Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6899results about "Piezoelectric/electrostrictive device manufacture/assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

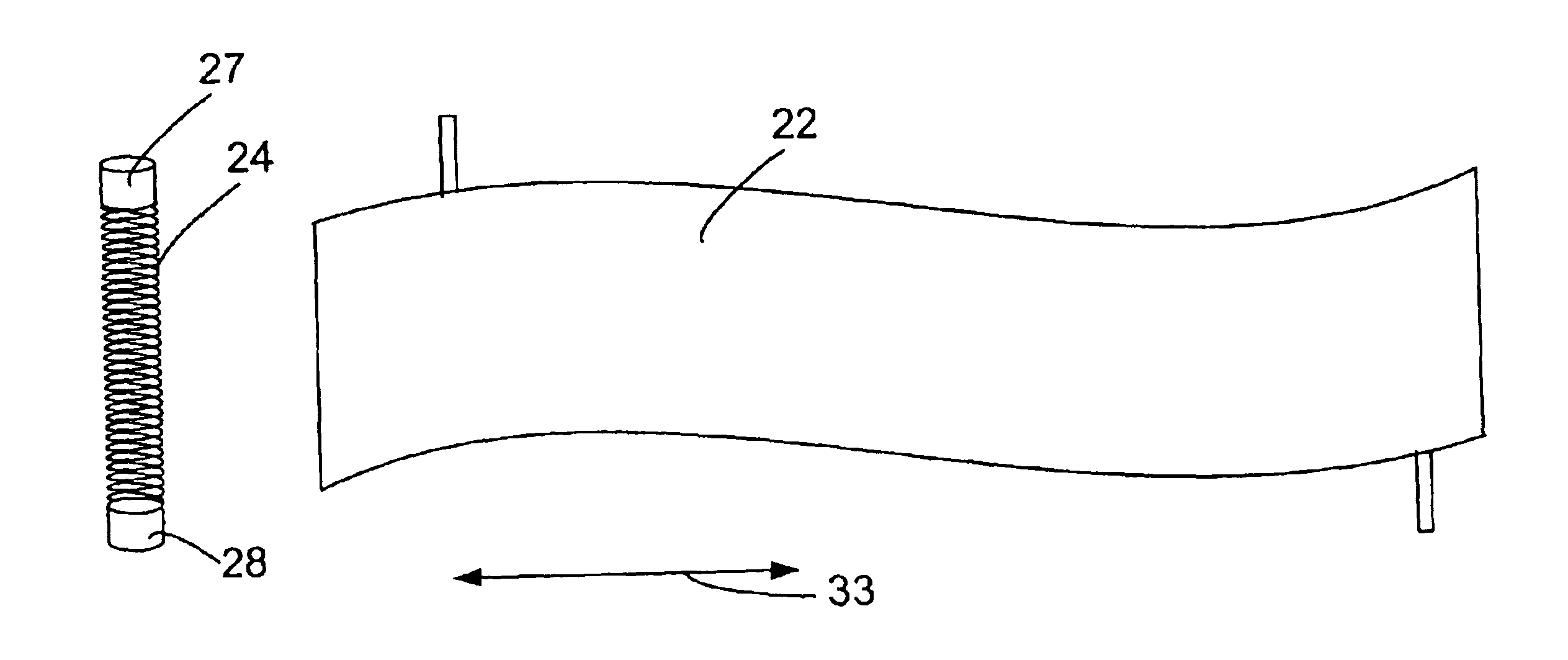

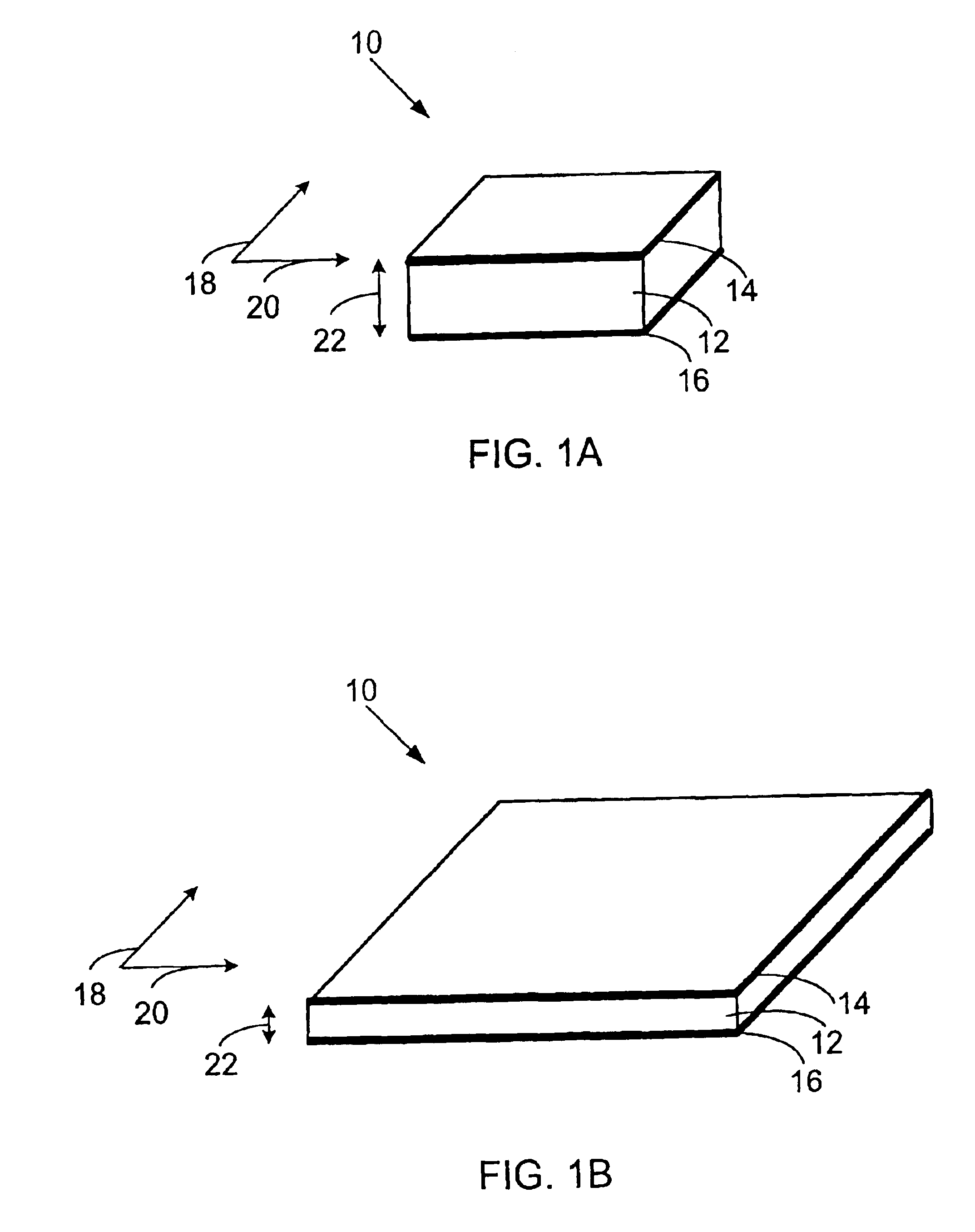

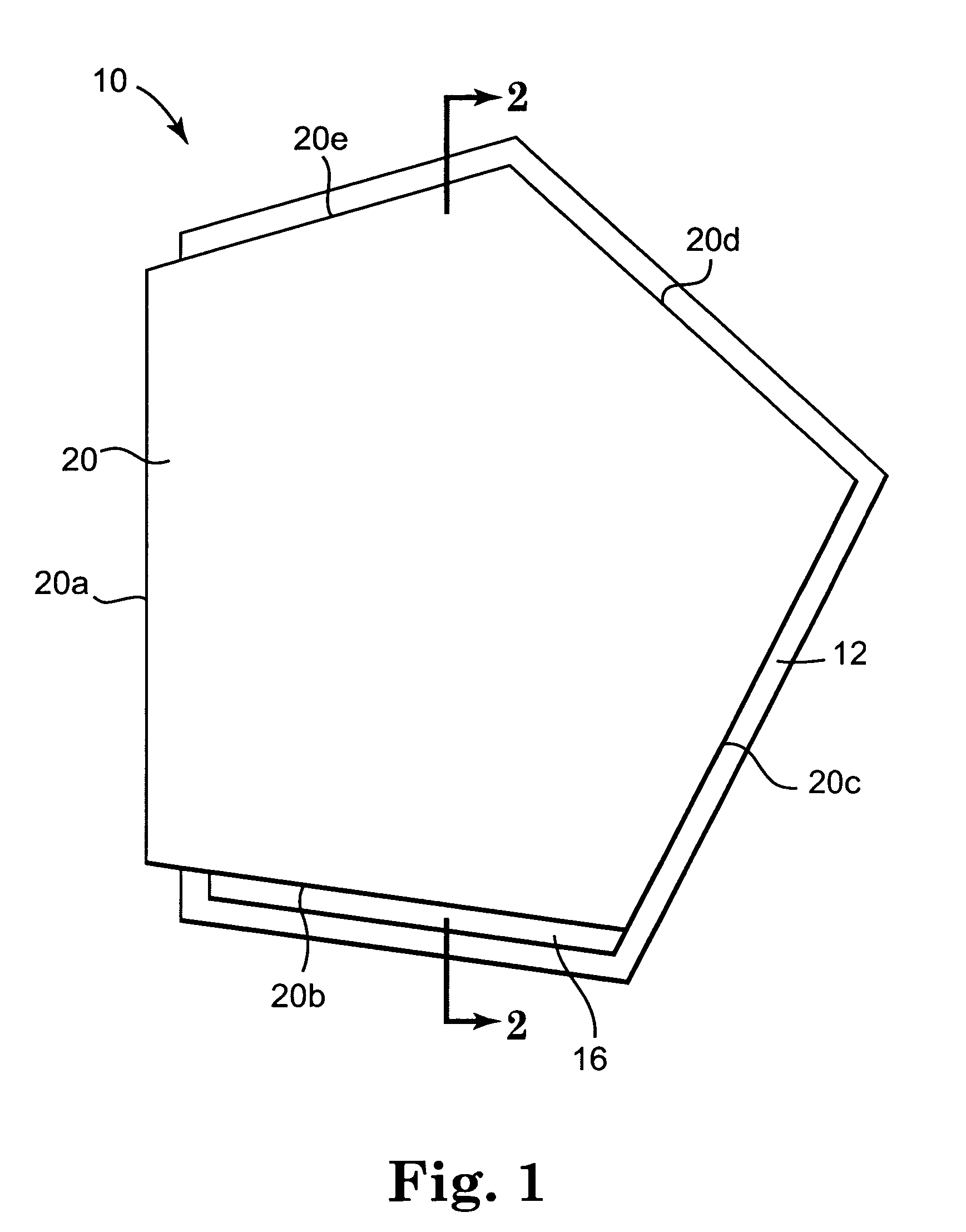

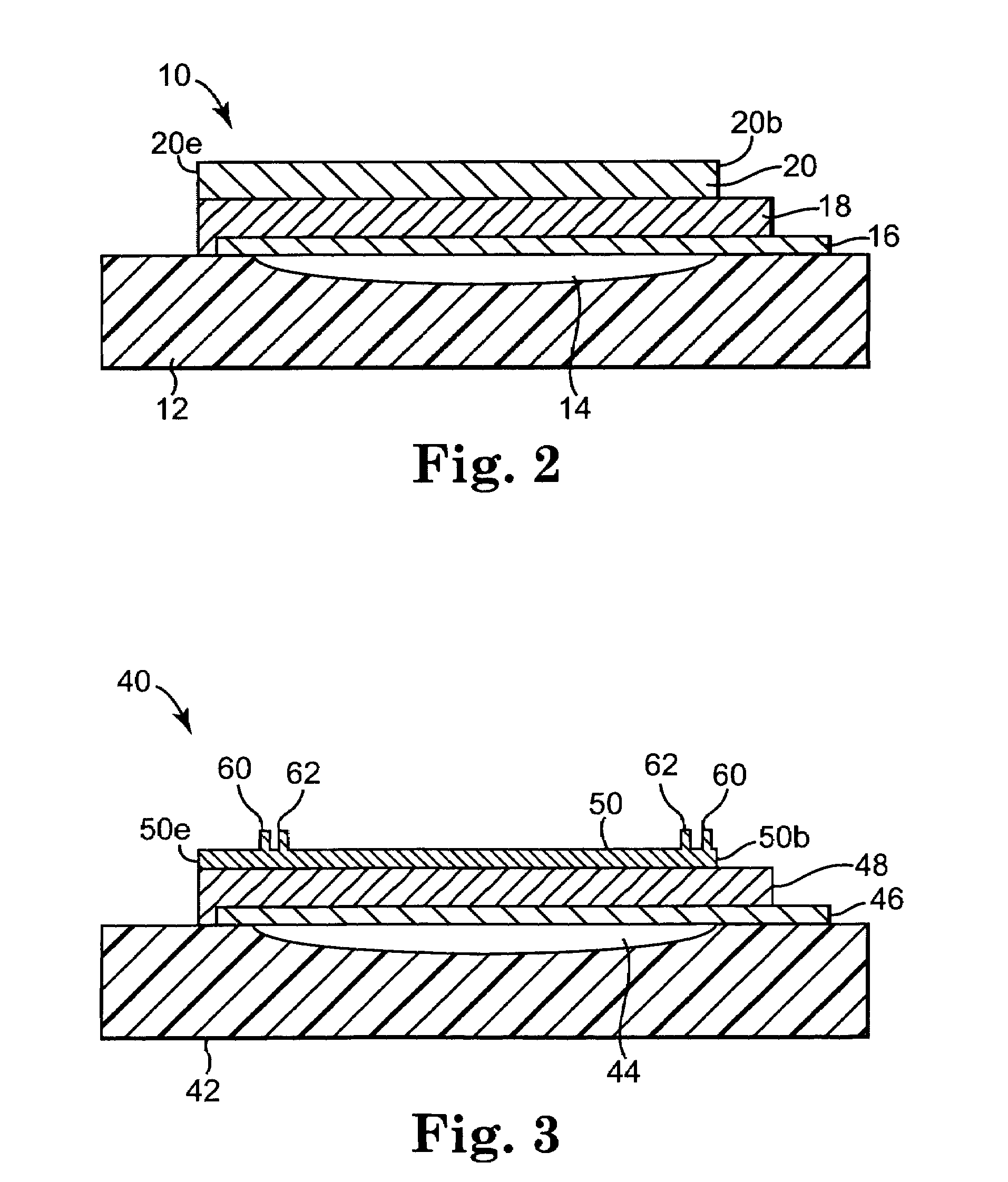

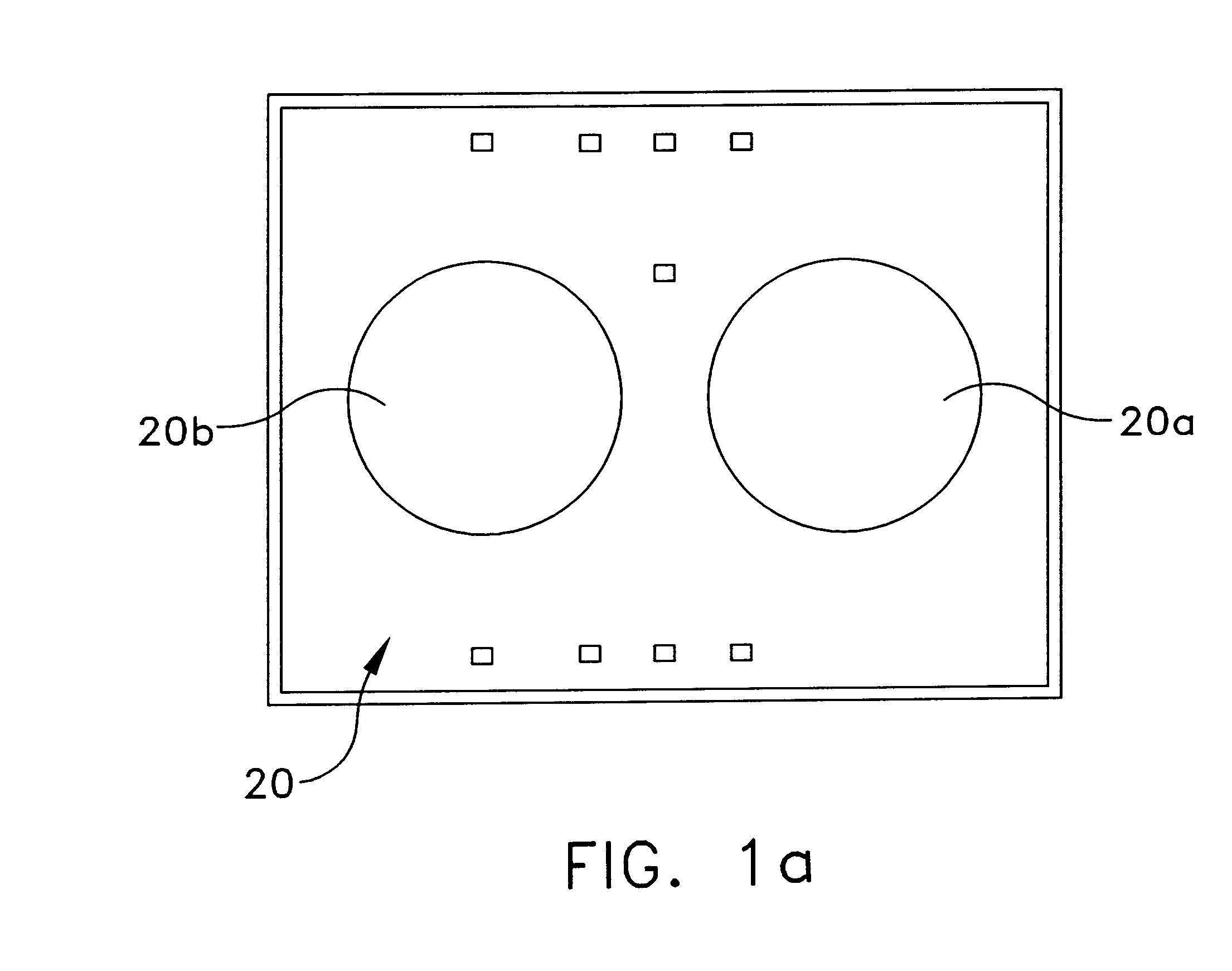

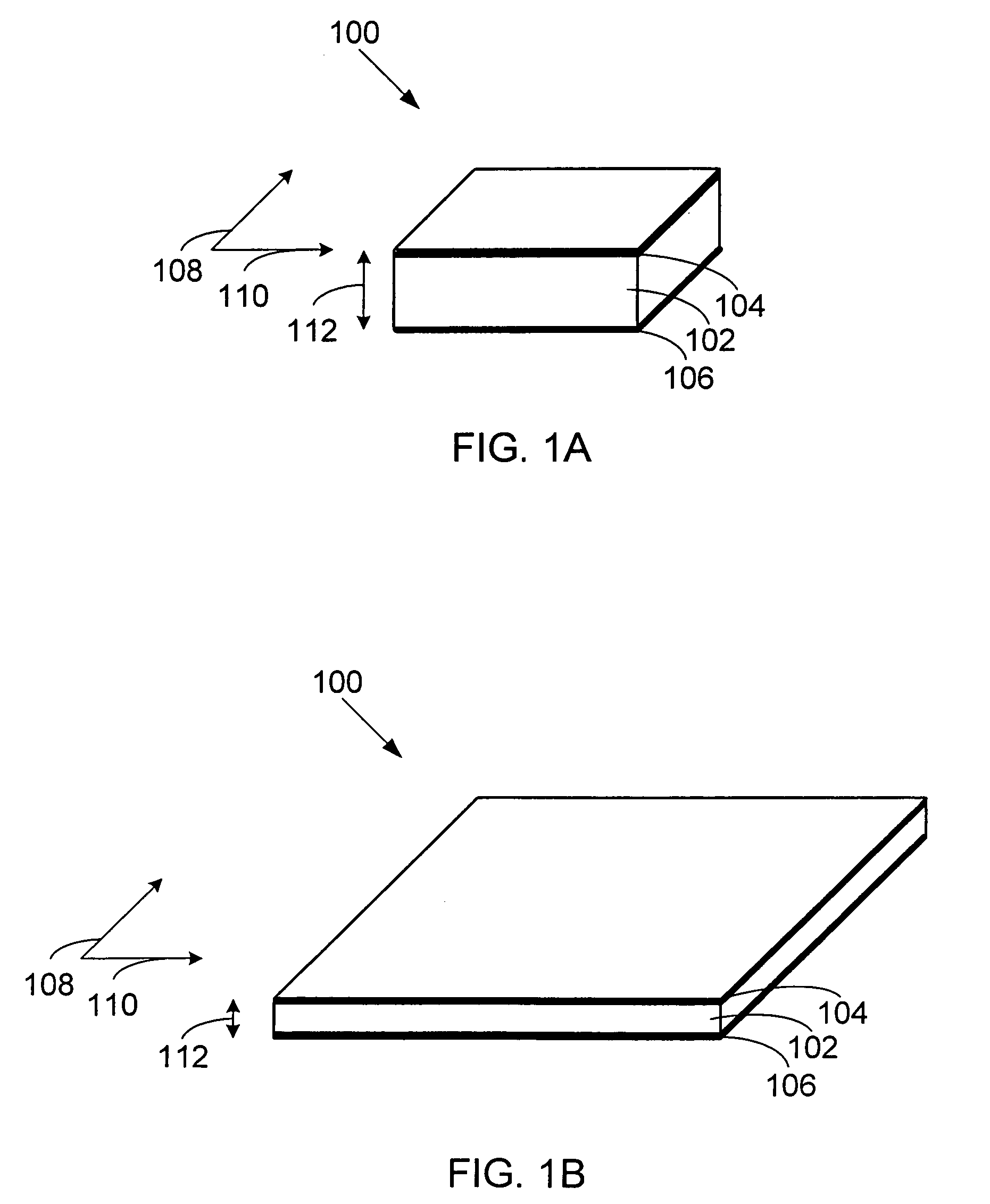

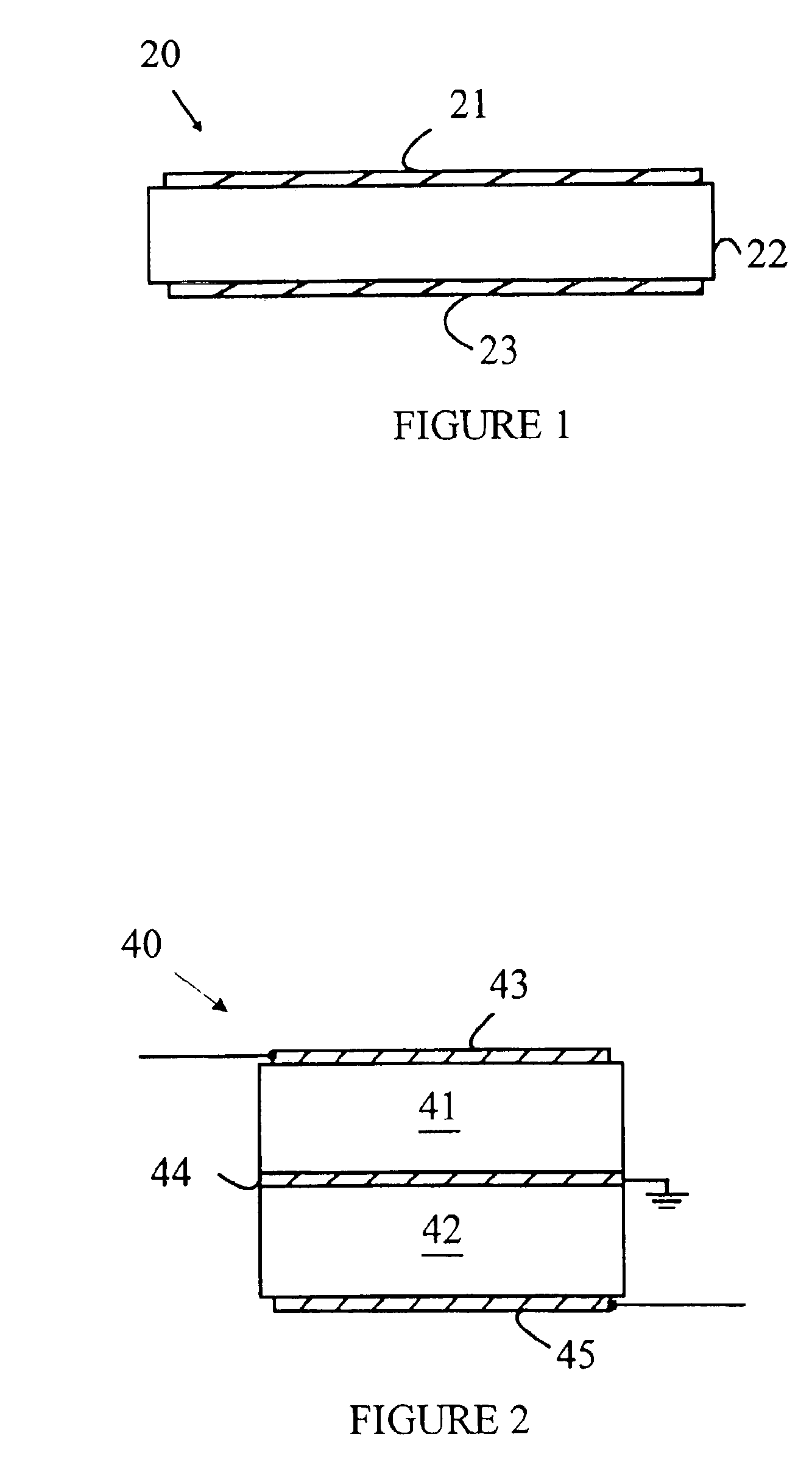

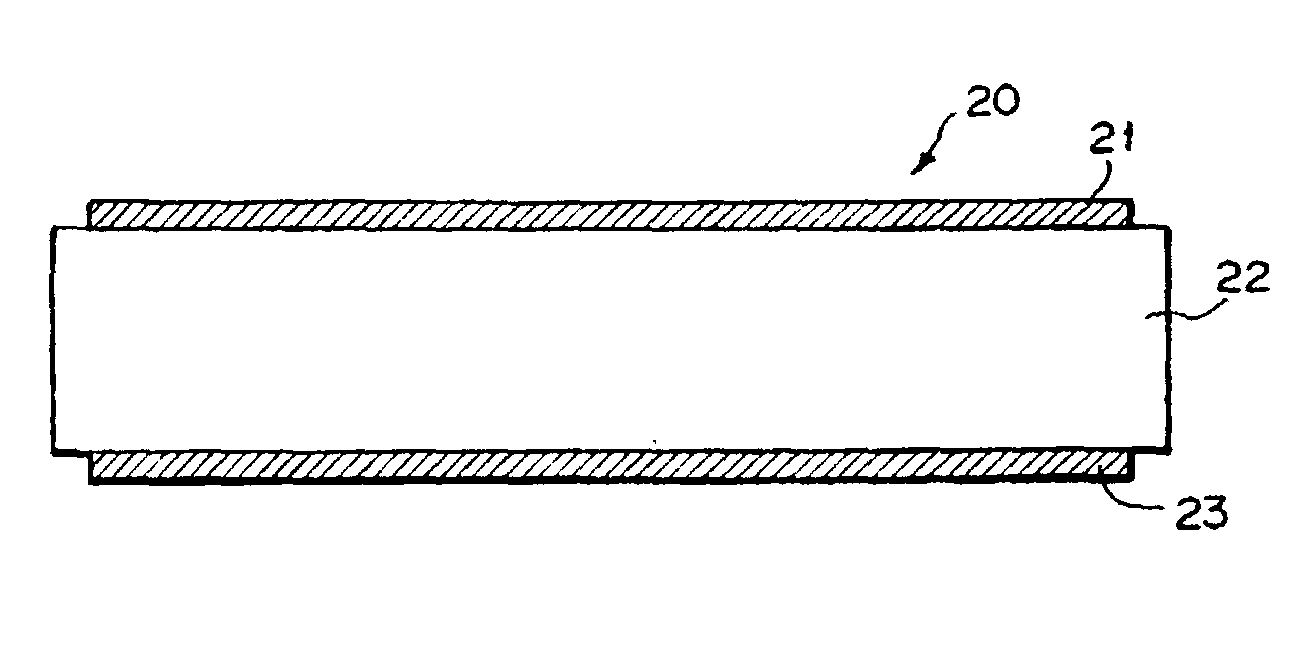

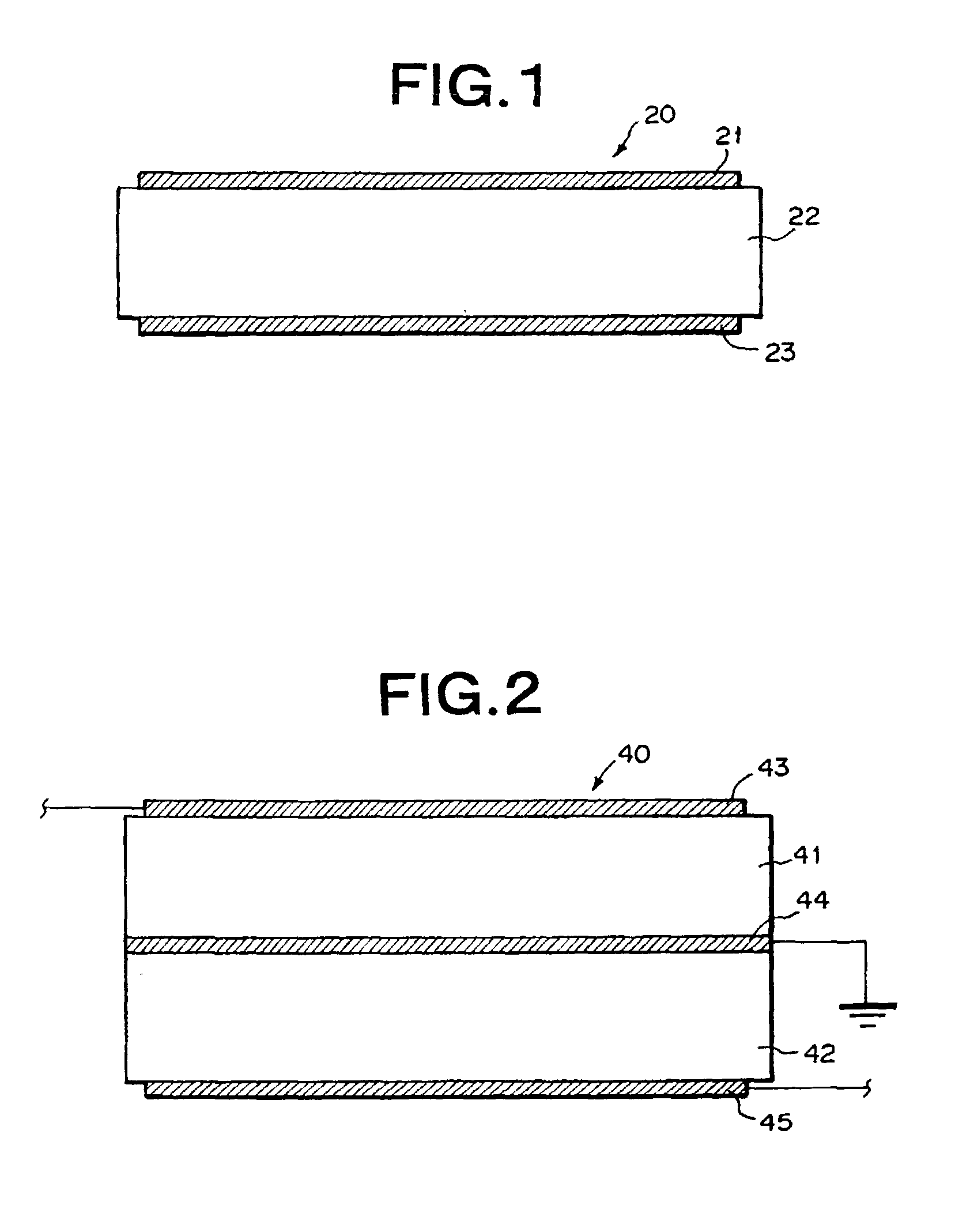

Rolled electroactive polymers

InactiveUS6891317B2Increase conversionsImprove performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPolymer scienceMechanical energy

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

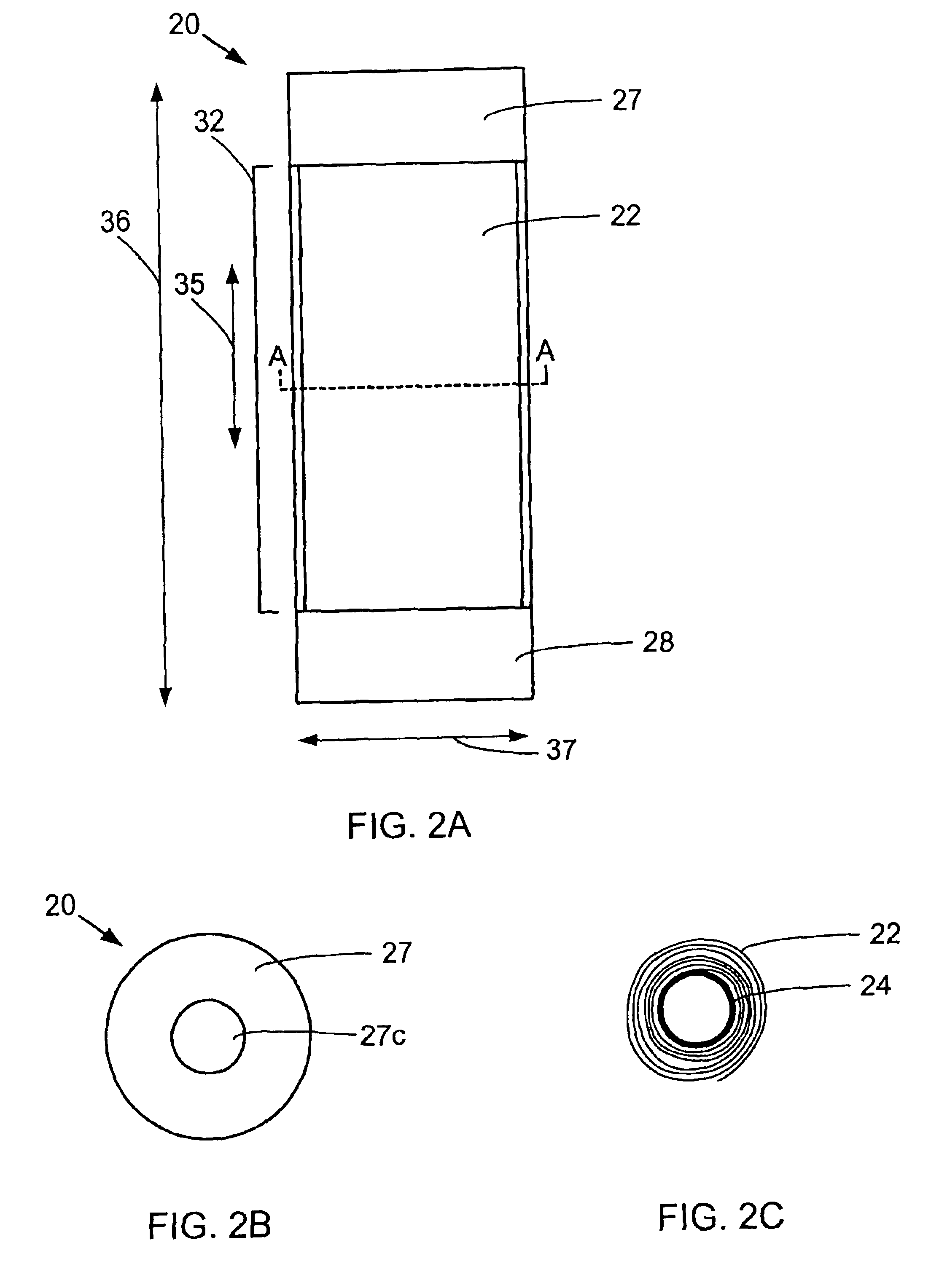

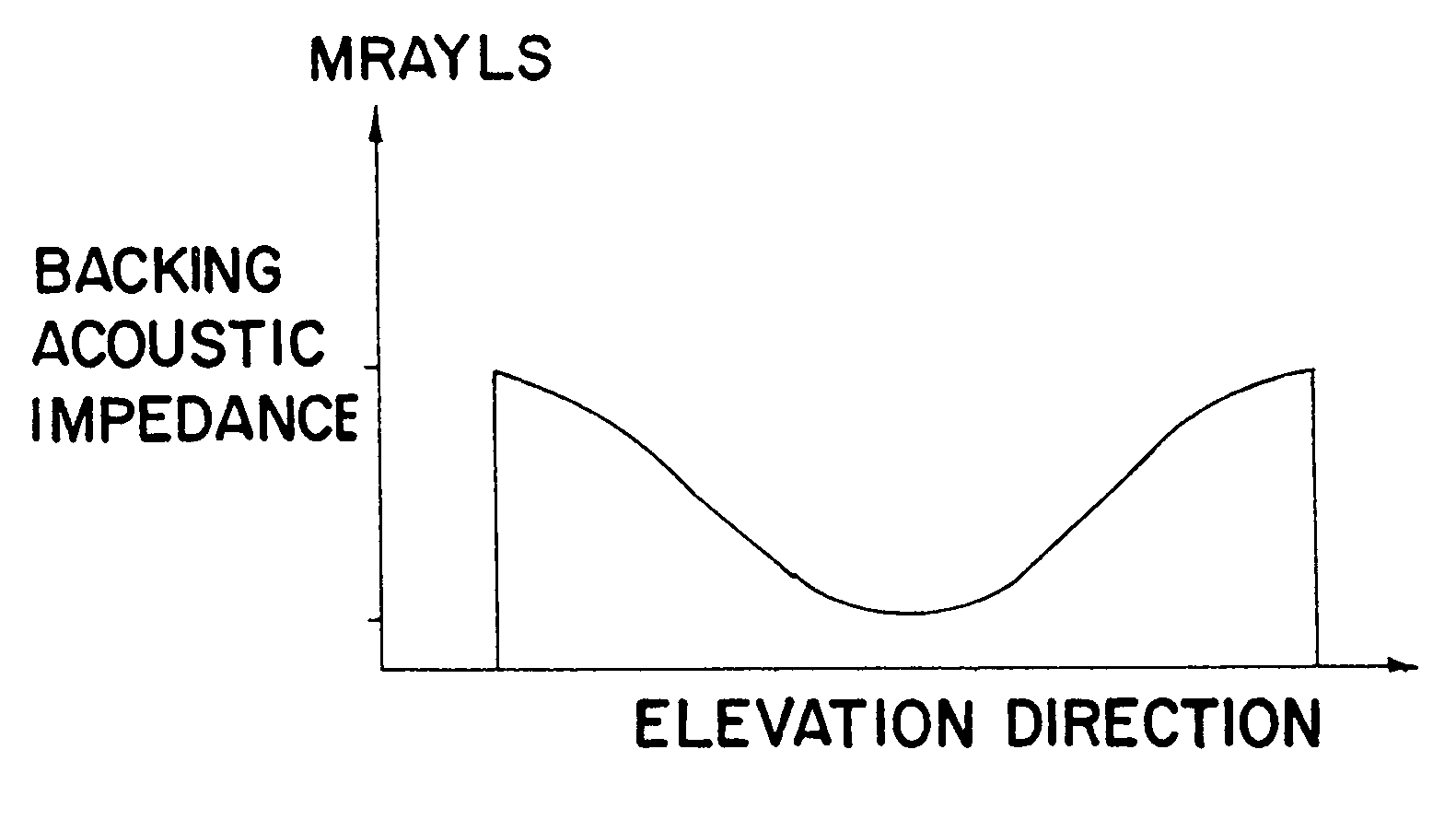

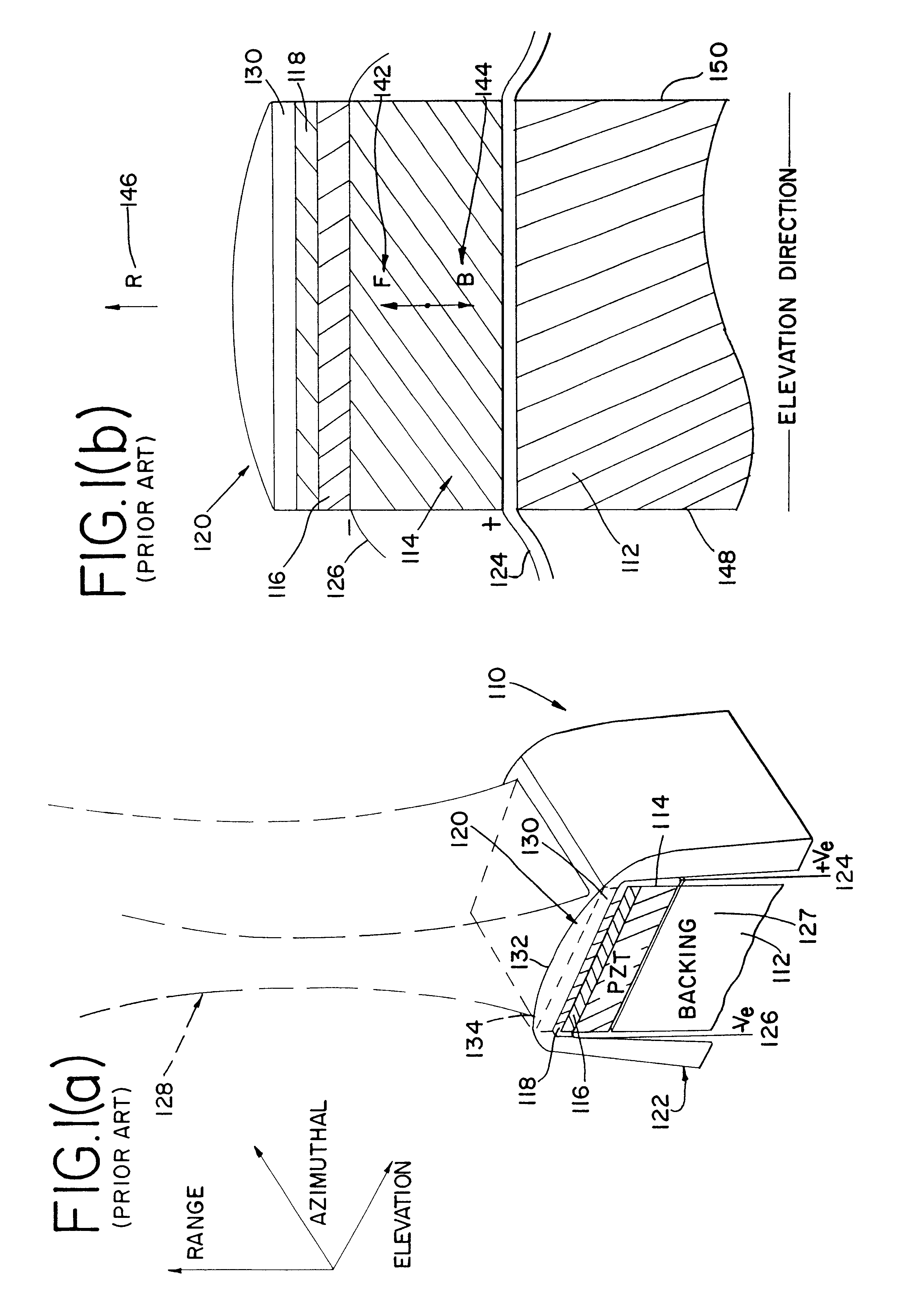

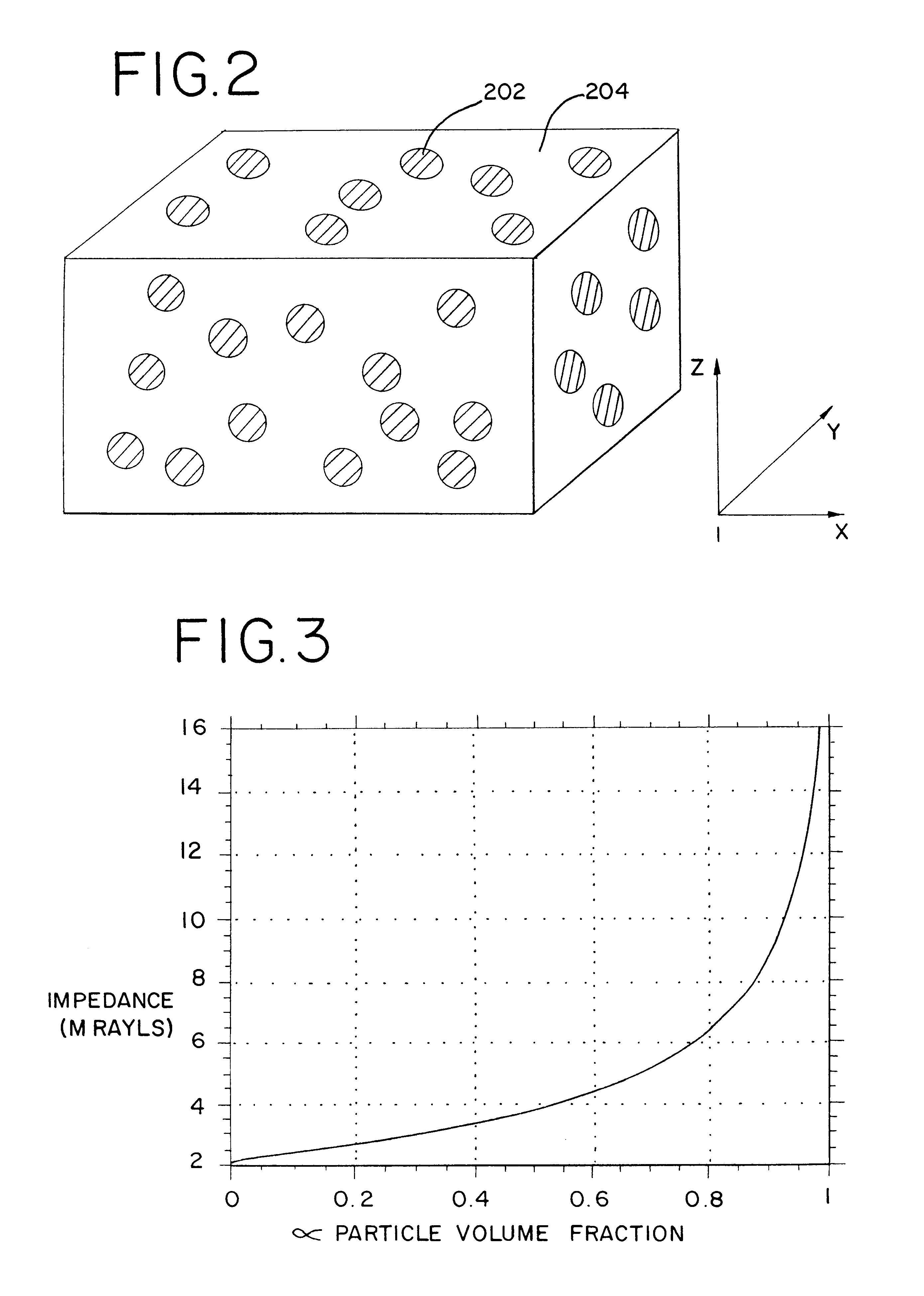

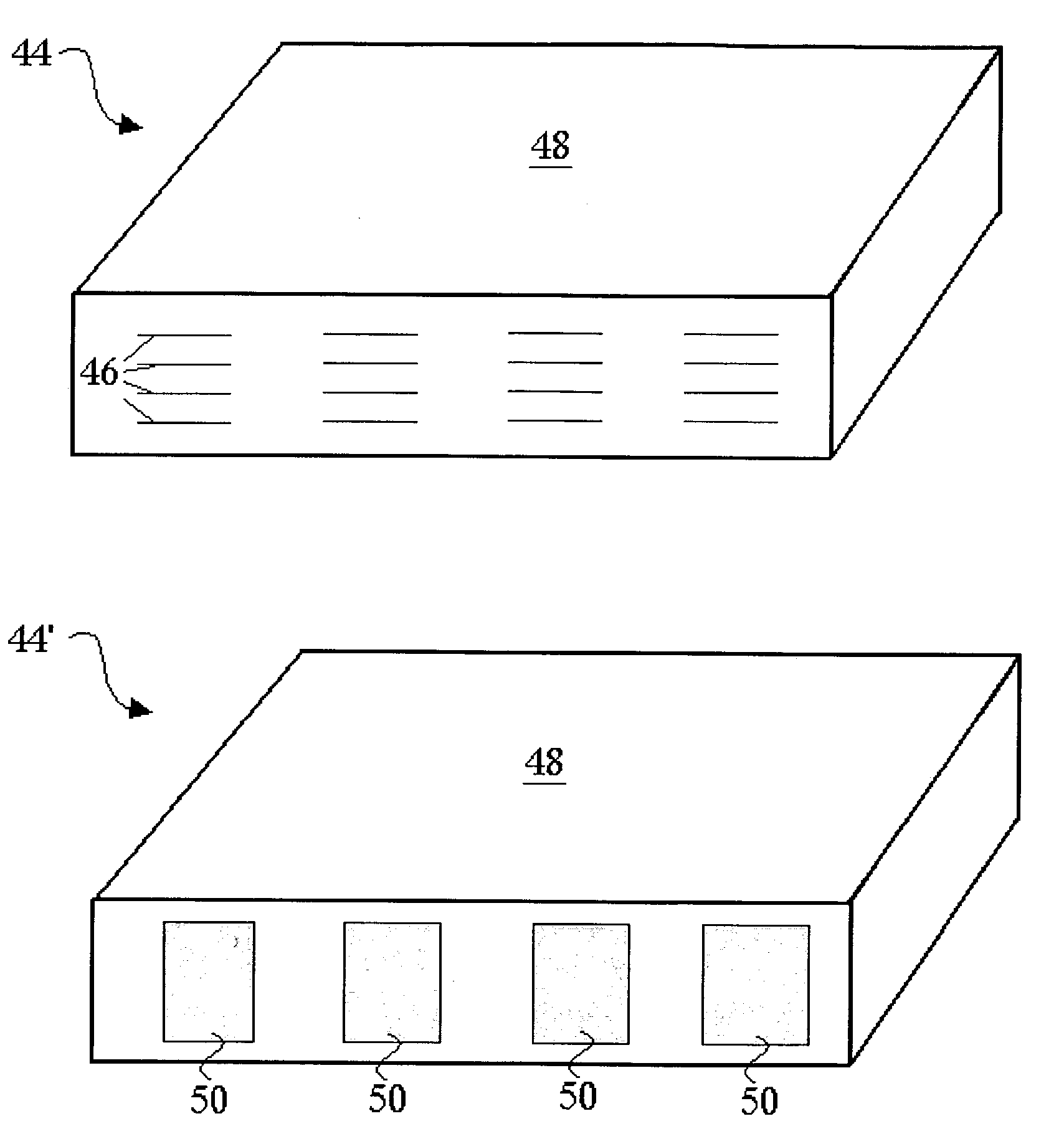

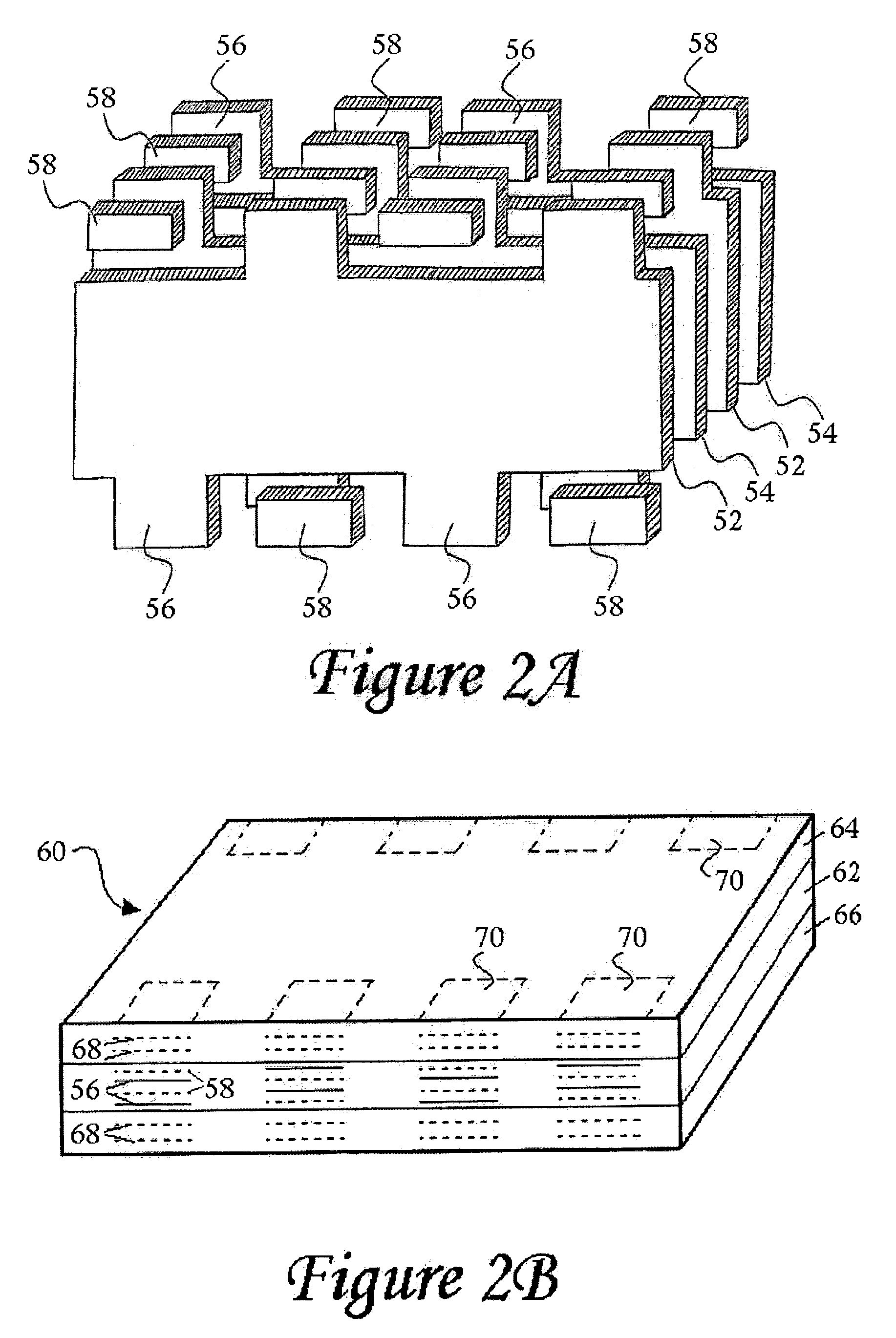

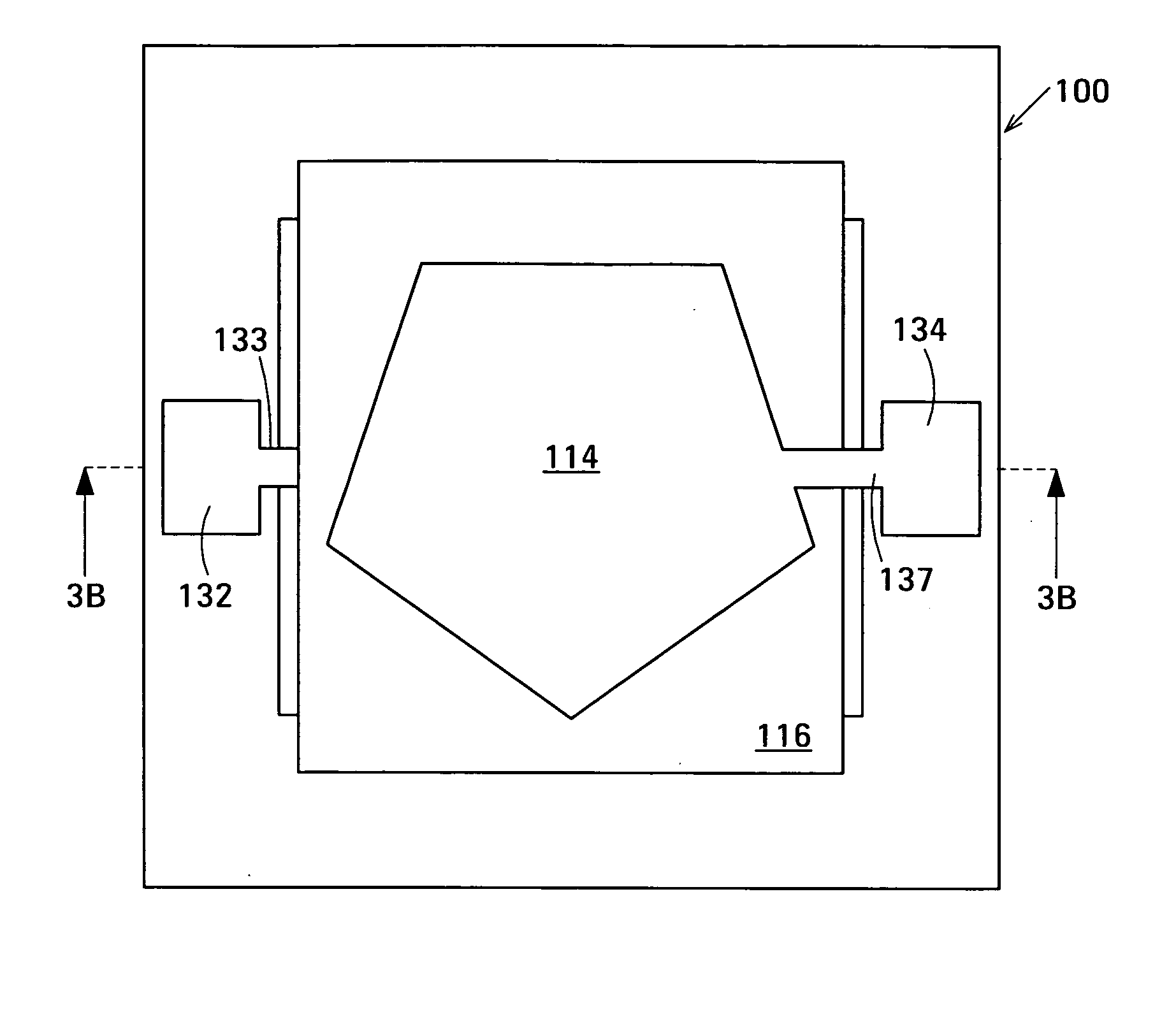

Apodization methods and apparatus for acoustic phased array aperture for diagnostic medical ultrasound transducer

InactiveUS6258034B1Reduce side lobe side lobe image artifactLow costUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device manufacture/assemblyUltrasonographyAzimuth direction

An apparatus and method using a backing block having a variable acoustic impedance as a function of elevation or azimuth, to achieve a desirable apodization of the aperture of an ultrasound transducer stacked with the backing block. The backing block has a gradient profile in acoustic impedance that changes from a minimum value to a maximum value along the elevation direction and / or azimuthal direction of the stacked ultrasound transducer. Typically, the backing block has an elevation gradient profile in acoustic impedance that increases from a minimum value of acoustic impedance near the center of the backing block to a maximum value of acoustic impedance at opposing lateral faces of the backing block. The backing block can be discretely segmented in acoustic impedance, with as many segments as are practically manufacturable. An individual segment can have a uniform or variable acoustic impedance. The backing block can be continuous in acoustic impedance, with a minimum acoustic impedance in the center and a maximum acoustic impedance at two or more planar lateral faces.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

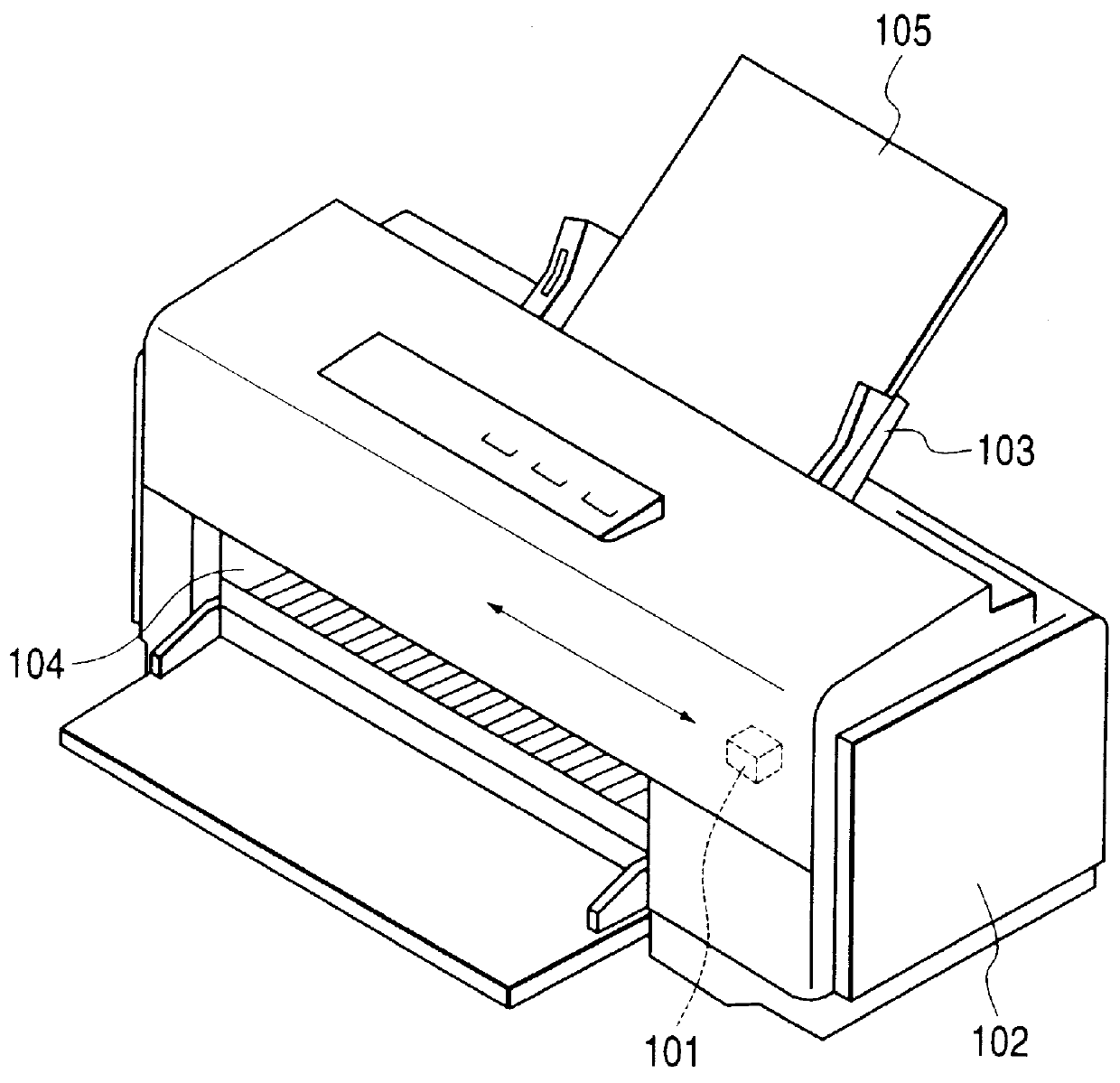

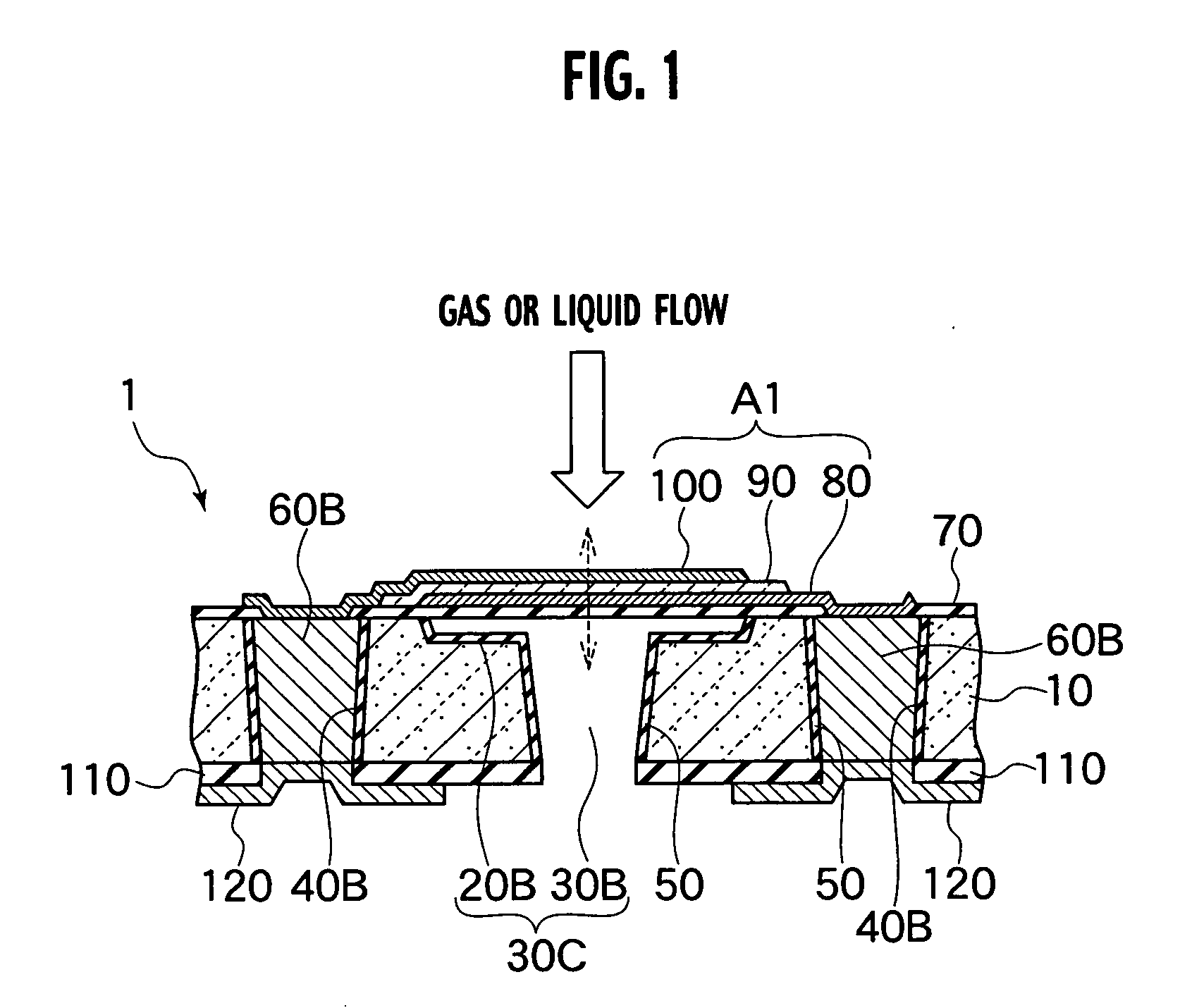

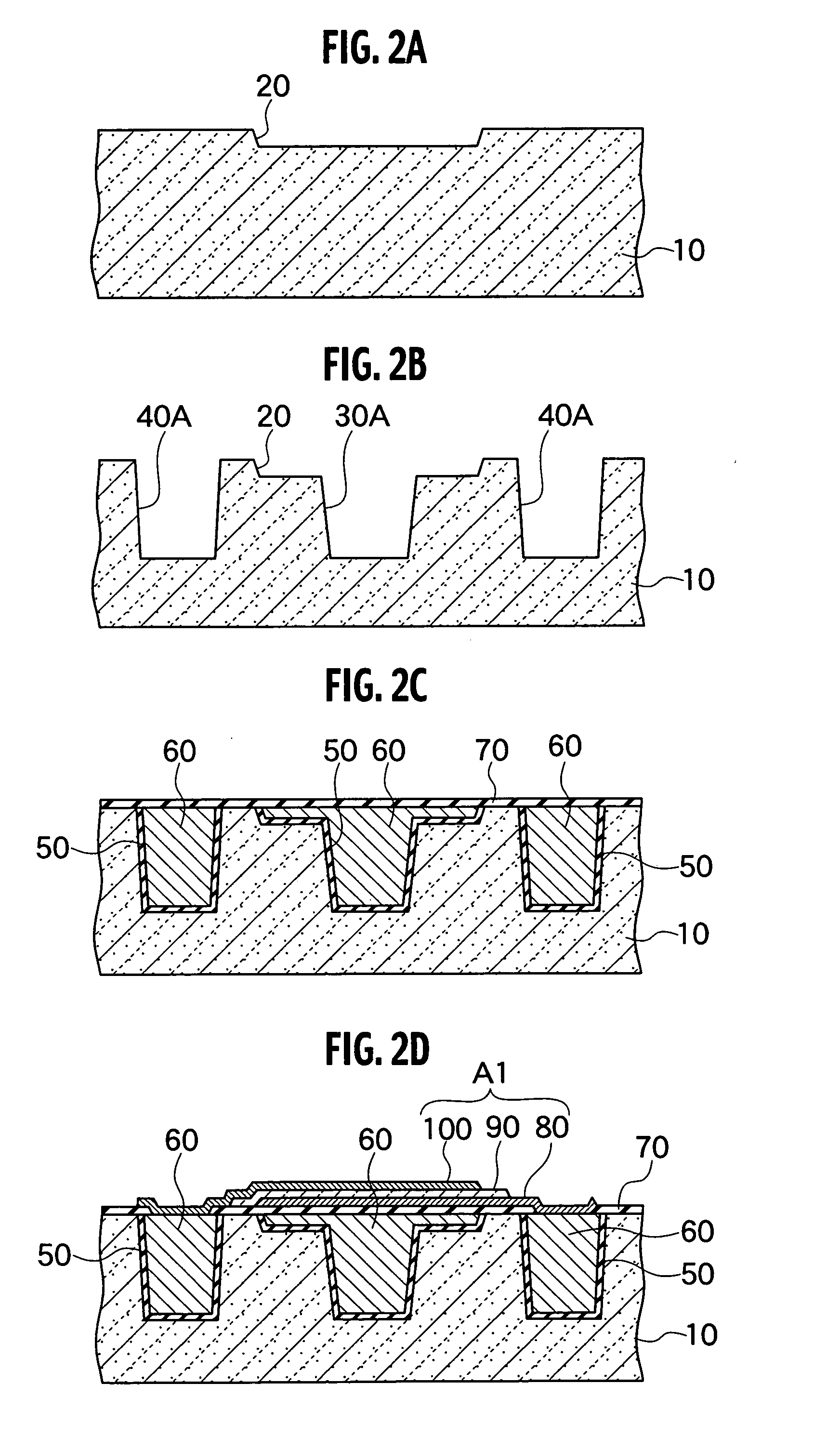

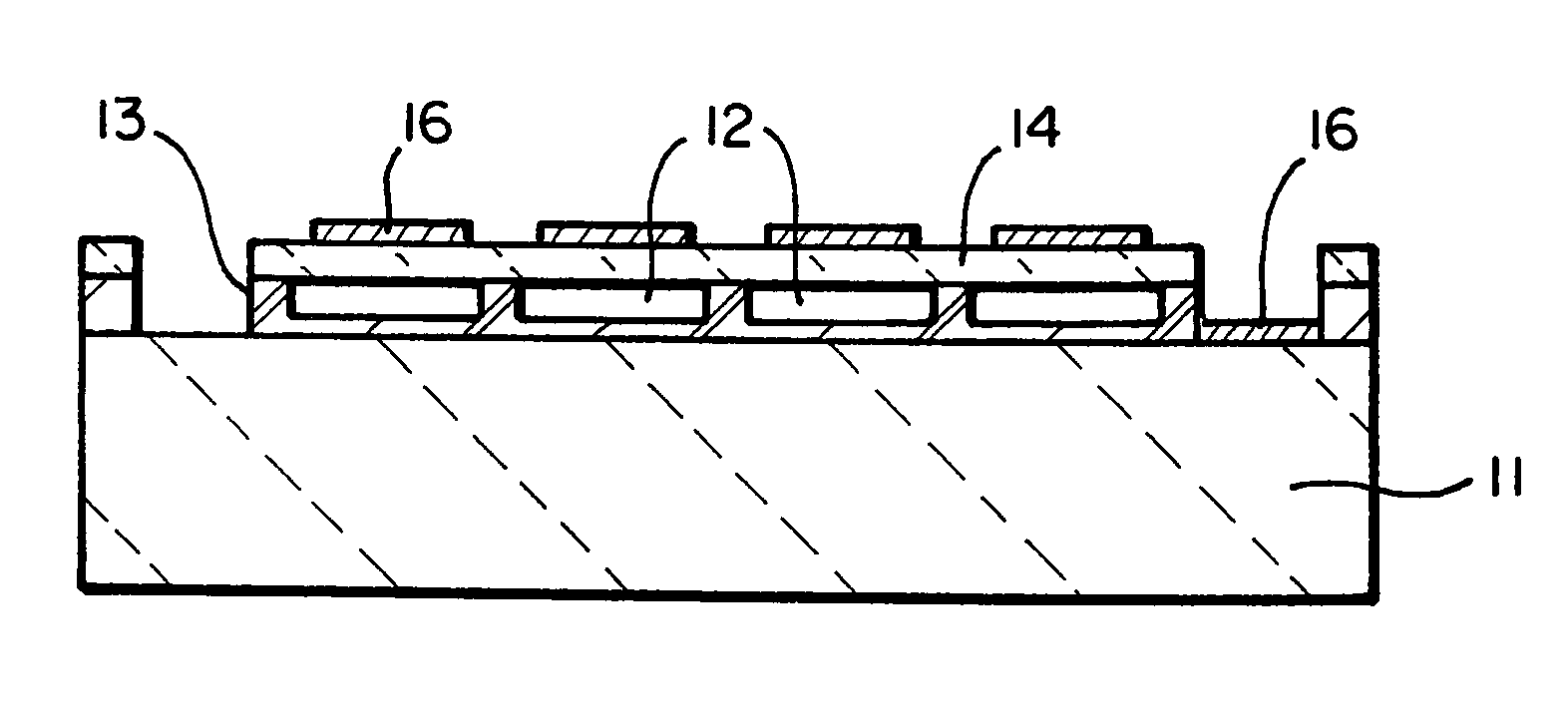

Ink-jet recording head with piezoelectric device and method for manufacturing the same

InactiveUS6142615AIncrease in piezoelectric constantIncrease the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsPiezoelectric coefficient

A piezoelectric device for an ink jet print head that has a greater displacement at a low drive voltage. The ink-jet recording head includes a vibration plate, on which is mounted one or more piezoelectric devices that change the volumes of pressure chambers upon application of a voltage. The device is mounted at least on one face of a pressure chamber substrate that is to be filled with ink. Such piezoelectric device includes a second piezoelectric layer having a piezoelectric constant g of a constant value or higher; and a first piezoelectric layer having a dielectric constant of a specific value or higher. Since the piezoelectric constant d of the piezoelectric device correlates with the product of the largest piezoelectric constant g and the largest dielectric device of the piezoelectric devices, a piezoelectric constant d larger than in the conventional case, i.e., having a greater displacement, can be obtained.

Owner:SEIKO EPSON CORP

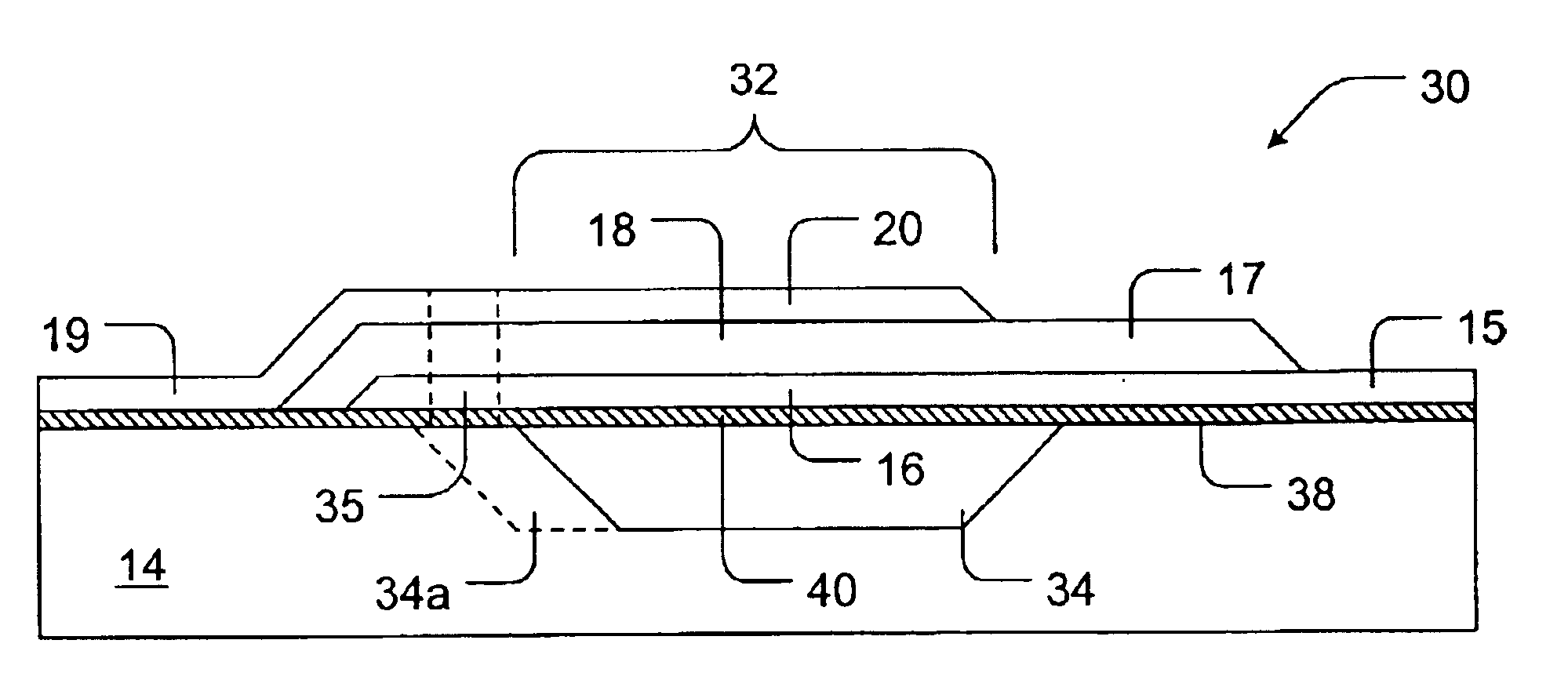

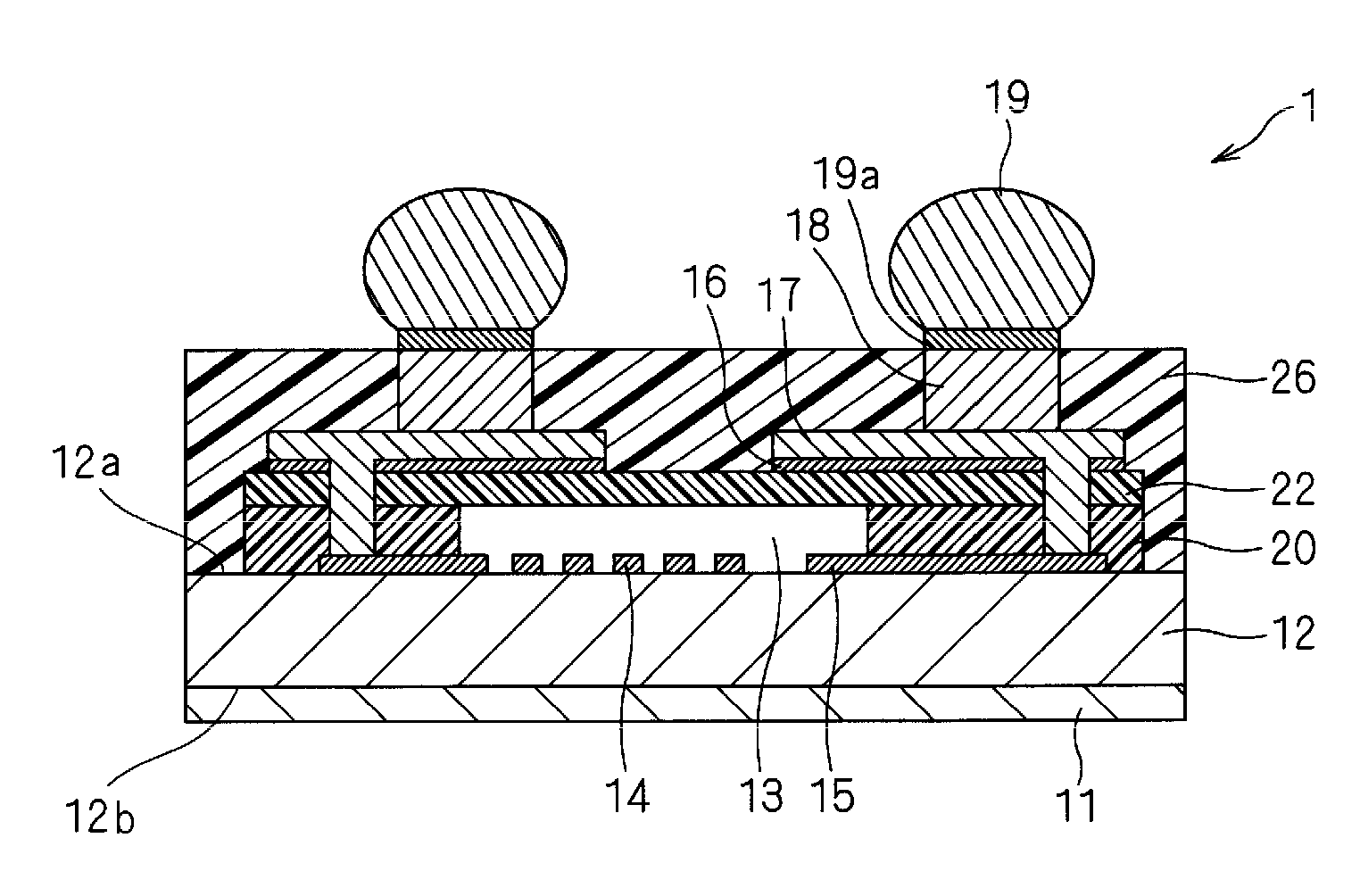

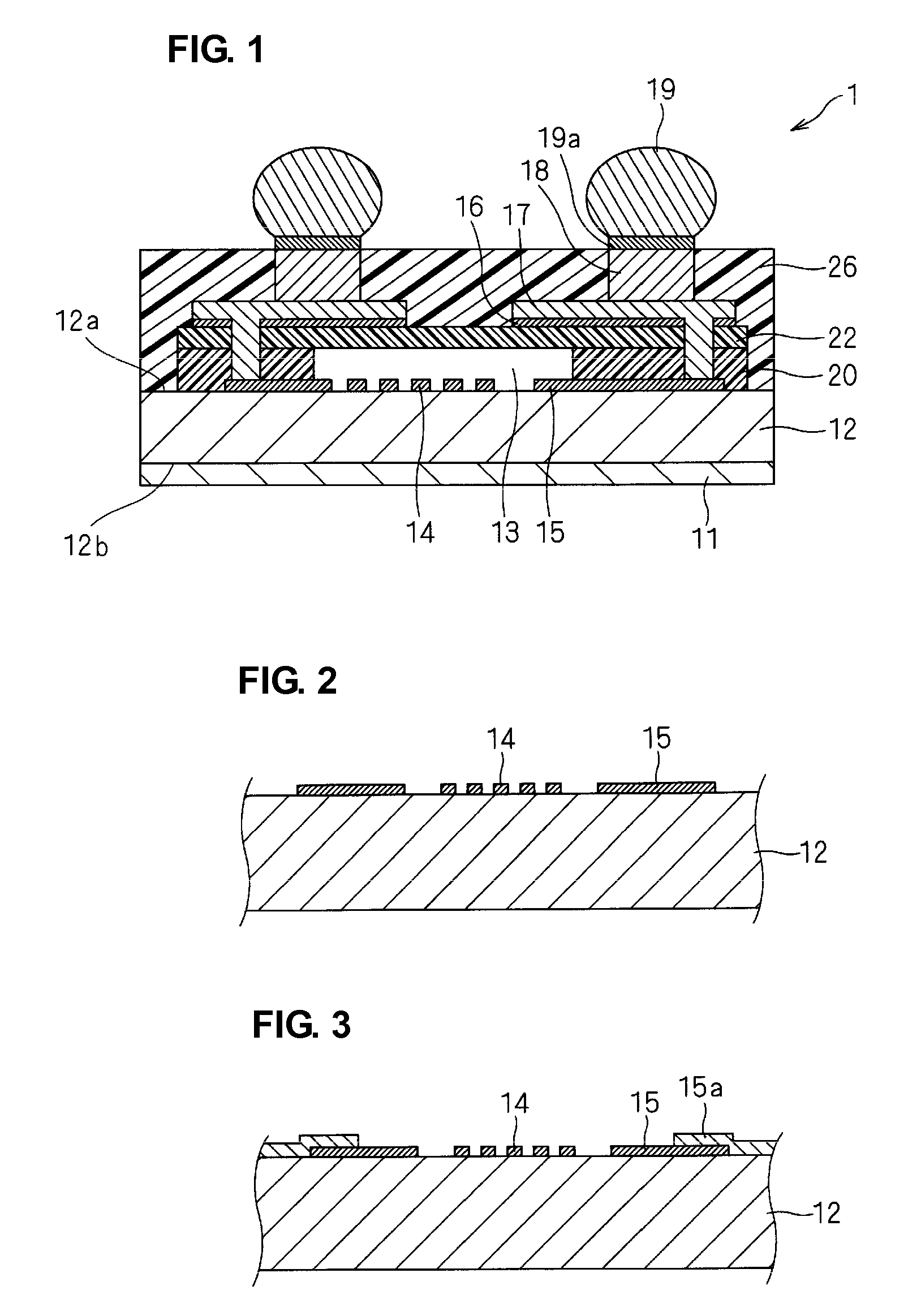

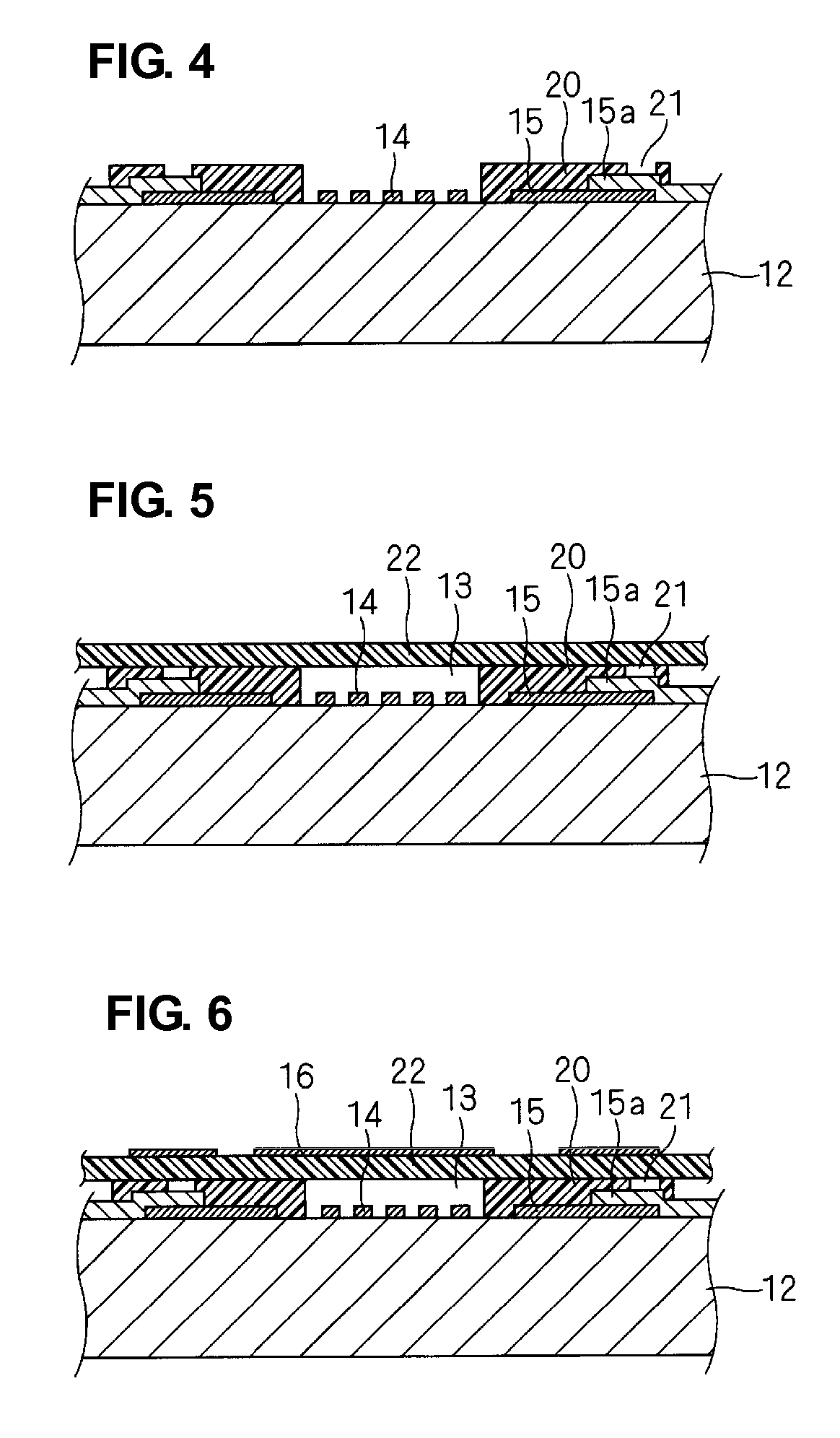

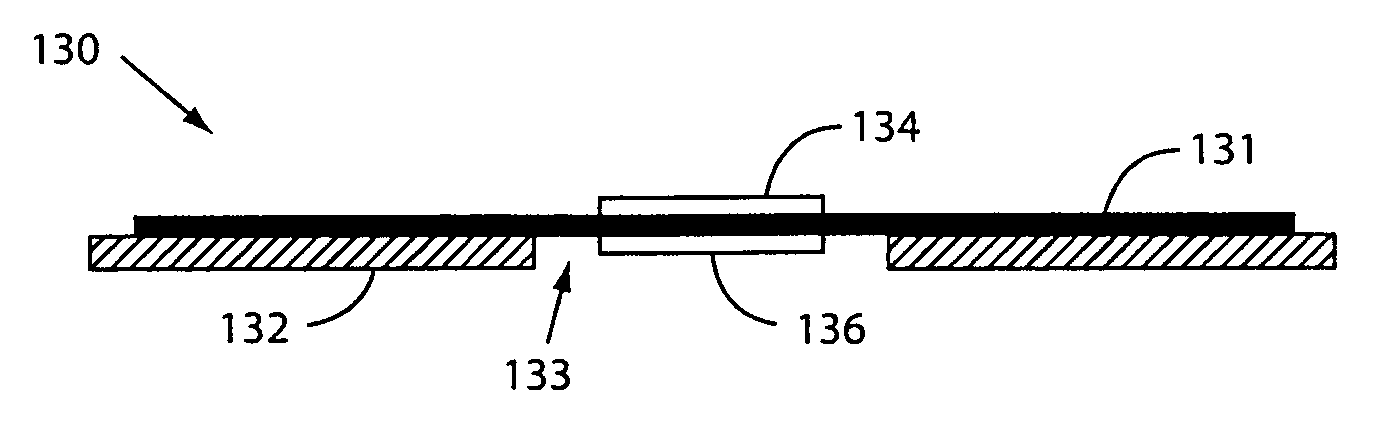

Electronic component having micro-electrical mechanical system

ActiveUS20050218488A1Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityEngineering

An electronic component includes a semiconductor substrate having a first surface and a second surface opposite to the first surface, a cavity that penetrates from the first surface to the second surface of the semiconductor substrate, and an electrical mechanical element that has a movable portion formed above the first surface of the semiconductor substrate so that the movable portion is arranged above the cavity. The electronic component further includes an electric conduction plug, which penetrates from the first surface to the second surface of the semiconductor substrate, and which is electrically connected to the electrical mechanical element.

Owner:KIOXIA CORP

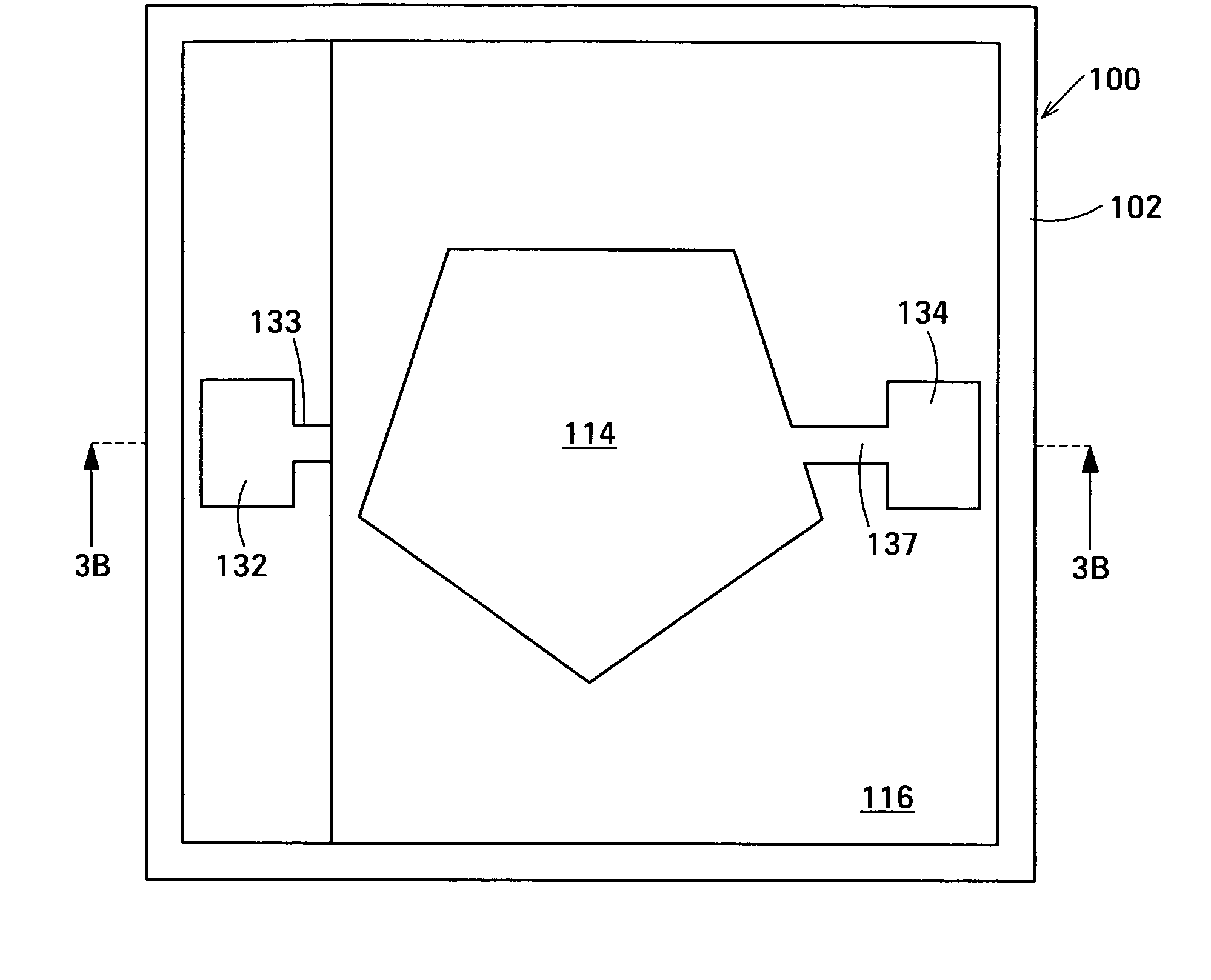

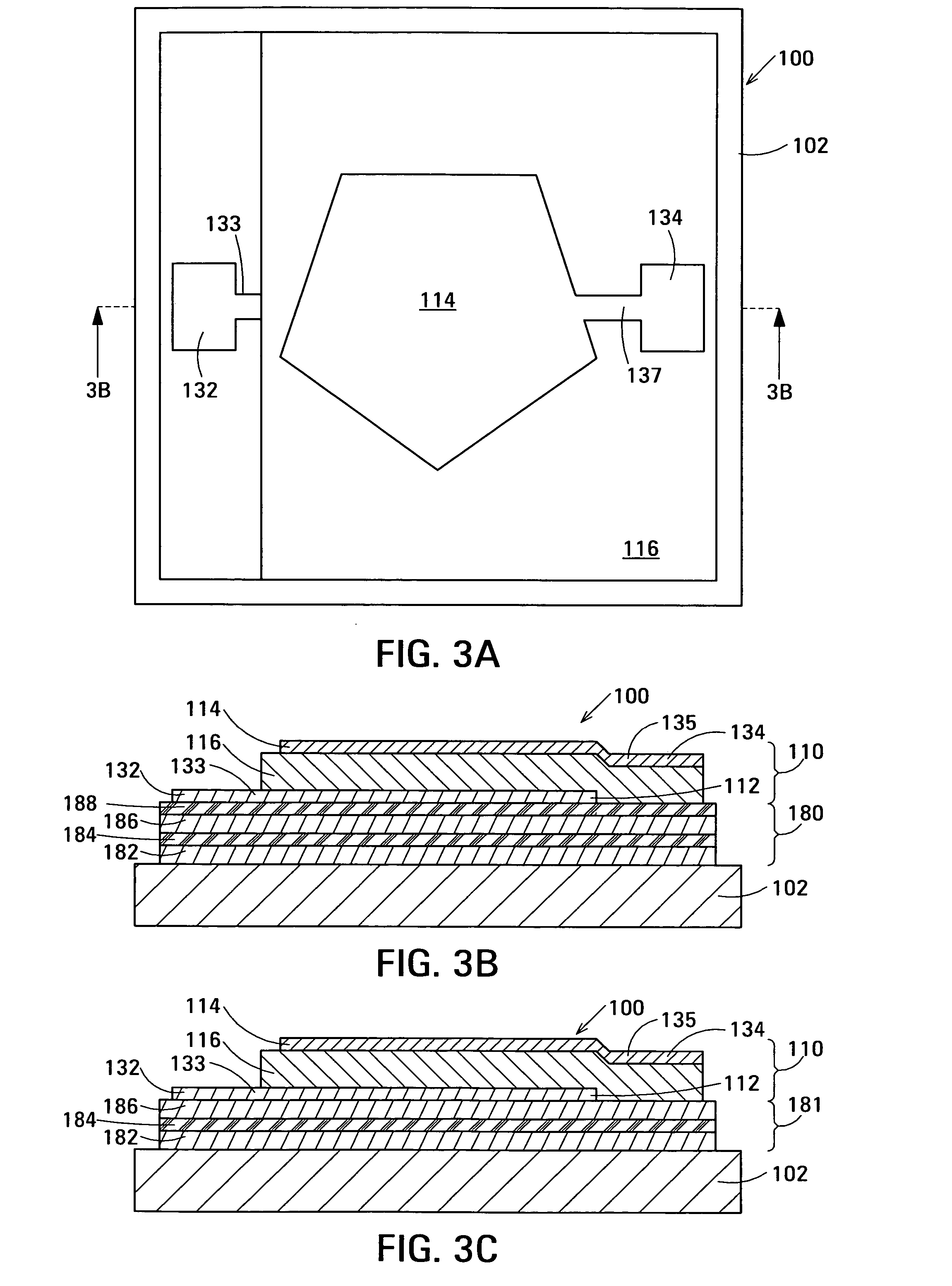

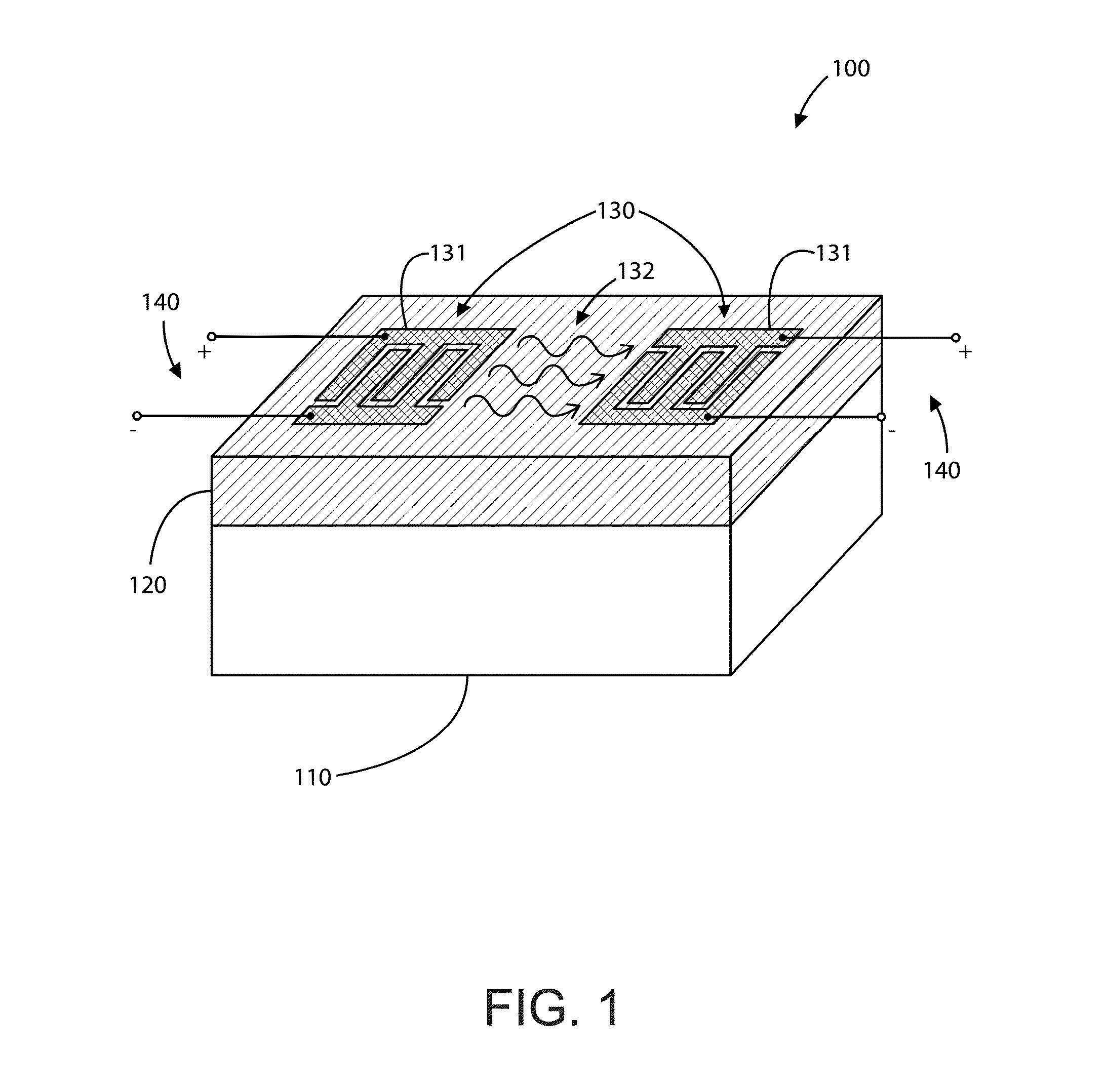

Acoustic resonator performance enhancement using alternating frame structure

ActiveUS7388454B2Impedence networksPiezoelectric/electrostriction/magnetostriction machinesPerformance enhancementAcoustics

Disclosed is an acoustic resonator that includes a substrate, a first electrode, a layer of piezoelectric material, a second electrode, and an alternating frame region. The first electrode is adjacent the substrate, and the first electrode has an outer perimeter. The piezoelectric layer is adjacent the first electrode. The second electrode is adjacent the piezoelectric layer and the second electrode has an outer perimeter. The alternating frame region is on one of the first and second electrodes.

Owner:AVAGO TECH INT SALES PTE LTD

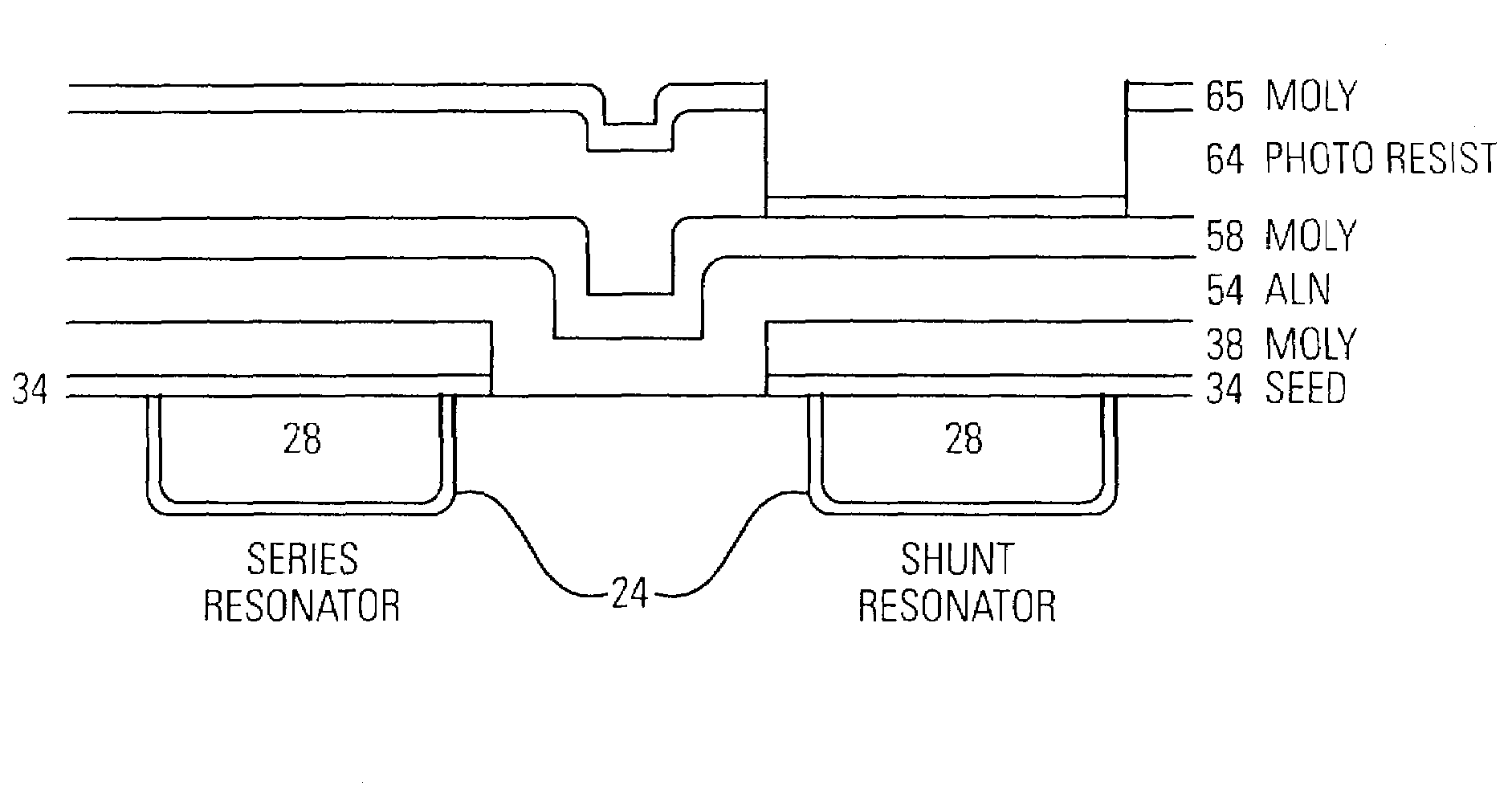

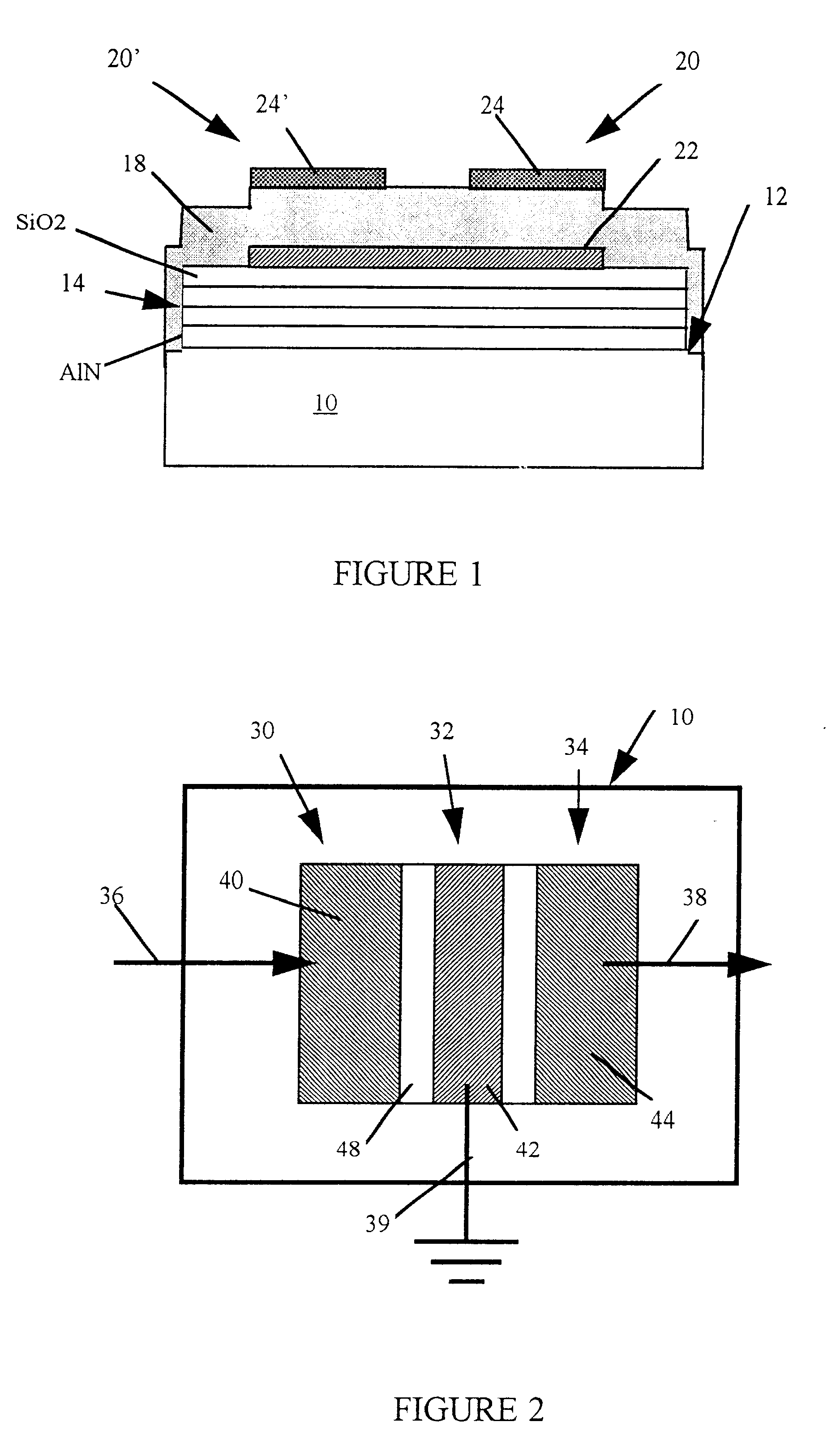

Resonator with seed layer

InactiveUS6828713B2Quality improvementPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksNitrideResonator

A thin-film resonator having a seed layer and a method of making the same are disclosed. The resonator is fabricated having a seed layer to assist in the fabrication of high quality piezoelectric layer for the resoantor. The resonator has the seed layer, a bottom electrode, piezoelectric layer, and a top electrode. The seed layer is often the same material as the piezoelectric layer such as Aluminum Nitride (AlN).

Owner:AVAGO TECH INT SALES PTE LTD

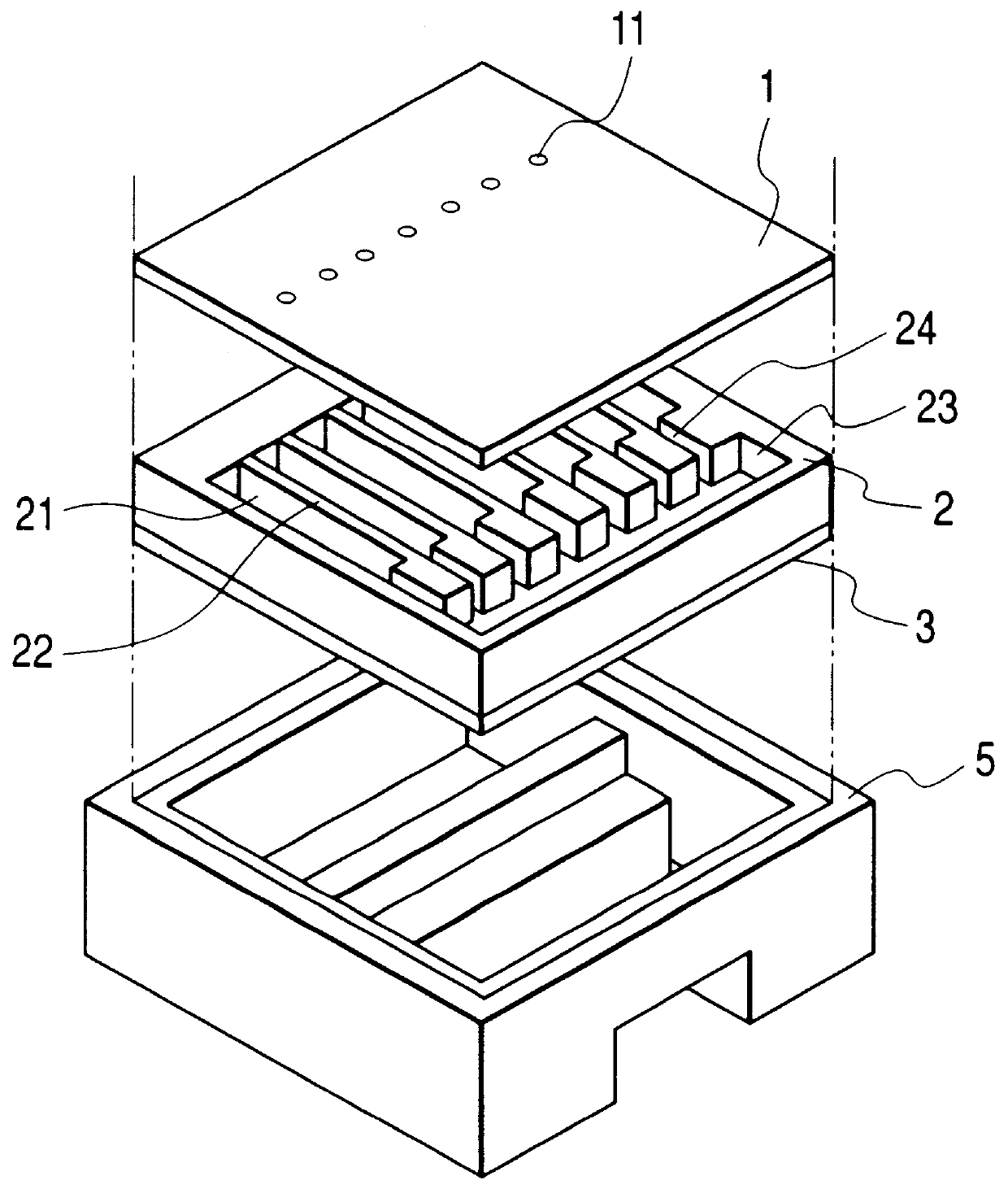

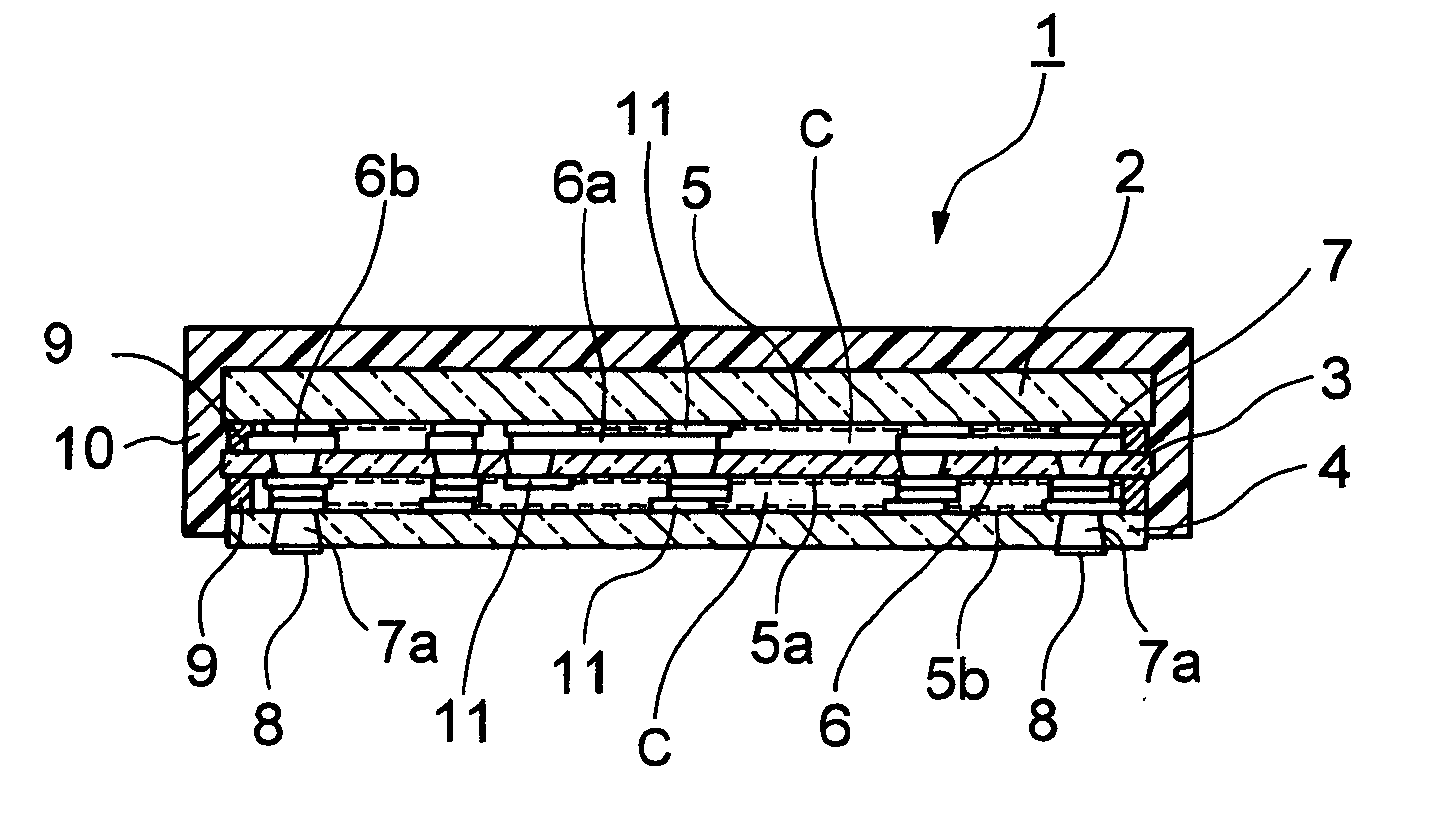

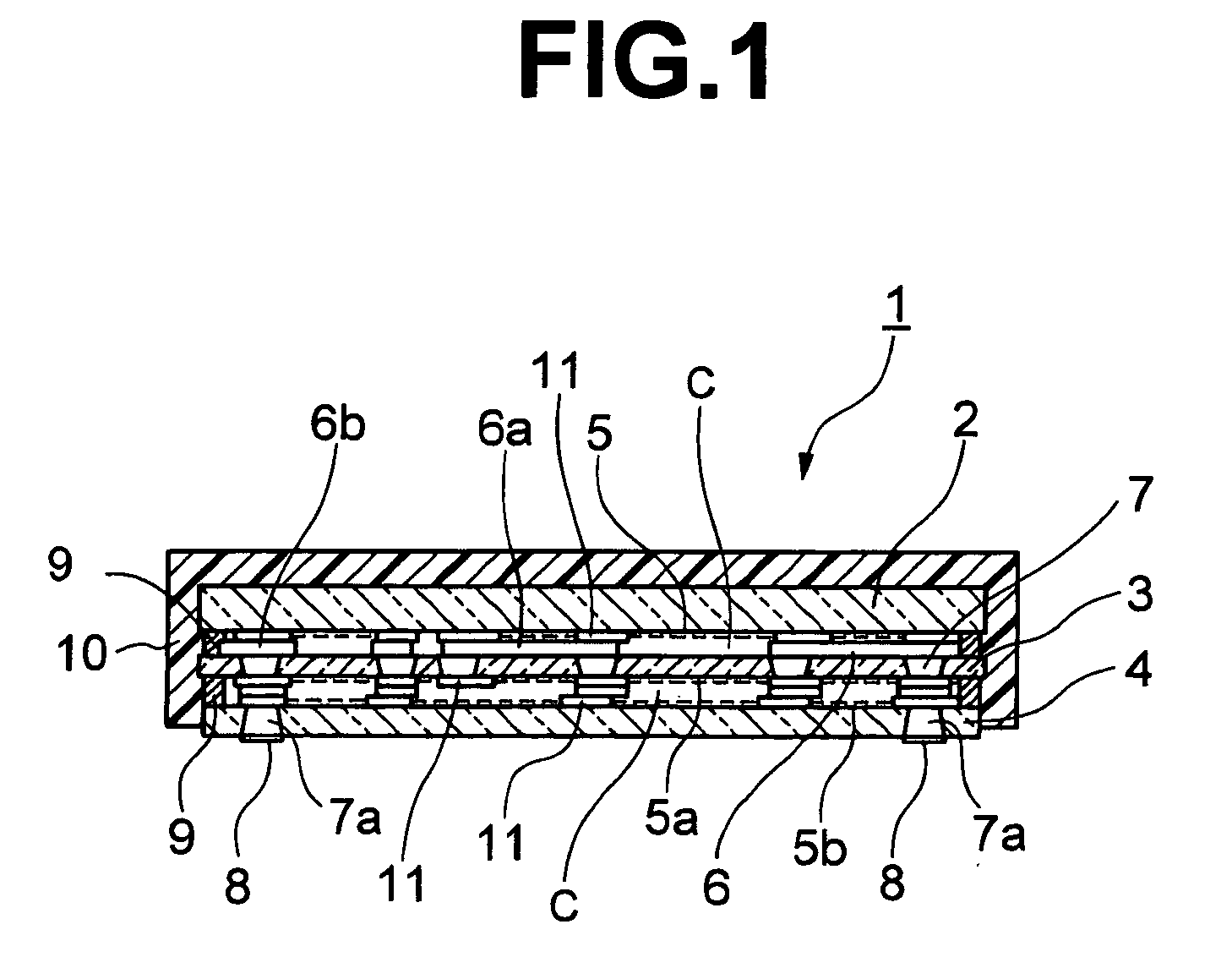

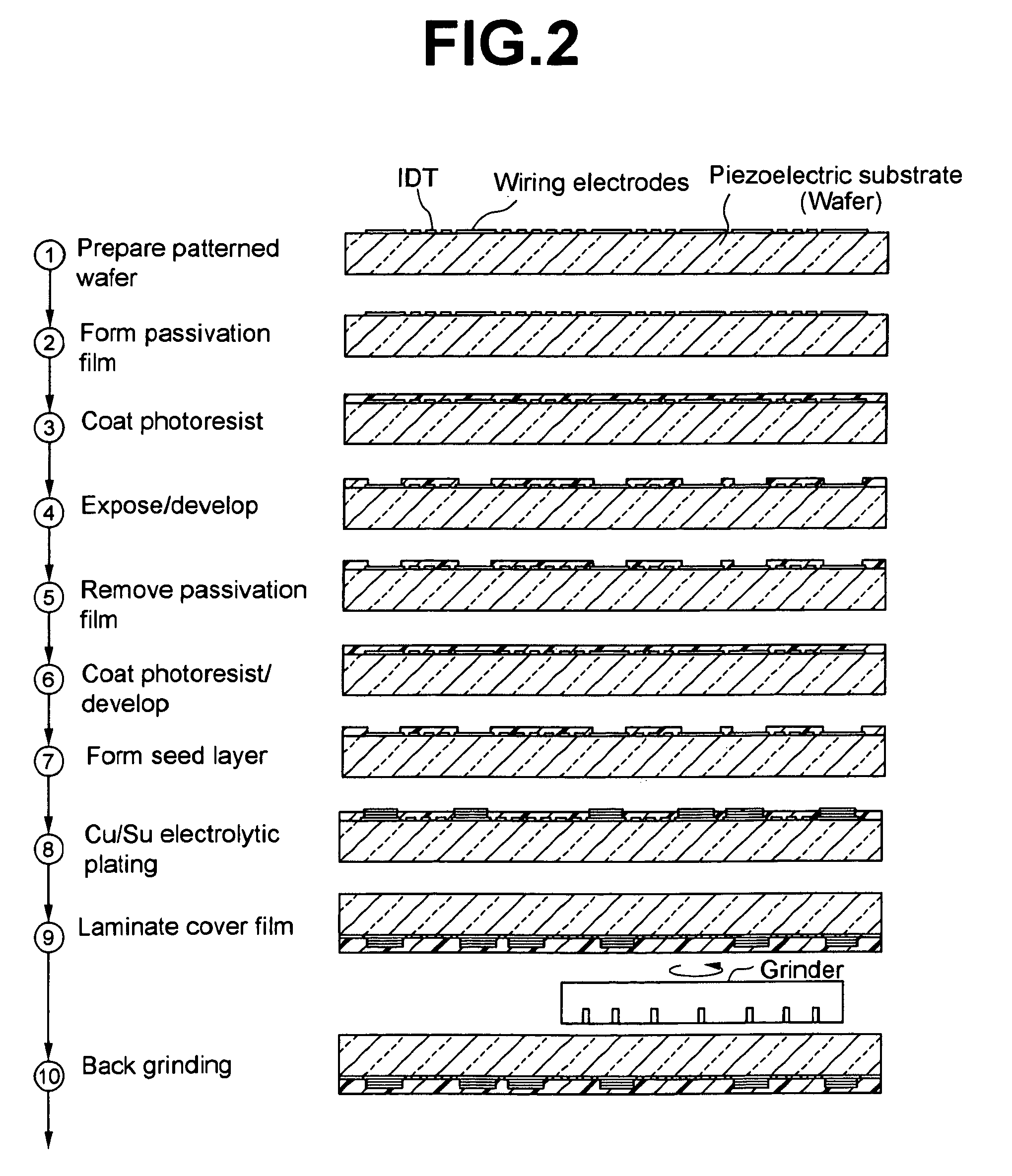

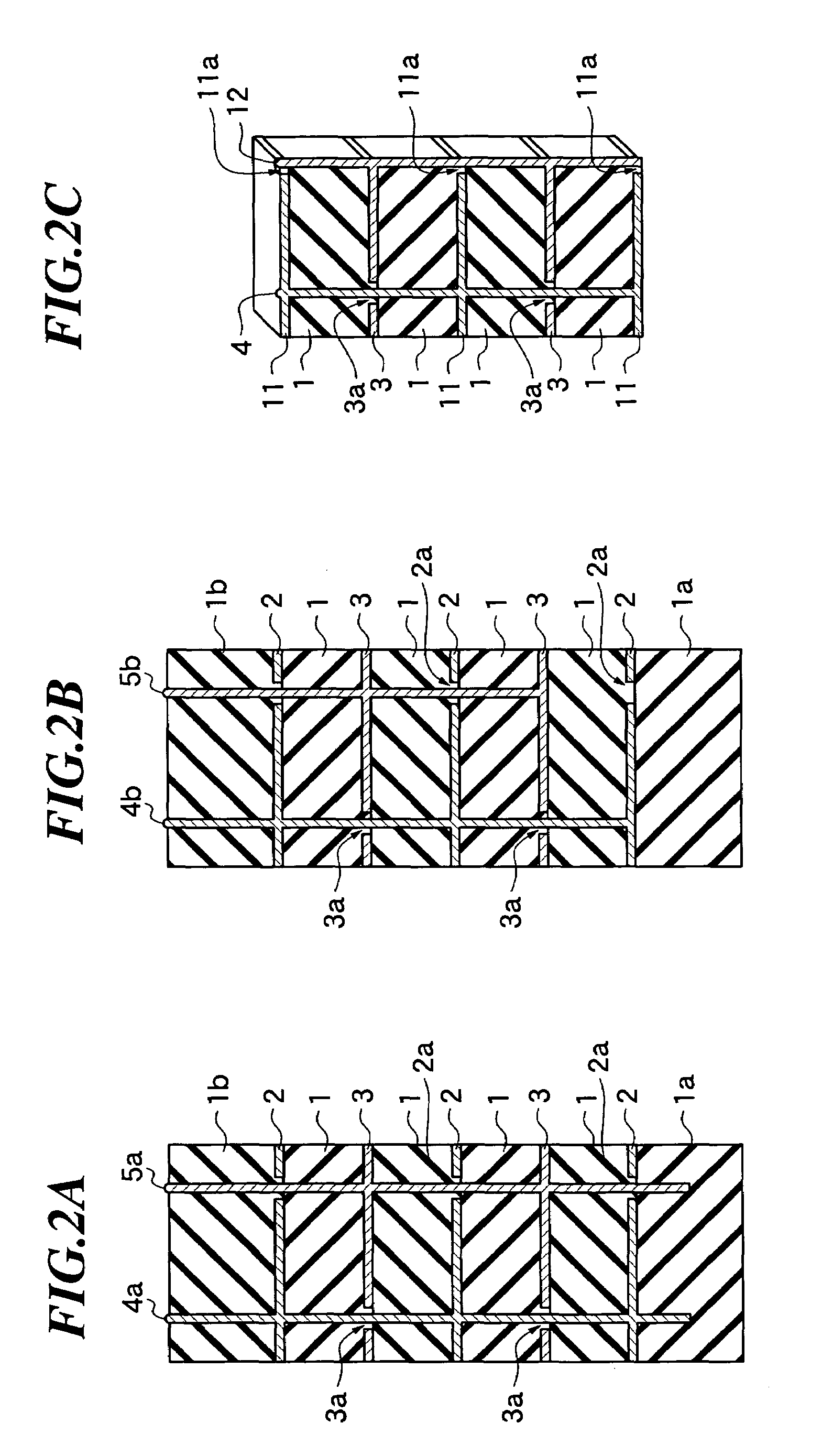

Piezoelectric component and manufacturing method thereof

InactiveUS20100045145A1Small sizeIncrease the number ofPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectrical and Electronics engineeringPiezoelectric substrate

An object of the present invention is to; miniaturize, increase the capacity, and reduce the price of piezoelectric components. The present invention relates to a piezoelectric component and a manufacturing method thereof, characterized in that: there are bonded and laminated at least two or more piezoelectric elements in which comb-teeth electrodes, wiring electrodes having element wirings that are arranged adjacent to the comb-teeth electrodes, and electrode terminals connected to the wiring electrodes, are formed on a principal surface of a plurality of piezoelectric substrates, while forming hollow sections between the respective piezoelectric elements; through electrodes are formed in the respective piezoelectric substrates so as to pass therethrough; the through electrodes are connected to the electrode terminals; and the piezoelectric substrates are sealed by a resin sealing layer.

Owner:NIHON DEMPA KOGYO CO LTD

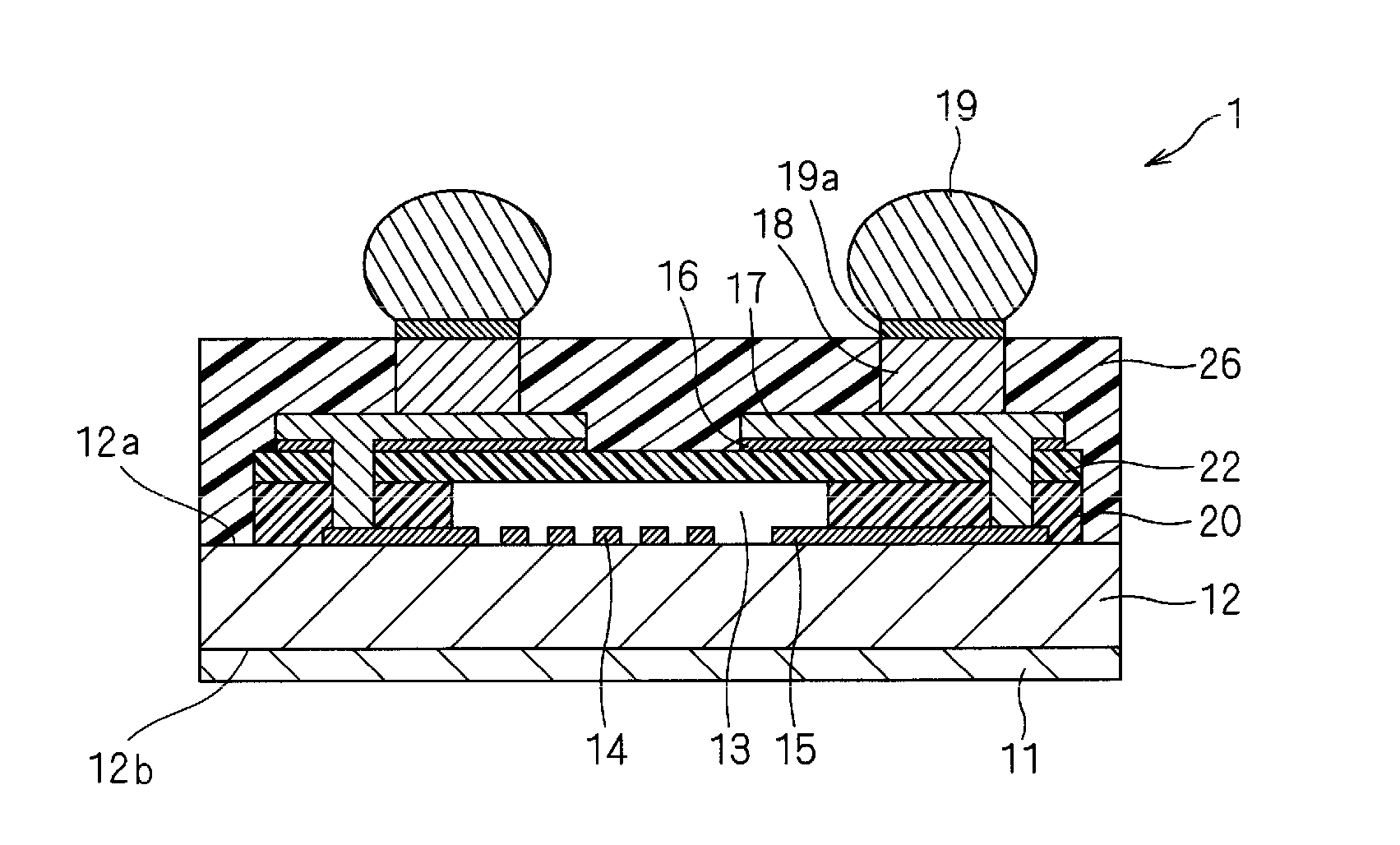

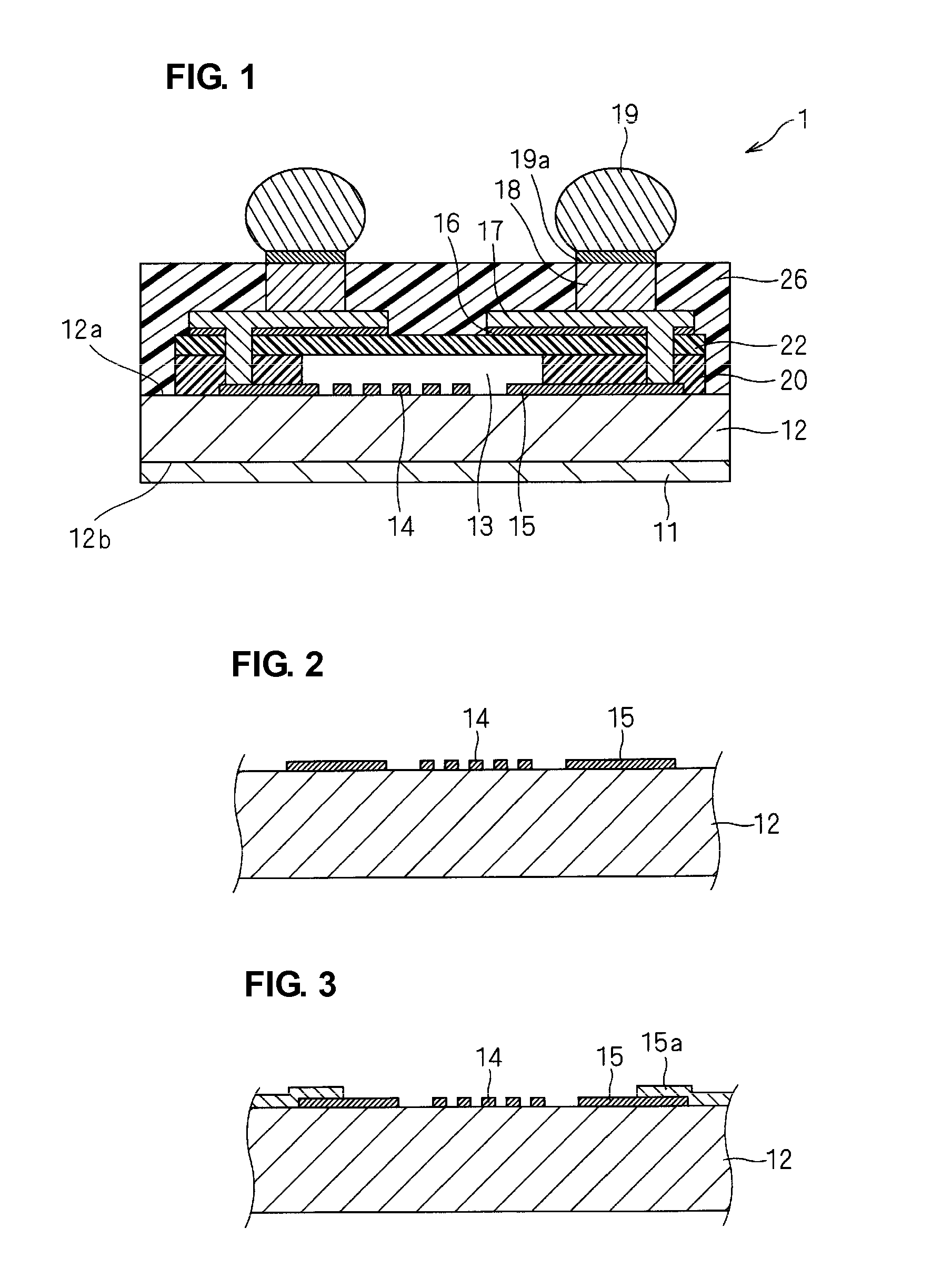

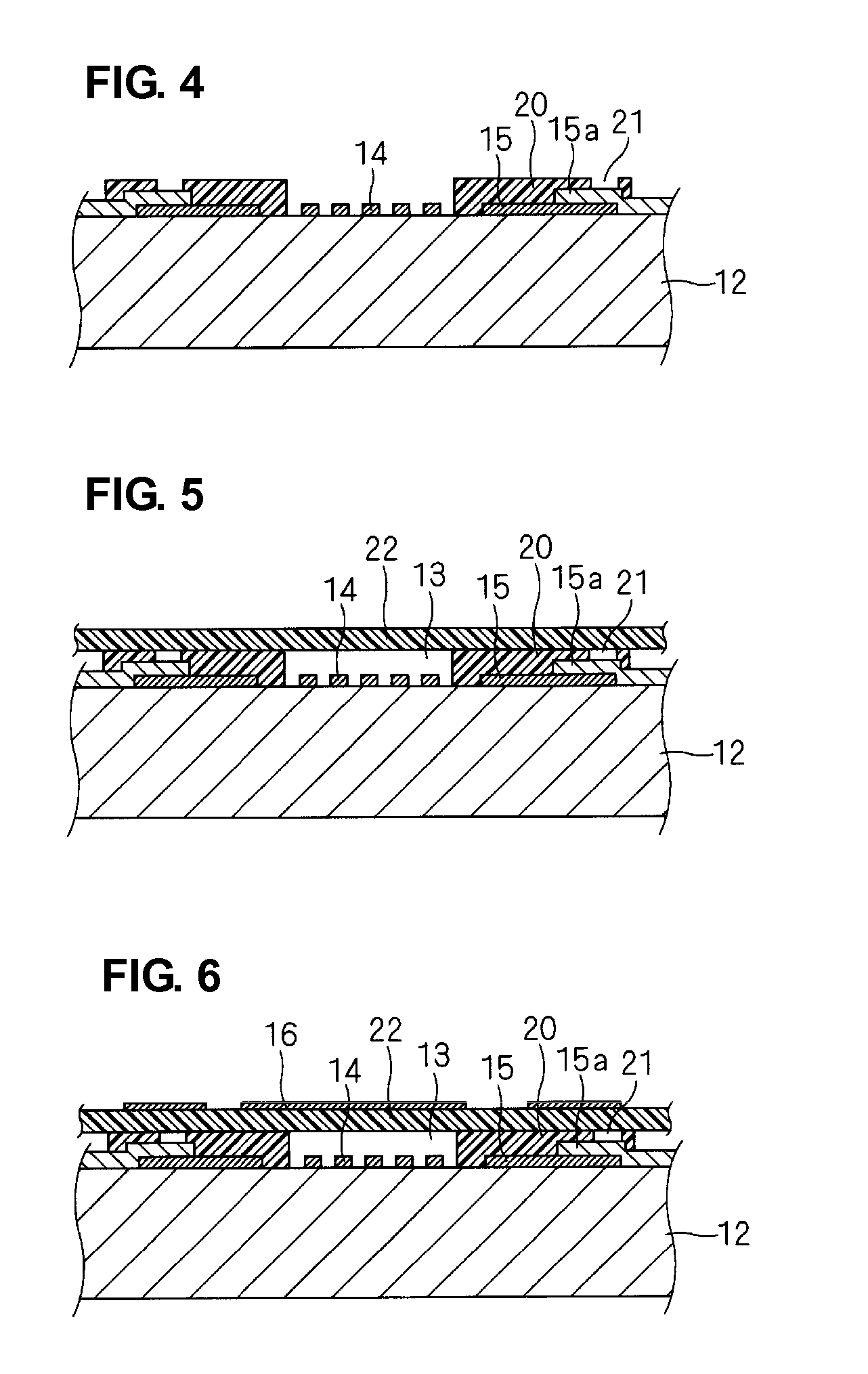

Piezoelectric device and method for producing same

ActiveUS20070252481A1Low costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectrical conductor

Owner:MURATA MFG CO LTD

Piezoelectric device and method for producing same

ActiveUS7427824B2Low costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectrical conductorEngineering

Owner:MURATA MFG CO LTD

Thin film acoustic resonator and method of producing the same

InactiveUS6842088B2Improve temperature stabilityImprovement factorNanotechPiezoelectric/electrostrictive device manufacture/assemblyThin-film bulk acoustic resonatorElectromechanical coupling coefficient

Owner:MEMS SOLUTIONS INC

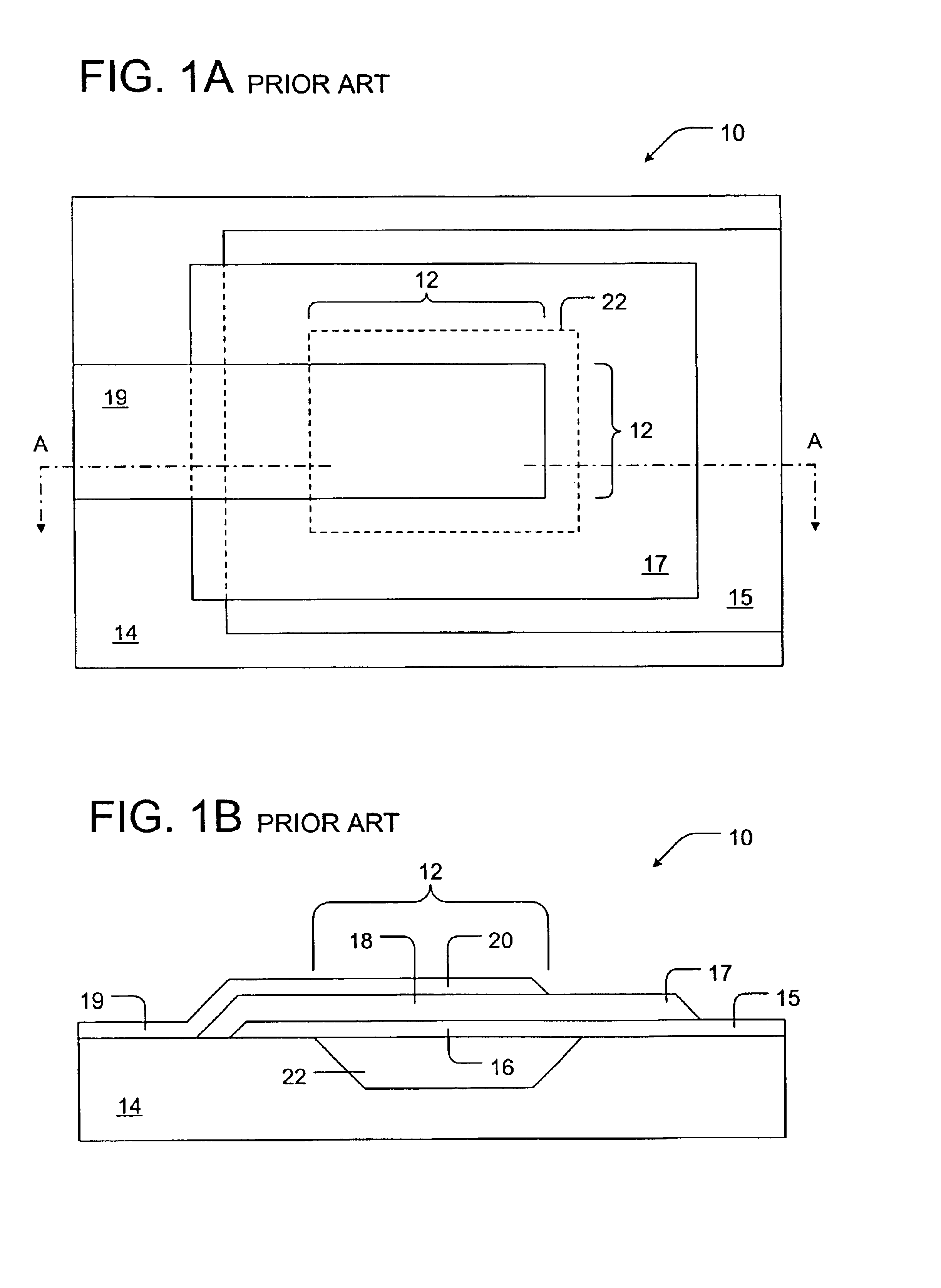

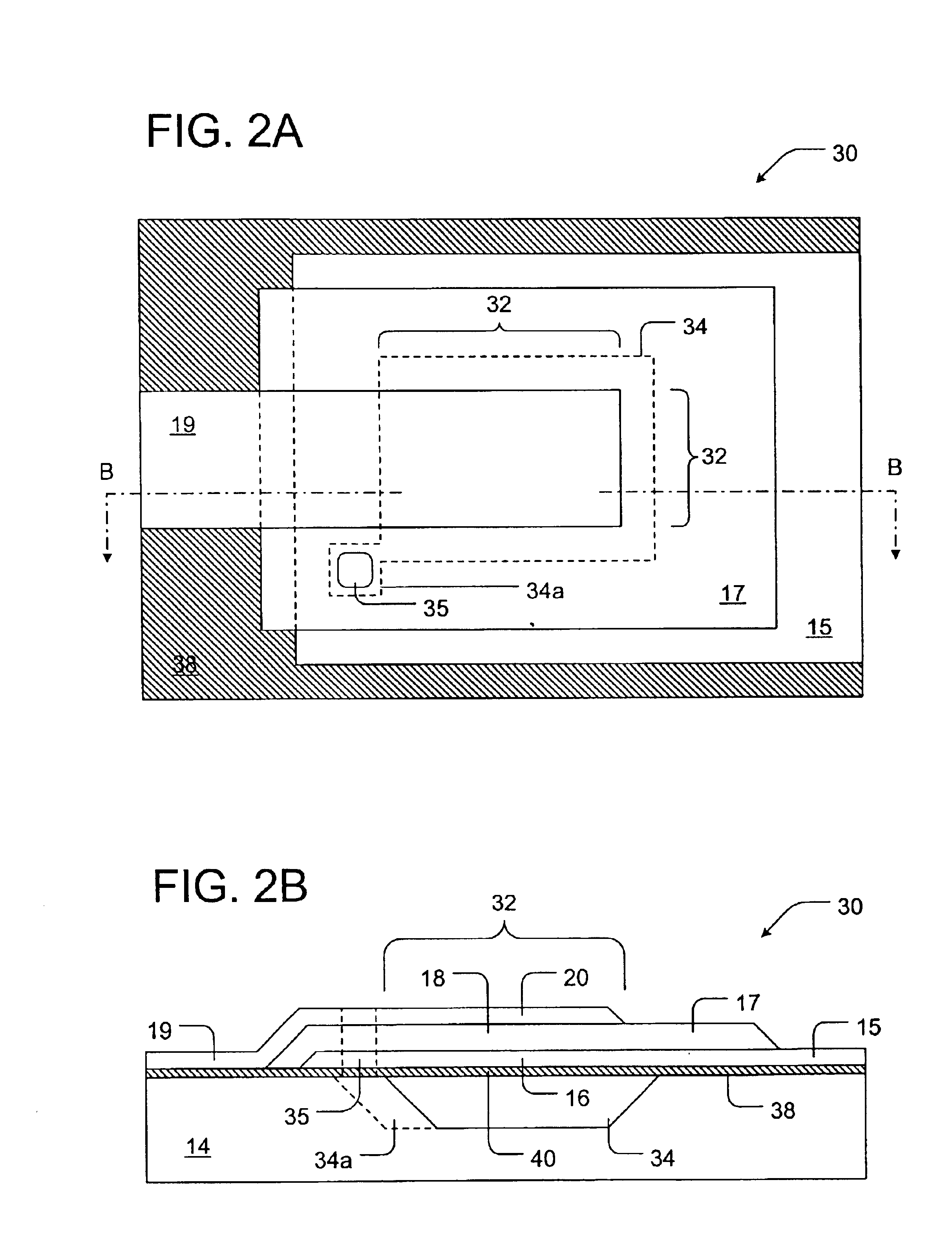

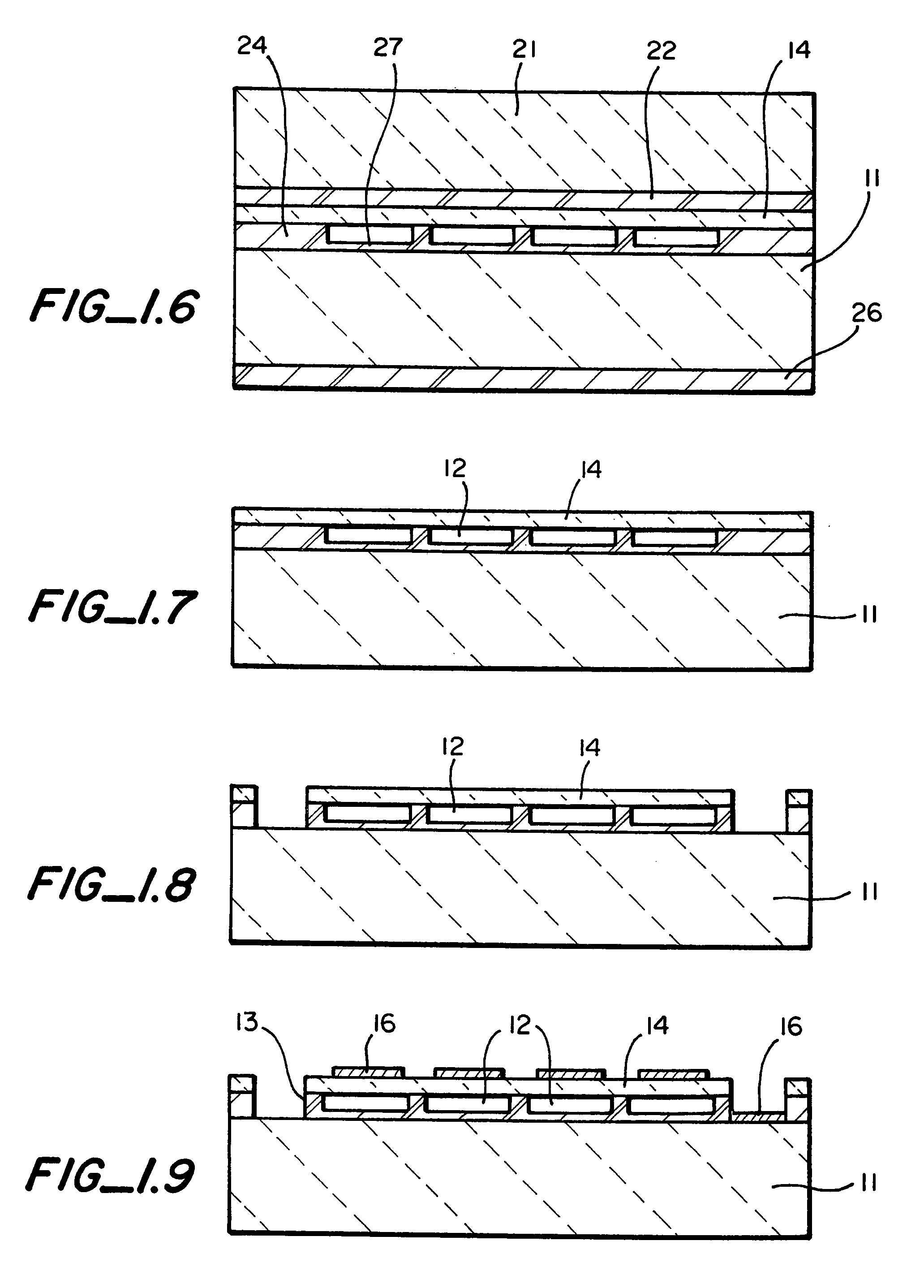

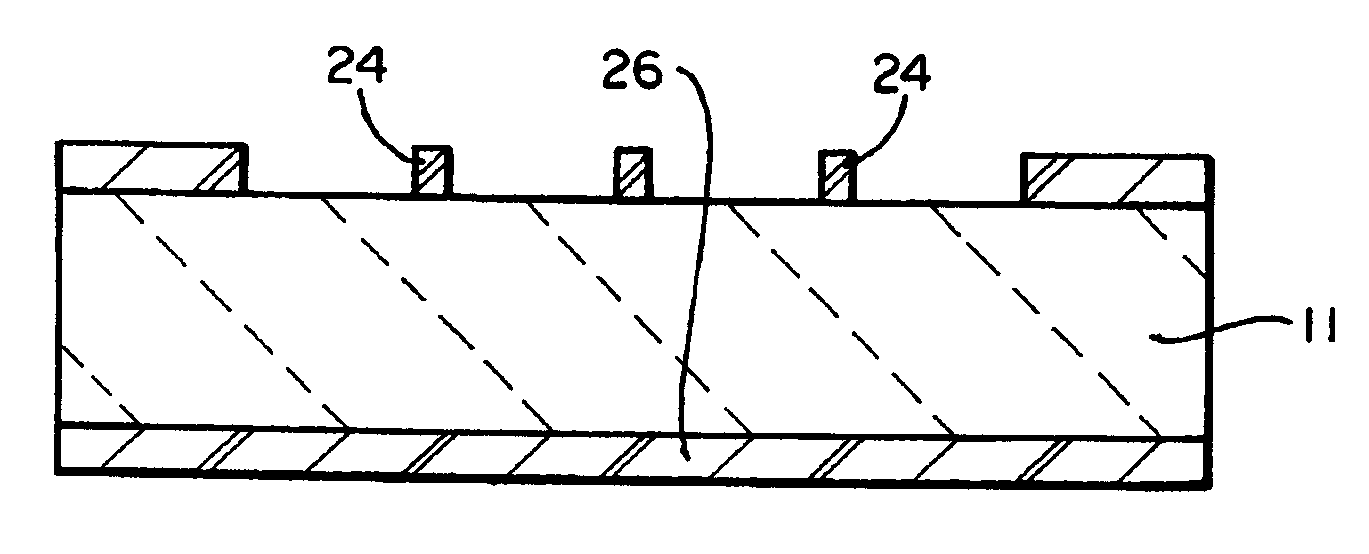

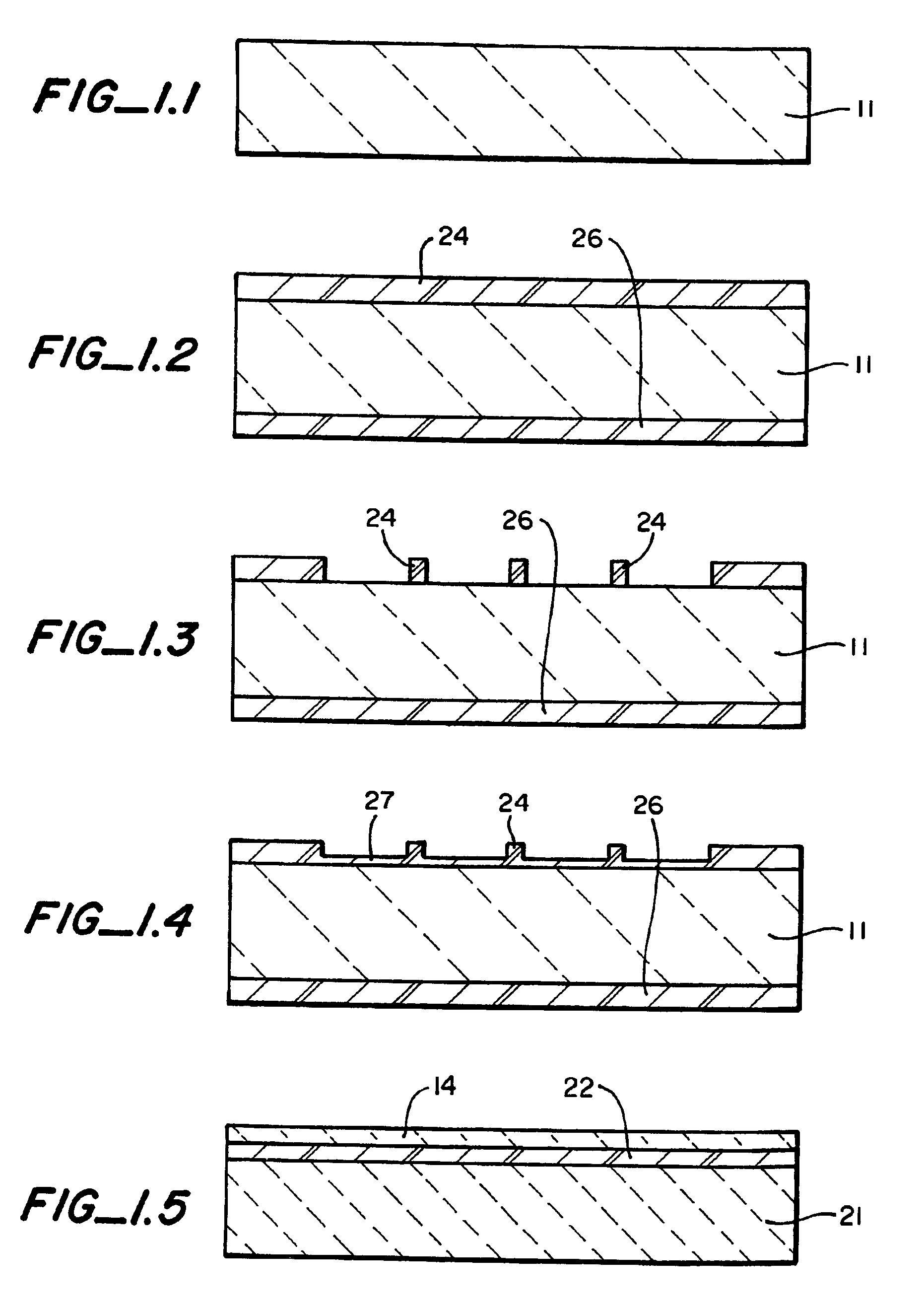

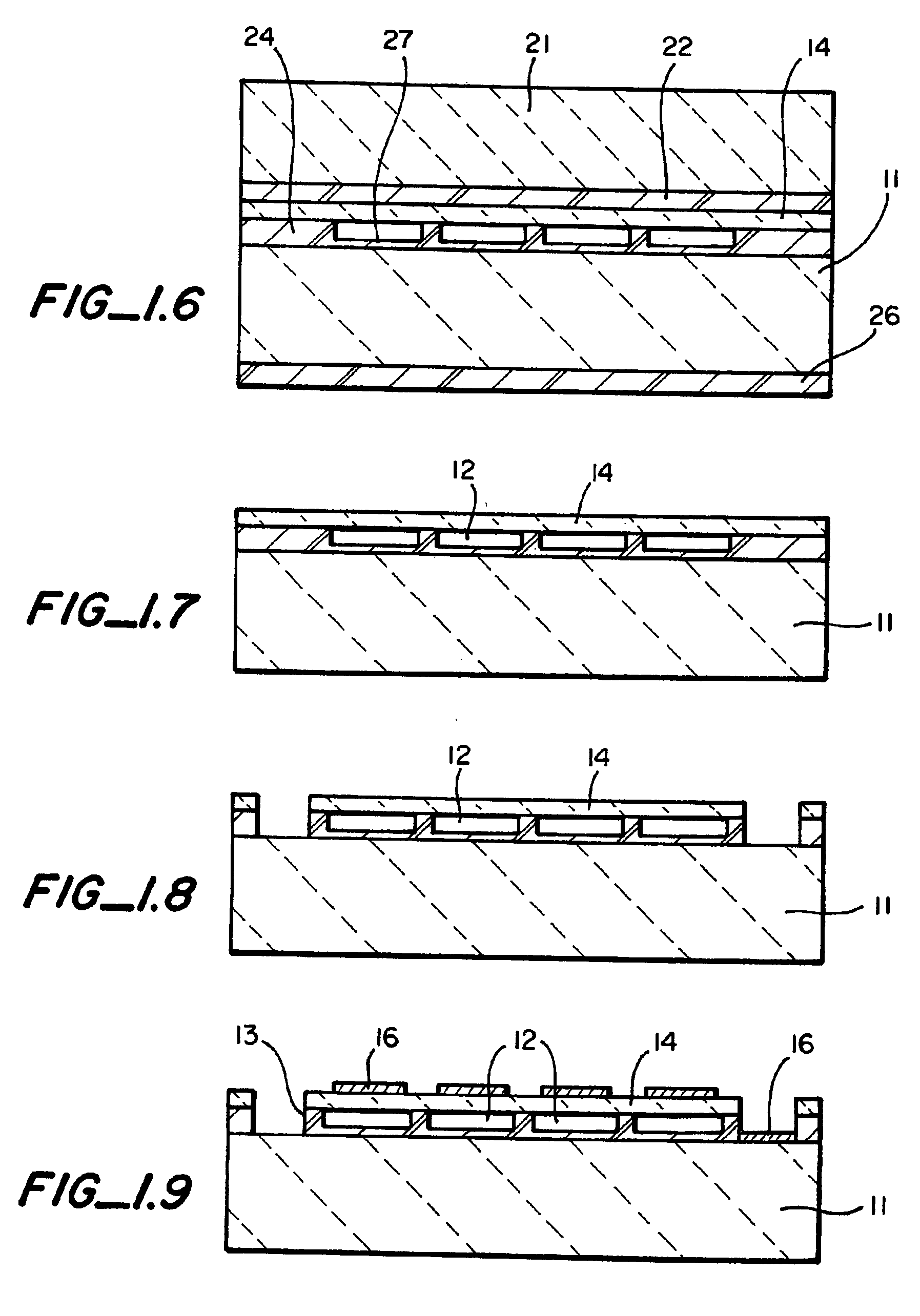

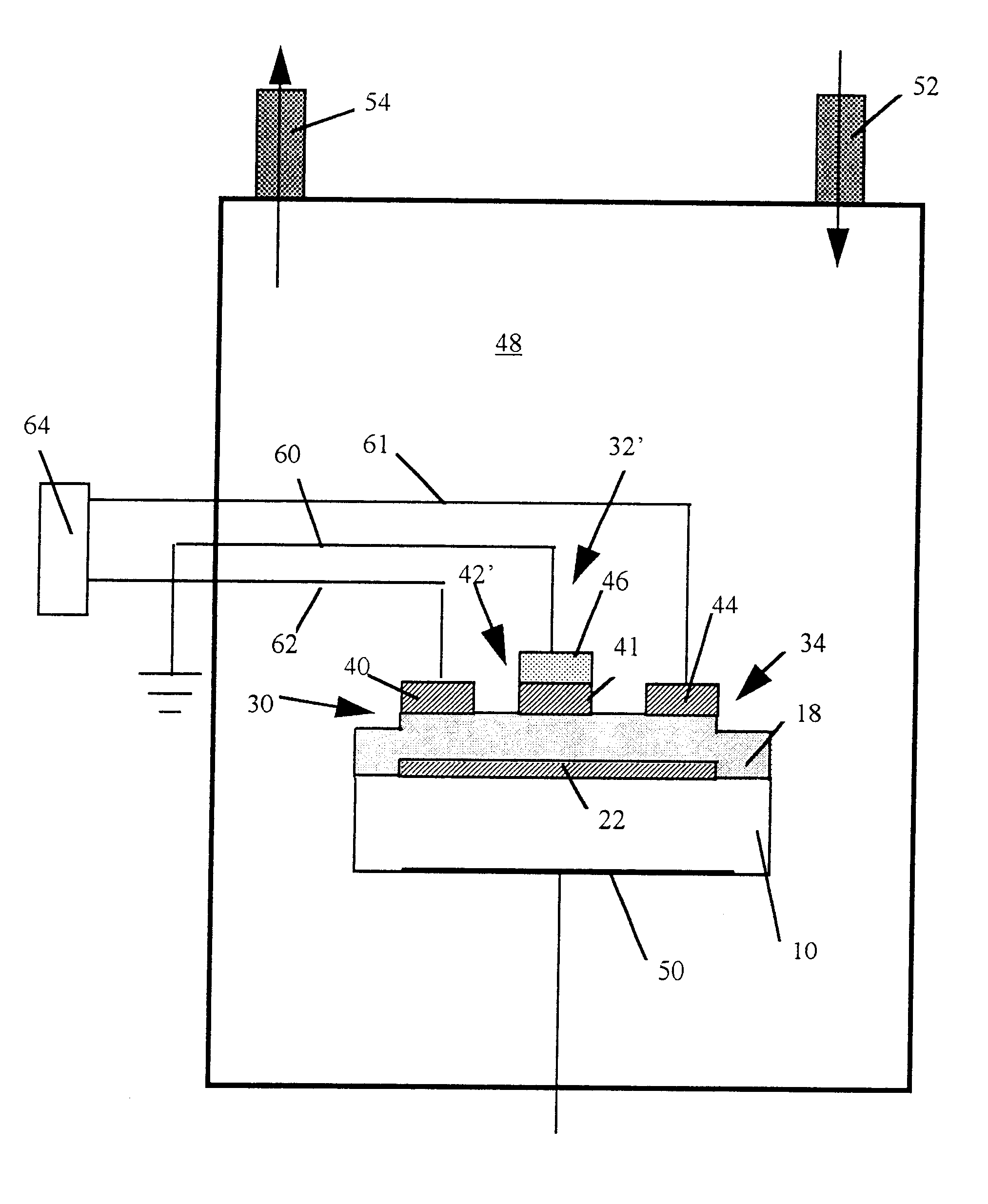

Micromachined ultrasonic transducers and method of fabrication

InactiveUS20040085858A1Decorative surface effectsSemiconductor/solid-state device manufacturingPMUTSilicon nitride

There is described a micromachined ultrasonic transducers (MUTS) and a method of fabrication. The membranes of the transducers are fusion bonded to cavities to form cells. The membranes are formed on a wafer of sacrificial material. This permits handling for fusions bonding. The sacrificial material is then removed to leave the membrane. Membranes of silicon, silicon nitride, etc. can be formed on the sacrificial material. Also described are cMUTs, pMUTs and mMUTs.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Micromachined ultrasonic transducers and method of fabrication

InactiveUS6958255B2Piezoelectric/electrostrictive device manufacture/assemblySubsonic/sonic/ultrasonic wave measurementPMUTSilicon nitride

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

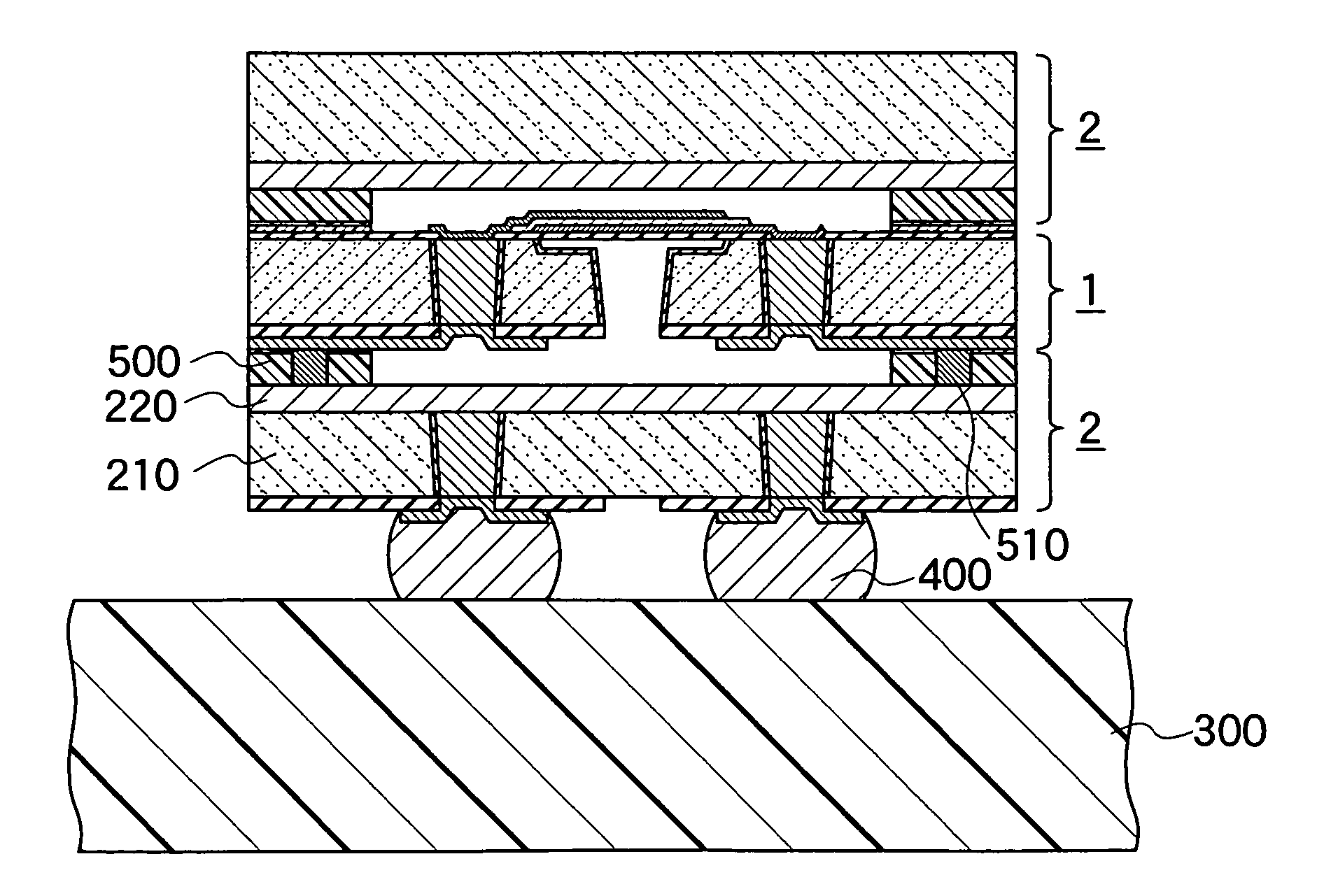

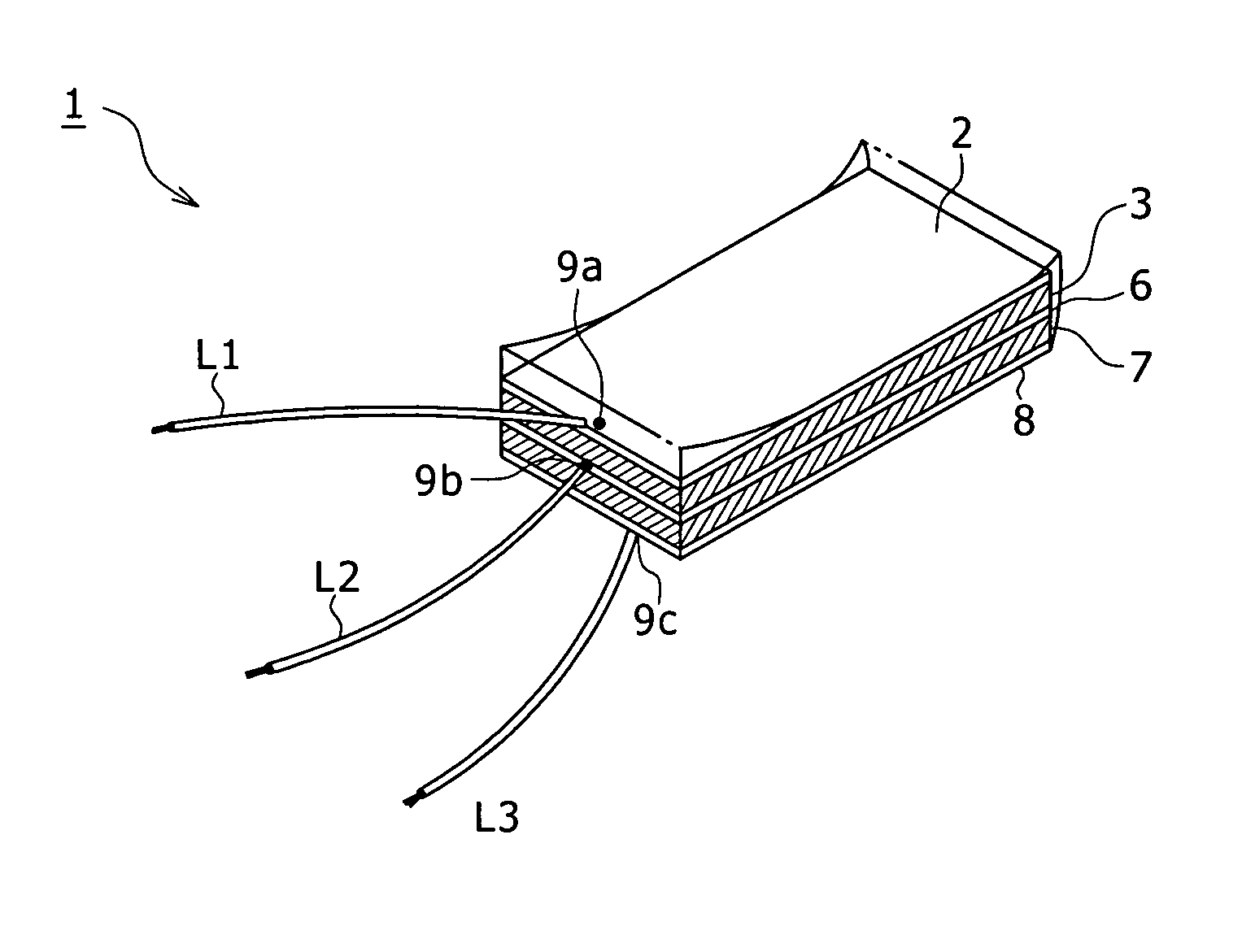

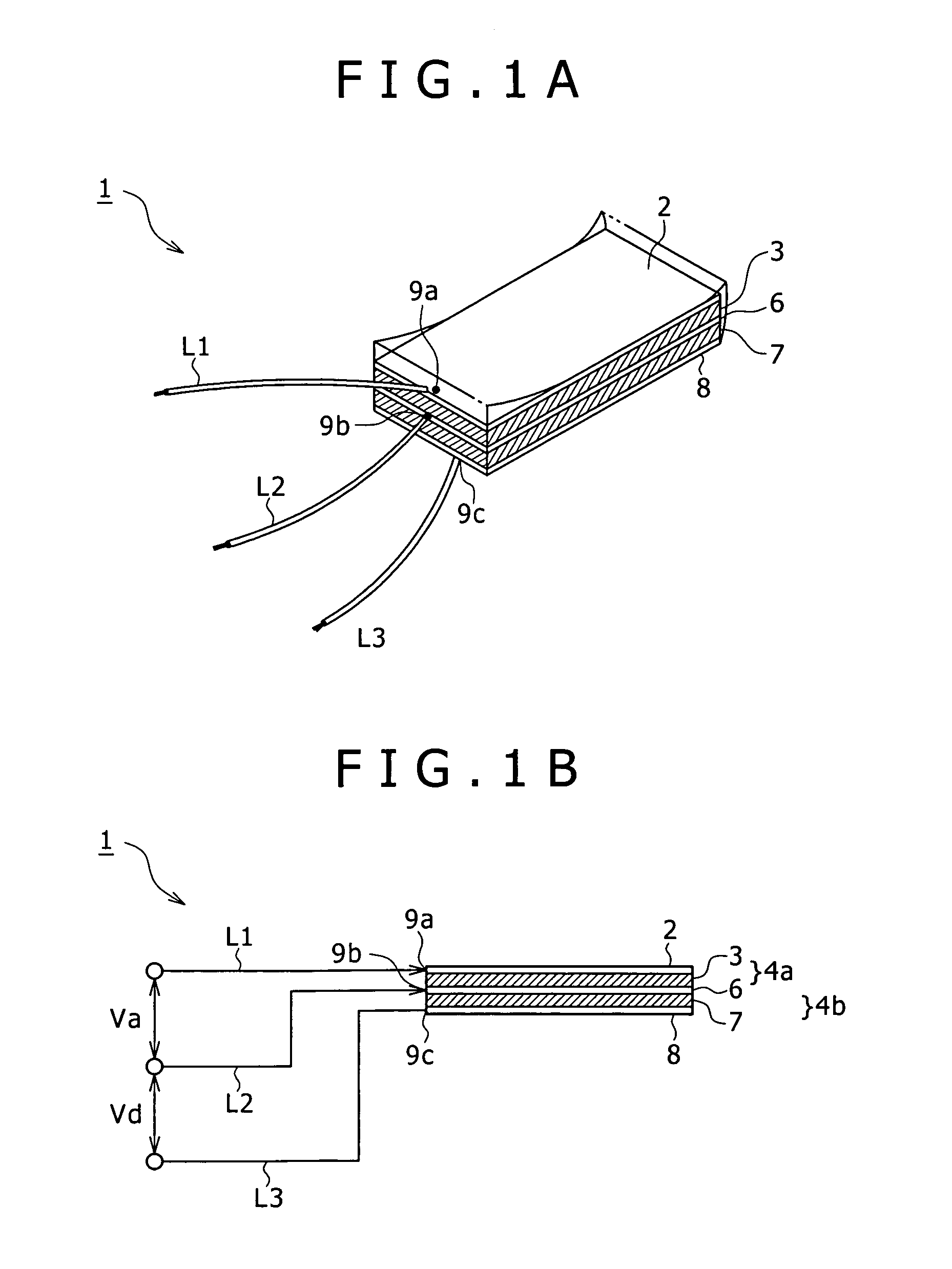

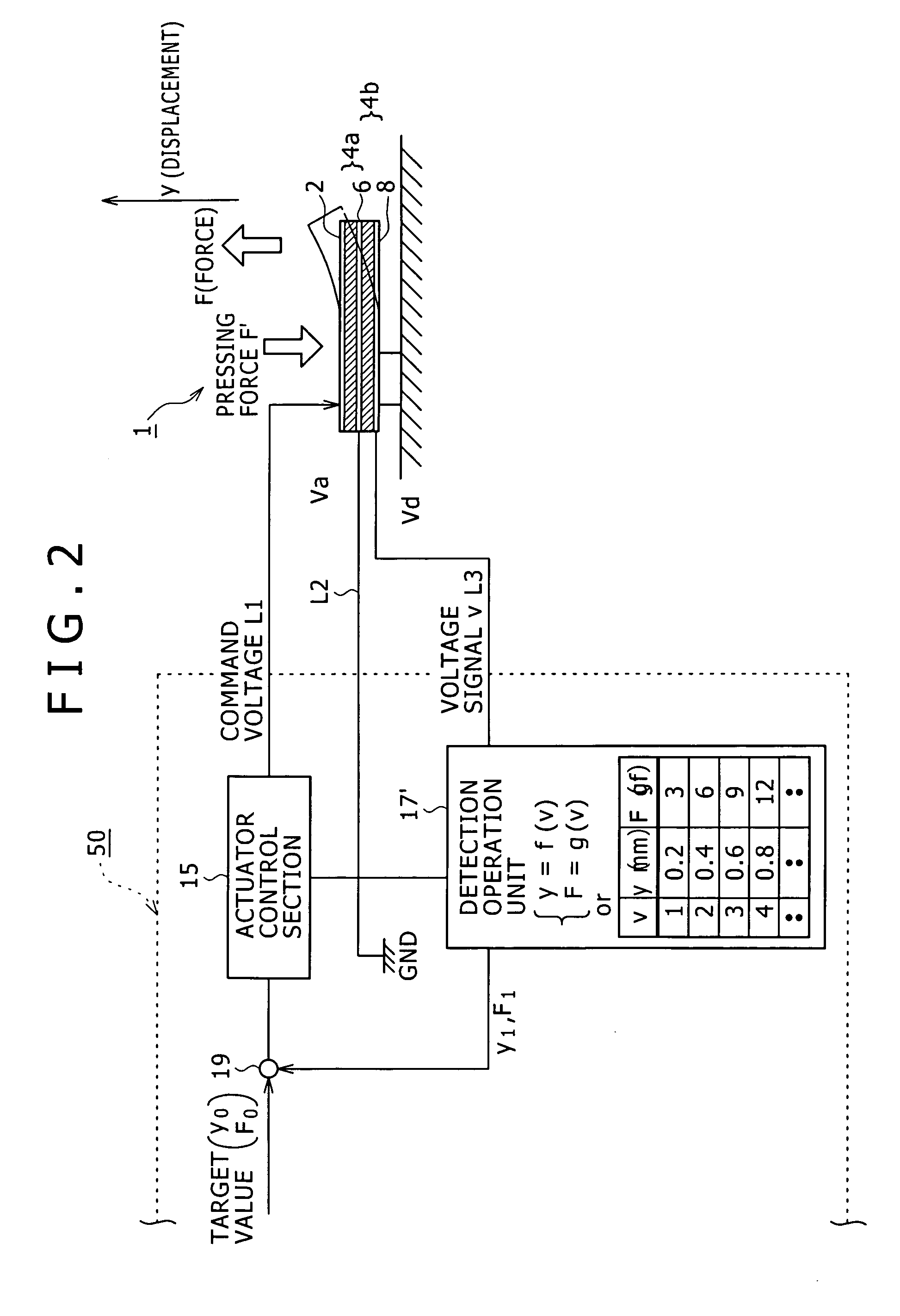

Piezoelectric composite device, method of manufacturing same, method of controlling same, input-output device, and electronic device

InactiveUS20060028095A1MorePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

Disclosed herein is a piezoelectric composite device including: a feeding electrode; a common electrode; a signal detecting electrode; a first piezoelectric element joined between the feeding electrode and the common electrode; and a second piezoelectric element joined between the common electrode and the signal detecting electrode; a predetermined voltage being supplied between the feeding electrode and the common electrode; and a force detection signal based on an external force being extracted from the detecting electrode.

Owner:SONY CORP

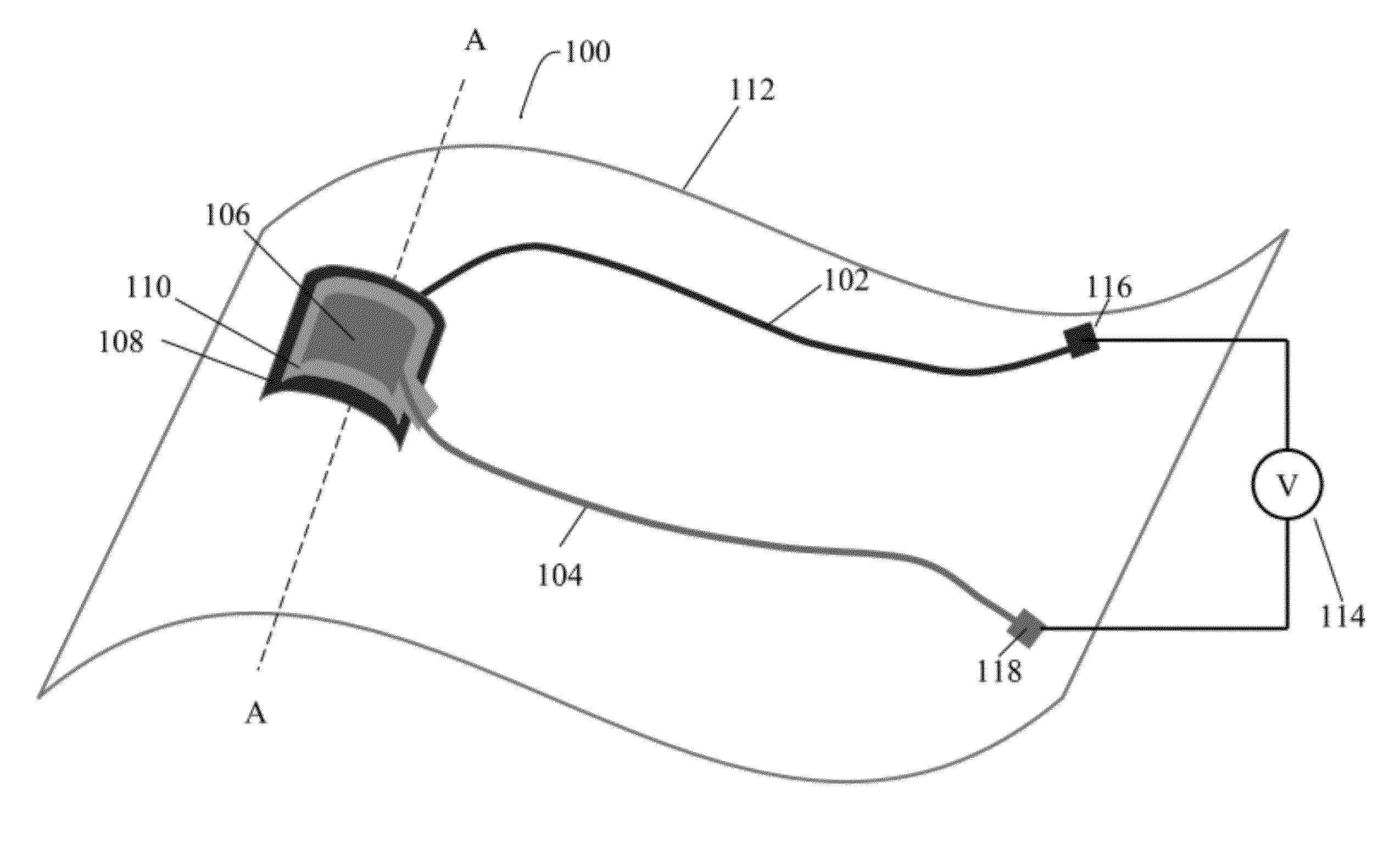

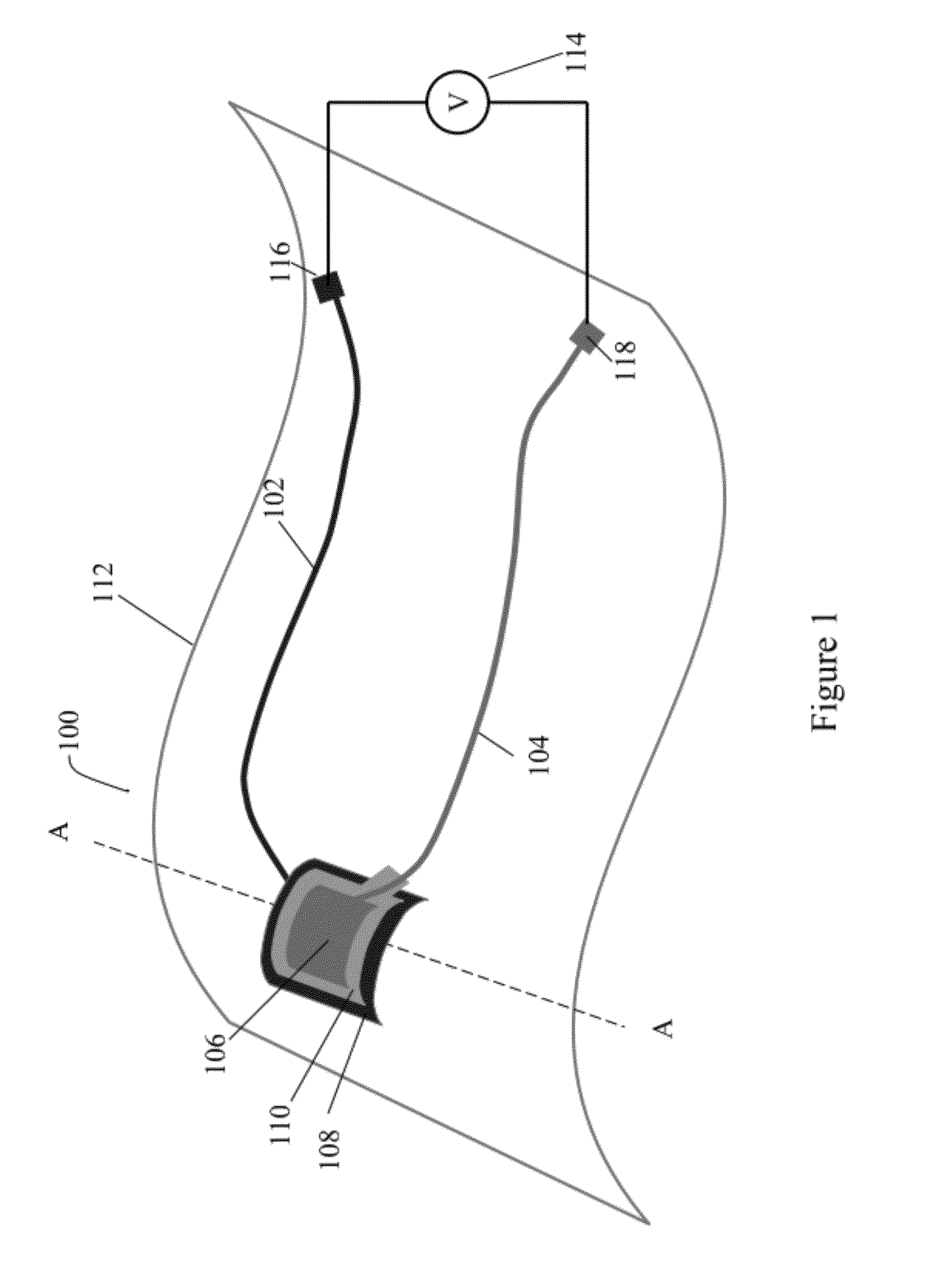

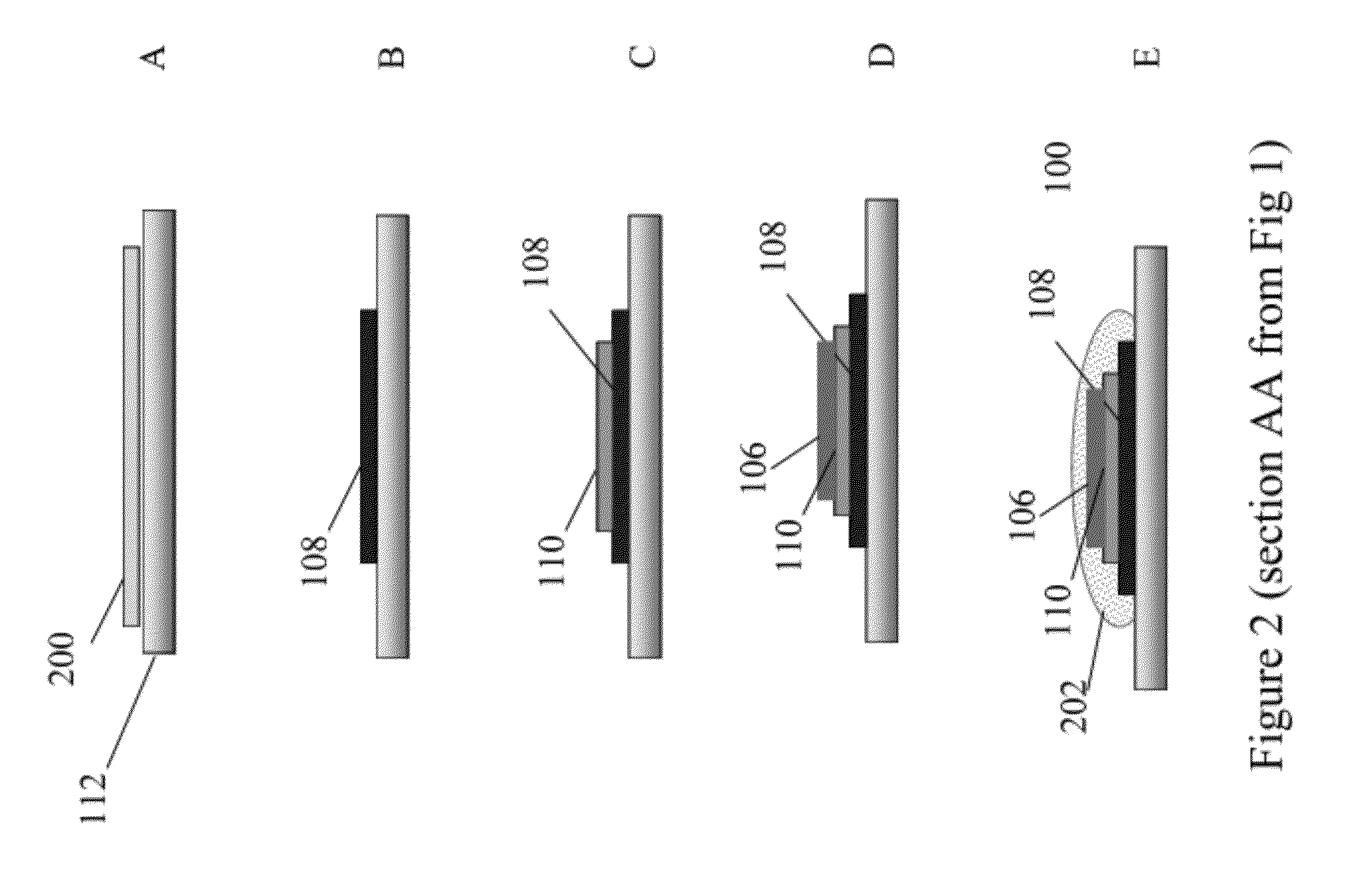

Pressure sensing or force generating device

ActiveUS20120055257A1Few contactsShorten the counting processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCapacitanceCapacitive effect

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

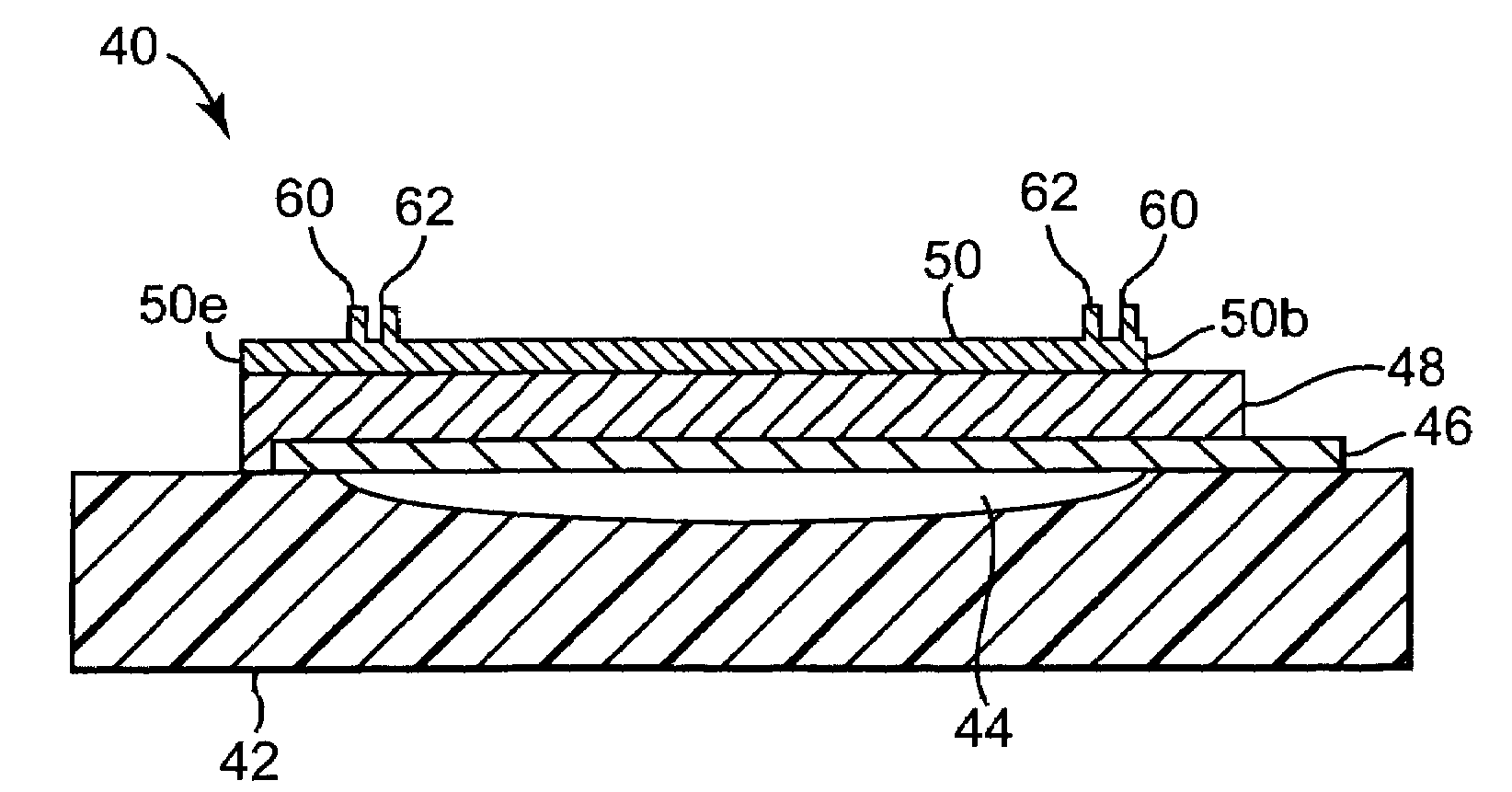

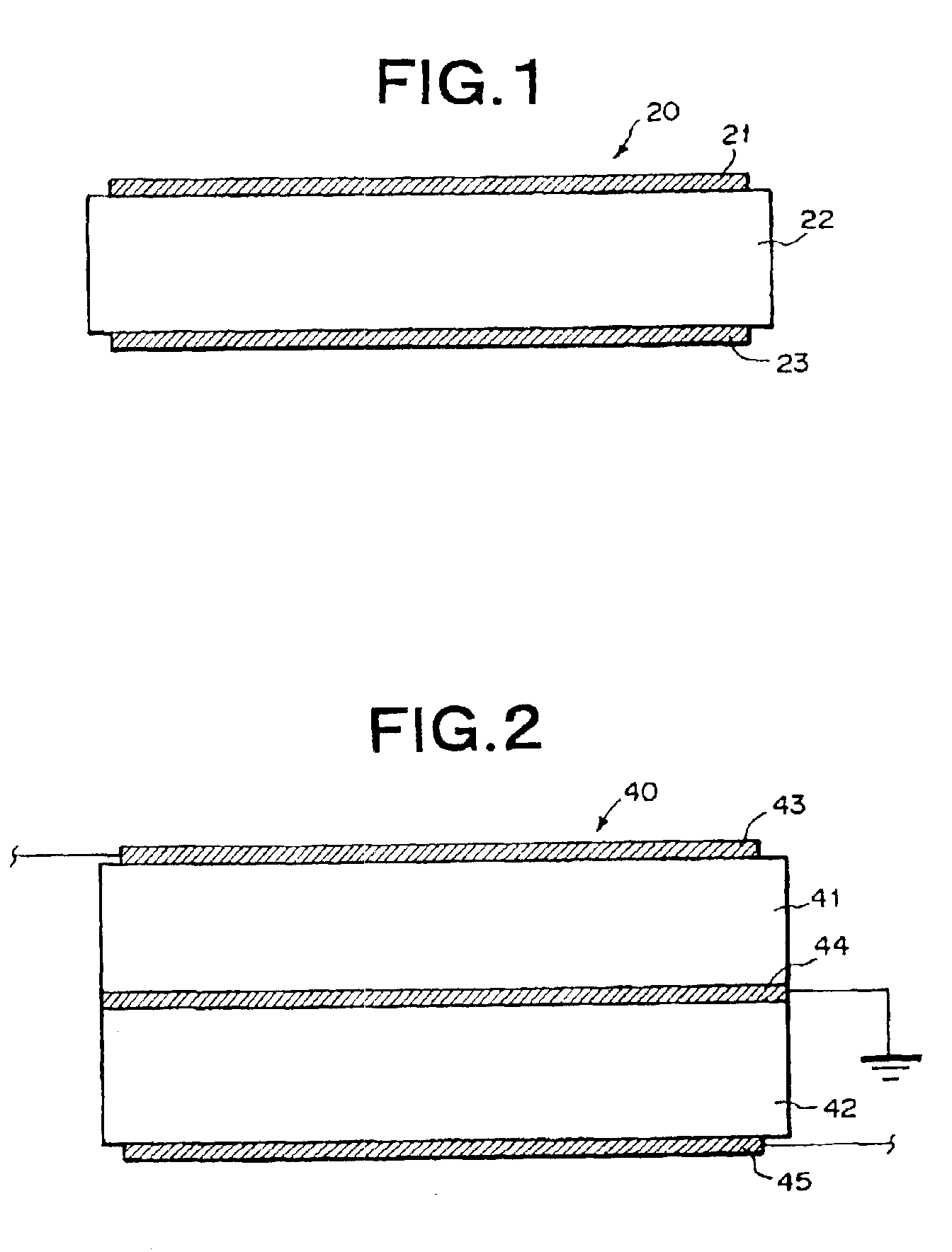

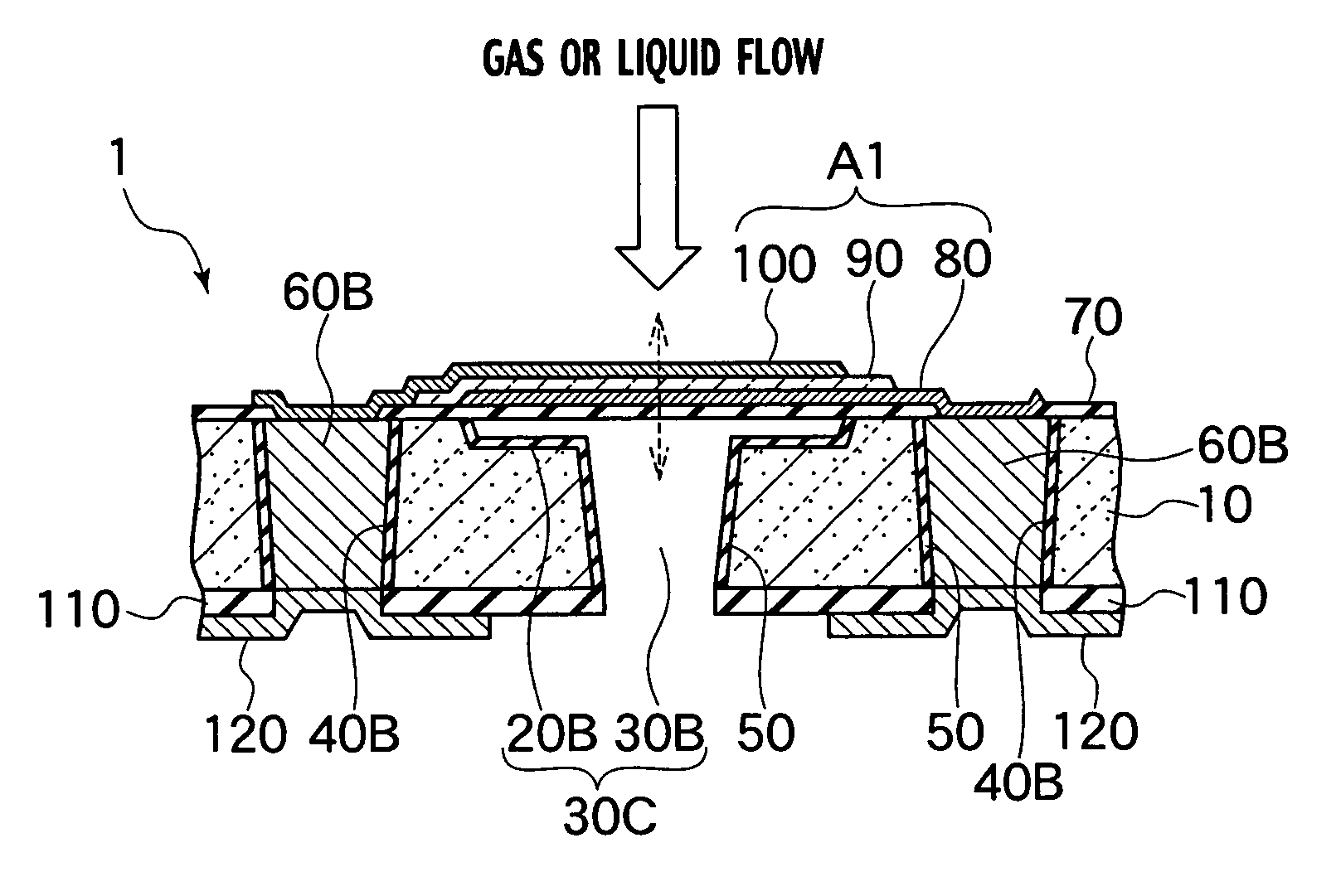

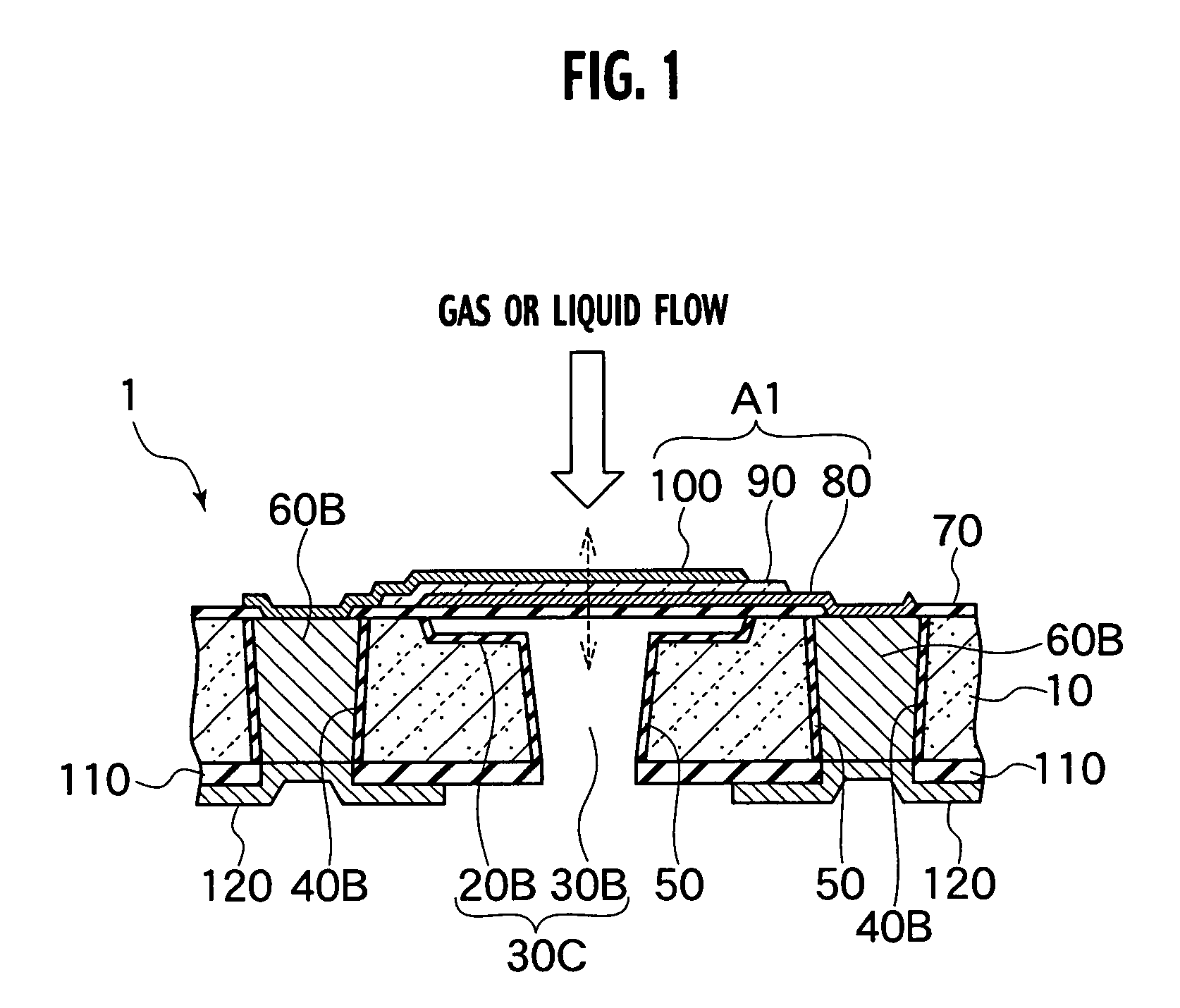

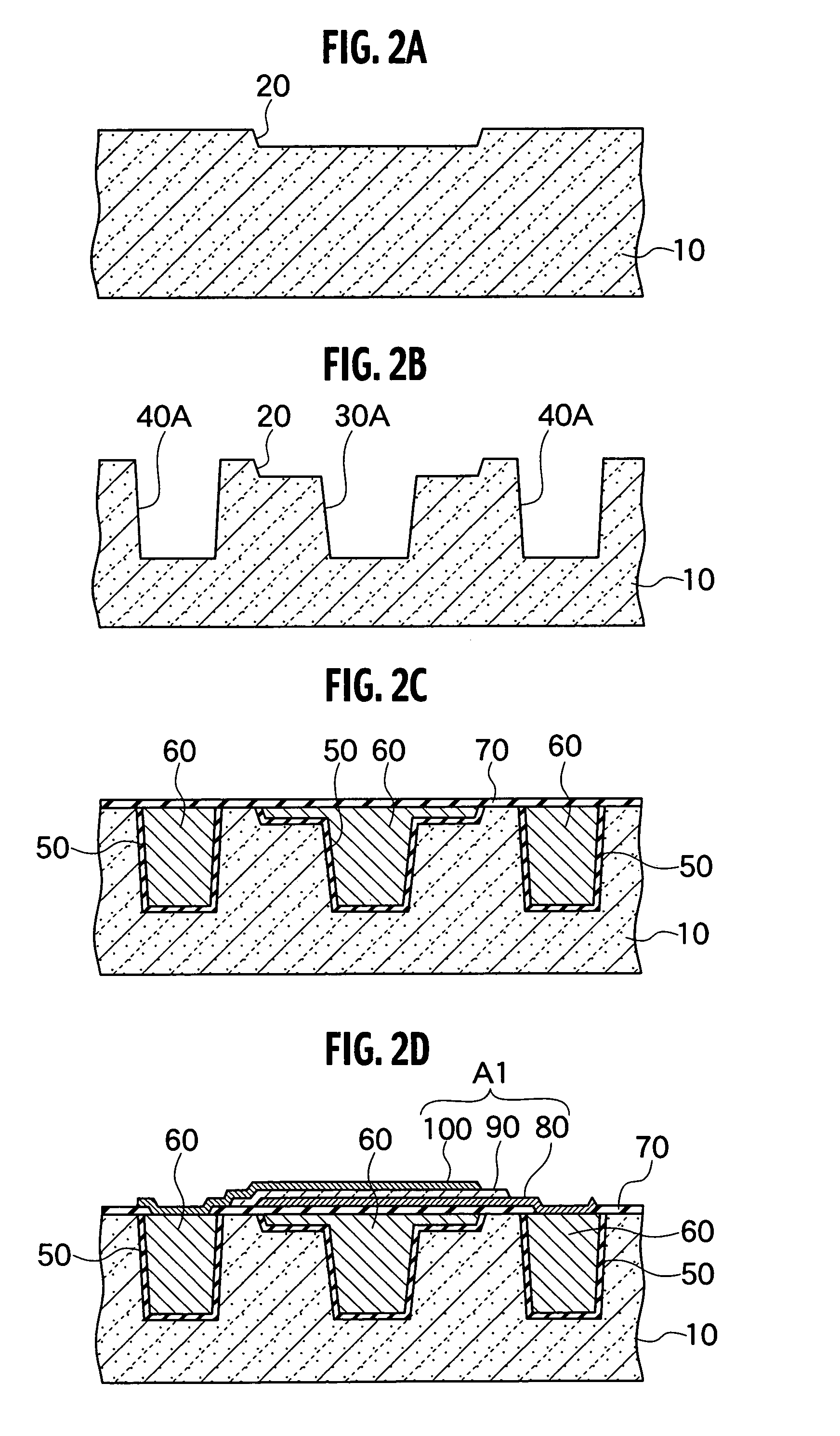

Bistable microactuator with coupled membranes

InactiveUS6168395B1Improves pneumaticImproves liquid couplingCircuit elementsDecorative surface effectsMetallic electrodeCoupling

A bistable electrostatic actuator with pneumatic or liquid coupling. The actuator has enclosed metallic electrodes. It can be used for a microvalve or micropump. The actuator has buckled membrane sections in pairs and curved substrate electrodes, locally associated with said membrane sections.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

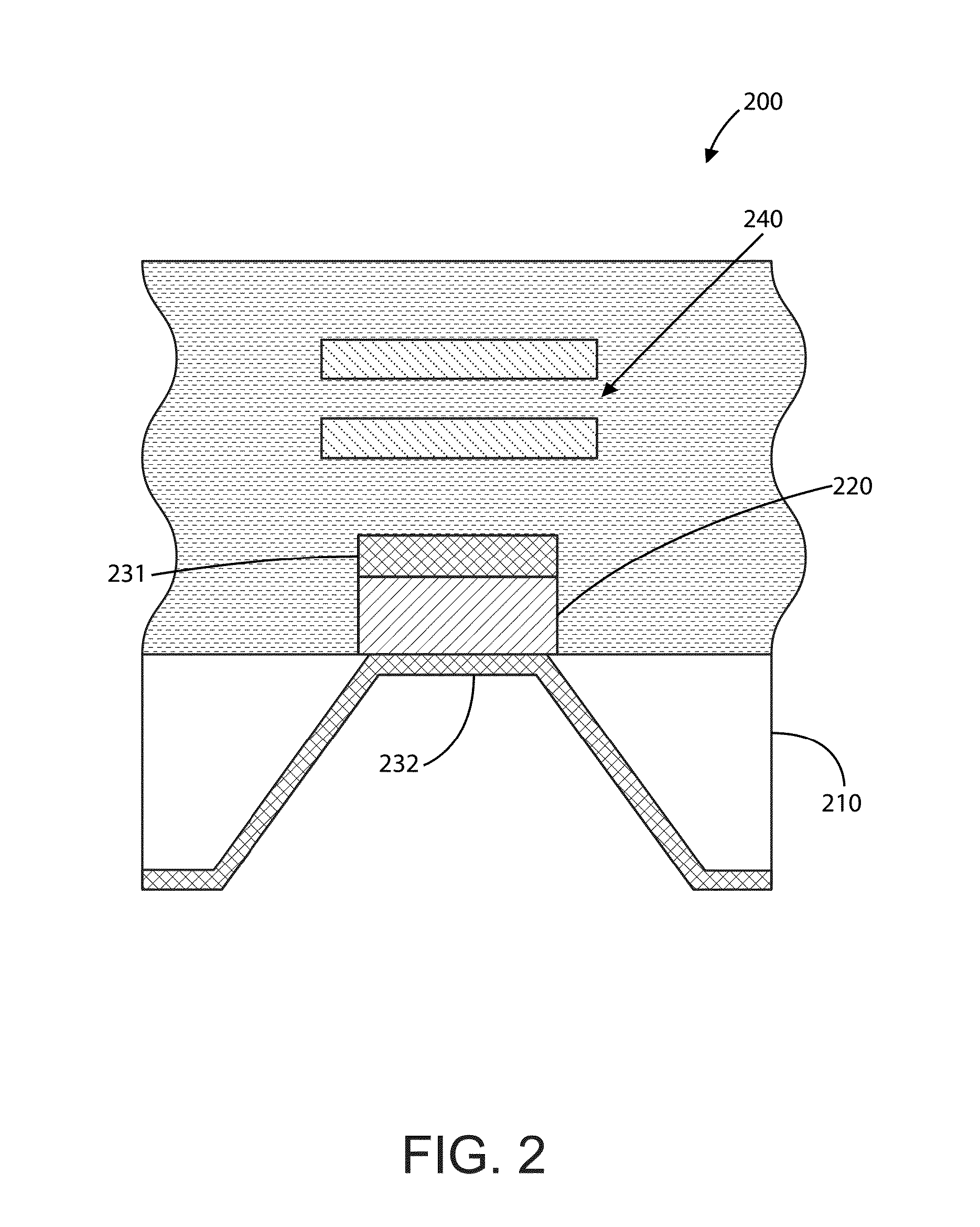

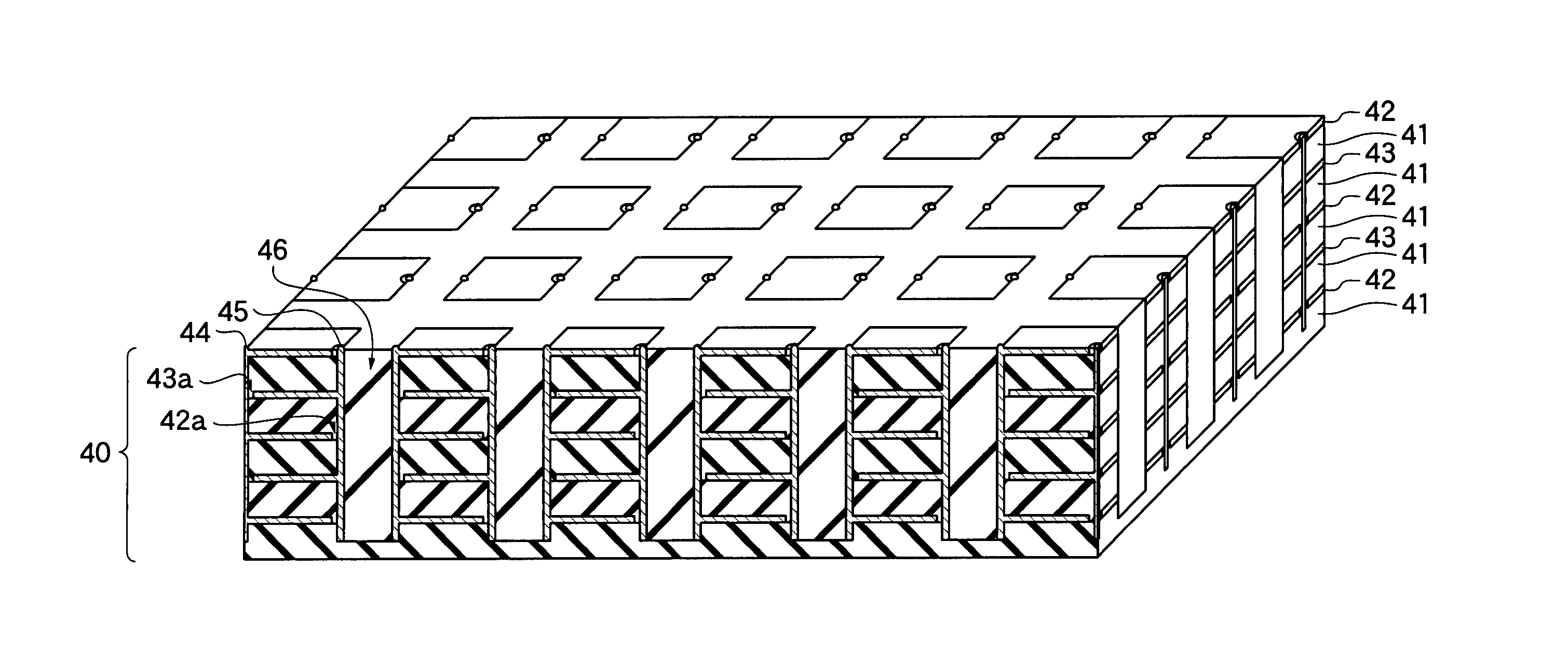

Cavity-less film bulk acoustic resonator (FBAR) devices

ActiveUS20050104690A1Manufacturing process is complexPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksCouplingPlastic materials

The film bulk acoustic resonator (FBAR) device comprises a substrate, an acoustic Bragg reflector over the substrate, a piezoelectric element over the acoustic Bragg reflector, and a remote-side electrode over the piezoelectric element. The acoustic Bragg reflector comprises a metal Bragg layer juxtaposed with a plastic Bragg layer. The large ratio between the acoustic impedances of the plastic material of the plastic Bragg layer and the metal of the metal Bragg layer provides sufficient acoustic isolation between the FBAR and the substrate for the frequency response of the FBAR device to exhibit minor, if any, spurious artifacts arising from undesirable acoustic coupling between the FBAR and the substrate.

Owner:AVAGO TECH INT SALES PTE LTD

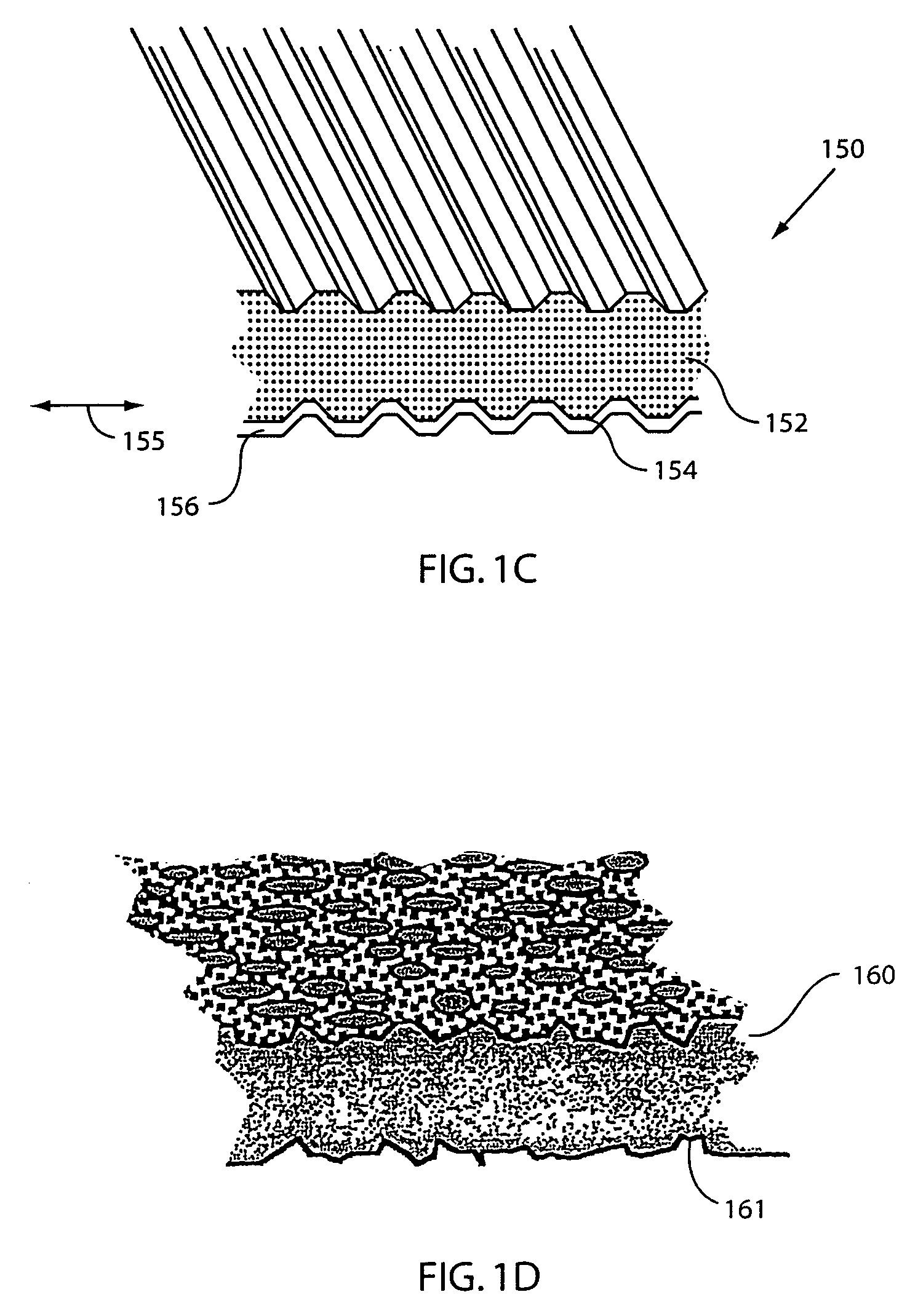

Electroactive polymers

InactiveUS7049732B2Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPolymer sciencePolymer chemistry

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

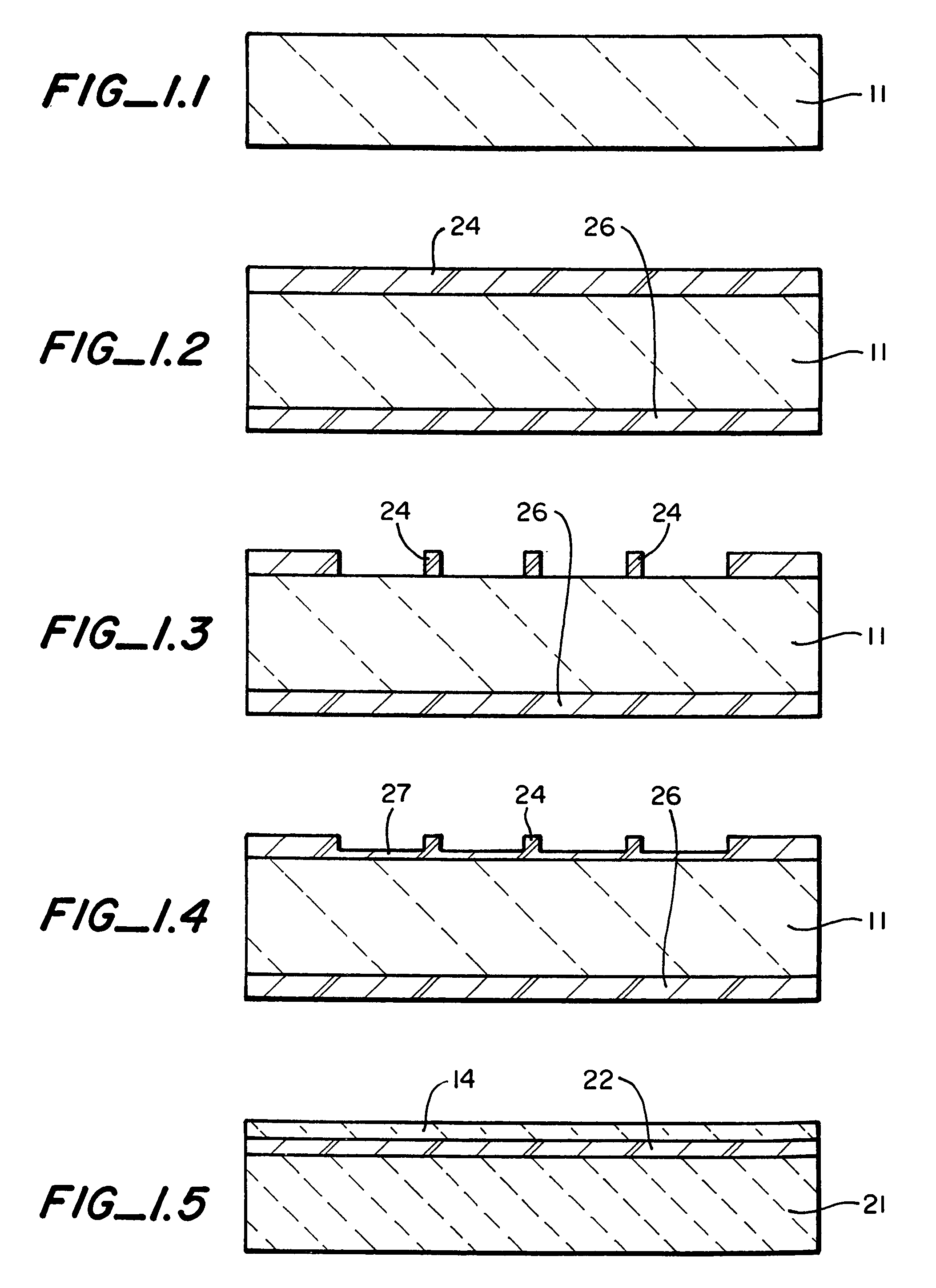

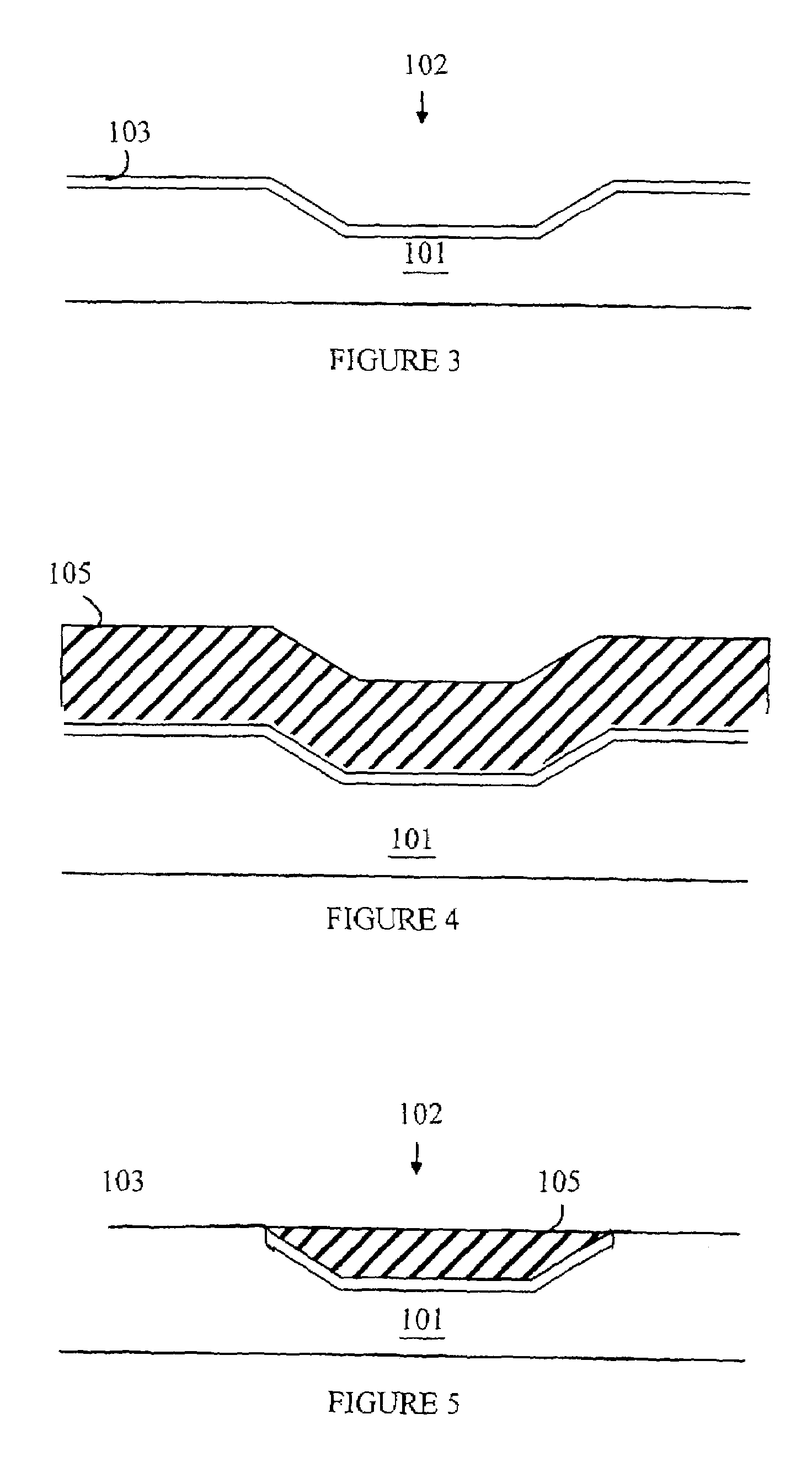

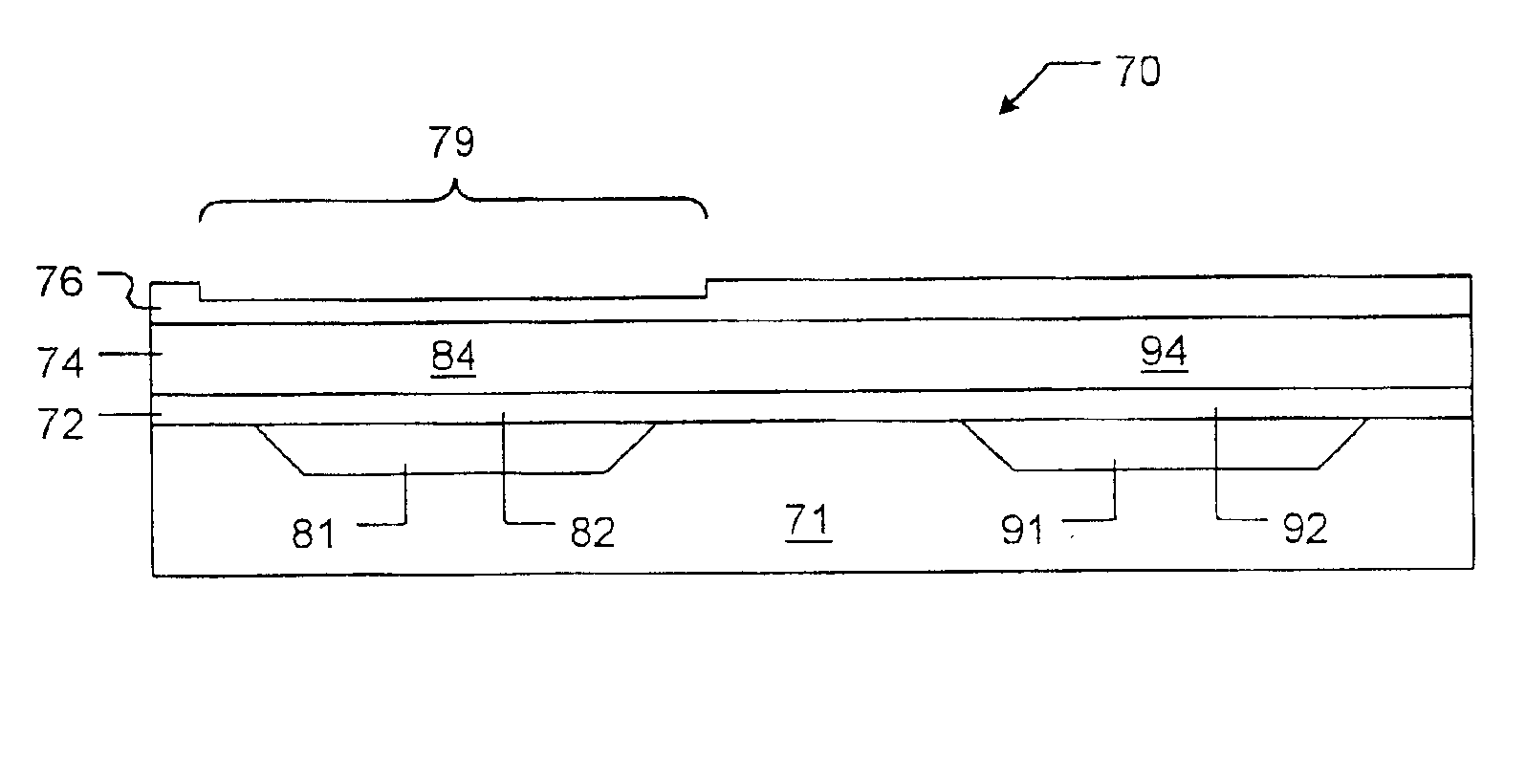

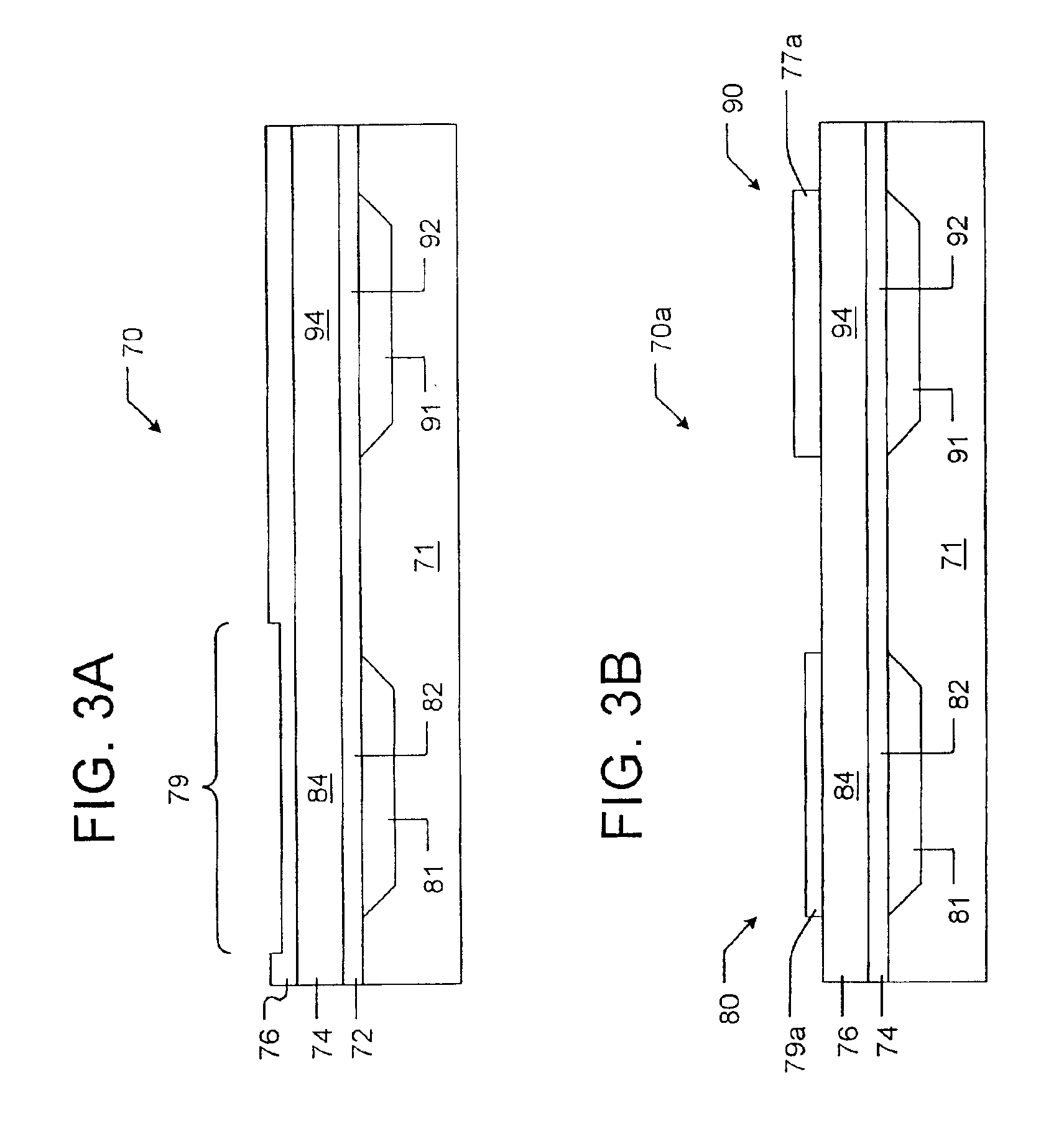

Method for fabricating an acoustical resonator on a substrate

InactiveUS7275292B2Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksSurface levelMaterials science

Method for fabricating an acoustical resonator on a substrate having a top surface. First, a depression in said top surface is generated. Next, the depression is filled with a sacrificial material. The filled depression has an upper surface level with said top surface of said substrate. Next, a first electrode is deposited on said upper surface. Then, a layer of piezoelectric material is deposited on said first electrode. A second electrode is deposited on the layer of piezoelectric material using a mass load lift-off process.

Owner:AVAGO TECH INT SALES PTE LTD

Method for forming plated terminations

InactiveUS7152291B2Improved termination featureEliminate or greatly simplify thick-film stripesElectrolytic capacitorsSemiconductor/solid-state device detailsTermination problemEngineering

Improved method steps for terminating multilayer electronic components are disclosed. Monolithic components are formed with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. Electrode and dielectric layers are provided in an interleaved arrangement and selected portions of the electrode layers are exposed. Electrically isolated anchor tabs may optionally be provided and exposed in some embodiments. Termination material is then plated to the exposed portions of the electrode layers until exposed portions of selected such portions thereof are connected. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

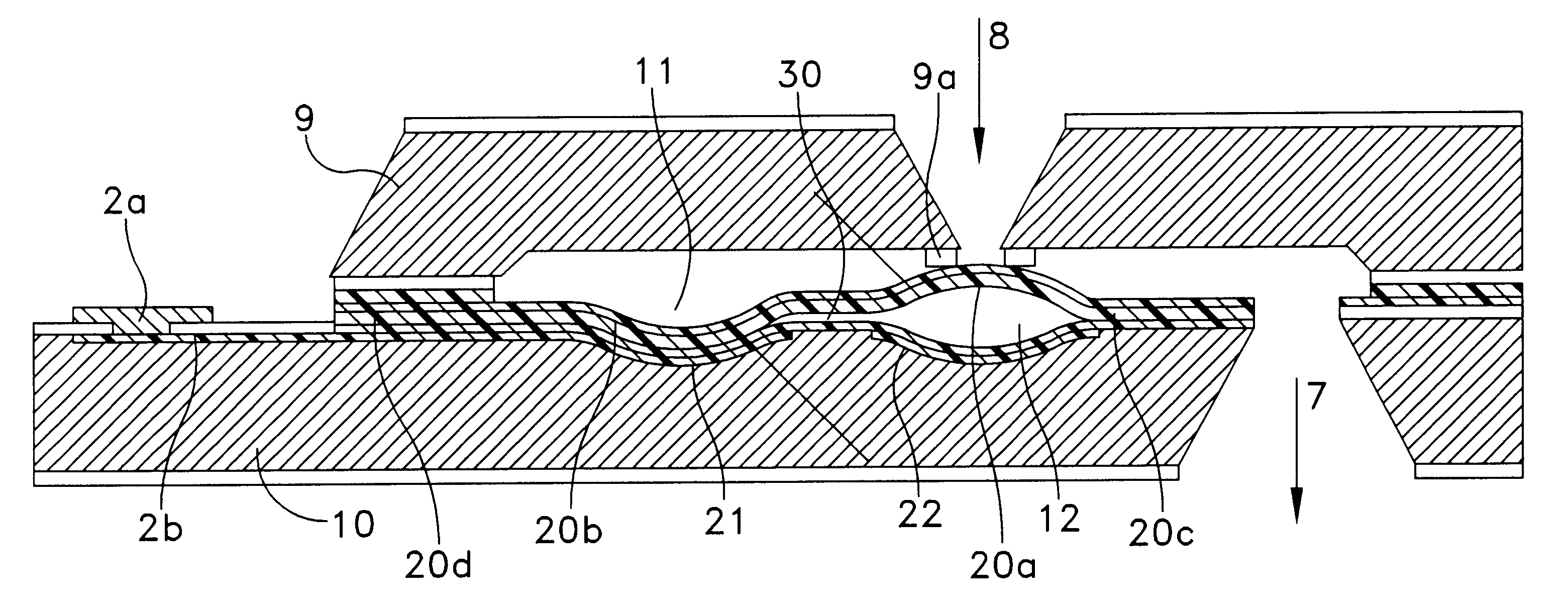

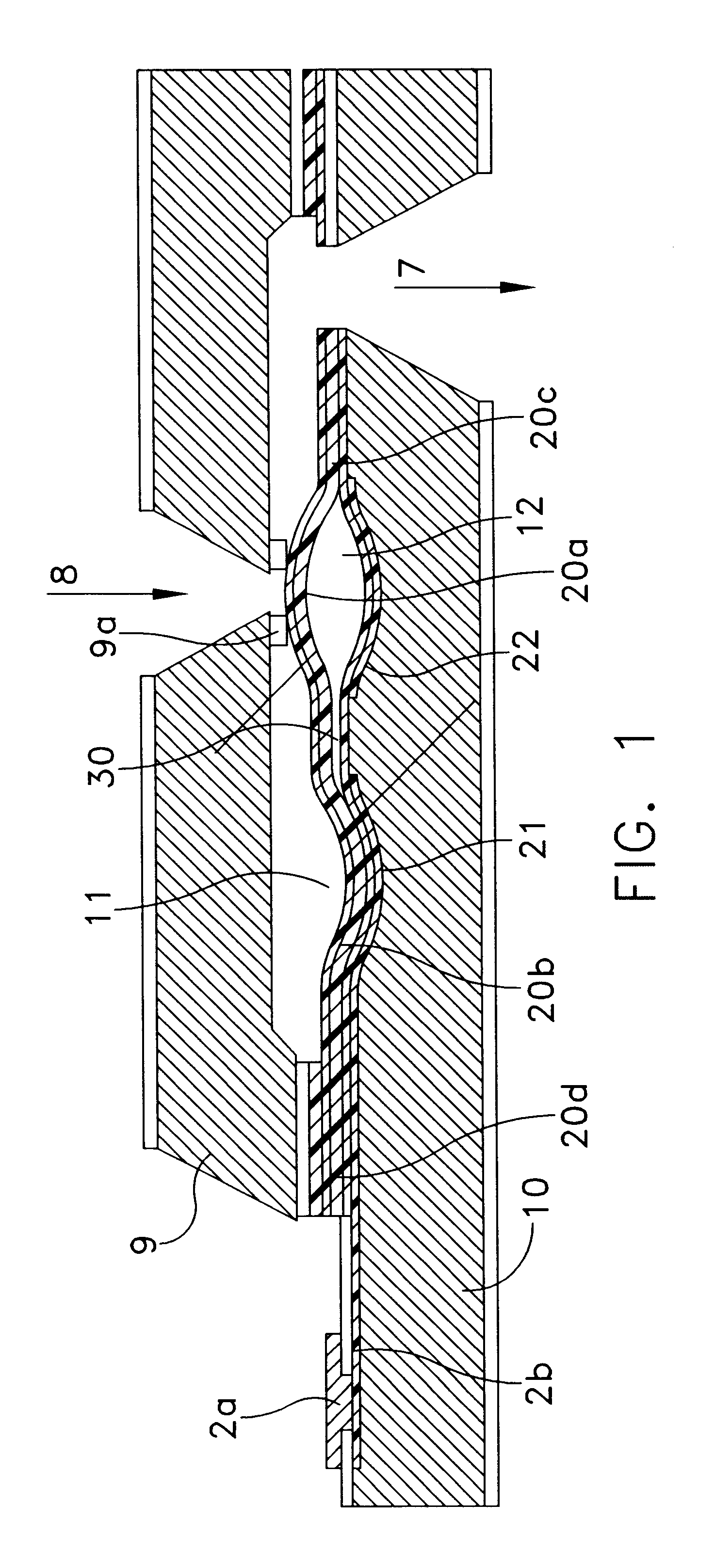

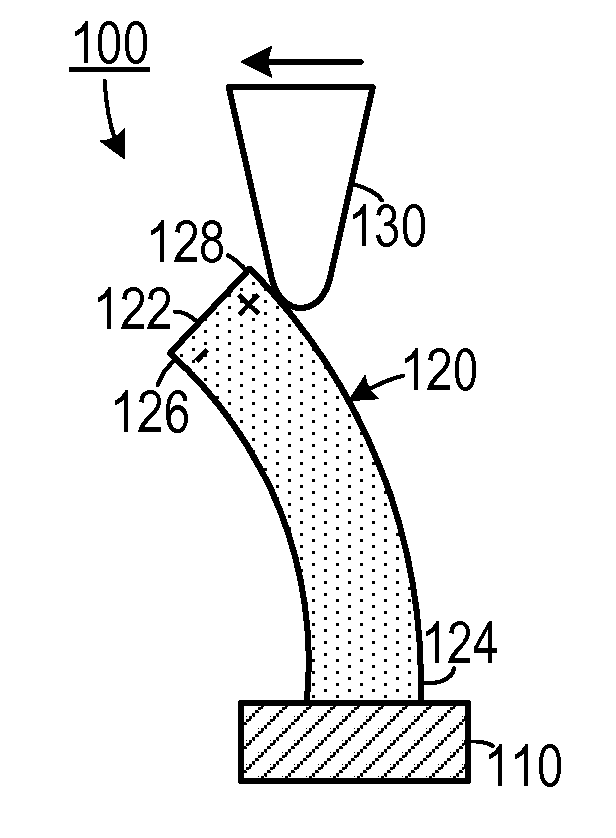

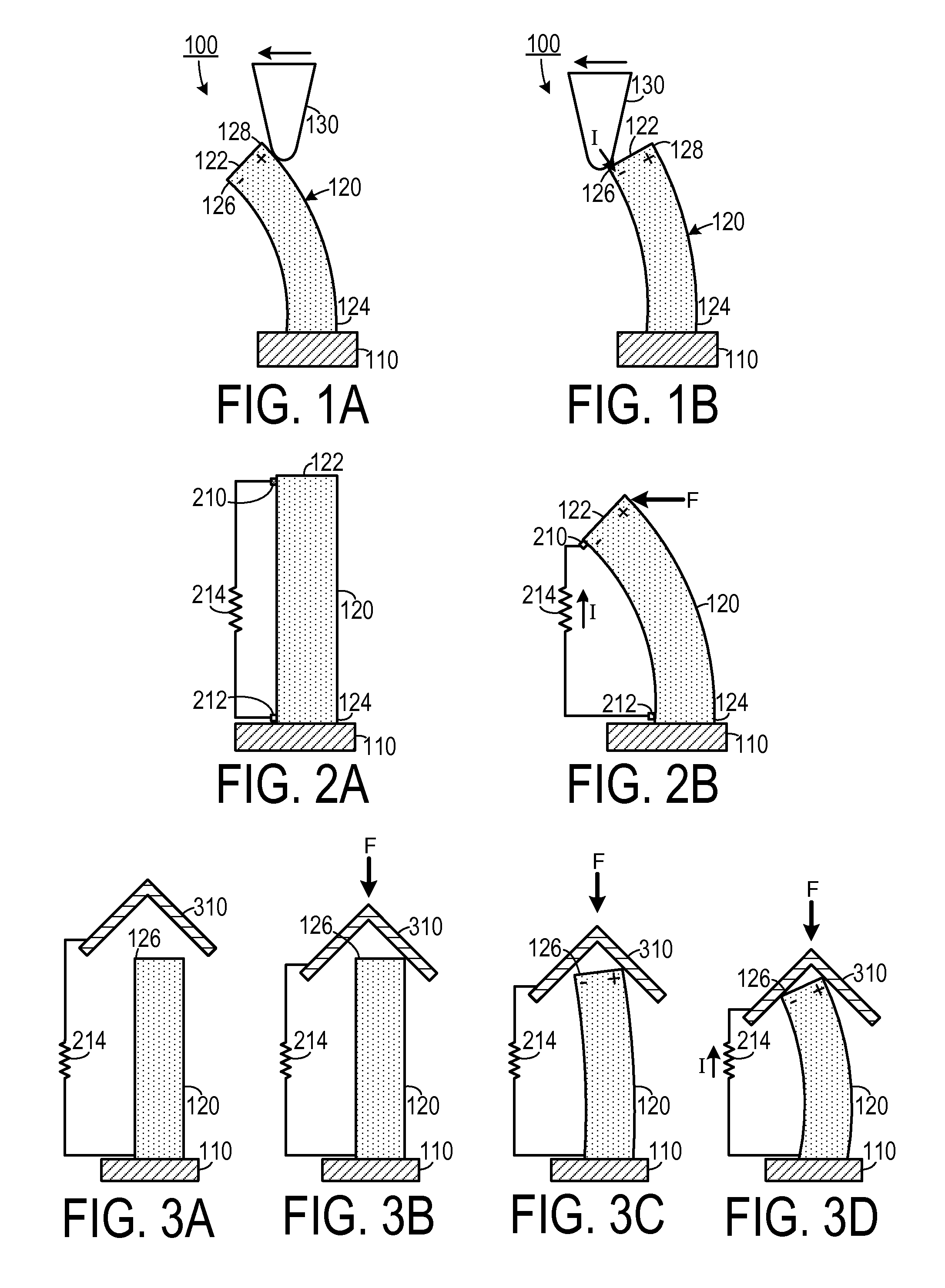

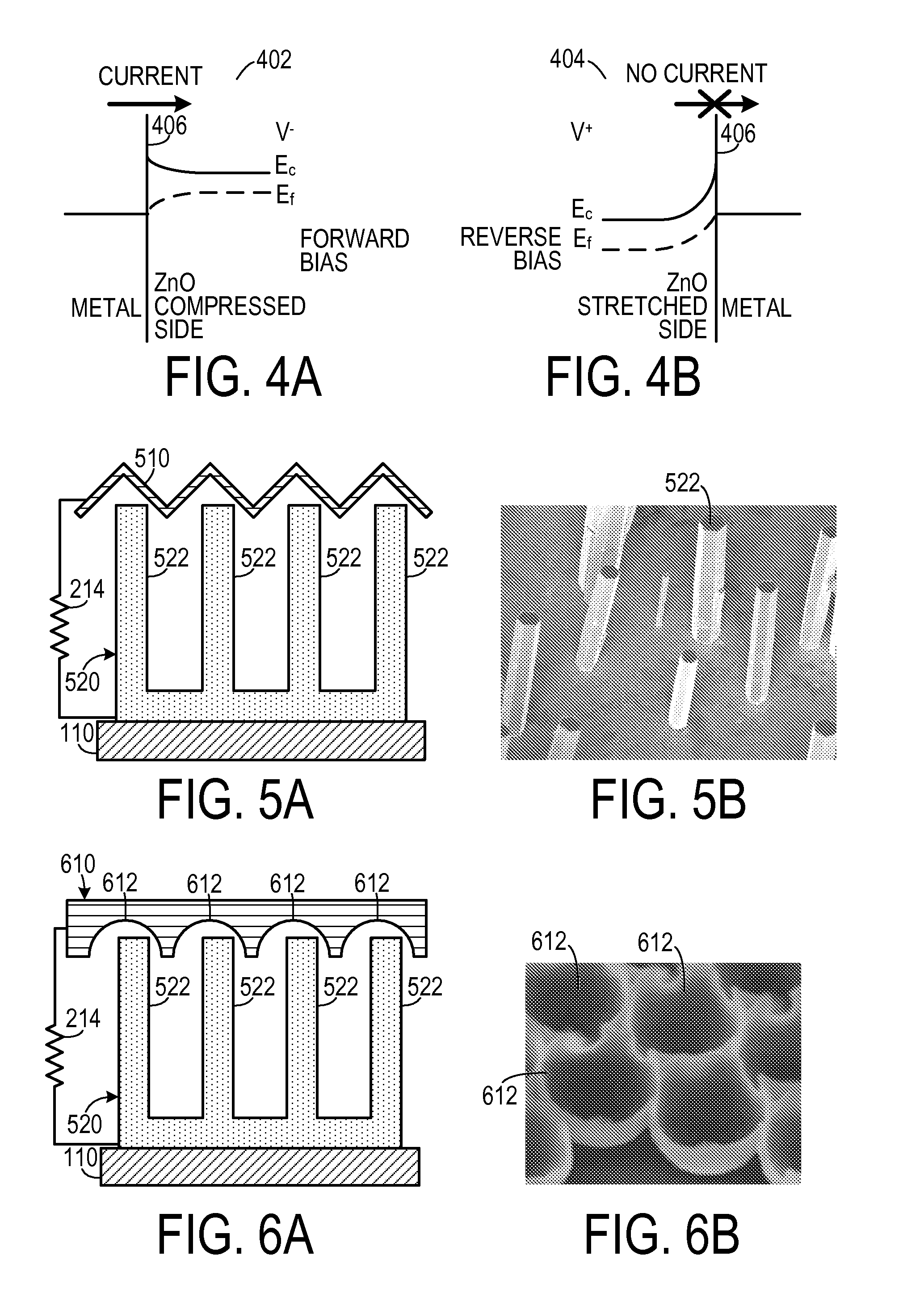

Nano-Piezoelectronics

InactiveUS20080067618A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesNanometreSemiconductor

A semiconducting device includes a substrate, a piezoelectric wire, a structure, a first electrode and a second electrode. The piezoelectric wire has a first end and an opposite second end and is disposed on the substrate. The structure causes the piezoelectric wire to bend in a predetermined manner between the first end and the second end so that the piezoelectric wire enters a first semiconducting state. The first electrode is coupled to the first end and the second electrode is coupled to the second end so that when the piezoelectric wire is in the first semiconducting state, an electrical characteristic will be exhibited between the first electrode and the second electrode.

Owner:GEORGIA TECH RES CORP

Electronic component having micro-electrical mechanical system

ActiveUS7053456B2Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityElectronic component

Owner:KIOXIA CORP

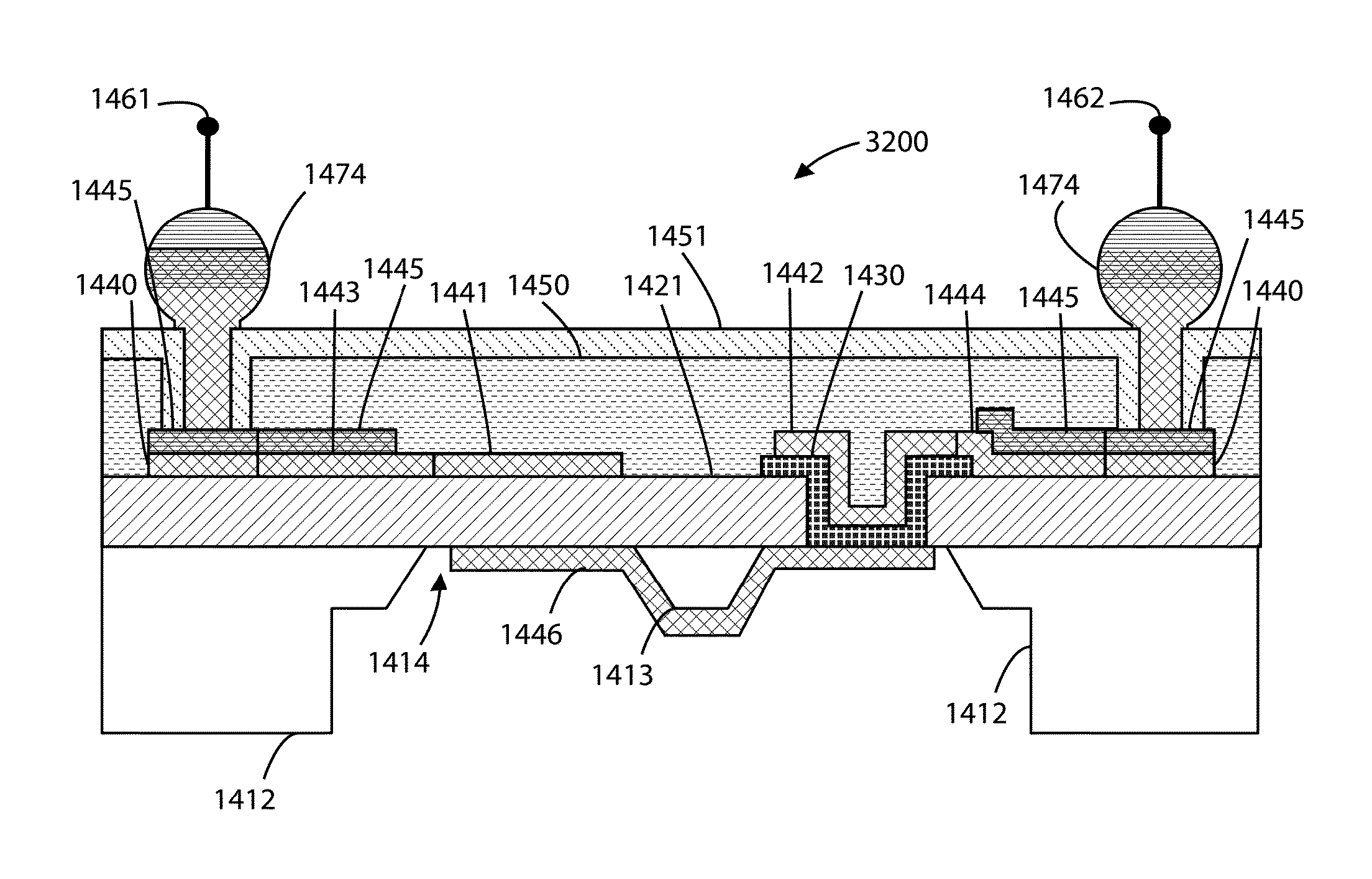

Single crystal acoustic resonator and bulk acoustic wave filter

ActiveUS20160028367A1AdvantageSimple and cost-effectivePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallic materialsCarbide

A method of wafer scale packaging acoustic resonator devices and an apparatus therefor. The method including providing a partially completed semiconductor substrate comprising a plurality of single crystal acoustic resonator devices provided on a silicon and carbide bearing material, each having a first electrode member, a second electrode member, and an overlying passivation material. At least one of the devices to be configured with an external connection, a repassivation material overlying the passivation material, an under metal material overlying the repassivation material. Copper pillar interconnect structures are then configured overlying the electrode members, and solder bump structures are form overlying the copper pillar interconnect structures.

Owner:AKOUSTIS INC

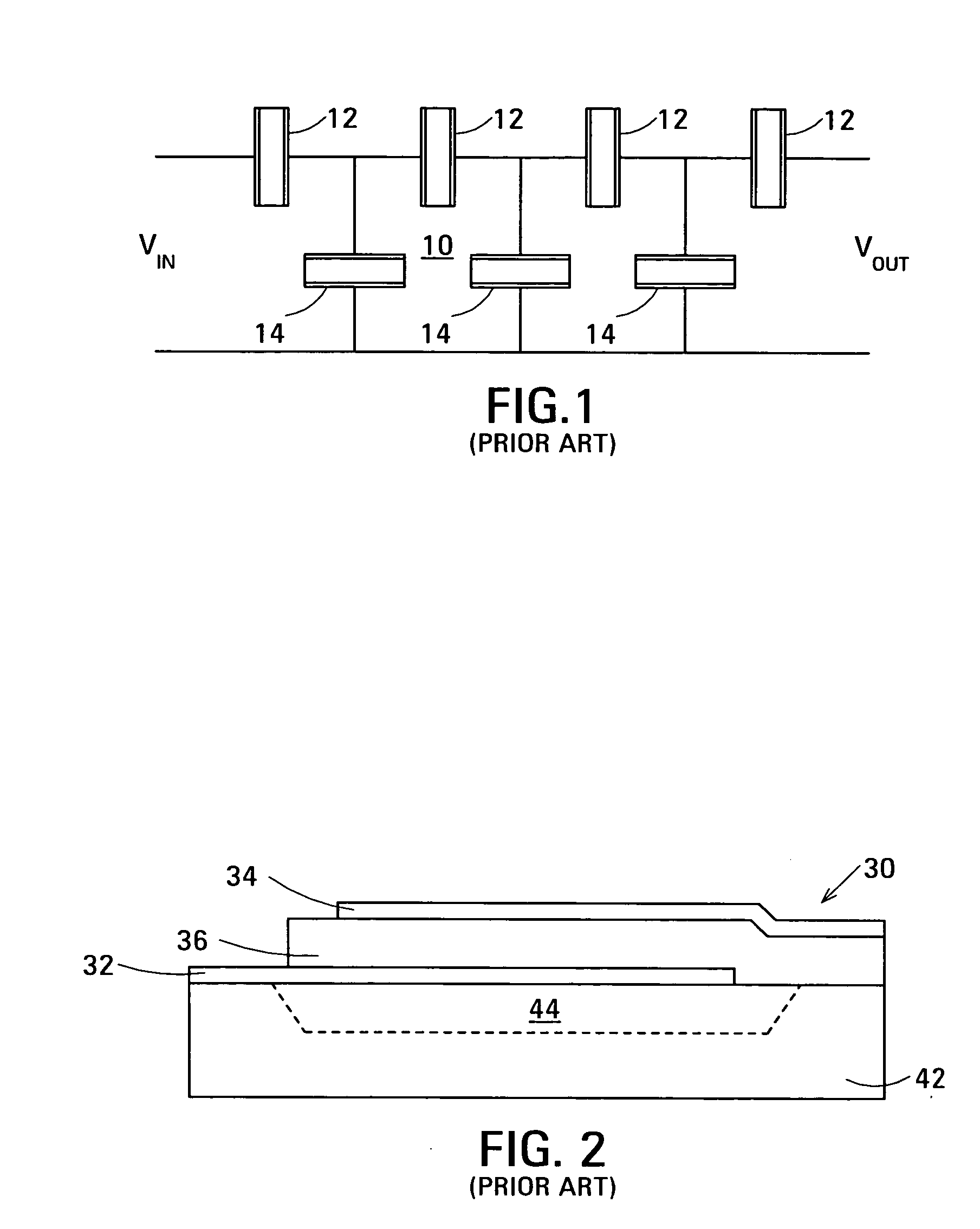

Tuning mechanical resonators for electrical filter

InactiveUS6307447B1Multiple-port networksPiezoelectric/electrostrictive device manufacture/assemblyHelical resonatorPhysics

The present invention is a method for adjusting different resonant frequencies of a plurality of mechanical resonators formed on a common substrate, in a case where the resonant frequencies of the resonators are a function of each resonator thickness. According to this method the resonators are each formed with an etchable top electrode layer which includes a material having different etching properties as a topmost layer for each of the resonators having different resonant frequencies. By selectively etching these etchable layers one at a time in the presence of the others, one may adjust the resonant frequencies of each of the resonators without need to mask the resonators during the etching process. Associated with this method there is a resonator structure having a top electrode structure having a topmost layer having different etching characteristics for different resonators.

Owner:AVAGO TECH INT SALES PTE LTD

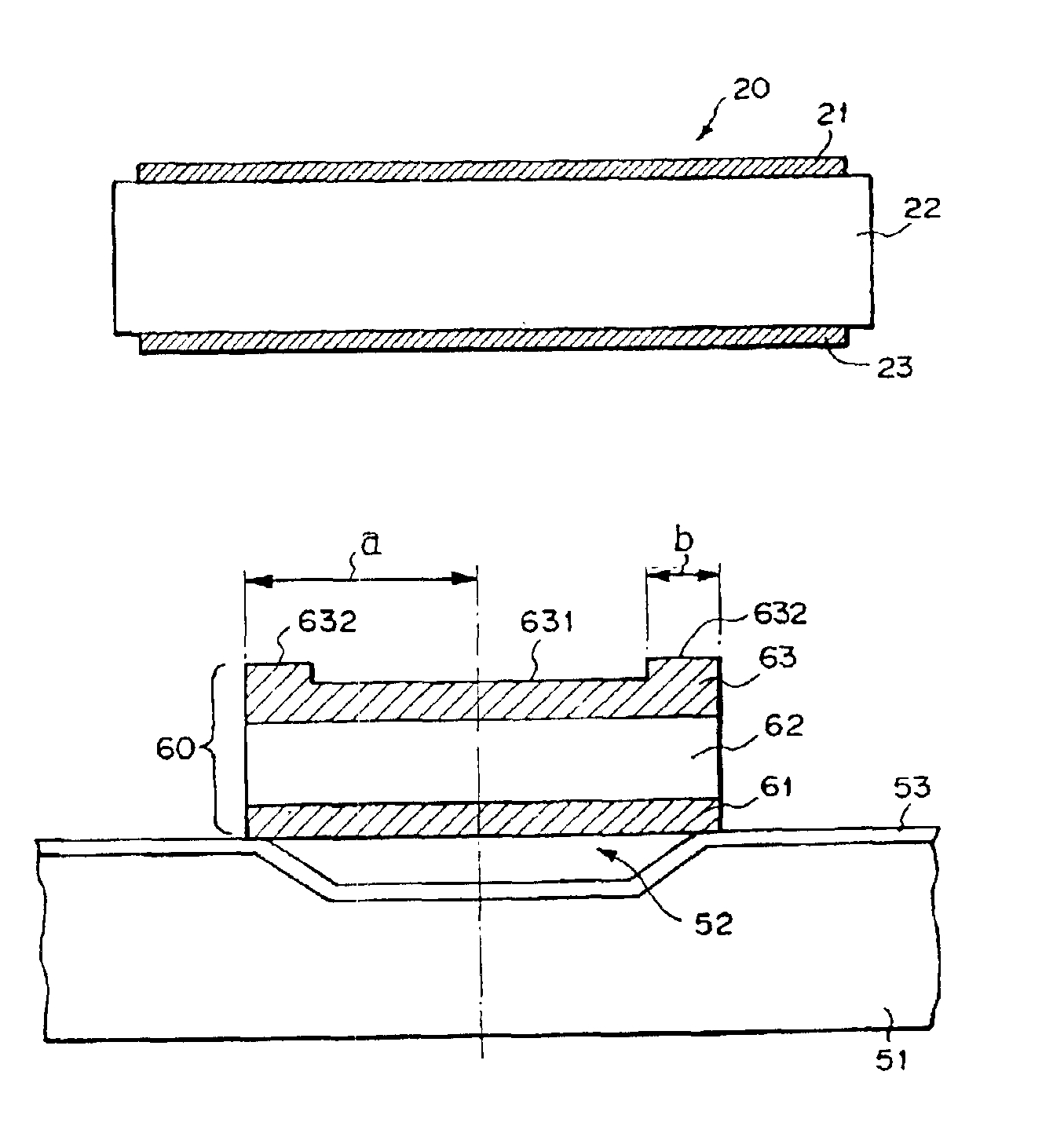

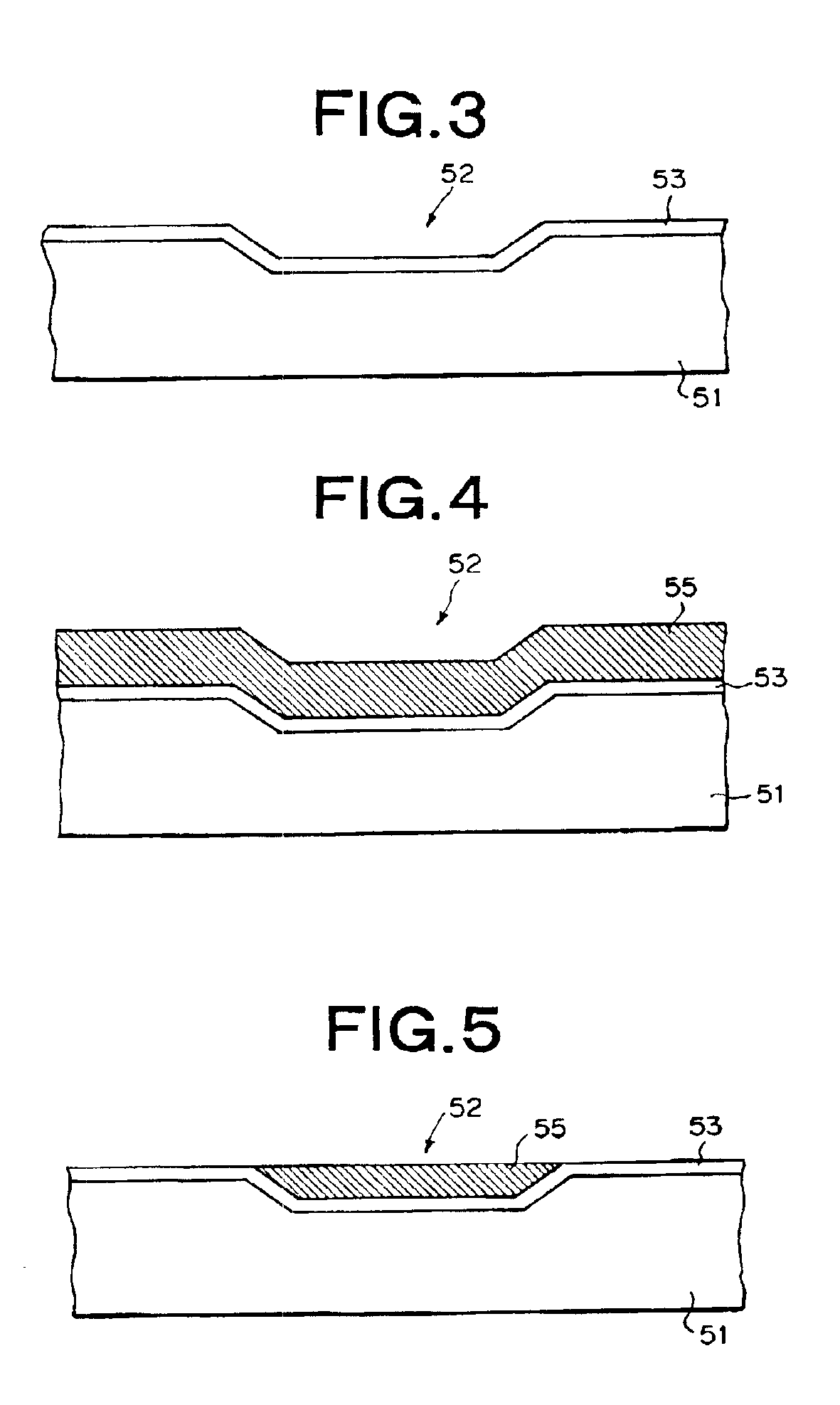

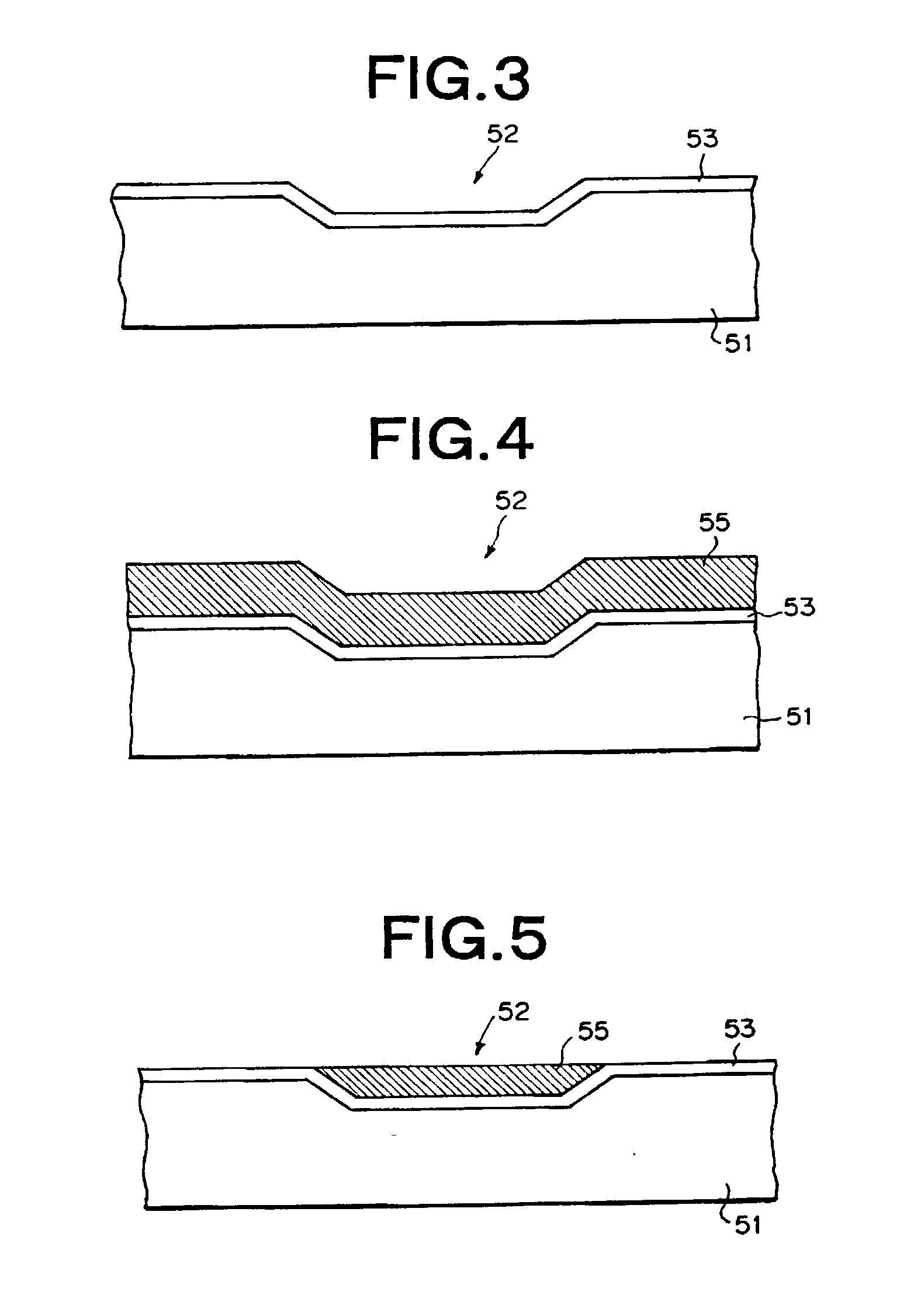

Thin film bulk acoustic resonator and method of producing the same

InactiveUS20020190814A1Improve featuresPiezoelectric/electrostrictive device manufacture/assemblyNanotechThin-film bulk acoustic resonatorElectromechanical coupling coefficient

A pit (52) is formed in a substrate comprising a silicon wafer (51) on a surface of which a silicon oxide thin layer (53) is formed. A sandwich structure (60) comprising a piezoelectric layer (62) and lower and upper electrodes (61, 63) joined to both surfaces of the piezoelectric layer is disposed so as to stride over the pit (52). The upper surface of the lower electrode (61) and the lower surface of the piezoelectric layer (62) joined to the upper surface of the lower electrode are treated so that the RMS variation of the height thereof is equal to 25 nm or less. The thickness of the lower electrode (61) is set to 150 nm or less. According to such a structure, there is provided a high-performance thin film bulk acoustic resonator which are excellent in electromechanical coupling coefficient and acoustic quality factor.

Owner:MEMS SOLUTIONS INC

Temperature-compensated film bulk acoustic resonator (FBAR) devices

InactiveUS20050110598A1Reduce impactPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPlanar electrodeThin-film bulk acoustic resonator

The temperature-compensated film bulk acoustic resonator (FBAR) device comprises an FBAR stack. The FBAR stack comprises an FBAR and a temperature-compensating element. The FBAR is characterized by a resonant frequency having a temperature coefficient, and comprises opposed planar electrodes and a piezoelectric element between the electrodes. The piezoelectric element has a temperature coefficient on which the temperature coefficient of the resonant frequency depends at least in part. The temperature-compensating element has a temperature coefficient opposite in sign to the temperature coefficient of the piezoelectric element.

Owner:AVAGO TECH INT SALES PTE LTD

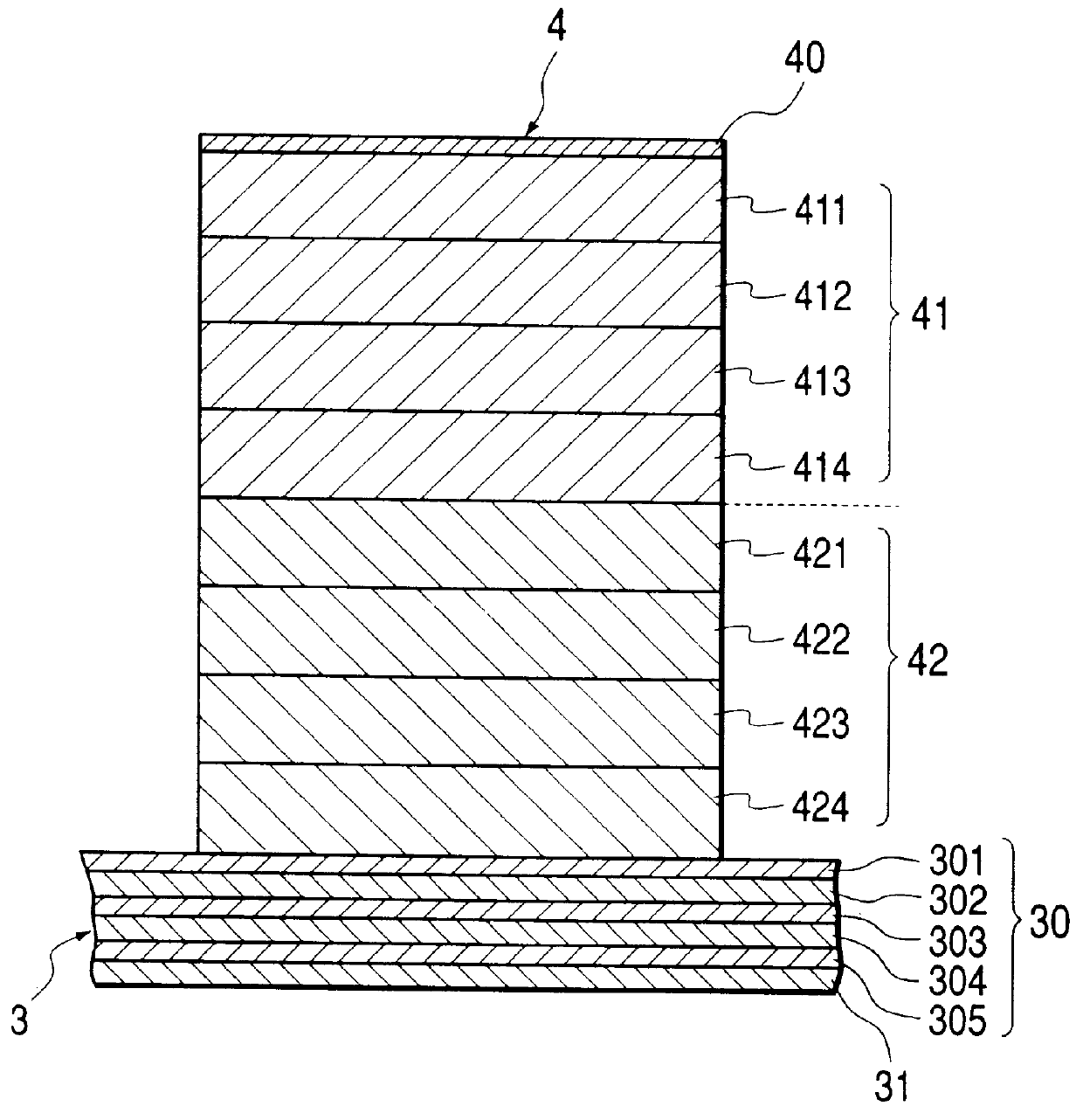

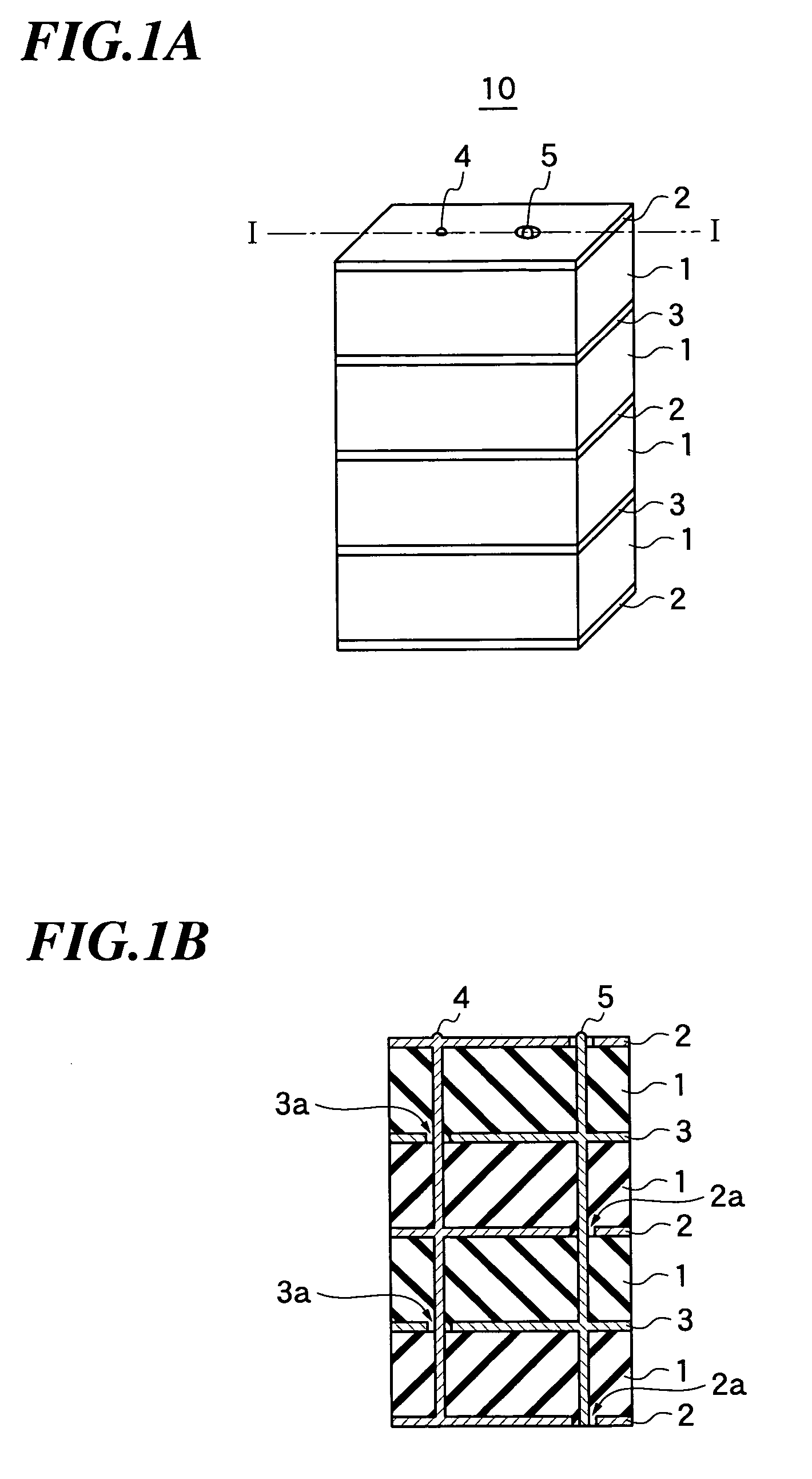

Laminated structure and method of manufacturing the same

InactiveUS7061166B2Not easy to damageWell formedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringInterconnection

A laminated structure in which interconnections can be easily formed for electrodes and in which the damage of an insulating layer attributed to stress is relieved. The laminated structure includes a laminated piece having a first electrode layer provided with a first insulating region, a piezoelectric material layer, and a second electrode layer provided with a second insulating region at a position different from that of the first insulating region, a first interconnection line electrically connected to the first electrode layer while passing through the second insulating region provided in the second electrode layer, and a second interconnection line electrically connected to the second electrode layer while passing through the first insulating region provided in the first electrode layer.

Owner:FUJIFILM HLDG CORP +1

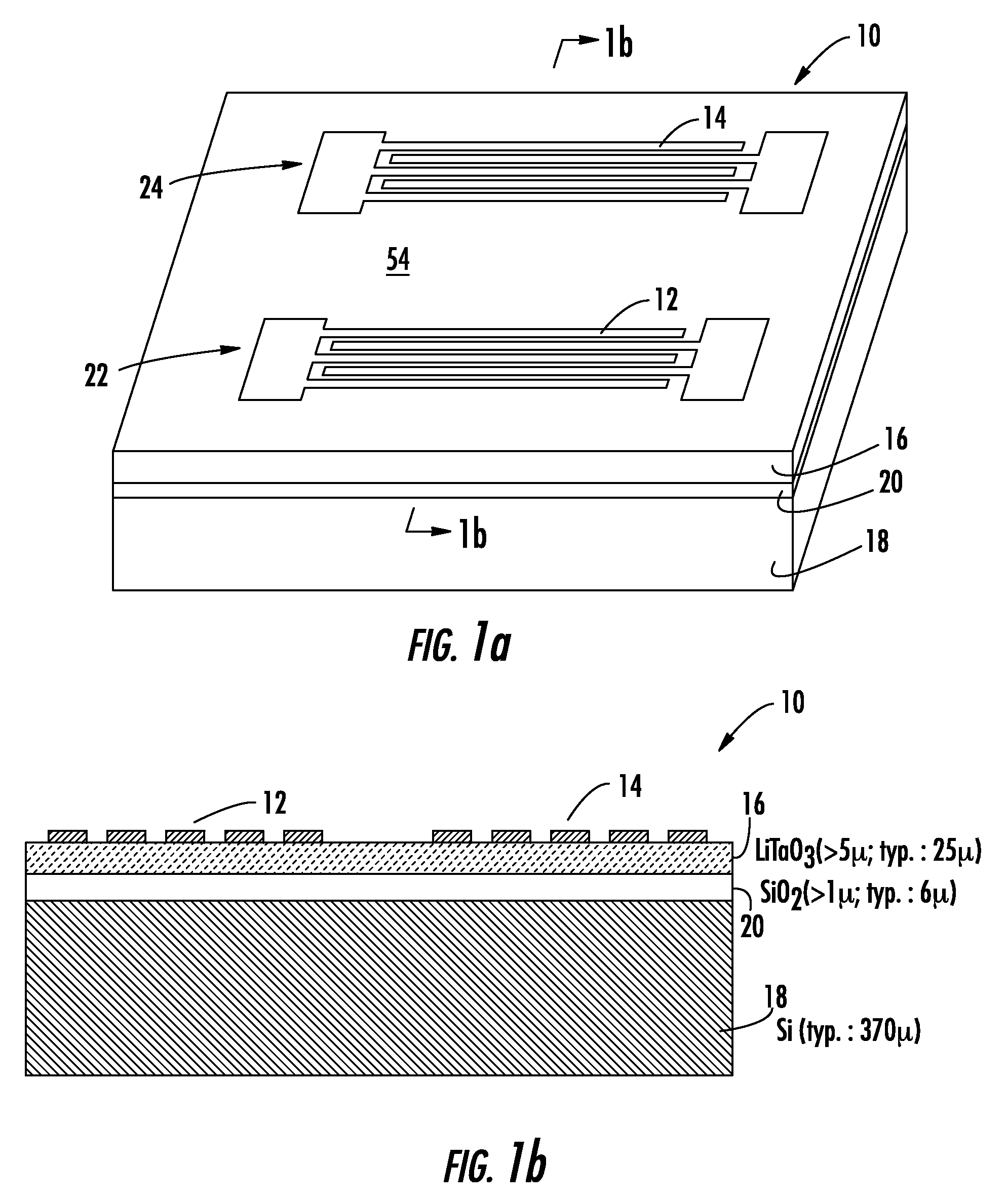

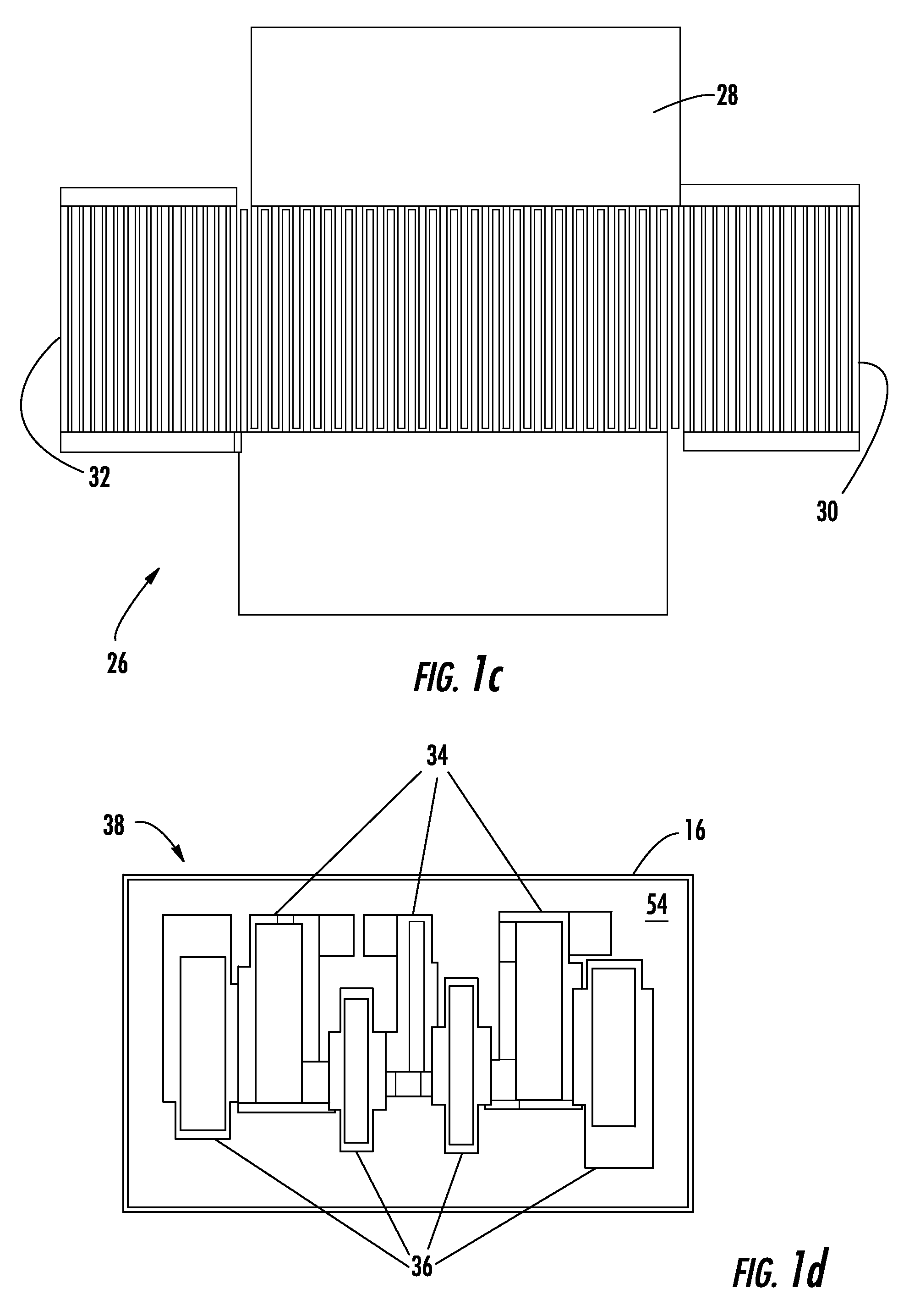

Method of forming a surface acoustic wave (SAW) filter device

InactiveUS7213314B2Improve reliabilityReduce heat sensitivityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveLength wave

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

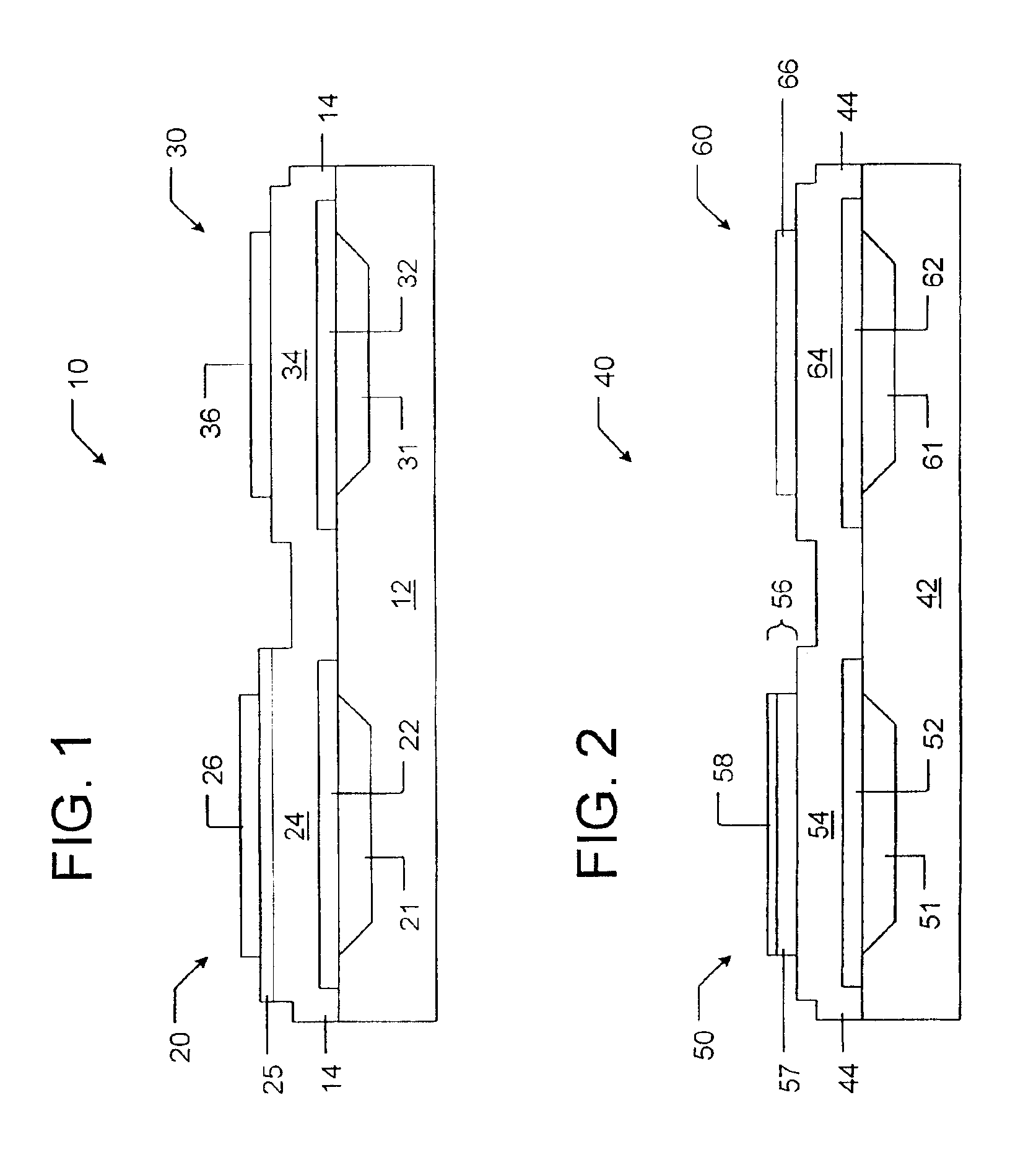

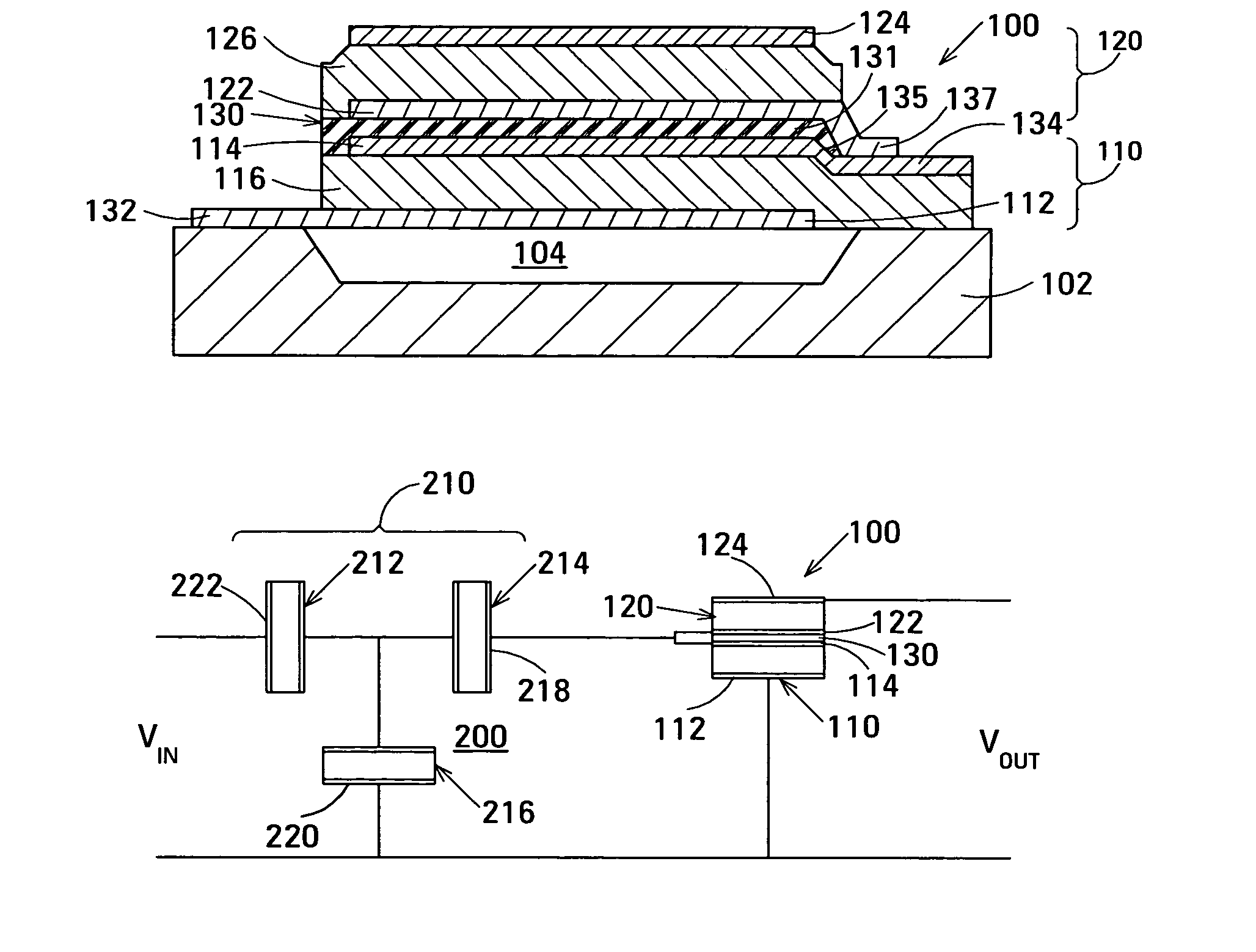

Method for producing thin film bulk acoustic resonators (FBARs) with different frequencies on the same substrate by subtracting method and apparatus embodying the method

InactiveUS6874211B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesThin-film bulk acoustic resonatorAcoustics

A method for fabricating a resonator, and in particular, a thin film bulk acoustic resonator (FBAR), and a resonator embodying the method are disclosed. An FBAR is fabricated on a substrate by reducing mass from a top electrode layer. For a substrate having multiple resonators, mass is reduced from only selected resonator to provide resonators having different resonance frequencies on the same substrate.

Owner:AVAGO TECH INT SALES PTE LTD

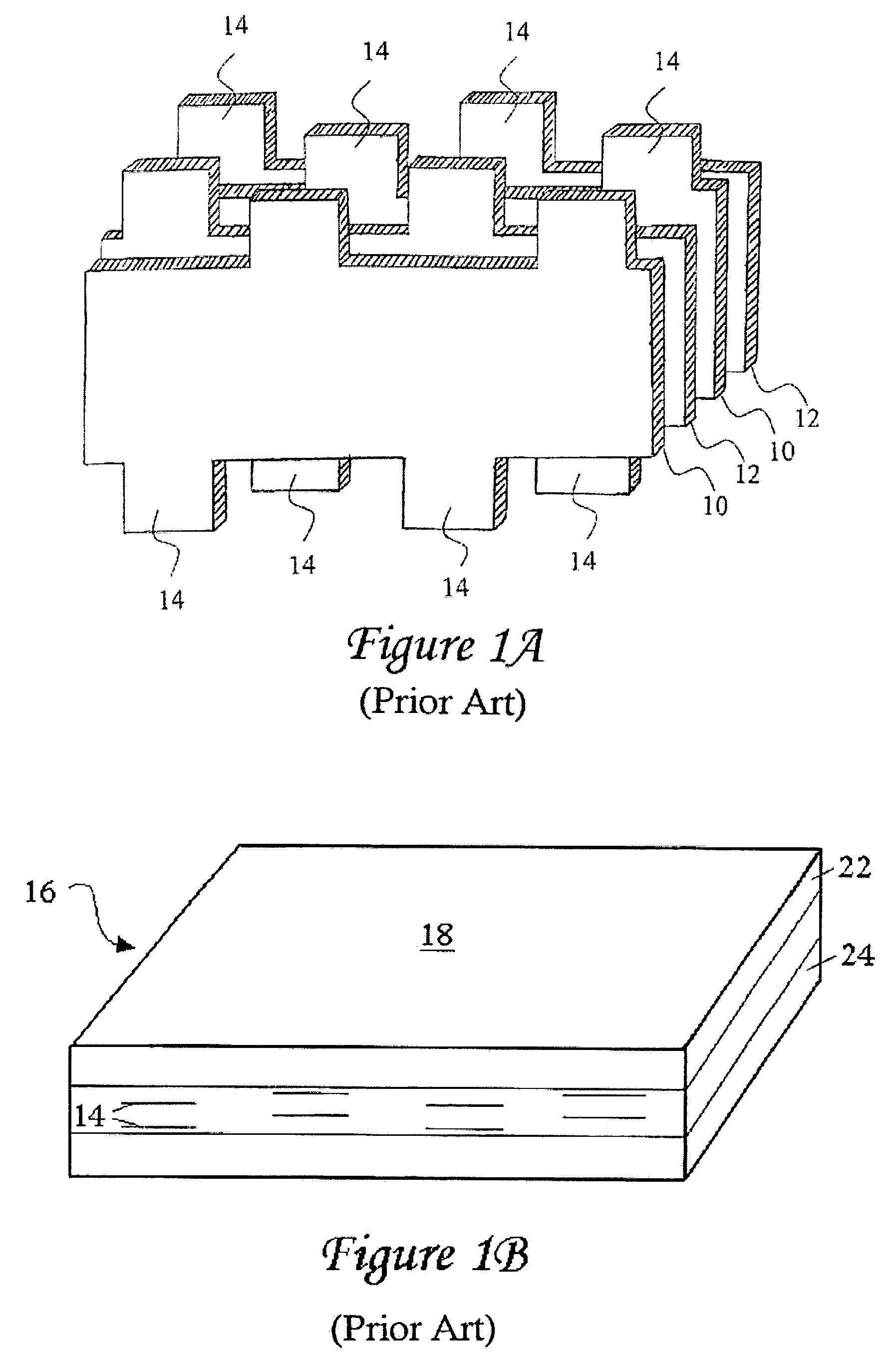

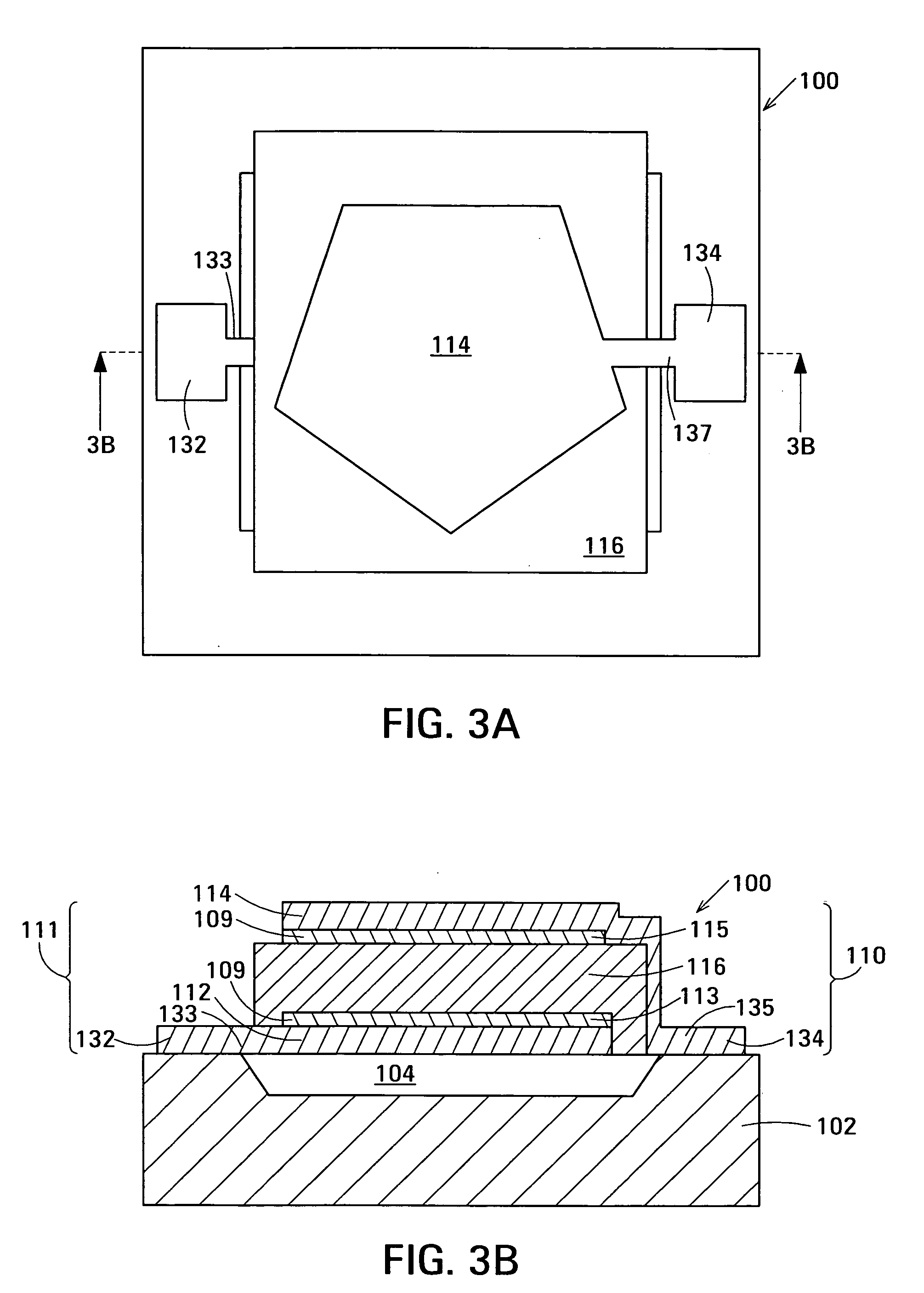

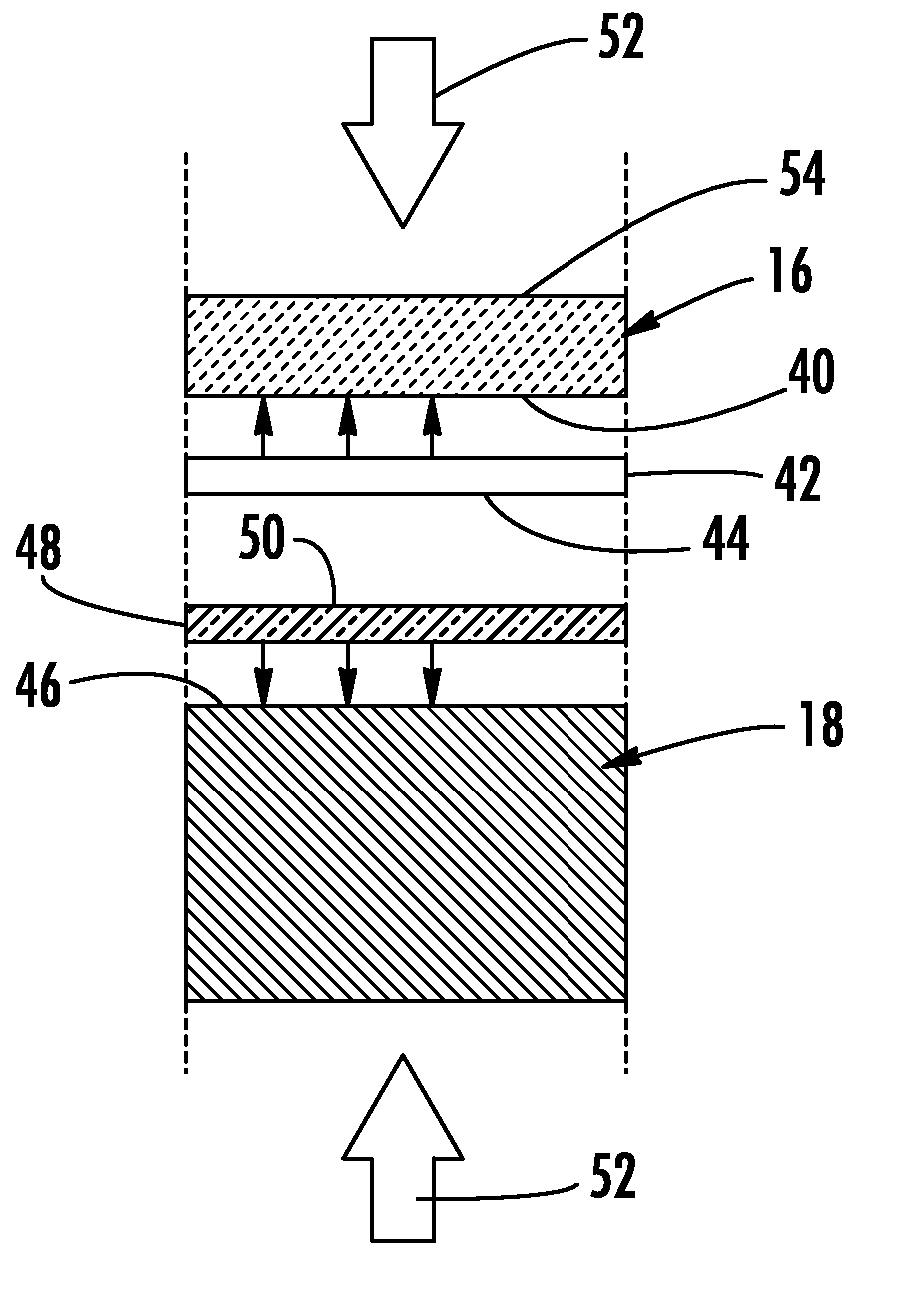

Stacked bulk acoustic resonator band-pass filter with controllable pass bandwidth

InactiveUS7019605B2Less acoustic energyLow insertion lossPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPlanar electrodeAcoustic energy

The band-pass filter has a stacked pair of film bulk acoustic resonators (FBARs) and an acoustic decoupler between the FBARs. Each of the FBARs has opposed planar electrodes and a layer of piezoelectric material between the electrodes. The acoustic decoupler has a single layer of acoustic decoupling material having a nominal thickness equal to an odd integral multiple of one quarter of the wavelength in the acoustic decoupling material of an acoustic wave having a frequency equal to the center frequency. The acoustic decoupling material comprises plastic. The acoustic decoupler controls the coupling of acoustic energy between the FBARs. Specifically, the acoustic decoupler couples less acoustic energy between the FBARs than would be coupled by direct contact between the FBARs. The reduced acoustic coupling gives the band-pass filter desirable in-band and out-of-band properties.

Owner:AVAGO TECH INT SALES PTE LTD

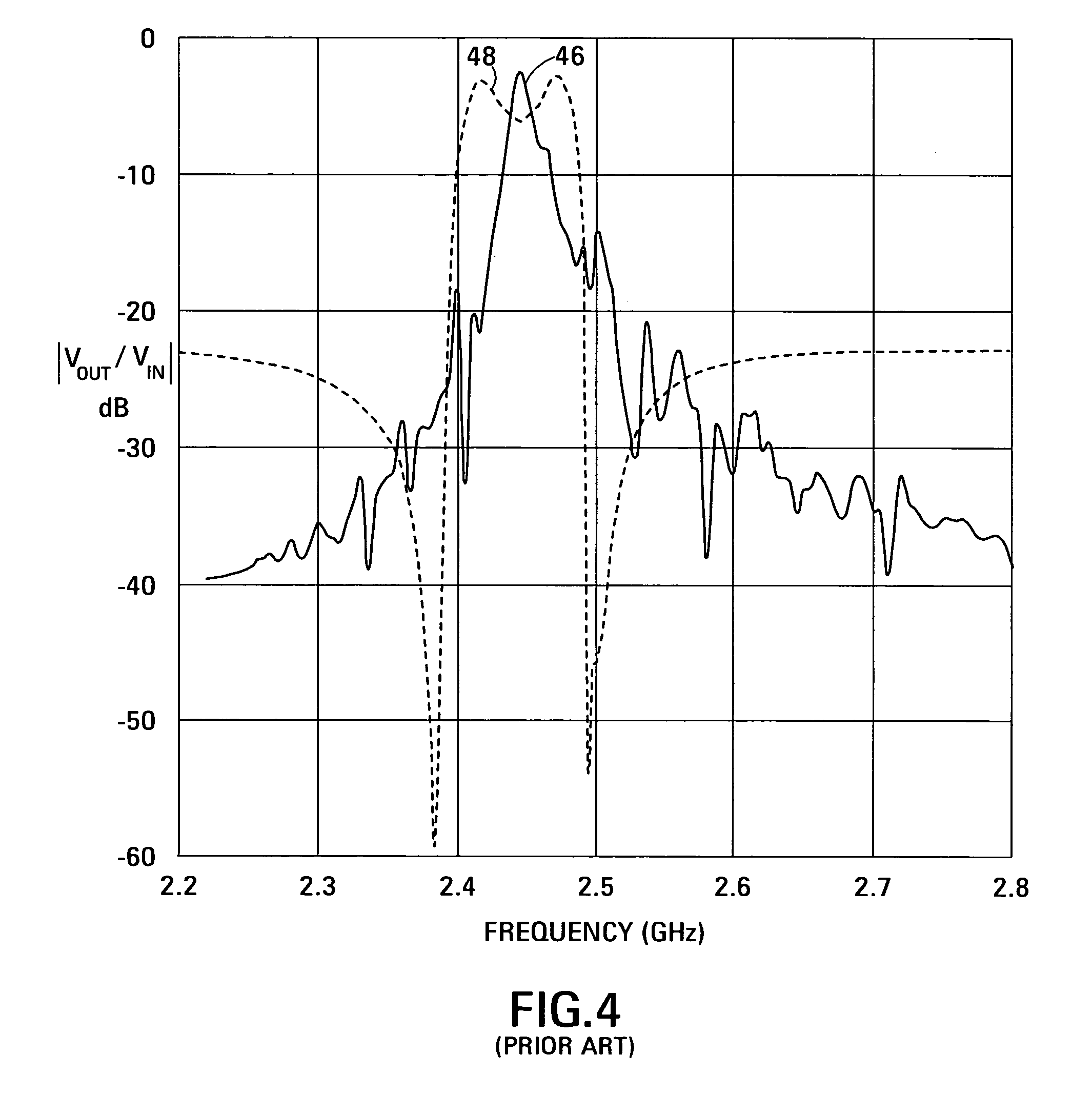

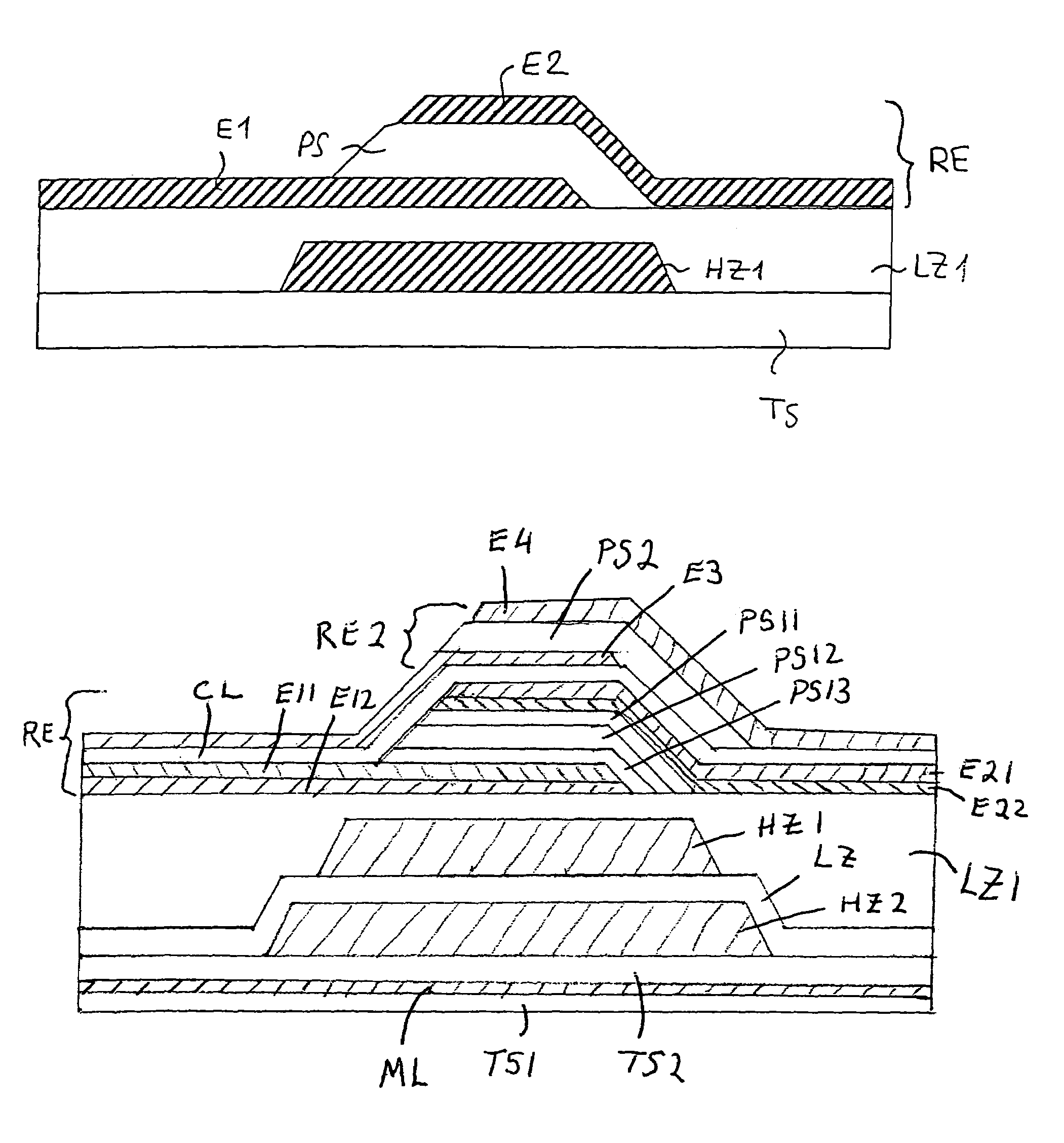

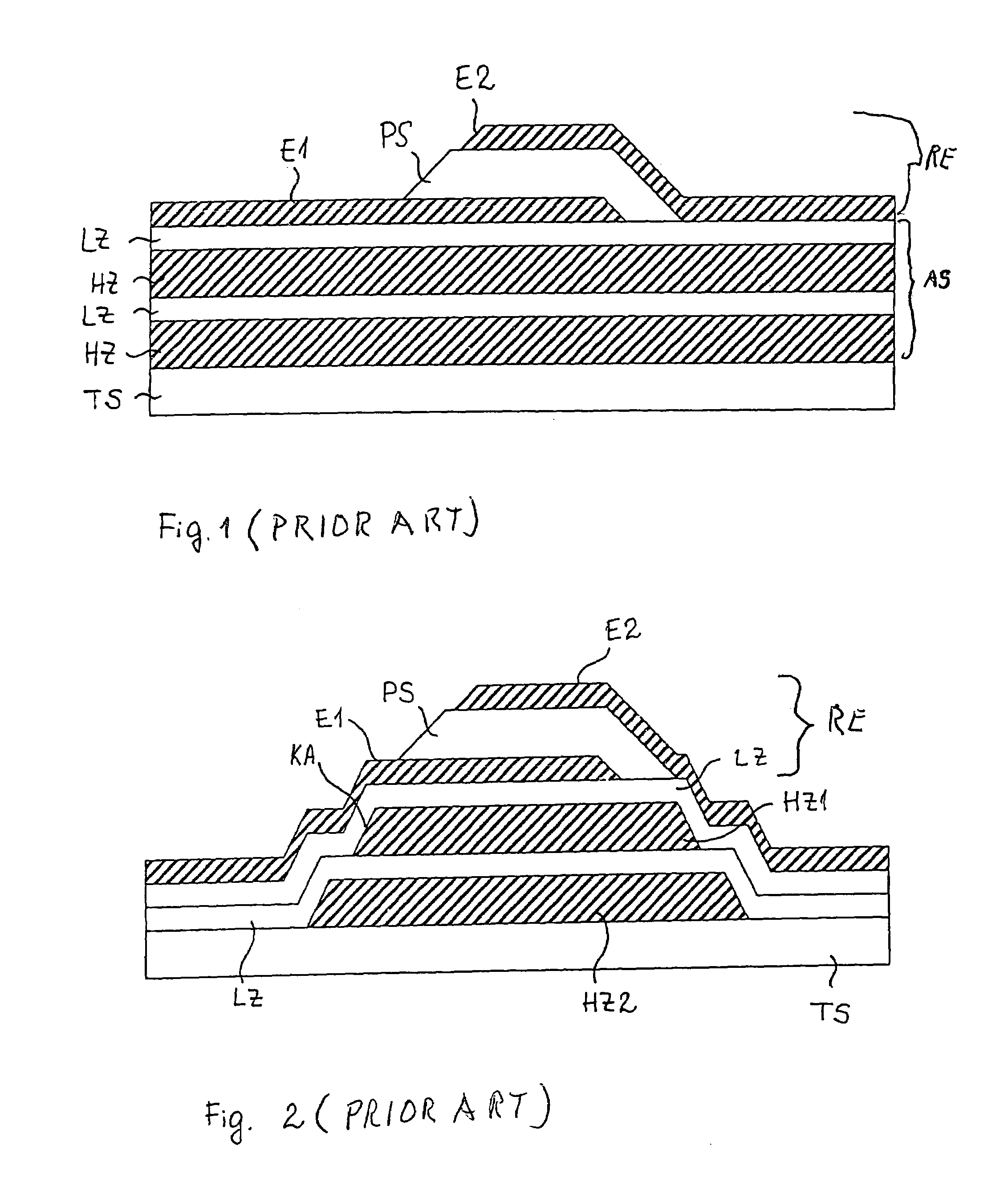

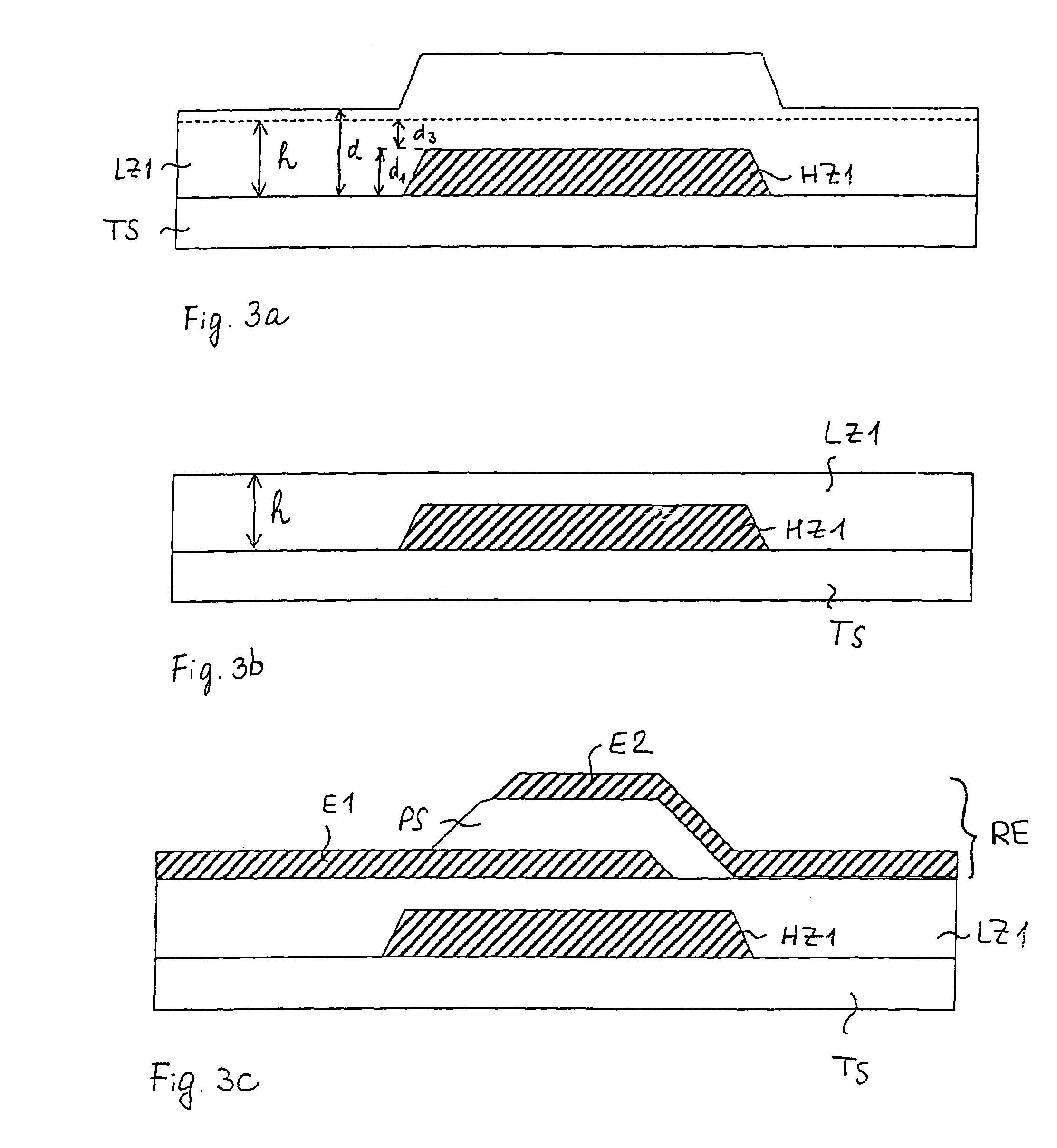

Component operating with bulk acoustic waves and a method for producing the component

ActiveUS6998940B2Contributed to reliabilityEasy to flattenPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveAcoustic impedance

A component operating with bulk acoustic waves has a carrier substrate, a thin-film resonator and an acoustic mirror arranged between the resonator and carrier substrate. The acoustic mirror is formed by at least one high acoustic impedance layer, which is covered by a low acoustic impedance layer and the uppermost low impedance acoustic layer is planarized to form a flat planar surface on which the thin-film resonator is formed.

Owner:SNAPTRACK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com