Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8524 results about "Pressure controlled ventilation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure control (PC) is a mode of mechanical ventilation alone and a variable within other modes of mechanical ventilation. Pressure control is used to regulate pressures applied during mechanical ventilation.

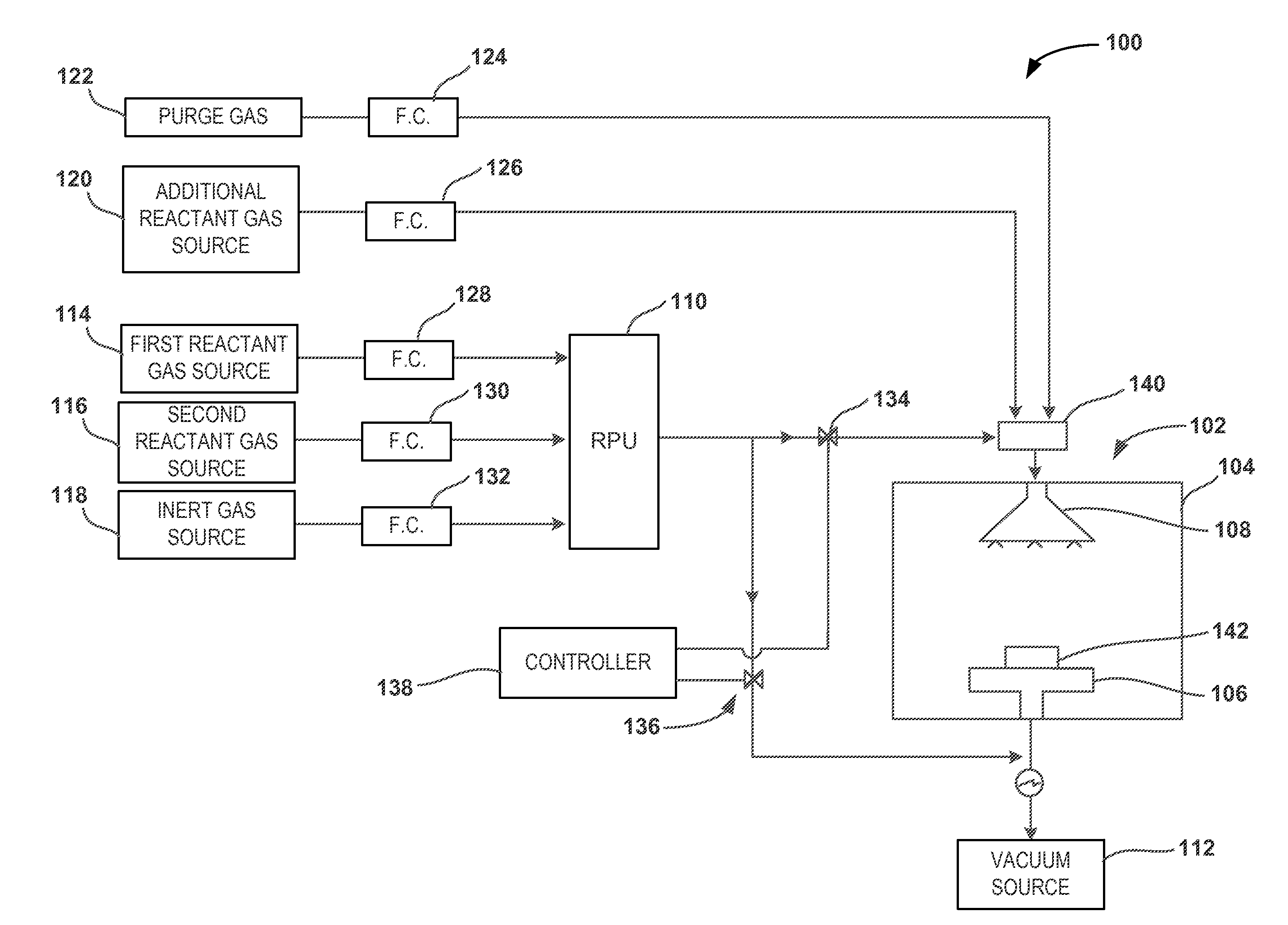

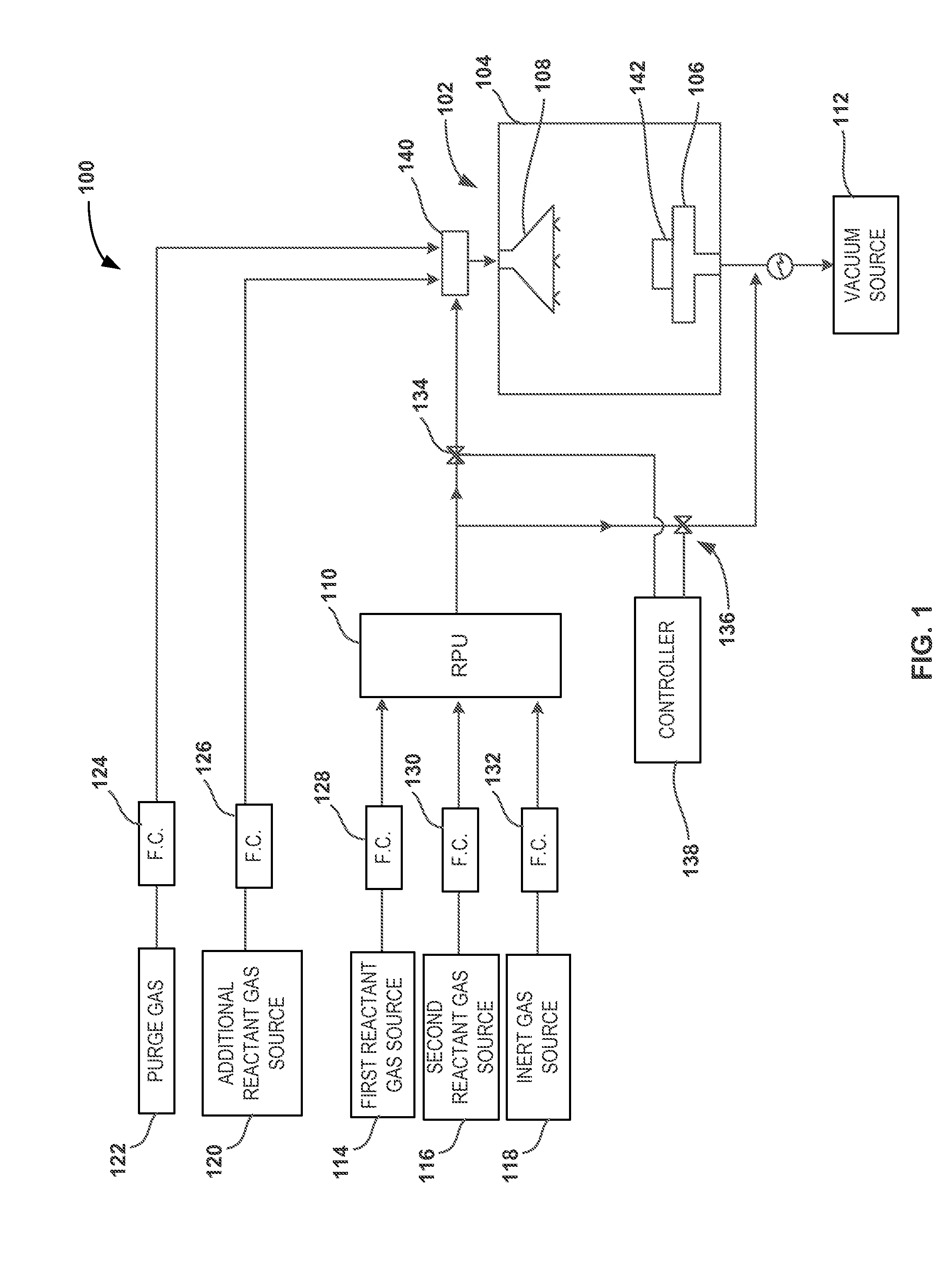

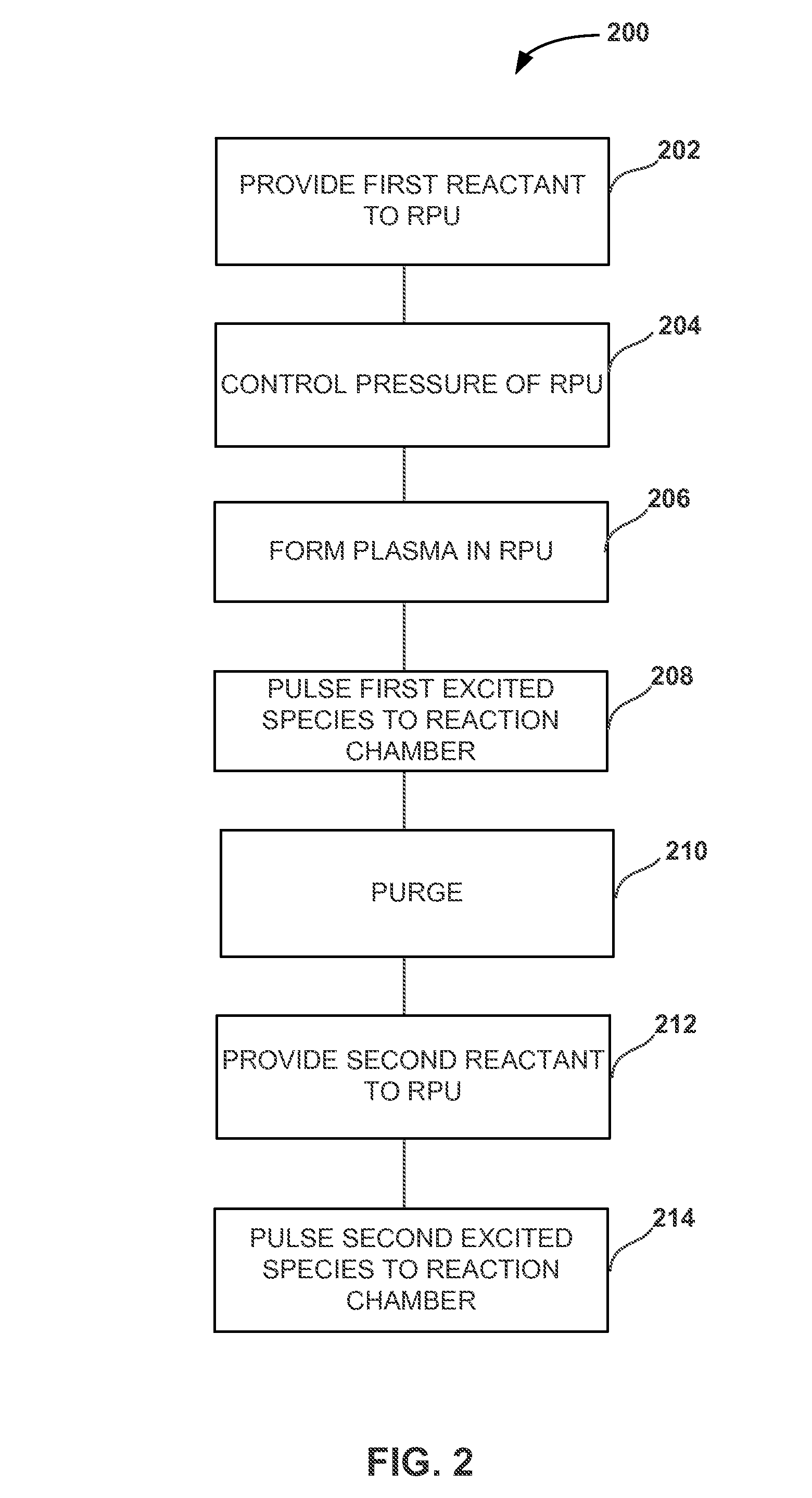

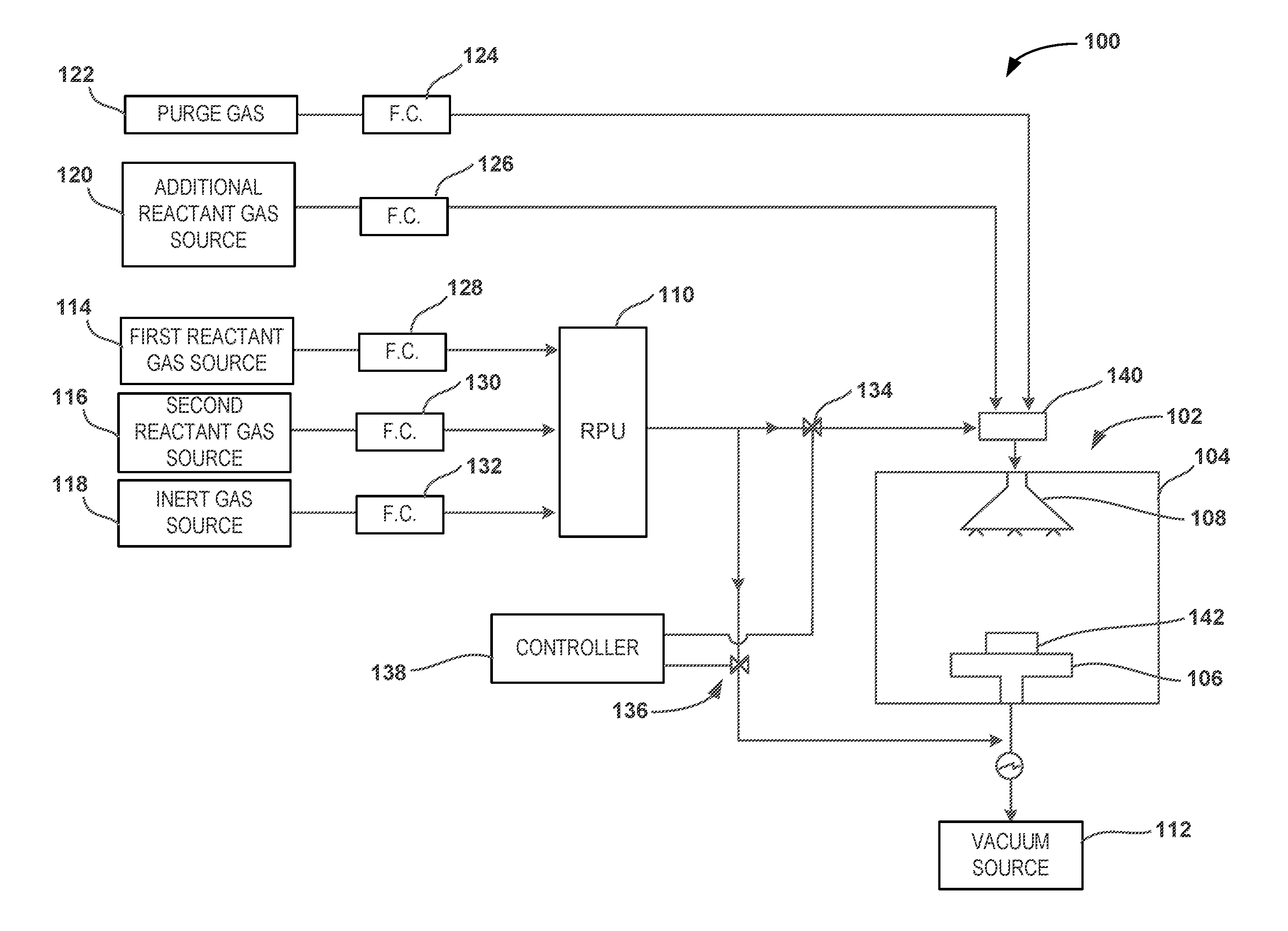

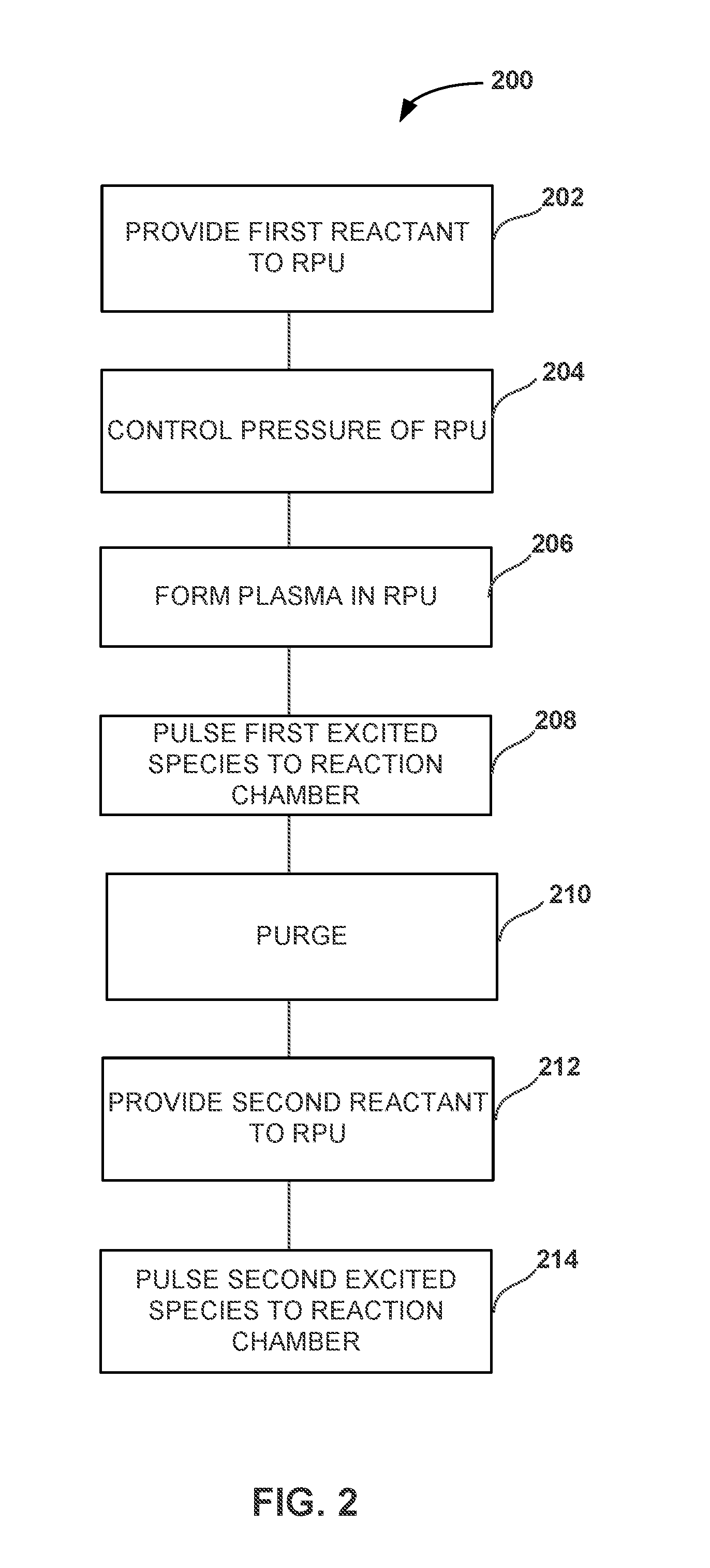

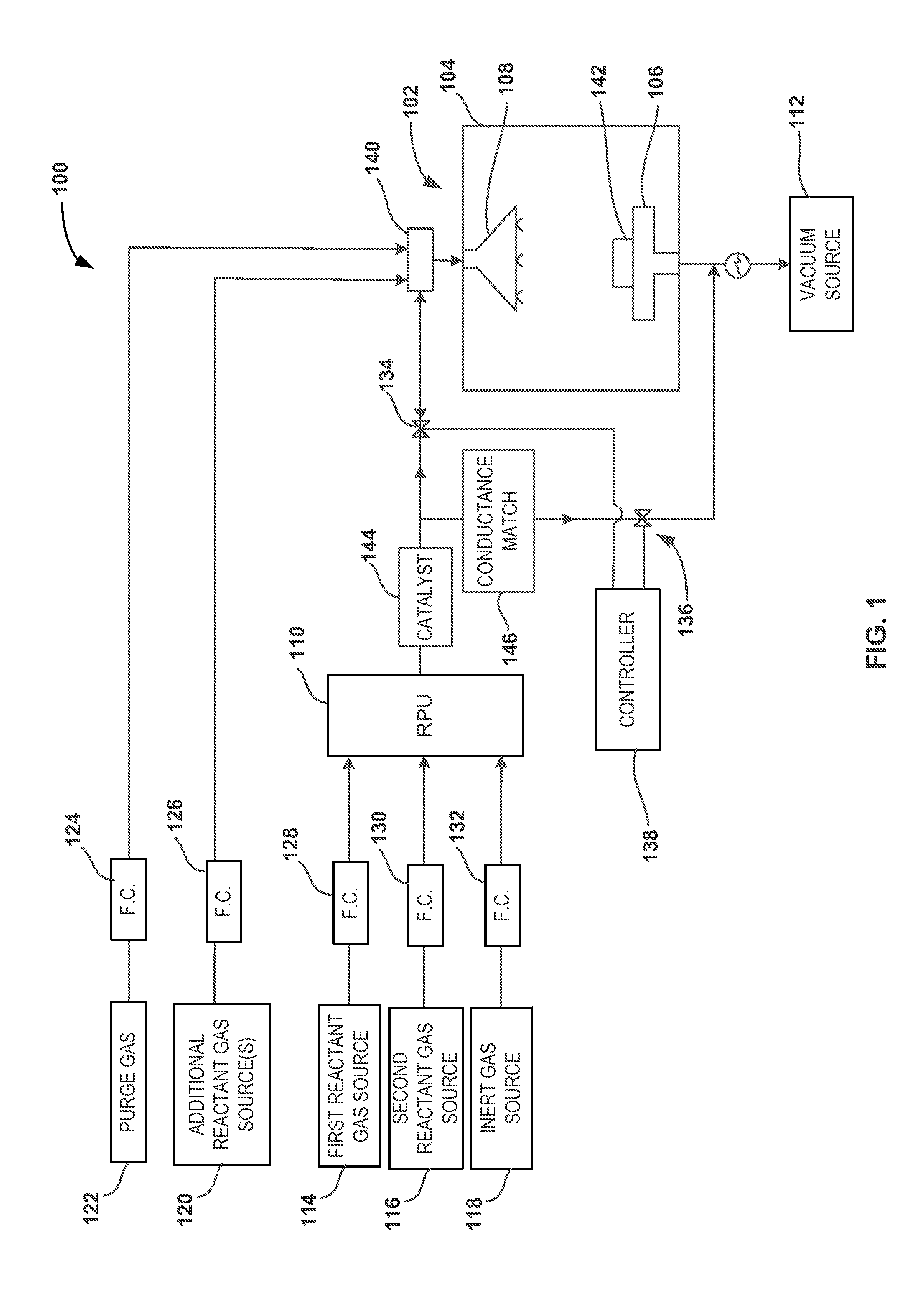

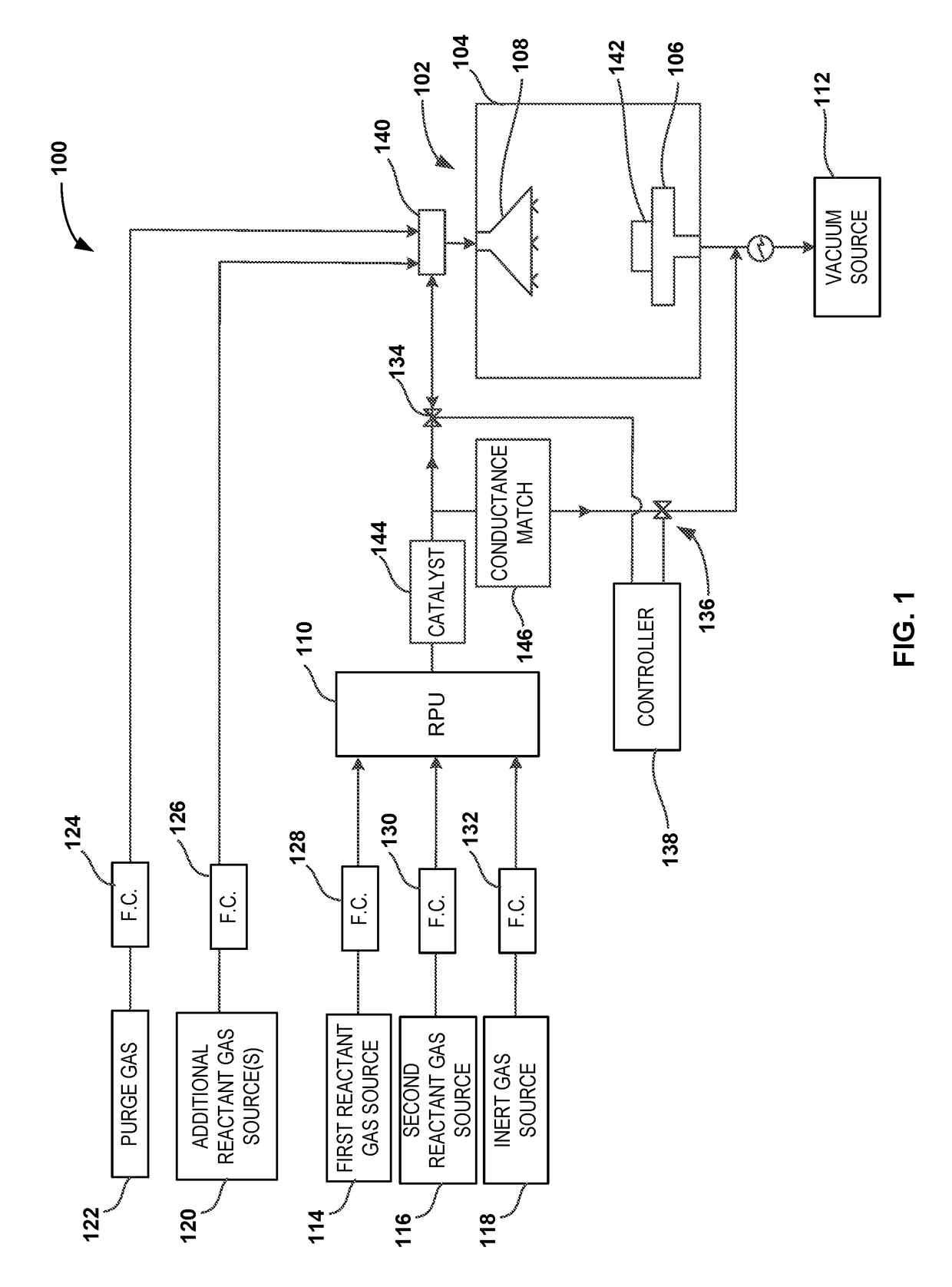

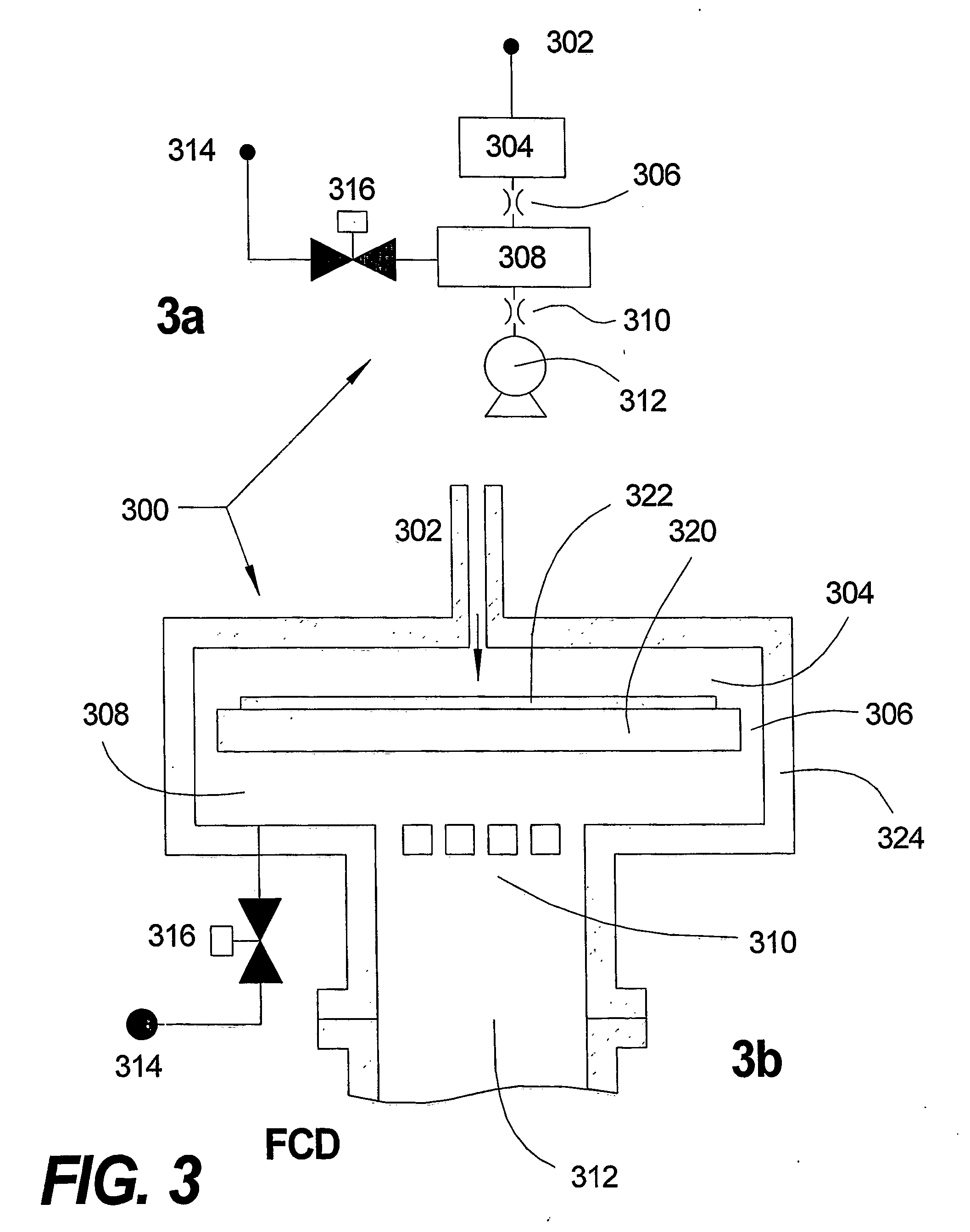

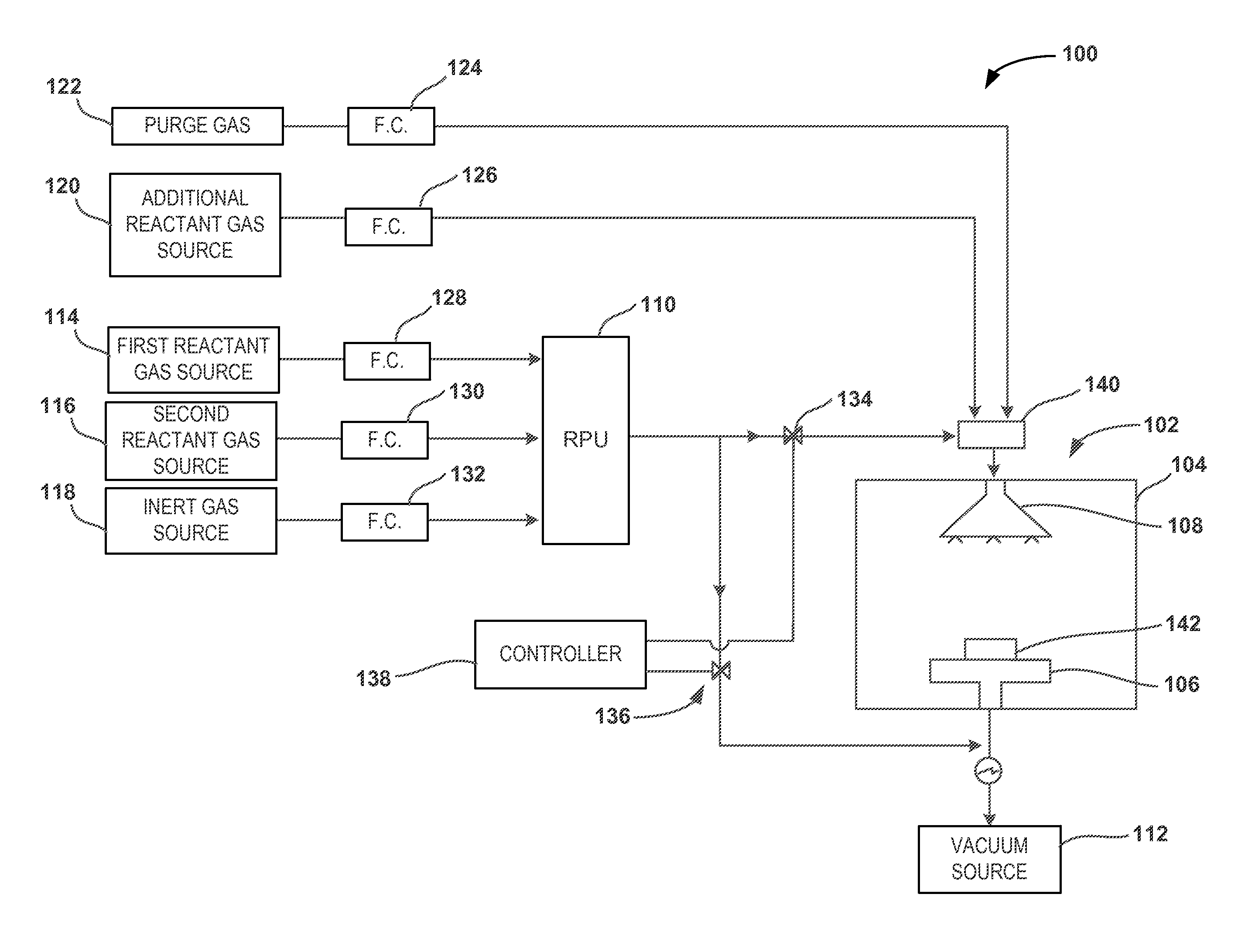

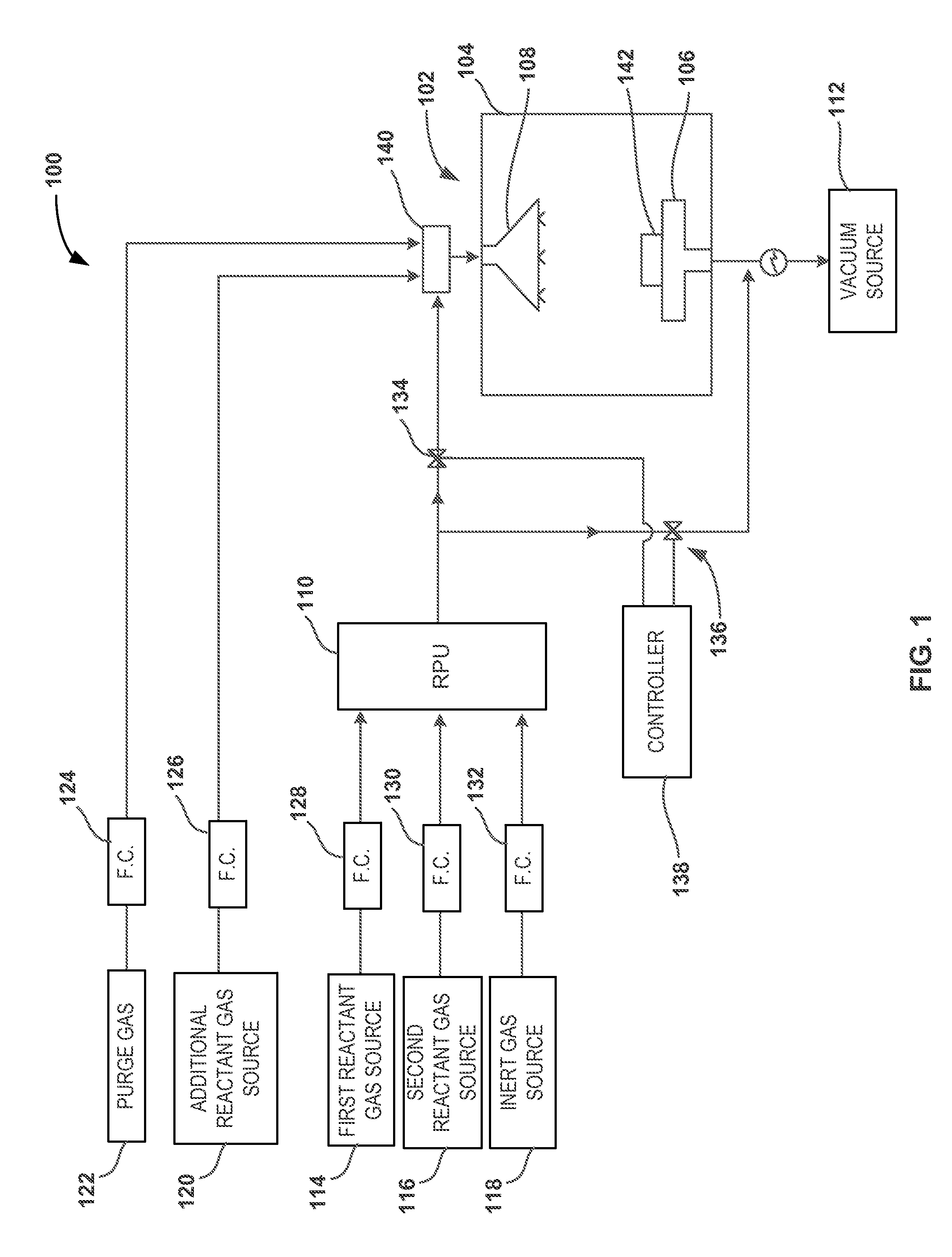

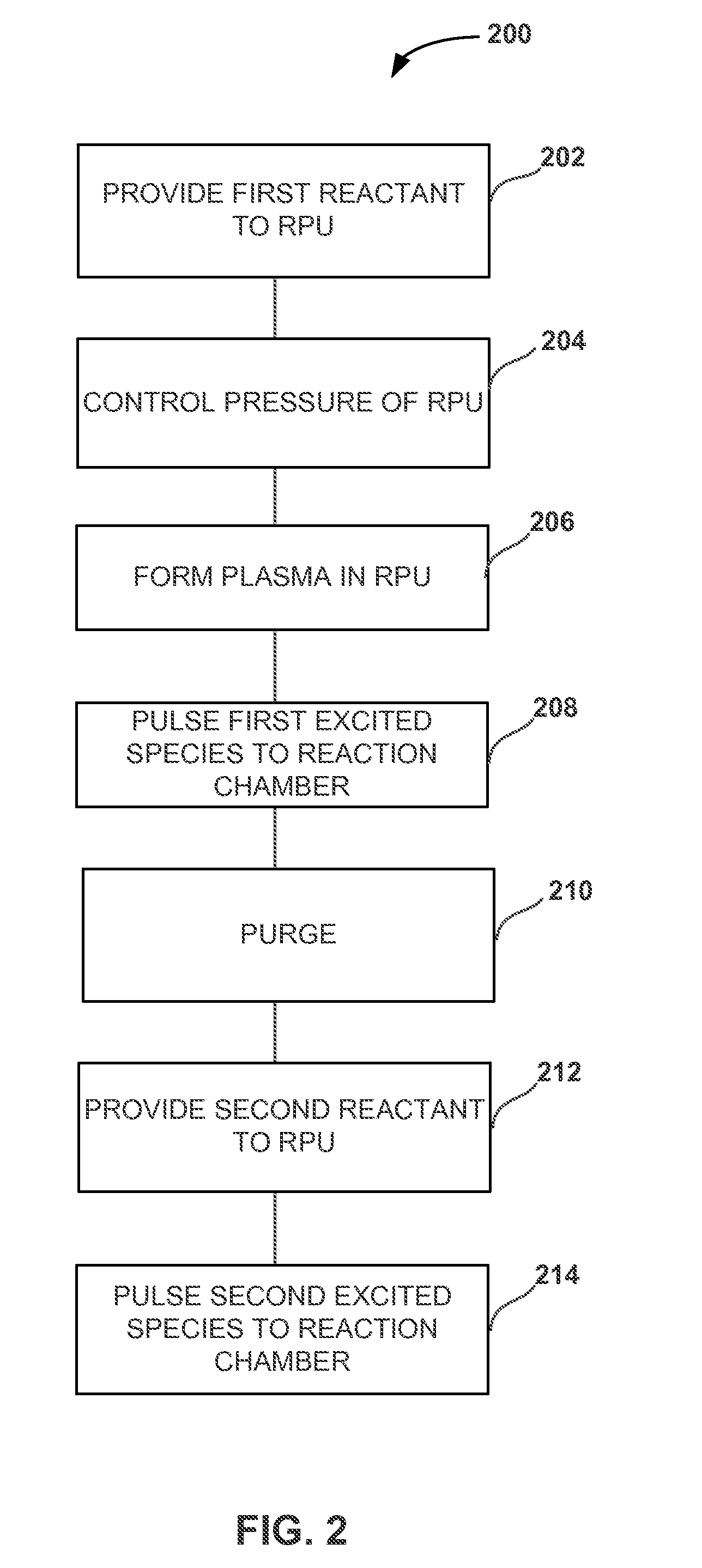

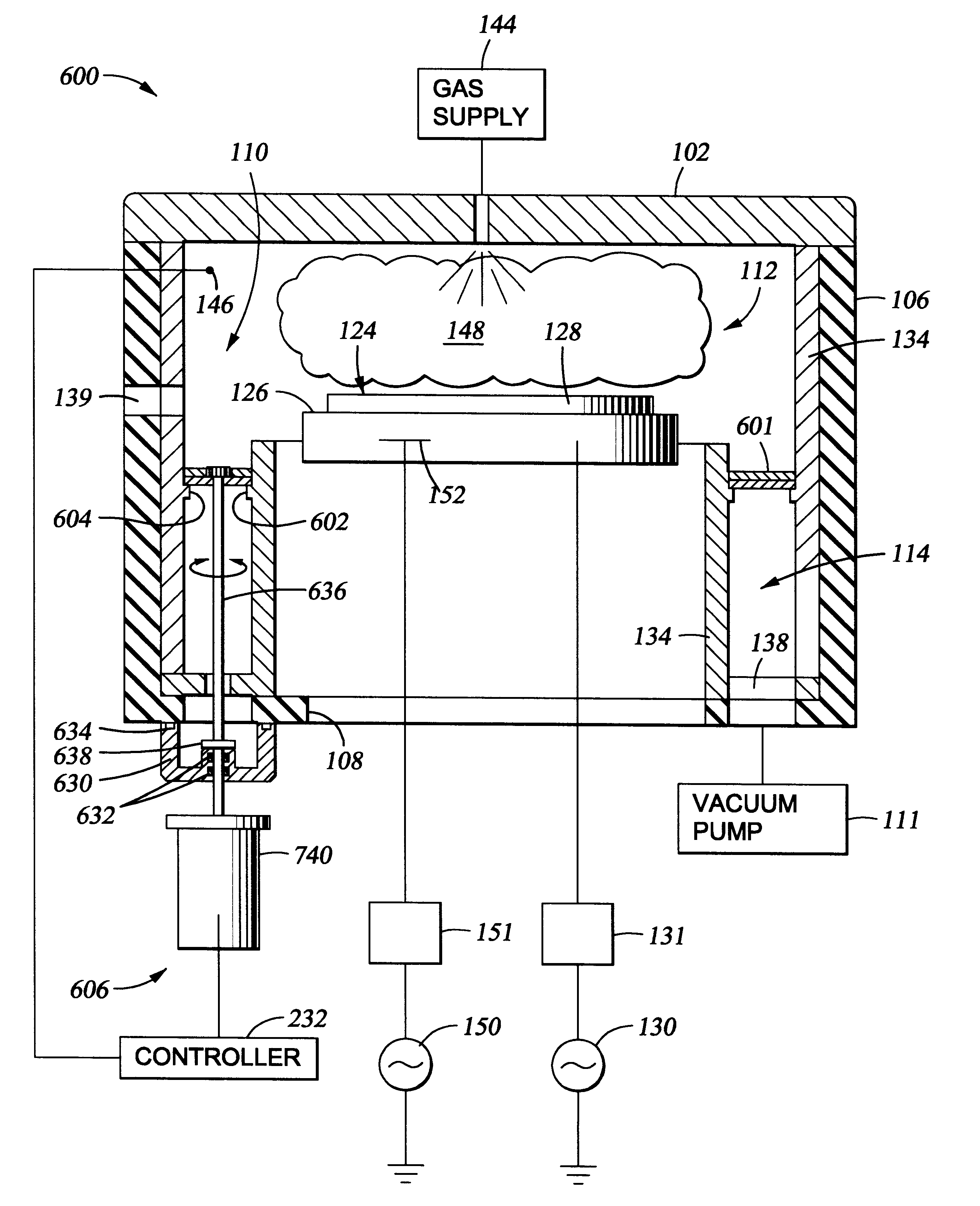

Pulsed remote plasma method and system

ActiveUS20140251954A1Decorative surface effectsSemiconductor/solid-state device manufacturingRemote plasmaEngineering

A system and method for providing pulsed excited species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as reactive species from the remote plasma unit are pulsed to the reaction chamber.

Owner:ASM IP HLDG BV

Pulsed remote plasma method and system

ActiveUS20170011889A1Electric discharge tubesChemical vapor deposition coatingRemote plasmaEngineering

A system and method for providing pulsed excited species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as reactive species from the remote plasma unit are pulsed to the reaction chamber.

Owner:ASM IP HLDG BV

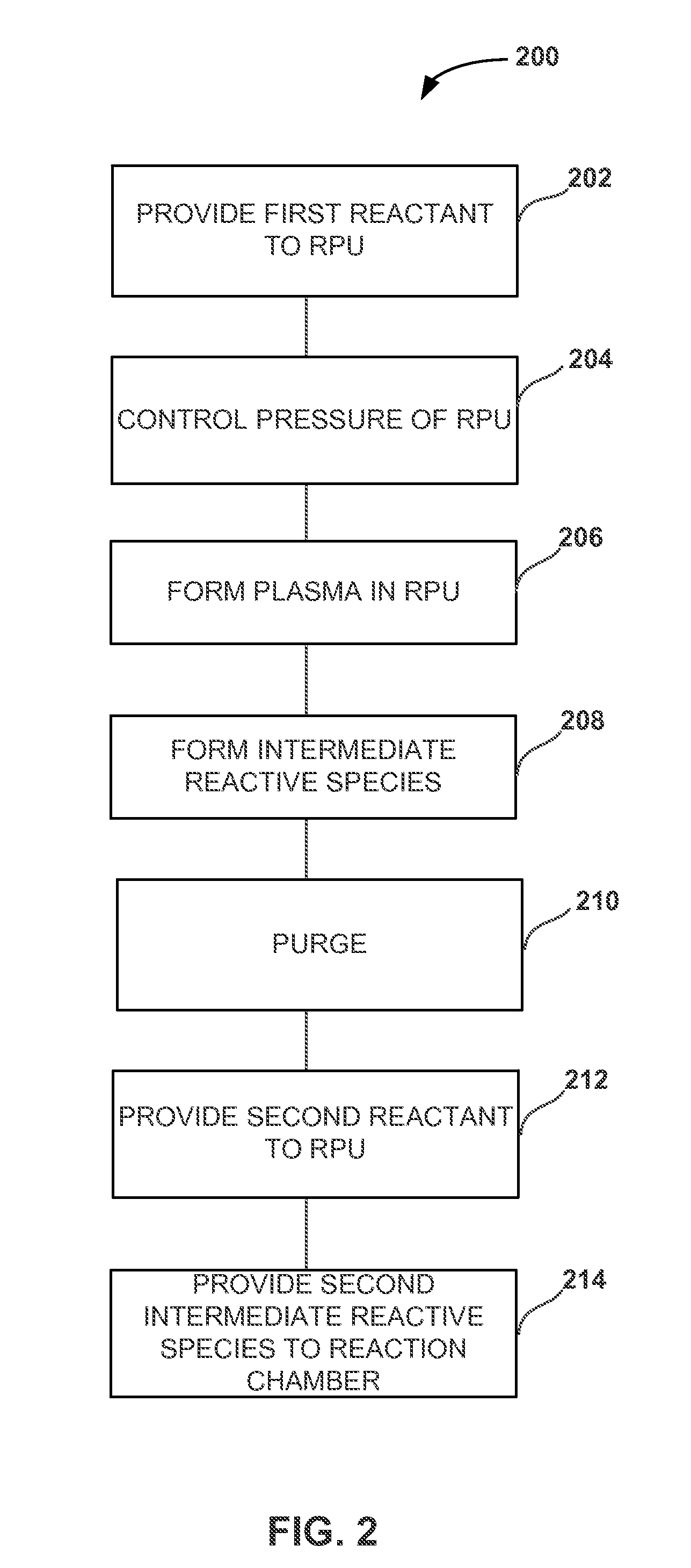

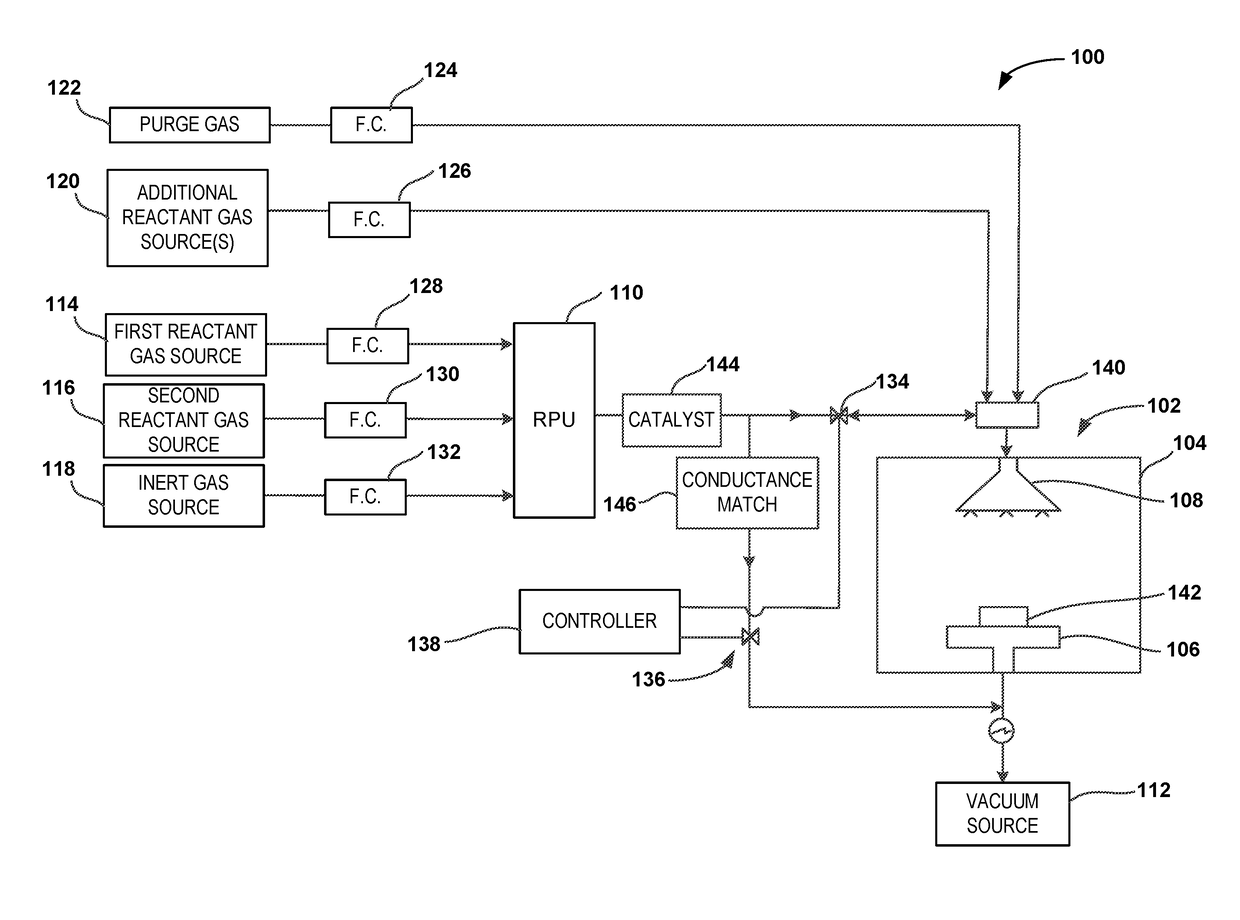

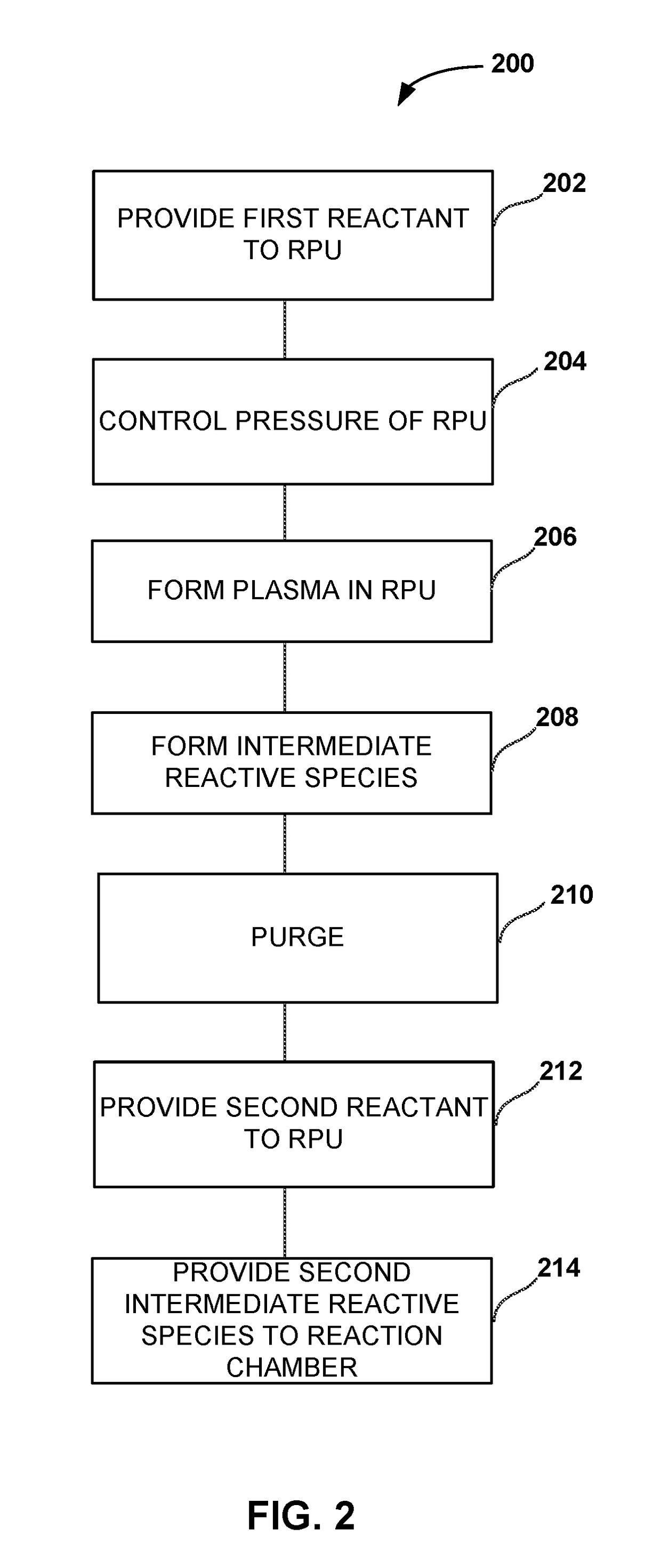

Method and systems for in-situ formation of intermediate reactive species

ActiveUS20140251953A1Stably formElectric discharge tubesDecorative surface effectsRemote plasmaEngineering

A system and method for providing intermediate reactive species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as intermediate reactive species from the remote plasma unit are provided to the reaction chamber.

Owner:ASM IP HLDG BV

Method and system for in-situ formation of intermediate reactive species

ActiveUS20170154757A1Electric discharge tubesChemical vapor deposition coatingRemote plasmaEngineering

Owner:ASM IP HLDG BV

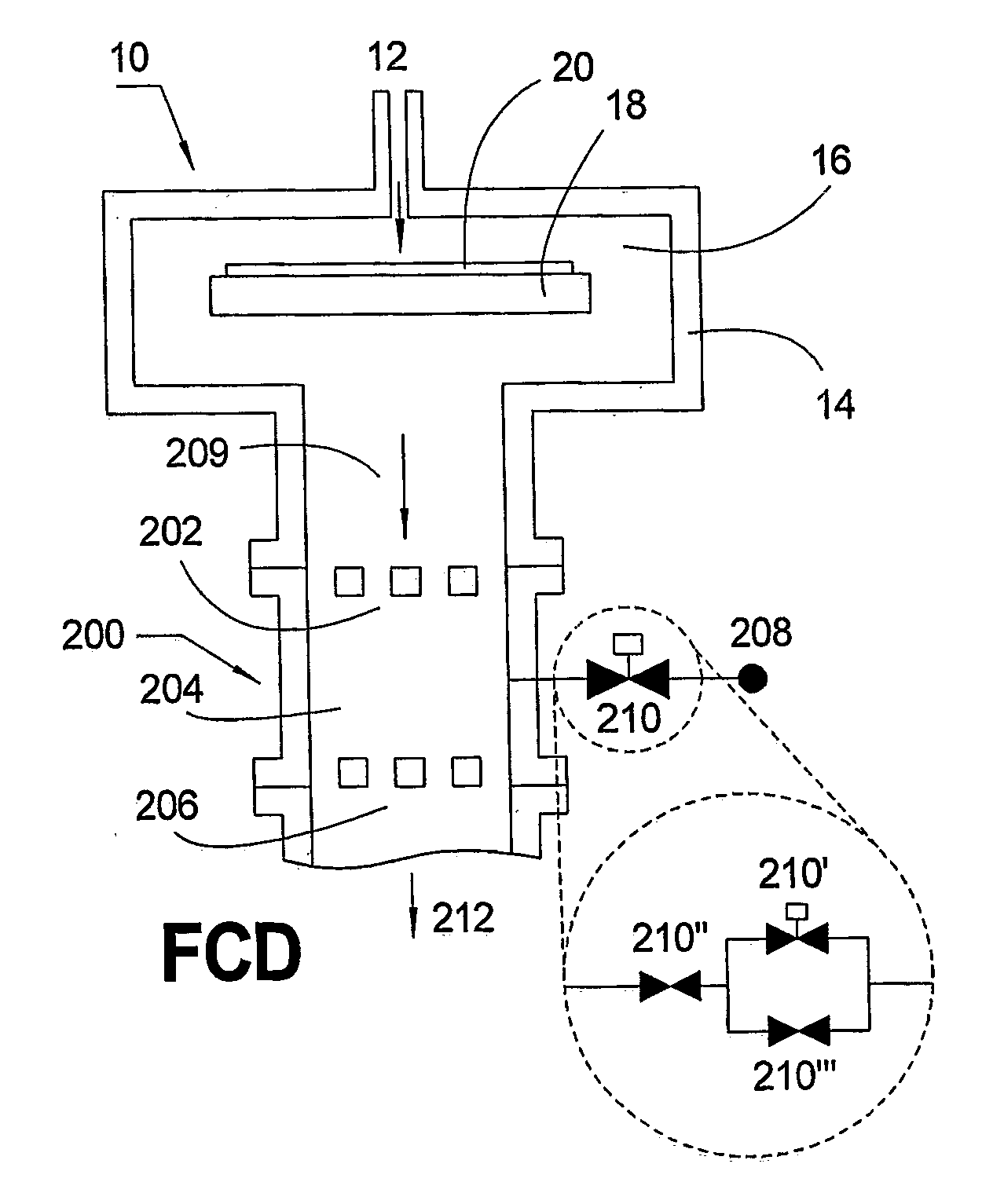

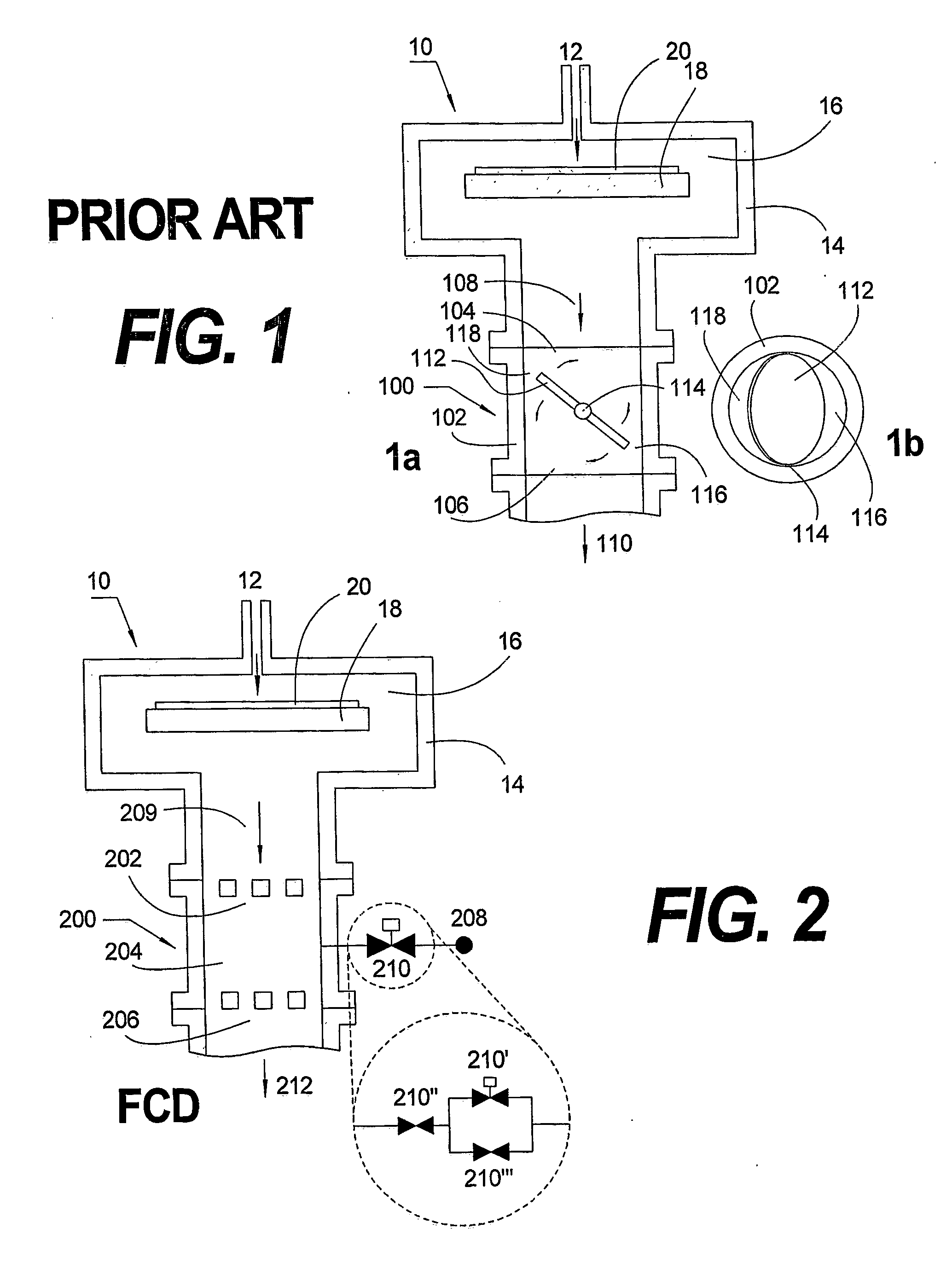

Apparatus and method for downstream pressure control and sub-atmospheric reactive gas abatement

InactiveUS20070012402A1Rapid responseOptimized and smooth flow passageSemiconductor/solid-state device manufacturingPipeline systemsReactive gasStream flow

A sub-atmospheric downstream pressure control apparatus (200) includes a first flow restricting element (FRE) (202); a pressure control chamber (PCC) (204) located in serial fluidic communication downstream from the first FRE; a second FRE (206) located in serial fluidic communication downstream from the PCC; a gas source (208); and a flow controlling device (210) in serial fluidic communication downstream from the gas source and upstream from the PCC.

Owner:SUNDEW TECH

Pulsed remote plasma method and system

ActiveUS9484191B2Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaEngineering

A system and method for providing pulsed excited species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as reactive species from the remote plasma unit are pulsed to the reaction chamber.

Owner:ASM IP HLDG BV

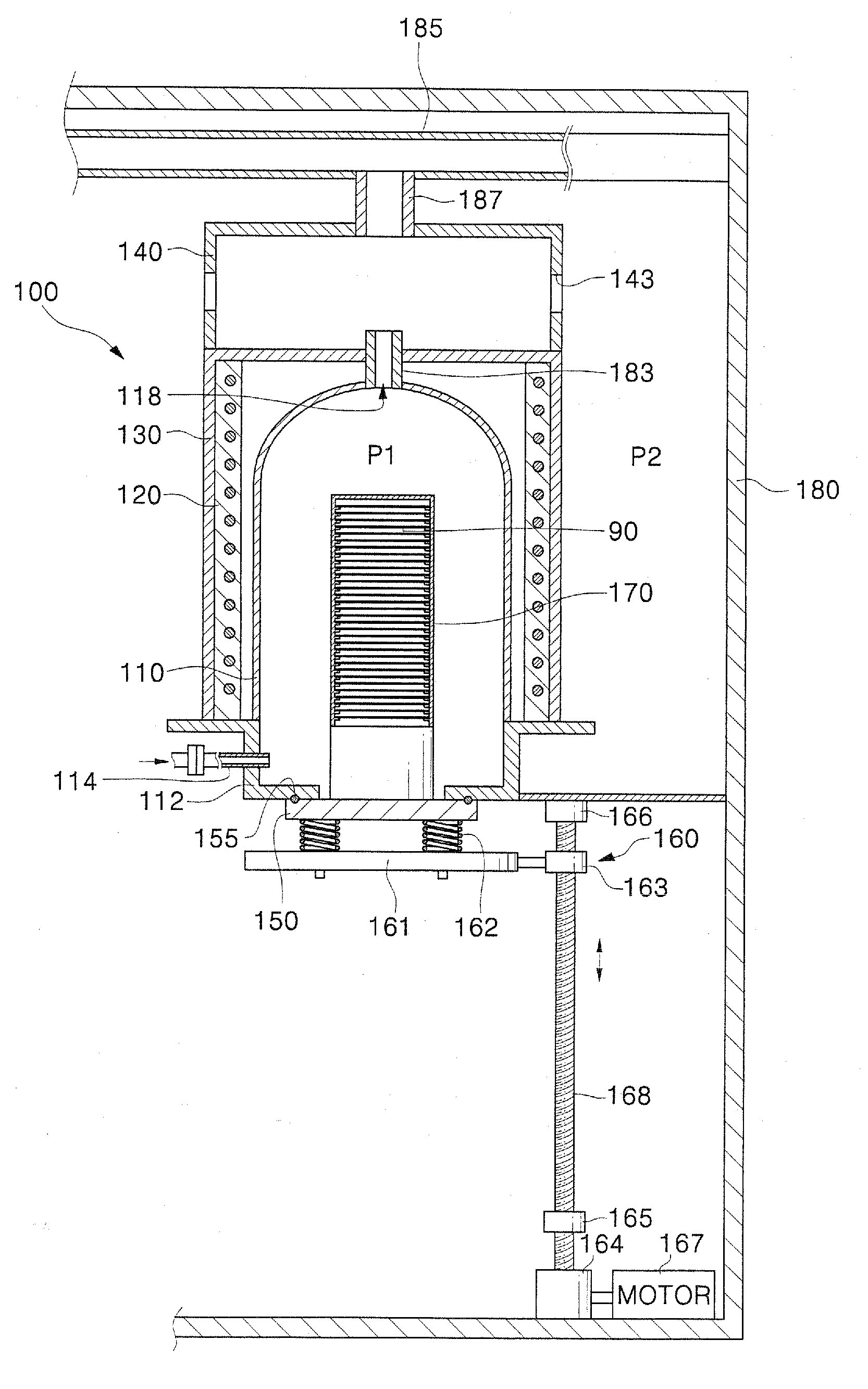

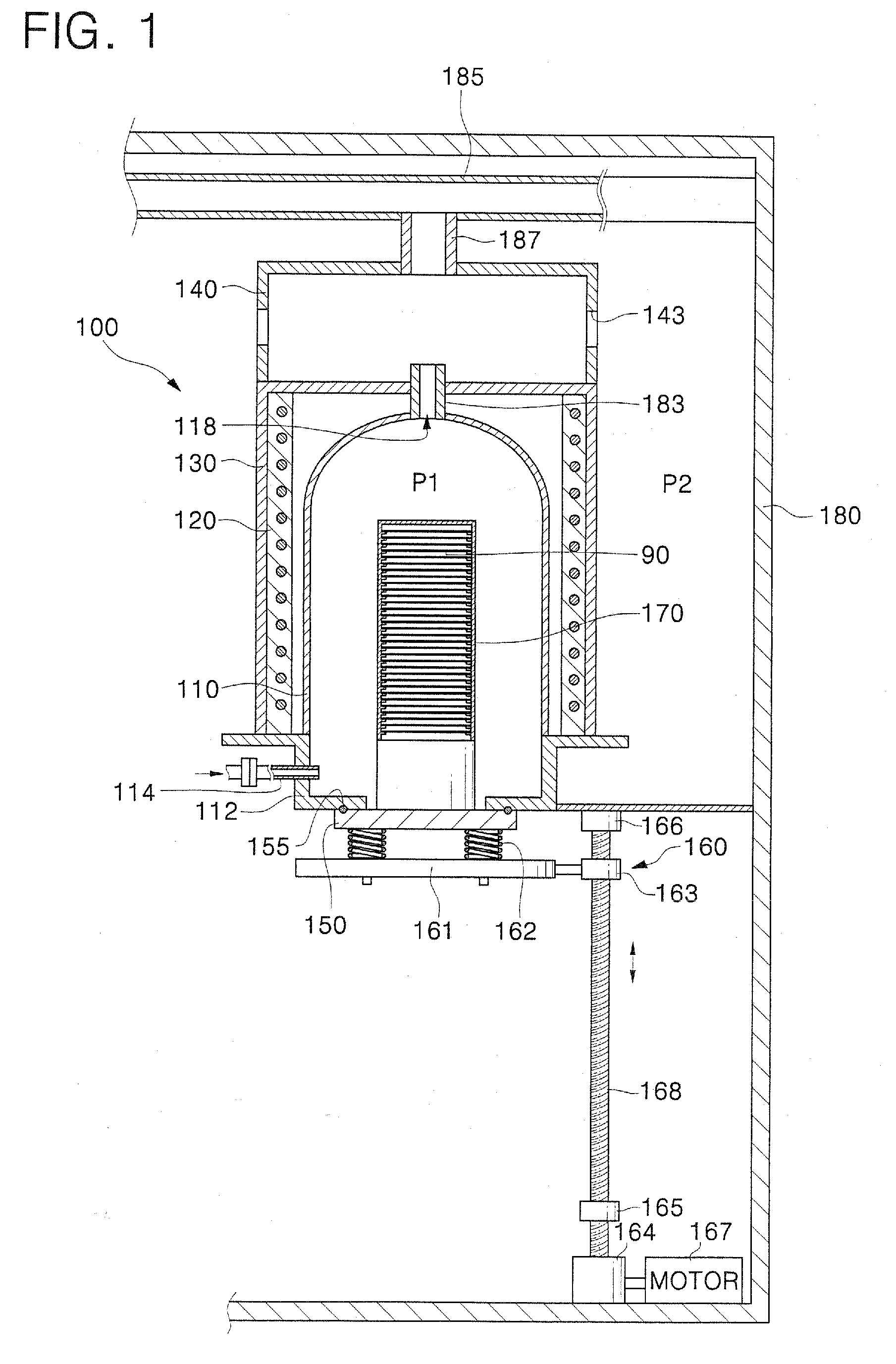

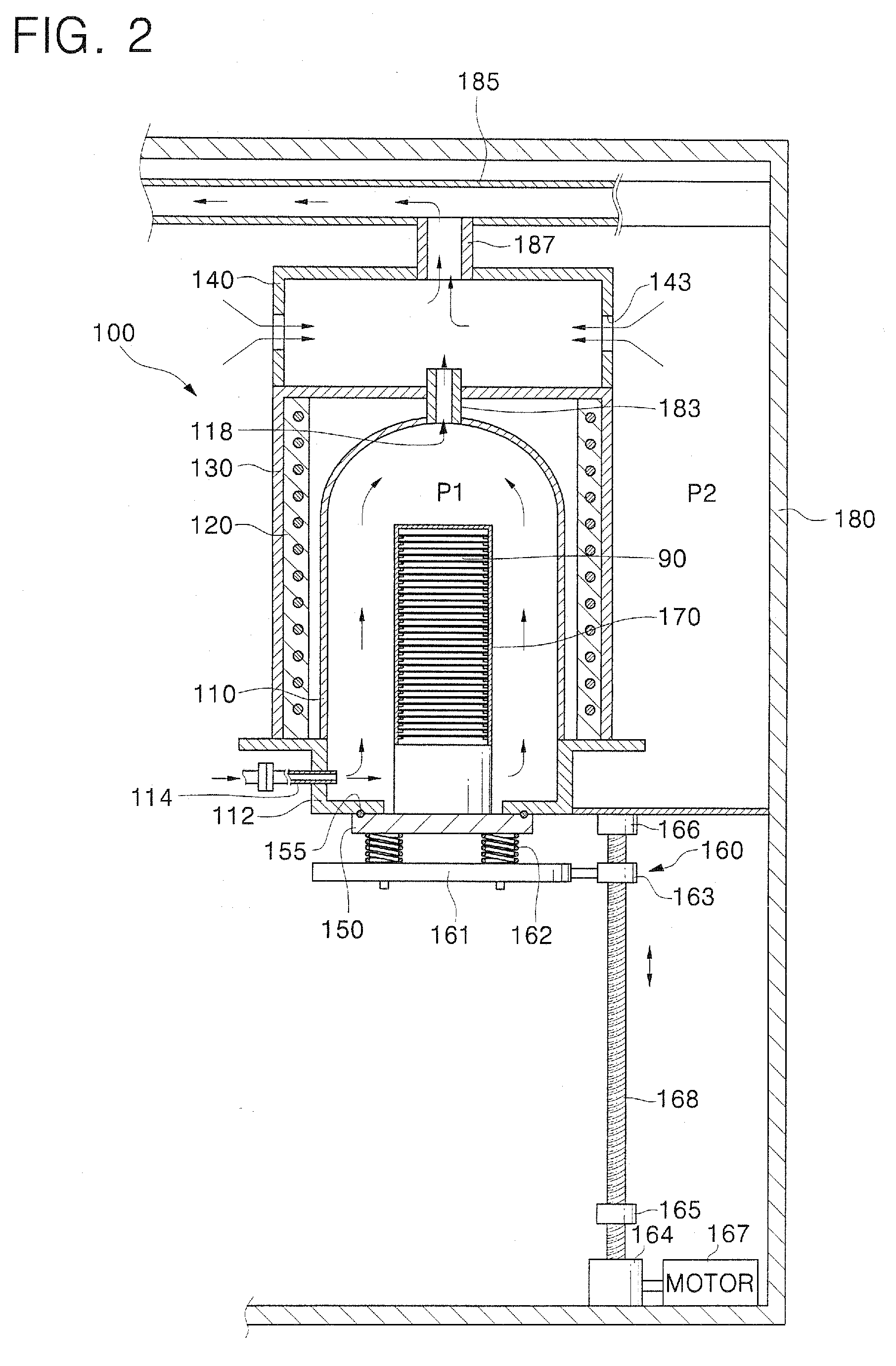

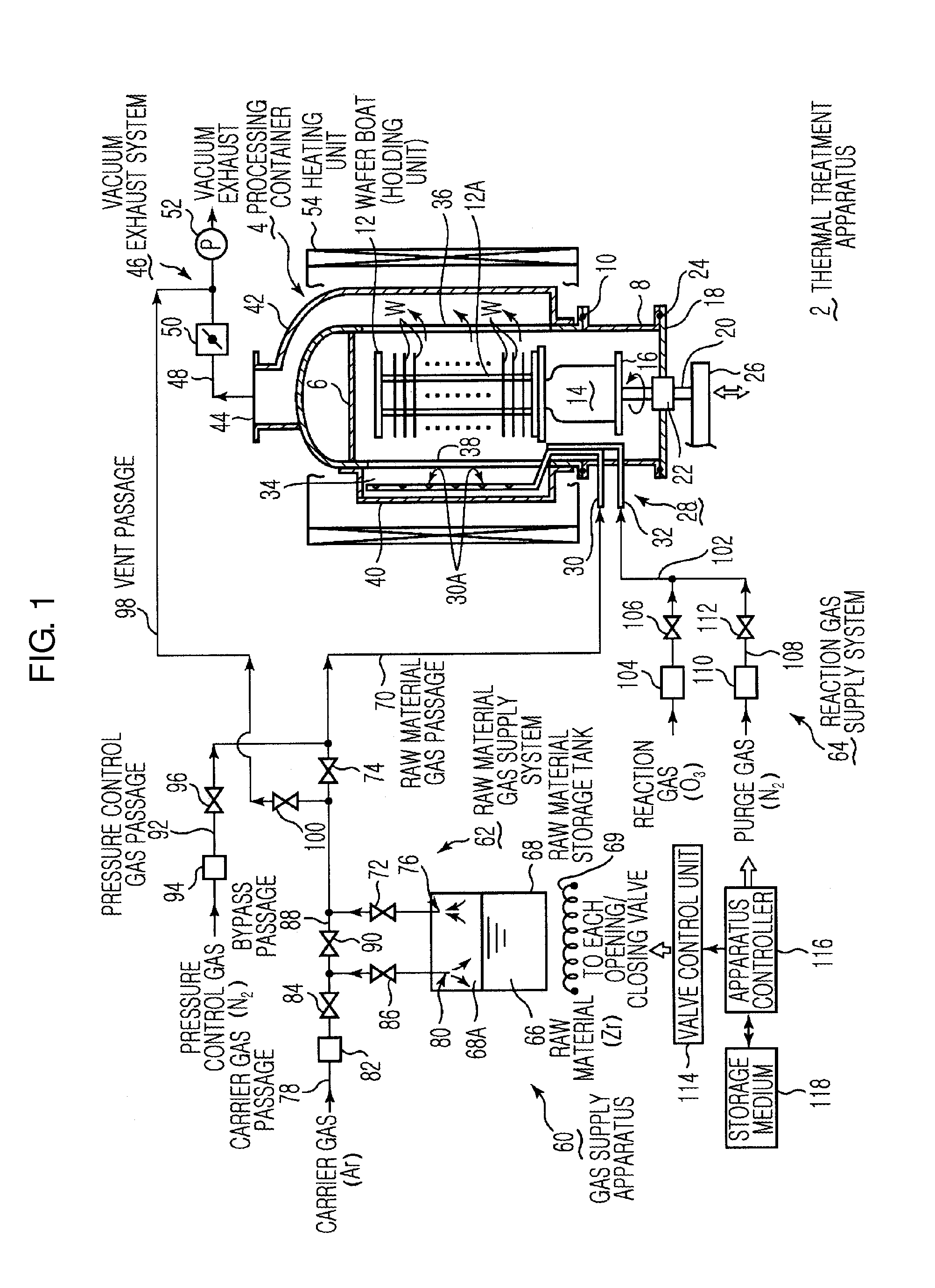

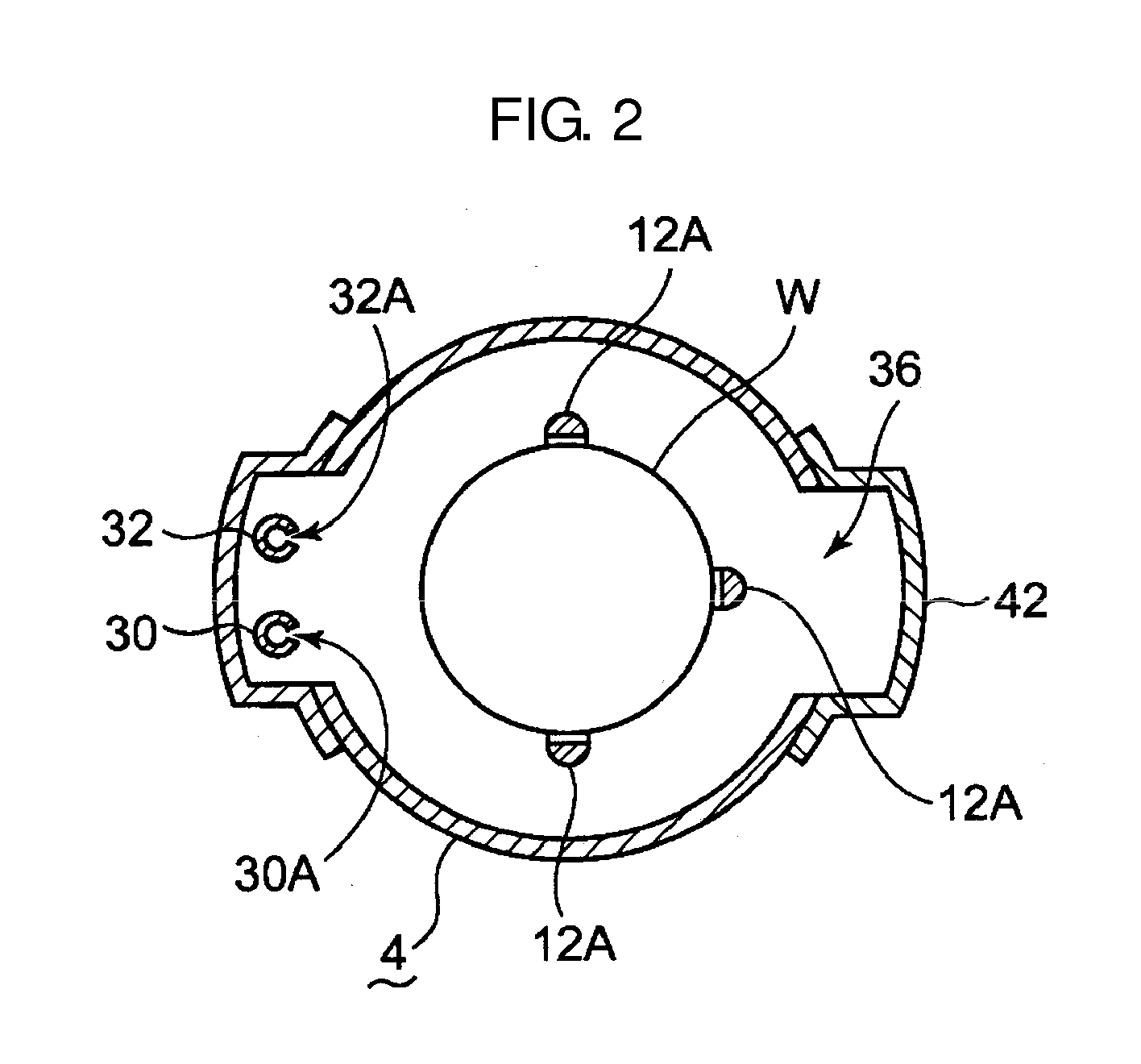

Heat treatment equipment

InactiveUS7850449B2Growth inhibitionReduce processing stepsMuffle furnacesBaking ovenProcess engineeringPressure controlled ventilation

In an embodiment, heat treatment equipment comprises a process tube, an exhaust duct connected to the process tube, and, during operation, exhausting gases present within the process tube. The heat treatment equipment also comprises a hollow pressure control member interposed between the process tube and the exhaust duct, the pressure control member being operatively connected to the process tube and the exhaust duct respectively, and including one or a number of openings. Negative pressure is avoided in the process tube during heat treatment processes so that unwanted gas and impurities cannot enter the process tube from outside.

Owner:SAMSUNG ELECTRONICS CO LTD

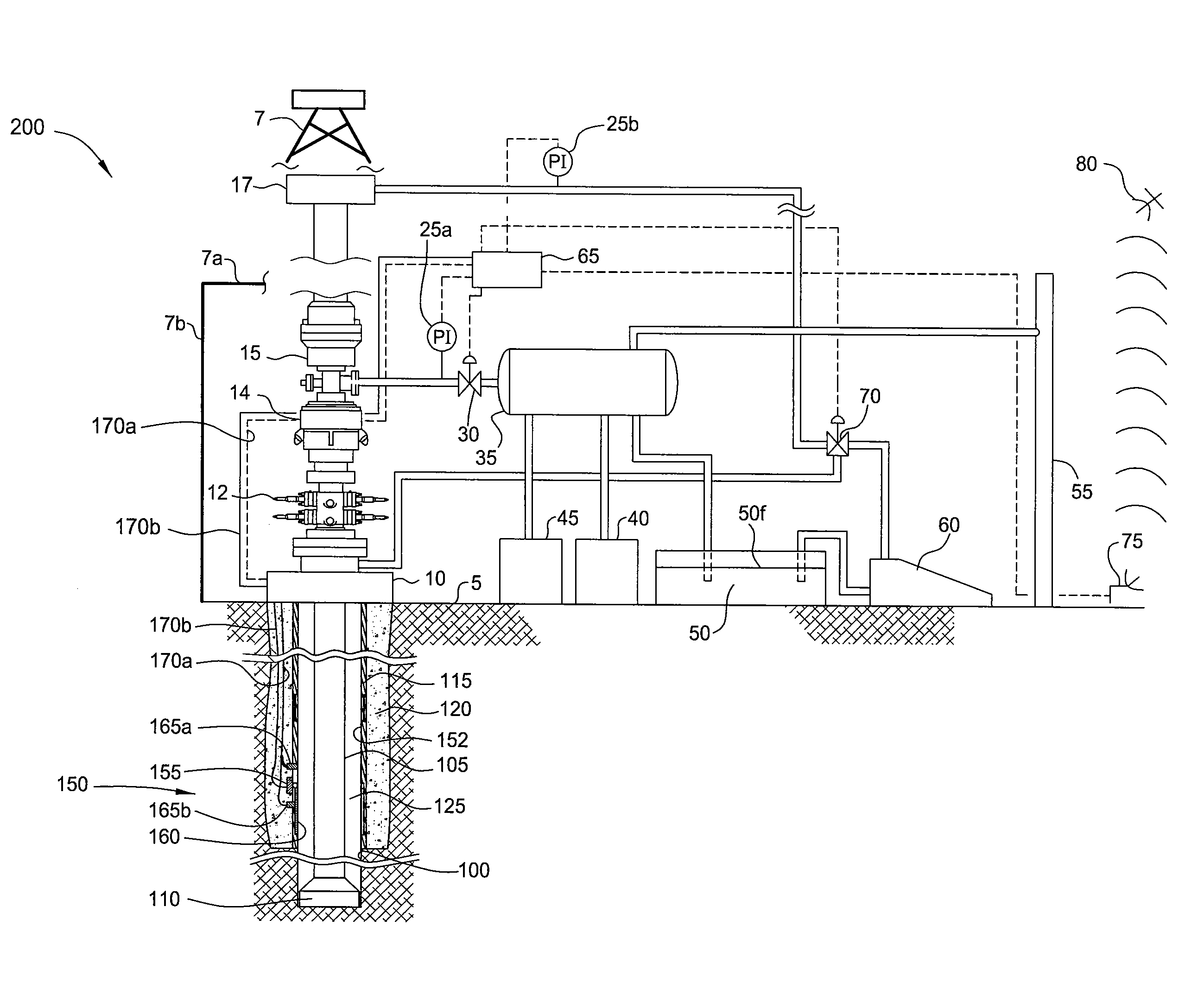

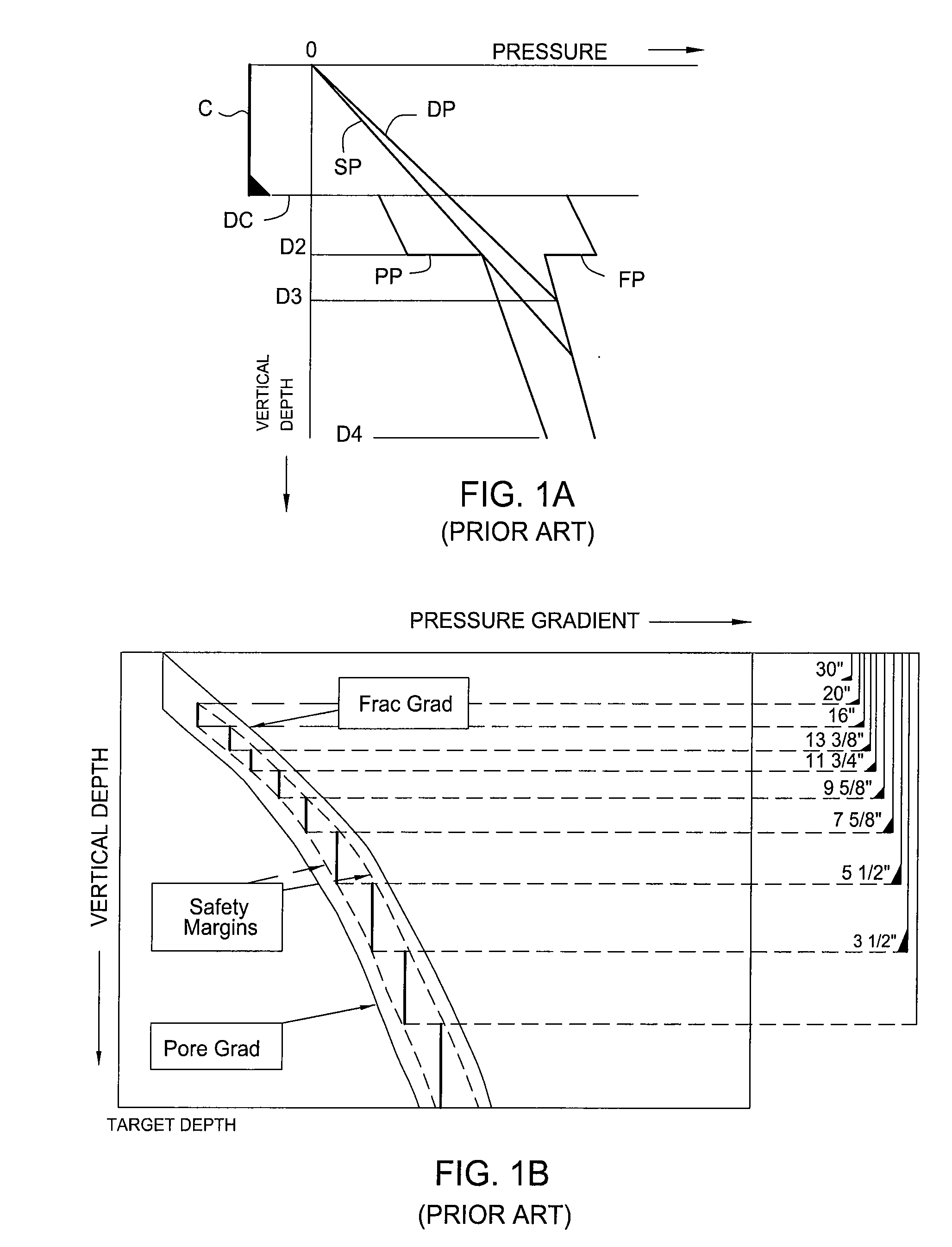

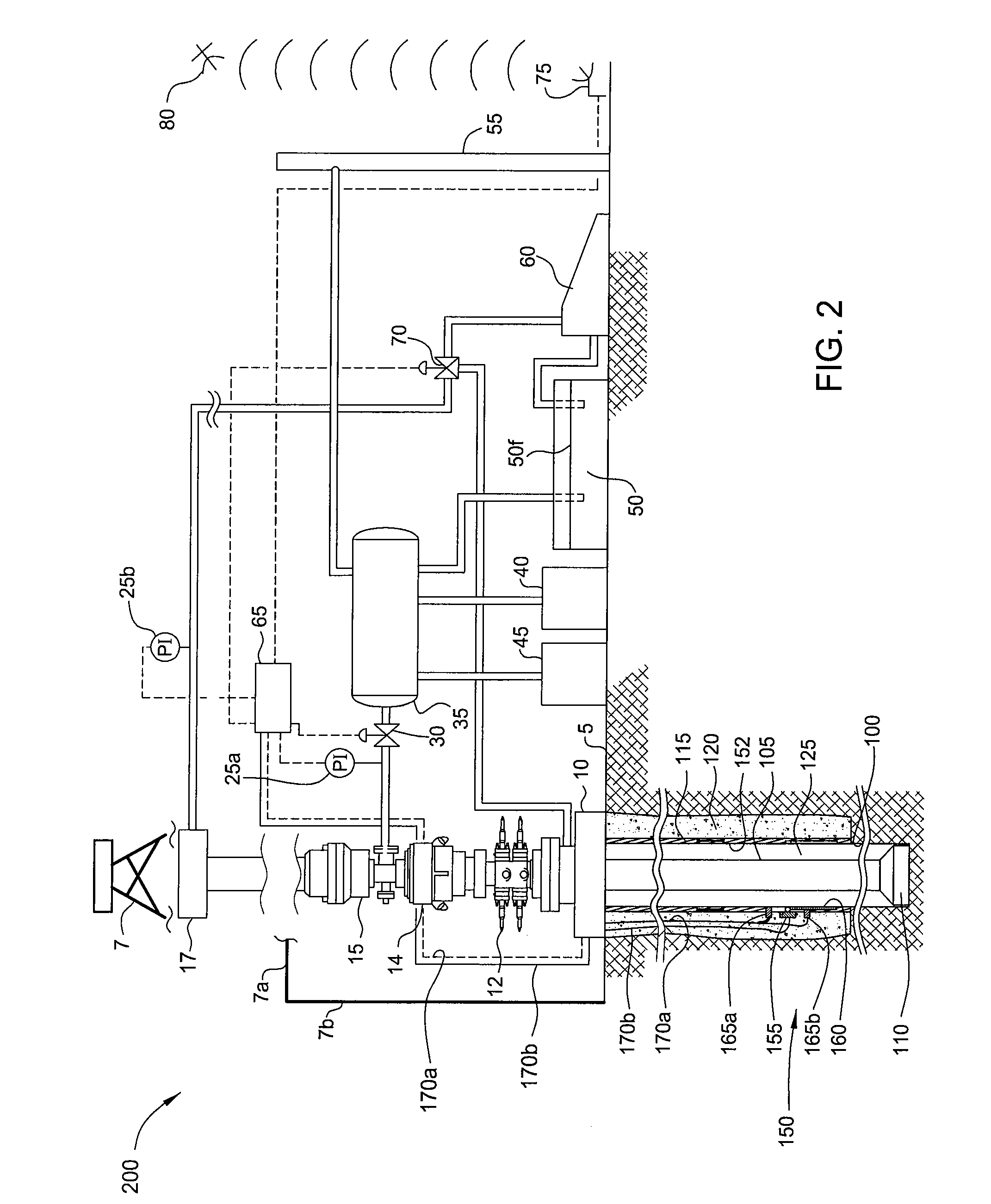

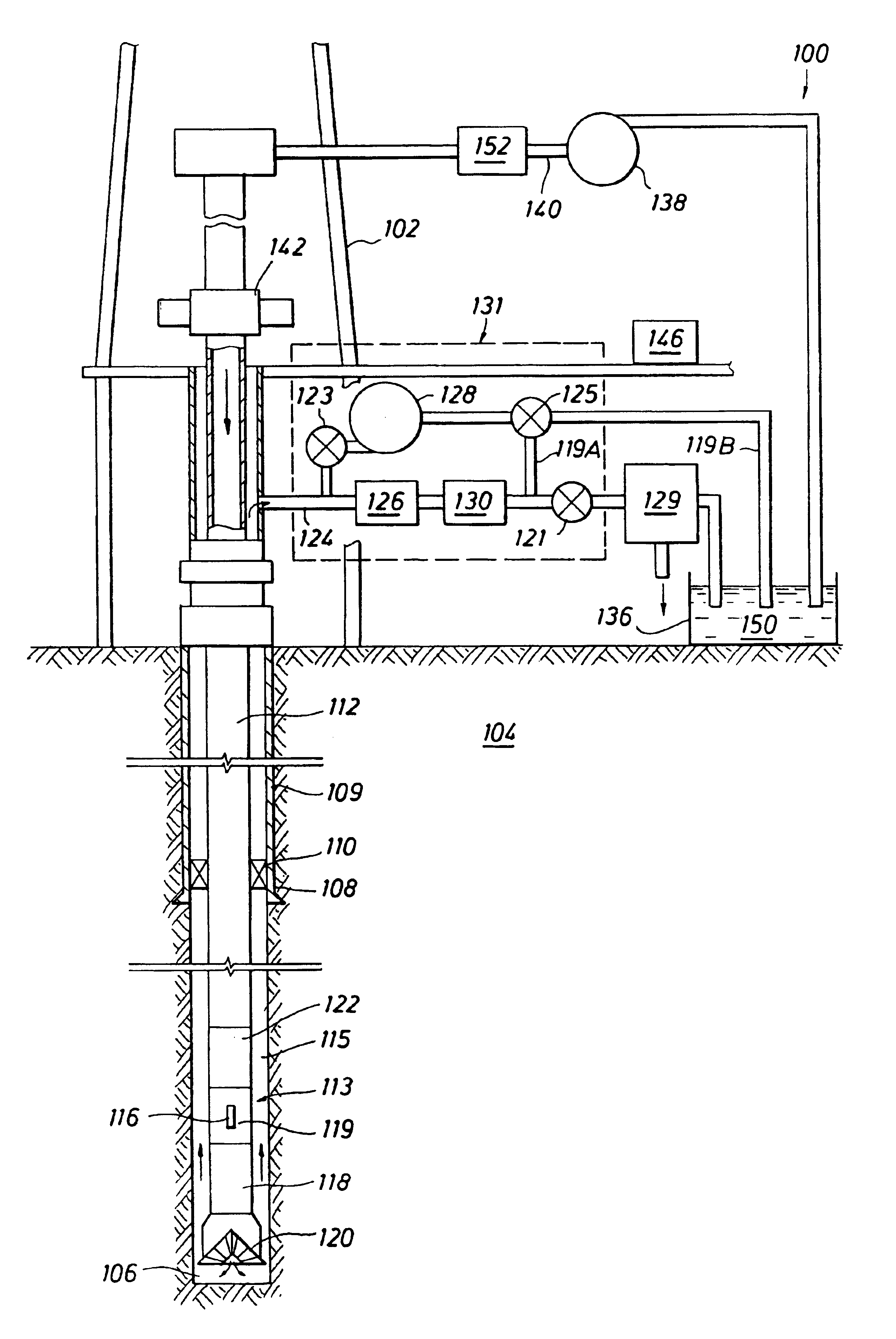

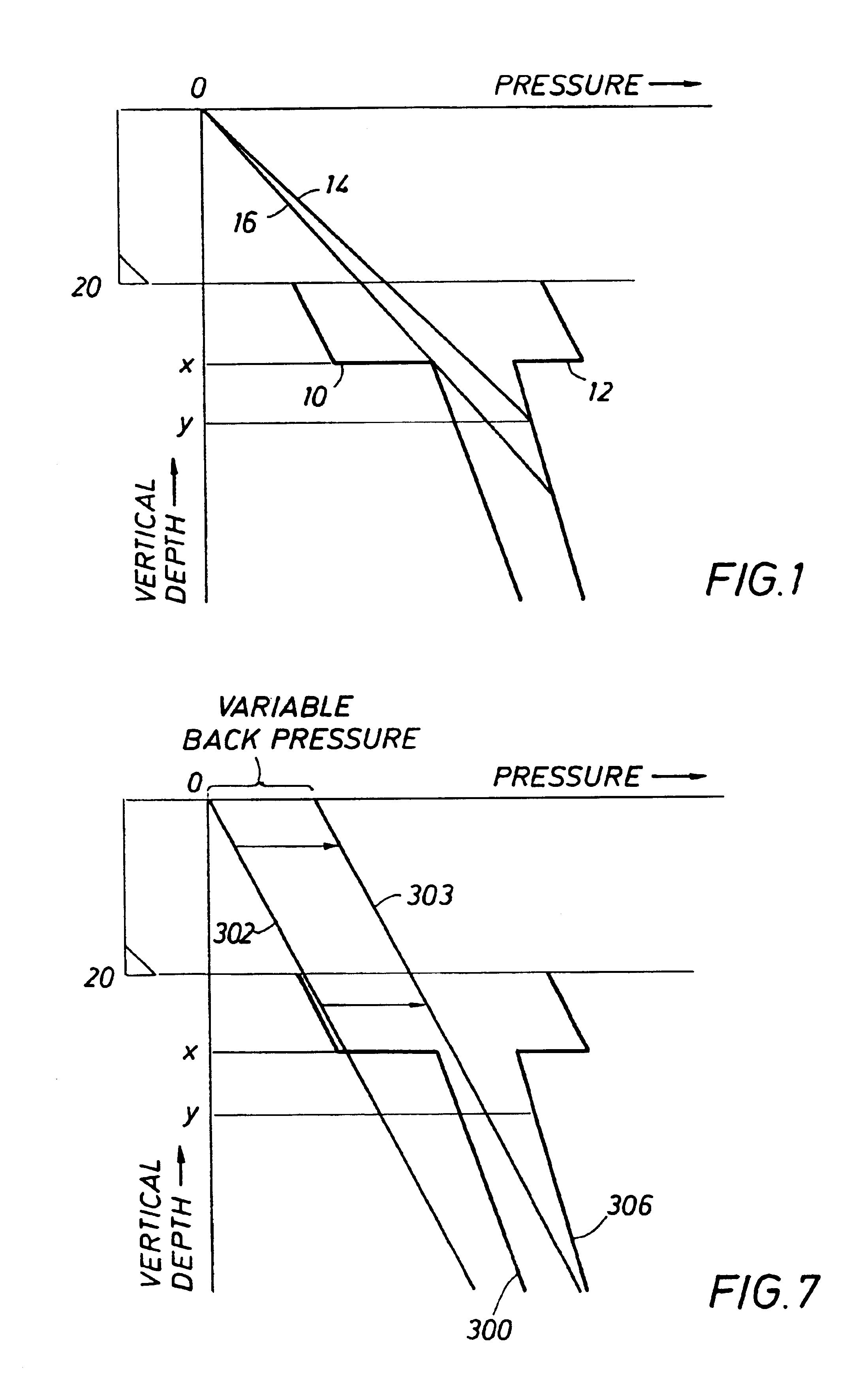

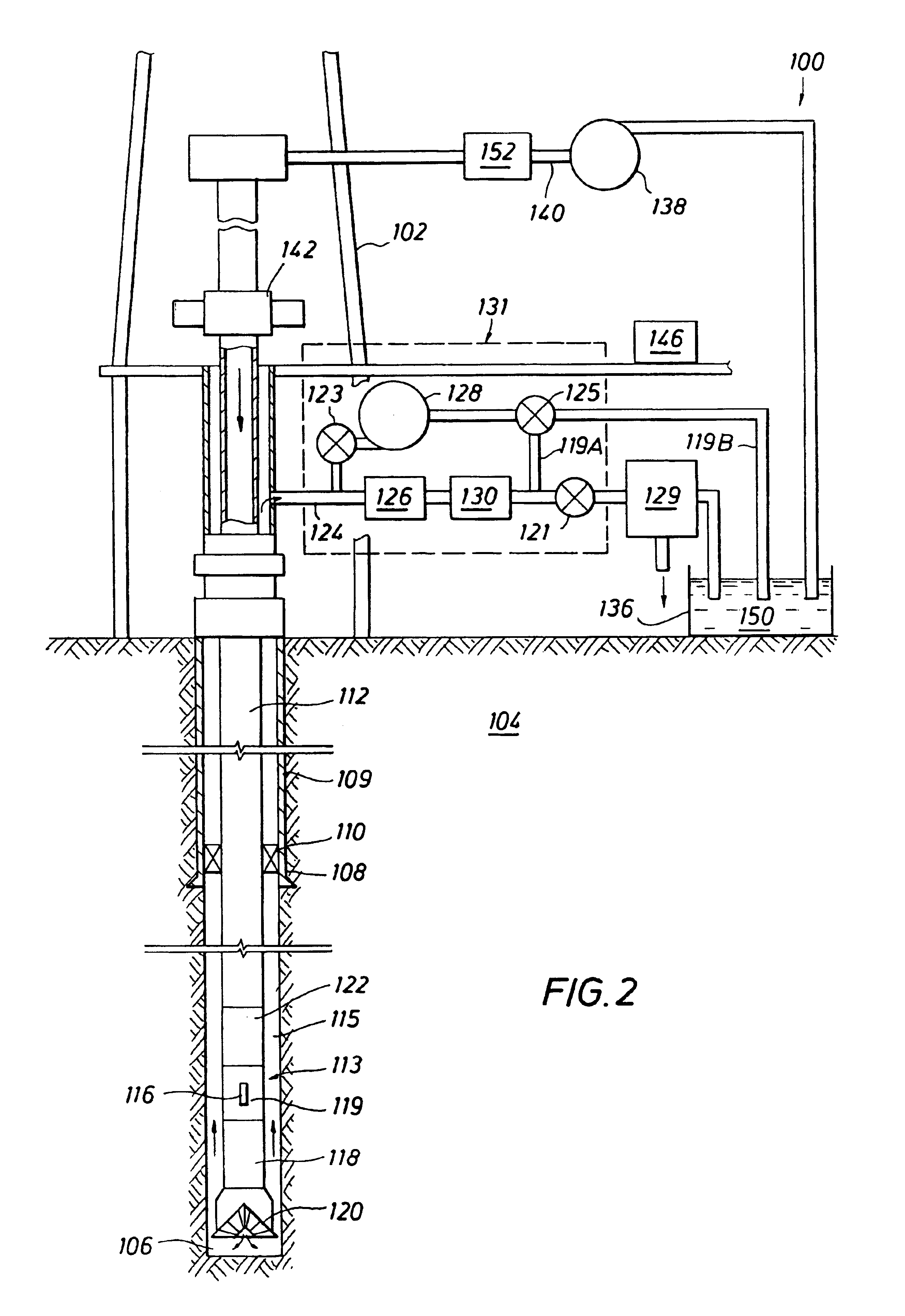

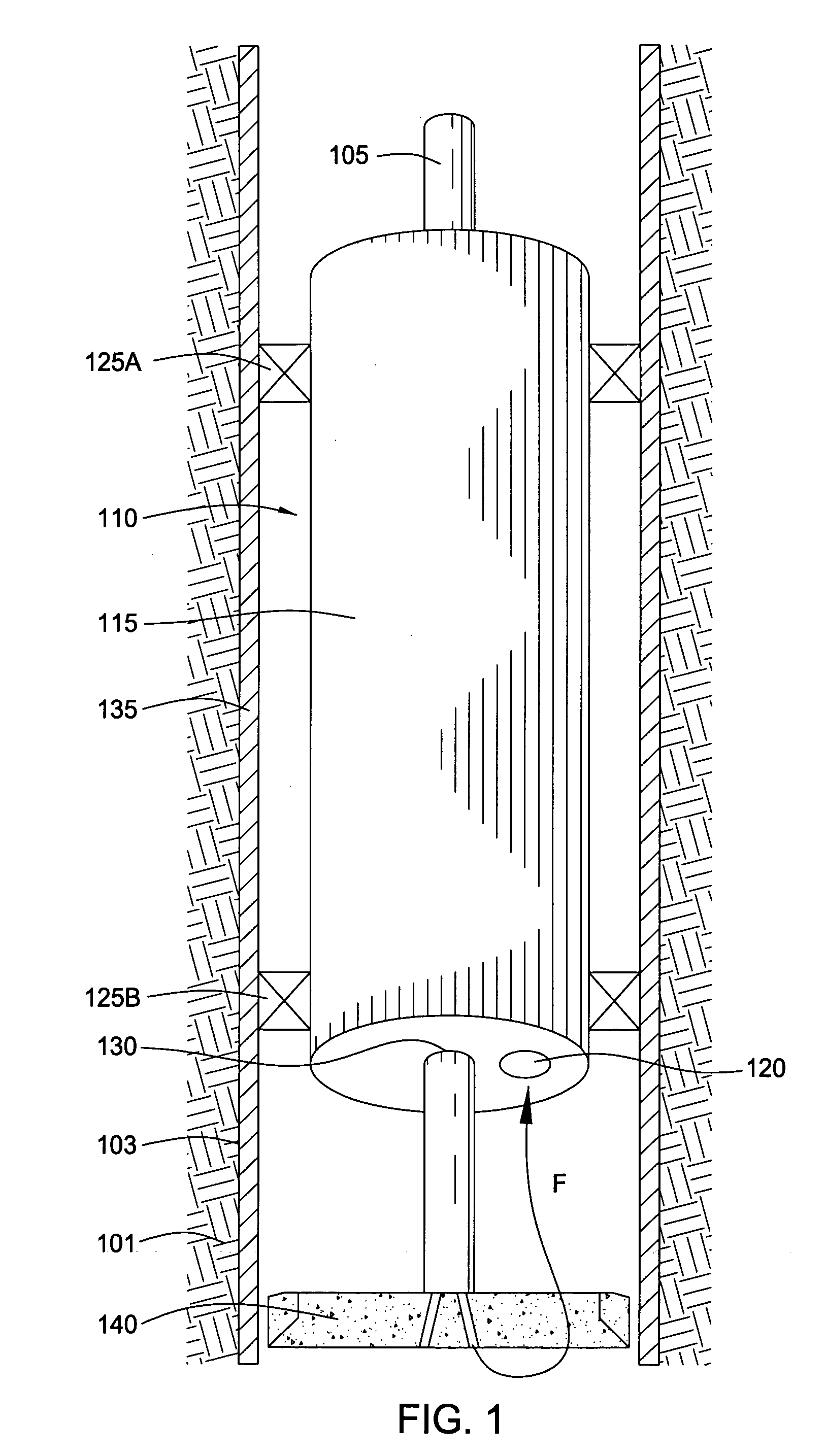

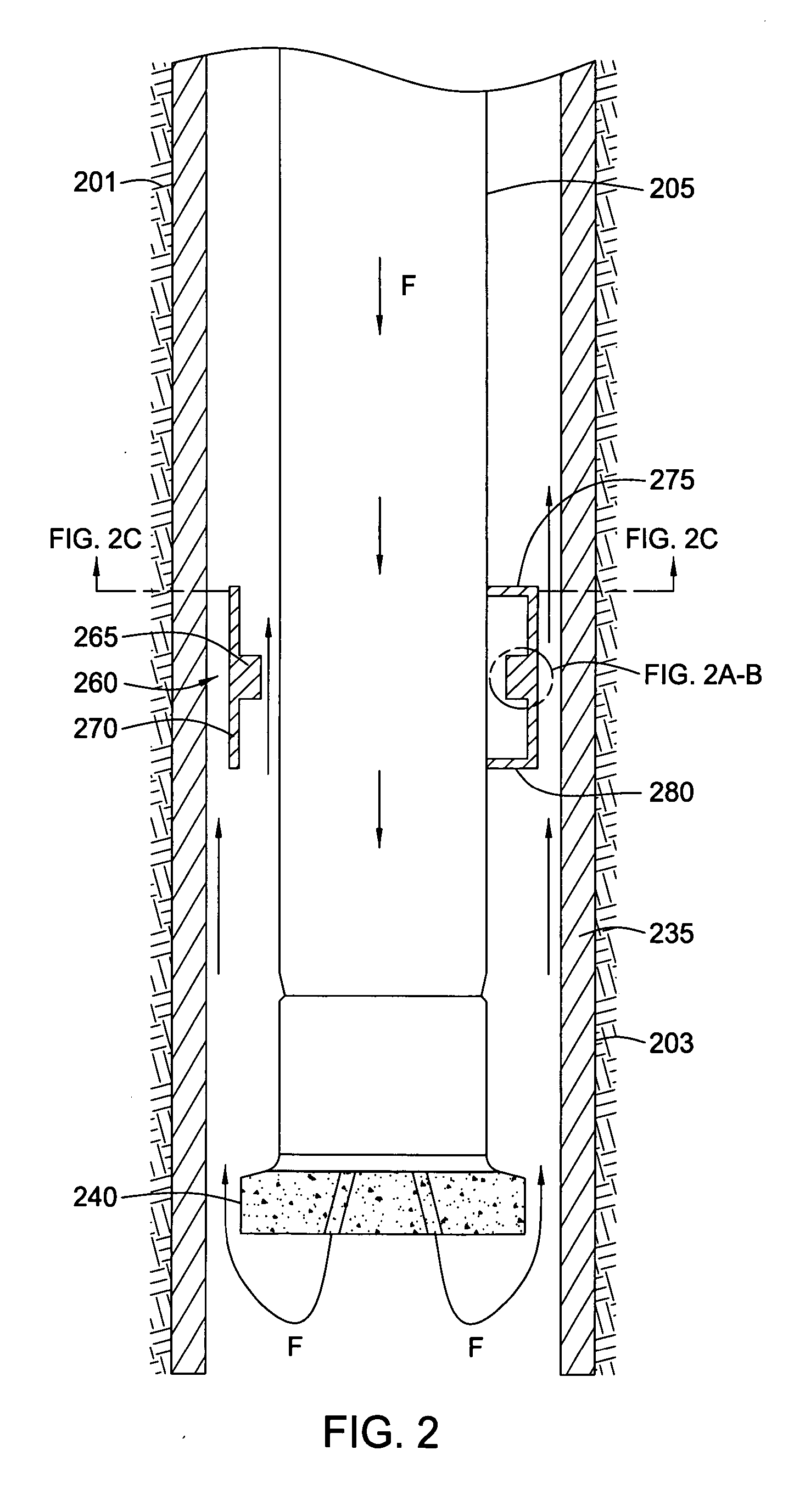

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

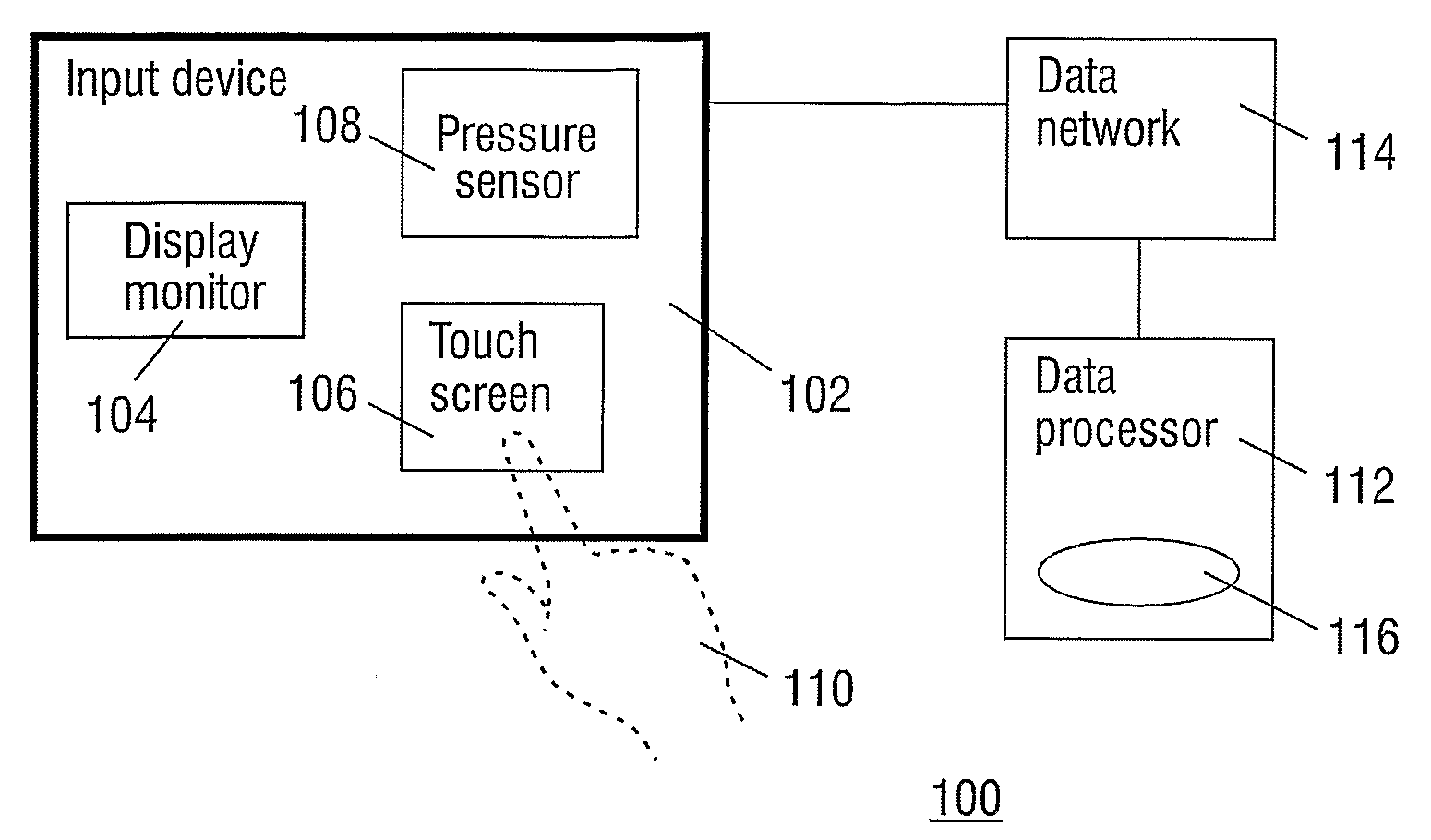

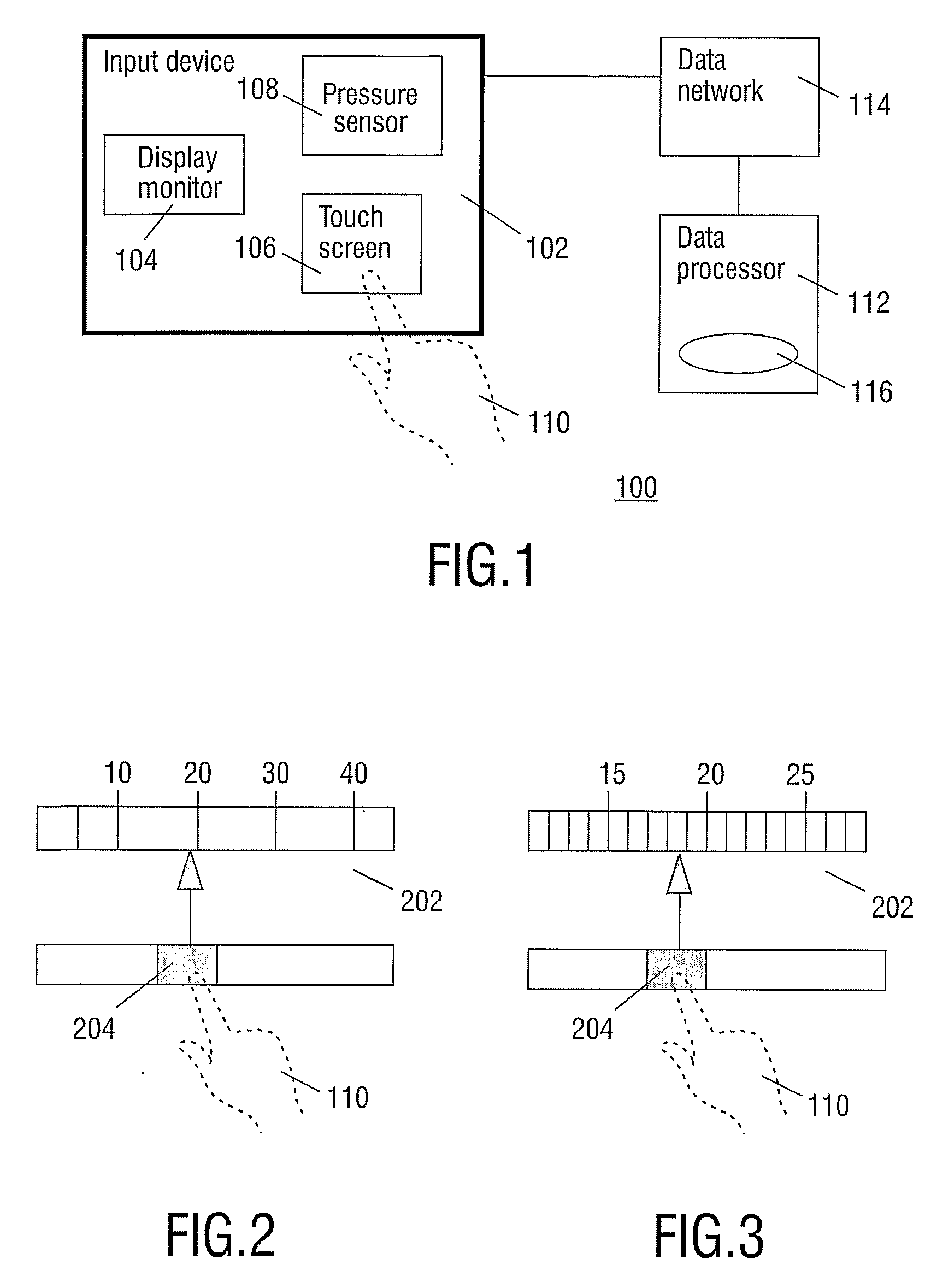

Pressure-Controlled Navigating in a Touch Screen

InactiveUS20080094367A1Improve user friendlinessUser-friendliness of the known systems can be further increasedInput/output processes for data processingRemote controlOperation mode

A remote control device has a display monitor for rendering an image and a touch screen for user interaction. The touch screen is pressure-sensitive. The device has an operational mode wherein the image is being scaled dependent on a value of the pressure registered by the touch screen.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

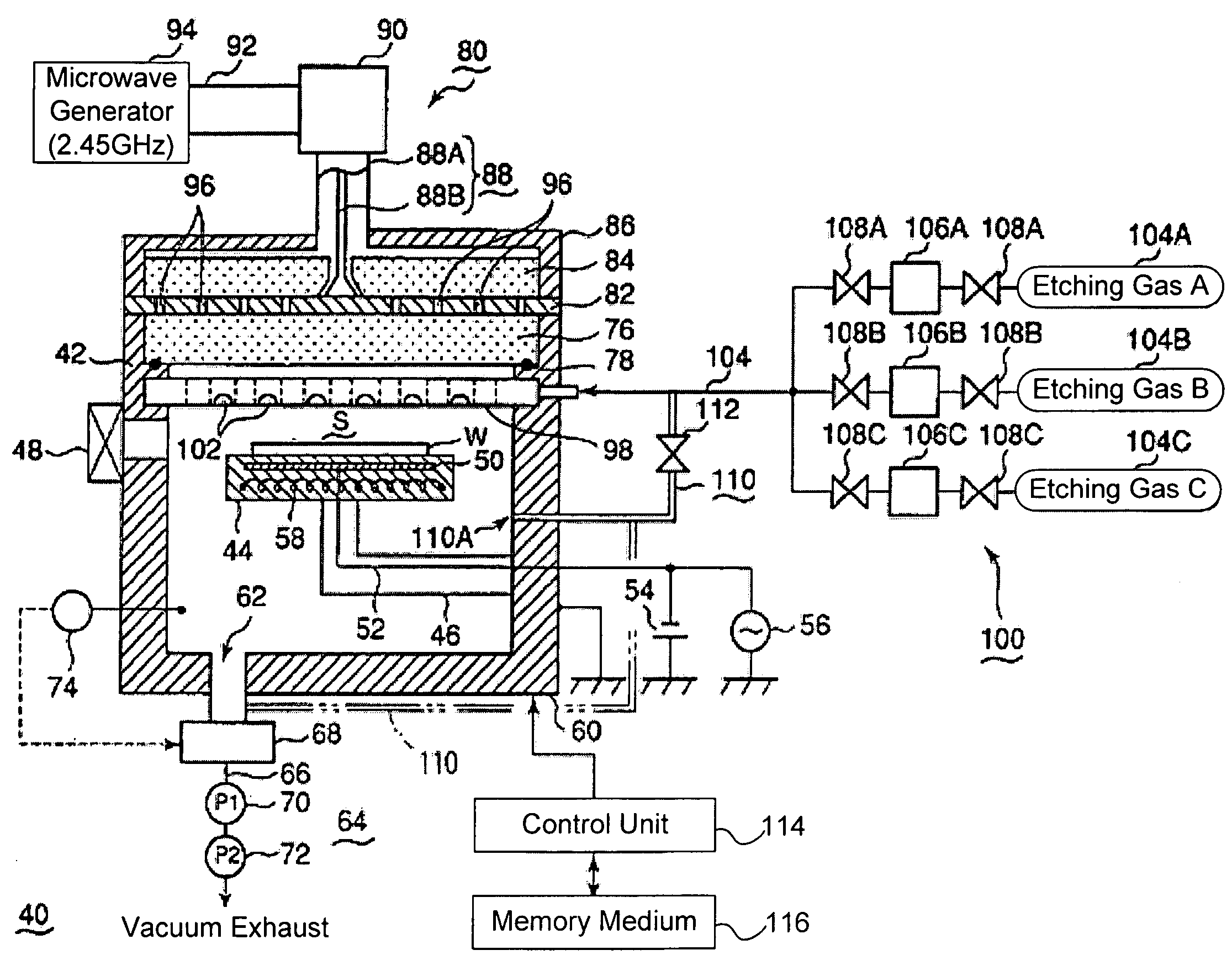

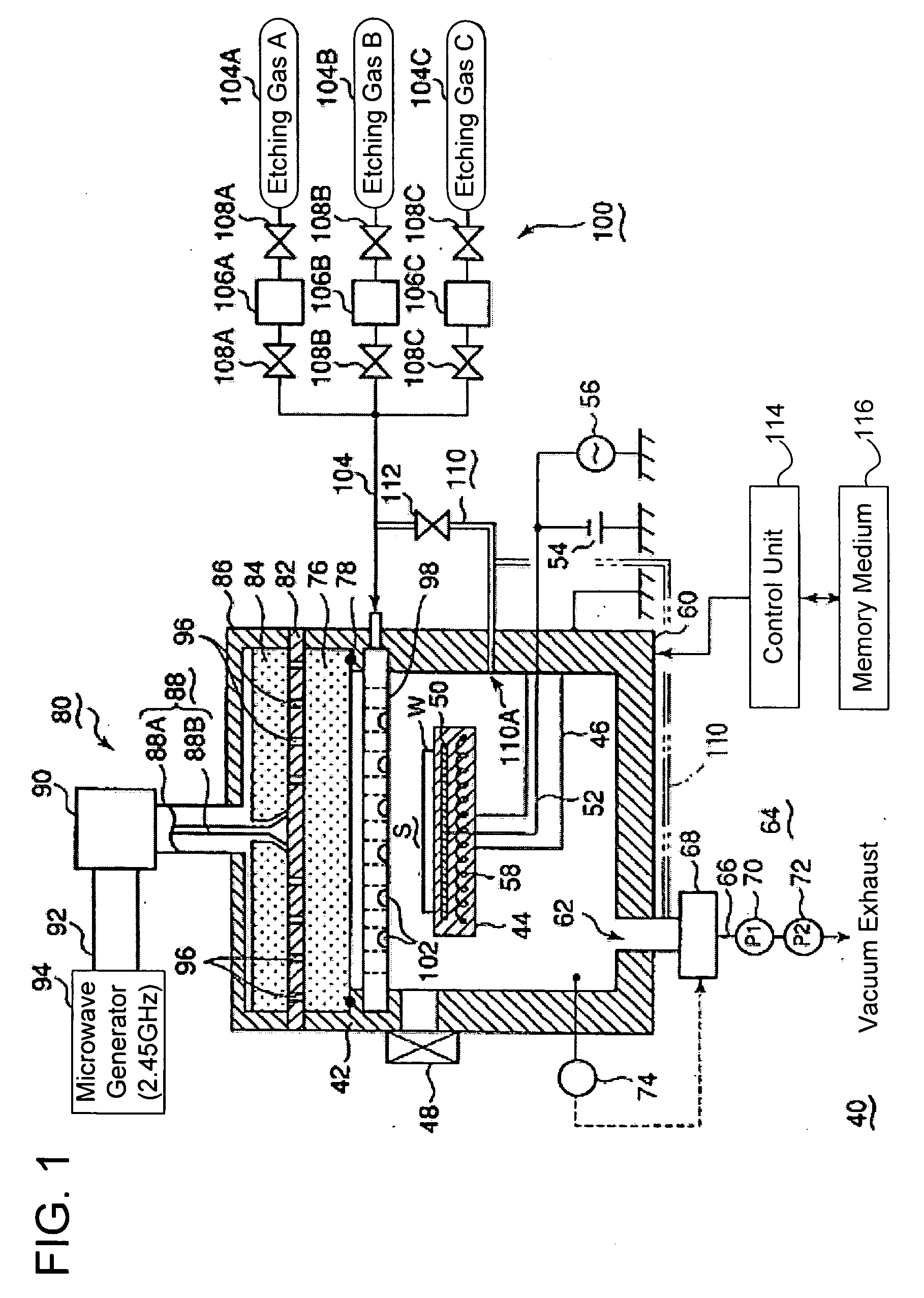

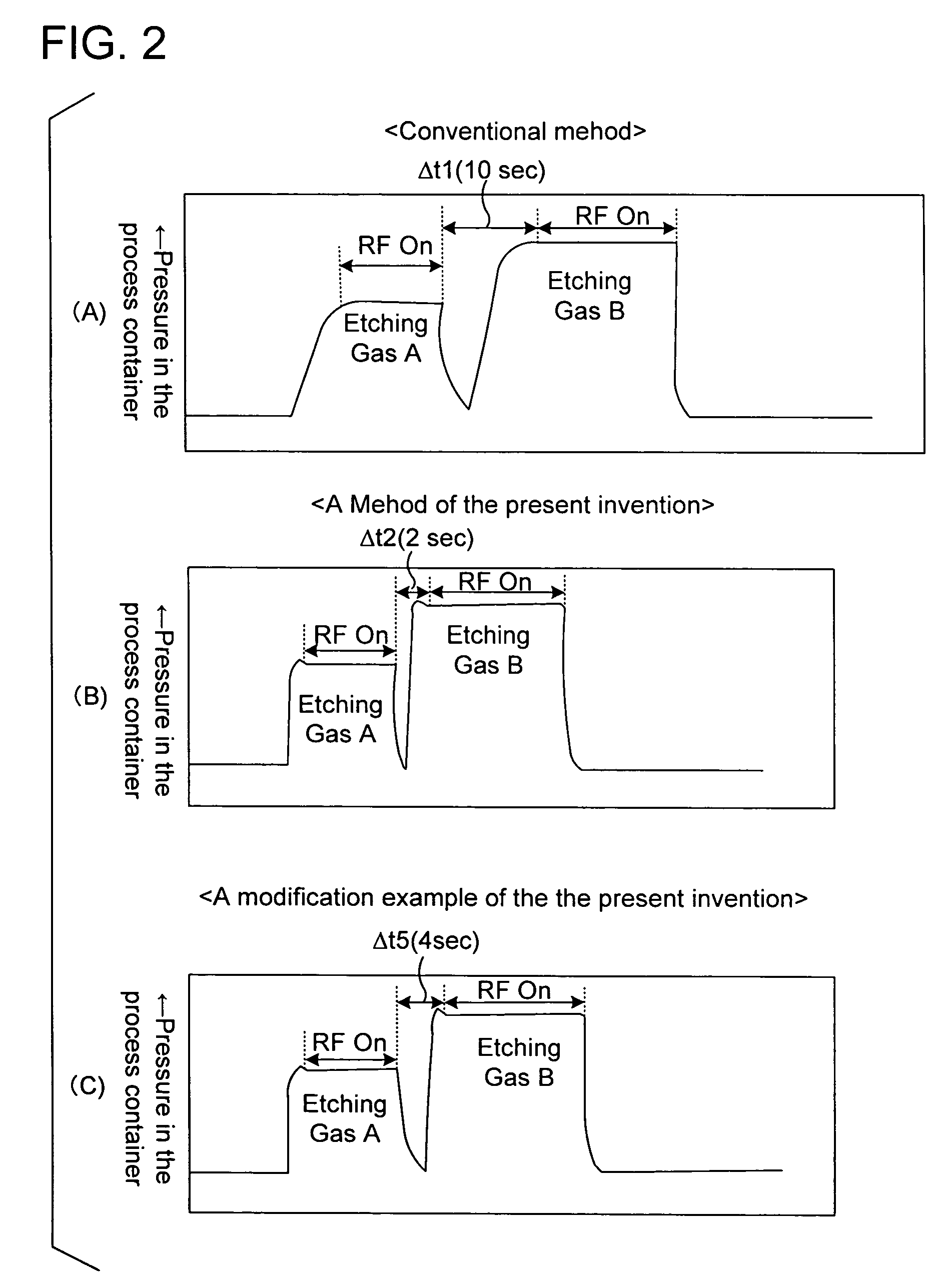

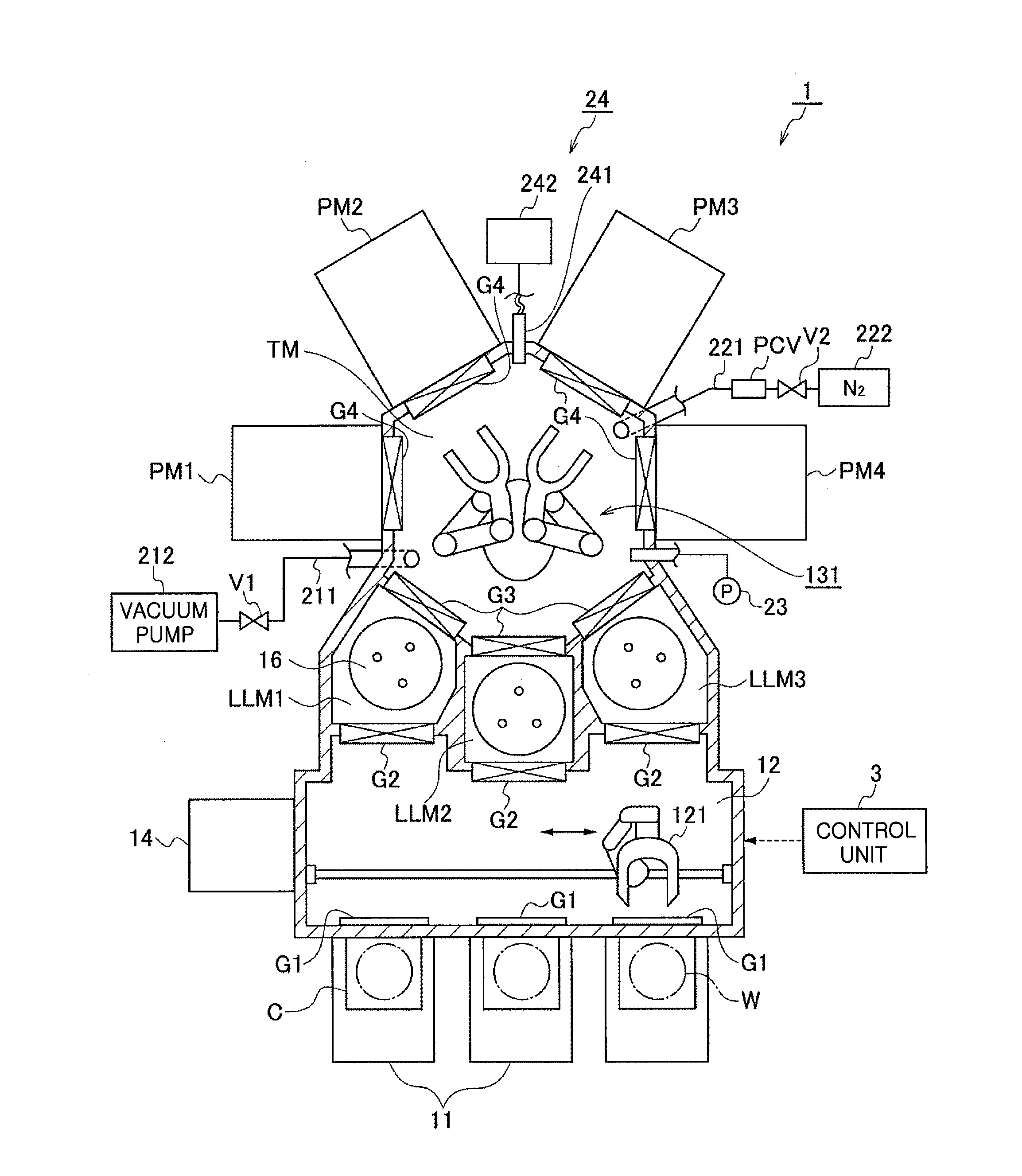

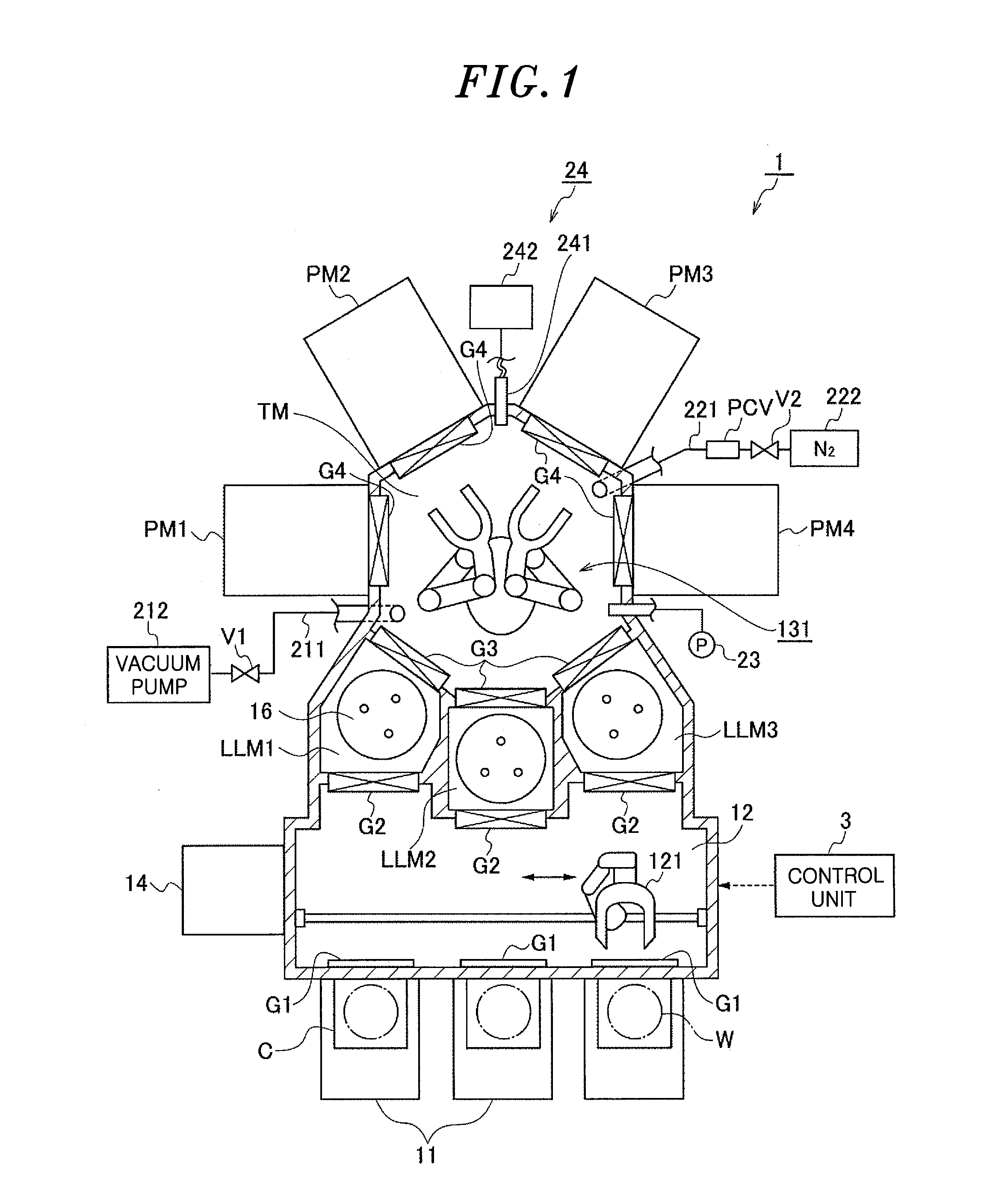

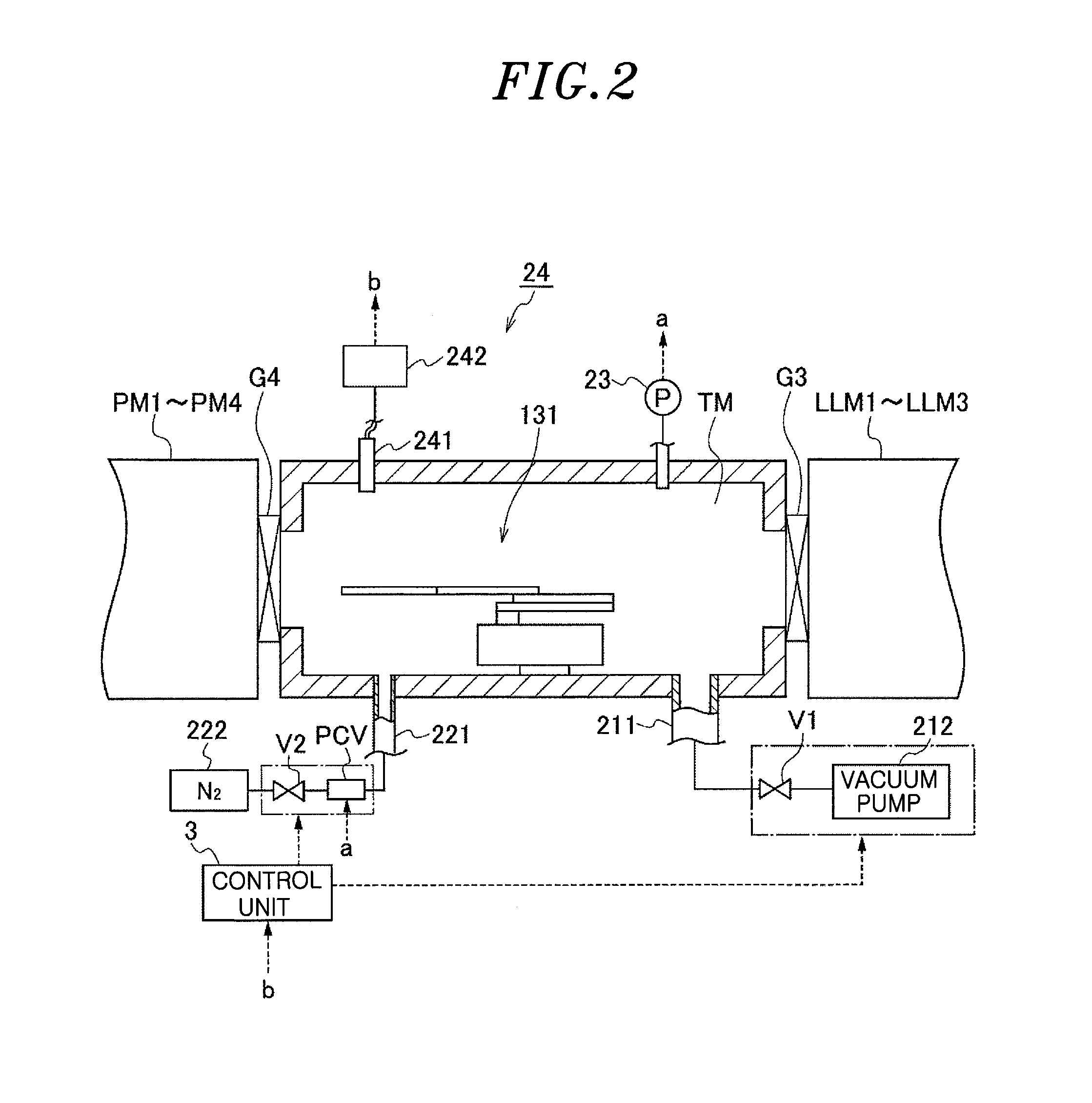

Processing Apparatus and Processing Method

ActiveUS20090053900A1Stable and fastAddressing slow performanceLiquid surface applicatorsElectric discharge tubesProduct gasEngineering

A processing apparatus includes a process container having a placing table for placing a processing object, an exhaust system having vacuum pumps and a pressure control valve for exhausting atmosphere in the process container. A gas injection unit having a gas ejection hole is provided in the process container, as well as a gas supplying unit for supplying a process gas to the gas injection unit. The entire process apparatus is controlled by a controlling unit. The control unit controls the exhaust system and the gas supplying unit. When starting a predetermined process, the process gas at a flow rate greater than a prescribed flow rate is supplied for a short time while exhausting the atmosphere in the process container by the exhaust system, and then the process gas at a prescribed flow rate is supplied.

Owner:TOKYO ELECTRON LTD

Dynamic annular pressure control apparatus and method

InactiveUS6904981B2Increased annular pressureBuildFluid removalFlushingPressure controlled ventilationPressure control

A system and method for controlling formation pressures during drilling of a subterranean formation utilizing a selectively fluid backpressure system in which fluid is pumped down the drilling fluid return system in response to detected borehole pressures. A pressure monitoring system is further provided to monitor detected borehole pressures, model expected borehole pressures for further drilling and control the fluid backpressure system.

Owner:SHELL OIL CO

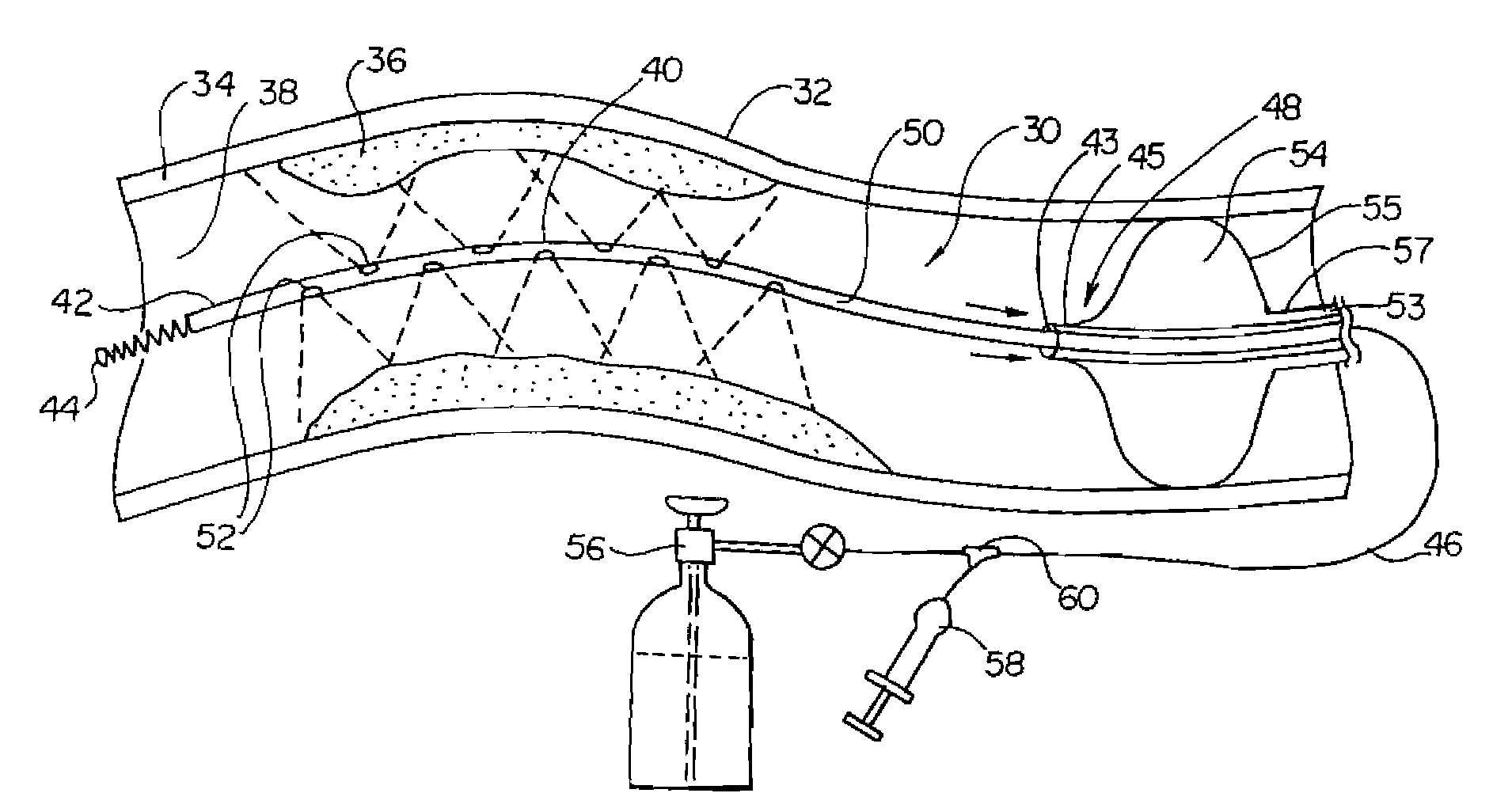

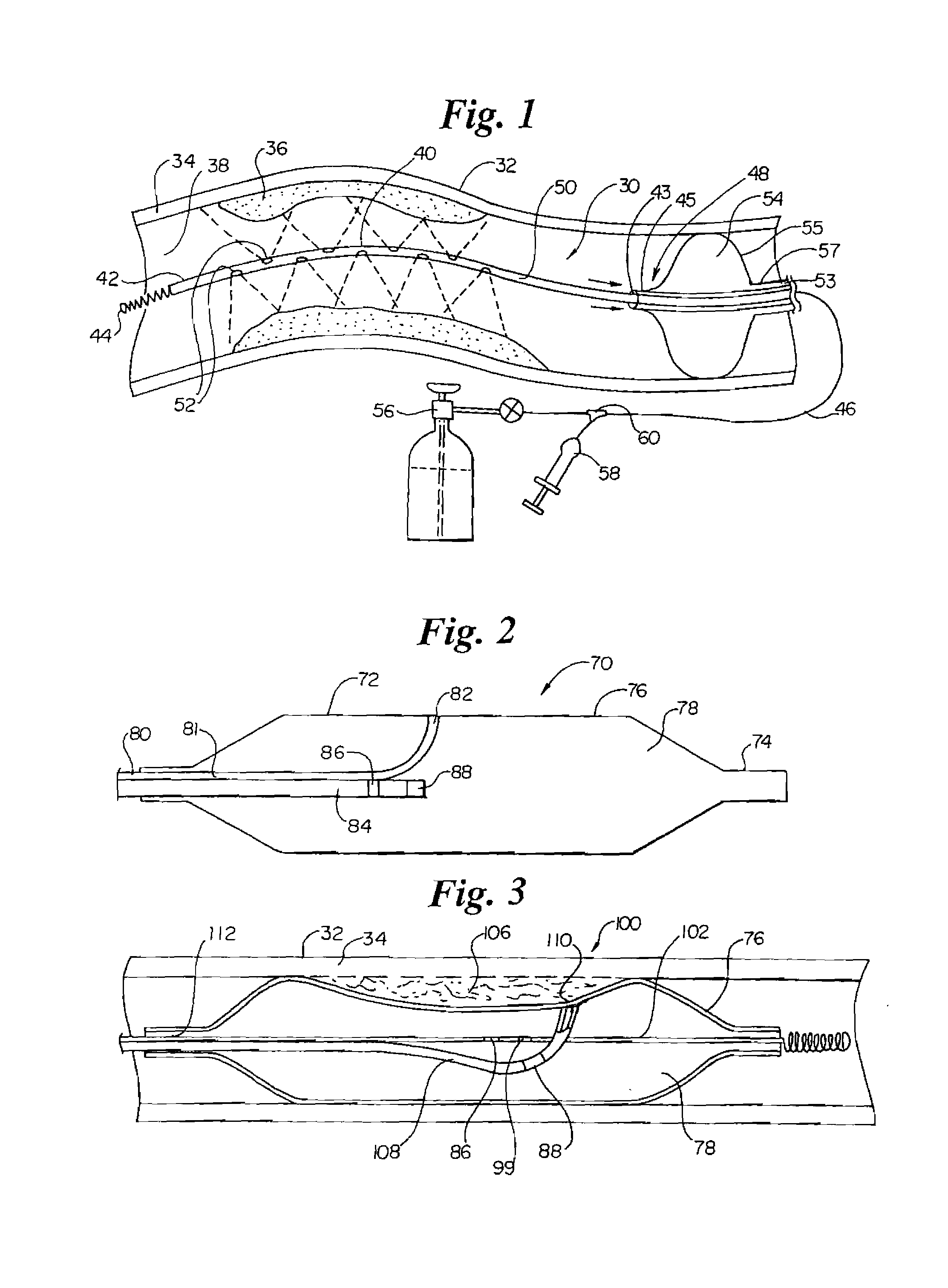

Cryotreatment device and method

InactiveUS7220257B1Reduce adverse reactionsReduced responseStentsOther blood circulation devicesCoronary artery angioplastyPercent Diameter Stenosis

Devices and methods for cooling vessel walls to inhibit restenosis in conjunction with medical procedures such as coronary artery angioplasty. Stenosed vessel walls can be cooled prior to angioplasty, after angioplasty, or both. The invention is believed to inhibit restenosis through cooling to a temperature near freezing, preferably without causing substantial vessel wall cell death. One catheter device includes a distal tube region having coolant delivery holes radially and longitudinally distributed along the distal region. In some devices, holes spray coolant directly onto the vessel walls, with the coolant absorbed into the blood stream. In other embodiments, a balloon or envelope is interposed between the coolant and the vessel walls and the coolant returned out of the catheter through a coolant return lumen. Some direct spray devices include an occlusion device to restrict blood flow past the region being cooled. Pressure, temperature, and ultrasonic probes are included in some cooling catheters. Pressure control valves are included in some devices to regulate balloon interior pressure within acceptable limits. In applications using liquid carbon dioxide as coolant, the balloon interior pressure can be maintained above the triple point of carbon dioxide to inhibit dry ice formation. Some cooling catheters are coiled perfusion catheters supporting longer cooling periods by allowing perfusing blood flow simultaneously with vessel wall cooling. One coiled catheter is biased to assume a coiled shape when unconstrained and can be introduced into the body in a relatively straight shape, having a stiffening wire inserted through the coil strands.

Owner:BOSTON SCI SCIMED INC

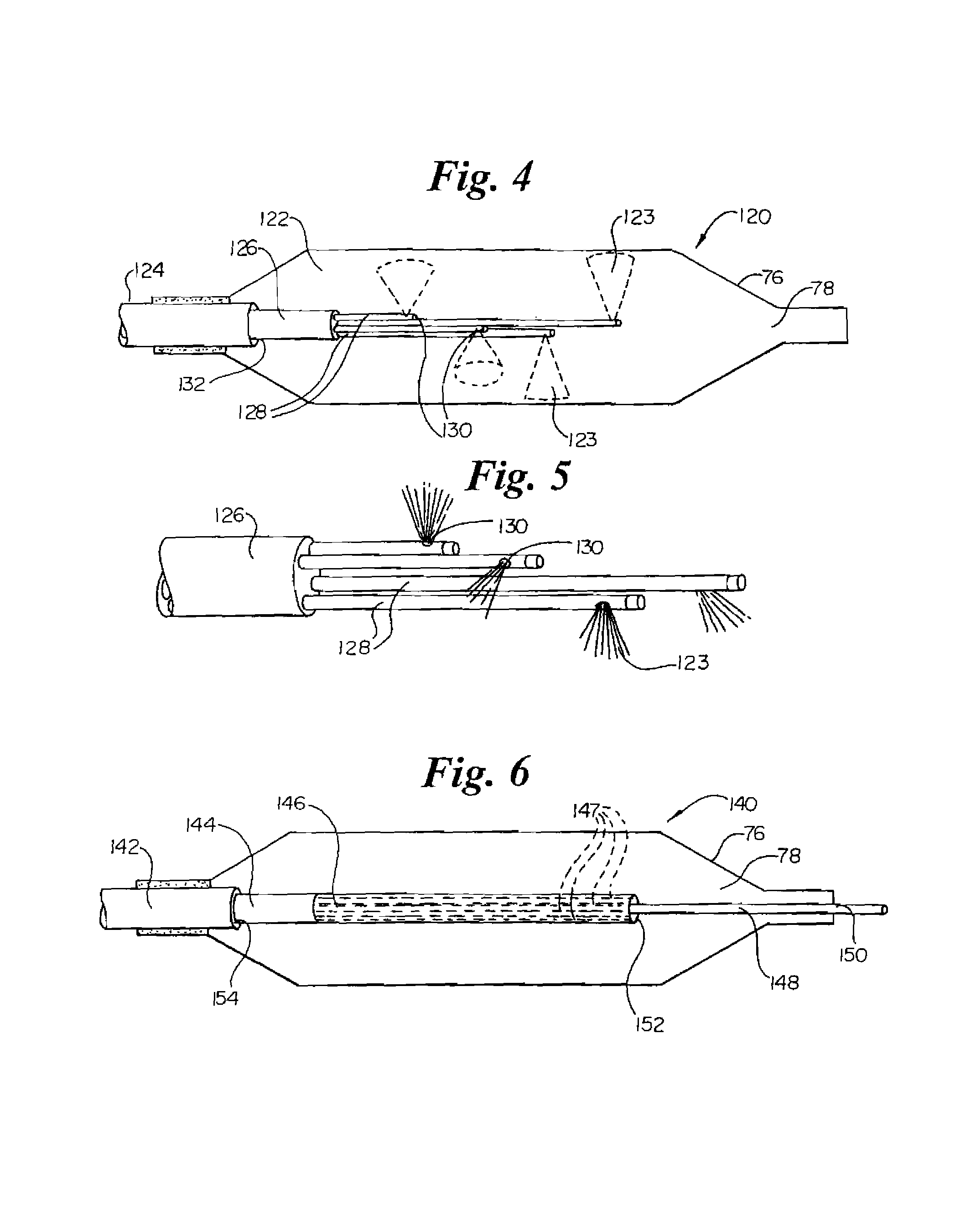

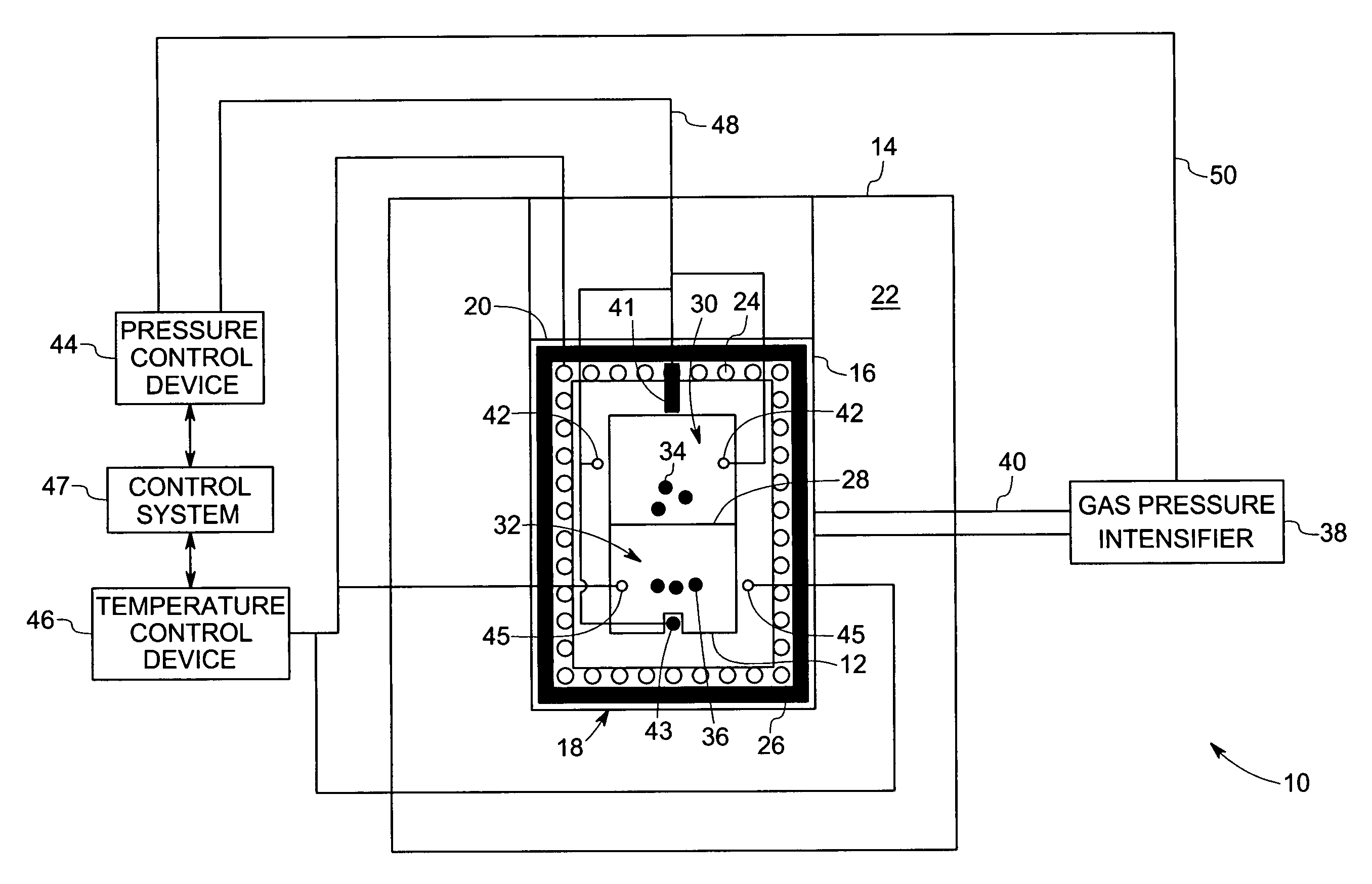

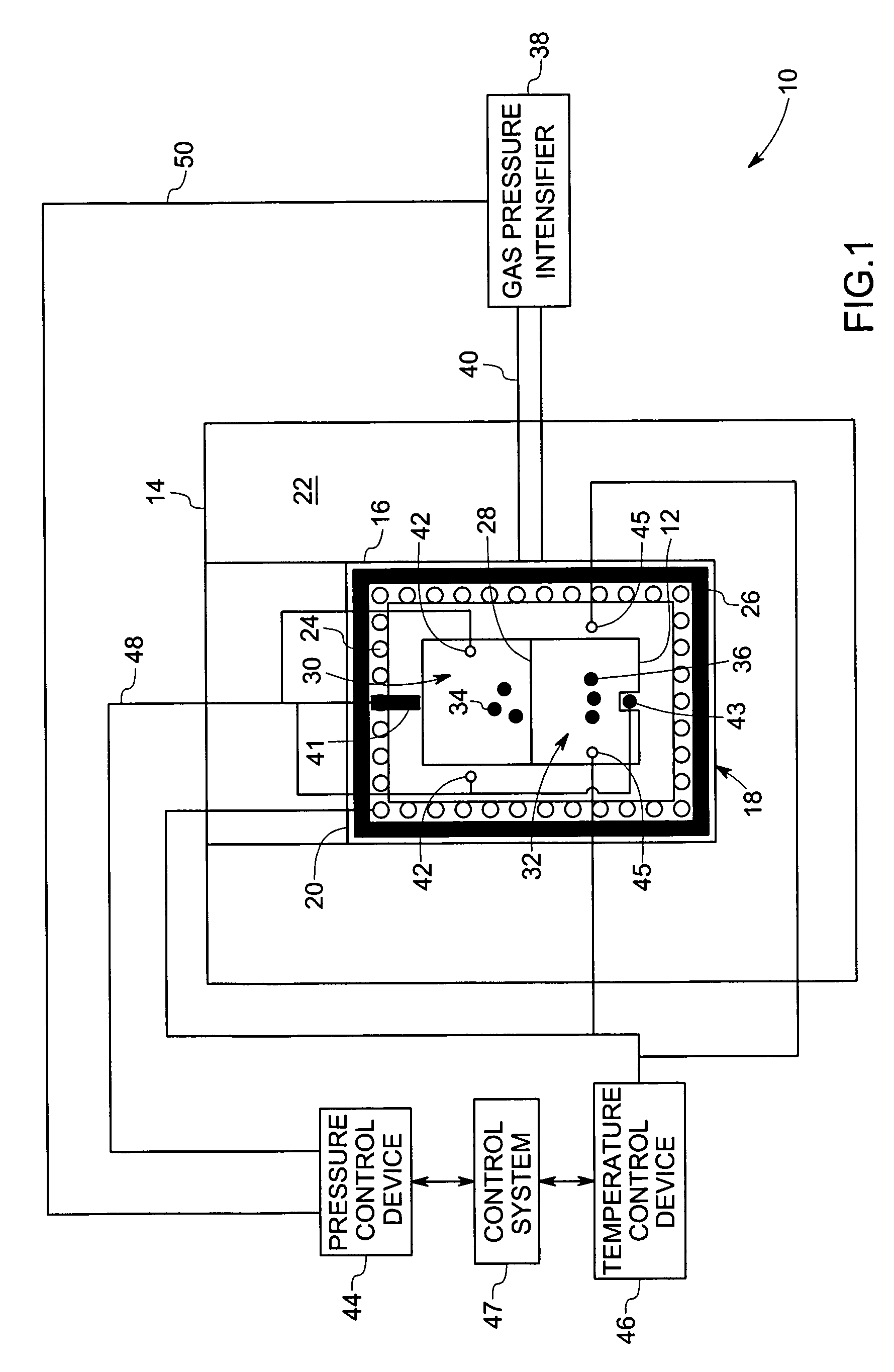

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS20060177362A1After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

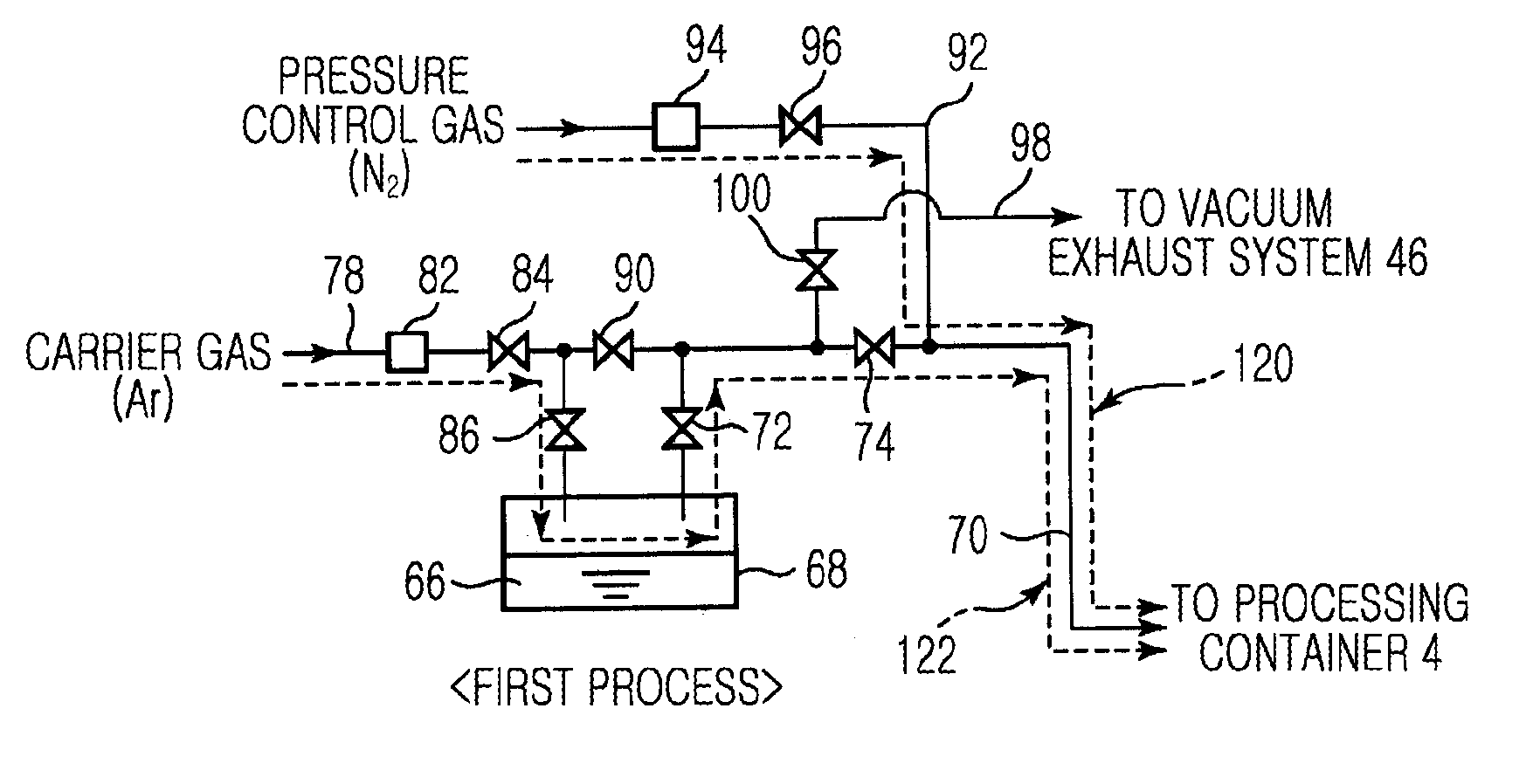

Gas supply apparatus, thermal treatment apparatus, gas supply method, and thermal treatment method

InactiveUS20120288625A1Avoid it happening againPressure differentialCheck valvesSemiconductor/solid-state device manufacturingProcess engineeringPressure controlled ventilation

A gas supply apparatus including a raw material gas supply system supplying a raw material gas inside a raw material storage tank into the processing container by the carrier gas, the gas supply apparatus includes: a carrier gas passage introducing the carrier gas into the raw material storage tank, a raw material gas passage connecting the raw material storage tank and the processing container to supply the carrier gas and the raw material gas; a pressure control gas passage being connected to the raw material gas passage to supply the pressure control gas; and a valve control unit controlling an opening / closing valve to perform for starting a supply of the pressure control gas into the processing container and simultaneously starting supply of the raw material gas into the processing container from the raw material storage tank, and stopping the supply of the pressure control gas.

Owner:TOKYO ELECTRON LTD

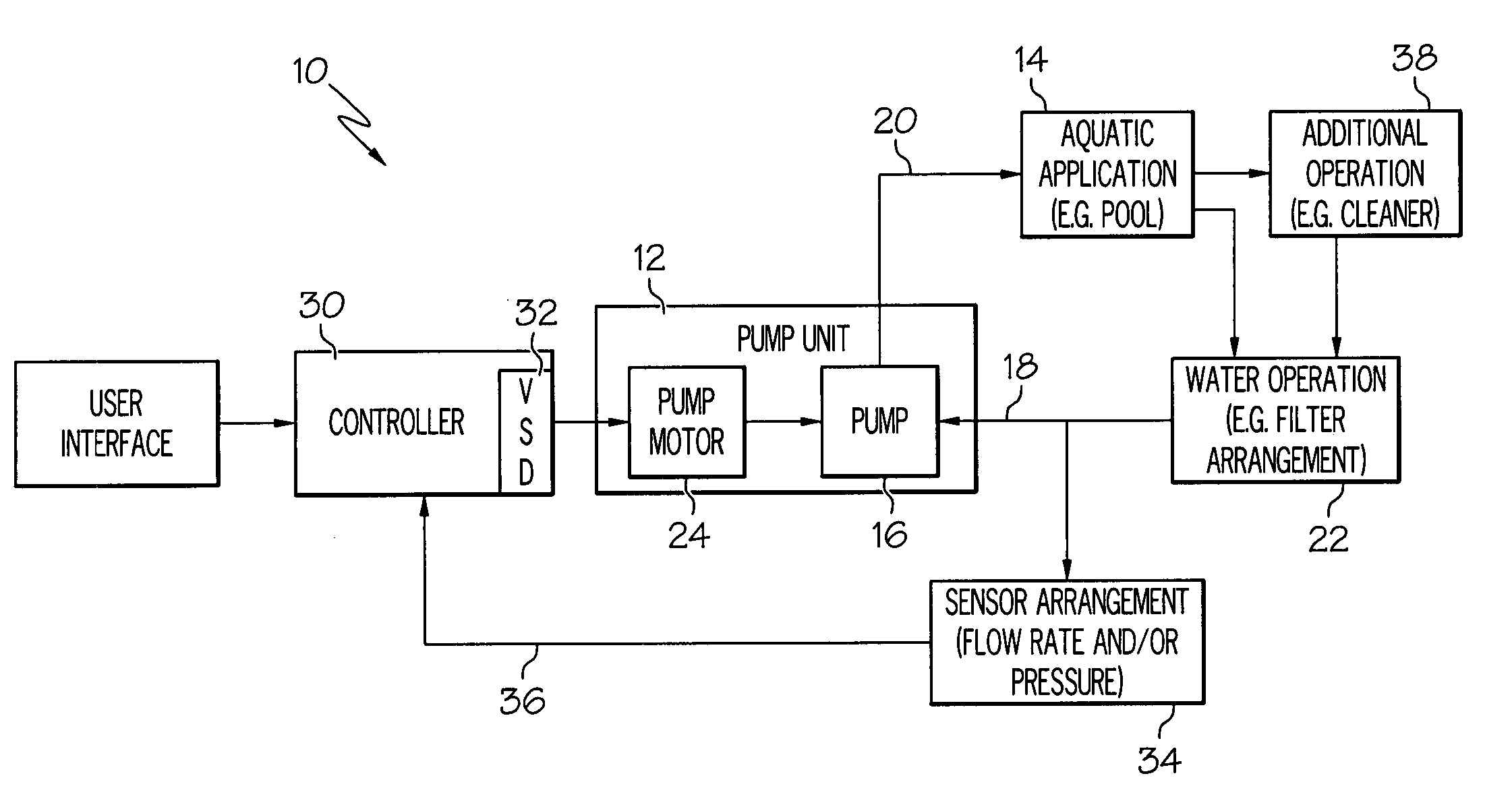

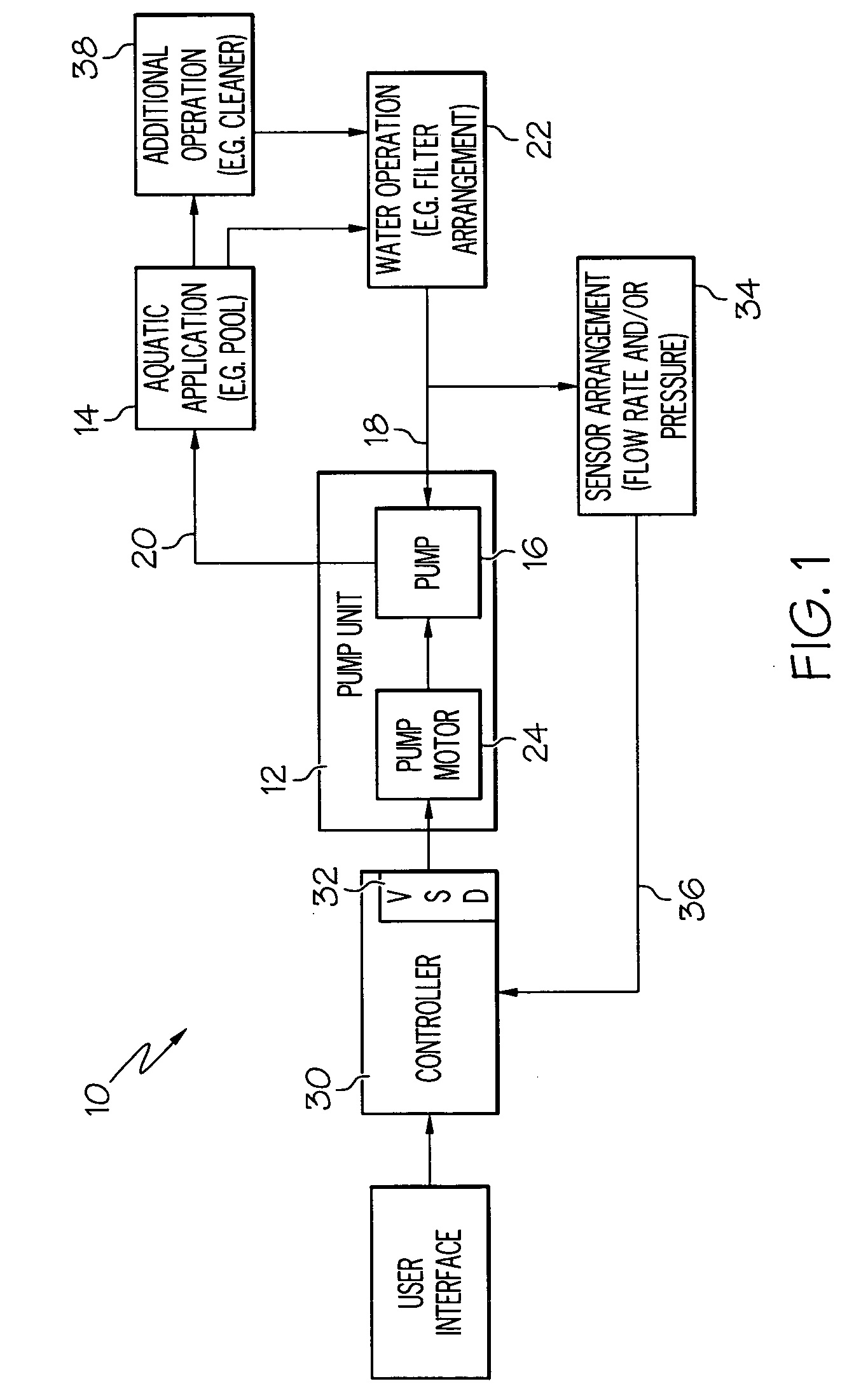

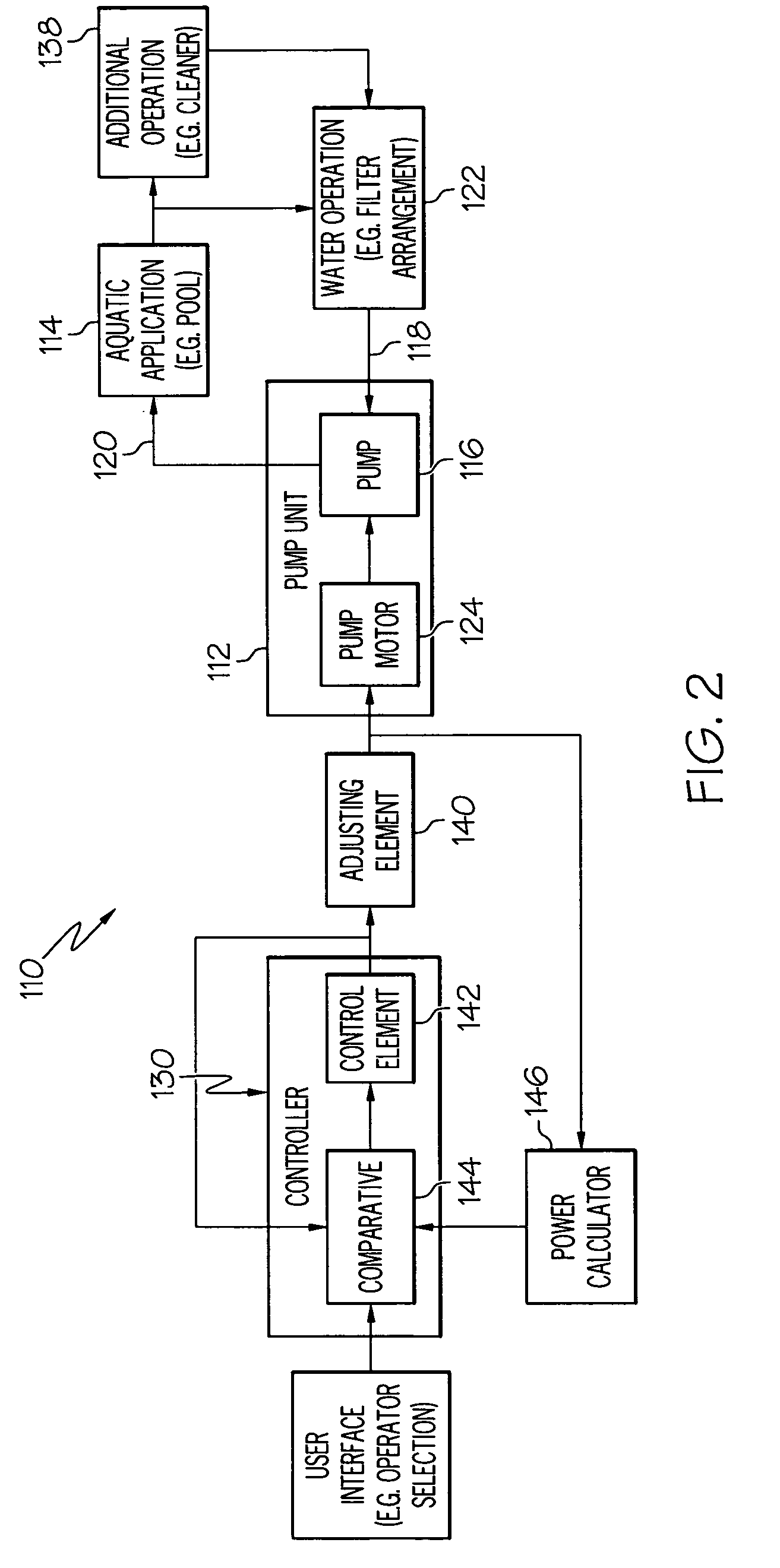

Control algorithm of variable speed pumping system

A pumping system includes a pump for moving water. In one aspect, this is in connection with performance of an operation. The system includes a variable speed motor operatively connected to drive the pump. A value indicative of flow rate of water is determined and the motor is controlled to adjust the flow rate indicative value toward a constant. A value indicative of flow pressure is determined and the motor is controlled to adjust the flow pressure indicative value toward a constant. A selection is made between flow rate control and flow pressure control. In another aspect, the pump is controlled to perform a first operation, and is operated to perform a second water operation. Control of operation of the pump to perform the first water operation is altered in response to operation of the pump to perform the second operation.

Owner:PENTAIR WATER POOL & SPA INC +1

System for surgical insufflation and gas recirculation

ActiveUS20090137943A1Avoid pressure lossAvoid lostCannulasInfusion syringesControl signalPressure controlled ventilation

A system for insufflation and recirculation of insufflation fluid in a surgical procedure. The system includes a control unit having a fluid pump, a supply conduit, a return fluid conduit and a pressure-controlled valve. The fluid pump is adapted and configured to circulate insufflation fluid through the system. The supply conduit is in fluid communication with an output of the fluid pump and configured and adapted for delivering pressurized insufflation fluid to an output port of the control unit. The return conduit is in fluid communication with an input of the fluid pump for delivering insufflation fluid to the fluid pump and is configured and adapted for returning insufflation fluid from an input port of the control unit. The pressure-controlled is in fluid communication with the supply conduit and the return conduit, and is adapted and configured to receive a control signal and respond to the control signal by opening, thereby fluidly connecting the supply conduit and the return conduit with one another.

Owner:SURGIQUEST

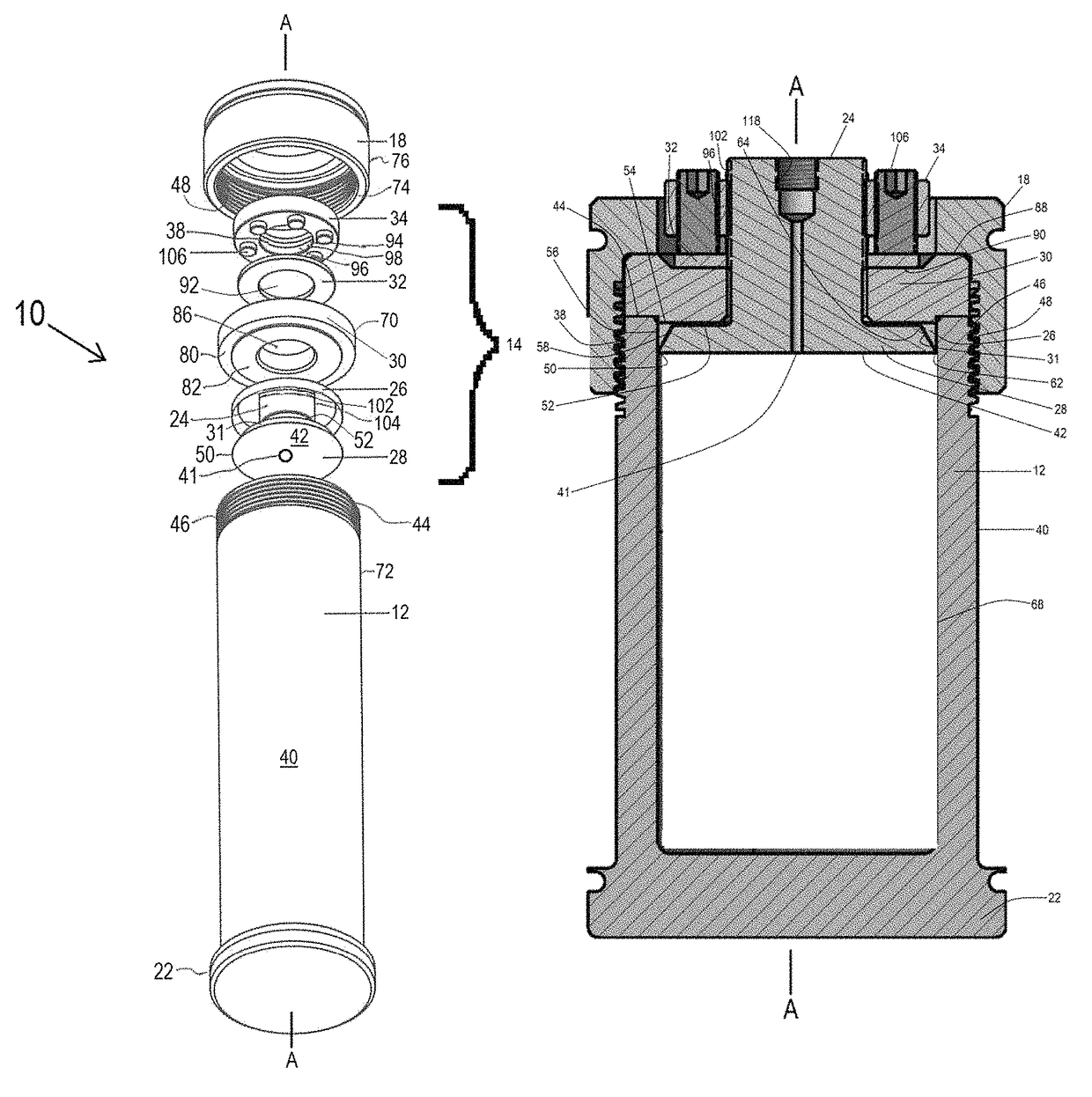

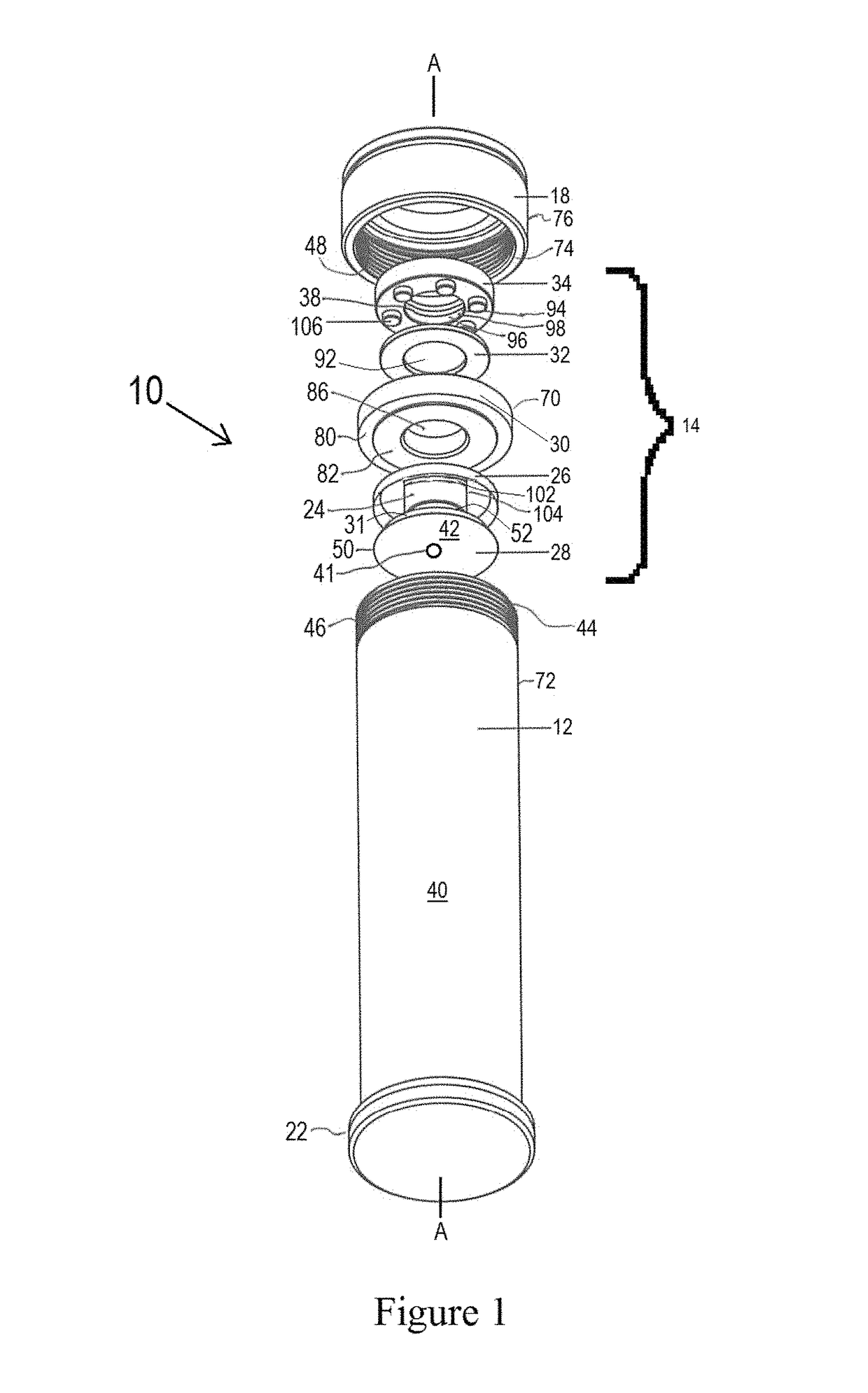

High temperature fluid sample aging cell

ActiveUS9784667B2Engine sealsWeather/light/corrosion resistanceAge methodPressure controlled ventilation

Owner:OFI TESTING EQUIP

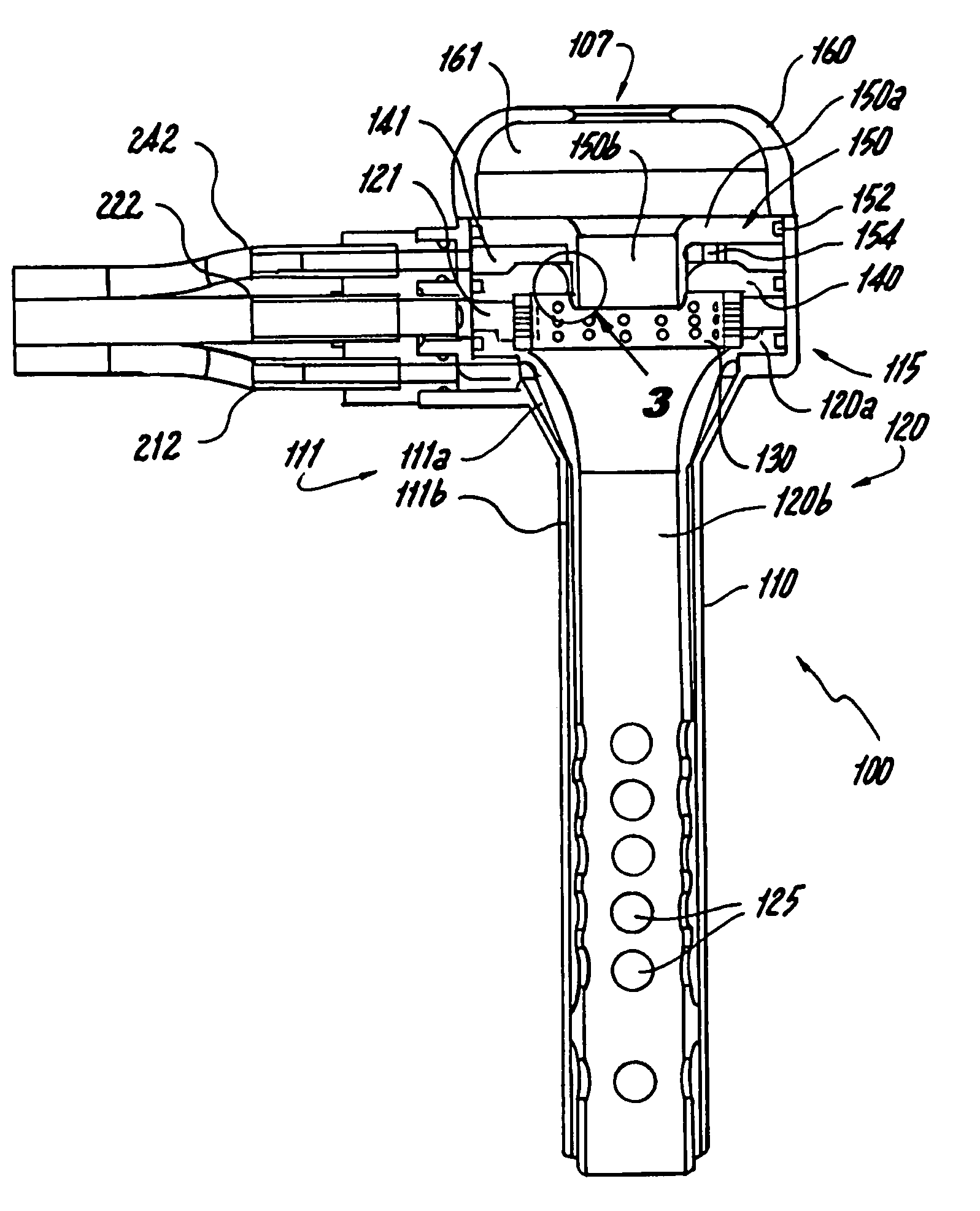

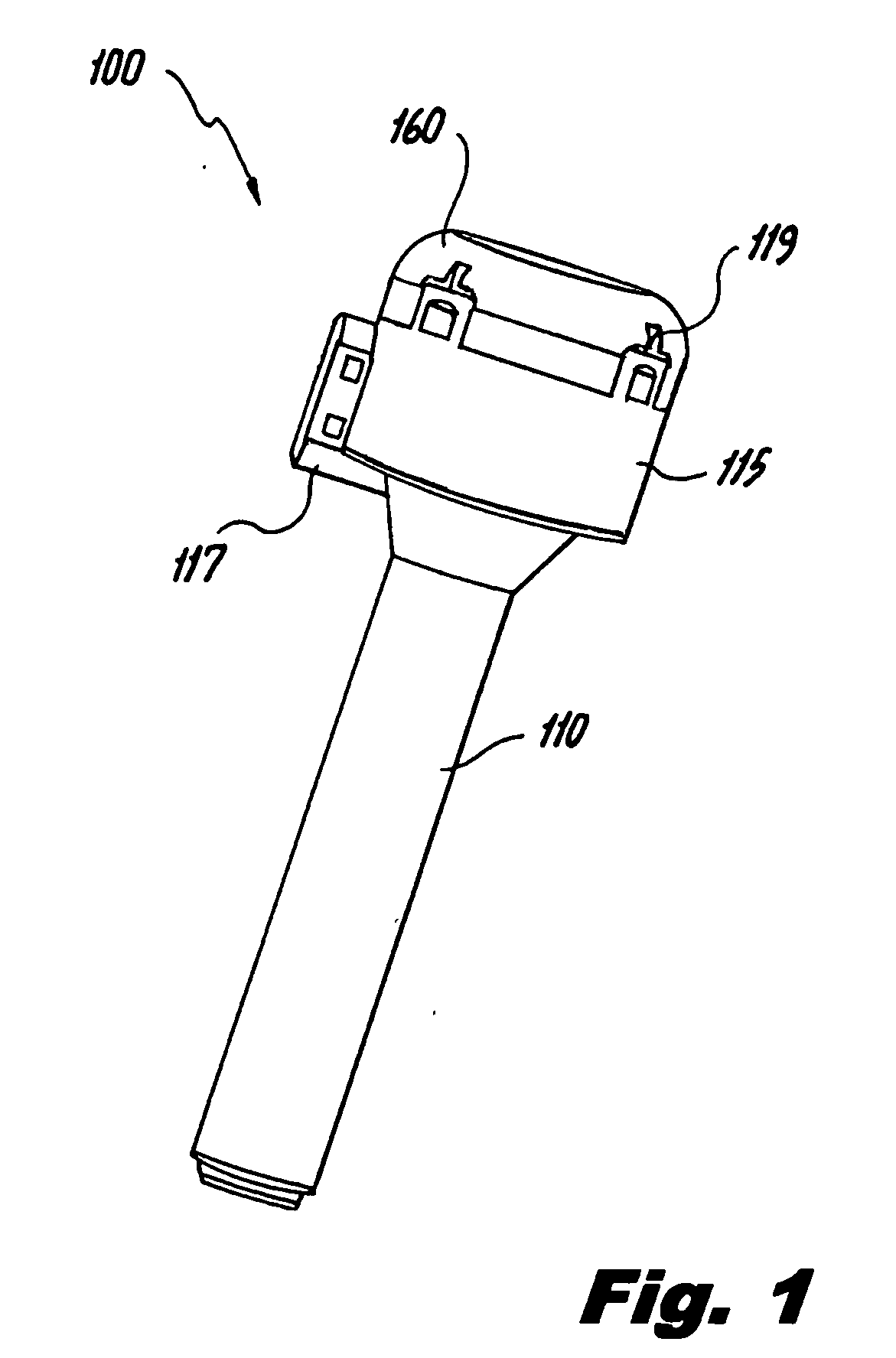

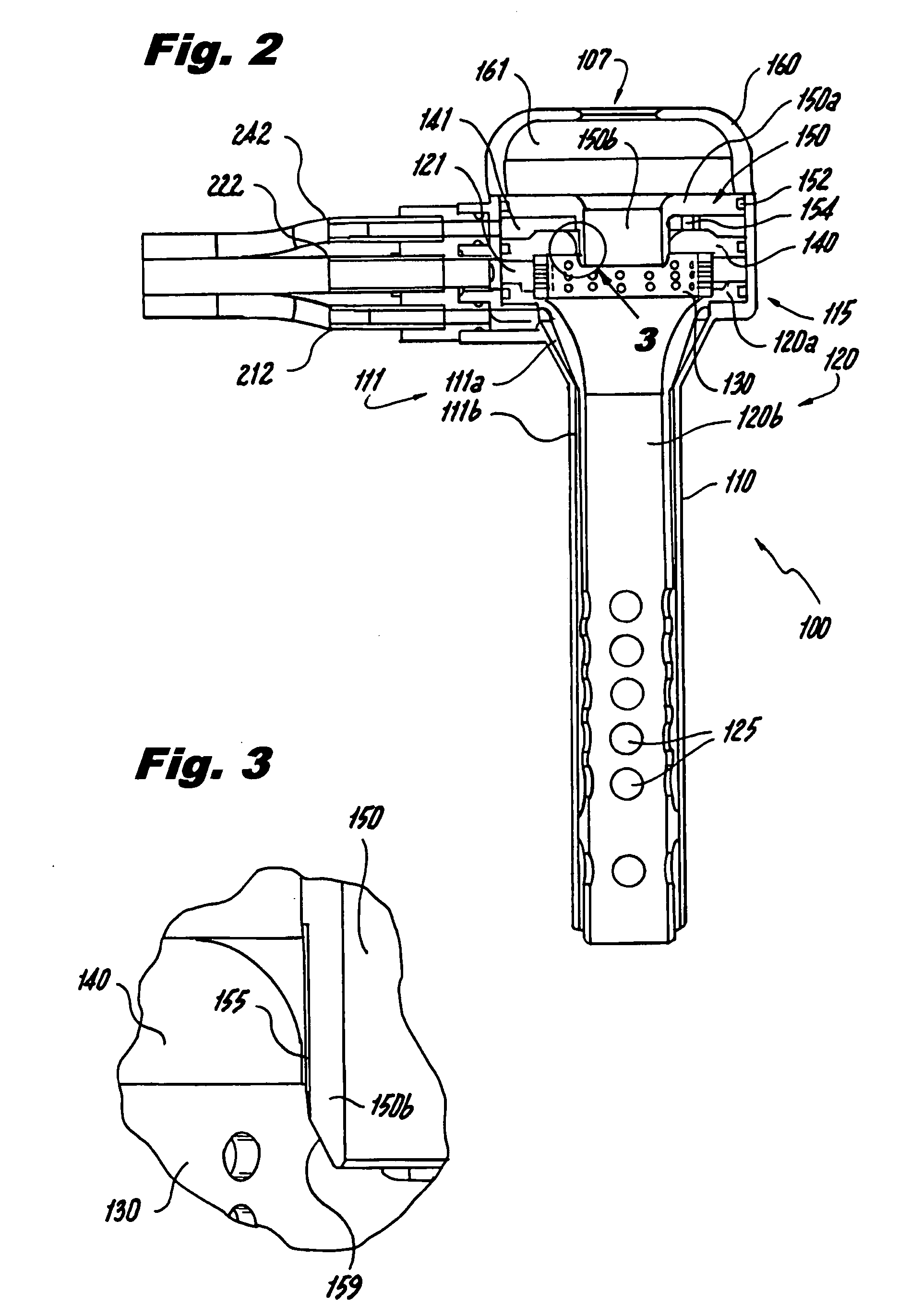

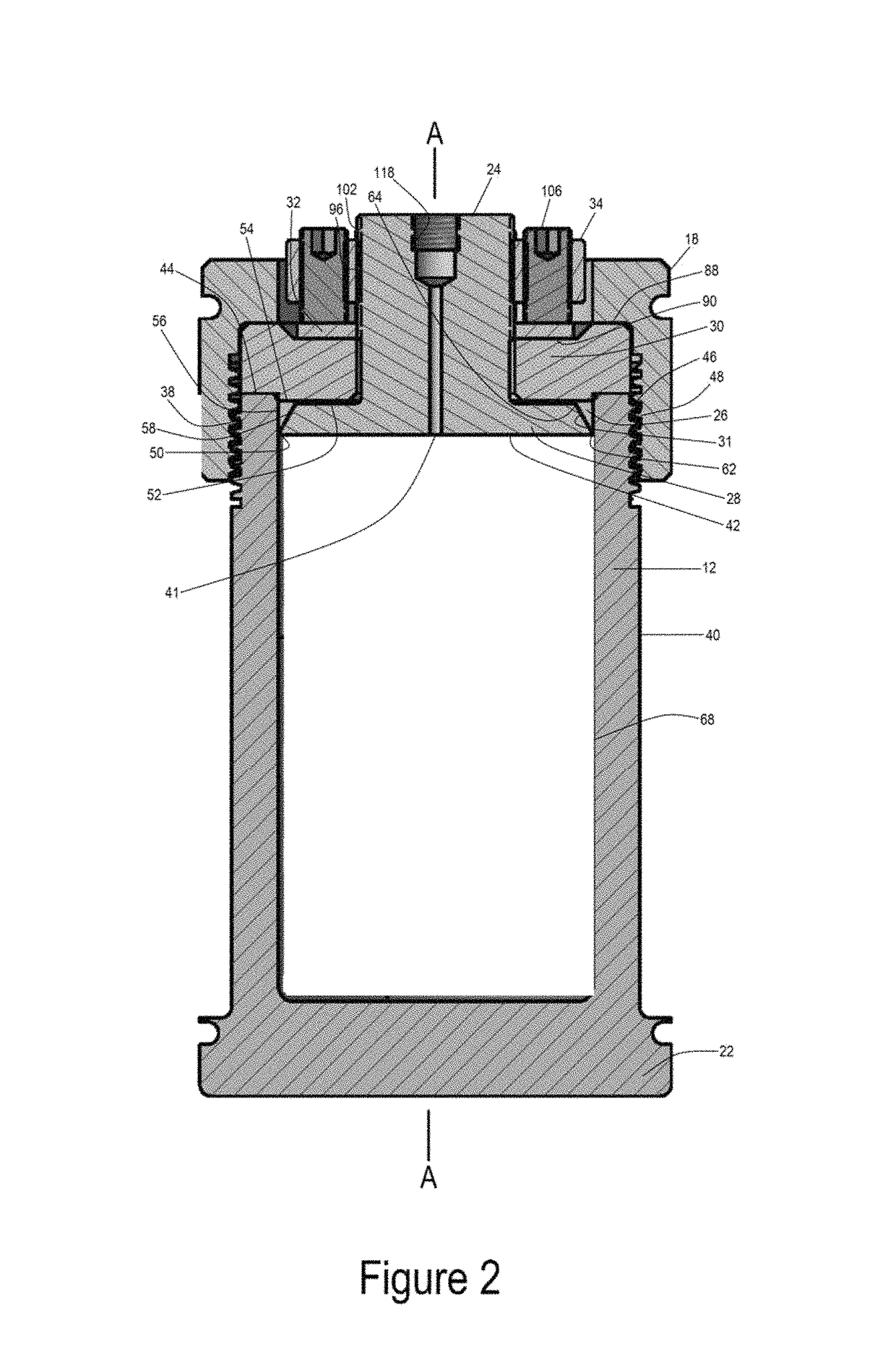

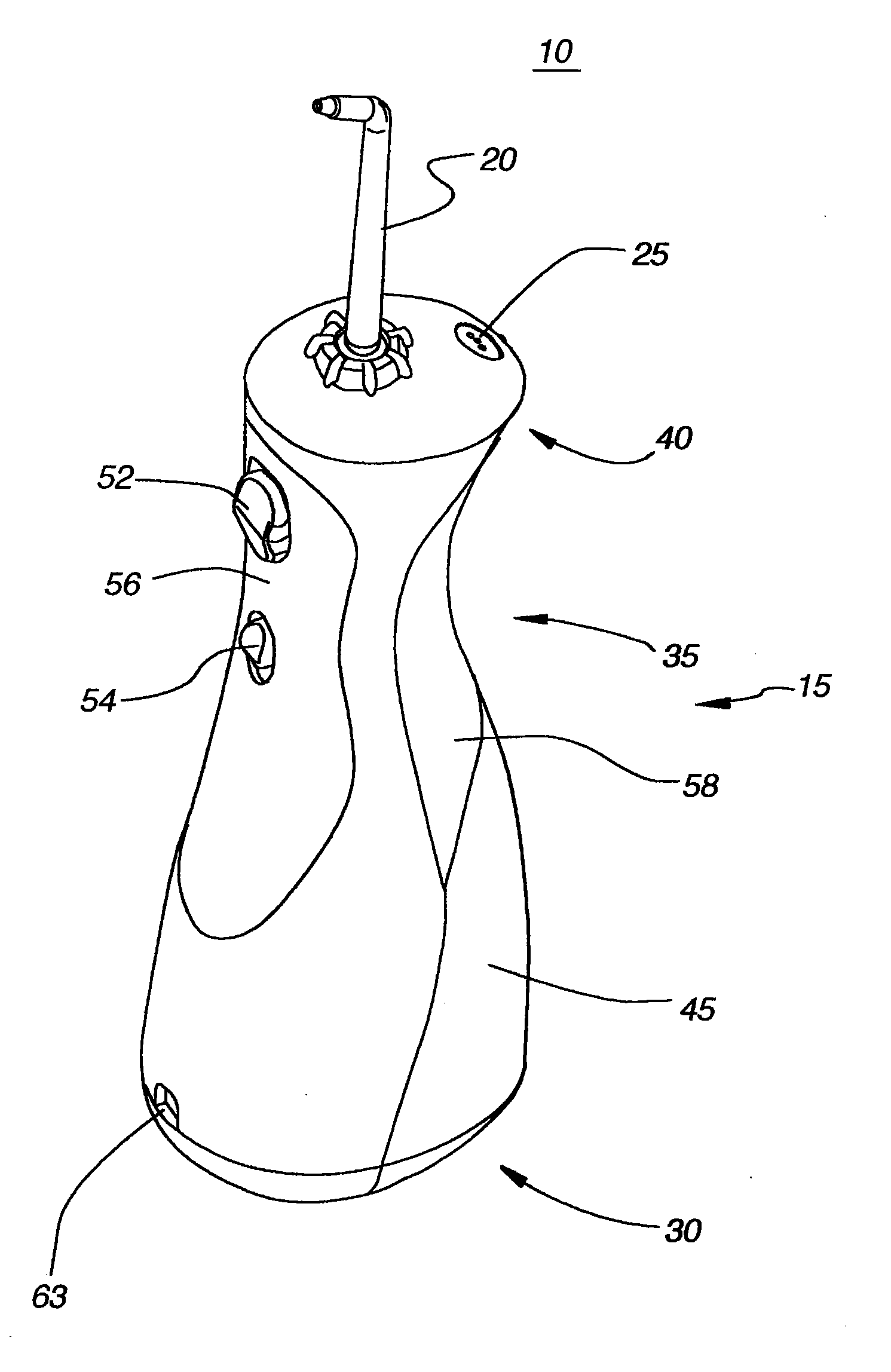

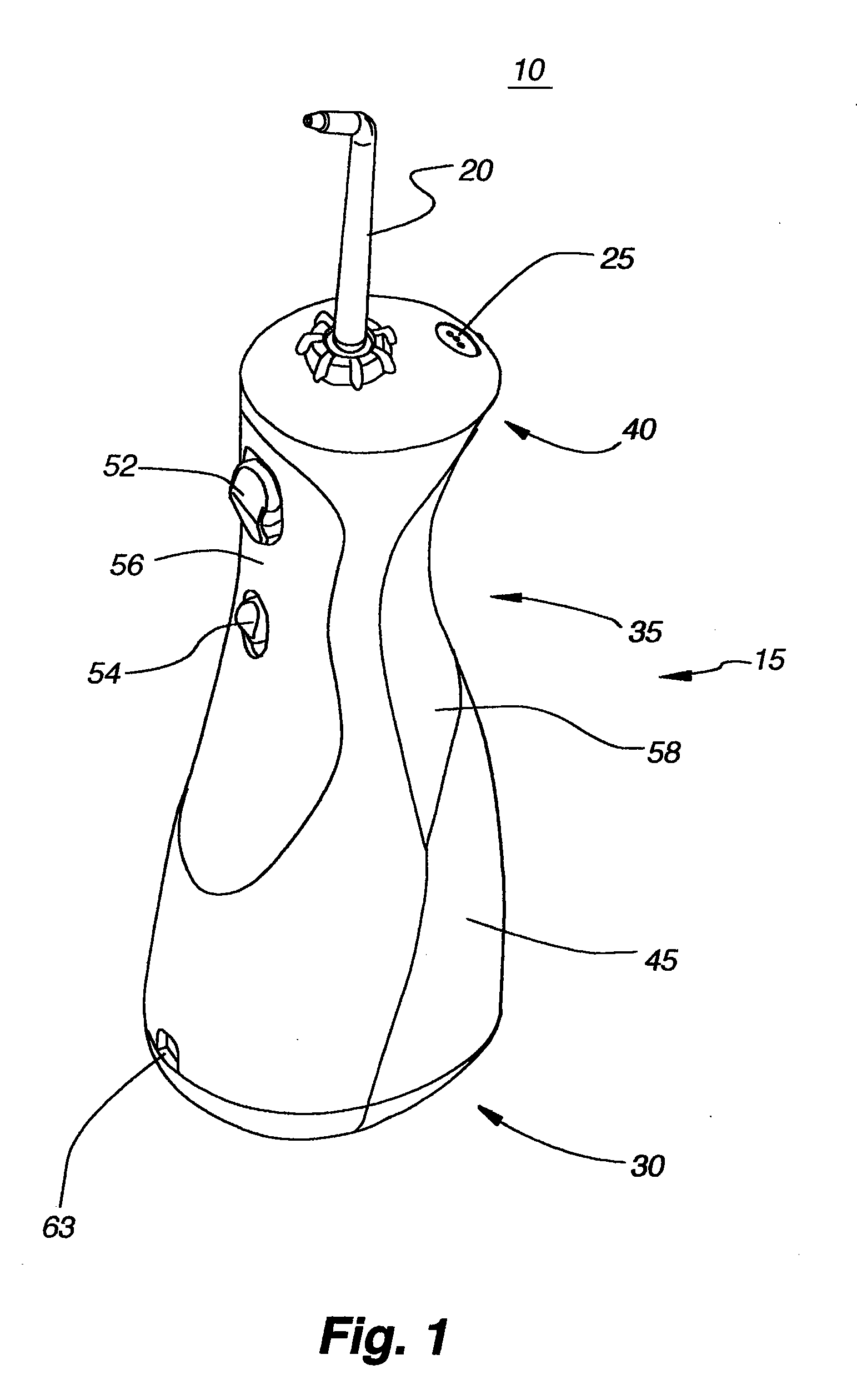

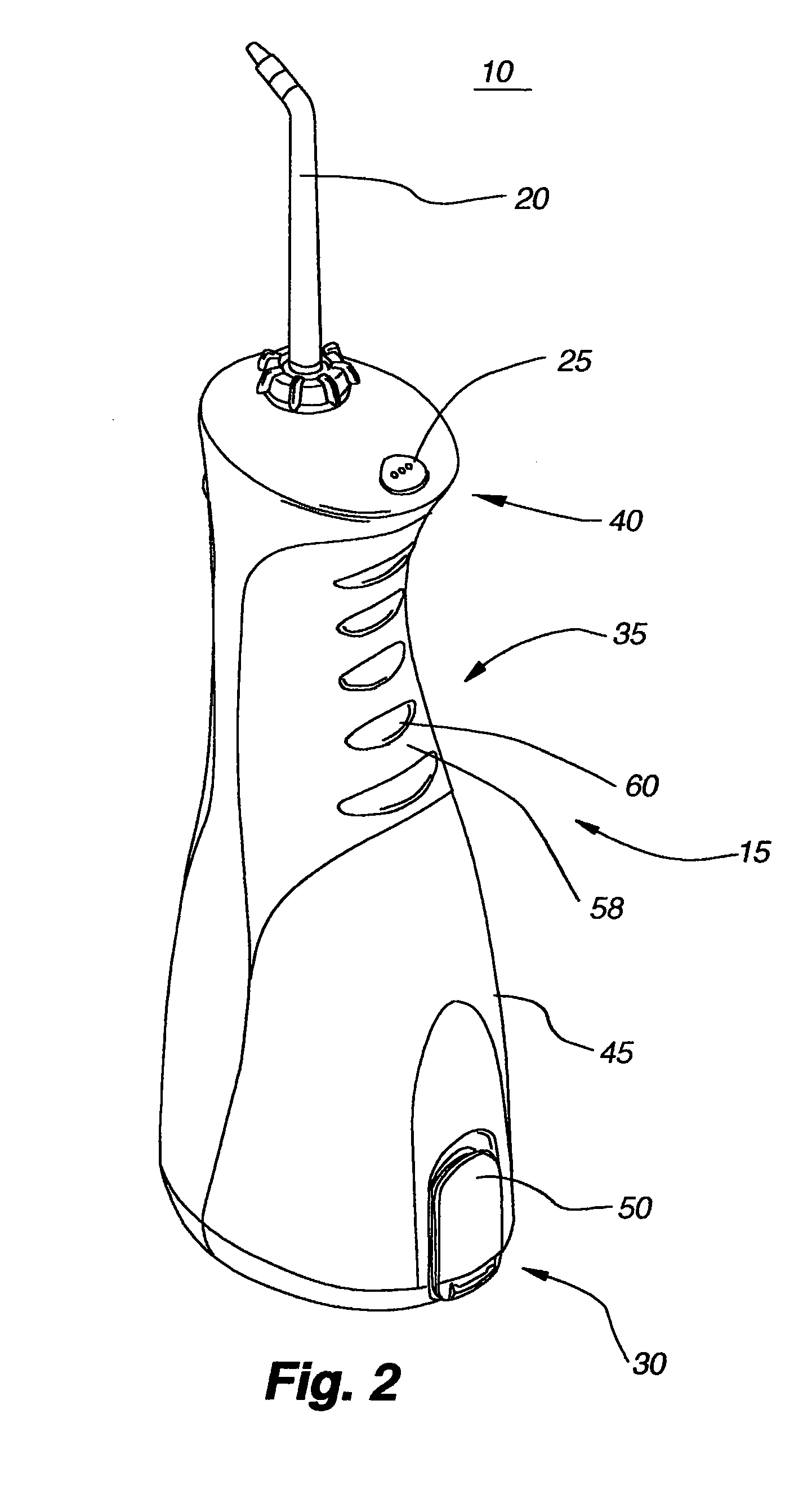

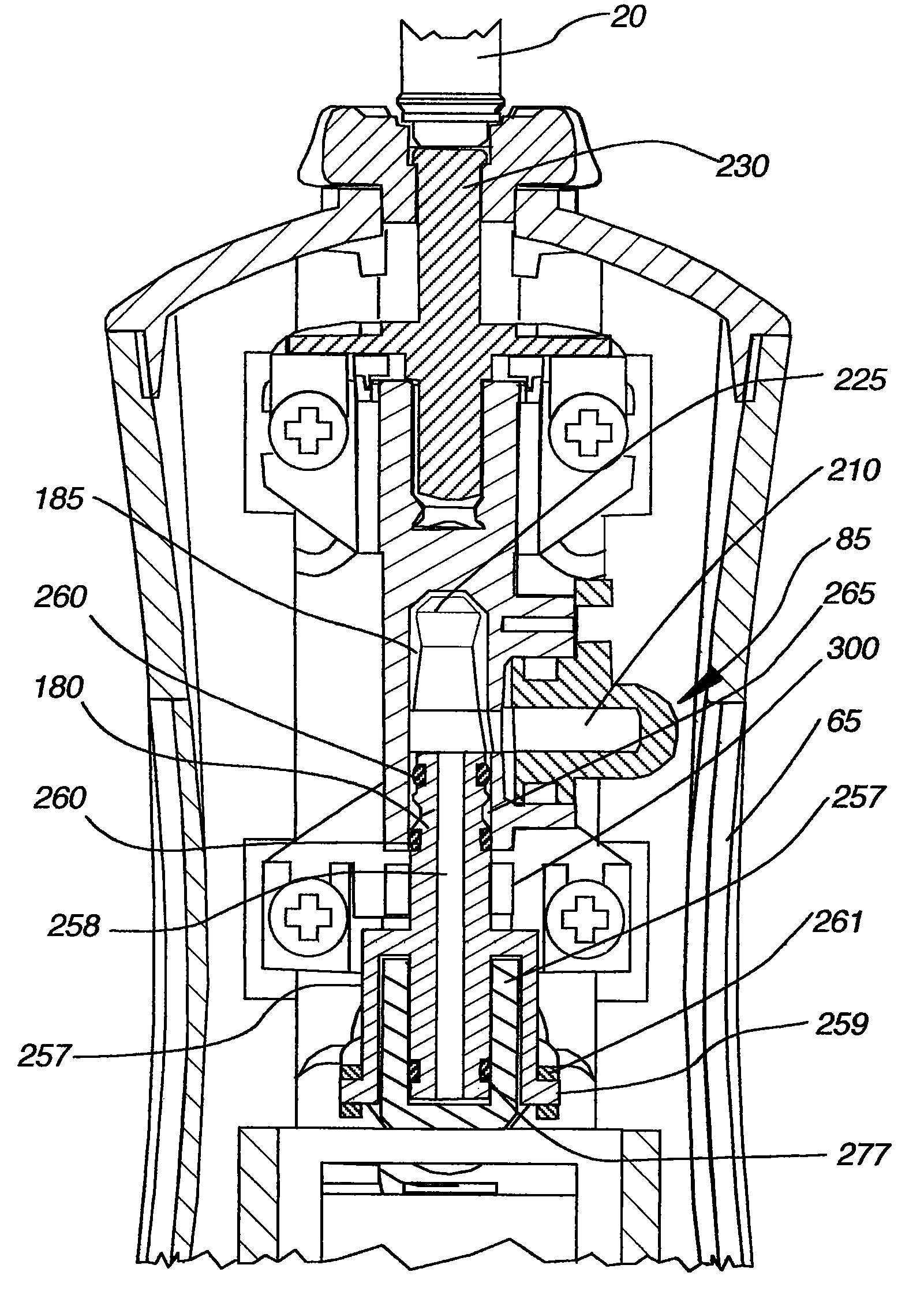

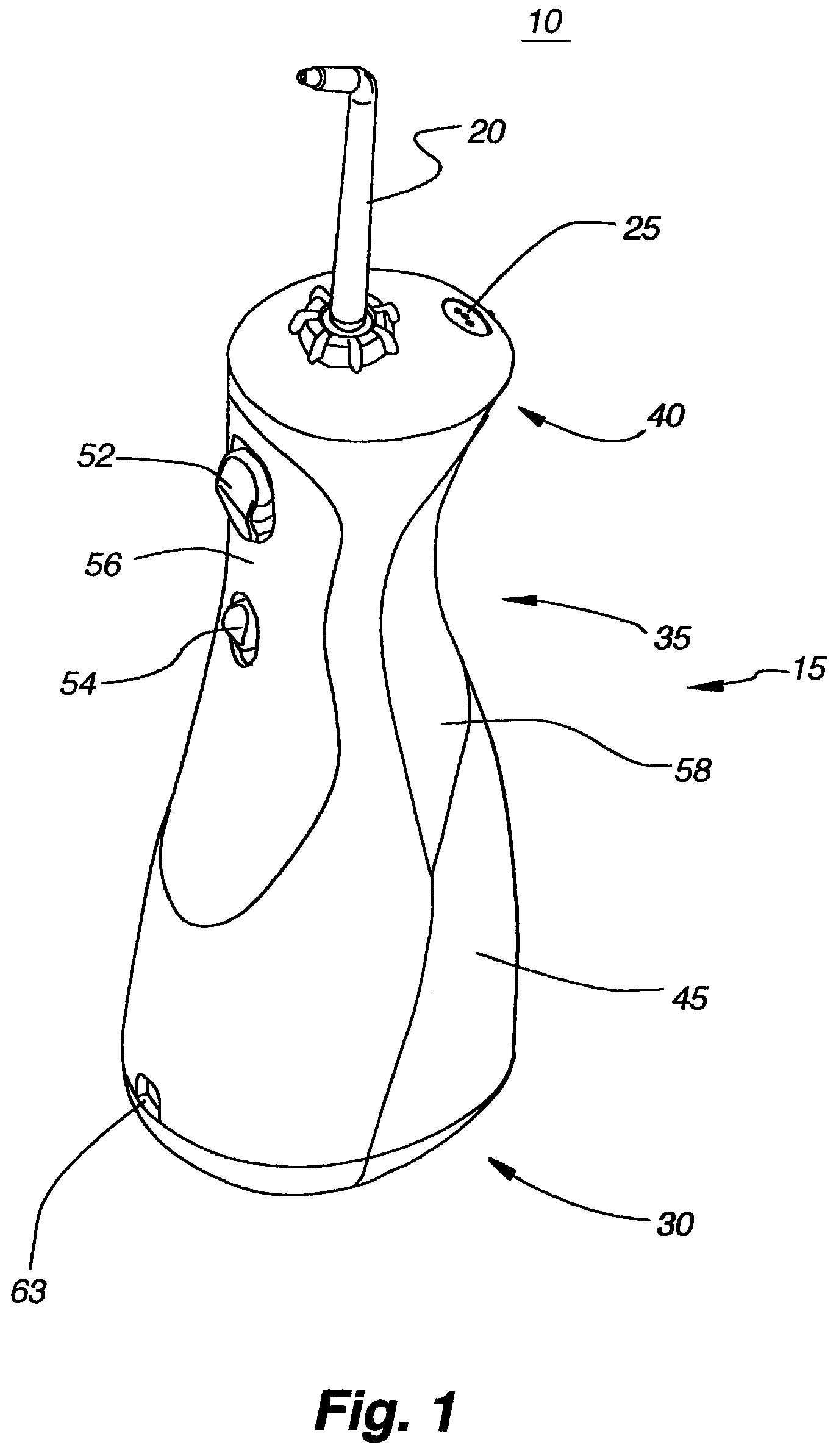

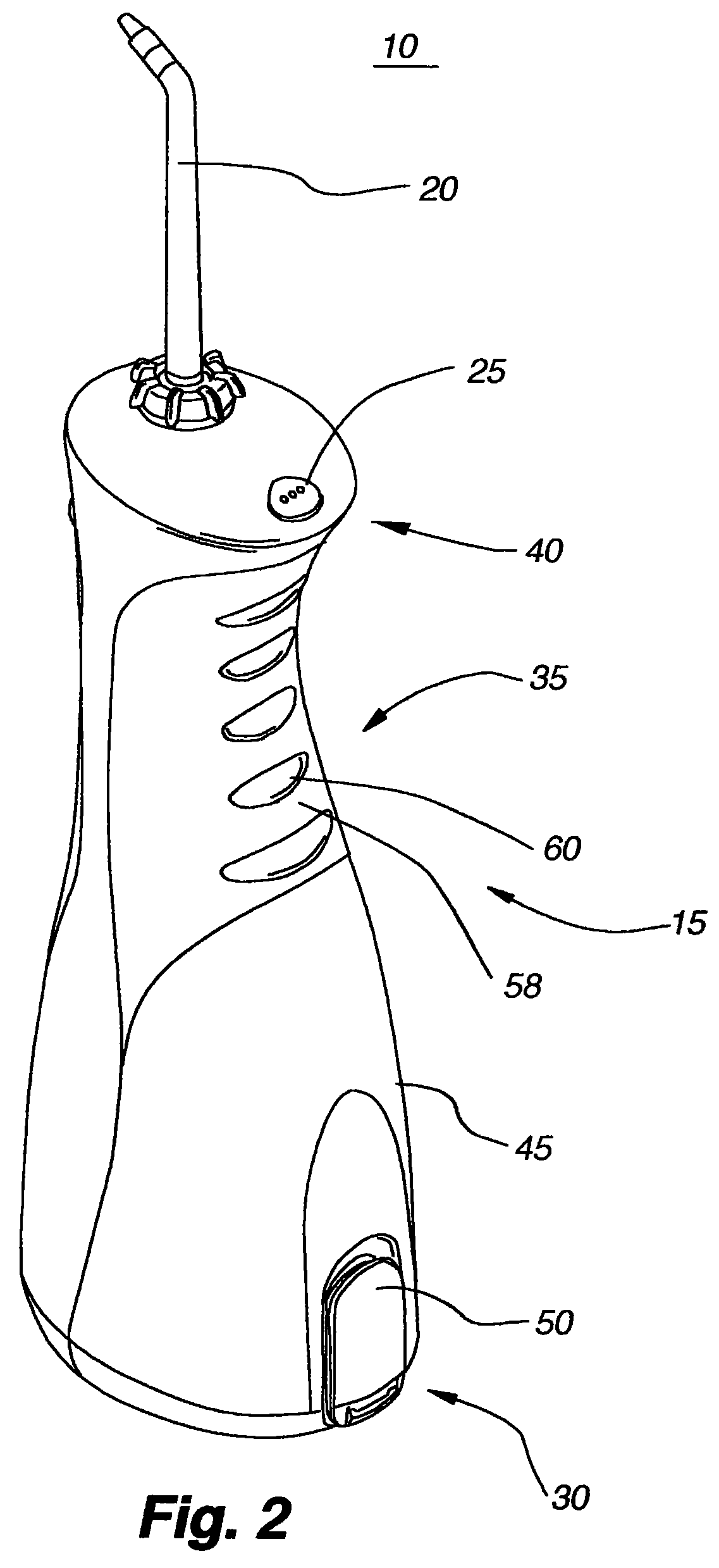

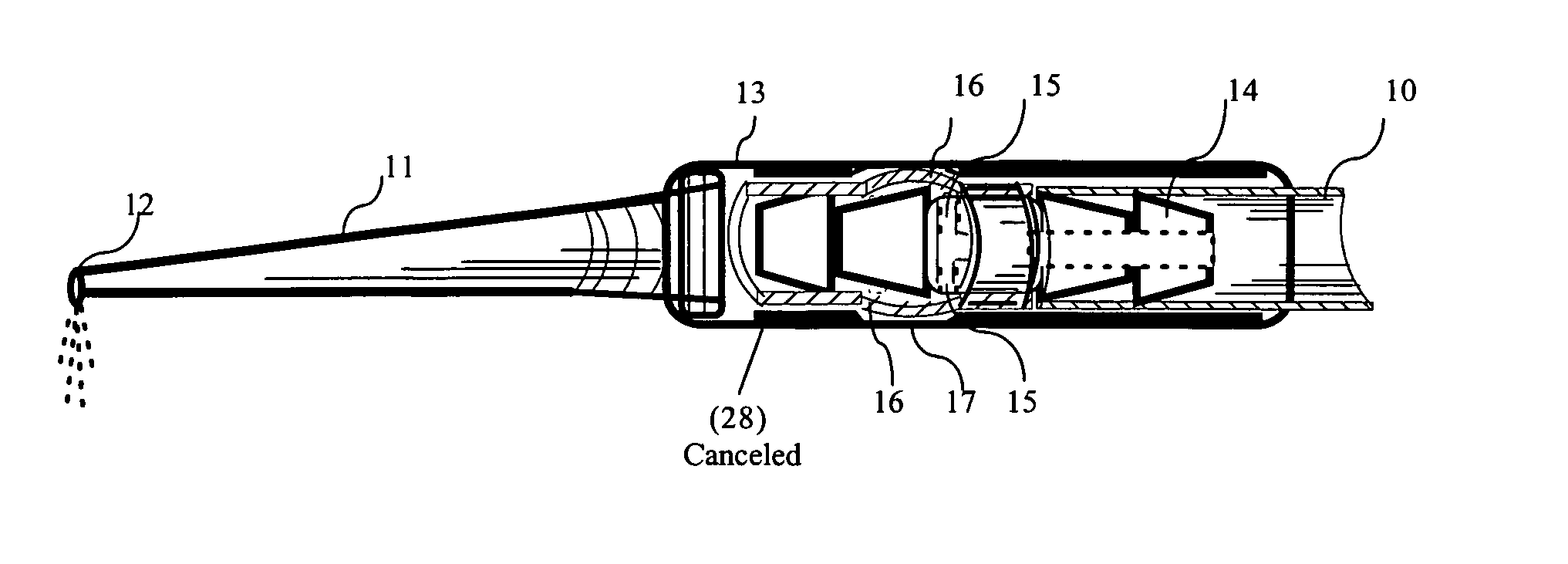

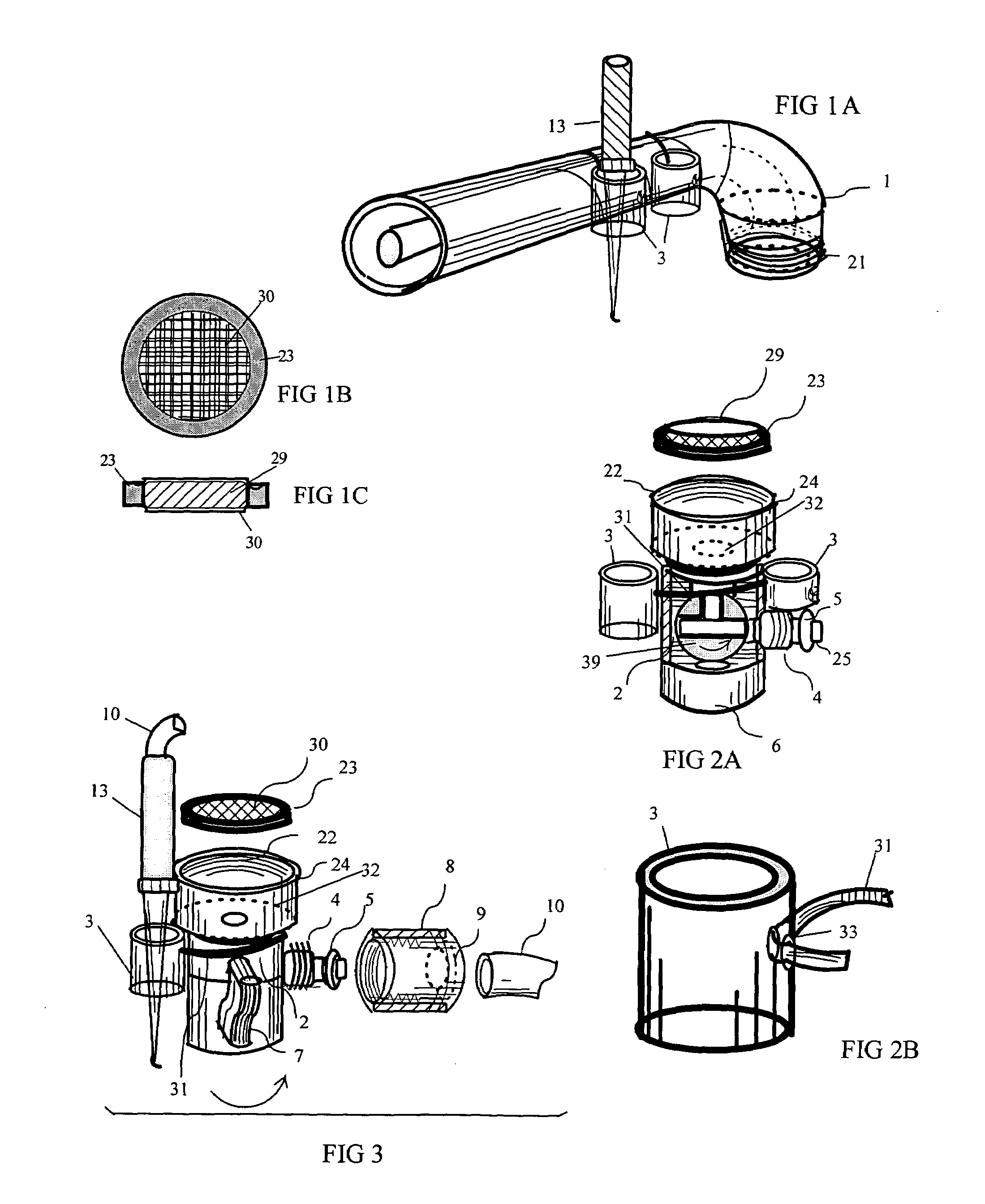

Oral irrigator

The present invention is an oral irrigator comprising a pump, a discharge nozzle and a pressure control. The pump has a generally constant operating speed and feeds the discharge nozzle. The pressure control is adapted to modify a discharge pressure at the nozzle without a significant change in pump speed. The pressure control modifies a level of fluid flow restriction between the pump and the nozzle. The modification of the level of fluid flow restriction is accomplished by modifying aspects of a fluid flow path extending through the pressure control. The aspects modified include the diameter, length and / or number of direction changes of the fluid flow path.

Owner:WATER PIK INC

Oral irrigator

The present invention is an oral irrigator comprising a pump, a discharge nozzle and a pressure control. The pump has a generally constant operating speed and feeds the discharge nozzle. The pressure control is adapted to modify a discharge pressure at the nozzle without a significant change in pump speed. The pressure control modifies a level of fluid flow restriction between the pump and the nozzle. The modification of the level of fluid flow restriction is accomplished by modifying aspects of a fluid flow path extending through the pressure control. The aspects modified include the diameter, length and / or number of direction changes of the fluid flow path.

Owner:WATER PIK INC

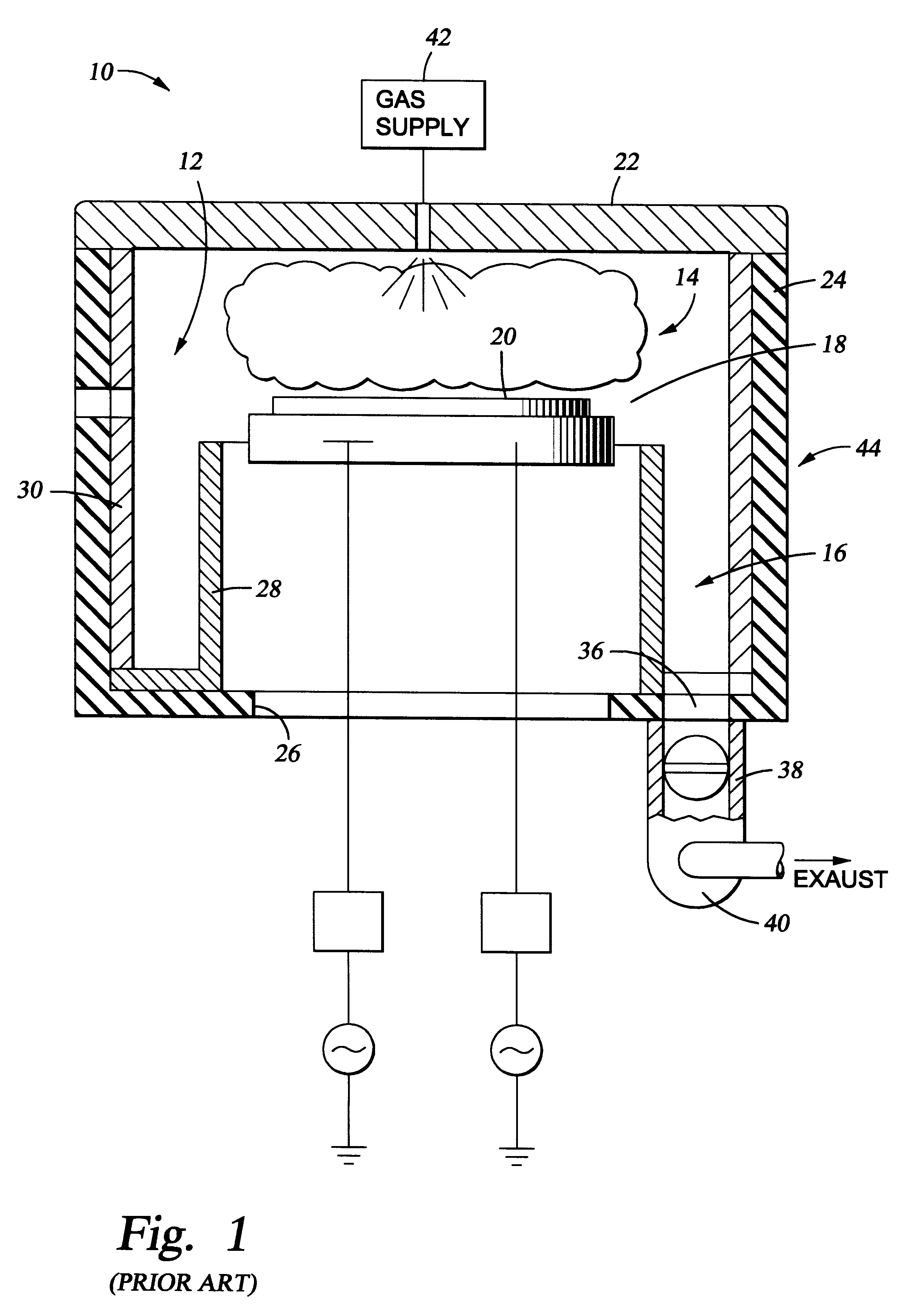

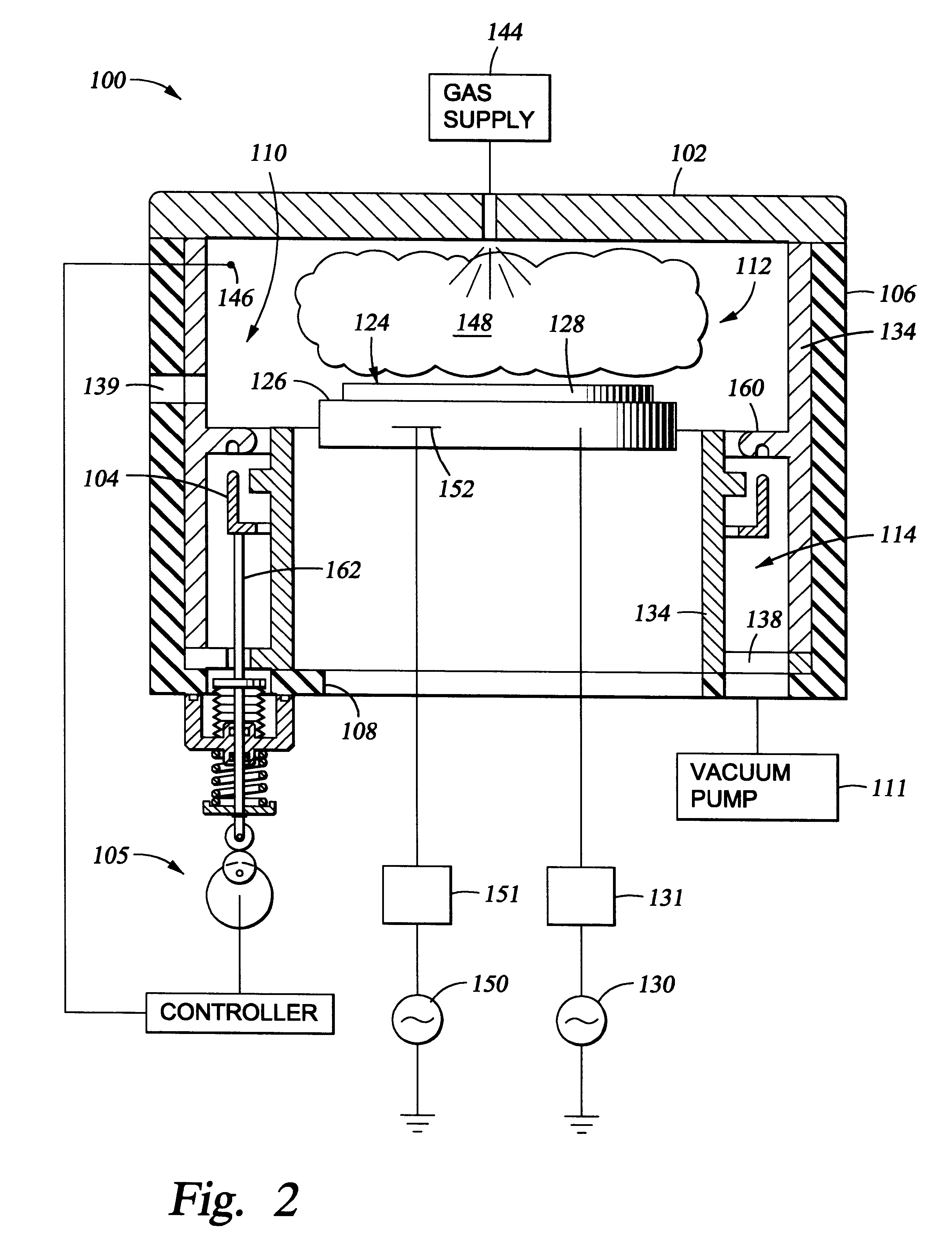

Method and apparatus for semiconductor processing chamber pressure control

InactiveUS6261408B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringActuator

A pressure controlled substrate processing chamber comprising a pressure control ring and a throttling ridge. The pressure control ring is movably disposed proximate the throttling ridge to define a variable flow orifice. The pressure control ring is translated by a ring actuator in response to pressure information retrieved from the processing chamber. The translation of the pressure control ring causes the size of the orifice to change, thus inducing a pressure change within the chamber.

Owner:APPLIED MATERIALS INC

Leakage determining method, substrate processing apparatus and storage medium

InactiveUS20160169766A1Reduce the amount requiredDetection of fluid at leakage pointSemiconductor/solid-state device manufacturingTemporal changeAtmospheric air

Owner:TOKYO ELECTRON LTD

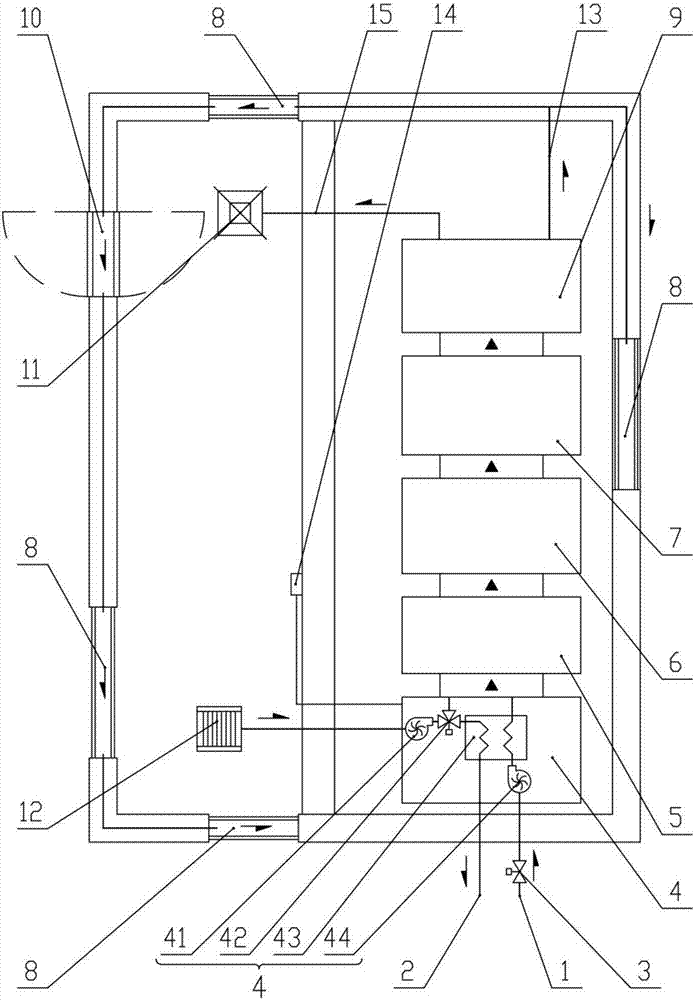

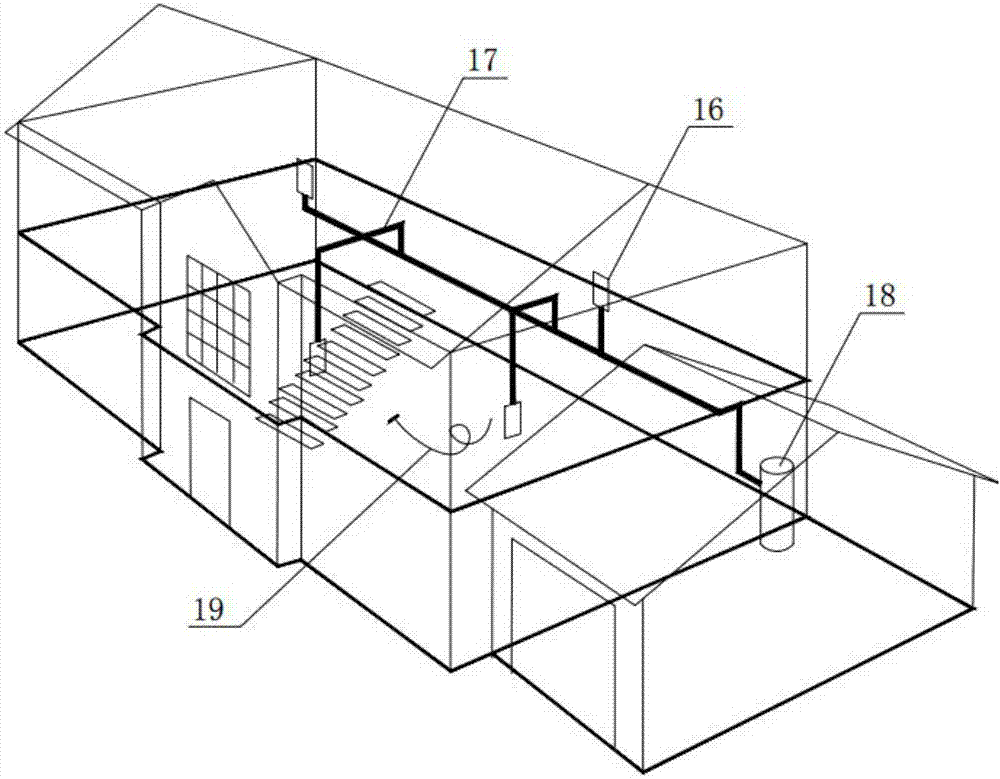

Constant-temperature, constant-humidity and constant-cleanliness silent indoor air system

InactiveCN106895521AAgainst intrusionAvoid damageMechanical apparatusSpace heating and ventilation safety systemsFiltrationFresh air

The invention provides a constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, belongs to the field of indoor intelligent adjustment, and relates to multiple techniques including indoor air pressure control, indoor air purification, an indoor central dedusting system, supercharging and compensation functions for interlayers of double windows and double doors, an outdoor haze isolating system, an indoor air internal-circulation cleaning method, air heat exchange, air heating, refrigeration, dehumidification and the like. According to the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, the pressure of fresh air is made positive through the interlayers of the double doors and the double windows, the air pressure in the interlayers of the double doors and the double windows is made higher than outdoor air pressure, and outdoor air is prevented from invading indoor air; a small primary-efficiency, medium-efficiency and high-efficiency filtering system is used for filtration, various types of automatic adjustment and control including heating, refrigerating, dehumidifying and the like are conducted on air, pollutant dust generated indoors is removed through the central dedusting system, and the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system is an omnidirectional intelligent air control system.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

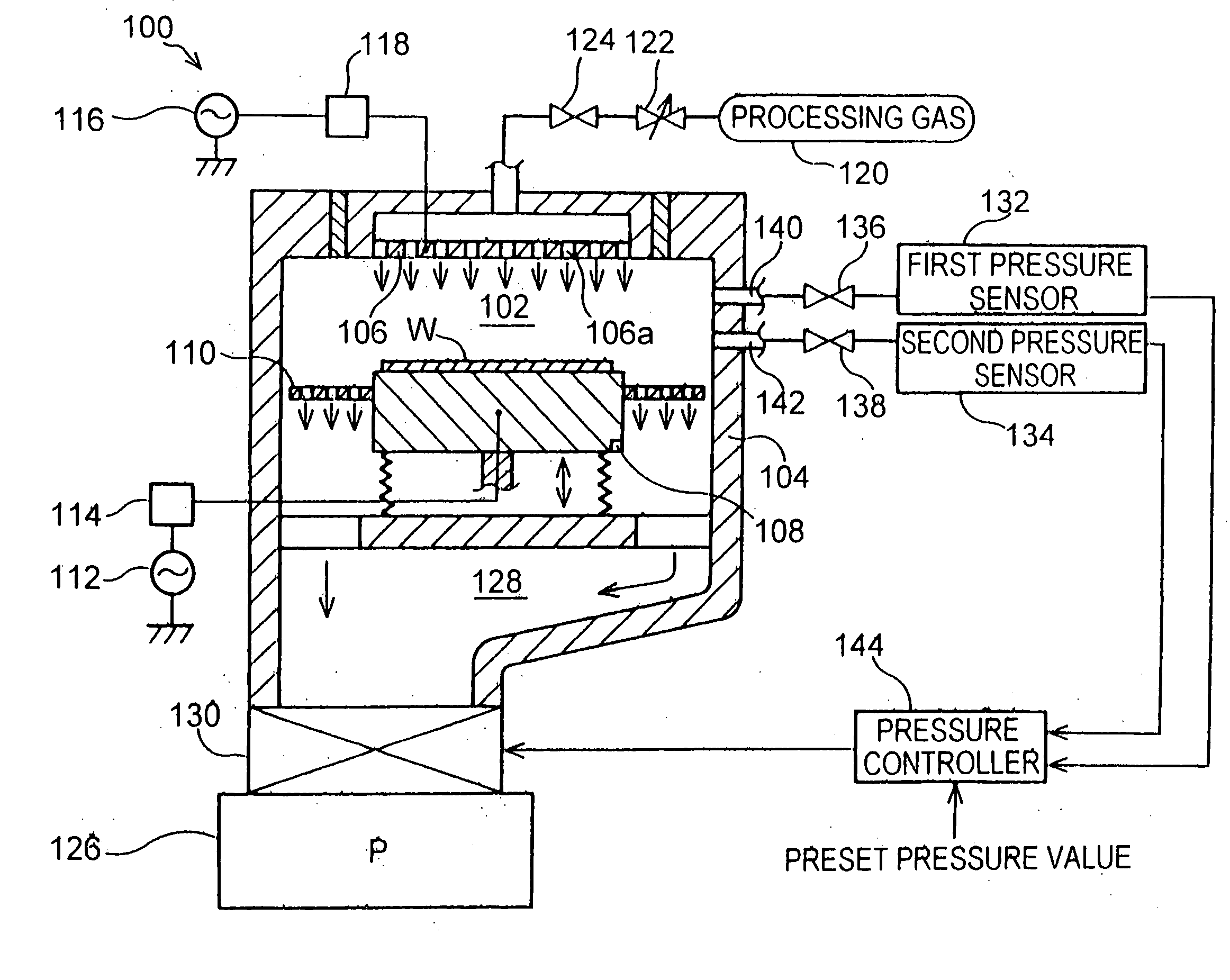

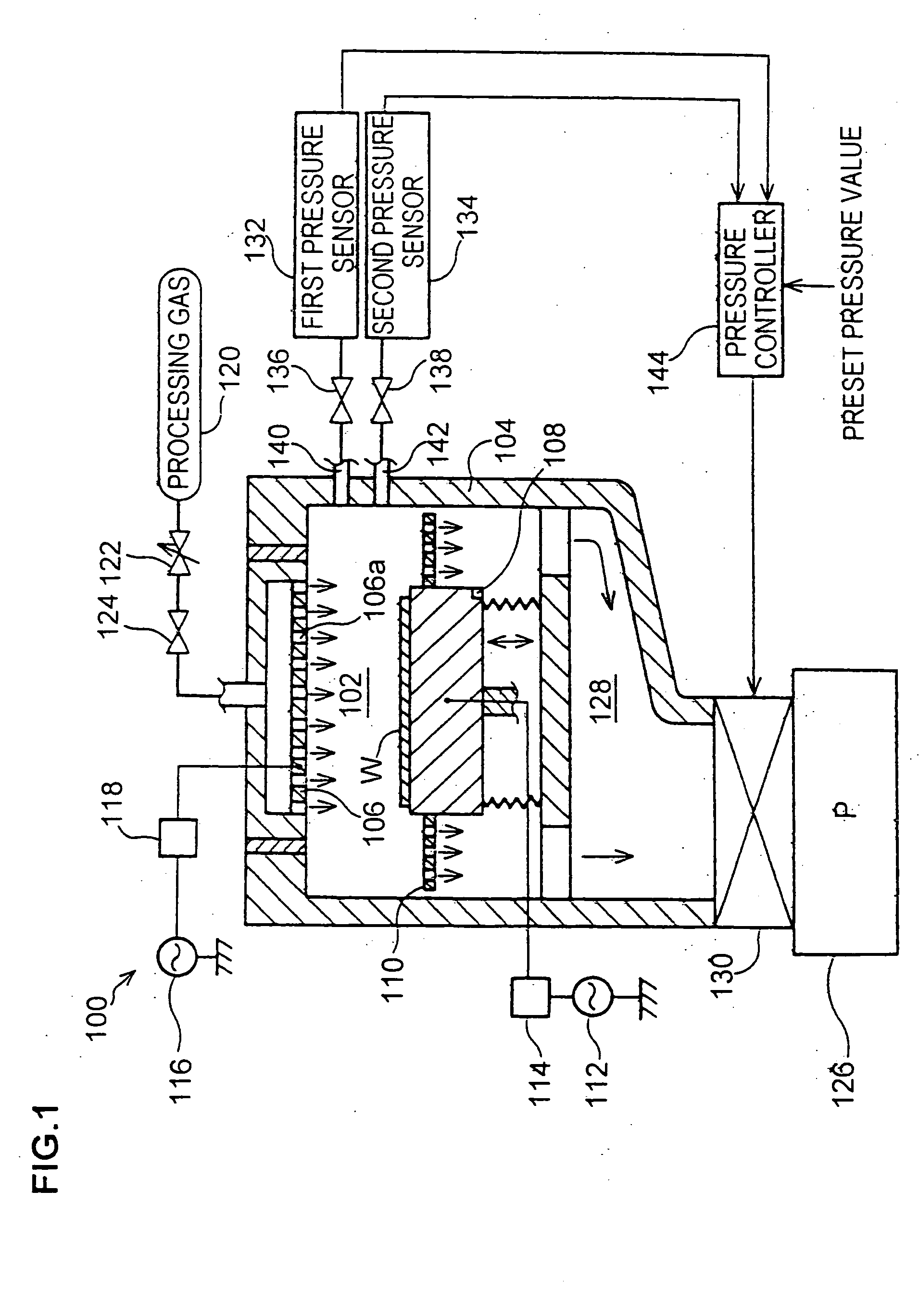

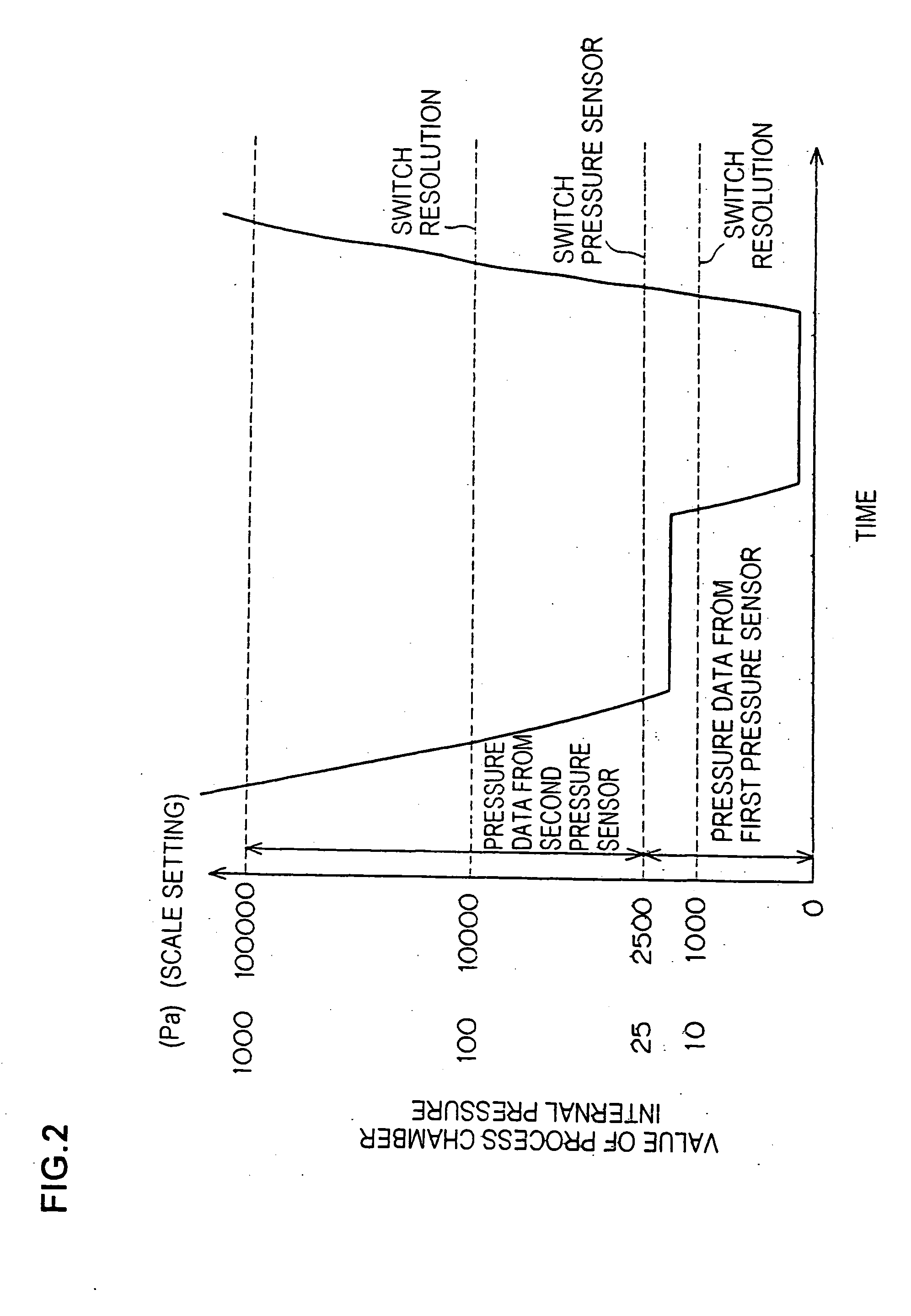

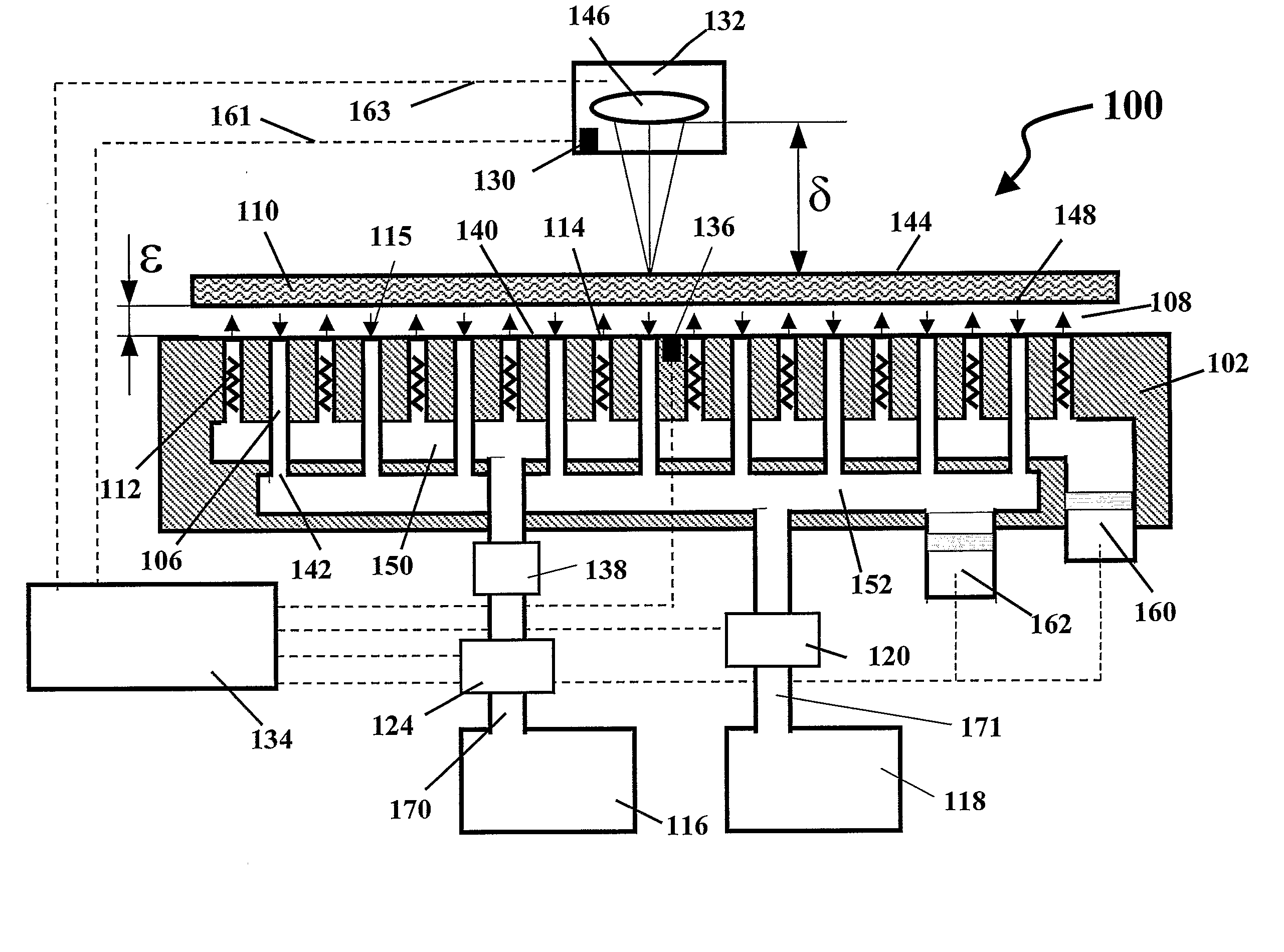

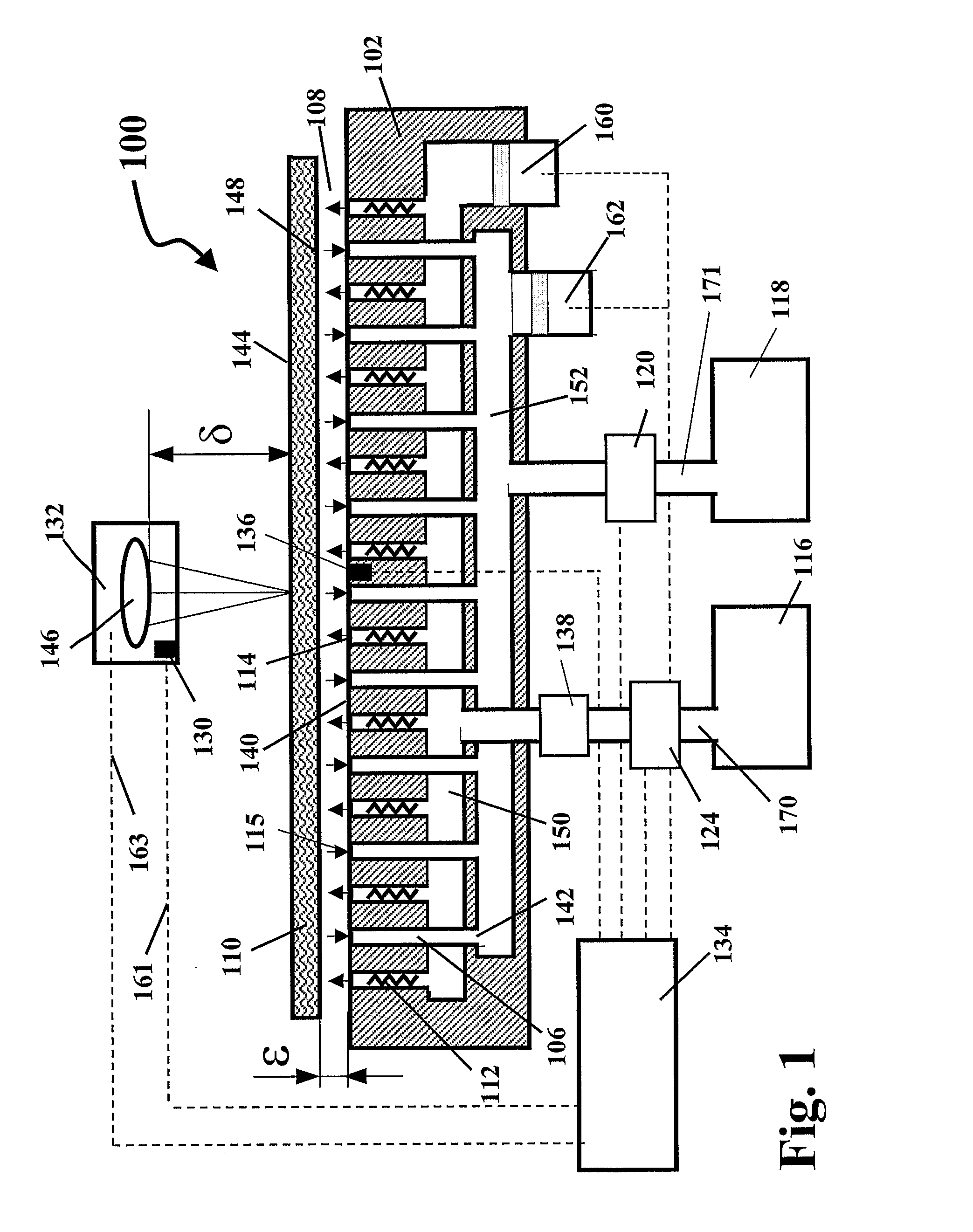

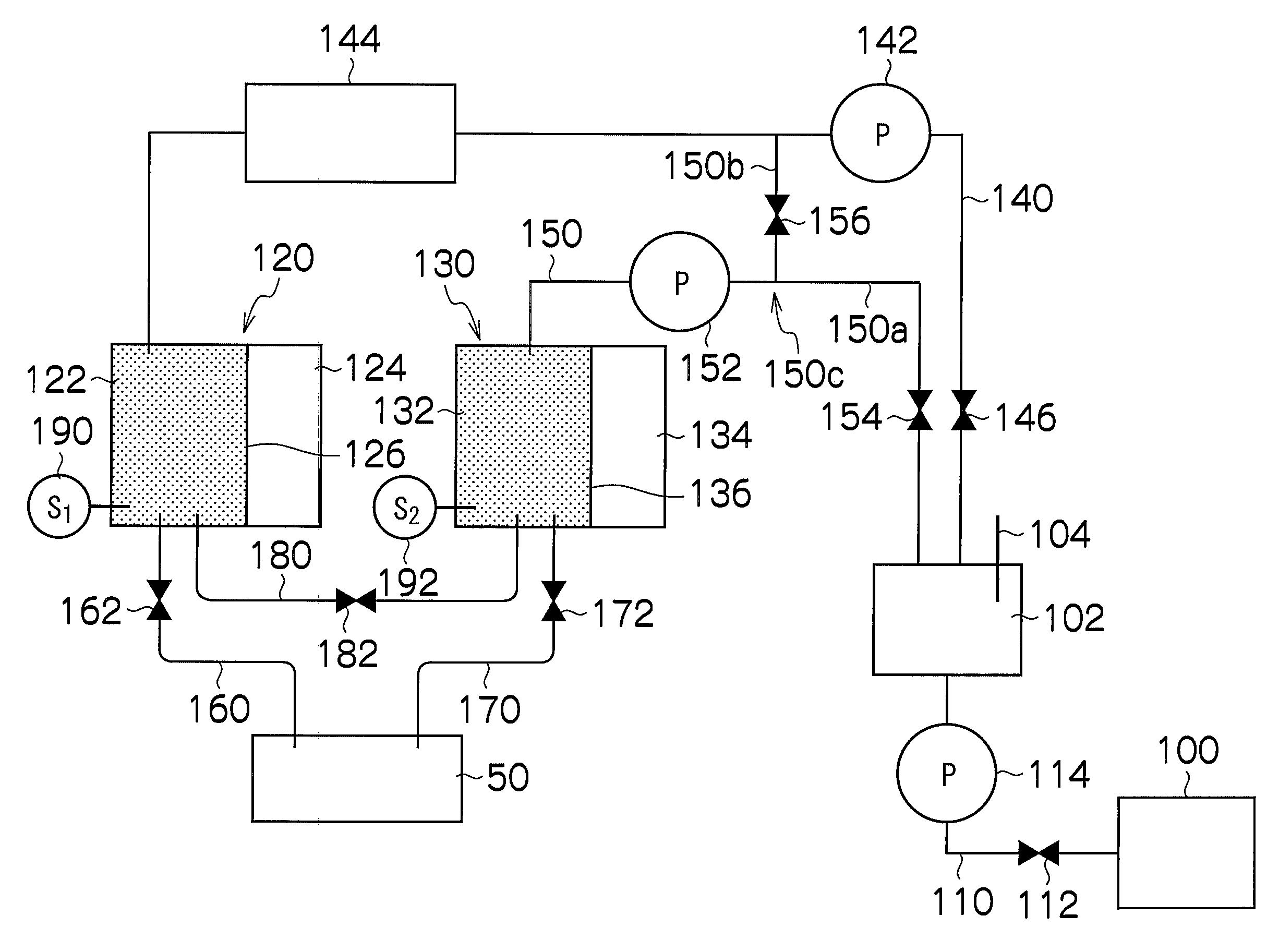

Pressure control method and processing device

InactiveUS20050176258A1Level of control performanceOptimize dataElectric discharge tubesSemiconductor/solid-state device manufacturingImage resolutionEngineering

First and second pressure sensors 132 and 134 that perform pressure detection over different pressure detection ranges from each other detect the pressure within a process chamber 102 of an etching device 100. A pressure controller 144 selects optimal pressure data in correspondence to the pressure inside the process chamber from the pressure data provided by the first and second pressure sensors 132 and 134. It also analyzes the selected pressure data at a resolution selected in correspondence to the pressure inside the process chamber 102 and thus obtains pressure data achieving a predetermined data density. The pressure controller 134 controls a pressure control valve 130 so as to ensure that the pressure data match preset pressure data.

Owner:TOKYO ELECTRON LTD

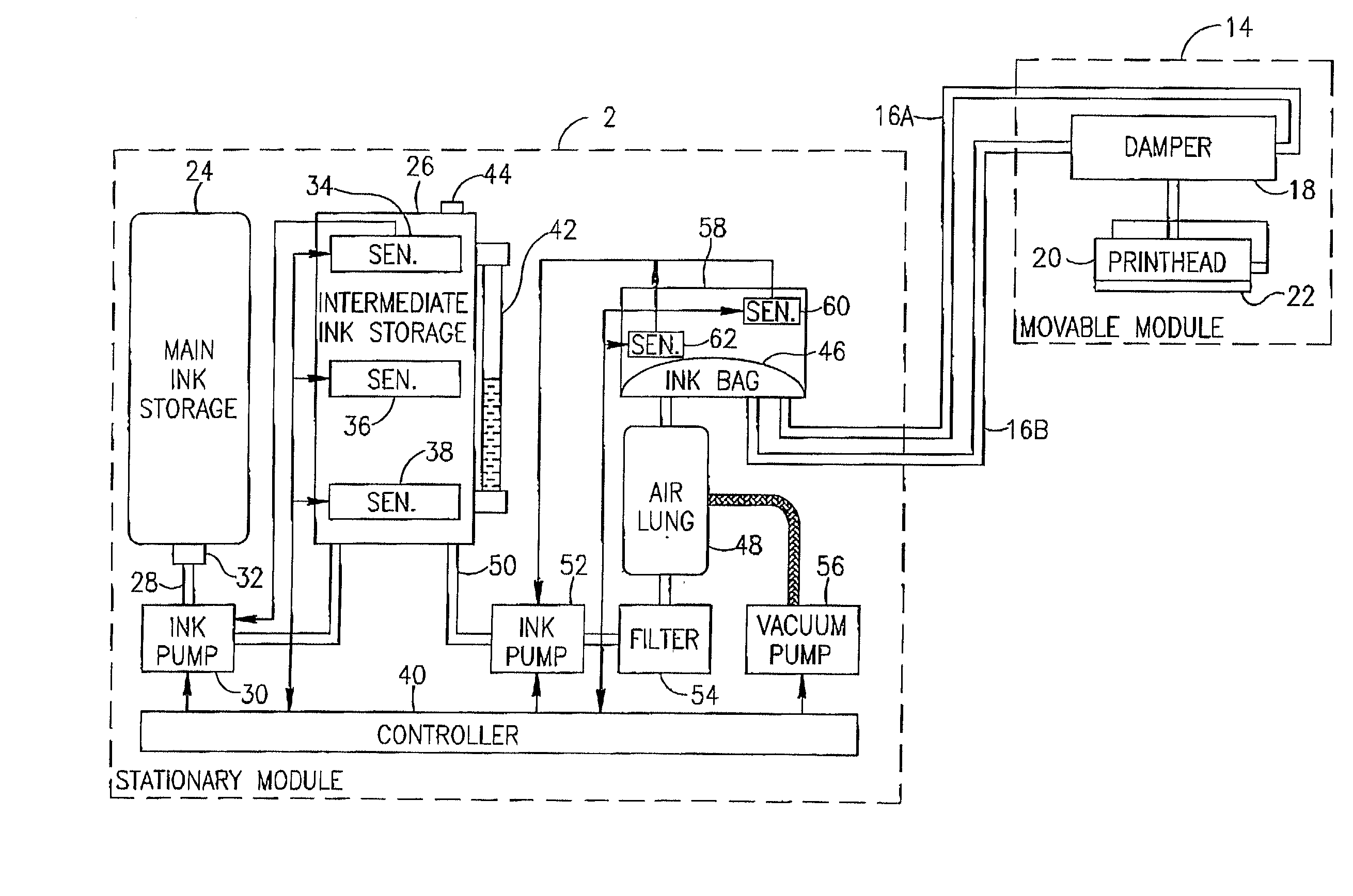

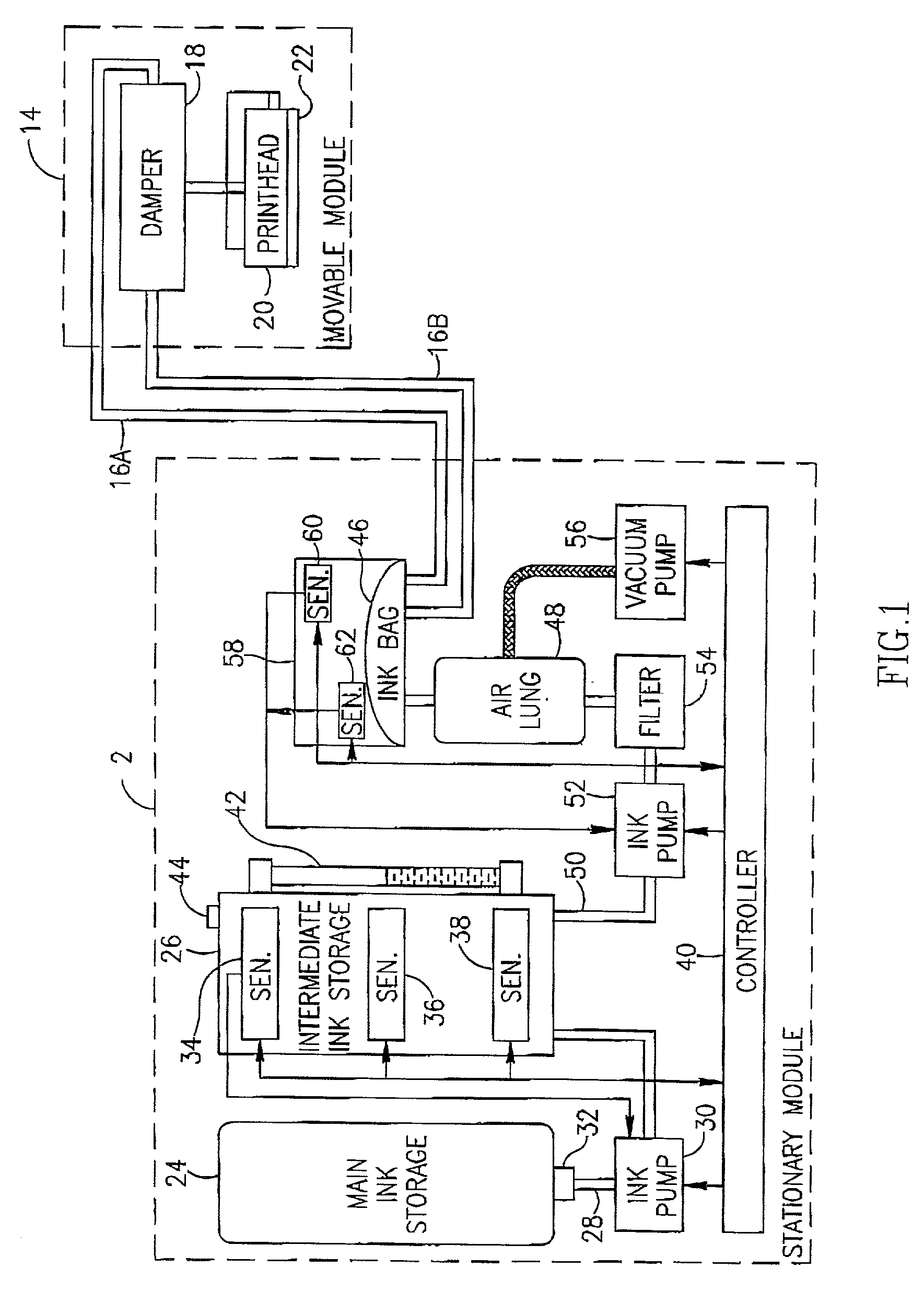

Closed ink delivery system with print head ink pressure control and method of same

In some embodiments of the present invention, an ink supply system is provided. The system is configured to expose ink to the ambient atmosphere only at the nozzles of one or more print heads coupled to the system.

Owner:HEWLETT PACKARD IND PRINTING LTD

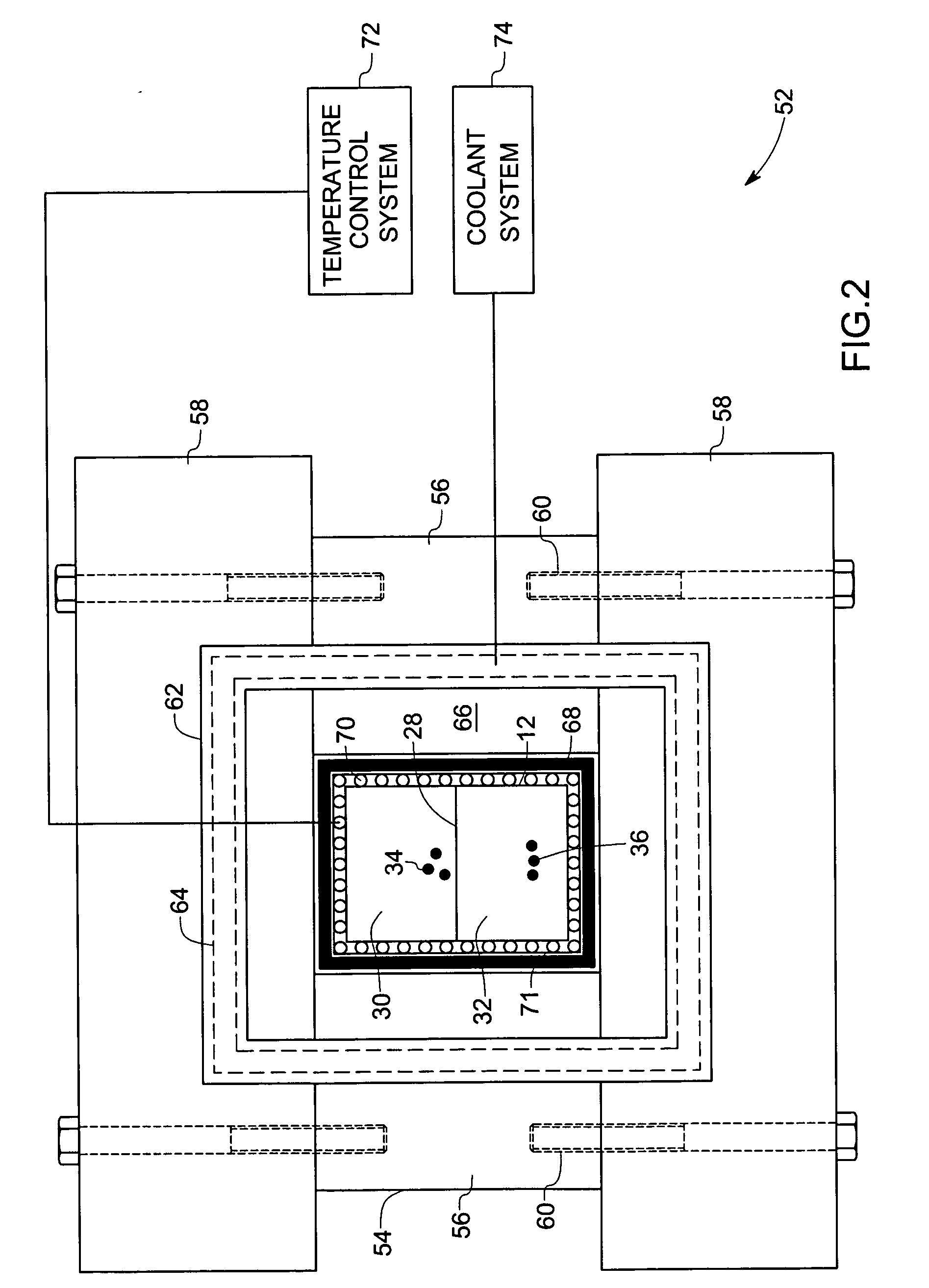

Non-contact support platforms for distance adjustment

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

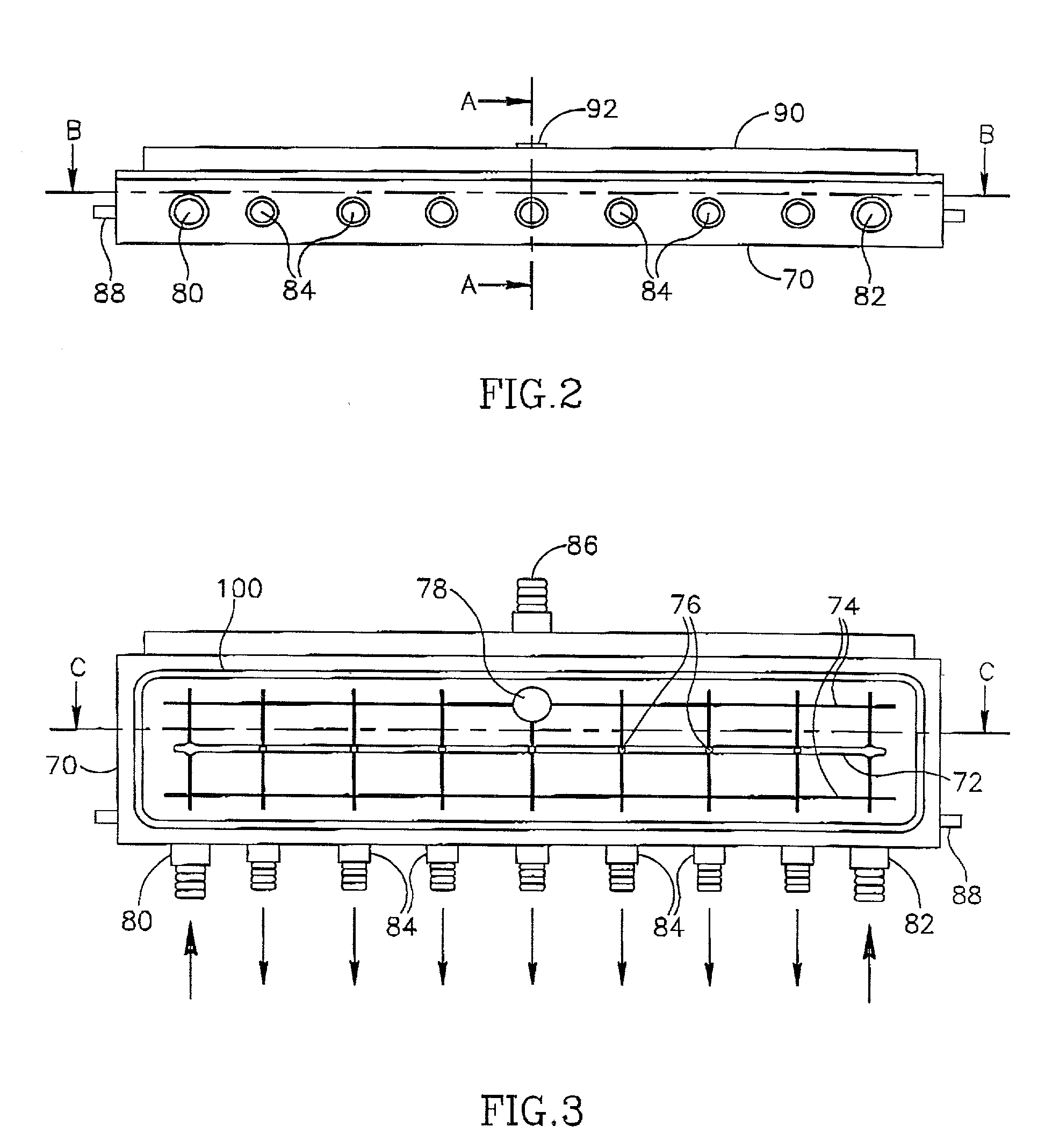

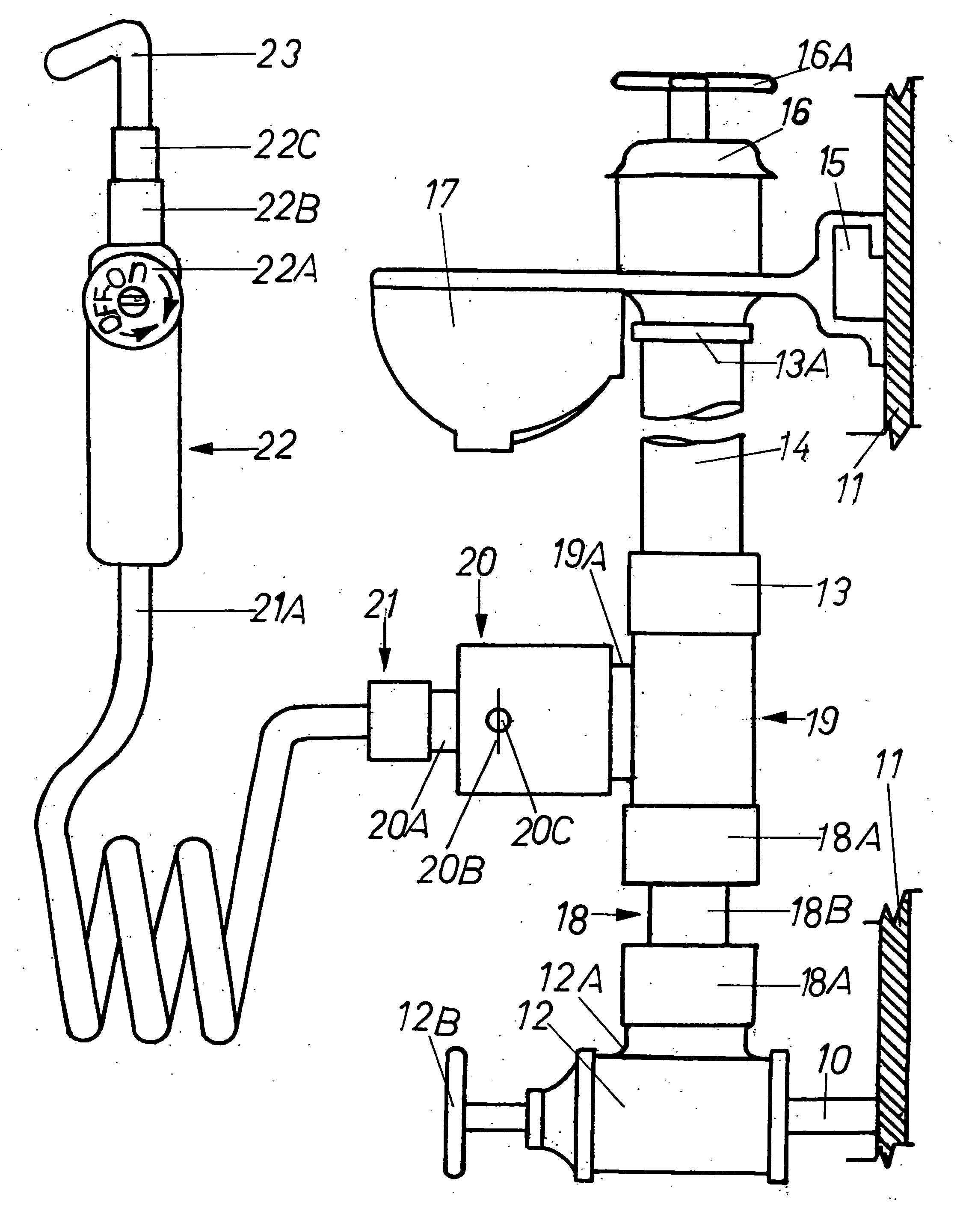

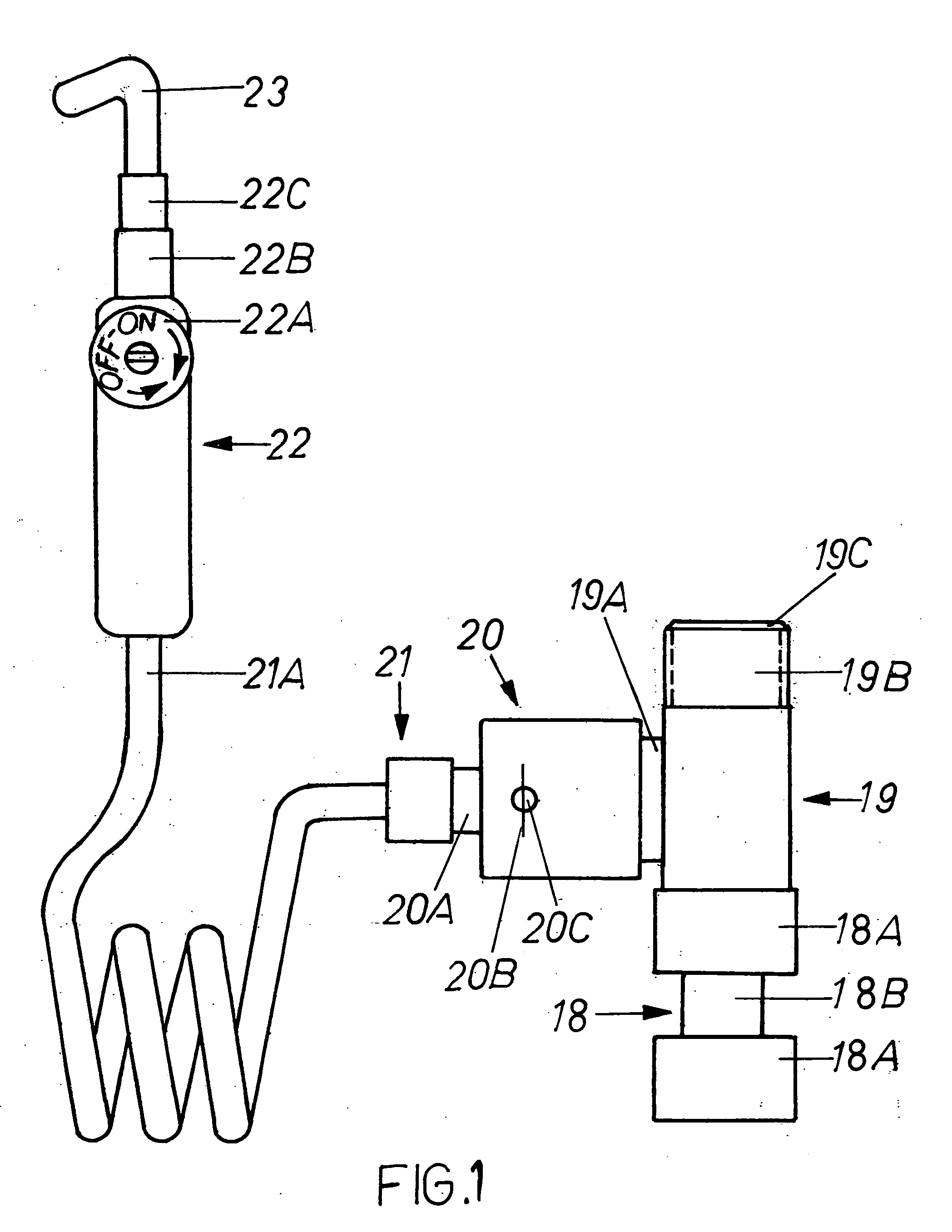

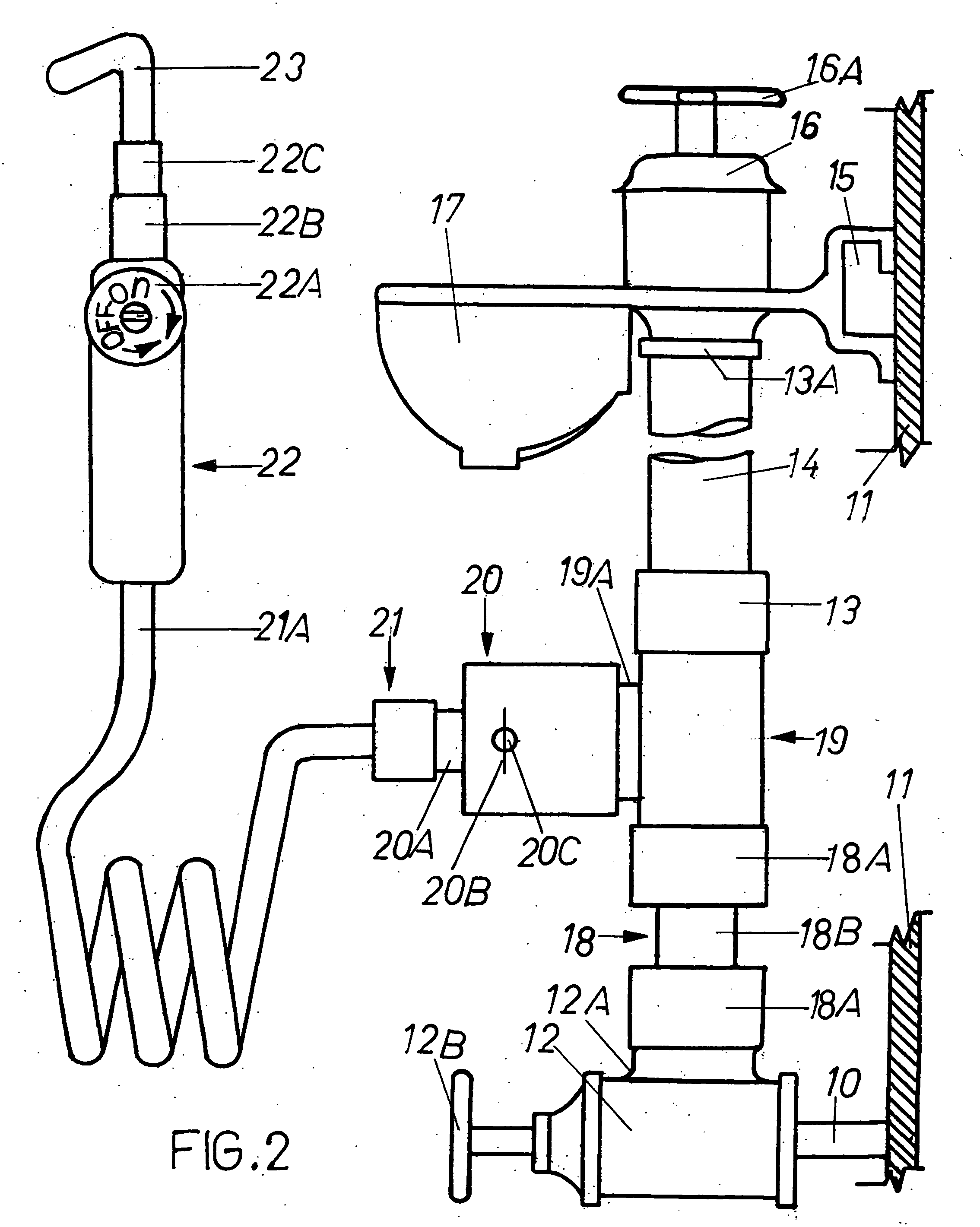

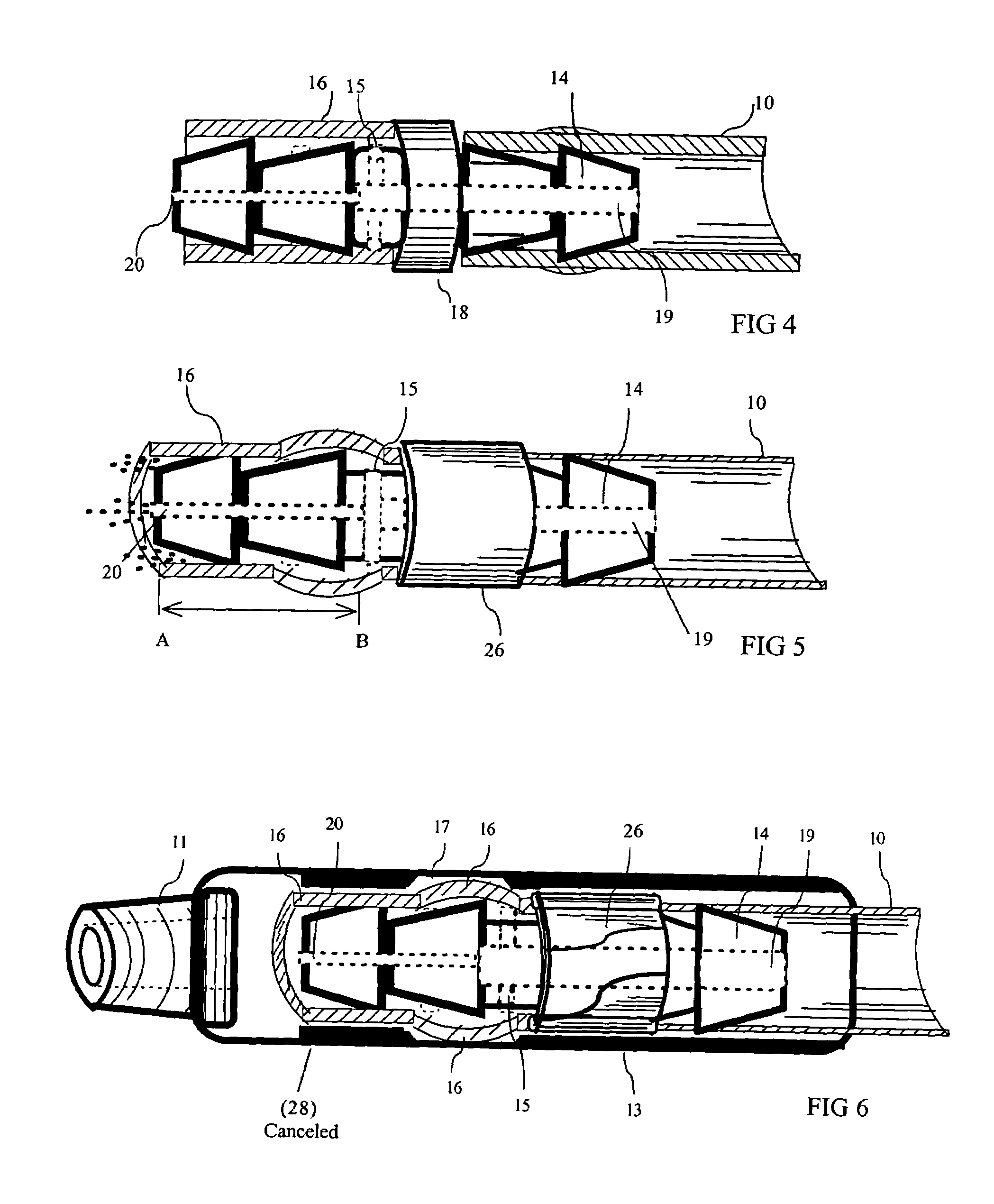

Dental hygiene pulsatory slit apparatus

InactiveUS20060079818A1No complicated mechanismEasy to useGum massageGenitals massageHand heldEngineering

An improved pulsatory slit apparatus to be connected for a dental hygiene. Supply line valves to be shutoff before connecting the devices. By disconnecting cold water conduit of a faucet of a sink from a domestic cold water supply line valve in a bathroom and reconnecting it to 19B, and by connecting the valve to 18A as shown in FIG. 1, it becomes an operative device as shown in FIG. 2. For a combination of hot and cold water, by disconnecting the cold water supply line valve as previously stated and by disconnecting the hot water conduit of the faucet from the hot water supply line valve in a bathroom and reconnecting the cold water connector to a top right side straight end 19B of an apparatus and the hot water connector to a top left side straight end 19B of the apparatus as shown in FIG. 3, this process completes a connection of the faucet and the apparatus. To complete the connection of the apparatus and the supply lines it requires two conduits of the same size hexagonal or of similar configurational nuts at the four ends of the conduits. One conduit connects to the cold water supply line valve and the other end of the conduit connects to the bottom right side straight end 19B of the apparatus. The second conduit connects to the hot water supply line valve and the other end of the conduit connects to a bottom left side straight end 19B of the apparatus as shown in FIG. 3. This process completes the connections of the supply lines of the apparatus and it becomes an operative device as shown in FIG. 4. An open-shutoff orifice valve directs the water to a hand held cylindrical device. The hand held cylindrical device having a pressure control valve assembly and the assembly having an off-on pressure control dial. A nipple of a slit orientation is attachable to the hand held cylindrical device. The hand held cylindrical device with the pressure control dial at fingertip redirects the water under pressure to the nipple for users' teeth and gums. The nipple provides the users strong pulsatory slits of thousands of tiny pulses, not just droplets as described in the prior arts. The pressure control dial let the users control the desirable pressure for comfortable use of the dental hygiene pulsatory slit apparatus.

Owner:YANDE CHANDRAKANT R

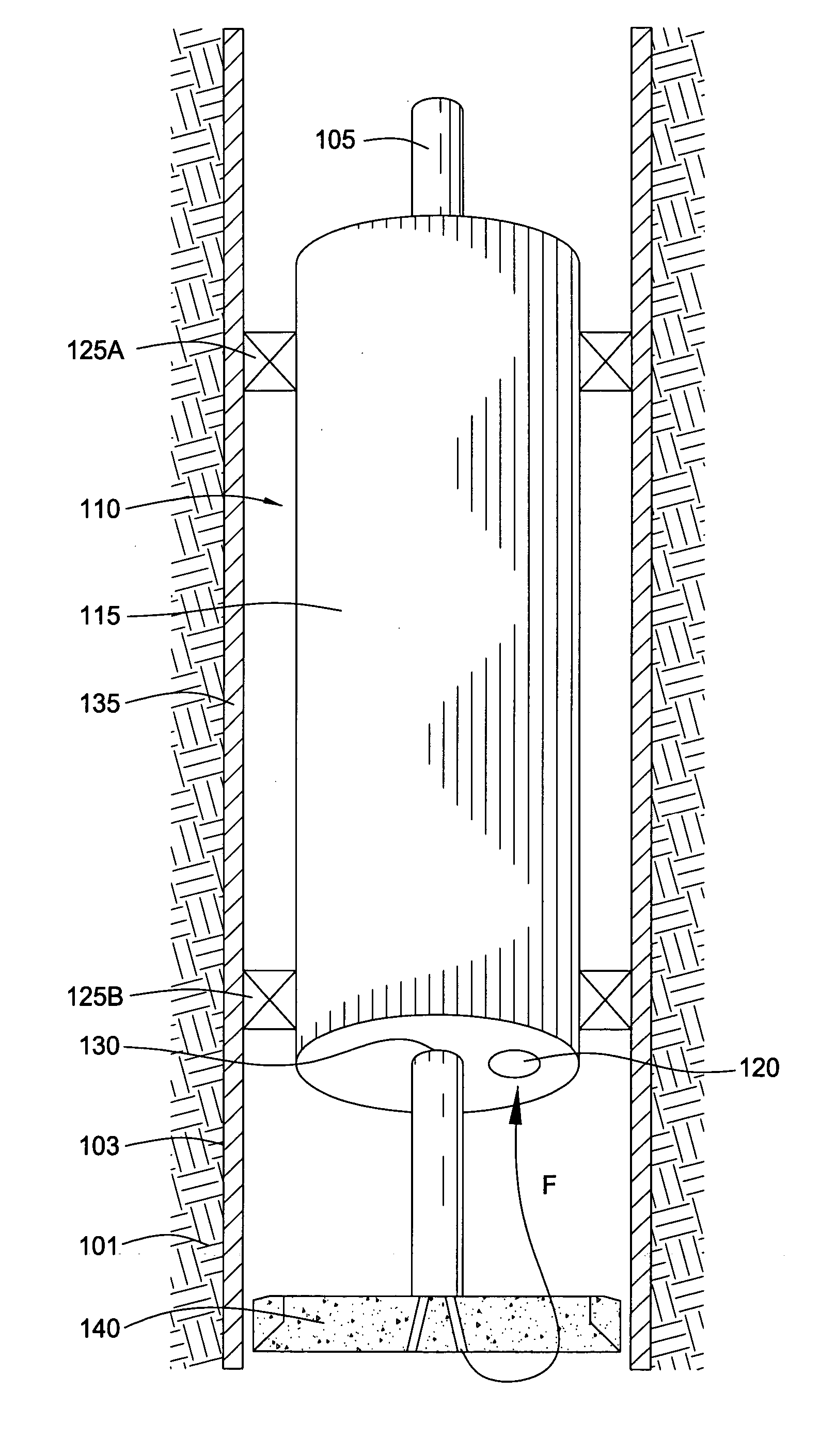

Managed pressure drilling

Embodiments of the present invention include methods and apparatus for dynamically controlling pressure within a wellbore while forming the wellbore. In one aspect, one or more pressure control apparatus are used to maintain desired pressure within the wellbore while drilling the wellbore. In another aspect, pressure is dynamically controlled while drilling using foam to maintain a substantially homogenous foam flow regime within the wellbore annulus for carrying cuttings from the wellbore.

Owner:WEATHERFORD TECH HLDG LLC

Multi user oral cleansing device, DentalJet

InactiveUS7367803B2Easy to useReduce manufacturing costGum massageGenitals massageEngineeringElectric power

This invention creates a convenient low cost water pressure driven multi user oral cleansing device, the DentalJet with exchangeable color coded nozzle / handle which is easy to use, needs no electricity. The invention uses a faucet attachable rotating diverter, a flexible longer food grade PVC tube and interchangeable color coded jet nozzle / handle. The diverter also functions as a fine water volume / pressure control with a preset temperature and filter. Water pressure bulges up the flexible rubber tube clamped to the end of the adapter and to the PVC tubing. Inside the handle the water pressure created friction keeps the hose adapter in solid coupling while the pressure is on. The rubber tube oscillates, as pulsating water exist at the nozzle. When the water pressure is removed, color coded nozzle / handle is exchangeable.

Owner:EGERESI ZOLTAN

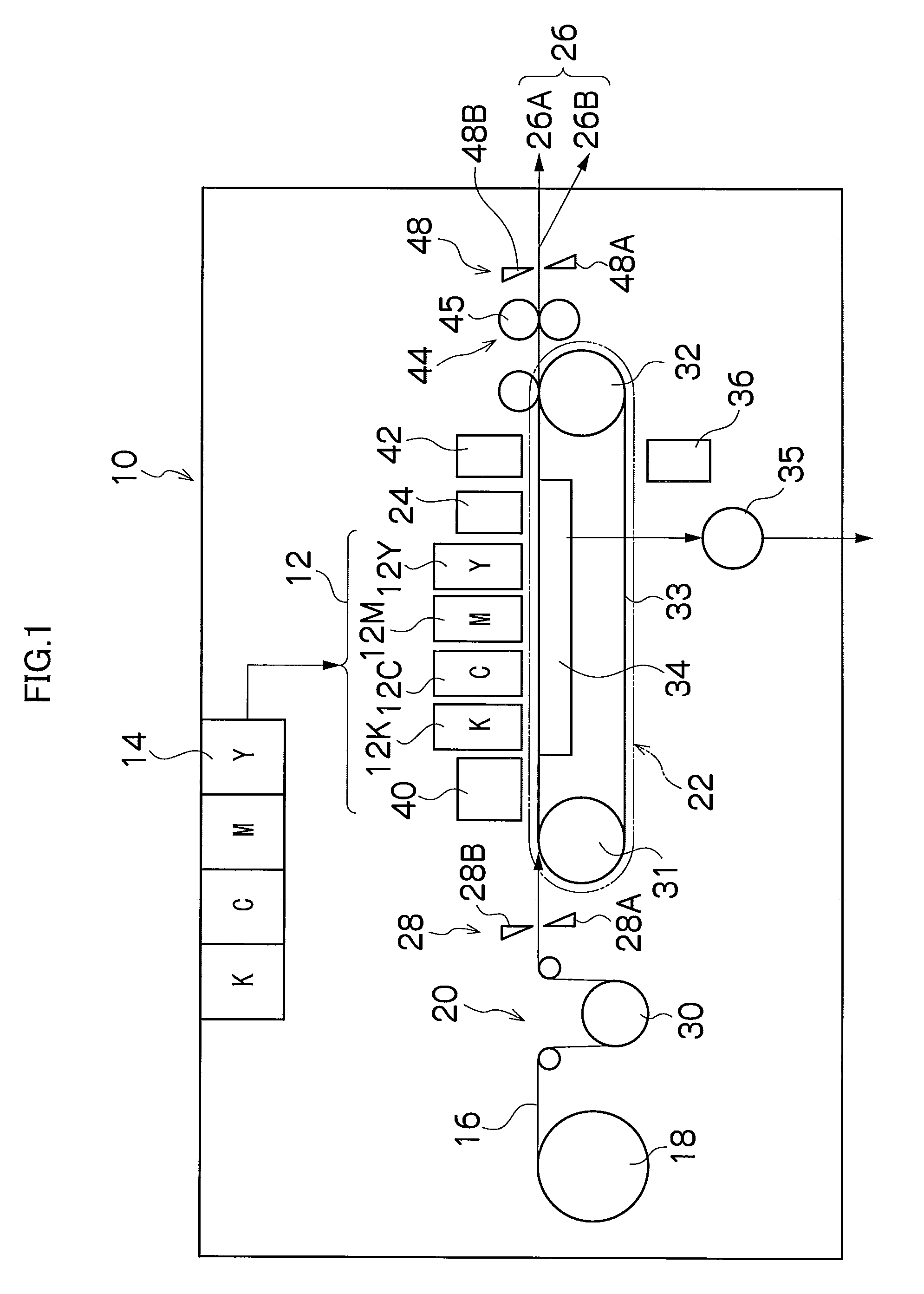

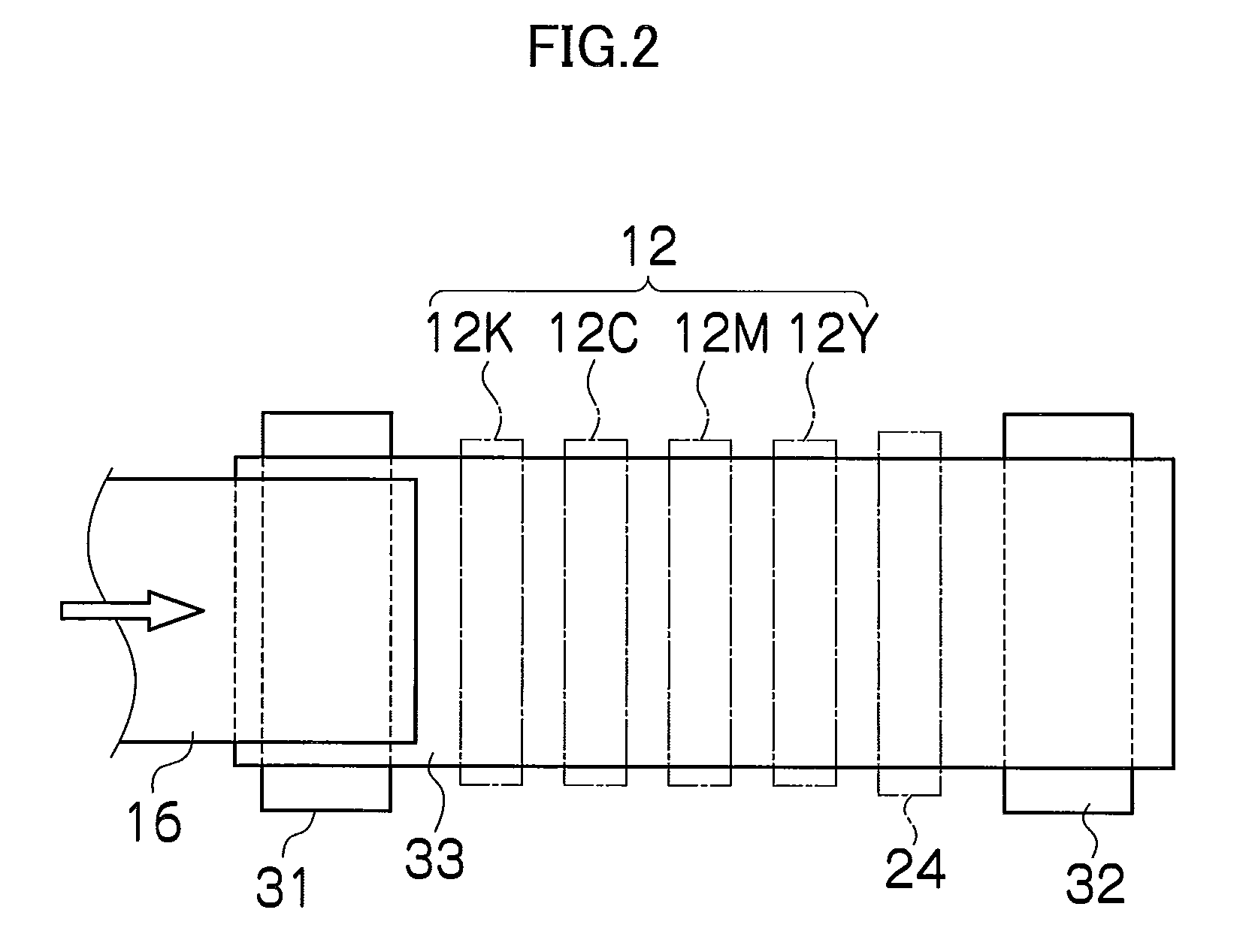

Inkjet recording apparatus

ActiveUS20100085396A1Improve printing qualityHighly accurate pressure adjustmentInking apparatusOther printing apparatusInternal pressureEngineering

Inkjet apparatus includes: a tank; a first flow channel; a first liquid chamber; a second flow channel; a second liquid chamber; a first liquid movement; a second liquid movement device; a first pressure determination device; a second pressure determination device; a pressure control device which controls pressures in the first and second liquid chambers by respectively controlling the first and second liquid movement devices, in accordance with determination results of the first and second pressure determination devices, in such a manner that the internal pressures of the first and second liquid chambers respectively remain at the target pressures; a circulation path through which the liquid inside the first liquid chamber is circulated without passing through the inkjet head; and a deaeration device which is provided at an intermediate point of the circulation path and which removes dissolved gas.

Owner:FUJIFILM CORP

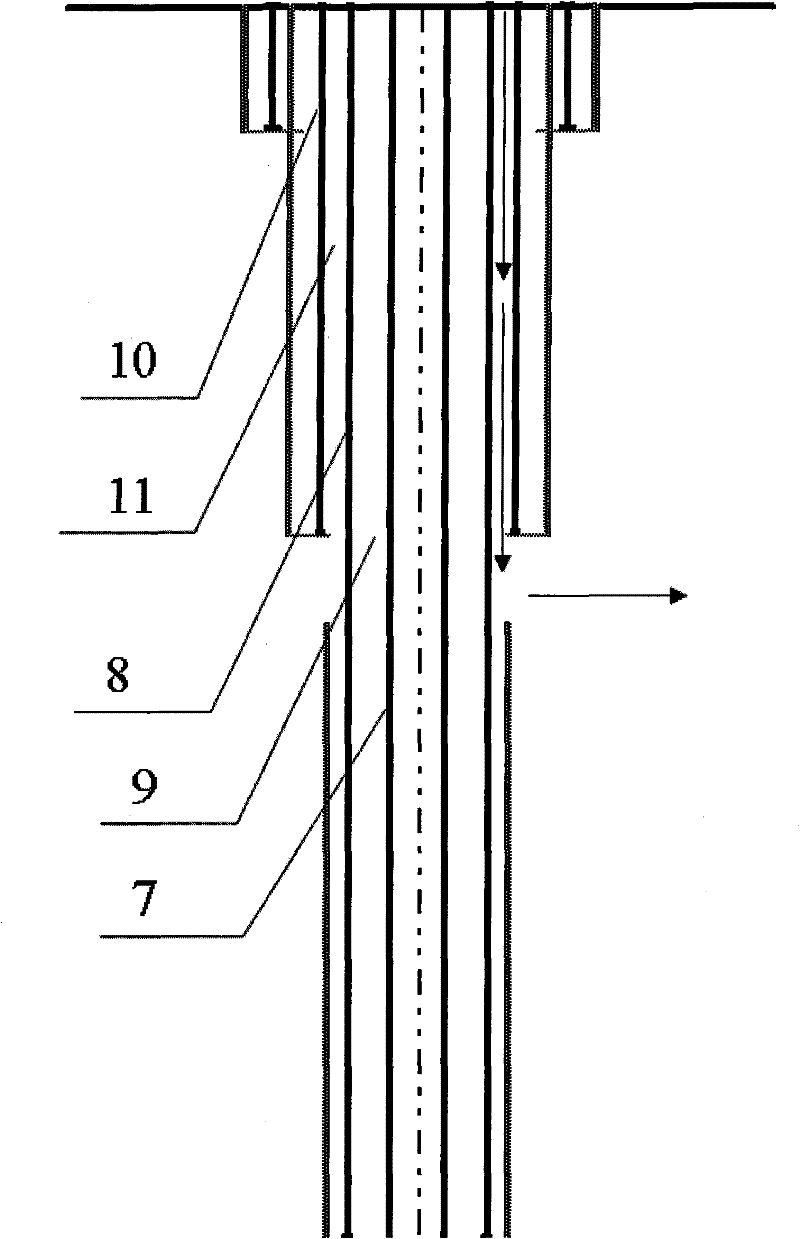

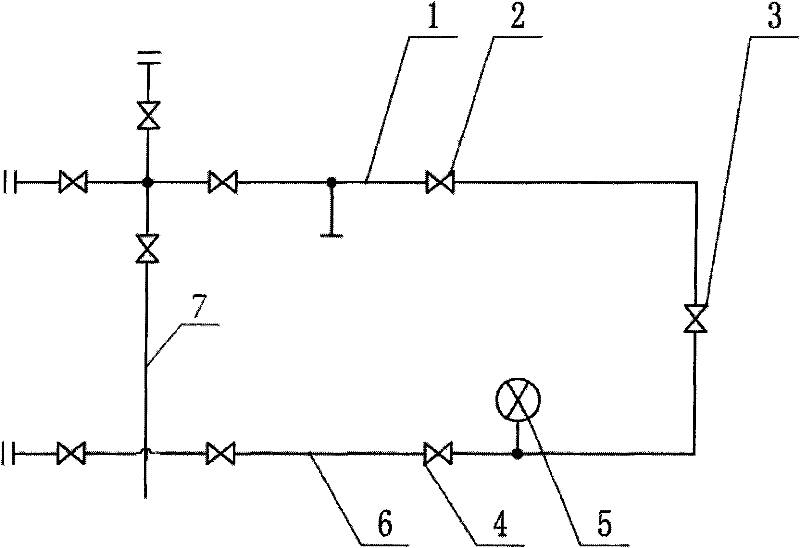

Rock debris annulus reinjection device and control method thereof

The invention discloses a rock debris annulus reinjection system. A water injection well is taken as a reinjection well, an inner annulus (9) is formed between a water injection pipeline (7) in the middle and a 9-5 / 8' sleeve (8), and an outer annulus (11) is formed between the 9-5 / 8' sleeve (8) and a 13-3 / 8' sleeve (10). The system is characterized in that: a water injection pipeline isolating valve (2), a pressure control valve (3), an inner annulus isolating valve (4) and an inner annulus pressure meter (5) are arranged between an extension pipe (1) of the water injection pipeline (7) and an outlet pipeline (6) of the inner annulus (9). The system is used for the rock debris reinjection operation technology of offshore oilfield drilling; and when rock debris is reinjected into the outer annulus between the 13-3 / 8' sleeve and the 9-5 / 8' sleeve, the allowable outlet pressure of the pressure control valve is adjusted, and the inner annulus is pressurized, so that rock debris reinjection slurry cannot flow into the inner annulus, the space of the inner annulus is protected, and the completeness of the water injection well is protected.

Owner:JEREH ENERGY SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com