Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2709results about "Piezoelectric/electrostrictive device material selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

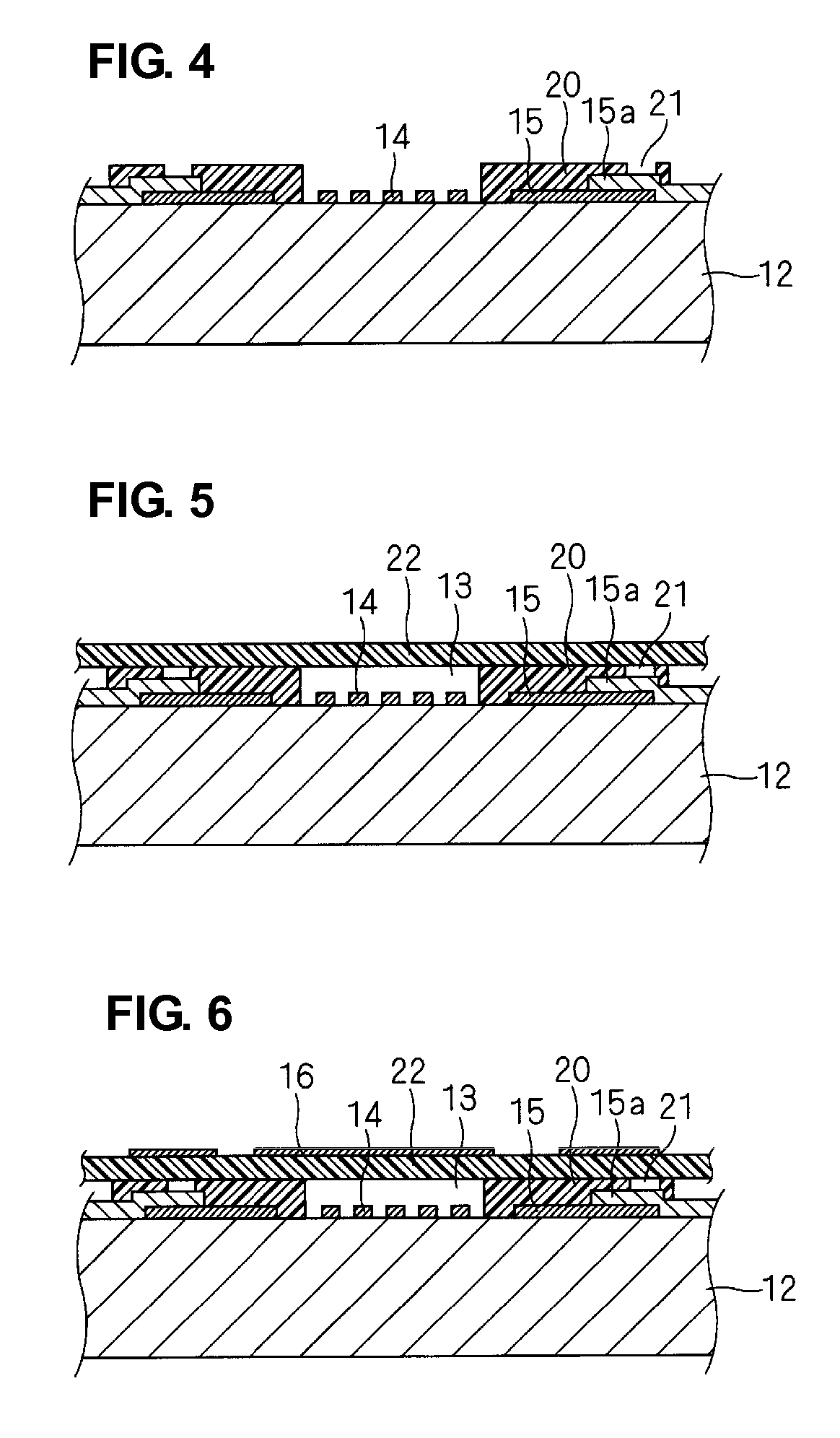

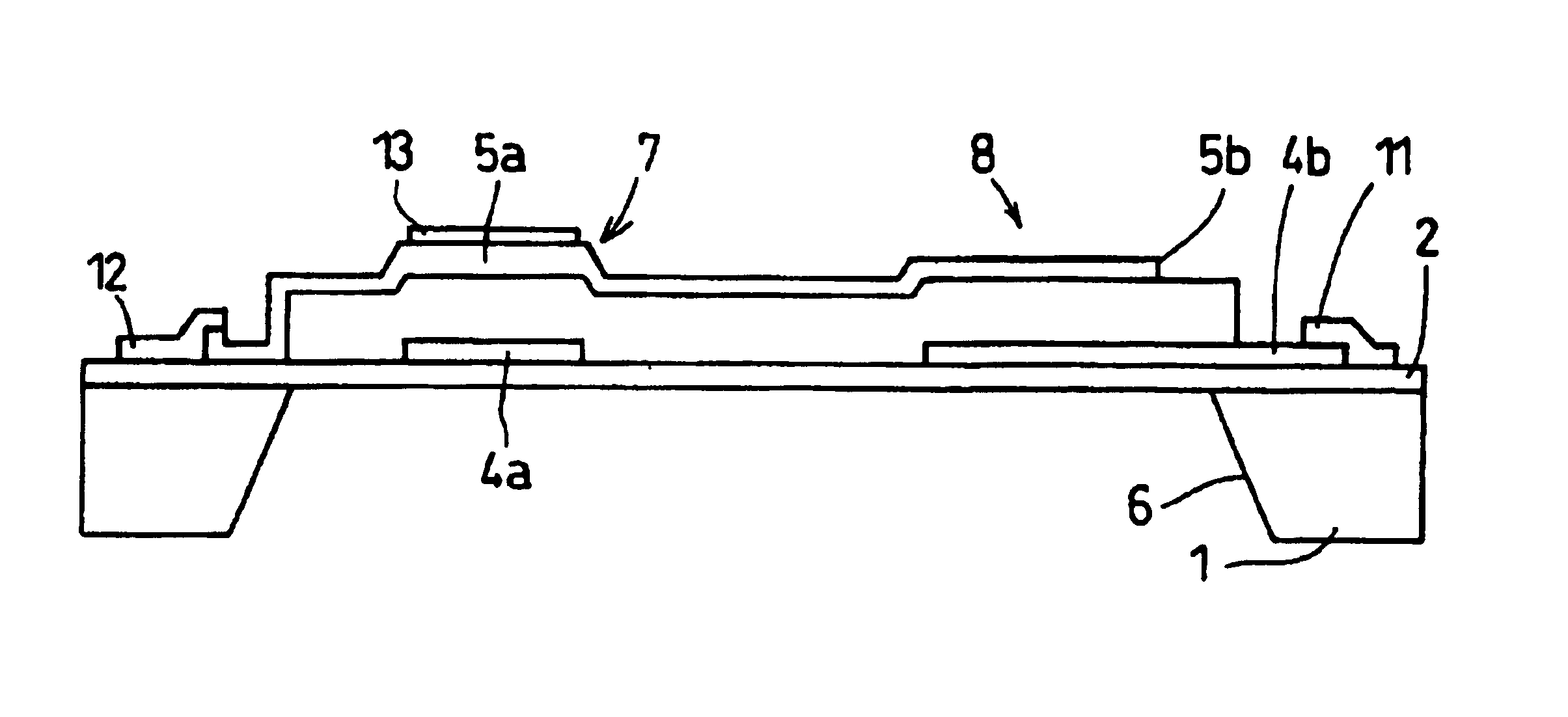

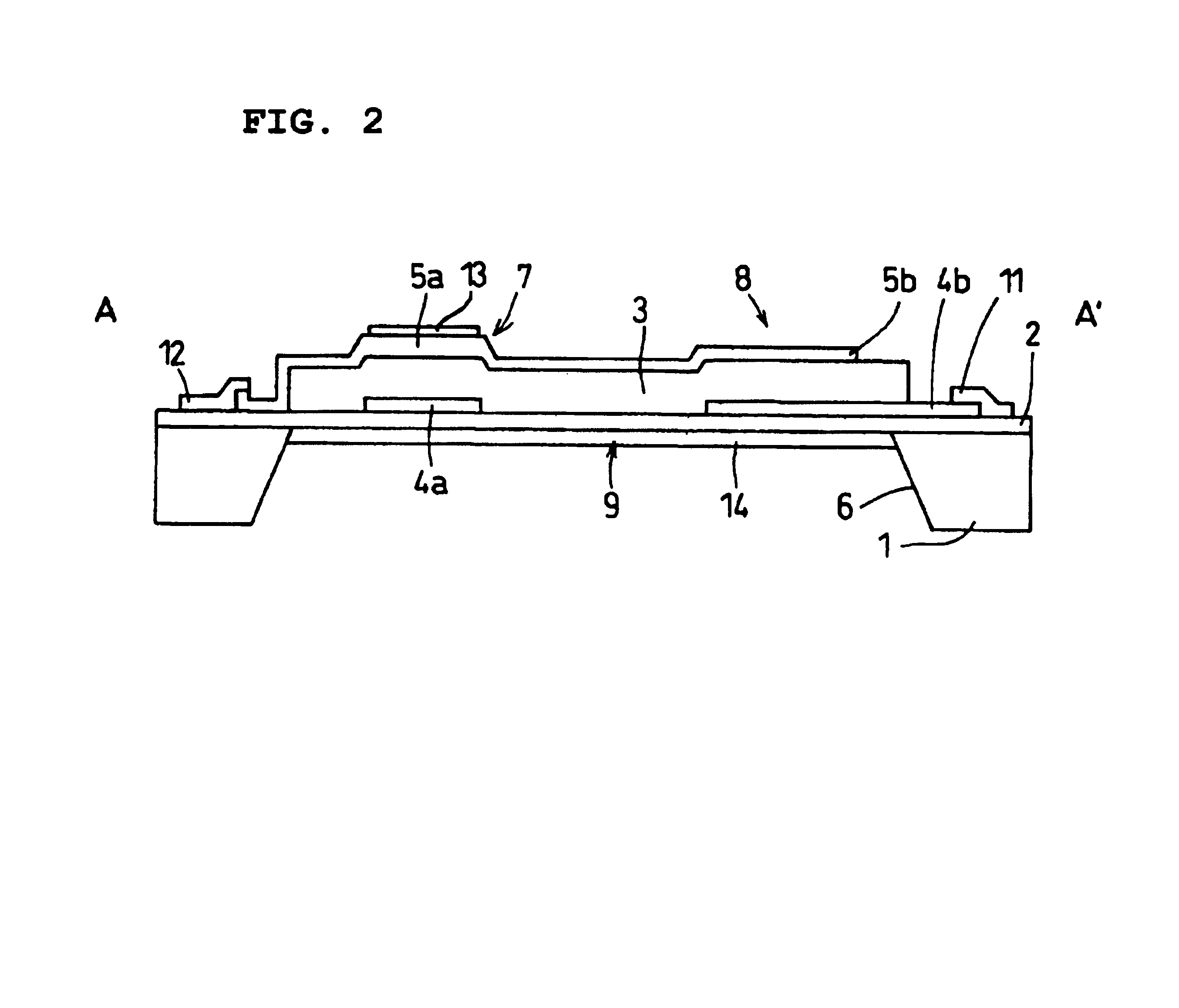

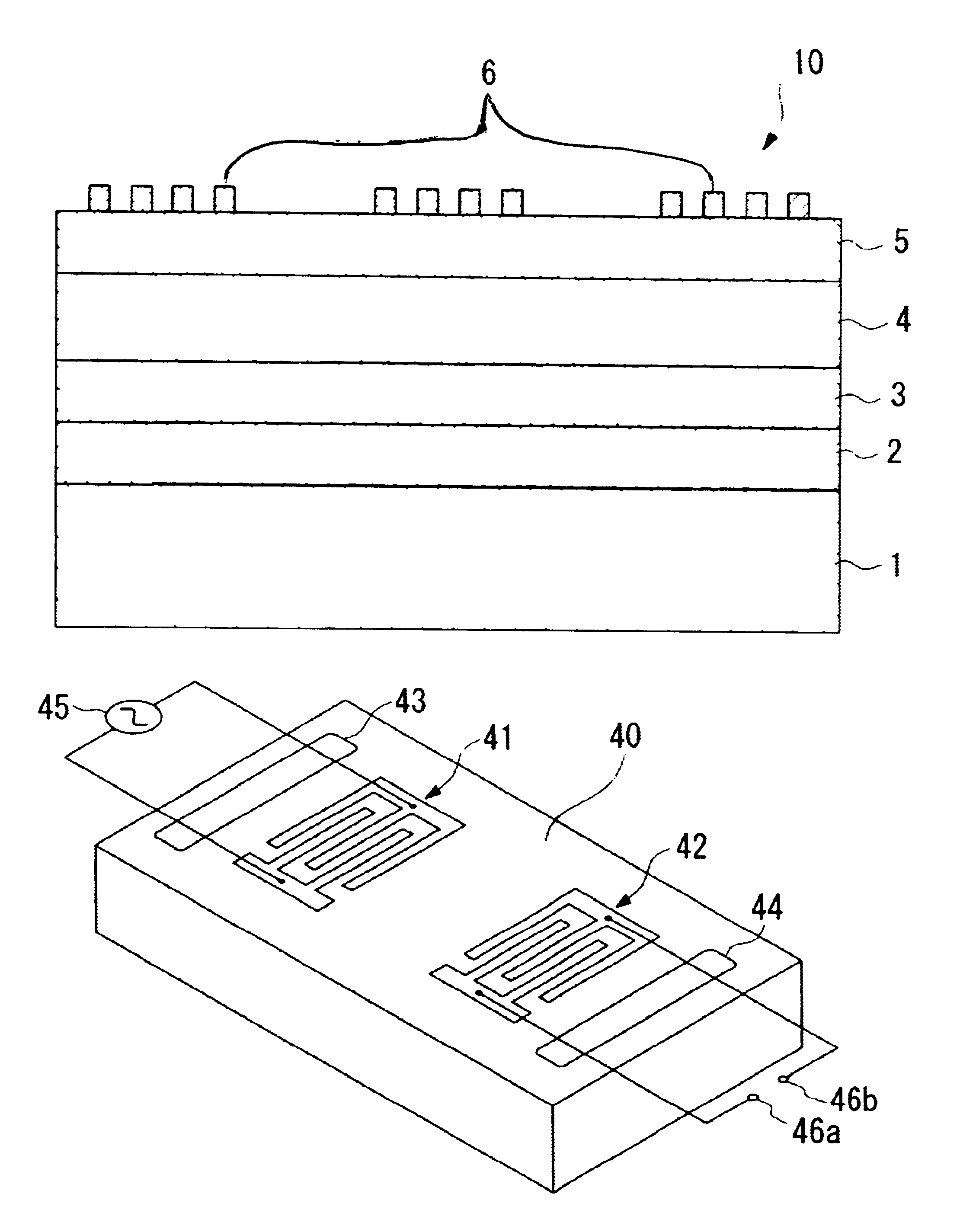

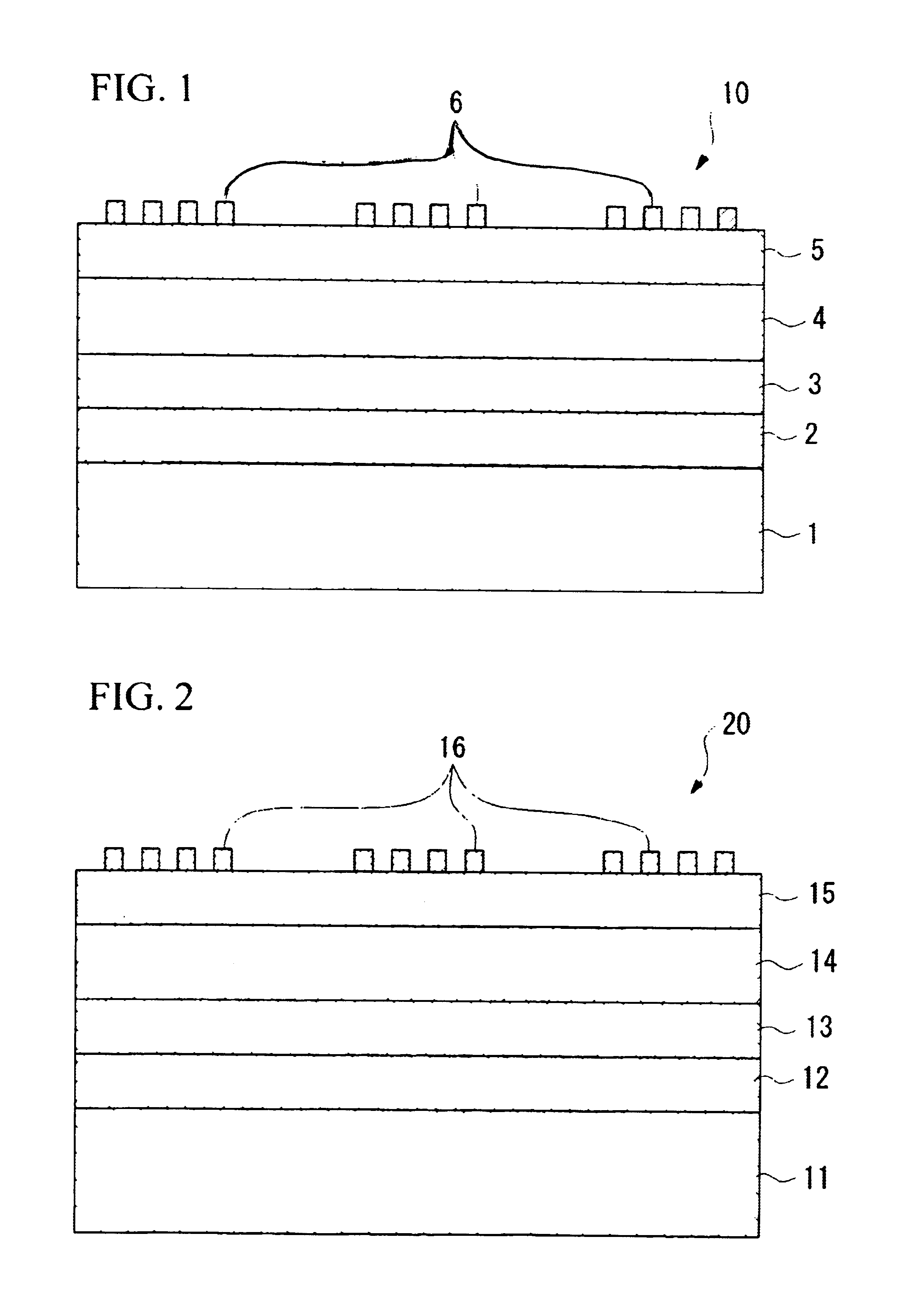

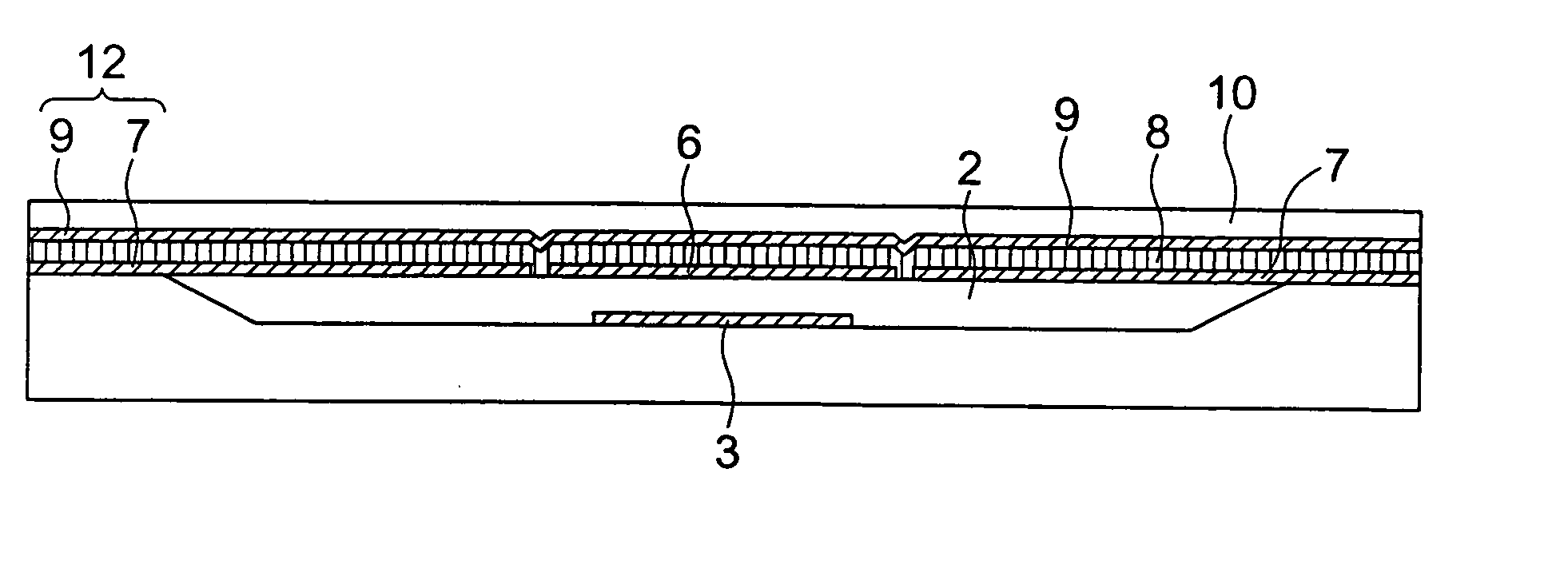

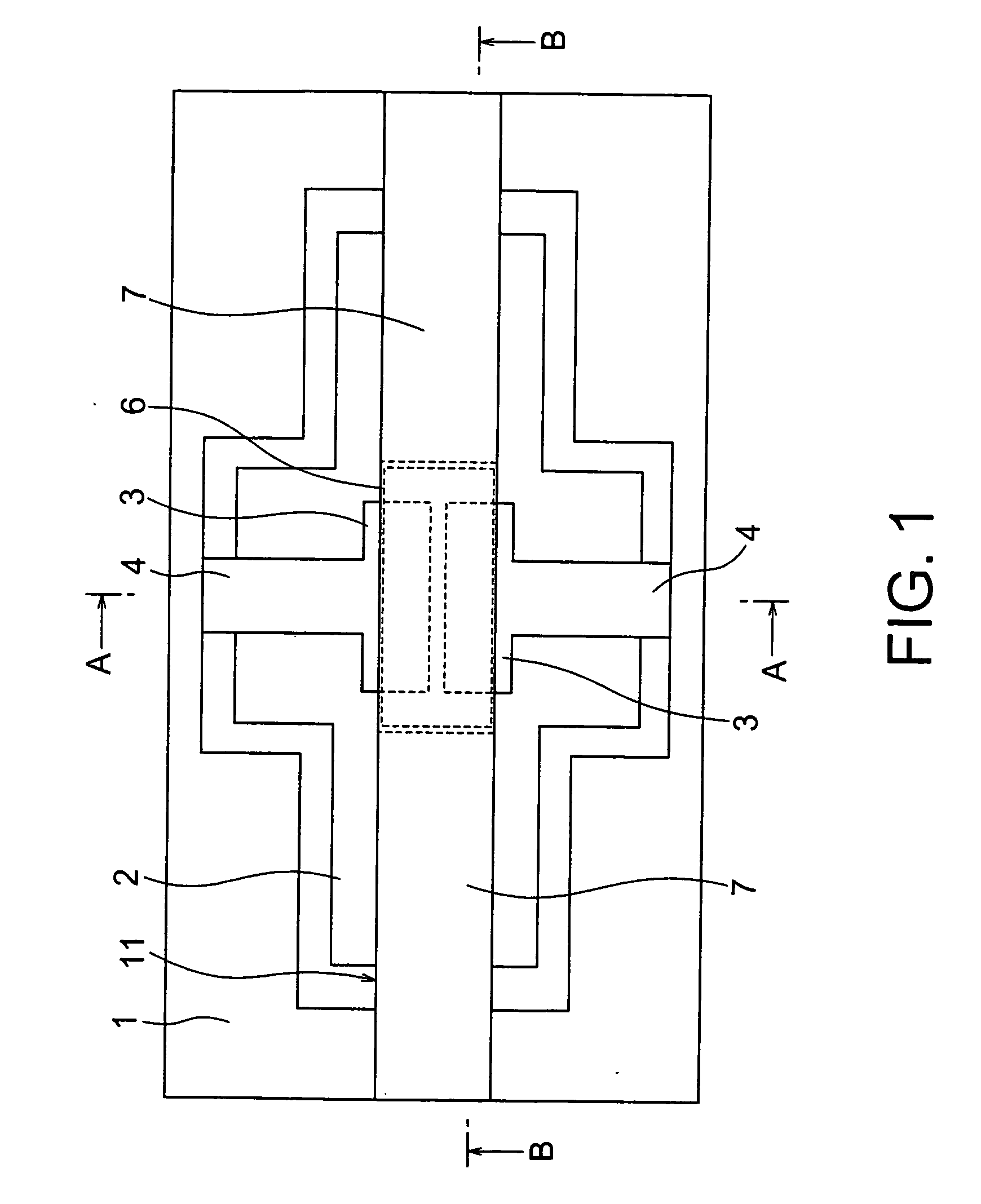

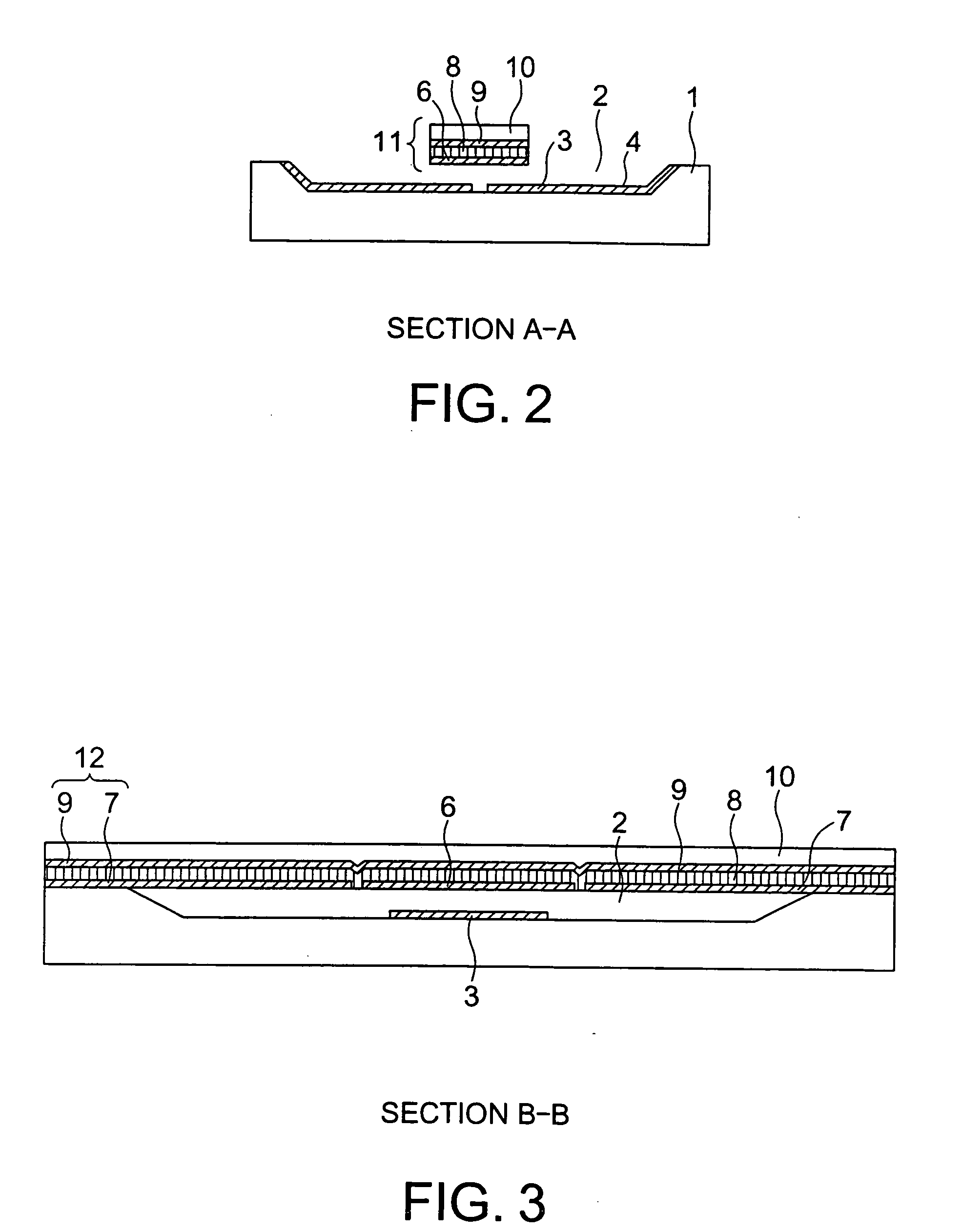

Ink-jet recording head with piezoelectric device and method for manufacturing the same

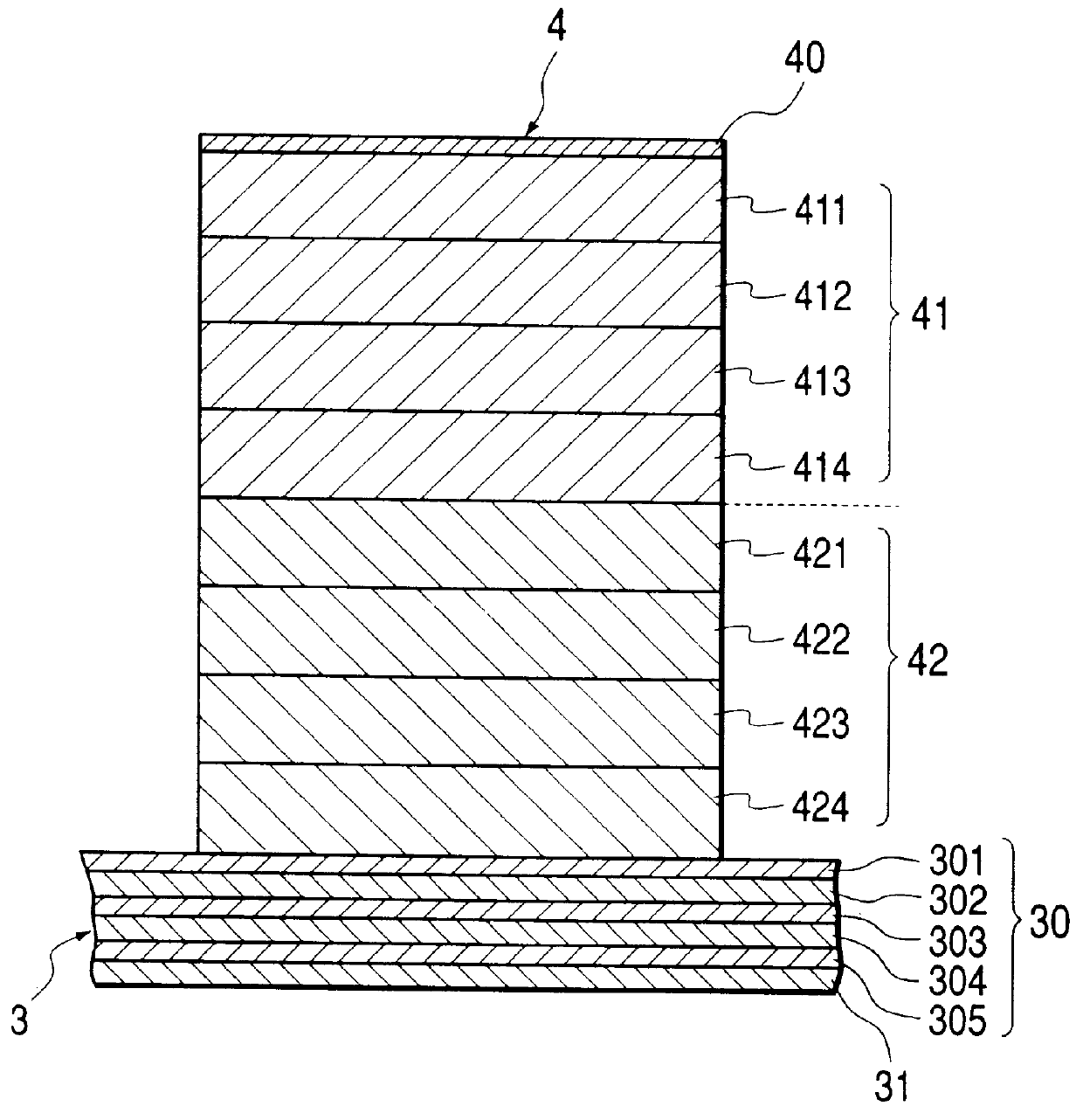

InactiveUS6142615AIncrease in piezoelectric constantIncrease the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsPiezoelectric coefficient

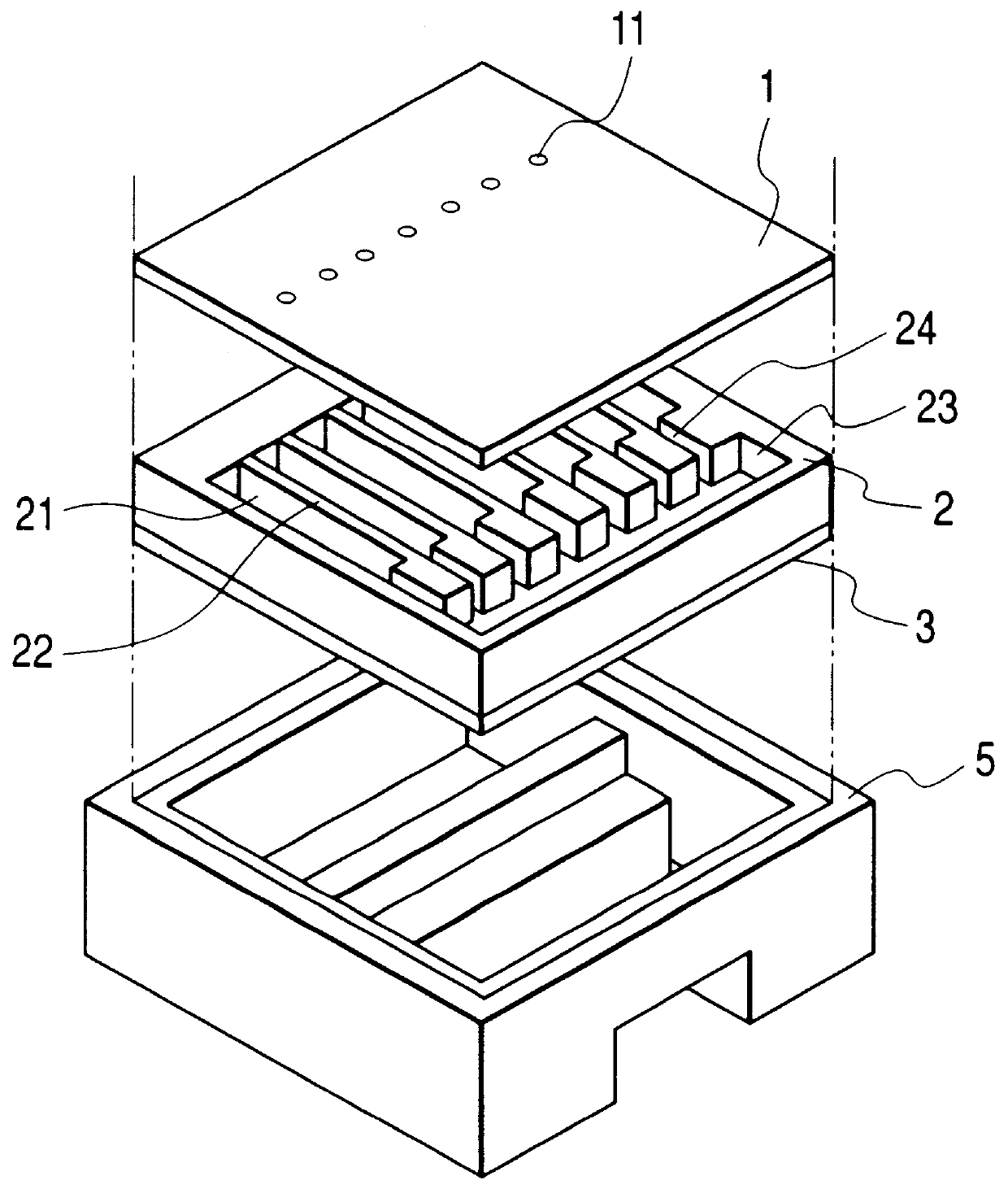

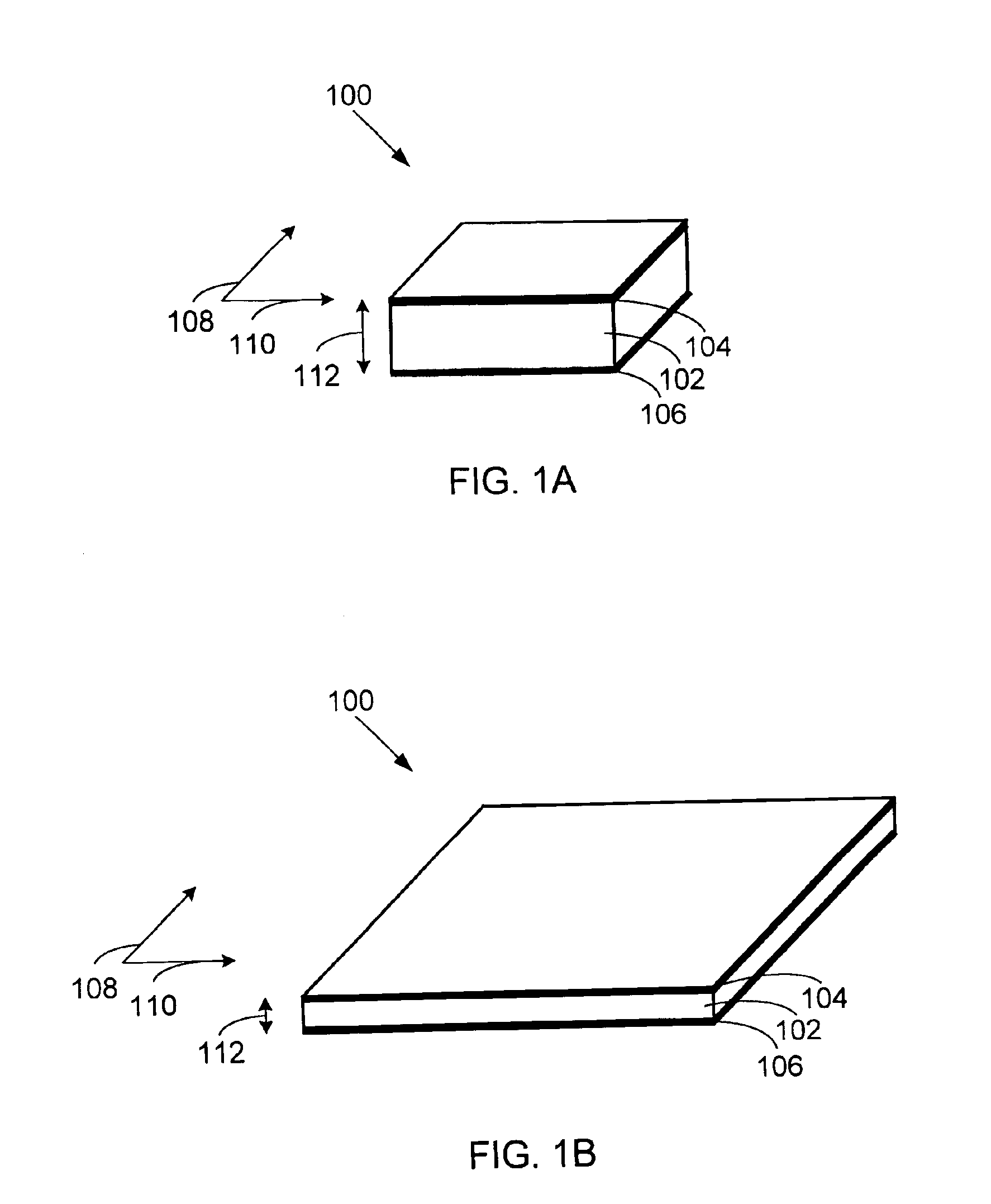

A piezoelectric device for an ink jet print head that has a greater displacement at a low drive voltage. The ink-jet recording head includes a vibration plate, on which is mounted one or more piezoelectric devices that change the volumes of pressure chambers upon application of a voltage. The device is mounted at least on one face of a pressure chamber substrate that is to be filled with ink. Such piezoelectric device includes a second piezoelectric layer having a piezoelectric constant g of a constant value or higher; and a first piezoelectric layer having a dielectric constant of a specific value or higher. Since the piezoelectric constant d of the piezoelectric device correlates with the product of the largest piezoelectric constant g and the largest dielectric device of the piezoelectric devices, a piezoelectric constant d larger than in the conventional case, i.e., having a greater displacement, can be obtained.

Owner:SEIKO EPSON CORP

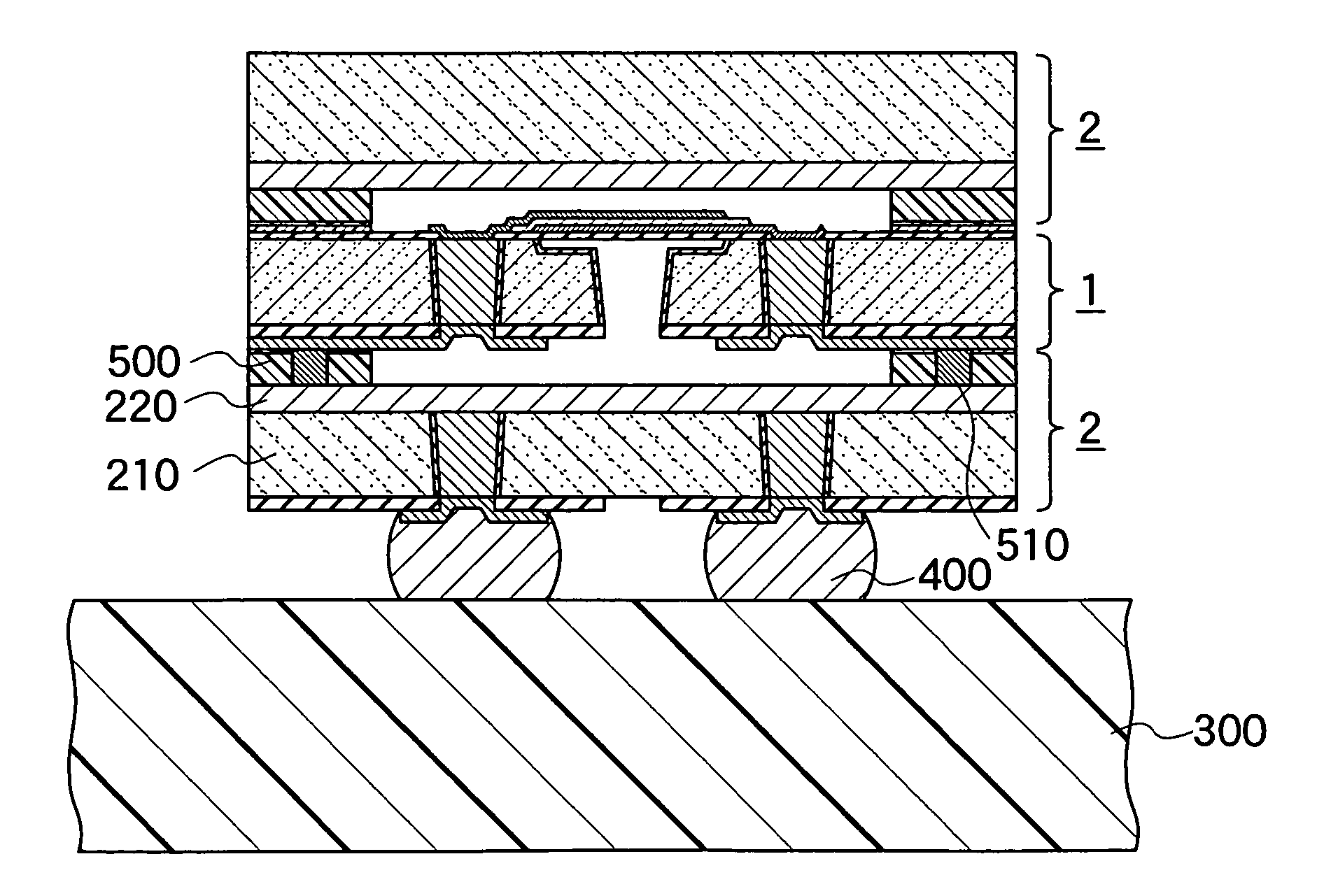

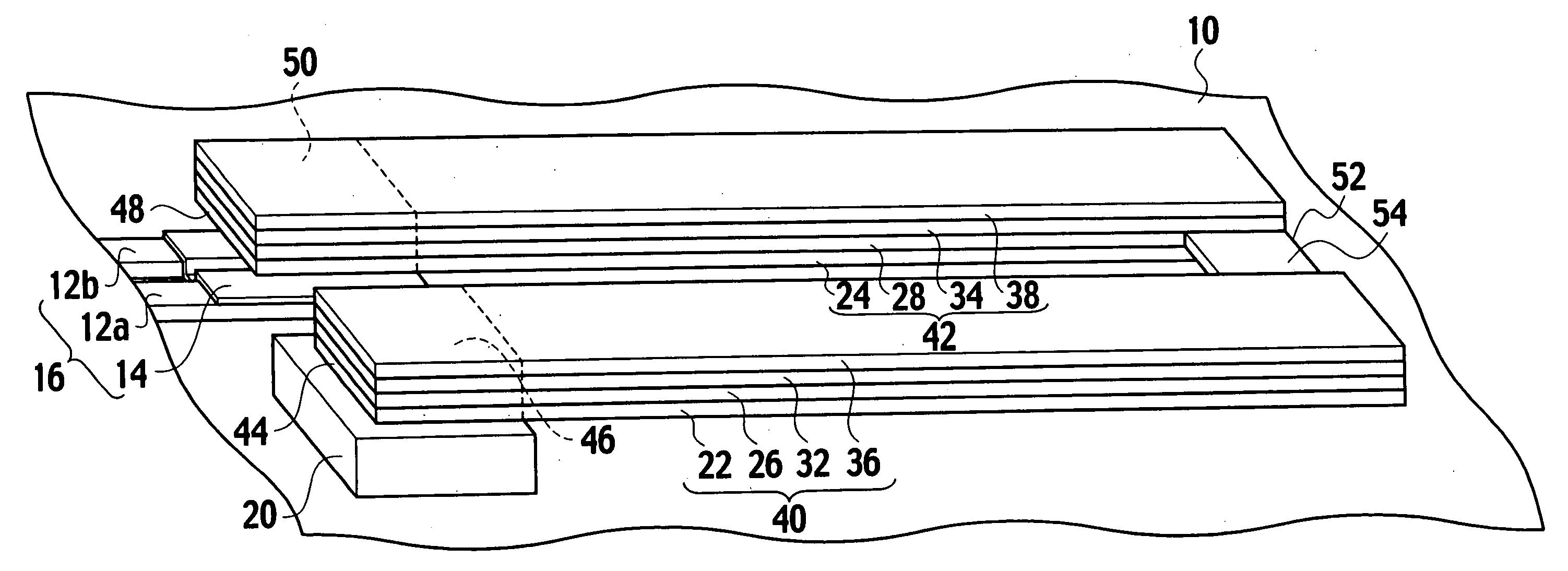

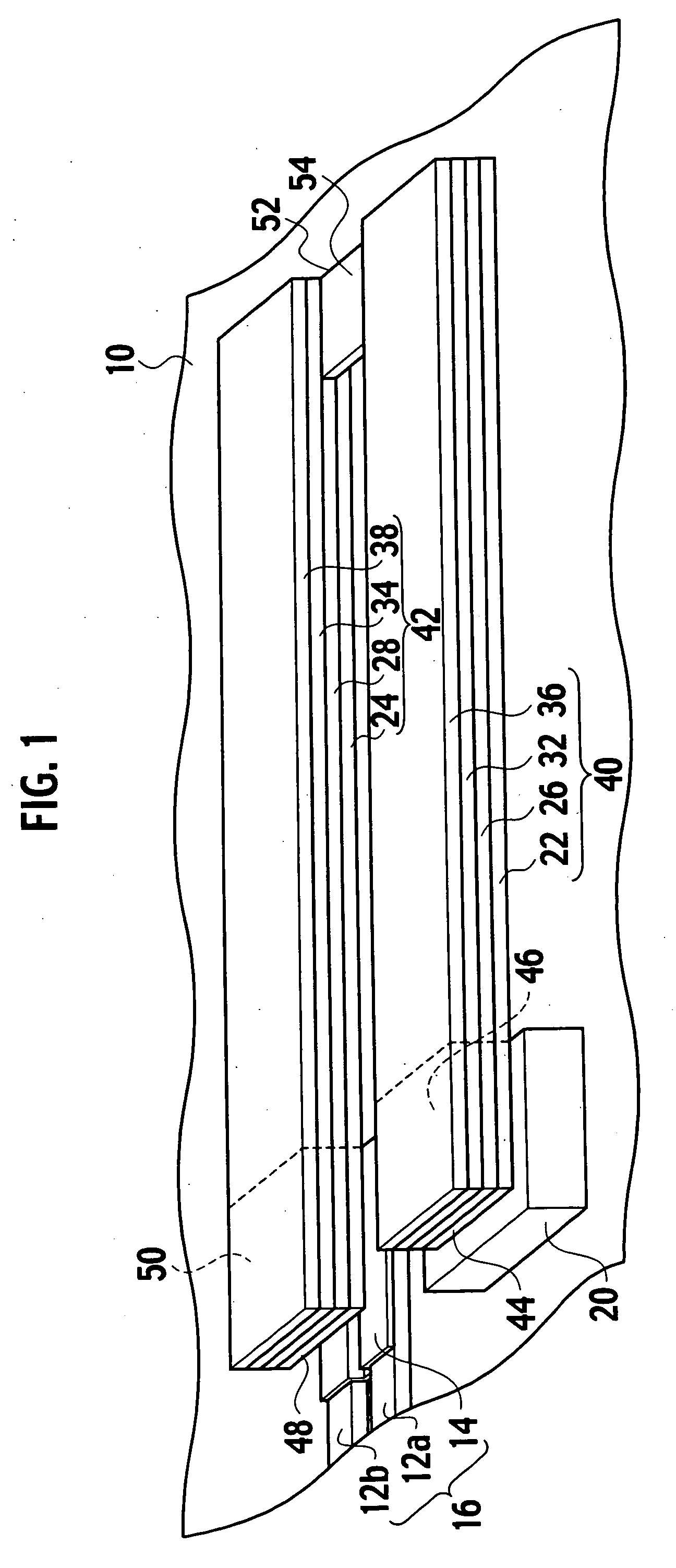

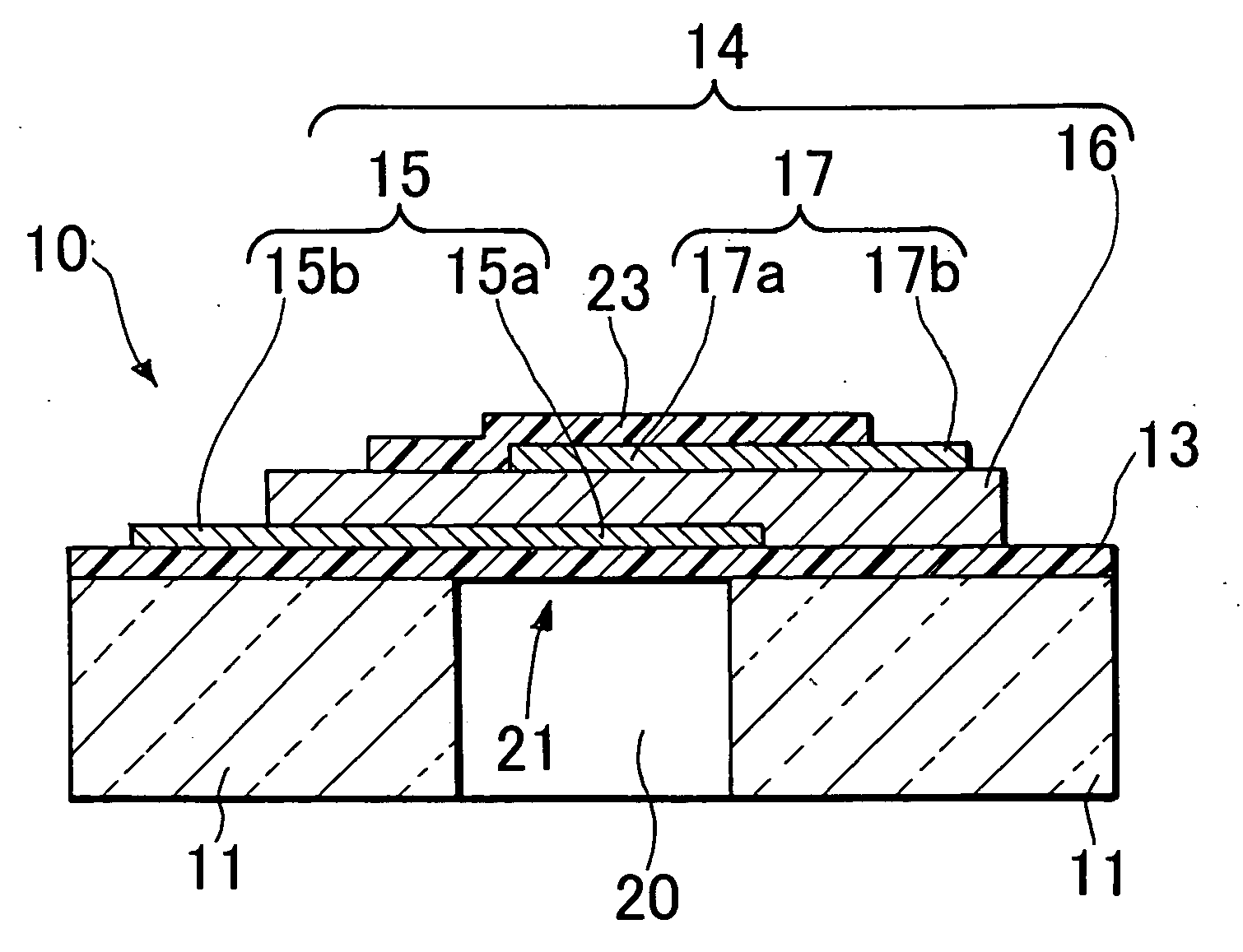

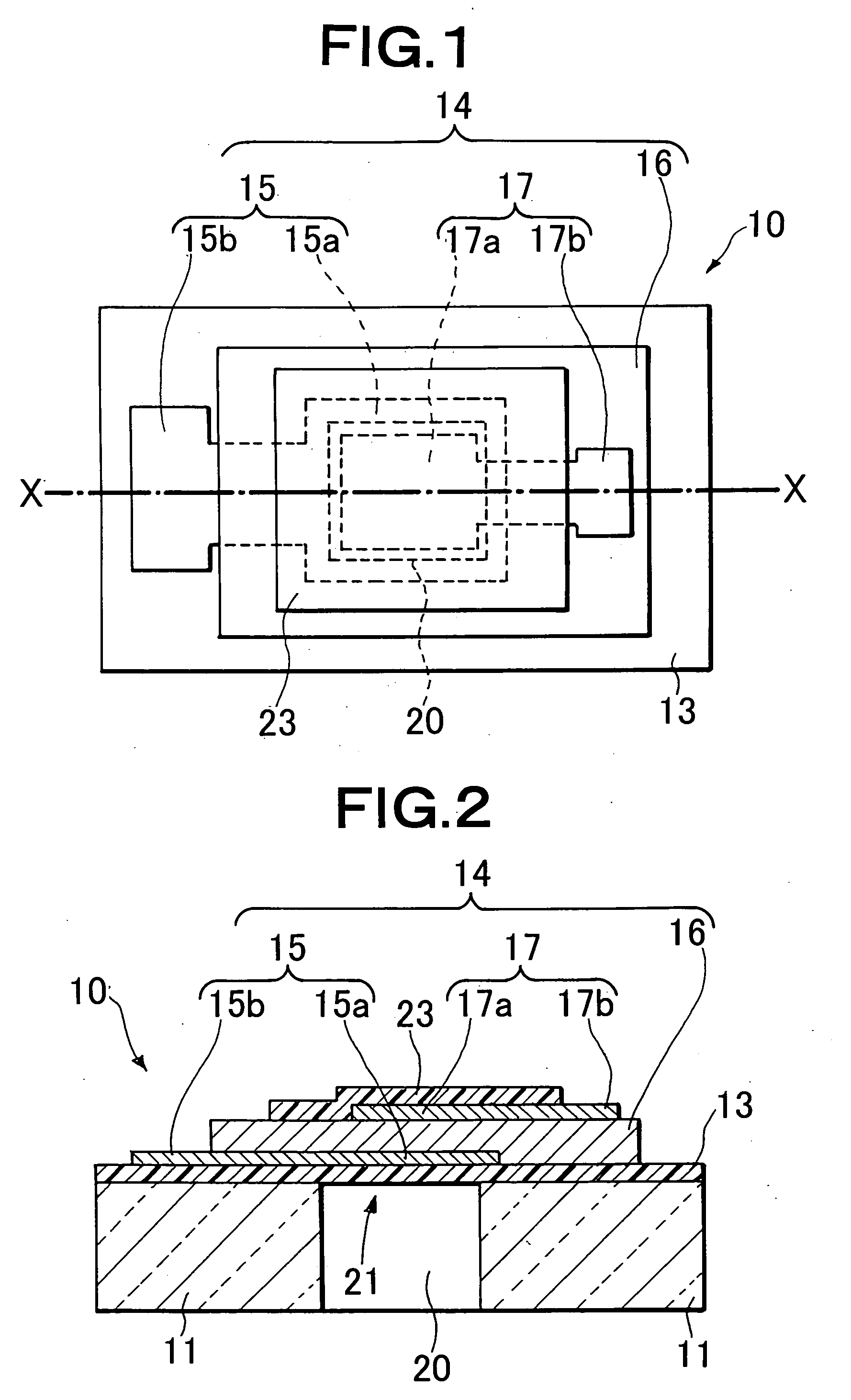

Electronic component having micro-electrical mechanical system

ActiveUS20050218488A1Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityEngineering

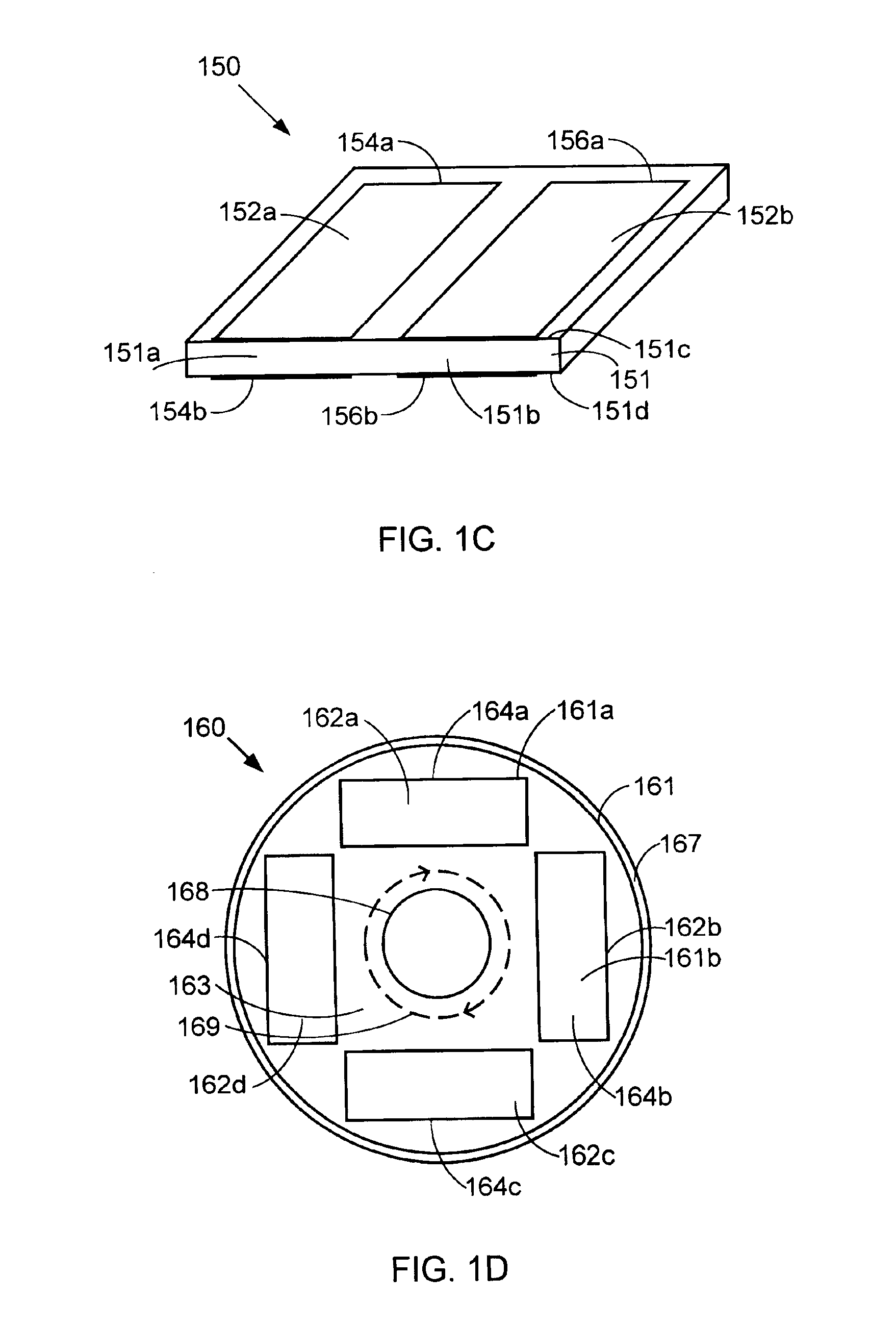

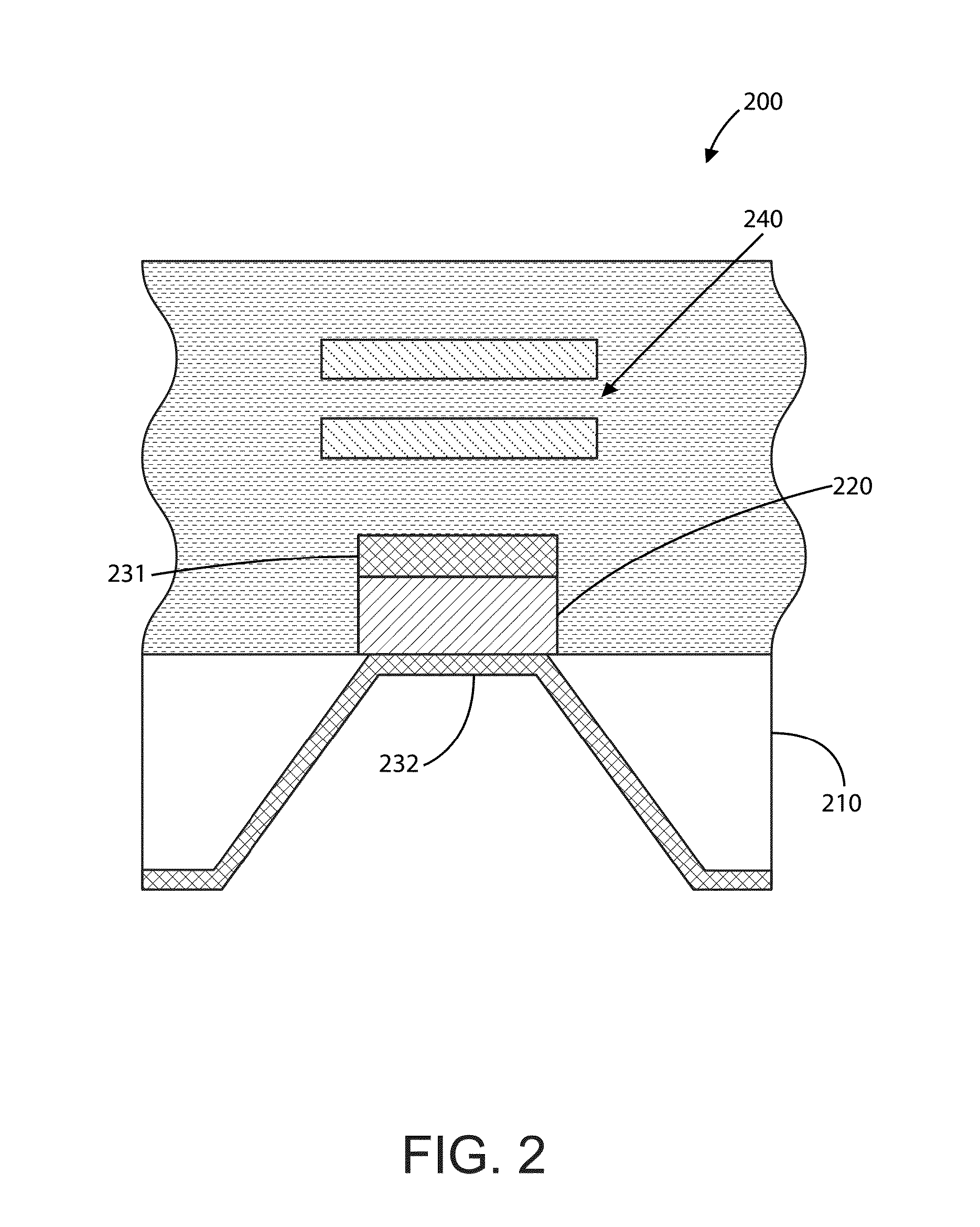

An electronic component includes a semiconductor substrate having a first surface and a second surface opposite to the first surface, a cavity that penetrates from the first surface to the second surface of the semiconductor substrate, and an electrical mechanical element that has a movable portion formed above the first surface of the semiconductor substrate so that the movable portion is arranged above the cavity. The electronic component further includes an electric conduction plug, which penetrates from the first surface to the second surface of the semiconductor substrate, and which is electrically connected to the electrical mechanical element.

Owner:KIOXIA CORP

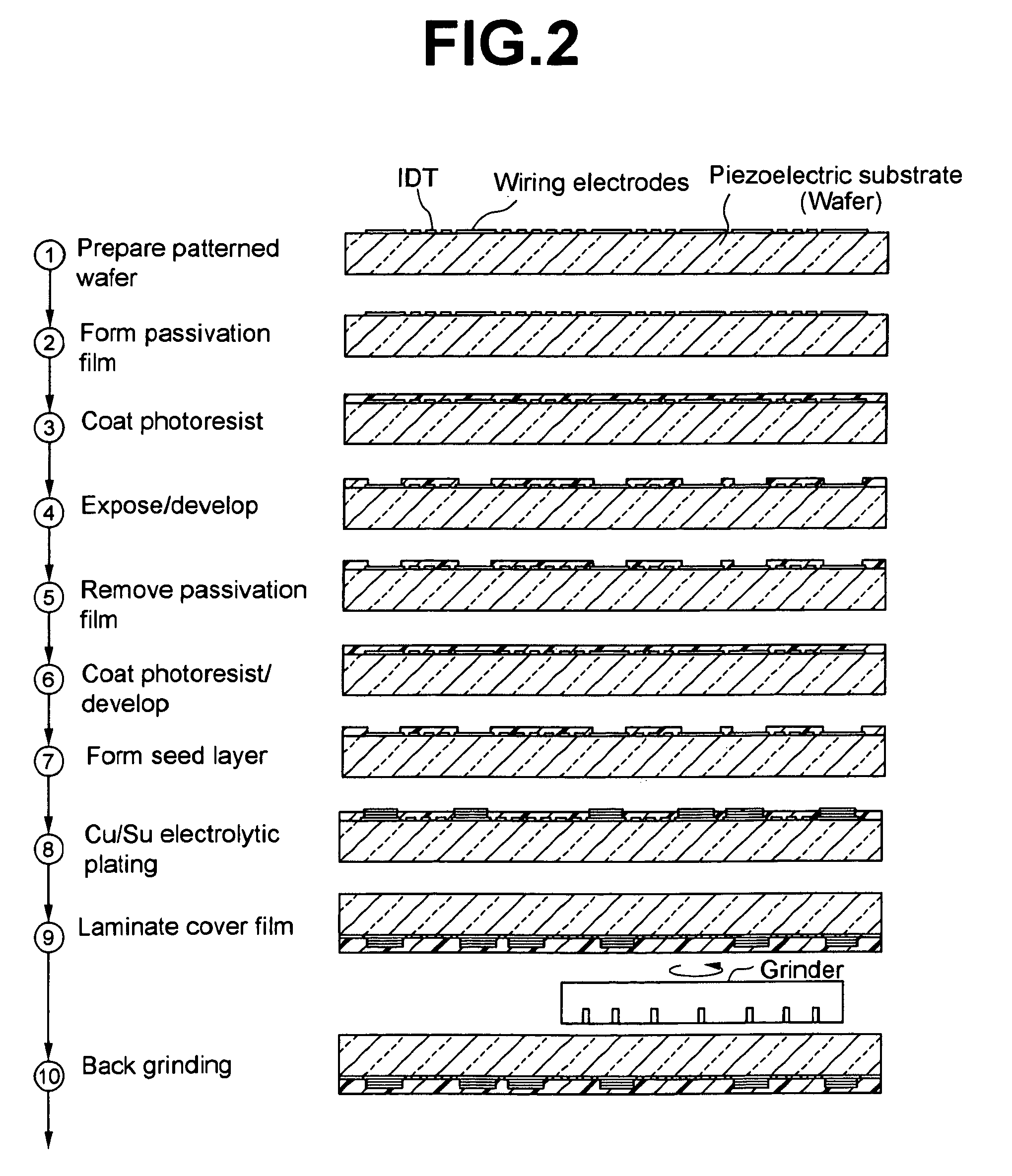

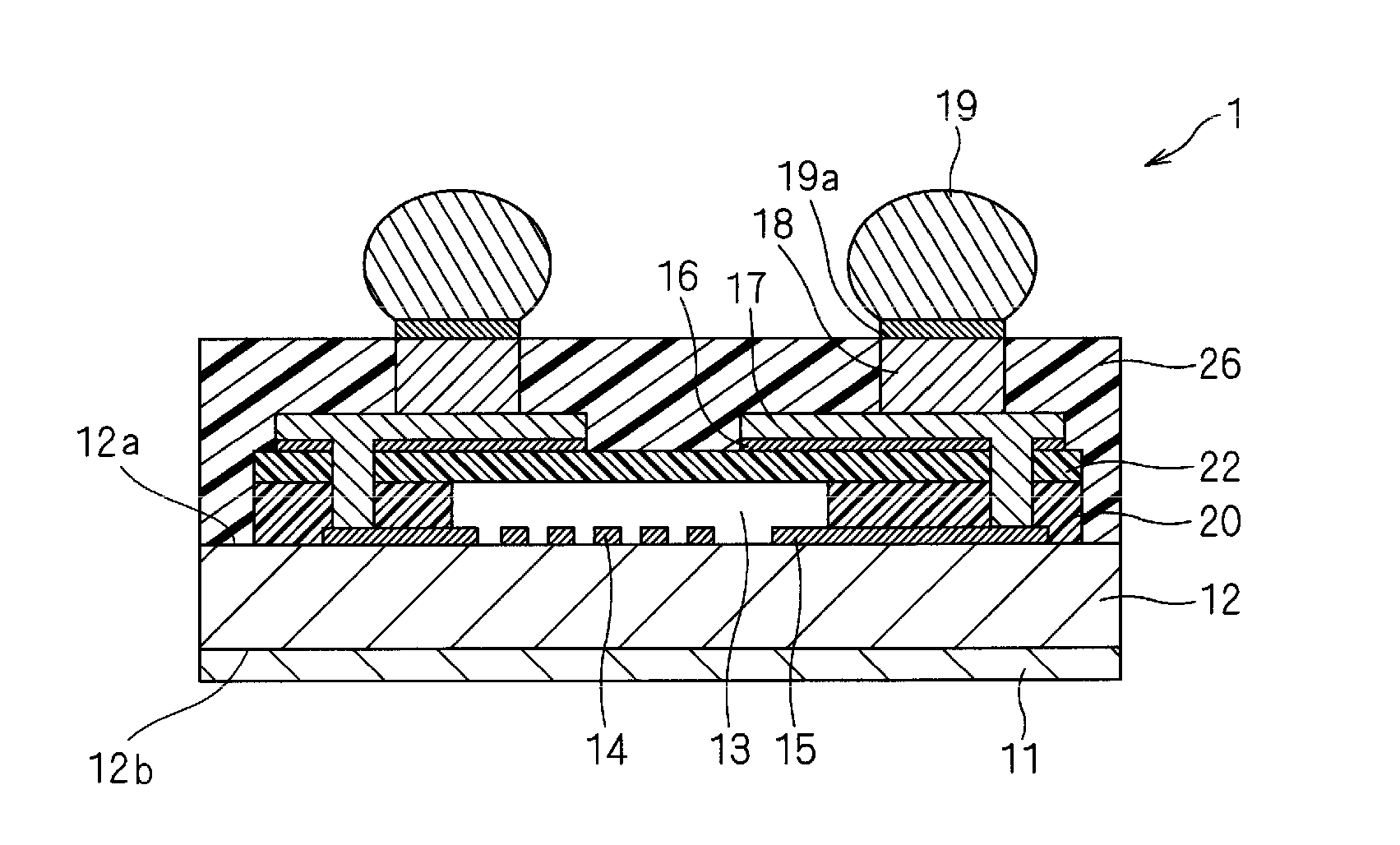

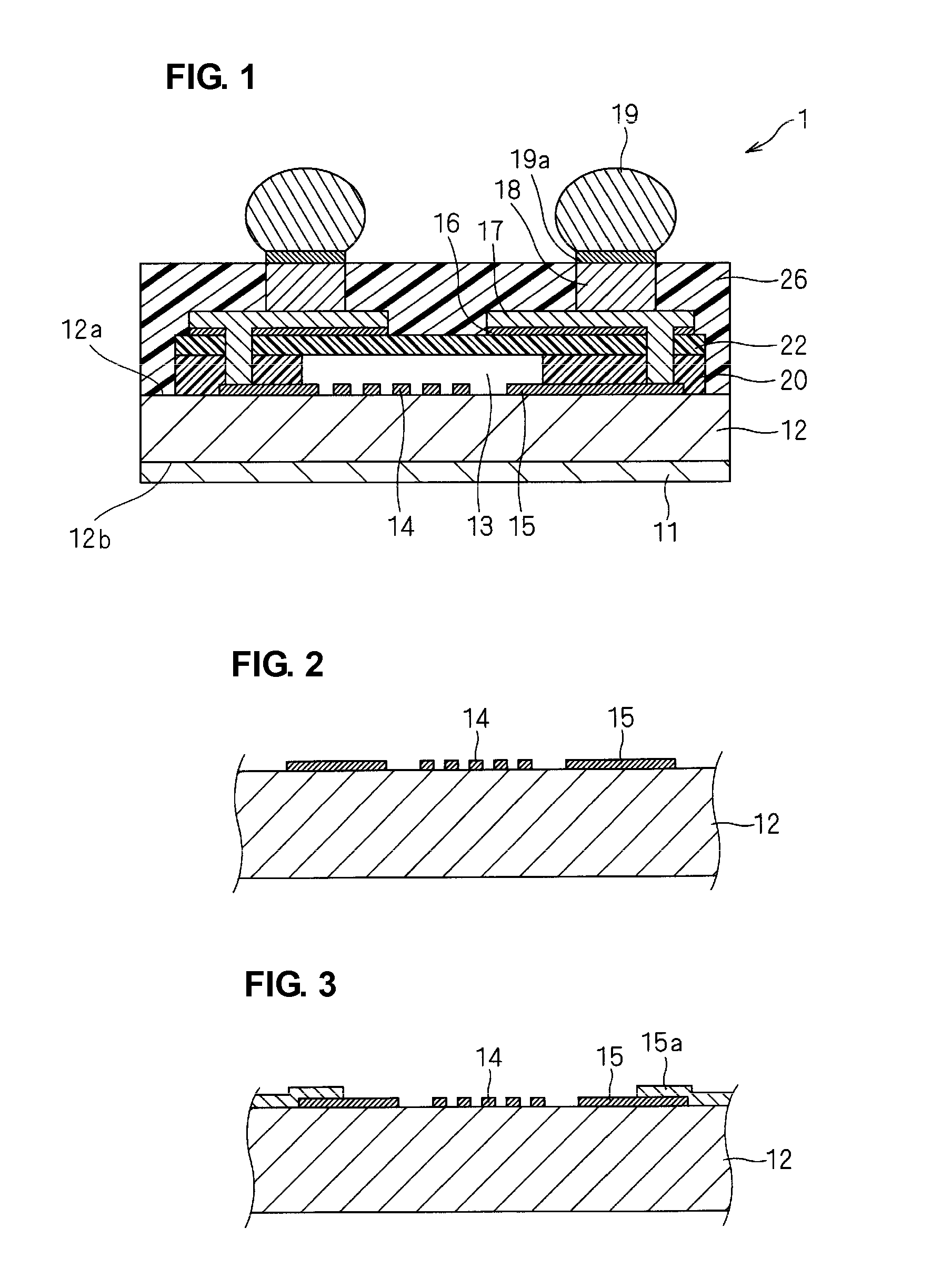

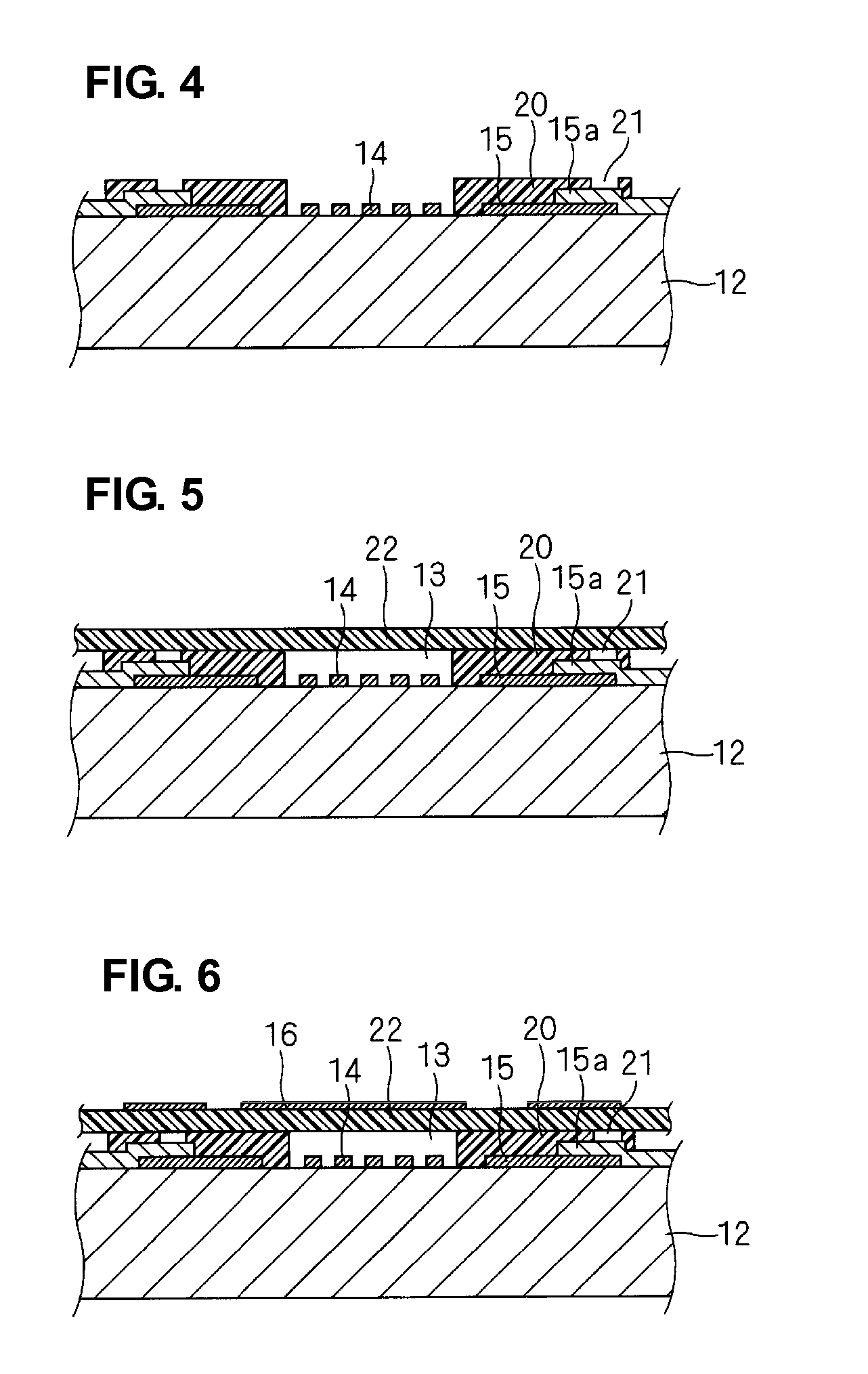

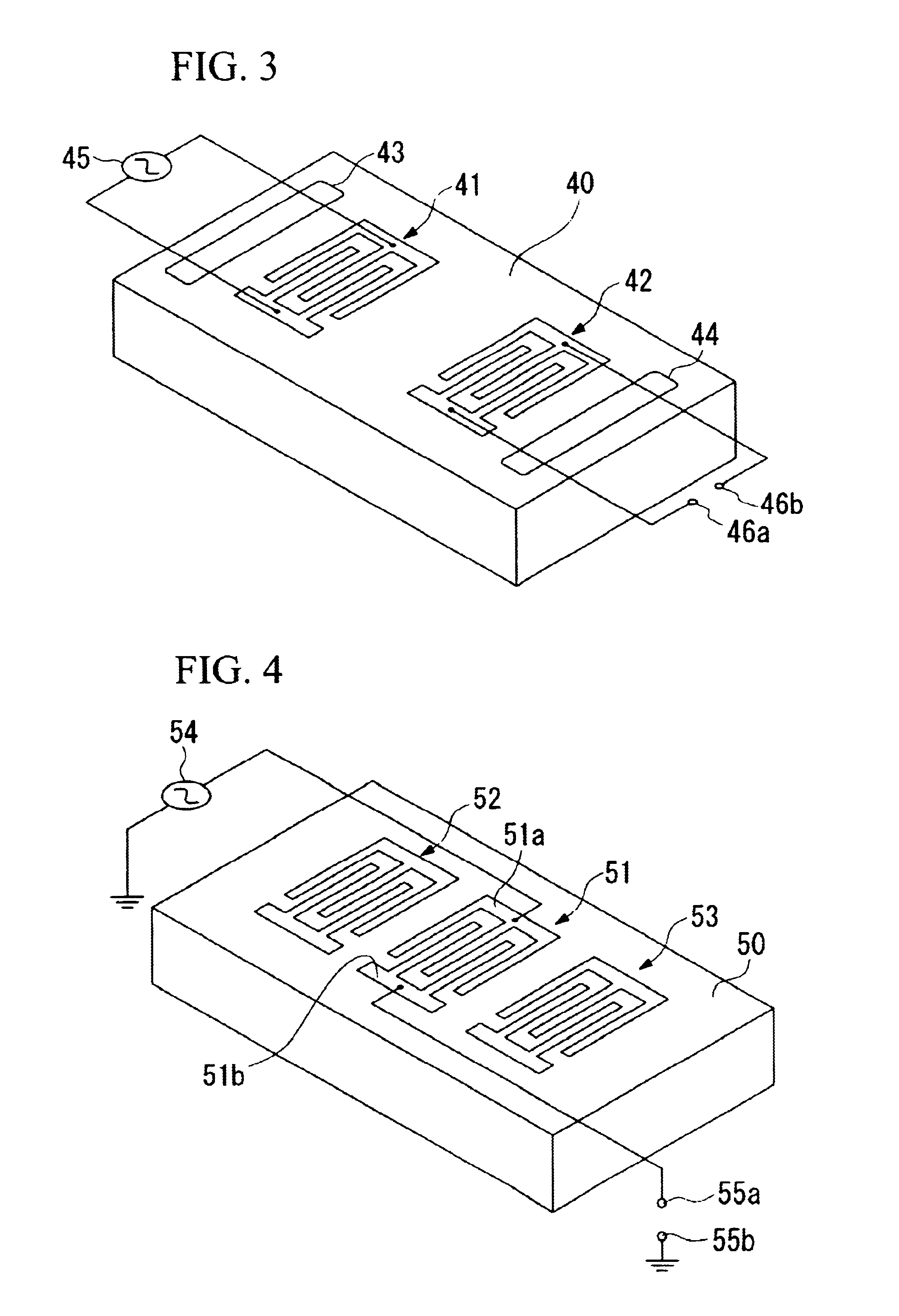

Piezoelectric component and manufacturing method thereof

InactiveUS20100045145A1Small sizeIncrease the number ofPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectrical and Electronics engineeringPiezoelectric substrate

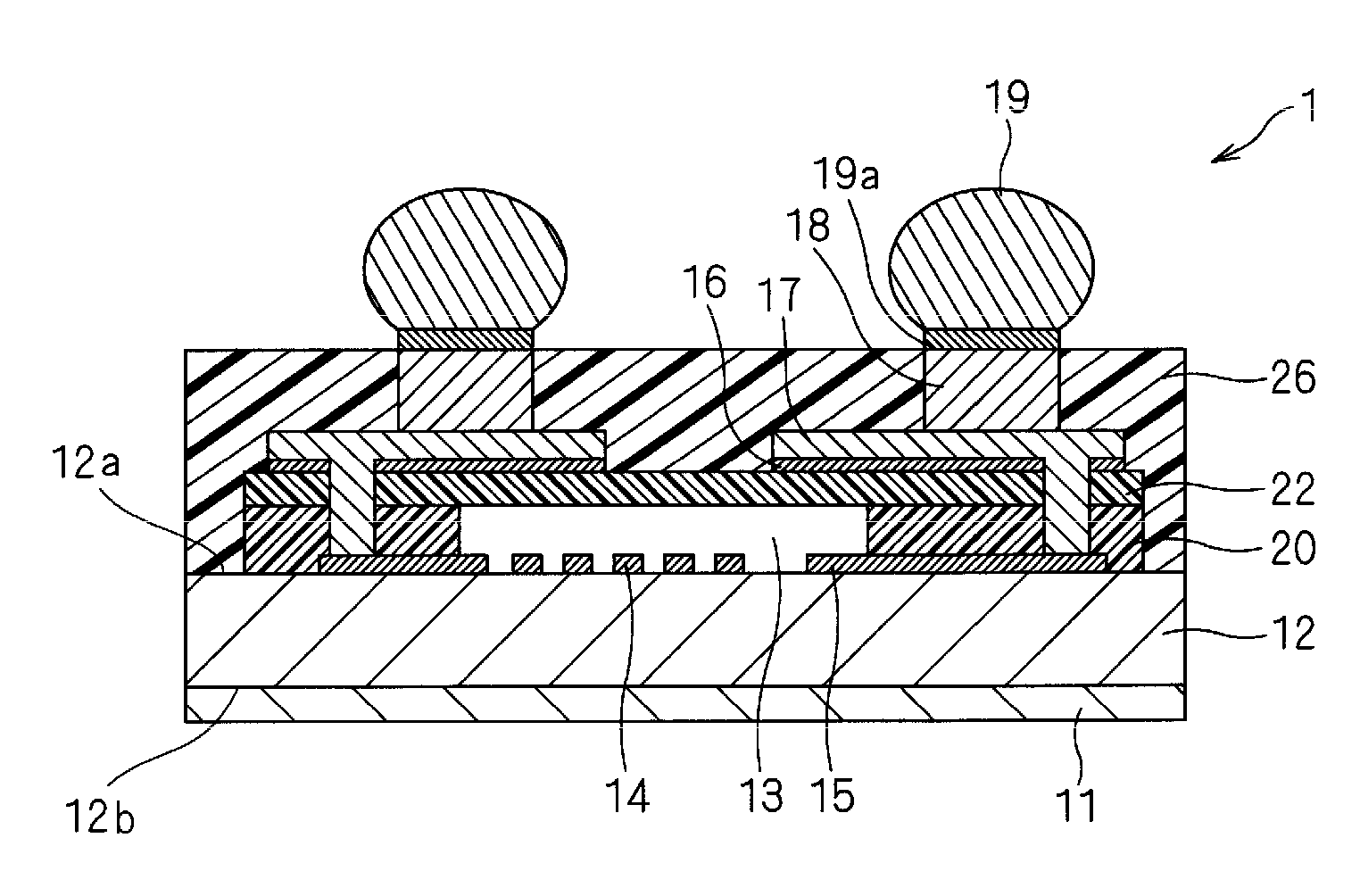

An object of the present invention is to; miniaturize, increase the capacity, and reduce the price of piezoelectric components. The present invention relates to a piezoelectric component and a manufacturing method thereof, characterized in that: there are bonded and laminated at least two or more piezoelectric elements in which comb-teeth electrodes, wiring electrodes having element wirings that are arranged adjacent to the comb-teeth electrodes, and electrode terminals connected to the wiring electrodes, are formed on a principal surface of a plurality of piezoelectric substrates, while forming hollow sections between the respective piezoelectric elements; through electrodes are formed in the respective piezoelectric substrates so as to pass therethrough; the through electrodes are connected to the electrode terminals; and the piezoelectric substrates are sealed by a resin sealing layer.

Owner:NIHON DEMPA KOGYO CO LTD

Piezoelectric device and method for producing same

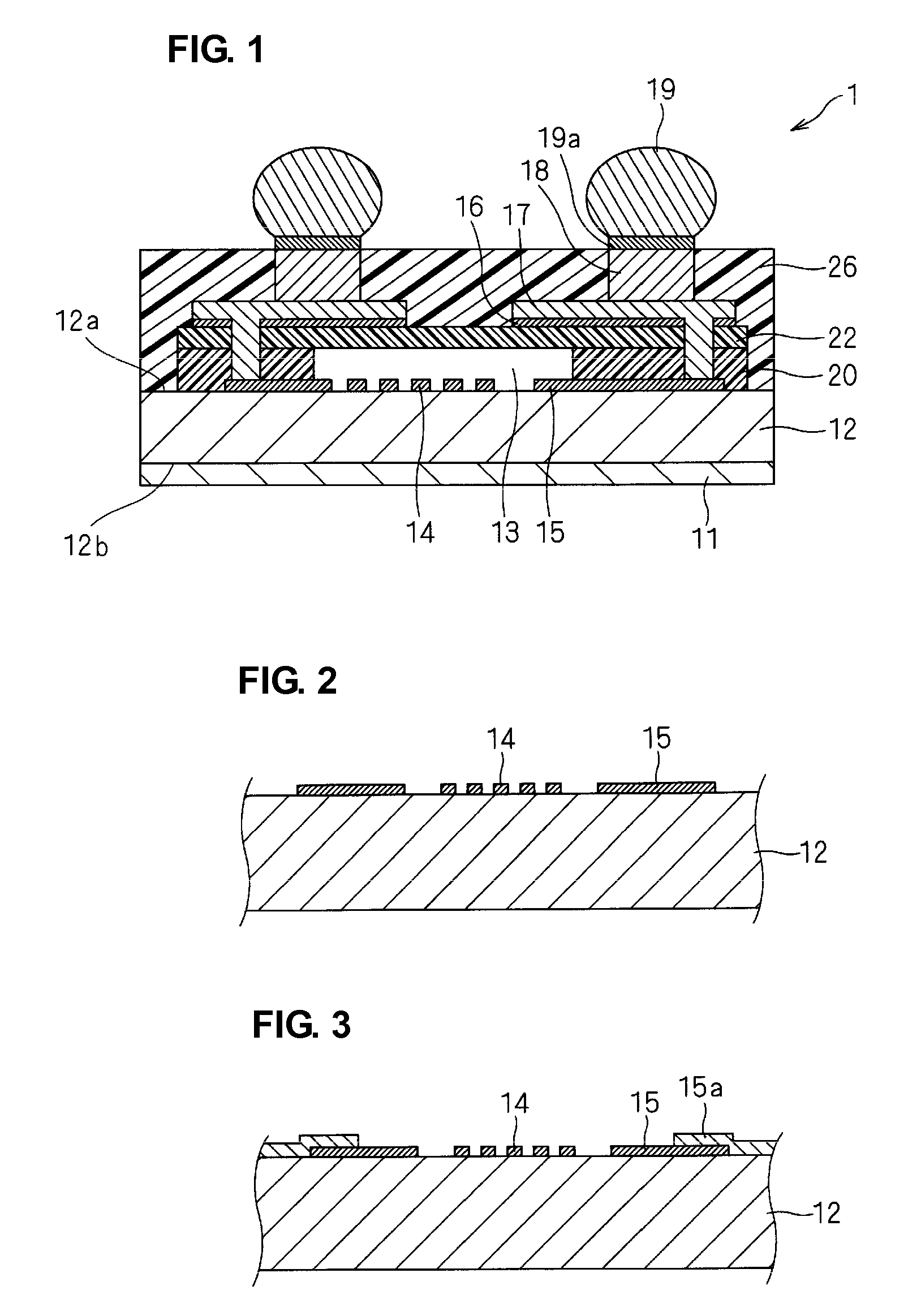

ActiveUS20070252481A1Low costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectrical conductor

Owner:MURATA MFG CO LTD

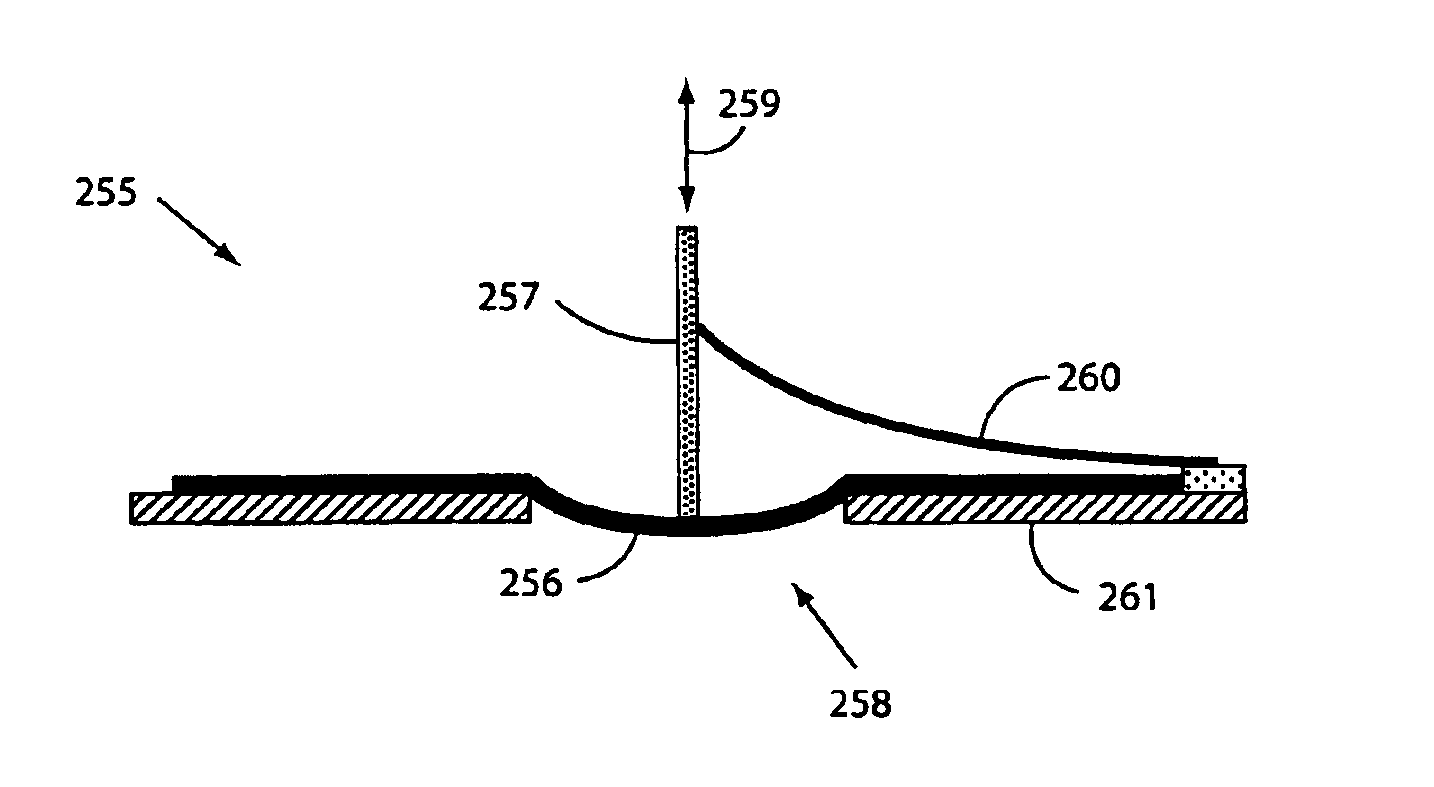

Master/slave electroactive polymer systems

InactiveUS6876135B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionActive polymerTransducer

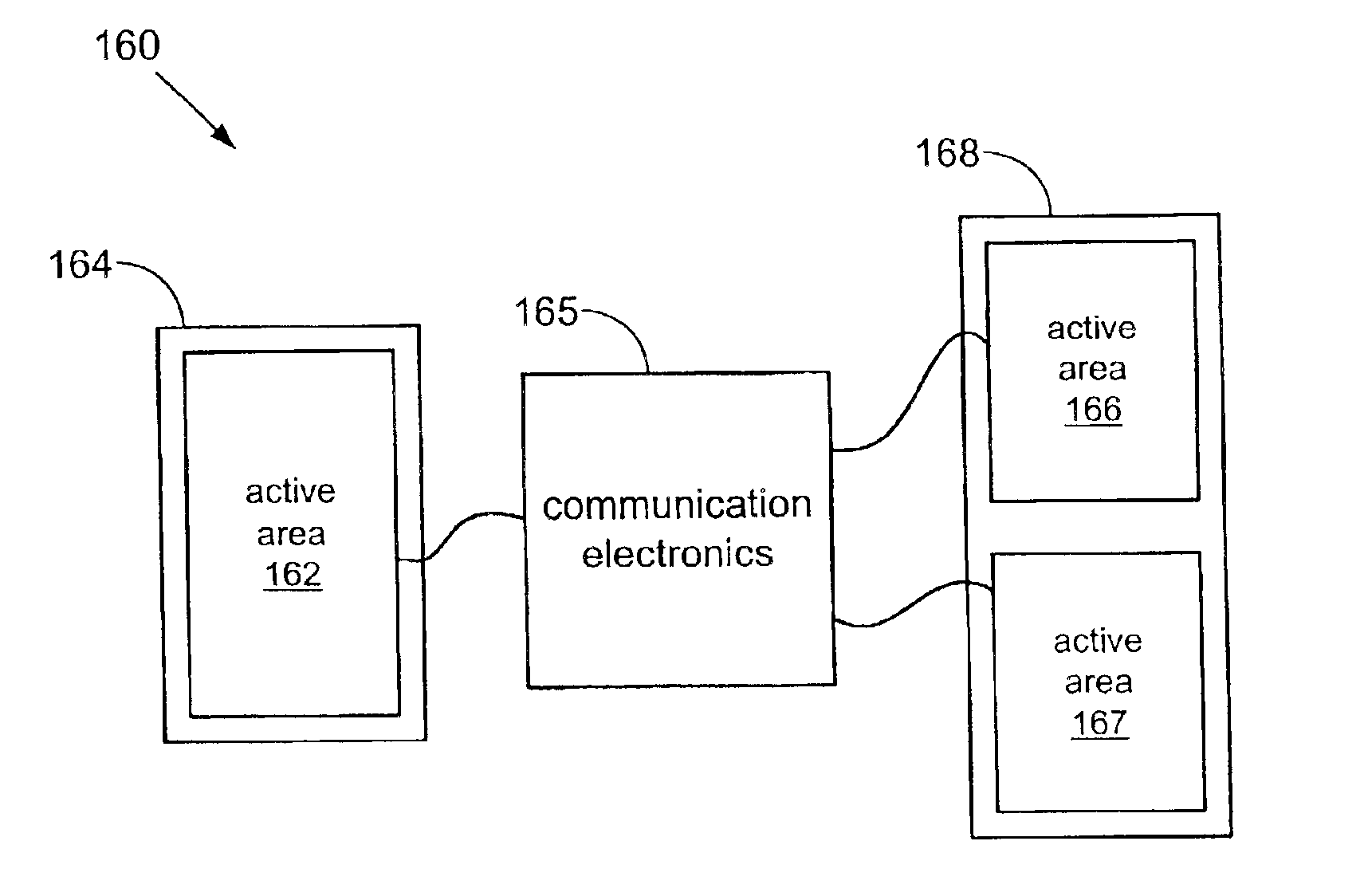

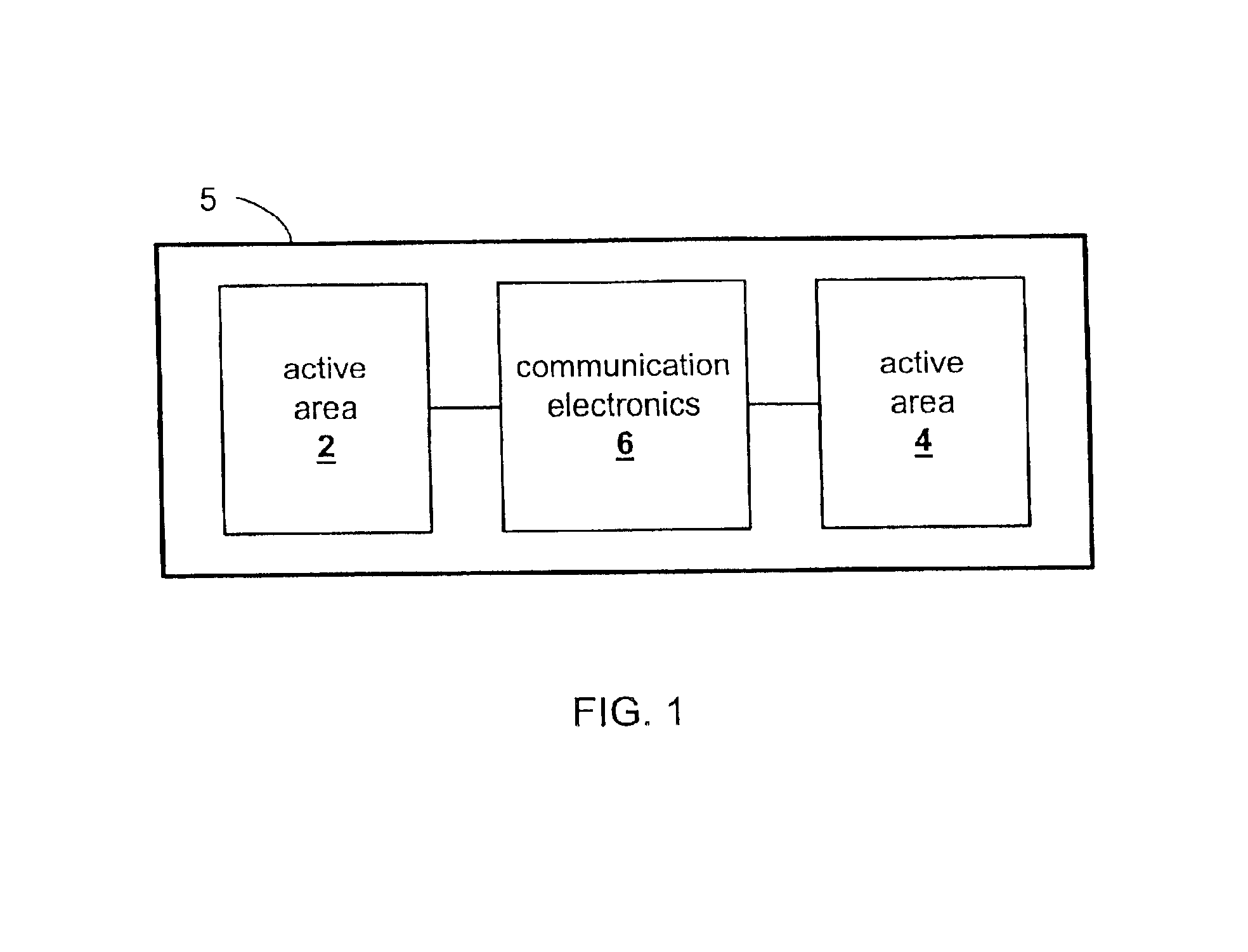

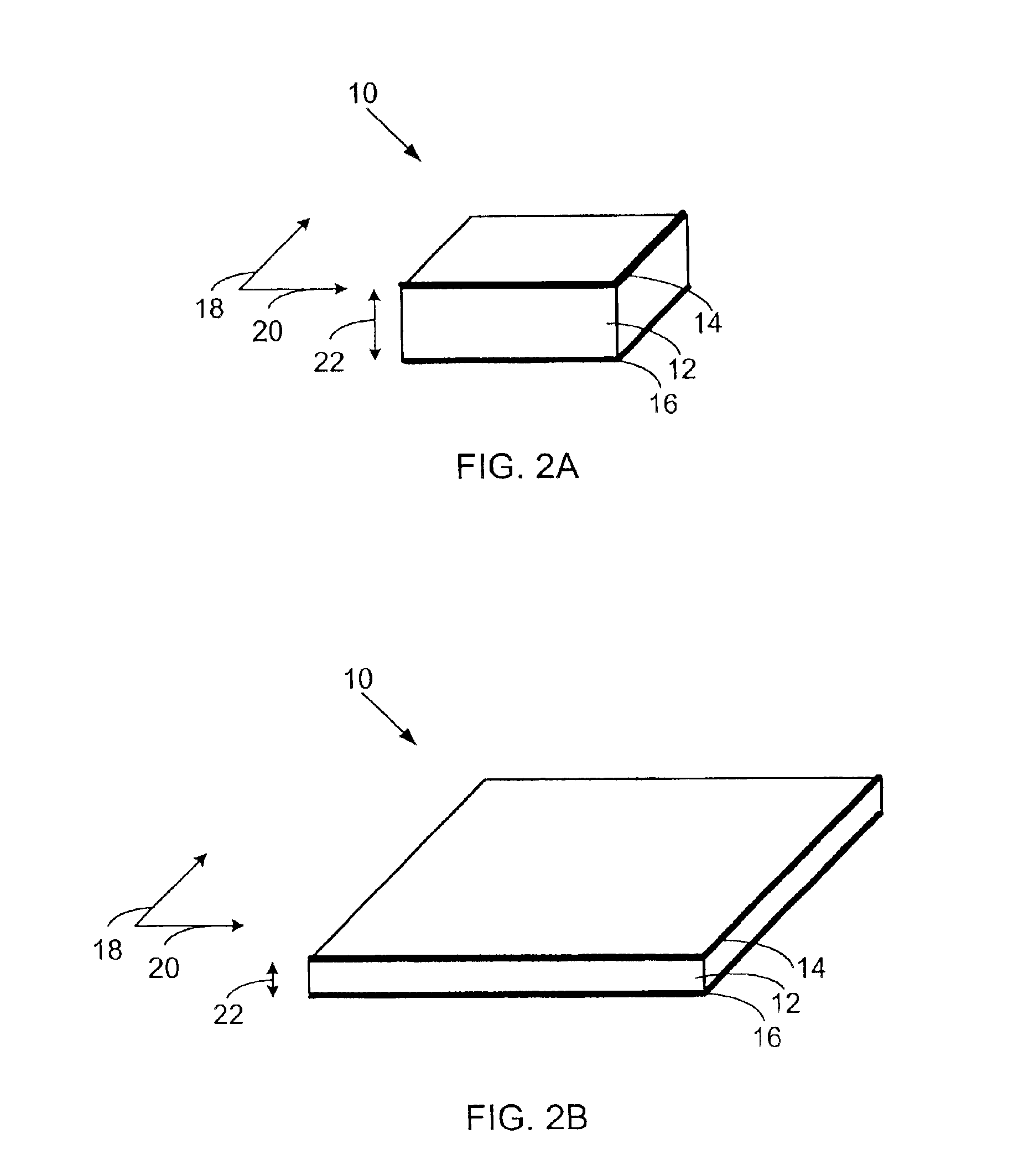

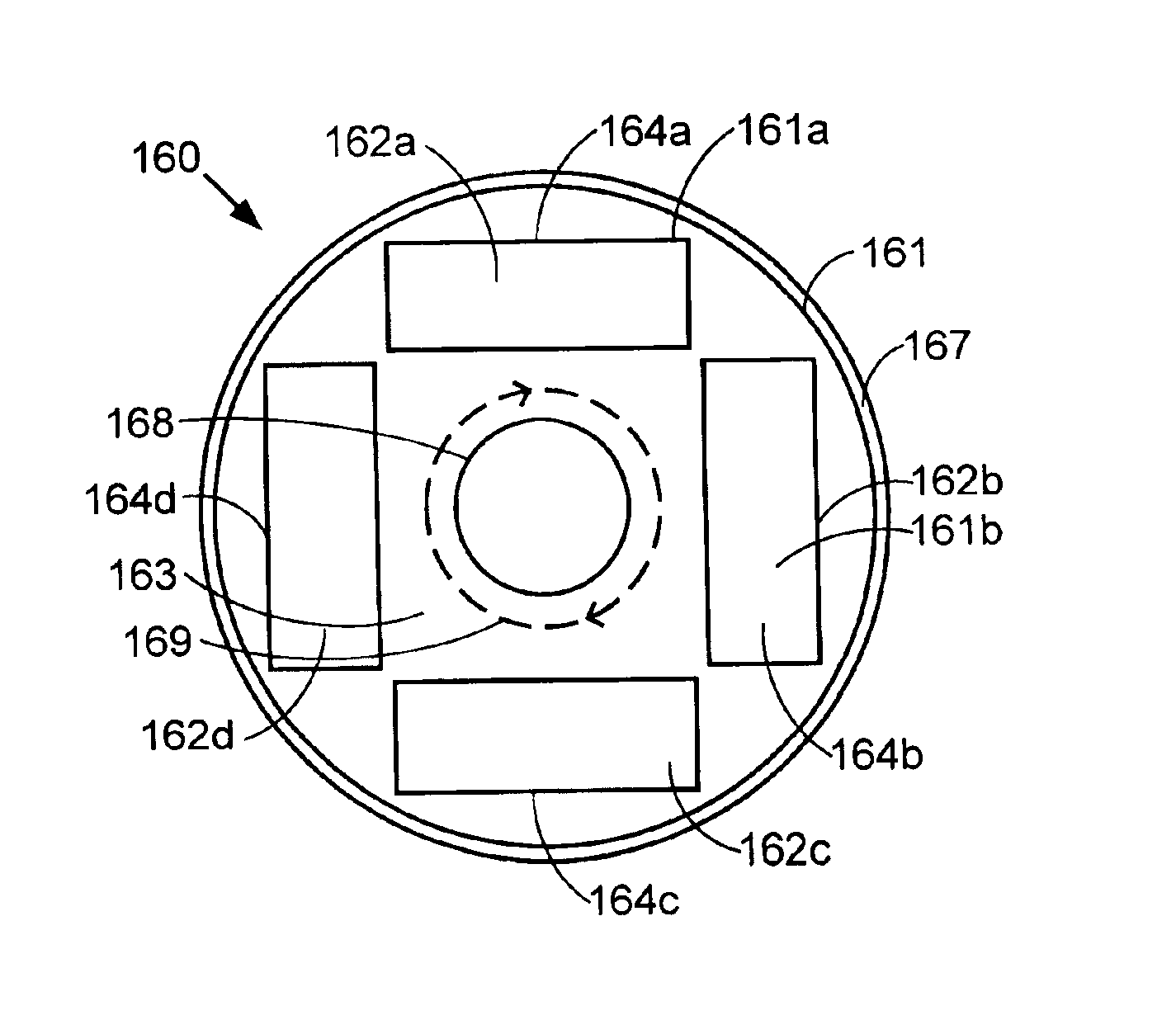

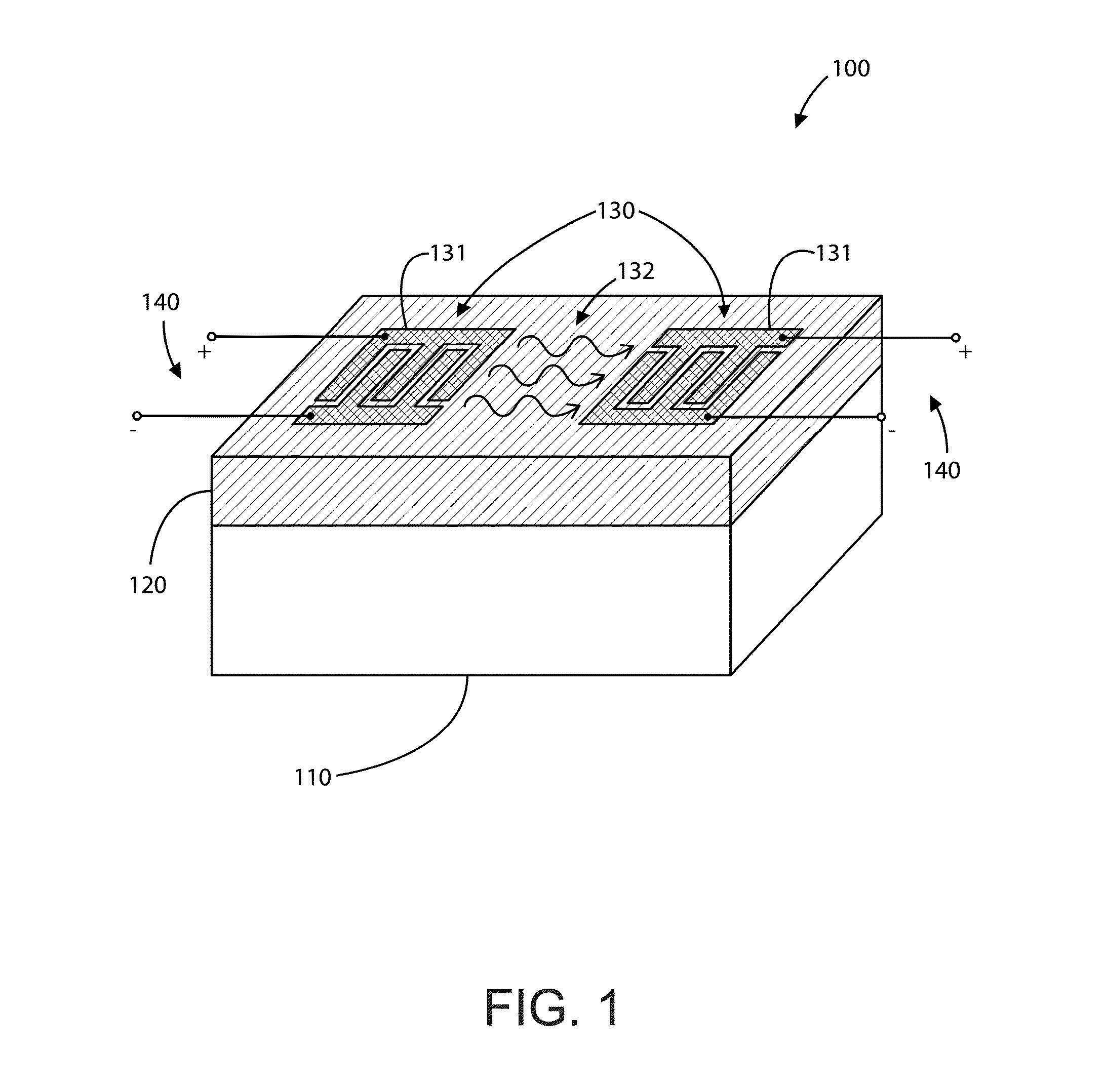

The present invention relates to improved devices, systems and methods that convert between electrical and mechanical energy. An electroactive polymer transducer converts between electrical and mechanical energy. An active area is a portion of an electroactive polymer transducer. The active area comprises a portion of an electroactive polymer and at least two electrodes that provide or receive electrical energy to or from the portion. The present invention relates to transducers and devices comprising multiple active areas that are in electrically communication. More specifically, the present invention relates to master / slave arrangements for multiple active areas disposed on one or more electroactive polymers. In a master / slave arrangement, a first active area deflects (a ‘master’), and a second active area reacts (a ‘slave’). Communication electronics in electrical communication with electrodes for the first active area and in electrical communication with electrodes for the second active area transfer electrical energy between the two active areas.

Owner:SRI INTERNATIONAL

Energy efficient electroactive polymers and electroactive polymer devices

InactiveUS6911764B2Increase deflectionImprove energy conversion efficiencyTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesActive polymerMechanical energy

Owner:SRI INTERNATIONAL

Piezoelectric device and method for producing same

ActiveUS7427824B2Low costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectrical conductorEngineering

Owner:MURATA MFG CO LTD

Electroactive polymers transducers and actuators

InactiveUS6940211B2Speed up the conversion processImprove mechanical responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

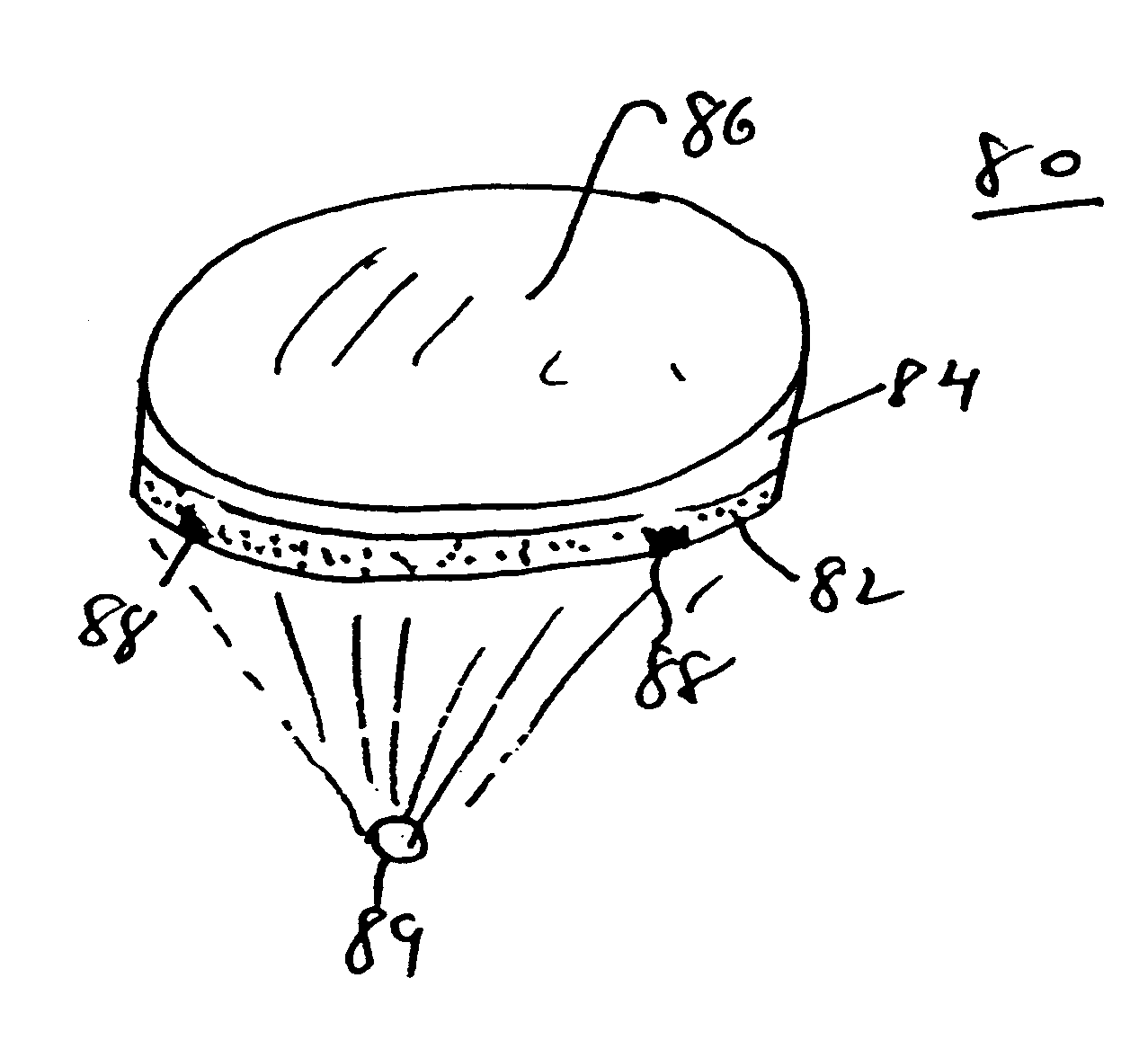

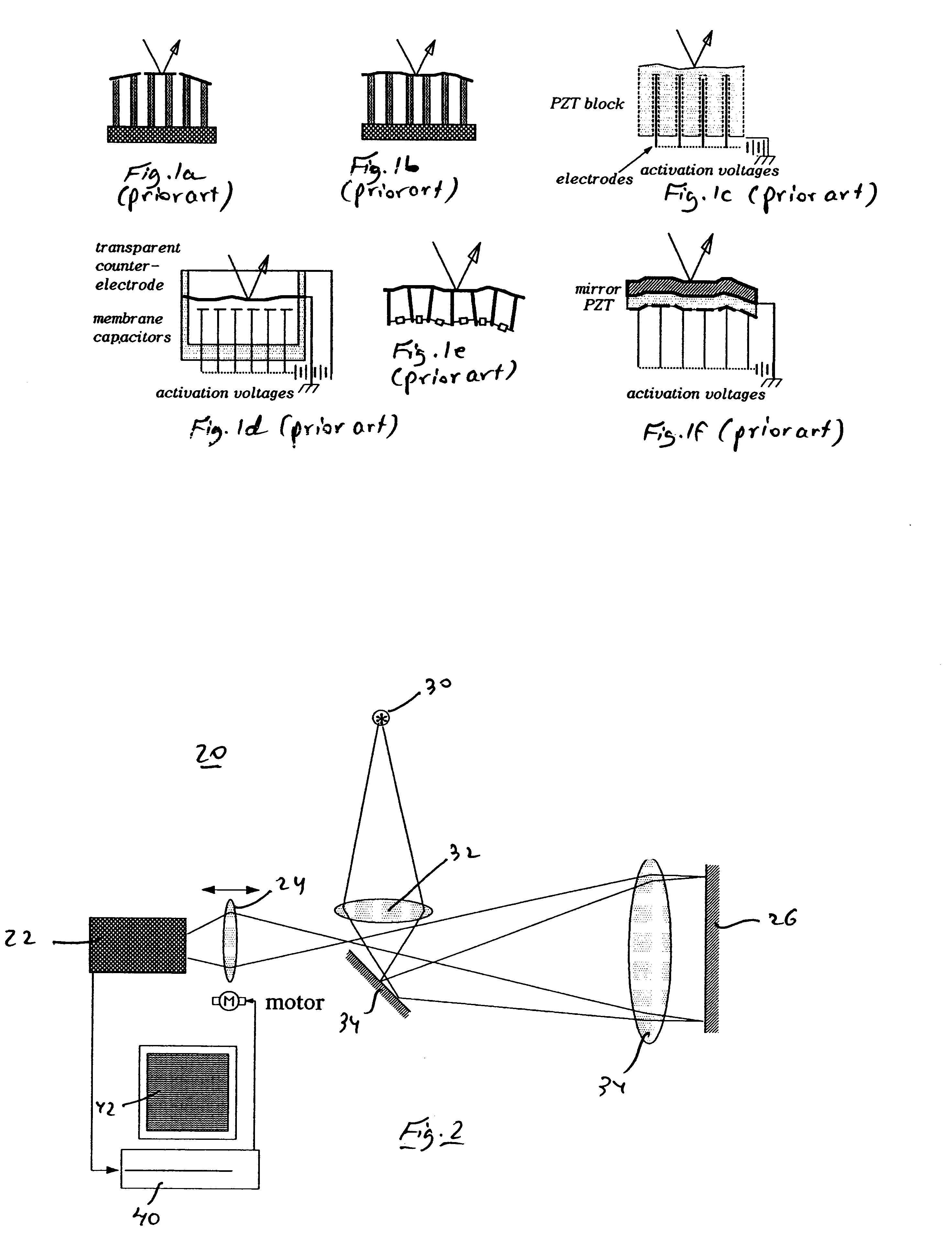

The present invention relates to electroactive polymers that are pre-strained to improve conversion from electrical to mechanical energy. When a voltage is applied to electrodes contacting a pre-strained polymer, the polymer deflects. This deflection may be used to do mechanical work. The pre-strain improves the mechanical response of an electroactive polymer. The present invention also relates to actuators including an electroactive polymer and mechanical coupling to convert deflection of the polymer into mechanical work. The present invention further relates to compliant electrodes that conform to the shape of a polymer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

Electronic component having micro-electrical mechanical system

ActiveUS7053456B2Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityElectronic component

Owner:KIOXIA CORP

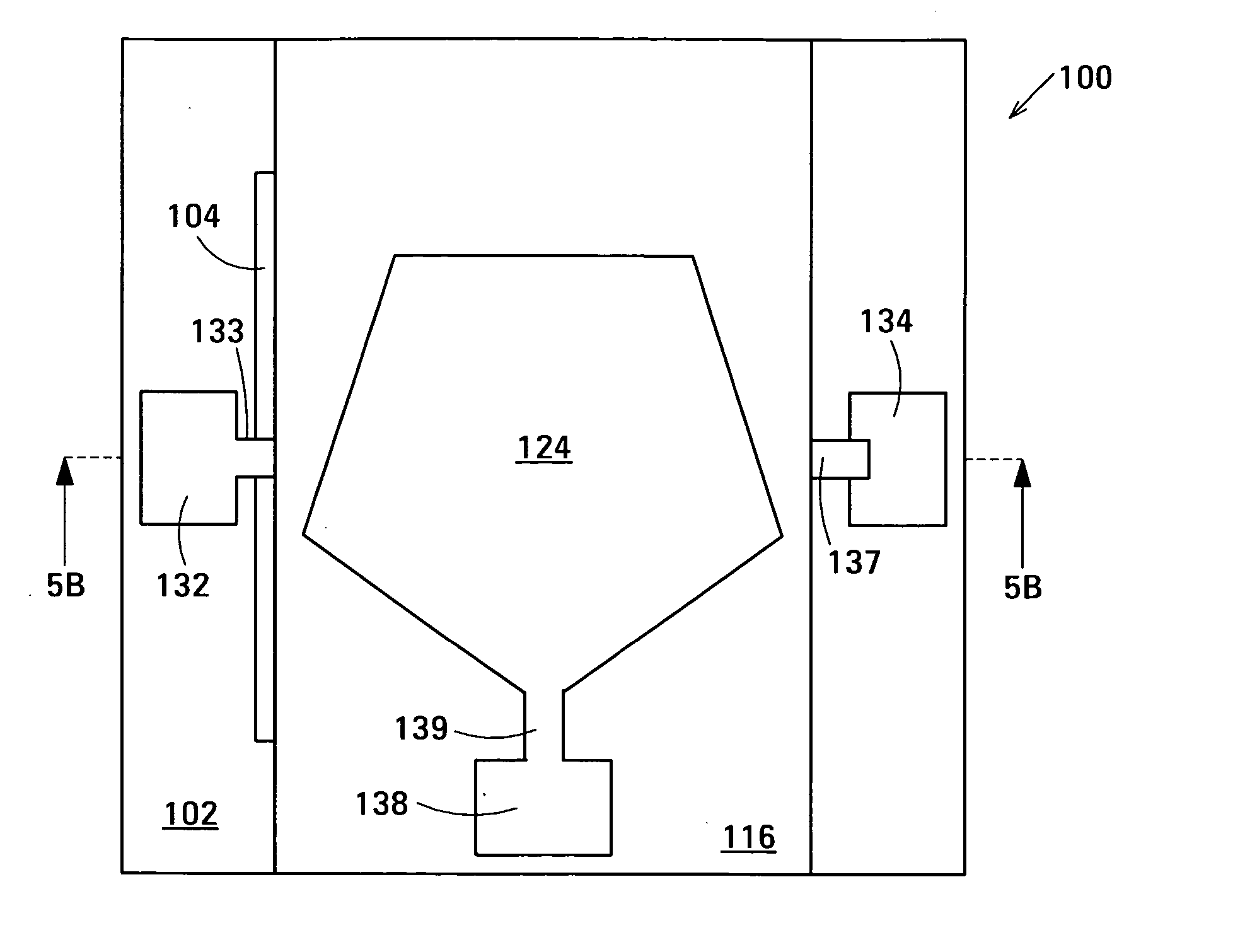

Single crystal acoustic resonator and bulk acoustic wave filter

ActiveUS20160028367A1AdvantageSimple and cost-effectivePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallic materialsCarbide

A method of wafer scale packaging acoustic resonator devices and an apparatus therefor. The method including providing a partially completed semiconductor substrate comprising a plurality of single crystal acoustic resonator devices provided on a silicon and carbide bearing material, each having a first electrode member, a second electrode member, and an overlying passivation material. At least one of the devices to be configured with an external connection, a repassivation material overlying the passivation material, an under metal material overlying the repassivation material. Copper pillar interconnect structures are then configured overlying the electrode members, and solder bump structures are form overlying the copper pillar interconnect structures.

Owner:AKOUSTIS INC

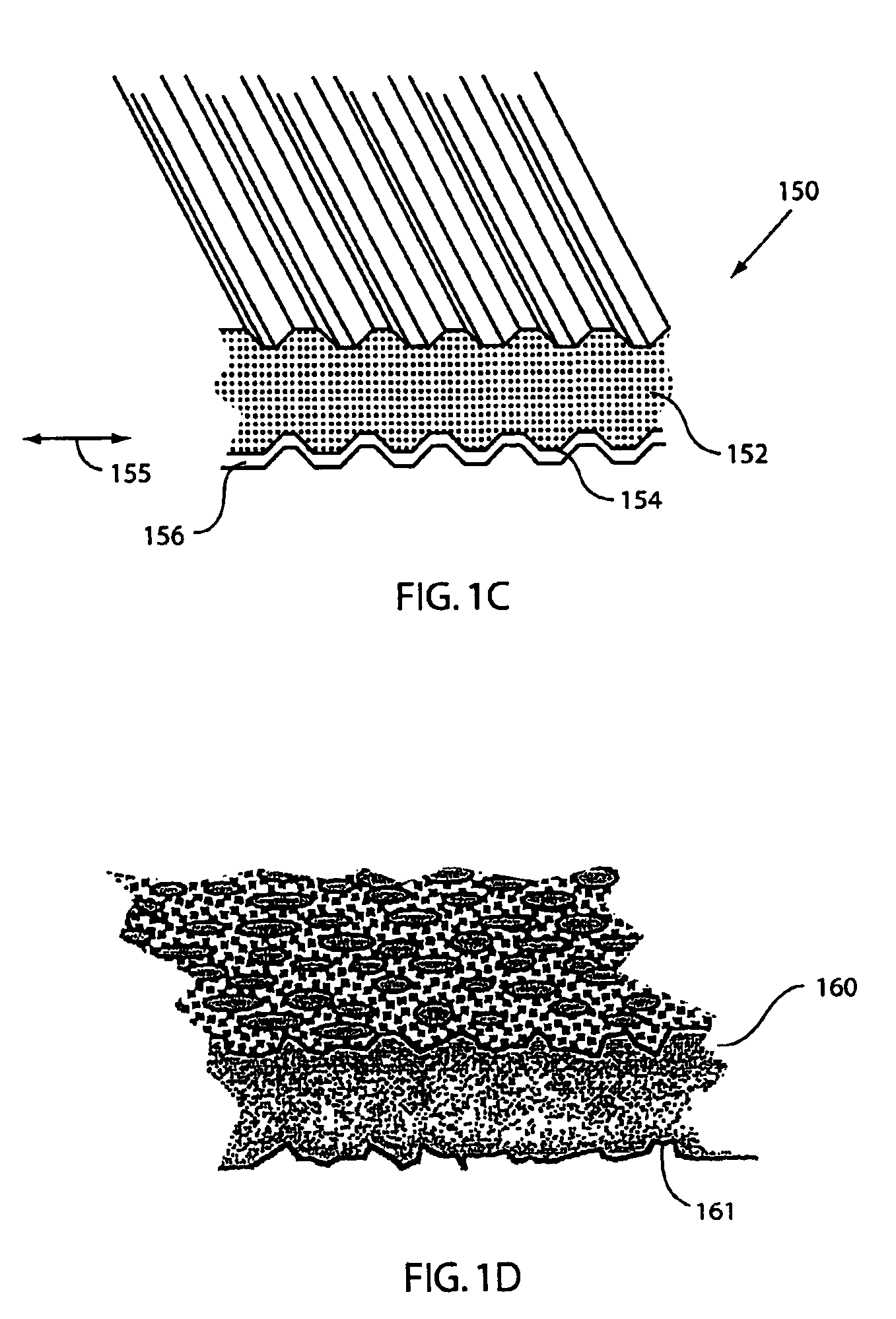

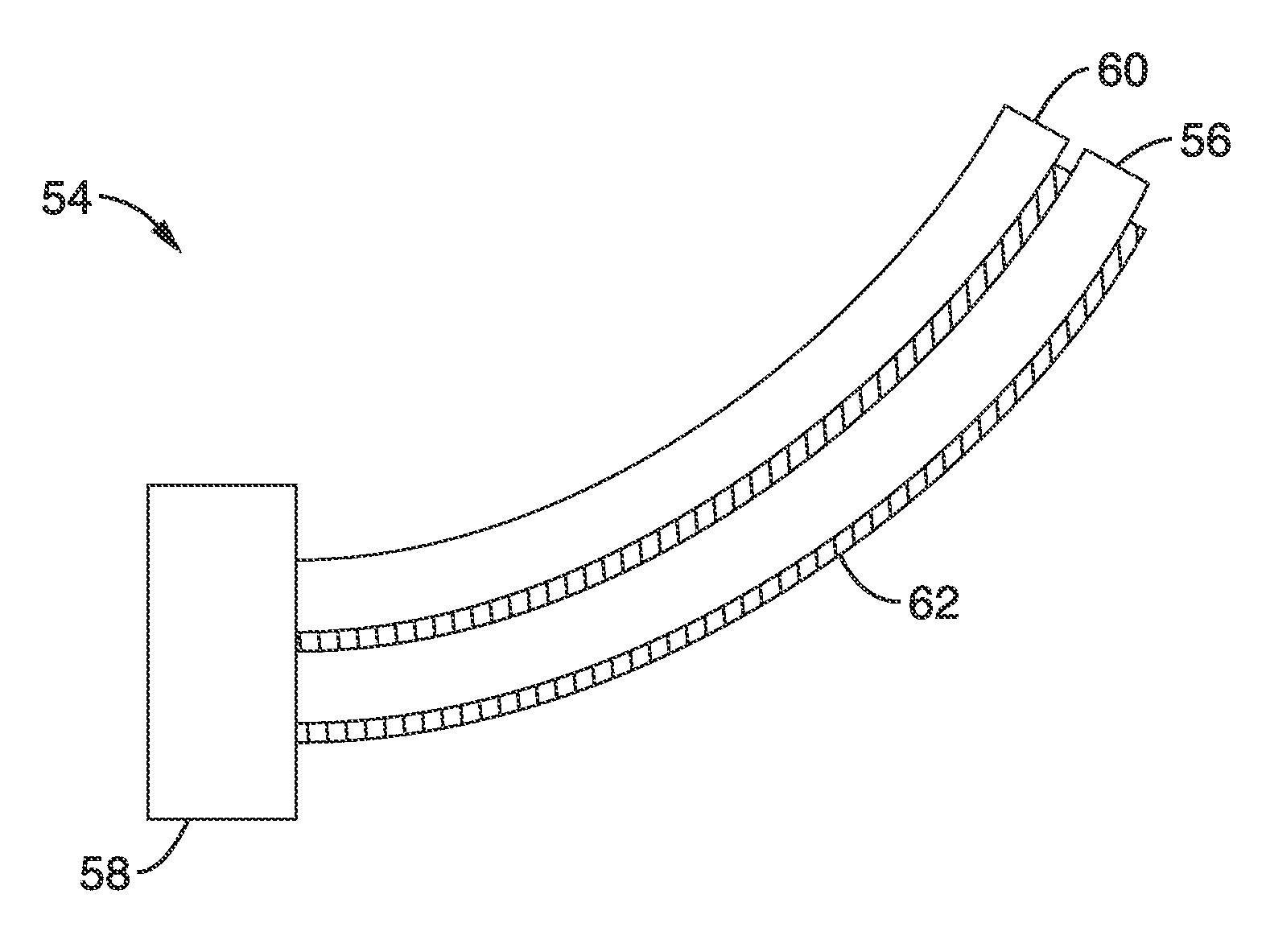

Piezocomposite transducers

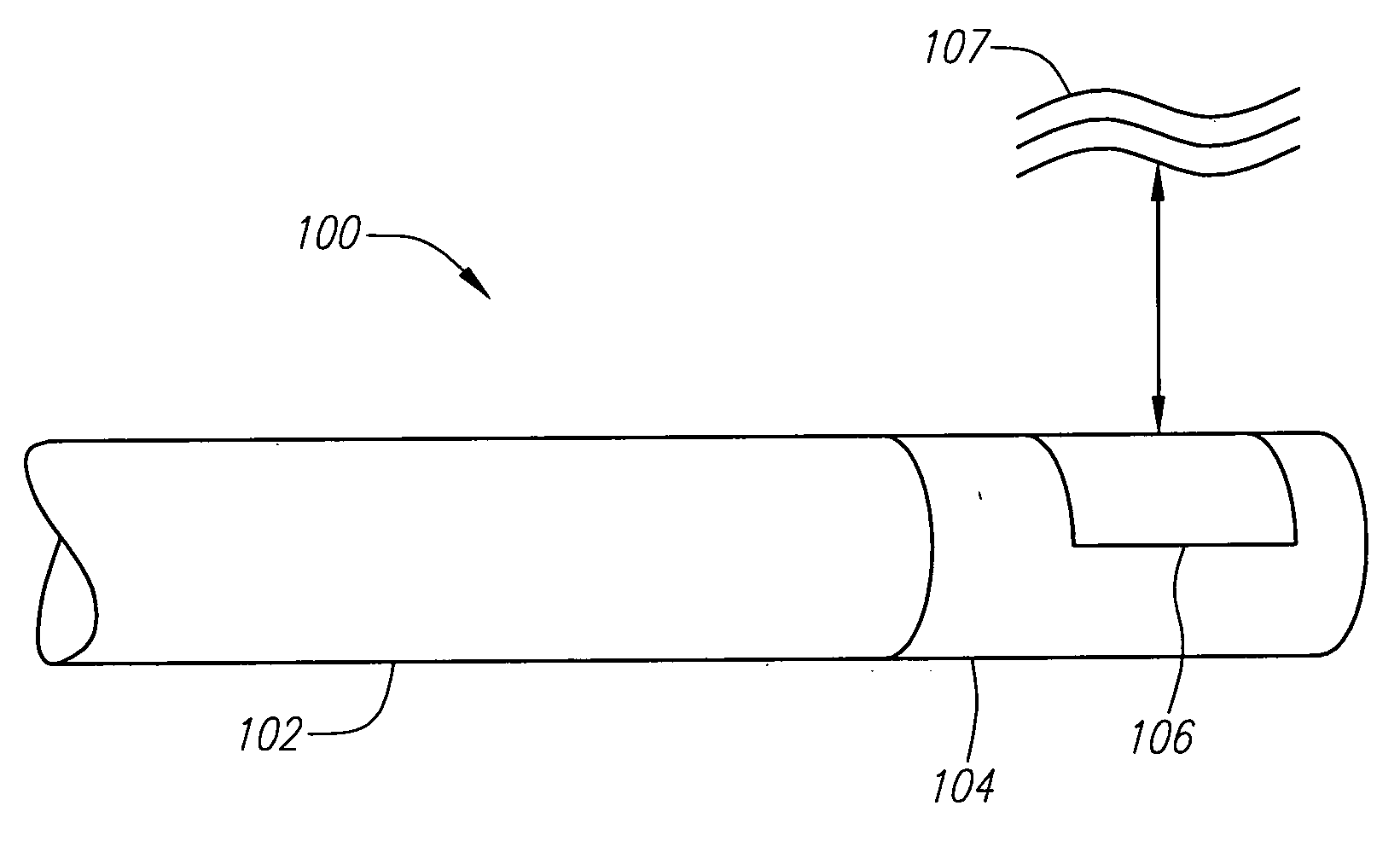

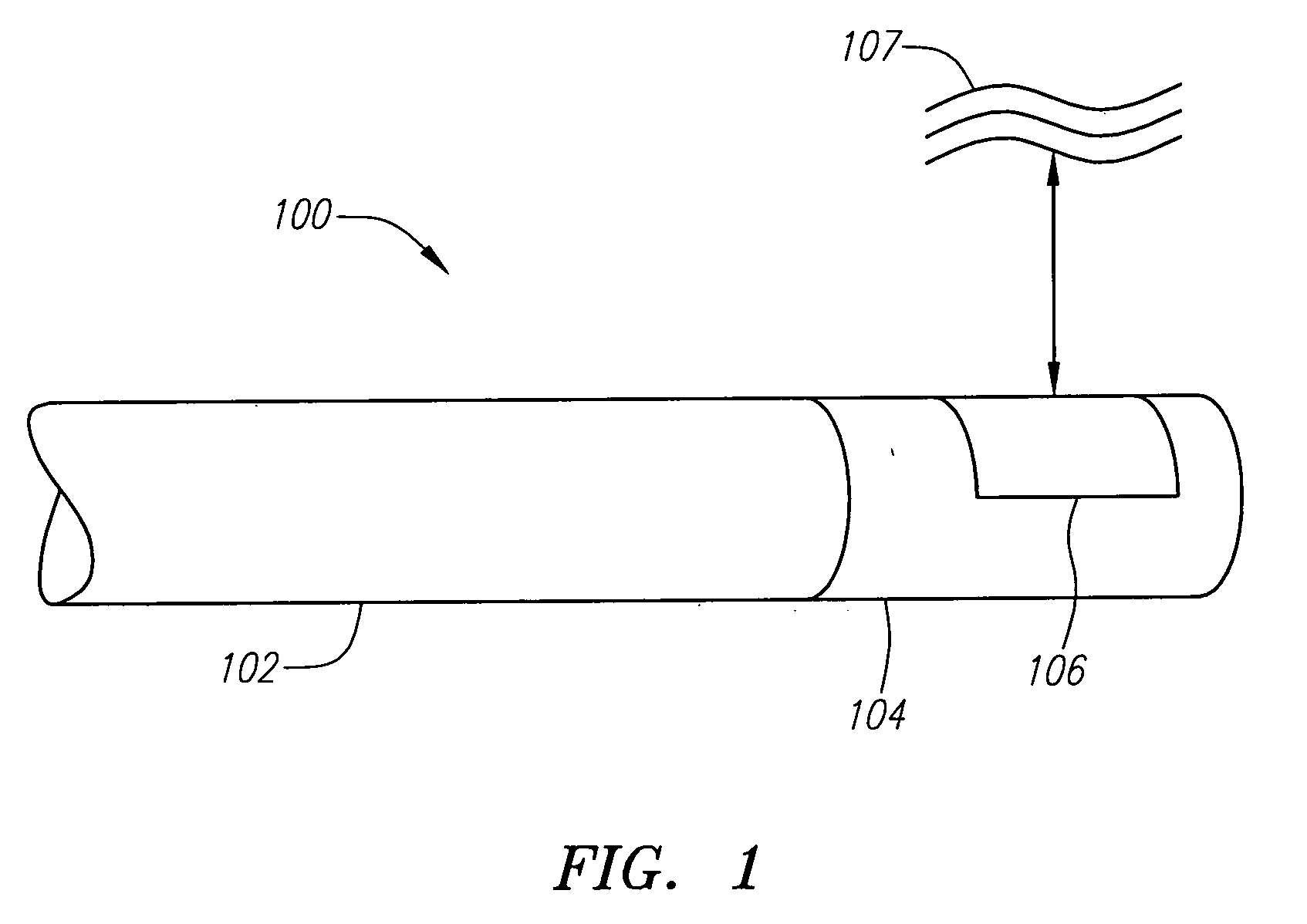

InactiveUS20060100522A1Ultrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device material selectionUltrasound imagingSingle element

The embodiments described herein provide for an ultrasound imaging device having a piezocomposite transducer. The imaging device is preferably insertable within a living being and configured to image the interior of the living being. The piezocomposite transducer can be formed from piezoceramic and polymeric materials. The piezocomposite transducer can be configured as a single element transducer or as a transducer array having one or more elements. Also provided is a method of manufacturing a piezocomposite transducer and a method of imaging with a piezocomposite transducer.

Owner:SCI MED LIFE SYST

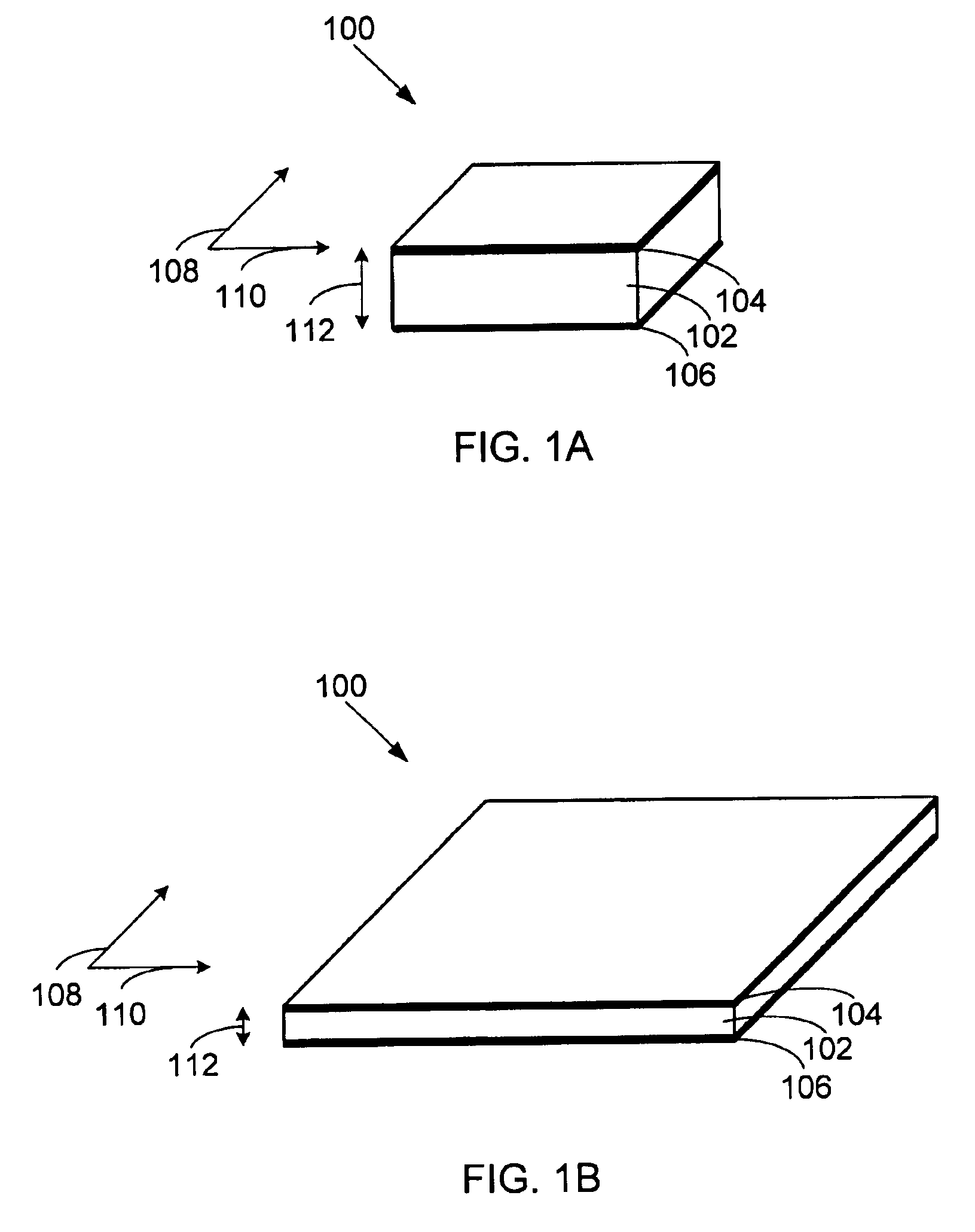

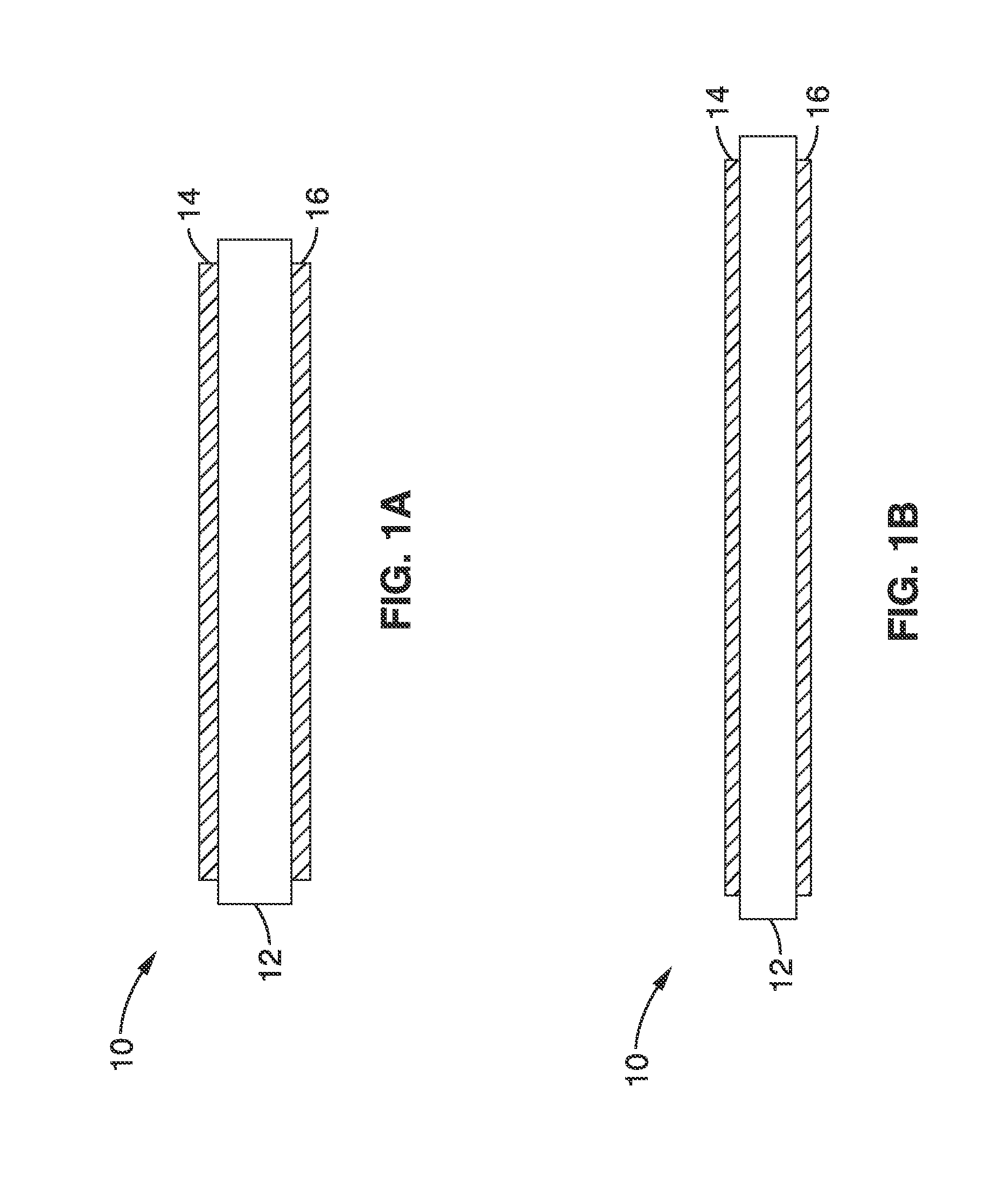

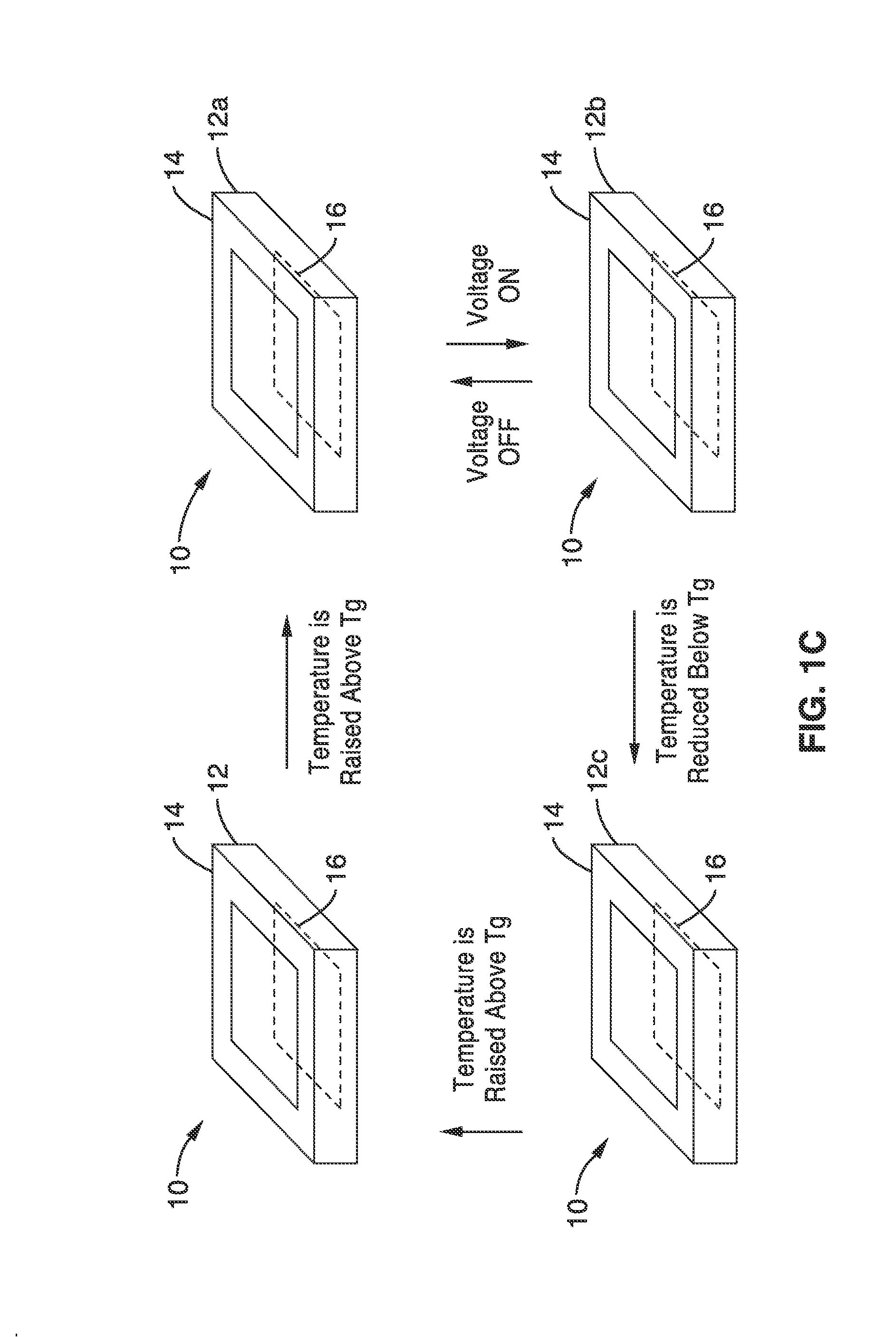

Bistable electroactive polymers

ActiveUS20100171393A1Improve mechanical energySpeed up the conversion processPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionHigh energyShock resistance

A bistable electroactive polymer transducer is provided for electrically actuated deformation of rigid electroactive polymer members. The polymers have glass transition temperatures (Tg) above ambient conditions and turn into rubbery elastomers above Tg and have high dielectric breakdown strength in the rubbery state. They can be electrically deformed to various rigid shapes with maximum strain greater than 100% and as high as 400%. The actuation is made bistable by cooling below Tg to preserve the deformation. The dielectric actuation mechanism includes a pair of compliant electrodes in contact with a dielectric elastomer which deforms when a voltage bias is applied between the pair of electrodes. In some of the transducers of the present invention, the dielectric elastomer is also a shape memory polymer. The deformations of such bistable electroactive polymers can be repeated rapidly for numerous cycles. The polymer transducers have such advantages as high energy and power densities, quietness, mechanical compliancy (for shock resistance and impedance matching), high efficiency, lightweight, and low cost.

Owner:RGT UNIV OF CALIFORNIA

Tunable bulk acoustic wave mems microresonator

InactiveUS20050162040A1Piezoelectric/electrostriction/magnetostriction machinesImpedence networksAcousticsBulk acoustic wave

A suspended film bulk acoustic micro-resonator that includes a beam made of a piezoelectric material fixed to a support and sandwiched between excitation electrodes. The resonator also includes a mechanism modifying limiting conditions of the resonator composed of the excited beam to modify the micro-resonator resonant frequency.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

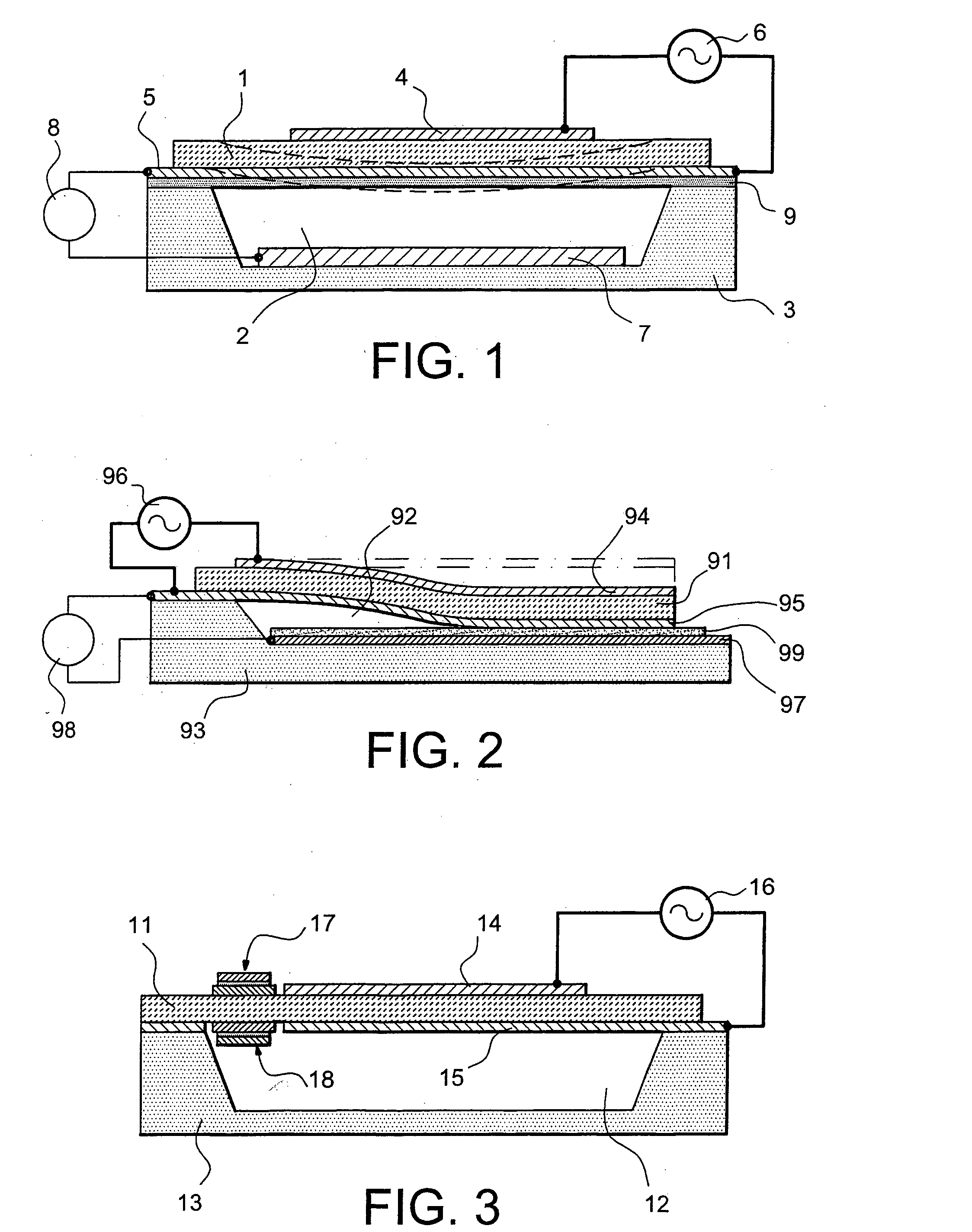

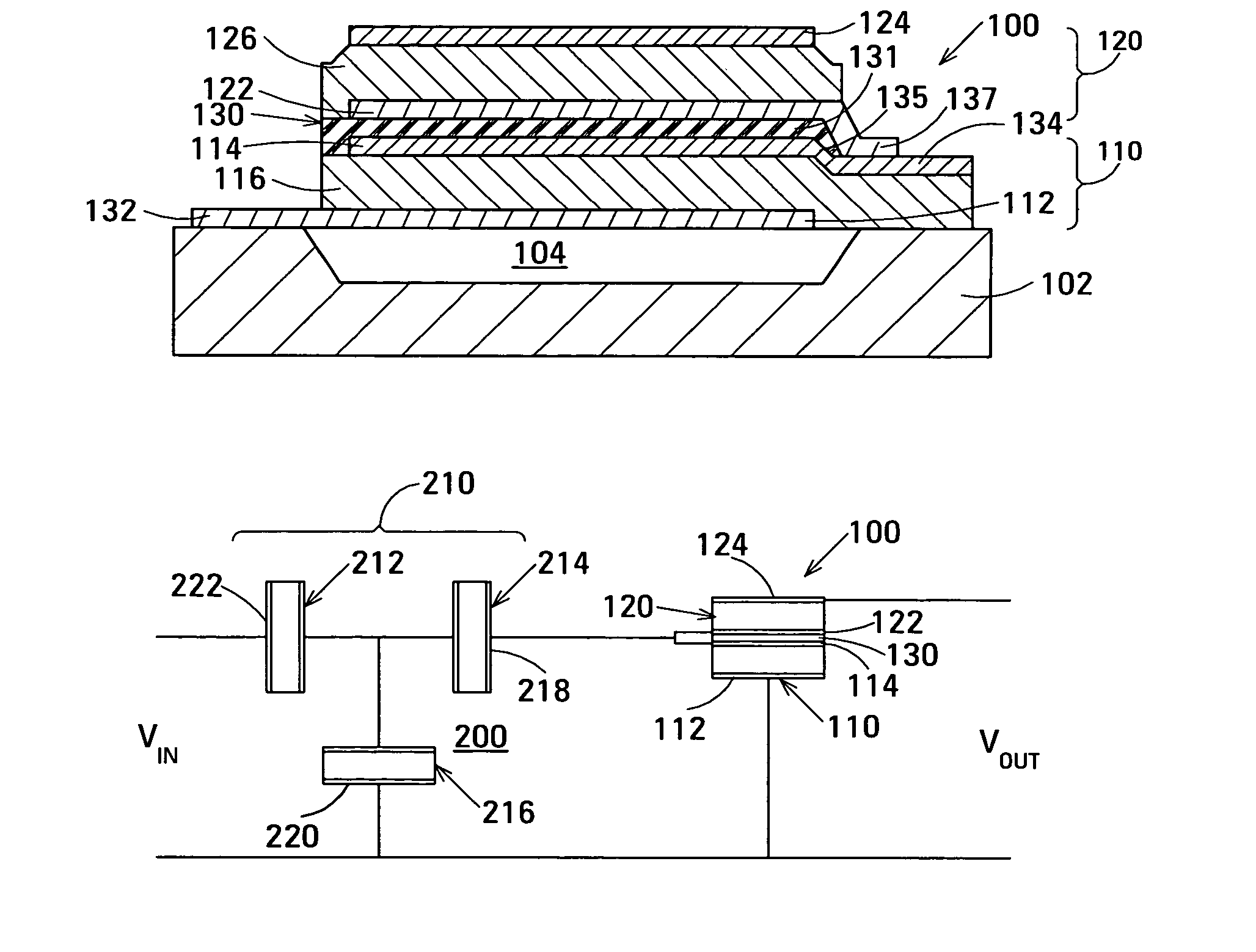

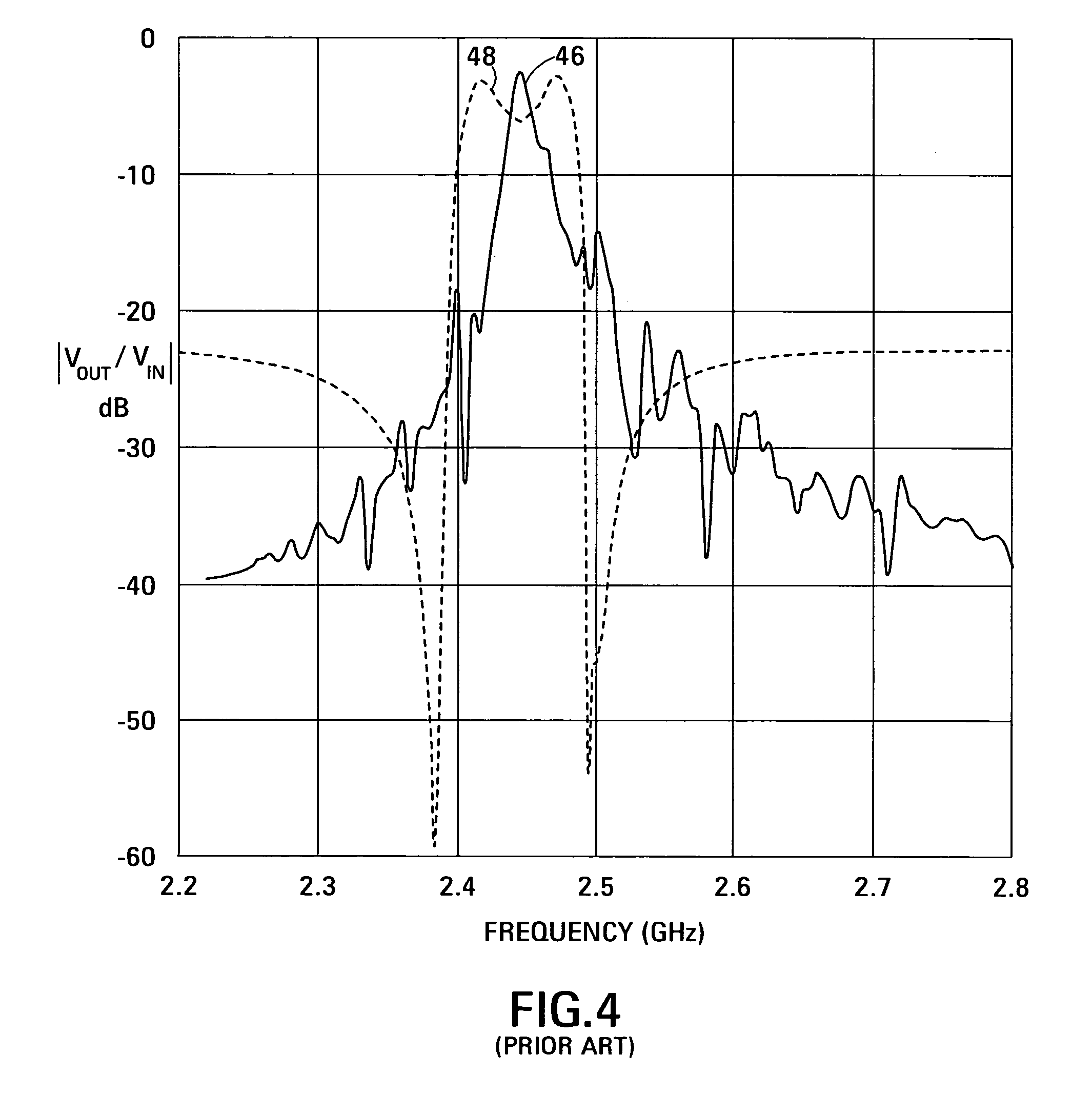

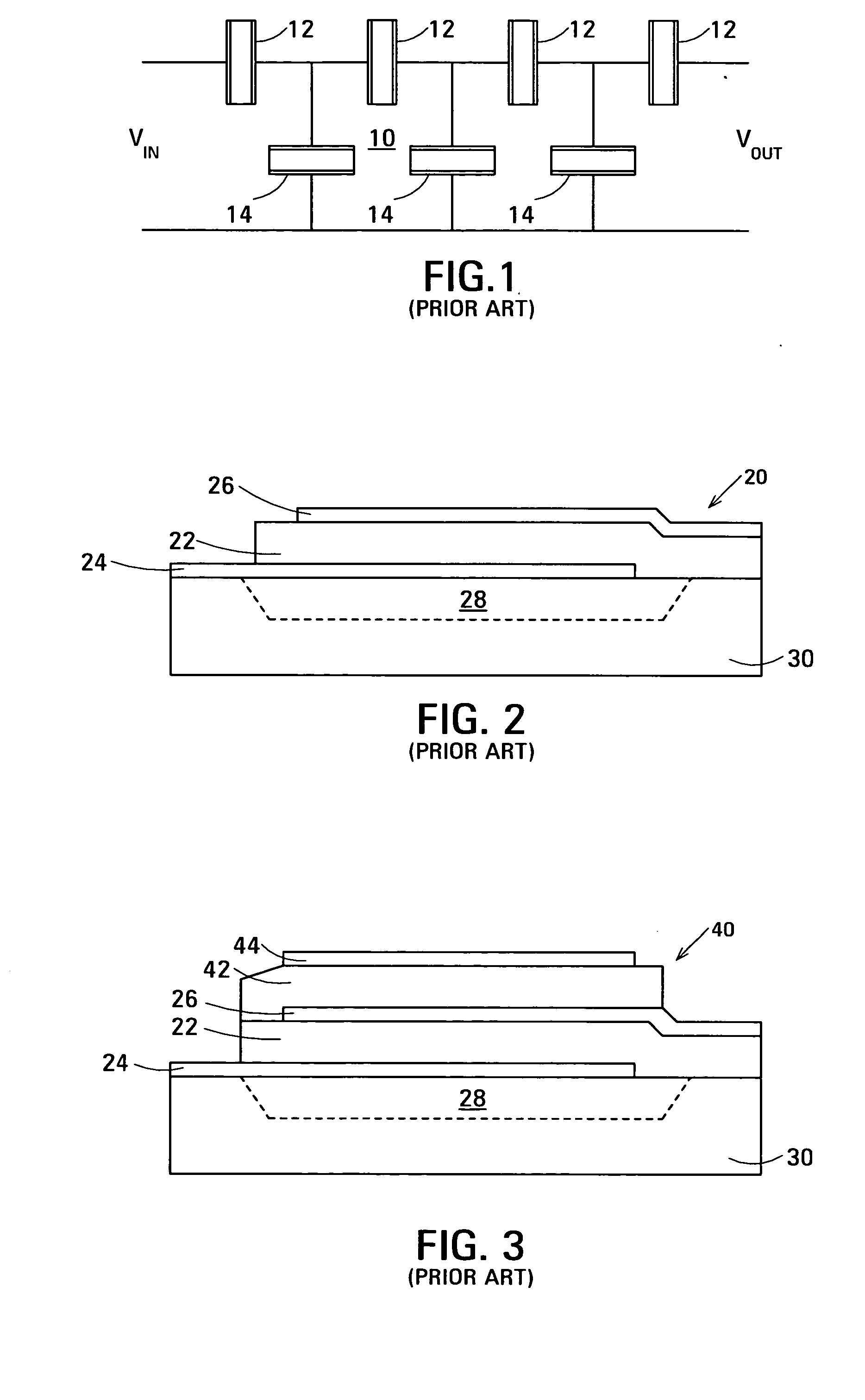

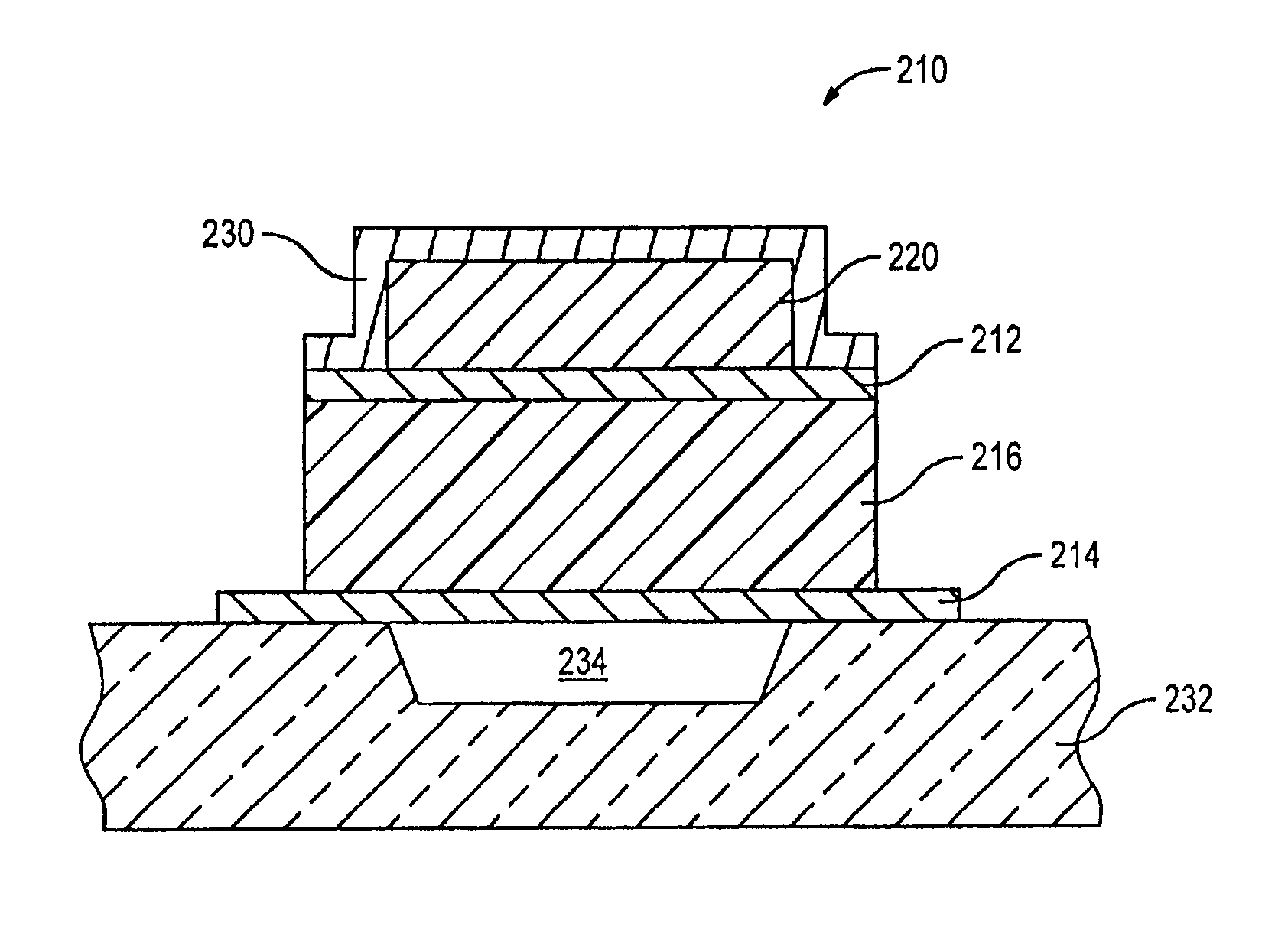

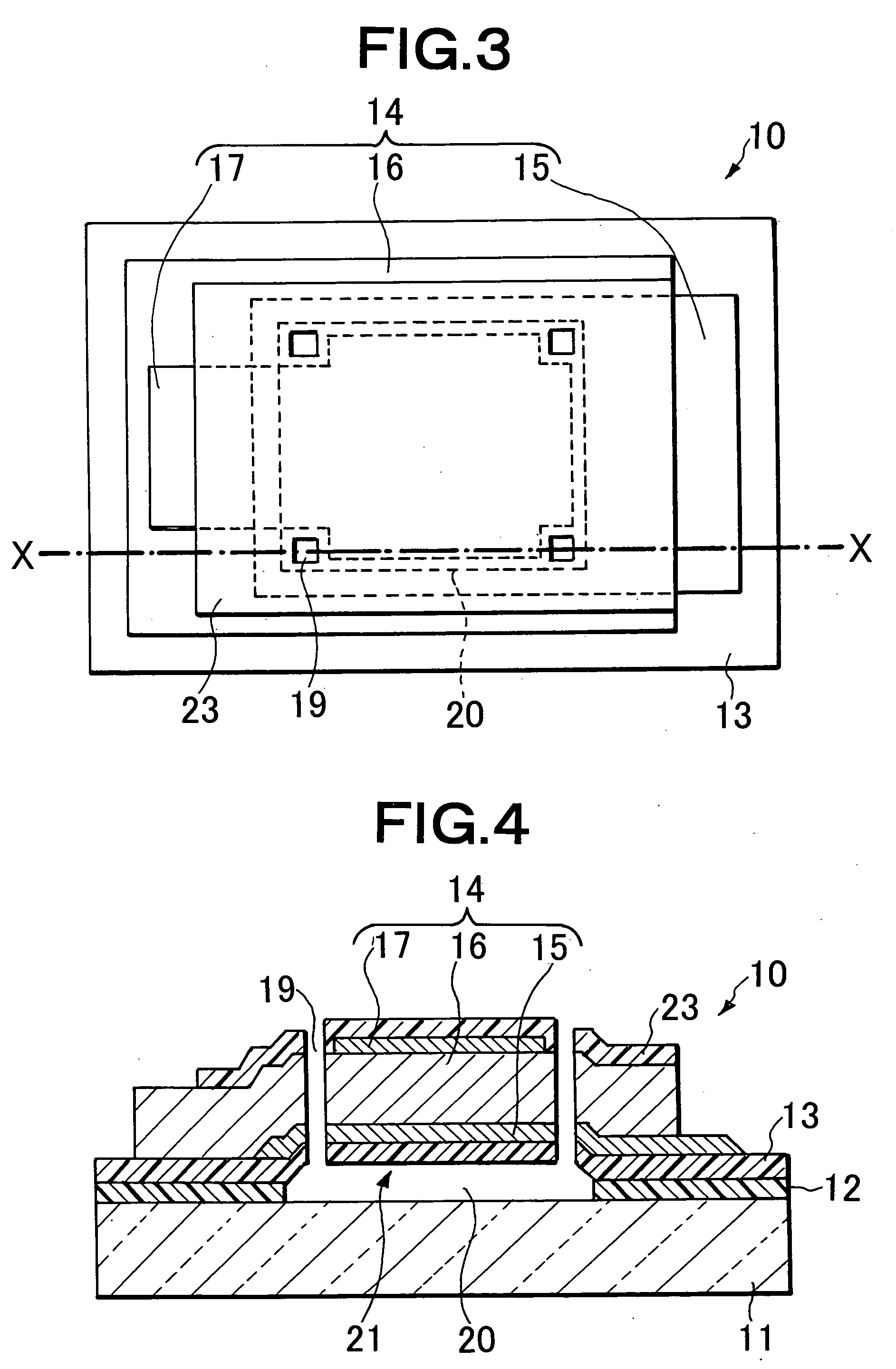

Stacked bulk acoustic resonator band-pass filter with controllable pass bandwidth

InactiveUS7019605B2Less acoustic energyLow insertion lossPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPlanar electrodeAcoustic energy

The band-pass filter has a stacked pair of film bulk acoustic resonators (FBARs) and an acoustic decoupler between the FBARs. Each of the FBARs has opposed planar electrodes and a layer of piezoelectric material between the electrodes. The acoustic decoupler has a single layer of acoustic decoupling material having a nominal thickness equal to an odd integral multiple of one quarter of the wavelength in the acoustic decoupling material of an acoustic wave having a frequency equal to the center frequency. The acoustic decoupling material comprises plastic. The acoustic decoupler controls the coupling of acoustic energy between the FBARs. Specifically, the acoustic decoupler couples less acoustic energy between the FBARs than would be coupled by direct contact between the FBARs. The reduced acoustic coupling gives the band-pass filter desirable in-band and out-of-band properties.

Owner:AVAGO TECH INT SALES PTE LTD

Piezoelectric filter, duplexer, composite piezoelectric resonator, communication device and method for adjusting frequency of piezoelectric filter

ActiveUS7019604B2Improve efficiencyHigh frequency accuracyPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectronic componentCommunication device

A piezoelectric filter and other electronic components are constructed such that the accuracy of frequency adjustment can be increased and an improvement in efficiency of the adjustment operation can be achieved. The piezoelectric filter includes a plurality of piezoelectric resonators including a substrate and a vibration portion provided on the substrate, the vibration portion having a structure in which the top and bottom surfaces of a thin film portion including at least one piezoelectric thin film are sandwiched between at least a pair of an upper electrode and a lower electrode facing each other, wherein the upper electrode of a predetermined piezoelectric resonator is made of a material having susceptibility to etching that is different from that of the upper electrode of the other piezoelectric resonator.

Owner:MURATA MFG CO LTD

Piezoelectric actuator and micro-electromechanical device

InactiveUS20060055287A1Warpage suppressionImprove accuracyNanotechPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric actuatorsEngineering

A piezoelectric actuator includes a first beam including a first bottom electrode, a first piezoelectric film on the first bottom electrode, and a first top electrode on the first piezoelectric film, a fixed end assigned at an end of the first beam and fixed on a substrate, a connecting end assigned at another end of the first beam and suspended over a free space; and a second beam including a second piezoelectric film connected to the first piezoelectric film at the connecting end, a second bottom electrode under the second piezoelectric film, and a second top electrode on the second piezoelectric film, a working end assigned at an end of the second beam opposite to another end to which the connecting end is assigned and suspended over the free space; wherein a distance between centers of the fixed end and the working end is shorter than a distance from the working end to the connecting end.

Owner:KK TOSHIBA

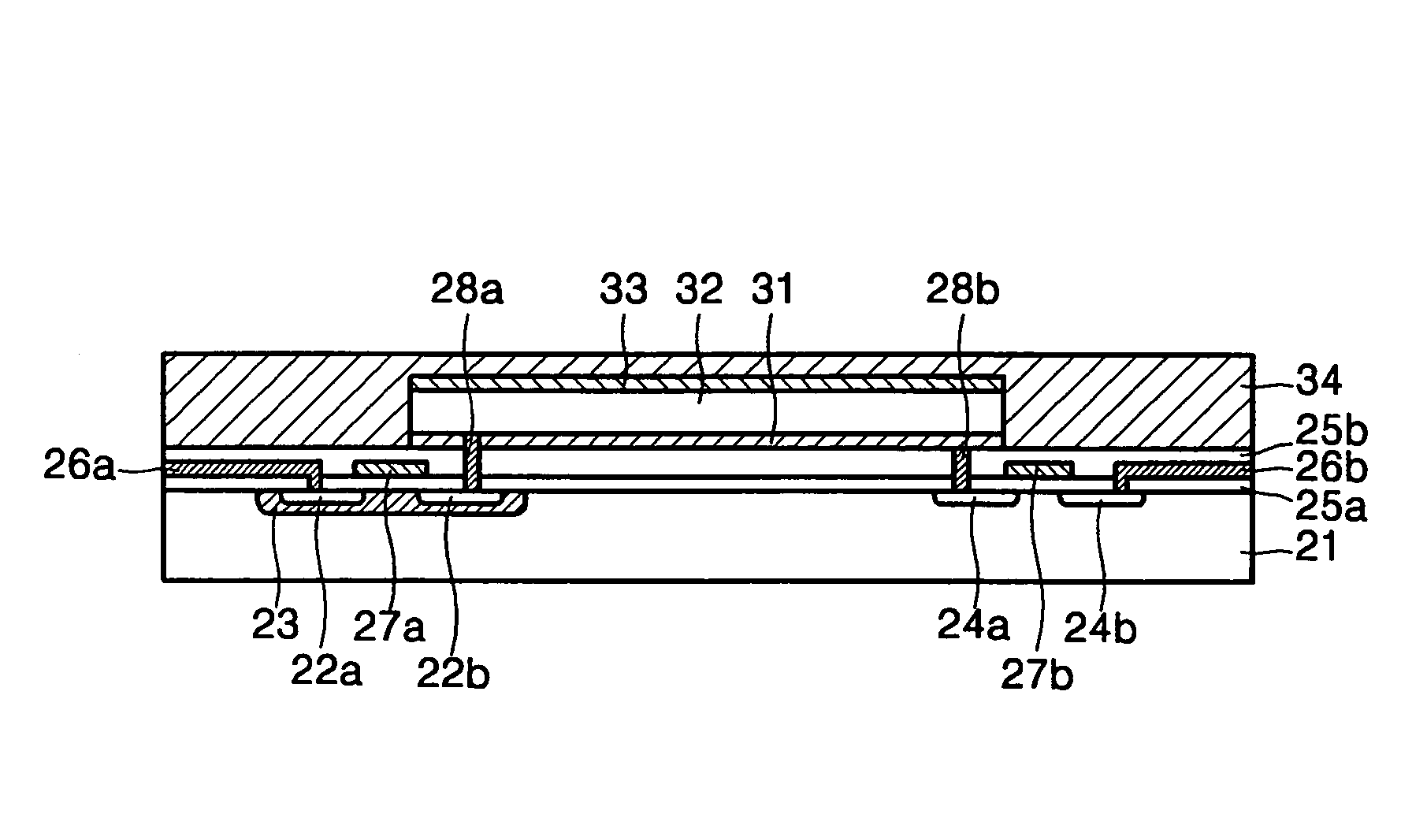

Fingerprint sensor and fabrication method thereof

InactiveUS7400750B2Improve authentication speedTransistorPiezoelectric/electrostrictive device manufacture/assemblyDopantEngineering

Provided are a fingerprint sensor and a fabrication method thereof. The fingerprint sensor includes: a complementary metal-oxide semiconductor structure which is formed on a substrate that is doped with a first type dopant; an insulating layer which is formed on the complementary metal-oxide semiconductor structure; a lower electrode which is formed in a central portion of the insulating layer; a piezoelectric region which is formed on the lower electrode; an upper electrode which is formed on the piezoelectric layer; and a fingerprint contact layer which is formed to cover a portion of an upper surface of the insulating layer on which the lower electrode has not been formed, the lower electrode, the piezoelectric region, and the upper electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Voltage and light induced strains in porous crystalline materials and uses thereof

InactiveUS6728024B2Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionCrystalline materialsElectric potential

A piezoelectric device is disclosed, which includes a first element of porous crystalline material, a second element being attached to, or integrally formed with, the first element, and at least one electrode being in electrical contact with the first element, such that subjecting the first element to an electric potential via the at least one electrode results in a strain induced by the first element on the second element. Also disclosed is a piezooptic device which includes a first element of porous crystalline material, a second element being attached to, or integrally formed with, the first element, and a light source, such that subjecting the first element to light originating from the light source results in a strain induced by the first element on the second element.

Owner:TECHNION RES & DEV FOUND LTD

Surface acoustic wave device with KNb03 piezoelectric thin film, frequency filter, oscillator, electronic circuit, and electronic apparatus

InactiveUS6720846B2Polycrystalline material growthPiezoelectric/electrostriction/magnetostriction machinesTectorial membraneFrequency filtering

Surface acoustic wave device having a high k<2>, and a frequency filter, oscillator, electronic circuit and electronic device employing this surface acoustic wave device is provided, wherein a first oxide thin film layer comprising SrO or MgO and a second oxide thin film layer comprising SrTiO3 are sequentially formed on top of a (110) Si substrate, or a first oxide thin film layer comprising CeO2, ZrO2 or yttrium-stabilized zirconia and a second oxide thin film layer comprising SrTiO3 are sequentially formed on top of a (100) Si substrate, a KNbO3 piezoelectric thin film being then formed on top of either of these second oxide thin film layers, and then, a protective film comprising oxide or nitride is formed on top of the KNbO3 piezoelectric thin film, finally, at least one electrode is formed on top of this protective film, to form a surface acoustic wave device, which surface acoustic wave device is employed to form a frequency filter, oscillator, electronic circuit, or electronic device.

Owner:SEIKO EPSON CORP

Stacked bulk acoustic resonator band-pass filter with controllable pass bandwidth

ActiveUS20050093653A1Less acoustic energyLow insertion lossPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPlanar electrodeAcoustic energy

The band-pass filter has a stacked pair of film bulk acoustic resonators (FBARs) and an acoustic decoupler between the FBARs. Each of the FBARs has opposed planar electrodes and a layer of piezoelectric material between the electrodes. The acoustic decoupler controls the coupling of acoustic energy between the FBARs. Specifically, the acoustic decoupler couples less acoustic energy between the FBARs than would be coupled by direct contact between the FBARs. The reduced acoustic coupling gives the band-pass filter desirable in-band and out-of-band properties.

Owner:AVAGO TECH INT SALES PTE LTD

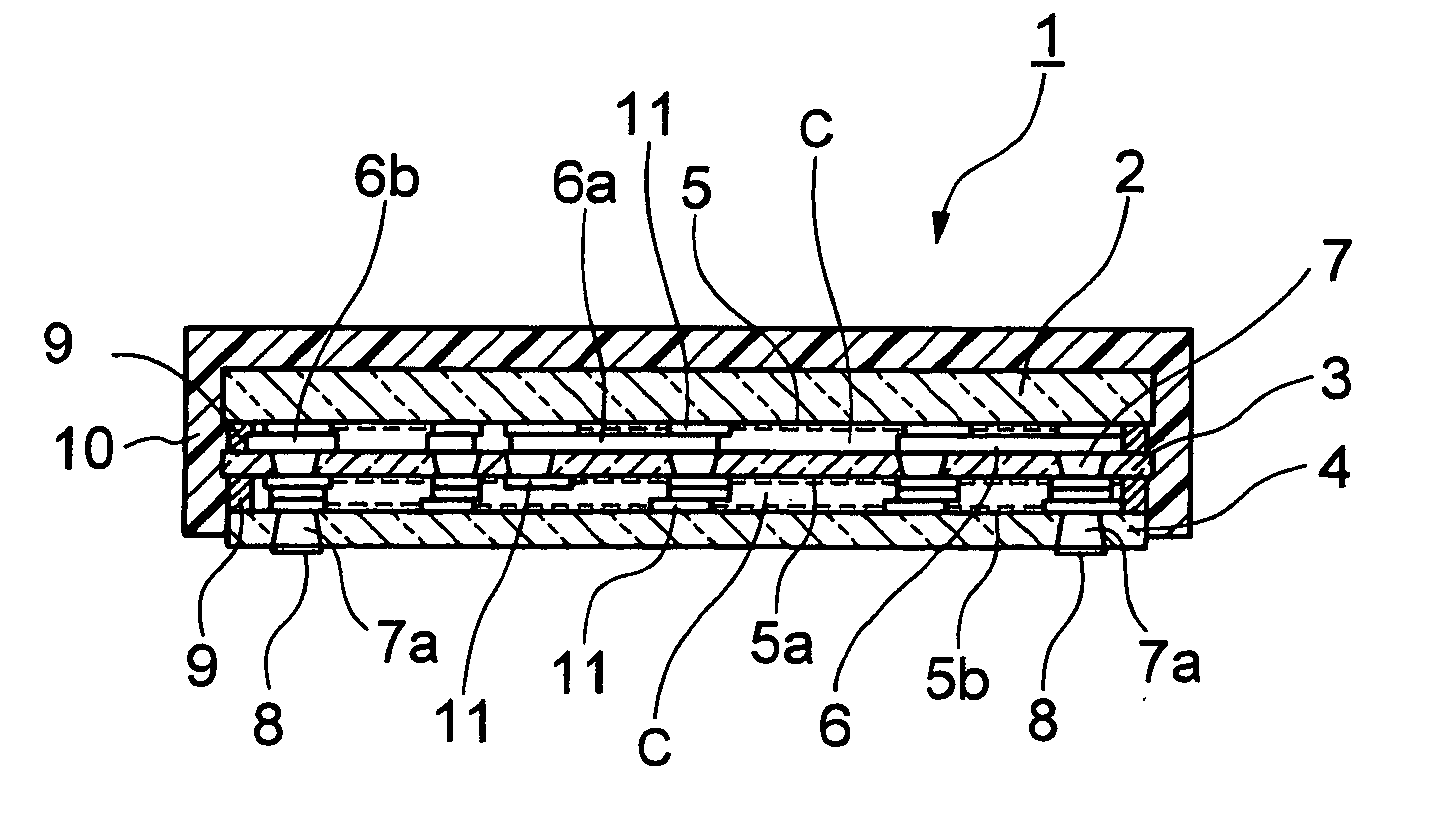

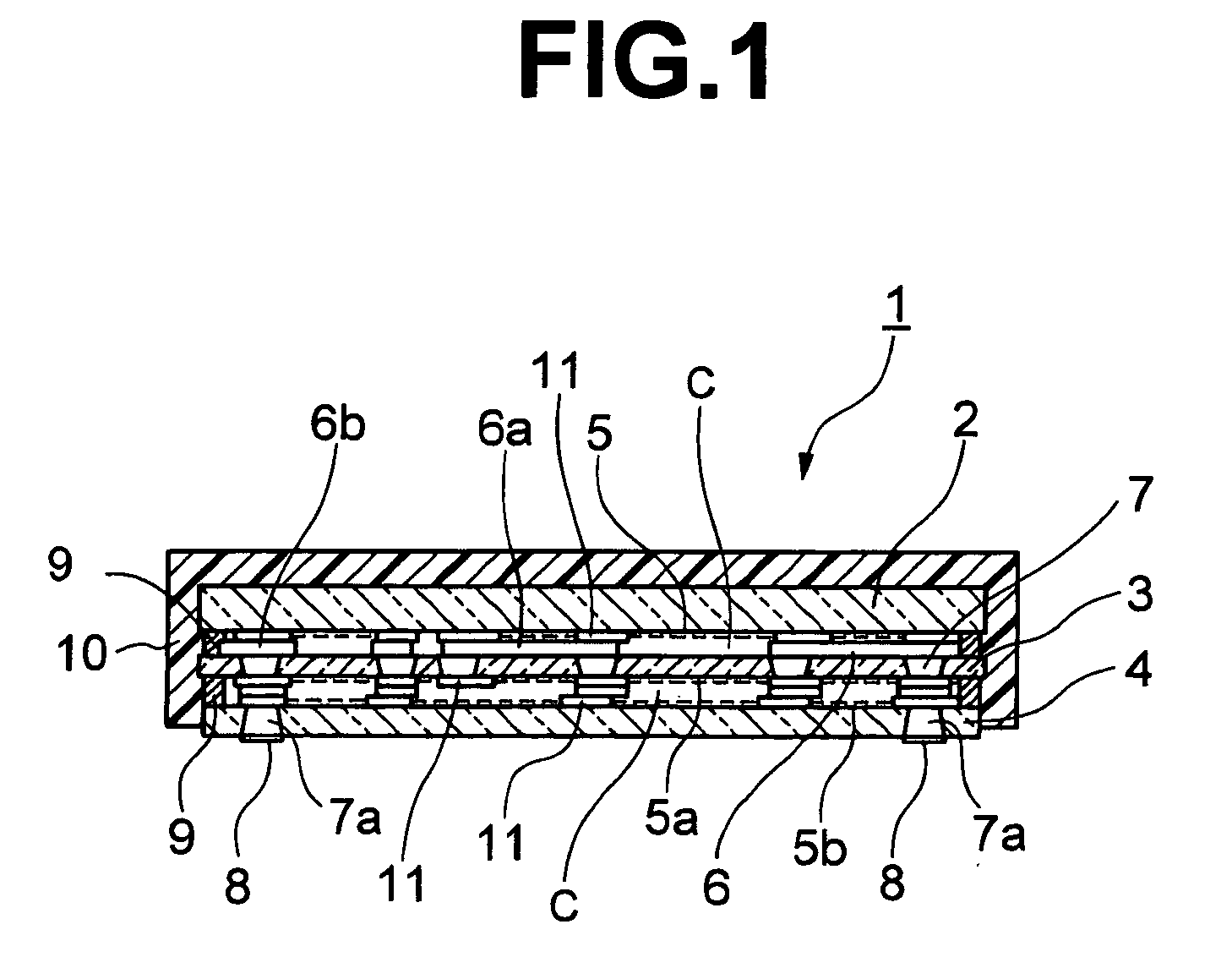

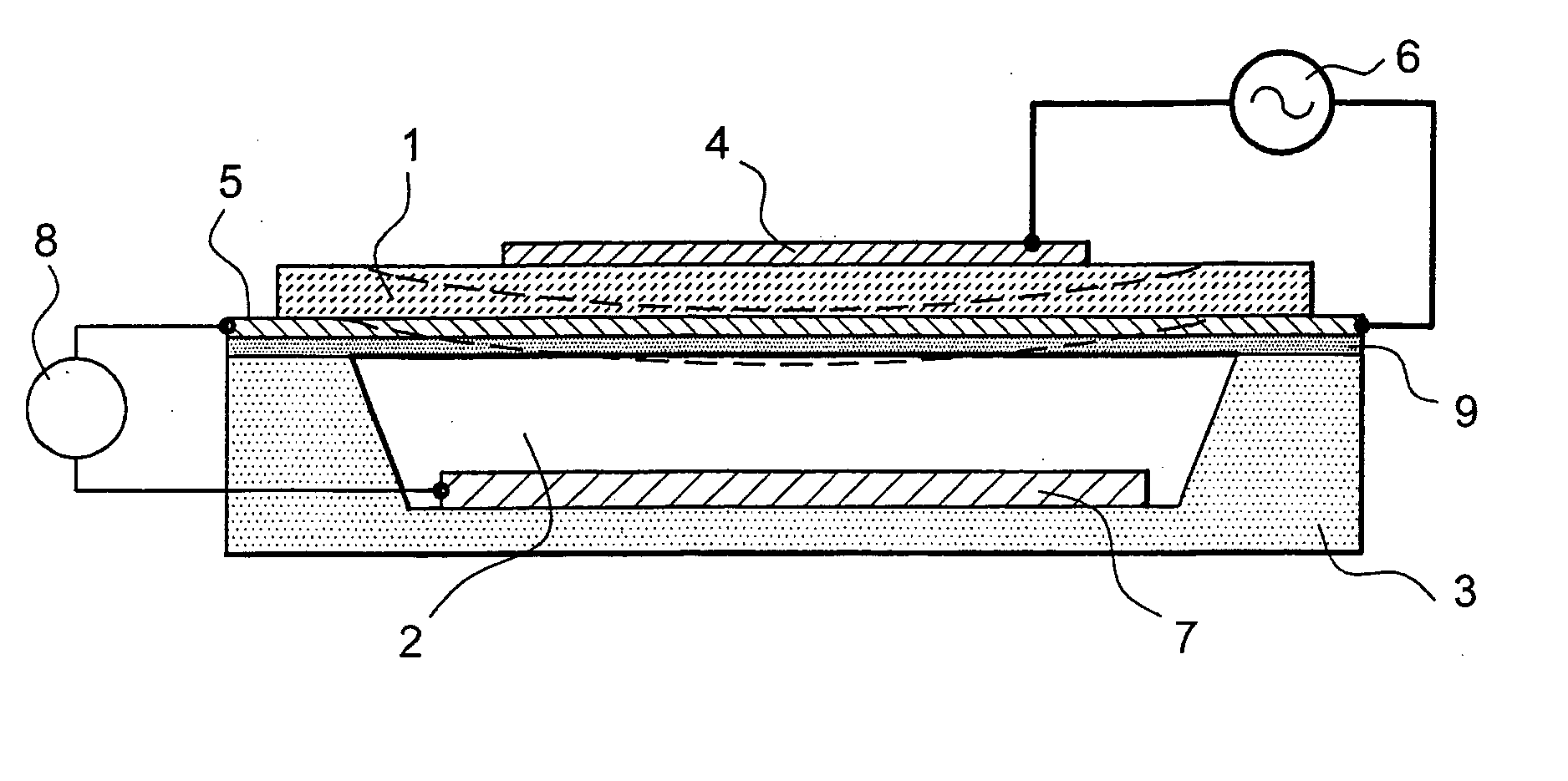

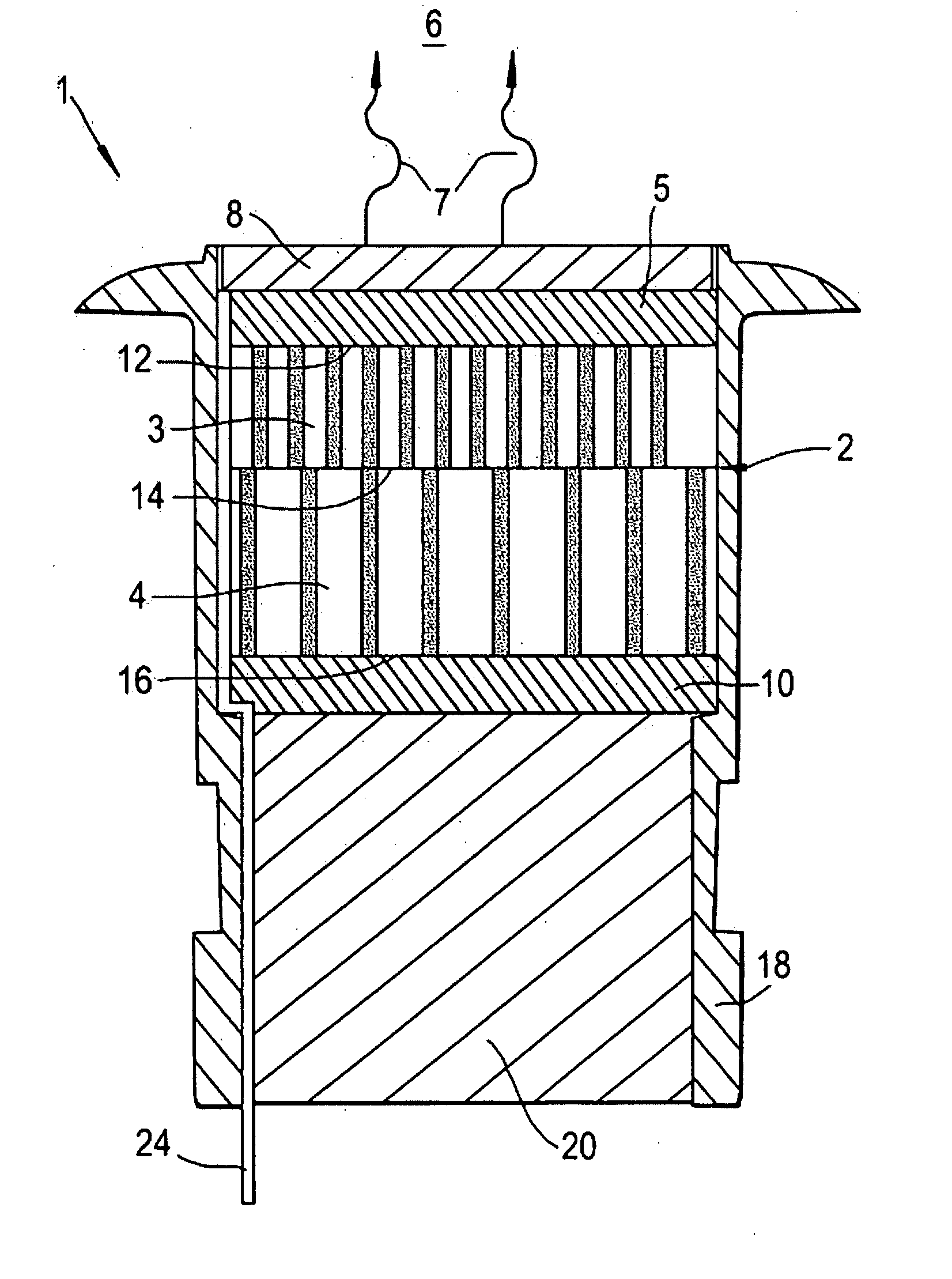

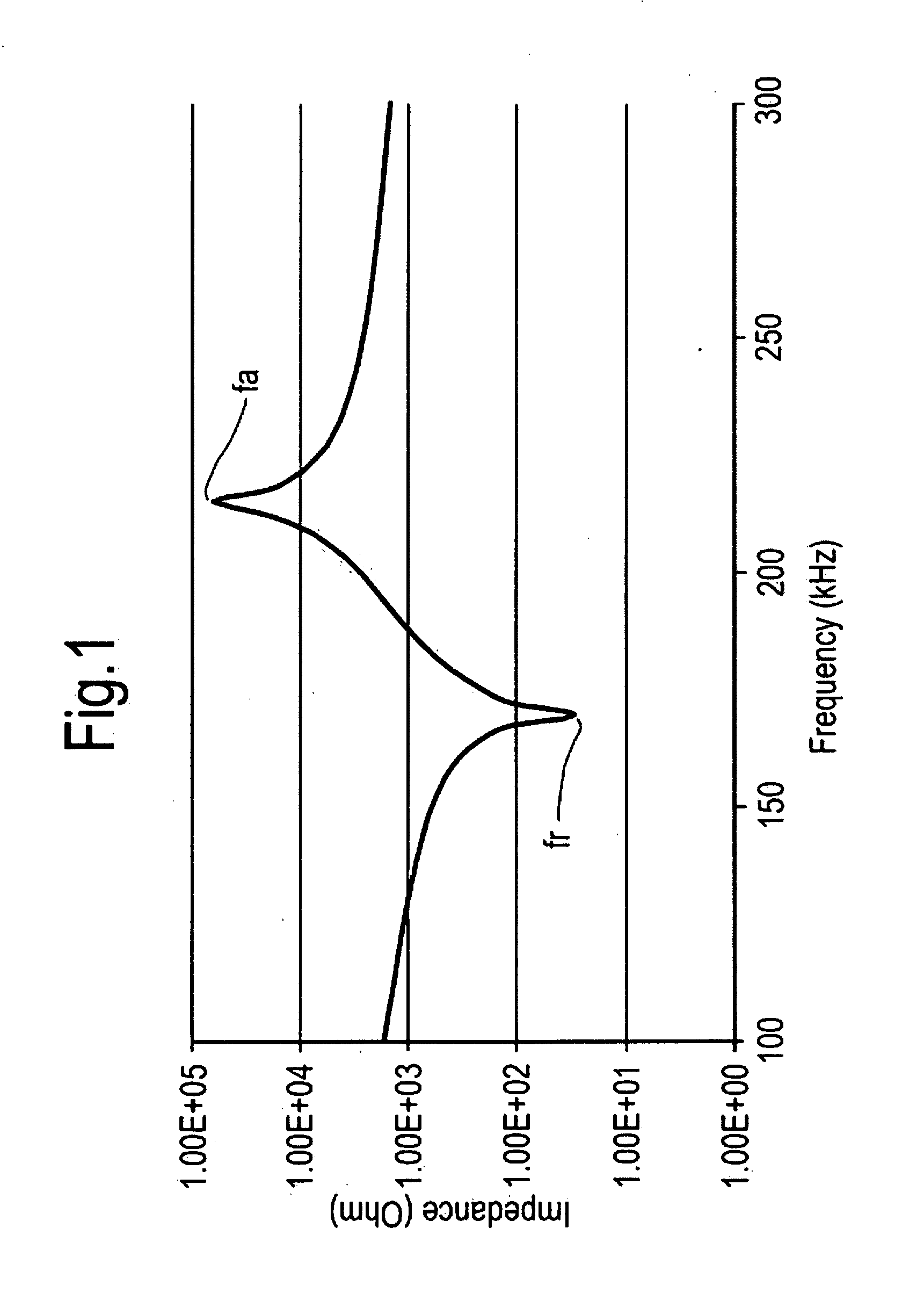

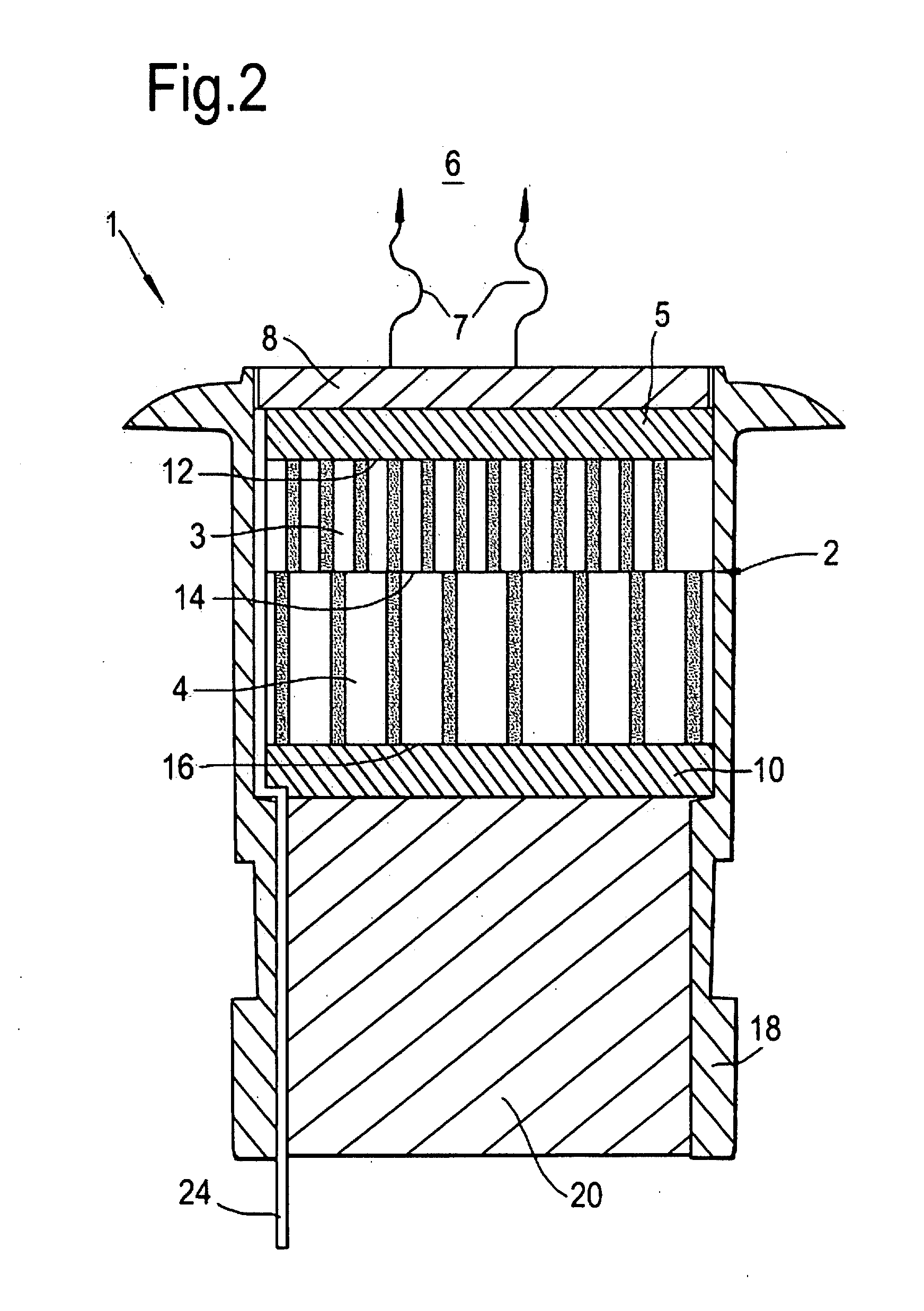

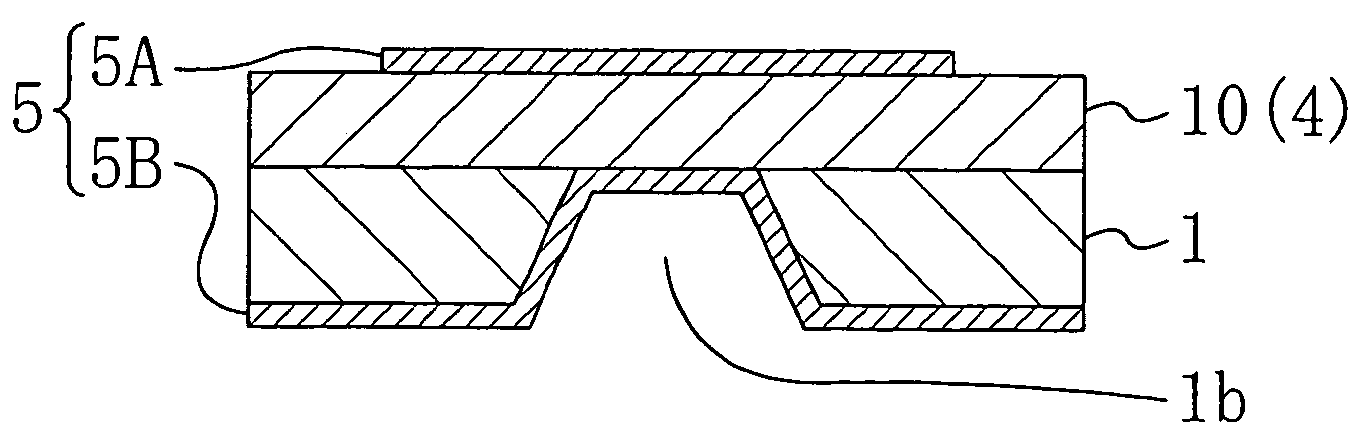

Ultrasonic/acoustic transducer

ActiveUS20120163126A1Affect bandwidthValid matchPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionTransducerAcoustic wave

A transducer 1b comprising a vibrator body 2b for generating and / or receiving acoustic or ultrasonic waves, acoustically coupled to a second part 4 for generating and / or receiving acoustic or ultrasonic waves and, a matching layer 5 coupled to said vibrator body 2 so as, in use, to acoustically match the vibrator body 2b to a medium 6 contacting said matching layer 5.

Owner:CERAMTEC

Method of making an acoustic wave resonator

InactiveUS6874212B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceAcoustic wave

Owner:AVAGO TECH INT SALES PTE LTD

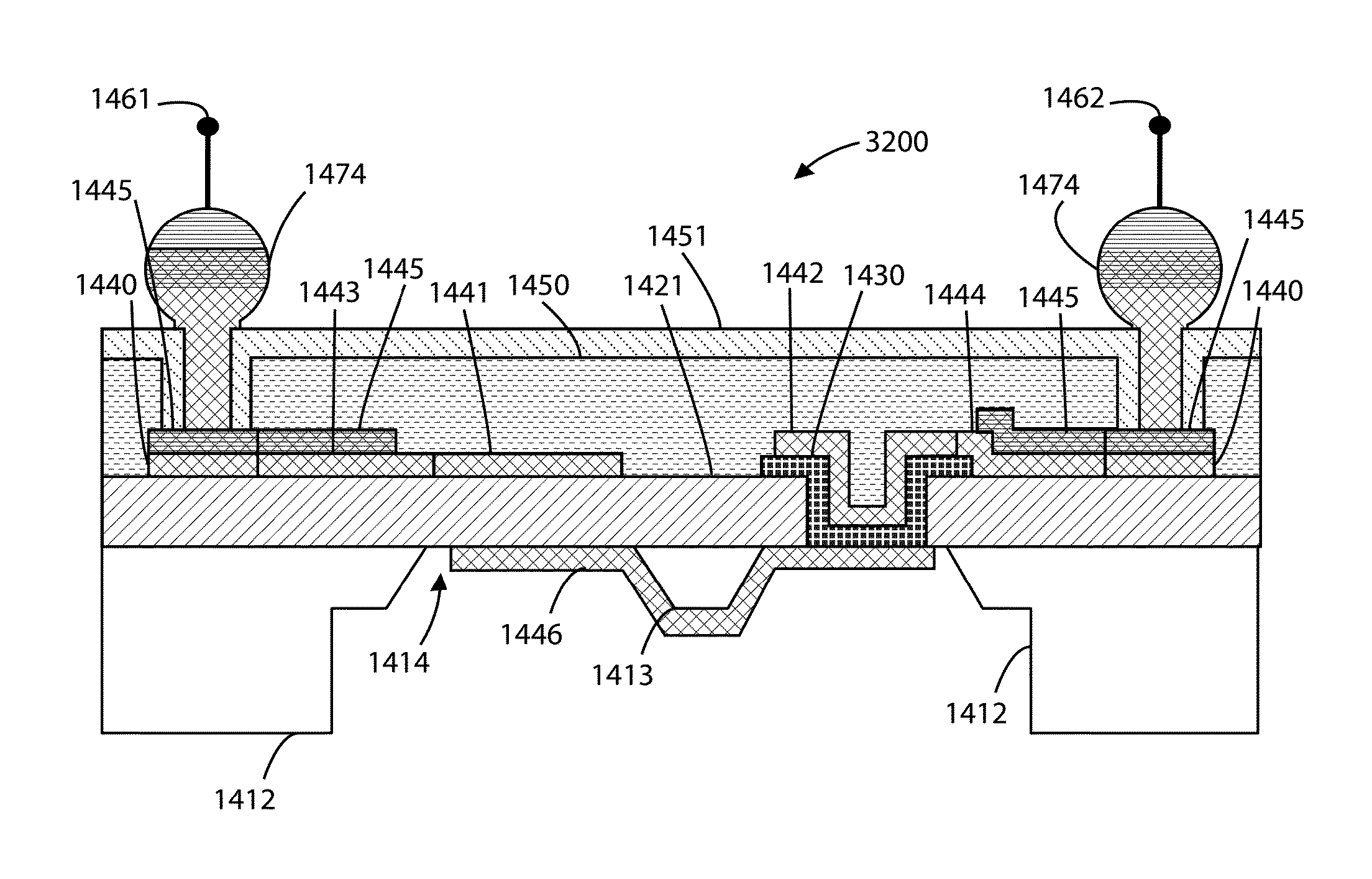

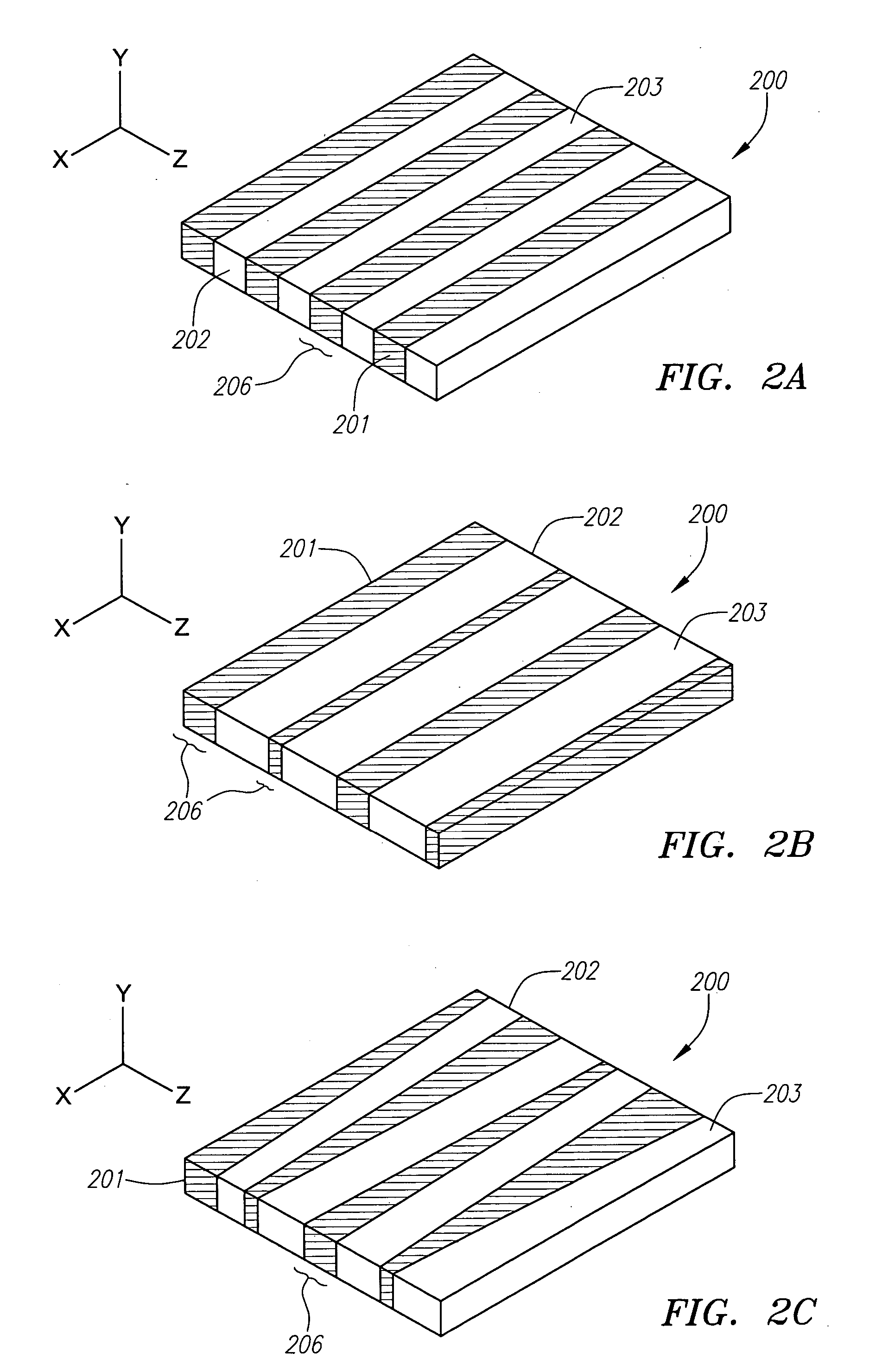

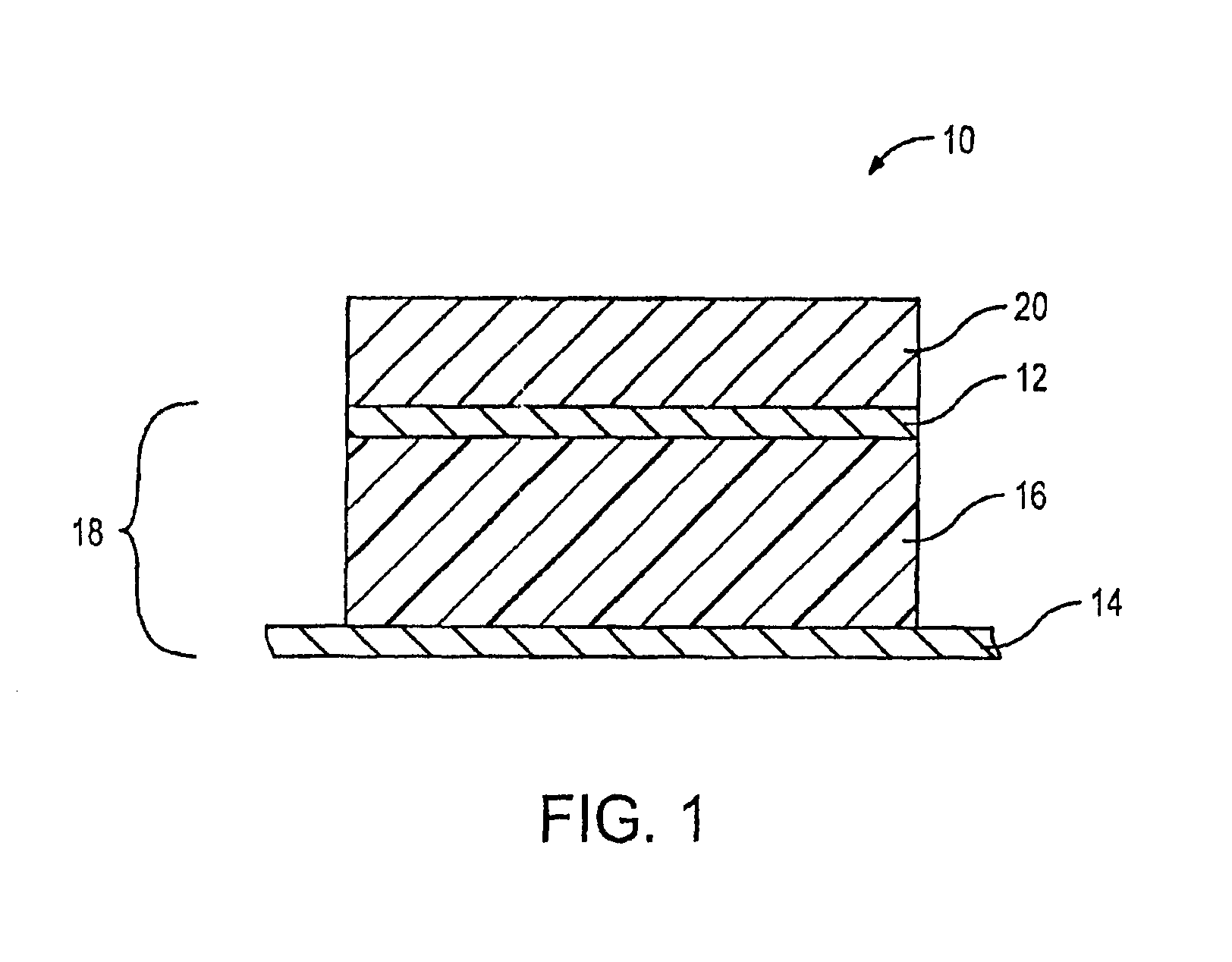

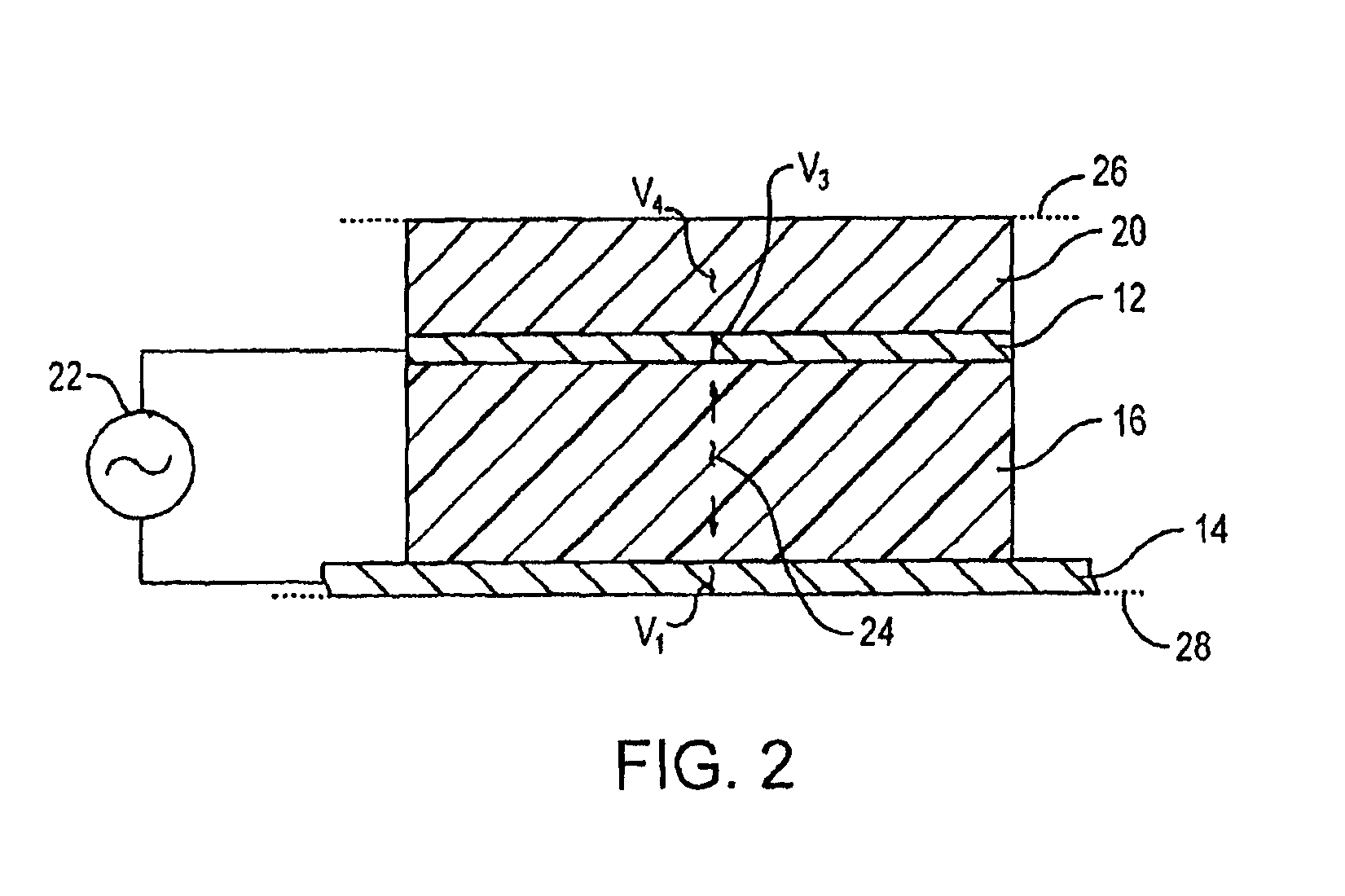

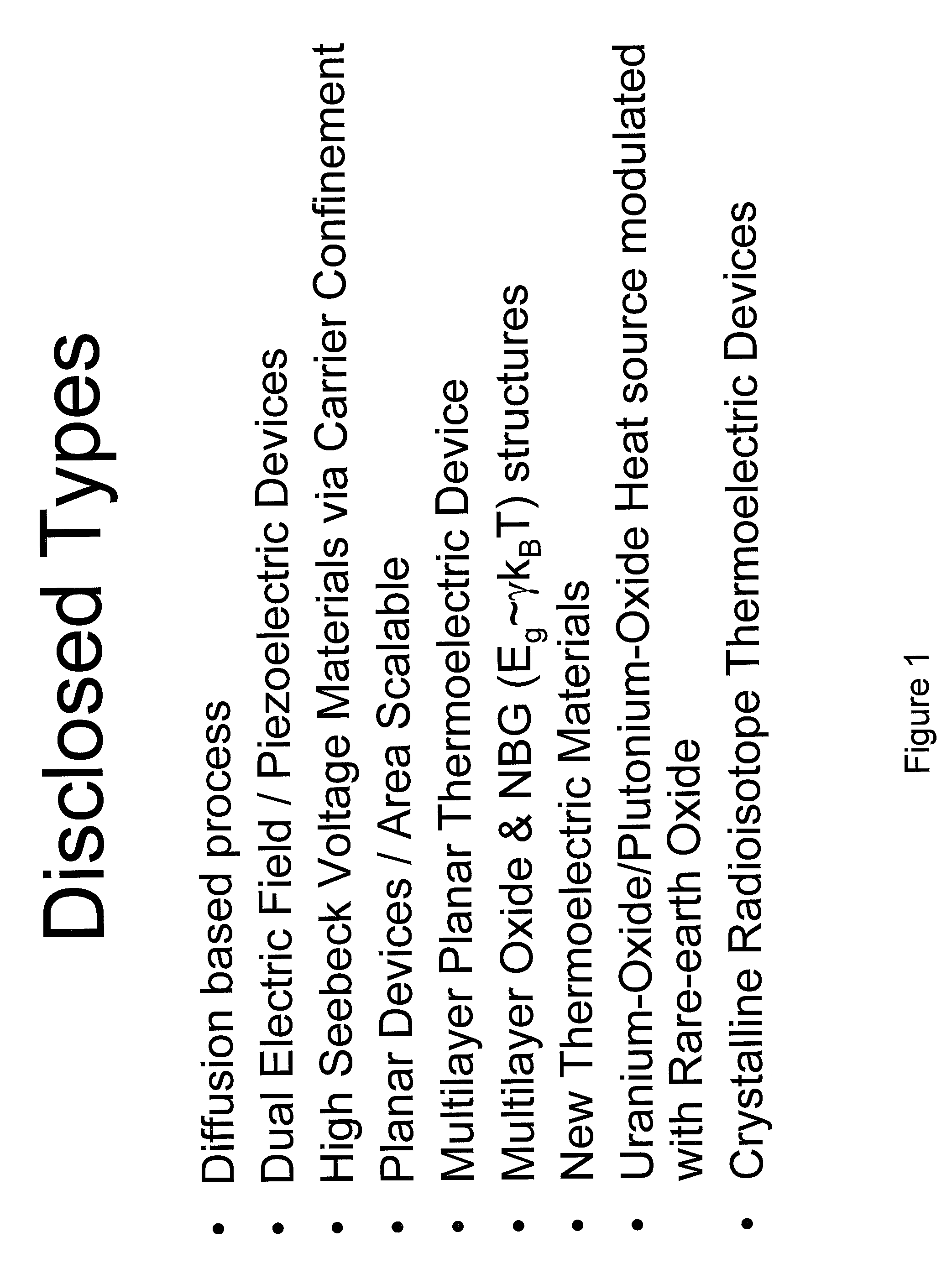

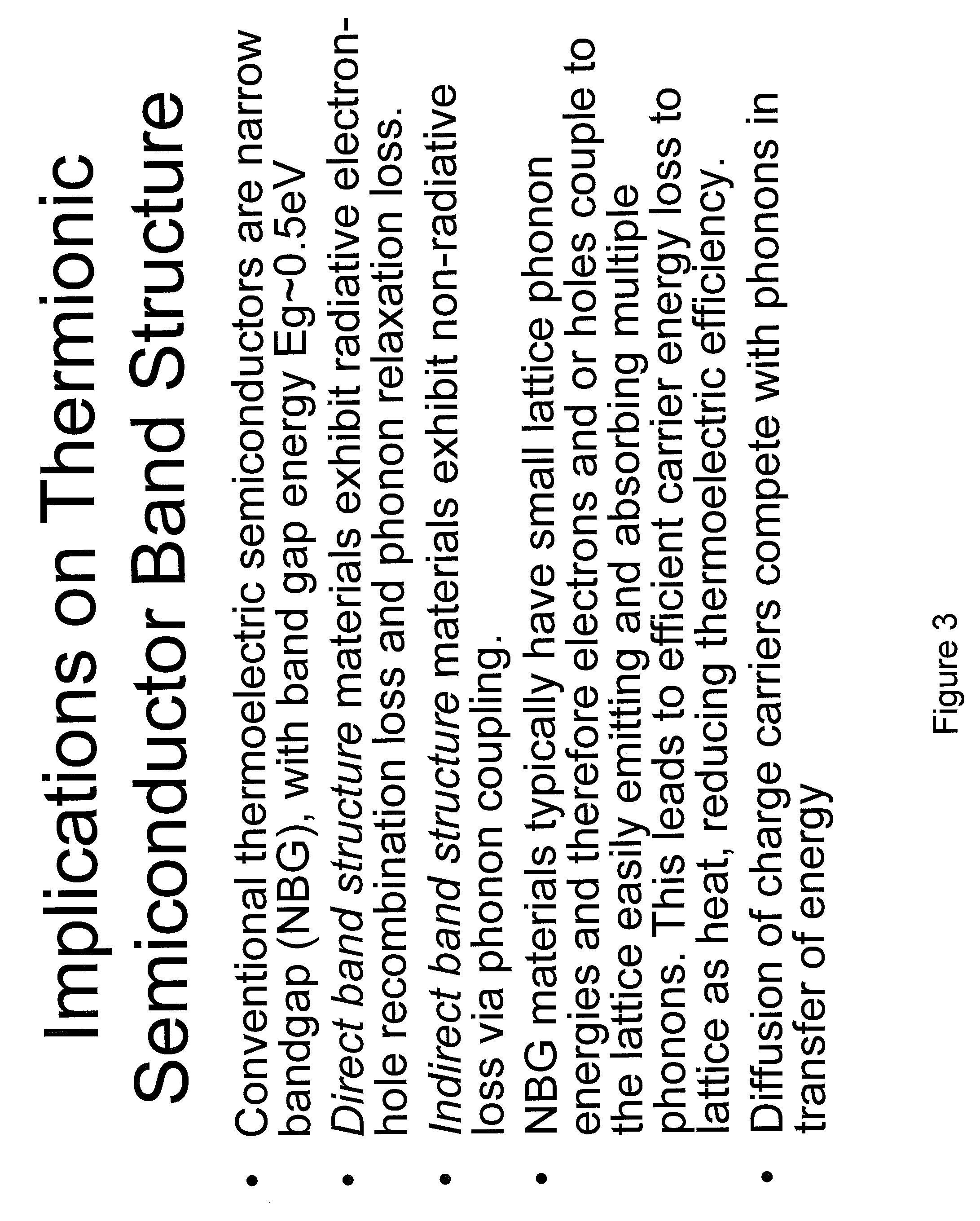

Thermoelectric and Pyroelectric Energy Conversion Devices

InactiveUS20080295879A1Improve efficiencyImprove thermoelectric conversion efficiencyRadiation pyrometryThermoelectric device with peltier/seeback effectThermoelectric materialsRare earth

New thermoelectric materials and devices are disclosed for application to high efficiency thermoelectric power generation. New functional materials based on oxides, rare-earth-oxides, rare-earth-nitrides, rare-earth phosphides, copper-rare-earth oxides, silicon-rare-earth-oxides, germanium-rare-earth-oxides and bismuth rare-earth-oxides are disclosed. Addition of nitrogen and phosphorus are disclosed to optimize the oxide material properties for thermoelectric conversion efficiency. New devices based on bulk and multilayer thermoelectric materials are described. New devices based on bulk and multilayer thermoelectric materials using combinations of at least one of thermoelectric and pyroelectric and ferroelectric materials are described. Thermoelectric devices based on vertical pillar and planar architectures are disclosed. The advantage of the planar thermoelectric effect allows utility for large area applications and is scalable for large scale power generation plants.

Owner:TRANSLUCENT PHOTONICS +1

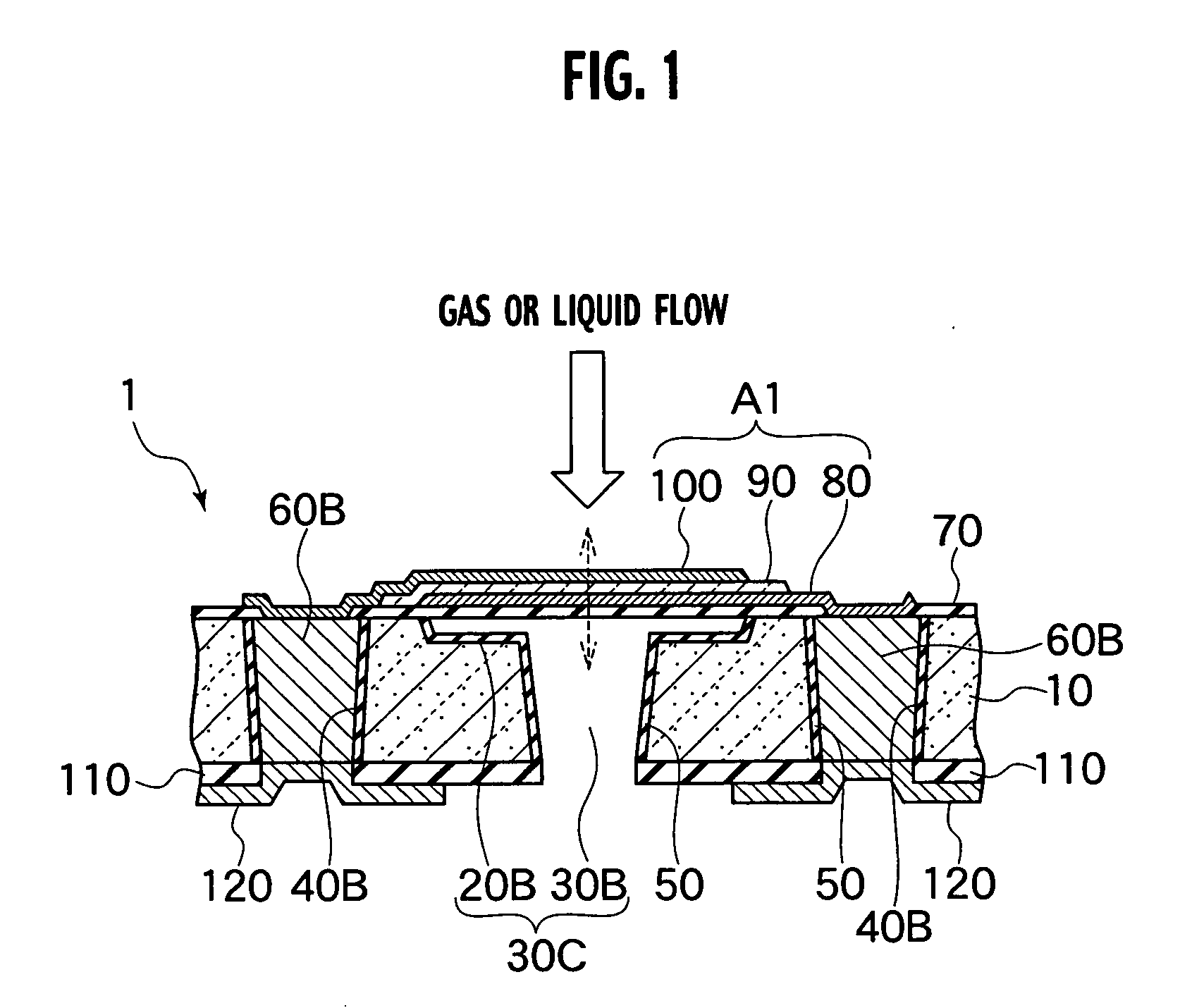

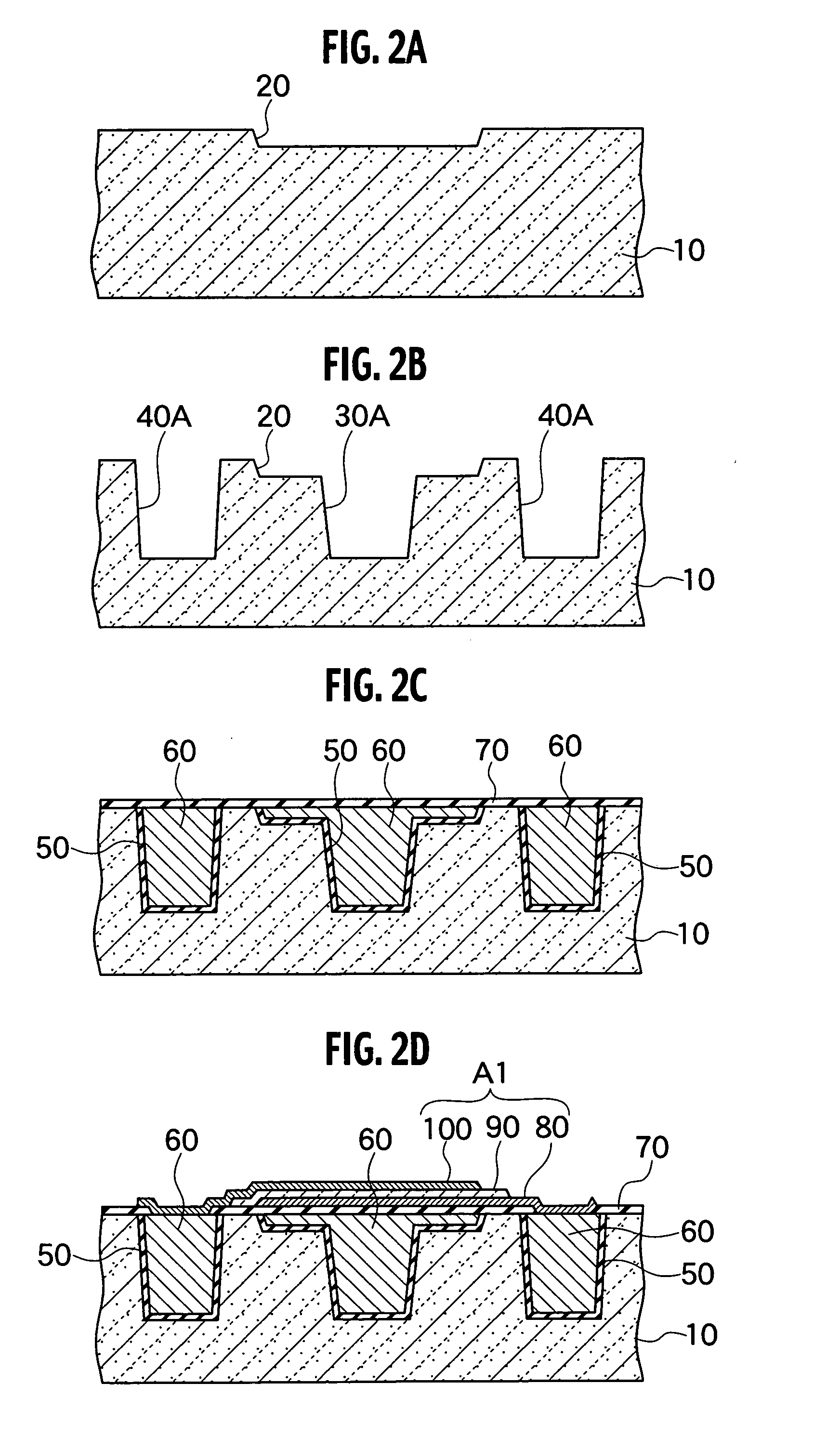

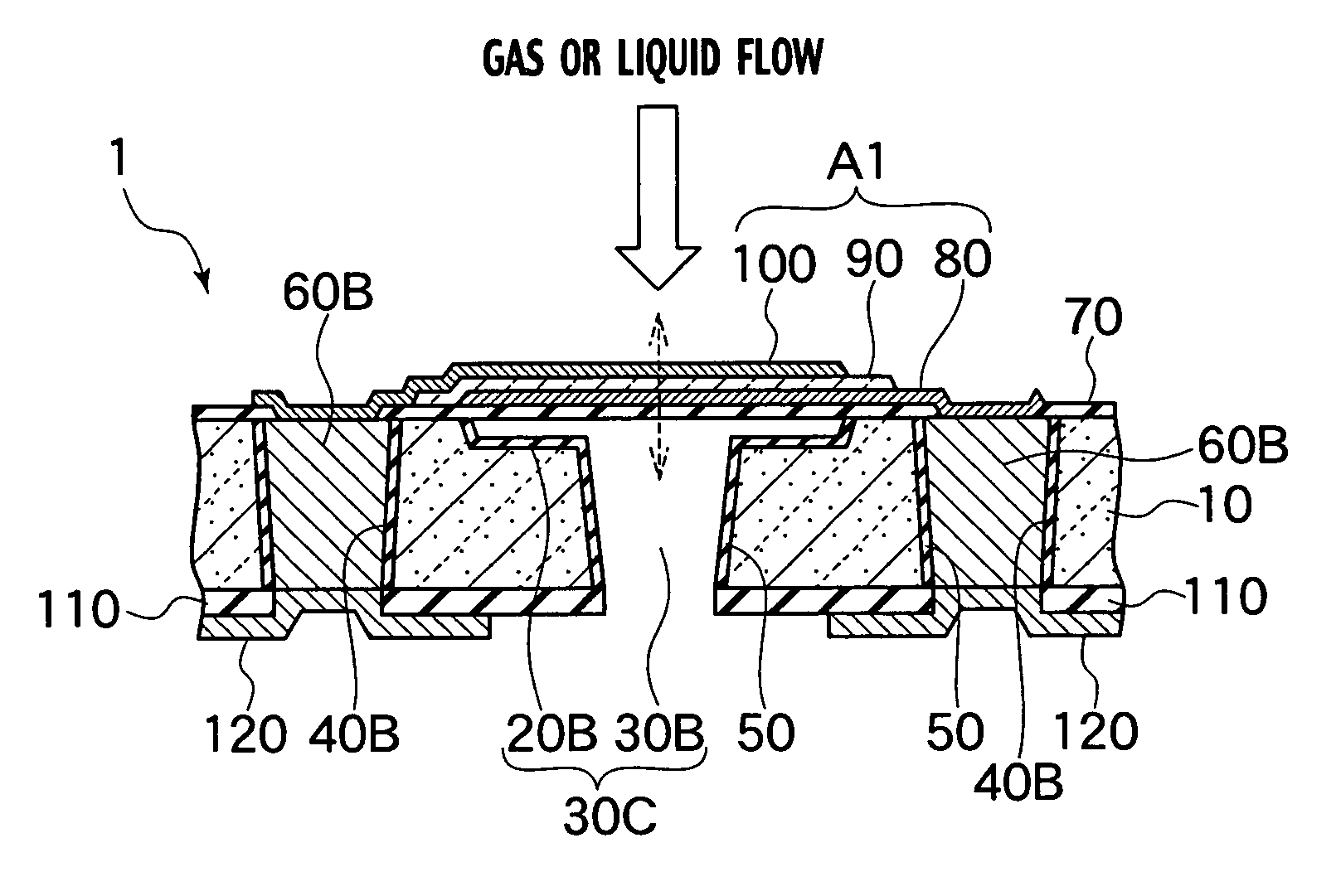

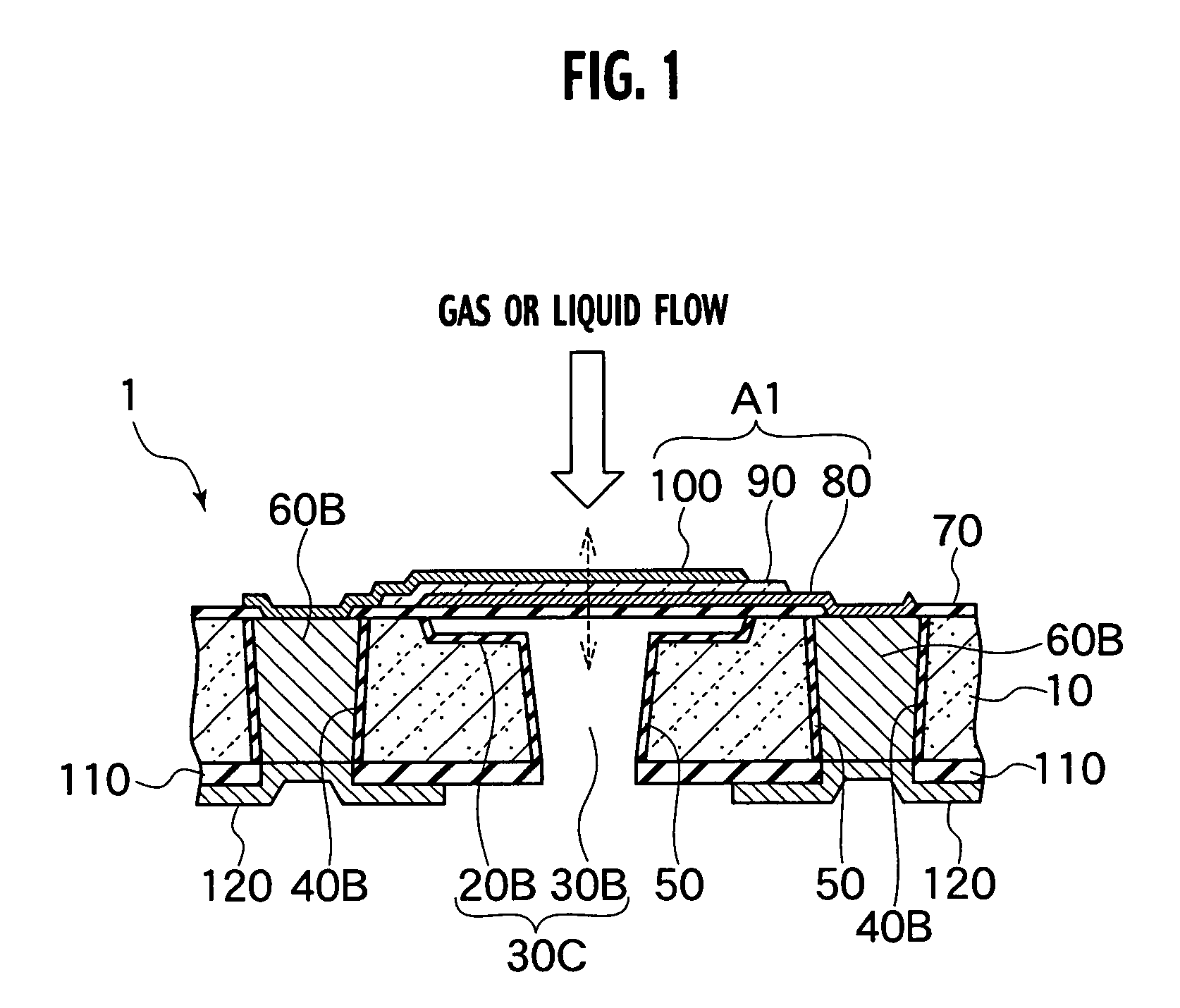

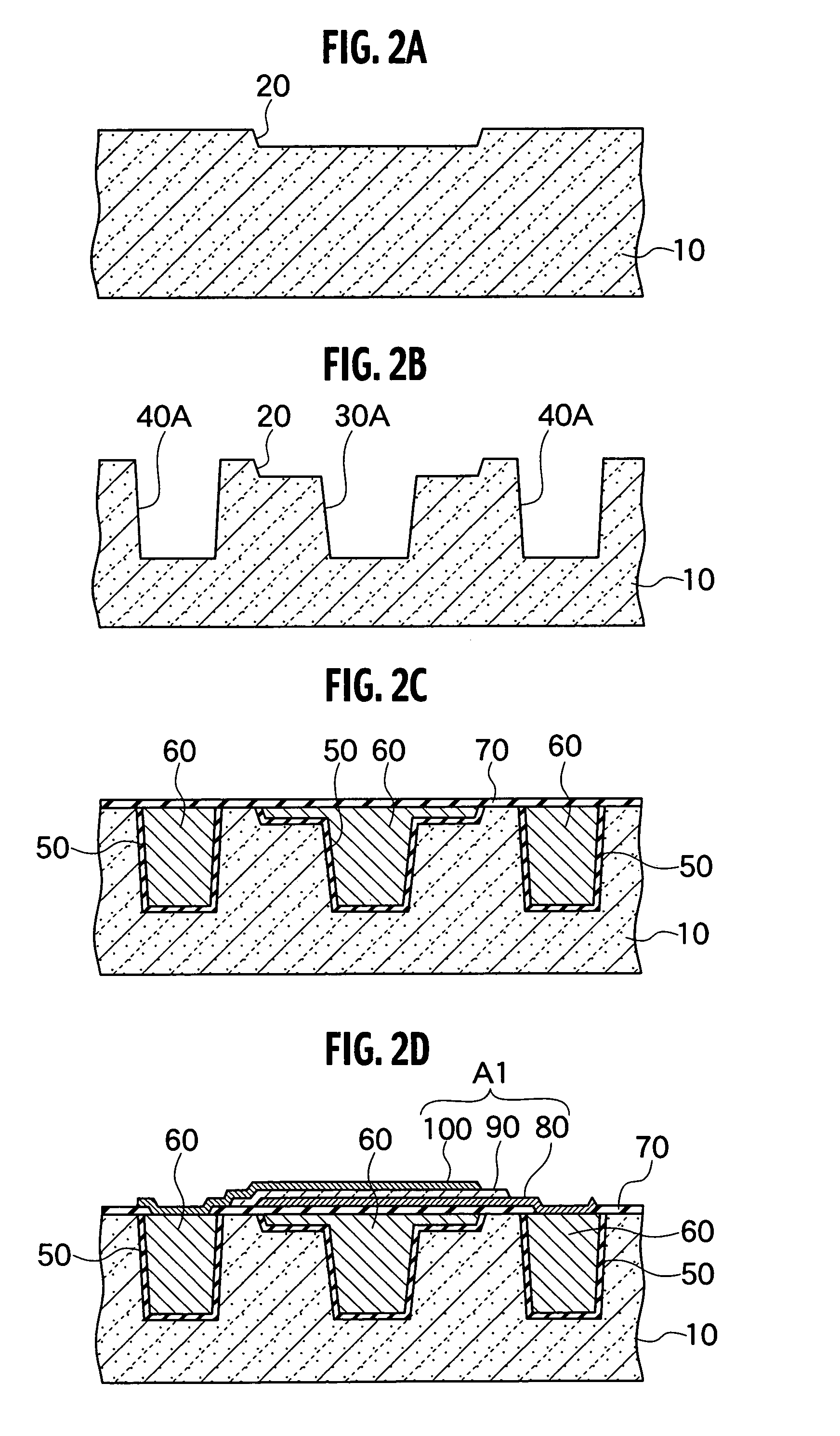

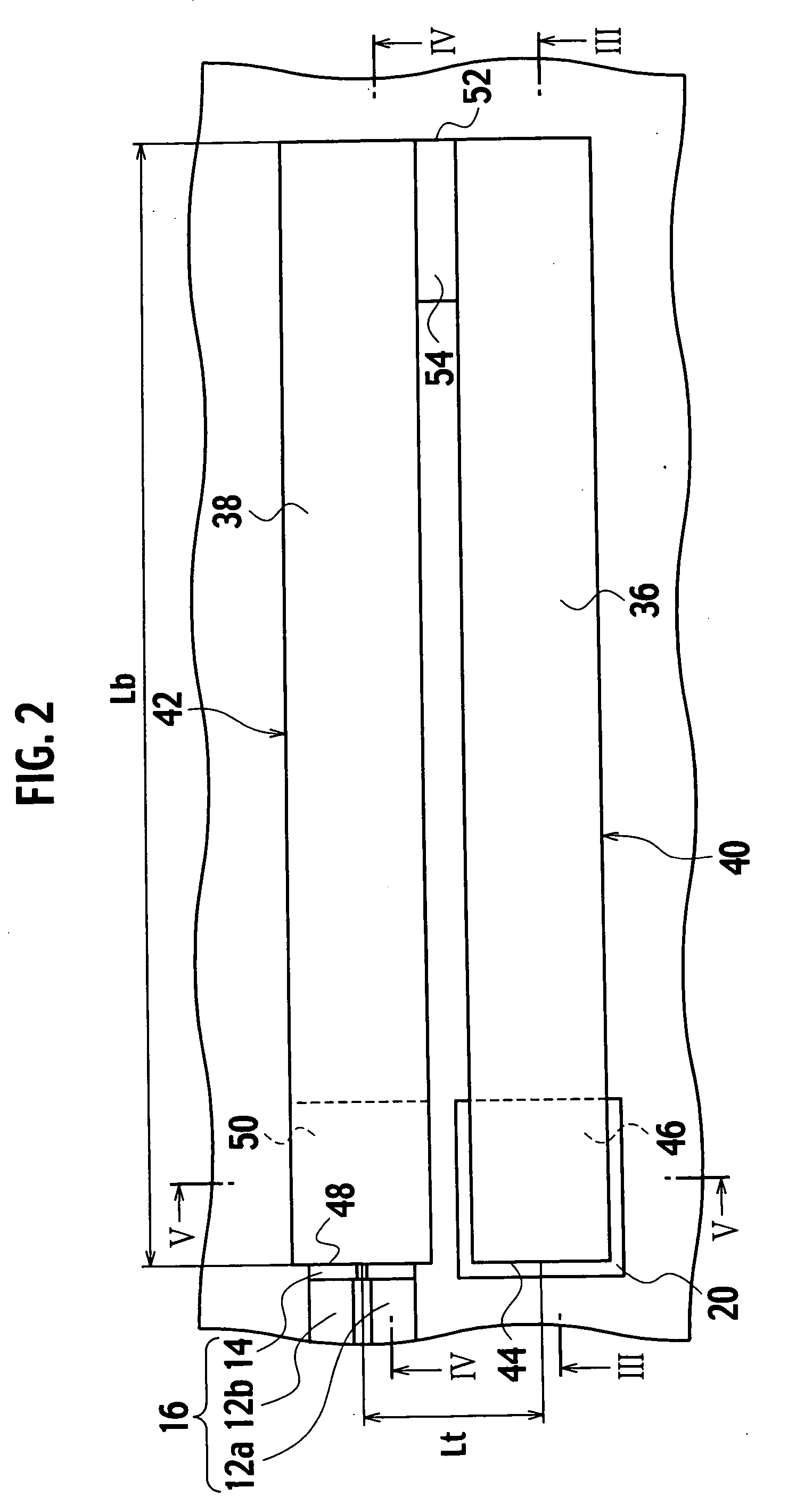

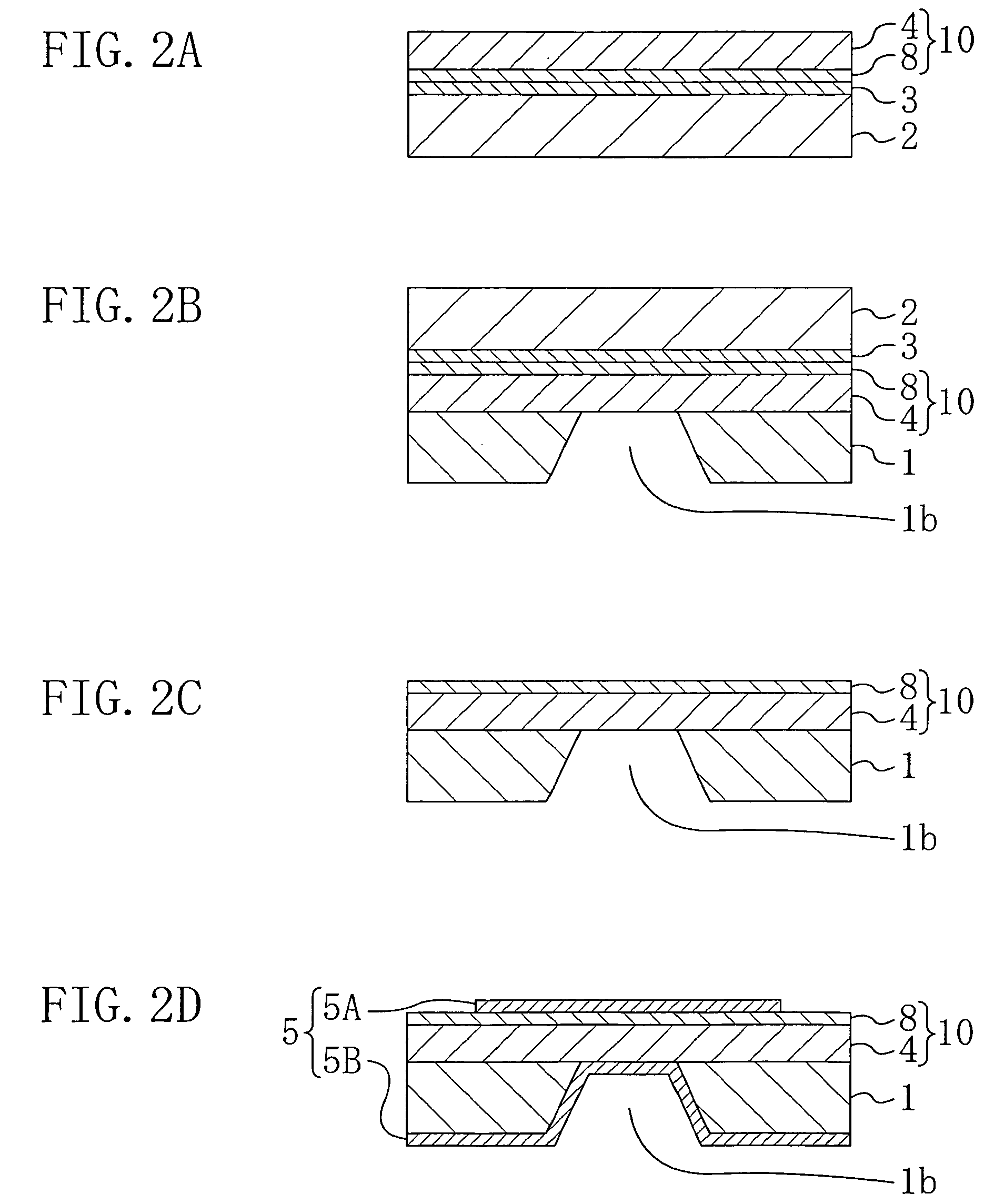

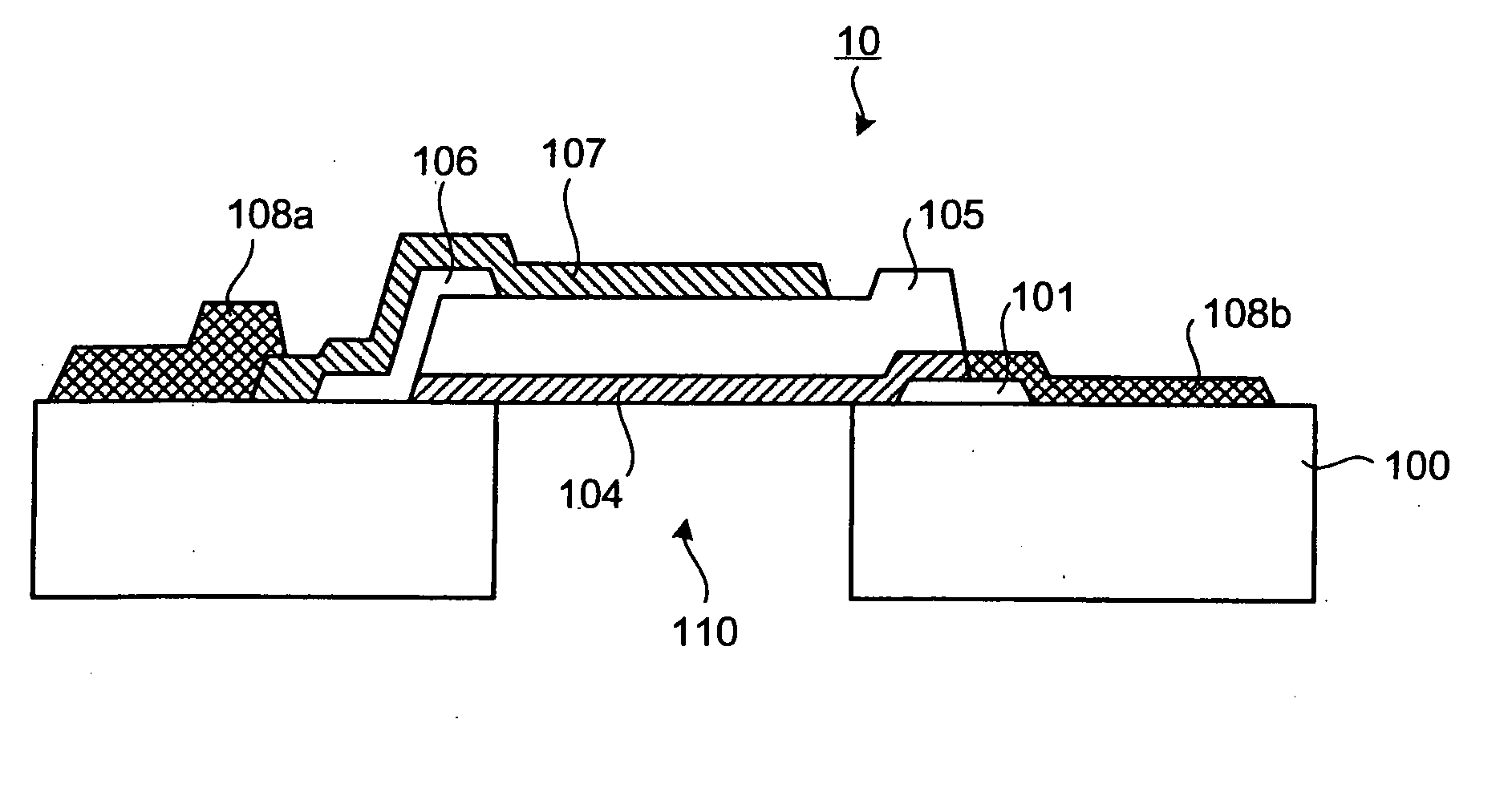

Piezoelectric-driven MEMS device and method for manufacturing the same

InactiveUS20050242687A1Fabricated reliably and consistentlyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesThin membraneEngineering

A piezoelectric-driven MEMS device can be fabricated reliably and consistently. The piezoelectric-driven MEMS device includes: a movable flat beam having a piezoelectric film disposed above a substrate with a recessed portion such that the piezoelectric film is bridged over the recessed portion, piezoelectric drive mechanisms disposed at both ends of the piezoelectric film and configured to drive the piezoelectric film, and a first electrode disposed at the center of the substrate-side of the piezoelectric film, and a second electrode disposed on a flat part of the recessed portion of the substrate and facing the first electrode of the movable flat beam.

Owner:KK TOSHIBA

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS20070080611A1Improve featuresHigh crystallinityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

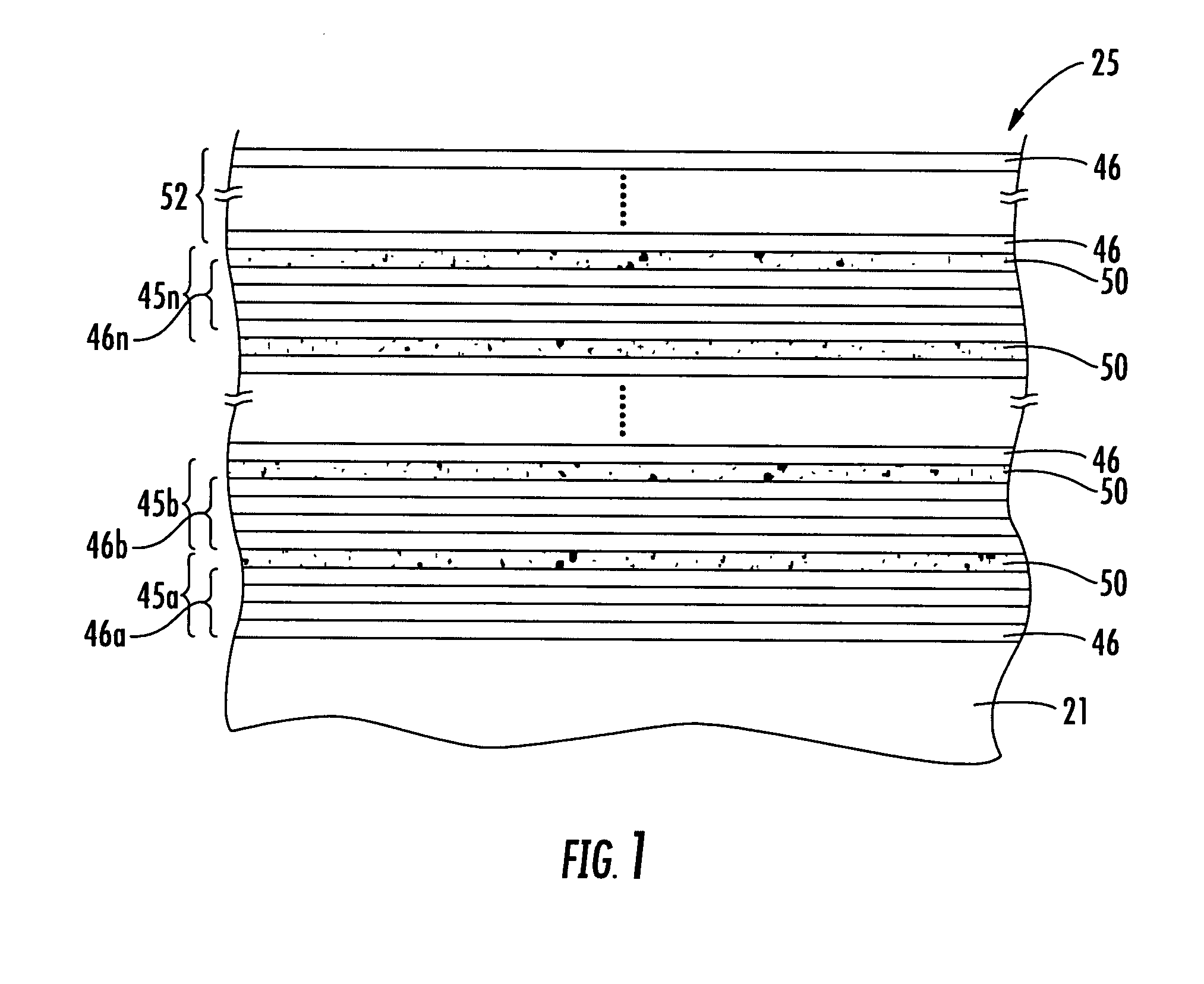

Method for making an electronic device including a poled superlattice having a net electrical dipole moment

A method for making an electronic device may include forming a poled superlattice comprising a plurality of stacked groups of layers and having a net electrical dipole moment. Each group of layers of the poled superlattice may include a plurality of stacked semiconductor monolayers defining a base semiconductor portion and at least one non-semiconductor monolayer thereon. The at least one non-semiconductor monolayer may be constrained within a crystal lattice of adjacent base semiconductor portions, and at least some semiconductor atoms from opposing base semiconductor portions may be chemically bound together through the at least one non-semiconductor monolayer therebetween. The method may further include coupling at least one electrode to the poled superlattice.

Owner:ATOMERA INC

Electromechanical actuators

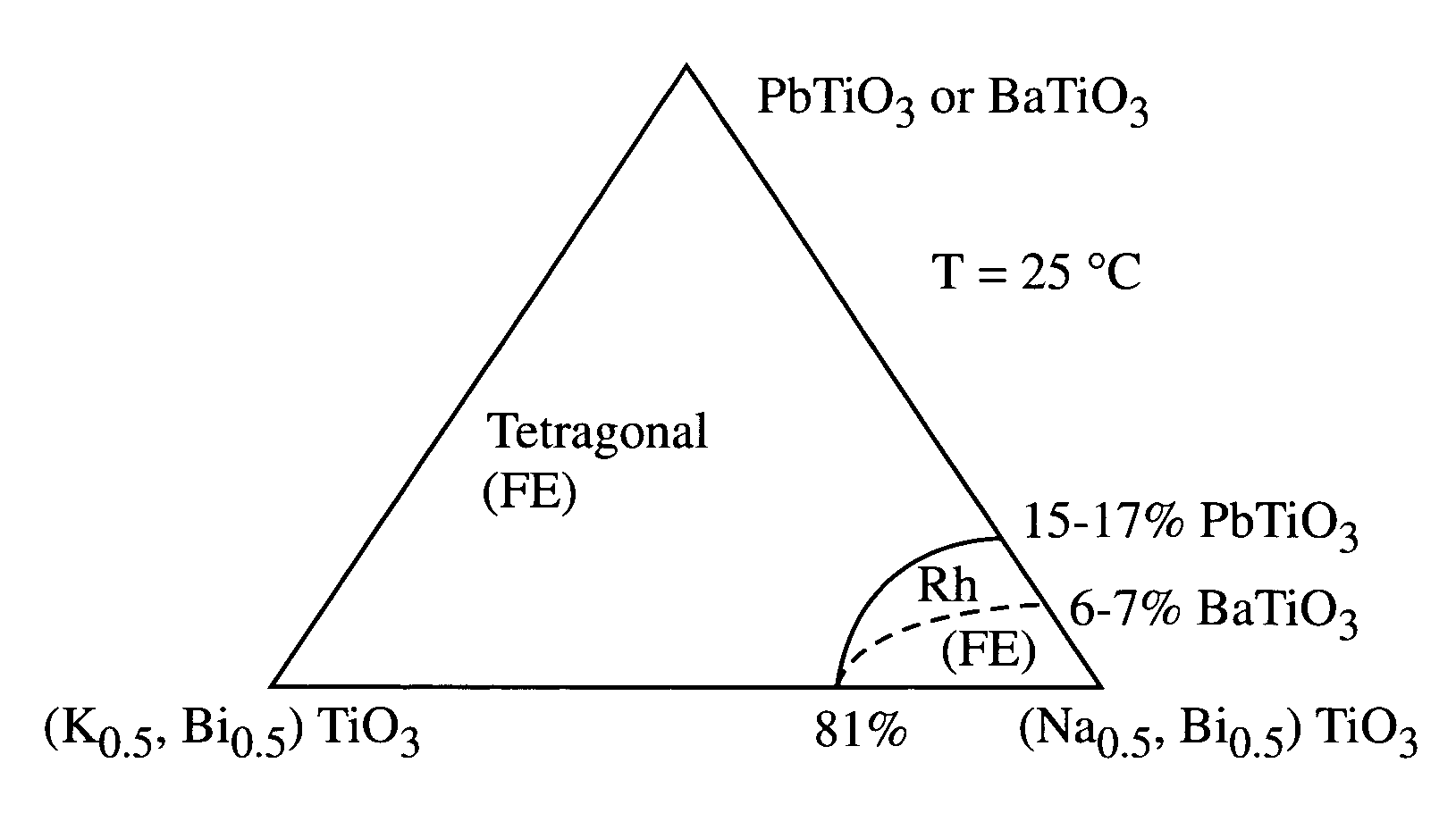

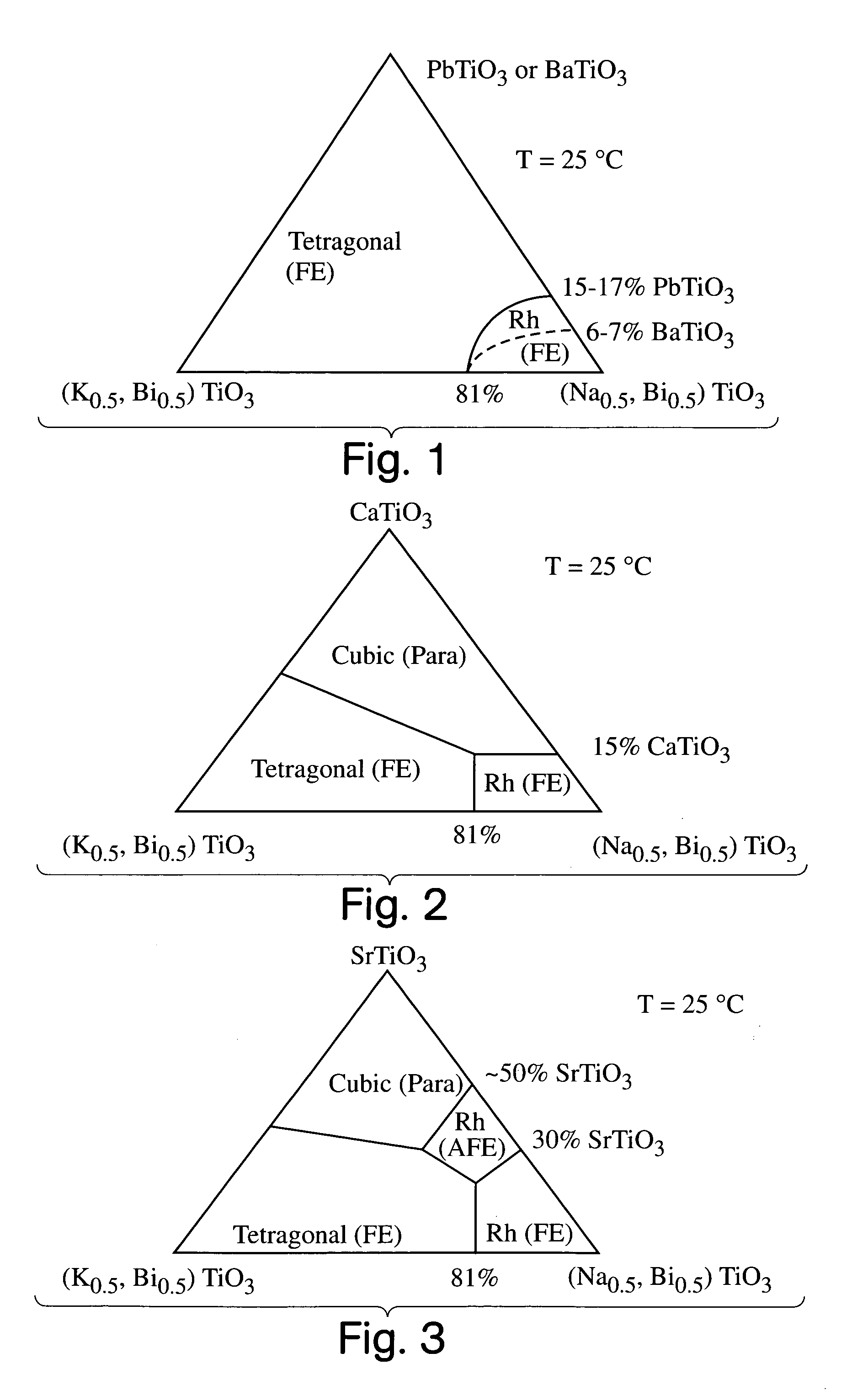

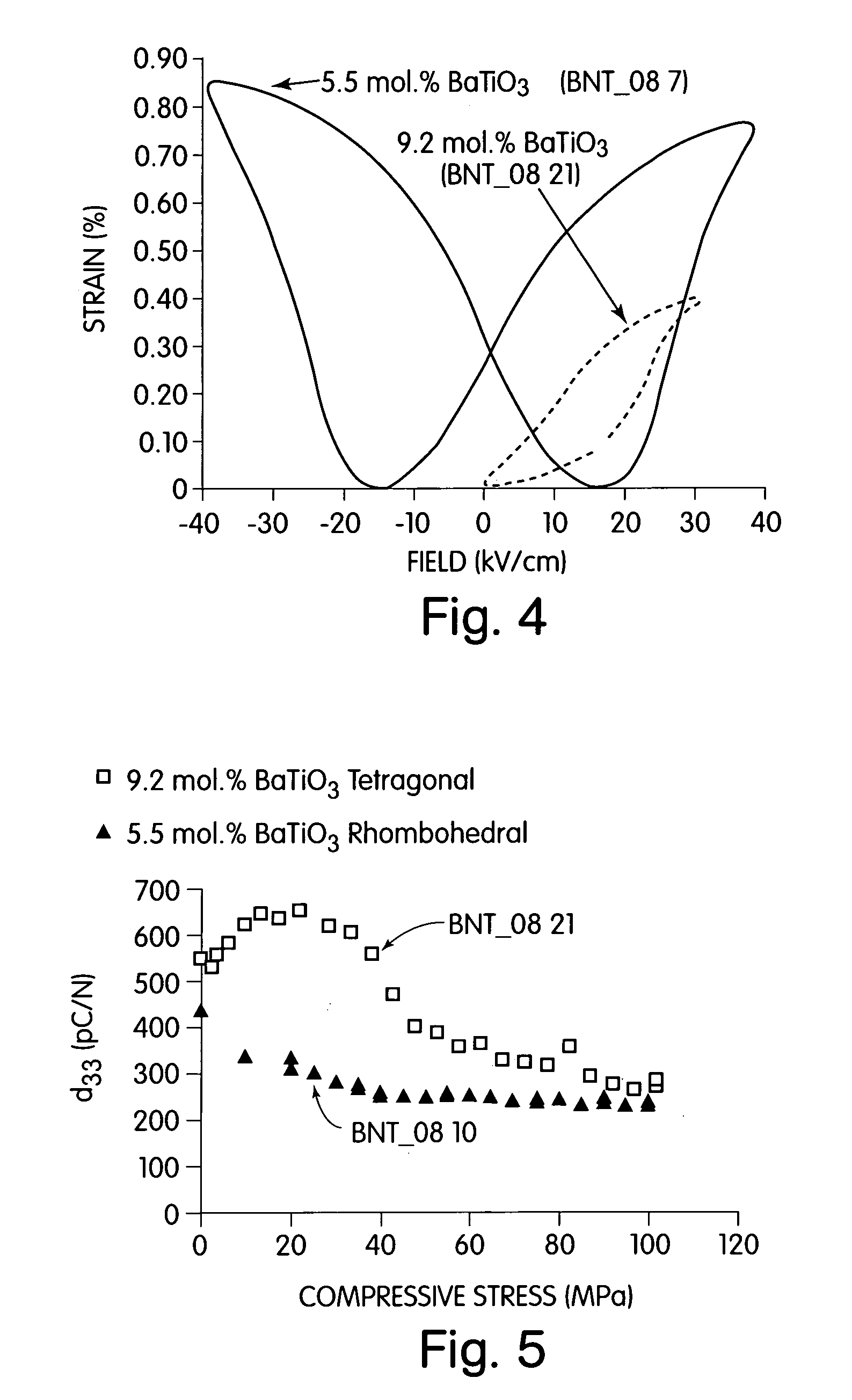

InactiveUS7090785B2Increased doping of BaTiOImprove propertiesAlkaline earth titanatesLighting support devicesElectroactive materialsMaterials science

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

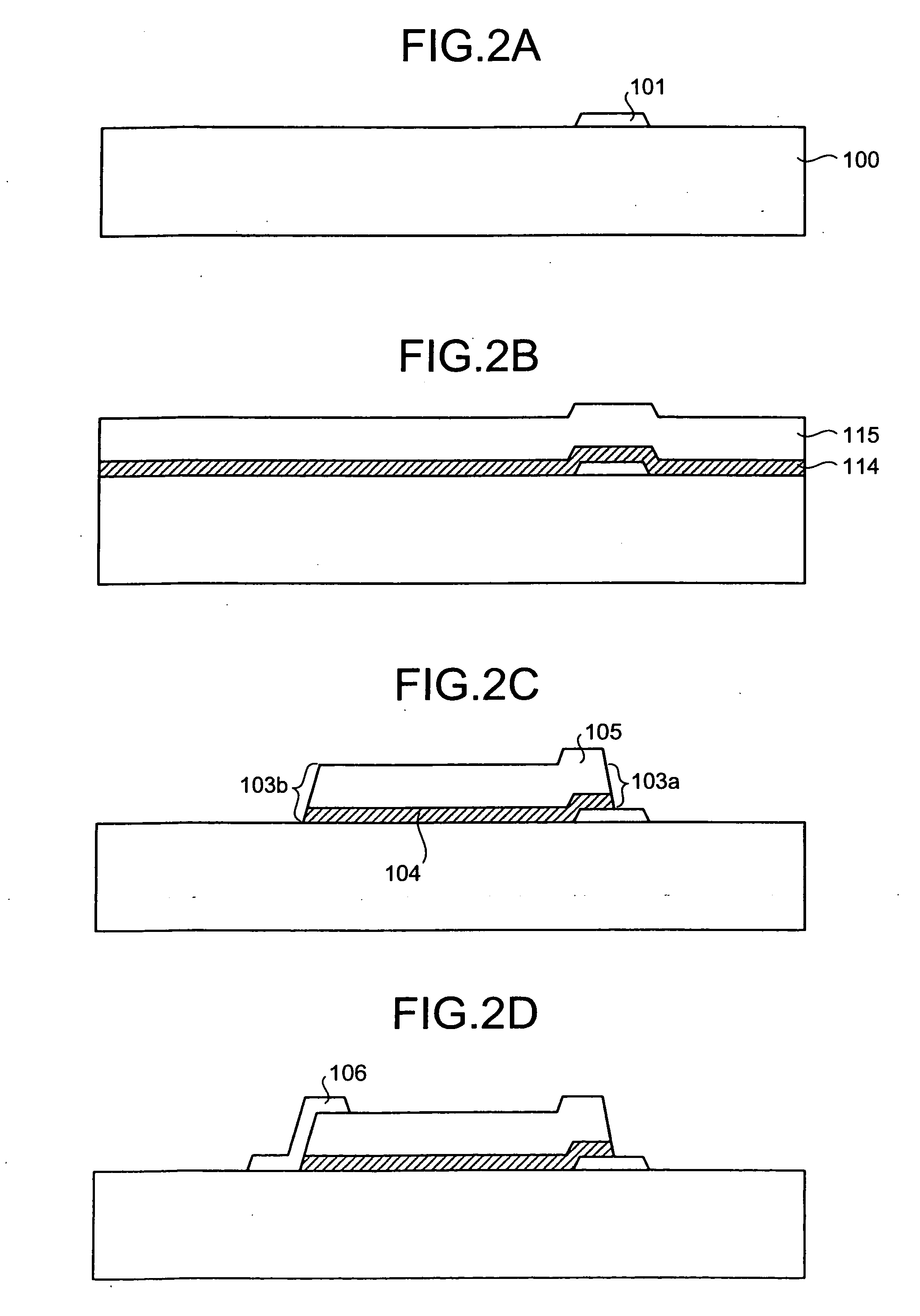

Method for manufacturing resonator

InactiveUS20050255234A1Uniform crystallinityUniform thicknessPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksResonatorFilm making

A method for manufacturing a resonator of the present invention includes the steps of (a) forming a resonator film including a piezoelectric film made of piezoelectric material and (b) preparing a resonator substrate for supporting the resonator film. The method further comprises the step of (c) bonding the resonator film formed in the step (a) and the resonator substrate prepared in the step (b).

Owner:PANASONIC CORP

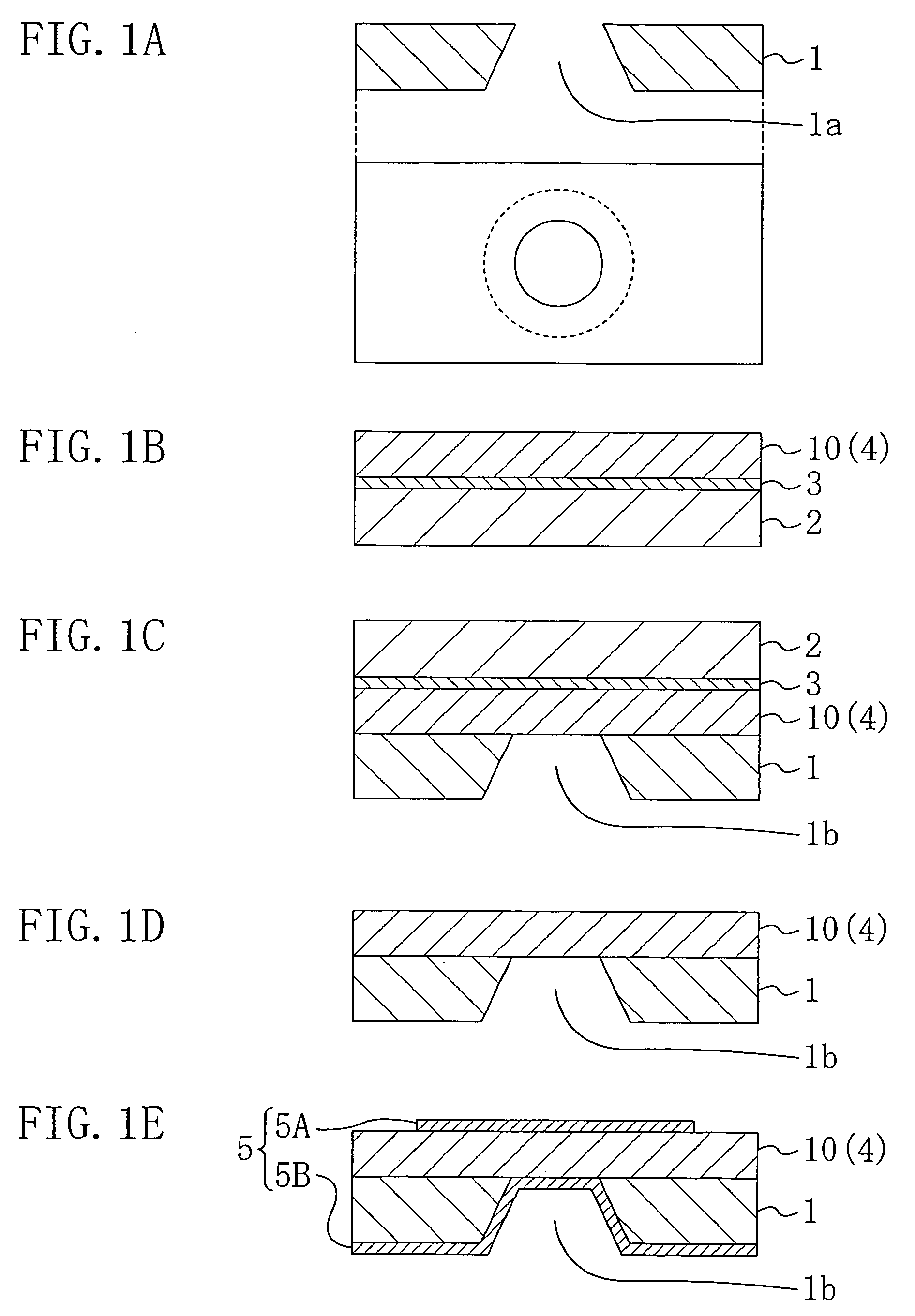

Thin film piezoelectric resonator and manufacturing process thereof

ActiveUS20050248232A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceOptoelectronics

a thin film piezoelectric resonator includes a substrate having a cavity, and a resonance portion located on the substrate and right above the cavity. The resonance portion includes a lower electrode layer located at a side of the cavity, an upper electrode layer opposite to the lower electrode layer, and a piezoelectric thin film located between the upper electrode layer and the lower electrode layer. A side of the piezoelectric thin film and a side of the lower electrode layer are located in a common plane.

Owner:KK TOSHIBA

Micromechanical resonator having short support beams

InactiveUS6930569B2Reduce the possibilitySmall sizePiezoelectric/electrostriction/magnetostriction machinesImpedence networksLength waveBeam resonator

The illustrative embodiment of the present invention is a vertical-mode, free-free beam resonator, and micromechanical circuits that include one or more such resonators. In accordance with the illustrative embodiment, the resonator comprises a movable beam that overlies a drive electrode. The movable beam is supported by a plurality of supports, the length of which is substantially less than one-quarter of a wavelength of the resonant frequency of the resonator.

Owner:MICREL

Popular searches

Printing Piezoelectric/electrostrictive devices Semiconductor/solid-state device details Fluid pressure measurement by electric/magnetic elements Solid-state devices Fluid speed measurement Flexible microstructural devices Microstructural device manufacture Semiconductor devices Acceleration measurement in multiple dimensions

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com