Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1590 results about "Liquid carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

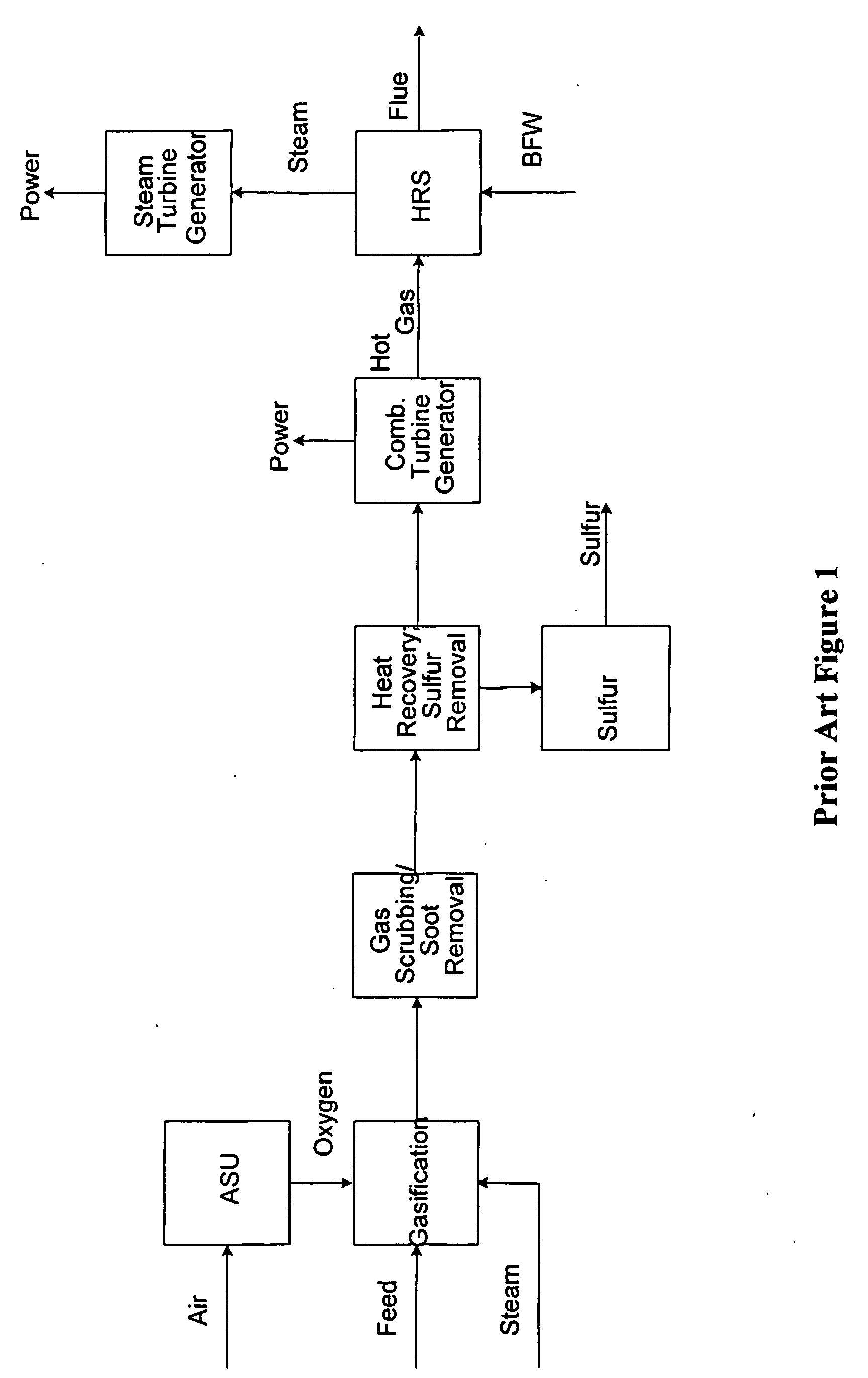

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

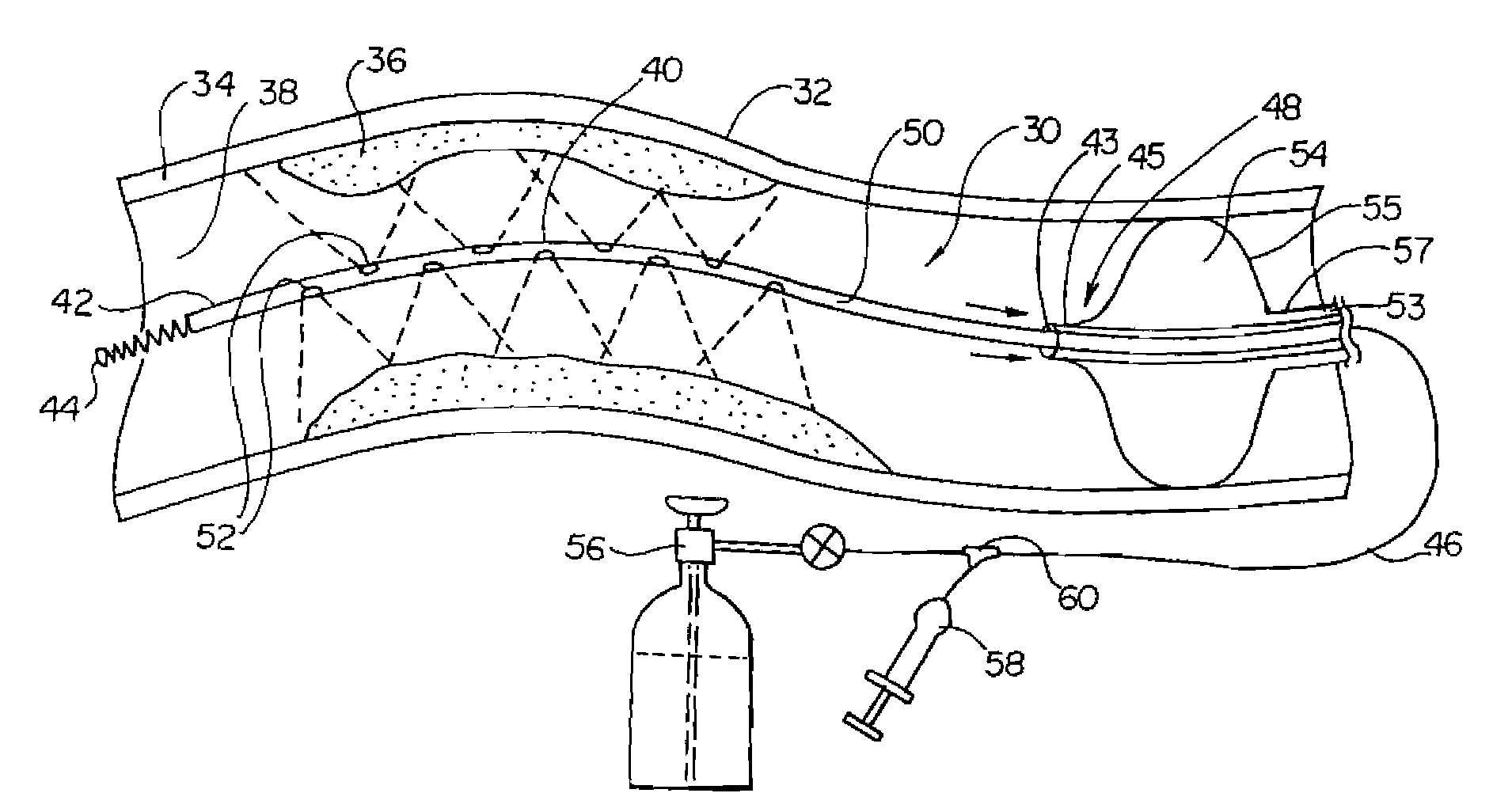

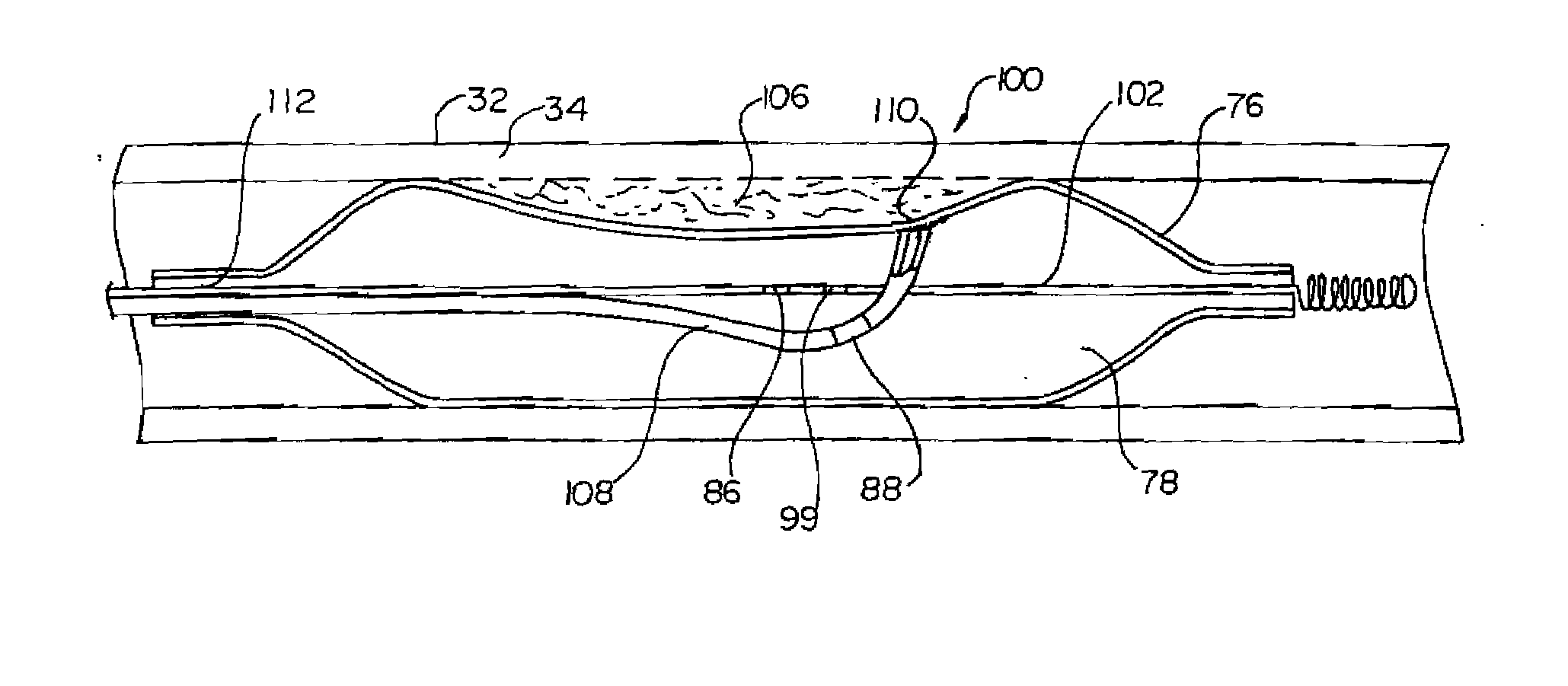

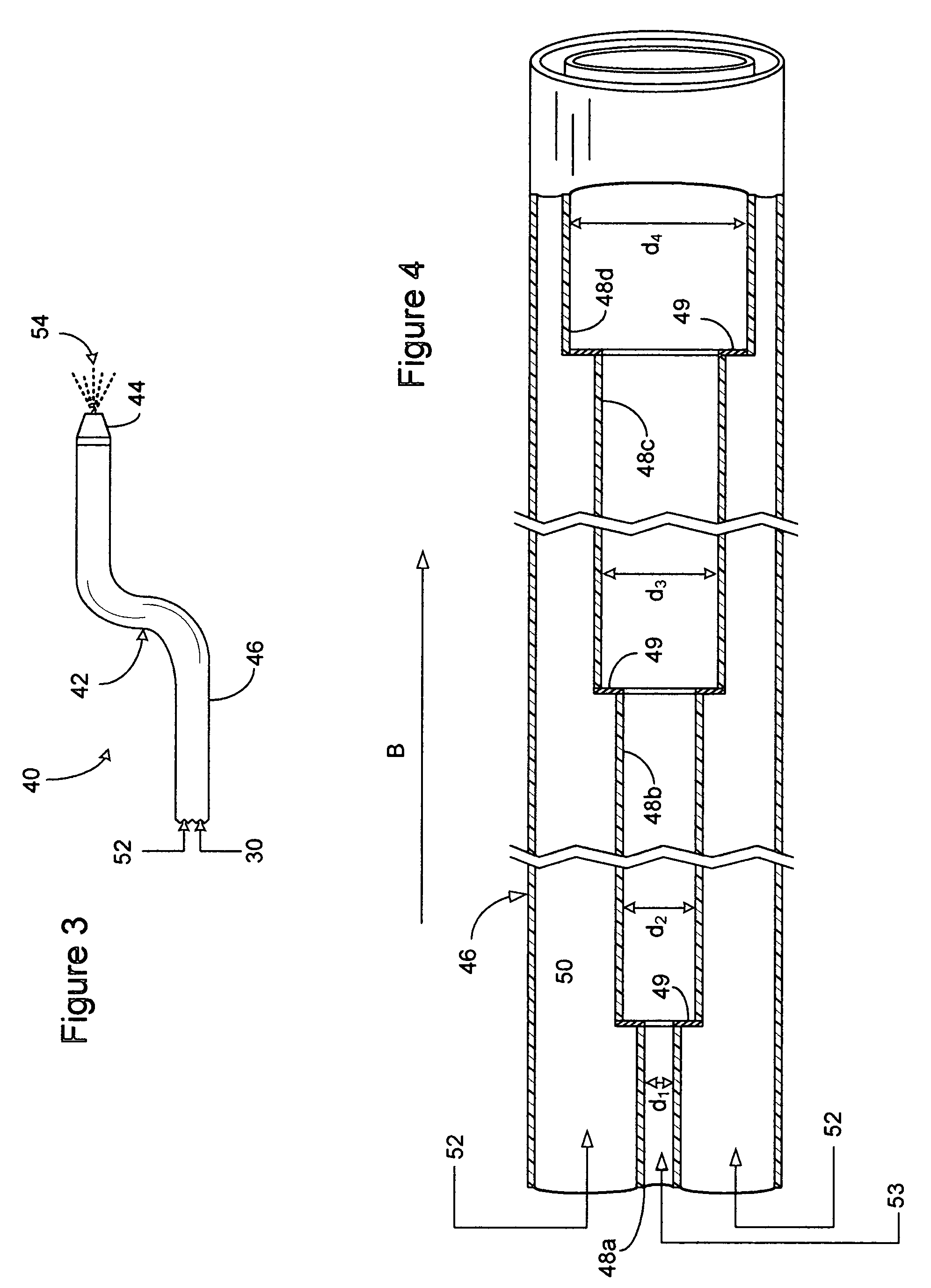

Cryotreatment device and method

InactiveUS7220257B1Reduce adverse reactionsReduced responseStentsOther blood circulation devicesCoronary artery angioplastyPercent Diameter Stenosis

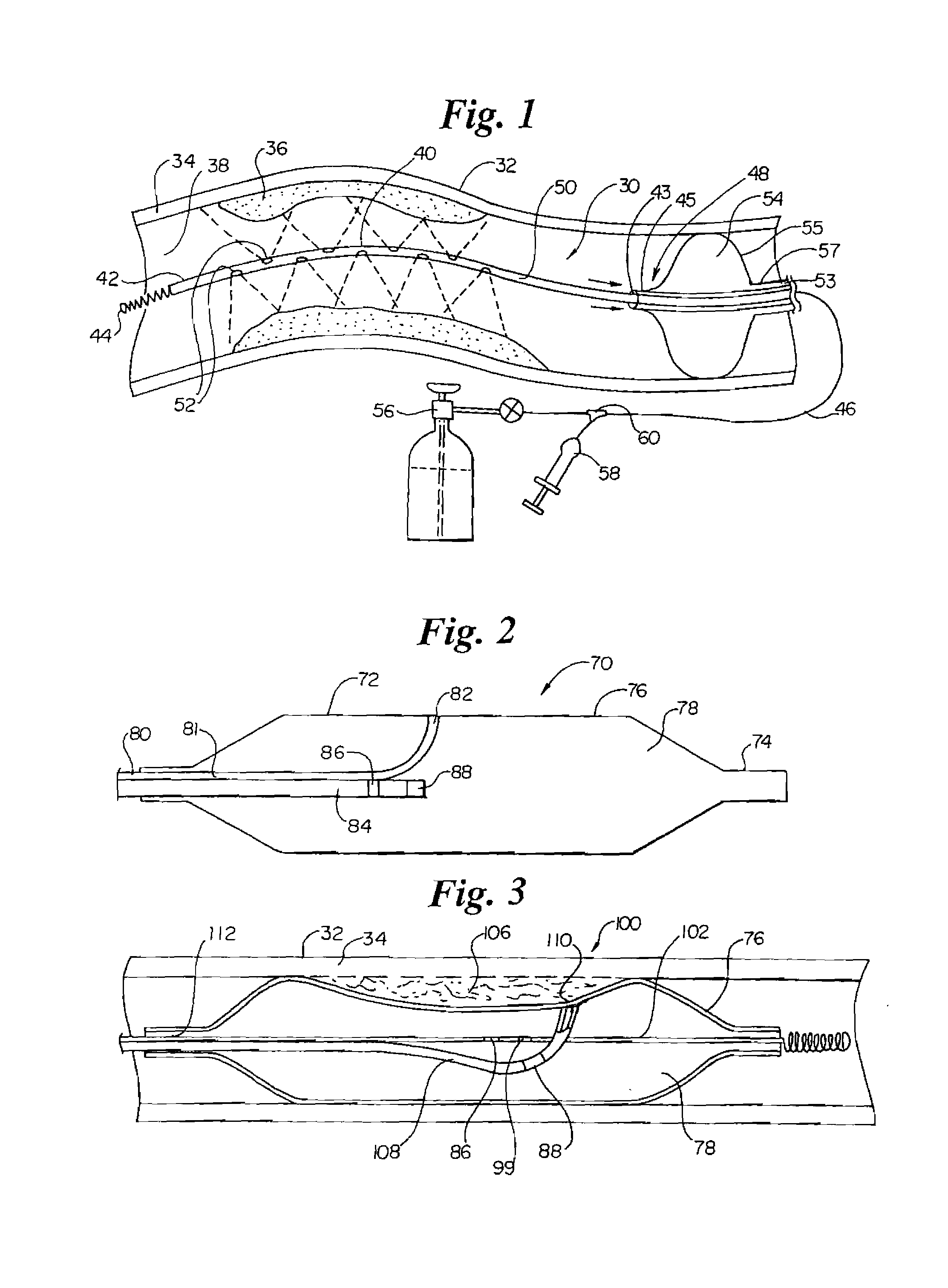

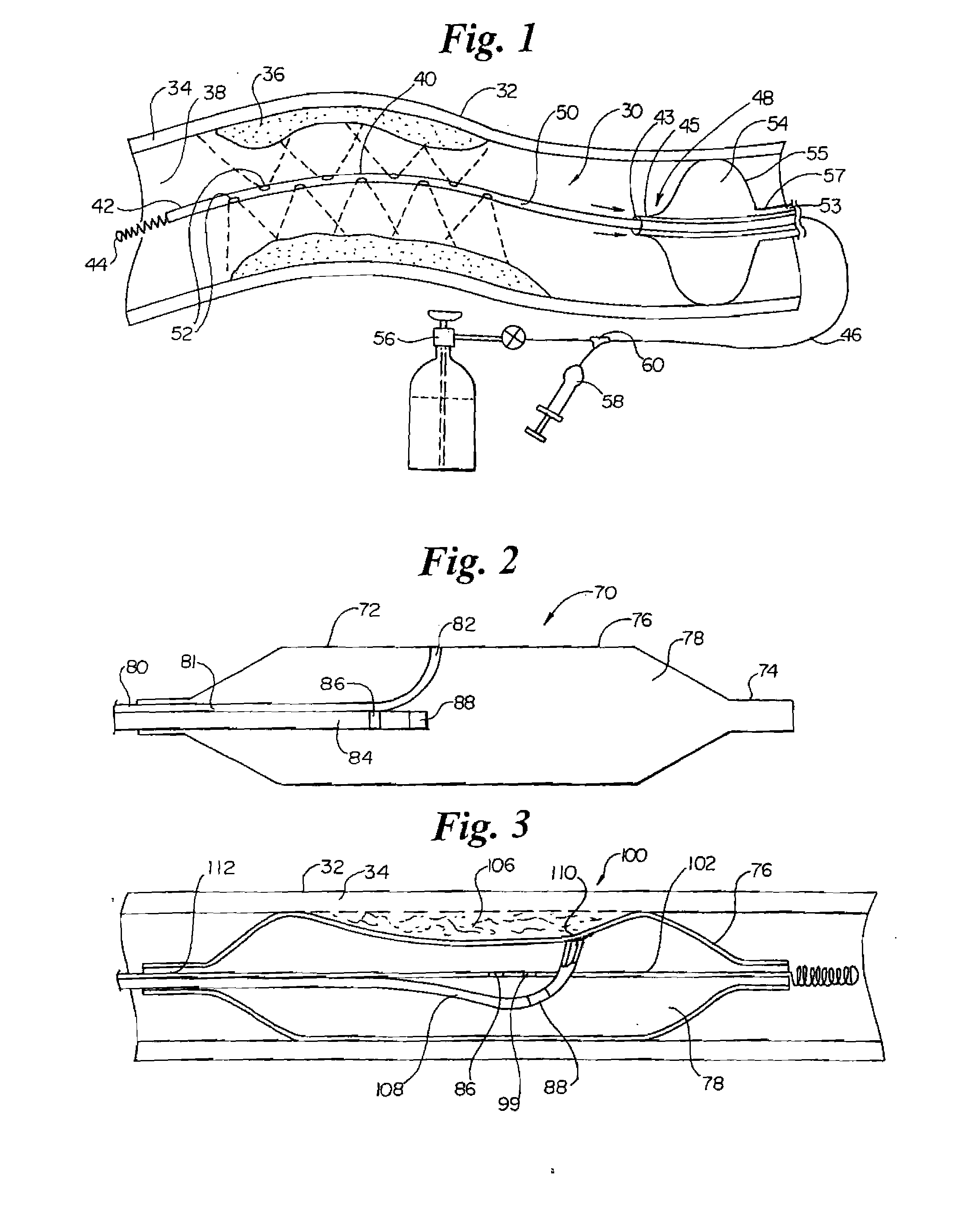

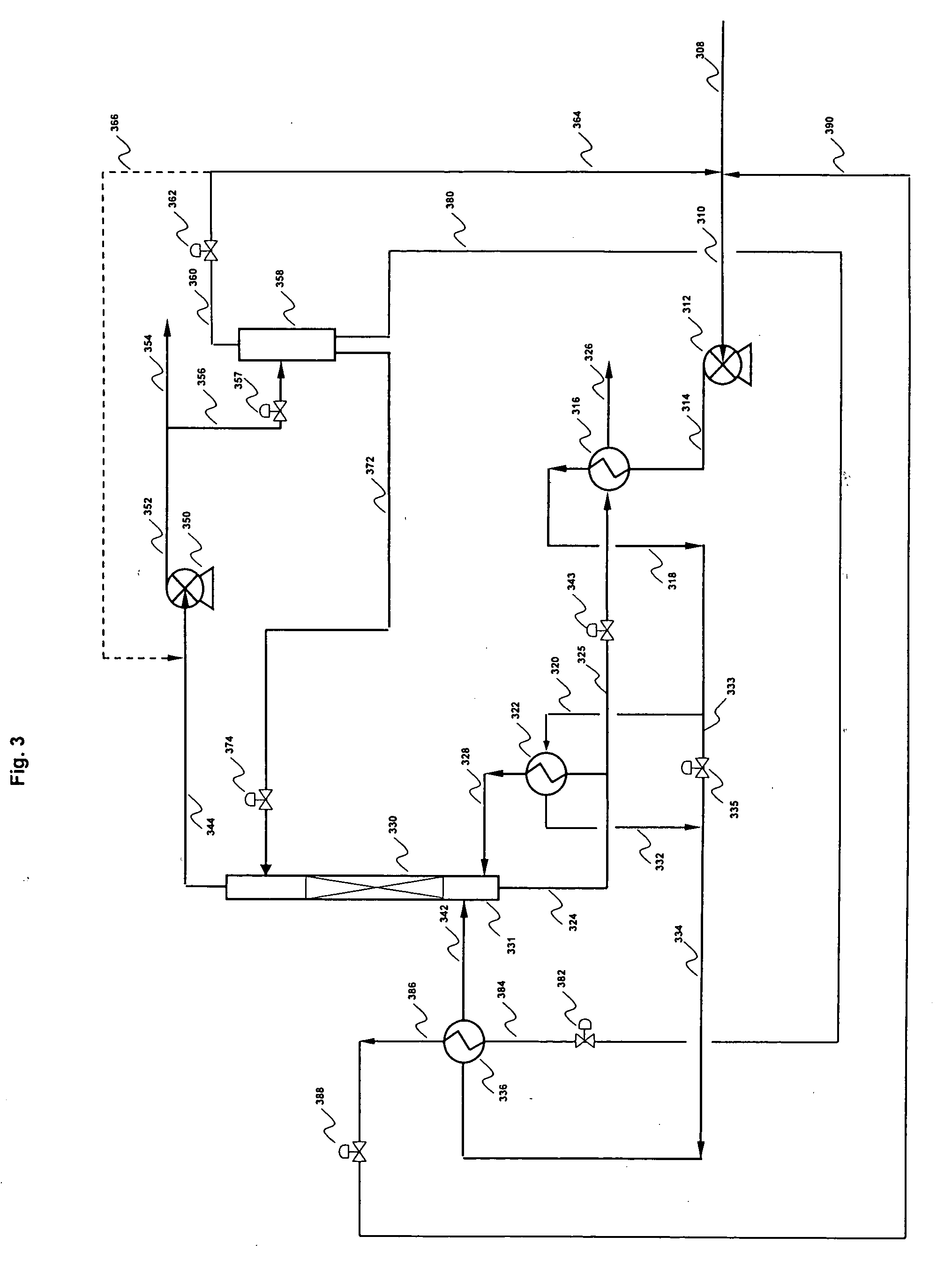

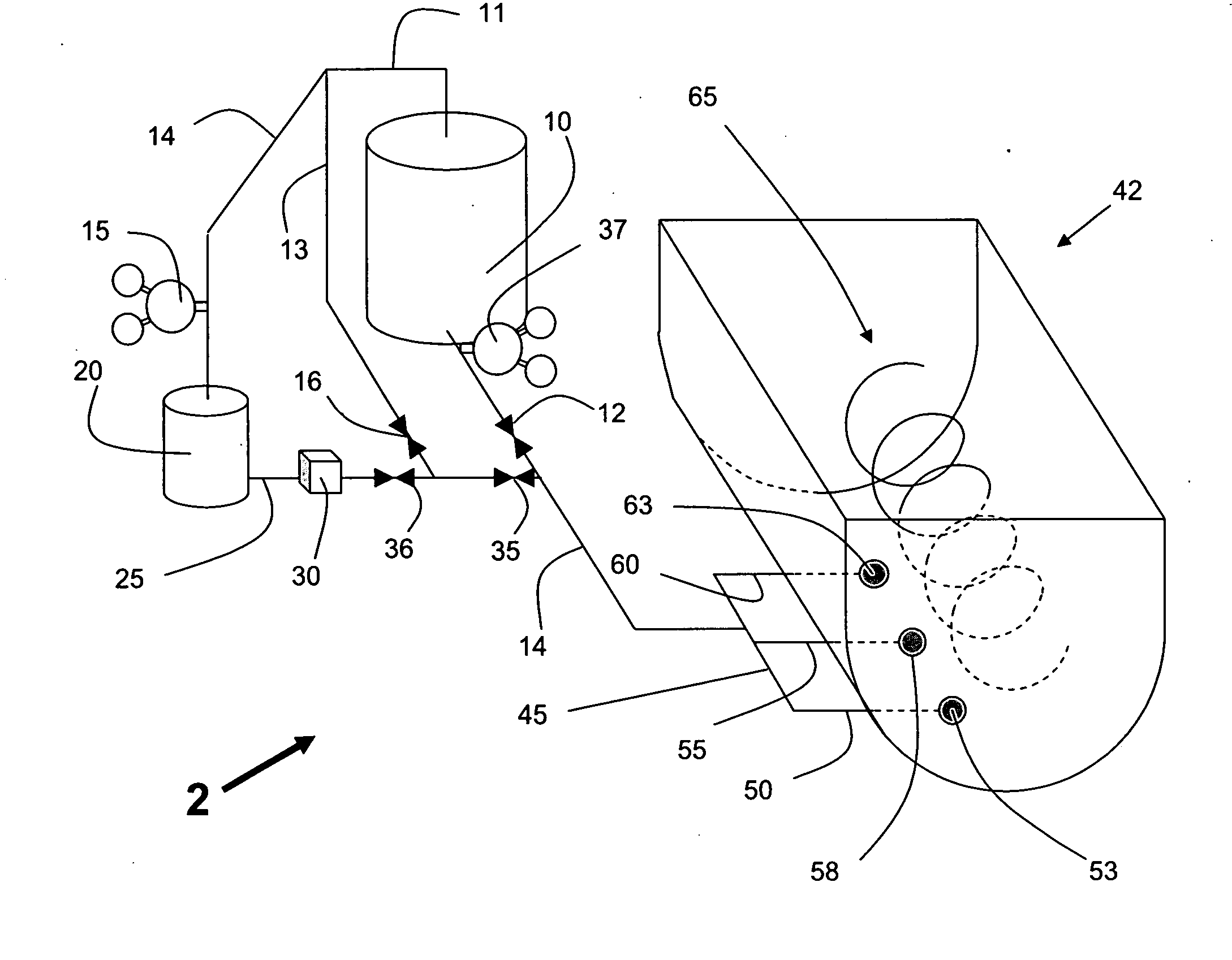

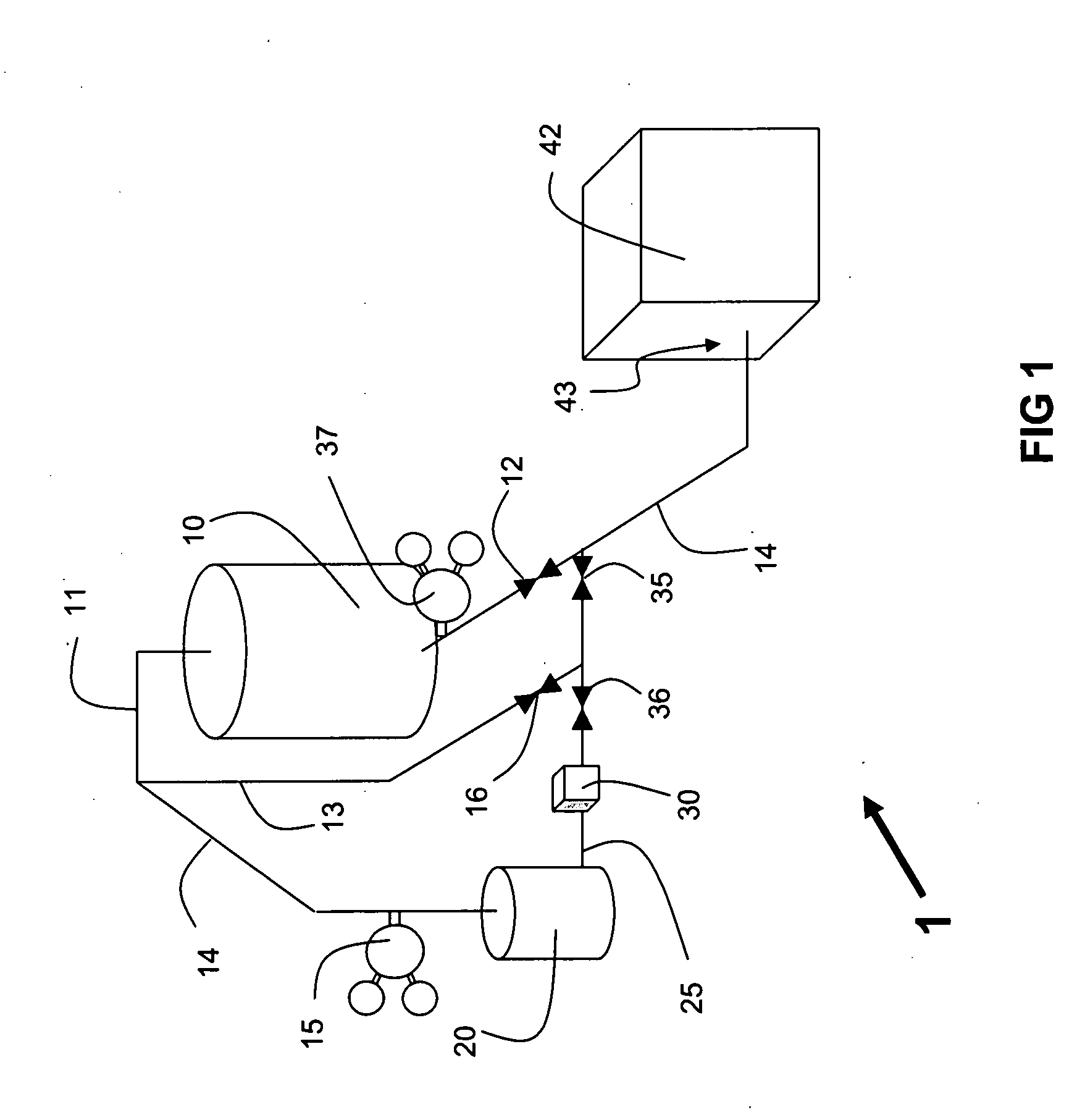

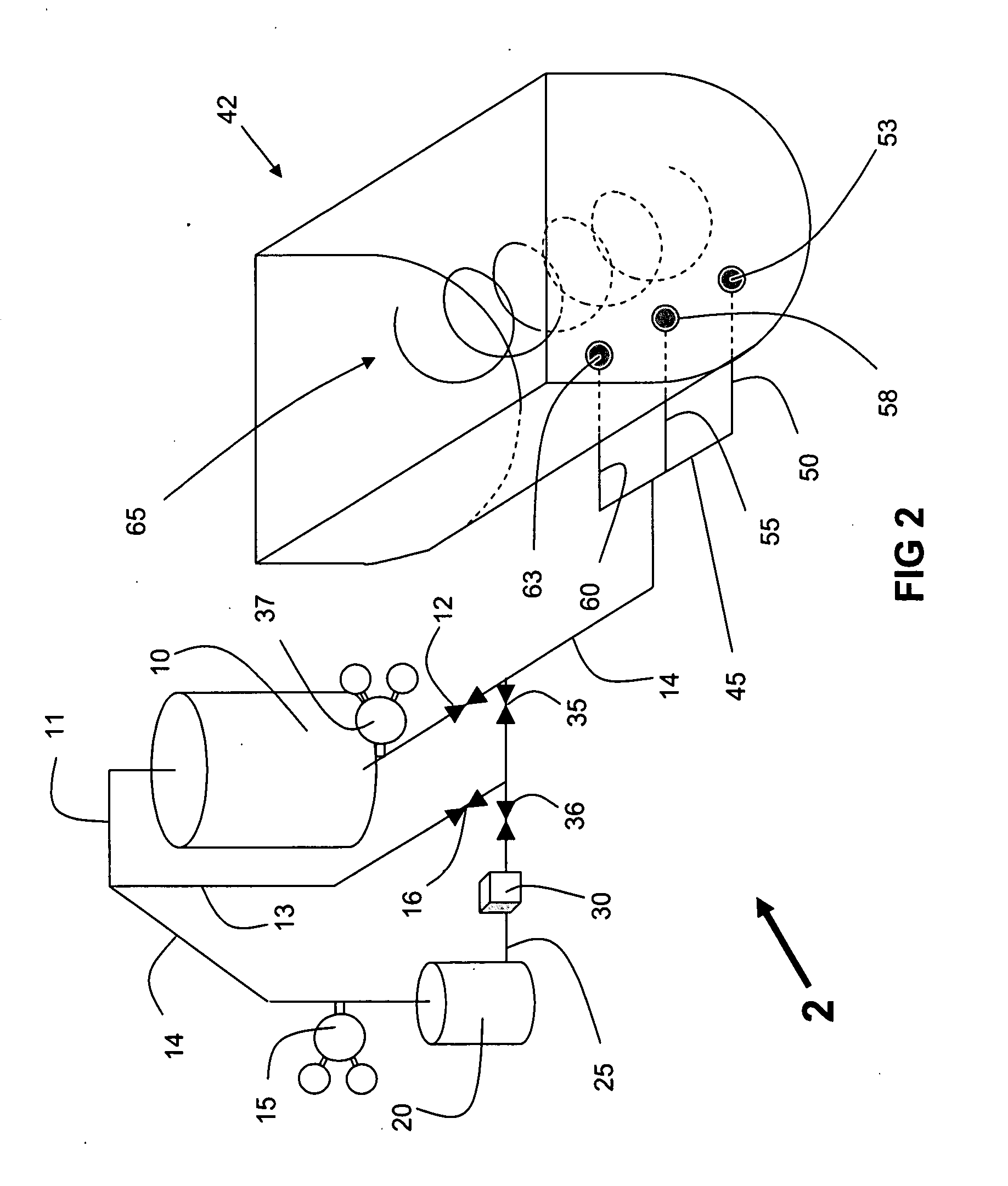

Devices and methods for cooling vessel walls to inhibit restenosis in conjunction with medical procedures such as coronary artery angioplasty. Stenosed vessel walls can be cooled prior to angioplasty, after angioplasty, or both. The invention is believed to inhibit restenosis through cooling to a temperature near freezing, preferably without causing substantial vessel wall cell death. One catheter device includes a distal tube region having coolant delivery holes radially and longitudinally distributed along the distal region. In some devices, holes spray coolant directly onto the vessel walls, with the coolant absorbed into the blood stream. In other embodiments, a balloon or envelope is interposed between the coolant and the vessel walls and the coolant returned out of the catheter through a coolant return lumen. Some direct spray devices include an occlusion device to restrict blood flow past the region being cooled. Pressure, temperature, and ultrasonic probes are included in some cooling catheters. Pressure control valves are included in some devices to regulate balloon interior pressure within acceptable limits. In applications using liquid carbon dioxide as coolant, the balloon interior pressure can be maintained above the triple point of carbon dioxide to inhibit dry ice formation. Some cooling catheters are coiled perfusion catheters supporting longer cooling periods by allowing perfusing blood flow simultaneously with vessel wall cooling. One coiled catheter is biased to assume a coiled shape when unconstrained and can be introduced into the body in a relatively straight shape, having a stiffening wire inserted through the coil strands.

Owner:BOSTON SCI SCIMED INC

Method of treating subterranean formations with porous particulate materials

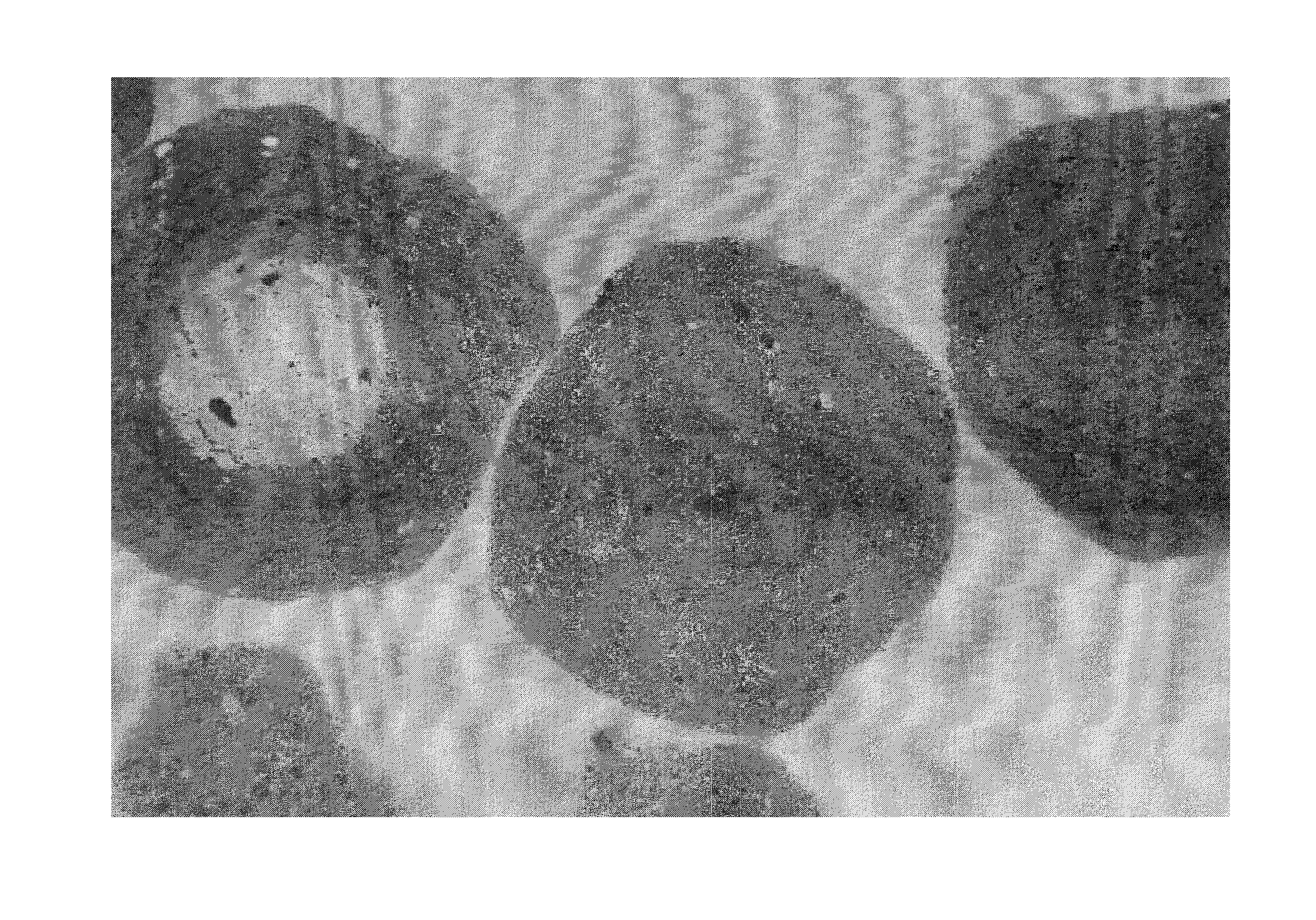

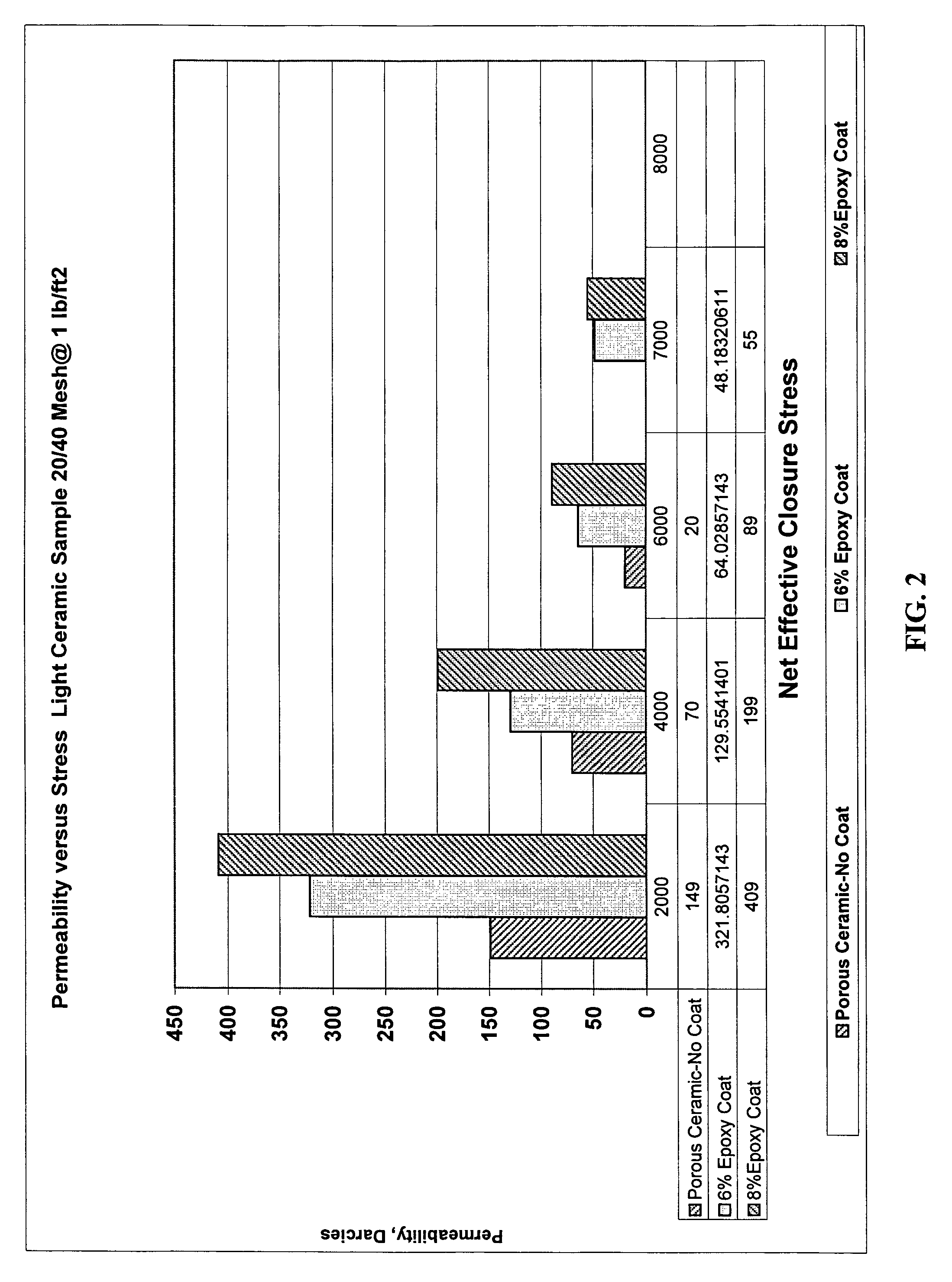

ActiveUS7426961B2Improve system performanceReduce and prevent productionFluid removalDrilling compositionApparent densityParticulates

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that include porous materials. Such porous materials may be selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials to have desired strength and / or apparent density to fit particular downhole conditions for well treating such as hydraulic fracturing treatments and sand control treatments. Porous materials may also be employed in selected combinations to optimize fracture or sand control performance, and / or may be employed as relatively lightweight materials in liquid carbon dioxide-based well treatment systems.

Owner:BAKER HUGHES INC

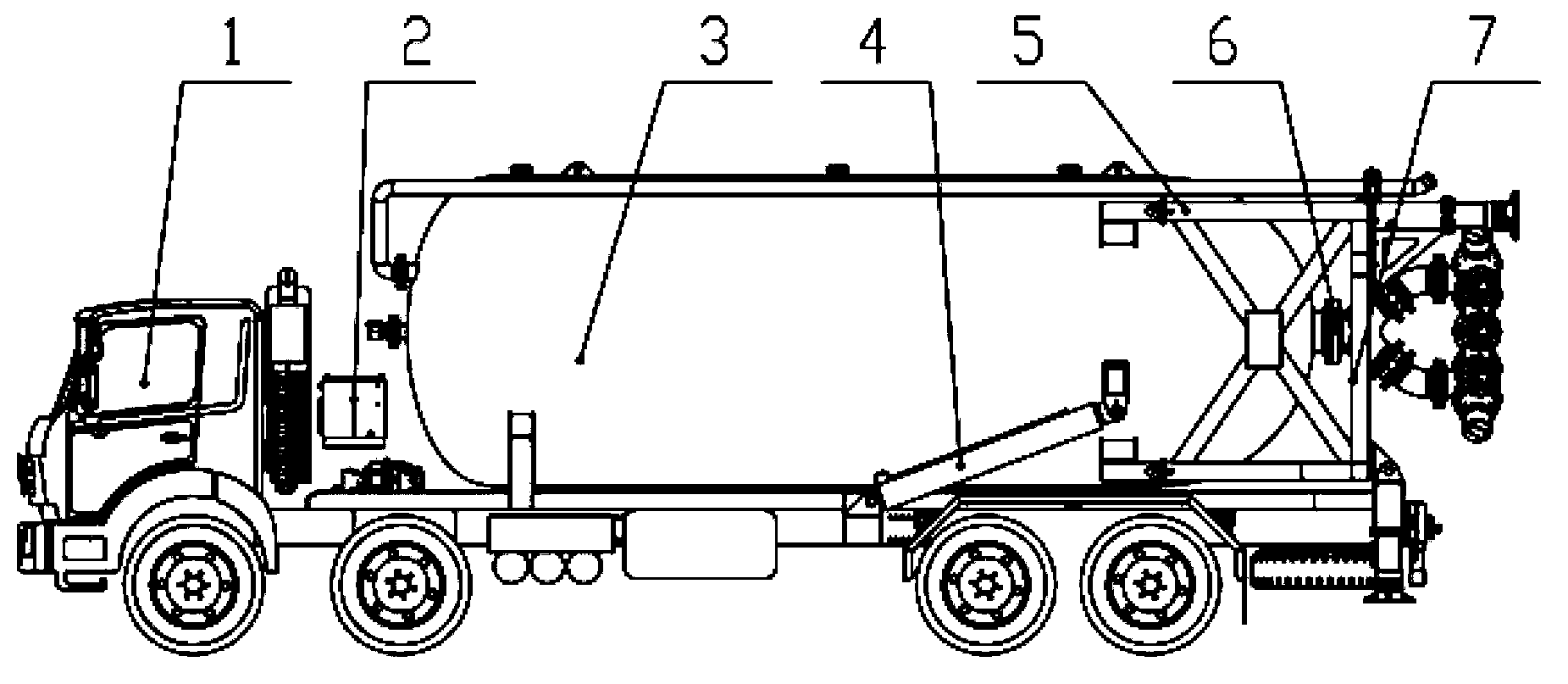

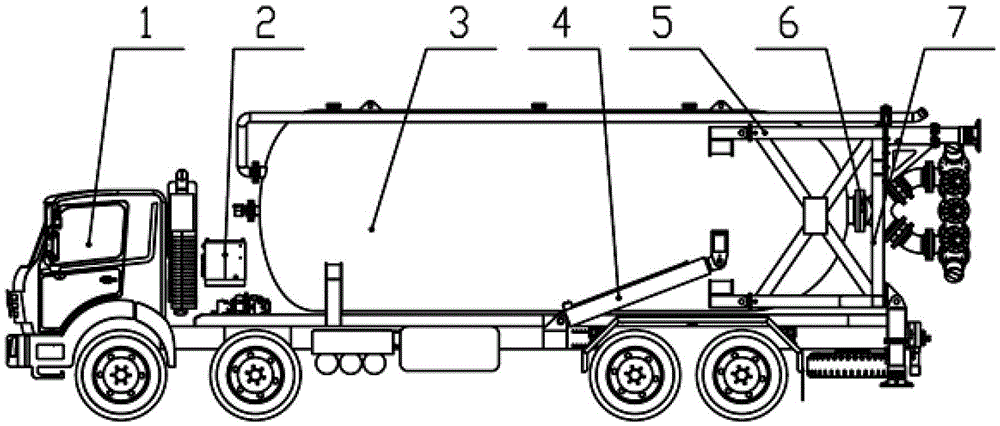

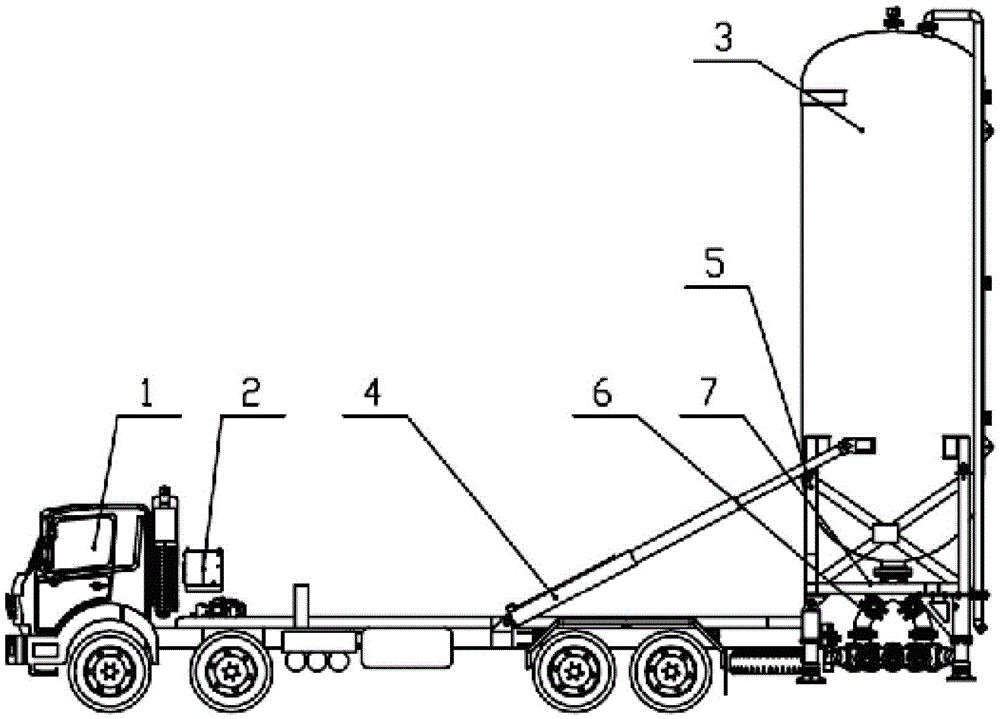

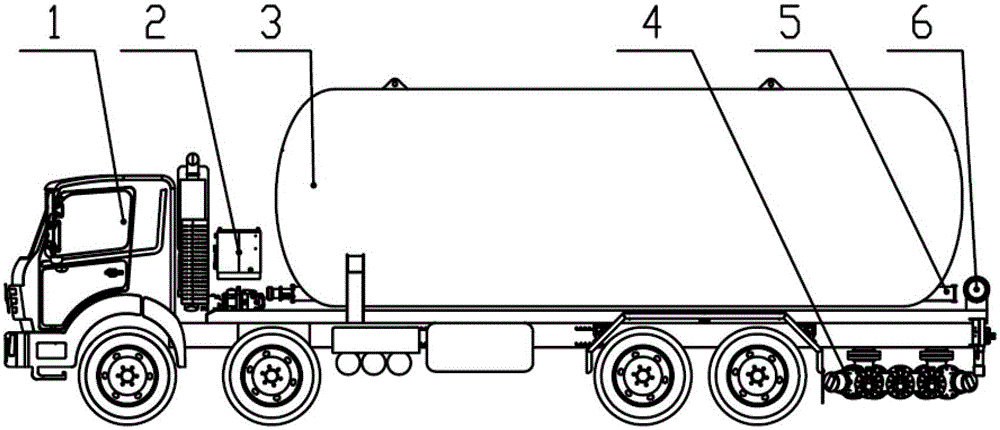

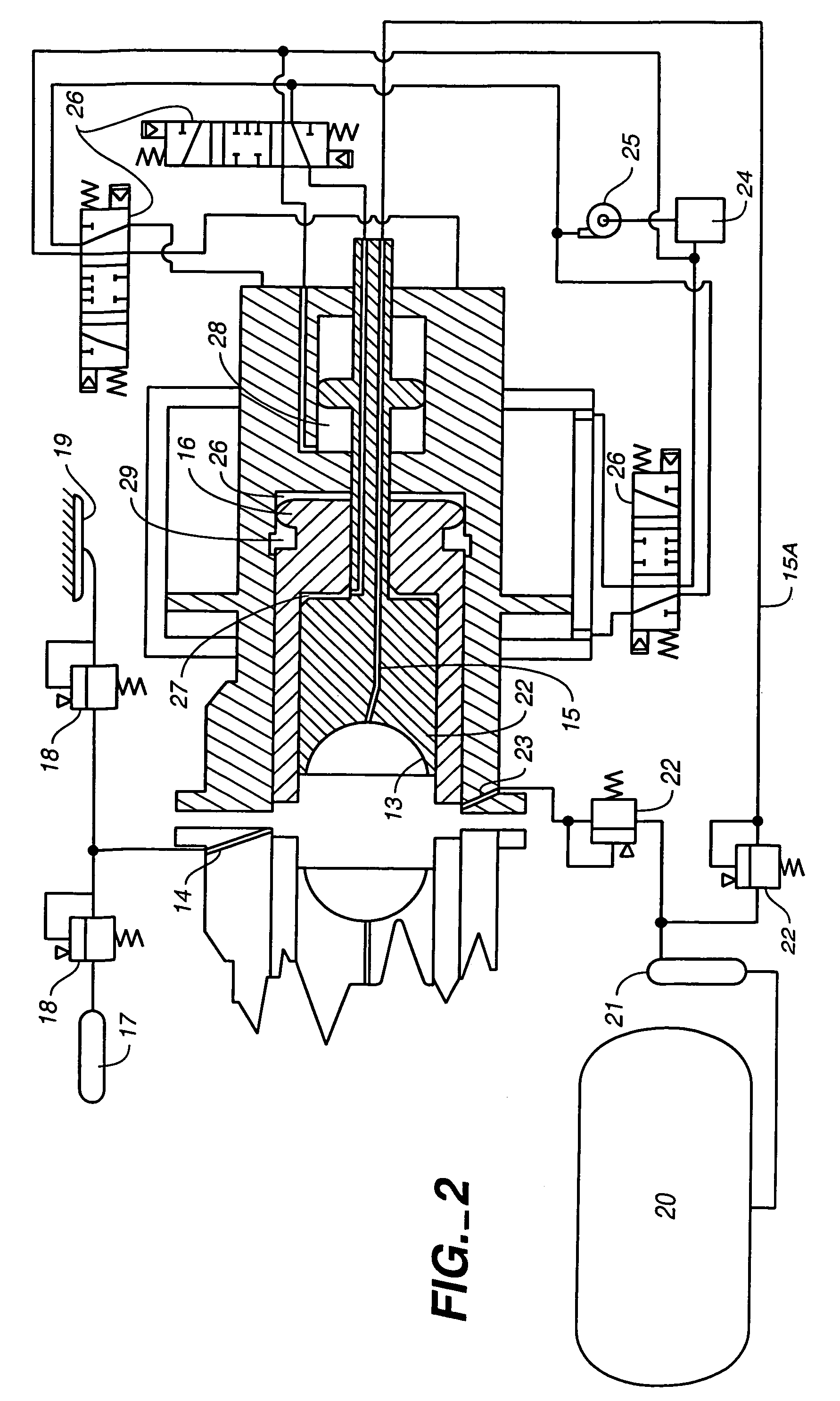

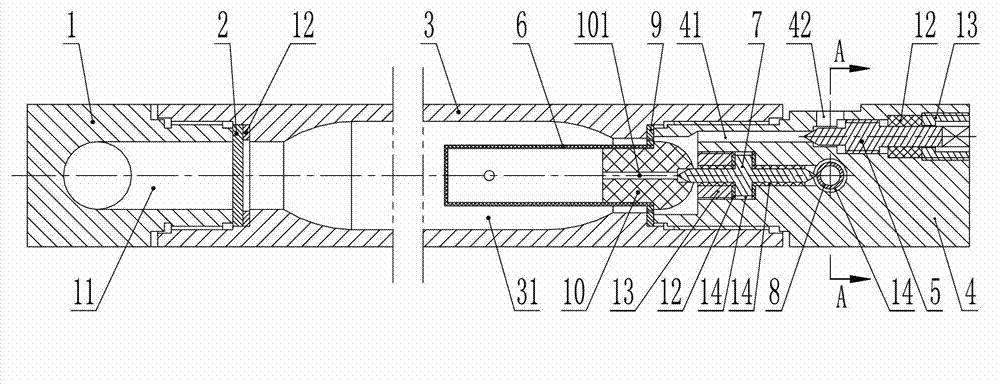

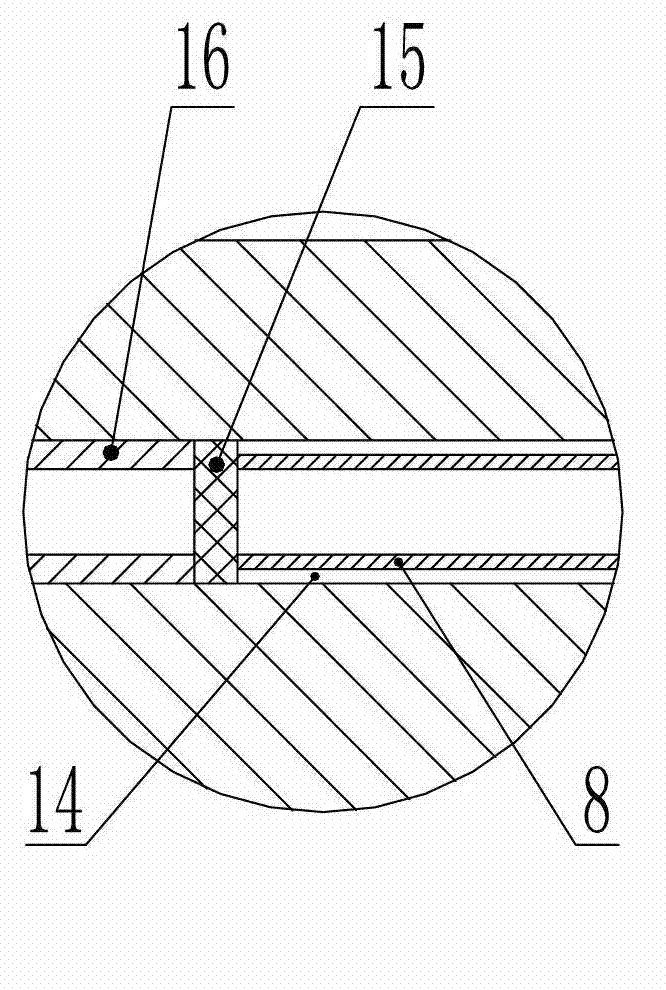

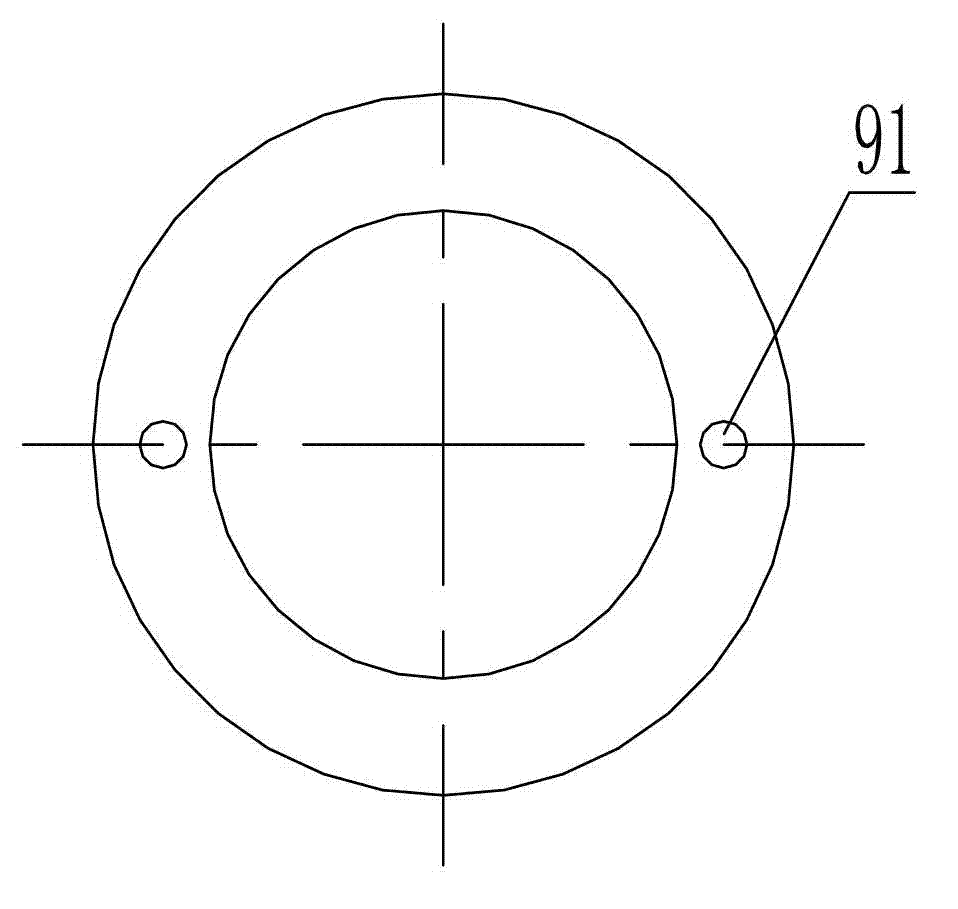

Fracturing sand mixing device

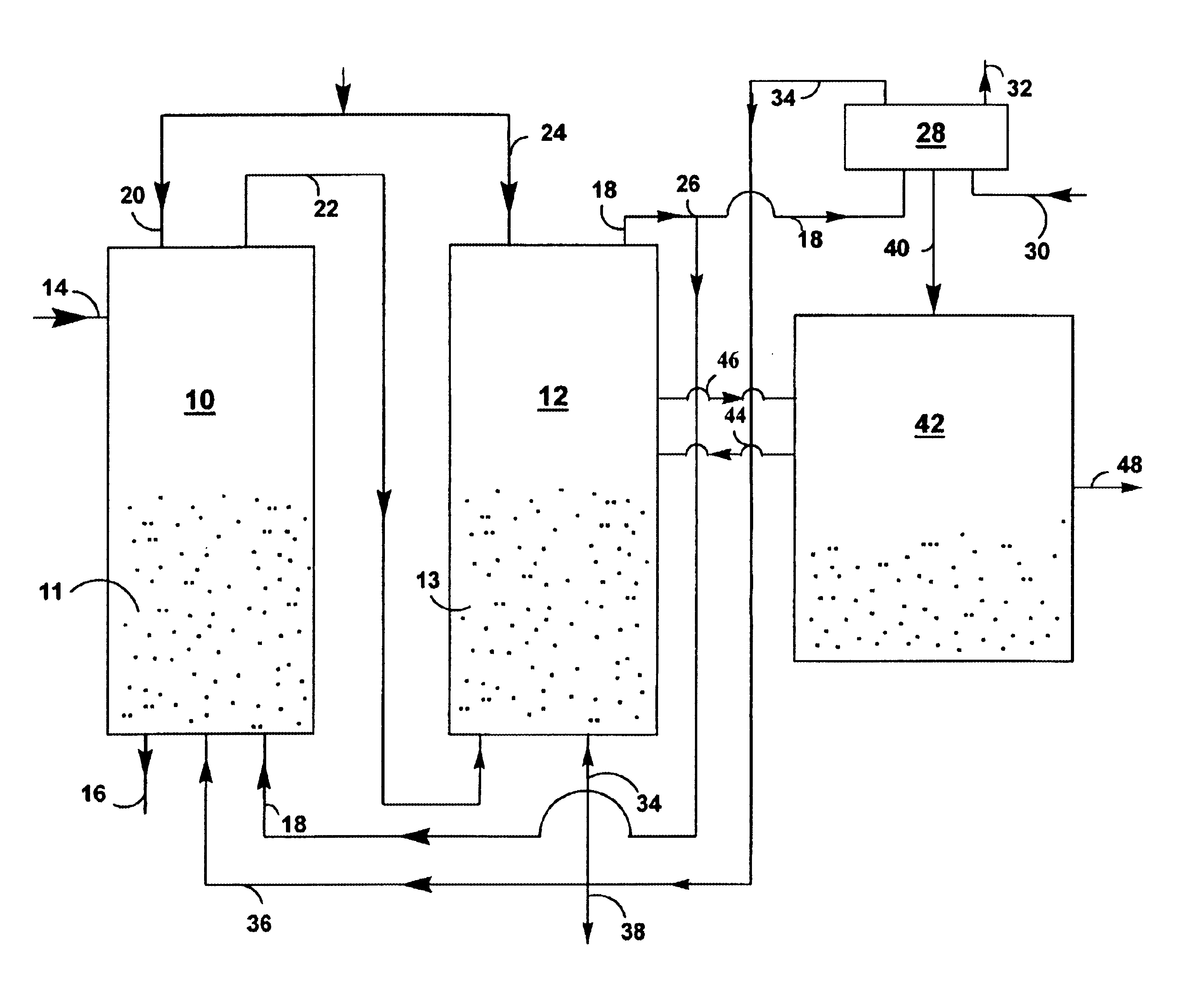

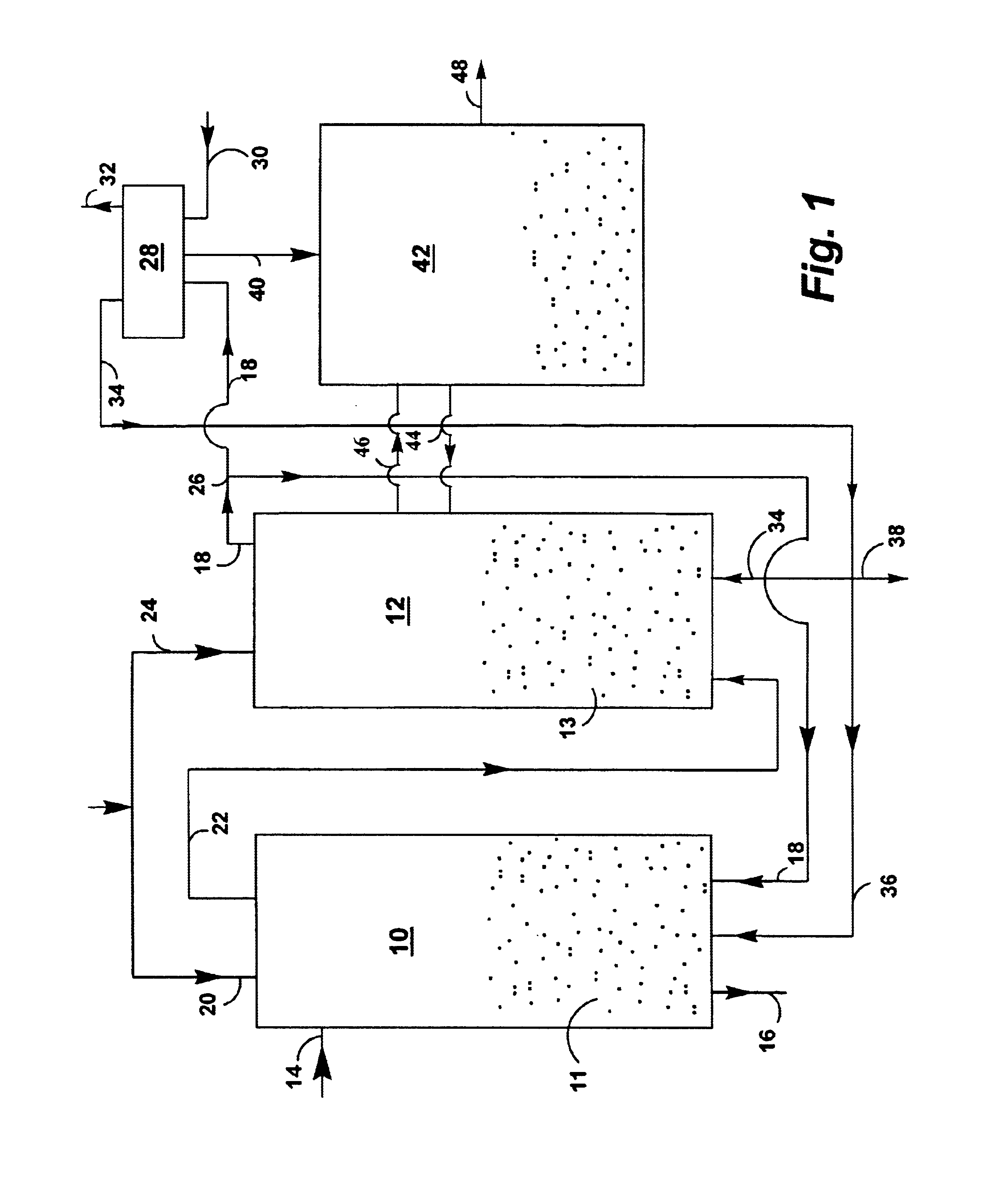

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

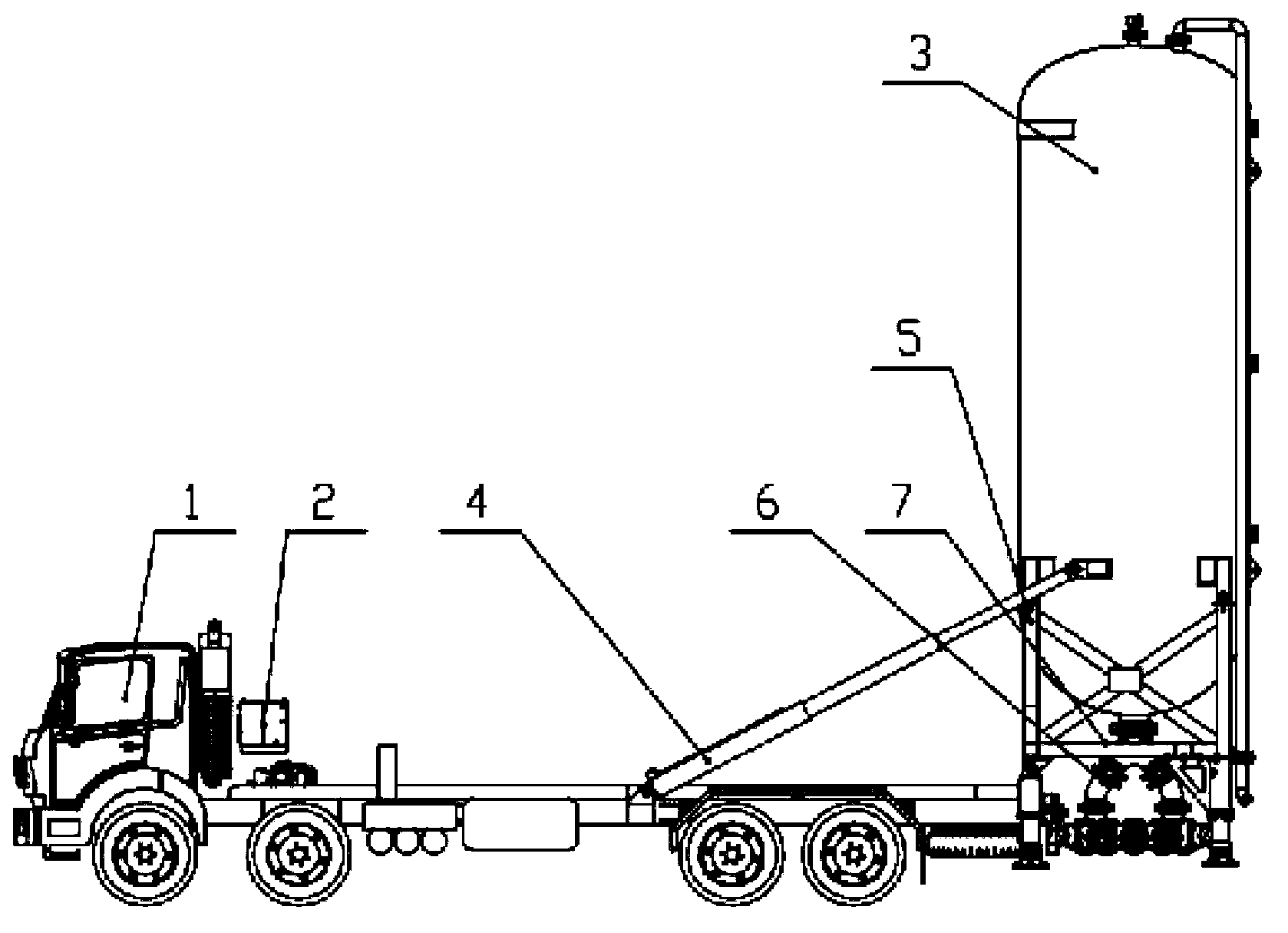

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

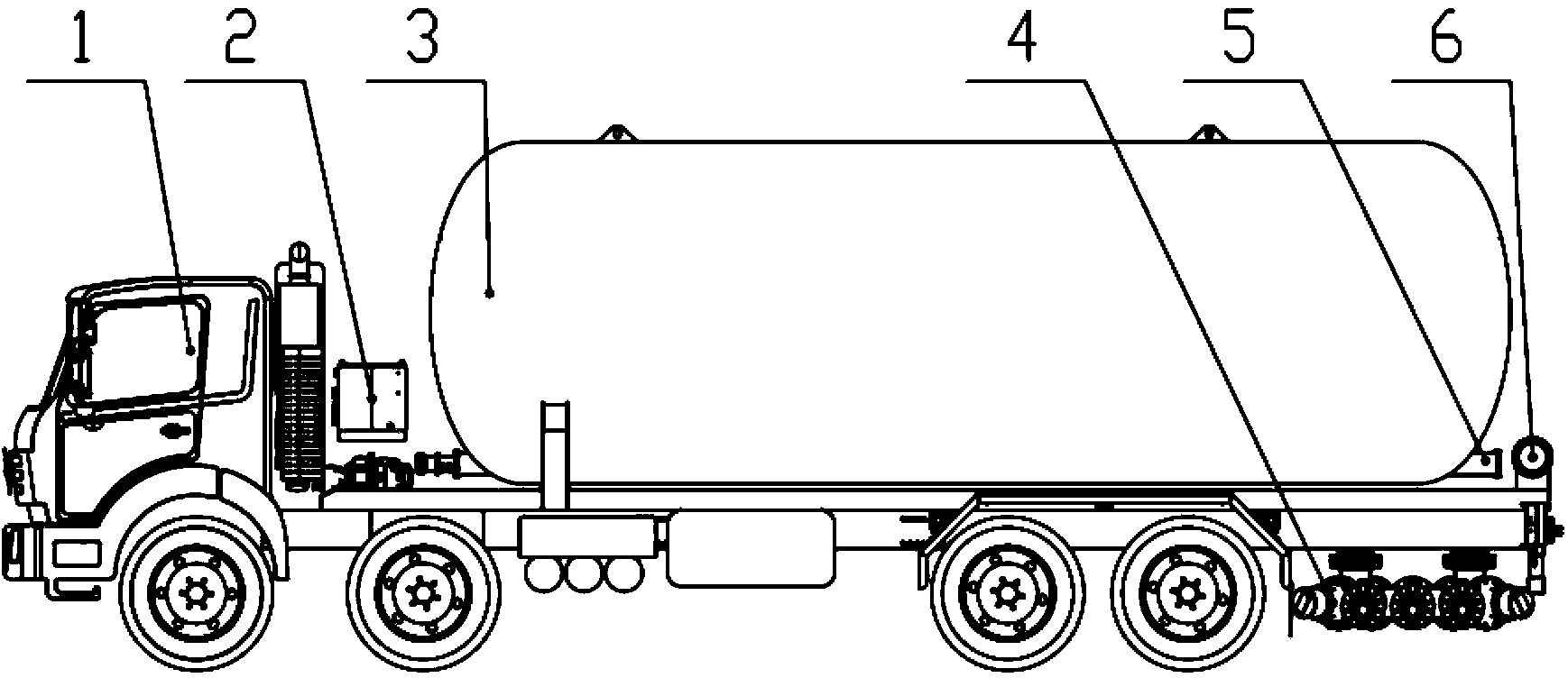

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

Cryotreatment device and method

InactiveUS20070250050A1Reduce adverse reactionsReduced responseStentsOther blood circulation devicesCoronary artery angioplastyPercent Diameter Stenosis

Devices and methods for cooling vessel walls to inhibit restenosis in conjunction with medical procedures such as coronary artery angioplasty. Stenosed vessel walls can be cooled prior to angioplasty, after angioplasty, or both. The invention is believed to inhibit restenosis through cooling to a temperature near freezing, preferably without causing substantial vessel wall cell death. One catheter device includes a distal tube region having coolant delivery holes radially and longitudinally distributed along the distal region. In some devices, holes spray coolant directly onto the vessel walls, with the coolant absorbed into the blood stream. In other embodiments, a balloon or envelope is interposed between the coolant and the vessel walls and the coolant returned out of the catheter through a coolant return lumen. Some direct spray devices include an occlusion device to restrict blood now past the region being cooled. Pressure, temperature, and ultrasonic probes are included in some cooling catheters. Pressure control valves are included in some devices to regulate balloon interior pressure within acceptable limits. In applications using liquid carbon dioxide as coolant, the balloon interior pressure can be maintained above the triple point of carbon dioxide to inhibit dry ice formation. Some cooling catheters are coiled perfusion catheters supporting longer cooling periods by allowing perfusing blood flow simultaneously with vessel wall cooling. One coiled catheter is biased to assume a coiled shape when unconstrained and can be introduced into the body in a relatively straight shape, having a stiffeninig wire inserted through the coil strands.

Owner:BOSTON SCI SCIMED INC

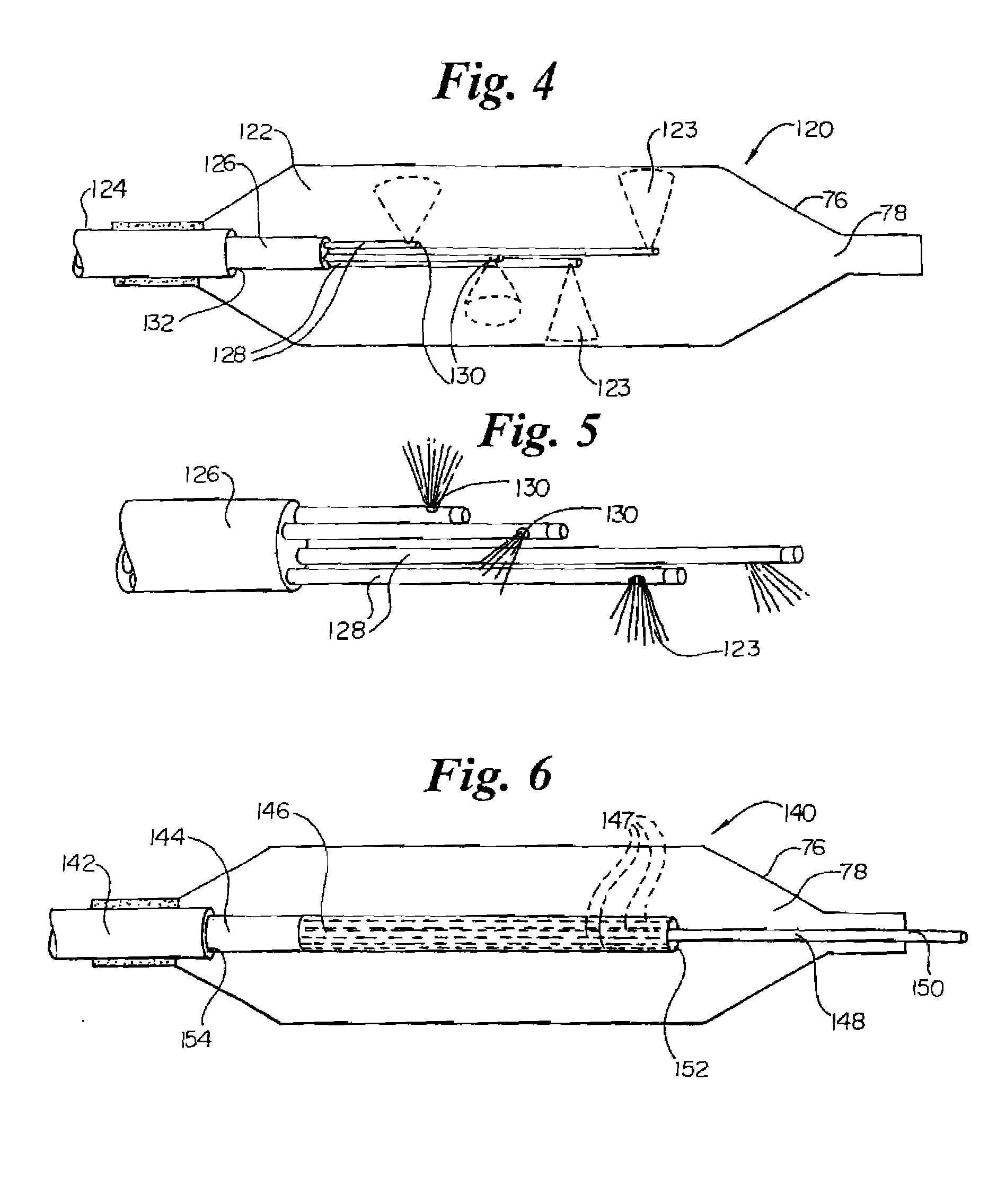

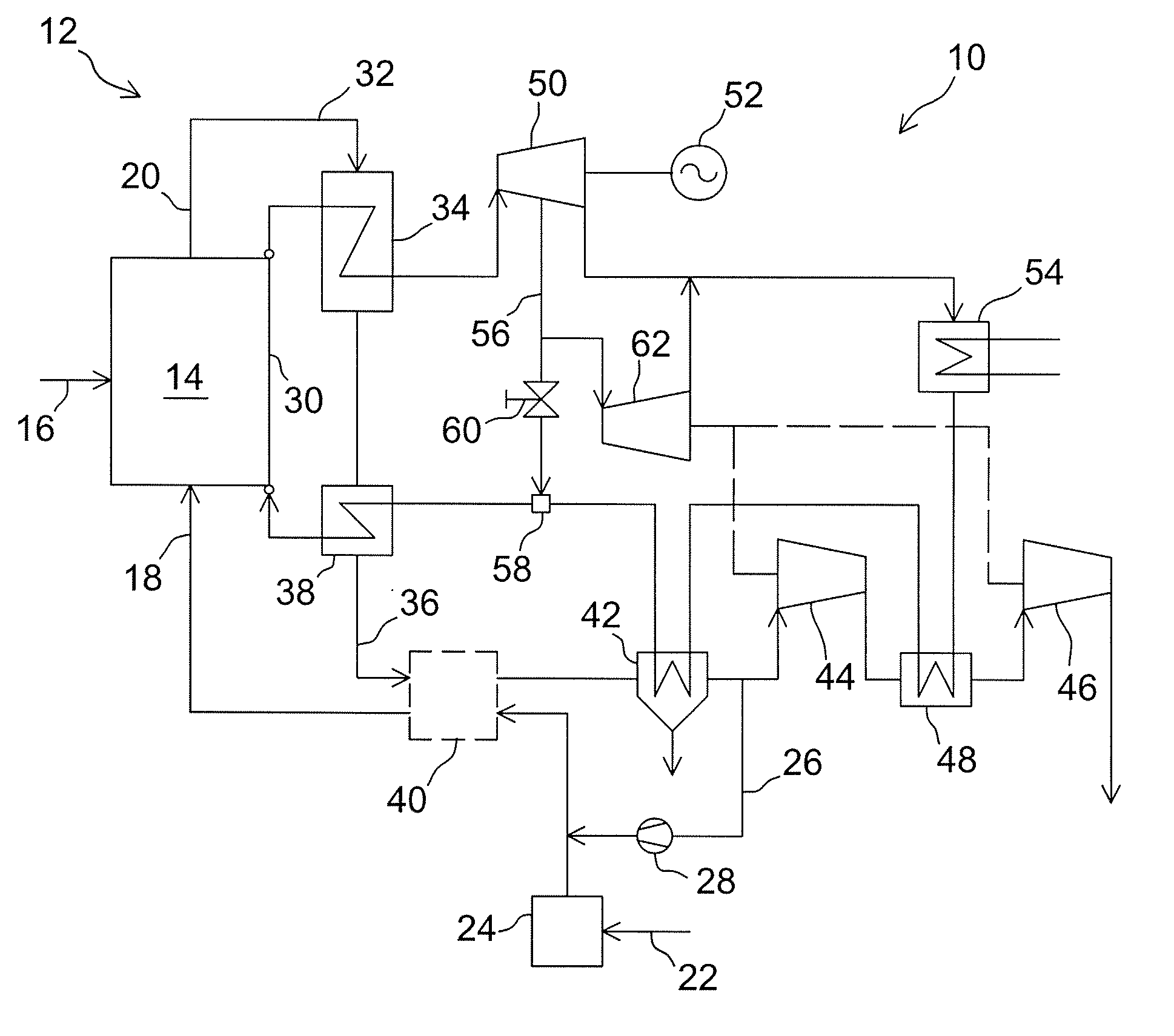

Method of and power plant for generating power by oxyfuel combustion

InactiveUS7874140B2Costs lossesLosses of powerGas turbine plantsHeat recoveryPower stationCombustion

Owner:AMEC FOSTER WHEELER POWER EQUIP CO INC

Purification of carbon dioxide

Owner:AIR PROD & CHEM INC

Removal of methyl mercaptan from gas streams

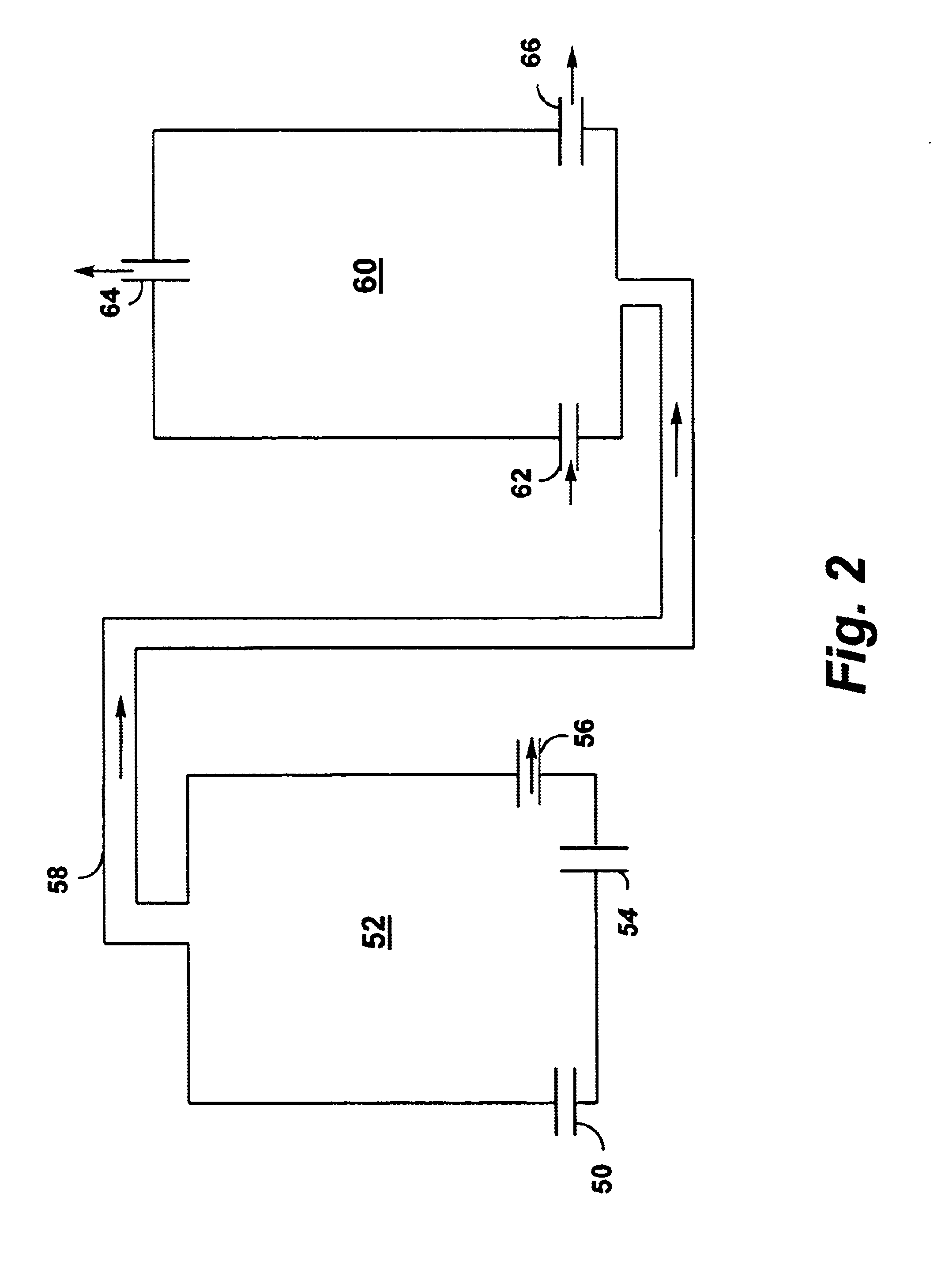

InactiveUS20050287056A1Efficient productionGas treatmentDispersed particle separationHigh concentrationThiol

The invention described herein is a method for selectively removing mercaptans such as methyl mercaptan from dry gas mixtures containing high concentrations of carbon dioxide. In the method, the carbon dioxide-rich gas (sour gas) is passed through an absorption vessel or distillation column in which it is contacted with an absorbent such as liquid carbon dioxide in order to selectively absorb the mercaptans. The treated gas, which is now free of mercaptans, leaves the top of the vessel as a sales gas suitable for use in enhanced oil recovery applications. Preferably, a portion of the carbon dioxide in the sales gas is condensed and the liquid is returned to the absorber or distillation column as the scrubbing agent. At least part of this scrubbing agent leaves the bottom of the absorber or distillation column enriched in methyl mercaptan and other sulfur compounds. The stream from the absorption vessel containing the mercaptans can be incinerated or otherwise processed to utilize or dispose of the methyl mercaptan.

Owner:DAKOTA GASIFICATION COMPANY

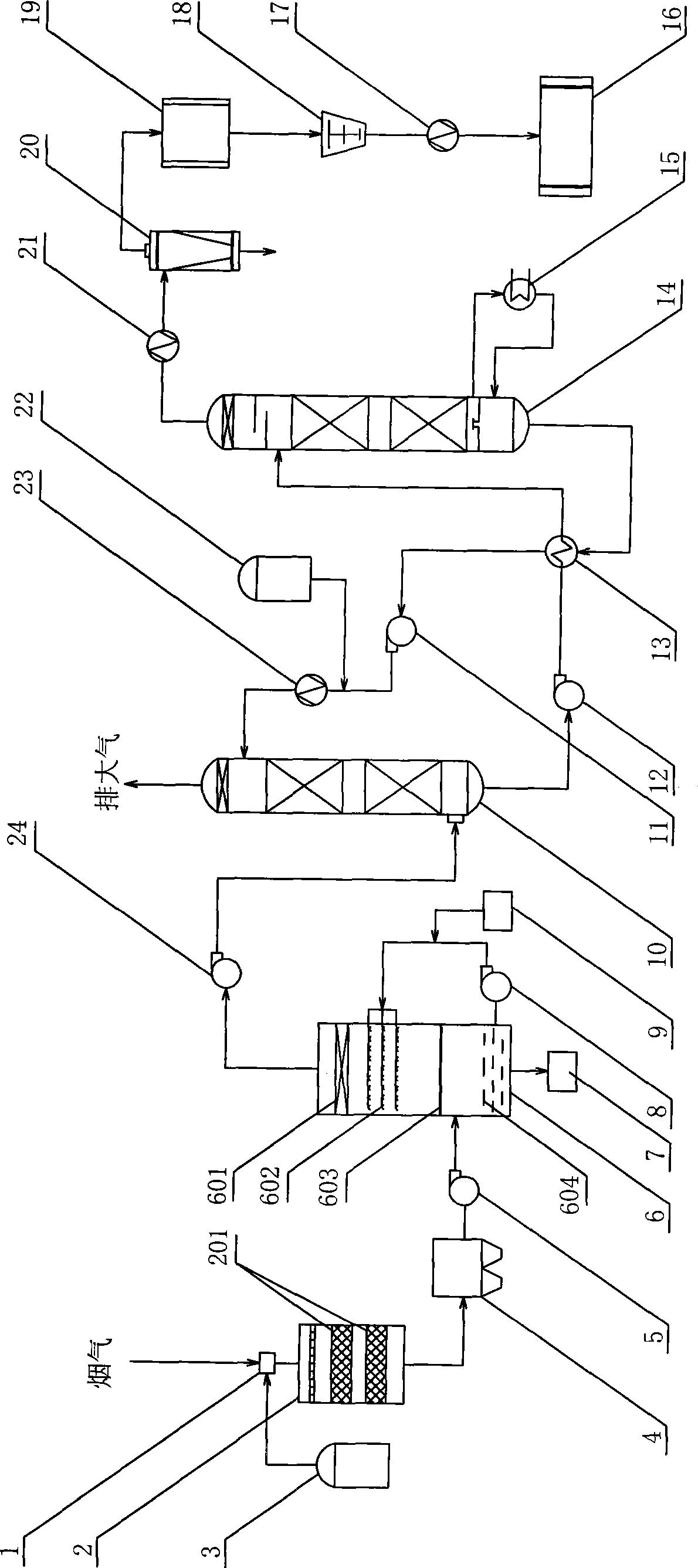

Multi-pollutant removing technique and device of fuel coal smoke

InactiveCN101422691ALow flow resistanceReduce investmentProductsCarbon compoundsHigh concentrationDecarburization

The invention discloses a removal technology of removing coal-fired flue gas pollutants and a device thereof. The technology is as follows: an SCR denitration method is first used for removing NOX in the flue gas; then a dust collector is used for removing dusts and ash particles in the flue gas; then a wet calcium-based desulphurization method is used for removing SO2 in the flue gas; then an MEA decarburization process is used for absorbing the SO2 in the flue gas; simultaneously, a pregnant solution of a generated alkanolamine solution is heated, analyzed and regenerated and the generated barren solution of the alkanolamine solution is continuously and cyclically used; and the analyzed CO2 gas with high concentration is produced to be liquid carbon dioxide of industrial grade with high purity after being cooled, gas-liquid separated, dried, compressed and condensed. The device consists essentially of an SCR denitration reactor, the dust collector, a wet calcium-based desulphurization reactor, an MEA decarburization absorption tower, a regeneration tower, a gas-liquid separator, a dryer, a compressor, a condenser and the like which are connected with each other by pipes. The device has simple and compact overall design, low investment and operation costs, and stable and reliable work and can conduct classified integration processing and highly efficient simultaneous removal on every pollutant in the coal-fired flue gas.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

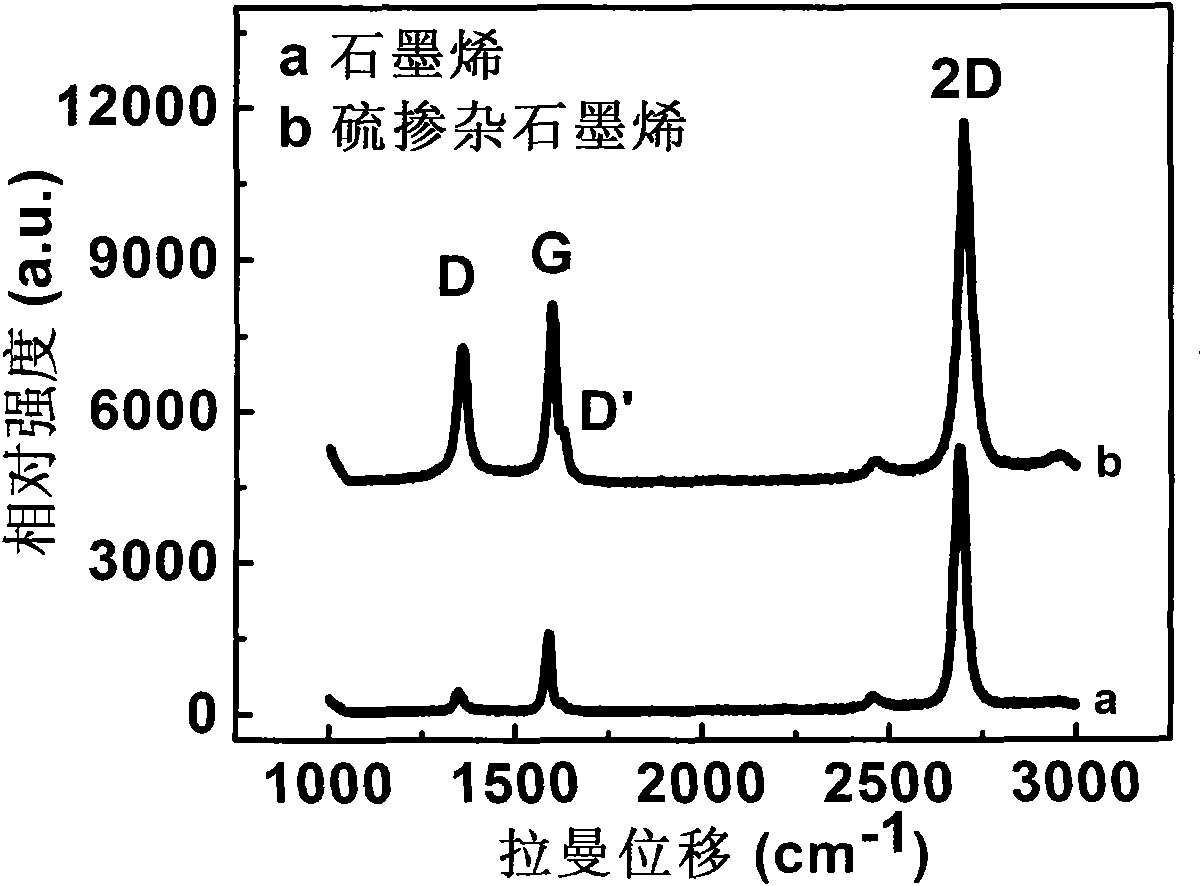

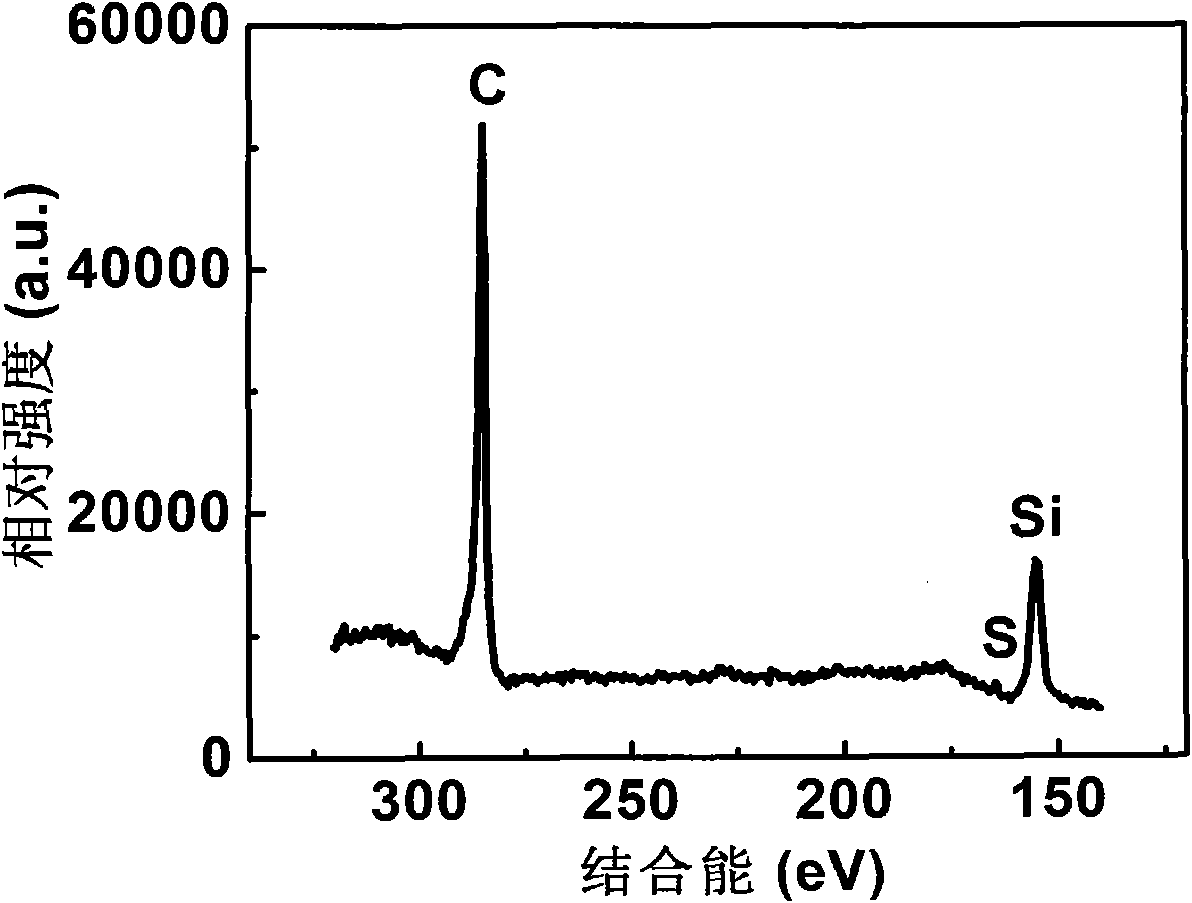

Method for preparing sulfur-doped graphene films

InactiveCN102191476AQuality improvementEasy to manufacturePolycrystalline material growthFrom chemically reactive gasesDoped grapheneSulfur

The invention relates to a method for preparing sulfur-doped graphene films. The sulfur-doped graphene films are prepared with chemical vapor deposition. The method comprises the following steps: a metal substrate is put in a reactor and preheated in heating and reduction protective atmosphere, then the metal substrate is heated to 900-1000 DEG C, the reduction protective gas is stopped to blow in the reactor, the vacuum degree of the reactor reaches 10-2 Torr to 10-3 Torr, then mixed liquid carbon source and sulfur source are introduced into the reactor in gas state, the required sulfur-doped grapheme films are grown on the metal substrate, a post-treatment is carried out, and the sulfur-doped graphene films are transferred to a substrate material.

Owner:LANZHOU UNIVERSITY

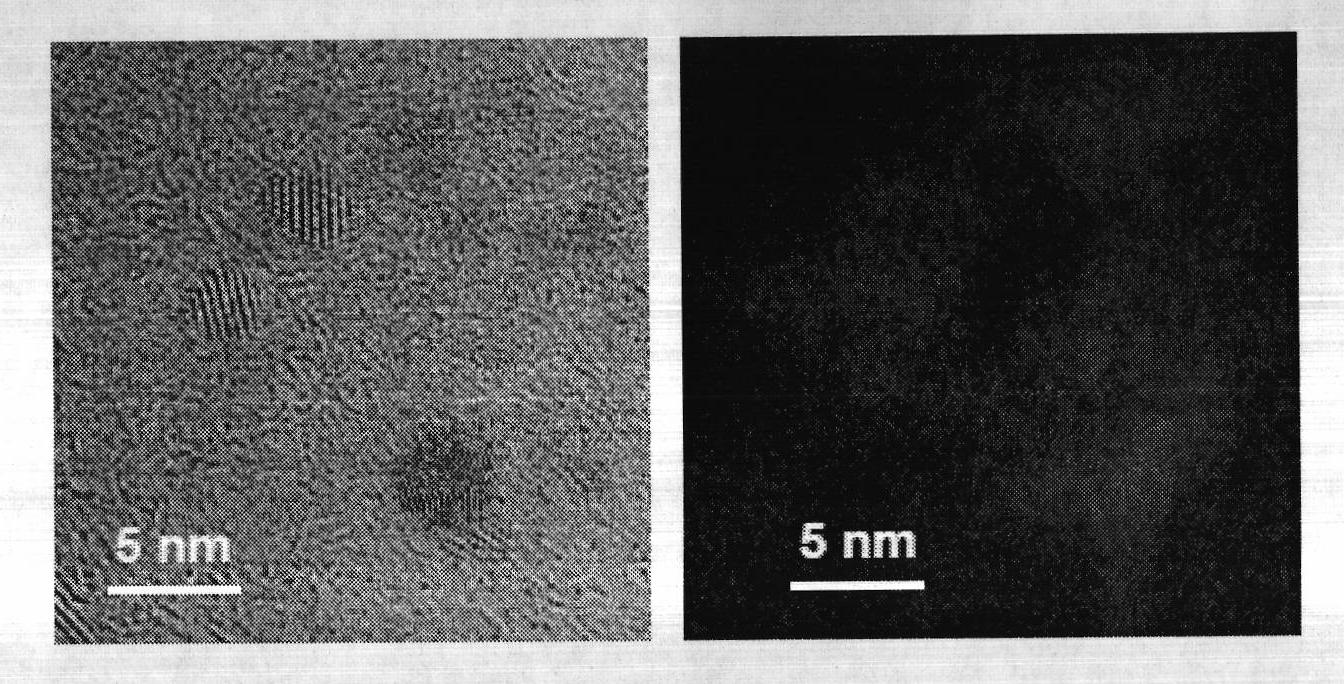

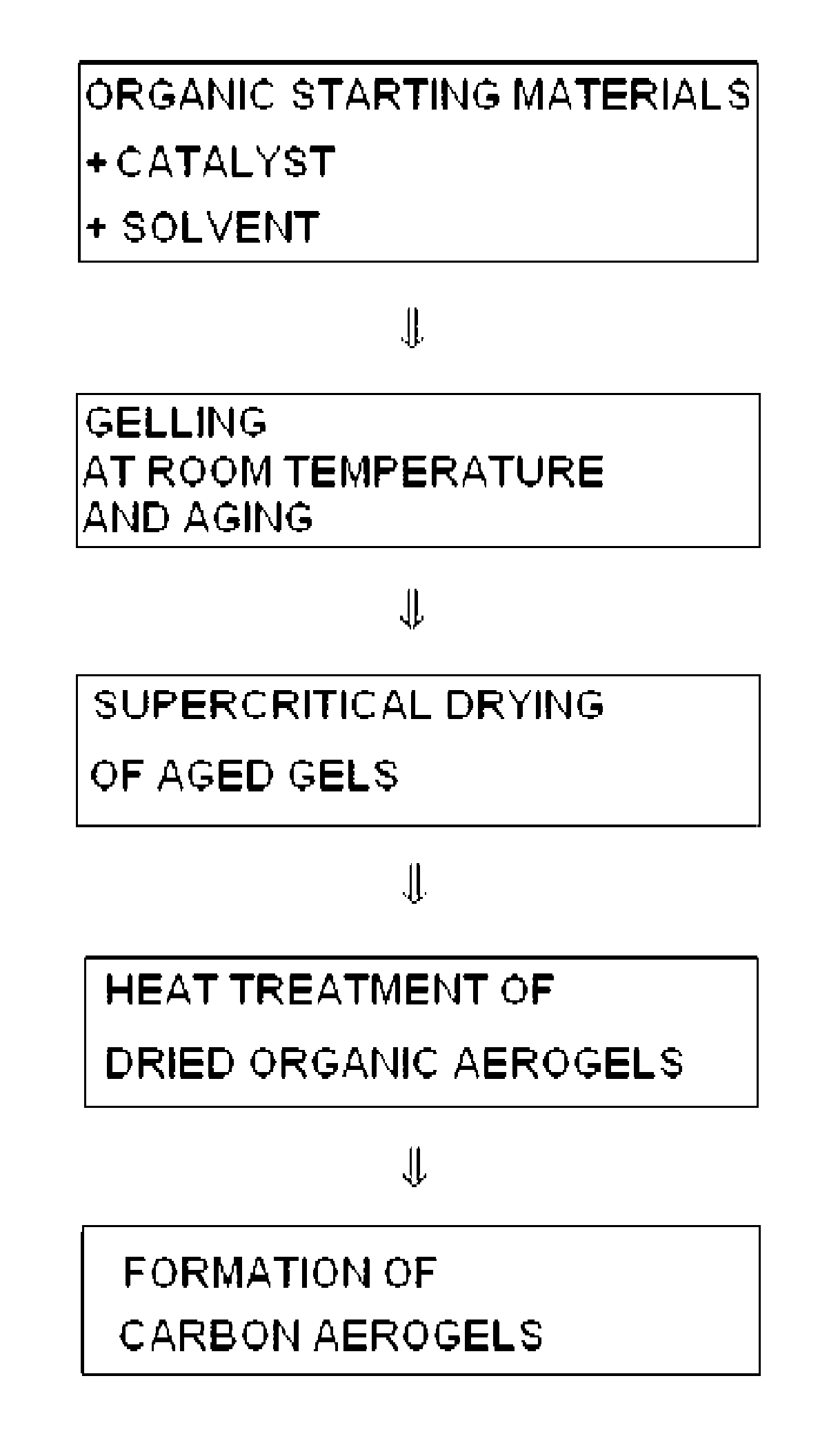

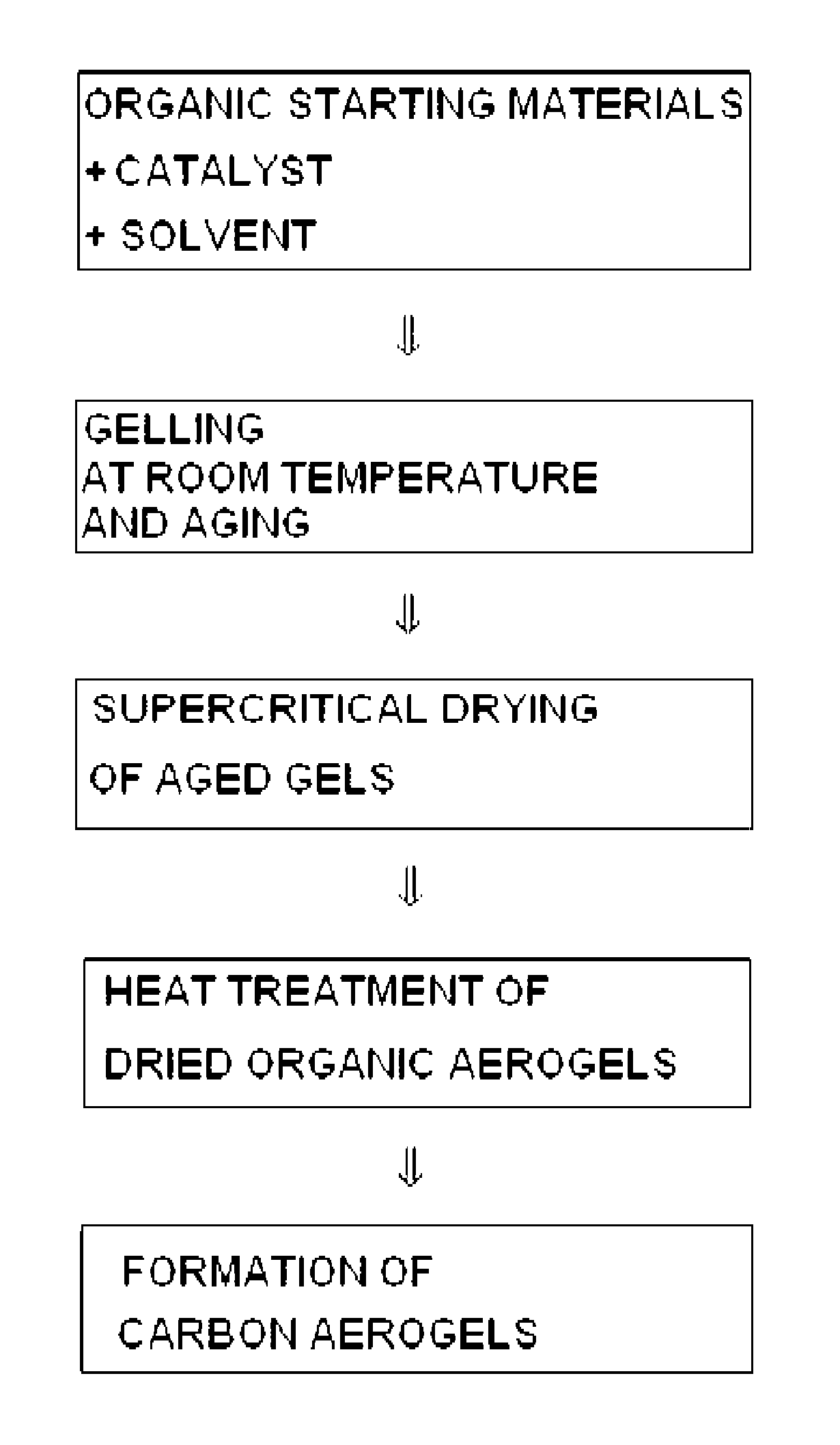

Carbon aerogels for supercapacitors and method of manufacturing the same

InactiveUS8480930B2Large specific surface areaShort processConductive materialNon-conductive material with dispersed conductive materialSupercritical dryingFurfural

A method for preparing carbon aerogels and carbon aerogels obtained therefrom are disclosed. The method for preparing carbon aerogels comprises: mixing organic starting materials including phloroglucinol and furfural with a solvent capable of dissolving the organic materials in a predetermined ratio to form a sol solution; adjusting pH of the sol solution adequately by using an acidic or basic catalyst, gelling the sol solution at room temperature under atmospheric pressure, and aging the resultant gels; substituting the solvent in thus obtained gels with liquid carbon dioxide, followed by drying in a supercritical state, to form organic aerogels; and pyrolyzing the organic aerogels in an electric furnace under inert atmosphere to obtain carbon aerogels. Particularly, the gels are formed at room temperature in a short period of time by adequately adjusting pH of the sol solution. Therefore, the method provides improved time efficiency and energy efficiency as compared to existing methods for preparing gels. Additionally, the method allows supercritical drying while avoiding a need for an additional solvent substitution, thereby simplifying the overall process. Further, the method enables preparation of carbon aerogels for supercapacitors having a high specific surface area and high capacitance even in the absence of additional activation step.

Owner:KOREA INST OF SCI & TECH

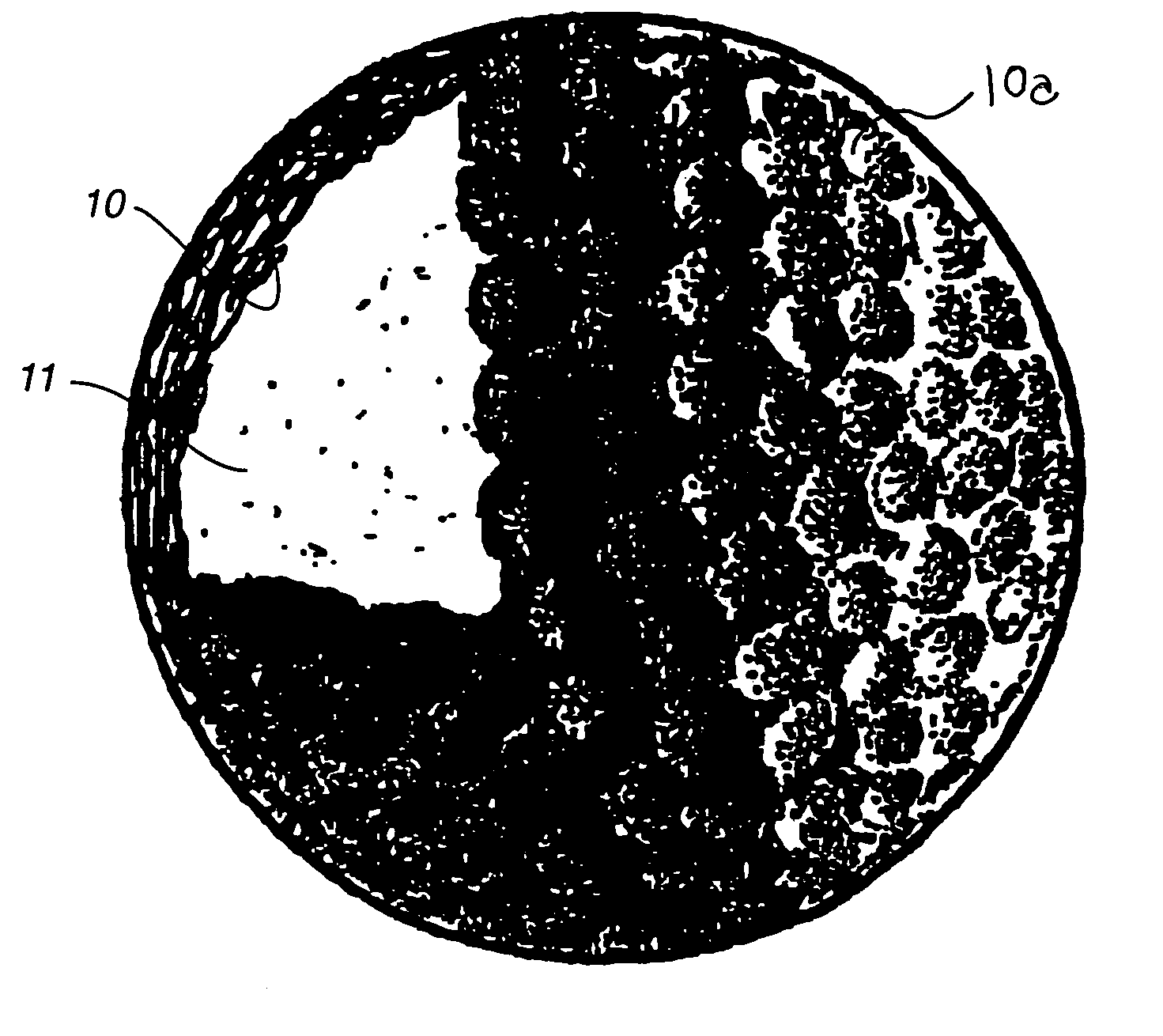

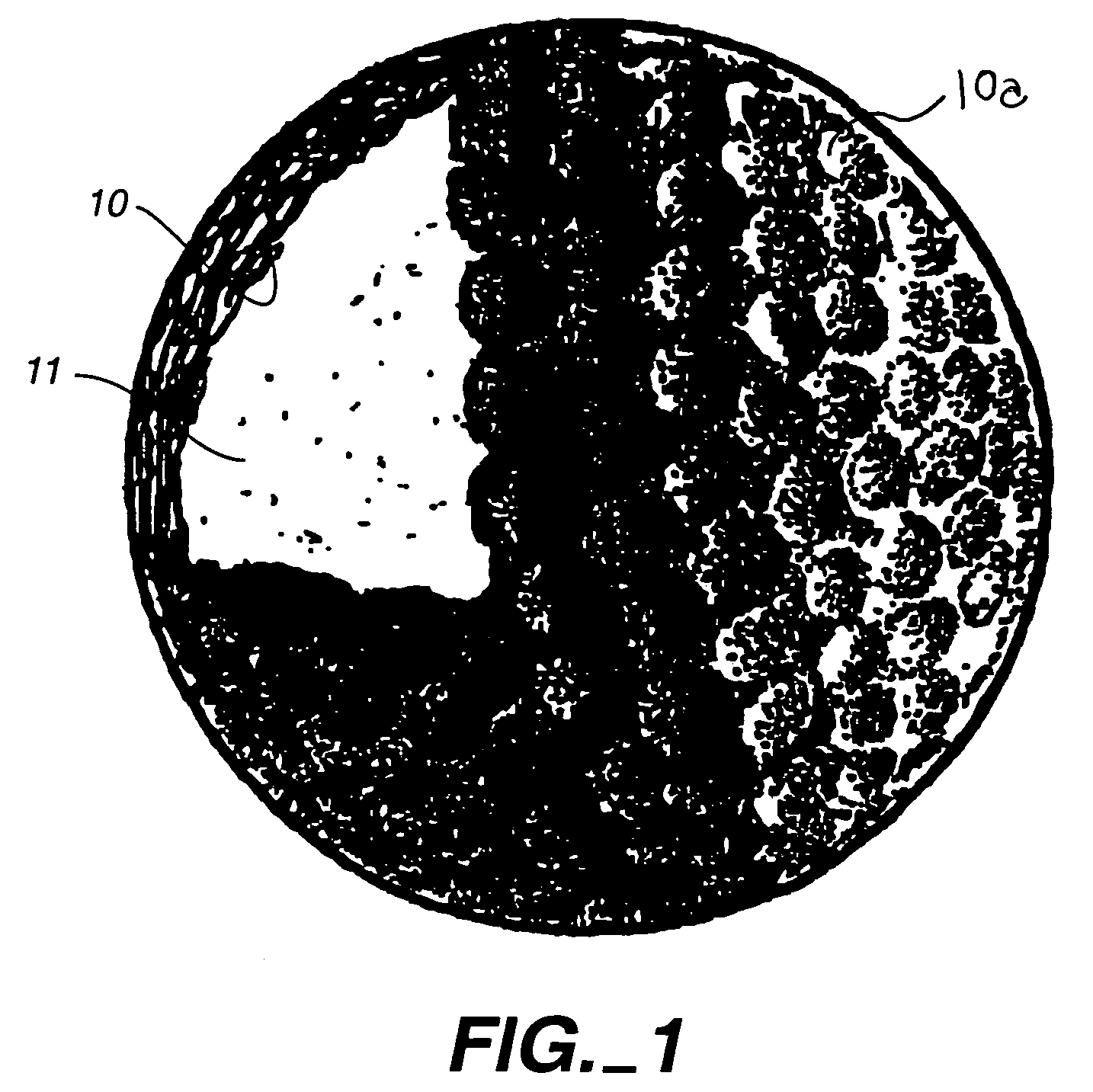

Carbon-carbon composite article manufactured with needled fibers

InactiveUS20060177663A1Manufacturing EaseReduce layeringLayered productsTextiles and paperCarbon compositesCarbon fibers

Method of making a carbon-carbon composite article such as an aircraft brake disc. The method includes: selecting carbon fiber precursors, having limited shrinkage in the axial direction when carbonized, in the form of individualized chopped or cut fibers; placing the selected chopped or cut carbon fiber precursors into a preform mold configured in the form of a brake disc to form a fibrous matrix; and then needling the molded fibrous matrix to provide it with three-dimensional structural integrity and to reduce layering. The carbon fiber precursor matrix may subsequently be infused with liquid carbon matrix precursor, the impregnated matrix may be carbonized; e.g., at 600-1800° C. for 1-10 hours to provide a preform having a density of at least about 1.1 g / cc, and the carbonized preform may be further densified to a density of at least about 1.6 g / cc by known liquid resin infiltration techniques and / or by conventional CVI / CVD processing.

Owner:HONEYWELL INT INC

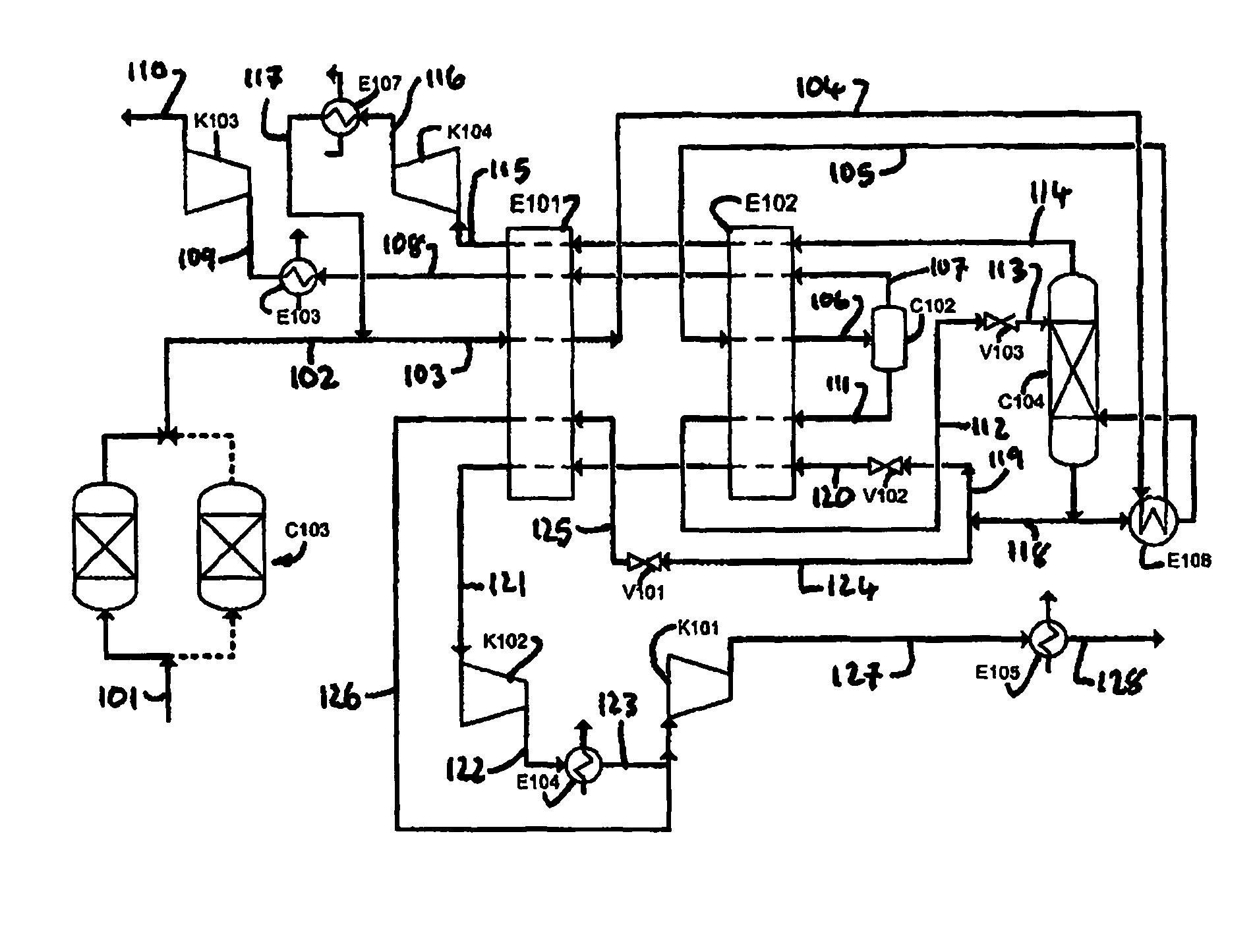

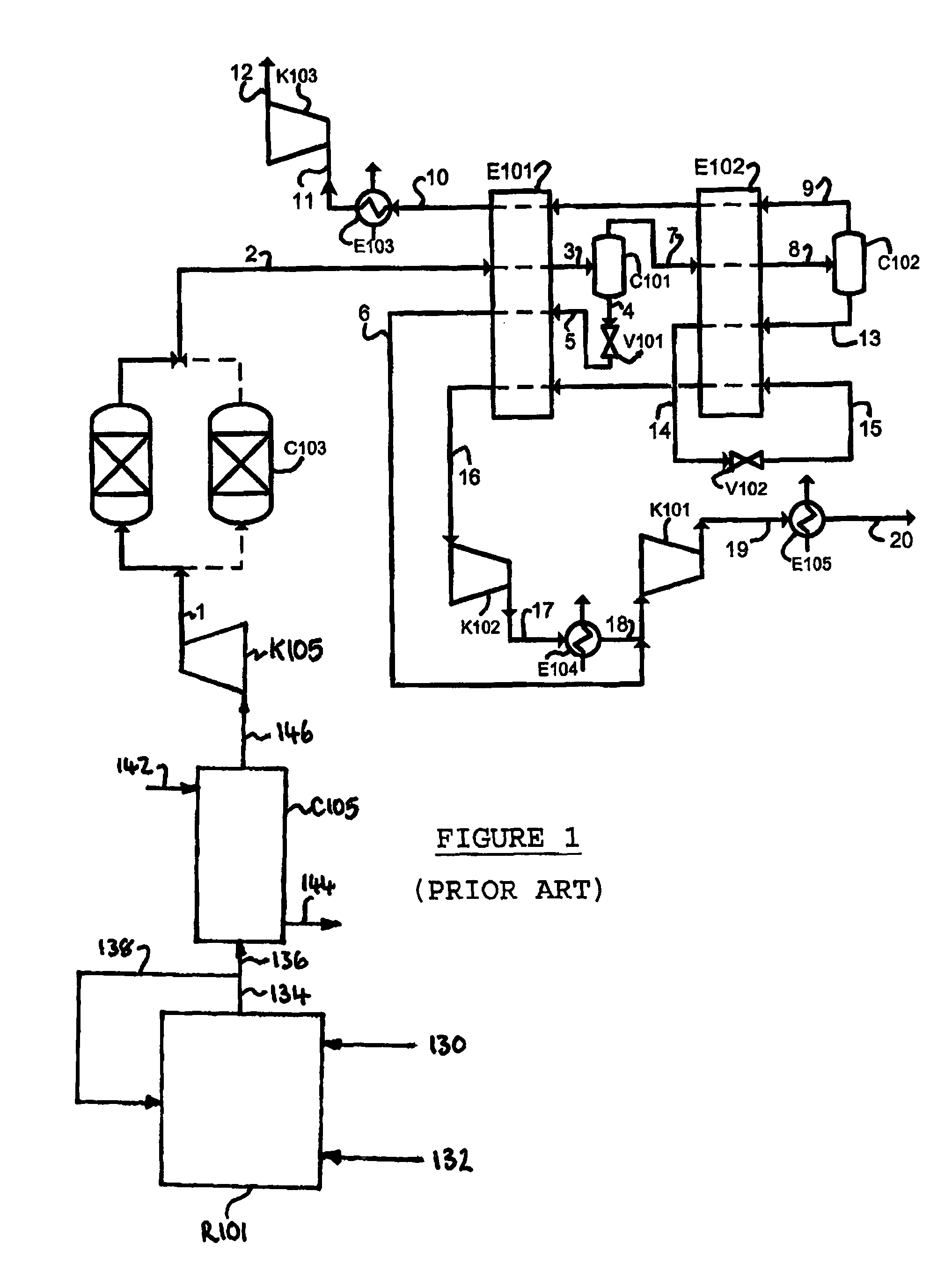

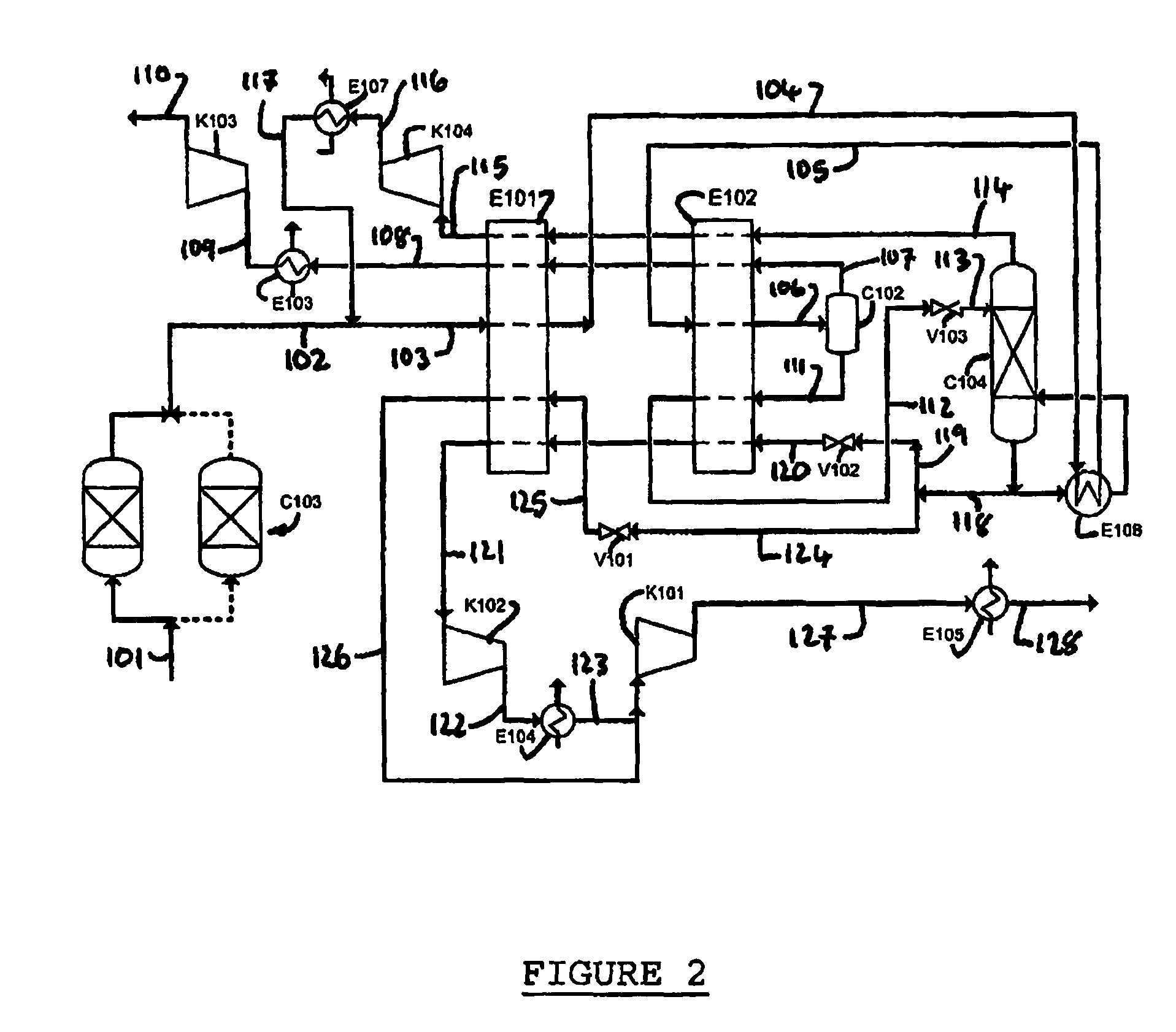

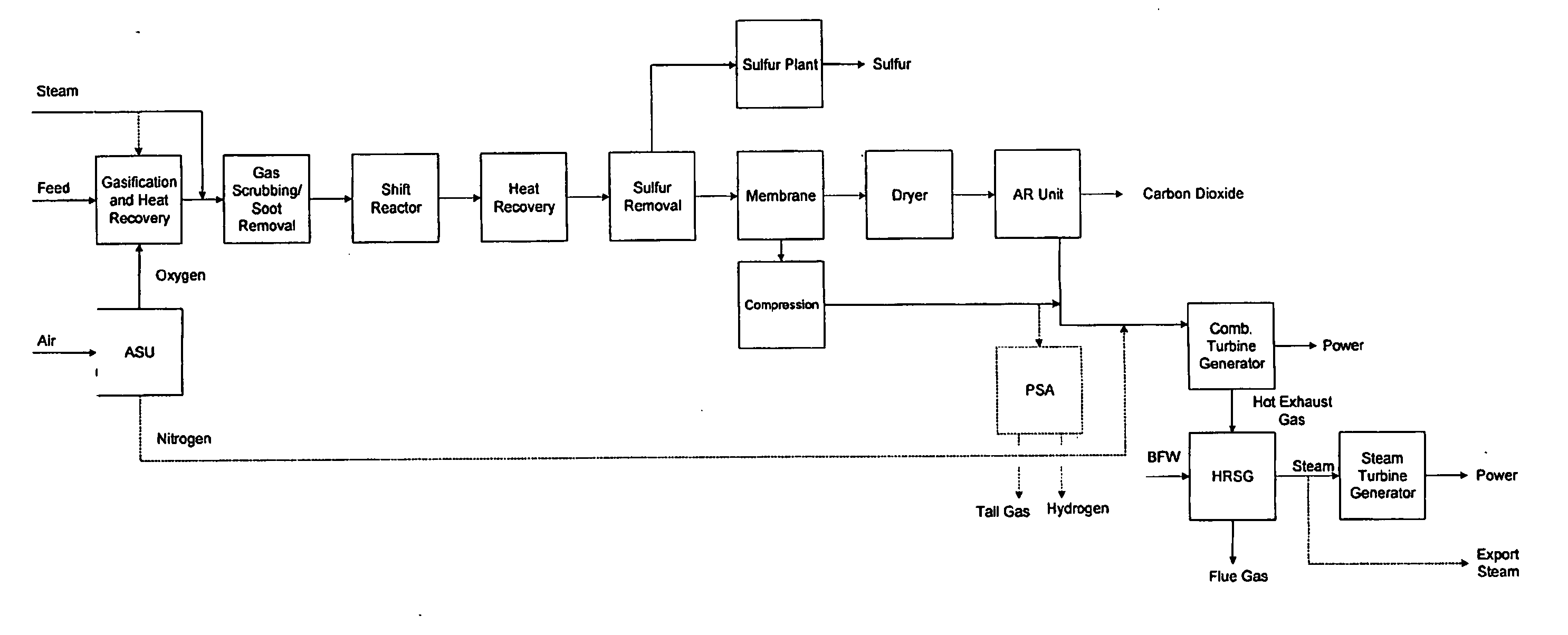

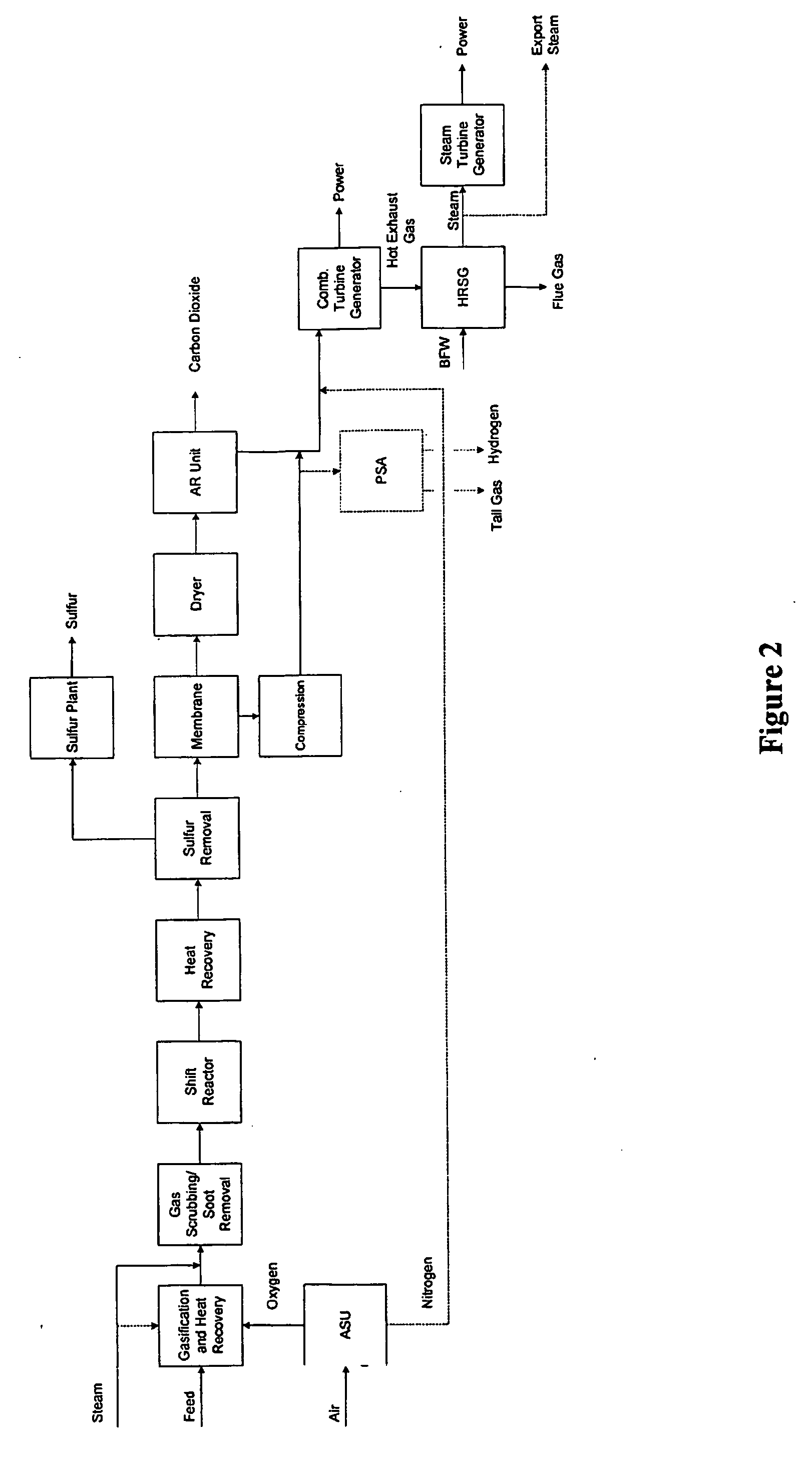

Configurations and methods of carbon capture

An IGCC plant has a precombustion decarbonization unit in which acid gas is removed from a combustion gas before the combustion gas enters a combustion turbine. In one preferred configuration, a sulfur removal unit removes hydrogen sulfide from a feed gas before the desulfurized feed gas enters an autorefrigeration unit in which carbon dioxide is removed. In another preferred configuration, hydrogen sulfide is converted to carbonyl sulfide in a dryer, and the carbonyl sulfide is absorbed in the liquid carbon dioxide that is prepared from the feed gas using autorefrigeration.

Owner:FLUOR TECHSE CORP

Fire retardant delivery system

A fire extinguishing and fire retarding method is provided comprising the step of confining a fire extinguishing and fire retarding agent in slurry, liquid or gaseous form within a shell wherein the shell comprises such an agent in solid form. An agent such as ice water, or liquid carbon dioxide is useful when employing the shell as “non-lethal” device. The solid shell is sublimable and will burst upon impact or upon exposure to the environmental conditions at the target site to release the contents of the shell as well as the fragments of the shell onto the target site.

Owner:EDWARDS PAUL +1

Process for the preparation of middle distillates

InactiveUS6858127B2Low conversionImprove cold flowCatalytic crackingOrganic compound preparationSyngasHydrocotyle bowlesioides

A process for the preparation of one or more hydrocarbon fuel products boiling in the kero / diesel range from a stream of hydrocarbons produced in a Fischer-Tropsch process, in which process synthesis gas is converted into liquid hydrocarbons, at least a part of the hydrocarbons boiling above the kero / diesel range, having the following steps:[0002](1) hydrocracking / hydroisomerizing at least a part of the Fischer-Tropsch hydrocarbons stream at a conversion per pass of at most 80 wt % of the material boiling above 370° C. into material boiling below 370° C.;[0003](2) separating the product stream obtained in step (1) into one or more light fractions boiling below the kero / diesel boiling range, one or more fractions boiling in the kero / diesel boiling range and a heavy fraction boiling above the kero / diesel boiling range;[0004](3) hydrocracking / hydroisomerizing the major part of the heavy fraction obtained in step (2) at a conversion per pass of at most 80 wt % of the material boiling above 370° C. into material boiling below 370° C.;[0005](4) separating the product stream obtained in step (3) into one or more light fractions boiling below the kero / diesel boiling range, one or more fractions boiling in the kero / diesel boiling range and a heavy fraction boiling above the kero / diesel boiling range; and,[0006](5) hydrocracking / hydroisomerizing the major part of the heavy fraction obtained in step (4) in the hydrocracking / hydroisomerizing process described in step (1) and / or step (3), in which process the Fischer-Tropsch hydrocarbons stream comprises at least 35 wt % C30+ (based on total amount of hydrocarbons in the Fischer-Tropsch hydrocarbons stream) and in which stream the weight ratio C60+ / C30+ is at least 0.2.

Owner:SHELL USA INC

Method and system for treating food items with an additive and solid carbon dioxide

ActiveUS20100293969A1Reduce pressureMixing methodsStationary refrigeration devicesLiquid carbonSolid carbon dioxide

Embodiments of the invention generally provide methods and systems that distribute an additive in solid carbon dioxide in an interior of food processing equipment. The additive may be injected into a flow of liquid carbon dioxide upstream of an expander at or adjacent to the interior. Injection of the additive into the interior may be alternated with directing a flow of expanded carbon dioxide into the interior. In some embodiments, the freezing point of the additive with or without a diluent composition and / or additive(s) is lower than a temperature of the liquid carbon dioxide.

Owner:AIR LIQUIDE AMERICA INC +1

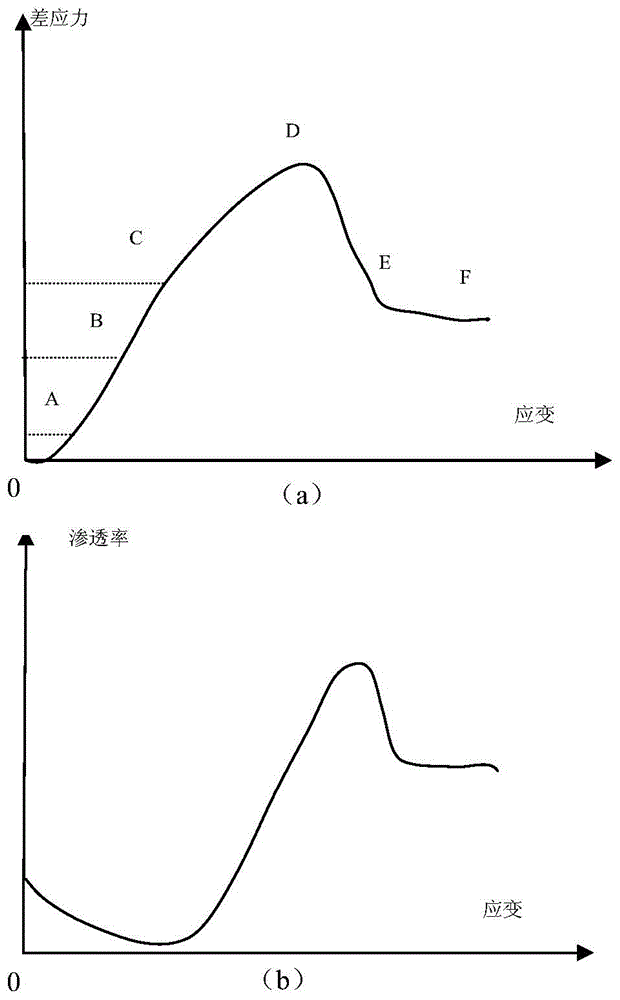

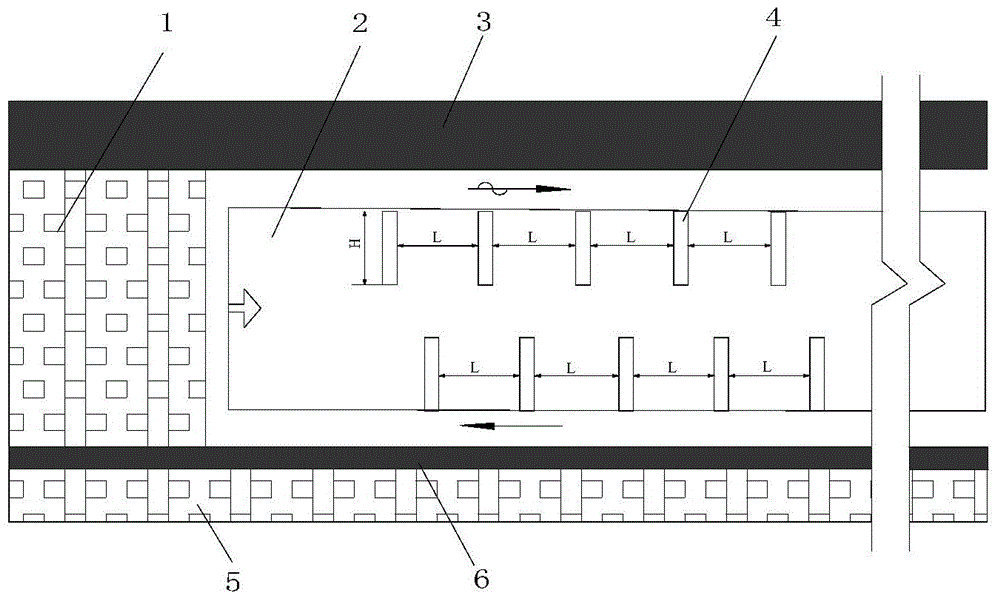

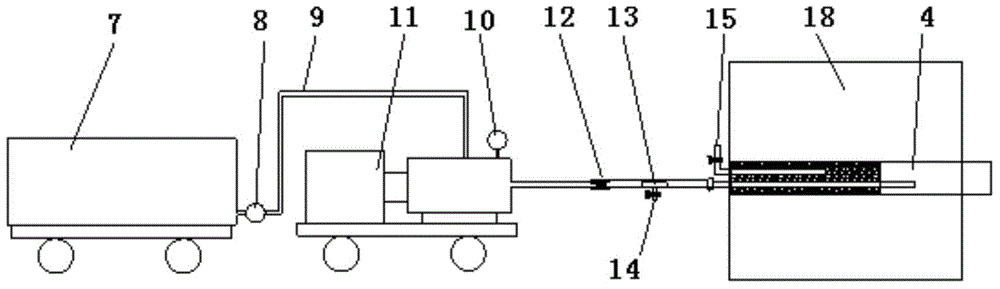

Coal seam liquid carbon dioxide fracturing device and method

The invention discloses a coal seam liquid carbon dioxide fracturing device and method. The device comprises a supplying unit for supplying liquid carbon dioxide, a fracturing pump, a hole packer, a first pipeline and a second pipeline; the hole packer is used for being placed in a drill hole in a coal seam to be fractured and comprises an grouting pipe, a first hole sealing capsule, a second hole sealing capsule and a fracturing pipe, one end of the grouting pipe and one end of the fracturing pipe penetrate through the first hole sealing capsule and are fixed on the first hole sealing capsule, the other end of the fracturing pipe penetrates through the second hole sealing capsule and is fixed on the second hole sealing capsule, and the other end of the grouting pipe is located between the first hole sealing capsule and the second hole sealing capsule. The coal seam liquid carbon dioxide fracturing device and method are capable of increasing the output of a mine and improving permeability of the coal seam and lump coal output rate.

Owner:XIAN UNIV OF SCI & TECH

Viscoelastic polyurethane foams

A viscoelastic foam is produced by reacting (a) an isocyanate component that includes at least 25% by weight of diphenylmethane diisocyanate having a monomeric content of from 50 to 90% by weight, (b) an isocyanate-reactive component, (c) at least one catalyst, (d) at least one surface active agent, and (e) liquid carbon dioxide. These foams are characterized by a ball rebound of less than 20%. Particularly preferred foams are characterized by a 95% height recovery time greater than 4 seconds.

Owner:COVESTRO LLC +1

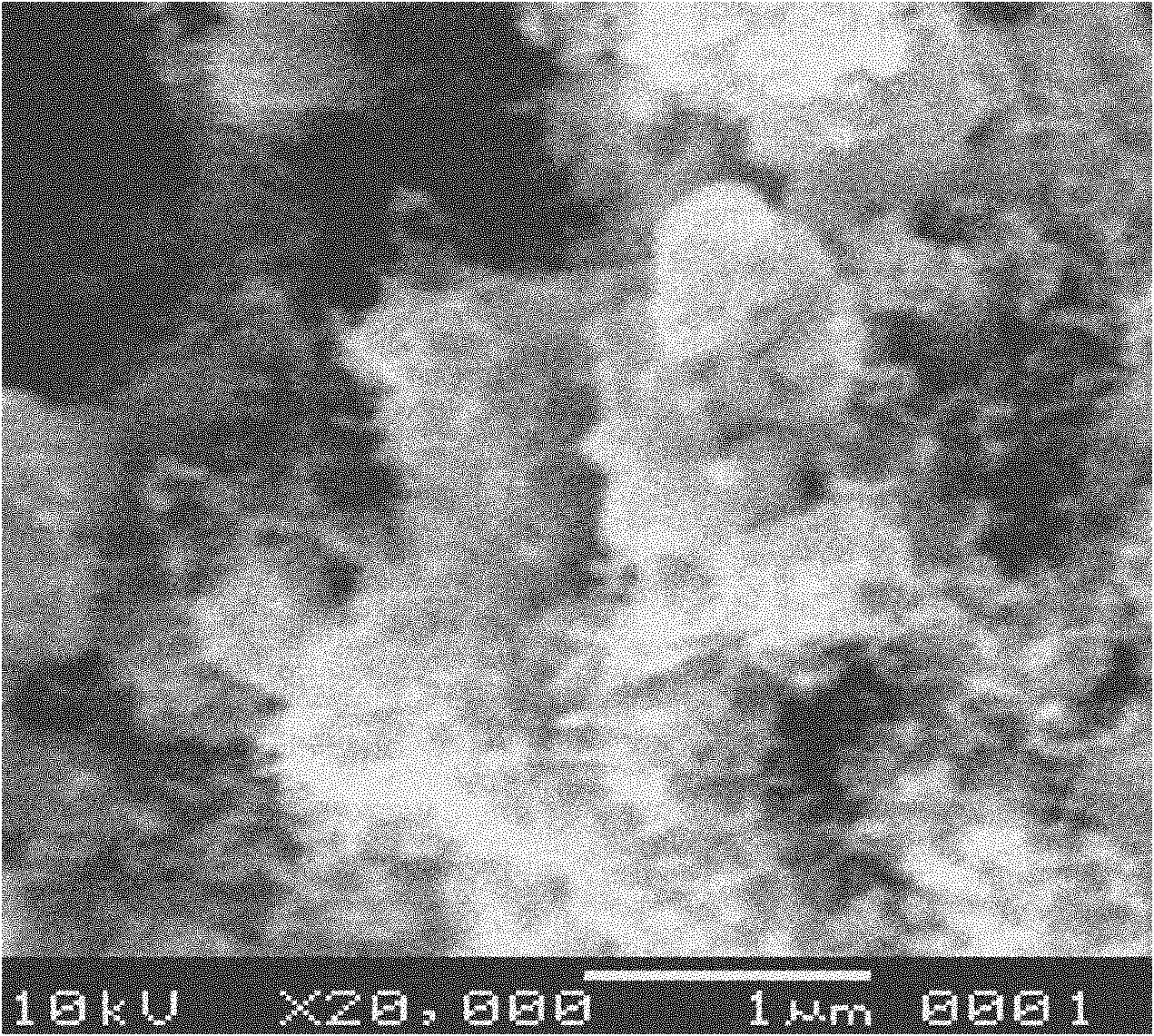

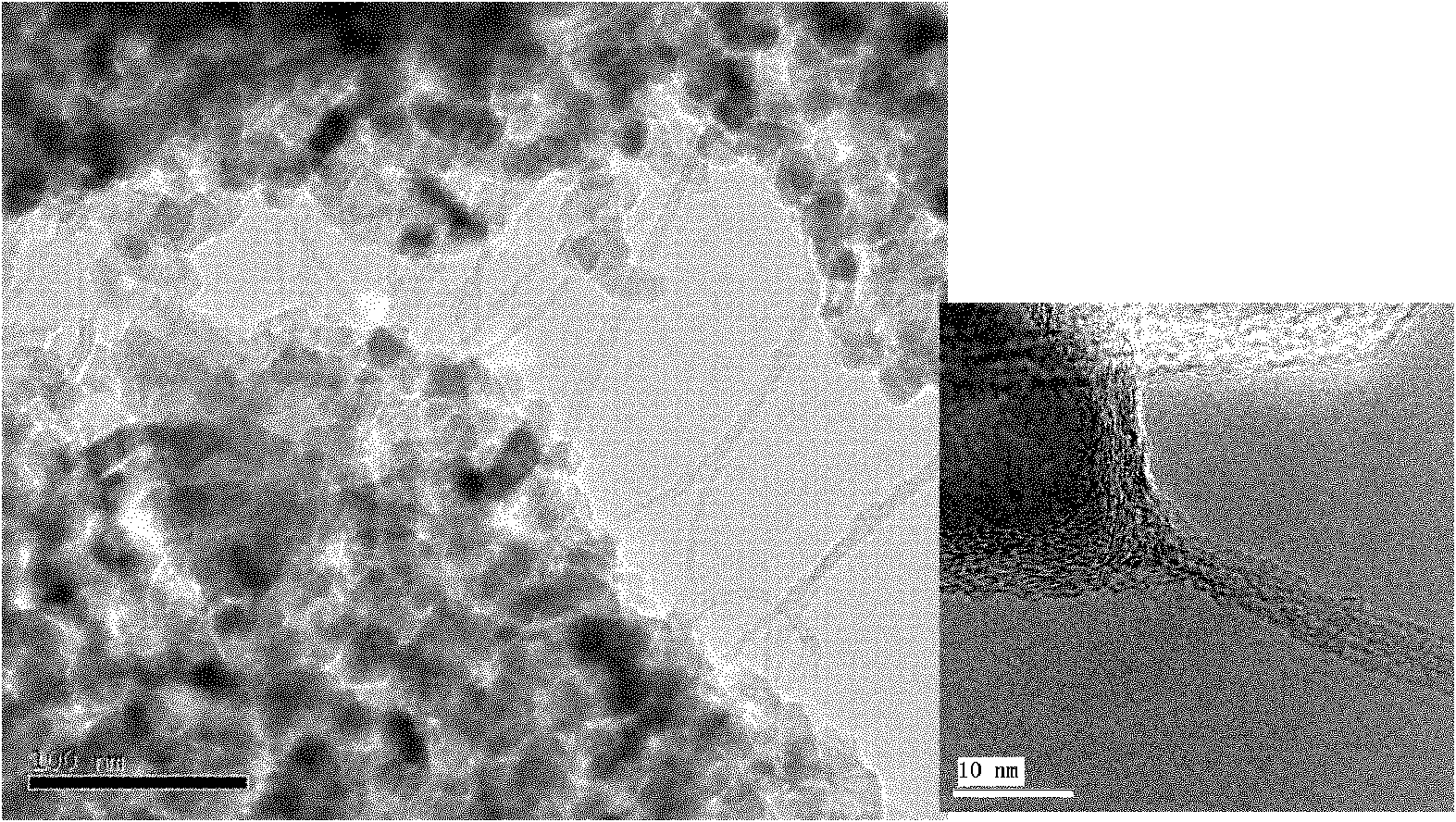

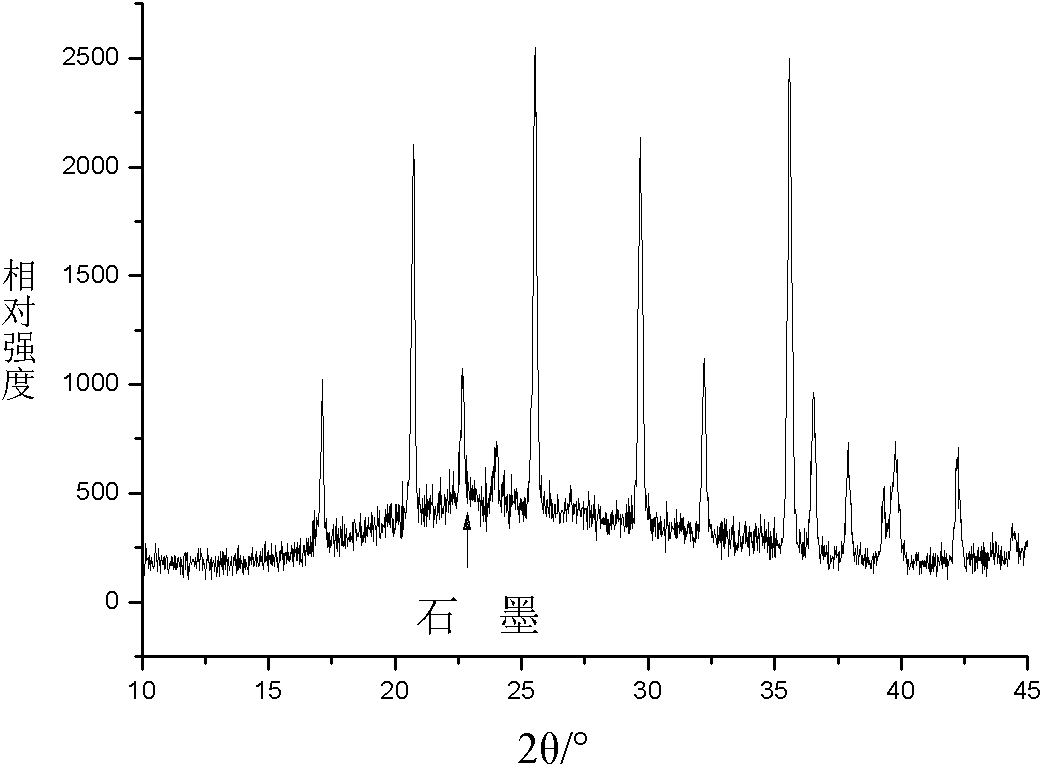

Lithium iron phosphate-carbon nanotube composite material, preparation method, and application thereof

ActiveCN102427130AThe phase is pure and the crystal form is goodLow resistivityCell electrodesLithium iron phosphateCarbon nanotube

The present invention discloses a lithium iron phosphate-carbon nanotube (LiFePO4-CNTs) composite material. The composite material comprises LiFePO4 particles, a nano-carbon layer and CNTs, wherein the nano-carbon layer is positioned outside the LiFePO4 particles, and the CNTs grow in the nano-carbon layer in an in situ growth manner by a chemical vapor deposition (CVD) process. In addition, the present invention further discloses a preparation method for the composite material. The method comprises: uniformly mixing and coating the prepared LiFePO4 precursor powder, a catalyst and liquid carbon source to prepare into the slurry; adopting a spraying feeding device to convey the slurry to a high-temperature reaction furnace to form a floating CVD process; carrying out heat insulation calcination for the resulting mixture so as to complete the treatments of granulation of the LiFePO4 precursor, in situ growth and coating of the CNTs and synthesis sintering of the LiFePO4 in one step, such that the uniform nano-carbon layer and the CNTs are formed on the surfaces of the LiFePO4 particles. In addition, the present invention further discloses an application of the composite material in battery preparation. According to the composite material of the present invention, the nano-carbon layer and the CNTs have good crystallization, the total carbon content is low, the electrical conductivity and the specific capacity are high so as to substantially increase the rate performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

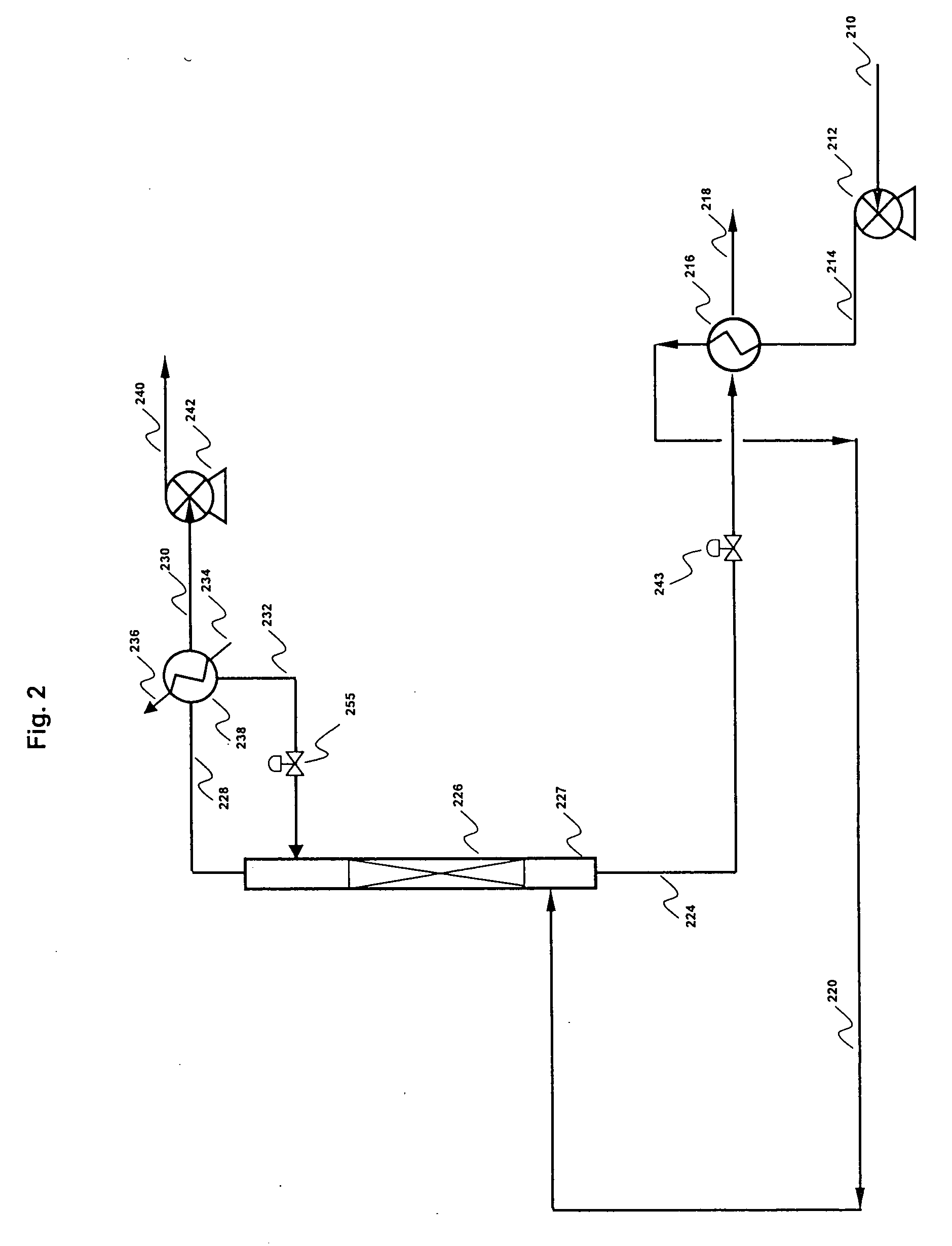

Structural fumigation process and apparatus

InactiveUS6047496AReduce the amount requiredNot extending current fumigant exposure timeFood preservationFumigatorsCombustible gasLiquid carbon

Processes and devices for producing a heated non-flammable gaseous fumigant for structural fumigation use by the application of a carrier gas, such as carbon dioxide (102), to a heater (103) either prior or subsequent to mixing the gas with a toxic agent gas, such as methyl bromide (213), such as by means of a mixer (214) and applying the mixture of gasses as a structural fumigant to eradicate target pests within a structure (106). In the preferred embodiment, the gaseous carbon dioxide is formed by flashing liquid carbon dioxide (614) directly to the gaseous state in a heater (630) prior to being mixed with methyl bromide (654) in a mixer (648) and applying the mixture of gasses as a structural fumigant within a structure (668).

Owner:LEITNER KENNETH D +1

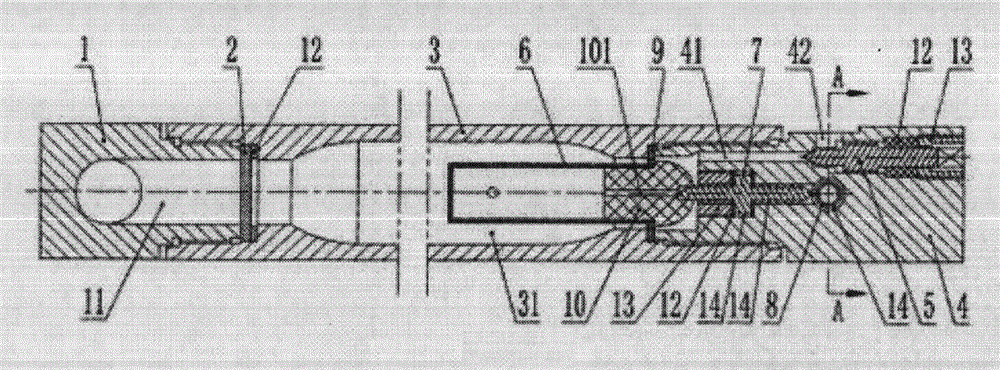

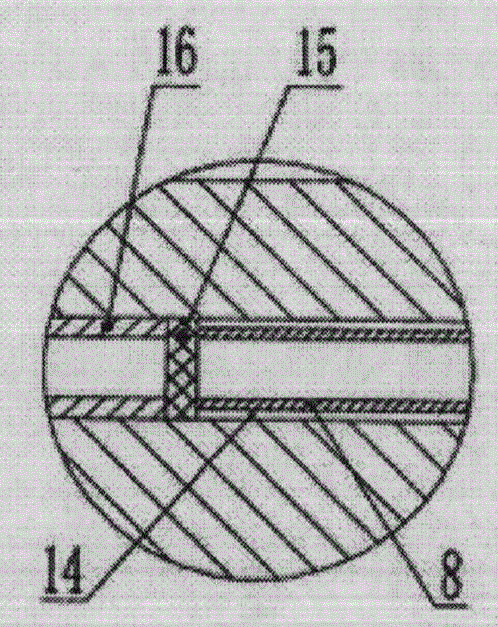

Carbon dioxide fracturing device

A carbon dioxide fracturing device comprises an energy relief head, a constant-pressure energy relief piece, a main pipe and a filling head, wherein the energy relief head and the filling head are respectively screwed with the two ends of the main pipe; a filling channel leading to a filling cavity of the main pipe and a thimble capable of opening and closing the filling channel are arranged on the filling head; an energy relief channel is arranged on the energy relief head; one end of the energy relief channel leads to the filling cavity of the main pipe, and the other end of the energy relief channel leads to the outside of the carbon dioxide fracturing device; the constant-pressure energy relief piece is arranged between the energy relief channel of the energy relief head and the filling cavity of the main pipe in a sealed manner; a heating device is arranged in the filling cavity of the main pipe; and the constant-pressure energy relief piece fractures when the heating device heats up and gasify liquid carbon dioxide in the filling cavity of the main pipe and the carbon dioxide gas expands to a certain pressure. The carbon dioxide fracturing device can replace detonators and explosives, which are frequently used in mine mining, avoids gas explosion caused by open fire to realize safety production of mines, can also enable coal to pre-split in the gas exhausting and mining process, effectively increases the air permeability of coal beds and improves the gas exhausting and mining efficiency of coal beds.

Owner:河北亿科金属制品有限公司

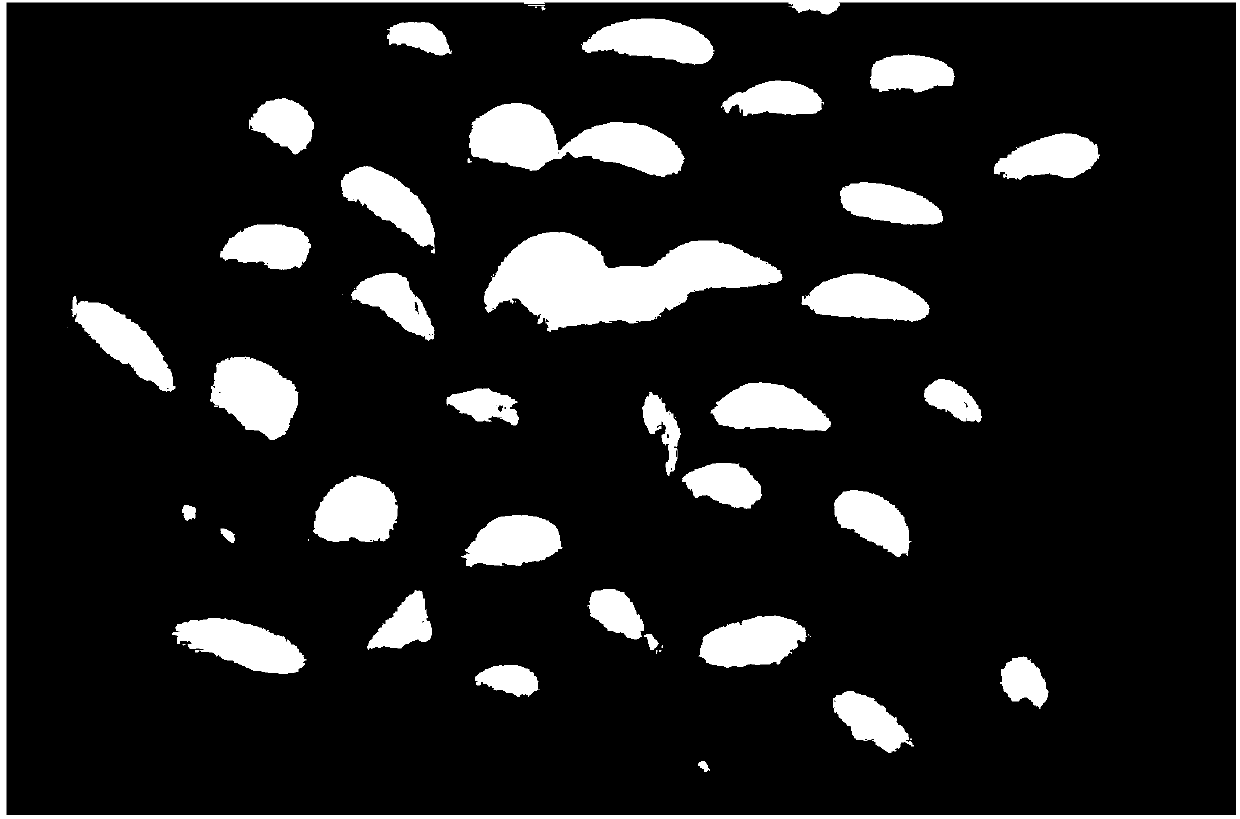

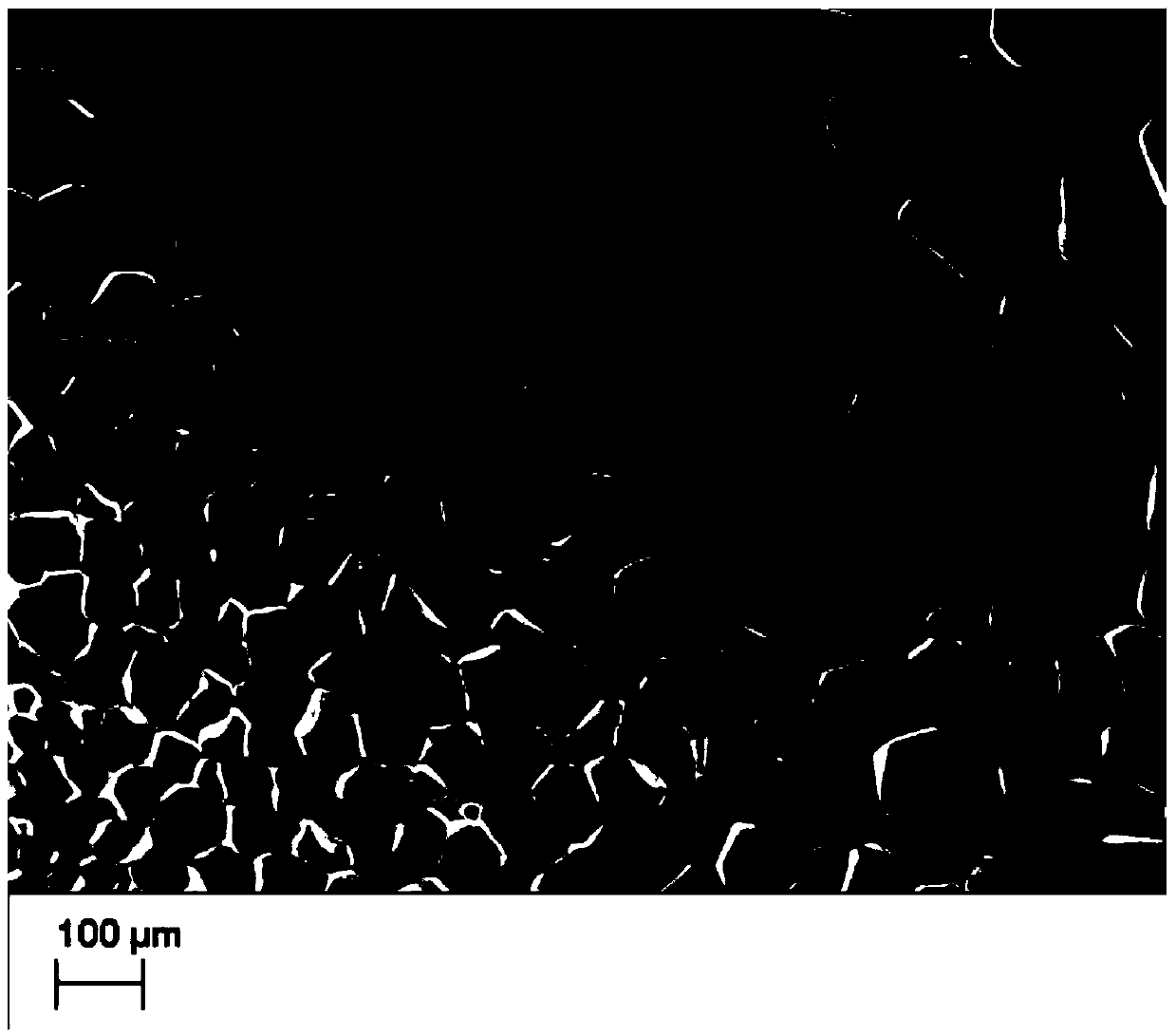

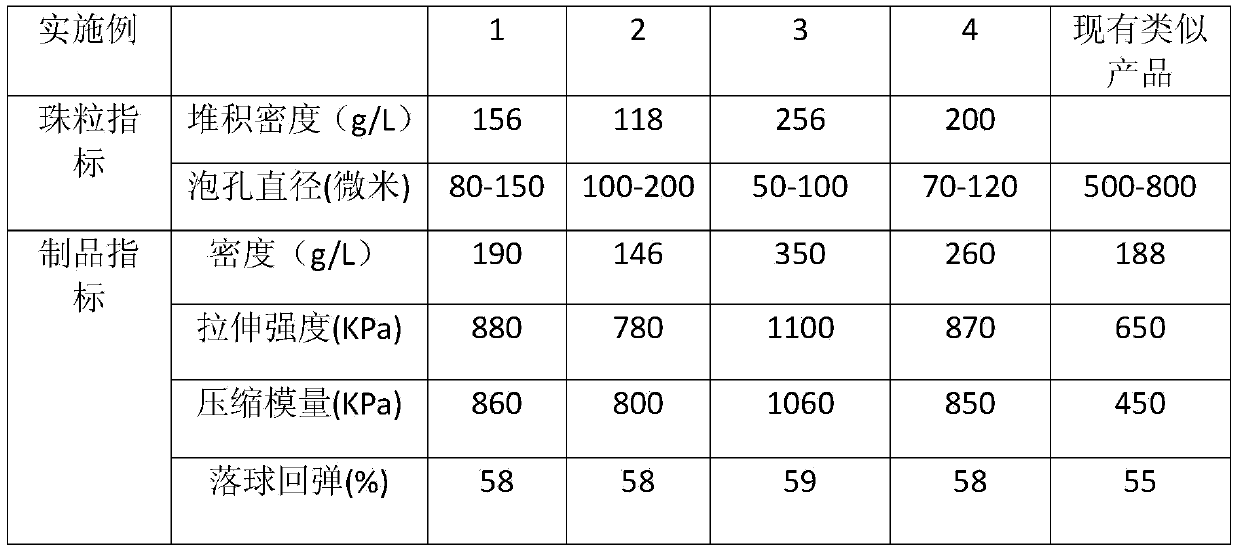

Thermoplastic polyurethane elastomer foam bead and preparation method thereof

The invention discloses a thermoplastic polyurethane elastomer foam bead and a preparation method thereof. The method comprises the following steps: firstly, adding thermoplastic polyurethane particles and water to a reaction kettle according to the mass ratio of 1 to (0.8-4); adding liquid carbon dioxide to the reaction kettle, and controlling the intensity of pressure and the temperature in the reaction kettle, so that the carbon dioxide in the reaction kettle is in a super-critical state; raising the temperature inside the reaction kettle to 90-140 DEG C; carrying out heat preservation; putting the materials in the kettle into a pressure tank, maintaining pressure, and cooling to below 70 DEG C; foaming the thermoplastic polyurethane elastomer particles once, and controlling the volume ratio of the reaction pressure to the pressure tank to be 1 to (15-30); putting the disposable foam particles into a storage tank, and carrying out secondary normal pressure foaming to obtain thermoplastic polyurethane elastomer foam beads; and removing the surface moisture of the foam beads, and curing the foam beads at normal pressure and normal temperature for over 48 hours, so as to obtain the product. The product disclosed by the invention has the characteristics of even and compact cells, small size, high percentage of closed area, high molding product strength, good rebound resilience and the like.

Owner:新辉新材料(常州)有限公司

Carbon dioxide mining device

The invention discloses a carbon dioxide mining device. The carbon dioxide mining device comprises an energy release head, a fixed pressure energy release sheet, a main pipe and a filling head, wherein the energy release head and the filling head are respectively fastened at the two ends of the main pipe; a filling passage and an ejector pin are arranged on the filling head; the filling passage is led to a main pipe filling chamber, and the ejector pin is used for opening and closing the filling passage; an energy release passage is formed in the energy release head; one end of the energy release passage is led to the main pipe filling chamber; the other end of the energy release passage is led outside the carbon dioxide mining device; the fixed pressure energy release sheet is arranged between the energy release passage of the energy release head and the main pipe filling chamber in a sealed way; a heating device is arranged in the main pipe filling chamber; and the fixed pressure energy release sheet is fractured when liquid carbon dioxide filled into the main pipe filling chamber is heated, gasified and expanded to a certain pressure by the heating device. The carbon dioxide mining device disclosed by the invention can be used instead of common detonators and explosives in mine mining; gas explosion caused by fire explosion is avoided and safety production of the mine is also achieved; and a coal body can be also pre-cracked in the gas mining process, so that the air permeability of a coal layer is effectively improved, and the gas mining efficiency of the coal layer is increased.

Owner:CCTEG CHINA COAL RES INST

Carbon dioxide snow apparatus

ActiveUS7293570B2Increased Joule-Thompson coolingReduce cloggingBlast gunsSpray nozzlesLiquid carbonMachining process

A carbon dioxide snow apparatus of the present invention includes a carbon dioxide snow generation system and a propellant generation system connected to a common carbon dioxide gas source. The carbon dioxide snow generation system includes a condenser having a at least two connected segments, wherein a first segment has a lesser diameter than the a second segment to provide a stepped expansion cavity for cooling and condensing liquid carbon dioxide into solid carbon dioxide snow. Several snow generation systems, each separately controllable with separate condensers, may be integrated with the propellant generation system and common carbon dioxide source to provide for a multiplicity of carbon dioxide snow applicators for integration into both manual and automated machining processes.

Owner:COOL CLEAN TECH

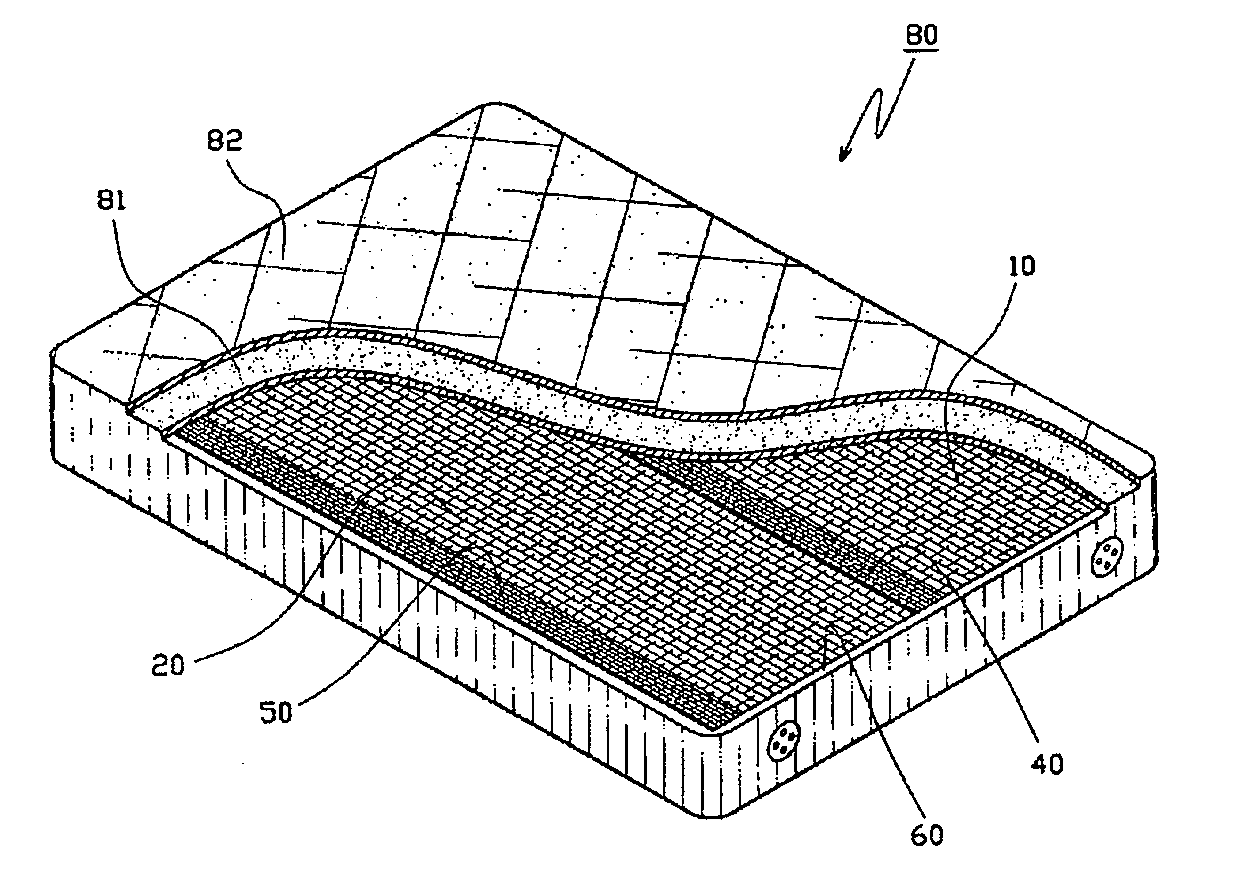

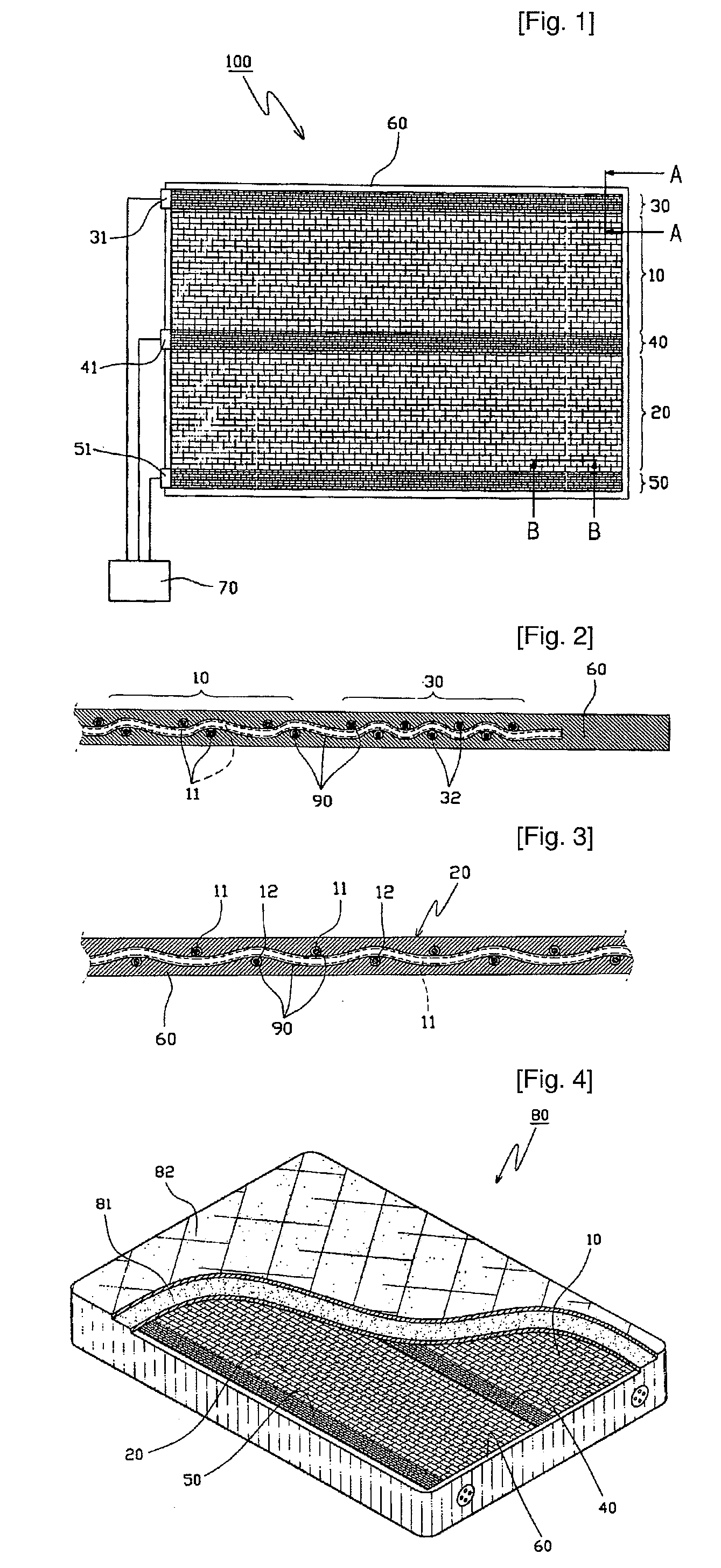

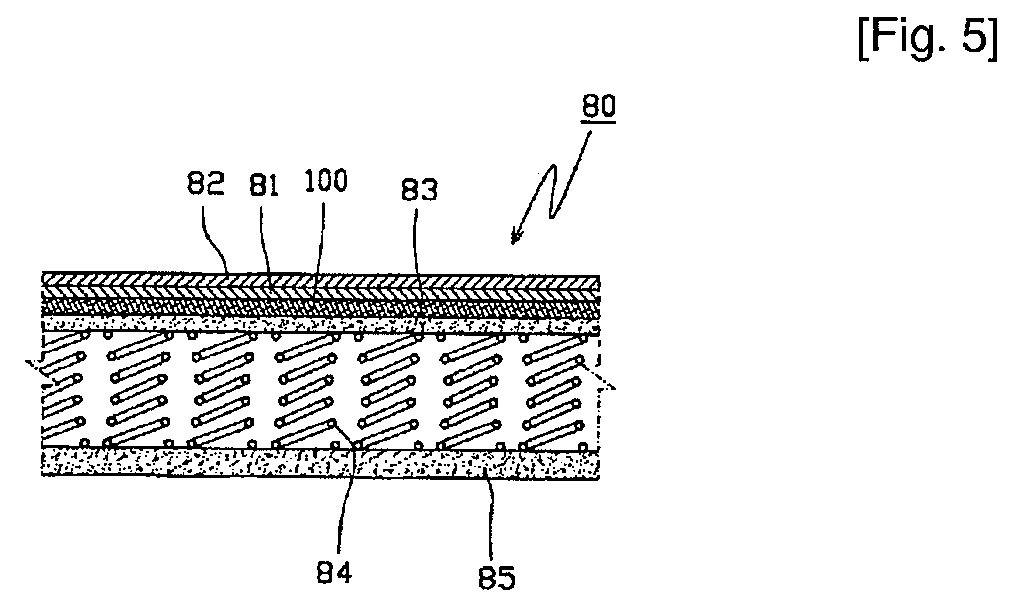

Fiber reinforced heating unit and mattress with thereof

InactiveUS20090078690A1Uniform temperature distributionKeep the distanceSofasBedsCopper wireLiquid carbon

Disclosed herein are a fiber-reinforced heating unit (100) and a mattress comprising the fiber-reinforced heating unit (100) installed therein. The heating unit (100) comprises flexible filaments (11) woven vertically and horizontally in a net, a stiff synthetic resin filament (12) alternately woven with the flexible filament (11) in either a vertical direction or a horizontal direction, and copper wires (32) woven together with the flexible filaments (11) on the longitudinal edges at both sides and the center and the woven material is dipped in liquid carbon, followed by drying. The copper wires (32) on the both longitudinal edges are connected to positive (+) terminal (31, 51) and the copper wires at the center are connected to a negative (−) terminal (41). The carbon-coated woven material has coating layers (90) formed by compression or impregnation with a gel type flexible synthetic resin at the top and the bottom. The heating unit (100) can maintain an original net structure by the stiff synthetic resin filament (12) while maintaining flexibility. The heating unit (100) has excellent durability since the flexible filament (11) is not disconnected even when heating unit is bent or folded. Also, the heating unit (100) can provide partial heating by selectively applying electricity to the positive (+) terminals (31, 51) at the both edges.

Owner:LEE MI AE +1

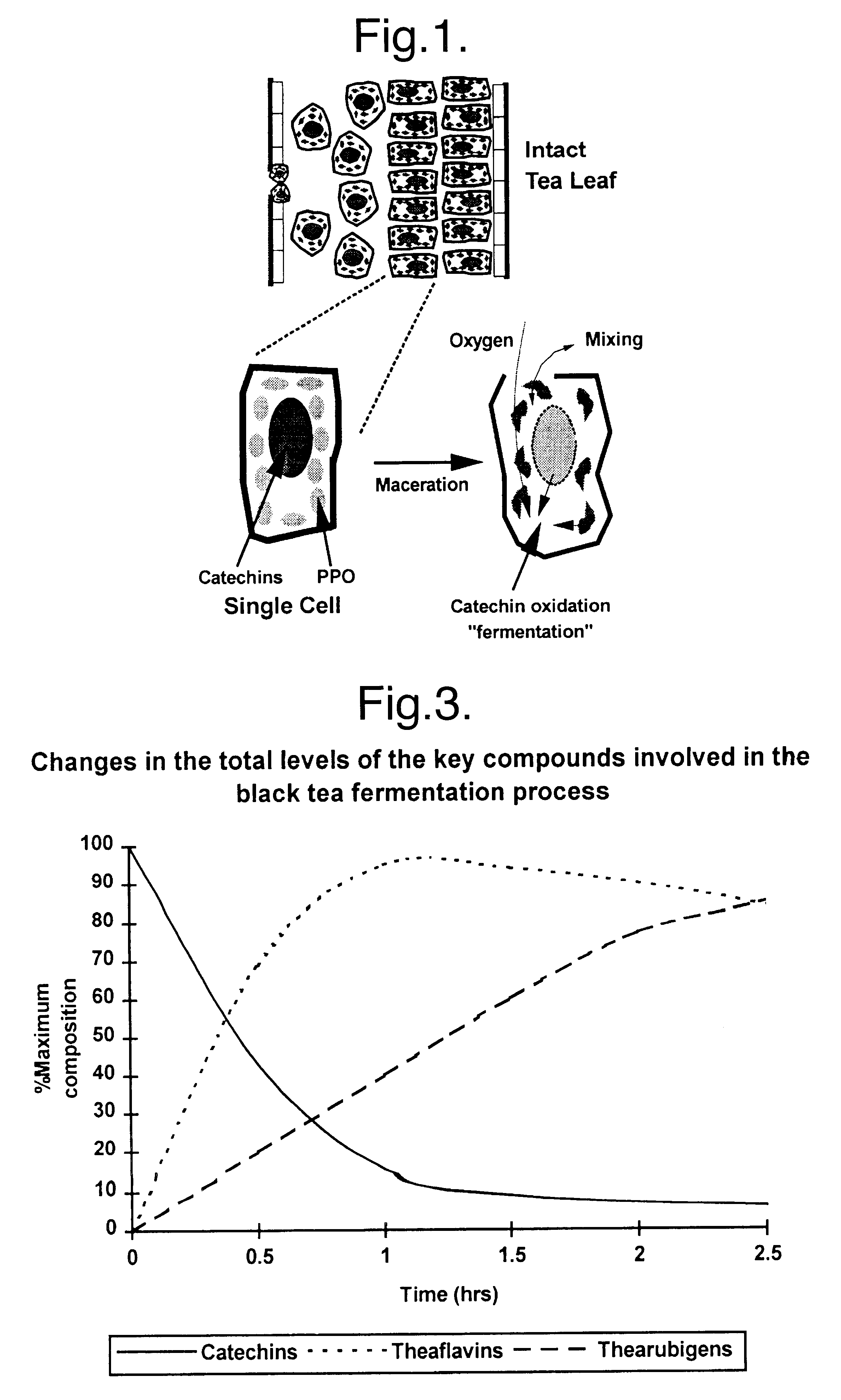

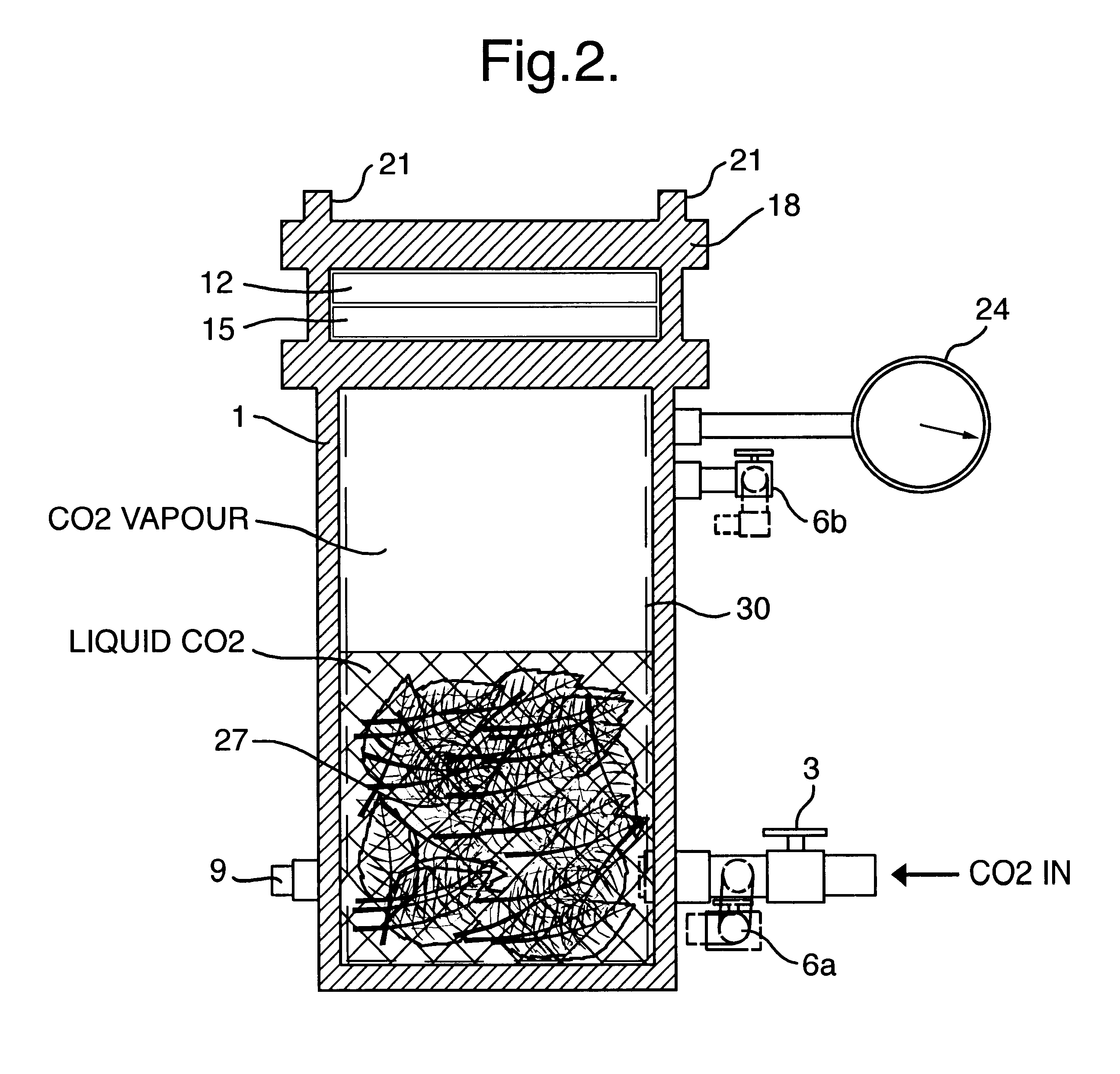

Tea manufacture

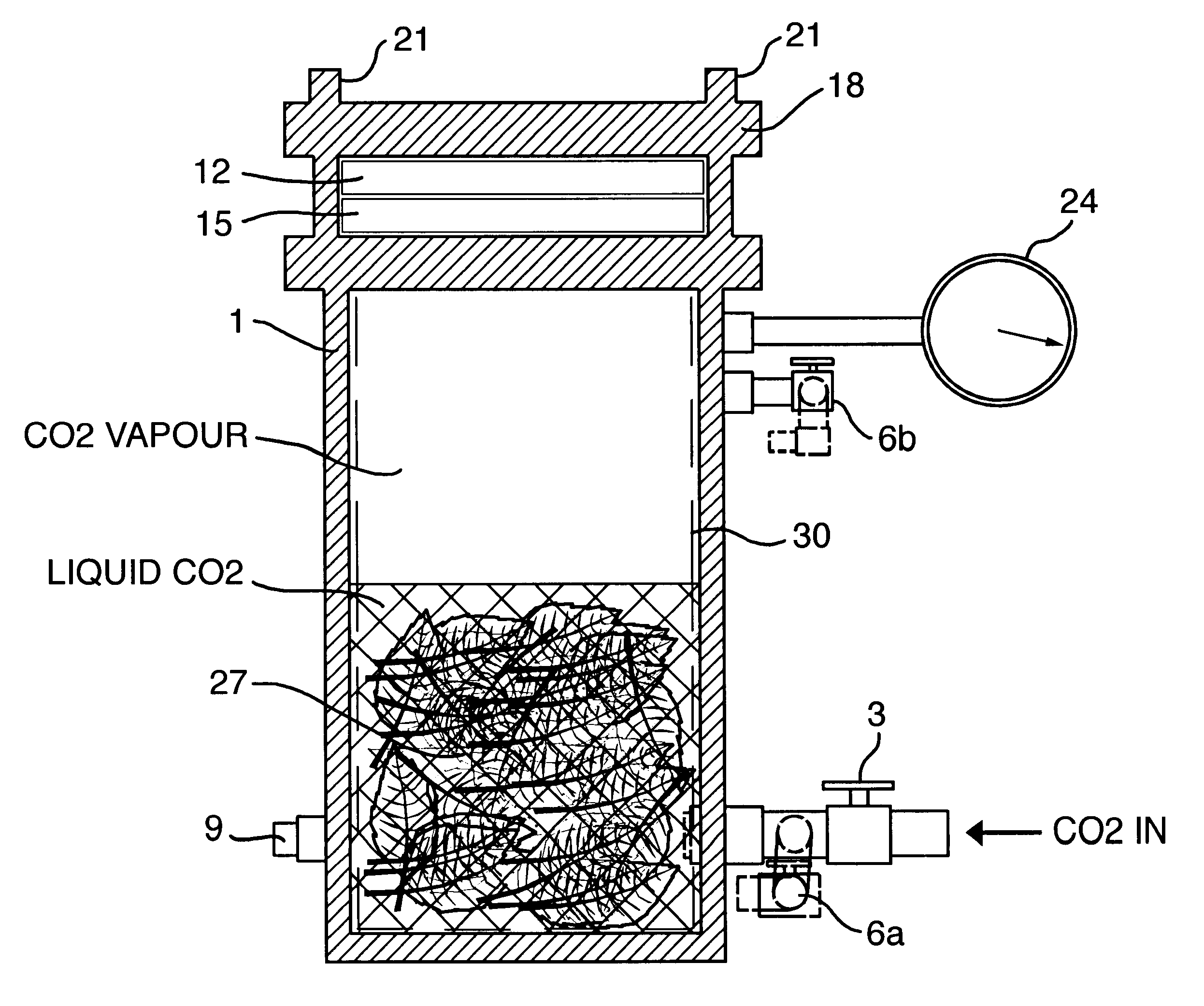

InactiveUS6254902B1Aid onsetIncrease contentPre-extraction tea treatmentAnimal feeding stuffLiquid carbonFermentation

A method for processing whole leaf tea that involves impregnating tea leaves with liquid carbon dioxide within a pressure vessel, depressurising the vessel at a rate that is sufficient to freeze the liquid carbon dioxide, applying sufficient heat to cause the frozen carbon dioxide to sublime and consequently initiate fermentation within the leaves, allowing the tea to ferment for a time that is sufficient to achieve desired liquor properties, and drying the fermented product to yield the whole leaf tea. An apparatus for manufacturing such a leaf tea is also described.

Owner:THOMAS J LIPTON DIV OF CONOPCO

Method of removing solid carbon dioxide

The invention provides a method of removing solid carbon dioxide from cryogenic equipment, including the steps of: (a) introducing a stream including ethane to the cryogenic equipment to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. In particular, the method can be used in a liquefied natural gas (LNG) plant wherein cryogenic equipment contains LNG, and the method includes the steps of: (a′) removing the LNG from the cryogenic equipment; (a) introducing a stream including ethane to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. The result is an effective cleaning method for fouled LNG equipment.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com