Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Carbon Dioxide Snow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dioxide snow the solid formed by rapid evaporation of liquid carbon dioxide, giving a temperature of about −79°C (−110°F). It has been used in cryotherapy to freeze the skin, thus producing local anesthesia and arrest of blood flow.

Carbon dioxide snow apparatus

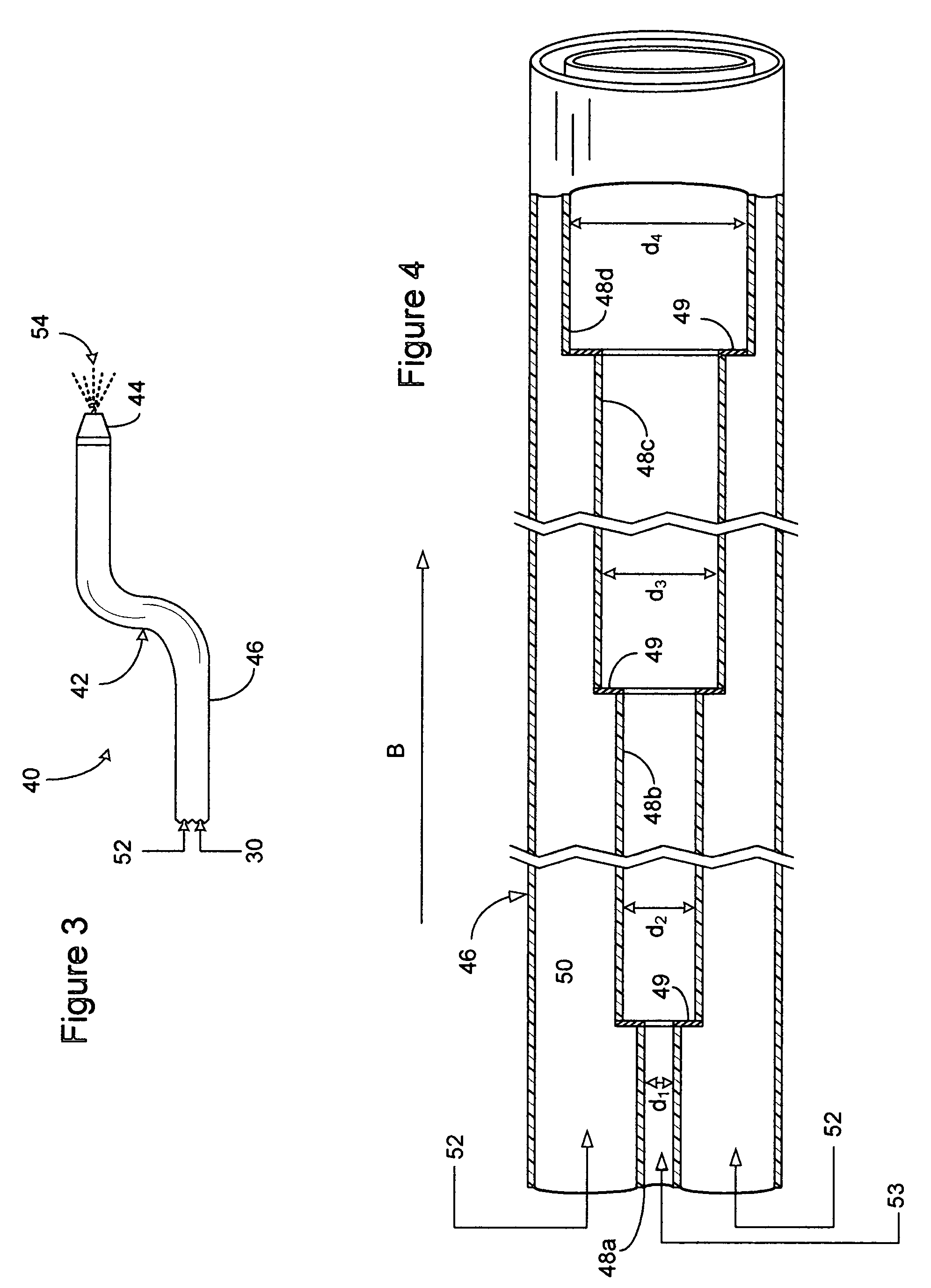

ActiveUS7293570B2Increased Joule-Thompson coolingReduce cloggingBlast gunsSpray nozzlesLiquid carbonMachining process

A carbon dioxide snow apparatus of the present invention includes a carbon dioxide snow generation system and a propellant generation system connected to a common carbon dioxide gas source. The carbon dioxide snow generation system includes a condenser having a at least two connected segments, wherein a first segment has a lesser diameter than the a second segment to provide a stepped expansion cavity for cooling and condensing liquid carbon dioxide into solid carbon dioxide snow. Several snow generation systems, each separately controllable with separate condensers, may be integrated with the propellant generation system and common carbon dioxide source to provide for a multiplicity of carbon dioxide snow applicators for integration into both manual and automated machining processes.

Owner:COOL CLEAN TECH

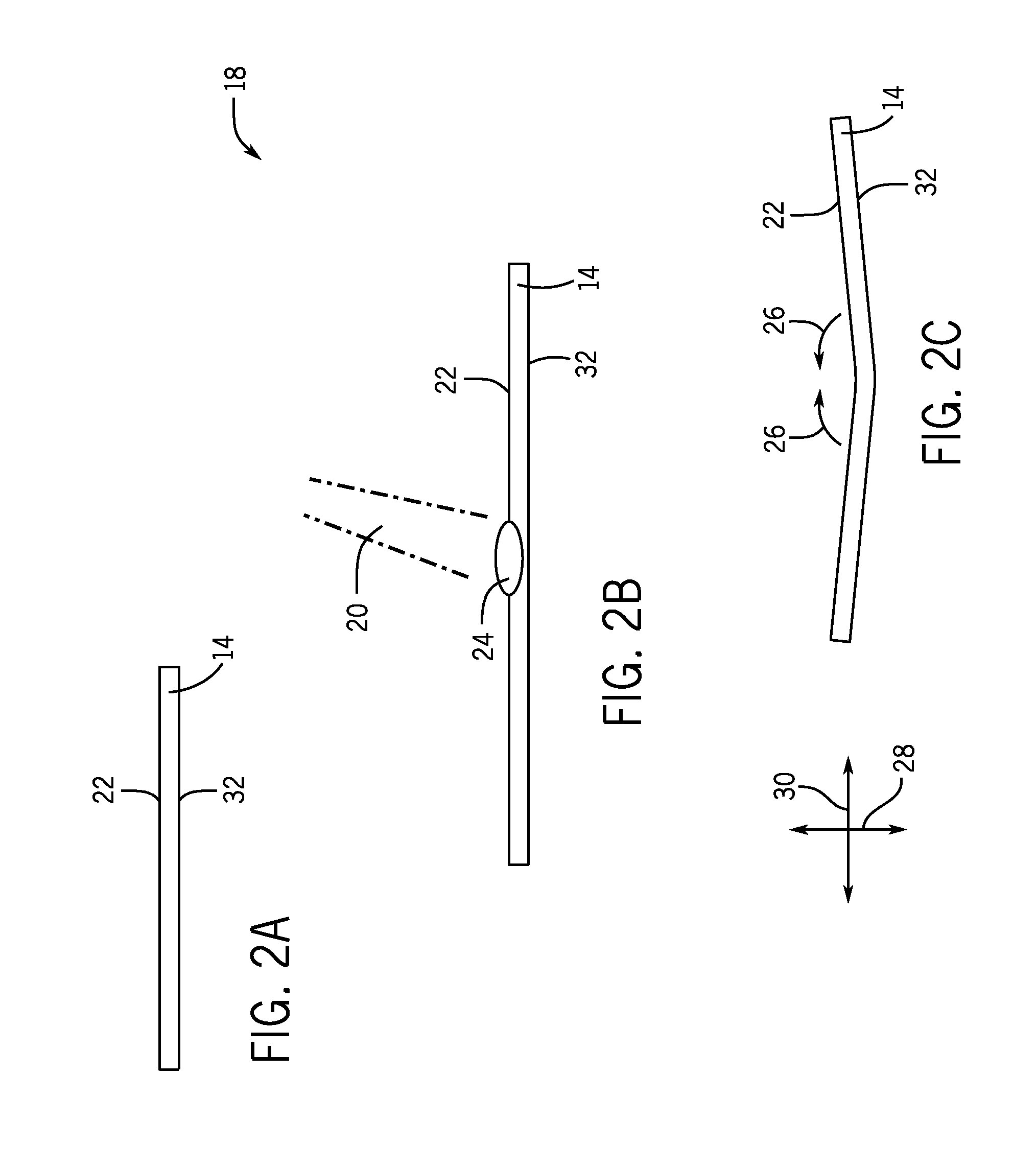

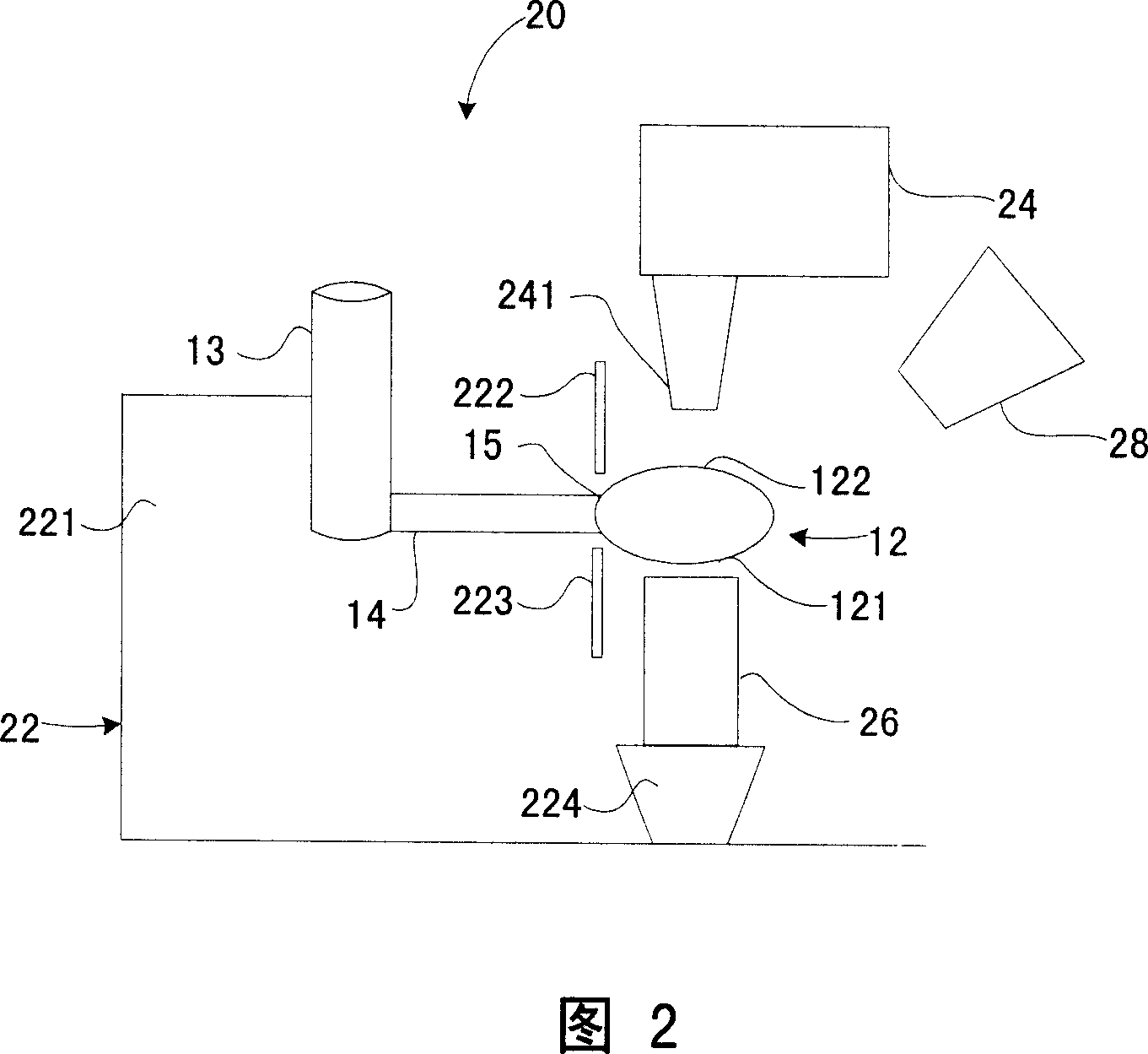

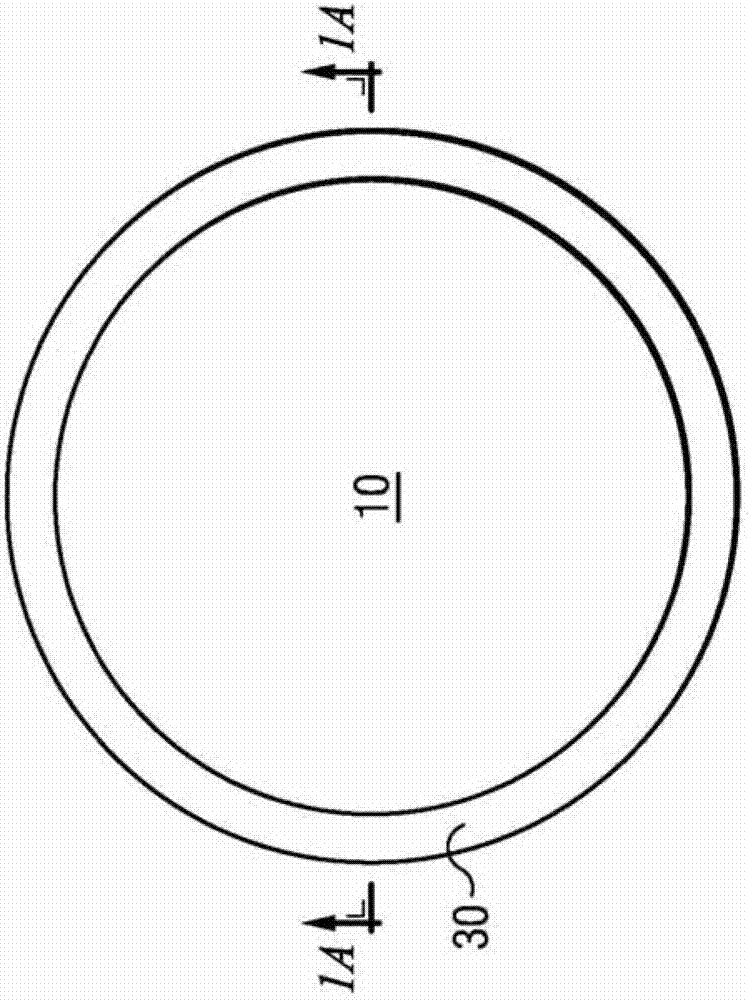

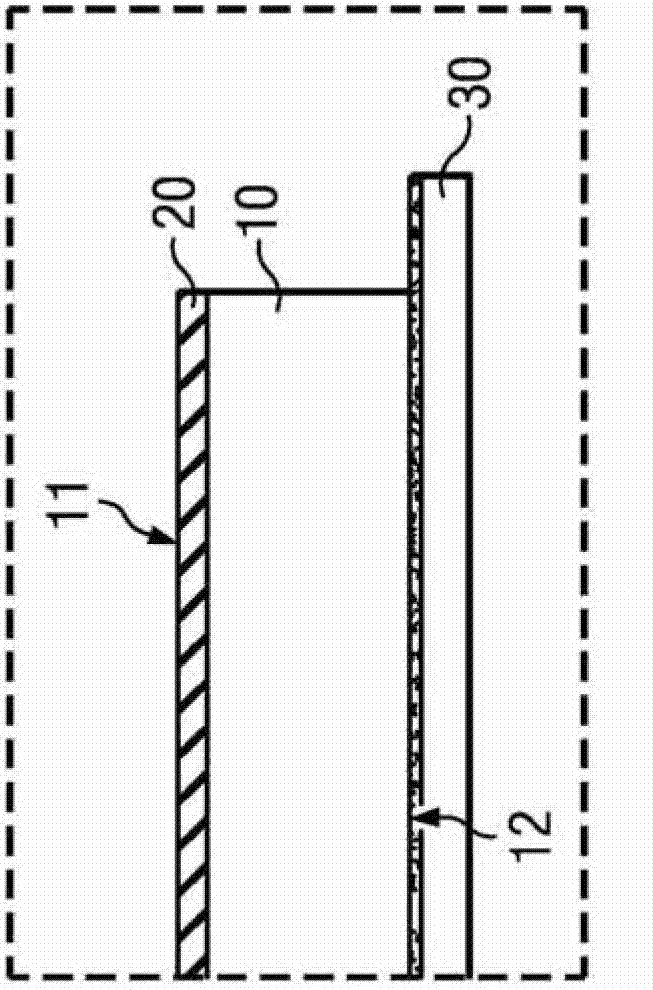

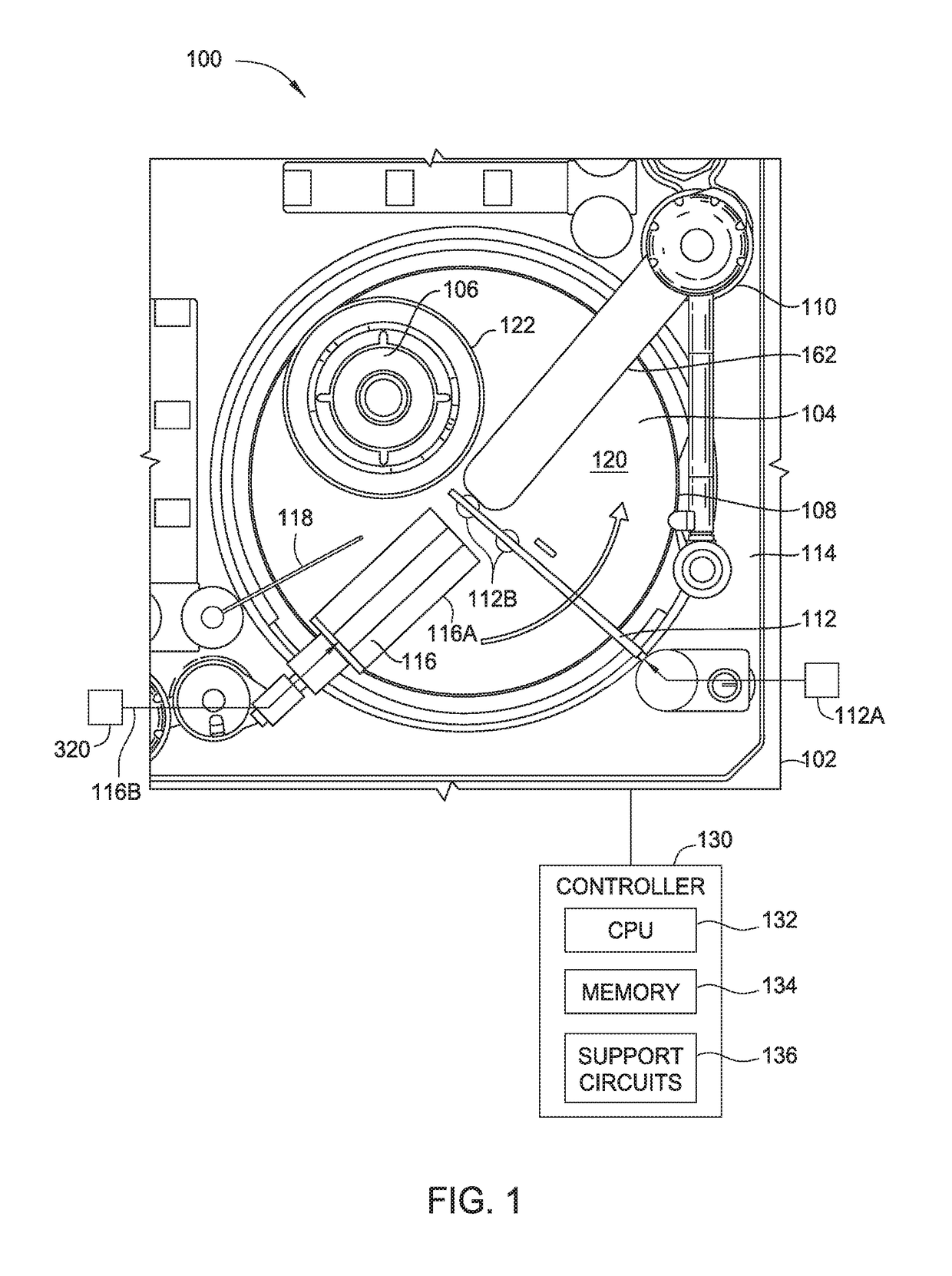

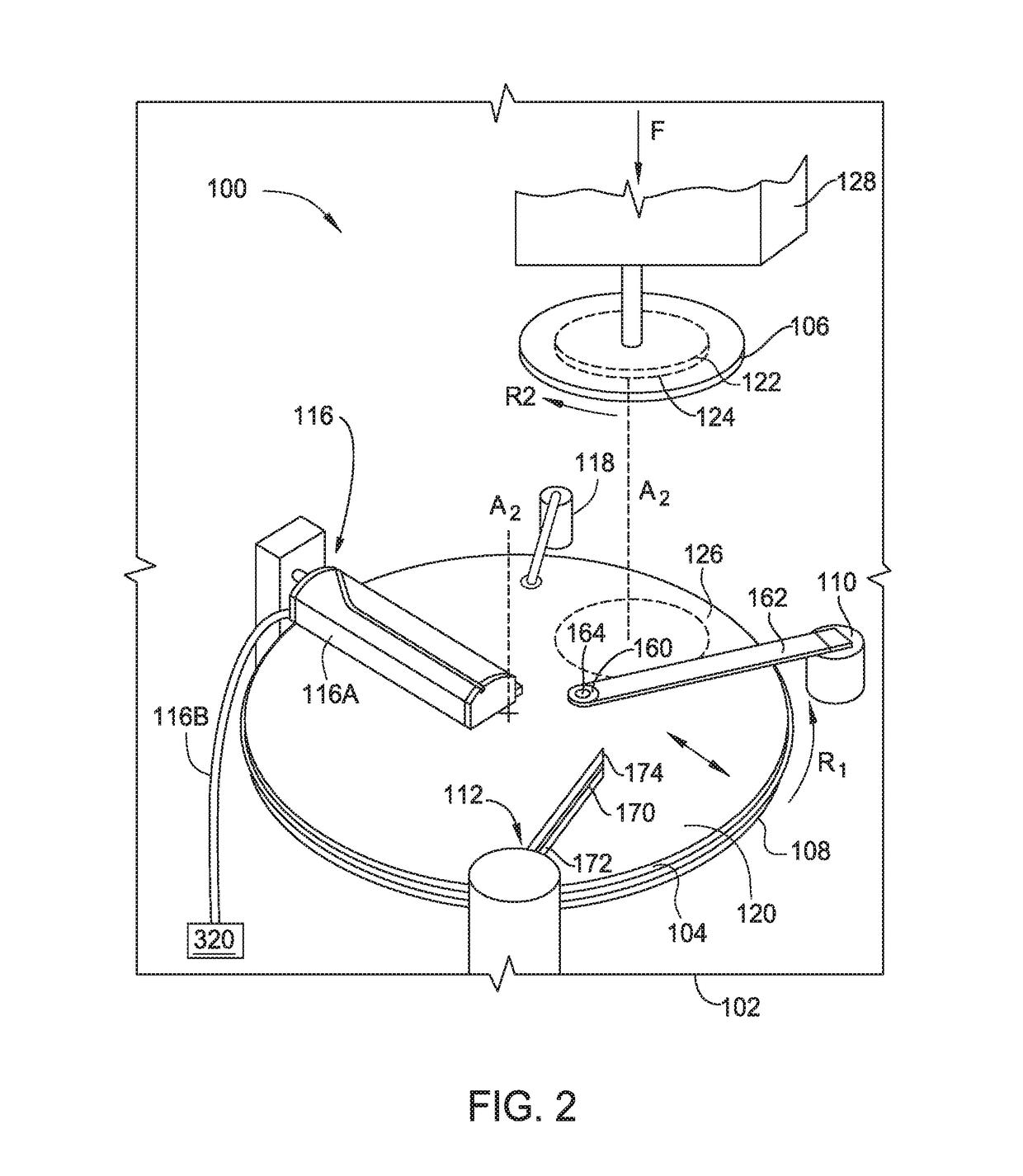

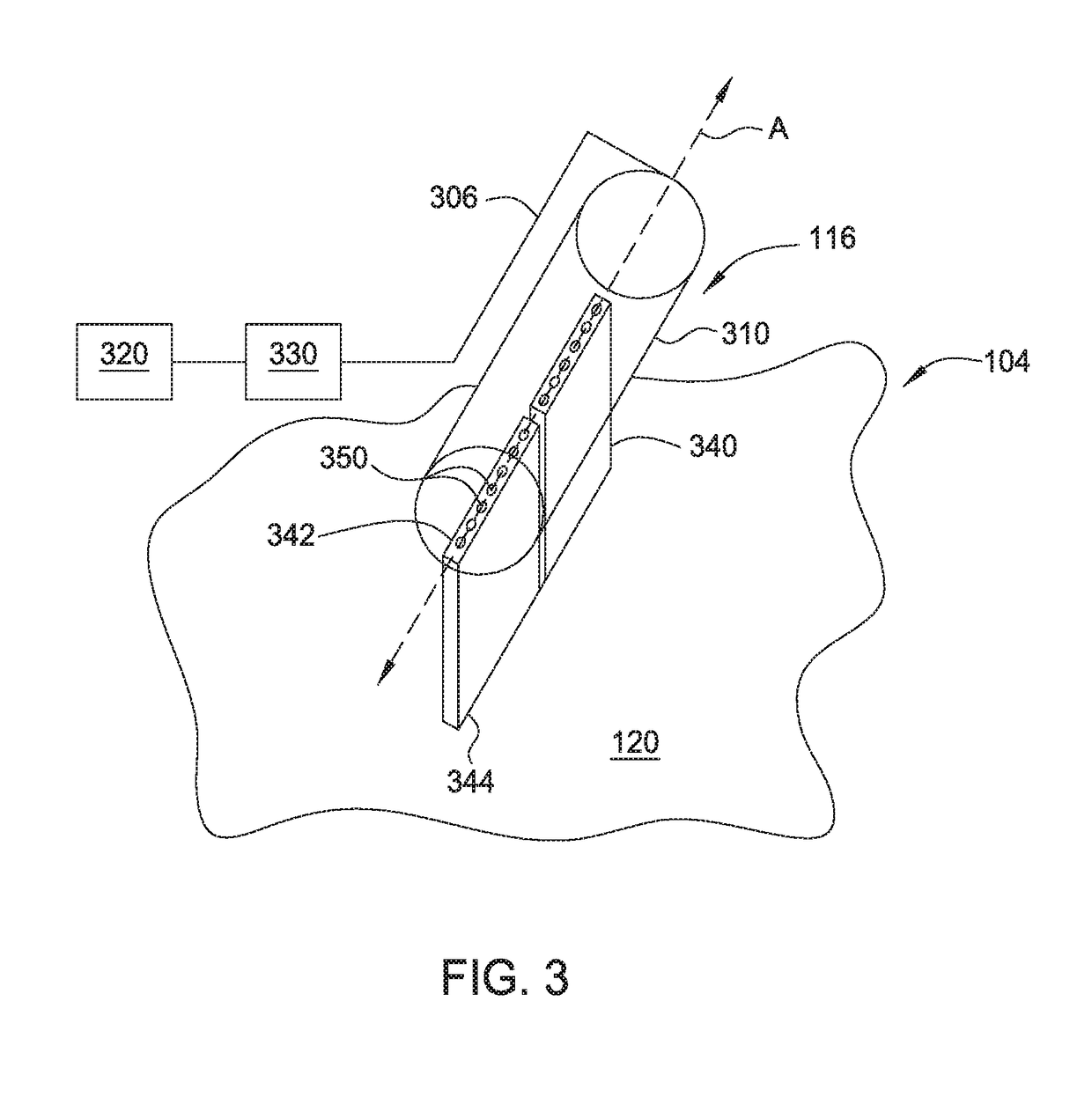

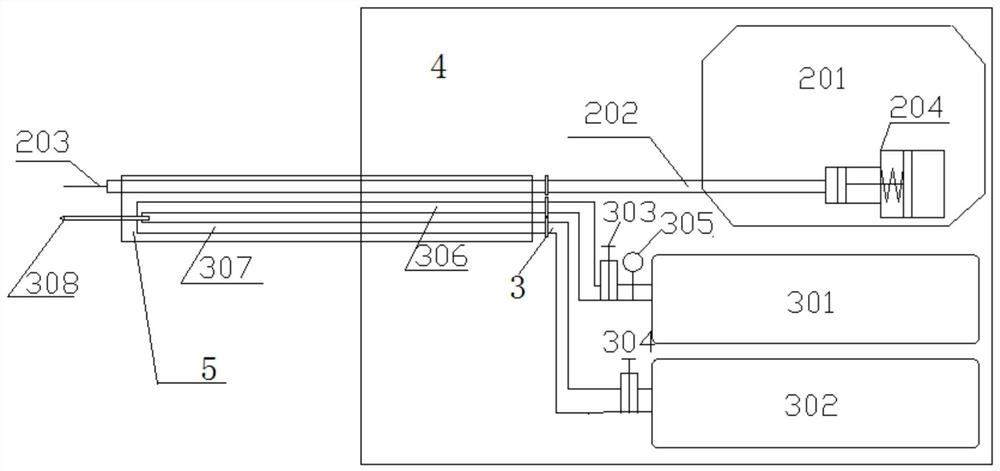

In-situ temperature control during chemical mechanical polishing with a condensed gas

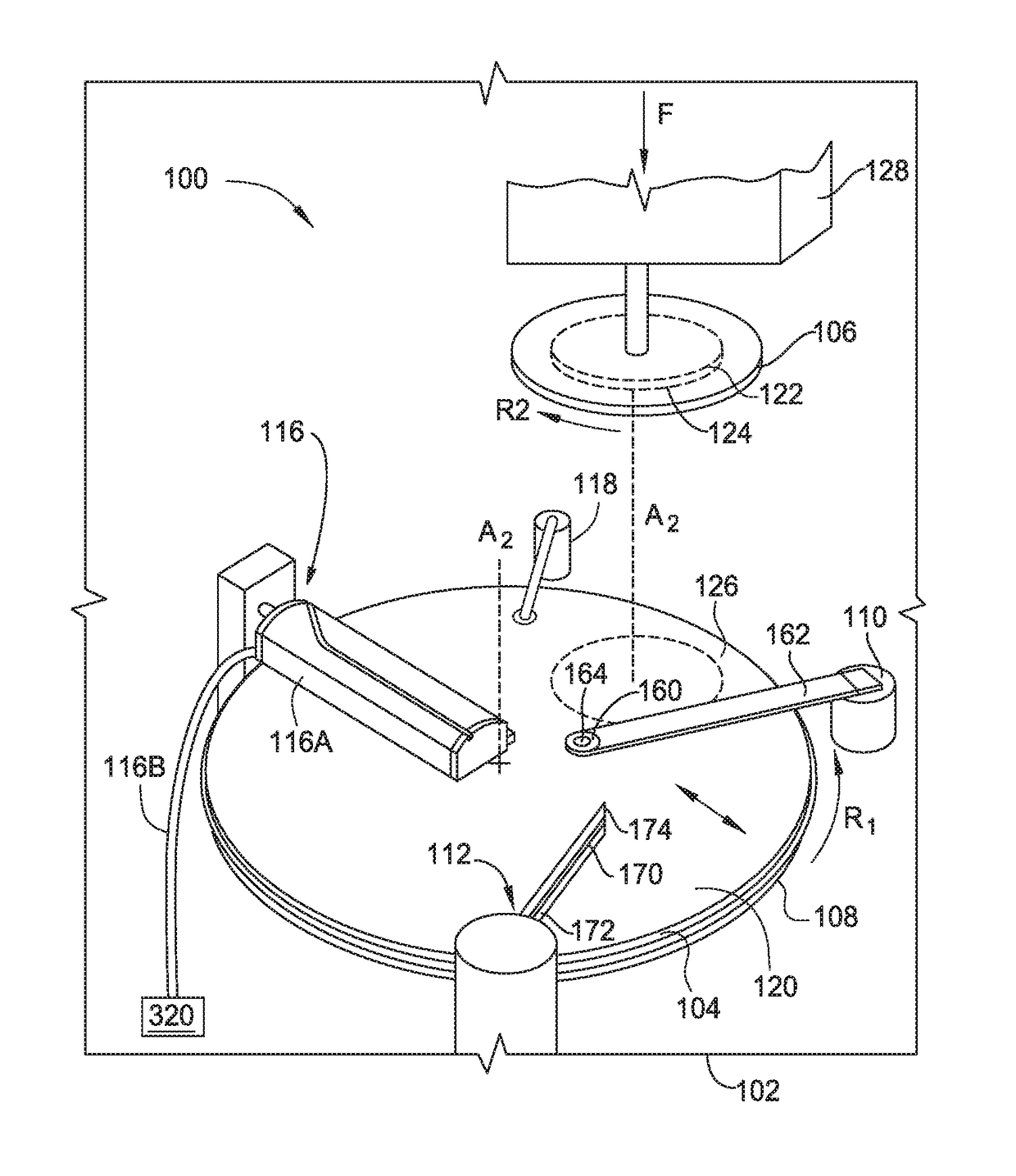

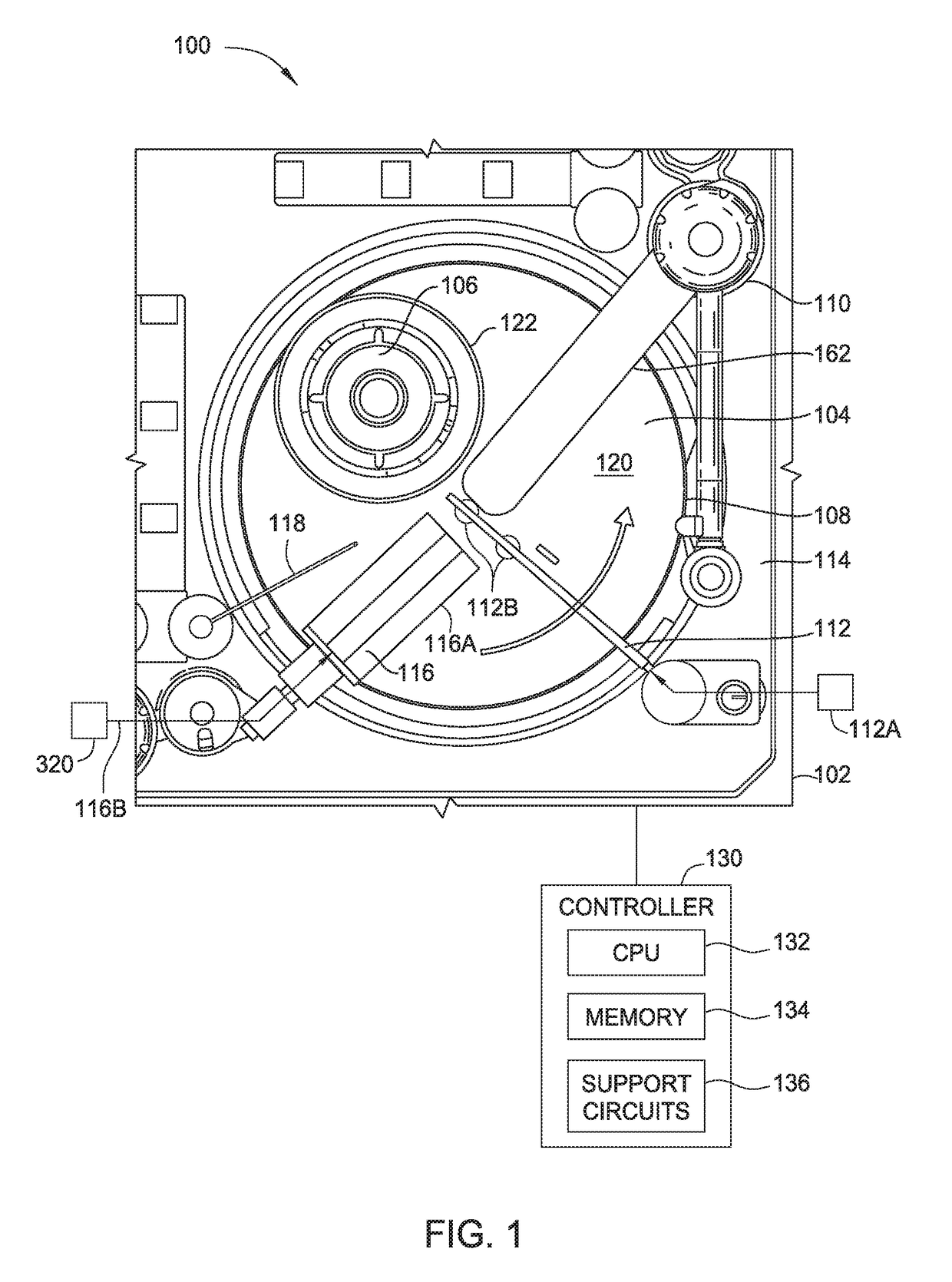

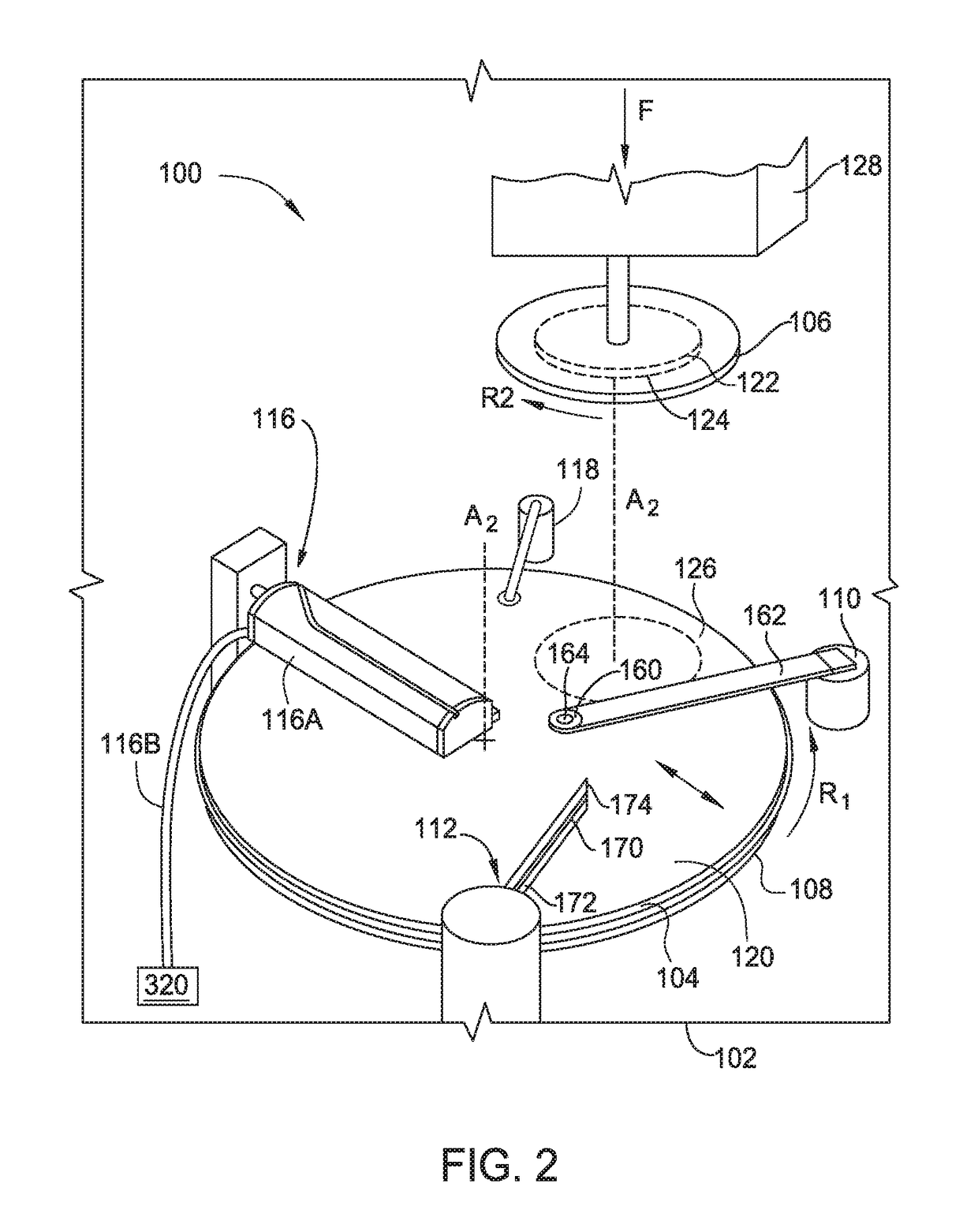

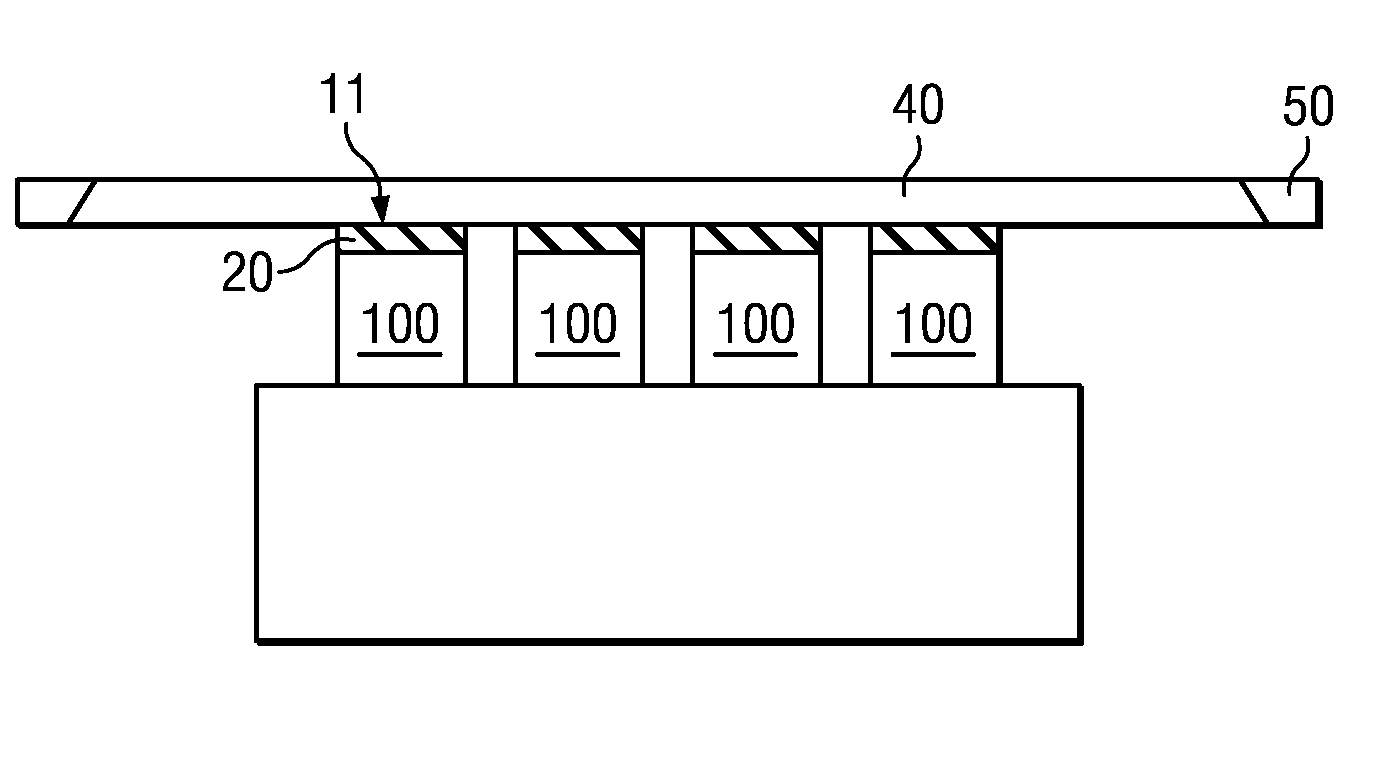

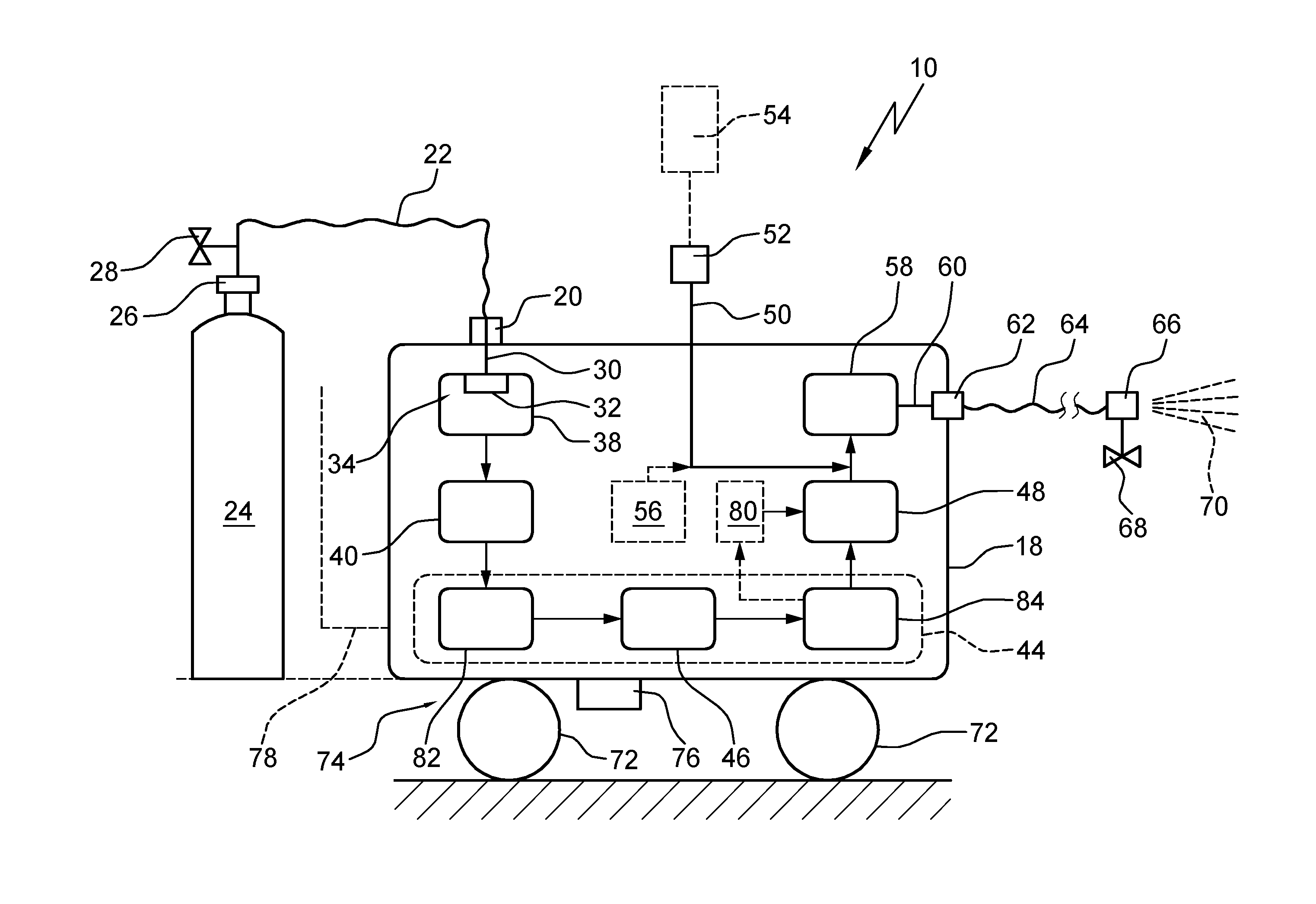

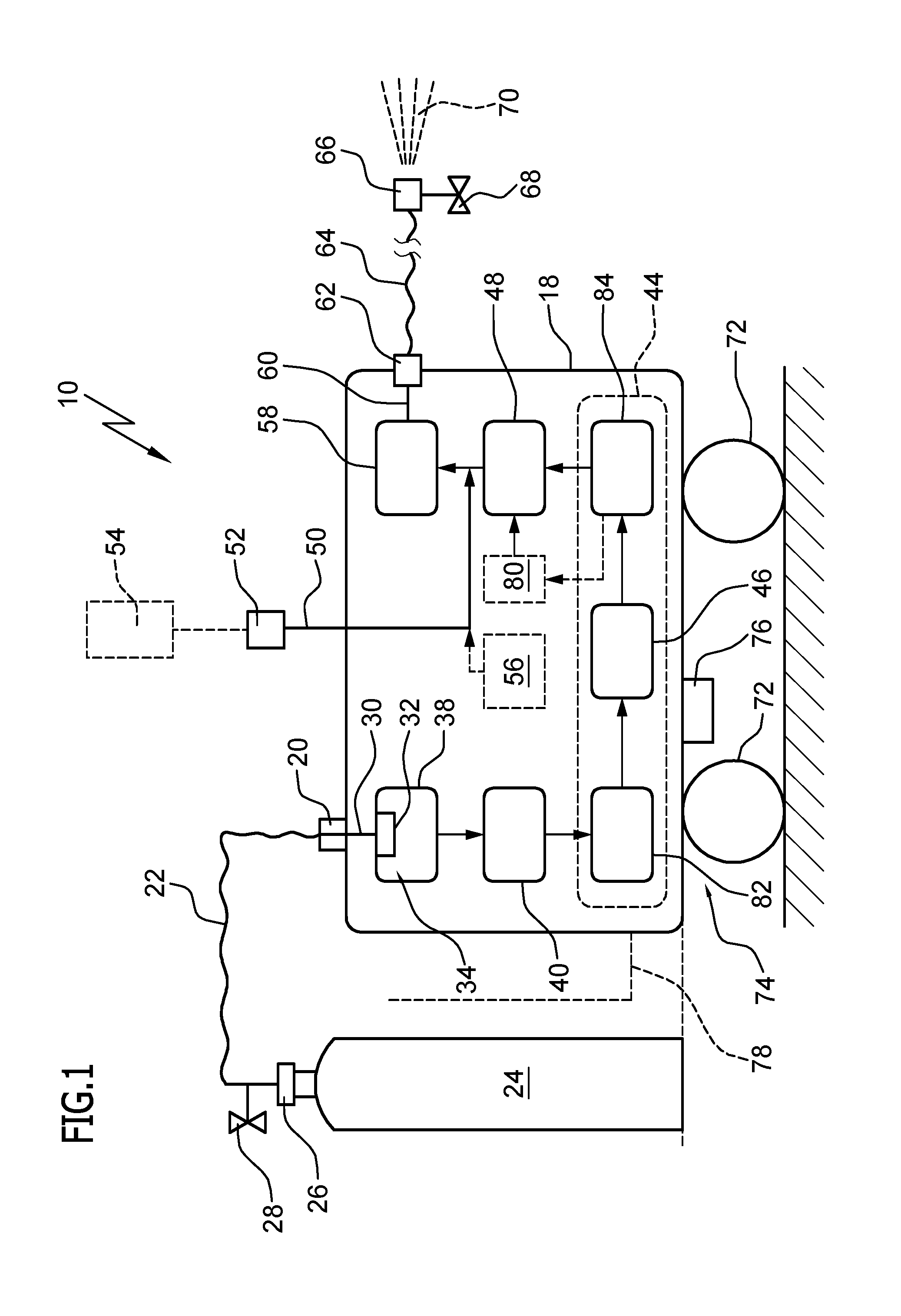

ActiveUS20170232572A1Maintain temperatureLapping machinesGrinding feed controlTemperature controlProcess engineering

Implementations of the present disclosure generally relate to planarization of surfaces on substrates and on layers formed on substrates, including an apparatus for in-situ temperature control during polishing, and methods of using the same. More specifically, implementations of the present disclosure relate to in-situ temperature control with a condensed gas during a chemical-mechanical polishing (CMP) process. In one implementation, the method comprises polishing one or more substrates against a polishing surface in the presence of a polishing fluid during a polishing process to remove a portion of a material formed on the one or more substrates. A temperature of the polishing surface is monitored during the polishing process. Carbon dioxide snow is delivered to the polishing surface in response to the monitored temperature to maintain the temperature of the polishing surface at a target value during the polishing process.

Owner:APPLIED MATERIALS INC

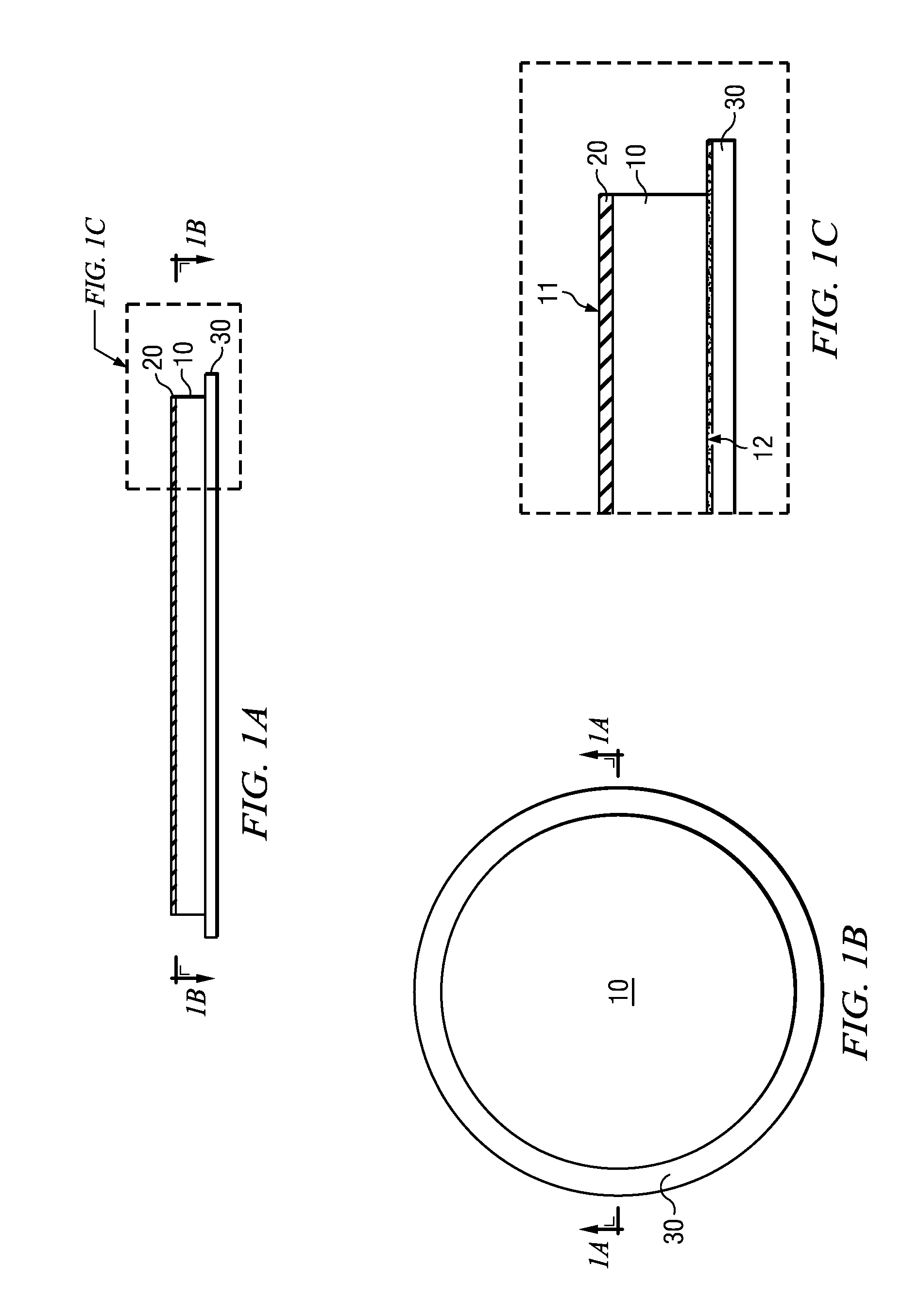

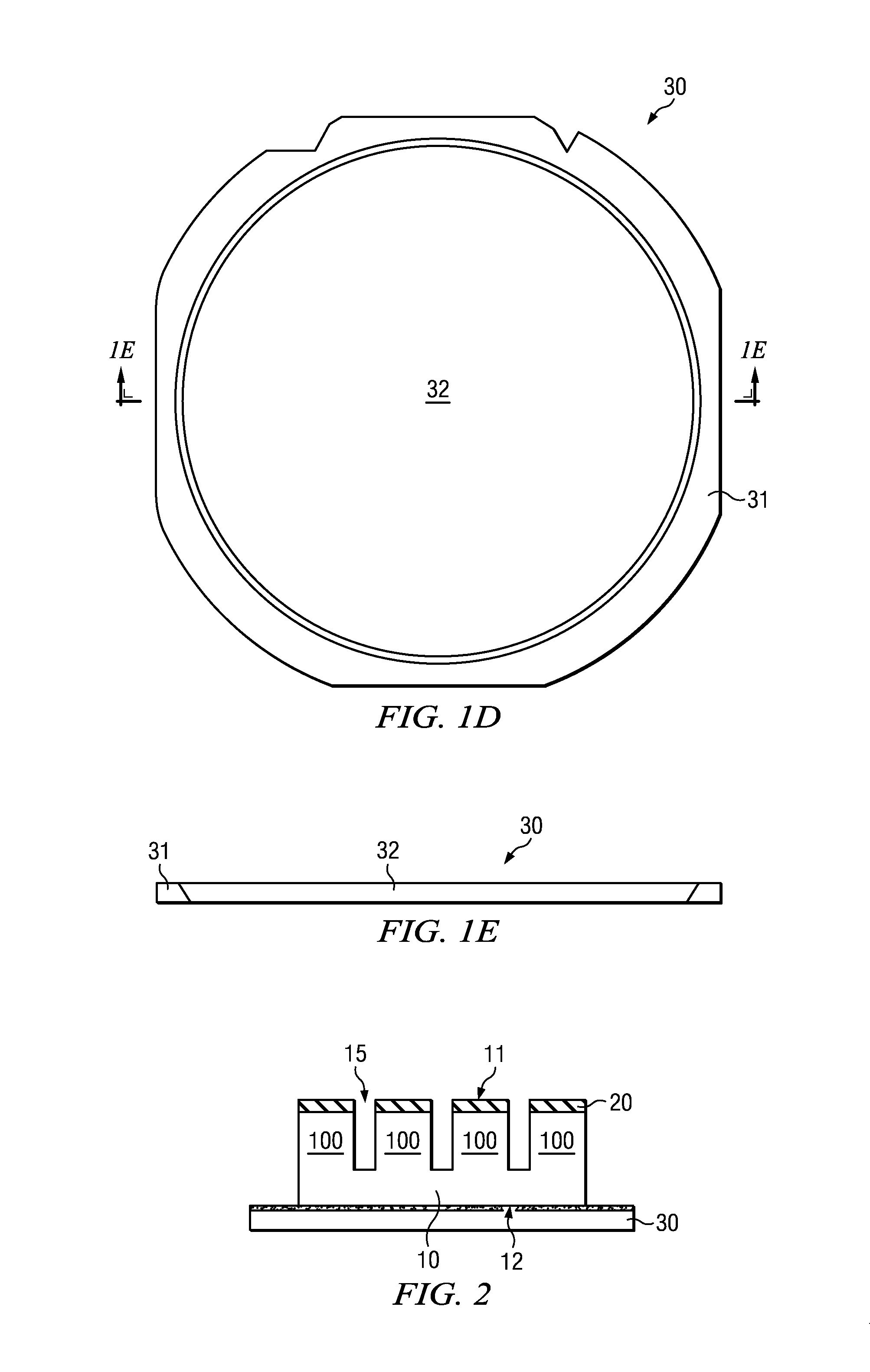

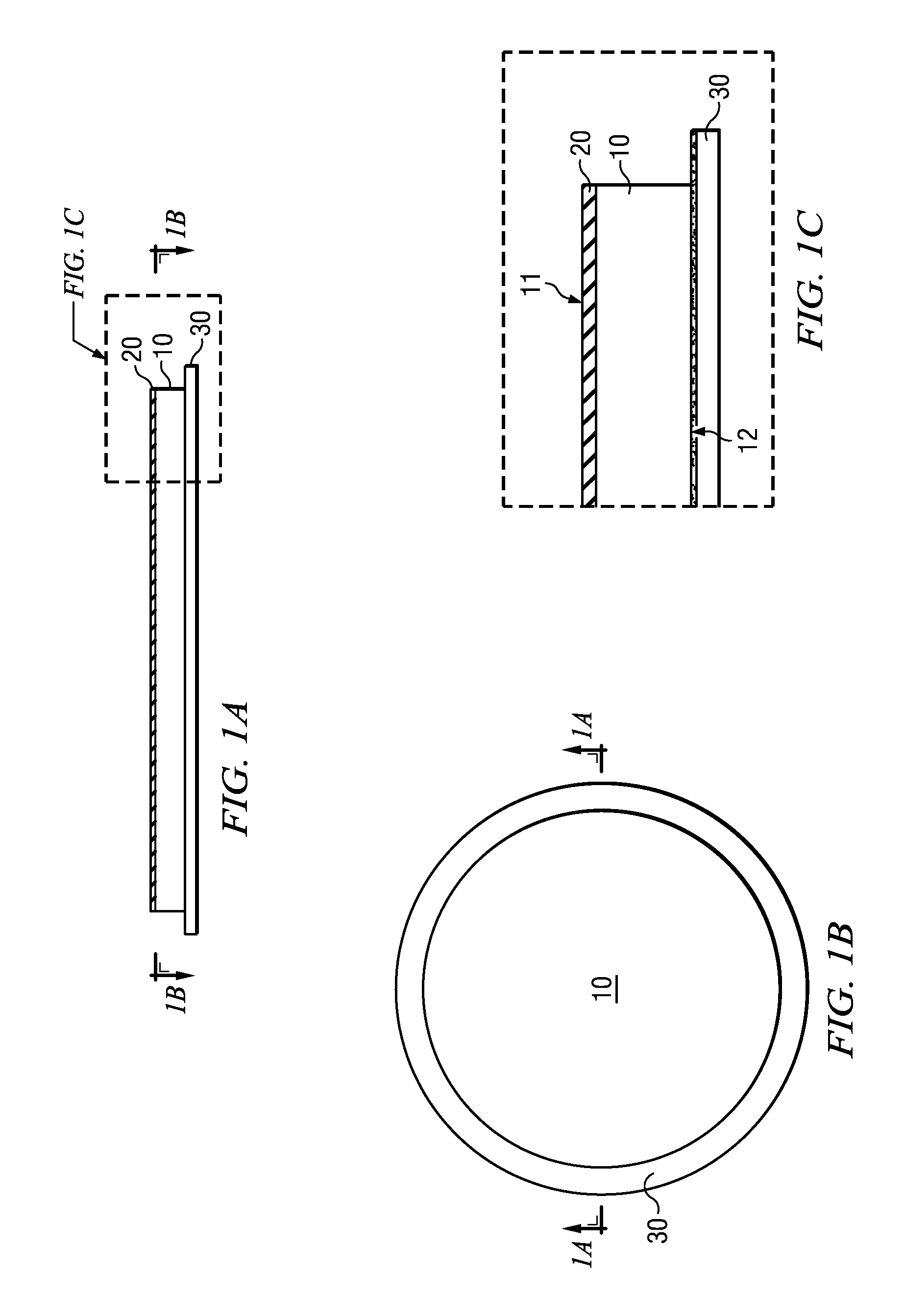

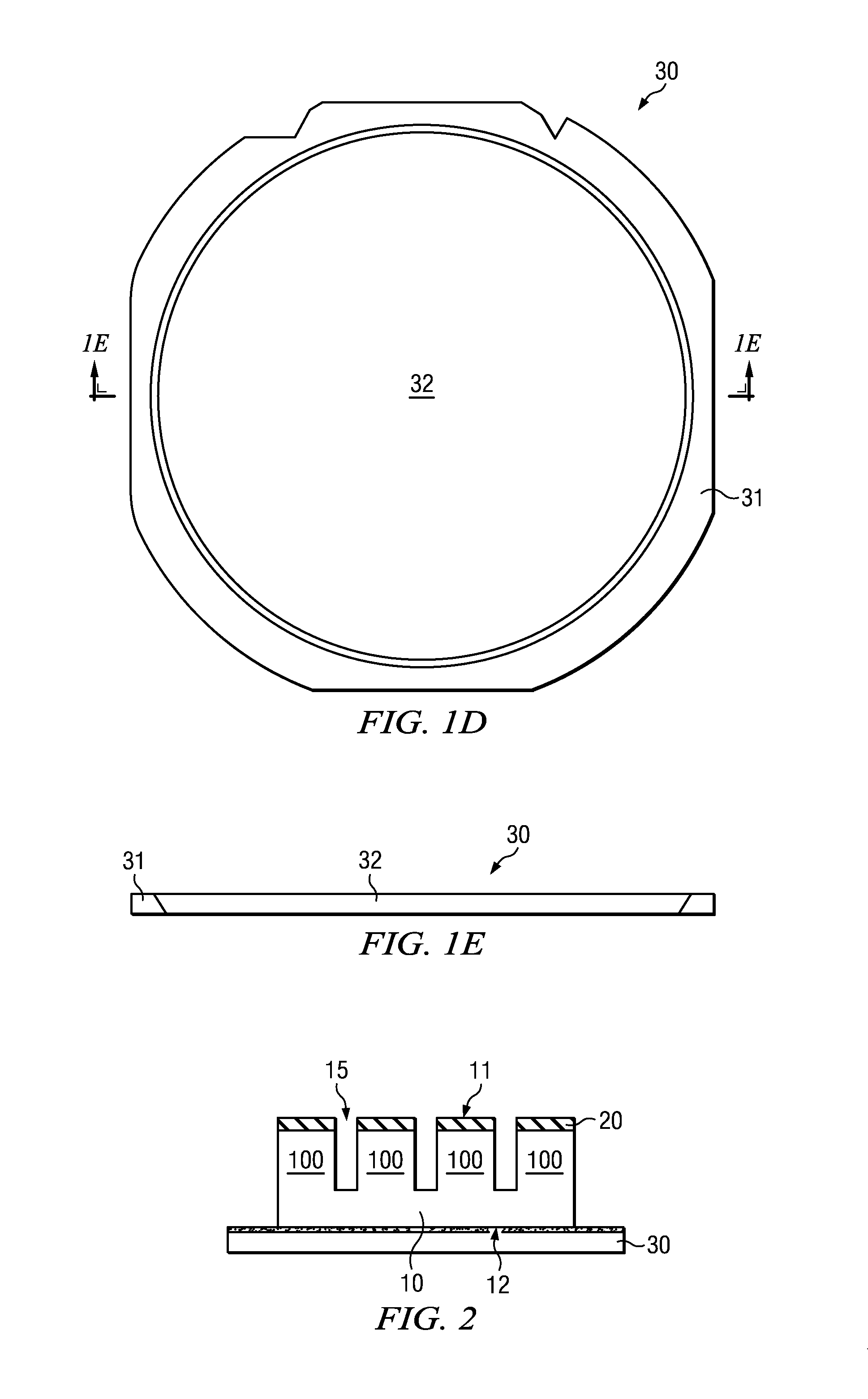

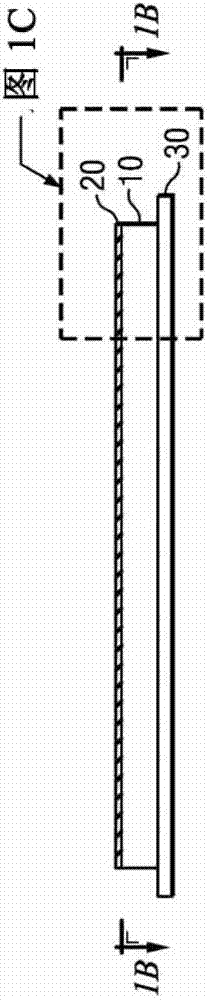

Separation of Semiconductor Devices from a Wafer Carrier

ActiveUS20130084658A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringSemiconductor

In accordance with an embodiment of the present invention, a semiconductor device is manufactured by arranging a plurality of semiconductor devices on a frame with an adhesive foil. The plurality of semiconductor devices is attached to the adhesive foil. The plurality of semiconductor devices is removed from the frame with the adhesive foil using a carbon dioxide snow jet and / or a laser process.

Owner:INFINEON TECH AG

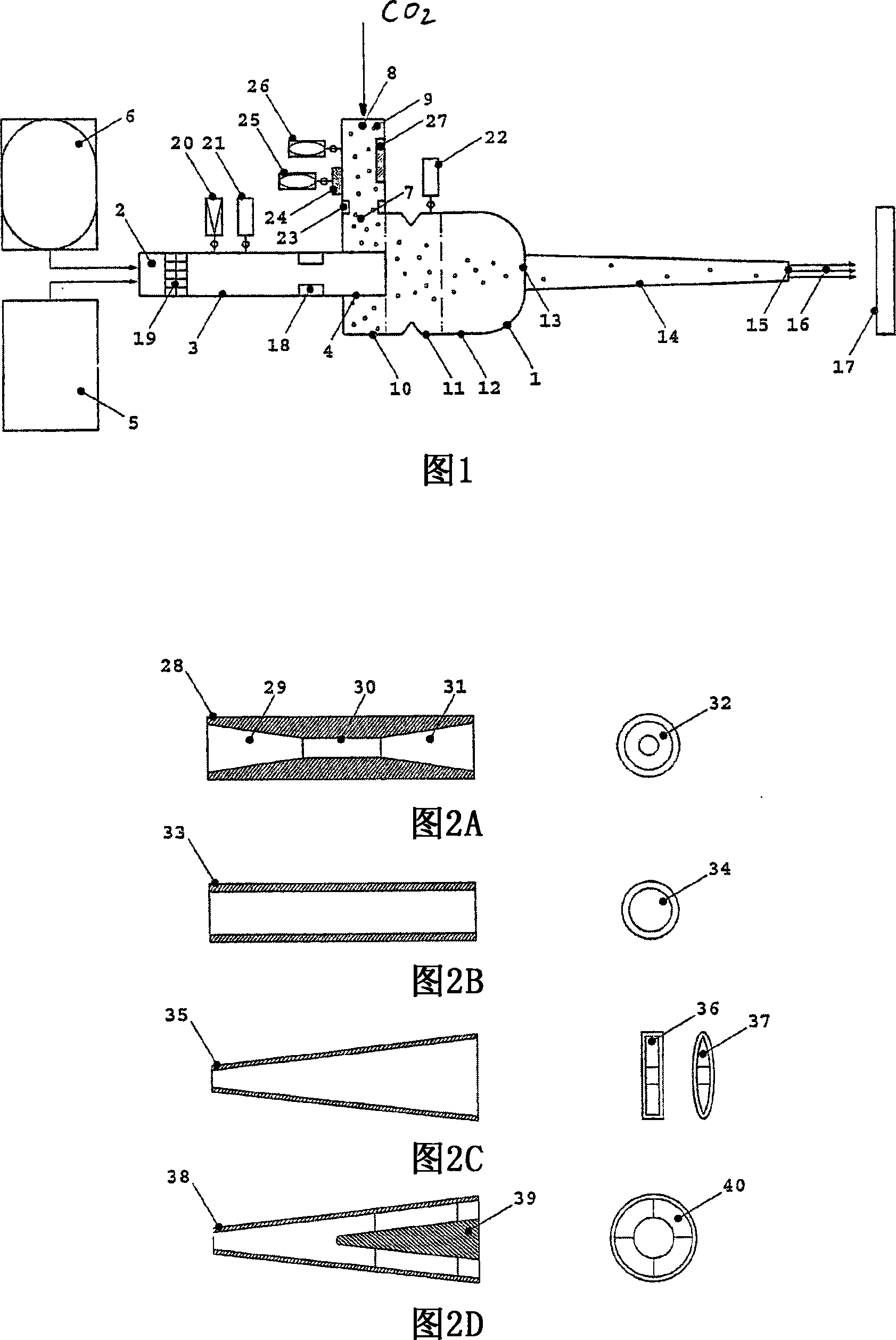

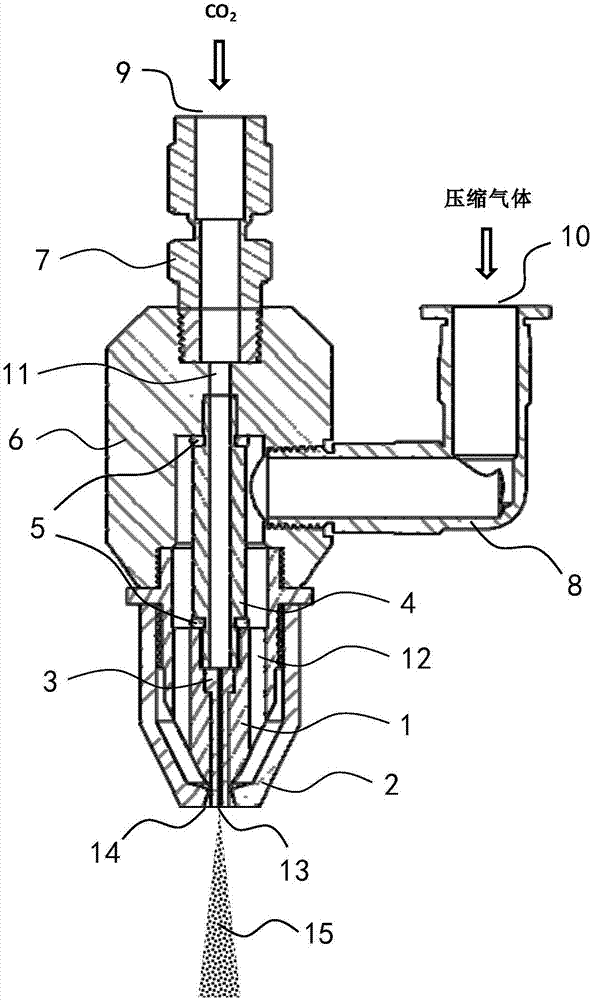

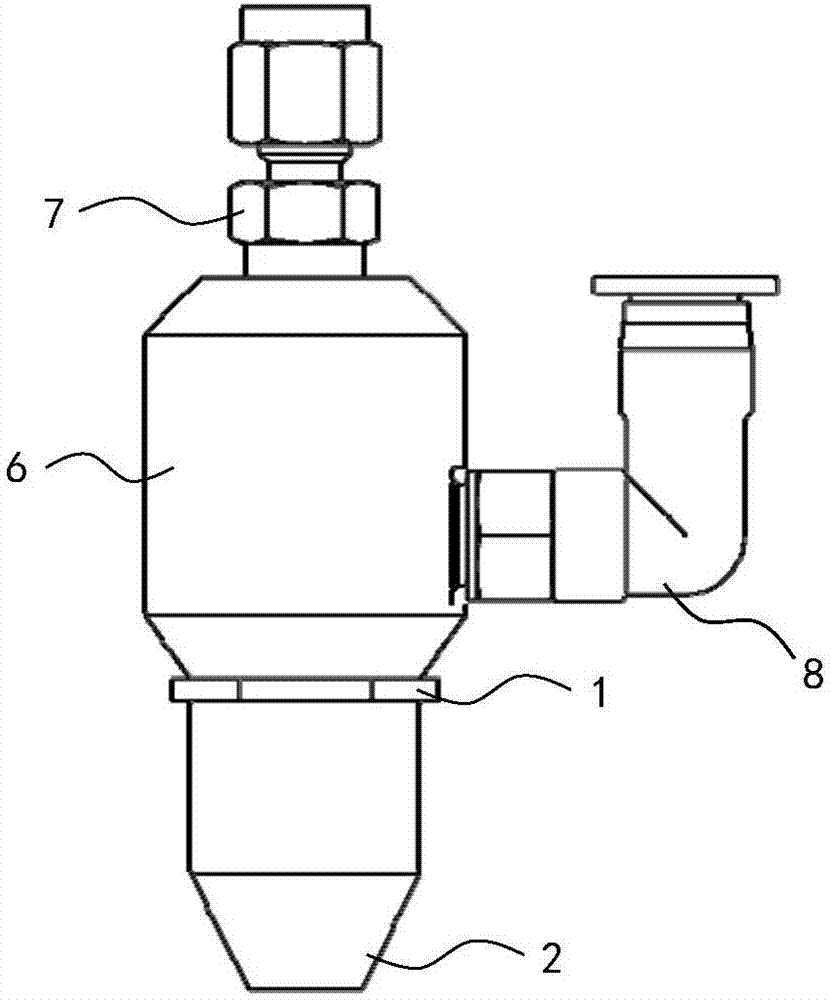

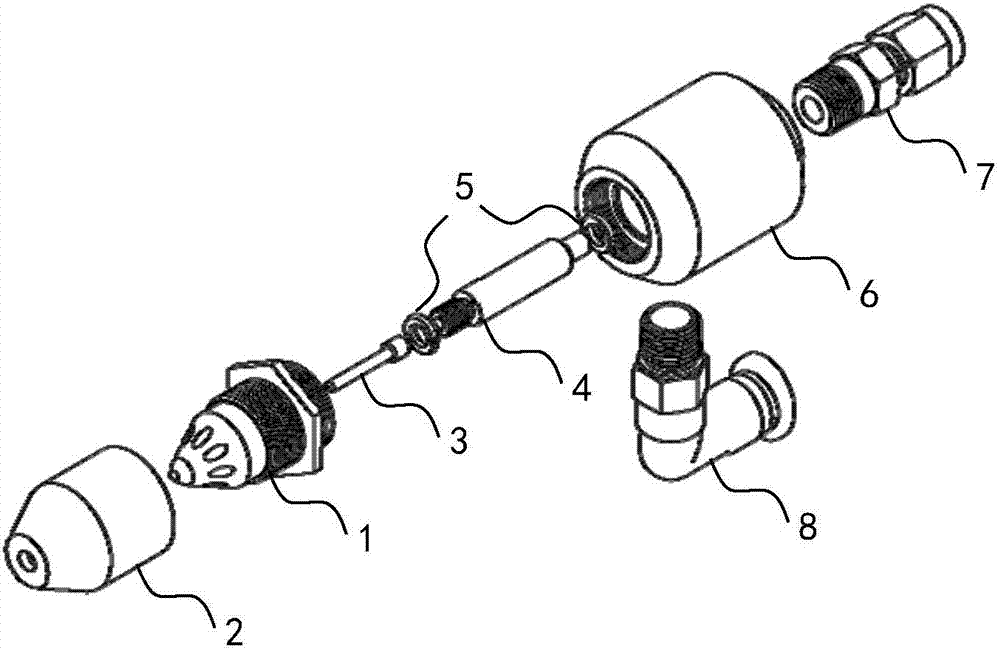

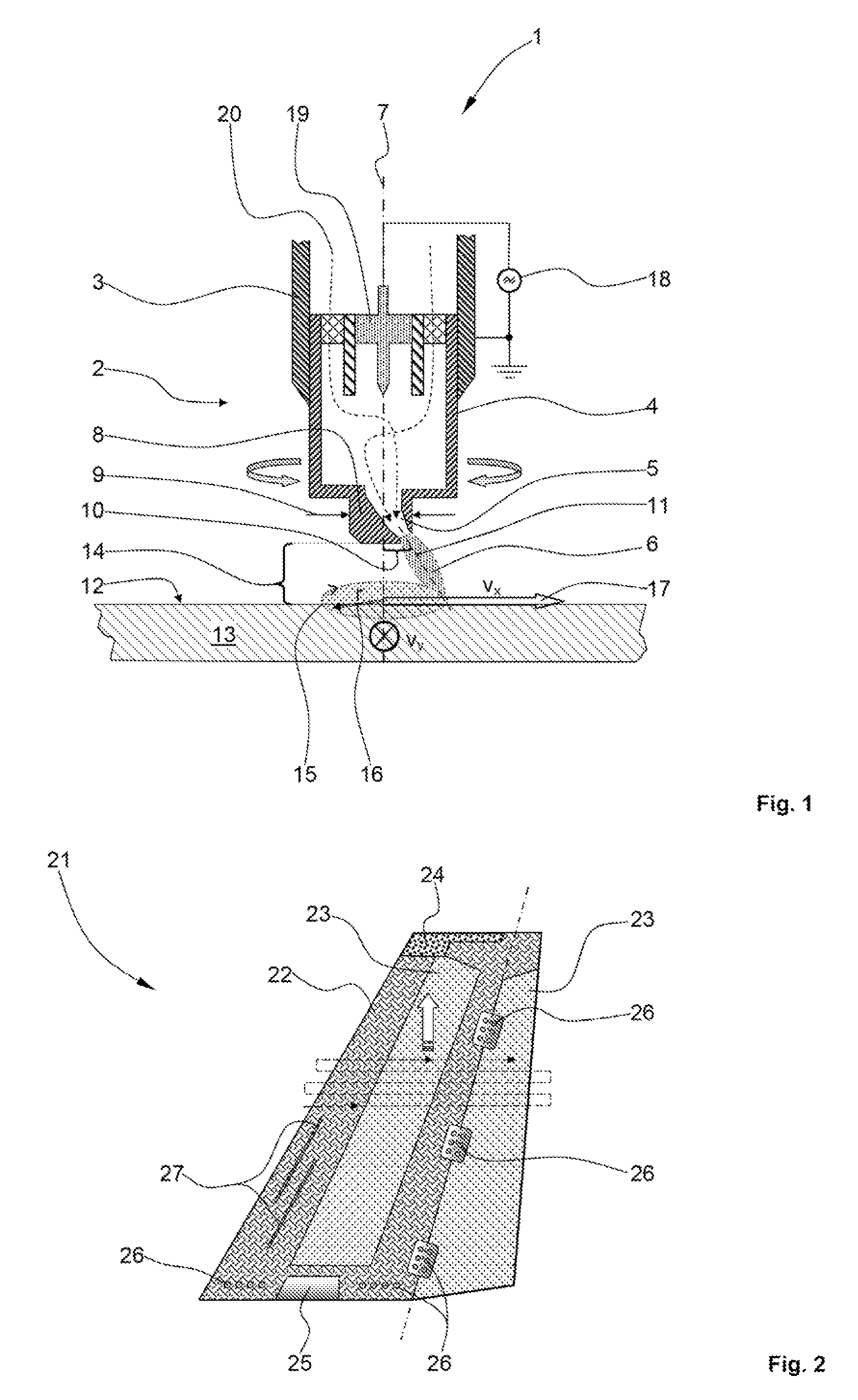

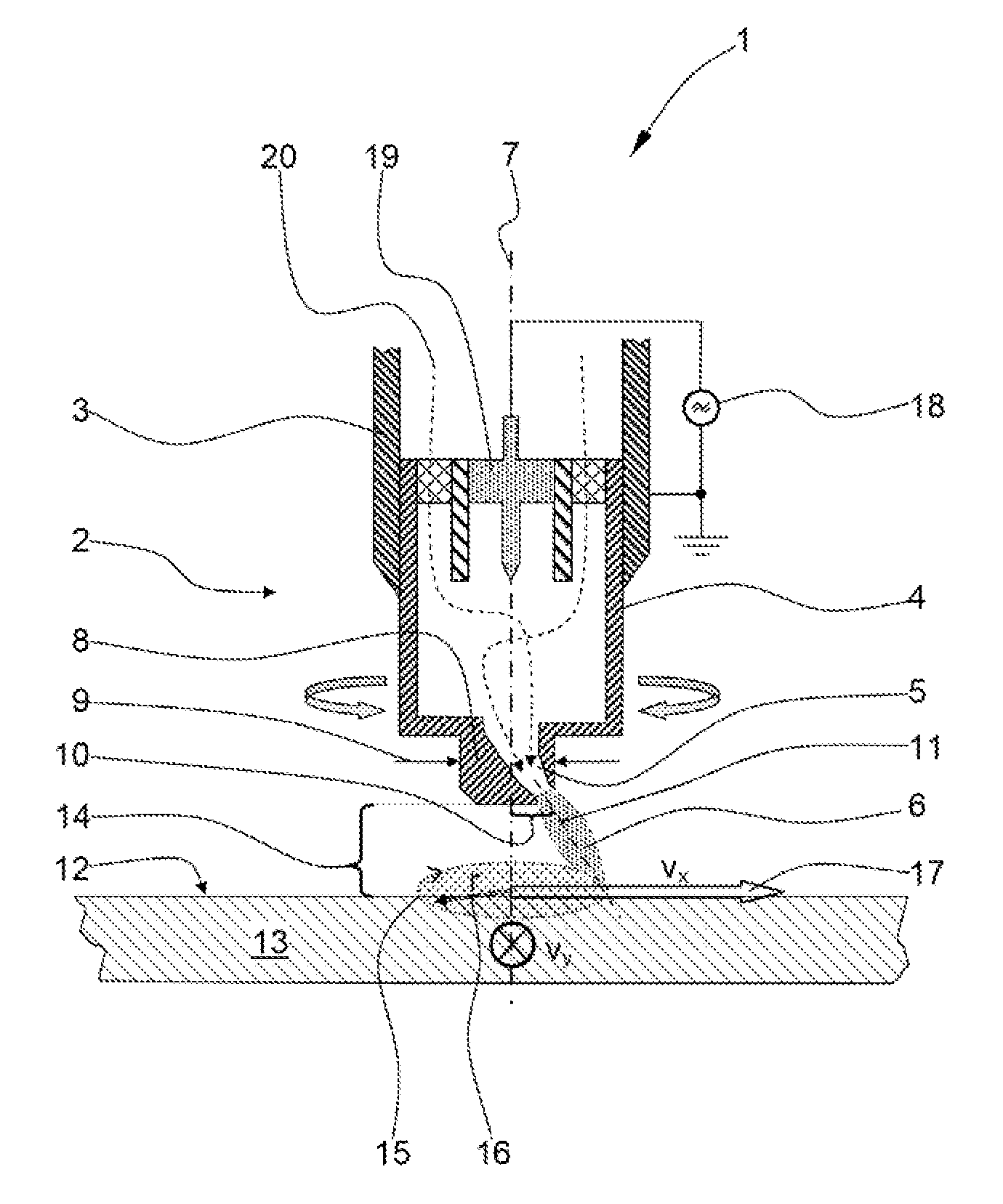

Device and method for cleaning, activating or pre-treating workpieces by blasting carbon dioxide snow

ActiveCN101124065AMixed Effects FavorableImprove stabilityBlast gunsCarbon compoundsPhysical chemistryEnvironmental engineering

The invention relates to a device and method for cleaning, activating or pre-treating workpieces by blasting a carbon dioxide snow which is produced from pressurised CO2-containing fluids and at least one type of carrying compressed gas and is accelerated by means of a discharge nozzle (14), wherein a two-phase carbon dioxide mixture of a carbon dioxide gas and carbon dioxide particles is produced in an agglomeration chamber (8) by agglomerating and compressing carbon dioxide snow crystals which are radially added to the carrying gas in a multistage mixing chamber (10, 11, 12) comprising a central jet pipe (4), around which the carbon dioxide mixture circulates and which is used for supplying said carrying gas in such a manner that a high-energy turbulent gas flow for processing a workpiece is obtainable.

Owner:CRYOSNOW GMBH

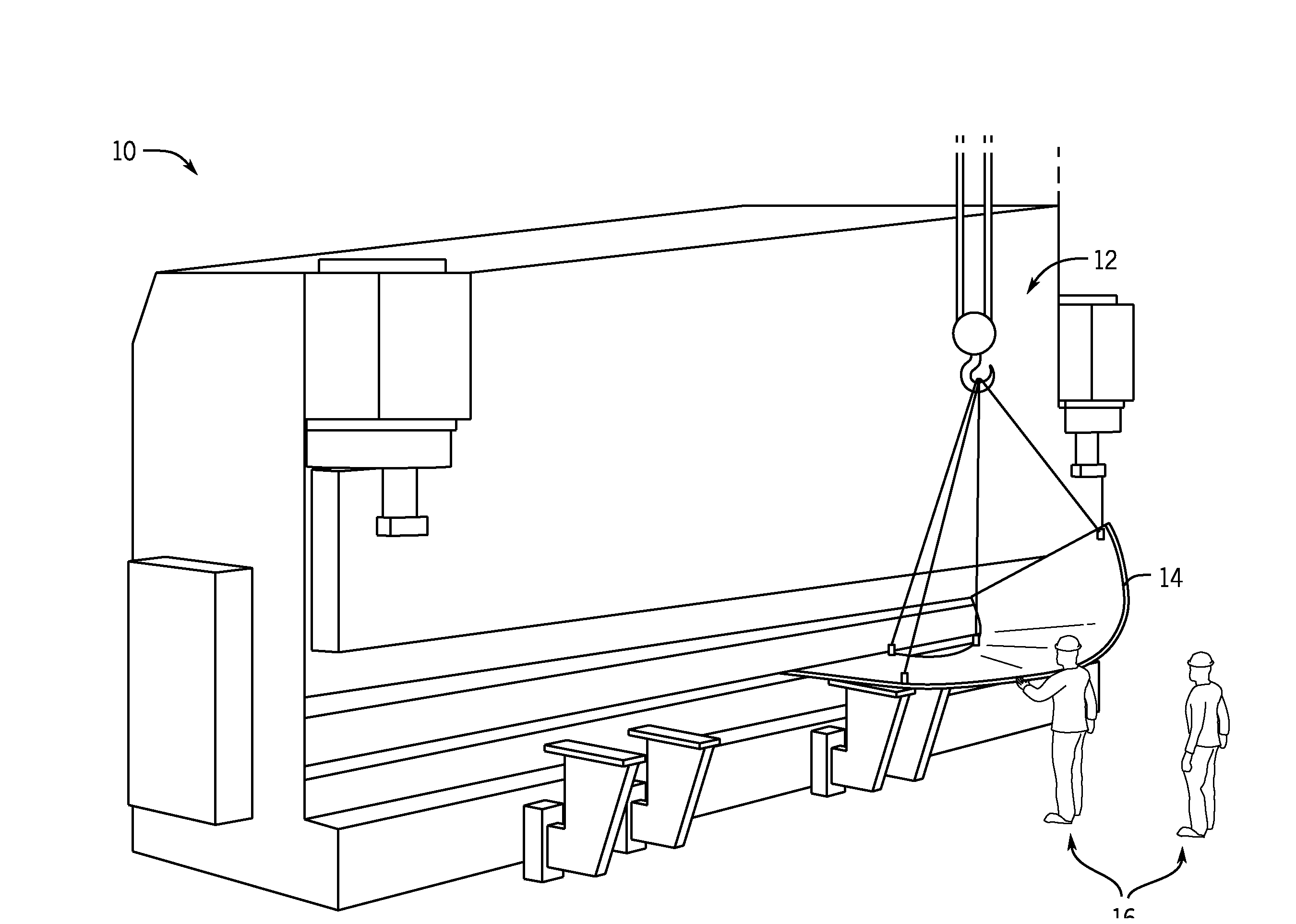

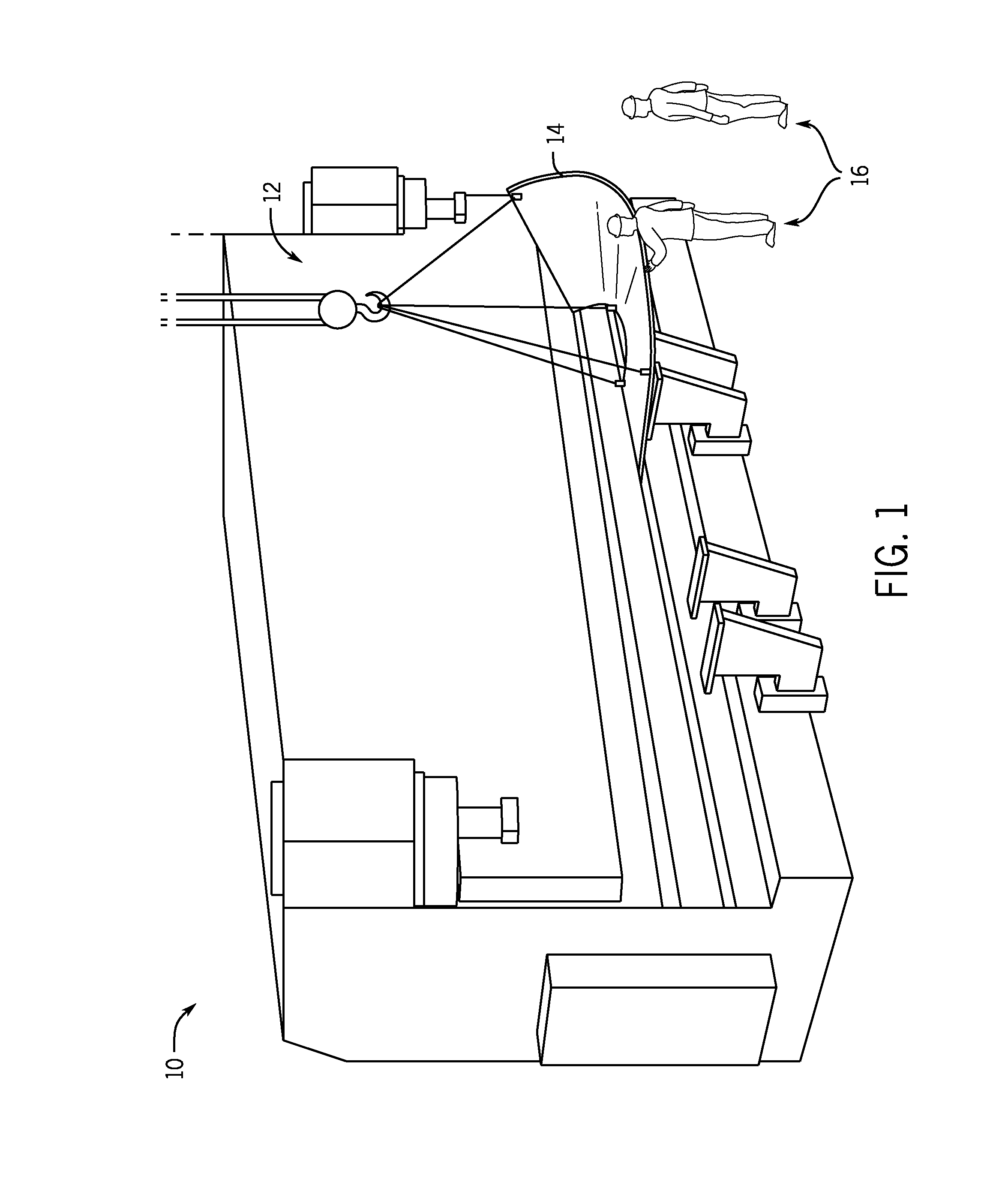

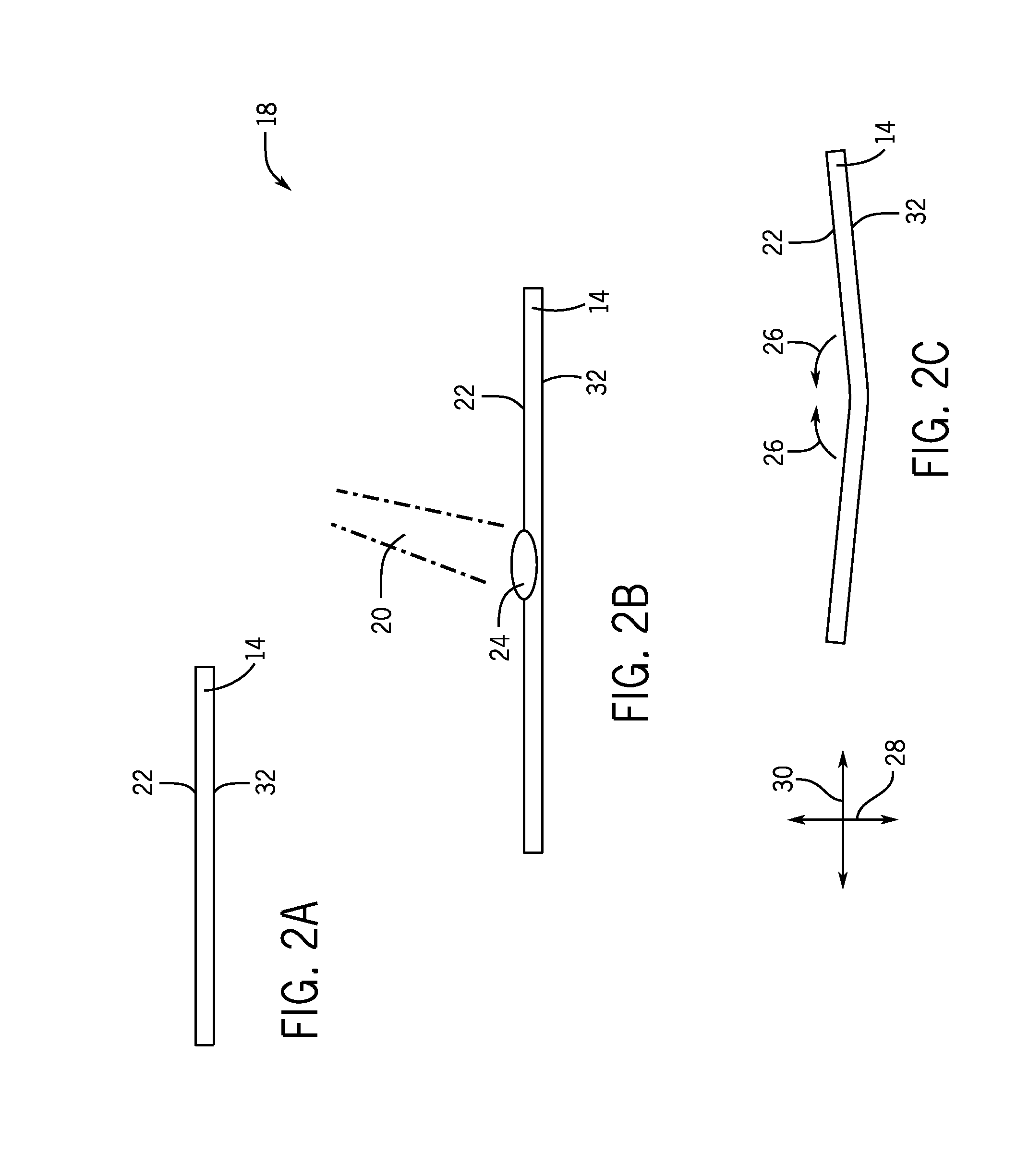

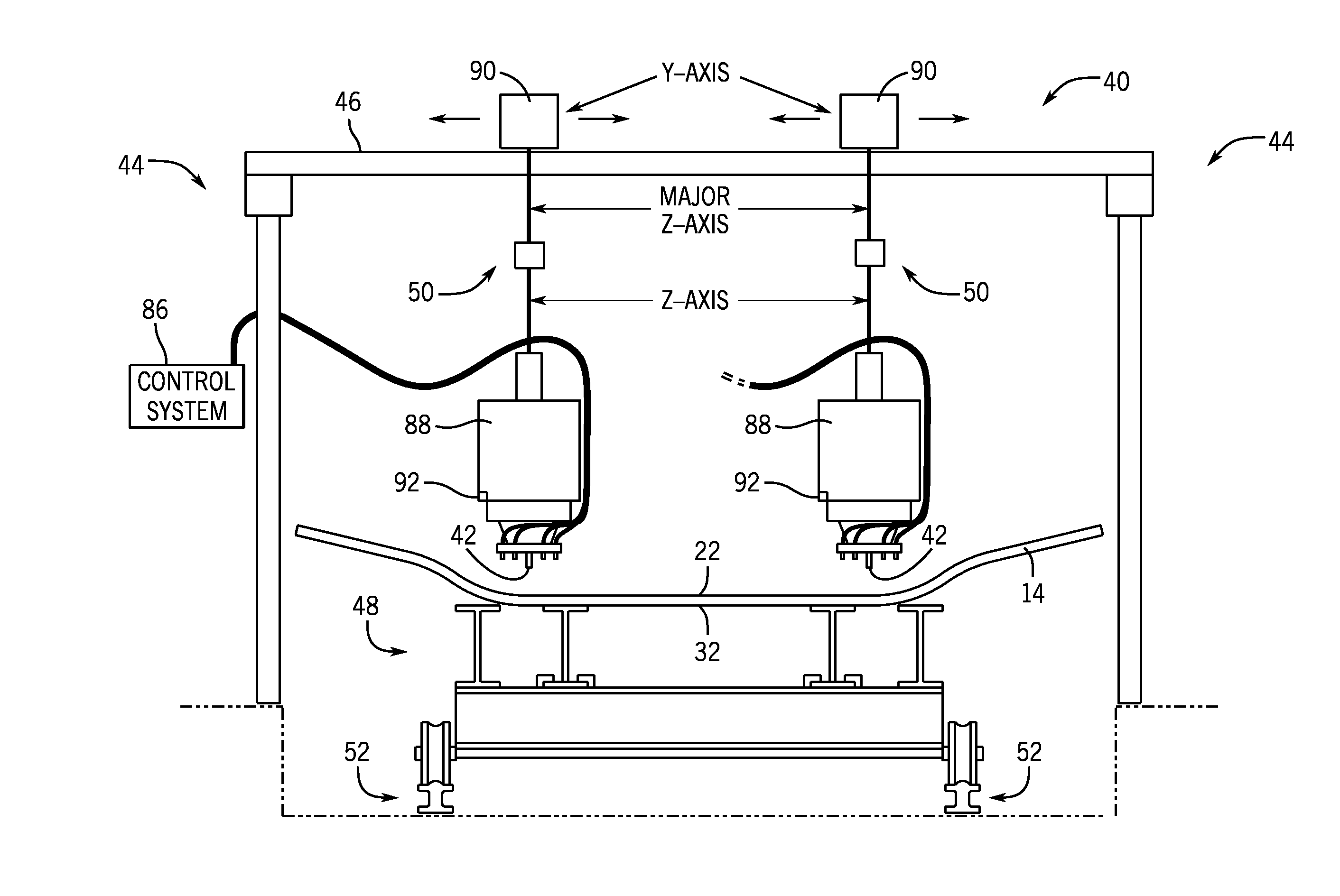

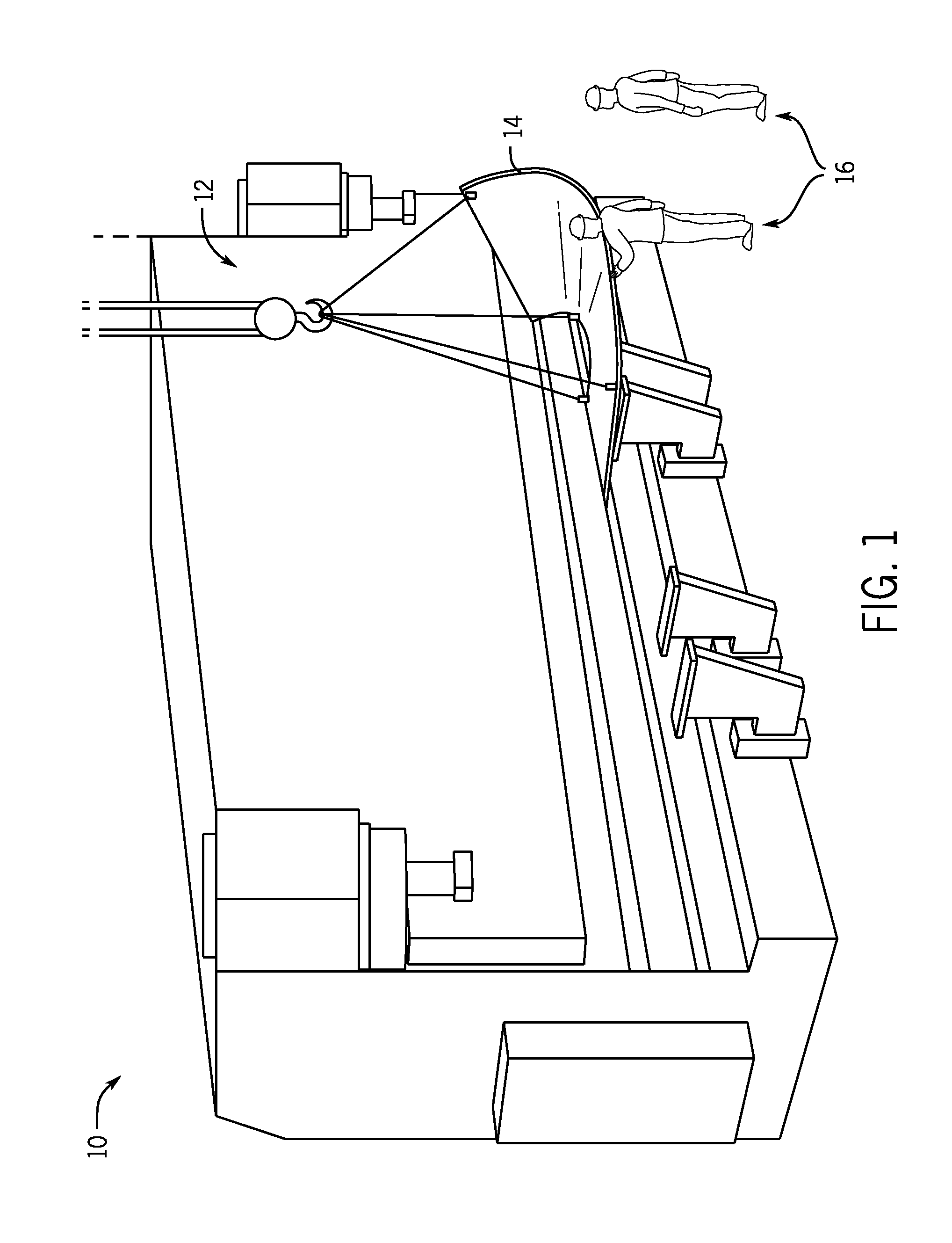

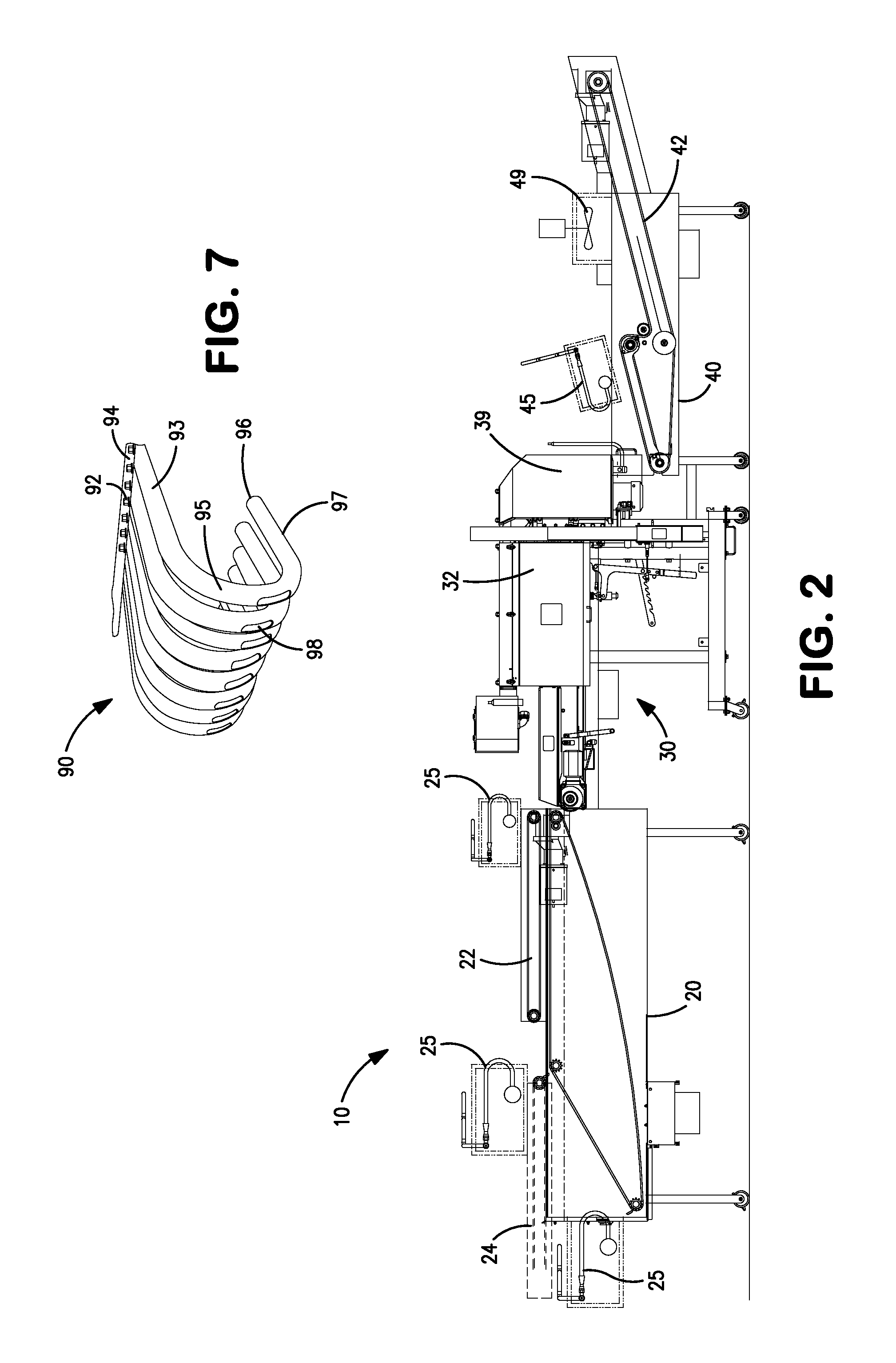

Large scale metal forming control system and method

In certain embodiments described herein, a heated line forming system includes a heating coil system configured to produce a heated line on a surface of a metal part. The heated line forming system also includes an air knife cooling system configured to maintain a dry area for the heated line, and to direct a coolant (e.g., cooling water, liquified gases such as liquid argon, solidified gases such as carbon dioxide snow, and so forth) around the heated line via a spray mechanism such that the coolant does not flow or splash into the heated line on the metal part. In certain embodiments, the heated line forming system includes multiple induction coils arranged along a line and spaced a short distance apart, but which, when operated simultaneously together, form a heated line on a surface of a metal part.

Owner:ILLINOIS TOOL WORKS INC

Large scale metal forming

In certain embodiments described herein, a heated line forming system includes a heating coil system configured to produce a heated line on a surface of a metal part. The heated line forming system also includes an air knife cooling system configured to maintain a dry area for the heated line, and to direct a coolant (e.g., cooling water, liquified gases such as liquid argon, solidified gases such as carbon dioxide snow, and so forth) around the heated line via a spray mechanism such that the coolant does not flow or splash into the heated line on the metal part. In certain embodiments, the heated line forming system includes multiple induction coils arranged along a line and spaced a short distance apart, but which, when operated simultaneously together, form a heated line on a surface of a metal part.

Owner:ILLINOIS TOOL WORKS INC

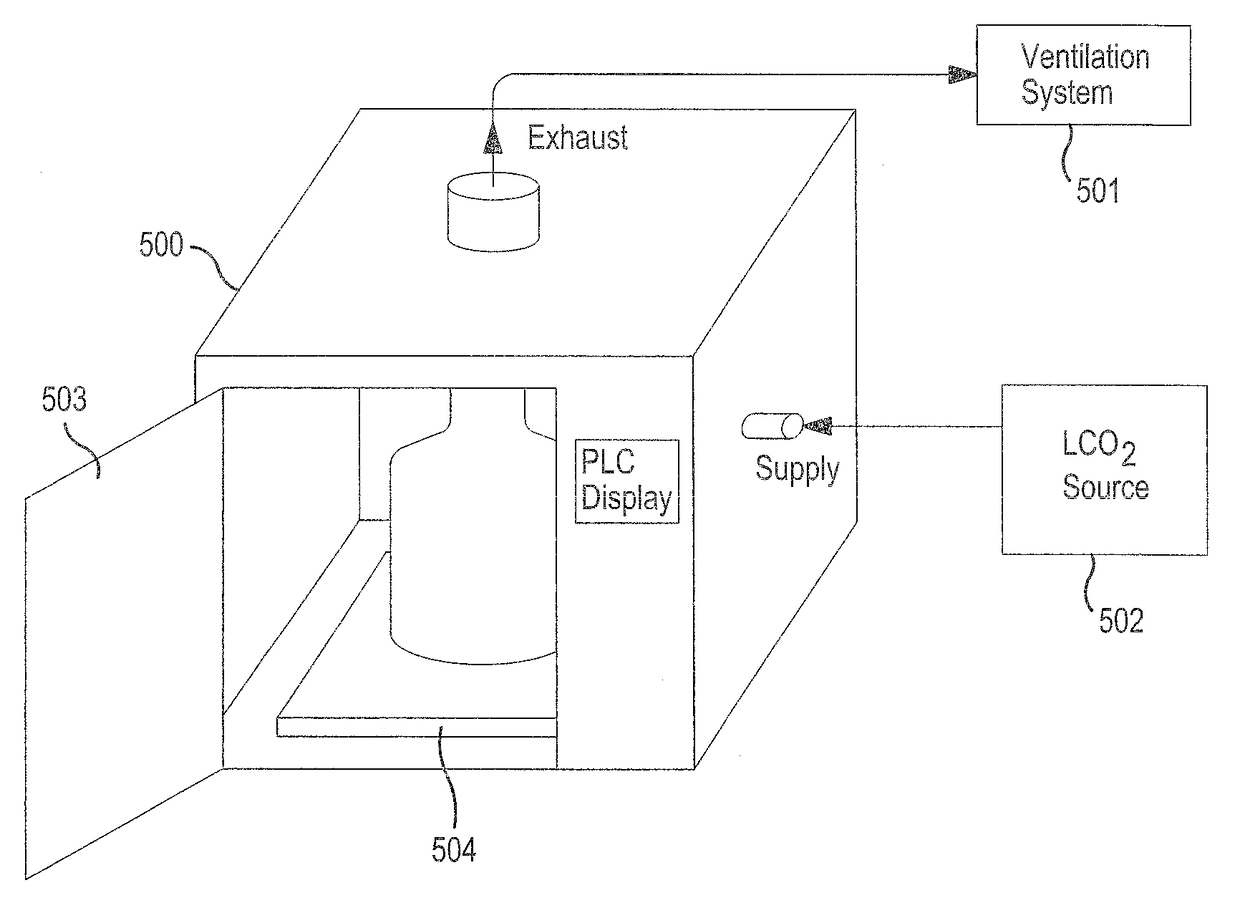

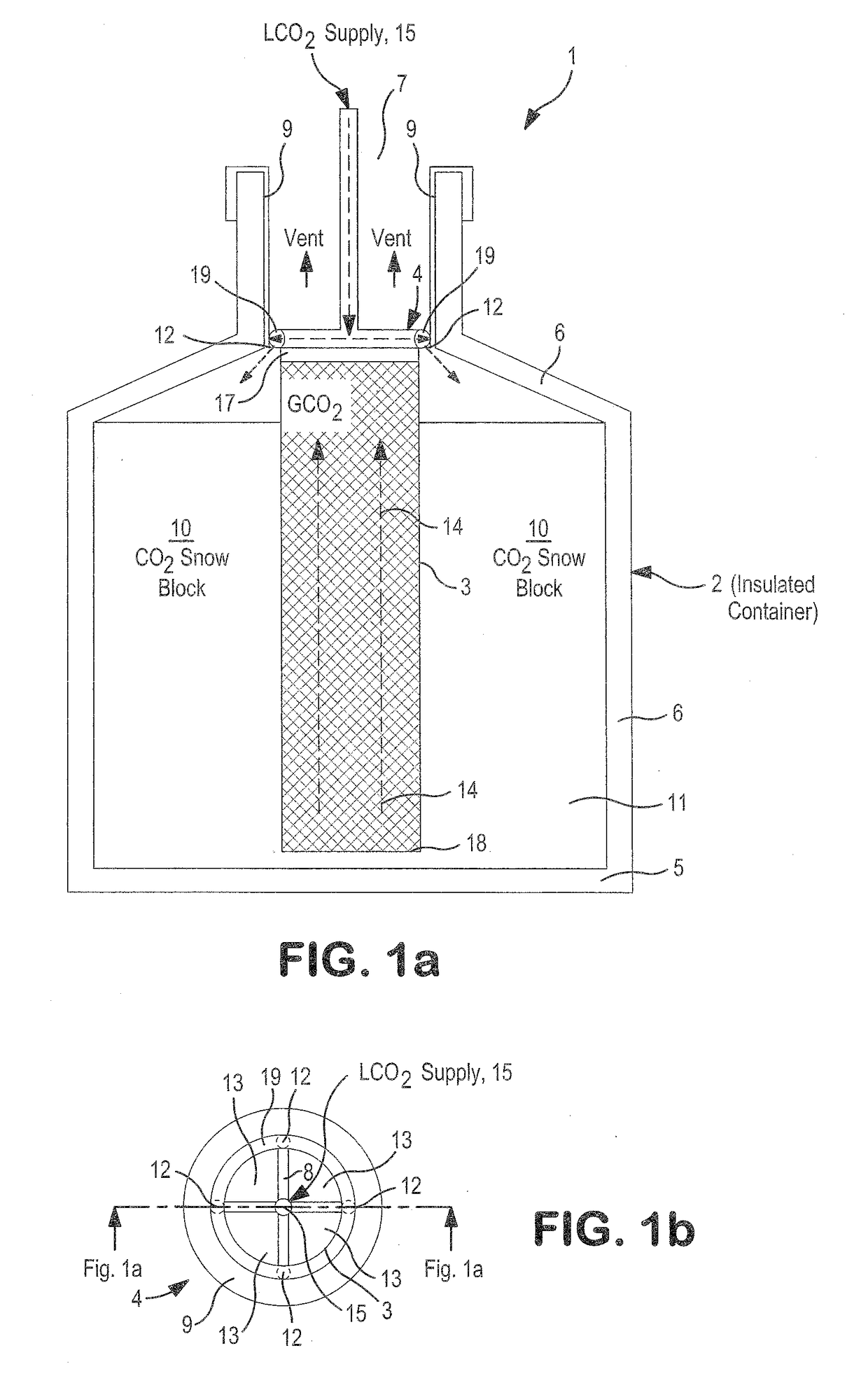

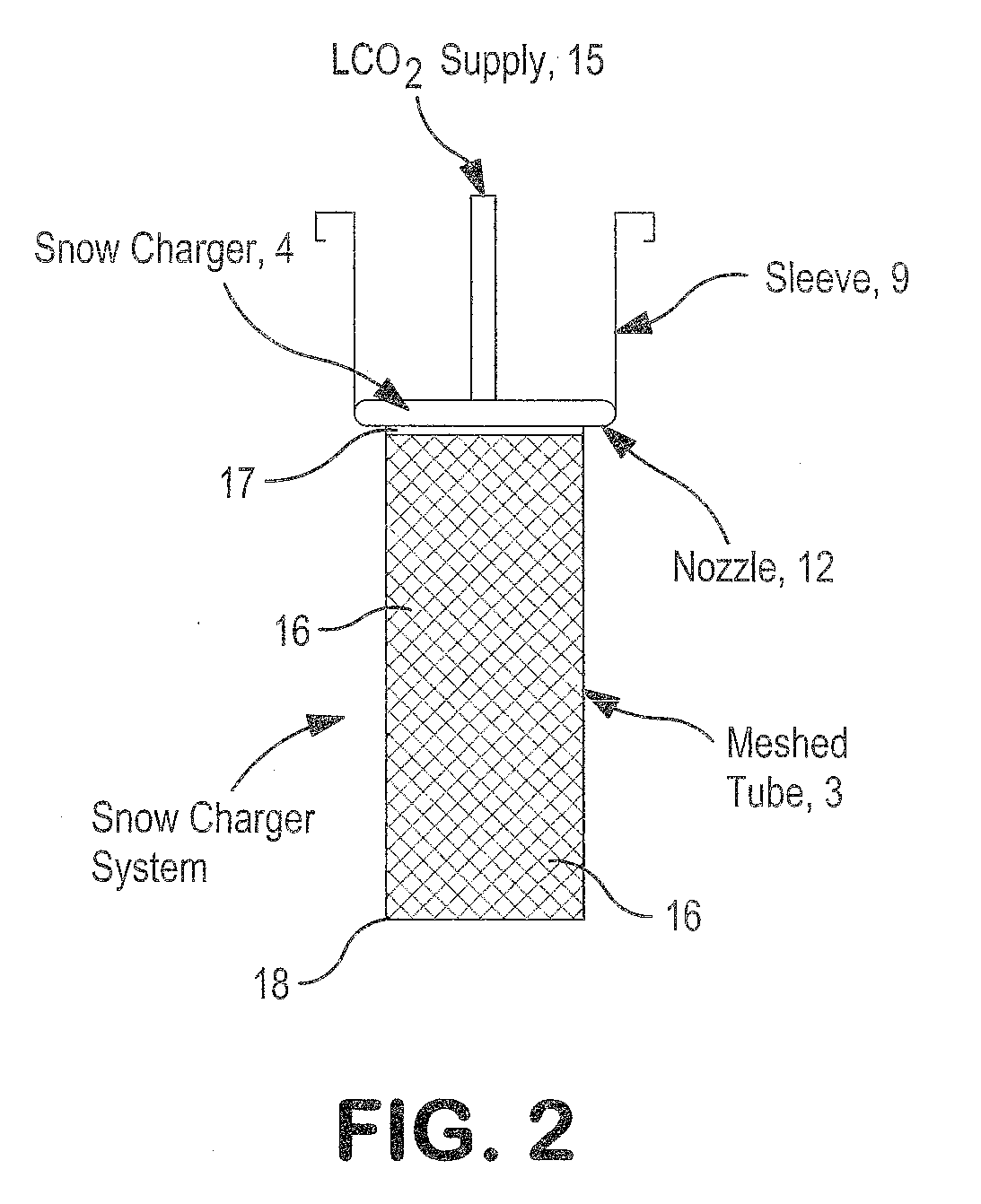

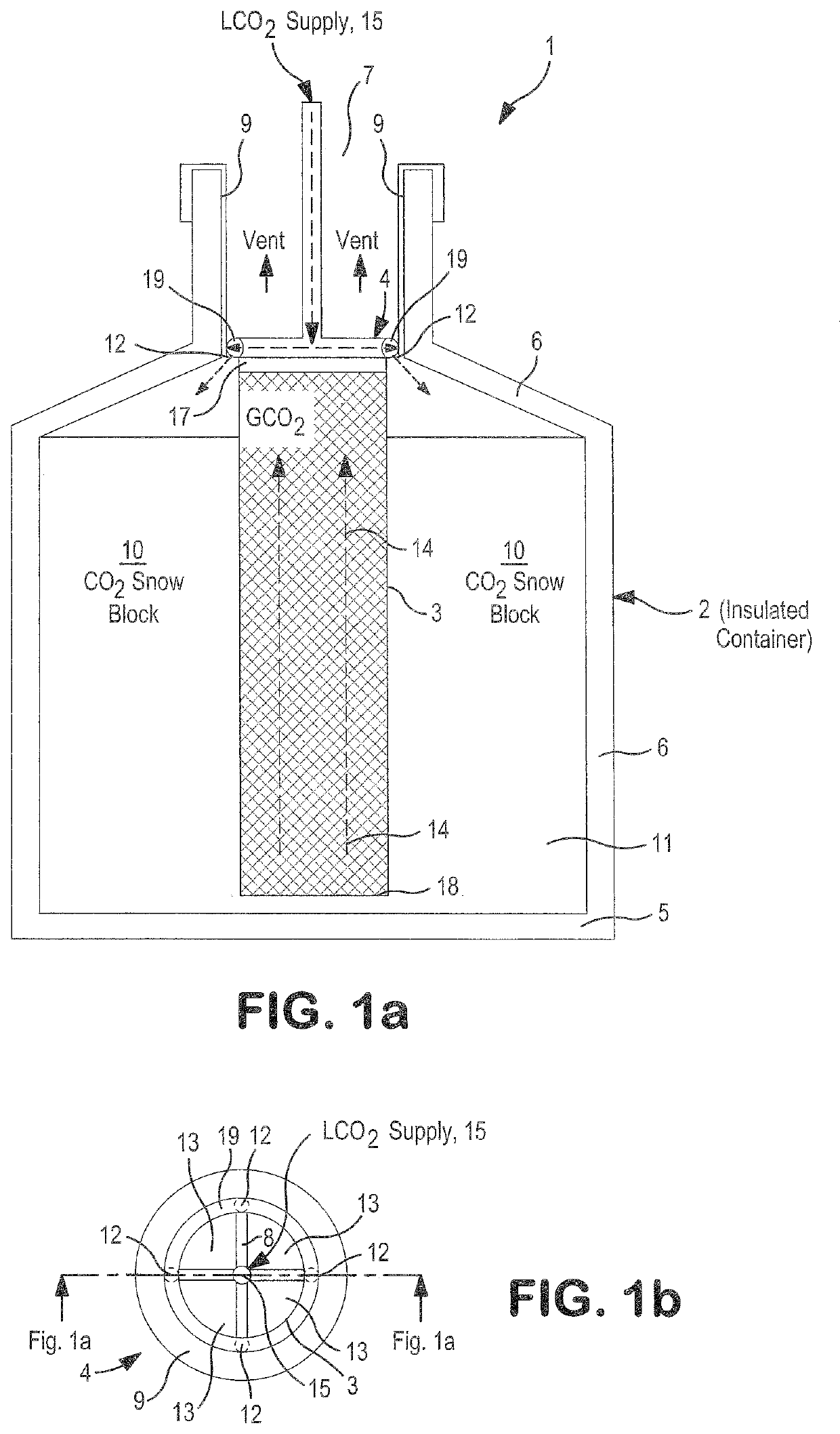

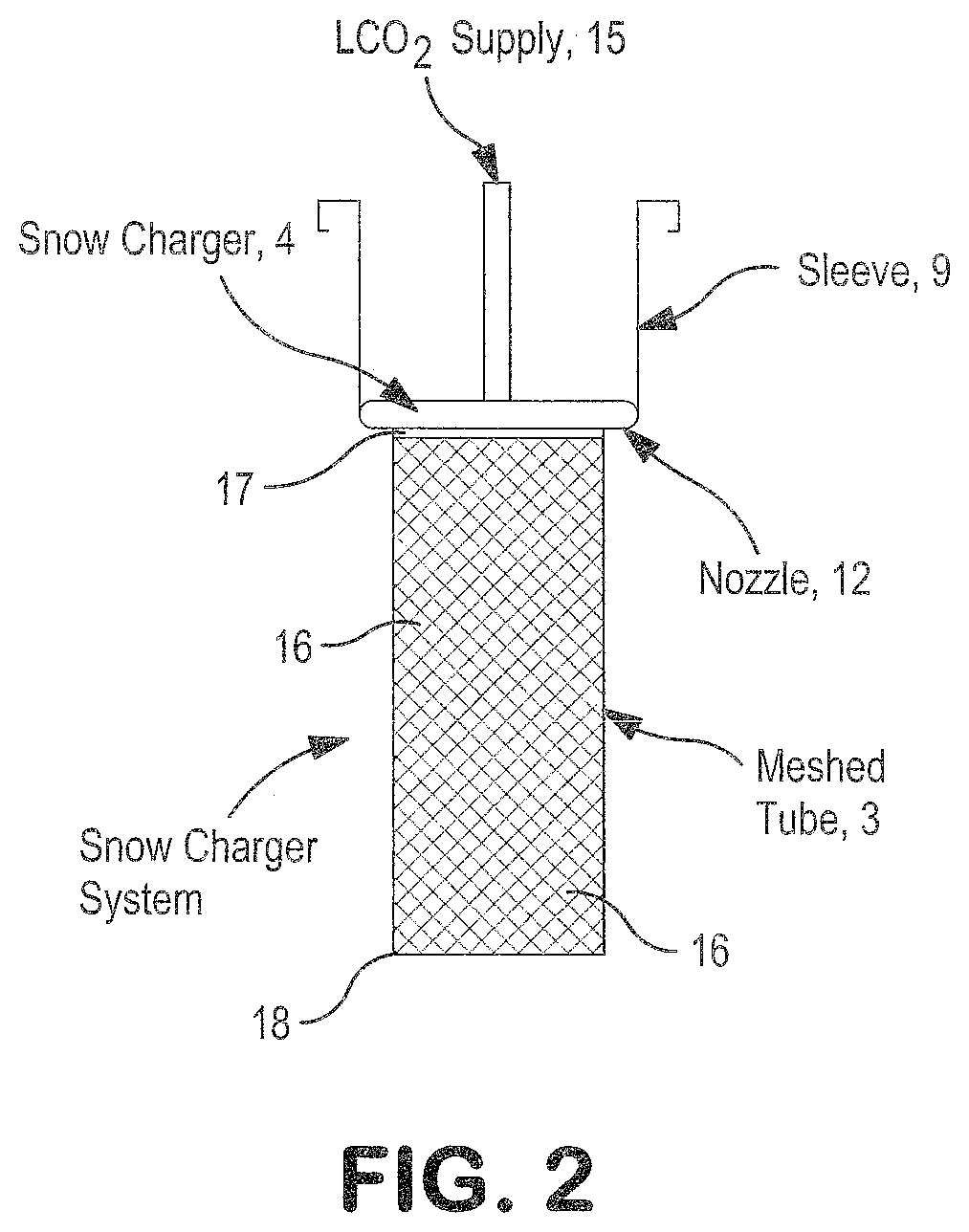

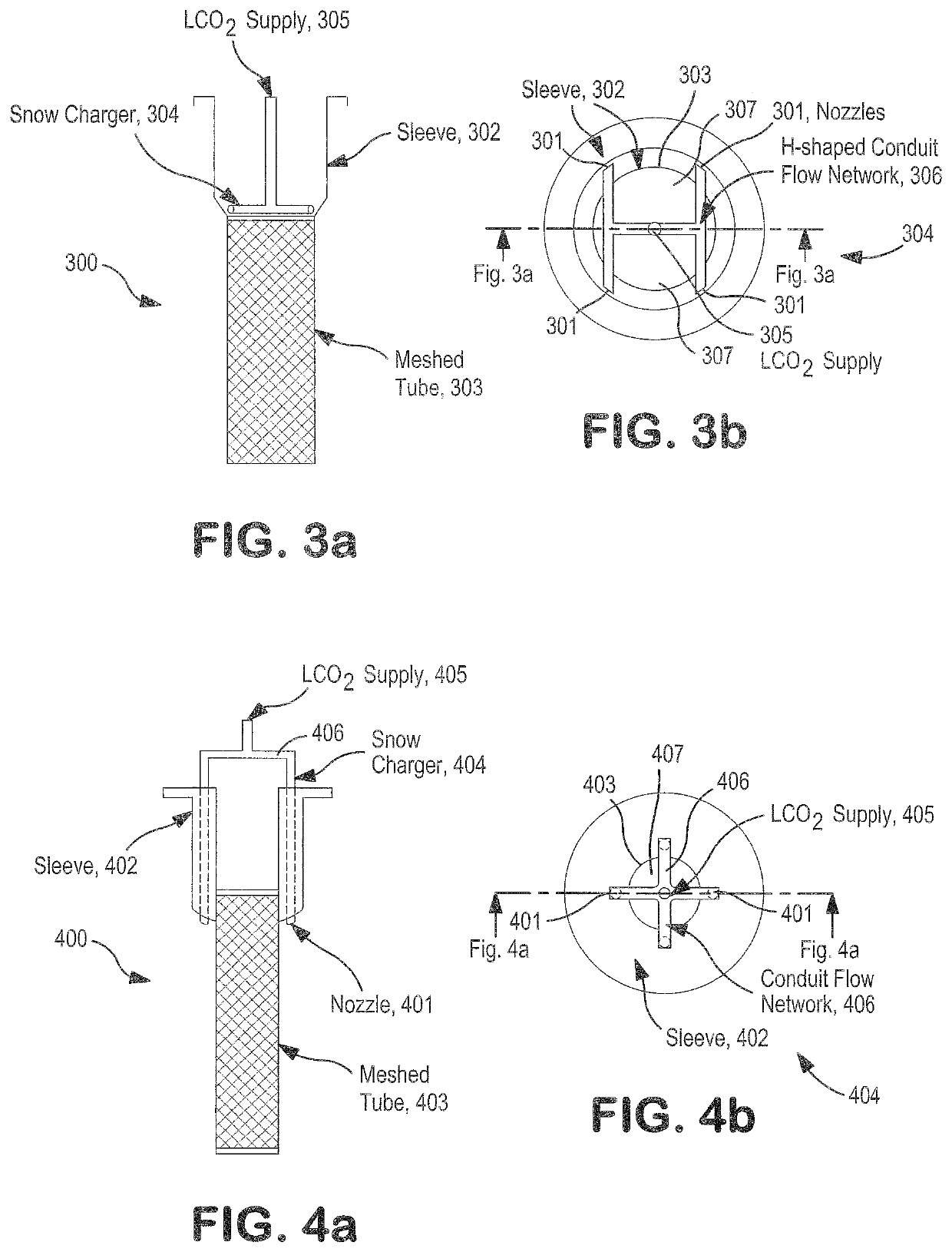

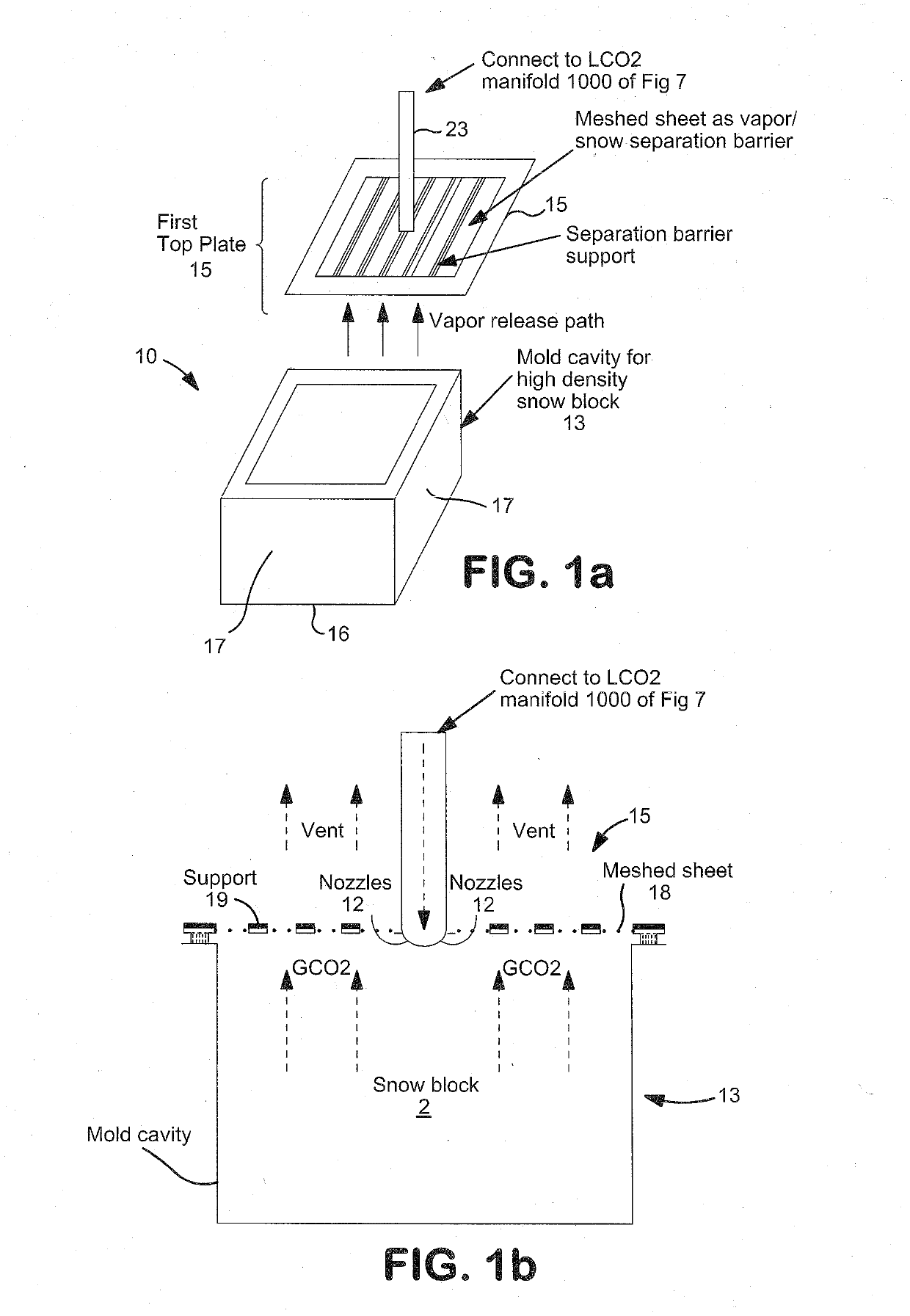

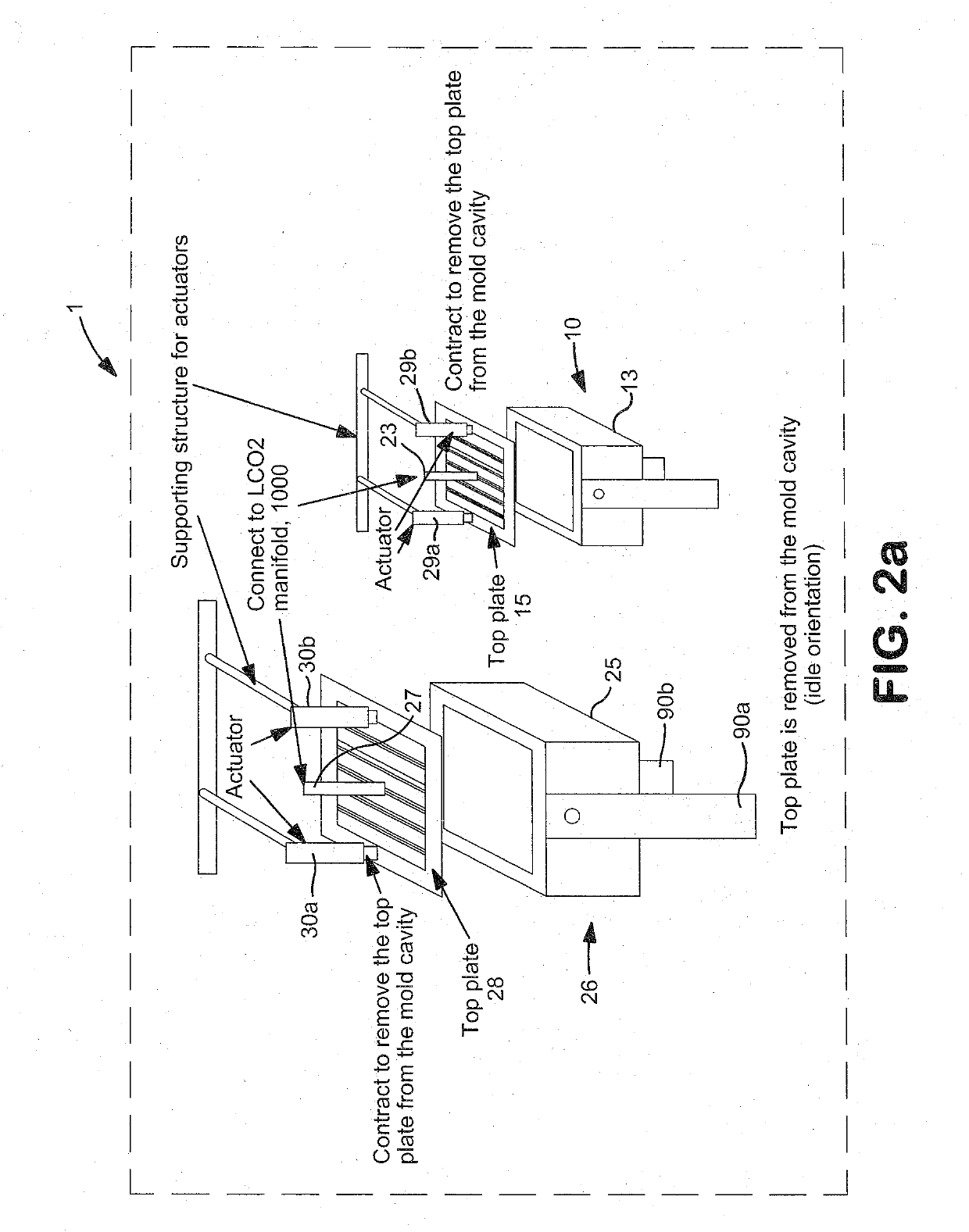

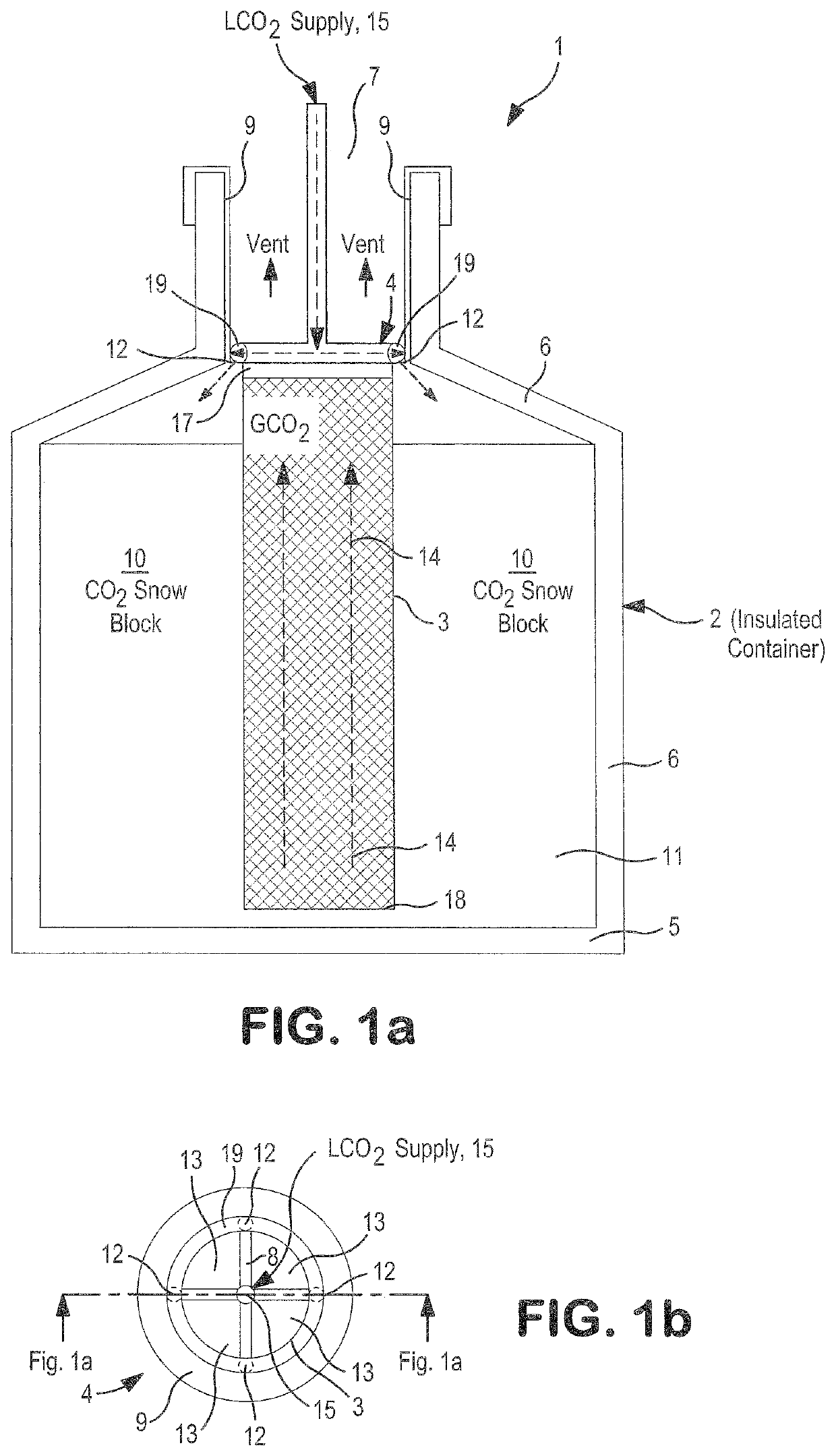

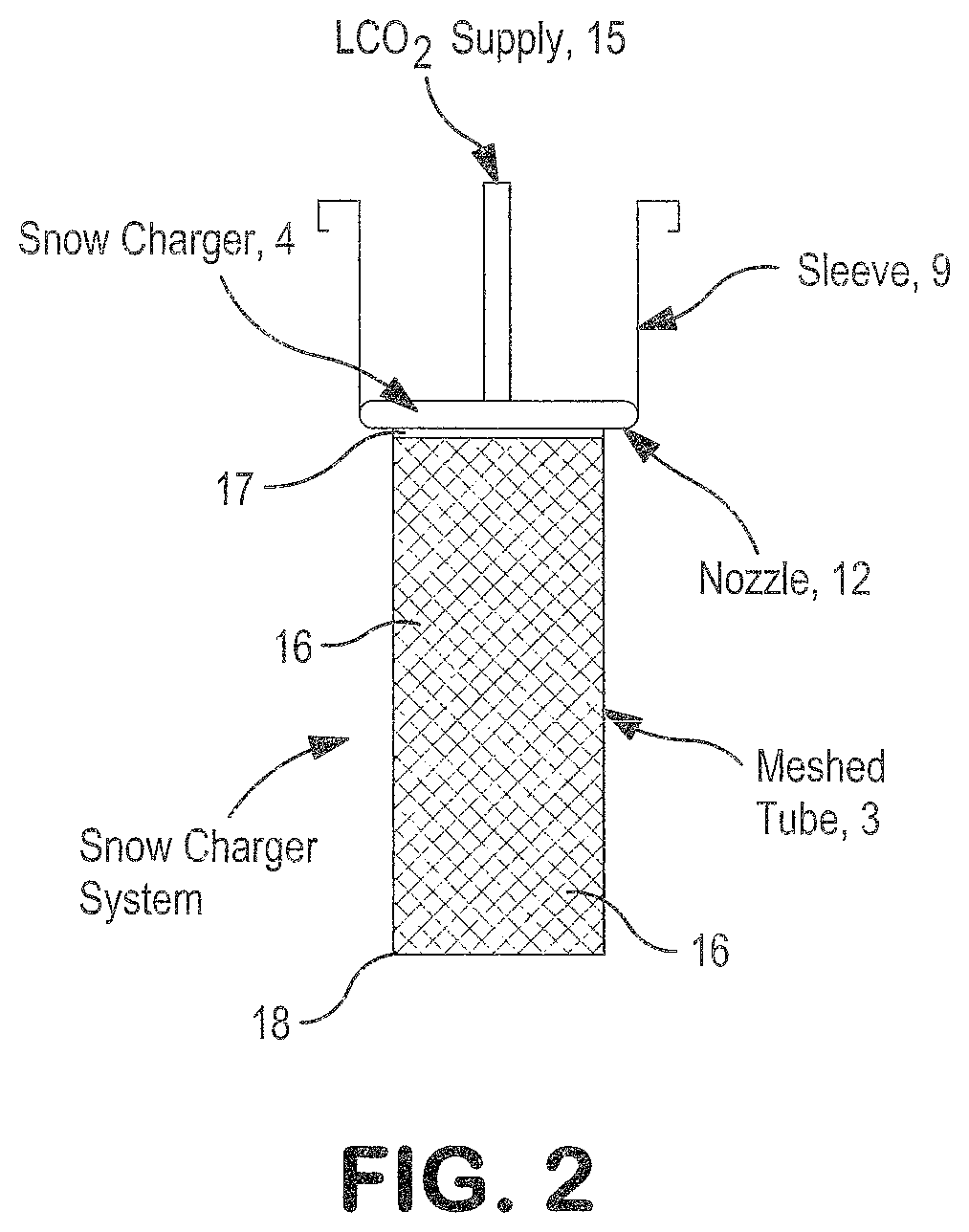

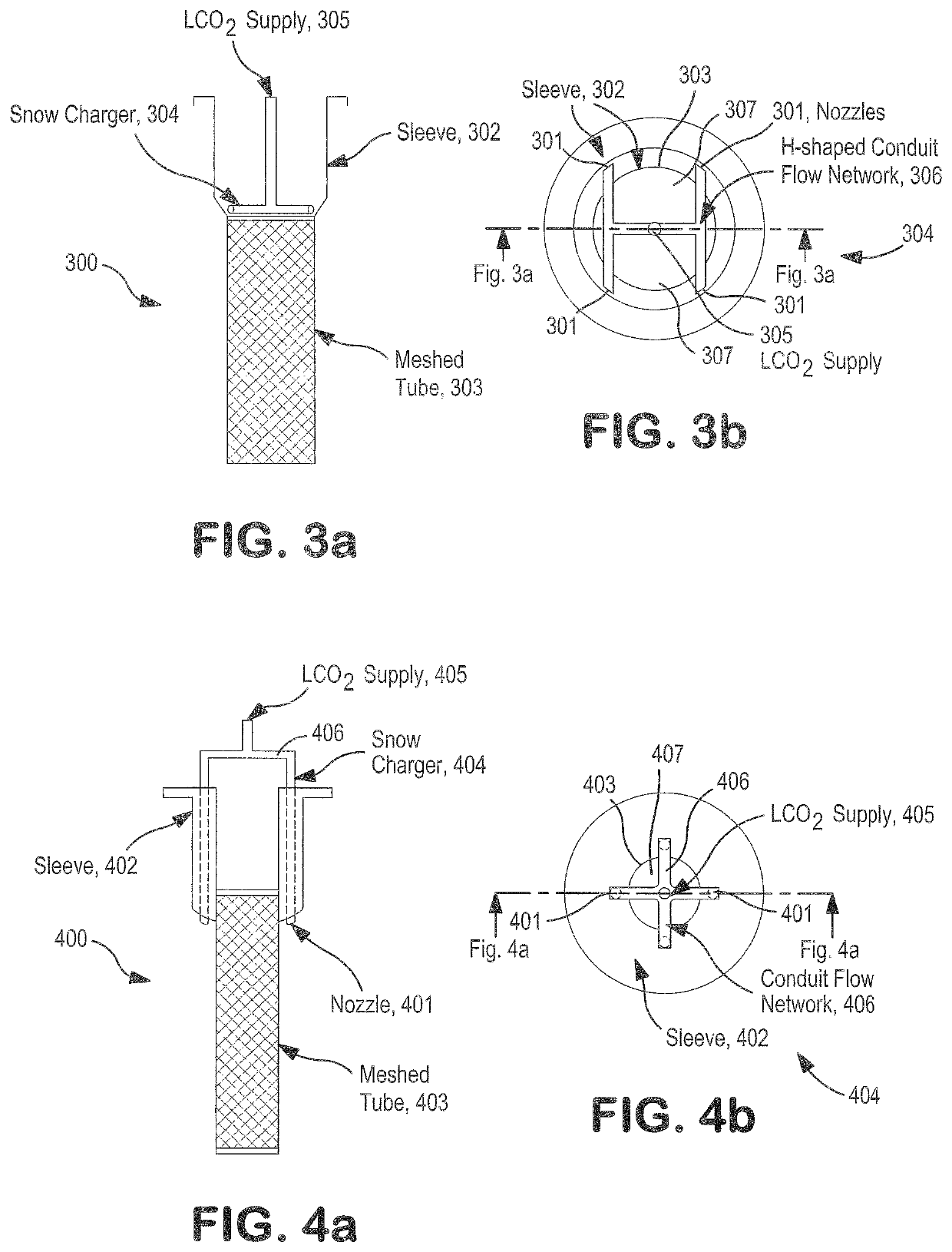

Transportable container, charger system, method and kit for generation of carbon dioxide snow block in-situ within the transportable container for preservation of items stored therewithin

ActiveUS20180010839A1Rigid enoughLighting and heating apparatusDead animal preservationCarbon Dioxide SnowProcess engineering

This invention relates to a novel kit, transportable apparatus and method for generating in-situ CO2 snow block within the apparatus. An item such as a biological sample can be stored and transported within the same apparatus that is employed for creating the CO2 snow block. The apparatus is capable of preserving the sample during transport. The invention also includes a specially designed CO2 snow charger system including a charger and meshed conduit. The charger system is operated in accordance with the methods of the present invention to create the in-situ CO2 snow block within a container that can be also used for transport.

Owner:PRAXAIR TECH INC

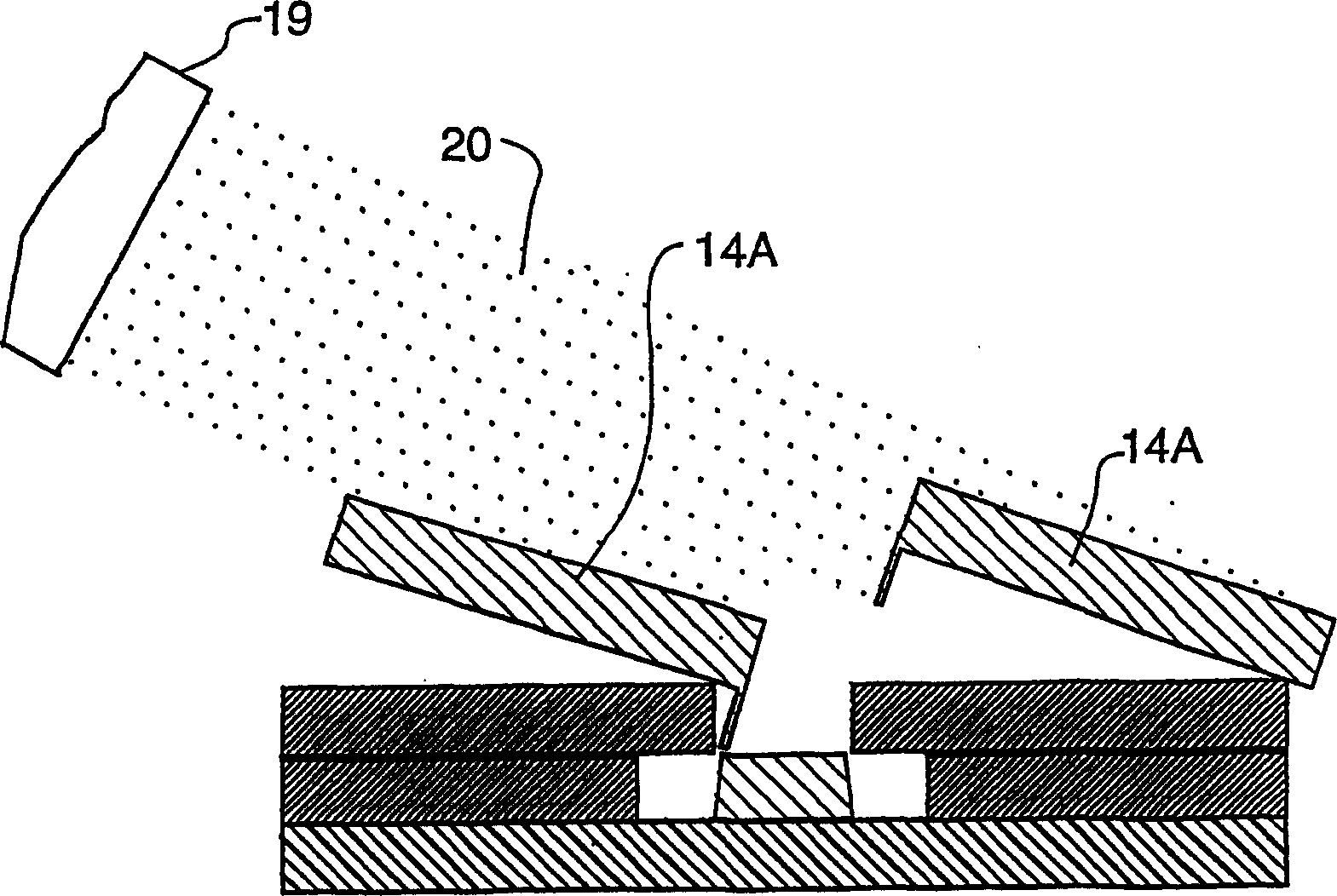

Method for selective metal film layer removal using carbon dioxide jet spray

InactiveCN1502118AQuick removalPromote absorptionSemiconductor/solid-state device manufacturingSemiconductor devicesResistCross-link

A method for the selective removal of the metal film layer (14) accumulated upon a photoresist layer (10) during processing of substrates using a stream of carbon dioxide spray (20) without disturbing conductor portions is provided. A constant stream (20) of high pressure CO2 snow is applied to the metal film layer thereby rapidly cooling the metal layer on top of said resist layer causing it to shrink rapidly, and to debond, and peel from the photoresist layer underneath. The temperature of the substrate is raised and maintained at significantly higher than room temperature. Continuing the application of the CO2 spray causes thermal shock to the photoresist under the metalized layer causing large cracks in the remaining metal layer portions, said cracks typically including at least one loose metal edge. The CO2 spray is continually applied to the cracks thereby peeling away the remaining metal portions, leaving the exposed photoresist and underlying surface features. Preferably, continued treatment of the surface with CO2 snow particals erodes a surface layer of the photoresist and heavily cross-linked layers created during the metalization process. After the metal layer and the surface layer of the photoresist are removed, a simple chemical strip, such as acetone, completely removes all the remaining resist, leaving the wafer with undamaged conductor portions.

Owner:RAVE N P

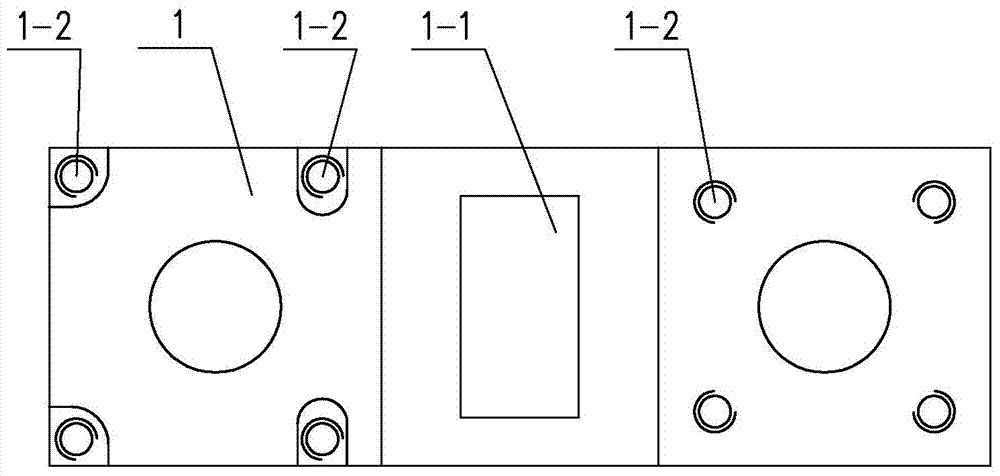

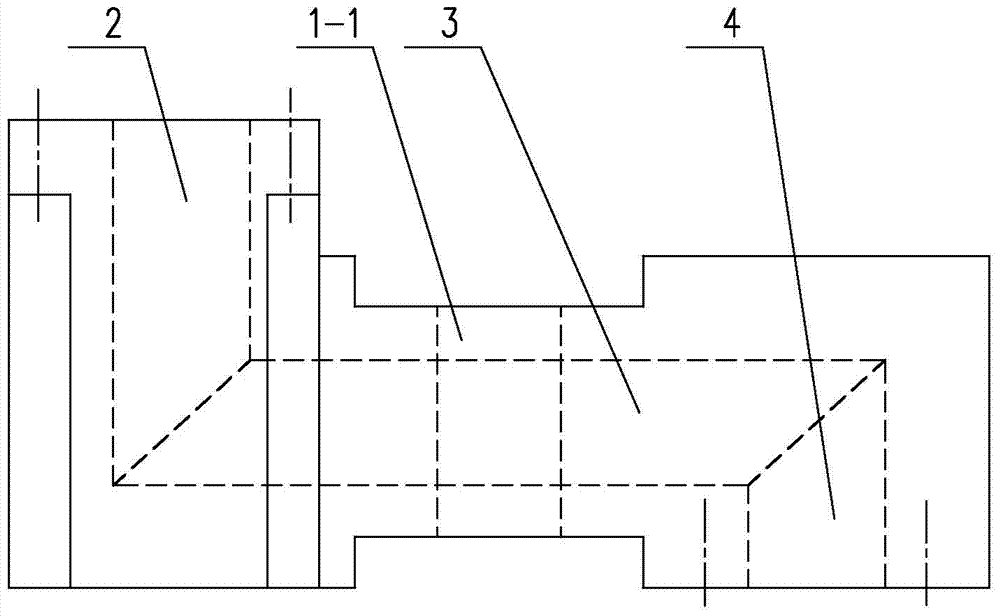

Glass lens processing equipment and method

InactiveCN1966218AReduce manufacturing costEfficient removalOptical articlesMetal working apparatusEngineeringLens plate

The invention relates to a method used to process plastic lens, wherein it comprises a shearing tool to shear and separated shaped plastic lens, a carbon dioxide snow ejector for ejecting the snow to clean lens, and a vacuum absorber for absorbing the plastic lens. The invention also provides relative method, which can effectively remove the dust and dirt in shearing process and reduce the cost.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

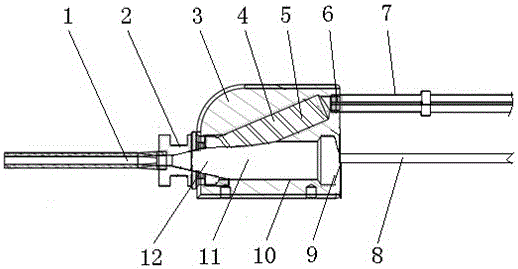

Carbon dioxide snowflake cleaning nozzle device

InactiveCN107377531AAchieve cleaning effectReduce energy consumptionCleaning using gasesGas passingDry ice

The invention discloses a carbon dioxide snowflake cleaning nozzle device. The nozzle device comprises a nozzle body, an outer cover and a base, wherein the outer cover and the base are connected with the nozzle body. A CO2 spray head is arranged inside the nozzle body and tightly pressed by a CO2 connection pipe installed inside the base. The side wall of the base is provided with a compressed gas inlet, a CO2 channel is formed between a CO2 inlet of the base and a CO2 outlet of the CO2 spray head, and a plurality of compressed gas passing holes are annularly formed in the nozzle body around the CO2 spray head. A compressed gas channel is defined by the CO 2 connection pipe, the base and the inner wall of the nozzle body. The front end of the outer cover is provided with a compressed gas outlet hole, the front end of the nozzle body stretches out of the outer cover and then extends into the compressed gas outlet hole, and a compressed gas outlet is formed between the front end of the nozzle body and the inner wall of the compressed gas outlet so that compressed gas can be exhausted through the compressed gas passing holes and a gas flow channel between the nozzle body and the outer cover. Through the carbon dioxide snowflake cleaning nozzle device, a mixture quickly formed by gaseous CO2 and snowflake-like dry ice crystals can be sprayed out at a supersonic speed, so that the surface of an object is cleaned.

Owner:AUTOMOTIVE ENG CORP

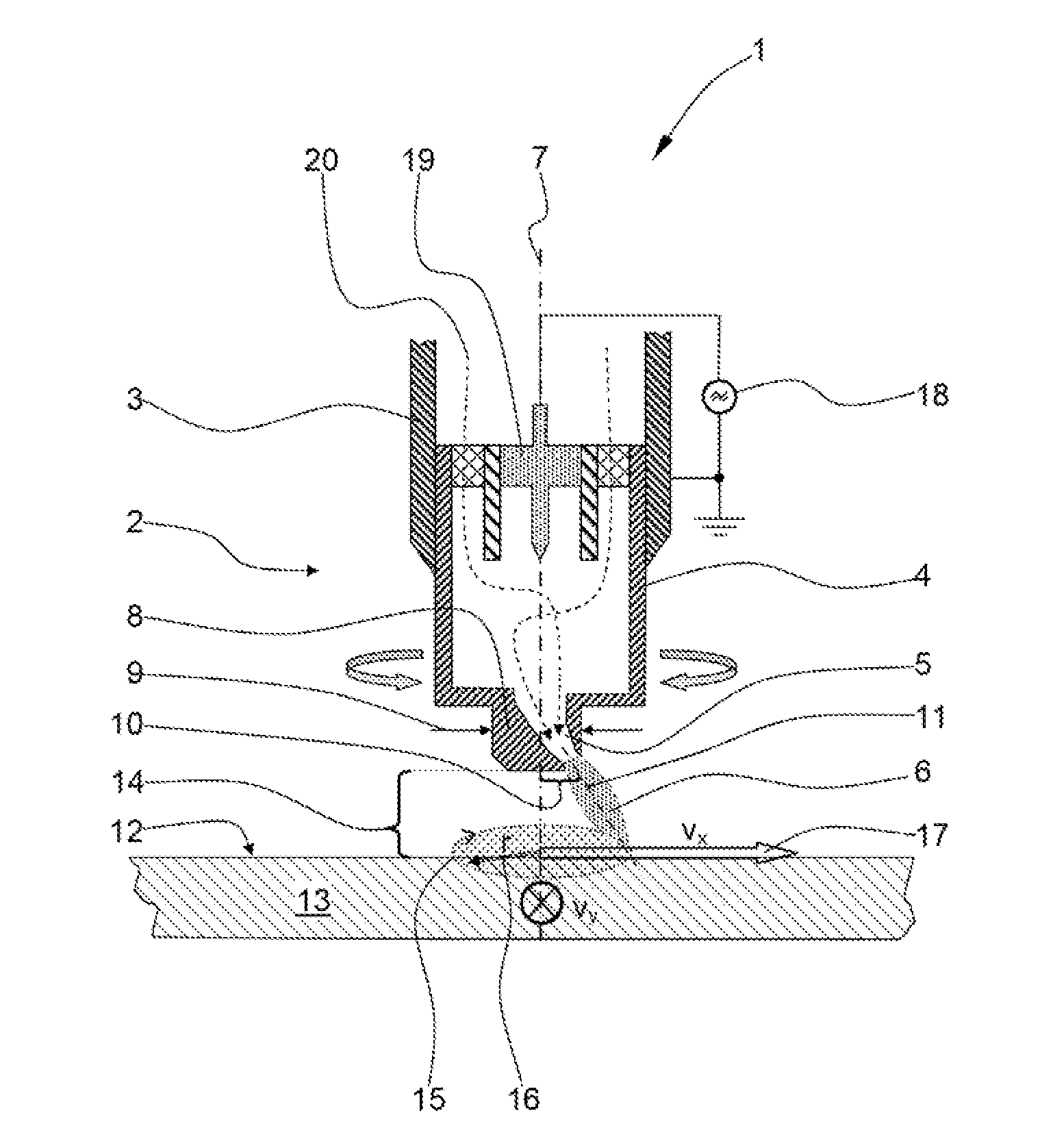

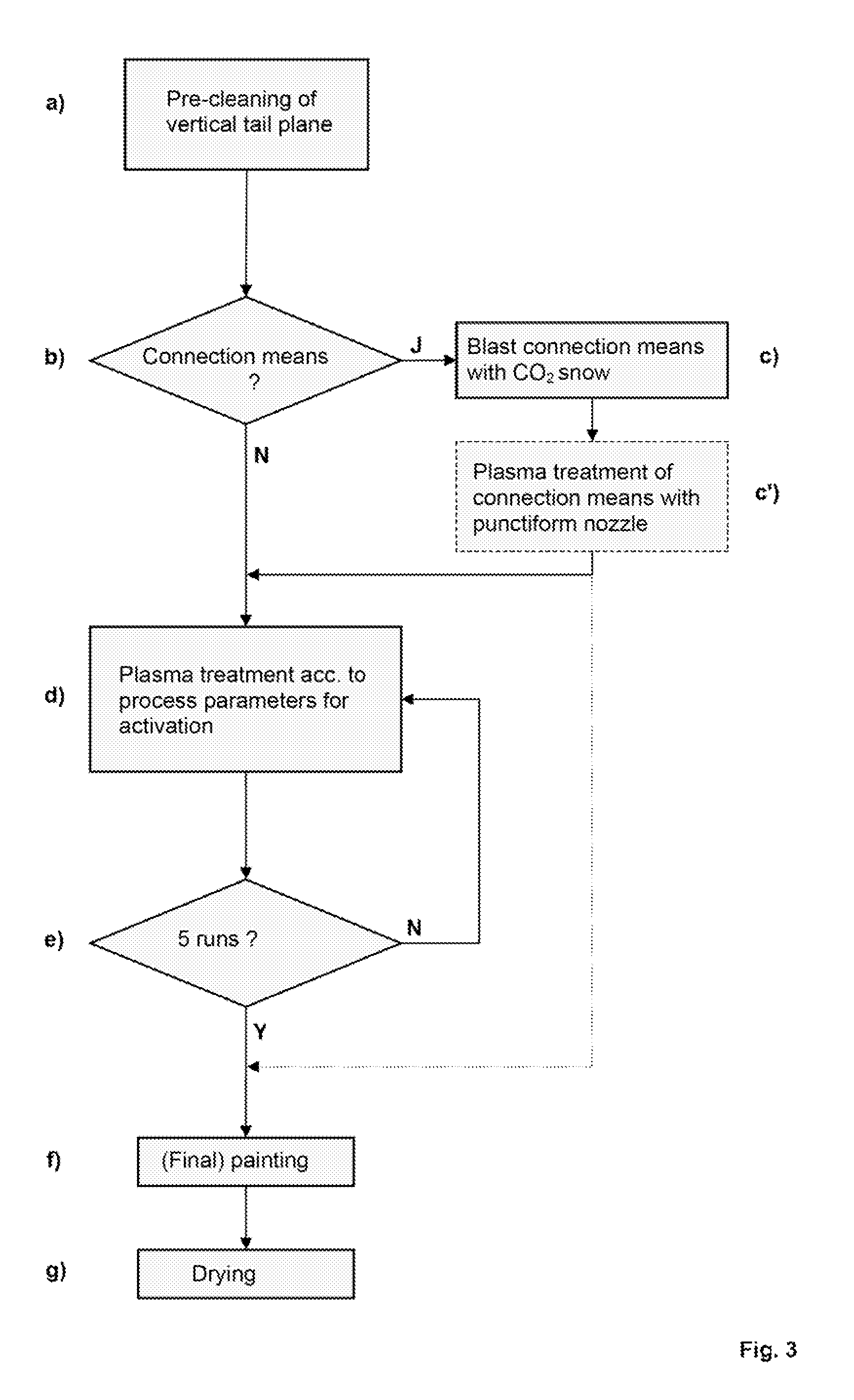

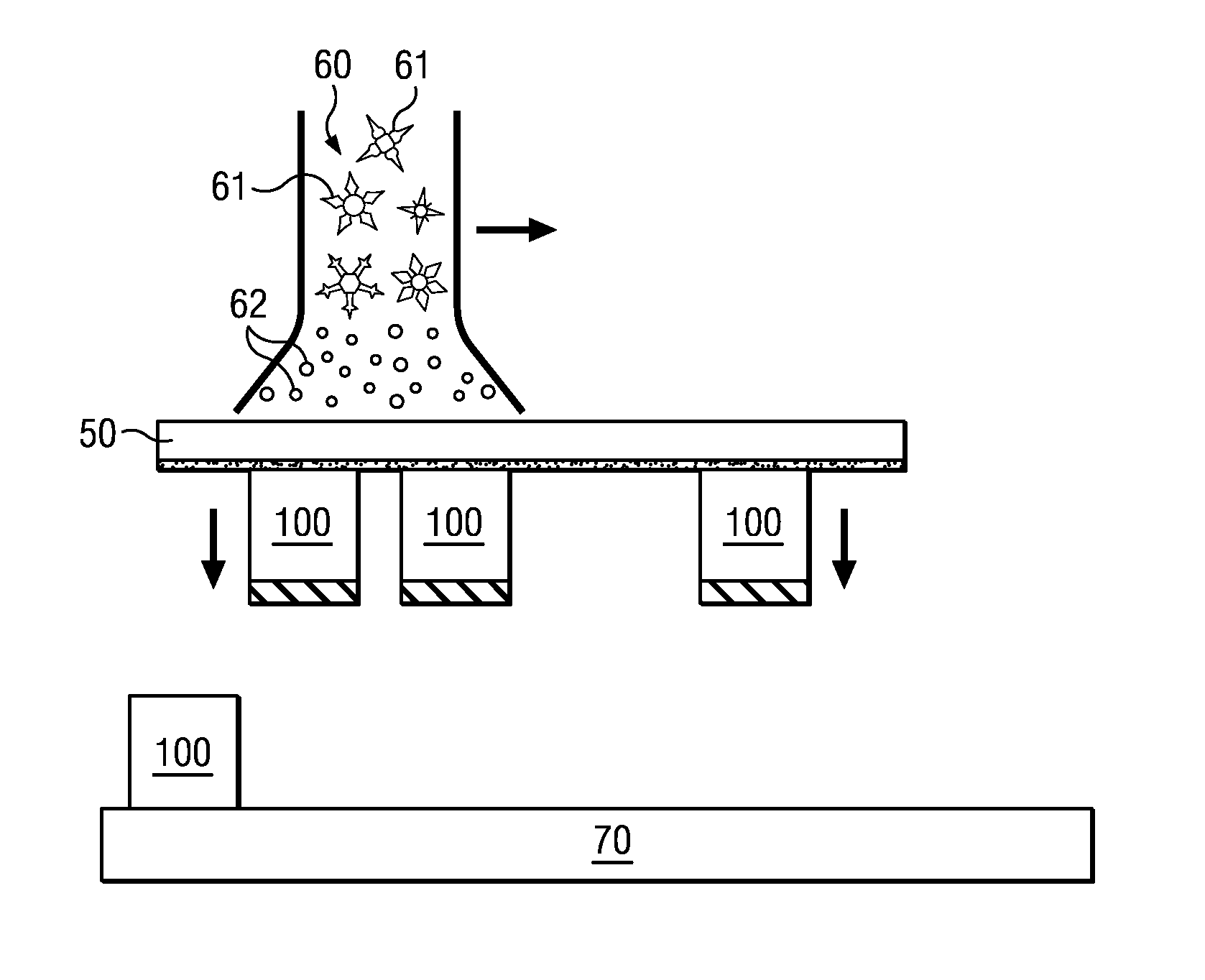

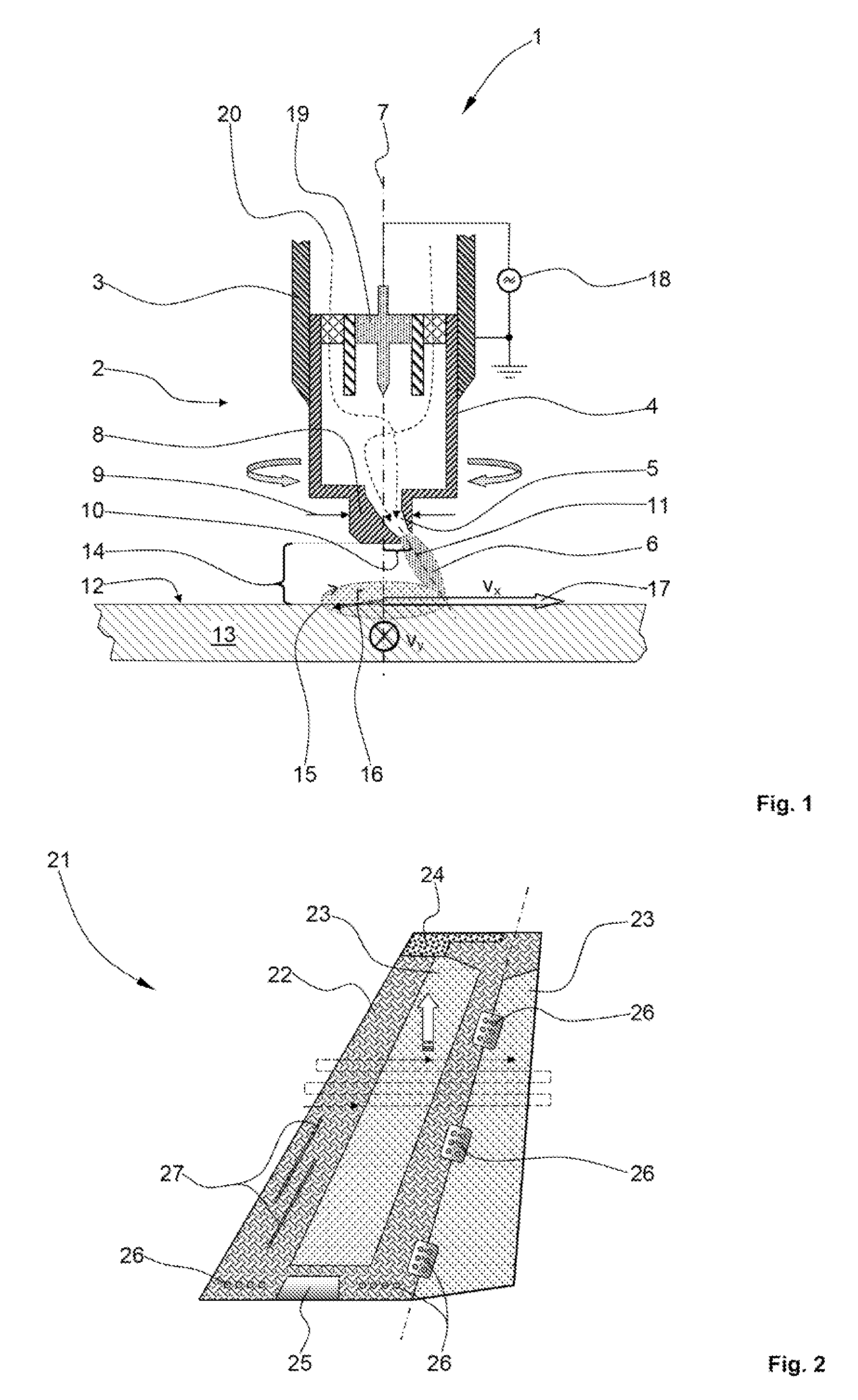

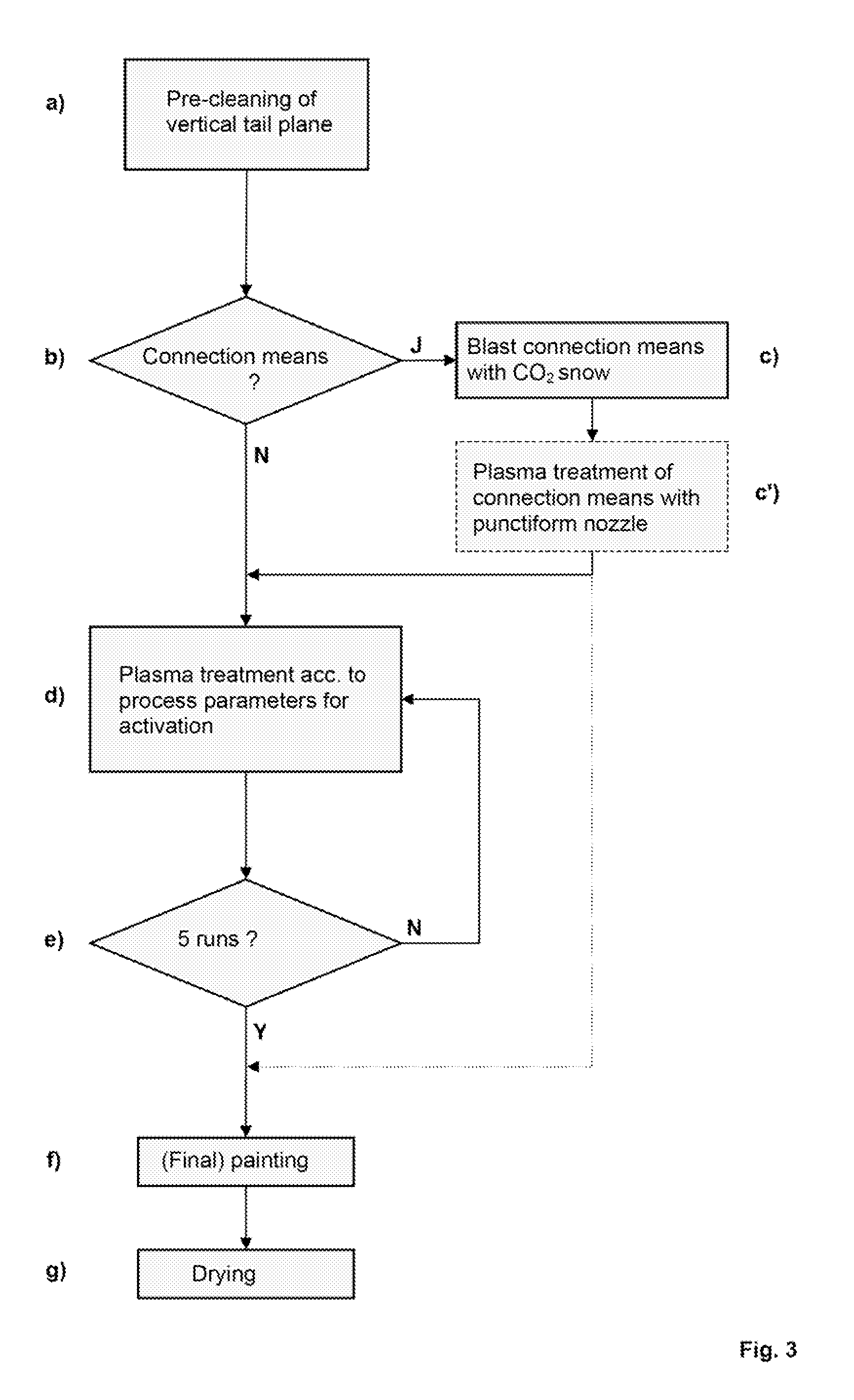

Method for plasma treatment and painting of a surface

InactiveUS8361565B2Improve adhesionAvoid polluting the environmentVacuum evaporation coatingPretreated surfacesAbrasive blastingSurface plasmon

A method for plasma treatment and painting of a surface, the surface including a plurality of different materials includes blasting the surface with a carbon dioxide snow so as to activate the surface to improve an adhesive strength; and treating the surface with a plasma treatment using at least one plasma nozzle following the blasting step, the treating including guiding the at least one plasma nozzle at a distance of not more than 15 mm from the surface at a feed rate of not more than 50 m / min.

Owner:AIRBUS OPERATIONS GMBH

Separation of semiconductor devices from a wafer carrier

ActiveUS8883565B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

In accordance with an embodiment of the present invention, a semiconductor device is manufactured by arranging a plurality of semiconductor devices on a frame with an adhesive foil. The plurality of semiconductor devices is attached to the adhesive foil. The plurality of semiconductor devices is removed from the frame with the adhesive foil using a carbon dioxide snow jet and / or a laser process.

Owner:INFINEON TECH AG

Method for manufacturing semiconductor device

ActiveCN103035572ASemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

In accordance with an embodiment of the present invention, a semiconductor device is manufactured by arranging a plurality of semiconductor devices on a frame with an adhesive foil. The plurality of semiconductor devices is attached to the adhesive foil. The plurality of semiconductor devices is removed from the frame with the adhesive foil using a carbon dioxide snow jet and / or a laser process.

Owner:INFINEON TECH AG

Method for plasma treatment and painting of a surface

InactiveUS20100209618A1Improve adhesionAvoid polluting the environmentVacuum evaporation coatingPretreated surfacesSurface plasmonSpray nozzle

A method for plasma treatment and painting of a surface, the surface including a plurality of different materials includes blasting the surface with a carbon dioxide snow so as to activate the surface to improve an adhesive strength; and treating the surface with a plasma treatment using at least one plasma nozzle following the blasting step, the treating including guiding the at least one plasma nozzle at a distance of not more than 15 mm from the surface at a feed rate of not more than 50 m / min.

Owner:AIRBUS OPERATIONS GMBH

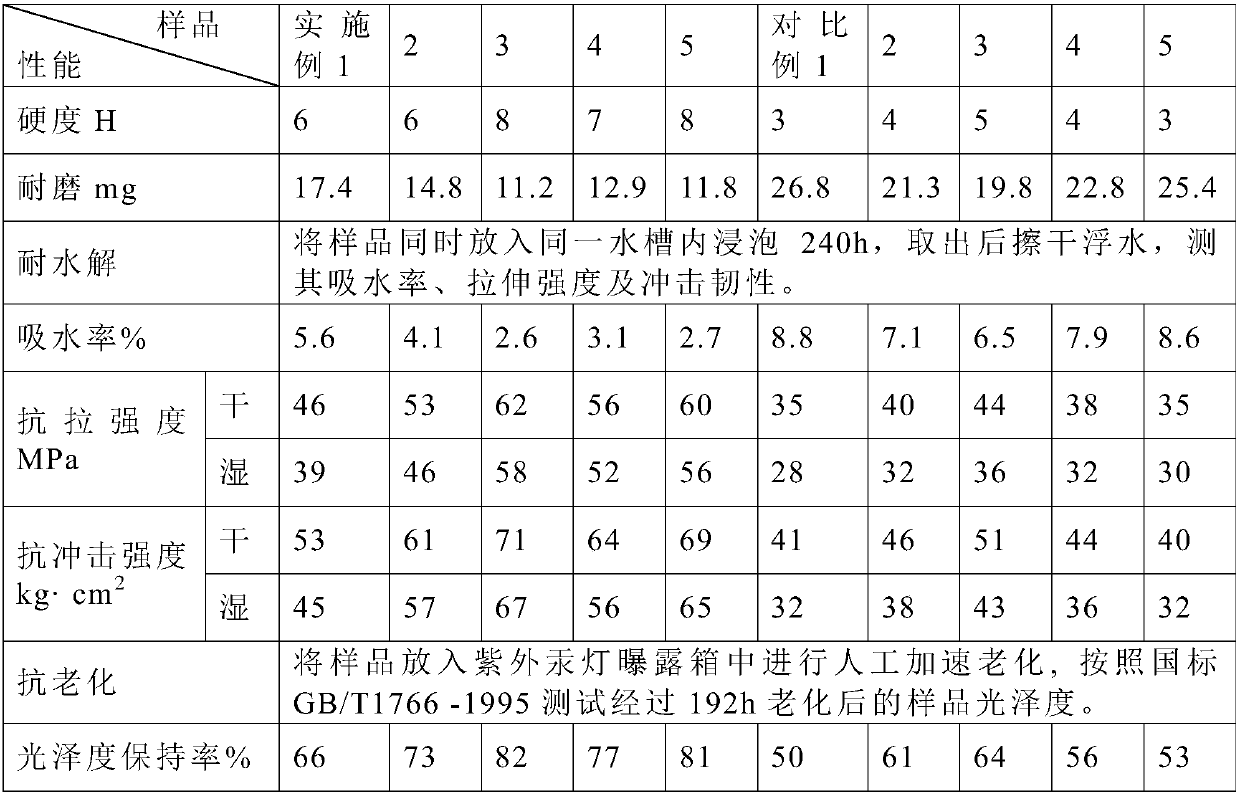

Coating process of automotive upholstery

ActiveCN107694868AHigh tensile strengthImprove flexibilityPretreated surfacesCoatingsEpoxyElectricity

The invention belongs to the field of automobile parts and relates to a coating process of an automotive upholstery. The coating process comprises the steps that S1, pretreatment is conducted, specifically, carbon dioxide snowflake cleaning is conducted, and dust and electricity removing treatment is conducted; S2, primer is sprayed, specifically, the waterborne polyurethane epoxy resin primer issprayed; S3, finishing coat is sprayed, specifically, the coat is sprayed, and levelling is conducted for 10-20 min after spraying; and S4, solidifying and cooling are conducted, specifically, solidifying is conducted at 70-90 DEG C, and cooling is conducted. The coating process further comprises the step that ultrasonic treatment is conducted after the S3, specifically, the automotive upholsterycoated with the finishing coat is coated with polyethylene, and ultrasonic treatment is conducted for 80-120 s at the pressure of 10-20 MPa. The finishing coat comprises 12-20 parts of hydroxy acrylicemulsion, 53-63 parts of polystyrene grafted polyurethane, 9-15 parts of carboxy methyl cellulose, 8-14 parts of cyclodextrin wrapped filler, 3-8 parts of a coalescing agent and 10-15 parts of deionized water.

Owner:NINGBO SHUAITELONG GRP

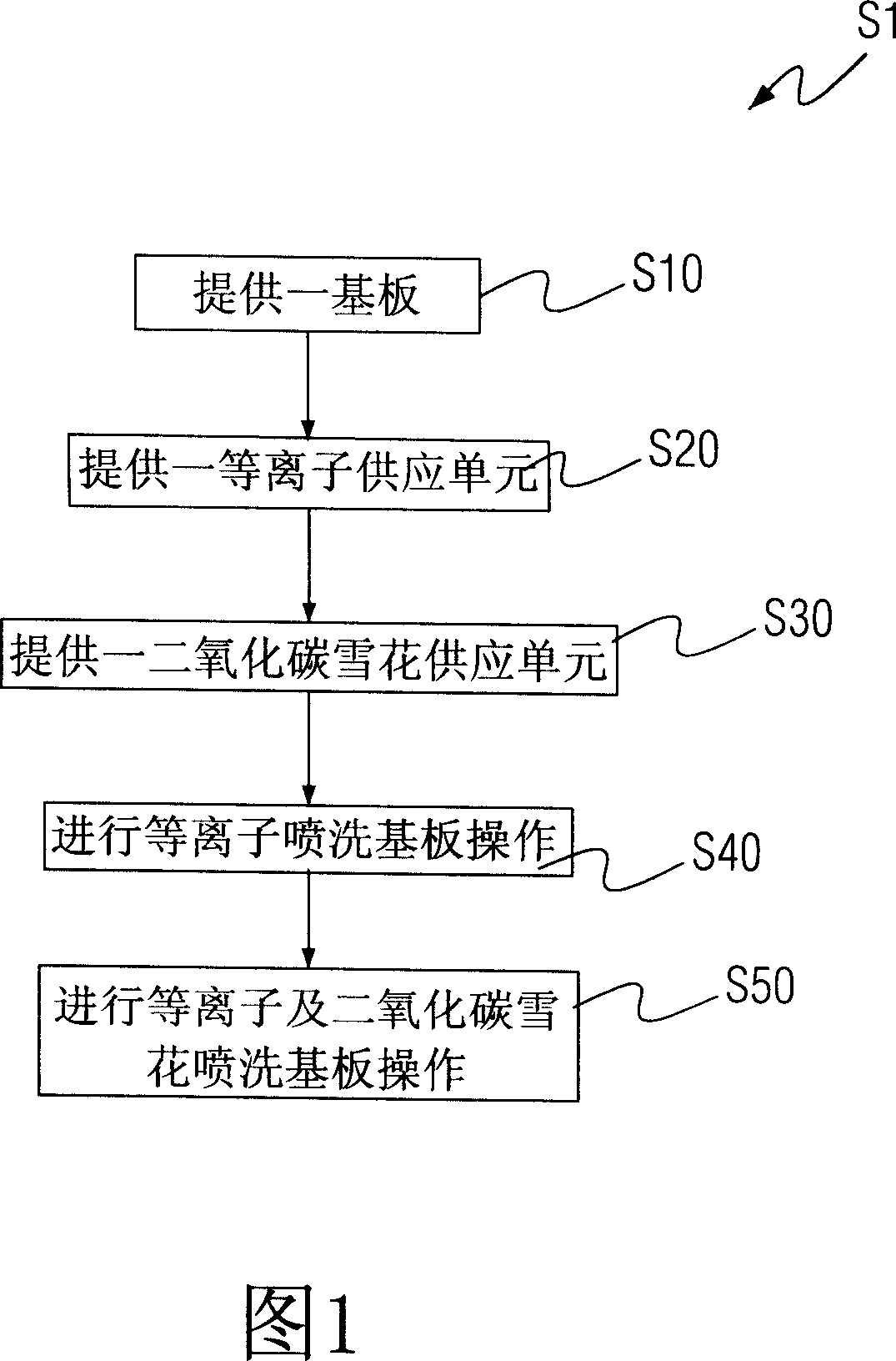

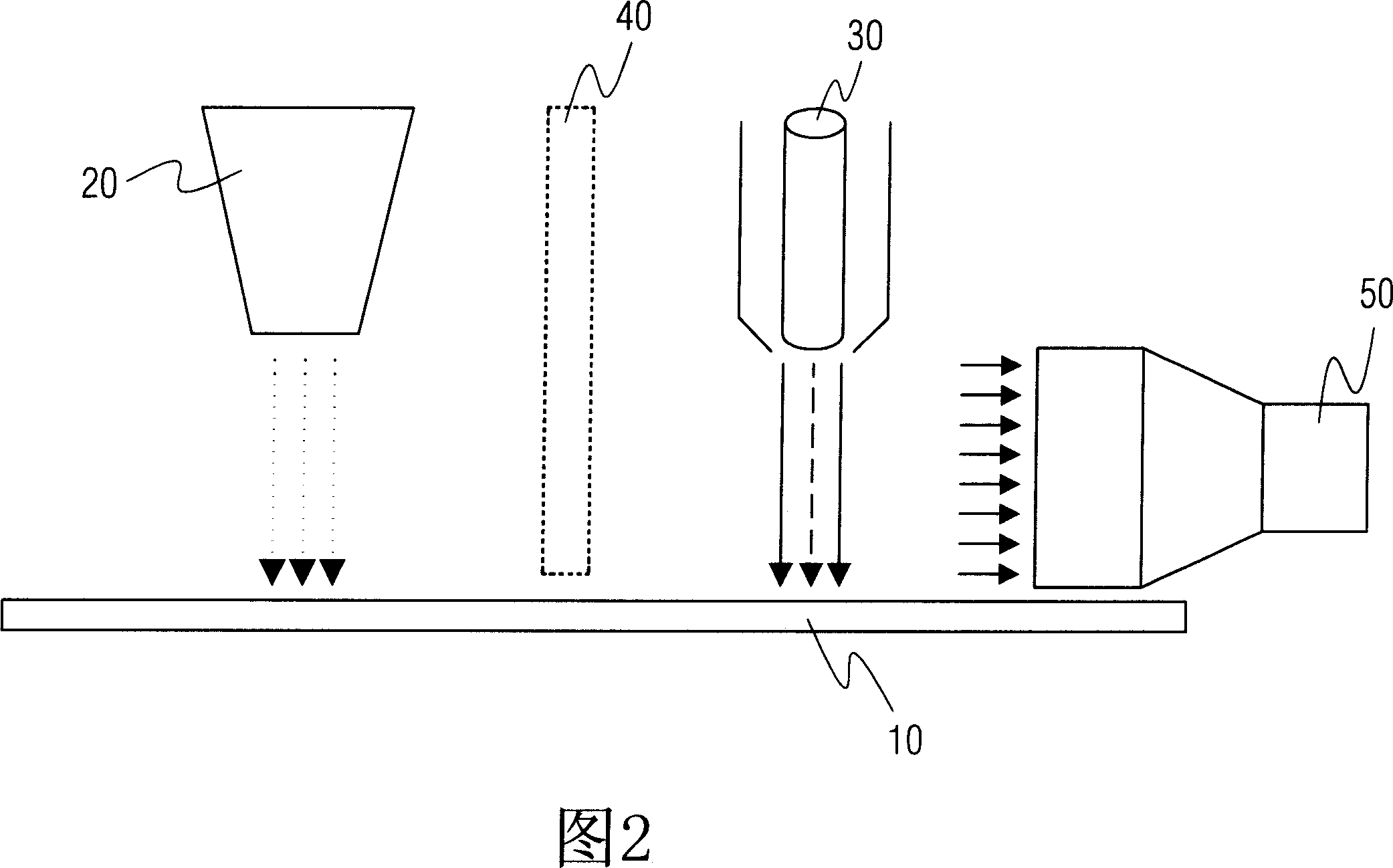

Combined process for cleaning infectant on the surface of cardinal plate

ActiveCN101081395AImprove cleanlinessLow costCleaning using gasesElectrostatic chargesWater resourcesEnvironmental engineering

The composite process of eliminating surface pollutant from base plate includes the steps of: providing one base plate, providing one plasma supply unit, providing one CO2 flake supplying unit, performing plasma cleaning of the base plate, and performing plasma and CO2 flake cleaning of the base plate. The composite process can eliminate organic pollutants and particles from the surface of the base plate, and has low water consumption, low power consumption and no environmental pollution.

Owner:METAL INDS RES & DEV CENT

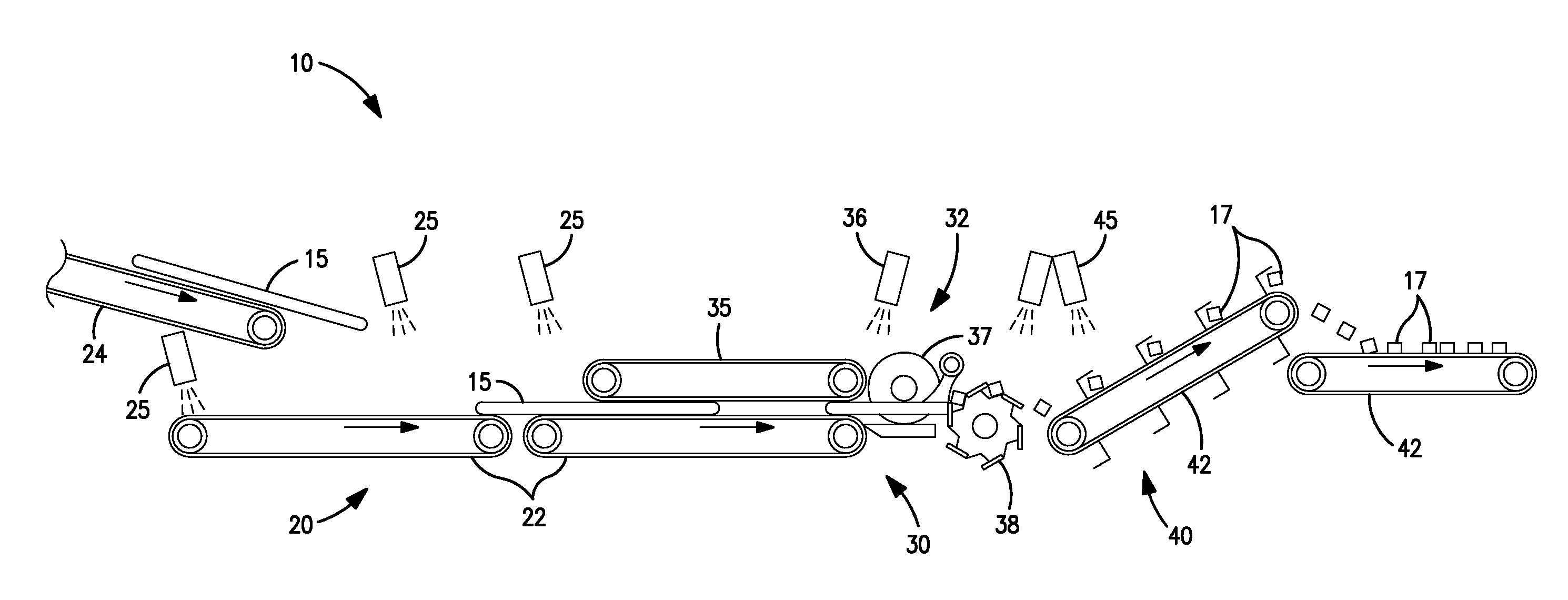

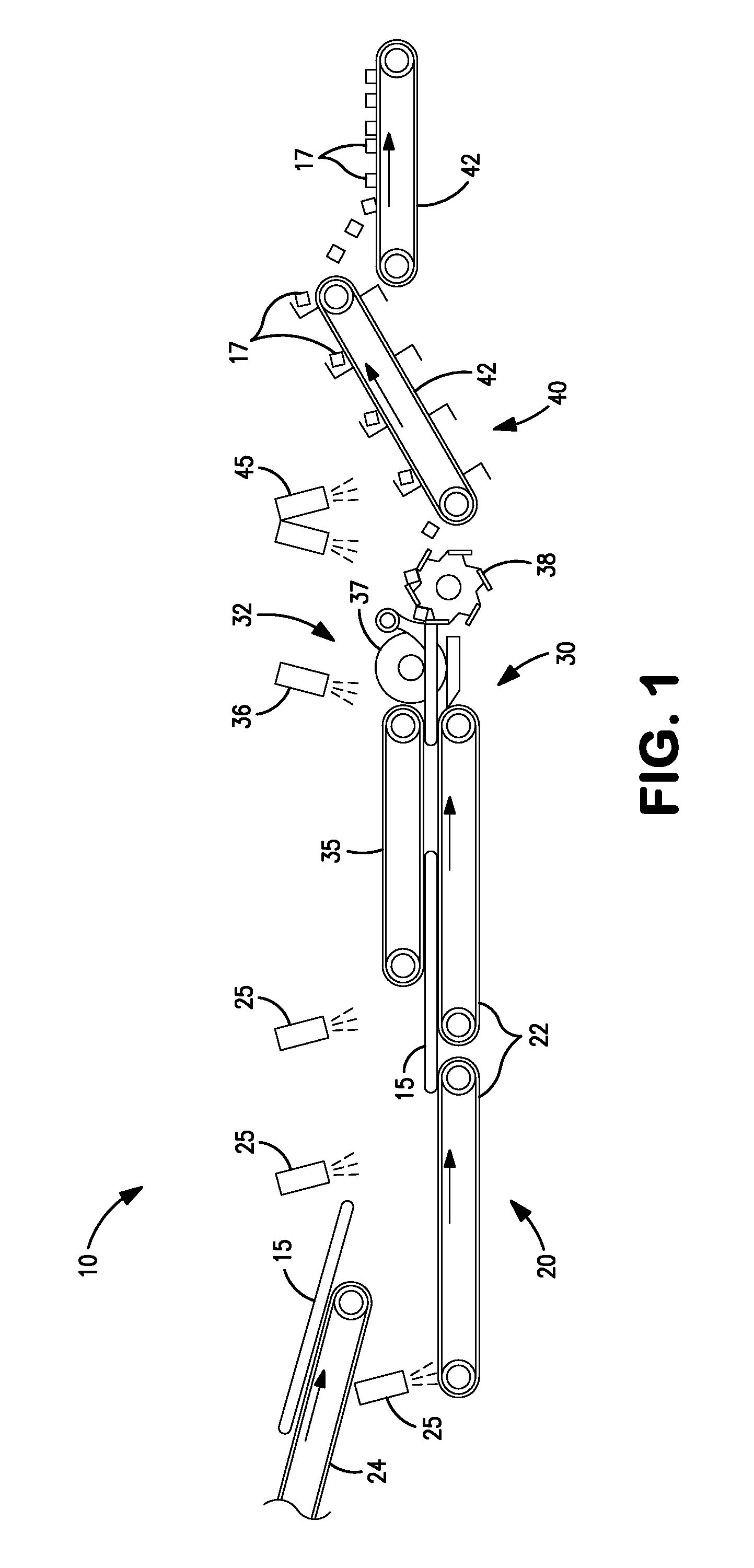

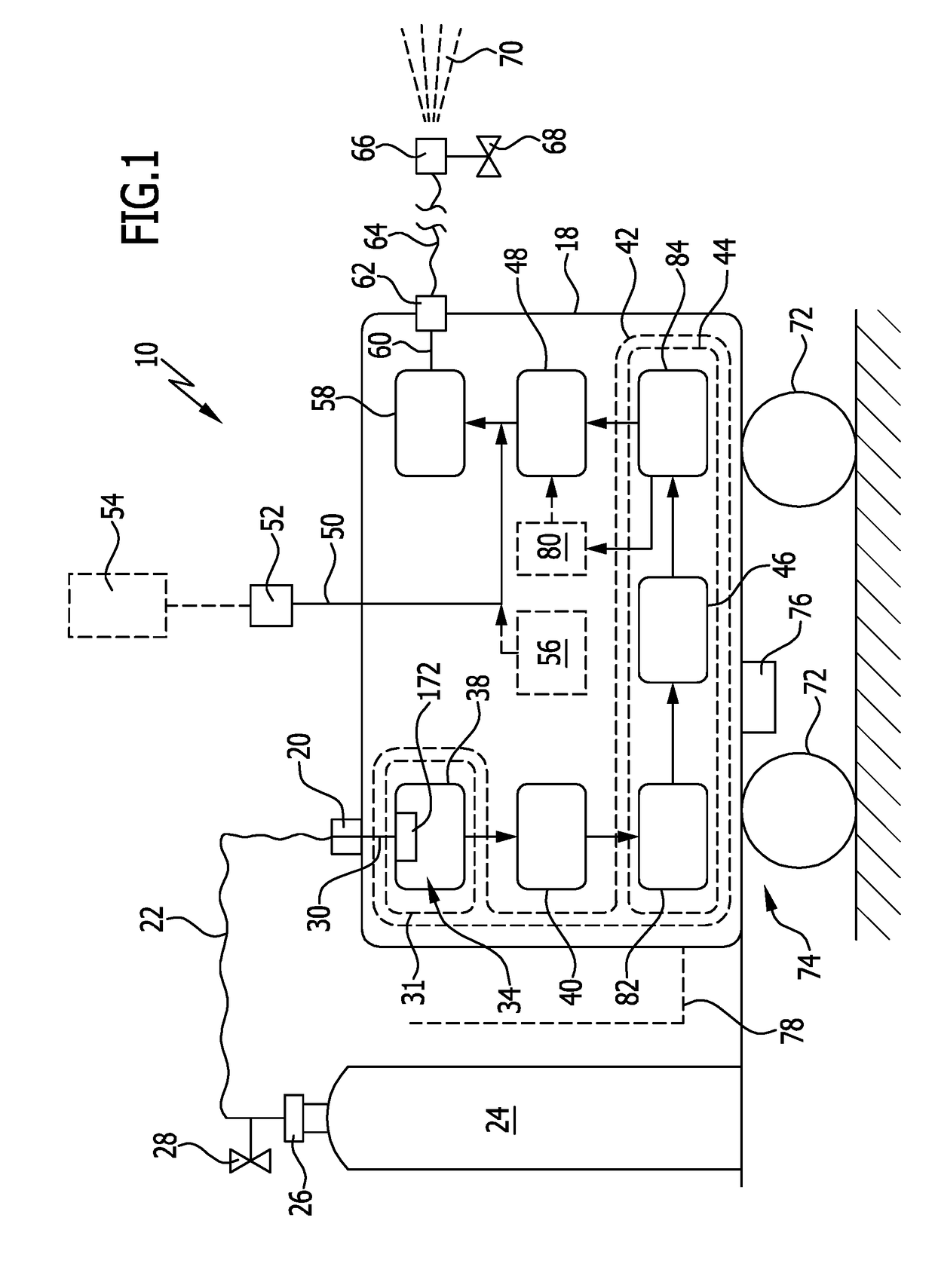

System and method of chilling a food product proximate to and in a food processing device

InactiveUS20110311700A1Lighting and heating apparatusMeat/fish preservation by freezing/coolingThree stageEngineering

A system and method for chilling a food product in or proximate to a food processing device adapted to dice, slice, shred, chop, or cut the food product is disclosed. The disclosed system and method involves a two or three stage application of a liquid cryogen or carbon dioxide snow to cool the food product. The cooling stages include a first stage of cryogen application upstream of the entrance of the food processing device, a second stage of cryogen application or delivery into one or more zones within the food processing device, and a third stage of cryogen application to the region proximate to and downstream of the exit to the food processing device.

Owner:PRAXAIR TECH INC

Device for producing co2 pellets from co2 snow and cleaning device

The present invention relates to a device for producing high-strength CO2 pellets from CO2 snow, in particular, for a cleaning device for blasting surfaces to be treated with a mixed-flow consisting of a compressed gas and CO2 pellets, including a main compressing device for compressing CO2 snow for forming CO2 pellets, further including a pre-compressing device for pre-compressing CO2 snow produced by expanding liquid CO2, wherein the pre-compressing device is in the form of a fluid-mechanical pre-compressing device, wherein the pre-compressing device includes an expansion device for producing CO2 snow from liquid or gaseous CO2 and a pre-compression chamber for receiving and pre-compressing the produced CO2 snow and wherein the expansion device and the pre-compression chamber are connected to one another in fluidic manner.

Owner:ALFRED KARCHER GMBH & CO KG

Preparation method fo granular fertilizer for pollution-free vegetables and its application method

InactiveCN1769247APromote rapid growthGrow vigorouslyClimate change adaptationBioloigcal waste fertilisersDry iceCarbide

The invention discloses a method for preparation of particle fertilizer for pollution-free vegetables and the method for use, which contains: polymerizing liquid carbon dioxide into carbon dioxide snow with a polymerizer, stirring uniformly the mixture of carbon dioxide snow, carbide powder and lees by weight ratio of (2-4): 1: (0.2-0.5) by a stirrer and sending into pelletizer to prepare particle fertilizer; putting the particle fertilizer into a bucket of a fertilizer applicator, spraying into the space earth of the vegetable by the gas pressure of air compressor, the spraying usage being 40-60kilogram / unit of area. The invention is characterized in that the method for preparation is simple, it is convenient to operate, and it is highly effective and nontoxic.

Owner:徐玉庆

Transportable container, charger system, method and kit for generation of carbon dioxide snow block in-situ within the transportable container for preservation of items stored therewithin

ActiveUS20200300541A1SolidificationLiquefactionProcess engineeringElectrical and Electronics engineering

This invention relates to a novel kit, transportable apparatus and method for generating in-situ CO2 snow block within the apparatus. An item such as a biological sample can be stored and transported within the same apparatus that is employed for creating the CO2 snow block. The apparatus is capable of preserving the sample during transport. The invention also includes a specially designed CO2 snow charger system including a charger and meshed conduit. The charger system is operated in accordance with the methods of the present invention to create the in-situ CO2 snow block within a container that can be also used for transport.

Owner:PRAXAIR TECH INC

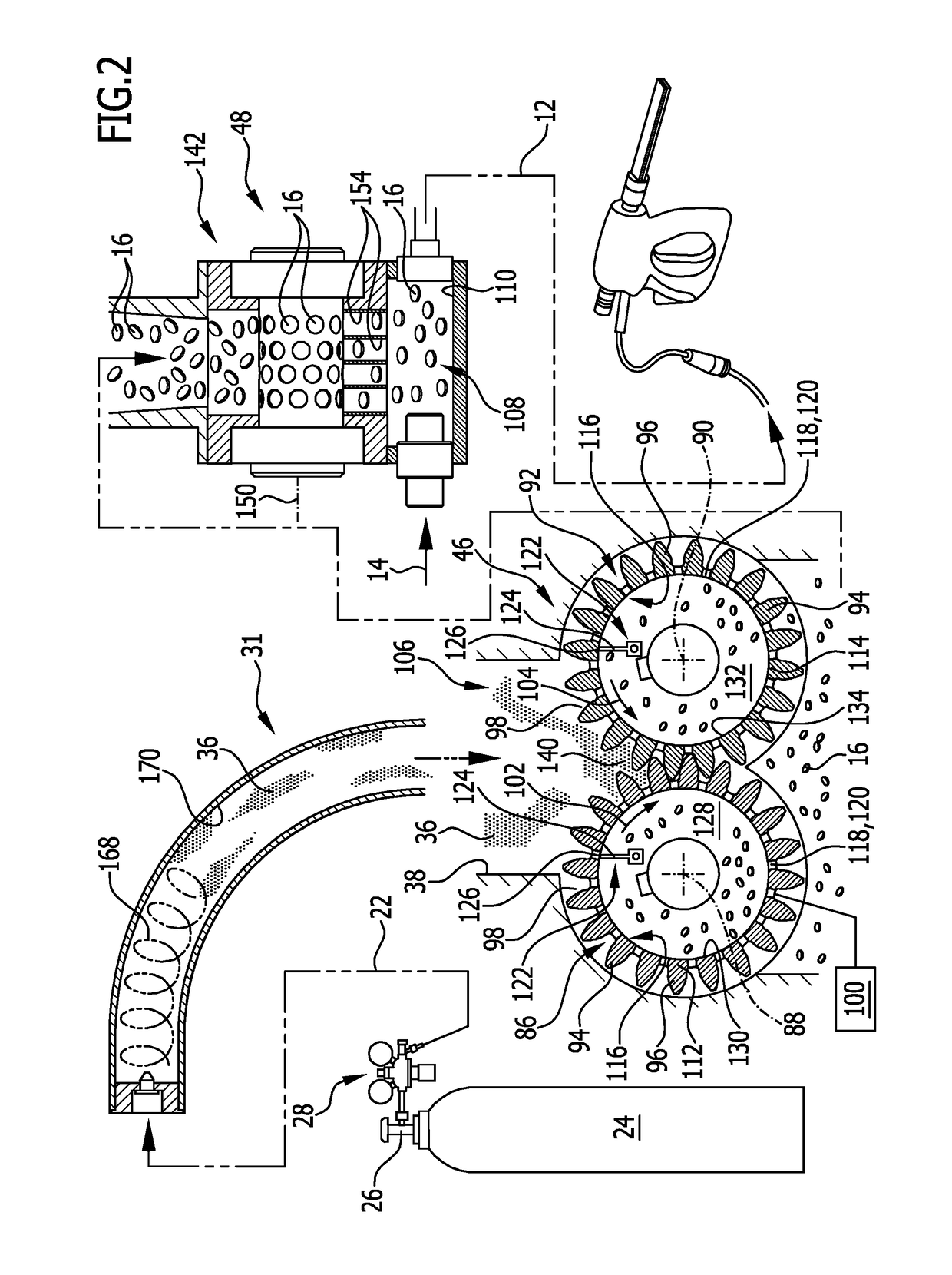

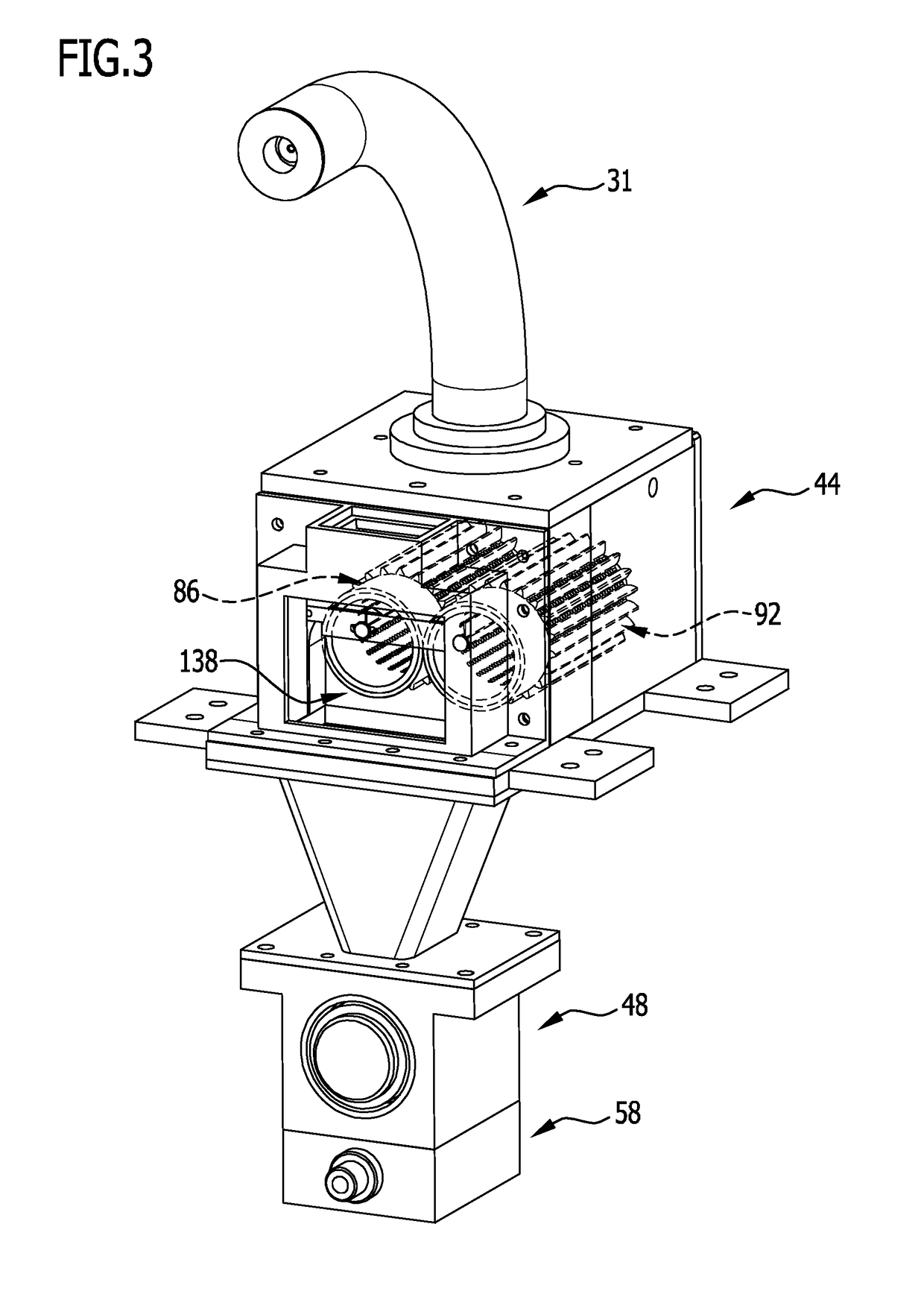

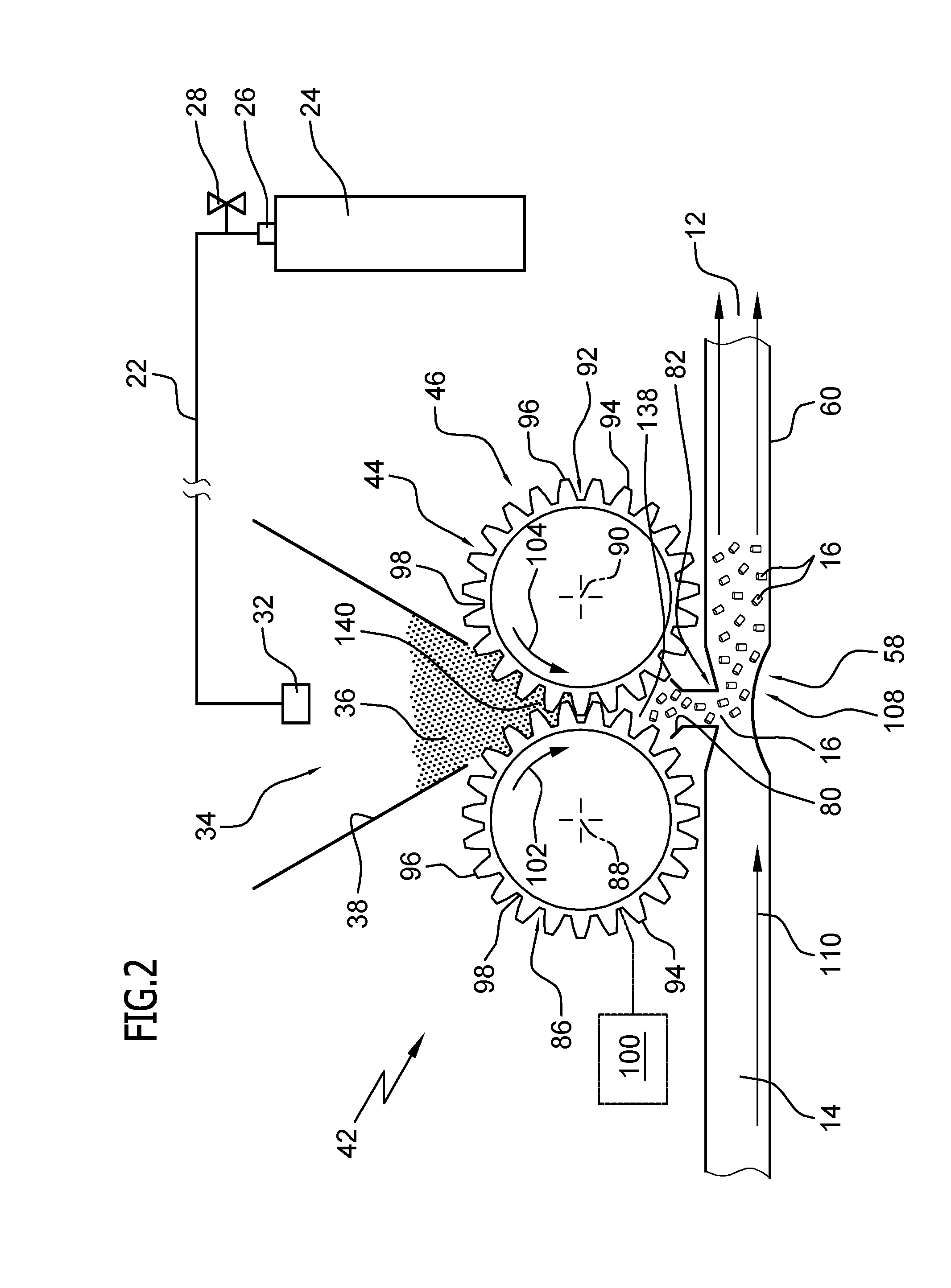

Apparatus for producing co2 pellets from co2 snow and cleaning device

The invention relates to an apparatus for producing CO2 pellets from CO2 snow, in particular, for a cleaning device for spraying surfaces to be treated with a mixed stream of a pressurized gas and CO2 pellets, includes a compressor device for compressing CO2 snow to form CO2 pellets. The compressor device includes a gear compressor. The gear compressor includes at least one compressor wheel which is mounted rotatable about a first rotation axis and has a plurality of compressing elements, and includes at least one intake wheel which has a plurality of snow intakes for accepting CO2 snow. The snow intakes are configured corresponding to the compressing elements. The intake wheel is mounted rotatable about a second rotation axis and cooperates with the at least one compressor wheel. The intake wheel includes an intake wheel sleeve with an intake wheel sleeve wall.

Owner:ALFRED KARCHER GMBH & CO KG

Cleaning treatment method for metal film circuit on ferrite substrate before electroplating

InactiveCN112452936ASolving Consistency IssuesSolve efficiency problemsCleaning using gasesCleaning using liquidsFerrite substrateIsolator

The invention discloses a cleaning treatment method for a metal film circuit on a ferrite substrate before electroplating, and belongs to the field of microelectronic device processing. The cleaning treatment method comprises the following steps: carrying out primary spray cleaning on a ferrite substrate by using carbon dioxide snow fluid, carrying out soaking treatment by using an acid solution,carrying out secondary spray cleaning on the ferrite substrate by using the carbon dioxide snow fluid, flushing the ferrite substrate by using pure water and the like. By adopting the method providedby the invention, the processing time is shortened by at least 50% compared with the original processing time, the reliability of an electroplated film layer is improved, and the requirements of circulator / isolator devices on the electroplating process efficiency and reliability are met.

Owner:中国电子科技集团公司第九研究所

Methods for pre-charging carbon dioxide snow

Manual and automated methods of pre-charging an empty or partially empty insulated container with CO2 snow are provided. A first location such as a charging location charges CO2 liquid into a container to create a pre-charged container with CO2 snow. The charging location prepares the pre-charged container for delivery to a second location, either by itself, or through a third party. The second location may be a clinical site, which upon receipt of the pre-charged container, loads a perishable item such as a biological sample into the pre-charged container. A user receives the pre-charged container with perishable item and removes the perishable item from the pre-charger container for testing (e.g., biological testing). Depending on the level of depletion of the CO2 snow in the pre-charged container, the user returns the depleted container to the first location or the intermediate location.

Owner:PRAXAIR TECH INC

In-situ temperature control during chemical mechanical polishing with a condensed gas

Implementations of the present disclosure generally relate to planarization of surfaces on substrates and on layers formed on substrates, including an apparatus for in-situ temperature control during polishing, and methods of using the same. More specifically, implementations of the present disclosure relate to in-situ temperature control with a condensed gas during a chemical-mechanical polishing (CMP) process. In one implementation, the method comprises polishing one or more substrates against a polishing surface in the presence of a polishing fluid during a polishing process to remove a portion of a material formed on the one or more substrates. A temperature of the polishing surface is monitored during the polishing process. Carbon dioxide snow is delivered to the polishing surface in response to the monitored temperature to maintain the temperature of the polishing surface at a target value during the polishing process.

Owner:APPLIED MATERIALS INC

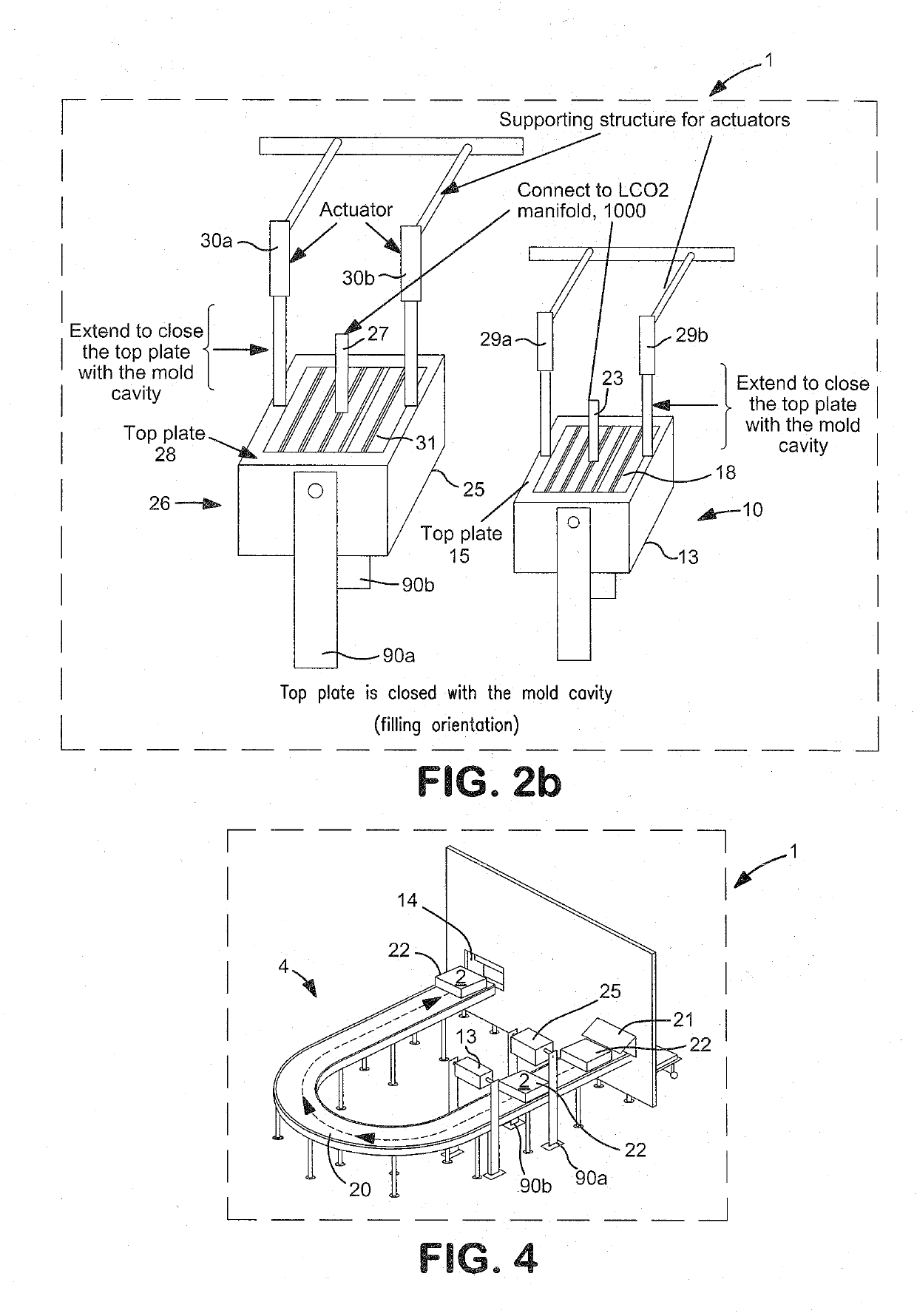

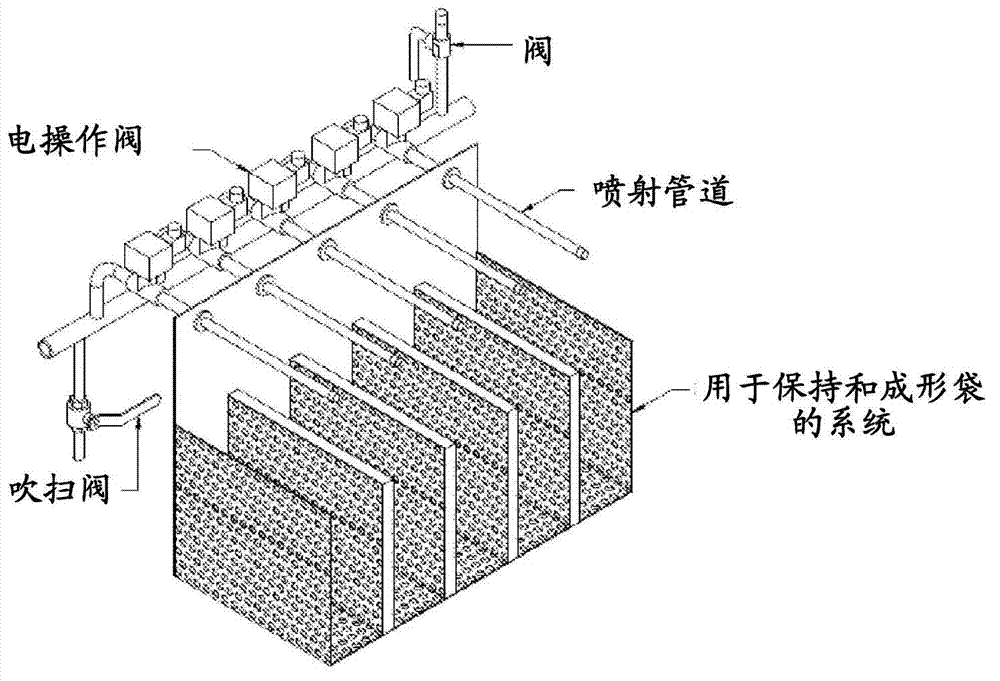

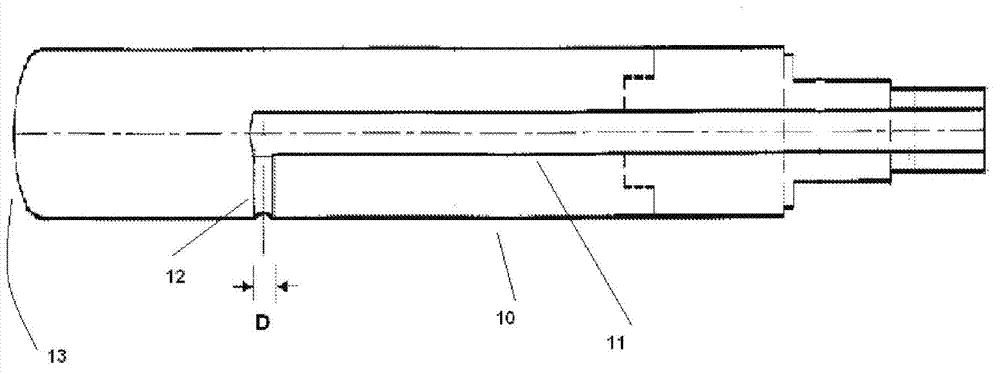

Equipment for producing cooling packs consisting of a shell made of a porous material containing an amount of carbon-dioxide snow enclosed and retained inside the casing

ActiveCN103168206AIncrease flexibilityEasy to changeDomestic cooling apparatusLighting and heating apparatusInjection portSpray nozzle

The invention relates to equipment for producing cool packs containing an amount of carbon-dioxide snow, which includes: a set of at least two cells, each of which is capable of receiving and supporting a shell to be filled; a feeding tube connected, at the upstream portion thereof, to a liquid CO2 source; a set of at least two injection manifolds, each injection manifold being located opposite a cell in which a casing to be filled is to be positioned, and each manifold being connected, at the upstream portion thereof, to the feeding tube, wherein each manifold comprises an injection port at at least one location along the length thereof, the equipment being characterized in that: i) the end of each manifold opposite the feeding tube is formed as a sealed end provided in the form of a substantially rounded tip; j) each injection port located on a manifold is a provided as a threaded opening having a given diameter D and is capable of receiving an injection nozzle by means of screwing; k) said equipment comprises at least two injection nozzles, each injection nozzle being provided in the form of a part that is cylindrical over at least a portion of the length thereof, said cylinder being a hollow cylinder, the threaded outer diameter of which is equal to the diameter D of at least one of the threaded openings of at least one of the manifolds, and the inner diameter d of which is less than D.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

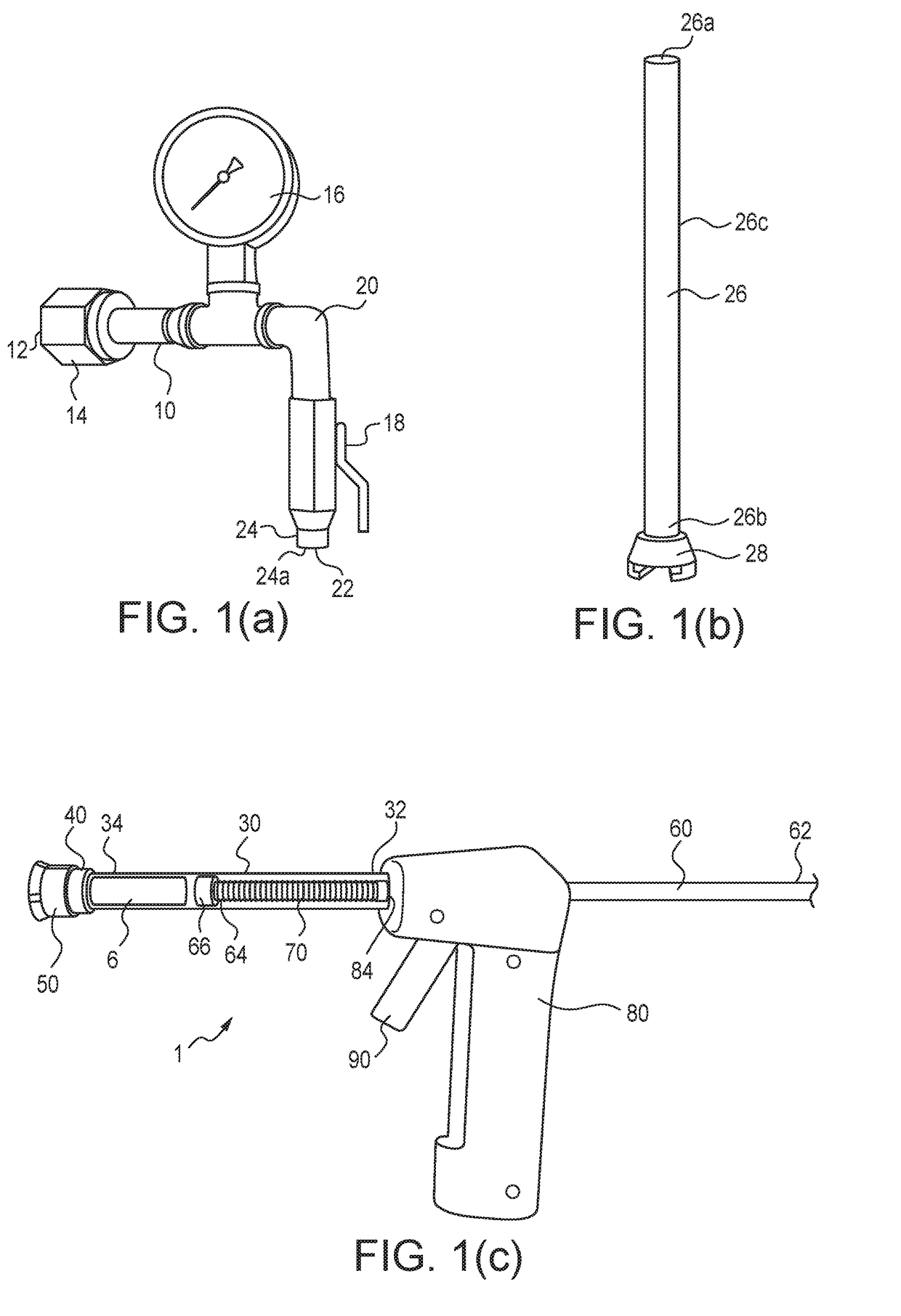

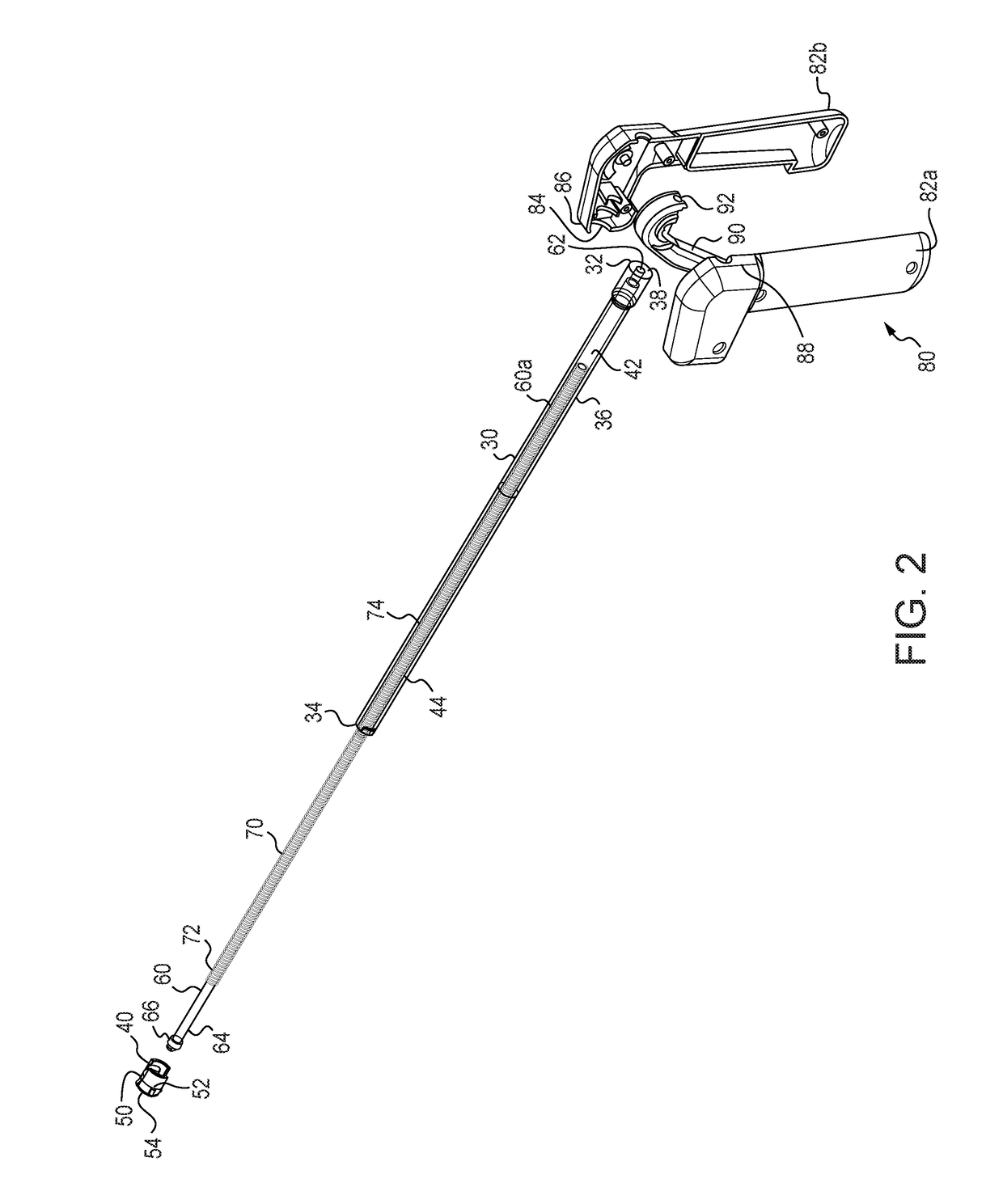

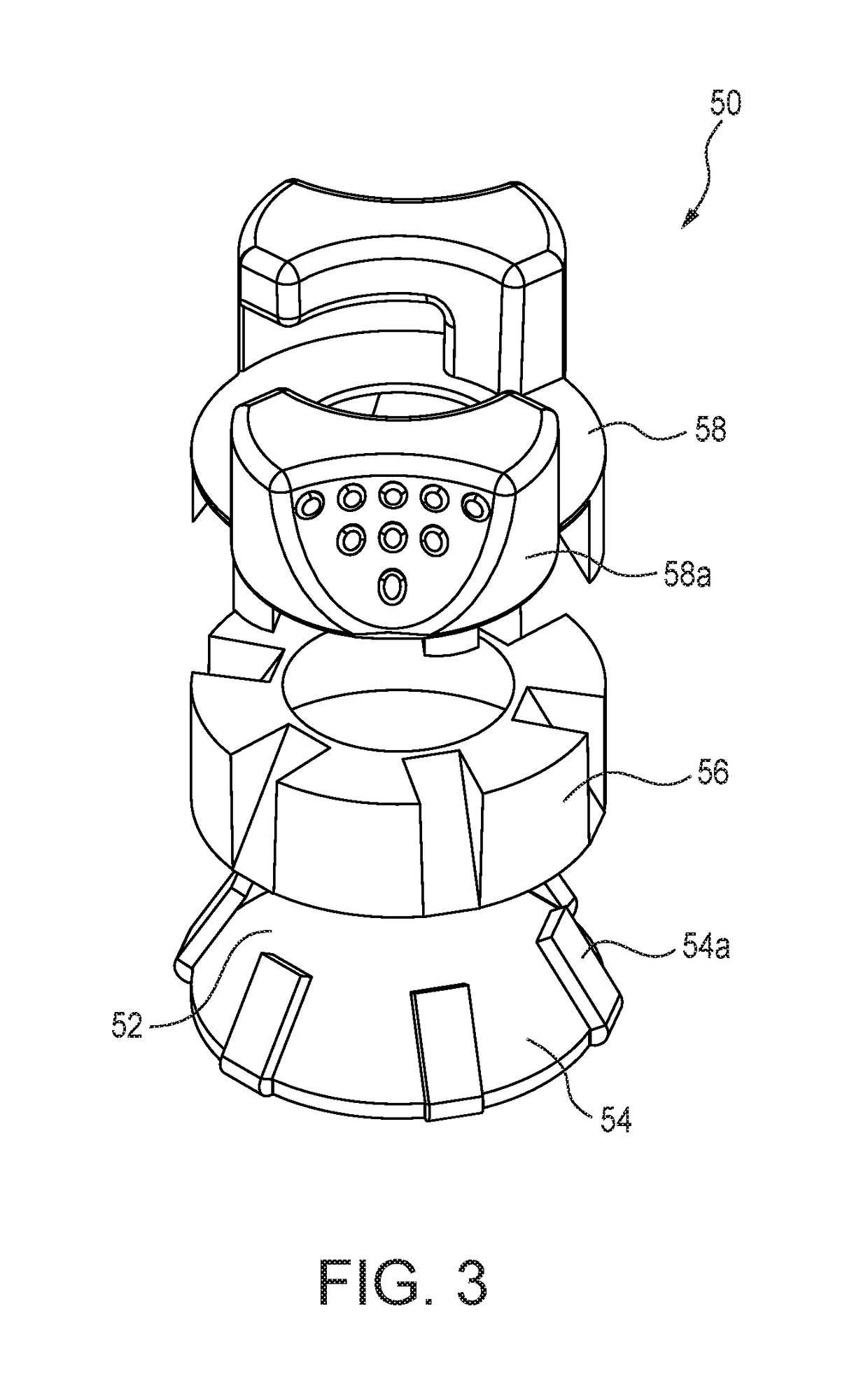

Cryotherapy Device For The Treatment of Cervical Precancerous Lesions

InactiveUS20190021777A1Satisfies needCatheterSurgical instruments for coolingMetalPrecancerous lesion

A device for providing a patient with a cryotherapy process that is directed to the ablation of a lesion on the patient, includes: (a) a piping assembly adapted to create a spray of carbon dioxide snow, (b) a snow horn having a pressure relief means and a boundary wall, (c) a tubular applicator with ends between which extends an interior wall that has an interior diameter that increases in value between these ends, (d) an applicator tip with a metal portion and adapted to allow it to connect to the applicator's distal end, and (e) a push rod having a distal end with a base to which is attached an anchor.

Owner:JHPIEGO CORP

Solar photovoltaic panel surface cleaning system and cleaning method

ActiveCN113458088AImprove photoelectric conversion rateReduce load weightAircraft componentsPhotovoltaicsSurface cleaningUncrewed vehicle

The invention provides a solar photovoltaic panel surface cleaning system and a cleaning method. The system is characterized in that the whole cleaning device is arranged on an unmanned aerial vehicle, an infrared camera and a visible light camera which are used for shooting are arranged on the unmanned aerial vehicle, a stain positioning system used for positioning is further arranged on the unmanned aerial vehicle, and meanwhile, a device for loading cleaning liquid and a device for loading carbon dioxide are arranged. Compared with an existing photovoltaic panel decontamination technology, the system adopts an environment-friendly stain cleaning agent, the surface of a solar photovoltaic panel is sprayed with the stain cleaning agent, meanwhile, a carbon dioxide snow decontamination technology is matched, so that residual stains are cleaned again without leaving water stains; and therefore, the problem of water shortage in regions such as deserts or gobi is solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Efficient carbon dioxide snow spray gun

InactiveCN106076687AExtended phase transition pathImprove the conversion rate of phase changeLiquid spraying apparatusCleaning processes and apparatusAgricultural engineeringEngineering

The invention provides an efficient carbon dioxide snow spray gun. The efficient carbon dioxide snow spray gun comprises a casing, a carbon dioxide expansion cavity, a compressed air cavity, a mixing nozzle arranged at the front end of the casing as well as a carbon dioxide inlet and a compressed air inlet which are arranged at the rear end of the casing, wherein the carbon dioxide expansion cavity and the compressed air cavity are formed in the casing and mutually communicate. The efficient carbon dioxide snow spray gun is characterized in that a spiral slot is formed in the inner wall of the carbon dioxide expansion cavity. After the spiral slot is formed in the inner wall of the carbon dioxide expansion cavity, when sent high-pressure carbon dioxide gas is rapidly decompressed in the carbon dioxide expansion cavity and has phase change, the phase change route of carbon dioxide is effectively prolonged due to arrangement of the spiral slot, more carbon dioxide has phase change, small-particle solids are formed, the phase change conversion rate of carbon dioxide is increased, and the efficient cleaning requirement is met. The efficient carbon dioxide snow spray gun is simple in structure, convenient to use and remarkable in cleaning effect.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

Transportable container, charger system, method and kit for generation of carbon dioxide snow block in-situ within the transportable container for preservation of items stored therewithin

ActiveUS10712072B2Rigid enoughLighting and heating apparatusDead animal preservationProcess engineeringElectrical and Electronics engineering

Owner:PRAXAIR TECH INC

A kind of dry ice particle processor and the processing method of dry ice particle

InactiveCN105170298BReduce labor intensityImprove work efficiencyGrain treatmentsParticulatesDry ice

A dry ice particle processor and a dry ice particle processing method relate to a processor and a processing method thereof. The present invention solves the problem that existing dry ice particles have larger particle diameters and greater destructive power, and cannot clean instruments or equipment with high precision requirements, resulting in blank particle cleaning in the domestic dry ice cleaning industry. A dry ice particle processor comprises an outer shell, a first pipeline, a second pipeline, a third pipeline, a throat and a sieve plate, the first pipeline, the second pipeline and the third pipeline are respectively arranged in the housing, and one end of the first pipeline It is connected with the discharge port of the feeding assembly, the other end of the first pipe is vertically connected with one end of the second pipe, the other end of the second pipe is vertically connected with one end of the third pipe, and the throat is set on the first pipe Inside, the sieve plate is inserted vertically on the second pipe. Processing method: set the position of the outer shell; convey and feed the material; crush four times; output the particles. The invention is used for crushing treatment of dry ice particles.

Owner:HARBIN DERUISIWO SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com