircraft. The apparatus includes a defueling fitting comprising one or more structural connectors, which may include one or more suction cups. The one or more structural members are attached to a mount. The mount may be of any shape, including generally straight, angled, polygonal, or circular. An actuator assembly is attached to the mount for opening an aircraft defueling valve. The first and second suction cups are operatively connected to a vacuum source to connect the defueling fitting to an aircraft body, with the actuator assembly positioned at the aircraft defueling valve. The defueling fitting facilitates safe and convenient defueling of certain aircraft that have recessed or covered fuel drain valves. For example, the Boeing C-17 has fuel drain valves that are recessed behind doors, heretofore presenting a great obstacle to appropriate defueling. The defueling fitting described herein may be used in small and tight spaces, even when other conventional defueling fittings are not helpful.

Owner:SPOKANE STAINLESS TECH INC

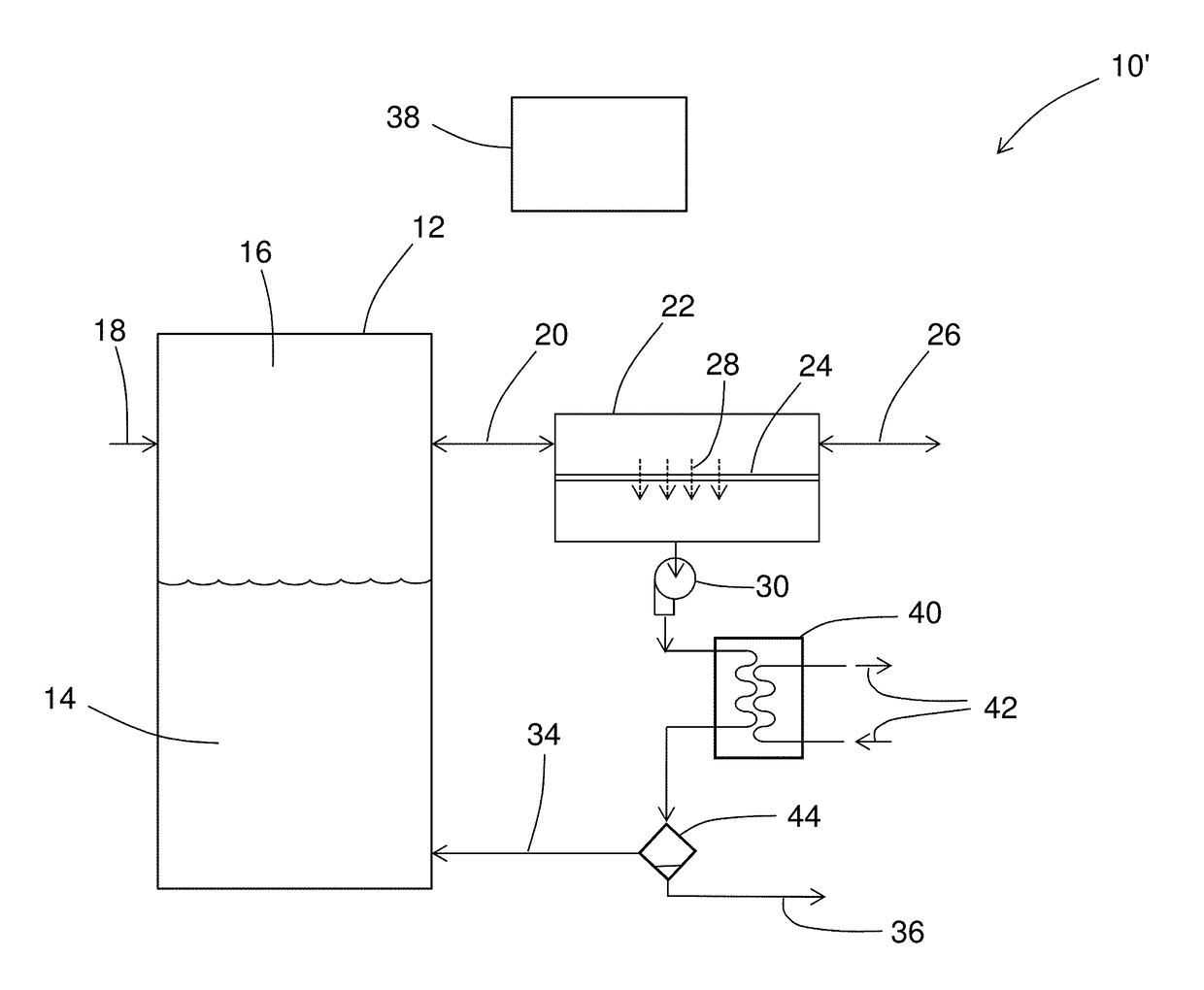

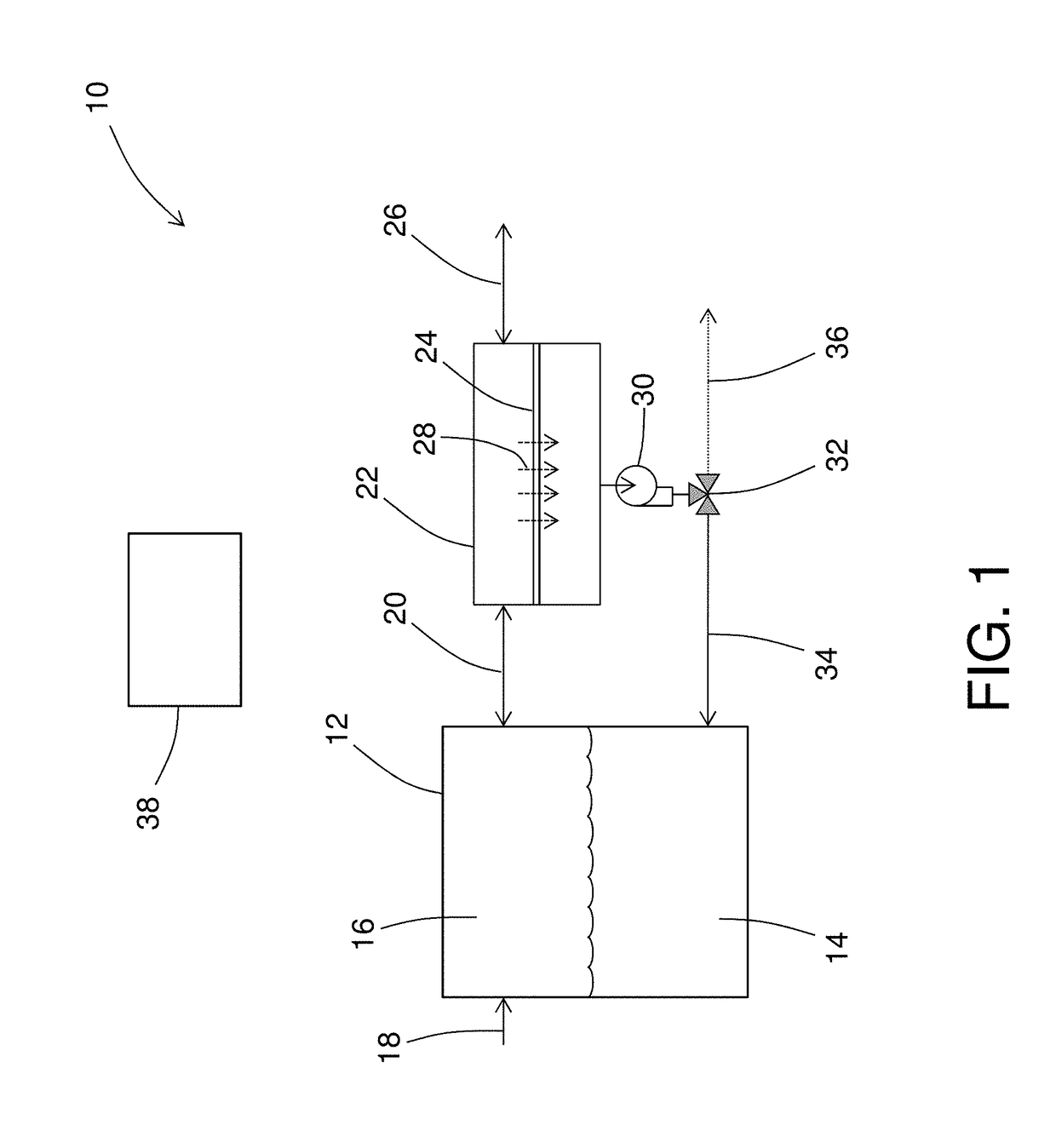

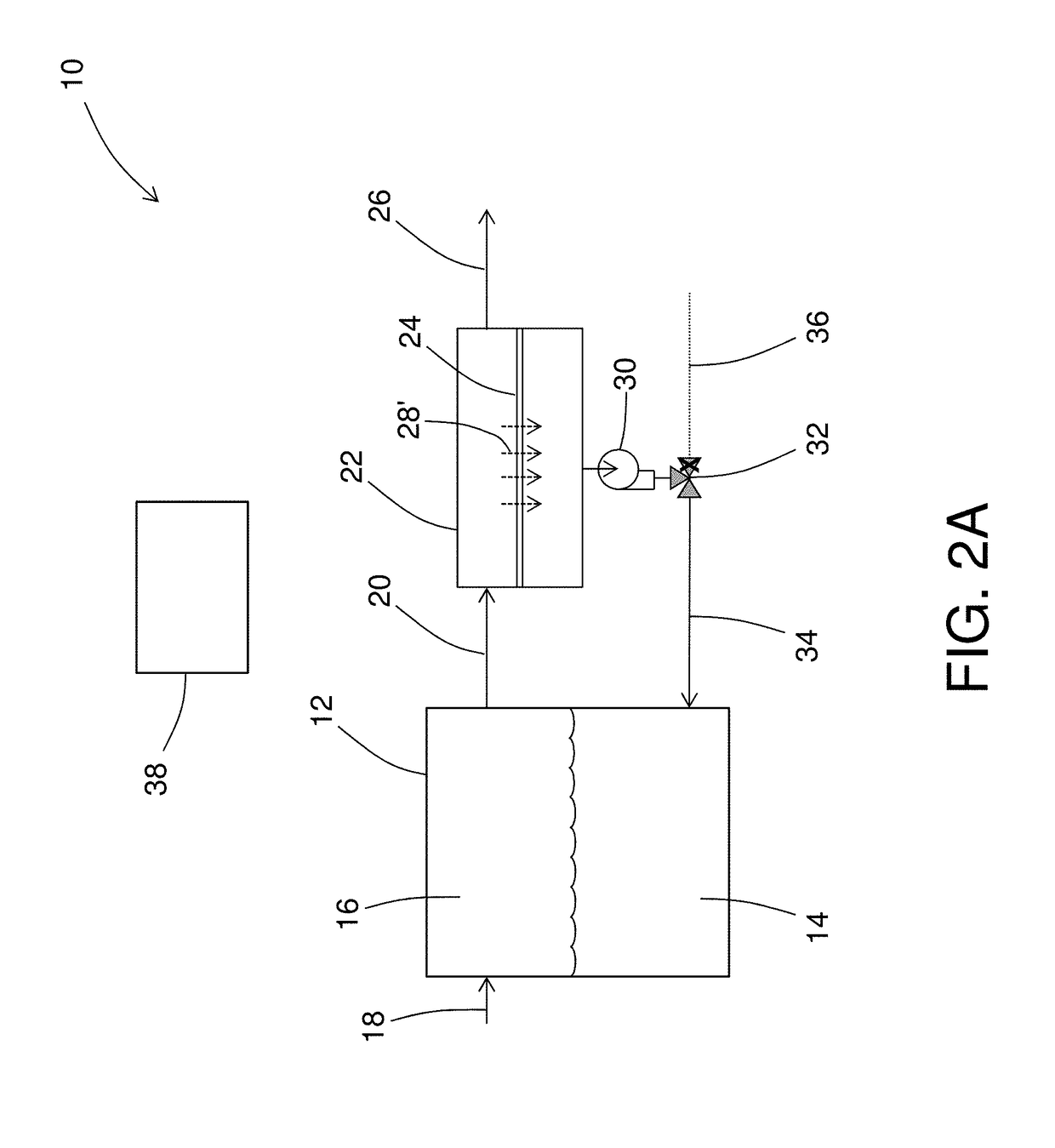

Fuel tank system and method

A fuel tank system is disclosed that includes a fuel tank and a first fluid flow path between a gas space in the fuel tank and outside of the fuel system. A gas separation membrane is disposed with a first side in communication with the first fluid flow path and a second side in communication with a second fluid flow path. A fluid control device is in communication with the second fluid flow path and is configured to provide fluid flow from the second fluid flow path to a liquid space in the fuel tank or to outside of the fuel system. A prime mover is disposed in communication with the second fluid flow path, and is configured to move fluid on the second fluid flow path from the second side of the separation membrane to the fuel tank liquid space or to outside of the fuel system.

Owner:HAMILTON SUNDSTRAND CORP

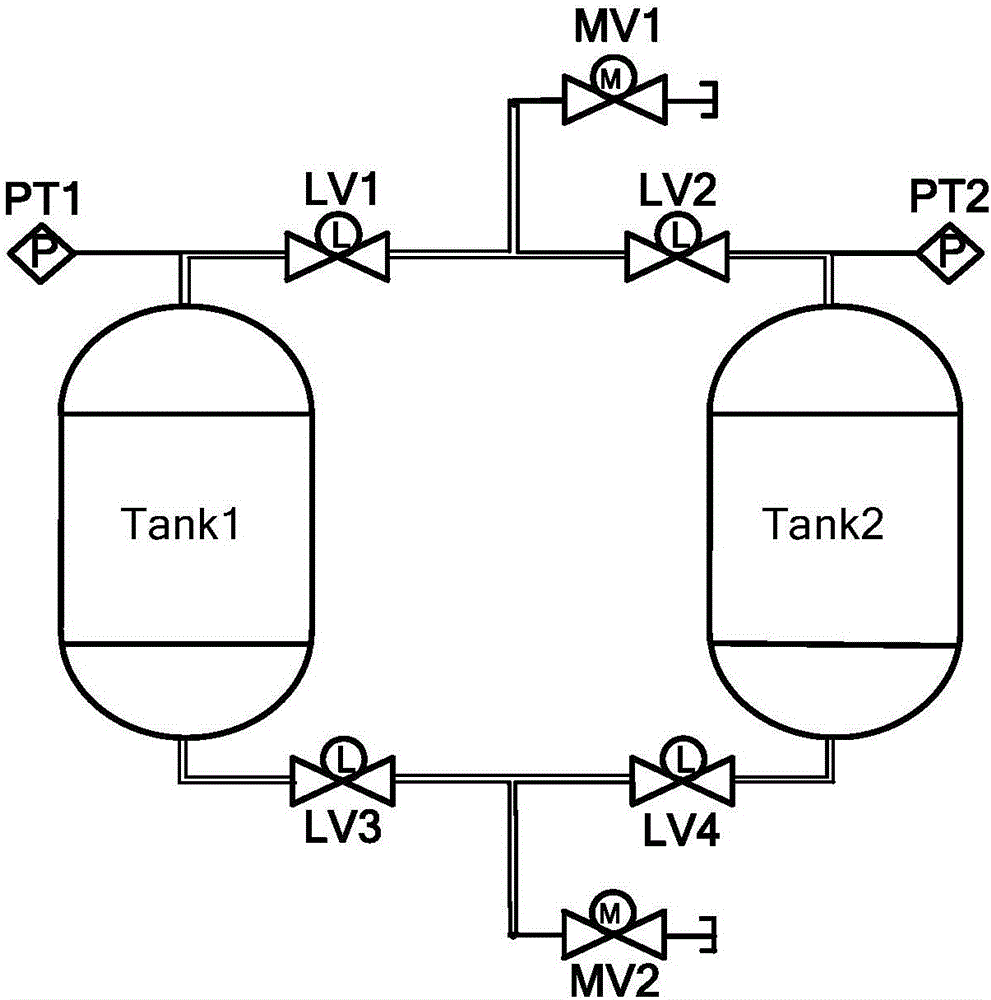

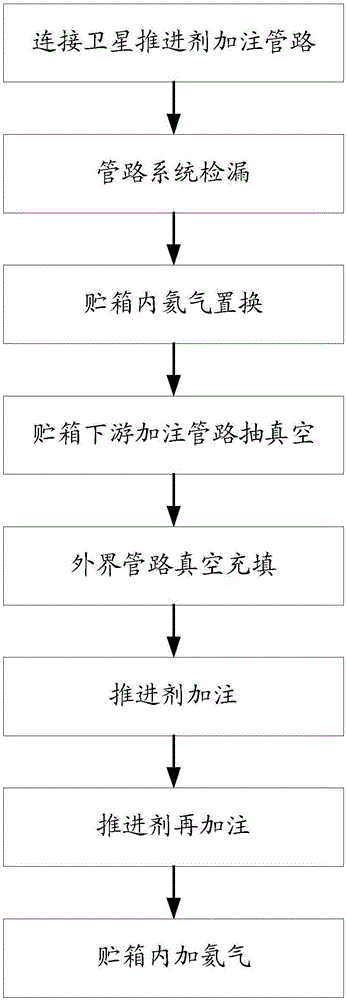

Parallel balanced filling method for high-capacity semi-management surface tension storage tank

ActiveCN106762224AReal-time display of total filling amountReal-time monitoring of parallel balanceLiquid handling installationsCosmonautic propulsion system apparatusEngineeringHelium

A parallel balanced filling method for a high-capacity semi-management surface tension storage tank comprises steps as follows: (1) a satellite propellant filling pipeline is connected, and the leakage rate of a filling pipeline system is ensured to meet the requirements; (2) two parallel storage tanks are simultaneously filled with helium or release helium for replacement until sampled gas is tested to be qualified; (3) the propellant filling pipeline and pipelines at the downstream of the parallel storage tanks are vacuumized; (4) valve ports of filling and drainage valves of the parallel storage tanks are filled with the propellant; (5) the parallel storage tanks are simultaneously and stably filled until 90% or above of the rated filling quantity is reached; (6) refilling is performed on the parallel storage tanks until the filling quantity of each storage tank meets the task requirement; (7) air cushions are added to the storage tanks until required air cushion pressure is reached. By means of the method, parallel balanced filling of the high-capacity semi-management surface tension storage tank can be realized, time for filling the parallel storage tanks with the propellant is shortened, and the reliability and the safety of the satellite filling process are guaranteed.

Owner:BEIJING INST OF CONTROL ENG

System and method for distributing fuel from a hydrant pit valve at an airport

A fuel delivery system of an aircraft refueling vehicle that is configured to distribute fuel from a hydrant pit valve at an airport. The fuel delivery system includes a first hose including a coupler that is configured to be fluidly connected to a hydrant pit valve at an airport to receive fuel from the hydrant pit valve. A fuel passageway is fluidly coupled to the first hose. An on-board fuel tank is fluidly coupled to the fuel passageway. A second hose is fluidly coupled to the fuel passageway. The second hose includes a nozzle that is configured to be coupled to a refueling point on an aircraft to distribute fuel into a fuel tank of an aircraft. A valve is coupled to the fuel passageway to control the flow of fuel to and from the aircraft refueling vehicle.

Owner:GENERAL TRANSERVICE

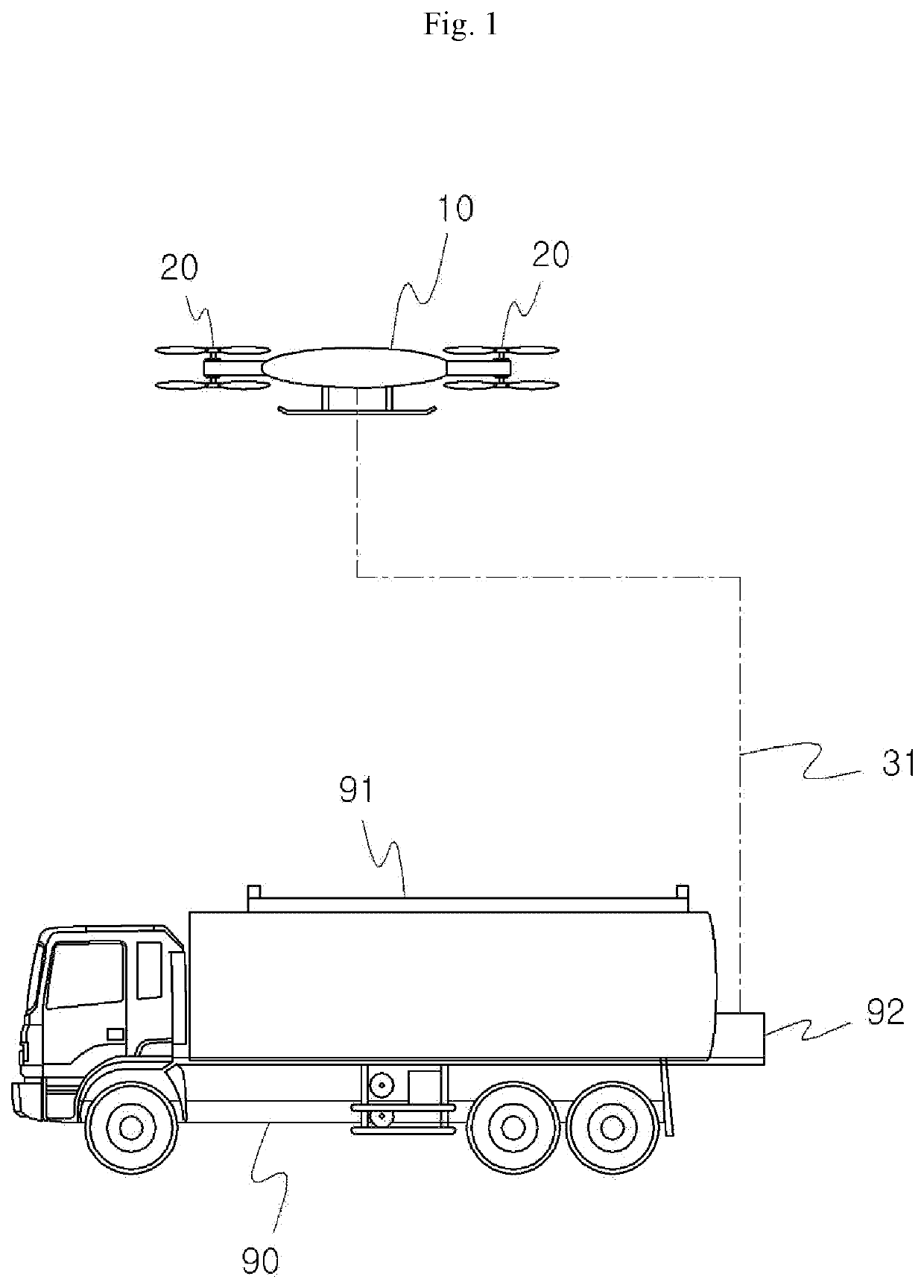

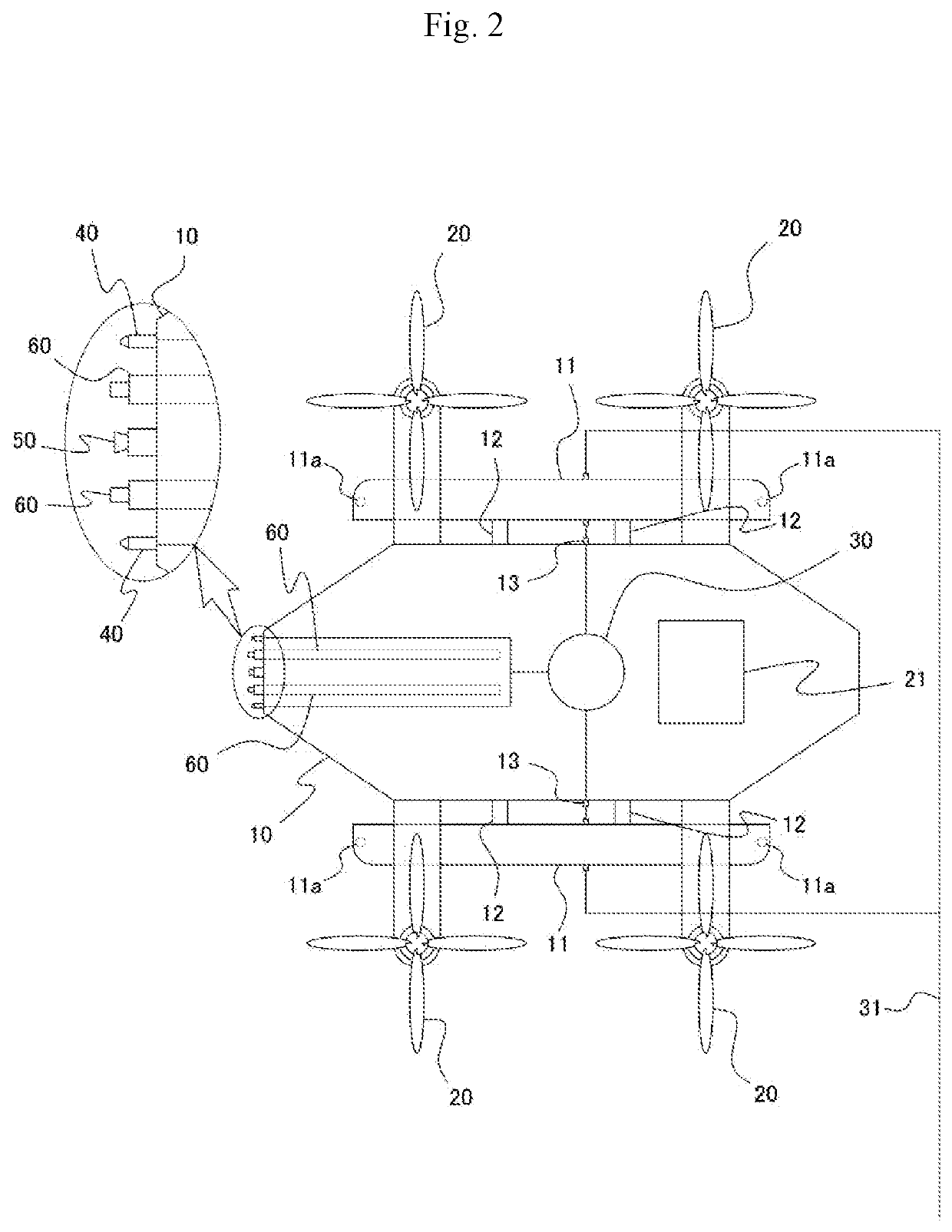

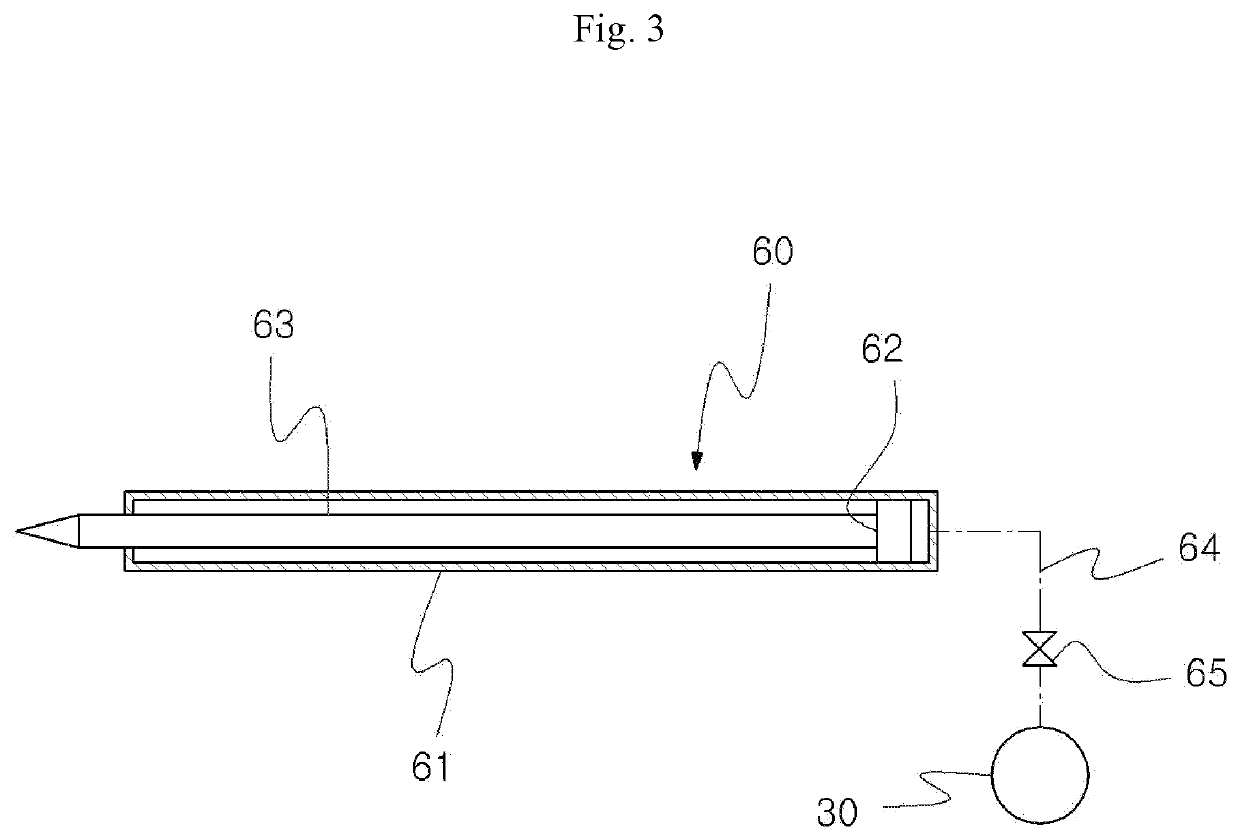

Fire suppression drone for skyscrapers

InactiveUS20200047884A1Effectively suppress fireFire suppressionLiquid handling installationsUnmanned aerial vehiclesUncrewed vehiclePropeller

A fire suppression drone comprises a main body, a plurality of propellers provided on an outer circumference of the main body and driven by a driving motor, a pump provided in the main body and connected to a water feeding vehicle through a water feeding hose, at least one water jet nozzle provided on the outer circumference of the main body to jet water supplied by the pump, a camera provided on the outer circumference of the main body, and a controller connected with the driving motor, the pump, and the camera and connected with a remote controller to be wirelessly communicable with the remote controller, wherein the remote controller includes a monitor, the monitor capable of display, in real-time, an image captured by the camera.

Owner:DAESHIN IVE CO LTD

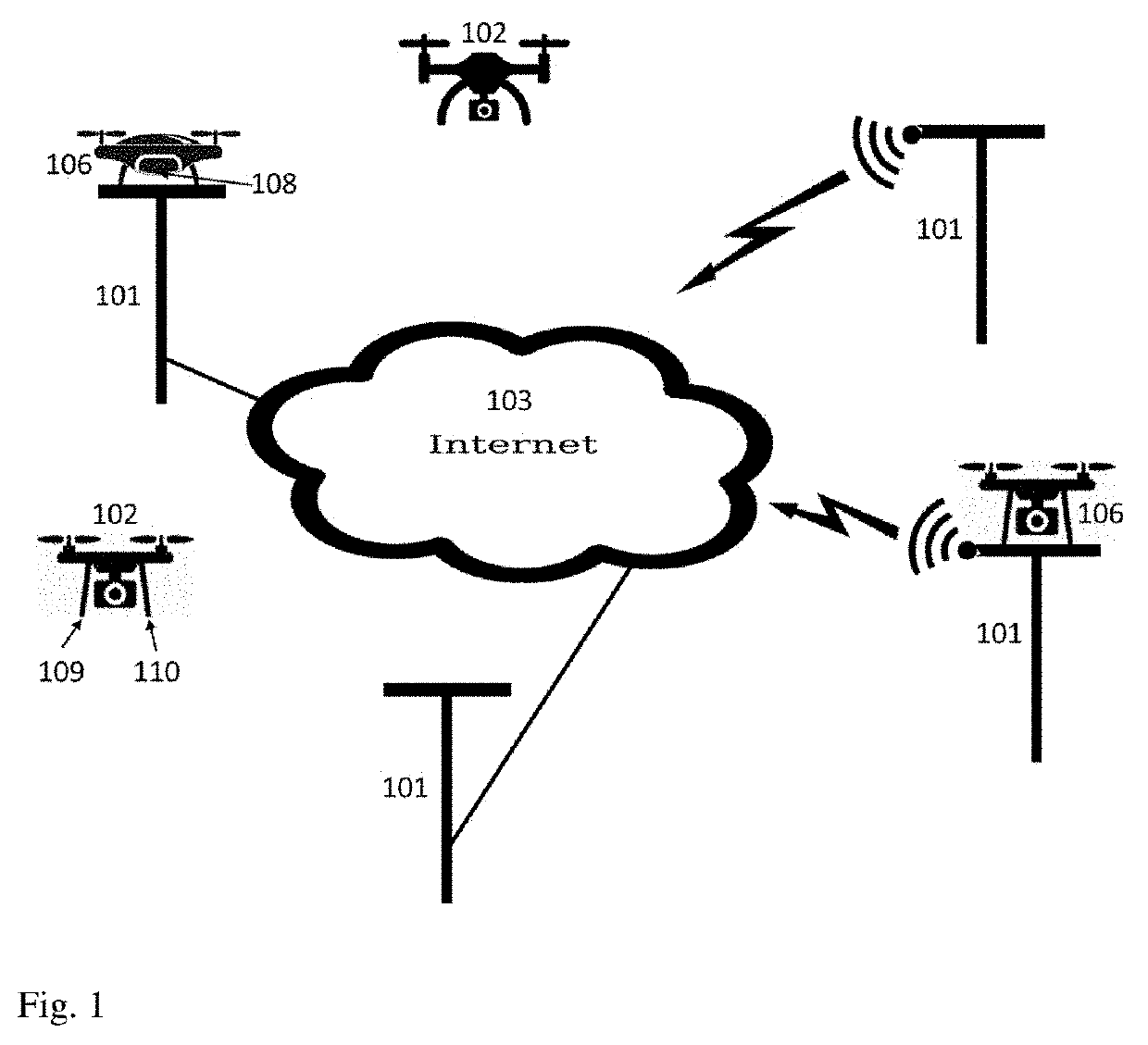

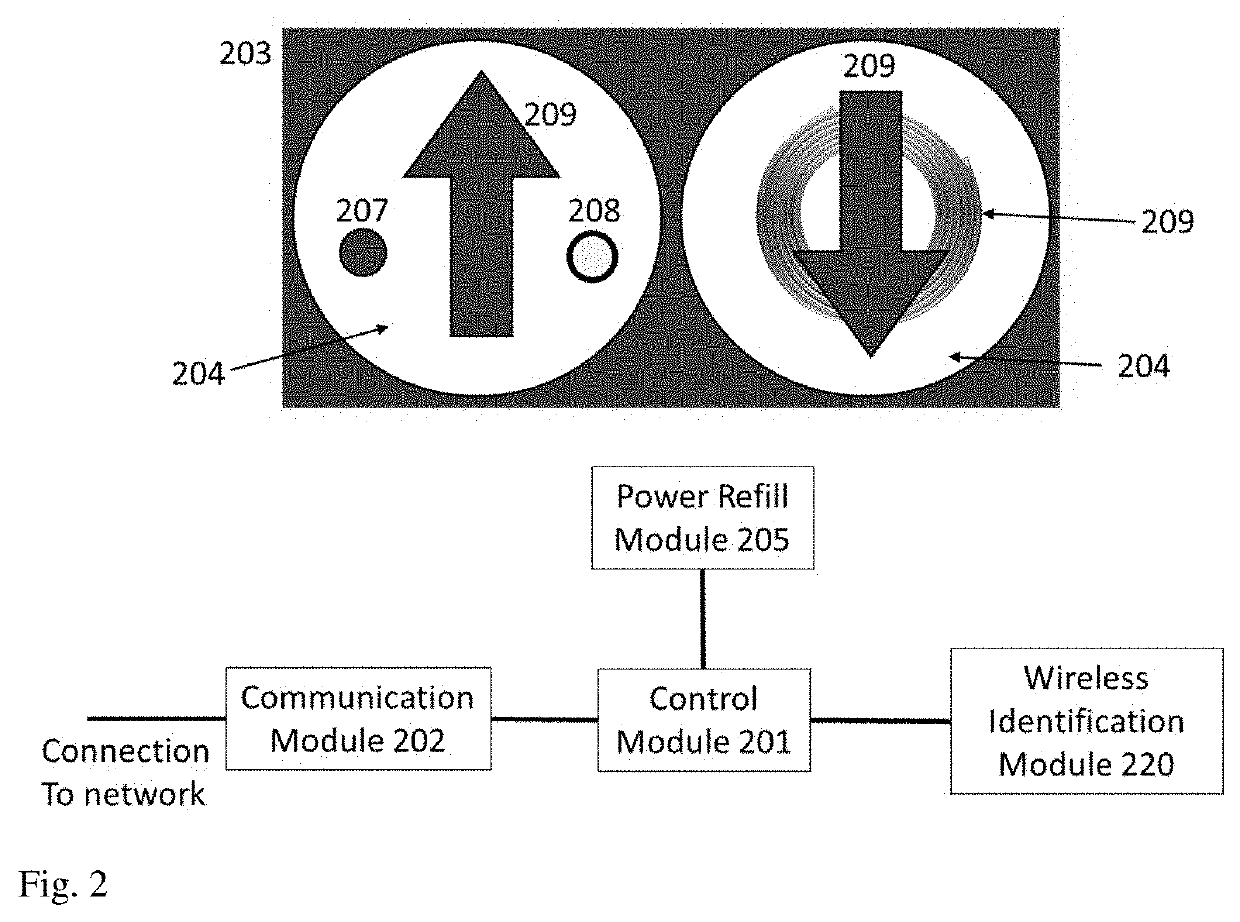

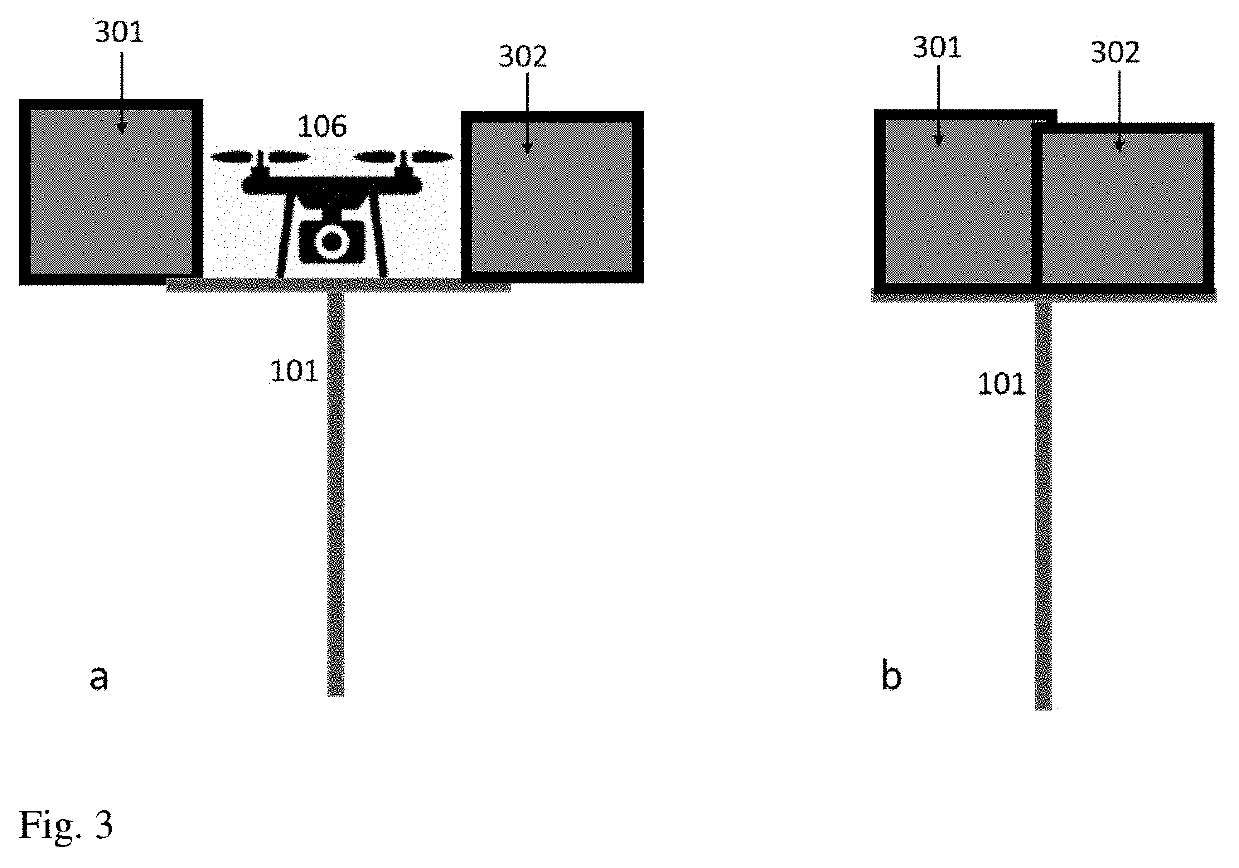

Network of distributed drone system and parking pads

ActiveUS10479528B1Accurate operationAvoid accessLiquid handling installationsCoin-freed apparatusParking spaceUncrewed vehicle

This invention discloses a distributed parking system for drones comprising a network of parking pads for drones distributed over a geographic area, each of which comprising a parking surface of one or more parking spots on which a drone can land and park securely, a power refill module that replenish the power source of a parked drone, a control module that controls functions of the parking pad, and a communication module through which the control module is connected to a communication network; and a master controller that controls functions of the parking pads and communicates commands to and receives reports from the parking pads through the communication network.

Owner:LIANG PING

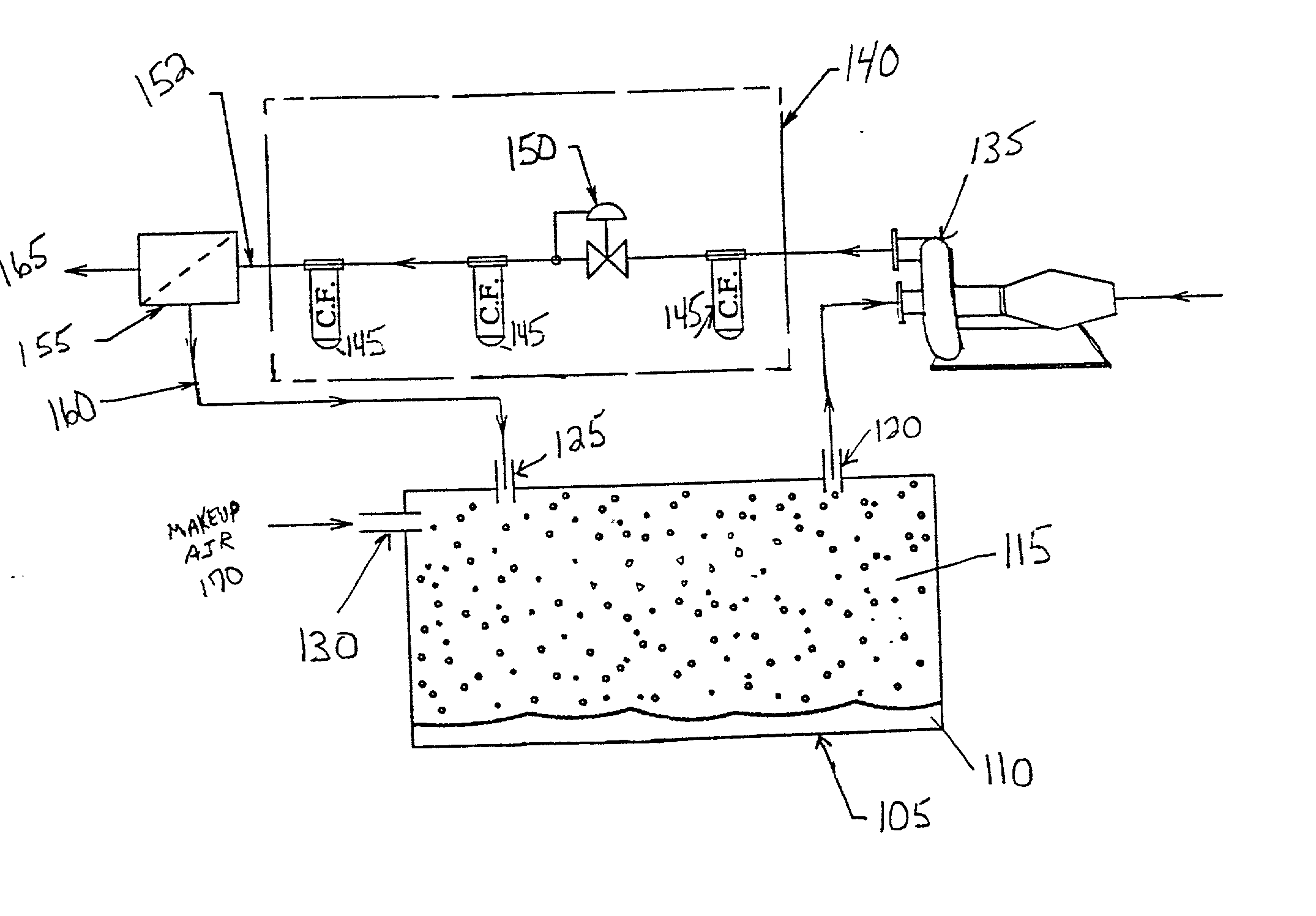

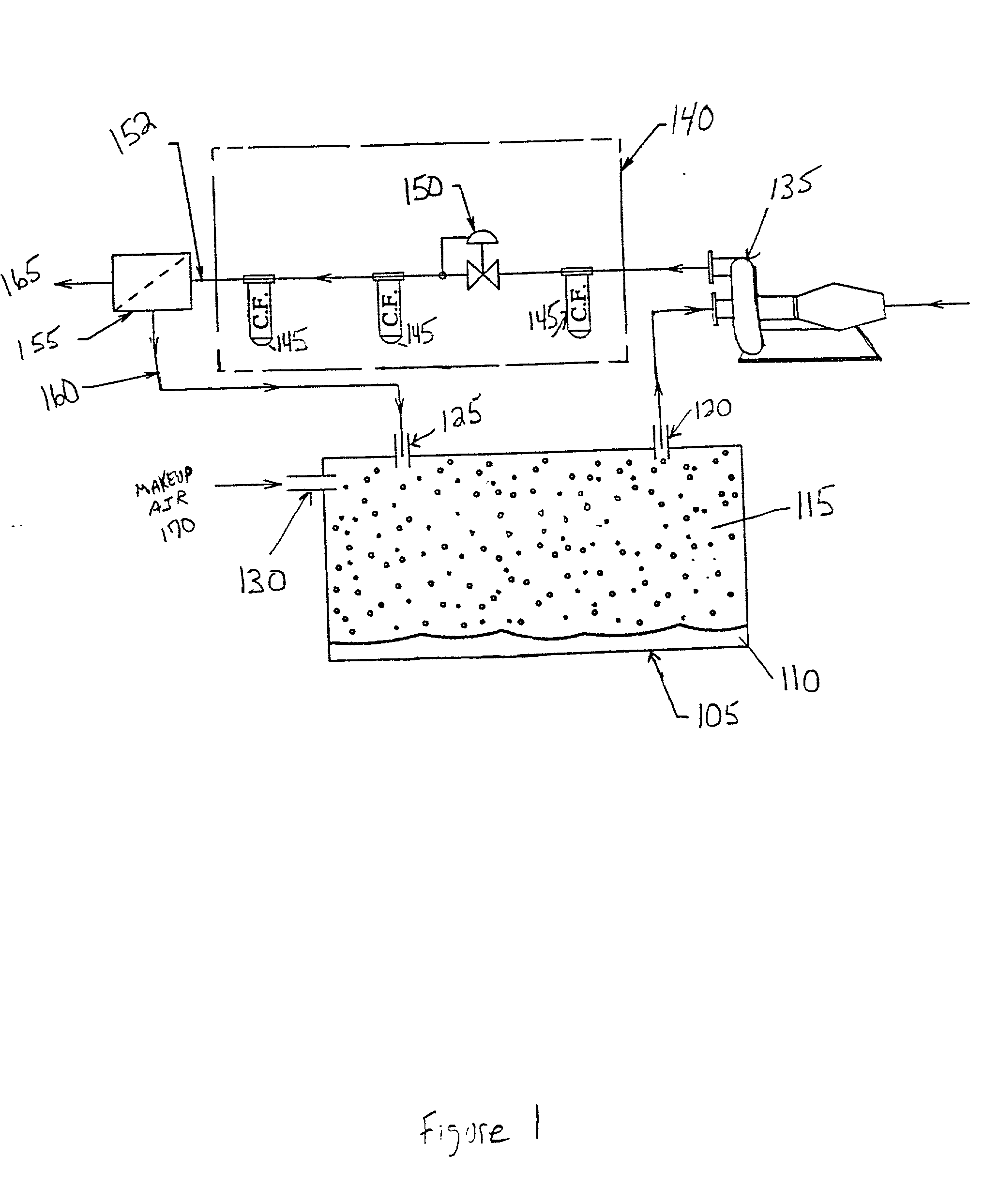

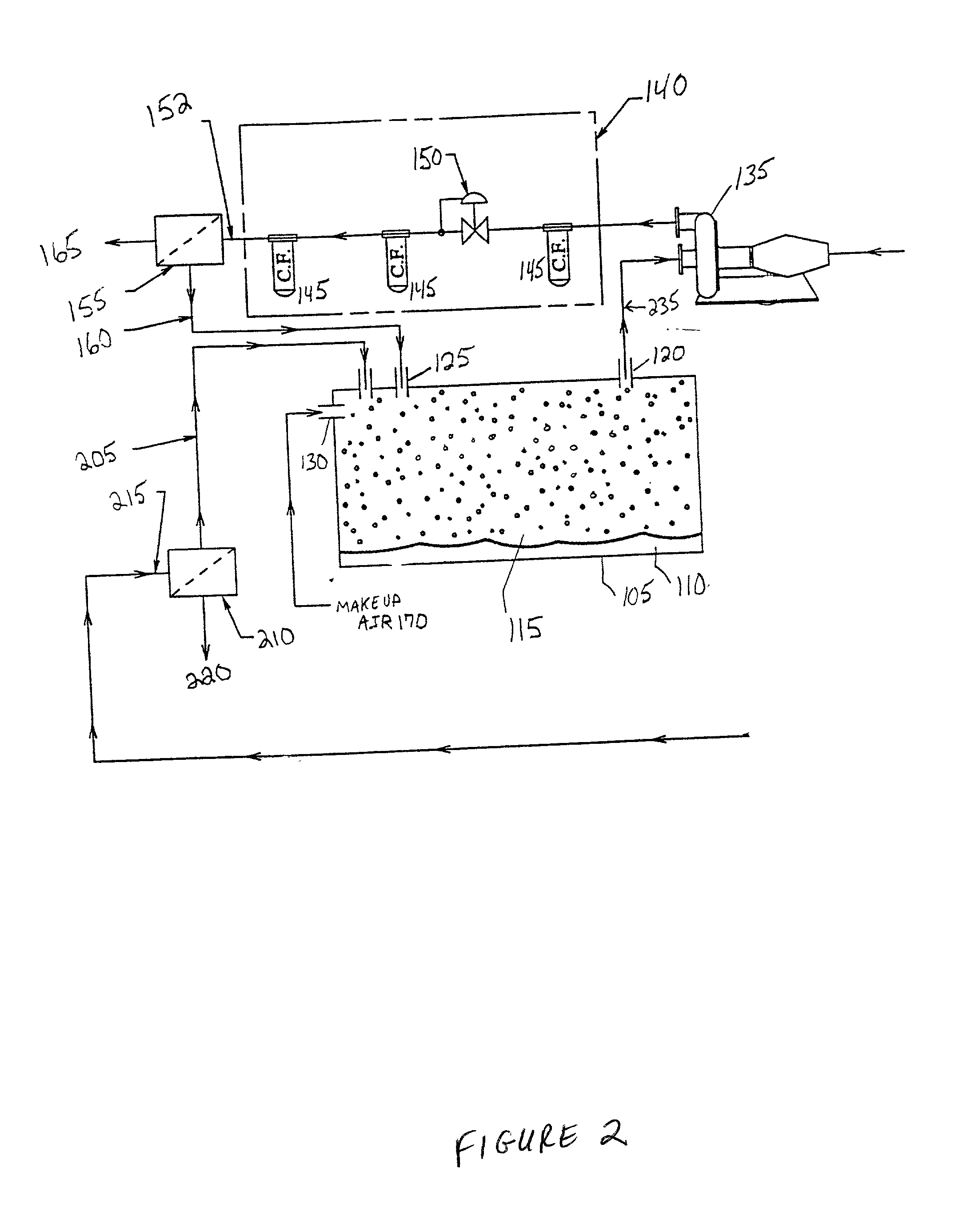

Vented compartment inerting system

InactiveUS20020117052A1Combination devicesLiquid handling installationsInerting systemProcess engineering

1. An inerting system for a vented controlled atmosphere container, for inerting a flammable gas comprising a flammable vapor and oxygen, comprising: (i) a container; (ii) an outlet in the container for the flammable gas; (iii) a compressor, in fluid communication with the outlet, which compresses the flammable gas from the container; (iv) a separator, in fluid communication with the compressor, for removing oxygen from the flammable gas to produce an oxygen-depleted flammable gas; (v) an inlet in the container, which is in fluid communication with the separator; through which the oxygen-depleted flammable gas is fed into the container.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

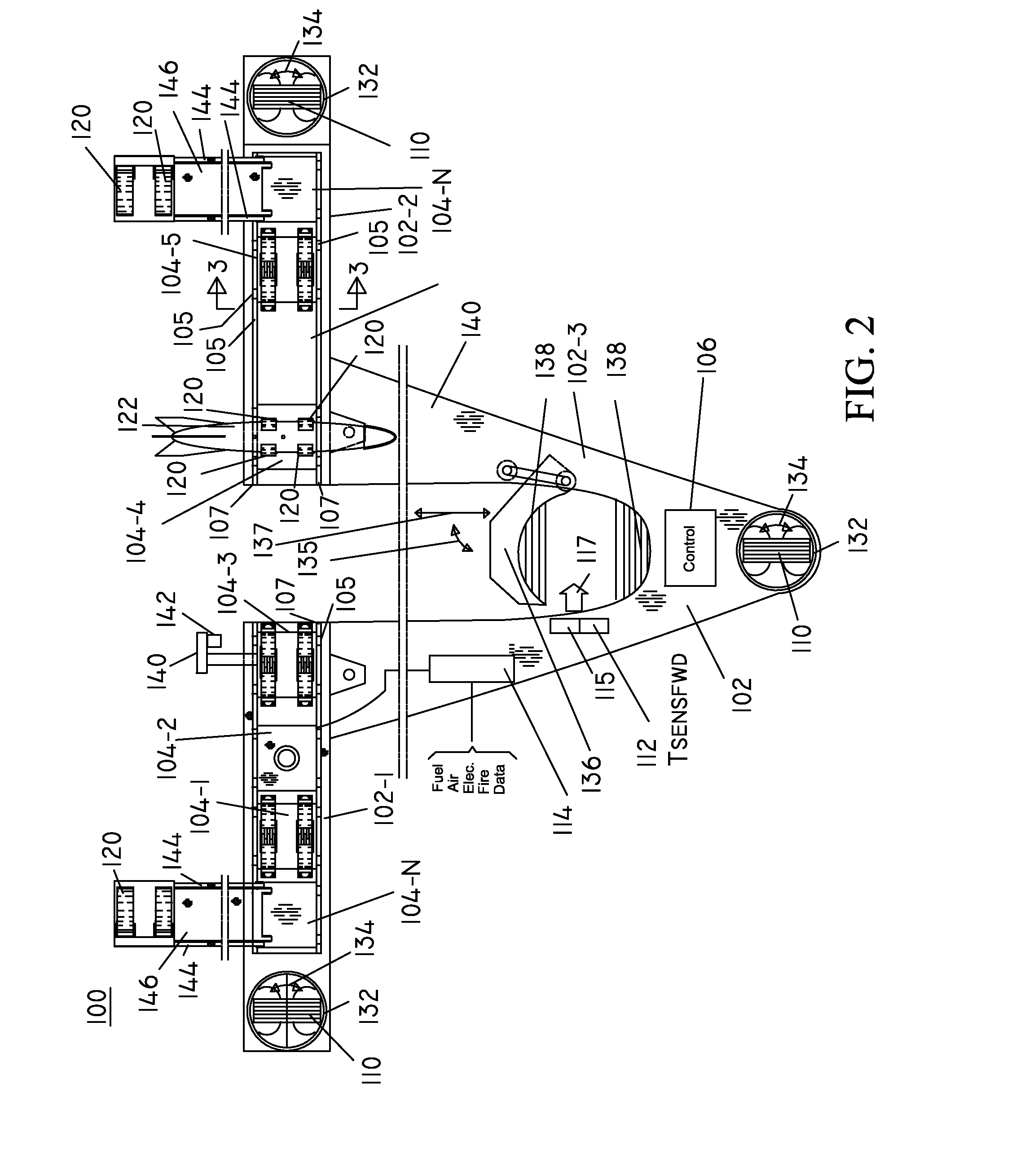

Operational ground support system having automated fueling

InactiveUS20060237591A1Minimal human interventionDecrease tarmac congestionLiquid handling installationsEnergy efficient operational measuresAircraft fuel systemFuel supply

An aircraft fueling system (890) includes an underground fuel supply (904). A fuel pump (906) is coupled to the underground fuel supply 904 and is used to supply fuel to an aircraft (902). A fuel probe (908) is coupled to the fuel pump (906) and is extendible to an aircraft fueling port (926). A fuel probe connection sensor (938) generates a connection signal. A controller (924) is coupled to the fuel pump (906) and the fuel probe connection sensor (938) and adjusts the supply of the fuel (904) to the aircraft (902) in response to the connection signal.

Owner:THE BOEING CO

Compressed Natural Gas Vehicle Safety System and Method

ActiveUS20170233243A1Liquid handling installationsCosmonautic ground equipmentsCompressed natural gasRocket

A multiply-redundant system that protects fueling of rockets, aircraft and other vehicles using Liquefied Natural Gas (LNG) along with an oxidizer such as Liquefied Oxygen. One or more sensors in combination with one or more optional microswitches combine to detect any leaks, fire or explosion hazards quickly locking out further fueling. For different levels of safety, different combinations of sensors can be used.

Owner:MCNICHOLAS DANIEL

Suspended containment system

Owner:SPOKANE INDS

Venting gas from a tank

ActiveUS20120025026A1No loadingStructure miniaturizationLiquid handling installationsPower plant fuel tanksEngineeringThermodynamics

Owner:AIRBUS OPERATIONS LTD

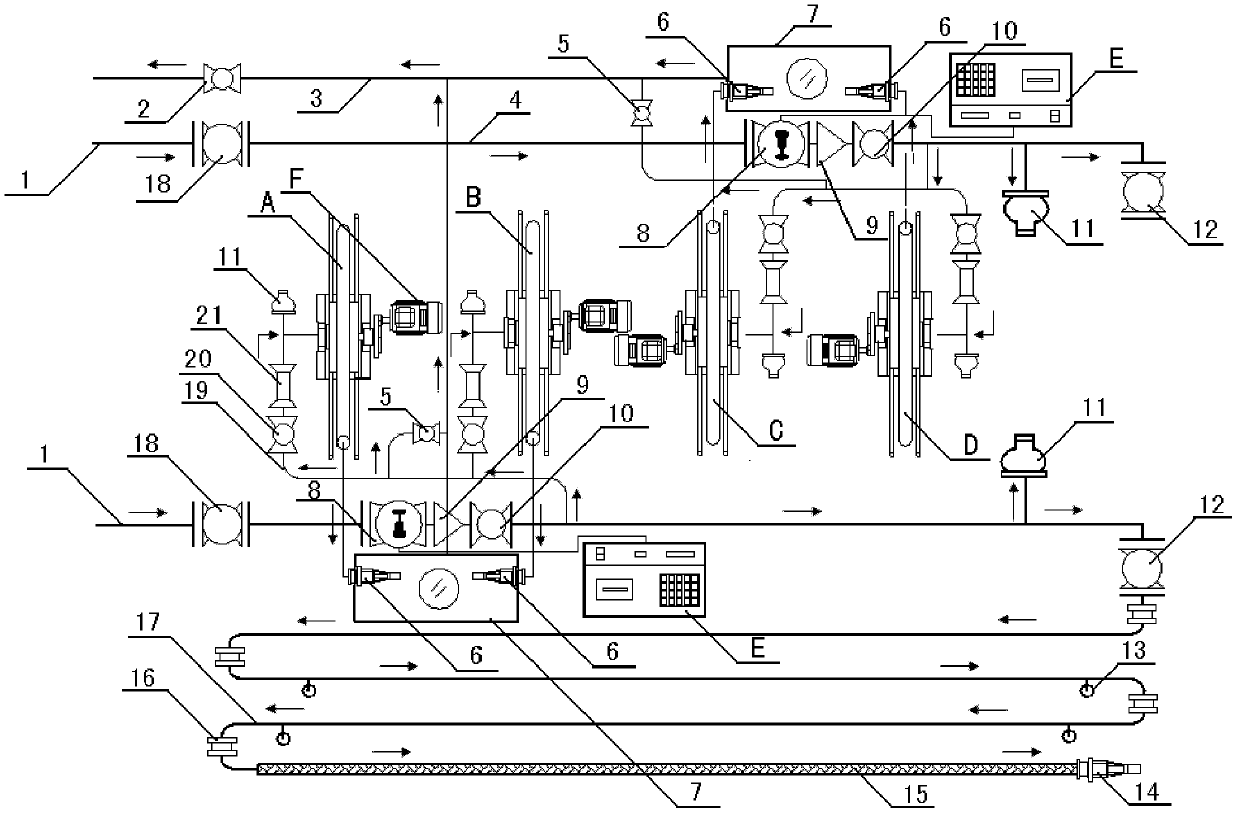

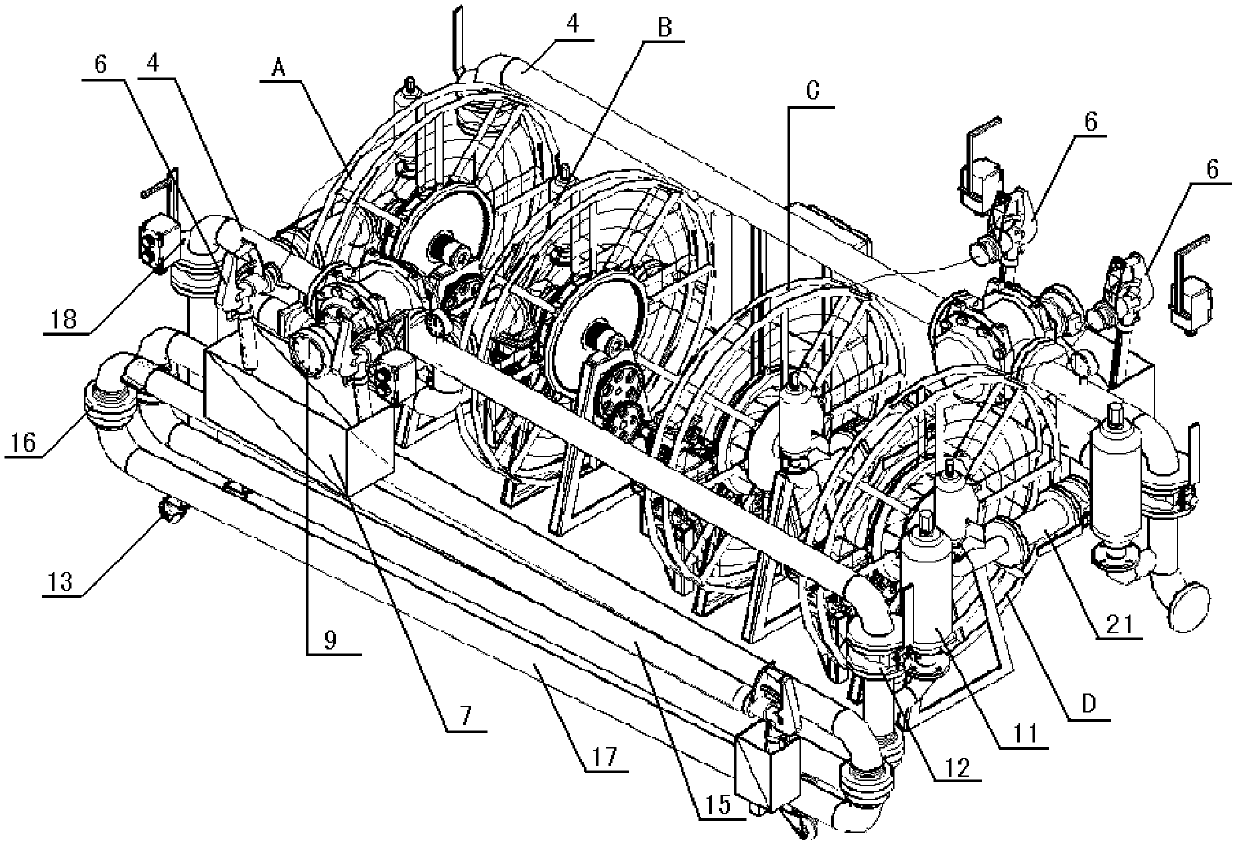

Box type multifunctional aircraft refueling equipment

ActiveCN102700722AAchieve shrinkageImprove cleanlinessLiquid handling installationsMarine engineeringOil transportation

The invention relates to box type multifunctional aircraft refueling equipment, which is characterized by comprising an openable box, and two sets of oil transportation refueling mechanisms which are arranged in the same box, consist of metering devices and a pipeline valve system for realizing oil transportation and comprise a four-channel gravity fueling mechanism and a two-channel concealed telescopic fueling mechanism. By the box type multifunctional aircraft refueling equipment, normal aircraft refueling operation is realized in a four-channel gravity fueling mode and a two-channel pressure fueling mode, so that the fueling radius is greatly enlarged, and after the fueling is finished, an oil transportation pipeline can be shrunk, and the occupied space of the whole equipment is reduced; and moreover, the box type multifunctional aircraft refueling equipment contributes to keeping the operating site neat and standardizing the requirements of environment friendliness.

Owner:株洲市自强油气储运设备制造有限公司 +1

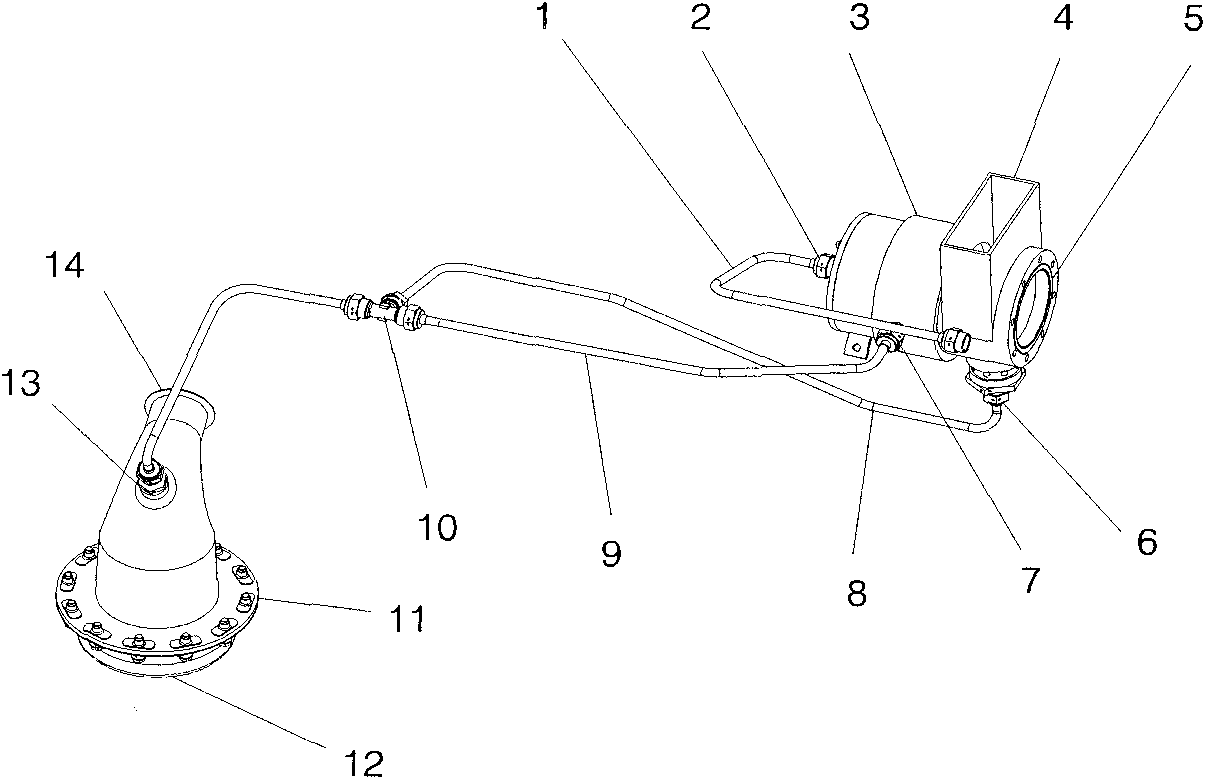

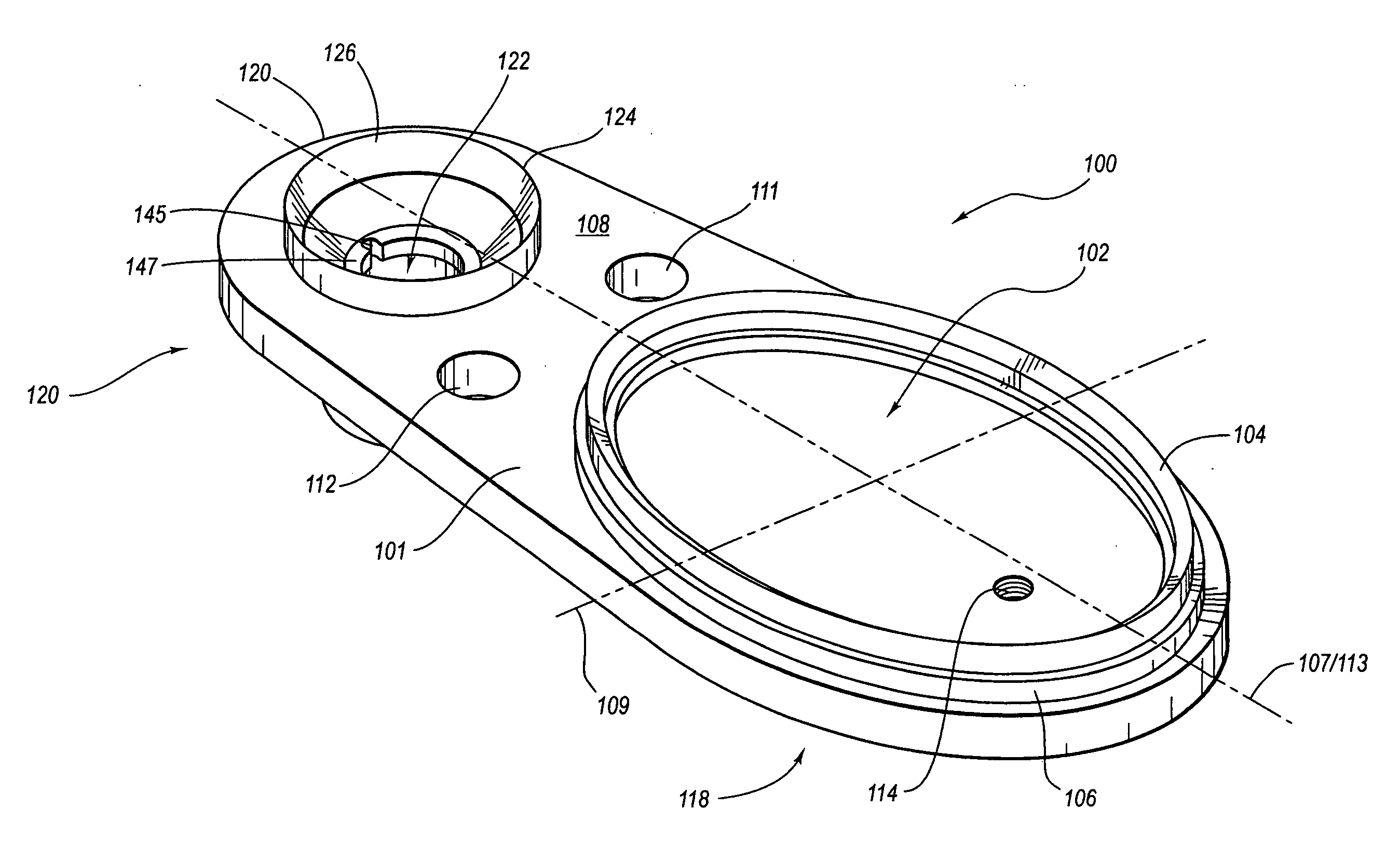

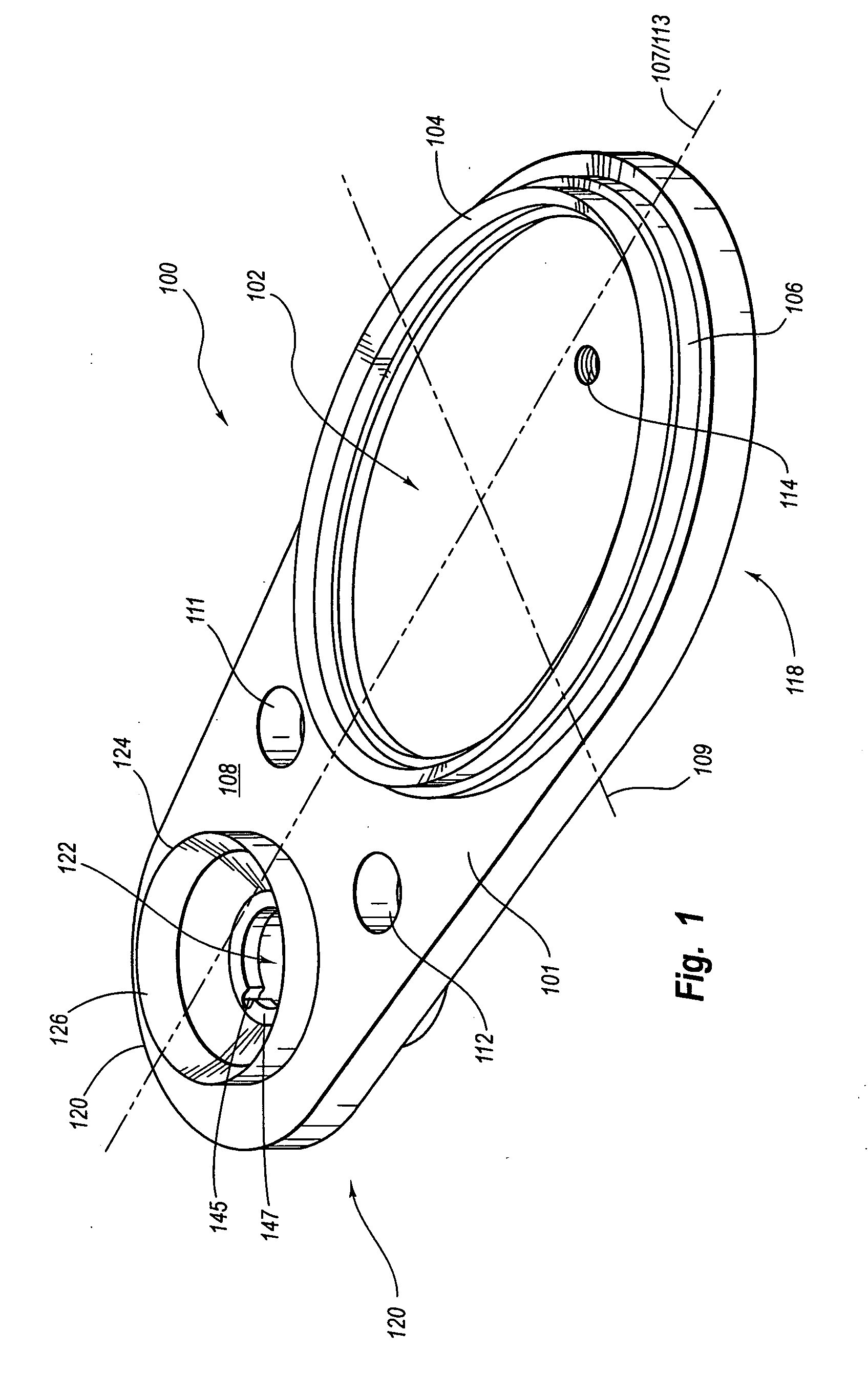

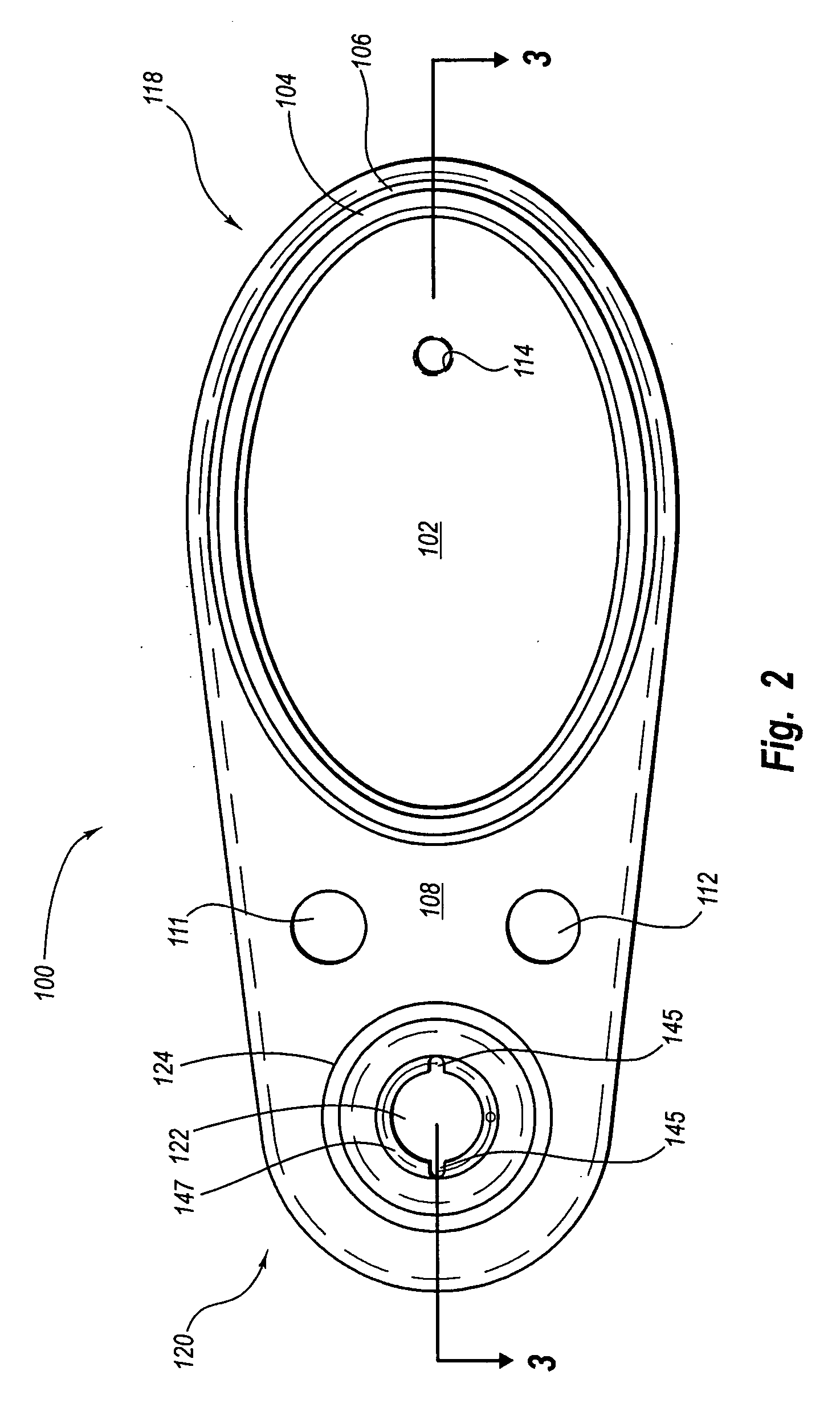

Contoured surface defueling fitting

ActiveUS20060254669A1Improve securityFacilitates convenient defuelingCrankshaftsLiquid handling installationsActuatorFuselage

A method and apparatus for defueling an aircraft. The apparatus includes a defueling fitting comprising one or more structural connectors, which may include one or more suction cups. The suction cups are disposed in a mount. The suction cups may be raised from a surface in the mount and arranged in a non-circular pattern to facilitate connection to contoured surfaces. An actuator assembly may be attached to the mount for opening an aircraft defueling valve. The suction cups may be operatively connected to a vacuum source to connect the defueling fitting to an aircraft body, with the actuator assembly positioned at the aircraft defueling valve. The defueling fitting facilitates safe and convenient defueling of aircraft, even aircraft with significantly contoured surfaces.

Owner:SPOKANE STAINLESS TECH INC

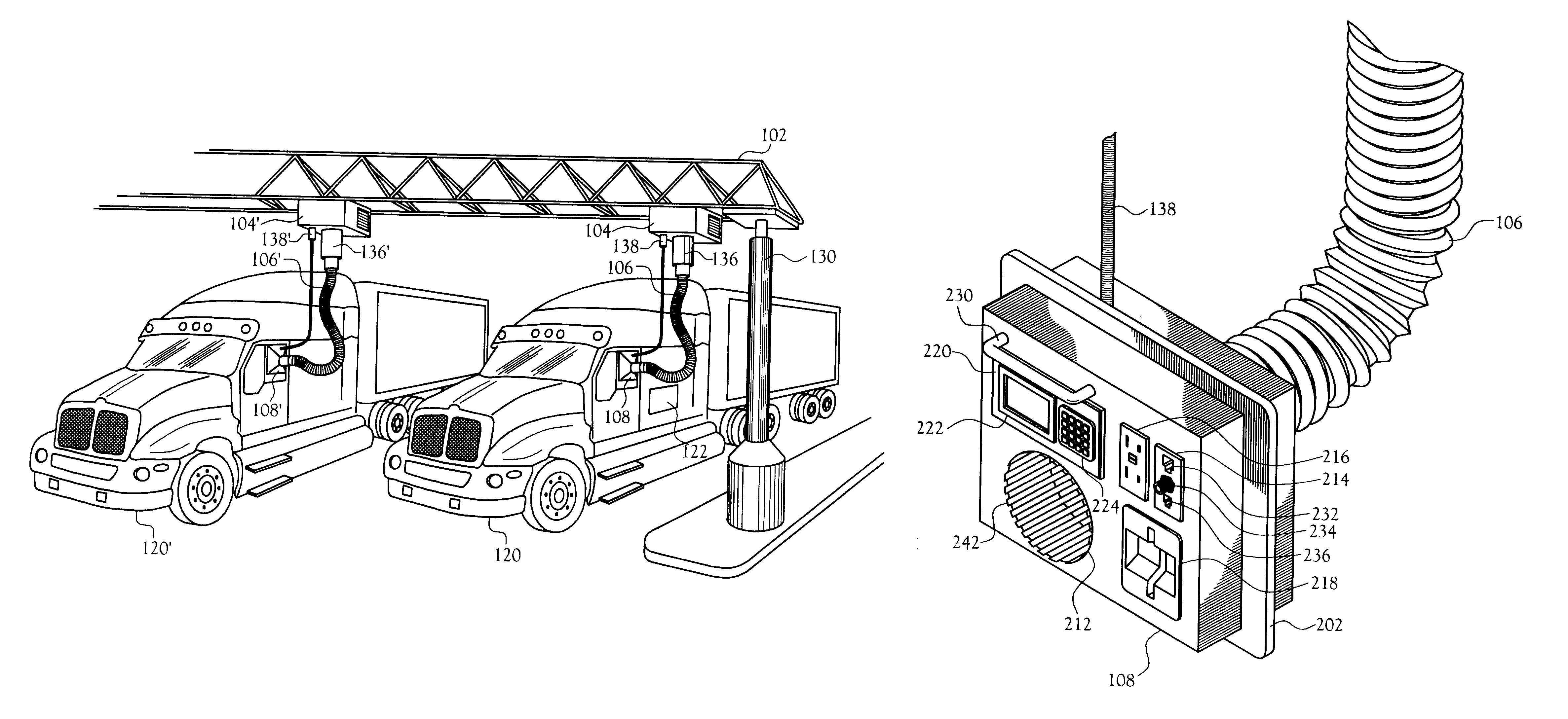

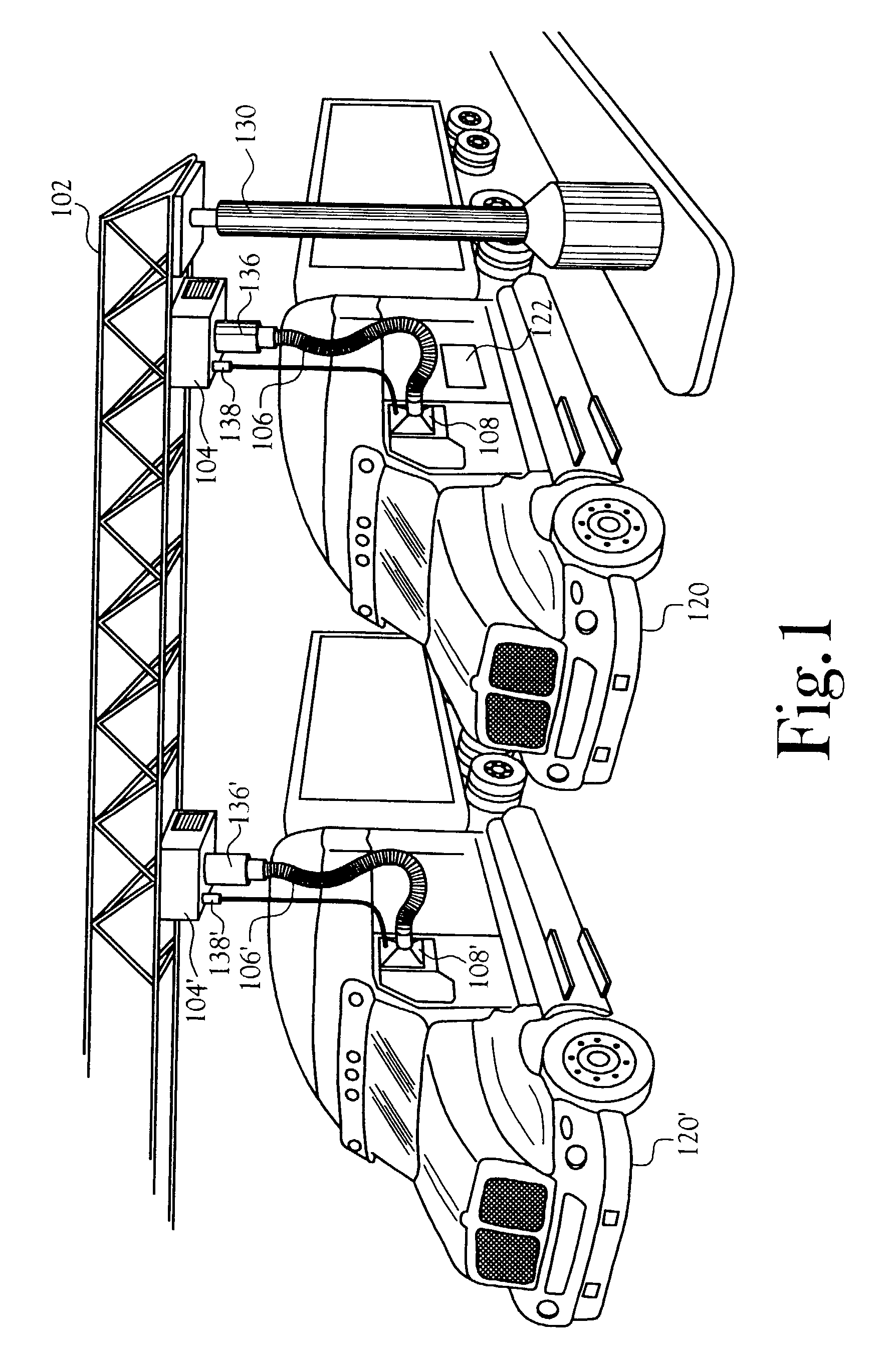

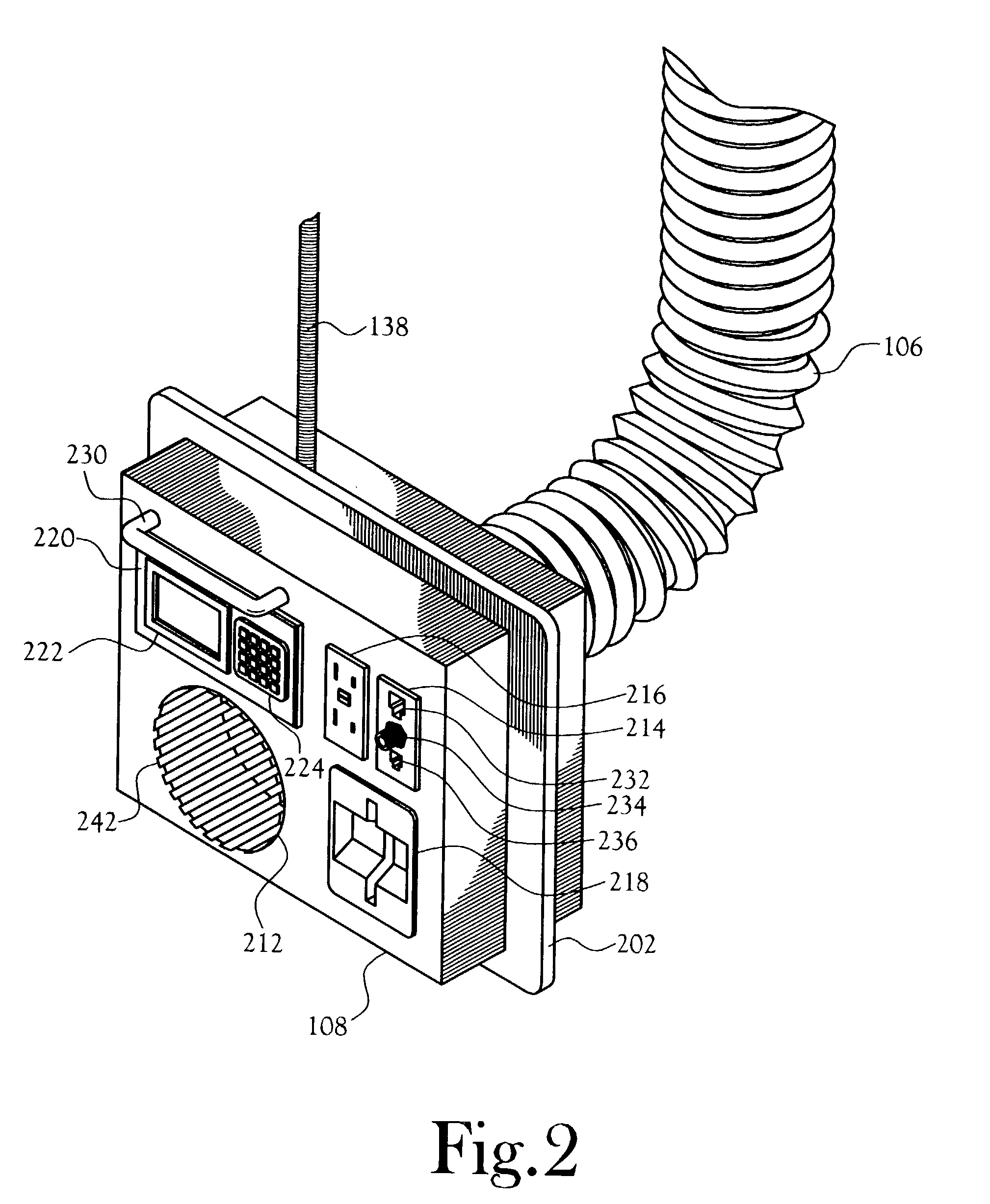

Apparatus for providing convenience services to stationary vehicles

InactiveUS7811159B2Reduce the amount requiredLiquid handling installationsWindowsNetwork communicationGuide tube

An apparatus for providing convenience services to a stationary vehicle independent of the vehicle's electrical system. At least one conduit is attached to a housing for transferring the services to a supply panel. The supply panel includes a face on which the various controls and connectors associated with the supplied convenience services, such as heating, cooling, electrical power, compressed air, computer network communications, telephone, video, and television, are disposed. The supply panel is dimensioned to interface with the stationary vehicle through an opening in the vehicle, such as a window or service door, and includes means for providing a substantially airtight seal for climate control.

Owner:CONVOY SOLUTIONS

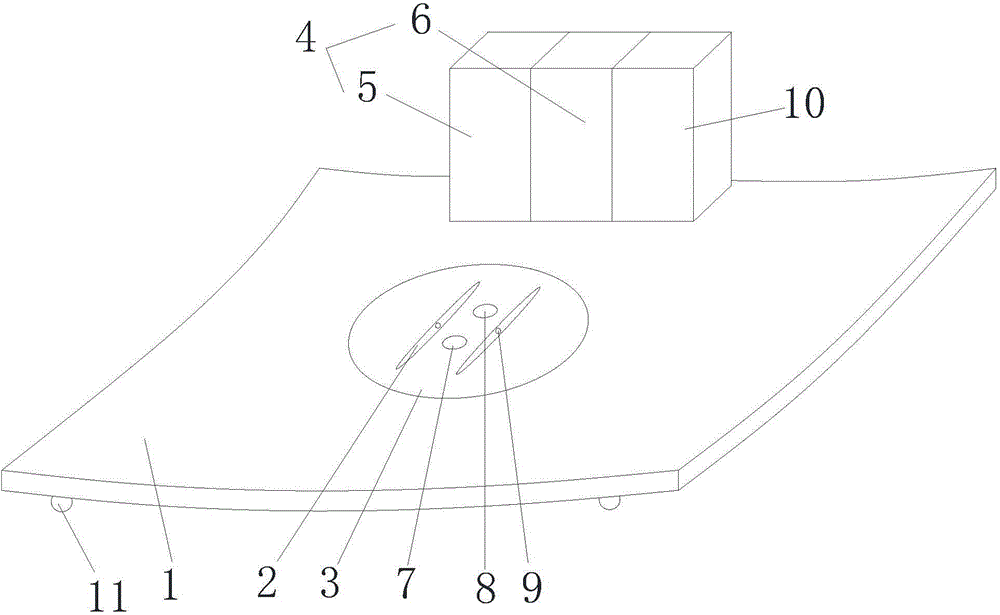

Unmanned aerial vehicle replenishing device and unmanned aerial vehicle

ActiveCN104908973AImprove the efficiency of spraying pesticidesReduce workloadLiquid handling installationsElectricityUncrewed vehicle

The invention discloses an unmanned aerial vehicle replenishing device and an unmanned aerial vehicle, and belongs to the field of the unmanned aerial vehicles. The unmanned aerial vehicle replenishing device comprises a parking apron, wherein a parking position and a replenishing device part are arranged on the parking apron; the replenishing device part comprises an oil tank, an oil pump, a pesticide liquor box and a pesticide liquor pump; an oil pipe and a pesticide liquor pipe are arranged on the oil pump and the pesticide liquor pump respectively; grooves are formed in the parking position; press-type switches are arranged in the grooves; the surface of the parking apron rises along the direction far away from the grooves; an outlet of the oil pipe and an outlet of the pesticide liquor pipe are formed beside the grooves; and a driver capable of driving the oil pipe and the pesticide liquor pipe to rise or fall is arranged on the parking apron, and is electrically connected with the press-type switches. The unmanned aerial vehicle is characterized in that the shape of an undercarriage of the unmanned aerial vehicle is matched with those of the grooves of the unmanned aerial vehicle replenishing device, and an oil receiving port of the unmanned aerial vehicle and a sac inlet of sac of the unmanned aerial vehicle face downwards. The unmanned aerial vehicle replenishing device can automatically replenish fuel and a pesticide liquor for the matched unmanned aerial vehicle.

Owner:山东领信信息科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com