Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16642results about How to "Increasing the thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

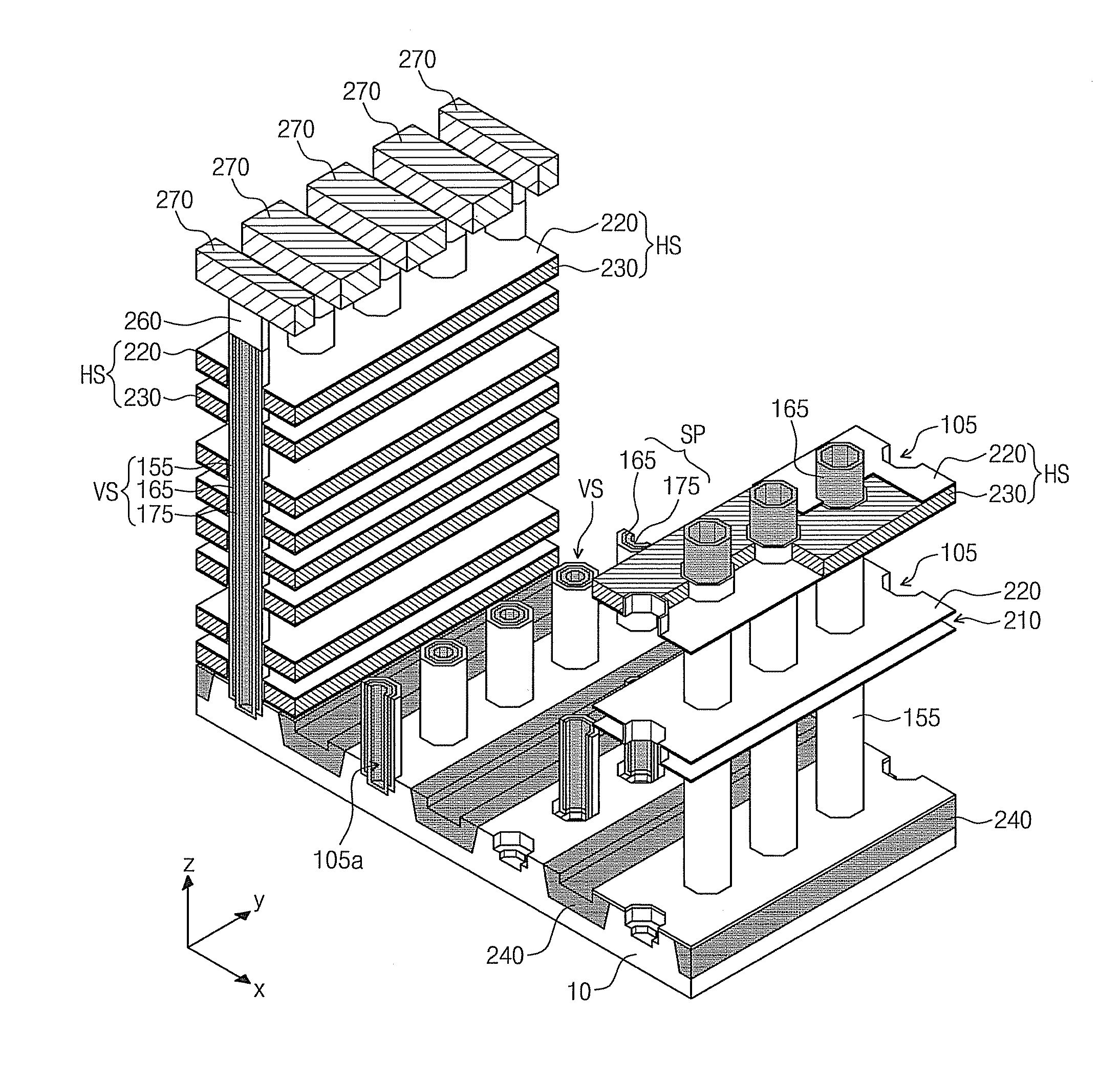

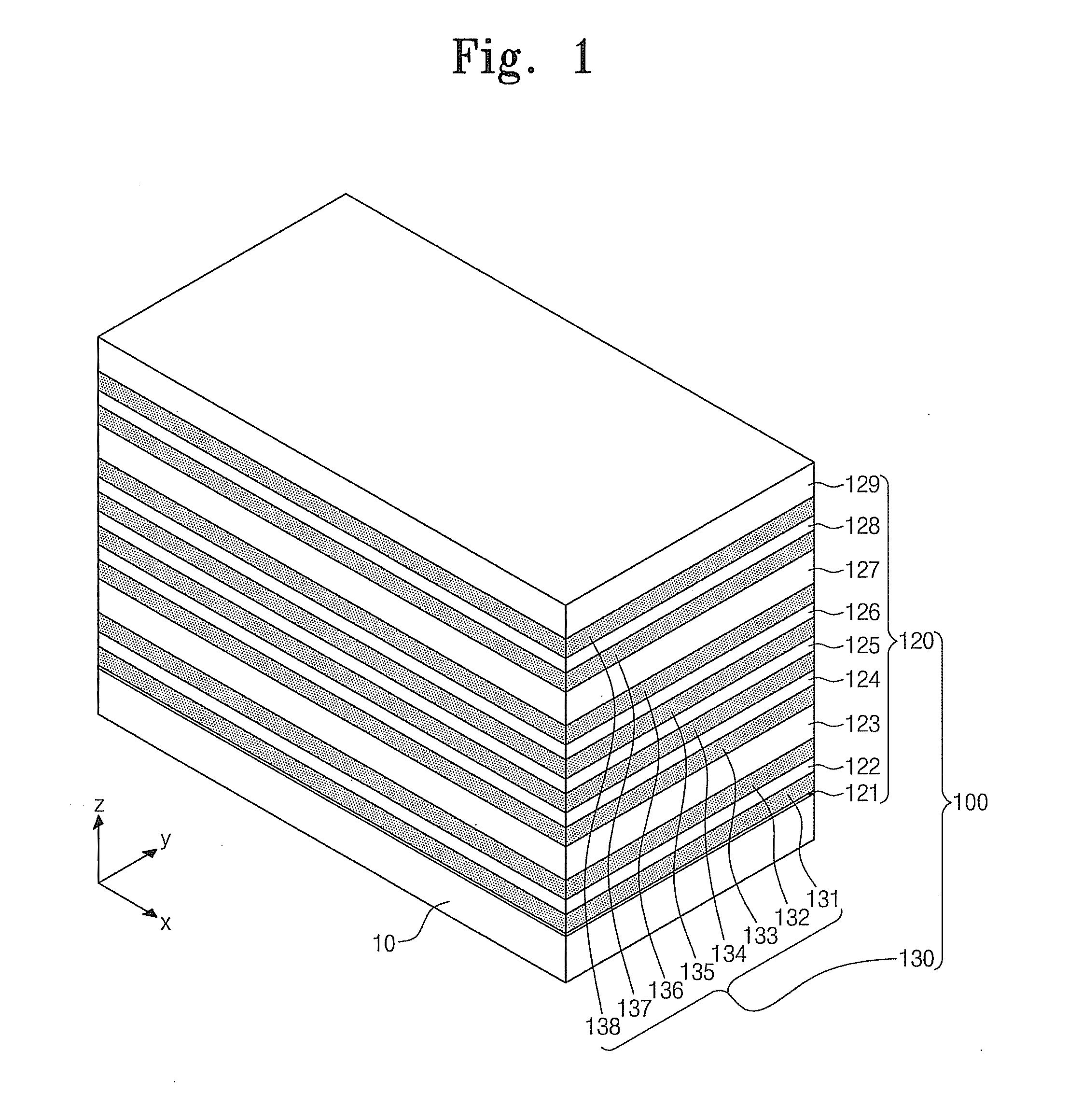

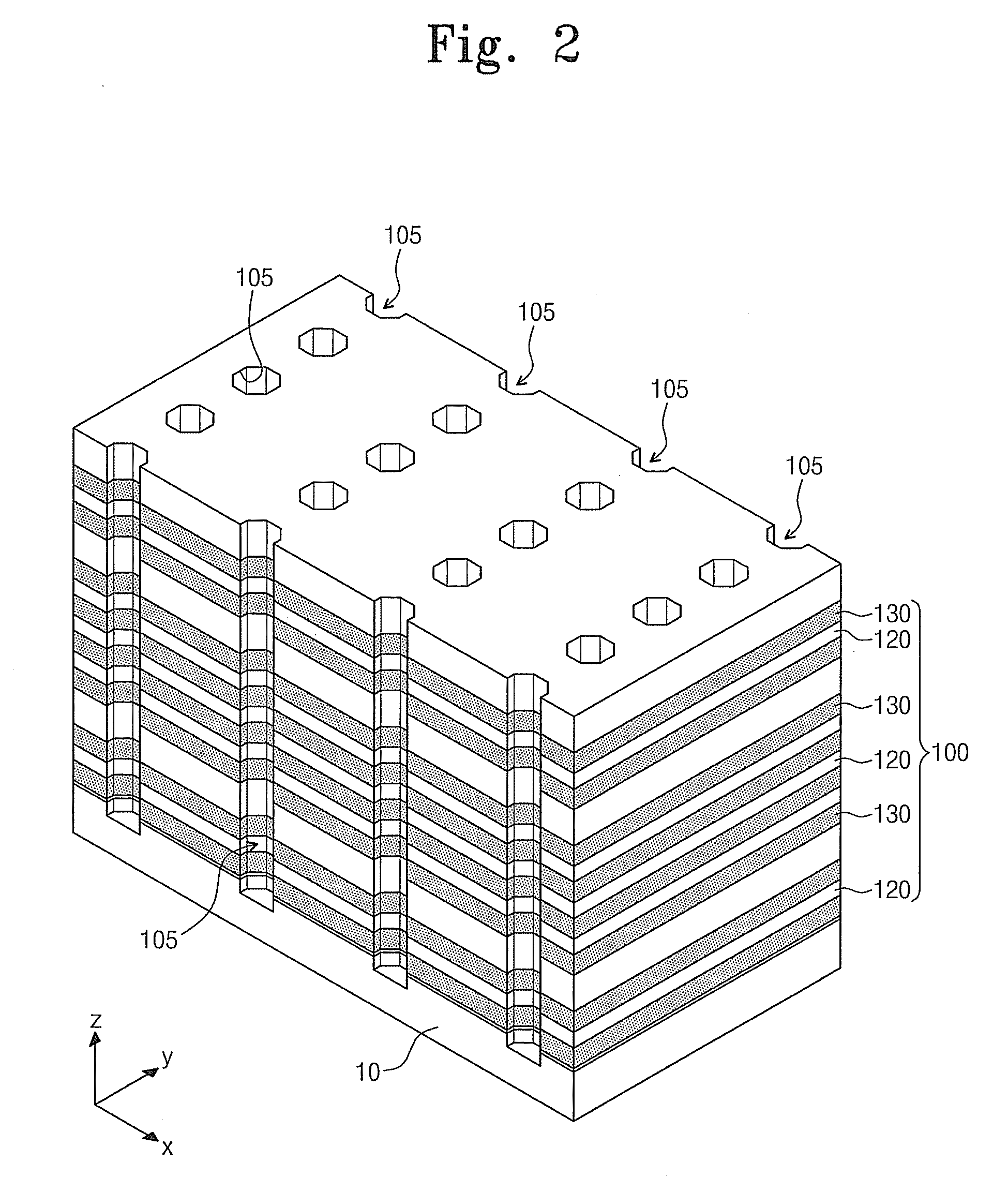

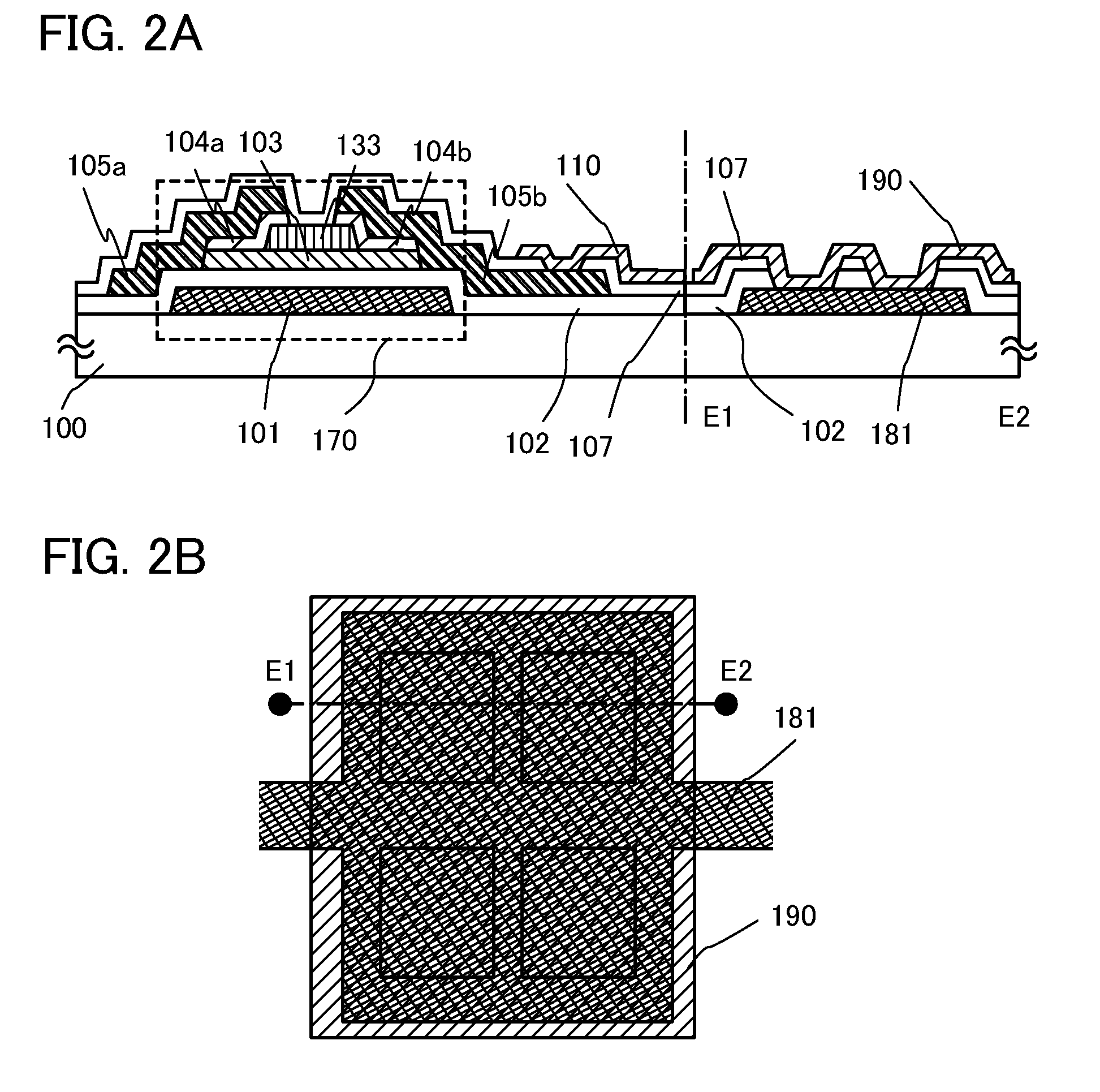

Three-Dimensional Semiconductor Memory Devices And Methods Of Fabricating The Same

ActiveUS20110233648A1Increasing the thicknessReduce resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Three-dimensional semiconductor memory devices and methods of fabricating the same. The three-dimensional semiconductor devices include an electrode structure with sequentially-stacked electrodes disposed on a substrate, semiconductor patterns penetrating the electrode structure, and memory elements including a first pattern and a second pattern interposed between the semiconductor patterns and the electrode structure, the first pattern vertically extending to cross the electrodes and the second pattern horizontally extending to cross the semiconductor patterns.

Owner:SAMSUNG ELECTRONICS CO LTD

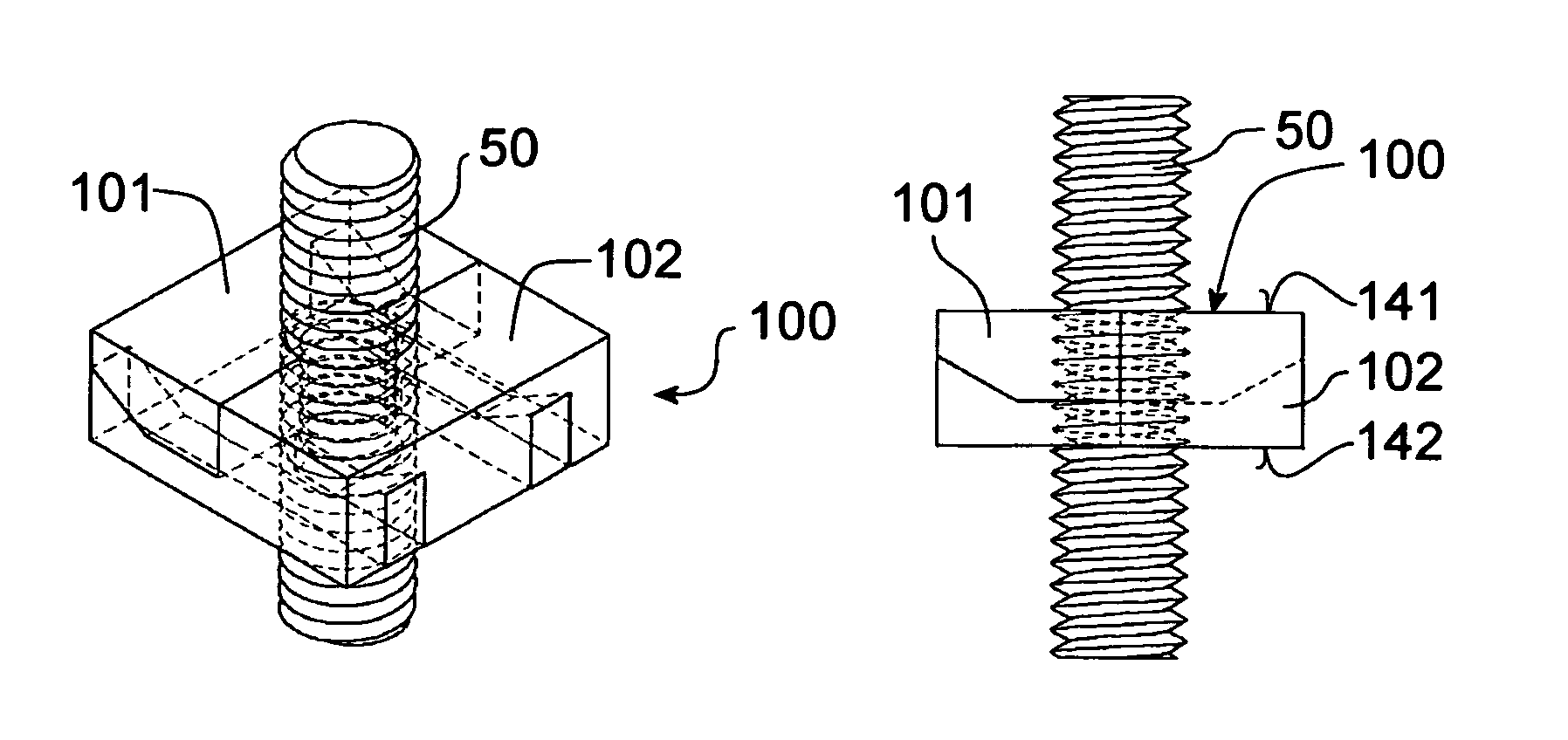

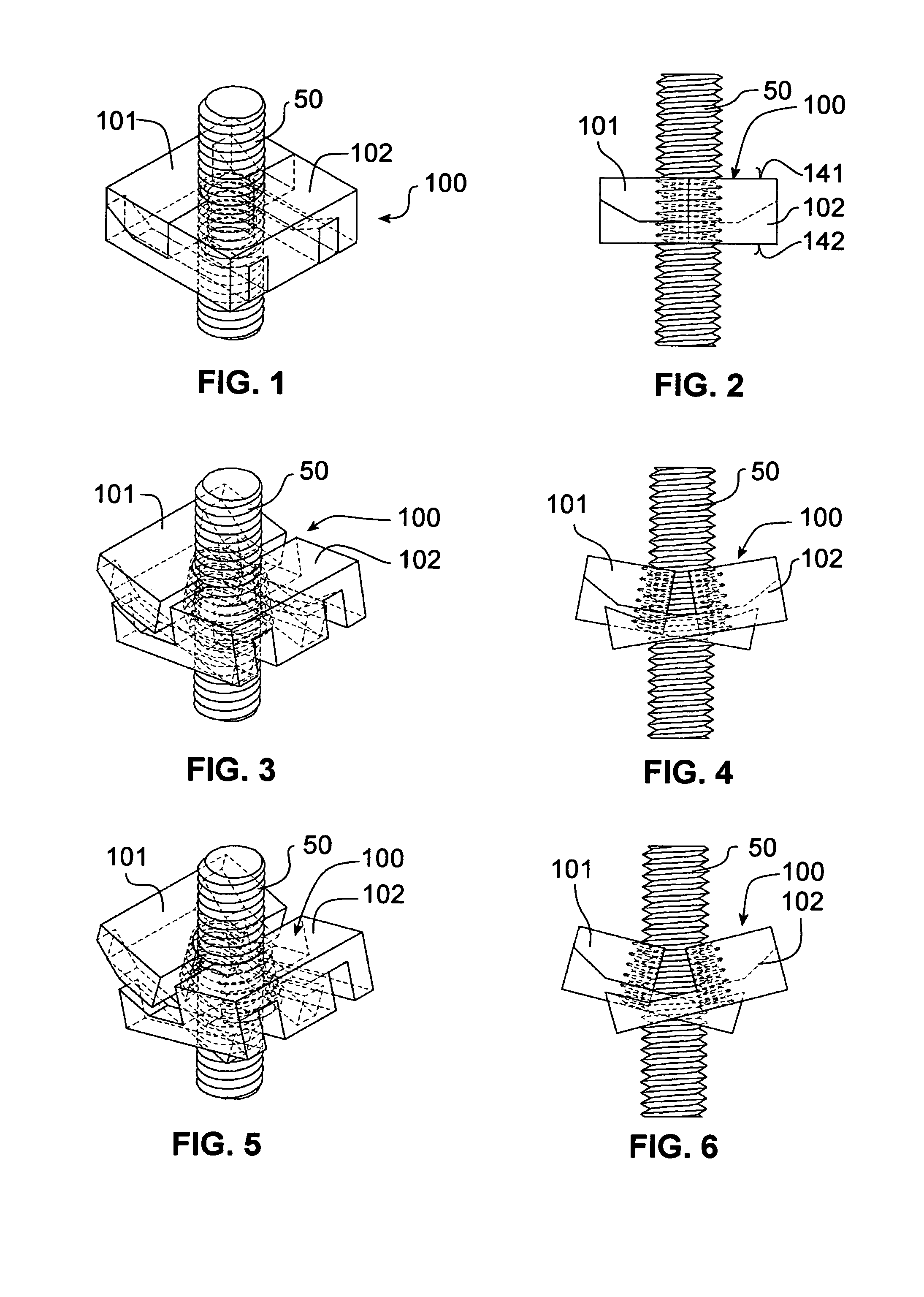

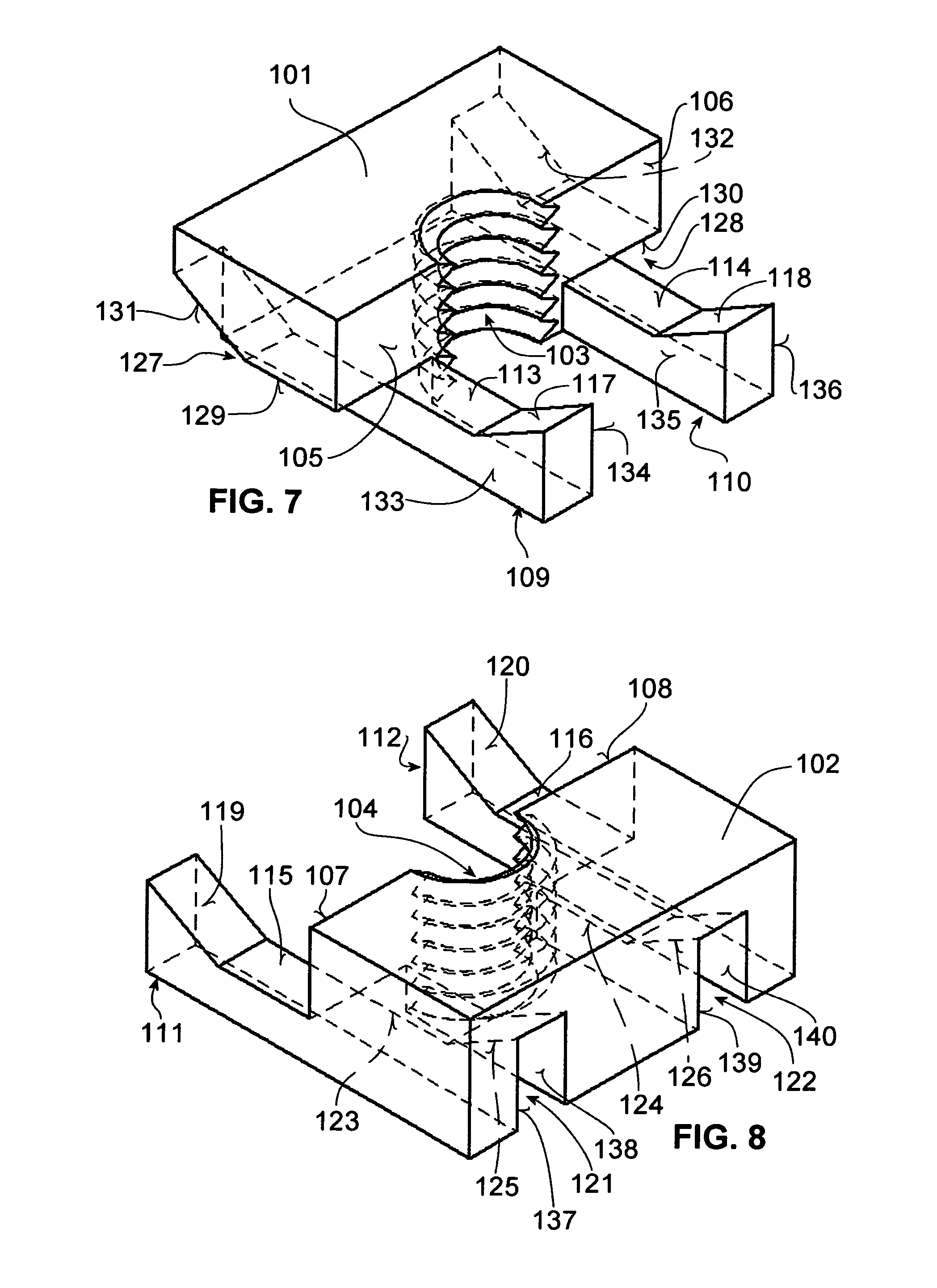

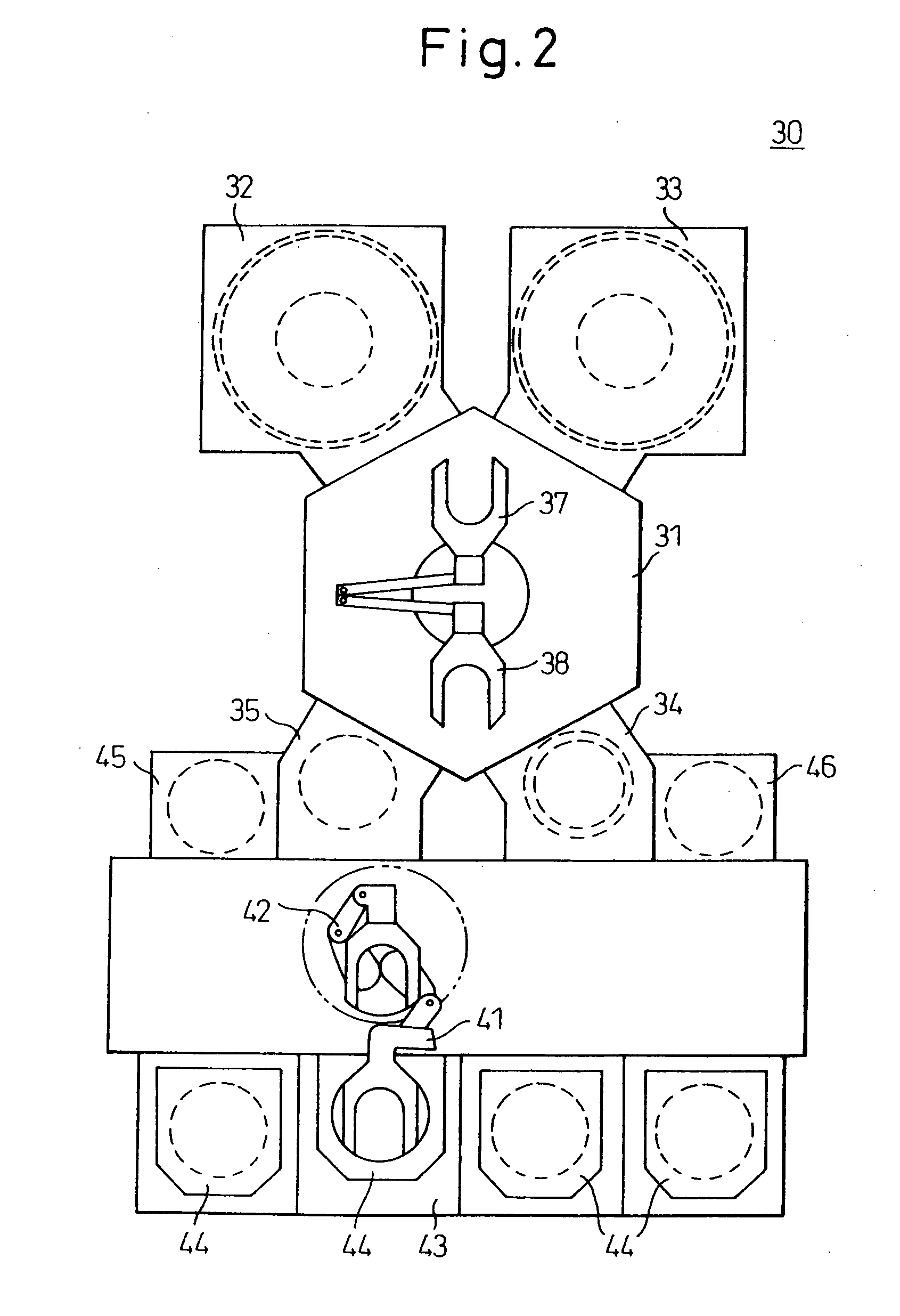

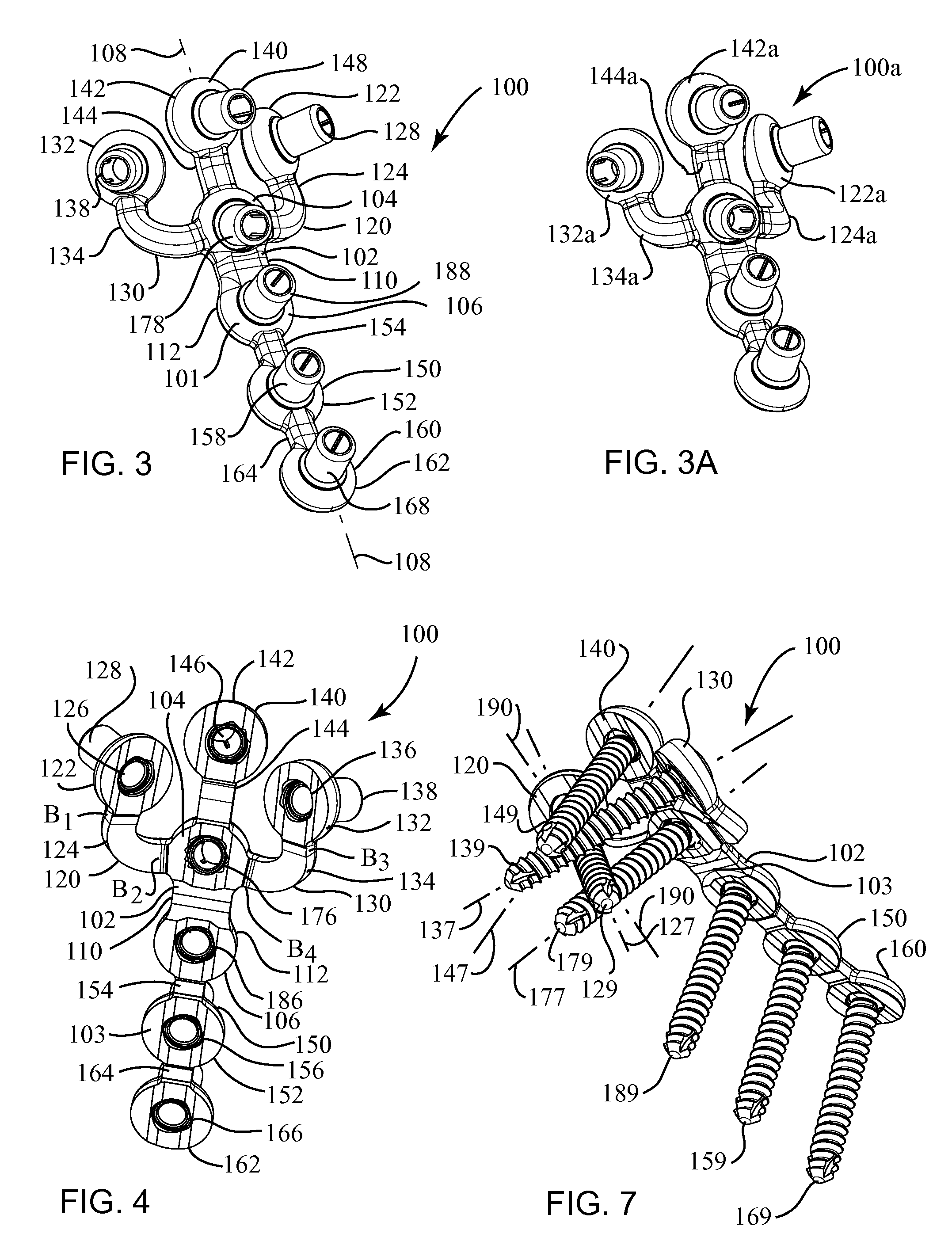

Nut having at least two parts

ActiveUS7934896B2Avoid cloggingIncrease the number ofDrilling rodsNutsRelative displacementEngineering

A nut includes an internal thread and at least two parts, each of the parts having a section of the internal thread which can be pushed onto an external thread in the radial direction. The parts may have connecting elements which interact and permit a relative displacement of the parts in a direction running radially to the axis of the internal thread into a position of use. The connecting elements may have guide surfaces which are inclined at an angle to the plane running radially to the axis of the internal thread and guide the parts in a rotational movement about an axis of rotation running transversely to the axis. A part may have a locking arm with a guide surface only on one side which produces the rotational movement during the displacement of the parts and bears against a complementary guide surface of the other part.

Owner:SCHNIER DIETMAR

Expandable intervertebral spacer

ActiveUS20050143827A1Prevent crashIncrease contact surfaceDental implantsInternal osteosythesisBiomedical engineering

Owner:KYPHON

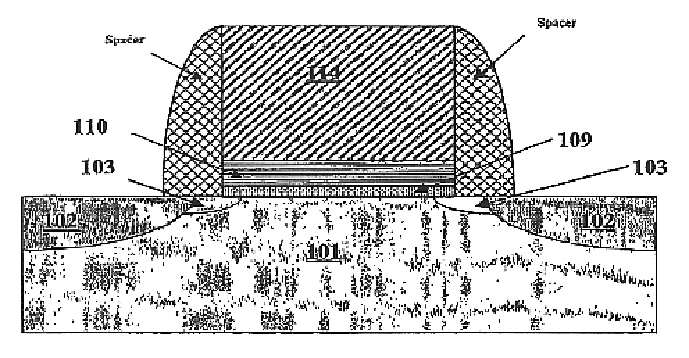

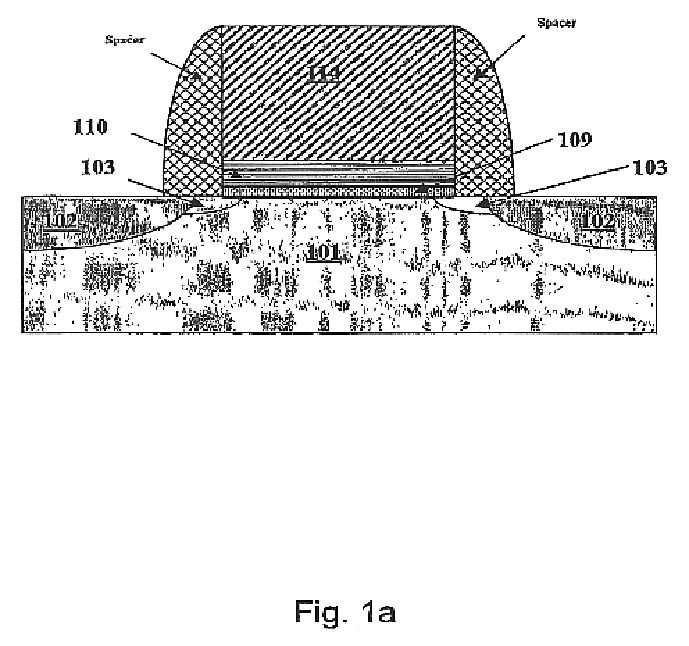

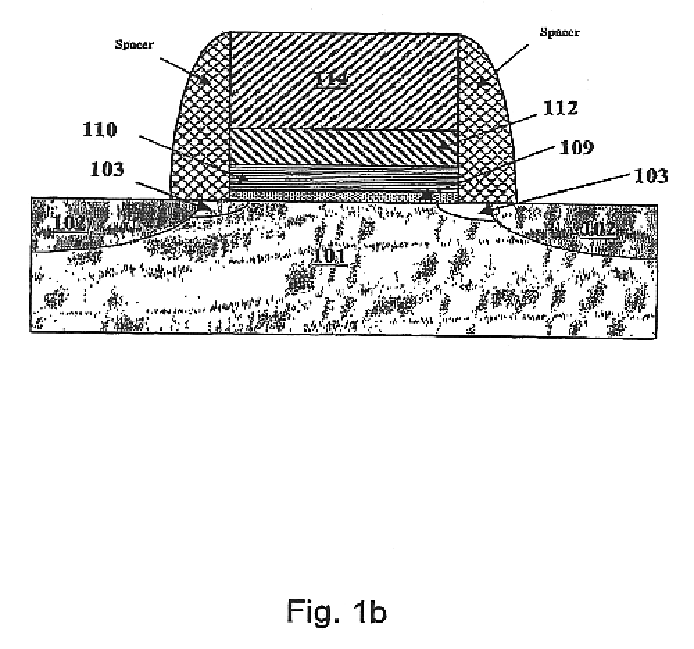

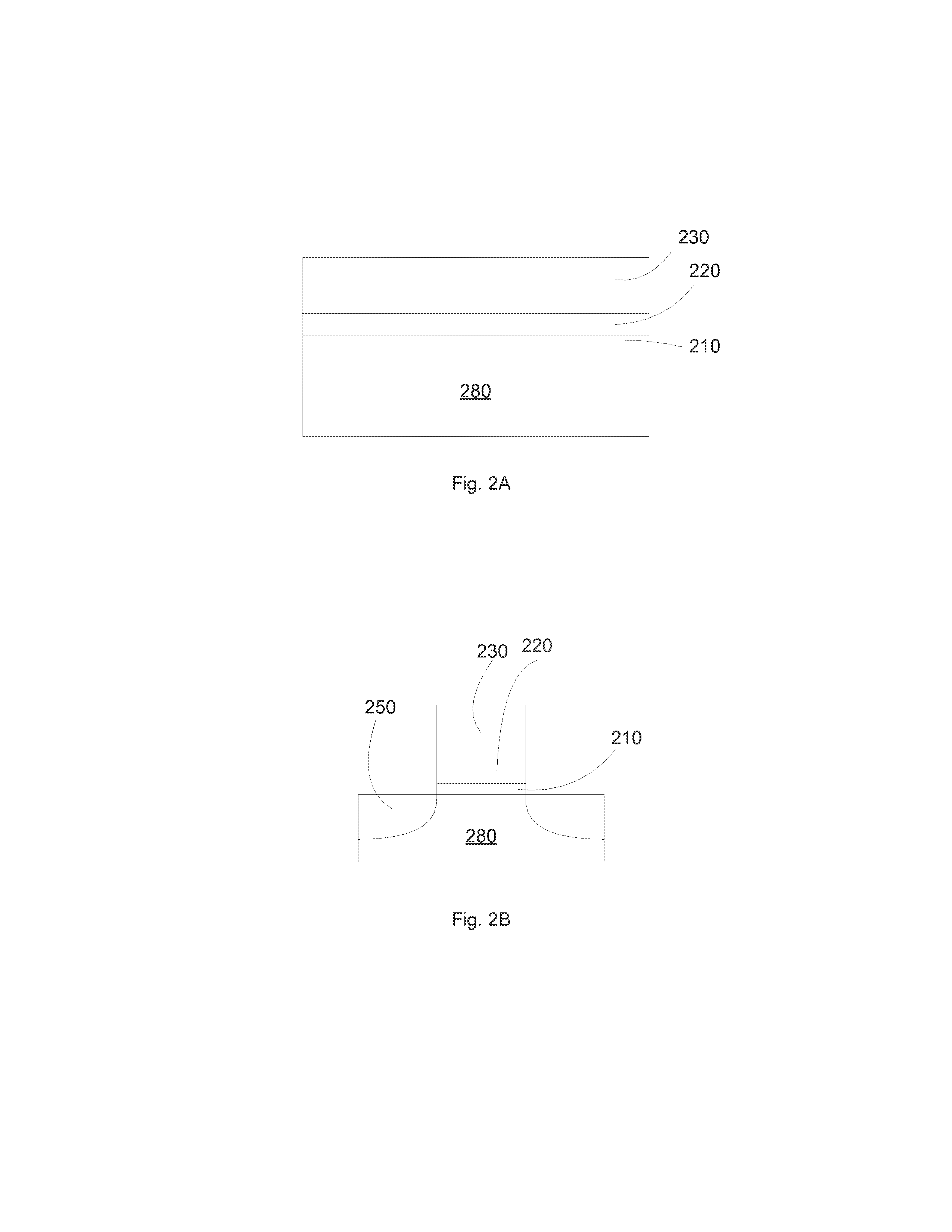

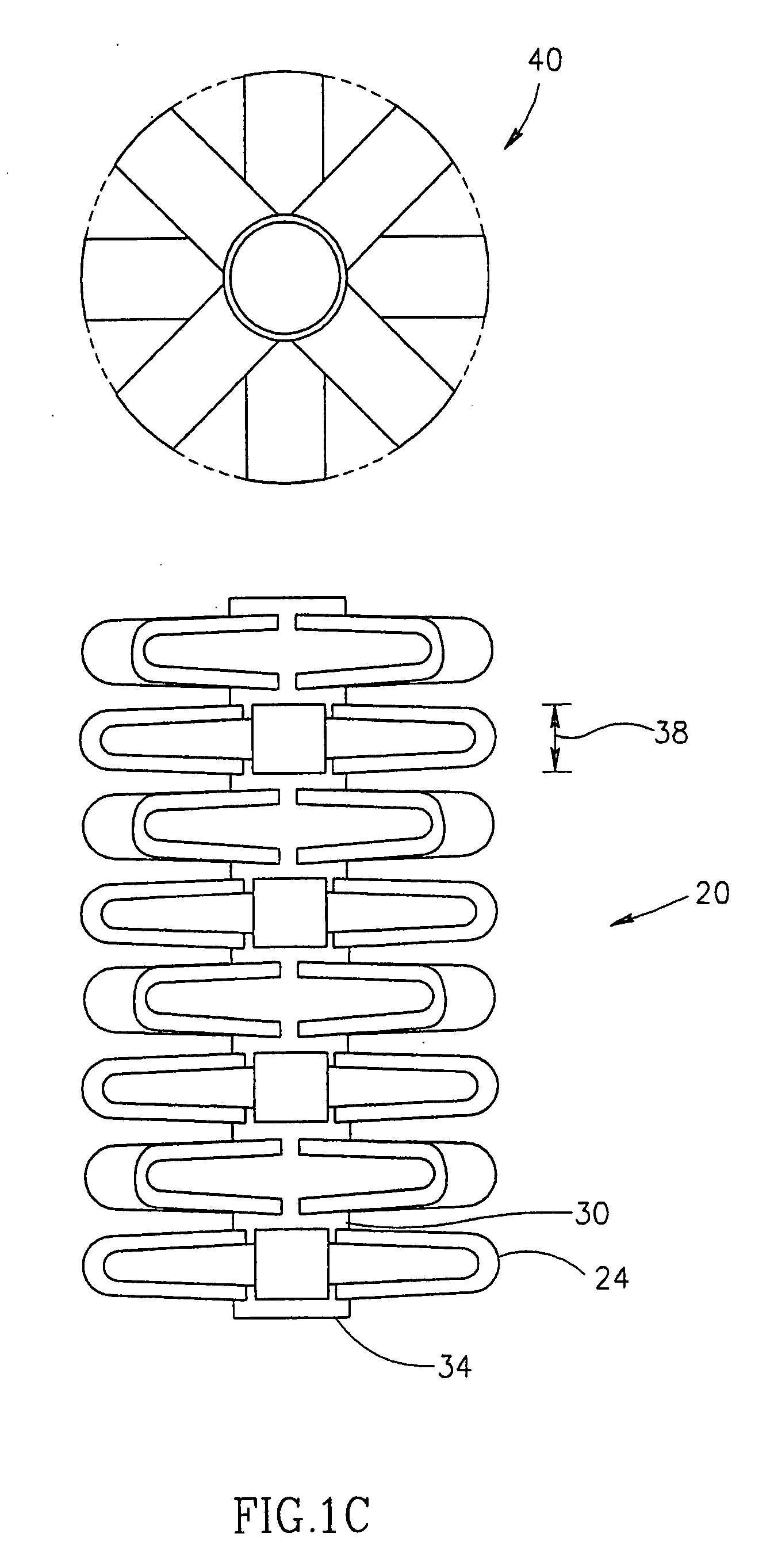

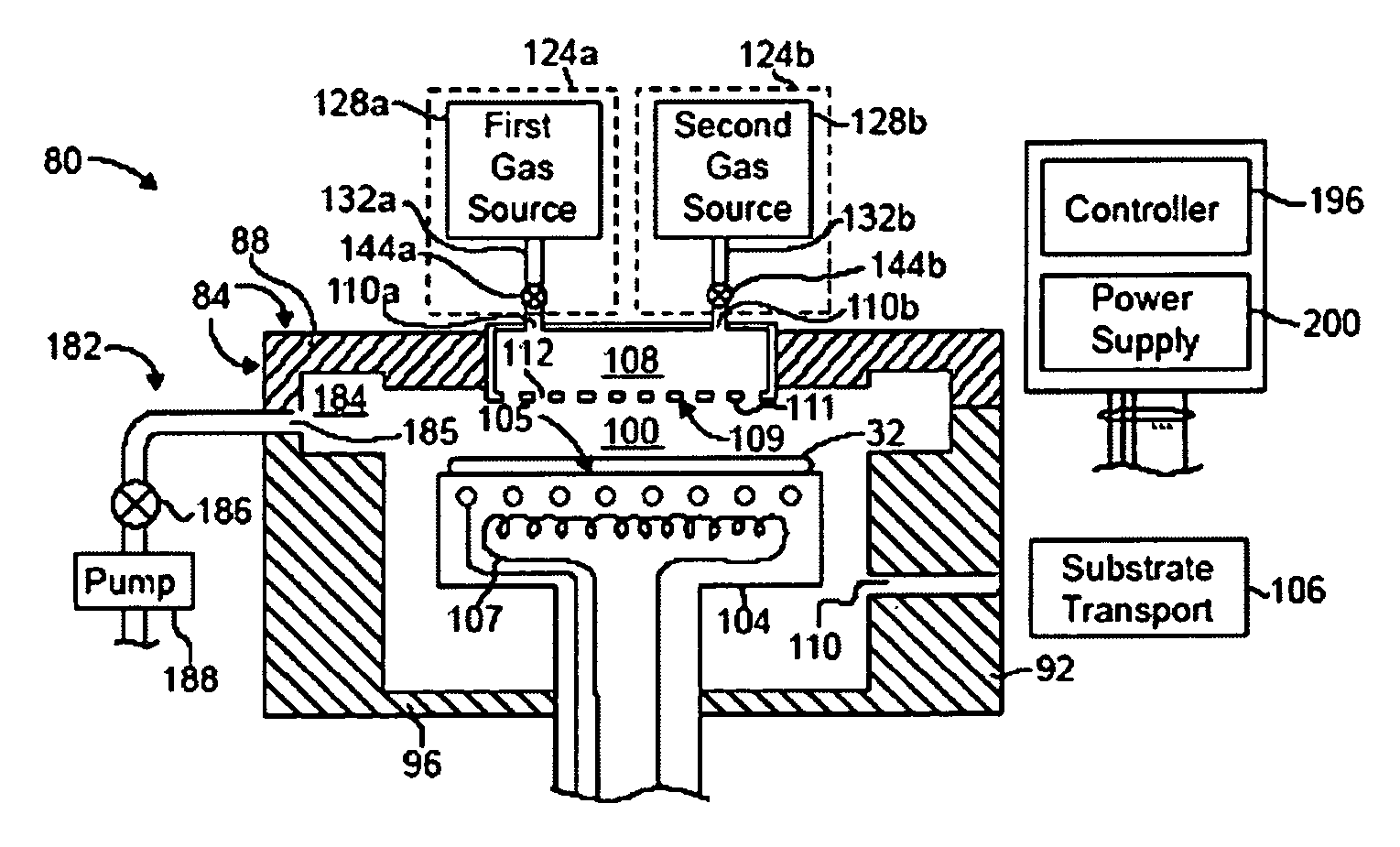

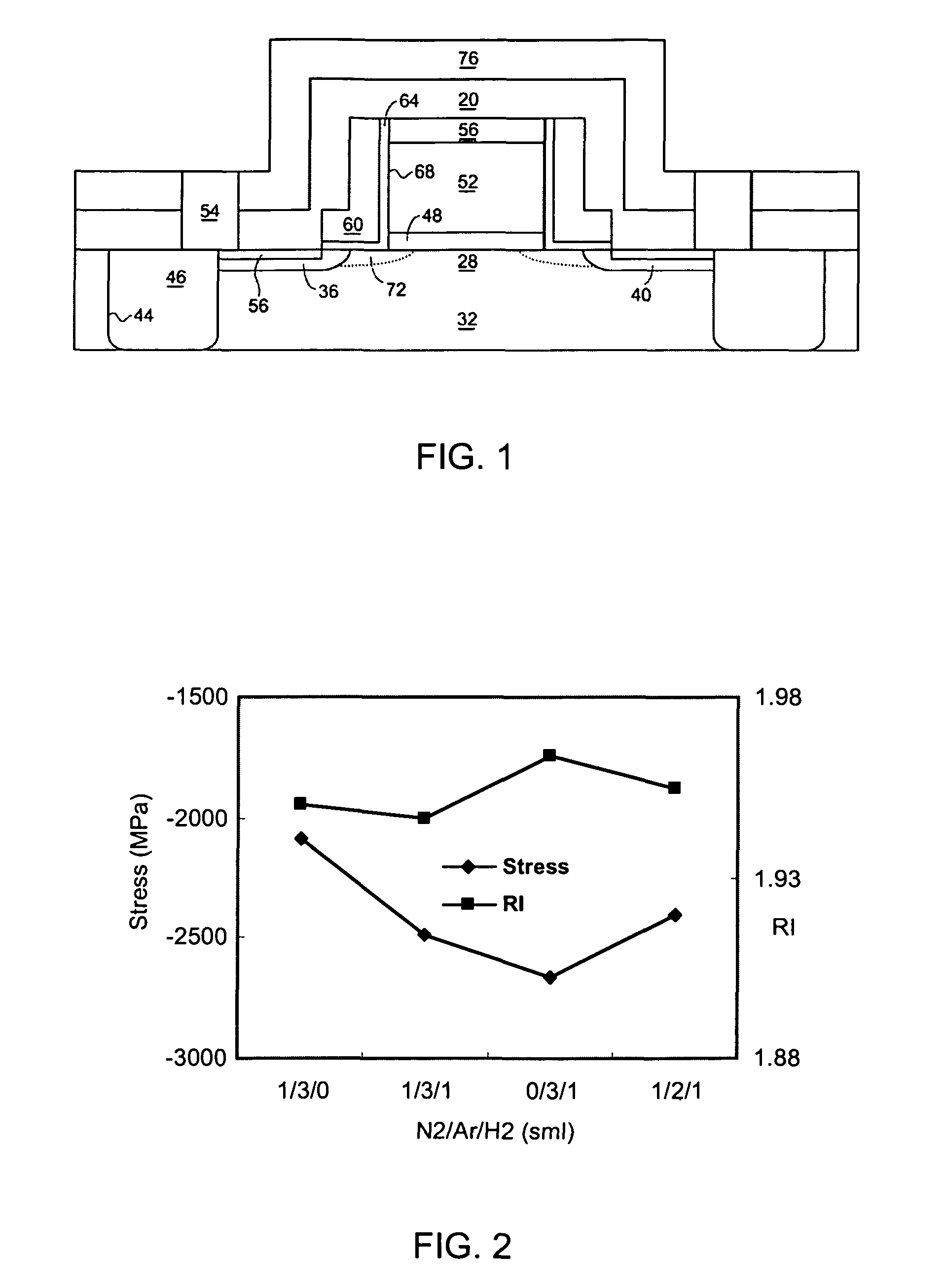

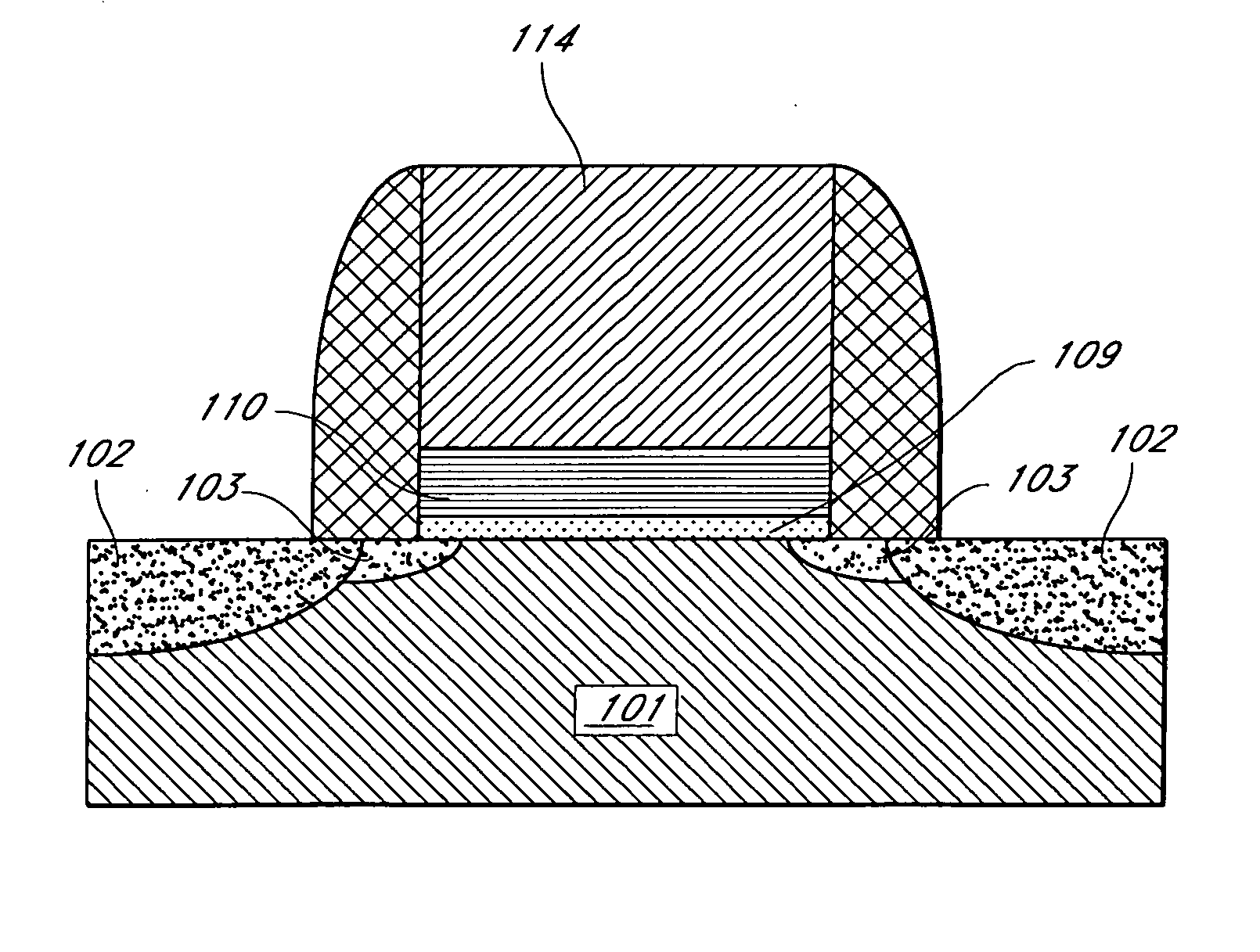

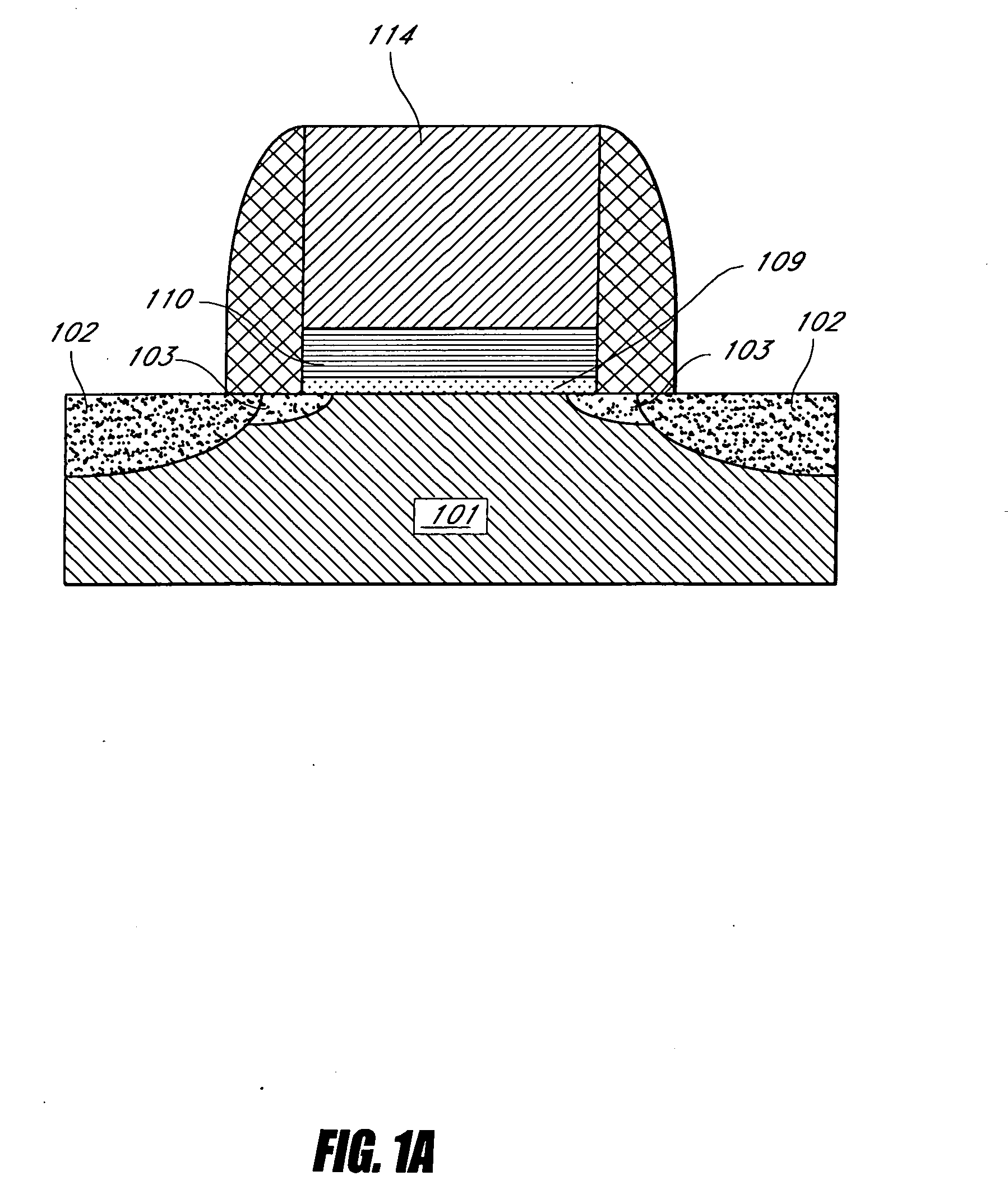

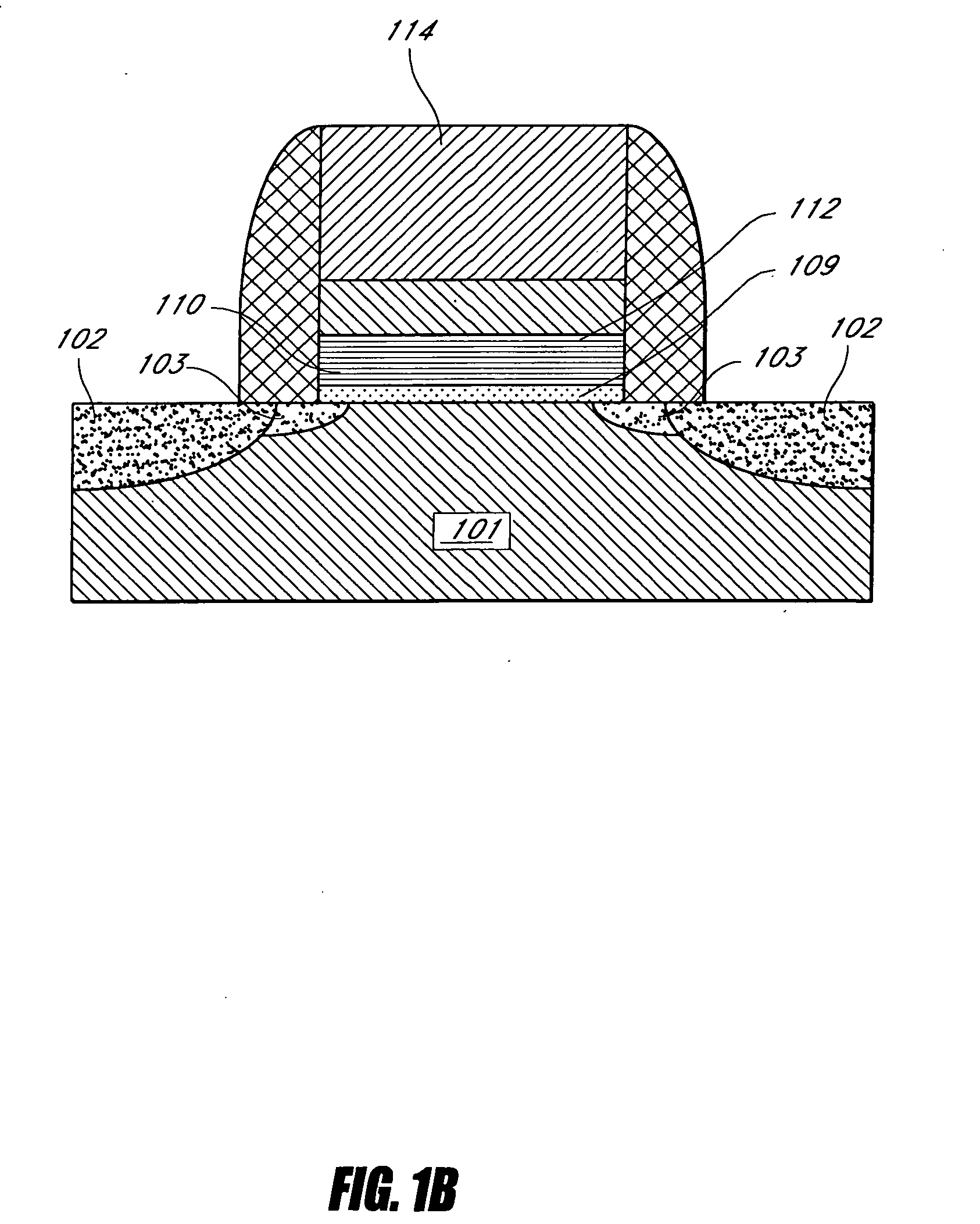

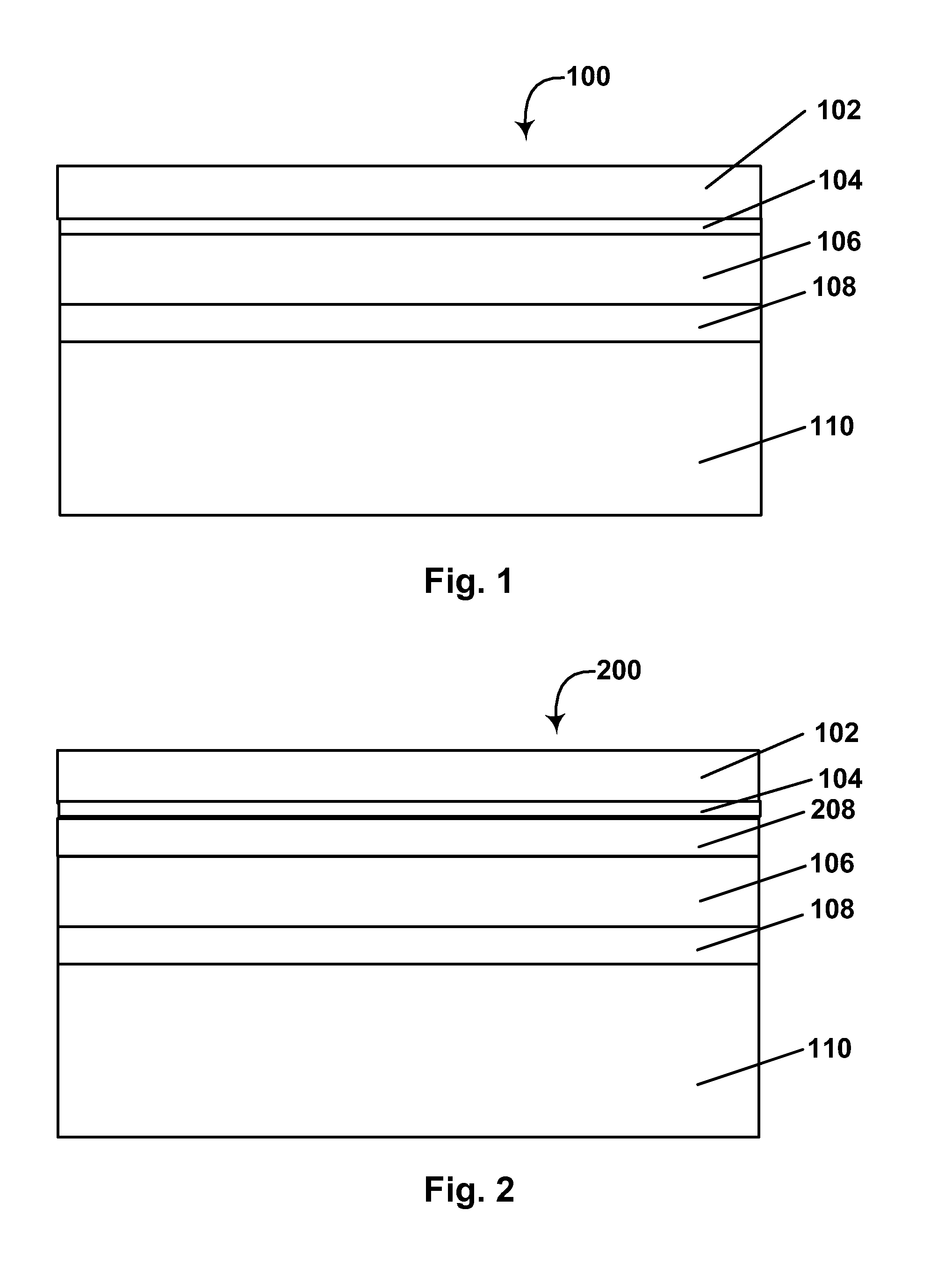

Method of depositing barrier layer for metal gates

InactiveUS6858524B2Eliminate the problemEasy to controlSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricRemote plasma

A method of manufacturing a high performance MOS device and transistor gate stacks comprises forming a gate dielectric layer over a semiconductor substrate; forming a barrier layer over the gate dielectric layer by an ALD type process; and forming a gate electrode layer over the barrier layer. The method enables the use of hydrogen plasma, high energy hydrogen radicals and ions, other reactive radicals, reactive oxygen and oxygen containing precursors in the processing steps subsequent to the deposition of the gate dielectric layer of the device. The ALD process for forming the barrier layer is performed essentially in the absence of plasma and reactive hydrogen radials and ions. This invention makes it possible to use oxygen as a precursor in the deposition of the metal gates. The barrier film also allows the use of hydrogen plasma in the form of either direct or remote plasma in the deposition of the gate electrode. Furthermore, the barrier film prevents the electrode material from reacting with the gate dielectric material. The barrier layer is ultra thin and, at the same time, it forms a uniform cover over the entire surface of the gate dielectric.

Owner:ASM INTERNATIONAL

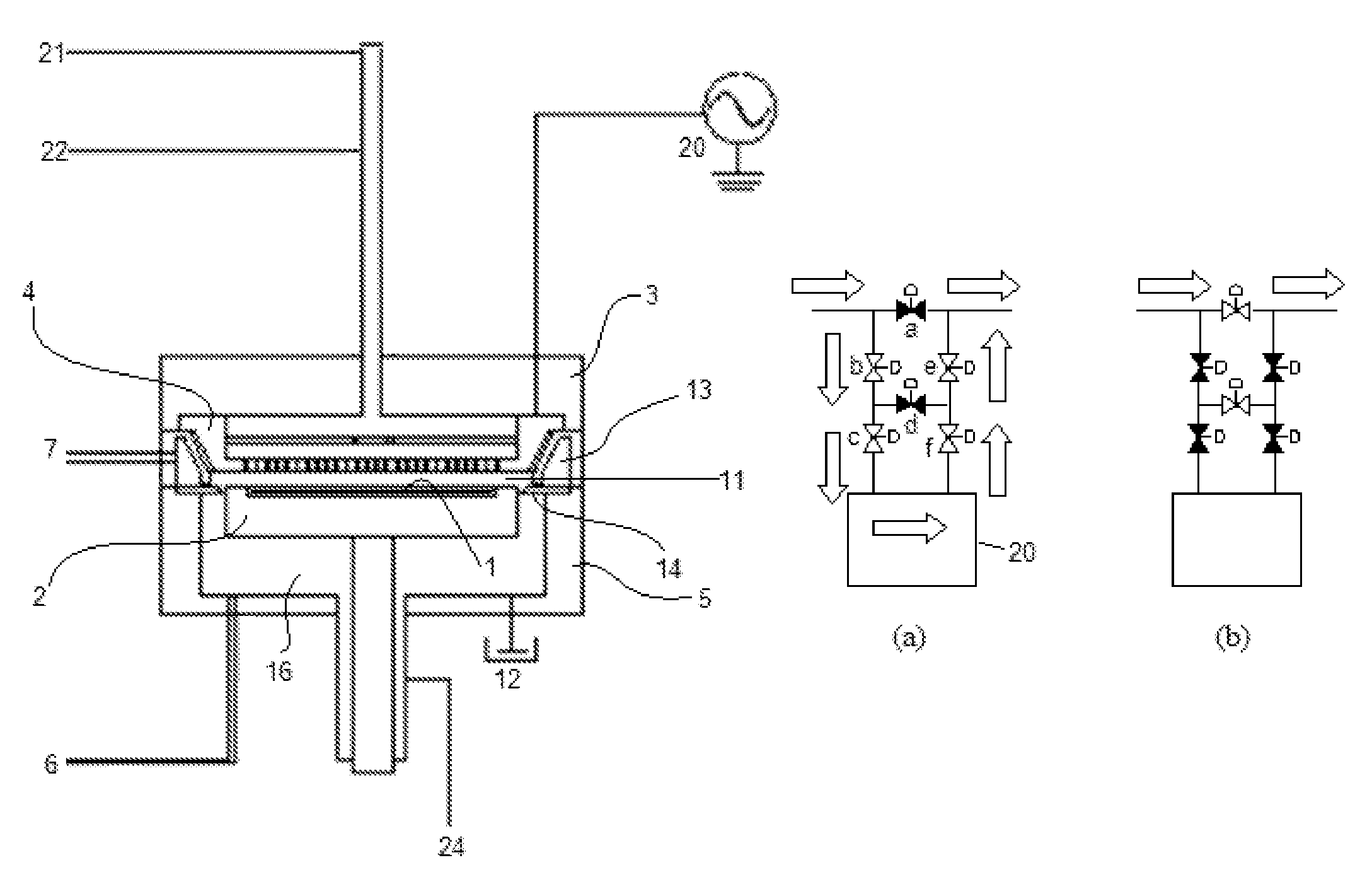

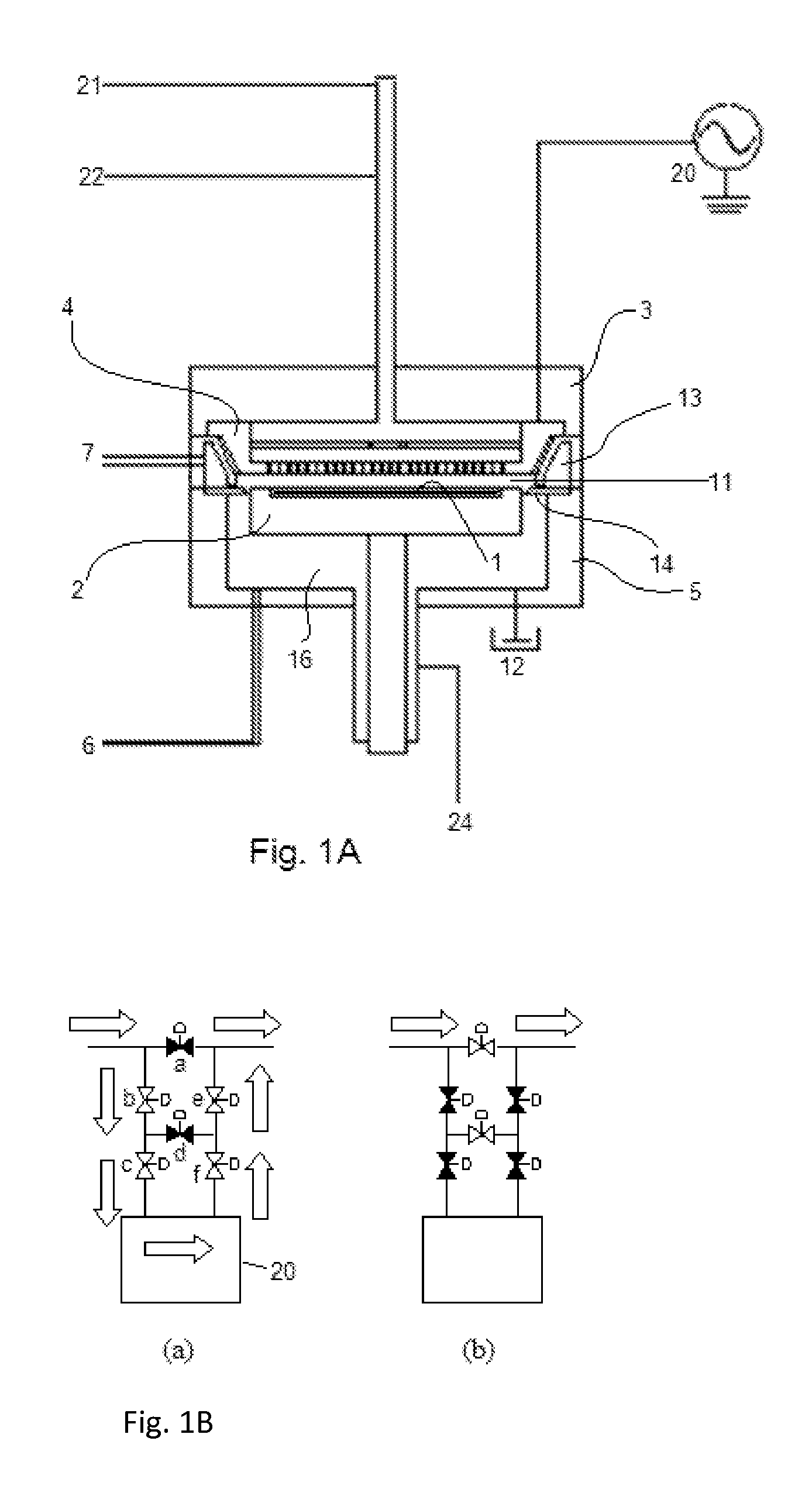

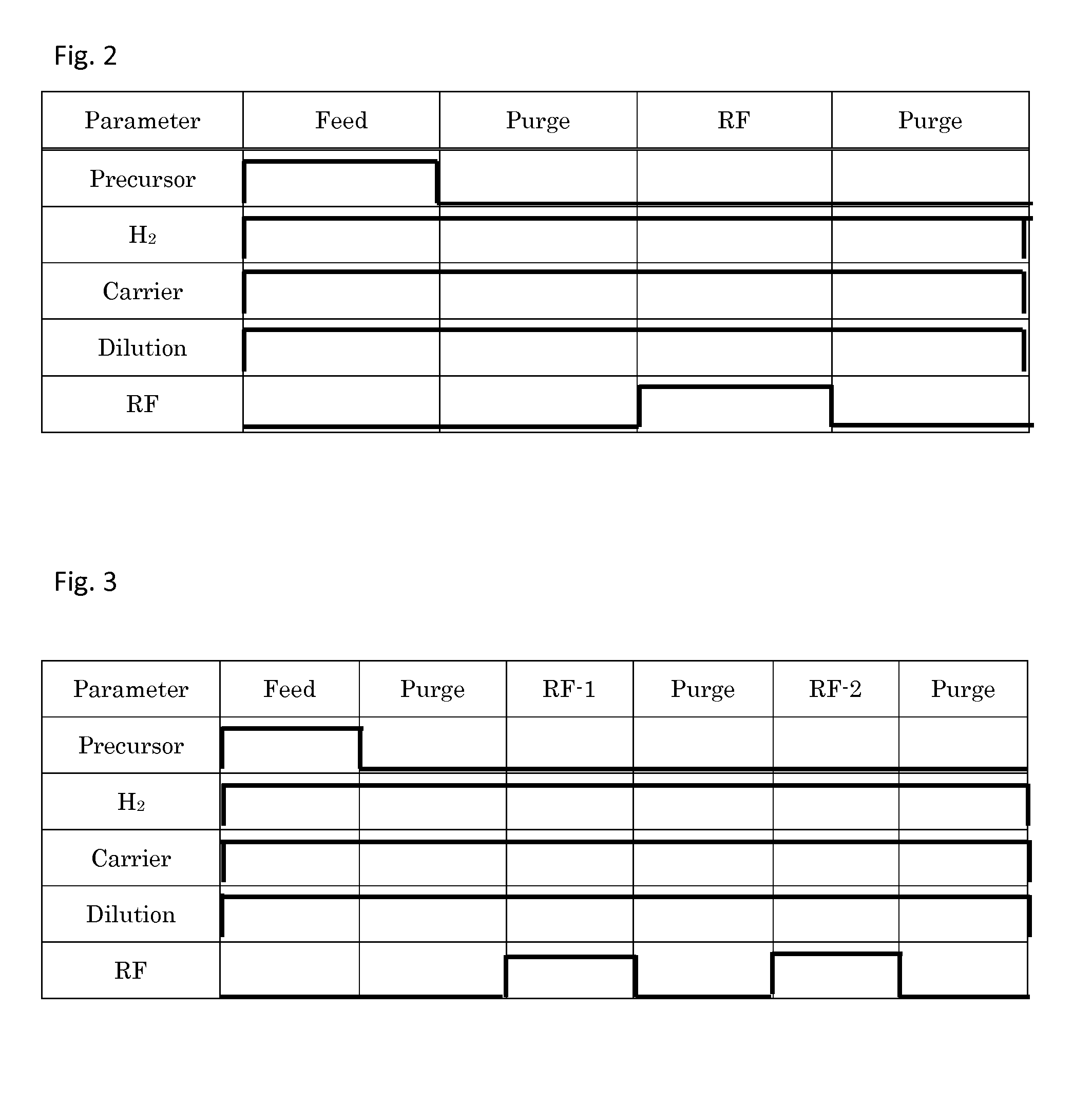

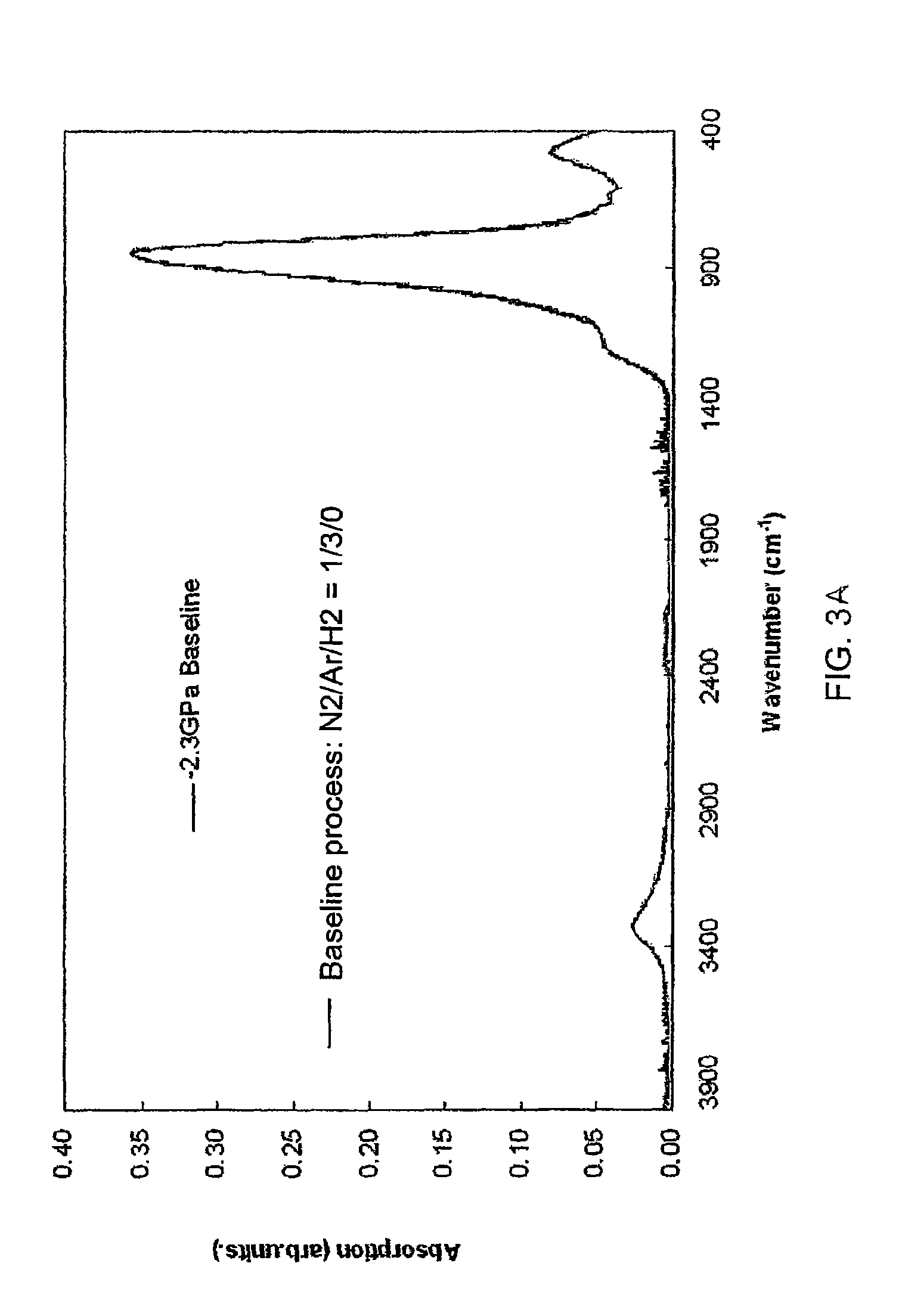

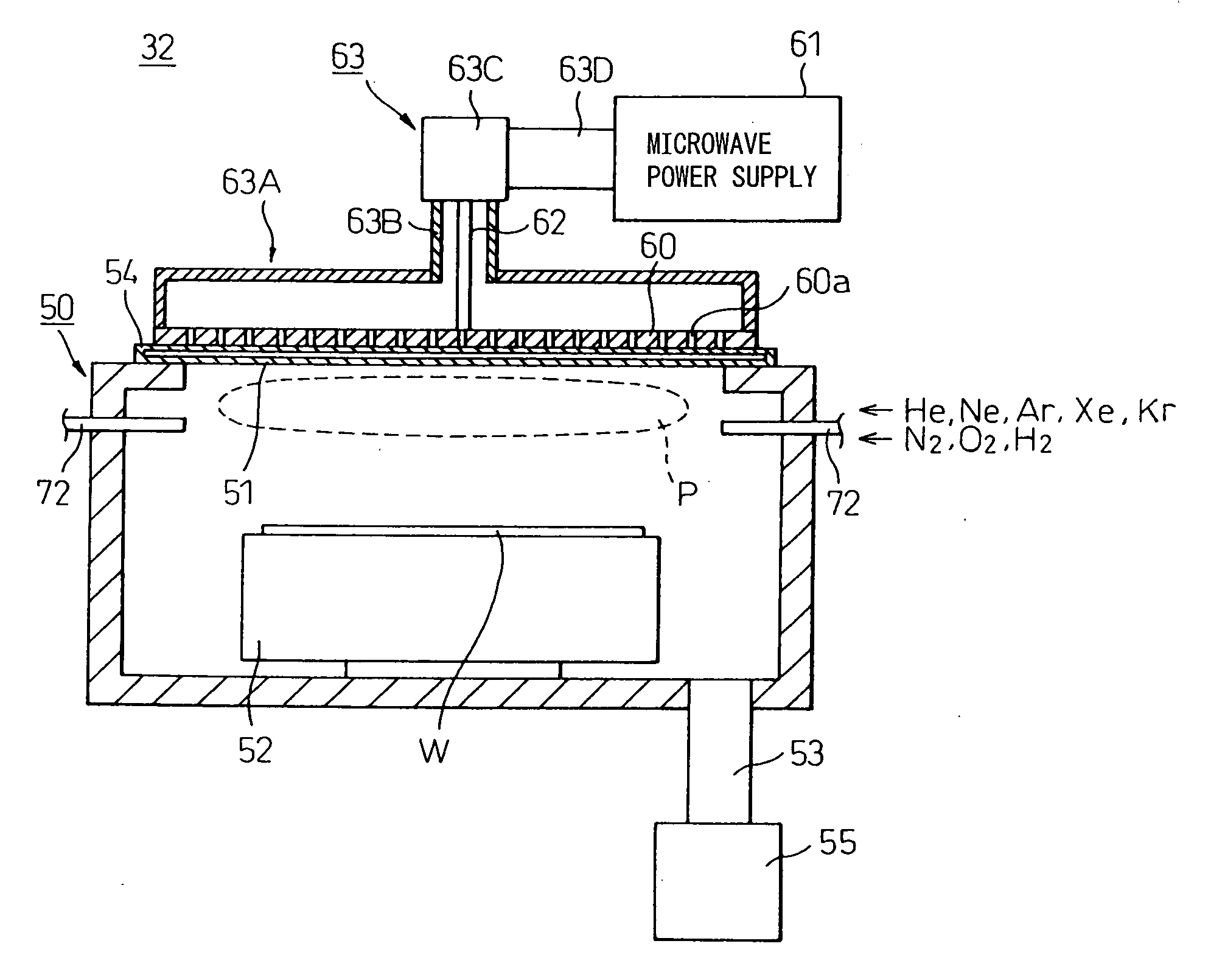

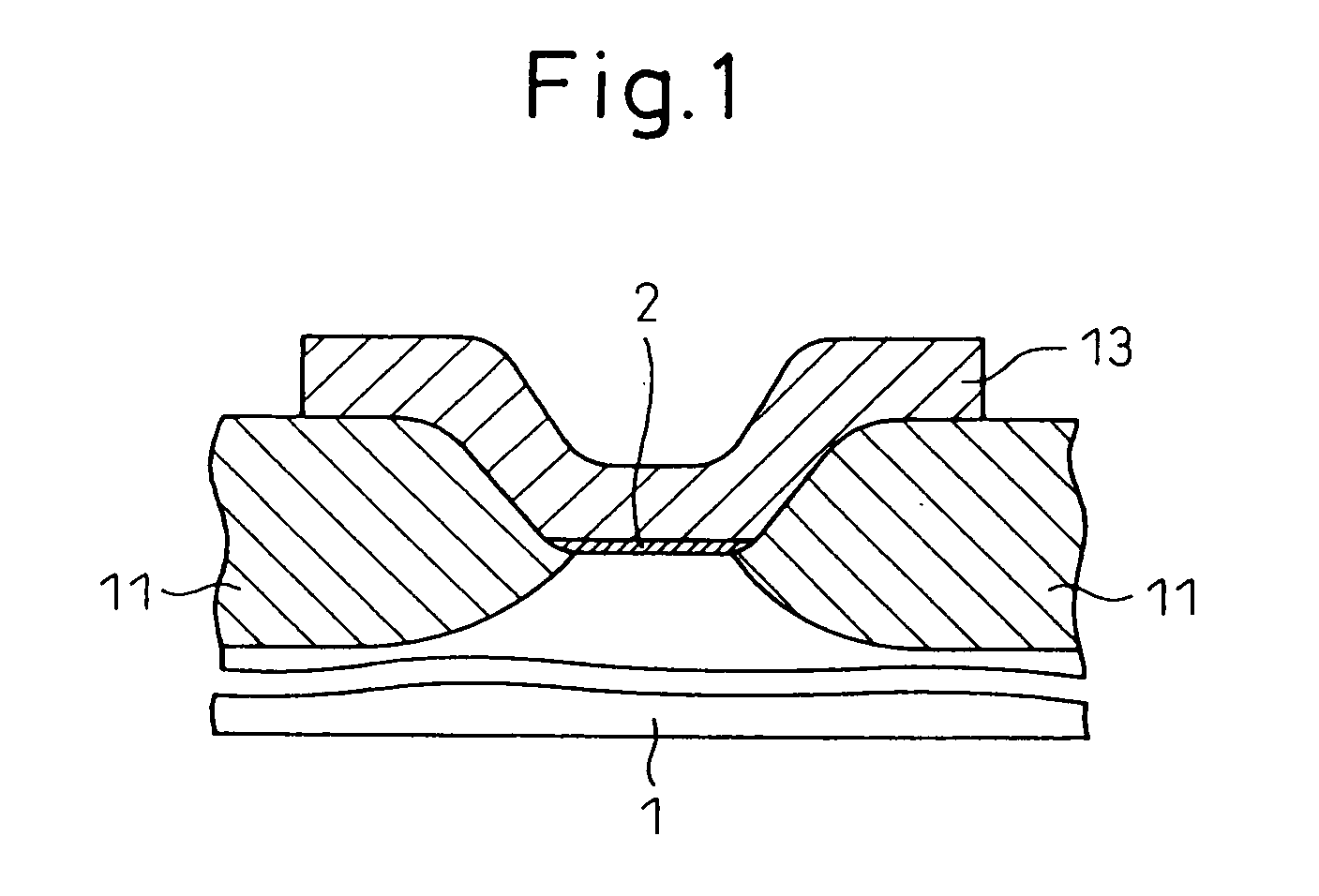

Method for forming dielectric film in trenches by PEALD using H-containing gas

ActiveUS9455138B1Increase deposition rateHigh film thicknessSemiconductor/solid-state device manufacturingChemical physicsNoble gas

A method for forming a dielectric film in a trench on a substrate by plasma-enhanced atomic layer deposition (PEALD) performs one or more process cycles, each process cycle including: (i) feeding a silicon-containing precursor in a pulse; (ii) supplying a hydrogen-containing reactant gas at a flow rate of more than about 30 sccm but less than about 800 sccm in the absence of nitrogen-containing gas; (iii) supplying a noble gas to the reaction space; and (iv) applying RF power in the presence of the reactant gas and the noble gas and in the absence of any precursor in the reaction space, to form a monolayer constituting a dielectric film on a substrate at a growth rate of less than one atomic layer thickness per cycle.

Owner:ASM IP HLDG BV

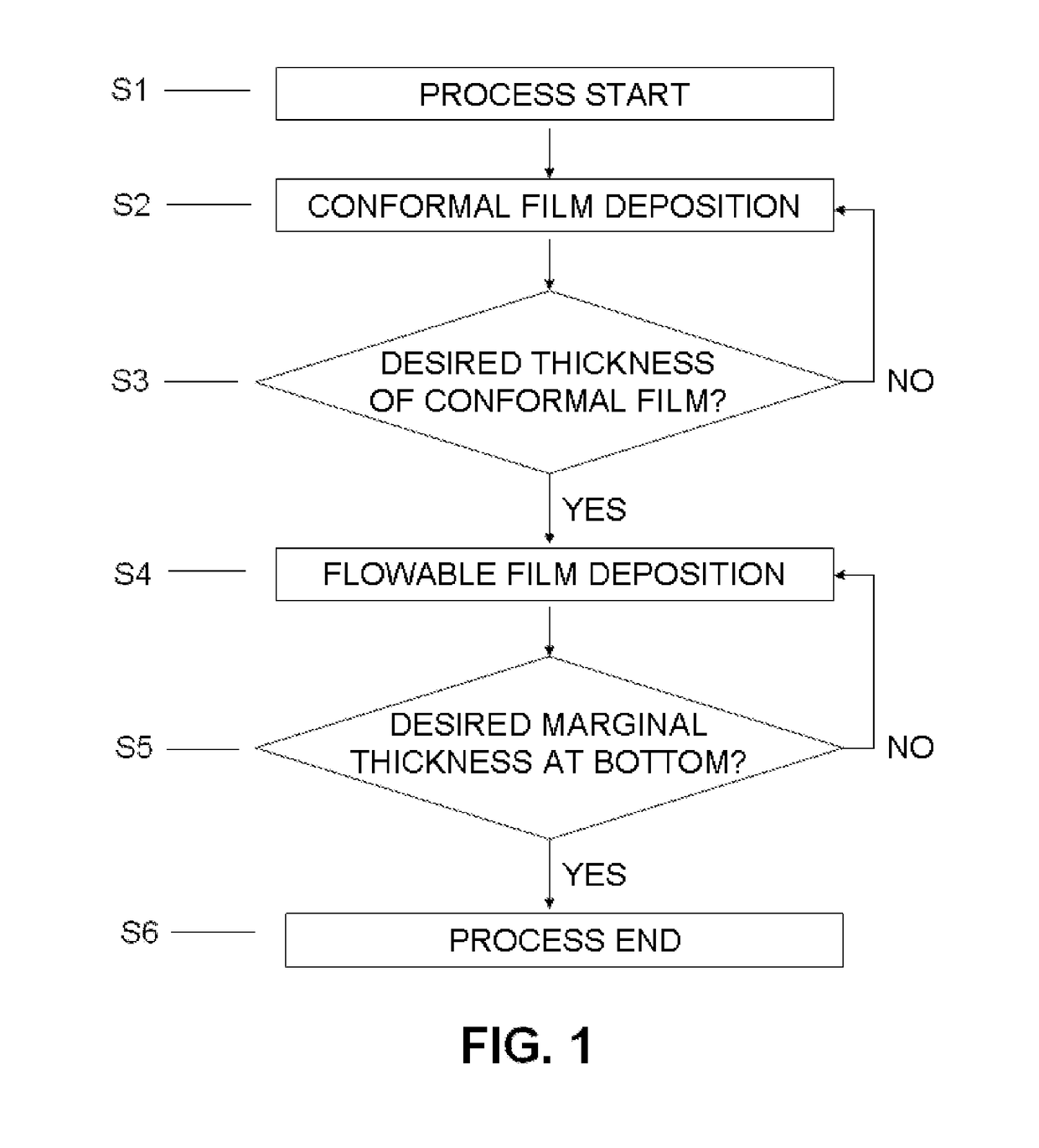

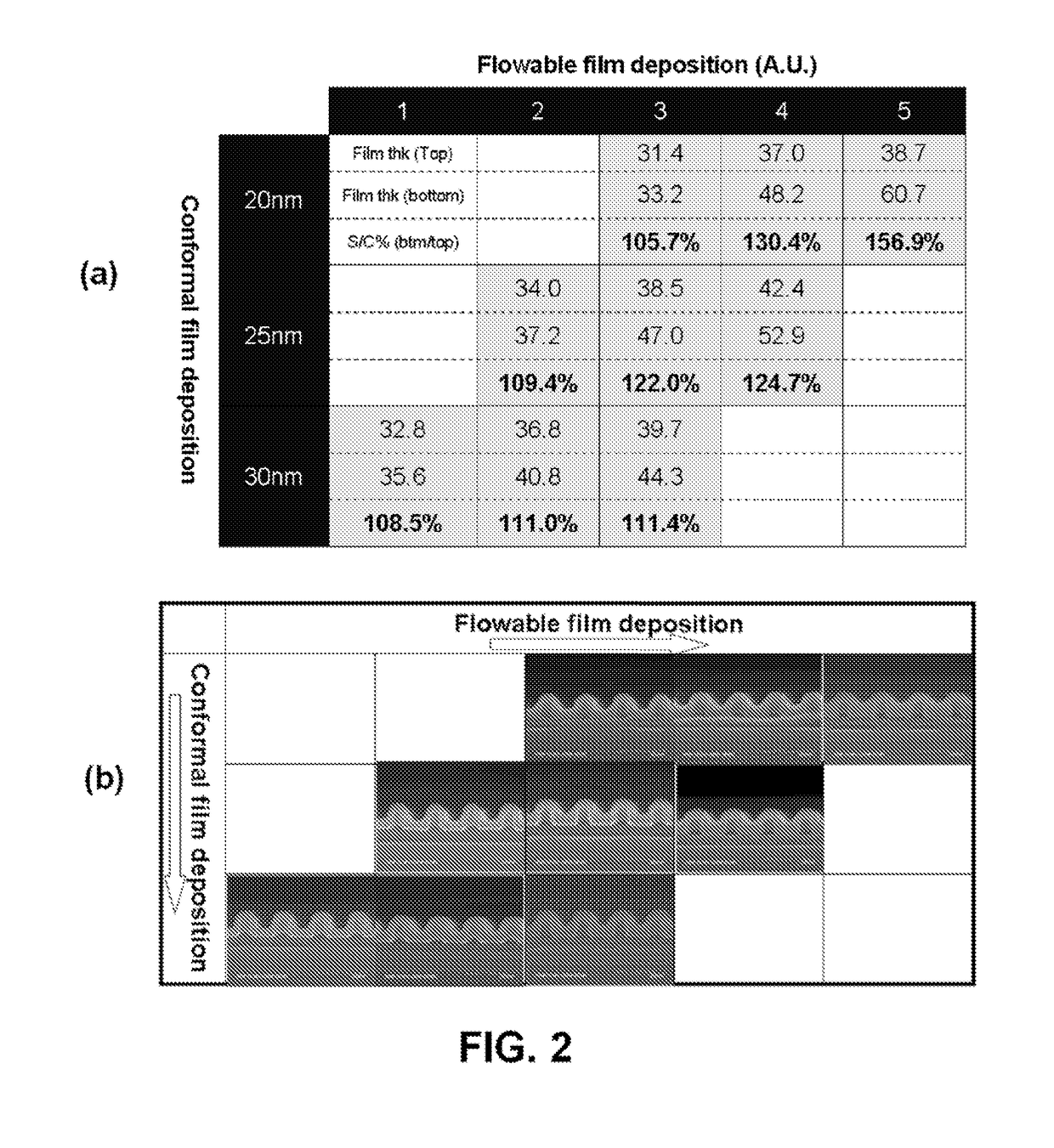

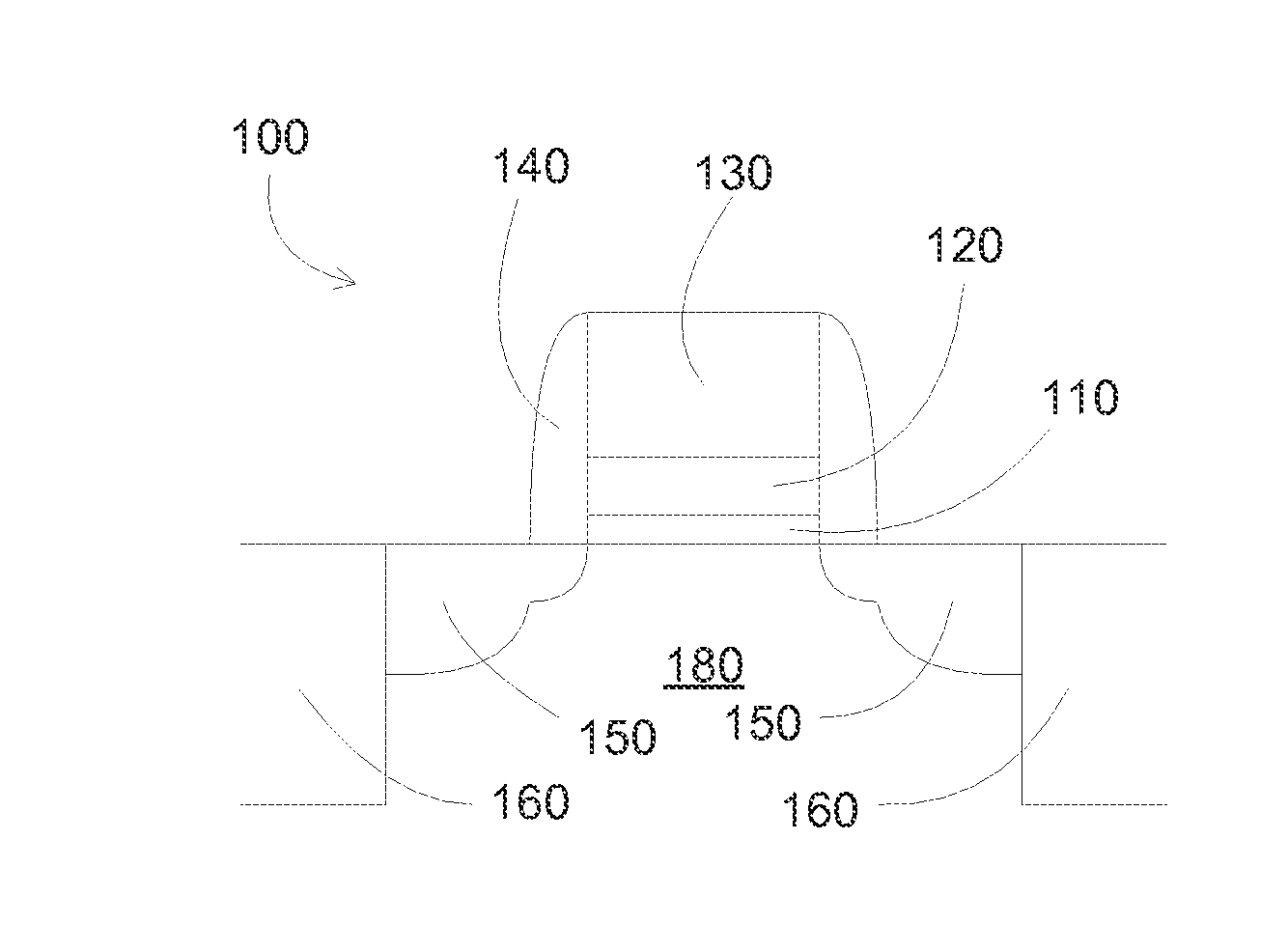

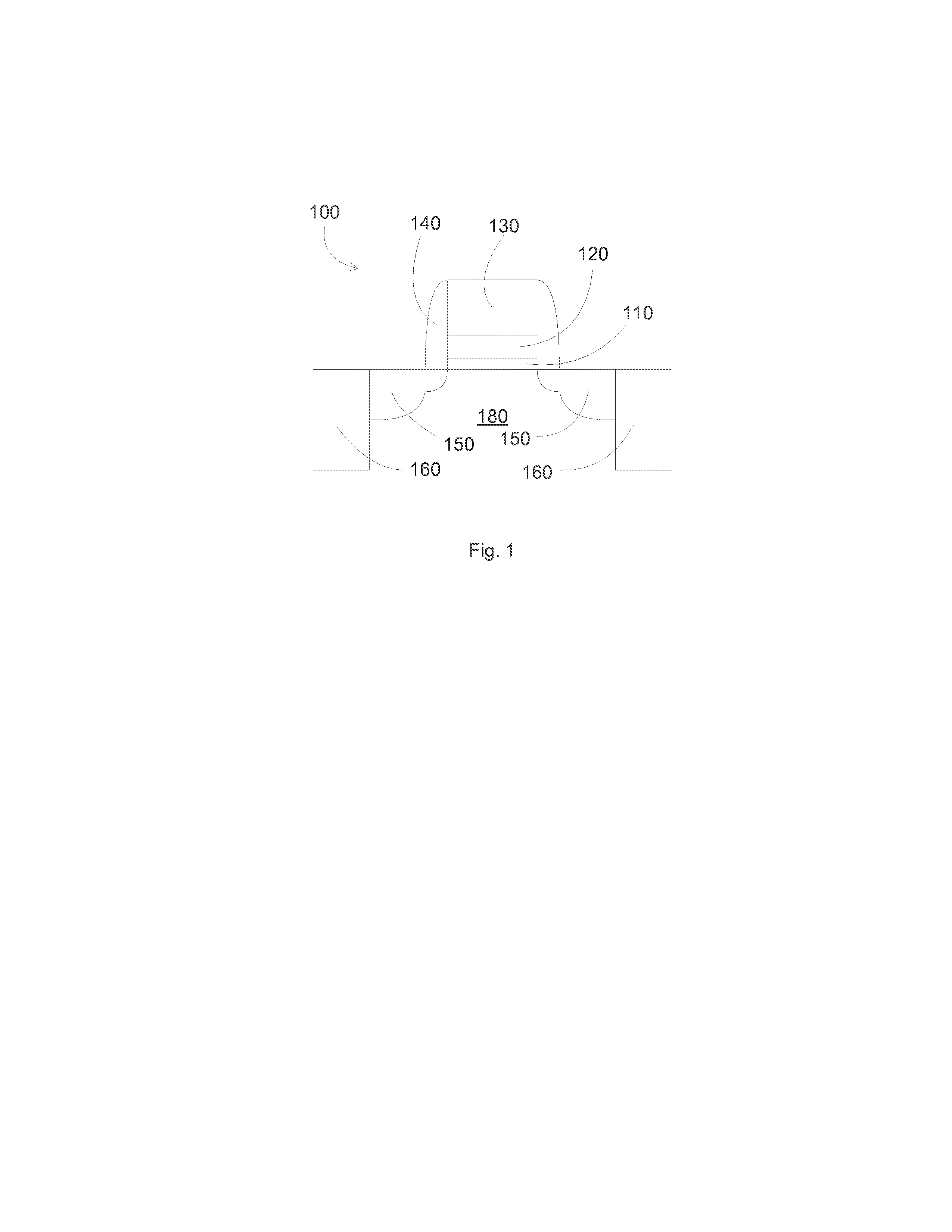

Method of depositing film with tailored comformality

ActiveUS8470187B2Easy to controlAvoid damageDecorative surface effectsPretreated surfacesEngineeringPatterned substrate

A method of depositing a film with a target conformality on a patterned substrate, includes: depositing a first film on a convex pattern and a bottom surface; and depositing a second film on the first film, thereby forming an integrated film having a target conformality, wherein one of the first and second films is a conformal film which is non-flowable when being deposited and has a conformality of about 80% to about 100%, and the other of the first and second films is a flowable film which is flowable when being deposited.

Owner:ASM JAPAN

Methods of atomic layer deposition of hafnium oxide / erbium oxide bi-layer as advanced gate dielectrics

InactiveUS20130313656A1Improve electrical performanceFew defectSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricHafnium

Provided is a two-step ALD deposition process for forming a gate dielectric involving an erbium oxide layer deposition followed by a hafnium oxide layer deposition. Hafnium oxide can provide a high dielectric constant, high density, large bandgap and good thermal stability. Erbium oxide can act as a barrier against oxygen diffusion, which can lead to increasing an effective oxide thickness of the gate dielectric and preventing hafnium-silicon reactions that may lead to higher leakage current.

Owner:INTERMOLECULAR

Expandable intervertebral spacer

InactiveUS7621950B1Increase contact surfaceEasy to fillInternal osteosythesisBone implantBiomedical engineering

Owner:KYPHON

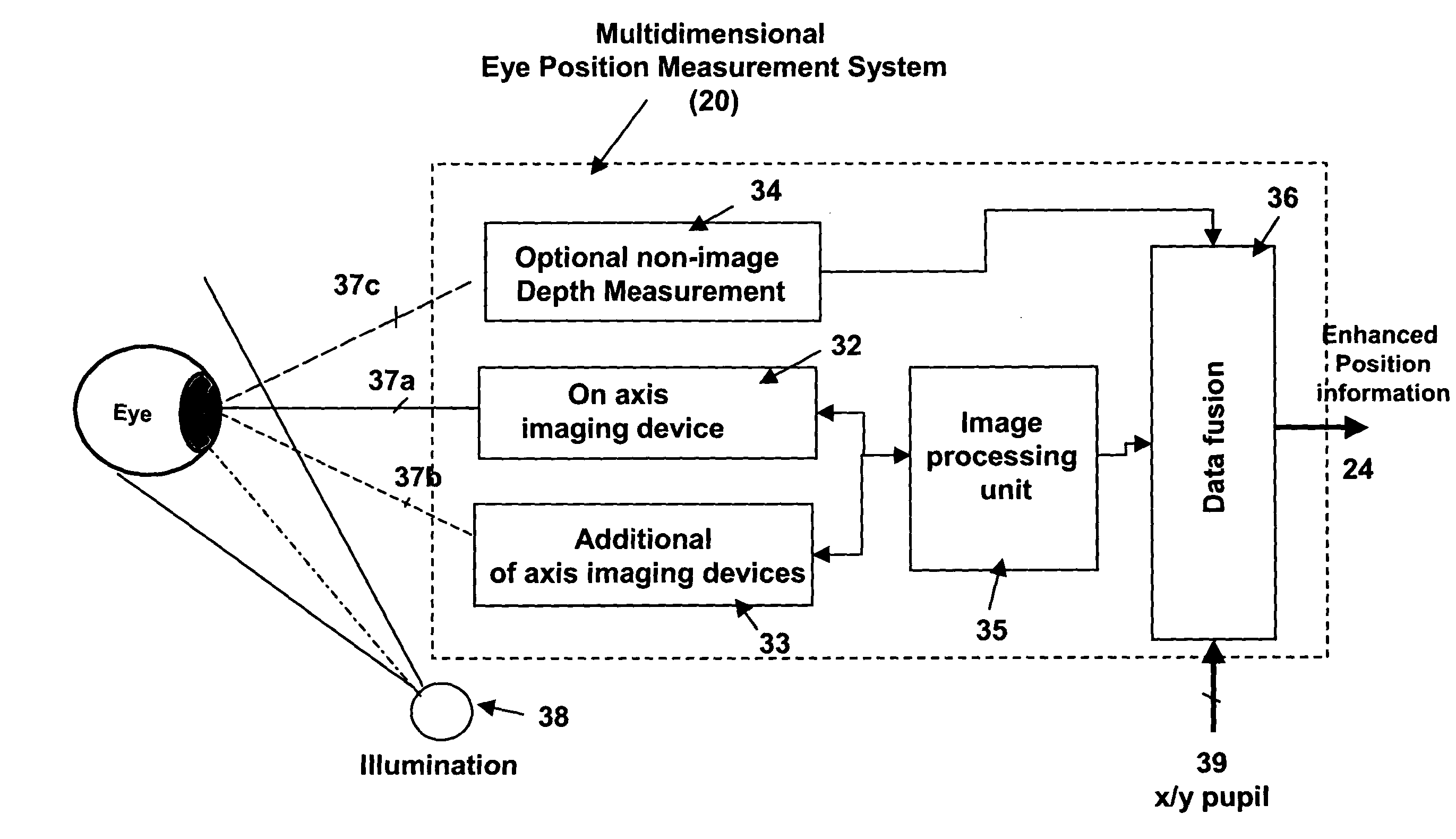

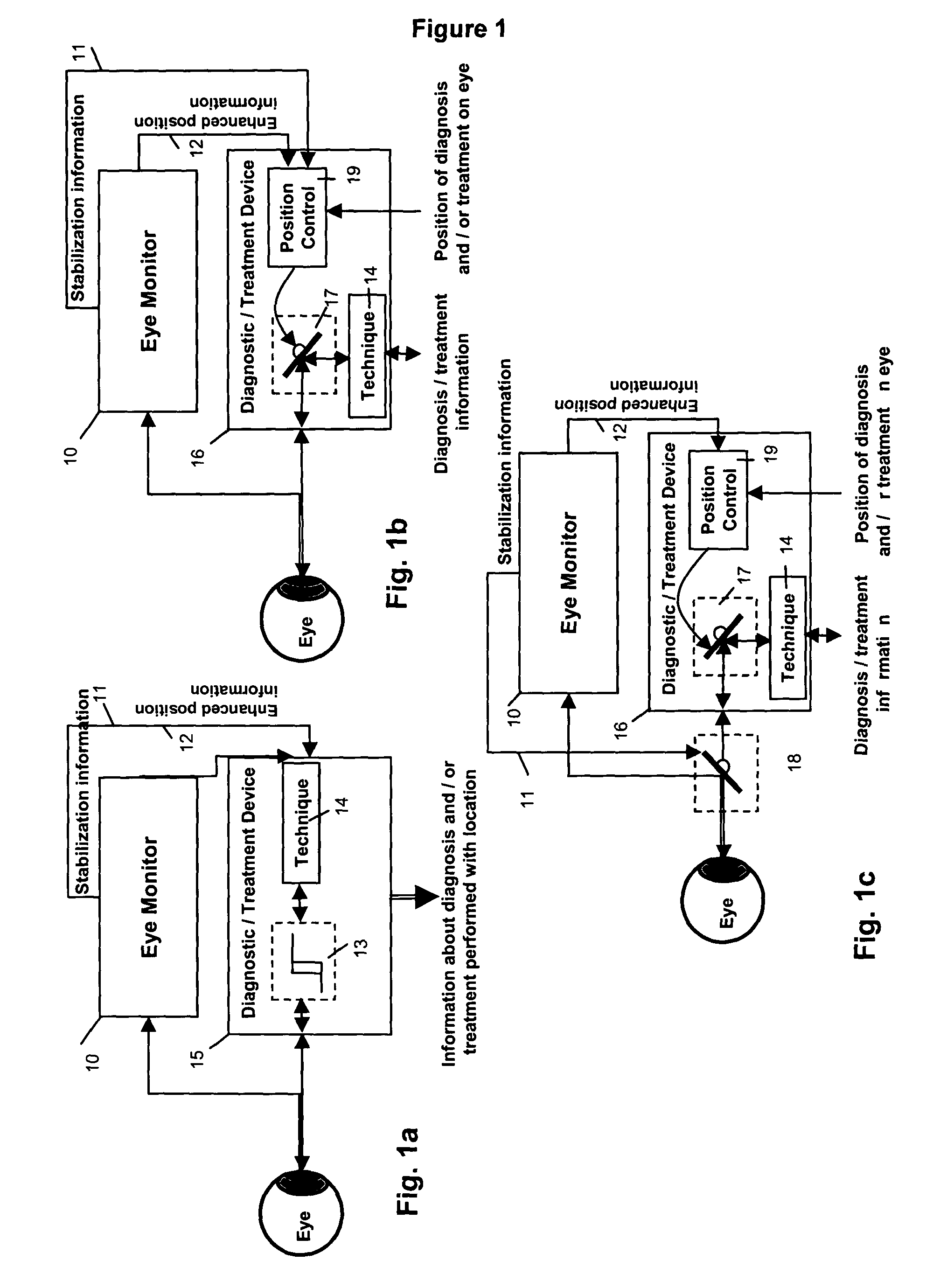

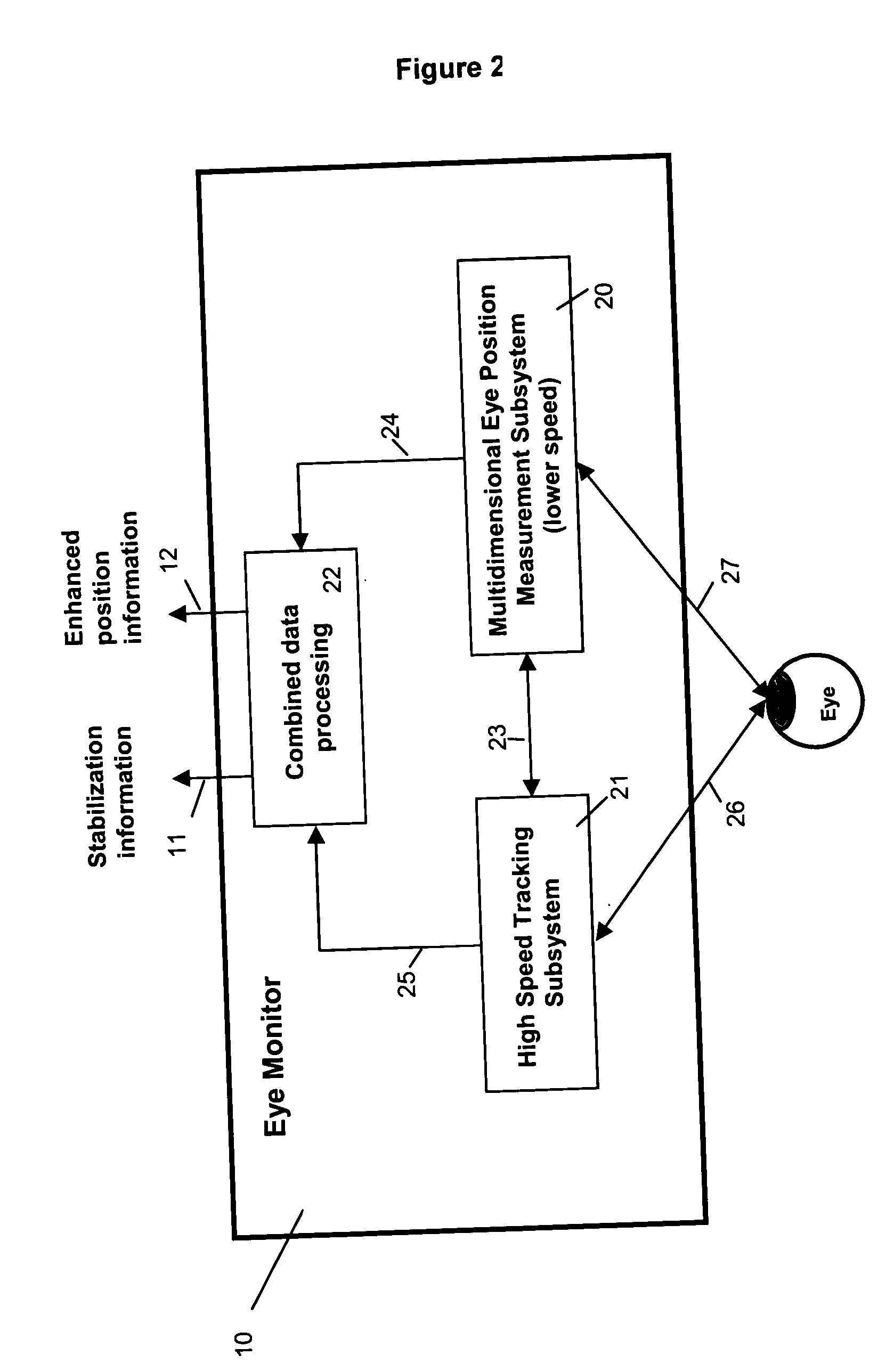

Multidimensional eye tracking and position measurement system for diagnosis and treatment of the eye

ActiveUS20050024586A1Improve spatial resolutionLess field of viewLaser surgeryCharacter and pattern recognitionMeasurement deviceSaccadic movements

The present invention relates to improved ophthalmic diagnostic measurement or treatment methods or devices, that make use of a combination of a high speed eye tracking device, measuring fast translation or saccadic motion of the eye, and an eye position measurement device, determining multiple dimensions of eye position or other components of eye, relative to an ophthalmic diagnostic or treatment instrument.

Owner:SENSOMOTORIC INSTR FUR INNOVATIVE SENSORIK MBH D B A SENSOMOTORIC INSTR

Expandable element

InactiveUS20070282443A1Prevent crashIncrease contact surfaceDental implantsInternal osteosythesisEngineeringBiomedical engineering

Owner:KYPHON

Method to increase tensile stress of silicon nitride films using a post PECVD deposition UV cure

ActiveUS8129290B2Increasing the thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaThin membrane

High tensile stress in a deposited layer such as silicon nitride, may be achieved utilizing one or more techniques, employed alone or in combination. High tensile stress may be achieved by forming a silicon-containing layer on a surface by exposing the surface to a silicon-containing precursor gas in the absence of a plasma, forming silicon nitride by exposing said silicon-containing layer to a nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride created thereby. High tensile stress may also be achieved by exposing a surface to a silicon-containing precursor gas in a first nitrogen-containing plasma, treating the material with a second nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride formed thereby. In another embodiment, tensile film stress is enhanced by deposition with porogens that are liberated upon subsequent exposure to UV radiation or plasma treatment.

Owner:APPLIED MATERIALS INC

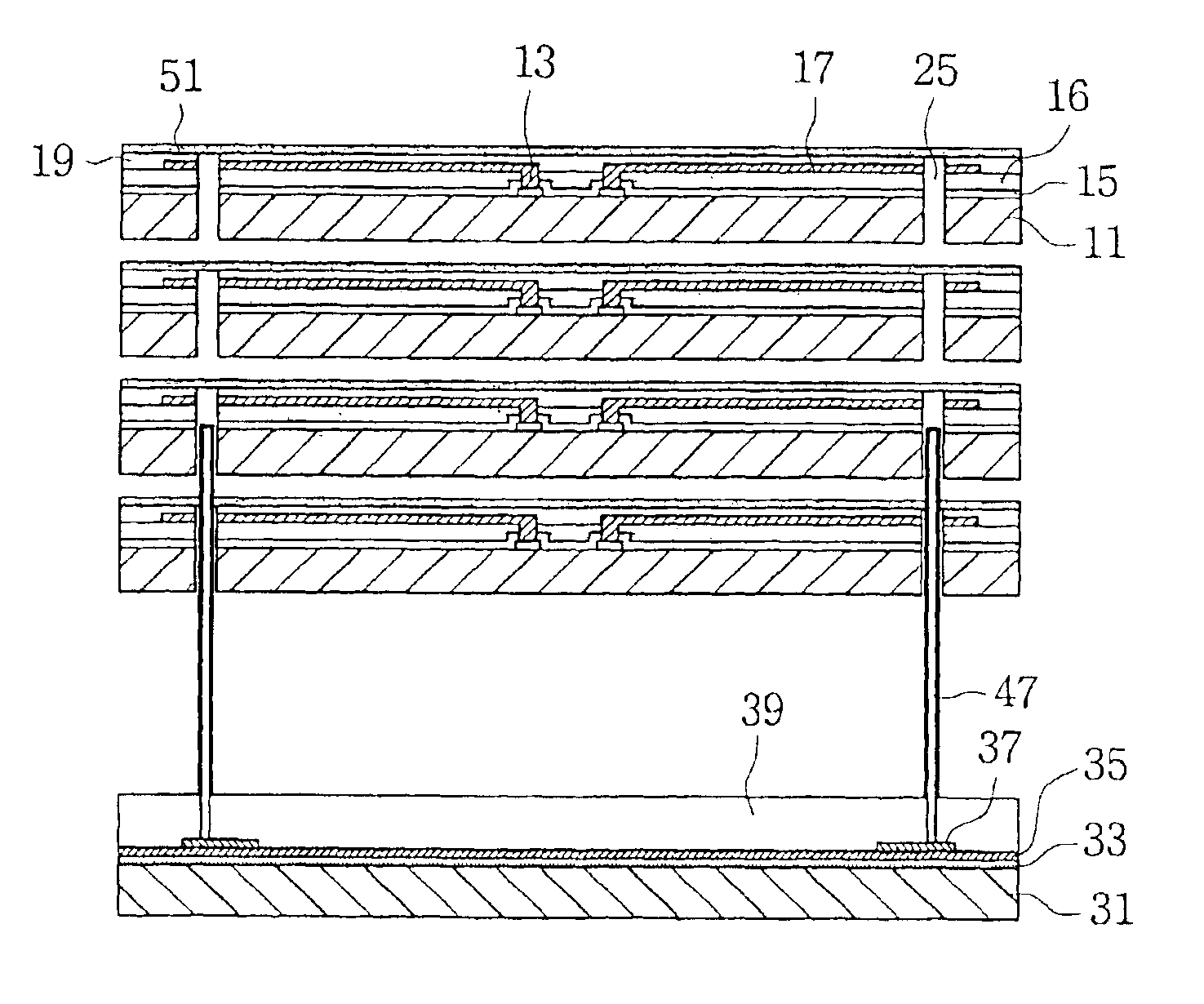

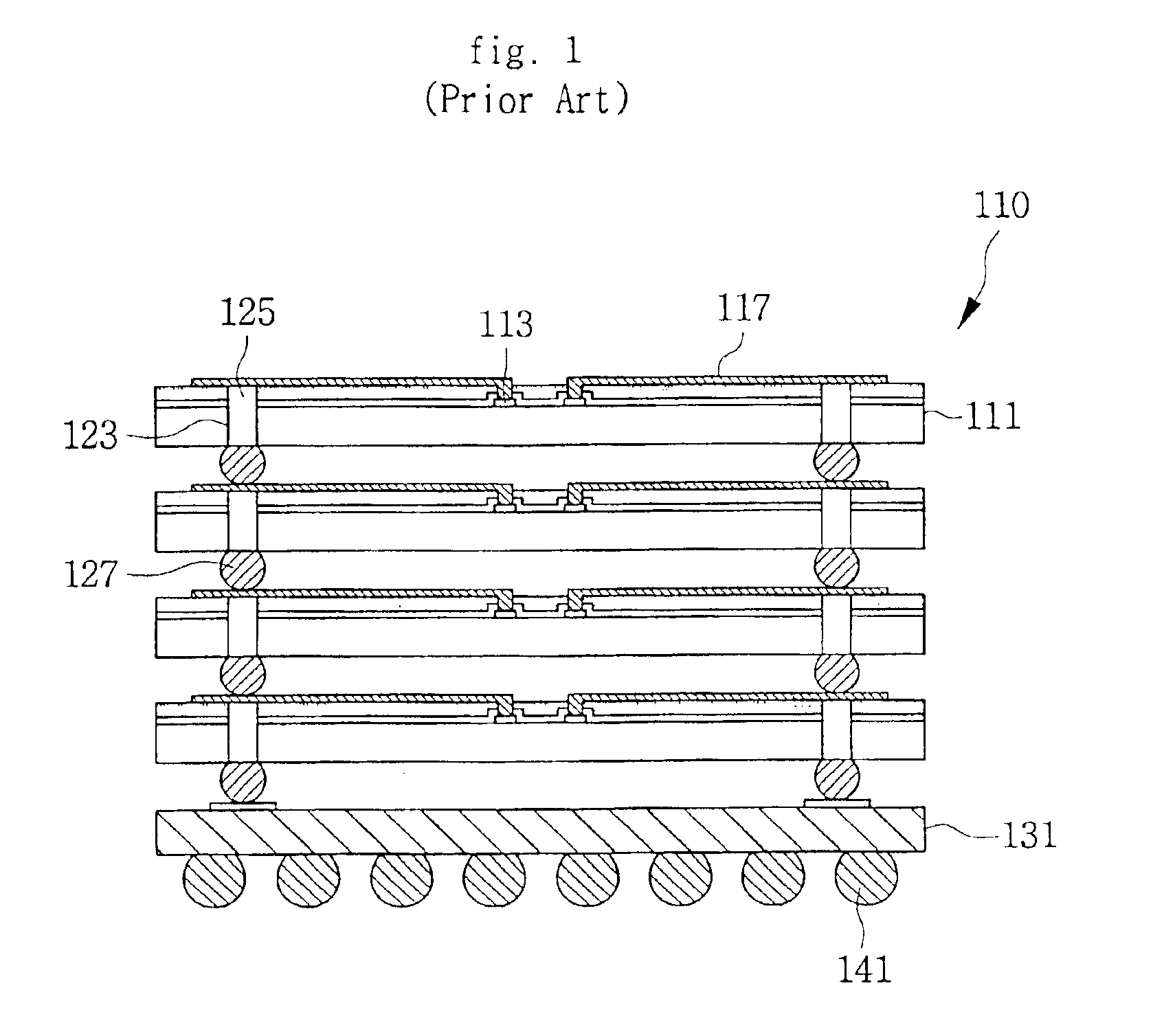

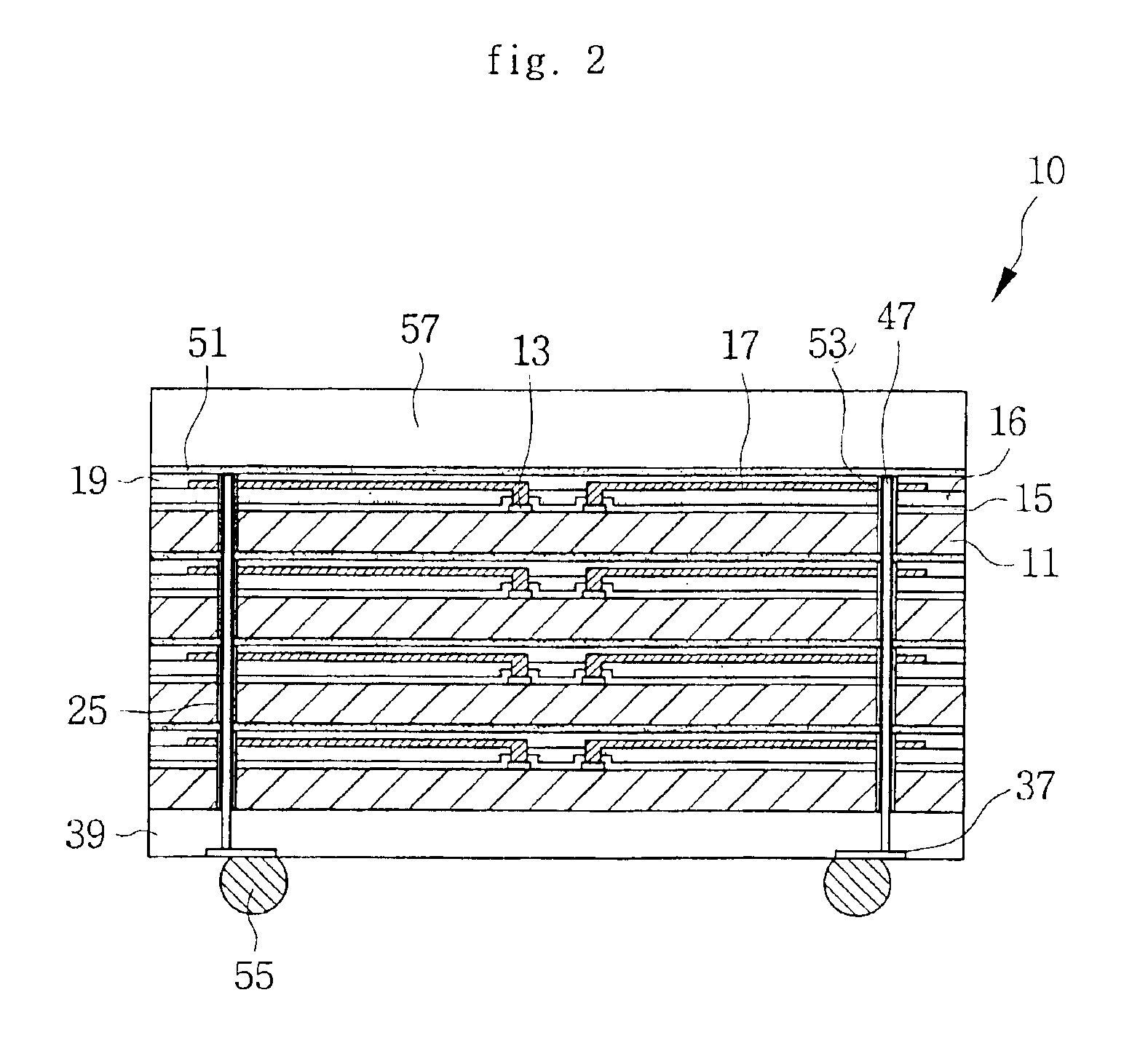

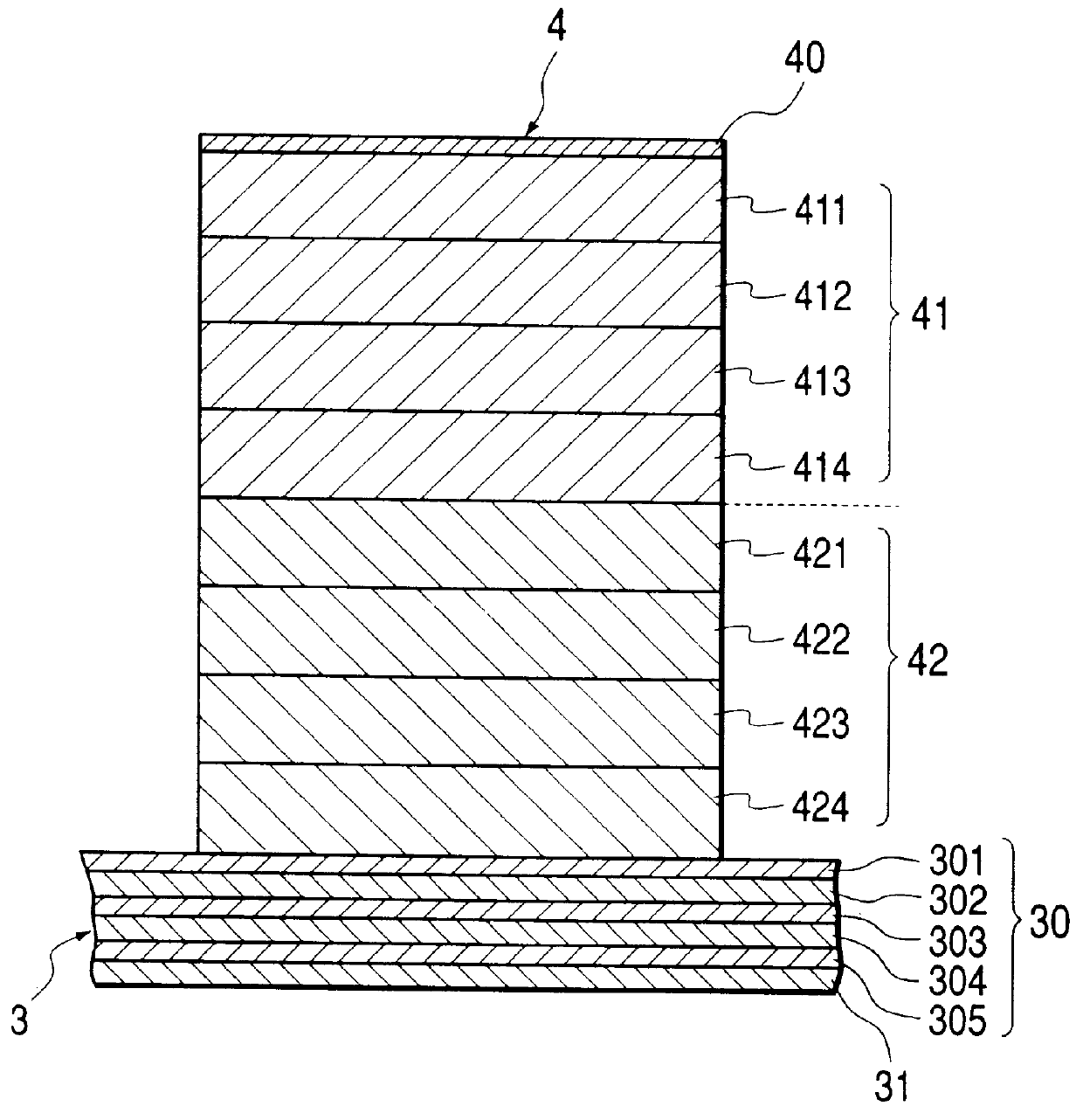

Multi-chip package (MCP) with a conductive bar and method for manufacturing the same

InactiveUS6908785B2Prevents adhesive strength failureIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A multi-chip package (MCP) is provided. The MCP comprises a plurality of stacked semiconductor chips, each including a chip pad and a first insulating layer overlying the chip pad with an opening to expose a portion of the chip pad. Each chip additionally includes a pad redistribution line formed on the first insulating layer and a second insulating layer covering the pad redistribution line. A via hole is formed through the chip, the first insulating layer, a pad redistribution line and the second insulating layer. The MCP further includes a protective layer formed on the bottom of the lowest semiconductor chip. The protective layer includes a conductive pad formed opposite the bottom of the lowest semiconductor chip. A conductive bar extends through the via holes of the stacked semiconductor chips, from the conductive pad, and is electrically connected to the pad redistribution line of the stacked semiconductor chips.

Owner:SAMSUNG ELECTRONICS CO LTD

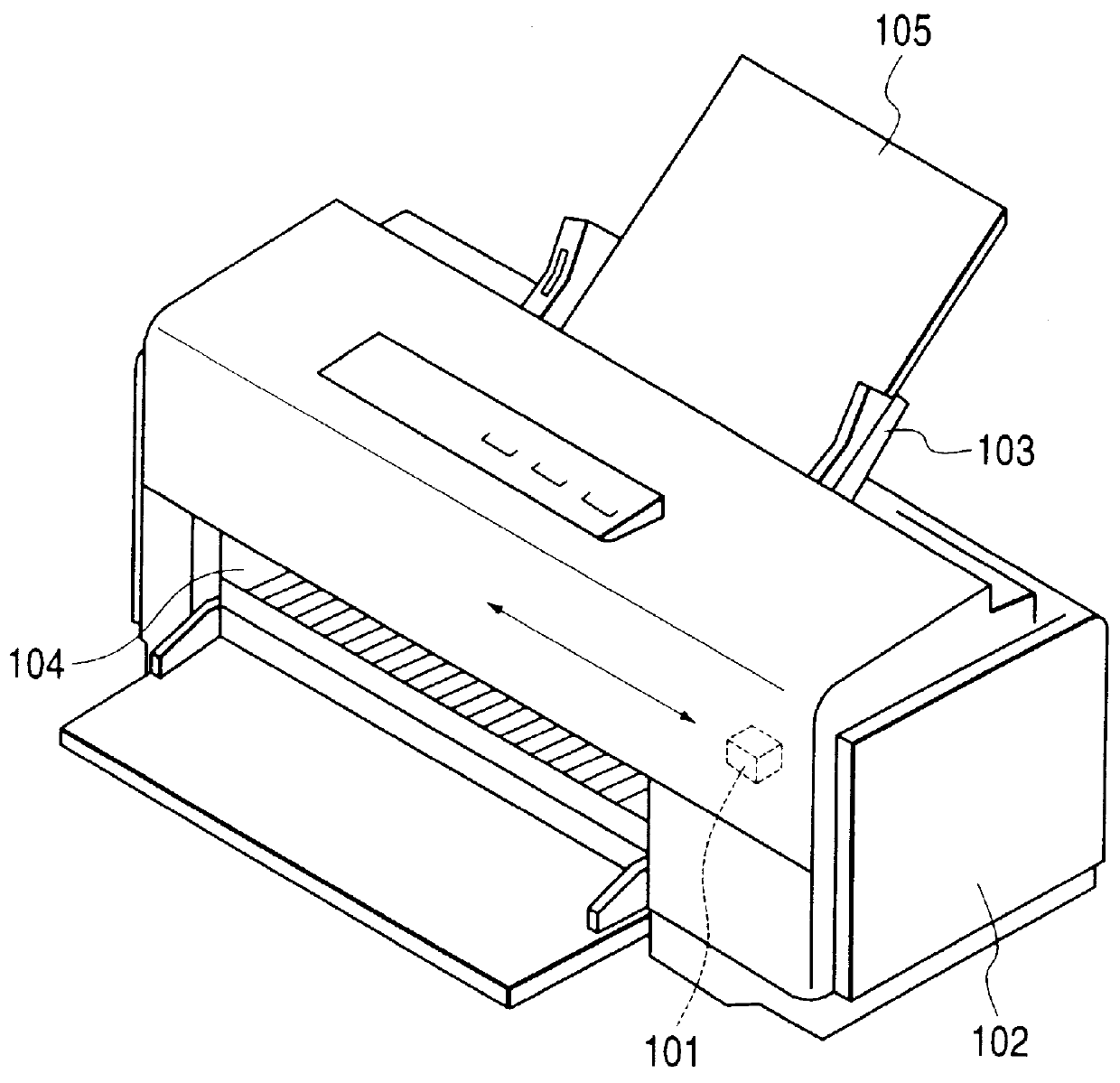

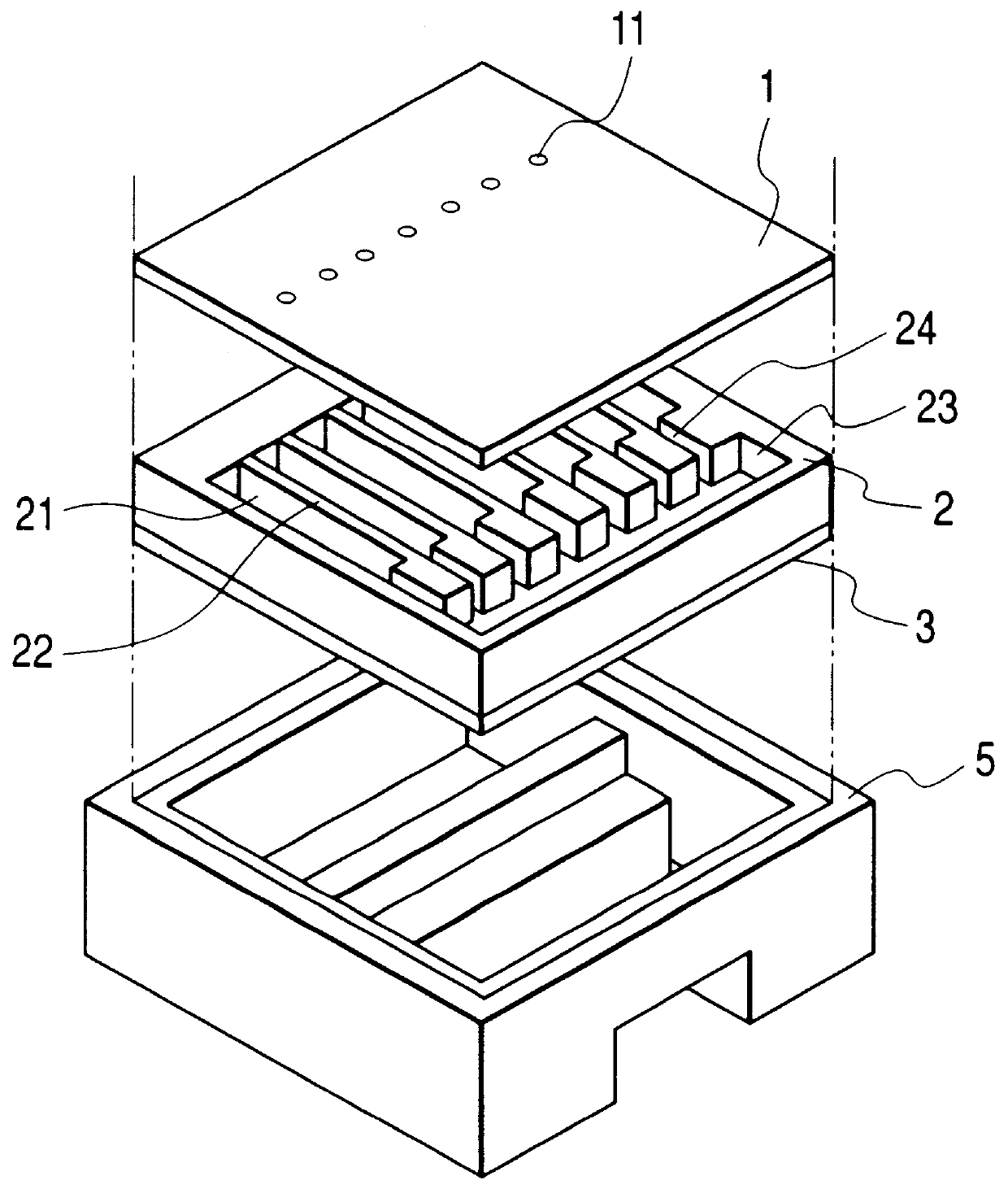

Ink-jet recording head with piezoelectric device and method for manufacturing the same

InactiveUS6142615AIncrease in piezoelectric constantIncrease the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsPiezoelectric coefficient

A piezoelectric device for an ink jet print head that has a greater displacement at a low drive voltage. The ink-jet recording head includes a vibration plate, on which is mounted one or more piezoelectric devices that change the volumes of pressure chambers upon application of a voltage. The device is mounted at least on one face of a pressure chamber substrate that is to be filled with ink. Such piezoelectric device includes a second piezoelectric layer having a piezoelectric constant g of a constant value or higher; and a first piezoelectric layer having a dielectric constant of a specific value or higher. Since the piezoelectric constant d of the piezoelectric device correlates with the product of the largest piezoelectric constant g and the largest dielectric device of the piezoelectric devices, a piezoelectric constant d larger than in the conventional case, i.e., having a greater displacement, can be obtained.

Owner:SEIKO EPSON CORP

Method for forming insulation film

InactiveUS20050161434A1Quality improvementIncreasing the thicknessElectrical controlDecorative surface effectsSubstrate surfaceElectron

In a process involving the formation of an insulating film on a substrate for an electronic device, the insulating film is formed on the substrate surface by carrying out two or more steps for regulating the characteristic of the insulating film involved in the process under the same operation principle. The formation of an insulating film having a high level of cleanness can be realized by carrying out treatment such as cleaning, oxidation, nitriding, and a film thickness reduction while avoiding exposure to the air. Further, carrying out various steps regarding the formation of an insulating film under the same operation principle can realize simplification of the form of an apparatus and can form an insulating film having excellent property with a high efficiency.

Owner:TOKYO ELECTRON LTD

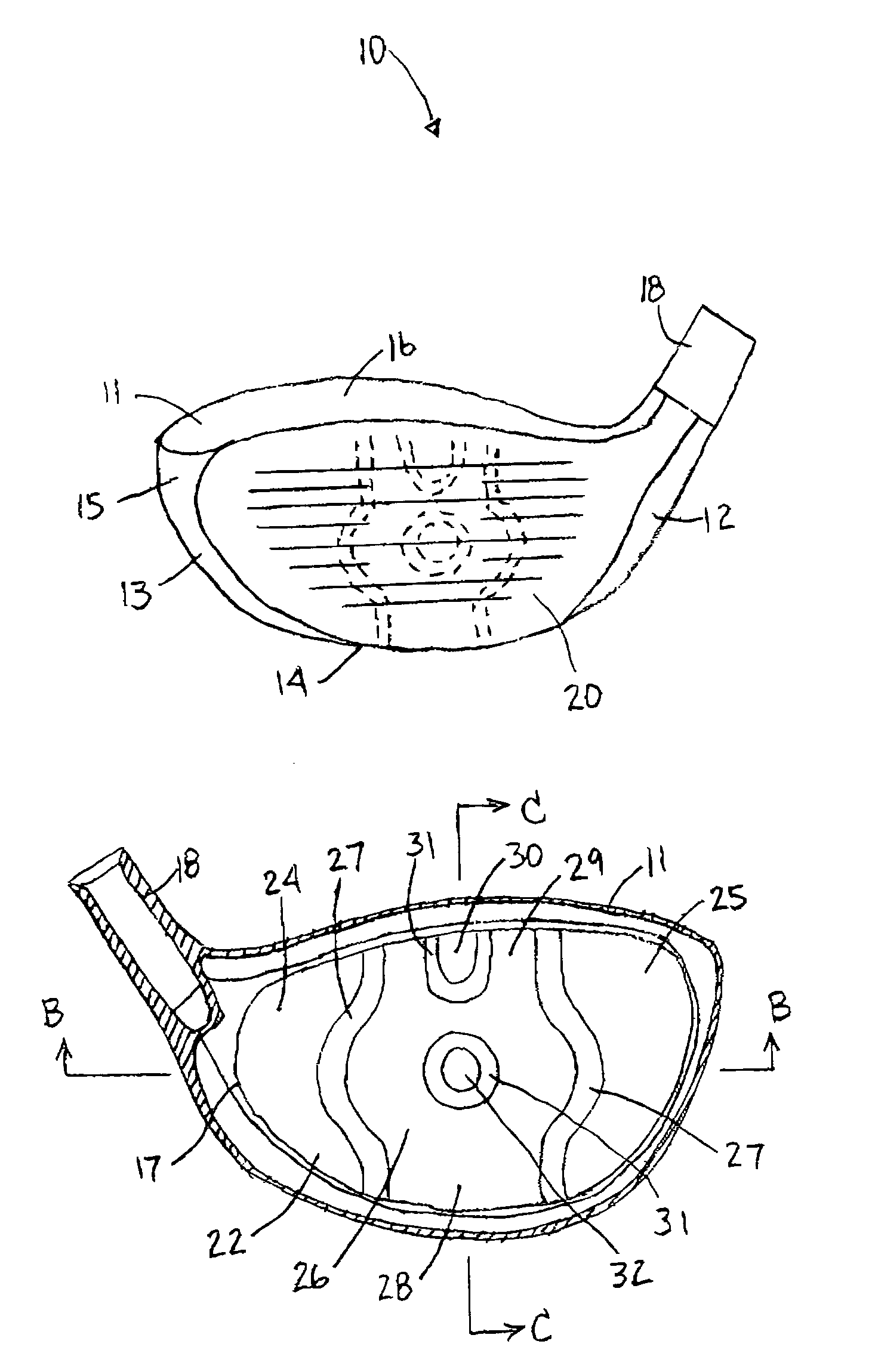

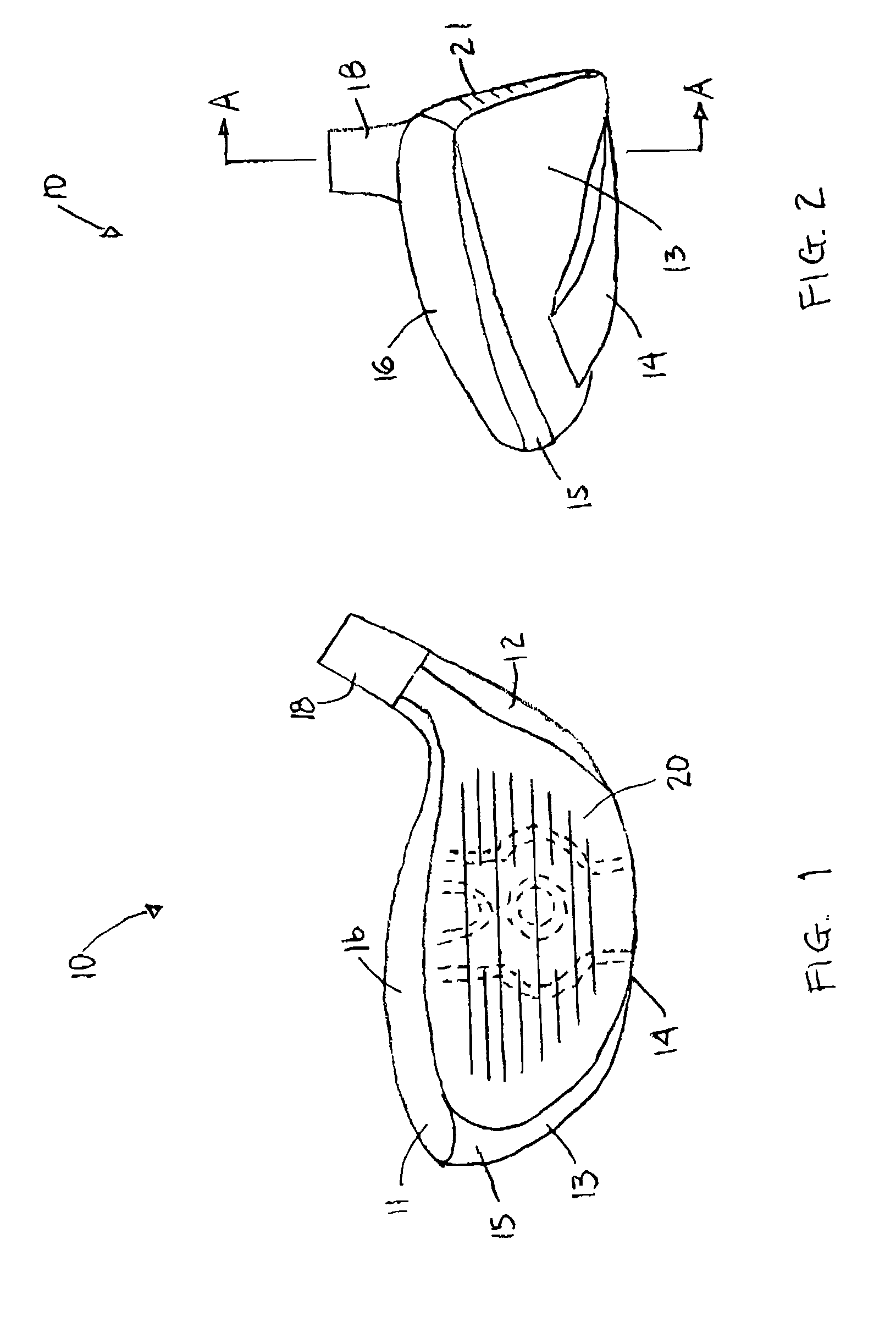

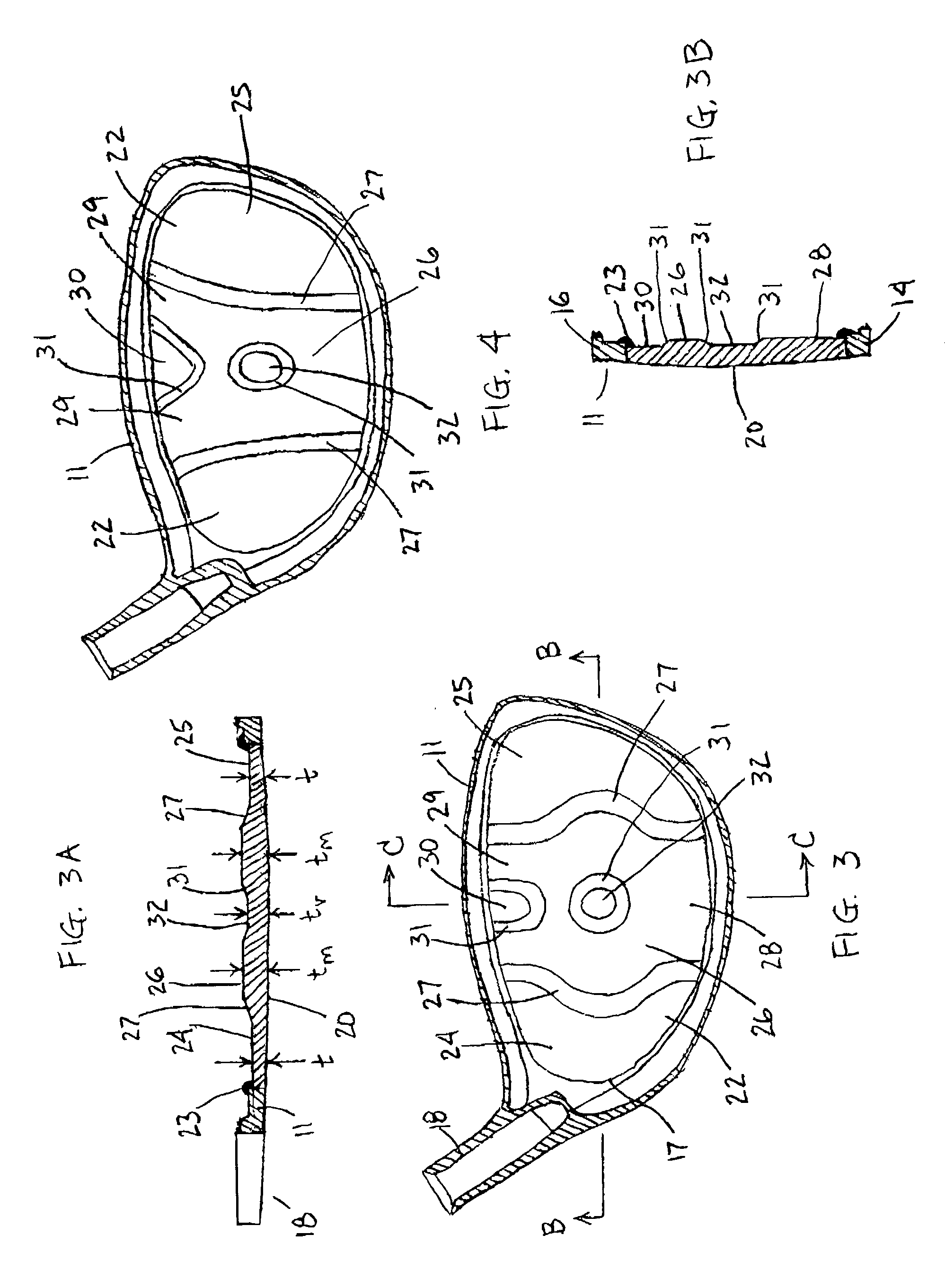

Golf club having an improved face plate

InactiveUS6997820B2Increasing the thicknessReduce thicknessGolf clubsRacket sportsEngineeringMetallic materials

A golf club head is provided having an increased sweet spot across its club face. A preferred construction includes a face plate having vertical zone of increased thickness and a central region having a reduced thickness. An upward extension of the vertical zone comprises divergent segments separated by an upper region of reduced thickness. The face plate material is preferably metallic, but in alternative embodiments may be formed of a composite or non-metal material. Methods for manufacturing a golf club head having a face plate with the thicknesses of the present invention include forging and machining techniques. The club head may be a wood-type or iron.

Owner:TAYLOR MADE GOLF

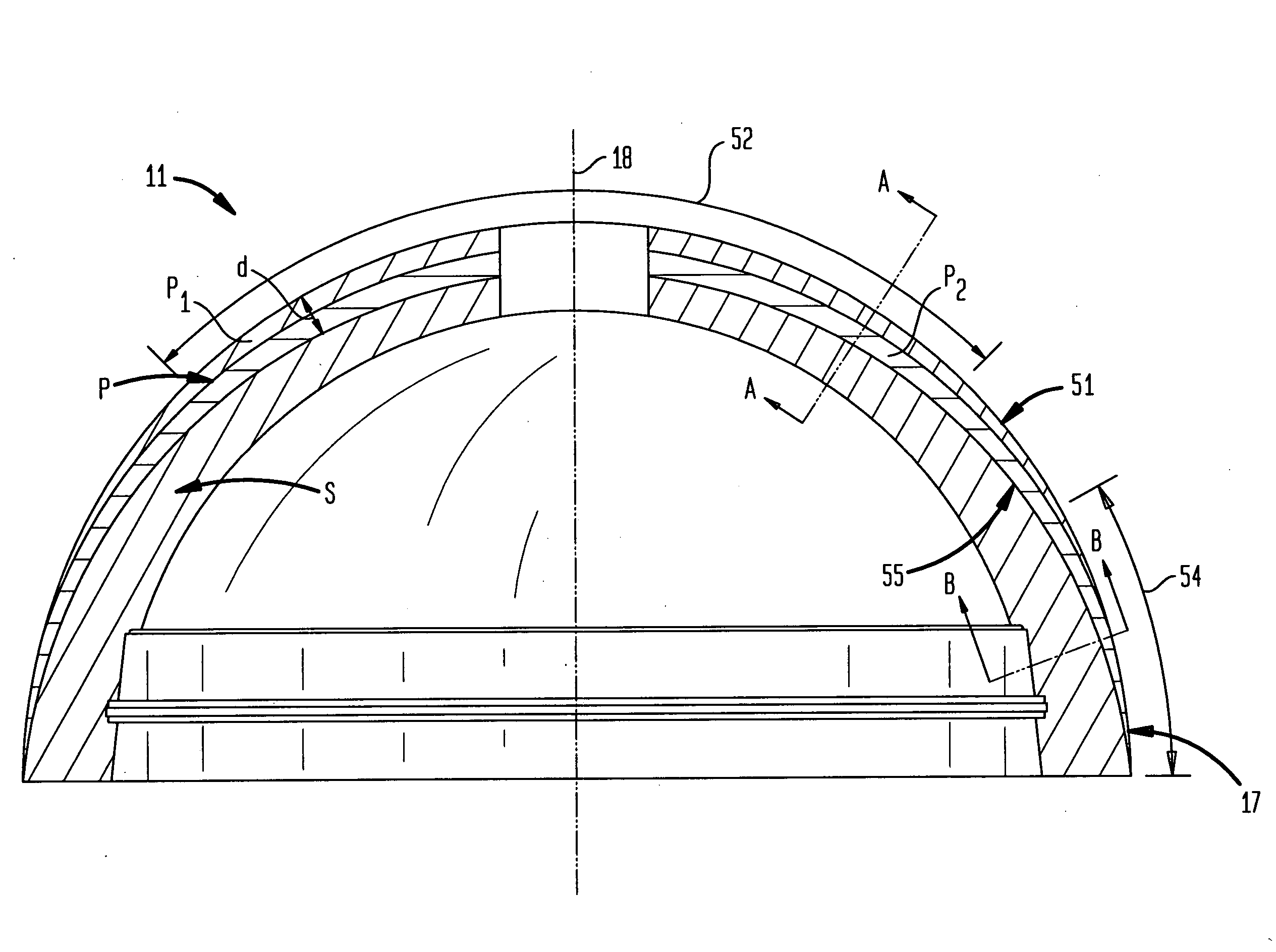

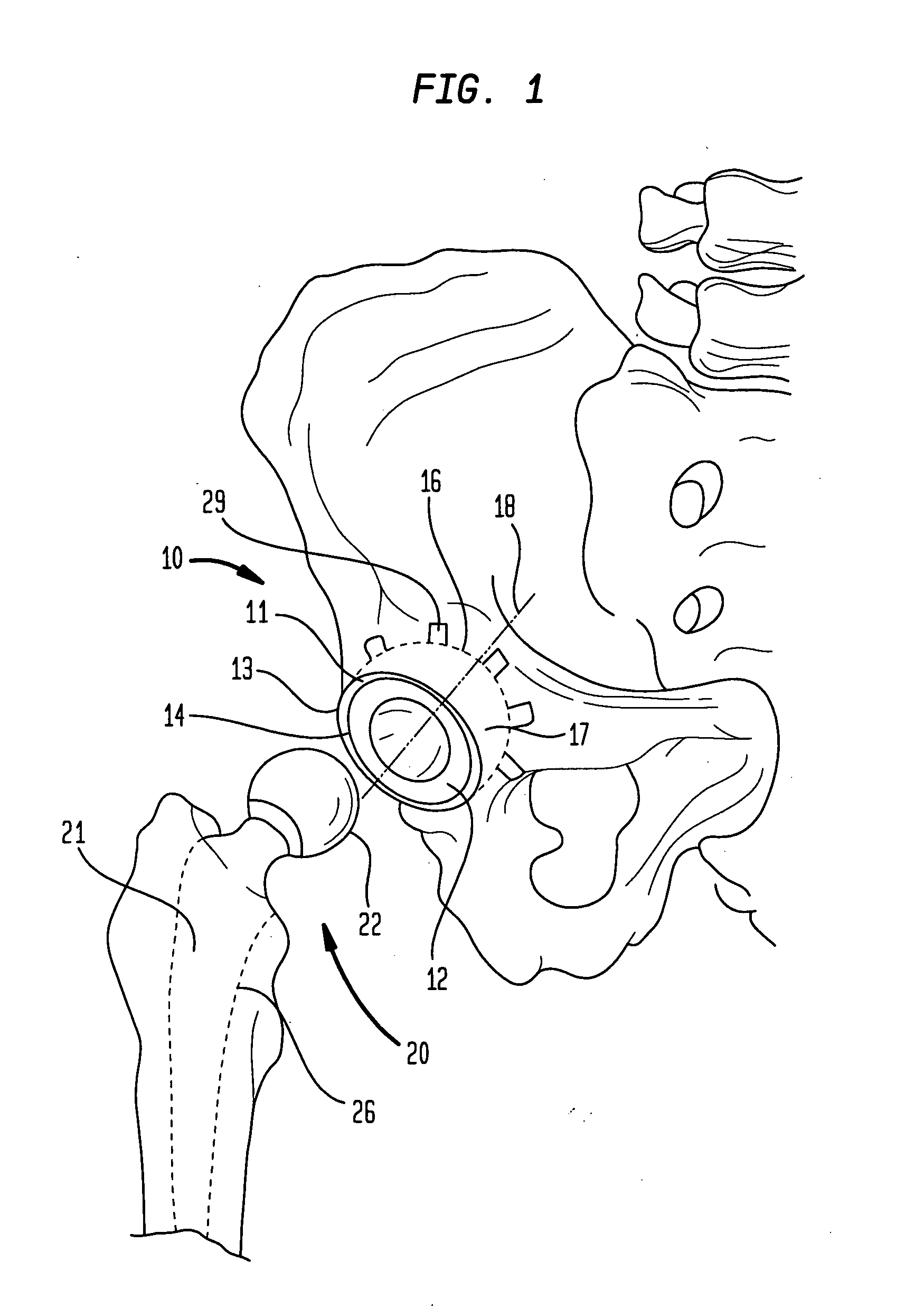

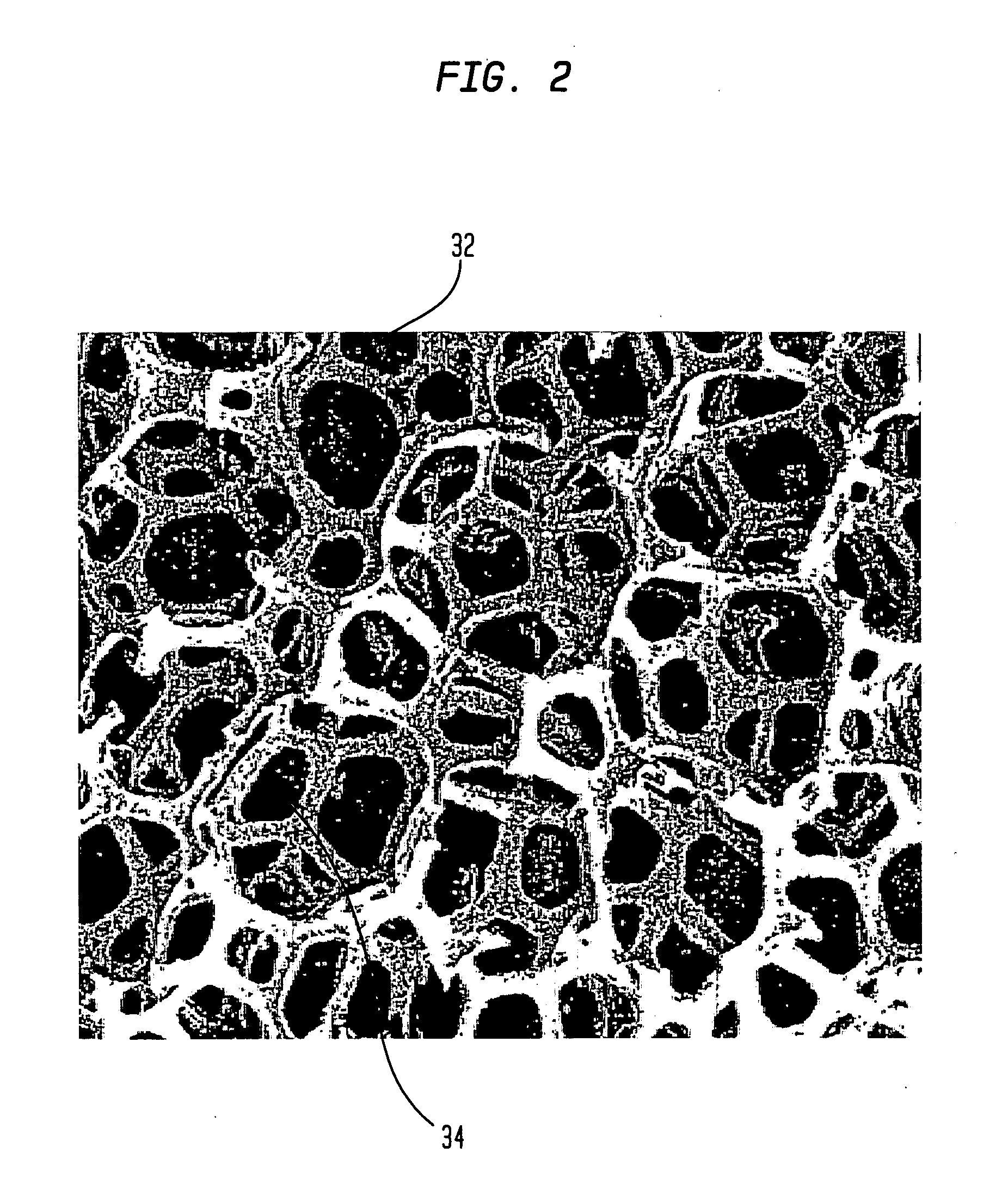

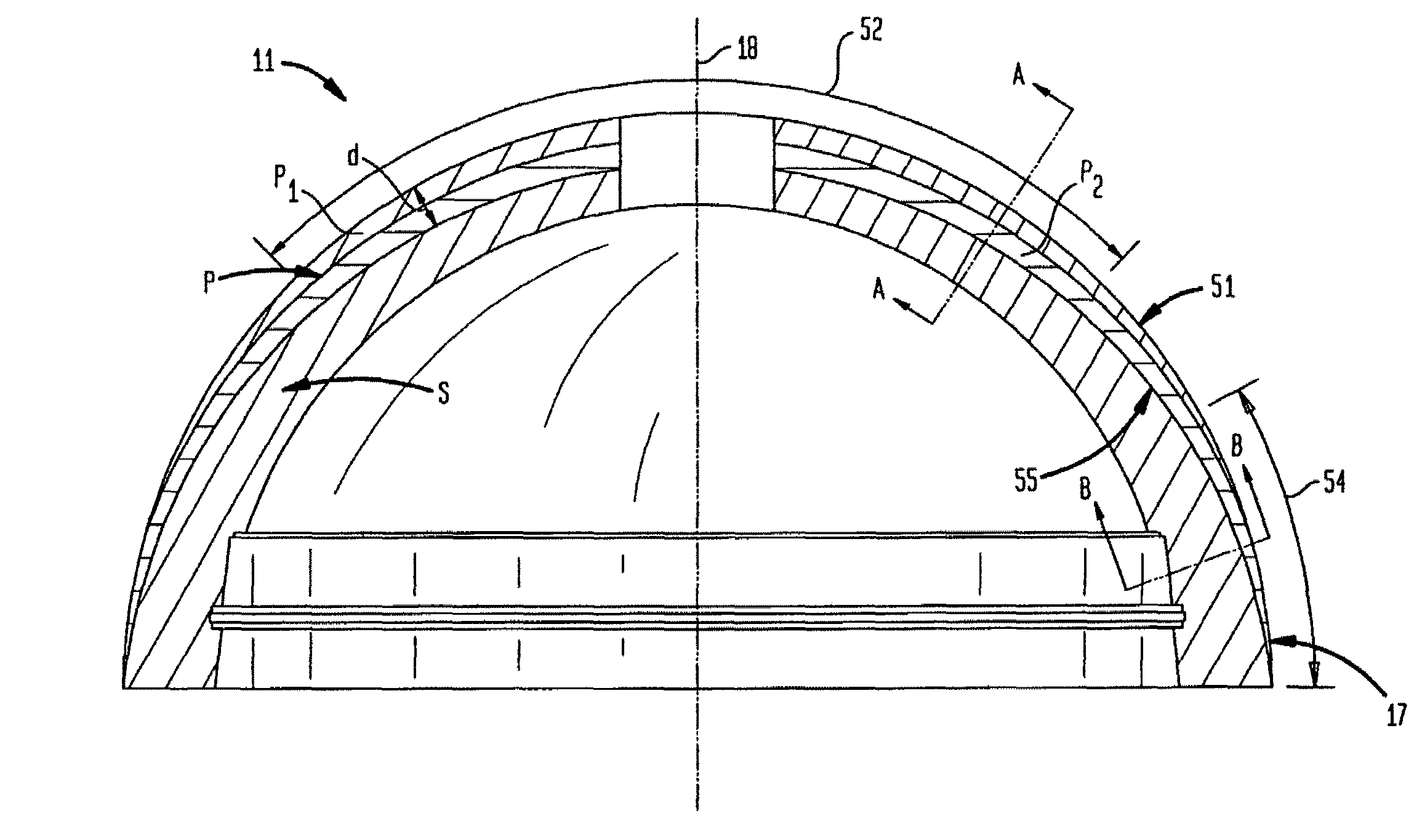

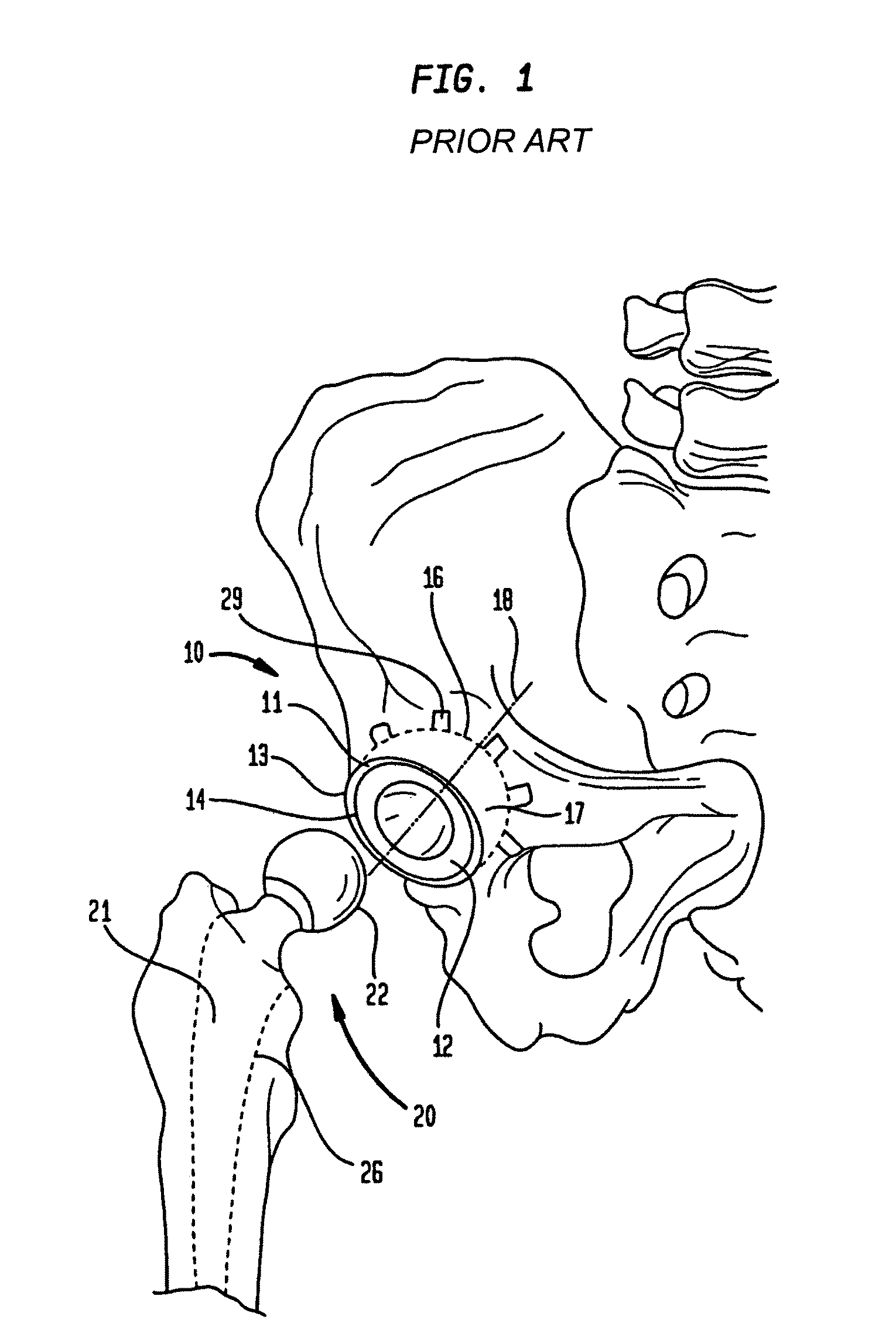

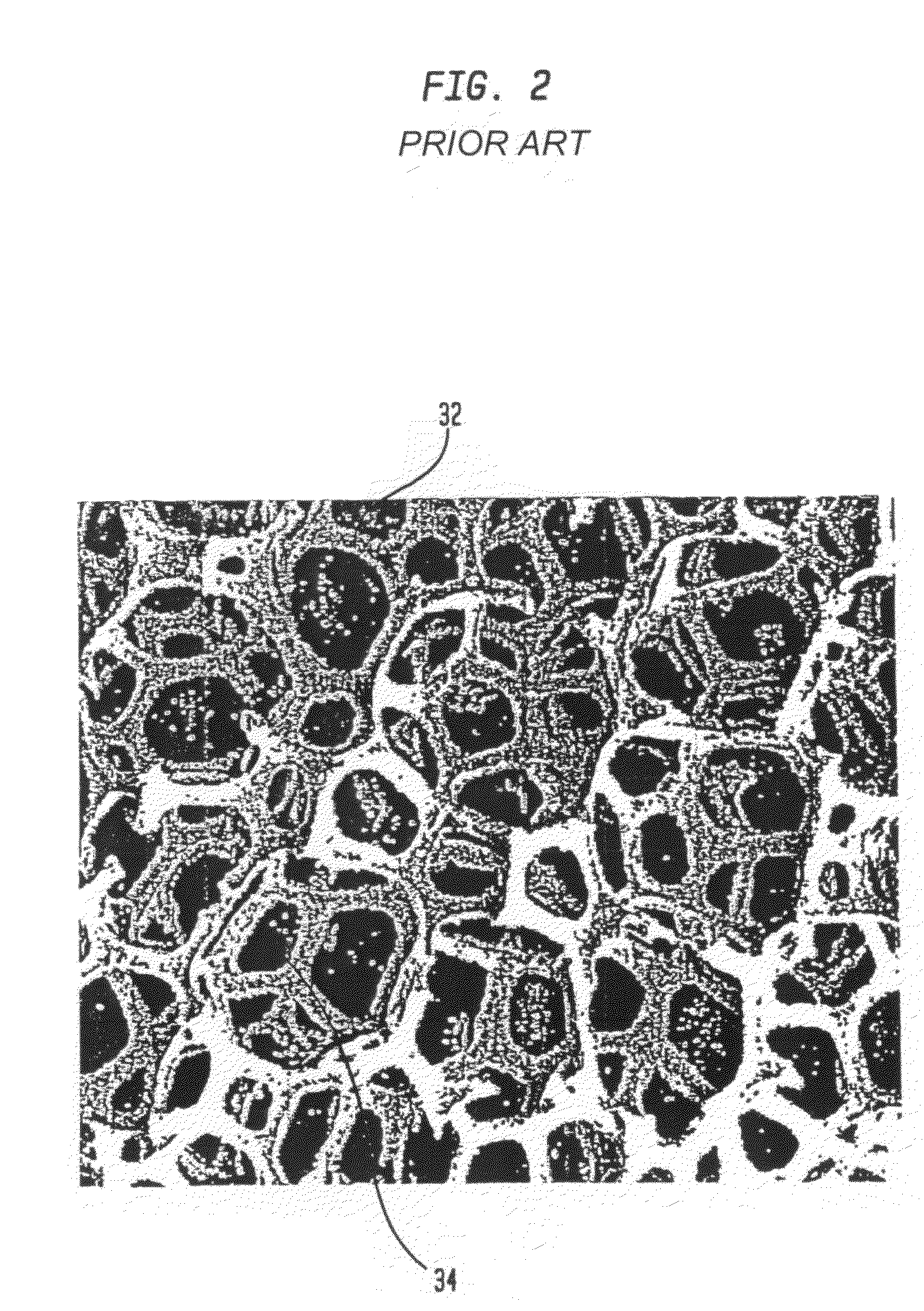

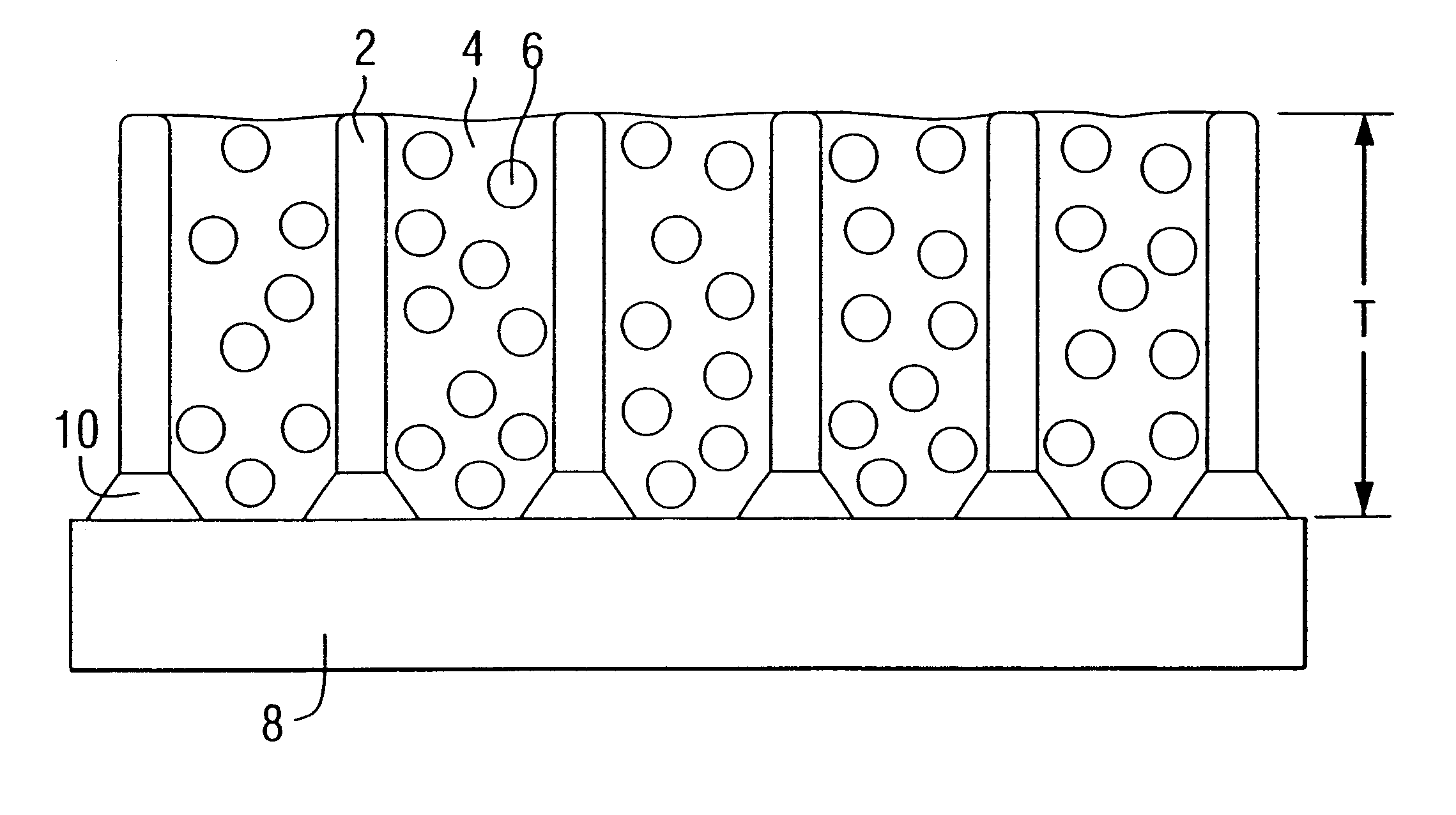

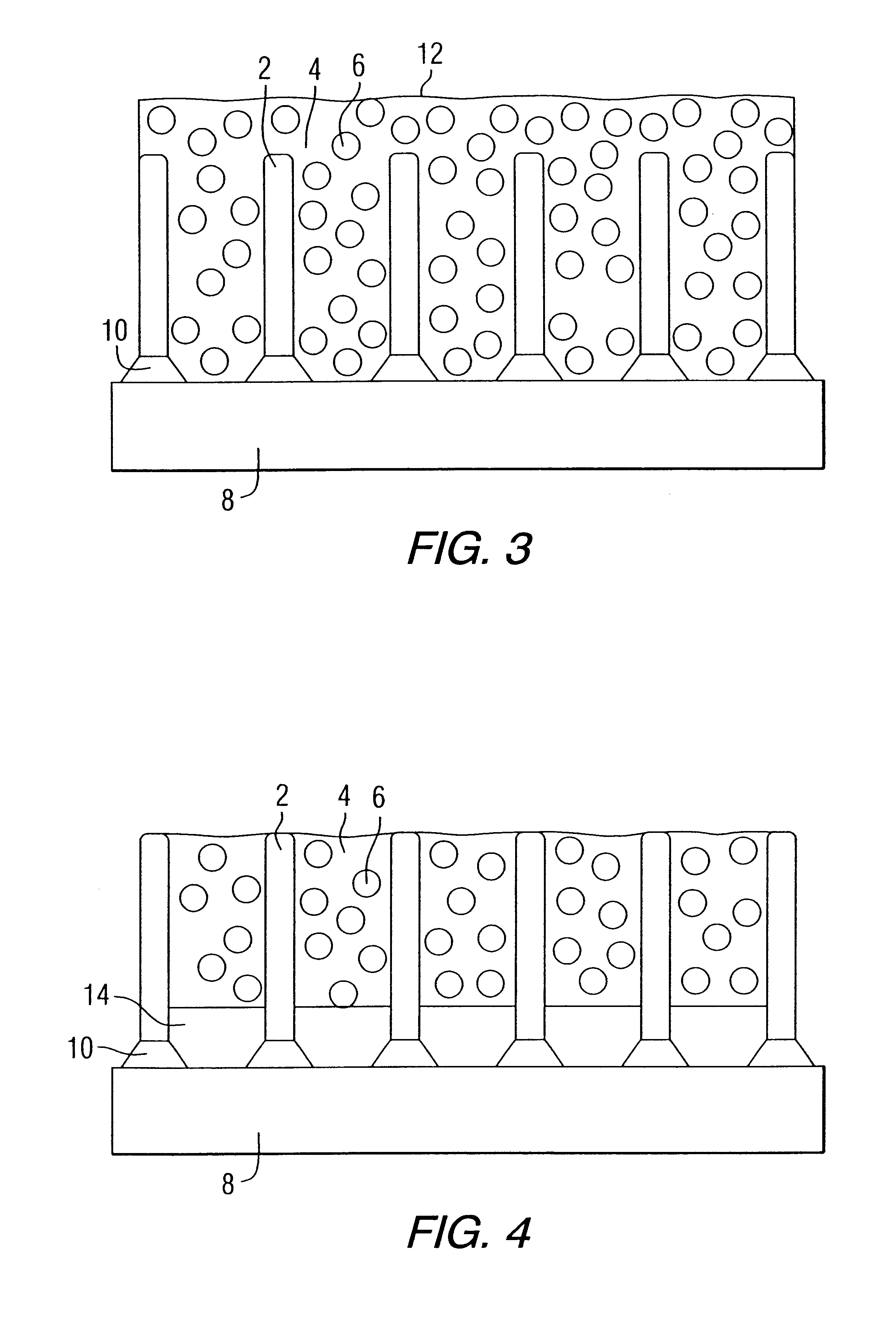

Gradient porous implant

ActiveUS20070150068A1Optimize performanceOptimizes various mechanical and biological requirements of the implants performanceAdditive manufacturing apparatusBone implantPorous metalMedical treatment

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

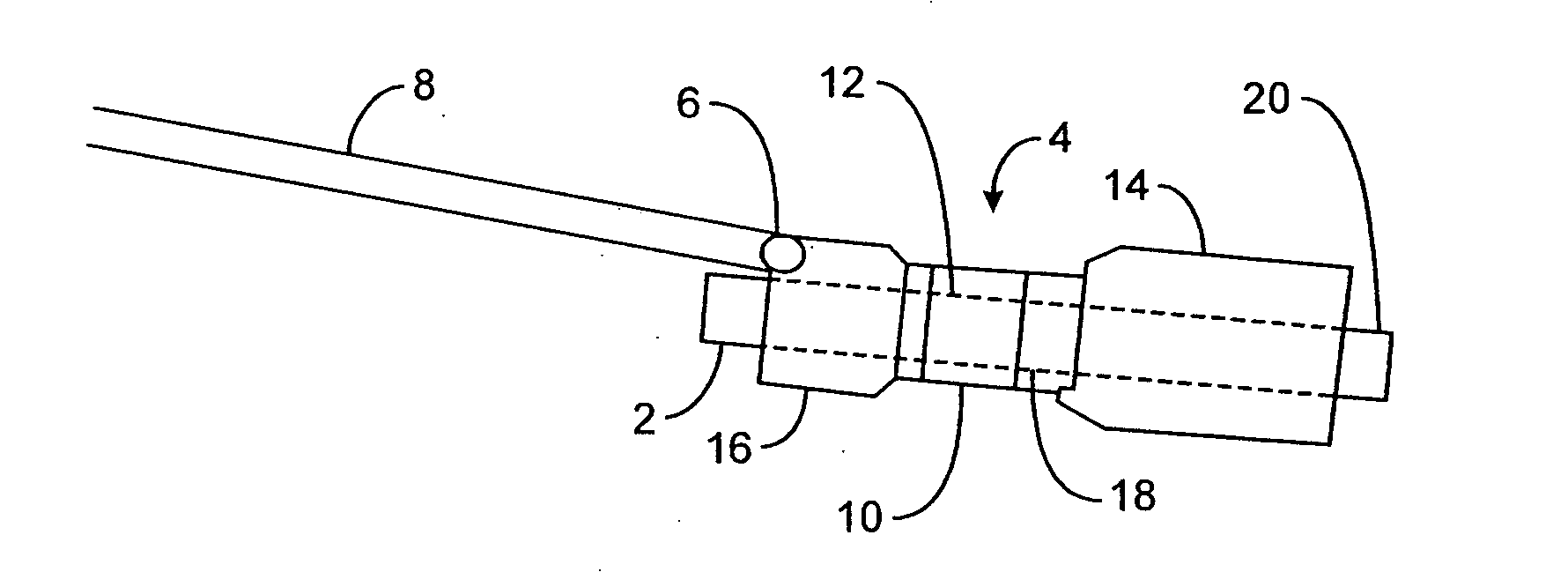

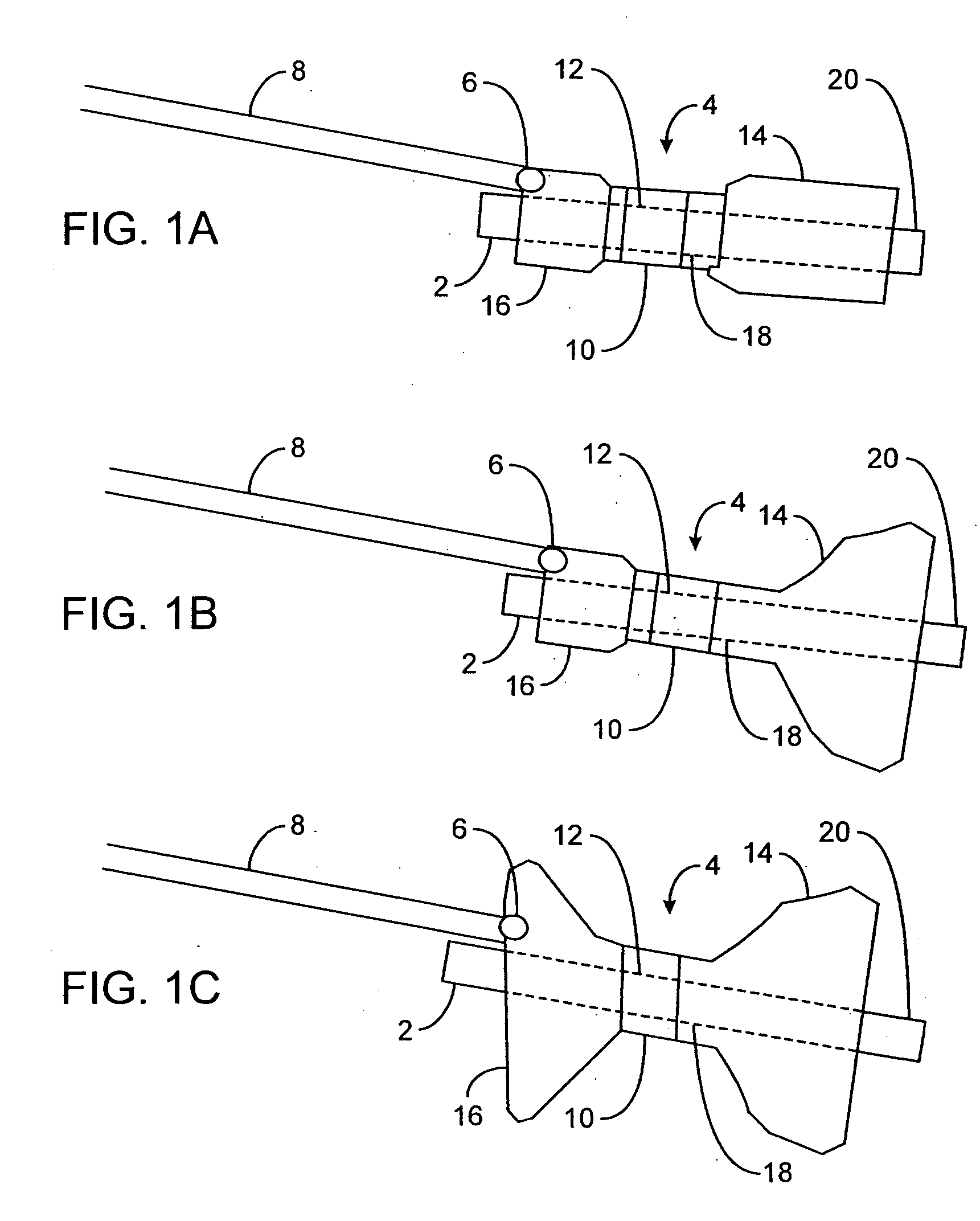

Pyloric valve obstructing devices and methods

ActiveUS20050033331A1Treat and ameliorate obesityReduced food intakeSuture equipmentsEndoradiosondesPylorusPartial obstruction

Methods, devices and systems facilitate intermittent and / or partial obstruction of a pyloric valve. Devices generally include a support portion for preventing the device from passing through the pyloric valve and a tissue engagement portion for contacting tissue adjacent the pyloric valve to obstruct the valve. Some embodiments also include a positioning member extending from the tissue engagement portion for helping position the device for obstructing the valve. A retaining member may optionally be included on the distal end of the positioning member for further maintaining a position of the device in the stomach. Some embodiments are deliverable into the stomach through the esophagus, either by swallowing or through a delivery tube or catheter. Some embodiments are fully reversible. Some embodiments self-expand within the stomach, while others are inflated or otherwise expanded.

Owner:BARONOVA

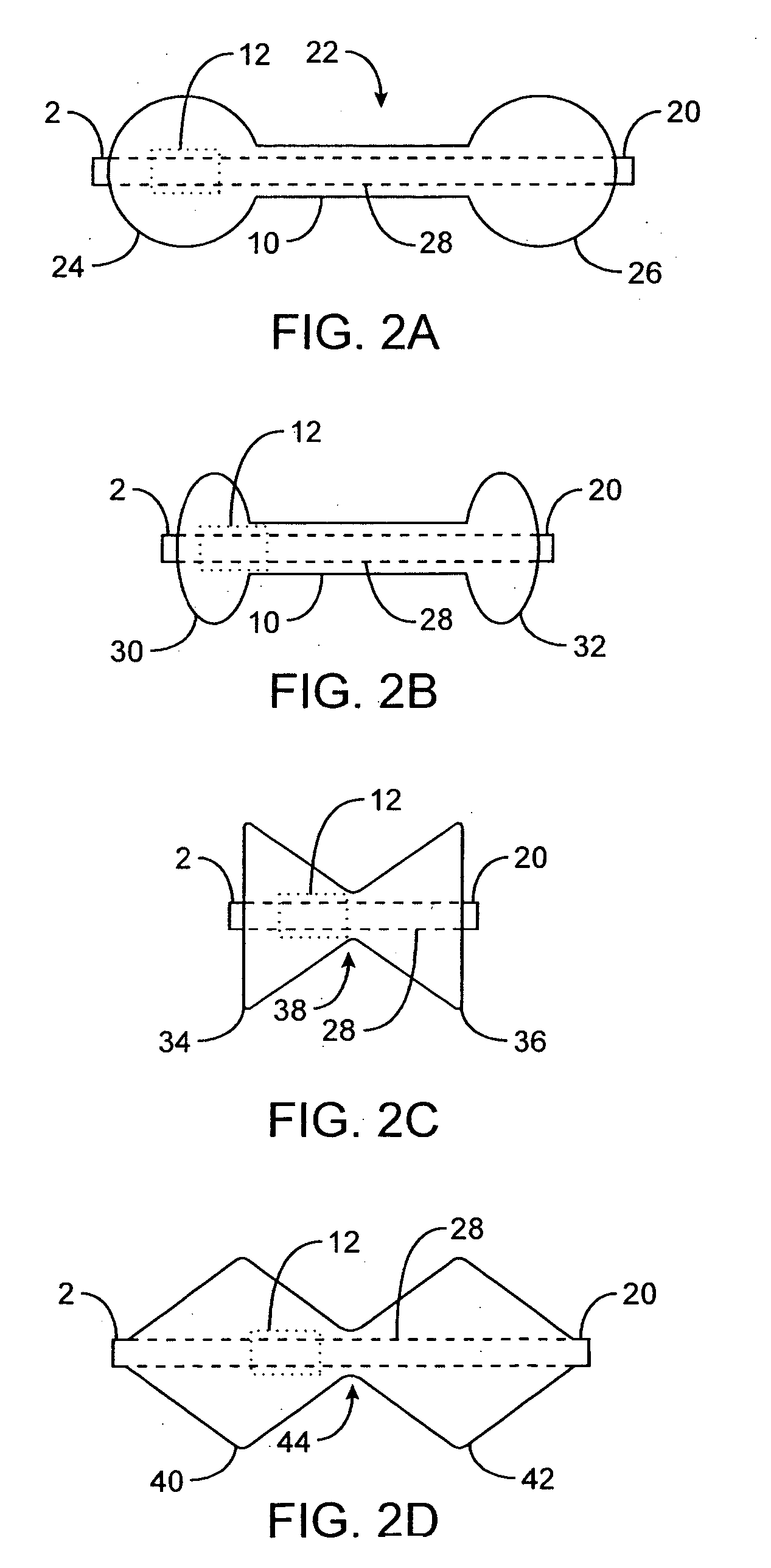

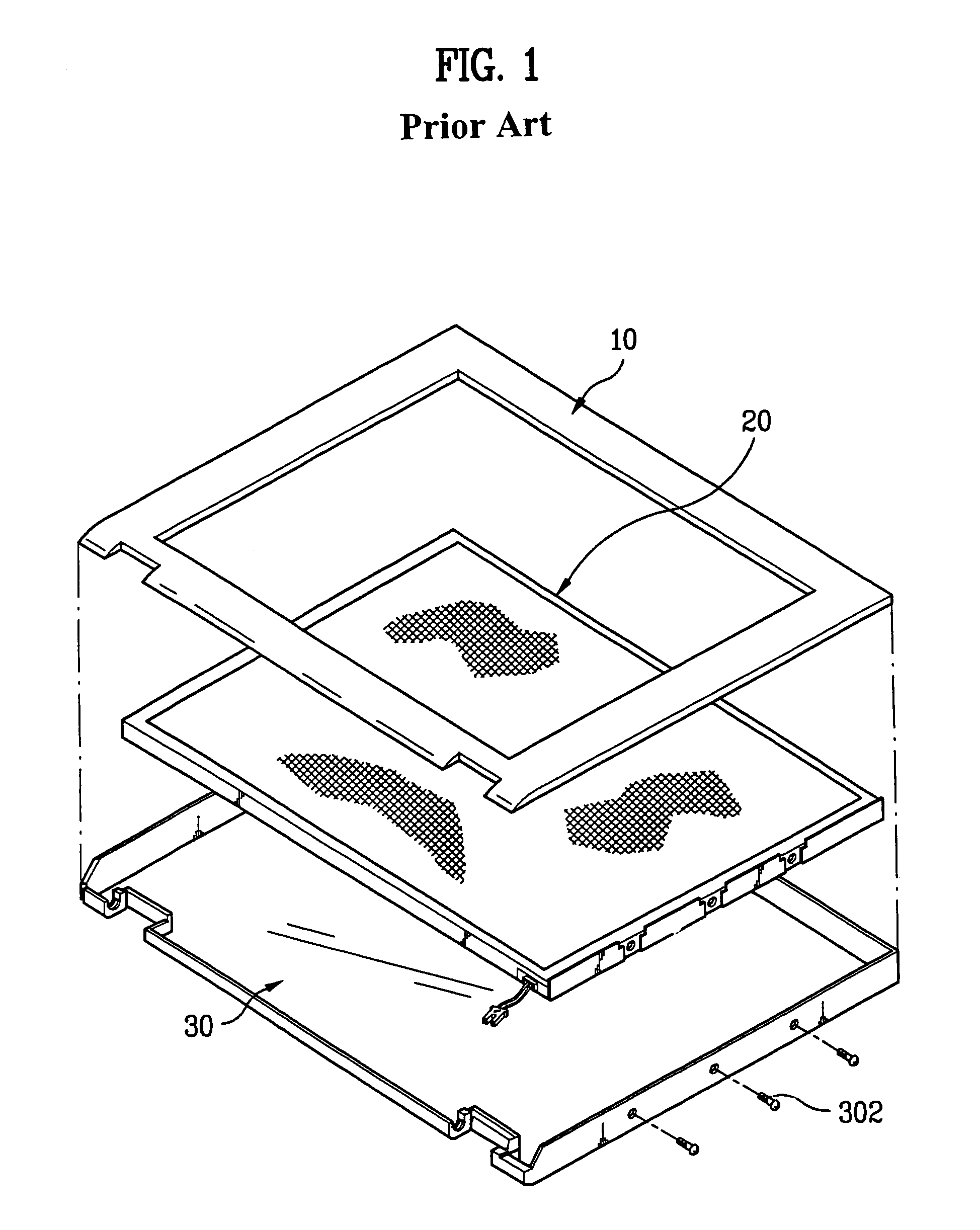

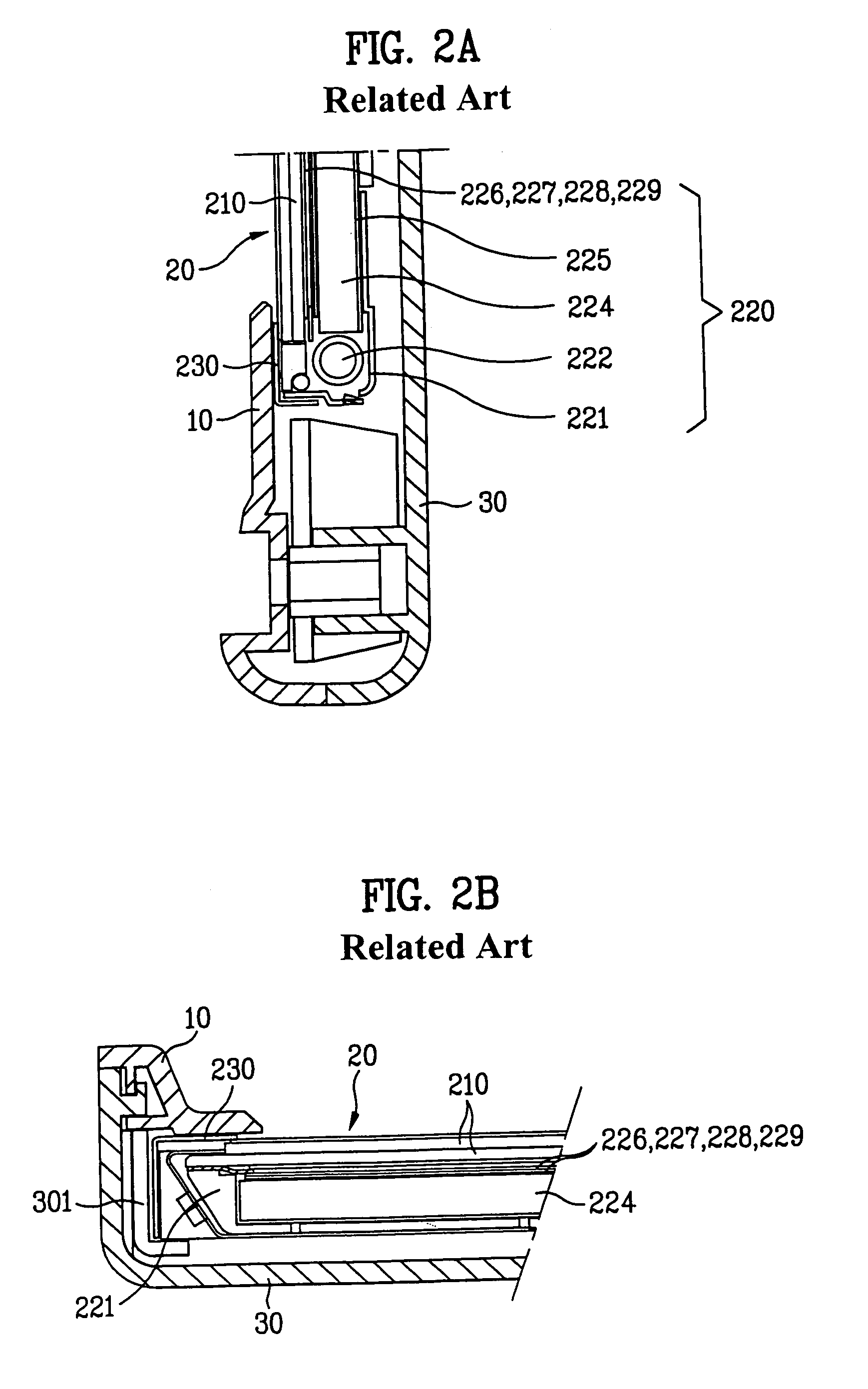

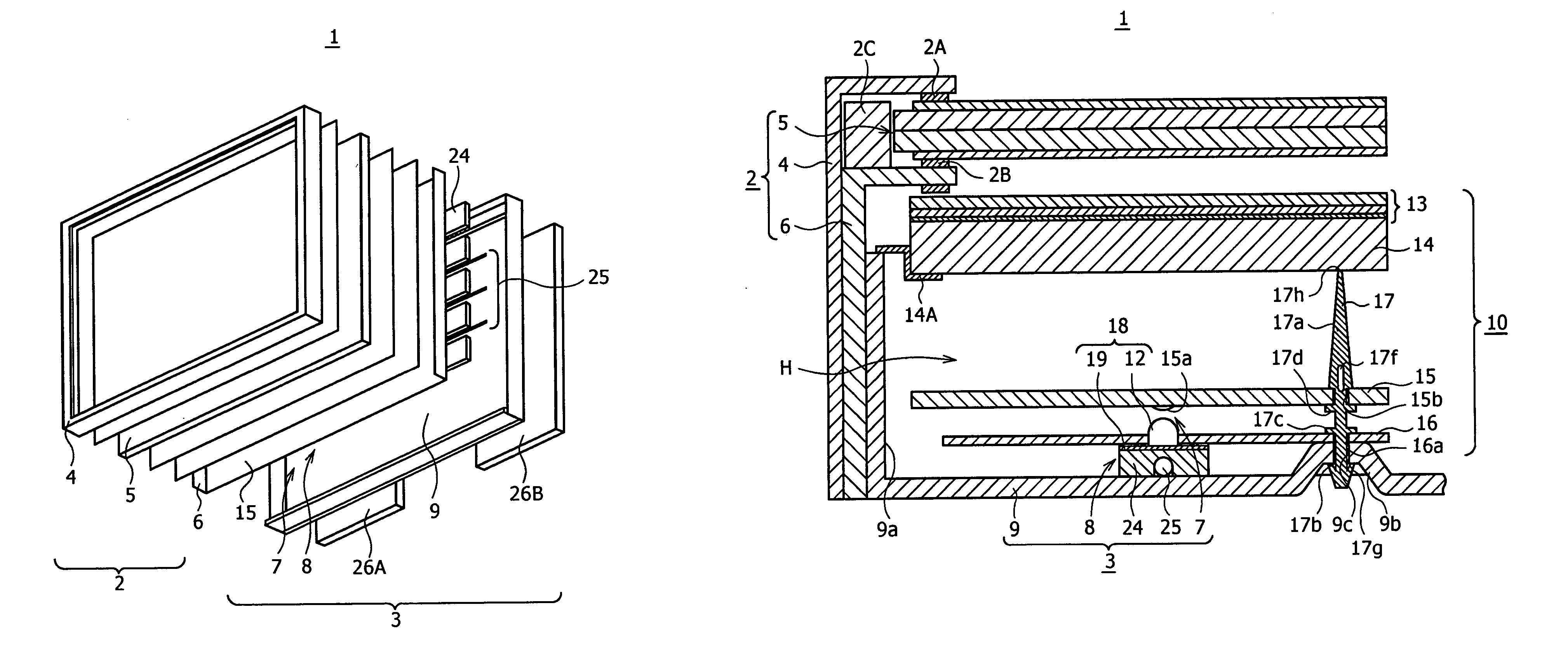

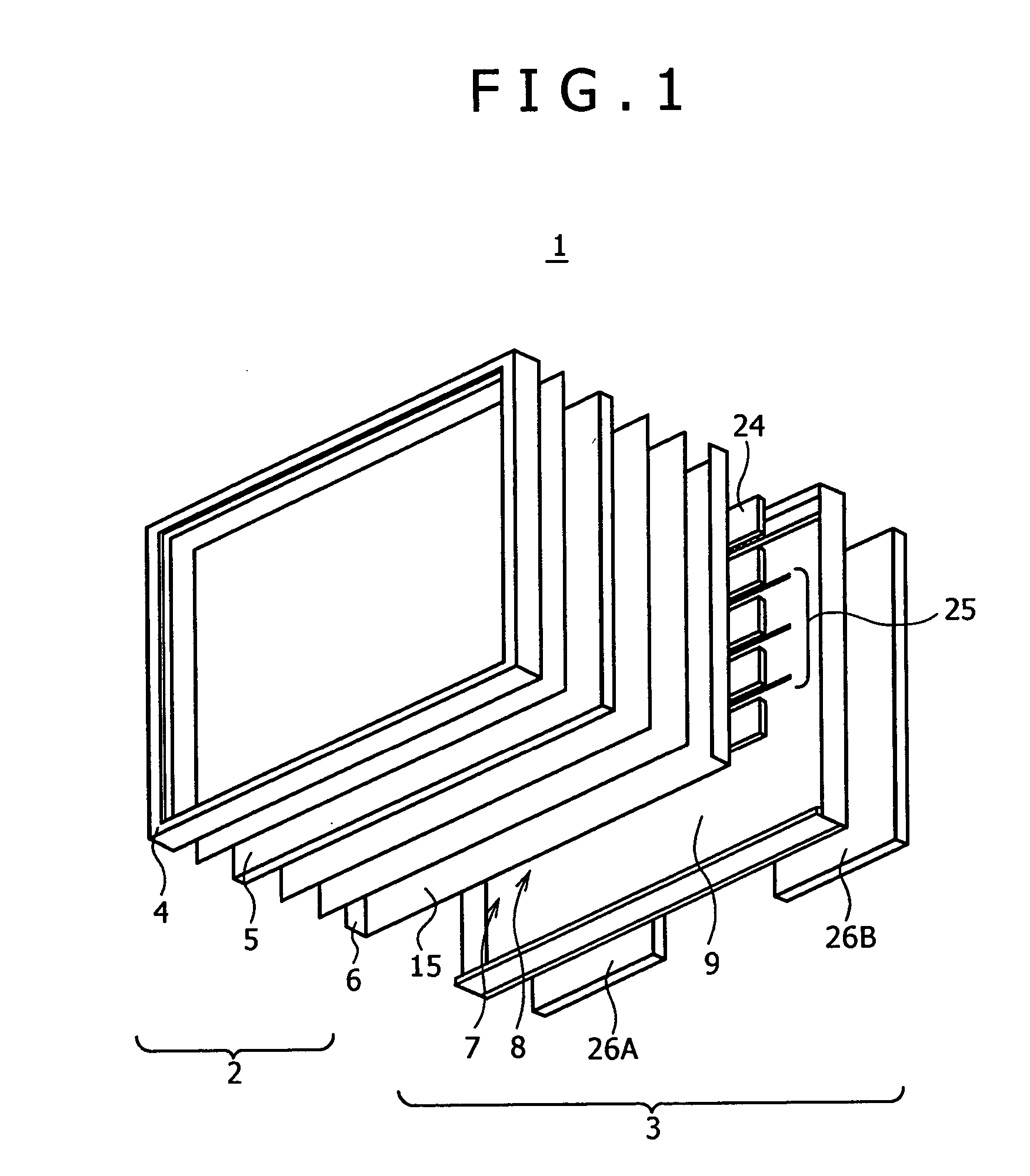

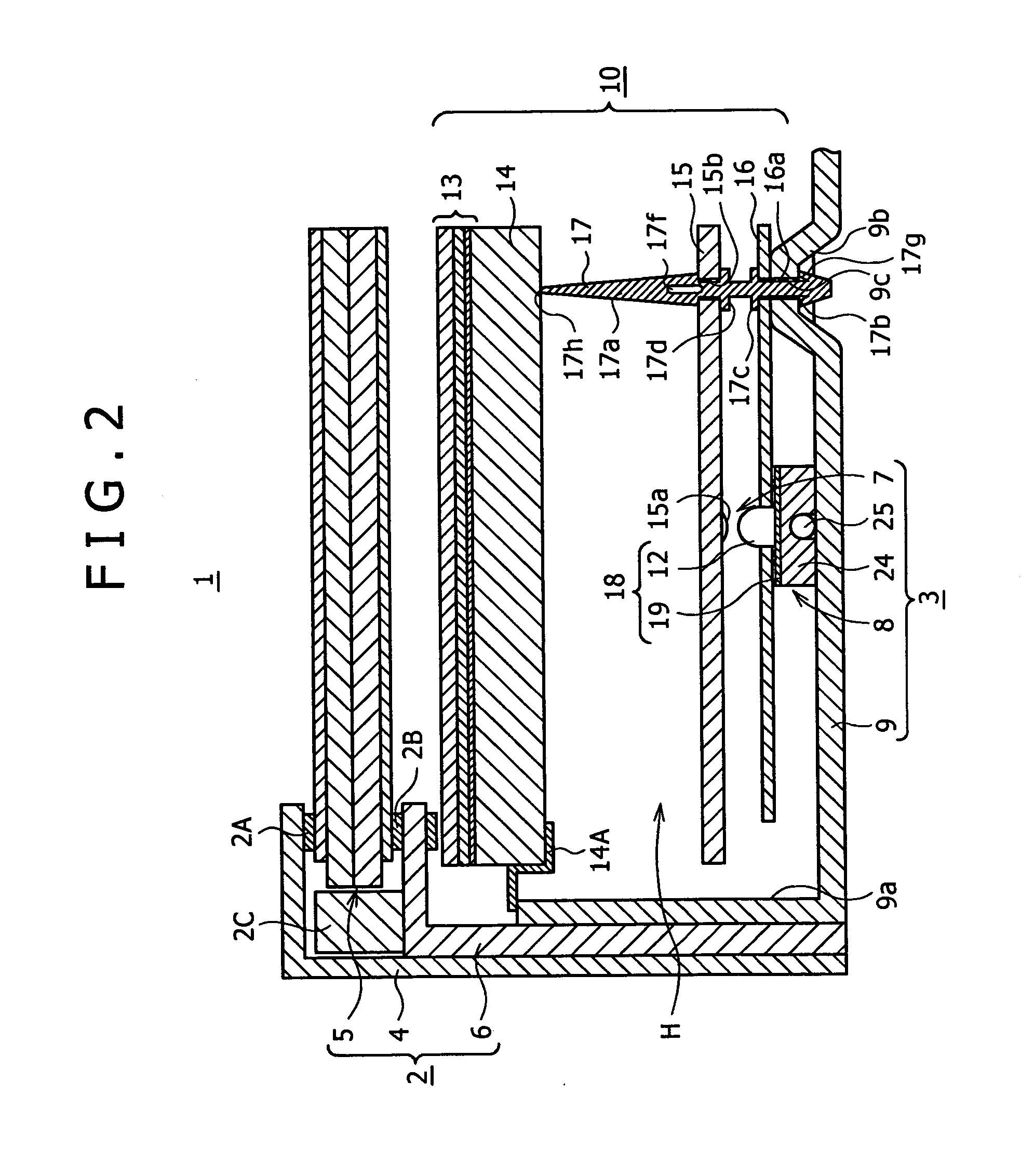

Structure for mounting flat panel display

InactiveUS7106392B2Reduce thickness and weightImprove stabilityStatic indicating devicesDetails for portable computersFlat panel displayEngineering

A structure for mounting a flat panel display module constituting a screen display device of a portable computer system wherein the weight and a thickness of a display device are reduced. For example, the structure for mounting a flat panel display includes a display module having a flat panel display panel, a backlight assembly, and a supporting member for supporting edges of the flat panel display panel and the back light assembly, a rear cover to which the display module is fitted, and a front cover fitted to a frontal edge of the rear cover to cover a frontal edge of the display module. In this structure the supporting member is formed at an inner side of the front cover.

Owner:LG DISPLAY CO LTD

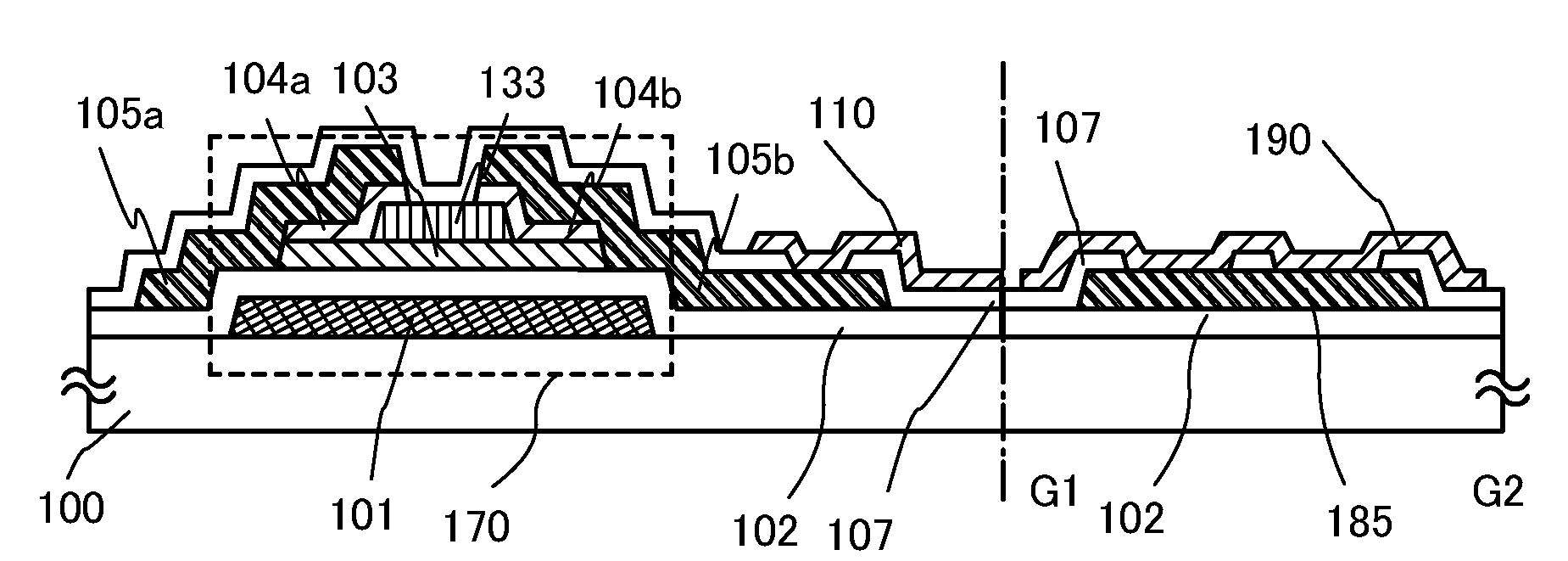

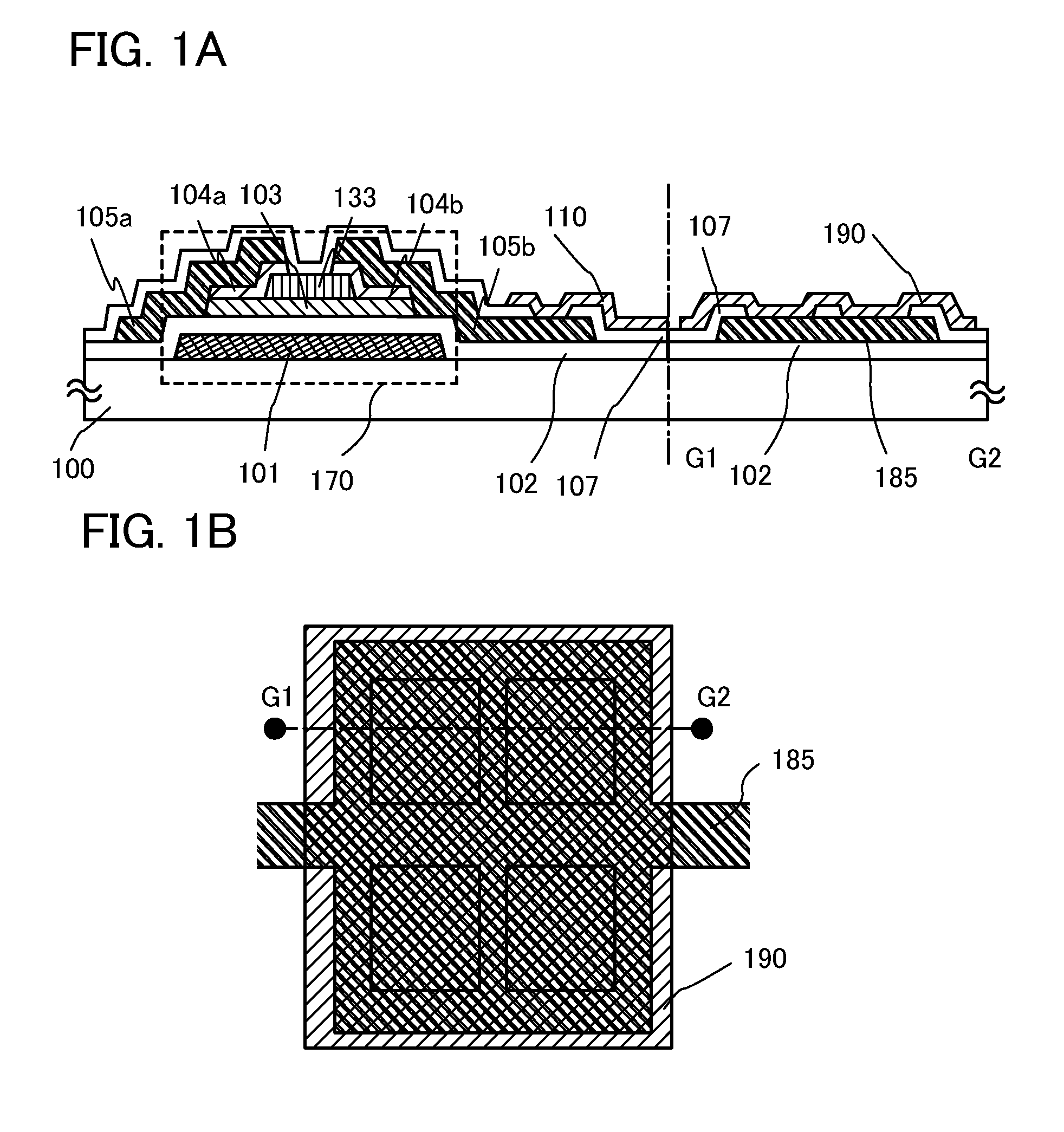

Semiconductor device

ActiveUS20100072467A1Increasing the thicknessAvoid separationTransistorElectroluminescent light sourcesDisplay deviceSemiconductor package

A display device includes a pixel portion in which a pixel is arranged in a matrix, the pixel including an inverted staggered thin film transistor having a combination of at least two kinds of oxide semiconductor layers with different amounts of oxygen and having a channel protective layer over a semiconductor layer to be a channel formation region overlapping a gate electrode layer and a pixel electrode layer electrically connected to the inverted staggered thin film transistor. In the periphery of the pixel portion in this display device, a pad portion including a conductive layer made of the same material as the pixel electrode layer is provided. In addition, the conductive layer is electrically connected to a common electrode layer formed on a counter substrate.

Owner:SEMICON ENERGY LAB CO LTD

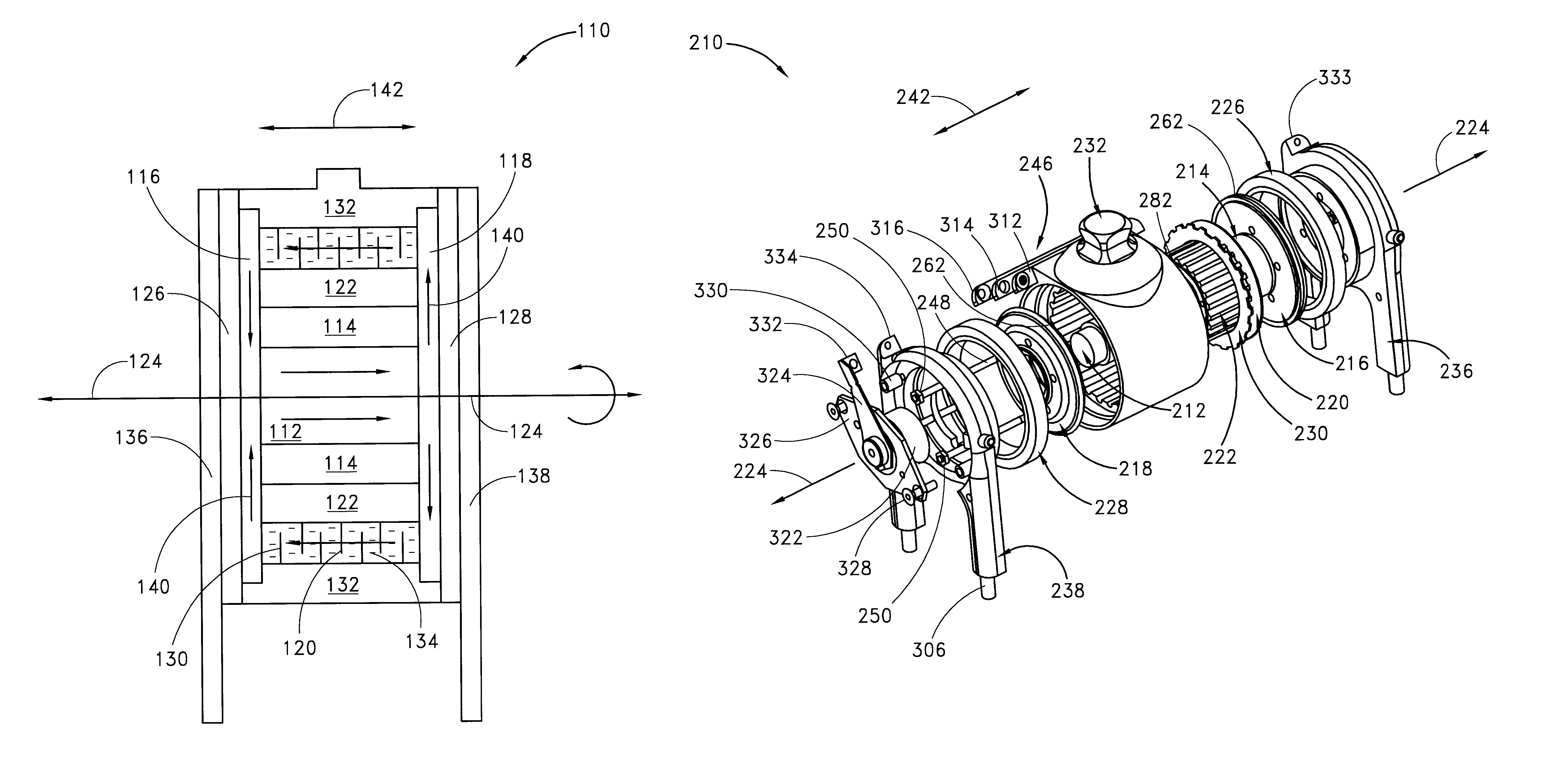

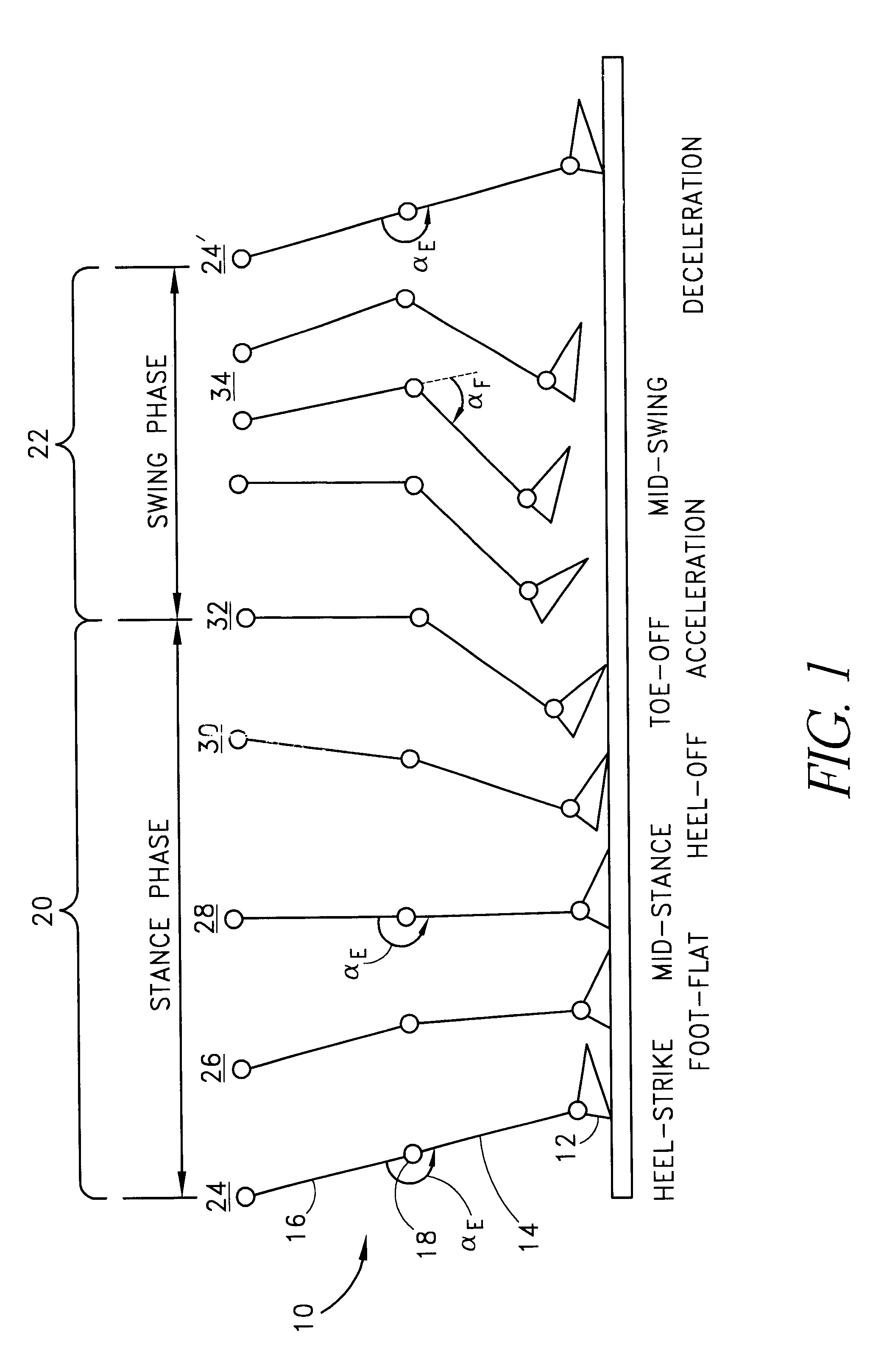

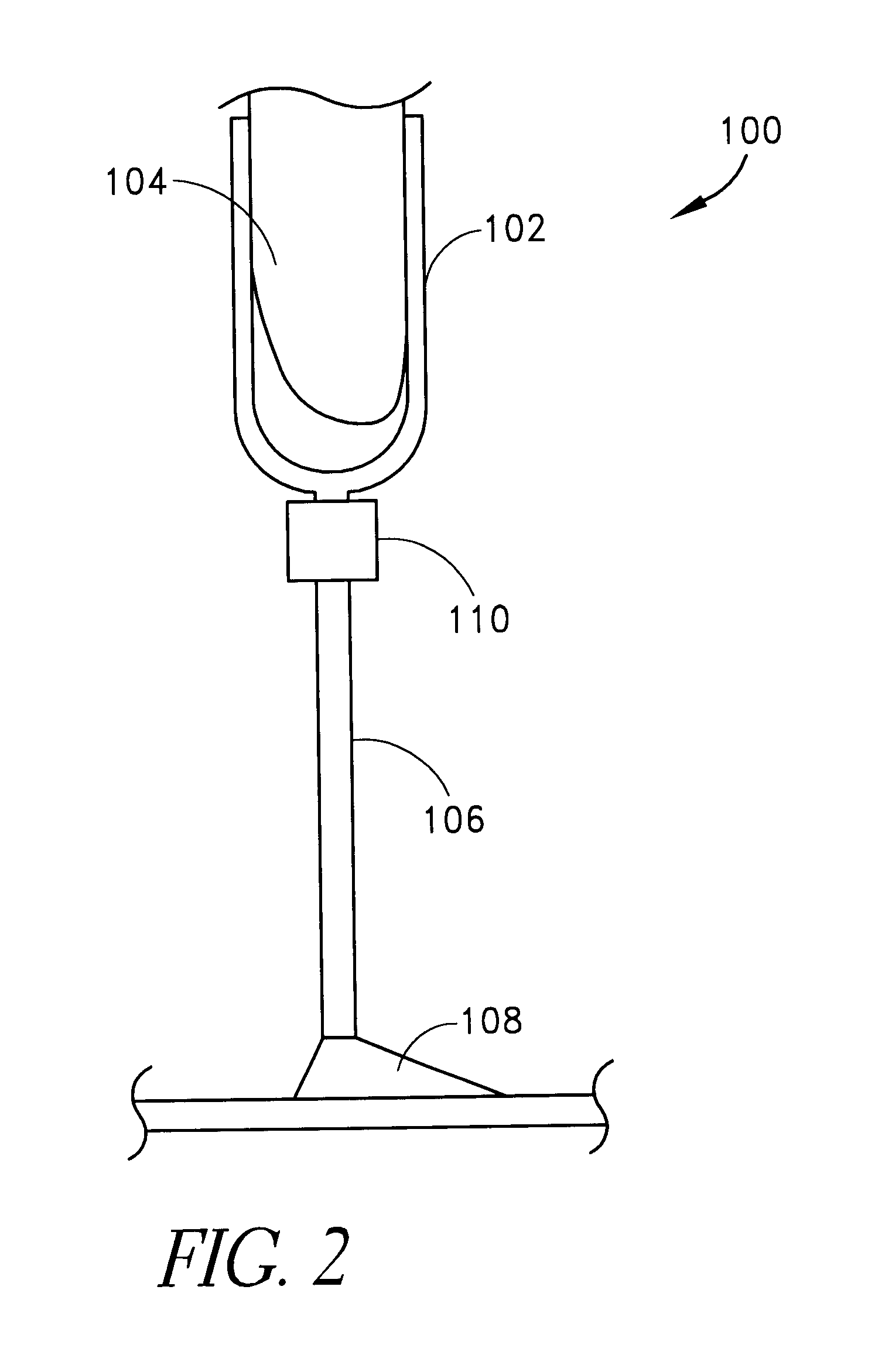

Electronically controlled prosthetic knee

InactiveUS6764520B2Improve efficiencyImprove practicalitySpringsNon-rotating vibration suppressionLow speedMagnetorheological fluid

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the "shear mode" there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed-eliminating the need for a transmission-and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a "hybrid" braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

Gradient porous implant

ActiveUS7578851B2Optimizes various mechanical and biological requirements of the implants performanceIncreasing the thicknessAdditive manufacturing apparatusBone implantPorous implantMedical device

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

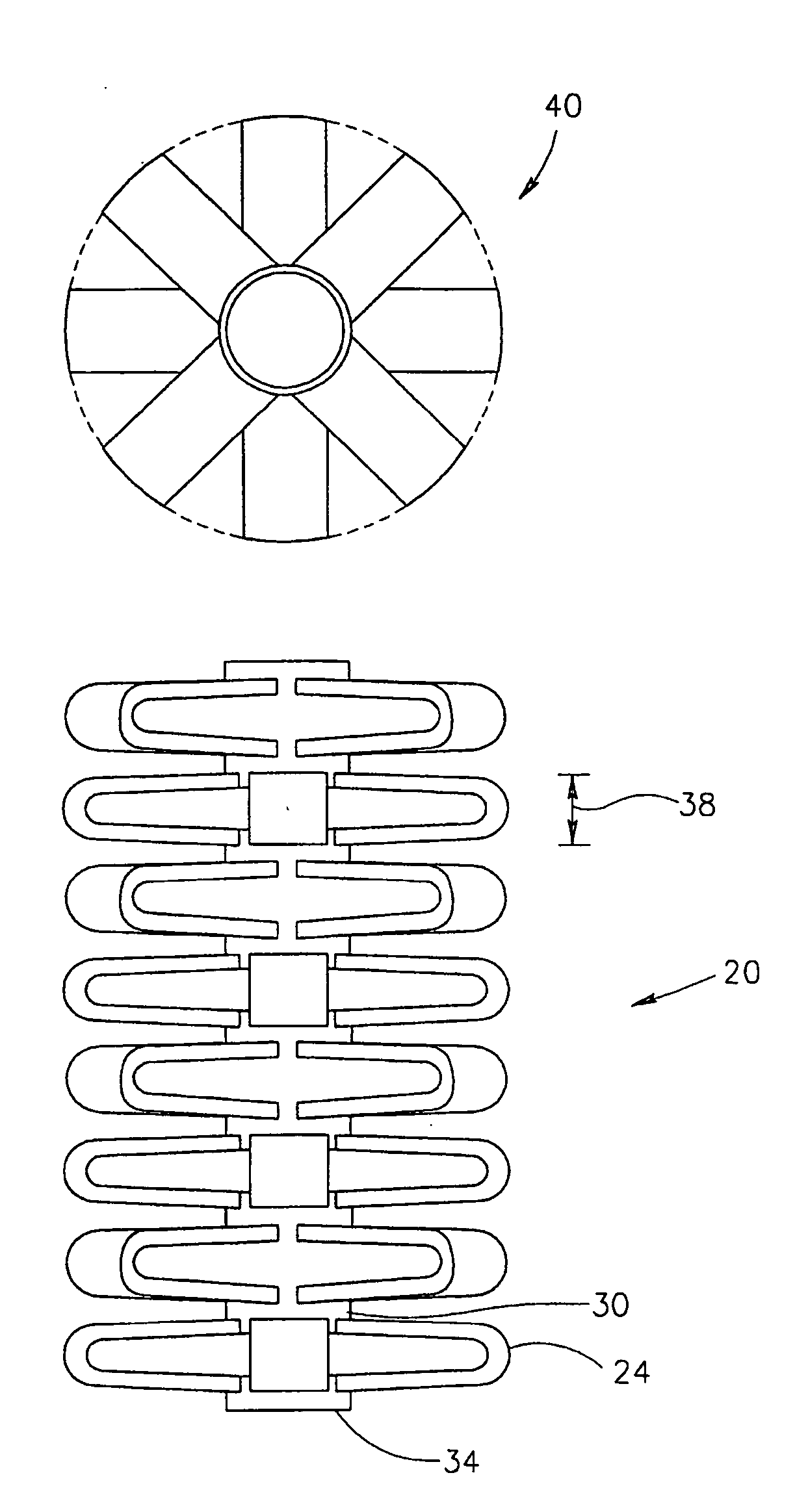

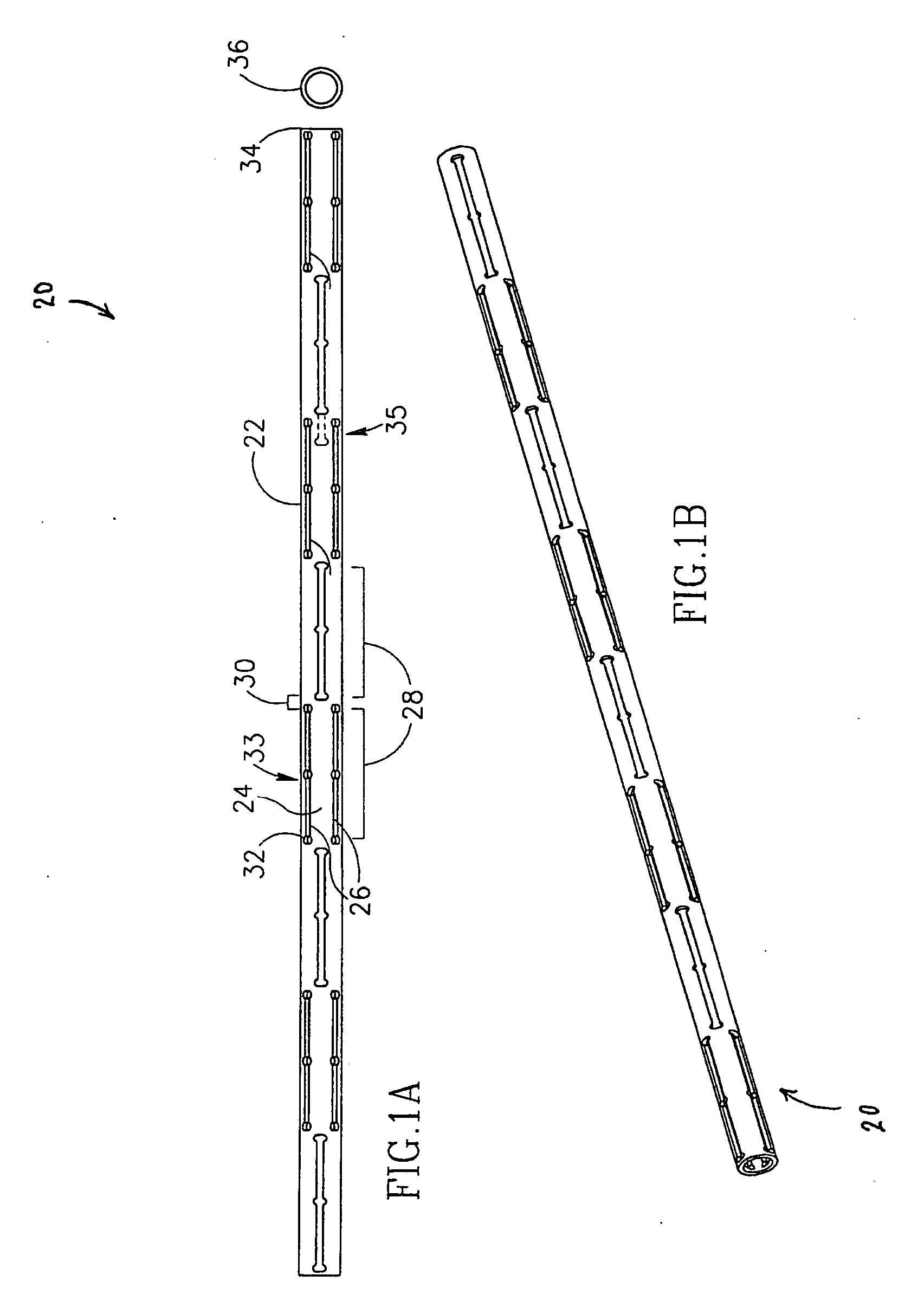

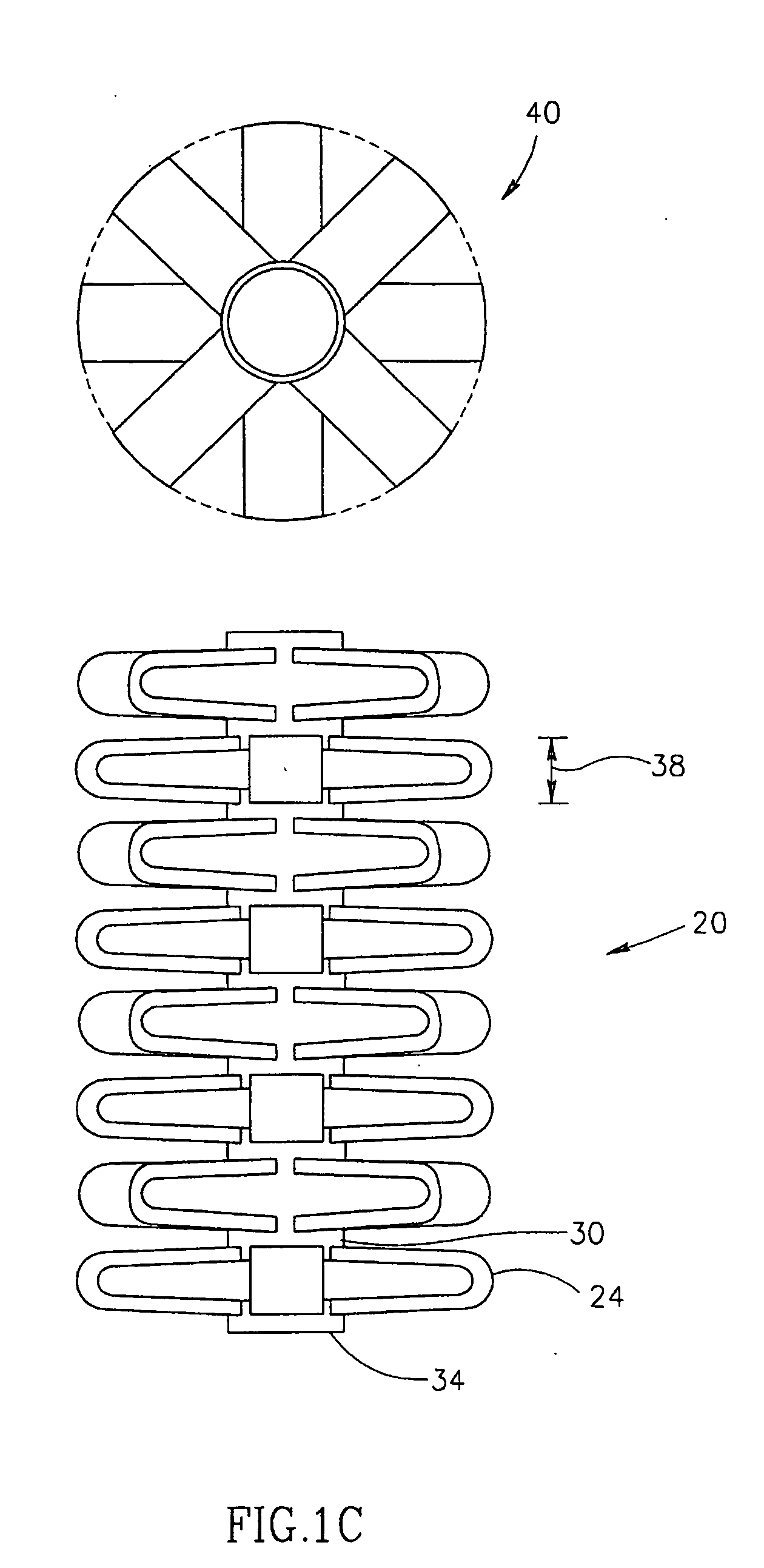

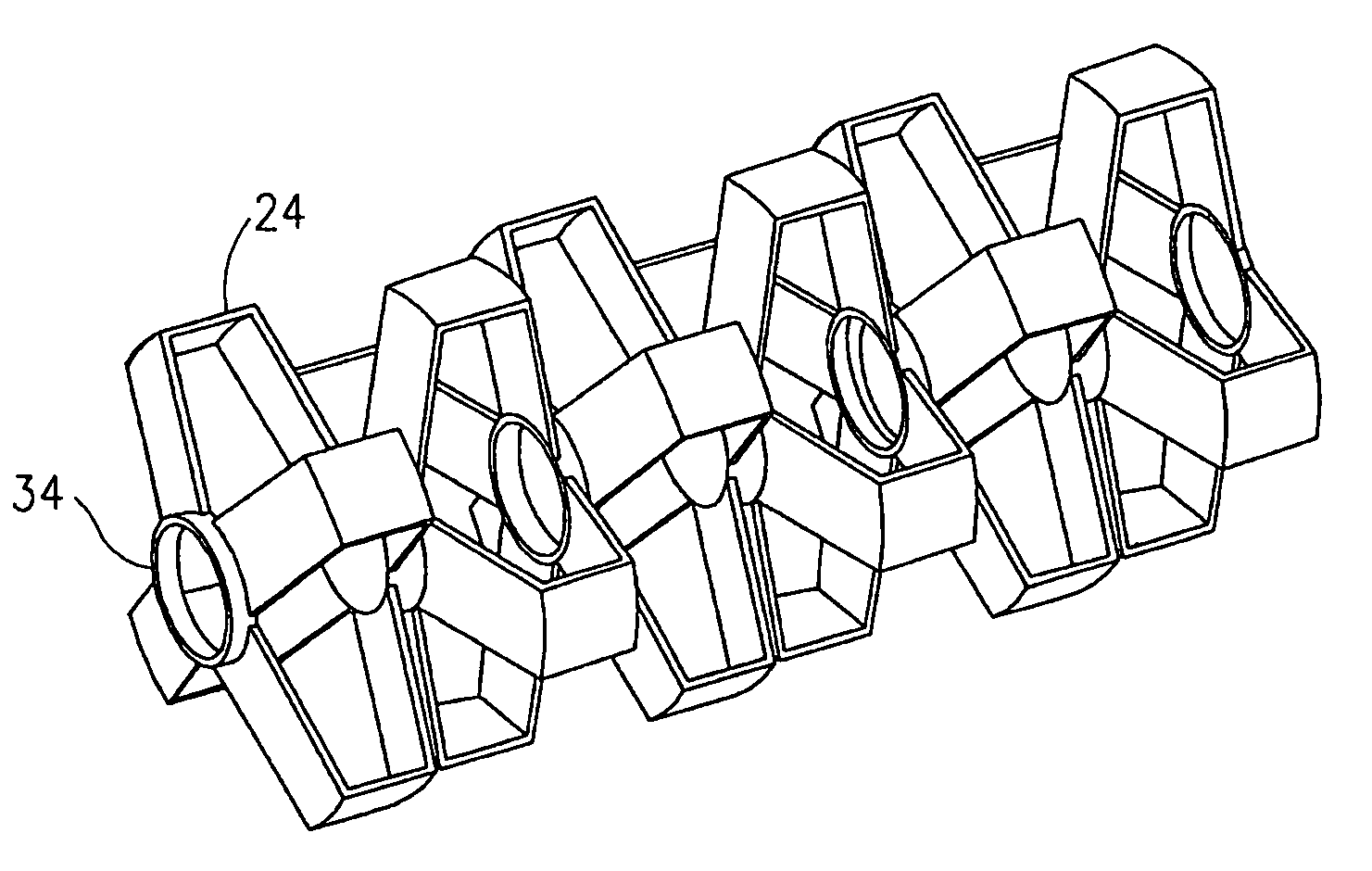

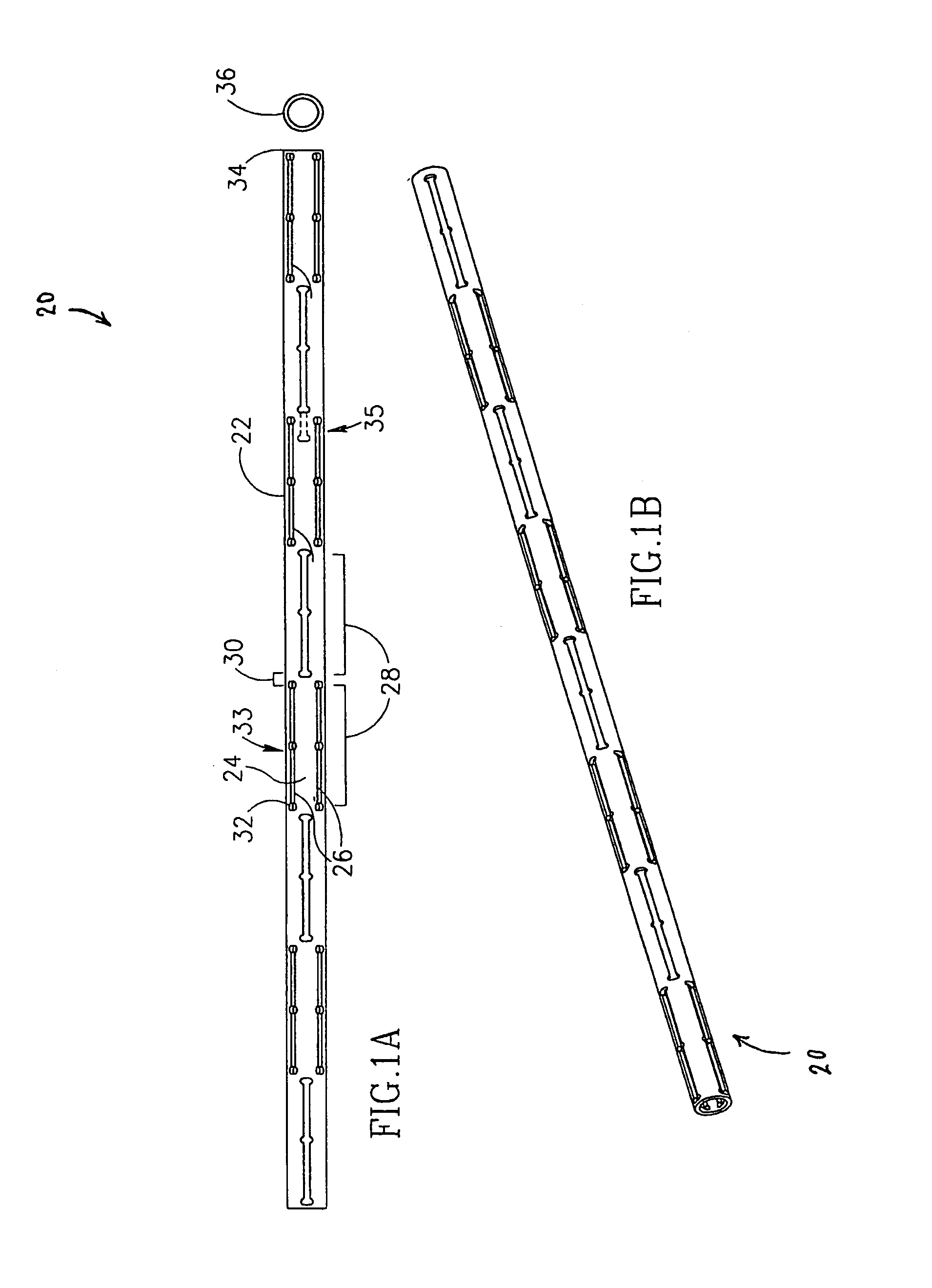

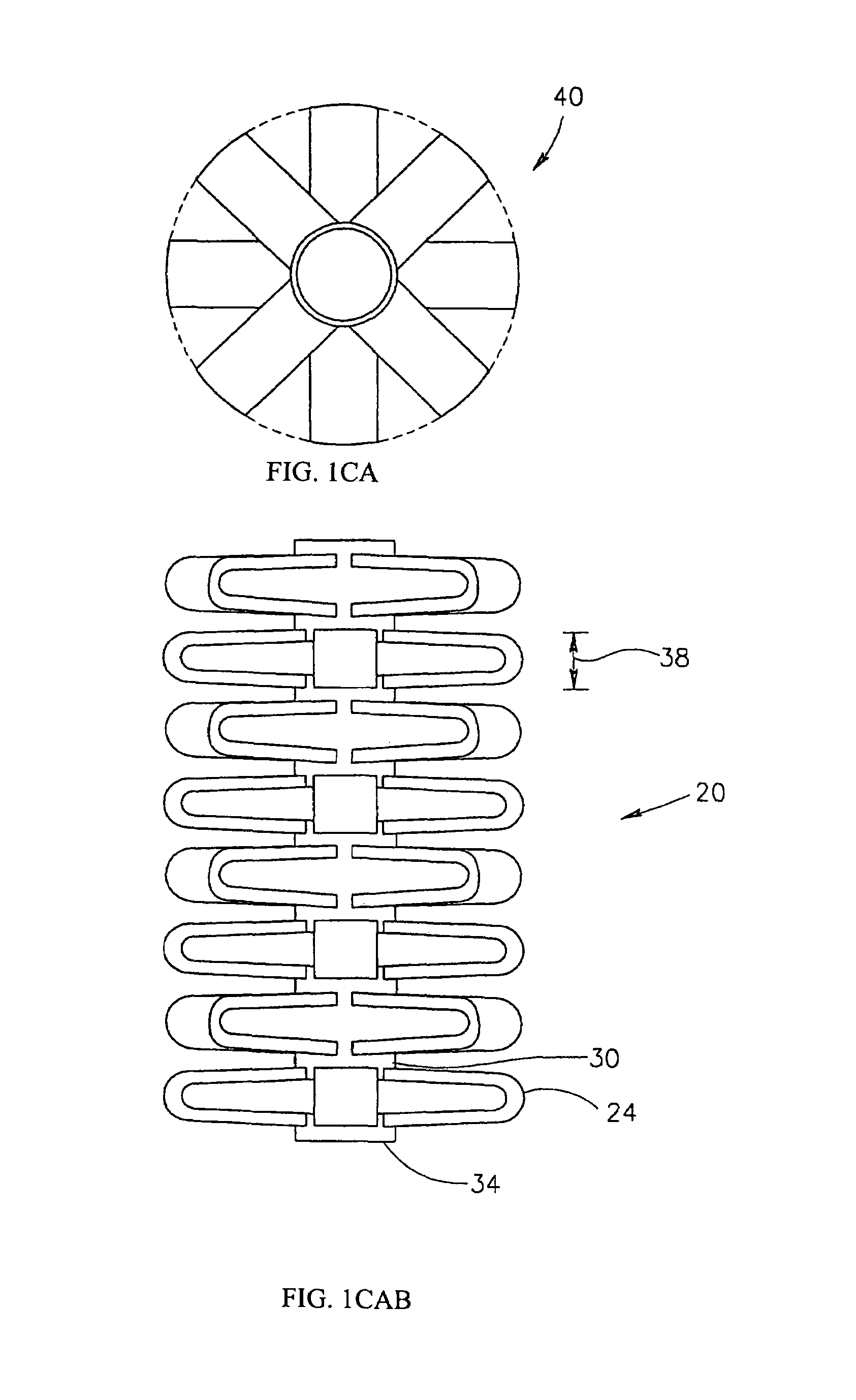

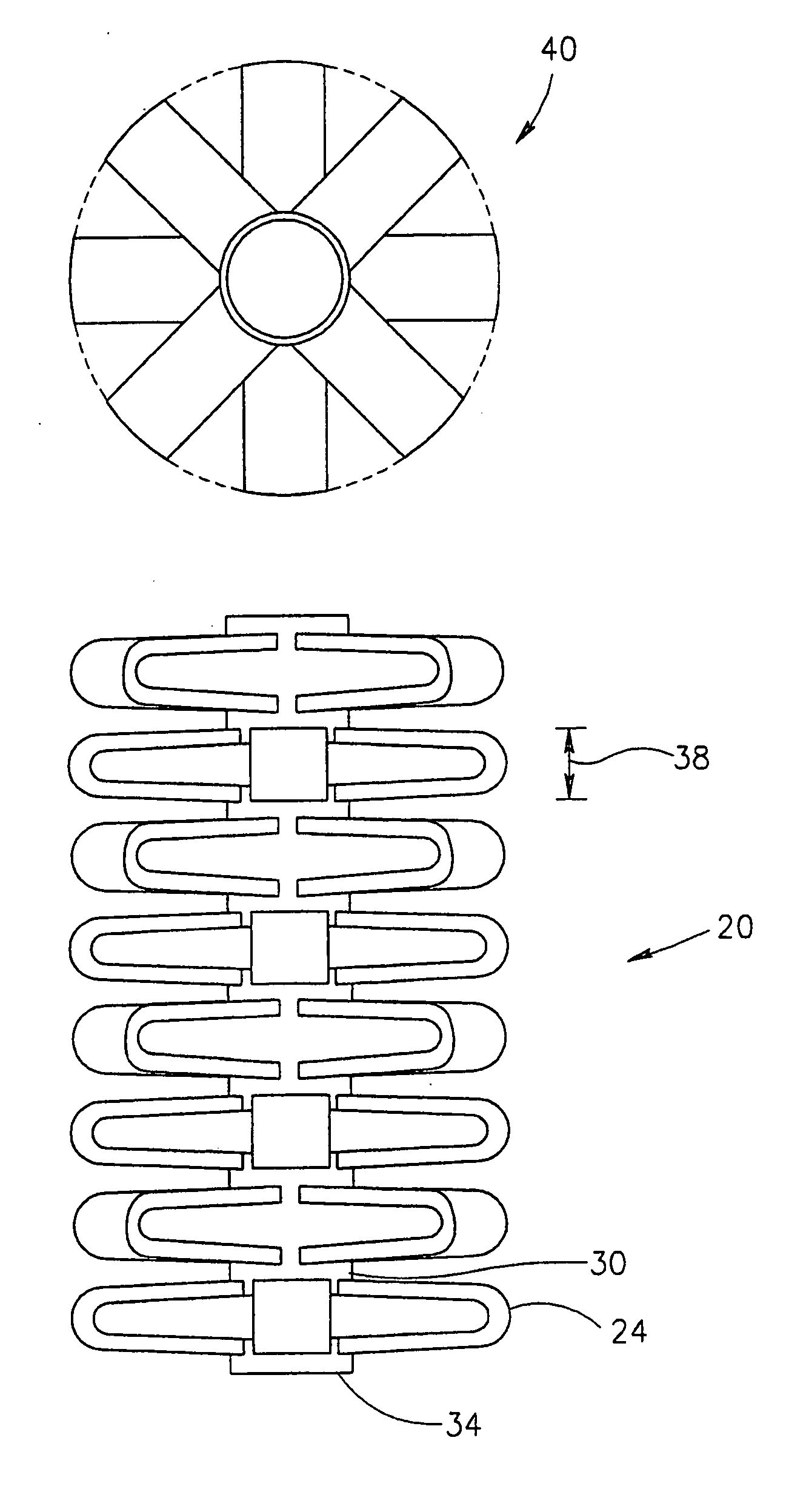

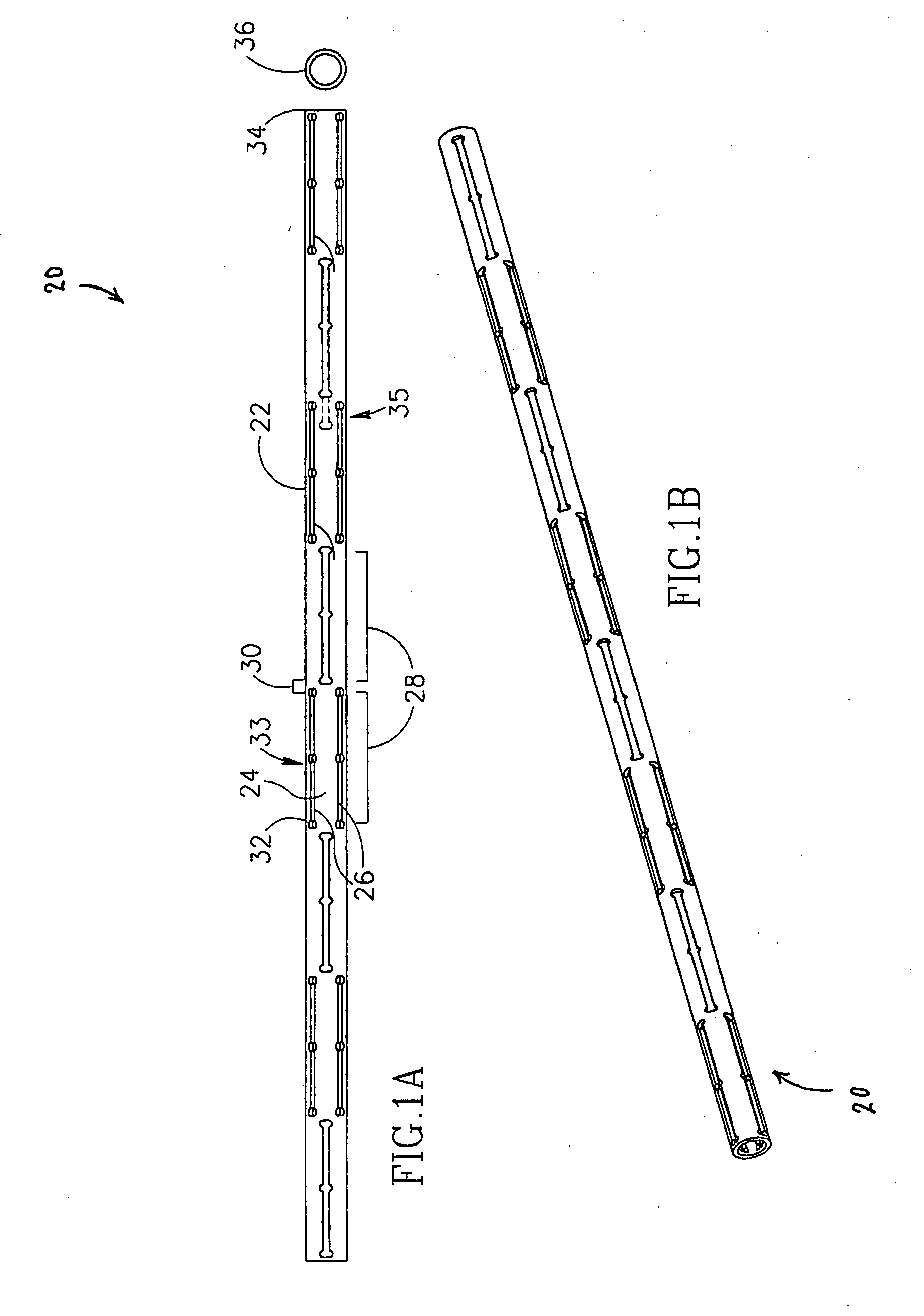

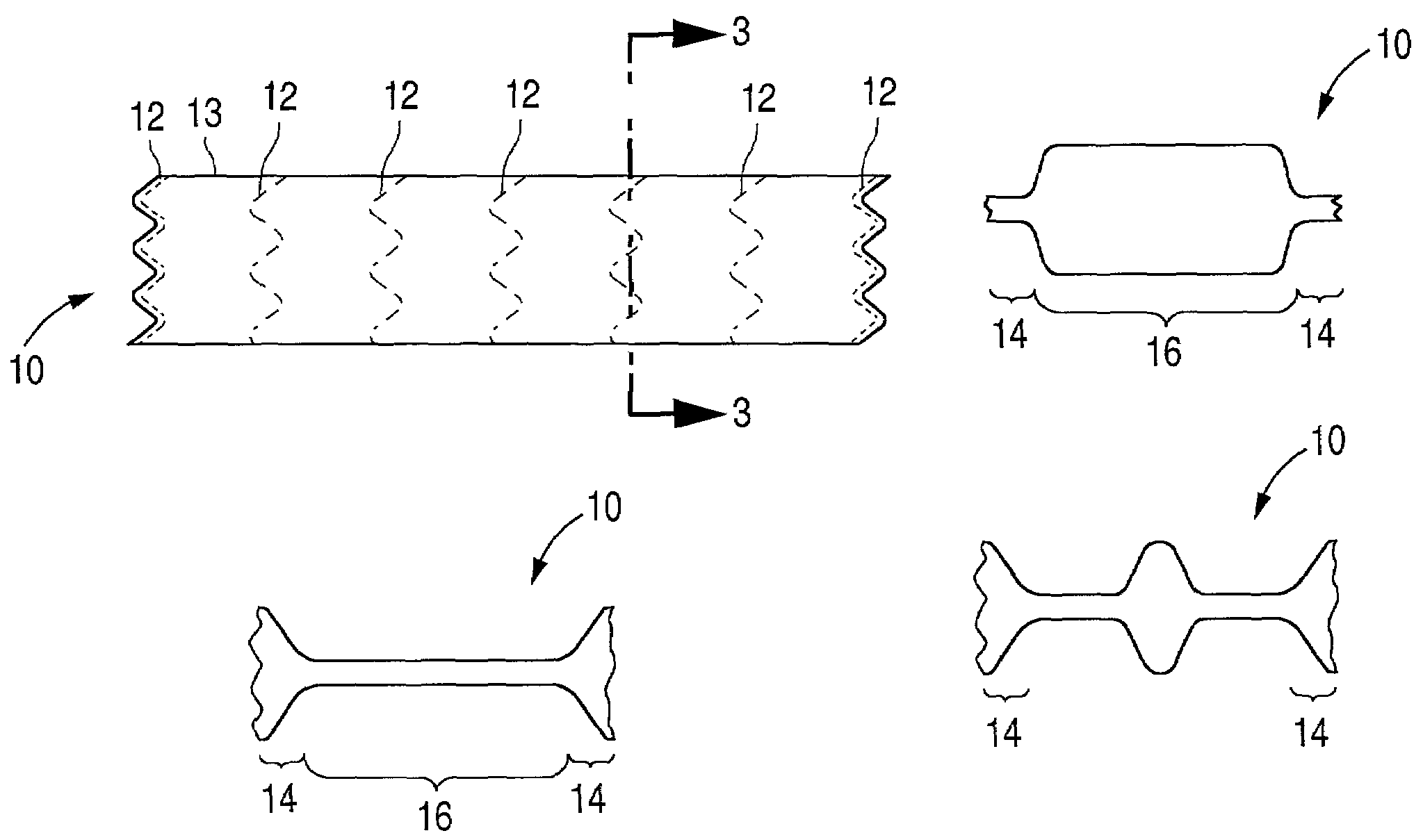

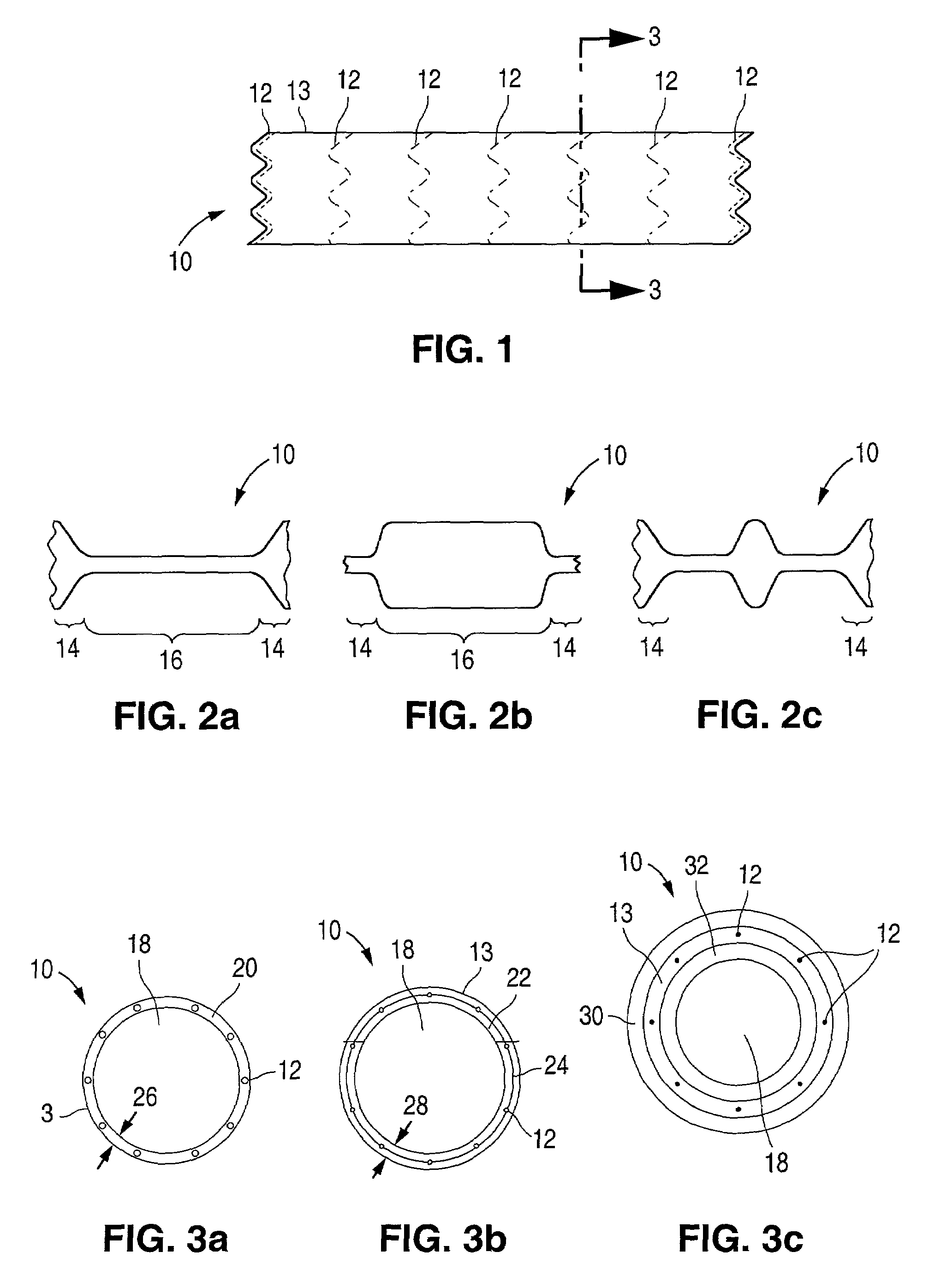

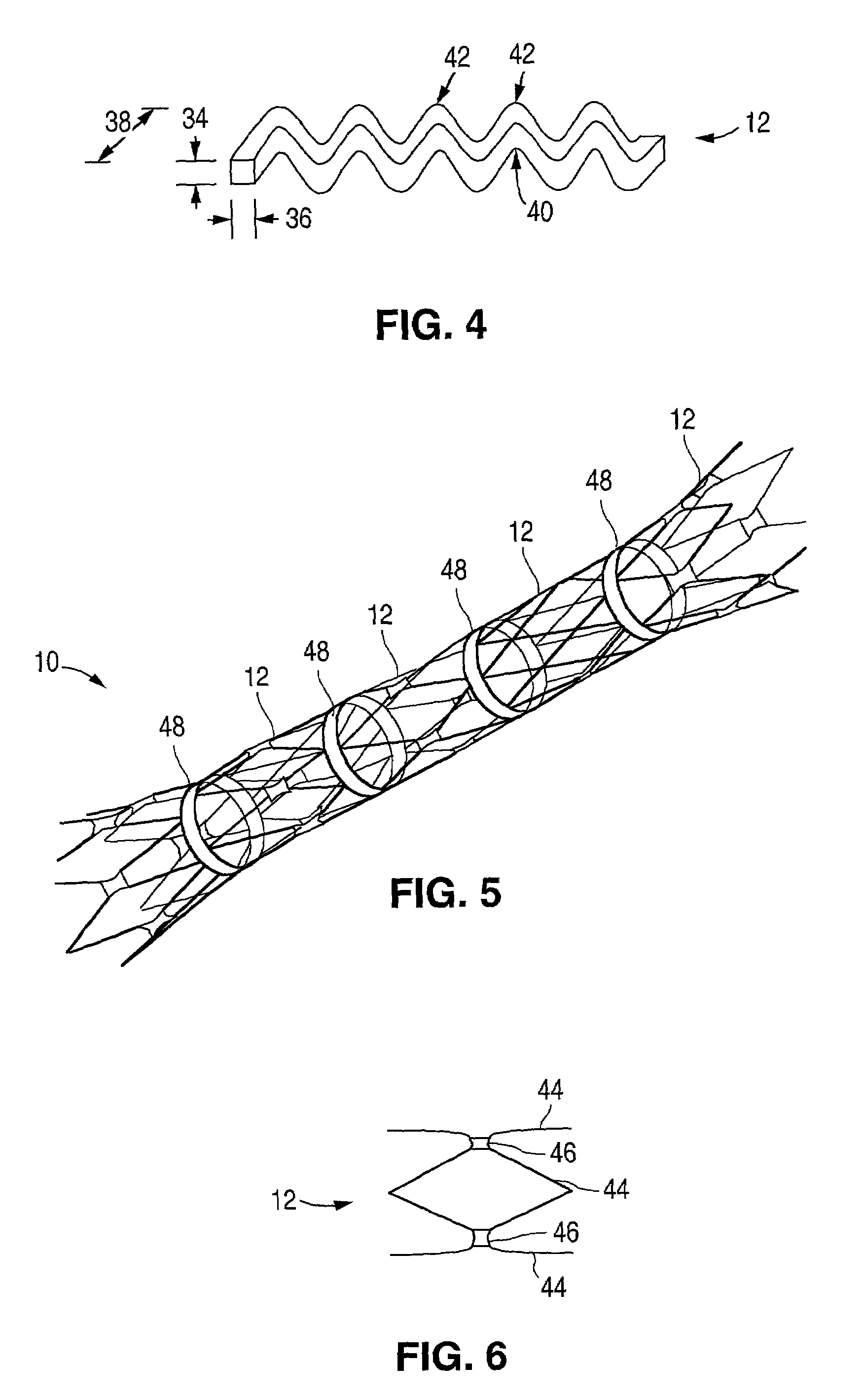

Flexible stent and method of making the same

InactiveUS7288111B1Increasing the thicknessFlexible connectionStentsBlood vesselsPolymerSelf expandable

Owner:TC1 LLC

Method of depositing barrier layer from metal gates

InactiveUS20050104112A1Improve performanceEasy to useTransistorSolid-state devicesGate dielectricRemote plasma

A method of manufacturing a high performance MOS device and transistor gate stacks comprises forming a gate dielectric layer over a semiconductor substrate; forming a barrier layer over the gate dielectric layer by an ALD type process; and forming a gate electrode layer over the barrier layer. The method enables the use of hydrogen plasma, high energy hydrogen radicals and ions, other reactive radicals, reactive oxygen and oxygen containing precursors in the processing steps subsequent to the deposition of the gate dielectric layer of the device. The ALD process for forming the barrier layer is performed essentially in the absence of plasma and reactive hydrogen radials and ions. This invention makes it possible to use oxygen as a precursor in the deposition of the metal gates. The barrier film also allows the use of hydrogen plasma in the form of either direct or remote plasma in the deposition of the gate electrode. Furthermore, the barrier film prevents the electrode material from reacting with the gate dielectric material. The barrier layer is ultra thin and, at the same time, it forms a uniform cover over the entire surface of the gate dielectric.

Owner:HAUKKA SUVI +1

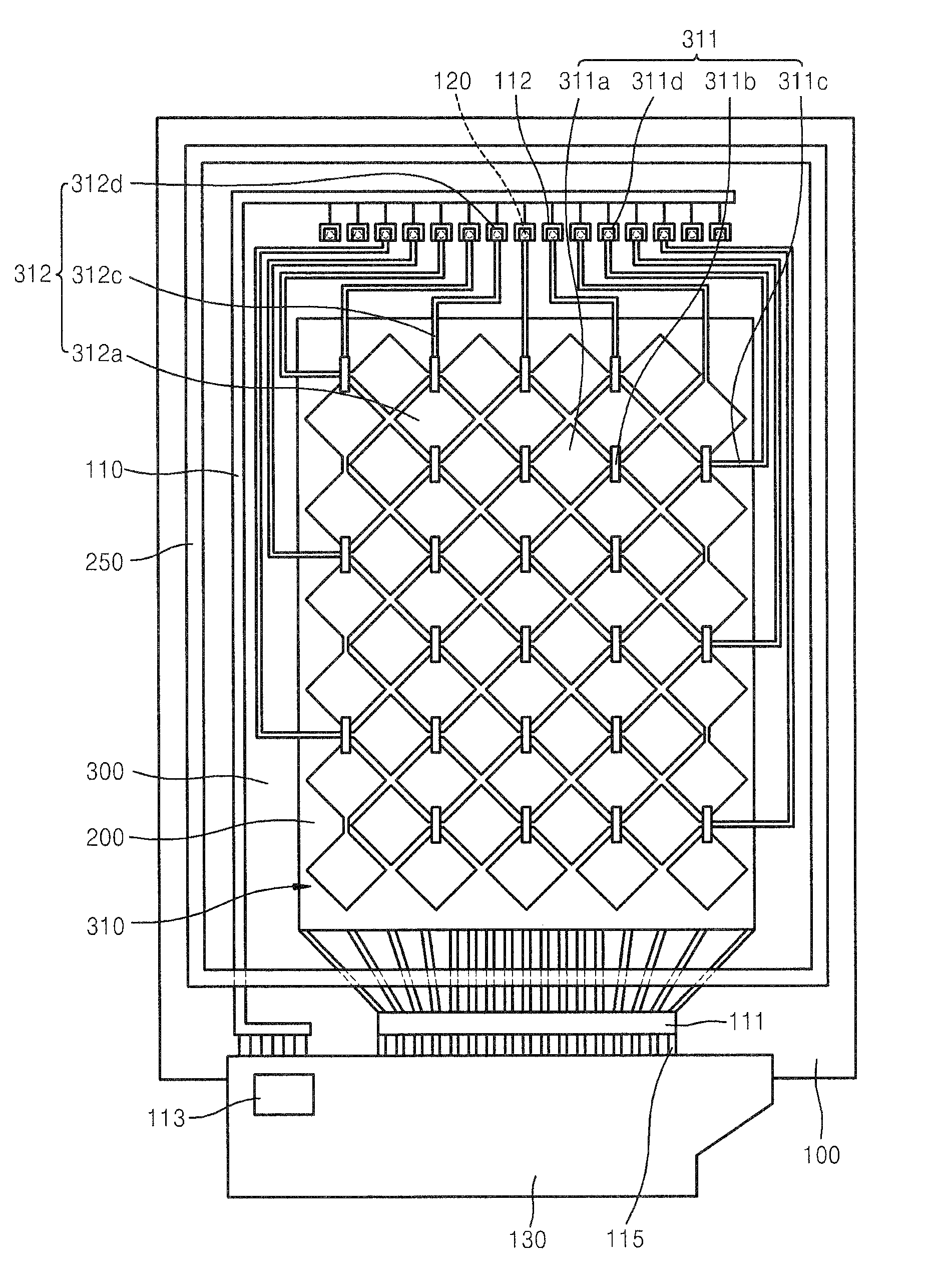

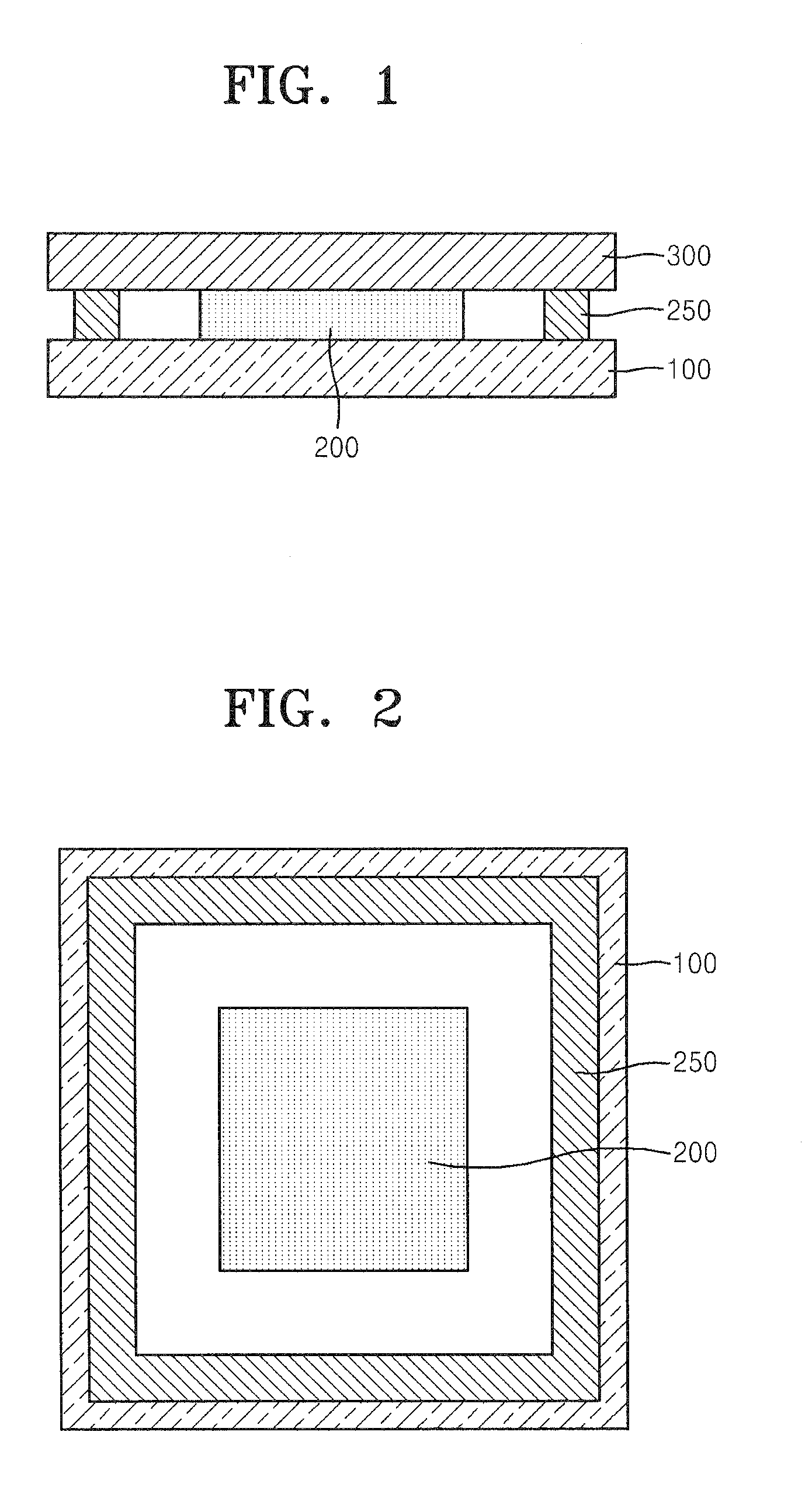

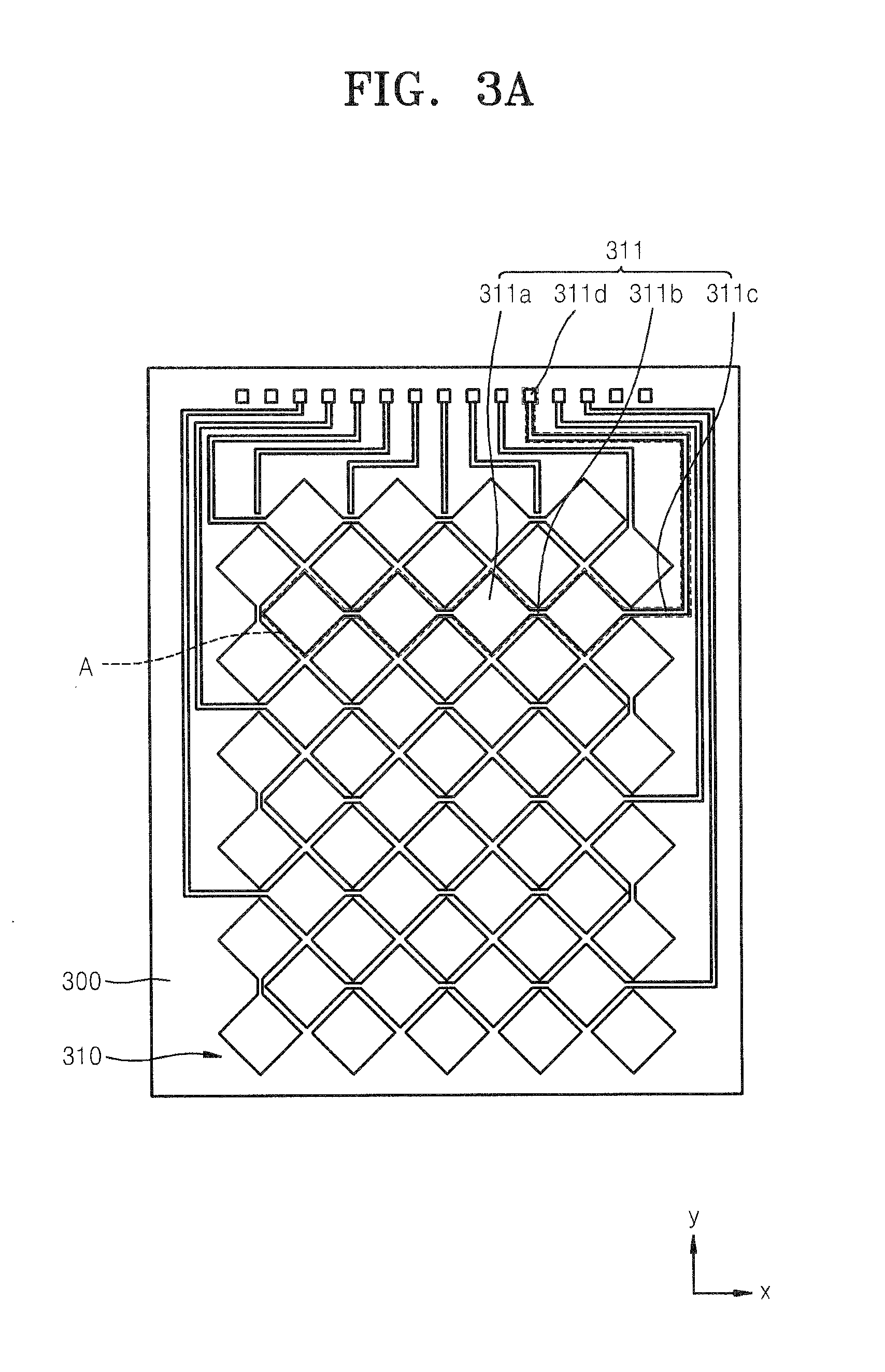

Organic light emitting display device

ActiveUS20100110041A1Increasing the thicknessStatic indicating devicesSolid-state devicesDisplay deviceEngineering

An organic light emitting display device capable of having an electrostatic capacitive type touch panel function without substantially increasing the thickness of the display device and / or including a touch panel with an improved interface between a touch panel module of the touch panel and a touch panel drive integrated circuit (IC) of the touch panel.

Owner:SAMSUNG DISPLAY CO LTD

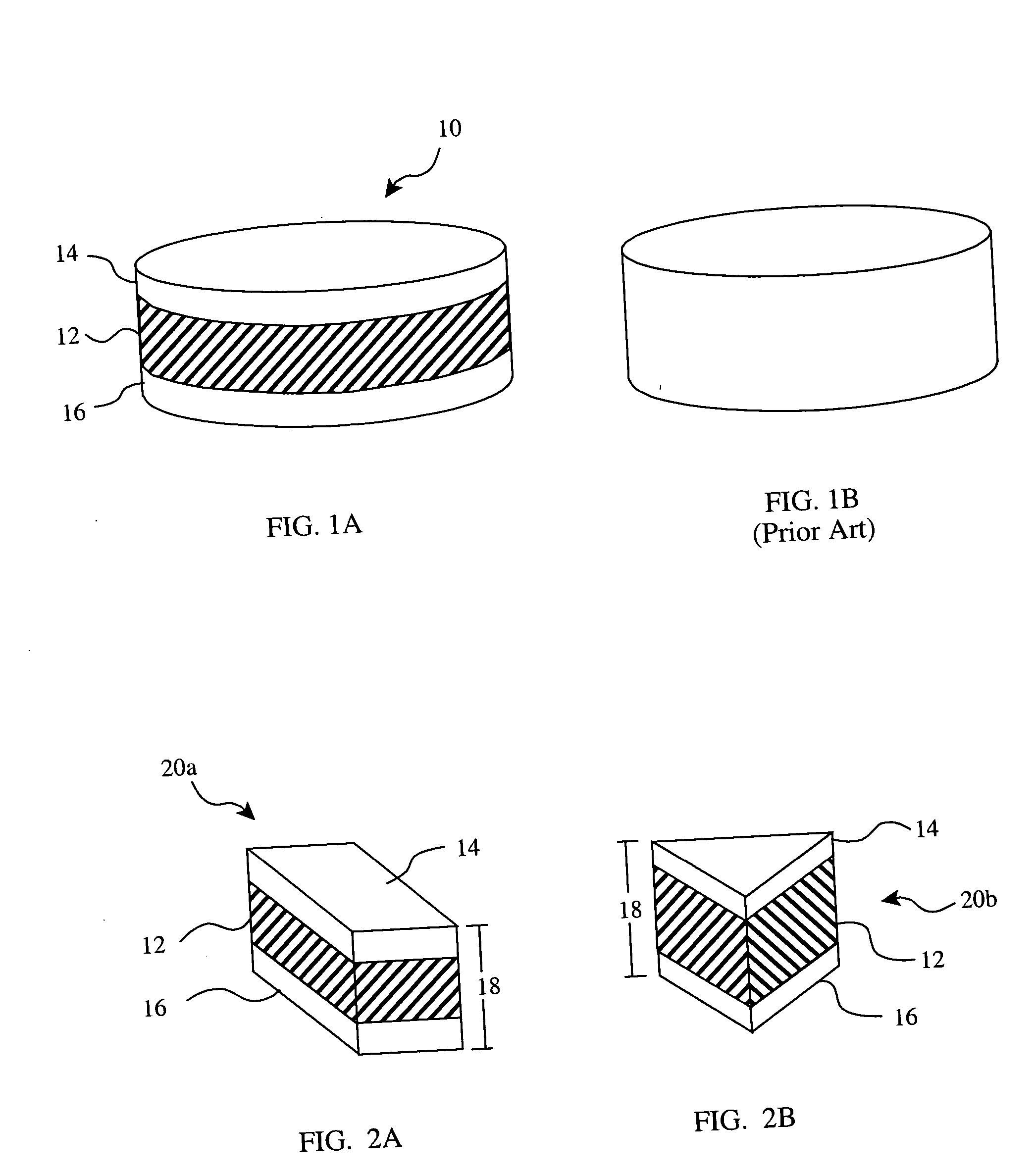

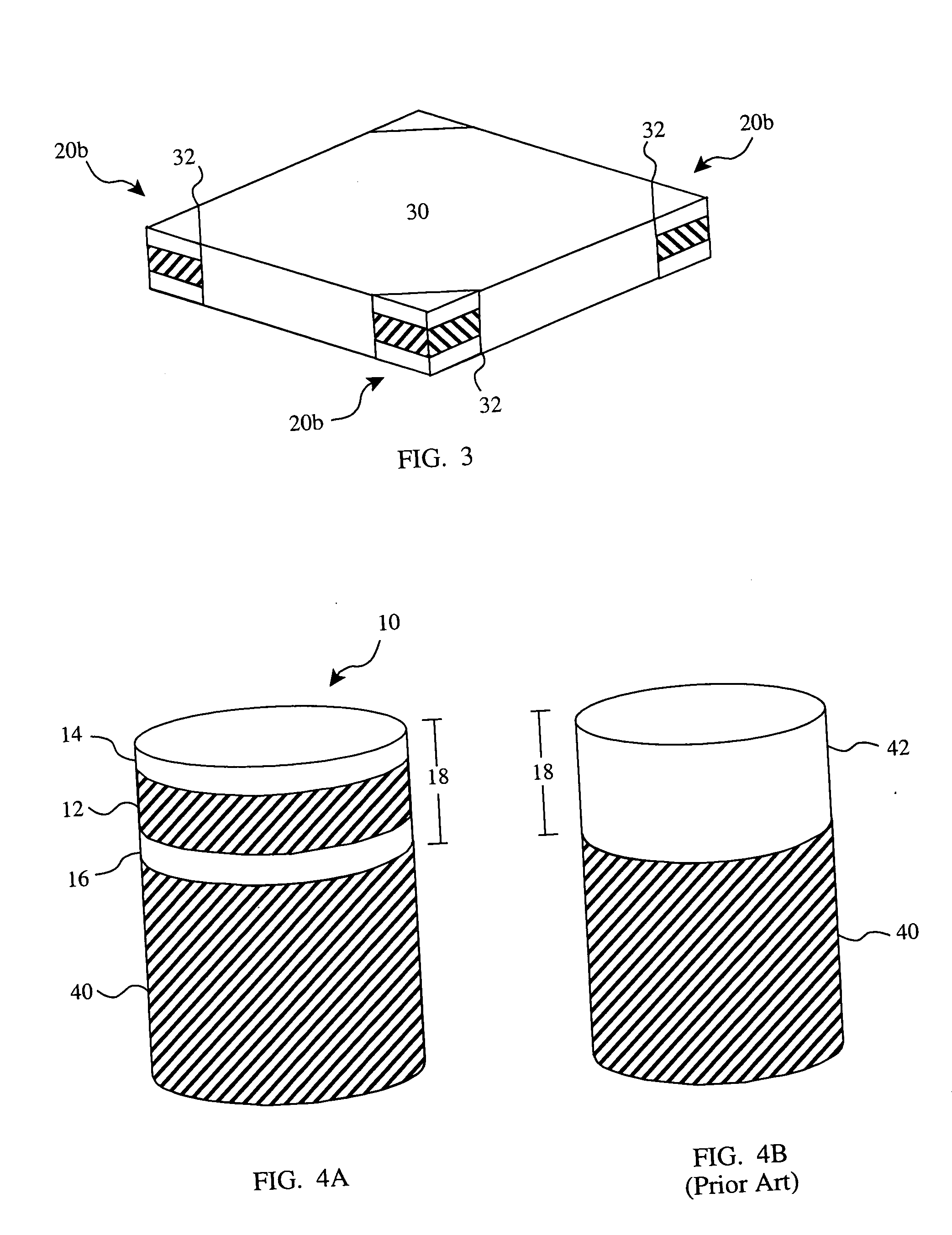

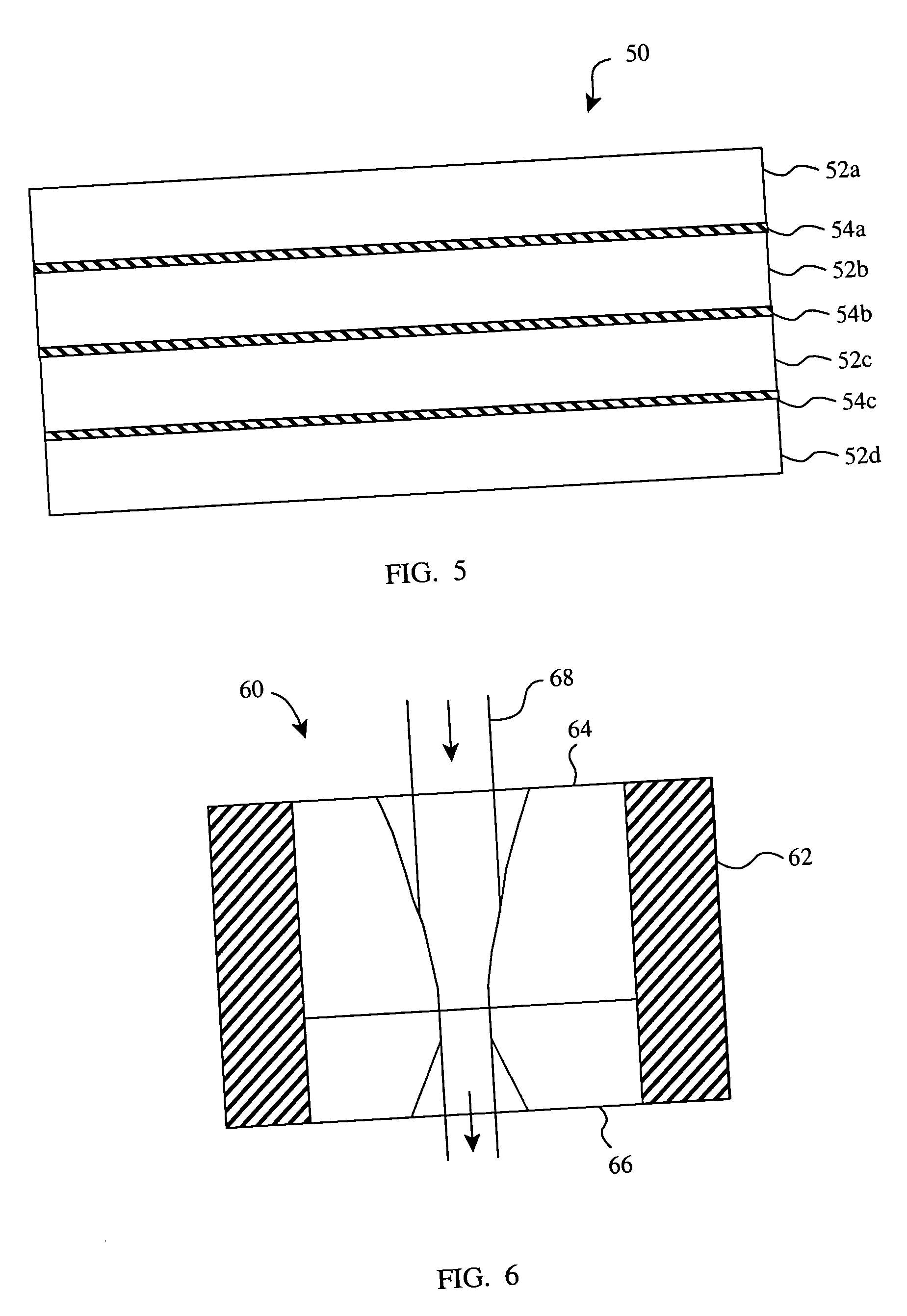

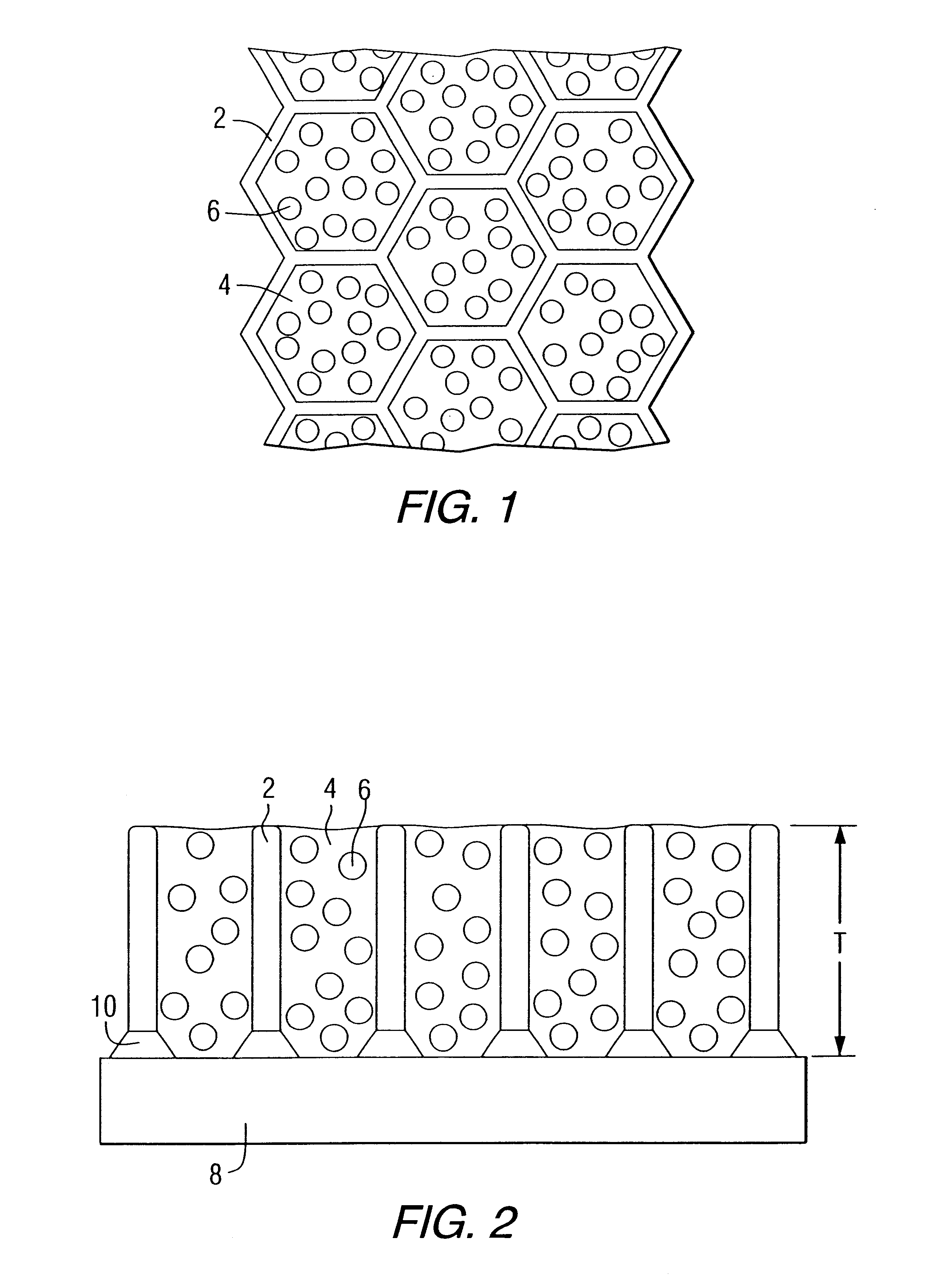

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

Radiator for light emitting unit, and backlight device

InactiveUS20070019419A1Increase brightnessGuaranteed uptimeMeasurement apparatus componentsLighting heating/cooling arrangementsHeat spreaderClose contact

Owner:SONY CORP

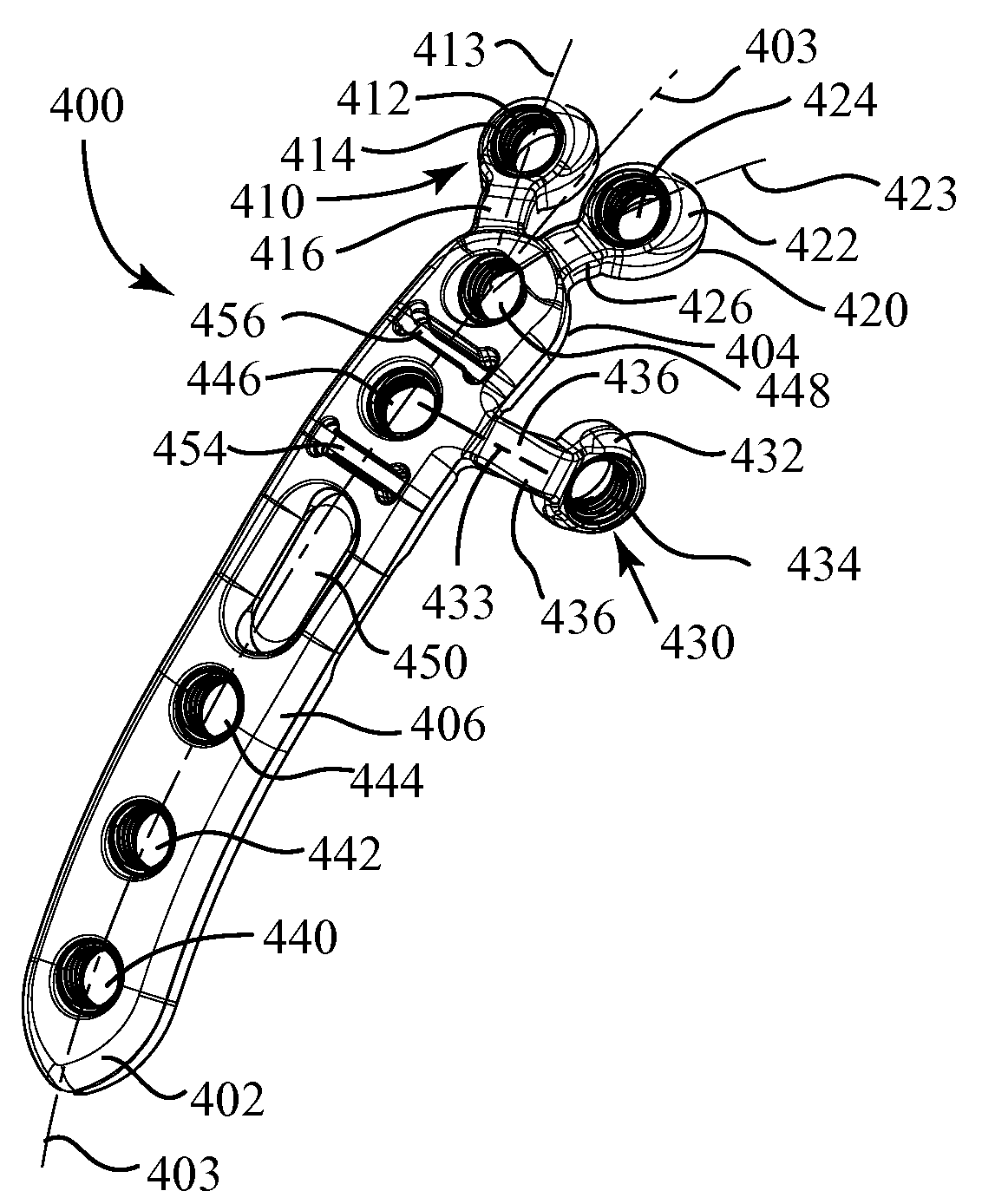

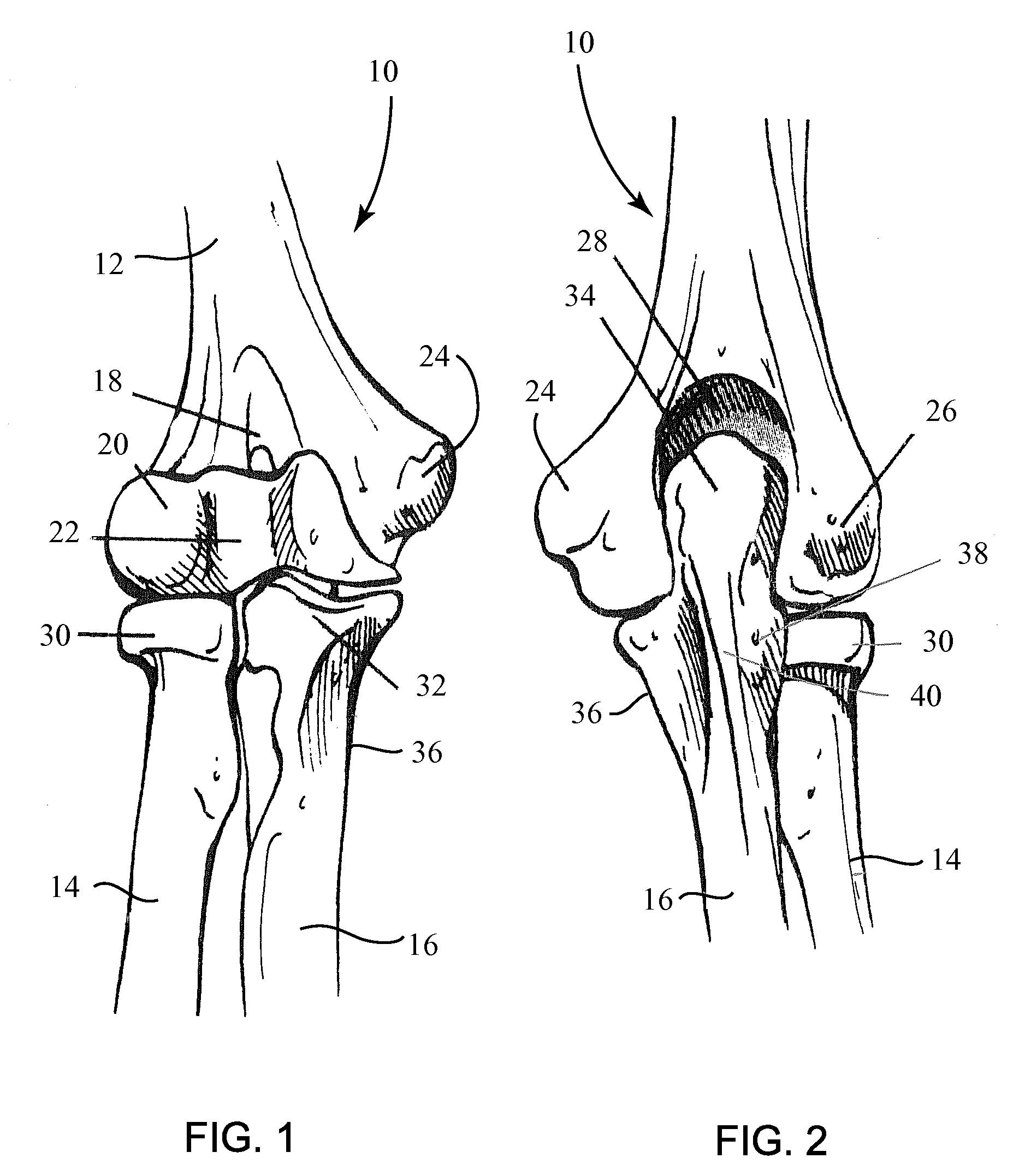

Fracture Fixation Plate for the Proximal Radius

ActiveUS20090118769A1Simple and safe processEasily and safely reconfiguredInternal osteosythesisMetal-working hand toolsProximal radiusInternal fixation

A system for the internal fixation of a fractured bone of an elbow joint of a patient includes at least one bone plate, each bone plate having a plurality of holes and generally configured to fit an anatomical surface of the fractured bone. The at least one plate is adapted to be customized to the shape of a patient's bone. The system also includes a plurality of fasteners including at least one locking fastener for attaching the bone plate to the bone. At least one of the holes is a threaded hole. Guides for plate benders, drills, and / or K-wires can be pre-assembled to the threaded holes, and the locking fastener can lock into any of the threaded holes after the guides are removed.

Owner:BIOMET CV

Electro-optic displays, and color filters for use therein

ActiveUS8098418B2Solve the lack of adhesionEliminate needLayered product treatmentStatic indicating devicesDisplay deviceColor filter array

A process for producing a color electro-optic display uses an electro-optic sub-assembly comprising an electro-optic layer and a light-transmissive electrically-conductive layer. This sub-assembly is laminated to a backplane comprising a plurality of electrodes with the electro-optic layer disposed between the backplane and the electrically-conductive layer. A flowable material is placed over the sub-assembly and a color filter array is placed over the electrically-conductive layer and aligned with the electrodes of the backplane to form the color electro-optic display.

Owner:E INK CORPORATION

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

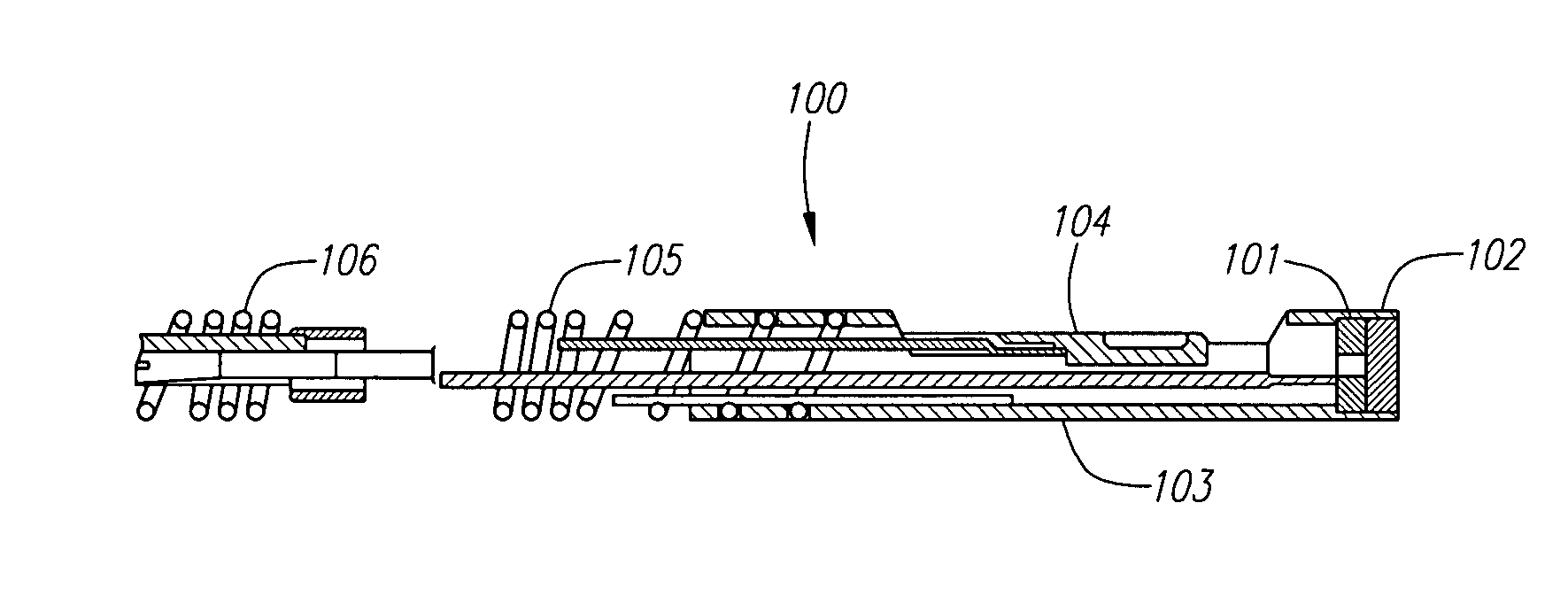

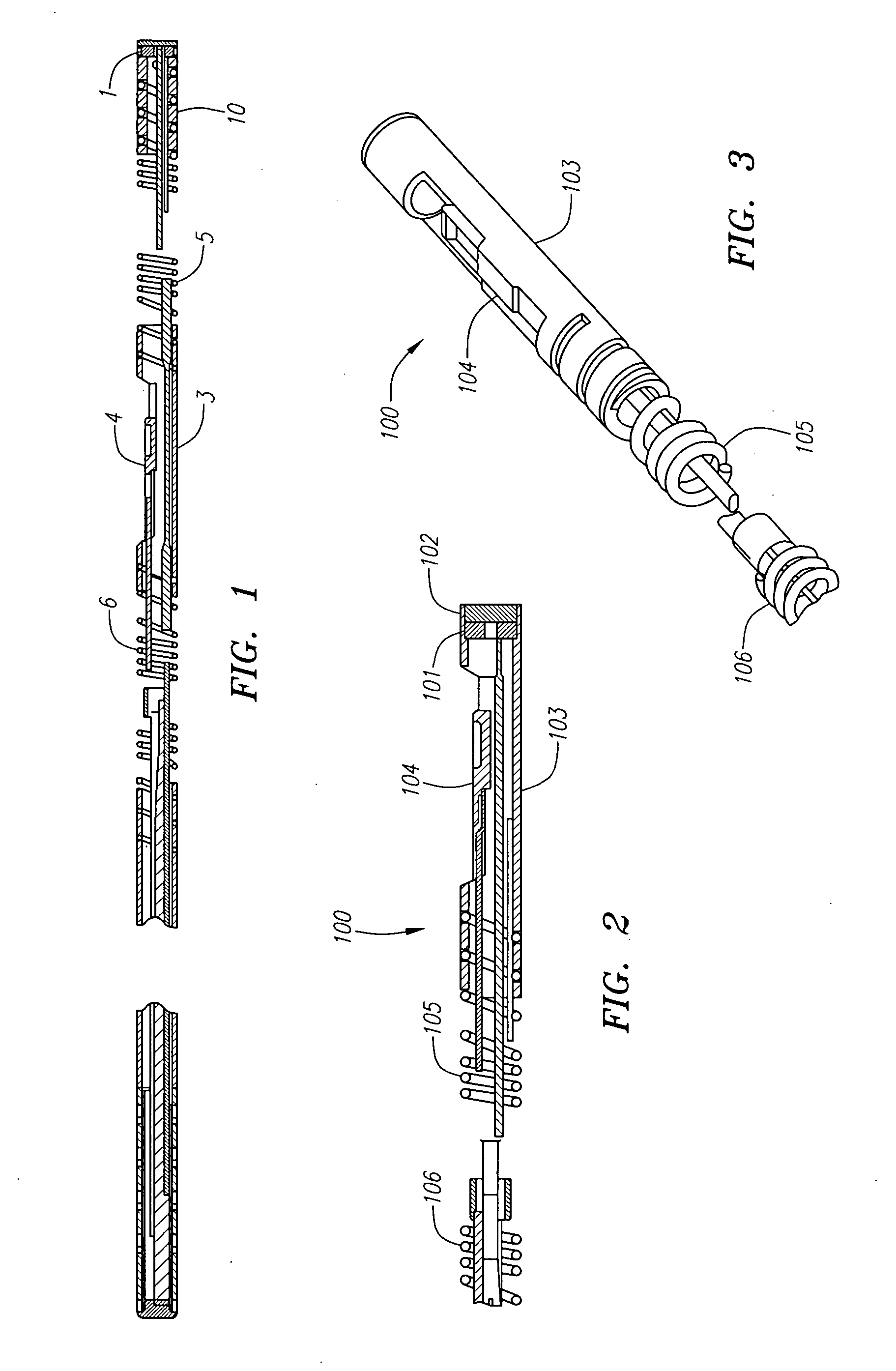

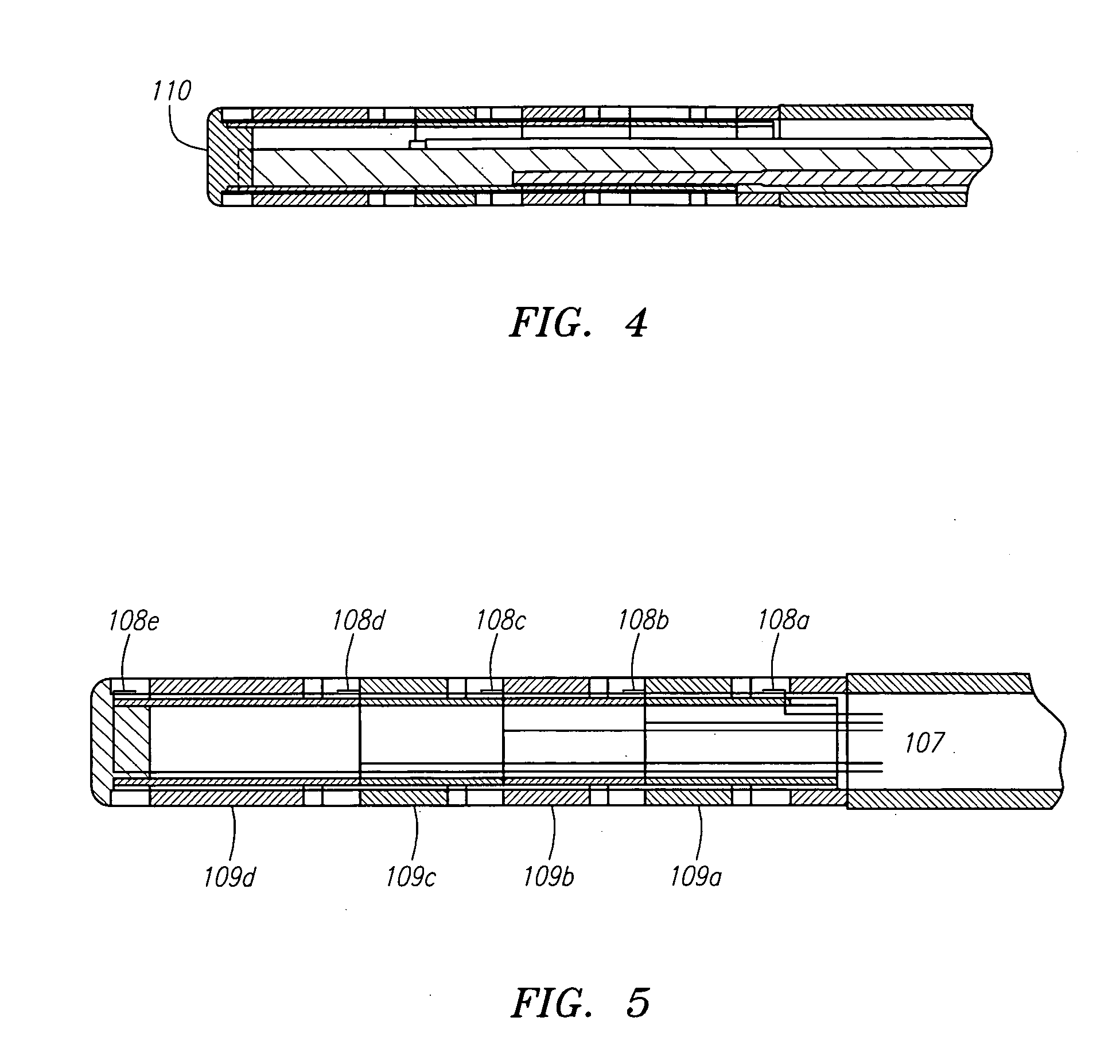

Combination sensor guidewire and methods of use

ActiveUS20060074318A1Improve accuracyImprove consistencyBlood flow measurement devicesCatheterUltrasonic sensorTransducer

The present invention provides for an improved combination sensor tip that includes an ultrasound transducer and a pressure sensor both disposed at or in close proximity to the distal end of the combination sensor tip. The present invention also provides for an improved connector to couple a guide wire to a physiology monitor that reduces torsional resistance when maneuvering the guide wire.

Owner:VOLCANO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com