Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4260 results about "Piezoelectric actuators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric Actuators. A piezoelectric actuator (piezo actuator) is a type of solid-state actuator based on the change in shape of a piezoelectric material when an electric field is applied.

Indicia reading terminal including focus element with expanded range of focus distances

ActiveUS8596543B2Television system detailsColor television detailsElectricityPiezoelectric actuators

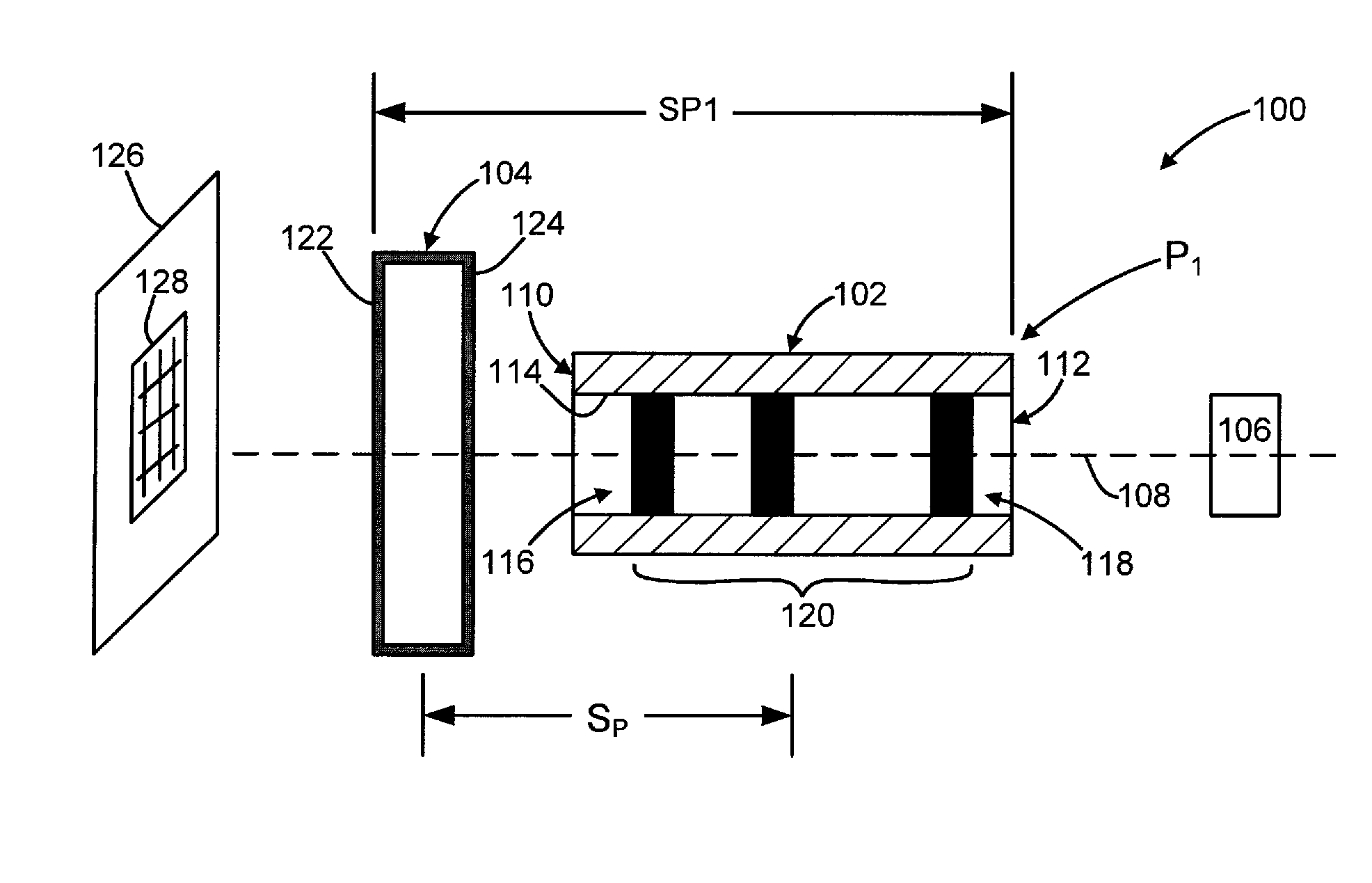

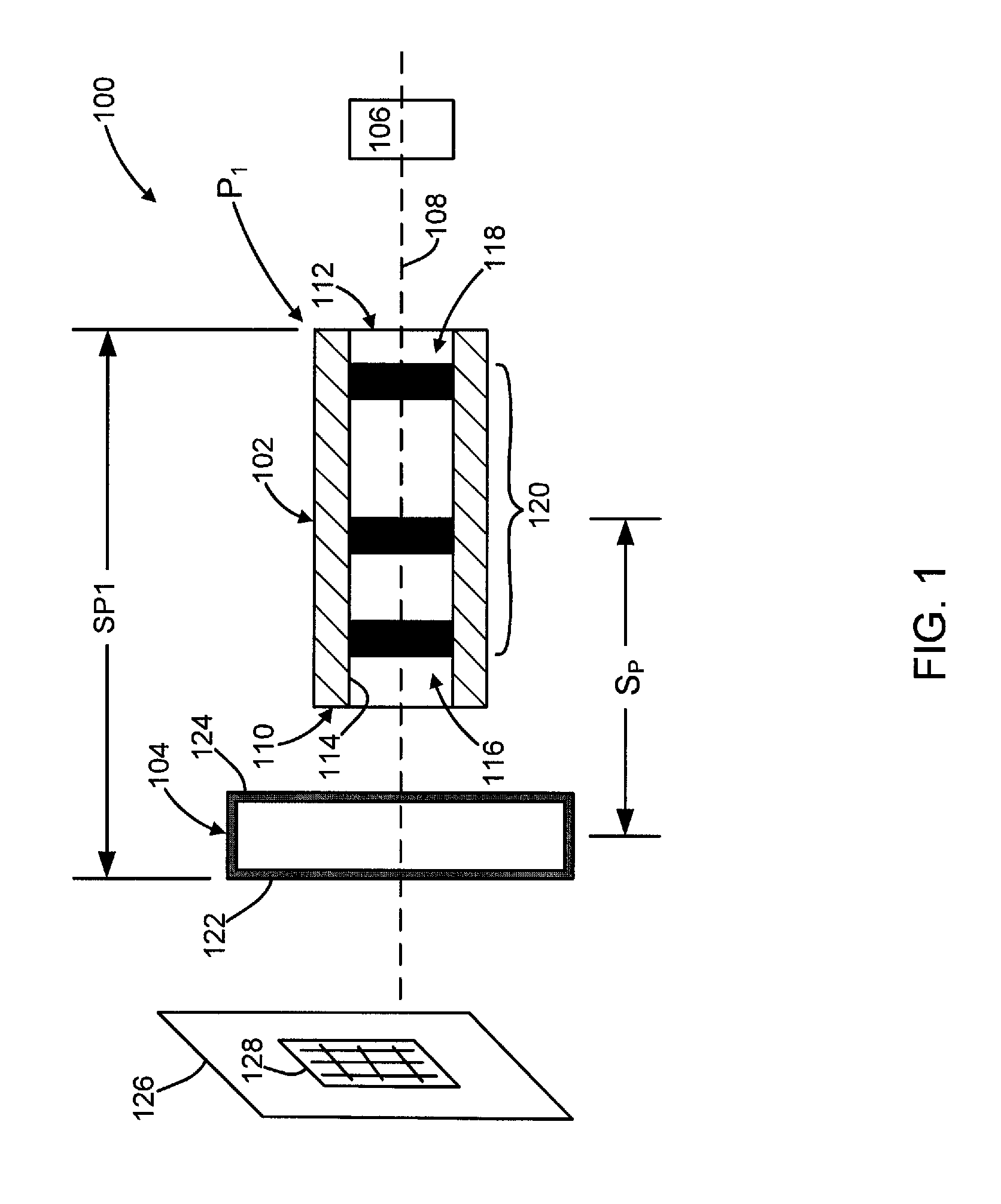

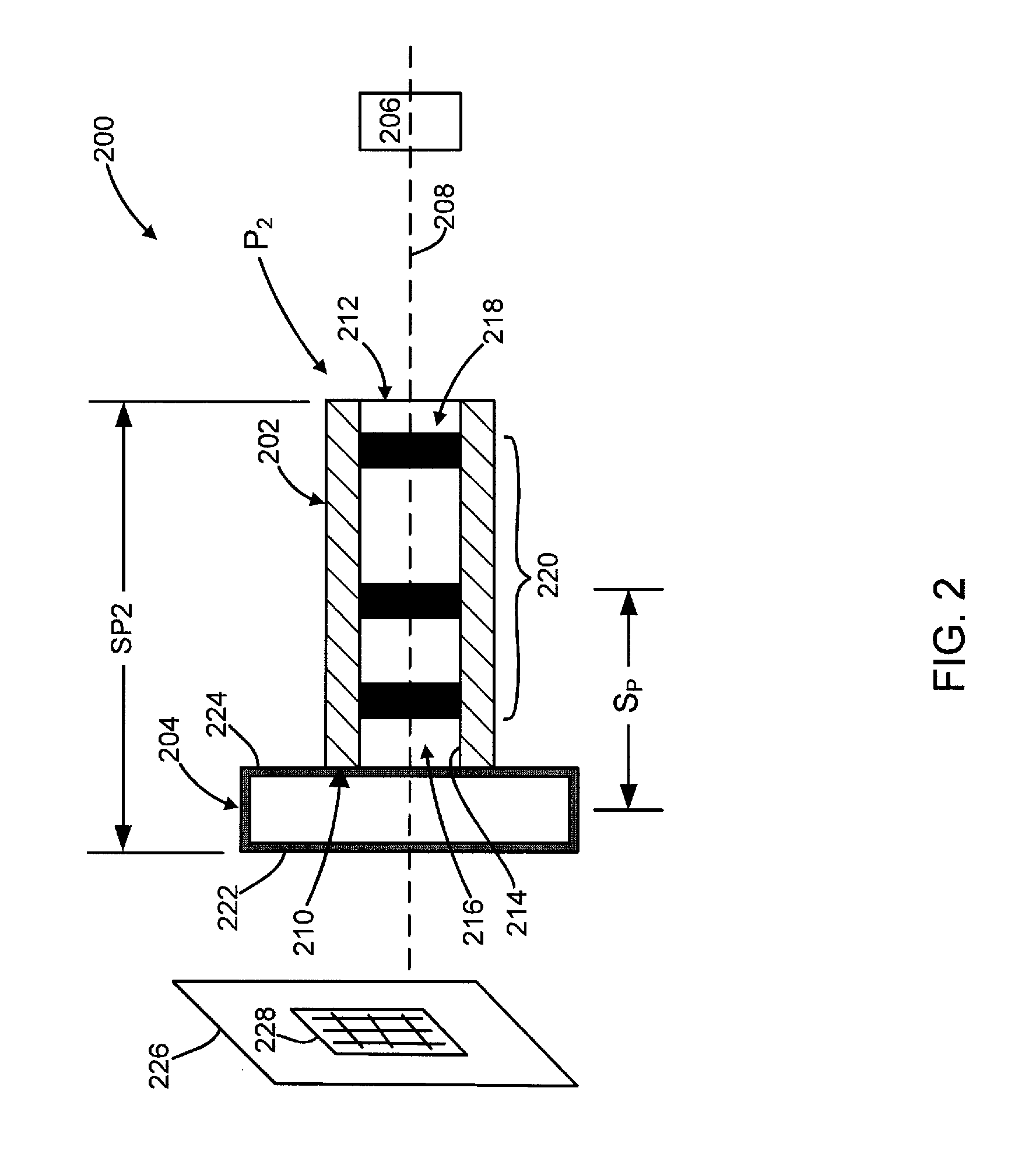

Embodiments of the present invention comprise an indicia reading terminal including a focus element that extends the range of focus distances at which the indicia reading terminal can decode decodable indicia. In one embodiment, the focus element comprises a variable form element and a variable position element, the combination of which causes an image distance that can change in accordance with a separation distance between these two elements. The focus element can comprise an actuator, e.g., a piezoelectric actuator, which can be coupled to the variable position element in a manner that can cause the variable position element to deform the variable form element, and in one example, the deformation changes the focal length of the variable form element.

Owner:HAND HELD PRODS

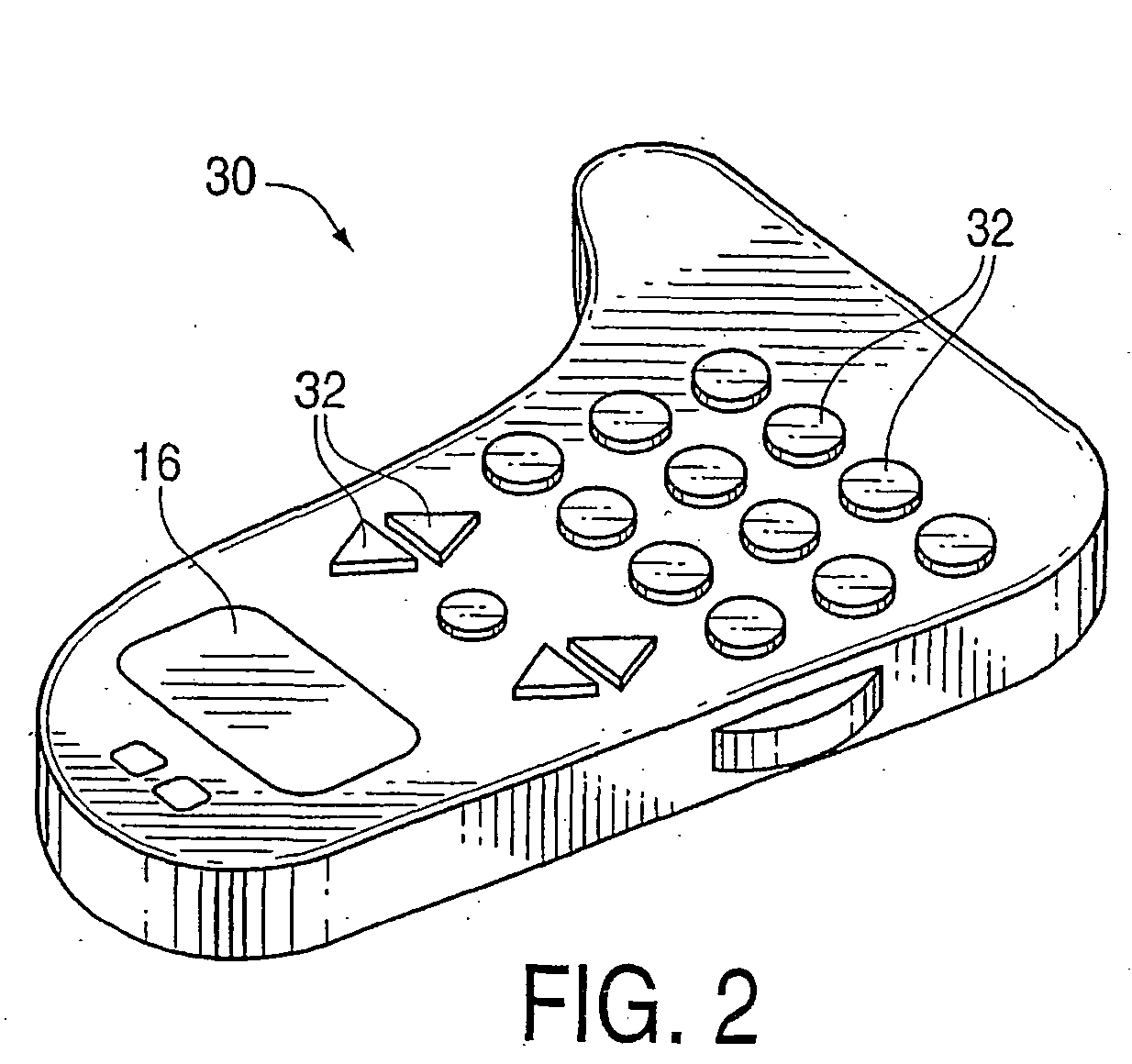

Multi-touch display screen with localized tactile feedback

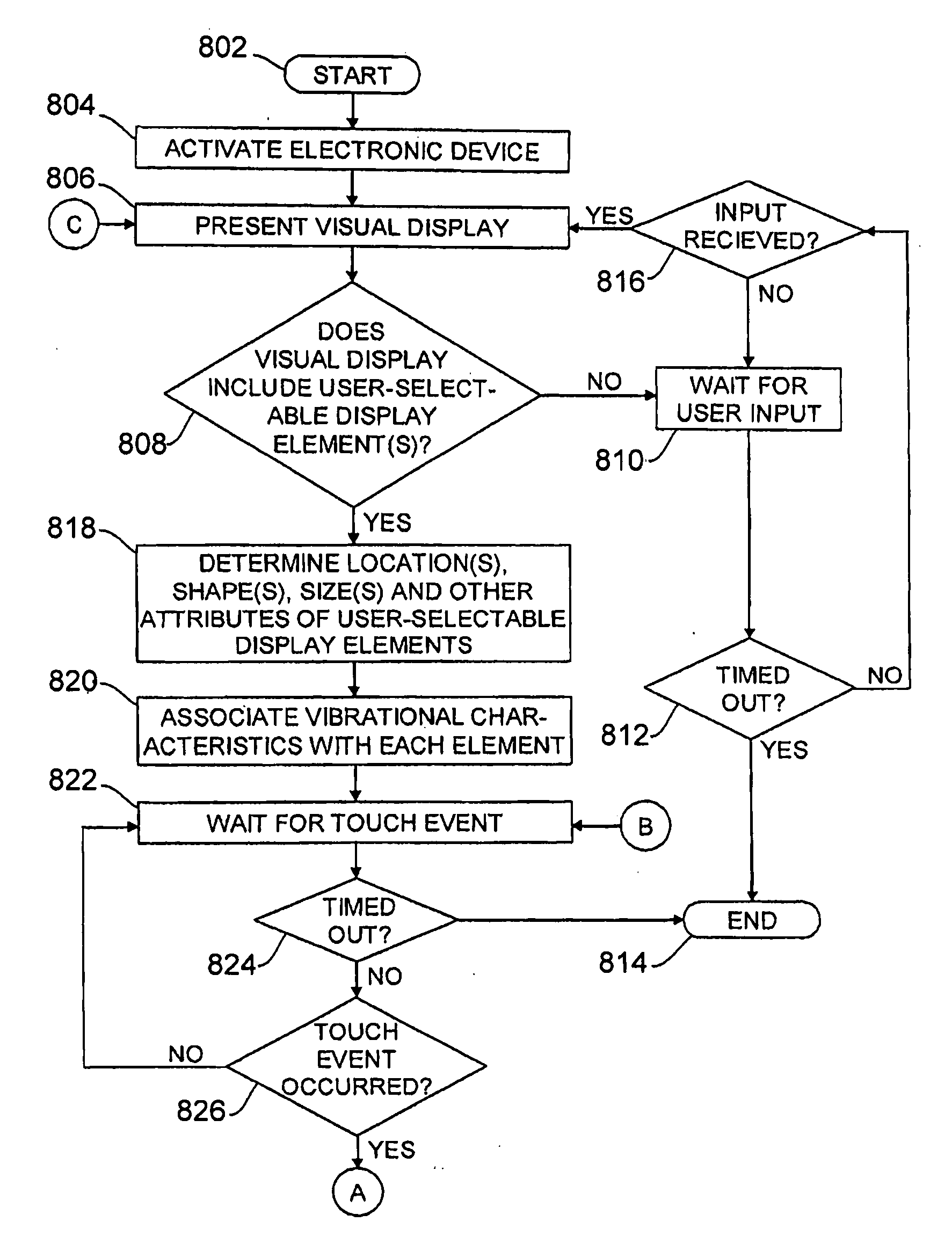

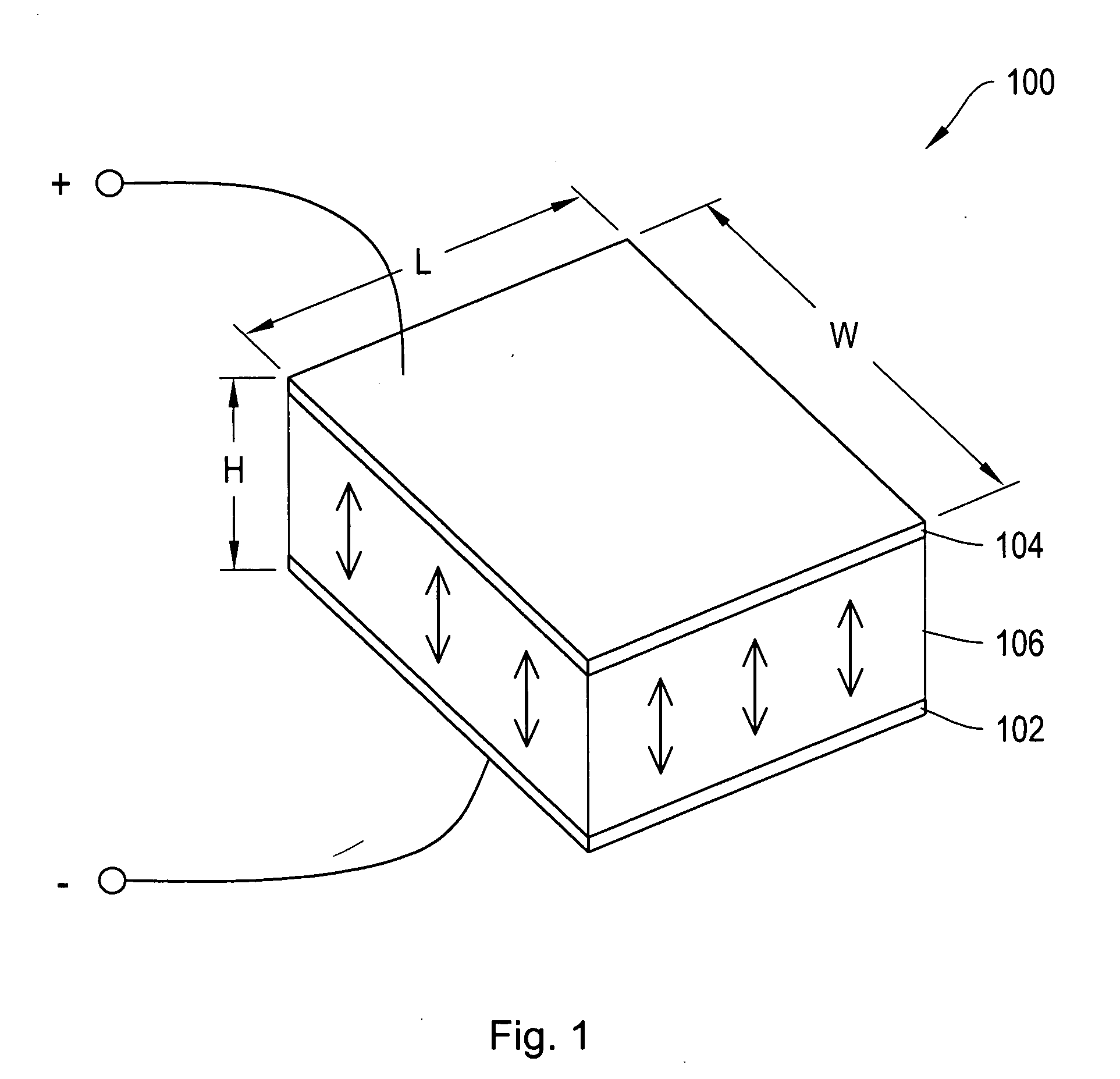

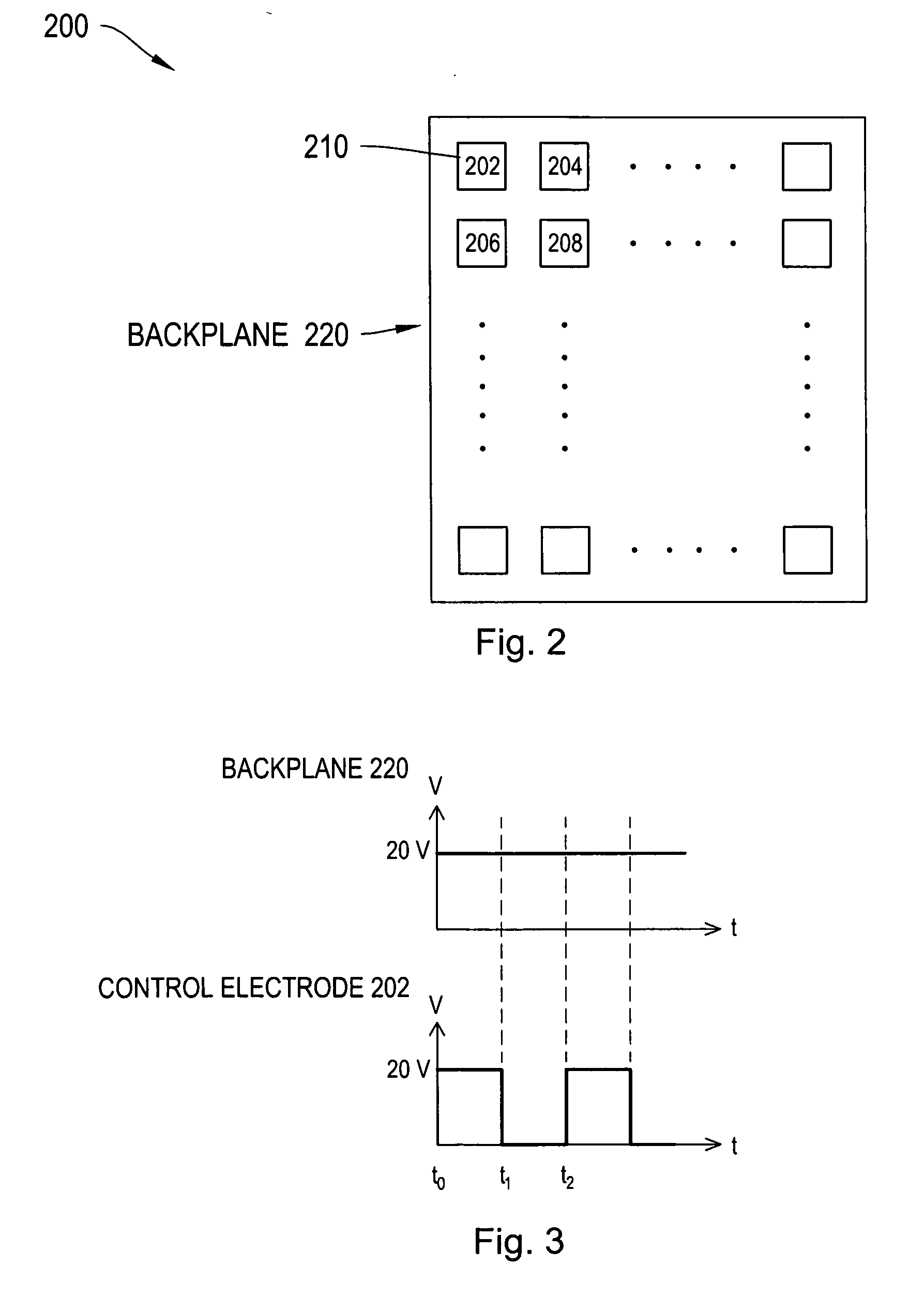

Systems, methods, computer-readable media, and other means are described for utilizing touch-based input components that provide localized haptic feedback to a user. The touch-based input components can be used and / or integrated into any type of electronic device, including laptop computers, cellular telephones, and portable media devices. The touch-based input components can use, for example, a grid of piezoelectric actuators to provide vibrational feedback to a user, while the user scrolls around a click wheel, slides across a trackpad, or touches a multi-touch display screen.

Owner:APPLE INC

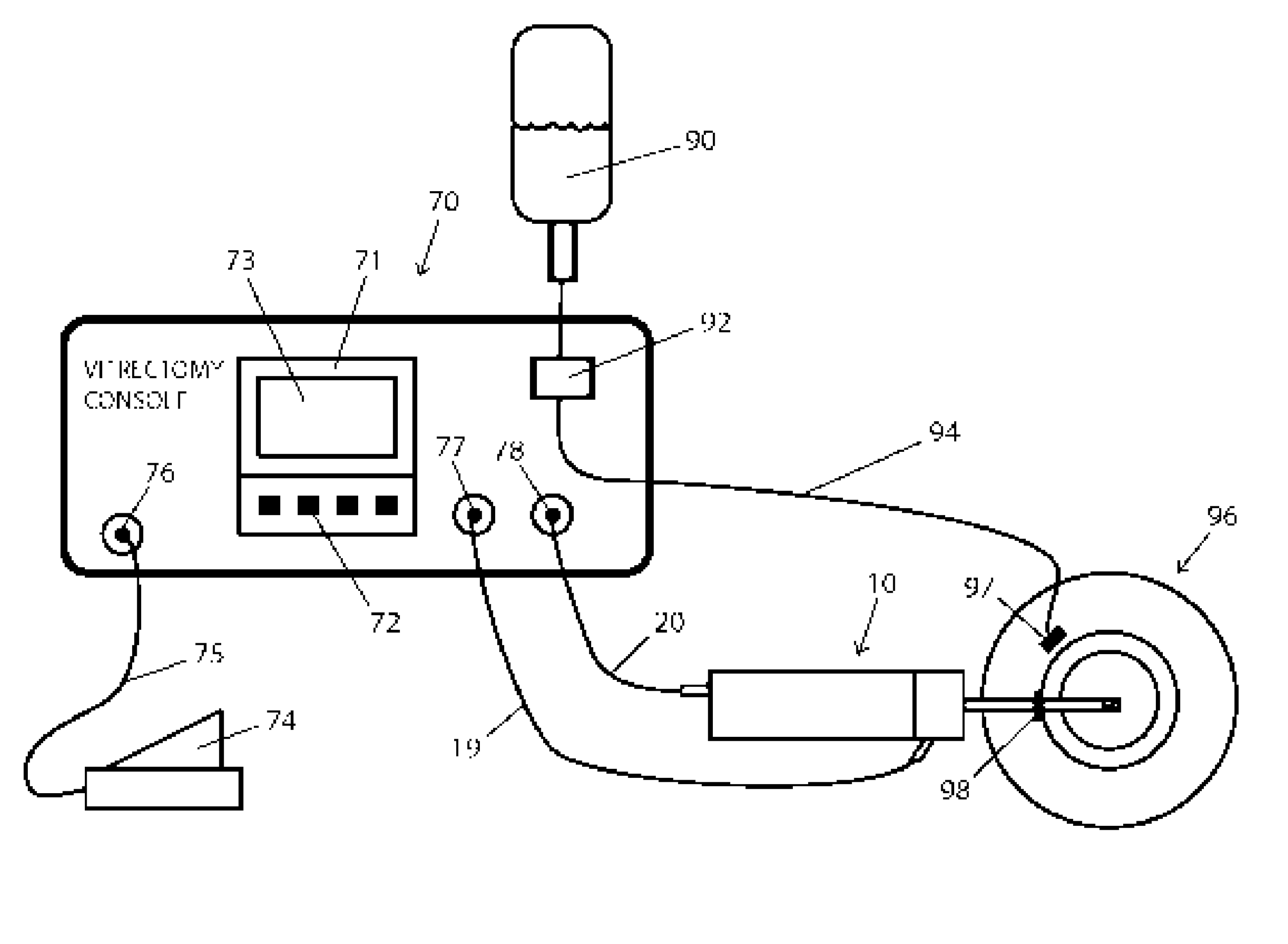

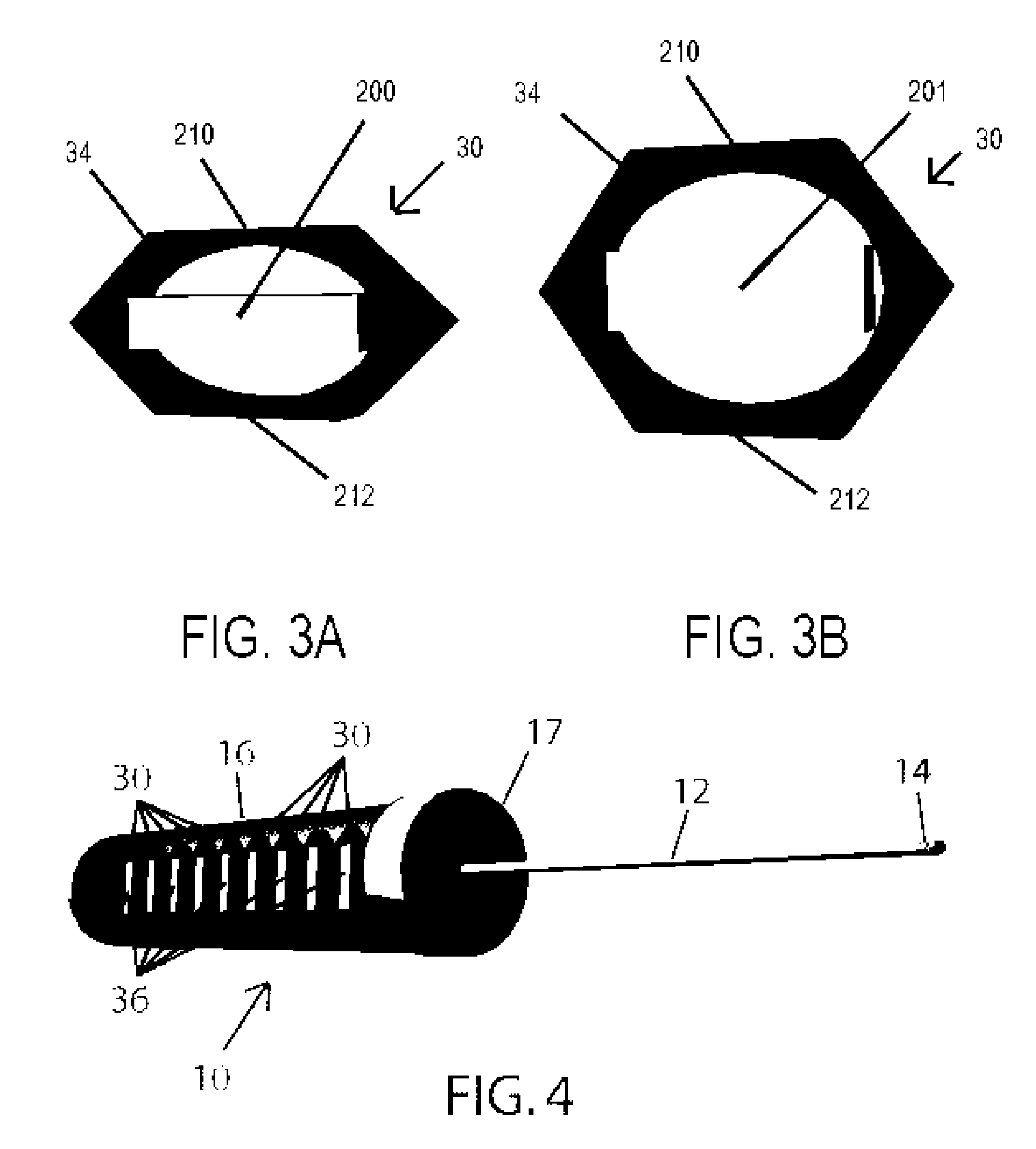

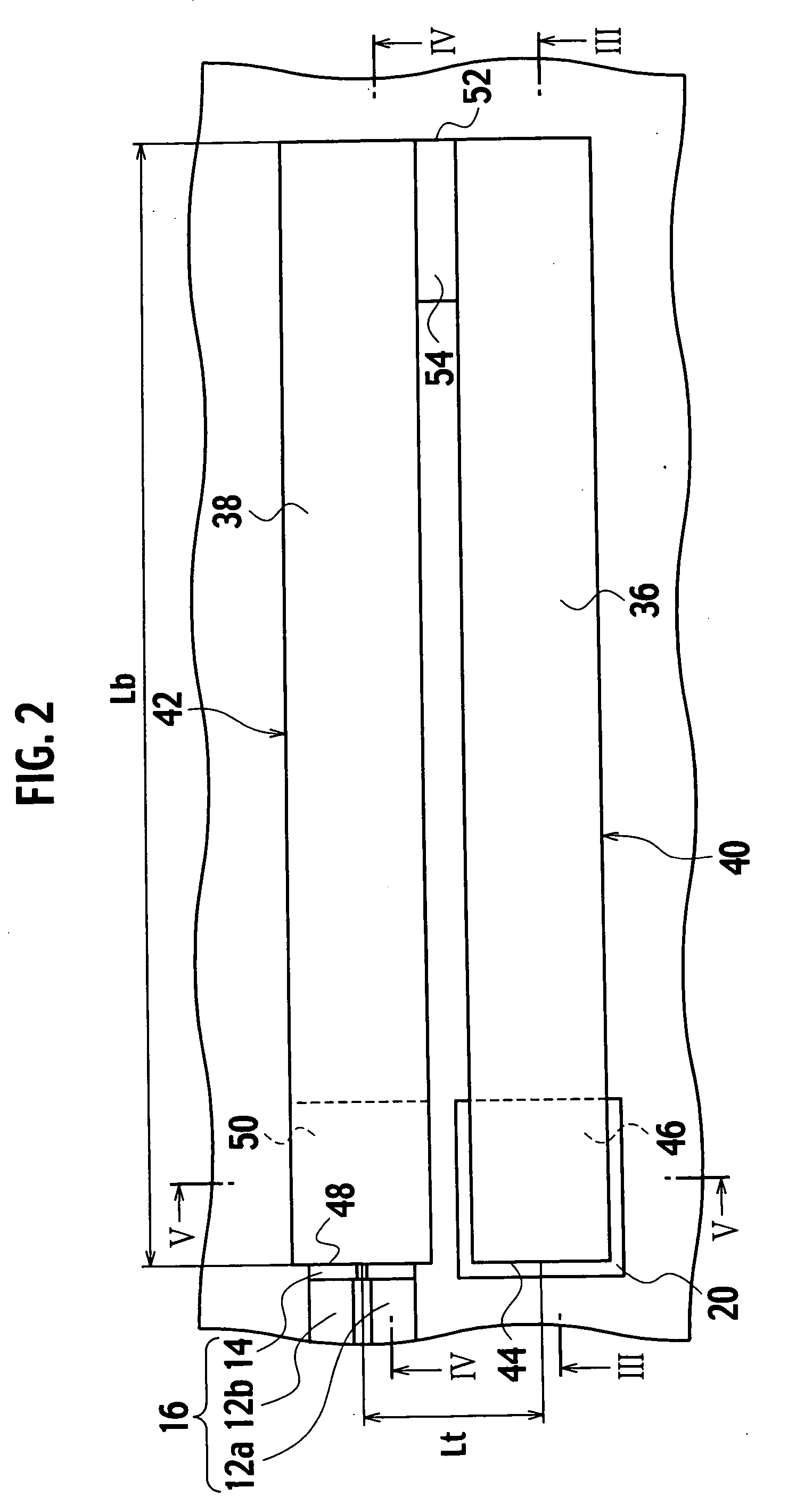

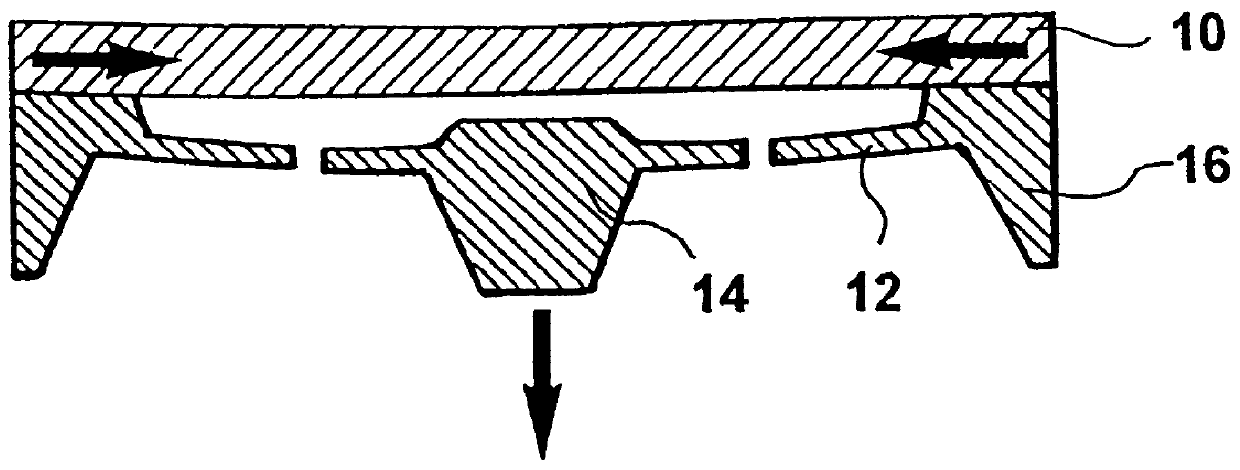

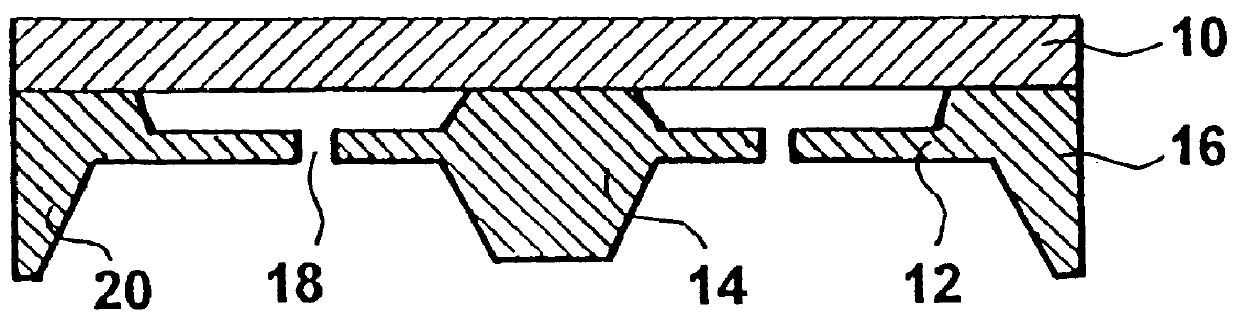

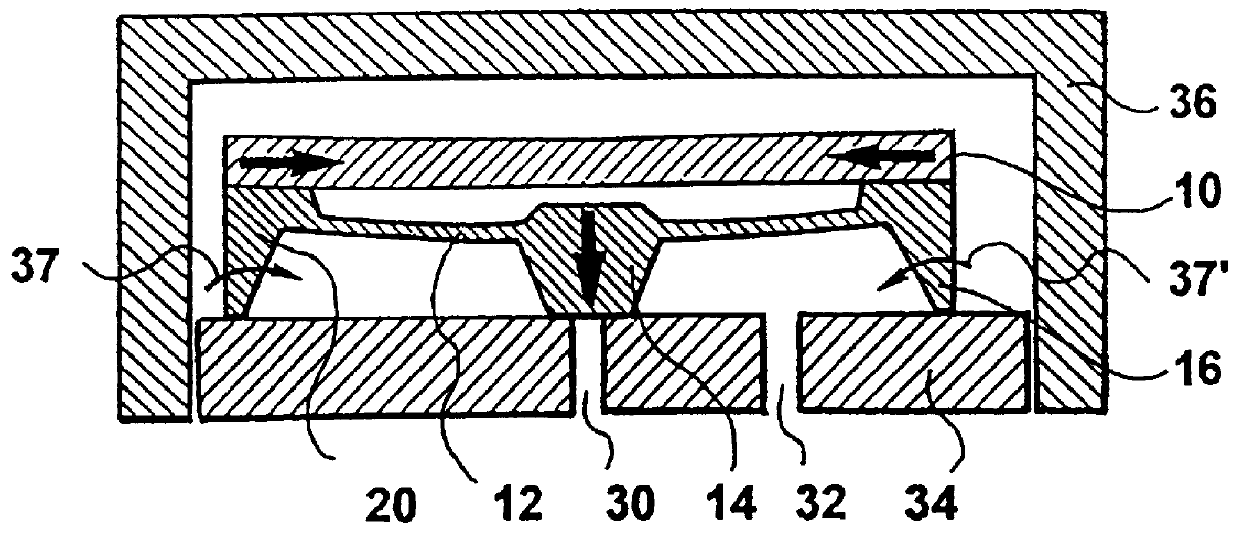

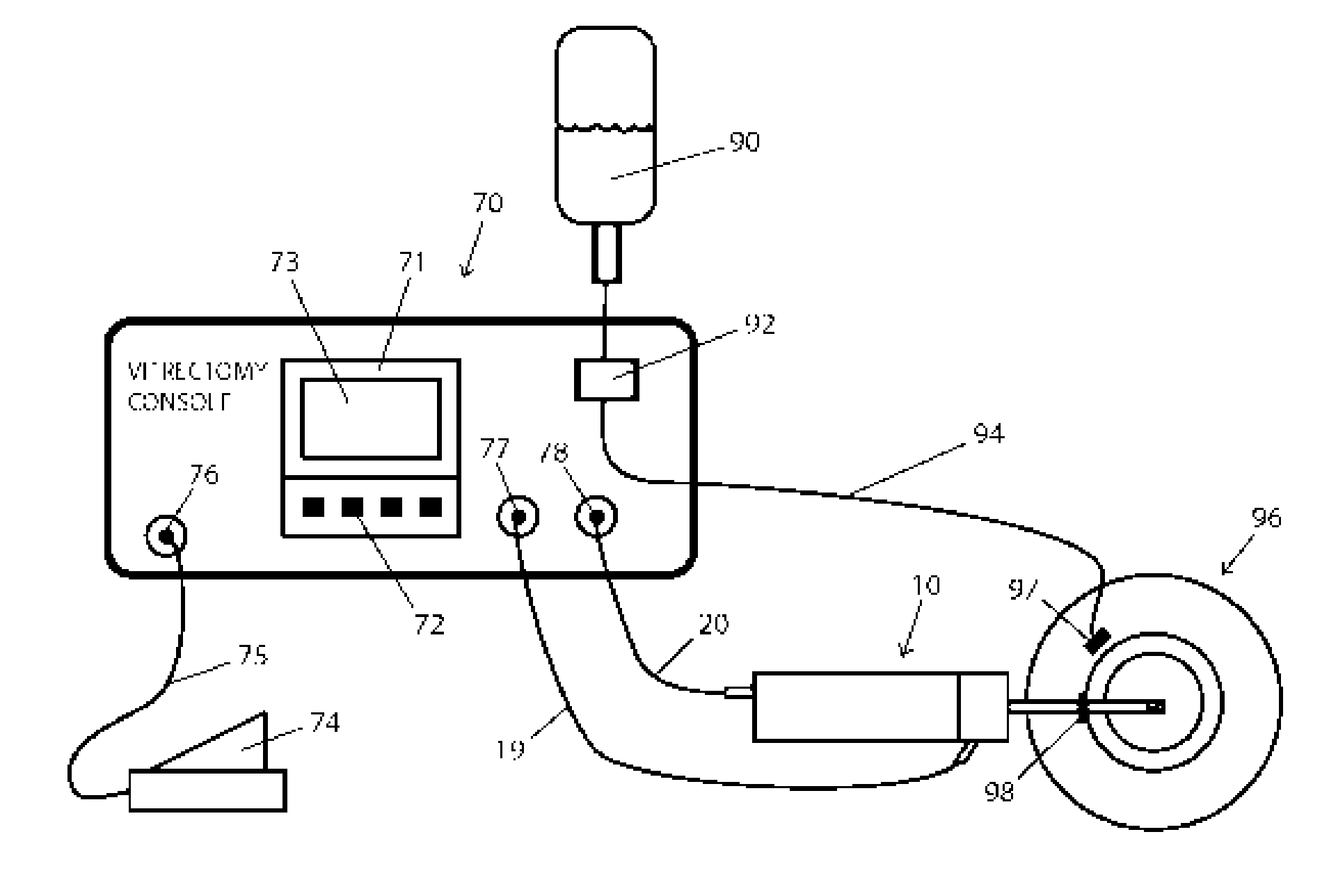

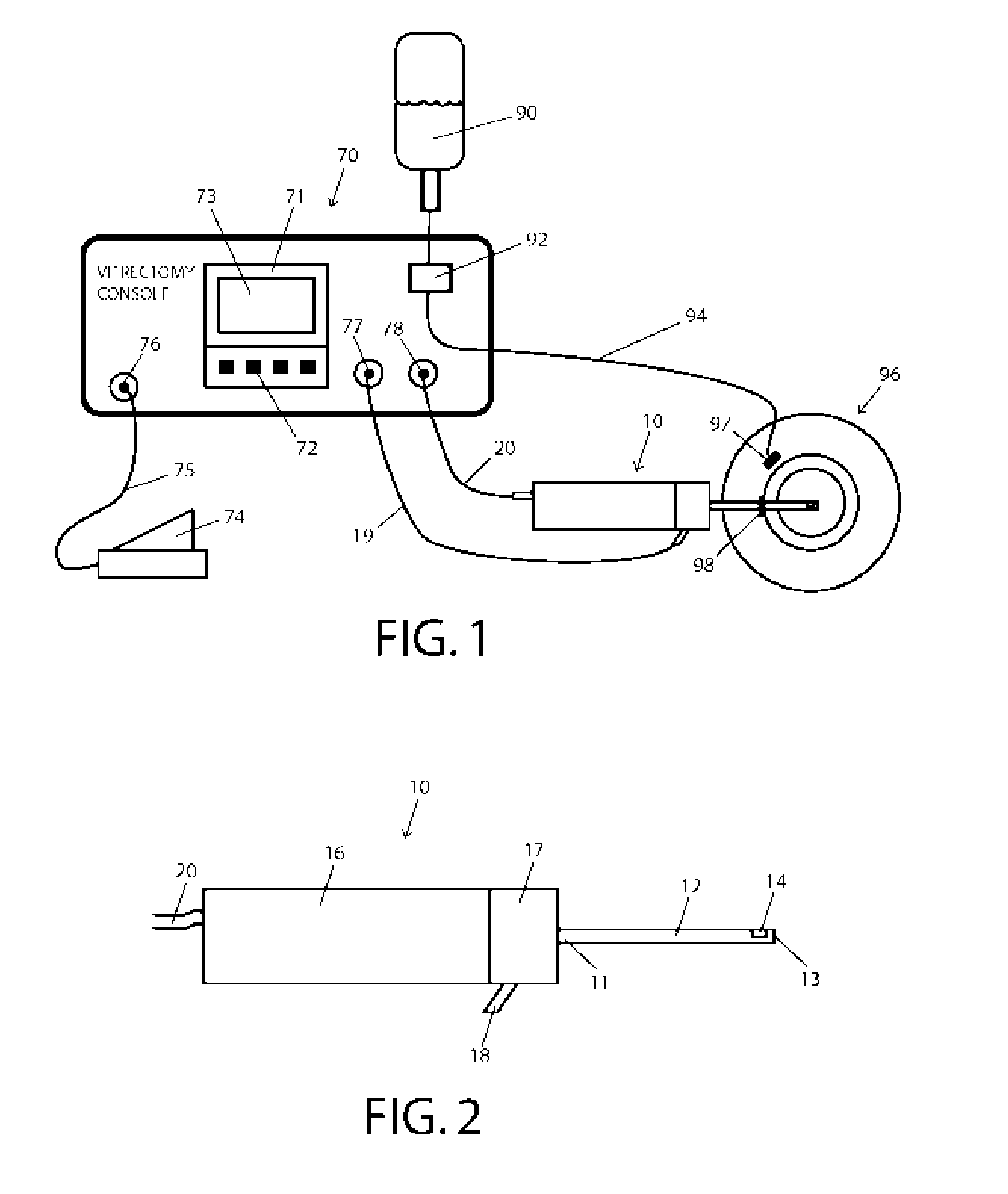

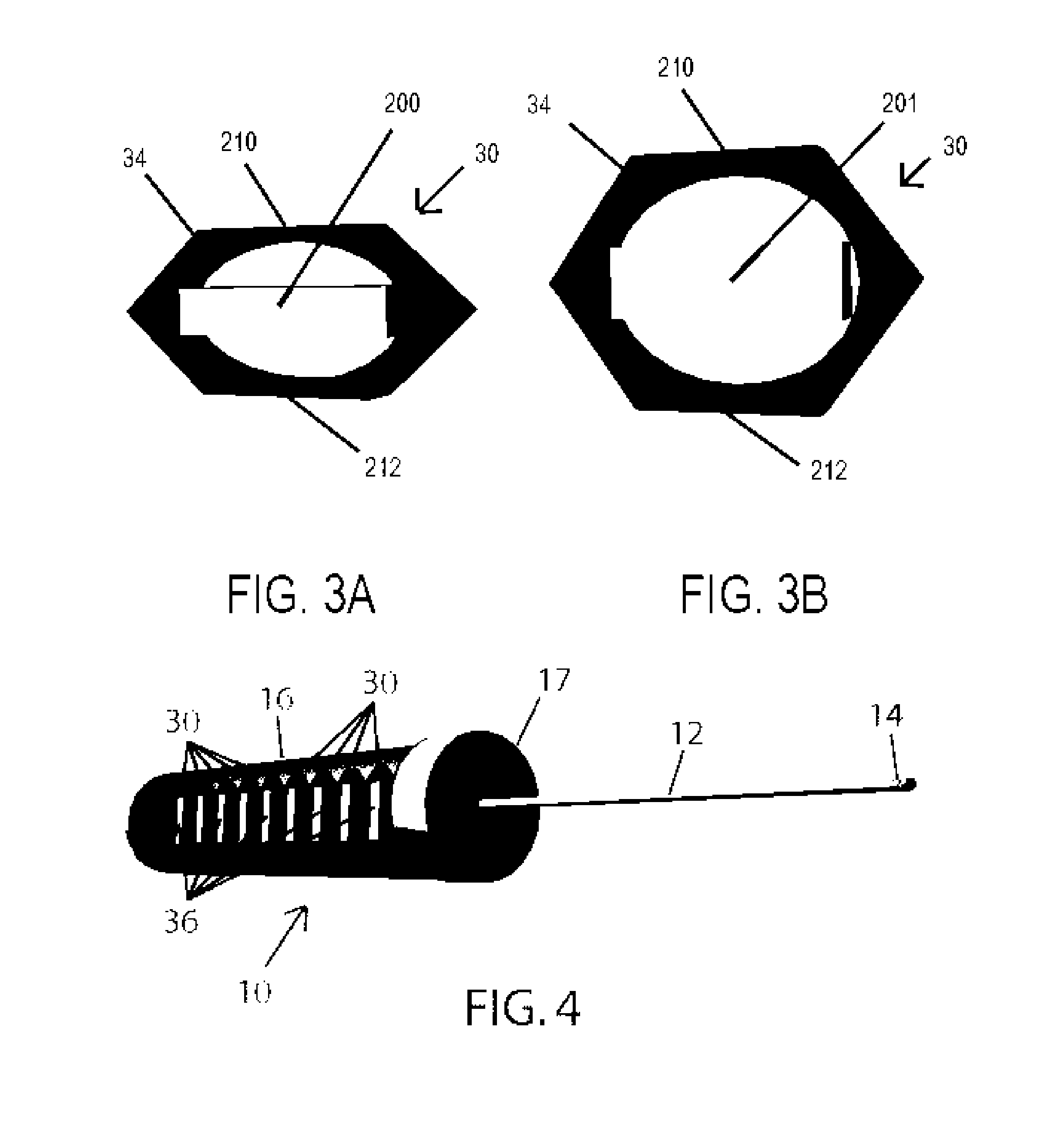

Precision surgical system

InactiveUS20070088376A1Fast cutting speedEasy to operateEye surgeryEndoscopic cutting instrumentsElectricityNoise generation

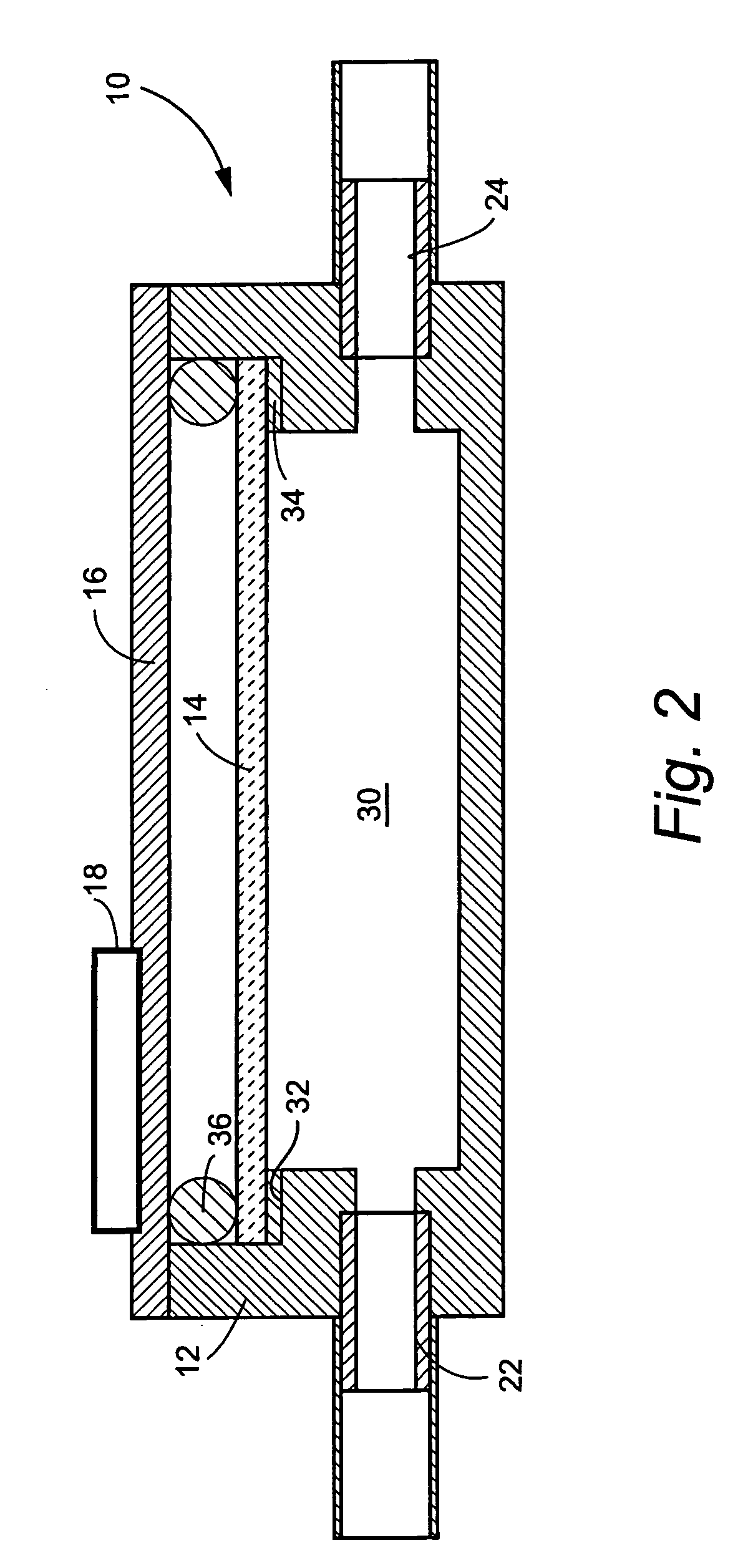

A high-speed surgical handpiece (10) suitable for vitreoretinal surgery having a cutter (42) and actuators (36). The cutter (42) is a guillotine-type cutter activated by an array of leveraged piezoelectric actuators (30) that receive a driving signal from a driving controller. The controller can have control and display units with a plurality of input mechanisms receiving input from a user who selects a desired cutting rate and frequency for the cutter. The control unit produces a piezoelectric actuator output signal based on the inputs received. Fast cutting rates with reduced duty cycle as well as a proportional mode of operation are available, allowing slow controlled cutting action, for example proportional to depression of a foot-pedal (74). Low degrees of vibration and noise generation are produced.

Owner:DR ZACHARIAS JAIME

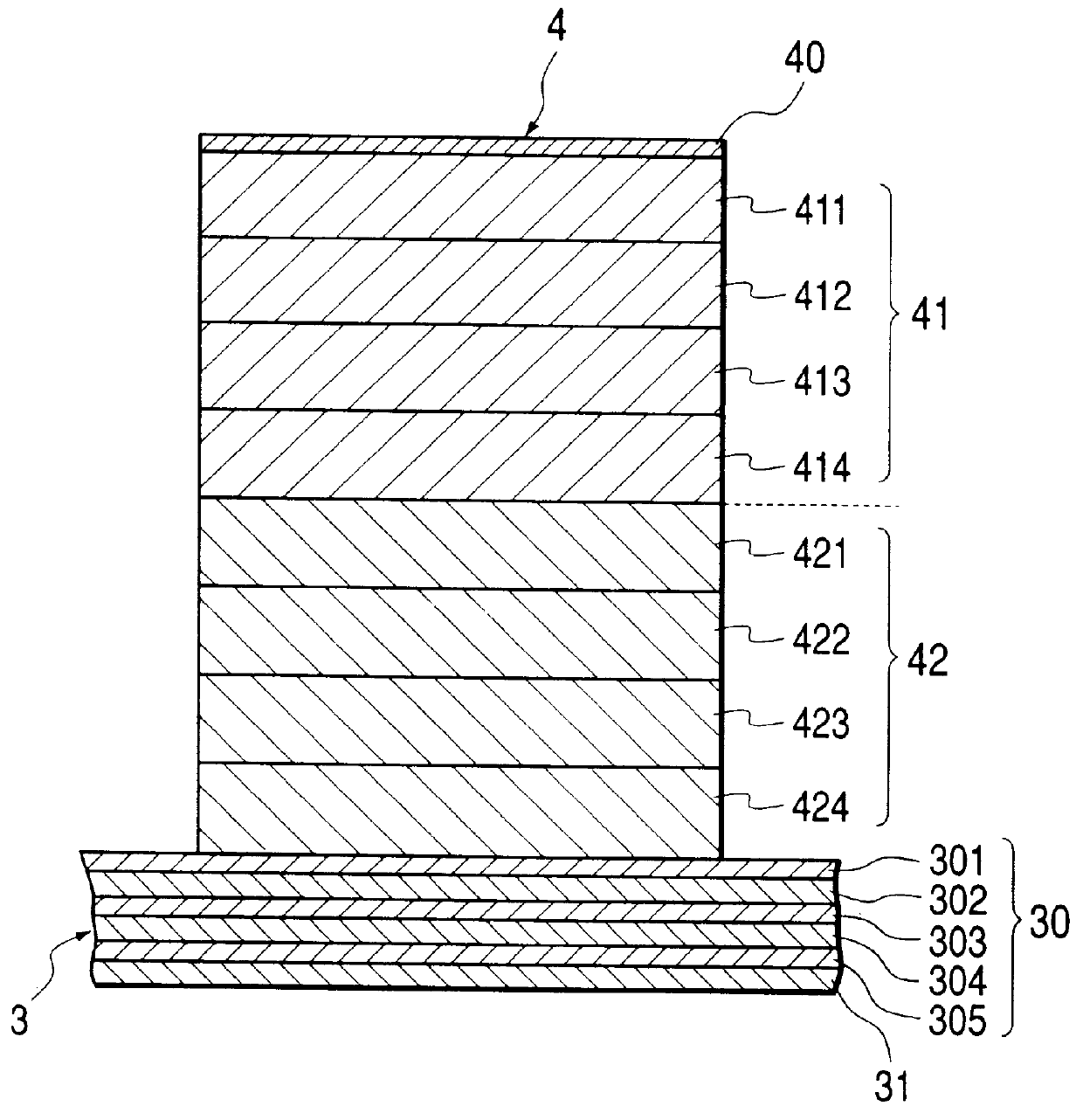

Ink-jet recording head with piezoelectric device and method for manufacturing the same

InactiveUS6142615AIncrease in piezoelectric constantIncrease the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsPiezoelectric coefficient

A piezoelectric device for an ink jet print head that has a greater displacement at a low drive voltage. The ink-jet recording head includes a vibration plate, on which is mounted one or more piezoelectric devices that change the volumes of pressure chambers upon application of a voltage. The device is mounted at least on one face of a pressure chamber substrate that is to be filled with ink. Such piezoelectric device includes a second piezoelectric layer having a piezoelectric constant g of a constant value or higher; and a first piezoelectric layer having a dielectric constant of a specific value or higher. Since the piezoelectric constant d of the piezoelectric device correlates with the product of the largest piezoelectric constant g and the largest dielectric device of the piezoelectric devices, a piezoelectric constant d larger than in the conventional case, i.e., having a greater displacement, can be obtained.

Owner:SEIKO EPSON CORP

Driving apparatus

InactiveUS7408288B2Improving an operating defective state of an impact actuatorEliminating an operation disabled state easily and securelyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesResonancePiezoelectric actuators

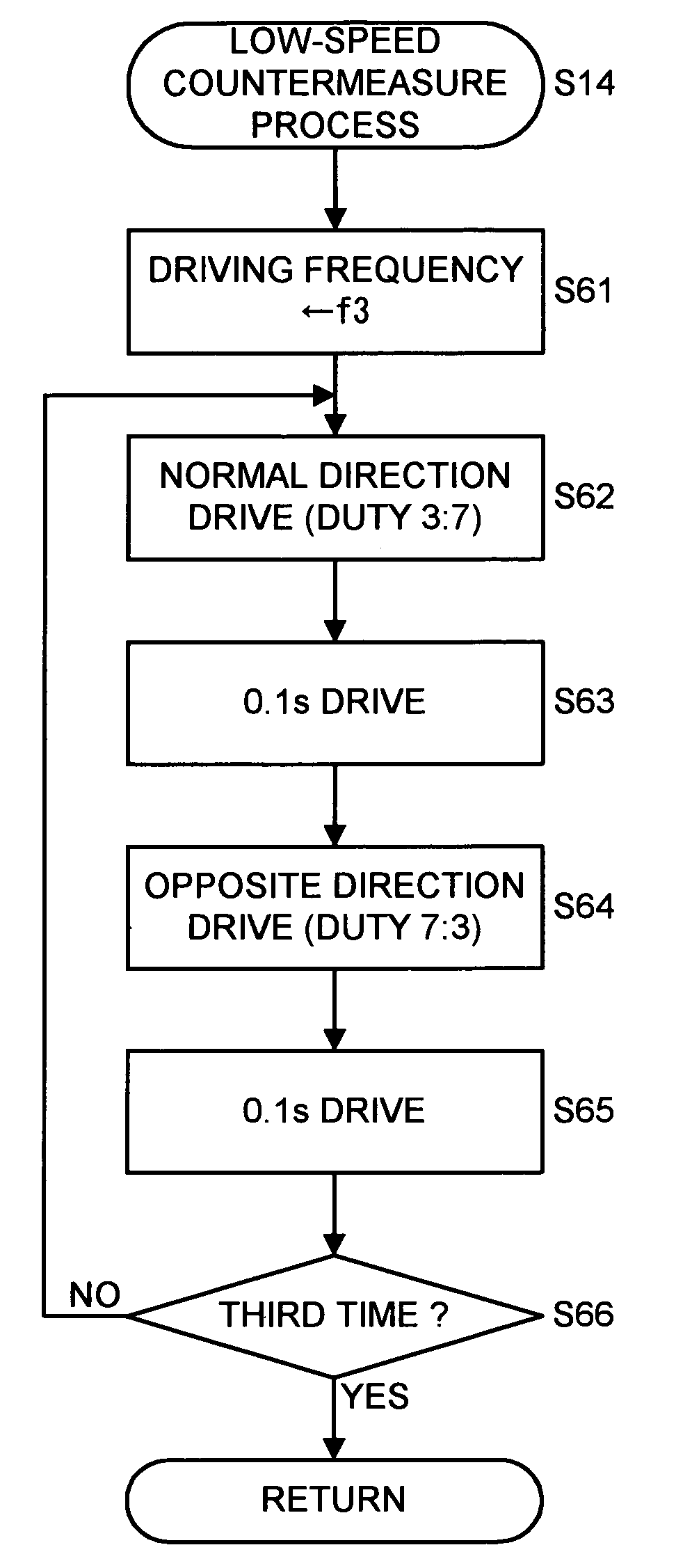

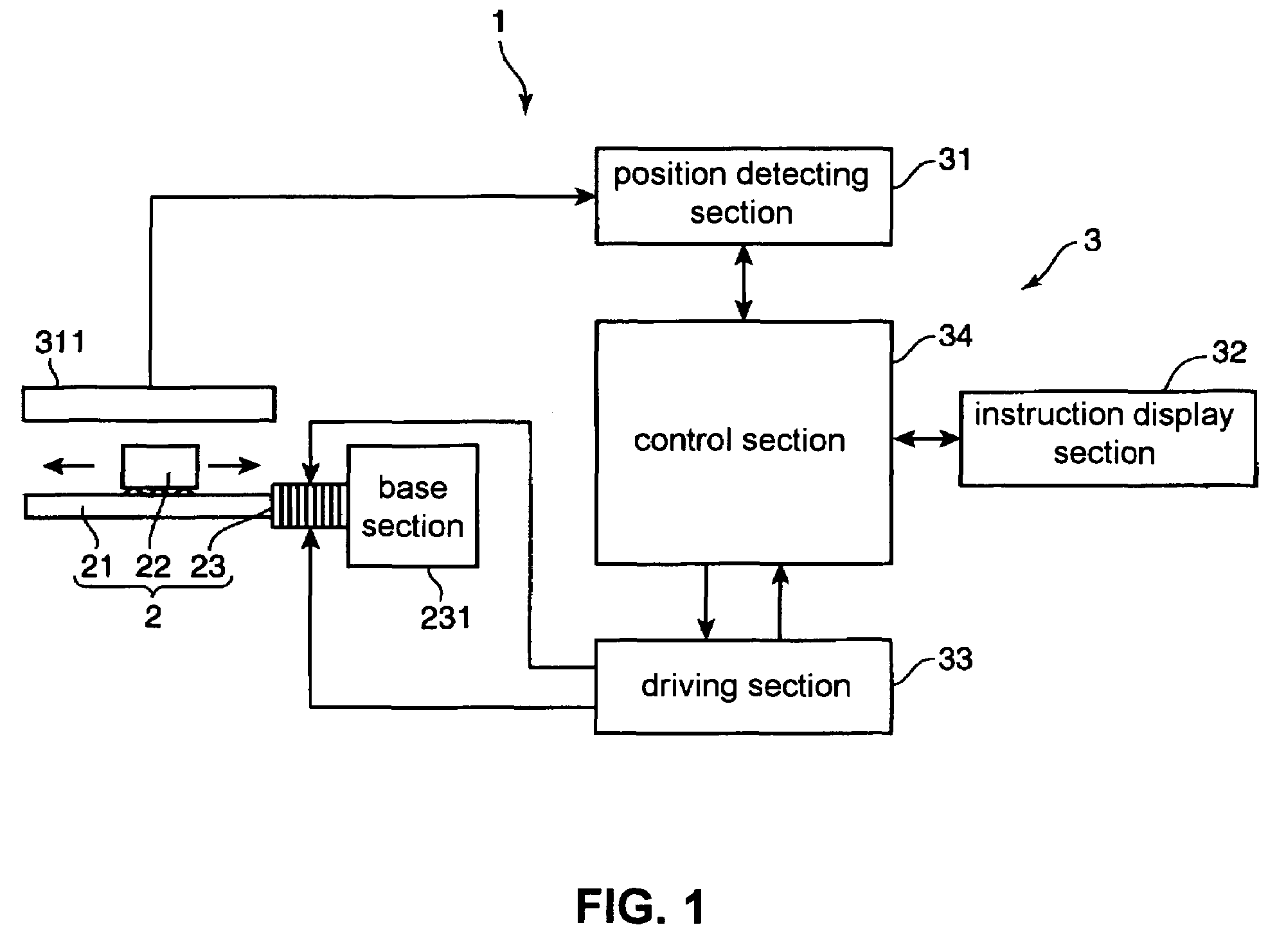

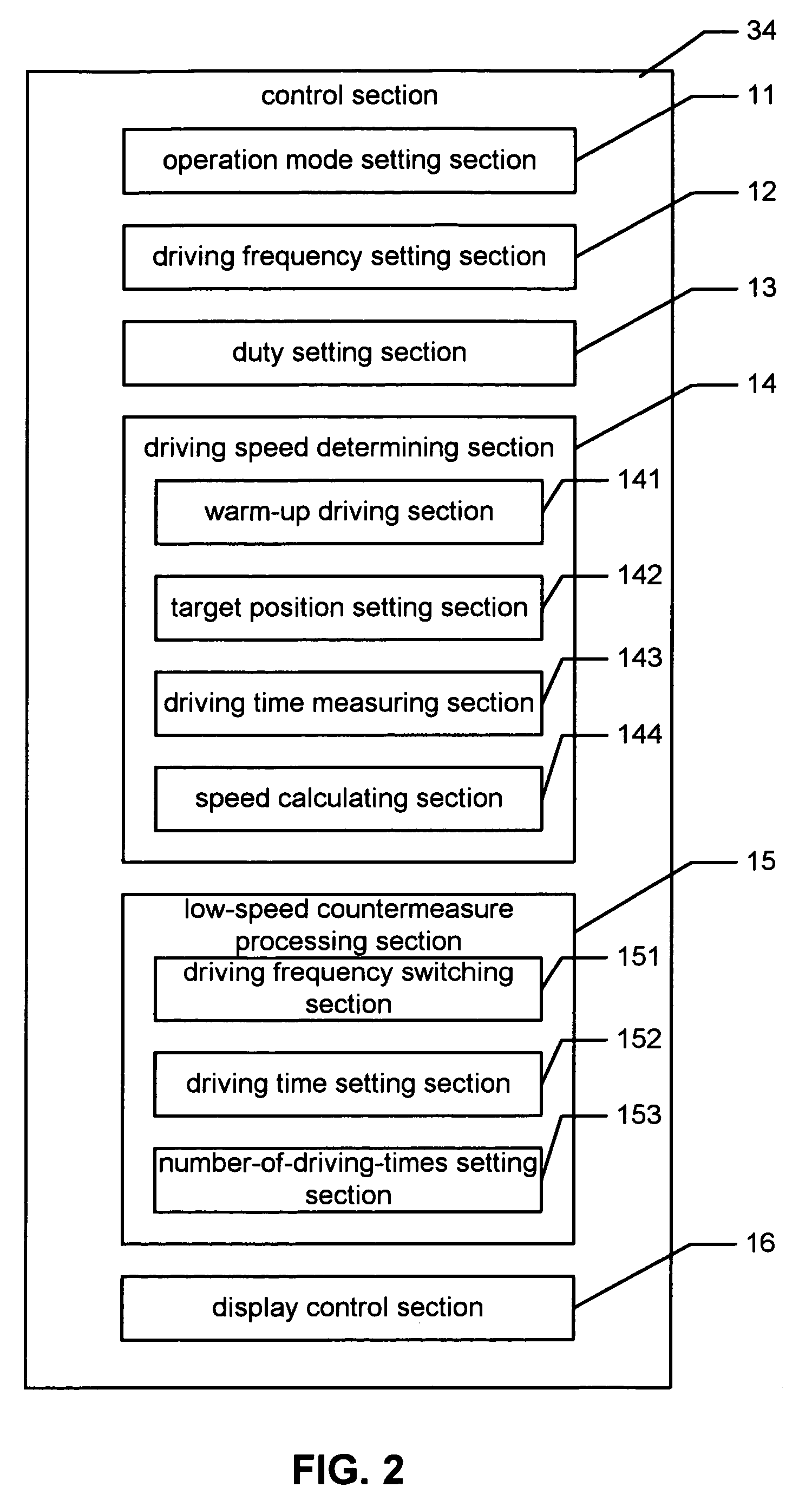

A determination is made whether a moving speed of a slider section with respect to a rod section in a piezoelectric actuator is lower than a predetermined speed. When the moving speed is lower than the predetermined speed, it is considered that a friction-bonded portion between the rod section and the slider section is in a fastened state or a nearly fastened state. A resonance frequency of the piezoelectric actuator or a frequency proximity to the resonance frequency is set as a driving frequency for the piezoelectric actuator. The slider section is moved in a reciprocating manner plural times with respect to the rod section. As a result, an abnormal state is eliminated from the piezoelectric actuator.

Owner:KONICA MINOLTA INC

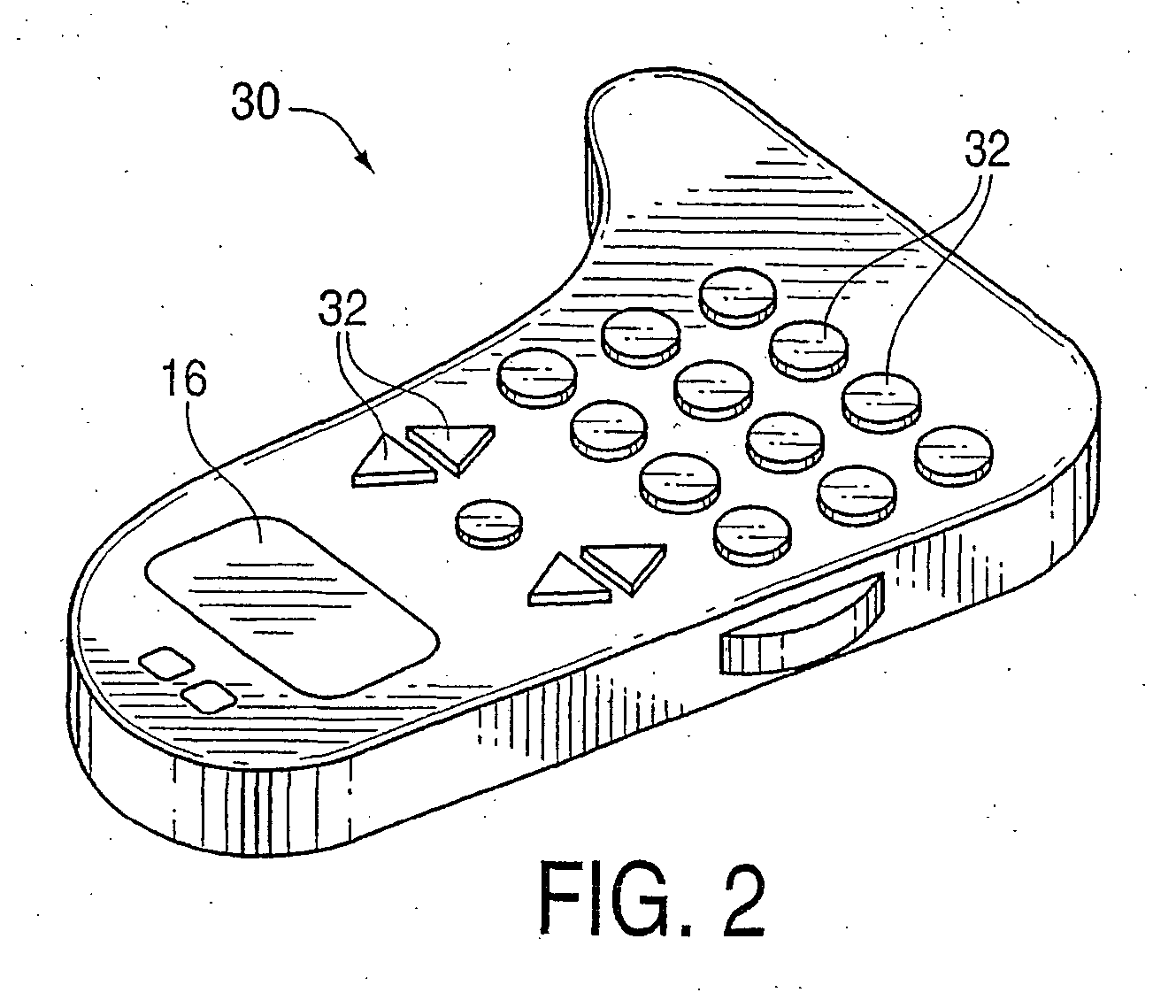

Haptic input devices

InactiveUS20050017947A1Enhanced interactionEnhance manipulationInput/output for user-computer interactionCathode-ray tube indicatorsGraphicsPiezoelectric actuators

A haptic feedback touch control used to provide input to a computer. A touch input device includes a planar touch surface that provides position information to a computer based on a location of user contact. The computer can position a cursor in a displayed graphical environment based at least in part on the position information, or perform a different function. At least one actuator is also coupled to the touch input device and outputs a force to provide a haptic sensation to the user. The actuator can move the touchpad laterally, or a separate surface member can be actuated. A flat E-core actuator, piezoelectric actuator, or other types of actuators can be used to provide forces. The touch input device can include multiple different regions to control different computer functions.

Owner:IMMERSION CORPORATION

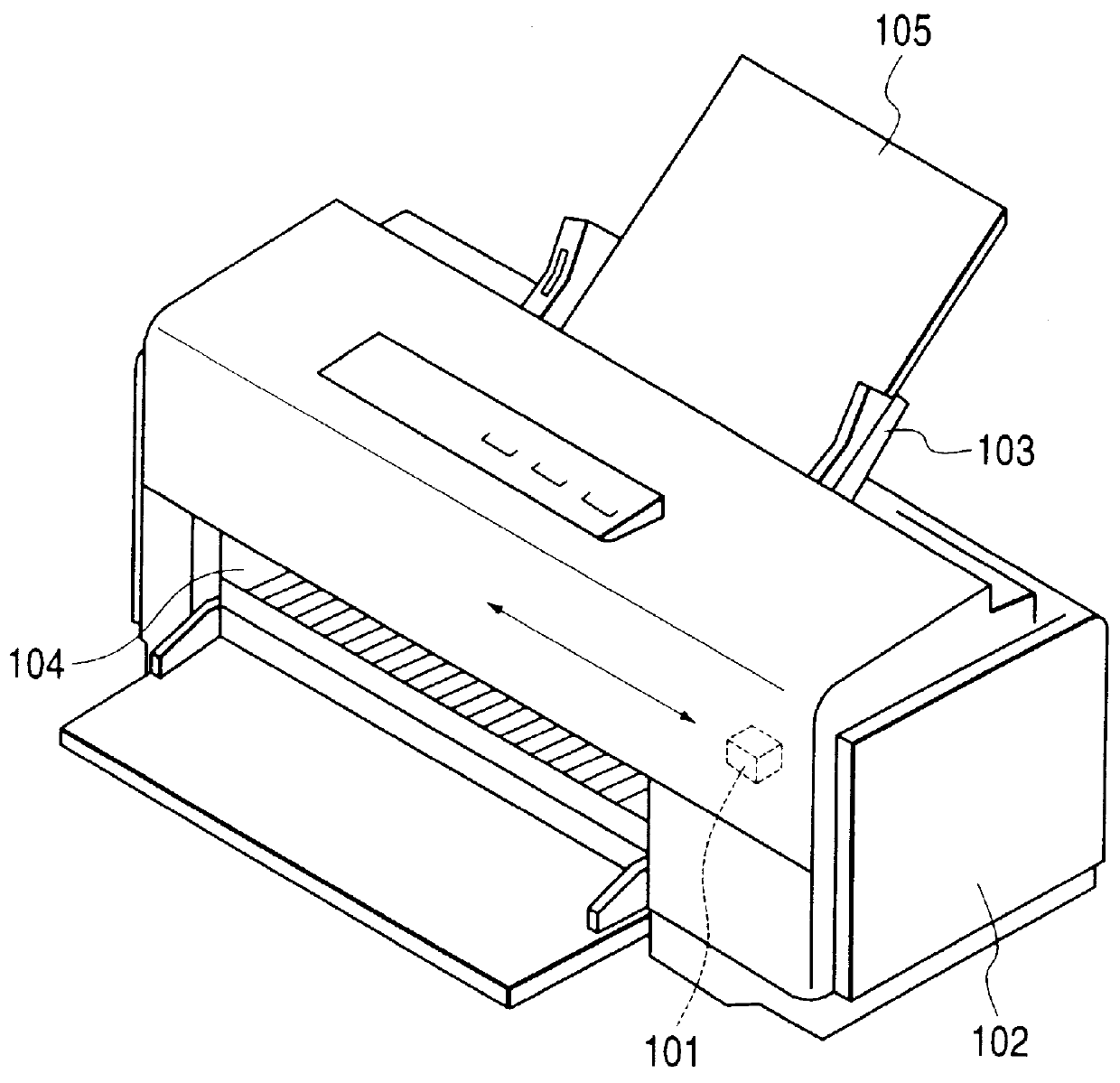

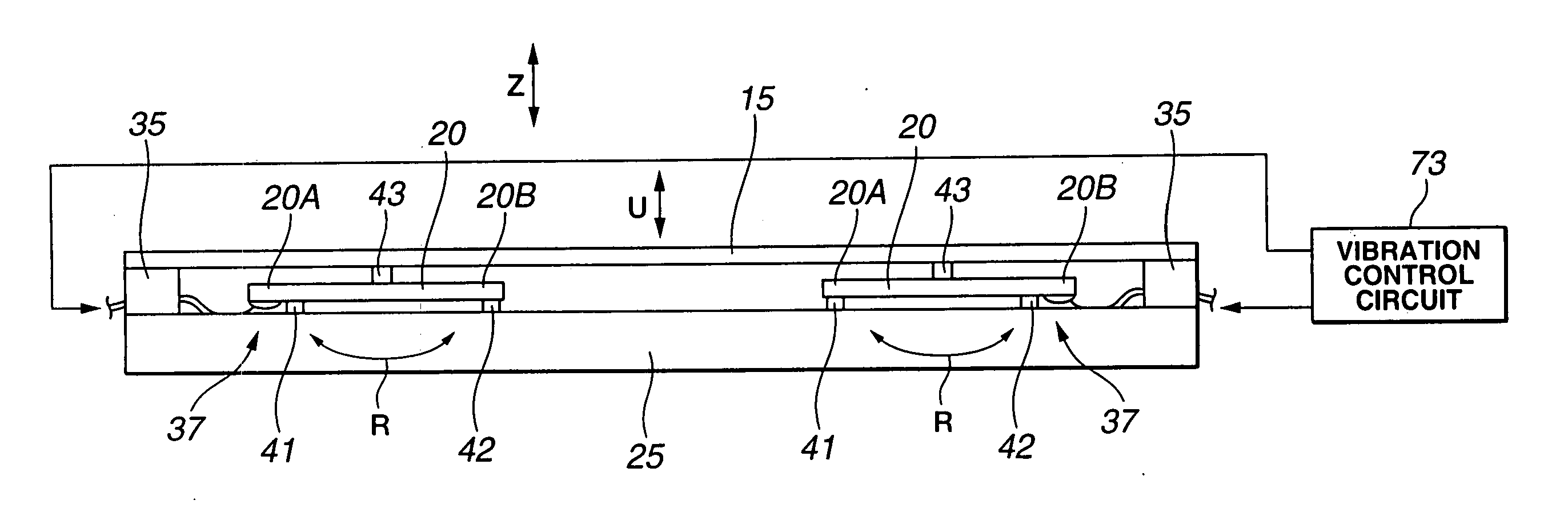

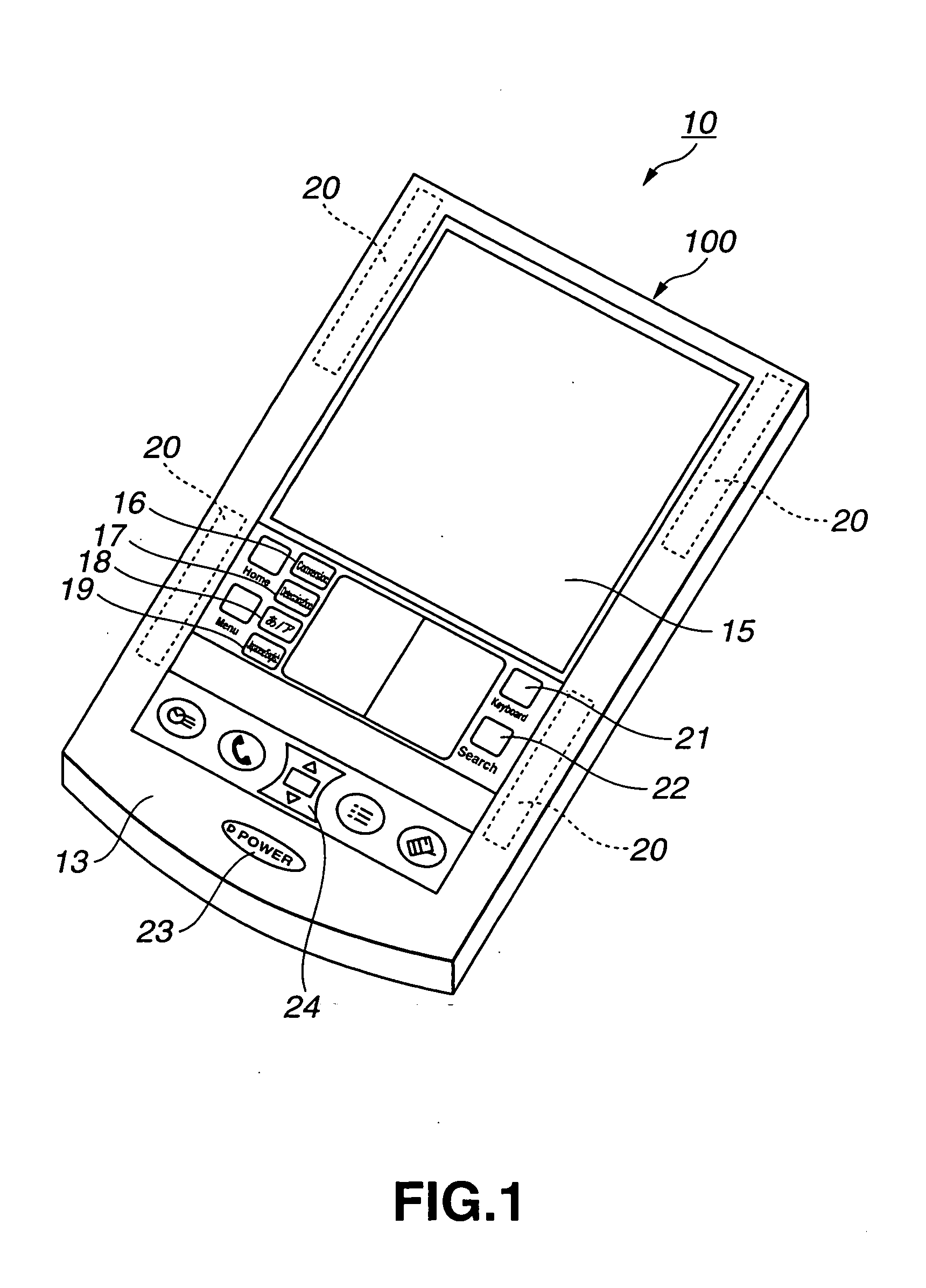

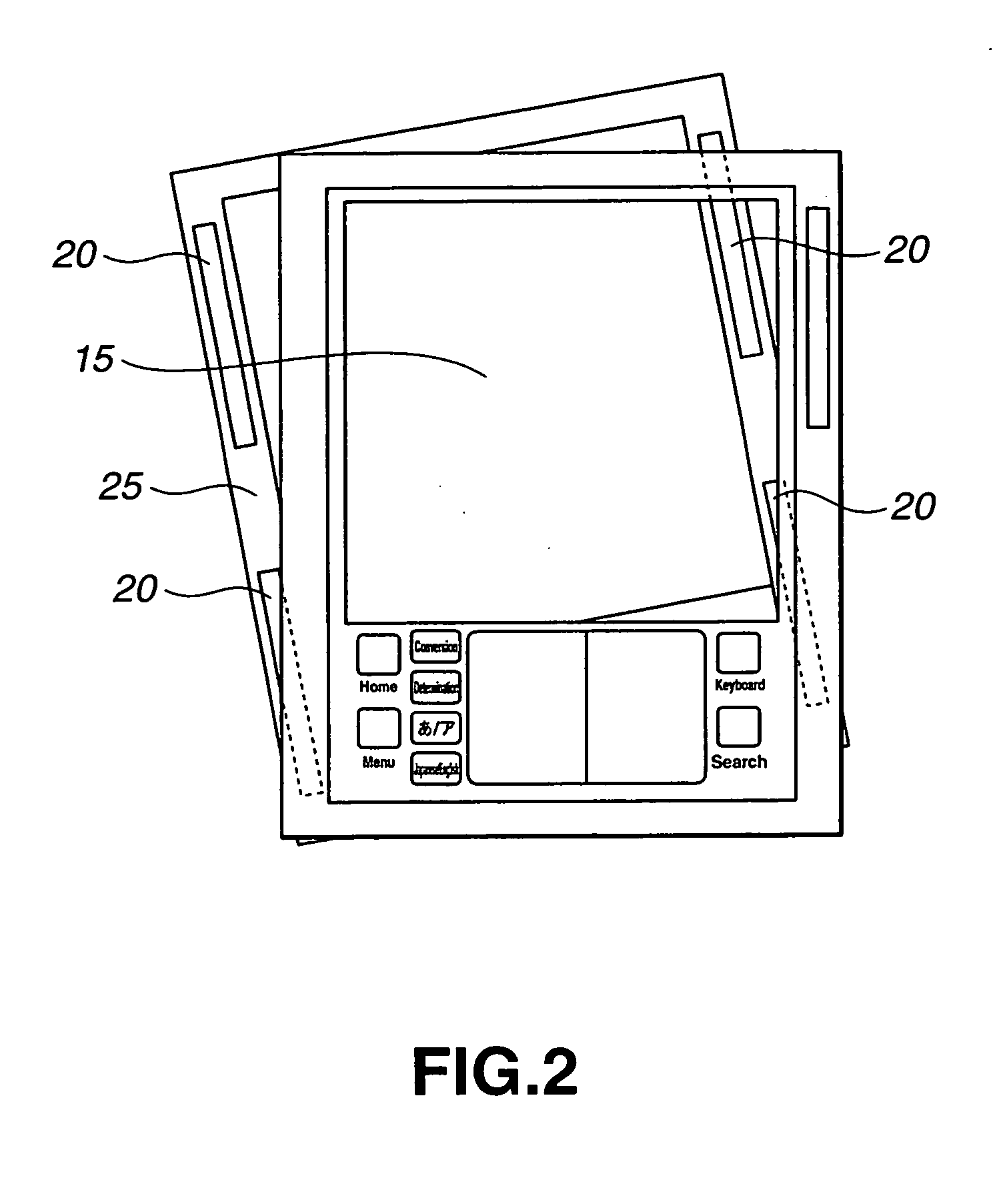

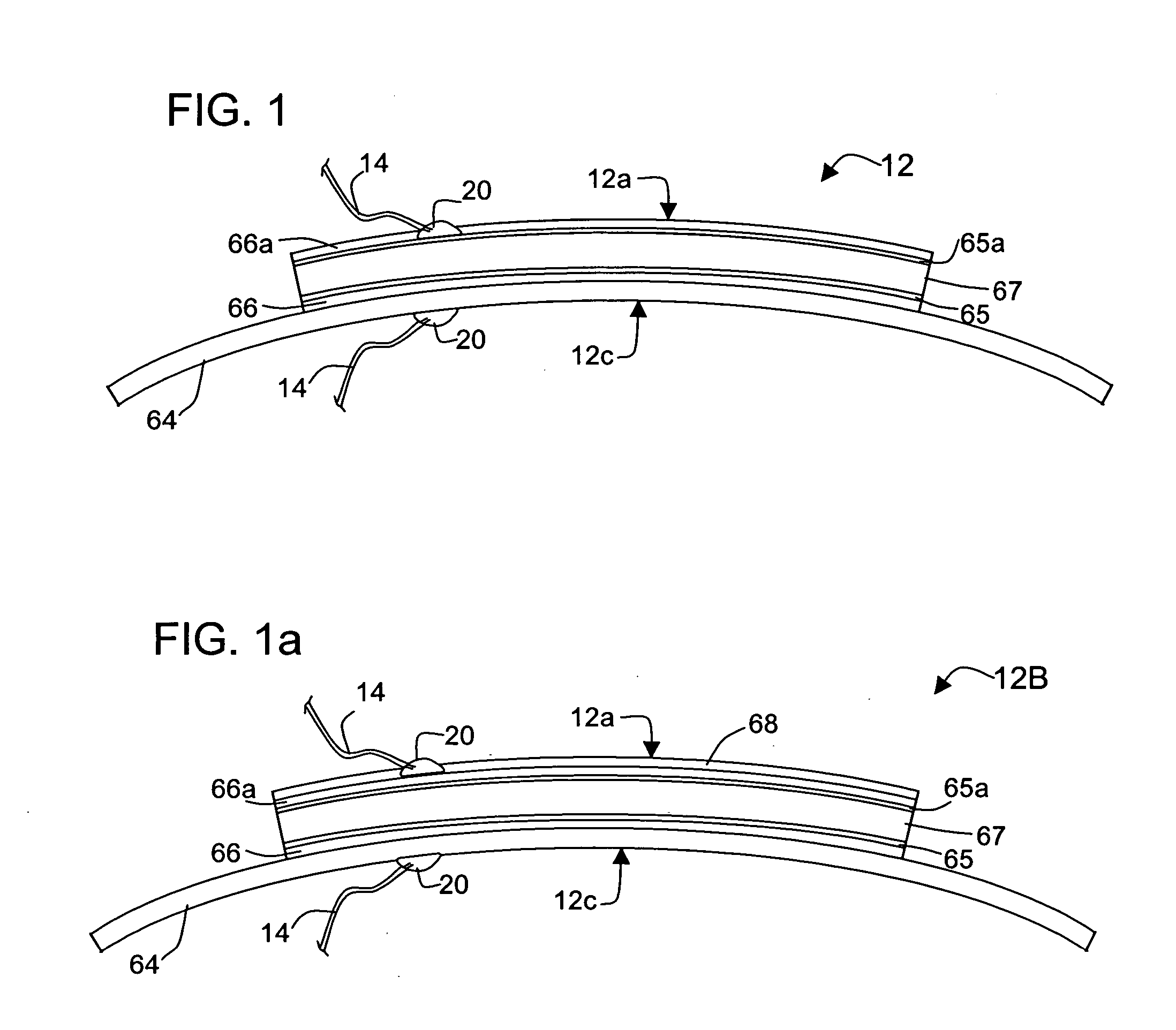

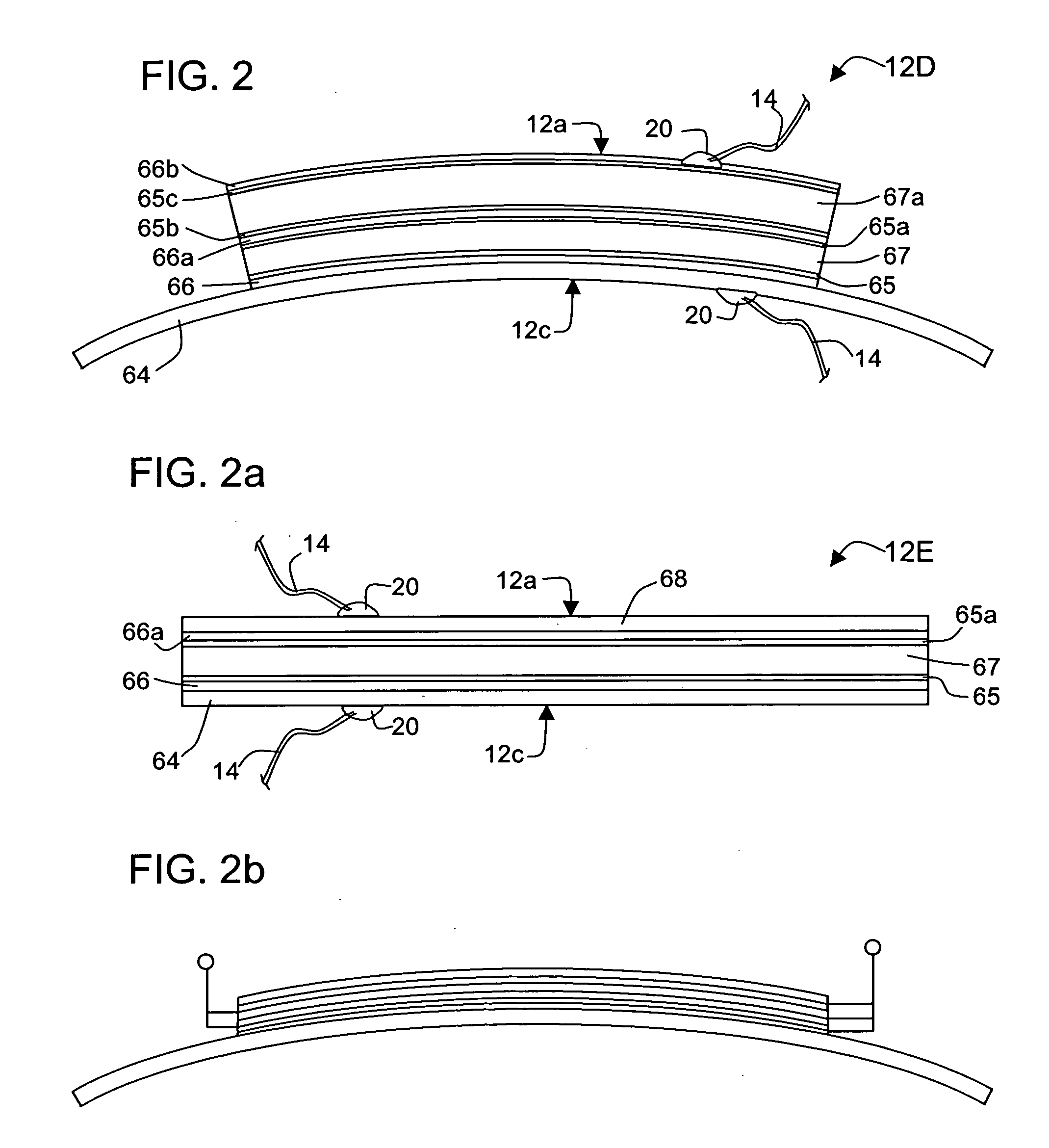

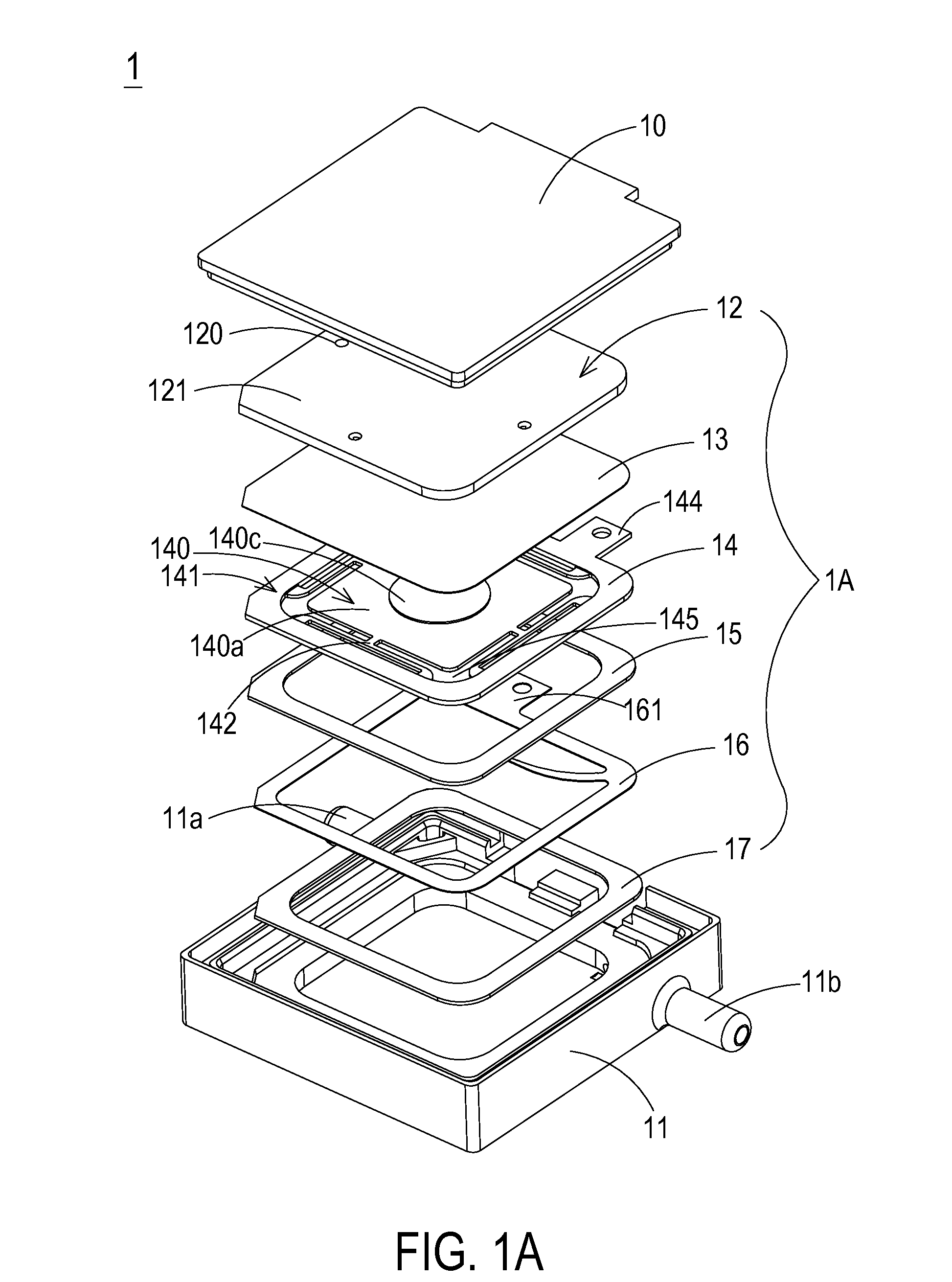

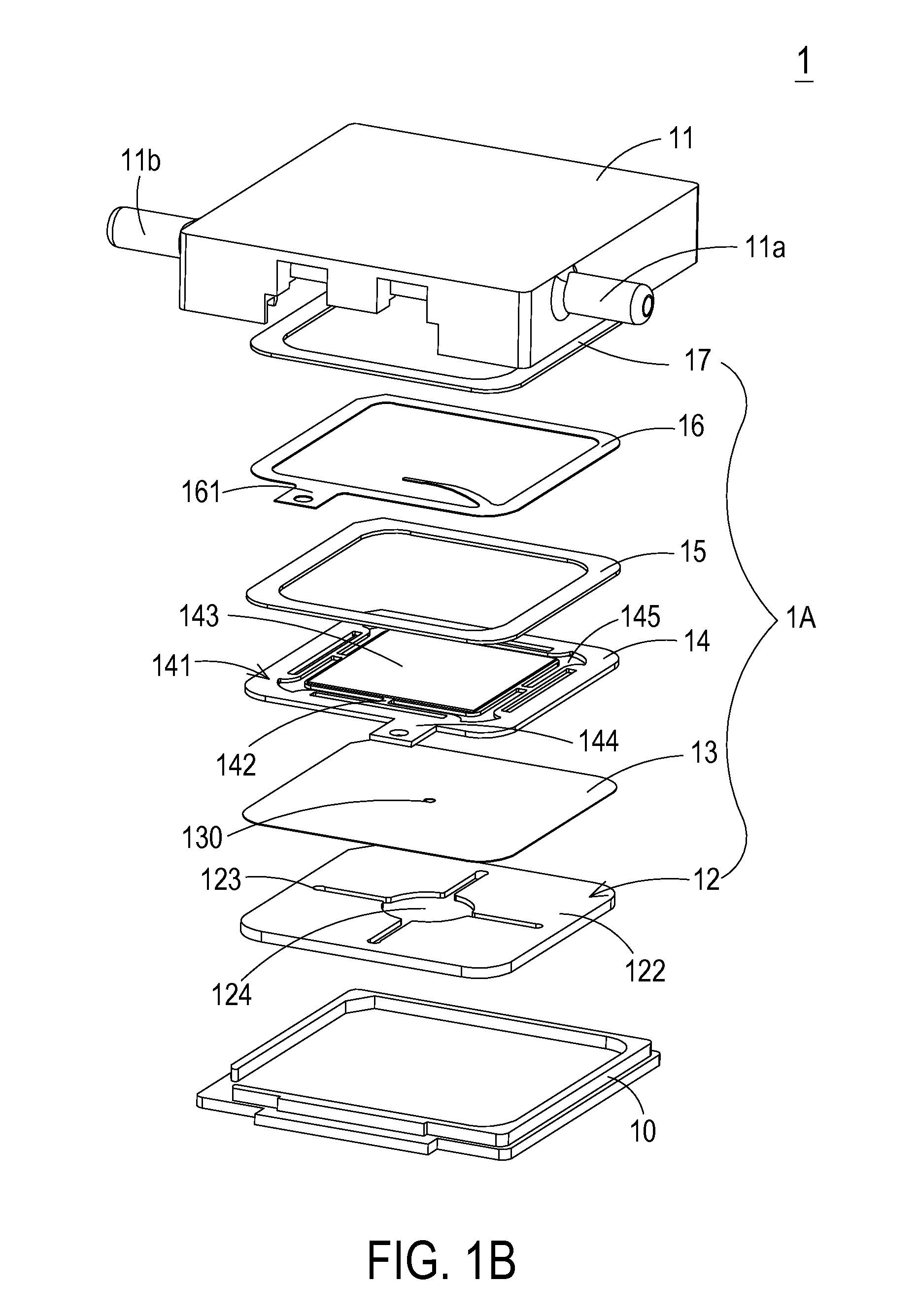

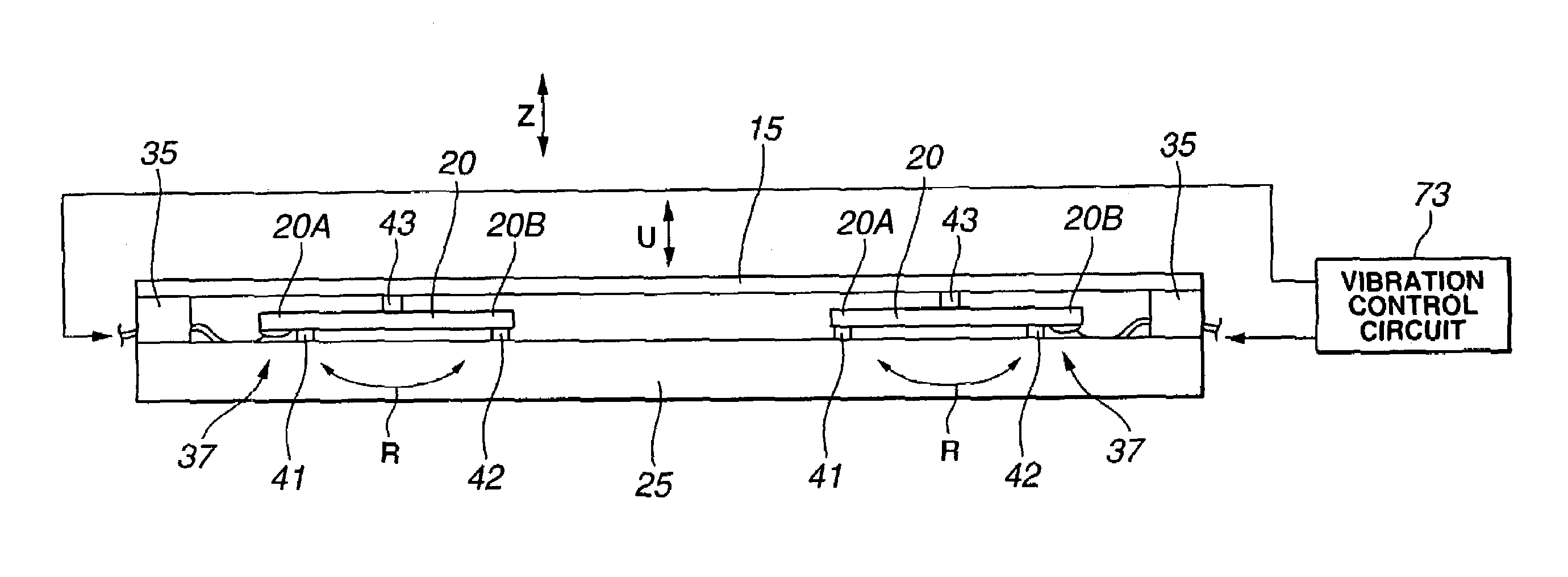

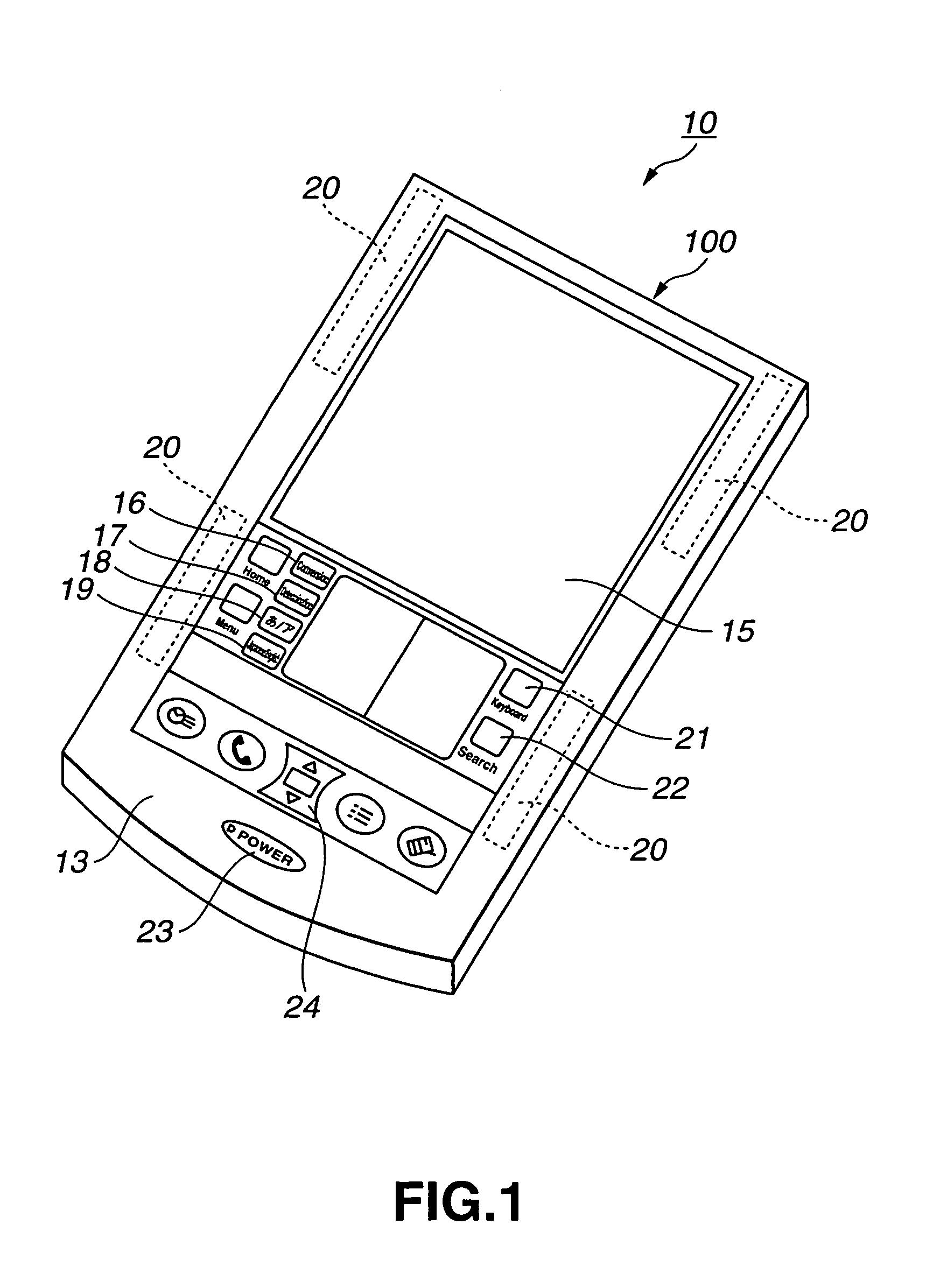

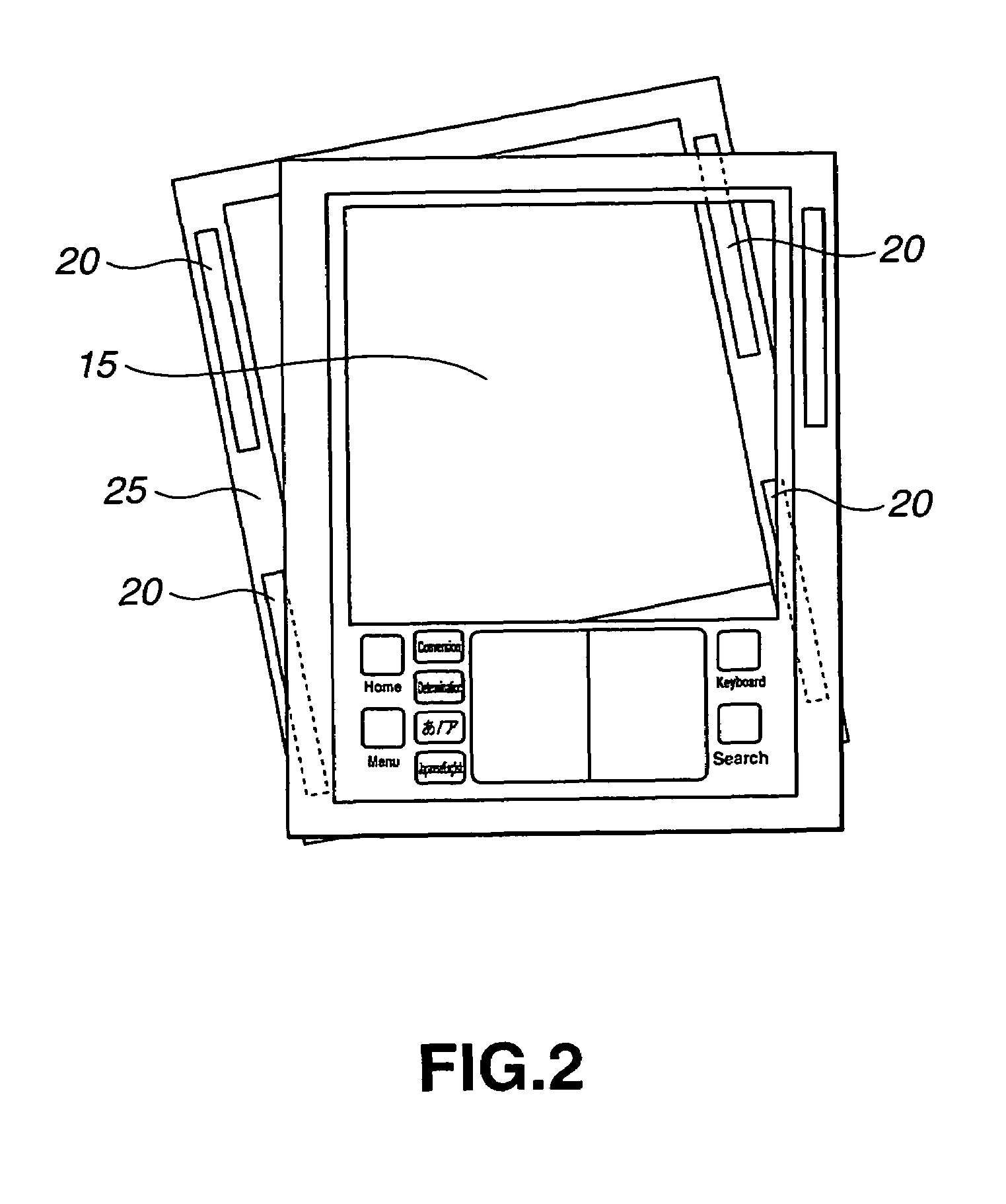

Input device and electronic device using the input device

InactiveUS20070080951A1Great deflection (bending) displacementInput/output for user-computer interactionDigital data processing detailsElectricityInformation type

The present invention related to an input device including: an image display unit (30) that displays information; a touch panel (15) with which a user performs input operation of information by touching a portion corresponding to the position at which the information of the image display unit is displayed; a vibration generation device (71) disposed in the image display unit and feeds back, to the user, various kinds of sense of touch in accordance with the type of the information through the touch panel; and a vibration control circuit (73) for allowing the vibration generation device to generate various forms of vibrations in accordance with the type of the information. The vibration generation device is a bimorph piezoelectric actuator. Each of first and second actuator units has multi-layered piezoelectric elements (63). By this way, it is possible to provide an input / output device capable of surely realizing a feedback to user's input operation performed in accordance with the type of information through the sense of touch when the user performs an input operation of information to a touch panel using the sense of touch.

Owner:SONY CORP

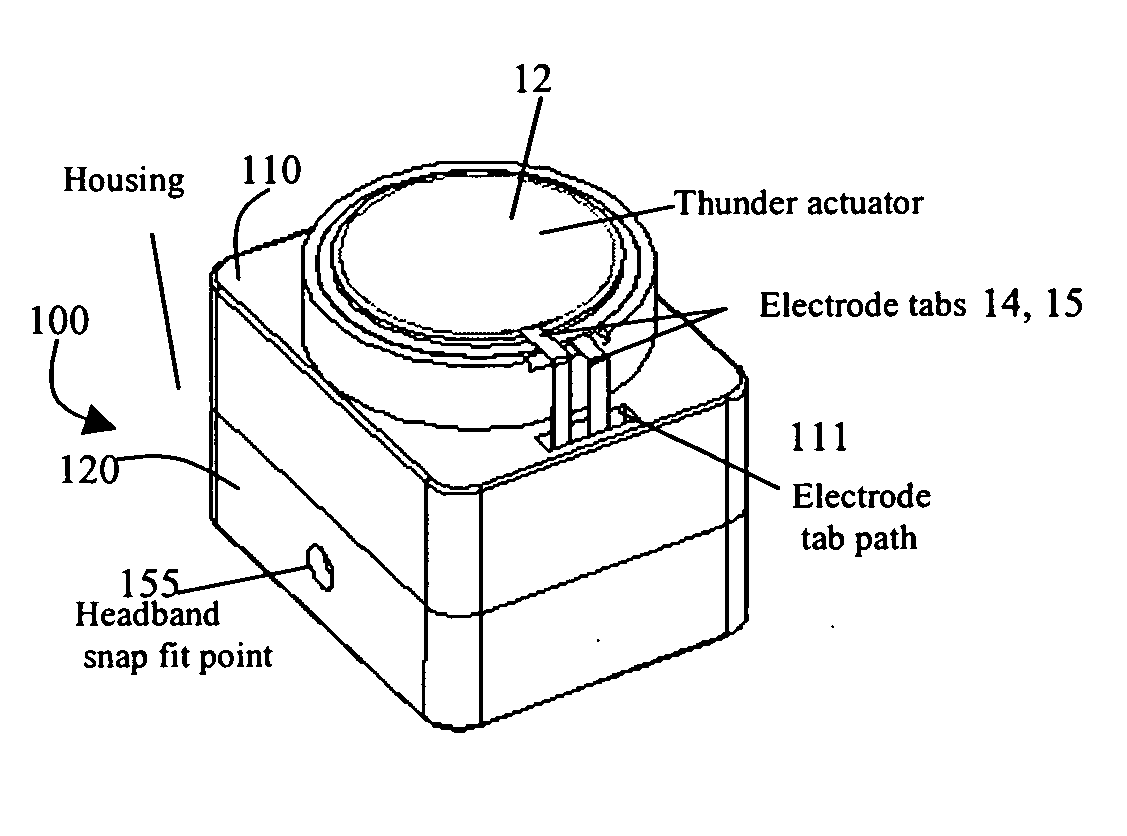

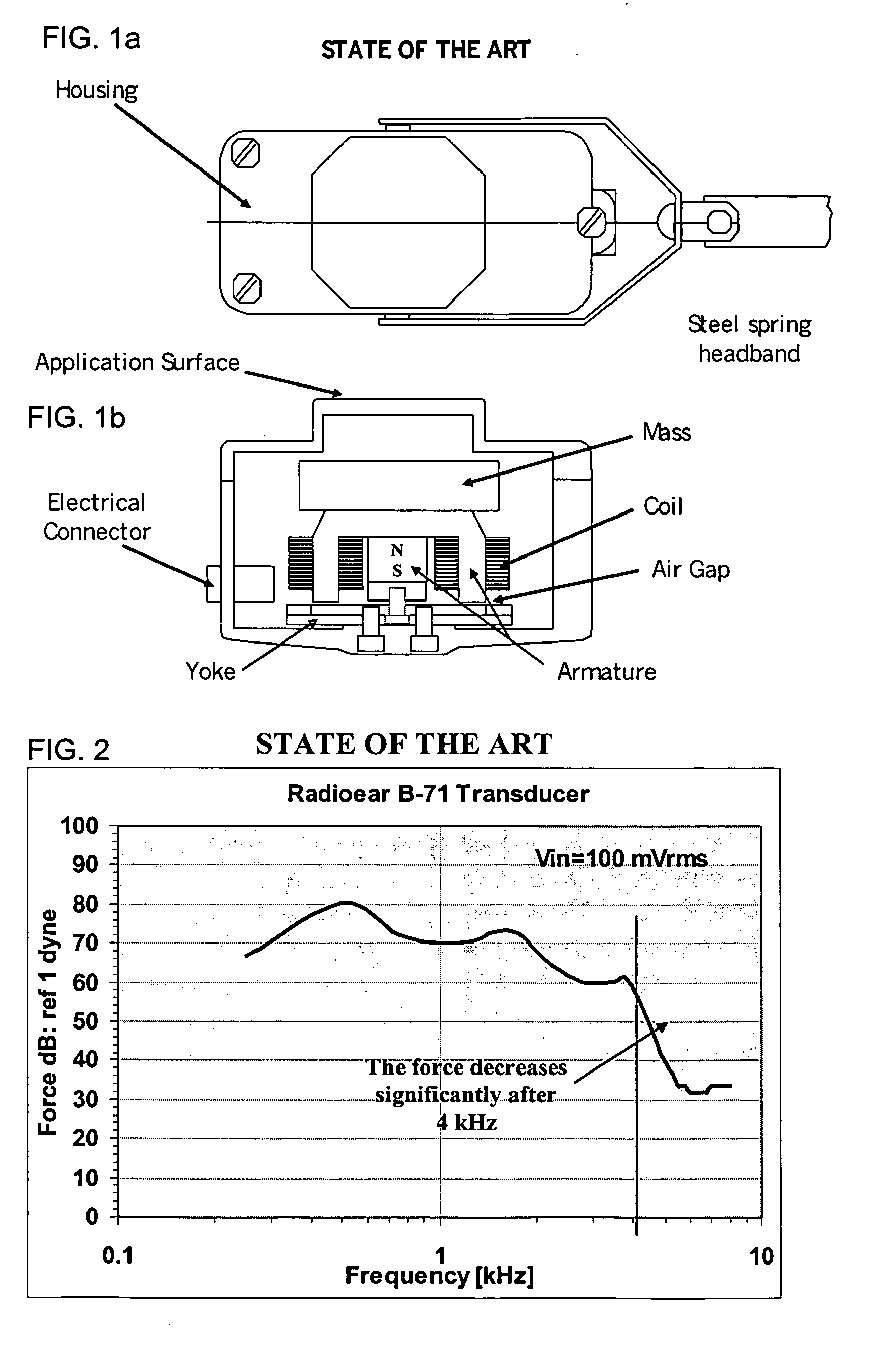

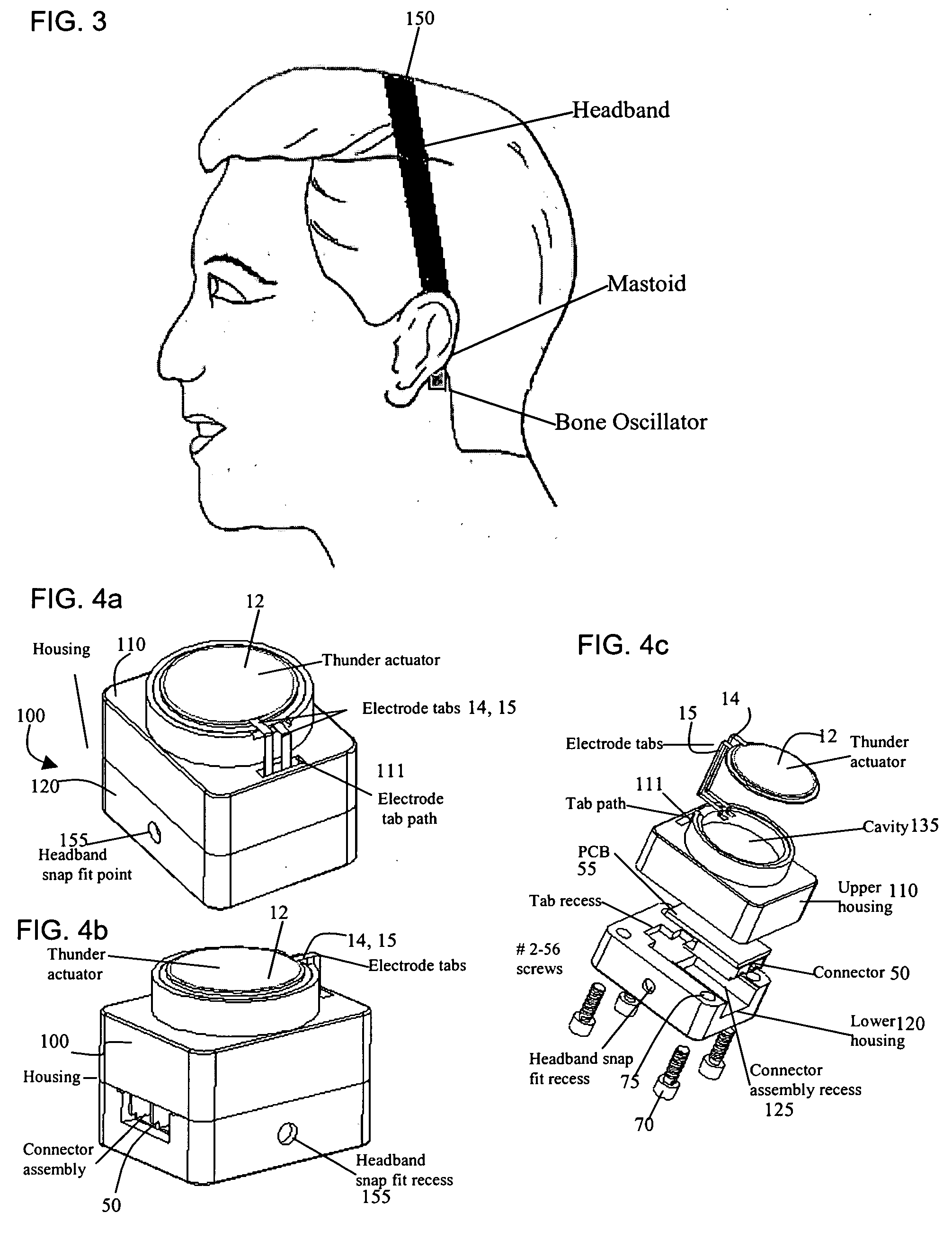

Bone-conduction hearing-aid transducer having improved frequency response

InactiveUS20070041595A1Eliminates soldering wireEliminate useRecord carriersPiezoelectric/electrostrictive transducersFrequency spectrumBone structure

A hearing-aid device and a method for transmitting sound through bone conduction are disclosed. The hearing-aid device comprises a piezoelectric-type actuator, housing and connector. The piezoelectric actuator is preferably a circular flextensional-type actuator mounted along its peripheral edge in a specifically designed circular structure of the housing. During operation, the bone-conduction transducer is placed against the mastoid area behind the ear of the patient. When the device is energized with an alternating electrical voltage, it flexes back and forth like a circular membrane sustained along its periphery and thus, vibrates as a consequence of the inverse piezoelectric effect. Due to the specific and unique designs proposed, these vibrations are directly transferred trough the human skin to the bone structure (the skull) and provide a means for the sound to be transmitted for patients with hearing malfunctions. The housing acts as a holder for the actuators, as a pre-stress application platform, and as a mass which tailors the frequency spectrum of the device. The apparatus exhibits a performance with a very flat response in the frequency spectrum 200 Hz to 10 kHz, which is a greater spectrum range than any other prior art devices disclosed for bone-conduction transduction which are typically limited to less than 4 kHz.

Owner:FACE INT

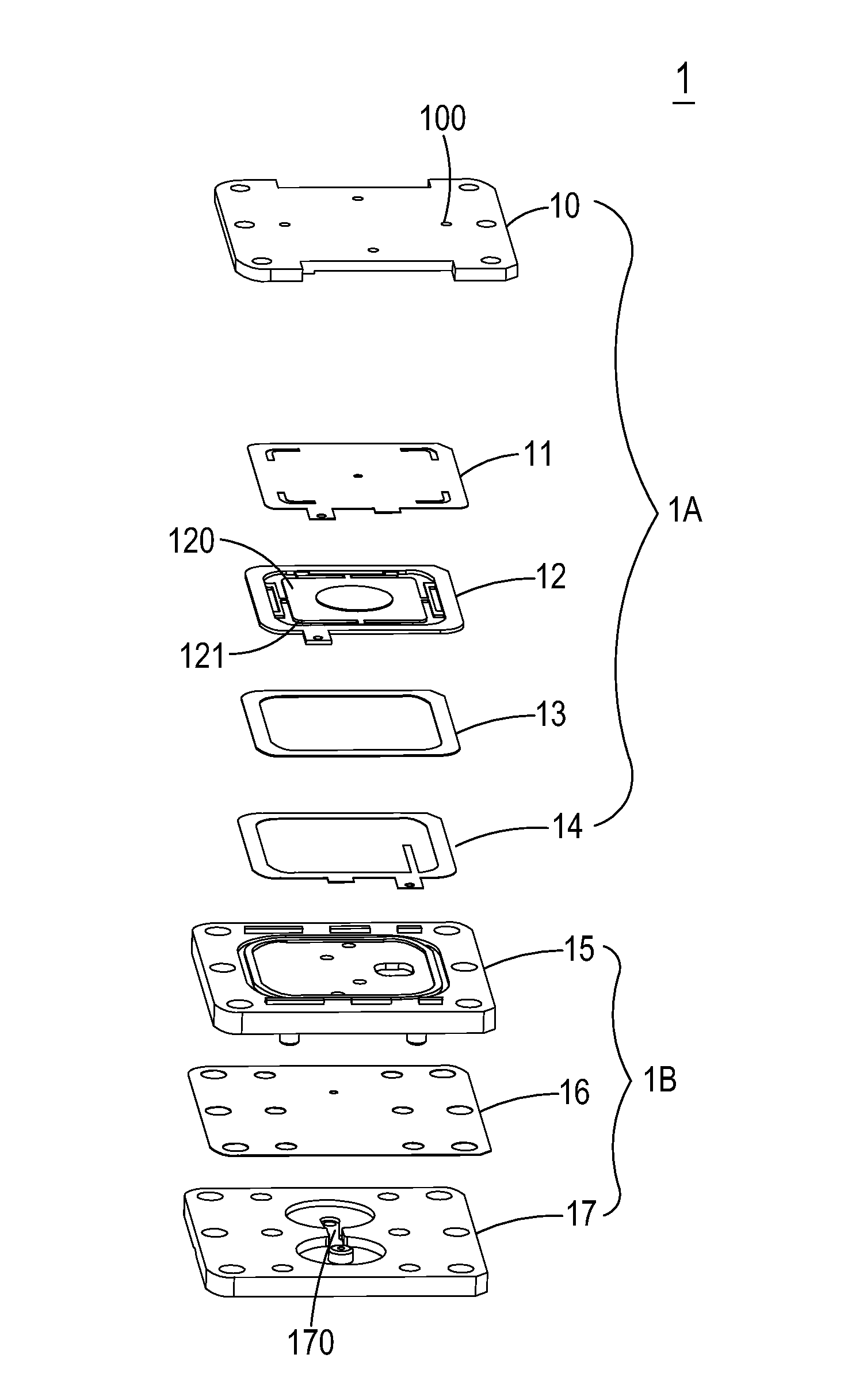

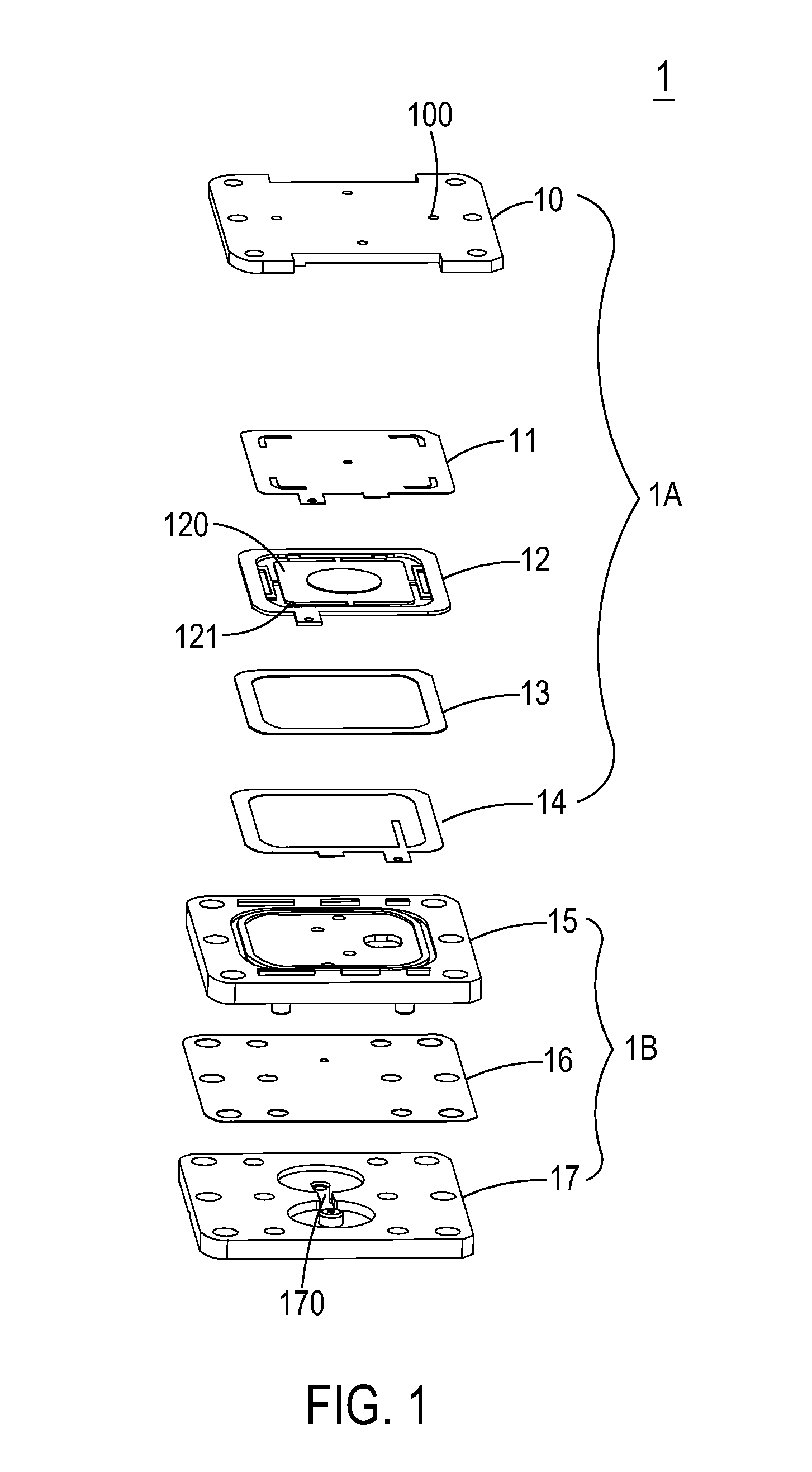

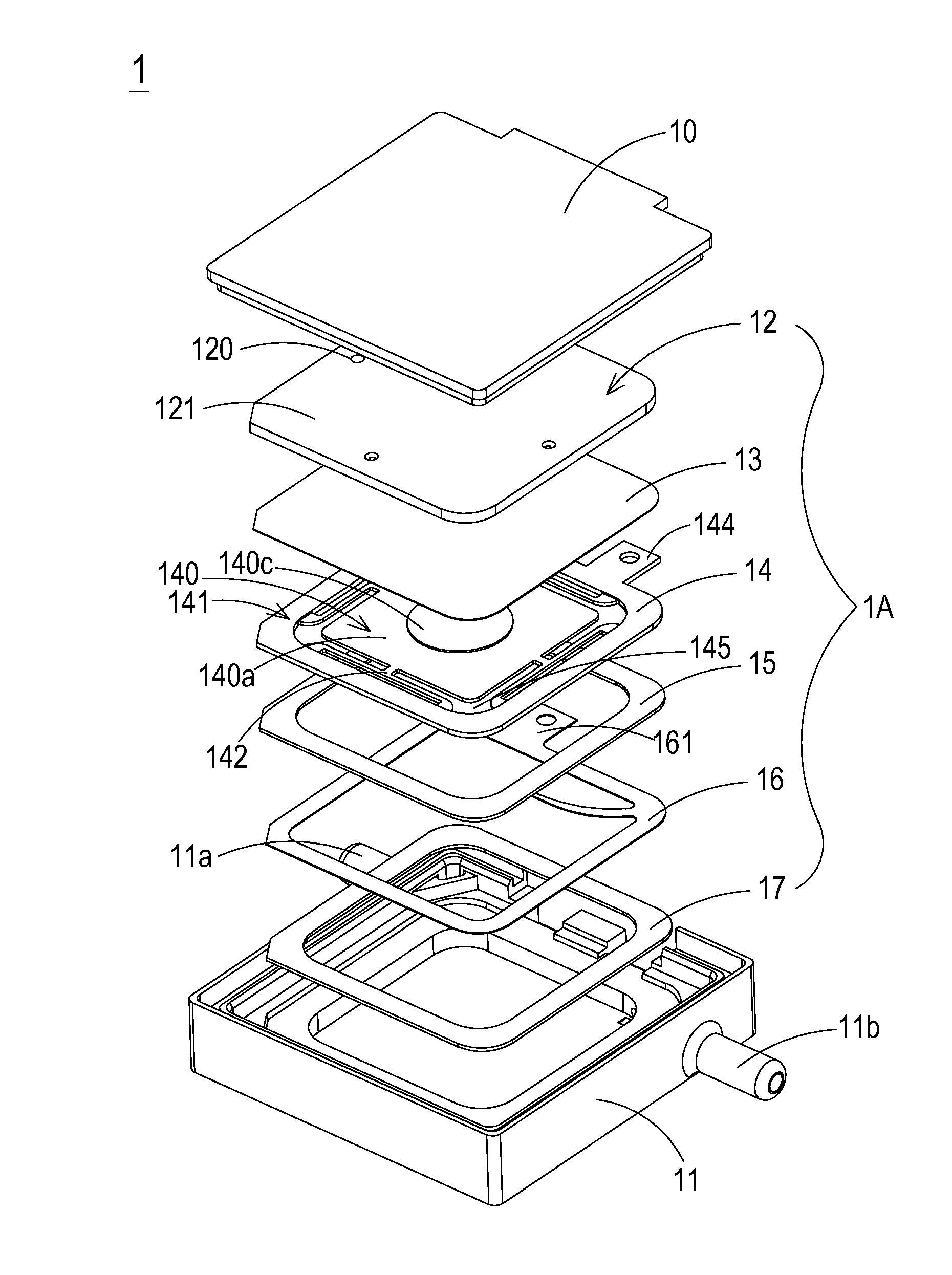

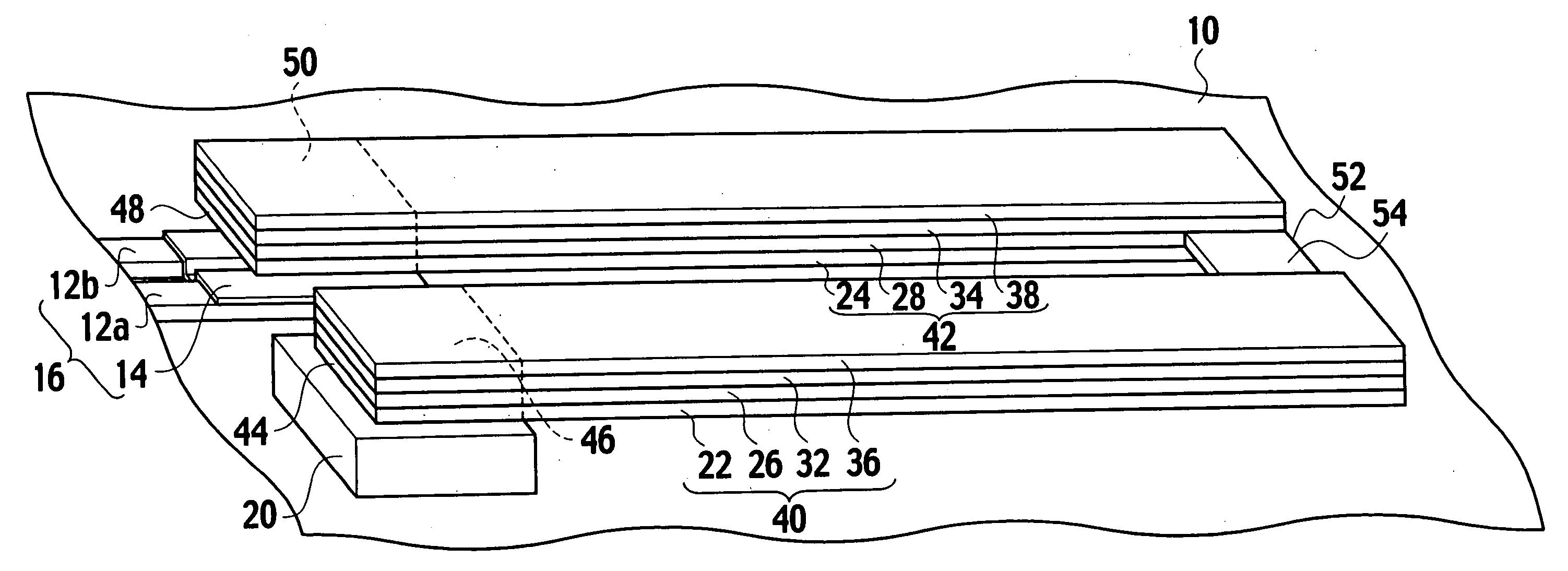

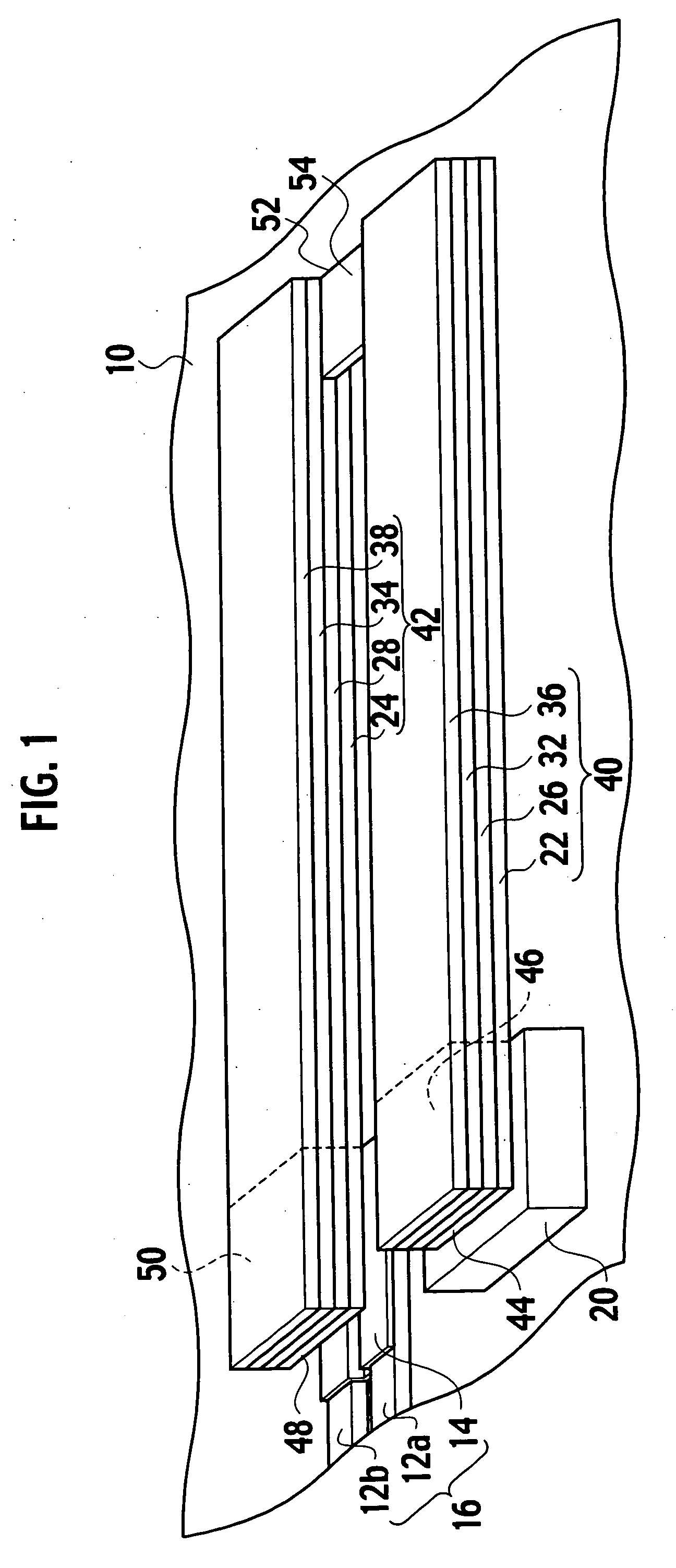

Micro-gas pressure driving apparatus

A micro-gas pressure driving apparatus includes a miniature gas transportation module and a miniature valve module. The miniature gas transportation module includes a gas inlet plate, a fluid channel plate, a resonance membrane and a piezoelectric actuator. A first chamber is defined between the resonance membrane and the piezoelectric actuator. After the piezoelectric actuator is activated to feed a gas through the gas inlet plate, the gas is transferred to the first chamber through the fluid channel plate and the resonance membrane and then transferred downwardly. Consequently, a pressure gradient is generated to continuously push the gas. The miniature valve module includes a gas collecting plate, a valve membrane and a gas outlet plate. After the gas is transferred from the miniature gas transportation module to the gas-collecting chamber, the gas is transferred in one direction, so that a pressure-collecting operation or a pressure-releasing operation is selectively performed.

Owner:MICROJET TECH

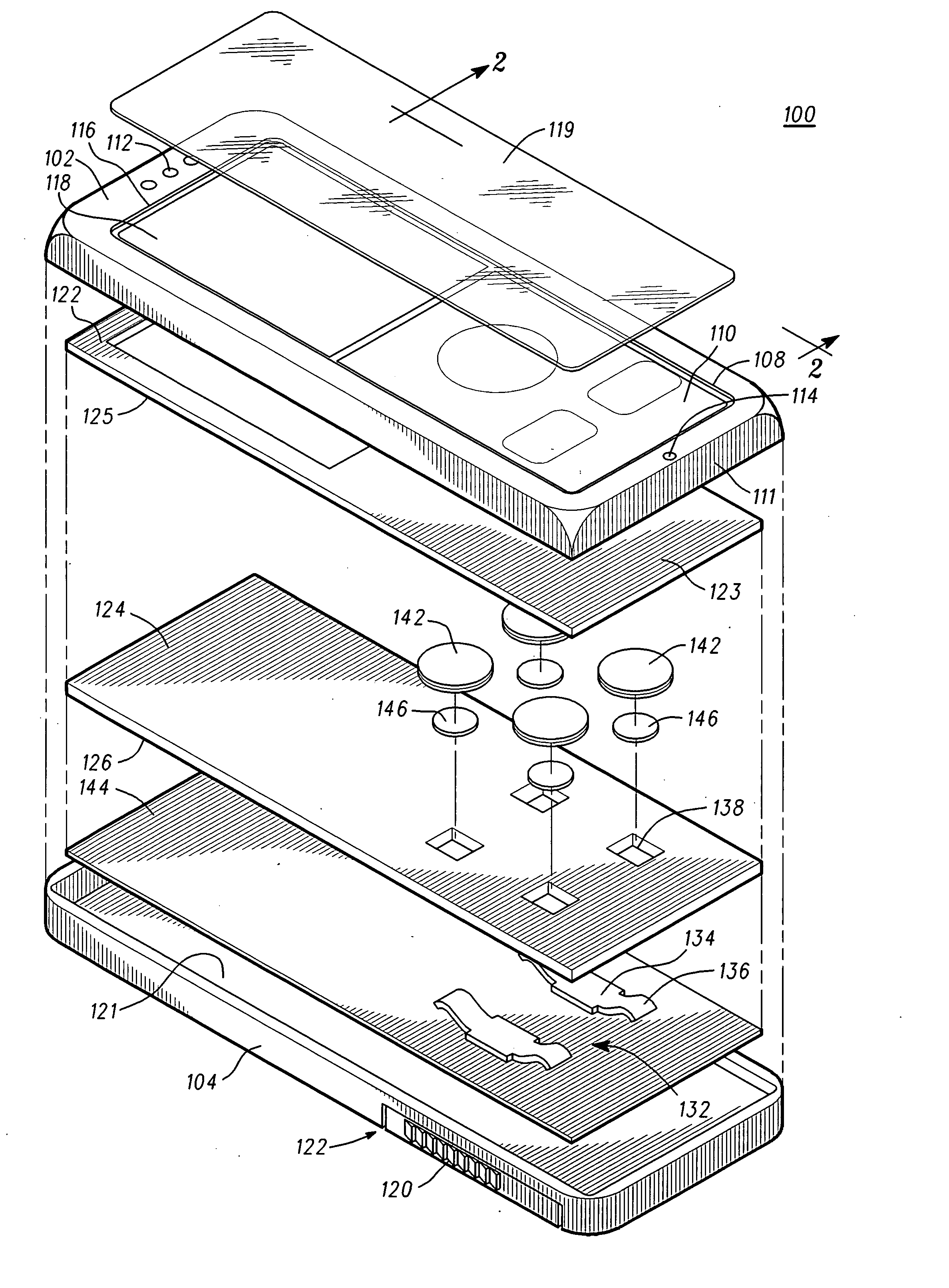

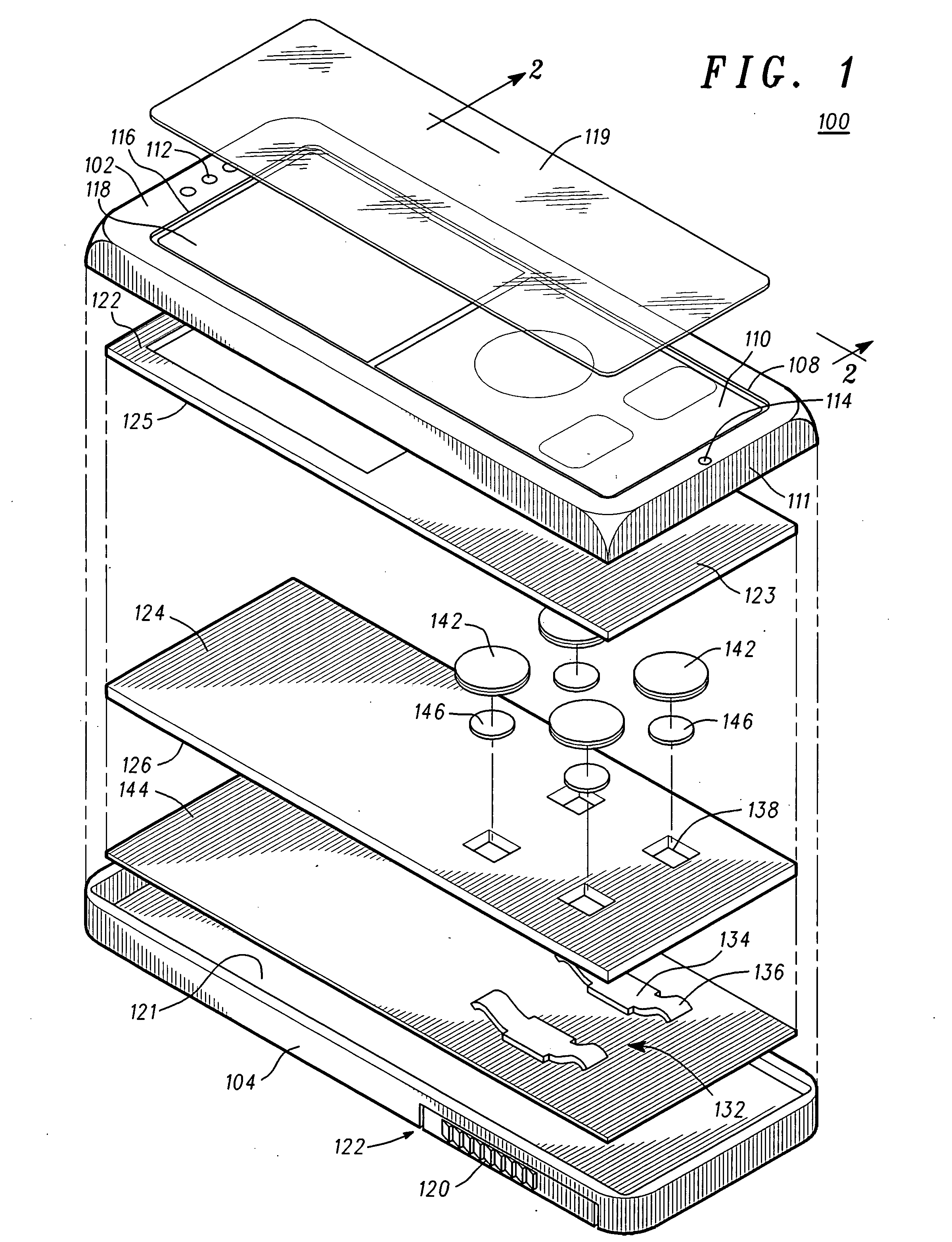

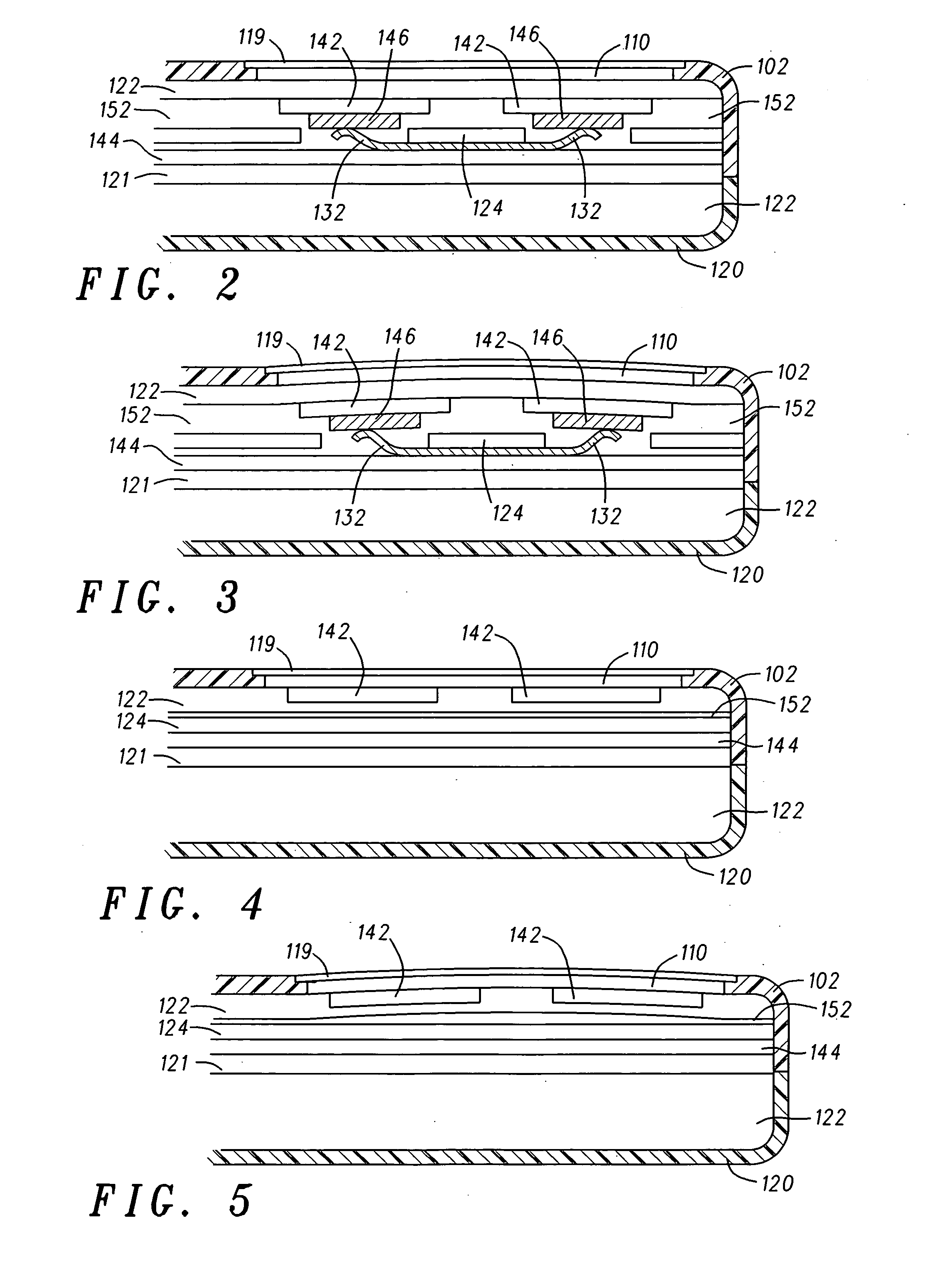

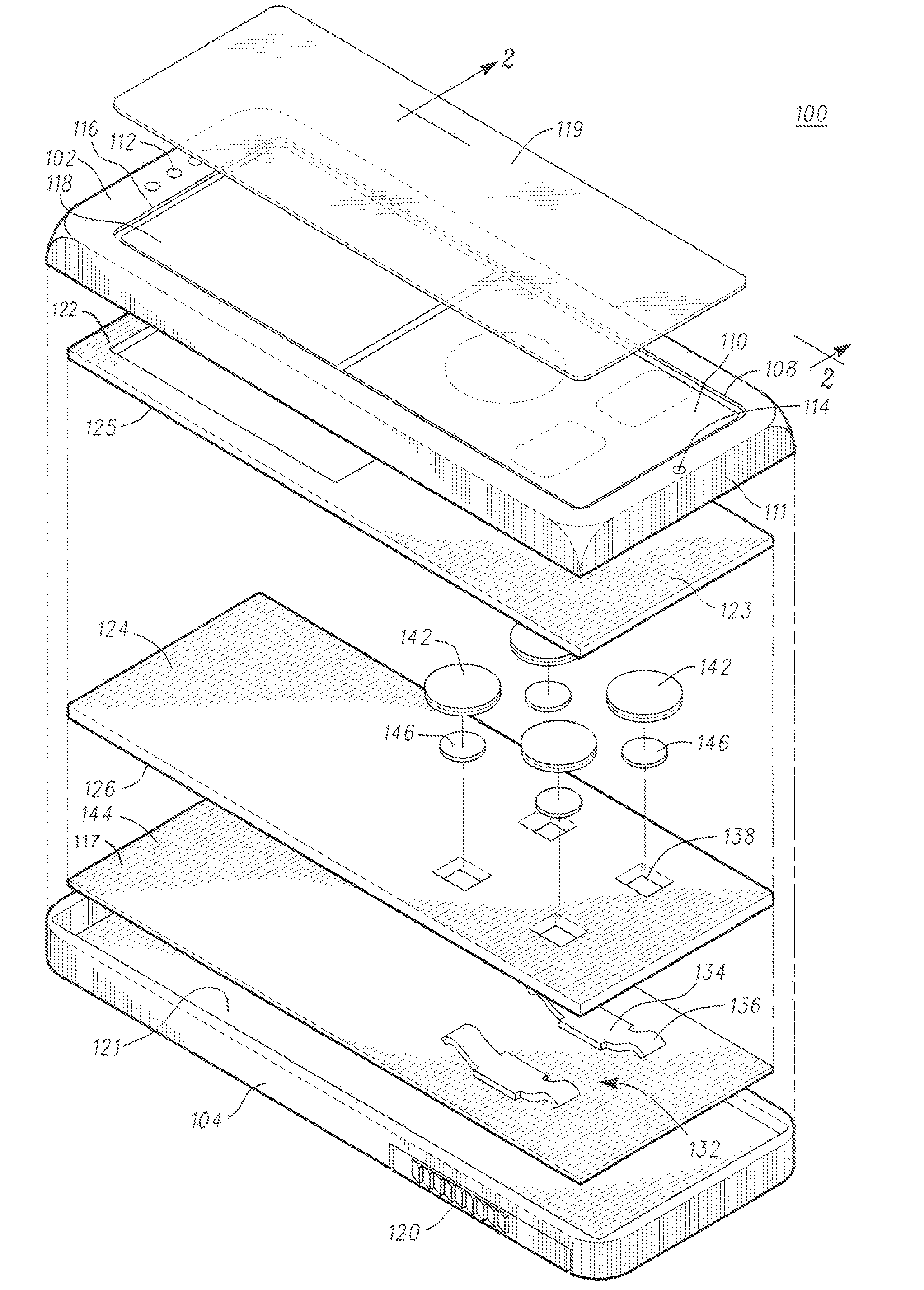

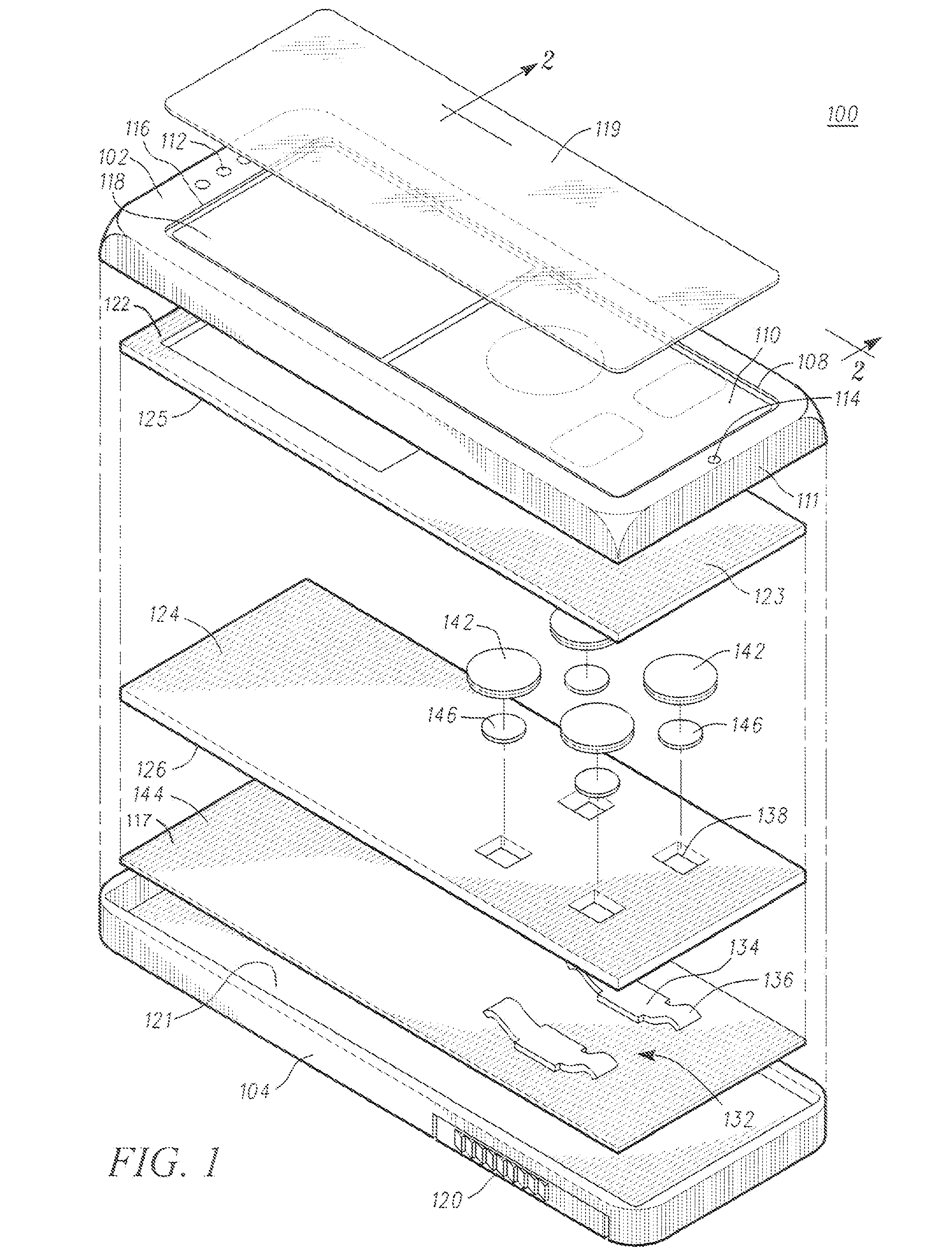

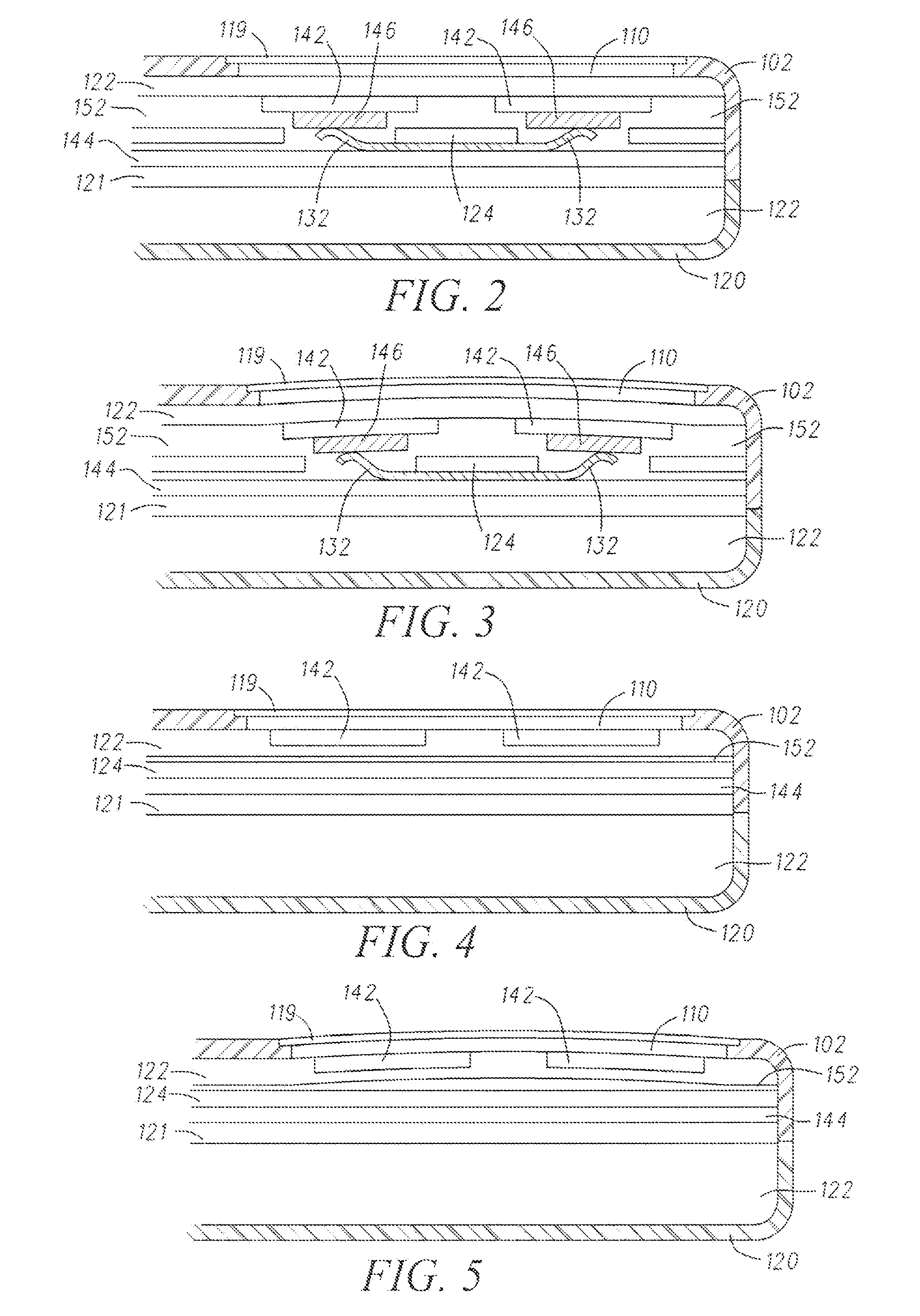

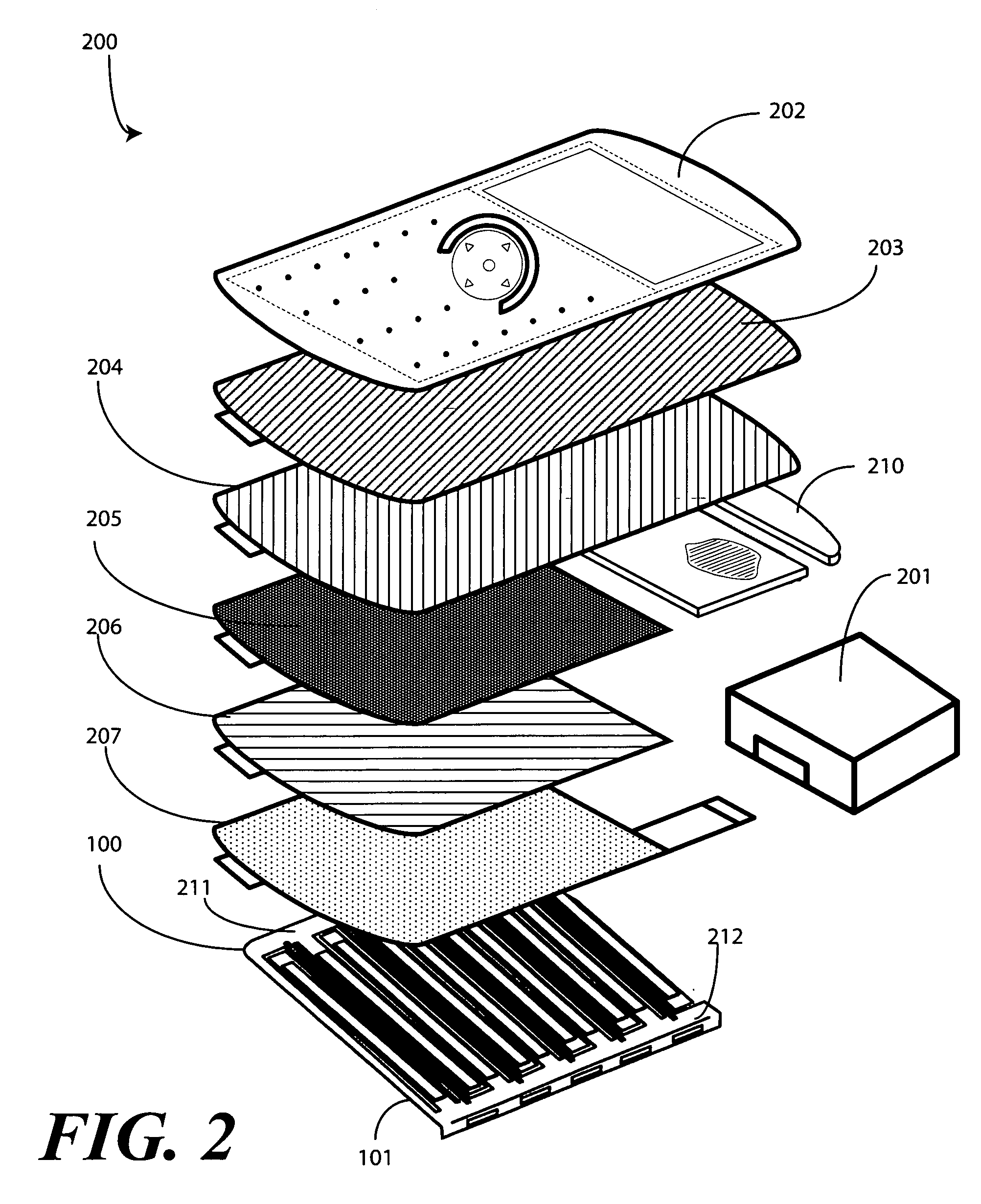

Electronic device providing tactile feedback

InactiveUS20080100568A1Low costCathode-ray tube indicatorsInput/output processes for data processingPiezoelectric actuatorsEngineering

An electronic device (100) provides tactile feedback provided by a low cost, thin piezoelectric actuator (142) giving tactile feedback emulating a click like feed. The electronic device (100) comprises a chassis plate (122) having a periphery secured to a housing (102, 104) and comprising a flexible material having a first planer side (123), and a second planer side (125) opposed to the first planer side (123). An input device (110) has a planer side (111) positioned adjacent to and in contact with to the first planer side (123) of the chassis (122) and extends through an opening (108) in the housing (102, 104). One or more piezoelectric actuators (142) are secured to the second planer side (125) and within the periphery of the chassis plate (122). Electronic circuitry (208) positioned within the housing (102, 104) drives the piezoelectric actuators (142) in response to the input device (110) being actuated. The input provided to the input device (110) is sensed by the electronic circuitry (208). The circuitry (208) provides a voltage waveform to activate the one or more piezoelectric actuators (142), which flexes the chassis plate (122) and the input device (110) to emulate the click like feed. A second exemplary embodiment positions the piezoelectric actuators (142) between the chassis plate (122) and the input device (110).

Owner:MOTOROLA INC

Electronic device and circuit for providing tactile feedback

ActiveUS20090072662A1Low costPiezoelectric/electrostriction/magnetostriction machinesDigital data processing detailsElectricityControl signal

A circuit (800) for controlling at least one piezoelectric actuator (142) includes a piezoelectric drive circuit (802) that generates unidirectional voltage drive signal, also referred to as Vout, at node (804). The piezoelectric actuator drive circuit (802) includes a boost switcher circuit or charging circuit (806), a buck switcher circuit or pulsed current sink discharge circuit (808) and a control signal generating circuit (810) that receives an input control signal (812) from, for example, a keyboard processor or other suitable processor (604) indicating that the device has requested generation of haptic feedback utilizing the piezoelectric actuator (142). The control signal generating circuit (810) provides at least two pulse-with-modulated control signals, one to control the charging circuit and one to control the discharging circuit to produce the unidirectional voltage drive signal, that in one example is a raised cosine drive signal (904).

Owner:GOOGLE TECH HLDG LLC

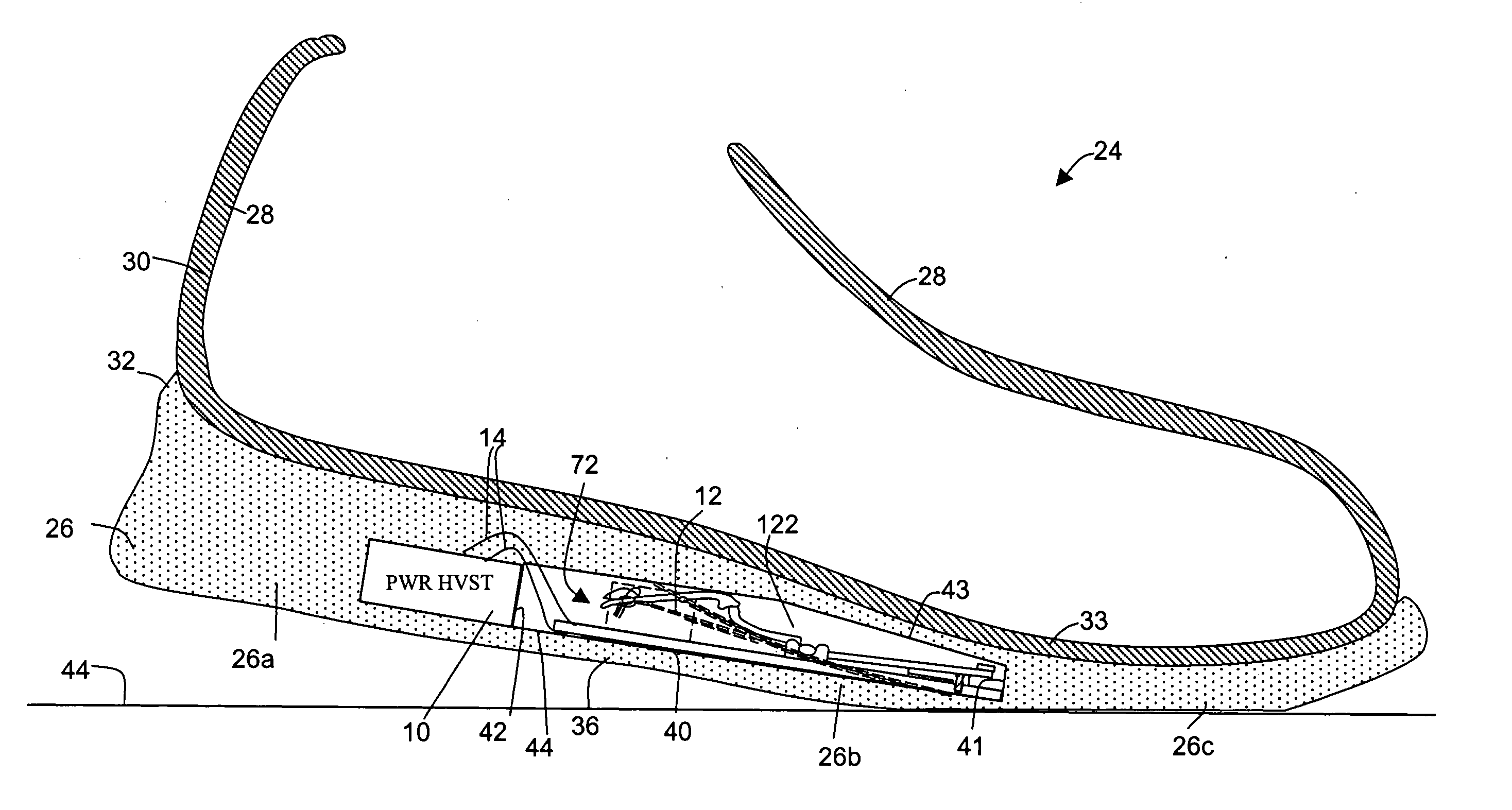

Footwear incorporating piezoelectric energy harvesting system

InactiveUS20060021261A1Simple and uncluttered designSolesPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

An article of footwear having a piezoelectric energy harvesting apparatus in the sole member. Walking or running applies a first force deforming a piezoelectric actuator, thereby generating electrical energy. An energy storage circuit stores electrical energy generated by the piezoelectric actuator for later application to electrical devices.

Owner:FACE BRADBURY R

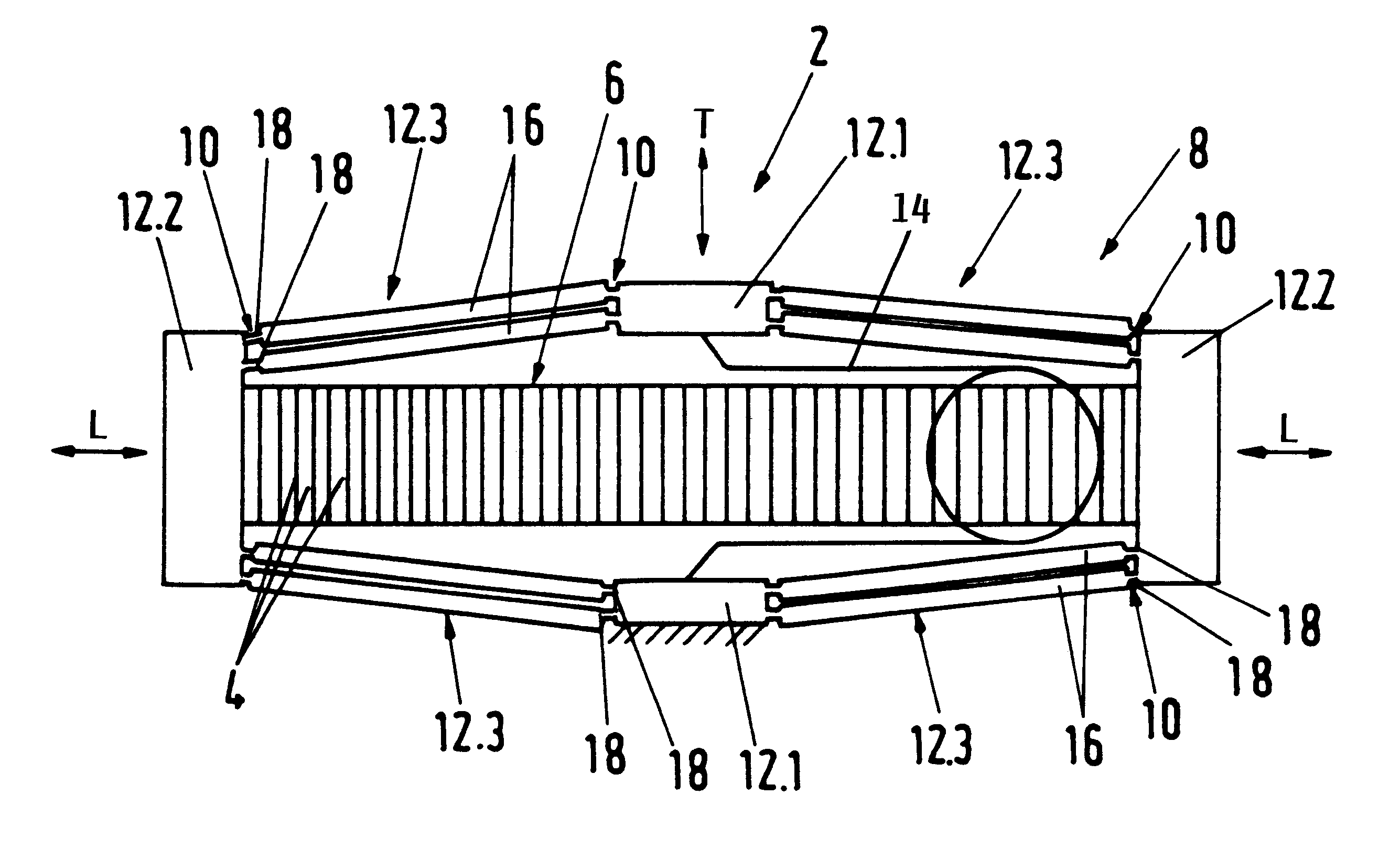

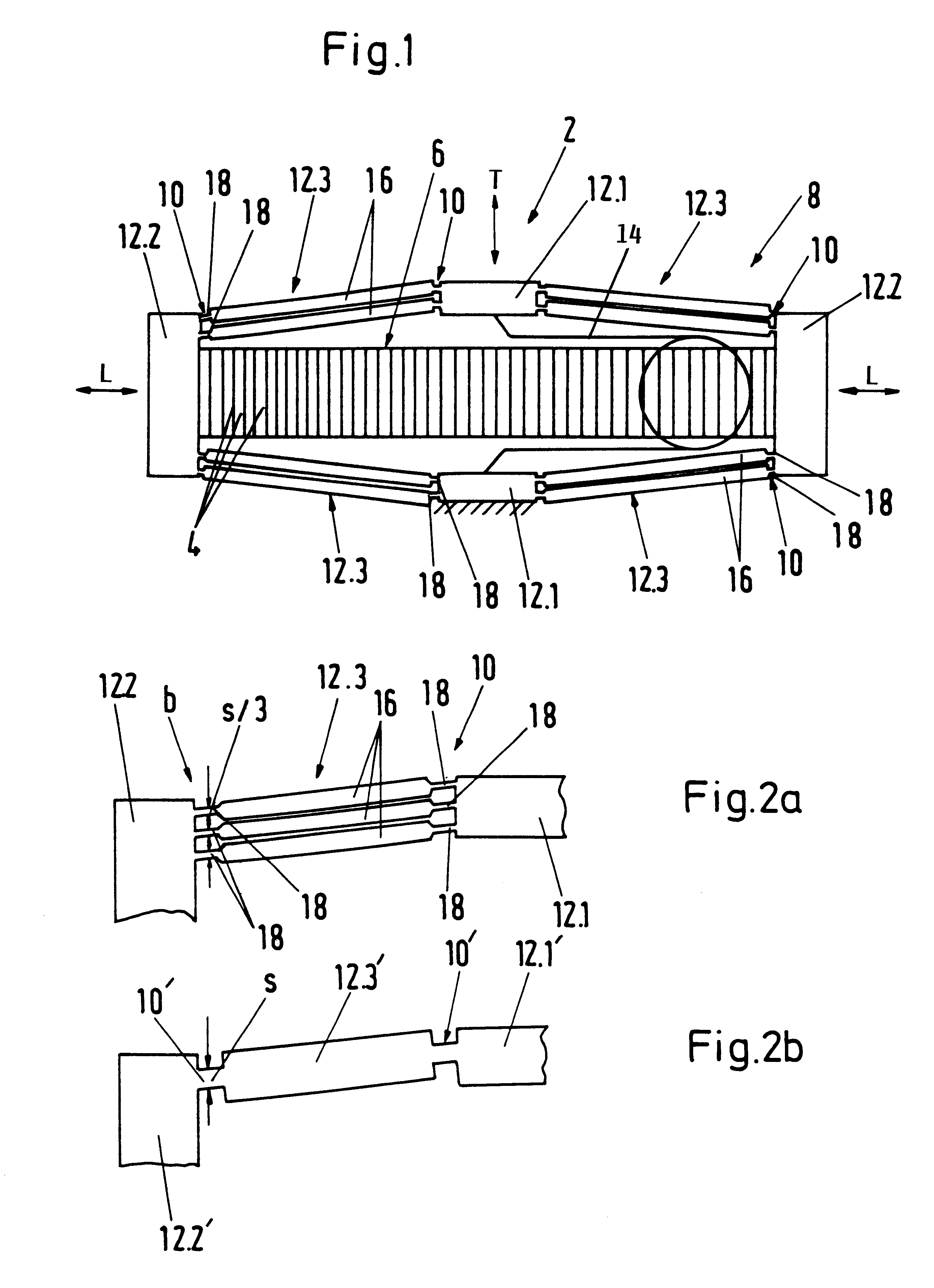

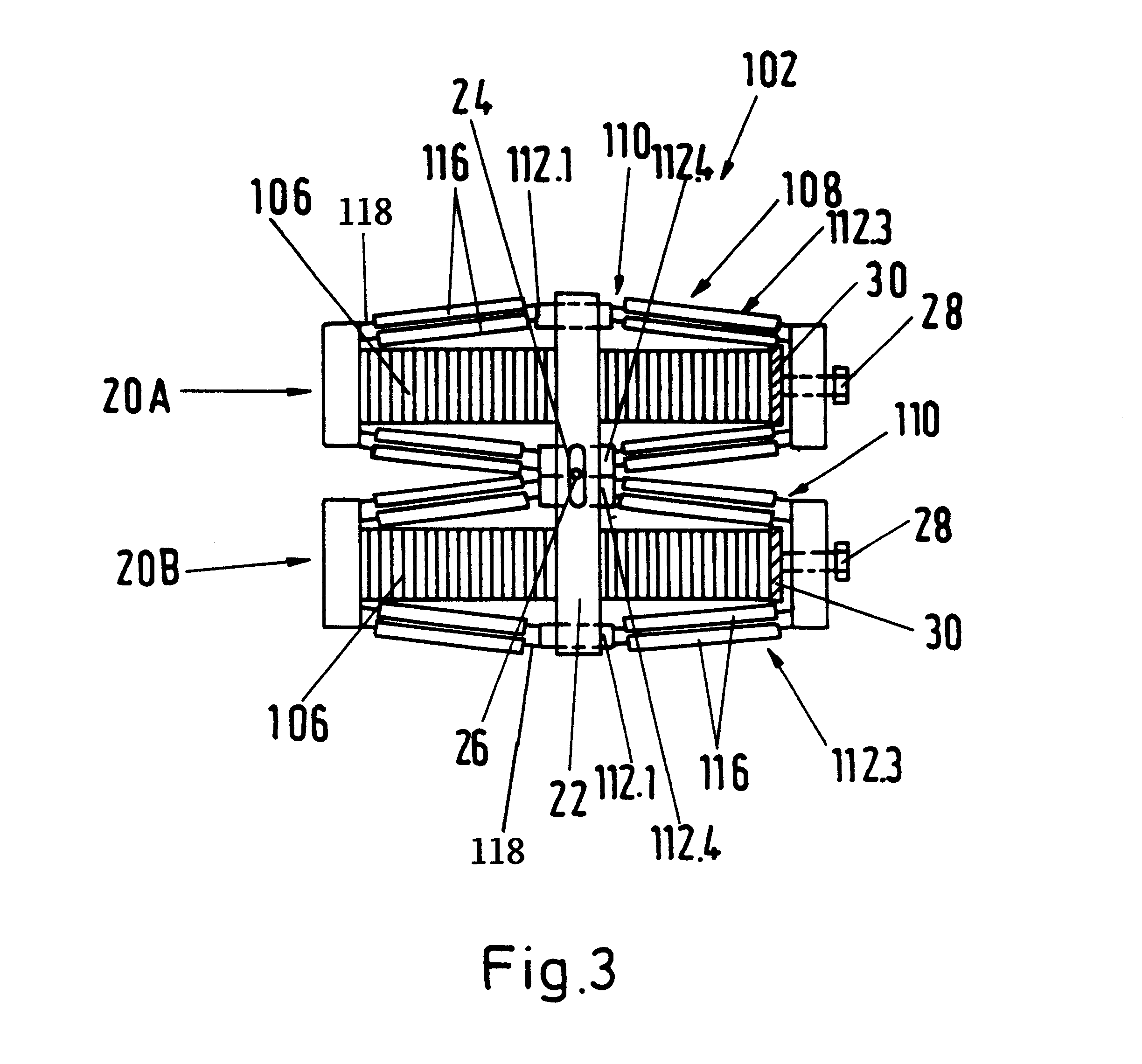

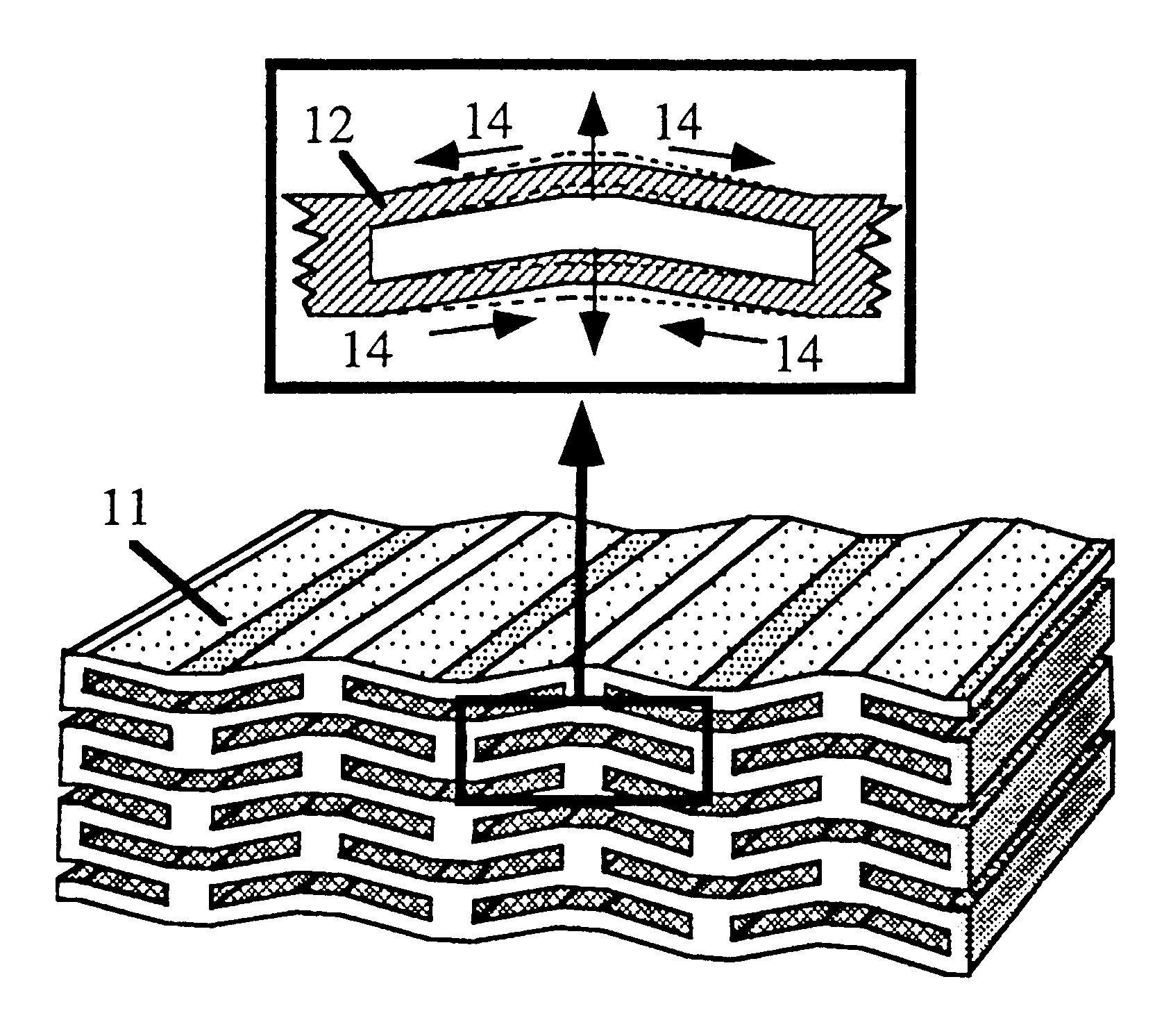

Electrostrictive or piezoelectric actuator device with a stroke amplifying transmission mechanism

InactiveUS6294859B1Low bending stiffnessReduce joint stiffnessPiezoelectric/electrostriction/magnetostriction machinesGearingFiber strainPiezoelectric actuators

An actuator device (2) includes a piezoelectric or electro-strictive solid state actuator element (6) that is elongated upon application of an electric voltage thereto, and a transmission mechanism (8) that amplifies the stroke displacement of the actuator element. The transmission mechanism (8) includes a plurality of rigid frame members (12), including unitary frame members (12.1, 12.2) and divided frame members (12.3), and elastically flexible joints (10) that respectively interconnect the frame members. Each one of the divided frame members (12.3) is made up of a plurality of separate parallel link rods (16). Each flexible joint (10) is made up of a plurality of individual parallel hinge members (18) that respectively connect an end of each one of the link rods (16) to the adjacent unitary frame member (12.1, 12.2). By this division of the flexible joints and of the divided frame members into parallel sub-components, the cross-sectional thickness of each individual hinge member is reduced, and thereby the bending stiffness and the outer fiber strain of the material of the hinge members is significantly reduced while providing the same total tensile strength and tensile stiffness. The link rods of each divided frame member effectively form a parallelogram linkage for moving and guiding the output members (12.1) in a parallel manner.

Owner:EADS DEUT GMBH

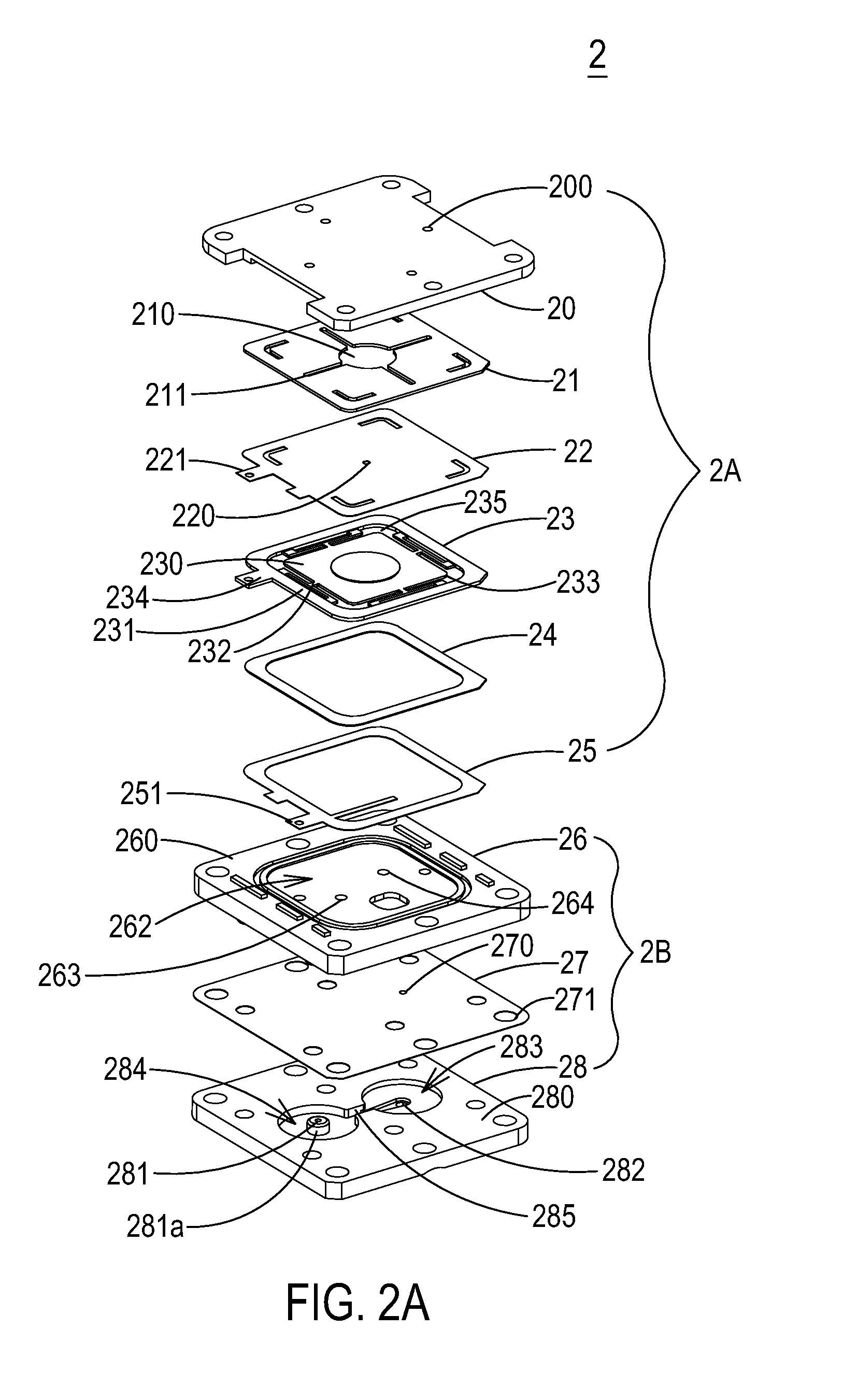

Micro-gas pressure driving device

A micro-gas pressure driving device includes a miniature gas transportation module, a covering plate and a tube plate. The miniature gas transportation module includes a convergence plate, a resonance membrane and a piezoelectric actuator. When the piezoelectric actuator is activated to feed a gas into an input tube of the tube plate, the gas is sequentially transferred through a first input chamber, a second input chamber, an inlet, a convergence channel and a central opening of the convergence plate, a central aperture of the resonance membrane, and transferred downwardly through the piezoelectric actuator and an output chamber, and outputted from an output tube of the tube plate. The first input chamber is arranged between the covering plate and the input tube. The second input chamber is defined between the covering plate and the convergence plate. The output chamber is defined between the tube plate and the piezoelectric actuator.

Owner:MICROJET TECH

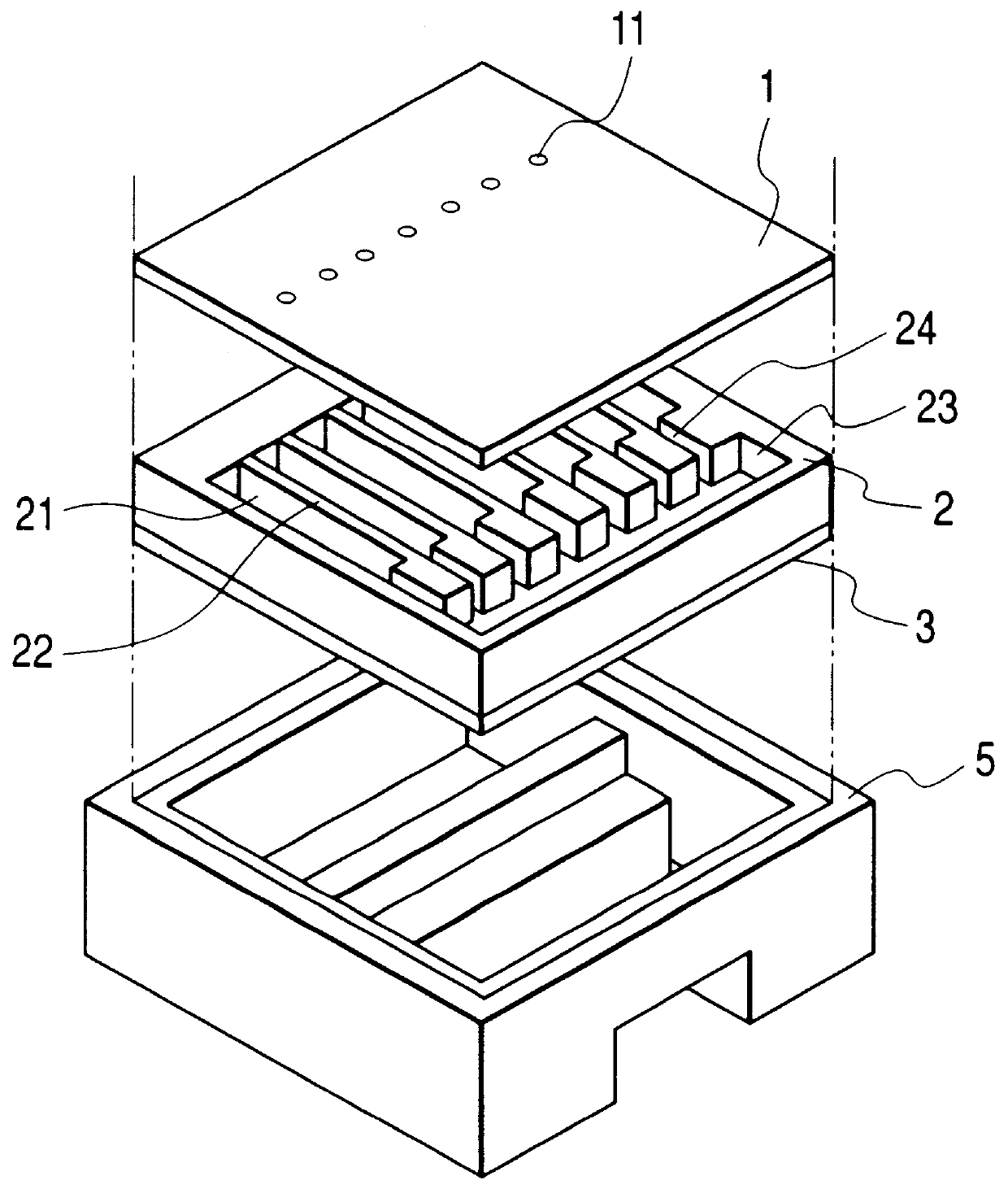

Piezoelectric actuator and micro-electromechanical device

InactiveUS20060055287A1Warpage suppressionImprove accuracyNanotechPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric actuatorsEngineering

A piezoelectric actuator includes a first beam including a first bottom electrode, a first piezoelectric film on the first bottom electrode, and a first top electrode on the first piezoelectric film, a fixed end assigned at an end of the first beam and fixed on a substrate, a connecting end assigned at another end of the first beam and suspended over a free space; and a second beam including a second piezoelectric film connected to the first piezoelectric film at the connecting end, a second bottom electrode under the second piezoelectric film, and a second top electrode on the second piezoelectric film, a working end assigned at an end of the second beam opposite to another end to which the connecting end is assigned and suspended over the free space; wherein a distance between centers of the fixed end and the working end is shorter than a distance from the working end to the connecting end.

Owner:KK TOSHIBA

Electronic vaporiser system

An electronic cigarette vaporiser system includes a piezo-electric pump (6) with multiple piezo-actuators, in which a microcontroller independently adjusts the phase or timing or power of each voltage pulse that triggers a piezo-actuator. The microcontroller continuously or regularly monitors the efficiency or performance of the entire pump (6) and adjusts the phase, timing, or power delivered to each piezo-actuator relationship until or so that the optimum pumping performance is achieved.

Owner:AYR LTD

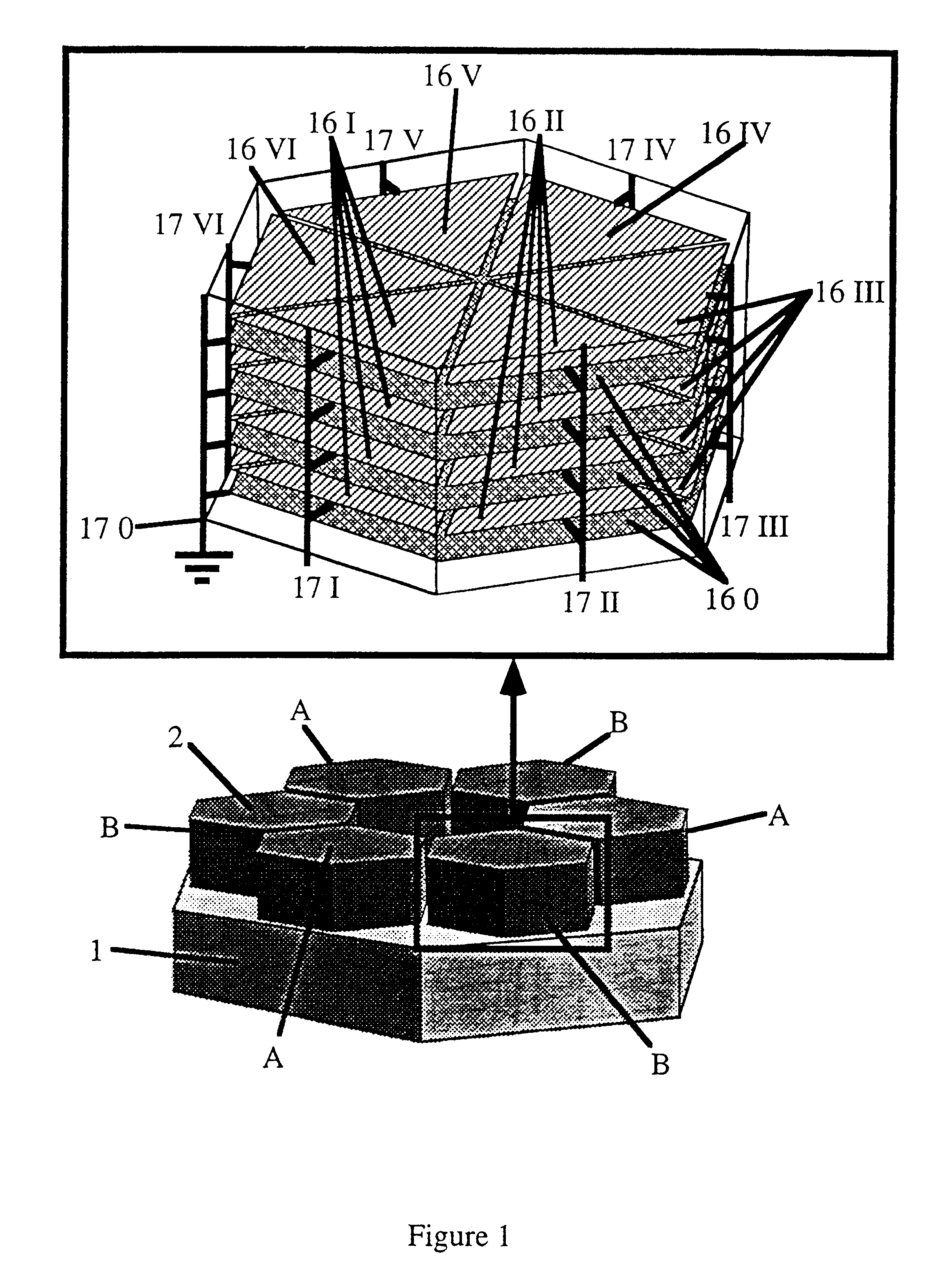

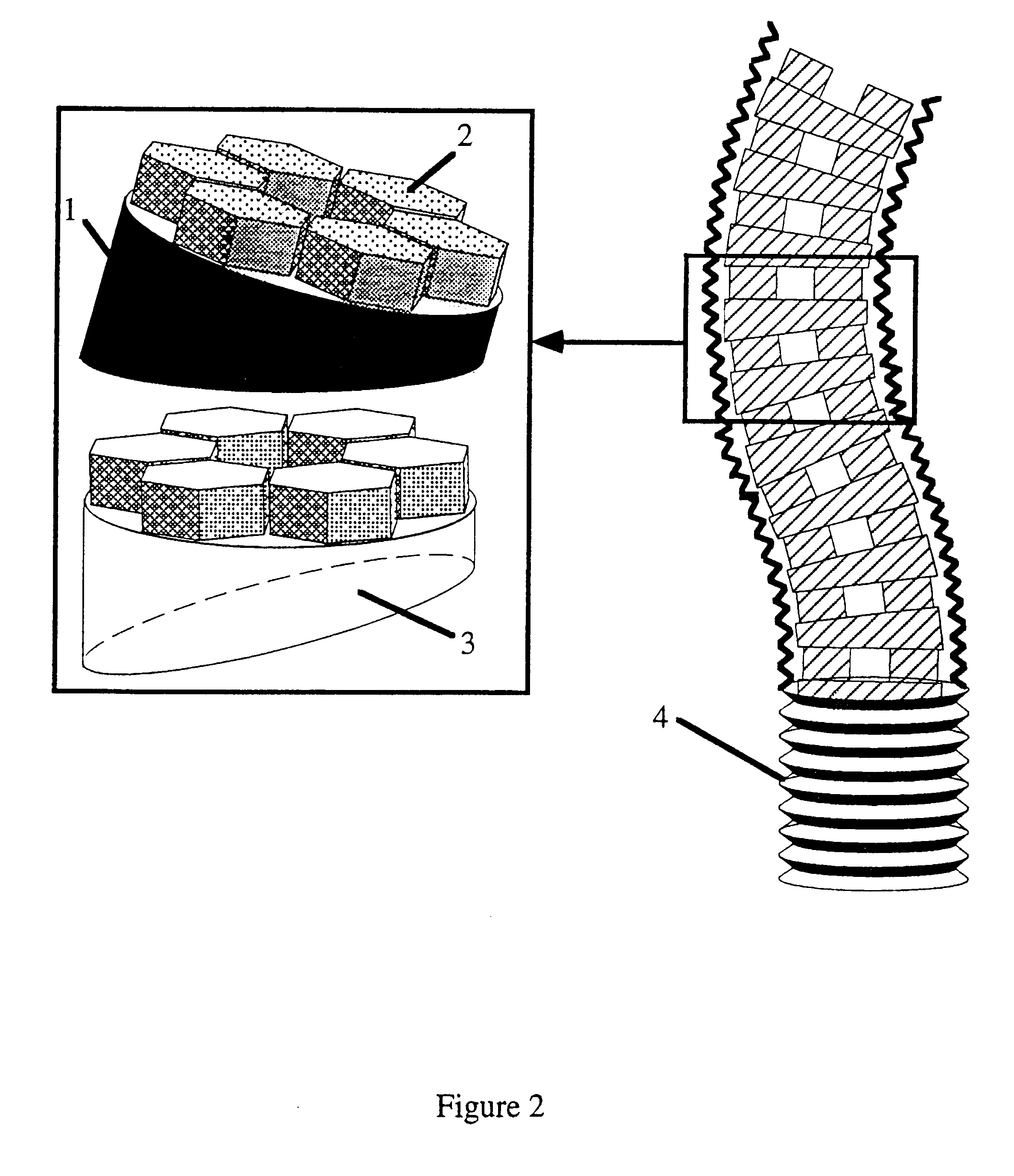

Piezoelectric actuator or motor, method therefor and method for fabrication thereof

InactiveUS6184609B1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesShape changePiezoelectric actuators

This invention relates to an actuator or motor comprising an electromechanical material which alters its shape under the influence of an electrical voltage. Said actuator comprises at least a monolitic module (1,2) with electrodes integrated in said electromechanical material and in that the force or displacement due to the applied voltages is transferred, to the point to be actuated or moved by the shape change of the material, using at least two independent contact points. The invention also relates to a method for fabricating said actuator or motor.

Owner:PIEZOMOTORS UPPSALA

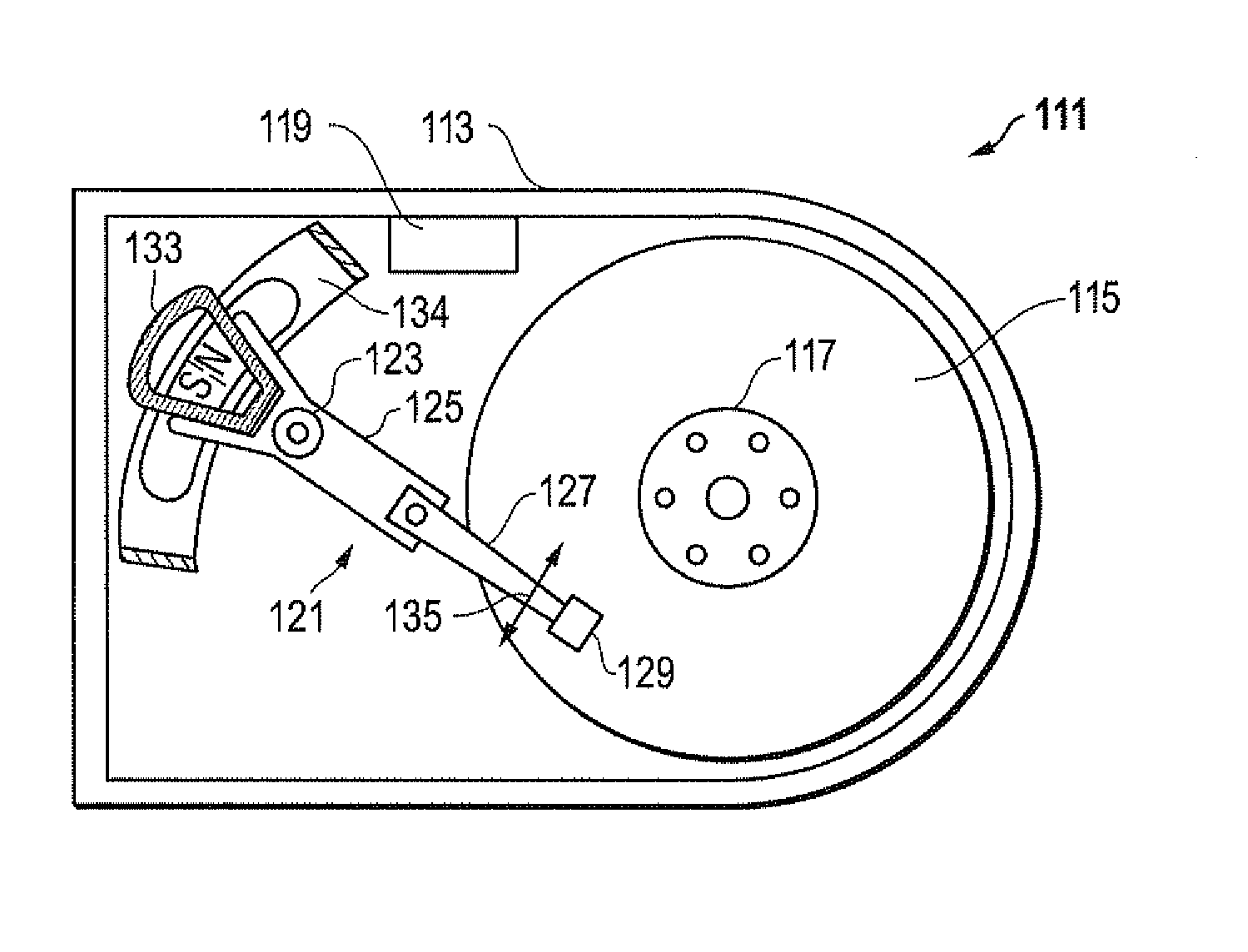

System, method and apparatus for flexure-integrated microactuator

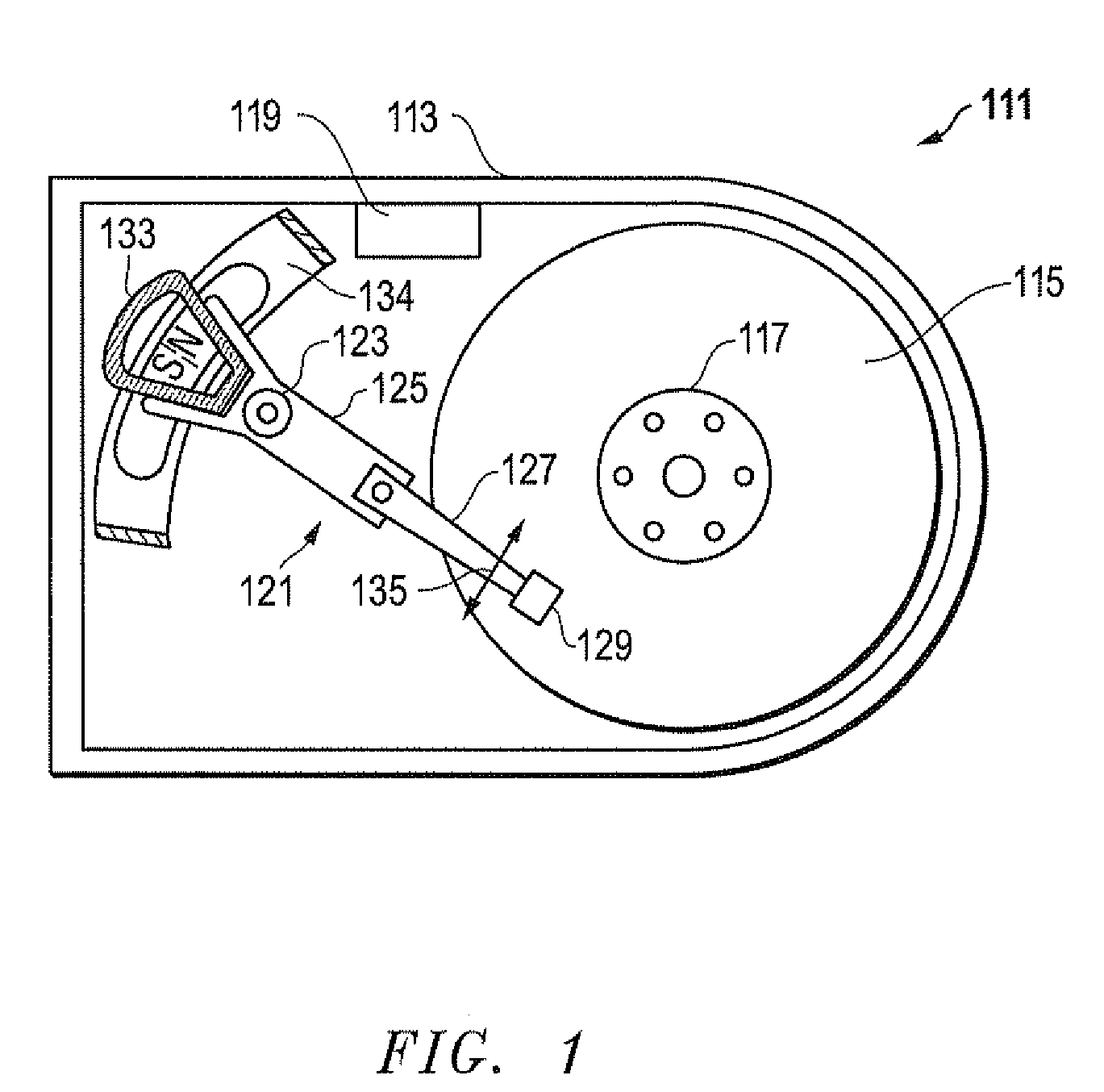

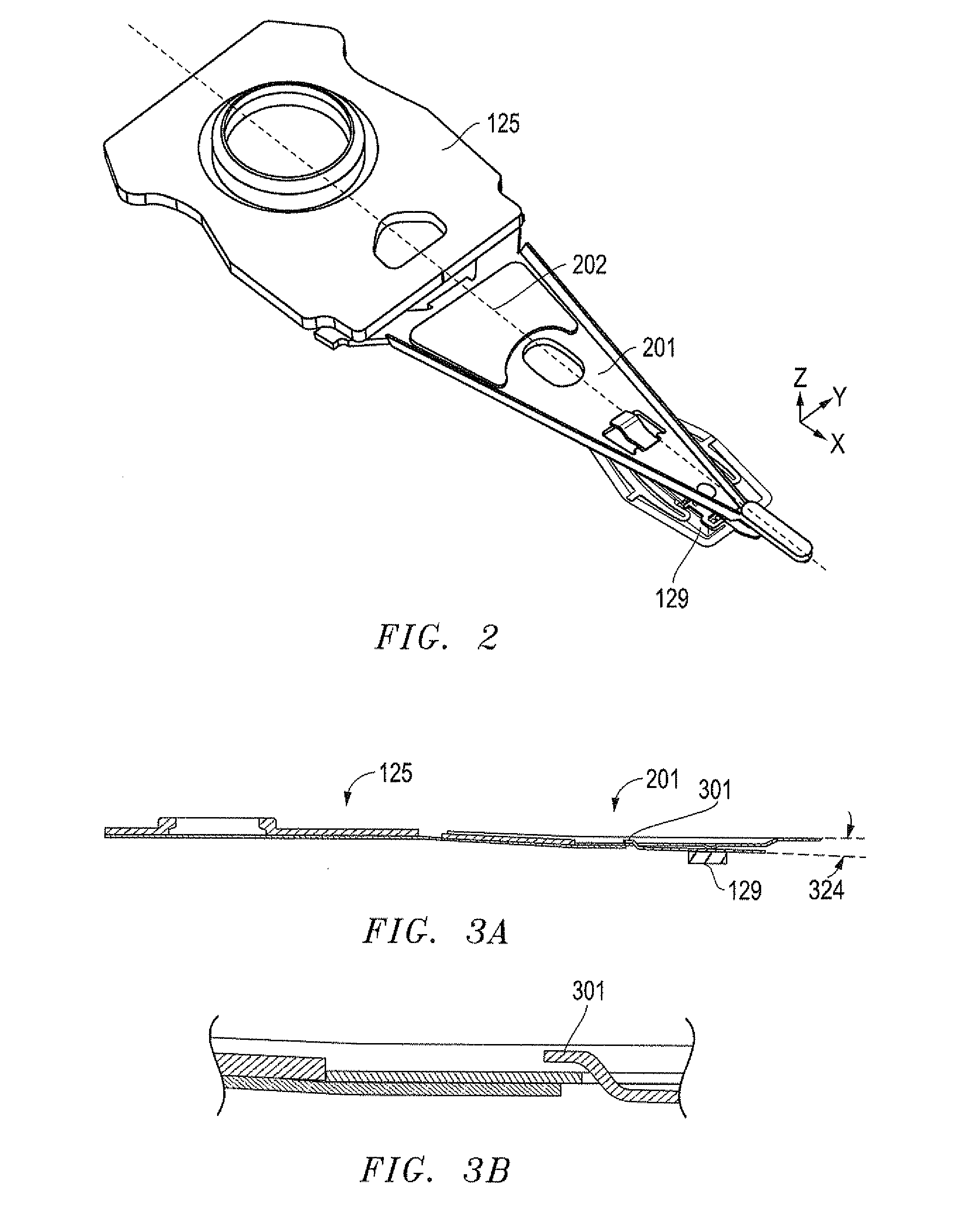

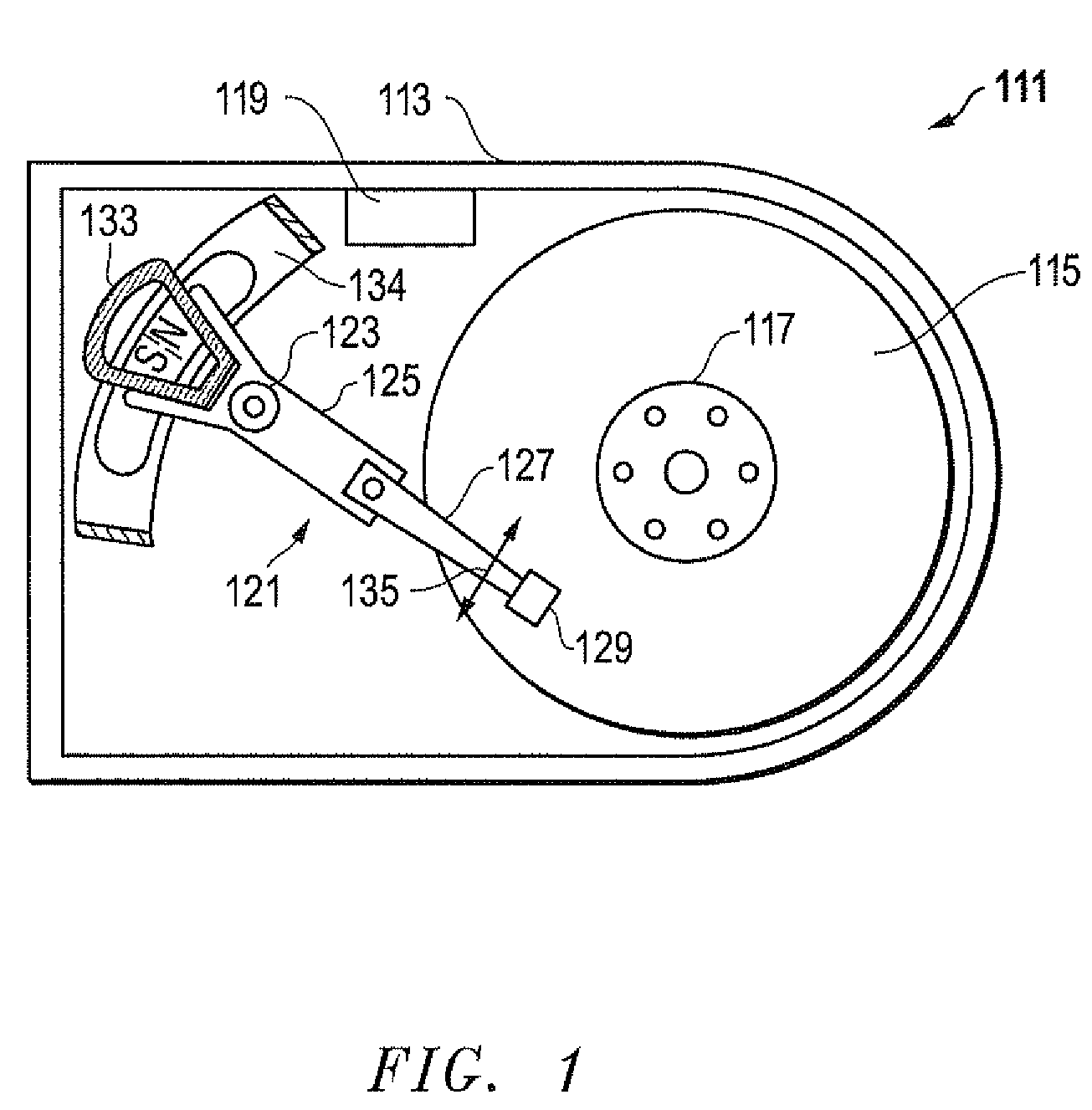

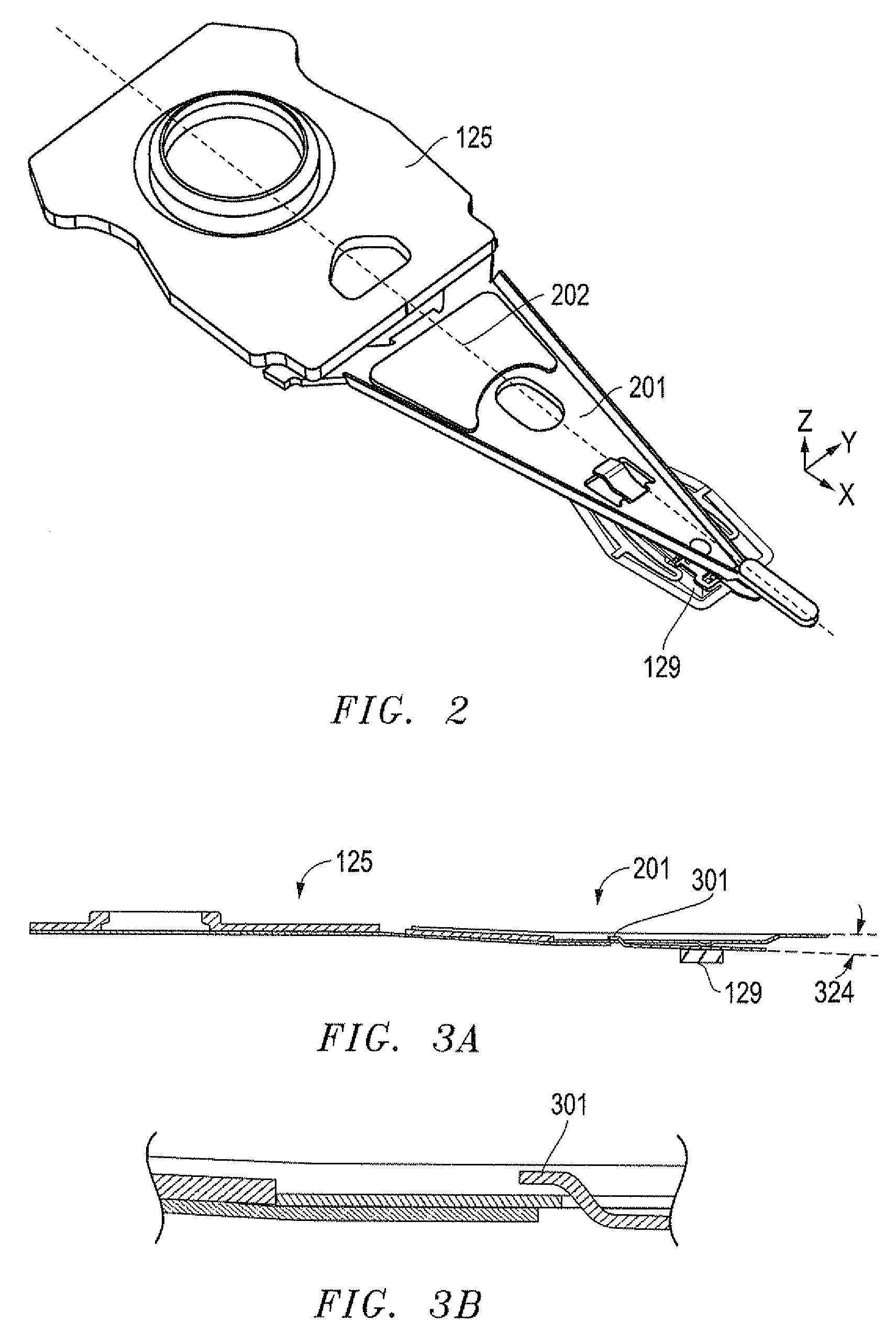

ActiveUS20090244786A1Overcome costsOvercomes manufacturabilityDriving/moving recording headsRecord information storageTrack densityHard disc drive

A piezo in-tongue microactuator includes a suspension assembly with a flexure tongue. The tongue has two slots that accept piezo actuators. The tongue also has multiple hinge flexible elements that translate the extension and / or contraction of the piezo actuators into rotary motion of the recording head. This rotary motion is then used to precisely position the recording element over the desired track on the hard disk drive and permits higher track density to be achieved.

Owner:WESTERN DIGITAL TECH INC

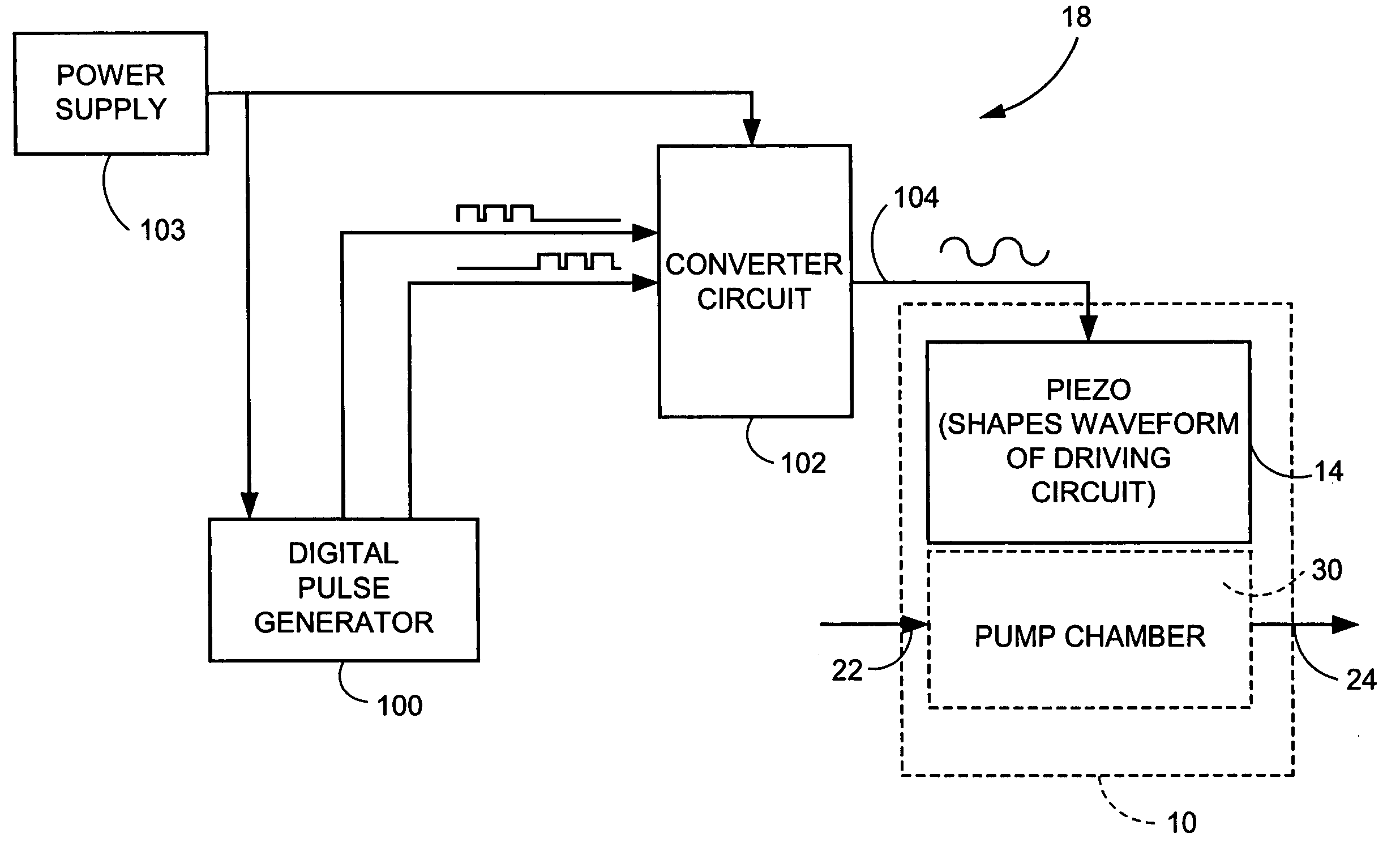

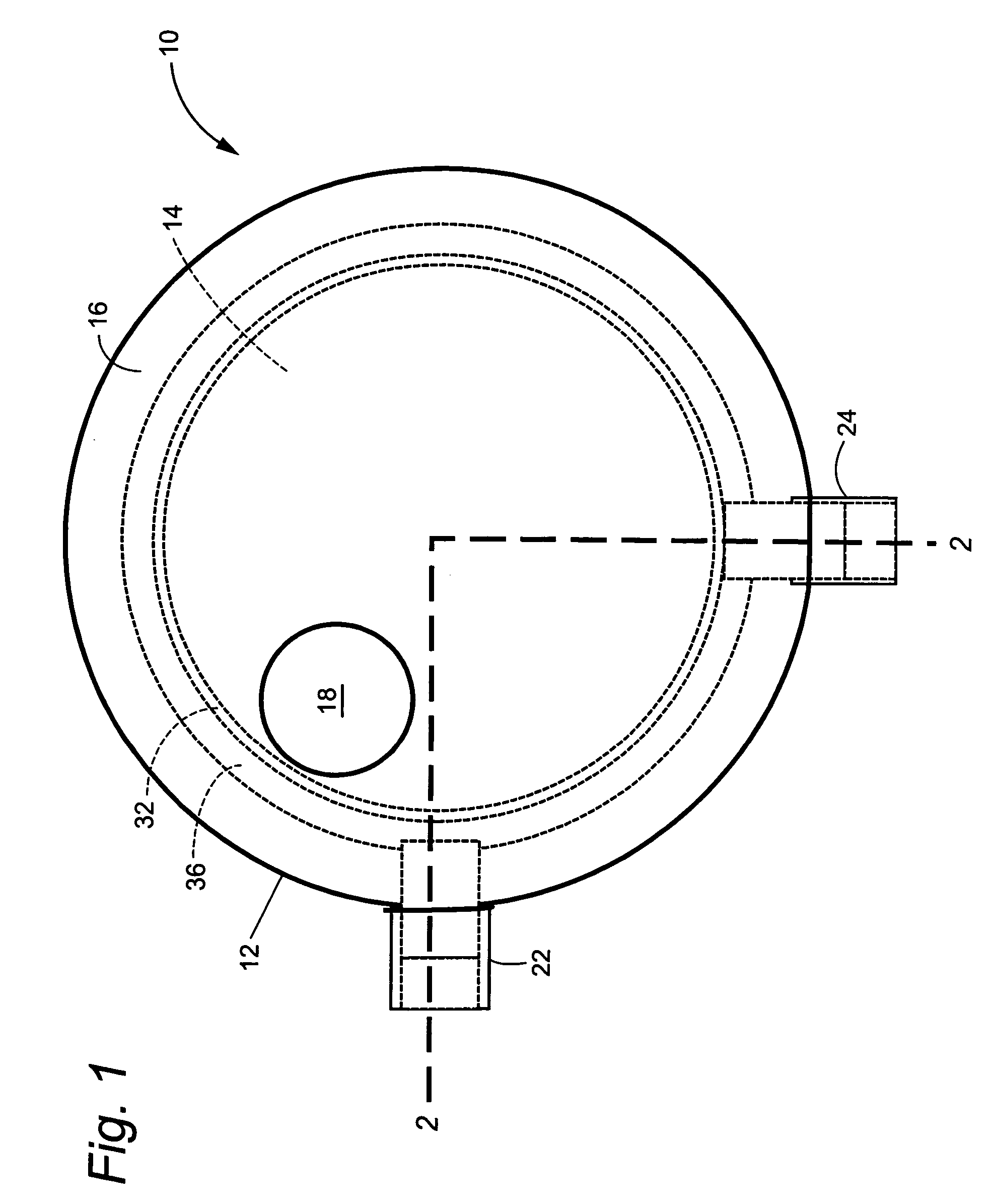

Piezoelectric devices and methods and circuits for driving same

A drive circuit (18) senses a parameter of a piezoelectric actuator (14) operating in a device (10) and adjusts a drive signal of the piezoelectric actuator in accordance with the parameter. The drive circuit comprises a controller (100) which controls a drive signal applied to the piezoelectric actuator (14); a feedback monitor (122) which obtains a feedback signal from the piezoelectric actuator while the piezoelectric actuator works; and, a processor (116) which uses the feedback signal to determine the parameter of the piezoelectric actuator. In one example mode, the parameter of the piezoelectric actuator which is determined by the piezoelectric actuator drive circuit is the capacitance or dielectric constant of the piezoelectric actuator. In other example modes, the parameter of the piezoelectric actuator which is determined by the piezoelectric actuator drive circuit is impedance or resonant frequency of the piezoelectric actuator.

Owner:PAR TECH

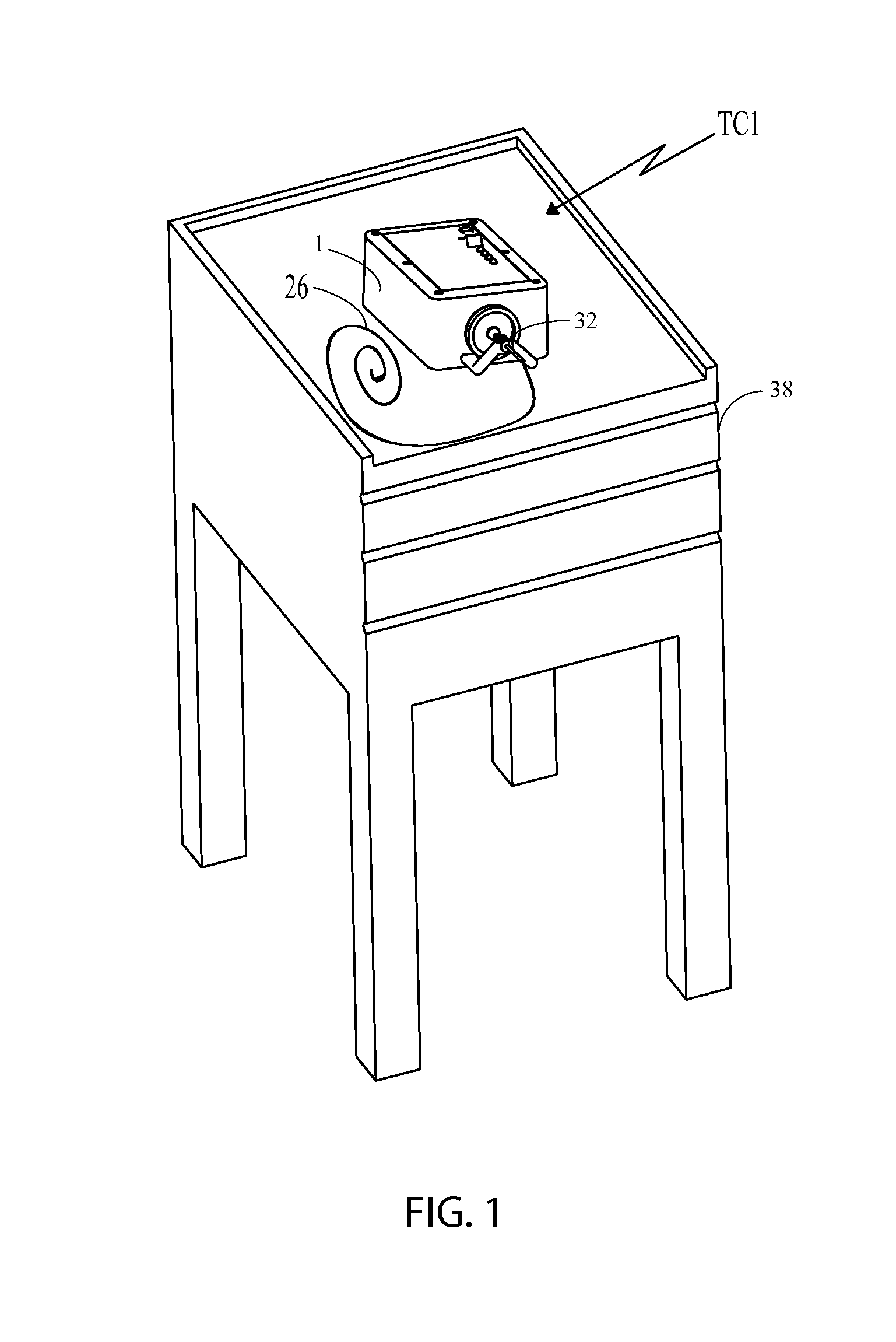

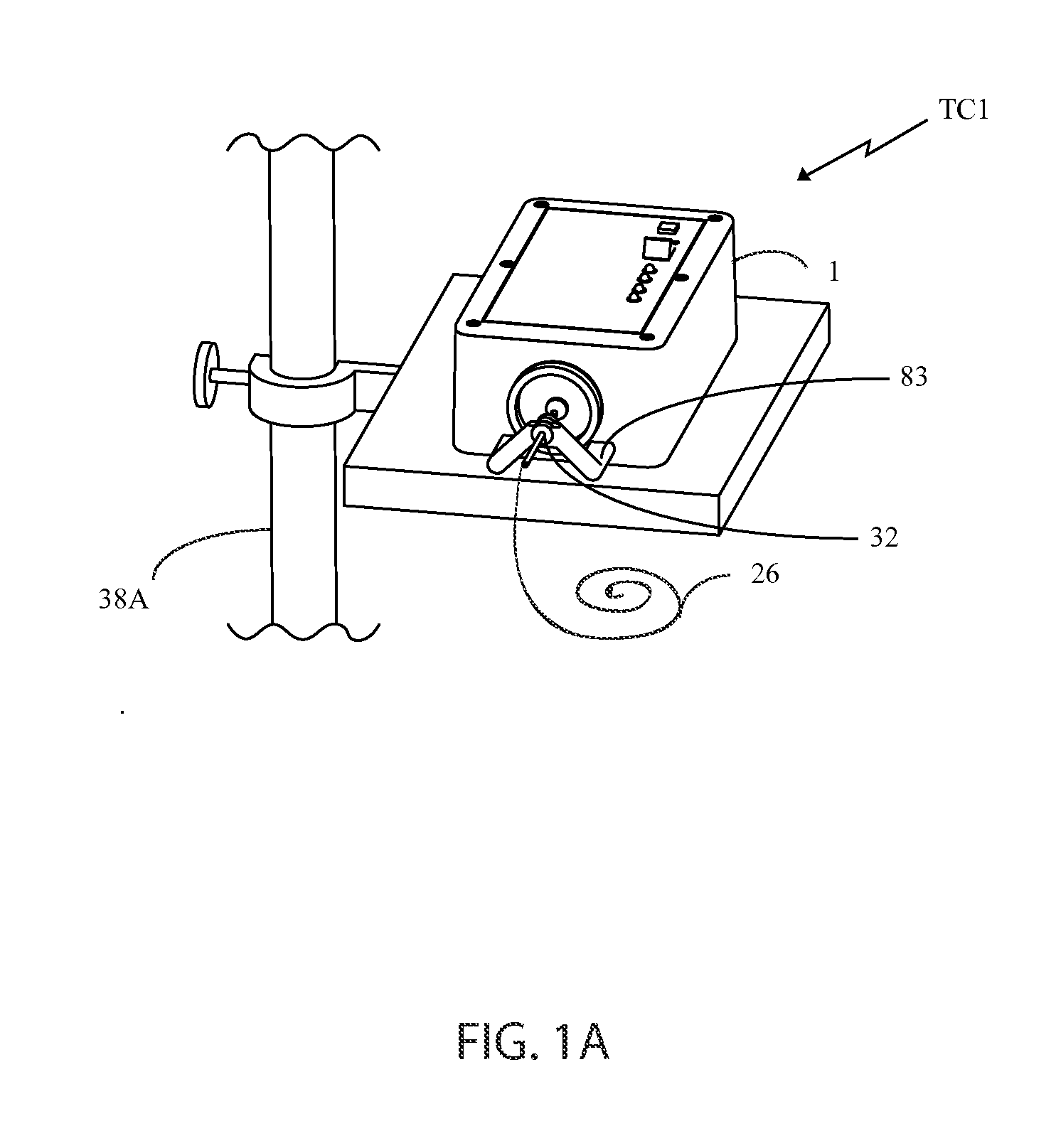

Devices for clearing blockages in in-situ artificial lumens

Devices and methods for the effective clearing of artificial tubes, especially in-situ clearing of artificial tubes in a living being are covered in this disclosure. The devices and methods provide an elongated clearing member having a first end that is coupled to a driving mechanism and having a second working end that is subjected to repetitive motion for clearing blockages within the artificial tube. The elongated clearing member includes either a fixed or an adjustable element that selectively defines the portion of the elongated clearing member that is insertable within the artificial tube. The proximal end of the clearing member is releasably secured to the driving mechanism and the driving mechanisms may comprise a wide variety of repetitive motion drivers such as voice coil motors, piezoelectric actuators, pneumatic actuators, DC motors, etc. These devices / methods may comprise a free-standing console for hands-free operation or may comprise hand-held versions. The distal working end of the clearing member may comprise tips of differing functions, including an irrigation / aspiration feature.

Owner:ACTUATED MEDICAL

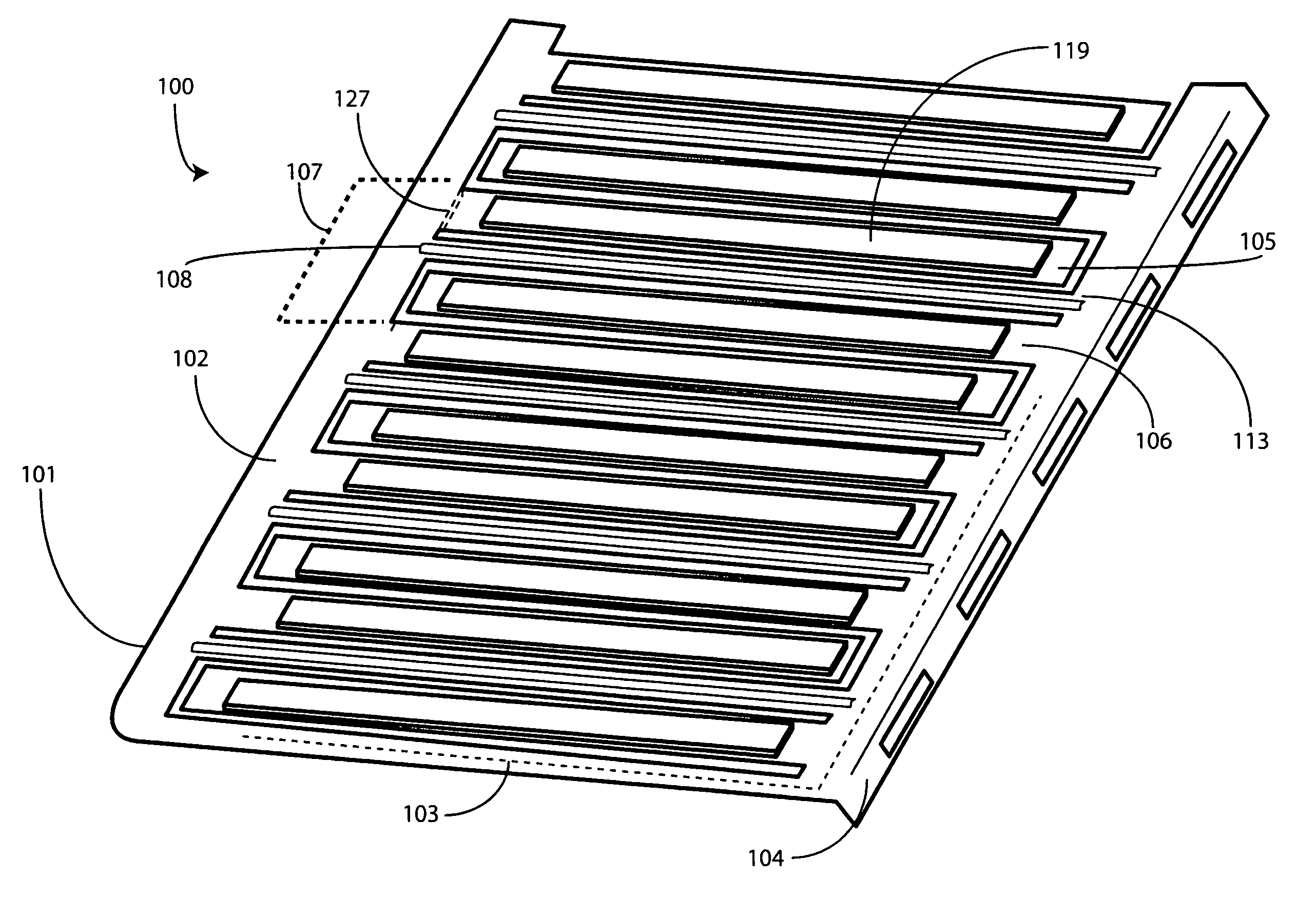

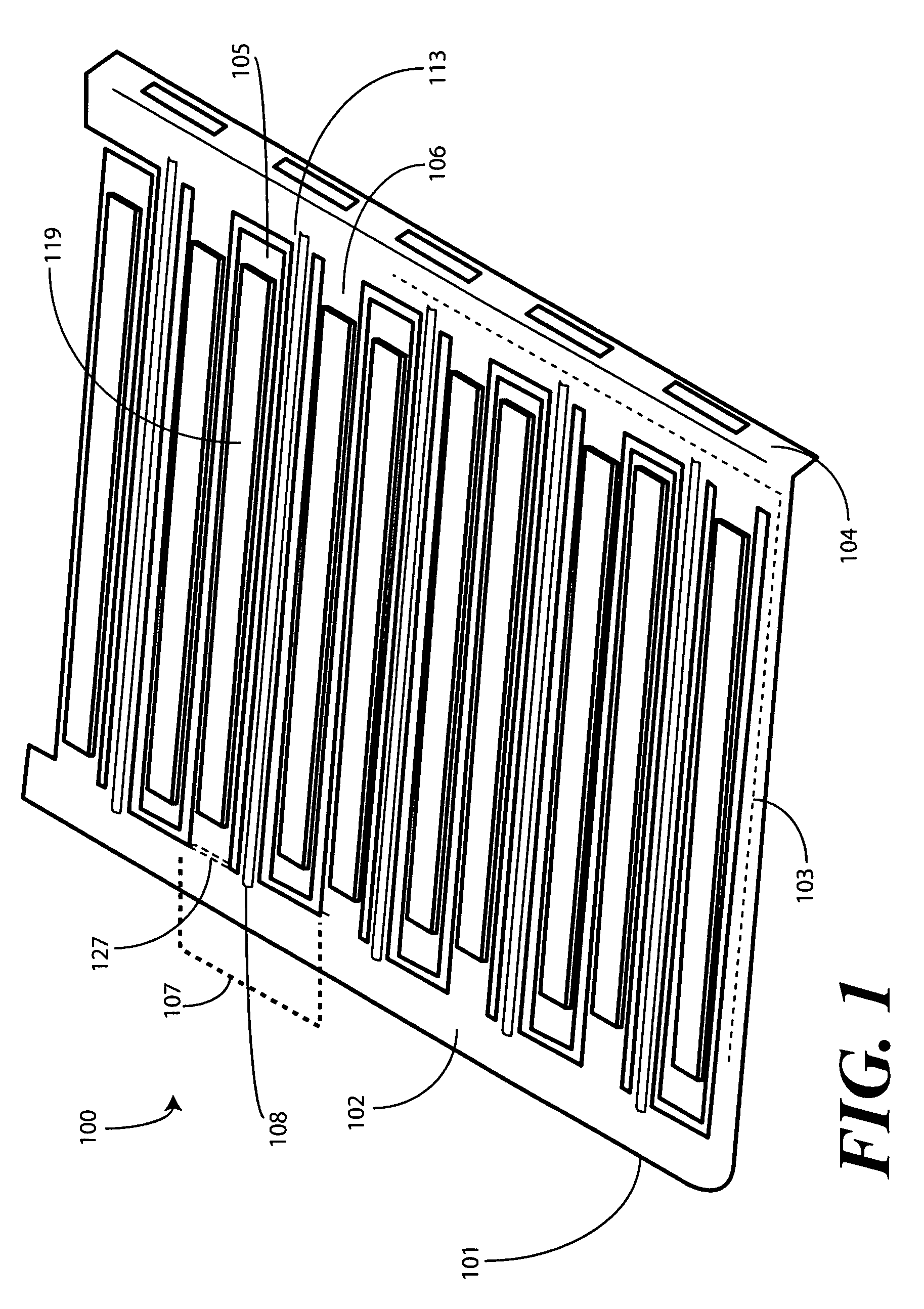

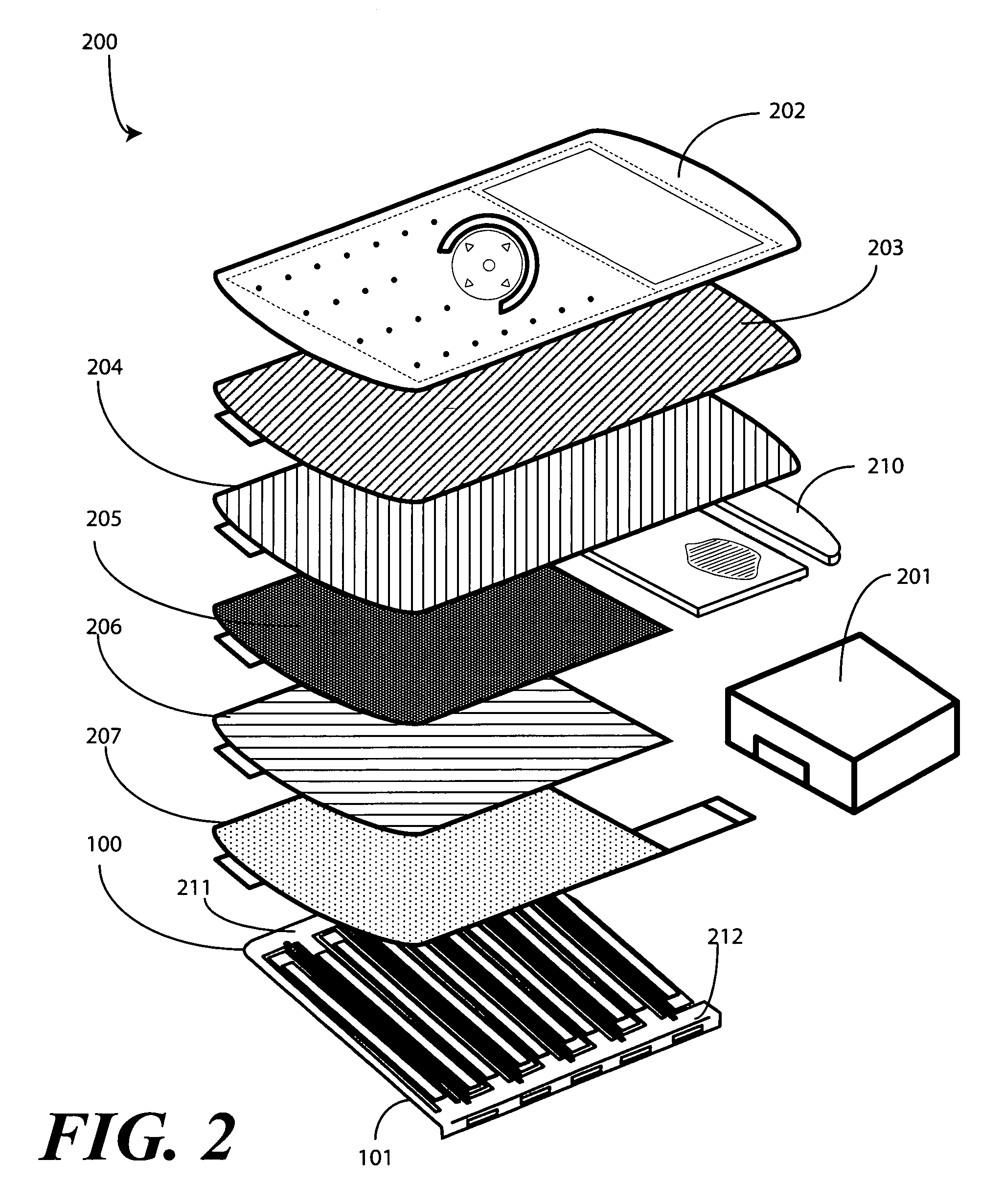

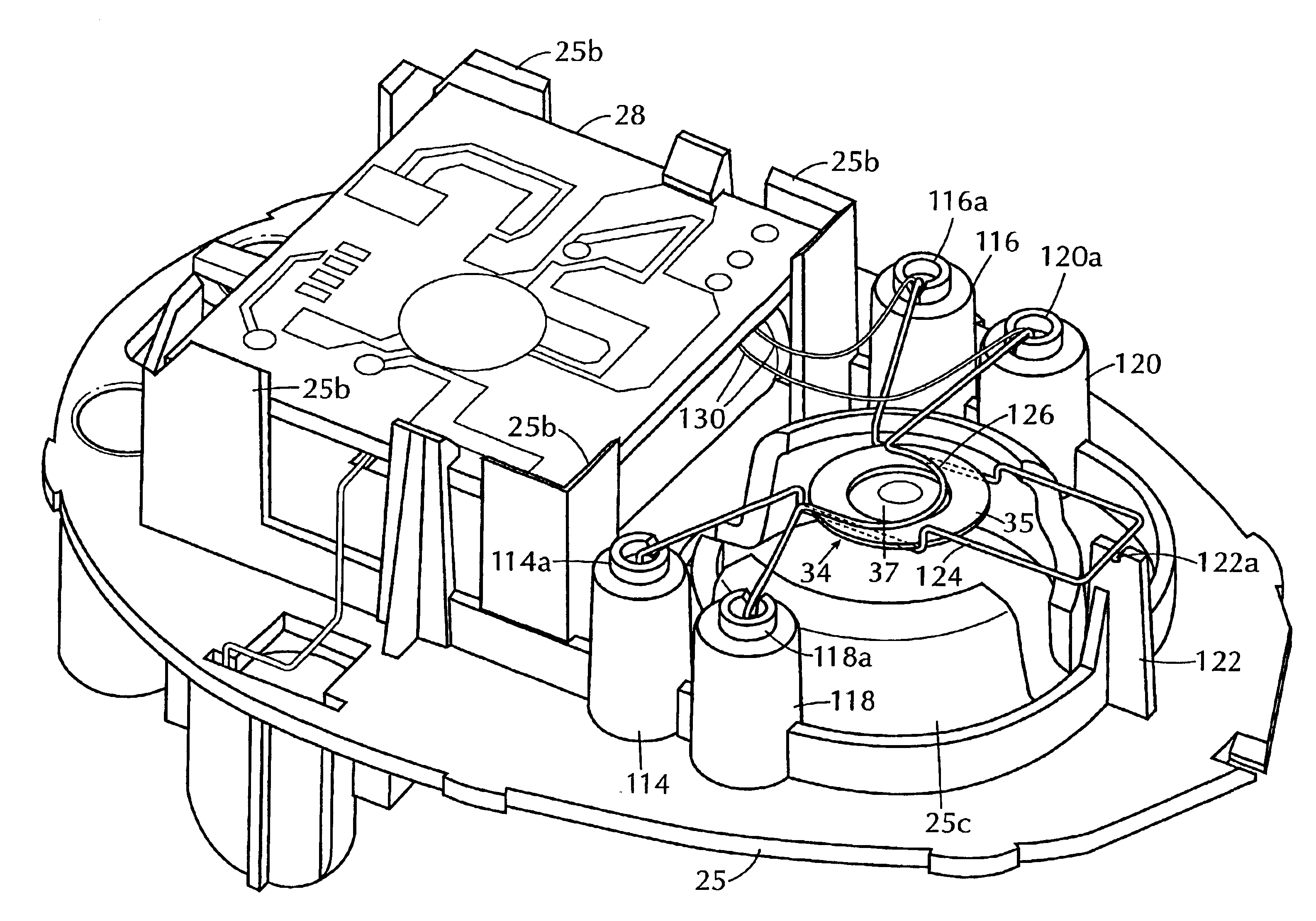

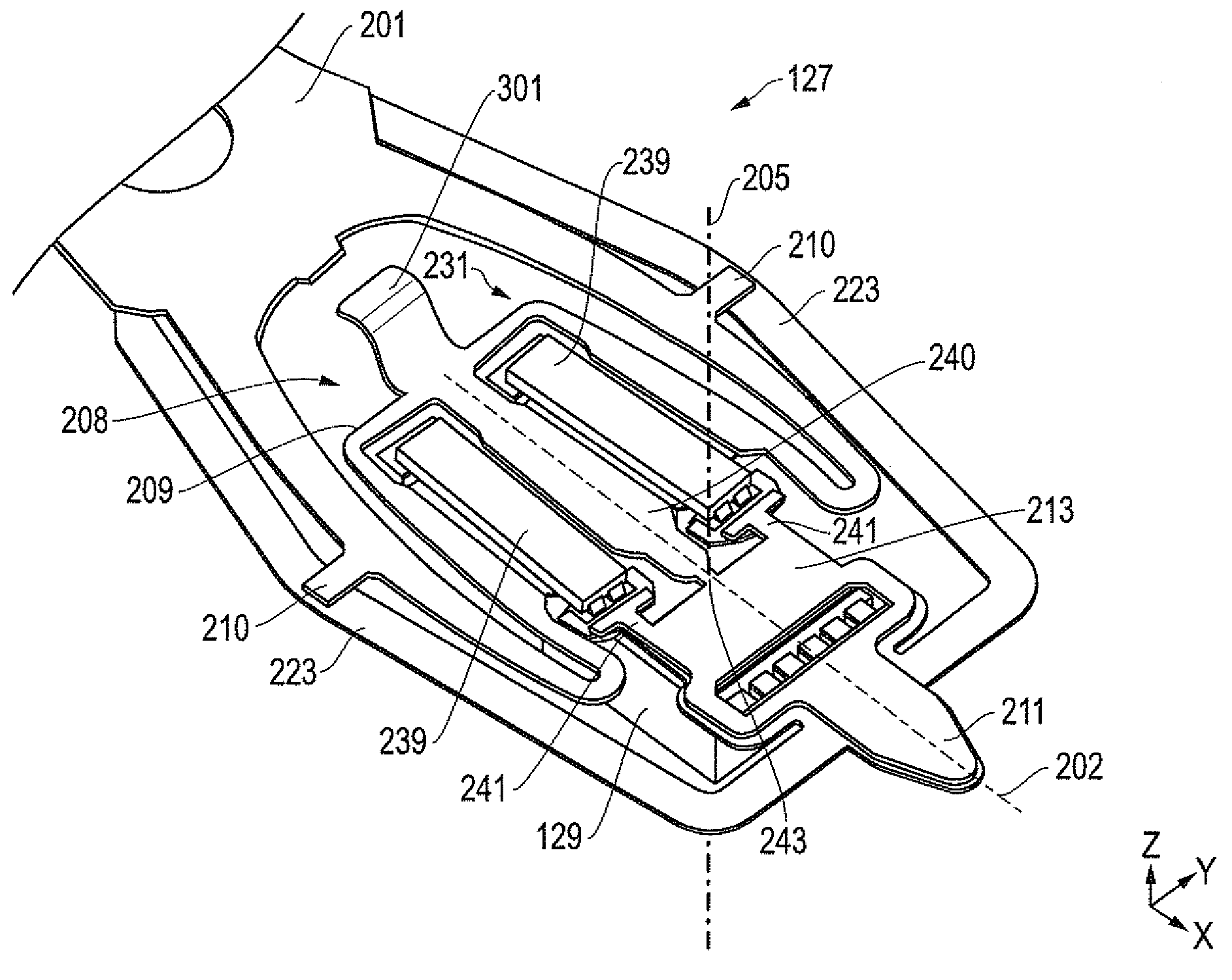

Haptic response apparatus for an electronic device

InactiveUS8395587B2Substation/switching arrangement detailsPiezoelectric/electrostriction/magnetostriction machinesElectricityUser input

A user input for an electronic device includes a haptic feedback layer (100) and a touch sensitive user interface (200). The haptic feedback layer (100) provides a tactile response to a user when the user actuates a user actuation target (301) on the touch sensitive user interface (200) to simulate a popple-style button. The haptic feedback layer (100) includes a chassis (101) and a plurality of oppositely facing, interlaced cantilever beams (105,106) emanating therefrom, further separated by a support beam (113), and spanning at least a portion of the haptic feedback layer (100). One or more piezoelectric actuators (119) are coupled to the cantilever beams and are responsive to a controller (201). When the controller detects user actuation of the touch sensitive user interface (200), the controller (201) causes at least one of the piezoelectric actuators to actuate in accordance with an actuation signal.

Owner:GOOGLE TECH HLDG LLC

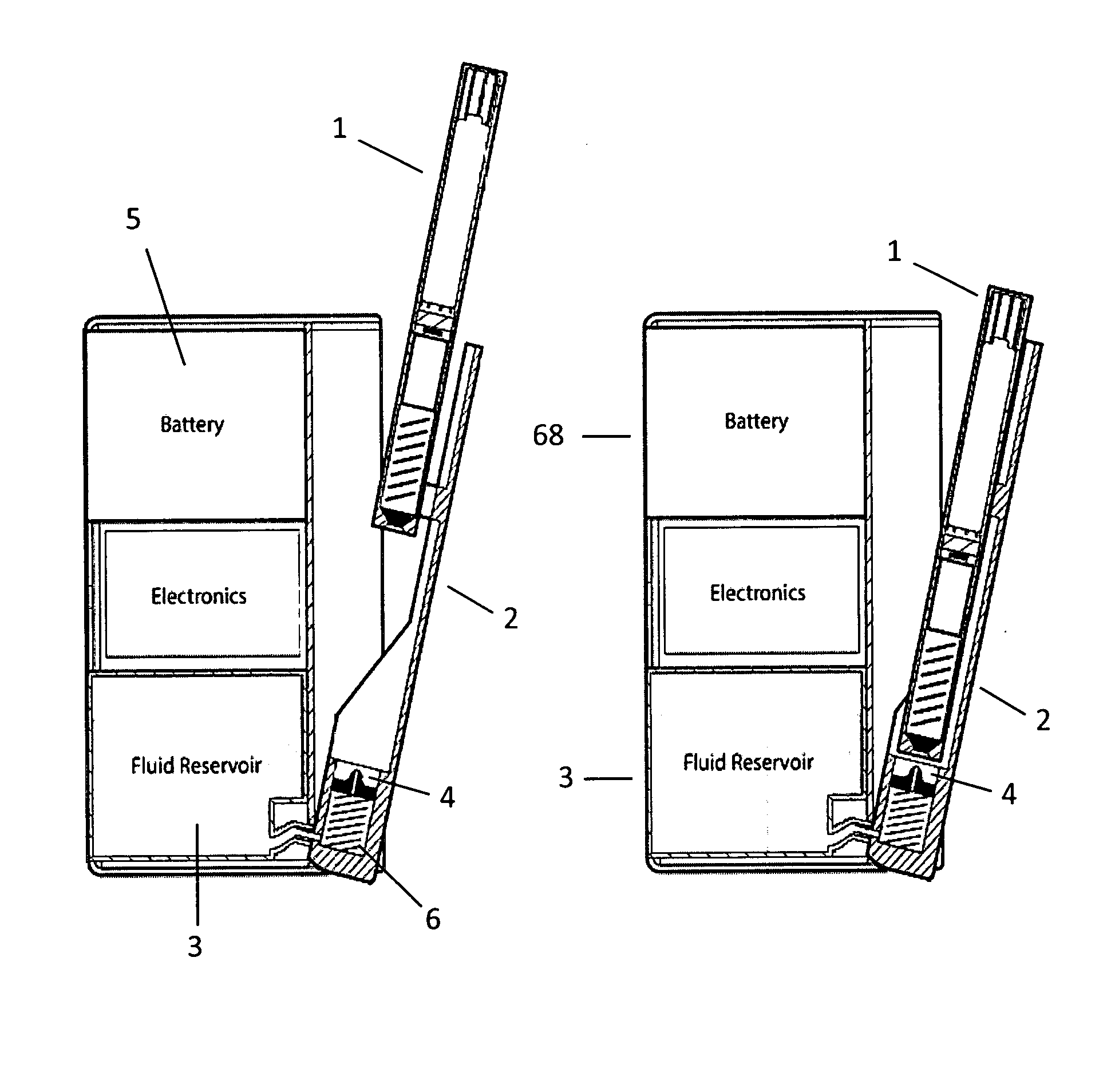

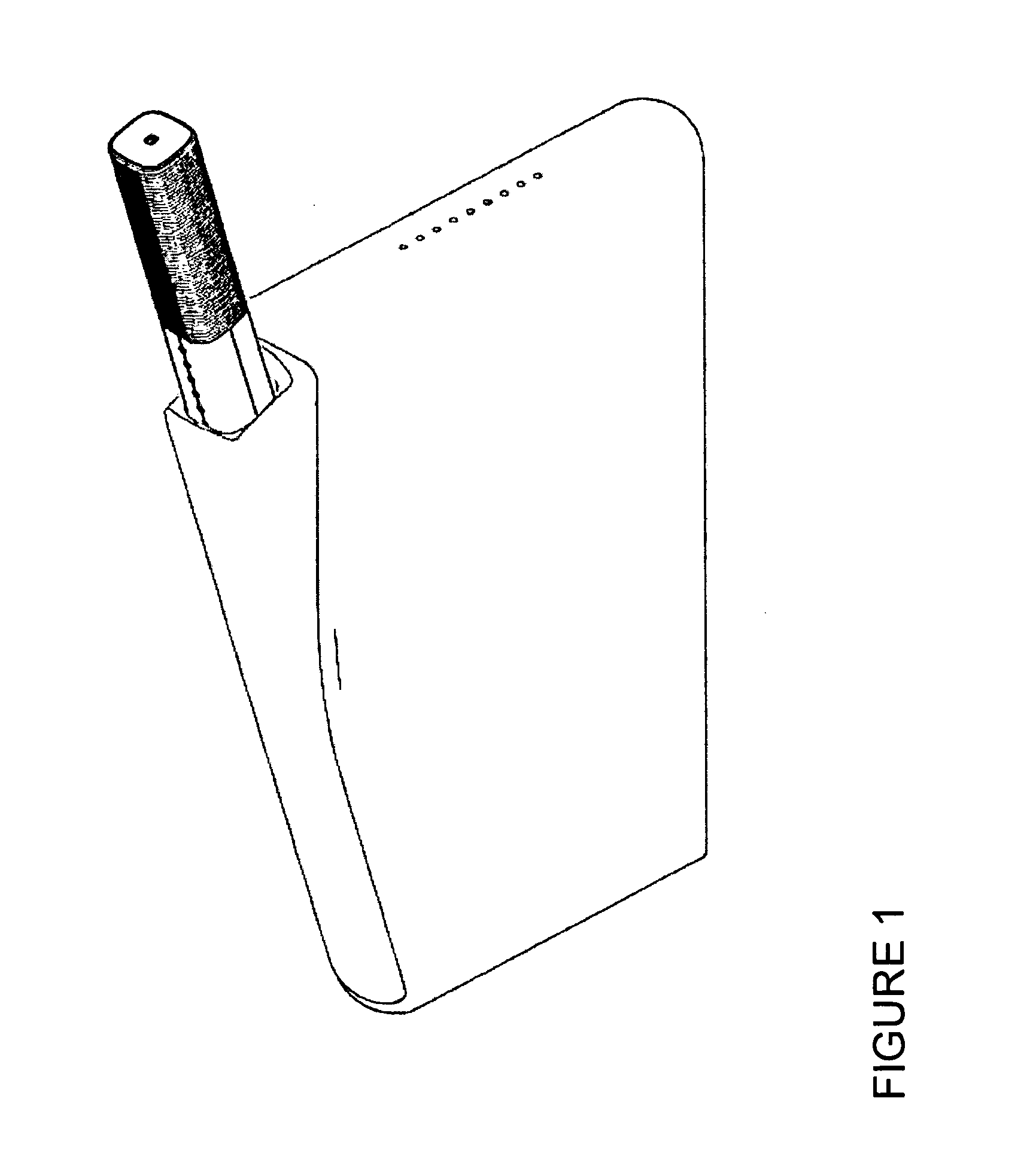

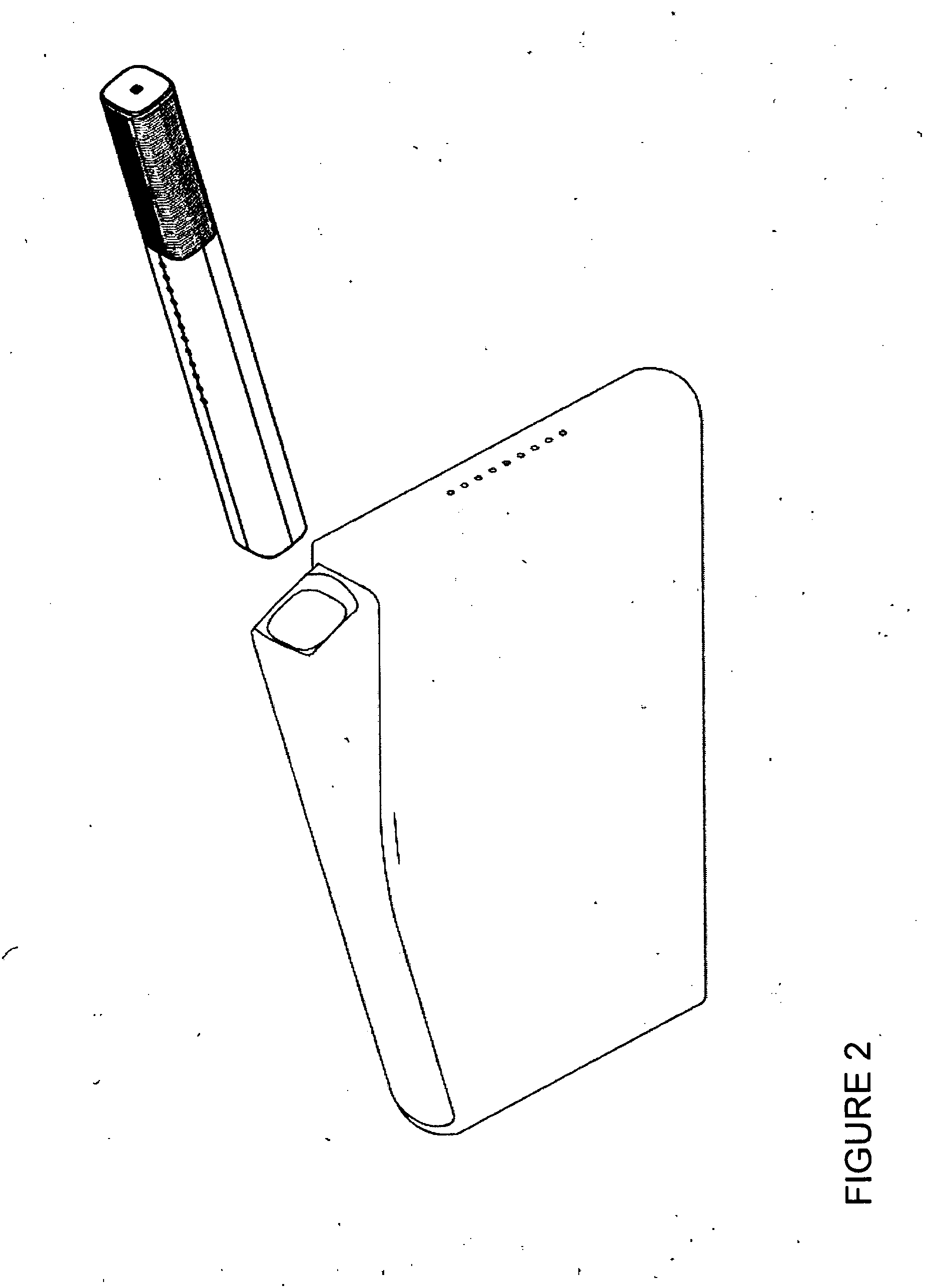

Low leakage liquid atomization device

InactiveUS6843430B2Minimize migrationImprove device performanceMovable spraying apparatusSpray nozzlesElectricityNebulizer

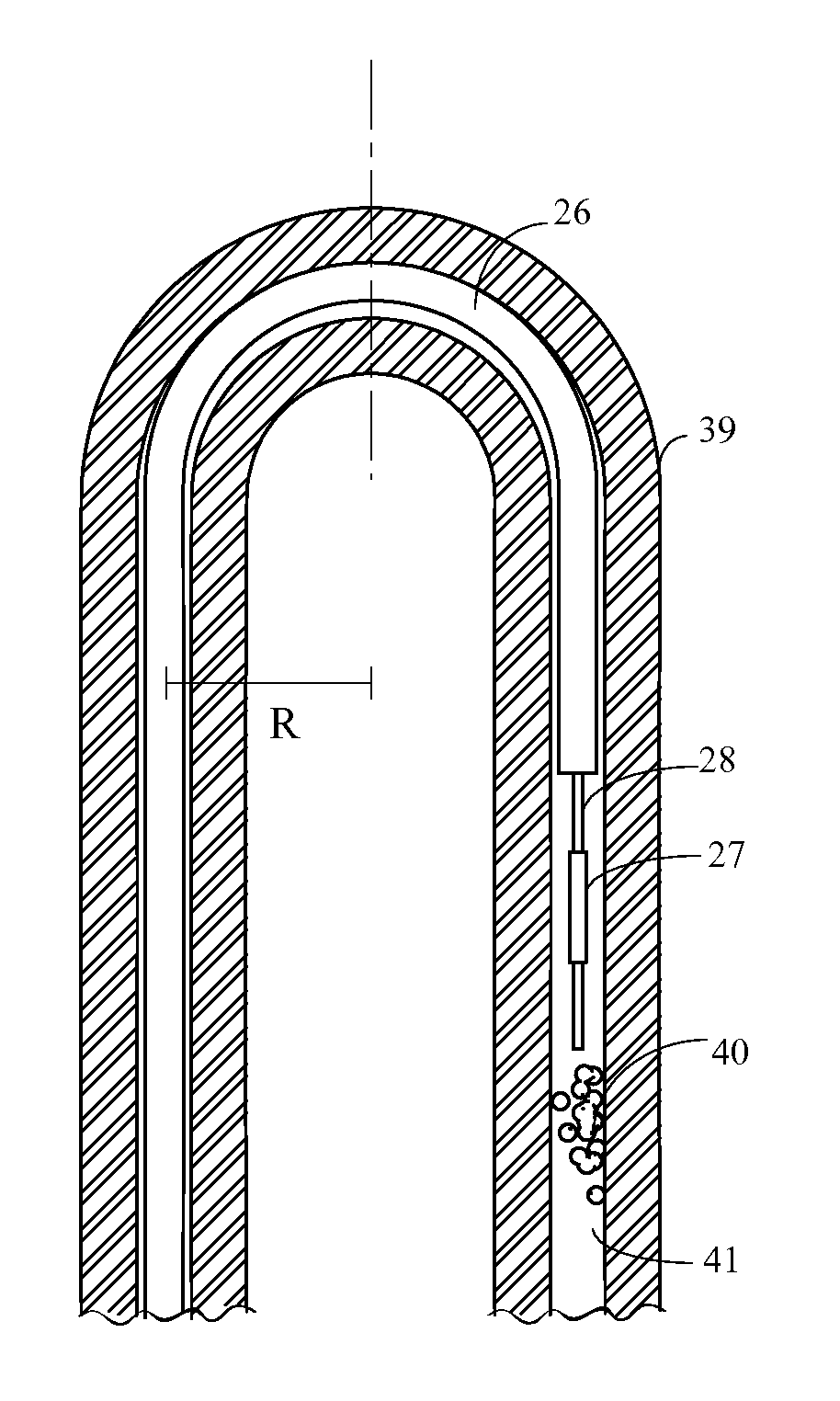

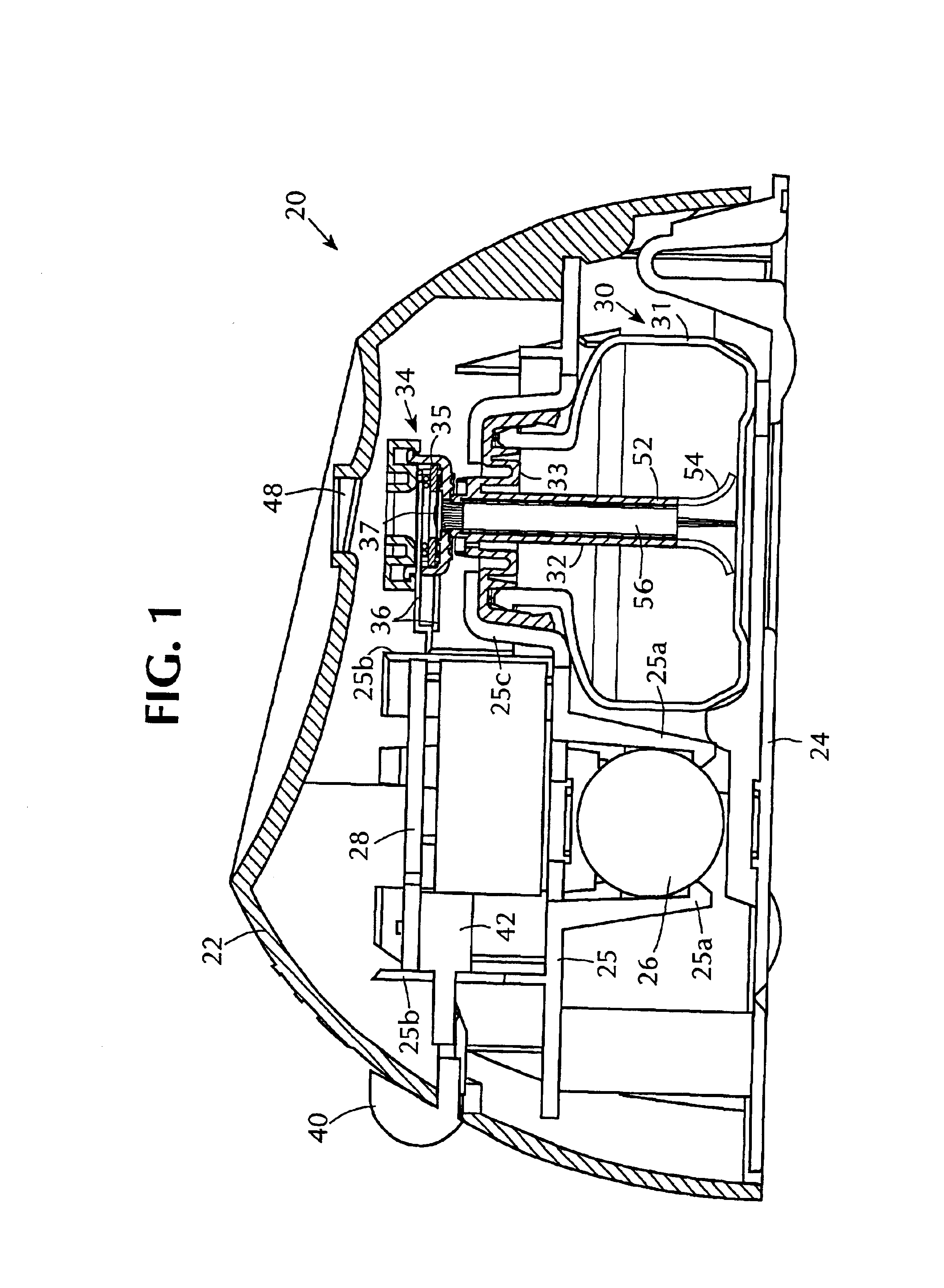

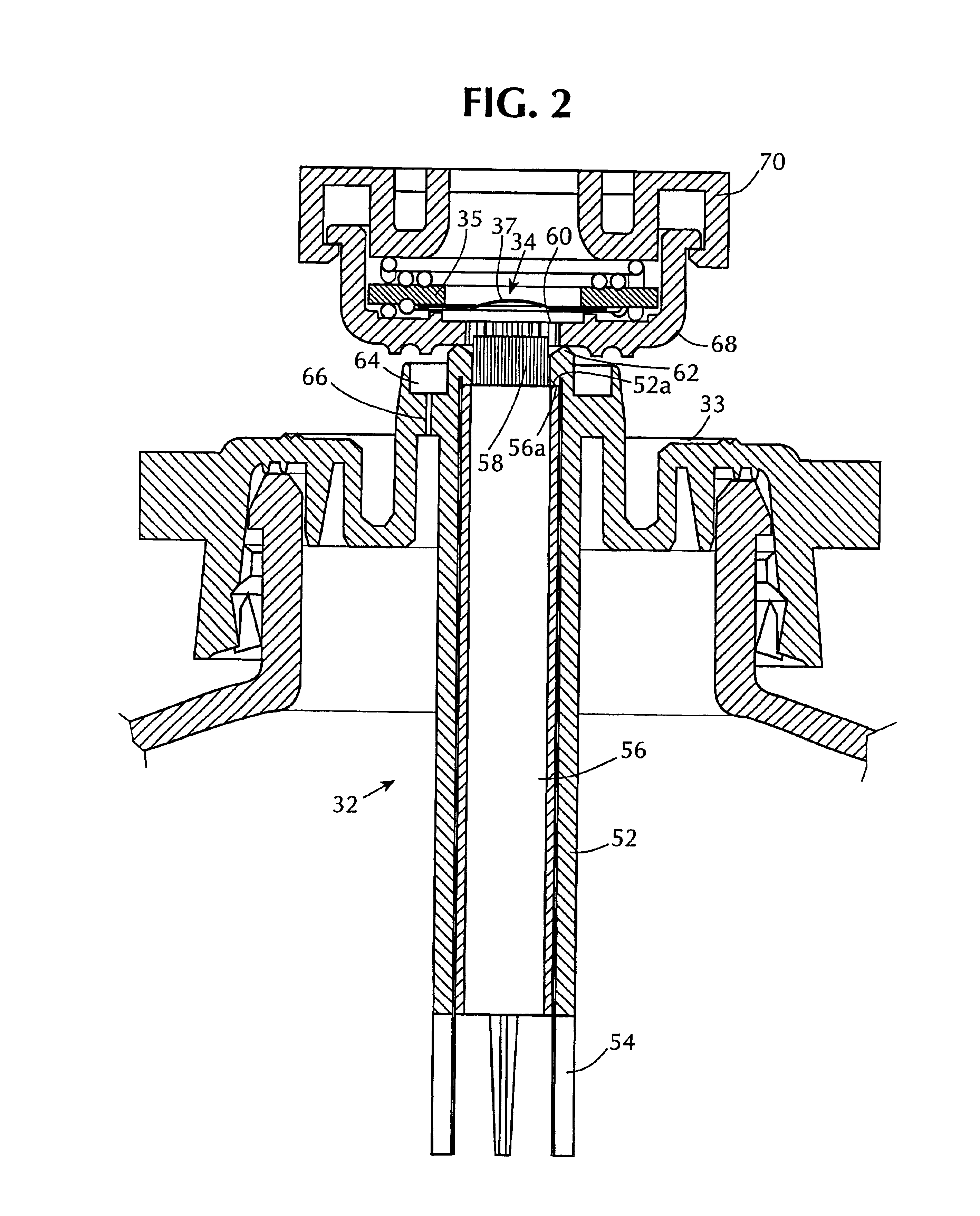

A battery operated atomizer device comprising, in a housing (22), a liquid reservoir (30) from which a capillary type liquid delivery system (38) extends to contact a piezoelectric actuator an atomization plate assembly (34), the assembly (34) being supported by means of wire-like elements (36) in cantilever fashion over the liquid delivery system, the liquid delivery system comprising an outer tubular member (52) and a solid rod (56) which have facing surfaces configured to define between them, longitudinal capillary liquid passages.

Owner:SC JOHNSON & SON INC

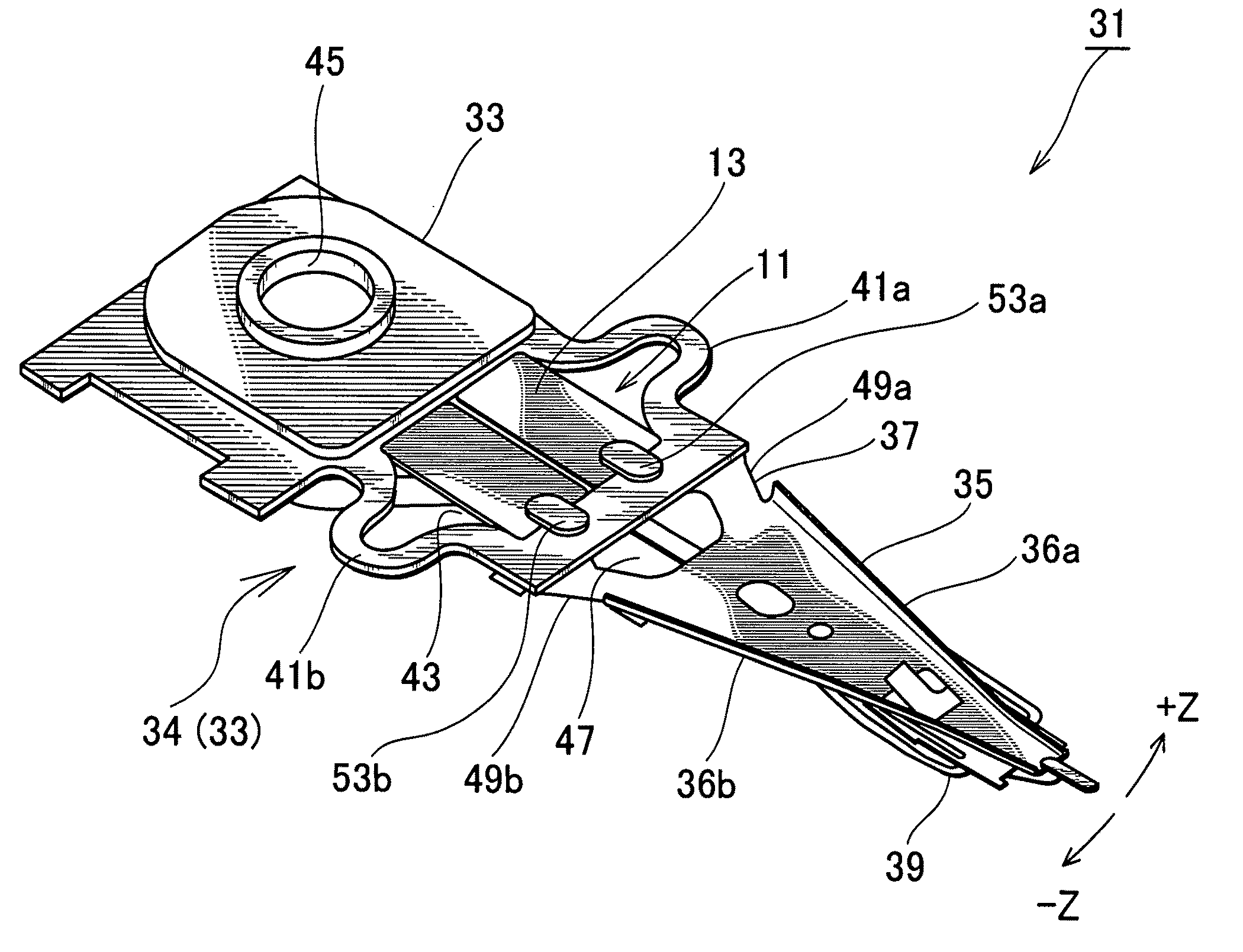

Electrical connecting structure for piezoelectric element, piezoelectric actuator, head suspension, and electrical connecting structure for conductive part

ActiveUS20100067151A1Accurate wiringReliability is deterioratedArm with actuatorsPiezoelectric/electrostriction/magnetostriction machinesAdhesivePiezoelectric actuators

A piezoelectric element 13 has a common electrode 19 that receives electricity from a terminal 57. The terminal 57 has a through hole 67 and an electric insulating layer 61. The piezoelectric element 13 is arranged so that the common electrode 19 faces the electric insulating layer 61 of the terminal 57. A liquid stopper 69 is formed around the through hole 67 so as to come between the common electrode 19 and the terminal 57 when the common electrode 19 and terminal 57 are set to face each other. A liquid conductive adhesive 71 is injected into the through hole 67 to fill a gap defined by the liquid stopper 69 between the terminal 57 and the common electrode 19 and secure electric connection between the terminal 57 and the common electrode 19. This configuration improves the reliability of wiring to the piezoelectric element and prevents the piezoelectric element from being damaged.

Owner:NHK SPRING CO LTD

System, method and apparatus for flexure-integrated microactuator

ActiveUS8085508B2Overcome costsOvercomes manufacturabilityTrack finding/aligningRecord information storageHard disc driveTrack density

Owner:WESTERN DIGITAL TECH INC

Haptic Response Apparatus for an Electronic Device

InactiveUS20090160763A1Digital data processing detailsCathode-ray tube indicatorsElectricityUser input

A user input for an electronic device includes a haptic feedback layer (100) and a touch sensitive user interface (200). The haptic feedback layer (100) provides a tactile response to a user when the user actuates a user actuation target (301) on the touch sensitive user interface (200) to simulate a popple-style button. The haptic feedback layer (100) includes a chassis (101) and a plurality of oppositely facing, interlaced cantilever beams (105,106) emanating therefrom, further separated by a support beam (113), and spanning at least a portion of the haptic feedback layer (100). One or more piezoelectric actuators (119) are coupled to the cantilever beams and are responsive to a controller (201). When the controller detects user actuation of the touch sensitive user interface (200), the controller (201) causes at least one of the piezoelectric actuators to actuate in accordance with an actuation signal.

Owner:GOOGLE TECH HLDG LLC

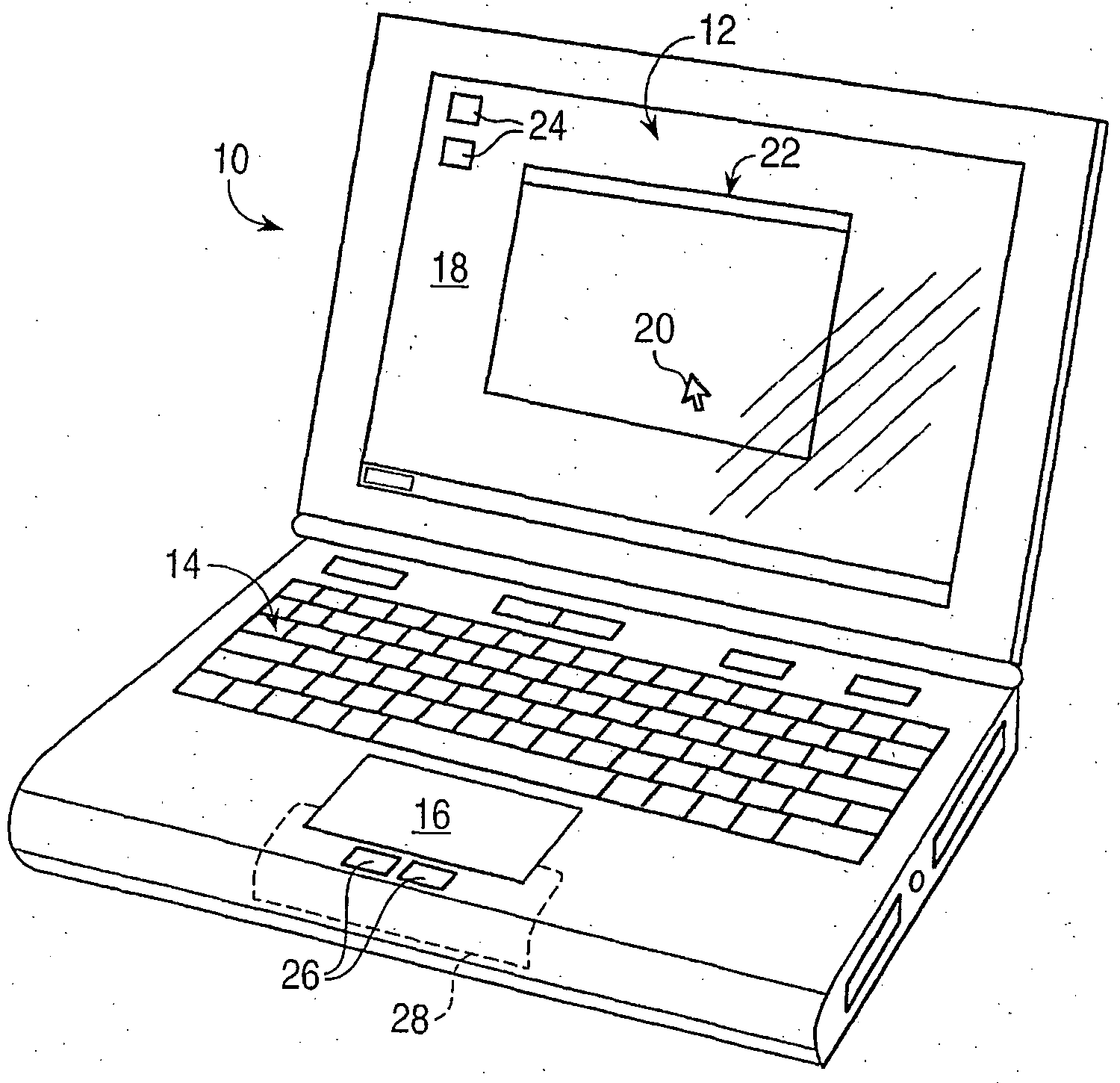

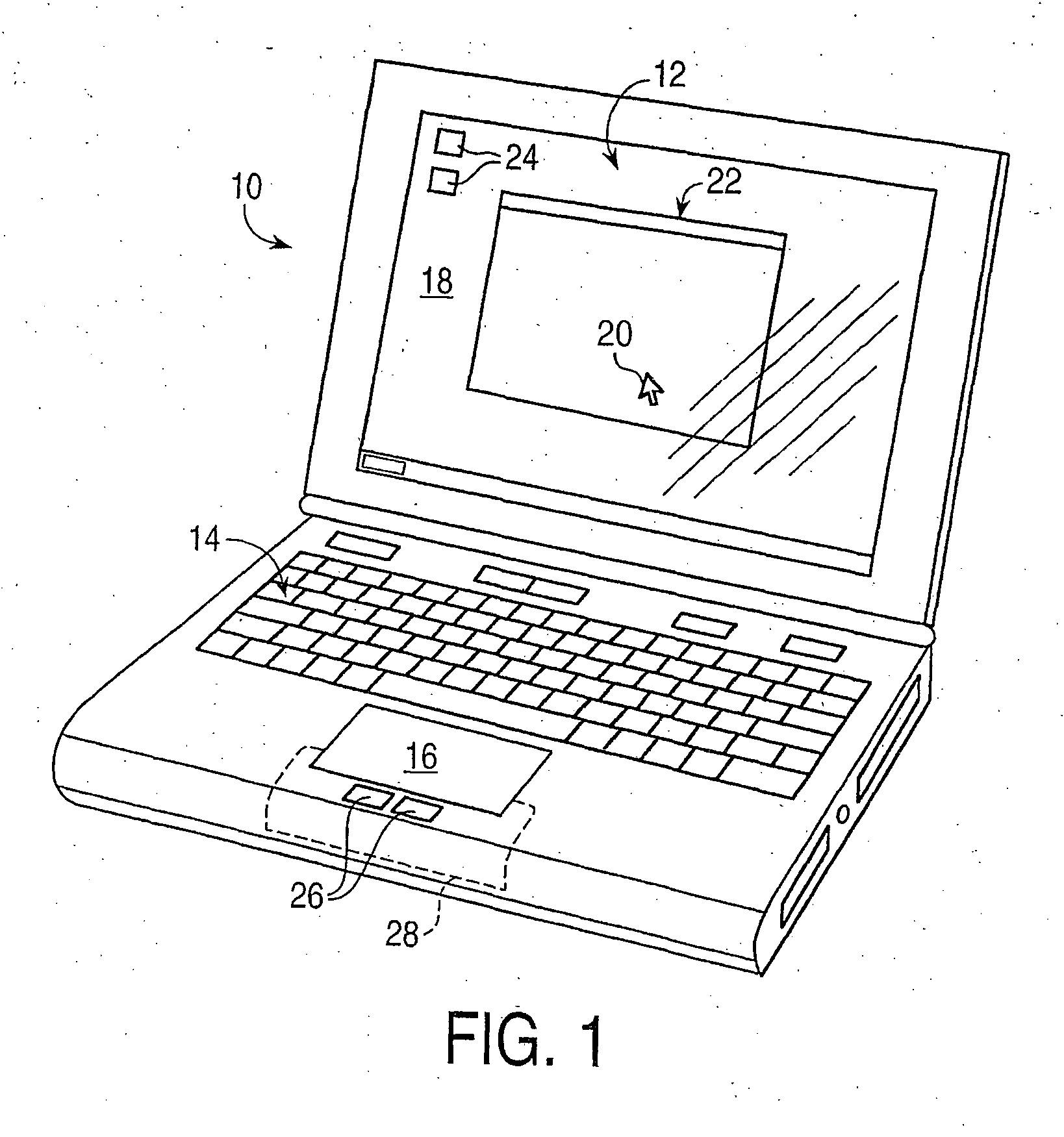

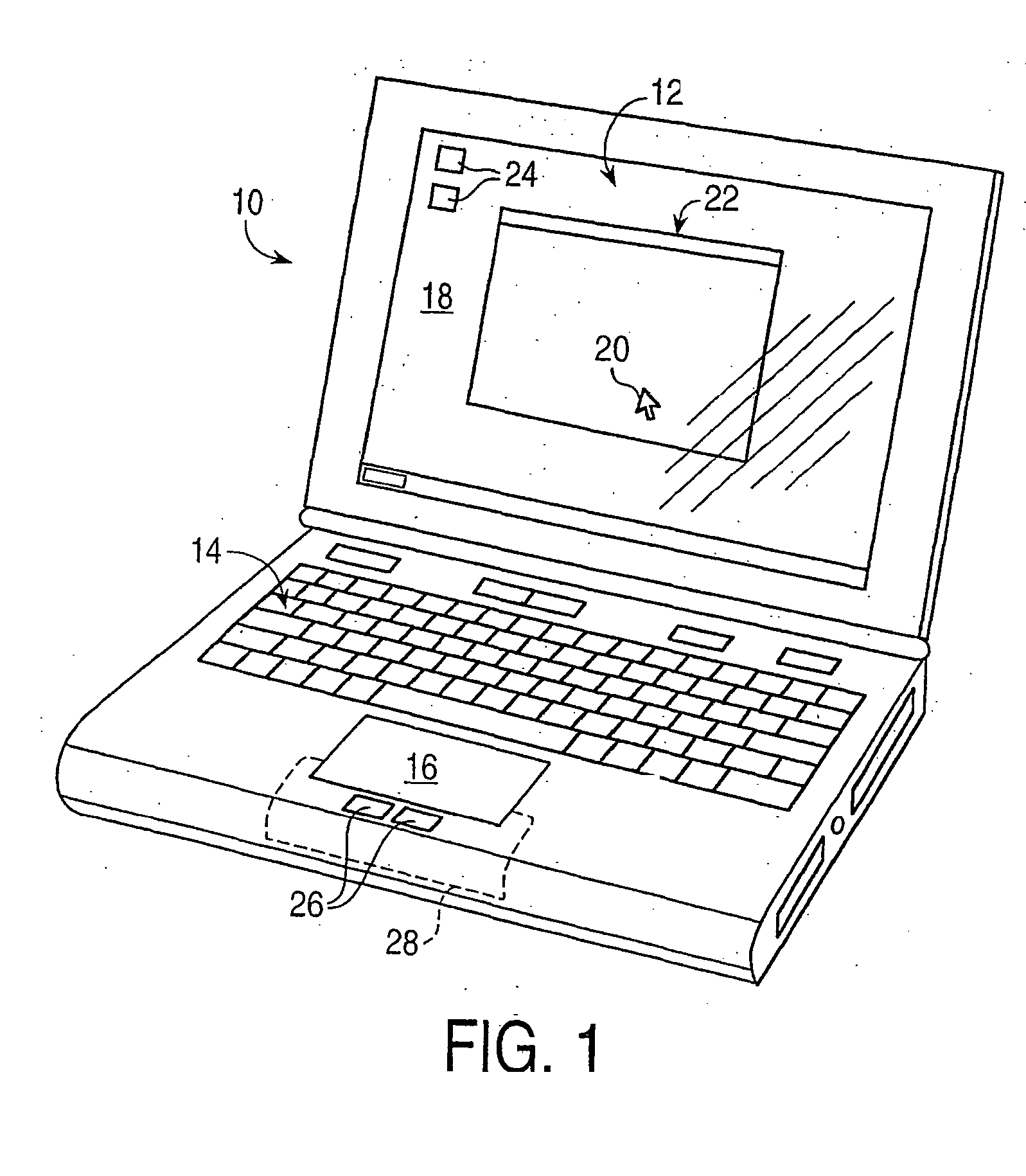

Haptic interface for laptop computers and other portable devices

InactiveUS20050052430A1Enhanced interactionEnhance manipulationInput/output for user-computer interactionCathode-ray tube indicatorsGraphicsPiezoelectric actuators

A haptic feedback touch control used to provide input to a computer. A touch input device includes a planar touch surface that provides position information to a computer based on a location of user contact. The computer can position a cursor in a displayed graphical environment based at least in part on the position information, or perform a different function. At least one actuator is also coupled to the touch input device and outputs a force to provide a haptic sensation to the user. The actuator can move the touchpad laterally, or a separate surface member can be actuated. A flat E-core actuator, piezoelectric actuator, or other types of actuators can be used to provide forces. The touch input device can include multiple different regions to control different computer functions.

Owner:IMMERSION CORPORATION

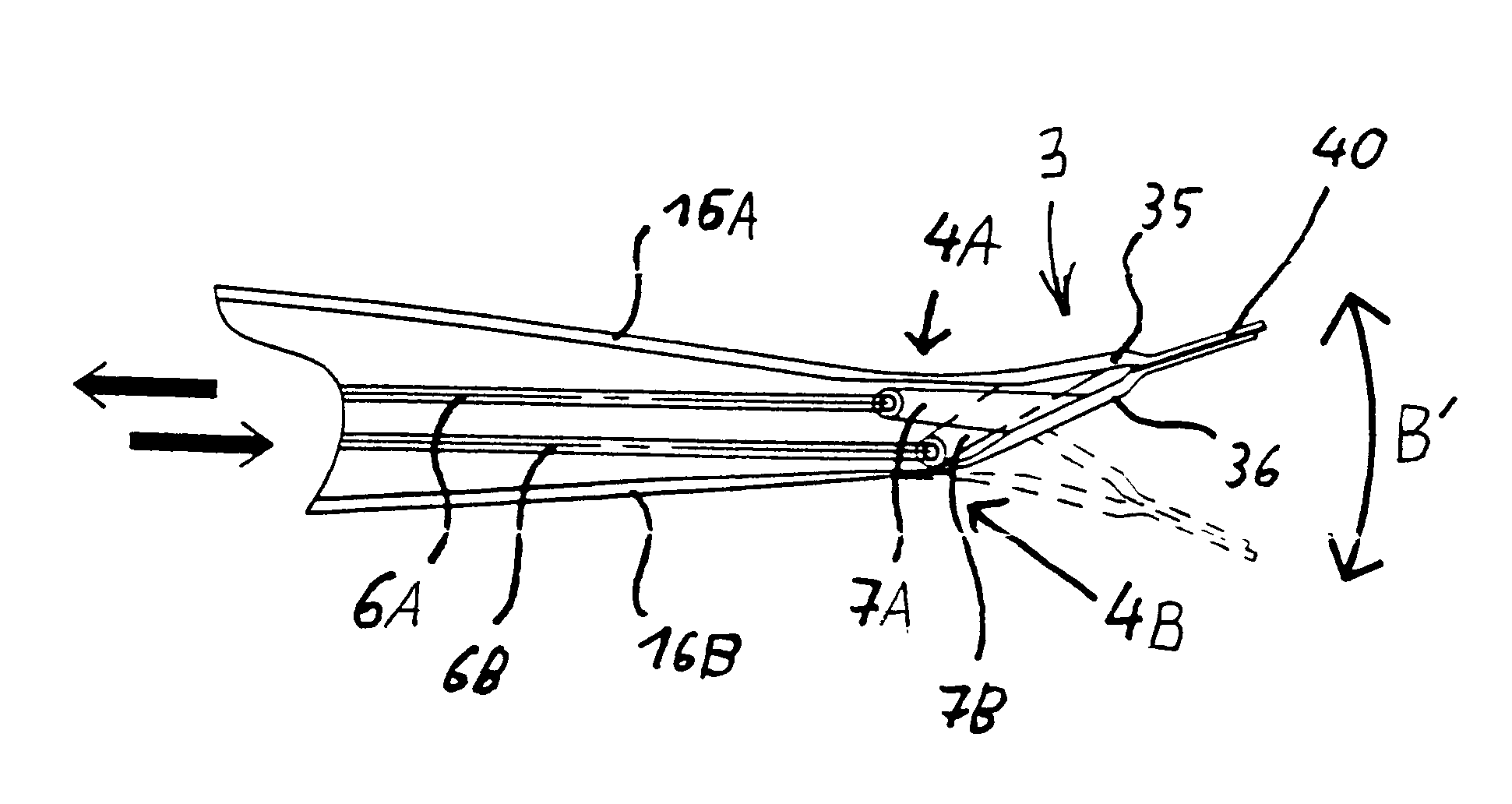

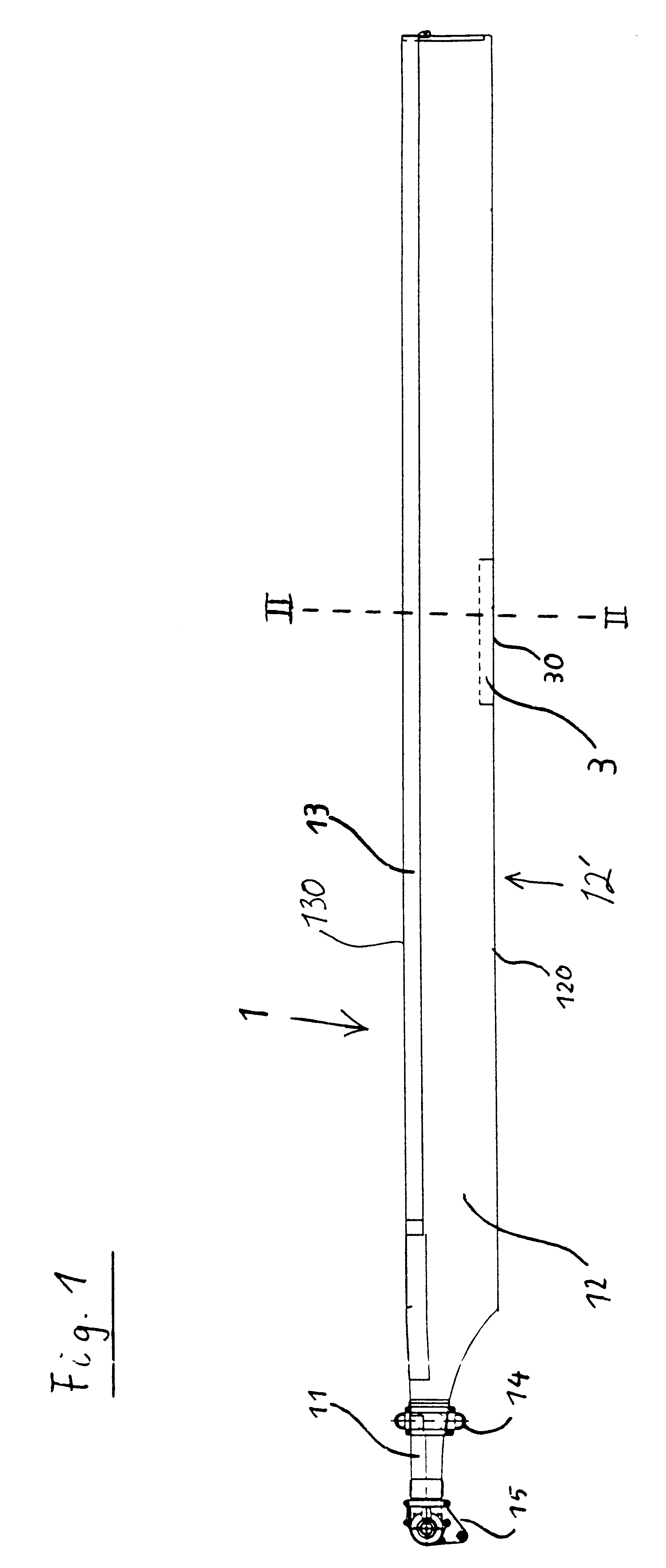

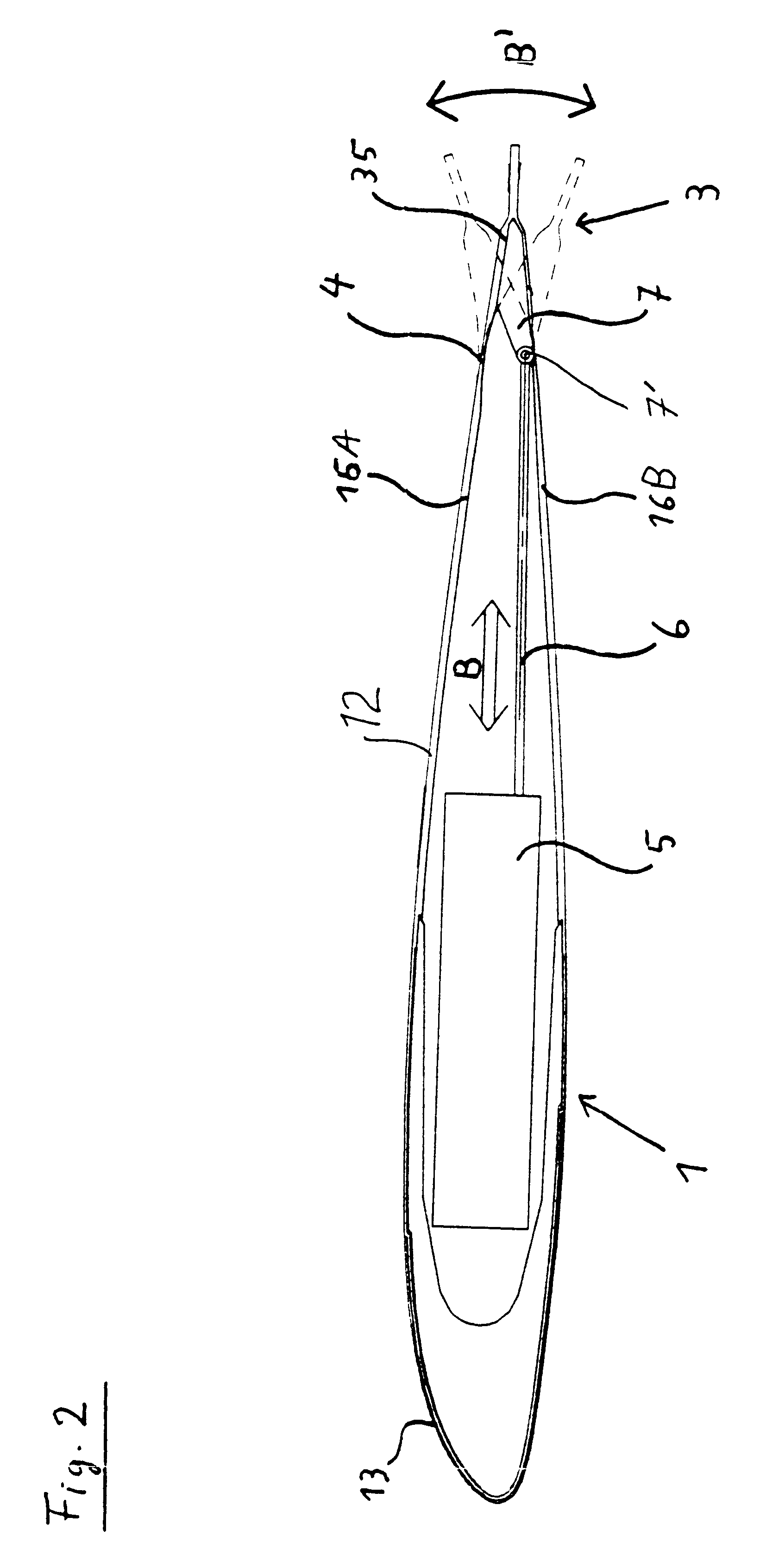

Helicopter rotor blade with a movable flap

InactiveUS6168379B1Durable and wear-resistant flexiblyImprove inspectionPropellersAircraft stabilisationPiezoelectric actuatorsFiber-reinforced composite

A helicopter rotor blade includes a main airfoil body (12) and a movable control flap (3) incorporated in the trailing edge profile of the airfoil body. The flap (3) is movably connected to the main airfoil body (12) by a flexibly bendable junction element (4), and is actuated by a piezoelectric actuator unit (5) via a push / pull rod (6) and a lever arm (7), whereby the control flap is deflected relative to the main airfoil body. The junction element (4) is preferably a continuous integral fiber-reinforced composite component having a flexible bending portion (42) with a reduced thickness in comparison to the adjoining portions, whereby the reinforcing fibers extend continuously through the joint in the direction of the connection between the main airfoil body and the flap.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Piezoelectrically actuated microvalve

InactiveUS6142444AIncreasing the thicknessIncrease deflectionOperating means/releasing devices for valvesCircuit elementsPiezoelectric actuatorsValve seat

PCT No. PCT / EP97 / 06498 Sec. 371 Date May 20, 1999 Sec. 102(e) Date May 20, 1999 PCT Filed Nov. 20, 1997 PCT Pub. No. WO98 / 23869 PCT Pub. Date Jun. 4, 1998A microvalve includes a micromechanically structured chip defining a valve seat with a flow opening therethrough, an elastic suspension device and an edge region. A valve plate is defined by a piezoelectric actuator and is connected to the edge region of the micromechanically structured chip. The longitudinal dimension of the piezoelectric actuator are able to be changed by the application of an electric voltage. A decrease in the longitudinal dimension of the piezoelectric actuator caused by the application of an electric voltage is mechanically converted into a movement of the valve plate relative to the valve seat essentially at a right angle to the longitudinal direction. The connection of the piezoelectric actuator with the edge region of the micromechanically structured chip and the suspension device causes the conversion. Thus, the valve plate will open or close the flow opening in the valve seat.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

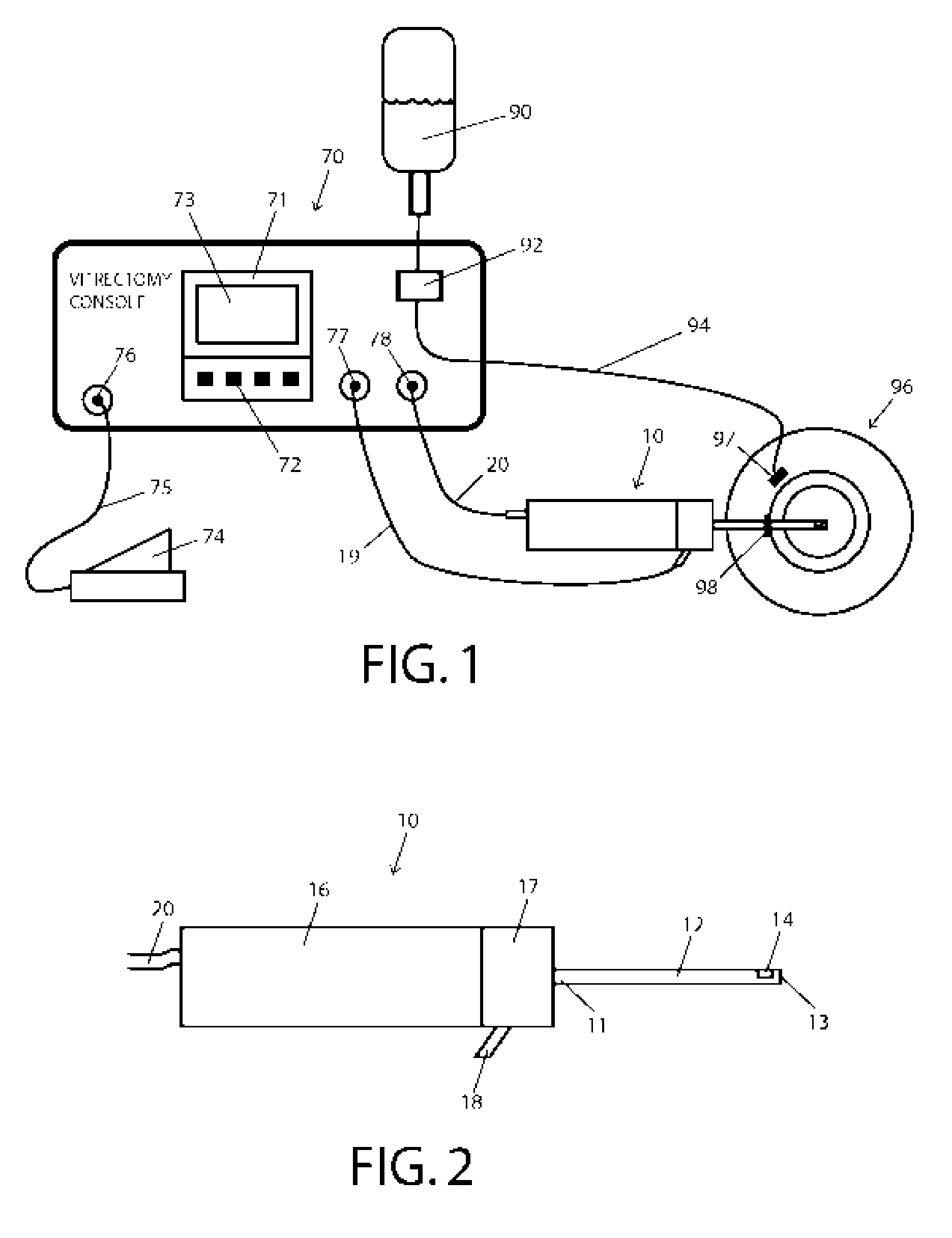

Precision Surgical System

InactiveUS20070173870A2Extended speed rangeIncrease speedEye surgeryEndoscopic cutting instrumentsNoise generationElectricity

A high-speed surgical handpiece (10) suitable for vitreoretinal surgery having a cutter (42) and actuators (36). The cutter (42) is a guillotine-type cutter activated by an array of leveraged piezoelectric actuators (30) that receive a driving signal from a driving controller. The controller can have control and display units with a plurality of input mechanisms receiving input from a user who selects a desired cutting rate and frequency for the cutter. The control unit produces a piezoelectric actuator output signal based on the inputs received. Fast cutting rates with reduced duty cycle as well as a proportional mode of operation are available, allowing slow controlled cutting action, for example proportional to depression of a foot-pedal (74). Low degrees of vibration and noise generation are produced.

Owner:DR ZACHARIAS JAIME

Input device and electronic device using the input device

InactiveUS7663604B2Great deflection (bending) displacementInput/output for user-computer interactionDigital data processing detailsElectricityVibration control

An input device includes a touch panel with which a user performs an input operation of information by touching the touch panel. The input device further includes a vibration generation device for feeding back, to the user, various kinds of sense of touch in accordance with the type of the information through the touch panel. Additionally, the input device includes a vibration control circuit for allowing the vibration generation device to generate various forms of vibrations in accordance with the type of the information. The vibration generation device is a bimorph piezoelectric actuator including a first actuator unit and a second actuator unit stacked on the first actuator unit in which when one of the first and second actuator units expands, the other contracts. Further, each of the first and second actuator units has a multi-layered piezoelectric element layer.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com