Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Pre strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

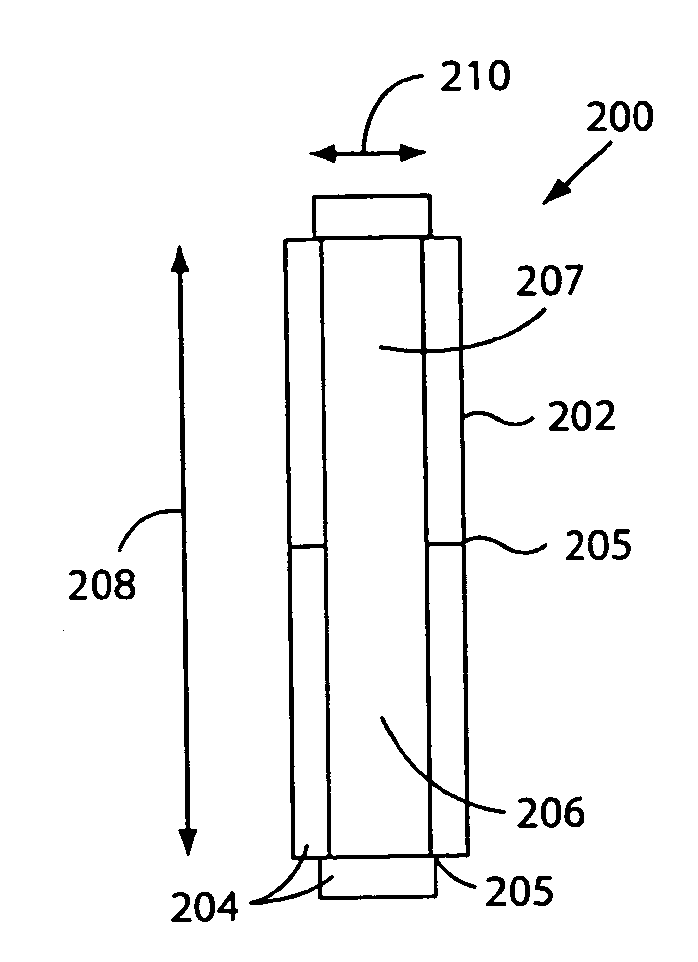

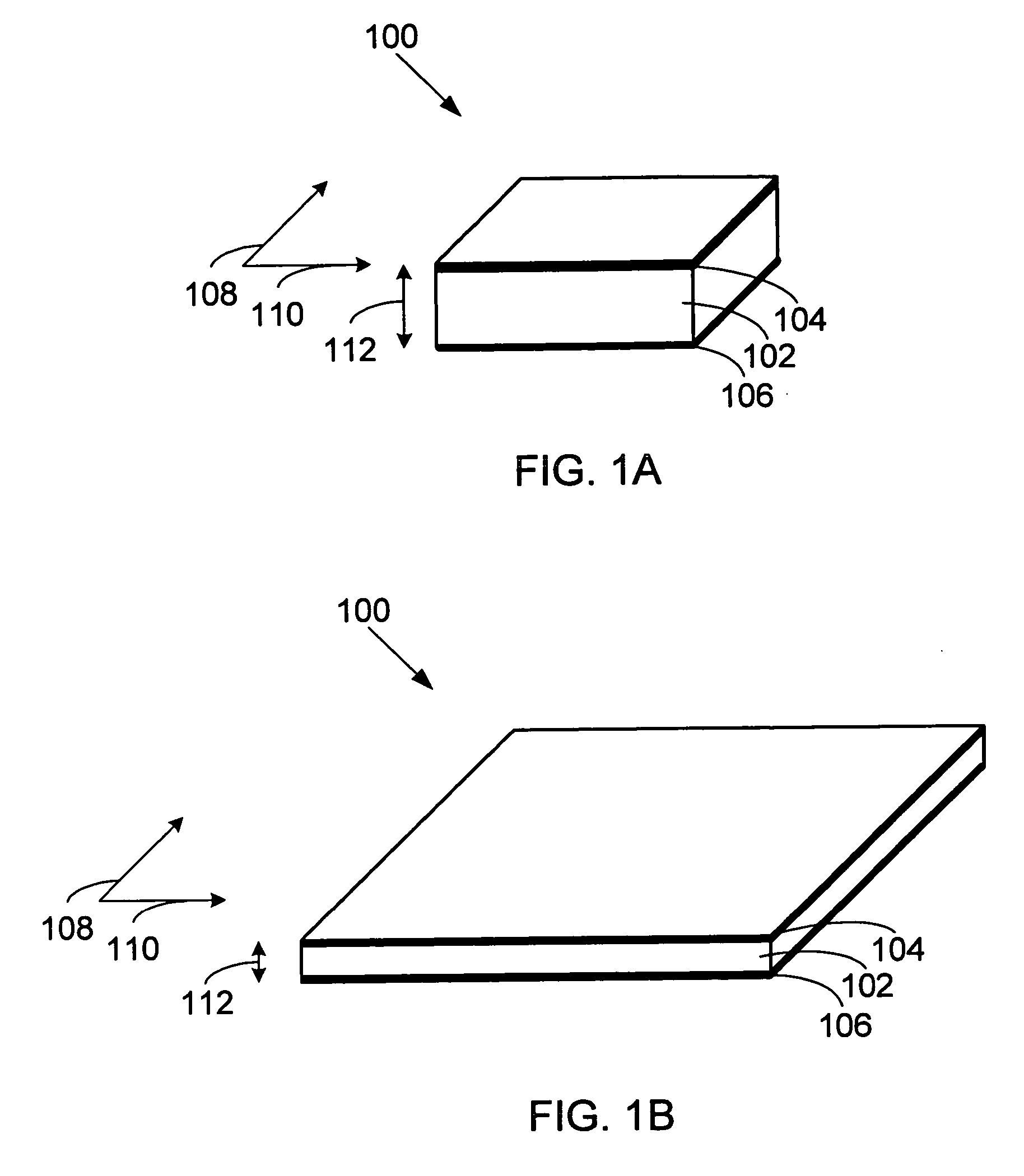

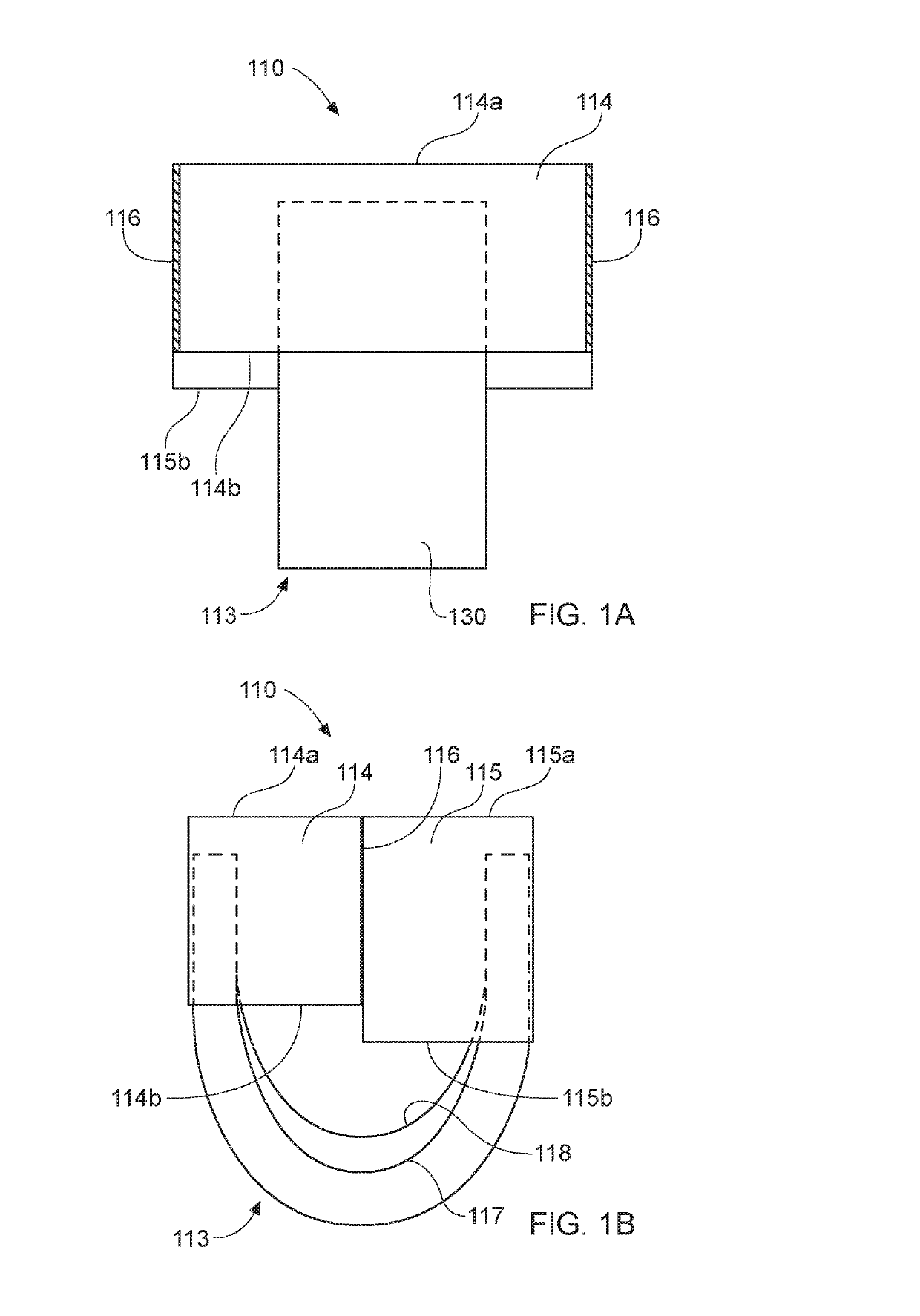

Electroactive polymer generators

InactiveUS7034432B1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

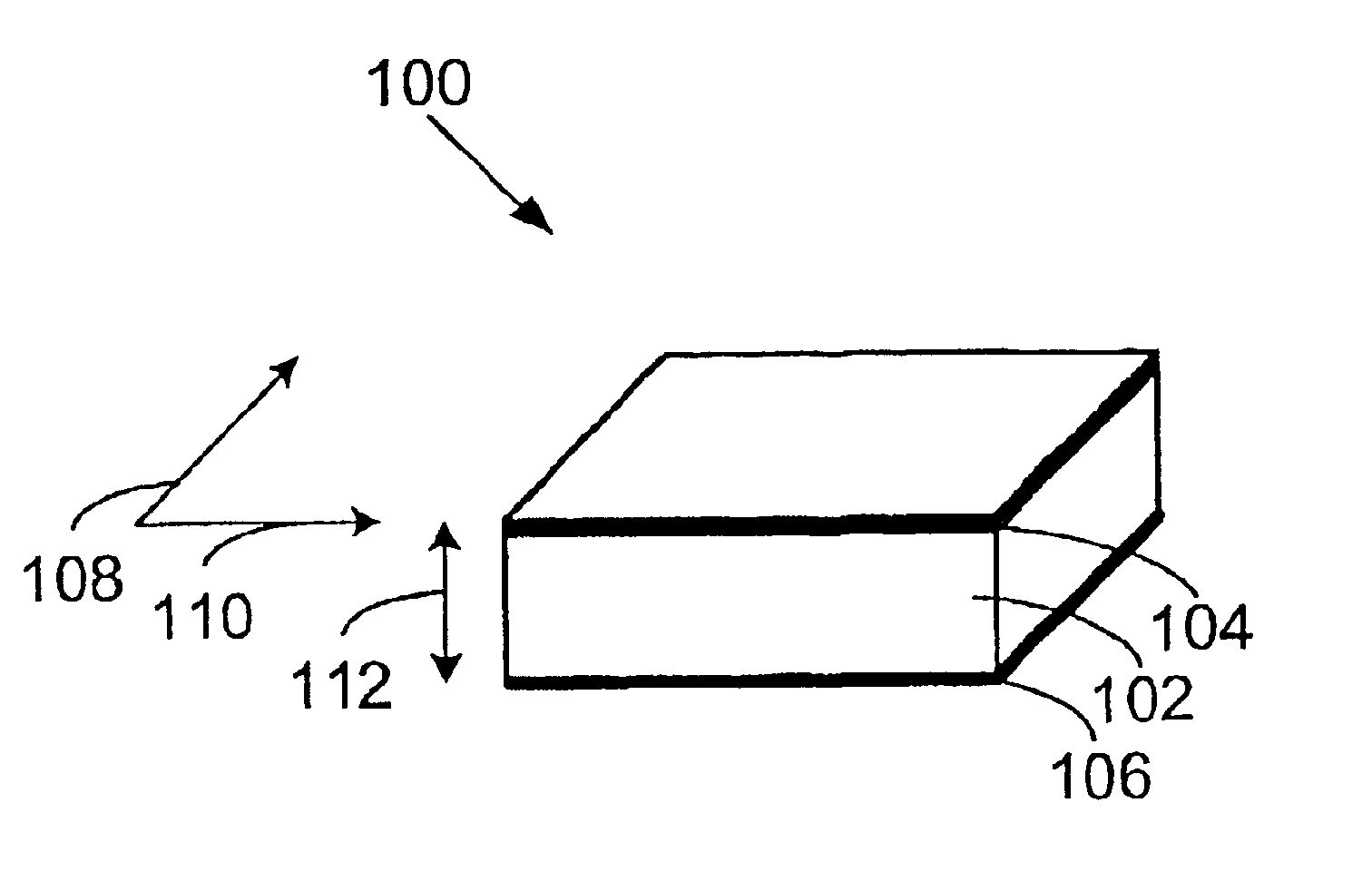

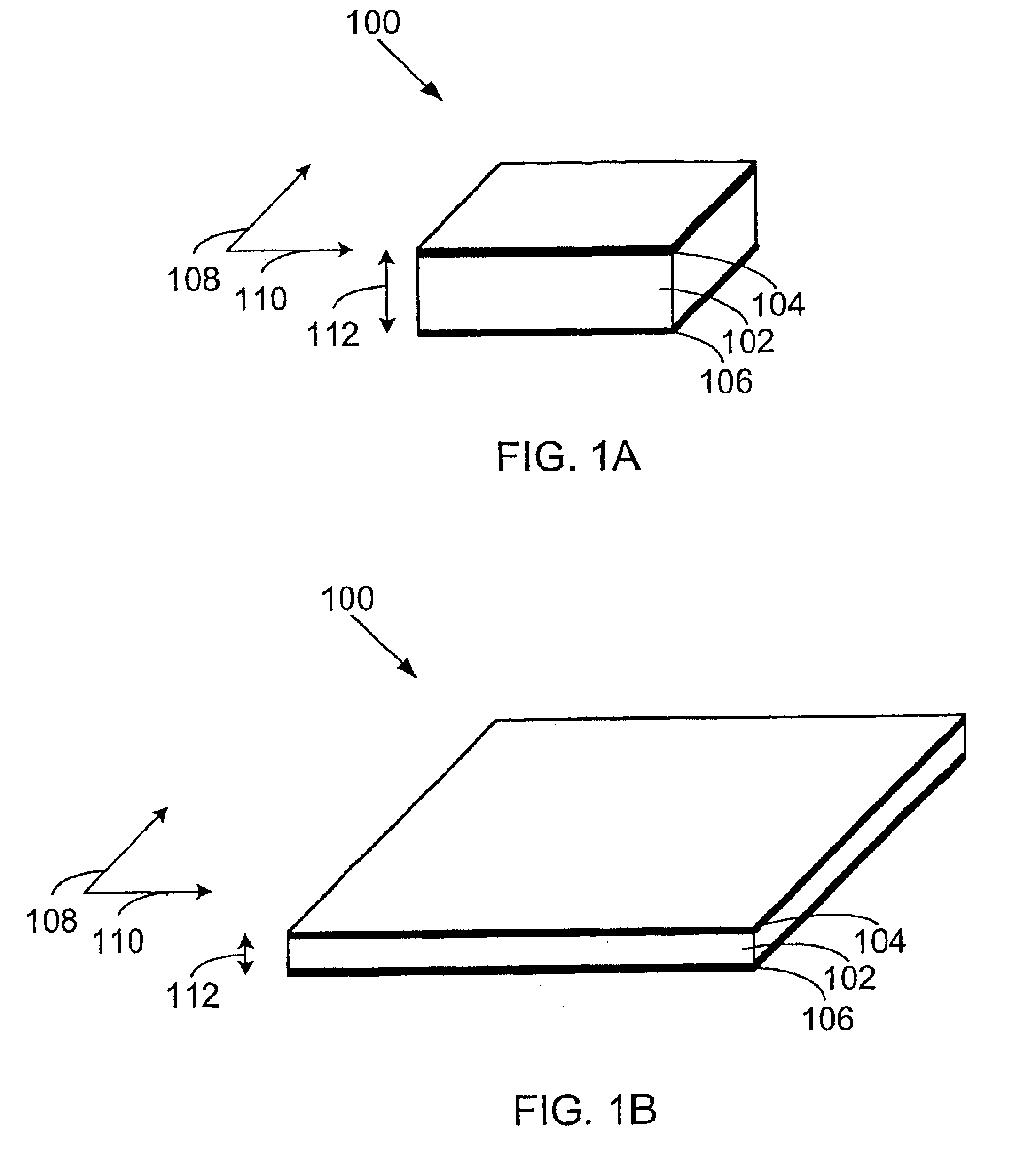

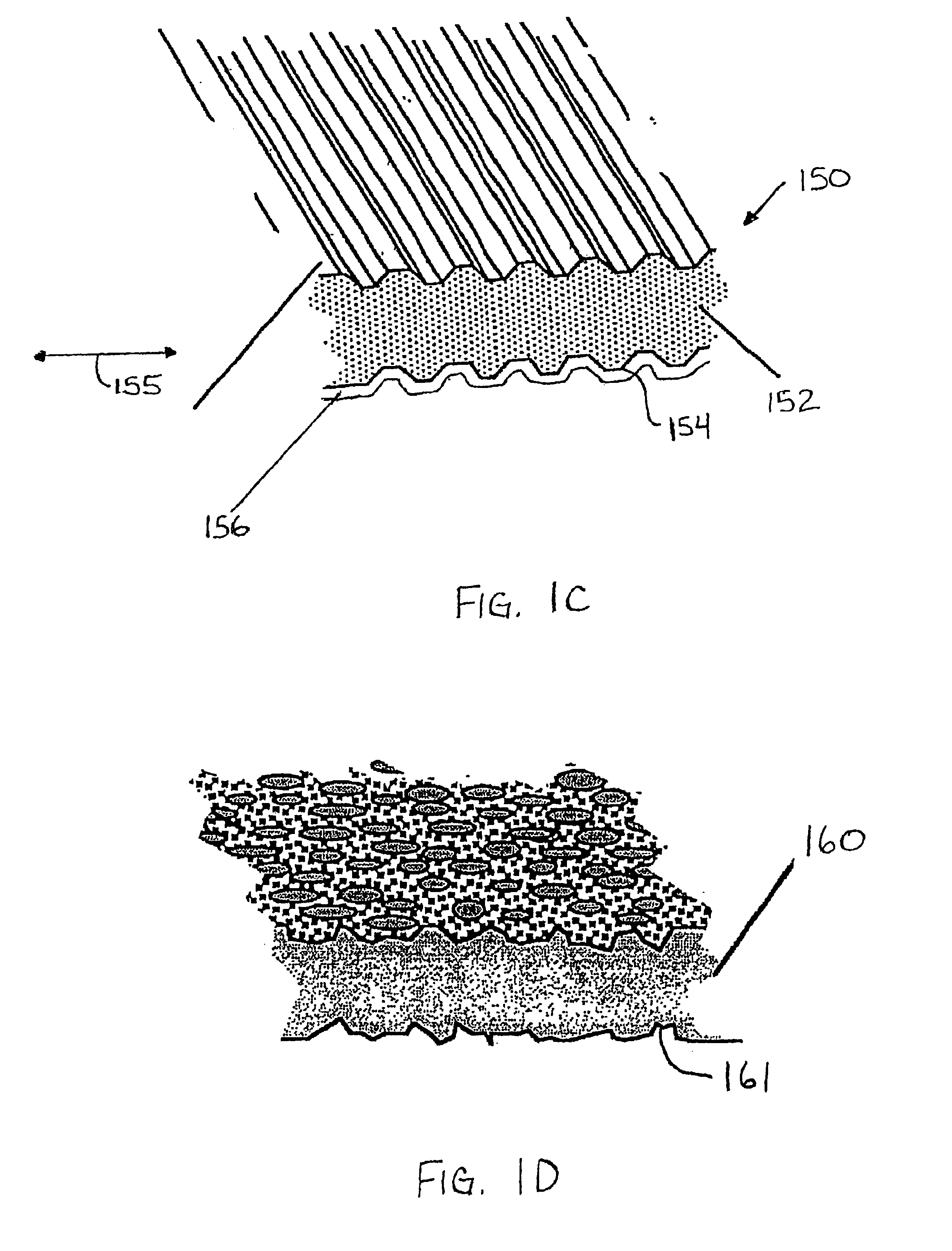

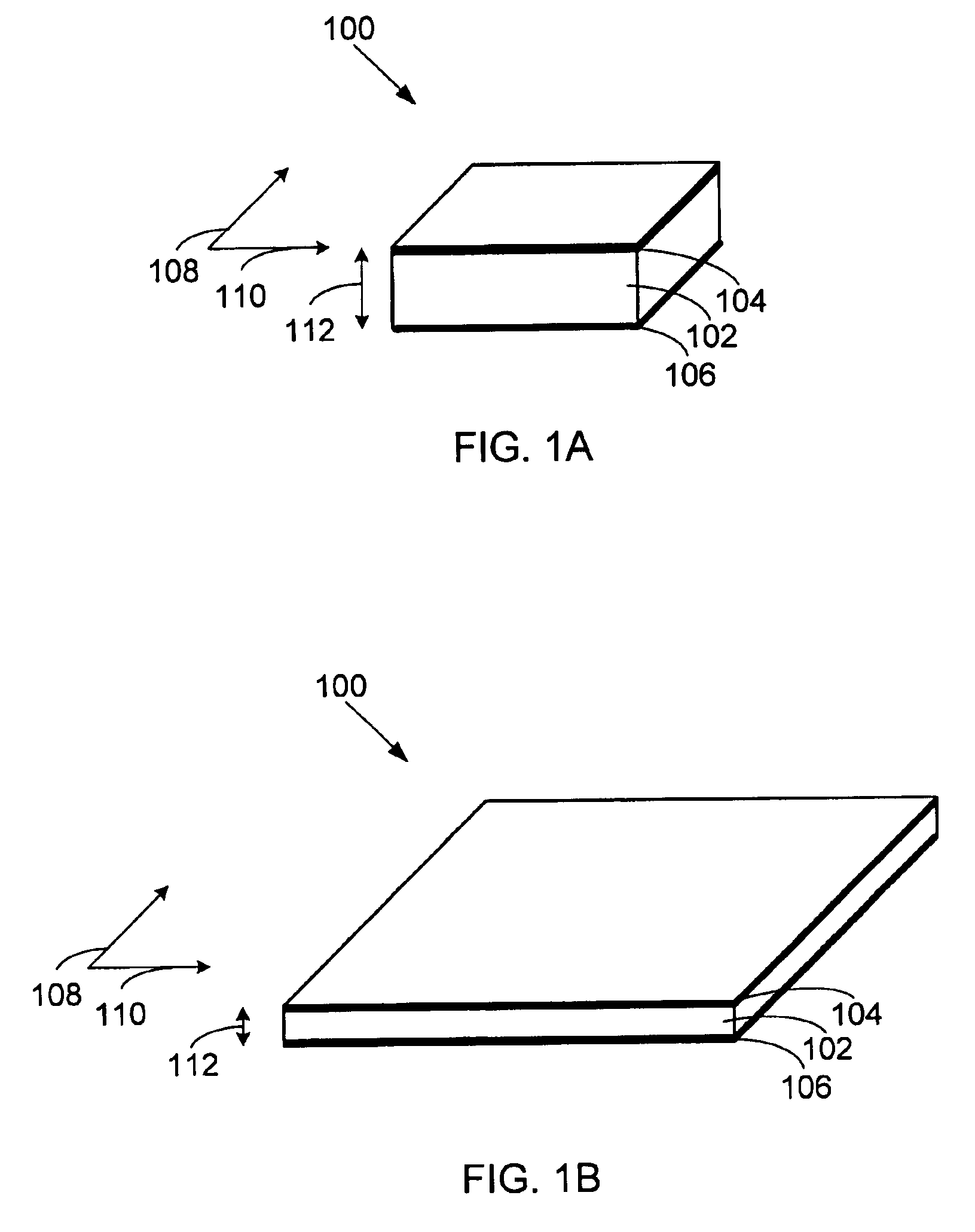

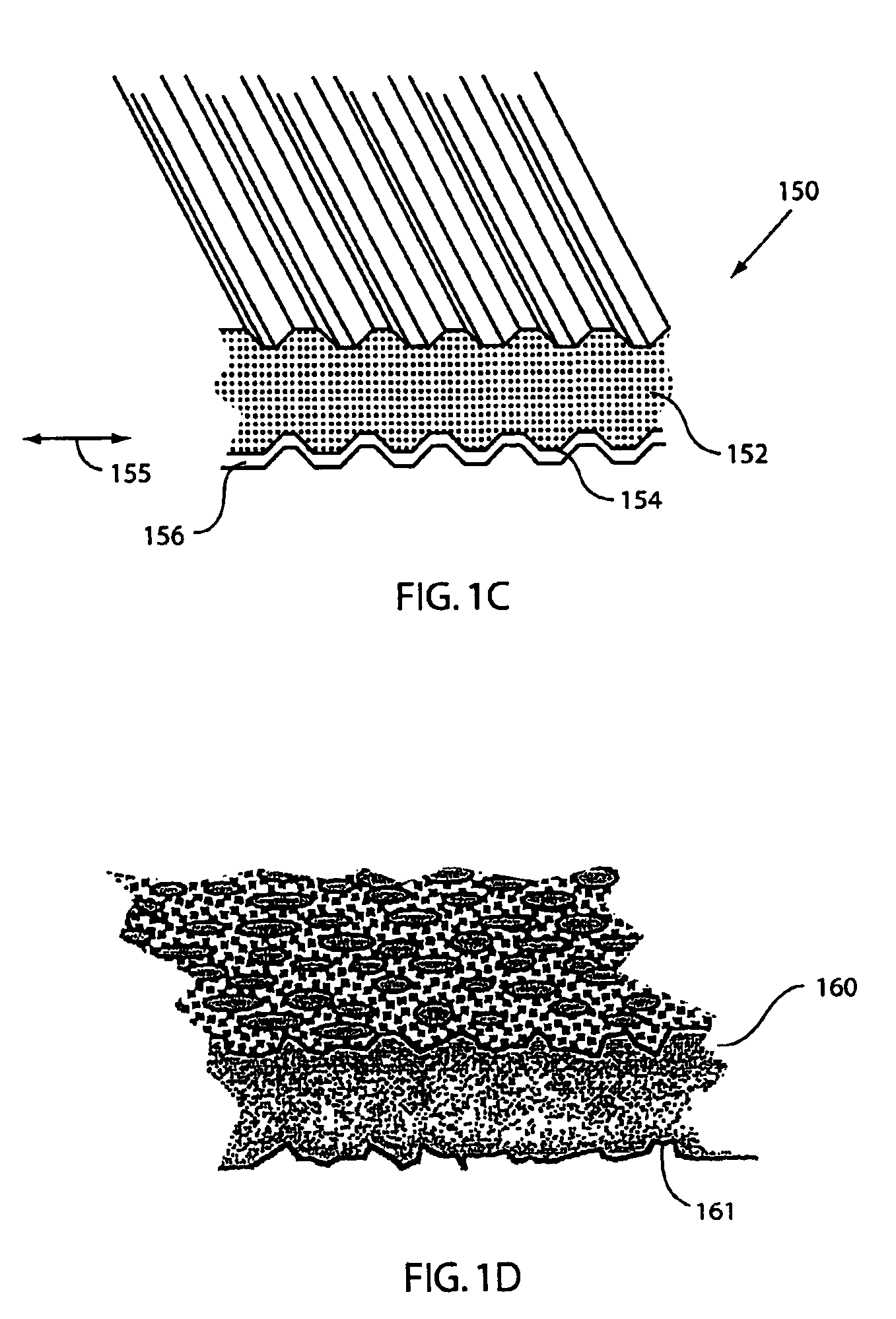

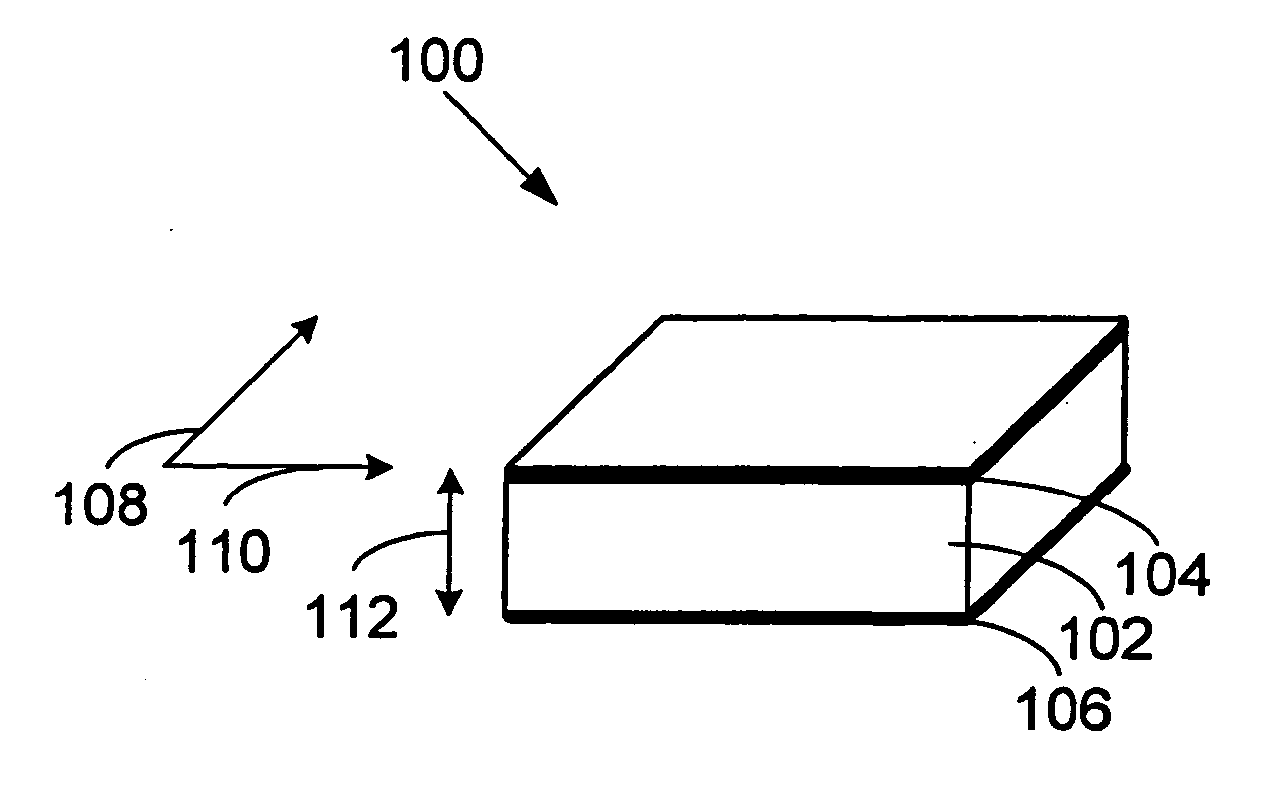

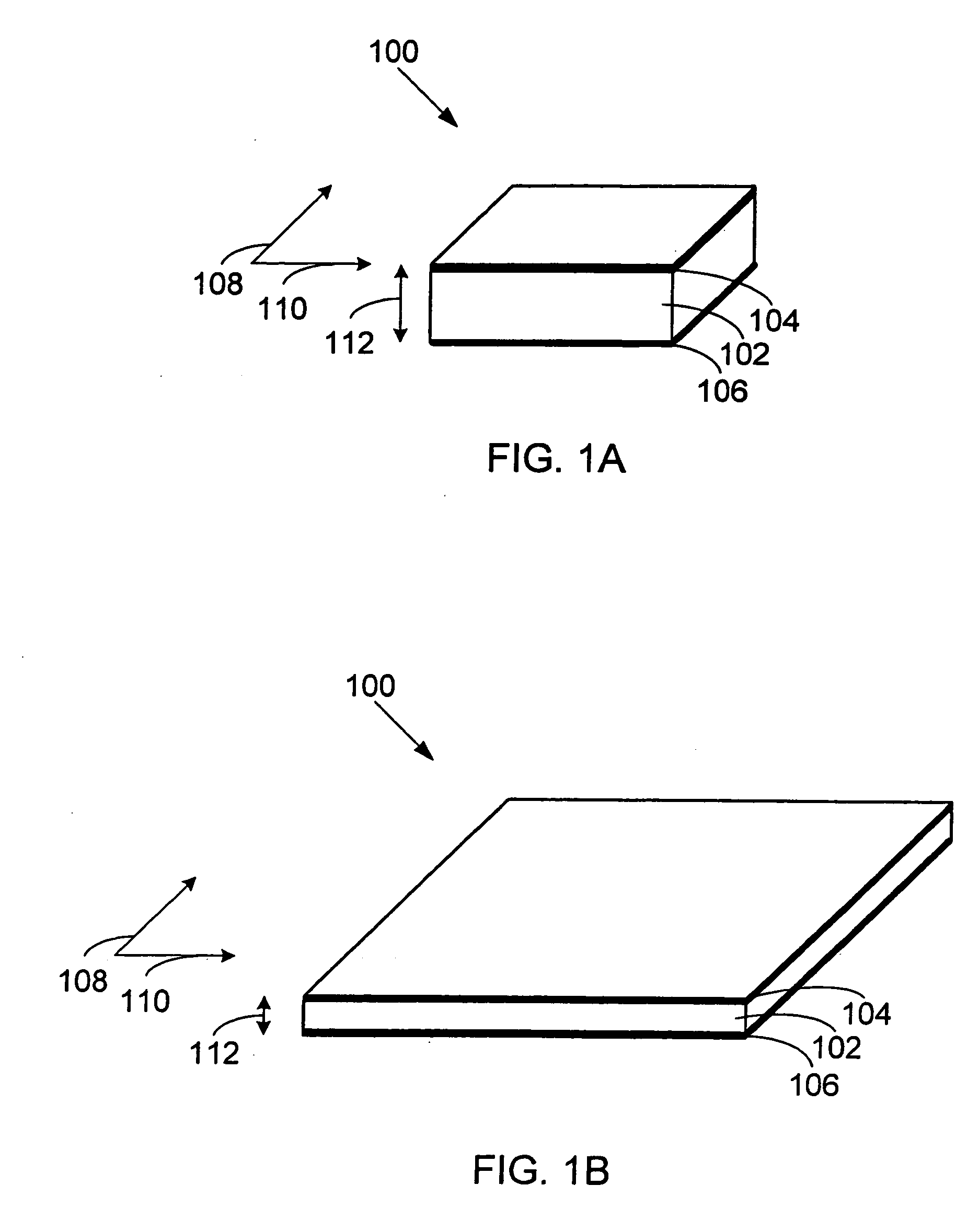

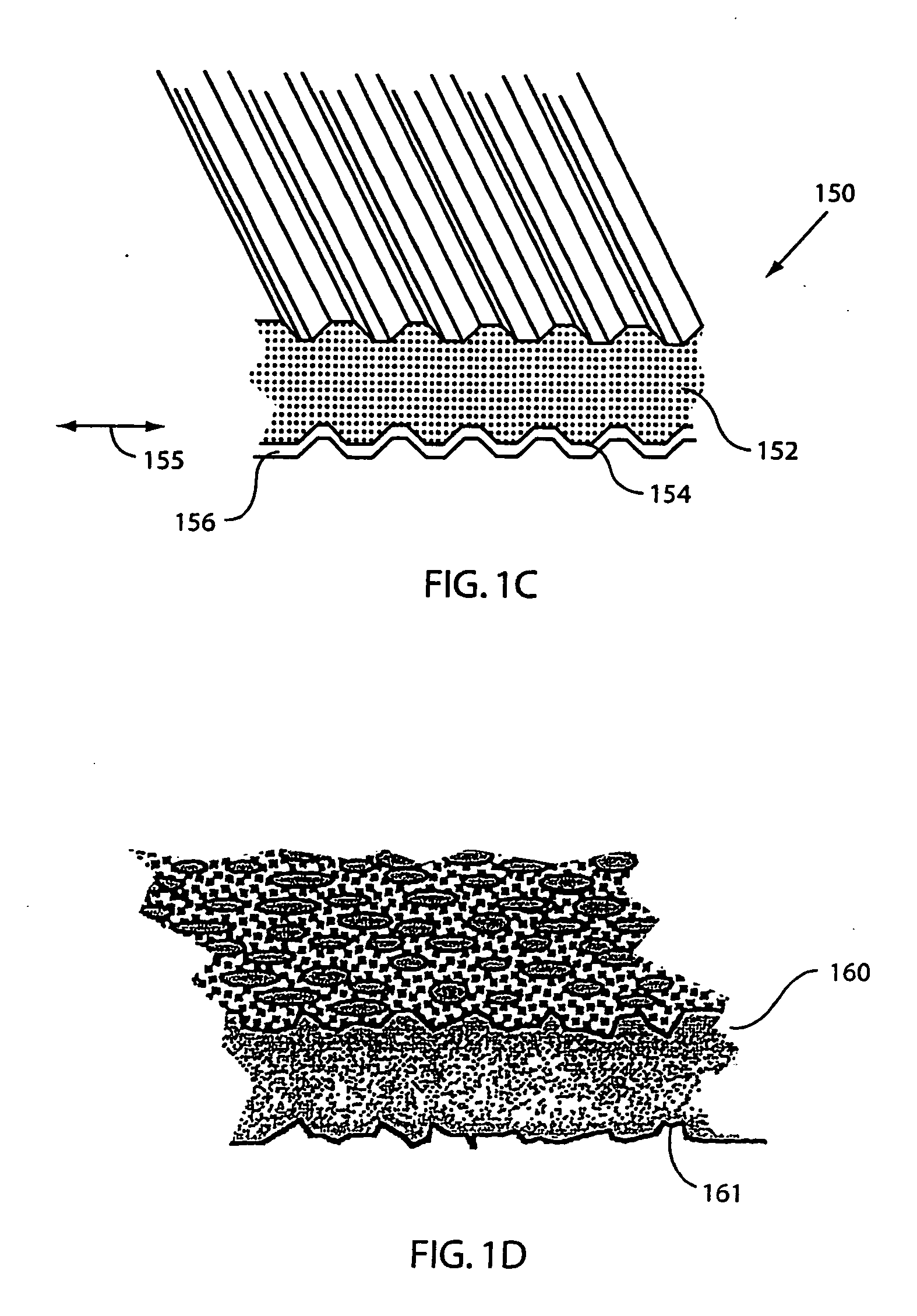

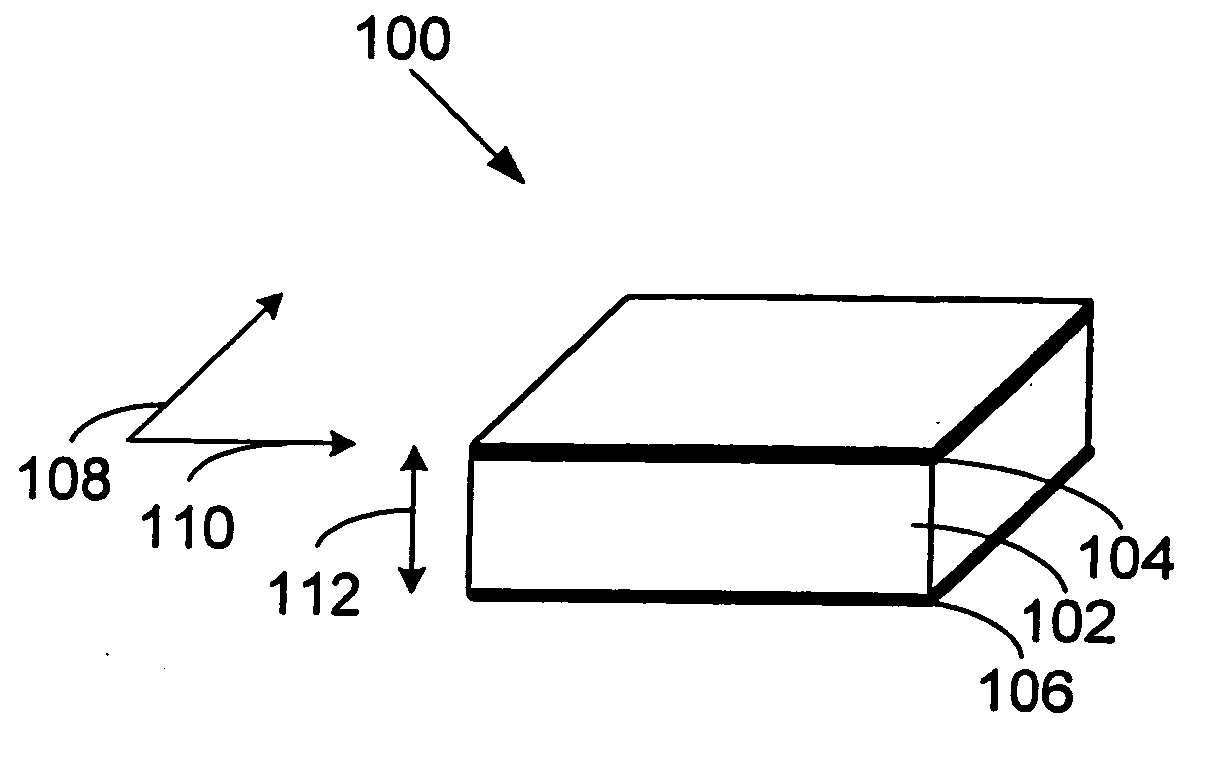

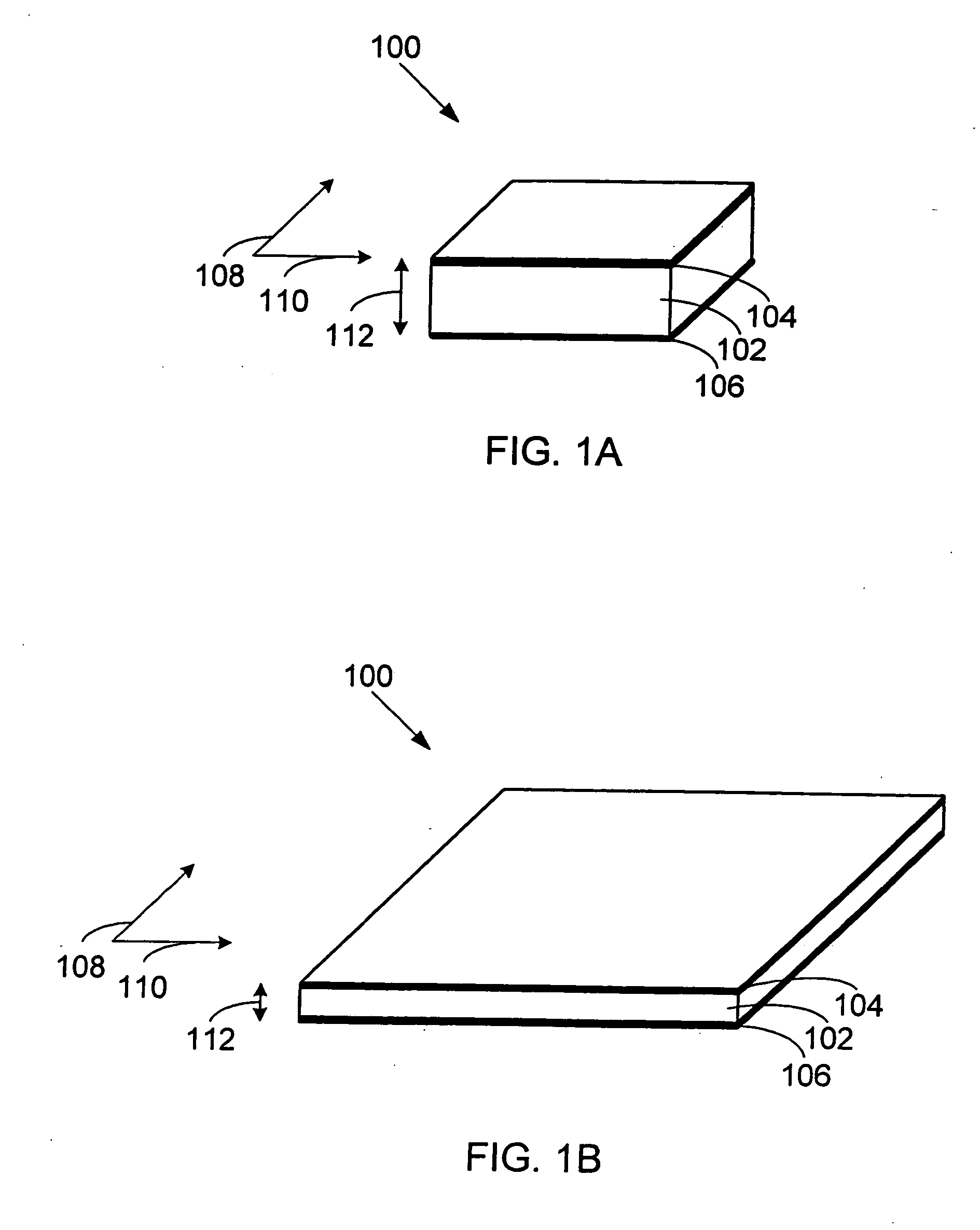

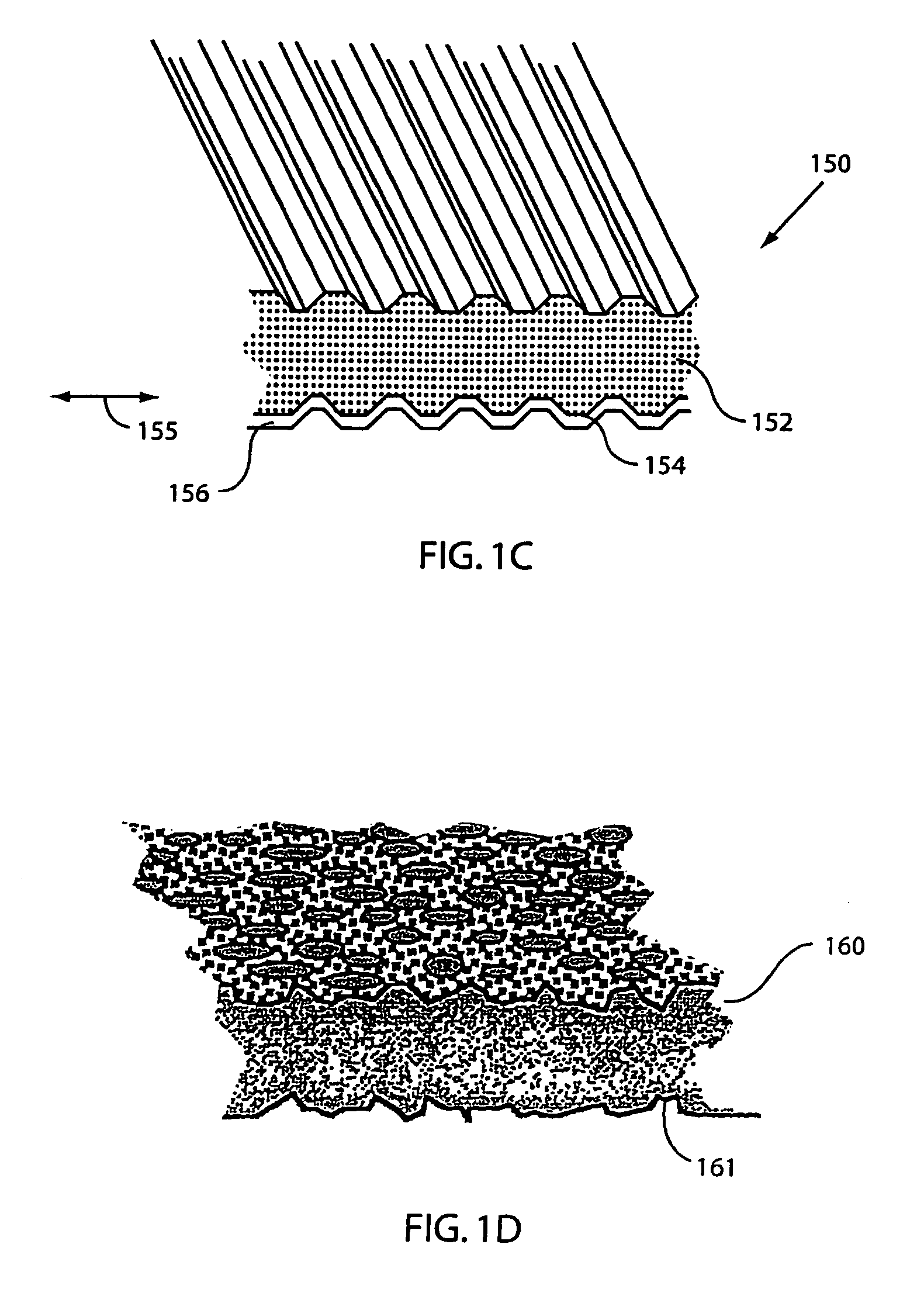

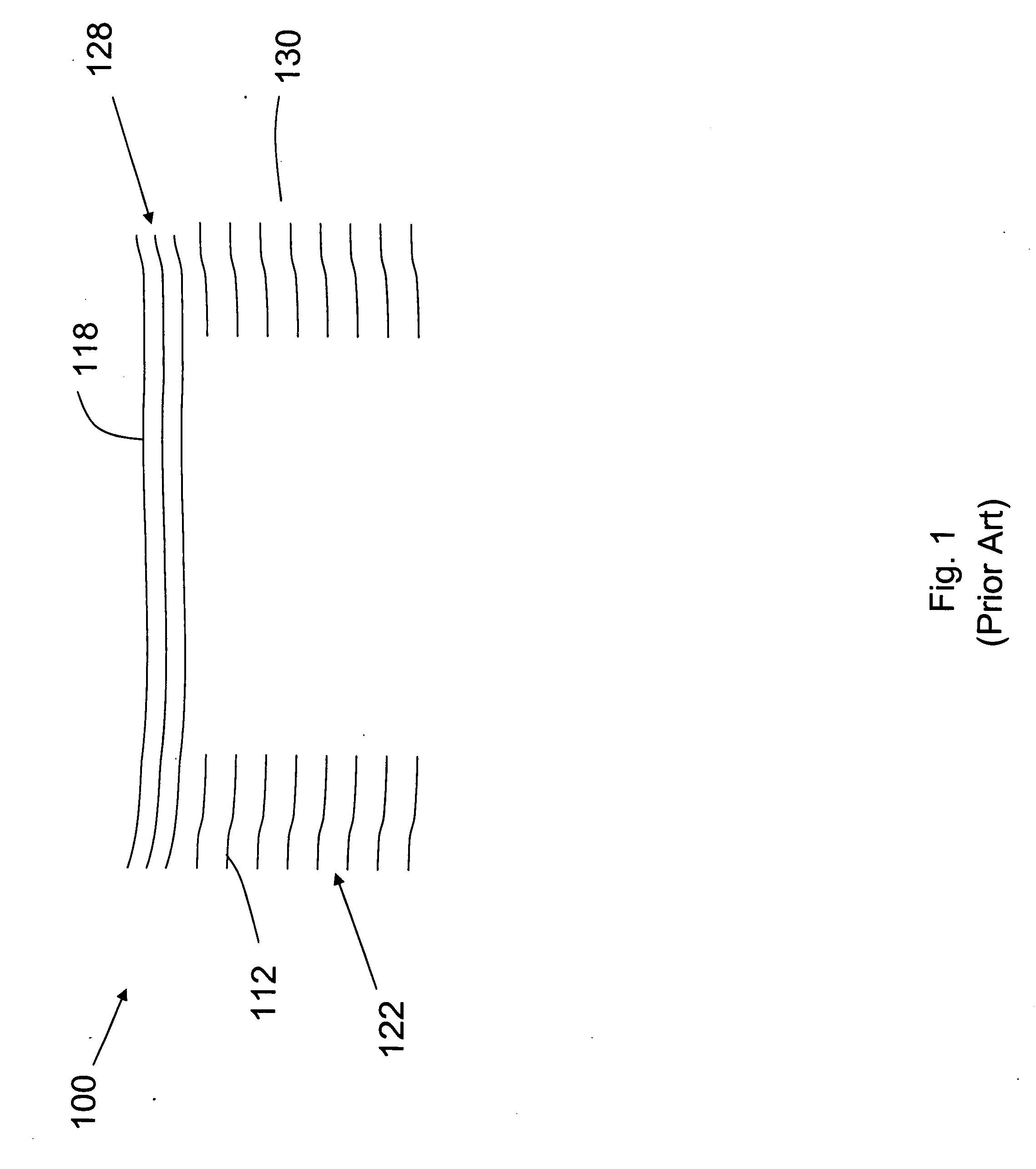

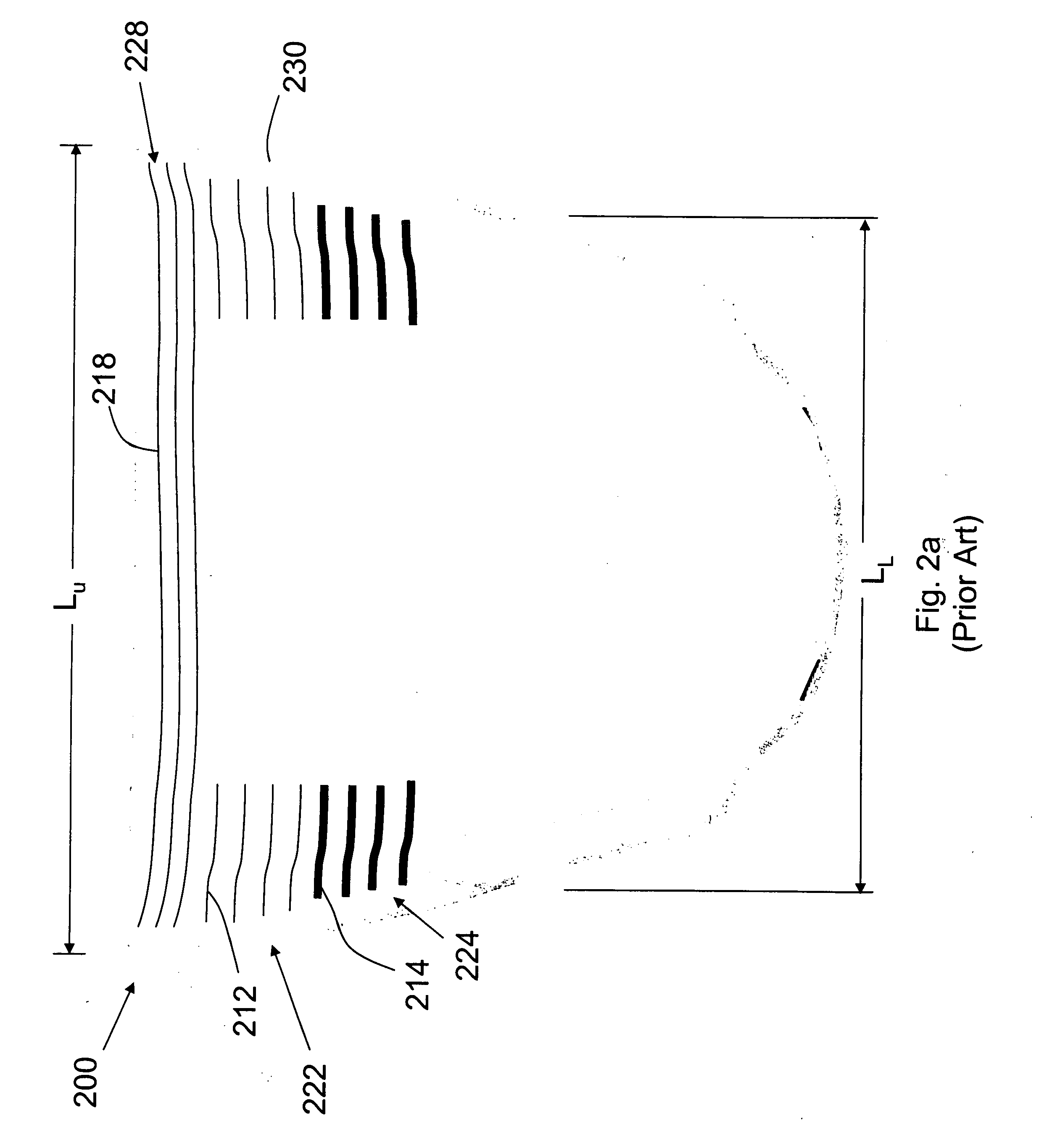

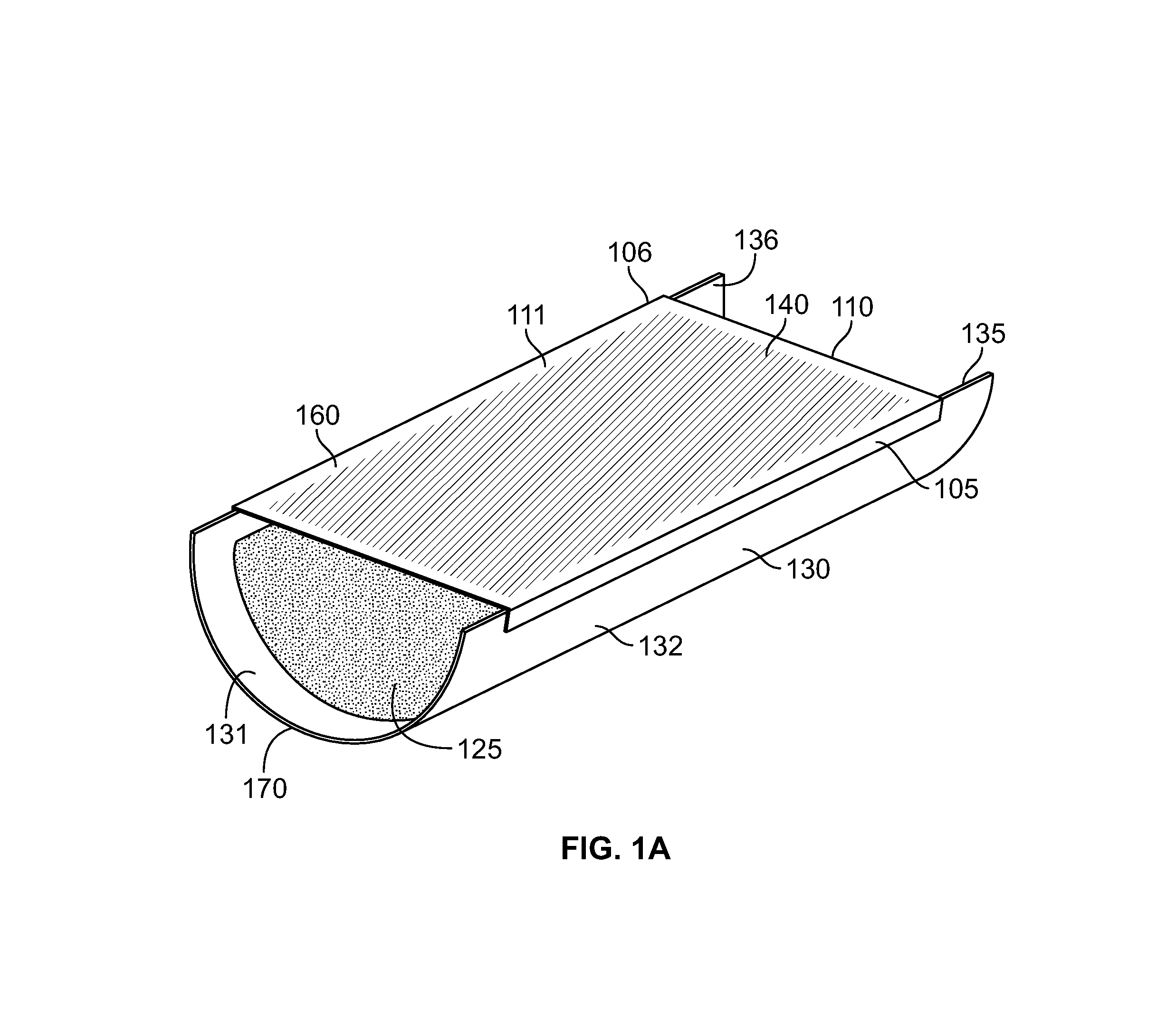

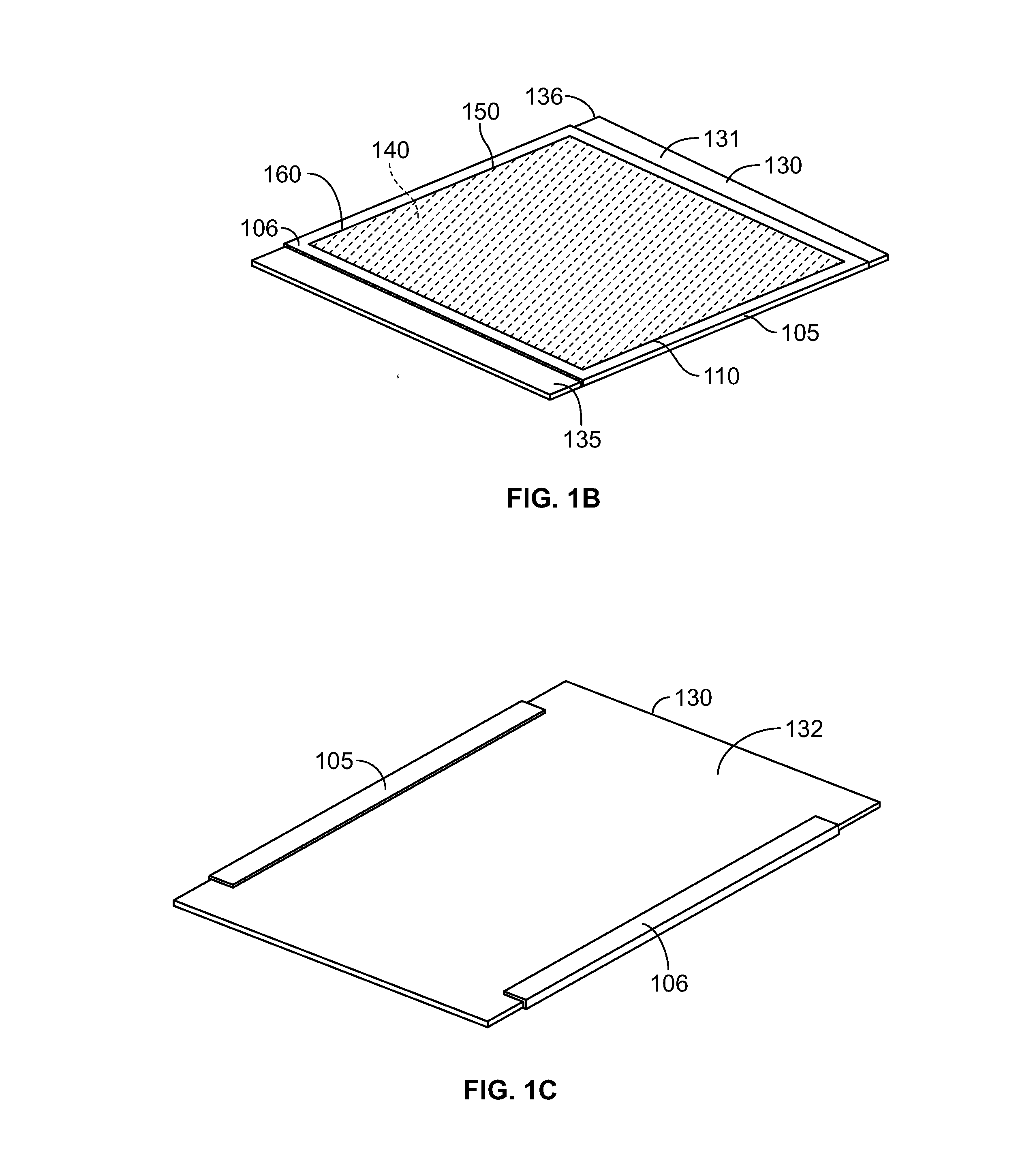

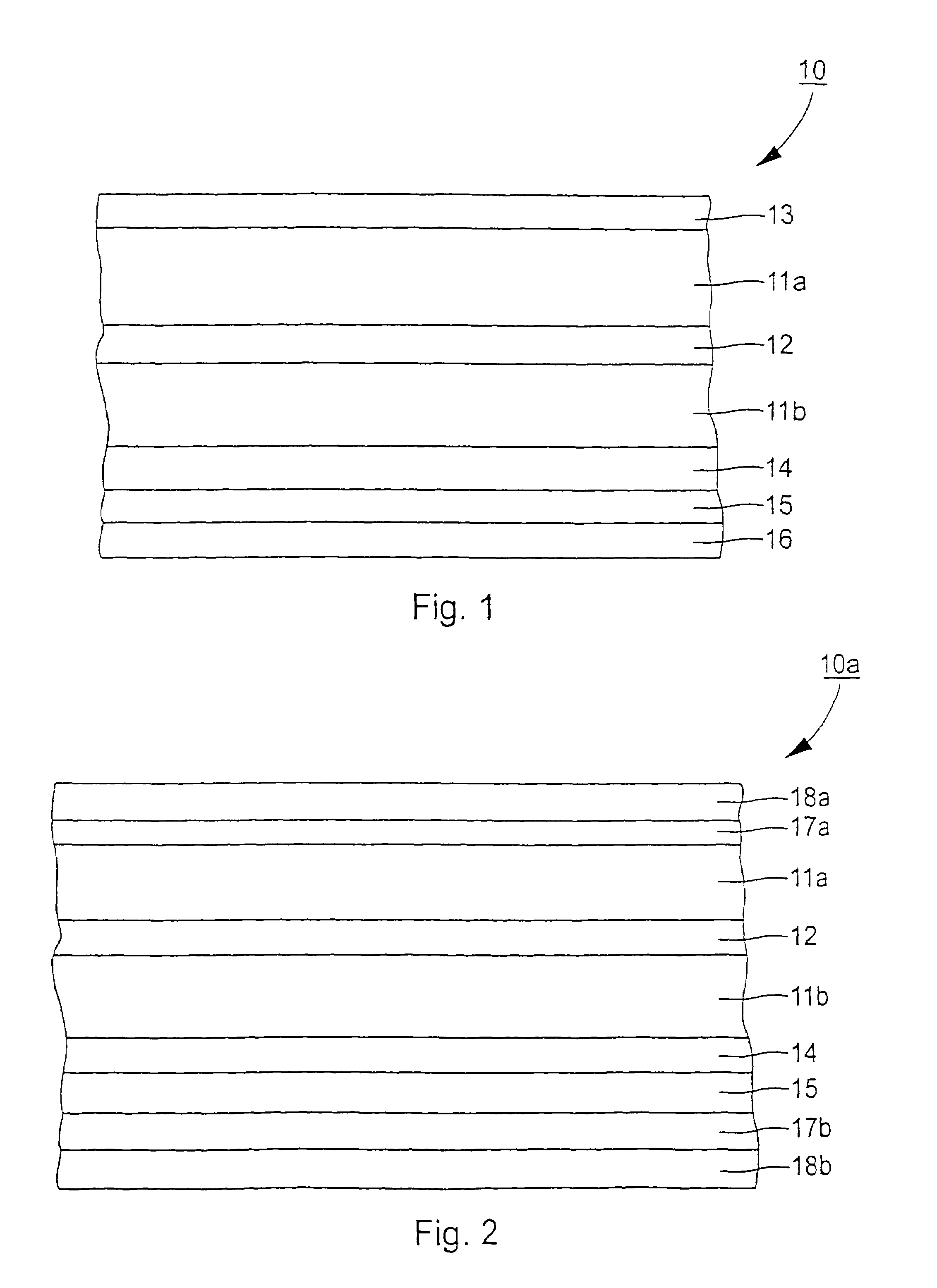

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

Electroactive polymers transducers and actuators

InactiveUS6940211B2Speed up the conversion processImprove mechanical responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

The present invention relates to electroactive polymers that are pre-strained to improve conversion from electrical to mechanical energy. When a voltage is applied to electrodes contacting a pre-strained polymer, the polymer deflects. This deflection may be used to do mechanical work. The pre-strain improves the mechanical response of an electroactive polymer. The present invention also relates to actuators including an electroactive polymer and mechanical coupling to convert deflection of the polymer into mechanical work. The present invention further relates to compliant electrodes that conform to the shape of a polymer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

Electroactive polymers

InactiveUS20060113878A1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

Owner:SRI INTERNATIONAL

Electroactive polymers

InactiveUS20060113880A1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

Electroactive polymer generators

InactiveUS20060238066A1Speed up the conversion processImprove responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

The present invention relates to transducers, their use and fabrication. The transducers convert between mechanical and electrical energy. Some transducers of the present invention include a pre-strained polymer. The pre-strain improves the conversion between electrical and mechanical energy. The present invention also relates to devices including an electroactive polymer to convert between electrical and mechanical energy. The present invention further relates to compliant electrodes that conform to the shape of a polymer included in a transducer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

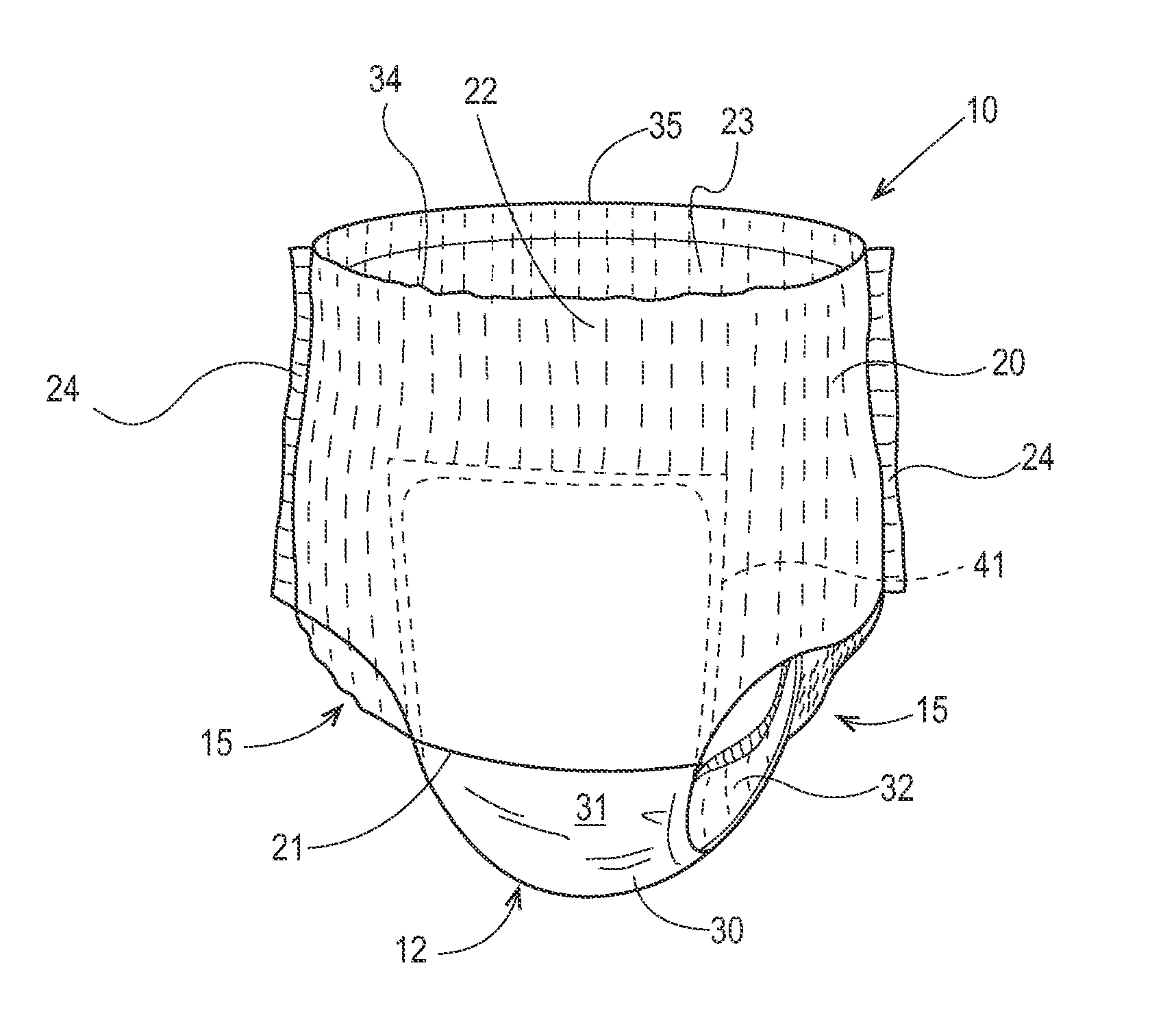

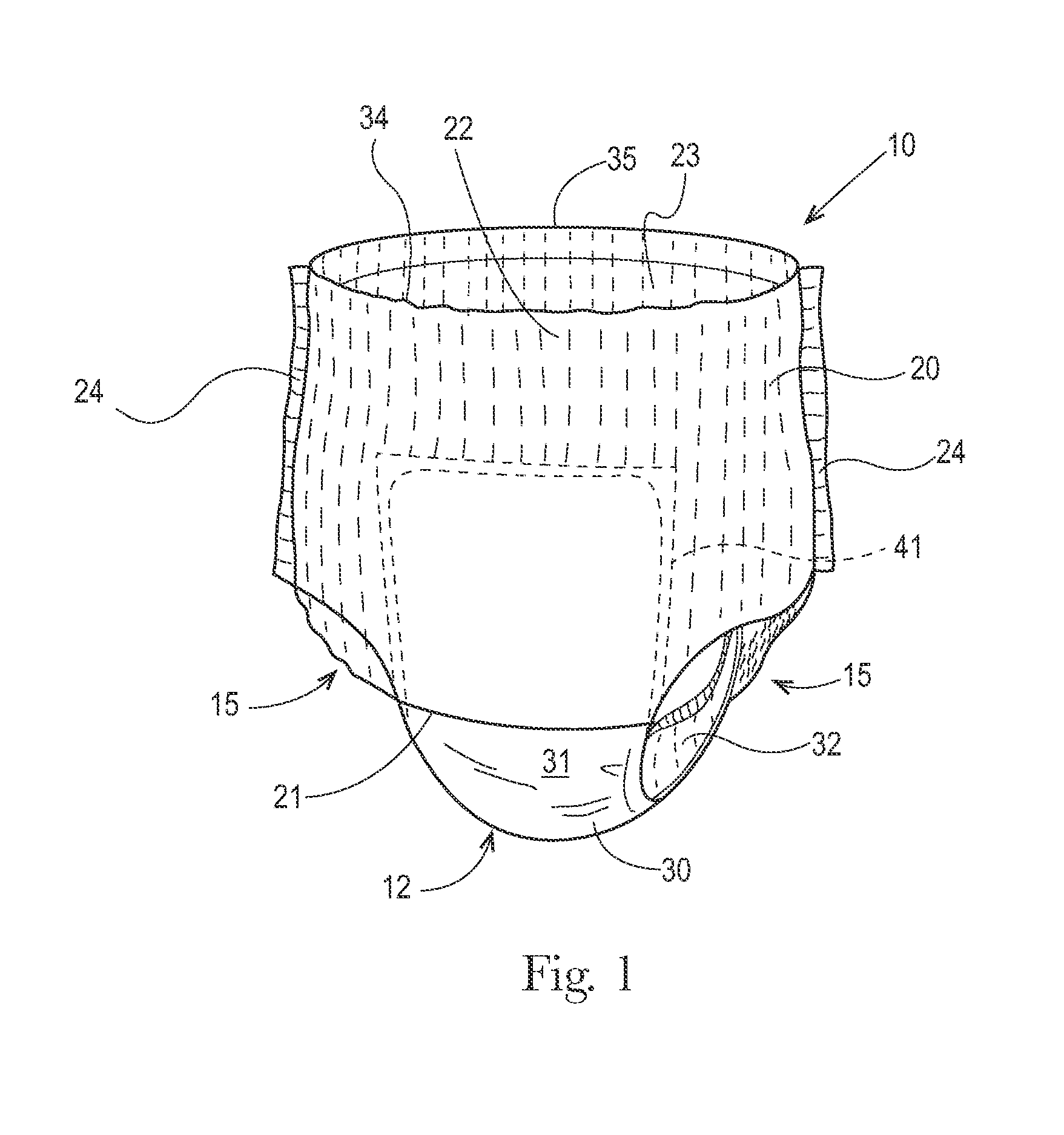

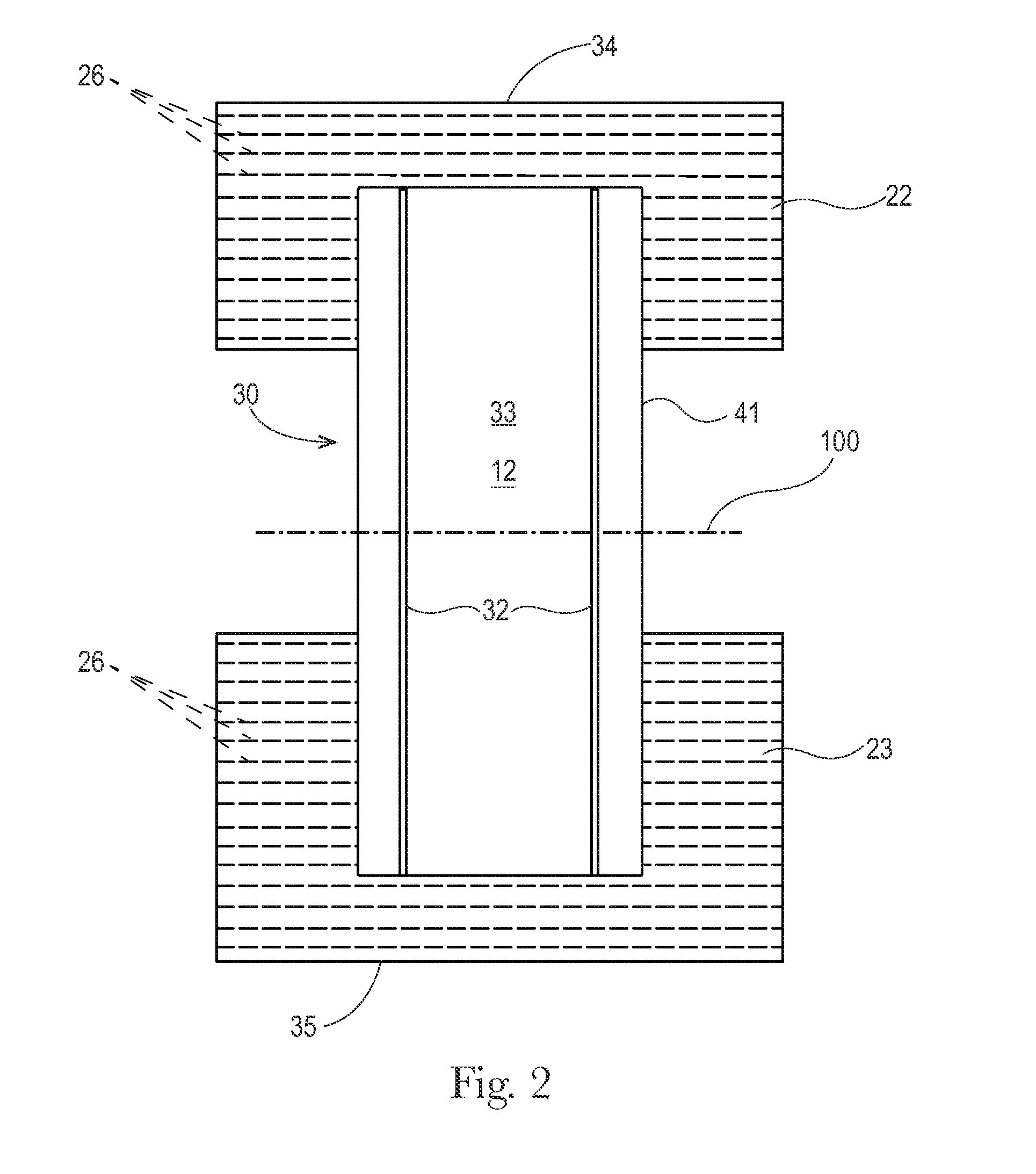

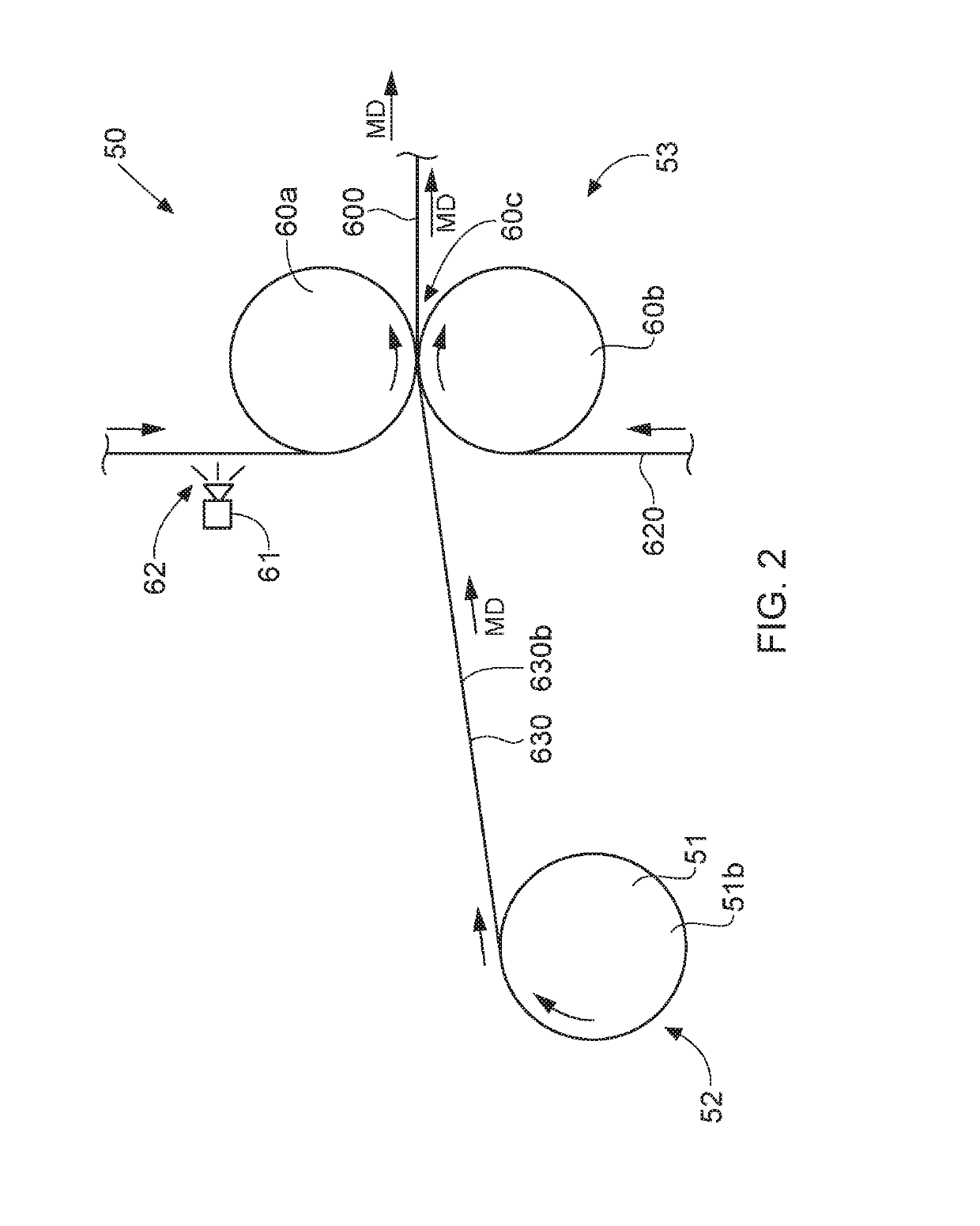

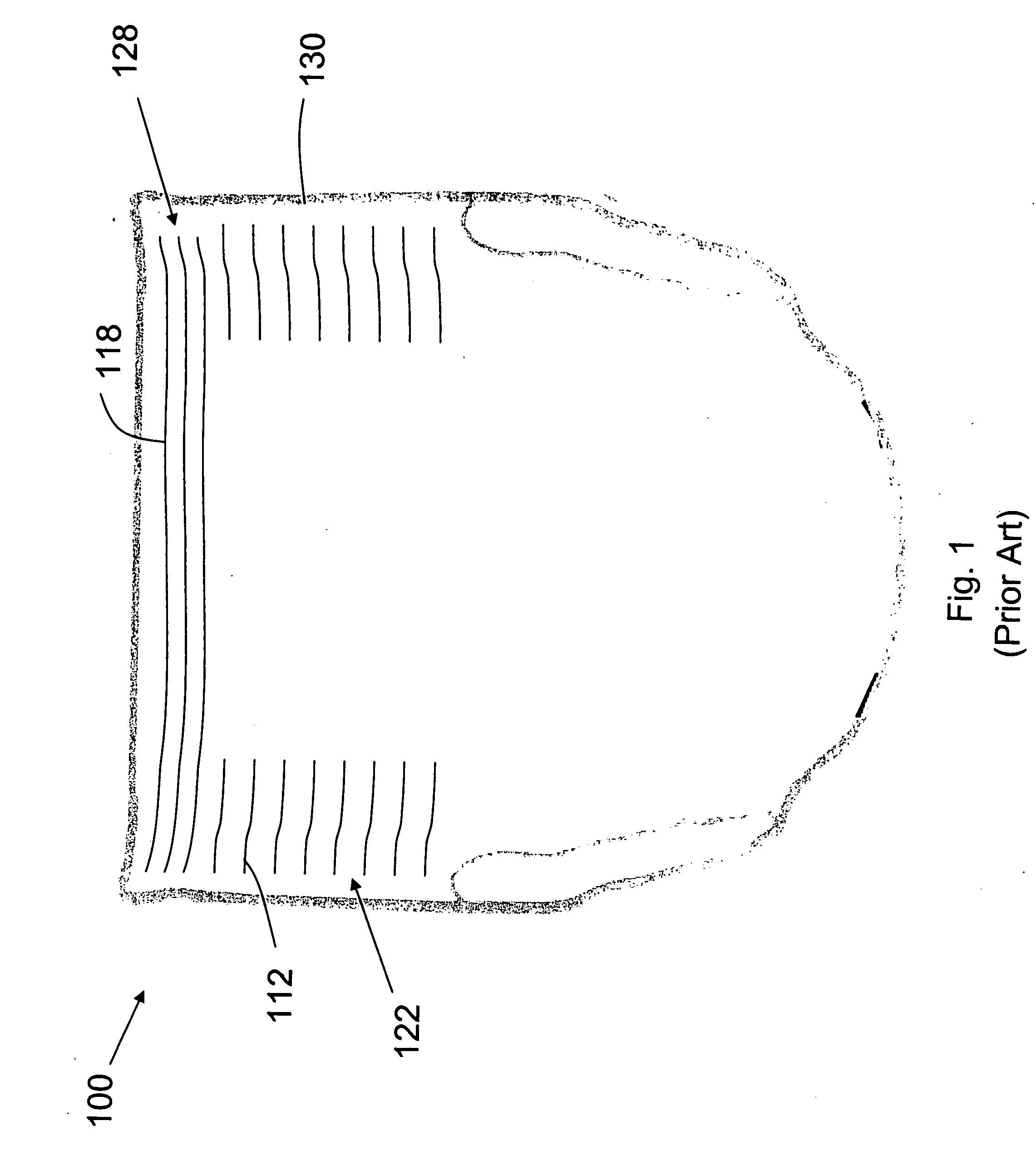

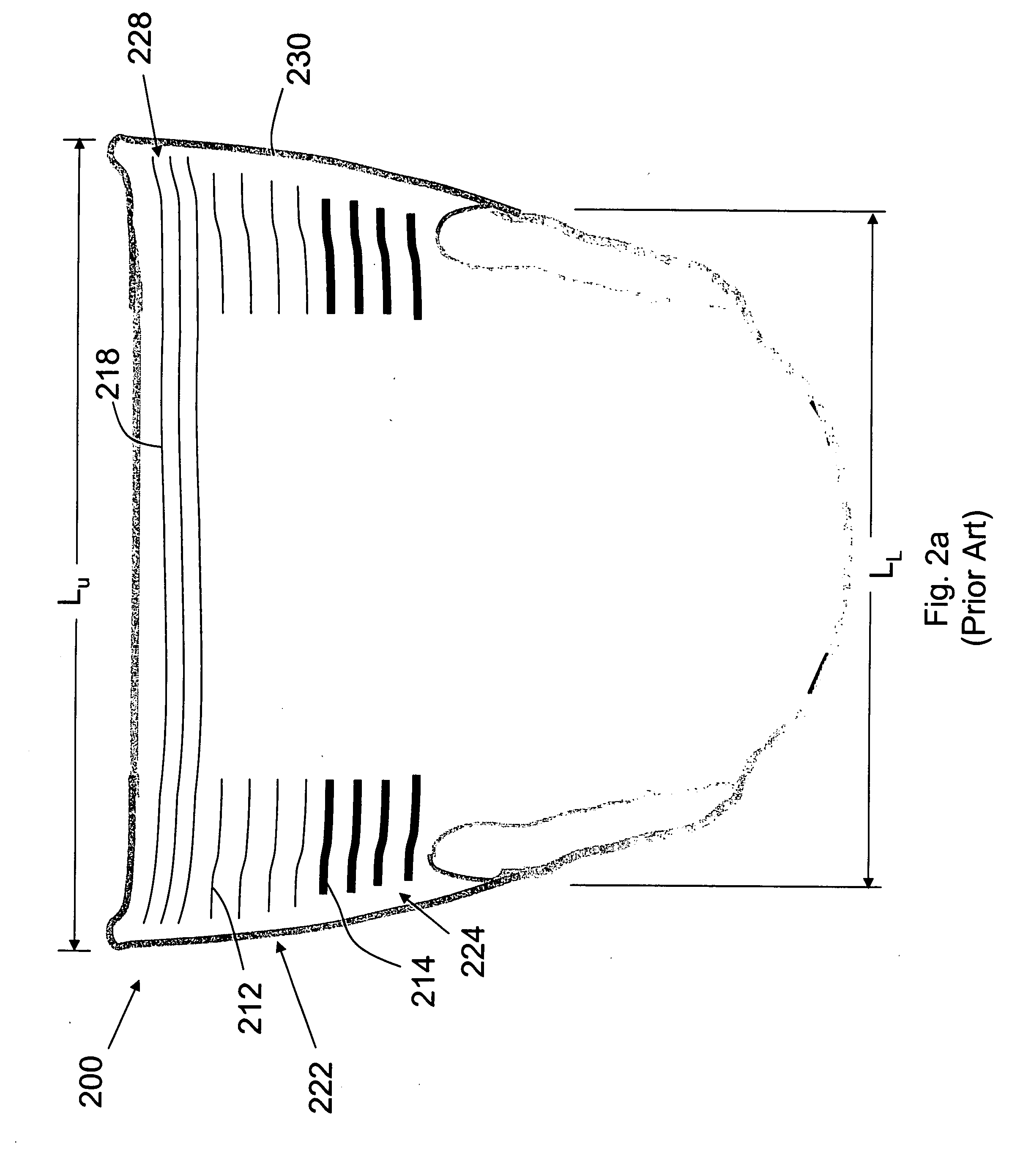

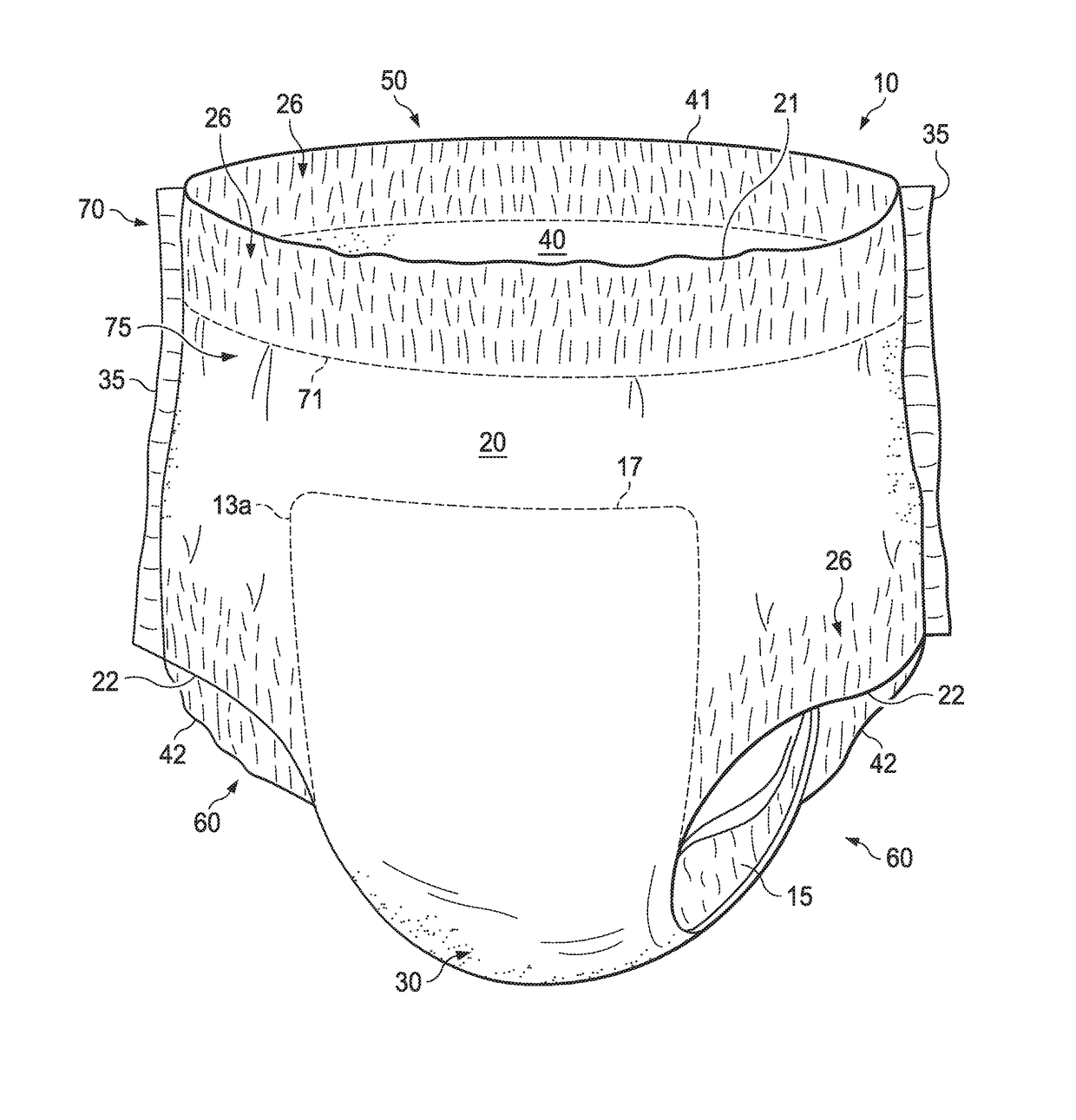

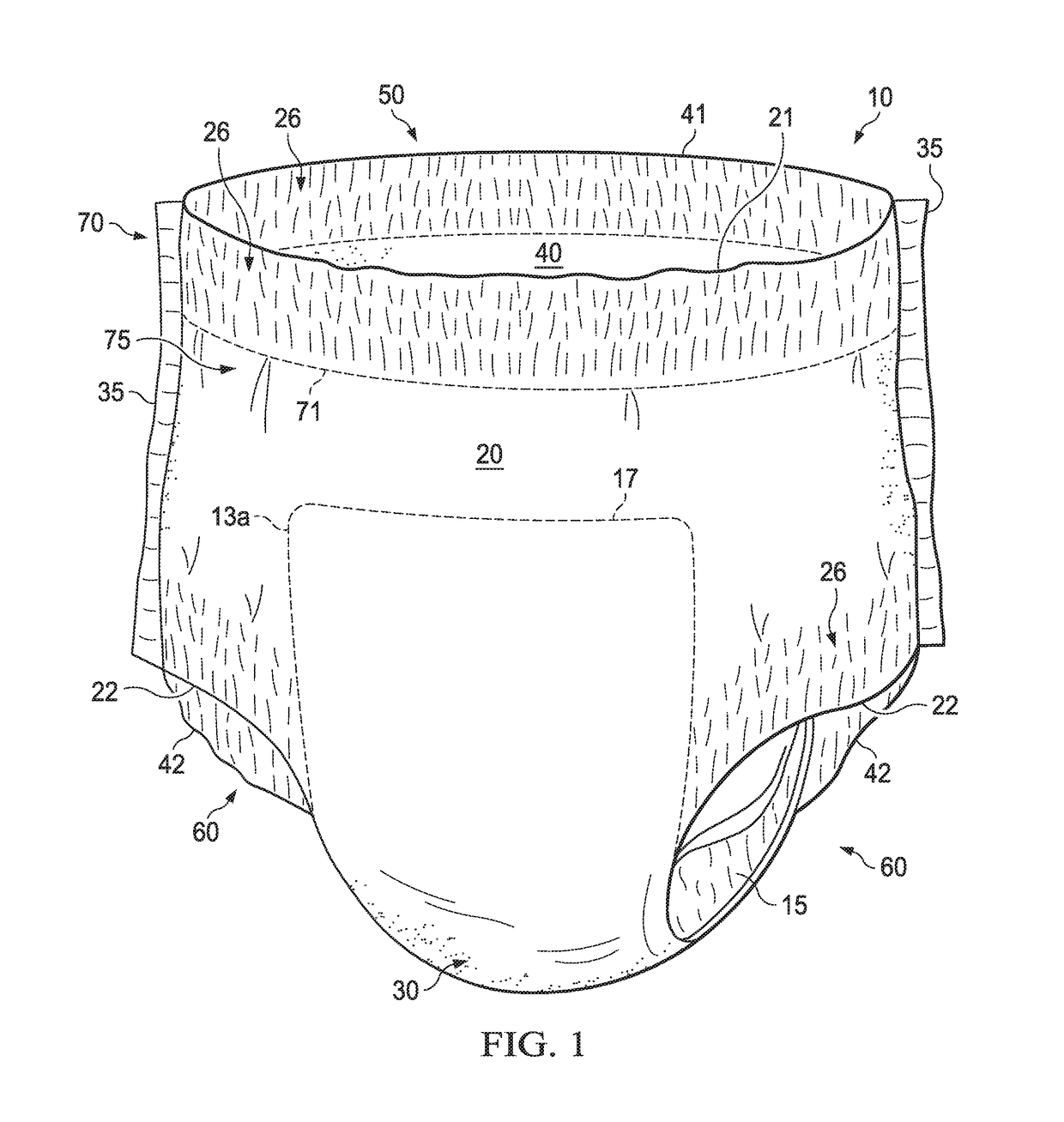

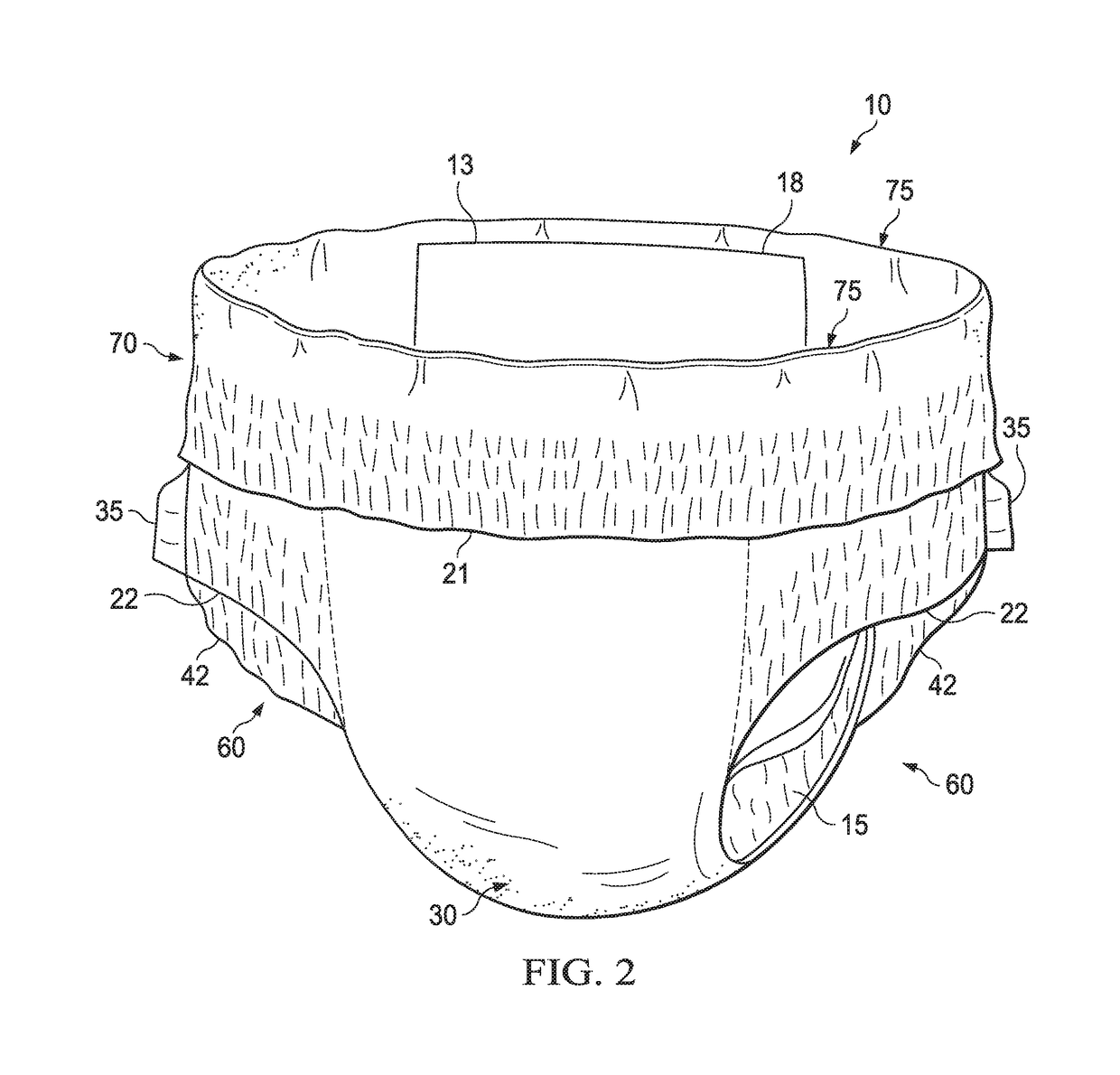

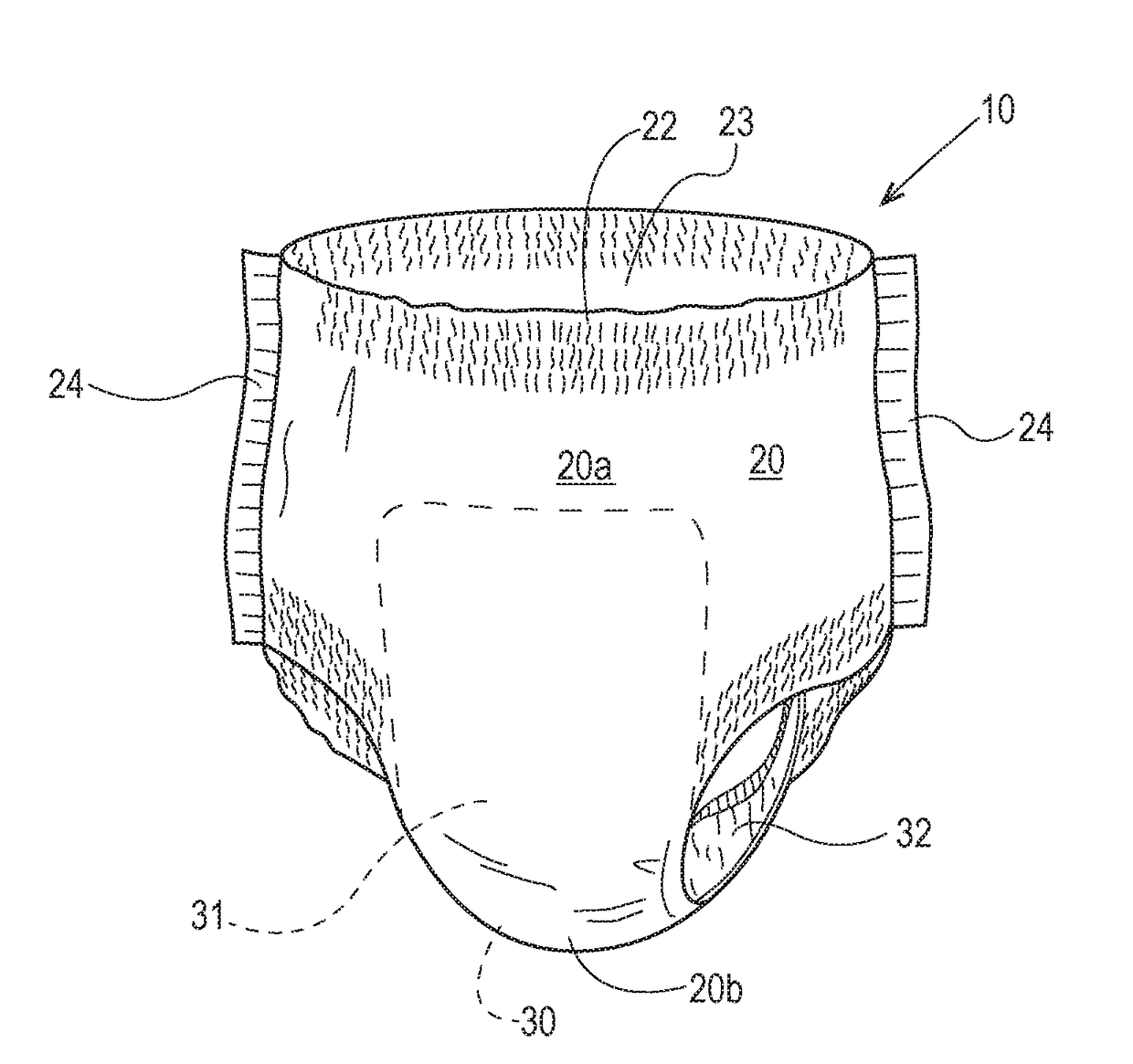

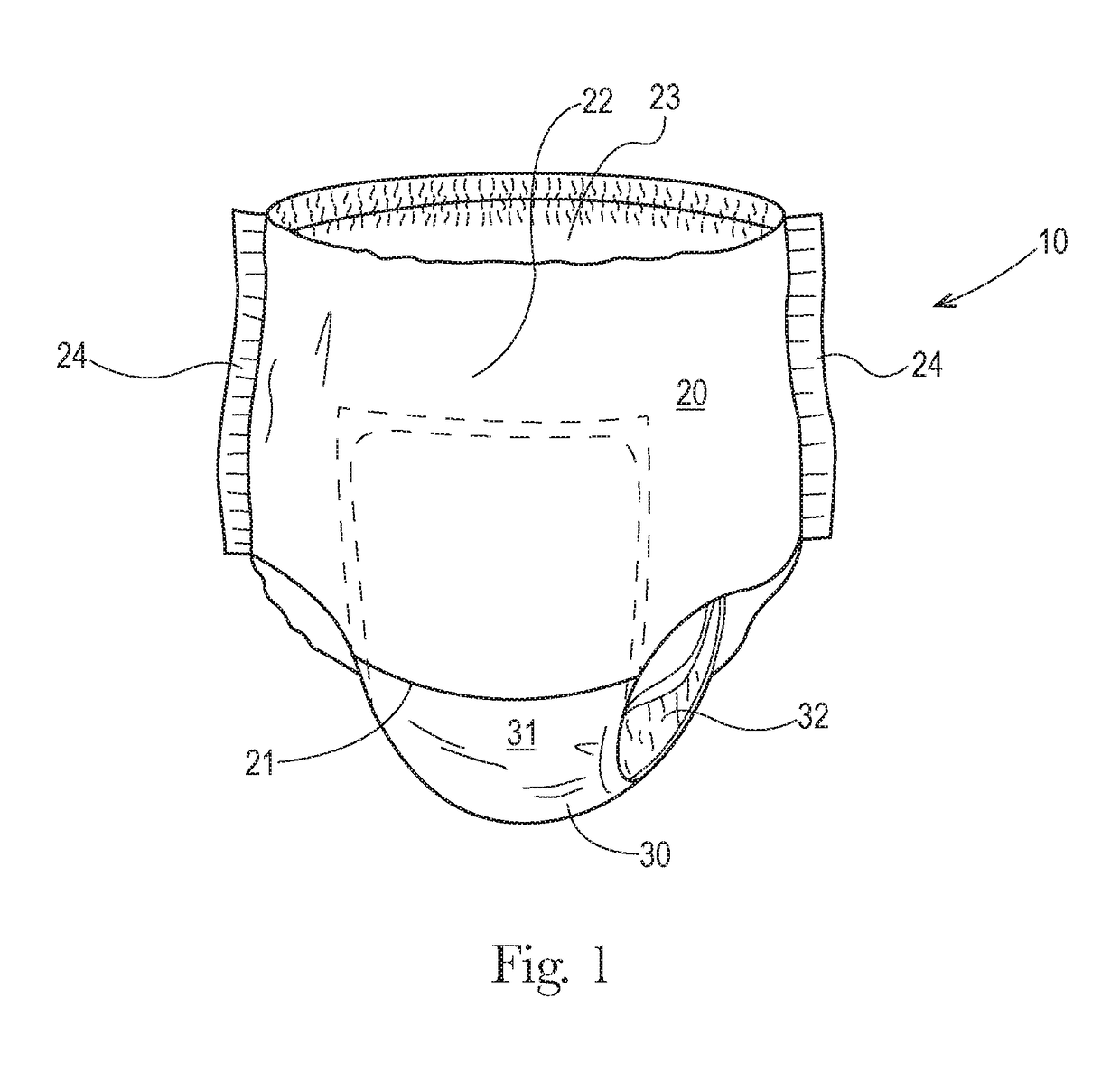

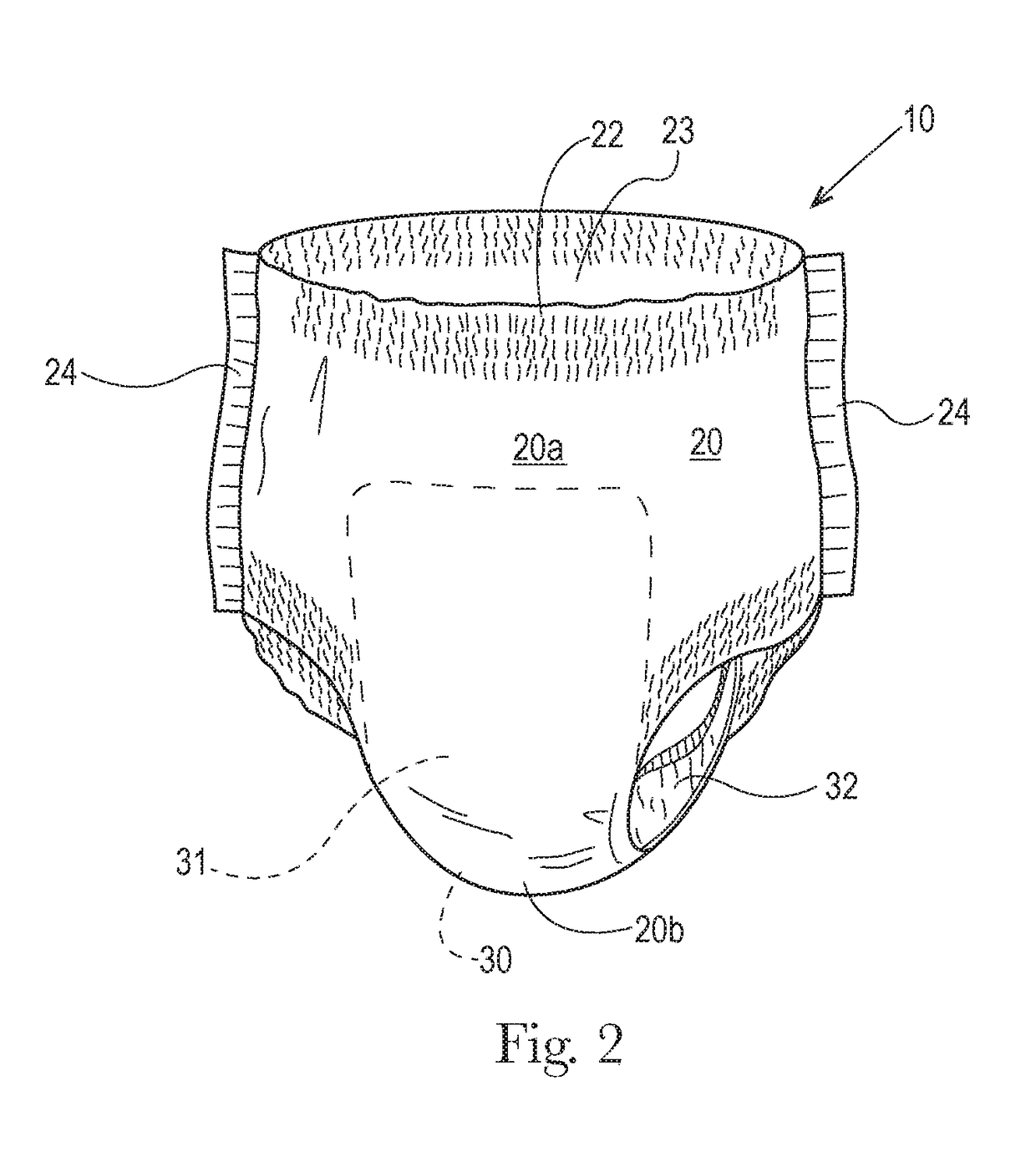

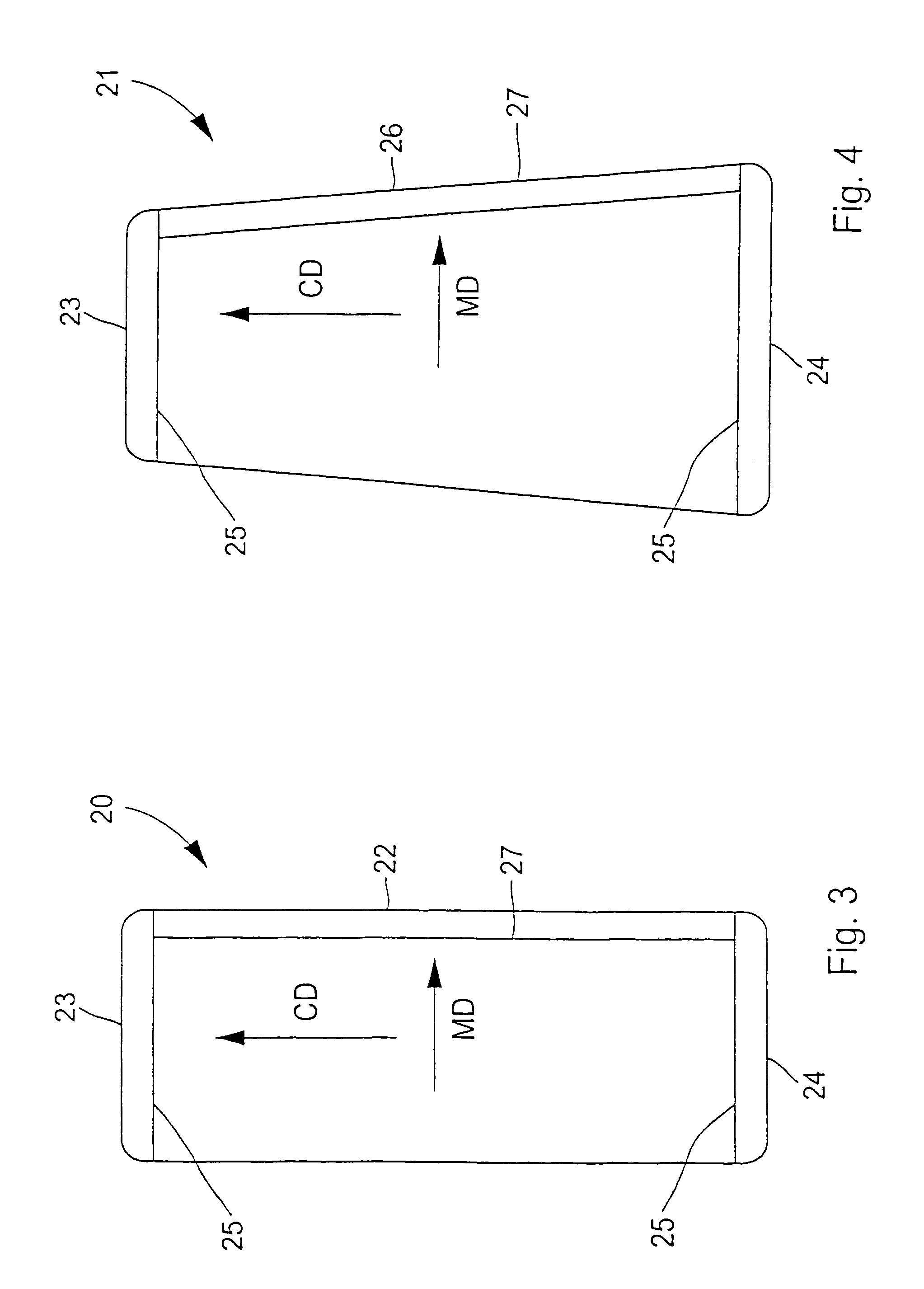

Pant structure with efficiently manufactured and aesthetically pleasing rear leg edge profile

A disposable absorbent pant having a front belt portion and a rear belt portion is disclosed. The front and rear belt portions are joined at side seams and the rear belt portion has a greater length than the front belt portion. A lower edge of the rear belt portion forms at least in part edges of left and right leg openings to the rear of the side seams. The rear belt portion includes first and second layers of nonwoven web material sandwiching a plurality of laterally extending and laterally pre-strained elastic strands, disposed below the side seams. A first of the plurality of elastic strands differs from a second of the plurality of elastic strands by one or more of amount of pre-strain, tensile modulus, decitex, and combinations thereof.

Owner:THE PROCTER & GAMBLE COMPANY

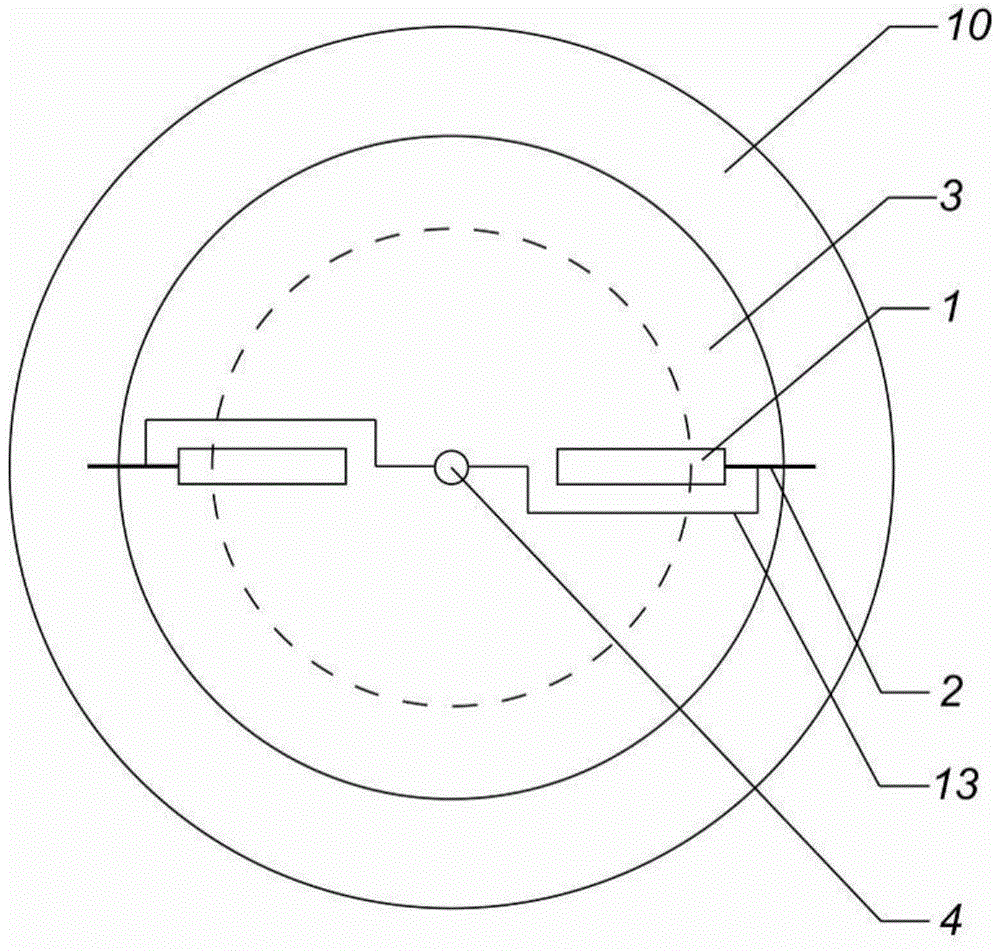

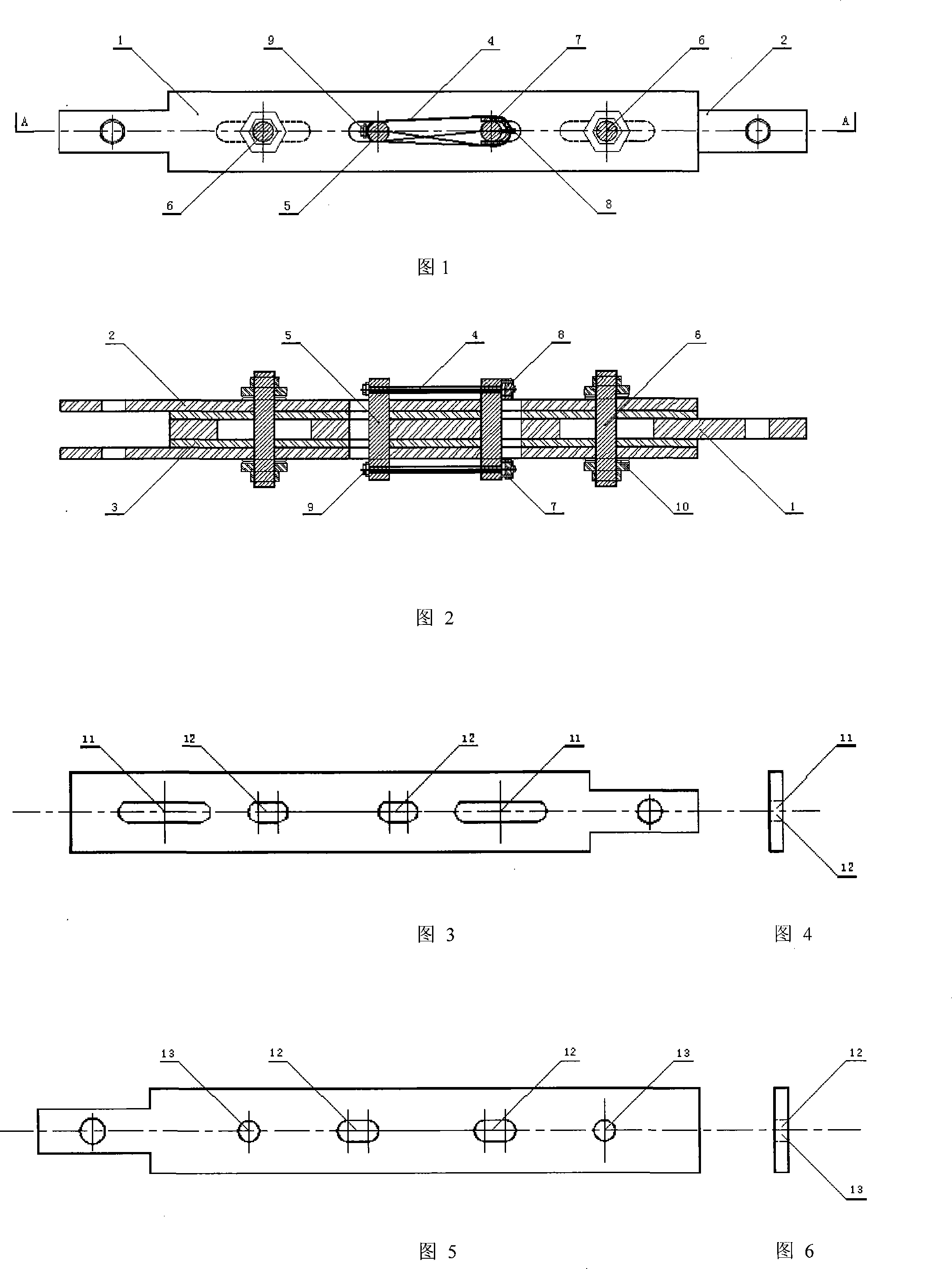

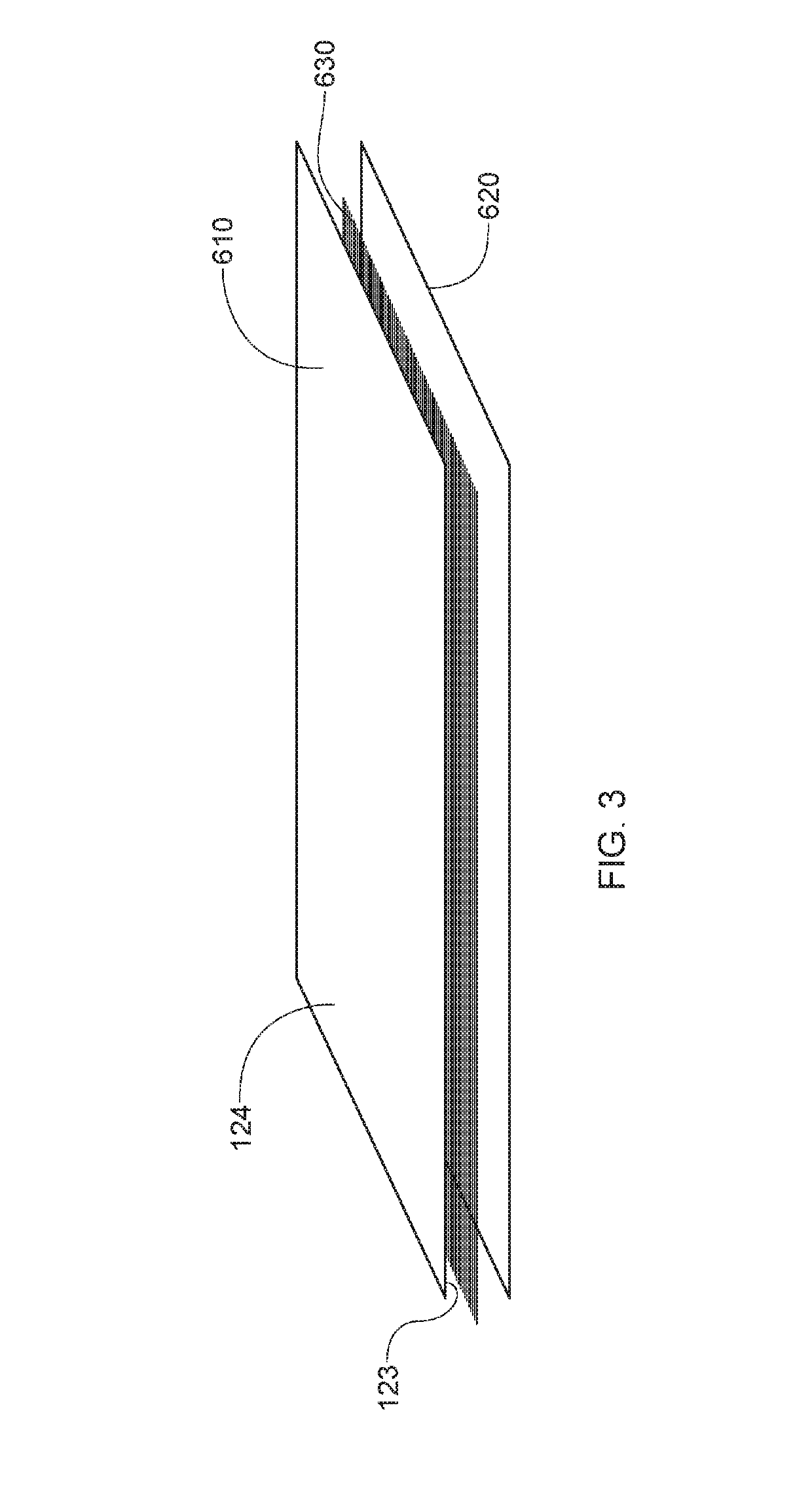

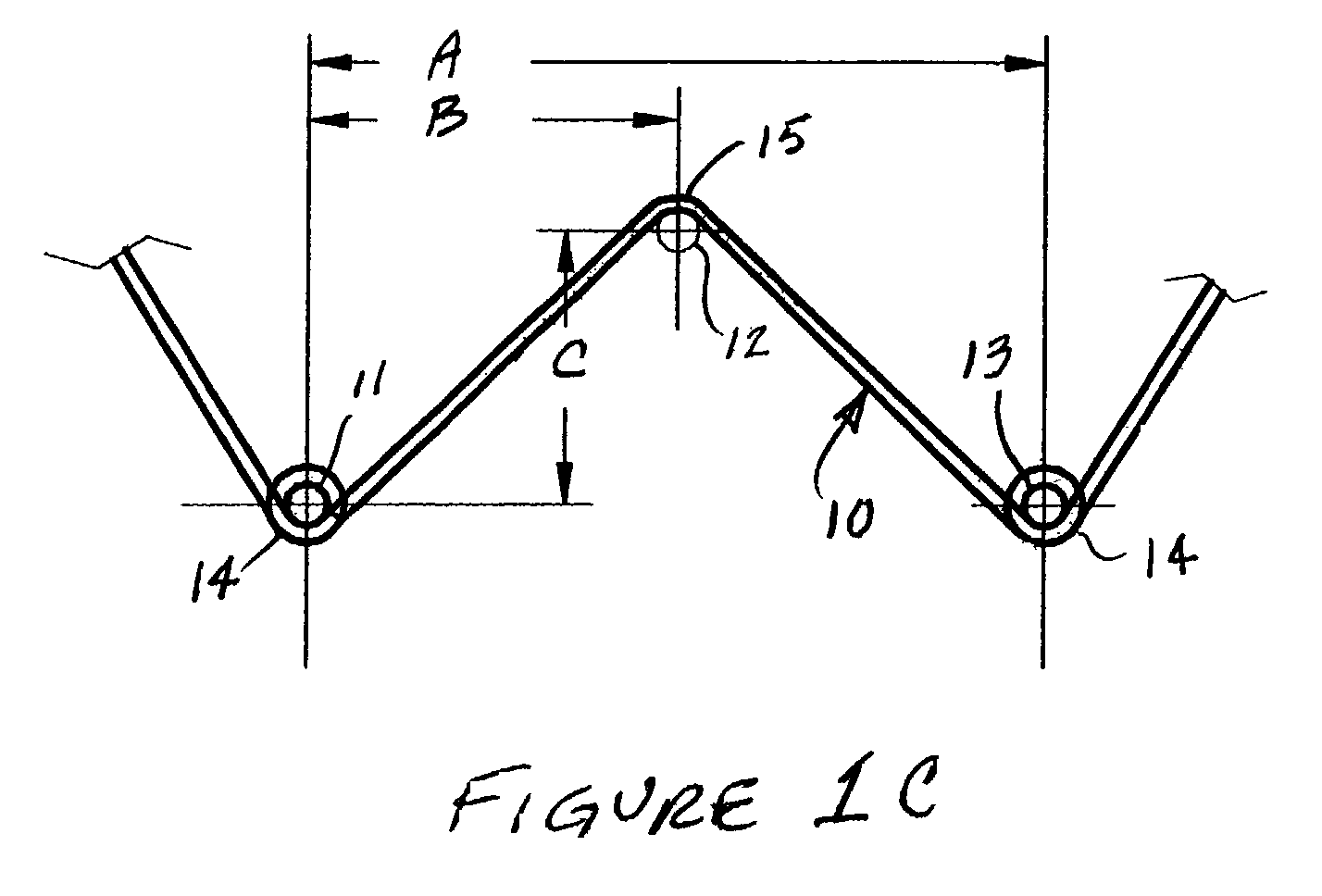

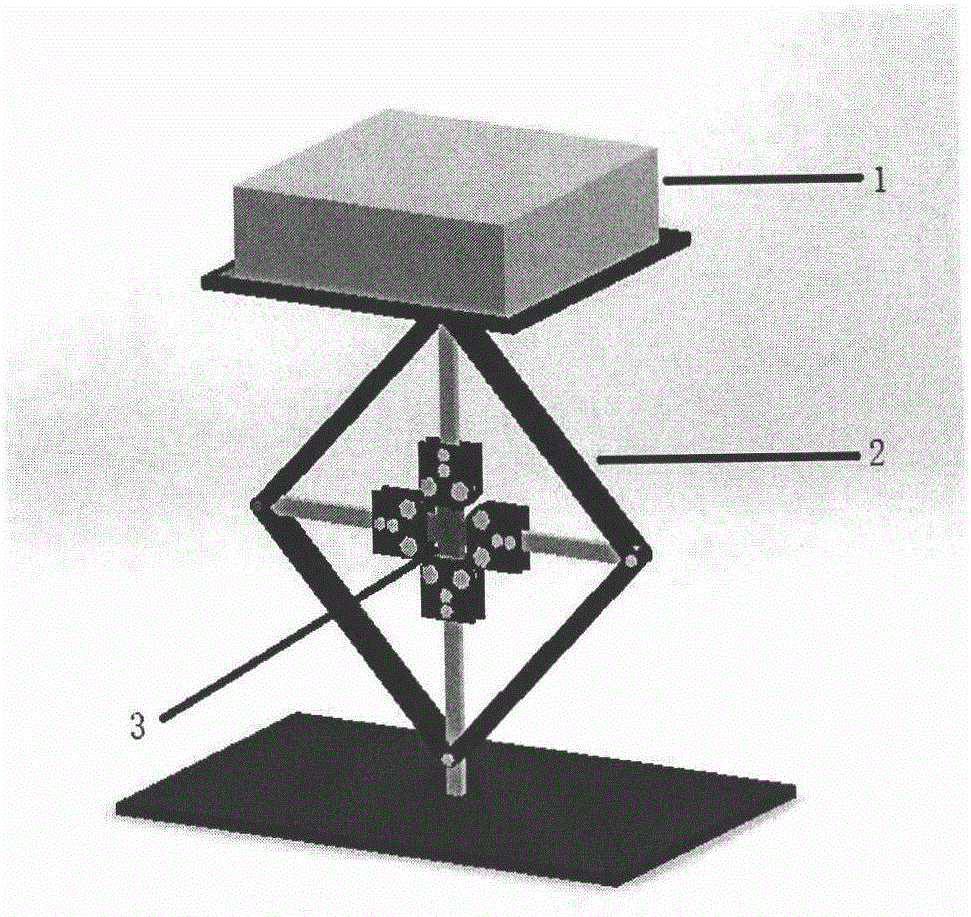

Method for producing a composite structure including a piezoelectric element

InactiveUS6162313AMaximize rangeSuitably producedPiezoelectric/electrostriction/magnetostriction machinesLaminationPre strainElectricity

A composite structure (3) includes a piezoelectric element (1) sandwiched between fiber composite panels (2). The composite structure can be used as an actuator element. In a method for producing the composite structure, the fiber composite panels are pre-stressed and pre-strained by applying respective pre-stressing forces (F1, F2) in opposite directions along two substantially perpendicular axes in the plane of the panel. The pre-stressed and pre-strained condition of the fiber composite panels (2) is maintained, while the panels are adhesively bonded (5) surfacially onto the piezoelectric element (1). After the bonding is completed, the pre-stressing forces are removed from the fiber composite panels. As a result, in the finished composite structure (3), the fiber composite panels (2) are under internal tension, while the piezoelectric element (1) is under internal compression. The pre-stressing forces (F1, F2) are particularly selected in magnitude and direction to achieve the required resultant balance of tension and compression within the composite structure (3). The pre-compression of the piezoelectric element (1) should be sufficient so that operating loads on the composite structure do not result in tension loading of the piezoceramic element, while substantially maintaining the useful active strain range of the overall composite structure.

Owner:AIRBUS HELICOPTERS DEUT GMBH

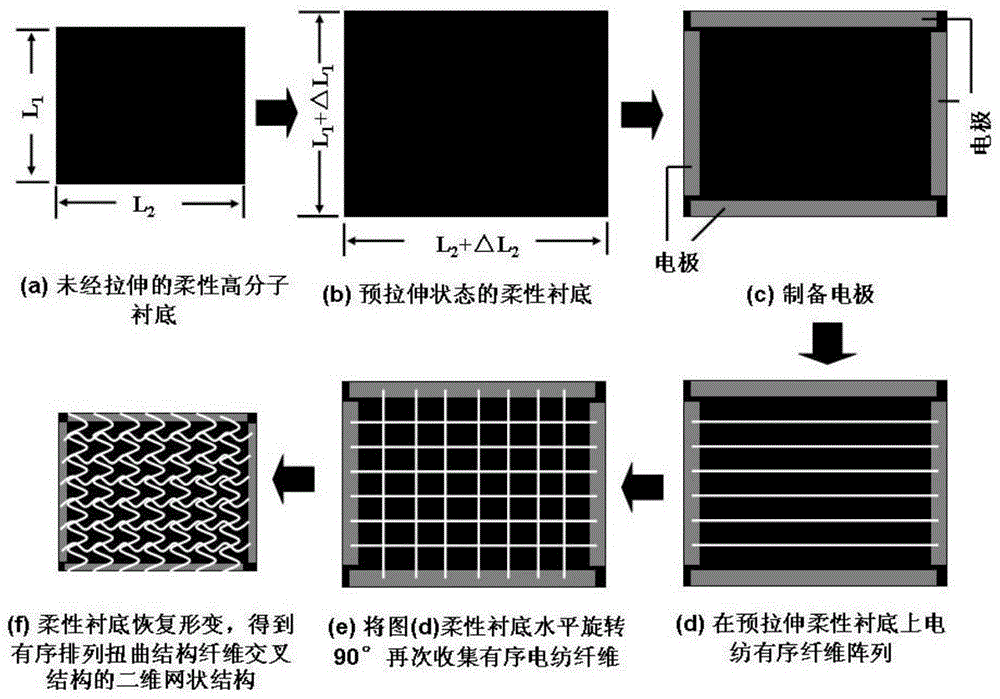

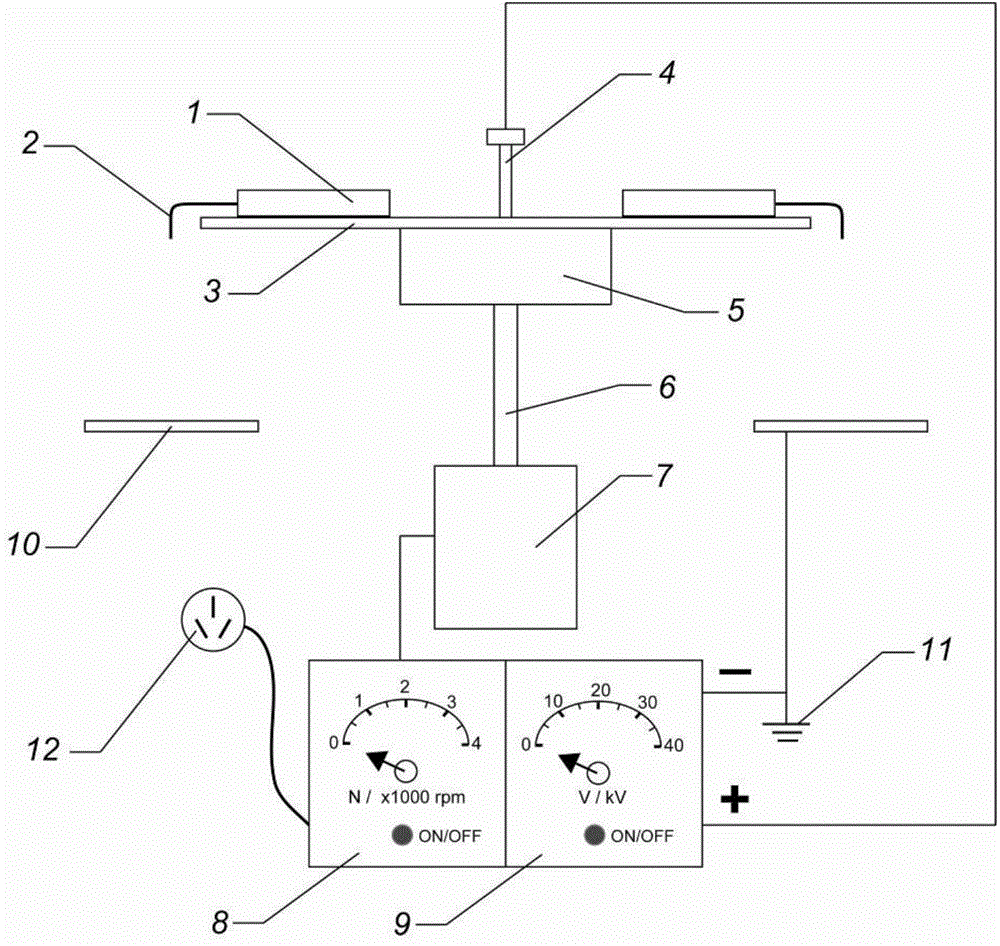

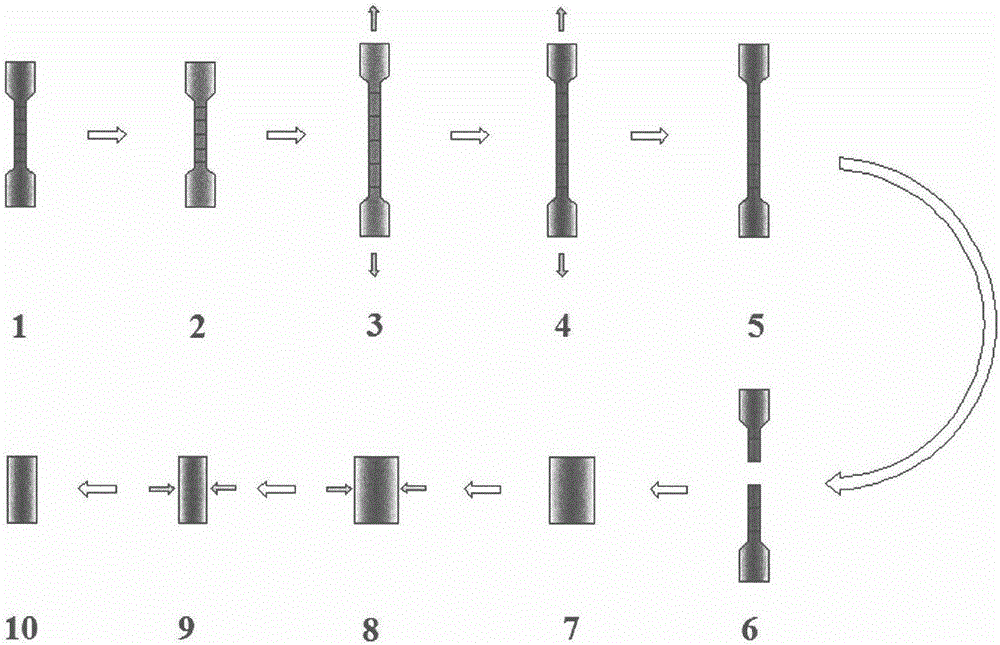

Method for manufacturing flexible stretchable device based on ordered arrangement torsion structure

InactiveCN104153128AAccurate realization of pre-strain controlAchieve pre-strain controlNew-spun product collectionFilament/thread formingPre strainElectrospinning

The invention belongs to the technical field of flexible device manufacturing, and relates to a method for manufacturing a flexible stretchable device based on an ordered arrangement torsion structure. The method includes the steps that firstly, a flexible macromolecule substrate is pre-stretched to be fixed to a glass sheet, and electrodes are manufactured at the four edges of the pre-stretched flexible macromolecule substrate; secondly, the flexible macromolecule substrate is placed on an annular metal collector connected with the negative electrode of a power source to serve as a collecting substrate, and a machined hollow stainless steel needle serves as a spinning spraying head; a spinning solution is injected into a spinning solution container for electrospinning; the flexible macromolecule substrate is horizontally rotated by 90 degrees for continuous electrospinning and then taken down from the glass sheet, and the flexible stretchable device based on an ordered arrangement torsion structure is obtained. The method is simple in manufacturing process and convenient to operate; the manufactured flexible stretchable device can be stressed and tensioned in one or two of the two-dimensional directions respectively, pre-strain control over materials in the two directions can be accurately achieved, and the application range is wide.

Owner:QINGDAO UNIV

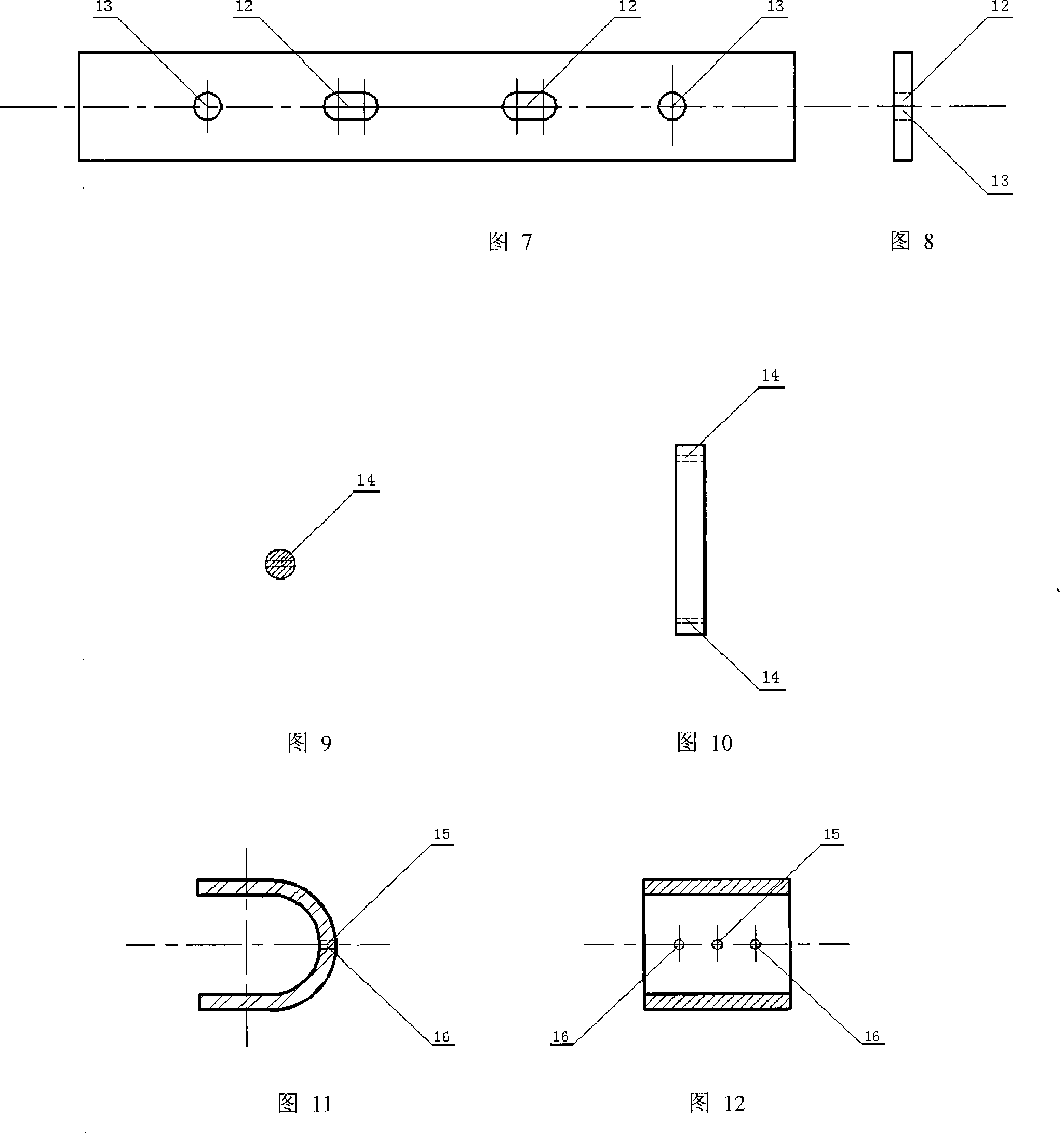

Mixed mode shape memory alloy frictional damper

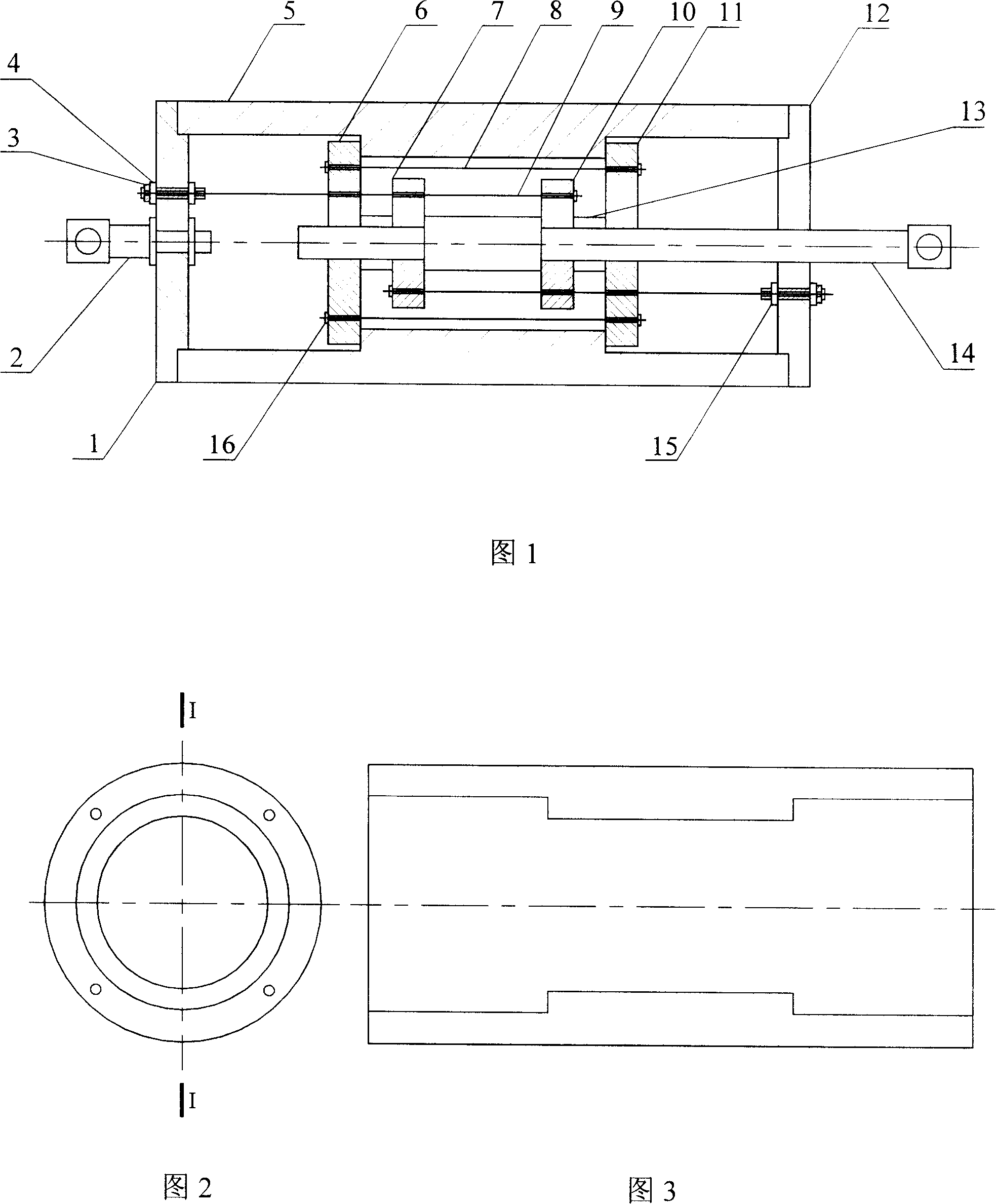

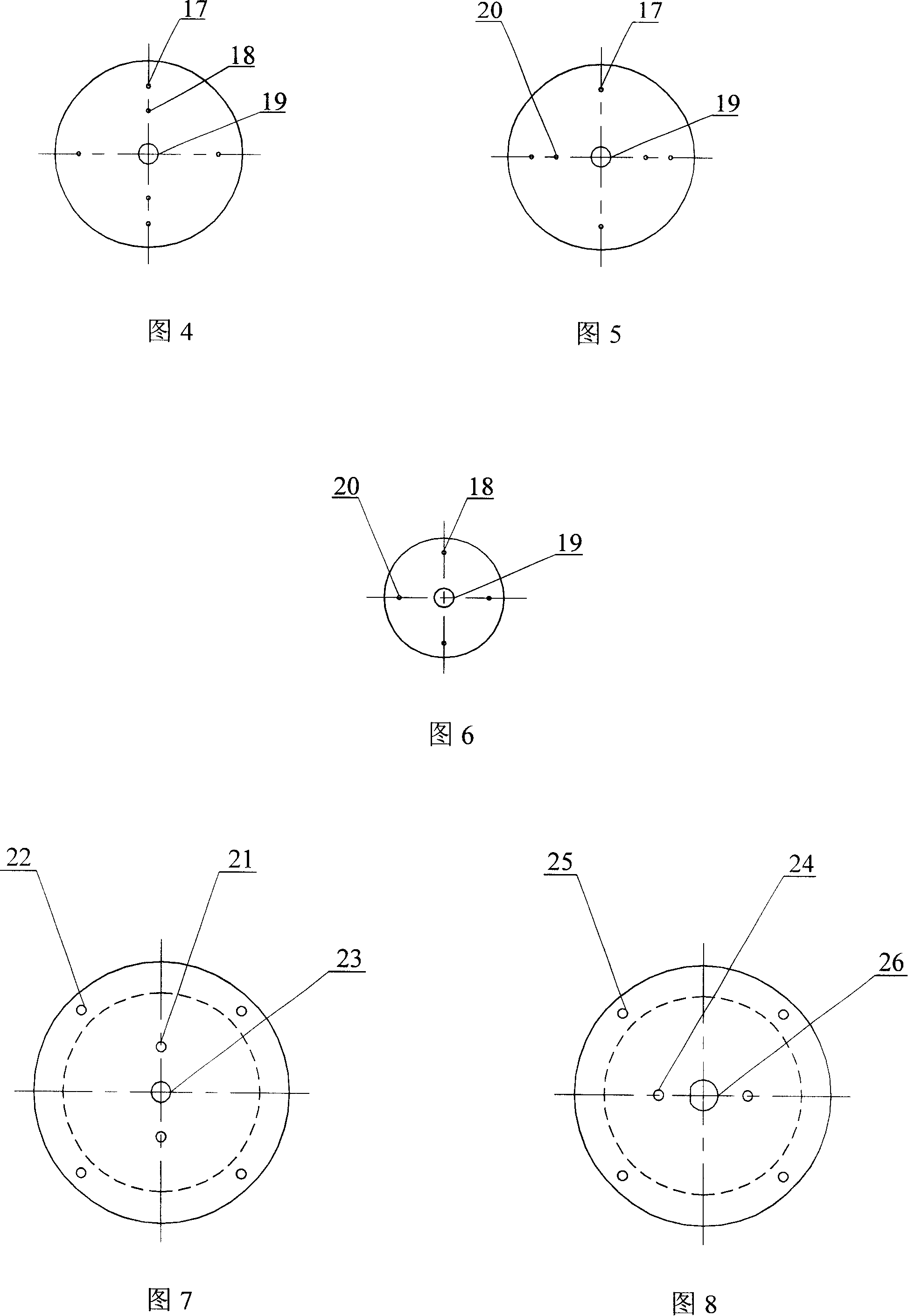

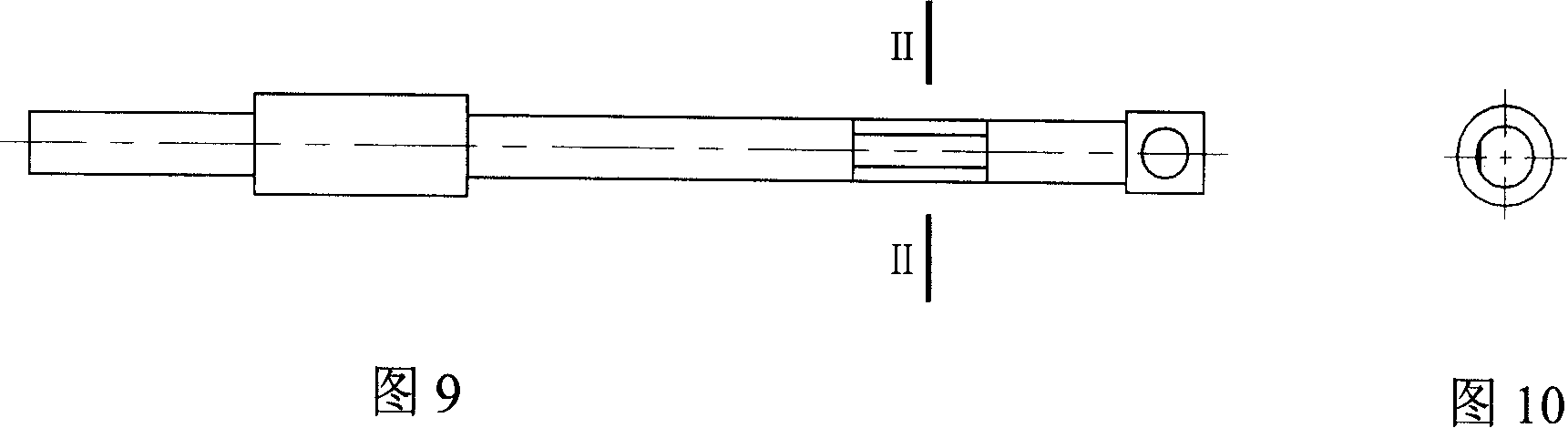

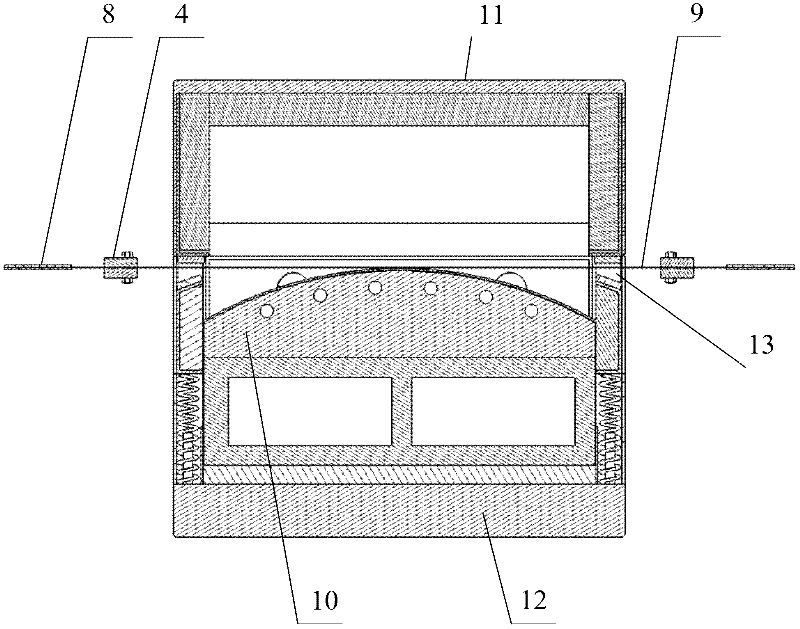

InactiveCN101196017AImprove survivabilityWith self-resetting functionShock proofingPre strainShape-memory alloy

The invention relates to a compound type memory alloy friction damper, which is mainly composed of a main board, a sub board, a friction plate, a hyperelastic shaped memory alloy wire, a resetting pulling rod, a U-shaped pre-strained adjusting plate and a high strength bolt. The invention is characterized in that the friction plate is inserted between the main board and the sub board, a bolt movable hole and a pulling rod movable hole are reserved on the main board, and a bolt hole and the pulling rod movable hole are reserved on the sub board and the friction plate; the high strength bolt penetrates through the bolt hole on the sub board and the friction plate and the bolt movable hole on the main board; the resetting pulling rod penetrates through the pulling rod movable hole on the main board, the sub board and the friction plate; the hyperelastic shaped memory alloy wire penetrates through the resetting pulling rod and the U shaped pre-strained adjusting plate, and the both ends are respectively pulled tightly and fixed with a clamping device, the interval between the U shaped pre-strained adjusting plate and the resetting pulling rod is adjusted through an adjusting bolt, to ensure the hyperelastic shaped memory alloy wire to reach the required initial strain. The invention has the advantages that the capacity of the energy dissipation is strong, the resetting is automatic, the structure type is simple, and the invention is convenient for the application of the engineering.

Owner:DALIAN UNIV OF TECH

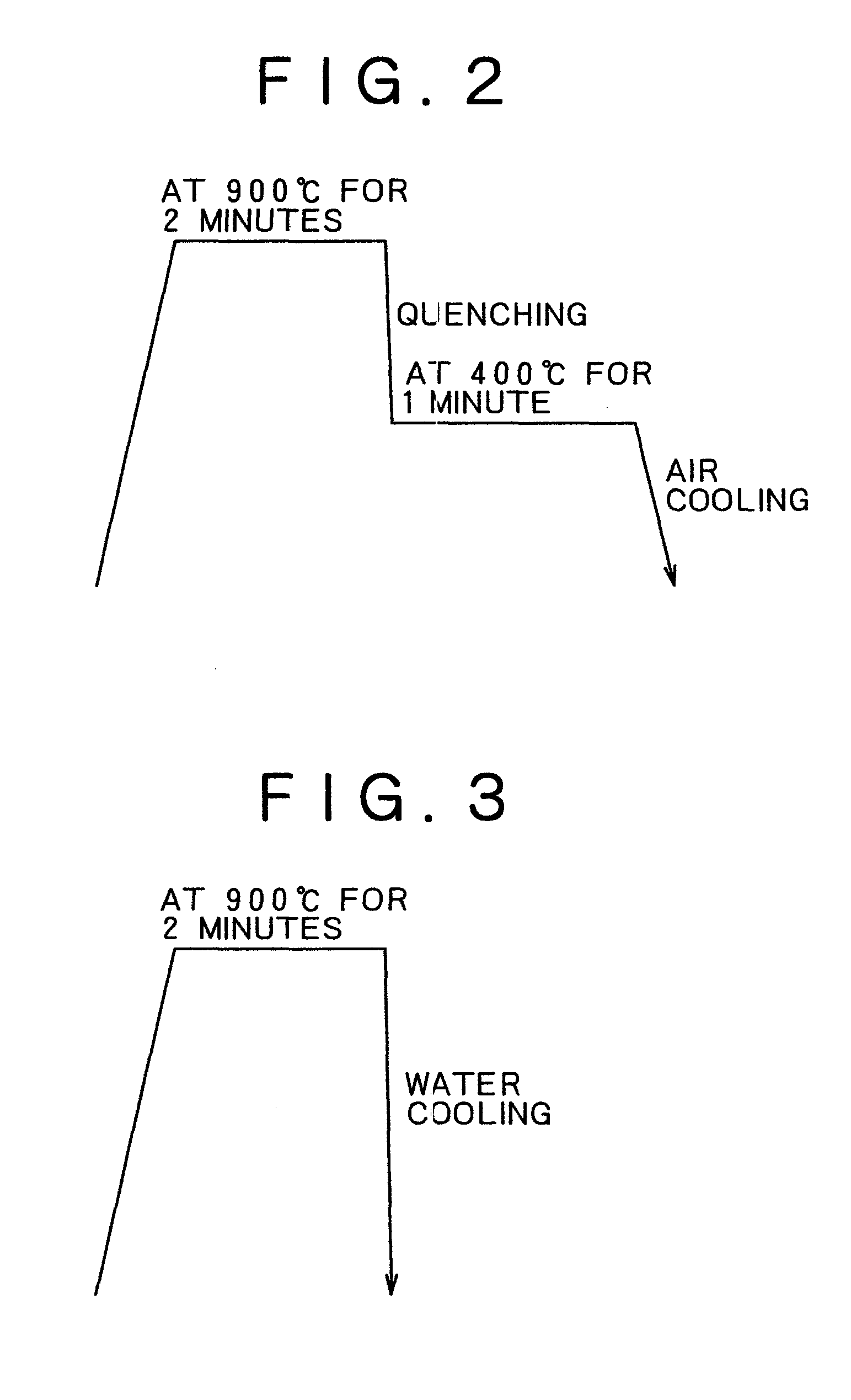

Dual phase steel sheet with good bake-hardening properties

ActiveUS20090242085A1Well-balanced strengthWell-balanced workabilityFurnace typesHeat treatment furnacesPre strainCooking & baking

A dual phase steel sheet with good bake-hardening properties is provided. The steel sheet is characterized in containing (in terms of percent by mass) C: no less than 0.06% and less than 0.25%; Si+Al: 0.5 to 3%; Mn: 0.5 to 3%; P: no more than 0.15%; and S: no more than 0.02%; and also meeting the following condition (in terms of space factor) that retained austenite is at least 3%, bainite is at least 30%, and ferrite is no more than 50%, and further characterized in differing in stress larger than 50 MPa before and after application of 2% pre-strain and ensuing heat treatment for paint baking at 170° C. for 20 minutes. The steel sheet has well-balanced strength and workability, exhibits good bake-hardening properties at the time of paint baking, and offers good resistance to natural aging.

Owner:KOBE STEEL LTD

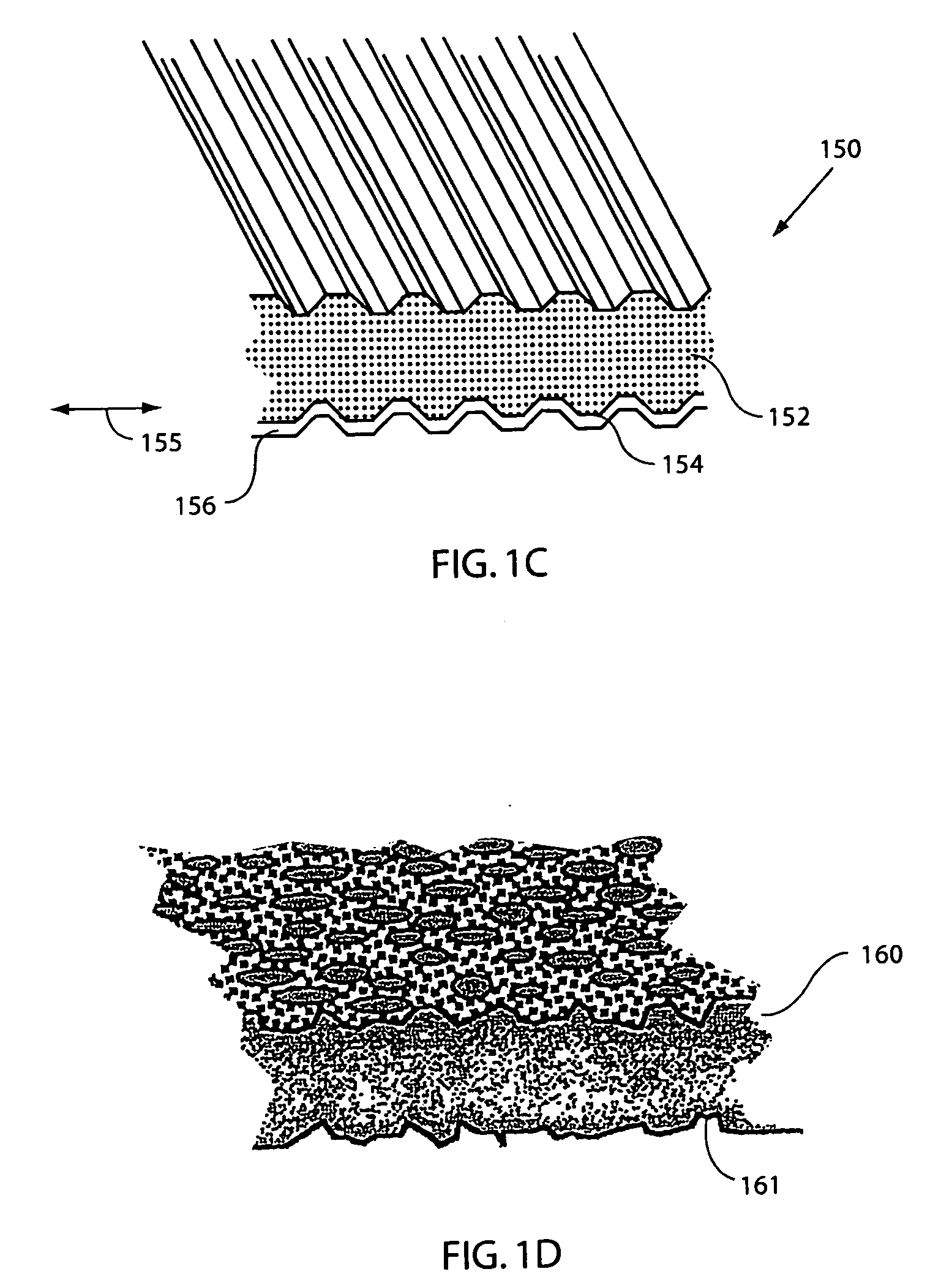

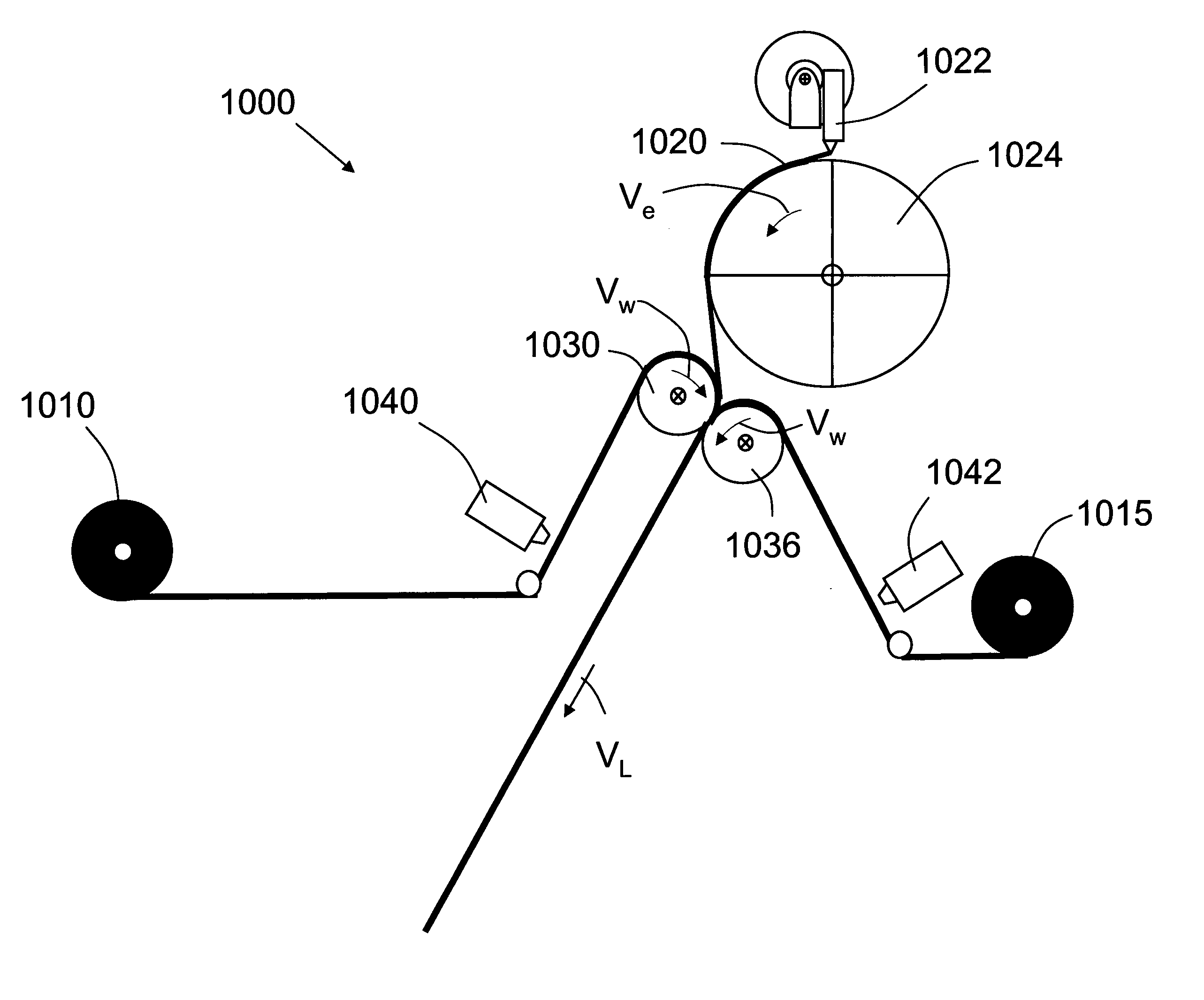

Stretch laminate with beamed elastics and formed nonwoven layer

A stretch laminate is disclosed. The stretch laminate may include a layer of nonwoven material that includes an accumulation of filaments and has an inner surface and an outer surface, the outer surface having an ordered arrangement of zones, each zone having an attenuated region adjacent to a build-up region wherein the attenuated region has a first basis weight and the build-up region has a second basis weight greater than the first basis weight, the difference in basis weights corresponding to disposition of the filaments according to the ordered arrangement. The stretch laminate may include a plurality of elastic strands space apart from each other in a crotch-stretch direction. In some examples the elastic strands may have an Average Strand Spacing no greater than 3 mm and / or an Average Decitex no greater than 300, and / or an Average Pre-Strain no greater than 250 percent.

Owner:THE PROCTER & GAMBLE COMPANY

Method for producing a laminate having varying pre-strained elastics

Owner:THE PROCTER & GAMBLE COMPANY

Self-resetting super-elastic shape memory alloy damper

InactiveCN101070716ASimple structureEasy to installShock proofingPre strainMechanical engineering technology

Automatic-resetting super elasticity shape memory alloy damper is a damping control device used in the areas of civil construction and mechanical engineering technique .It is characteristiced by its framework that consisted of a working piston , a fixing piston , a cylinder ,a cover and a joint rod .The machine uses its alloy wire to restrict the left and right pistons to the partition-wall of the cylinderand the spacing nut. when the pull bar works, piston in one side works follow it ,the piston in the other side is resisted by the partition-wall of the cylinder and keep the resetting alloy wire on running and produce a great anamorphosis restoration ability.The pre-strain resetting super elasticity shape memory alloy wires are divided into tow groups, one of which is used to connect the right fixing piston to the left coverand, the other is used to bind the left fixing piston to the right cover.the two groups doing a interchange push and pull in the pull bars in order to create a bigger energy consumption. The invention simultaneously has the functions of good energy consumption and resetting.It can reduce the vibration of fabrics, components or the remained deformation and has simple structure.

Owner:DALIAN UNIV OF TECH

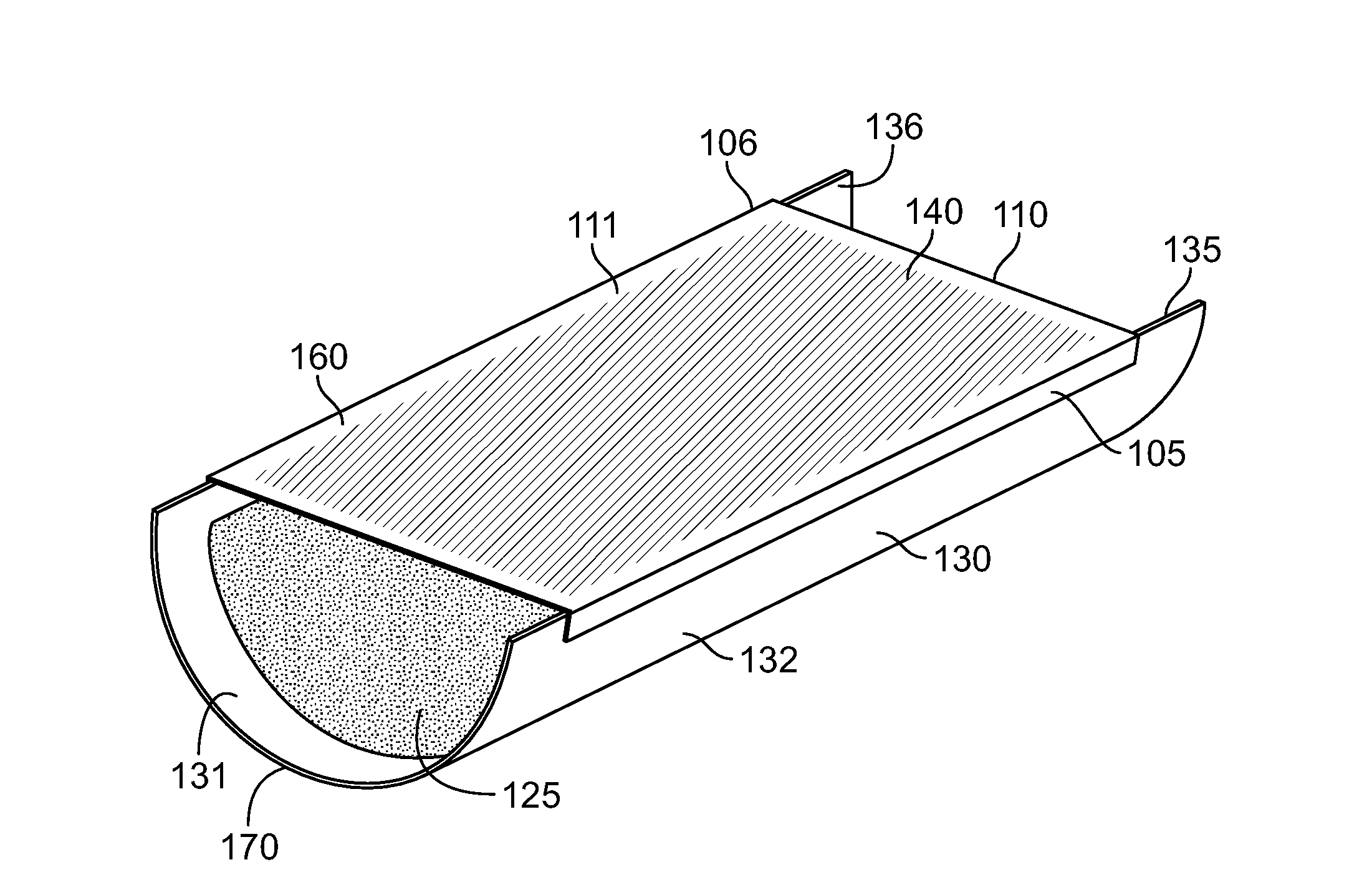

Strained skin treatment devices and methods

Devices, kits and methods described herein may include a dressing that is pre-strained and stored for a period of time after which the dressing is applied to the skin of a subject.

Owner:NEODYNE BIOSCI INC

Titanium alloy thin-wall part hot-stretch creep deformation composite molding method

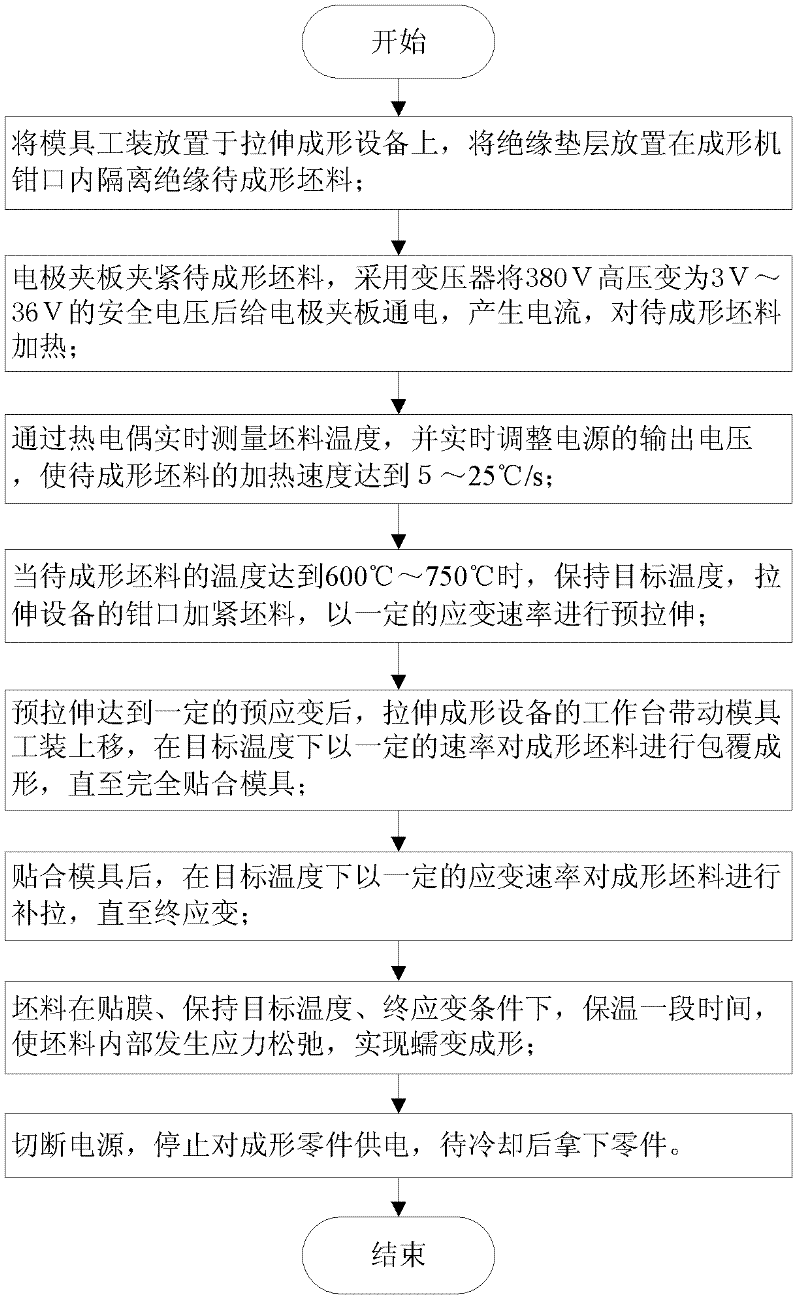

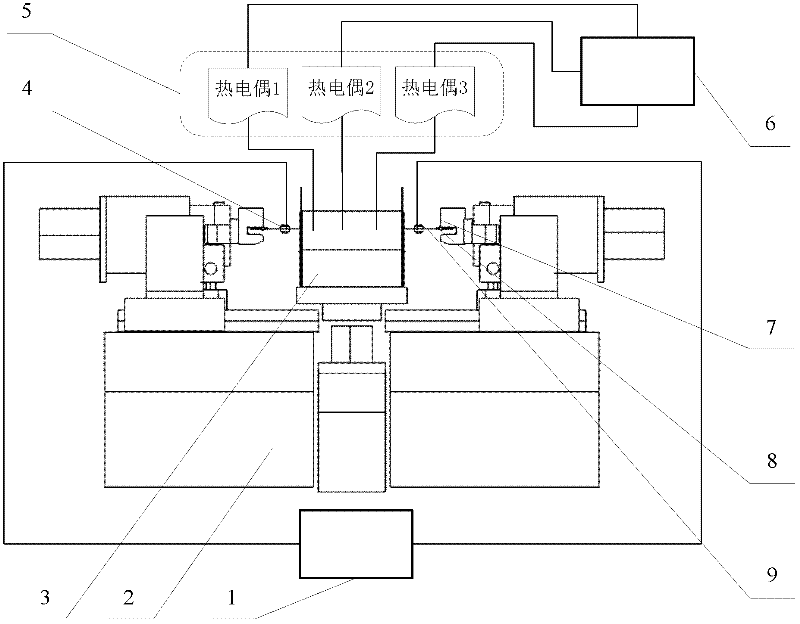

The invention discloses a titanium alloy thin-wall part hot-stretch creep deformation composite molding method. The titanium alloy thin-wall part hot-stretch creep deformation composite molding method comprises eight steps that 1, equipment and raw materials are prepared; 2, electrode splints are electrified and a blank material needing to be molded is heated; 3, real-time measure of a temperature of the blank material needing to be molded is carried out and output voltage of a power supply is adjusted in real time to realize a blank material heating rate of 5 to 25 DEG C per second; 4, when a temperature of the blank material needing to be molded is in a range of 600 to 750 DEG C, jaws of a stretch molding device clamp the blank material needing to be molded and the blank material needing to be molded is subjected to pre-stretch at a preset strain rate; 5, when a pre-strain ratio is in a range of 0.1 to 4%, the molded blank material is subjected to coating at a temperature of 600 to 750 DEG C and a preset strain rate until the molded blank material is completely fitted to a mold; 6, the molded blank material treated by the step 5 is subjected to stretch supplement at a temperature of 600 to 750 DEG C and a preset strain rate until an end strain ratio is in a range of 0.1 to 8%; 7, the molded blank material treated by the step 6 is subjected to heat preservation for a period of time so that stress relaxation in the molded blank material occurs and creep deformation molding is realized; and 8, the powder supply is cut off and the molded blank material treated by the step 7 is cooled and is taken down.

Owner:BEIHANG UNIV

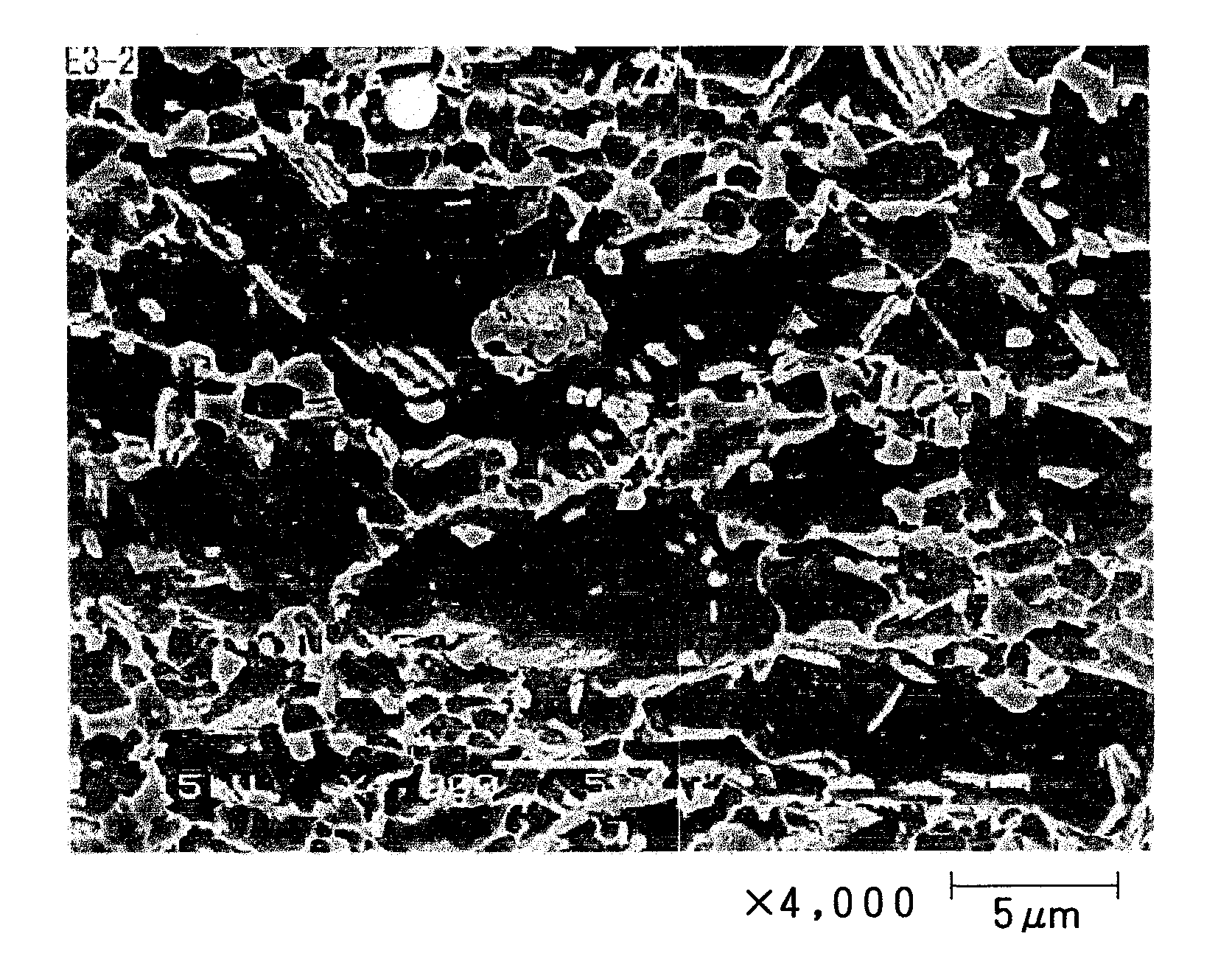

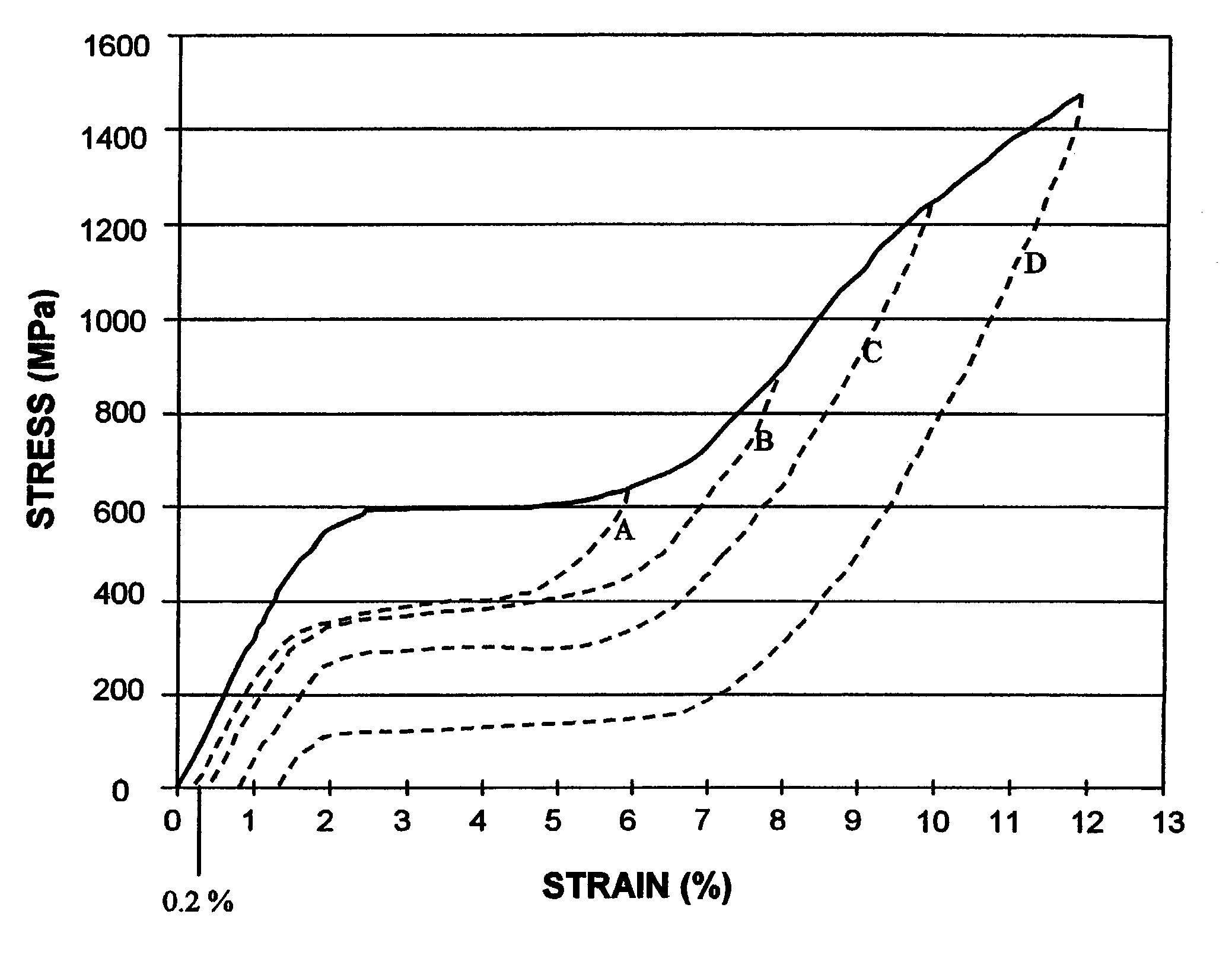

Shape memory alloy articles with improved fatigue performance and methods therefor

InactiveUS7789979B2Improve fatigue performanceImprove fatigue lifeStentsSurgeryPre strainControl manner

Articles made of shape memory alloys having improved fatigue performance and to methods of treating articles formed from shape memory alloy materials by pre-straining the articles (or desired portions of the articles) in a controlled manner so that the resultant articles exhibit improved fatigue performance. The shape memory articles are preferably medical devices, more preferably implantable medical devices. They are most preferably devices of nitinol shape memory alloy, most particularly that is superelastic at normal body temperature. The pre-straining method of the present invention as performed on such articles includes the controlled introduction of non-recoverable tensile strains greater than about 0.20% at the surface of a desired portion of a shape memory alloy article. Controlled pre-straining operations are performed on the shape-set nitinol metal to achieve nonrecoverable tensile strain greater than about 0.20% at or near the surface of selected regions in the nitinol metal article. The pre-straining operations result in a significant increase in fatigue life of the selectively treated regions and an overall improvement in the fatigue performance of the device.

Owner:WL GORE & ASSOC INC

Pre-deformation method capable of endowing cement pavement calking material with shape memory function

The invention provides a pre-deformation method capable of endowing a cement pavement calking material with a shape memory function, belongs to the technical field of cement pavement calking material preparation, and solves the problems of one-way shape memory function endowing , poor self-healing effect, complex temperature control requirement, high cost, limited preparation amount, poor durability and the like in the current pre-deformation method for the cement pavement calking material. The pre-deformation method comprises the following steps: stretching and deforming a calking material vertically to a design strain value at the temperature which is higher than a calking material glass transition temperature, and freezing a pre-stretching strain; applying compressive stress at a constant speed to a test piece in a vertical stretching direction at a normal temperature to enable the test piece to reach a preset compressive strain level, fixing the pre-compressive strain value, and endowing the calking material with the shape memory function in a two-dimensional direction; measuring the shape memory effect and other pavement performance of the calking material, and preferably selecting a group of reasonable stretching and compressive pre-strain value combination. According to the method provided by the invention, the difficulty in two-dimensional pre-deformation is reduced, so that the calking material has a better shape memory effect, and the durability of the calking material and a cement pavement are improved.

Owner:NANJING FORESTRY UNIV

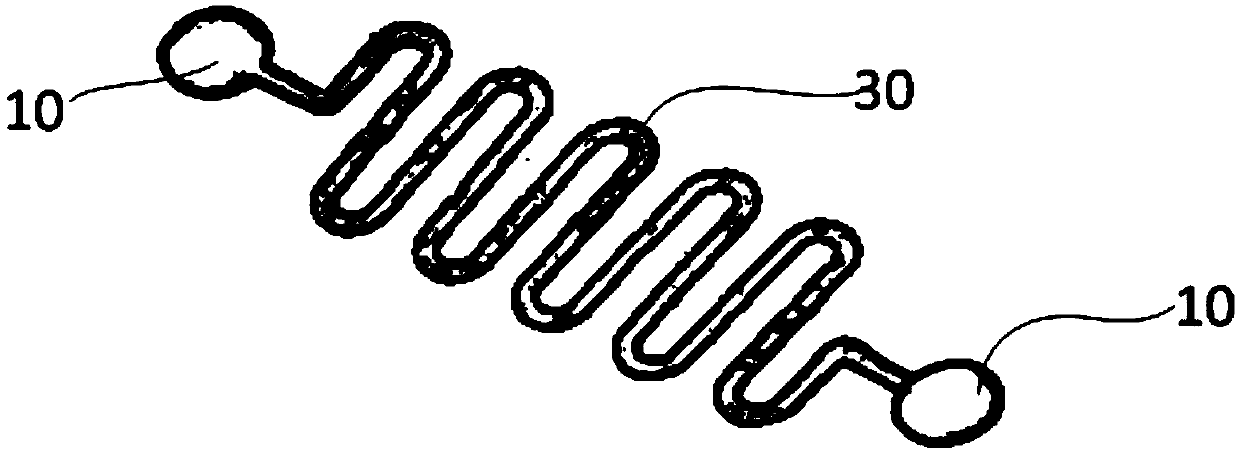

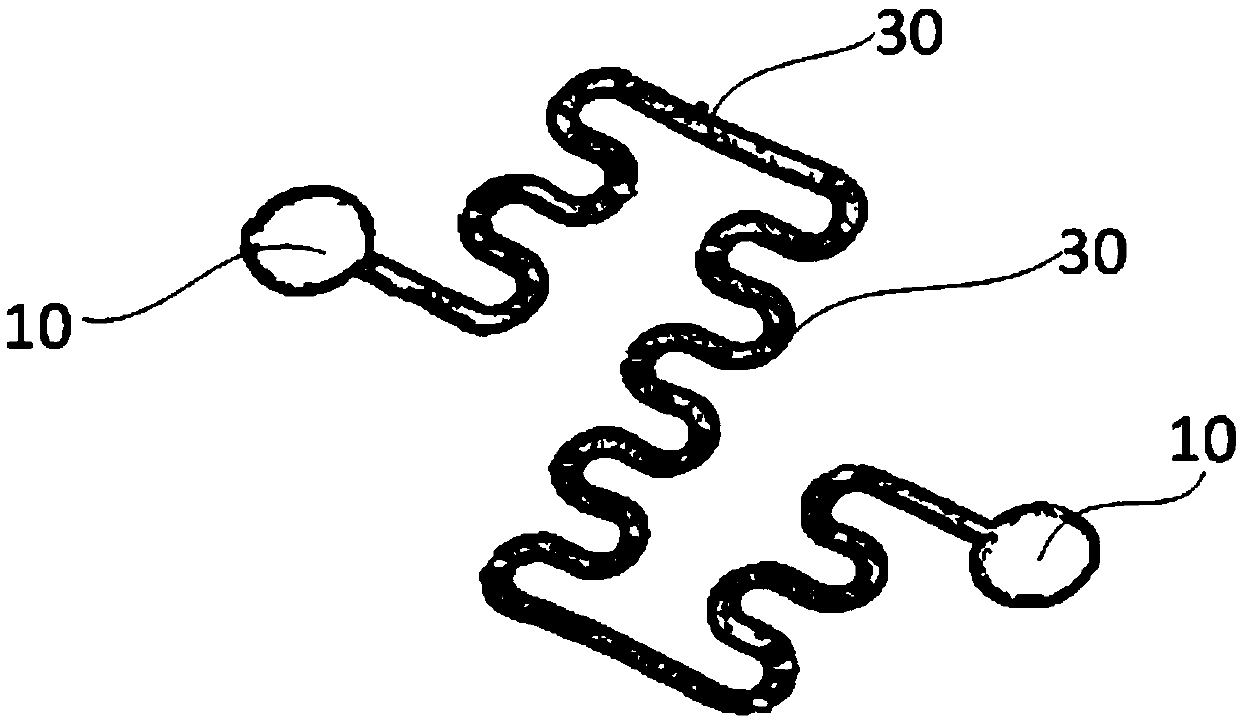

Flexible lead, preparation method of flexible electronic device and flexible wireless energy supply device

ActiveCN109545450AHigh precisionLarge scale preparationConductive layers on insulating-supportsParticular array feeding systemsPre strainResource utilization

The invention provides a flexible lead, a preparation method of a flexible electronic device and a flexible wireless energy supply device. The method comprises steps that a base material formed through combining a rigid substrate, a sacrificial layer and a functional film is provided; a femtosecond laser is utilized to cut the functional film of the base material such that the functional film is formed with a planar wire structure; the sacrificial layer is removed, and the planar wire structure is separated from the rigid substrate; a two-dimensional flexible wire is formed on the planar wirestructure; or the planar wire structure is assembled to a pre-stretched flexible substrate, pre-strain of the flexible substrate is released, and the planar wire structure is bent to form a three-dimensional flexible wire . The method is advantaged in that the flexible wire with high precision, large scale and no pattern limitation can be prepared, unique advantages of fast property, environmentalprotection, low cost, high resource utilization rate and insensitivity to the external environment can be further realized, and the method is suitable for preparing 2D and 3D flexible wires.

Owner:TSINGHUA UNIV

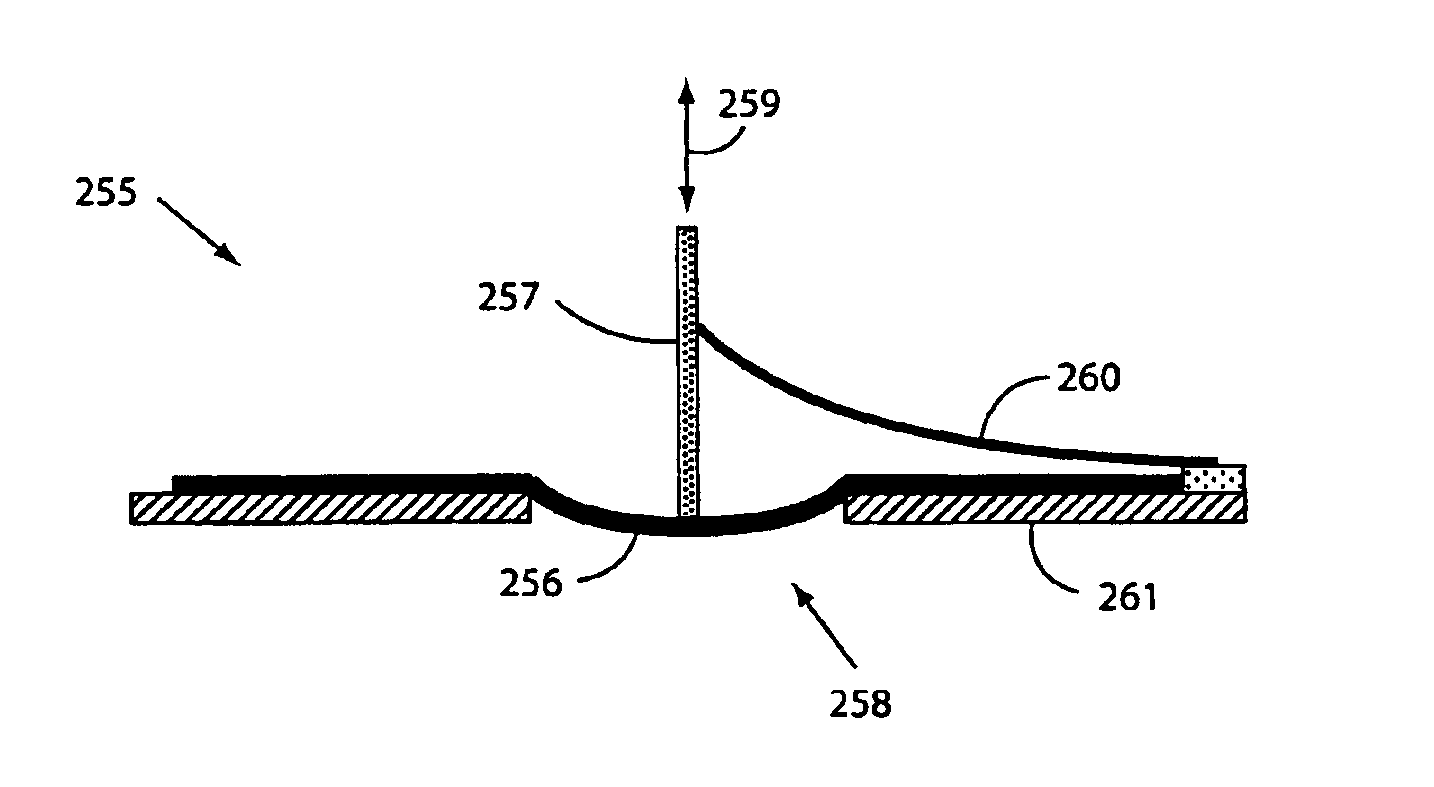

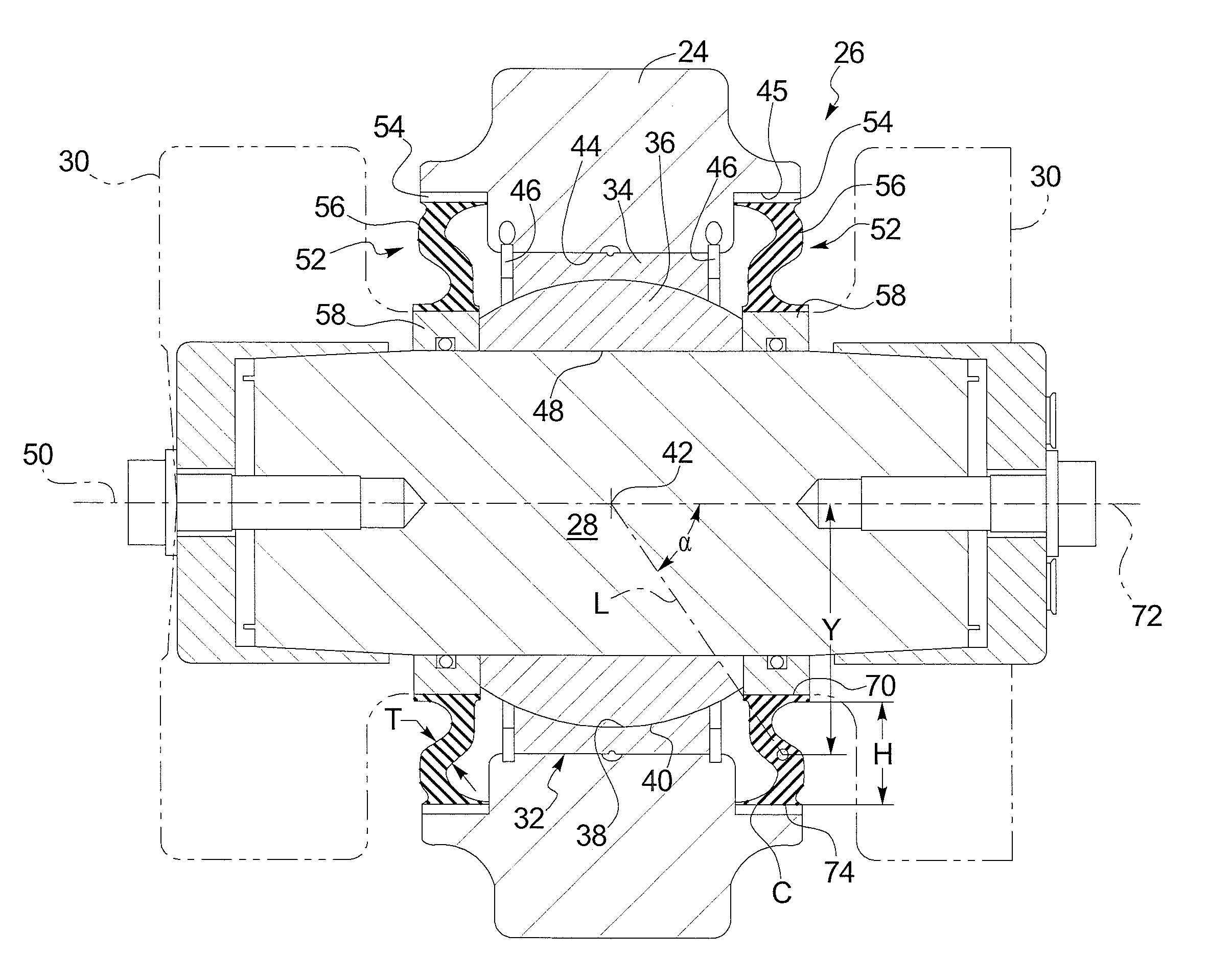

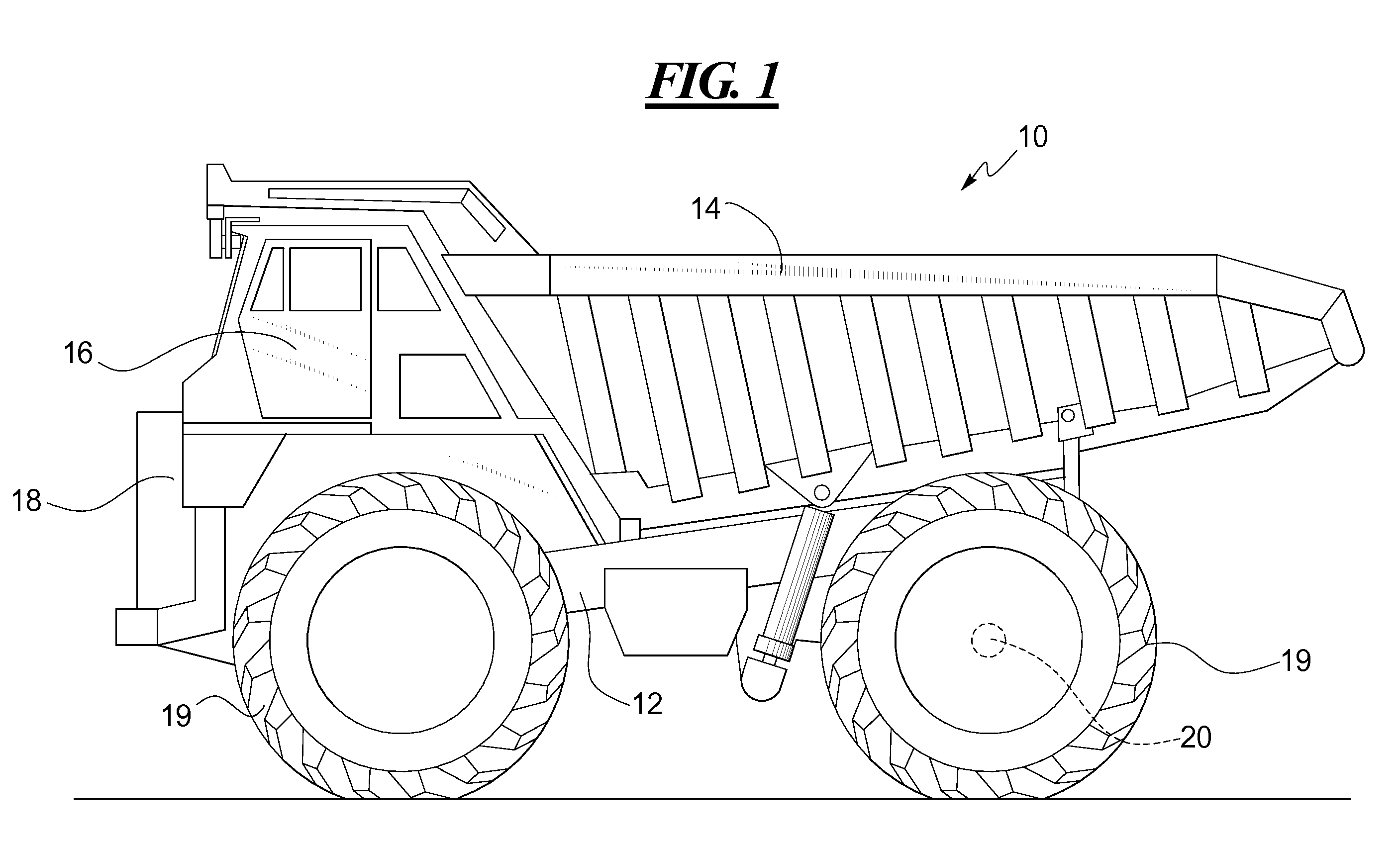

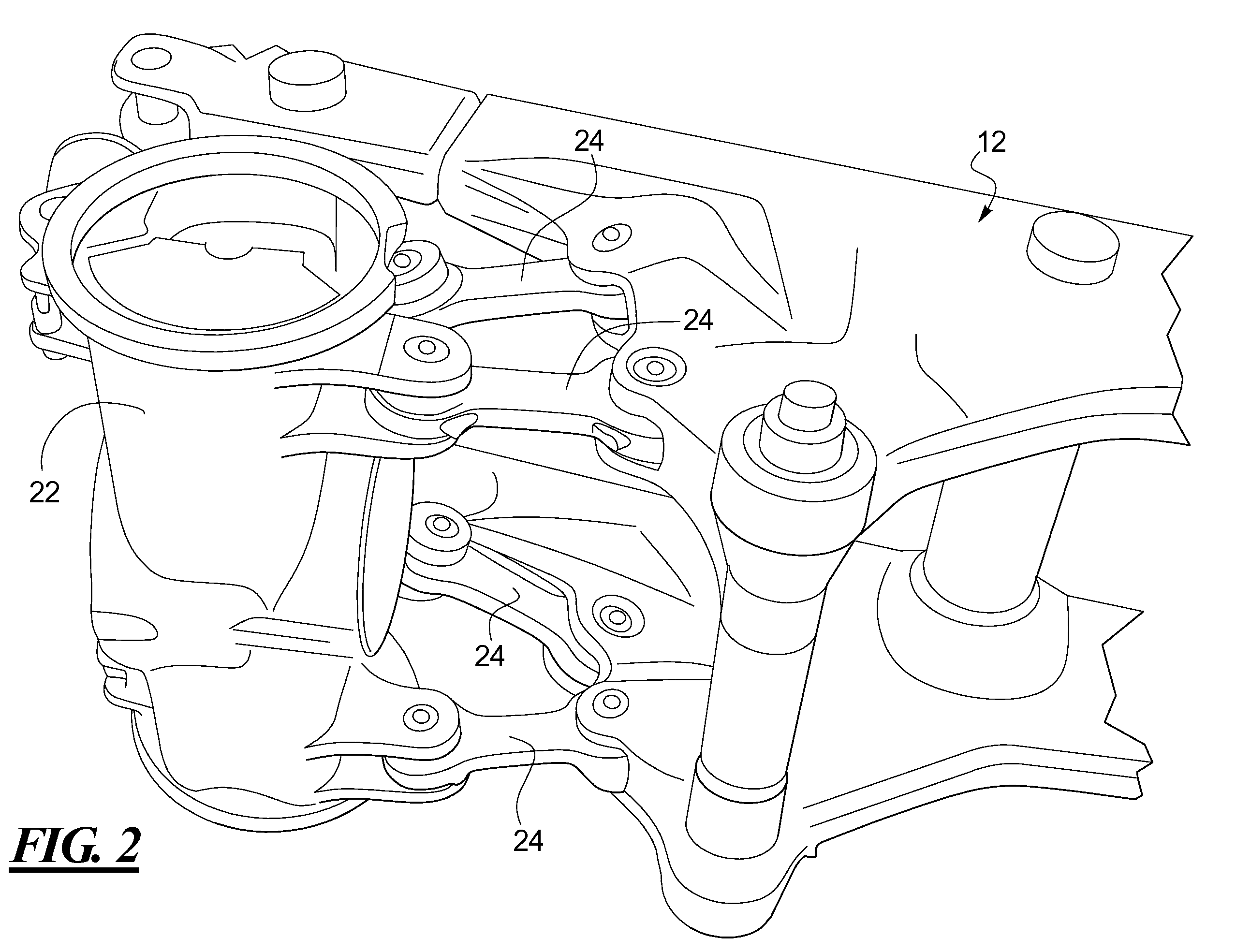

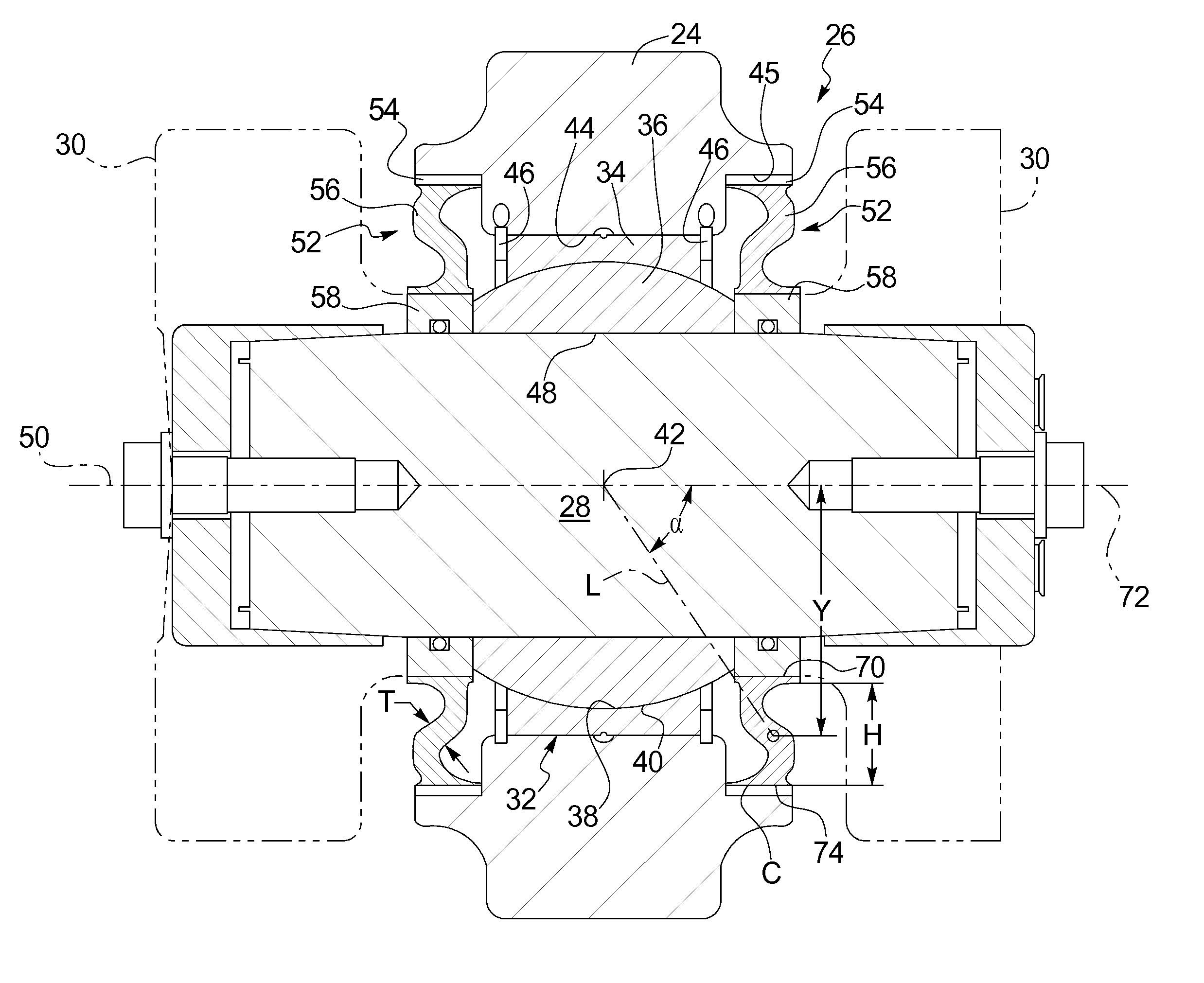

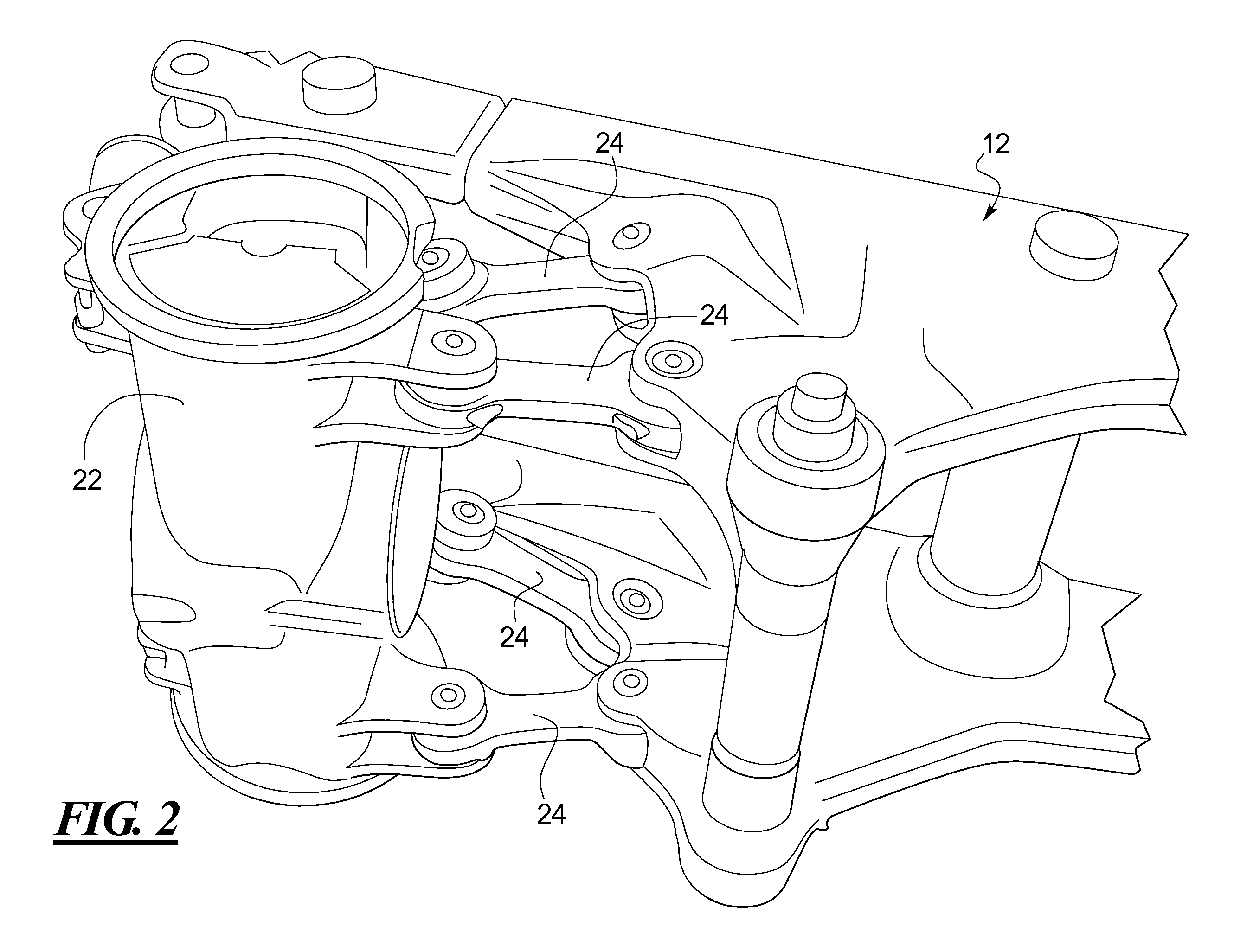

Seal assembly and method for forming a seal assembly

A seal assembly and method of forming a seal assembly provides a seal body having reduced strain during use, thereby increasing service life. The seal body may be formed within certain parameters, such as ranges of height-to-thickness and offset-to-height ratios, which have been found to reduce strain. Additionally or alternatively, the seal body may be modified from an initial configuration to a pre-strained configuration by axially displacing an inner section of the seal with respect to an outer section of the seal, which also reduces strain.

Owner:CATERPILLAR INC

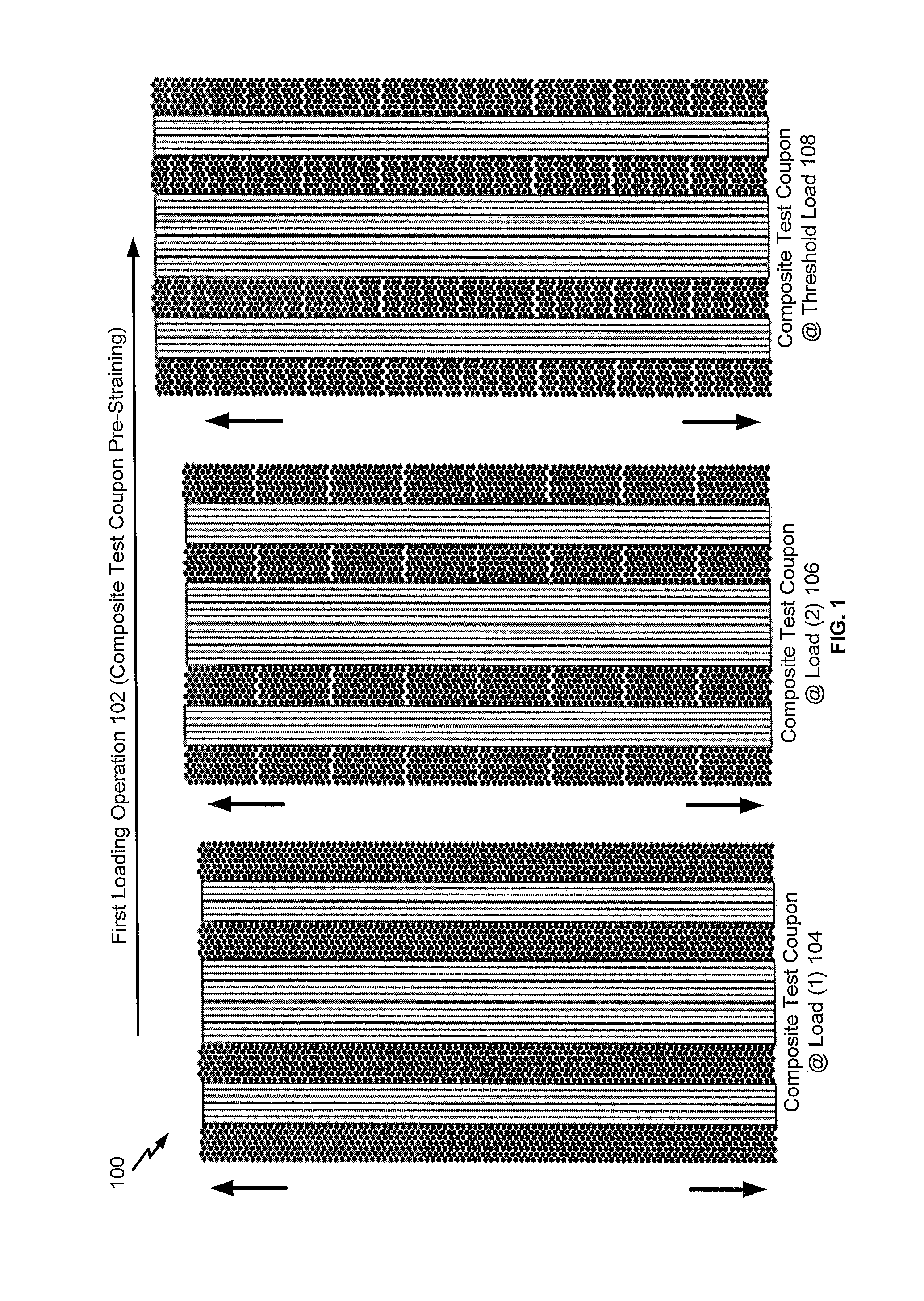

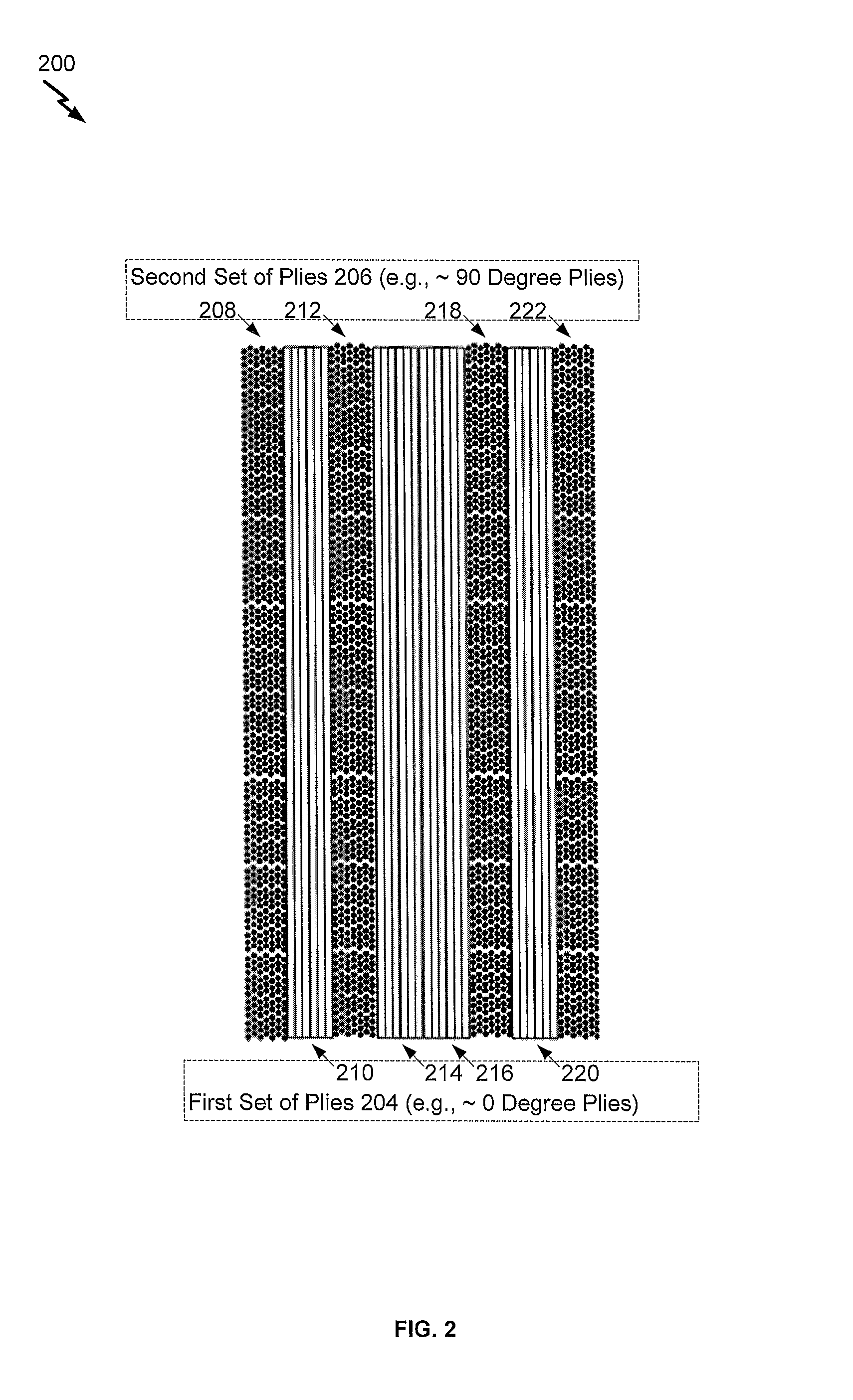

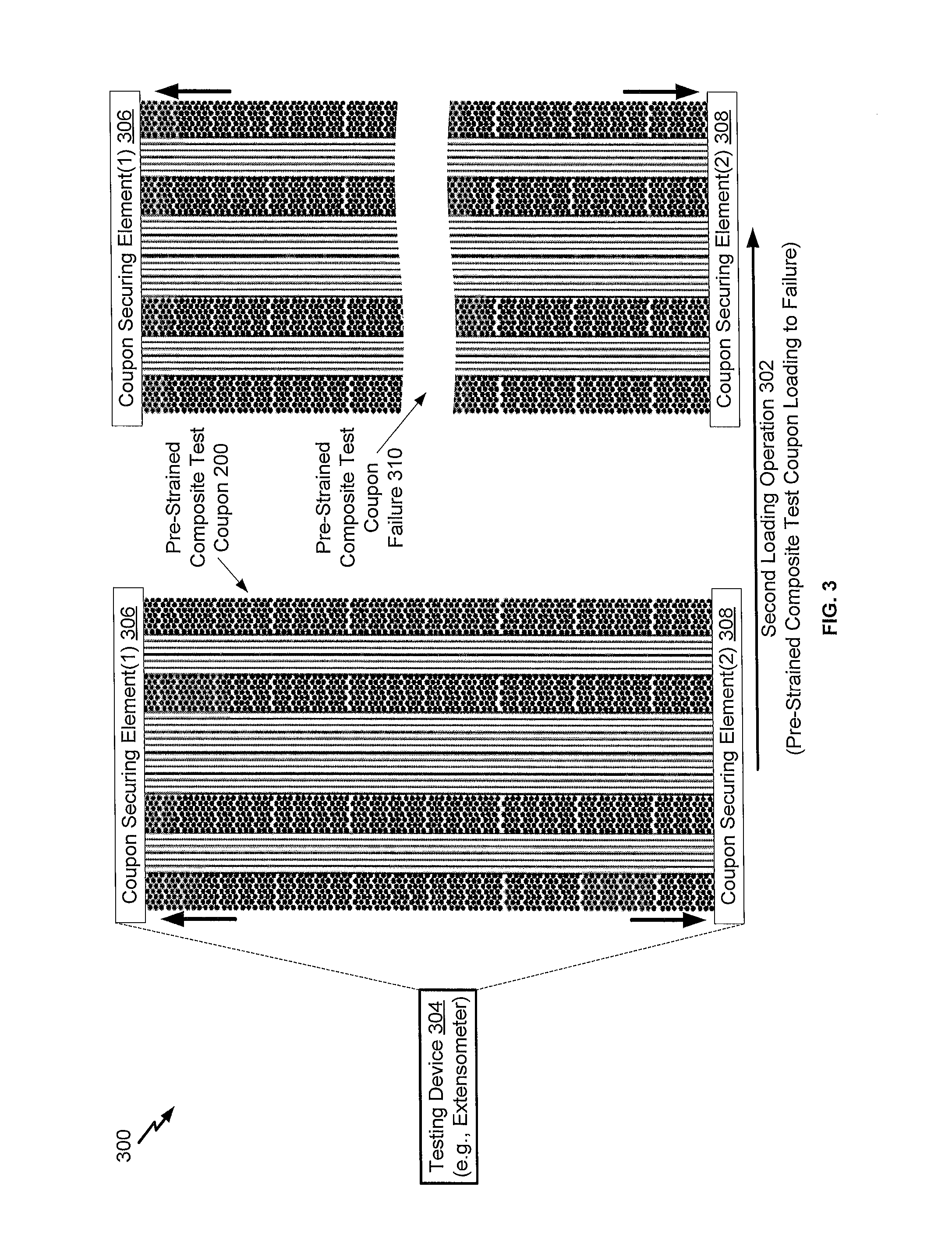

Pre-strained composite test coupons

A composite test coupon includes a plurality of plies. The plurality of plies include first ply layers and second ply layers. The first ply layers have first fibers and a substantially uniform matrix material associated with the first fibers. The second ply layers have second fibers and a pre-stressed matrix material associated with the second fibers. The first fibers are oriented in a first direction, and the second fibers are oriented in a second direction that is different from the first direction. The pre-stressed matrix material includes stress induced cracks between the second fibers of each of the second ply layers.

Owner:THE BOEING CO

Seal Assembly and Method for Forming a Seal Assembly

A seal assembly and method of forming a seal assembly provides a seal body having reduced strain during use, thereby increasing service life. The seal body may be formed within certain parameters, such as ranges of height-to-thickness and offset-to-height ratios, which have been found to reduce strain. Additionally or alternatively, the seal body may be modified from an initial configuration to a pre-strained configuration by axially displacing an inner section of the seal with respect to an outer section of the seal, which also reduces strain.

Owner:CATERPILLAR INC

Extensible laminate having elastics of differing elastic properties

Owner:THE PROCTER & GAMBLE COMPANY

Dual-mode high-waist foldover disposable absorbent pant

A dual-mode high-waist disposable absorbent pant with foldover waist features is disclosed. The pant may include a laterally extending folding region disposed longitudinally between the waist opening edge and the front and / or rear ends of an absorbent core structure; the folding region may include a first web structure. The pant may also include a waistband region disposed longitudinally between the waist opening edge and the folding region; the waistband region may include a second web structure and one or a plurality of laterally extending, pre-strained elastic member(s) disposed between a first pair of layers. The second web structure may differ in configuration from the first web structure. The longitudinal dimension between the waist opening edge of the pant and the leg opening edges may be at least 30 percent of the overall length of the pant when in an open, fully extended and flattened condition.

Owner:THE PROCTER & GAMBLE COMPANY

Nonwoven web material having bonding favorable for making directional stretch laminate, and directional stretch laminate

Owner:THE PROCTER & GAMBLE COMPANY

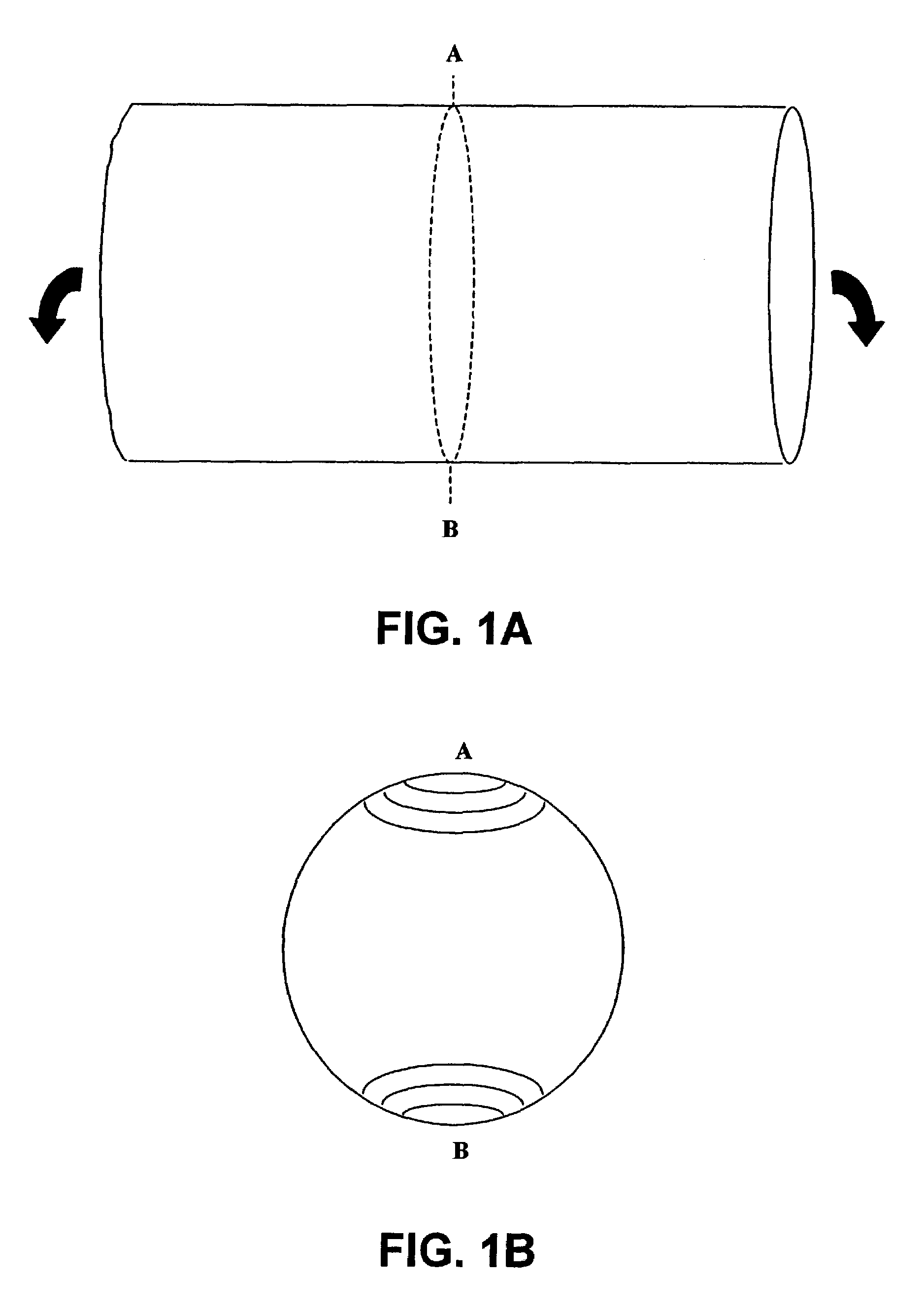

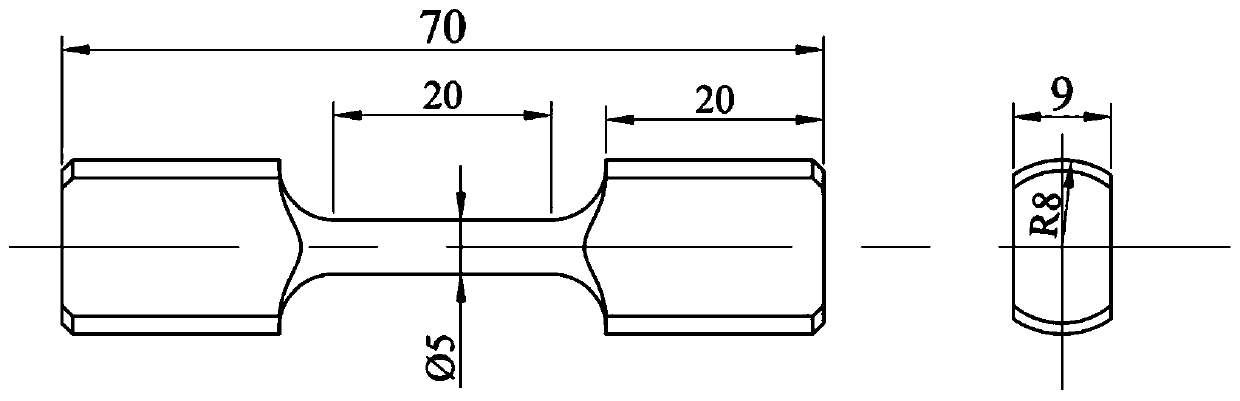

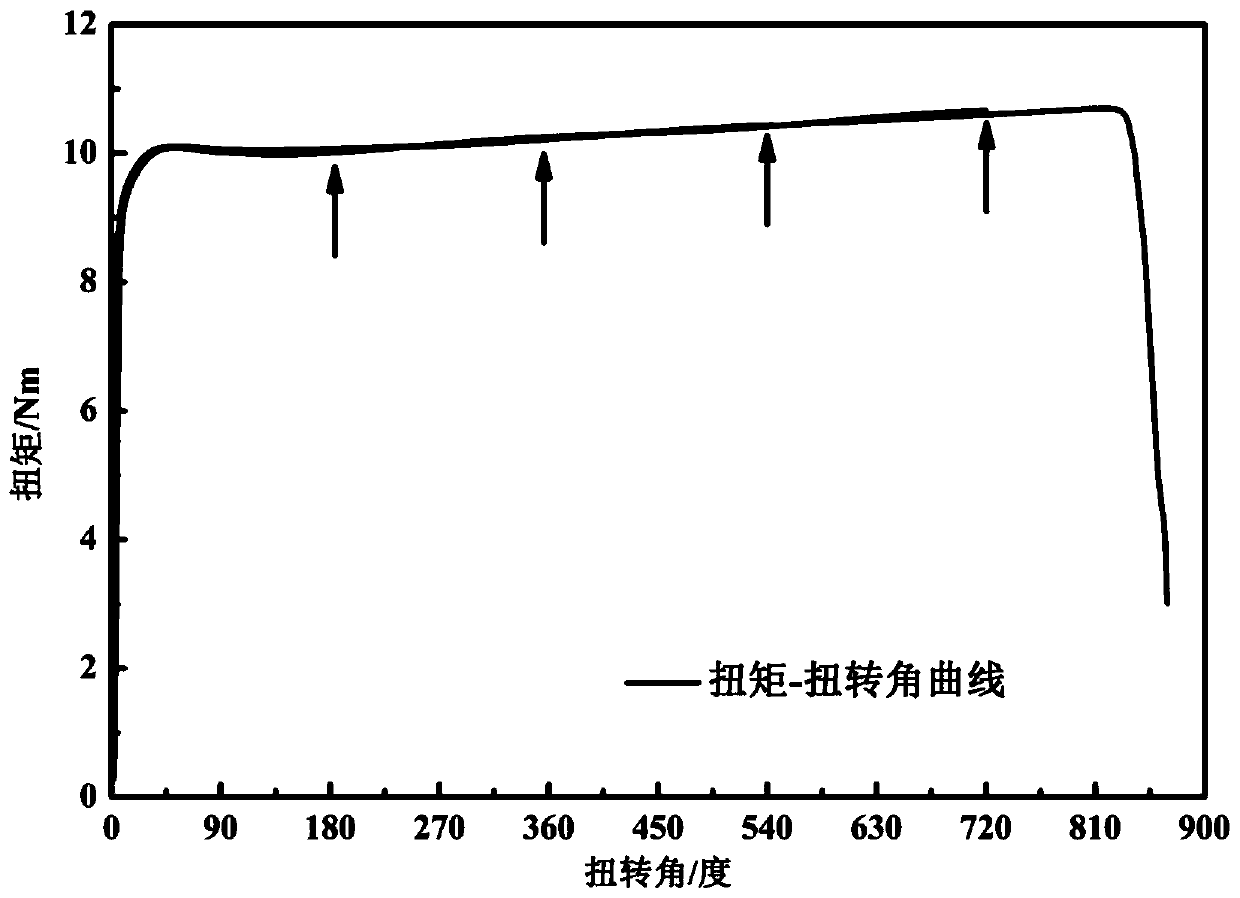

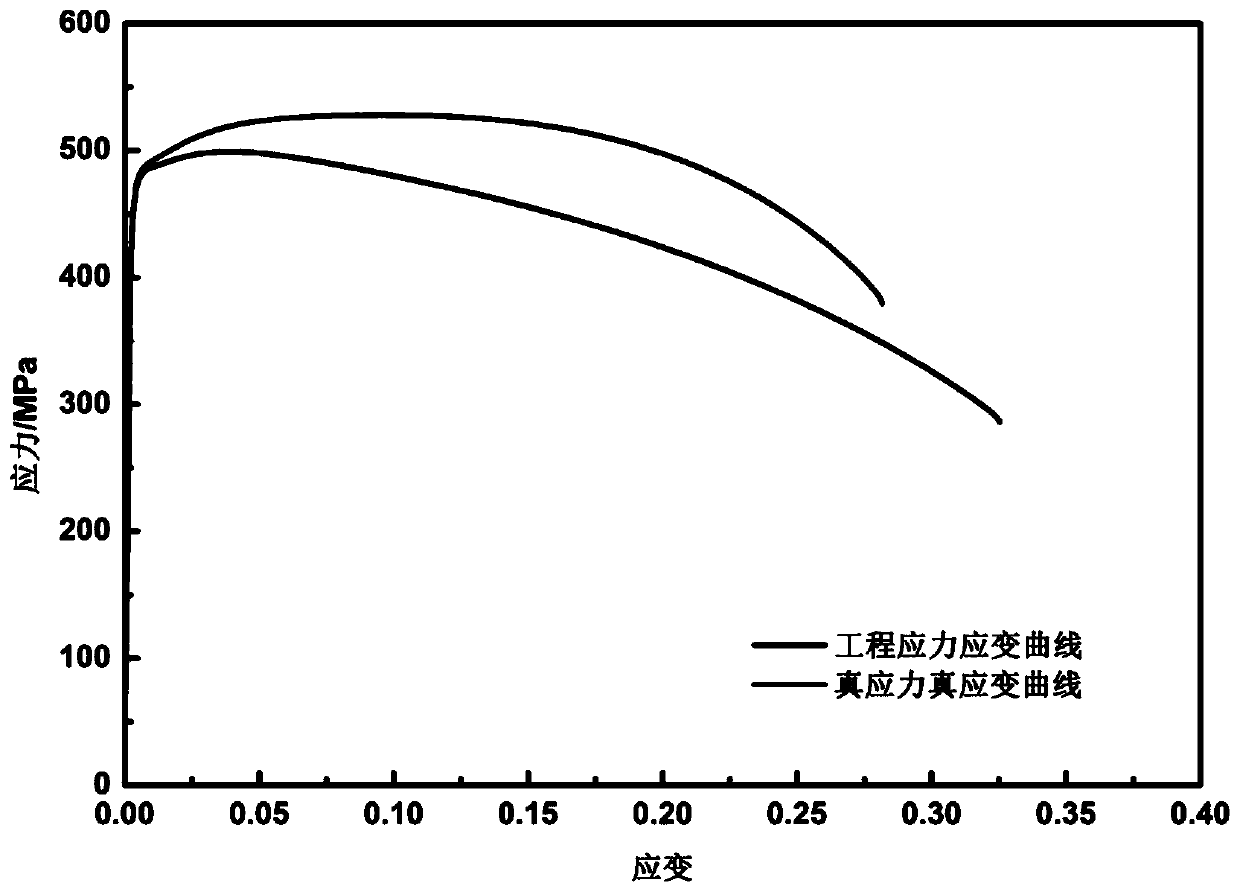

Testing and measurement method for hardening curve of metal bar under large strain range

ActiveCN110702513AEfficient accumulationAccumulate evenlyMaterial strength using tensile/compressive forcesPre strainTorsion test

The invention relates to a testing and measurement method for a hardening curve of a metal bar under a large strain range, and the method comprises the following steps of firstly carrying out round bar sample torsion test to determine an uniform torsion range, carrying out pre-torsion deformation of different levels on samples in the uniform torsion range, and calculating the corresponding pre-strain; subsequently carrying out round bar sample uniaxial tension test, carrying out uniaxial tension test respectively on torsion-free and torsion samples, determining an effective hardening curve before material necking according to the tension result of the torsion-free samples, determining a true stress and strain curve under different pre-strain levels of the samples by the torsion samples, and carrying out translation along a strain axis, wherein the amount of translation is the pre-strain cumulated by the corresponding pre-torsion deformation; finally extracting the true stress and totalplastic strain data corresponding to the maximum load point in the true stress and strain curves after each translation, fitting together with the pre-necking hardening curve determined by the samplewithout pre-torsion, and finally determining a hardening curve of the metal round bar samples under the large strain range.

Owner:JILIN UNIV

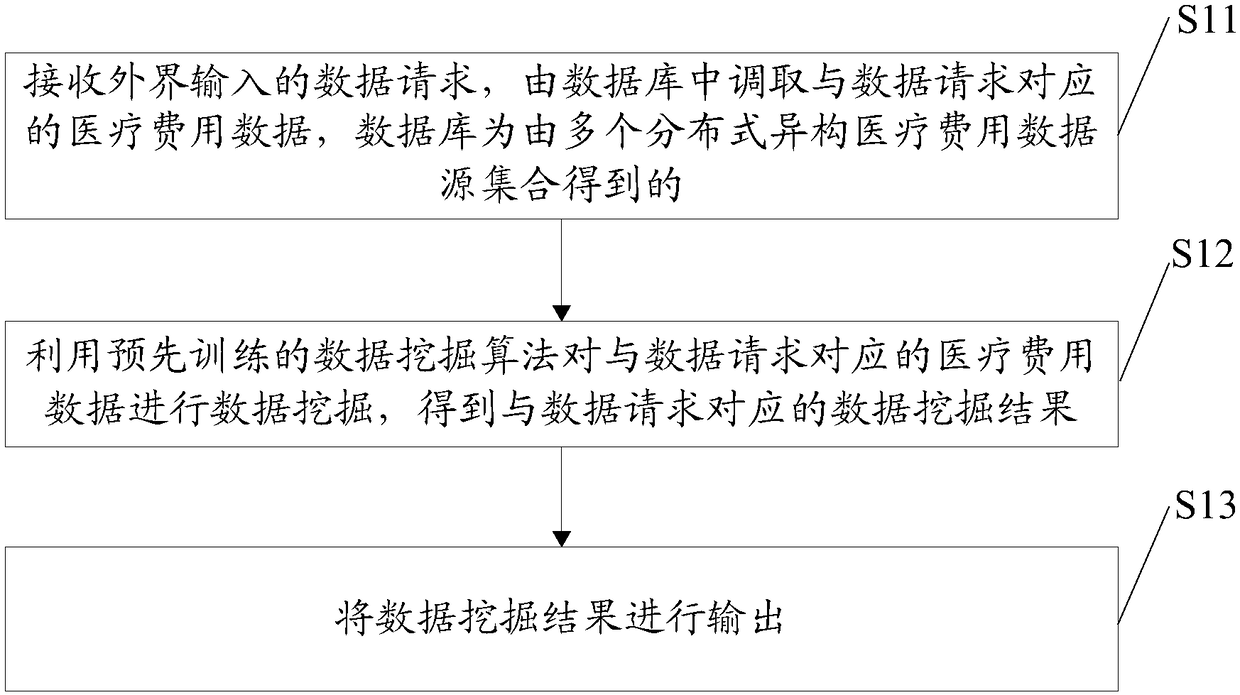

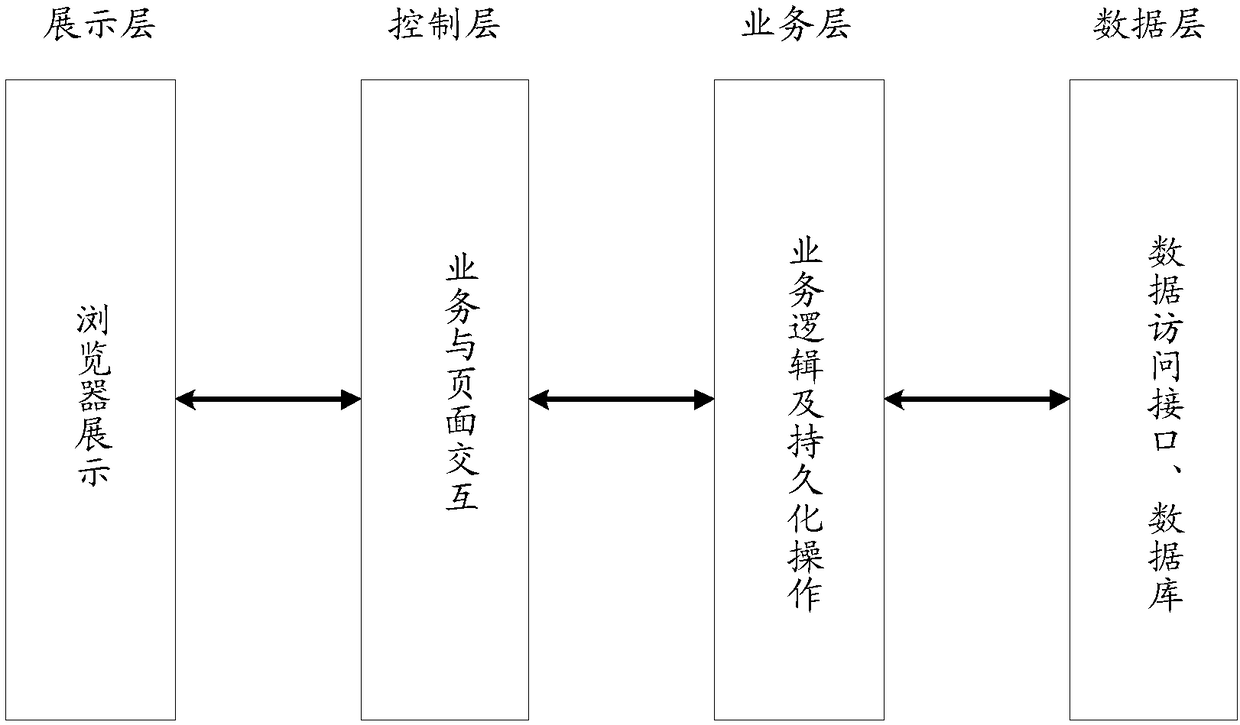

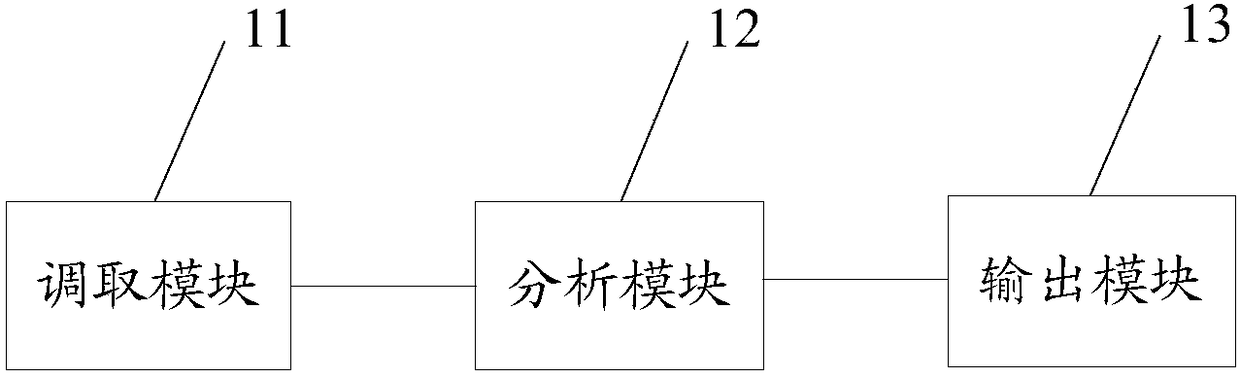

Medical expense big data analysis method, device and equipment

The invention discloses a medical expense big data analysis method, device and equipment and a computer readable storage medium. The method comprises the steps that a data request inputted from the outside is received, and the medical expense data corresponding to the data request are called from a database, wherein the database is obtained by integration of multiple distributed heterogeneous medical expense data sources; data mining is performed on the medical expense data corresponding to the data request by using the pre-strained data mining algorithm so as to obtain the data mining resultcorresponding to the data request; and the data mining result is outputted. According to the technical scheme, multiple distributed heterogeneous data sources are integrated in the unified database sothat unified analysis and management of the data can be facilitated; and the data useful for the user can be effectively acquired from the massive medical expense data and thus the method has great advantages in medical expense big data processing.

Owner:GUANGDONG UNIV OF TECH

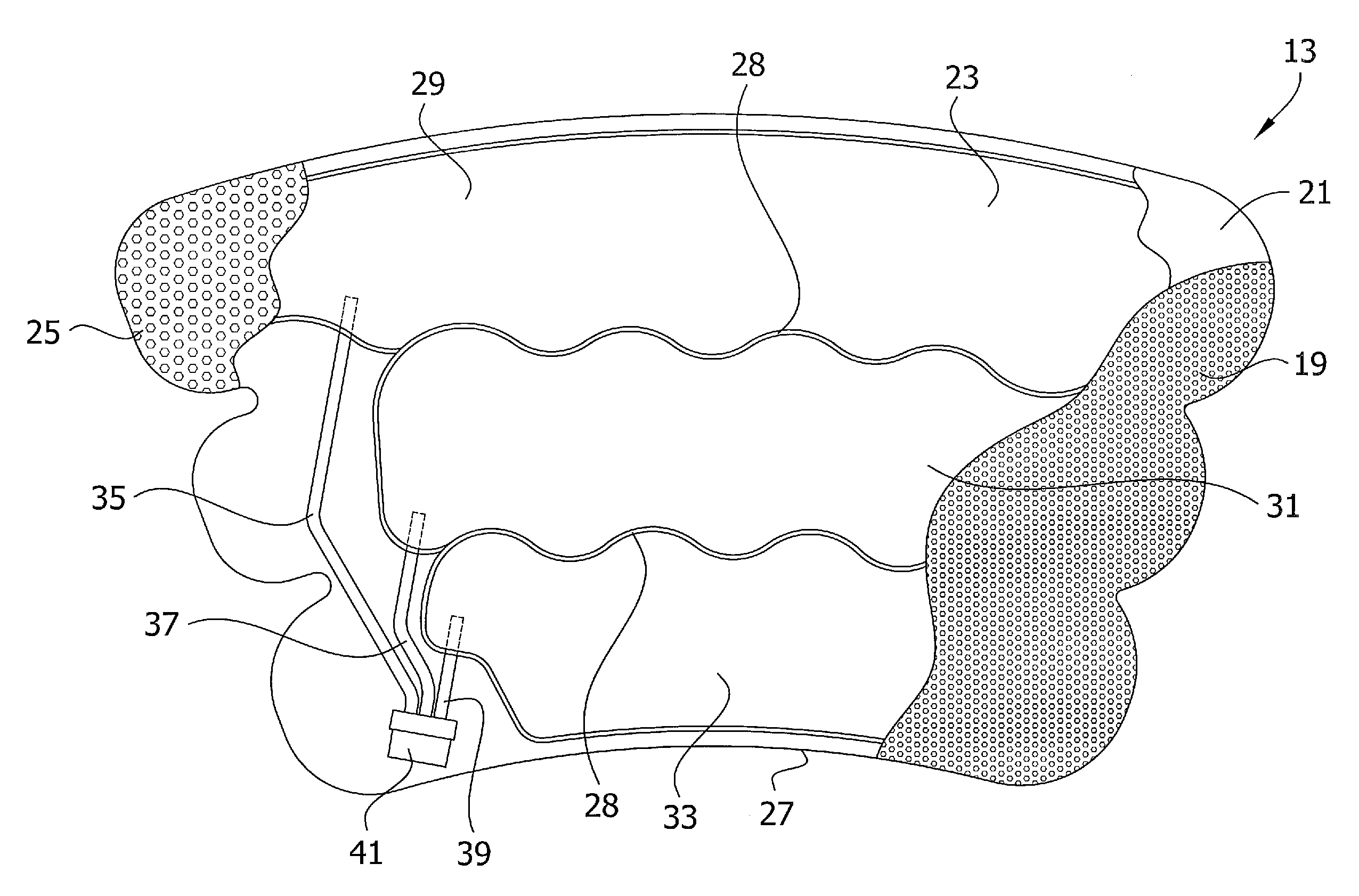

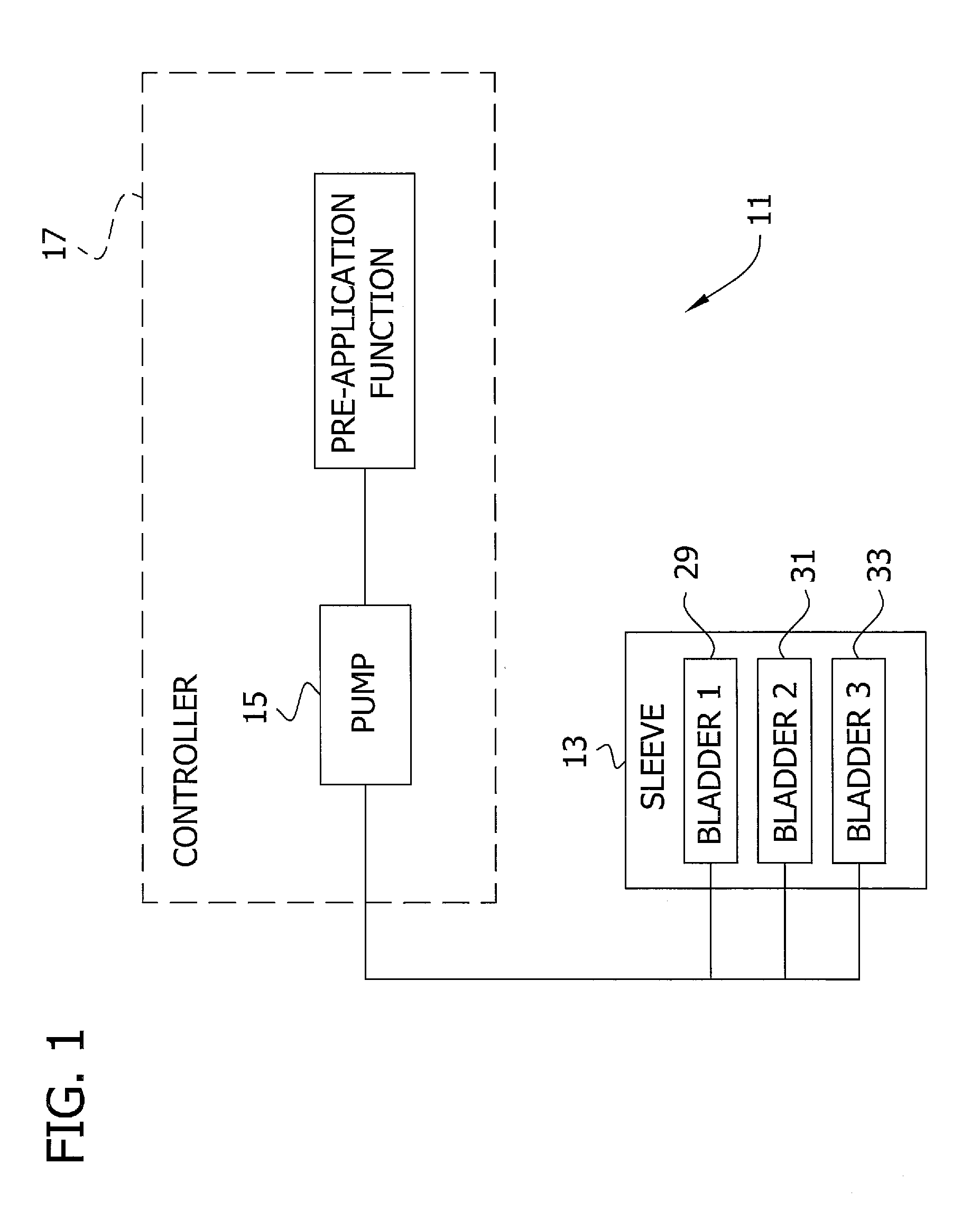

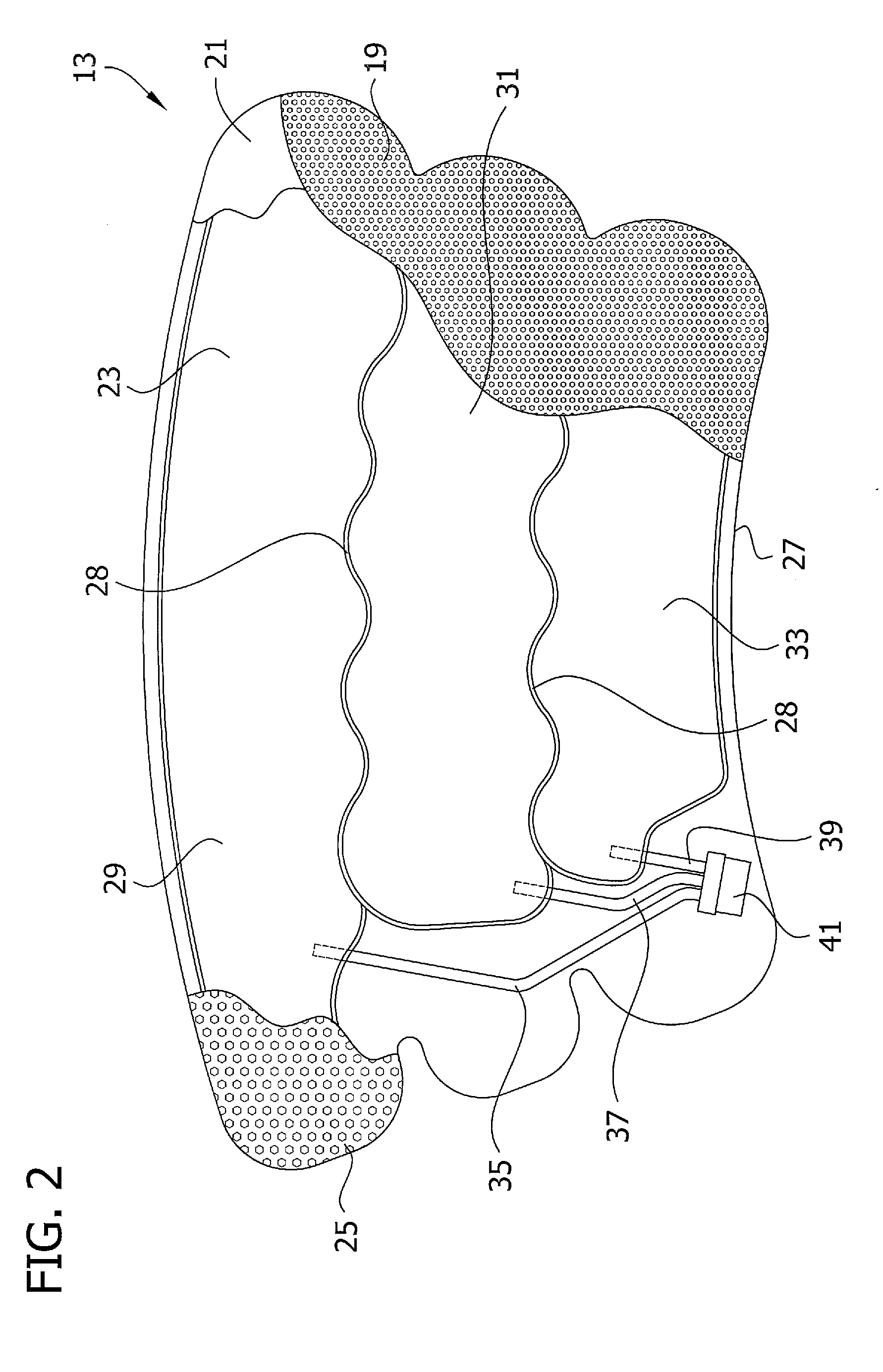

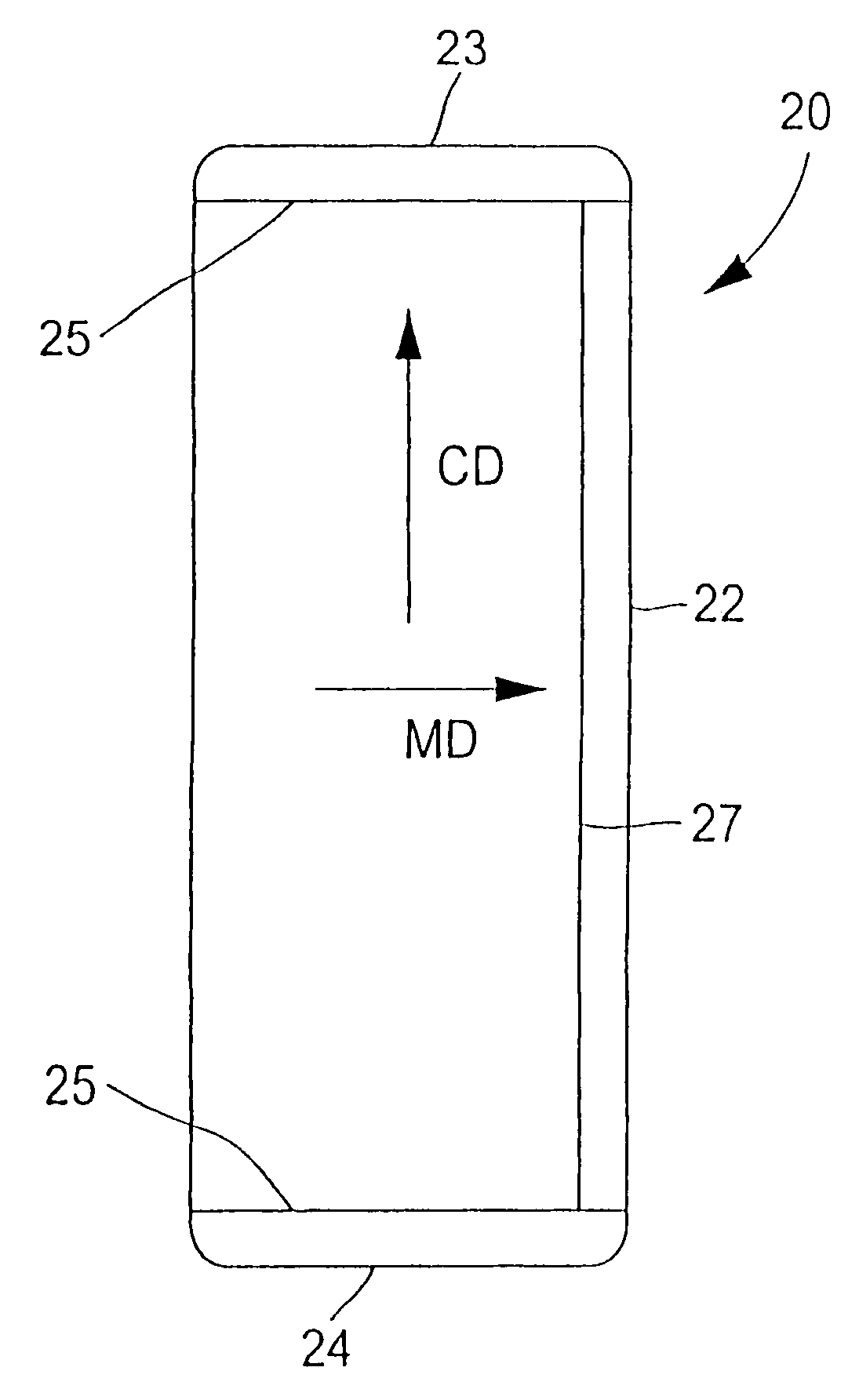

Compression bladder having pre-strained bladder material

InactiveUS20130085431A1High elastic modulusReduce gas volumeBlood stagnation preventionPneumatic massagePre strainCompression pressure

A compression apparatus for providing a therapeutic compression pressure to a wearer's body. The apparatus includes an inflatable bladder formed from bladder material, a controller, and a pump operatively connectable to the bladder for pressurizing the bladder. The controller has a pre-therapeutic compression function for instructing the pump to pressurize the bladder to an elevated pressure above the therapeutic compression pressure and to maintain the elevated pressure for a period of time before depressurizing the bladder.

Owner:TYCO HEALTHCARE GRP LP

Packaging container packaging laminate and a method of producing a packaging container

Owner:TETRA LAVAL HLDG & FINANCE SA

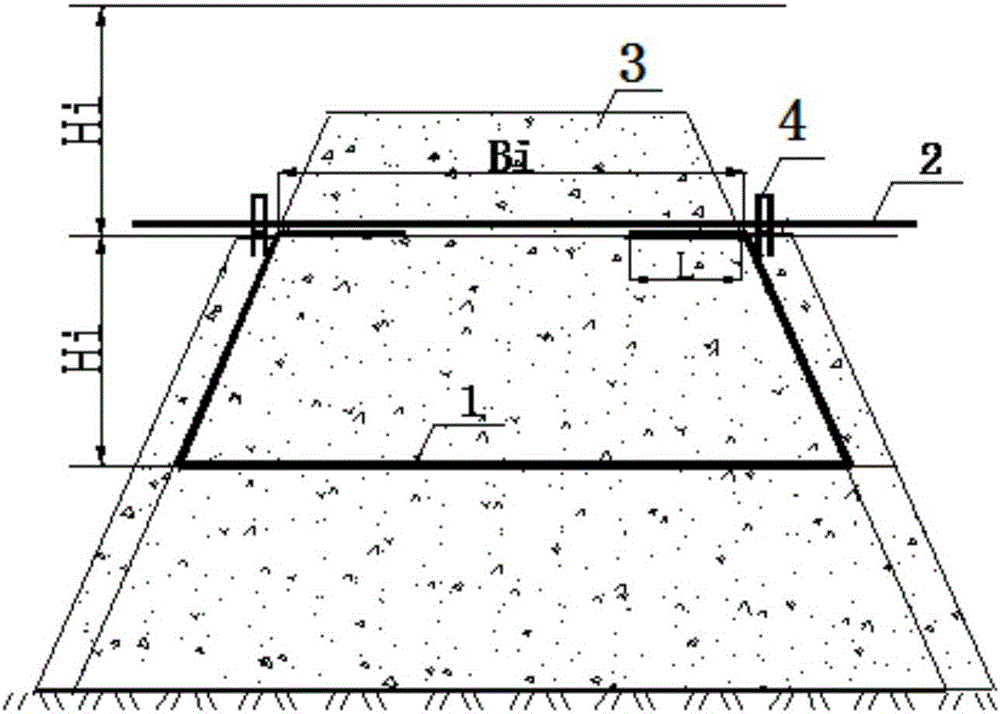

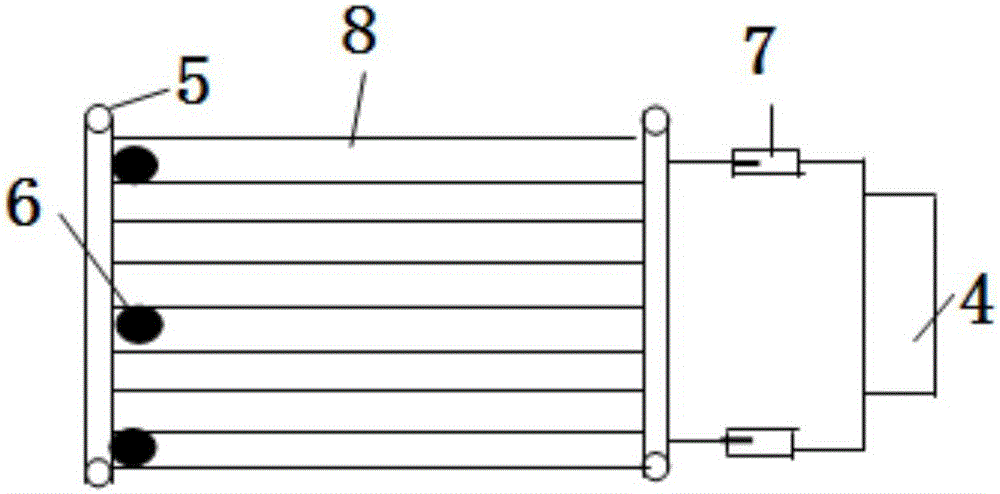

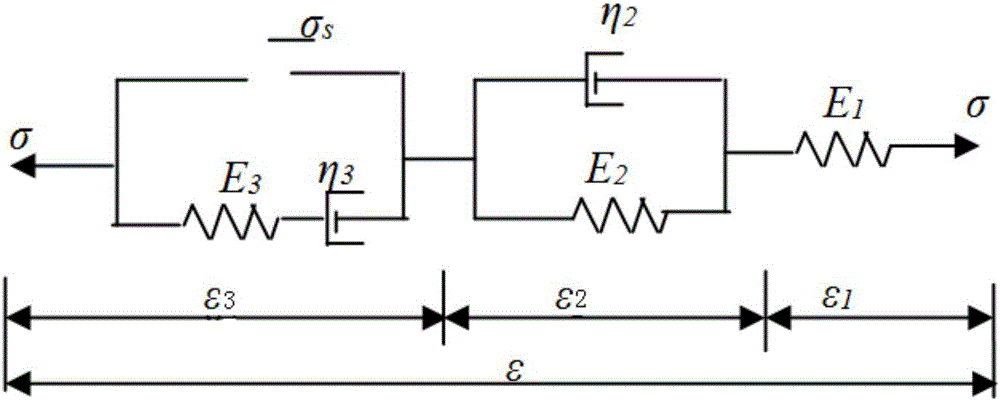

Reinforced earth body sticky, elastic and plastic deformation measuring method, construction method and tensioning system

InactiveCN105735074ARich measurement methodsReliable estimateRoadwaysIn situ soil foundationPre strainSteep slope

The invention provides a reinforced earth body sticky, elastic and plastic deformation measuring method, a construction method and a tensioning system. A computational formula for pre-strain reinforced earth body sticky, elastic and plastic deformation epsilon is shown in the specification. By the adoption of the sticky, elastic and plastic deformation measuring method, the pre-strain reinforced material total deformation generated after construction is more comprehensively, accurately and reliably estimated, and it is guaranteed that the initial deformation of a reinforced material is proper when the reinforced material is tensioned, so that the situation that the additional deformation of the reinforced material is too large due to the settlement deformation of an embankment is avoided, and the phenomenon that the allowing strain of the reinforced material is exceeded and consequently the reinforced material is broken and fails is prevented. By the adoption of the construction method, occurrence of geological disasters in the environments such as high and steep slope large slippage can be scientifically prevented and reduced.

Owner:CHANGSHA UNIVERSITY

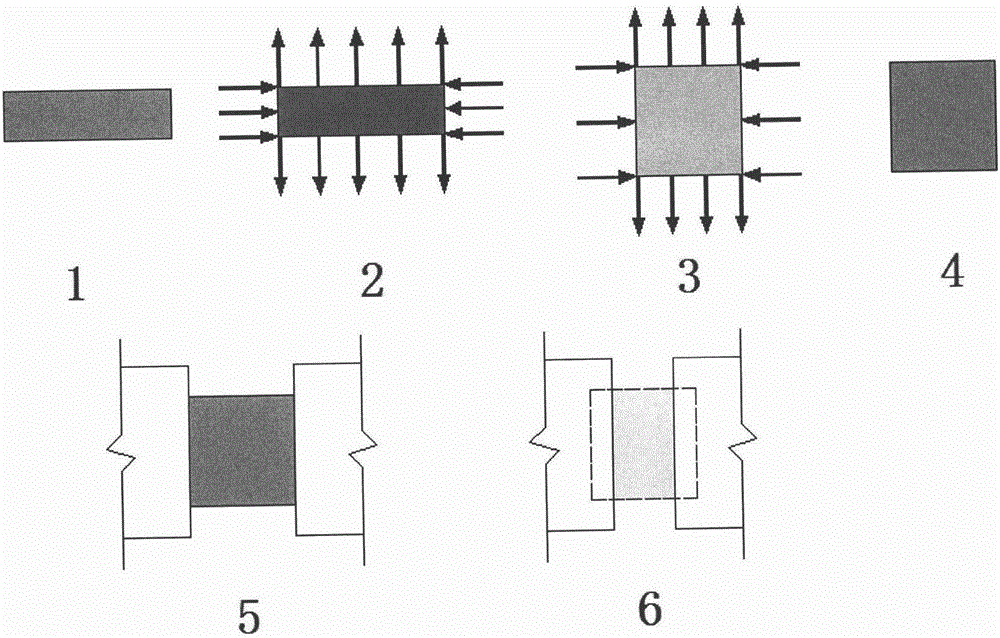

Single-stage double-shaft pre-deformation method for endowing pavement joint material with shape memory function

InactiveCN106638220AExtended service lifeImprove the quality of usePaving detailsSelf-healingPre strain

The invention provides a single-stage double-shaft pre-deformation method for endowing a pavement joint material with a shape memory function, belongs to the technical field of cement pavement, and solves the problem that existing single-stage single-shaft pre-deformation method can only endow the material with the shape memory function in one direction, and thus the material is poor in self-healing effect. A cruciform specimen of a shape memory polymer matrix composite is produced at first, pre-compaction deformation is performed along the vertical direction at the temperature higher than a glass-transition temperature, meanwhile prestretching deformation is performed along the horizontal direction, and thus the joint material is endowed with the shape memory function in both horizontal and vertical directions; then the shape memory effect of the joint material after pre-deformation is measured and further synthesized with other operational performance of the joint material to determine reasonable stretching and compression pre-strain values for endowing the joint material with the shape memory function. According to the pre-deformation method provided by the invention, the joint material actively adapt to cyclic change of the width of the cement pavement joint, usability and durability of the joint material are improved, and service life of the cement pavement is prolonged.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com