Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11680 results about "Carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a carbide is a compound composed of carbon and a less electronegative element. Carbides can be generally classified by the chemical bonds type as follows: (i) salt-like, (ii) covalent compounds, (iii) interstitial compounds, and (iv) "intermediate" transition metal carbides. Examples include calcium carbide (CaC₂), silicon carbide (SiC), tungsten carbide (WC; often called, simply, carbide when referring to machine tooling), and cementite (Fe₃C), each used in key industrial applications. The naming of ionic carbides is not systematic.

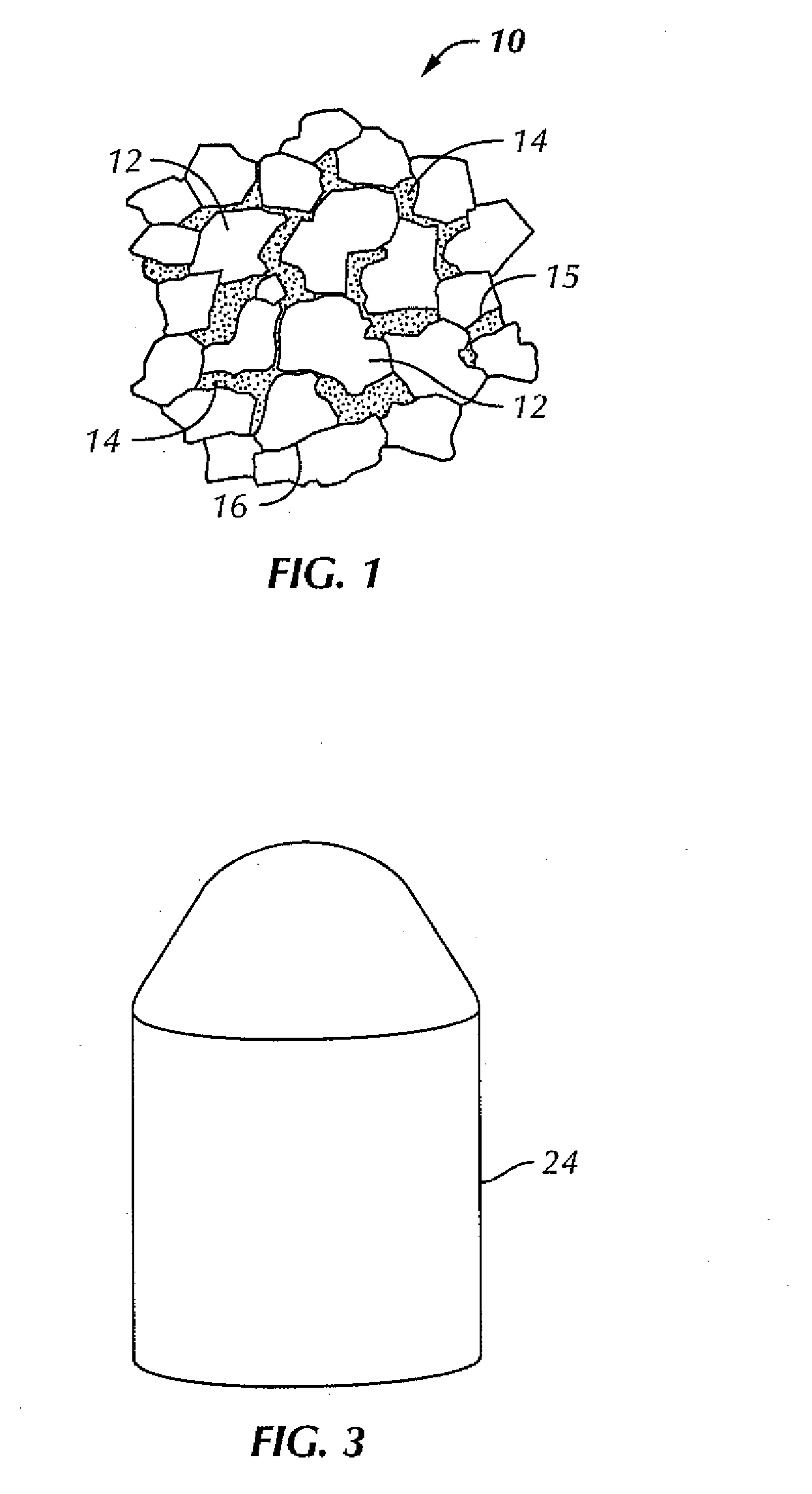

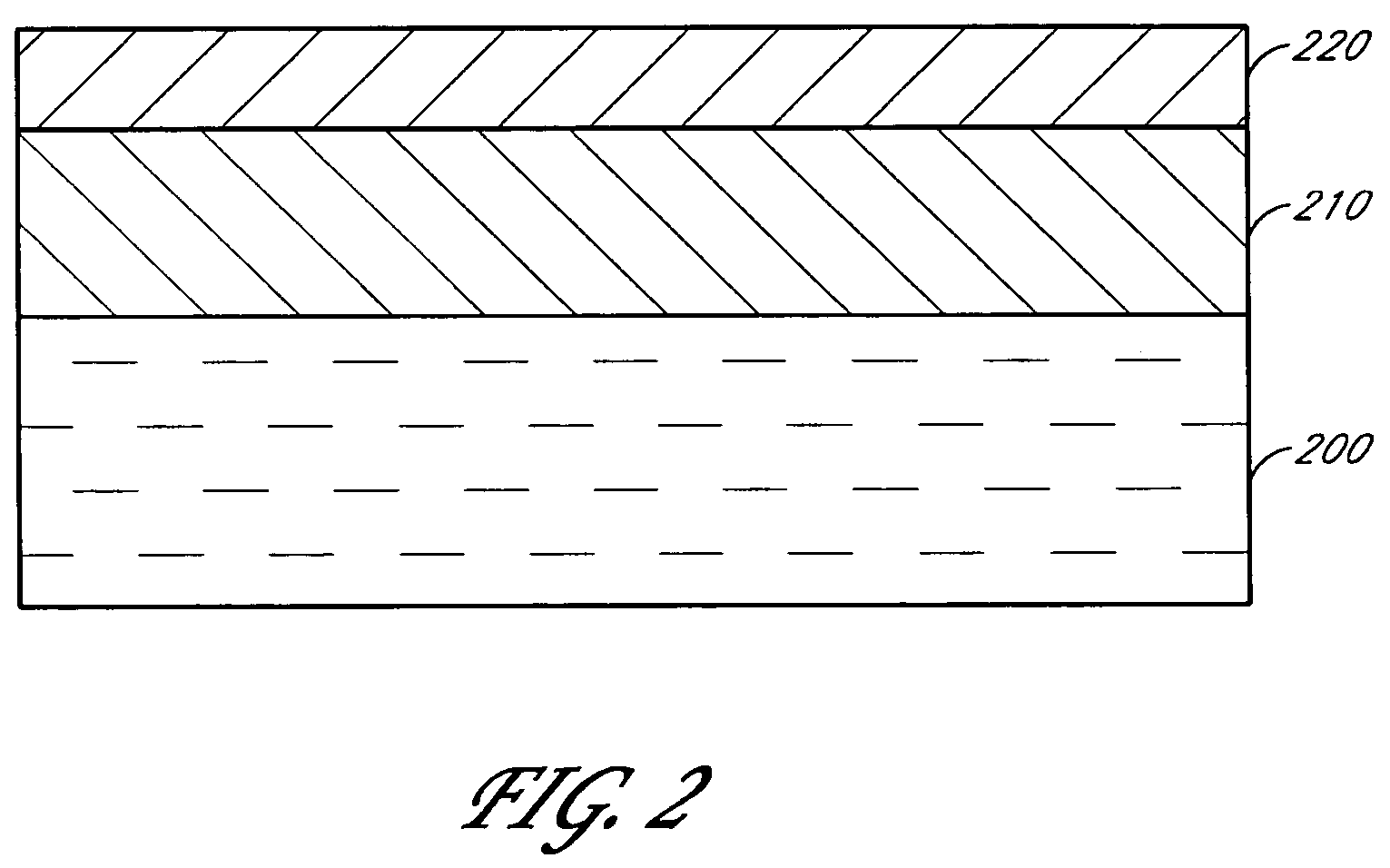

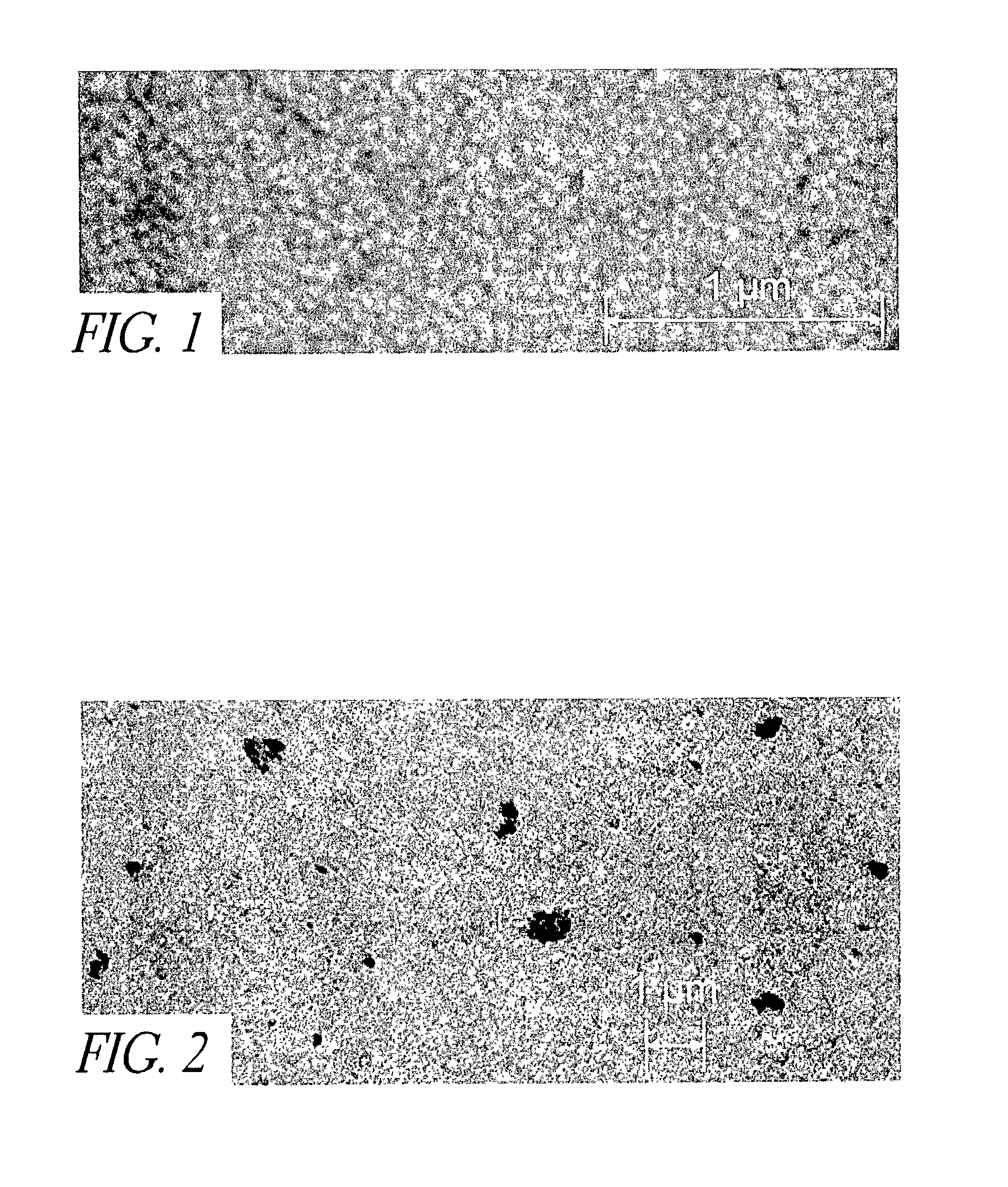

Aerogel metallic compositions

InactiveUS7071287B2Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologyCell electrodesImidePolymer science

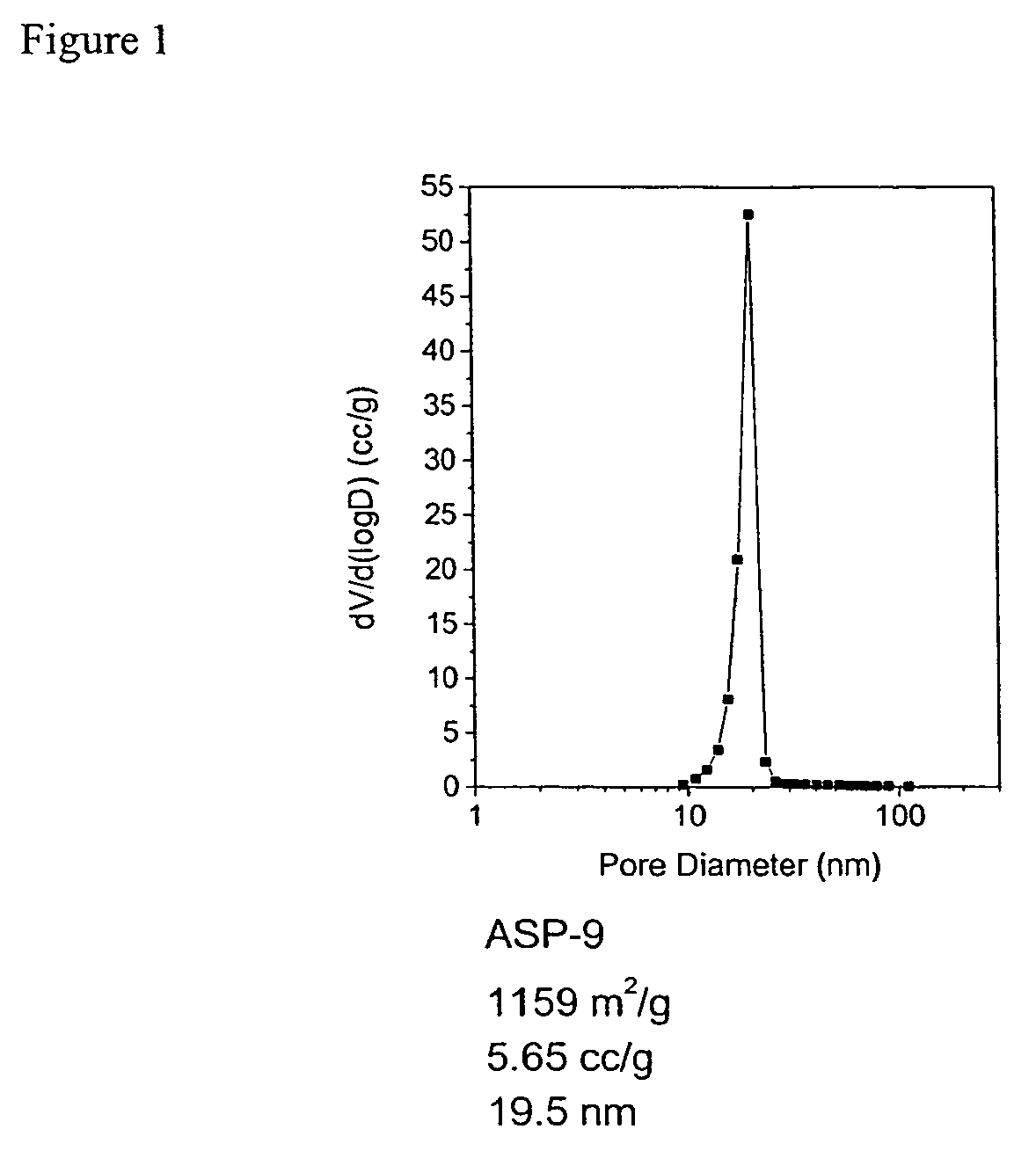

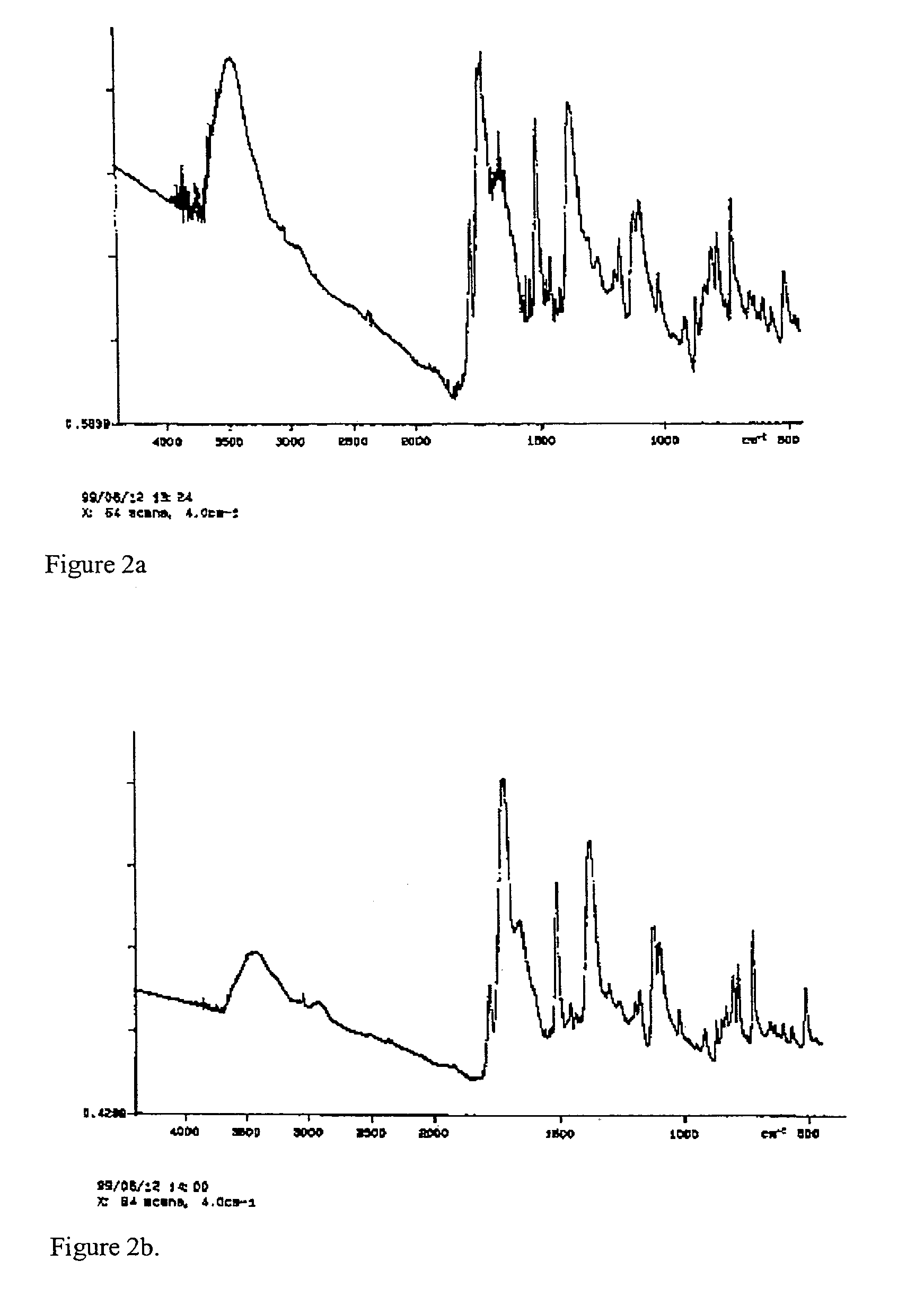

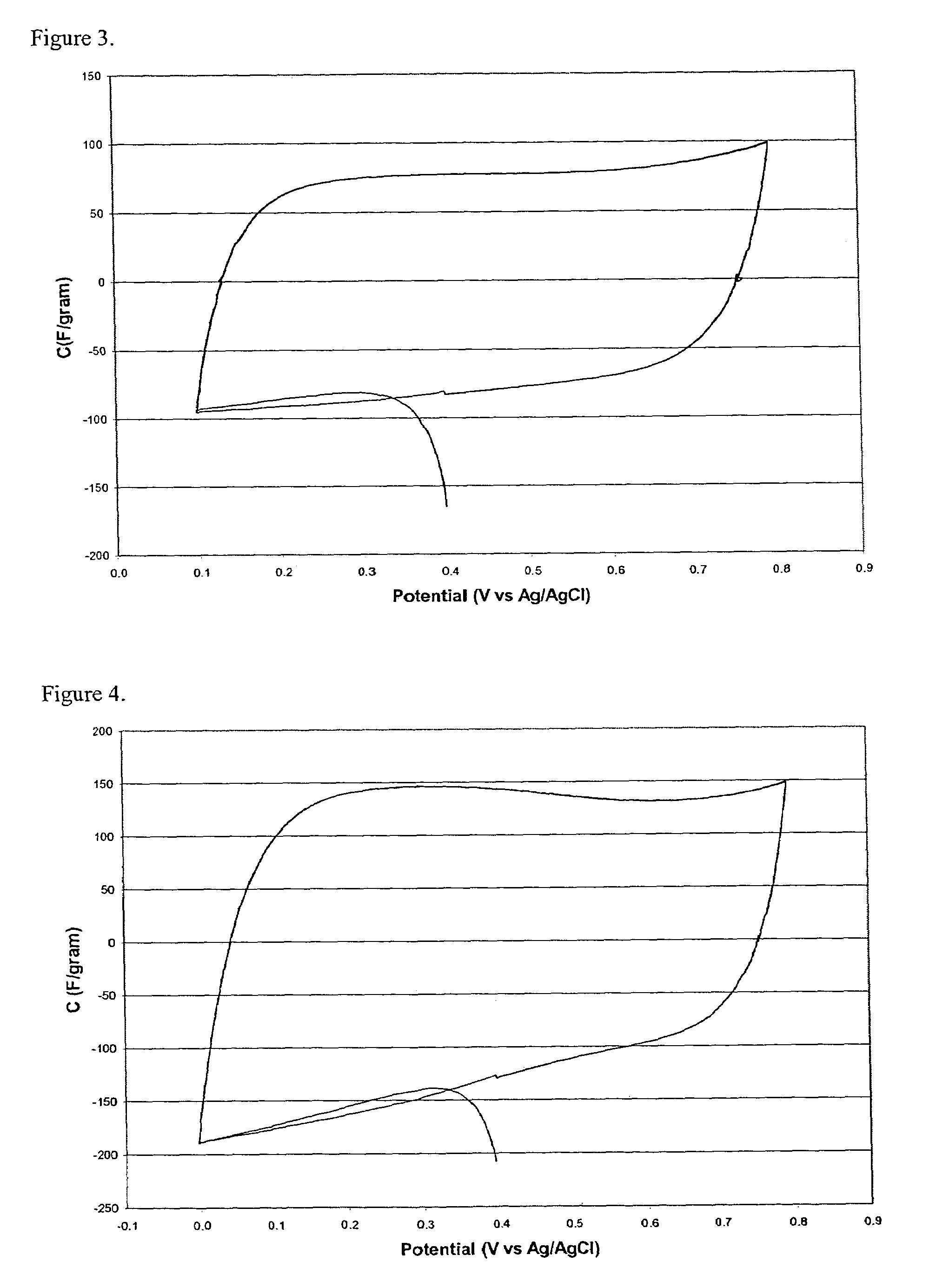

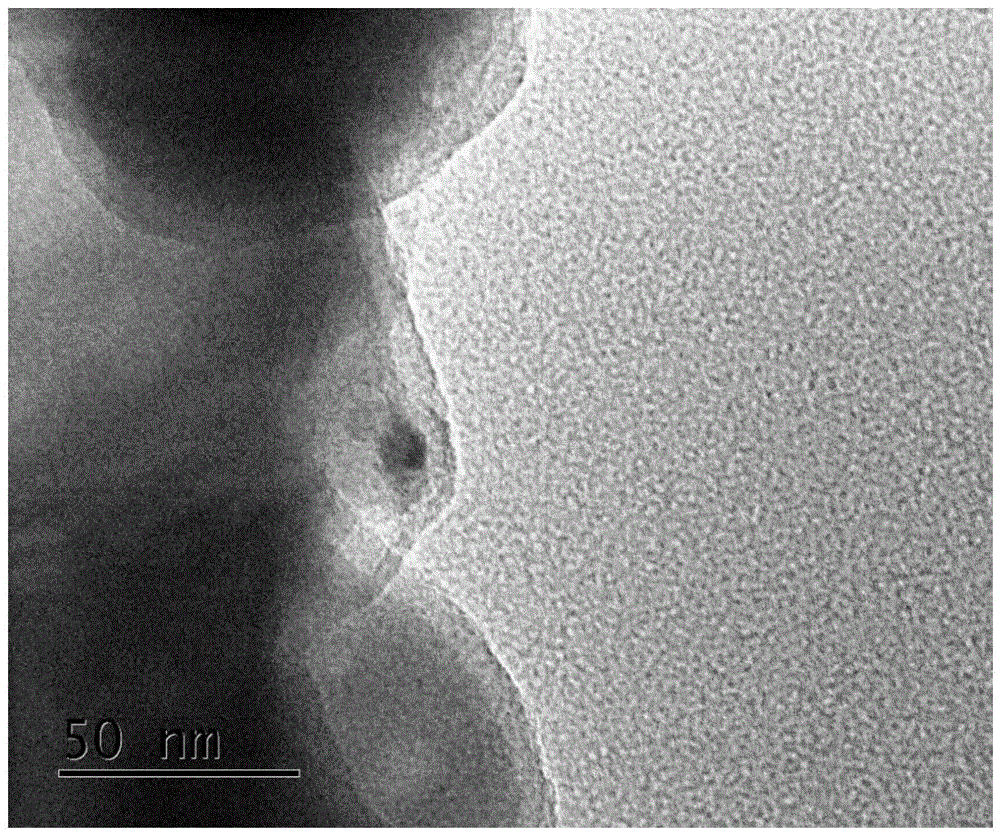

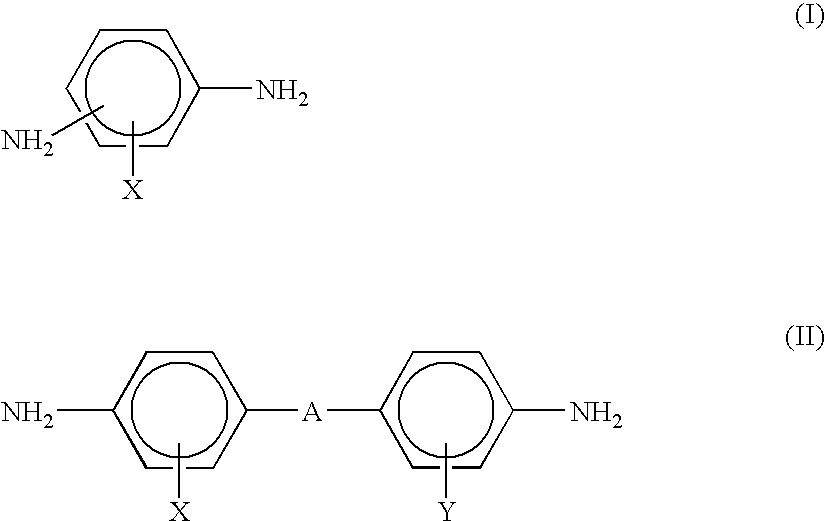

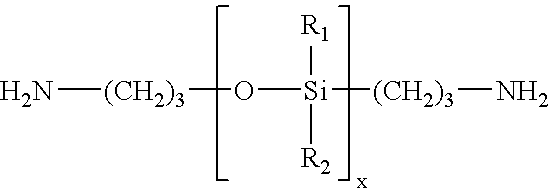

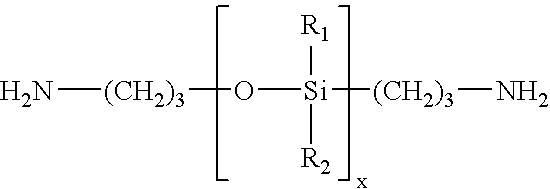

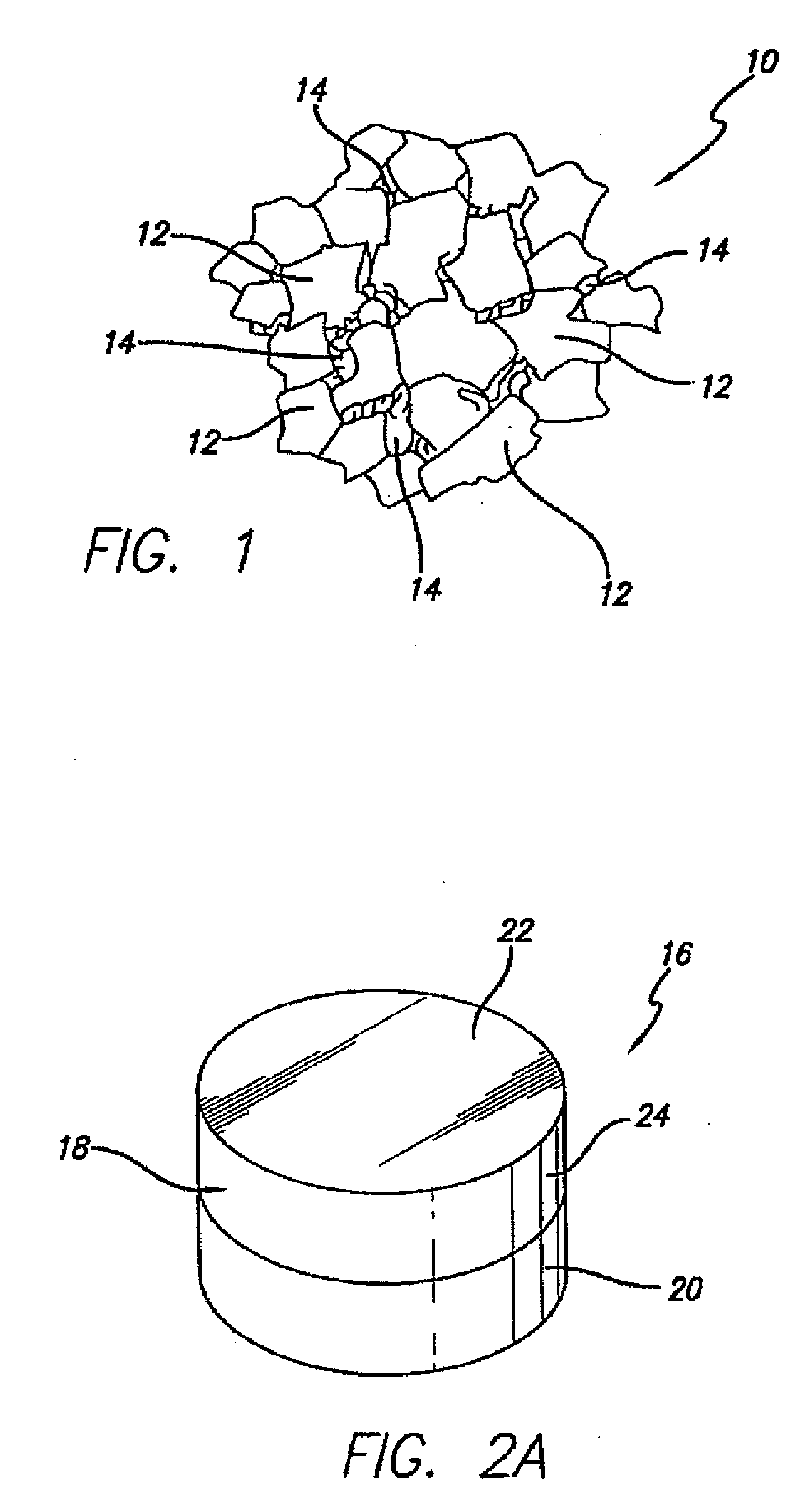

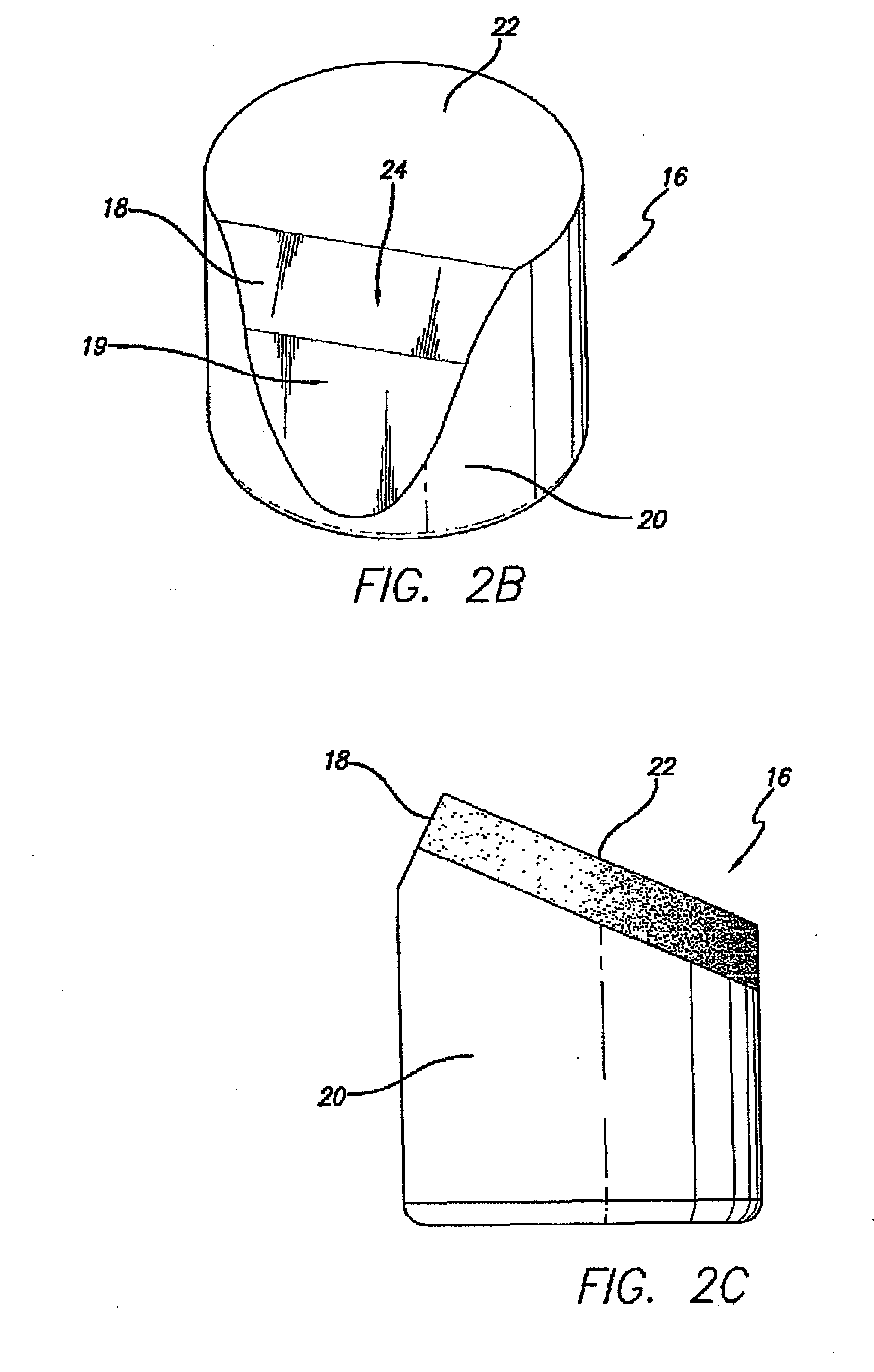

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m2 / g.

Owner:ASPEN AEROGELS INC

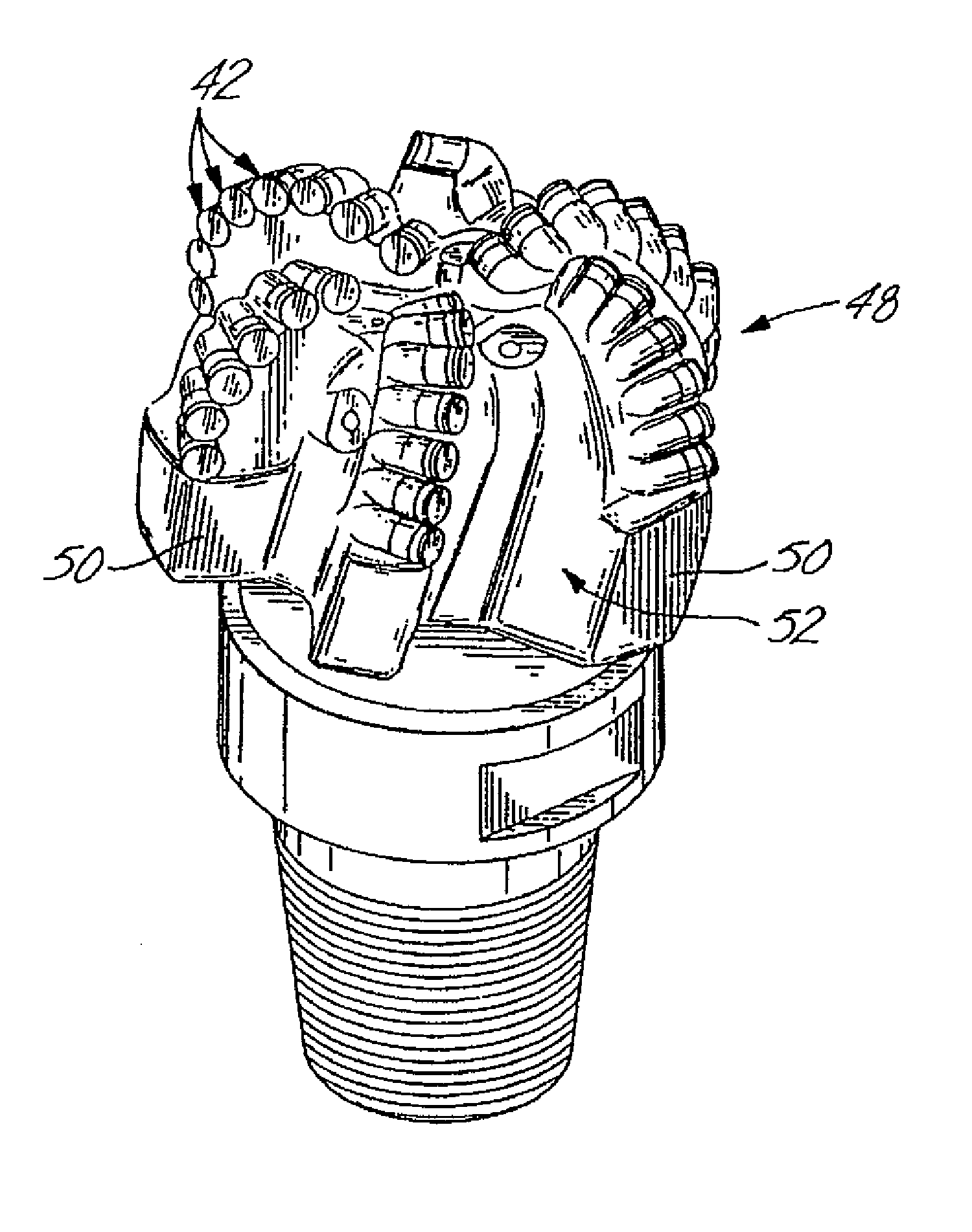

Nano-reinforced wc-co for improved properties

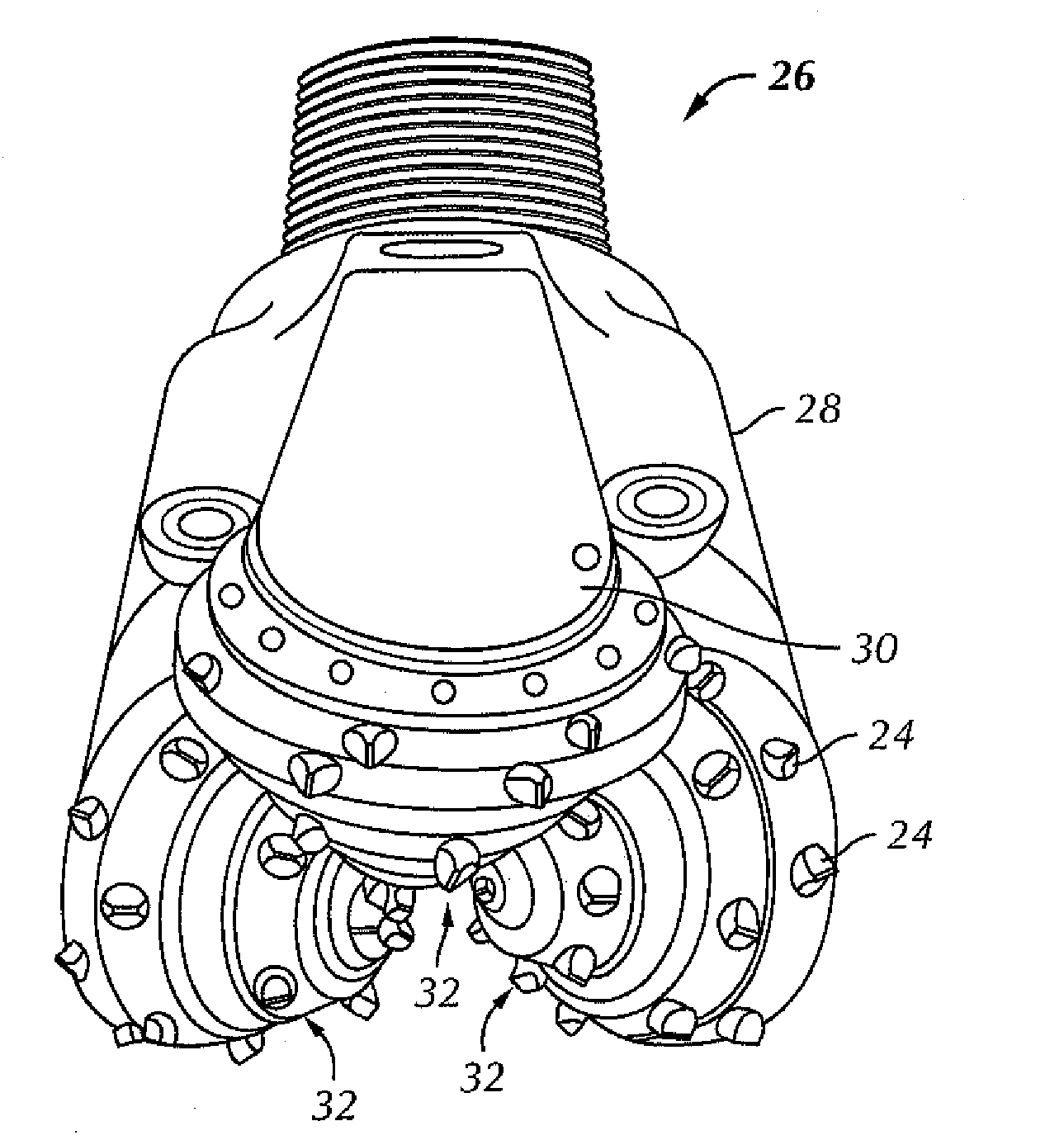

InactiveUS20080179104A1Increase resistanceImprove toughnessMaterial nanotechnologyDrill bitsCarbideNanometre

A drill bit that includes a bit body; and at least one cutting element for engaging the formation disposed on the bit body, the at least one cutting element comprising: a ductile phase; a plurality of carbide particles dispersed in the ductile phase; and a plurality of nanotubes integrated into the cutting element is disclosed.

Owner:SMITH INT INC

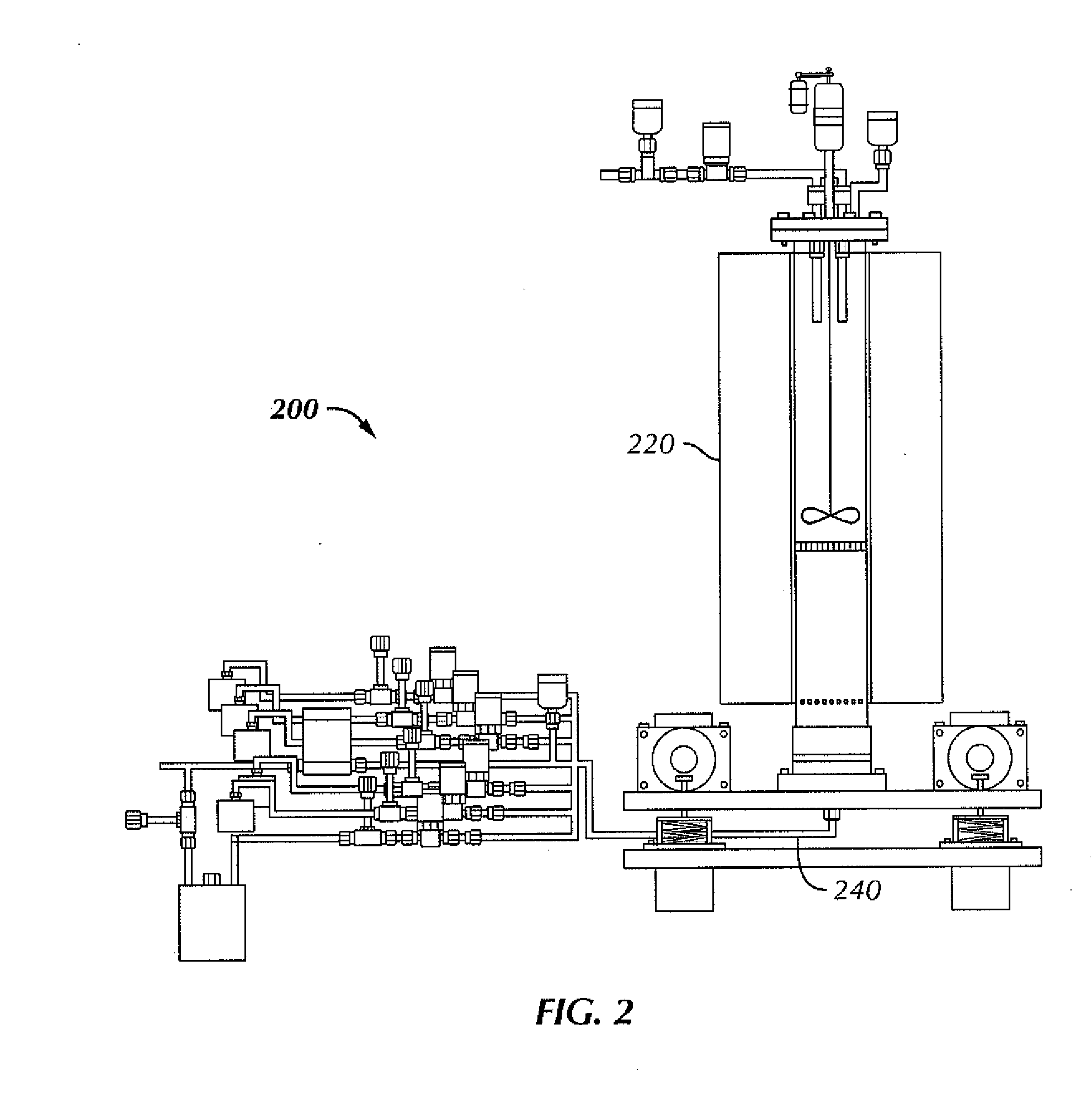

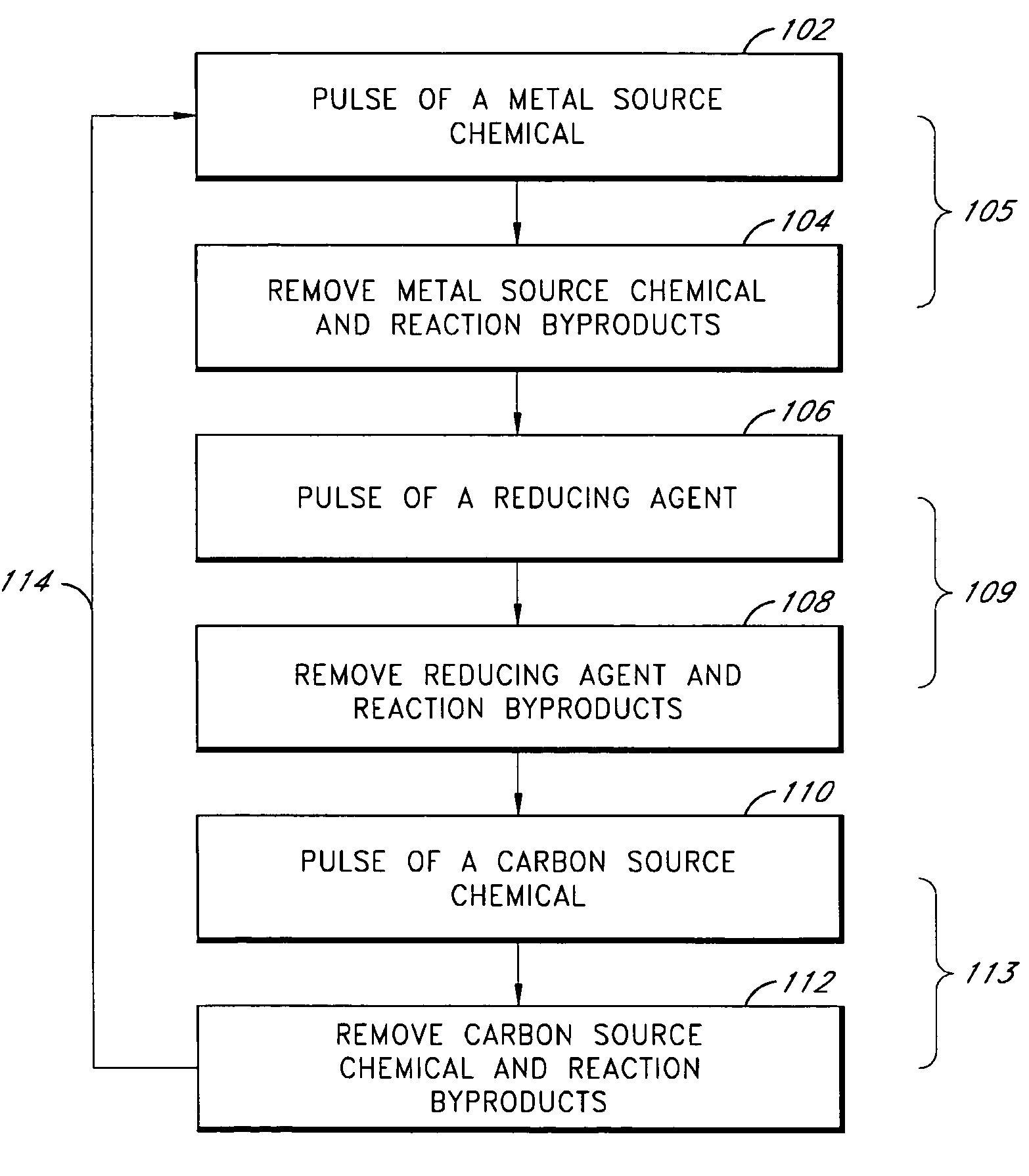

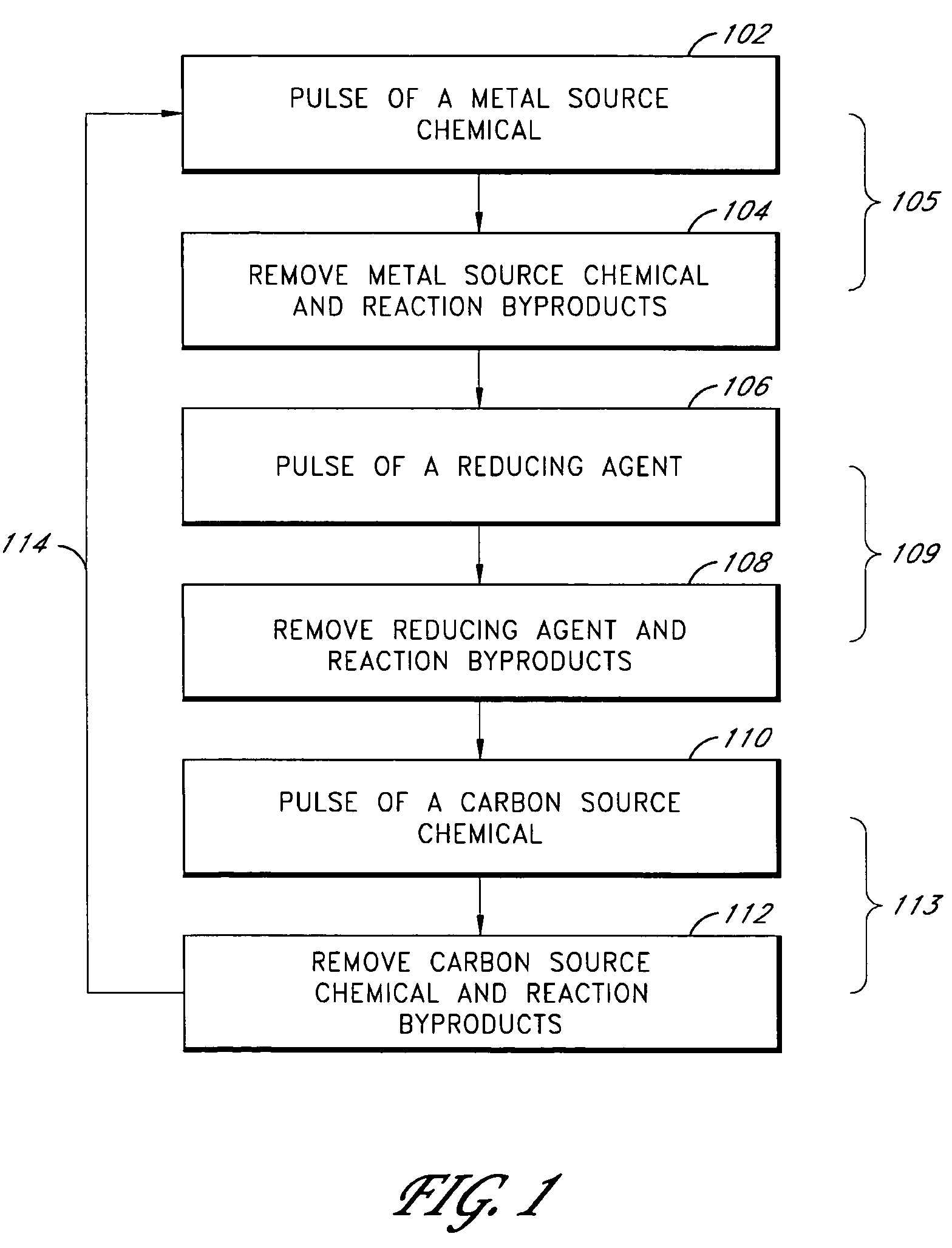

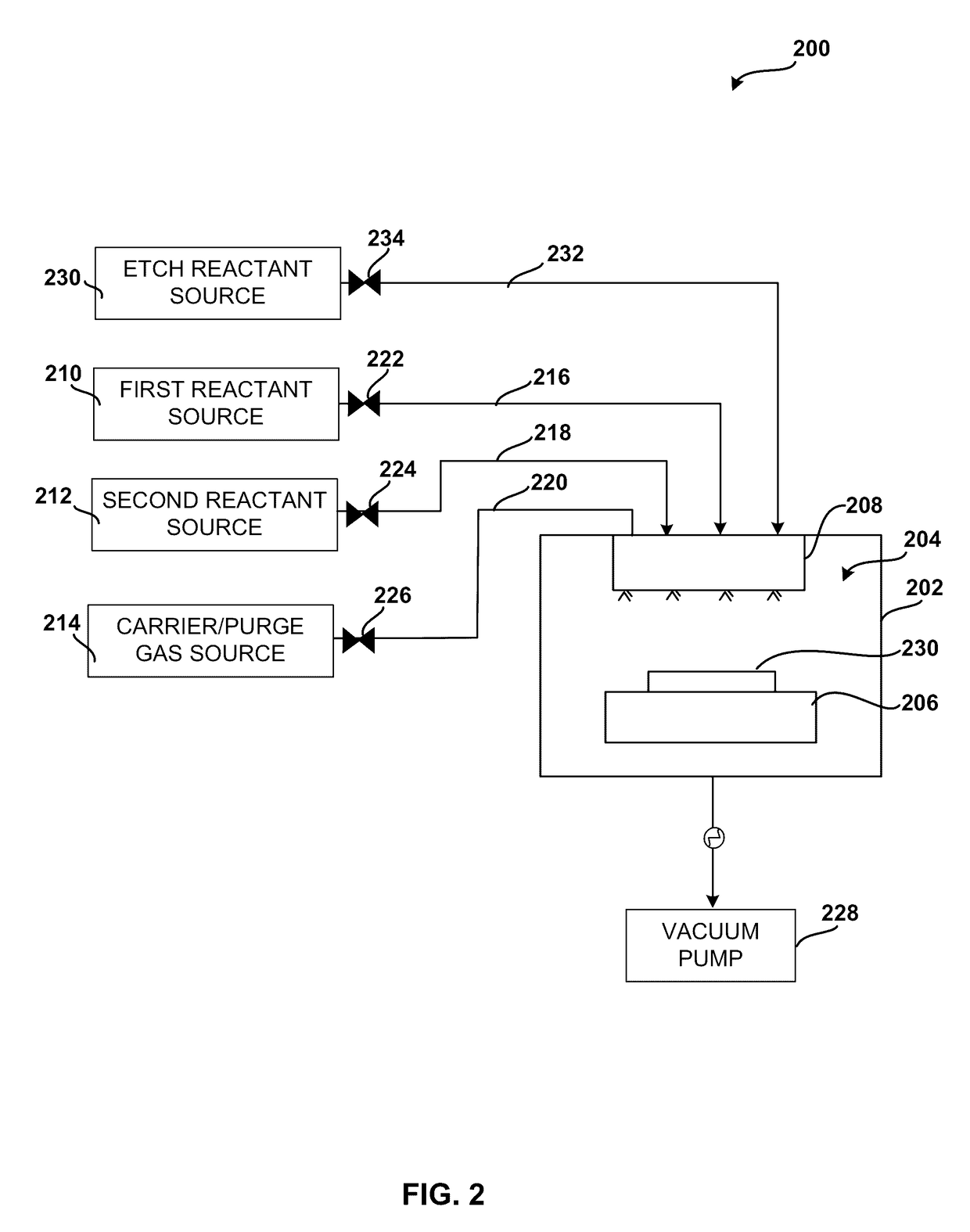

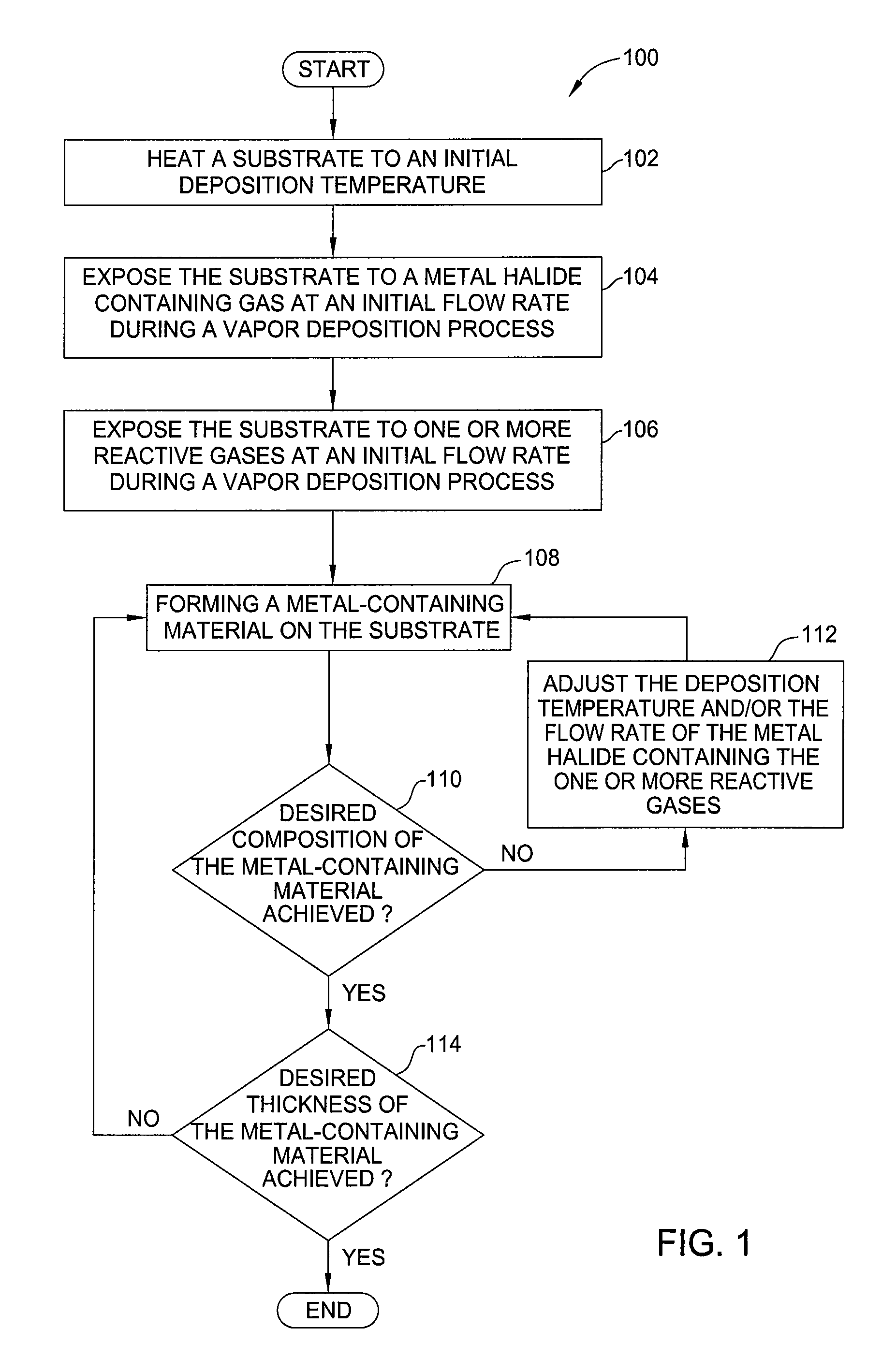

Vapor deposition of metal carbide films

Methods of forming metal carbide thin films are provided. According to preferred embodiments, metal carbide thin films are formed in an atomic layer deposition (ALD) process by alternately and sequentially contacting a substrate in a reaction space with spatially and temporally separated vapor phase pulses of a metal source chemical, a reducing agent and a carbon source chemical. The reducing agent is preferably selected from the group consisting of excited species of hydrogen and silicon-containing compounds.

Owner:ASM IP HLDG BV

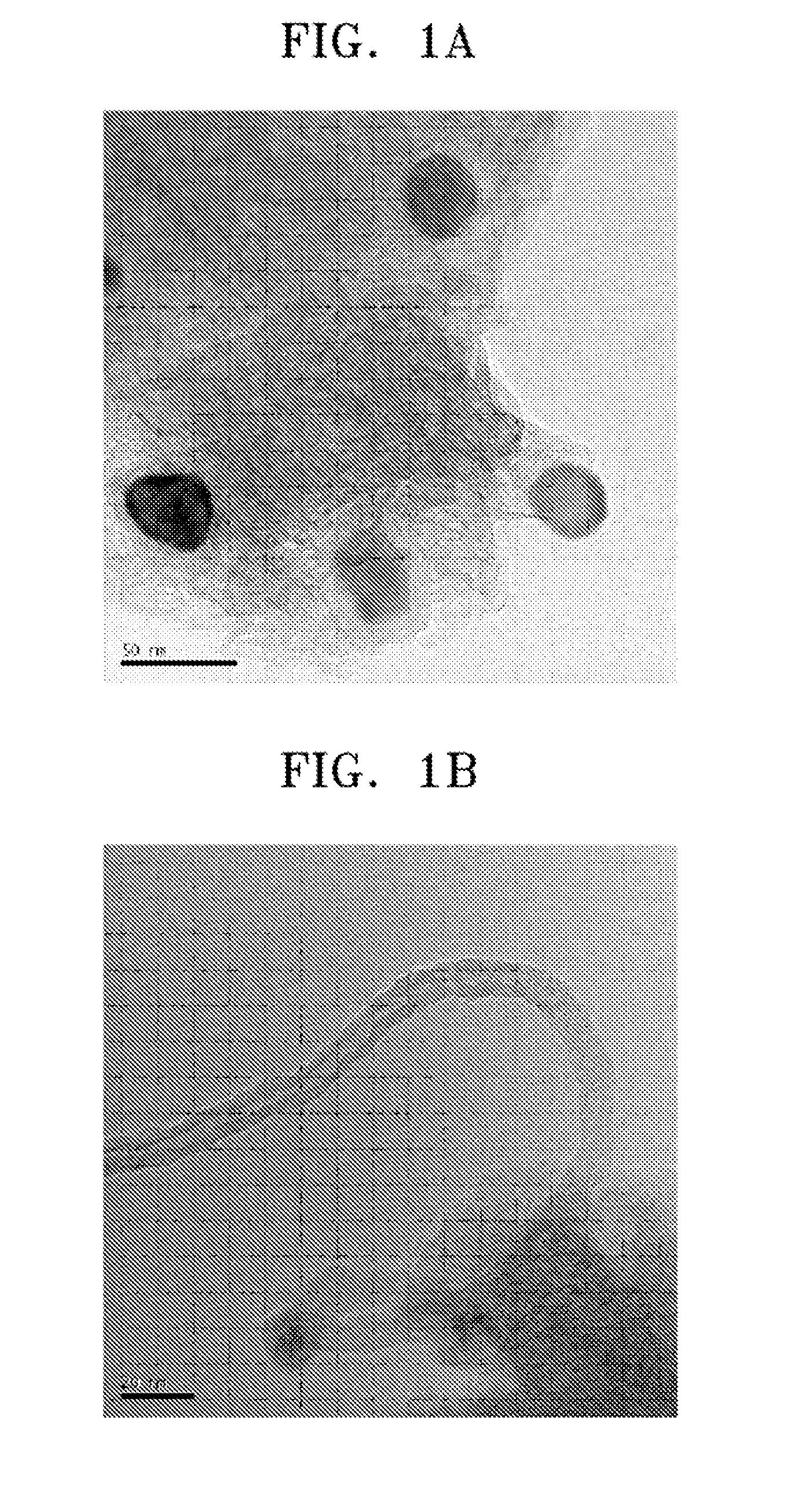

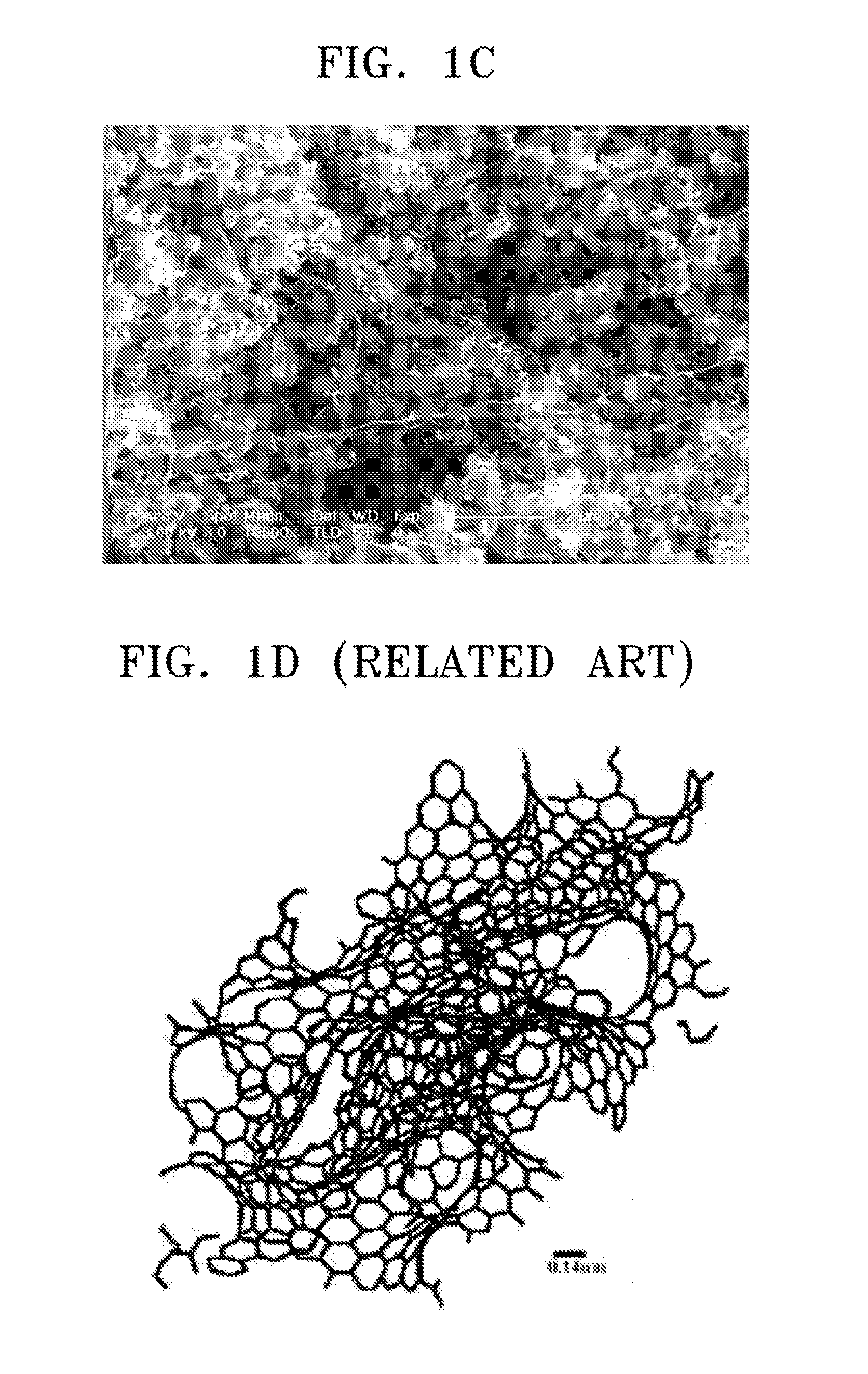

Carbon nanotube hybrid system using carbide-derived carbon, a method of making the same, an electron emitter comprising the same, and an electron emission device comprising the electron emitter

InactiveUS20080248310A1Improve uniformityLong life-timeMaterial nanotechnologyNanostructure manufactureHybrid systemHalogen

A carbon nanotube hybrid system includes: a carbide-derived carbon prepared by reacting a carbide compound and a halogen group containing gas to extract elements of the carbide compound except carbons; metals supported on the carbide-derived carbon or remaining in the carbide-derived carbon; and carbon sources from which carbon nanotubes are grown from the carbide-derived carbon. A method of preparing the carbon nanotube hybrid system includes preparing the carbide-derived carbon, extracting elements therefrom, and growing carbon nanotubes from the carbide-derived carbon. The carbon nanotube hybrid system has excellent uniformity and a long lifetime. An electron emitter having improved electron emitting properties can be inexpensively prepared using the carbon nanotube hybrid system compared to conventional carbon nanotubes. An electron emission device having excellent electron emitting properties can be prepared using the electron emitter.

Owner:SAMSUNG SDI CO LTD

Metal nitride carbide deposition by ALD

InactiveUS7410666B2Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

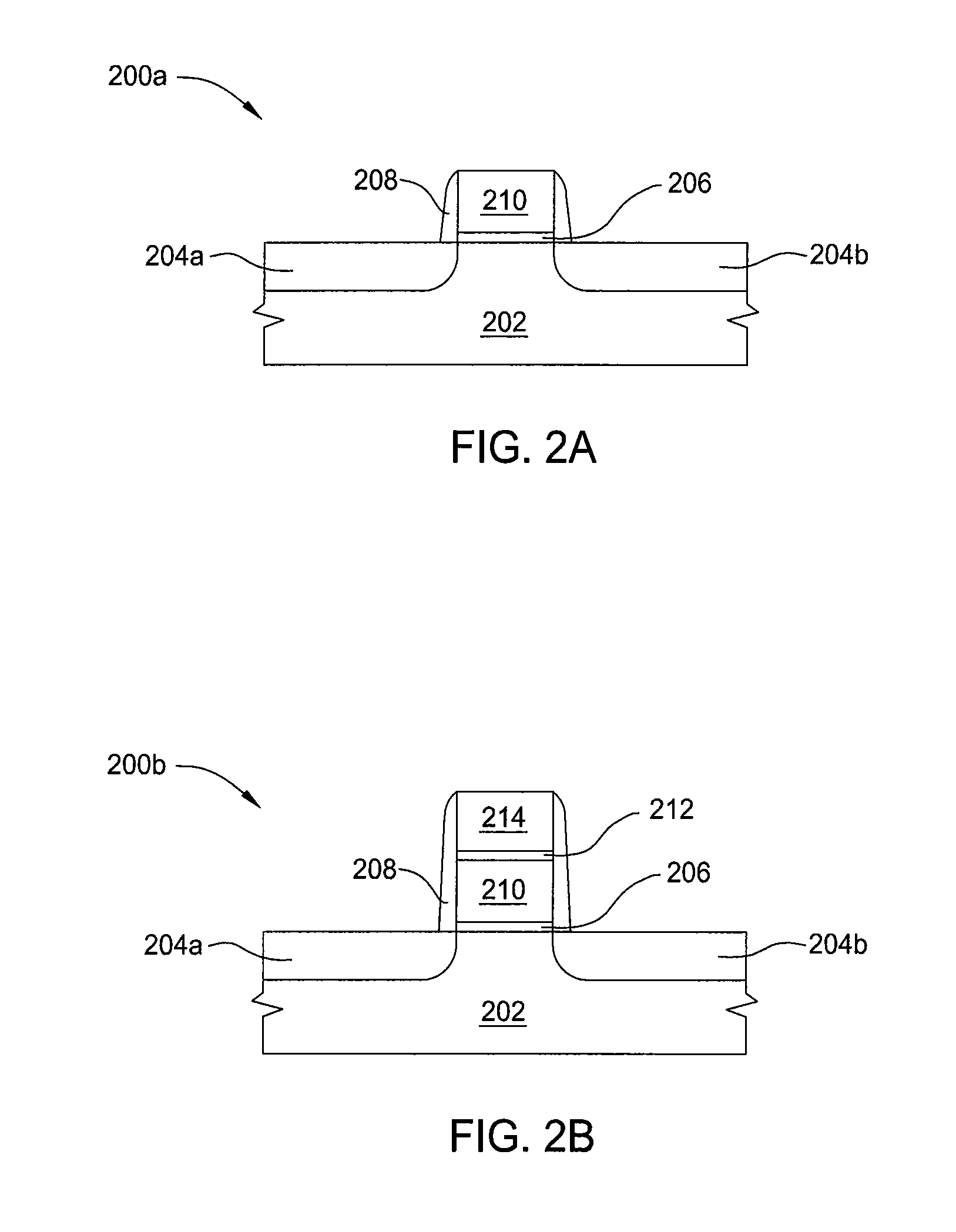

Method of forming a metal carbide or metal carbonitride film having improved adhesion

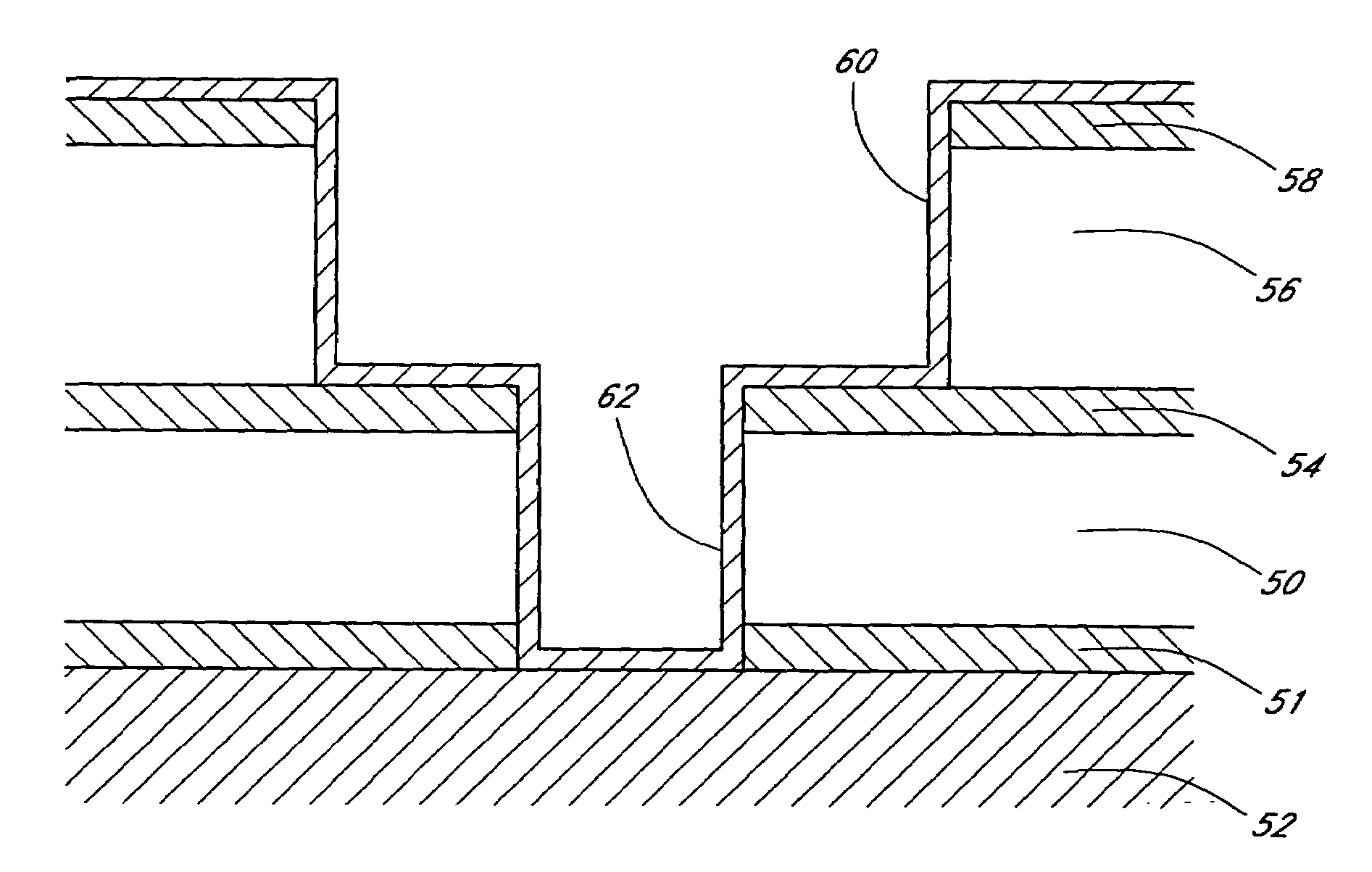

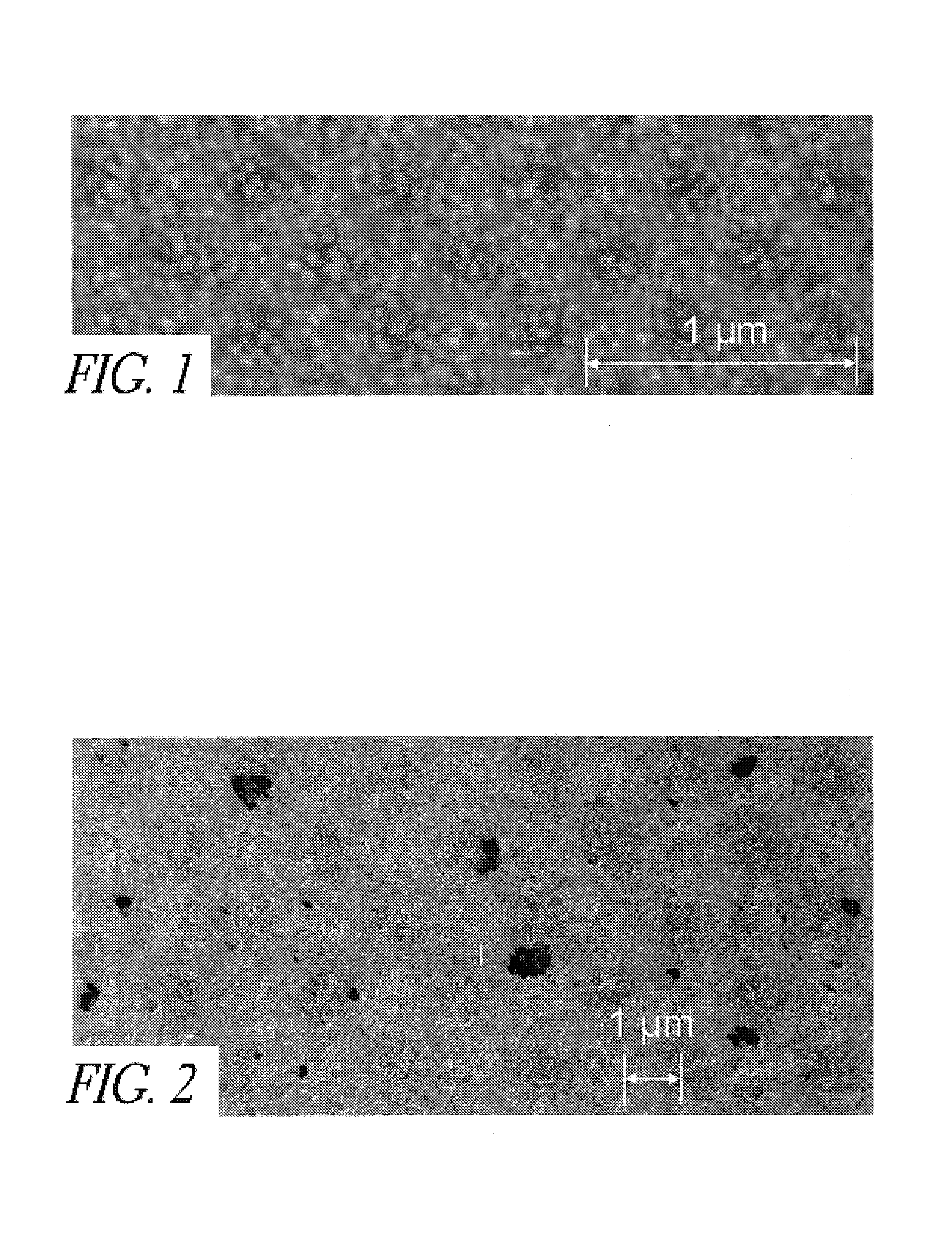

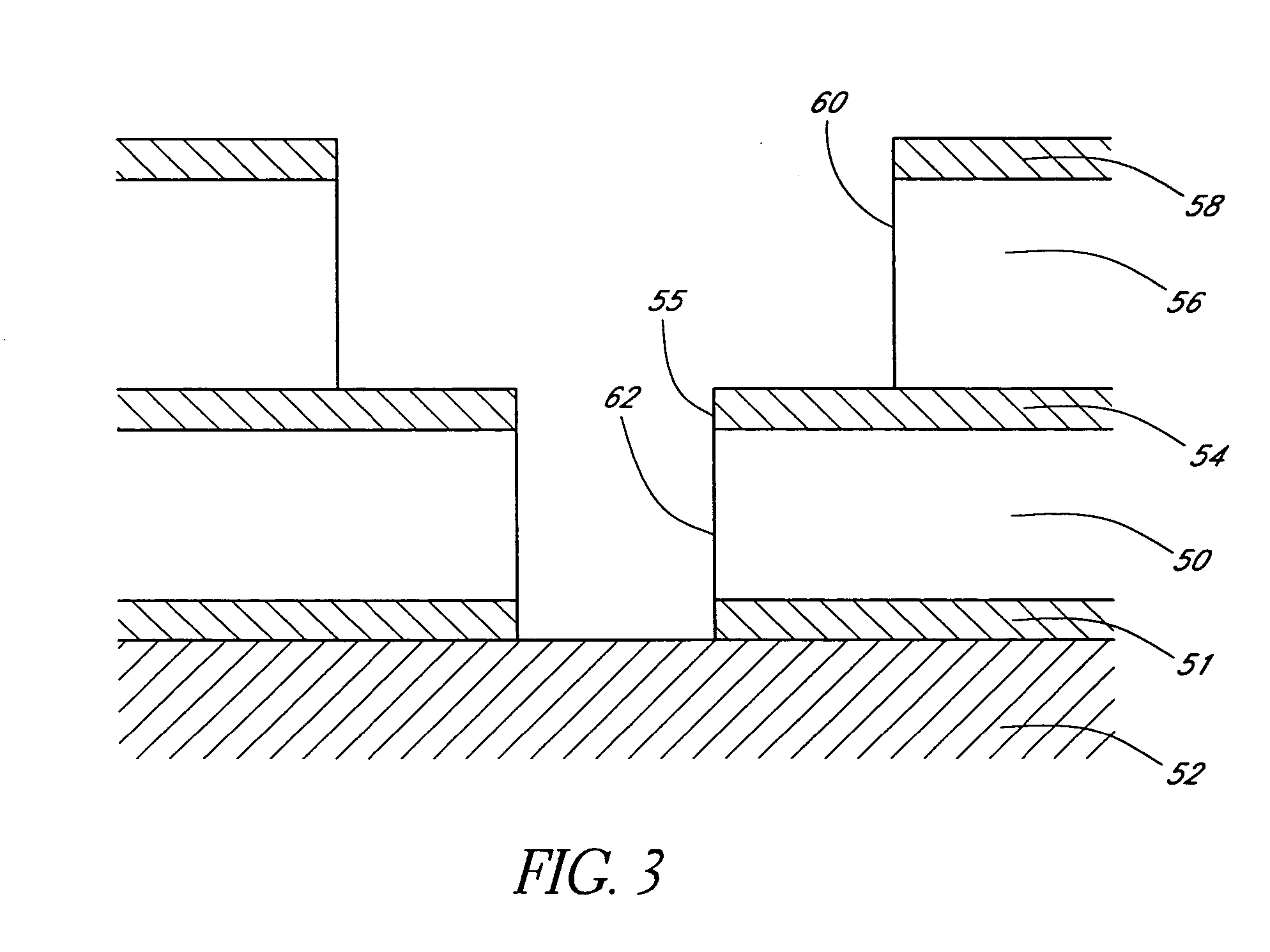

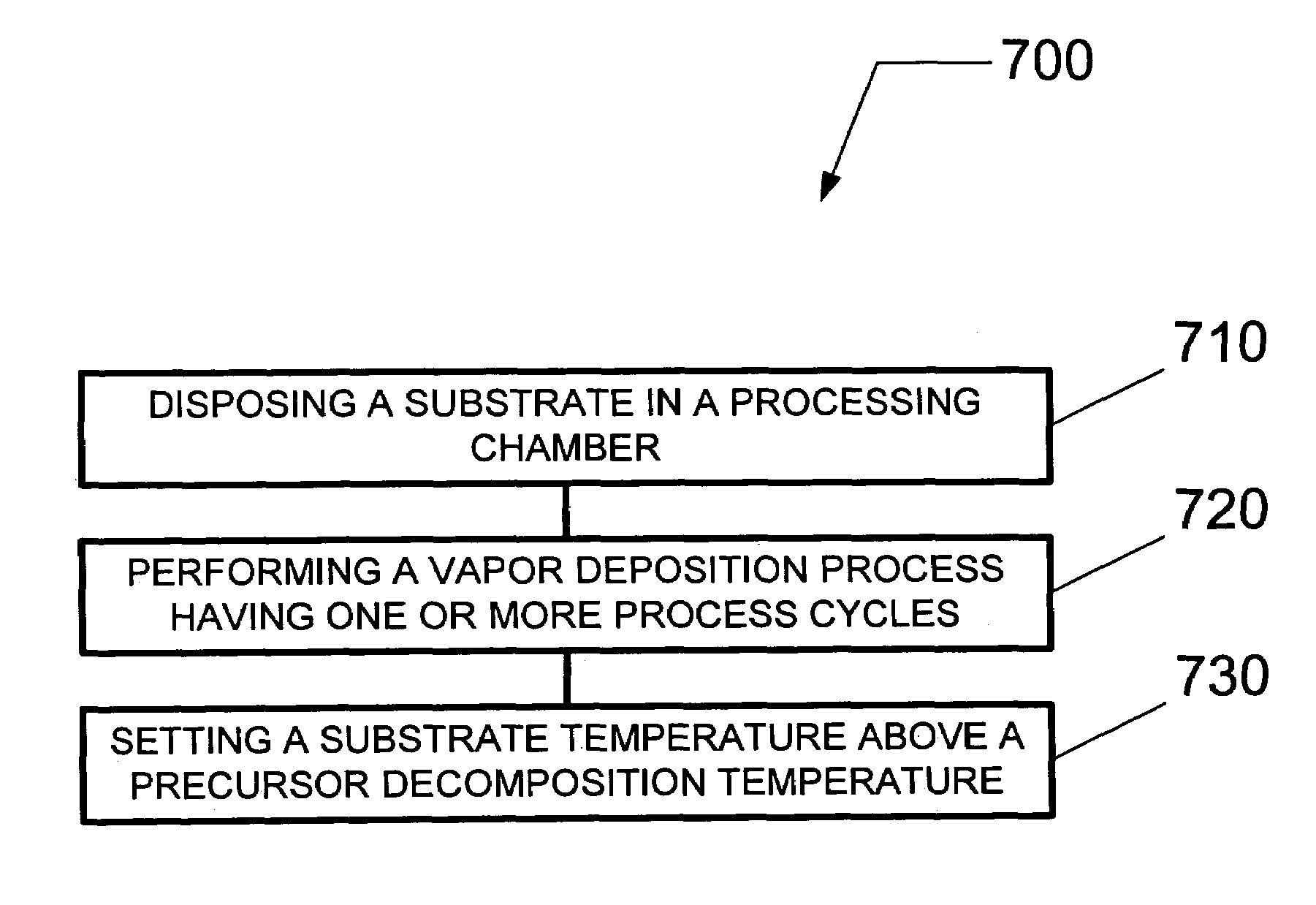

InactiveUS7645484B2Improve adhesionFacilitate depositionChemical vapor deposition coatingPlasma techniqueGas phaseDecomposition

A method for forming a metal carbide or metal carbonitride film on a substrate using a vapor deposition process. The method includes comprises introducing a first process material, such as a film precursor, to the substrate followed by introducing a second process material, such as a film reducing agent, to the substrate, whereby plasma can be formed during the introduction of the second process material in order to assist reduction of the first process material on the substrate. Additionally, the temperature of the substrate is elevated to a value approximately equal to or greater than the decomposition temperature of the first process material in order to improve adhesion properties for the metal carbide or metal carbonitride film.

Owner:TOKYO ELECTRON LTD

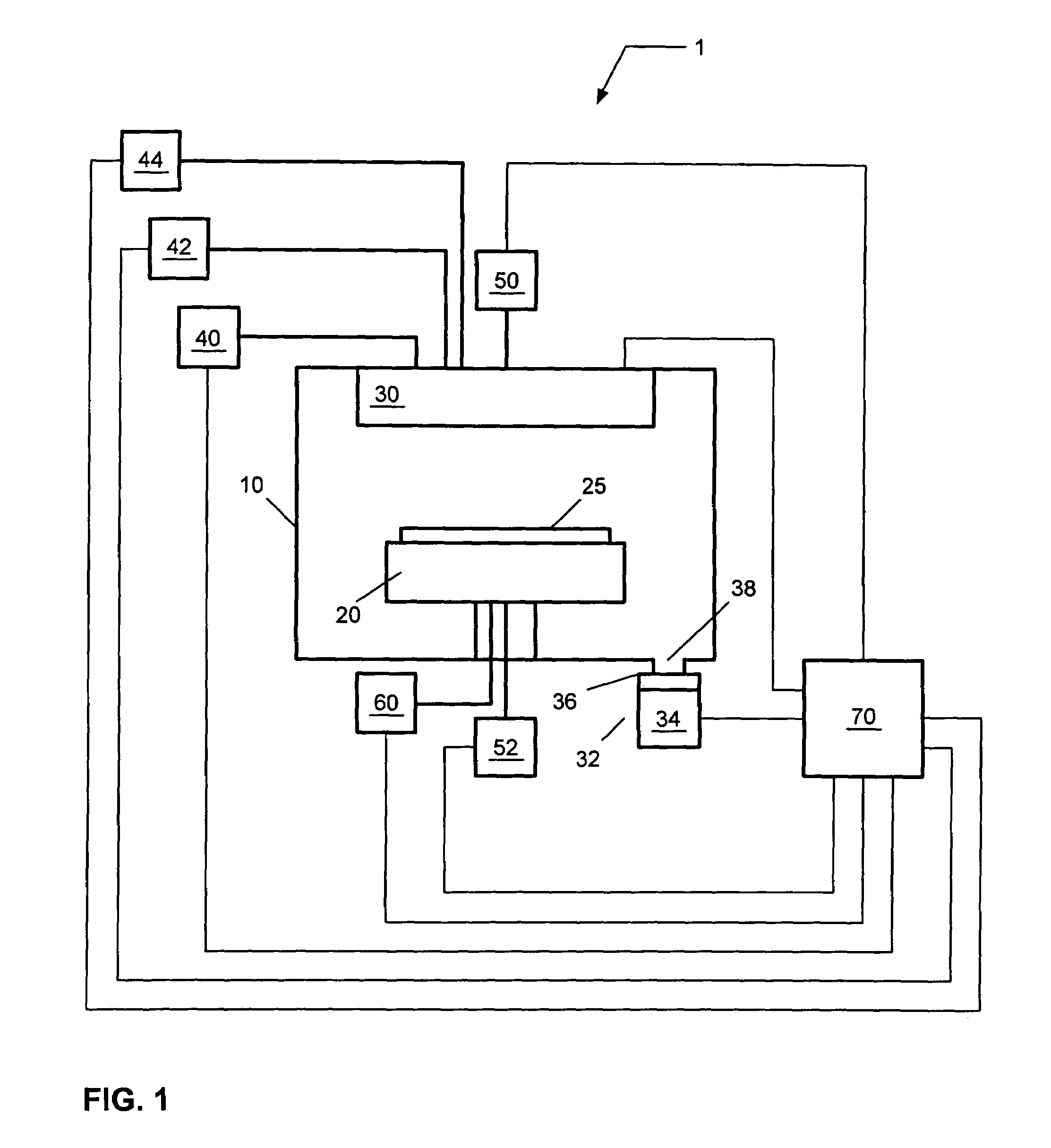

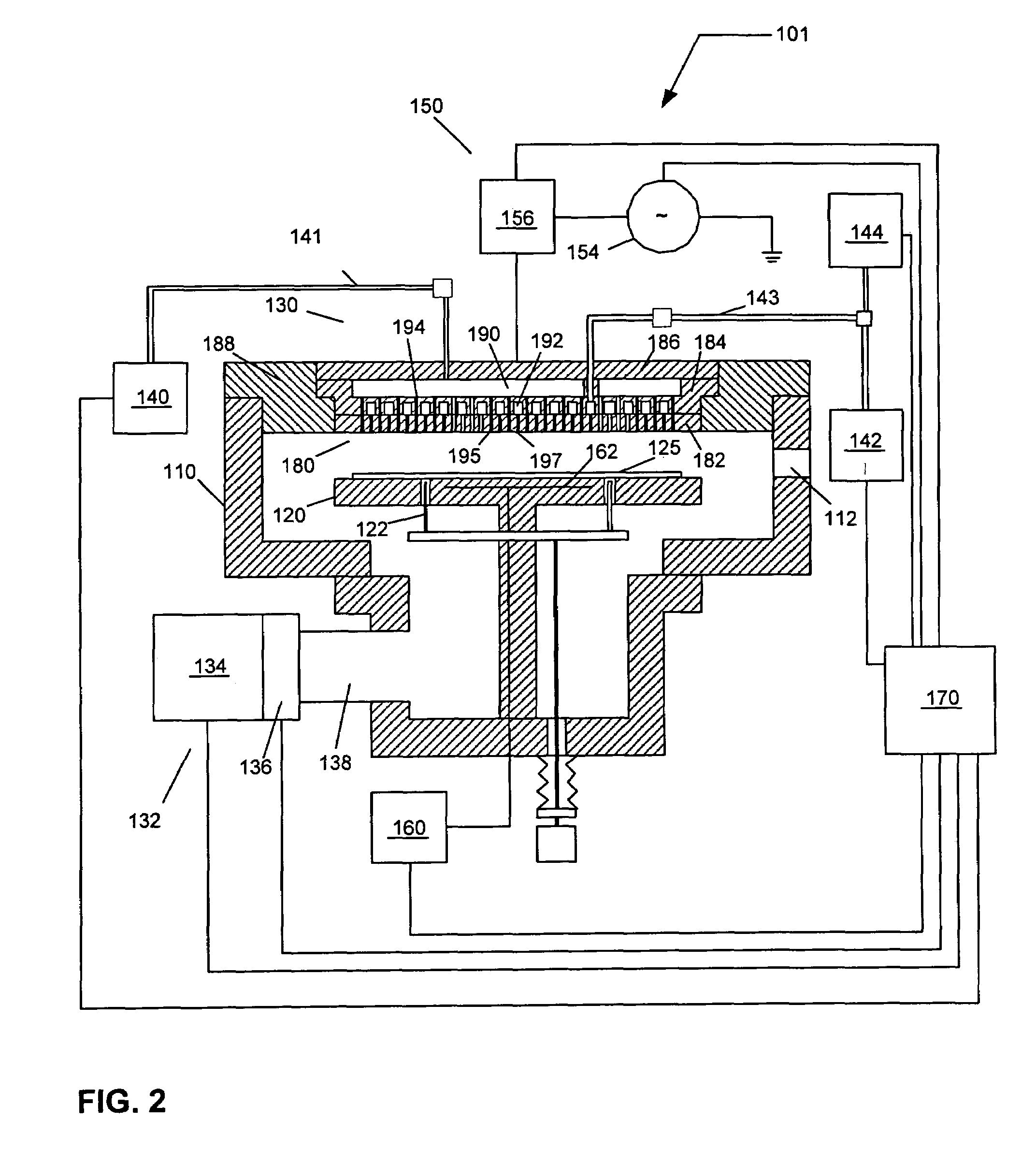

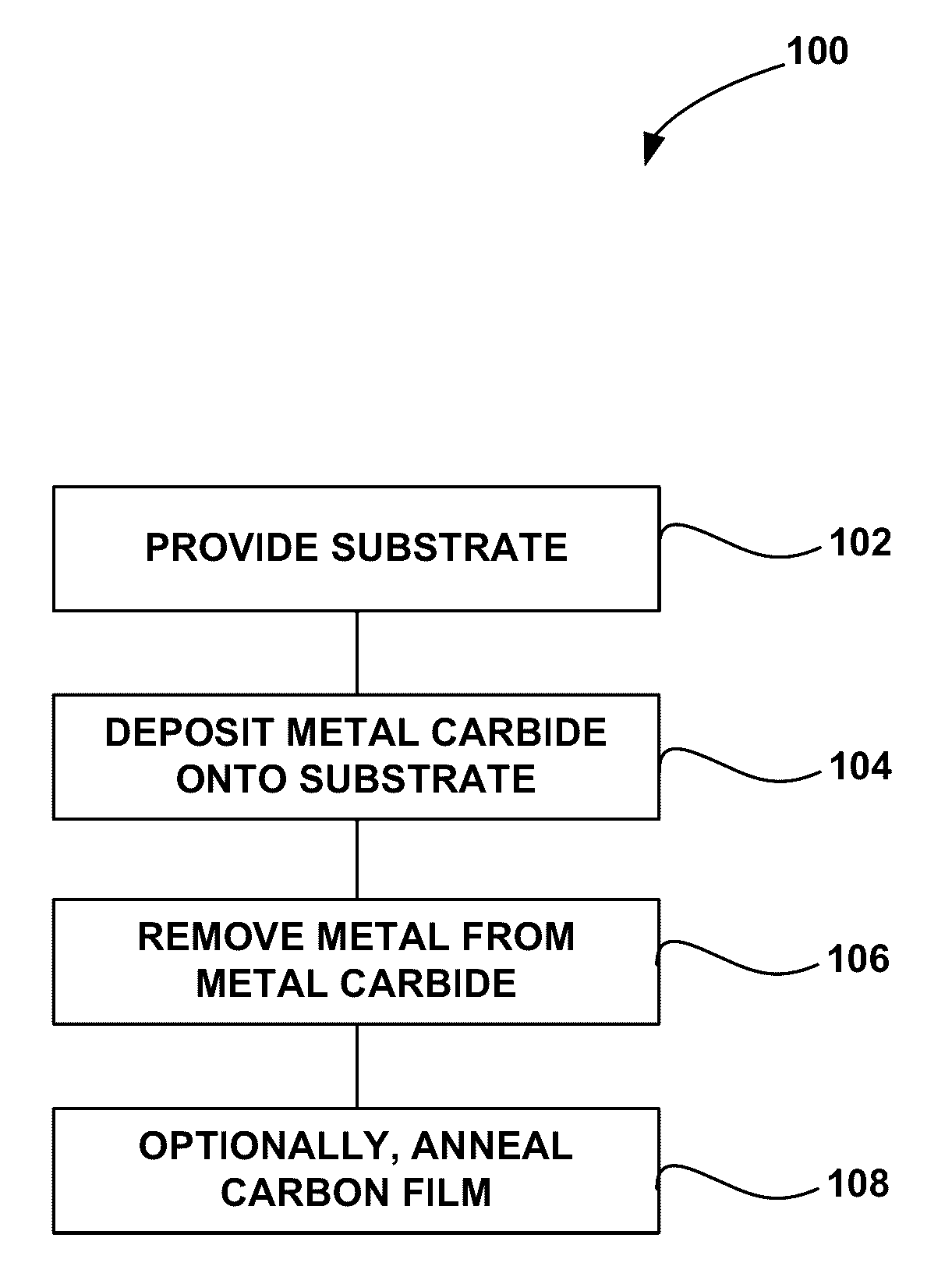

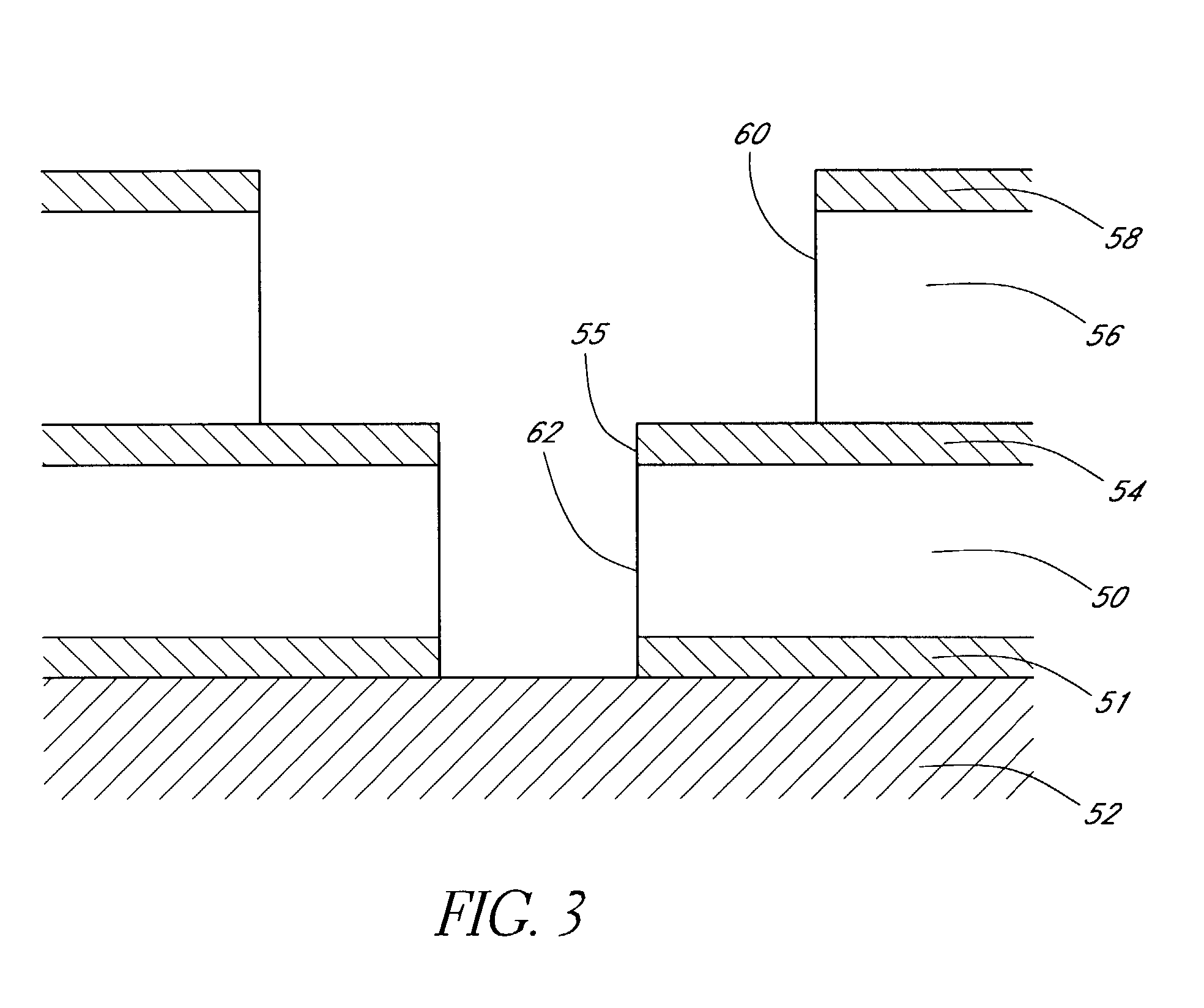

Method for forming conformal carbon films, structures conformal carbon film, and system of forming same

Methods of forming carbon films, structures and devices including the carbon films, and systems for forming the carbon films are disclosed. A method includes depositing a metal carbide film using atomic layer deposition (ALD). Metal from the metal carbide film is removed from the metal carbide film to form a carbon film. Because the films are formed using ALD, the films can be relatively conformal and can have relatively uniform thickness over the surface of a substrate.

Owner:ASM IP HLDG BV

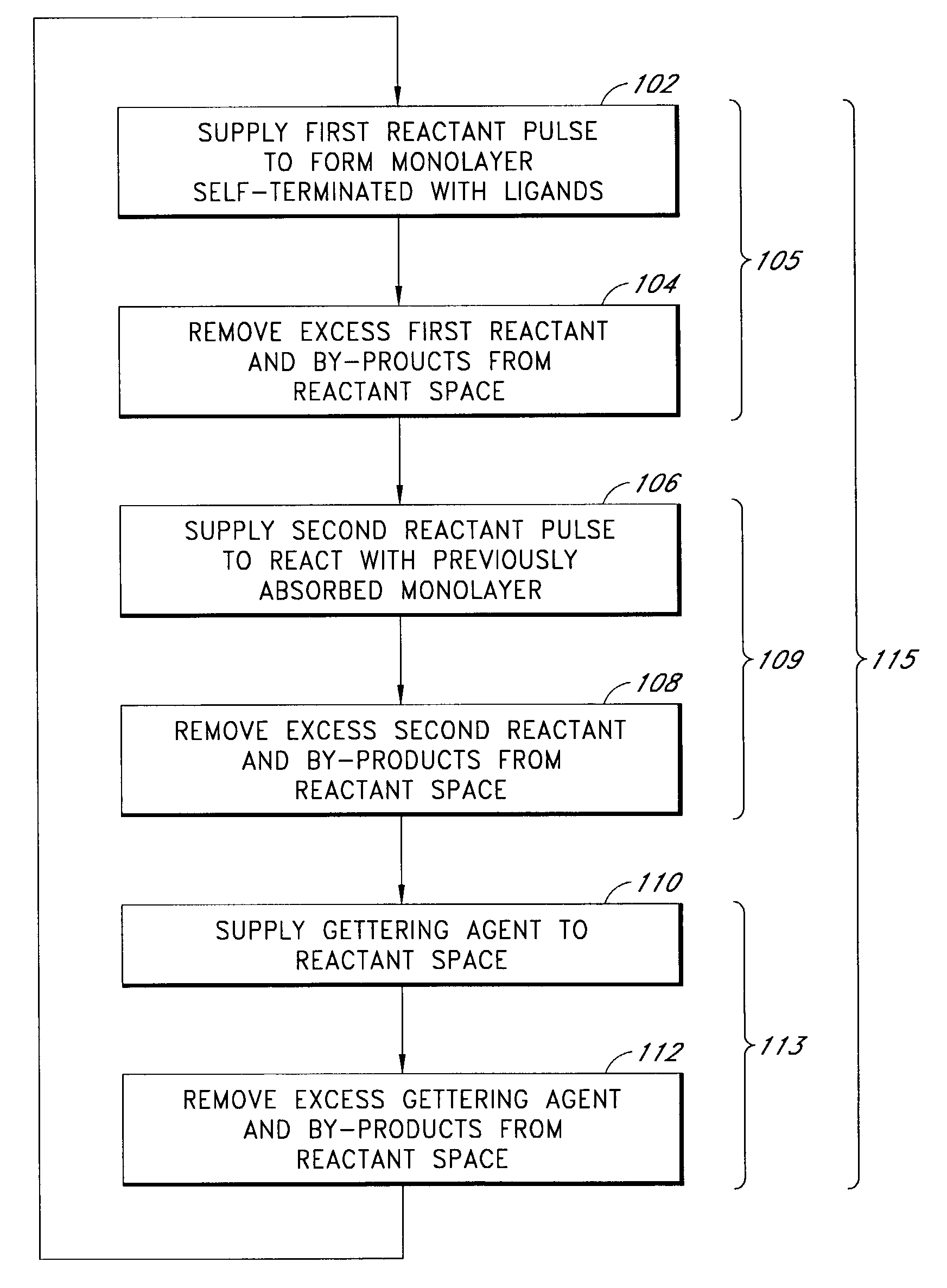

Metal nitride deposition by ALD with reduction pulse

The present methods provide tools for growing conformal metal thin films, including metal nitride, metal carbide and metal nitride carbide thin films. In particular, methods are provided for growing such films from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide, transition metal nitride and transition metal nitride carbide thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures incorporating metallic thin films, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

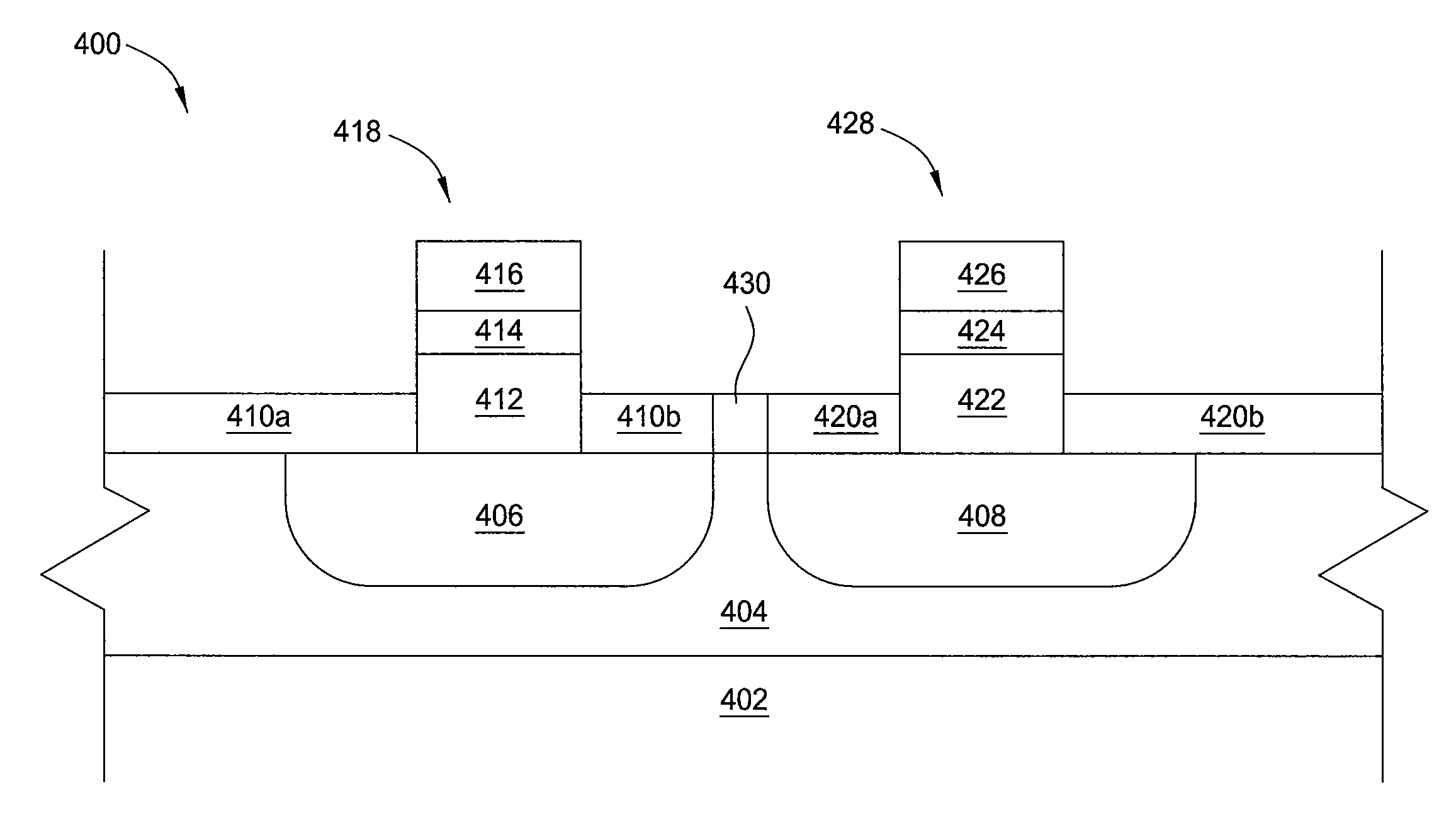

Nmos metal gate materials, manufacturing methods, and equipment using CVD and ald processes with metal based precursors

ActiveUS20110263115A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseMetallic materials

Embodiments of the invention generally provide methods for depositing metal-containing materials and compositions thereof. The methods include deposition processes that form metal, metal carbide, metal silicide, metal nitride, and metal carbide derivatives by a vapor deposition process, including thermal decomposition, CVD, pulsed-CVD, or ALD. In one embodiment, a method for processing a substrate is provided which includes depositing a dielectric material having a dielectric constant greater than 10, forming a feature definition in the dielectric material, depositing a work function material conformally on the sidewalls and bottom of the feature definition, and depositing a metal gate fill material on the work function material to fill the feature definition, wherein the work function material is deposited by reacting at least one metal-halide precursor having the formula MXY, wherein M is tantalum, hafnium, titanium, and lanthanum, X is a halide selected from the group of fluorine, chlorine, bromine, or iodine, and y is from 3 to 5.

Owner:APPLIED MATERIALS INC

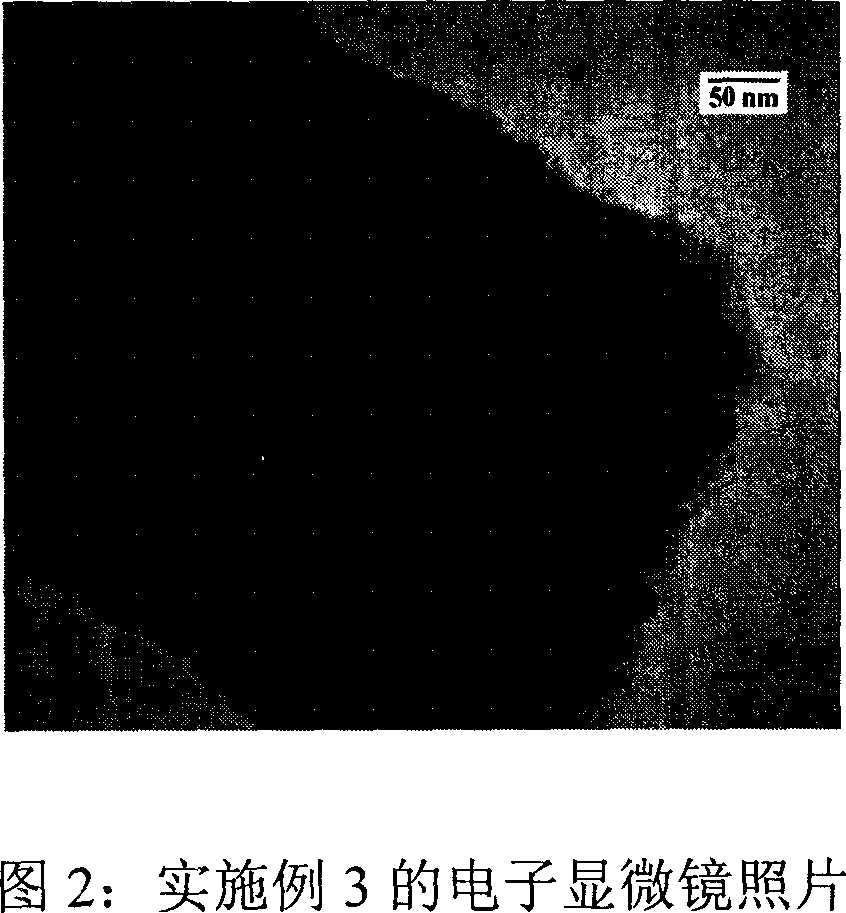

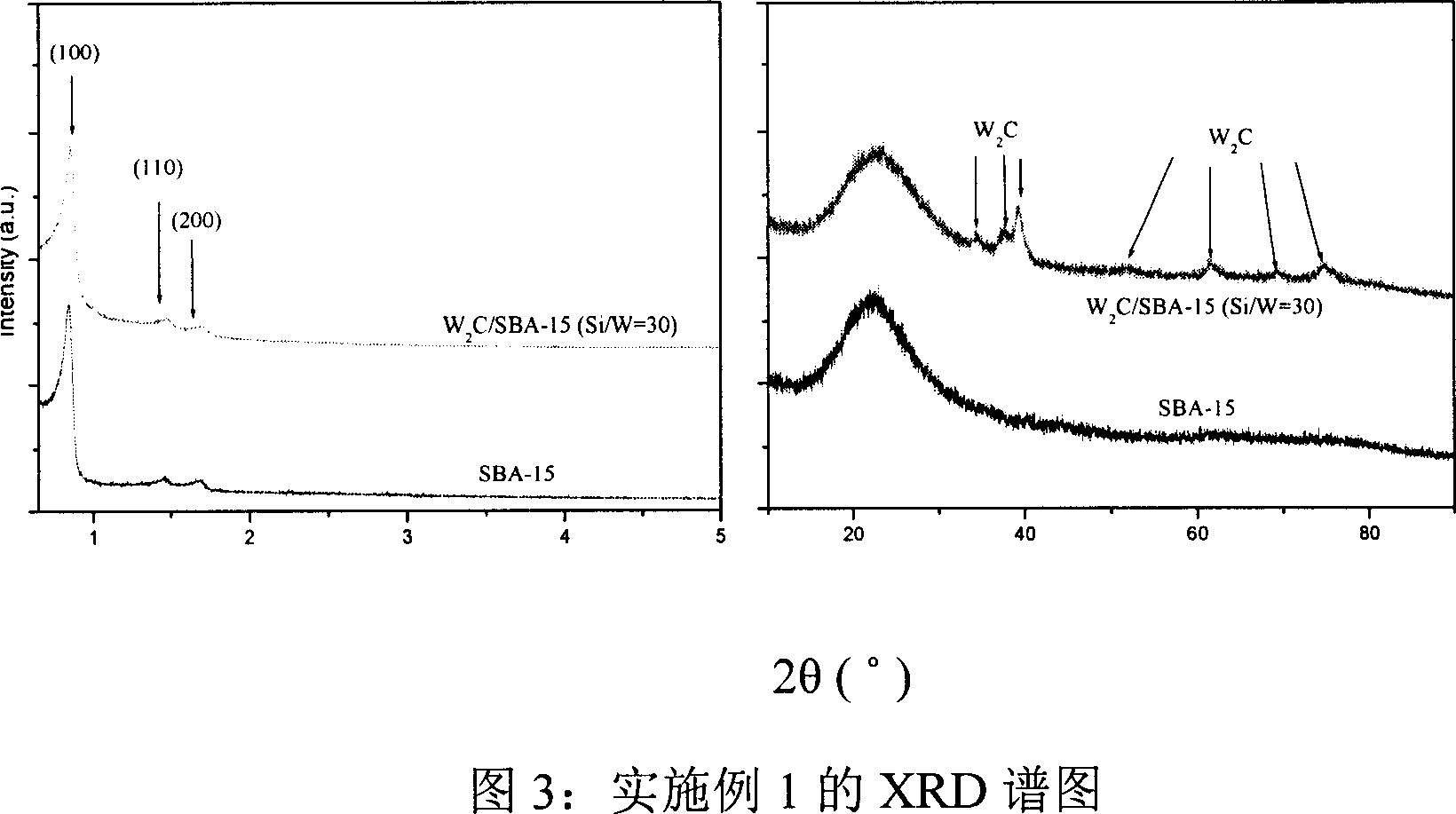

Porous molecular-sieve catalyst for assembling carbide and its preparation

InactiveCN1895777AImprove performanceImprove stabilityMolecular sieve catalystsMolecular sieveActive component

A meso-porous molecular sieve catalyst with carbide features that the carbide particles are assembled in the pores of meso-porous molecular sieve, resulting in high isolation and dispersion of active component particles and in turn high stability and activity.

Owner:BEIJING UNIV OF CHEM TECH

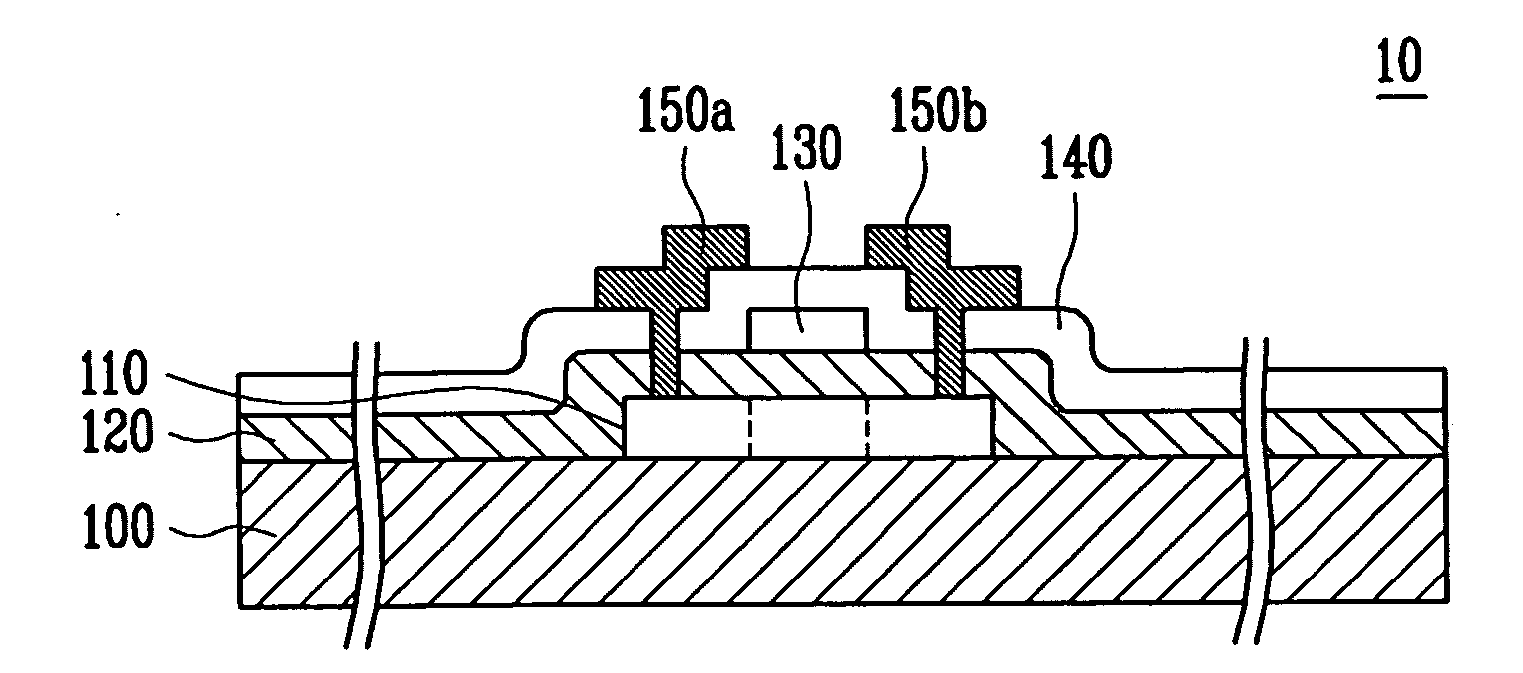

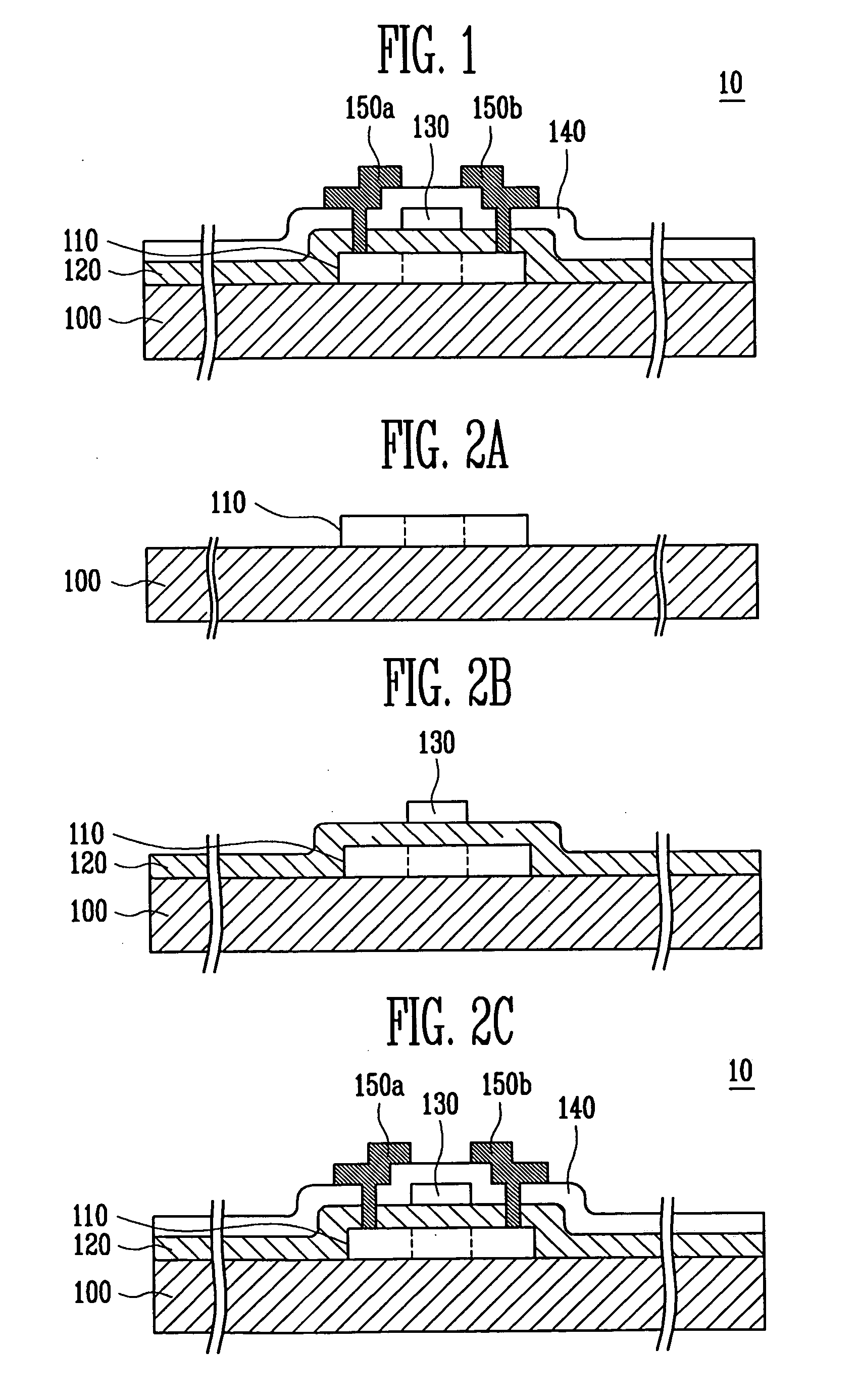

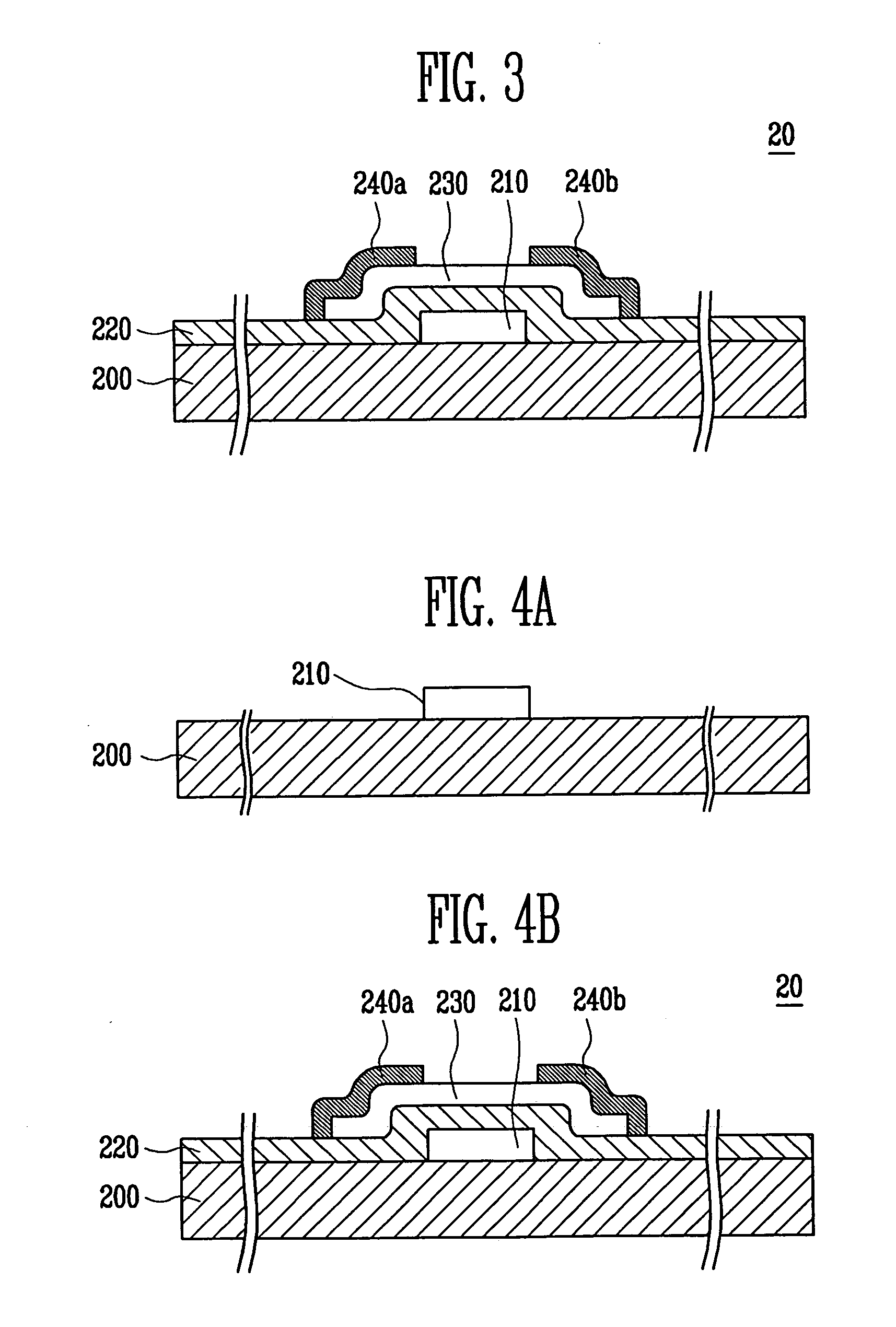

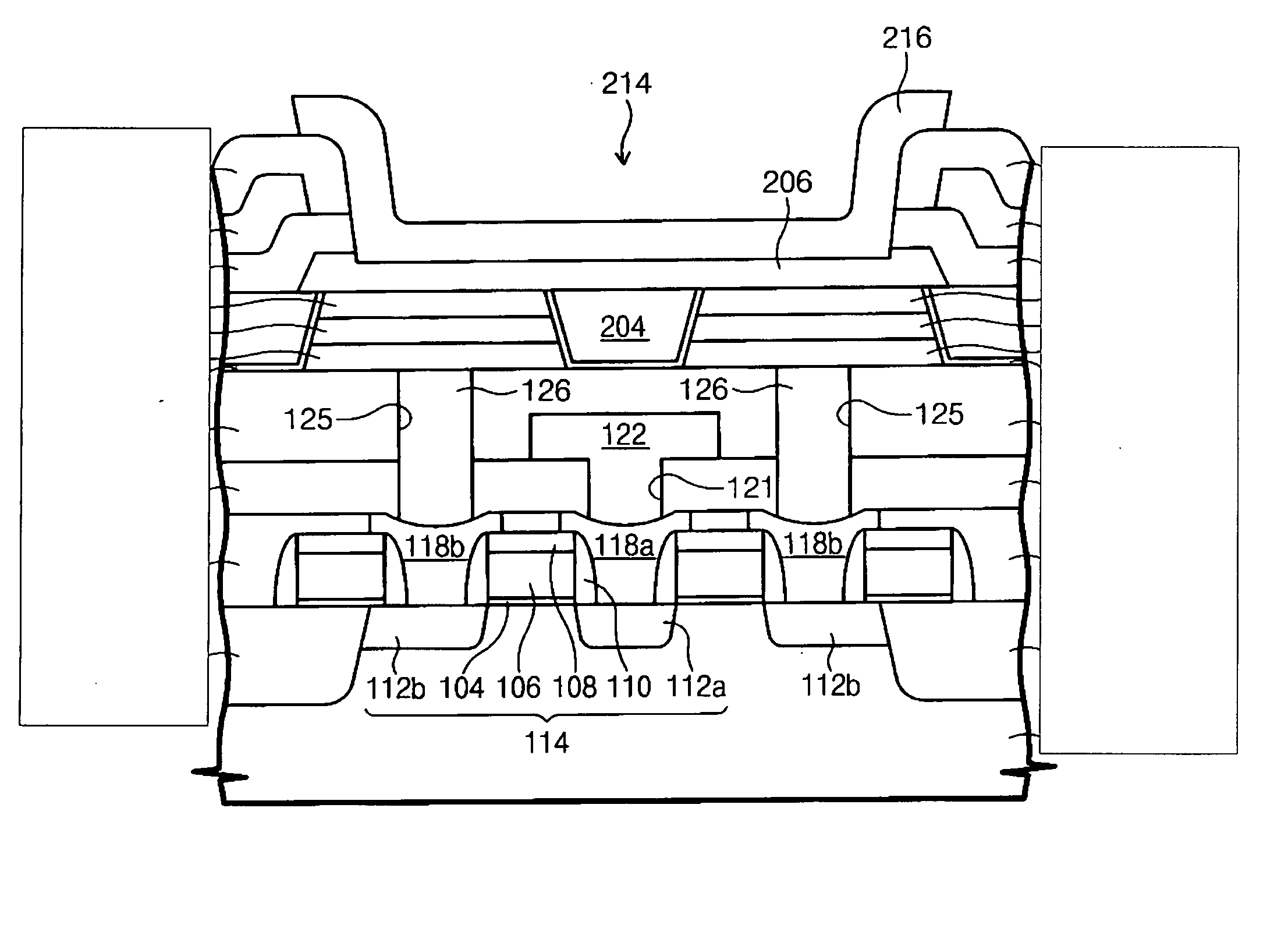

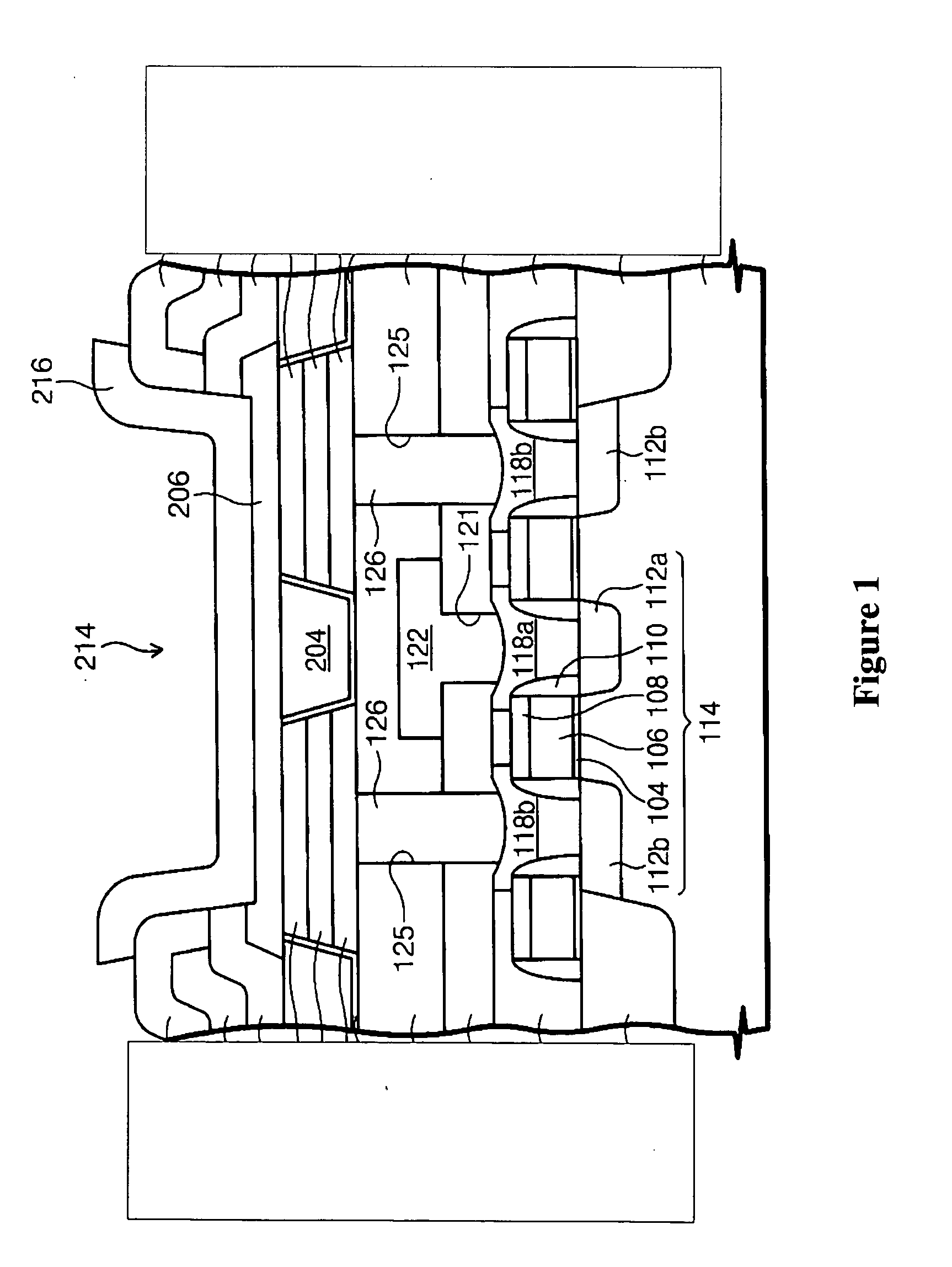

Transparent thin film transistor (TFT) and its method of manufacture

InactiveUS20070057261A1Increase the aperture ratioIncrease display resolutionNon-linear opticsSemiconductor devicesCarbideNitride

A transparent thin film transistor (TFT) and its method of manufacture includes: a substrate, a transparent semiconductor layer formed by coating the substrate with an oxide, a nitride, or a carbide to pattern the material, a gate insulating layer formed on the transparent semiconductor layer, a gate electrode formed on the gate insulating layer to correspond to the transparent semiconductor layer, an interlayer insulating layer formed on the gate electrode, and source and drain electrodes electrically connected to the transparent semiconductor layer through contact holes formed in the interlayer insulating layer and the gate insulating layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

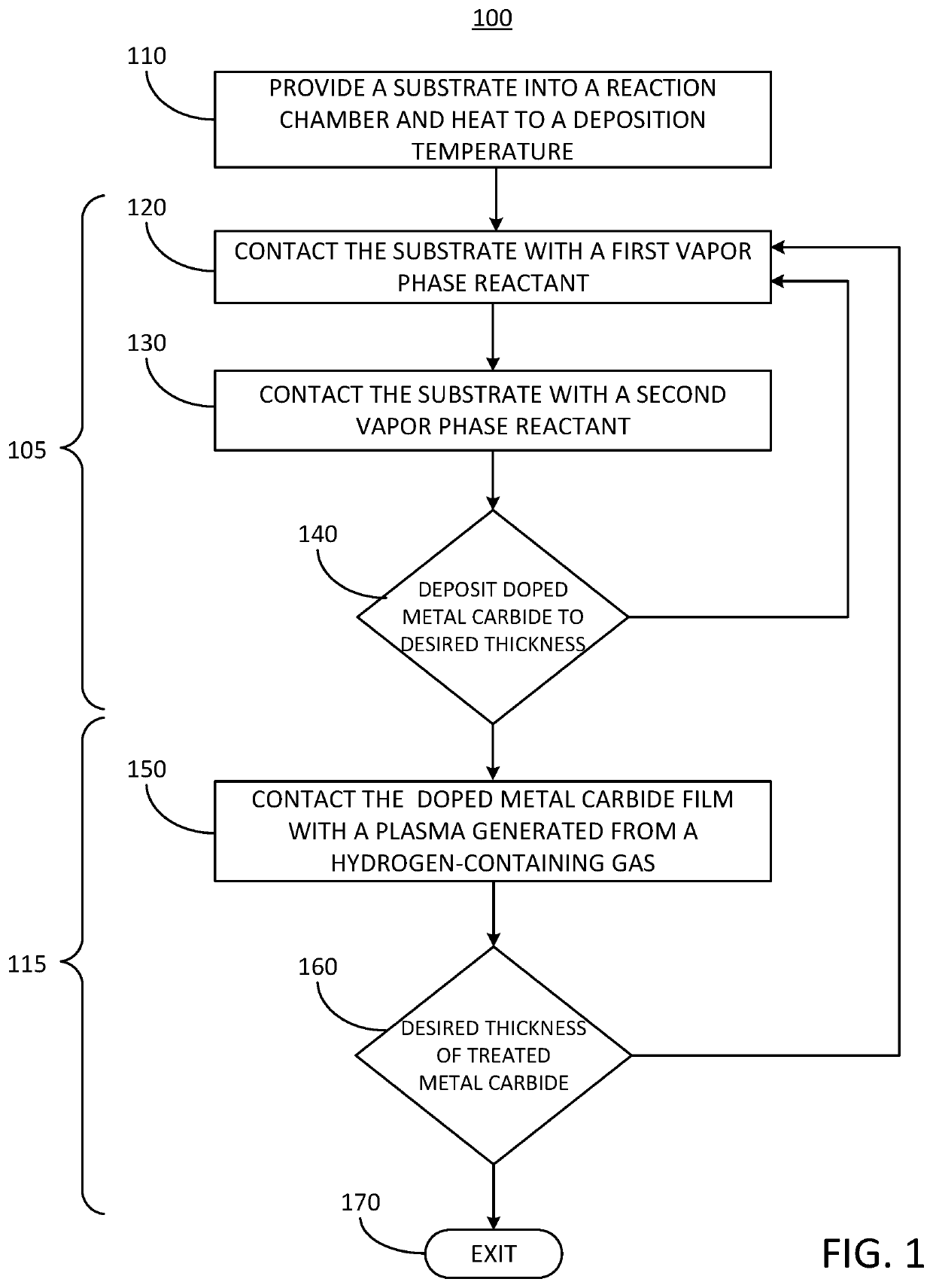

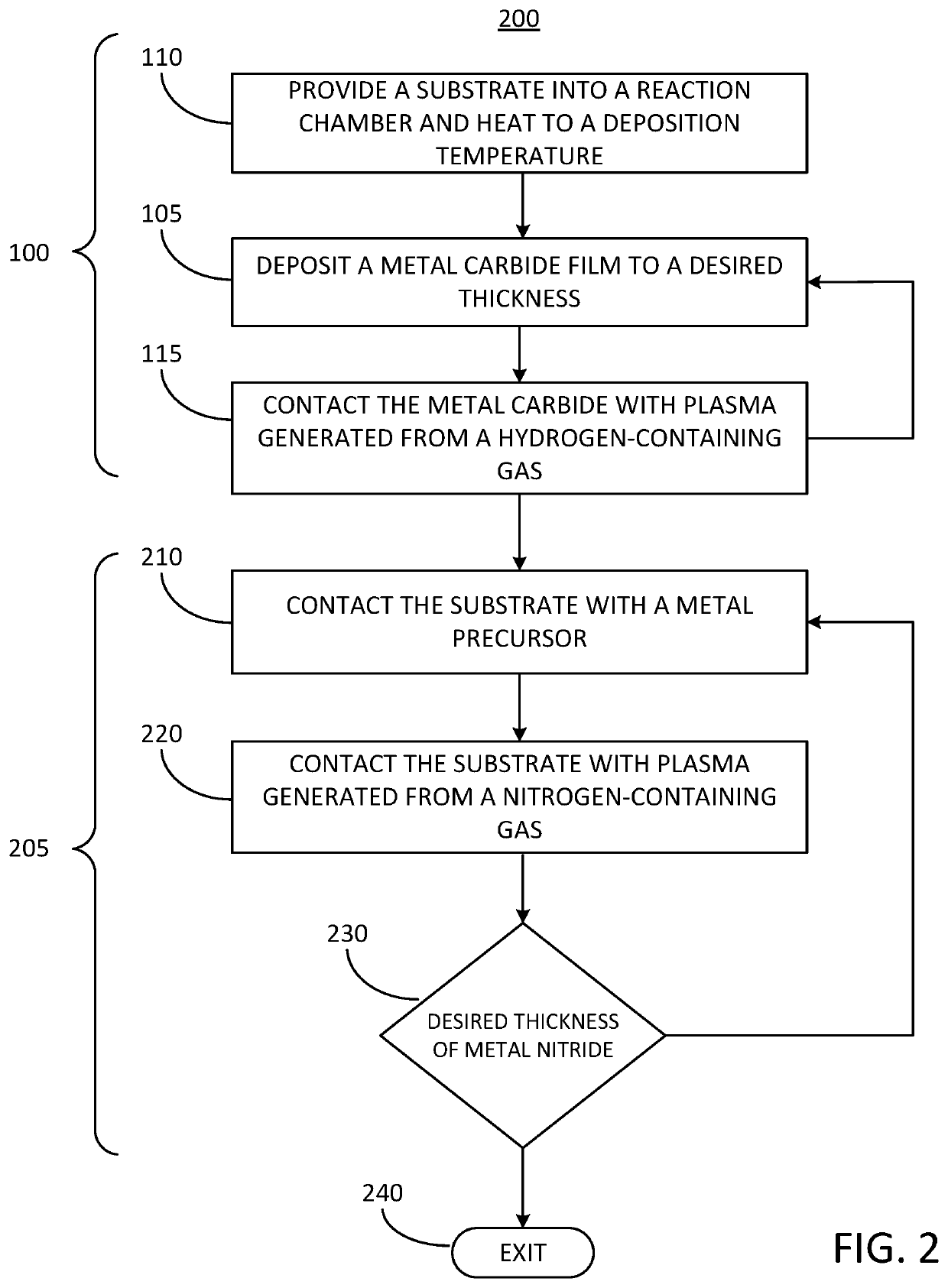

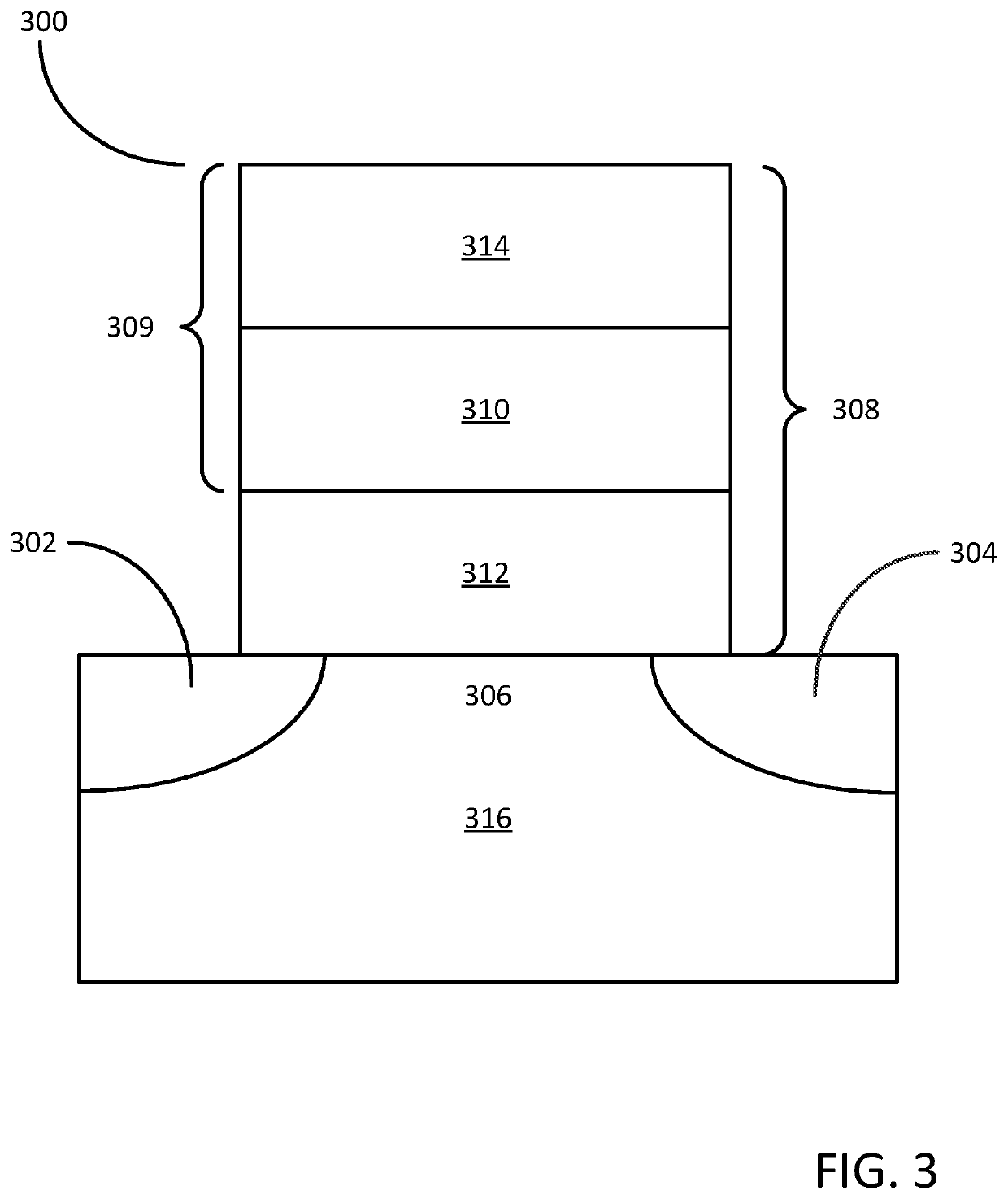

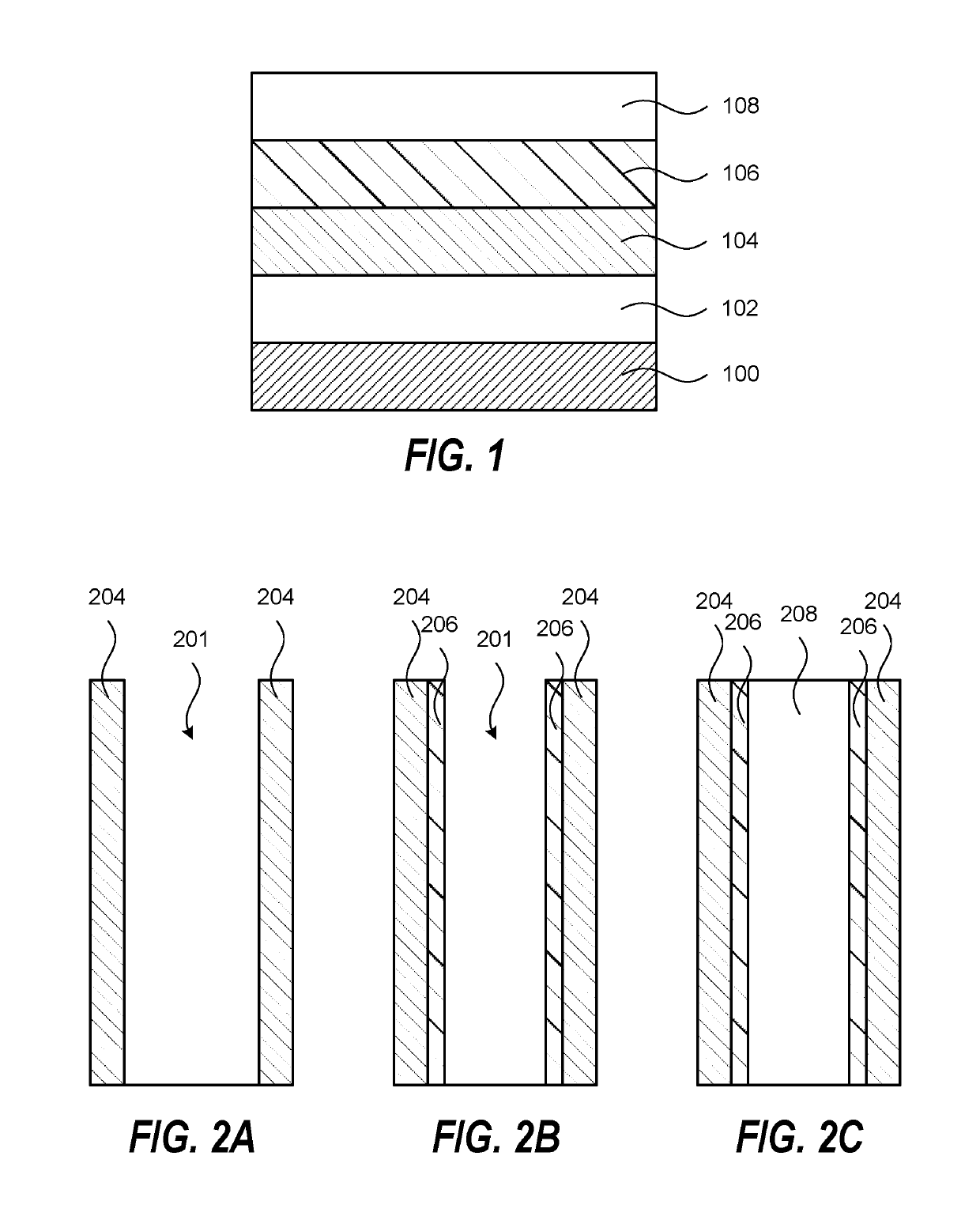

Method of forming a doped metal carbide film on a substrate and related semiconductor device structures

ActiveUS20190348515A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenCarbide

Methods for depositing a doped metal carbide film on a substrate are disclosed. The methods may include: depositing a doped metal carbide film on a substrate utilizing at least one deposition cycle of a cyclical deposition process; and contacting the doped metal carbide film with a plasma generated from a hydrogen-containing gas. Semiconductor device structures including a doped metal carbide film formed by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

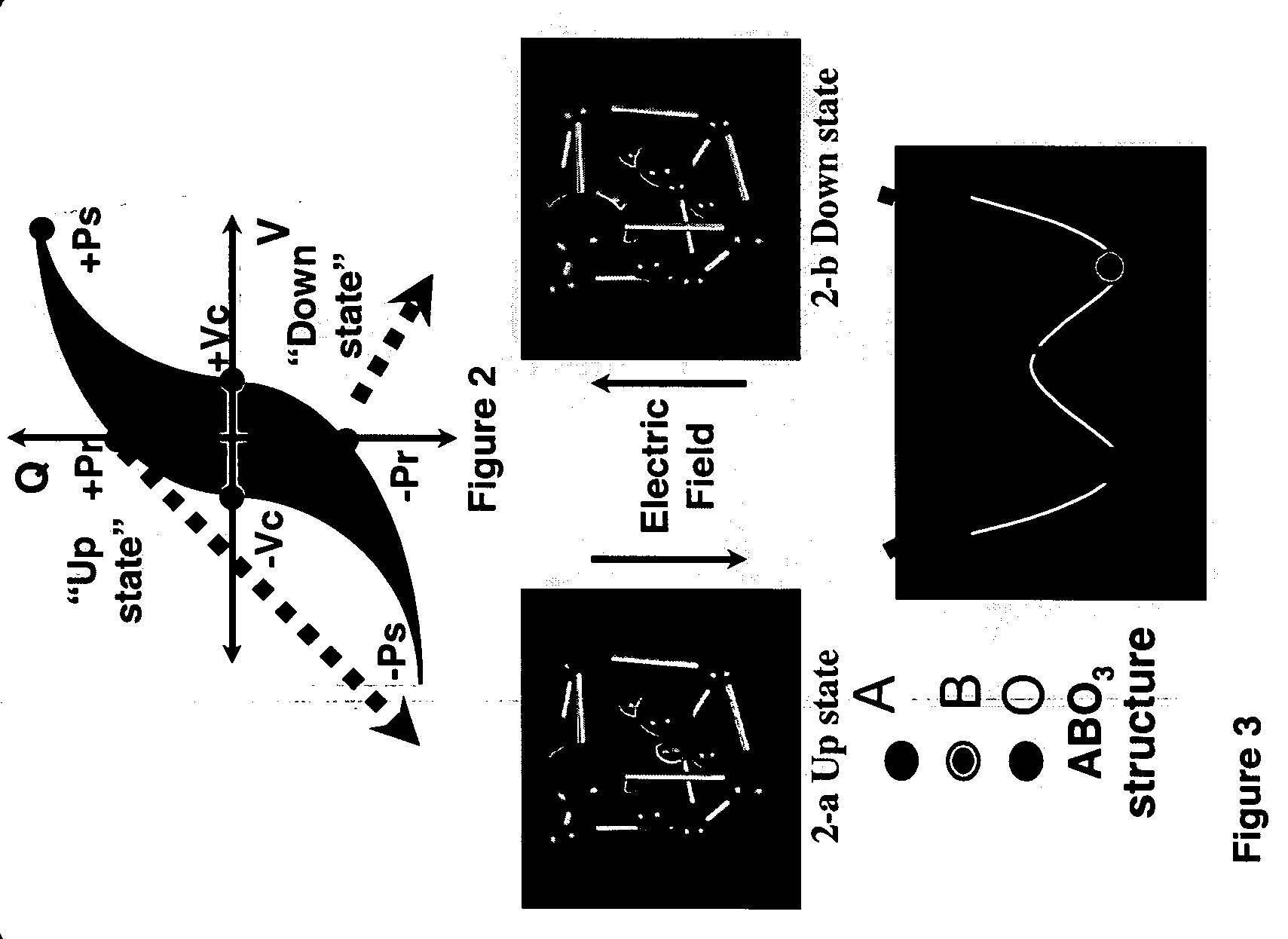

Method and apparatus for forming a ferroelectric layer

InactiveUS20050019960A1Improve crystal structureSolid-state devicesSemiconductor/solid-state device manufacturingCarbideChemical vapor deposition

Methods and apparatus for depositing a layer including providing at least one precursor vapor to a process chamber, providing a gas to the process chamber, separate from the at least one precursor vapor, and forming a compound layer from the at least one precursor vapor and the gas on a wafer in the process chamber. The deposition may be a chemical vapor deposition (CVD) deposition method, a metal organic chemical vapor deposition (MOCVD) deposition method, an atomic layer deposition (ALD) deposition method, or other similar deposition method. The compound layer may be at least one of an oxide, nitride, carbide, or other similar layer.

Owner:SAMSUNG ELECTRONICS CO LTD

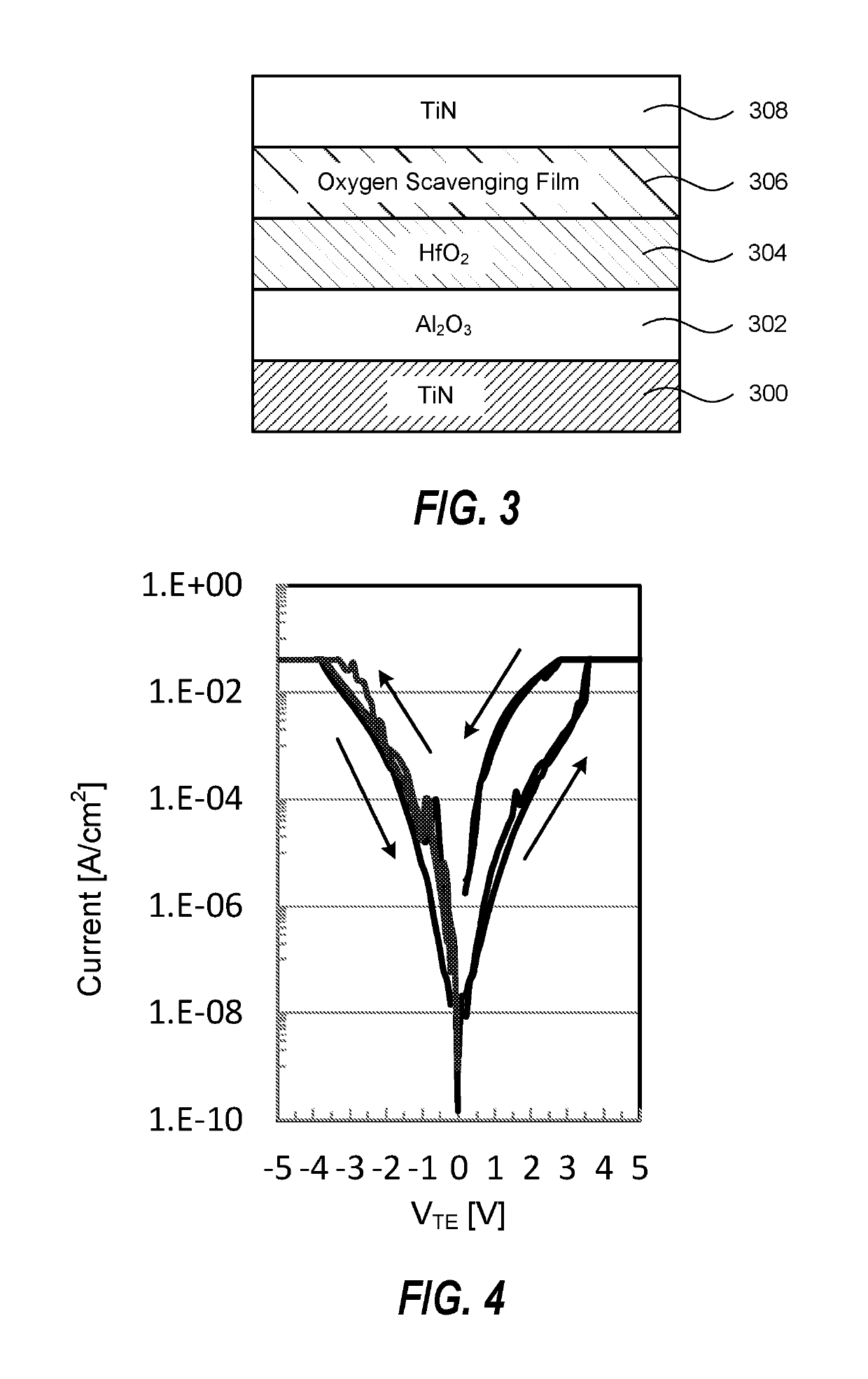

Resistive random accress memory containing a conformal titanium aluminum carbide film and method of making

ActiveUS10361366B2Digital storagePiezoelectric/electrostrictive devicesOxygen vacancyRandom access memory

A plurality of embodiments for ReRAM devices and method of making are described. According to one embodiment, the ReRAM device includes a first electrode film formed on a substrate, a metal oxide film with oxygen vacancies formed on a first electrode film, a conformal TiAlC film, oxidized by diffused oxygen atoms from the metal oxide film, formed on the metal oxide film, and a second electrode film formed on the TiAlC film. According to another embodiment, the ReRAM device includes a pair of vertical metal oxide films, a pair of vertical conformal TiAlC films formed on the pair of vertical metal oxide films, the pair of vertical conformal TiAlC films oxidized by diffused oxygen atoms from the pair of vertical metal oxide films, and an electrode film formed between the pair of vertical conformal TiAlC films.

Owner:TOKYO ELECTRON LTD

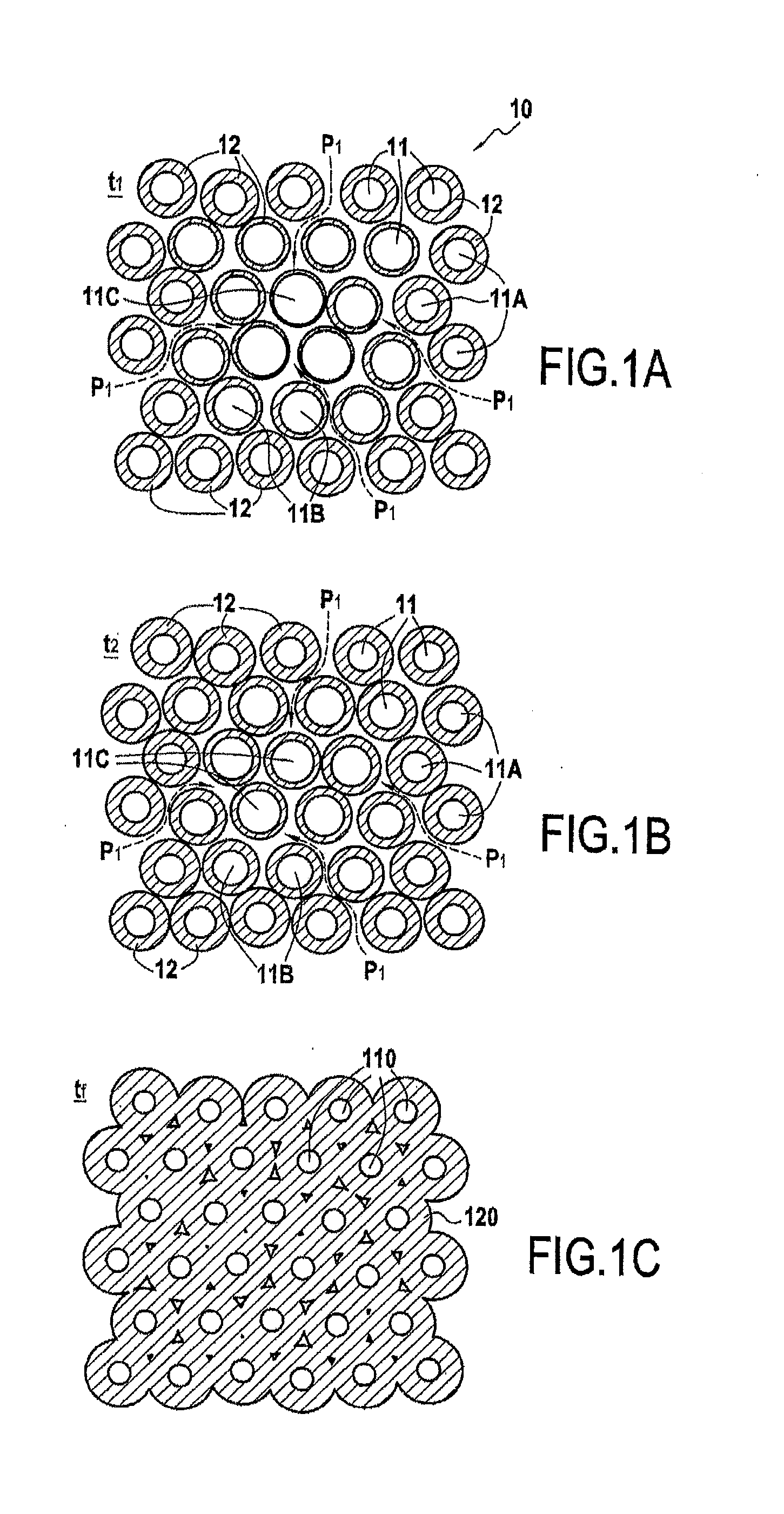

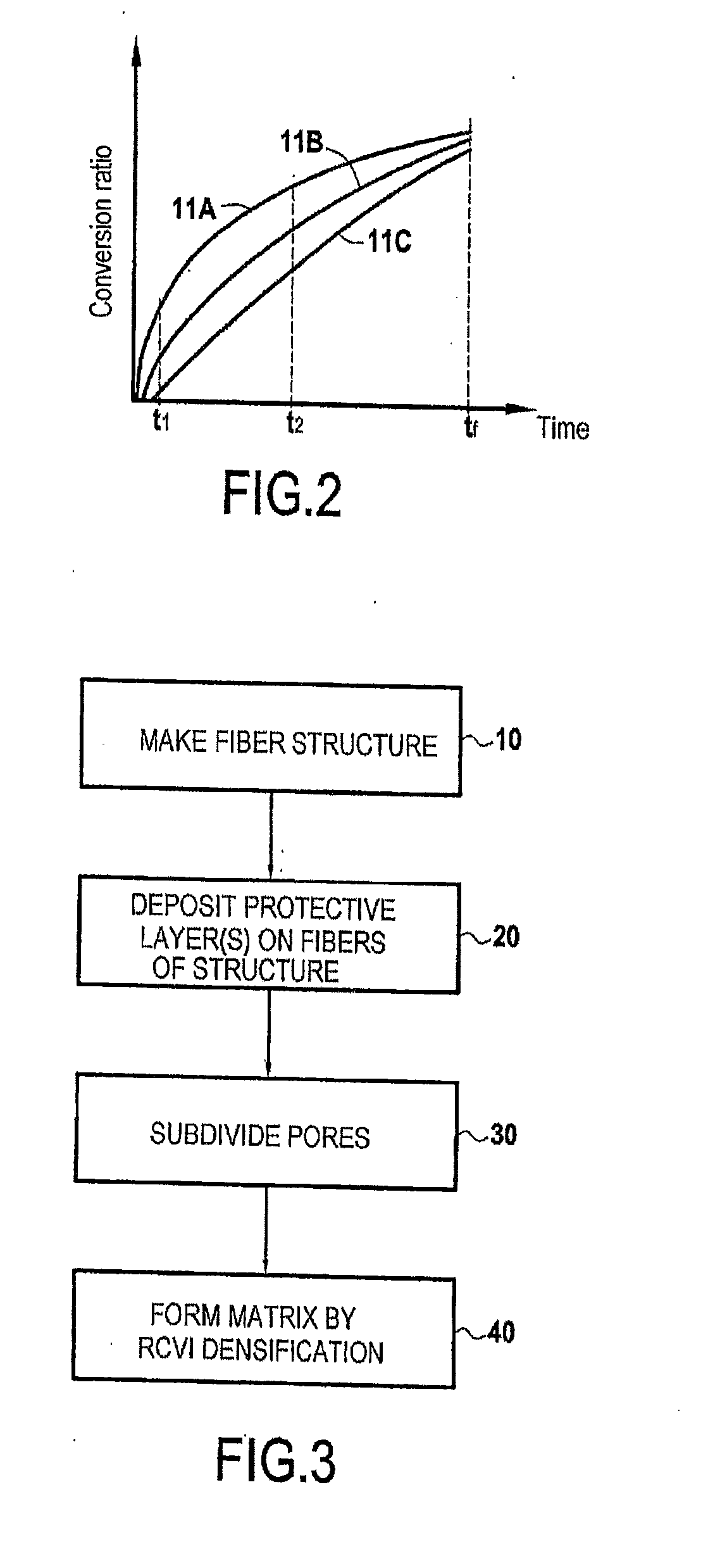

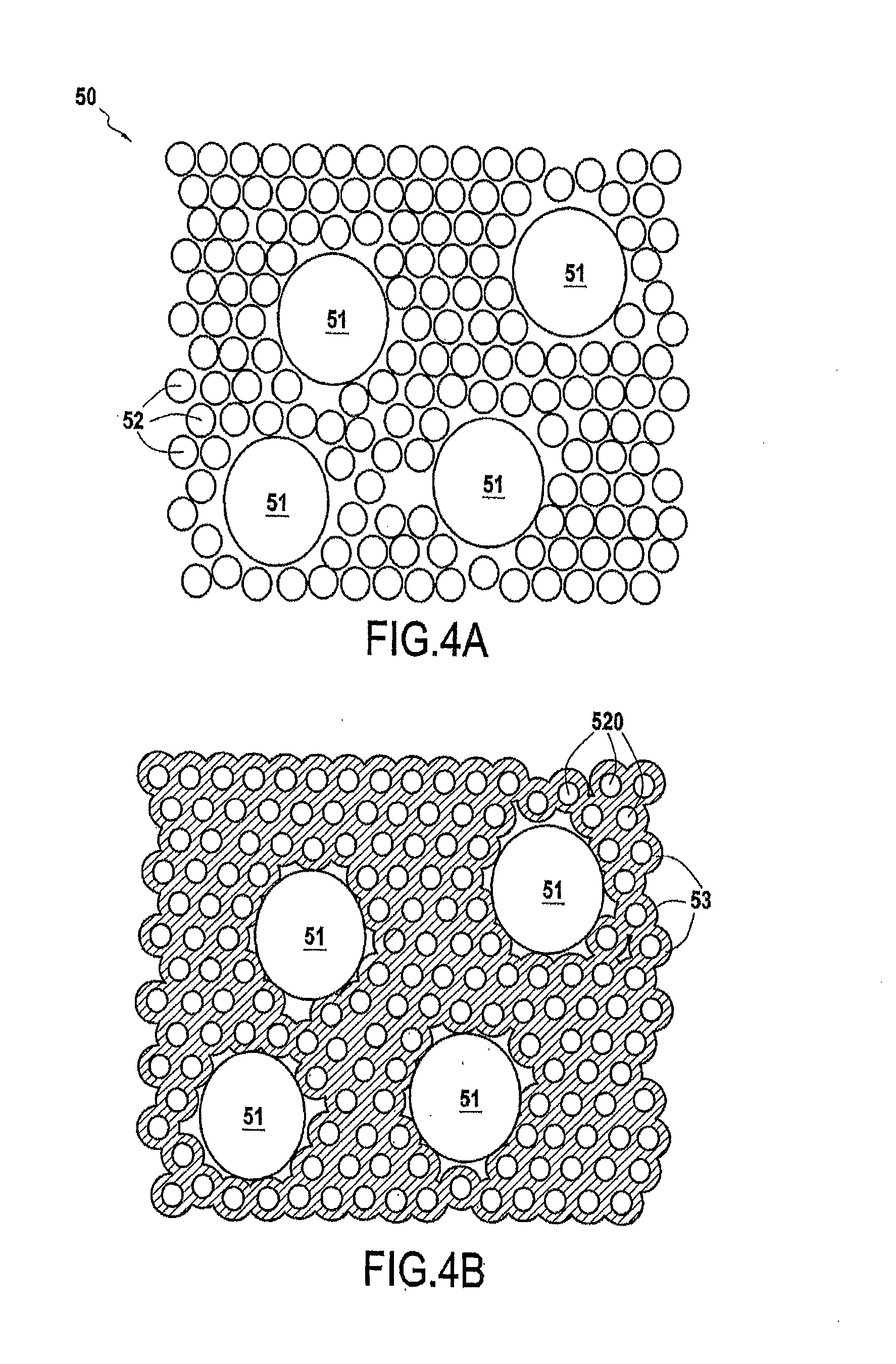

Method for producing a composite material with a carbide matrix

InactiveUS20160060752A1Good and uniform densificationImprove compactnessPretreated surfacesSpecial surfacesPorous substrateGas phase

A method of densifying a porous substrate with a matrix, includes subdividing the pores present in the porous substrate so as to form in the substrate a network of micropores, the subdividing being performed with a filler composition comprising at least one carbon-containing phase or carbide-containing phase that is accessible via the network of micropores; and infiltrating the network of micropores formed by the filler material by reactive chemical vapor infiltration, the infiltration being performed with a reactive gas composition that does not contain carbon and that includes at least one element suitable for reacting with the carbon of the filler composition in order to form a carbide.

Owner:SAFRAN CERAMICS SA

Heat and corrosion resistant cast CF8C stainless steel with improved high temperature strength and ductility

A CF8C type stainless steel alloy and articles formed therefrom containing about 18.0 weight percent to about 22.0 weight percent chromium and 11.0 weight percent to about 14.0 weight percent nickel; from about 0.05 weight percent to about 0.15 weight percent carbon; from about 2.0 weight percent to about 10.0 weight percent manganese; and from about 0.3 weight percent to about 1.5 weight percent niobium. The present alloys further include less than 0.15 weight percent sulfur which provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. The disclosed alloys also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon.

Owner:UT BATTELLE LLC

Proppants With Carbide and/or Nitride Phases

Owner:HALLIBURTON ENERGY SERVICES INC

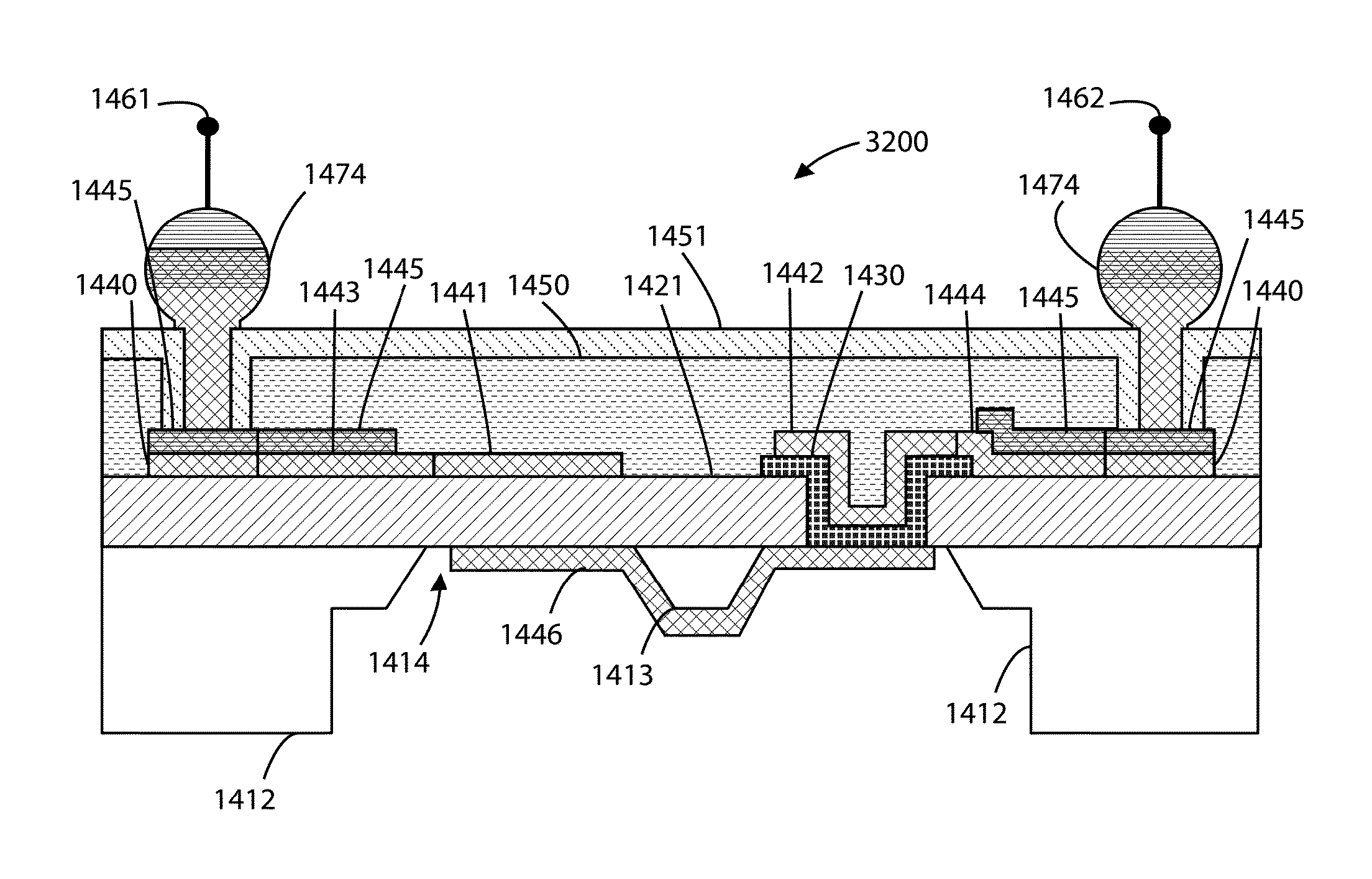

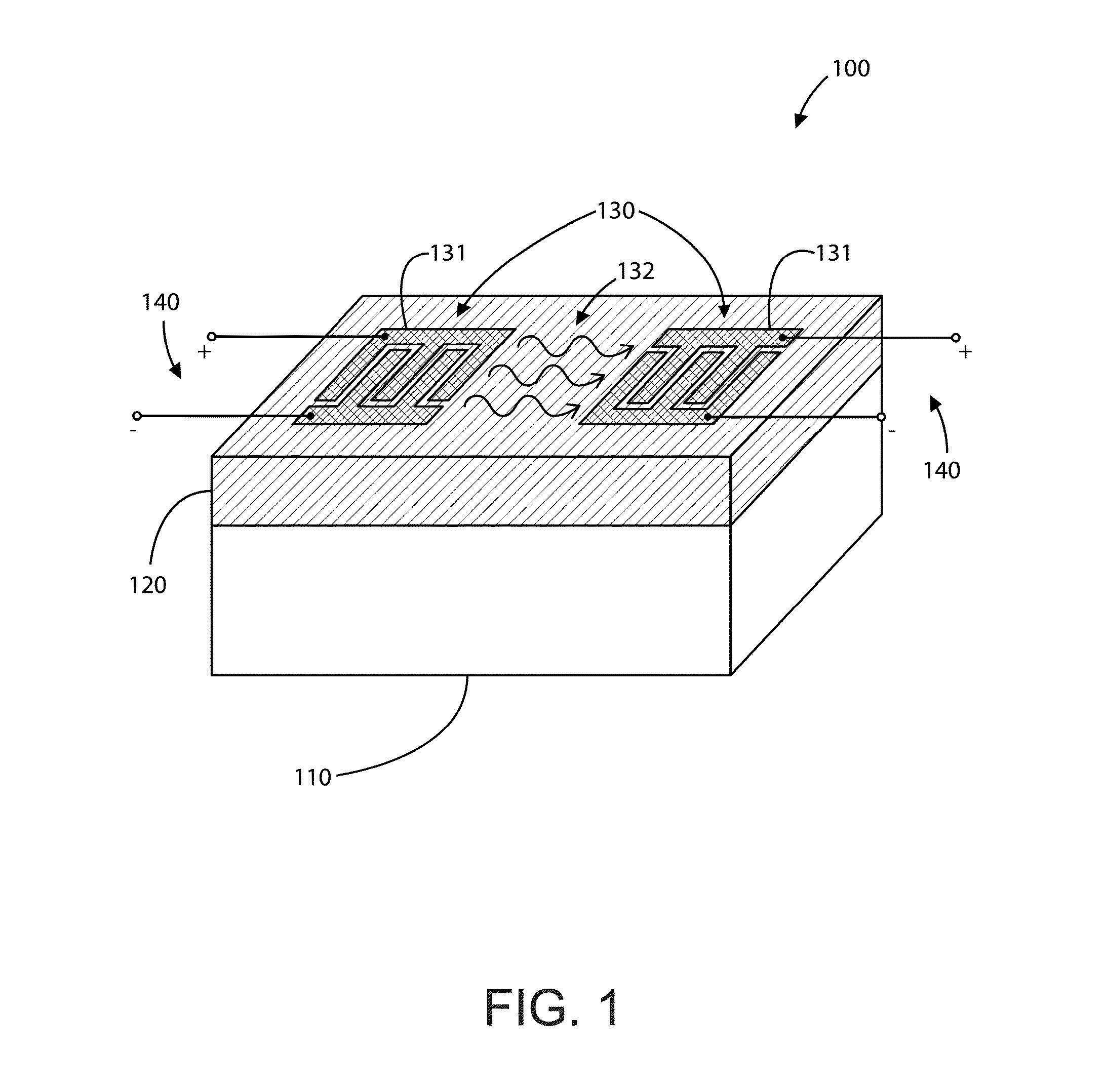

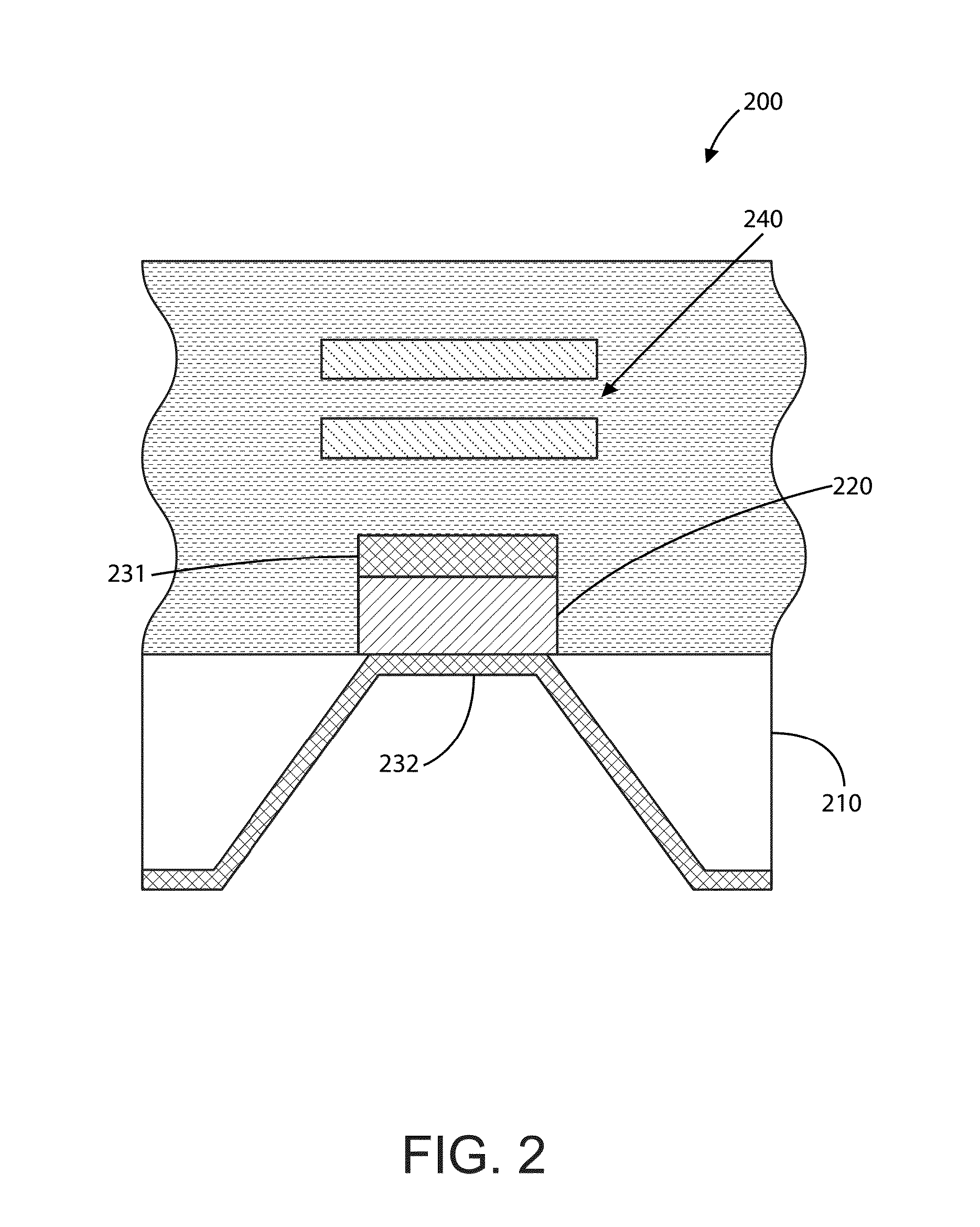

Single crystal acoustic resonator and bulk acoustic wave filter

ActiveUS20160028367A1AdvantageSimple and cost-effectivePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallic materialsCarbide

A method of wafer scale packaging acoustic resonator devices and an apparatus therefor. The method including providing a partially completed semiconductor substrate comprising a plurality of single crystal acoustic resonator devices provided on a silicon and carbide bearing material, each having a first electrode member, a second electrode member, and an overlying passivation material. At least one of the devices to be configured with an external connection, a repassivation material overlying the passivation material, an under metal material overlying the repassivation material. Copper pillar interconnect structures are then configured overlying the electrode members, and solder bump structures are form overlying the copper pillar interconnect structures.

Owner:AKOUSTIS INC

Alumina-coated granules, as well as preparation method and application thereof

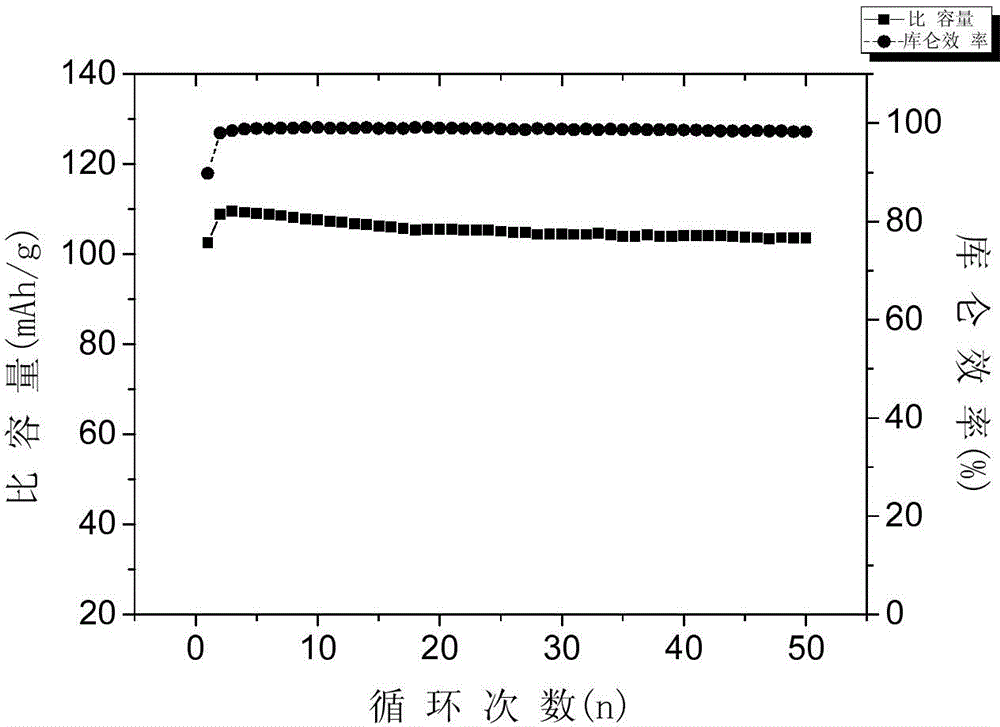

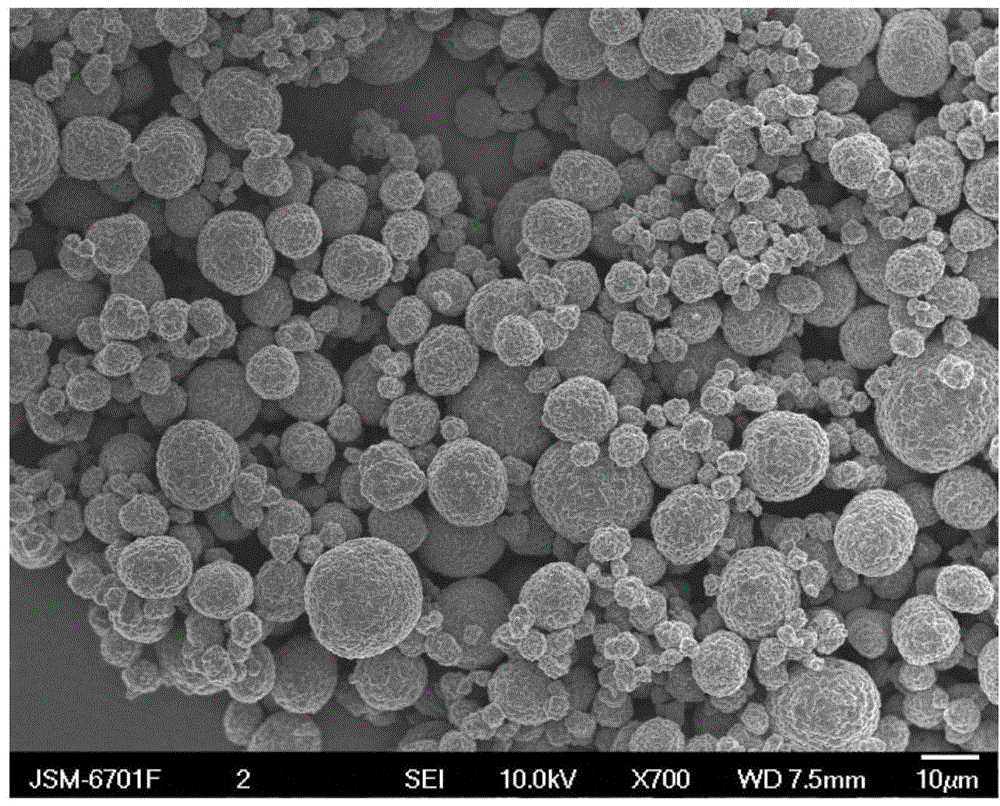

InactiveCN103606660AThickness adjustment and controlUniform thicknessCell electrodesLithium-ion batteryLithium electrode

The invention discloses alumina-coated granules, as well as a preparation method and application thereof. The alumina-coated granules consist of cores and shells which coat the cores. The cores are made of at least one of materials of metals, oxides, metal hydroxides, metal inorganic salts, non-metals, carbides, nitrides, lithium salts, semiconductors and organic compounds; the shell is made of Al2O3. By adopting a liquid phase method, the cores to be coated are mixed with aluminum salts, metal aluminum is precipitated by producing an alkaline environment in situ or externally adding alkaline, so that uniform, continuous and controllable coating can be formed on the surfaces of the cores. The coating method provided by the invention is simple, and has mild conditions and high universality; the coating layer has controllable thickness, completeness and uniformity; the alumina-coated granules has high practicability and a great application prospect in the field of catalysis, lithium ion batteries, surface-enhanced Raman, biomedicine and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyimide aerogels, carbon aerogels, and metal carbide aerogels and methods of making same

InactiveUS20040132845A1Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologySiliconPolymer scienceCarbide

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m<2> / g.

Owner:ASPEN AEROGELS INC

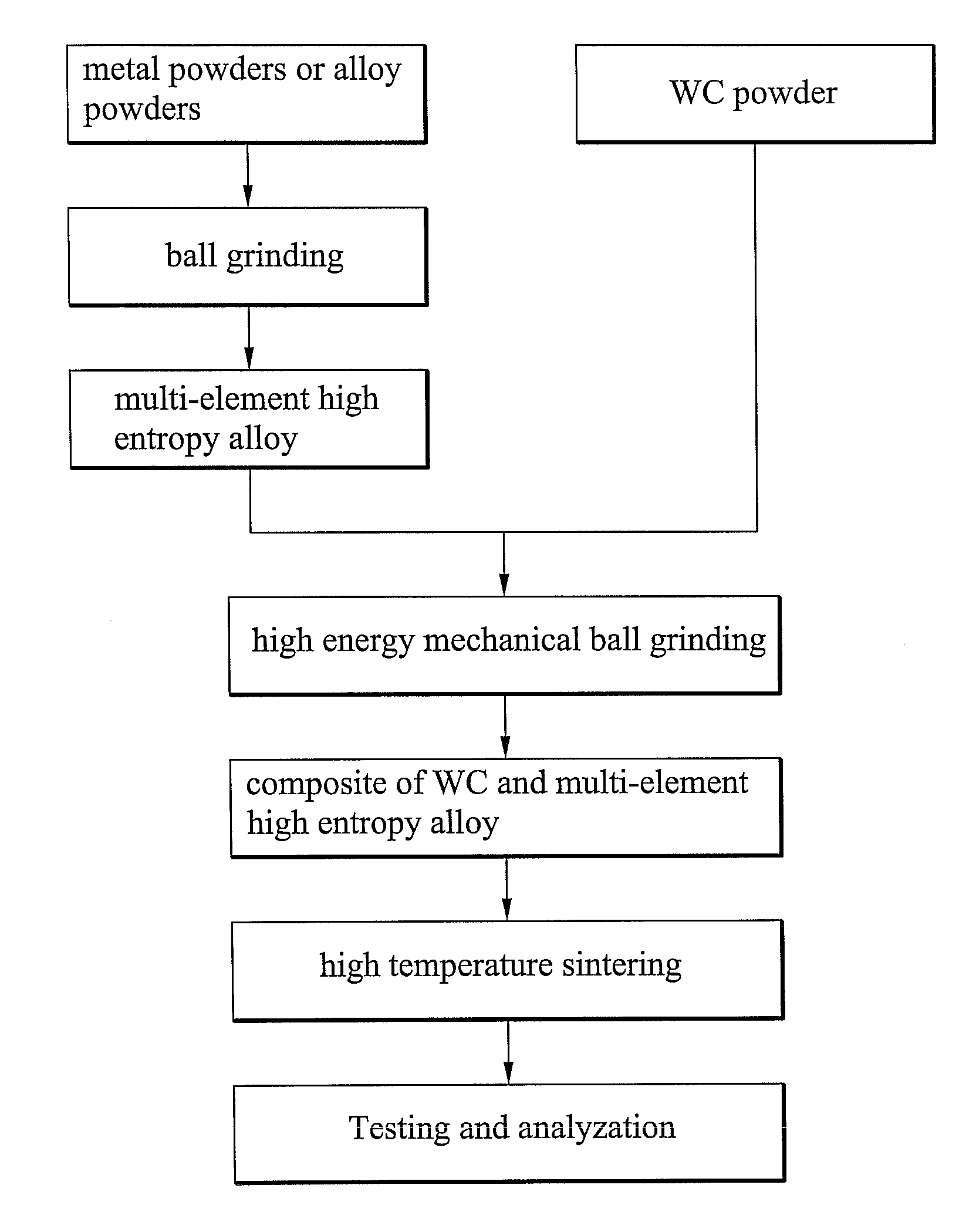

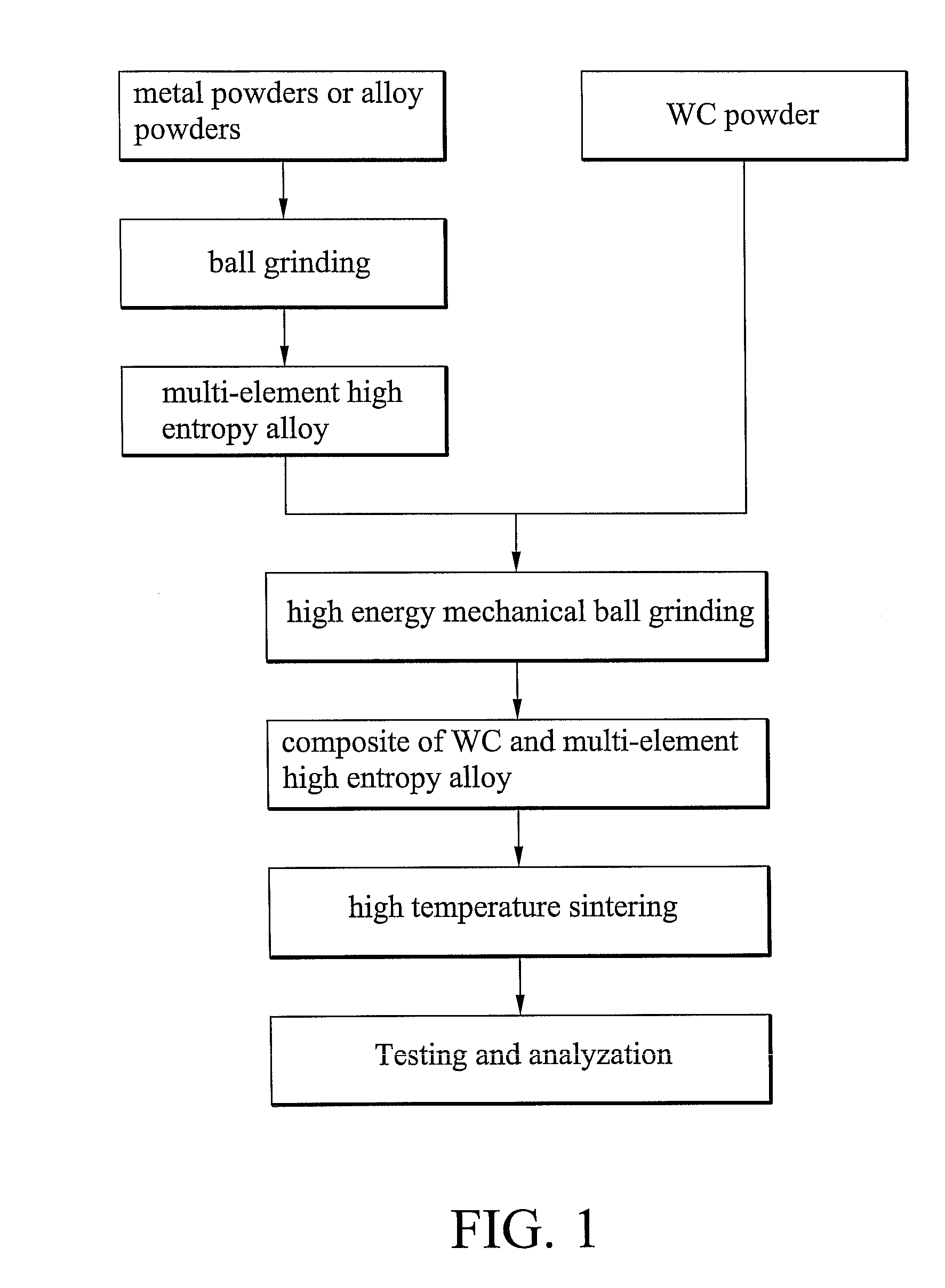

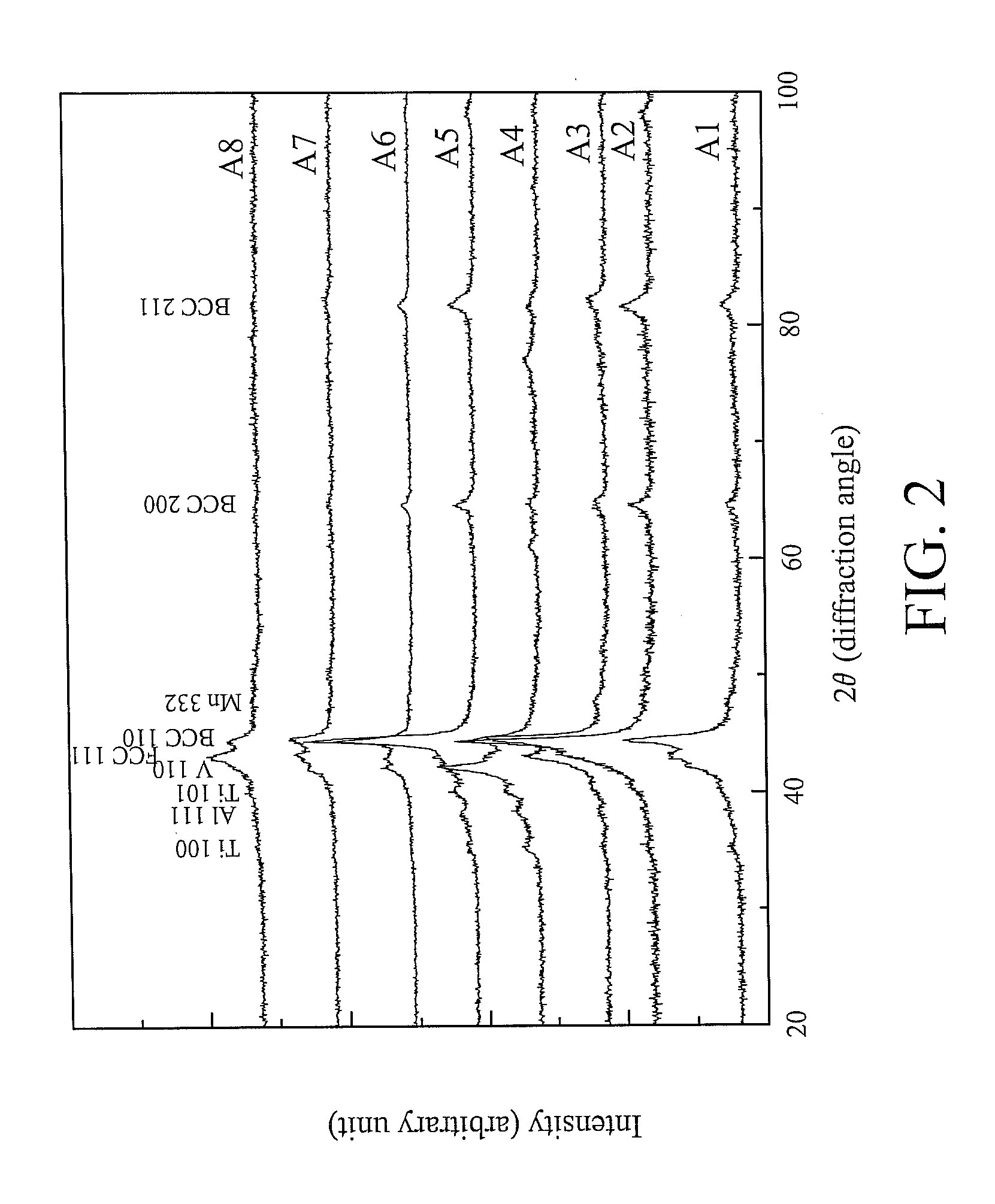

Ultra-hard composite material and method for manufacturing the same

The disclosed is an ultra-hard composite material. The method for manufacturing the ultra-hard composite material includes mixing a metal carbide powder and a multi-element high-entropy alloy powder to form a mixture, green compacting the mixture, and sintering the mixture to form the ultra-hard composite material. The described multi-element high-entropy alloy consists of five to eleven principal elements, with every principal element occupying a 5 to 35 molar percentage of the alloy.

Owner:IND TECH RES INST

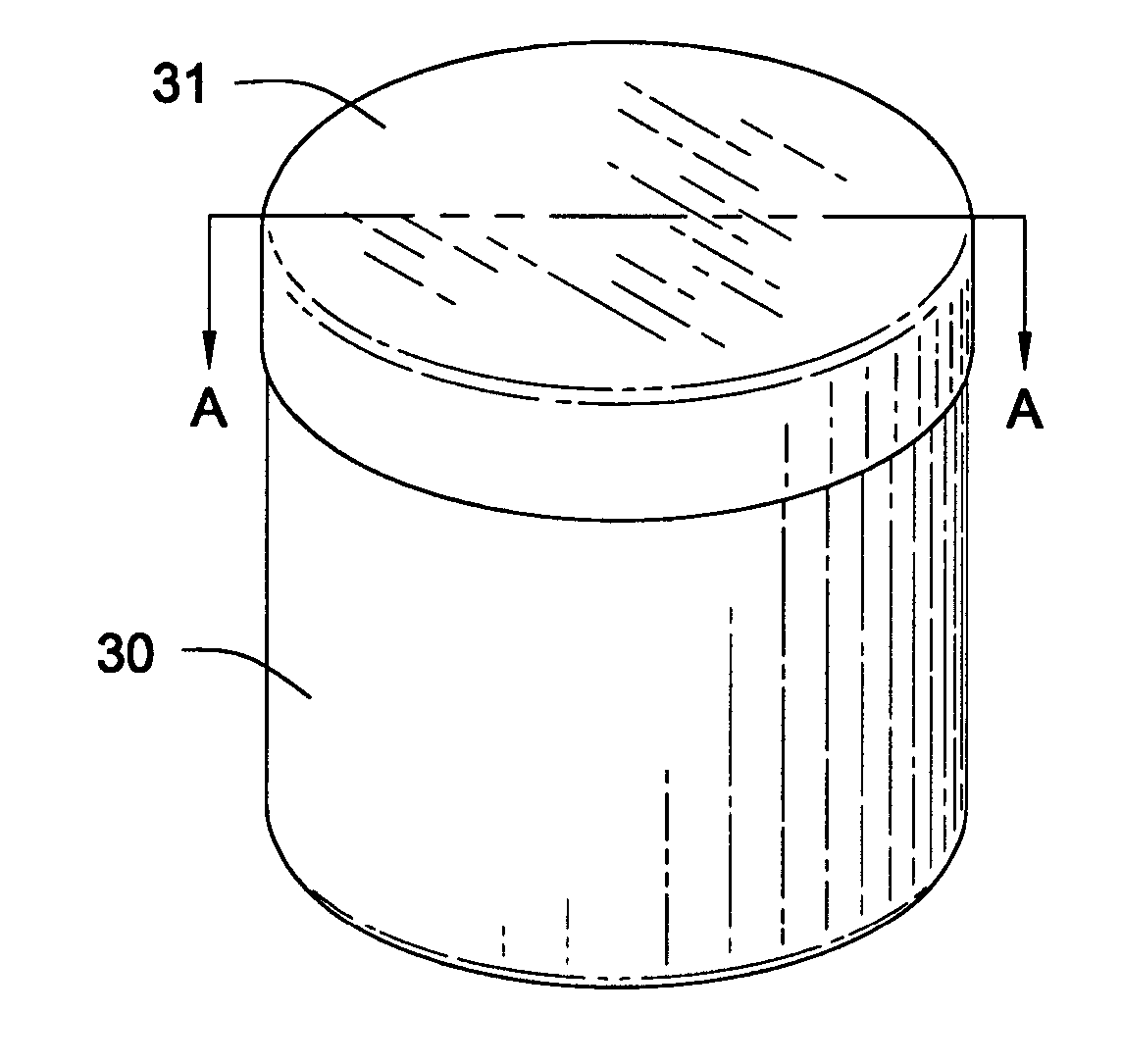

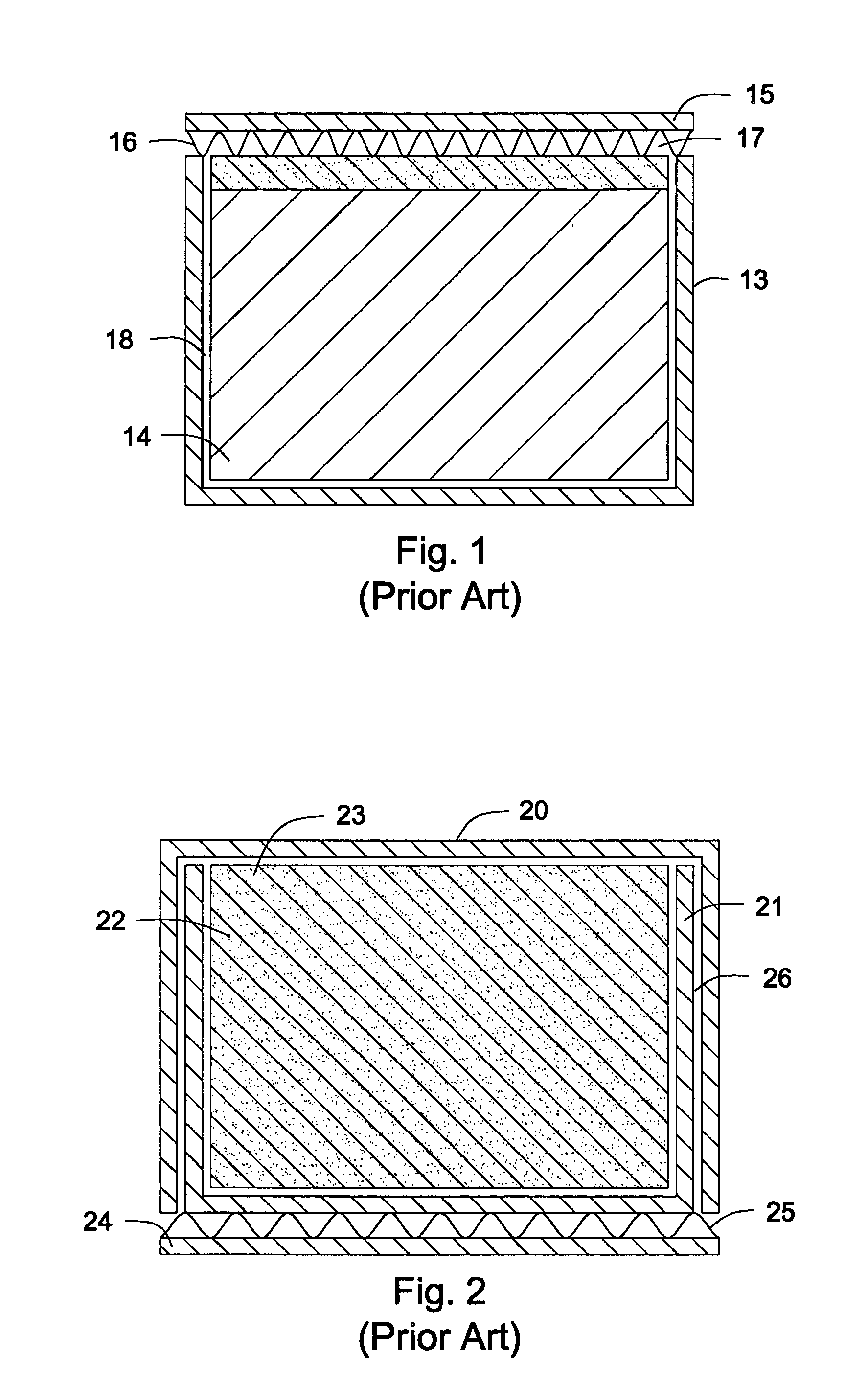

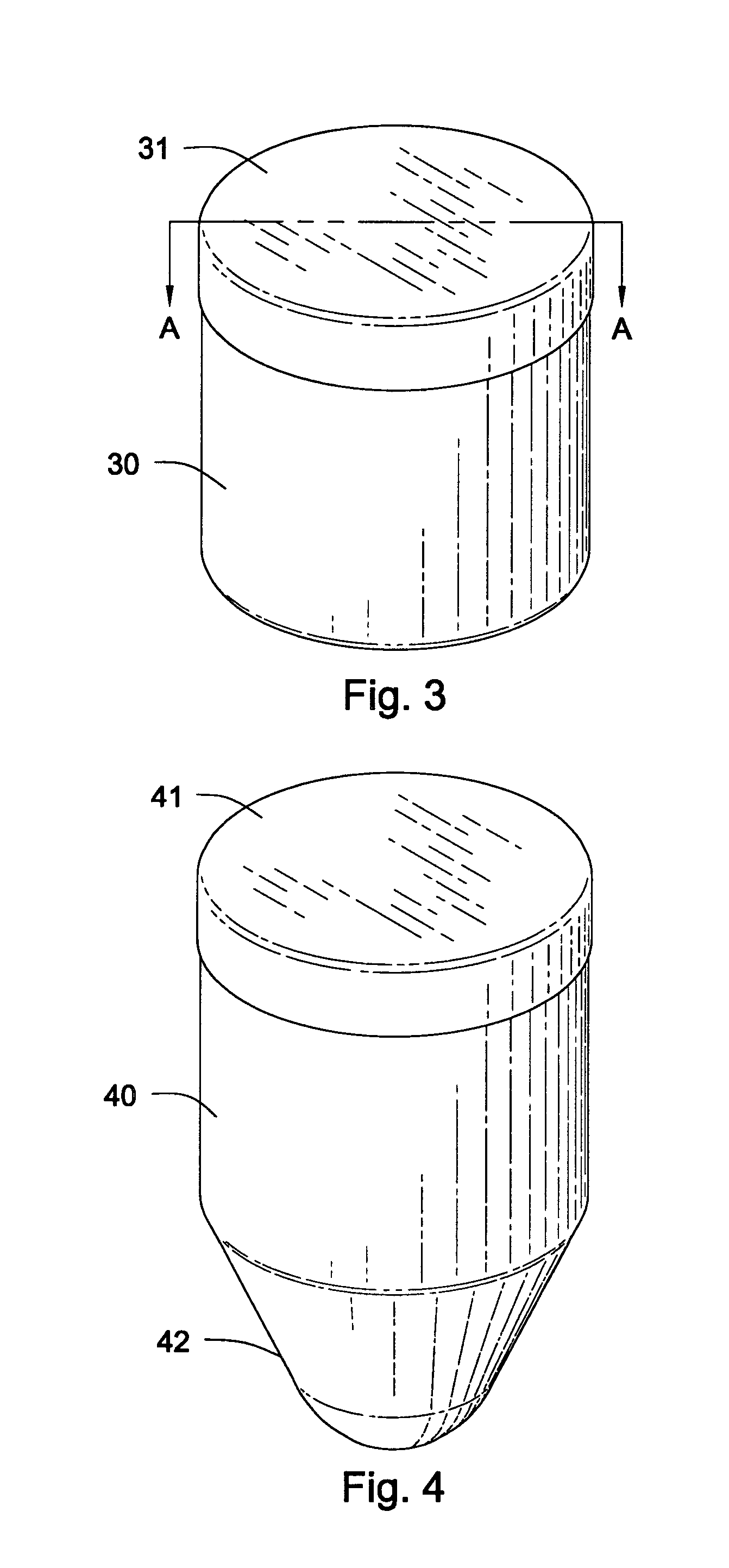

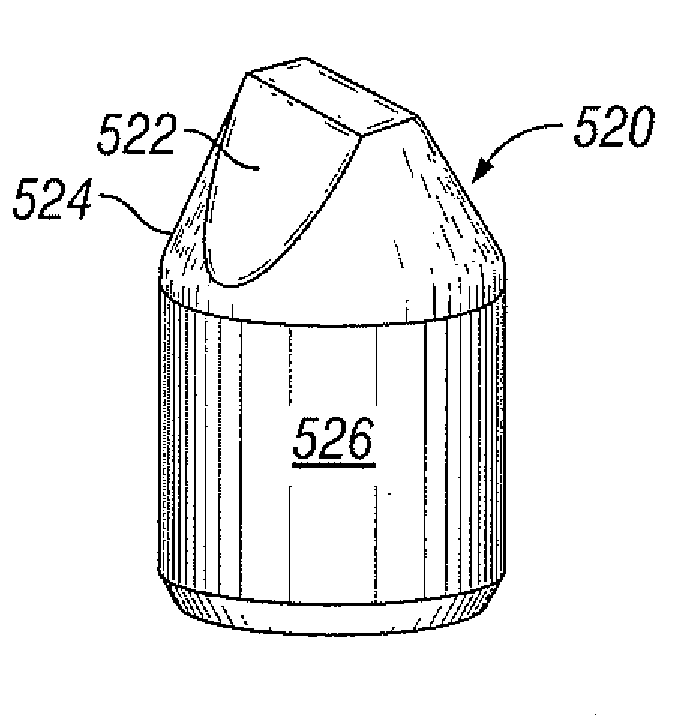

Container assembly for HPHT processing

InactiveUS20050044800A1Extended pathPigmenting treatmentPressurized chemical processHermetic sealCarbide

An assembly for High-Pressure High-Temperature (HPHT) processing comprising a can, a cap, a meltable sealant and sealant barrier, and a superhard mixture comprising superhard particles. The superhard particles may be positioned adjacent a substrate of cemented metal carbide. The can and cap contain the superhard mixture with the sealant barrier positioned within the assembly so as to be intermediate the sealant and at least a portion of the mixture, thereby preventing the sealant from coming in contact with the mixture during processing. The assembly is placed within a vacuum chamber and heated to a temperature sufficient to cleanse the assembly and then melt the sealant providing a hermetic seal for the assembly in preparation for further HPHT processing.

Owner:REEDHYCALOG UTAH LLC

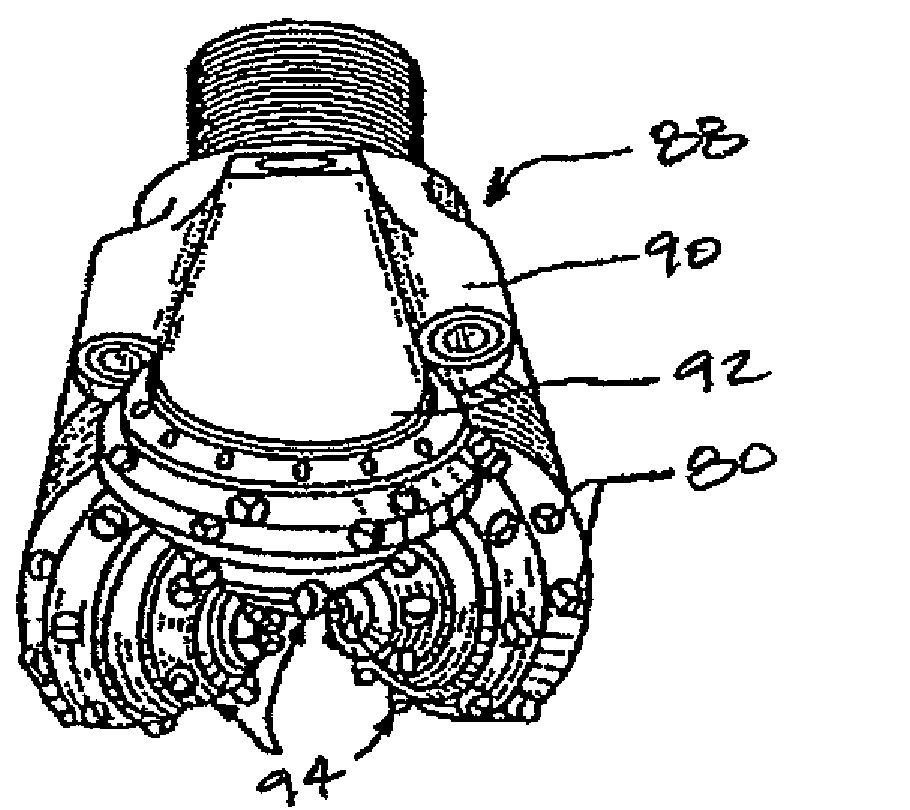

Diamond-bonded constrcutions with improved thermal and mechanical properties

InactiveUS20090090563A1Excellent characteristicsImprove thermal stabilityDrill bitsConstructionsDiamond crystalCarbide

Diamond-bonded constructions include a diamond-bonded body having a thermally stable region extending a distance below a diamond-bonded body surface. The thermally stable region comprises a matrix phase of bonded-together diamond crystals, and interstitial regions comprising a reaction product. The reaction product is formed by reaction between the diamond crystals and a reactive material. The reactant is a carbide former and the reaction product is a carbide. The diamond-bonded body includes a further diamond region extending from the thermally stable region that comprises the matrix phase and a Group VIII metal disposed within interstitial regions of the matrix phase. The thermally stable region is substantially free of a catalyst material used to initially form the diamond-bonded body. The diamond-bonded body may include a material layer formed from the reaction product that is disposed on a surface of the diamond-bonded body thermally stable region.

Owner:SMITH INT INC

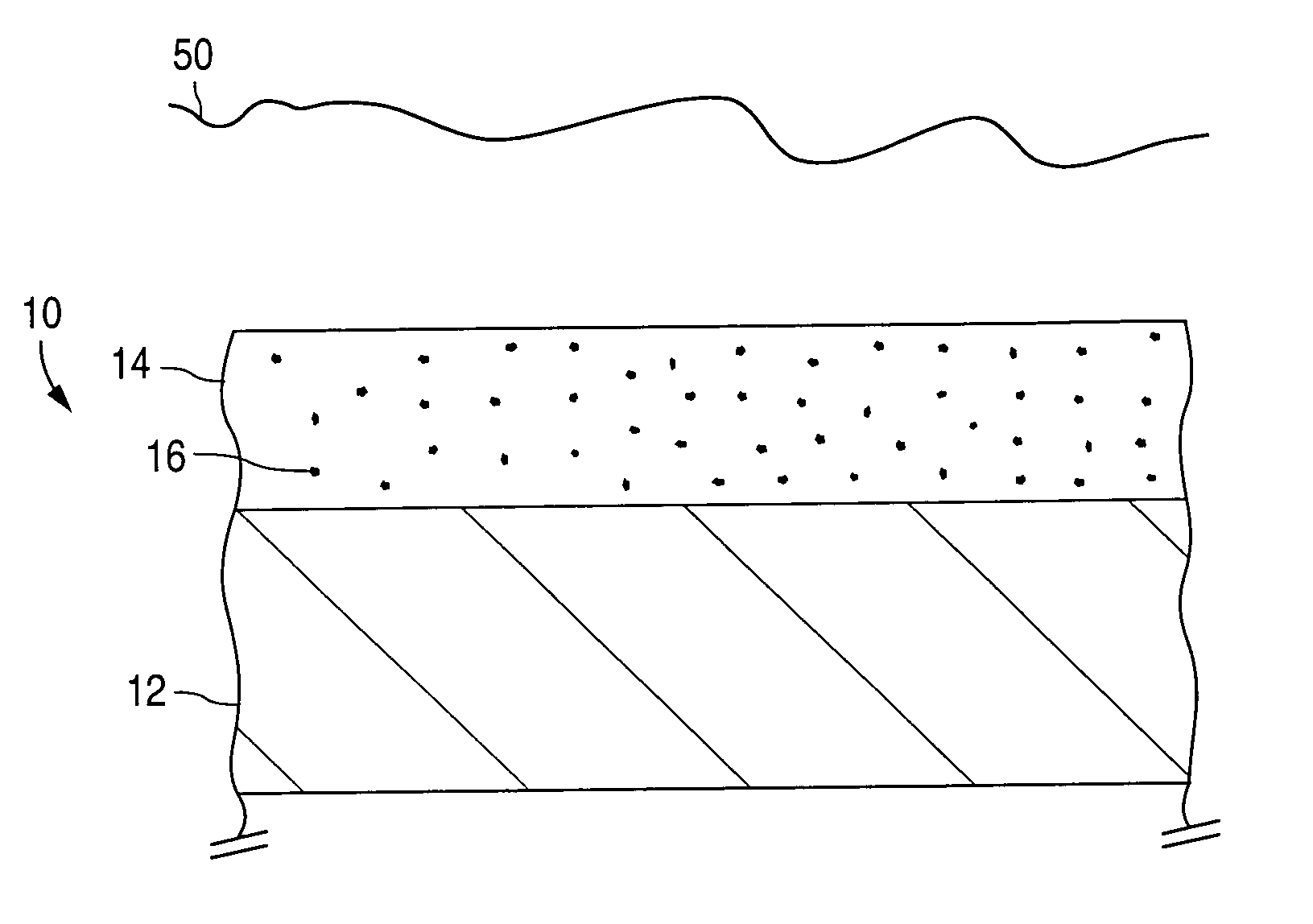

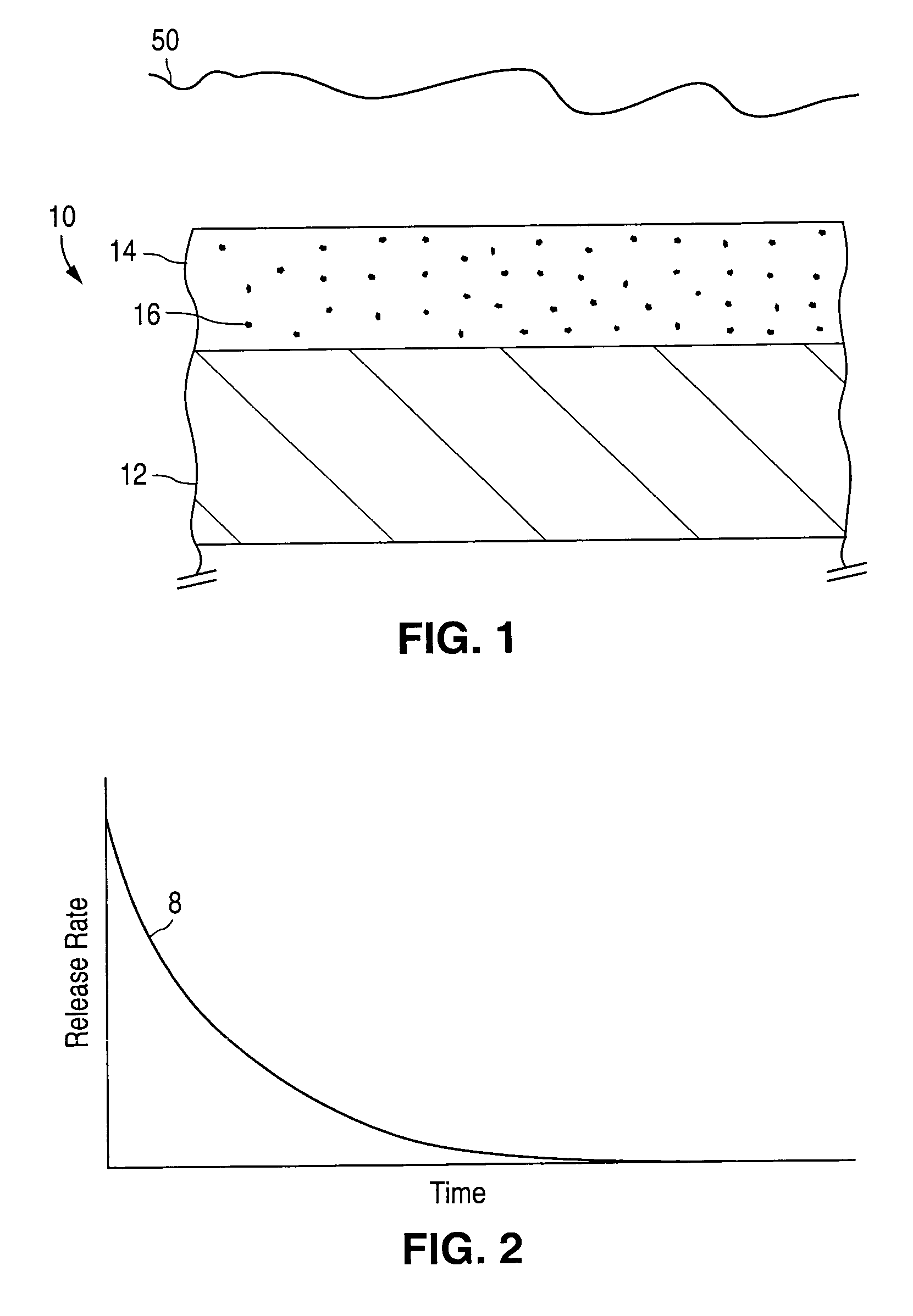

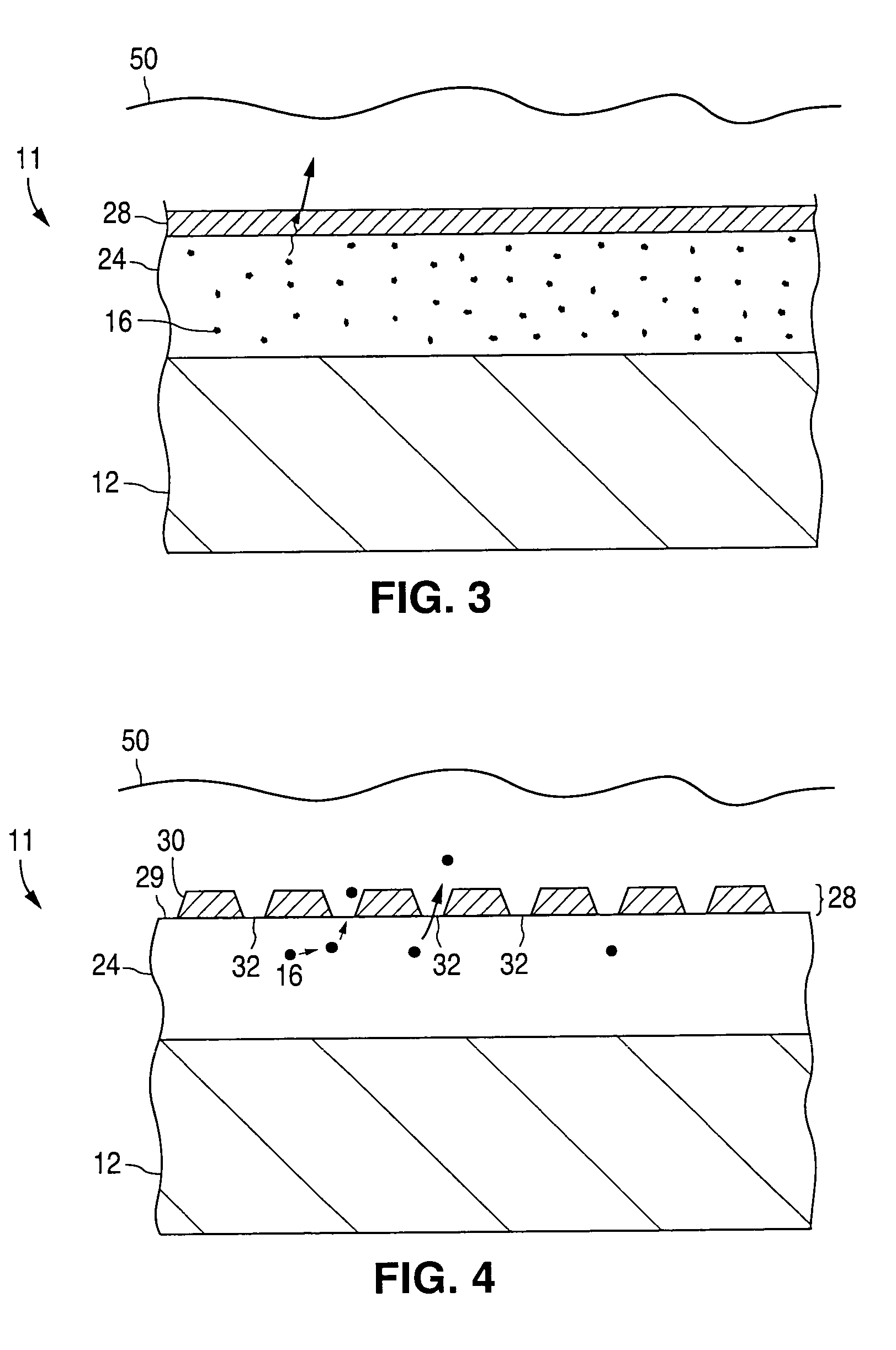

Barriers for polymer-coated implantable medical devices and methods for making the same

InactiveUS6953560B1Reduce and prevent and inflammationReduce and prevent proliferationStentsSurgeryHafniumPt element

An implantable medical device and methods for making the implantable medical device are disclosed. The implantable medical device includes a substrate. At least a portion of the substrate is coated with a first layer including a polymer containing a drug. A barrier overlies the first layer. The barrier significantly reduces the rate of release of the drug from the polymer, thereby sustaining release of the drug from the medical device for a longer time.The barrier may be a homogeneous layer overlying the first layer, or a number of discrete deposits over the first layer. Alternatively, the barrier may be intermixed with an outer portion of the first layer. The barrier material is biocompatible, and typically has a thickness ranging from about 50 angstroms to about 20,000 microns. Suitable materials for the barrier include, but are not limited to, inorganic compounds, such as inorganic silicides, oxides, nitrides, carbides, as well as pure metals such as aluminum, chromium, gold, hafnium, iridium, niobium, palladium, platinum, tantalum, titanium, tungsten, zirconium, and alloys of these metals. The barriers disclosed may be applied to the first layer by several techniques, depending on the material being applied. Exemplary deposition techniques include physical vapor deposition, alkoxide hydrolysis, and electroless plating.The implantable device may be a stent or a graft, among other possibilities.

Owner:ABBOTT CARDIOVASCULAR

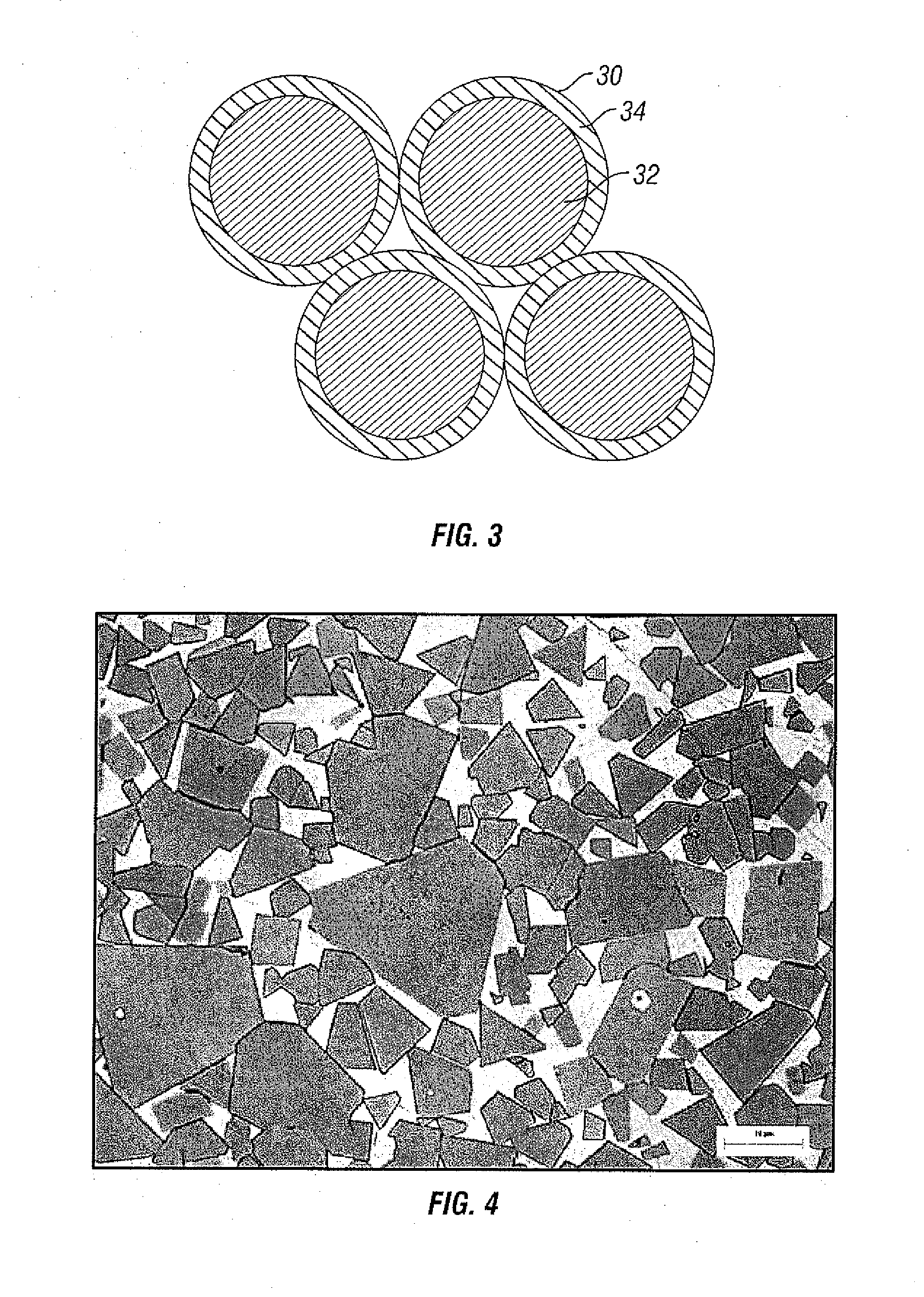

Microwave sintering

A carbide composite that includes carbide particles having an average particle size of less than about 100 nanometers and a metallic binder disposed around the carbide particles is disclosed. The carbide composite may also include carbide particles having an average particle size ranging from 3 to 10 microns.

Owner:SMITH INT INC

Aluminum oxide-coated article

InactiveUS6333103B1Improve featuresReduced durabilityPigmenting treatmentRecord information storageX-rayCarbide

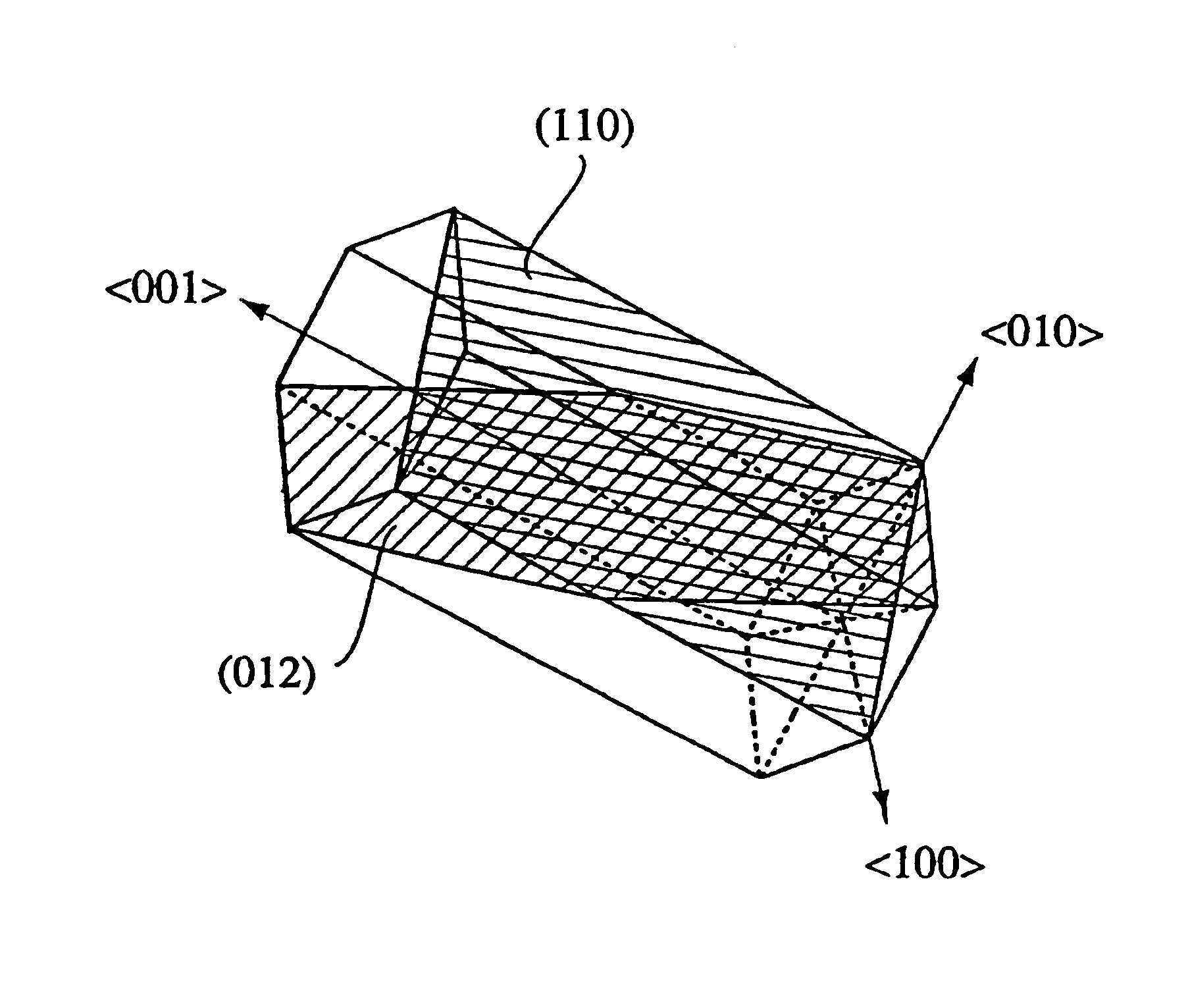

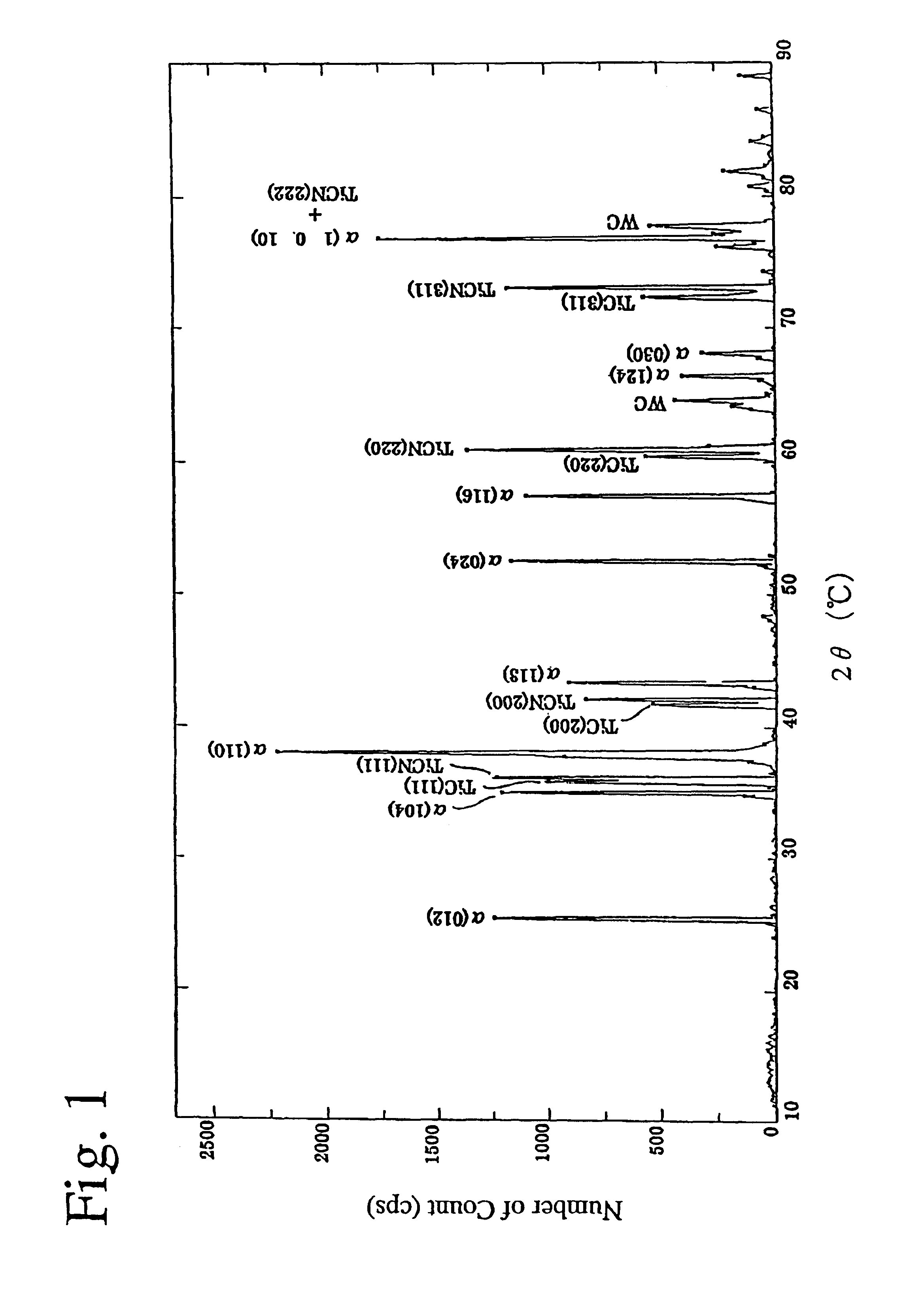

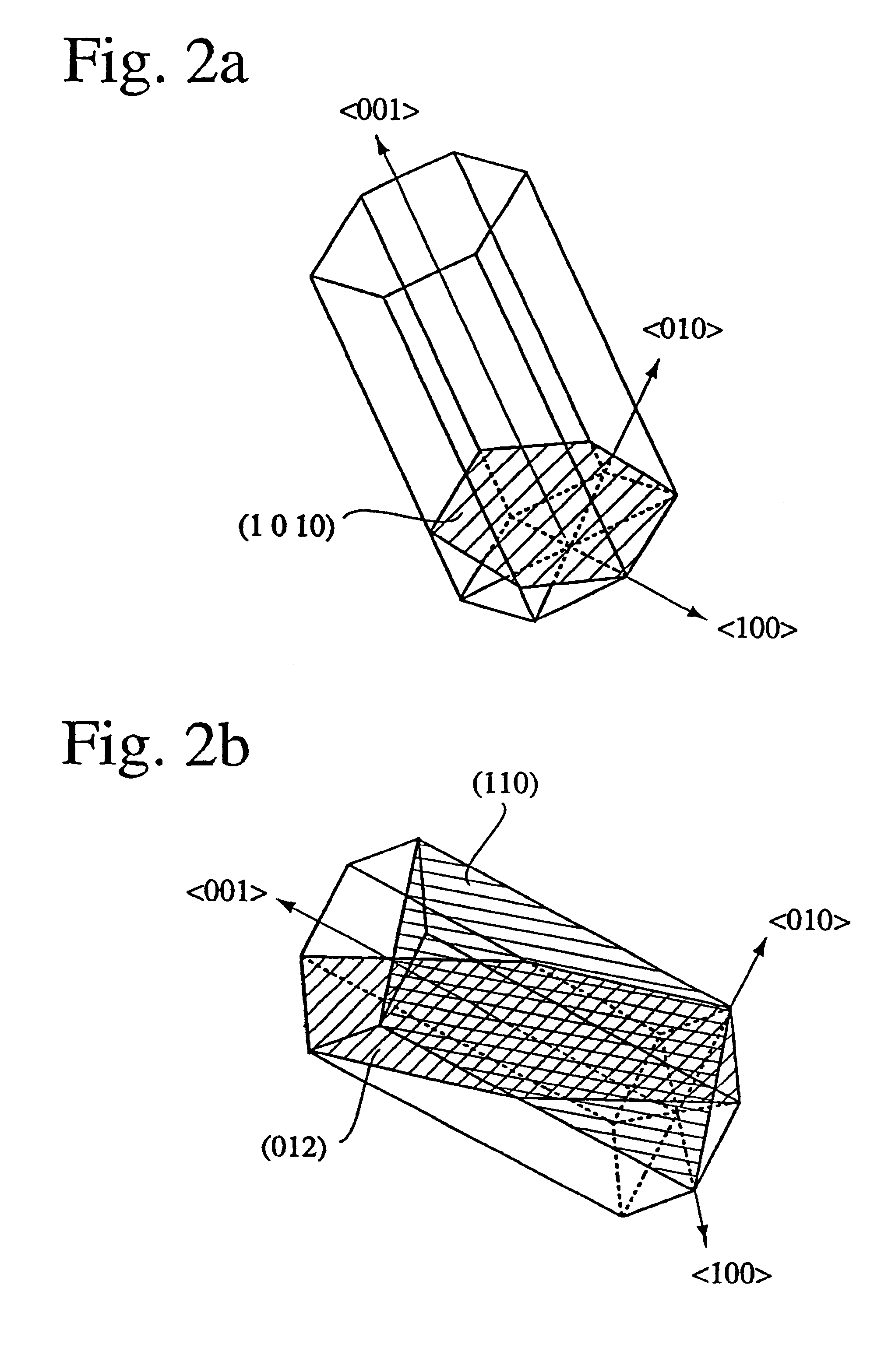

An aluminum oxde-coated article has a first coating layer and a second coating layer formed in this order on a substrate, the first coating layer having a single- or multi-layer structure and being made of at least one selected from the group consisting of carbides, nitrides, carbonitrides, oxides, oxycarbides, oxynitrides and oxycarbonitrides of metals in Groups IVa, Va and VIa of the Periodic Table, and the second coating layer being constituted by at least one alpha-aluminum oxide-based oxide layer, which has an equivalent X-ray diffraction peak ratio PR (1 0 10) of 1.3 or more in a (1 0 10) plane.

Owner:HITACHI TOOL ENG LTD

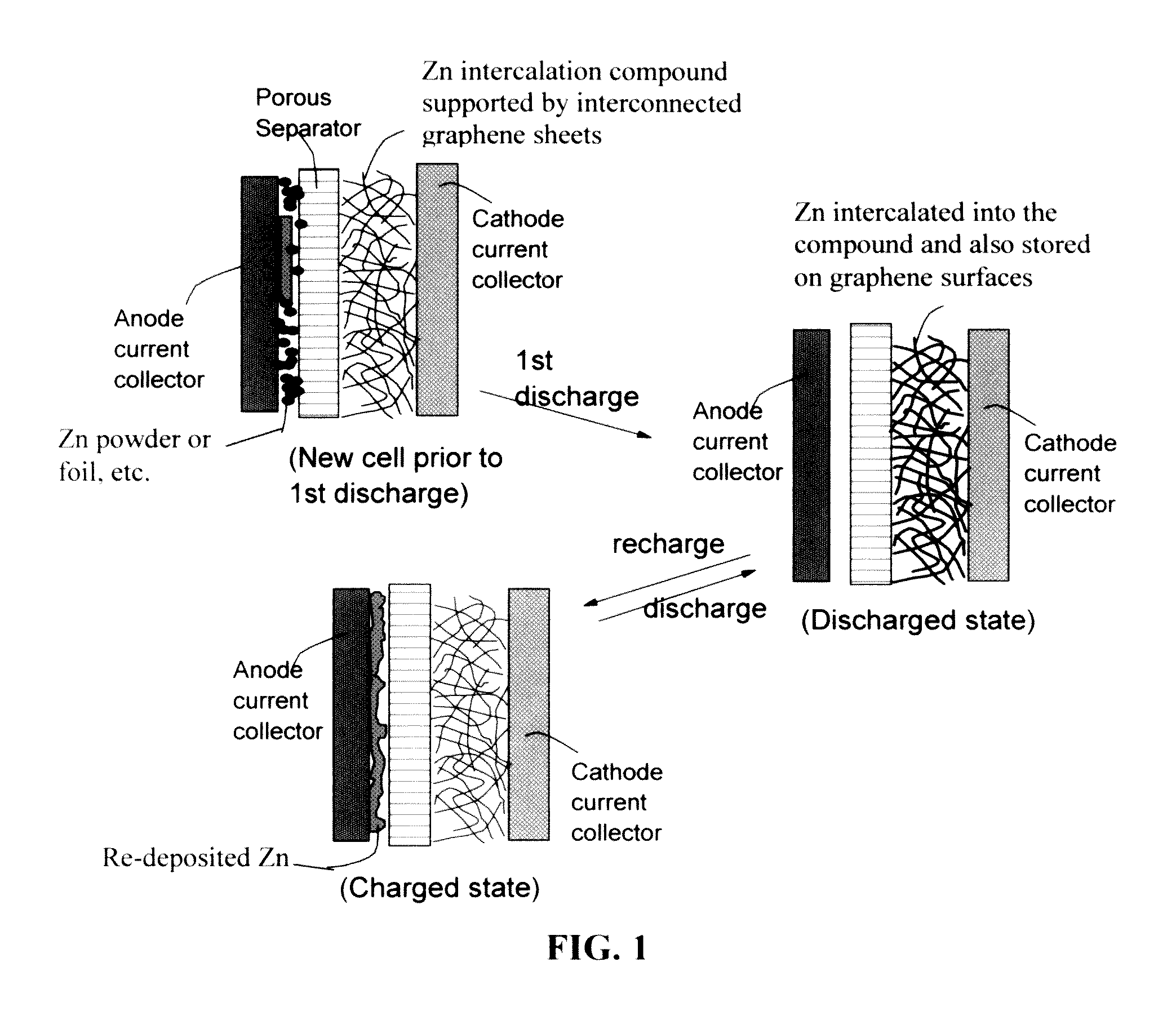

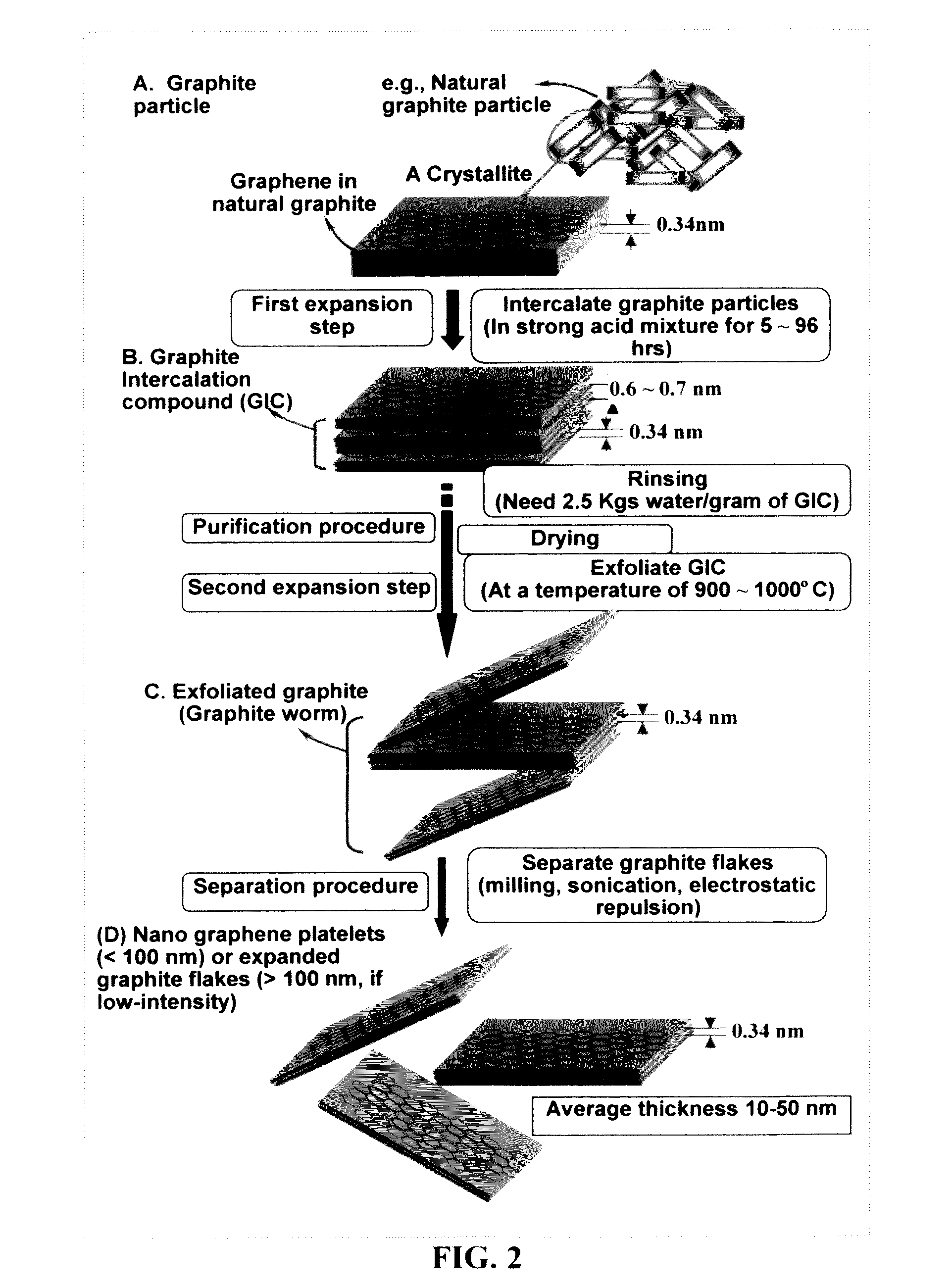

Zinc Ion-Exchanging Energy Storage Device

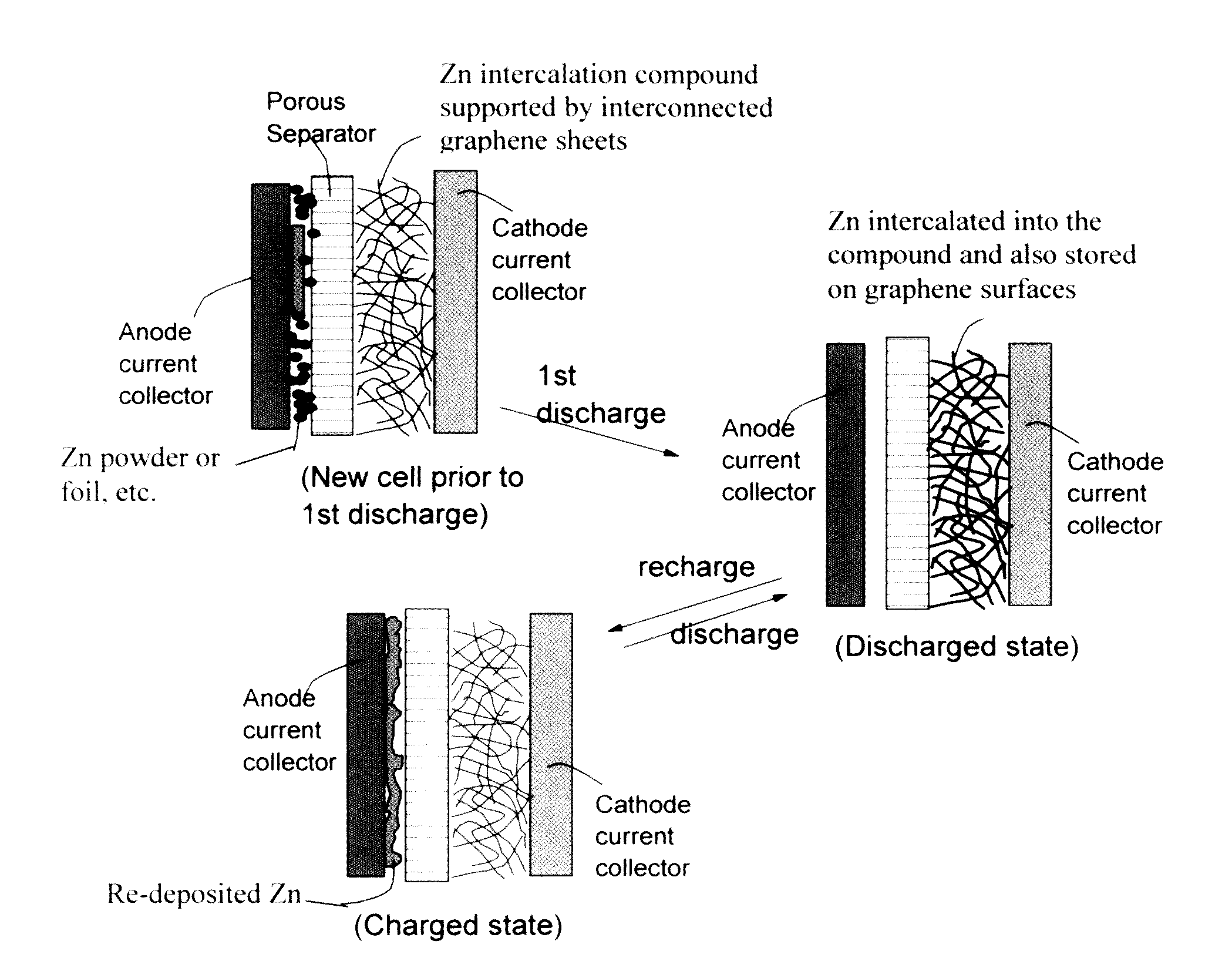

ActiveUS20160301096A1Quick releaseRapid depositionHybrid capacitor electrolytesAlkaline accumulatorsChemical treatmentZinc metal

A zinc ion-exchanging battery device comprising: (A) a cathode comprising two cathode active materials (a zinc ion intercalation compound and a surface-mediating material); (B) an anode containing zinc metal or zinc alloy; (C) a porous separator disposed between the cathode and the anode; and (D) an electrolyte containing zinc ions that are exchanged between the cathode and the anode during battery charge / discharge. The zinc ion intercalation compound is selected from chemically treated carbon or graphite material having an expanded inter-graphene spacing d002 of at least 0.5 nm, or an oxide, carbide, dichalcogenide, trichalcogenide, sulfide, selenide, or telluride of niobium, zirconium, molybdenum, hafnium, tantalum, tungsten, titanium, vanadium, chromium, cobalt, manganese, iron, nickel, or a combination thereof. The surface-mediating material contains exfoliated graphite or multiple single-layer sheets or multi-layer platelets of a graphene material.

Owner:GLOBAL GRAPHENE GRP INC

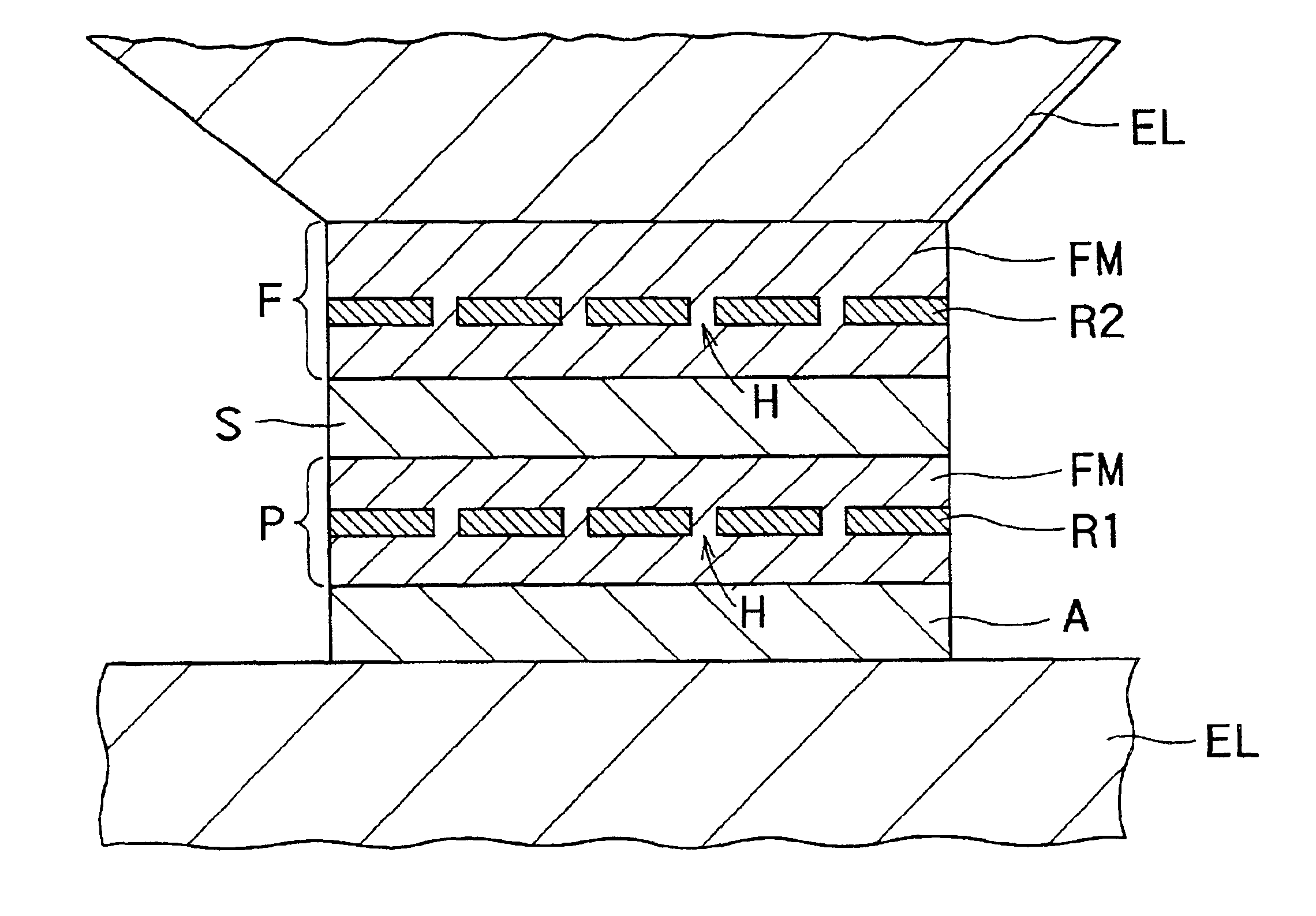

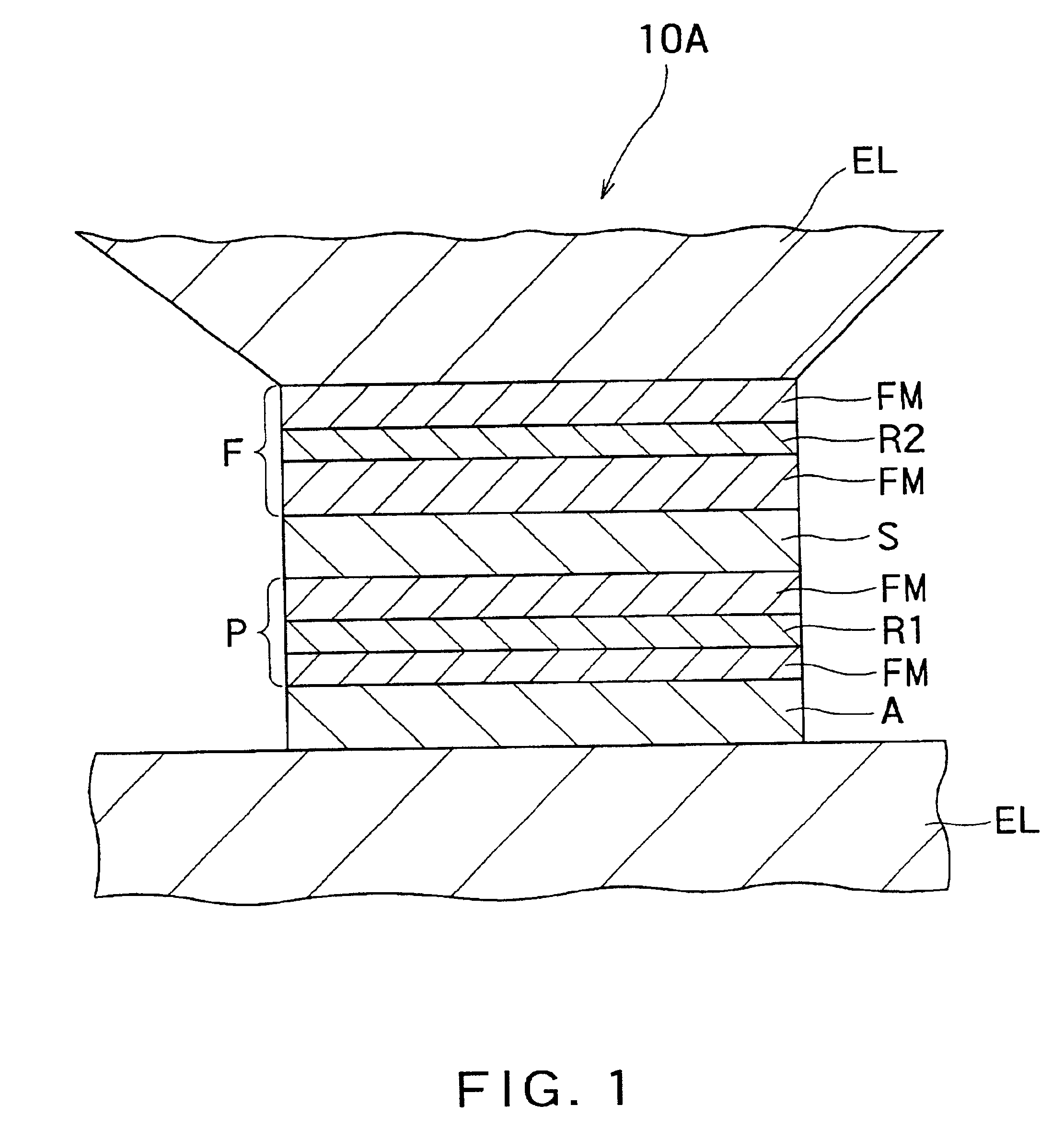

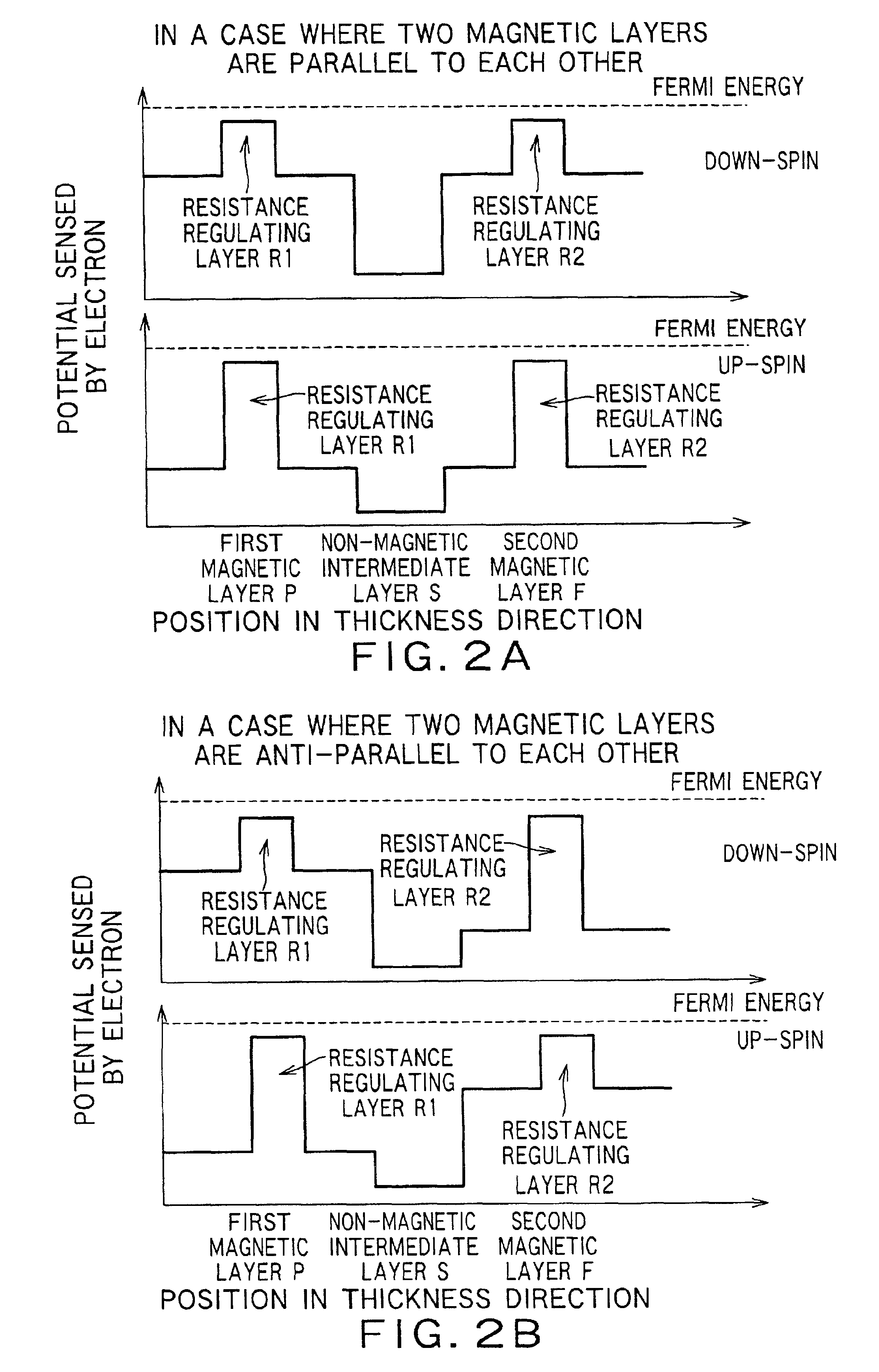

Magnetoresistance effect element, magnetic head and magnetic recording and/or reproducing system

InactiveUS6937446B2Efficient use ofControl quantityNanomagnetismMagnetic measurementsBorideScattering effect

There is provided a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers to be controlled, and a magnetic head and magnetic recording and / or reproducing system using the same. In a magnetoresistance effect element wherein a sense current is caused to flow in a direction perpendicular to the plane of the film, a resistance regulating layer is provided in at least one of a pinned layer, a free layer and an non-magnetic intermediate layer. The resistance regulating layer contains, as a principal component, an oxide, a nitride, a fluoride, a carbide or a boride. The resistance regulating layer may be a continuous film or may have pin holes. Thus, it is possible to provide a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers, while effectively utilizing the scattering effect depending on spin.

Owner:KK TOSHIBA

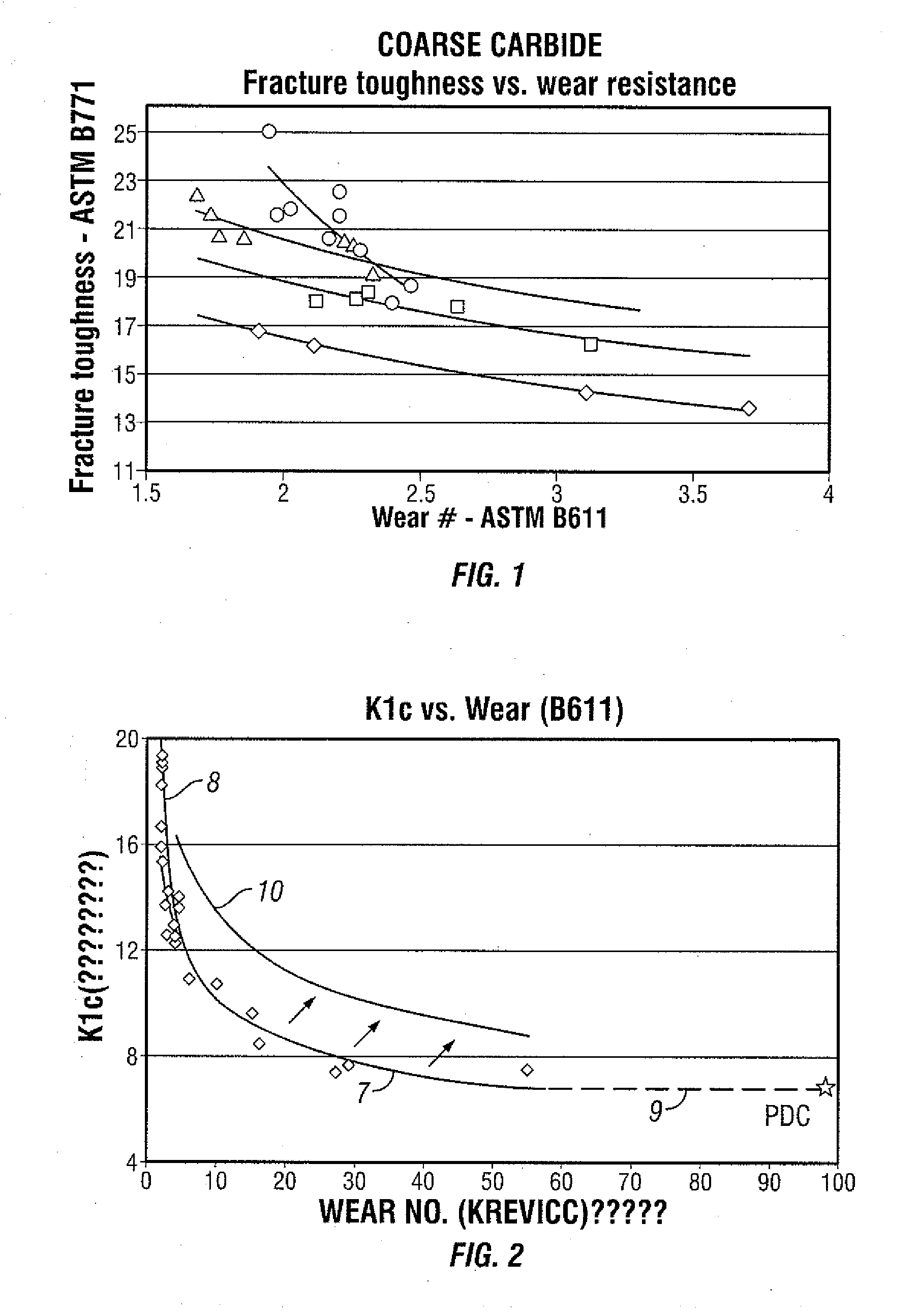

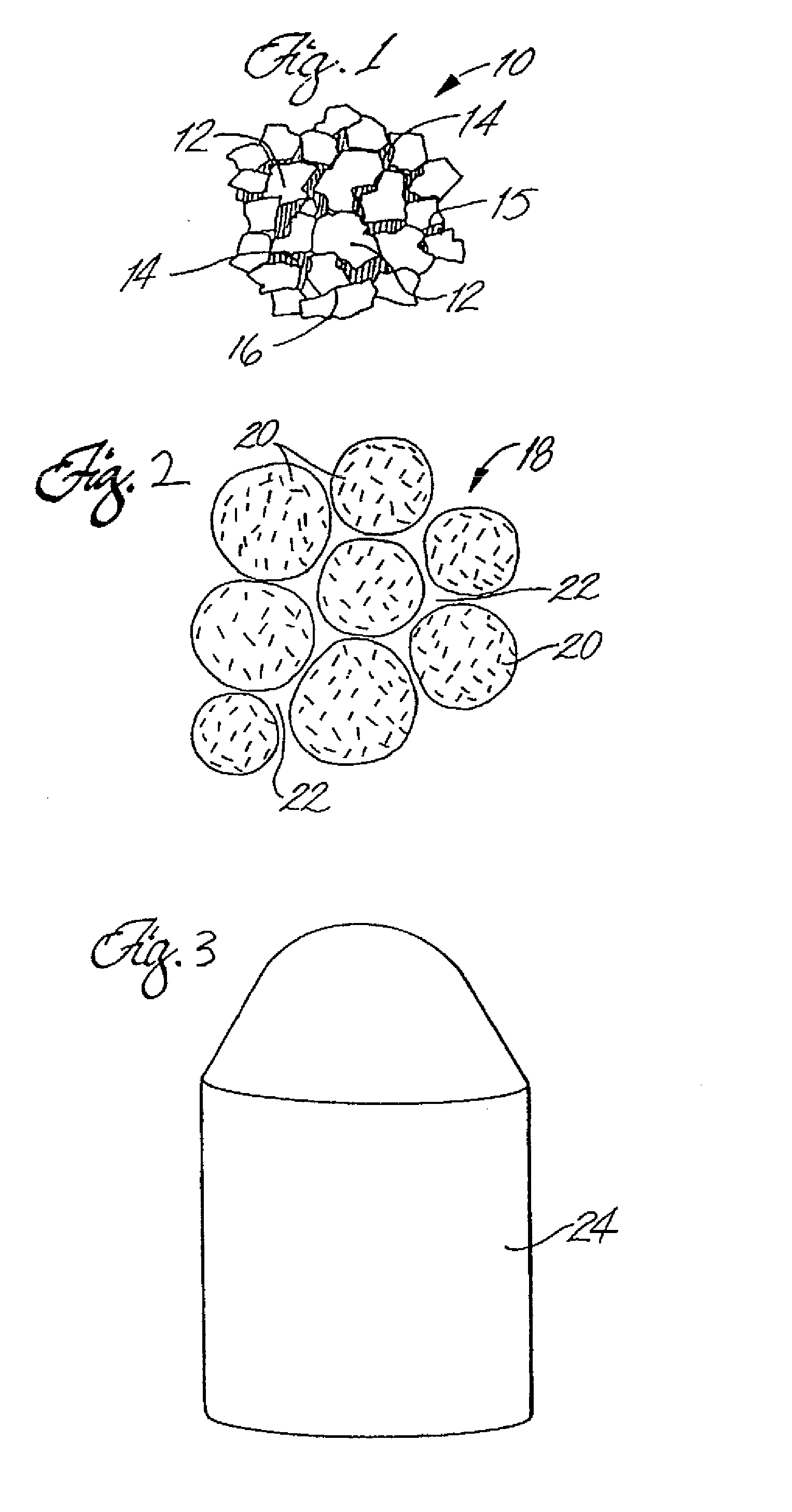

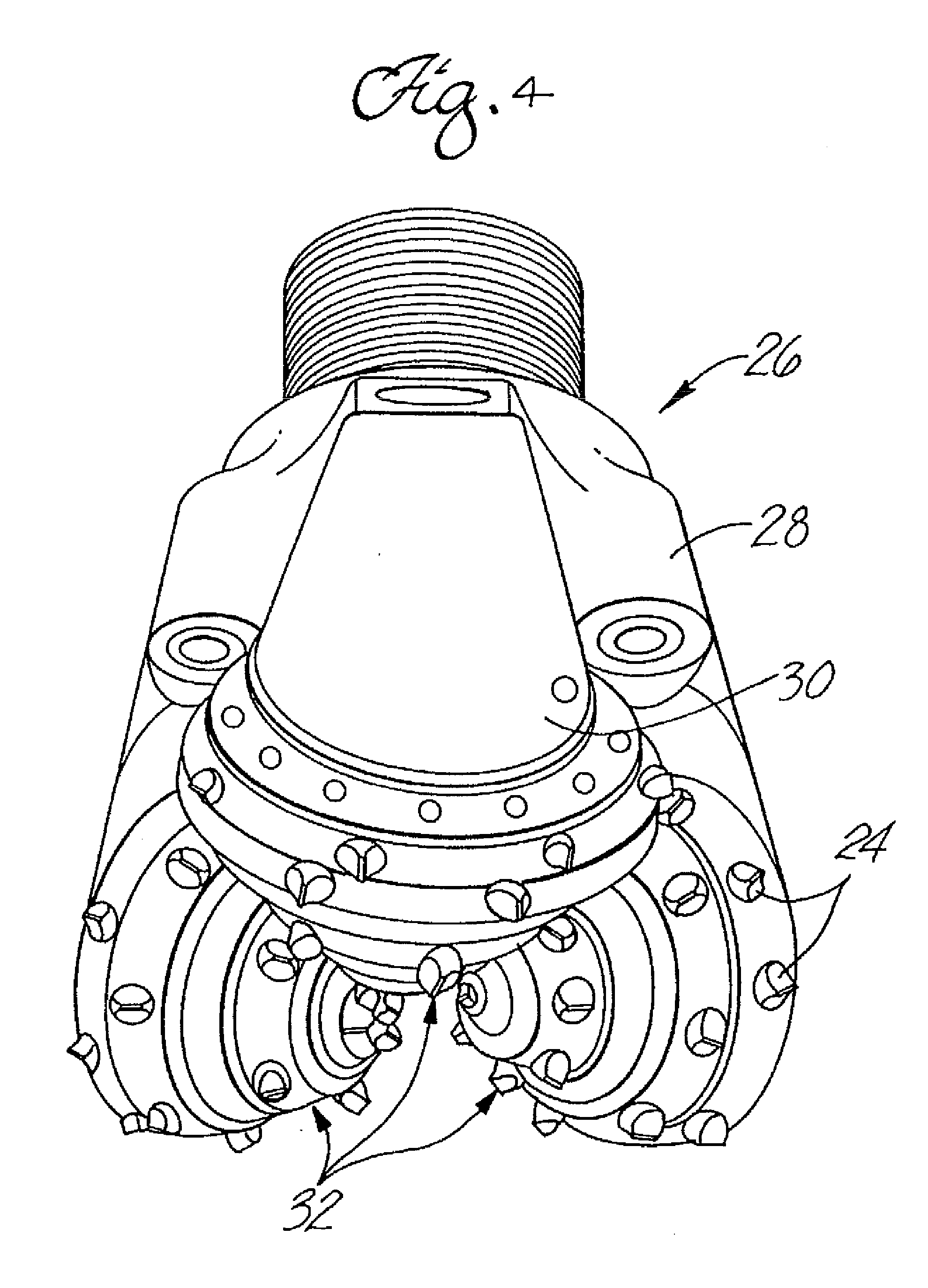

Polycrystalline diamond carbide composites

InactiveUS20070193782A1Improve fracture toughnessEasy to useDrill bitsOther chemical processesPolycrystalline diamondCarbide

Owner:SMITH INT INC

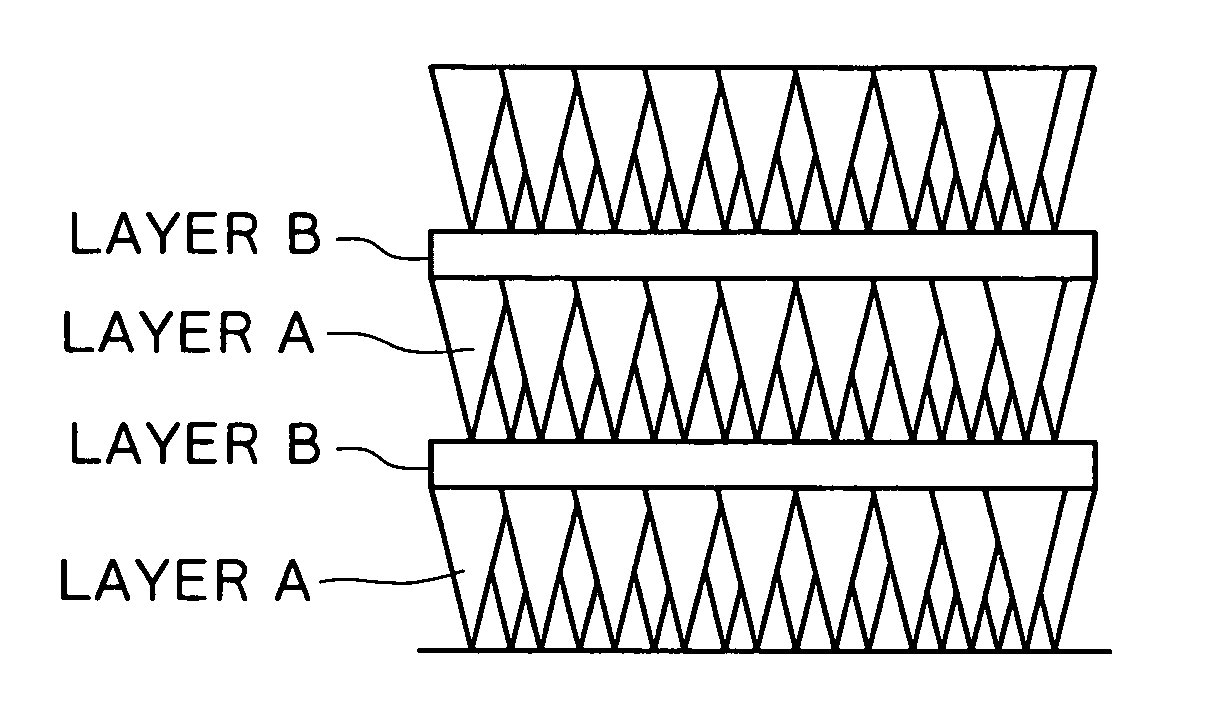

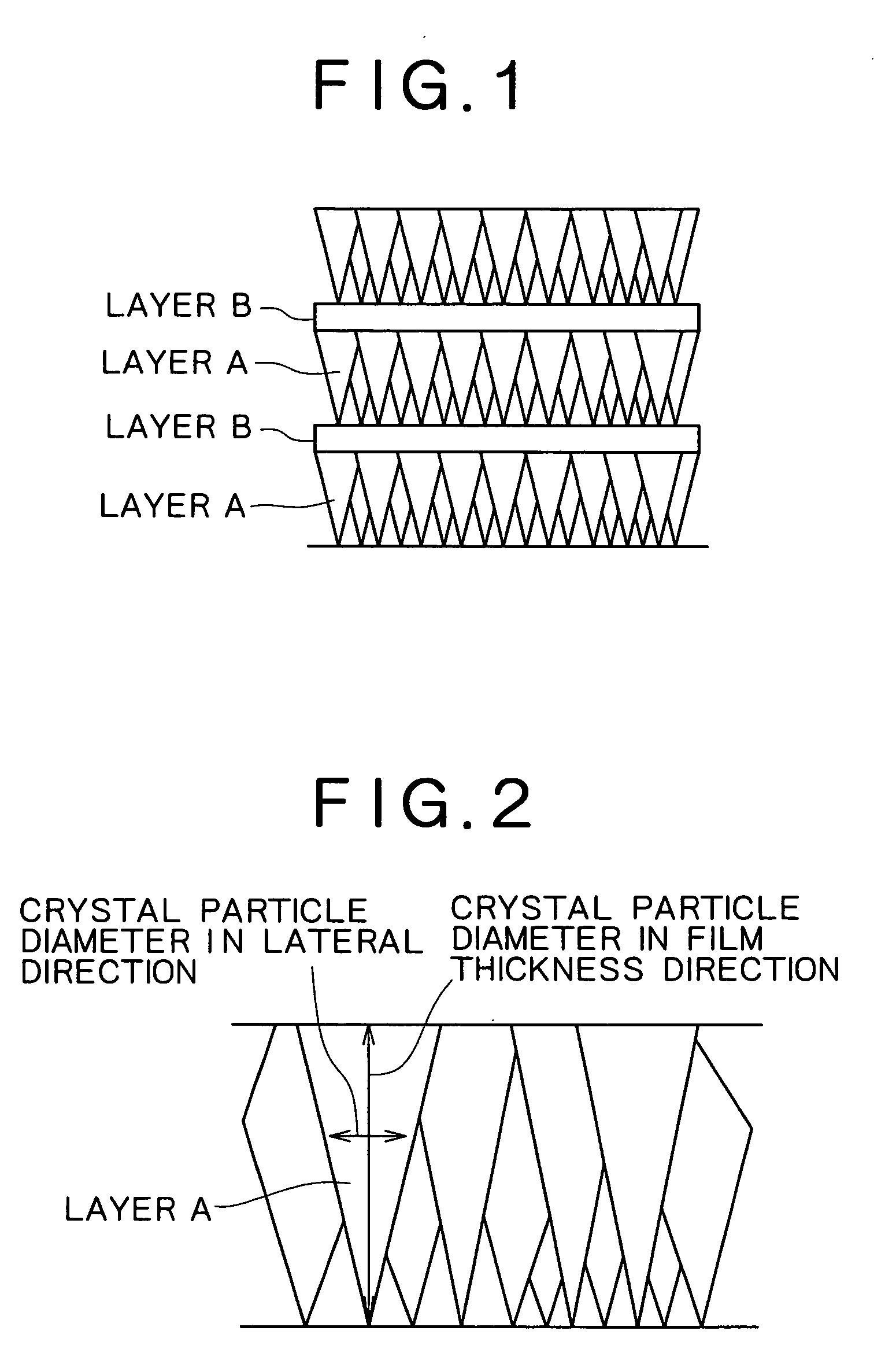

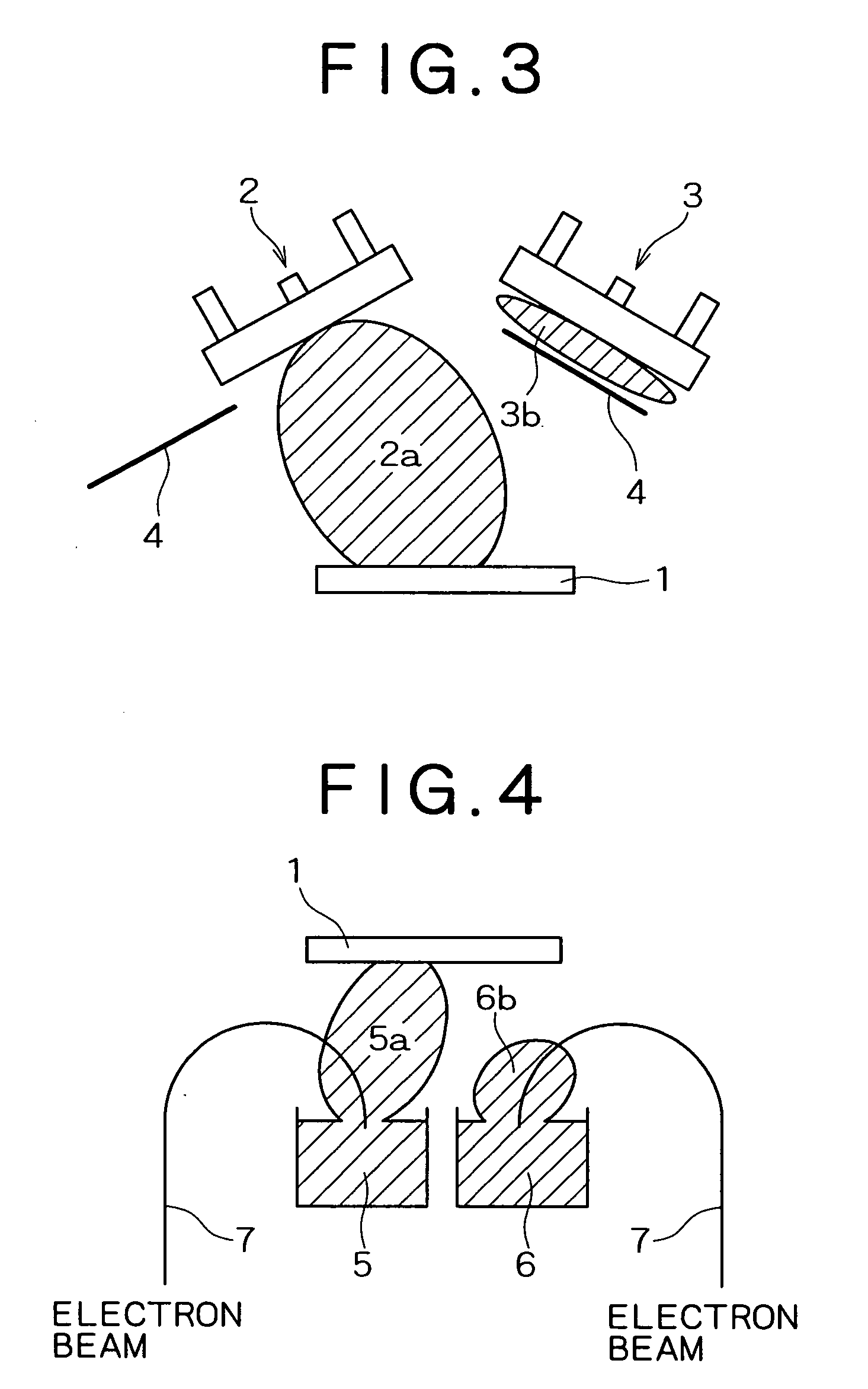

Hard laminated film, method of manufacturing the same and film-forming device

ActiveUS20050170162A1Simply and easily and finely controlledHigh ionizationVacuum evaporation coatingSputtering coatingChemical compositionCarbide

A hard laminated film wherein a layer A and a layer B having specific compositions are deposited alternately so that the compositions of layer A and layer B are different. The thickness of layer A per layer is twice or more the thickness of layer B per layer, the thickness of layer B per layer is 0.5 nm or more, and the thickness of layer A per layer is 200 nm or less. Layer A has a cubic rock-salt crystal structure such as that of Ti, Cr, Al, V nitride, carbonitride or carbide, and layer B is a hard film having a crystal structure other than cubic such as that of BN, BCN, SiN, SiC, SiCN, B—C, Cu, CuN, CuCN or metallic Cu. Alternatively, layer A has a chemical composition satisfying the following formula (1), and layer B has a chemical composition satisfying the following formula (2). Layer A: Cr(BaCbN1-a-b-cOc) 0≦a≦0.15, 0≦b≦0.3, 0≦c≦0.1, 0.2≦e≦1.1 (1) Layer B: B1-s-tCsNt 0≦s 0.25, (1−s−t) / t≦1.5 (2) Alternatively, Layer A has a specific atomic ratio composition of (Ti1-x-yAlxMy)(BaCbN1-a-b-cOc) and Layer B has one or more specific atomic ratio compositions selected from among the compositions B1-x-yCxNy, Si1-x-yCxNy, C1-xNx, Cu1-y(CxN1-x)y. Alternatively, Layer A has one of the following Compositional Formulae 1 or 2. Formula 1: (Ti1-x-yAlxMy), (BaCbN1-a-b-cOc), Formula 2: (Cr1-αXα)(BaCbN1-a-b-cOc)e (X is one or more metal elements selected from among Ti, Zr, Hf, V, Nb, Ta, Mo, W, Al, Si. Layer B has the following compositional formula 3. Formula 3 M(BaCbN1-a-b-cOc). M is one or more metal elements selected from among W, Mo, V, Nb.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com